Patents

Literature

242 results about "Slipway" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slipway, also known as boat ramp or launch or boat deployer, is a ramp on the shore by which ships or boats can be moved to and from the water. They are used for building and repairing ships and boats, and for launching and retrieving small boats on trailers towed by automobiles and flying boats on their undercarriage.

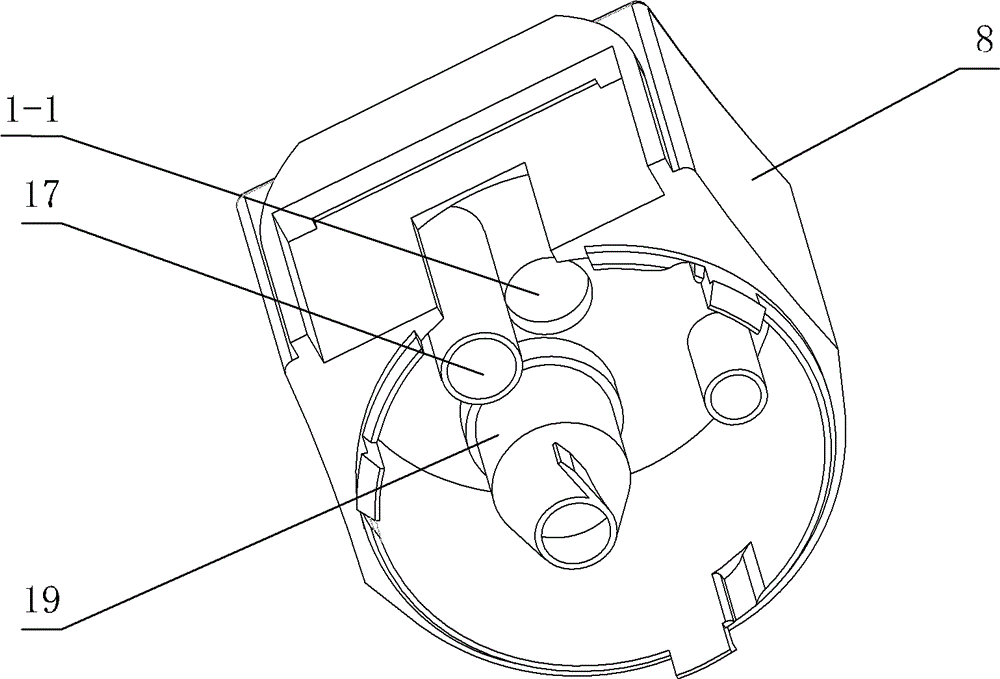

Flapping wing unit of flapping wing aircraft

The present invention relates to flapping wing aircraft, and is especially an improved flapping wing unit of flapping wing aircraft. The motors on the base respectively drive the two symmetrical steering engine drivers to rotated through a speed reducer, the motor of the steering engine driver is hinged through crank-link rod mechanism to lever driving shaft with a first bearing seat in the end, the roll on the lever driving shaft is fitted to the slipway inside the shell of the steering engine driver, the rotation shaft with bearings and second bearing seats is mounted on the casing, the lever driving shaft has the other end hinged to link rod hinged to wing handle, and the wing handle has one end with mounted wing and the other end hinged to the support arm of the rotation shaft. The present invention makes the flapping wing aircraft possess great lifting power, propelling power and stable flying state.

Owner:李玺芳

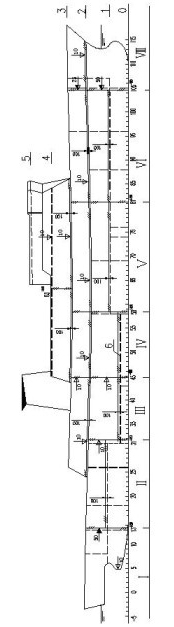

Mounting method of ship long axis system

The invention relates to a mounting method of a ship long axis system. Technical measures are respectively taken for the mounting processes and the mounting precision control of the mounting of the ship long axis system in all mounting stages of an inner site stage, a slipway construction stage and an axis system mounting and aligning stage to ensure that the mounting and the aligning of the axis system smoothly meet check and accept requirements, and the mounting and aligning period of the axis system is shortened so as to shorten a ship construction period.

Owner:WUHAN WUCHUAN MEASUREMENT & TEST

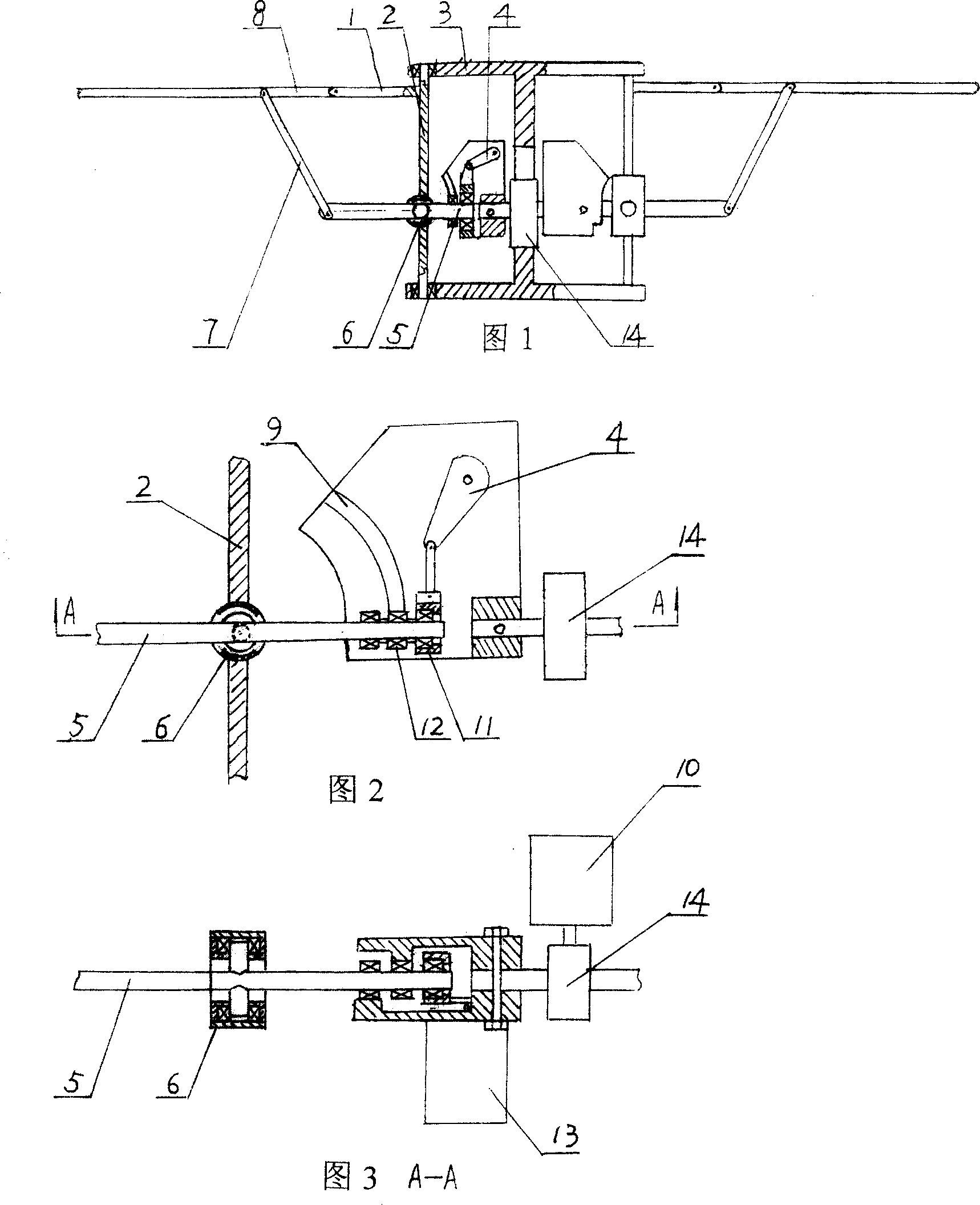

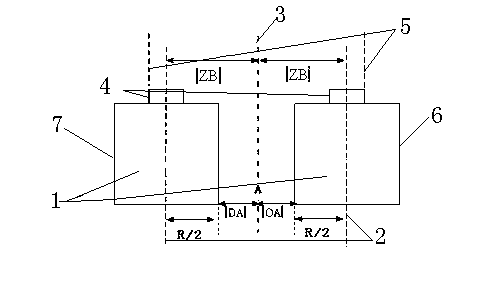

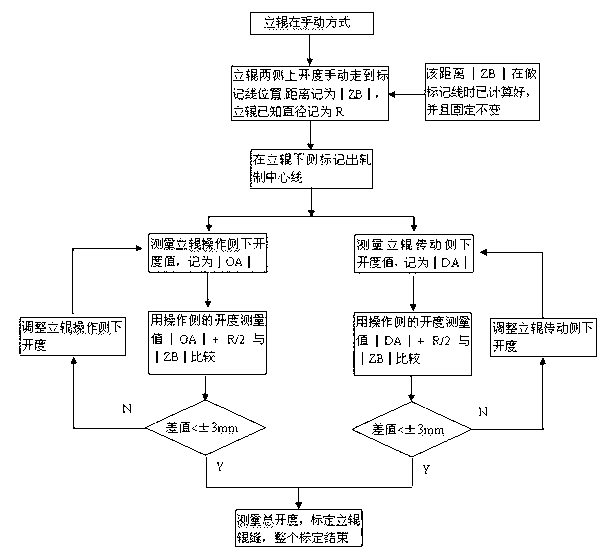

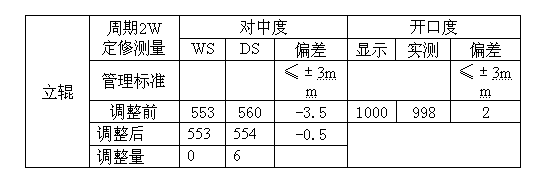

Calibration method for clearance between rolls of hot-rolling vertical rolls

InactiveCN102989792AProtective functionEliminate the problem of abnormal widthMetal rolling stand detailsMeasuring devicesStrip steelEngineering

The invention relates to a calibration method for clearance between rolls of hot-rolling vertical rolls, which mainly solves the technical problem that strip steel is deficient in quality because verticality and alignment to calibration of vertical rolls are not considered in current methods. The technical scheme is that the calibration method for clearance between rolls of hot-rolling vertical rolls comprises the steps of: 1, finding a rolling center line and marking; 2, additionally arranging two position marks on a transverse slipway of a hot-rolling vertical roll device, and marking the distance from the marks to the rolling center line as |ZB|; 3, hitting apertures on both sides of the vertical rolls to marked positions, wherein a roll block is inside a marking line and aligned with the marking line; 4, measuring the distance from the lower ends on both sides of the vertical rolls to the rolling center line, and marking the measuring point as a point A, the radius of the rolls as R / 2 and the distances from A to a vertical roll operating side and from A to a transmission side as |OA| and |DA|; 5, comparing the measured value |OA|+R / 2 on the operating side with |ZB|, wherein if the difference is in a precision range, the verticality is good, and if the difference is not in the precision range, the clearance between rolls on the operating side is adjusted so that the difference is in the precision control range; 6, adjusting the clearance between rolls on the transmission side by the adjusting method in the step 5; and 7, measuring the total aperture of the vertical rolls, inputting the measured values and calibrating the clearance between rolls of vertical rolls after adjusting the verticality and alignment.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for manufacturing and installing guide rail in container ship cargo hold

InactiveCN101885368AImprove installation accuracyAvoid welding deformationVessel partsEngineeringSlipway

The invention discloses a method for manufacturing and installing a guide rail in a container ship cargo hold, which comprises the following steps of: (a) manufacturing the guide rail; (b) two-dimensional preassembly: assembling and welding a processed guide plate and the guide rail on a platform by using a doubling plate as a basal plane; (c) hoisting and boarding: installing an eye ring of the guide rail on the guide rail a quarter away from the upper end, respectively installing one eye ring at the left side and the right side of the guide plate, correspondingly reinforcing the eye rings from the back side, and hoisting the whole guide rail to a slipway; adding a toggle plate behind the doubling plate to reinforce the guide rail with low intensity; and after manufacturing the guide rail of a following ship in two segments, connecting the two segments into one guide rail after correction, and hoisting the assembled guide rail; (d) slipway installation: marking, and installing the guide rail; and (e) packaging and testing. In the method, the guide rail is firstly preassembled on the platform by using the doubling plate as the basal plane, and then, the whole guide rail is hoistedonto the slipway and installed. The invention has simple and reasonable method, convenient construction and high guide rail installation accuracy. The upward and downward hoisting and the reasonable arrangement of containers in the cargo hold can be ensured, and thus, the working efficiency and the ship manufacturing quality are increased.

Owner:YANGFAN GROUP

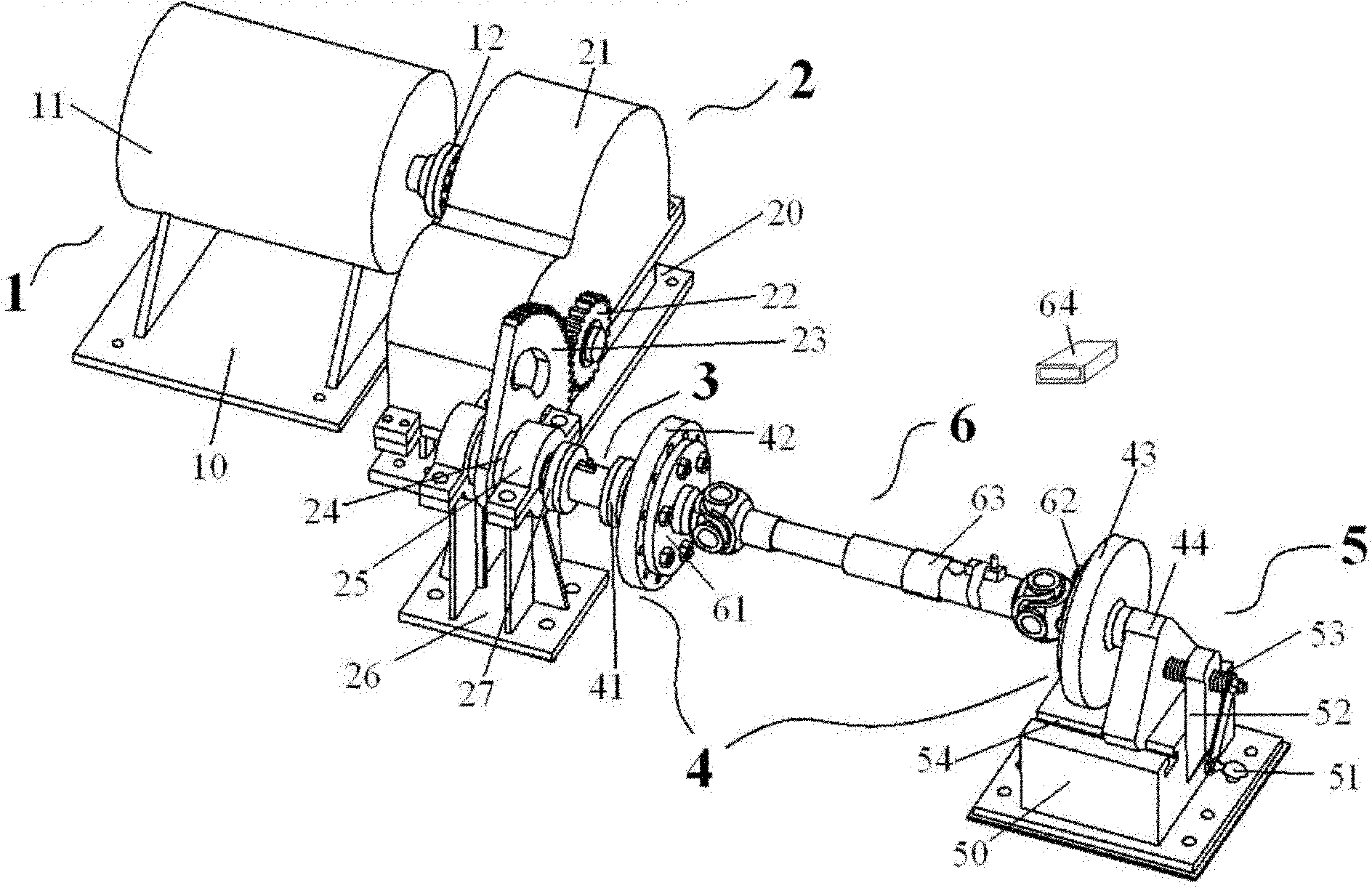

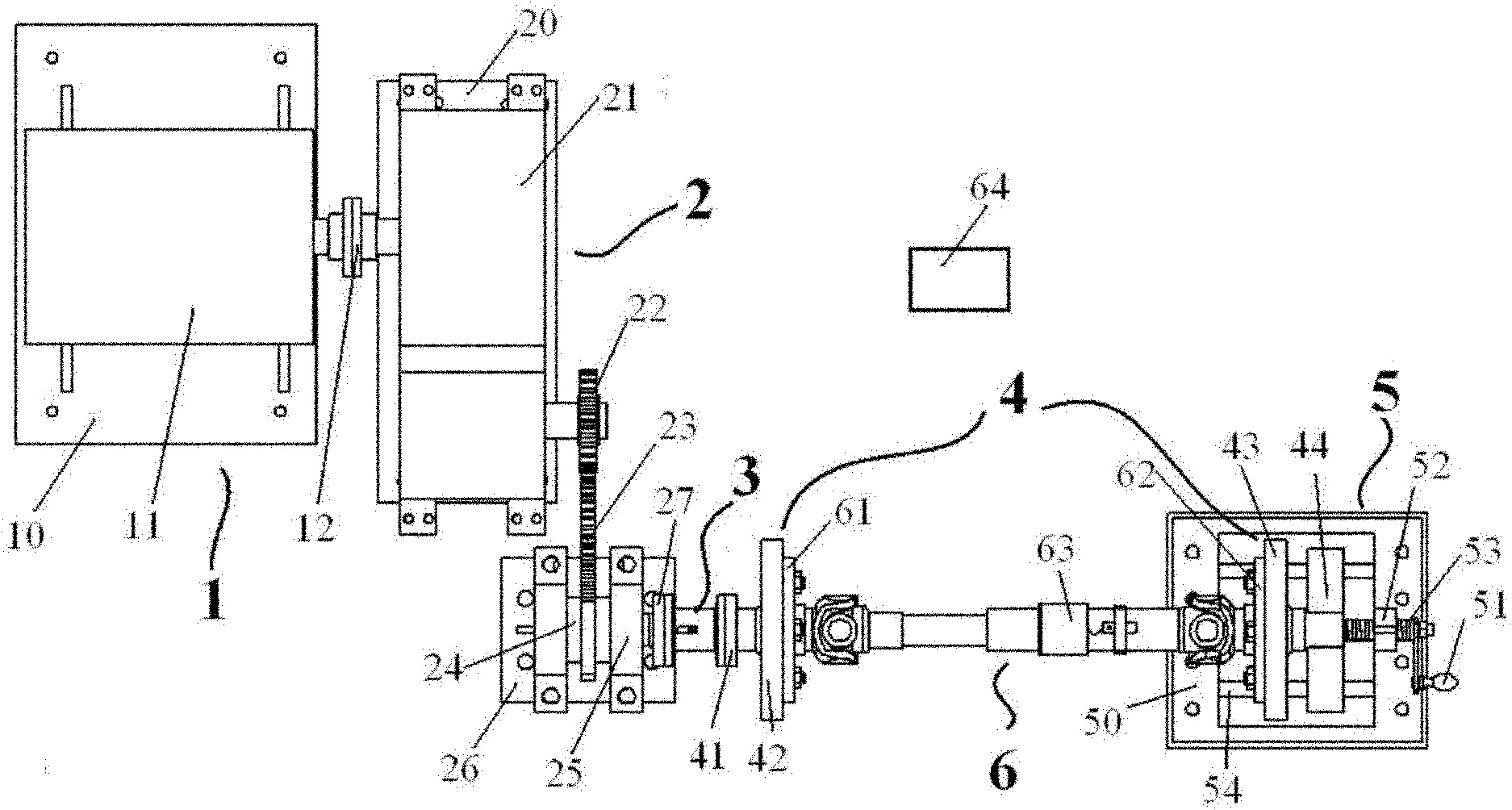

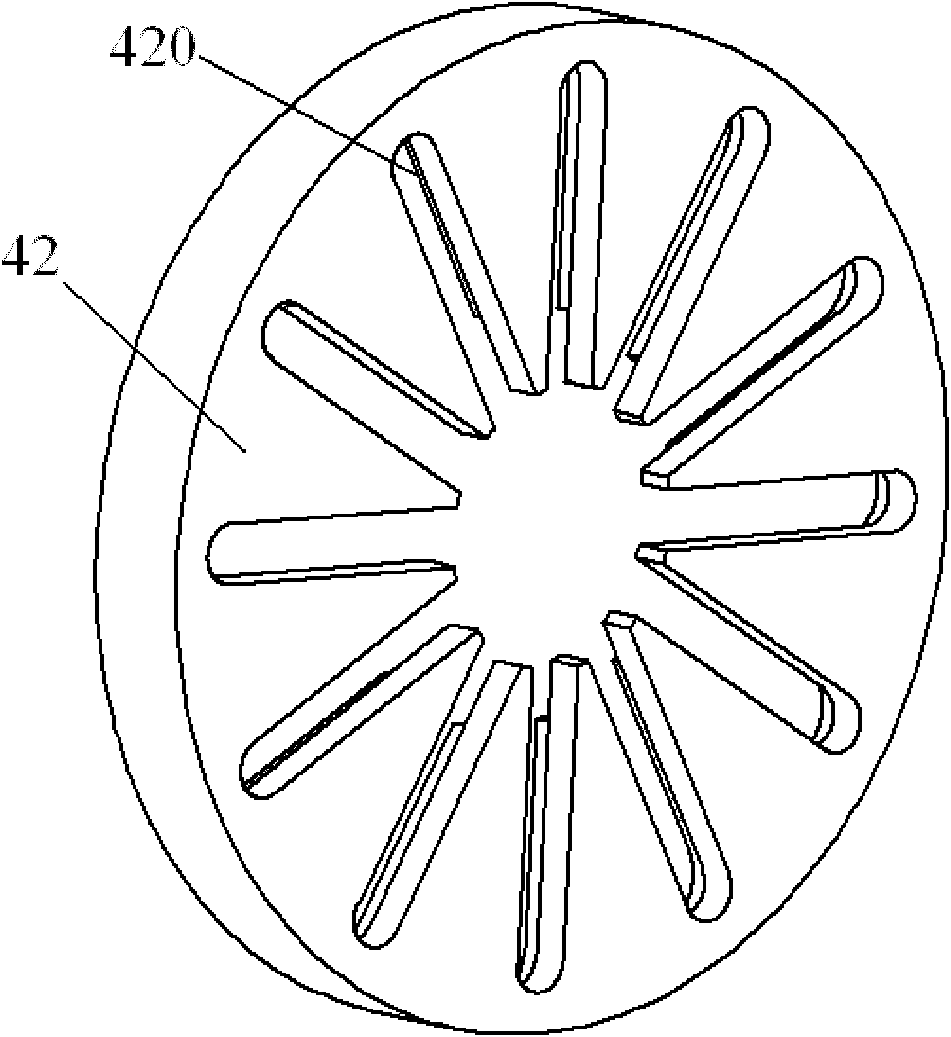

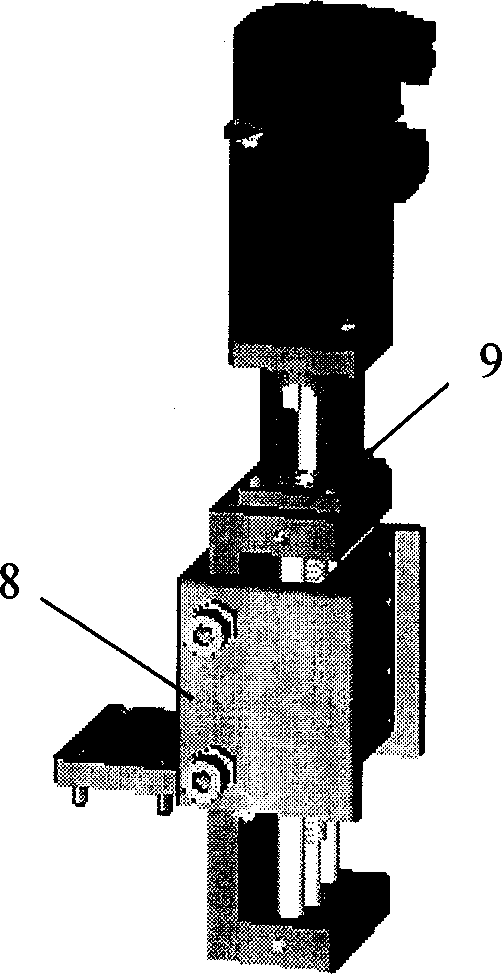

Torque calibration test bed for loader transmission shaft

InactiveCN102032967ATo achieve a fixed connectionReduce cost inputMachine gearing/transmission testingWork measurementReduction driveControl theory

The invention relates to a torque calibration test bed for a loader transmission shaft. The test bed mainly comprises a power module, a speed reducing module, a torque sensor, a switching module and an end part supporting module, wherein a motor in the power module is connected with a speed reducer in the speed reducing module through a shaft coupling; the speed reducer realizes gear transmission with a central shaft through a pinion and a large toothed sector; the central shaft is arranged on a bearing seat bracket through a bearing and a bearing seat; the torque sensor is coaxially fixed between the central shaft and a left deformed ring flange in the switching module through a flange; and a right deformed ring flange of the switching module is connected with a slipway of the end part supporting module in a sliding way through a slide block on a right deformed ring flange bracket. The limit of manual torque loading is overcome, the test bed is suitable for calibrating torques of loader transmission shafts of different specifications and different lengths, and quick calibration of the torques of different types of loader transmission shafts is realized.

Owner:JILIN UNIV

Shaft, rudder system mounting process of ten-thousand-ton grade special multipurpose vessel

The invention discloses a mounting process for shaft and rudder systems of a 10,000-ton class special multipurpose vessel, which comprises the following steps: a. before the vessel is launched, a center line of the shaft system and a center line of the rudder system are determined; b. a stern tube is positioned and poured with epoxy, the vessel is launched after a waterproof close board is arranged; and c. a screw shaft, a propeller, a tiller and a rudder blade are arranged. Through adopting the way, the mounting process for shaft and rudder systems of the 10,000-ton class special multipurpose vessel overcomes the inconvenience that the screw shaft, the propeller, the tiller and the rudder blade of the vessel are all placed on a slipway for installation before the vessel is launched in the prior art, and makes the vessel launch after the shaft line and the ruder line are determined and checked, thereby saving time for preparing the screw shaft, the propeller, the tiller and the rudder blade of the vessel, shortening the construction cycle of the vessel, improving the utilization rate of the longitudinal slipway for a ship-building unit to construct the vessel, and reducing the production cost.

