Patents

Literature

31results about How to "Solve difficult demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

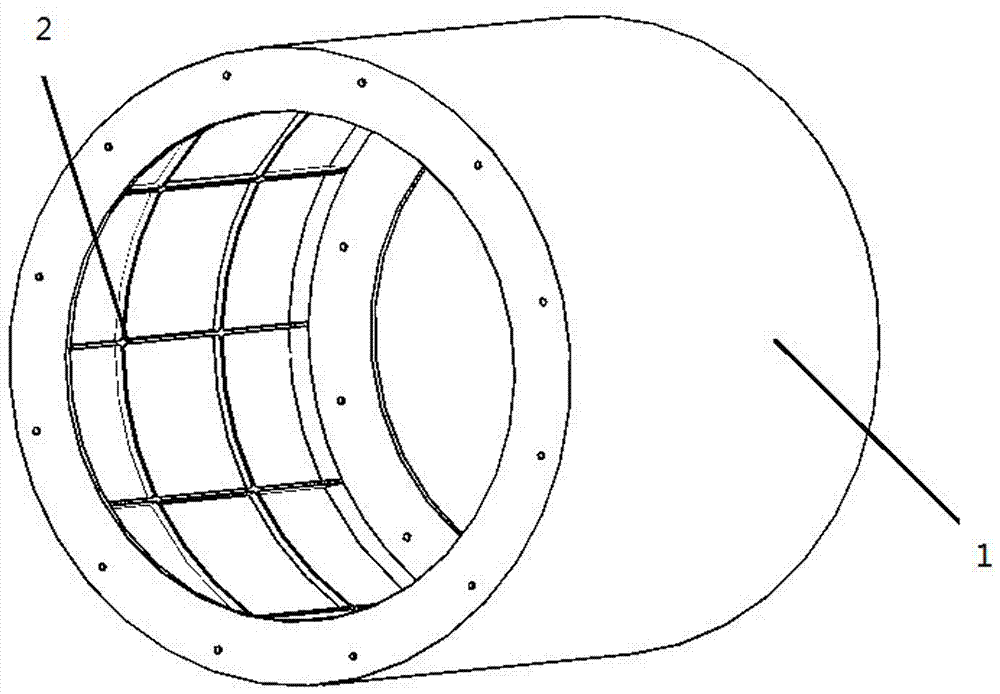

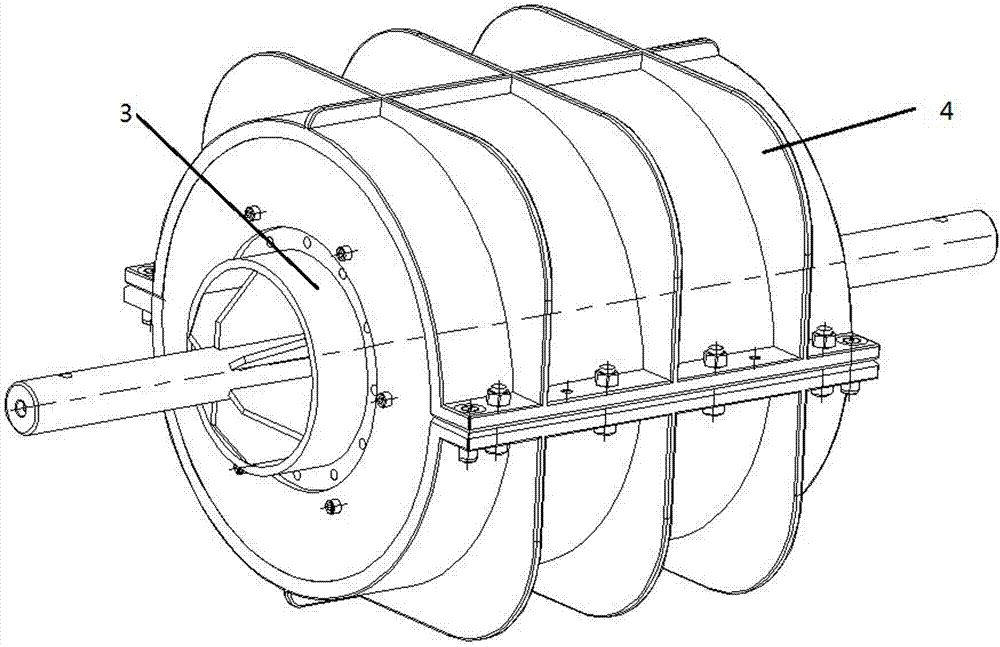

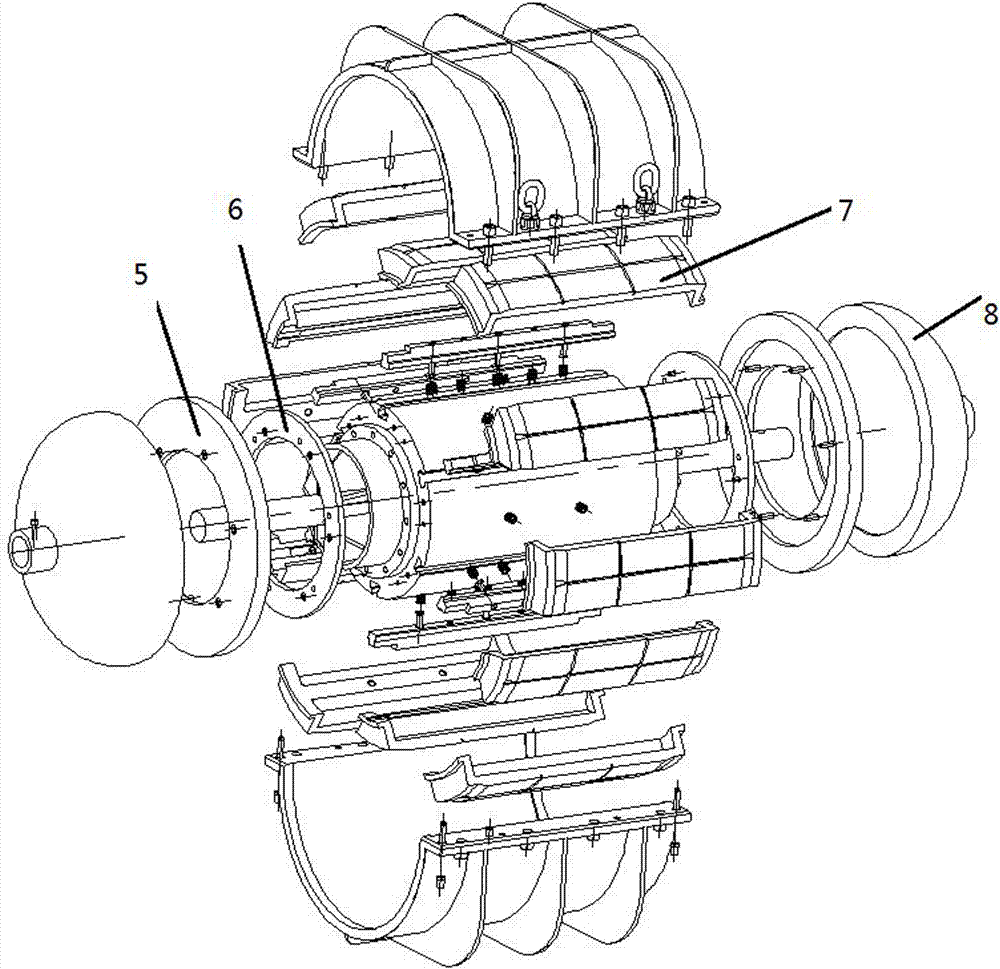

