Patents

Literature

578 results about "Lateral move" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

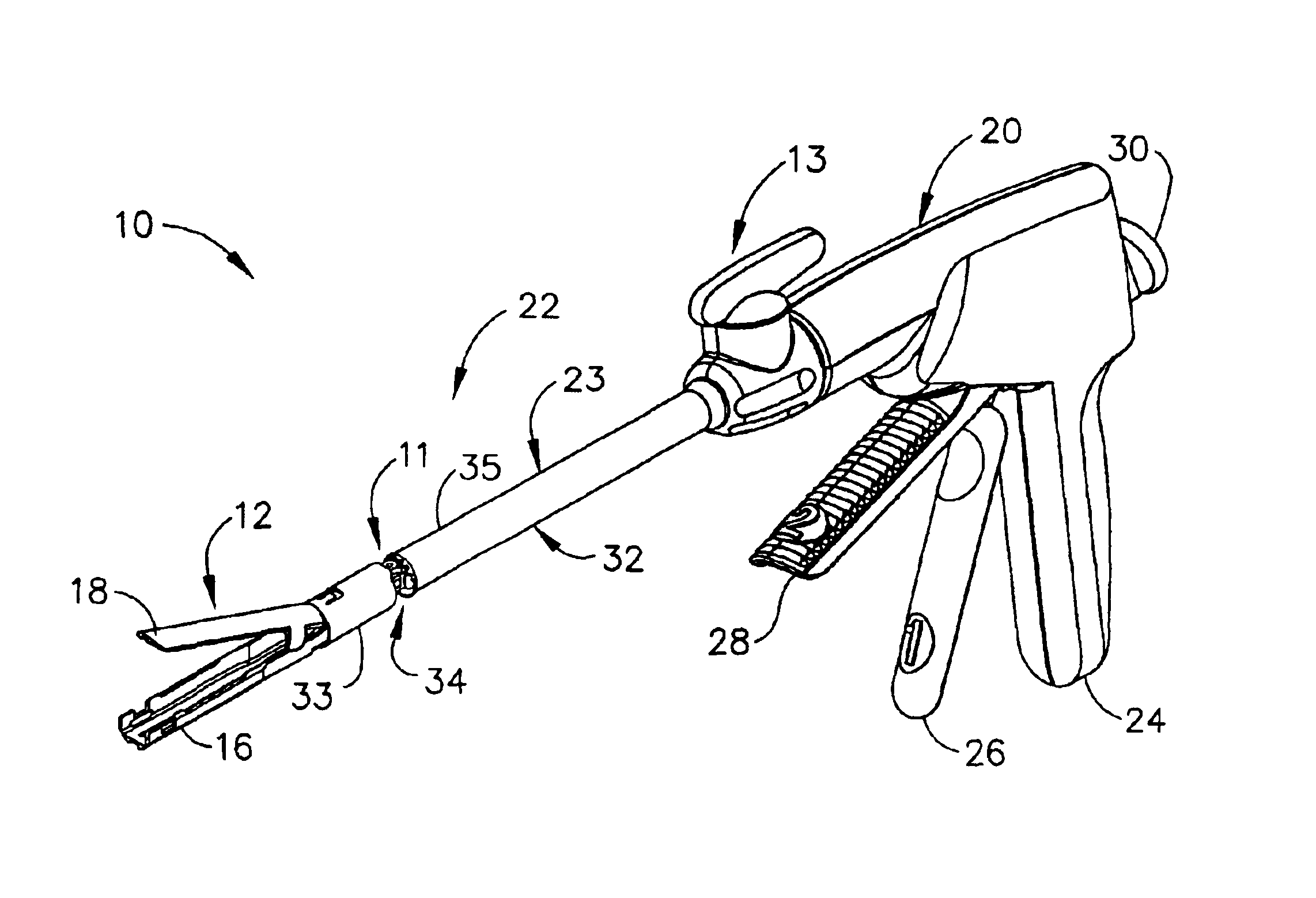

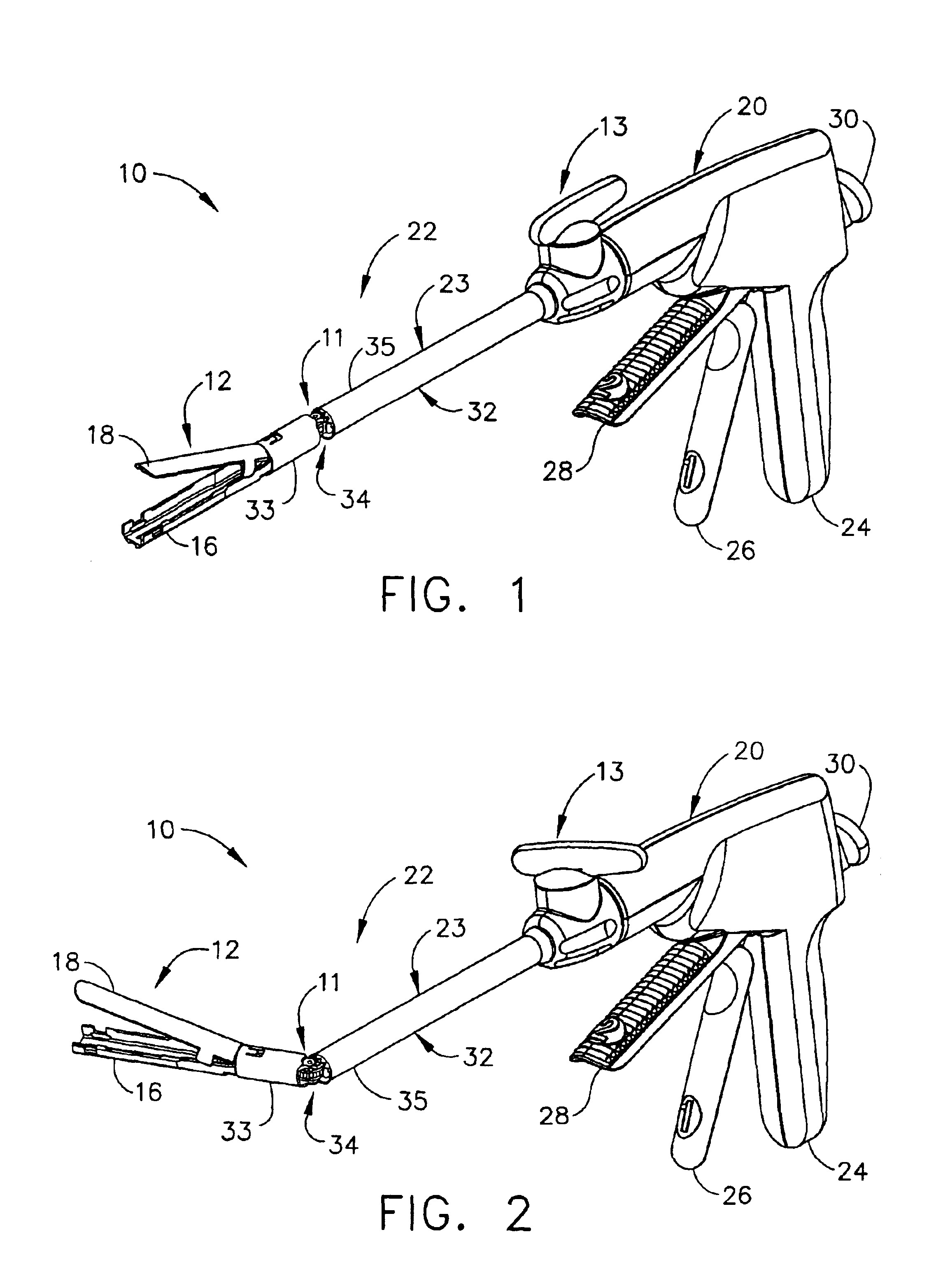

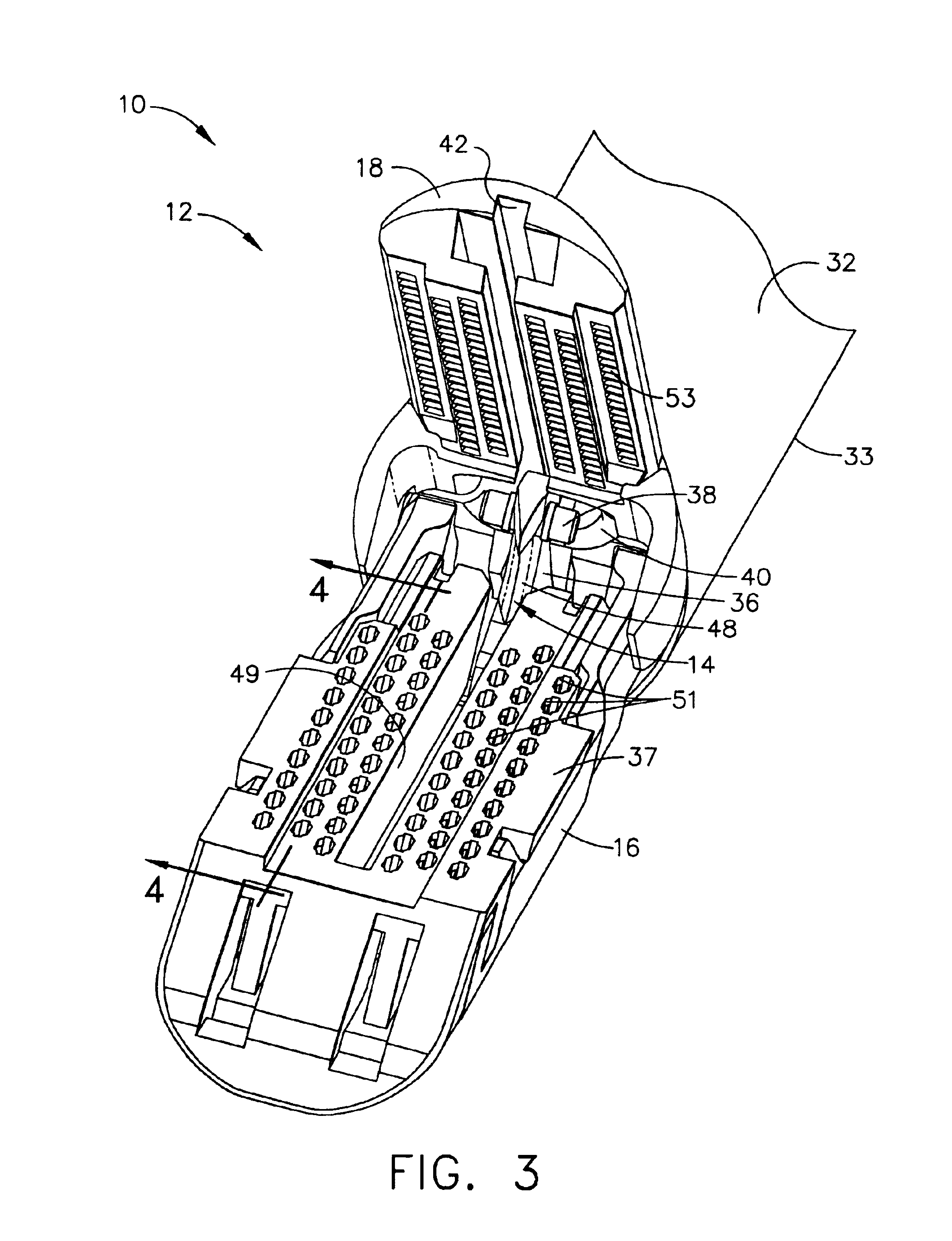

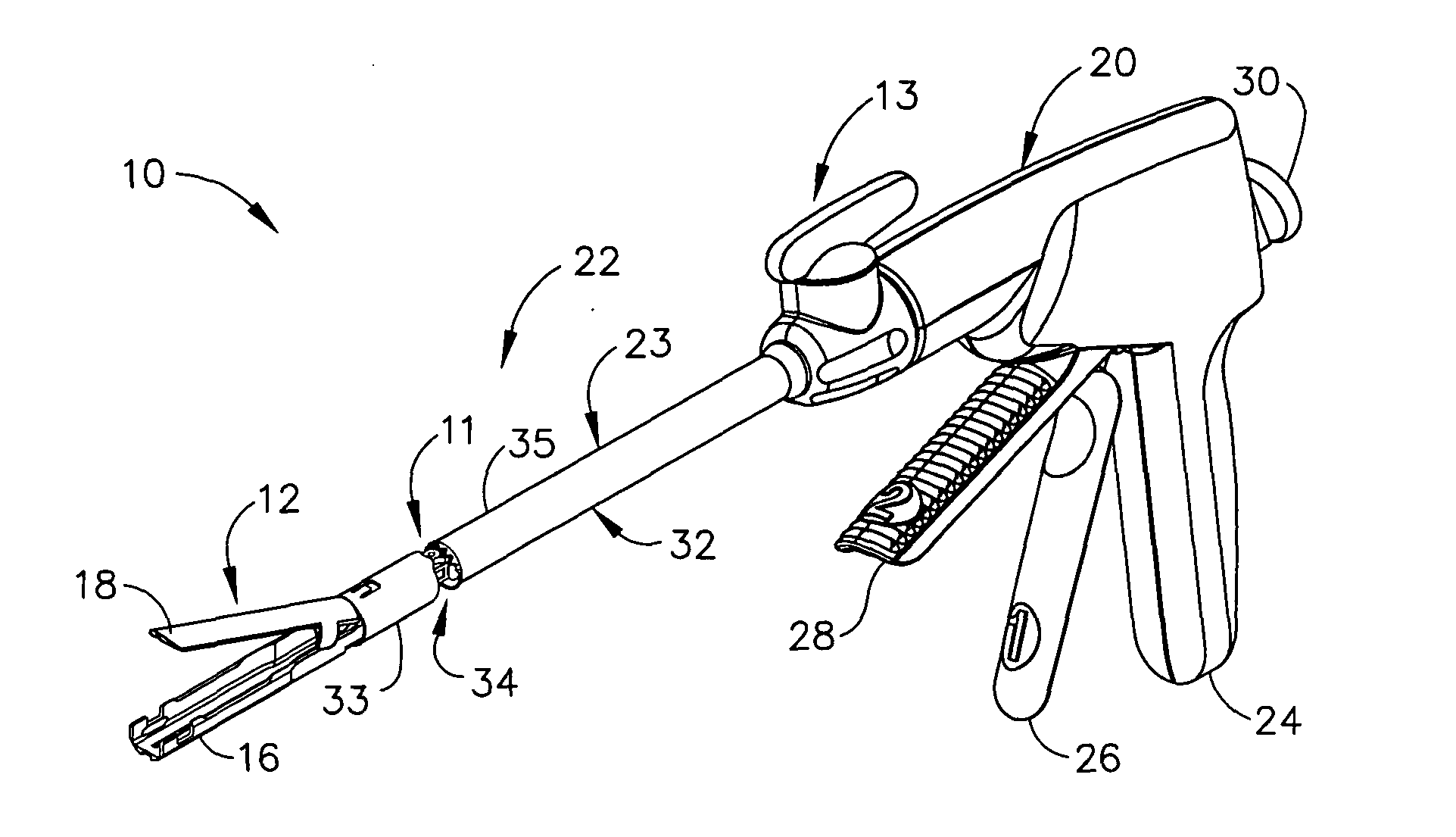

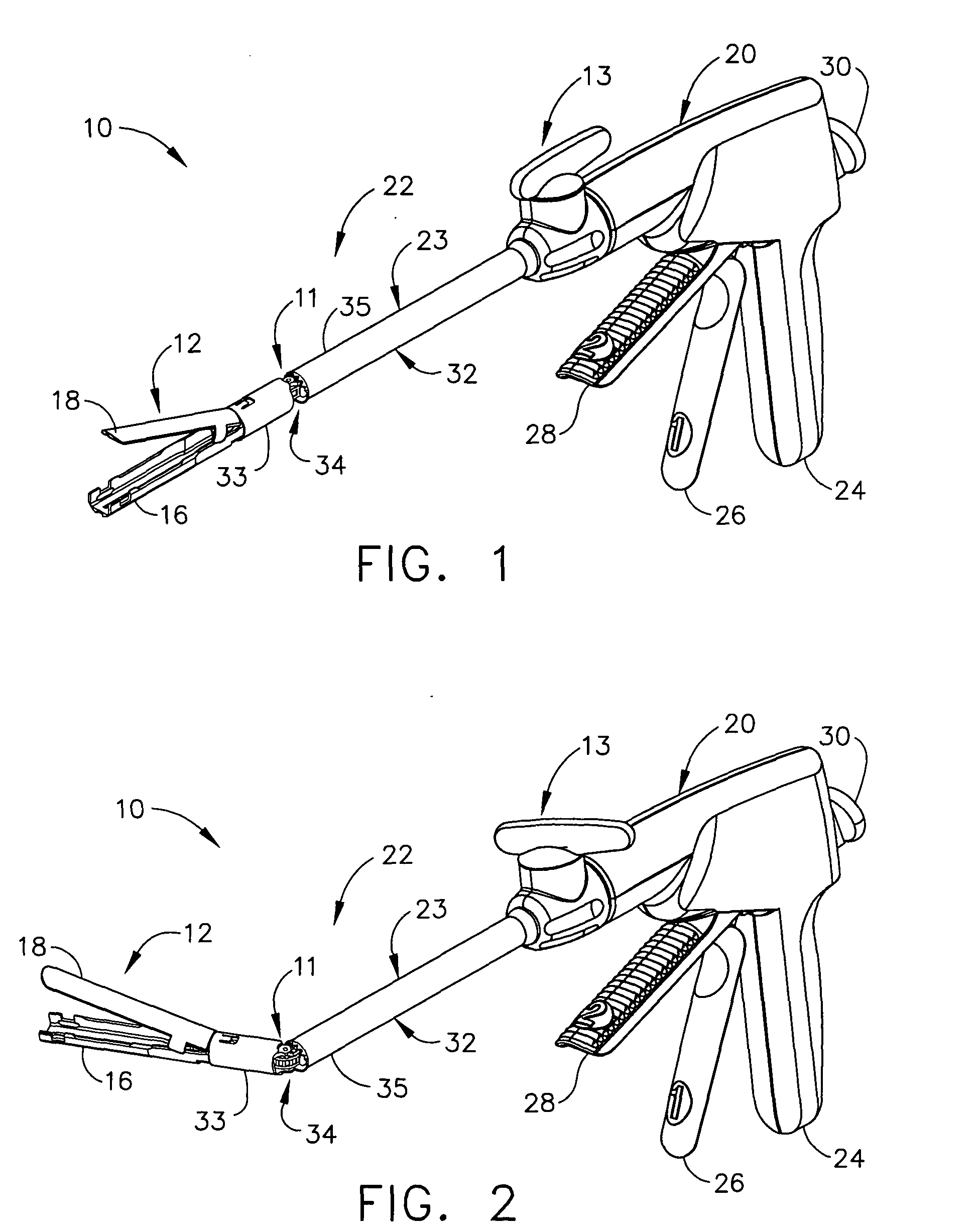

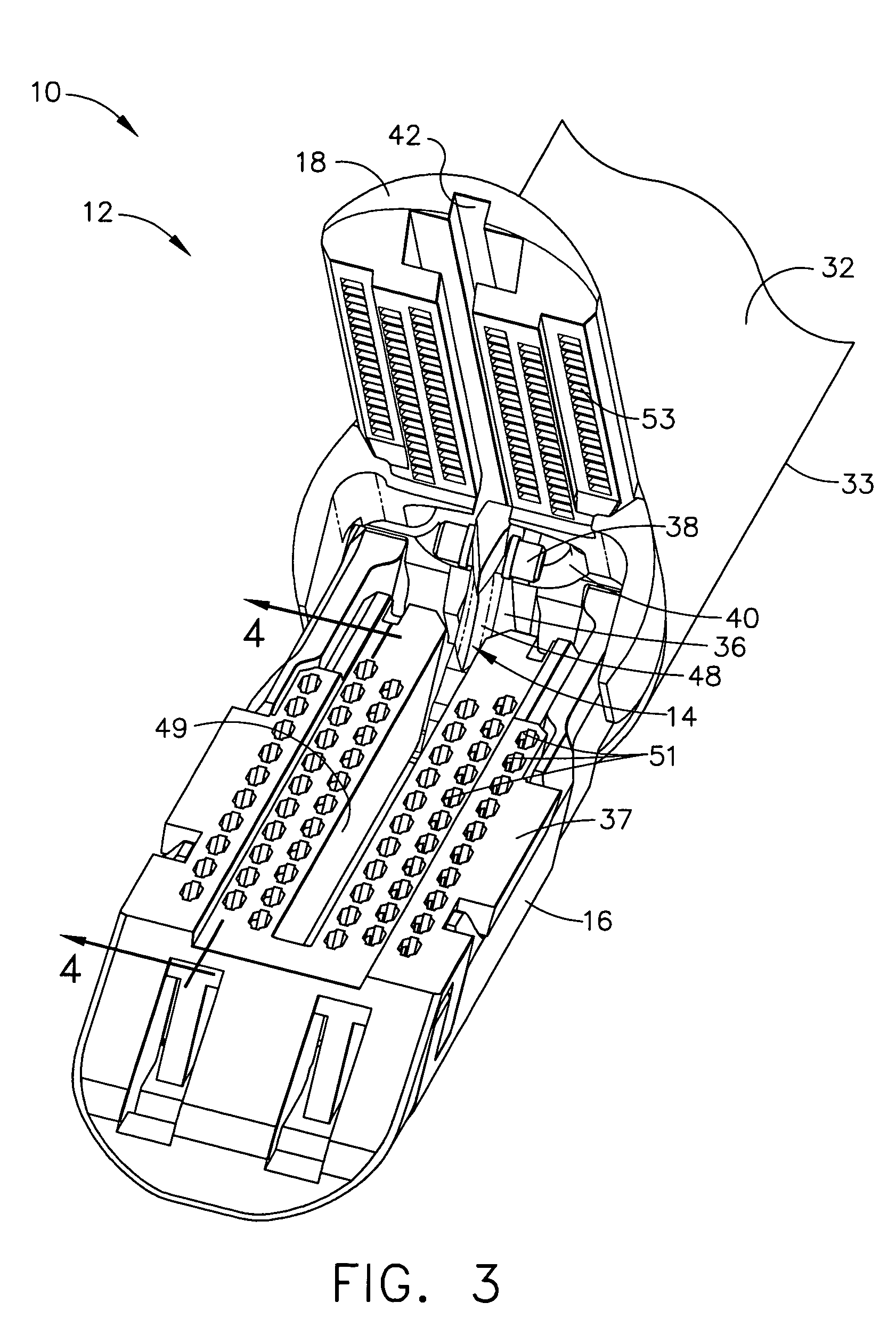

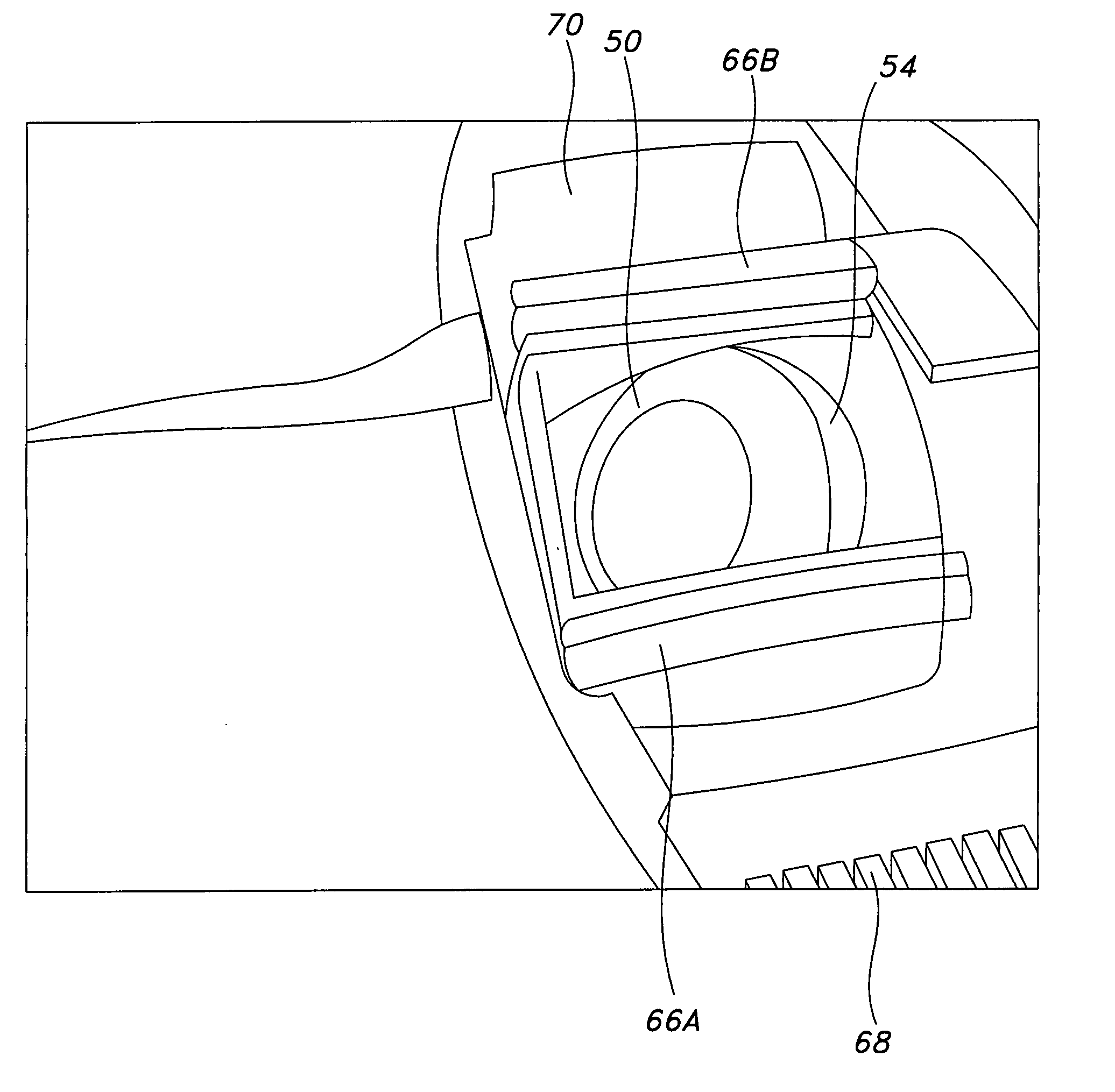

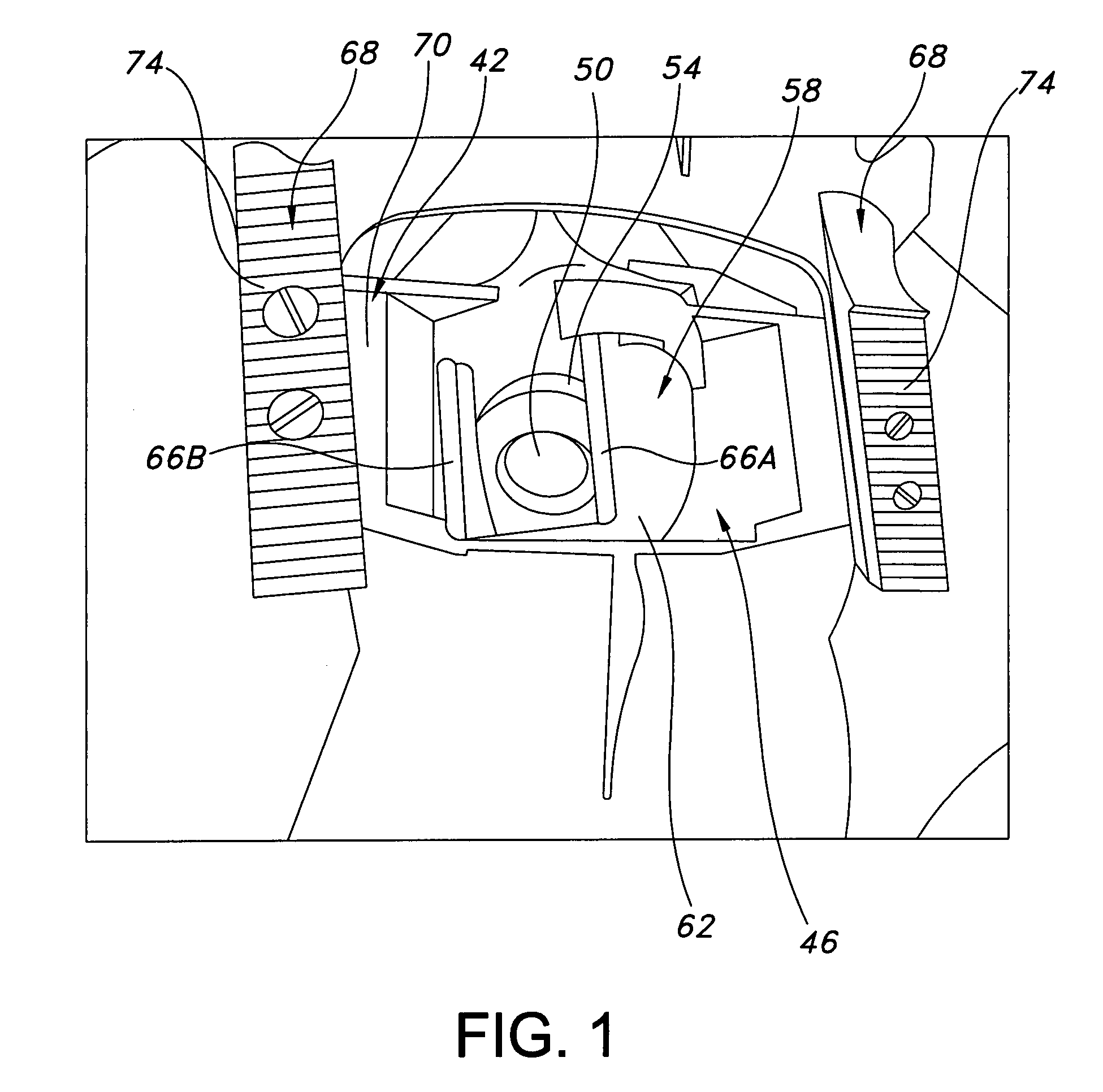

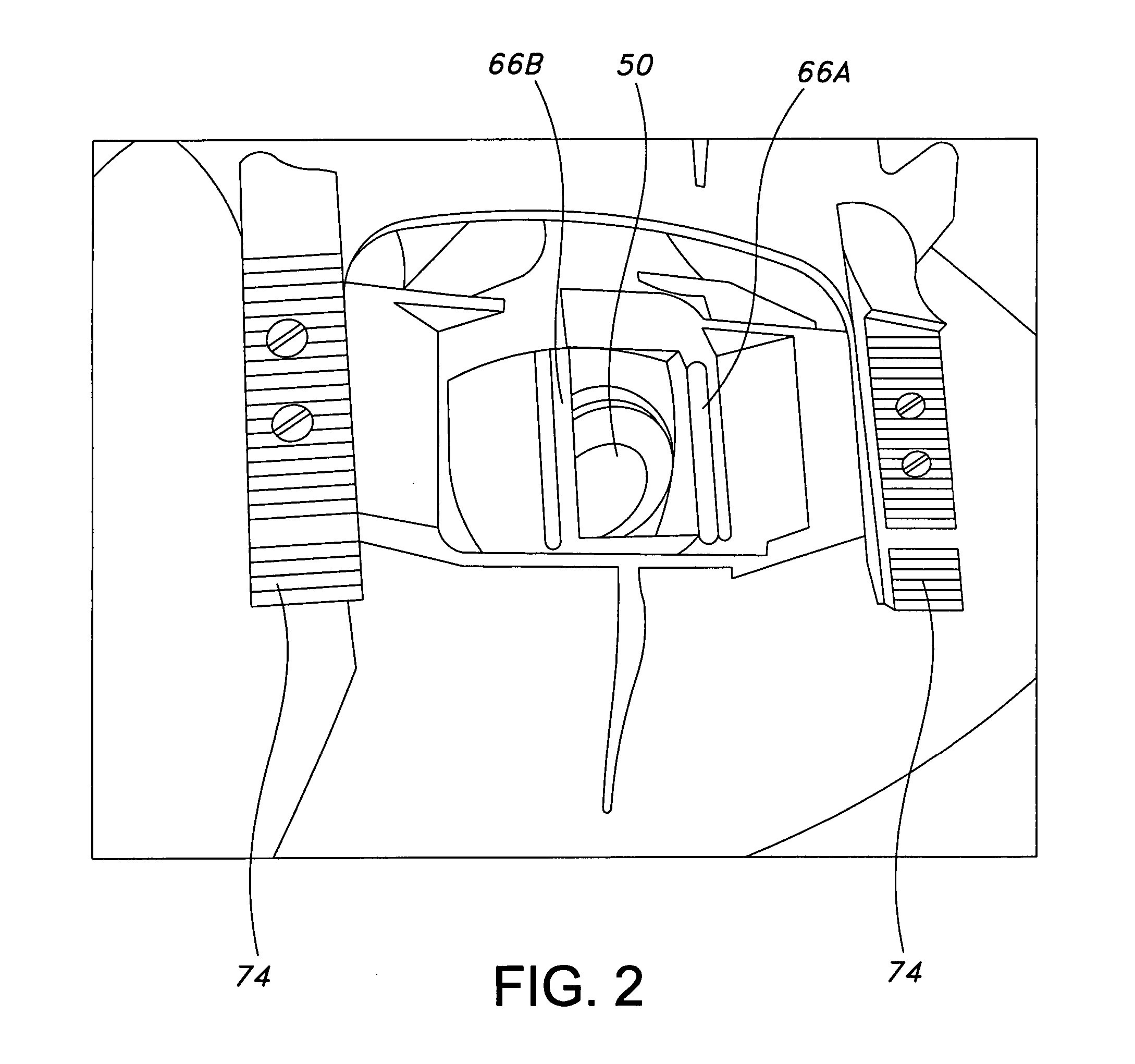

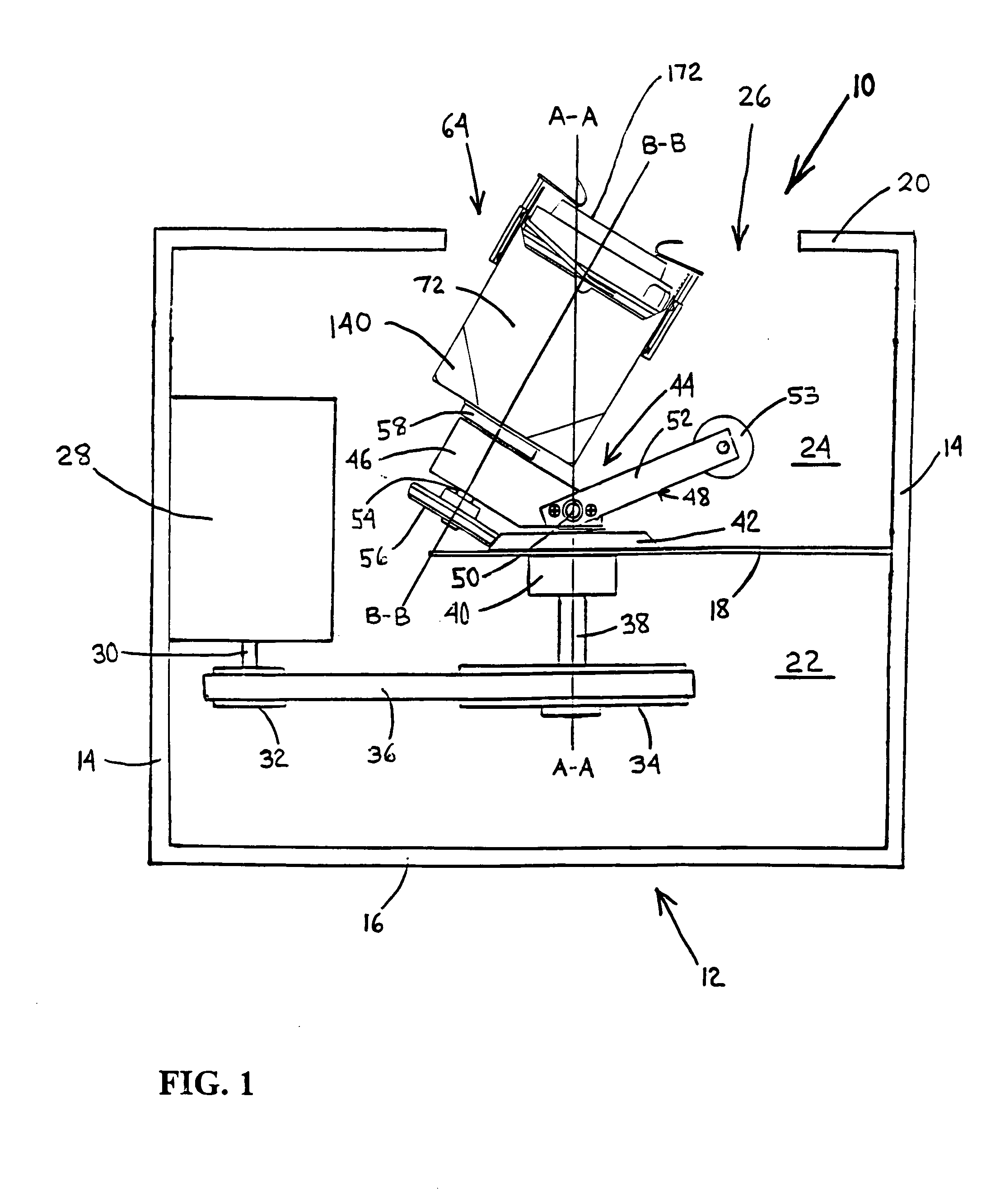

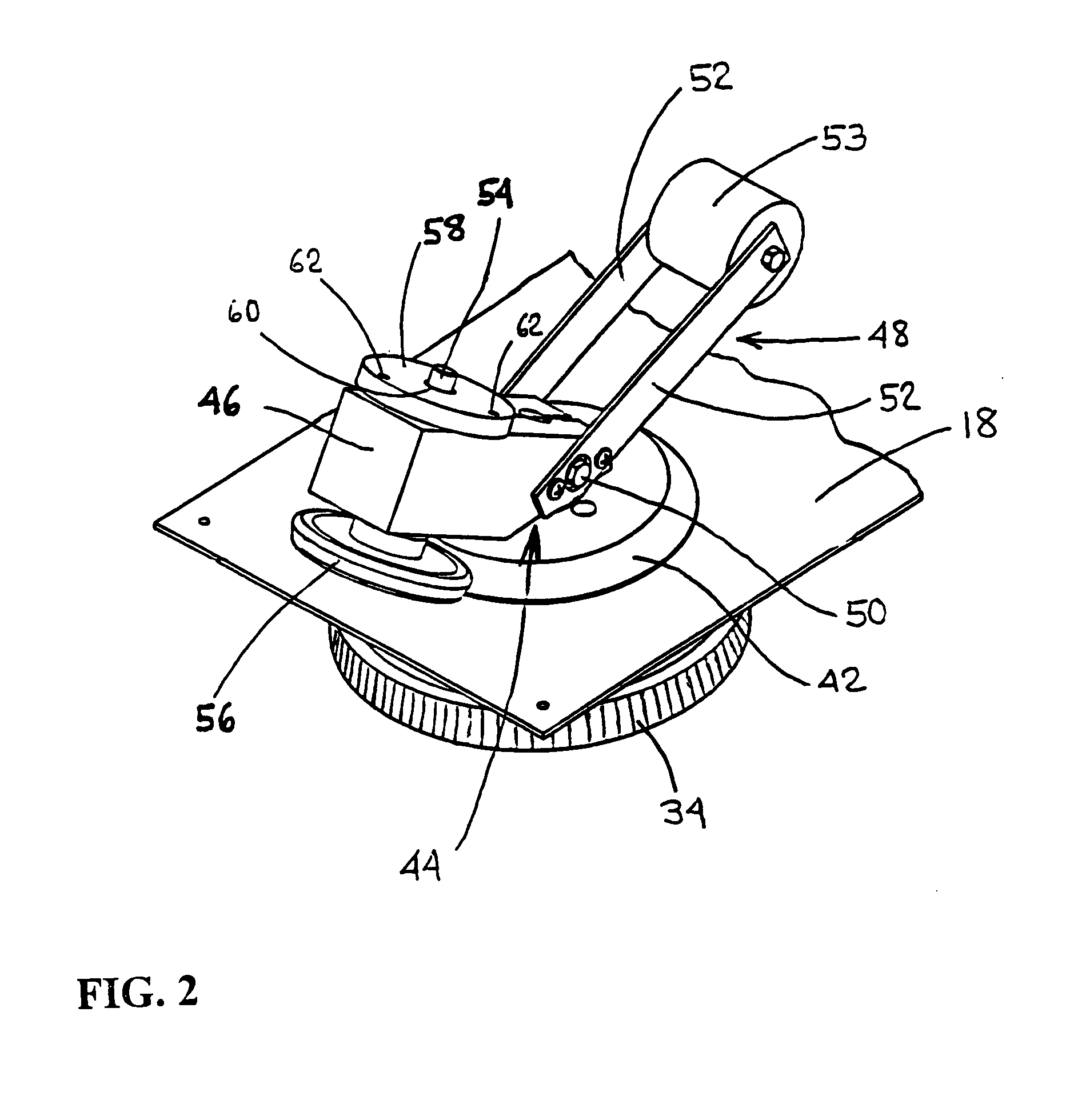

Surgical instrument with a lateral-moving articulation control

InactiveUS6981628B2Complicate amountComplicate directionSuture equipmentsStapling toolsEngineeringTarsal Joint