Owner:JIANGDONG SHIPYARD CHINA NAT CHANGJIANG SHIPPING COOPERATION

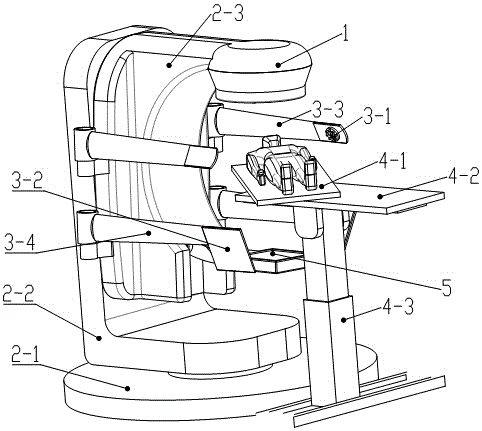

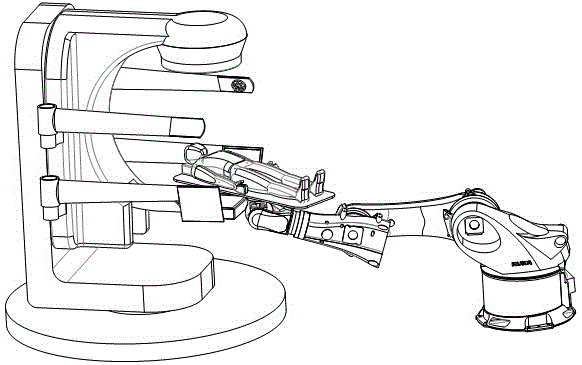

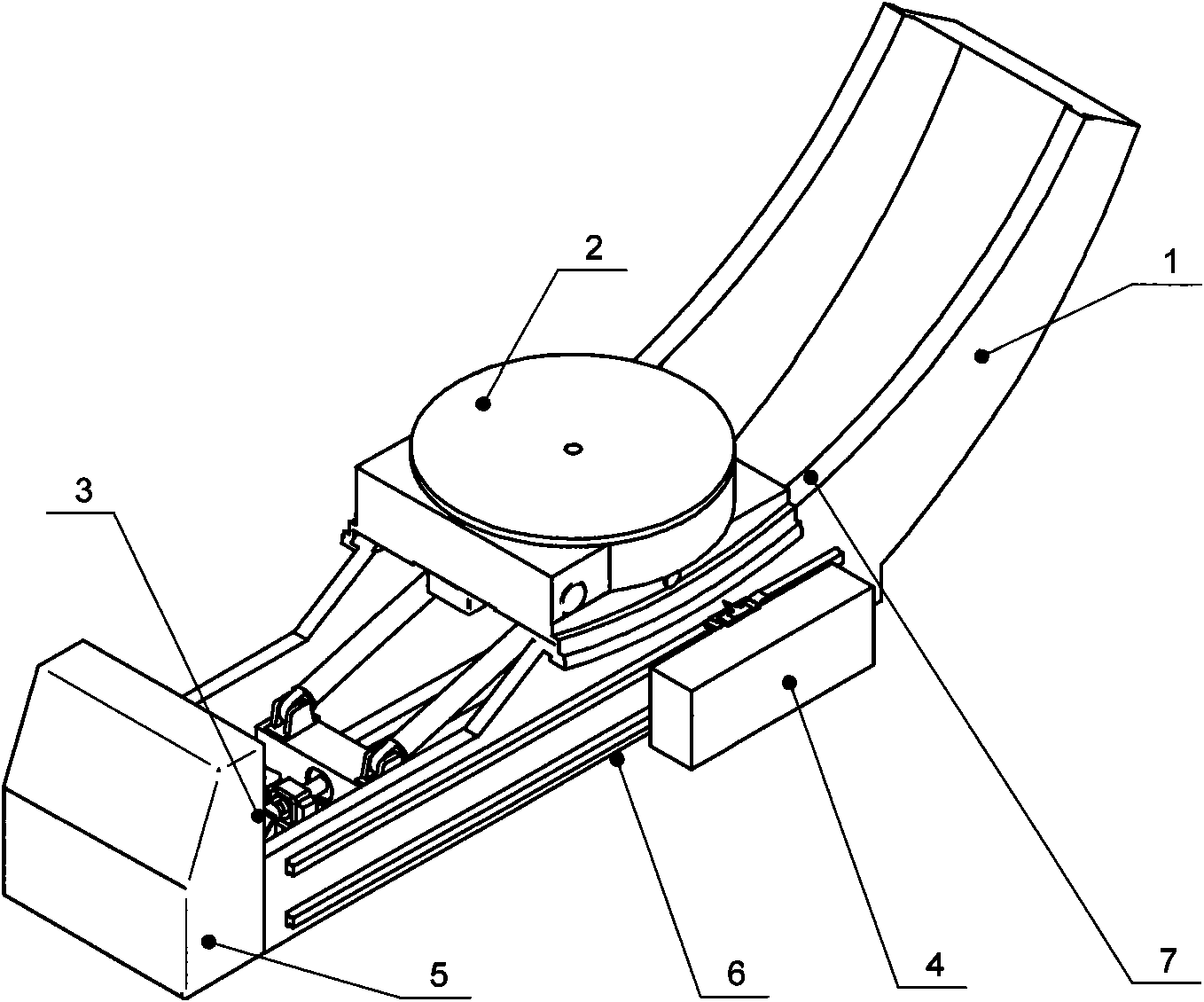

Non-coplanar radiotherapy system

ActiveCN105079986AIncrease flexibilityAchieve rotationX-ray/gamma-ray/particle-irradiation therapyMedical equipmentRange of motion

The invention relates to a non-coplanar radiotherapy system in the field of medical equipment, which comprises a radiation source, a frame, an image positioning system and a therapeutic bed. The frame is composed of a revolution base, an L-shaped rotation arm and a C-shaped rotation arm. The revolution base and the L-shaped rotation arm are connected via a revolute pair. The L-shaped rotation arm and the C-shaped rotation arm are connected via a second revolute pair. The radiation source is arranged at one end of the C-shaped rotation arm. The other end of the C-shaped rotation arm is provided with a dosimetric verification device. The image positioning system is composed of two sets of X-ray image systems. The two sets of X-ray image systems are arranged on the two sides of the C-shaped rotation arm in the crossed manner. The therapeutic bed is installed corresponding to the frame, and is composed of a therapeutic bed plate, a slipway and a therapeutic bed support mechanism. The therapeutic bed plate and the slipway are connected via a third revolute pair. The non-coplanar radiotherapy system can be used for the coplanar radiotherapy and the non-coplanar radiotherapy of head and neck neoplasms, bone neoplasms, spinal neoplasms and the like. Meanwhile, the frame is large in motion range and high in flexibility.

Owner:SICHUAN UNIV

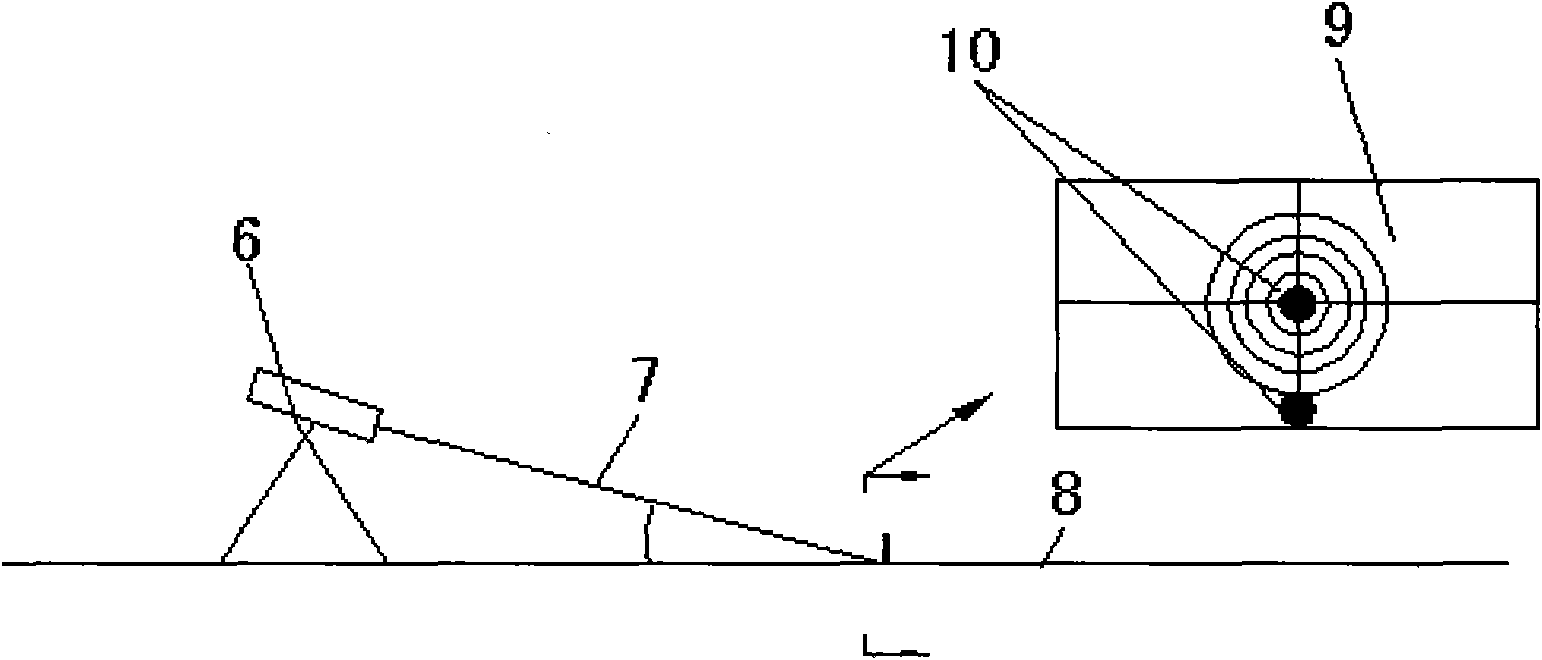

Method of applying total station to irradiating alignment and positioning of ship axis

InactiveCN102914278APromote generationMeet the construction precision requirementsUsing optical meansThree-dimensional spaceLight beam

A method of applying a total station to irradiating alignment and positioning of a ship axis includes: 1) arranging the reference total station on the slipway ground, generating a ray parallel to a slipway by the aid of a telescope of the total station, and transiting a theoretical reference point onto a reference target holder arranged on a stern according to a middle longitudinal line of the slipway ground and the perpendicular measuring design theory so that a reference target point is generated; and 2) arranging a working platform on one side of the reference target holder away from the stern, adjusting the three-dimensional space position of the aligning total station positioned on the horizontal working platform, and enabling a laser beam of the aligning total station to pass through the reference target point to generate a theoretical axis center line, namely an aligning total station laser beam ray. According to the method, irradiating alignment and positioning of the ship axis are achieved by the aid of the total station. During aligning construction of the ship axis, only one reference target point needs to be set on the slipway ground, and the three-dimensional space position and an emergent laser beam angle of the total station are adjusted, so that the theoretical axis center line beam for guiding axis alignment can be generated conveniently.

Owner:长航集团宜昌船厂有限公司

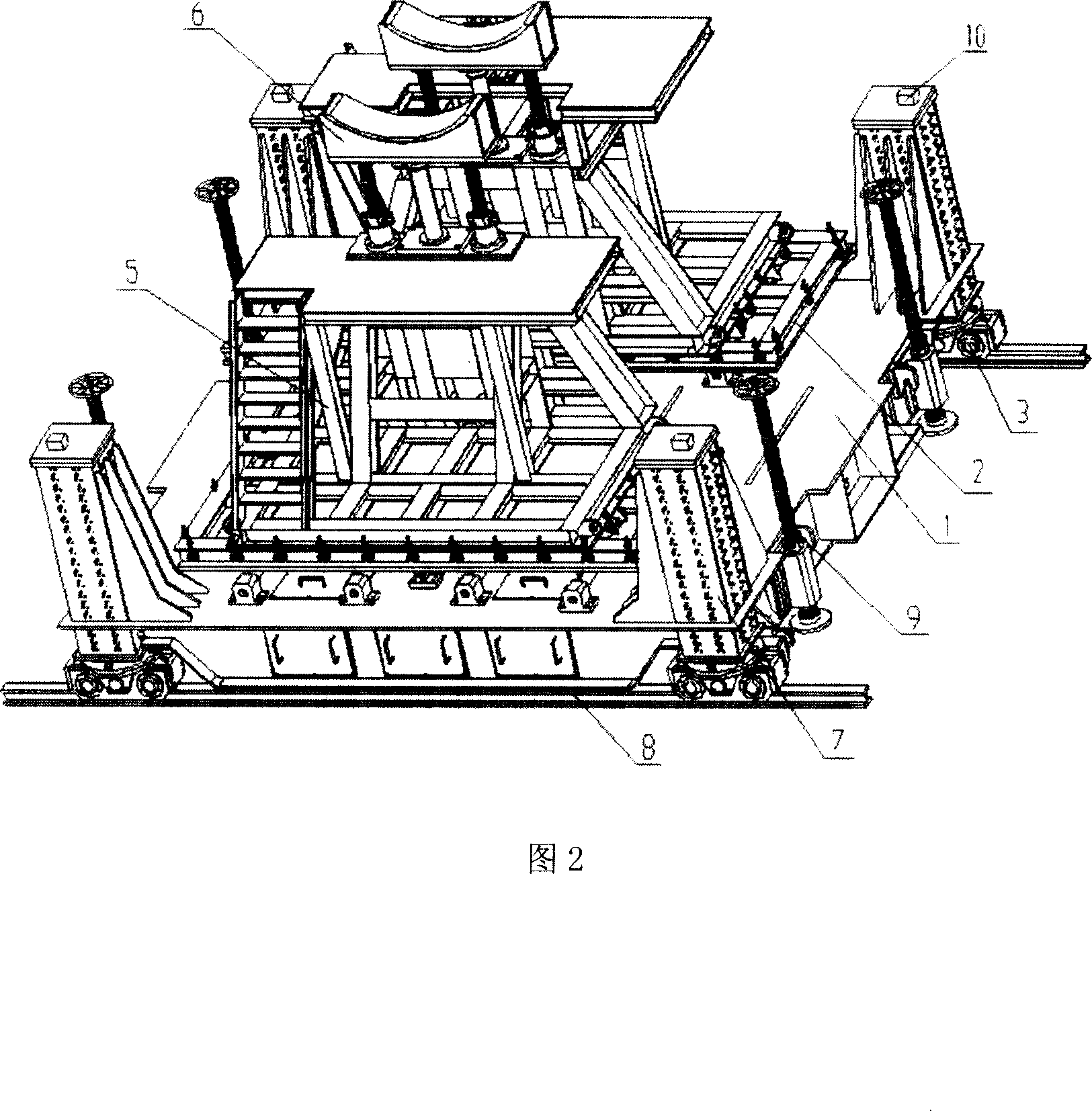

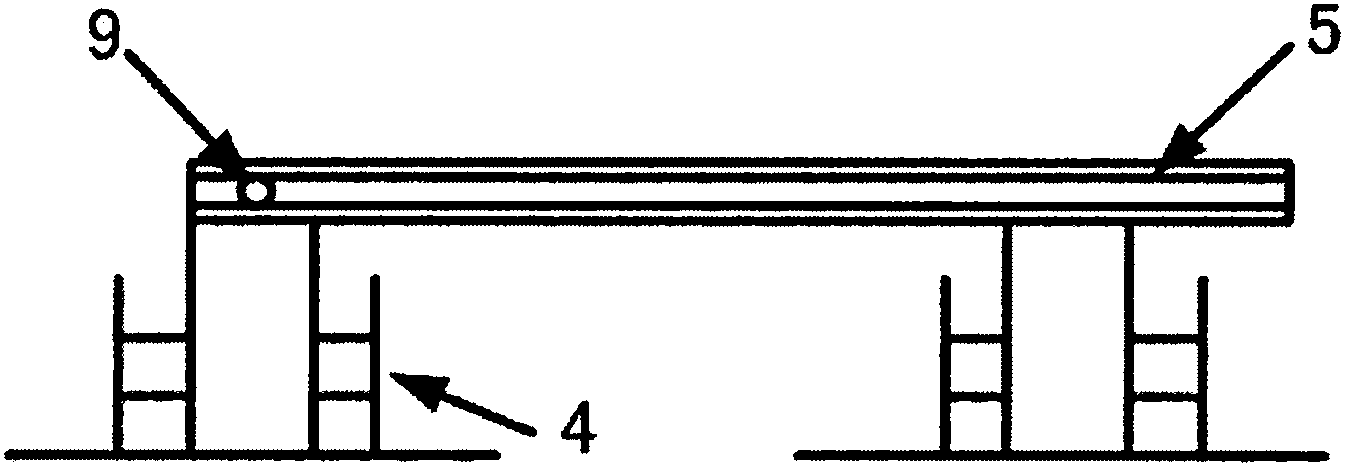

Hydraulic lifting stern platform

The present invention relates to ship building technology, and is especially one hydraulically lifting stern platform including working platform, planar slipway, rolling wheels, rudder blade floor stand, propeller floor stand and four main elevating hydraulic cylinders. Of the four main elevating hydraulic cylinders, one is the master one and the others are slave ones. There is one linear displacement sensor in each of the hydraulic cylinders for sensing the elevating displacement and controlling the synchronous displacement. The rolling wheels have separately limited rotating direction, and the rudder blade floor stand and the propeller floor stand separately for installing rudder blade and propeller are screwed to the planar slipway. The present invention is used for installation of rudder blades and propeller and can shorten installation period and raise operation safety greatly.

