Patents

Literature

359results about How to "Inhibition dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-density, high-rigidity and high-tenacity polypropylene nano composite material and preparation method thereof

InactiveCN101712780ALow content of inorganic componentsLow densityVolumetric Mass DensityLow density

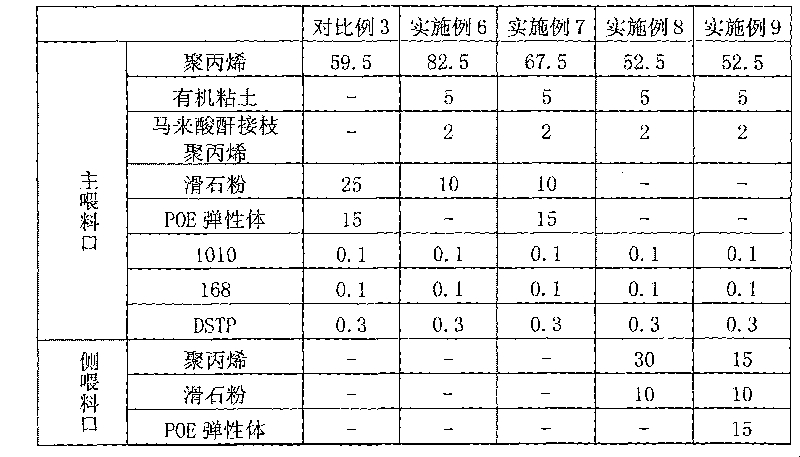

The invention discloses a low-density, high-rigidity and high-tenacity polypropylene nano composite material and a preparation method thereof. The low-density, high-rigidity and high-tenacity polypropylene nano composite material consists of the following raw materials in percentage by weight: 55 to 98 percent of polypropylene, 1 to 15 percent of organic clay, 0 to 30 percent of inorganic filler, 0.1 to 10 percent of compatilizer, 0 to 20 percent of toughening agent, 0.2 to 2 percent of stabilizing agent, and 0 to 5 percent of other additives. The low-density, high-rigidity and high-tenacity polypropylene nano composite material and the preparation method have the following advantages that: 1, the density and the weight of a product are reduced for the help of reducing the weight and the energy consumption of a finished product; 2, the rigidity and the tenacity are higher; 3, the process flow is simplified and the production cost is reduced effectively; and 4, the influences on the cutting of nano clay and the dispersion process caused by other components are avoided to the utmost extent to further improve the performance of the composite material.

Owner:SHANGHAI PRET COMPOSITES

Nano porous corrosion-resistant heat-insulated coating material taking thixotropic colloid as template agent and preparation method for corrosion-resistant heat-insulated coating material

ActiveCN105315743AAvoid reunion and scatter problemsSimple preparation processChemical industryAnti-corrosive paintsAqueous corrosionCorrosion prevention

The invention relates to an aqueous nano porous corrosion-resistant heat-insulated coating material and a preparation method for the corrosion-resistant heat-insulated coating material and particularly relates to an aqueous corrosion-resistant heat-insulated coating material, which has a nano porous structure, prepared through forming an aqueous-phase uniform three-dimensional-network nano porous structure by taking thixotropic colloid as a template agent and adding a film forming agent, a reinforcing powder material, a functional powder material and admixtures. The preparation method for the corrosion-resistant heat-insulated coating material, disclosed by the invention, is simple and easy in operation and low in production cost, is environment-friendly and safe and is beneficial to mass production. The nano porous corrosion-resistant heat-insulated coating material disclosed by the invention has excellent heat insulating and corrosion resisting properties and can be applied to the heat insulating and corrosion resisting of equipment such as high-temperature furnace hearths, pipelines and valves in the fields of aerospace and military industries, metallurgical forging, petroleum refining, electric power and the like, so that the safety of use and the level of energy saving and consumption lowering are improved.

Owner:浙江圣润纳米科技有限公司

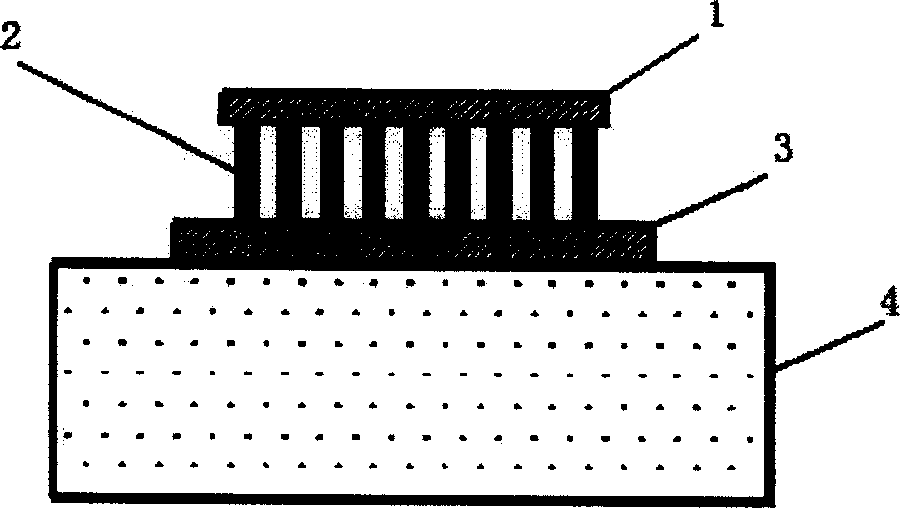

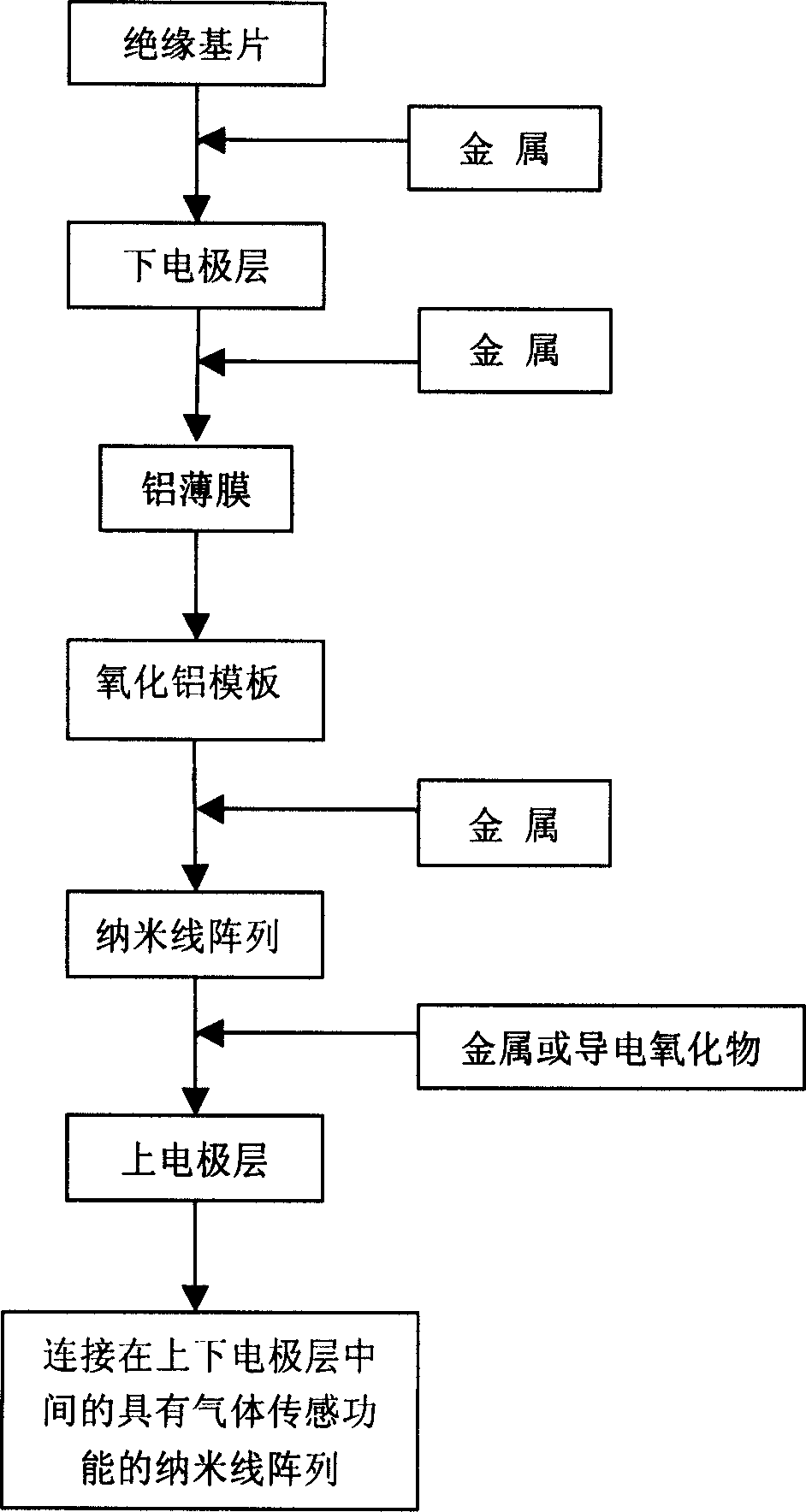

Gas sensor based on nanometer line array and its prepn process

The present invention relates to gas sensor with nanometer line array for detecting gas. The gas sensor includes insulating substrate, lower electrode layer, sensing conductor, and upper electrode layer; and features that the sensing conductor across between the lower electrode layer and the upper electrode layer is nanometer line array of metal or metal oxide nanometer lines with 30-800 nm diameter, micron level length and 25-550 nm intervals. The preparation process includes the steps of: preparing lower electrode layer, preparing porous alumina template, preparing nanometer line array, preparing upper electrode layer, and etching to eliminate the porous alumina template. The present invention adopts micron-nanometer processing technology to prepare gas sensor of nanometer line array and high gas detecting sensitivity.

Owner:FUJIAN NORMAL UNIV

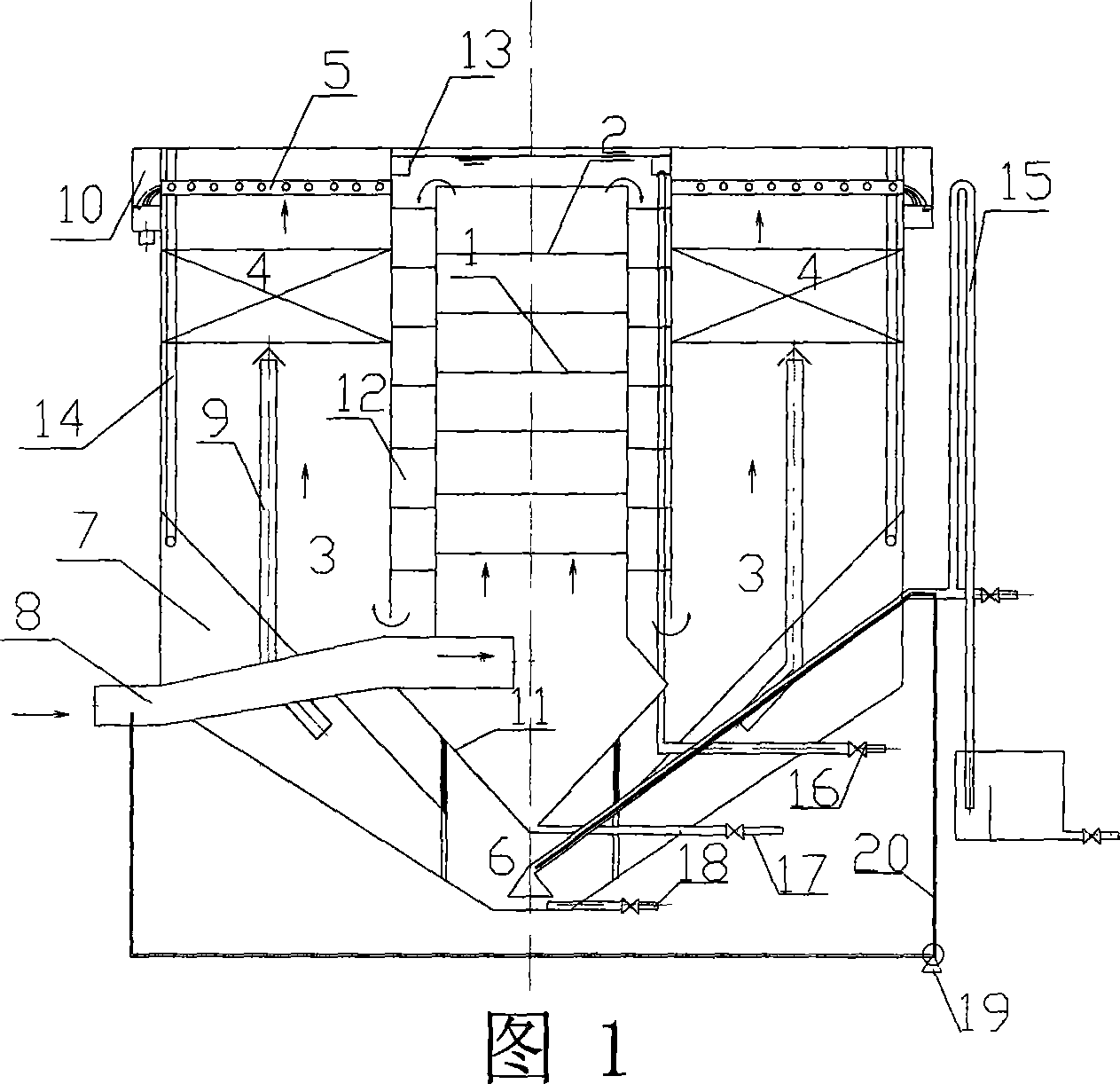

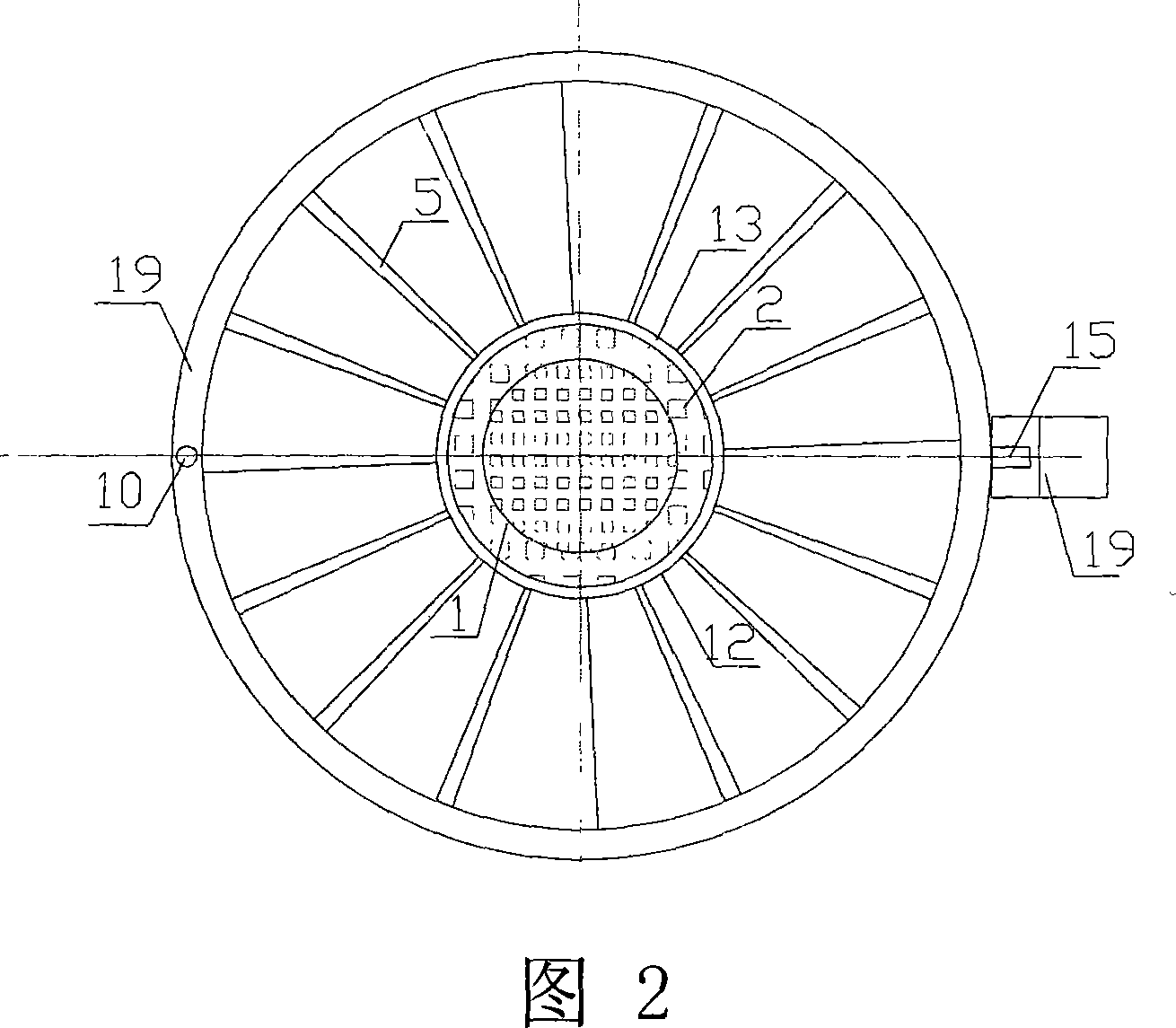

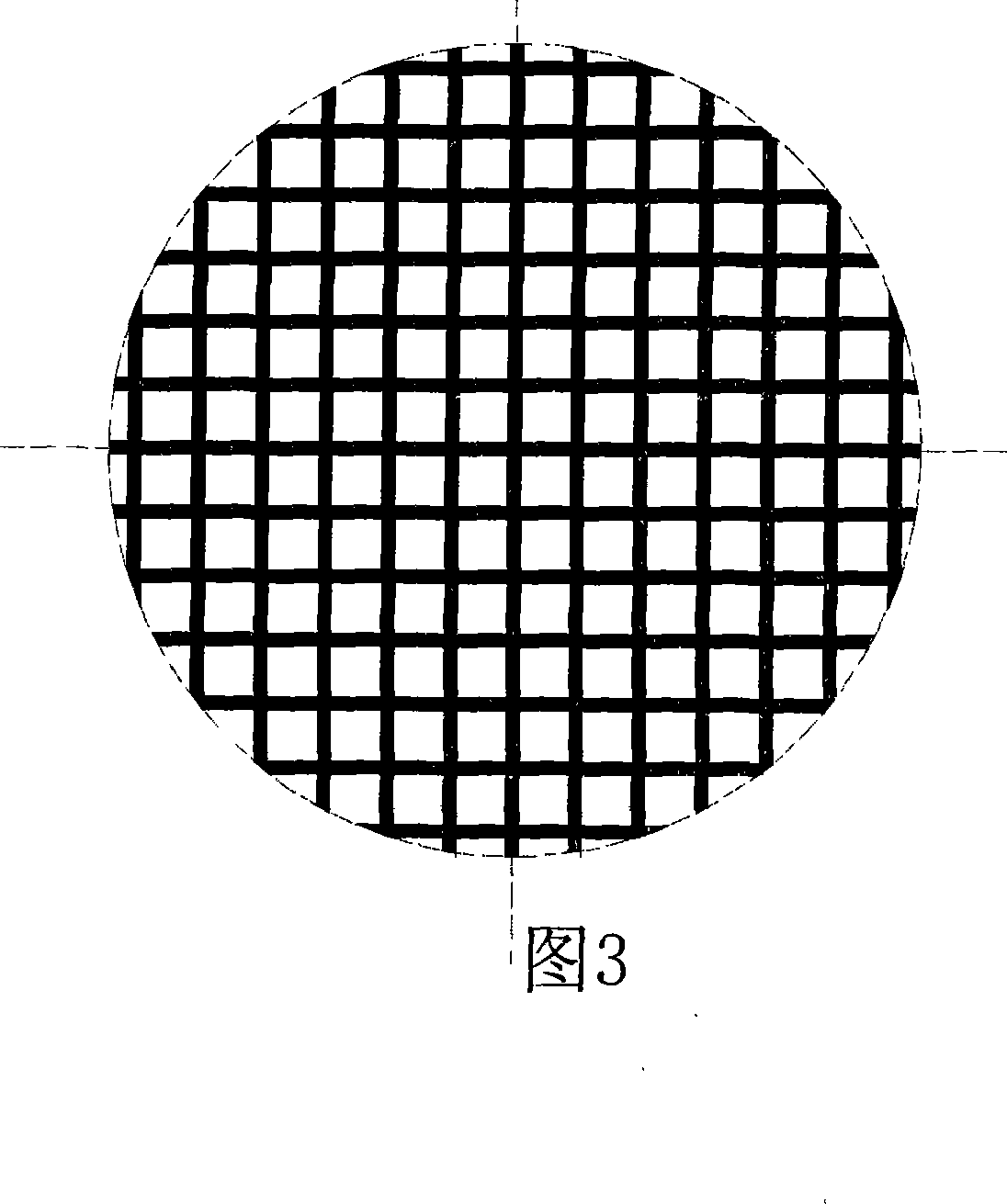

Apparatus and process for clarifying water efficiently

The invention is concerned with a kind of high efficiency water treatment equipment and technology belonging to water treatment field. The middle parts of the equipment are two flocculating rooms having mesh setting with disturbing flow, and the bottom of the flocculating room is precipitation tank. The suspending layer of active mud residue is out of the flocculating room and there is slanting pipe on top of it and concentrate room under it. The pipe excluding residue sets in the suspending layer of active mud residue, and the bottom of clean tank is filler to exclude residue, and there is siphon pipe connecting with the filler. There are grooves excluding residue at top of the flocculating room connecting with the pipe excluding residue and the siphon pipe connects with the residue reuse tank. The filler to exclude residue connects with a pump of reused residue. The equipment gathers the small air flotation, flocculating, active mud residue layer flocculating, and reused technology. Compared with traditional mixed and coagulate deposition technology, it saves 40 percent of field, reduces 10 percent of drug and enhances 15 percent disposal efficiency.