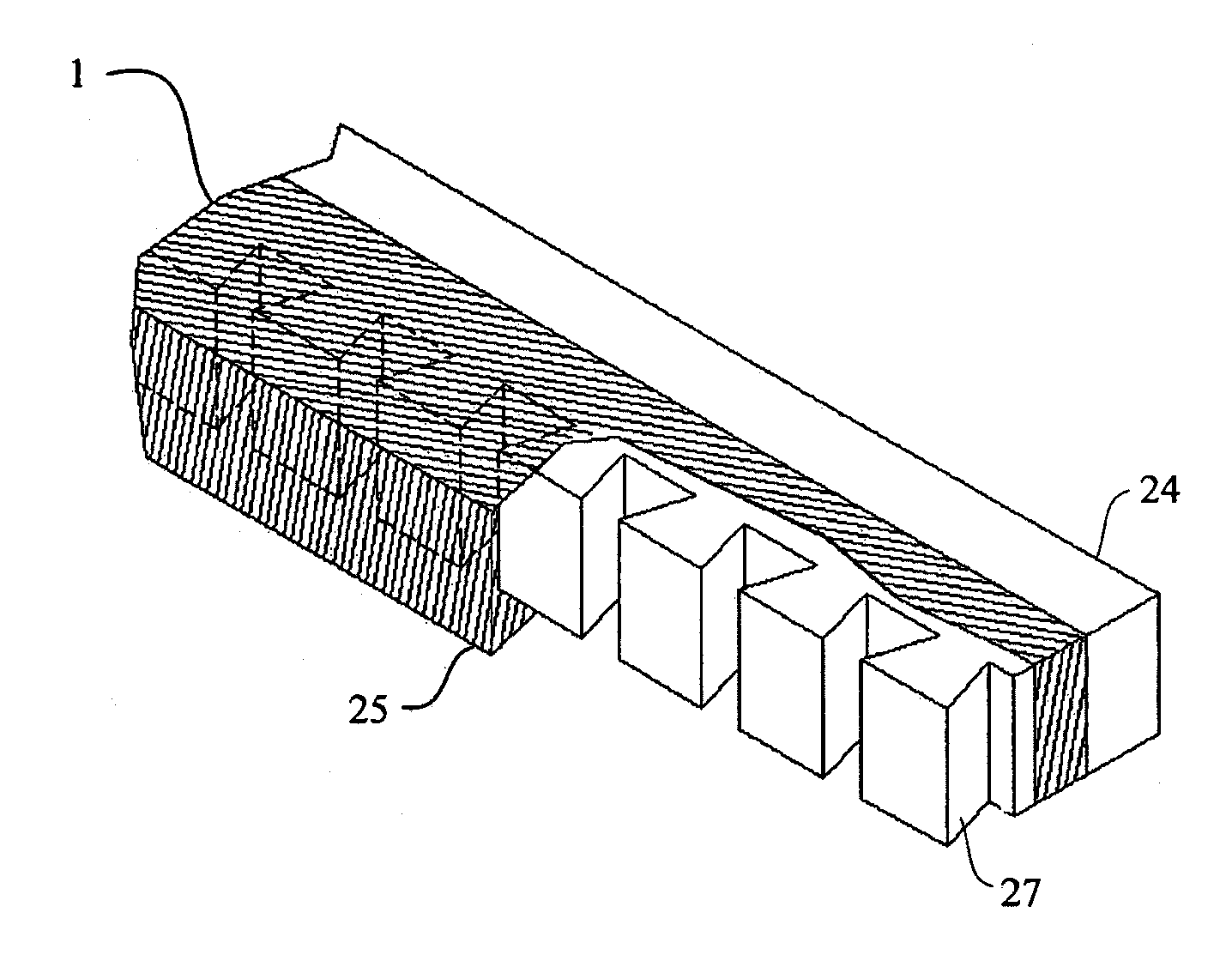

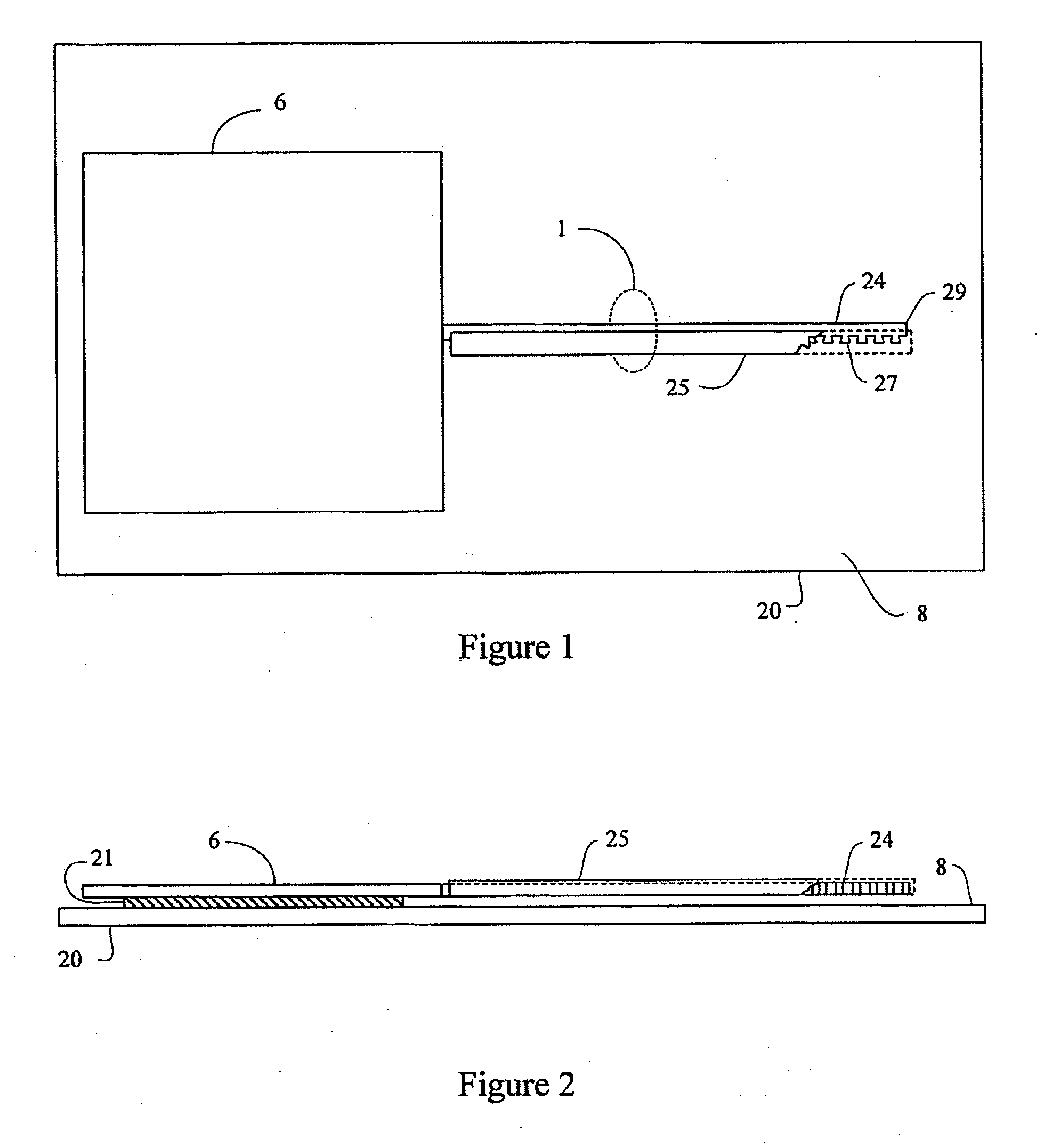

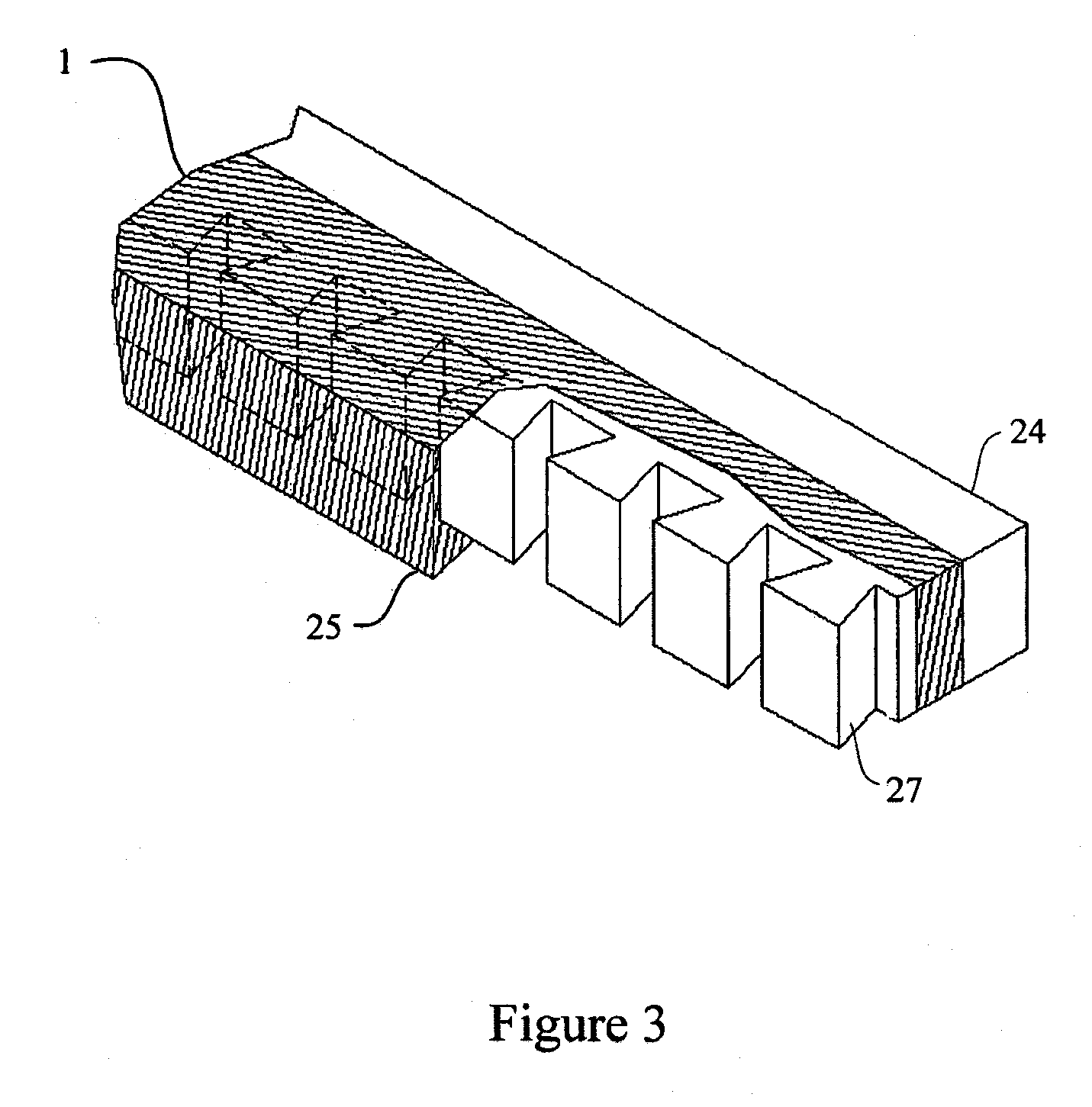

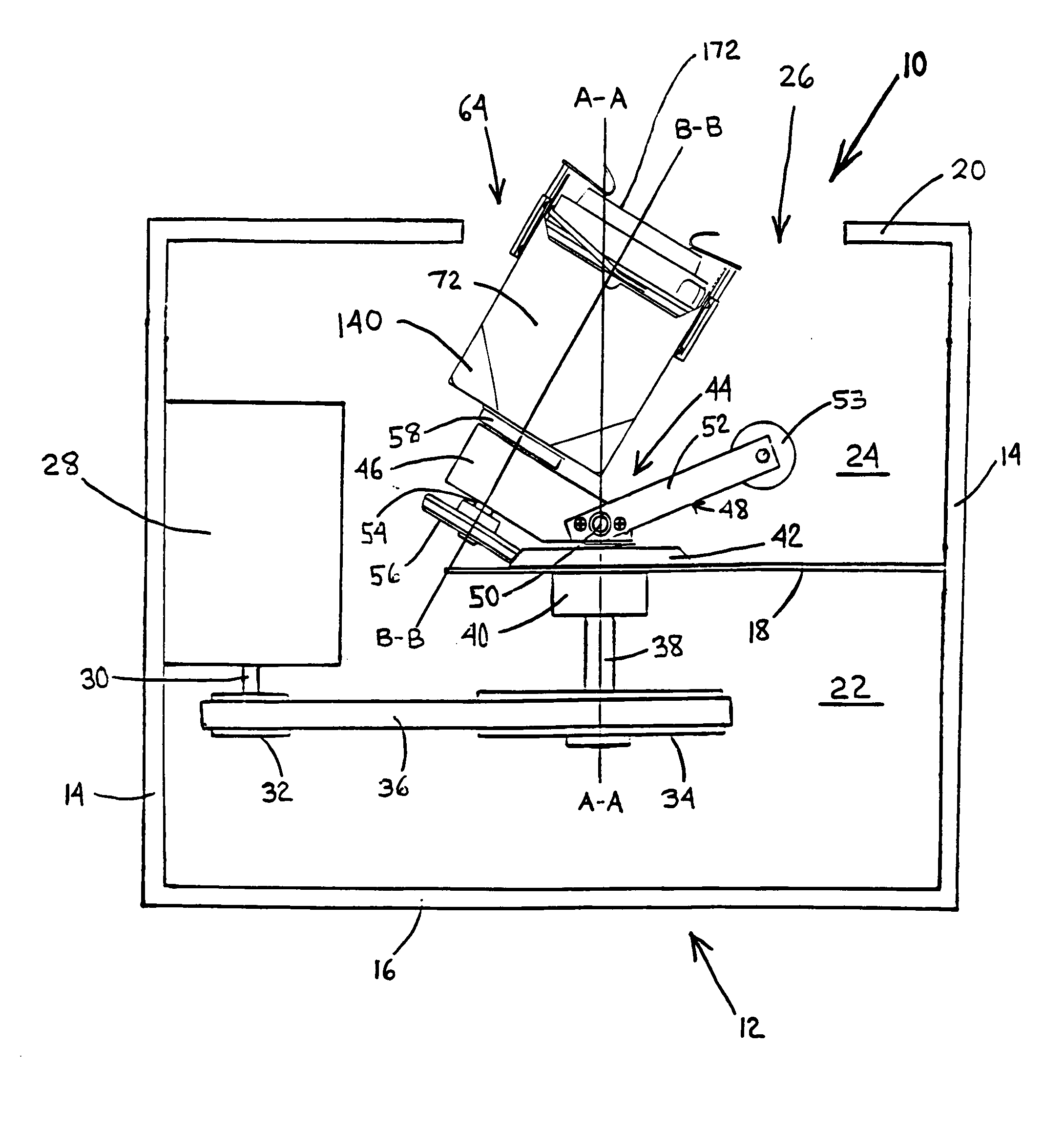

An articulating surgical instrument suited for endoscopic use includes a lateral articulation control into a handle portion that provides an intuitive visual and tactile indication to the clinician as to the amount and direction of articulation of an end effector at a distal end of a shaft. Lateral movement of a lateral control actuator is converted into a longitudinal motion or a rotational motion transferred by the shaft to an articulation mechanism. A version of a lateral articulation control for a rotationally driven articulation mechanism incorporates an articulation backdrive lockout that prevents forces on the end effector from causing the selected amount of articulation from being changed.

Owner:CILAG GMBH INT

Surgical instrument with a lateral-moving articulation control

InactiveUS20050006430A1Complicate amountComplicate directionSuture equipmentsStapling toolsEngineeringSacroiliac joint

An articulating surgical instrument suited for endoscopic use includes a lateral articulation control into a handle portion that provides an intuitive visual and tactile indication to the clinician as to the amount and direction of articulation of an end effector at a distal end of a shaft. Lateral movement of a lateral control actuator is converted into a longitudinal motion or a rotational motion transferred by the shaft to an articulation mechanism. A version of a lateral articulation control for a rotationally driven articulation mechanism incorporates an articulation backdrive lockout that prevents forces on the end effector from causing the selected amount of articulation from being changed.

Owner:CILAG GMBH INT

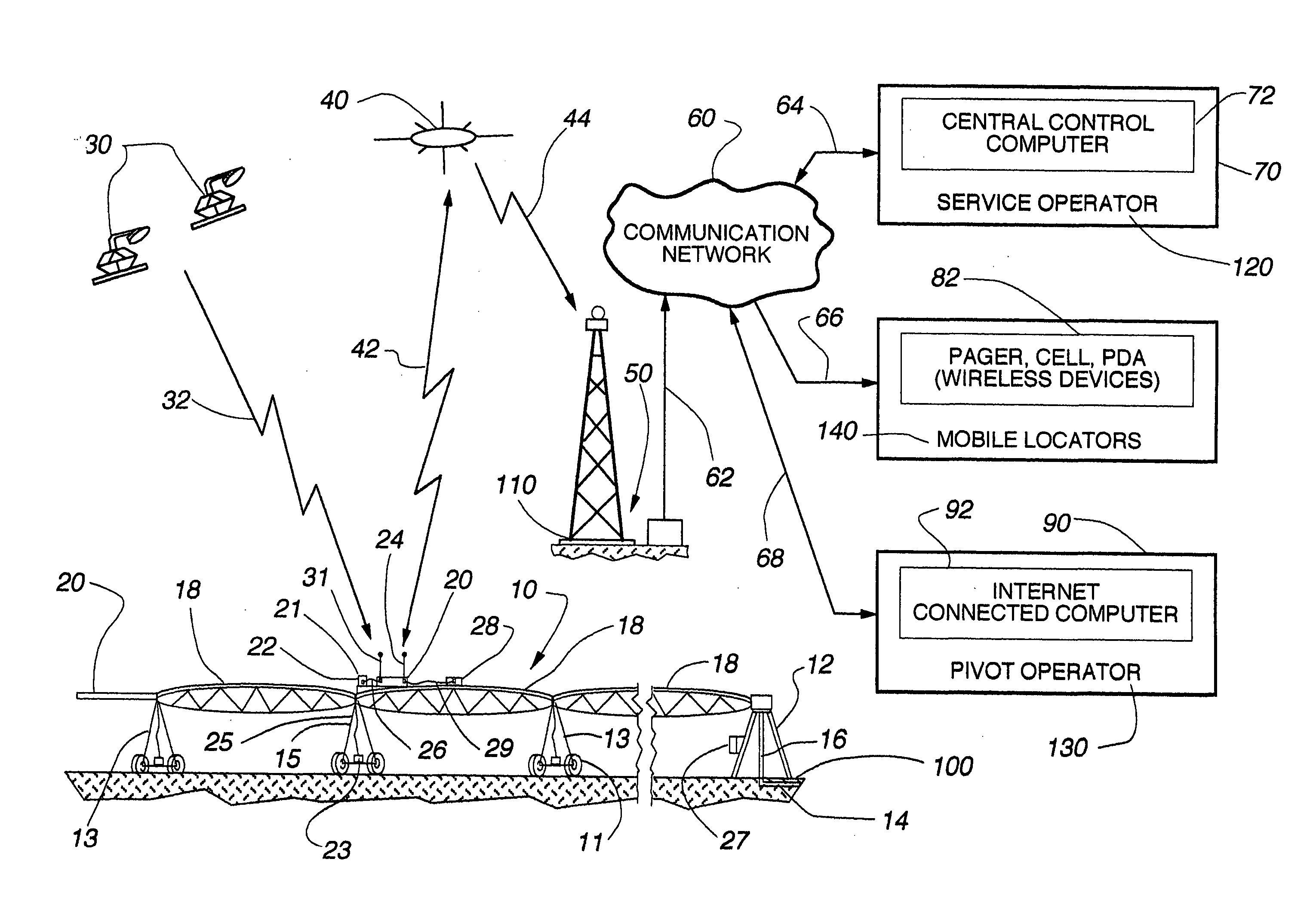

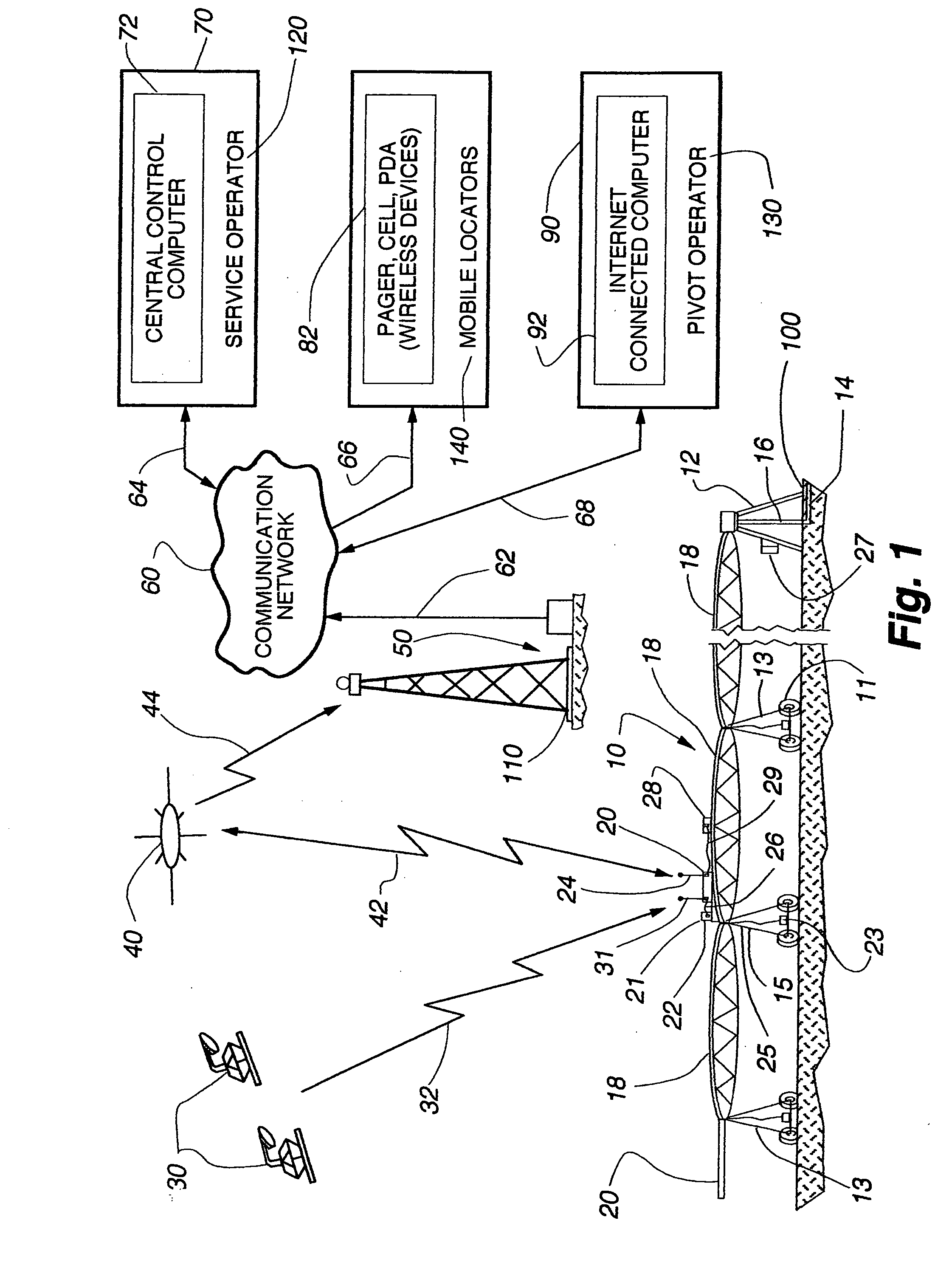

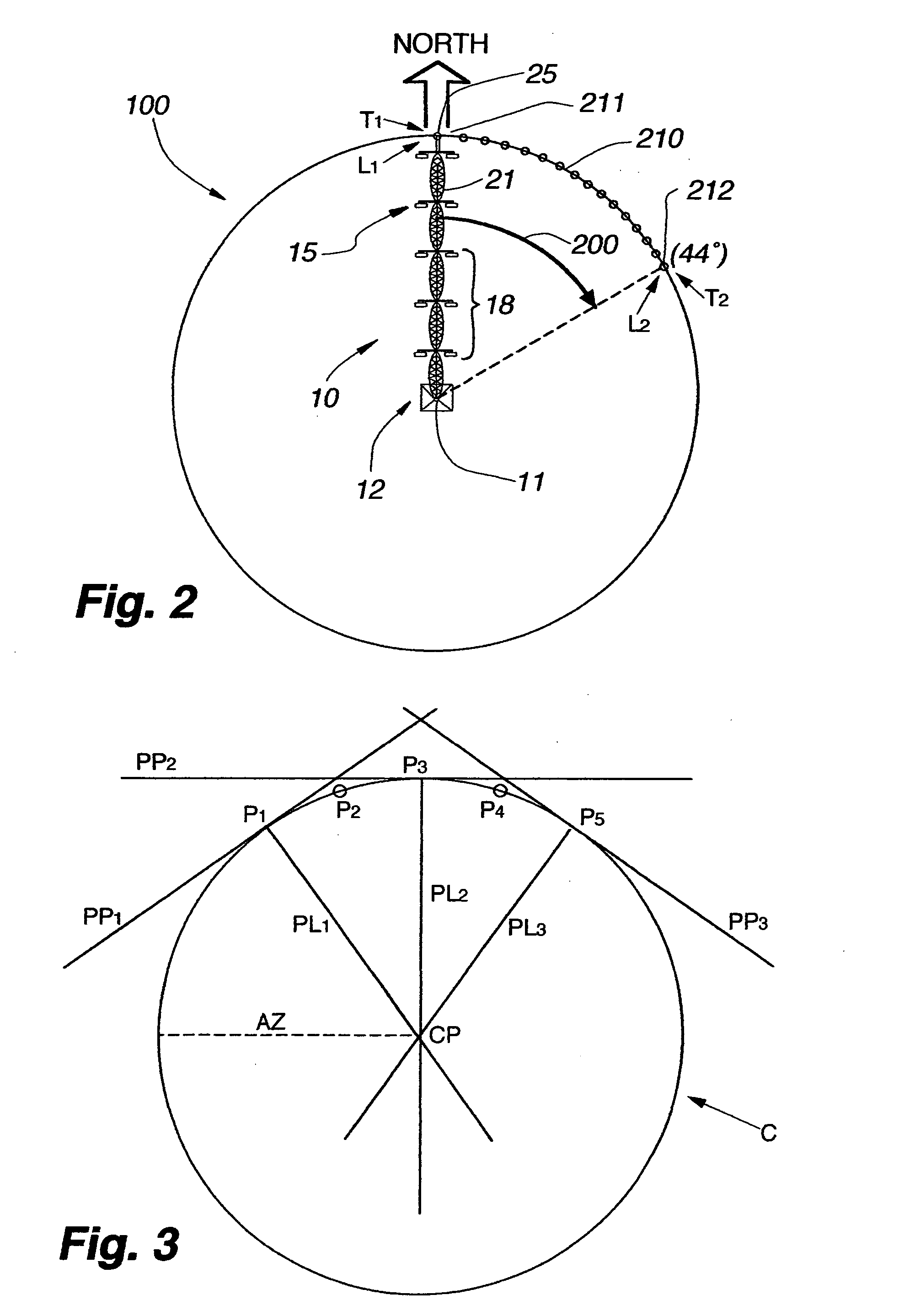

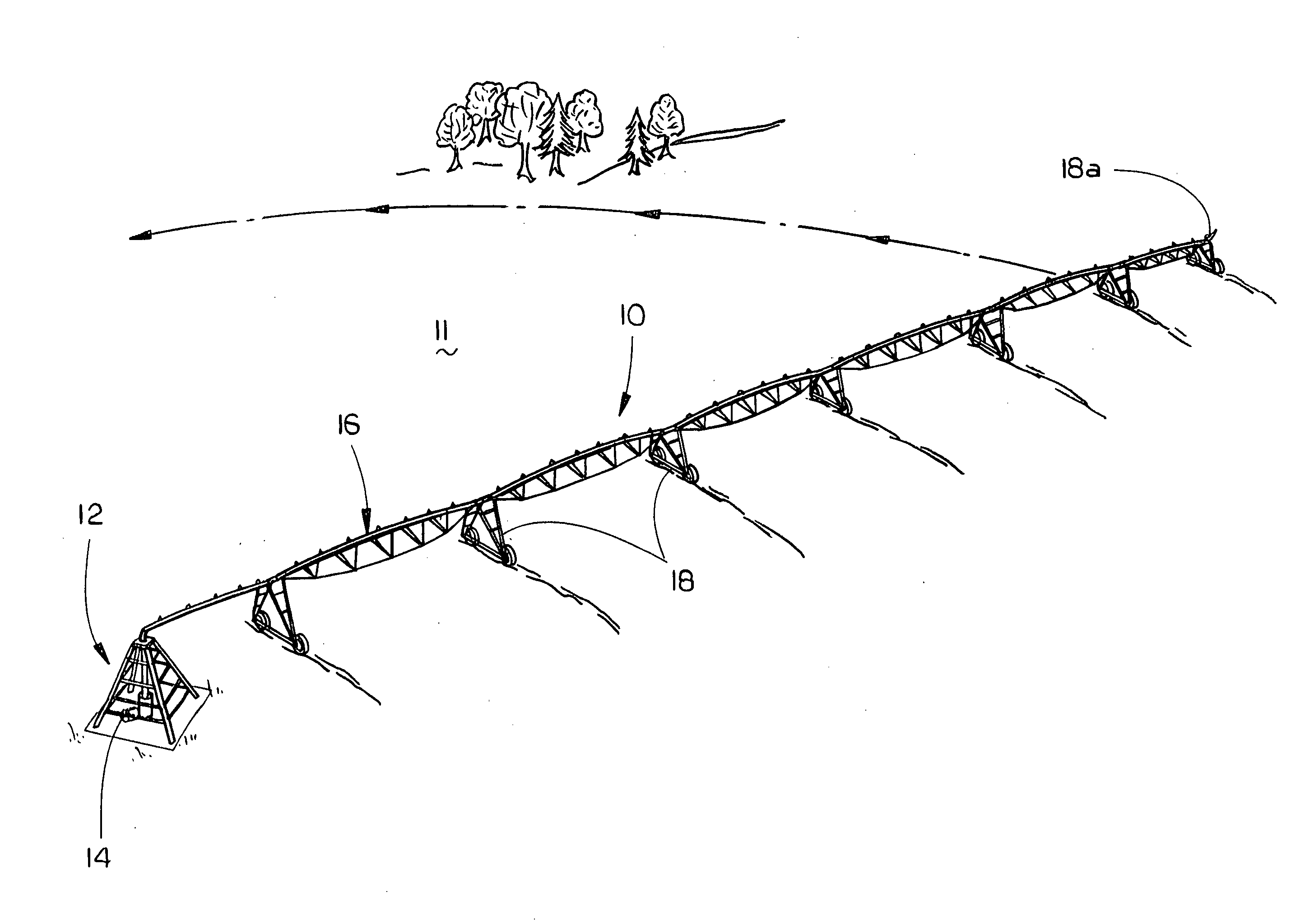

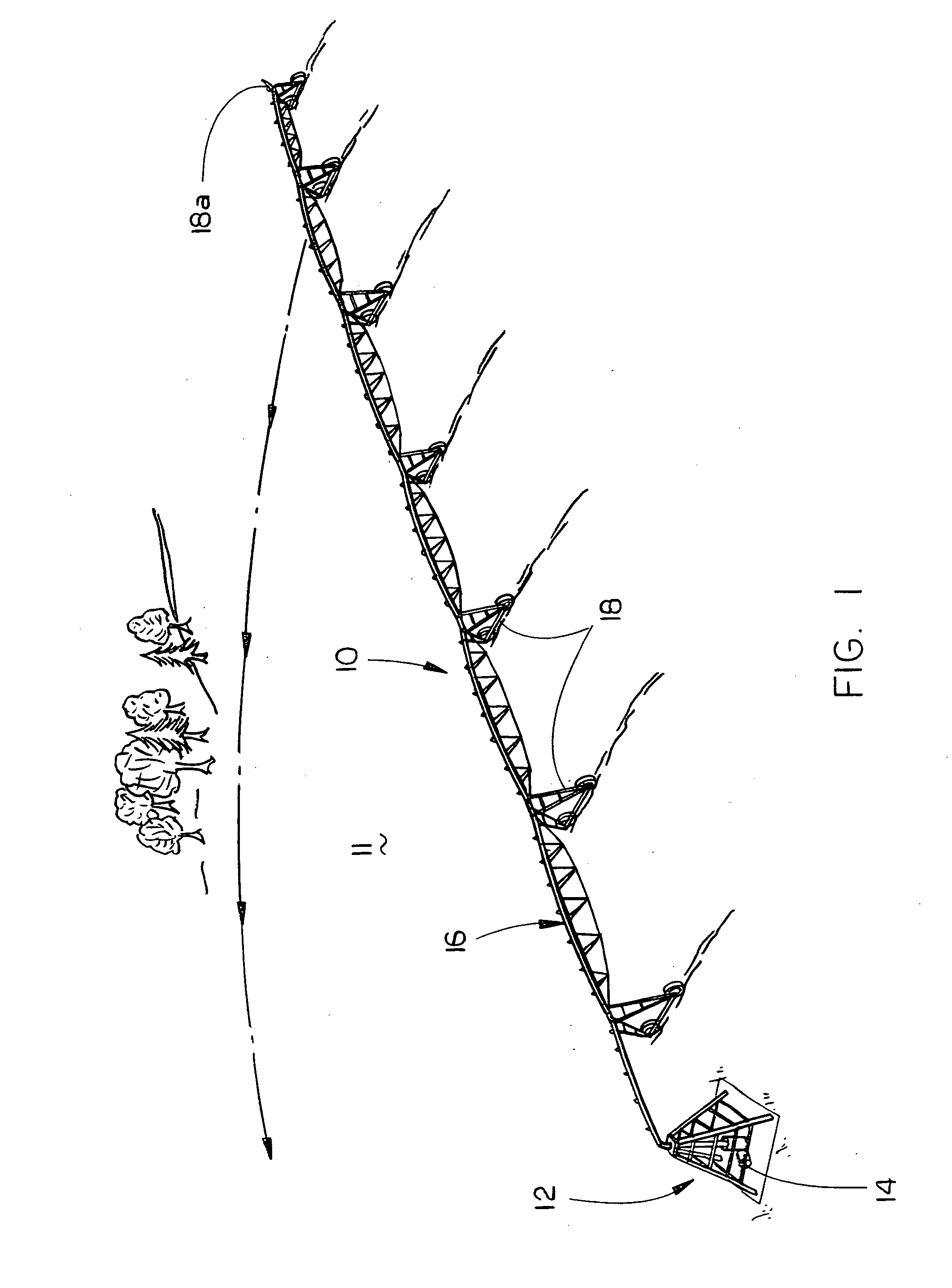

Remote current sensor monitoring system and GPS tracking system and method for mechanized irrigation systems

ActiveUS20060027677A1Low costImprove reliabilitySelf-acting watering devicesWatering devicesTransceiverCurrent sensor

A wireless interface remote monitoring system for self-propelled irrigation systems (center pivot and lateral move sprinklers) includes a remote terminal unit (RTU) mounted on an outer drive tower of the irrigation system. The RTU includes a radio transceiver capable of sending and receiving data packets over a satellite or terrestrial telemetry backbone to and from a central control computer. The RTU further includes a current sensor and a GPS receiver both for detecting movement or non-movement of the sprinkler, a microprocessor with nonvolatile memory for storing current data and GPS coordinate data from readings taken in series over time, and a pressure or flow sensor for detecting the presence or absence of water flow at the outer drive tower of the sprinkler. The current sensor connected between the RTU and a tower drive motor, allows the RTU to calculate the “movement” or “non-movement” of the irrigation system over a specified time period. Redundantly, the GPS receiver records changes in position to indicate movement or non-movement within the GPS error tolerance. Once a change from movement to non-movement or vice-versa is determined, the RTU transmits the data by satellite or radio telemetry to a central control computer which logs the movement or non-movement of the monitored drive tower, the GPS coordinate data and the water status readings, all with time and date stamp. The central control computer creates “page message” and “text message” updates as necessary on the status of individual irrigation systems and “groups” of irrigation systems that are in turn delivered to wireless devices and computers for sprinkler operators.

