Patents

Literature

3569 results about "Acrylonitrile butadiene styrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylonitrile butadiene styrene (ABS) (chemical formula (C₈H₈)ₓ·(C₄H₆)y·(C₃H₃N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point.

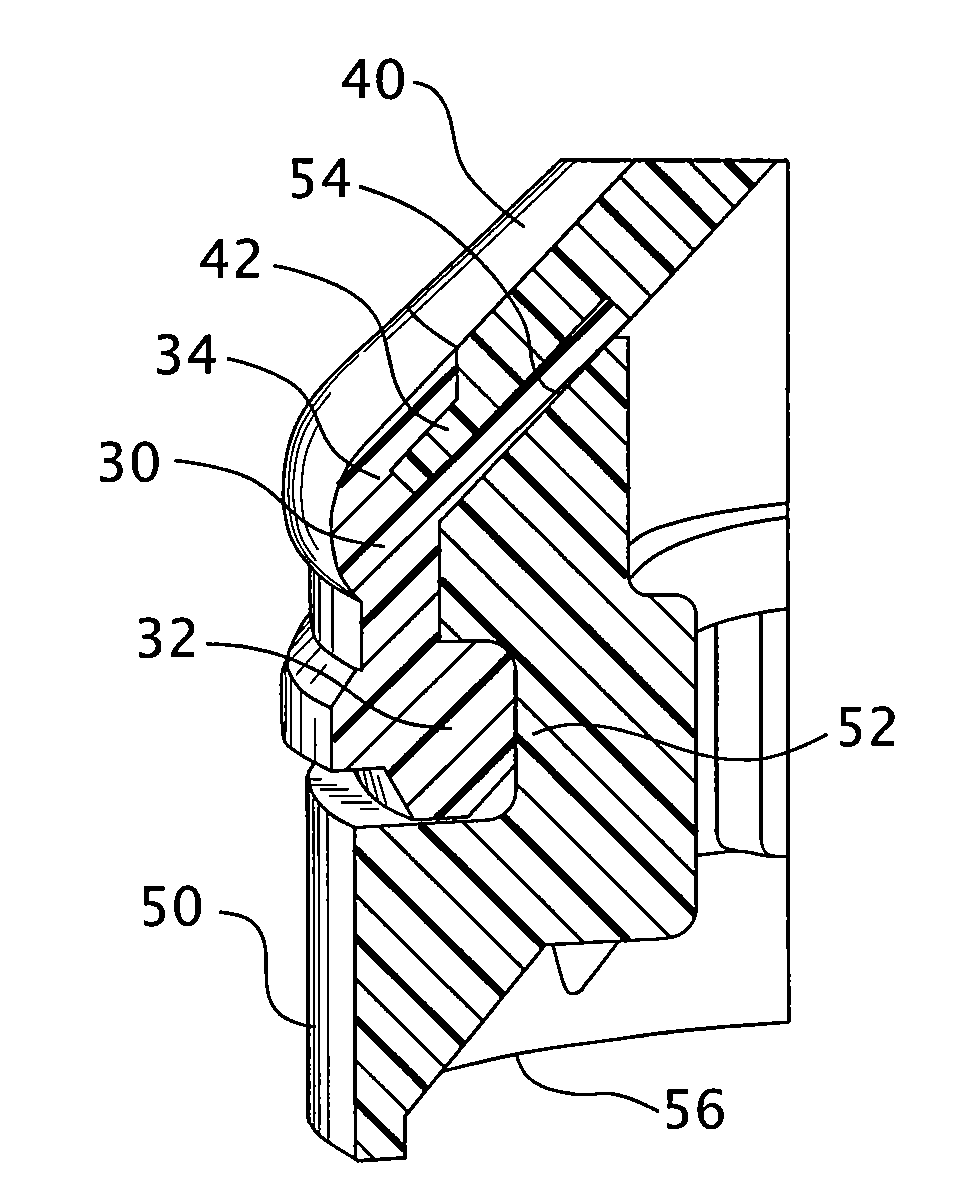

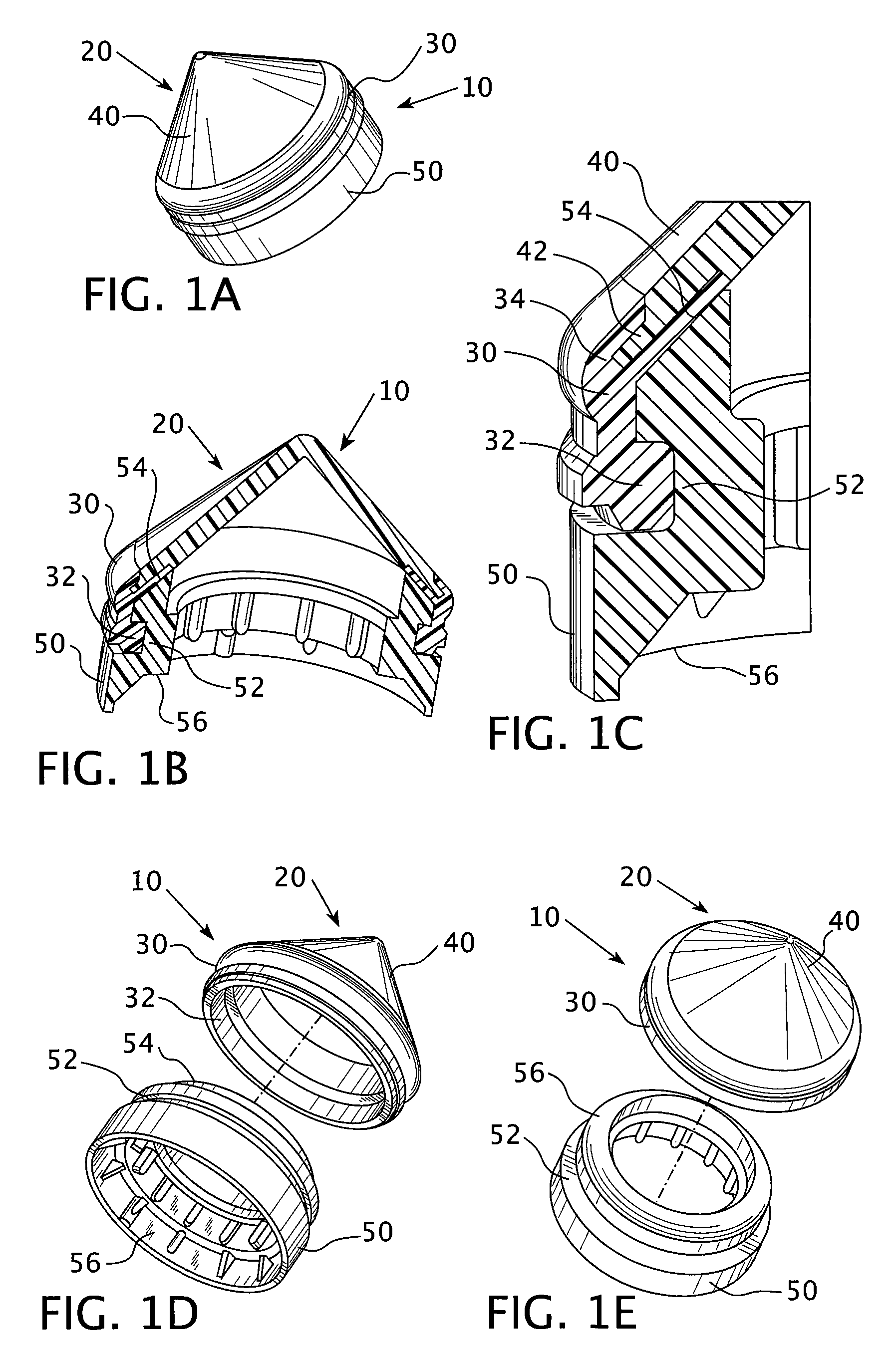

Plunger Covers and Plungers for Use in Syringes and Methods of Fabricating Plunger Covers and Plungers for Use in Syringes

A plunger cover for use with a syringe includes a sealing portion adapted to form a seal with the syringe and a central portion adapted to contact fluid within the syringe. The central portion can, for example, be more rigid than the sealing portion. The sealing portion and the central portion are connected in an overmolding process. The sealing portion can, for example, be formed from a thermoplastic elastomer or a thermoplastic polyurethane. The central portion can, for example, be formed from polypropylene, acrylonitrile butadiene styrene, polycarbonate or copolymers thereof.

Owner:BAYER HEALTHCARE LLC

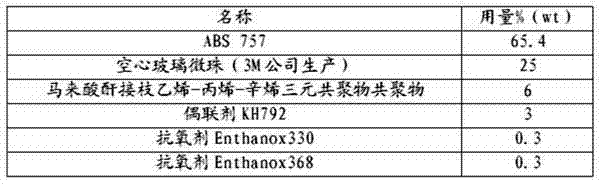

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218AExcellent surface hardnessImprove scratch resistanceGlass fiberPolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

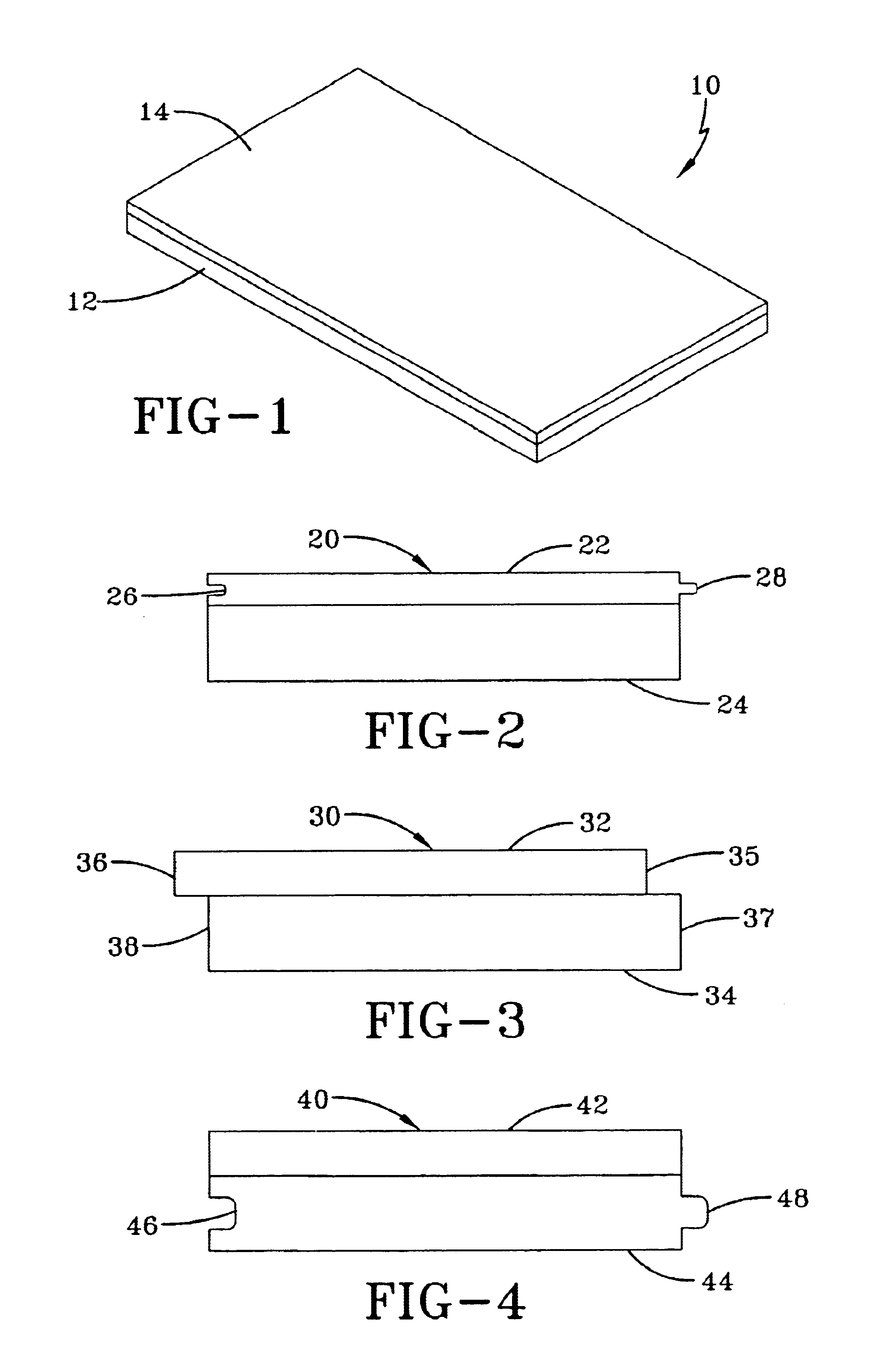

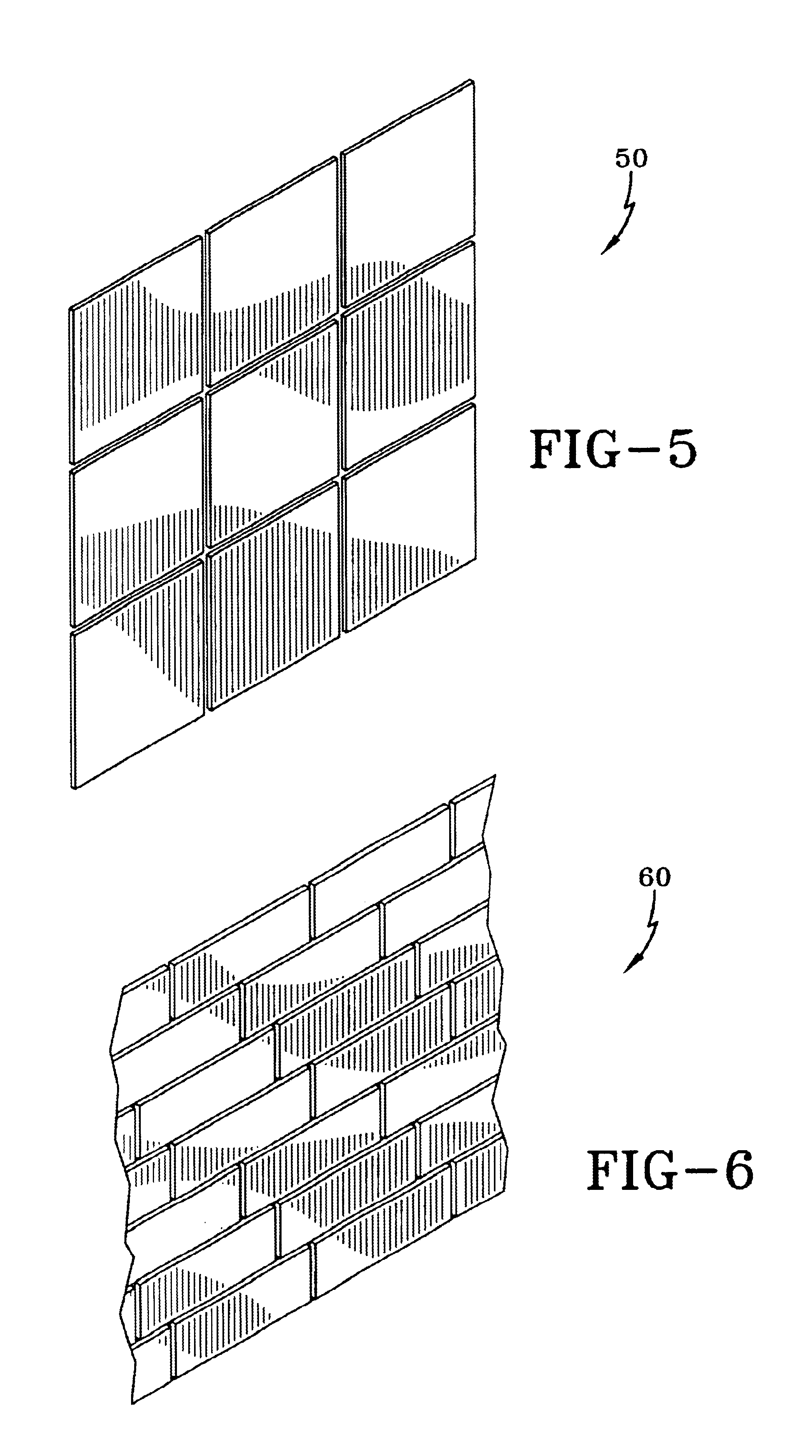

Synthetic wood component having a foamed polymer backing

InactiveUS6863972B2Superior resistance to wear and tearImprove the immunityHair accessoriesDead plant preservationLow-density polyethyleneLinear low-density polyethylene