Owner:SHANGHAI JIAO TONG UNIV +1

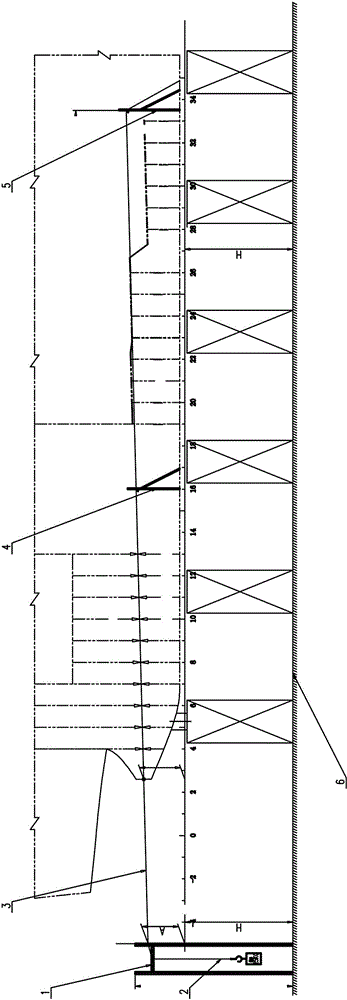

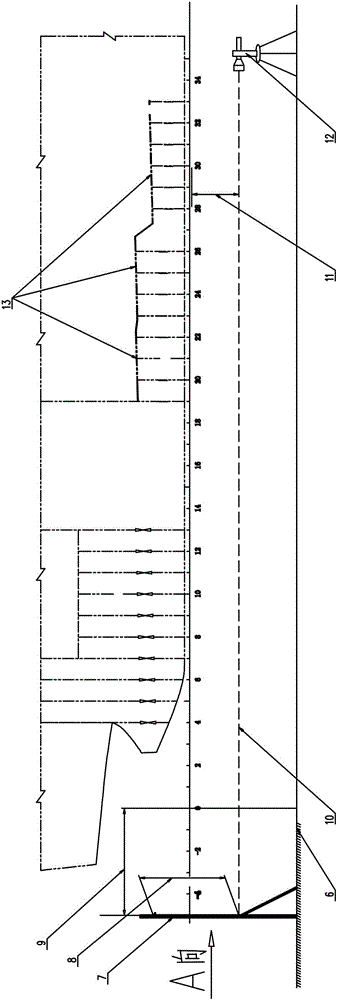

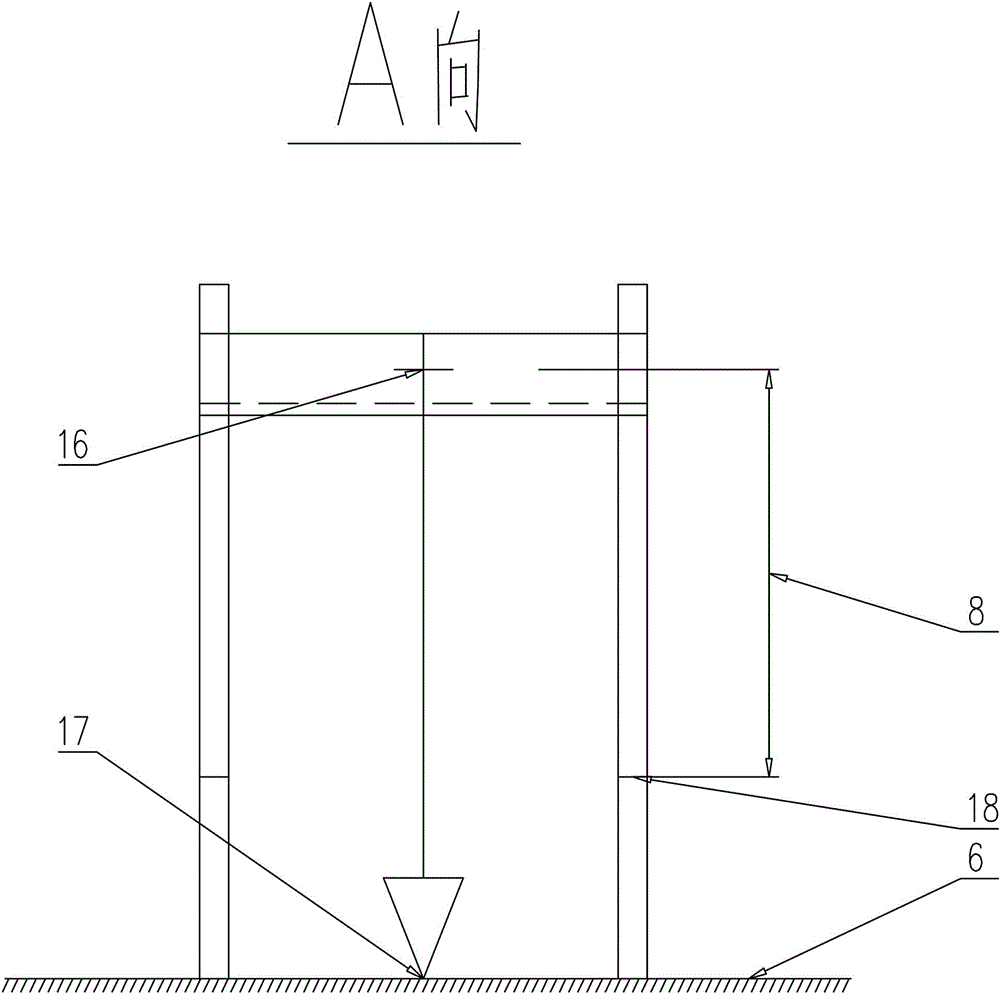

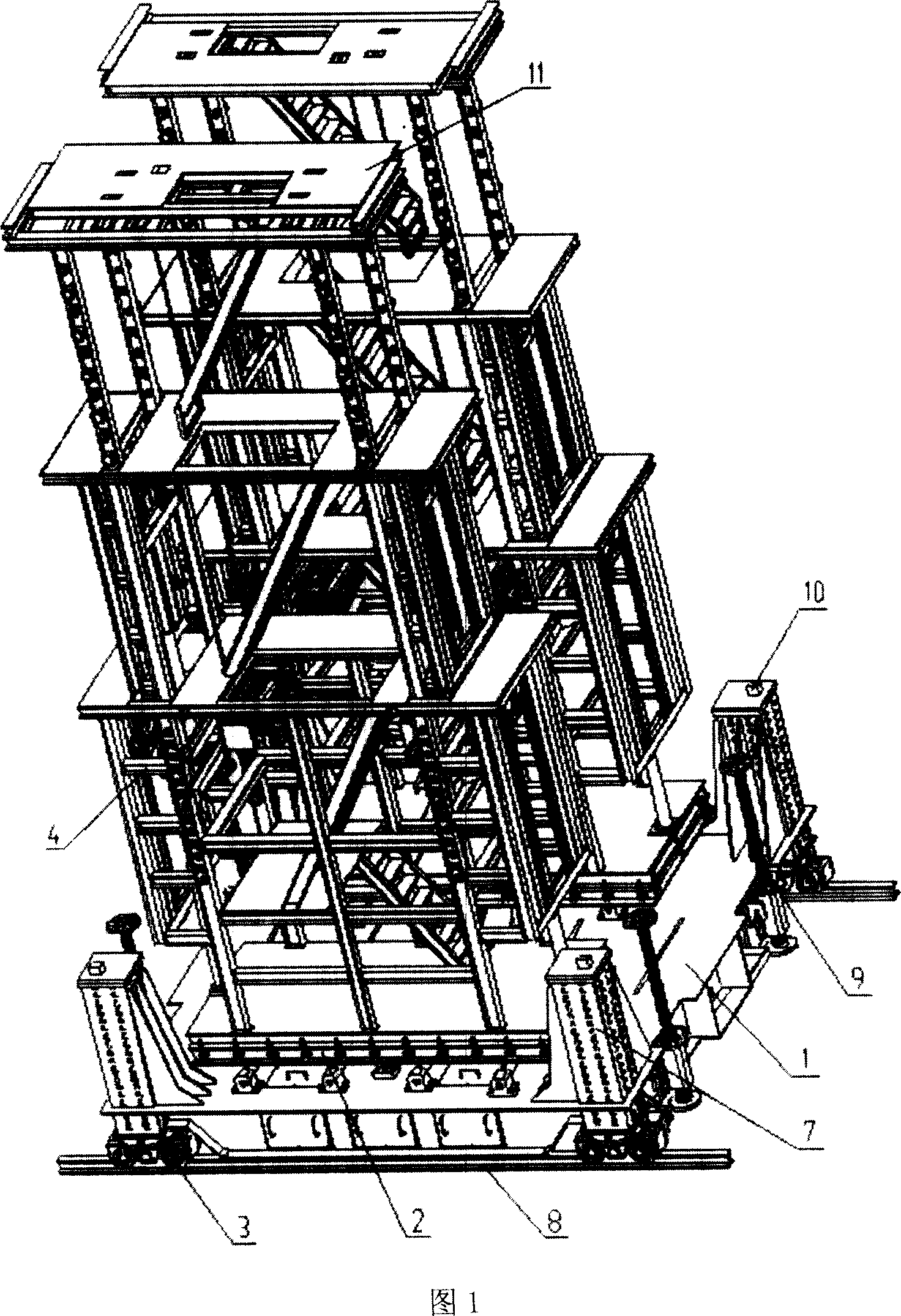

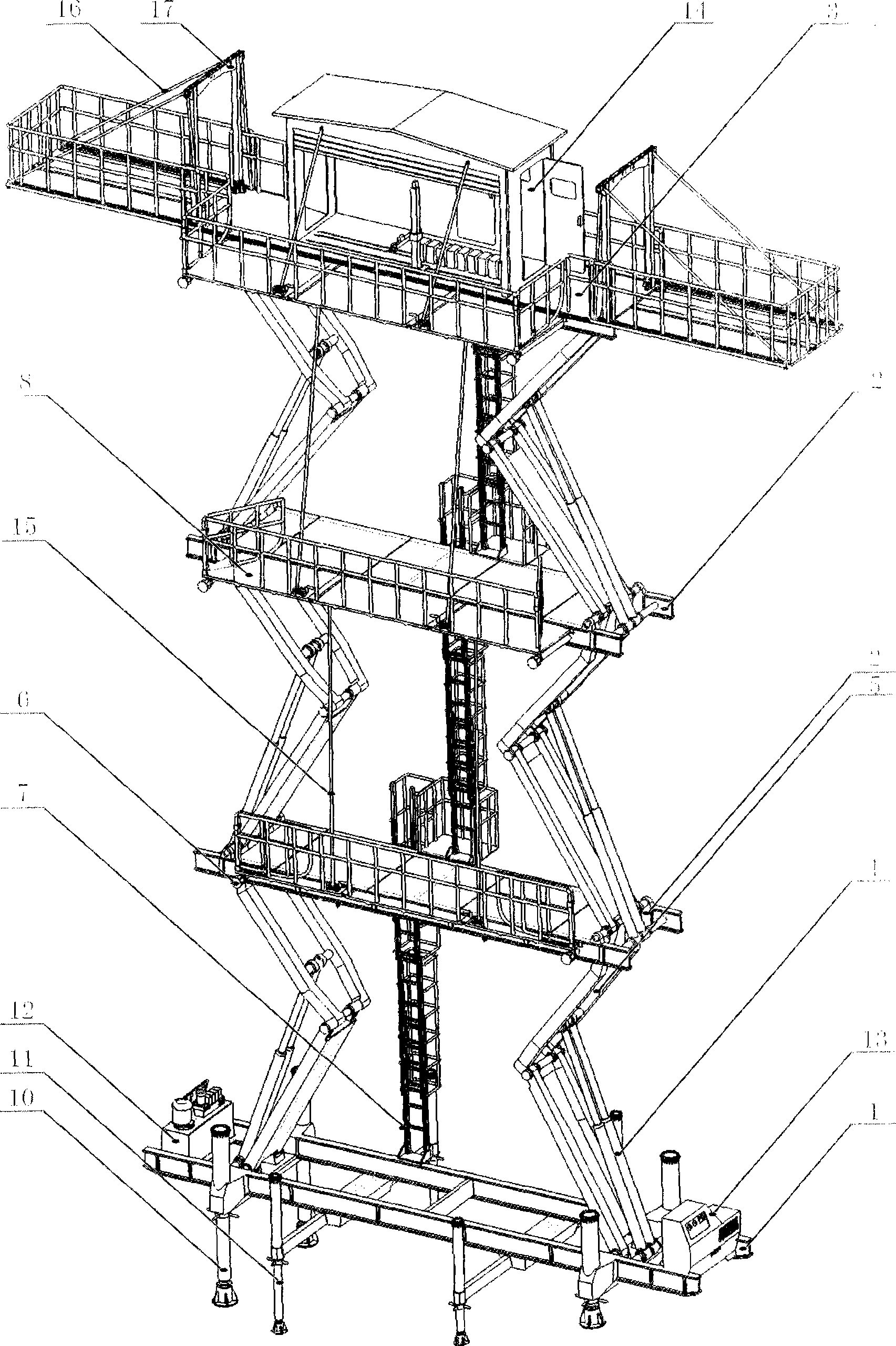

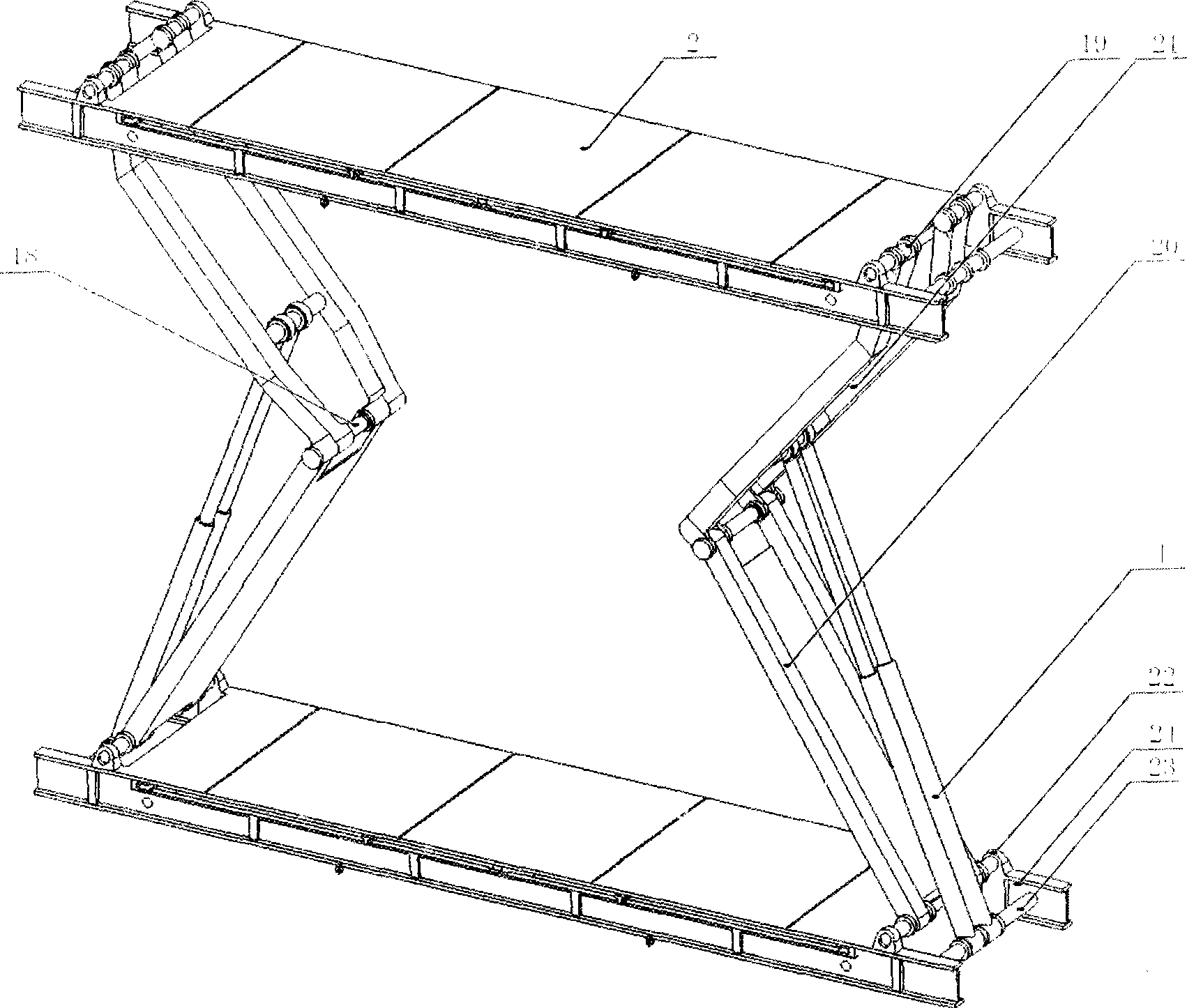

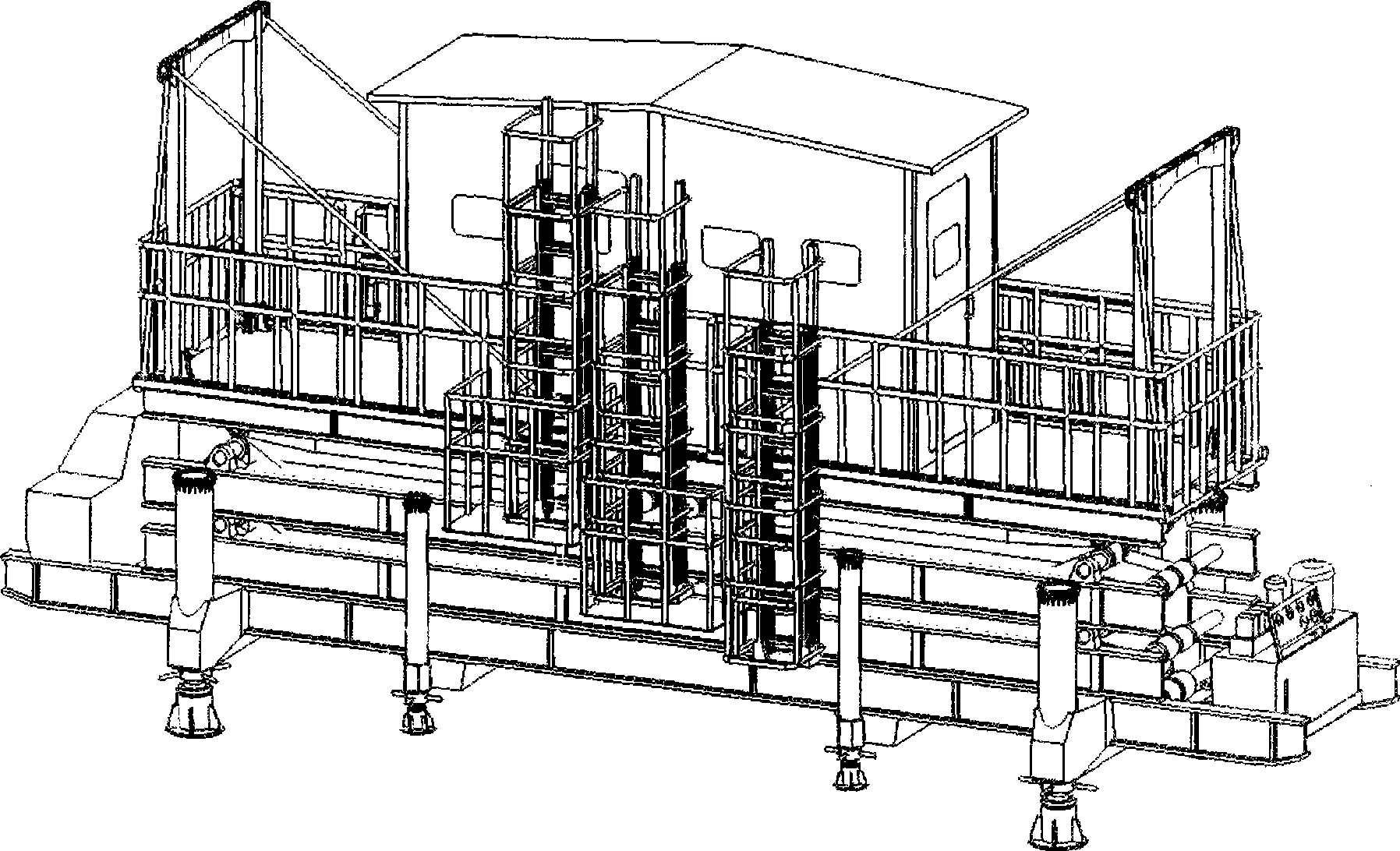

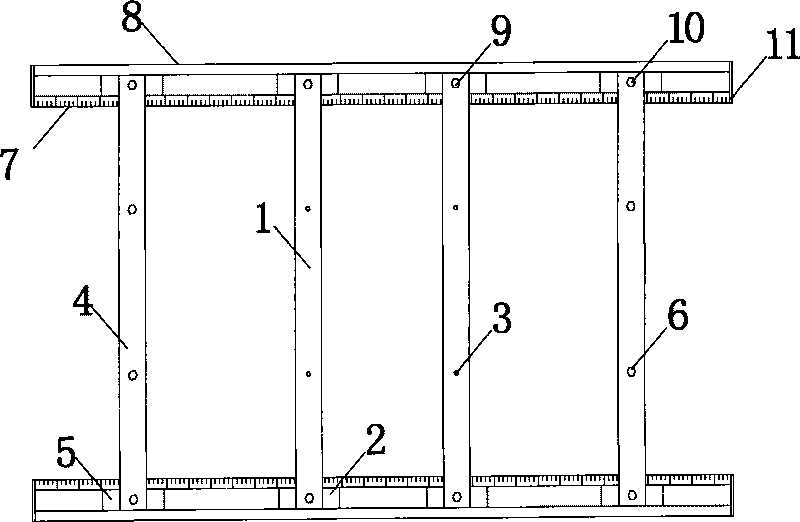

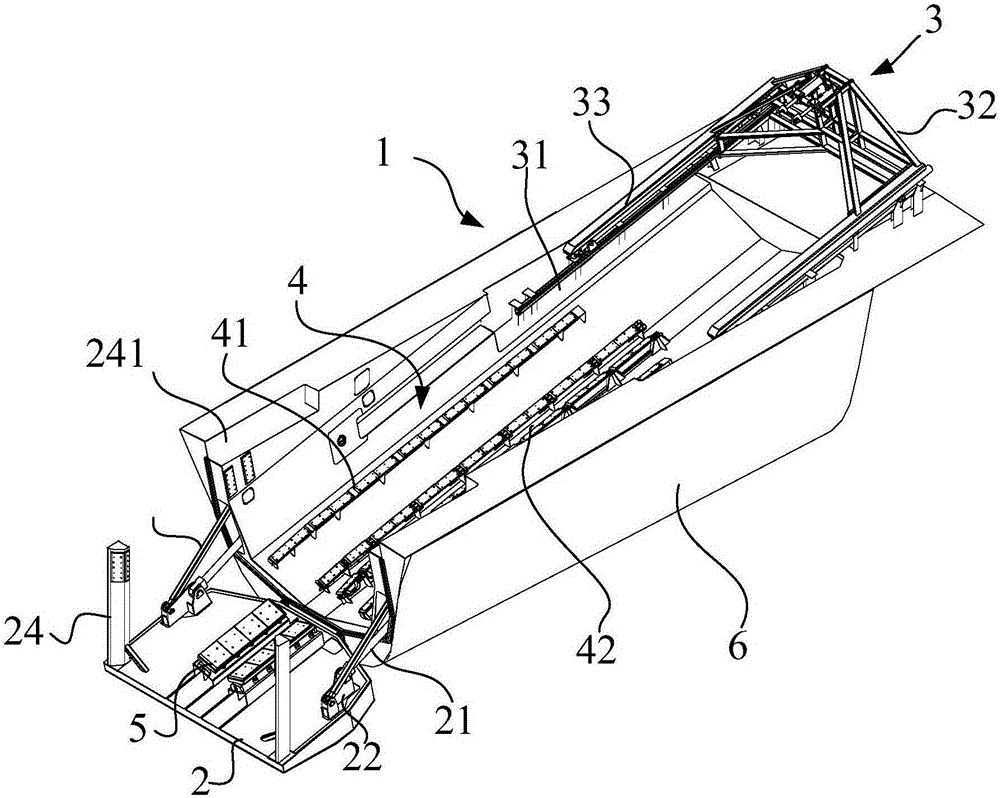

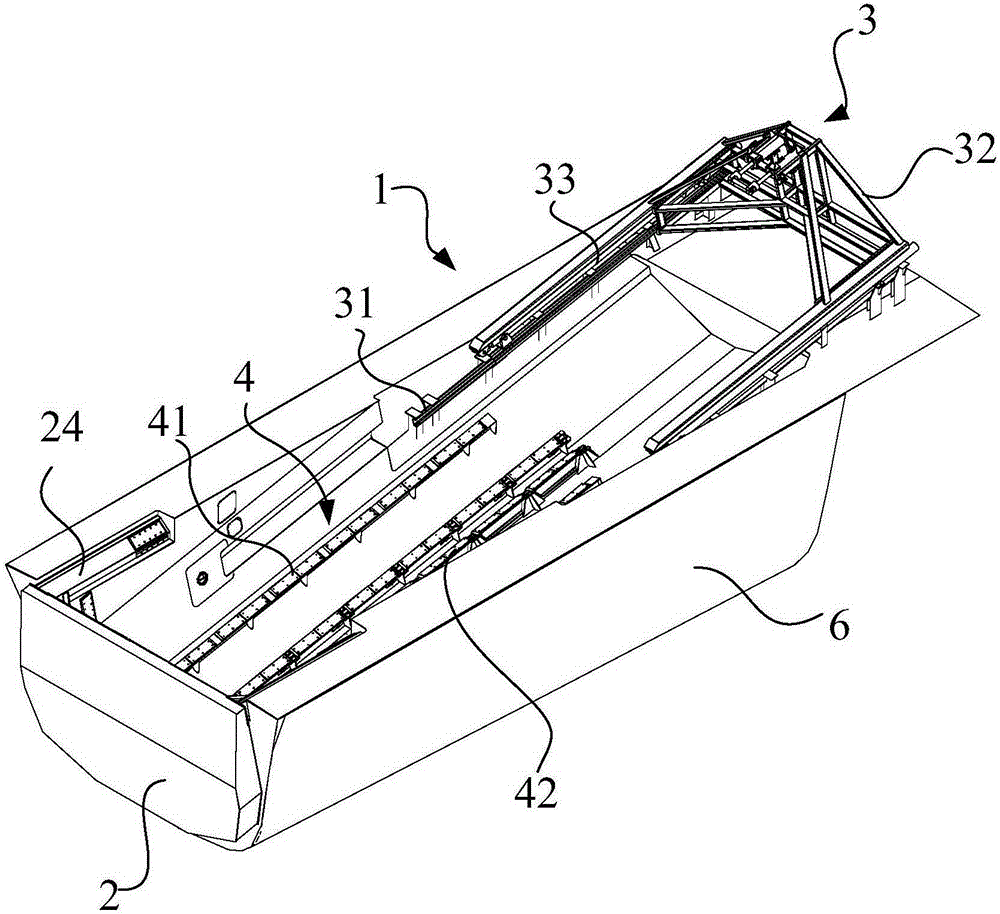

Large-sized aerial work platform for shipbuilding

InactiveCN101439757AImprove working environmentReduce labor intensityDry-dockingSlipwaysMarine engineeringWorking environment

The invention relates to a ship building and repairing large-size overhead work platform, which consists of a pedestal platform, a transitional platform, a top part platform, a hydraulic system, an electric control device, an electromagnetic fixing device, and a side supporting electromagnetic adsorption cylinder. All the platforms are connected and supported through a supporting frame with a lifting oil cylinder and are adsorbed to a ship body through the side supporting electromagnetic adsorption cylinder. Each platform is provided with a ladder for the convenience of climbing up and down temporarily in construction. The transitional platform and the top part platform are provided with a ship direction extending platform close to the ship direction, and the top part platform is further provided with a forward extending platform and a backward extending platform along the ship length direction. The pedestal platform is supported on a slipway by four fixed vertically telescopic supporting legs and four transversely and vertically telescopic supporting legs, the front end of the pedestal platform is provided with a hydraulic station, and the back end thereof is provided with the electric control device. The center of the top part platform can also be provided with a board house for work, rest and activity. The ship building and repairing large-size overhead work platform can build a safe three-dimensional working surface efficiently and quickly, shorten the cycle of occupying the slipway, improve the ship building and repairing efficiency, improve the working environment of workers, and reduce the labor intensity of the workers; besides, the hip building and repairing large-size overhead work platform is flexible, has small occupied area and is applicable to the ship building and repairing of various shipyards.

Owner:WUHAN UNIV OF TECH

Method for centering centerline of subsection hull constructed in two-island mode

The invention discloses a method for centering a centerline of a subsection hull constructed in a two-island mode, which comprises the following steps: (1) reasonably dividing subsections; (2) arranging an involution line through subsection modeling; (3) drawing a centerline of a slipway, modifying the centerline after hoisting and positioning the subsections and drawing a high-accuracy centerlineafter a deck of the hull is run through fully; (4) preventing the subsections from sliding downwards and moving; (5) manufacturing and positioning the subsections; and (6) surveying the centerlines of the deck and a benchmark platform. The method ensures the accuracy of the centerline of the hull by controlling key points of each link in the design and construction. The application of the methodgreatly shortens shipbuilding period so as to greatly save manufacturing cost and achieve the aim of improving the speed of ship construction, and simultaneously compared with the centerline accuracyof the prior ships, the centerline accuracy of the hull is improved greatly.

Owner:JIANGNAN SHIPYARD GRP CO LTD

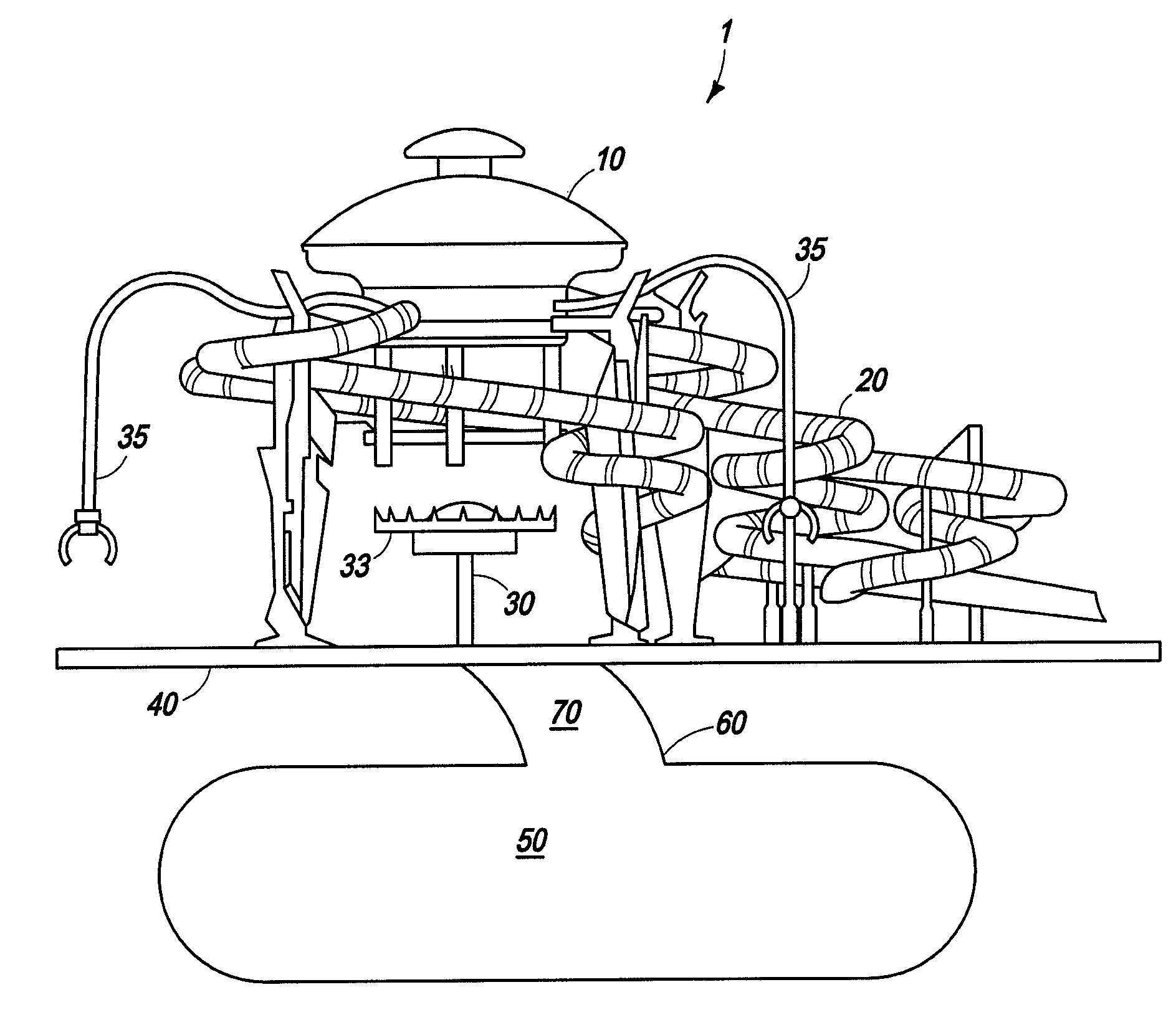

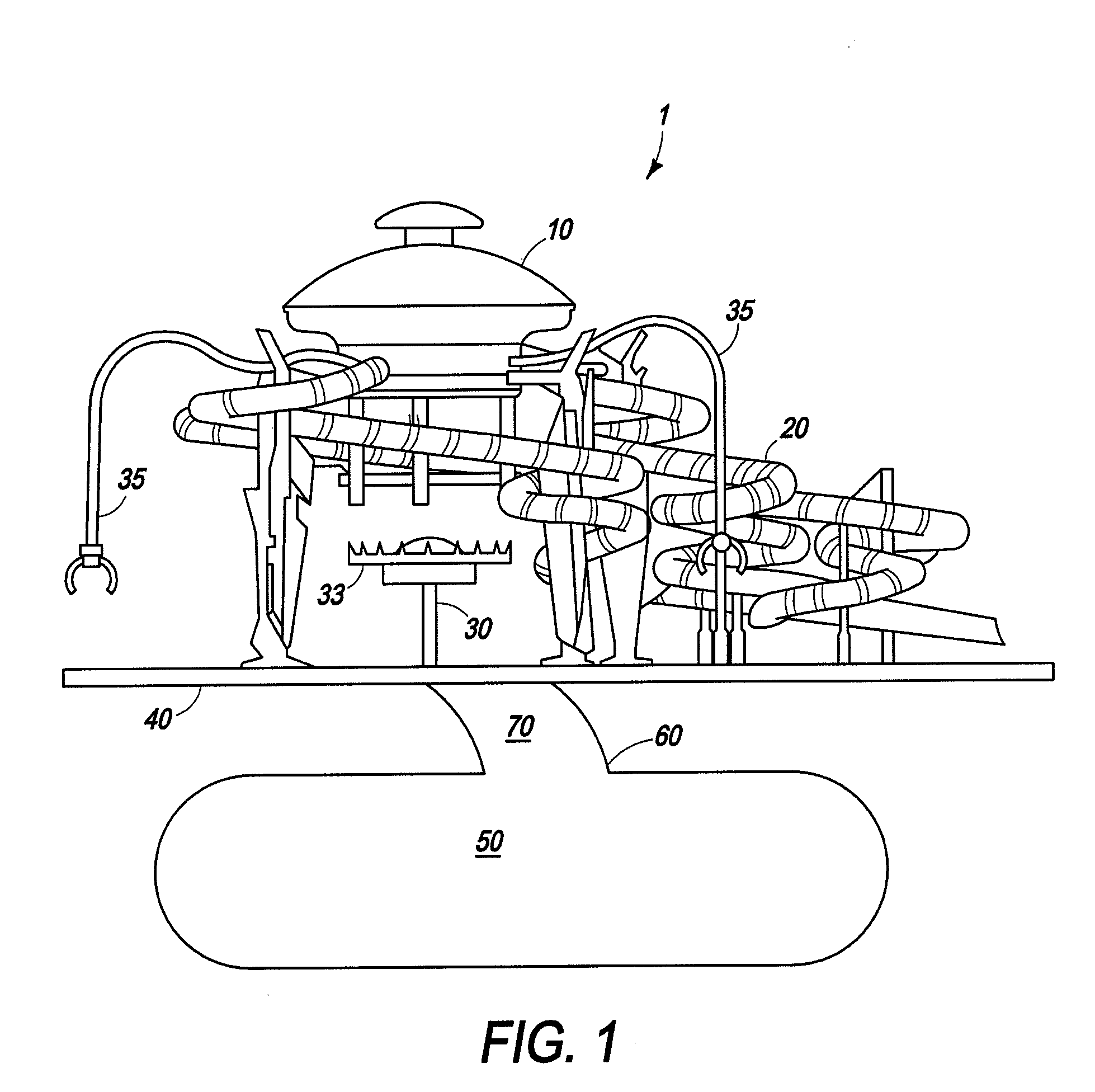

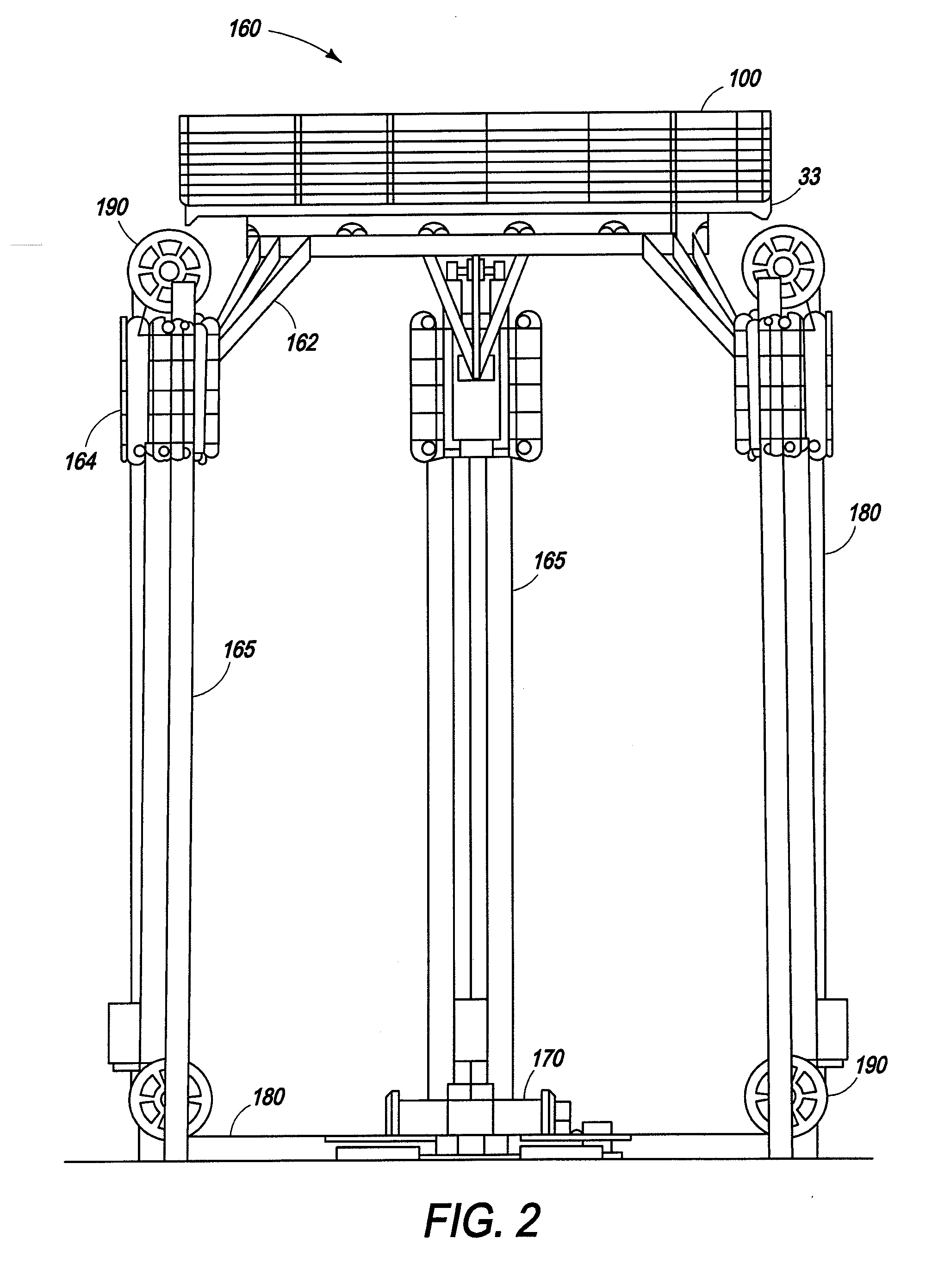

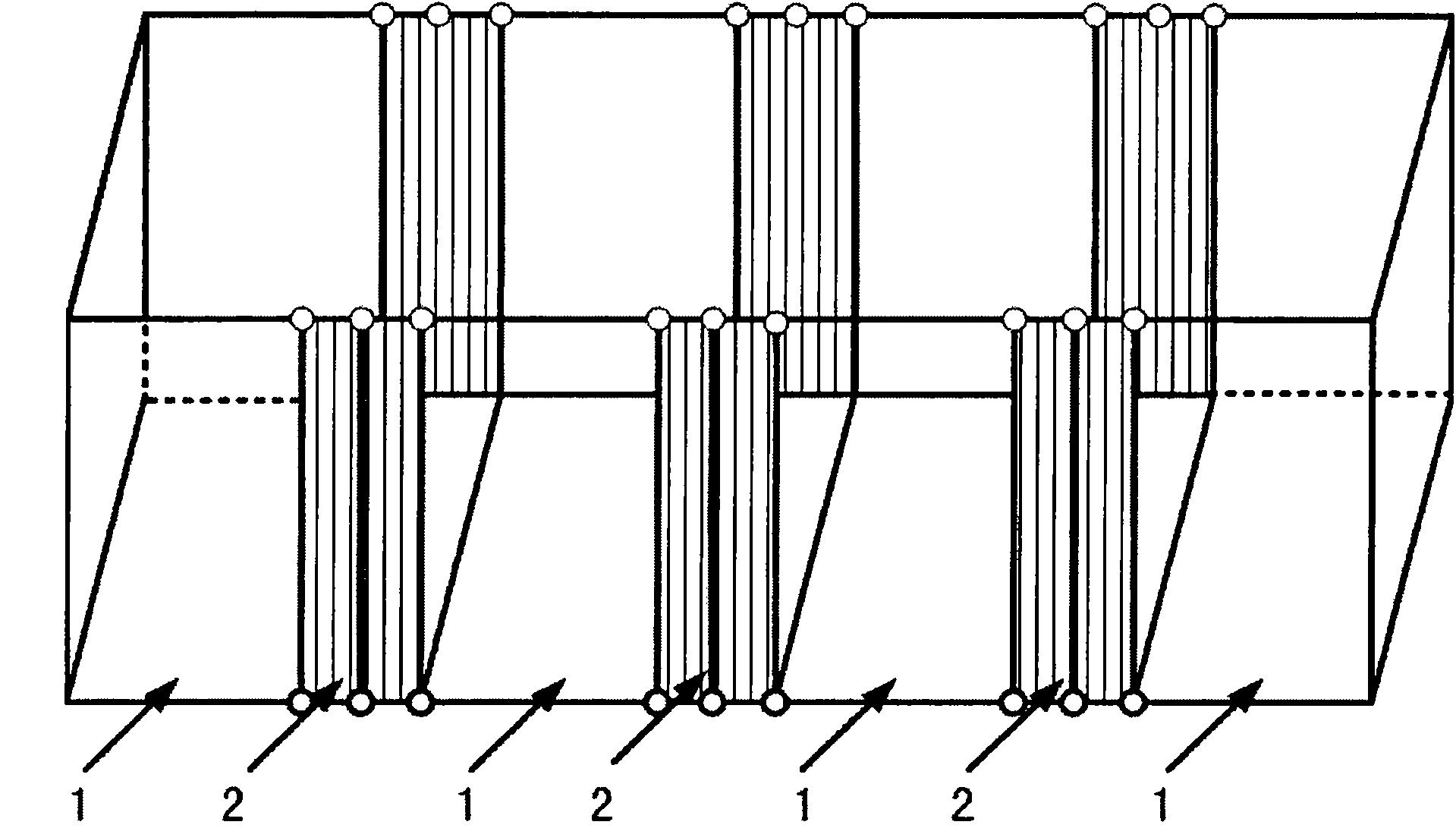

Amusement Ride With Mechanical Lift, Slides, Sequenced Ejections, And Show Systems