Owner:HAALAND KARLYLE

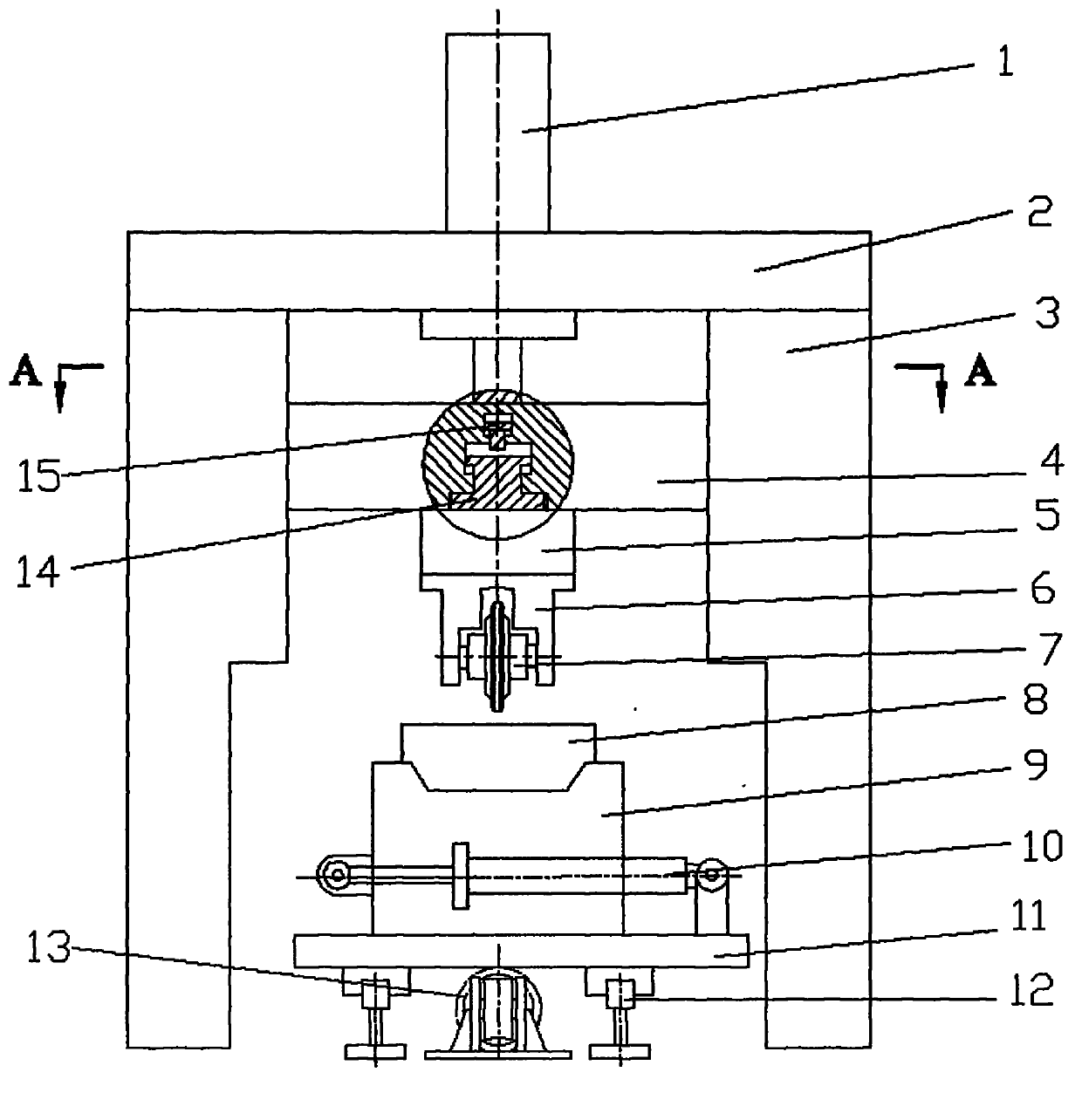

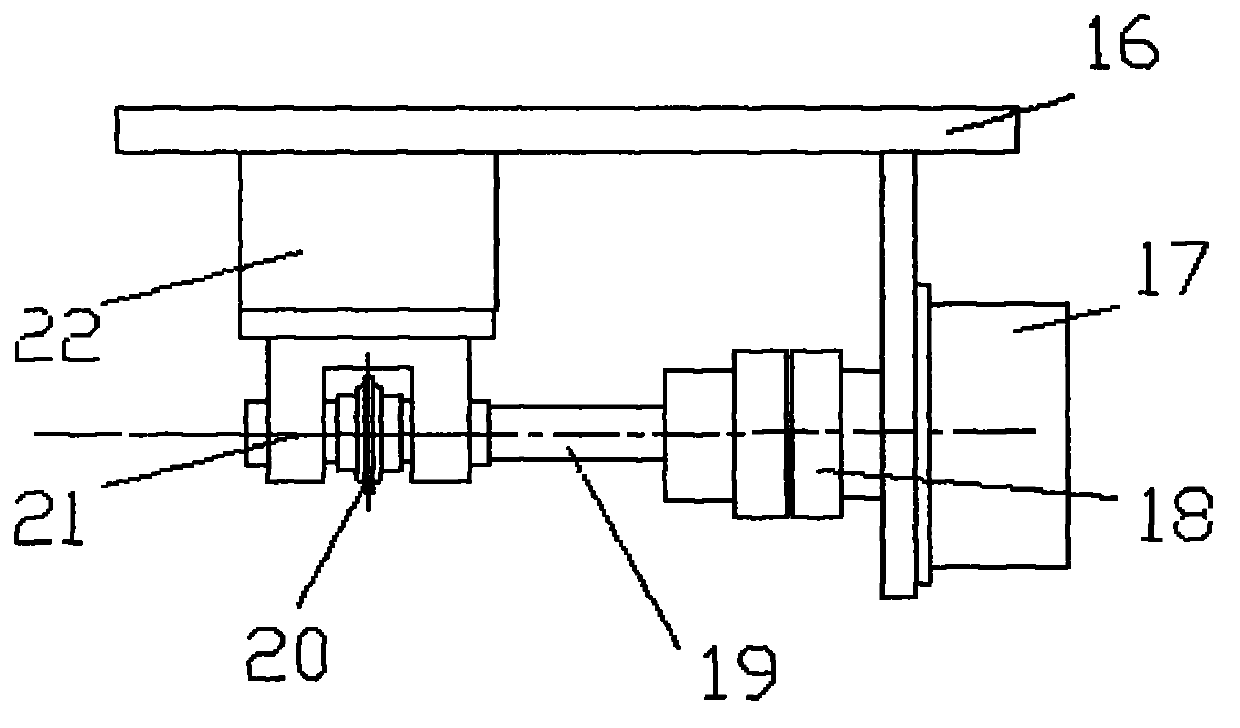

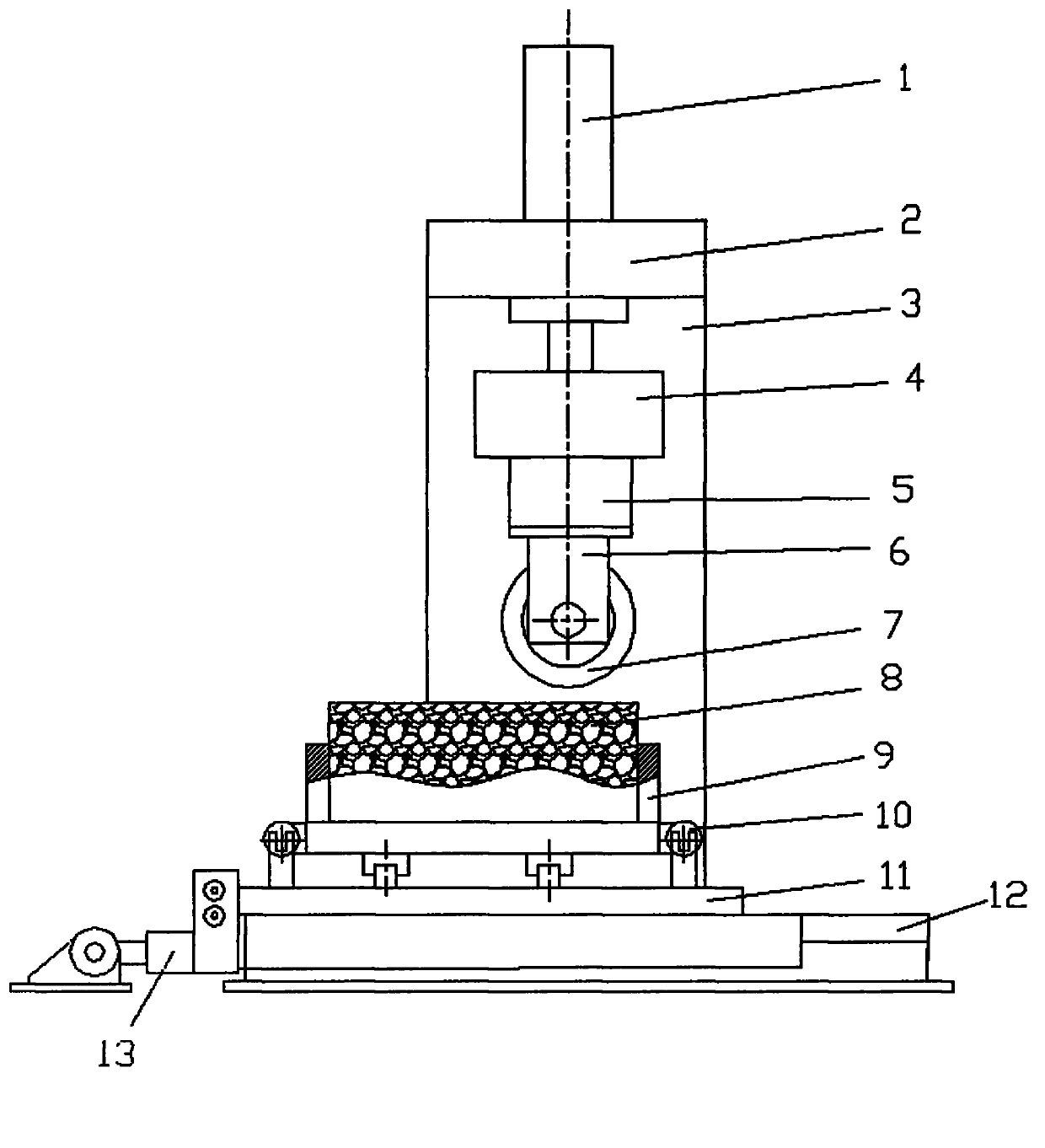

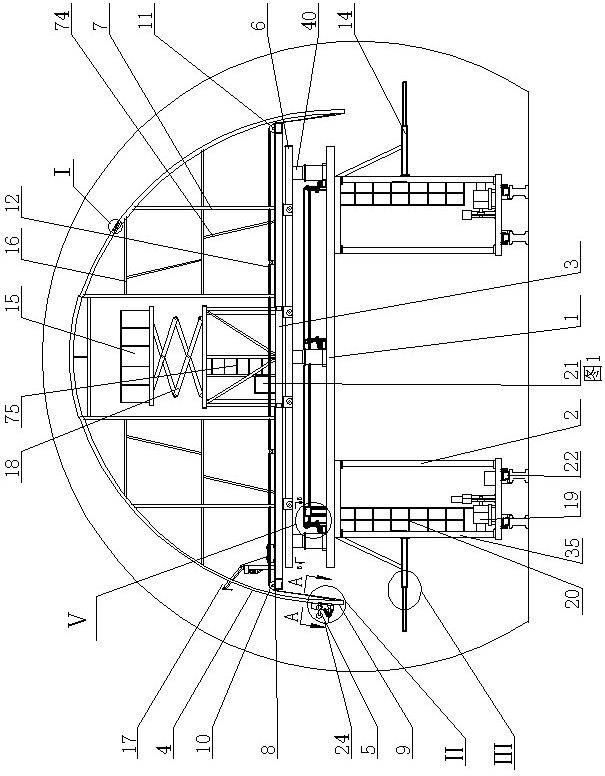

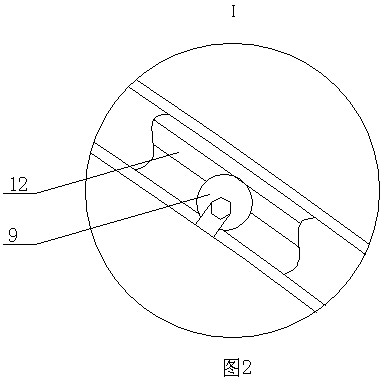

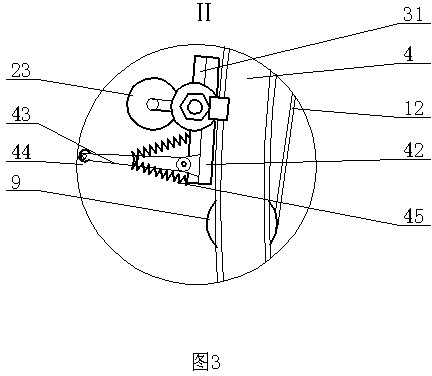

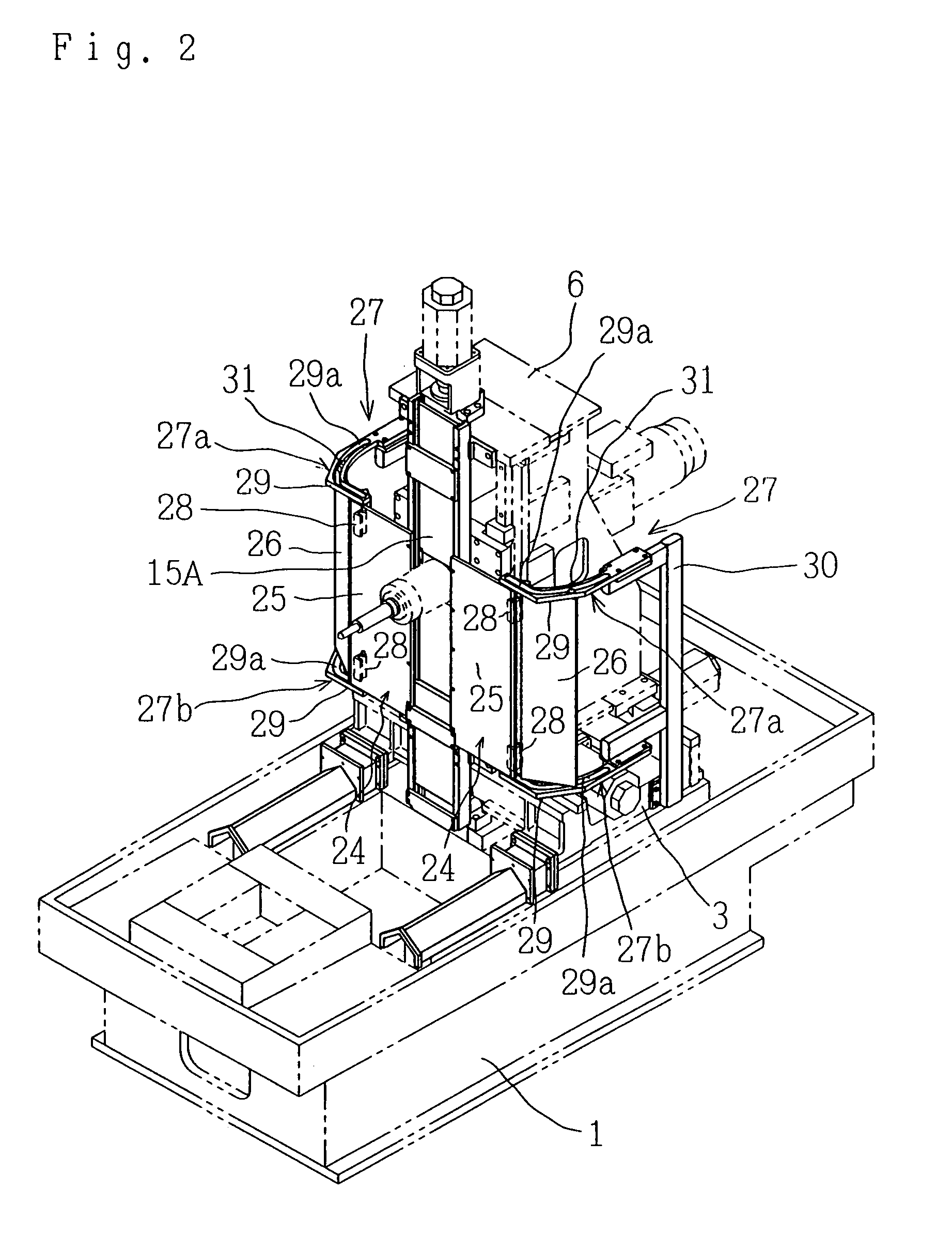

A hard rock hobbing cutter rock breaking characteristic testing device

InactiveCN103969141AObservable breakage featuresInvestigating abrasion/wear resistanceInvestigating machinabilityHobbingData acquisition

A hard rock hobbing cutter rock breaking characteristic testing device used in the field of tunnel engineering is provided. A rock silo supporting seat is positioned on a guide rail pair and realizes longitudinal motion by a longitudinal-moving hydraulic cylinder; a rock silo is positioned on the rock silo supporting seat and realizes lateral movement by lateral moving hydraulic cylindersfixed on the rock silo supporting seat; rock samples are positioned inside the rock silo. Two columns are vertically arranged at both sides of the rock silo, top ends of the columns are connected by a beam and thus a gantry structure is formed. A vertical hydraulic cylinder is fixed on the beam, and the lower part of the vertical hydraulic cylinder is connected with a walking beam. Under the walking beam, a hobbing cutter is installed to simulate the process of hobbing cutter rock breaking, or a similar hobbing cutter wearing module is installed to simulate the process of similar hobbing cutter wearing. An industrial computer, a data acquisition card, a three-axis force sensor, an acoustic emission device and a high-speed digital camera system are used to monitor the processes of hobbing cutter rock breaking and wearing. The device is capable of simulating the process of rolling-type rock breaking of the hobbing cutter, the process of rolling and impact-combined type rock breaking of the hobbing cutter and the process of similar hobbing cutter wearing.

Owner:CENT SOUTH UNIV

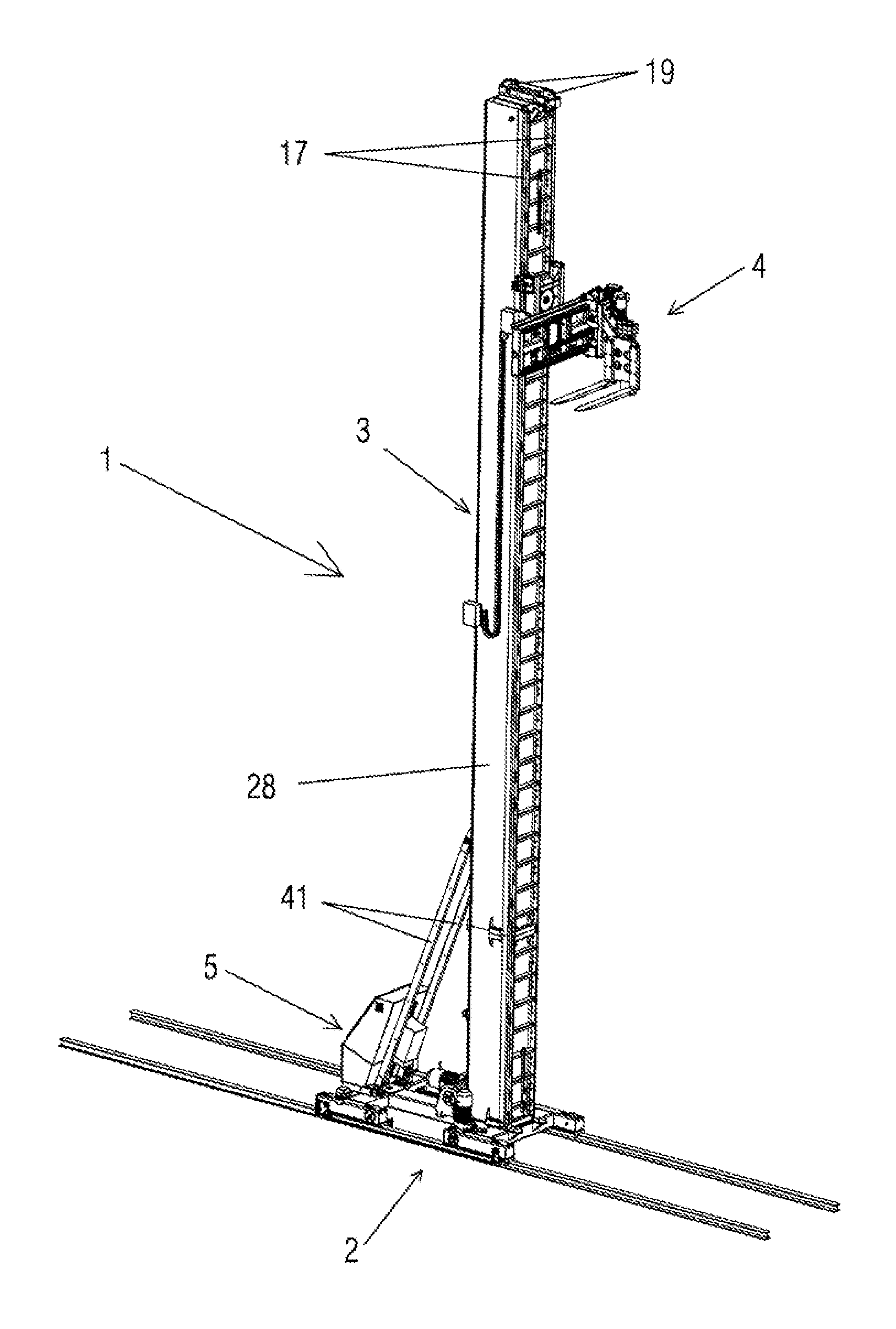

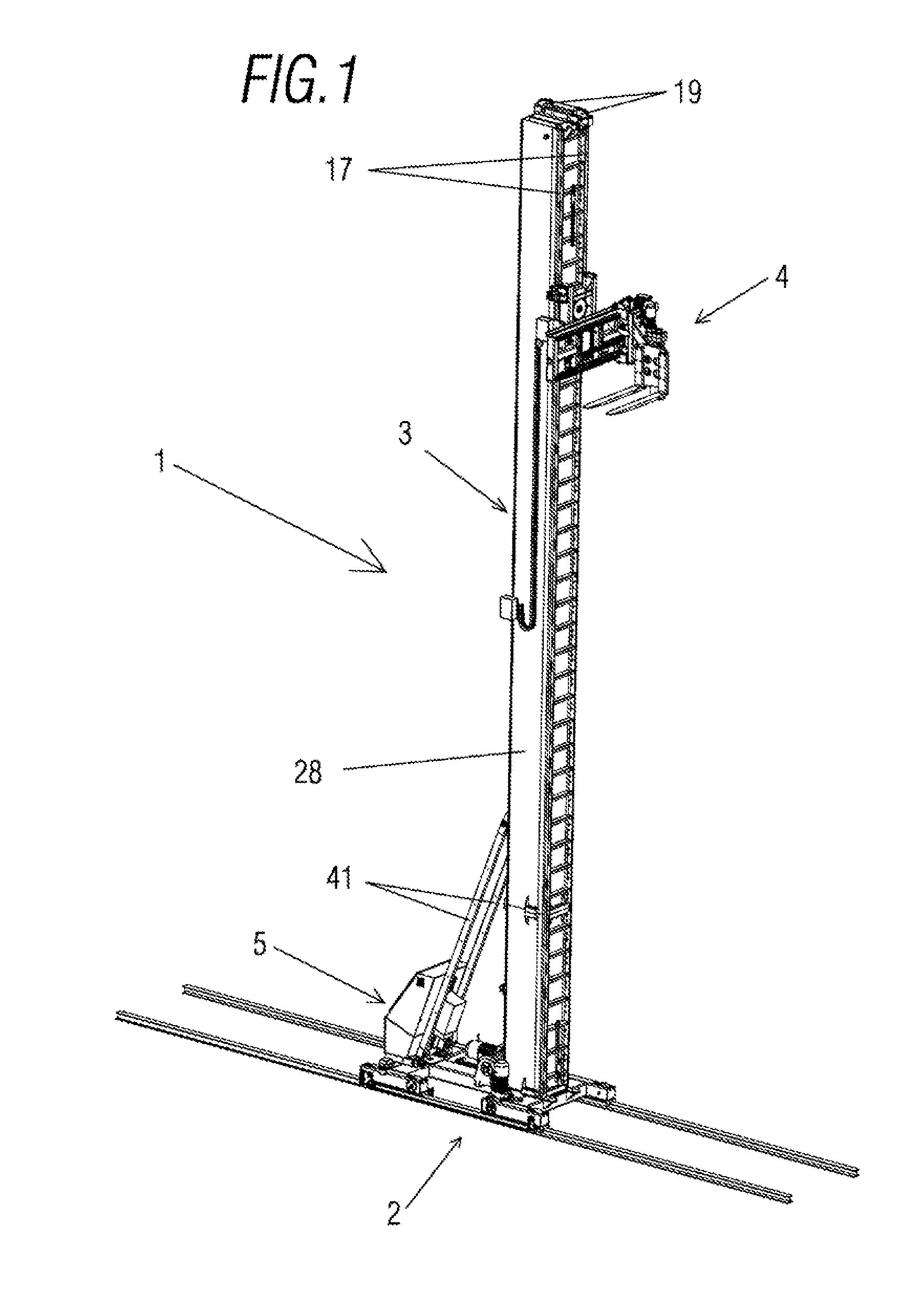

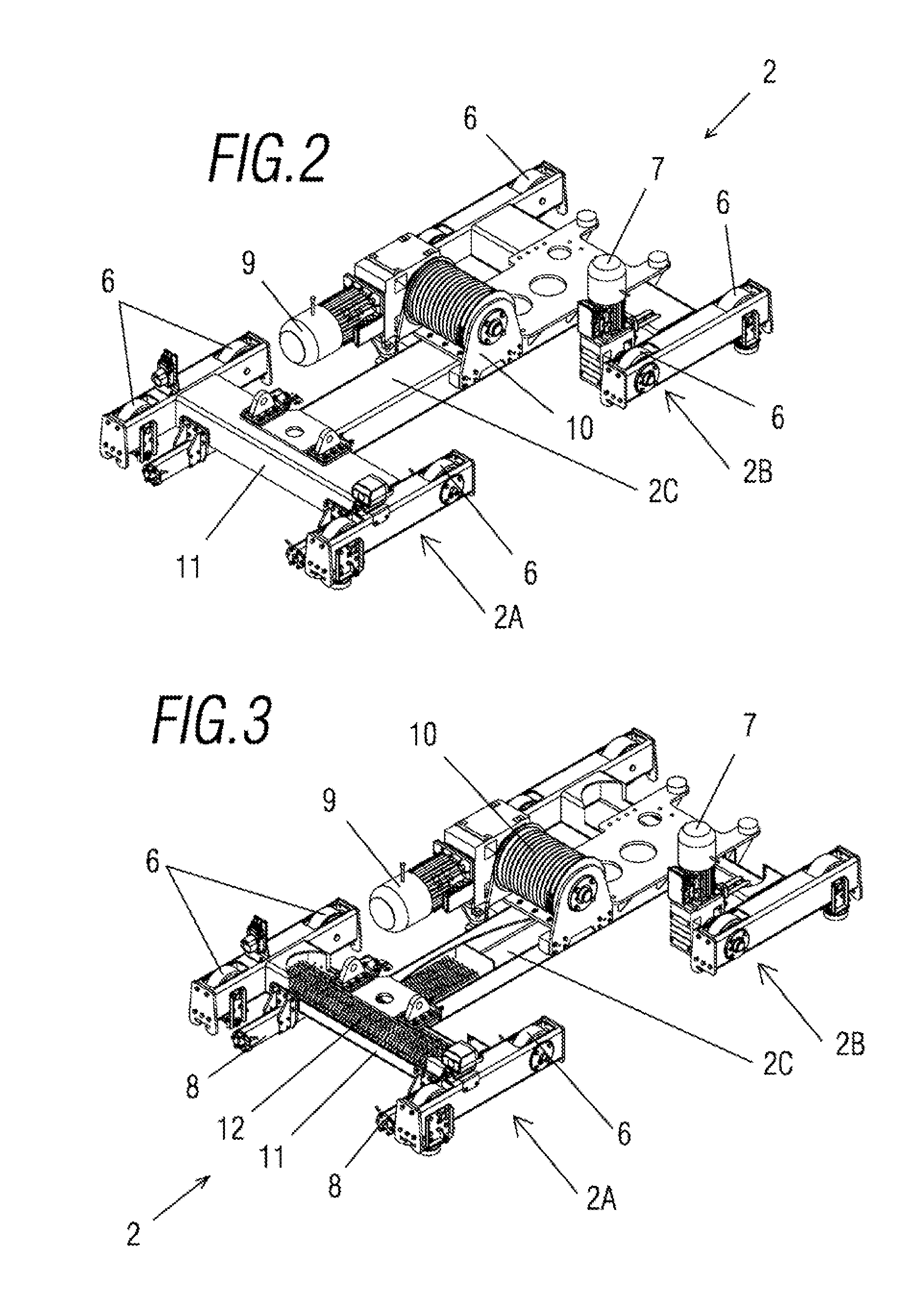

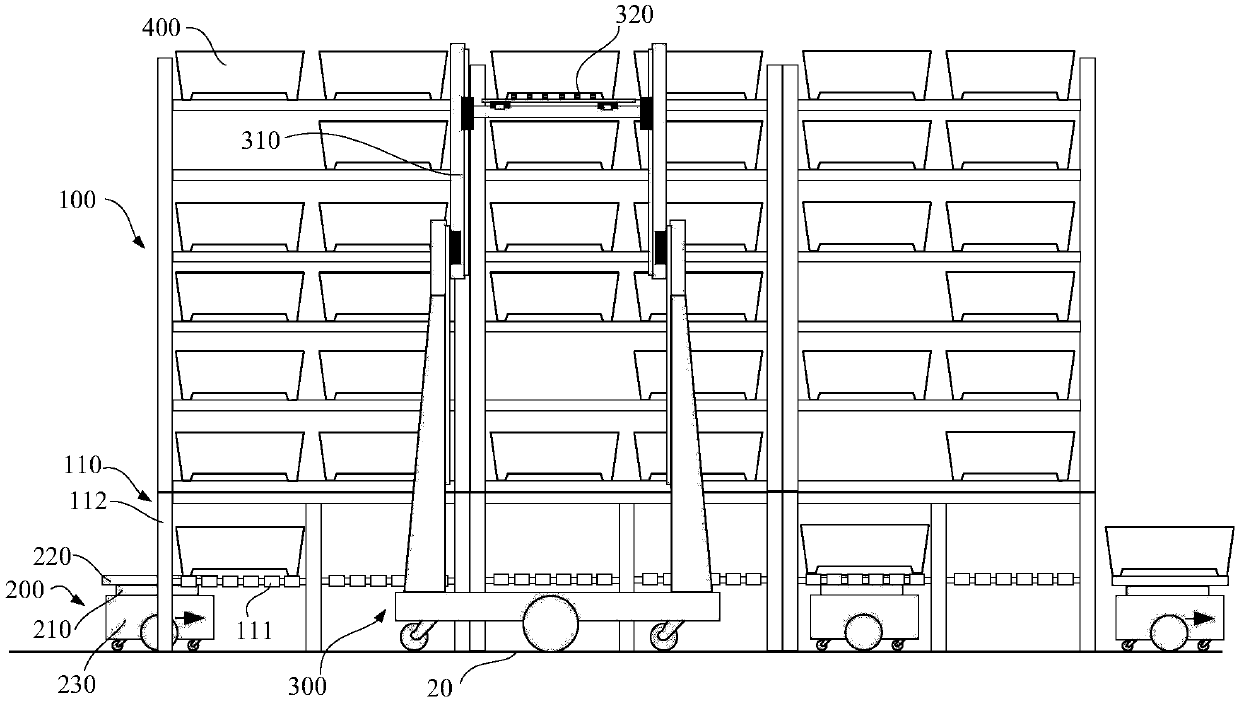

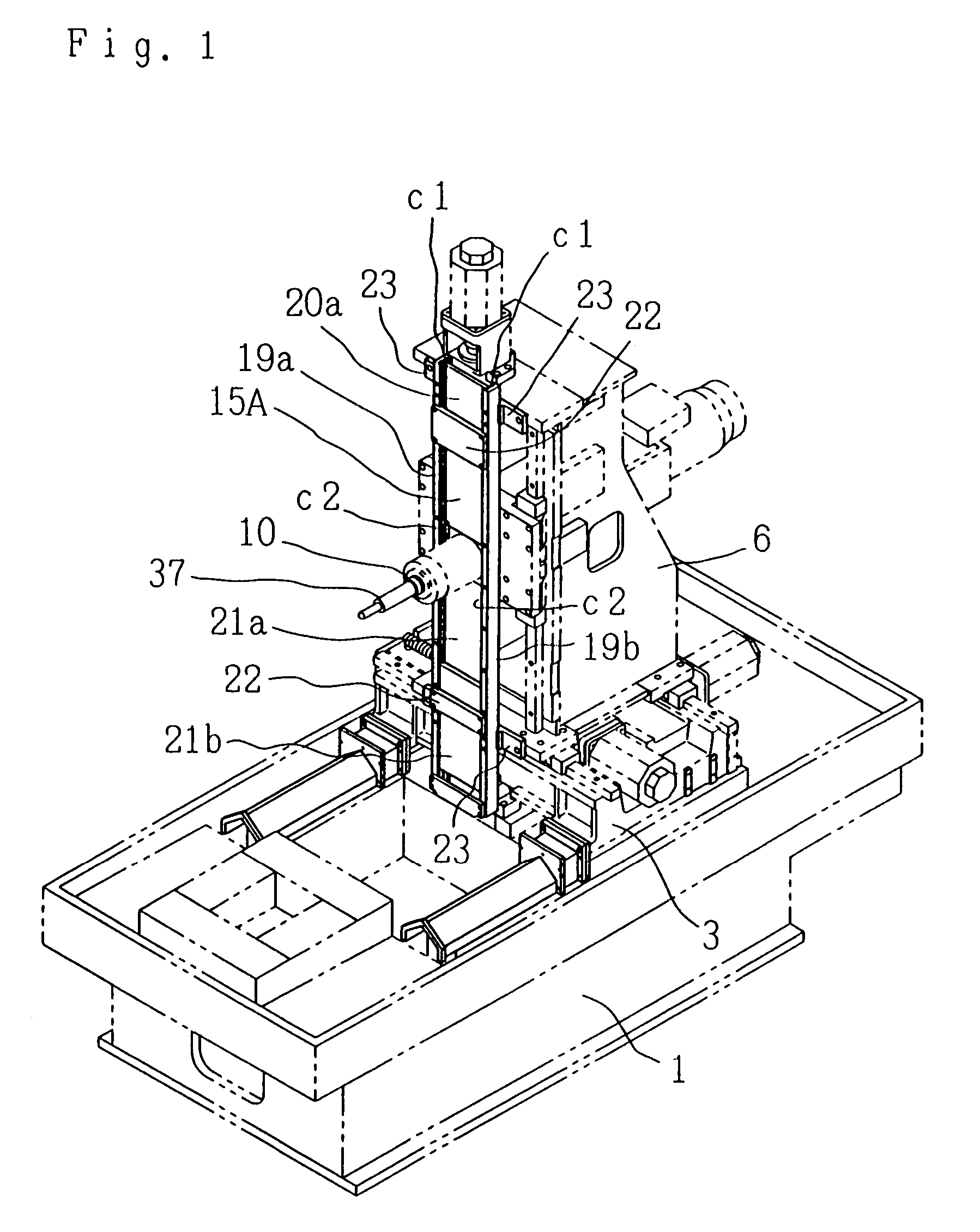

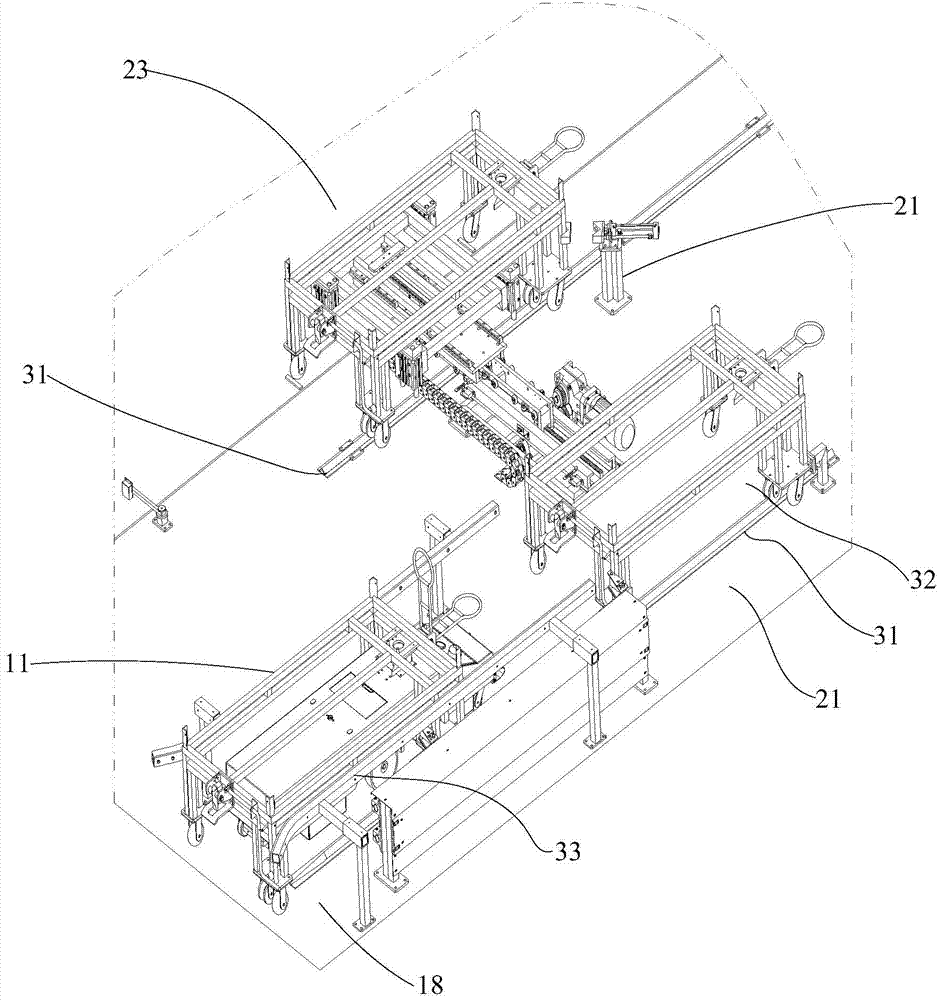

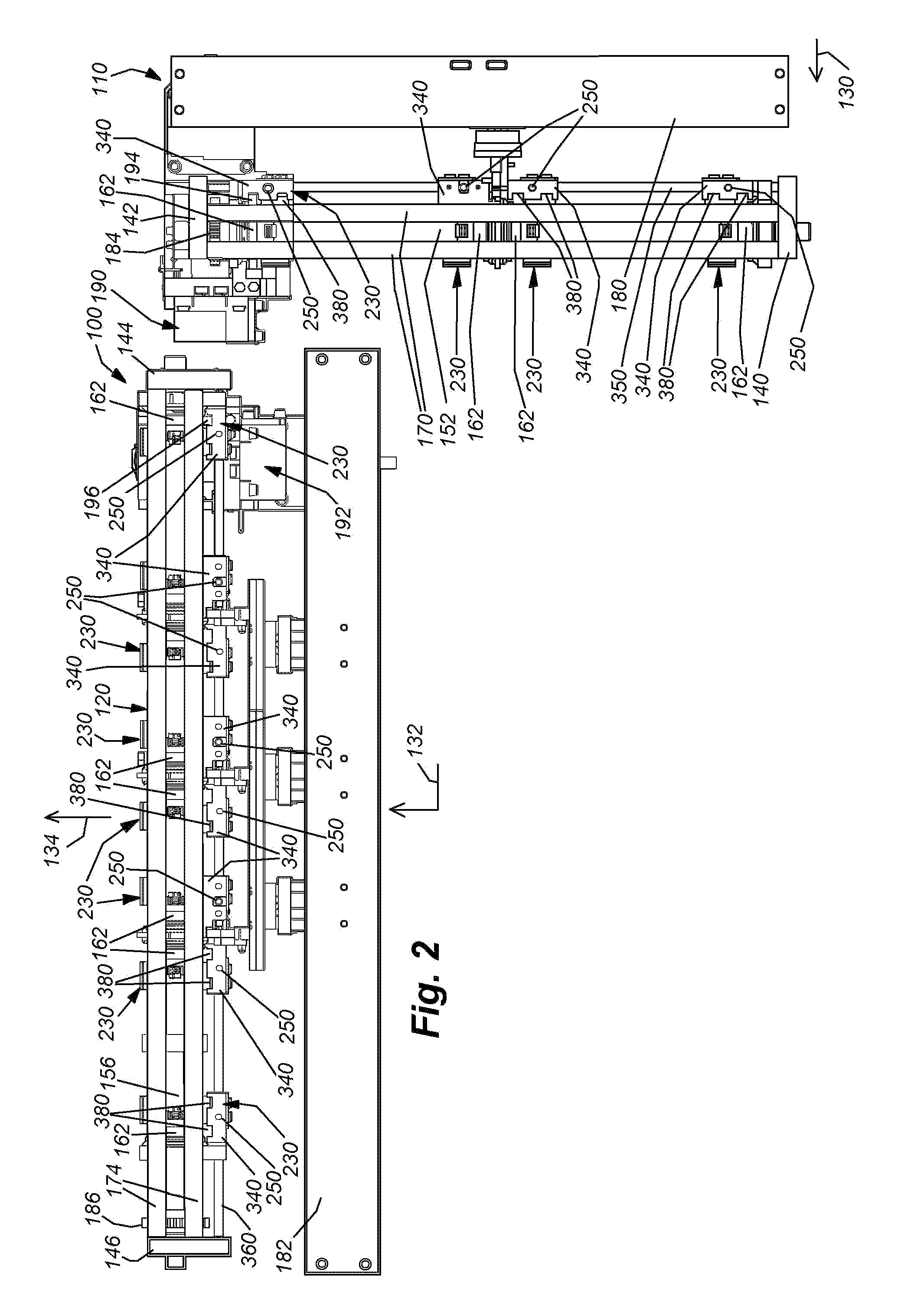

Transelevator for Handling Pallets, Pallet-Removal Device Mounted on Said Transelevator and Goods Storage System