The present invention is a component having a synthetic wood layer that is secured to a foamed polymer layer. The foamed polymer layer is comprised of a polymer selected from the group consisting of high density polyethylene, polypropylene, polyvinyl chloride, low density polyethylene, chlorinated polyvinyl chloride, acrylonitrile butadiene styrene, ethyl-vinyl acetate, and polystyrene. The component can be used for a variety of different purposes such as fencing, furniture, cabinets, storage devices, lawn edging, flower boxes, flooring, roofing, wall covering, building siding, basement flooring, basement wall covering, interior and exterior decorative house moldings, crown moldings, chair rails, picture frames, porch decks, deck railings, window moldings, window components, door components, door moldings, various other lawn and garden uses, various other below grade uses, and various other indoor and outdoor uses.

Owner:CRANE BUILDING PRODS

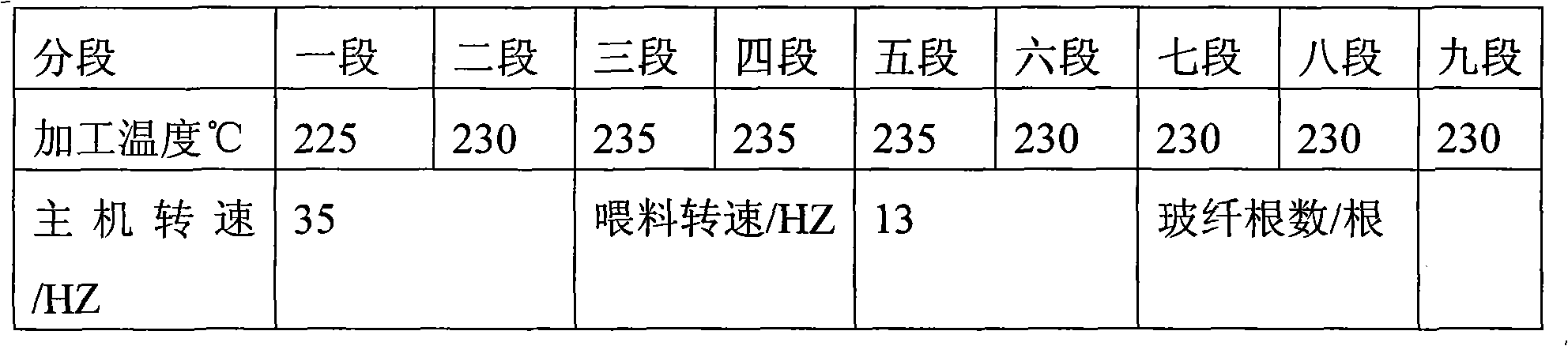

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

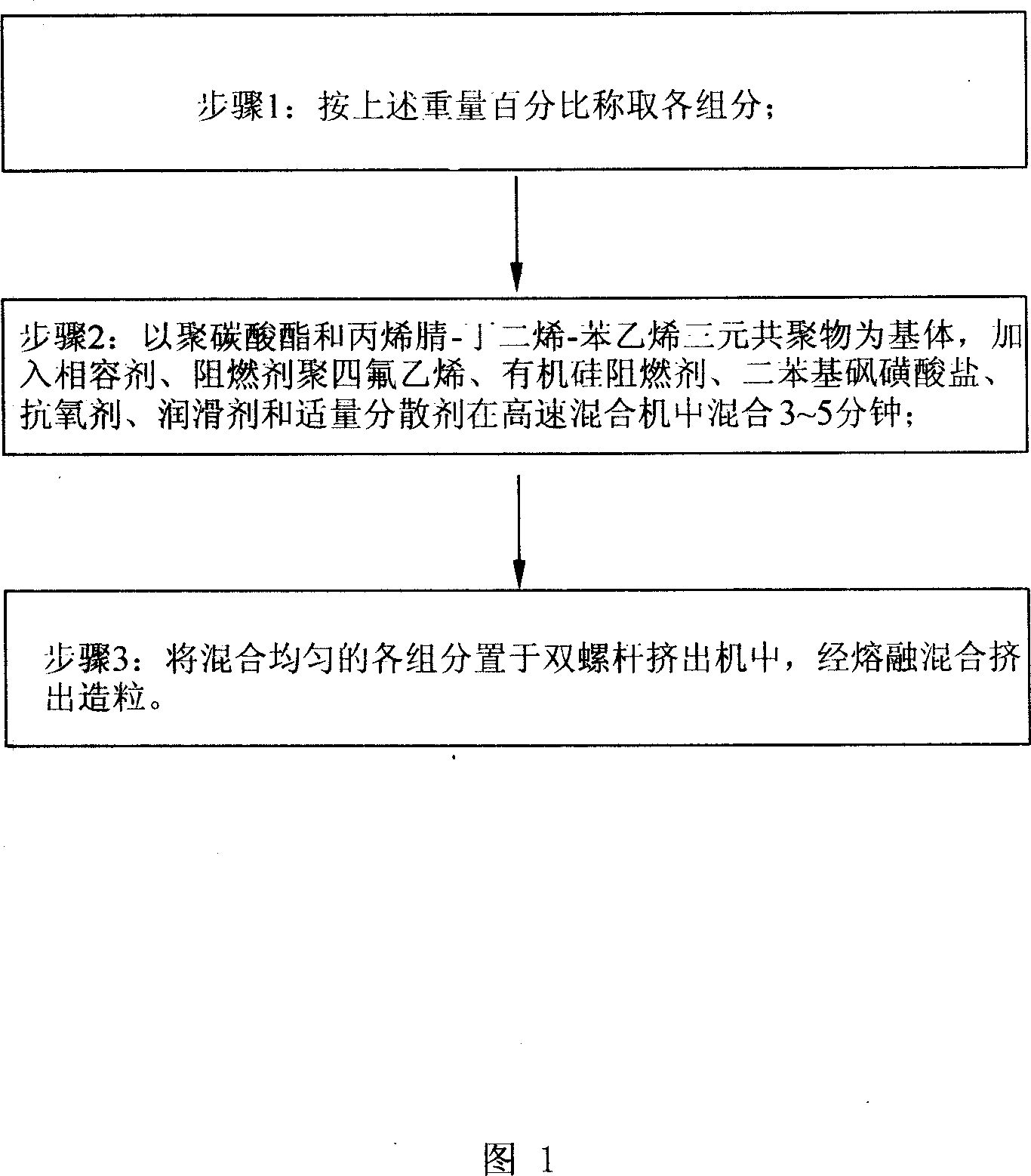

Fire retardant PC/ABS alloy material without halide and phosphate and its prepn process

The fire retardant PC / ABS alloy material without halide and phosphate consists of polycarbonate 65.5-91.2 wt%, acrylonitrile-butadiene-styrene ternary copolymer 6-17 wt%, compatilizer 1.0-4.0 wt%, fire retardant PTFE 0.3-1.5 wt%, organosilicon fire retardant 1.0-8.0 wt%, diphenyl sulfone sulfonate 0.1-1.0 wt%, antioxidant 0.1-1.0 wt% and lubricant 0.2-2.0 wt%. The present invention also provides the preparation process of the alloy material. The alloy material is environment friendly, and may be applied widely in automobile industry, electronic industry, electric industry and mechanical industry.

Owner:SHENZHEN KEJU NEW MATERIAL

Halogen-free flame retardant antistatic PC/ABS alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant antistatic PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) alloy material and a preparation method thereof, belonging to the technical field of alloy materials. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention comprises the following components in parts by weight: 1-30 parts of ABS resin, 40-90 parts of PC resin, 8-20 parts of fire retardant, 1-10 parts of flexibilizer, 0.02-0.5 part of antistatic agent, 0.1-1 part of photo-thermal stabilizing agent and 0.1-1 part of processing agent. The invention also discloses a preparation method of the halogen-free flame retardant antistatic PC / ABS alloy material, which comprises the following steps of: mixing the 1-30 parts of ABS resin, the 40-90 parts of PC resin, the 8-20 parts of fire retardant, the 1-10 parts of flexibilizer, the 0.02-0.5 part of antistatic agent, the 0.1-1 part of photo-thermal stabilizing agent and the 0.1-1 part of processing agent, and then sending to a dual-screw extruder, mixing, extruding, staying, cooling, sized-dicing and obtaining a finished product of the halogen-free flame retardant antistatic PC / ABS alloy material. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention has the advantages of simple process, continuity, high production efficiency and stable quality.

Owner:HEFEI GENIUS NEW MATERIALS

Ultrahigh heat-resistant and flame-retardant ABS (acrylonitrile butadiene styrene) composition and preparation method thereof