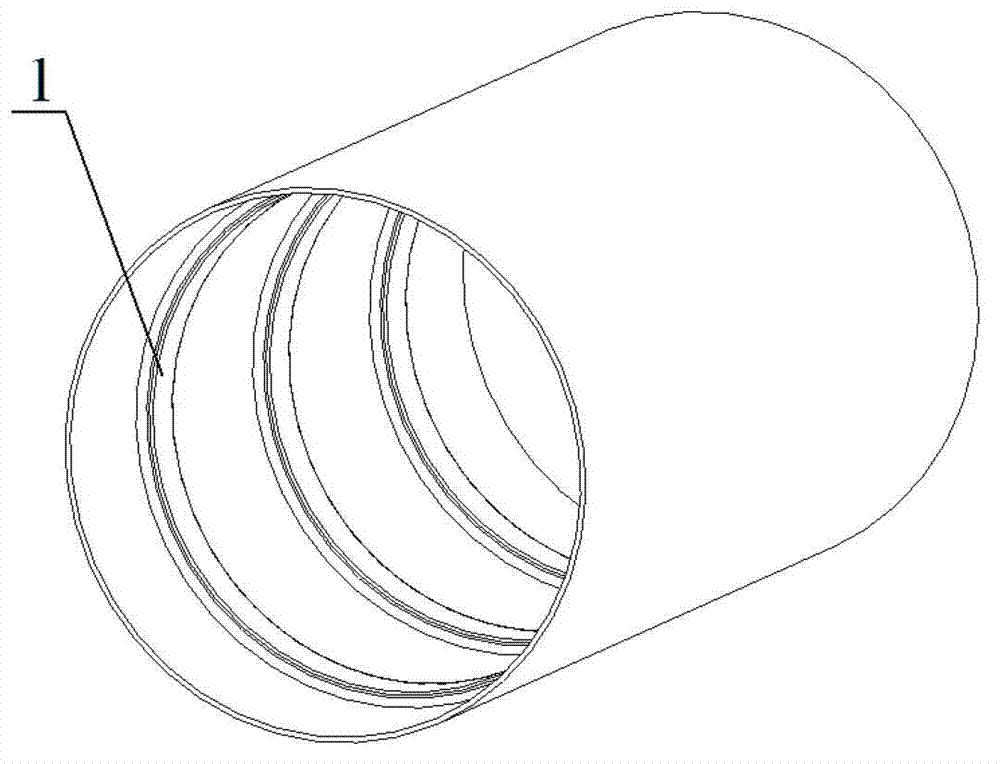

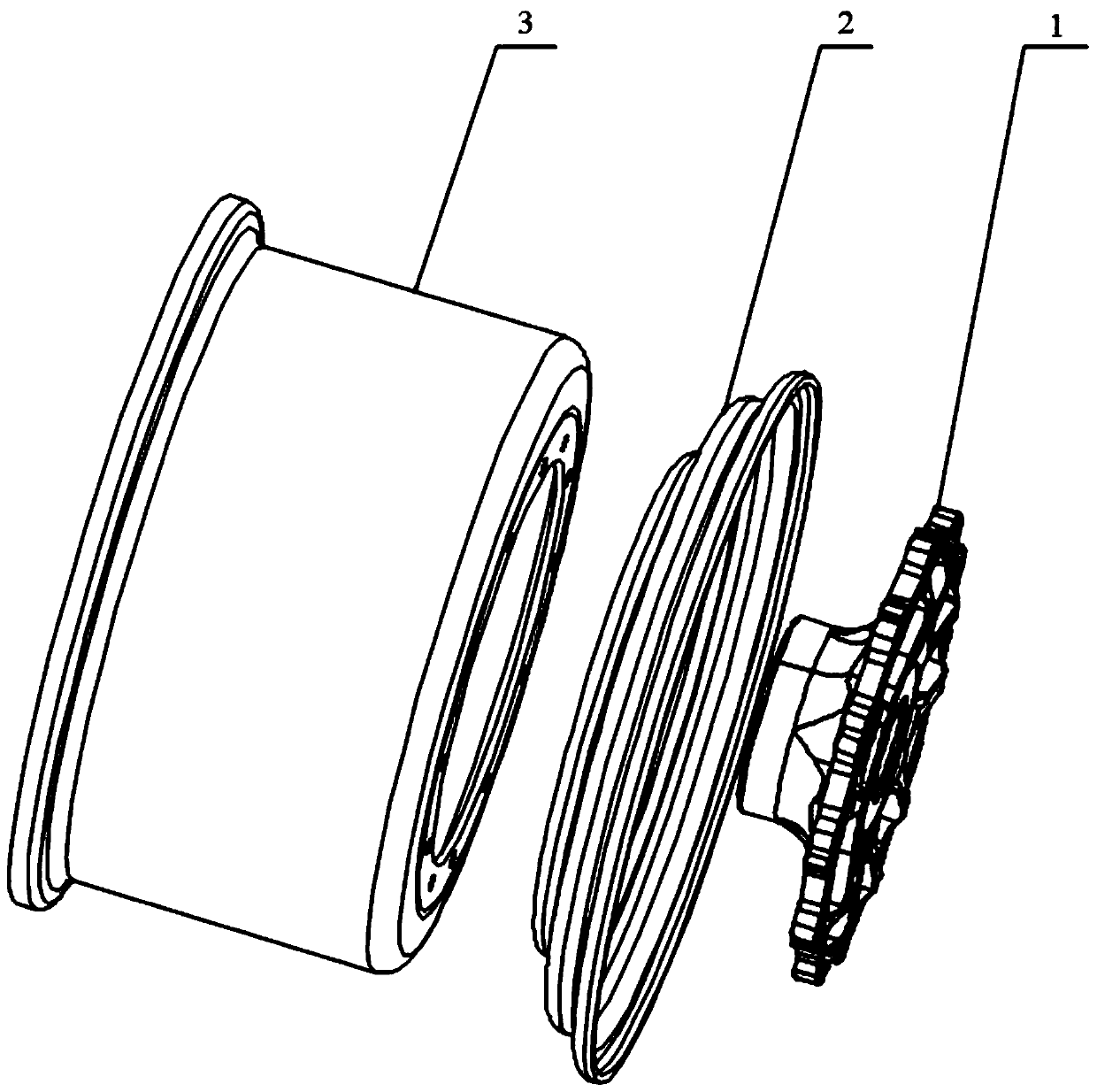

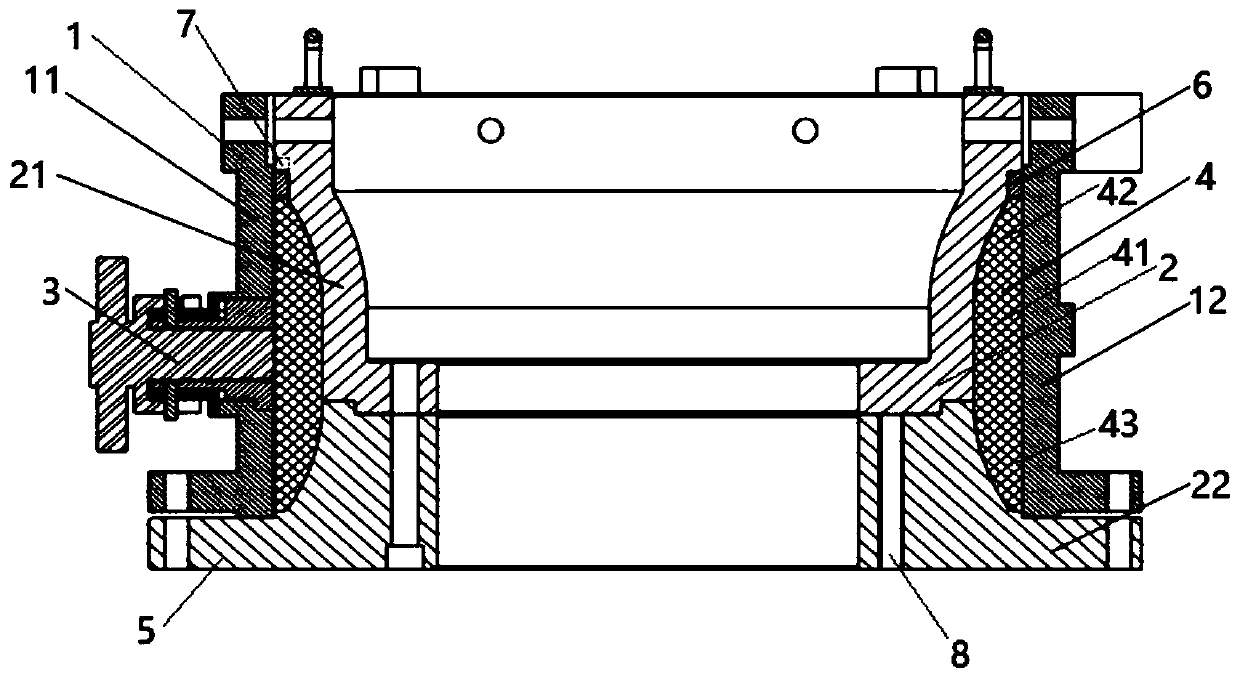