InactiveUS20130209203A1Increase investment costHigh maintenance costLifting devicesLoading/unloadingIn planeRotational axis

The invention relates to a transelevator (1) for handling pallets, suitable for use in a system for storing goods or similar, said transelevator comprising a lower mobile frame (2) fixedly supporting a vertical lifting column (3) along which a pallet-removal device can move. The invention also relates to a pallet removal device for a transelevator, comprising: a lifting frame (20) provided with lifting wheels which travel along the length of guide means; a laterally mobile fixed frame (21); and a mobile carriage (22) capable of mobile in relation to the fixed frame (21) and including a fork (23) which can be moved laterally along axis Z by means of a lateral movement shaft (29) actuated by motor means and which can be rotated in plane X-Z by means of a rotation shaft (44) actuated by motor means.

Owner:MECALUX

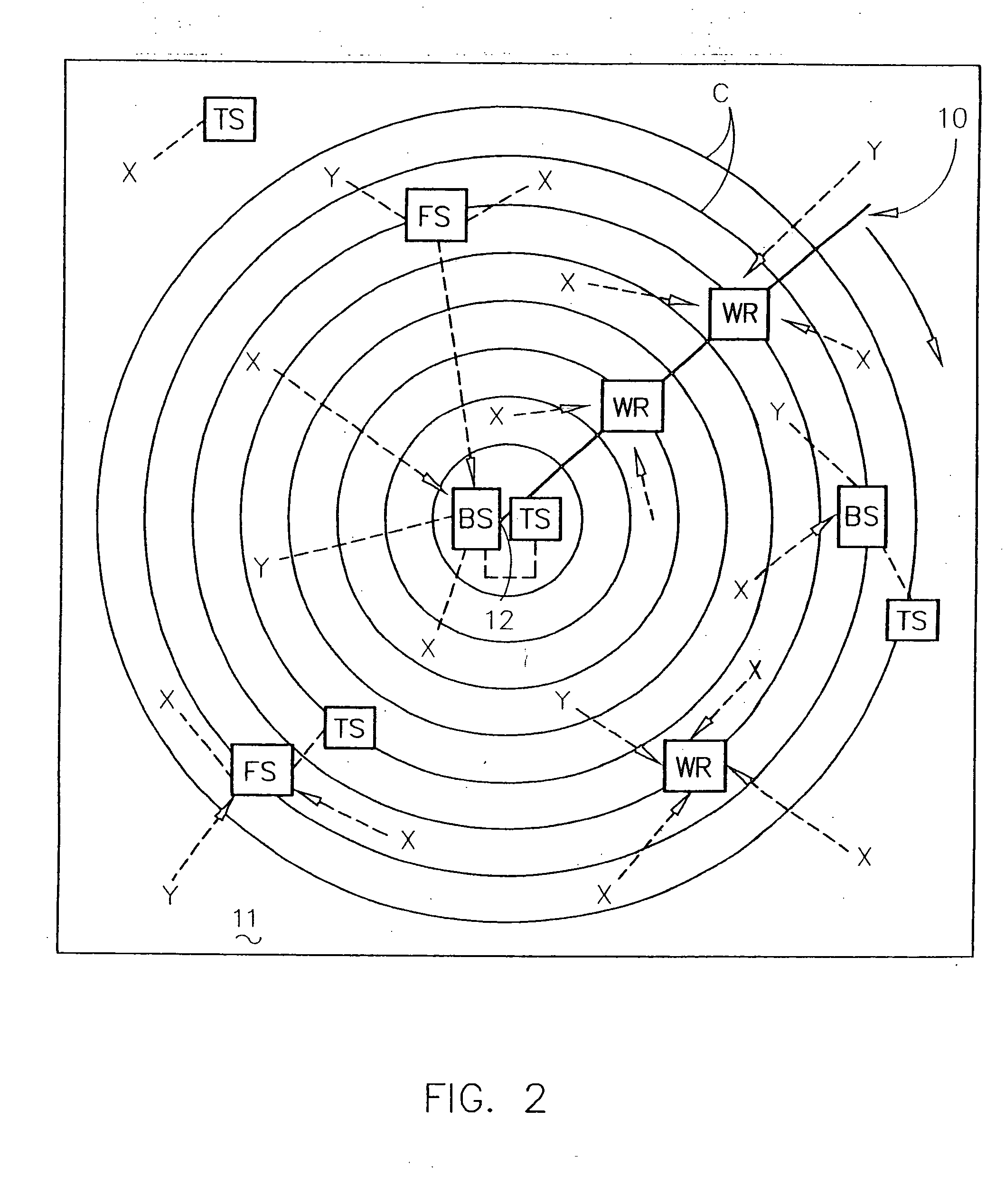

Environmental and biotic-based speed management and control of mechanized irrigation systems

InactiveUS20100032495A1Save waterReducing wasteful overwateringSelf-acting watering devicesClimate change adaptationEvapotranspirationMoisture

A system that based on changes in agricultural crop or plant characteristics or dynamics, e.g., heat stress, water deficit stress, stem growth, leaf thickness, plant turgidity, plant color, nutrient composition, etc., or changes in environmental conditions, e.g., temperature, wind, pressure, relative humidity, dew point, precipitation, soil moisture, solar radiation, etc. or a combination of both, e.g., evapotranspiration, either automatically increases or decreases the speed or rate of movement or rotation of a mechanized irrigation system, e.g., center pivot, corner, linear, or lateral move irrigation system or similar, or reports a recommended increased or decreased speed or rate of movement or rotation of a mechanized irrigation system either directly or indirectly to the end user. The system responds directly or indirectly to data outputted from monitoring systems that gather and compile environmental (non-biotic), biotic or similar information from agricultural fields and crops.

Owner:ABTS KEVIN

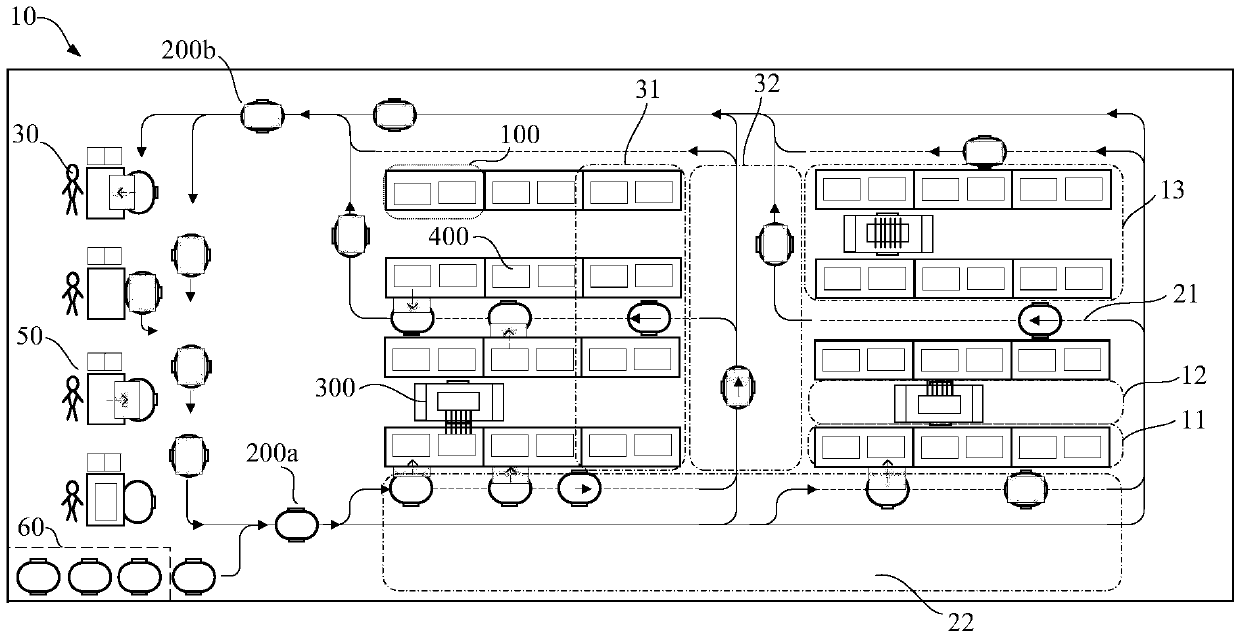

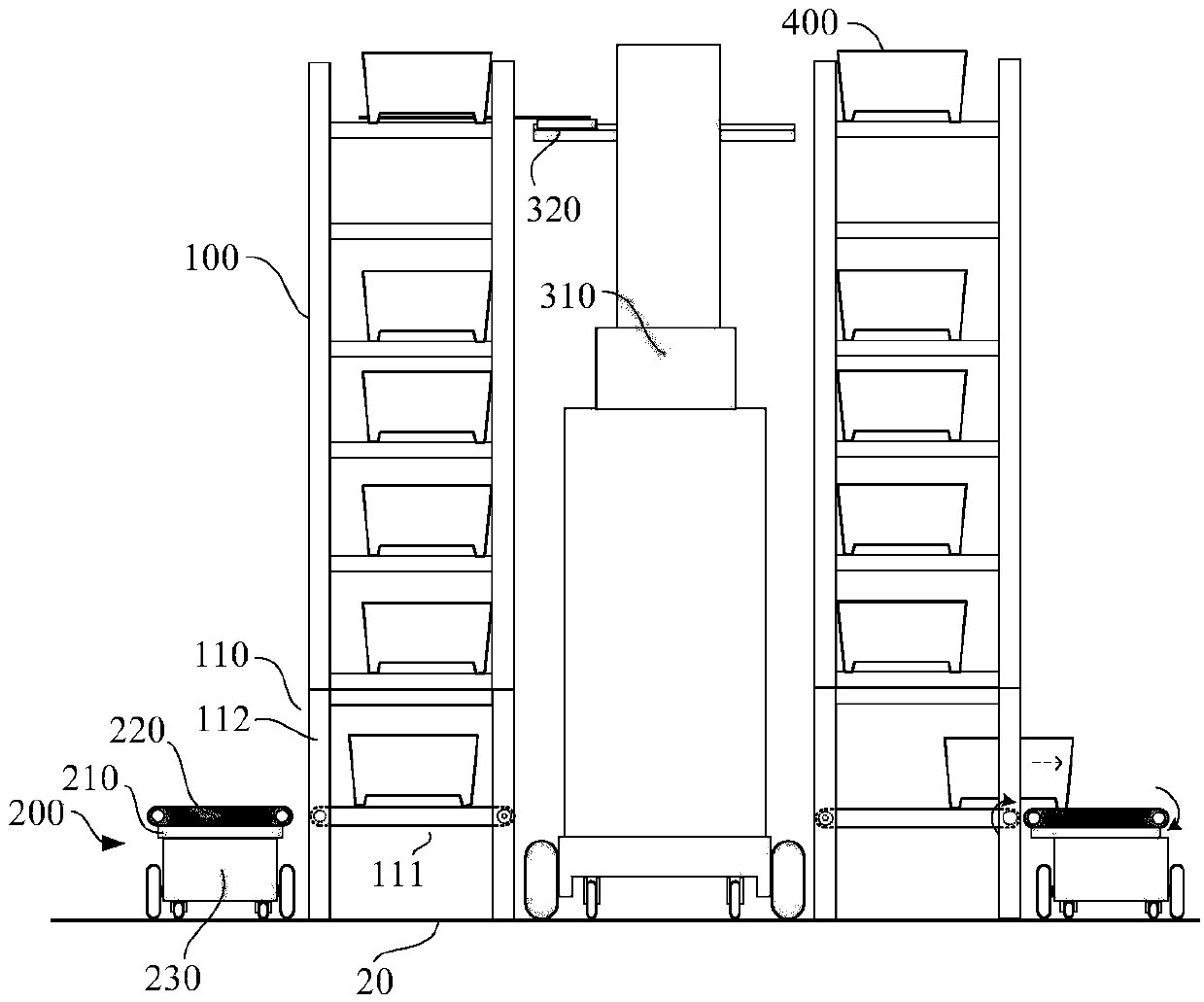

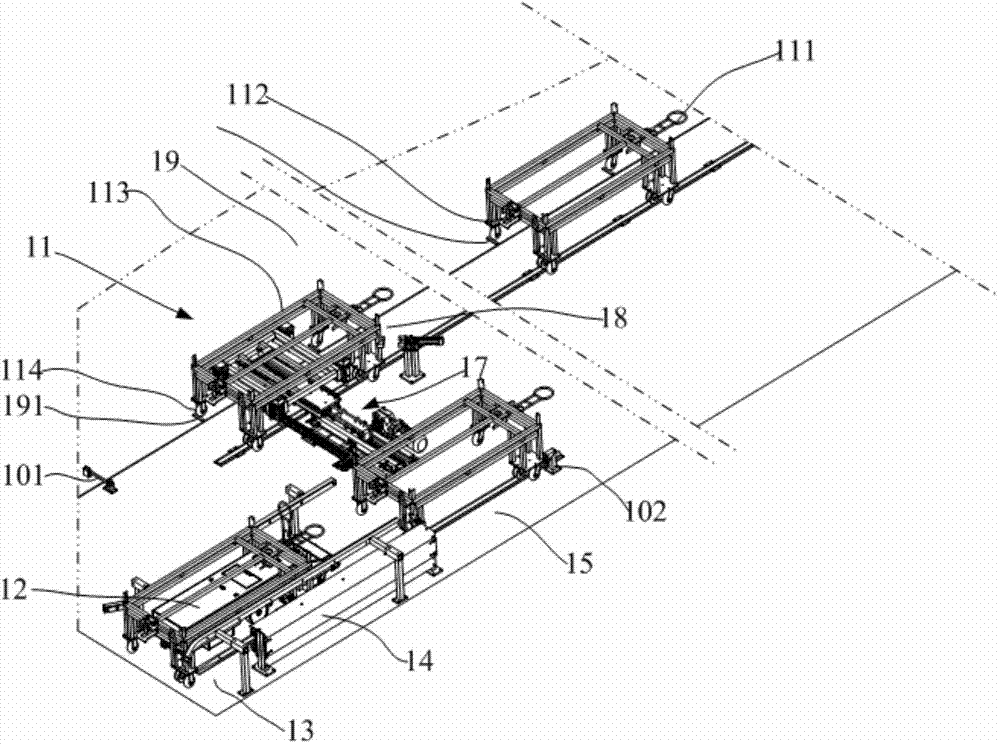

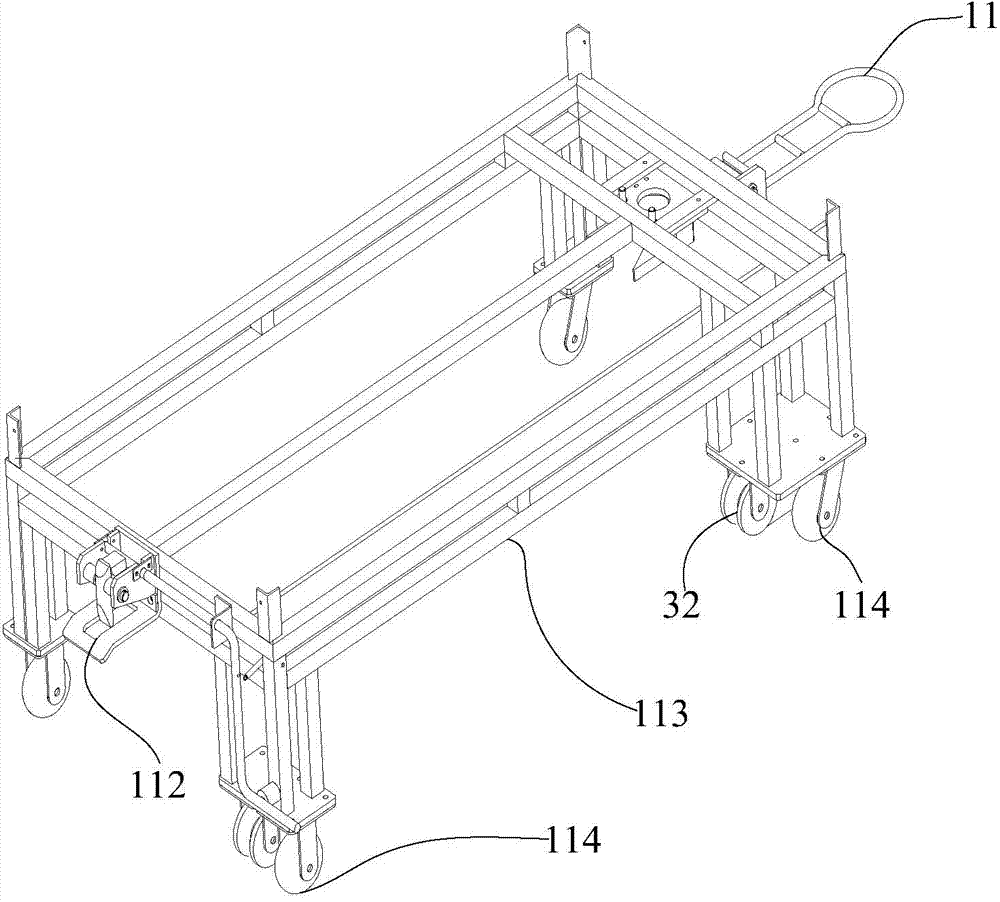

Storage sorting system

PendingCN109573443AIncrease flexibilityQuick relocationStorage devicesConveyor partsEngineeringWorkstation

The invention discloses a storage sorting system, and solves the problem that a conventional system is complex in deployment and inconvenient in maintenance. The storage sorting system is characterized in that modular support frames are arranged under ordinary goods shelves; a plurality of temporary storage conveyer belt devices are arranged on the support frames and allow objects to stay; a stacking trolley roadway and an automatic guiding trolley roadway are arranged on the two sides of the goods shelves separately; a lateral moving platform, a lateral conveying device and a selective lifting platform are arranged on a trolley; and during object sorting, a stacking trolley enters a target goods shelf, takes out objects and puts the objects on the temporary storage conveyer belt devices,the trolley enters the target goods shelf through the roadway special for the trolley, the lateral moving platform moves out of the goods shelf, the lateral conveying device and the temporary storageconveyer belt devices rotate in the same direction, the objects are transferred onto the lateral conveying device of the trolley, and the trolley drives through the roadway special for the trolley andsends the objects to a sorting work station. According to the storage sorting system, deployment is easy, maintenance is easy, robots perform concurrently operation through a scheduling algorithm, and integral efficiency is high.

Owner:杭州大氚智能科技有限公司

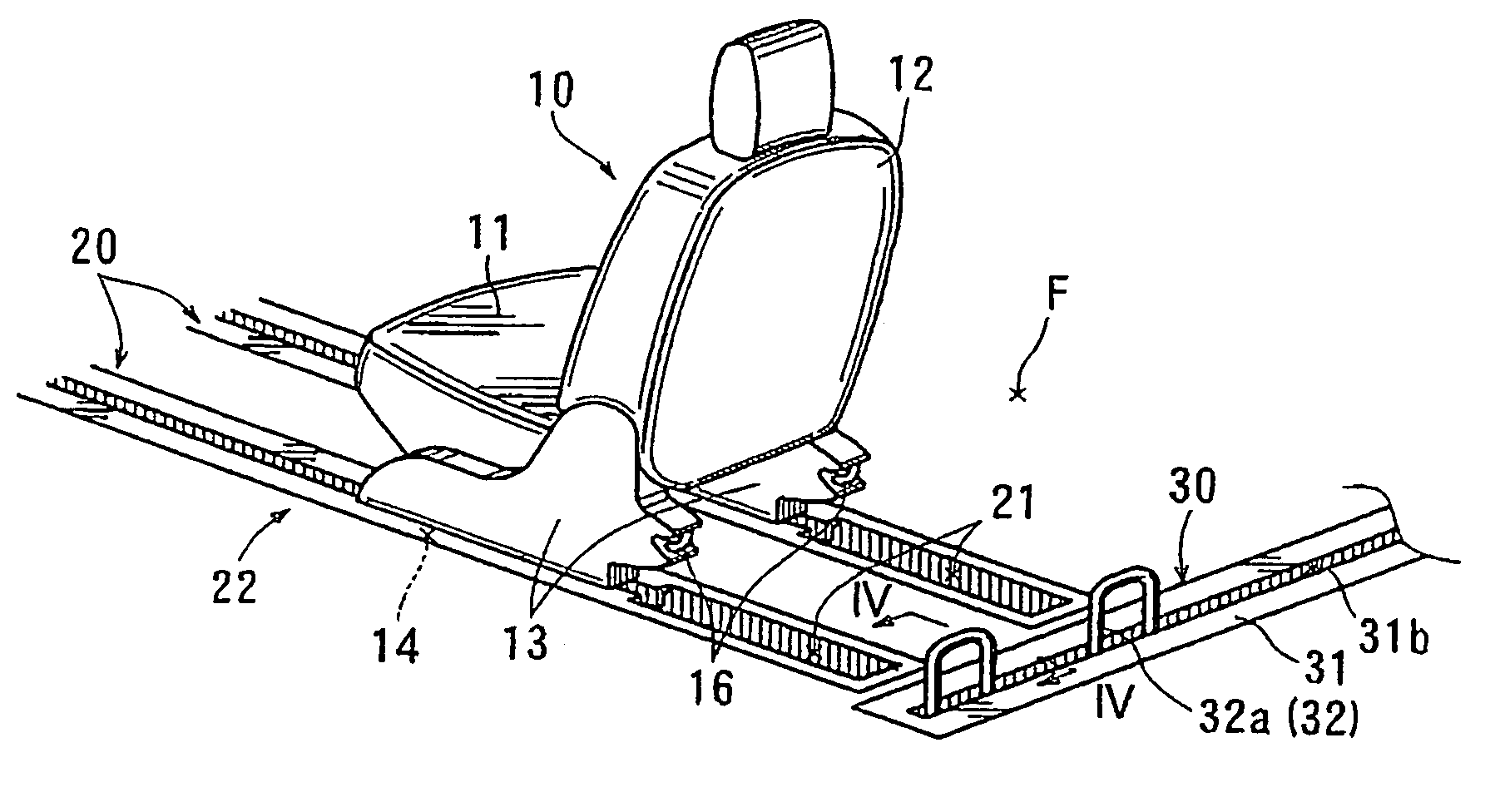

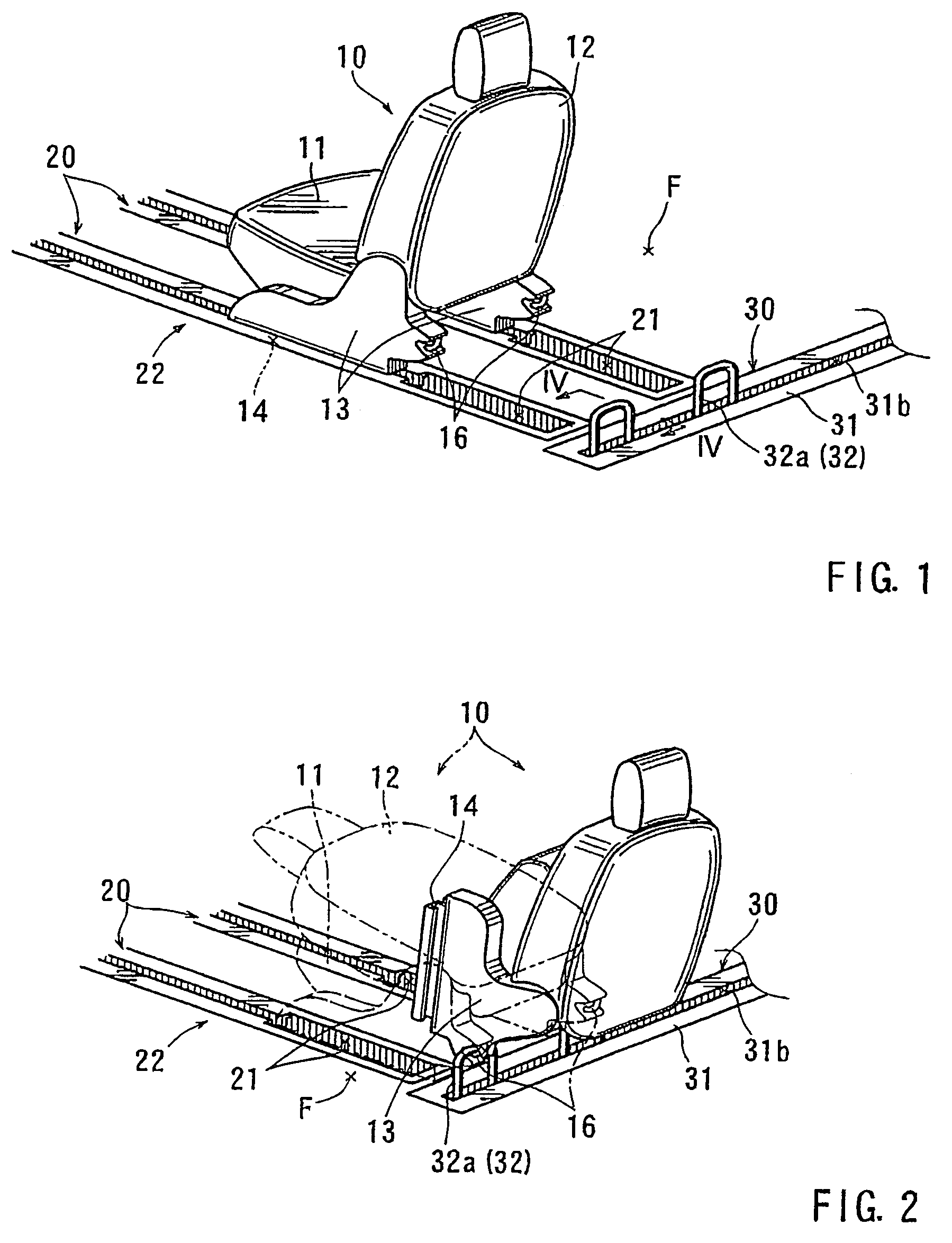

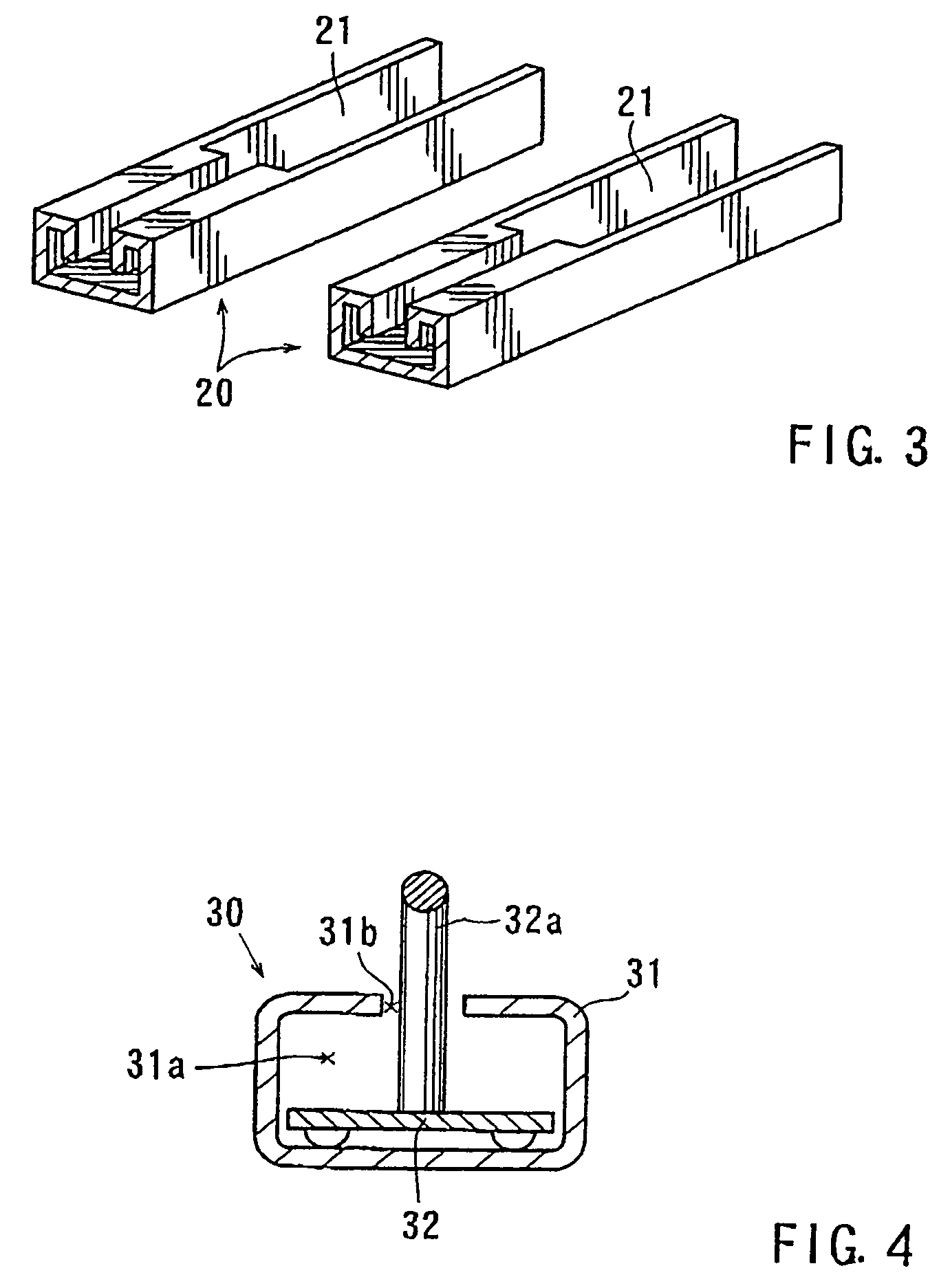

Vehicle seat moving devices

InactiveUS7229117B2Easy transferEasy to changeMovable seatsMonocoque constructionsEngineeringLateral move

A vehicle seat moving device may include first and second longitudinal moving mechanisms and a lateral moving mechanism. Each of the longitudinal moving mechanisms has a longitudinal slide rail that is attached to a vehicle floor and a longitudinal slider that is associated with a vehicle seat. The lateral moving mechanism has a lateral moving path that is attached to a vehicle floor and a lateral moving element that is movably attached to the lateral moving path. The lateral moving path is disposed between the first and second longitudinal moving mechanisms so that the lateral moving element can move between the first and second longitudinal moving mechanisms. The longitudinal slider is arranged and constructed to slidably engage to the longitudinal slide rail. Also, the longitudinal slider is arranged and constructed to be engaged with and disengaged from the longitudinal slide rail or the vehicle seat. Further, the lateral moving element can support the vehicle seat thereon when the longitudinal slider is removed from the longitudinal slide rail, thereby permitting lateral movement of the vehicle seat.