Owner:KINGFA SCI & TECH CO LTD +2

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Solid surface products

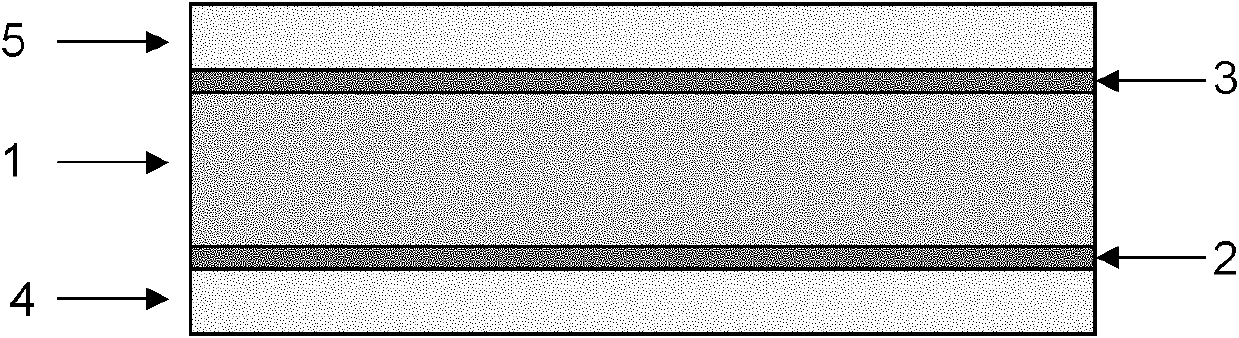

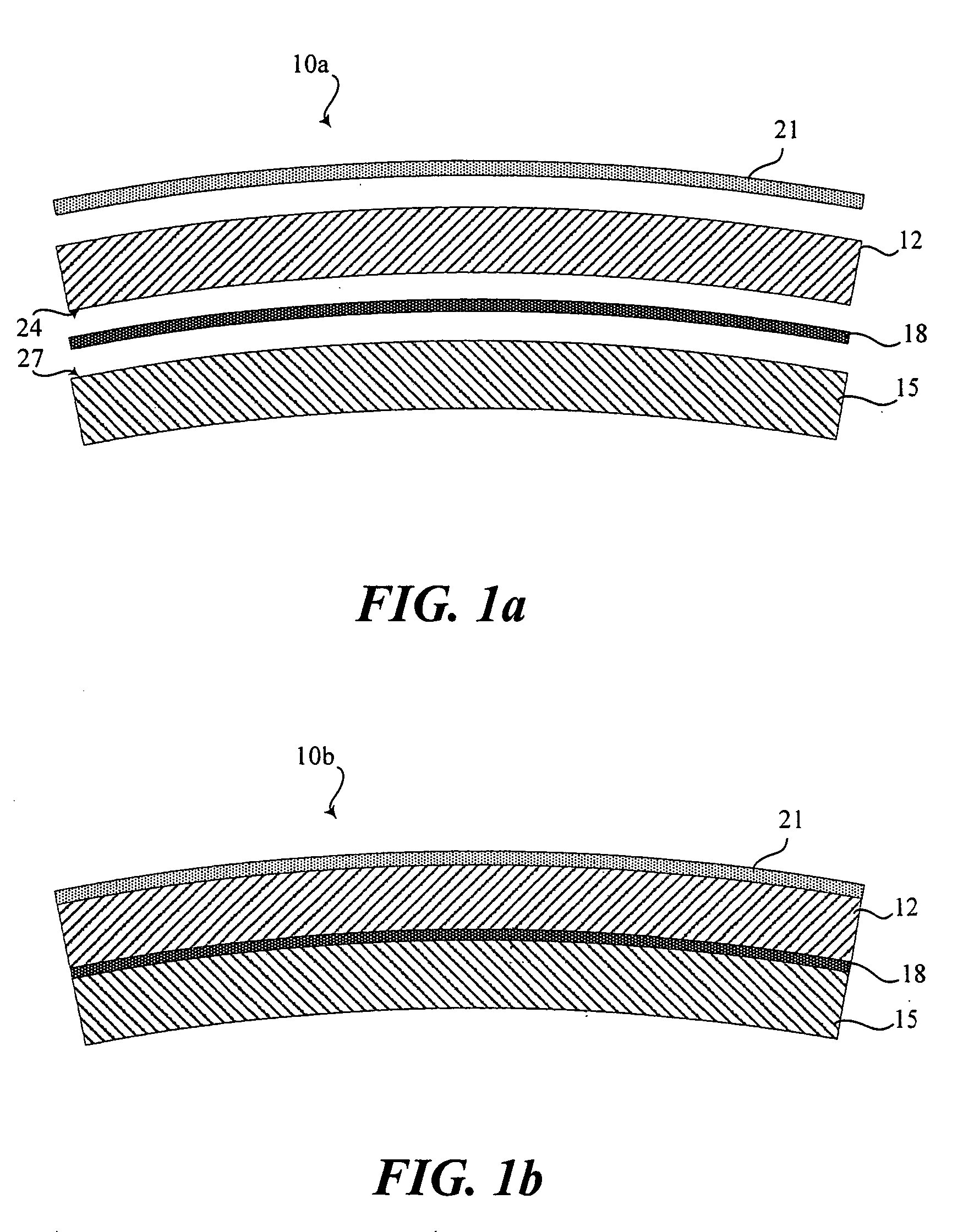

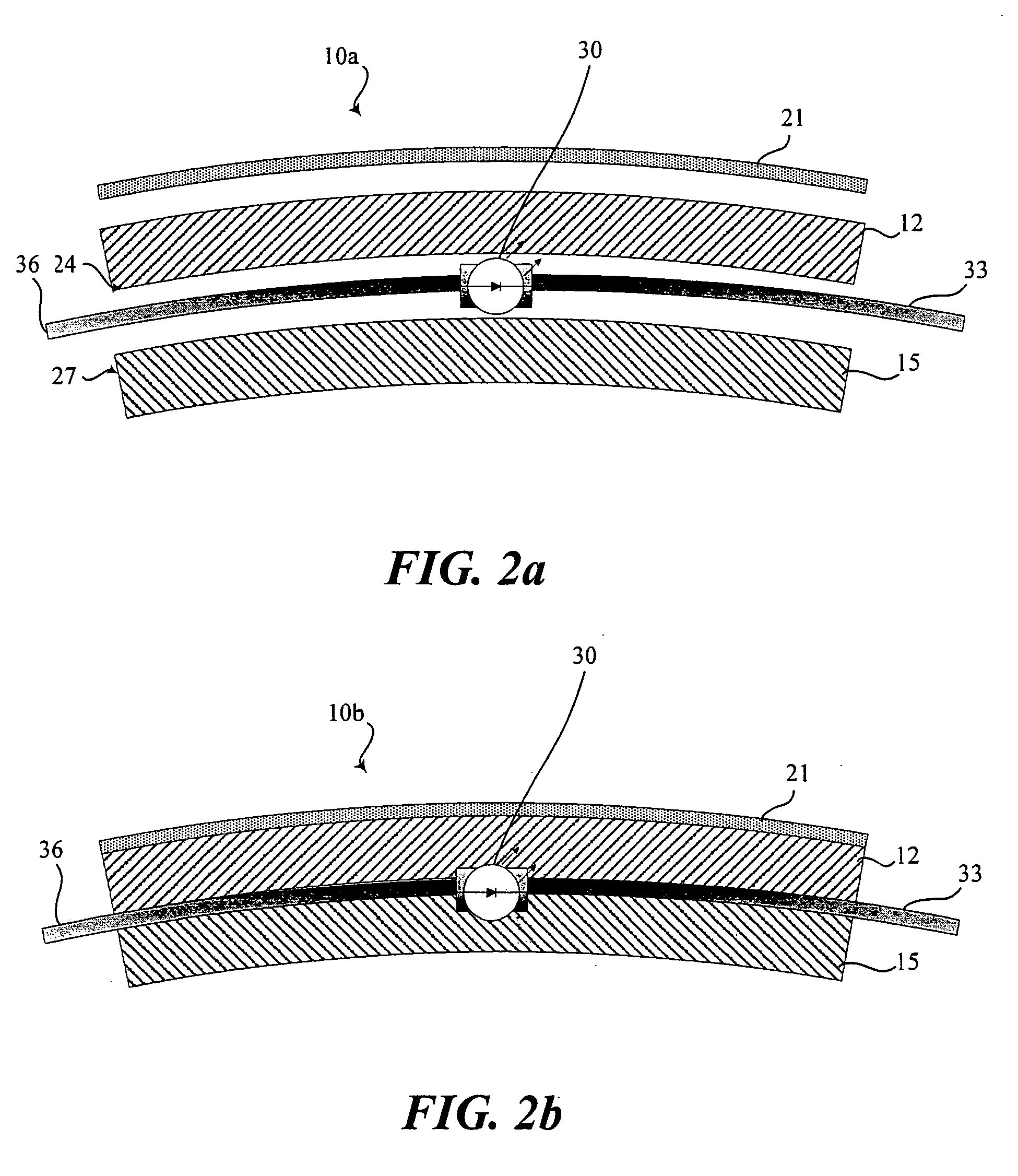

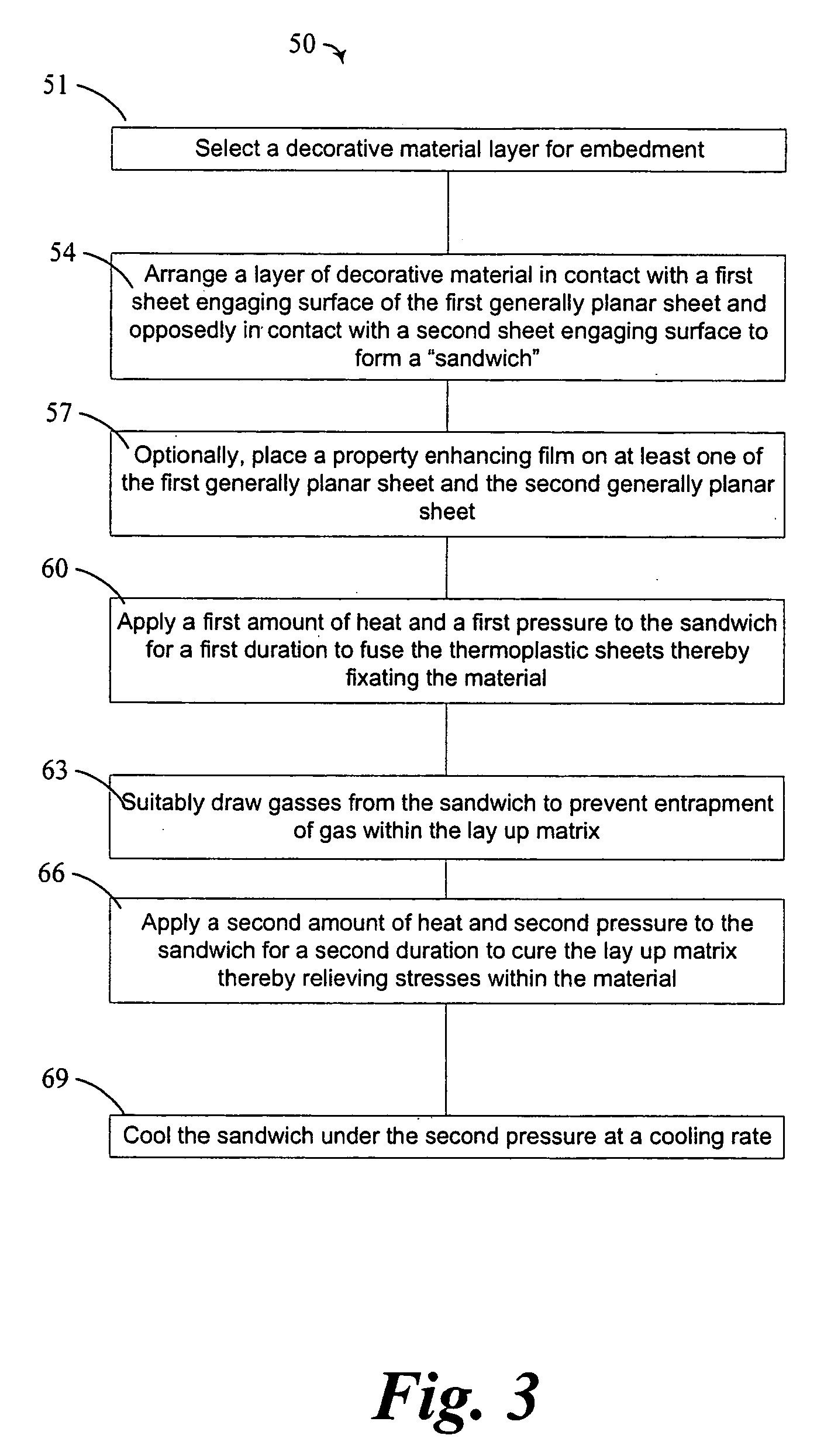

A bullet resistant, non-porous unitary solid surface structure. The structure includes a first non-porous unitary material, a decorative material, and a second non-porous unitary material. The second non-porous unitary material is fused to the first non-porous unitary material in opposed relation relative to the decorative material. The fused materials produce a bullet resistant structure. The first and second non-porous unitary materials include at least one of acrylic, cross-linked acrylic, polymethyl methacrylate, polycarbonate, polyvinyl chloride, polyethylene, polypropylene, polyester, nylon, polyurethane, polystyrene, fluoropolymers, acrylonitrile-butadiene-styrene, polylactic acid, and cellulosics.

Owner:LUMICOR

Phosphate flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy and preparation method thereof

The invention belongs to the technical field of high-polymer alloy materials, and relates to a phosphate flame-retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy and a preparation method thereof. The alloy material is prepared from the following components in parts by weight: 55-75 parts of PC resin, 25-45 parts of ABS resin, 2-10 parts of compatilizer, 2-10 parts of toughening agent, 10-20 parts of flame retardant, 2-10 parts of inorganic filler, 0.1-0.5 part of antioxidant, 0.2-1.0 part of lubricant and 0.2-1.0 part of anti-dripping agent. The compatilizer, toughening agent and inorganic filler are utilized to enhance the interfacial binding force between the PC resin and ABS resin and the mechanical properties of the PC / ABS alloy. Besides, the nano silicon dioxide and other inorganic fillers added into the PC / ABS alloy can effectively perform the synergic flame-retardant function; and the anti-dripping agent in the formula can effectively inhibit the melt from dripping in the alloy material combustion process, thereby enhancing the flame retardancy of the material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

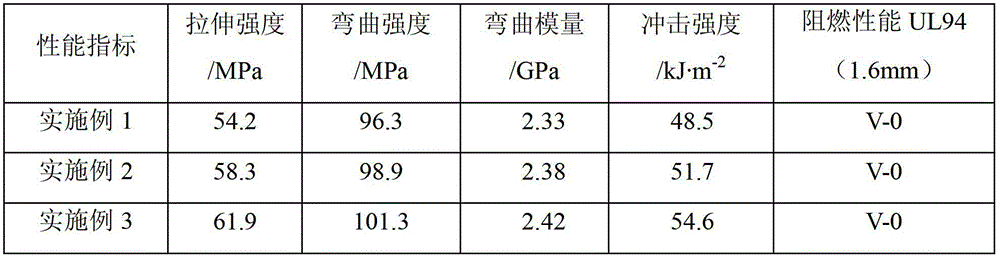

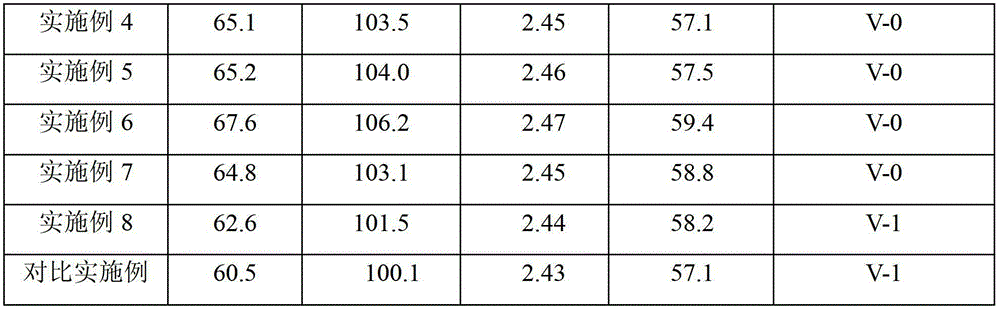

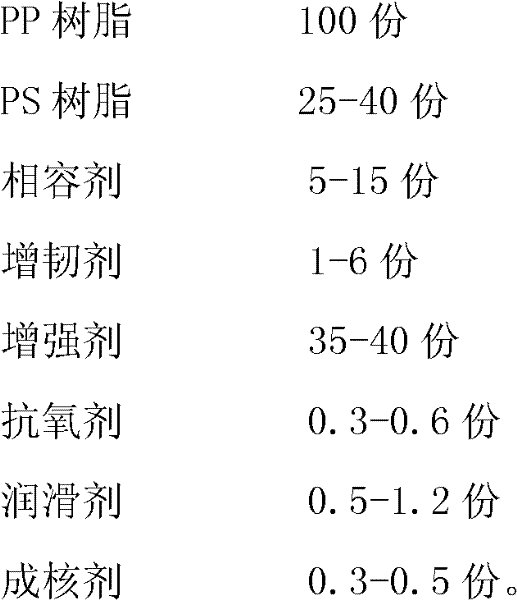

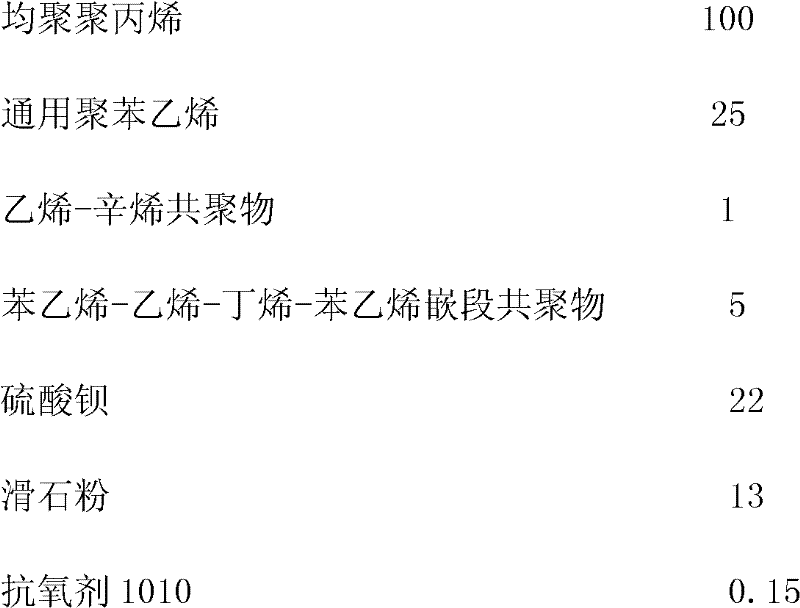

Modified polypropylene composite material of high gloss and low shrinkage and preparation method thereof

The invention discloses a modified polypropylene composite material of high gloss and low shrinkage and a preparation method thereof. The polypropylene composite material includes the raw materials of by weight: 100 parts of PP (polypropylene) resin, 25-40 parts of PS (polystyrene) resin, 5-15 parts of a compatilizer, 1-6 parts of a flexibilizer, 35-40 parts of a reinforcing agent, 0.3-0.6 parts of an anti-oxidant, 0.5-1.2 parts of a lubricant and 0.3-0.5 parts of a nucleating agent. The preparation method comprises the steps of: mixing the PP resin, the PS resin, the compatilizer, the flexibilizer, the anti-oxidant, the lubricant and the nucleating agent uniformly at a high speed, then adding the reinforcing agent into the mixture and continuing high-speed mixing, adding the obtained mixture into an extruder, conducting extrusion granulation after fusion, thus obtaining the composite material. The modified polypropylene composite material prepared by the method provided in the invention has the characteristics of high gloss and low shrinkage as well as the advantages of good impact strength and high flexural modulus. And the composite material of the invention can be used for material replacement under the precondition of not replacing the original ABS (acrylonitrile butadiene styrene) die and for production of household electrical appliance surface shell products.