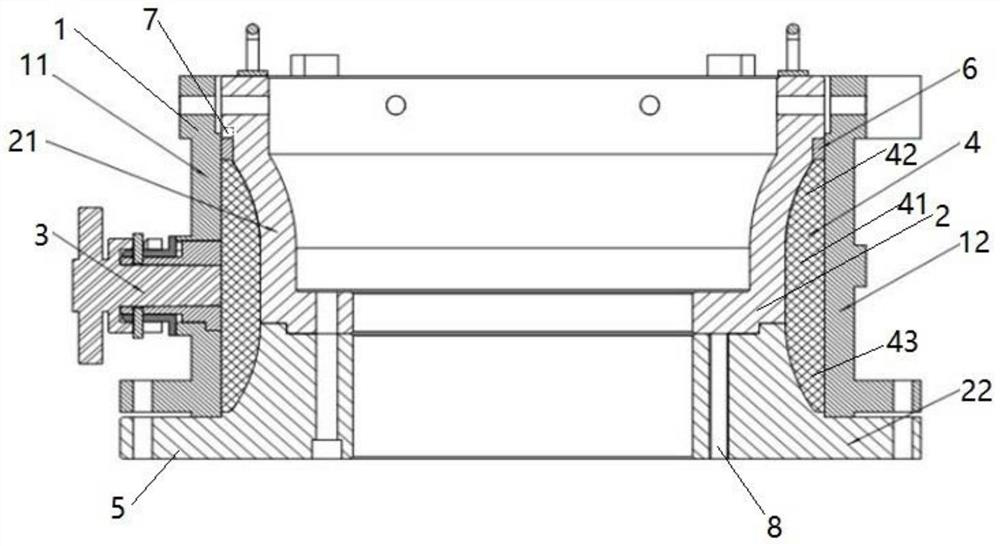

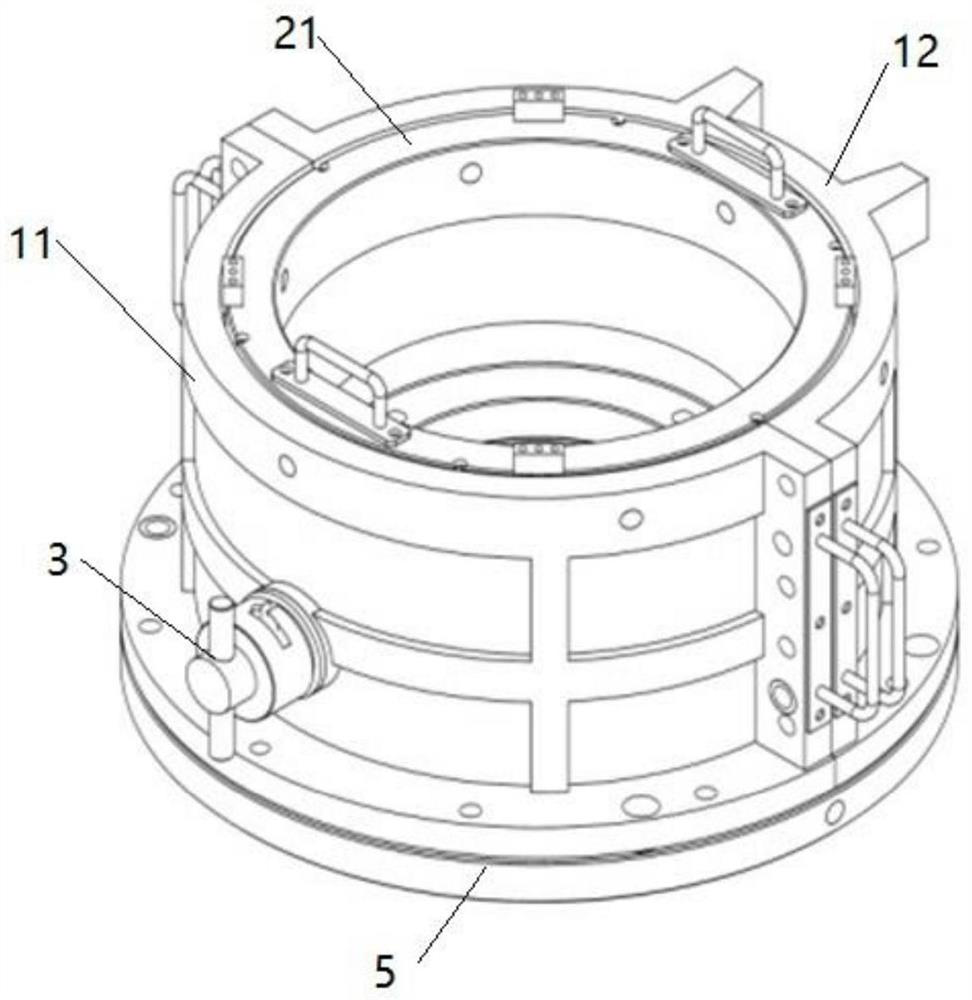

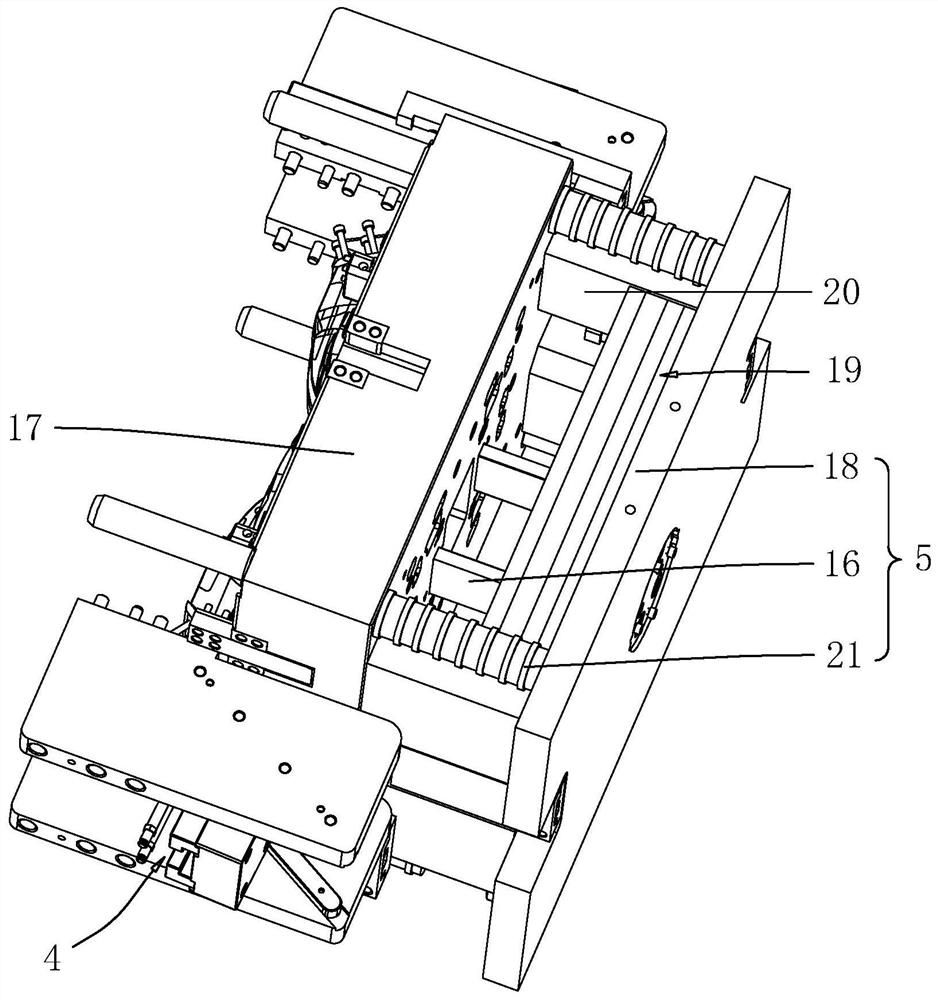