Owner:TOYOTA BOSHOKU KK

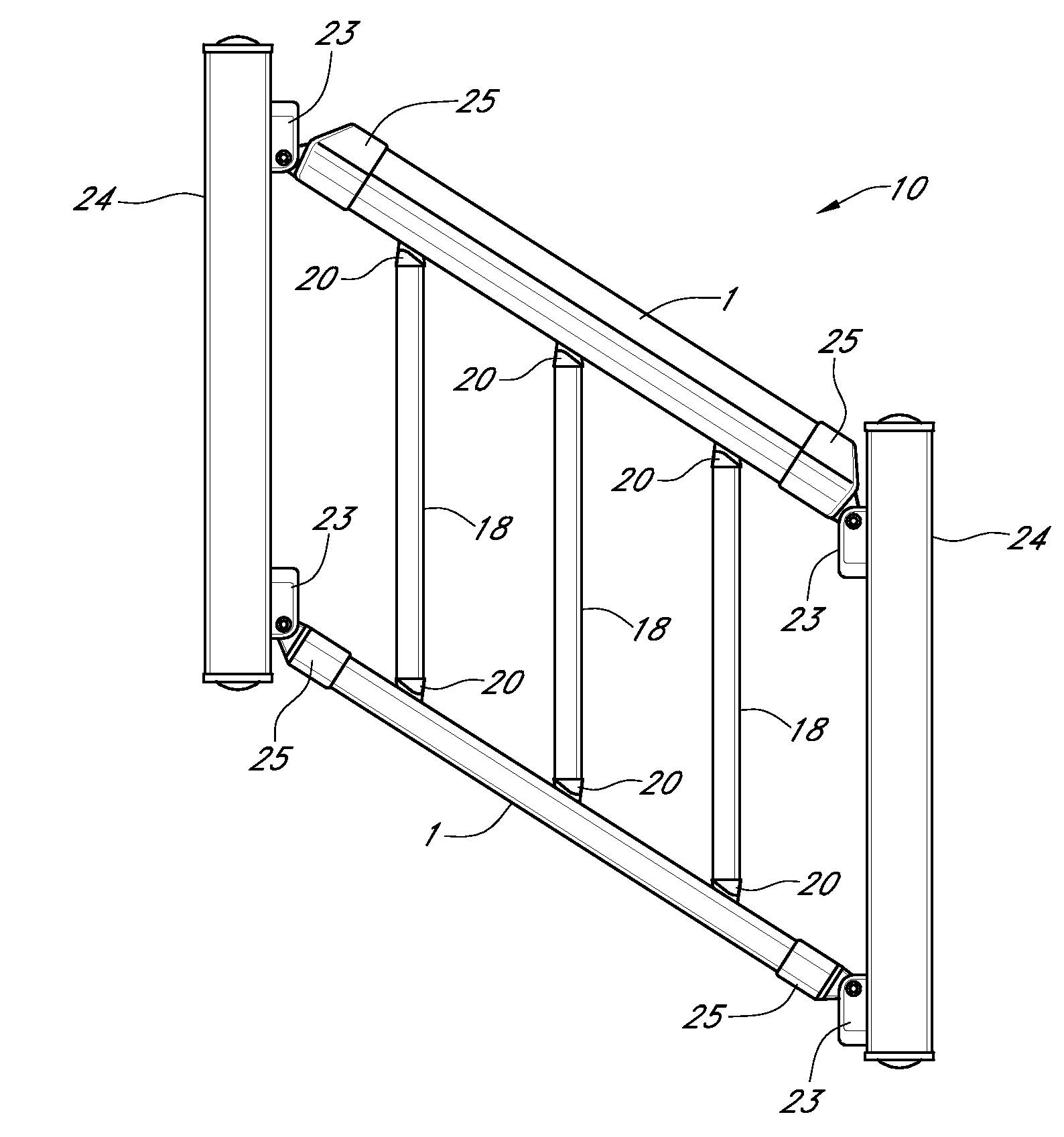

Slot Rail Assembly

The slot rail assembly, in combination with a rail portion, at least one baluster, at least one baluster connector, and a lateral slot and at least one spacer is disclosed and claimed. The baluster may be slid distally along a lateral slot to accommodate the pitch or slope of incline or decline addressed. Lateral movement of the balusters within the lateral slot and change in relative angle of the baluster in relation to the rail portion allows the balusters to stay “plumb” no matter what the pitch of the stairs may be. At least one spacer may be snapped into place to fix the horizontal position of the balusters and to provide a seal against ingress of debris and moisture into the lateral slot. The slot rail assembly may be deployed as a stair rail, a stairway or an improved connection system for balusters and stair rails.

Owner:KPB PROD L L C

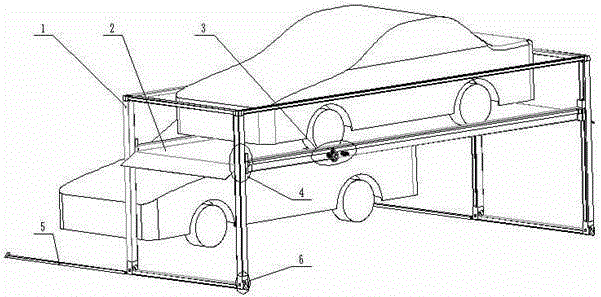

Tunnel waterproof board spreading and hanging device

ActiveCN102359385ACompact structureReduce manufacturing costUnderground chambersTunnel liningEngineeringMechanical engineering

Owner:CHINA RAILWAY SHISIJU GROUP CORP +1

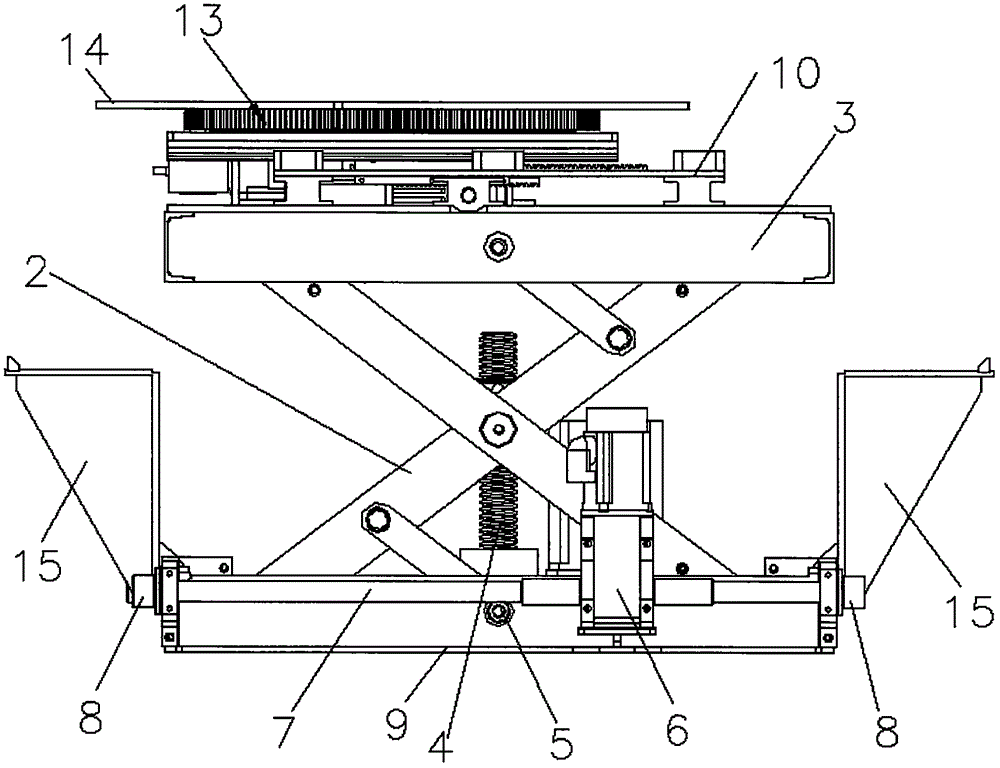

Battery replacement connection trolley

InactiveCN106364465APrecise and quick removalQuick installationCharging stationsElectric propulsion mountingElectricityElectrical battery

The invention discloses a battery replacement connection trolley. The battery replacement connection trolley comprises a lifting mechanism, a lateral moving mechanism, a traveling mechanism and a rotating mechanism, wherein the lifting mechanism is arranged on the traveling mechanism, the lateral moving mechanism is arranged on the lifting mechanism, and the rotating mechanism is arranged on the lateral moving mechanism. The battery replacement connection trolley can quickly travel to the bottom of an automobile, quickly adjust the height, plane position and plane angle of the trolley to be matched with a battery on an automobile chassis in position, take down the battery with insufficient voltage accurately and quickly, and transport the battery taken down back into a storage unit. The battery replacement connection trolley can also quickly transport a fully charged battery, accurately capture the position between the battery and the chassis and quickly install the fully charged battery onto the automobile chassis.

Owner:NANTONG COSCO HEAVY IND

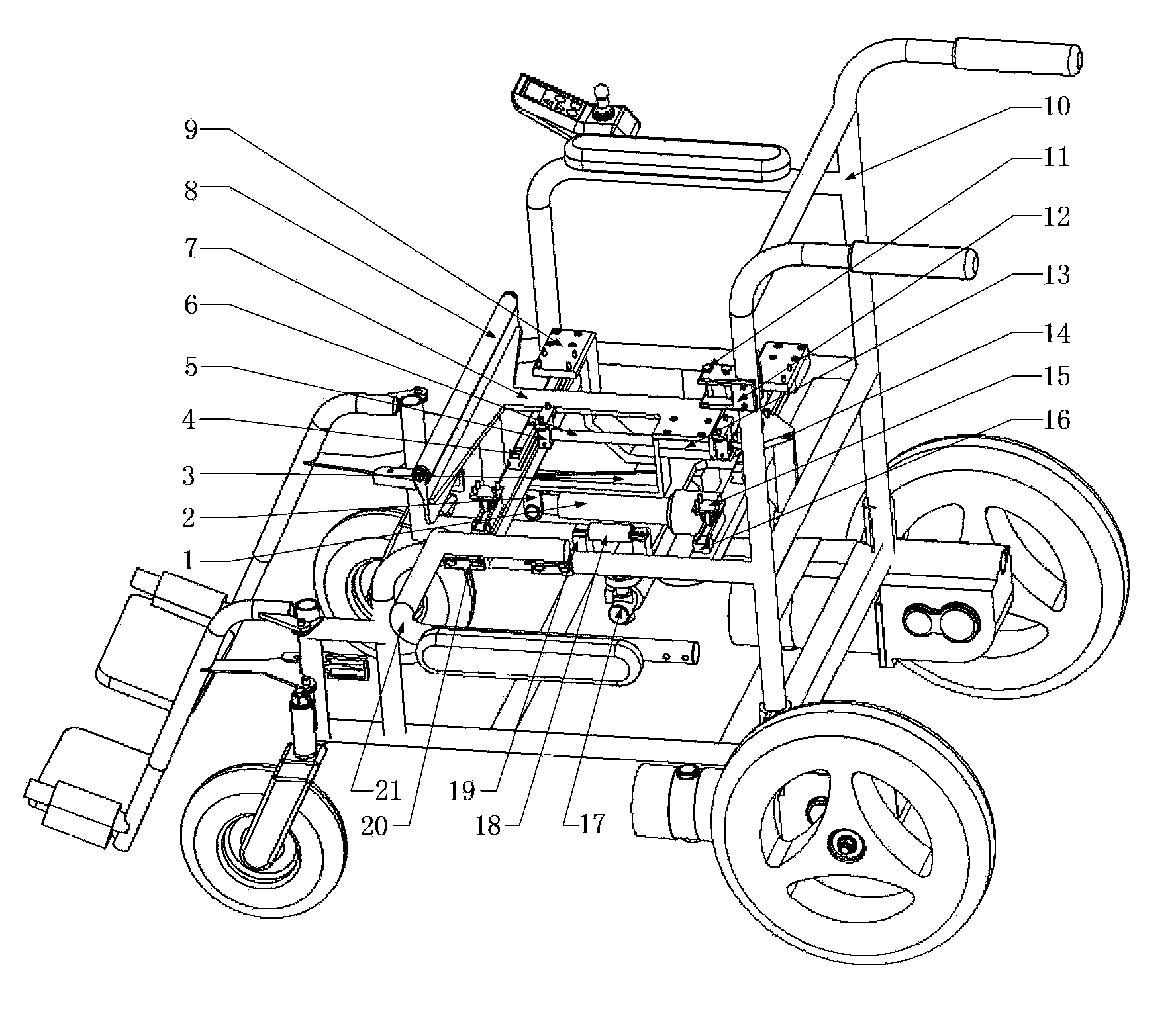

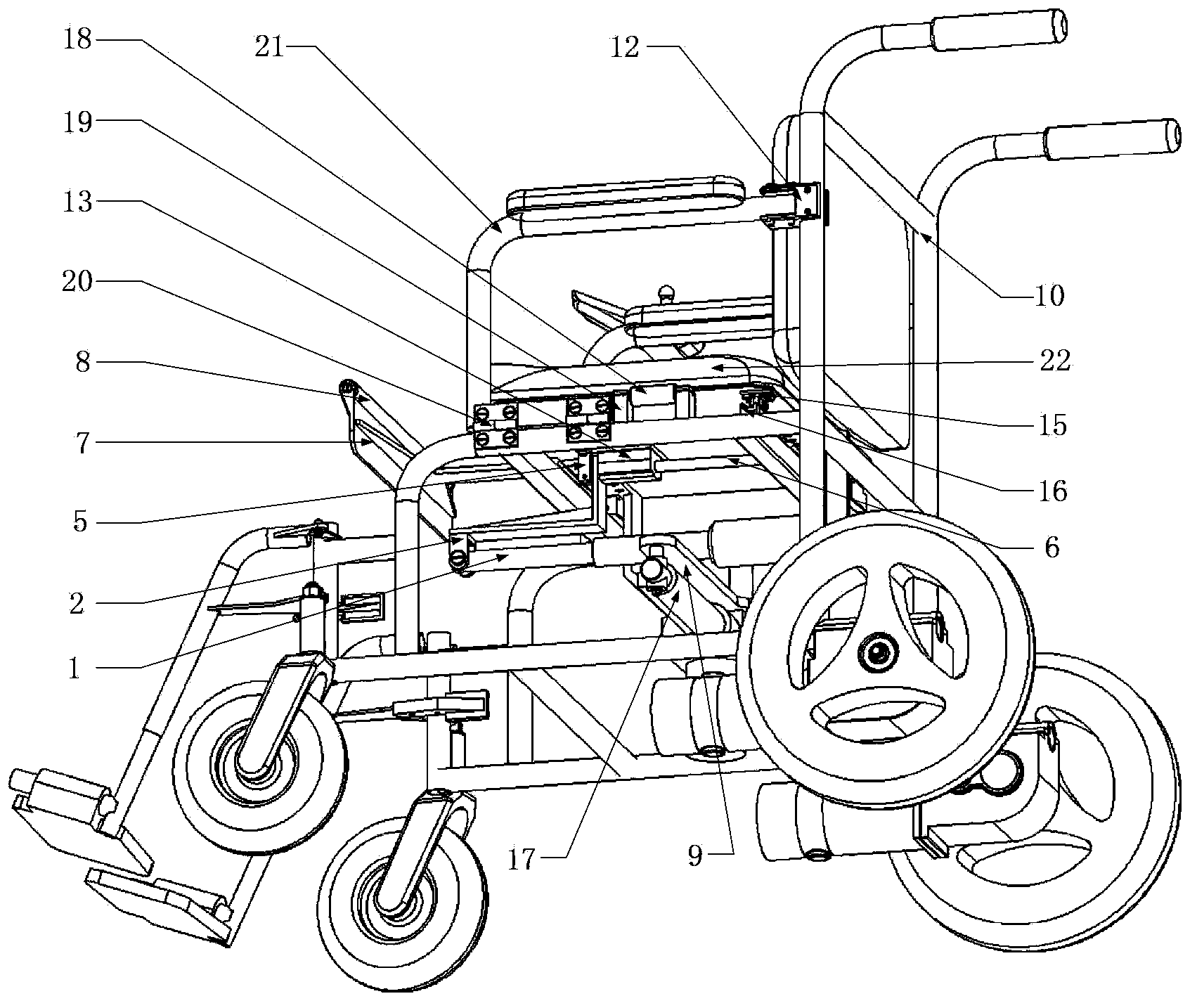

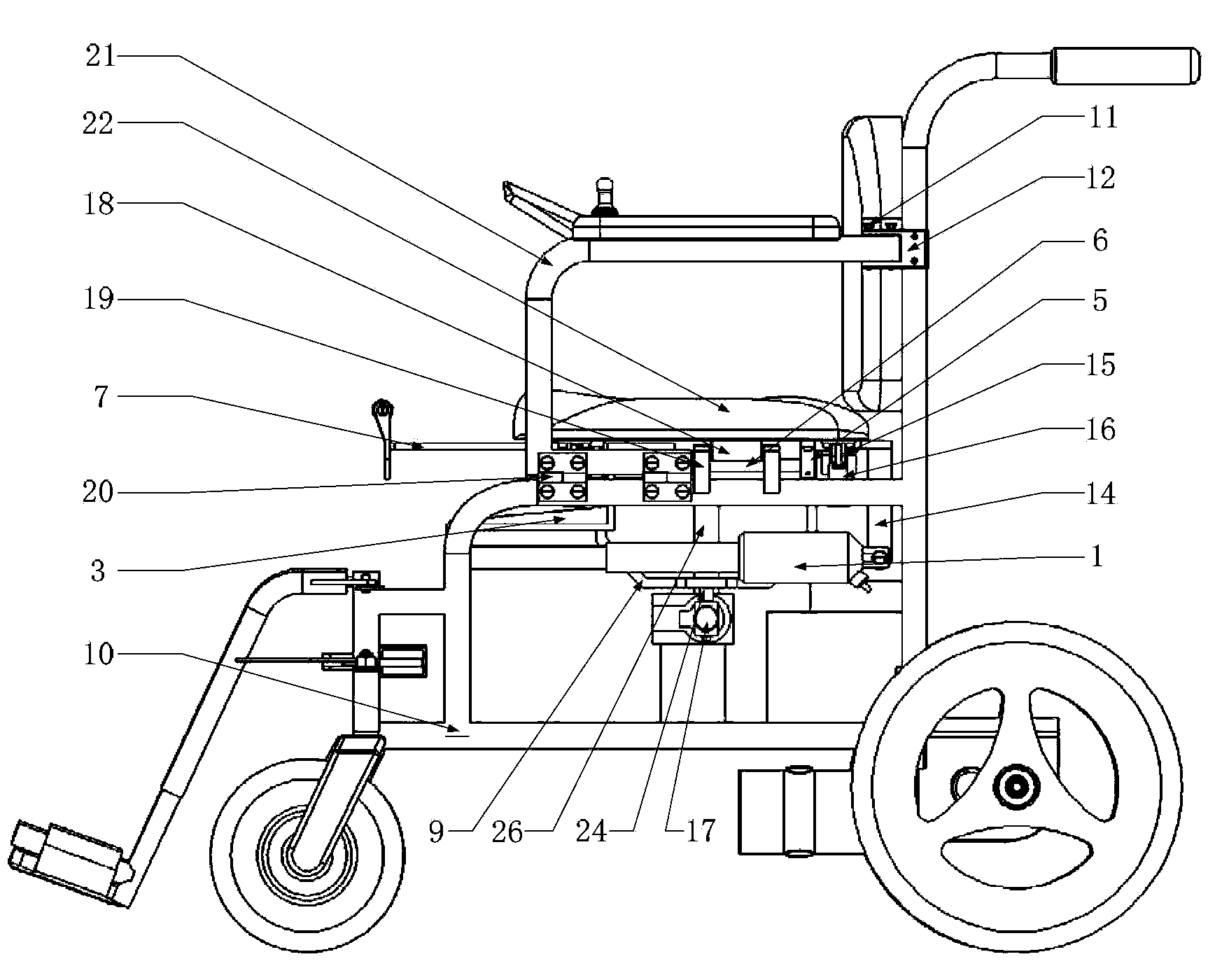

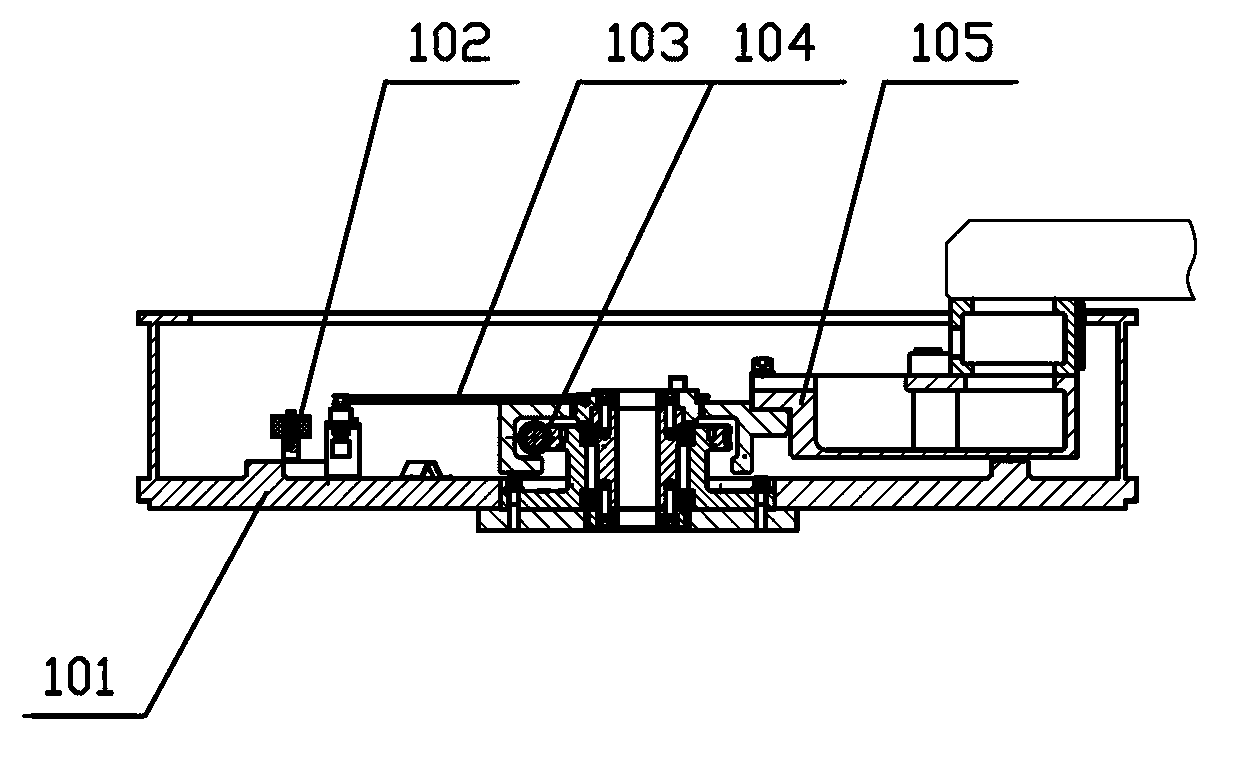

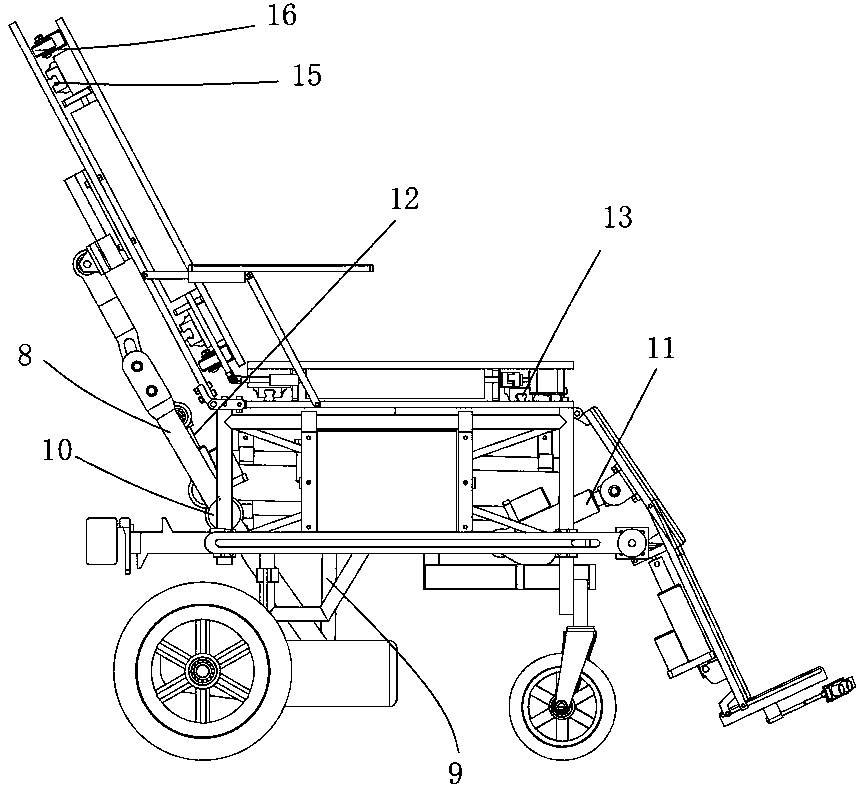

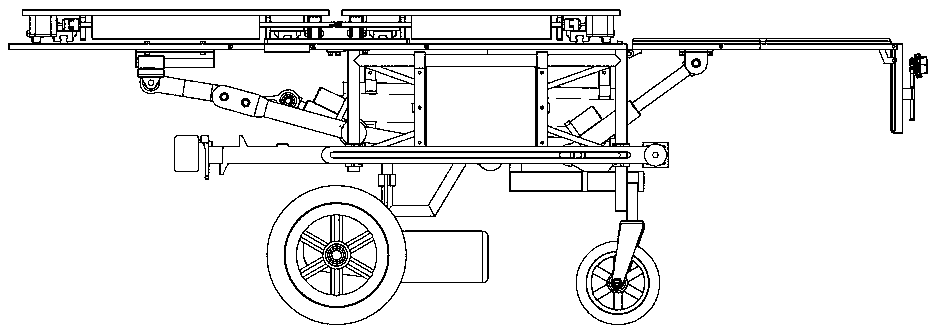

Electrically propelled wheelchair capable of helping patient get in and out of bed

InactiveCN103381119AReduce workloadEasy to operateWheelchairs/patient conveyanceWheelchairBlocked Connection

The invention aims to provide an electrically propelled wheelchair capable of helping a patient get in and out of a bed. The electrically propelled wheelchair comprises a wheelchair body, a seat, an openable armrest mechanism, a seat lateral moving mechanism and a leg raising mechanism, wherein the wheelchair body comprises two upright posts, two transverse square pipes, two side pipes and two lower pipes; the two transverse square pipes are fixed between the two side pipes in tandem; the lower pipes are located below the side pipes; the two upright posts are fixed left and right behind the side pipes and the lower pipes; the openable armrest mechanism comprises armrests and fixing blocks; the seat lateral moving mechanism comprises a first electric push rod, a slide block connection plate, a slide rail, a slide block, a pulley and a pulley guide rail; the leg raising mechanism comprises a support roller, a support frame, a guide mechanism and a second electric push rod. The electrically propelled wheelchair can realize lateral movement of the wheelchair seat and leg raising actions, is simple to operate, and enables the patient and the aged to independently finish the actions of getting in and out of the wheelchair or the bed, thereby reducing the workload of medical staff and families.

Owner:HARBIN ENG UNIV

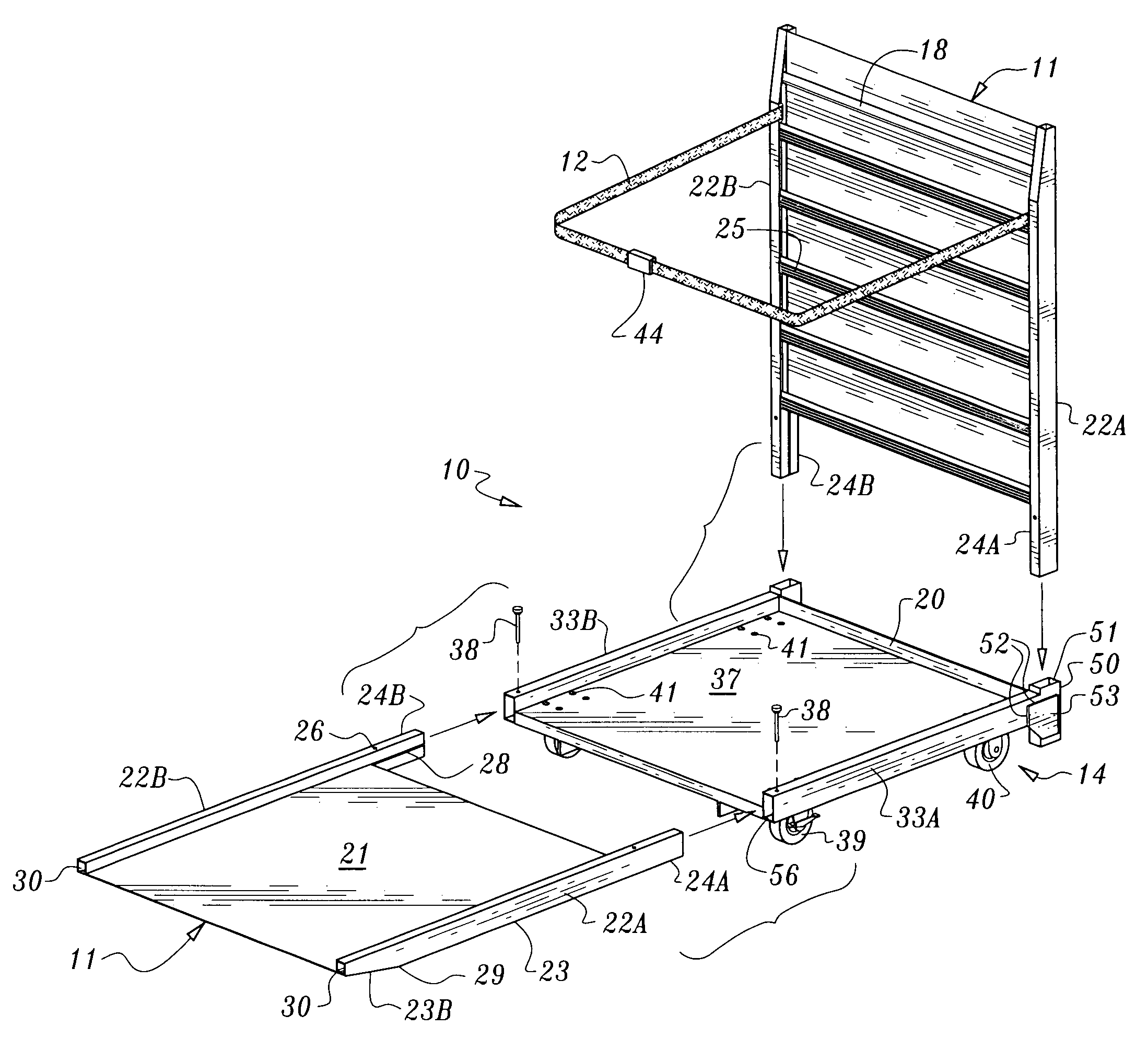

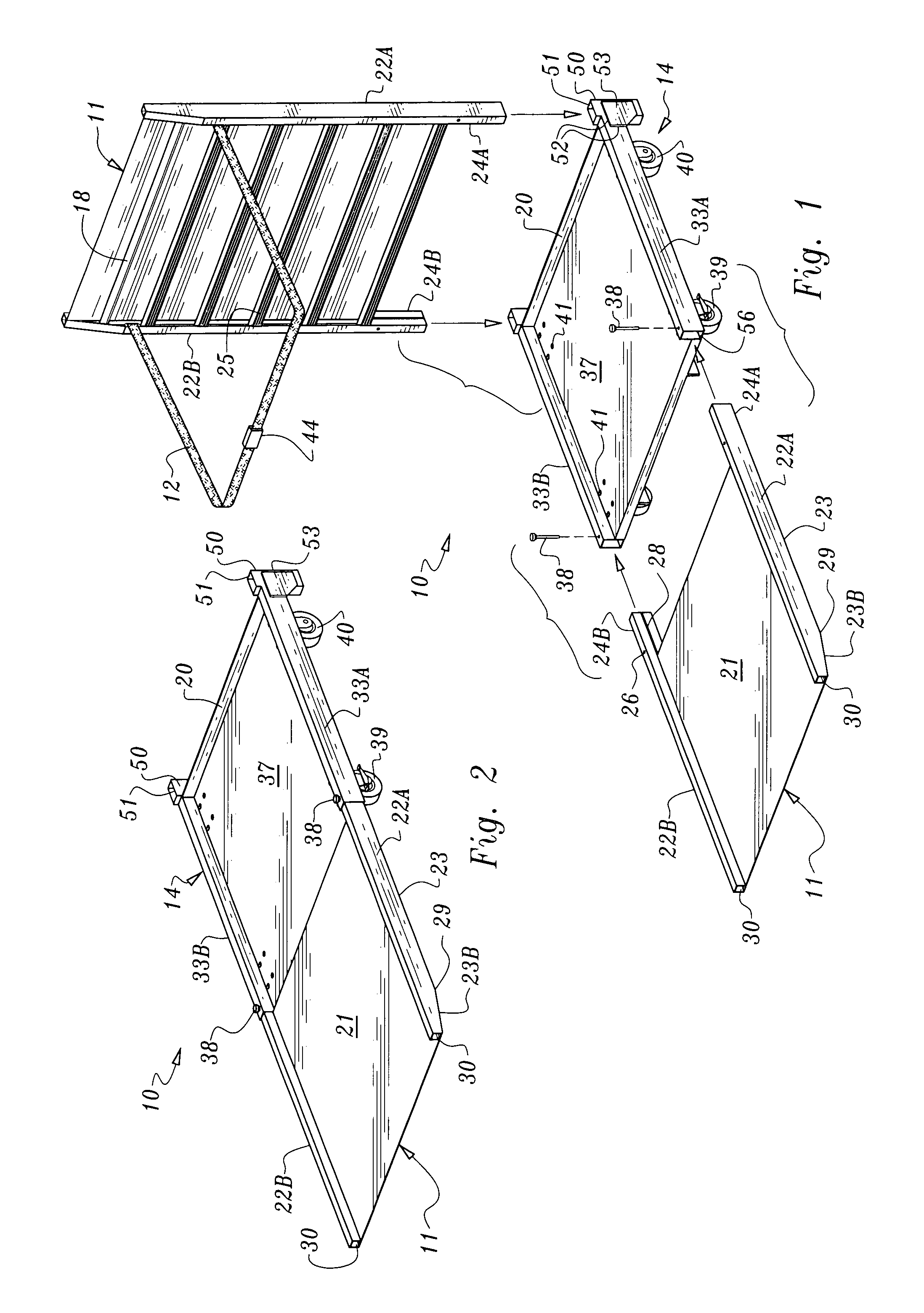

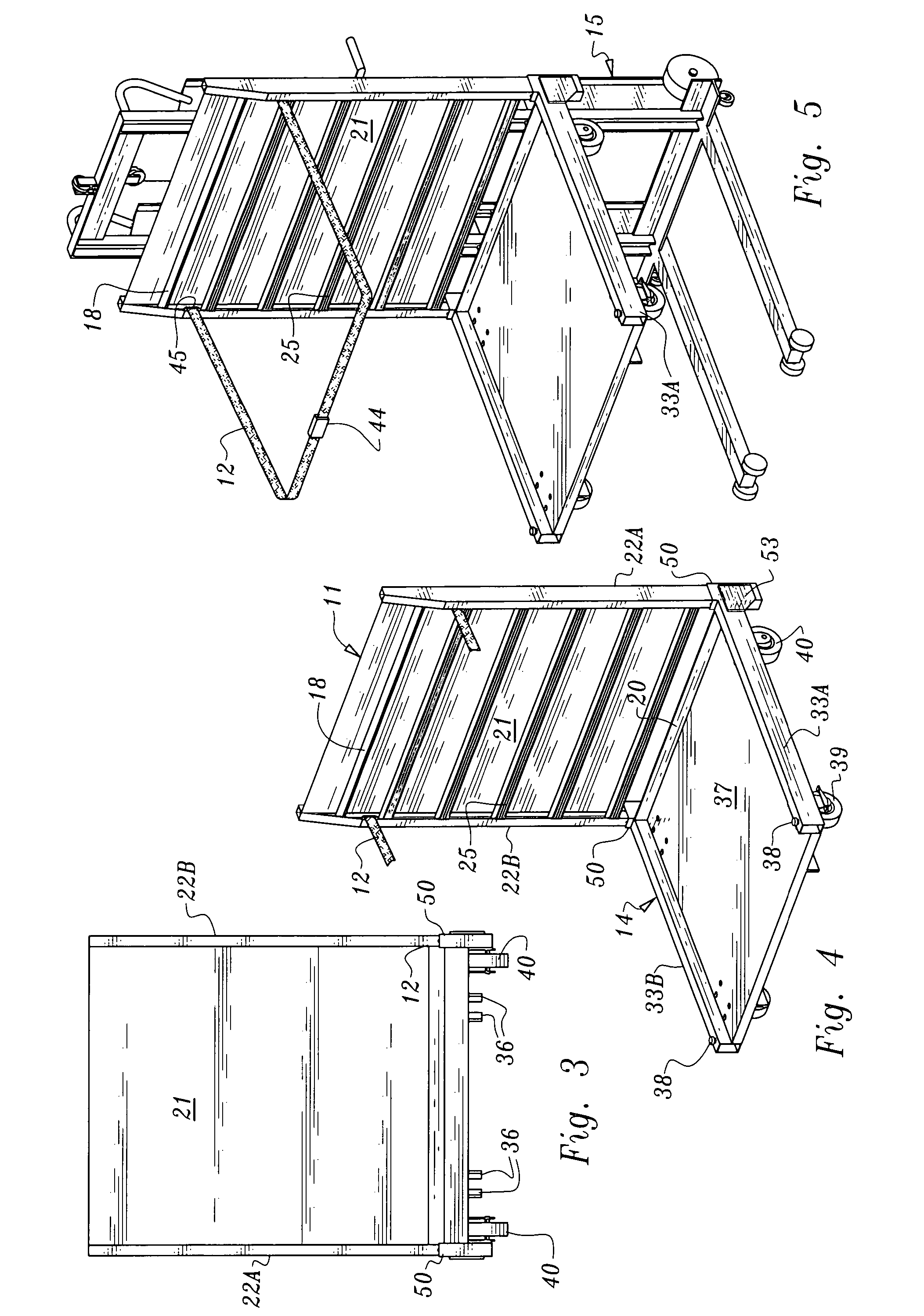

Cart & dual use ramp for console copier relocation

A cart having a two-positionable ramp and a wheeled platform portion, for the lateral transportation of console copiers and other major appliances. The ramp has a first tapered end, and a second engagable end, engagable in two positions with the platform portion. When the ramp's second end is engaged horizontally, the first end tilts down for loading, with the tapered end being on the ground. Once loaded, the weight shift causes the ramp's first end to rise. The ramp is removed, and re-engaged vertically to the platform's second end for lateral movement of the load. The cart can be attached to an adapted stair climbing hand truck for upward / downward movement on stairs with the load retained in place on the cart.