Owner:ORINKO NEW MATERIAL CO LTD

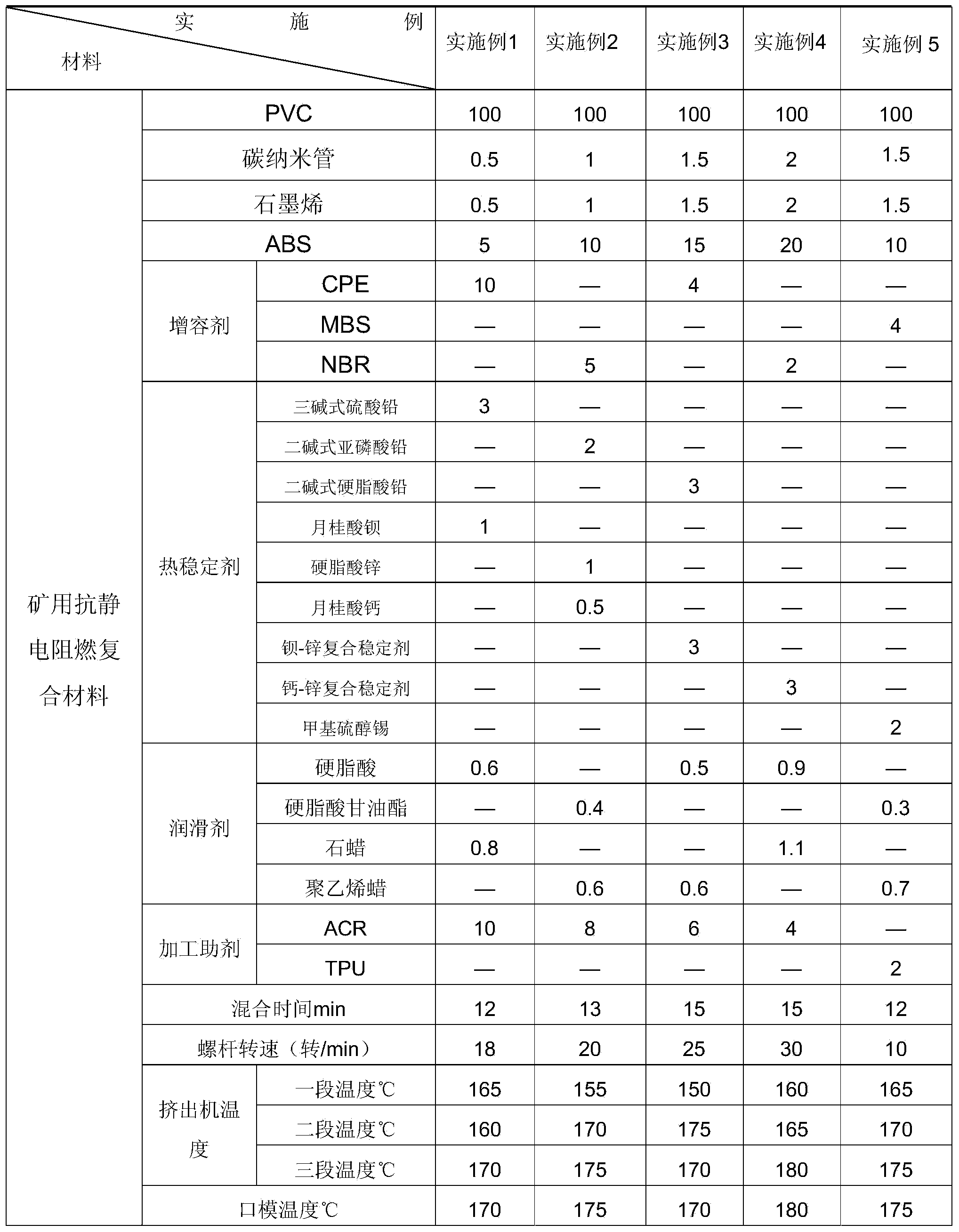

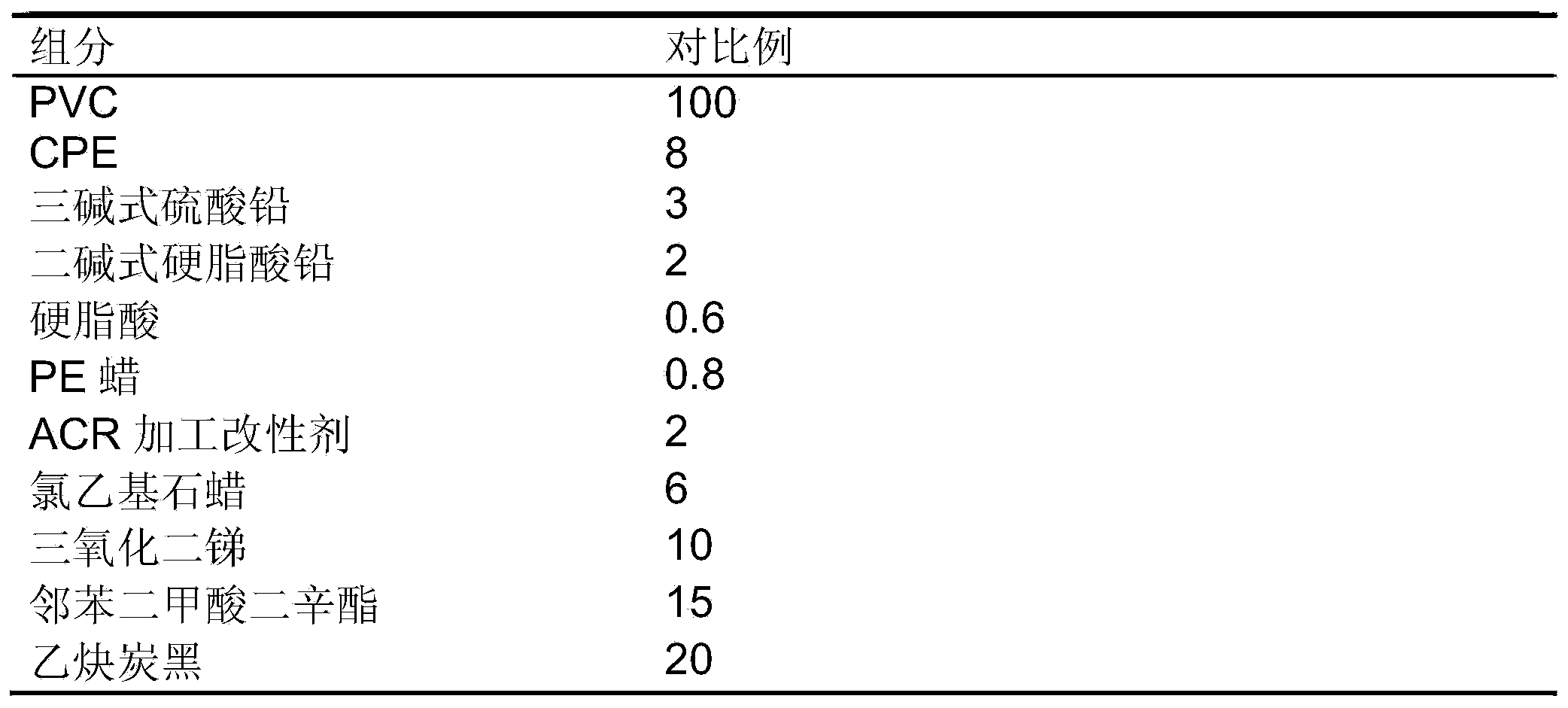

Antistatic flame-retardant composite material for coal mines and preparation method of antistatic flame-retardant composite material

ActiveCN104292699AGood anti-static and flame-resistant propertiesDoes not affect processing fluidityPolyvinyl chlorideCarbon nanotube

The invention discloses an antistatic flame-retardant composite material for coal mines and a preparation method of the antistatic flame-retardant composite material. The antistatic flame-retardant composite material comprises the following components in parts by weight: 100 parts of polyvinyl chloride (PVC) resin, 5-20 parts of acrylonitrile-butadiene-styrene copolymer (ABS), 2-10 parts of compatibilizer, 0.5-2 parts of carbon nano-tubes, 0.5-2 parts of graphene, 2-6 parts of thermal stabilizer, 1-2 parts of lubricant and 2-10 parts of processing aid. The preparation method comprises the following steps: preparing a conducting filler / PVC composite powder material from a mixture of the carbon nano-tubes and the graphene and part of the PVC resin in proportion; performing high-speed mixing on the obtained conducting filler / PVC composite powder material, the residual PVC resin, the ABS, the compatibilizer, the thermal stabilizer, the lubricant and the processing aid to obtain a compound; and putting the mixed compound into a conical twin-screw extruder, setting temperature section by section, and pelleting by extruding, thereby obtaining the antistatic flame-retardant composite material for the coal mines. The prepared PVC composite material has relatively high mechanical properties, excellent antistatic property and flame retardance, is a high-polymer composite material with good processibility, and can be used underground in the coal mines.

Owner:SHAANXI COAL & CHEM TECH INST

Halogen-free flame-retardant acrylonitrile butadiene styrene (ABS)/polycarbonate (PC) alloy material for electrical engineering and preparation method thereof

InactiveCN102190854AMeet safety and environmental protection requirementsGood value for moneyAntioxidantPhosphate

The invention relates to a halogen-free flame-retardant acrylonitrile butadiene styrene (ABS) / polycarbonate (PC) alloy material for electrical engineering and a preparation method thereof. The halogen-free flame-retardant ABS / PC alloy material for electrical engineering comprises the following components in part by weight: 55 to 63 parts of ABS, 21 to 34 parts of PC, 2 to 7 parts of maleic anhydride grafted ABS compatilizer, 7 to 15 parts of organic phosphate flame retardant, 0.1 to 0.5 part of anti-dripping agent FA500B, 1.0 to 3.0 parts of organic silicon Dymgard and 0.2 to 0.5 part of composite antioxidant. In the preparation method, the halogen-free flame-retardant ABS / PC alloy material for electrical engineering is prepared by mixing, plastifying, extruding and pelleting at one step by using a double-single-screw double-step extruder. The comprehensive properties of the product can meet shell performance requirements of storage batteries special for subway engineering, electric locomotives and mobile stations.

Owner:HUNAN KEOCT MATERIALS

High-temperature water-in-oil drilling fluid

InactiveCN102031095AOvercoming the problem of insufficient temperature resistanceMeet the requirements of temperature resistanceDrilling compositionMineral oilSODIUM DODECYL BENZENE SULFONATE

The invention relates to a high-temperature water-in-oil drilling fluid which is composed of the following components in parts by weight: 70-90 parts of base oil, 3-7 parts of organic bentonite, 2-5 parts of oxidized asphalt, 2-5 parts of sulfonated gilsonite, 20-60 parts of CaCl2 aqueous solution of which the mass concentration is 20%, 6-10 parts of calcium oxide, 1.5-5.5 parts of UZEMUL-S, 2-5 parts of ABS (acrylonitrile butadiene styrene) and barite, wherein the base oil is non-blooming mineral oil with low aromatic hydrocarbon; the UZEMUL-S is a main emulsifier, the HLB (hydrophile-lipophile balance) value is 2.5, and the UZEMUL-S is formed by synthetizing an organic acid and an organic acid amide; and the ABS auxiliary emulsifier is sodium dodecyl benzene sulfonate, and the HLB value is 10. The invention resists temperature of 240 DEG C, can overcome the difficulty of insufficient heat-resistant capability of the existing drilling fluid and is favourable for satisfying the requirement of drilling fluid heat-resistant capability for deep wells and ultra deep wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of antistatic glass fiber reinforced abs composite material

InactiveCN102276955AImprove antistatic performanceHigh mechanical strengthGlass fiberAntistatic agent

The invention relates to an antistatic glass fiber reinforcement ABS (acrylonitrile butadiene styrene) composite material and a preparation method thereof. In the invention, a reinforcing agent, an interface coupling agent and a toughening agent are added into ABS; an inorganic antistatic agent is matched with an organic antistatic agent; and in the existence of a dispersing lubricant and a thermal oxidative stabilizer, raw materials are mixed and extruded by a double-screw extruder so as to obtain the antistatic glass fiber reinforcement ABS composite material. The antistatic glass fiber reinforcement ABS composite material has a durable antistatic effect and excellent mechanical strength, is easy for flow processing, keeps the appearance of a product smooth, and can be used for manufacturing a paper transfer mechanism of an office machine and an IC chip bracket.

Owner:余姚市中发工程塑料有限公司

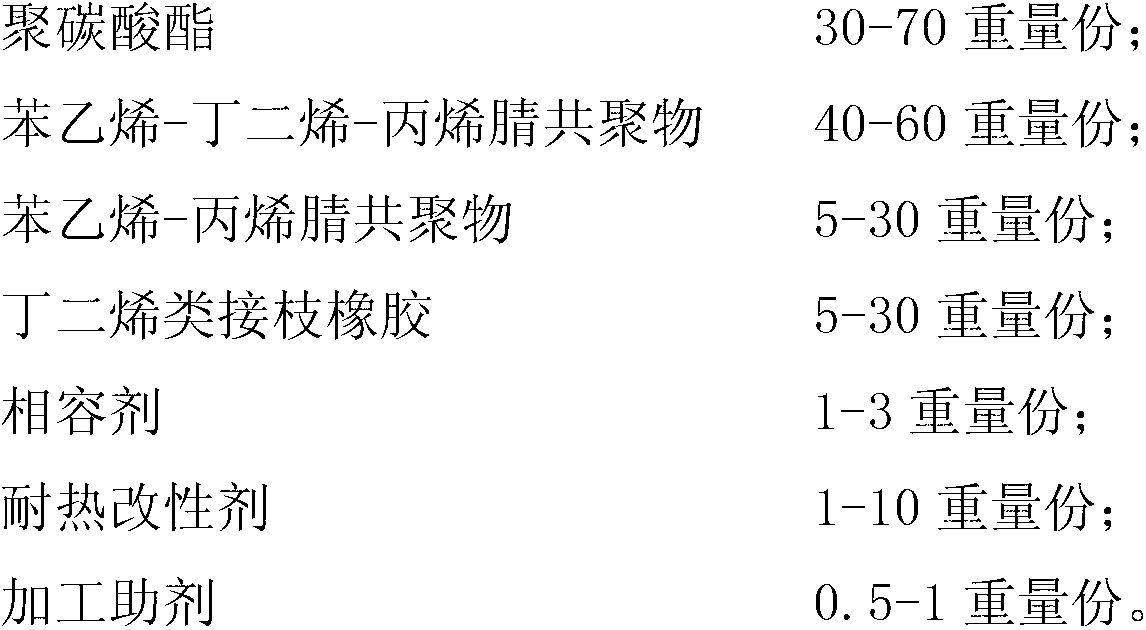

Electroplating PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

The invention provides an electroplating PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material and a preparation method thereof. The electroplating PC / ABS alloy material comprises the following components in parts by weight: 30-70 parts of PC, 40-60 parts of ABS, 5-30 parts of styrene-acrylonitrile copolymer, 5-30 parts of butadiene graft rubber, 1-3 parts of compatilizer, 1-10 parts of heat-resistance modifier and 0.5-1 part of processing assistant. The alloy material provided by the invention has the advantages of favorable electroplating properties, excellent mechanical properties and favorable heat resistance, and can be used for designing automobile internal and external ornaments, including heat dissipation grids, door grips, vehicle logos, instrument panel decorating strips and the like.