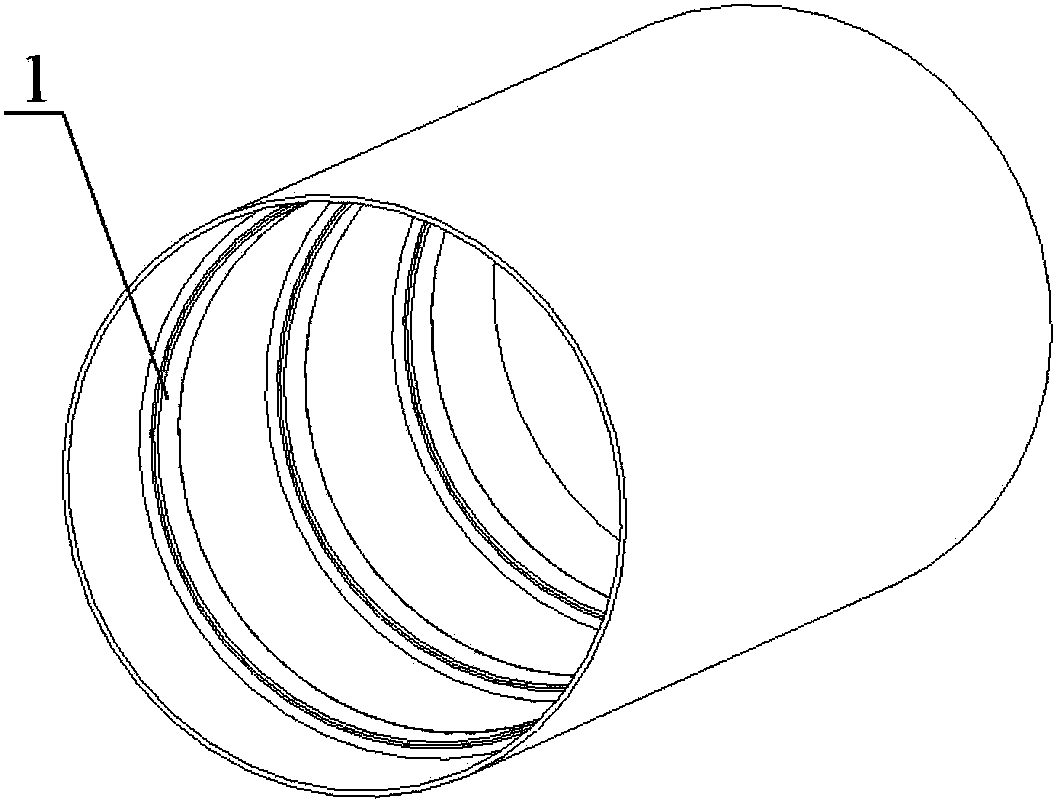

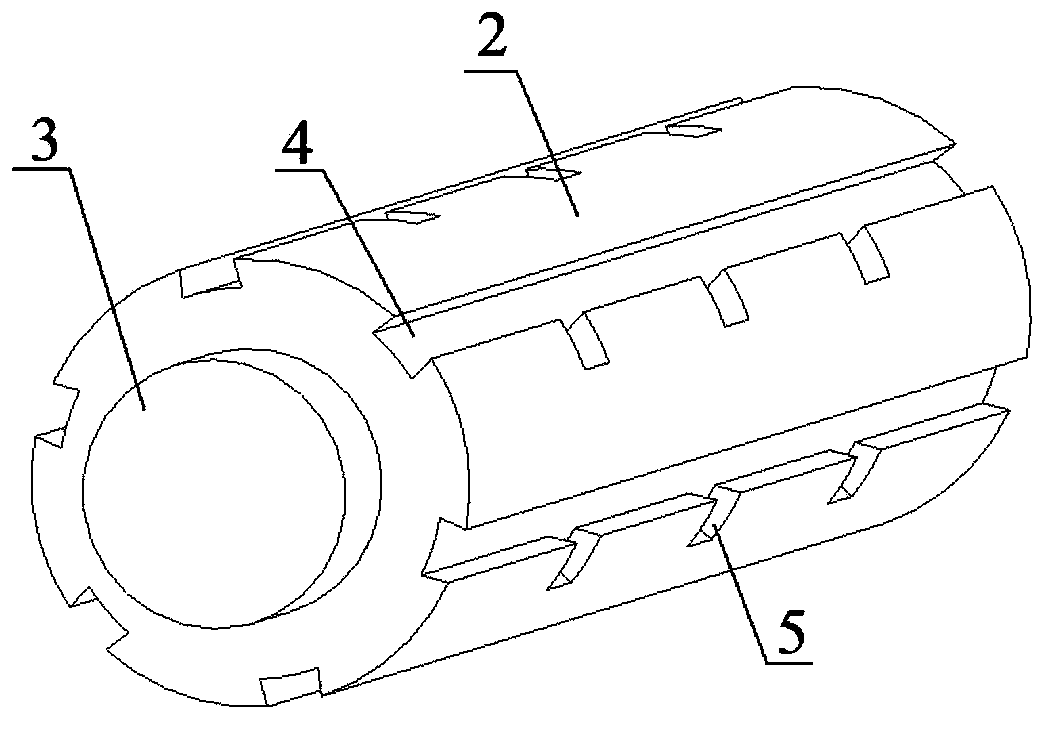

Winding die for molding interior grid stiffened cylindrical shell structure part and using step

InactiveCN106976250ASolve the difficulty of pressurization and demouldingImproved dimensional accuracy and positional accuracyDomestic articlesMesh gridEngineering