Owner:FUDAN UNIV +1

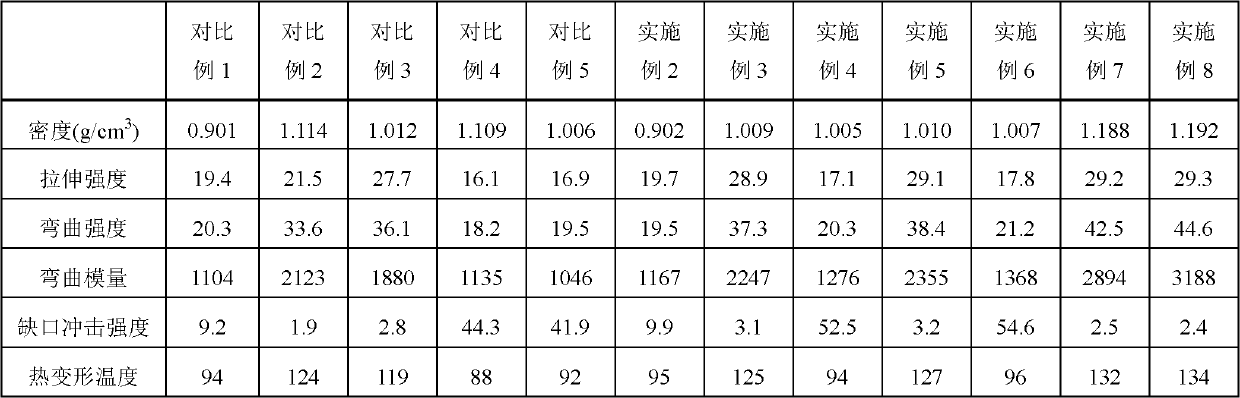

Nano talcpowder modified polypropylene composite material and preparation method thereof

ActiveCN102532685AHigh rigidity and toughnessWide range of applicationsMicron scalePolypropylene composites

The invention provides a nano talcpowder modified polypropylene composite material and a preparation method thereof. A nano-scale talcpowder filler is added and a proper amount of traditional micro-scale talcpowder is added for synergistic modification of polypropylene, an agglomeration phenomenon of the nano filler is avoided to the greatest extent by a special feed and extrusion process, and the composite material with higher comprehensive performance and wider application range is obtained under the conditions of relatively low material density and cost.

Owner:SHANGHAI PRET COMPOSITES

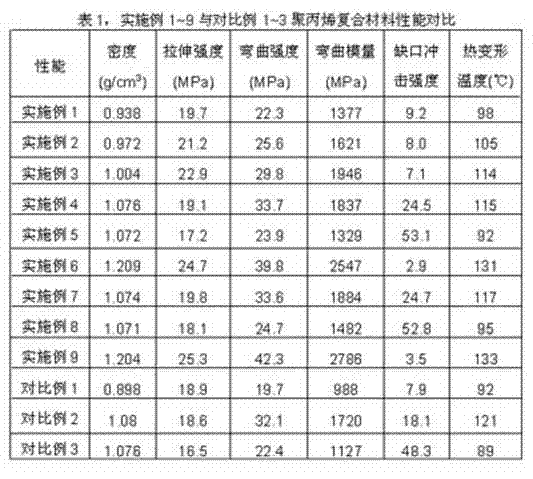

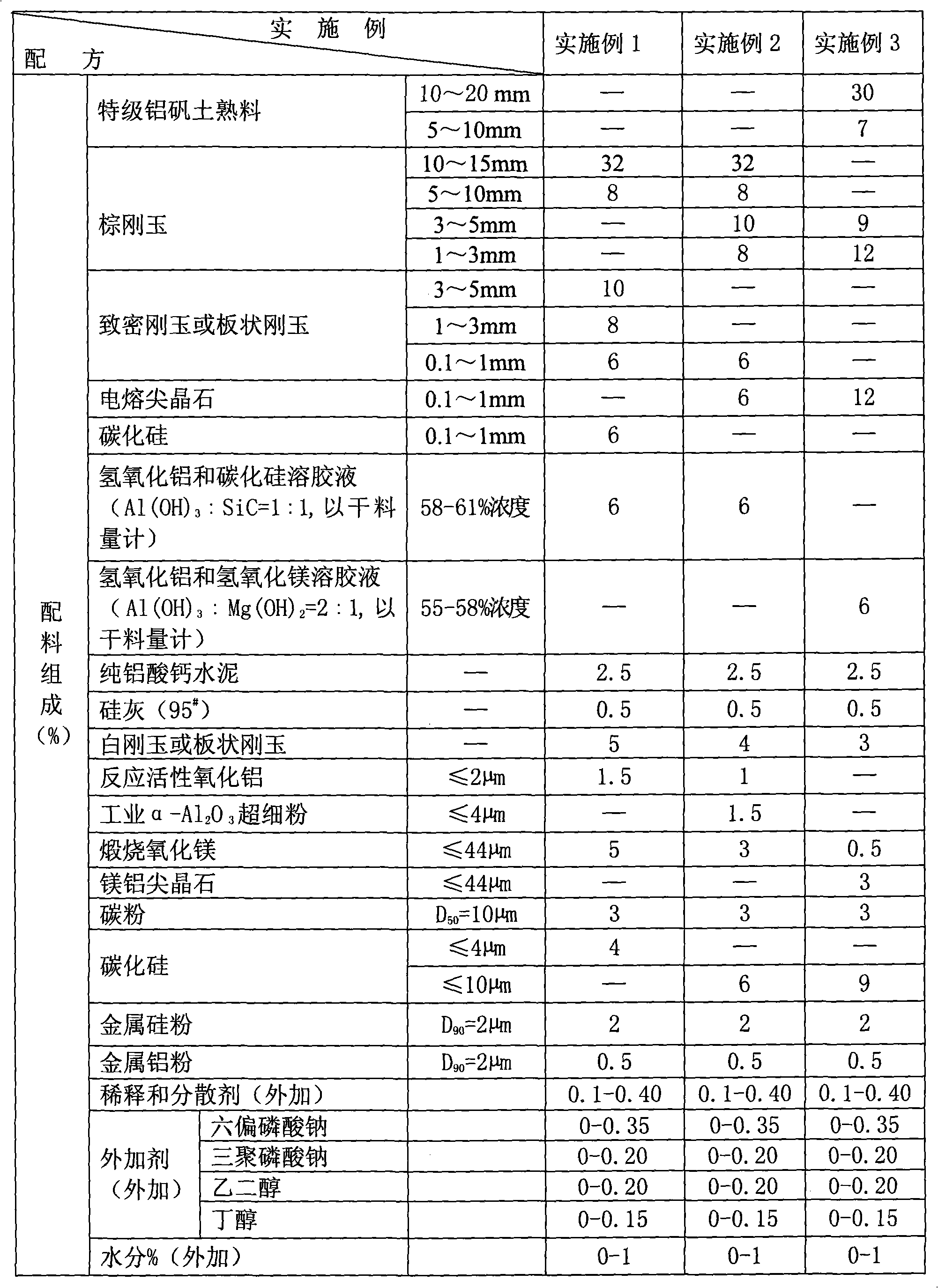

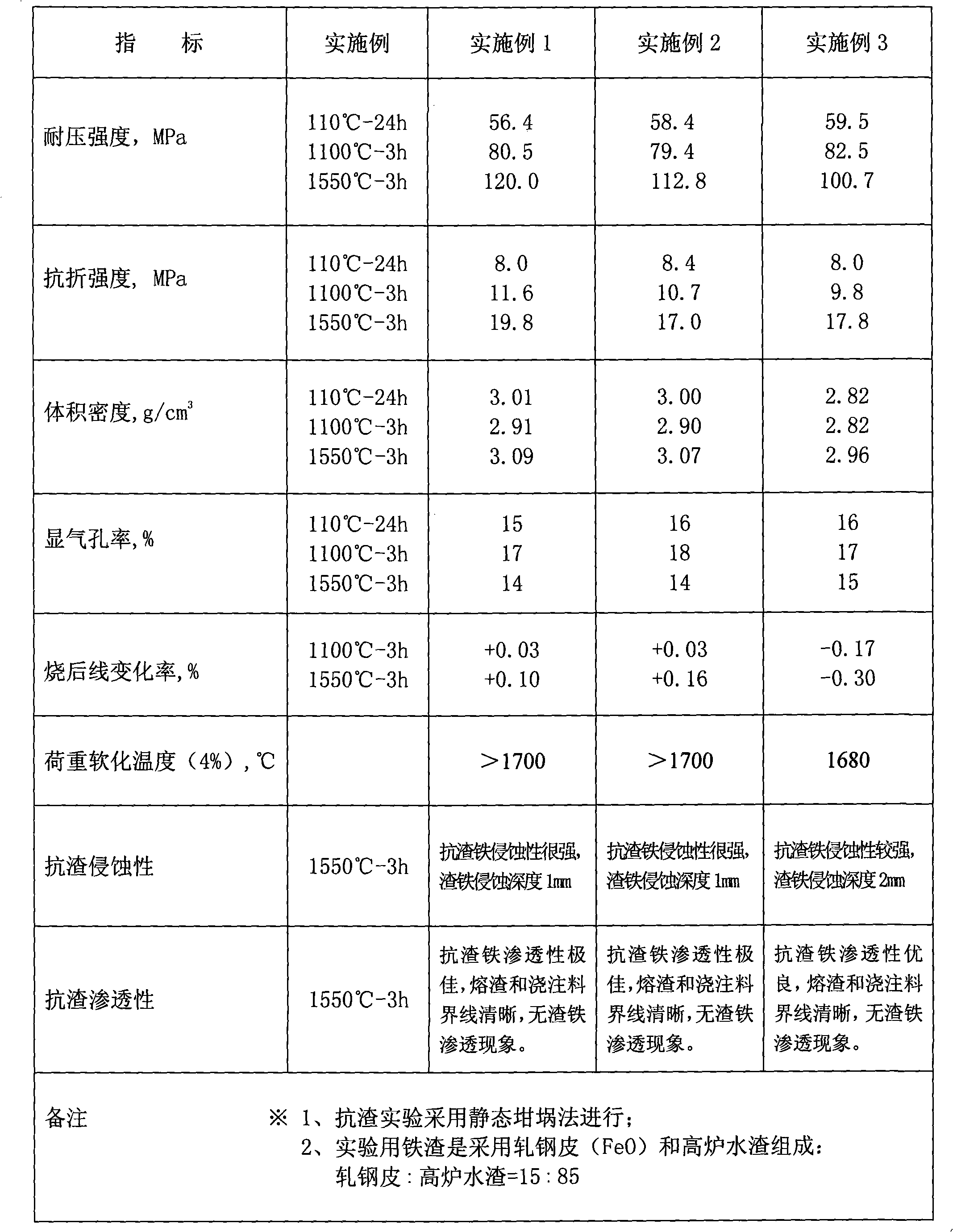

Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film and preparation method thereof

The invention relates to an Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film or nano Al2O3-MgO film, and a preparation method thereof. The preparation method of the nano carbon-containing castable material comprises: preparing carbon-containing sol suspension with Al(OH)3-SiC or Al(OH)3-Mg(OH)2 through a high-speed impact mixer, coating the carbon-containing sol suspension on the surface of carbon powder to form a compact carbon wrapping layer with complete coverage and no crack, and carrying in-situ synthesis of nano gel particles of Al2O3 and SiC or Al2O3 and MgO generated during transformation from sol to gel so as to generate a nano-sized matrix with carbon-containing nano secondary spinellite, Al2O3 and SiC as main crystalline phases, thereby completing the preparation of the Al2O3-MA-SiC-C refractory castable material made of nano material. The castable material has particularly excellent resistance against erosion and scouring of molten iron slag, and can satisfy the requirements for use in the iron tapping channel of the modern large-scale blast furnace. Moreover, the invention significantly prolongs the service life, reduces the cost and facilitates the environmental protection.

Owner:高树森

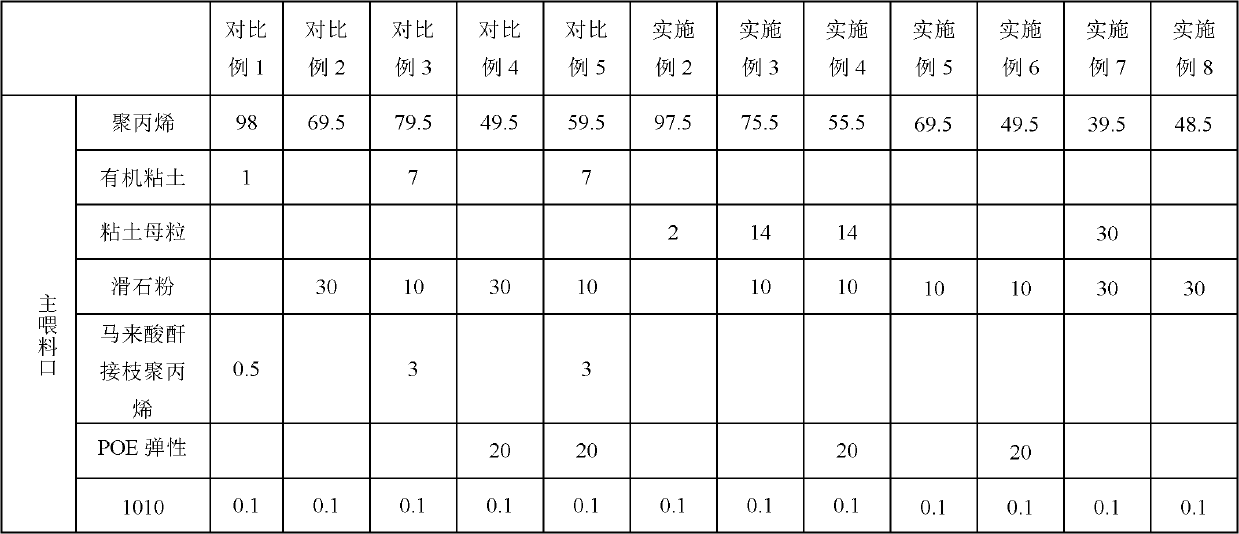

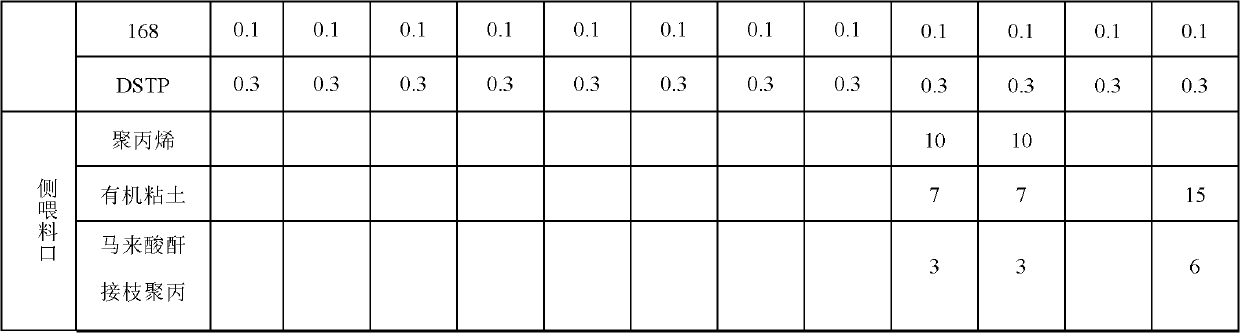

High-performance polypropylene nano composite material and preparation method thereof

The invention discloses a high-performance polypropylene nano composite material and a preparation method thereof, and belongs to the field of polymer modification and processing. The high-performance polypropylene nano composite material comprises the components in percent by weight: 39 to 98% of polypropylene, 1 to 15% organic clay, 0 to 30% of inorganic filling material, 0.1 to 6% of compatilizer, 0 to 20% of flexibilizer, 0.2 to 2% of stabilizer, and 0 to 4% of other additive. Through the cooperative modification of nanoscale organic clay and micron-sized talcum powder to polypropylene, a nano composite material with higher rigidity, higher tenacity and other performance is obtained at a lower material density.

Owner:SHANGHAI PRET COMPOSITES

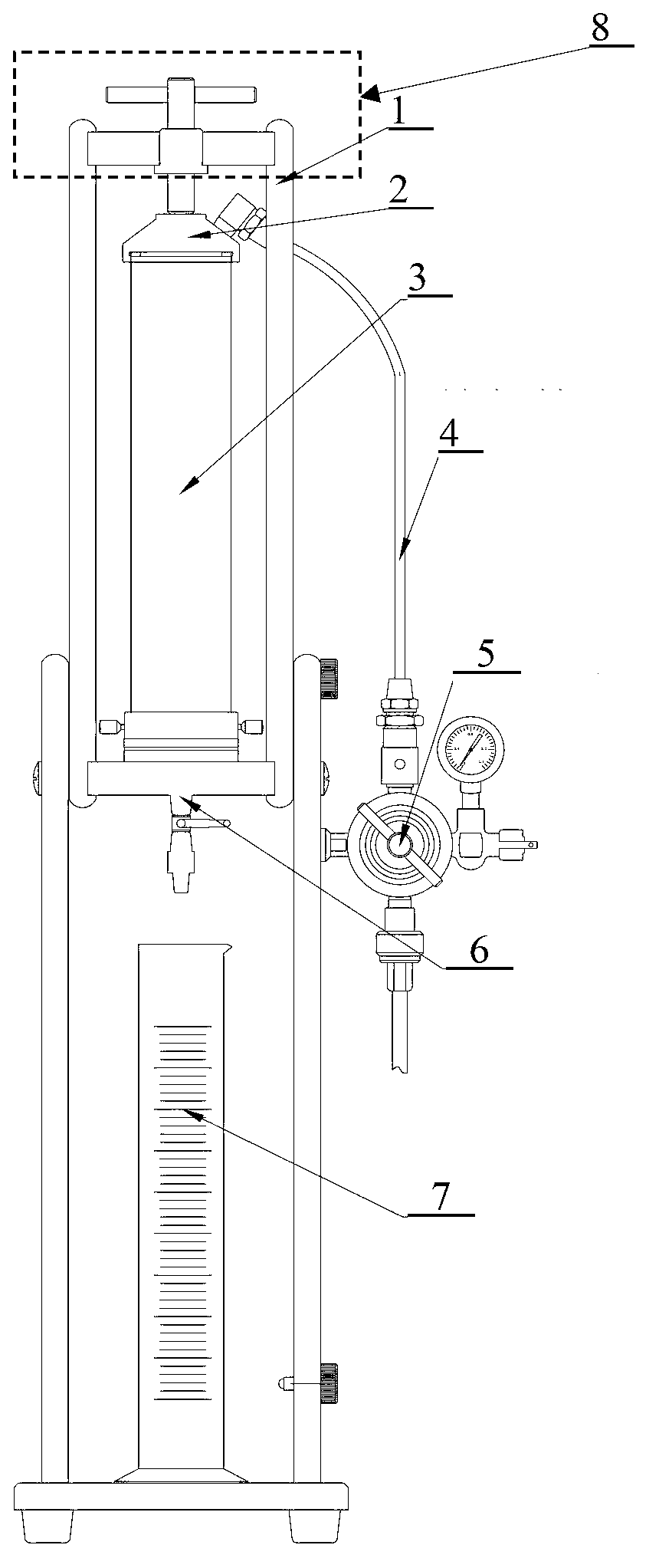

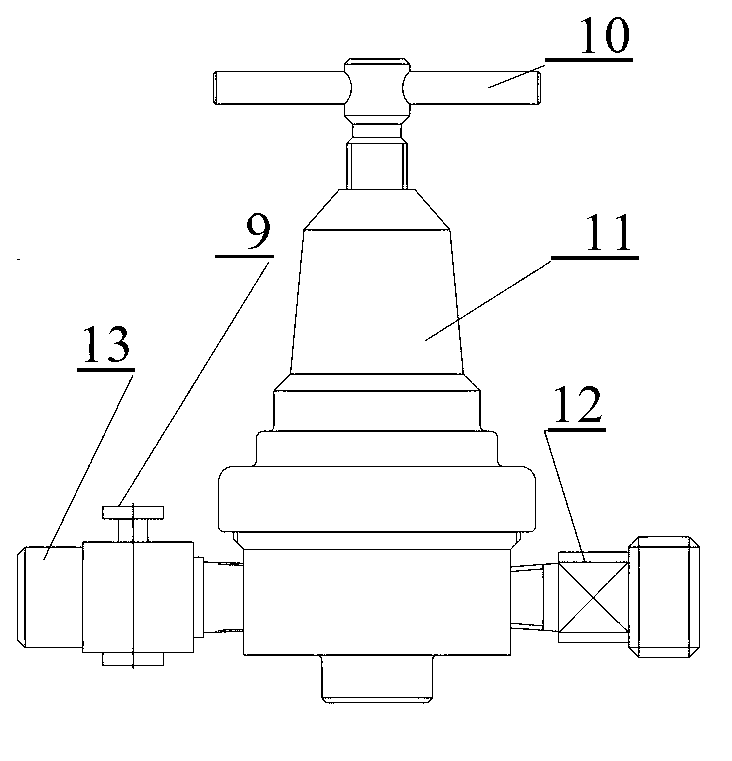

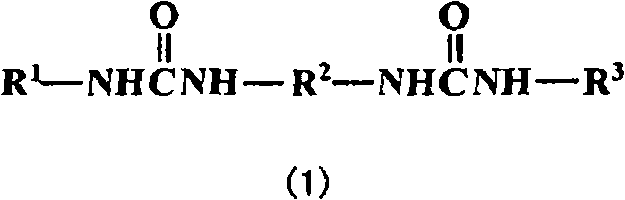

Strong-inhibition drilling fluid system

ActiveCN103013470AEnhanced inhibitory effectImprove stabilityDrilling compositionSlurryHigh pressure