Owner:ESCALERA

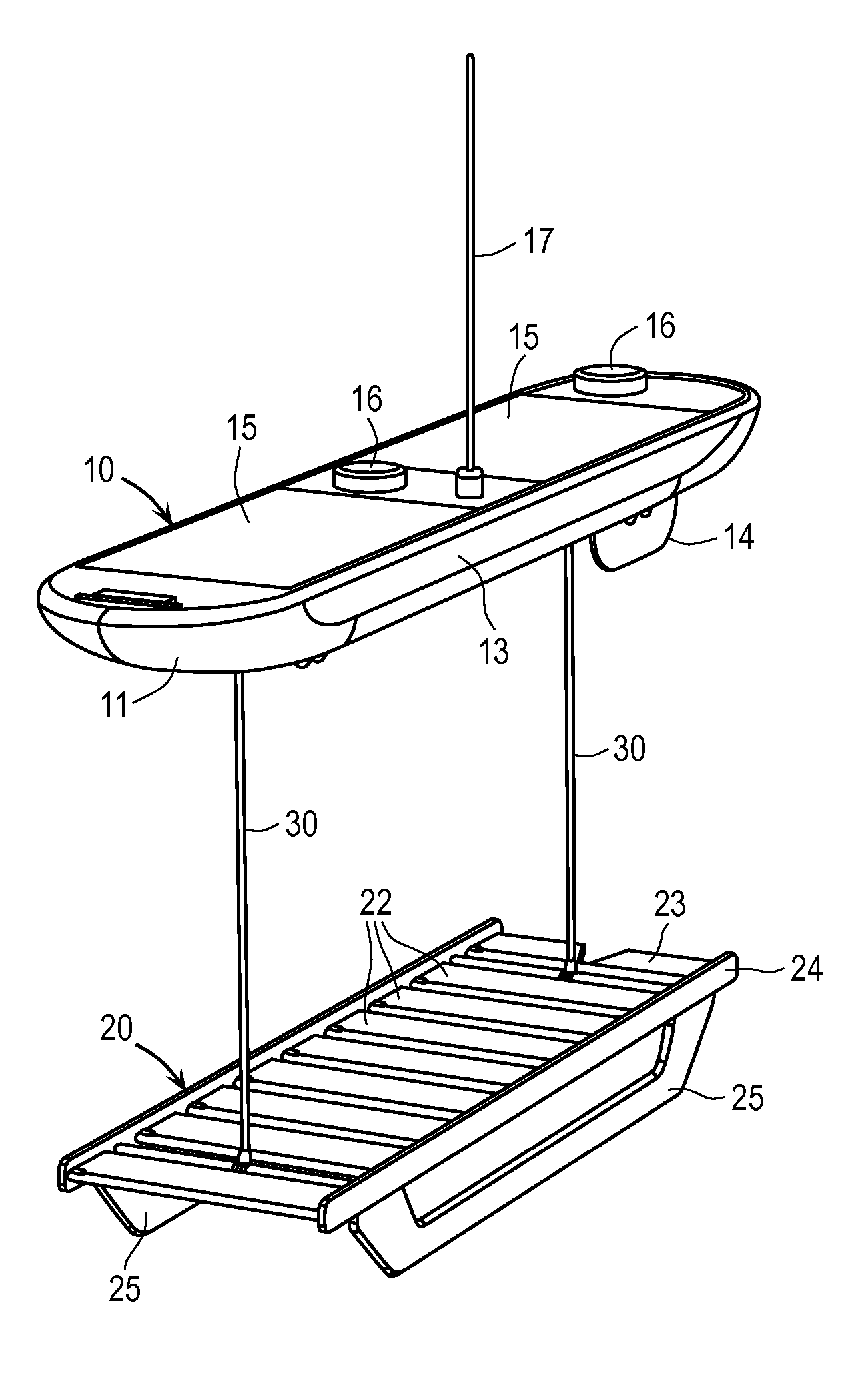

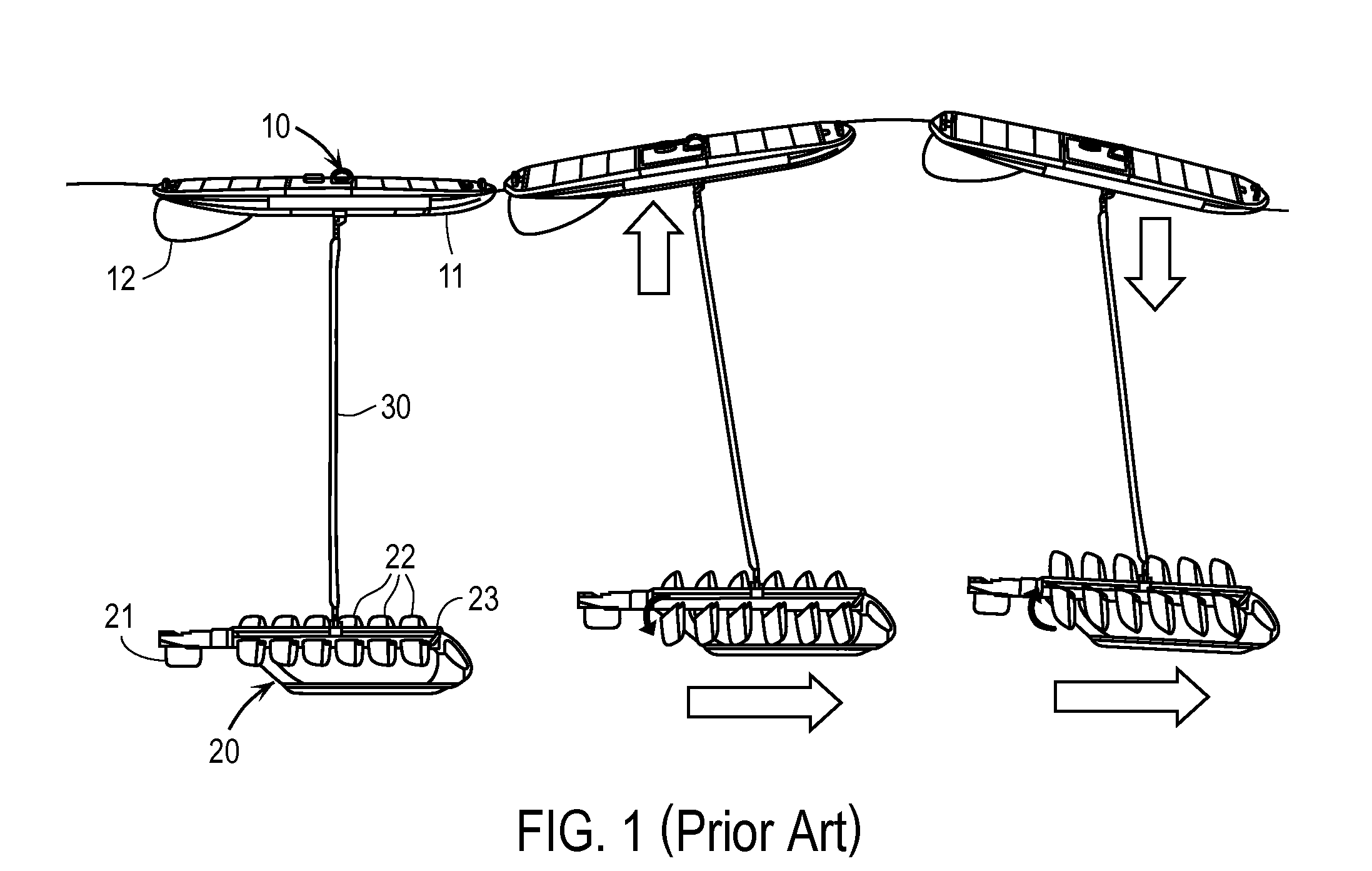

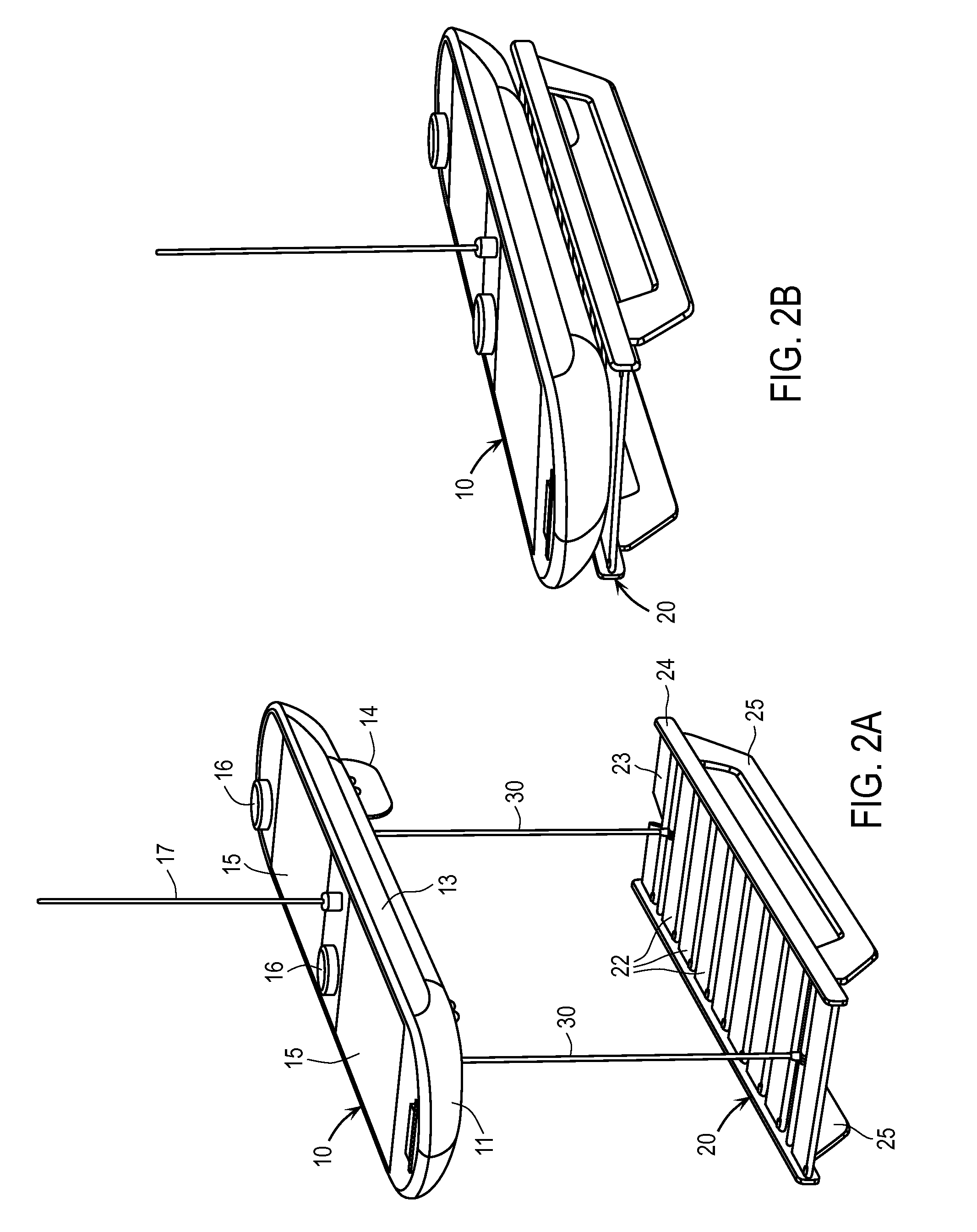

Wave-powered devices configured for nesting

ActiveUS20120285160A1Reducing bowingReduce flutterTowing/pushing equipmentPropulsion based emission reductionClassical mechanicsMechanical engineering

A wave-powered water vehicle includes a) a first component which is a float that travels on or near the water surface; b) a second component which is wave actuated and travels below the first component; and c) a means whereby the first component engages the second component and / or the second component engages the first component; wherein the engagement means provides lateral support of one component for the other, and thereby minimizes lateral movement of one against the other when the components are fitted together.

Owner:LIQUID ROBOTICS

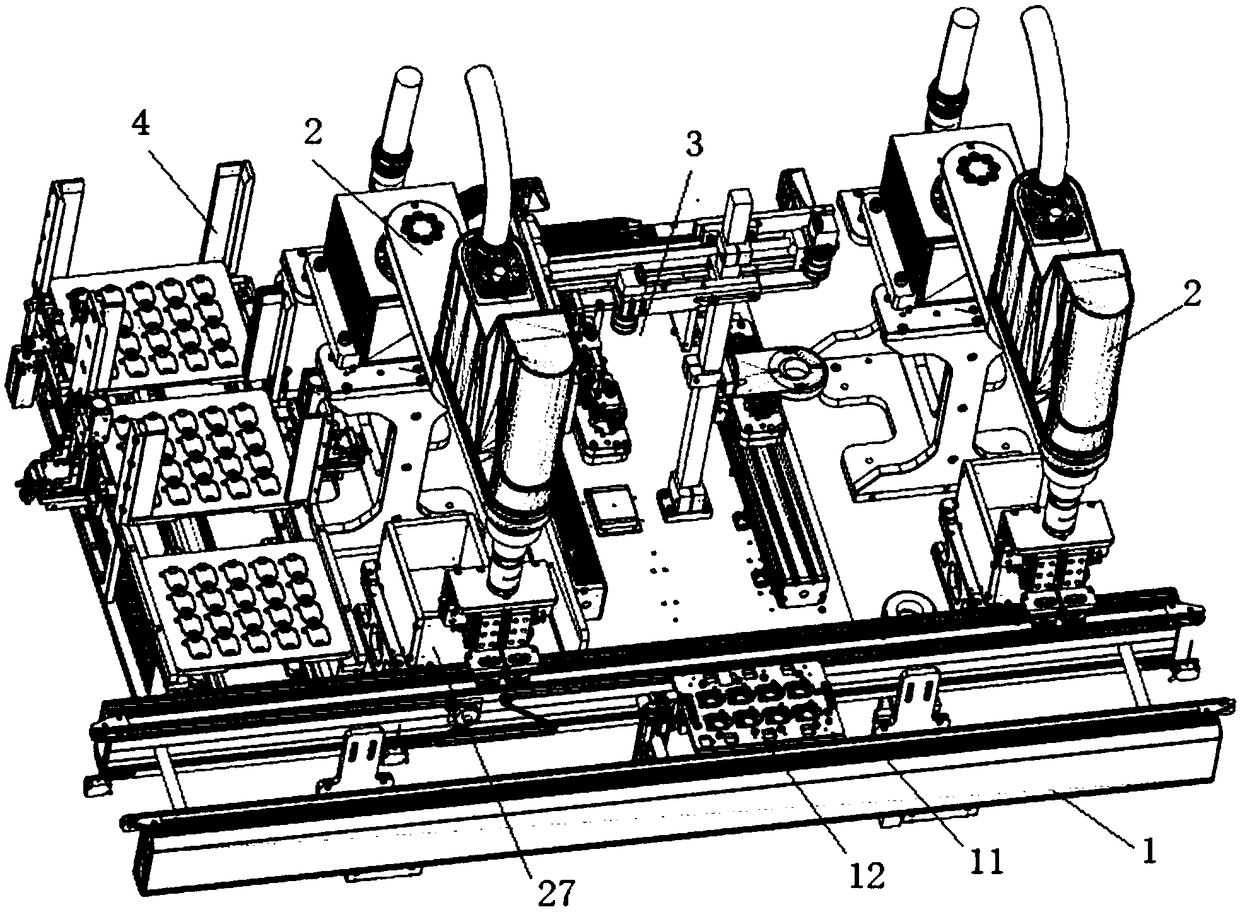

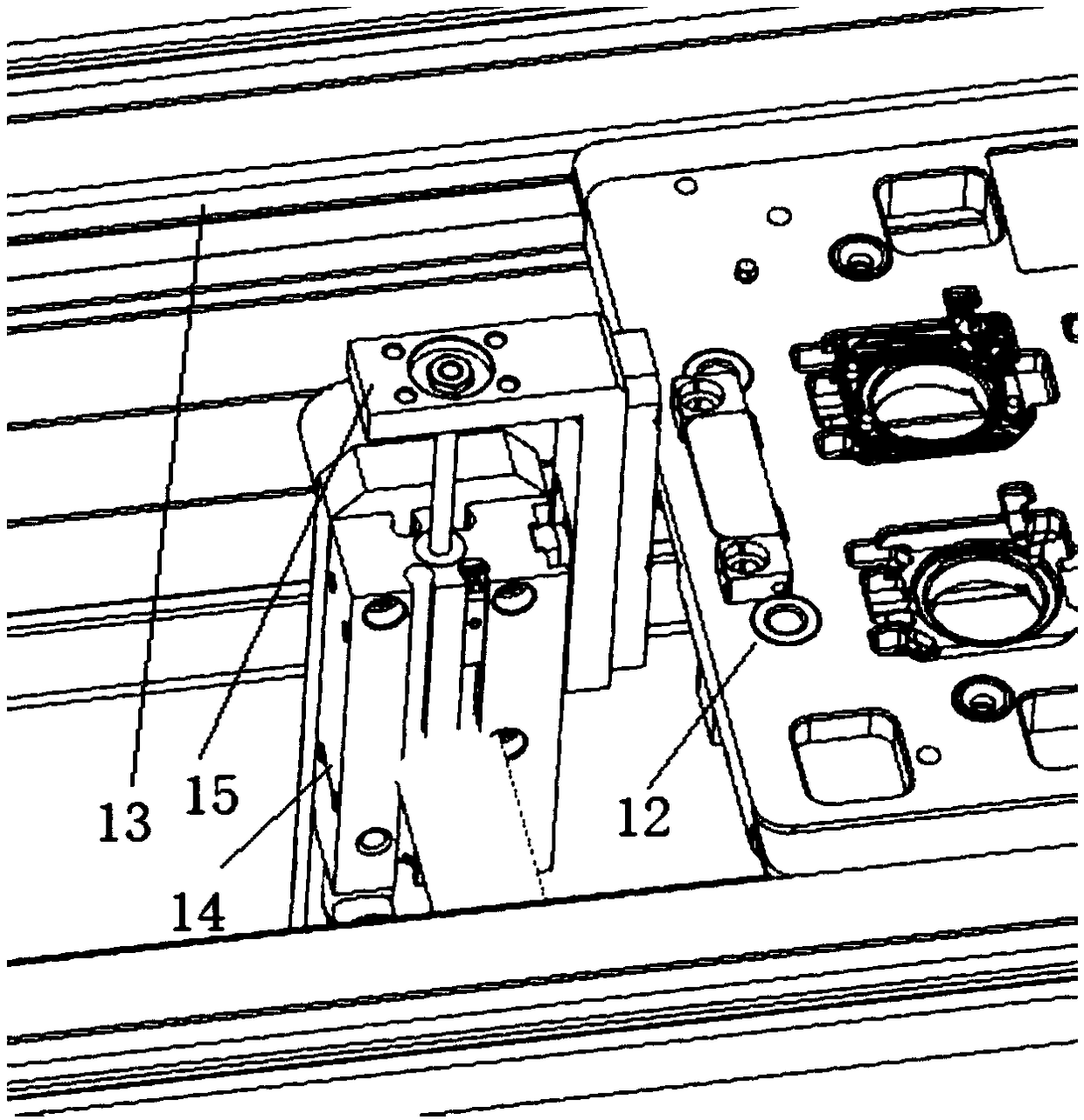

Automatic circulating feeding and material storing AOI detecting equipment

PendingCN109158335ARealize all-round data detection and analysisMaximizeSortingEngineeringMechanical engineering

The invention relates to automatic circulating feeding and material storing AOI detecting equipment. The automatic circulating feeding and material storing AOI detecting equipment comprises a feedingand transporting assembly, mechanical arm drawing assemblies, an AOI detecting assembly and a turnover carrier feeding bin assembly, wherein the AOI detecting assembly comprises lateral moving die sets which are symmetrically arranged, a longitudinal moving die set arranged on the symmetrical lateral moving die sets in a traversing manner, a sucker carrying die set located under the longitudinal moving die set, and CCD die sets which are arranged corresponding to the lateral moving die sets; the turnover carrier feeding bin assembly comprises a framework, a discharging region, an empty carriertemporary storage region, a full-material carrier temporary storage region and a turnover moving die set, wherein the discharging region, the empty carrier temporary storage region, the full-materialcarrier temporary storage region and the turnover moving die set are sequentially located on the framework; the turnover moving die set is used for orderly transferring product carriers from the empty carrier temporary storage region to a discharging region, and then to the full-material carrier temporary storage region. Through the adoption of the automatic circulating feeding and material storing AOI detecting equipment disclosed by the invention, products can be automatically circulated to be subjected to AOI detection and the operations of material storing and discharging.

Owner:KUNSHAN SYSTRONICS AUTOMATION TECH CO LTD

Apparatus for detecting parallelism of two planes of platelike workpiece

This invention relates to a test device for measuring the depth of parallelism of two planes of a board-like workpiece including: a base set with a lateral moving unit with a laser sensor vertical moving unit and a grating ruler, at the same time, the movement part of the grating ruler is connected with the vertical moving unit fixedly, the other side of the base is installed with a slipway with a workpiece platform on it, when working, the two laser sensors mounted up and down are above and below the platform.

Owner:SHANGHAI UNIV

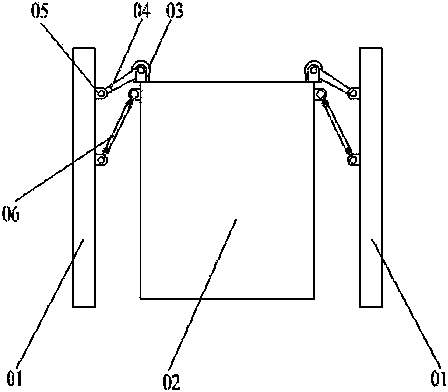

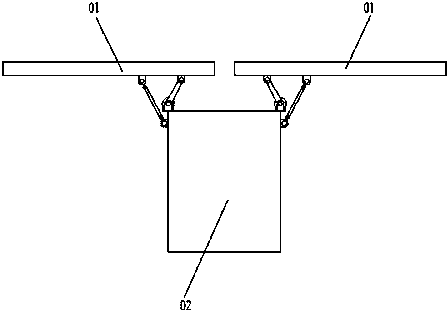

Splicing type unfolding device for planar antenna of aerospace craft

ActiveCN103700920AAddress non-generalizationSolve the weight problemCollapsable antennas meansAntenna supports/mountingsEngineeringCantilever

The invention discloses a splicing type unfolding device for the planar antenna of an aerospace craft. The device comprises an aerospace craft platform, the planar antenna, a mounting support, driving devices mounted on the aerospace craft platform, unfolding device driving rods and unfolding device driven rods, wherein the planar antenna is arranged in an H-shaped manner relative to the aerospace craft platform in a folded state, and the left wing and the right wing of the planar antenna are symmetric about the aerospace craft platform; the unfolding device driving rods and the unfolding device driven rods are connected with the planar antenna; the driving devices drive the unfolding device driving rods, the unfolding device driven rods and the planar antenna to move, so as to enable the planar antenna to complete folding and unfolding moving processes in two manners of lateral moving and rotating, finally to reach an appointed position of an unfolded state, to rotates 90 degrees relative to the aerospace craft platform from a folded position to an unfolded position, and to laterally move for a certain distance in the direction of the aerospace craft platform. According to the splicing type unfolding device for the planar antenna of the aerospace craft, antenna cantilevers of the aerospace craft platform can be reduced or eliminated.

Owner:SHANGHAI AEROSPACE SYST ENG INST

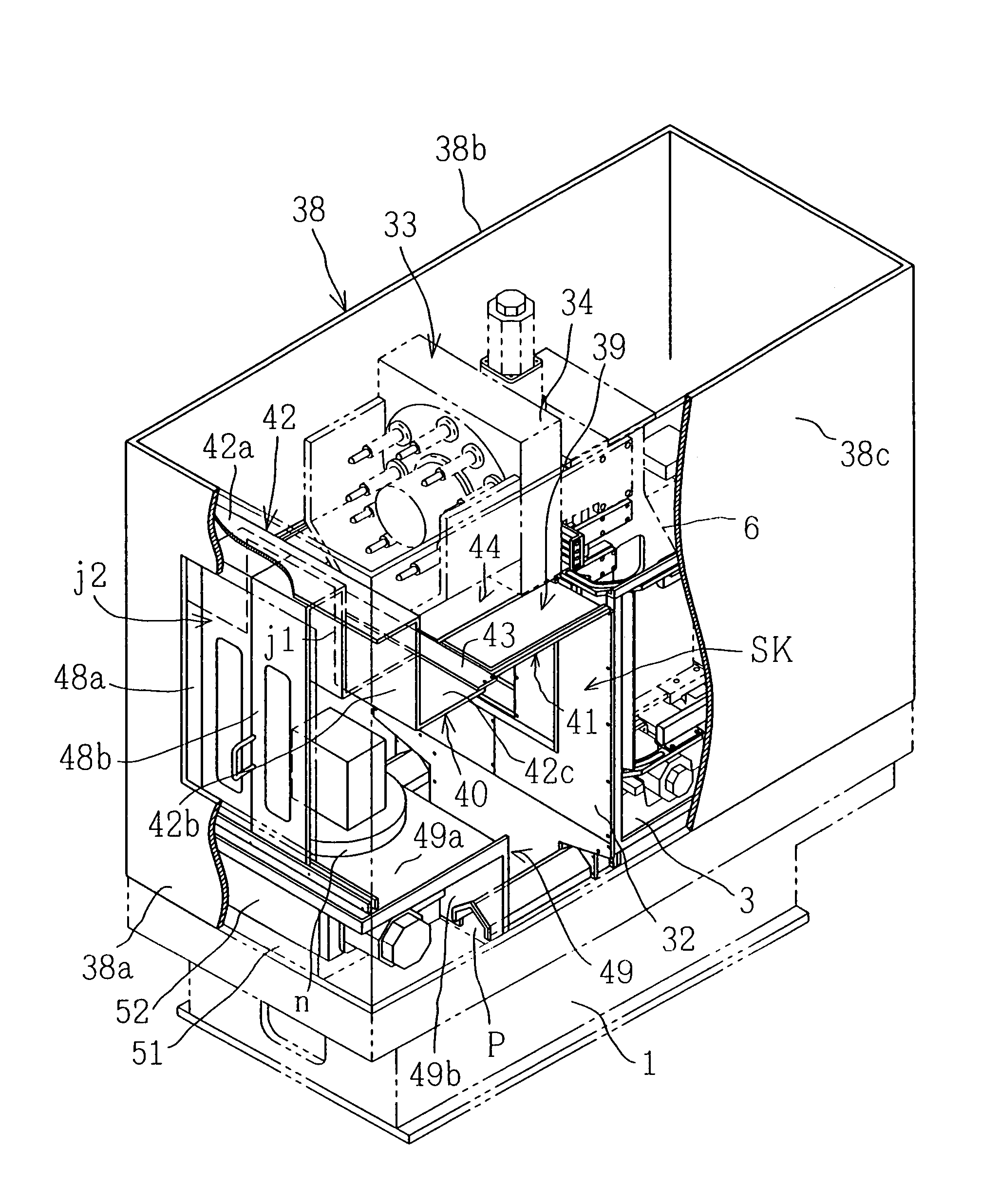

Column moving type machine tool with shield machining space

InactiveUS7223221B2Effective interceptionPrevent splashProtection and storage accessoriesGuardEngineeringMachine tool

A machine tool capable of reducing the lateral width of the upper part thereof by reducing the lateral width of a bed (1) while machining through the same lateral moving distance of a spindle (10) as before, comprising longitudinal guide rails (2) installed on the bed (1), a slide (3) installed through the guide rails (2) movably in a longitudinal direction, a column (6) movable in vertical direction, wherein first cover plates (25) are fixed at the right and left sides of a vertical moving route for the spindle (10), side cover plates (26) are installed continuously with the outer end edges of the first cover plates (25) so as to be turnable rearward, a second cover plate (32) is installed at the front sides of the first cover plates (25) and the side cover plates (26) integrally with the slide (3) so as to cover the front side of the moving range of the column (6), and a shielded machining space (SK) is formed at the front of the second cover plate (32).

Owner:HORKOS

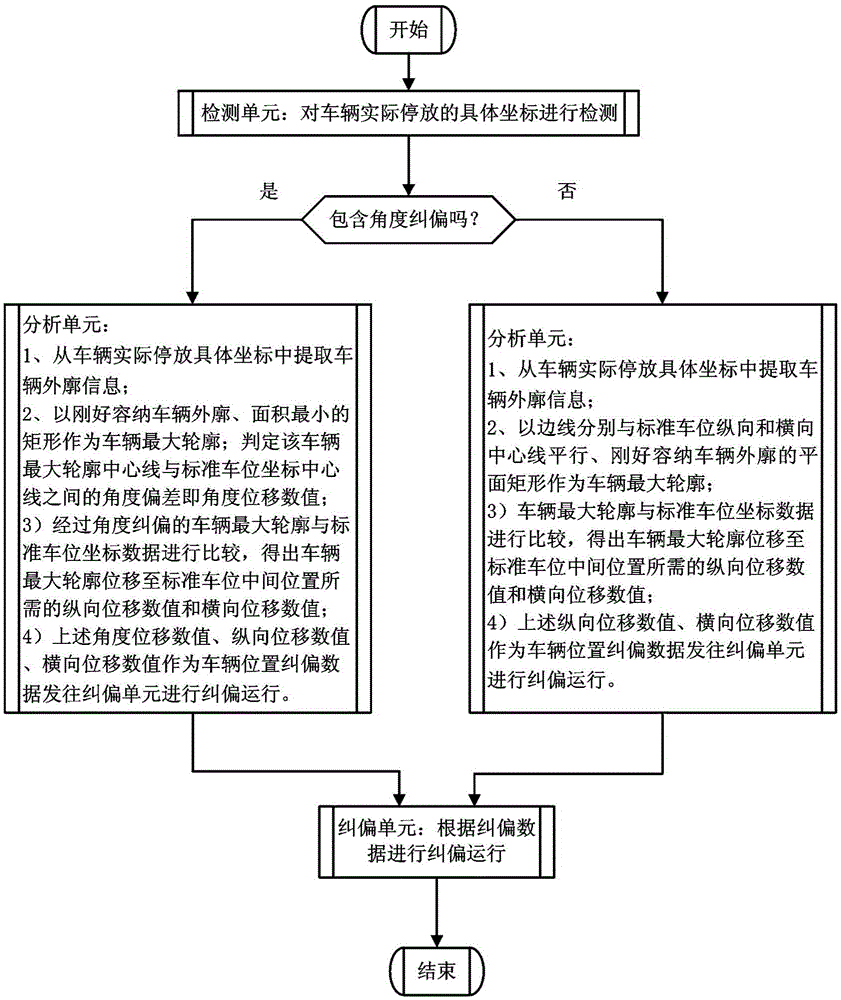

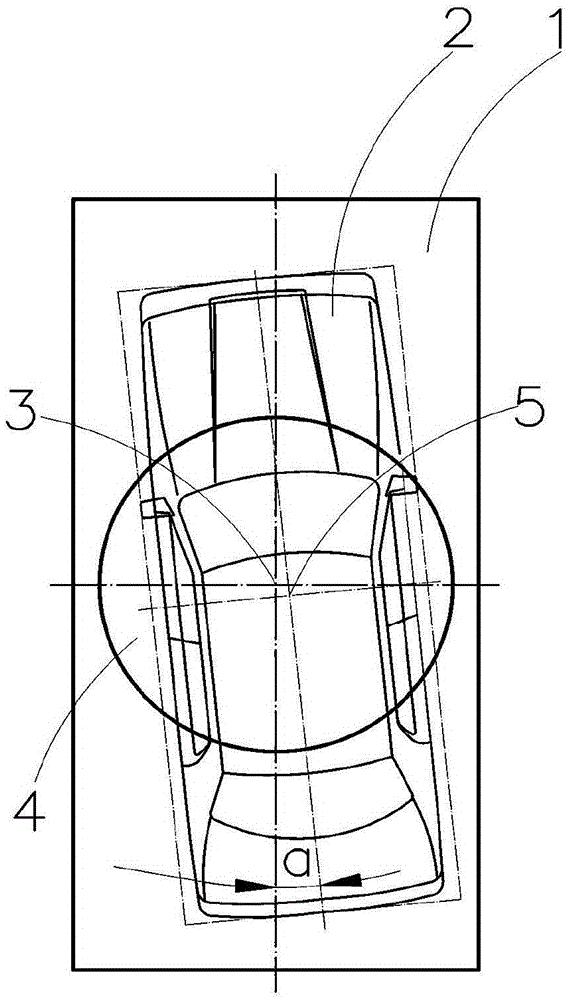

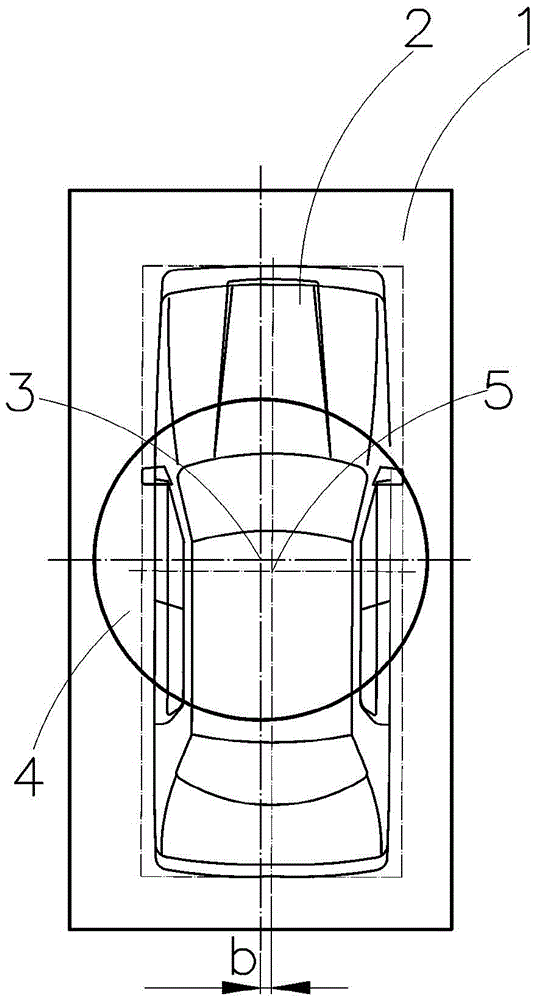

Method and device for rectifying vehicle position in parking equipment

The invention provides a method and a device for rectifying a vehicle position in parking equipment. The technical scheme of the method and the device is characterized in that a detection unit and an analysis unit are matched to automatically detect whether a positional deviation occurs during vehicle parking, and then transmit data to be rectified to a rectification unit to carry out automatic rectification. The method comprises the specific steps: additionally arranging a photographing device in a vehicle entry parking position space of conventional parking equipment, and photographing an external contour of a vehicle; extracting a current maximum external contour of the vehicle by an image processing device, and comparing the current maximum external contour with coordinate data of a standard parking place to obtain a rectifying value; then rectifying angular deviation, longitudinal deviation and lateral deviation of the original parked vehicle respectively by using an internal automatic turntable, a longitudinal moving component and a lateral moving component commonly used in the parking equipment. The method and the device provided by the invention are applicable to a new product design, can also be used for improvement of a product that has been used, and have relatively high social benefit and economic benefit while being promoted and used.