InactiveUS20090017927A1Reducing and eliminating wait in lineAvoid excessive delayHelter-skeltersMarine engineeringAnimation

A themed water amusement ride that raises guests in rafts on a lift platform to a dome. The lift platform has bays containing the rafts. The bays have tilting floors. The lift platform rotates, selectively aligning the bays with elevated slide entrances. The floors of the bays tilt the rafts into the slides, where the raft moves down the slide to a pool of water. The platform, dome, slides, lift structure, and pond are further provided with lights, sound production equipment, mechanical figures, water hoses, water outlets, and animation media to produce a show in accordance with the theme.

Owner:SHOZI PAUL TAKESHI +1

Test device for simulating soil-structure interaction during earthquake occurrence and spread

InactiveCN101957453AGuaranteed continuitySeismic signal processingUniversal jointEarthquake engineering

The invention relates to a test device for simulating soil-structure interaction during earthquake occurrence and spread in the research of earthquake engineering. The device consists of a rigid part and a flexible part, wherein the flexible part consists of a universal joint pair device, a U-shaped steel framework and a rubber film; one end of a steel connecting rod with a slipway is fixedly connected with the upper end of a universal joint upper member, while the other end is connected with another universal joint upper member through a roller; the U-shaped steel framework is connected with the steel connecting rod with the slipway through a slideable connecting member; and the rubber film is arranged in a U-shaped space formed by the U-shaped steel framework and the universal pair device and is rigidly and segmentally connected with a model casing. Earthquake occurrence is simulated by combining a plurality of array vibrating table systems and applying different excitations to two adjacent vibrating tables simulating faulting. Corresponding excitations with different speeds are applied to other vibrating tables according to a similar rule so as to further research the interaction between soil and structural power with the consideration of the spread of earthquake in a medium.

Owner:BEIJING UNIV OF TECH

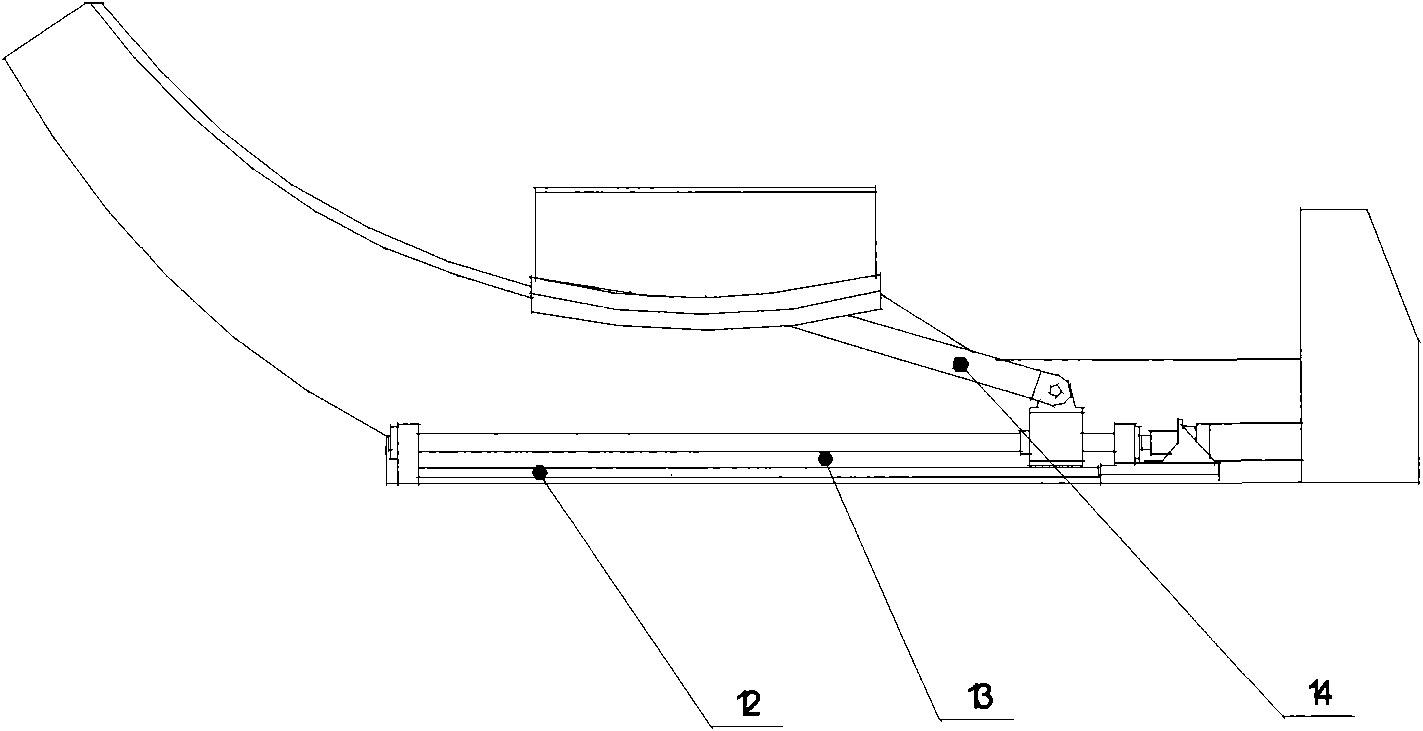

Method for mounting inclined shaft internal pressure steel tube

InactiveCN103277582ASafe and efficient constructionPipe laying and repairMathematical modelEngineering

The invention relates to a method for mounting an inclined shaft internal pressure steel tube. The method comprises the steps of hoisting a hauling system, enabling a rail to slide downwards, enabling a trolley to slide downwards to complete a load test, conveying a tube coupling to be mounted of the pressure steel tube to a site, hoisting, unloading and turning over an upper slipway vehicle and a lower slipway vehicle by a winch hoisting system, tying the vehicles, connecting a gliding hauling system and the steel tube, removing a hoisting cable, enabling the hauling system to work, finishing gliding and humping of the tube coupling, unloading the tube coupling and enabling the lower slipway vehicle to reset. According to the method for mounting the inclined shaft internal pressure steel tube, a mathematical model calculation achievement which is established according to the mechanics principle is combined with a model test and a prototype test to demonstrate the feasibility of two-point towing gliding, a series of technical problems of optimizing of the structure of an anchor inside a cave chamber, rope jumping and nesting of a winch in the heavy loading process, selecting, calculating and demonstrating of a gliding towing point, designing of the structure of the trolley, synchronization balancing of double-traction, preventing abnormal abrasion of a steel wire rope of a multiplying power pulley block and gliding in-place unloading of the steel tube are solved comprehensively and systematically, and construction is safe and efficient.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

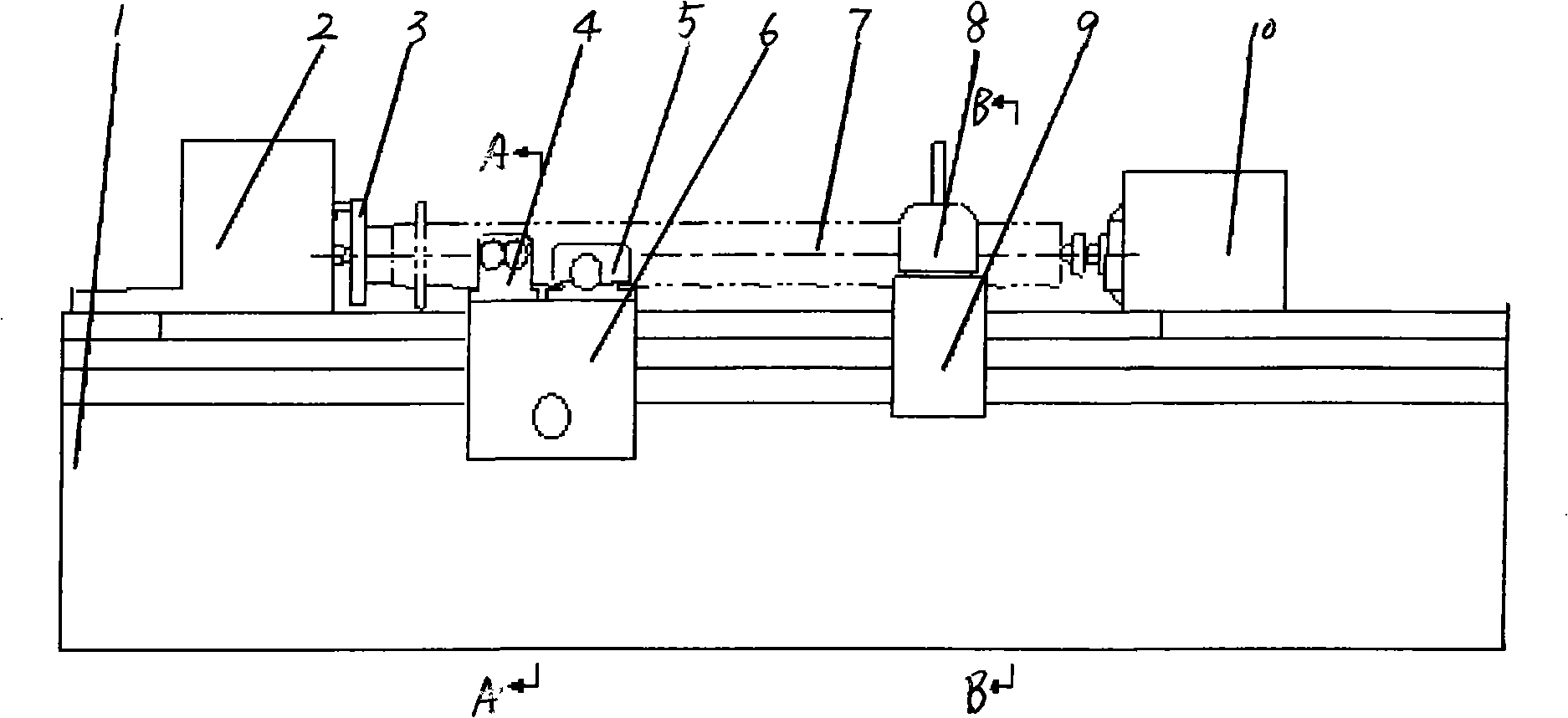

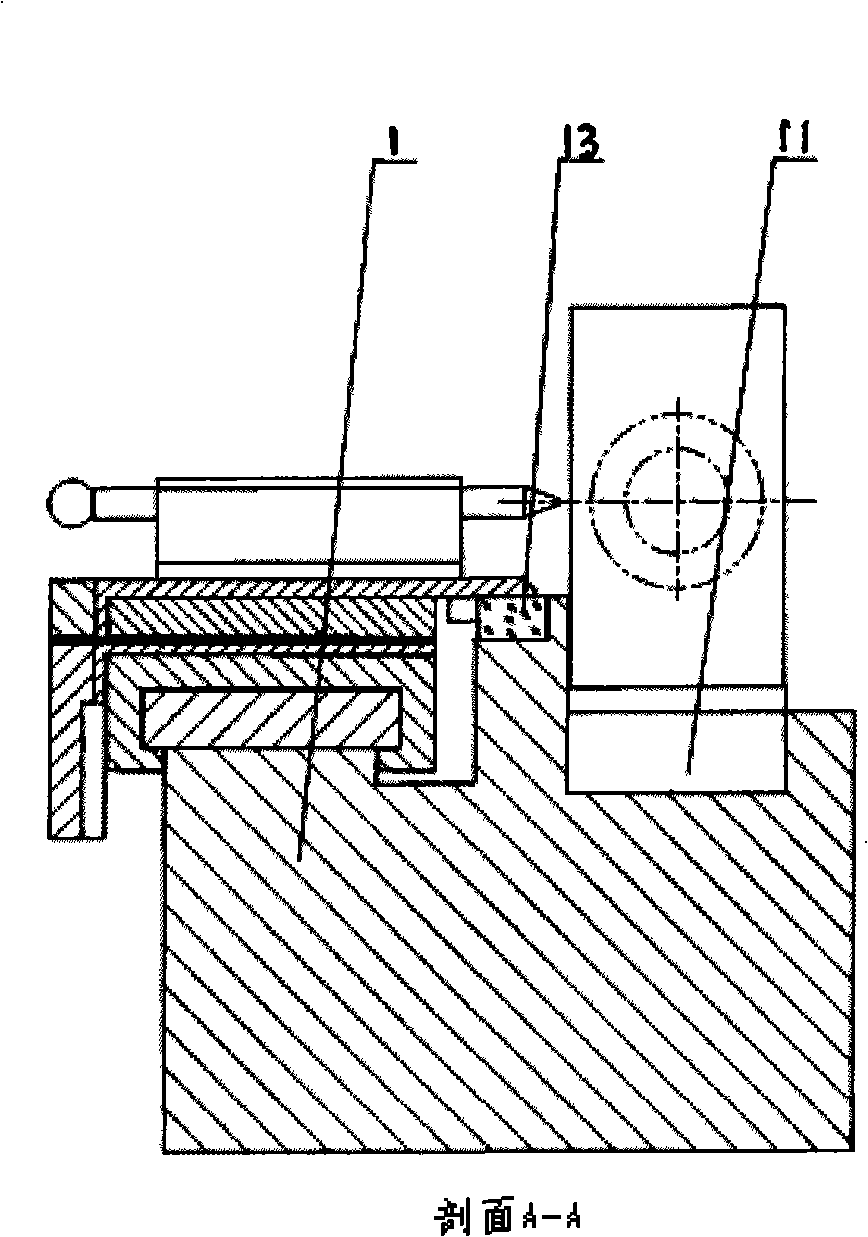

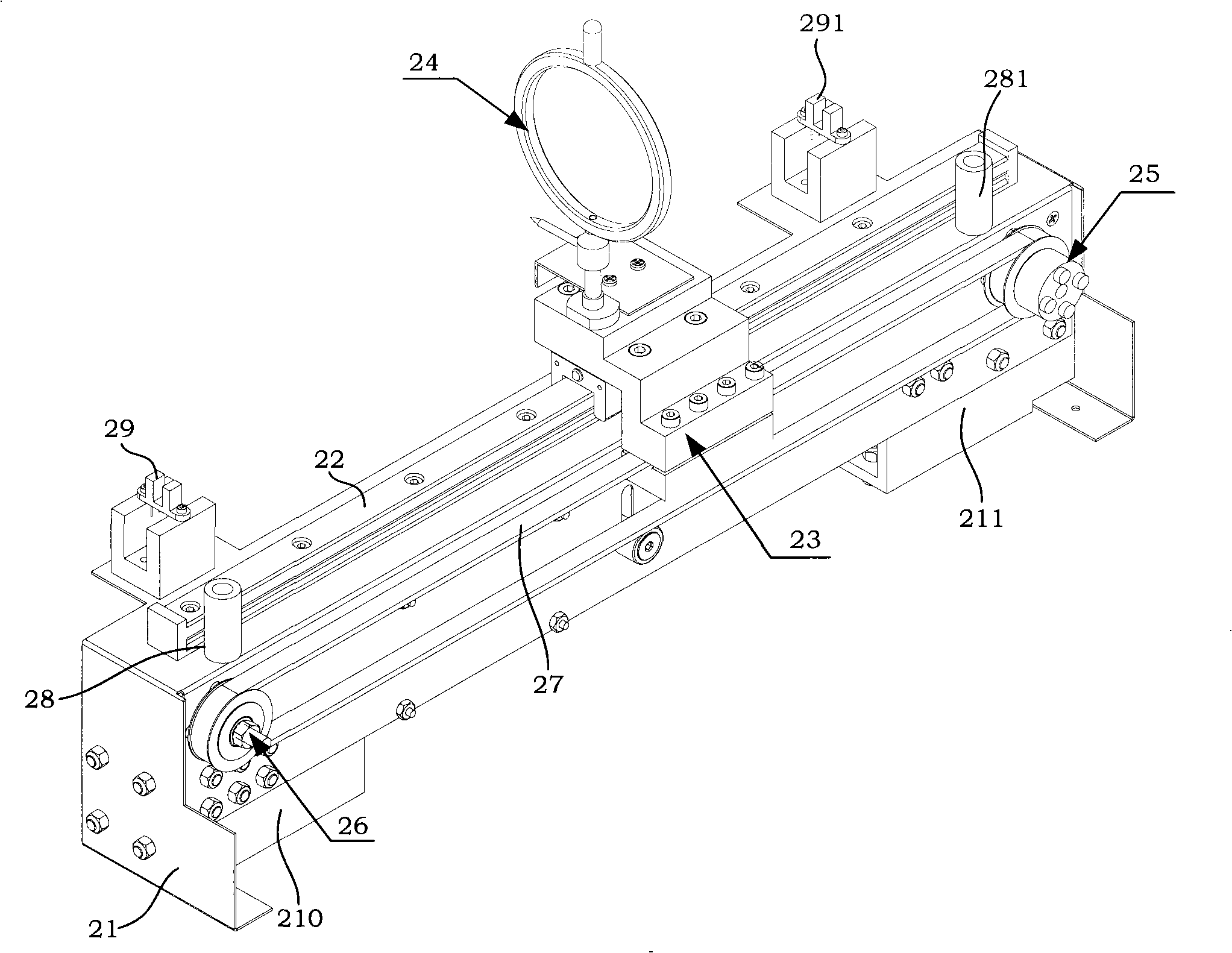

Synthetic inspection tester for shaft element

InactiveCN101403600AImprove machining accuracyReduce rigidityUsing electrical meansUsing optical meansGratingEngineering

The invention discloses an integrated inspection device of axis parts, which consists of a granite base, a granite air floating measuring guideway and slipway, a granite air floating bearing guideway and slipway, a head frame, a tail frame, a plurality of measuring modules and a long grating ruler. Adopting the structure can achieve the integrated measurement to the axis parts, the integrated measurement of the axial dimensions of the axis parts and a plurality of position errors can be achieved by one clamping, and the inspection device has the advantages of simple structure, easy operation, and high precision.