The invention relates to a strong-inhibition drilling fluid system, comprising the following components by mass percent of 2.5-4.5% of bentonite slurry, 0.1-0.3% of alkaline regulator, 0.3-2.0% of shale inhibitor, 0.2-0.4% of metal ion polymer, 2.0-5.0% of walchowite, 2.0-5.0% of sulfomethal phenolaldehy resin, 1.0-3.0% of cation emulsified asphalt, 0.5-3.0% of lubricating agent, 0.2-0.8% of emulsifier, 2.0-8.0% of crude oil, and 1.0-3.0% of calcium carbonate superfine powder according to 100% of water. The compound in a general formula (I) is also provided; R1 is H or CH3; R2 is H, CH3 or C2H5; and X is an integer between 2 and 20 and applied to the shale inhibitor. The compound and the cation emulsified asphalt are applied to the drilling liquid system; the drilling liquid system is strong in shale inhibition; the shale recovery rate can be up to 90.33% and is improved by over 35.02% in comparison with that of water shale; the high temperature resistance can be up to 150 DEG C; the lubricating friction coefficients before and after aging respectively are smaller than 0.1; the strong-inhibition drilling fluid system is strong in capacity of resisting poor soil, salt and calcium contamination, strong in rejection capability, and good in blocking effect; the API (American petroleum institute) water loss of the drilling fluid is smaller than 4.5mL, and the HTHP (high temperature and high pressure) water loss is smaller than 12mL.

Owner:CHINA PETROLEUM & CHEM CORP

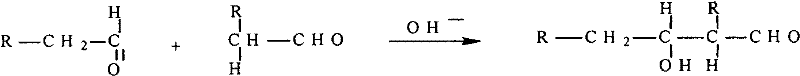

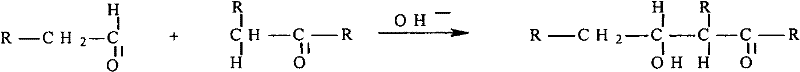

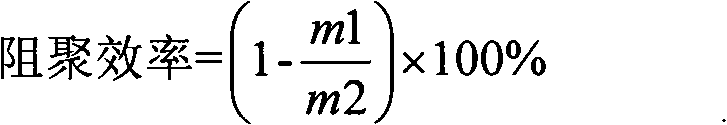

Aldehyde and ketone inhibitor for alkaline washing tower of ethylene unit

ActiveCN102531822AInhibition formationSuppress generationHydrocarbon purification/separationHydrocarbonsAntioxidantKetone

The invention relates to an aldehyde and ketone inhibitor for an alkaline washing tower of an ethylene unit, wherein the inhibitor comprises the components by mass percent: 10-25% of antioxidant, 10-20% of metal deactivator, 15-20% of polymerization inhibitor, 10-20% of dispersing agent and the balance of solvent. The aldehyde and ketone inhibitor can be used for effectively inhibiting the condensation reaction between aldehyde and ketone in oil phase and water phase in the alkaline washing tower with pertinence; the aldehyde and ketone inhibitor has antioxidant and polymerization inhibition functions at the same time, thus having an effective inhibition function for polymerization reaction caused by unsaturated hydrocarbon; the aldehyde and ketone inhibitor can be reacted with sulfide, so that polysulfide can further be prevented from being formed by the sulfide, and the generation of scaling substance can be inhibited; and the dispersing agent is added into the aldehyde and ketone inhibitor, so that the generated large polymers can be dispersed into small polymers; and therefore, the small polymers can be dispersed and dissolved in waste alkali liquid to be discharged, the blockage of equipment can be reduced, and the operation cycle of the equipment can be prolonged.

Owner:天津市瑞德赛恩新材料开发有限公司

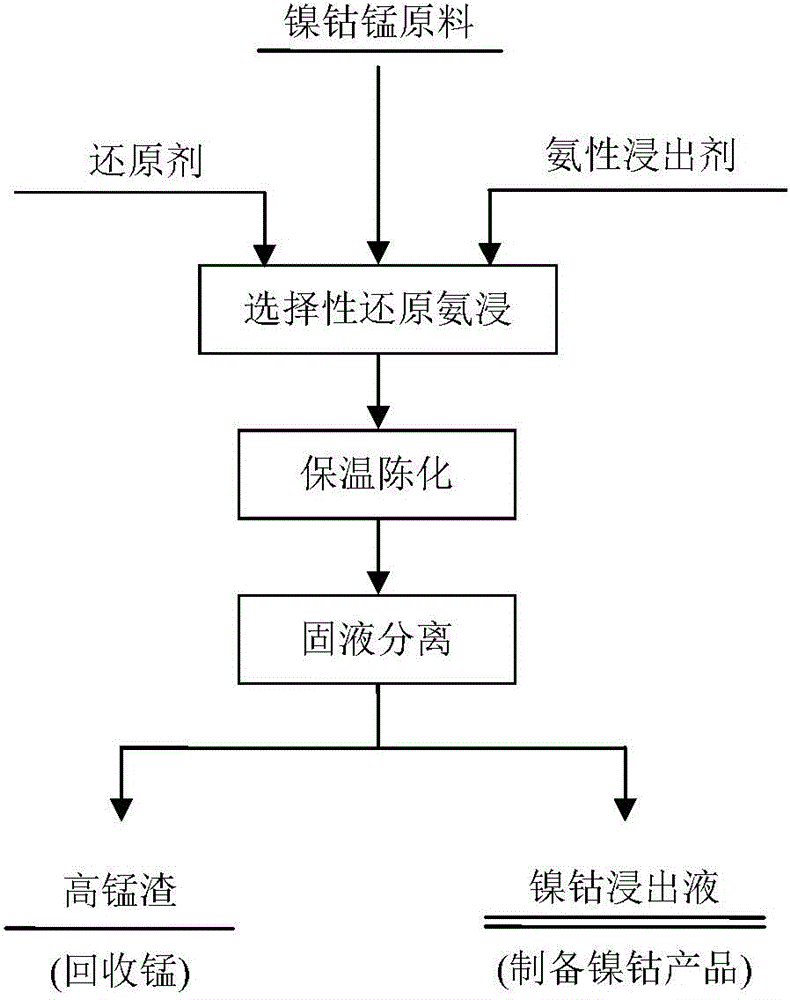

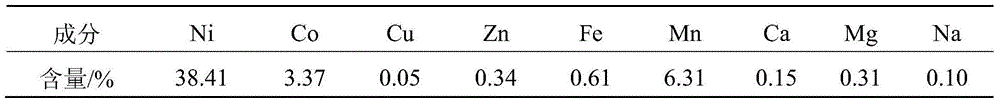

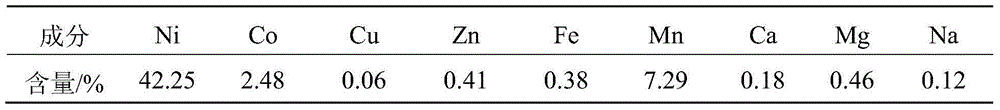

Method for separating nickel and cobalt from manganese in high manganese-cobalt ratio nickel-cobalt-manganese raw material

ActiveCN104831065AShort processSimple process operationProcess efficiency improvementThermal insulationNickel

The invention discloses a method for separating nickel and cobalt from manganese in a high manganese-cobalt ratio nickel-cobalt-manganese raw material. The method comprises the following steps of mixing a high manganese-cobalt ratio nickel-cobalt-manganese raw material and an ammoniacal leaching agent under control of an ammoniacal leaching agent initial concentration, leaching time and a leaching temperature, adding a reducer into the high manganese-cobalt ratio nickel-cobalt-manganese raw material-ammoniacal leaching agent mixed leaching system, after full reaction, and carrying out thermal insulation aging and solid-liquid separation to obtain nickel-cobalt ammoniacal leachate and high-manganese leaching residue. The method realizes separation of nickel and cobalt from manganese in the high manganese-cobalt ratio nickel-cobalt-manganese raw material. The method has simple processes, realizes thorough separation of nickel and cobalt from manganese and high nickel and cobalt content and low impurity content of the leachate, has a high valuable metal comprehensive recovery rate, and has less equipment investment and a low production cost.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

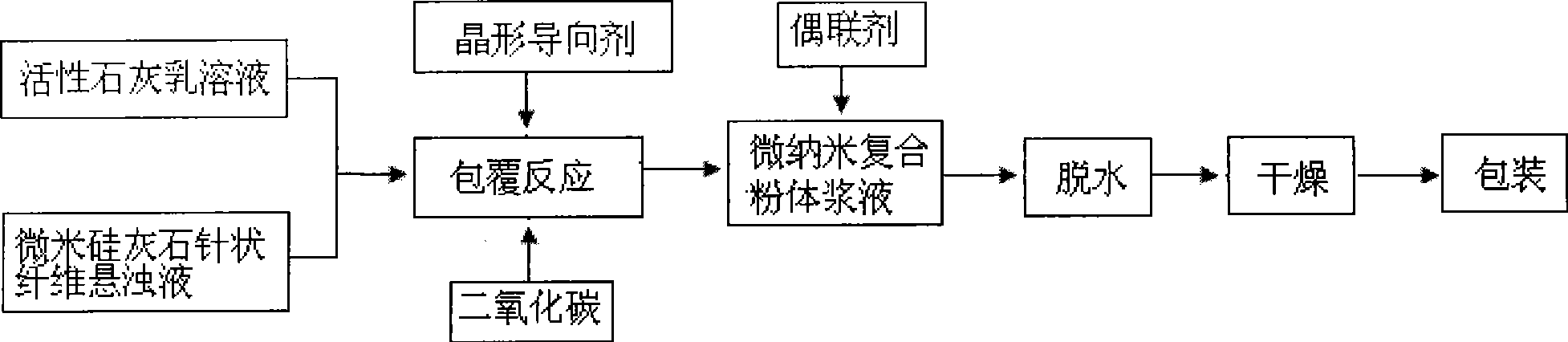

Grammite raphioid fibre crystal-nano calcium carbonate micro-nano composite powder material and production method

InactiveCN101498052AHigh surface energyHigh chemical activityPolycrystalline material growthAfter-treatment detailsMicro nanoFiber crystal

The invention relates to a surface modified product of an acicular wollastonite crystal and a production method thereof. The product is micro-nano composite powder by coating a nanometer calcium carbonate crystal on the surface of the acicular wollastonite fiber crystal. The method comprises the following steps: firstly, preparing an active lime milk solution and an acicular wollastonite fiber solution; compounding the two solutions into a suspension; adding a crystalline directing agent to the suspension and filling CO2 gas for a coating reaction so that the nanometer calcium carbonate crystal gradually grows on the surface of an acicular aedelforsite fiber, and the micro-nano composite powder by coating a nanometer calcium carbonate crystal on wollastonite is obtained; and coating a layer of coupling agent on the surface of the micro-nano composite powder to obtain the acicular wollastonite fiber crystal-nanometer calcium carbonate crystal-coupling agent composite powder material. The product keeps the superior characteristics of the acicular wollastonite crystal and the nanometer calcium carbonate crystal, improves the surface energy and the chemical activity of wollastonite composite particles and can be well stuck with organic polymers so as to form a favorable interface and improve the bonding force between fillings and basal bodies, such as plastics, pulp, and the like.

Owner:颜鑫 +3

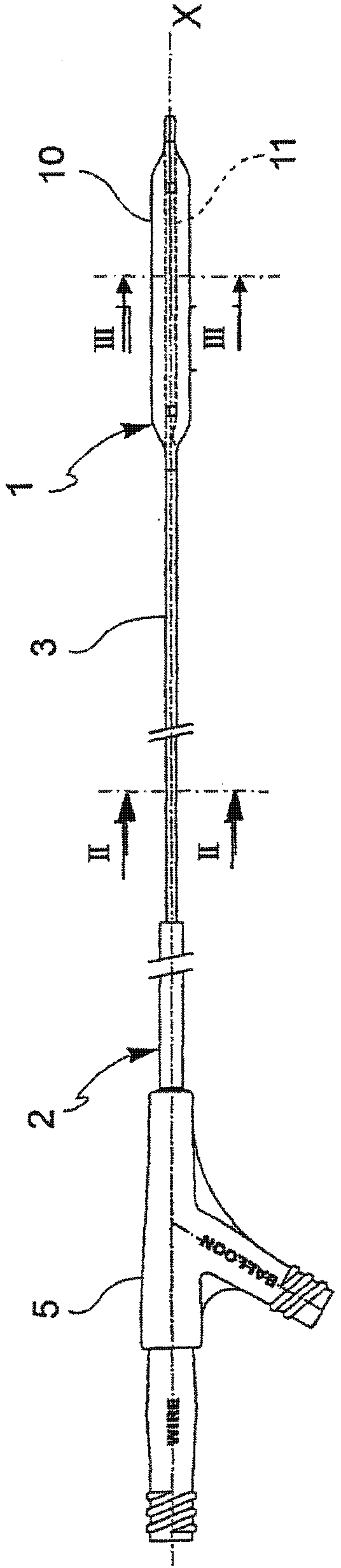

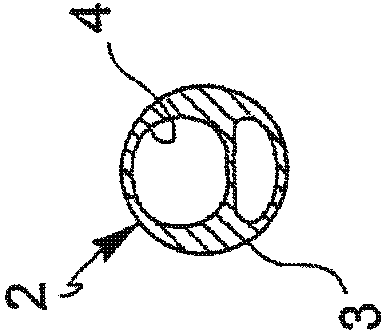

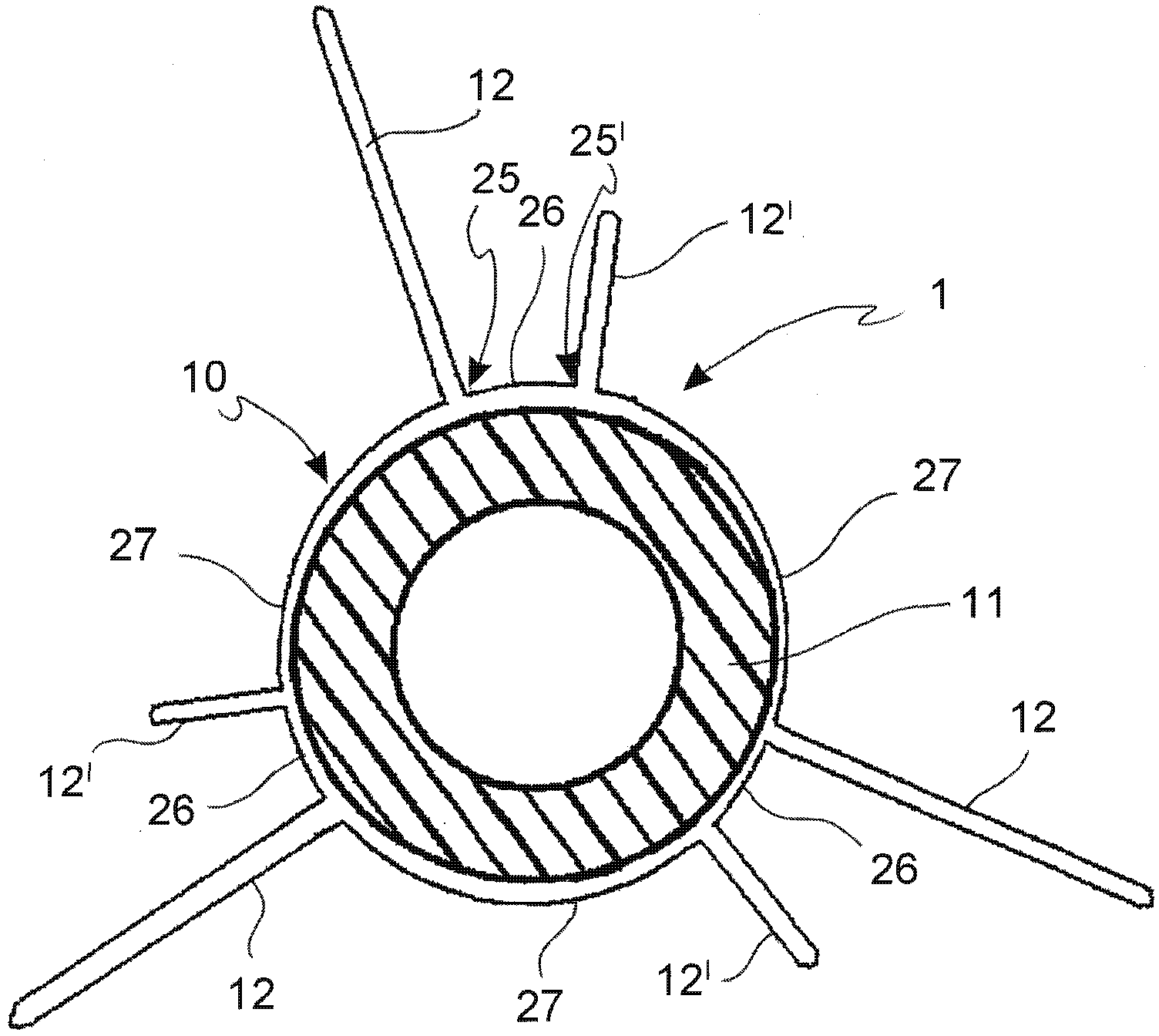

Drug eluting balloon for the treatment of stenosis and method for manufacturing the balloon

InactiveCN103260692AInhibition dispersionPrevent washout effectBalloon catheterSurgeryAngioplasty balloonPharmaceutical drug