Owner:佛山市诺行科技有限公司

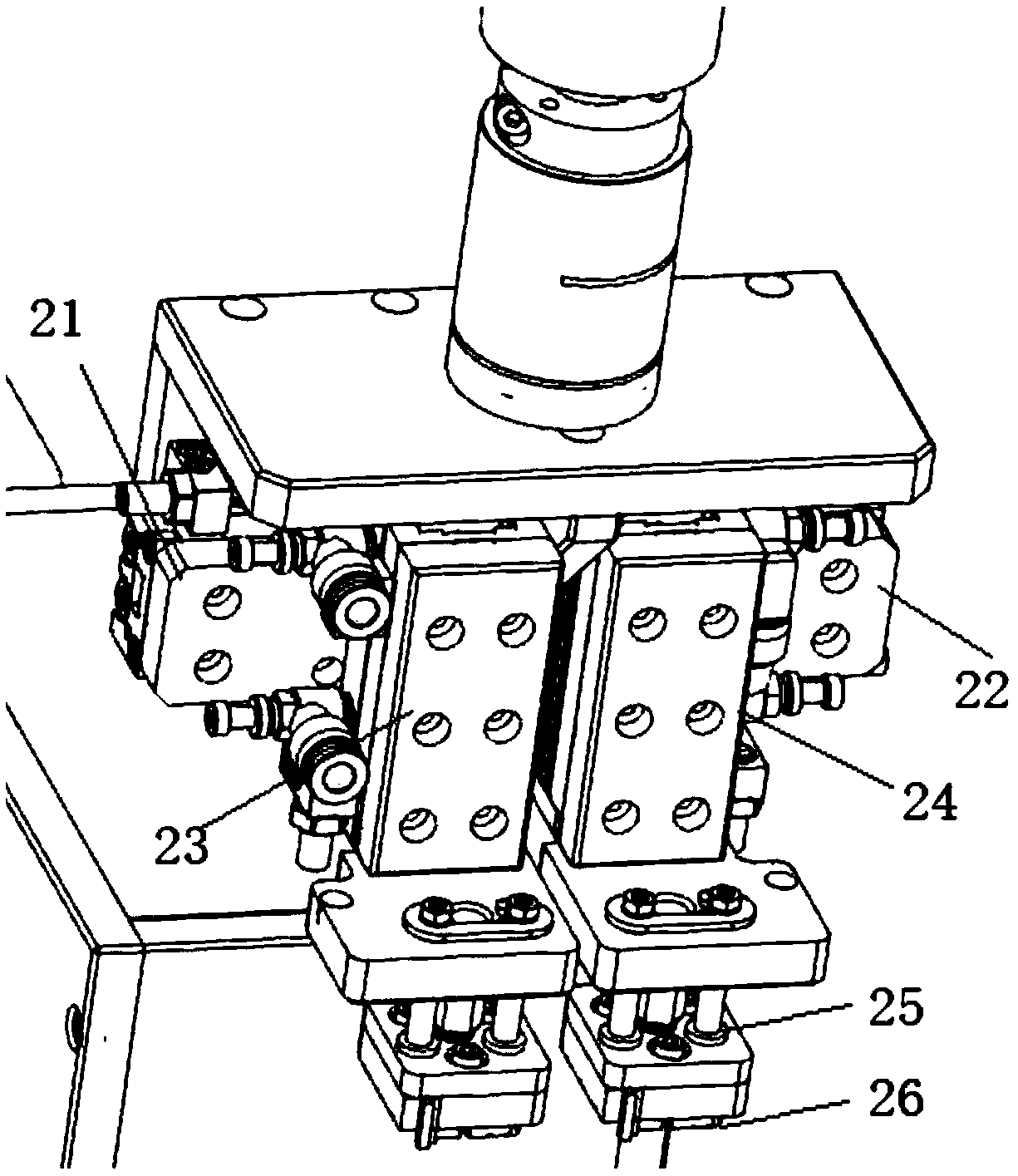

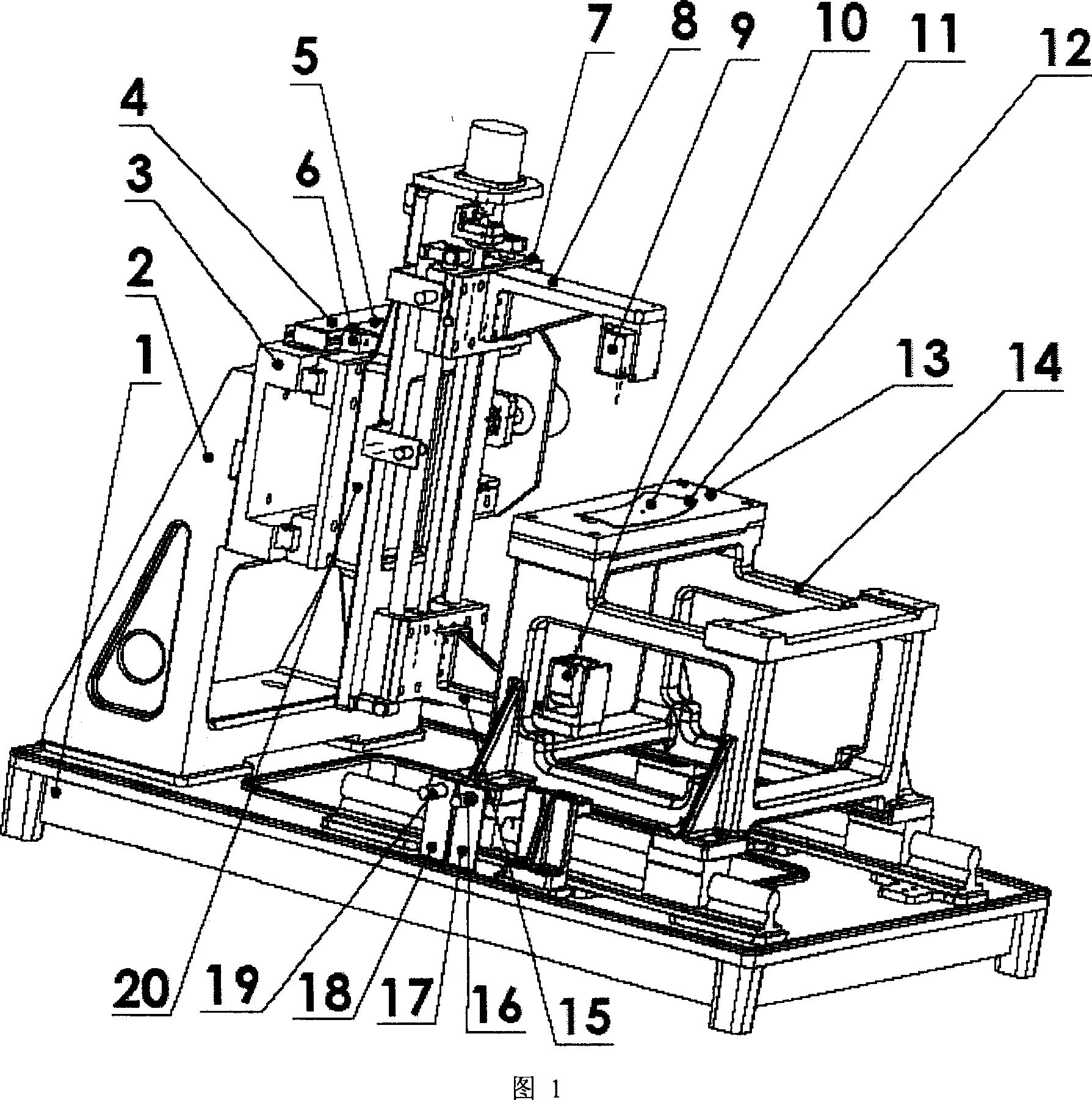

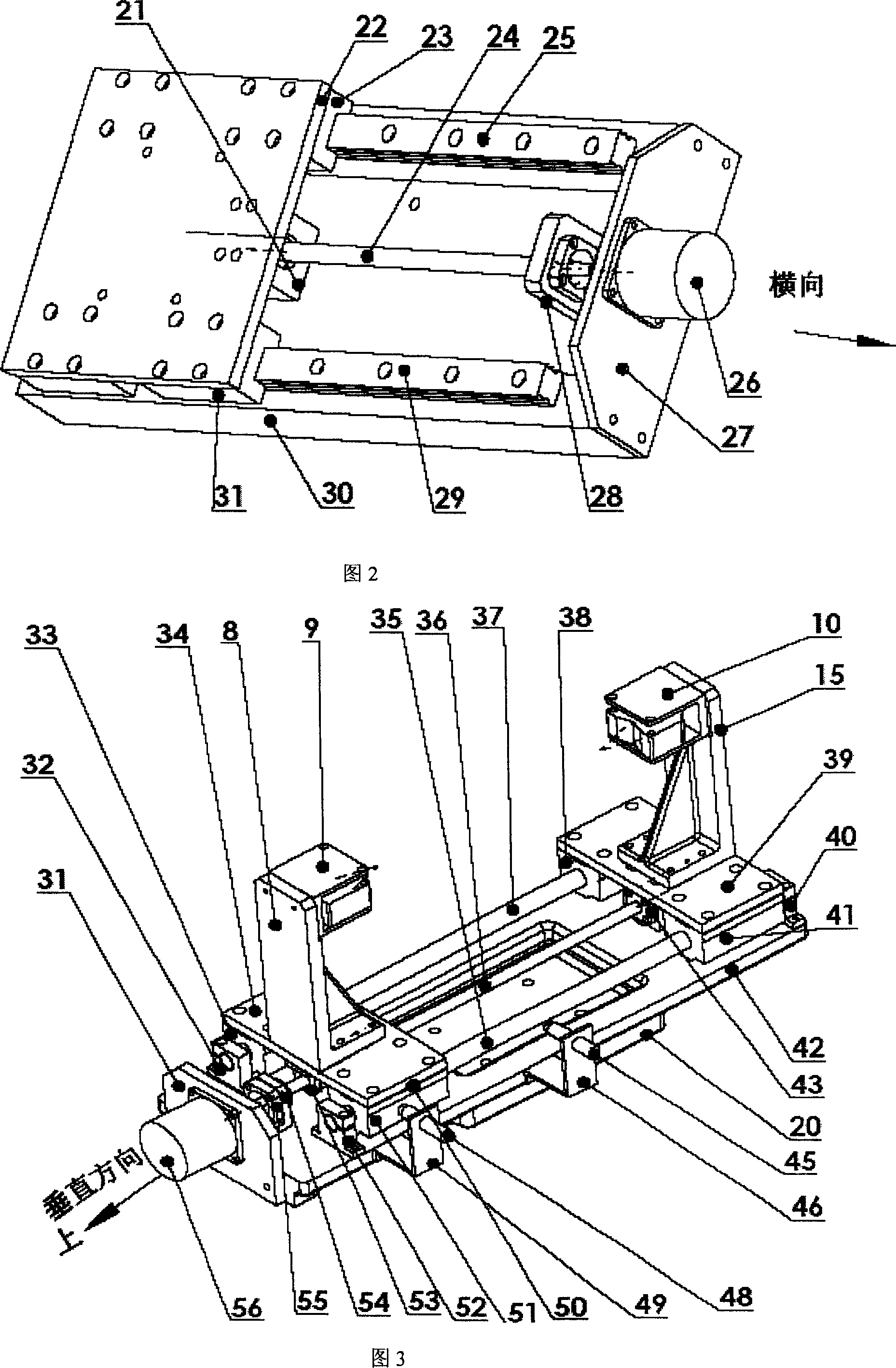

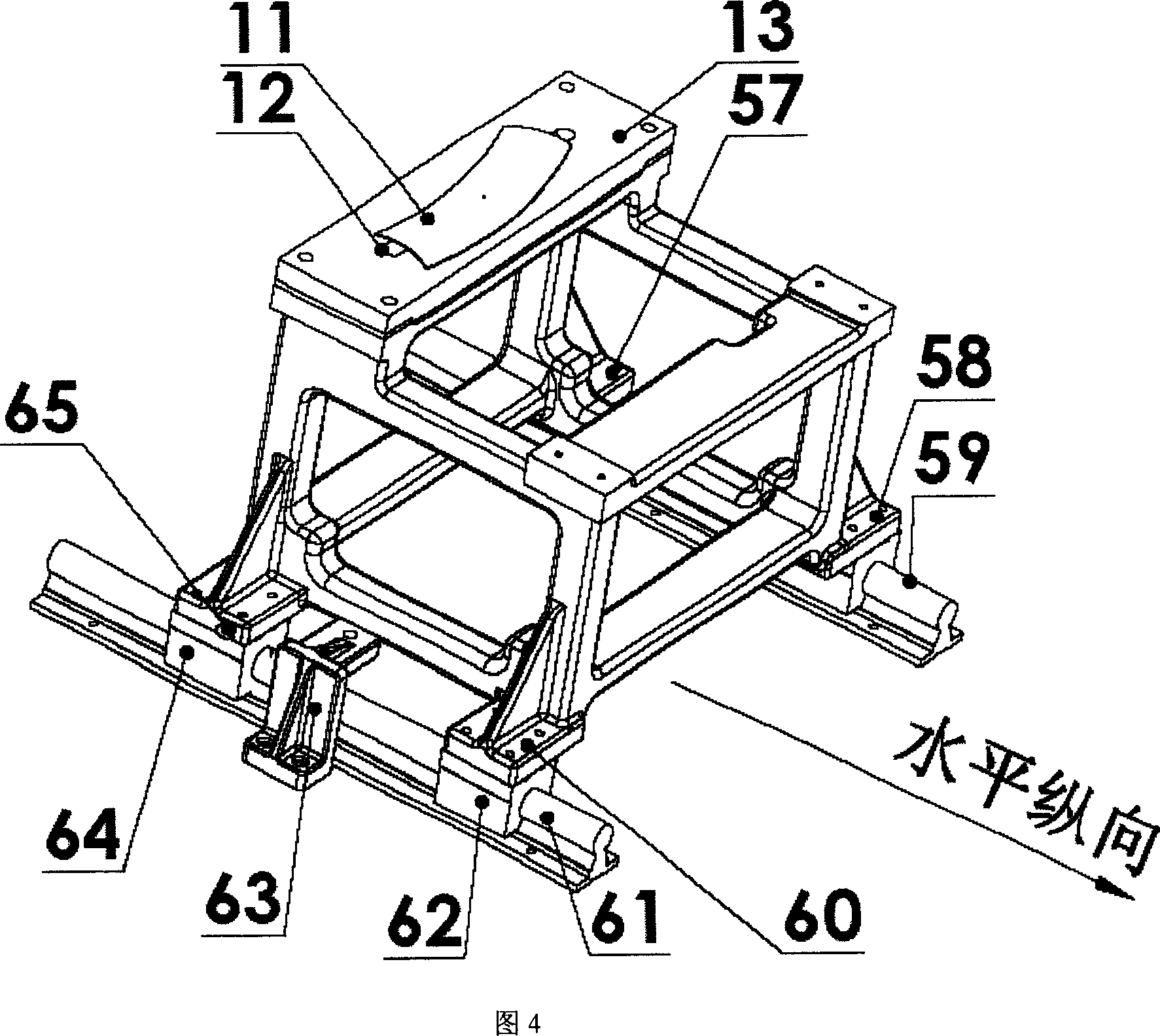

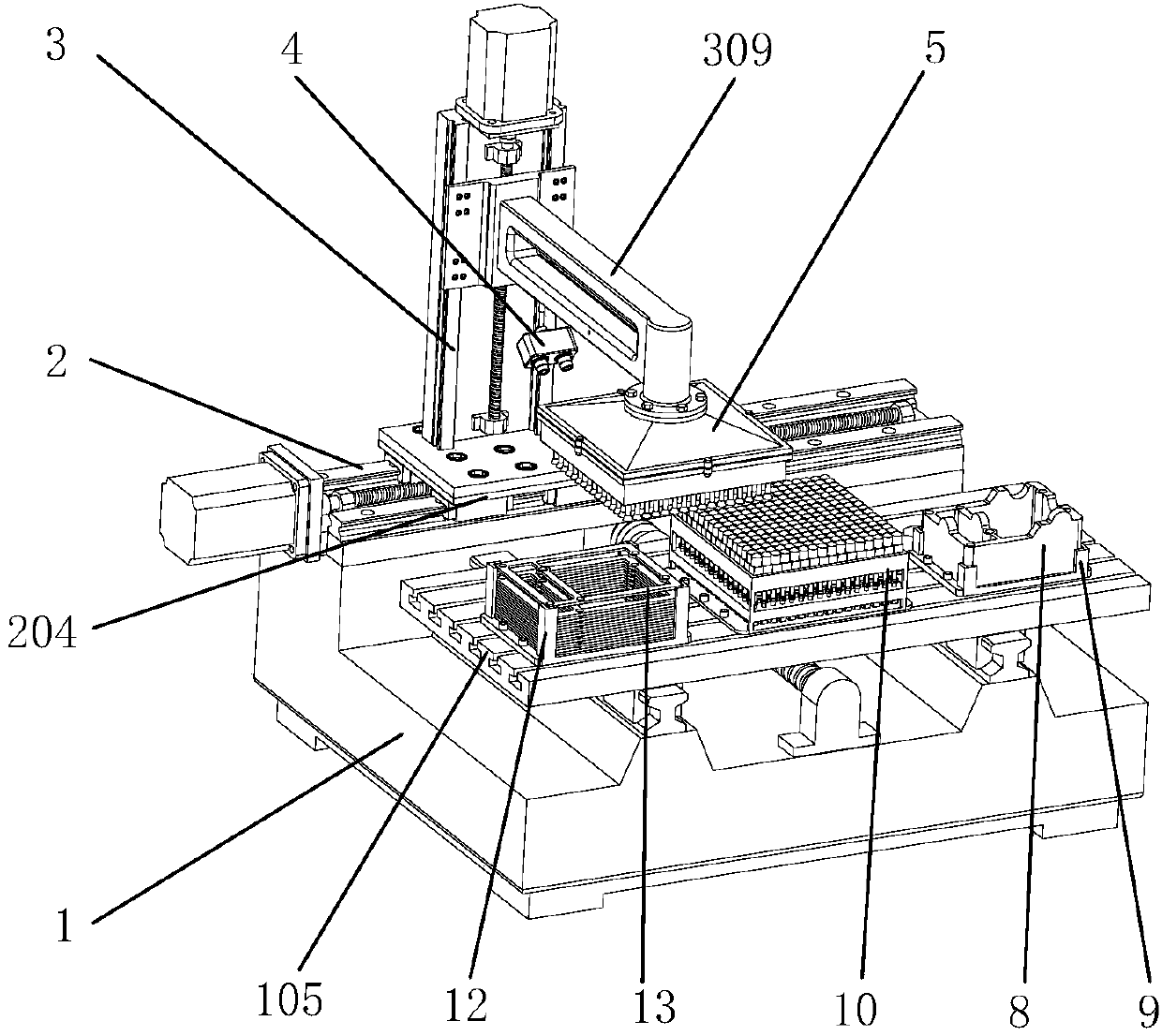

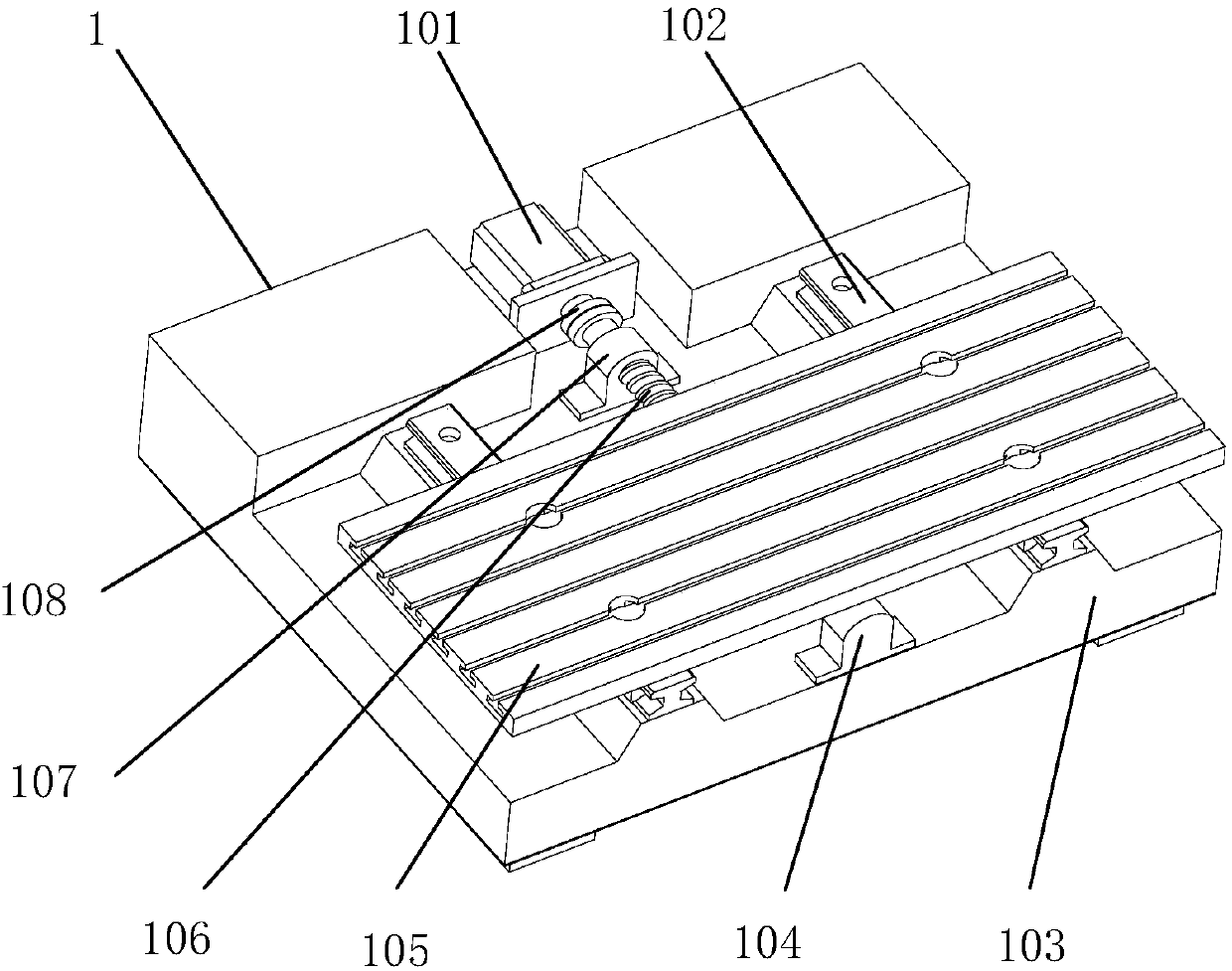

Multi-point sucking disc automatic-sucking installing machine for three-dimensional flexible gasket

PendingCN107825407ASolve the problem of forming a three-dimensional gasket and assembling it preciselyNovel structureProgramme-controlled manipulatorGripping headsBall screwEngineering

The invention relates to a multi-point sucking disc automatic-sucking installing machine for a three-dimensional flexible gasket, and belongs to the field of mechanical manufacturing. A transverse moving device, a longitudinal ball screw used for completing longitudinal movement of T-shaped grooves, longitudinal sliding rails and the like are fixedly installed on a base; a transverse moving mechanism is vertically distributed with the longitudinal ball screw and the longitudinal sliding rails; a T-shaped groove workbench is fixed on the longitudinal sliding rails, and the T-shaped groove workbench can longitudinally move along the longitudinal sliding rails; a vertical moving device is fixed on a transverse sliding plate of the transverse moving device, and the vertical moving device can transversely move along with the transverse sliding plate; and a sucking disc is fixed on a cross arm of the vertical moving device, and can move up and down along with the cross arm, and the sucking disc is located above the T-shaped groove workbench. According to the installing machine, the gasket is converted from two-dimensional to three-dimensional, meanwhile, accurate and automatic assembly is carried out, so that labor is liberated, and assembly efficiency of a system is improved.

Owner:JILIN UNIV

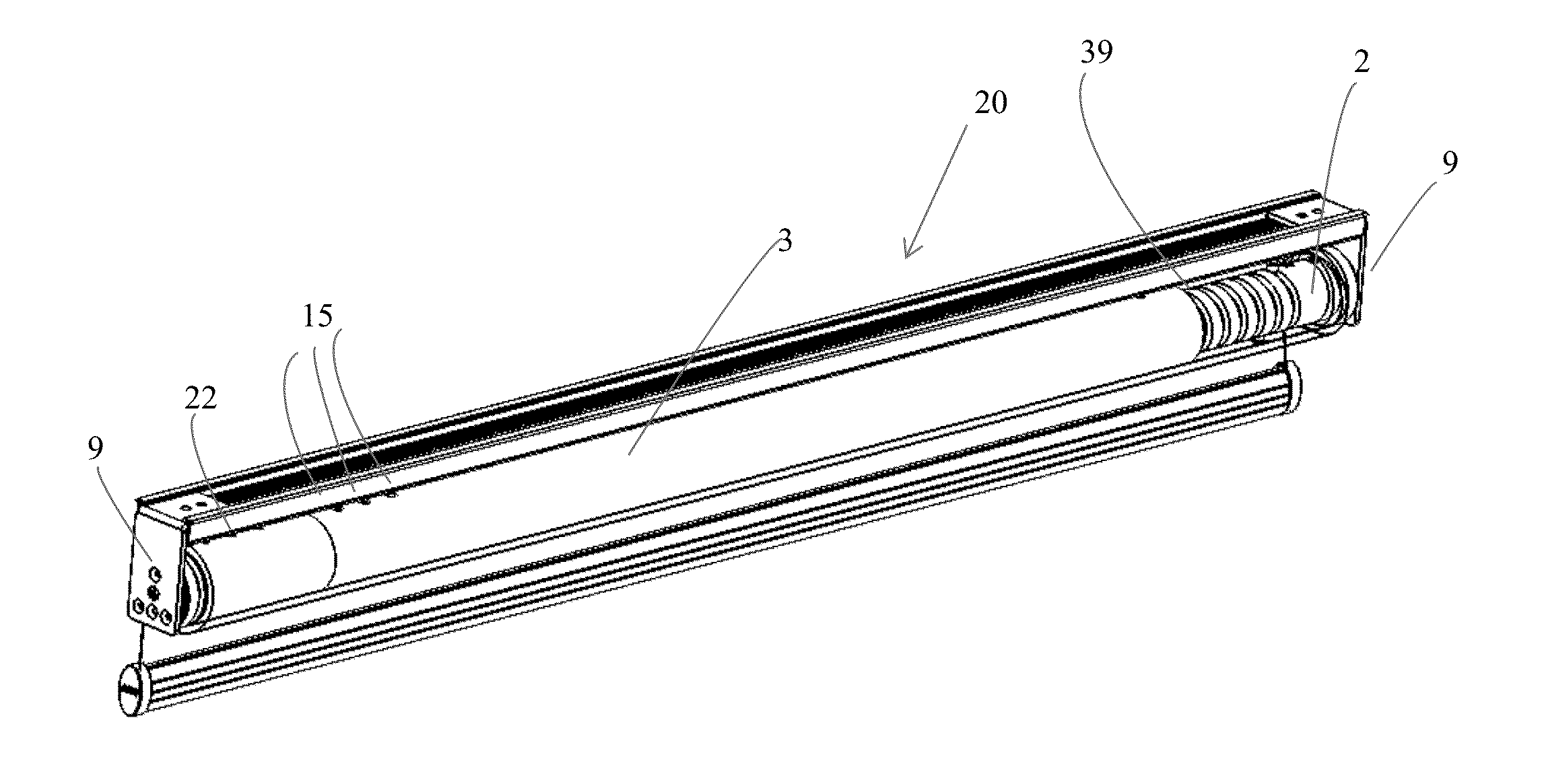

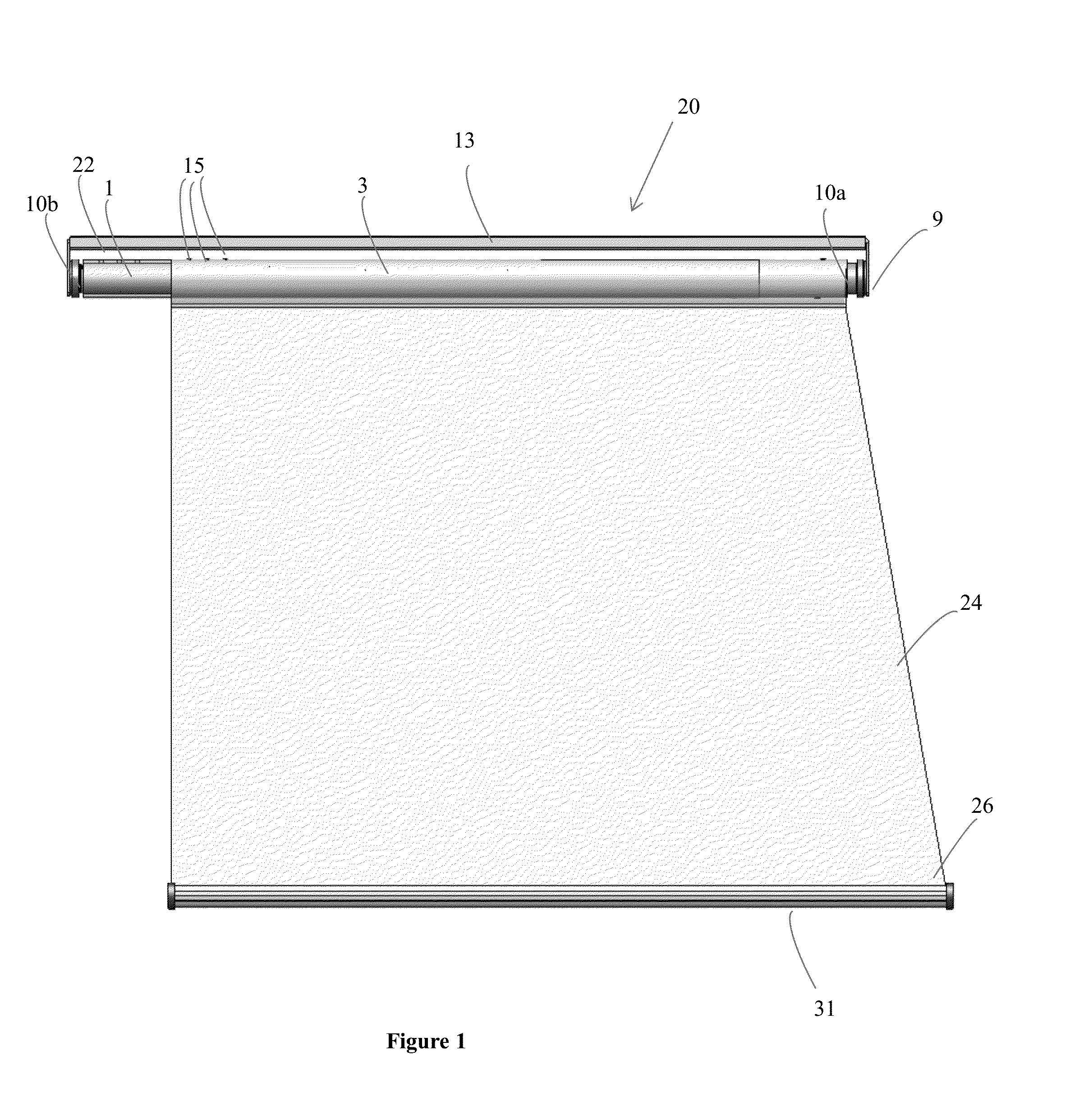

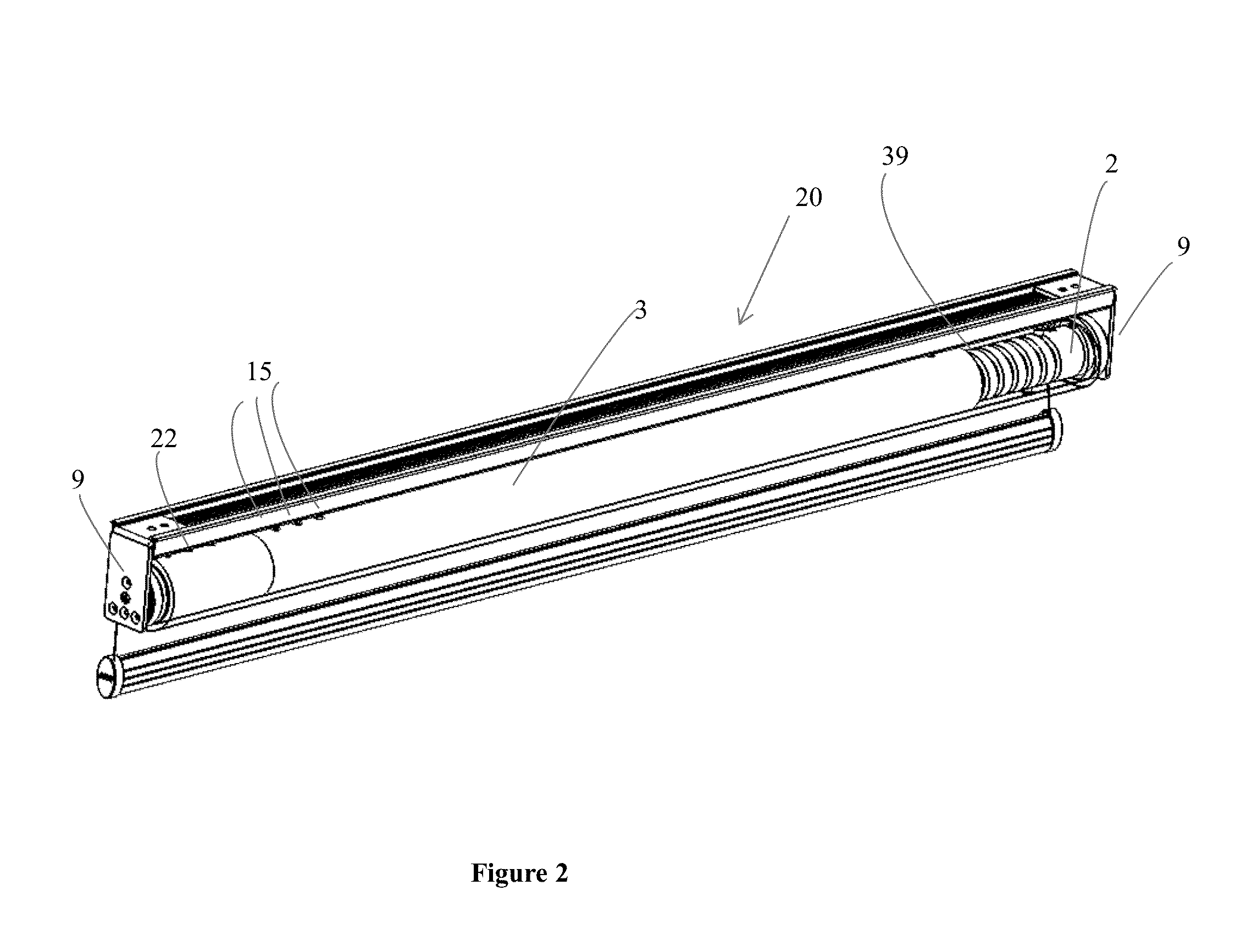

Laterally moving shade roller tube

ActiveUS20160083998A1Easy to adjustPrevent rotationScreensWindowsClassical mechanicsStructural engineering

A roller shade assembly comprising a roller tube having an inner surface defining an axial bore, a spindle including an outer threaded portion defining a helical groove, the spindle configured to be received in the axial bore of the roller tube for axial movement in the roller tube at one end roller tube and at least one tracking element operatively associated with the roller tube, the at least one tracking element configured for riding in the helical groove to convert axial rotation of roller tube into axial movement of the roller tube on the support tube. The tracking element engages the helical groove from a position more proximal to one end of the roller tube. The starting axial position of the roller tube in relation to the support tube is configured to be adjustable by manually rotating the spindle without rotating the support tube.

Owner:AUTO MOTION SHADE

Automatic material line-following conveying system

The invention discloses an automatic material line-following conveying system, and relates to the technical field of material conveying. The automatic material line-following conveying system aims to solve the problem that an automatic material line-following conveying system in the prior art needs a plurality of operating workers and is limited by the space and arrangement of a production workshop. The automatic material line-following conveying system comprises a material trolley set. An automatic guide trolley guides the material trolley at the forefront portion to a first position and is separated from the material trolley set at the first position. A lateral moving unit is arranged on the right side of the material trolley set and can move the material trolley at the forefront portion from the first position to a second position in the moving direction of the material trolley. When the material trolley at the forefront portion is arranged at the second position, a horizontal moving unit is arranged on the right side of the material trolley at the forefront portion and can lift the material trolley at the forefront portion to a certain height and move the material trolley at the forefront portion to a third position. The third position is reserved on a sliding plate, and then the horizontal moving unit returns to an initial position. The automatic material line-following conveying system further comprises a controller and a plurality of sensors electrically connected with the controller, and the sensors are used for determining the positions where the material trolleys are located and sending signals to the controller.

Owner:精诚工科汽车系统有限公司

Automatic swimming pool cleaners and bodies, feet, discs, and other components thereof

ActiveUS20070261183A1Reduce the possibilityReduce riskSuction nozzlesGymnasiumCircular discEngineering

Owner:ZODIAC POOL CARE EURO

Method for fabricating lateral-moving micromachined thermal bimorph

ActiveUS20090219128A1Semiconductor/solid-state device manufacturingThermal micromechanical switchesIn planeManufacturing technology

A method of making a Lateral-Moving Micromachined Thermal Bimorph which provides the capability of achieving in-plane thermally-induced motion on a microchip, as opposed to the much more common out-of-plane, or vertical, motion seen in many devices. The present invention employs a novel fabrication process to allow the fabrication of a lateral bimorph in a fundamentally planar set of processes. In addition, the invention incorporates special design features that allow the bimorph to maintain material interfaces.

Owner:MORGAN RES CORP

Apparatus and method for mixing a fluid dispersion disposed in a container having either a cylindrical or a square shape

InactiveUS20050002273A1Rotating receptacle mixersShaking/oscillating/vibrating mixersEngineeringSquare Shape

Apparatus and method for mixing a fluid dispersion disposed in a container having either a cylindrical or a square shape. The apparatus includes a holding structure having a retaining structure connected to a base. The retaining structure prevents lateral movement of the container both when the container has a cylindrical shape and when the container has a generally square shape with a width substantially equal to the diameter of the cylindrical shape. The apparatus rotates the container about at least one axis.

Owner:THE SHERWIN-WILLIAMS CO

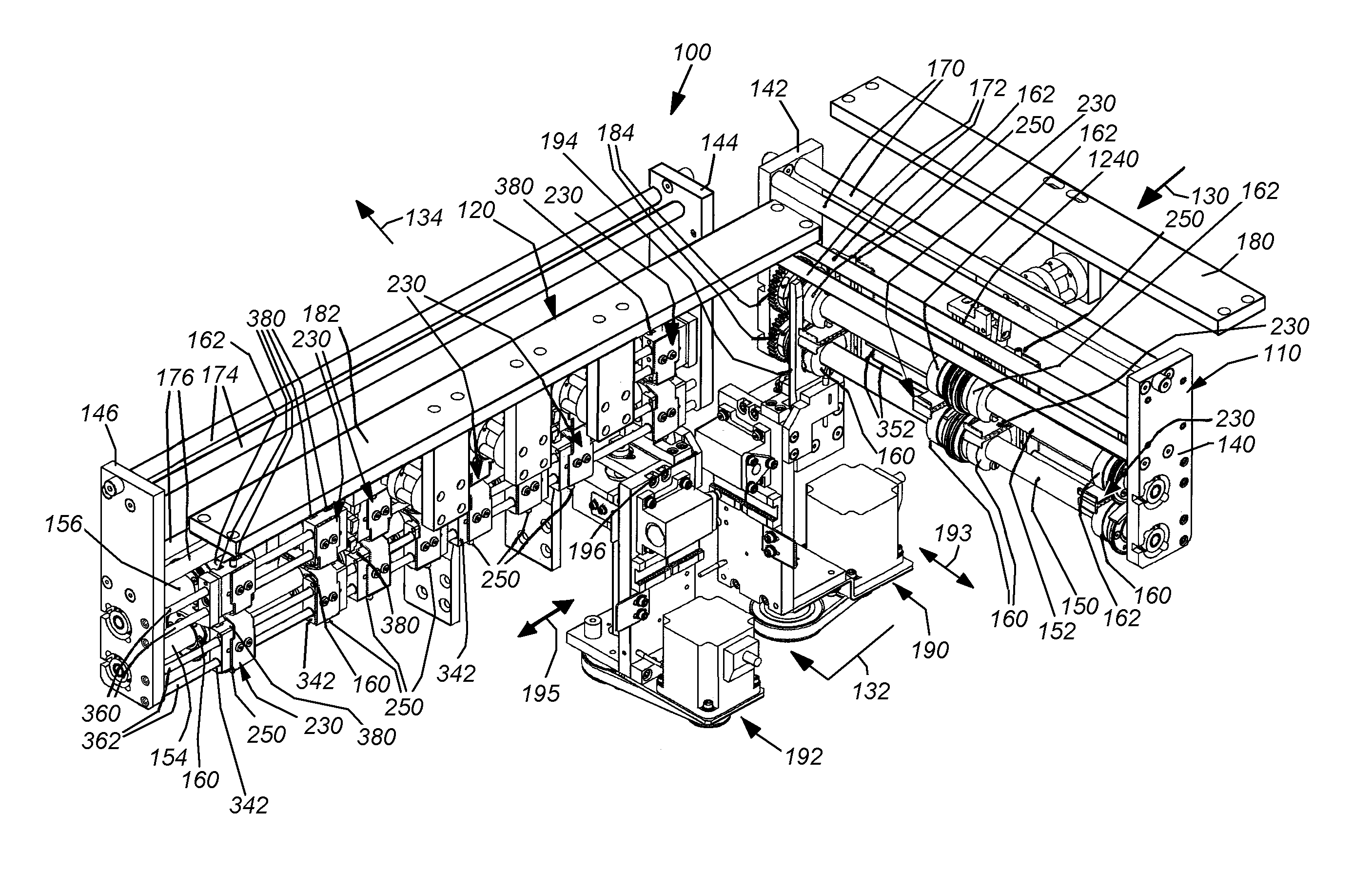

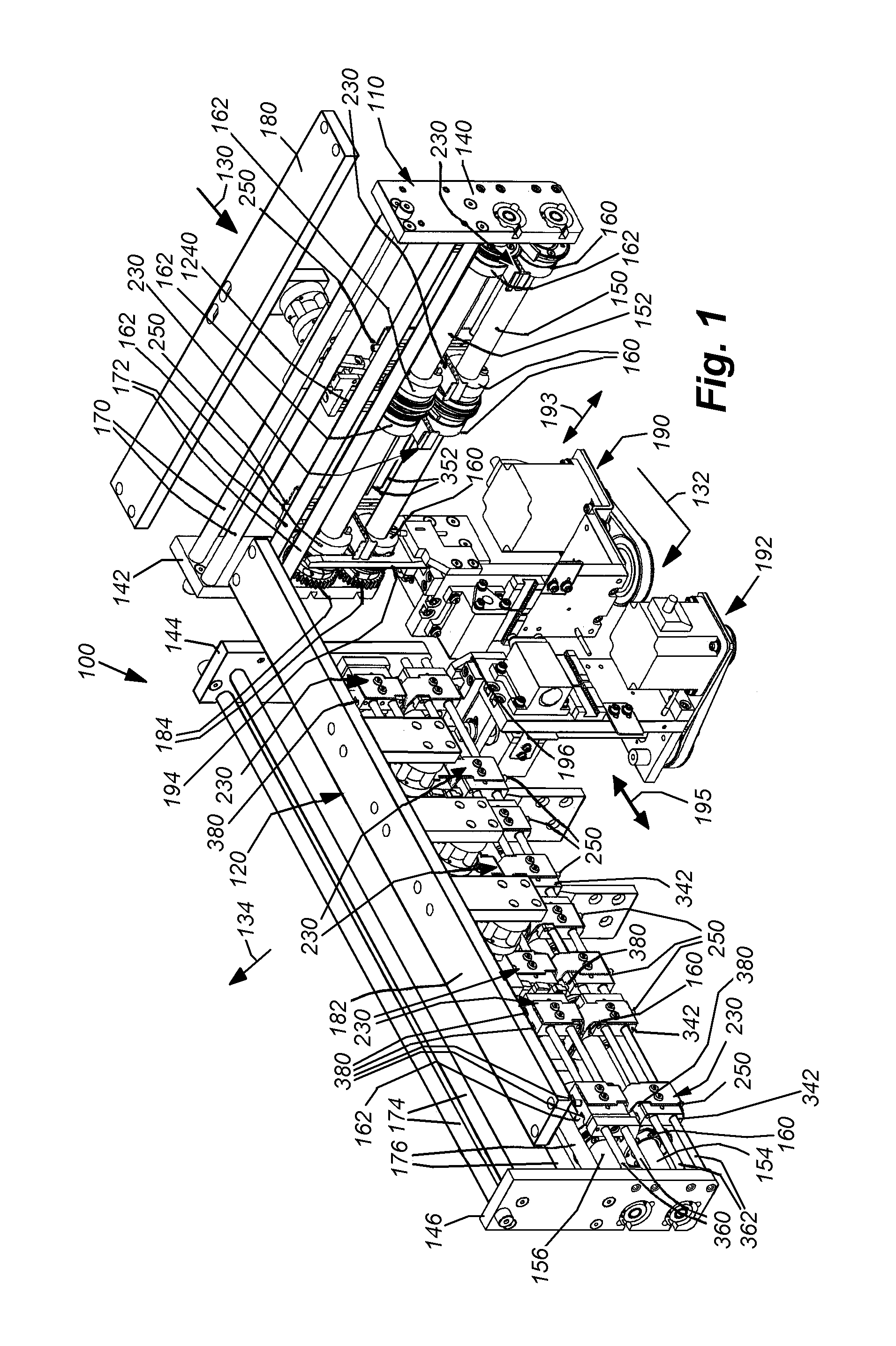

Sheet slitting mechanism with automated size adjustment

ActiveUS20130112055A1Overcome disadvantagesCross-cut reciprocating sawsMetal working apparatusSize adjustmentCam

This invention provides a slitter assembly with automated adjustment of slitter elements that allows for driven rotation of elements on the associated drive shaft during operation while enabling the elements to be moved freely along the drive shaft during setup and subsequently secured to the shaft free of lateral movement. This ensures that adjustment of the slitter elements is accurate, repeatable and reliable. In an illustrative embodiment, the slitter elements each comprise a pair of coaxial members including a blade member and a locking member. The blade member contains a slitter blade and overlies the locking member which is nested therewith. The locking member directly engages the drive shaft surface with a wedge assembly structure. The members are spring-loaded with respect to each other so that the two surfaces are normally biased to cam together and exert a hoop stress on the drive shaft.