Owner:中广核俊尔(上海)新材料有限公司

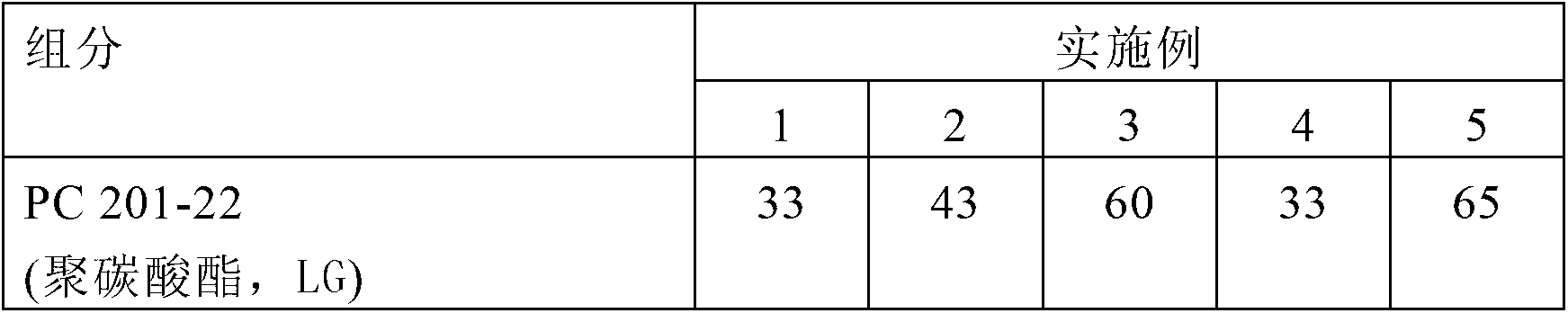

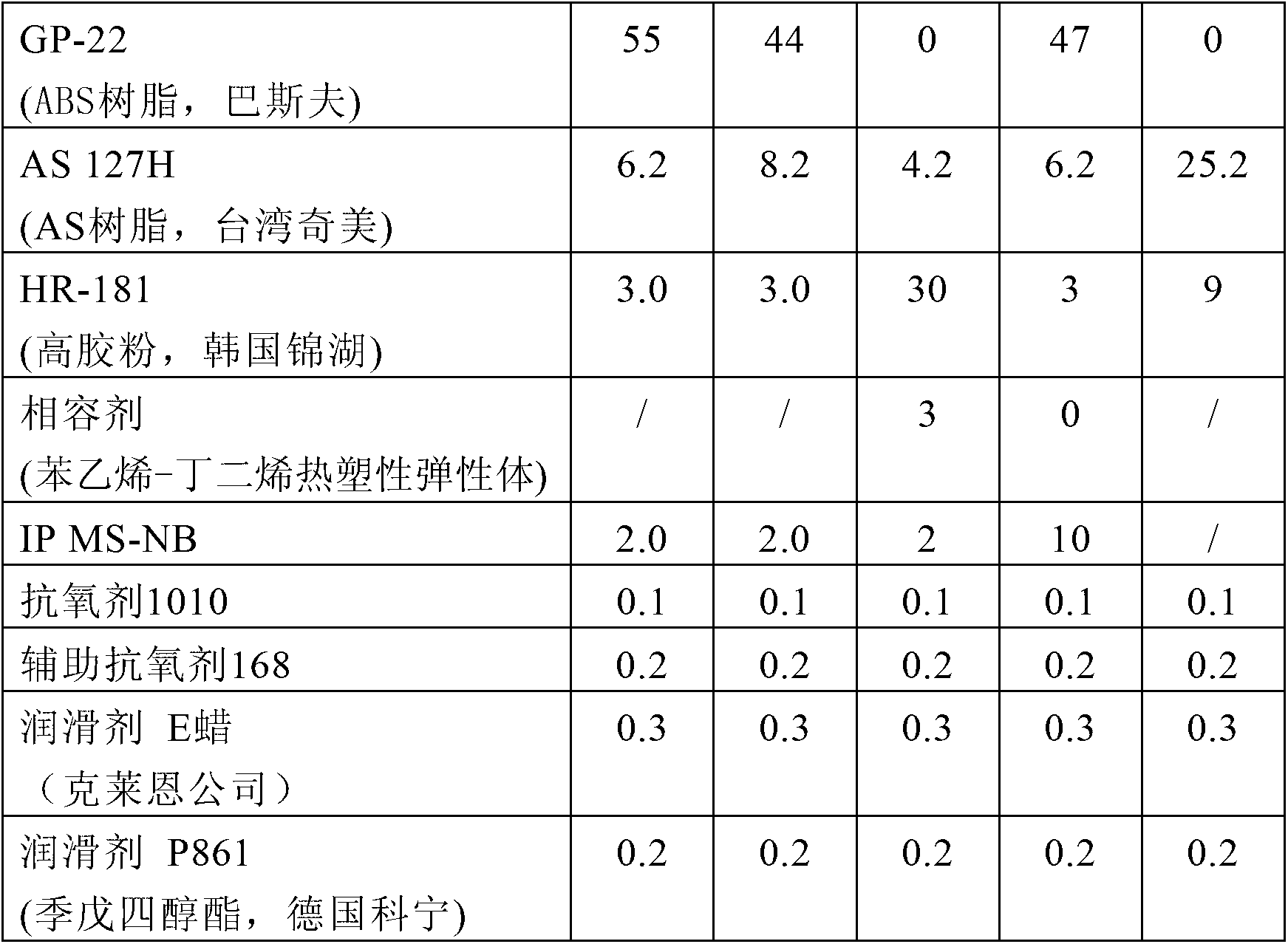

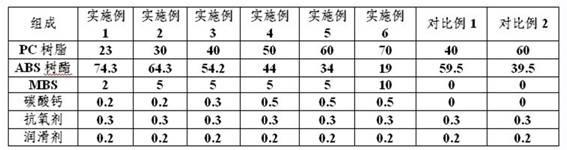

Platable polycarbonate/acrylonitrile-butadiene-styrene alloy material with high heat resistance and impact resistance

The invention relates to a platable polycarbonate / acrylonitrile-butadiene-styrene (PC / ABS) alloy material with high heat resistance and impact resistance. The alloy material comprises the following raw materials by weight percent: 20%-70% of PC (polycarbonate), 20%-75% of ABS (Acrylonitrile Butadiene Styrene), 2%-10% of butadiene type graft rubber, 0.2%-0.5% of calcium carbonate, 0%-1% of antioxidant and 0%-1% of lubricant. As butadiene type graft rubber MBS and calcium carbonate used as inorganic filler are added in the raw material formula of the PC / ABS alloy material, the electroplating performance of the material can be effectively increased while the material still has excellent mechanical properties, heat resistance and processability; and the material is easy to fill the large mould and can be used in the electroplating products in the vehicle and home appliance fields with higher heat resistant demands.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

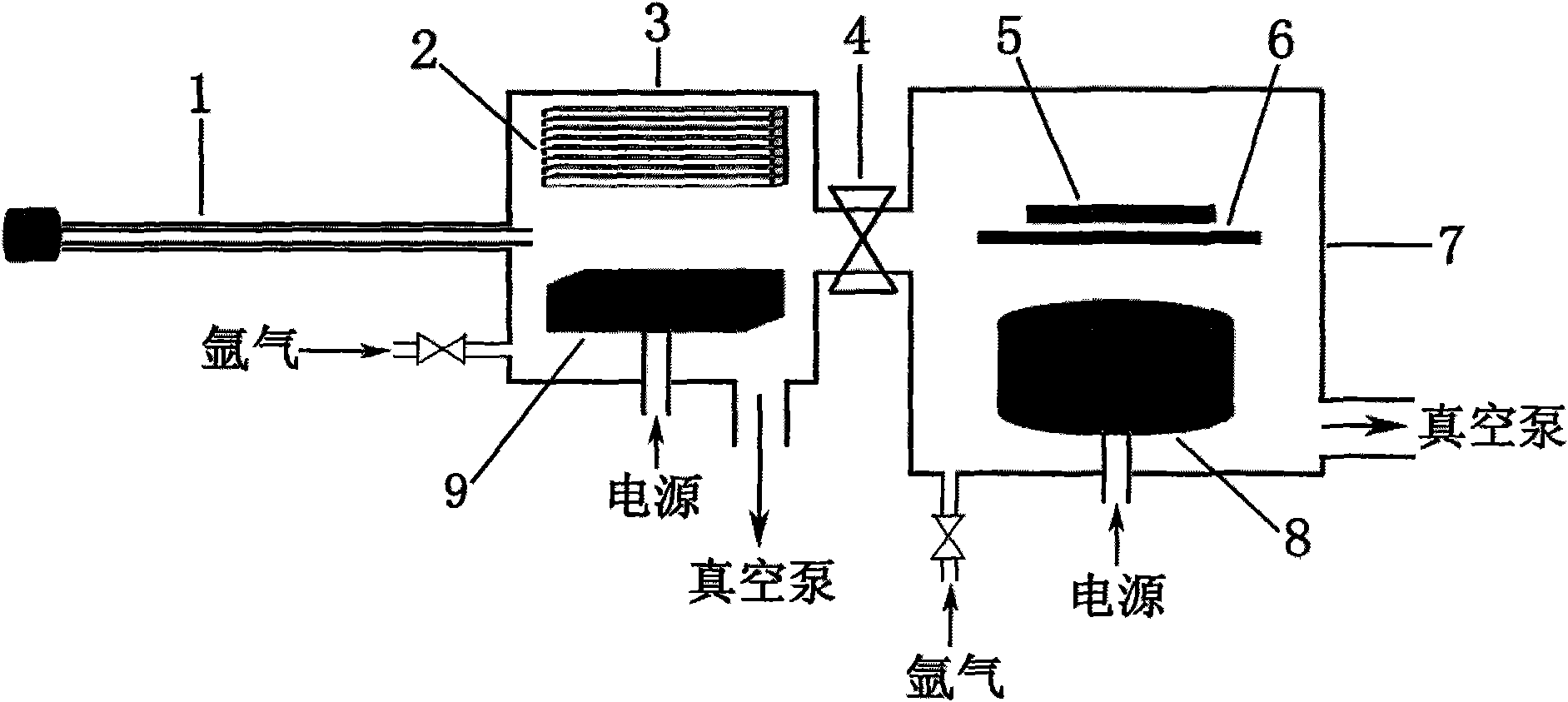

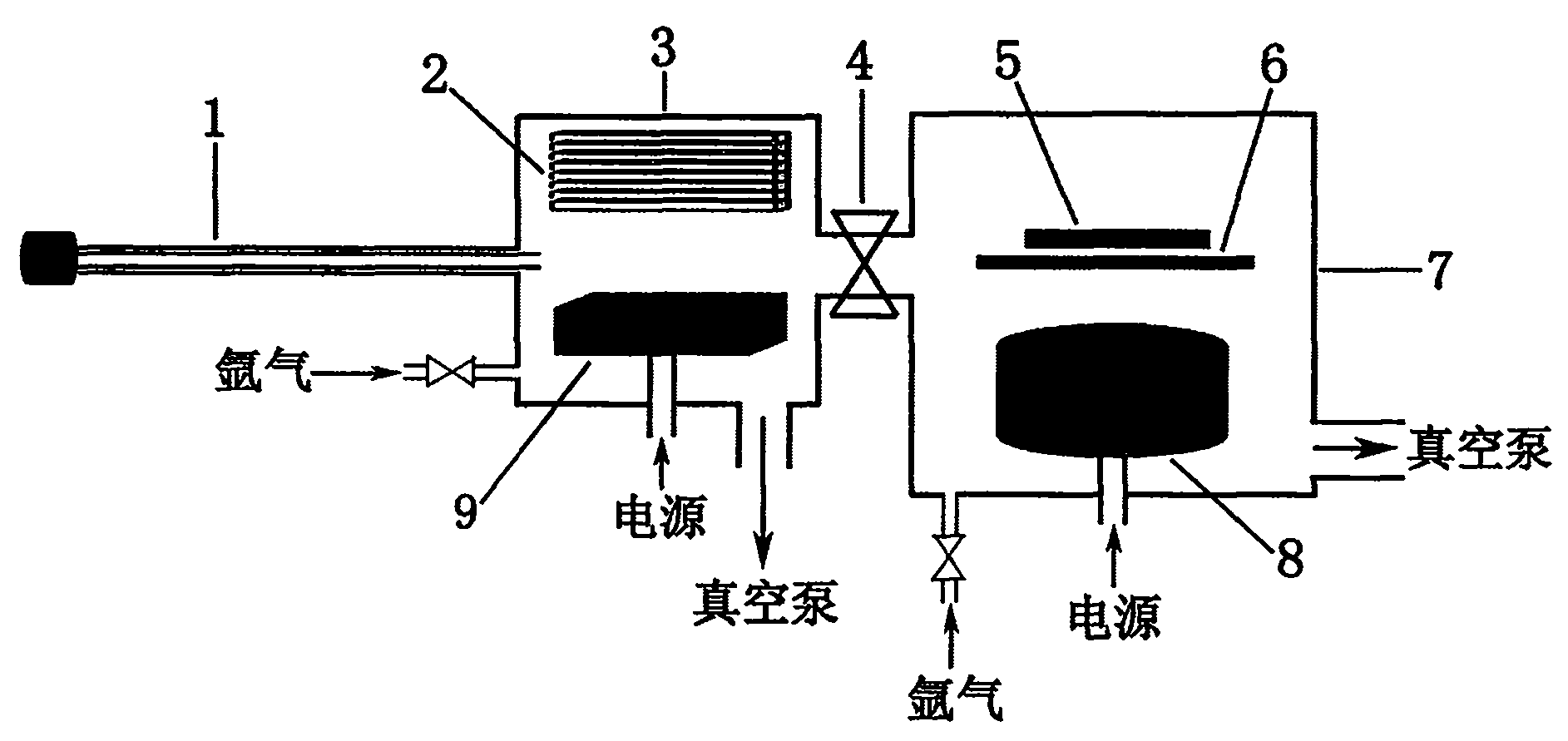

Method for depositing metal or hard ornament film on plastic substrate

InactiveCN101985738AImprove bindingAvoid strippingVacuum evaporation coatingSputtering coatingIridiumRadio frequency magnetron sputtering