Owner:INVATEC TECH CENT

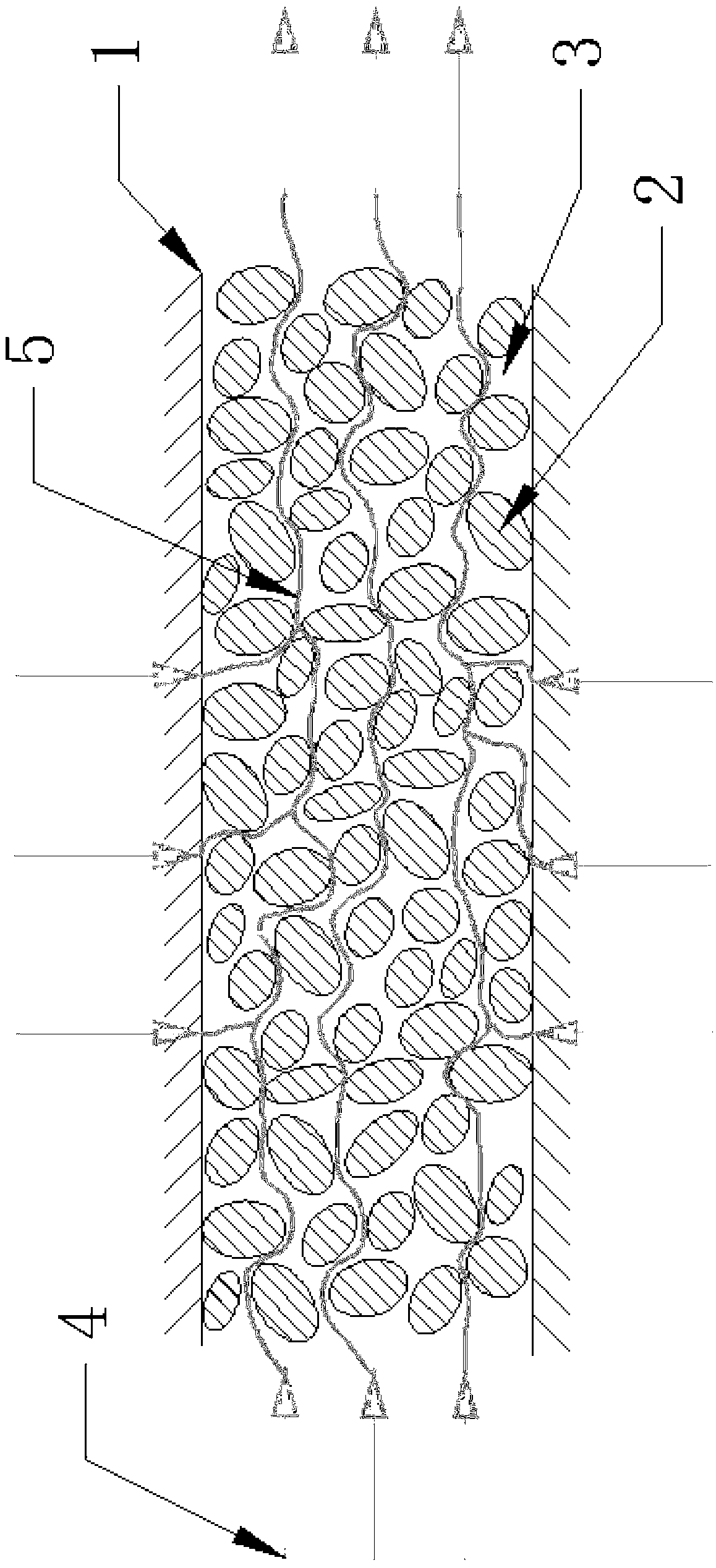

Fracturing technology for implementing ultrahigh flow conductivity

ActiveCN103306659ALow effective concentrationReduce the overall heightFluid removalMaterial PerforationOrder of magnitude

The invention relates to a fracturing technology for implementing the ultrahigh flow conductivity, which comprises the following steps: 1, judging whether geomechanics parameters of a target reservoir is suitable for the fracturing technology disclosed by the invention or not; 2, judging whether completion perforation of a target well is suitable for the fracturing technology disclosed by the invention or not, and if no, changing a perforating scheme of a well bottom; 3, before fracturing, selecting related fracturing materials; 4, carrying out fracturing on the target well by using a unique pumping program of the fracturing technology disclosed by the invention. According to the fracturing technology, proppant struts are formed in a stratum; flow conductivity of a stratum fracture is not improved by a filling layer of a proppant, but oil gas passes through by passages between the proppant struts; the flow conductivity is obviously improved by the open flowing passages; the flow conductivity of an existing conventional fracturing technology is not more than 200mum<2>*cm generally, but the flow conductivity of the fracturing technology for implementing the ultrahigh flow conductivity, which is disclosed by the invention, is higher than that of the conventional fracturing technology by 1 to 3 orders of magnitude; the fracturing technology reduces a pressure drop in the fracture, is helpful for improving drainage capacity and increases the effective fracture half-length and the production increase volume of the reservoir so as to improve yield.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

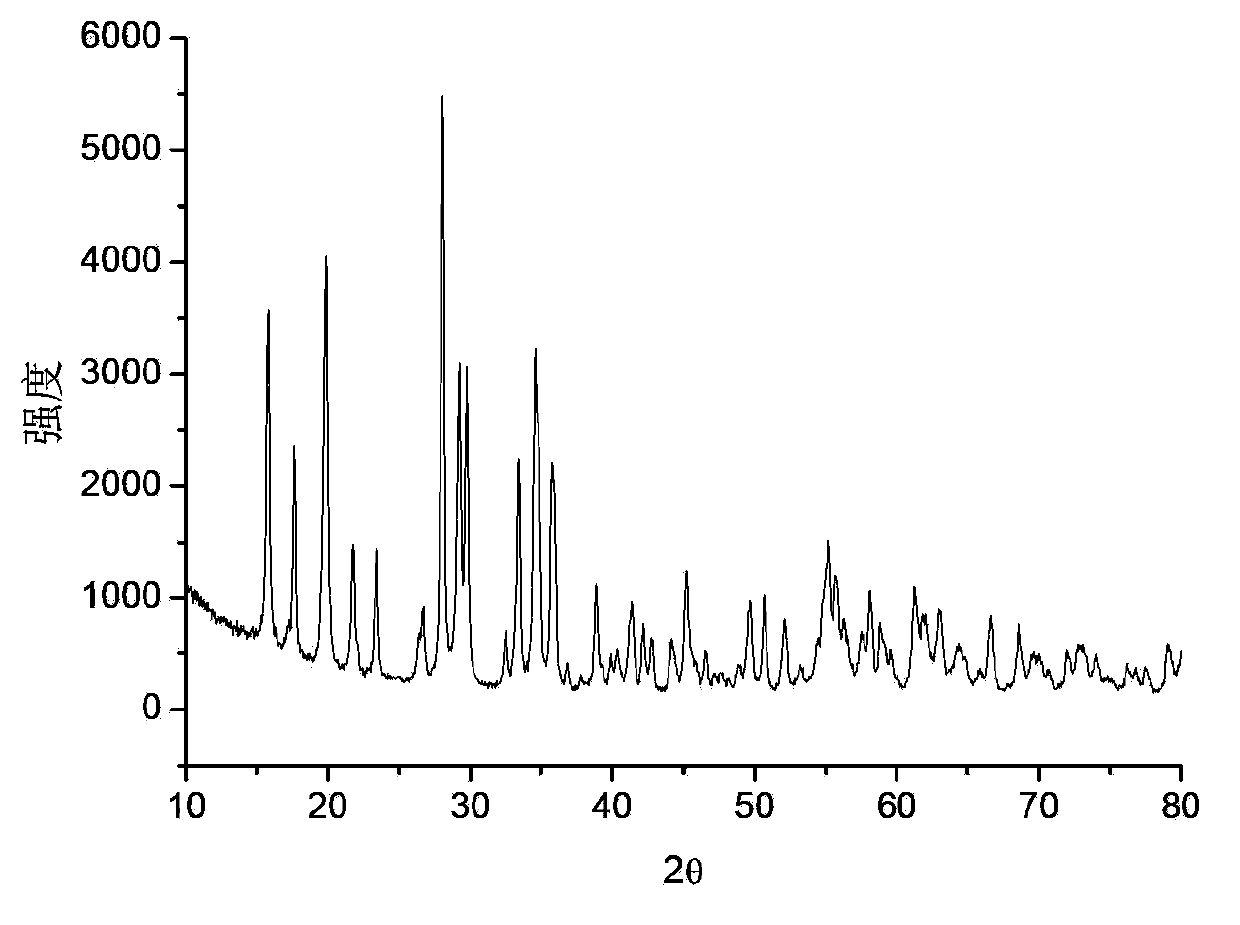

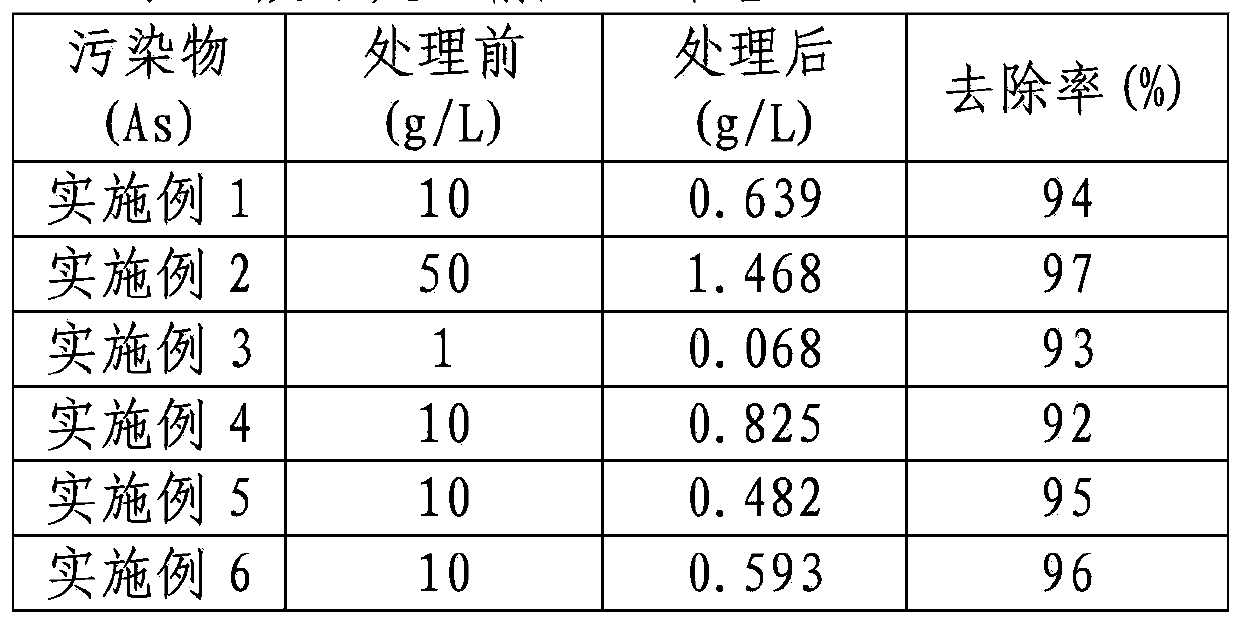

Method for treating arsenic-containing industrial wastewater

ActiveCN103964601AReduce productionReduce the risk of secondary pollutionMultistage water/sewage treatmentEnvironmental resistanceWastewater

The invention belongs to the wet metallurgy and environmental protection technical fields, and particularly, discloses a method for treating arsenic in arsenic-containing industrial wastewater. Under a condition of high temperature, an iron solution is slowly added into the arsenic-containing industrial wastewater, arsenic in the wastewater forms a stable scorodite crystal (FeAsO4.2H2O), and thus arsenic in the wastewater is removed. The method is simple in process, can obtain the stable arsenic-containing solid waste, and reduces secondary pollution caused to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

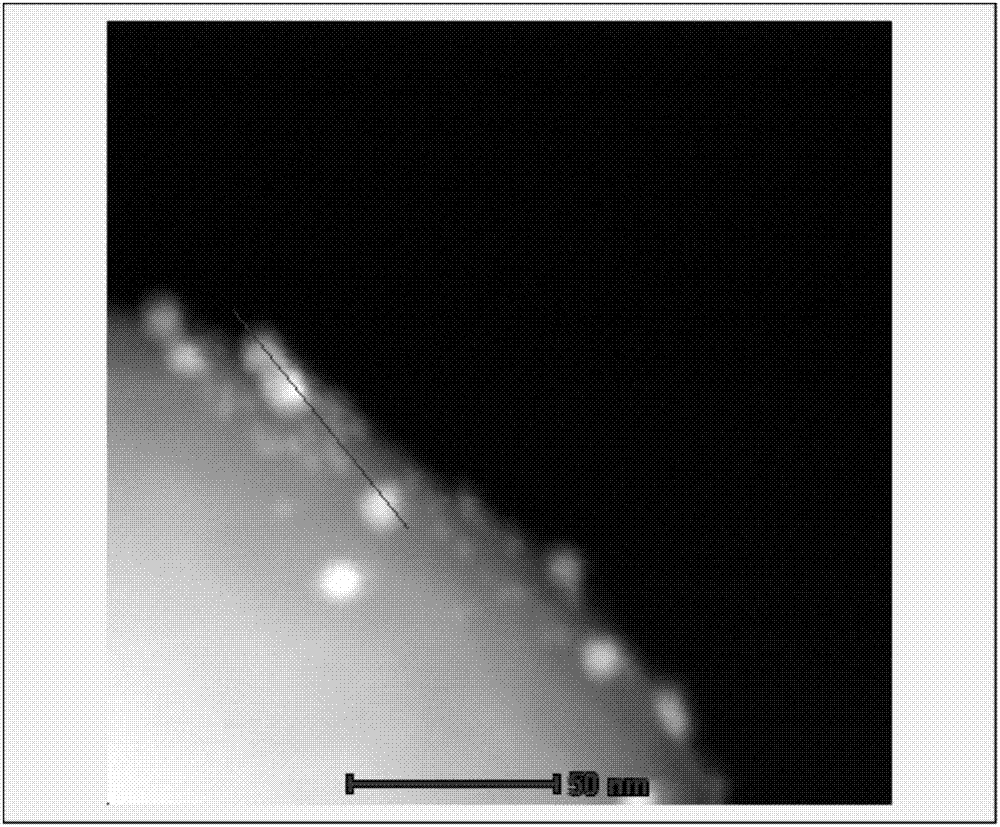

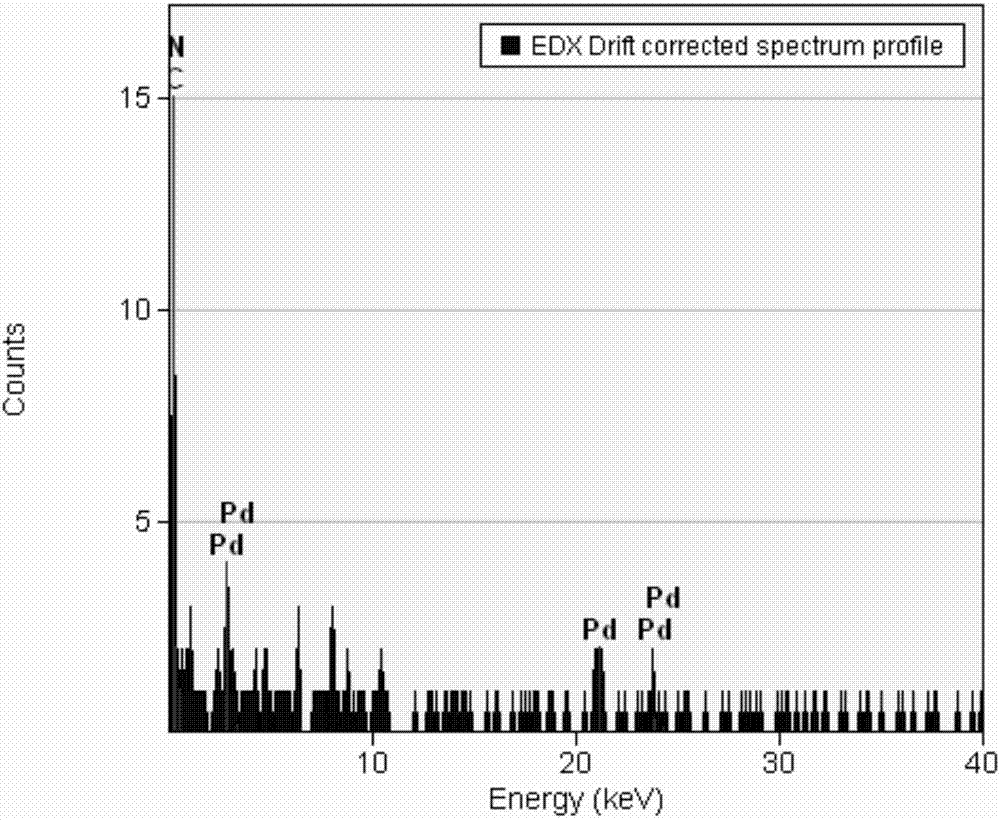

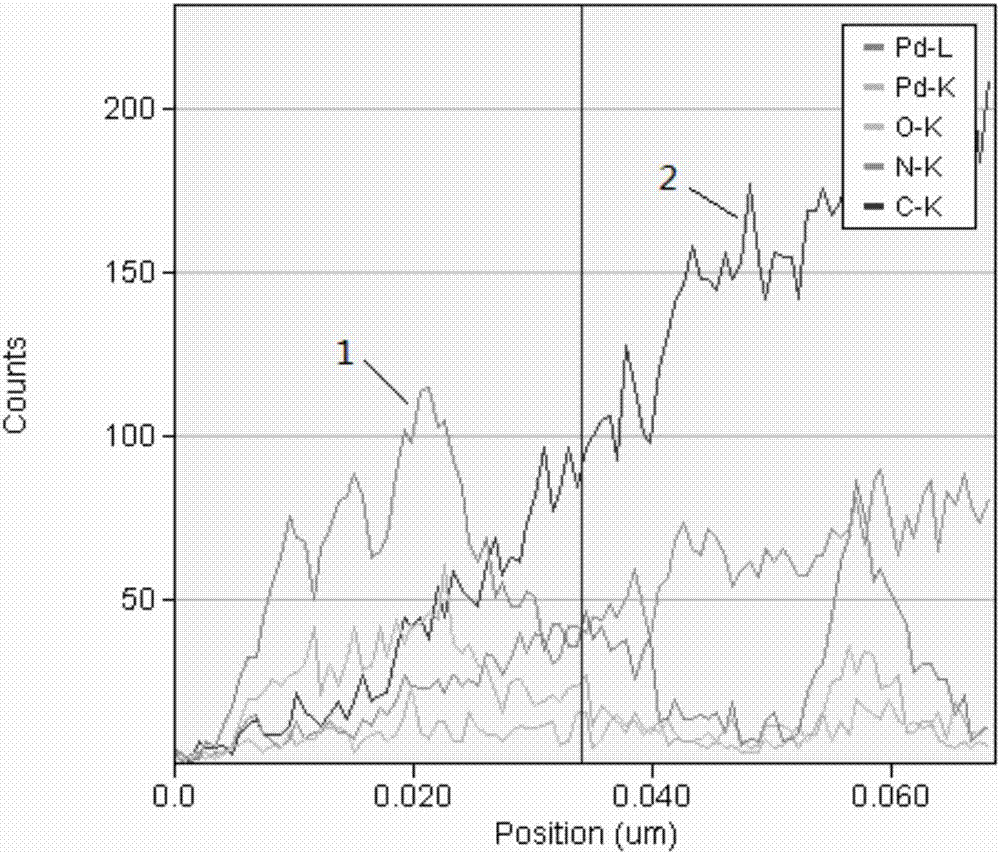

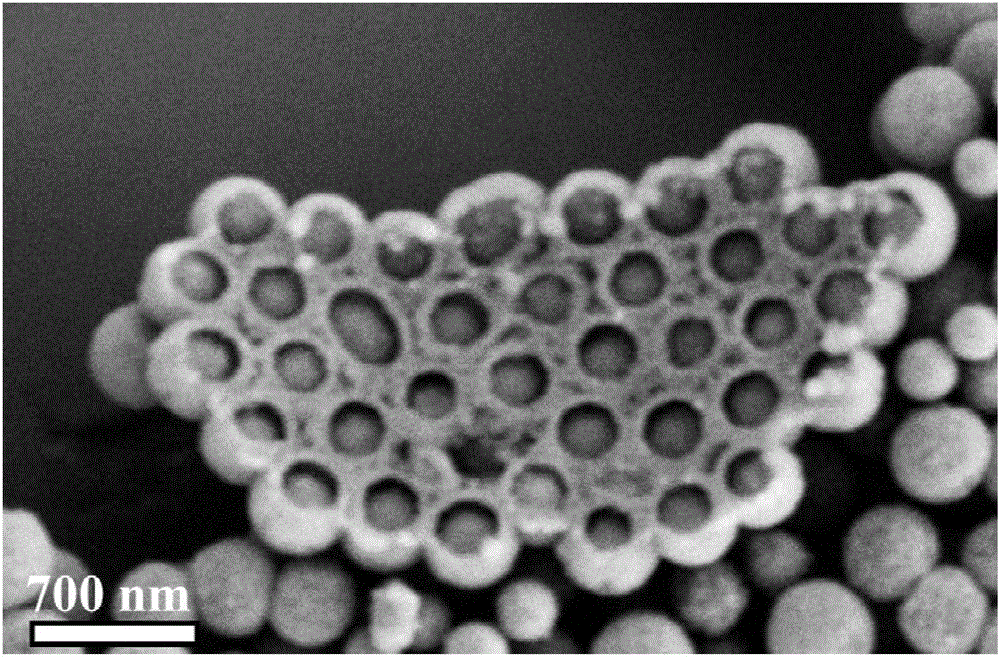

Catalyst as well as preparation method and application of catalyst

ActiveCN107413330AThe synthesis method is simpleLow costMaterial nanotechnologyCatalyst carriersNitro compoundIridium

The invention discloses a catalyst as well as a preparation method and application of the catalyst. The catalyst is composed of a carrier and a composite carbon-metal quantum dot supported on the carrier; the particle size of the catalyst ranges from 100nm to 1000nm; the carrier is a mesoporous carbon microsphere; the composite carbon-metal quantum dot is not larger than 15nm and contains 10-90% of metal; the metal in the composite carbon-metal quantum dot is one or a combination of several of platinum, palladium, iridium, ruthenium and rhodium; the loads of platinum, palladium, iridium, ruthenium and rhodium are respectively 0-10.0%, 0-10.0%, 0-10.0%, 0-10.0% and 0-5.0% based on the mass of the carrier, and the loads of palladium, platinum and rhodium are not equal to zero; and the total load of the metal is 1.0-11.5%. The invention provides the application of the catalyst to reaction for synthesizing a chlorinated aromatic amine compound shown as a formula (II) by carrying out selective catalytic hydrogenation on a chlorinated aromatic nitrocompound shown as a formula (I), and the catalyst has the characteristics of high hydrogenation reaction rate, high conversion rate, high catalytic activity and high stability.