Owner:HEFEI UNIV OF TECH

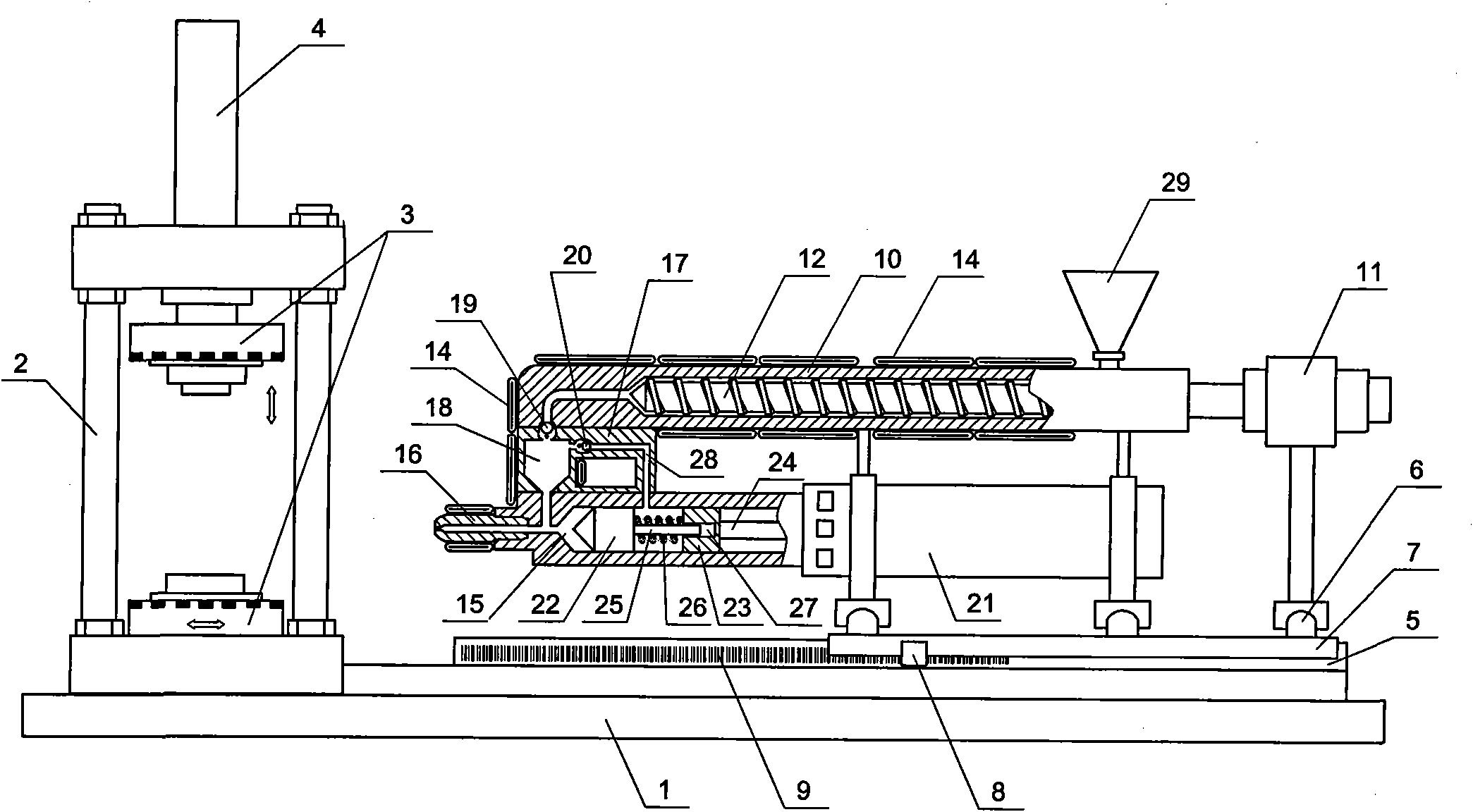

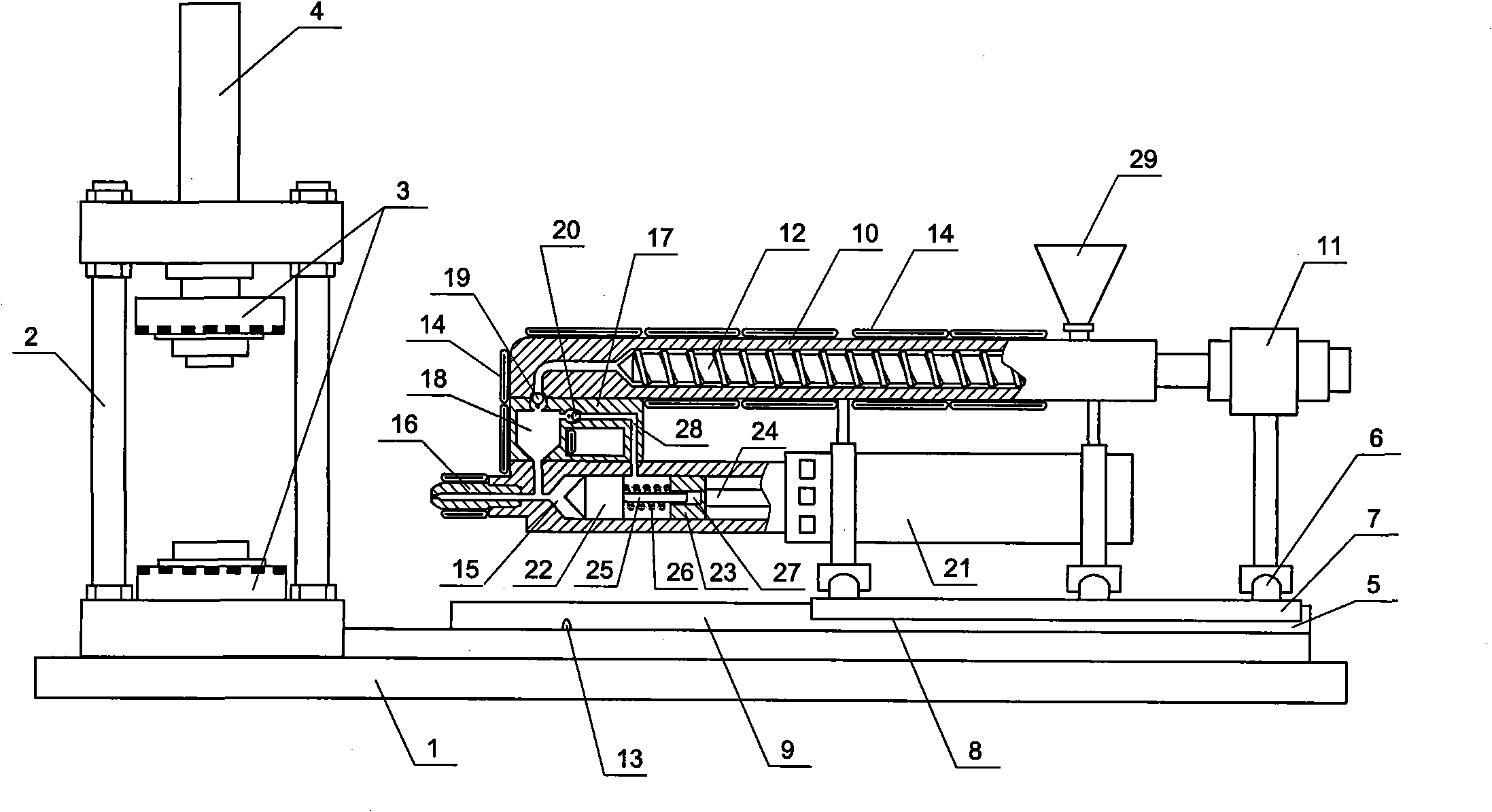

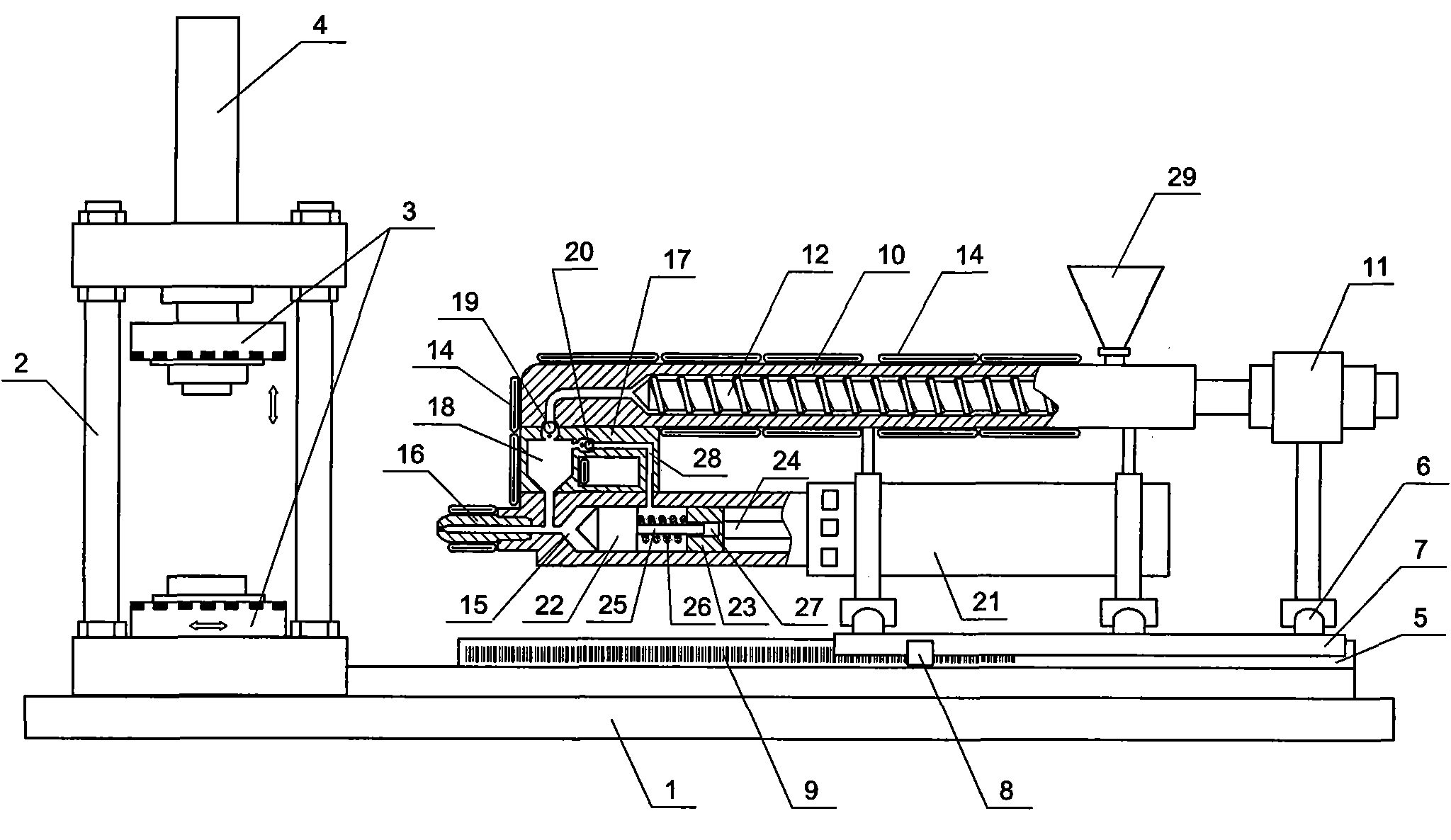

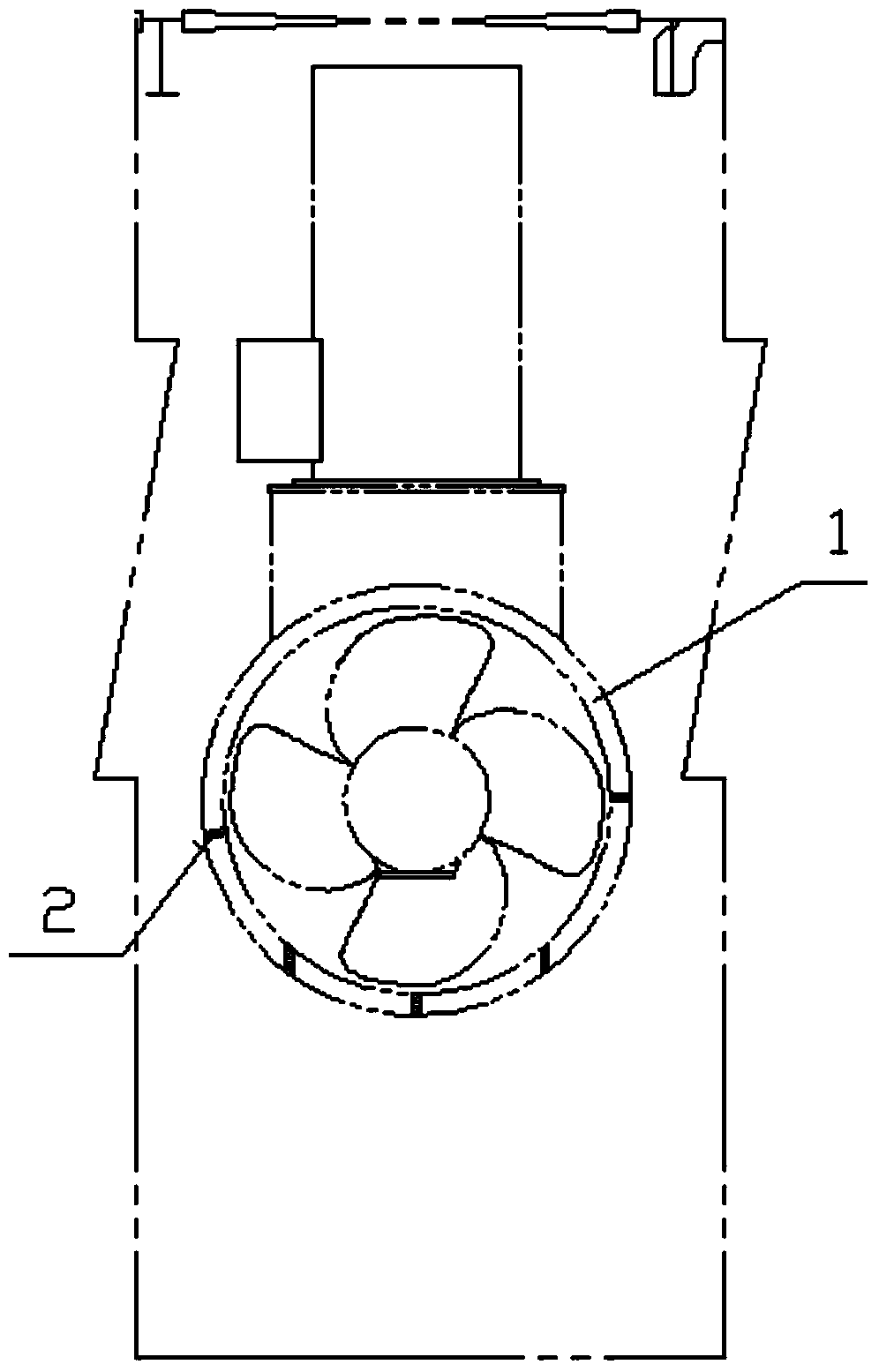

Energy-efficient type injection molding machine

InactiveCN101954727AAdjust output flowEliminate overflowFrequency changerProgrammable logic controller

The invention relates to an energy-efficient type injection molding machine. A positioning system is arranged on the side of a lateral slipway and / or longitudinal slipway, and a sensing device of the positioning system is connected with a signal input end of a PLC (Programmable Logic Controller) or a host machine. A cylinder motor of the storage extrusion cylinder is connected with a power supply through a frequency converter, a control end of the frequency converter is connected with a control output end of the PLC or the host machine, and the PLC or the host machine controls the frequency converter to output driving signals with corresponding frequencies according to the movement distance of the storage extrusion cylinder on a lateral or longitudinal guide rail. The energy-efficient type injection molding machine enables a system to automatically track the operating state, the operating pressure and the flow signal of the injection molding machine per se, can timely and properly regulate the output flow of a constant delivery pump and can meet the requirements of energy saving. The invention has the advantages of simple structure, reasonable design, good use effect, energy saving and high efficiency and is applicable to popularization and implementation.

Owner:陈志华 +1

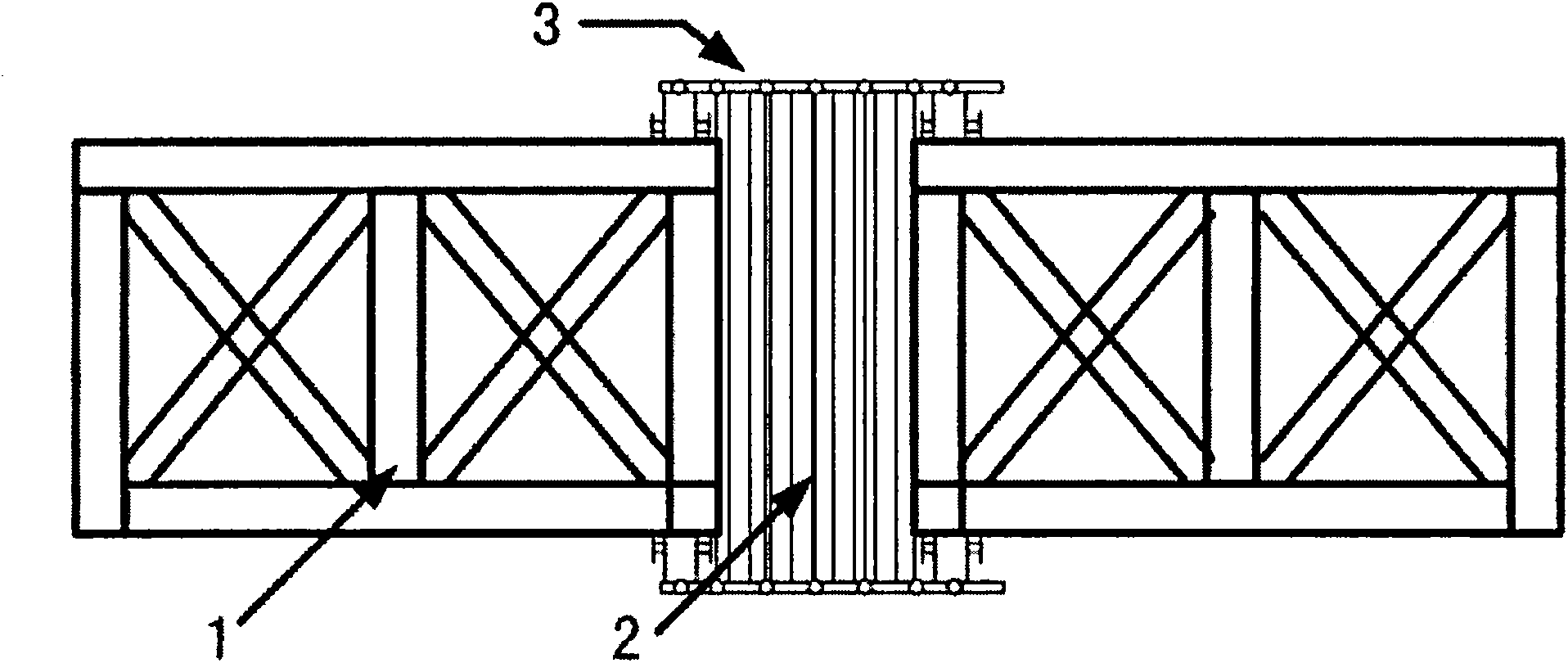

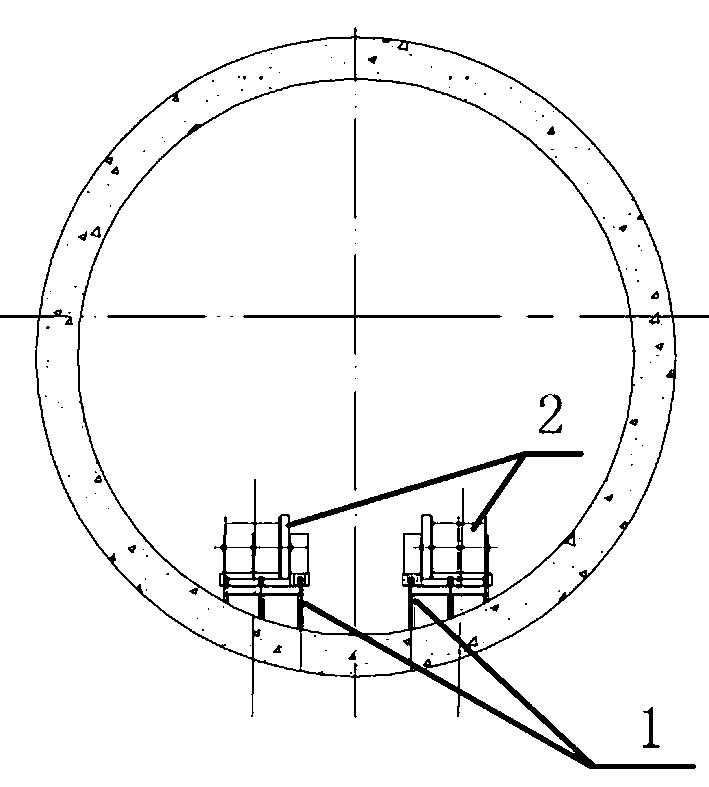

Assembling and welding method of side thrust device

ActiveCN103803018ARelieve welding stressControl deformationVessel partsClassical mechanicsElectric machinery

The invention relates to the technical field of ship construction, in particular to an assembling and welding method of a side thrust device. The assembling and welding method of the side thrust device comprises the steps that lofting is conducted so as to machine extension pipes, and four generatrices of each extension pipe are drawn; by making the four generatrices of each extension pipe as benchmarks, bearing blocks, annular reinforcing rib plates, longitudinal reinforcing rib plates and motor fixing bases are assembled and welded to constitute two side thrust seal cover modules; the side thrust seal cover modules are integrally annealed so as to eliminate welding stress, and the inner surfaces of the bearing blocks and the upper surfaces of the motor fixing bases are machined; the two side thrust seal cover modules are welded to two sides of a side thrust cylinder body respectively, and after welding is finished, the side thrust seal cover modules and the side thrust cylinder body are integrally assembled and welded in a segmented mode; after a slipway is folded, the integral segment comprising the side thrust seal cover modules and the side thrust cylinder body is provided with blades, a shaft, a bearing assembly, a seal part, a transmission mechanism and a driving mechanism. The assembling and welding method of the side thrust device can avoid welding deformation of the side thrust device, guarantee concentricity of bearings and shorten the period of ship construction.

Owner:WUCHANG SHIPBUILDING IND

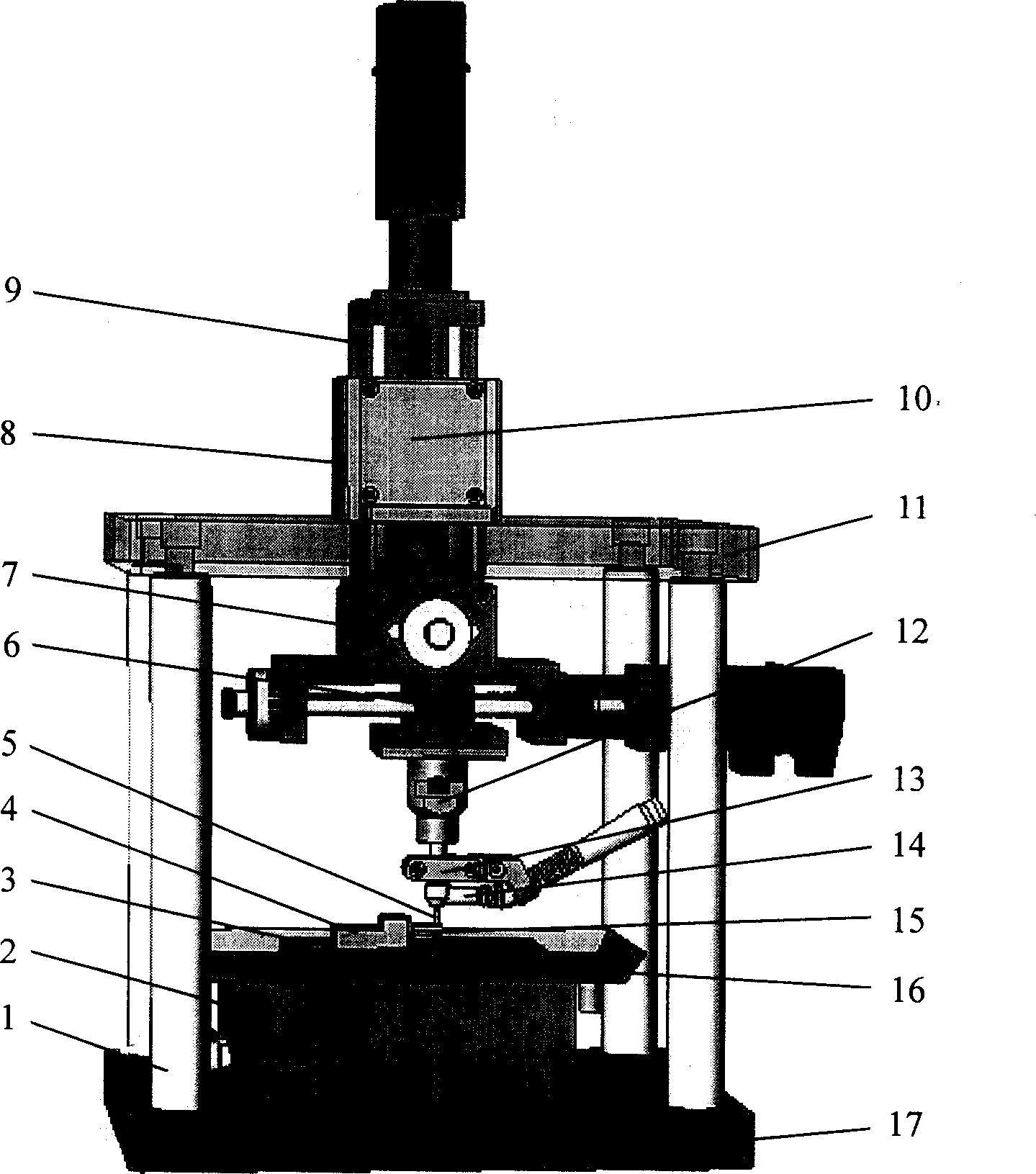

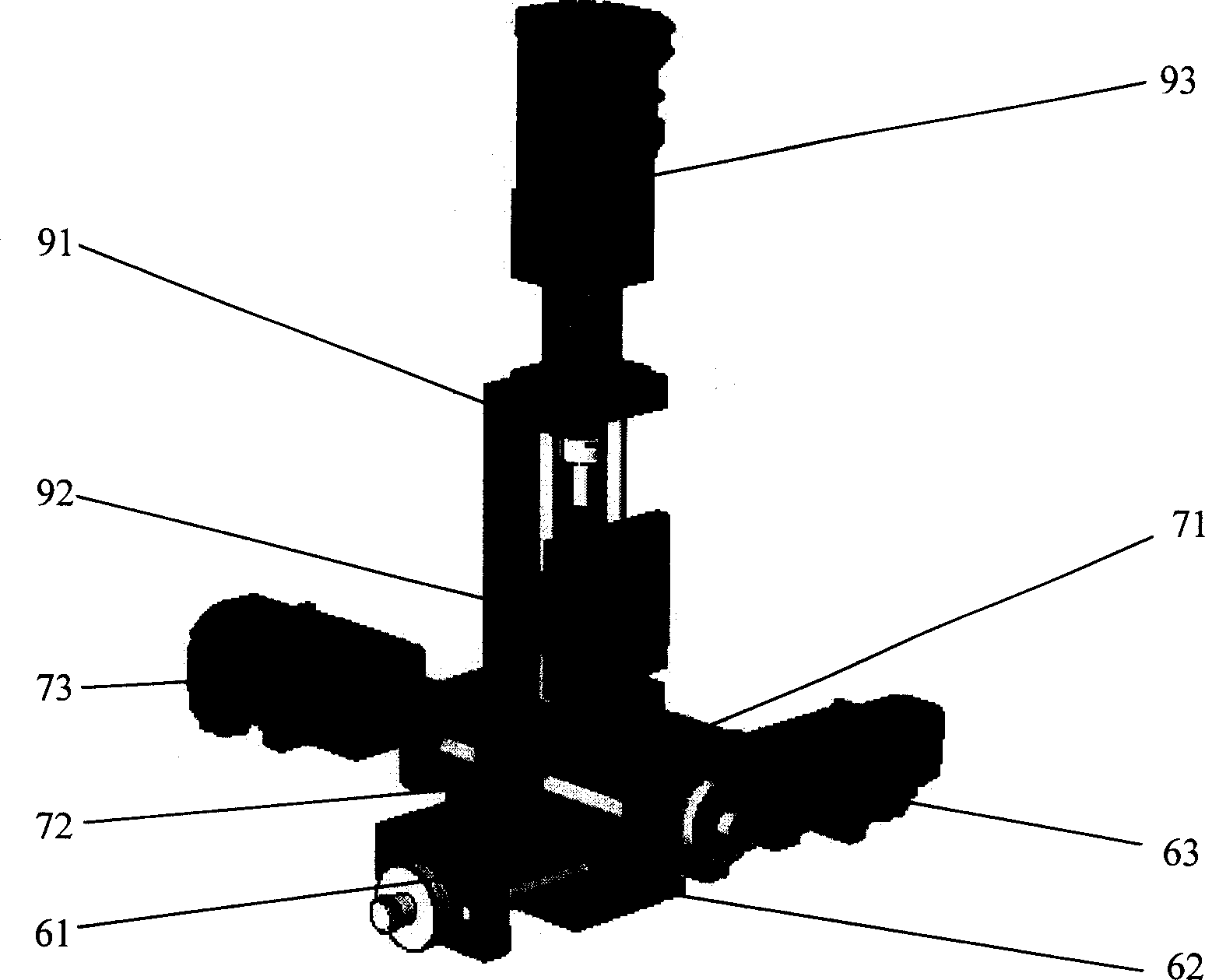

Tri-dimensional oral prosthesis in vitro grinding and repairing emulated testing machine

InactiveCN1828266ARealize three-dimensional controllable movementUsing mechanical meansDental prostheticsBall screwOral Prosthesis

The disclosed tester comprises a frame with four posts, bottom plate with a dynamometer, an accommodate-liquid pan, a clamp bottom plate, and a clamp; the top plate with a lock right angle plate and right plate; a 3D digital-control operation platform with X-direction connected to dentistry hand piece, Y-direction and Z-direction platforms every with a straight line slipway of ball screw gear connected to platform motor. This invention fits to fine repair and on-line monitor.

Owner:TIANJIN UNIV

Process for shafting and rudder system installation of multi-purpose ship

InactiveCN107640282AShorten the construction periodShorten the timeVessel partsPropellerBuilding unit

The invention discloses a process for shafting and rudder system installation of a multi-purpose ship. The process includes a step a of determination of a shafting center line and a rudder system center line before ship launching; a step b of stern tube positioning and epoxy casting, installation of a waterproof closure plate and ship launching; and a step c of installation of a tail shaft, a propeller, a rudder stock and a rudder blade. The process for shafting and rudder system installation of the 10000-ton special multi-purpose ship is in such a mode such that the problem that in the priorart, the ship tail shaft, the propeller, the rudder stock and the rudder blade must be all complete on a shipway before the ship launching to be installed, so that inconvenience is caused is solved; after the shafting and the rudder system are determined and undergo inspection on the shipway, the ship launches, the time of preparing the ship tail shaft, the propeller, the rudder stock and the rudder blade is saved, the ship building cycle is shortened, the utilization rate of a longitudinal slipway of the ship built by a ship building unit is improved, and the manufacturing cost is reduced.

Owner:南通如港船舶配套机械有限公司

Technology for reducing allowance cutting during ship building

The invention relates to a technology for reducing allowance cutting during ship building. In the technology, a hull is firstly divided into a plurality of general sections for building; and the general sections are gathered up. The invention is characterized in that in the step of lofting and baiting of parts, section allowance, slipway allowance, compensation dosage and material cutting are additionally and respectively placed once on a deck, a strake, a longitudinal bone, a rib, an enforced bone, a wall plate and other structures of each typical node according to section splicing or section butt joint and other different forms; in the step of the whole building of the general sections, when the joint of one of two general sections is provided with a transversal bulkhead, the two general sections adopt a splicing form, and the general section without the transversal bulkhead is inserted with the general section with the transversal bulkhead for carrying out sintered ceramsite liner welding; and when the joint of the two general sections are not provided with the transversal bulkhead, the two general sections adopt a sintered ceramsite liner welding butt joint form. The invention can determine the size of parts once, and improve the precision of parts manufacturing, thereby avoiding on-site secondary cutting quantity, and providing guarantee for general section construction; and the procedures are shifted forward, thus reducing slipway working capacity and waste backflow volume, shortening building ship period and reducing building ship cost.

Owner:WUCHANG SHIPBUILDING IND

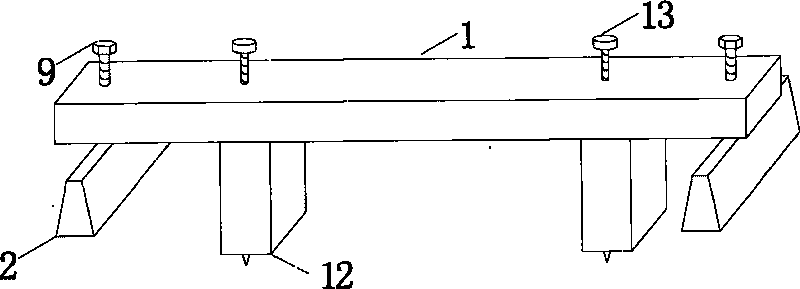

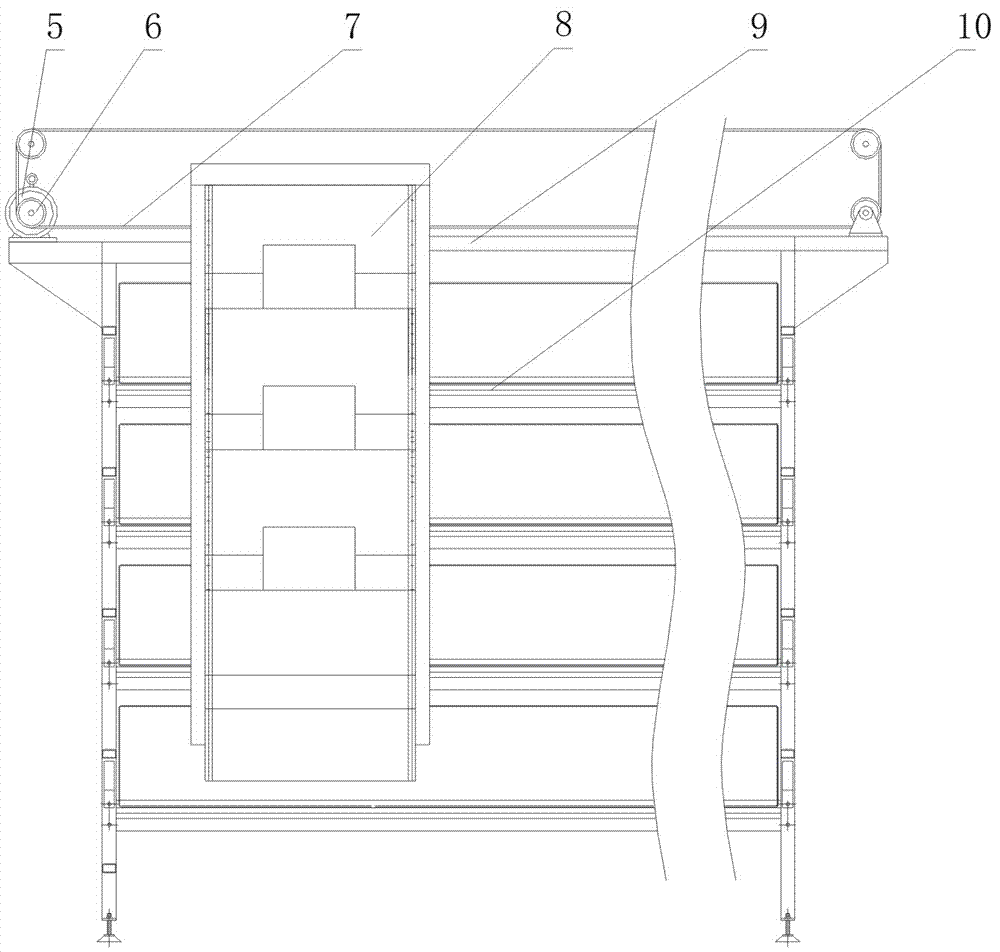

Trimaran model test alignment jig

InactiveCN101734347ASimple structureEasy to useVessel partsStructural/machines measurementEngineeringSlipway

The invention provides a trimaran model test alignment jig comprising a main body connection adjusting part, a lateral body connection adjusting part and a transverse slipway part, wherein the main body connection adjusting part comprises two substrates, two ends of each substrate are provided with a slide block A and a top thread A, and each substrate is connected with two bases; the lateral body connection adjusting part comprises two clevises, two ends of each clevis are provided with a slide block B and a top thread B, the clevis is provided with a connection adjusting hole, and a connection adjusting bolt is arranged in the connection adjusting hole and is provided with a fastening nut; the transverse slipway part comprises two chutes; and the slide blocks A on two ends of the substrates and the slide blocks B on two ends of the clevises are arranged in the chutes. The invention can adjust the lateral body space and the lateral body draught of the trimaran and is suitable for various widths of main bodies and lateral bodies. The alignment jig has simple structure and convenient use and can improve the precision and the efficiency of the trimaran resistance prediction and lateral body layout optimization model tests.

