Apparatus for detecting parallelism of two planes of platelike workpiece

A technology for plane parallelism and plate-shaped workpieces, which is applied in the field of detection devices, can solve the problems of inability to simultaneously collect workpiece position data, expensive measurement methods, and impracticality, and achieve the effects of reduced measurement costs, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

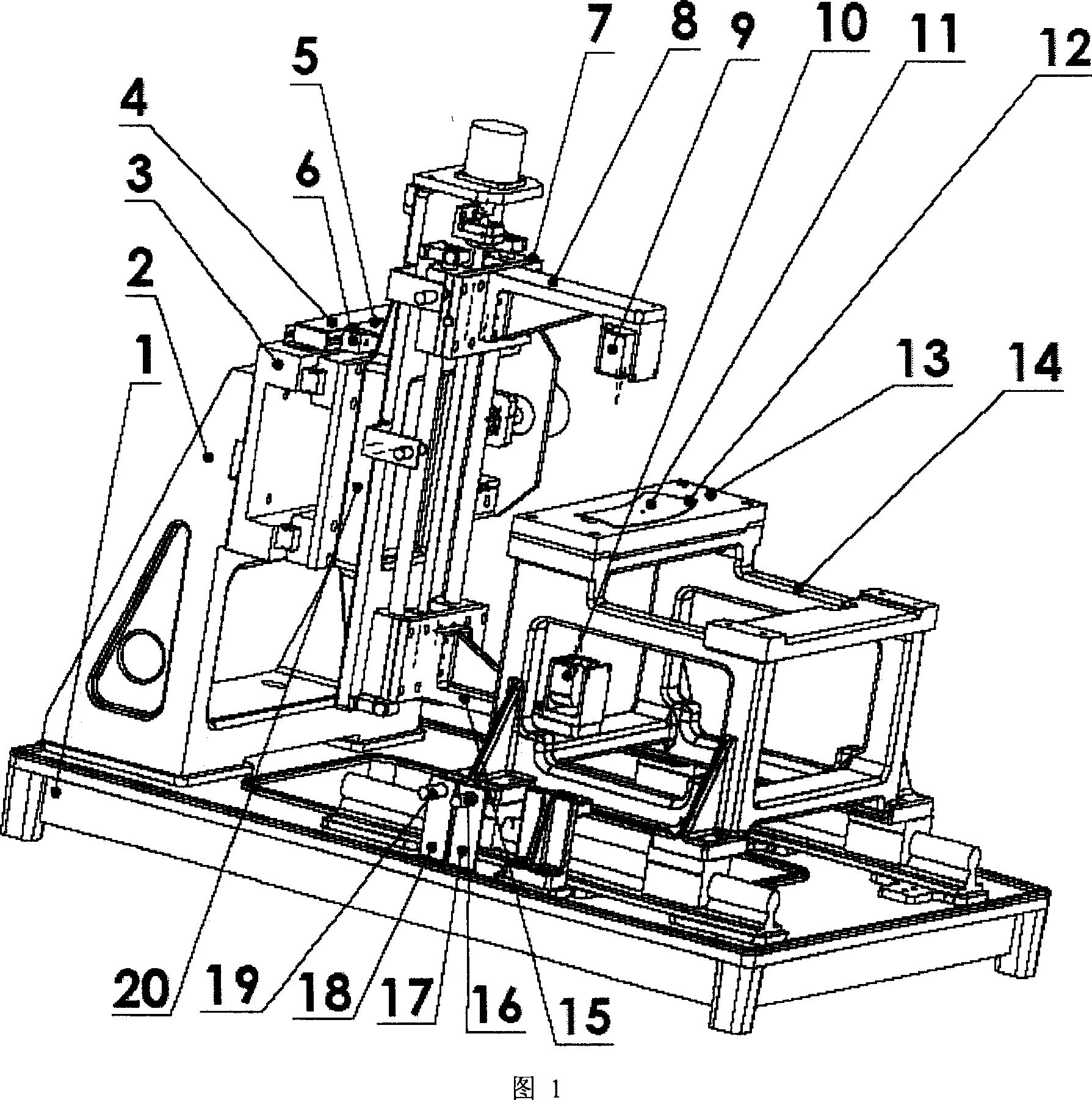

[0016] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

[0017] Fig. 1 is a perspective view of the structure of the device for detecting the parallelism of two planes of a plate-shaped workpiece, which includes: a base 1, on which a vertical side plate 2 is arranged, and a lateral movement is installed on the side of the vertical side plate 2 located directly above the base 1 Mechanism 3, the lateral movement mechanism 3 is connected with the vertical movement mechanism 7 of the laser sensor through the vertical connecting plate 20, and drives the vertical movement mechanism 7 of the laser sensor to reciprocate laterally, at the same time, a grating ruler 4 is installed above the transverse movement mechanism 3, The movable part 6 of the grating ruler 4 is connected with the vertical connecting plate 20 through the connection plate 5, so that the grating ruler 4 can collect the displacement value of the lateral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com