Owner:ZHEJIANG UNIV OF TECH

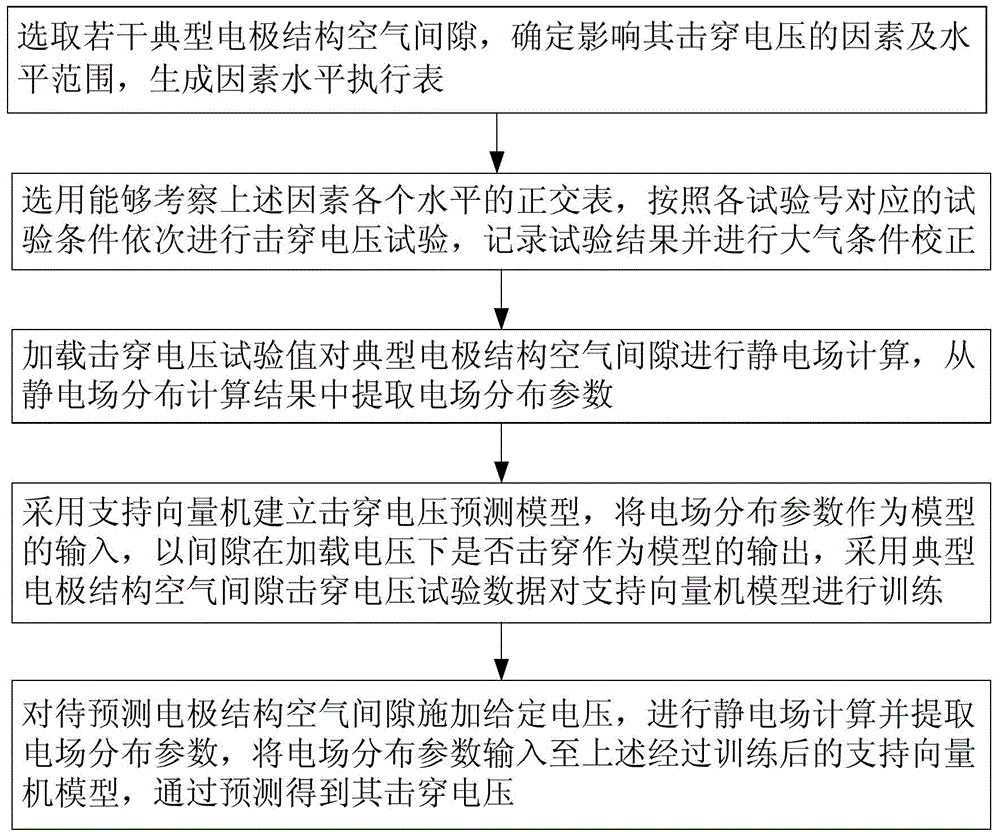

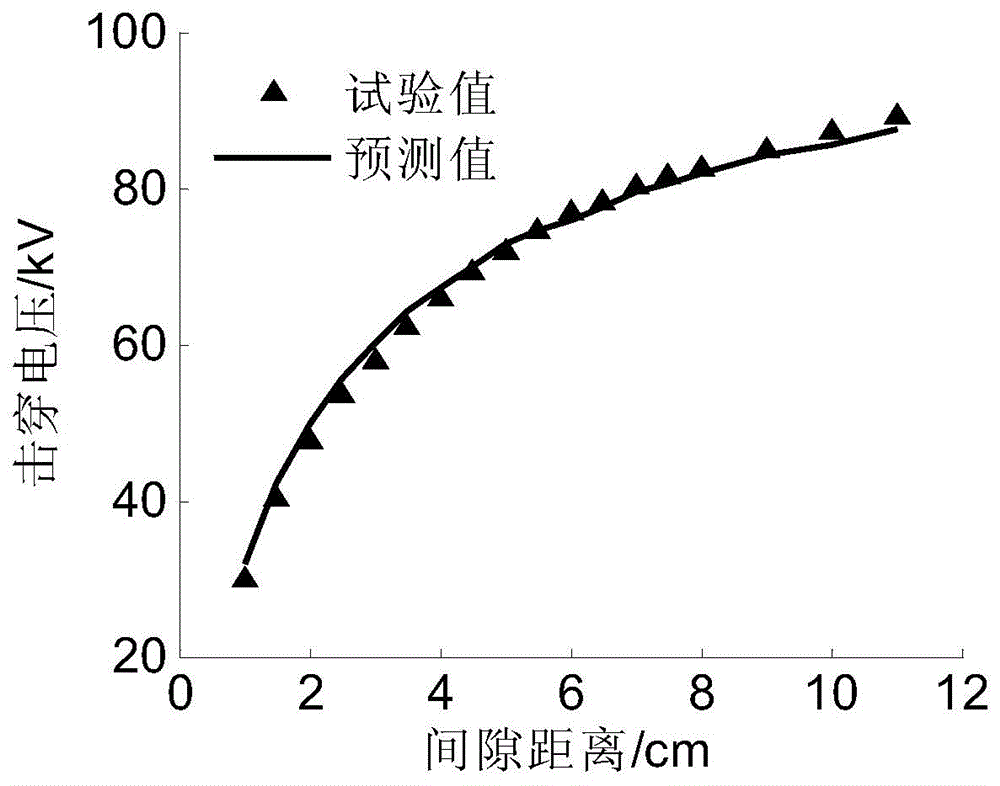

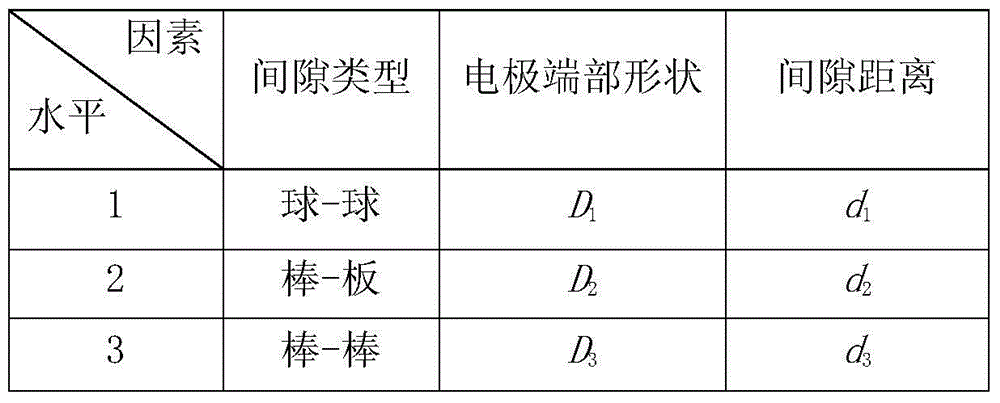

Air gap breakdown voltage prediction method

InactiveCN104880650APrediction is simpleImprove accuracyTesting dielectric strengthSupport vector machineElectric field

The invention relates to an air gap breakdown voltage prediction method. The method is characterized by selecting several typical electrode structure air gaps and determining a factor and a level range which influence a breakdown voltage; selecting an orthogonal table which can be used to inspect each level of the above factor and successively carrying out breakdown voltage tests according to a test condition corresponding to each test number; loading a breakdown voltage test value so as to carry out electrostatic field calculation on the typical electrode structure air gaps and extracting an electric field distribution parameter from a calculation result; using a support vector machine to establish a breakdown voltage prediction model, taking the electric field distribution parameter as an input of a model, taking whether the gap is in a breakdown state under a loading voltage as an output of the model, using typical electrode structure air gap breakdown voltage test data to train a support vector machine model so that an air gap breakdown voltage of another electrode structure is predicted and obtained. By using the method in the invention, a prediction process is simple; accuracy is high; a test quantity needed by air gap discharge characteristic research can be decreased and test cost is reduced.

Owner:WUHAN UNIV +1

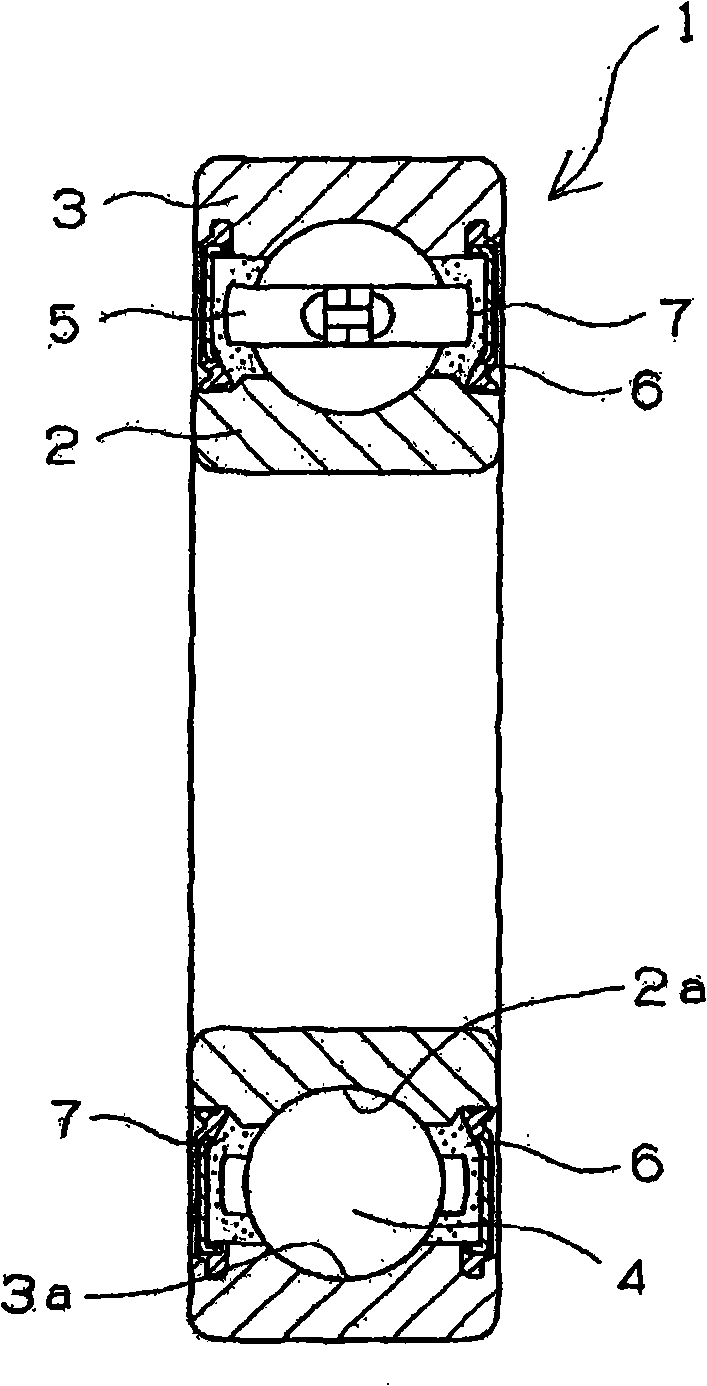

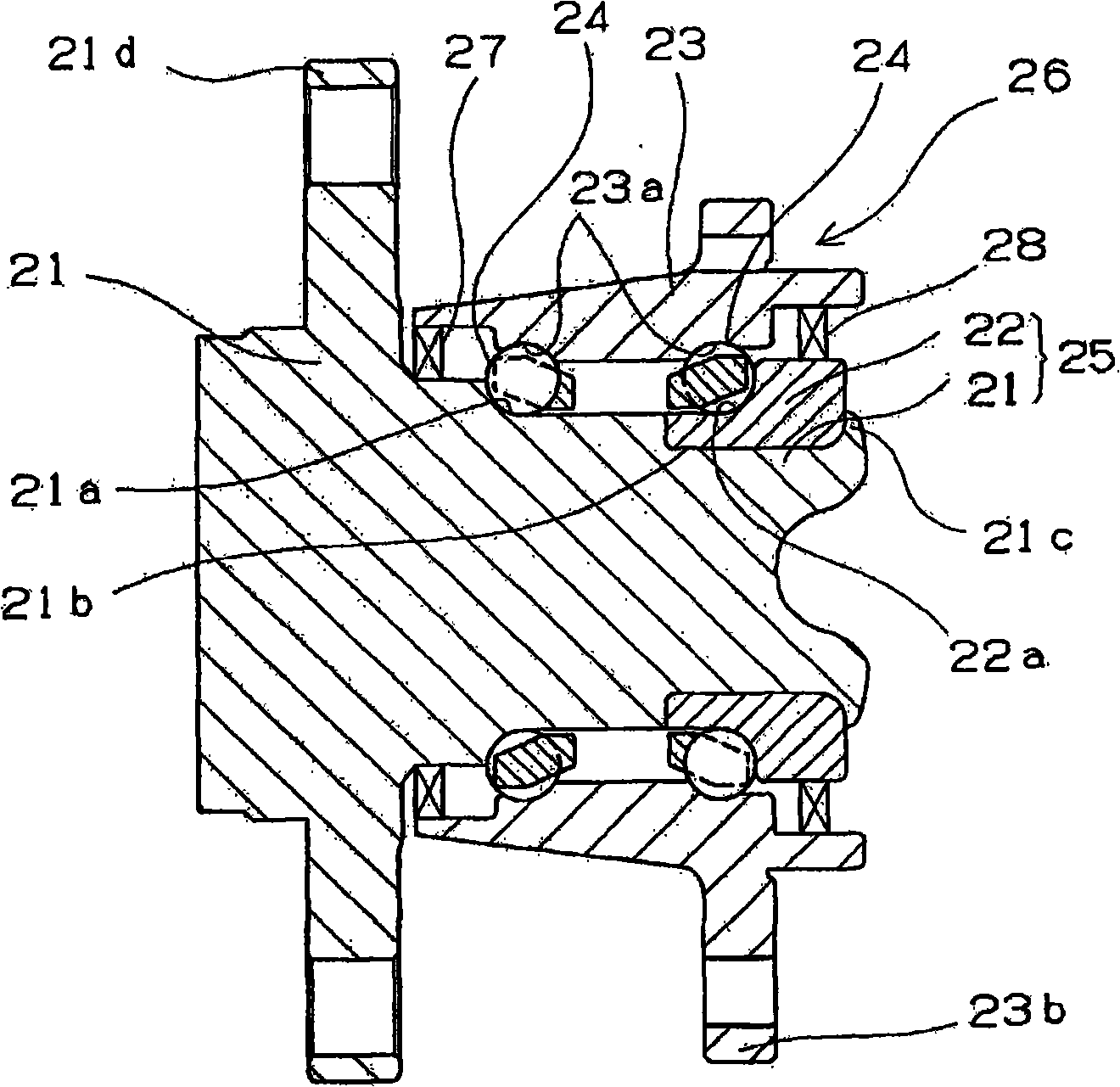

Waterproof grease and hermetically filled with the grease, rolling bearing and hub bearing

InactiveCN101273117AInhibition dispersionInhibition of moistureRolling contact bearingsBearing componentsEngineeringBase oil

A waterproof grease that even under harsh lubrication conditions such as those causing water mixing in grease at the time of bearing operation, improves the resistance to surface starting peeling of bearing of, for example, carbon steel for mechanical structure; and making use of the grease and exhibiting prolonged life, a rolling bearing and hub bearing. There is provided a waterproof grease comprising a nonaqueous base oil, a thickening agent and, as an additive, a water dispersant, wherein the saturated water content dispersible in the waterproof grease is in the range of 30 to 60 wt.%, and wherein the water dispersant capable of dispersing water in the waterproof grease is a surfactant, and wherein the nonaqueous base oil is a mineral oil and the thickening agent is a urea compound. Further, there are provided, hermetically filled with the grease, a rolling bearing and hub bearing.

Owner:NTN CORP

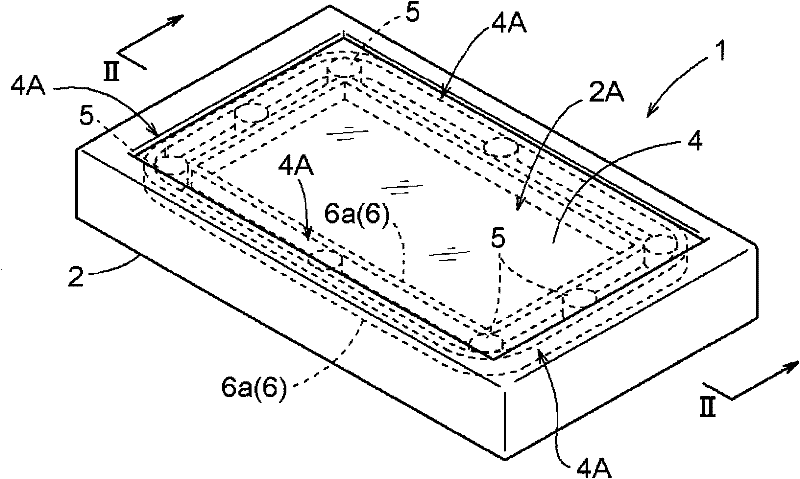

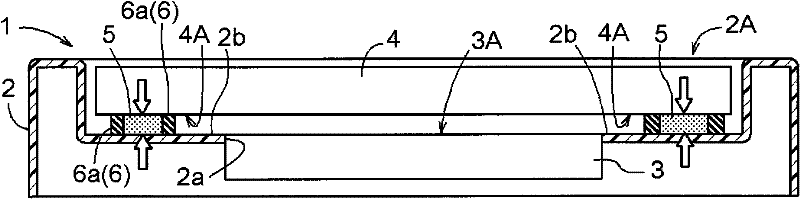

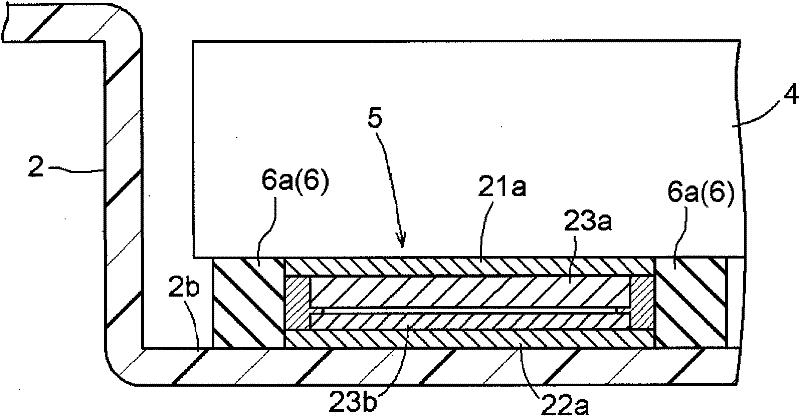

Information input device and pressure detection unit used for information input device

ActiveCN102365608AInhibition dispersionInput/output processes for data processingInformation deviceContact type