Owner:HARBIN ENG UNIV

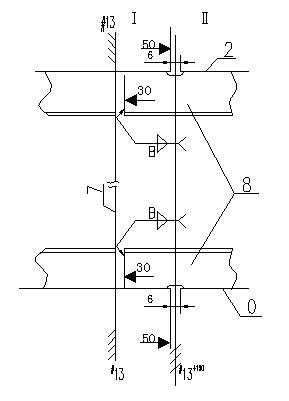

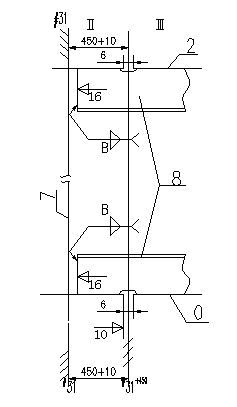

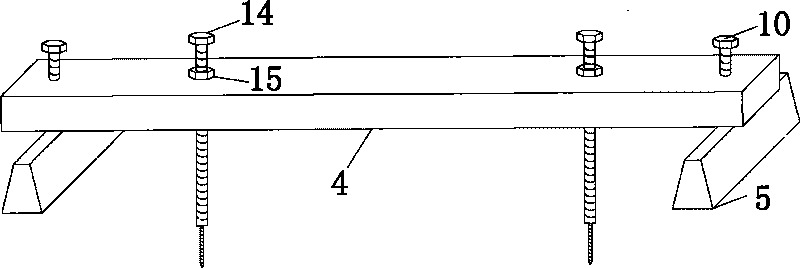

Push-type rebounding slide rail of drawer box

The invention discloses a push-type rebounding slide rail of a drawer box. The push-type rebounding slide rail comprises an upper slipway (2), a middle slipway (8) and a lower slipway (7), wherein, the upper slipway (2) is movably connected with the middle slipway (8), and the middle slipway (8) is movably connected with the lower slipway (7); a clamping foot (1) is arranged on the front end of the upper slipway (2), and a clasp (6) is fixed at one side of the upper slipway (2); a plurality of backrests (5) are fixed on the lower slipway (7); a rebounding device (9) is internally equipped with a locating trench (10) and is fixed at the tail part of the lower slipway (7); and the rebounding device (9) and the clasp (6) are positioned at the same side. The push-type rebounding slide rail of the drawer box has the beneficial effects that the slide rail is stable in operating performances, environmentally-friendly and energy-saving; the selected plastic materials are nontoxic and has small friction coefficient; a motor is not needed, thus the machining process is simple and the cost is low; and the drawer box can automatically pop up only by pressing, thus being convenient for use and saving labor.

Owner:CHUNCHENG LOCKS IND ZHEJIANG

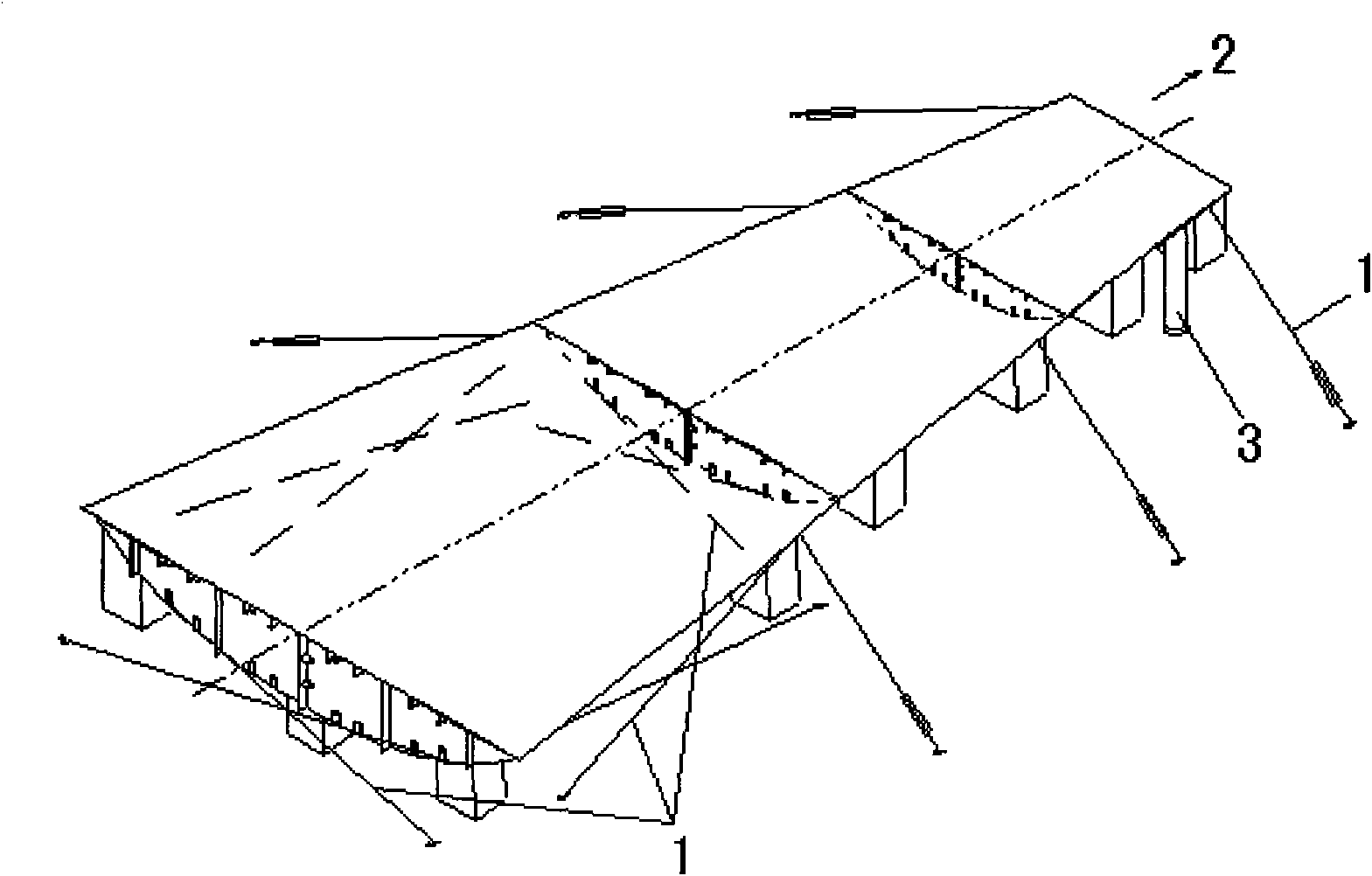

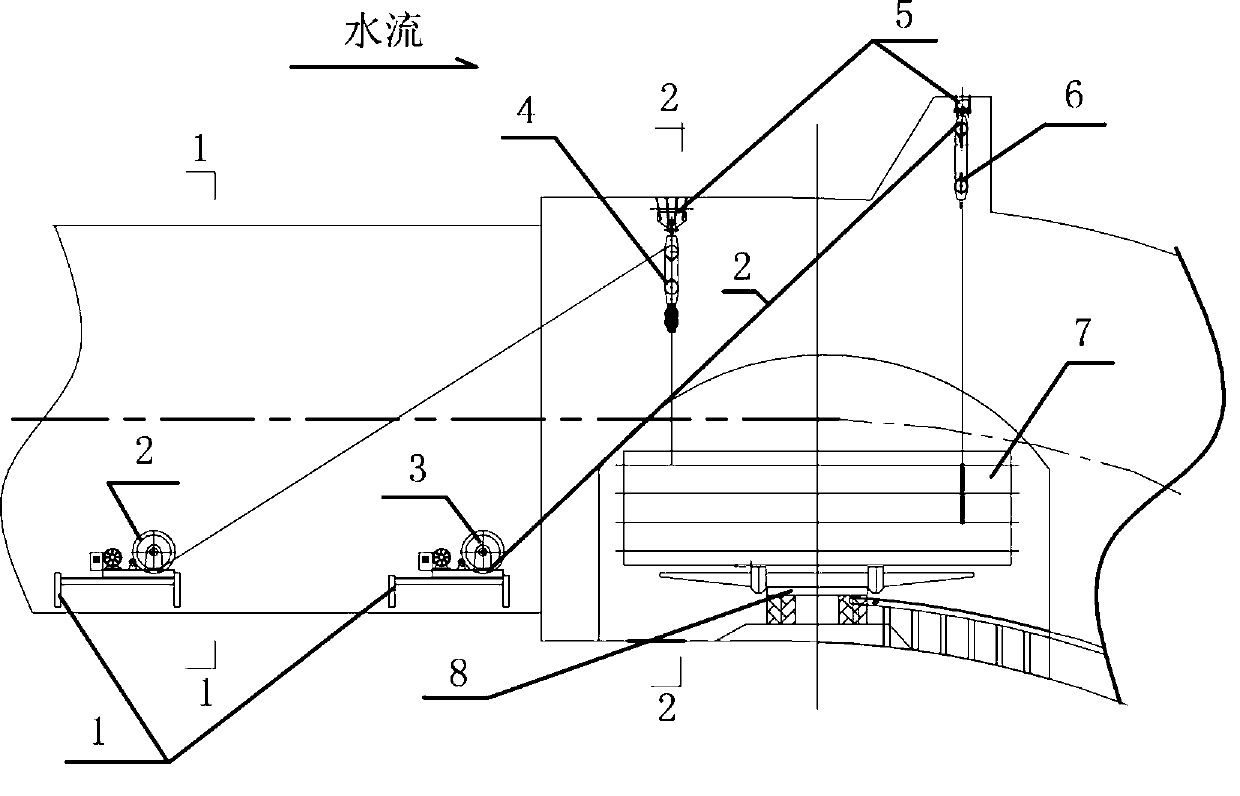

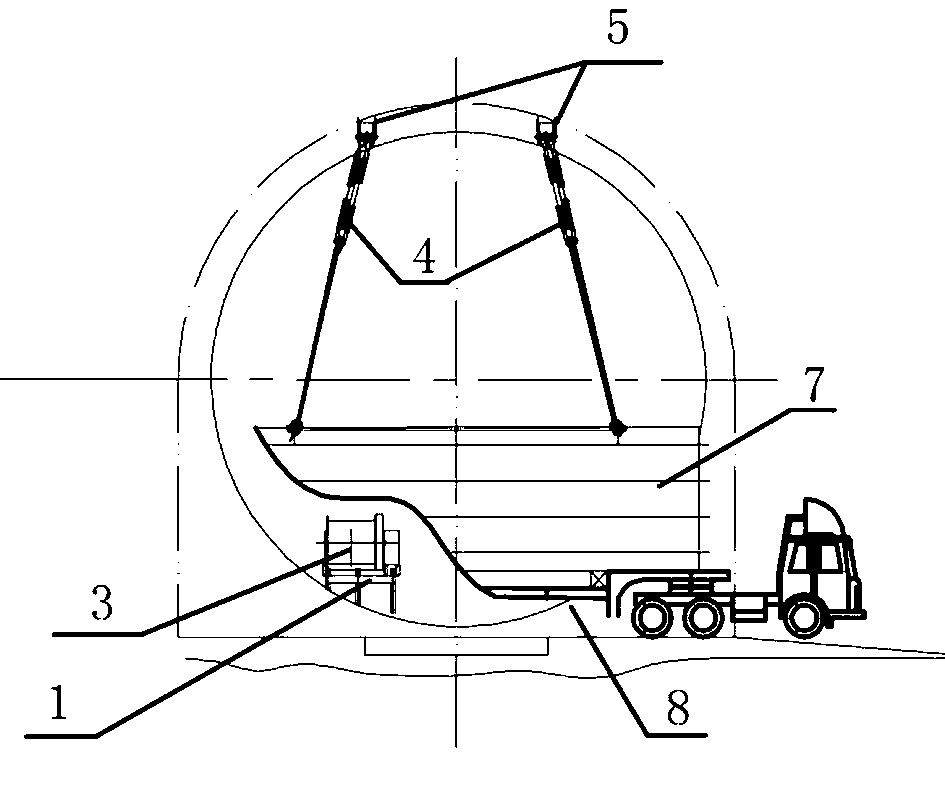

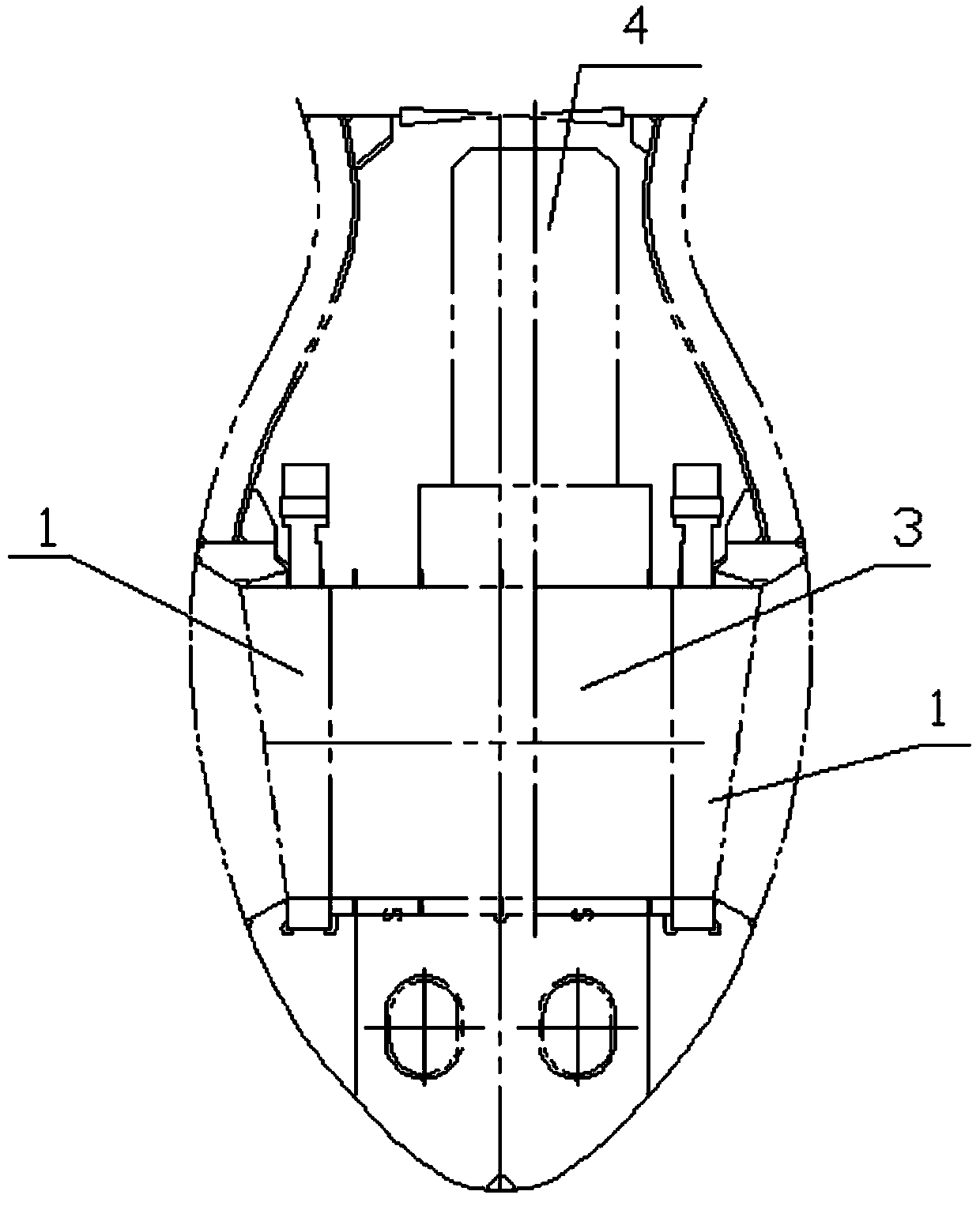

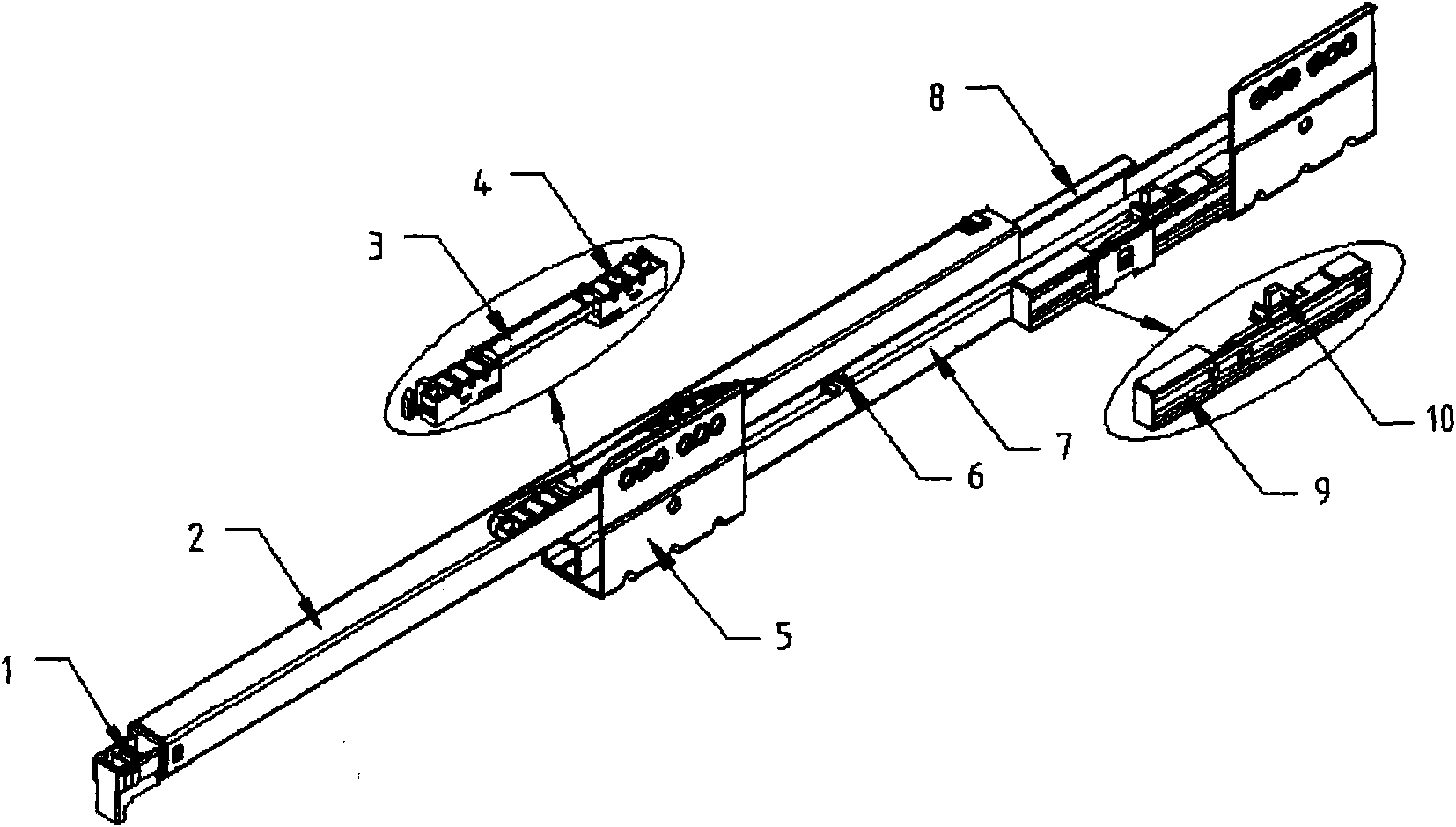

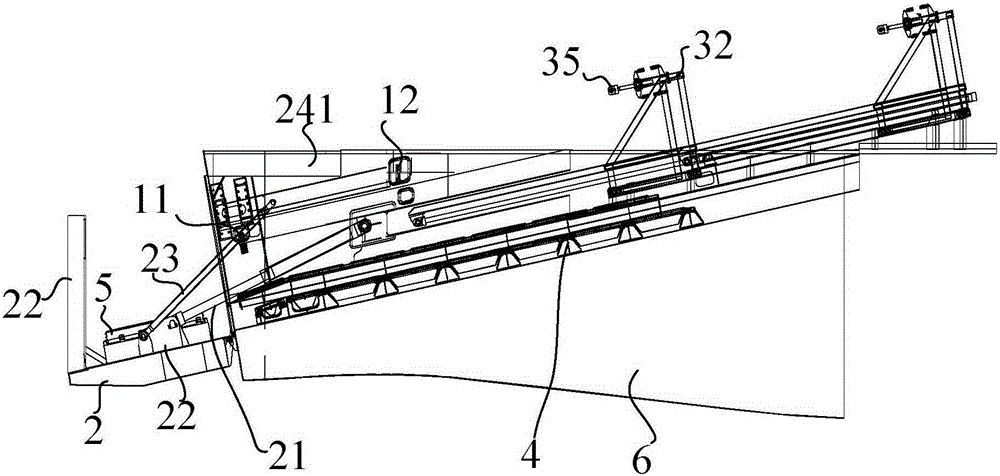

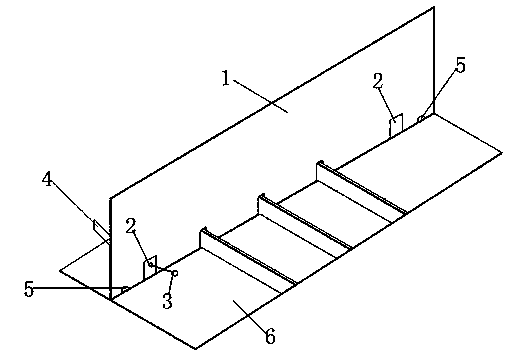

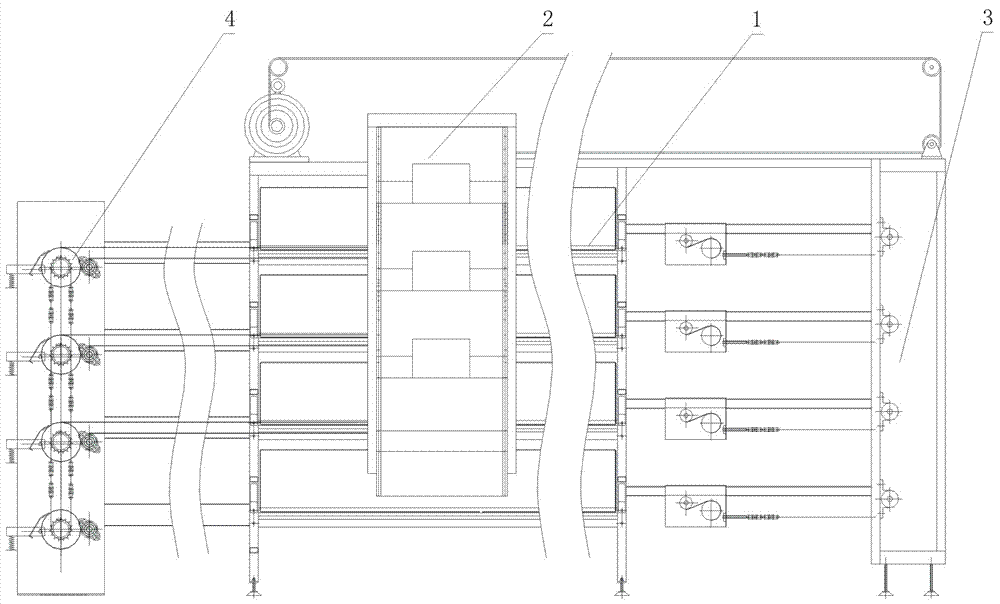

Stern slipway type work boat launching and restoring device

The invention belongs to the field of auxiliary equipment of ships and relates to a work boat launching and restoring device, in particular to a stern slipway type work boat launching and restoring device. The stern slipway type work boat launching and restoring device comprises a chute which is obliquely and downwardly arranged on a stern portion of a ship body, the tail end of the chute is movably connected with a stern door, a traction device is arranged on the two sidewalls of the chute, a traction slipway assembly matched with a line type of the work boat is arranged in the chute along the oblique direction of the chute, and a stern door slipway matched with the traction slipway assembly is arranged on the stern door. By arranging the chute on the stern portion and the stern door matched with the chute, a passageway allowing the work boat to go in and go out of the ship body is formed; the traction device arranged on the chute is used for providing power for the work boat to go in / go out; the stern slipway type work boat launching and restoring device is simple in structure, highly reliable, capable of working in severe sea conditions or sailing processes of a mother ship and free from potential safety hazards.

