ABS flame-retardant composite material with high impact resistance and low volume resistance and preparation method thereof

A technology of flame-retardant composite materials and volume resistance, which is applied in the field of composite materials and its preparation, can solve problems such as easy accumulation, flammability, and decline in mechanical properties such as impact strength of composite materials, and achieve excellent impact strength and excellent flame-retardant properties , Improve the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

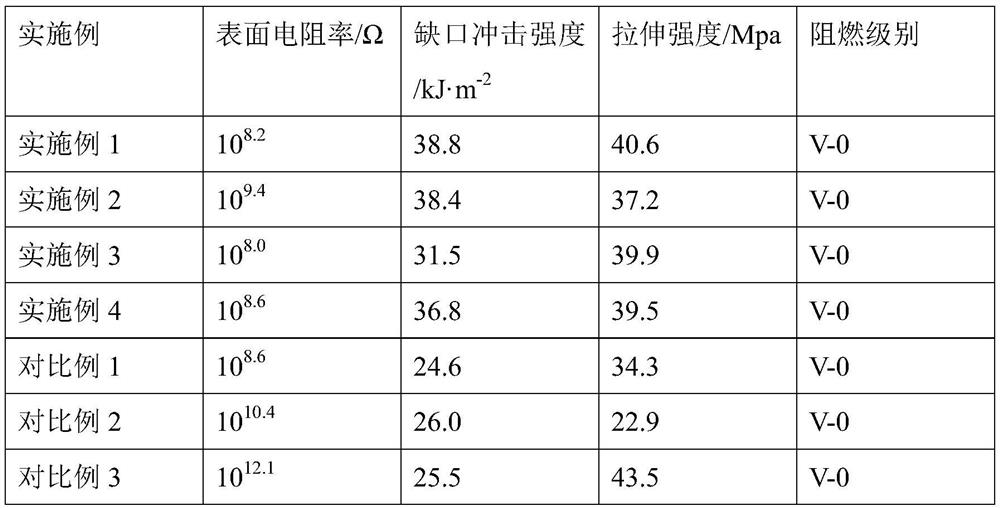

Examples

Embodiment 1

[0019] Embodiment 1: A kind of ABS flame retardant composite material with high impact resistance and low volume resistance, the raw materials of which are composed of ABS resin, styrene-butadiene copolymer, flame retardant, antistatic agent, structural strength enhancer and adaptation modifier. The raw material is composed of 100 parts by mass of ABS resin, 25 parts of styrene-butadiene copolymer, 6 parts of flame retardant, 3 parts of antistatic agent, 1 part of structural strength enhancer and suitable Modifier 3 parts.

[0020] Further, the butadiene content of the styrene-butadiene copolymer is above 60%.

[0021] Further, the structural strength enhancer is hydrophobically modified powder of light rod waste; the preparation method of the hydrophobically modified powder of light rod waste includes the following steps: drying, crushing, and sieving the fiber preform waste Obtain 50-60 mesh granules, roast the obtained granules at 550°C for 2 hours, take them out and place...

Embodiment 2

[0023] Embodiment 2: A kind of ABS flame retardant composite material with high impact resistance and low volume resistance, the raw materials of which are composed of ABS resin, styrene-butadiene copolymer, flame retardant, antistatic agent, structural strength enhancer and adaptation modifier. The raw material is composed of 100 parts by mass of ABS resin, 20 parts of styrene-butadiene copolymer, 3 parts of flame retardant, 1 part of antistatic agent, 0.5 part of structural strength enhancer and suitable 1 part of modifier.

[0024] Further, the butadiene content of the styrene-butadiene copolymer is above 60%.

[0025] Further, the structural strength enhancer is hydrophobically modified powder of light rod waste; the preparation method of the hydrophobically modified powder of light rod waste includes the following steps: drying, crushing, and sieving the fiber preform waste Obtain 50-60 mesh pellets, roast the obtained pellets at 500 ° C for 1.5 hours, take out and place...

Embodiment 3

[0027] Embodiment 3: A kind of ABS flame retardant composite material with high impact resistance and low volume resistance, the raw materials of which are composed of ABS resin, styrene-butadiene copolymer, flame retardant, antistatic agent, structural strength enhancer and adaptation modifier. The raw material is composed of 100 parts by mass of ABS resin, 30 parts of styrene-butadiene copolymer, 10 parts of flame retardant, 4 parts of antistatic agent, 2 parts of structural strength enhancer and suitable 5 parts of modifier.

[0028] Further, the butadiene content of the styrene-butadiene copolymer is above 60%.

[0029] Further, the structural strength enhancer is hydrophobically modified powder of light rod waste; the preparation method of the hydrophobically modified powder of light rod waste includes the following steps: drying, crushing, and sieving the fiber preform waste Obtain 50-60 mesh pellets, roast the obtained pellets at 600 ° C for 2.5 hours, take out and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com