Owner:NISSHA PRINTING COMPANY

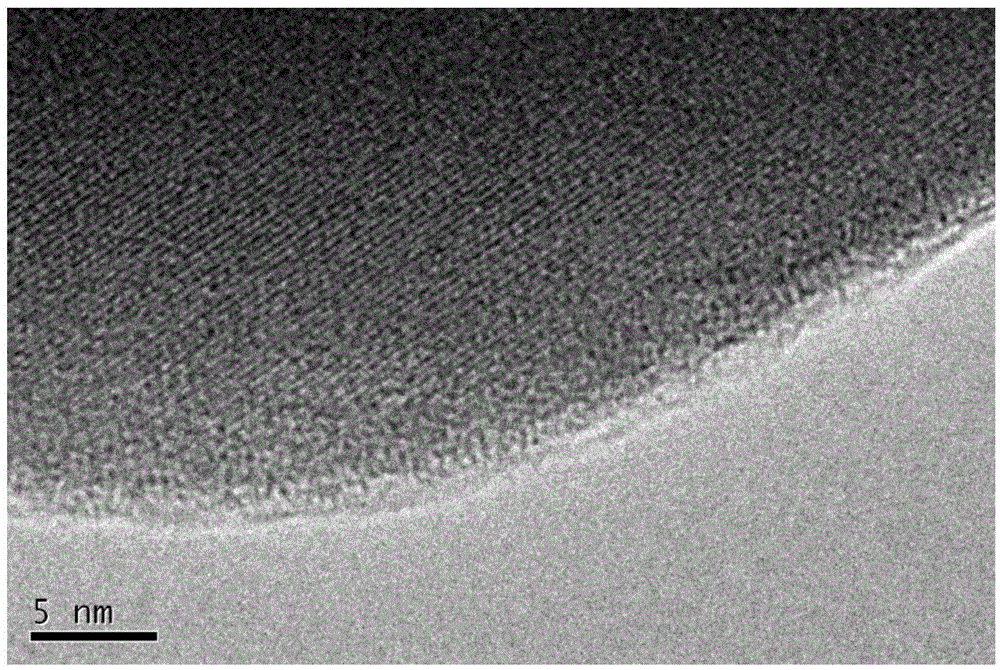

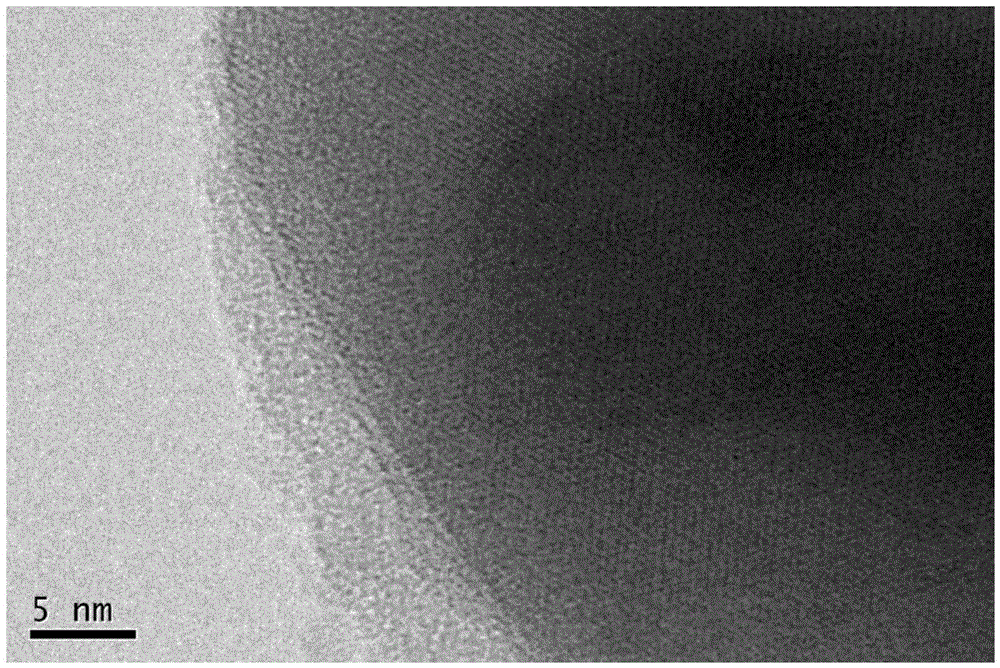

Synthesis method of silicon dioxide coated lithium-rich manganese-based cathode material

ActiveCN105655566AImprove electrochemical performanceImproved magnification performanceCell electrodesSecondary cellsSynthesis methodsDecomposition

The invention discloses a synthesis method of a silicon dioxide coated lithium-rich manganese-based cathode material, belonging to the technical field of cathode materials of lithium ion batteries. The synthesis method is realized mainly in the following way: the surfaces of the lithium-rich manganese-based cathode material and precursor thereof are coated with silicon dioxide through the hydrolysis of tetraethyl orthosilicate; by controlling the dispersing agent composition and reaction temperature, a uniform and dense coating layer with controllable thickness can be formed on the material surface by the synthesis method; and the uniform and controllable coating layer can effectively separate electrode from electrolyte, the decomposition of electrolyte is inhibited, the HF generated by LiPF6 decomposition is absorbed, and the electrochemical performance and particularly the rate performance, high-temperature performance and safety performance of the lithium-rich manganese-based cathode material are improved. The synthesis method has the advantages of easily available raw materials, simplicity in operation, mild conditions and environment-friendly and recyclable dispersing agents while industrial production is facilitated.

Owner:BEIJING UNIV OF TECH

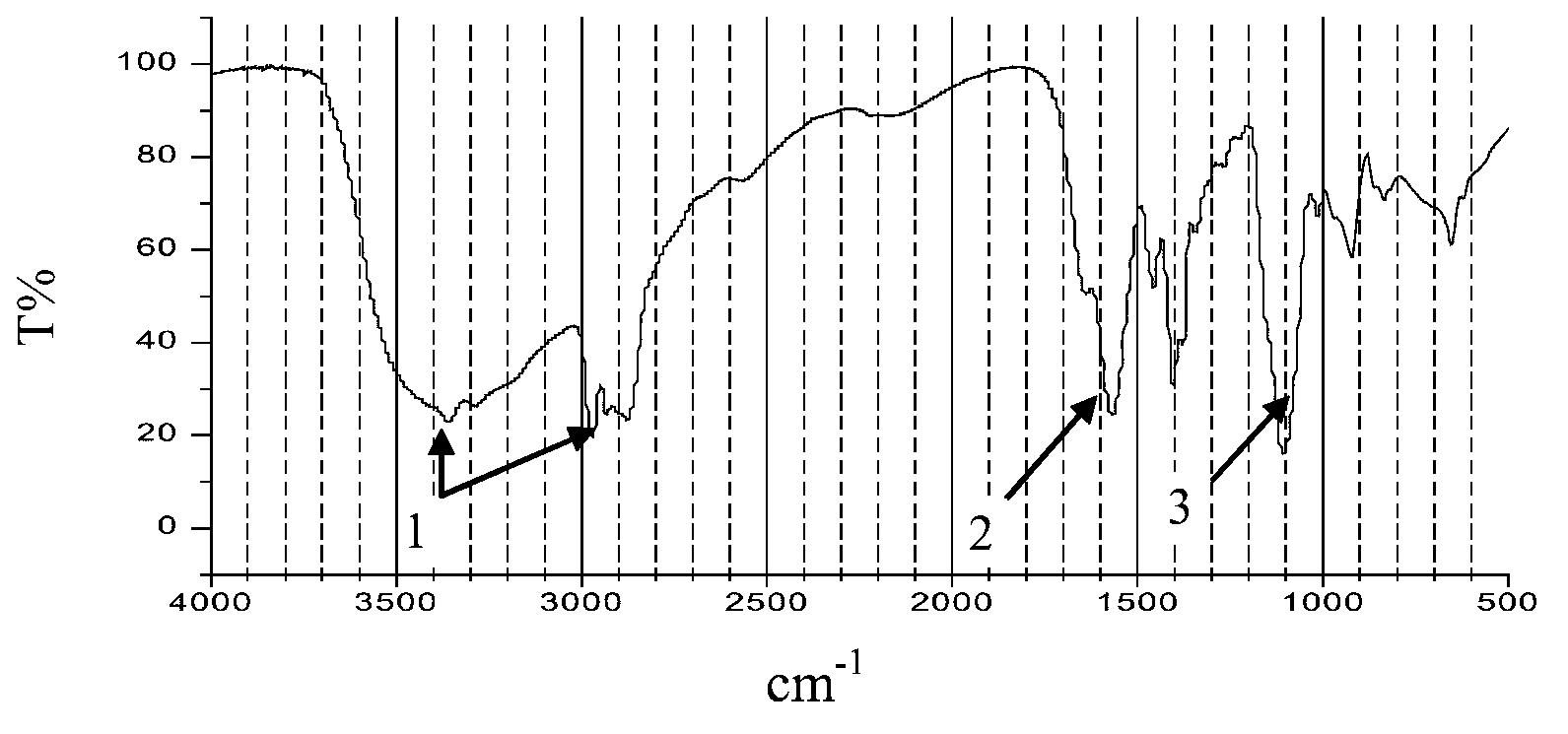

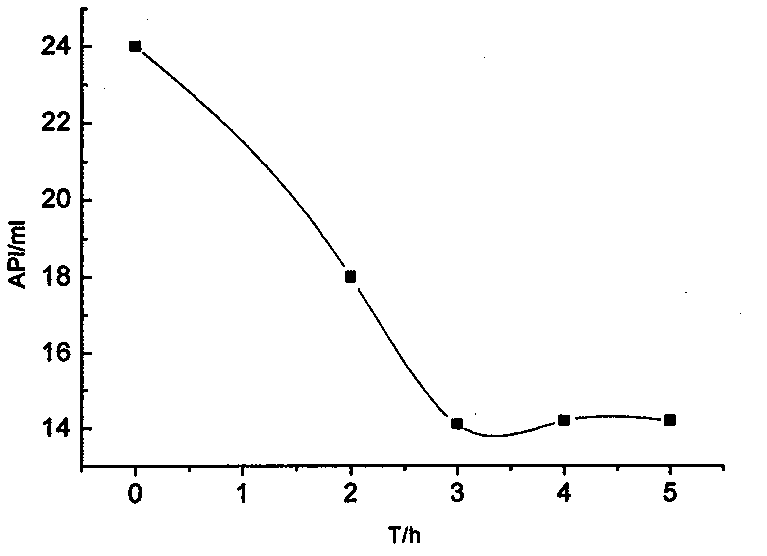

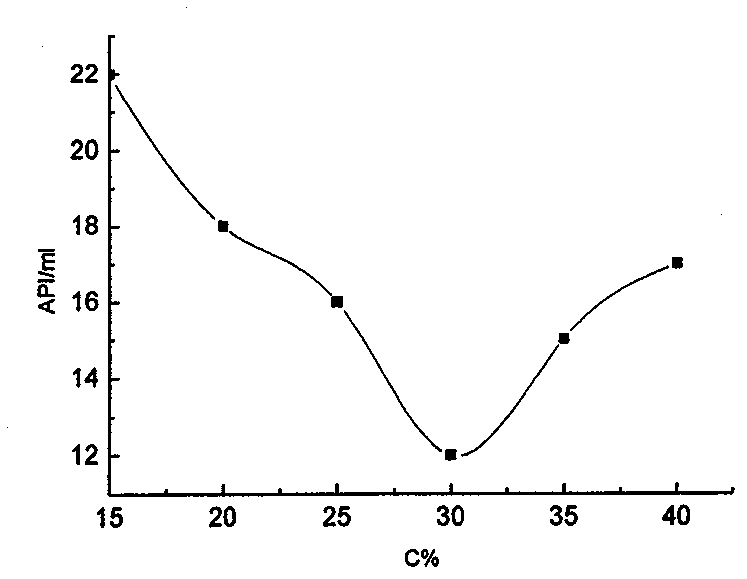

Inorganic-organic salt-resisting and high temperature-resisting polymer fluid loss additive for drilling fluid

ActiveCN102220112AGood fluid lossImprove temperature resistanceDrilling compositionPolymer scienceFiltration

The invention discloses an inorganic-organic salt-resisting and high temperature-resisting polymer fluid loss additive for drilling fluid, which is characterized in that: 2-acrylamide group-2-methyl sodium propanesulfonic acid, dimethyl diene propyl group ammonium chloride, acrylamide and sodium acrylate are used as main polymers, and inorganic salt is used as transformation temperature stabilizing agent. Aqueous solution is prepared according to a certain mass ratio, initiators are added for polymerization at certain temperature, so as to generate macromolecule polymer of elastic colloid, and after drying and grinding are carried out, a target compound is obtained. The additive is easy to dissolve in water, has good capacity of filtration loss reduction, temperature resistance, salt resistance, calcium resistance and magnesium pollution resistance, has good tackifying effect, can effectively control mud making of the stratum and inhibit the dispersion of clay and drilling cuttings, and has good compatibility with the common treating agents.

Owner:北京兴有丰科科技发展有限公司

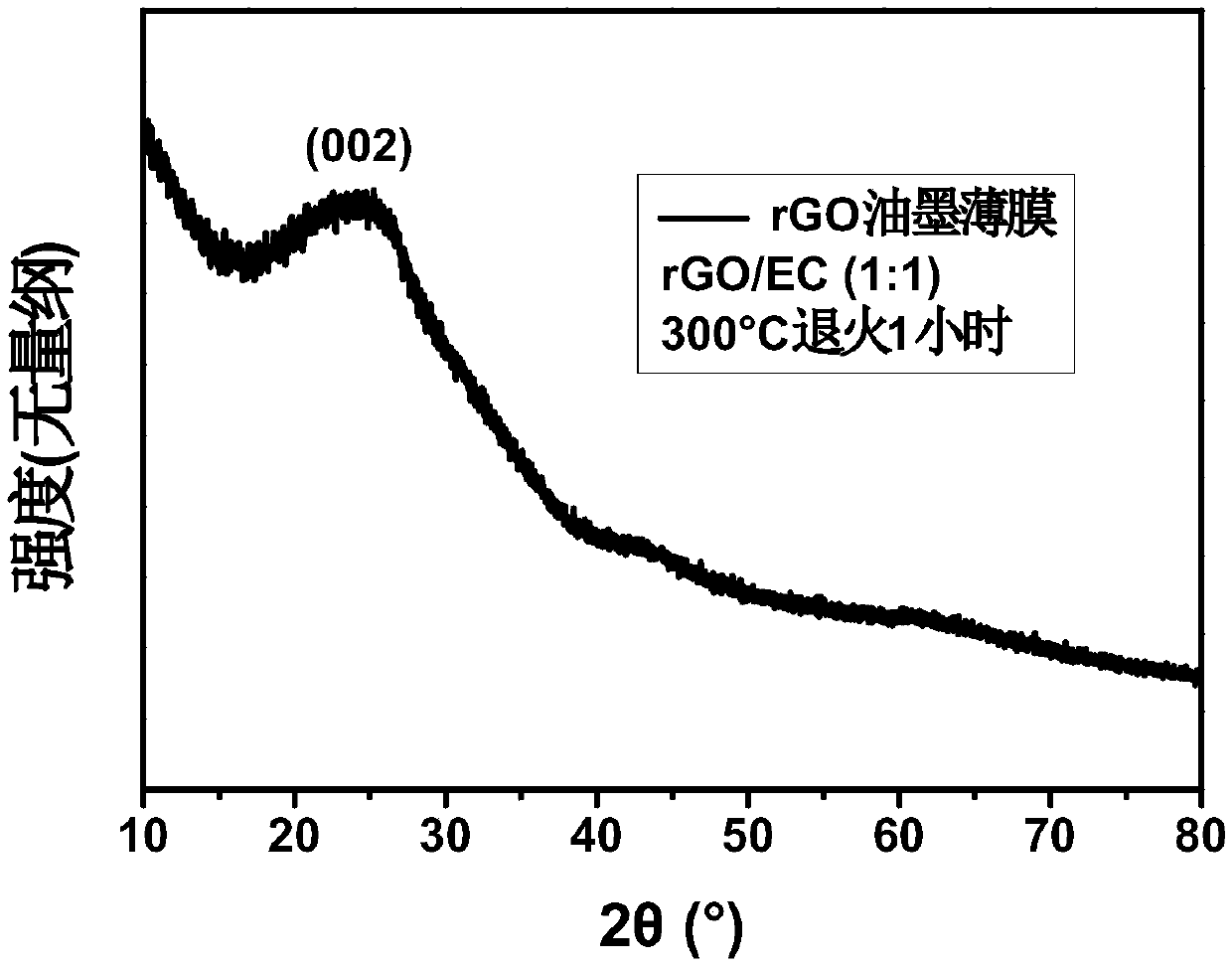

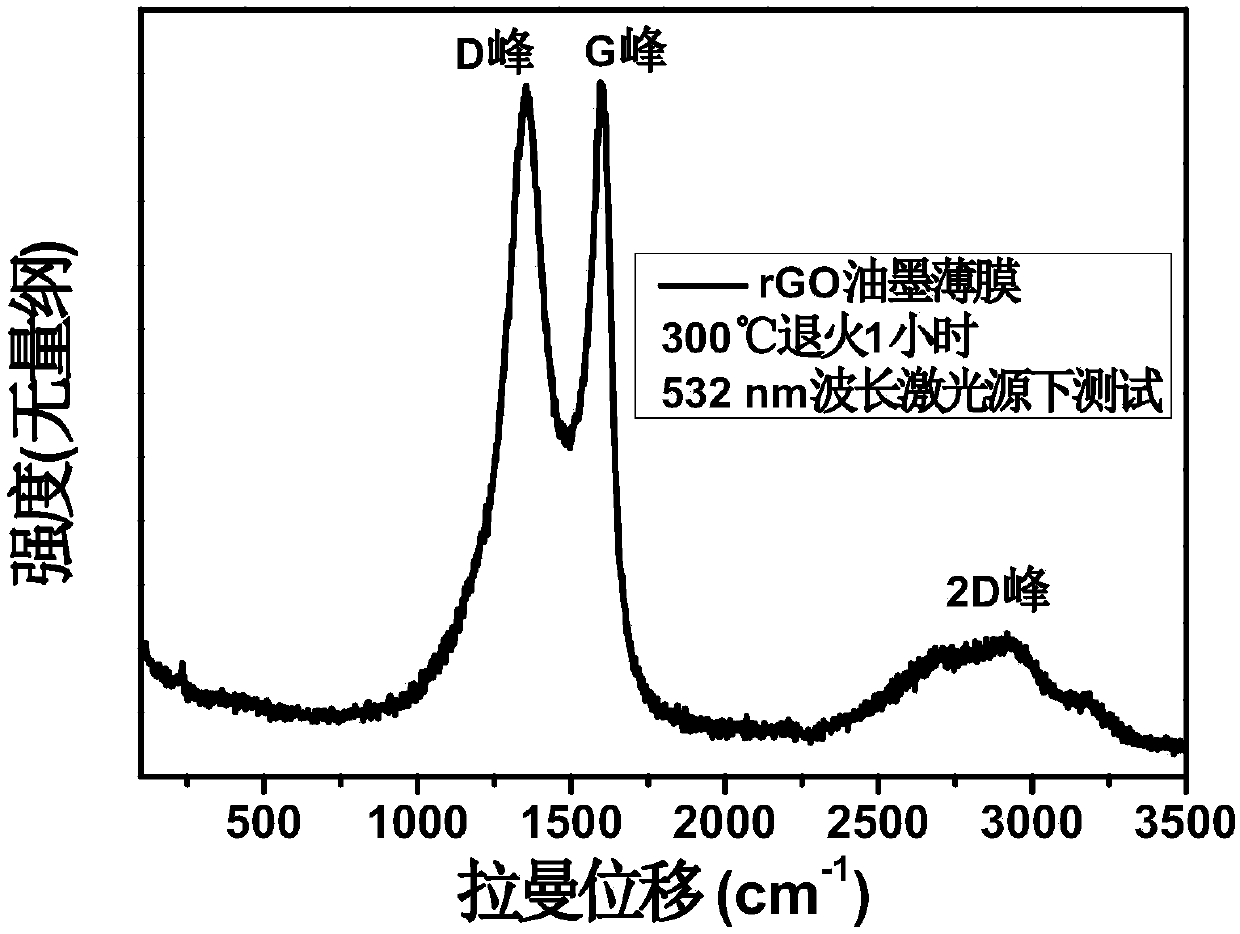

Graphene electric-conduction ink preparation method, graphene electric-conduction ink film and graphene electric-conduction ink film composite material film

The invention discloses a graphene electric-conduction ink preparation method, a graphene electric-conduction ink film and a graphene electric-conduction ink film composite material film. According tothe present invention, a graphene electric-conduction filler is uniformly dispersed in an alcohol / ketone / ester / ether solvent under the assisting of a cellulose-based dispersing agent through room-temperature stirring and ultrasonic dispersion to obtain high-quality high-stability high-conductivity graphene ink, and further the high-quality high-stability high-conductivity graphene ink is compounded with other functional materials to obtain graphene-based composite ink; the method has characteristics of simple formula, simple process, high efficiency, environment friendliness, low cost and thelike; and the graphene ink and the composite ink are suitable for scrape coating, screen printing, direct writing, ink-jet printing and other processes, and can firmly form pure graphene or graphenecomposite films and patterns on common hard / soft substrates.