Owner:PENGLAI QINHAI SHIP EQUIP

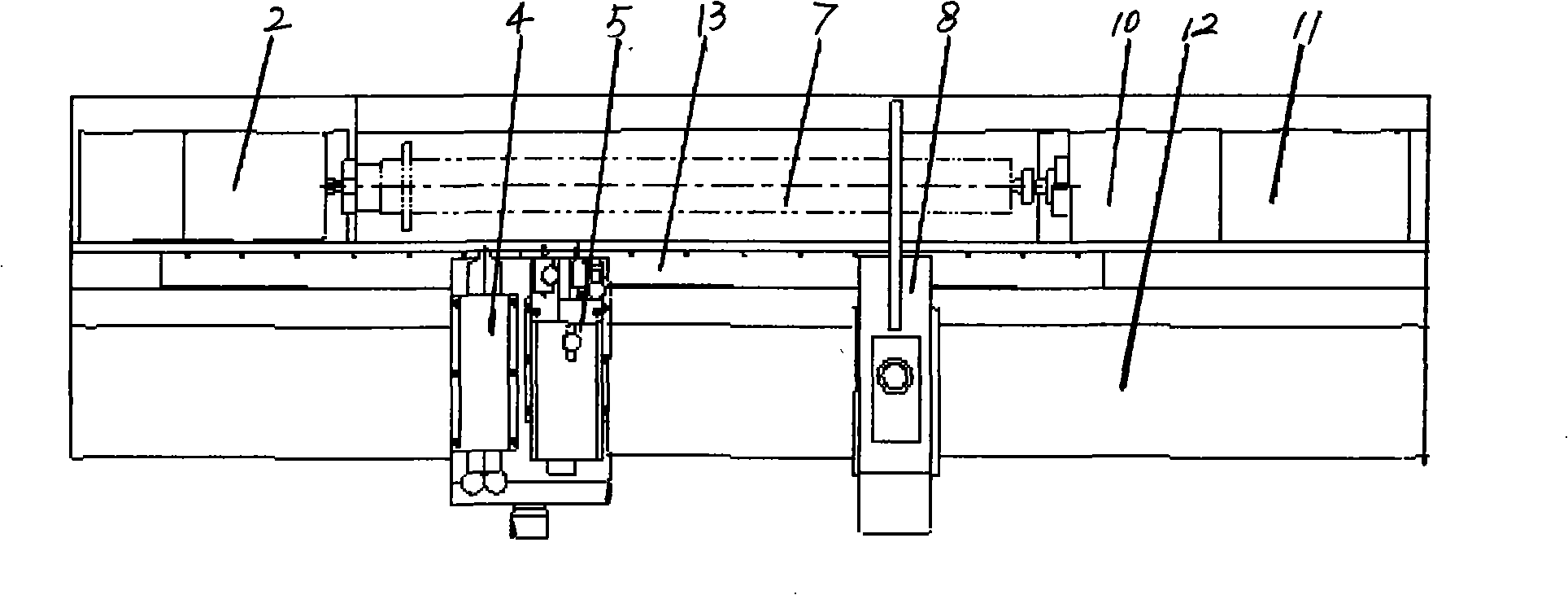

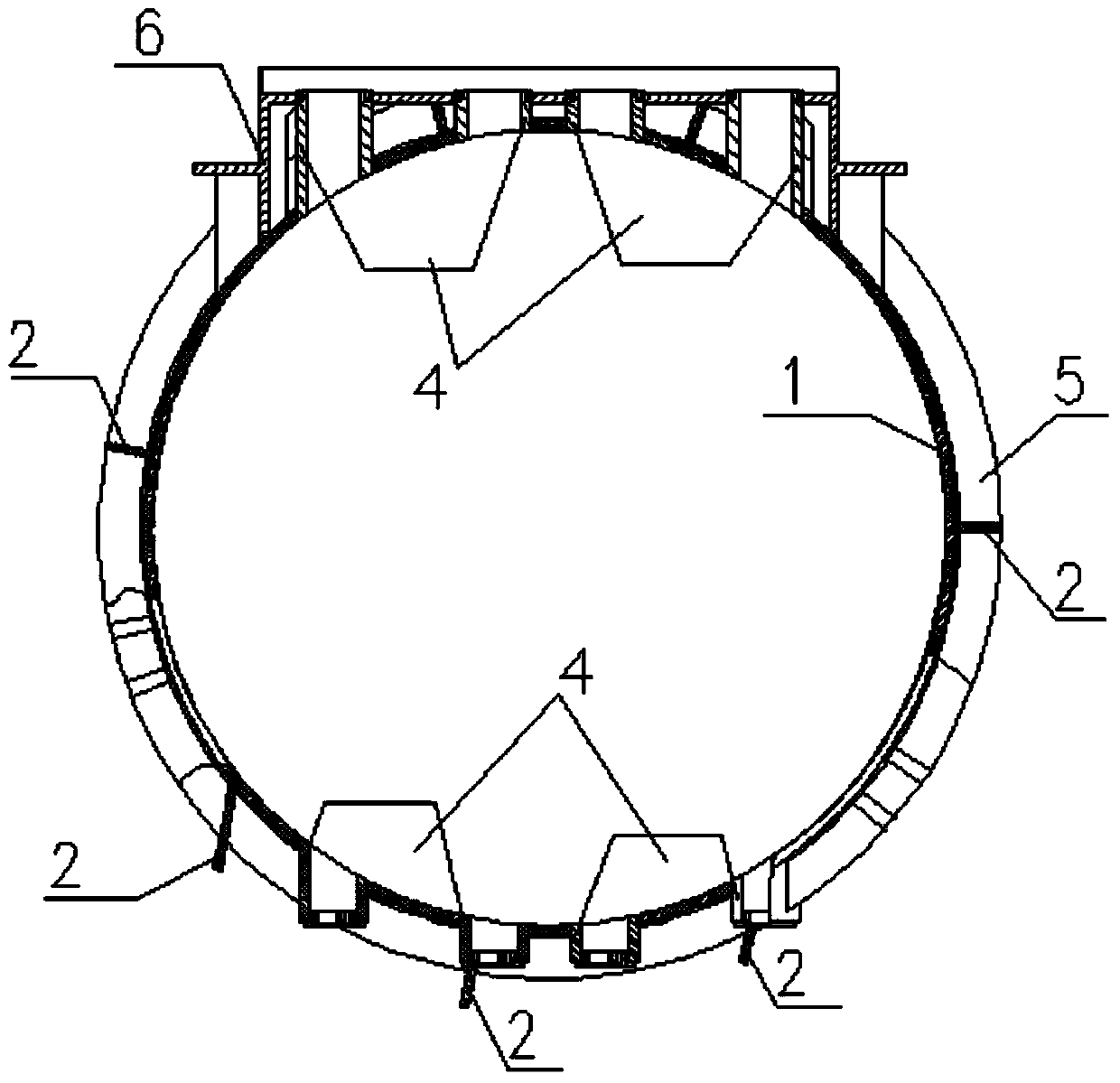

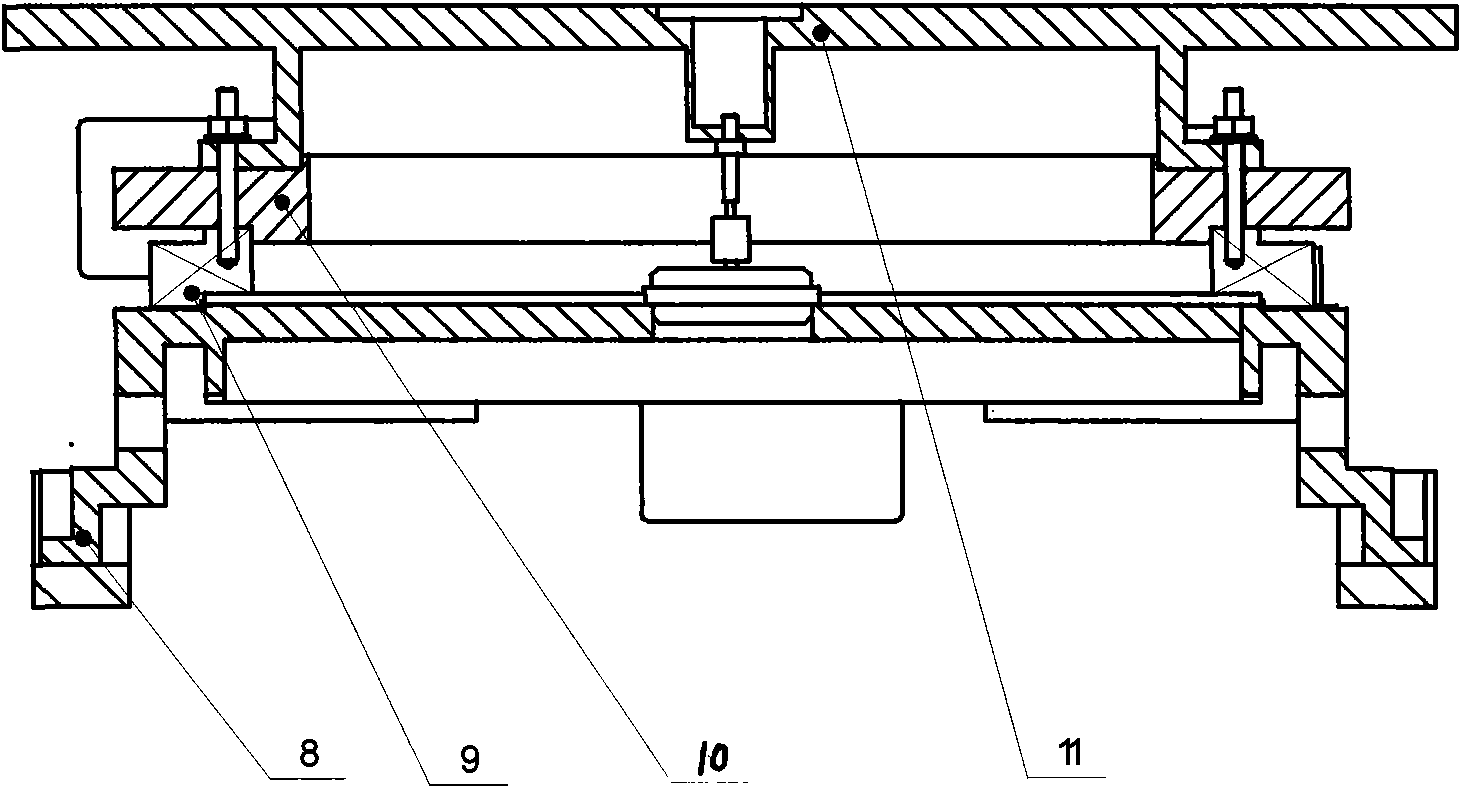

Three coordinate converting machine for integrated testing of quality characteristics

InactiveCN101603874AImplement integration testsSimple structureStatic/dynamic balance measurementIntegration testingSlipway

The invention discloses a three coordinate converting machine for integrated testing of quality characteristics. An arc substrate is provided with an arc surface matched with arc guide rails, and a horizontal plane used for fixedly mounting the arc substrate; two arc guide rails are respectively arranged on the arc surface of the arc substrate, and arc sections of the arc guide rails are parallel to an arc section of the arc substrate; a slipway is arranged on the arc guide rails and slides along the arc guide rails under the action of a driving mechanism; the slipway can rotate along the normal direction of each point of the arc sections of the arc guide rails; the driving mechanism is arranged in the arc substrate; and a workpiece to be tested is arranged on the slipway, and the automatic conversion between quality characteristic parameters of the workpiece to be tested at a vertical position under Cartesian coordinates and quality characteristic parameters of the workpiece to be tested at any position under the Cartesian coordinates is realized through the movement of the slipway on the arc guide rails. The three coordinate converting machine has simple structure and convenient operation, and can be used for integrated testing of the quality characteristics of large equipment such as spacecrafts and the like.

Owner:BEIJING SATELLITE MFG FACTORY

Fillet weld inflation test method

InactiveCN103645018AReduce the workload of tightness testReduce lossDetection of fluid at leakage pointMeasurement of fluid loss/gain rateFillet weldWorkload

The invention discloses a fillet weld inflation test method which comprises the following steps: step one: opening a valve, injecting compressed air to a fillet weld root gap, and when a pointer of a pressure gage reaches a pressure specified value, closing the valve and calming the pressure for 15 minutes; step two: checking whether the pointer of the pressure gage goes down, if the pointer goes down obviously within the 15 minutes of pressure calming, examining leakage conditions of joint welding seams and finding the reasons for pressure drop, if the pressure does not drop, applying soap liquid to the surface of the fillet weld and checking whether bubbles appear on the surface of the fillet weld, and when test liquid on the fillet weld does not generate bubbles, the fillet weld is deemed to be up to standard; step three: during the testing process, if leakage occurs, marking the leakage place with a chalk; and step four: after testing, small holes in a web must be filled through electrowelding. The method is used for testing whether weld defects, such as air holes, and impurity mixing and the like exist in a continuous welding portion of a watertight region, thereby ensuring no leakage occurring at the watertight region, reducing workload of the slipway tightness test, and reducing in-dock production period.

Owner:JIANGSU NEW TIMES SHIPBUILDING

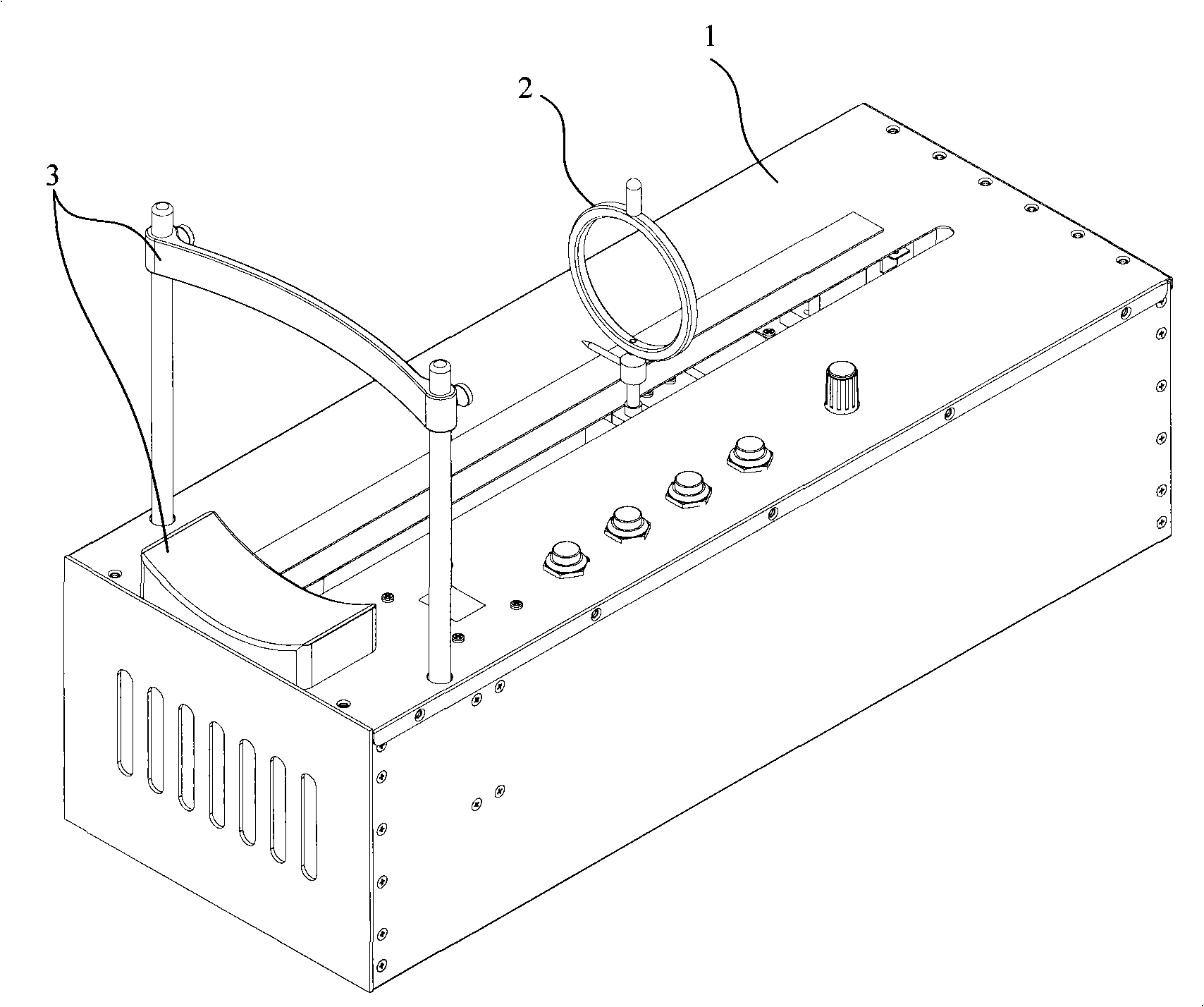

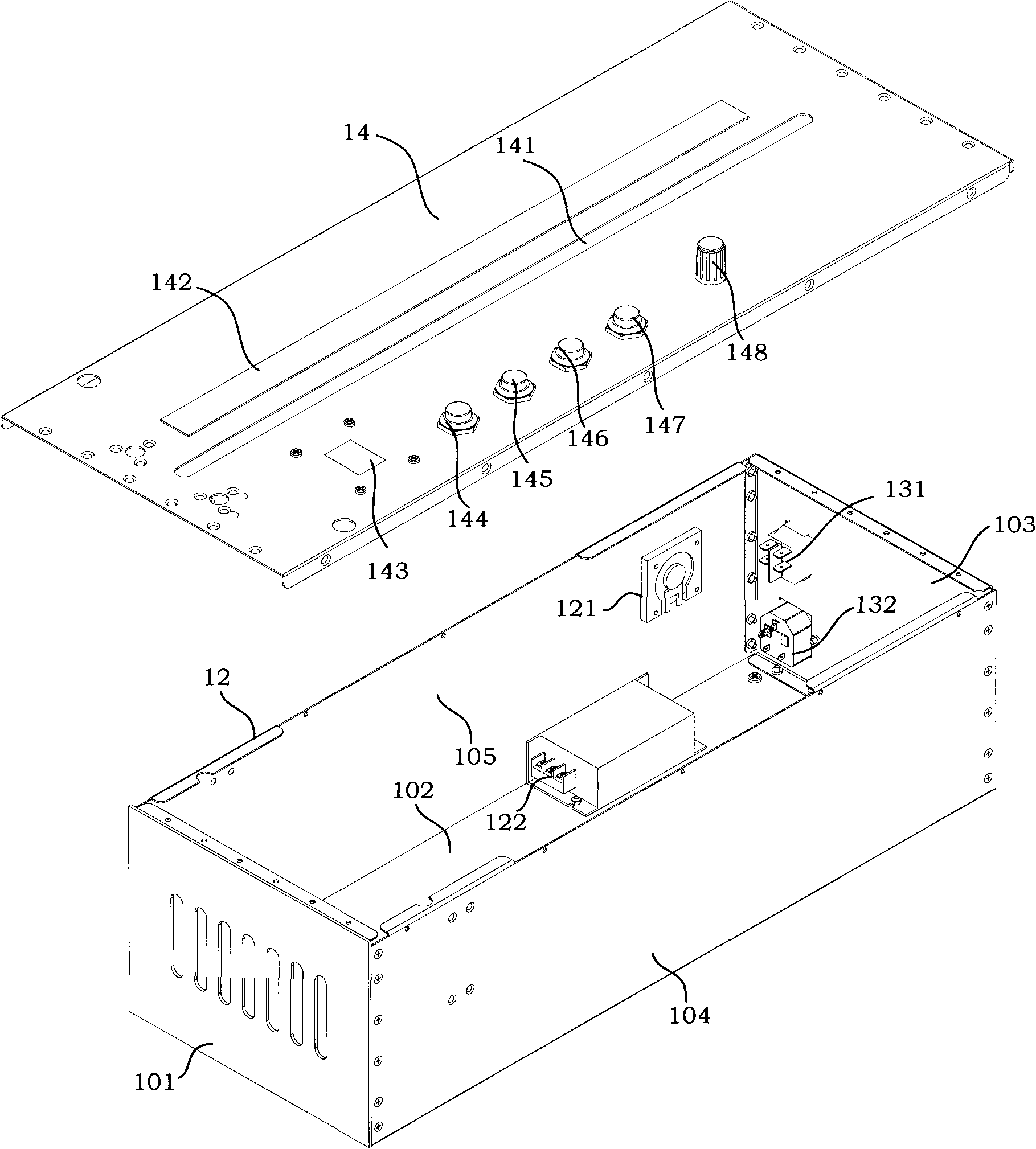

Vision fusion function trainer and training method thereof

InactiveCN101301237ADevelop stereopsisEasy to trainEye exercisersEye treatmentElectrical connectionEngineering

The invention discloses a visual fusion functional trainer and a training method of the same, mainly used to rectify child strabismus and belonging to the ophthalmic medical apparatus technical field. The trainer comprises an outer casing component, a marker moving device, a head fixing device and a circuit control unit, wherein the head fixing device is arranged on the outer casing component to fix the head of a user; the marker moving device and the circuit control unit are arranged inside the outer casing component; a marker component on the marker moving device extends out of the outer casing component through an opening on the slipway on the outer casing component so as to be corresponding to the position of the head fixing device; and the circuit control unit is in electrical connection with the control end of the power-driven device of the marker moving device, thereby controlling the movement or the stop of the marker component on the marker moving device. The fusion functional trainer designed by the invention can realize quick and effective rectification of strabismus and trains the stereoscopic vision of a patient, thereby reaching the effect of improving eyesight.

Owner:BEIHANG UNIV

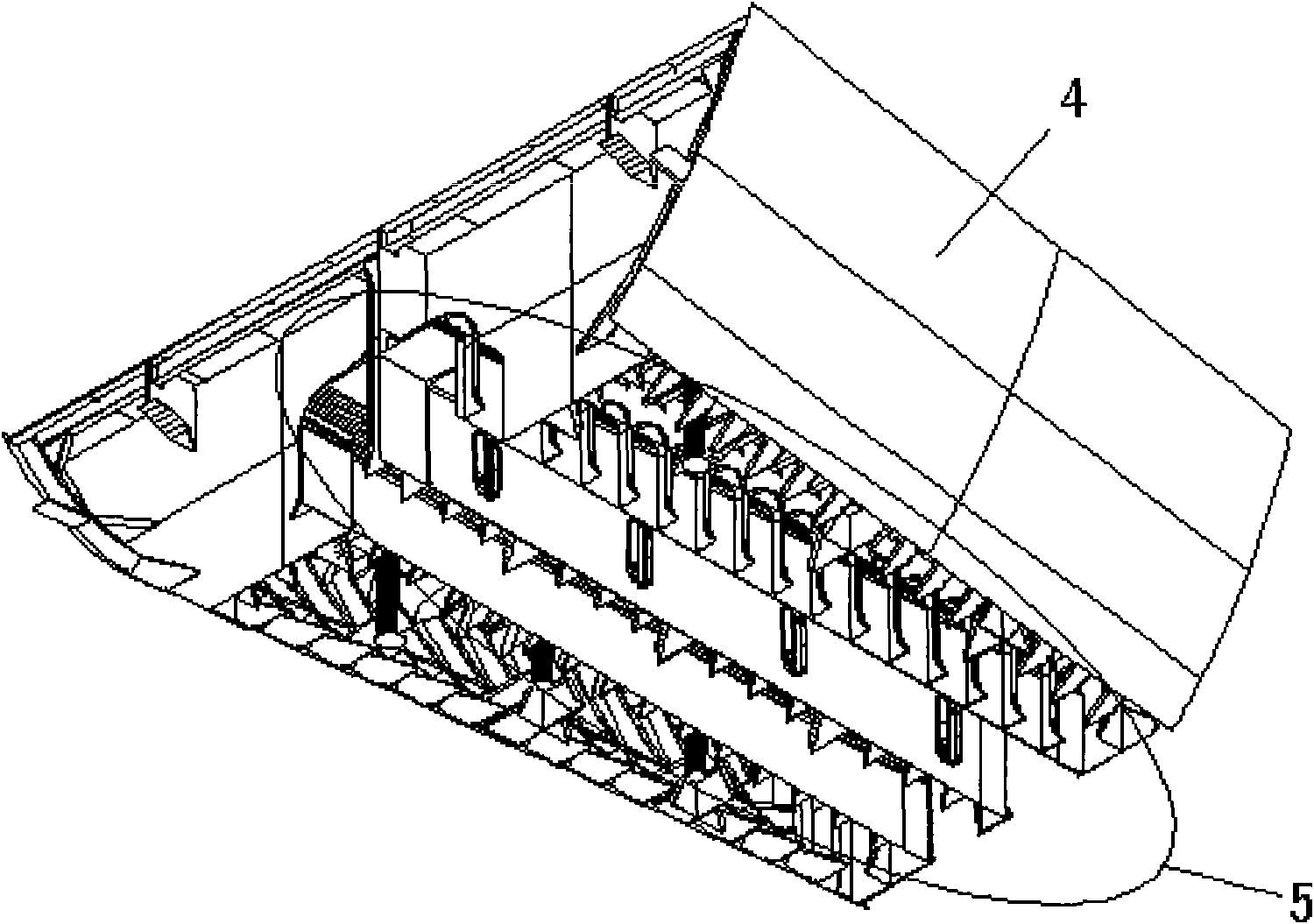

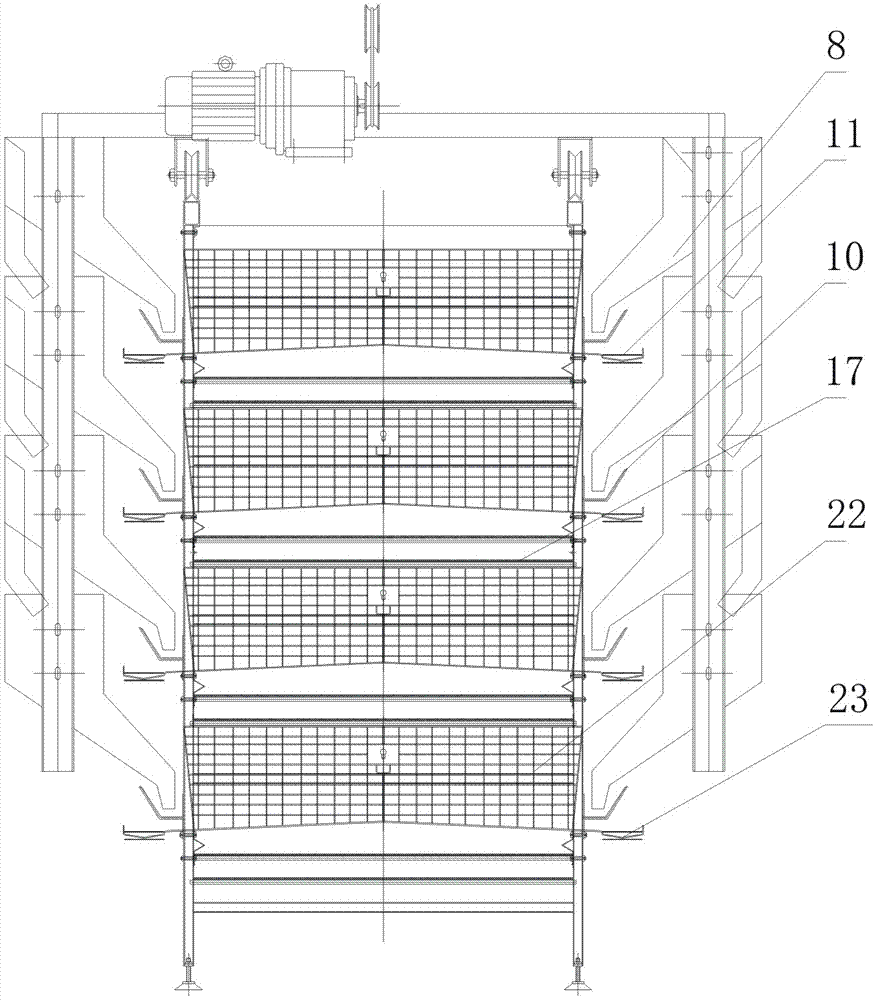

Full-automatic quail cultivating cage

The invention discloses a full-automatic quail cultivating cage, which comprises laminated frames consisting of upright posts and transverse beams, wherein every layer of frames is correspondingly provided with cages; both sides of corresponding cages are provided with feeding devices; the feeding devices slide along the cages through slipways formed on the frames; the bottoms of the cages are inclined bottoms; both sides of the frames are provided with egg receiving grooves corresponding to the inclined sides of the cages; the egg receiving grooves are provided with egg belts; the egg belts are arranged together with egg collecting devices arranged on the frames; the bottoms of the cages are provided with excrement belts; and the excrement belts are arranged together with excrement removing devices arranged on the frames. Compared with the prior art, the full-automatic quail cultivating cage has the beneficial effects that: functions such as automatic water feeding, feeding, automatic excrement removing, automatic egg collecting and the like are integrated, contact of people with quails is reduced effectively, the transmission of diseases is reduced, the operation efficiency is increased, and labor cost is lowered.