The invention relates to a method for depositing a metal or hard ornament film on a plastic substrate. In the method, the metal or hard ornament film is prepared on the surface of a plastic substrate material by using a radio frequency magnetron sputtering technology, and good binding force exists between the prepared ornament film and the substrate. The plastic substrate material comprises ABS plastic (terpolymer of acrylonitrile-butadiene-styrene), PMMA (polymethyl methacrylate) organic glass, PE (poly ethylene) plastics, PP (polypropylene) plastics and the like. The metal ornament film comprises chromium, nickel, titanium, aluminum, aurum, silver, iridium or alloys and the like, and the hard ornament film comprises metal nitrides, carbon compounds, oxides, diamonds and the like. The method has the advantages of simple operation, no pollution and low cost, and the prepared film is good in adhesive force.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

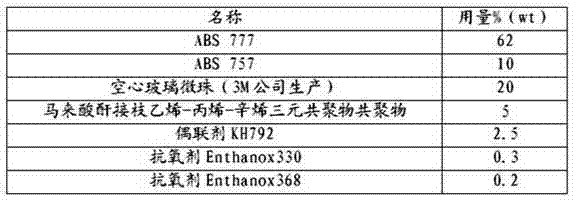

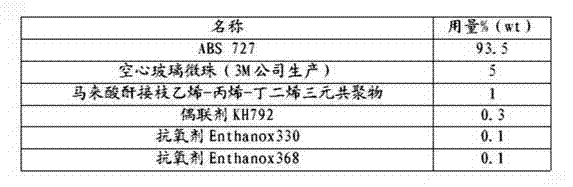

Lightweight noise-reduction modified ABS (Acrylonitrile Butadiene Styrene) material and preparation method thereof

The invention relates to a lightweight noise-reductio modified ABS (Acrylonitrile Butadiene Styrene) material which comprises the following raw materials in percentage by weight: 39-93.5% of ABS resin, 5-45% of inorganic filler, 1-10% of dispersing agent, 0.3-5% of coupling agent and 0.2-1% of antioxygen, wherein the inorganic filler is a hollow inorganic particle. Since the hollow inorganic particle is added to the formula of the material, the low density of the material is maintained while the mechanical property of the material is improved; meanwhile, the material is endowed with a certainnoise reduction function because of the special hollow particle structure, therefore, the material has a very high application value in lightweight automobile manufacture, damping and noise reductionand the like. The lightweight noise-reduction modified ABS material is prepared by the step of processing the inorganic filler fed into a screw extruder respectively from multiple lateral feeding ports arranged at different positions, so that the hollow structure of the inorganic filler is not damaged when the inorganic filler is melt and extruded, the inorganic filler can be dispersed more evenly in a substrate, and the prepared material is endowed with better properties.