Owner:LASERMAX ROLL SYST

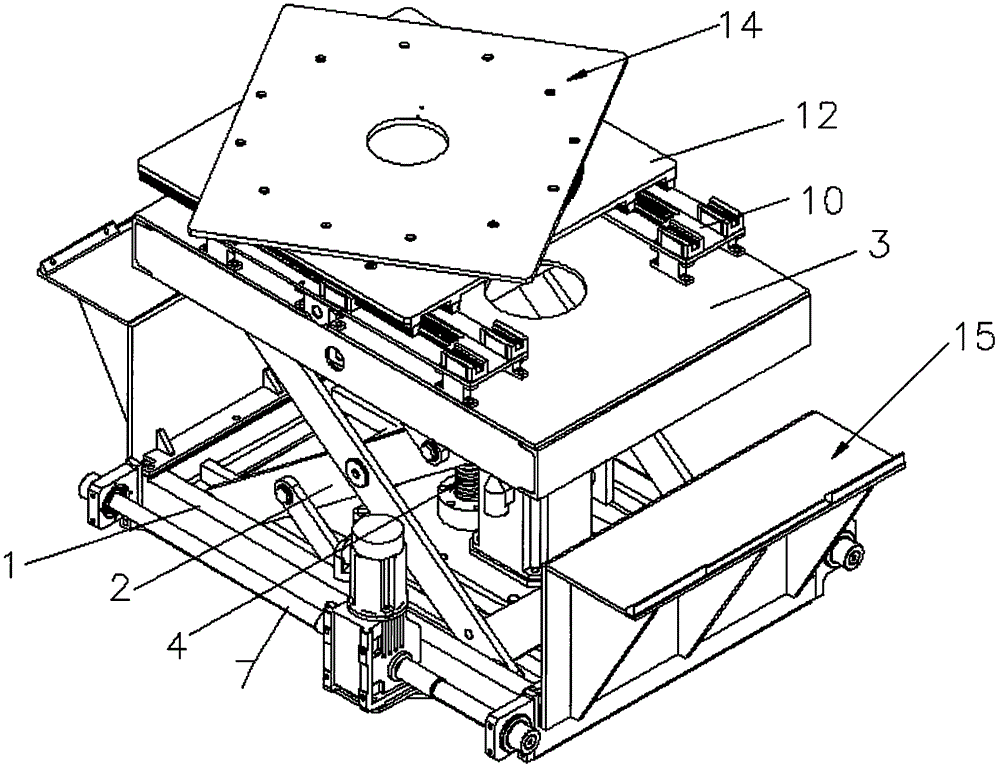

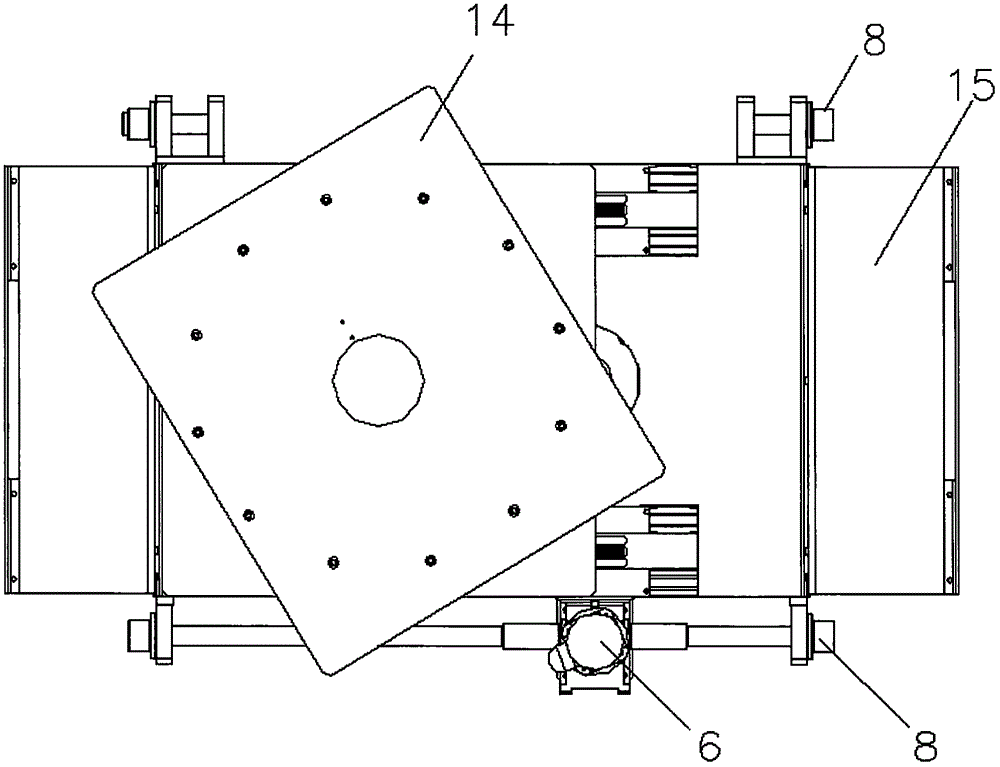

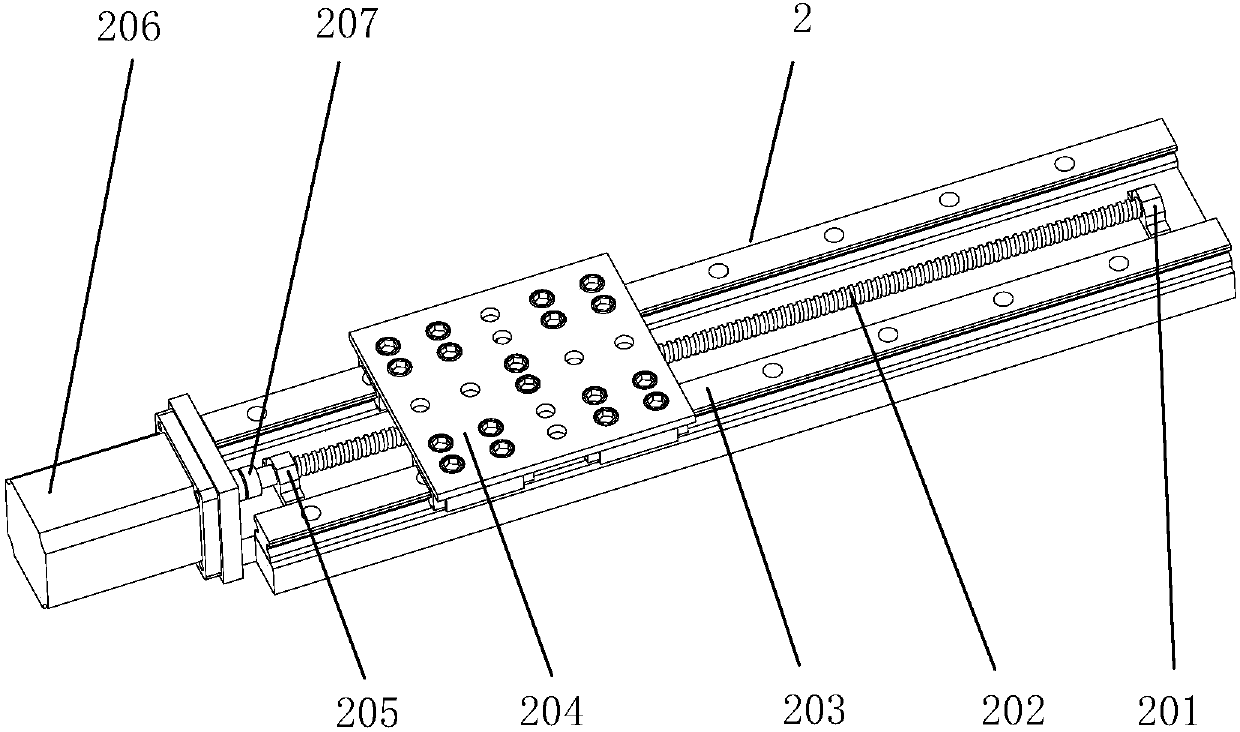

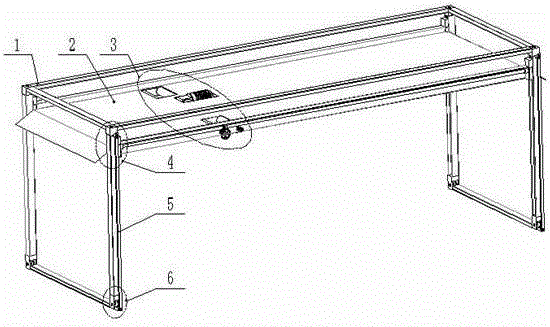

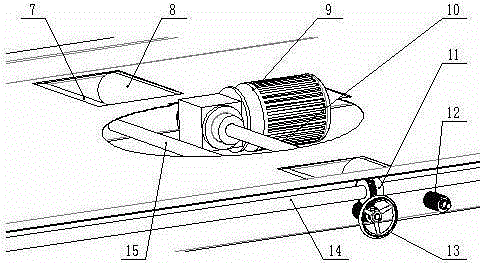

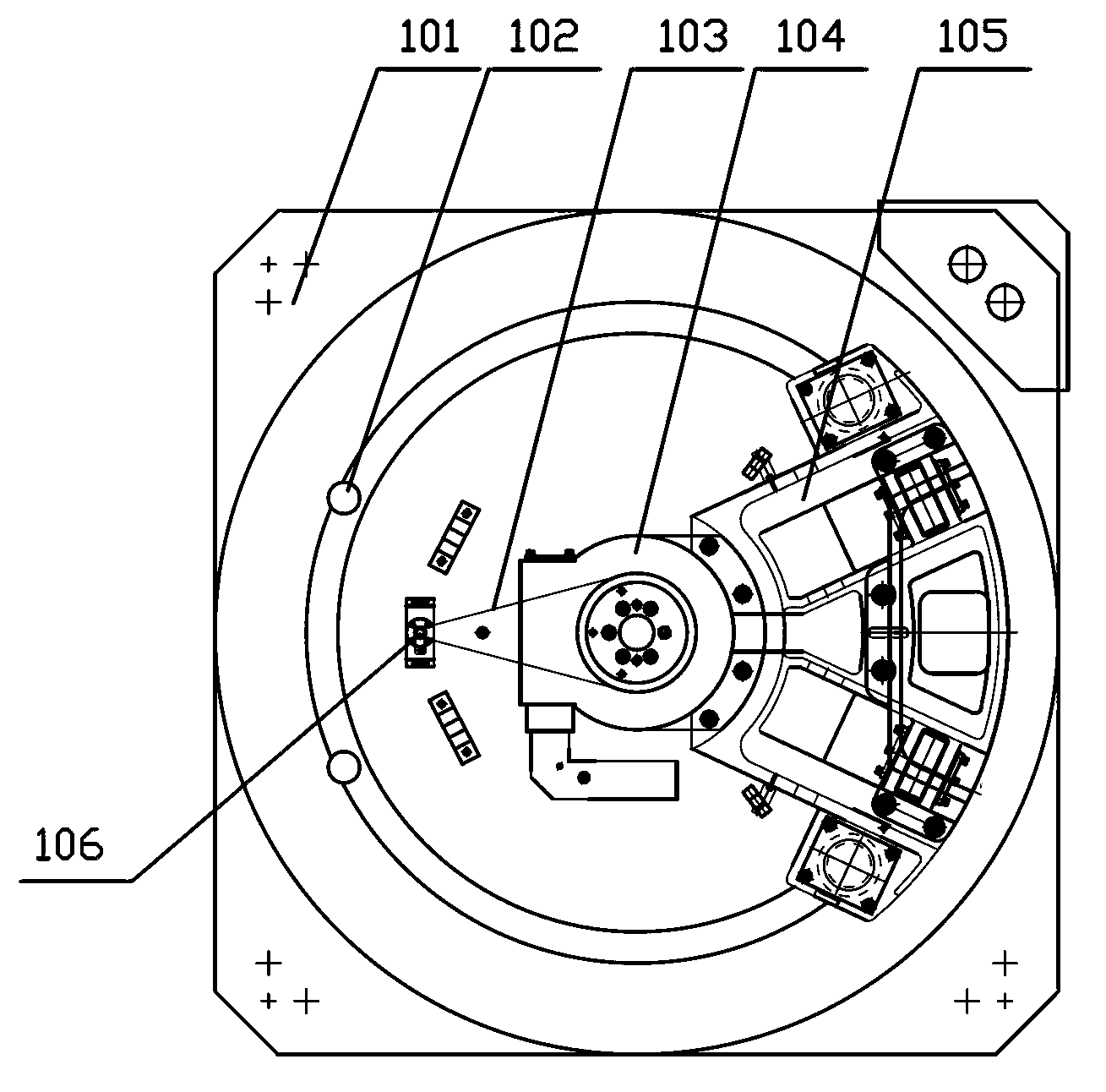

Hybrid driving device of avoidance-free three-dimensional garage

The invention discloses a hybrid driving device of an avoidance-free three-dimensional garage. The hybrid driving device comprises a power source switching device 3, lifting and lateral moving switching devices 4 and traveling devices 6, wherein the power source switching device 3 is mounted into a car loading platform 2, each lifting and lateral moving switching device 4 is driven by a transmission shaft and mounted in the corresponding standing column of a parking space frame 1, and each travelling device 6 is driven by a screw, is mounted at the lower end of the corresponding standing column of the parking space frame 1 and moves along a lateral moving guide rail 5. The hybrid driving device has the advantages that by the hybrid driving device, parking and taking of cars in the parking spaces of each layer of the avoidance-free three-dimensional garage can be performed by using a car engine as a power source or using a single motor as the power source, avoidance-free parking and taking of cars in various layers of parking spaces are achieved, normal car parking and taking under a power failure condition are achieved, and simple operation and use convenience are achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

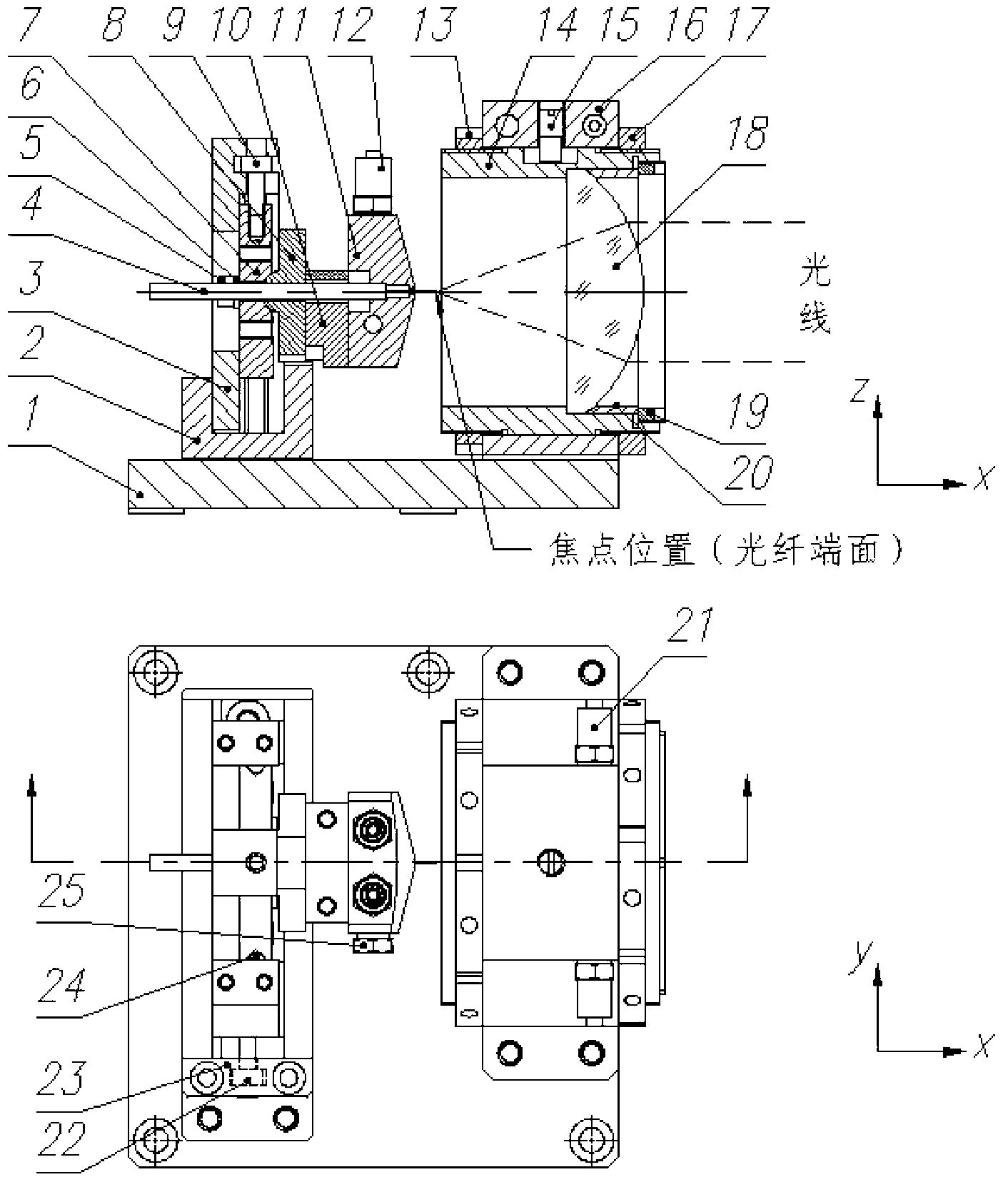

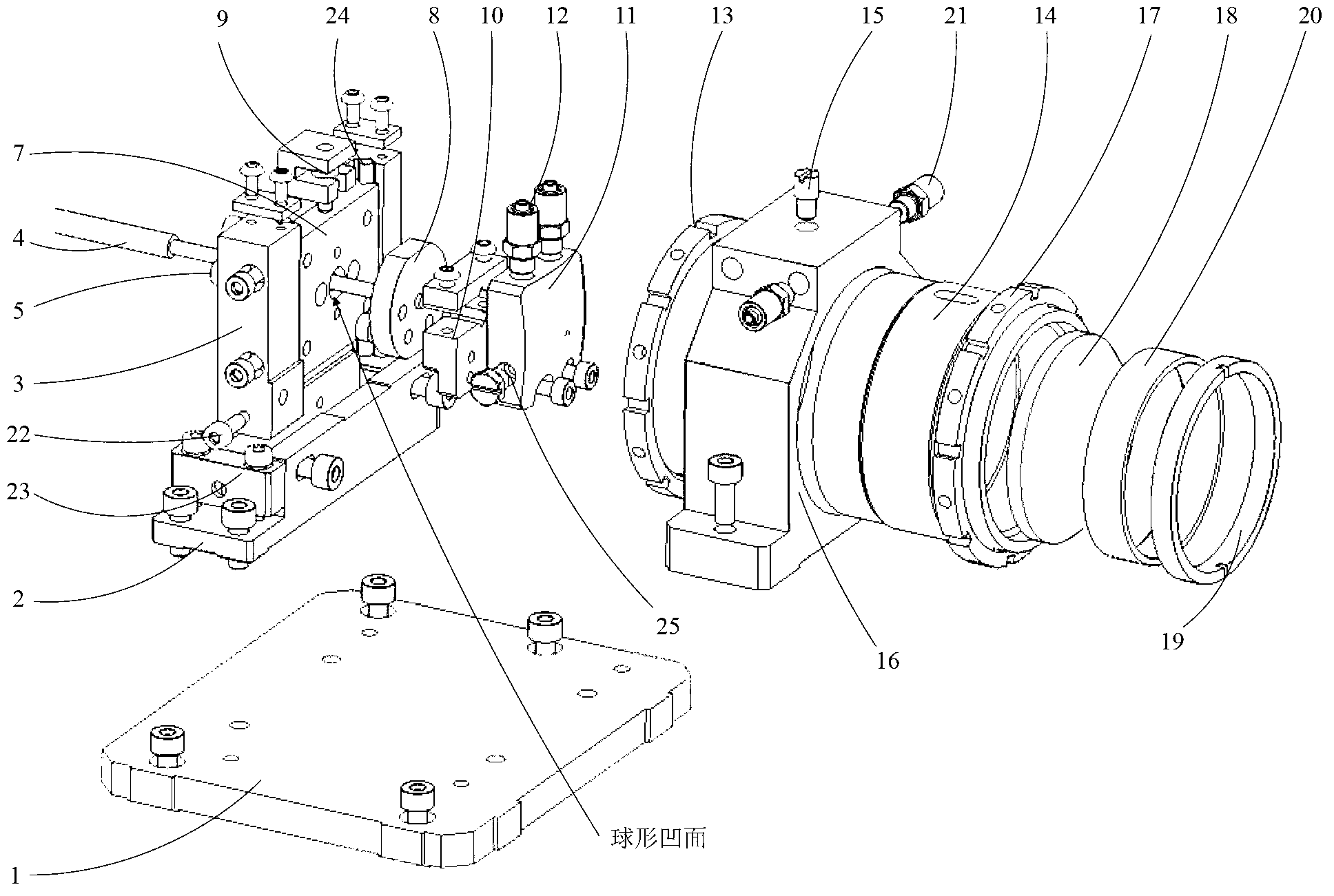

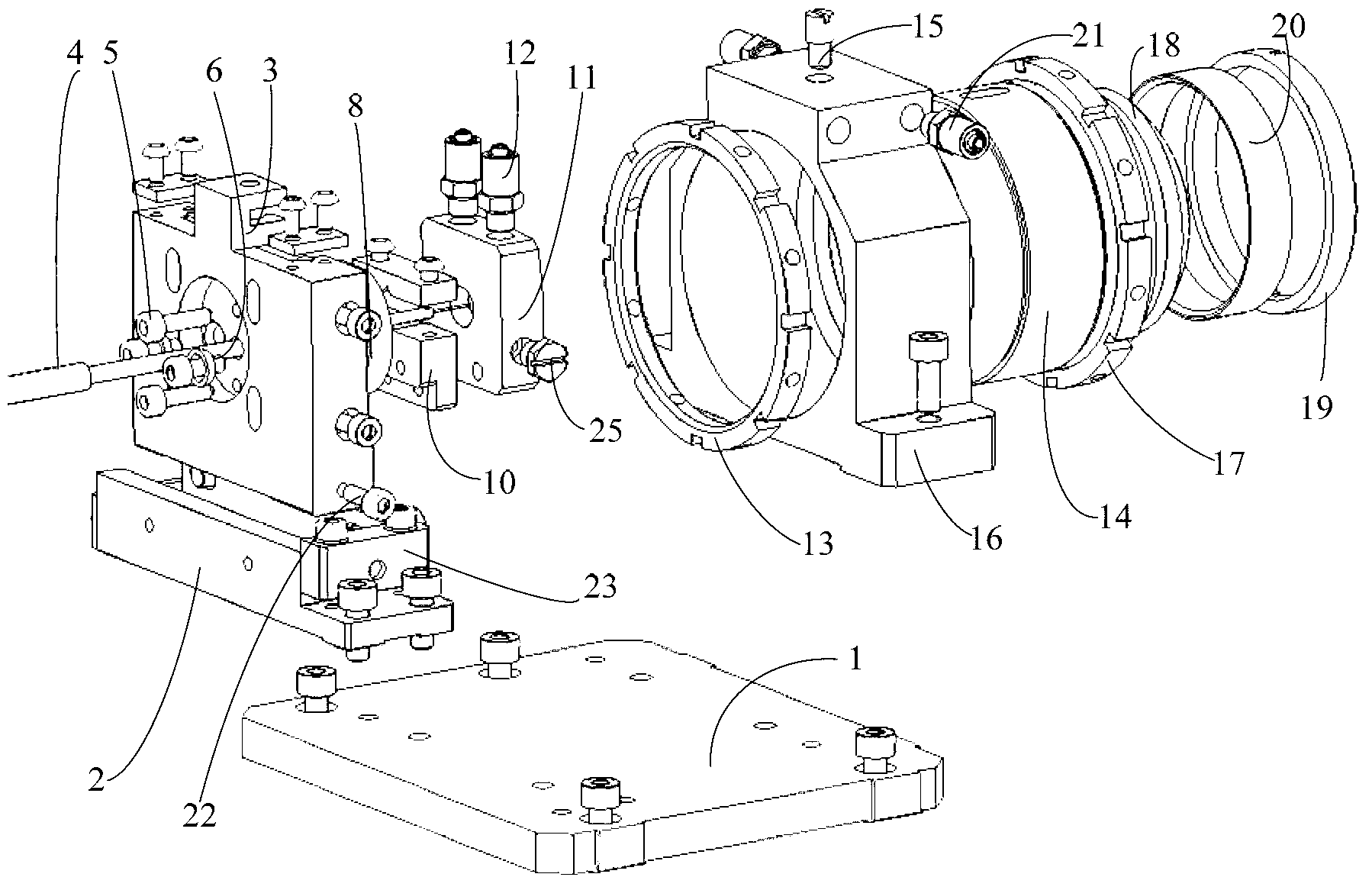

Optical fiber coupling device of fiber laser

InactiveCN102798944AReduce usageCompact structureLaser arrangementsCoupling light guidesEngineeringFiber disk laser

The invention provides an optical fiber coupling device of a fiber laser comprises bottom plate, an optical fiber support base, an optical fiber support lateral moving plate, an angle adjustment screw, a spherical washer, an optical fiber support longitudinal moving plate, an optical fiber support angle adjustment plate, a longitudinal adjustment screw, an optical fiber fixed seat, an optical fiber water-cooling block, an optical fiber water-cooling block water nozzle, a rear end locking nut of a focusing lens barrel, the focusing lens barrel, a guide pin of the focusing lens barrel, a focusing lens barrel seat, a front end locking nut of the focusing lens barrel, a focus lens, a focus lens pressing ring, a focus lens washer, a focusing lens barrel seat water nozzle, a transverse adjustment screw, a limit block of the transverse adjustment screw, a guide rod and an optical fiber water-cooling screw plug. The optical fiber support lateral moving plate is matched with the U-shaped structure of the optical fiber support base, the optical fiber support longitudinal moving plate is matched with the U-shaped structure of optical fiber support lateral moving plate, the optical fiber support angle adjustment plate is matched with the optical fiber support longitudinal moving plate through a spherical surface, and the excircle of the focusing lens barrel is matched with the bore of the focusing lens barrel seat. The optical fiber coupling device has a compact structure, is convenient to operate, and is stable and reliable.

Owner:BEIJING GK LASER TECH

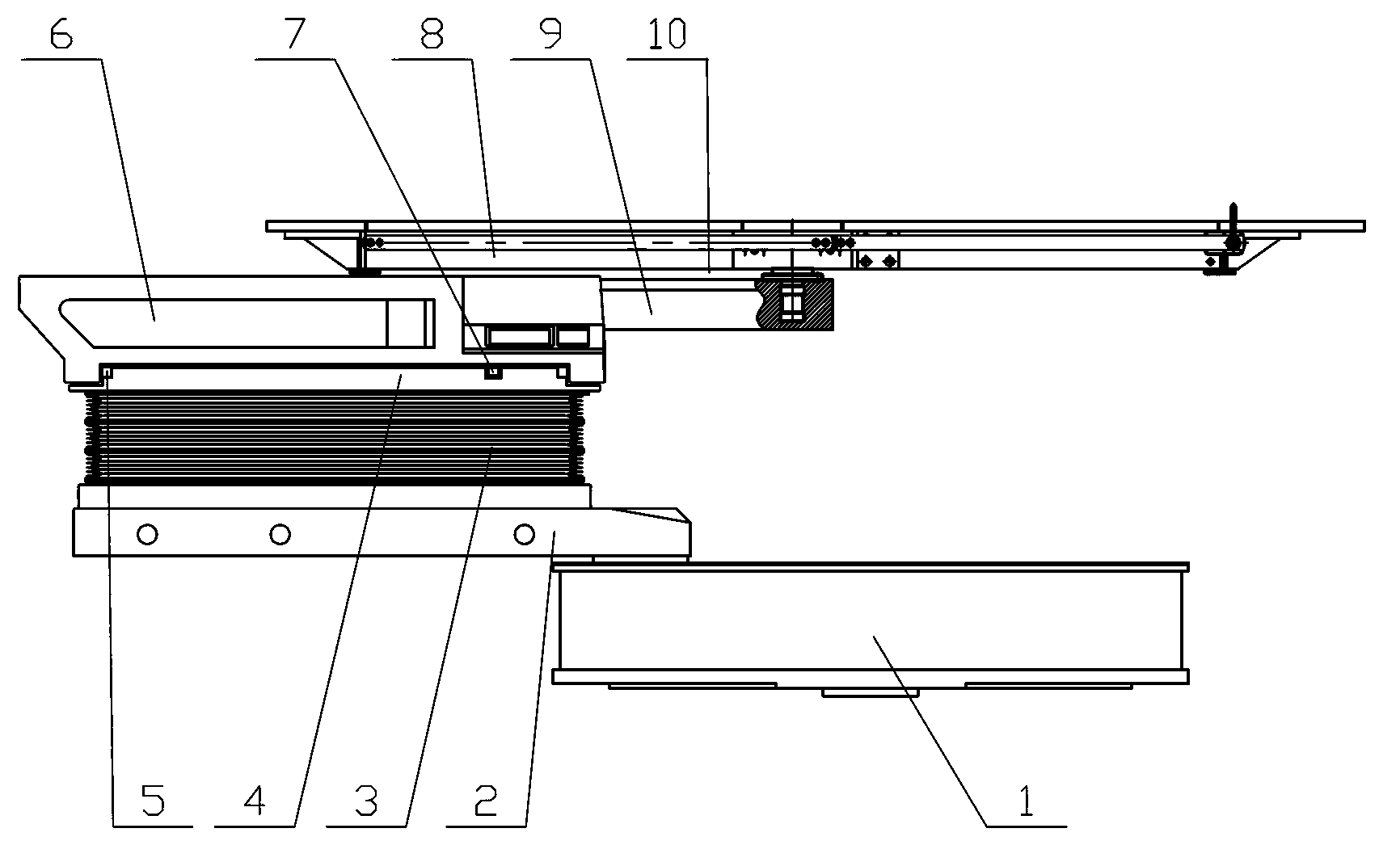

Large medical device treatment bed

ActiveCN103301581AGuaranteed uptimeImprove securityOperating tablesX-ray/gamma-ray/particle-irradiation therapyEngineeringMedical device

The invention relates to a large medical device treatment bed and belongs to the field of medical devices. The large medical device treatment bed comprises a bed rotating assembly. A bed base is hinged to the bed rotating assembly, a lifting assembly is fixed on the bed base and is provided with a bracket assembly, the bracket assembly is provided with a lateral moving assembly, the lateral moving assembly is connected with the bracket assembly through a horizontal bearing, a longitudinal assembly is connected with the lateral moving assembly through a longitudinal bearing, and the bracket assembly is provided with a driving device. The large medical device treatment bed can automatically accurately correct errors on line and is high in running precision, safe and reliable.

Owner:SHINVA MEDICAL INSTR CO LTD

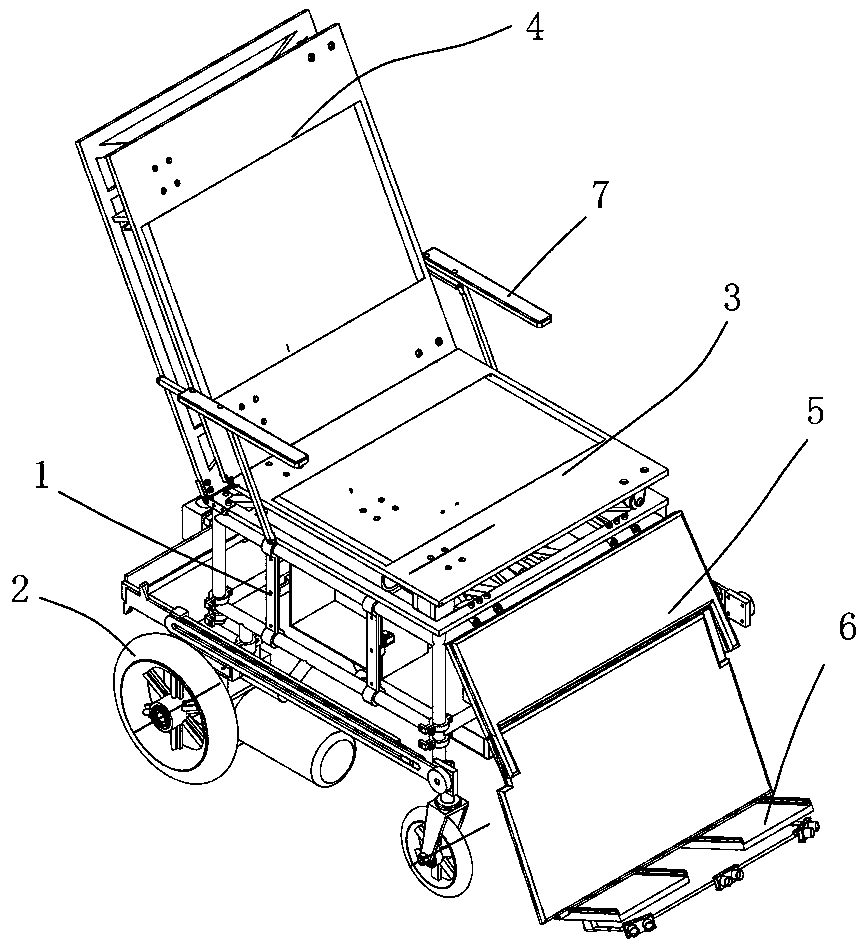

Wheelchair

The invention discloses a wheelchair, which comprises a frame, wheels, a seat cushion, a backrest, a front curtain plate, pedals and armrests, and is characterized in that a deformation driving deviceis arranged, and the deformation driving device drives the backrest and the front curtain plate to rise and fall, so that the wheelchair is changed between a chair shape and a lying state; a lateralmoving device is arranged, the seat cushion and the backrest are connected with the frame through the lateral moving device, and the lateral moving device moves the seat cushion and the backrest between a first position on the wheelchair and a second position overlapping the wheelchair and the bed body; the seat cushion and the backrest are provided with conveyor belts which move laterally. According to the invention, no modification is carried out on a bed body and a patient can be conveniently transferred between the wheelchair and the hospital bed.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com