Energy-efficient type injection molding machine

An injection molding machine, energy-saving technology, applied in the field of mold injection molding machine improvement, can solve problems such as electric energy waste, and achieve the effect of eliminating overflow phenomenon, good use effect and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

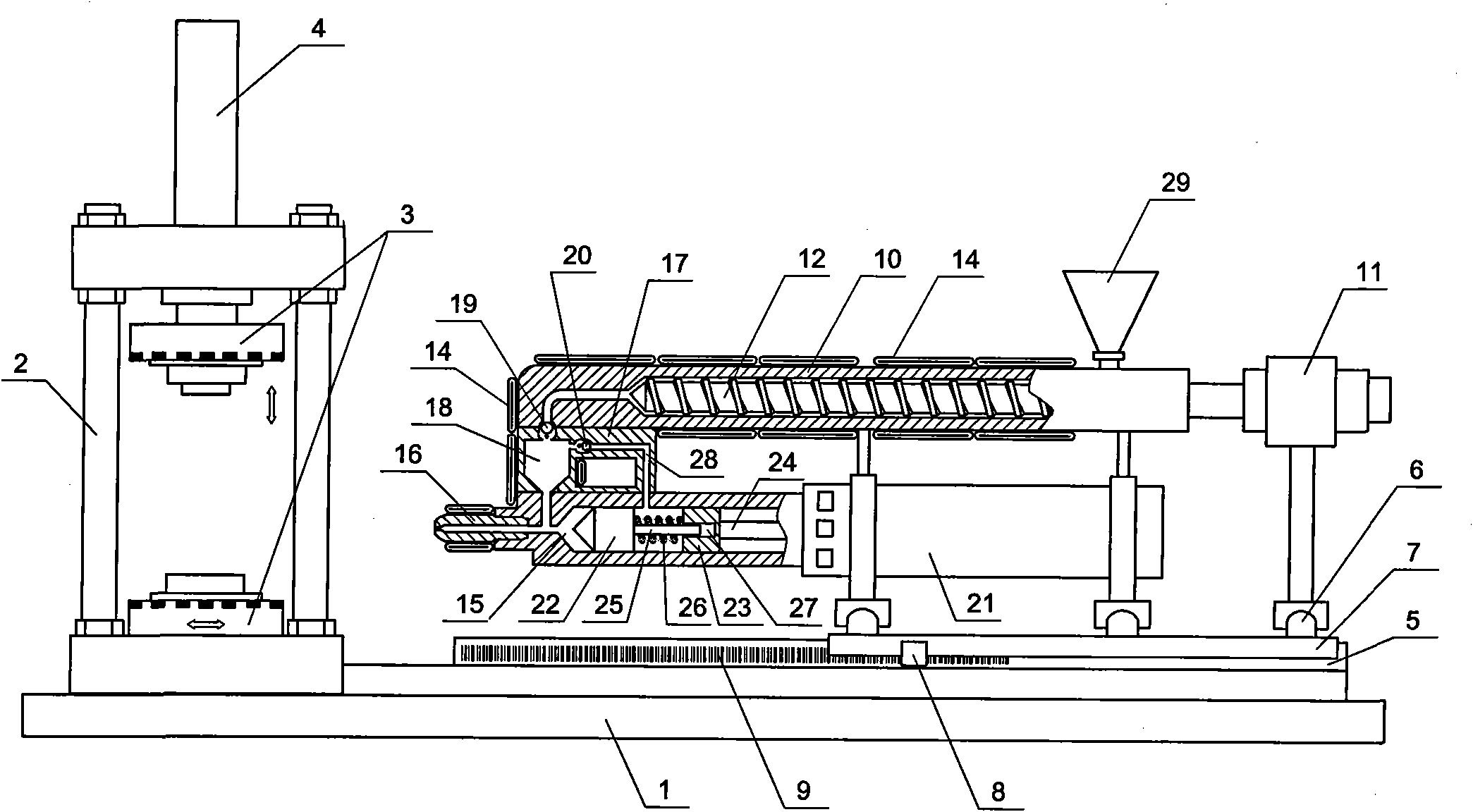

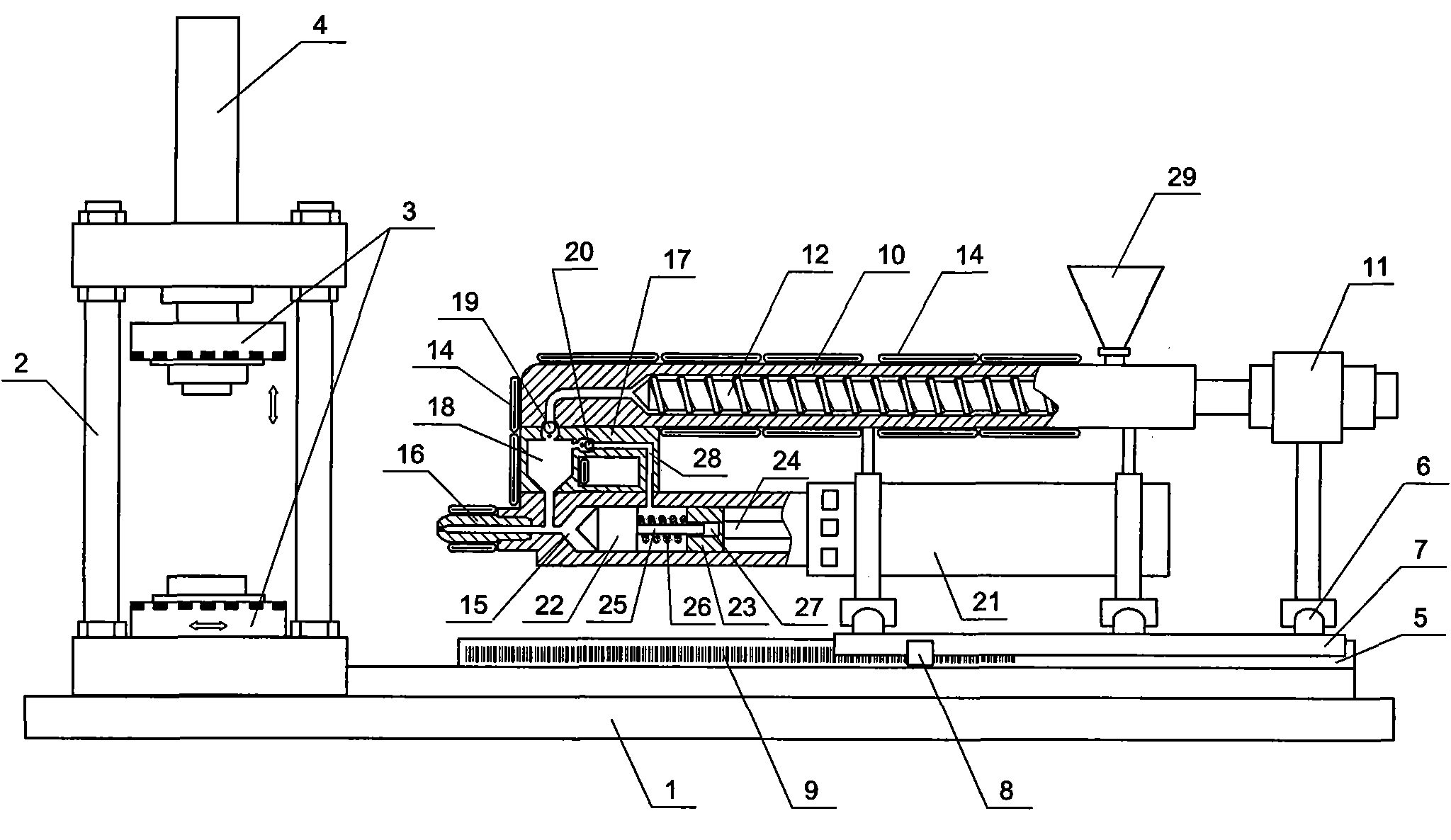

[0024] Embodiment one: see figure 1 , an energy-saving injection molding machine, number 1 is the base, 2 is the vertical mold clamping mechanism bracket, 3 is the mold, 4 is the hydraulic cylinder, 5 is the horizontal guide rail, 6 is the horizontal guide rail, 7 is the support frame, and 8 is the BPS reader Encoder, 9 is the bar code fixed on the guide rail, 10 is the plasticizing barrel, 11 is the driving machine, 12 is the plasticizing screw (screw propulsion shaft), 14 is the heater, 15 is the injection cylinder, 16 is the nozzle valve , 17 is a booster buffer mechanism, 18 is a material storage chamber, 19,20 are check valves, 21 is an oil cylinder, 22 is a front piston, 23 is a rear piston, 24 is a screw rod of a rear piston, and 25 is a screw rod of a front piston, 26 is pressure spring, and 27 is blind hole, and 28 is booster pipe, and 29 hoppers.

[0025] One end of the base 1 is fixed with a vertical mold clamping device, and the other end is fixed with an injectio...