Owner:XI AN JIAOTONG UNIV

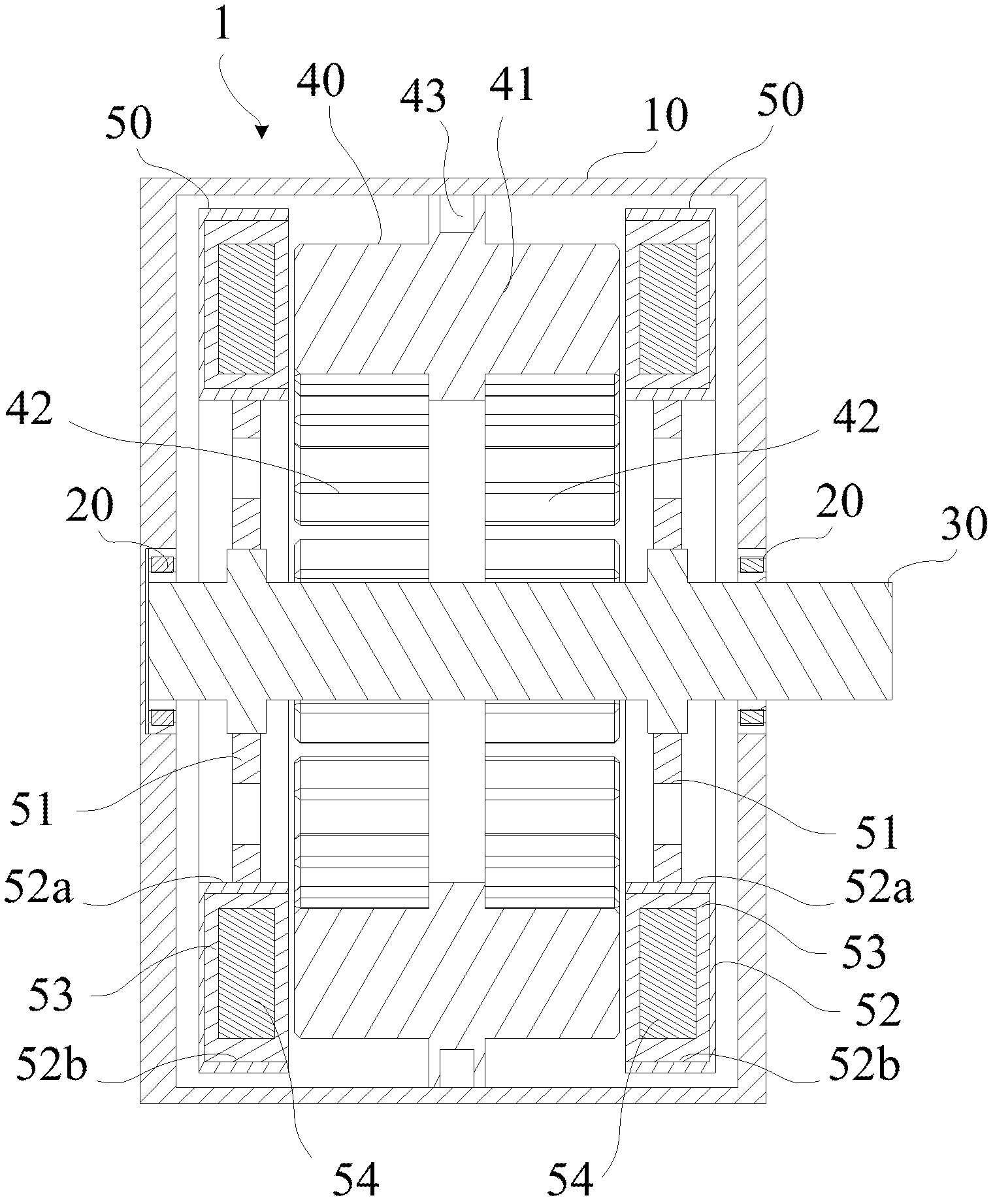

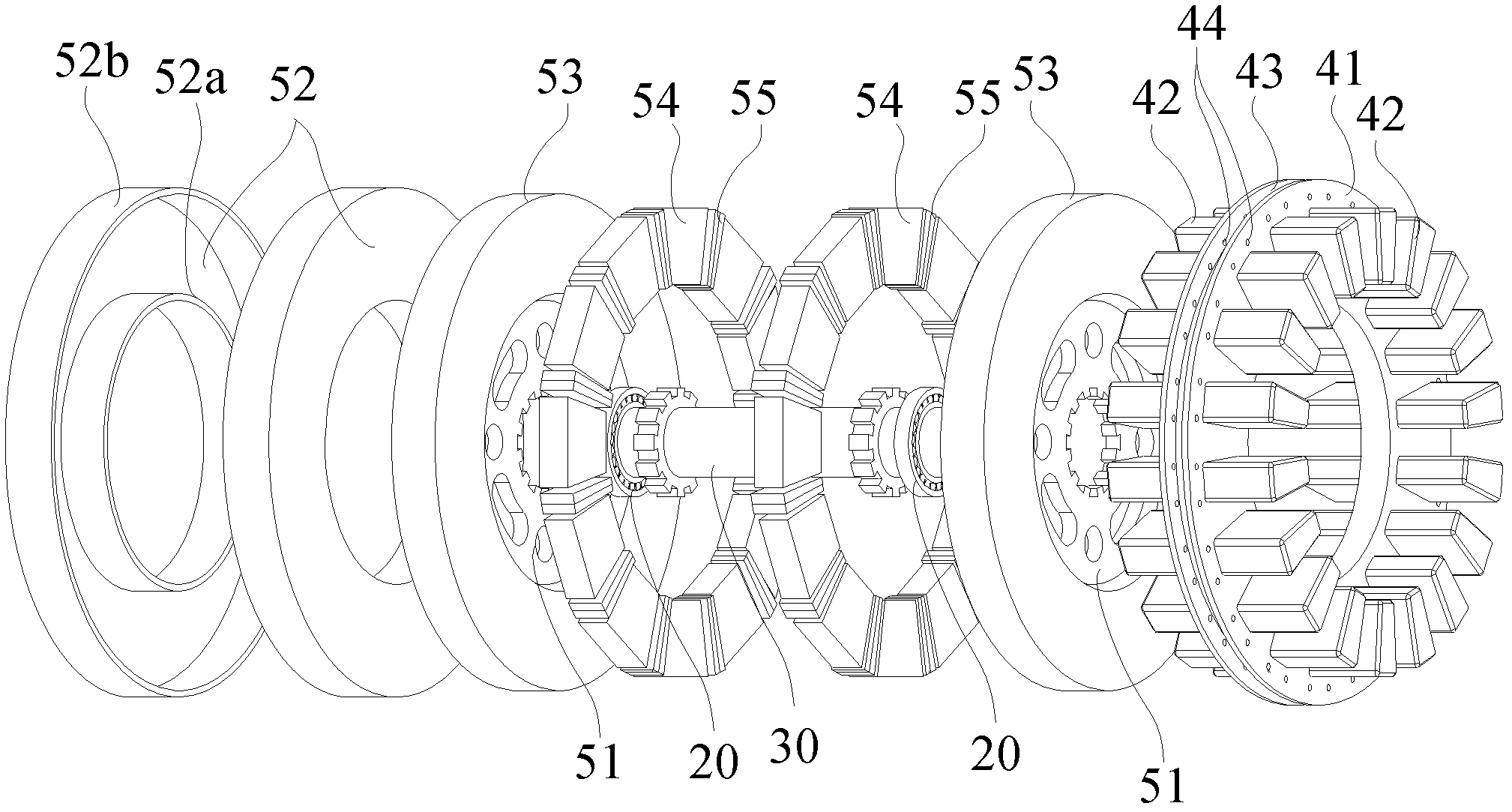

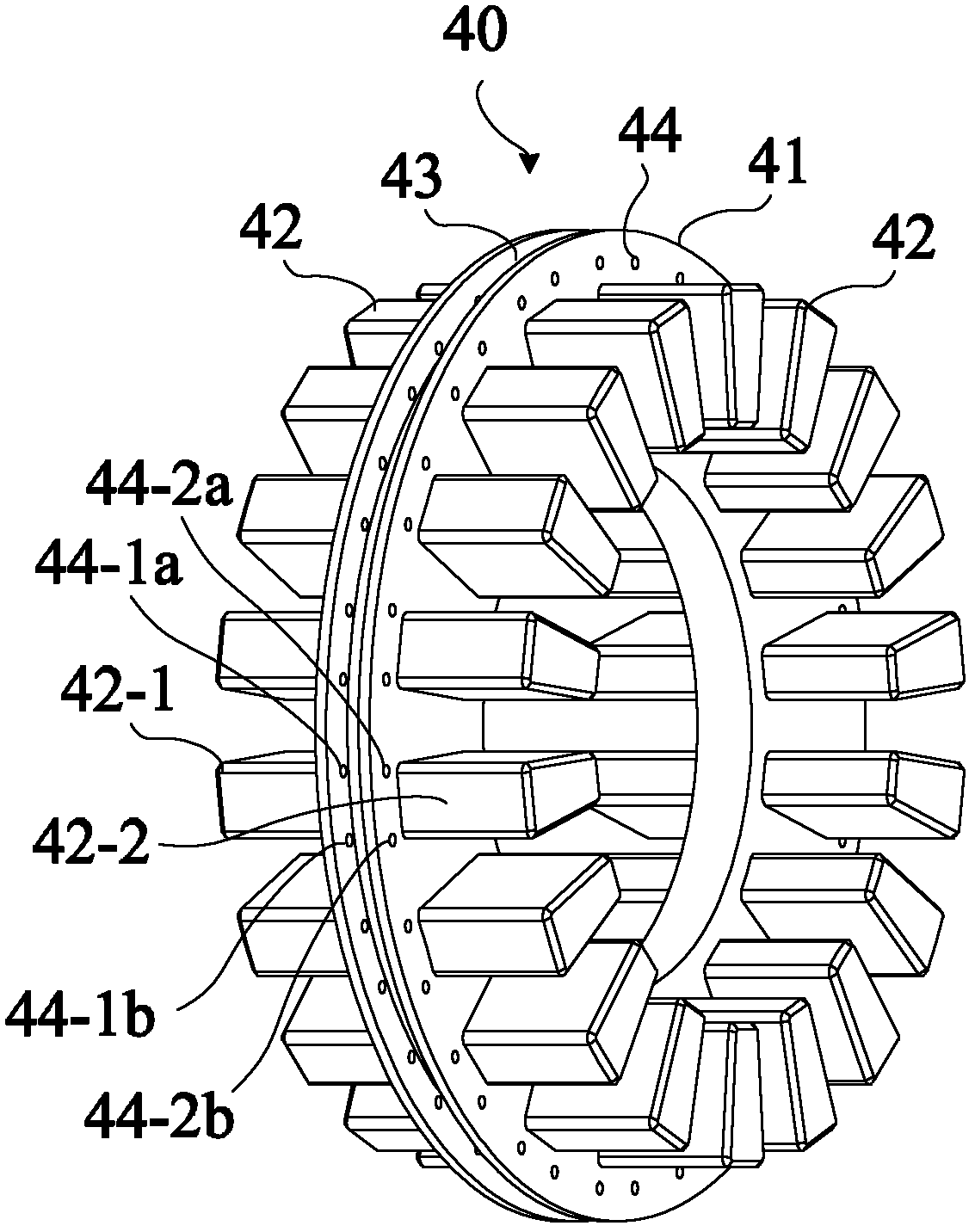

Stator for axial clearance type motor and axial clearance type motor

ActiveCN102624108AIncrease maximum powerHigh specific powerMagnetic circuit rotating partsMagnetic circuit stationary partsMaximum torqueControl theory

The invention provides a stator for an axial clearance type motor and the axial clearance type motor. Stator teeth stator windings are symmetrically arranged on the two end faces of the stator to support the axial clearance type motor to adopt a dual-rotor mode which can make the stress of a rotating shaft balanced, so that improvement in the bearable maximum torque and rotating speed of the axial clearance type motor is facilitated. In addition, a stator slot formed on the stator replaces a collector ring and a cooling shell, so that the structure of the axial clearance type motor can be simplified. Moreover, clearance slots of the stator are equal in width along a radial direction, so that the utilization of air clearances is improved; and chambers are formed at the end part edges of the stator teeth of the stator, so that the dispersion of lines of magnetic force can be suppressed. Therefore, the specific power of the axial clearance type motor can be improved.

Owner:HAIMA AUTOMOBILE CO LTD +2

Method for improving overlength high frequency circuit board hole site working accuracy

ActiveCN103079353AHigh precisionEliminates loss of hole position accuracyPrinted circuit manufactureDislocationMicroetching

The invention discloses a method for improving overlength high frequency circuit board hole site working accuracy. Through an interactive design of subsection drill holes and locating holes, the continuity and the consistency of a front section of drill holes and a rear section of drill holes are ensured, and the problems of dislocation, offset and the like are solved; an original mechanical plate grinding method is replaced with a chemical microetching method, so that the problem that the hole site accuracy is reduced caused by tensile deformation of panels is eliminated; and through baking before processing a circuit board and a finished product is delivered, so that the humidity in the board is effectively removed, the coefficient of thermal expansion of the panels is stabilized, and the problem of accuracy variation caused by deformation or tortuosity of the panels is solved. According to the method for improving overlength high frequency circuit board hole site working accuracy, the drilling accuracy of the overlength high frequency circuit board is effectively improved, the problems of disability in assembly, and severe signal interference caused by severe hole shift in an earlier stage are solved, the percent of pass of the overlength high frequency circuit board is improved, meanwhile, the product quality of enterprises is promoted, and the scrapping of products is reduced.

Owner:SHENZHEN BOMIN ELECTRONICS

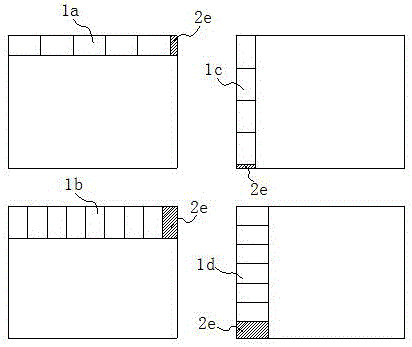

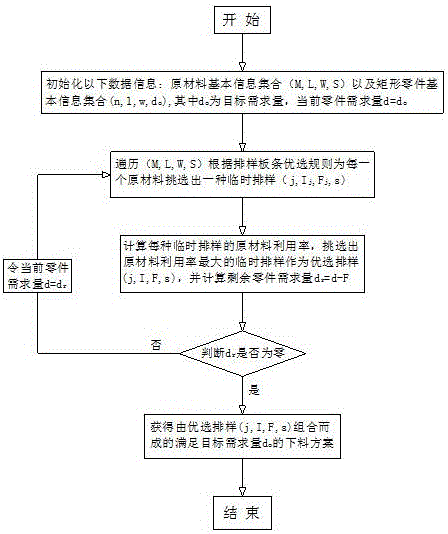

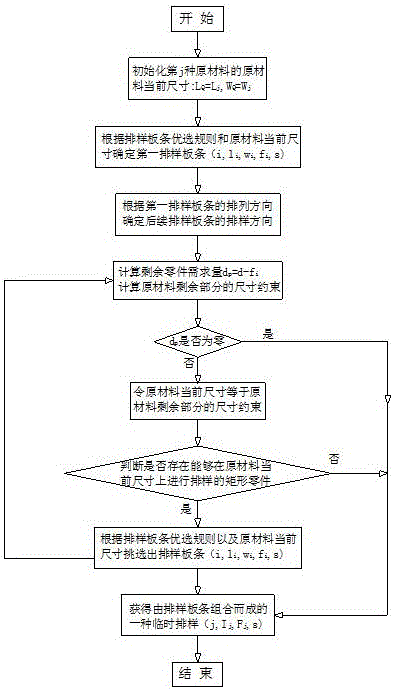

Excess-material-centralizing-oriented rectangular part optimizing discharging method

InactiveCN106845726AIncrease profitGuaranteed concentrationForecastingManufacturing computing systemsProcess engineeringIndustrial engineering

The invention relates to a discharging method of rectangular parts cut on a rectangular raw material, and aims at providing an excess-material-centralizing-oriented rectangular part optimizing discharging method. The method comprises the following steps that 1, a raw material basic information set (M, L, W, S) and a rectangular part basic information set (n, l, w, do) are initialized, and the current part need number d is made to be equal to do; 2, the raw material basic information set (M, L, W, S) is traversed, and a temporary stock layout (j, Ij, Fj, s) is screened out for each raw material based on a stock layout batten optimizing rule; 3, the raw material utilization rate of each temporary stock layout is calculated, the temporary stock layout with the maximum raw material utilization rate is selected out to serve as a preferred stock layout (j, I, F, s), and the remaining part need number dr is calculated to be equal to d-Fl; 4, whether the remaining part need number dr is 0 or not is judged, and if not, d is made to be equal to dr, the step 2 is executed till dr is equal to 0, and therefore a discharging scheme which is composed of the preferred stock layout (j, I, F, s) and meets the target need number do is obtained. On the premise of guaranteeing the high raw material utilization rate, centralizing of excess materials on the raw materials is achieved, and the rectangular part discharging cutting process is simplified.

Owner:CHONGQING UNIV

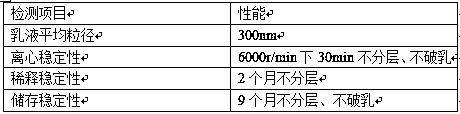

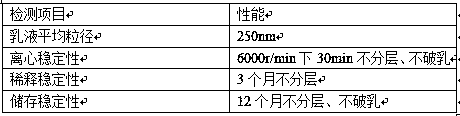

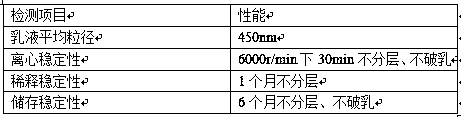

Graphene-containing water-borne epoxy resin emulsion and preparation method thereof

ActiveCN107556492AInhibition dispersionAvoid Compatibility IssuesAnti-corrosive paintsEpoxy resin coatingsChemistryEmulsion

The invention discloses graphene-containing water-borne epoxy resin emulsion and a preparation method thereof. The preparation method comprises the specific preparation steps: preparing a polyethyleneglycol / graphene composite material, preparing a water-borne epoxy resin emulsifying agent and preparing water-borne epoxy resin emulsion, wherein the polyethylene glycol / graphene composite material is prepared by an in-situ polymerization method, so that graphene can be uniformly dispersed and anchored in a polyethylene glycol matrix; when the emulsifying agent is prepared, hydroxyl radicals on the surface of polyethylene glycol react with epoxy resin under the action of a catalyst, so that the connection among polyethylene glycol, the graphene and the epoxy resin is realized; in the preparation process of the emulsion, the graphene enters the emulsion along with the emulsifying agent, so that the problems of difficult dispersion and poor compatibility and the like of the graphene in theemulsion are solved and the graphene-containing water-borne epoxy resin emulsion with uniform dispersion is obtained. The graphene-containing water-borne epoxy resin emulsion prepared by the inventionhas good centrifugation, dilution and storage stability, is lower in cost compared with that of the traditional epoxy resin, and is safe, environmentally friendly and free from toxicity; and when thegraphene-containing water-borne epoxy resin emulsion is applied in anti-corrosive coatings, the anti-corrosive property and the adhesive force are stronger, the impact resistance is good and the construction is easy.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

