High-performance polypropylene nano composite material and preparation method thereof

A technology of nanocomposite materials and polypropylene, which is applied in the field of high-performance polypropylene nanocomposites, preparation of composite materials, and polypropylene nanocomposites. Molding performance, improvement of material properties, and improvement of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 30% of polypropylene by weight, 50% of organoclay Nanocor I.44P, 20% of maleic anhydride grafted polypropylene, 0.2% of Irganox 1010, 0.2% of Igrafos 168, and 0.4% of Negonox DSTP. Dry-mix in the mixer for 5 minutes, then add to the twin-screw extruder to melt and extrude to granulate. The head temperature is 200°C, the speed of the twin-screw extruder is 600 rpm, and the clay masterbatch M50 is prepared.

Embodiment 2

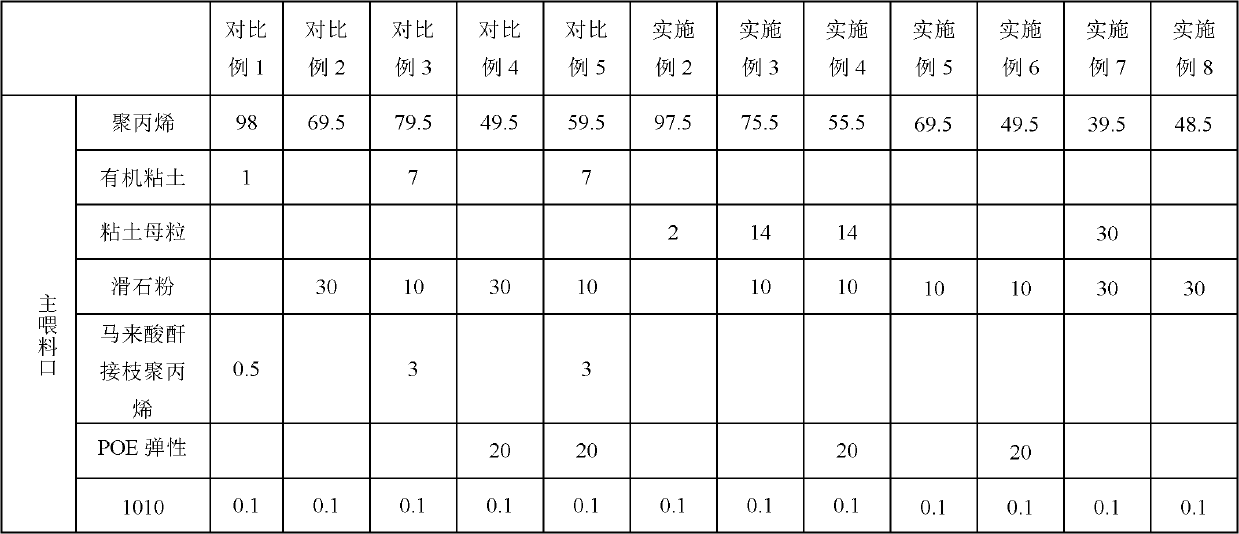

[0044] Take by weight 97.5% of polypropylene, the clay masterbatch M50 that embodiment 1 makes is 2%, Irganox 1010 is 0.1%, Igrafos 168 is 0.1%, Negonox DSTP is 0.3%, dry mixes 5 in high-speed mixer Minutes, then add to the twin-screw extruder to melt and extrude to granulate, wherein the temperature in the screw barrel is: 180°C in the first zone, 190°C in the second zone, 190°C in the third zone, 190°C in the fourth zone, 200°C in the head, twin-screw The extruder rotational speed was 500 rpm. After the particles are dried, they are injection molded on an injection molding machine to prepare samples.

Embodiment 3

[0046] Take by weight percentage polypropylene 75.5%, the clay masterbatch M50 that embodiment 1 makes is 14%, talcum powder 10%, Irganox 1010 is 0.1%, Igrafos 168 is 0.1%, Negonox DSTP is 0.3%, in high-speed mixing Dry mix in the container for 5 minutes, then add to the twin-screw extruder to melt and extrude to granulate. 200°C, the rotational speed of the twin-screw extruder is 500 rpm. After the particles are dried, they are injection molded on an injection molding machine to prepare samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com