Embodiment 2

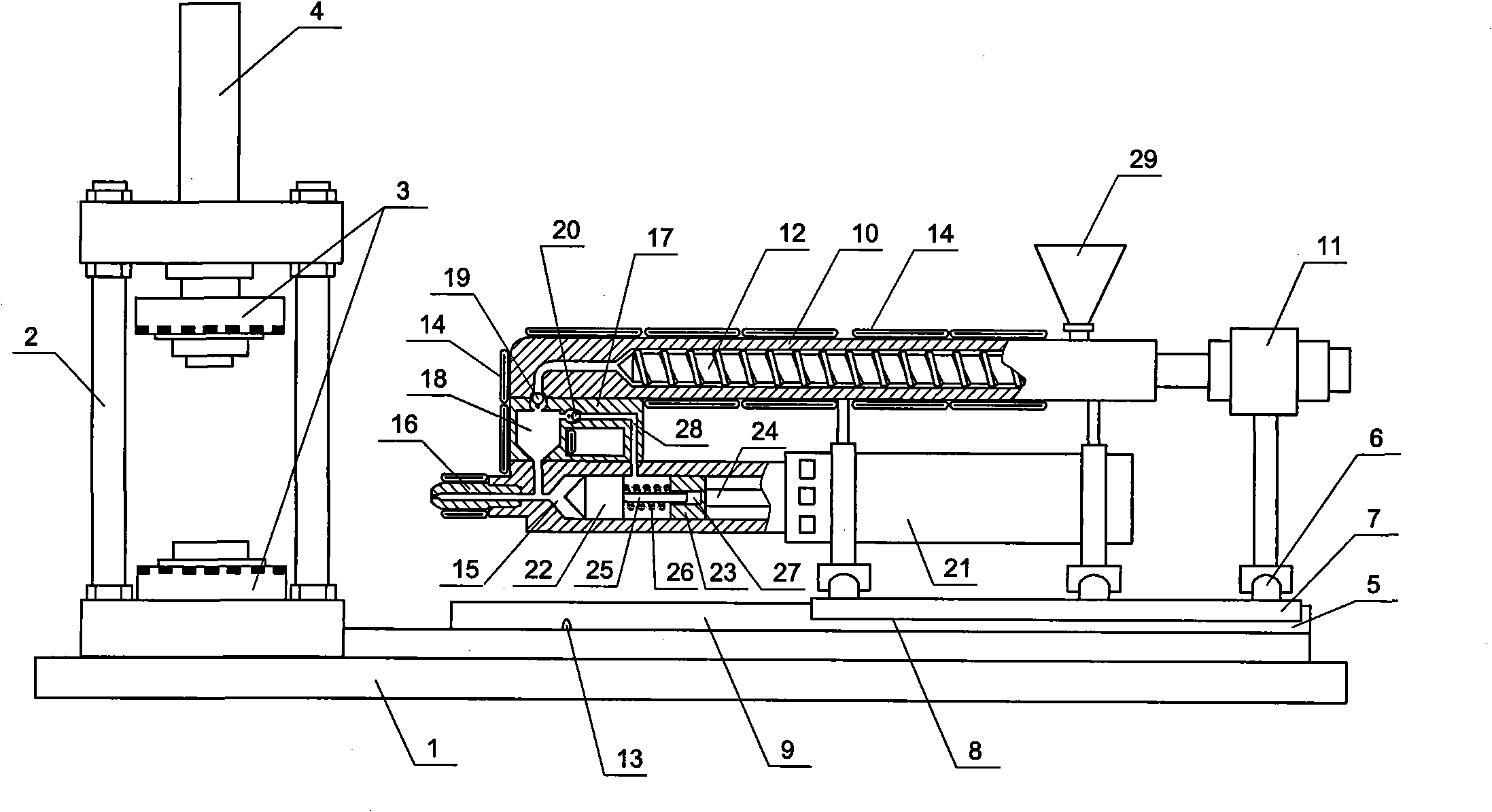

[0033] Embodiment two: see figure 2 , another energy-saving injection molding machine, the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the positioning system is provided with one or more photosensitive elements 13 on the horizontal and / or longitudinal guide rails. , when the material storage extrusion mechanism runs to a specific photosensitive element, the PLC or the host computer determines and controls the output frequency of the frequency converter according to the trigger signal of the photosensitive element.

Embodiment 3

[0034]Embodiment three: the accompanying drawings are not drawn, and the content is basically the same as that of embodiment one, and the similarities will not be repeated. The difference is that the positioning system is installed on the horizontal and / or longitudinal pulley shaft or on a bracket fixed to the pulley shaft There is a laser, and the position of the storage extrusion mechanism is determined by laser distance measurement, and the PLC or the host computer determines and controls the output frequency of the frequency converter according to the laser distance measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com