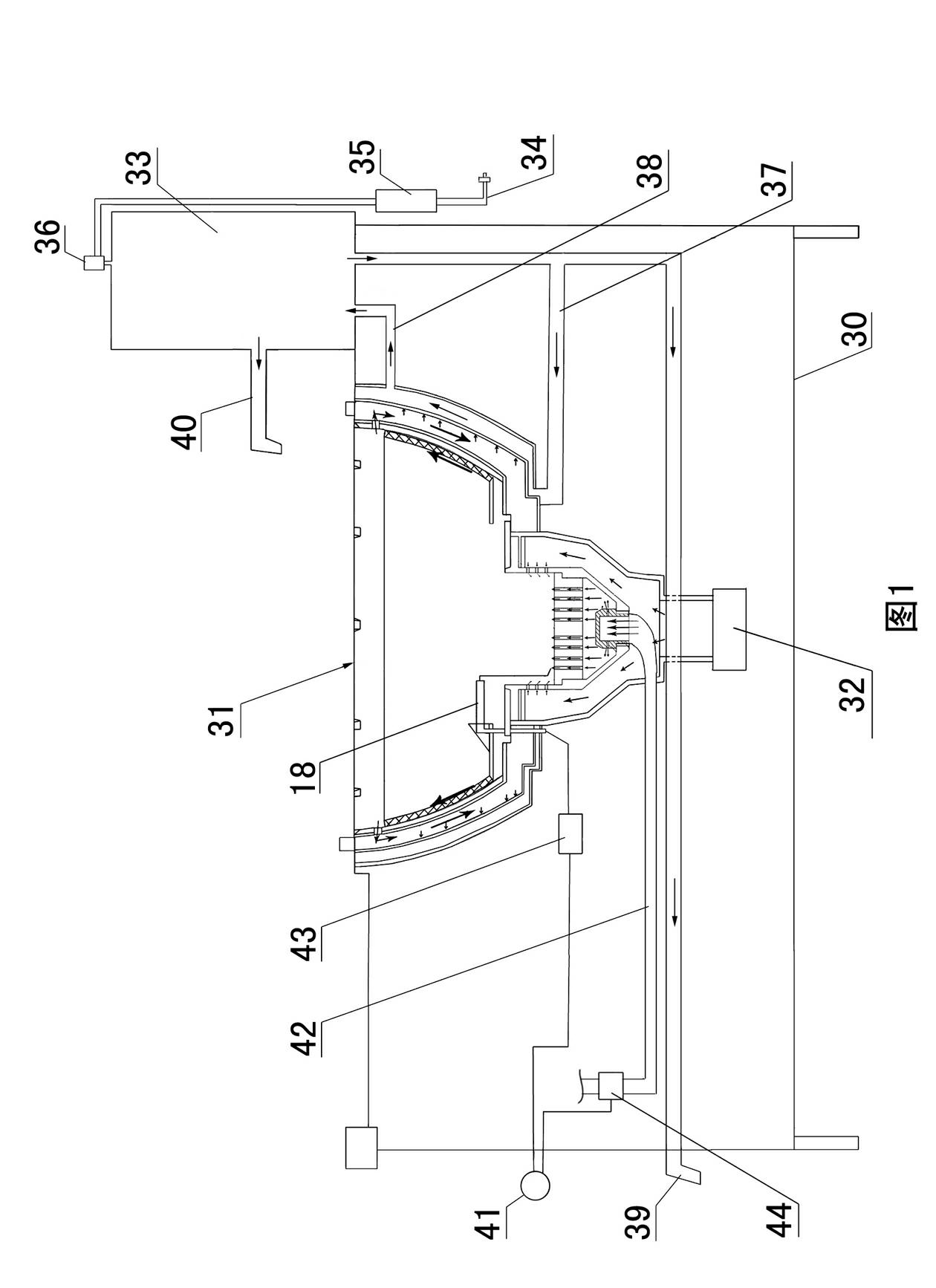

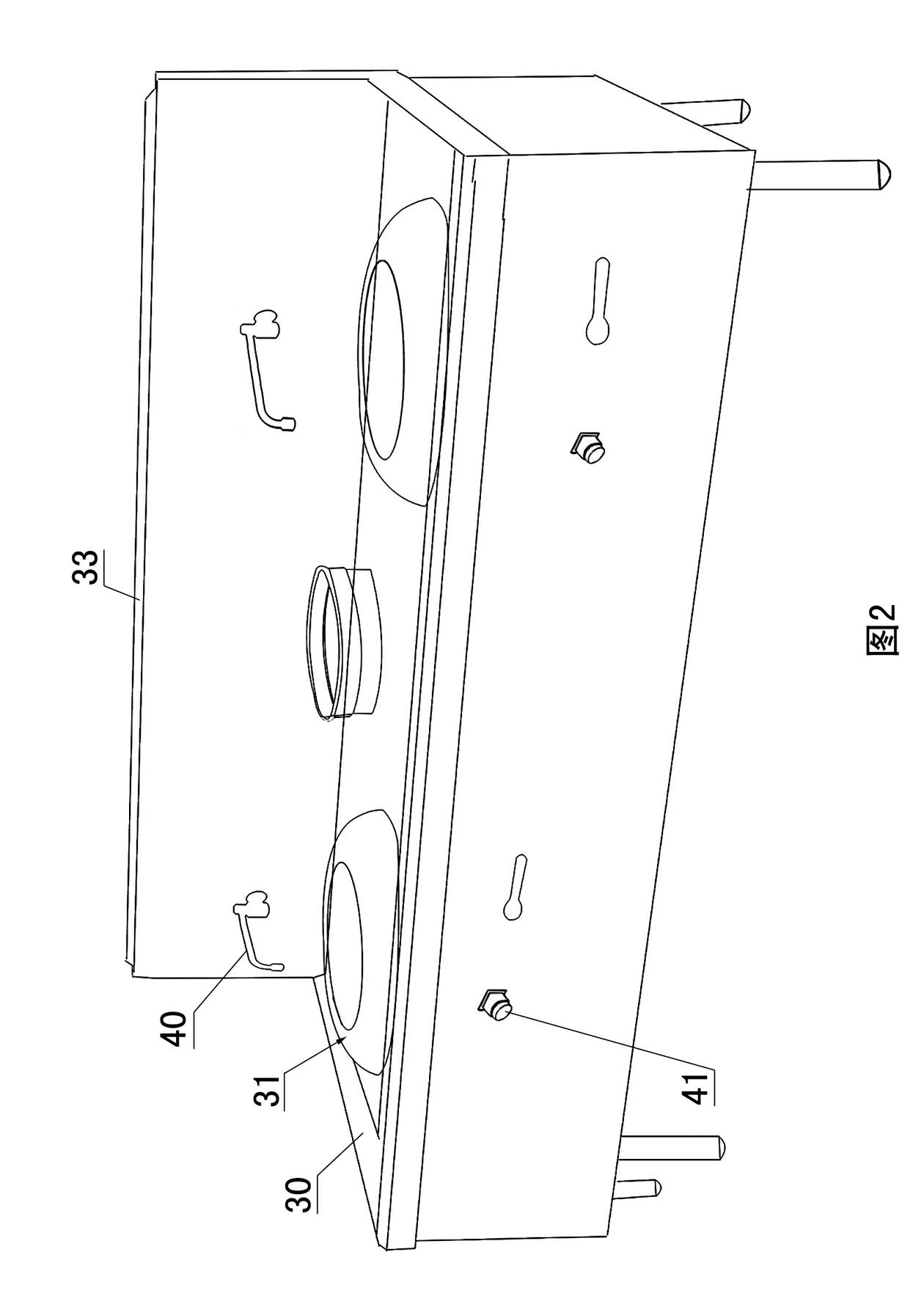

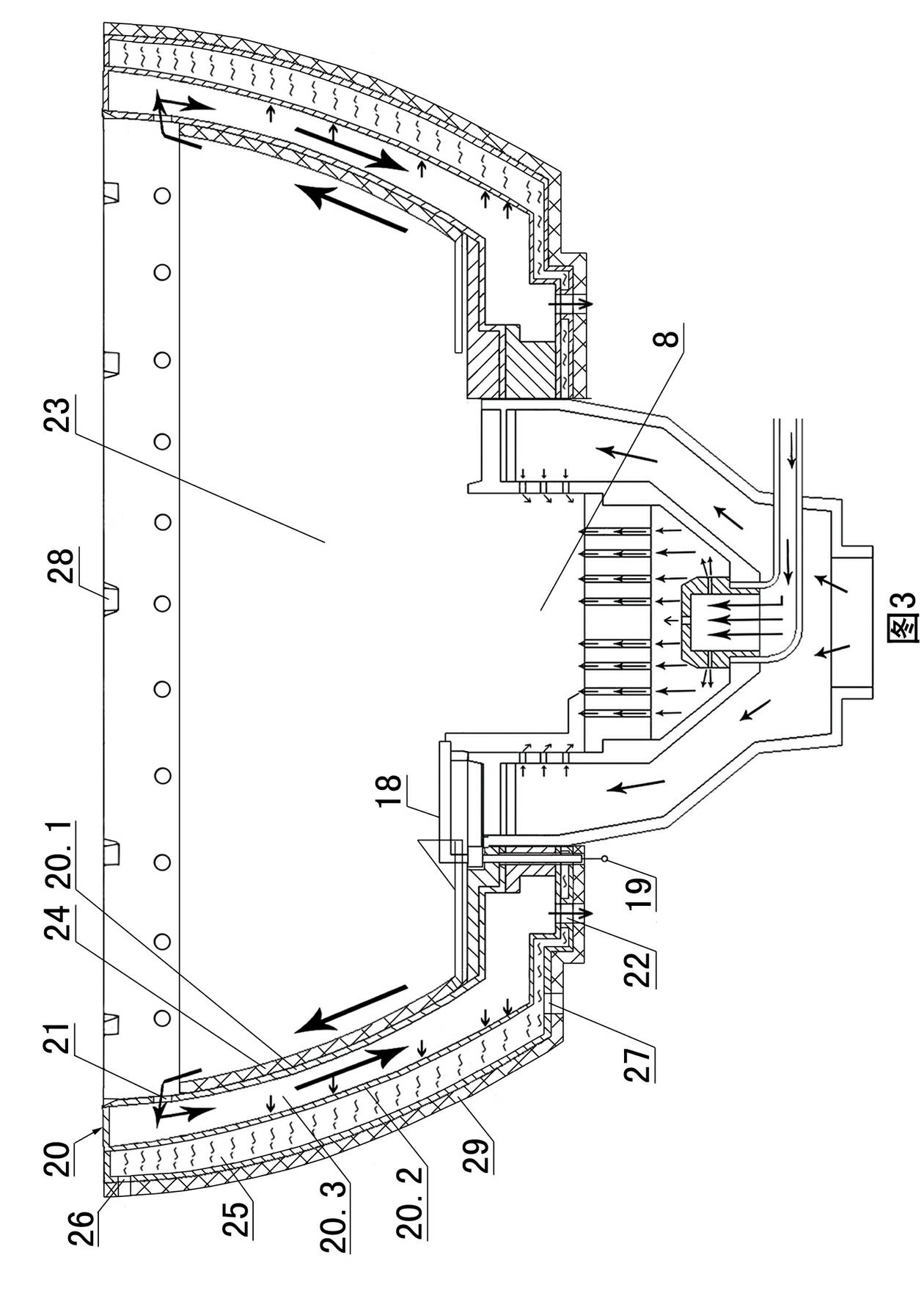

Collected heat type high efficient and energy-saving burning Chinese food frying-oven

InactiveCN102221228ATemperature does not dropSpeed will not decreaseWater heating stoves/rangesCooking fumes removalThermal energyCombustor

The invention relates to a collected heat type energy-saving burning Chinese food frying-oven which comprises a cooking stove and a burner assembly, a fan, a storage water tank, an electronic ignition device arranged on the cooking stove, wherein, the burner assembly comprises a burner and a hearth, the storage water tank is connected with a swing hot-water cock, the hearth comprises a side wall of the hearth and a waste heat collected jacket, the side wall of the hearth is of a hollow structure and comprises an inner side wall, an outer side wall and an air cavity clipped the inner side wall and the outer side wall, wherein, the upper part of the inner side wall is provided with a waste gas air hole which is communicated with the air cavity, the lower part of the outer side wall is provided with a waste gas air inlet which is communicated with the air cavity, the waste heat collected jacket is attached to the outer side surface tightly and is connected with the storage water tank to form a cycling water way through a water inlet and a return water pipe. The frying-oven has the advantages of energy-saving effect and high economic benefit, providing hot water to the kitchen, meanwhile, the frying-oven effective reduces the influence of the Chinese style frying-furnace on kitchen environment, and the capability of collecting the heat energy from hearth is greatly improved.

Owner:宫润涛

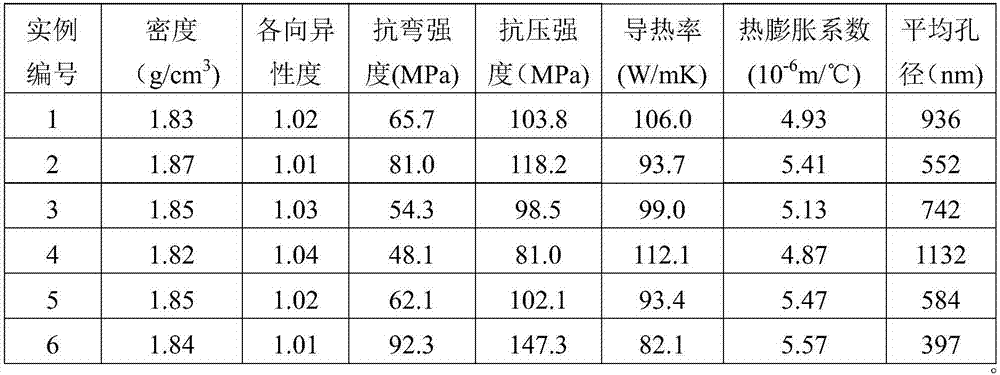

Preparation method of microstructure graphite

ActiveCN107265450AAvoid reunionInhibition dispersionCarbon compoundsCarbonizationInterfacial bonding

The invention relates to a preparation method of microstructure graphite. The preparation method comprises the following steps: adopting superfine particle pitch cokes as aggregates and high-softening point asphalt as a bonding agent, preparing a paste material in a manner of liquid phase dispersion mixing and crushing to prepare pressed powder; preparing isotropic graphite with compact microstructure and small pore size distribution through isostatic press molding, carbonization, impregnation and high-temperature graphitization. The preparation method provided by the invention has the advantages that with the adoption of a raw material uniform blending process, on one hand, interfacial bonding of aggregate carbon and bonding agent bitumen is improved, and on the other hand, the agglomeration and non-uniform dispersion of the superfine particle isostatic pressure graphite are avoided, so that the possibility of occurrence of heat treatment cracking phenomenon is greatly reduced, and a favorable technical support is provided for the preparation of the superfine particle isostatic pressure graphite with large size. Moreover, the preparation method is wide in raw material source, lower in cost, simple in process and easy for large-scale batch production.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

Nanometer titanium dioxide-silicon dioxide composite photocatalyst, and preparation method thereof

ActiveCN106607016AAvoids the problem of photocorrosion of the carrierEnable self-propelled mobilityPhysical/chemical process catalystsCore shellSilicon dioxide

The invention provides a preparation method for a nanometer titanium dioxide-silicon dioxide composite photocatalyst with a core shell structure. The preparation method comprises the following steps: (1) preparing a nanometer titanium dioxide-carbon-silicon dioxide compound with a core shell structure; (2) arraying the nanometer titanium dioxide-carbon-silicon dioxide compound with the core shell structure on a prepreg so as to form a single-layer structure; (3) corroding the prepreg with the nanometer titanium dioxide-carbon-silicon dioxide compound by using steam of a corrosive agent to remove a part of silicon dioxide shells in the nanometer titanium dioxide-carbon-silicon dioxide compound so as to form openings; (4) subjecting the corroded nanometer titanium dioxide-carbon-silicon dioxide compound to high-temperature oxidation to remove interlayer carbon so as to obtain the nanometer titanium dioxide-silicon dioxide composite photocatalyst with the core shell structure. The invention also provides the nanometer titanium dioxide-silicon dioxide composite photocatalyst with the core shell structure prepared by using the method.

Owner:HANGZHOU TONG KING ENVIRONMENT TECH CO LTD

Positive electricity production well treatment liquid and its preparation method

The invention provides a positively charged water-based production well treatment fluid system, which is equipped with a cationic fluid loss reducer while using a cationic viscosifier, and is optionally equipped with a positively charged production well treatment fluid Slurry compounding agent, electrical stabilizer, colloidal stabilizer, lubricant, oil reservoir protection agent and / or weighting agent make the production well treatment fluid system positively charged, and this positively charged production well treatment fluid can well solve the " To deal with the contradiction between "fluid stability" and "wellbore stability", it has the characteristics of strong ability to inhibit clay dispersion, good effect of protecting oil and gas layers, fast drilling speed, regular wellbore, and good salt resistance. The present invention also relates to the preparation method of the production well treatment fluid system and its use as drilling fluid and well completion fluid for oil drilling and well completion.

Owner:CHINA PETROLEUM & CHEM CORP +2

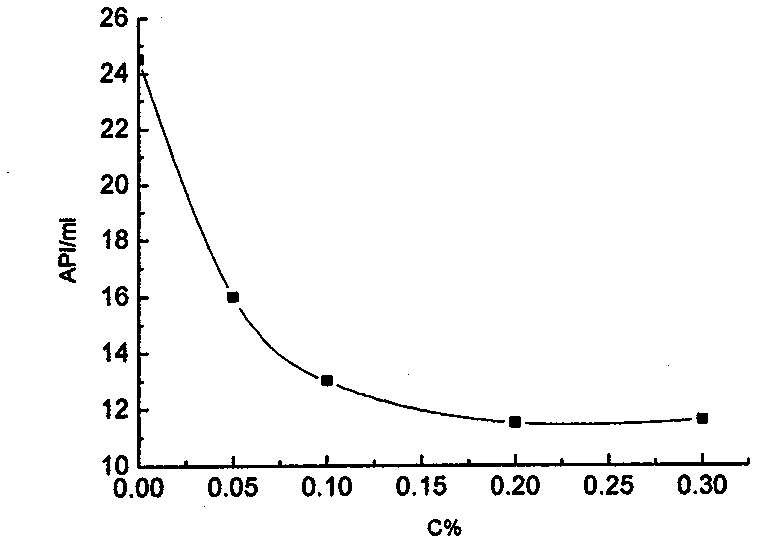

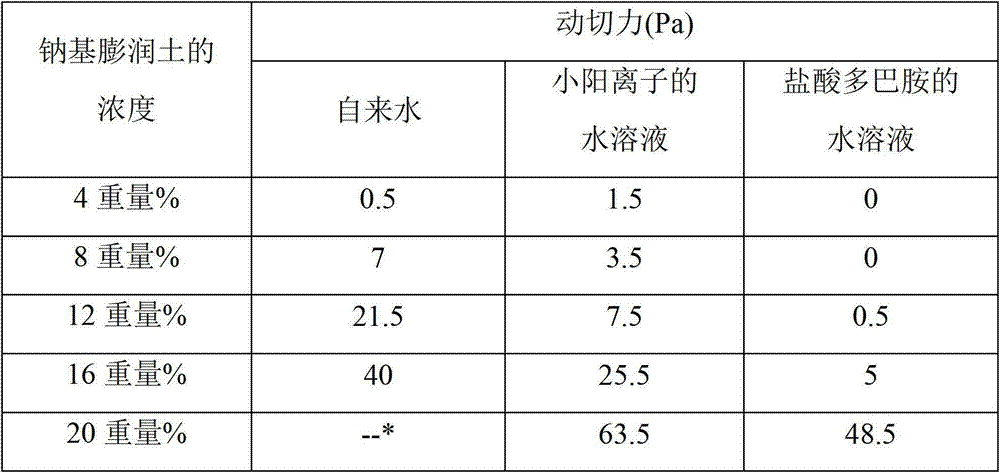

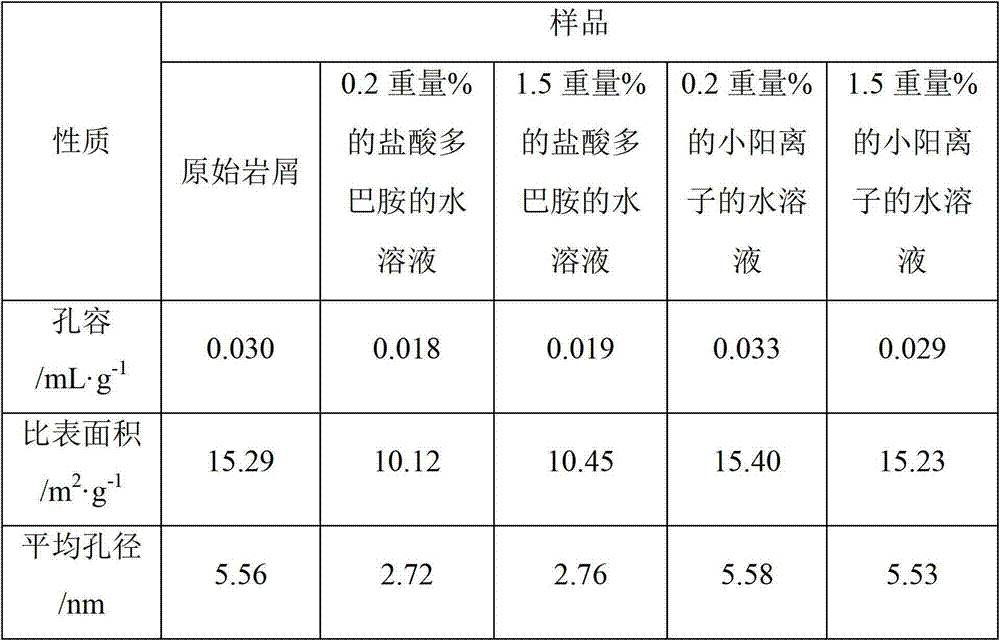

Application of aromatic amine hydrochloride serving as shale inhibitor for drilling fluid

ActiveCN103087690AInhibition dispersionInhibit flakingDrilling compositionAromatic amineHydrochloride

The invention discloses an application of aromatic amine hydrochloride serving as a shale inhibitor for a drilling fluid. The aromatic amine hydrochloride, specifically dopamine hydrochloride, can be used for effectively inhibiting clay hydration and swelling as well as inhibiting dispersion and flaking of the shale, and also can be used for effectively plugging the pores and micro cracks on the near surface of the shale.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com