Owner:辽宁金发科技有限公司

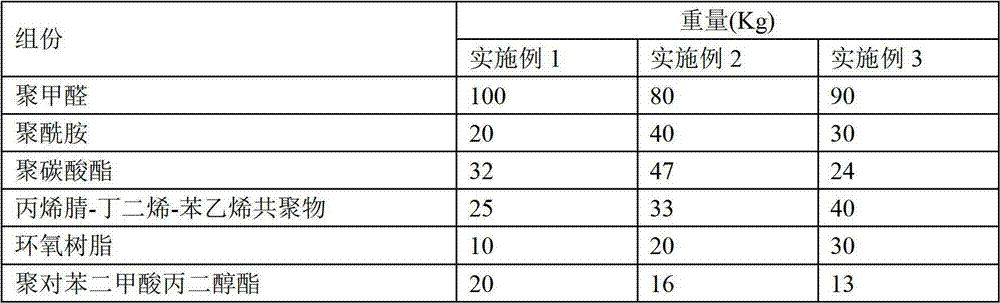

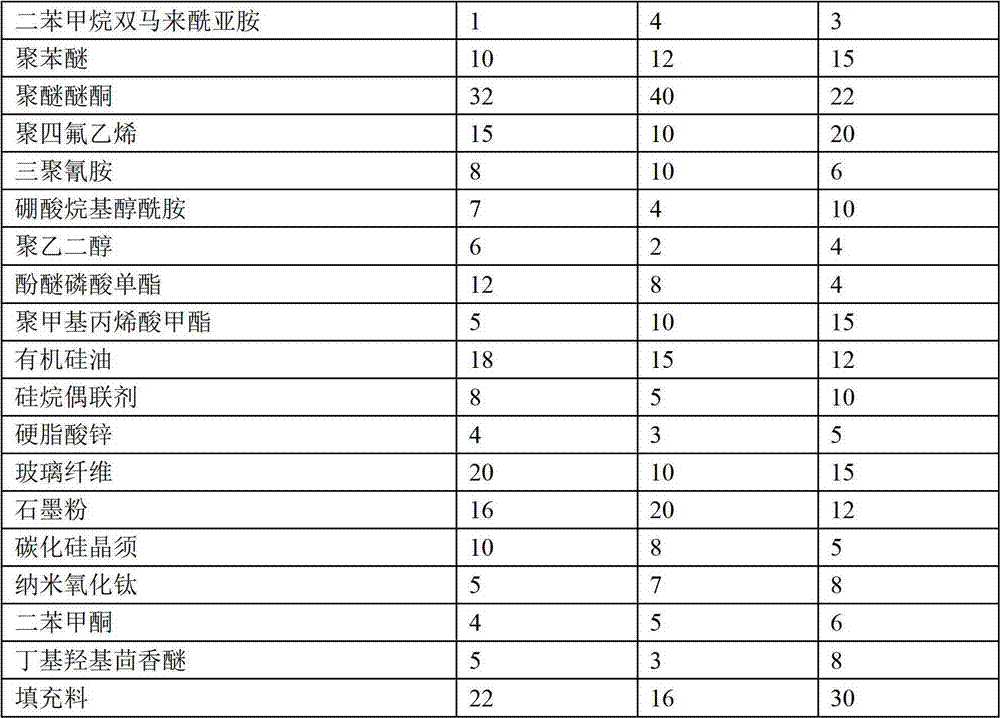

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

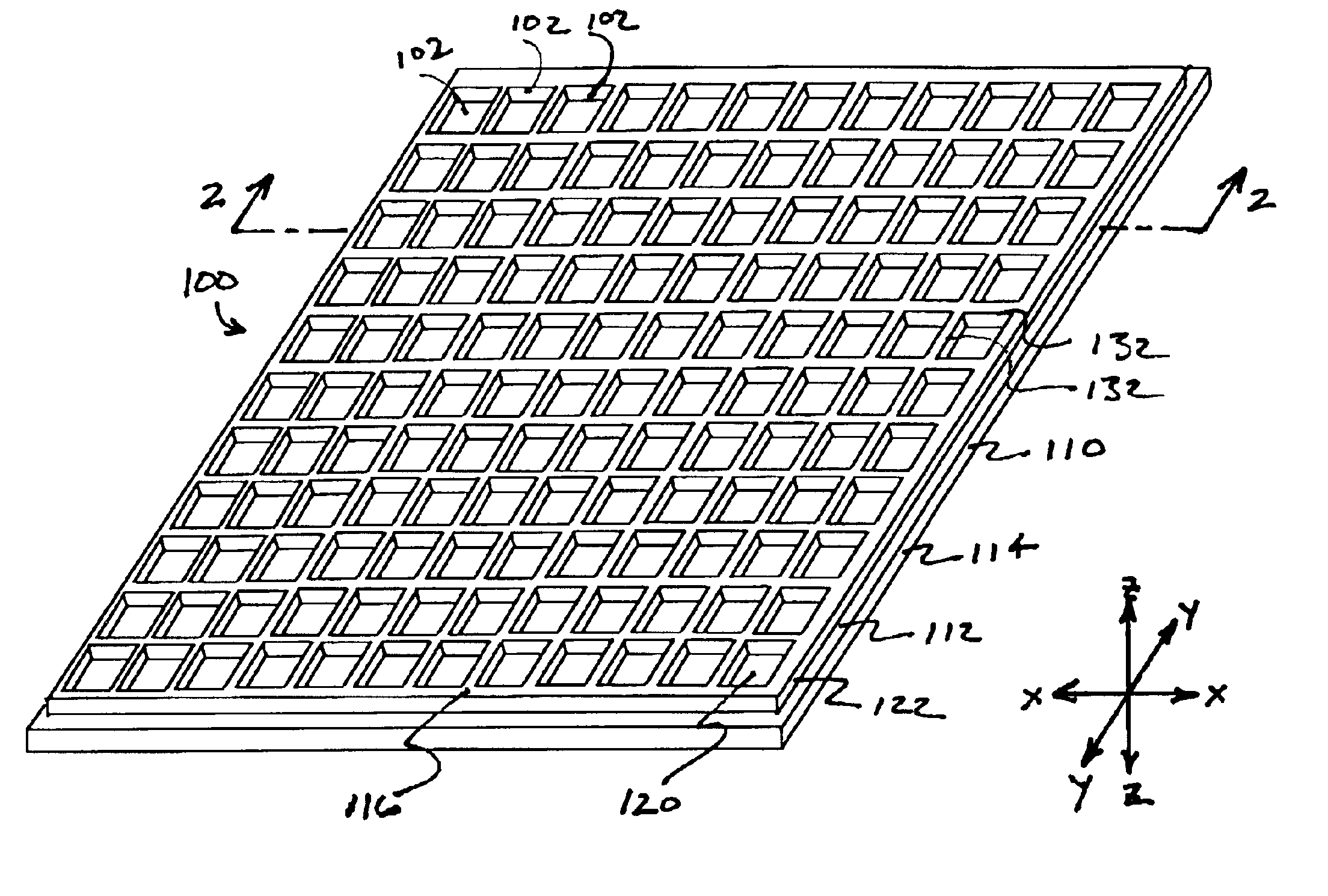

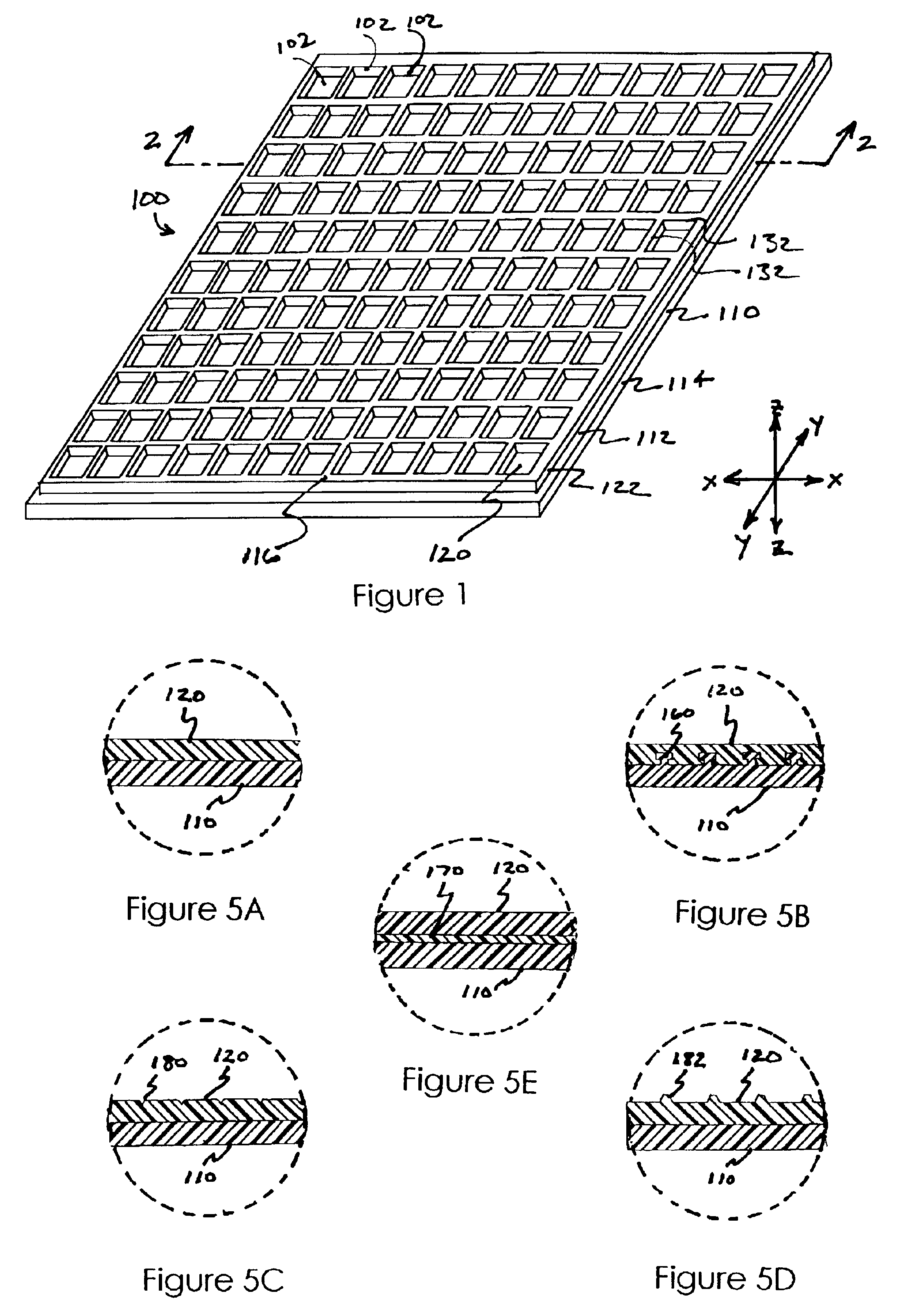

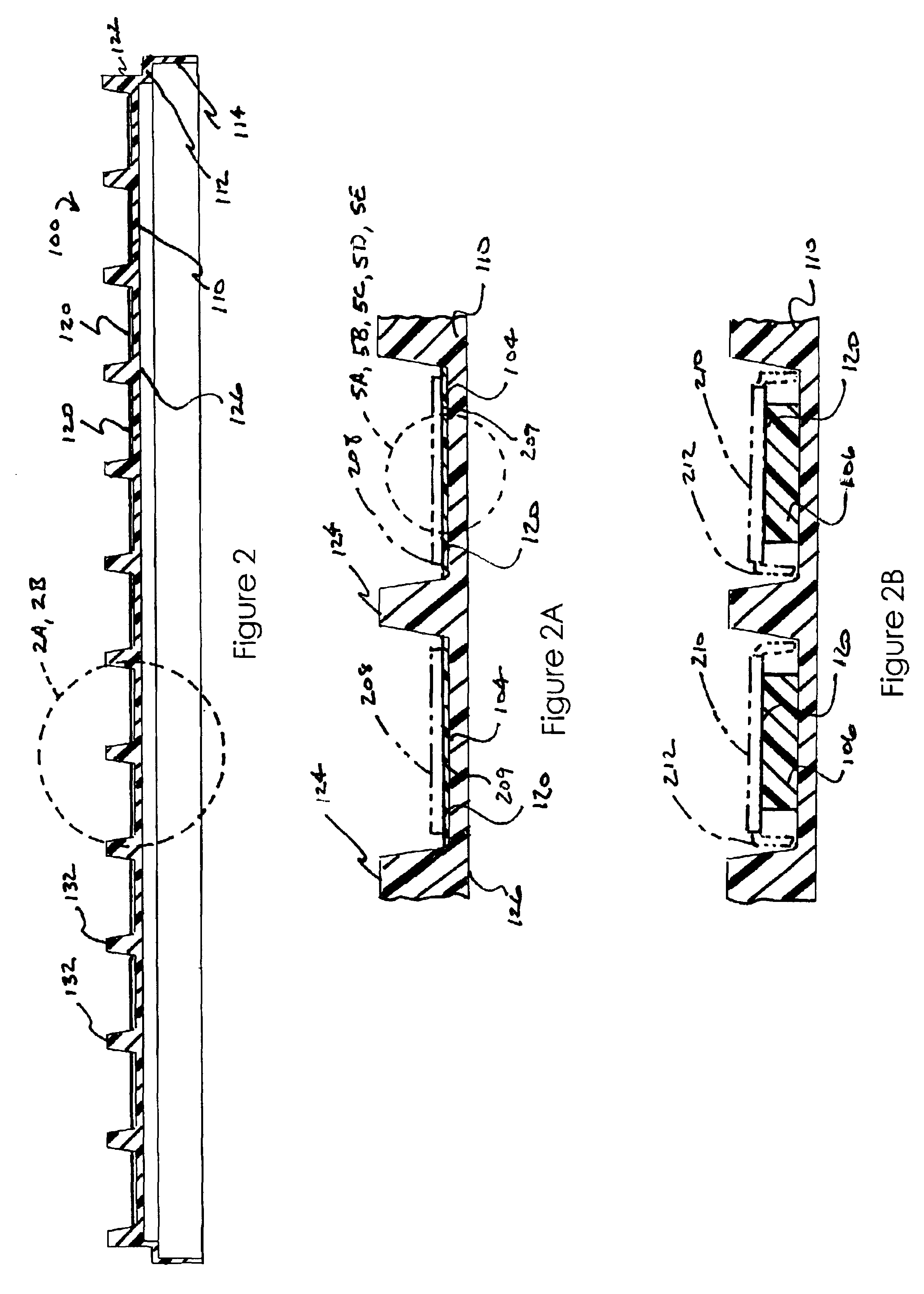

Matrix tray with tacky surfaces

InactiveUS6926937B2Widen meansSufficient forceEnvelopes/bags making machinerySemiconductor/solid-state device detailsPolyetherimidePolybutylene terephthalate

A tray for handling and retaining a plurality of small components comprising a rigid body portion with a plurality of pockets formed therein. Each of the pockets has an elastomeric contact surface for contacting and retaining a component. The contact surface may be formed from a thermoplastic material having a surface energy between 20 dyne / cm and 100 dyne / cm, and a surface electrical resistivity of between about 1×104 ohms / square and 1×1012 ohms / square. The material for the contact portion may be urethane, polybutylene terephthalate, polyolefin, polyethylene terephthalate, styrenic block co-polymer, styrene-butadiene rubber, polyether block polyamide, or polypropylene / crosslinked EDPM rubber. The body portion may be formed from acrylonitrile-butadiene-styrene, polycarbonate, urethane, polyphenylene sulfide, polystyrene, polymethyl methacrylate, polyetherketone, polyetheretherketone, polyetherketoneketone, polyether imide, polysulfone, styrene acrylonitrile, polyethylene, polypropylene, fluoropolymer, polyolefin, or nylon. The body portion may have a peripheral border region and a downwardly projecting skirt portion to facilitate stacking of multiple trays.

Owner:ENTEGRIS INC

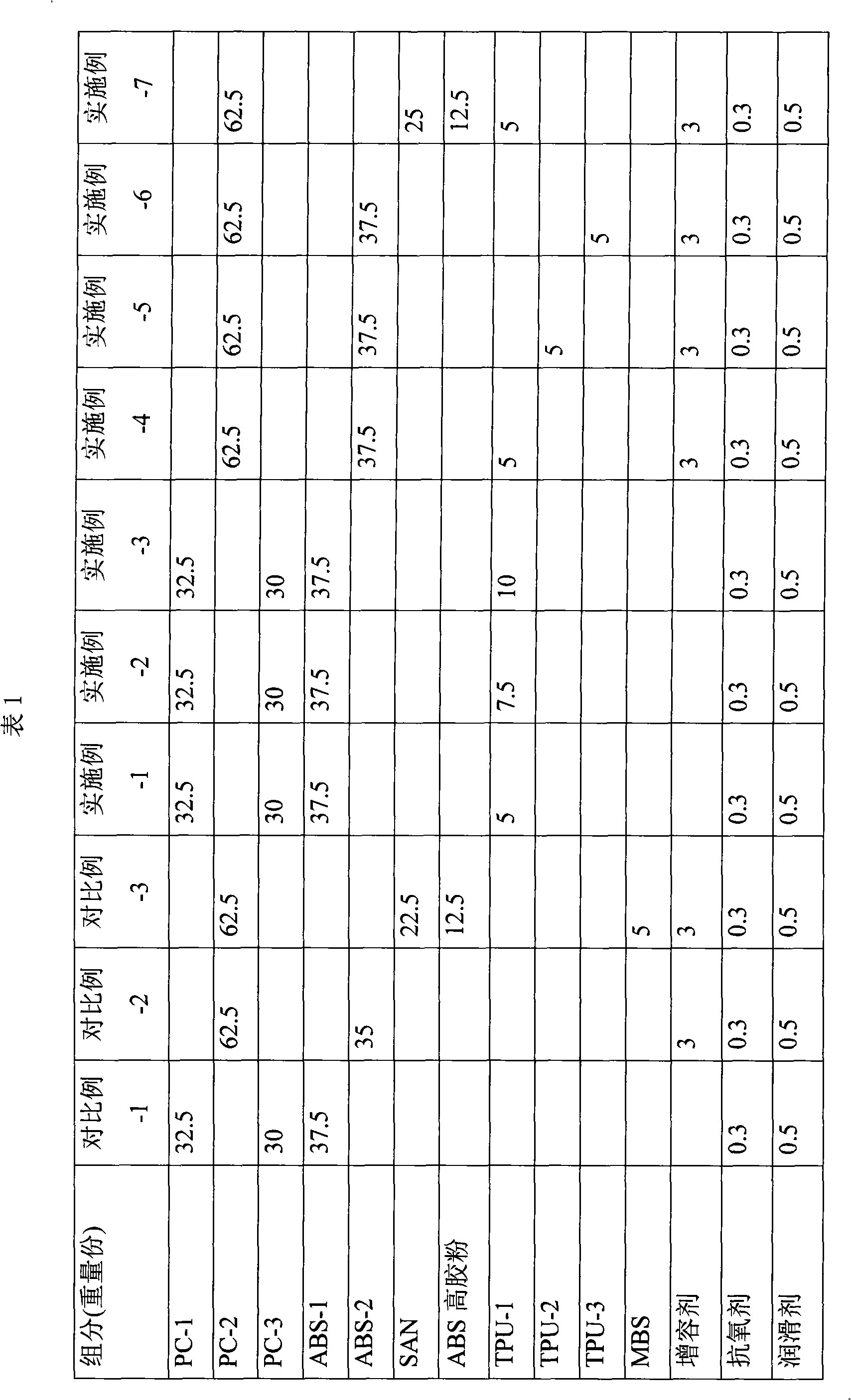

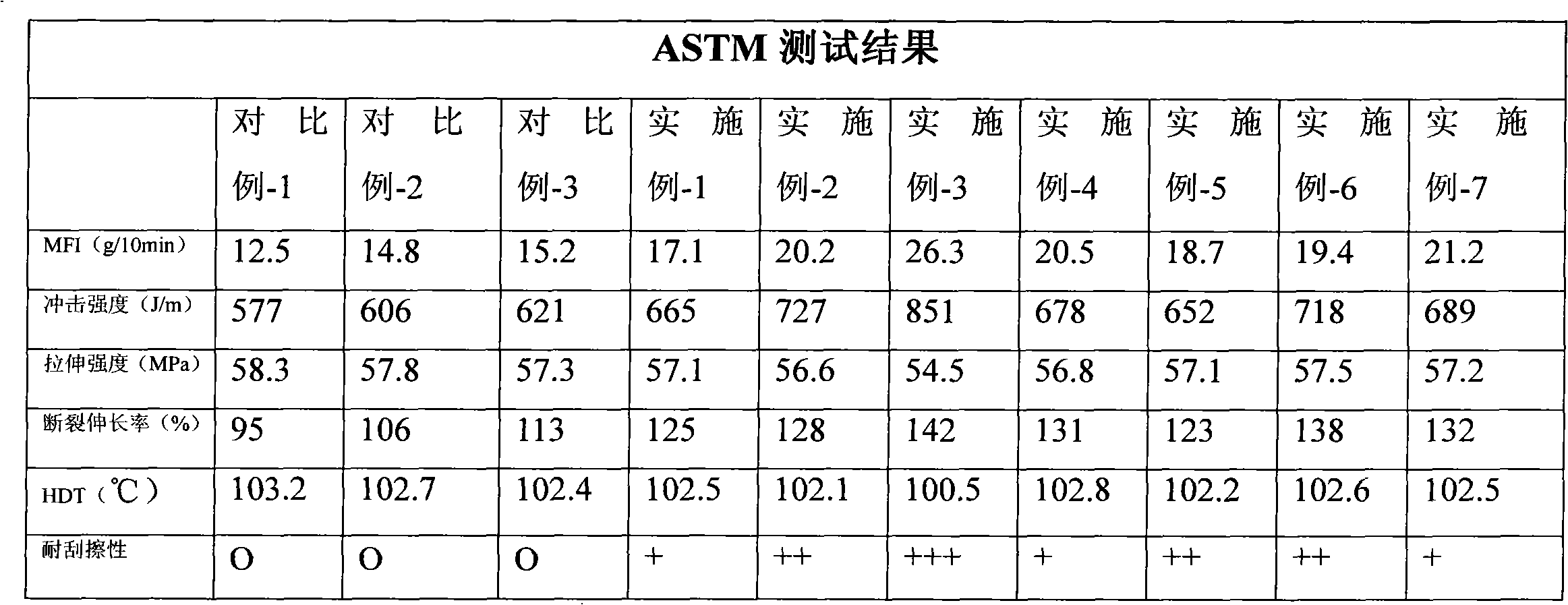

High-fluidity high-impact-resistance scraping-resistance polycarbonate composition and preparation method thereof

The invention relates to a high-fluidity high-impact-resistance scraping-resistance polycarbonate composition and a preparation method. The high-fluidity high-impact-resistance scraping-resistance polycarbonate composition mainly comprises the following ingredients in parts by weight: 45 to 85 parts of aromatic polycarbonate, 15 to 55 parts of acrylonitrile-butadiene-styrene (ABS), 0.5 to 20 parts of flowing impact-resistance modifying agents of thermoplastic polyurethane elastomers (TPU), 0 to 7 parts of compatibilizers, 0.05 to 1 part of antioxidants and 0.1 to 1 part of lubricating agents.The high-fluidity high-impact-resistance scraping-resistance polycarbonate composition provided by the invention is blended by a double-screw extruding machine, the thermoplastic polyurethane elastomer addition is used for further improving the fluidity and the impact resistance of the polycarbonate composition, and meanwhile, the scraping resistance and the low-temperature expansibility of the composition can be improved, so the application range of the composition is widened.

Owner:WANHUA CHEM GRP CO LTD +1

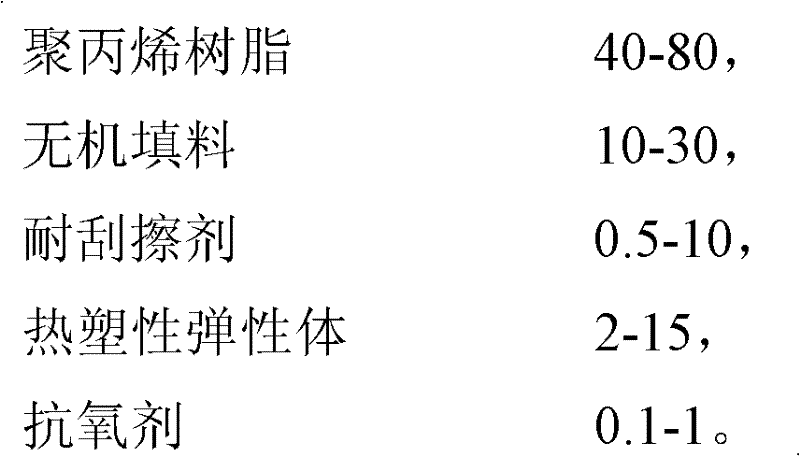

Polyurethane hot-melt adhesive for bonding and preparation method thereof

ActiveCN102585753AExcellent peelabilityEasy to apply glueNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a polyurethane hot-melt adhesive for bonding and a preparation method thereof, belonging to the technical field of preparation of automobile hot-melt adhesives. The preparation method comprises the following steps of: firstly, feeding high-crystalline polyester glycol, polyester polyol and tackifying resin into a reactor, heating, dehydrating at vacuum while stirring, andthen cooling; secondly, preheating diisocyanate, adding the preheated diisocyanate to the reactor to uniformly stir and carrying out prepolymerization reaction; after the prepolymerization is finished, sequentially adding weighed catalyst, antioxidant, coupling agent, viscosity stabilizer and grey paste under nitrogen circulation, and stirring till being mixed uniformly; discharging in the nitrogen protection condition, sealing and packaging so as to obtain the product, that is, the polyurethane hot-melt adhesive for bonding automobile lights. The hot-melt adhesive prepared by adopting the preparation method disclosed by the invention can be used for bonding a plurality of base materials such as PP (Polypropylene), PBT (polybutylece terephthalate), ABS (Acrylonitrile Butadiene Styrene), PMMA (polymethyl methacrylate), PC (Poly Carbonate) and inorganic glass.