Owner:HUBEI SHENDAN HEALTHY FOOD

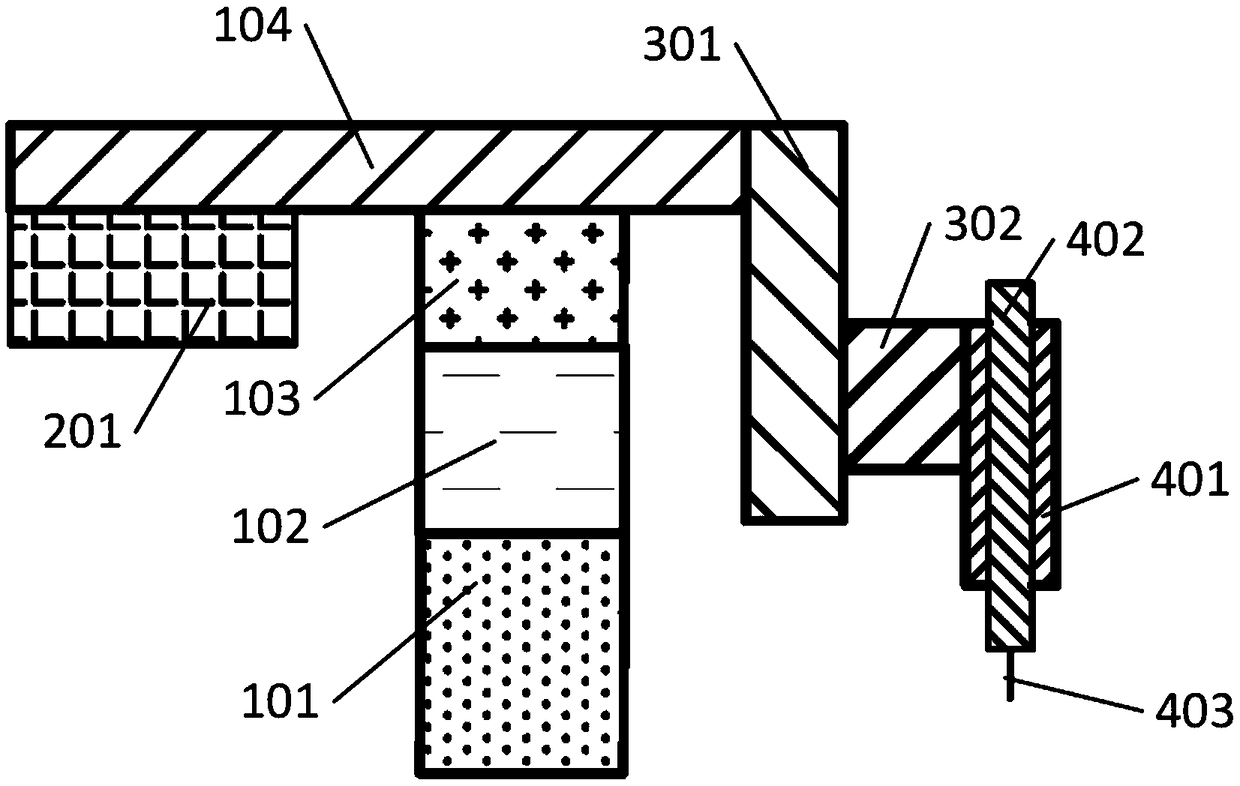

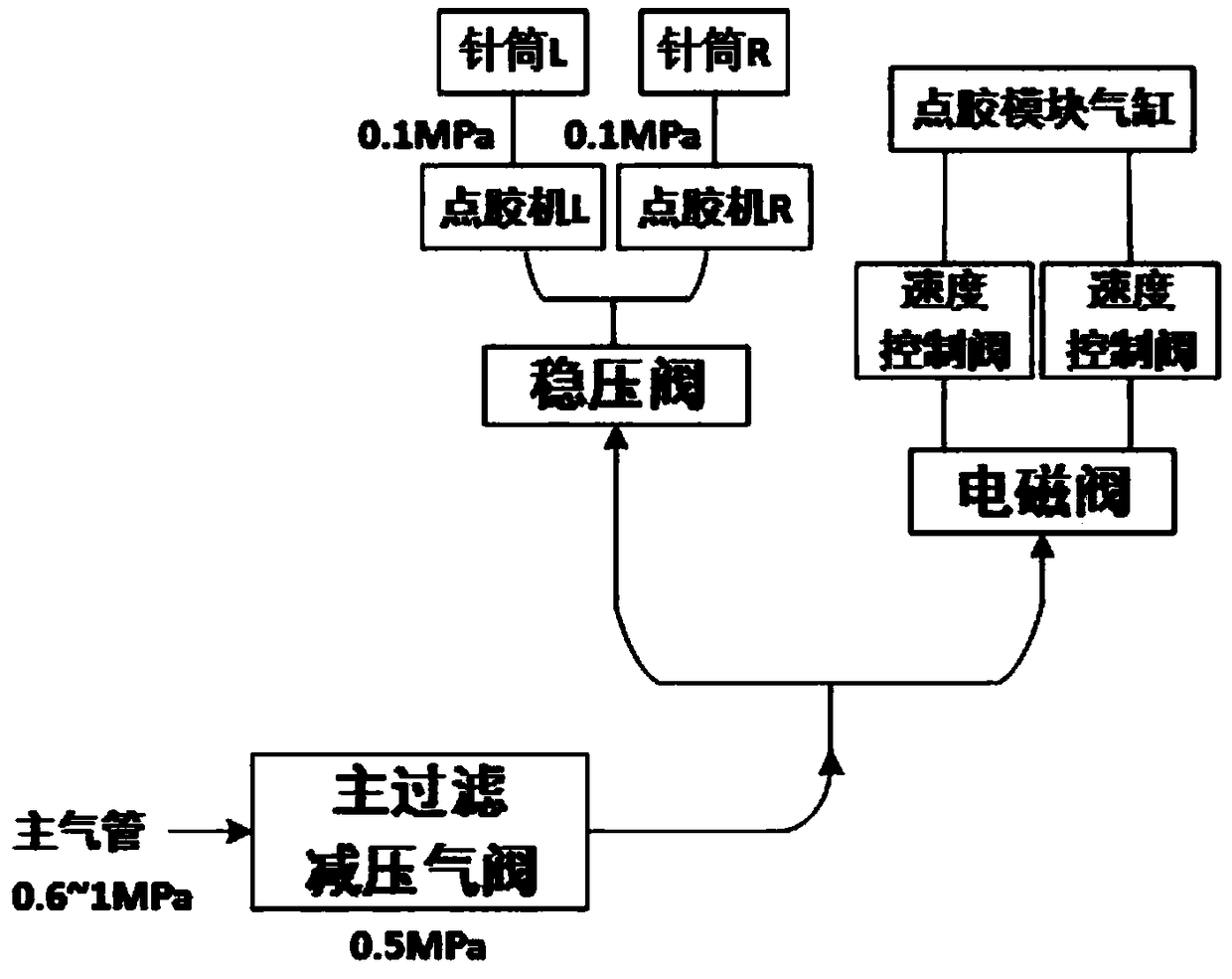

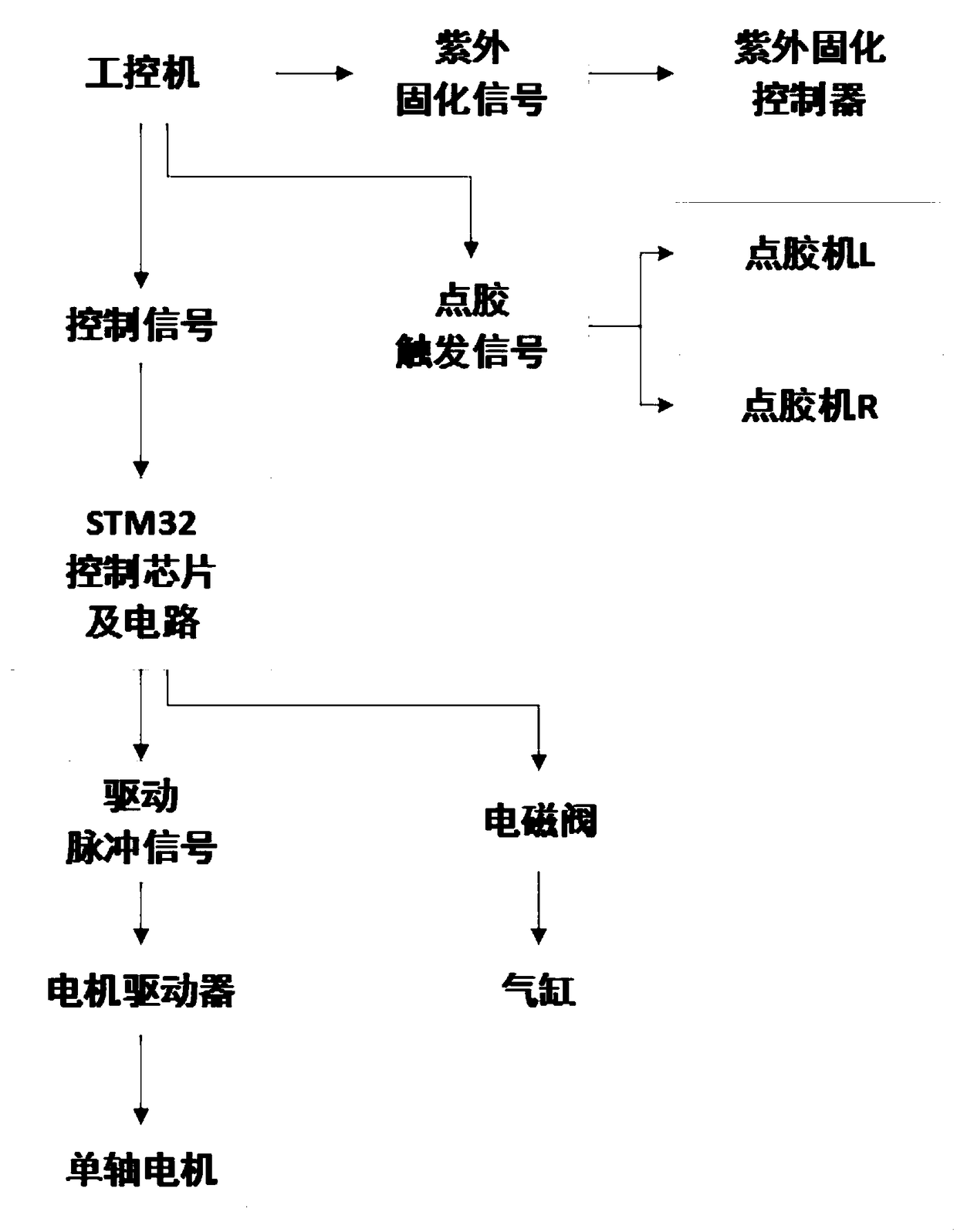

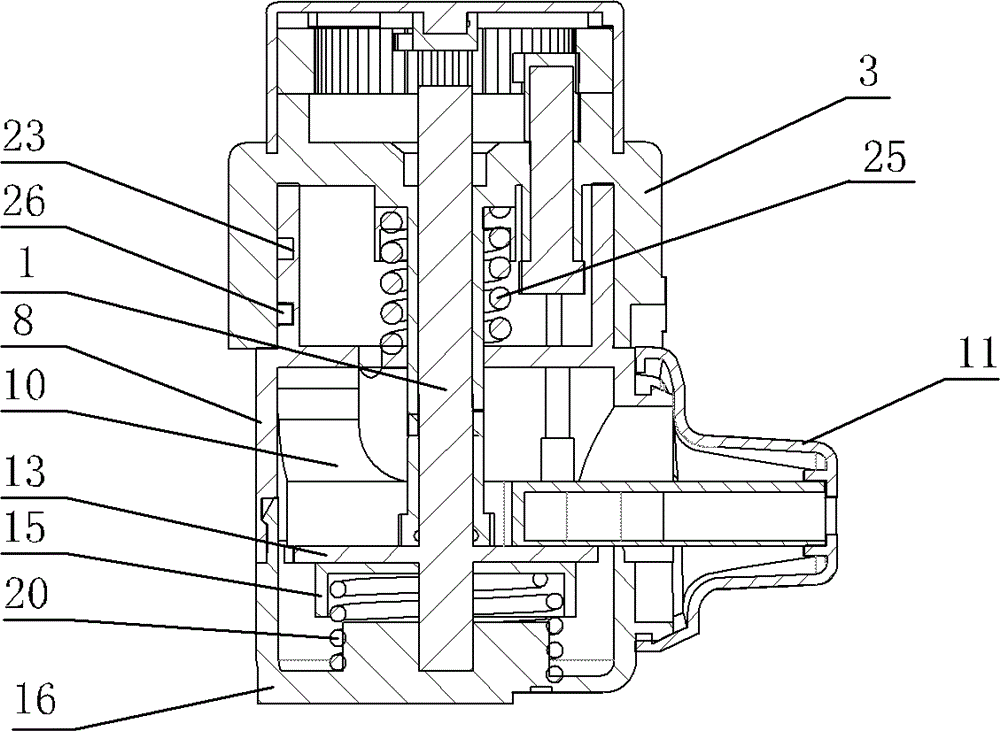

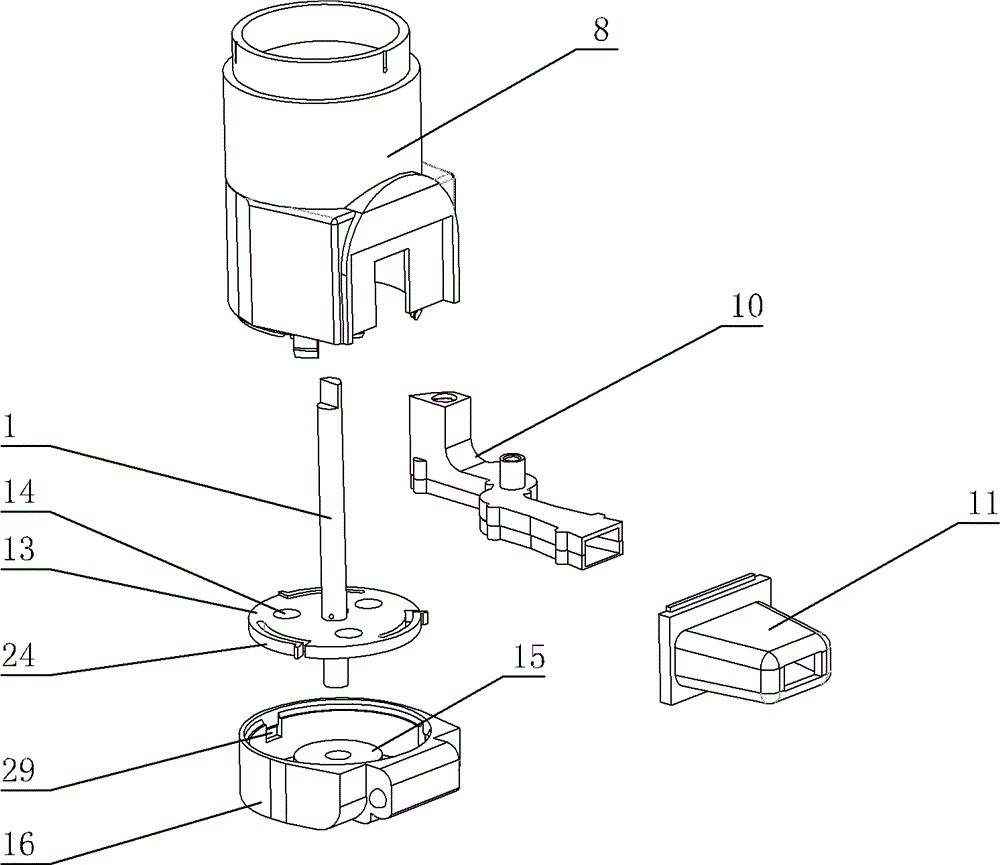

Automatic adhesive dispensing device and method for coupling of planar waveguide type components

The invention provides an automatic adhesive dispensing device and method for coupling of planar waveguide type components. The automatic adhesive dispensing device comprises a single-shaft movement controlling module, an air cylinder movement module and an adhesive dispensing module, wherein the single-shaft movement controlling module is used for driving the adhesive dispensing module to a predetermined adhesive dispensing position; the air cylinder movement module is used for driving the adhesive dispensing module to move up and down, so that adhesive dispensing syringe needles are alignedto the predetermined adhesive dispensing positions, and an air cylinder in the air cylinder movement module is connected with a movement end of the single-shaft movement controlling module; and the adhesive dispensing module comprises an adhesive dispensing syringe cylinder up-down position fine adjustment slipway, adhesive dispensing syringe cylinder front-rear position fine adjustment slipways,adhesive dispensing syringe cylinder left-right position fine adjustment slipways, adhesive dispensing syringe cylinders and adhesive dispensing syringe needles. According to the automatic adhesive dispensing device and method disclosed by the invention, the adhesive quantity and the adhesive dispensing quality are controlled through equipment, the automatic adhesive dispensing device has the advantages of being high in product consistency, reliable, capable of saving labor cost and the like, besides, automatic adhesive dispensing of various planar waveguide type components can be compatible.

Owner:GUANGXUN SCI & TECH WUHAN

Dry powder administration device

ActiveCN102228725BAvoiding "normally open" state problemsReduce moistureInhalatorsMedicineDrug powder

Owner:SHANGHAI CHENPON PHARM TECH CO LTD

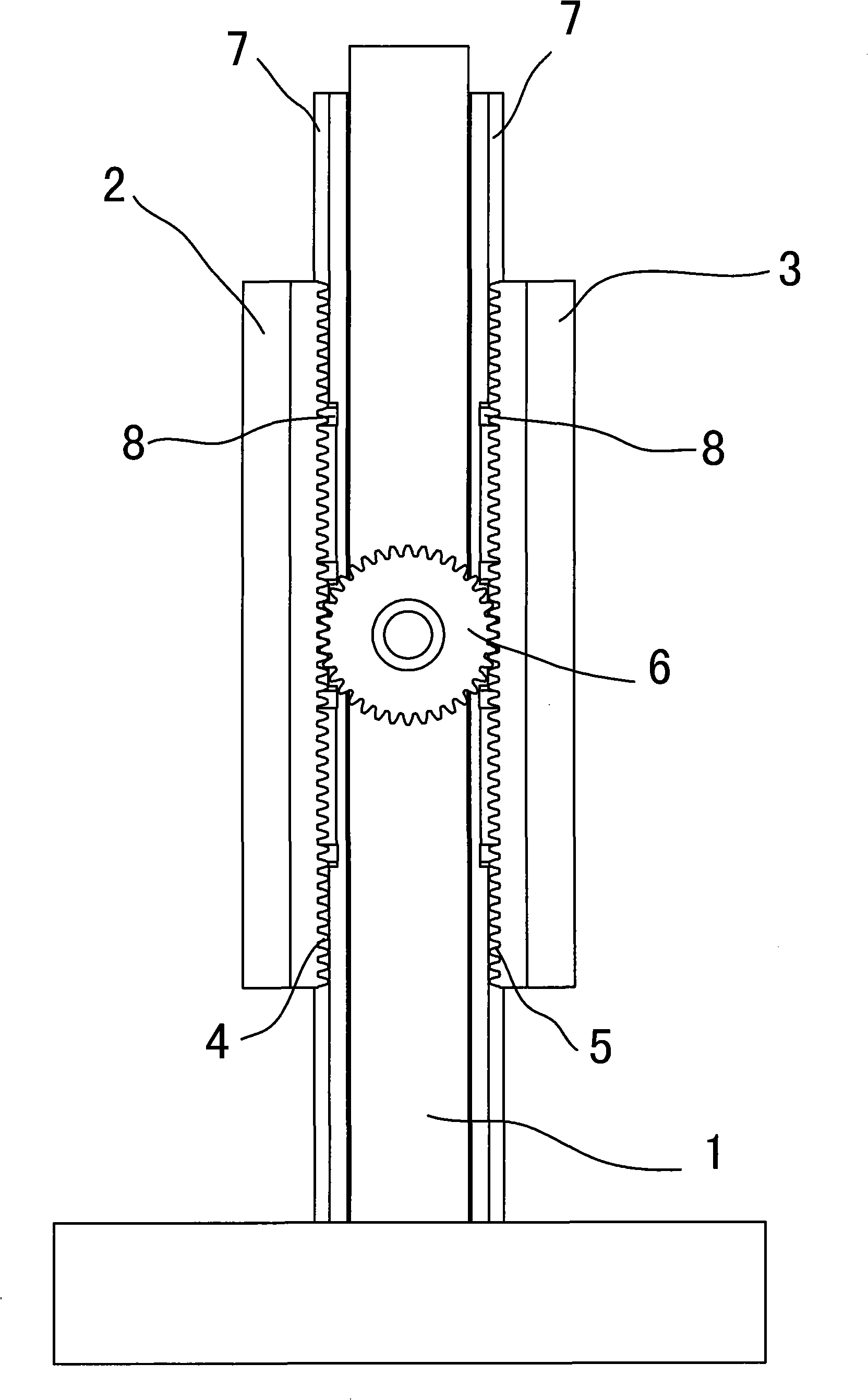

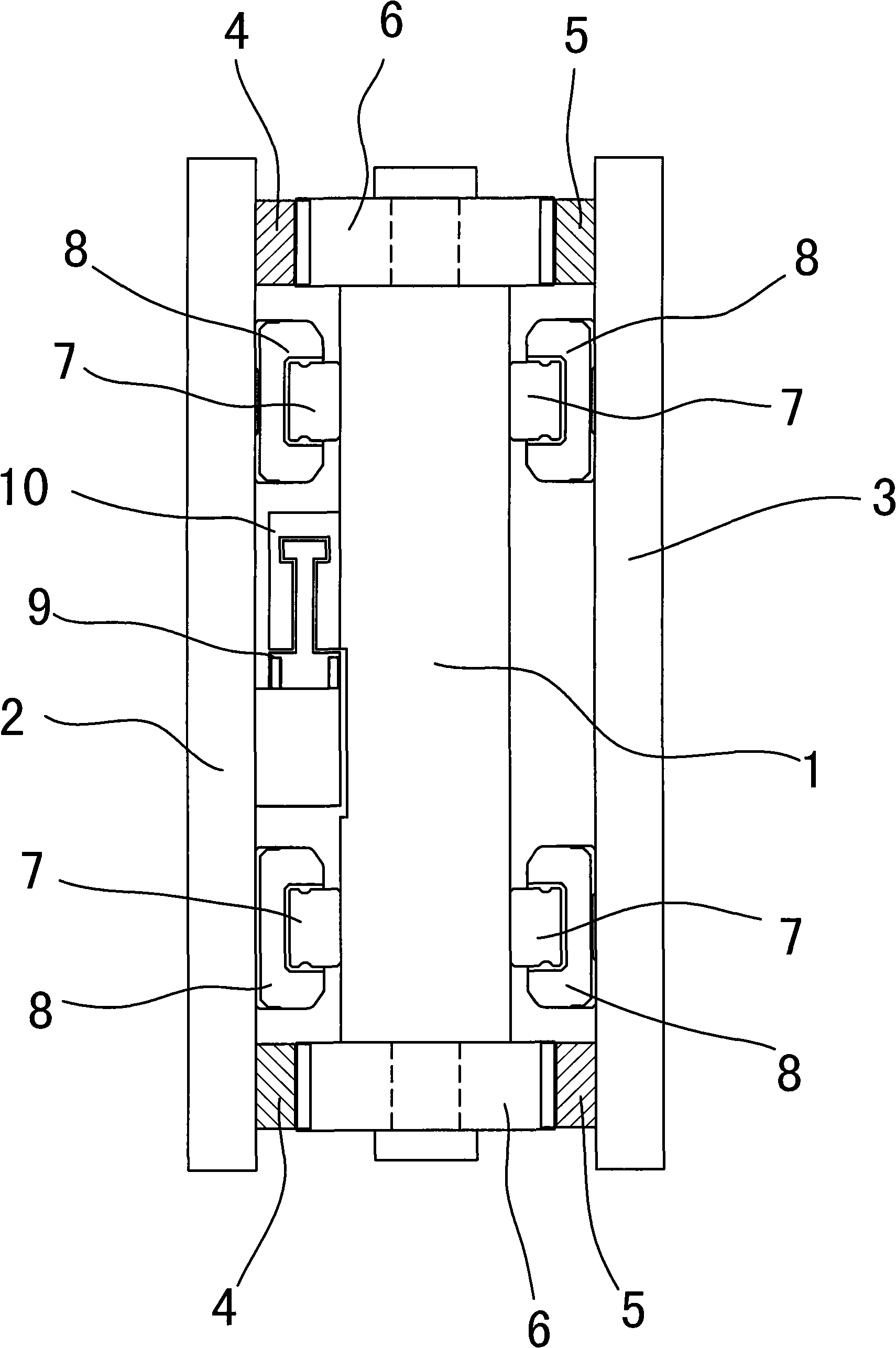

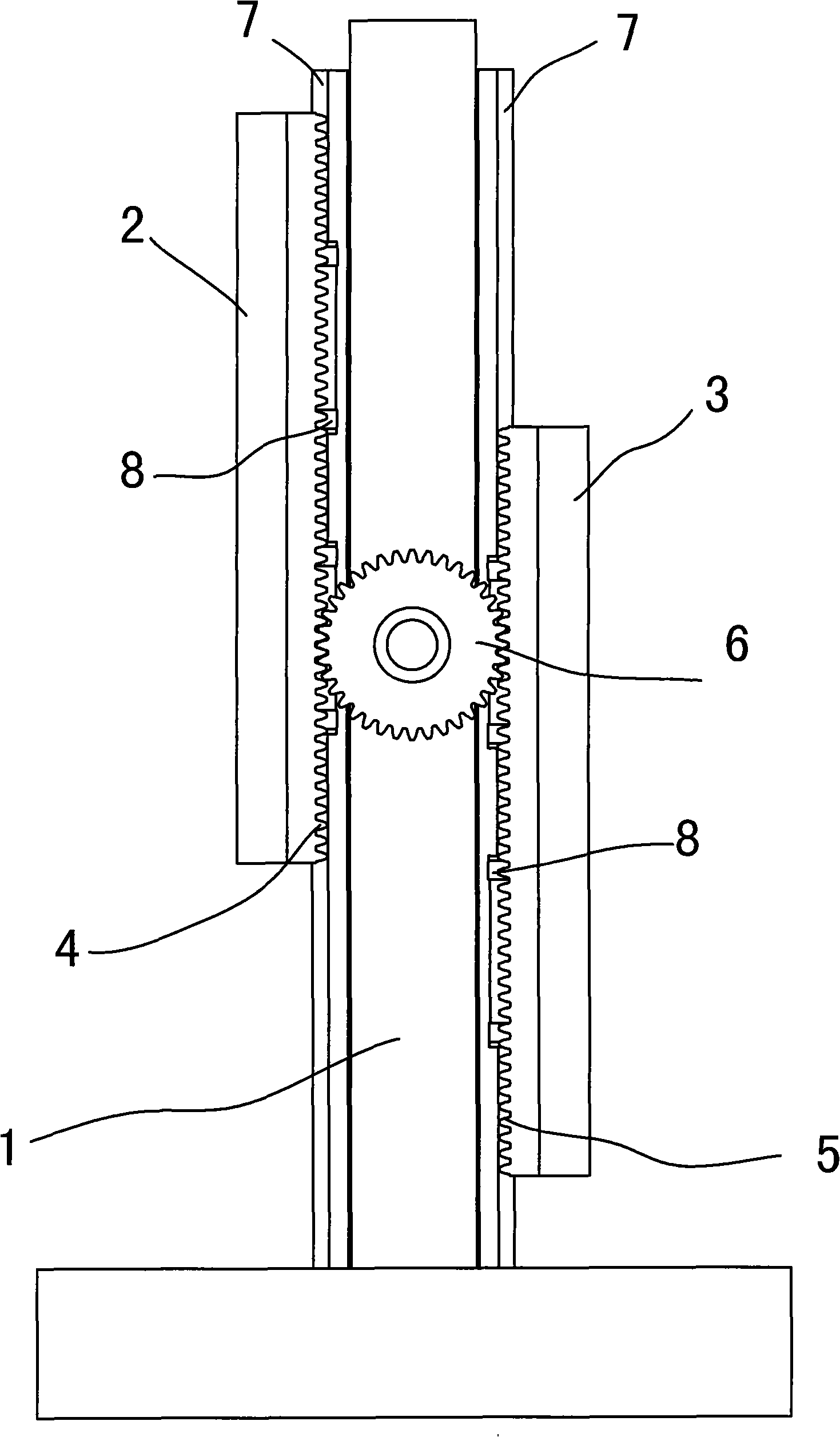

Balancing counterweight mechanism of straight line motor vertical motion

InactiveCN101279428AReduce volumeDoes not affect sizeCounterweightsMaintainance and safety accessoriesInsertion stentInstability

The invention relates to a balanced counterweight mechanism for vertical movement of a linear, which comprises a stent, the linear motor, an object carrying slipway and a counterweight slipway; wherein, the linear motor has effects in the vertical direction, a stator of the linear motor is fixedly connected with the stent relatively, while a mover of the linear motor is fixedly connected with the object carrying slipway; the object carrying slipway is glidingly connected in the vertical direction relative to a stent guide, and the counterweight slipway is glidingly connected in the vertical direction relative to the stent guide; the object carrying slipway and the counterweight slipway are respectively and fixedly provided with racks in the vertical motion direction, a gear is correspondingly arranged on the stent, and the gear is rotatablely and fixedly connected correspondingly to the stent; meanwhile, the gear is meshed with the racks on the object carrying slipway and the counterweight slipway. The technical scheme solves the problems of instability, complex mechanism and large size of a vertical motion system for linear motor existing in the prior art.

Owner:苏州钧信自动控制有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com