Owner:WUXI WANLI ADHESION MATERIALS

Method for preparing acrylonitrile-butadiene-styrene latex having high total solid content

The present invention relates to a method of acrylonitrile-butadiene-styrene (ABS) rubber latex, and the acrylonitrile-butadiene-styrene (ABS) rubber latex is prepared by graft-polymerizing butadiene rubber with the monomers of acrlylonitrile and styrene through emulsion-polymerization, so that the ABS rubber latex of the present invention has high solid content. The method of ABS rubber latex of the present invention comprises the step of emulsion-polymerizing i) polybutadiene rubber latex; ii) aromatic vinyl compound; and iii) vinyl cyanide with the addition of a reactive emulsifier. According to the method of the present invention, the ABS rubber latex has high solid content due to a decrease in the amount of coagulated materials and film which is formed on the rubber latex during polymerization, and an increase in the production volume.

Owner:LG CHEM LTD

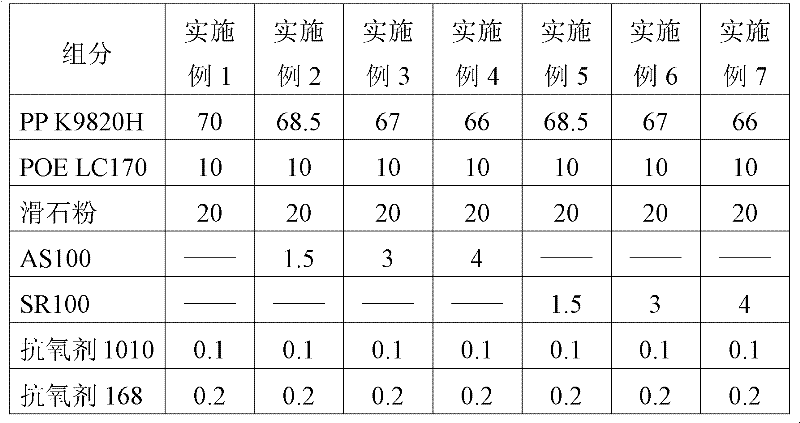

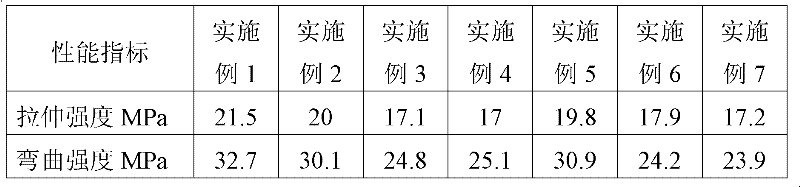

High-toughness low-odor scratch-resistant polypropylene composition and preparation method thereof

Owner:HEFEI GENIUS NEW MATERIALS

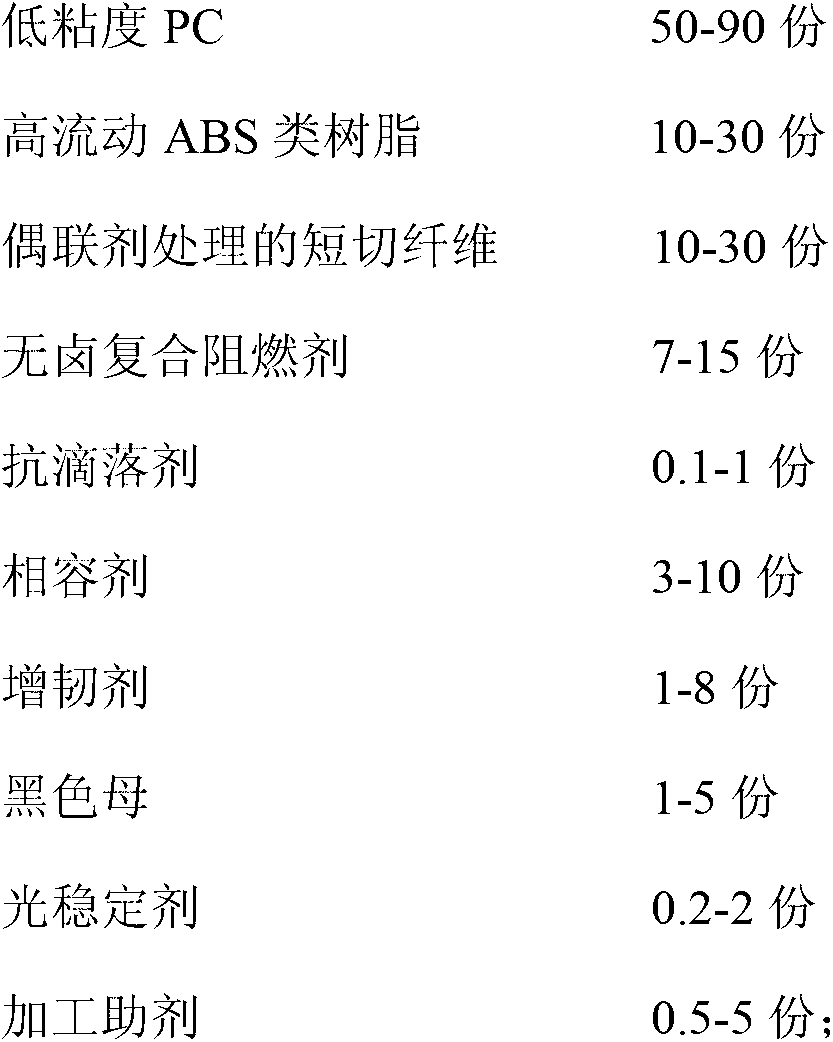

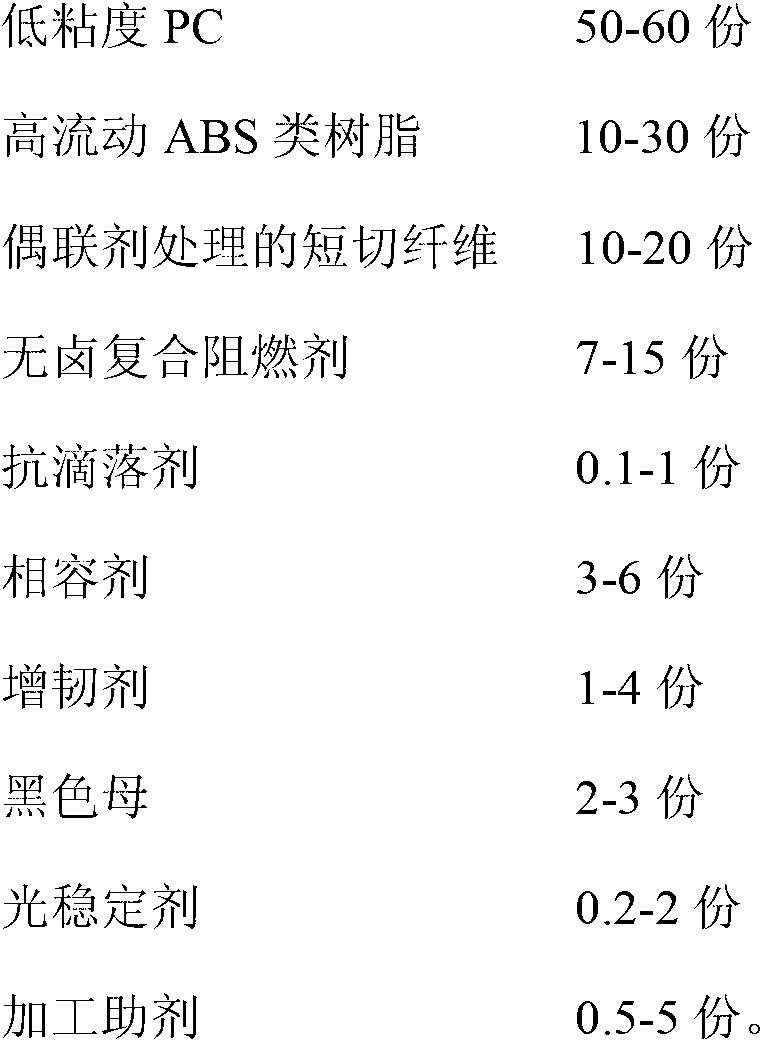

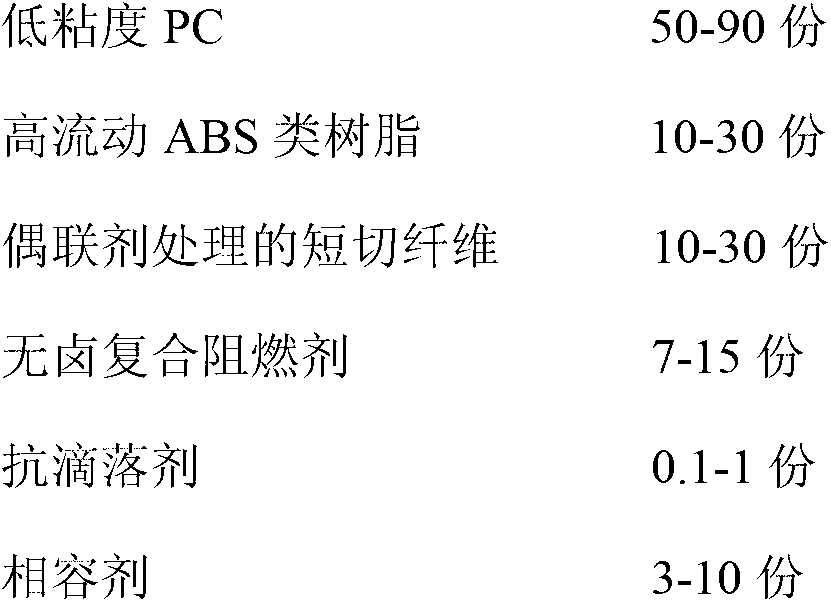

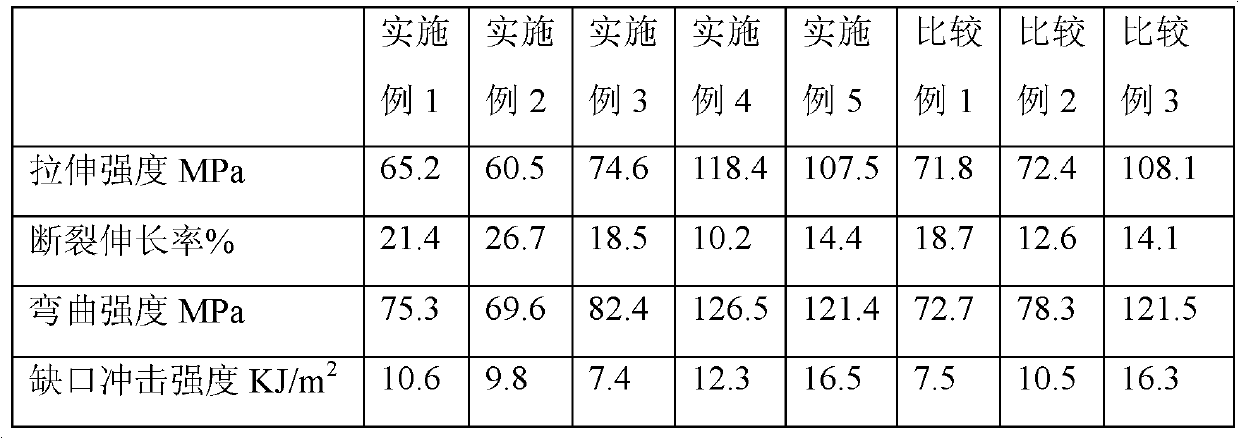

Flame-retardant glass fiber reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

The invention relates to a flame-retardant glass fiber reinforced PC (Polycarbonate) / ABS (Acrylonitrile Butadiene Styrene) composite material and a preparation method thereof. The preparation method comprises the steps of: respectively and fully drying low-viscosity PC, high-flow ABS resin, chopped fibers treated by using silane coupling agent, a halogen-free composite flame retardant, an anti-dripping agent, a black color base and a processing agent; fully mixing other raw materials except for the alkali-free chopped fibers treated by using the silane coupling agent in a high-speed mixer according to a proportion; then feeding the raw material into a double-screw extruder; laterally adding the alkali-free chopped fibers treated by using the silane coupling agent; and mixing, extruding, drawing, cooling, grain-sized dicing, and drying to obtain a finished injection molding raw material. The preparation method of the flame-retardant glass fiber reinforced PC / ABS composite material, disclosed by the invention, keeps certain impact intensity and rational MFR (Melt Flow Rate), thermal distortion temperature, vicat softening point and the like of the material while obtaining high intensity, high rigidity and flame retardant properties by selecting an assistant and proportions of the raw materials reasonably and adding the fibers as well as the flame retardant.

Owner:SHANDONG UNIV +1

3D (three dimensional) wood printing supply and preparation method thereof

The invention provides a 3D (three dimensional) wood printing supply which comprises components in percentage by mass as follows: 60%-90% of wood meal, 3%-15% of ABS (acrylonitrile butadiene styrene) plastics, 4%-15% of PLA (poly lactic acid), 2%-10% of PHA (polyhydroxyalkanoate), 1%-2% of PP (polypropylene) and 1%-2% of a compatilizer. The 3D wood printing supply has the characteristics such as water proofing, corrosion resistance, moisture resistance, freeness of worm damage, mildew and toxicity, acid and alkali resistance, environment protection and the like, the real flavor of wood is diffused; the wood printing supply is fused and deposited by a 3D printer at the temperature of 190-230 GDE C to form various different 3D models, the 3D models have the hand feel, the impression and the fragrance of natural wood and have an effect approaching to a solid wood effect and wood properties, and the printing supply can be nailed, drilled, planed, carved, adhered and painted as wood; and the comprehensive physical properties and chemical properties can be well improved and optimized, the performance requirement of the 3D printer can be effectively reduced, and accordingly, the printing supply is suitable for both high-end printers and low and medium-end 3D printers and has a wider application range.

Owner:广东傲趣三维科技有限公司

Flame-retardant heat-resisting high-strength ABS (Acrylonitrile Butadiene Styrene) modified material and preparation method

InactiveCN103289288AImprove heat resistanceImprove flame retardant performanceEnvironmental resistanceFiber

The invention belongs to the field of high-polymer material modification and machining technology, and relates to an ABS modified material. The material comprises the following compositions in parts by weight: 100 parts of ABS copolymer, 25-40 parts of reinforced fiber, 0-8 parts of toughener, 10-20 parts of flame retardant, 3-8 parts of flame-retardant synergist, 1.5-2 parts of antioxidant, 1-1.5 parts of light stabilizer, 10-20 parts of heat-resisting auxiliary, 4-10 parts of interface compatilizer, and 0.5-1.0 parts of dispersing agent. The flame-retardant heat-resisting high-strength ABS modified material is high in strength, good in toughness, impact-resistant, flame-retardant and environment-friendly, good in heat resistance, easy to machine, long in service life and low in cost, and can be widely used in various fields such as automobiles, electronic appliances and buildings.

Owner:滁州格美特科技有限公司

Shingle and mat tensile strength with urea formaldehyde resin modifier

InactiveUS7272915B2Tensile strength of glass fiber matsHigh tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberAsphalt

Owner:BMIC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com