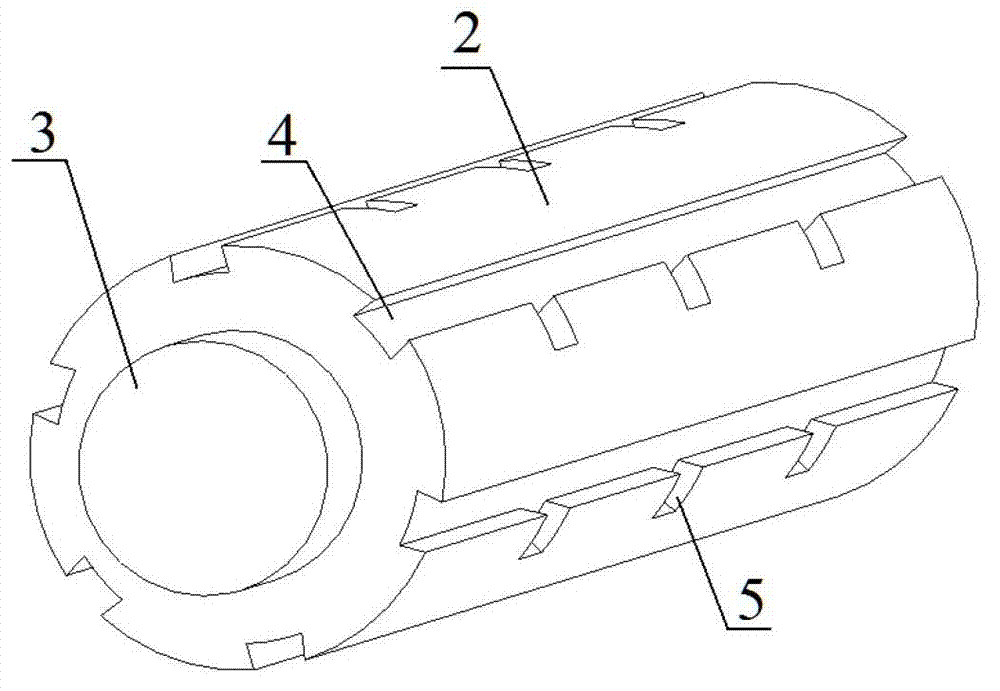

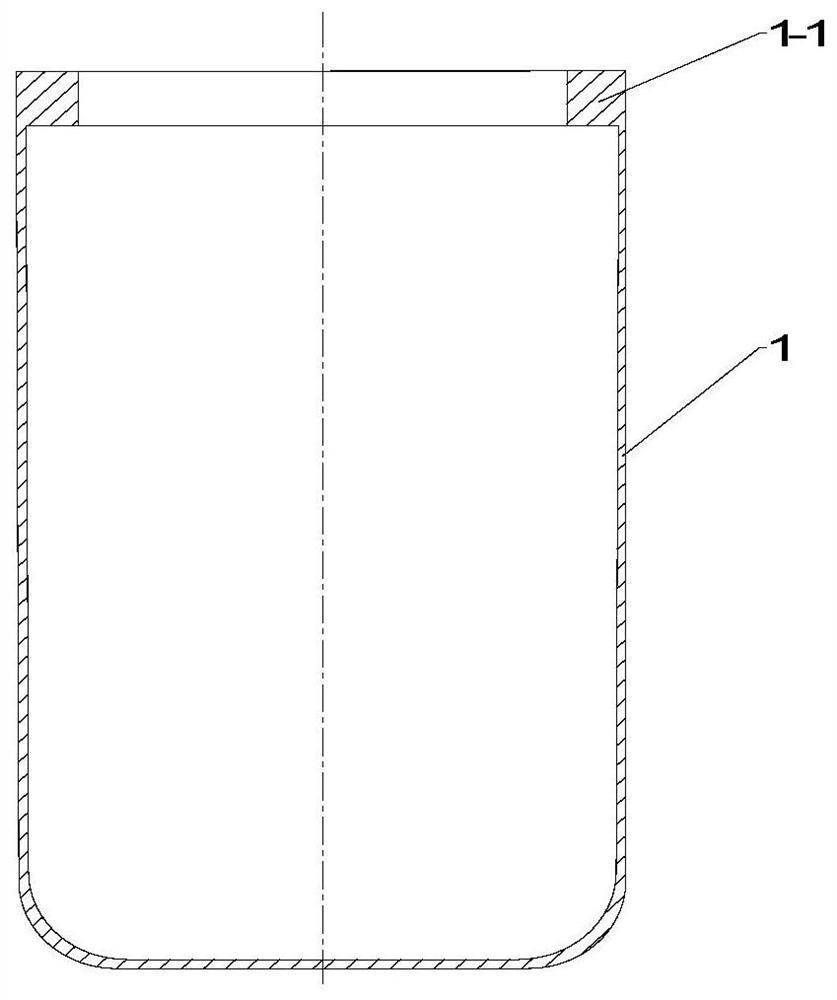

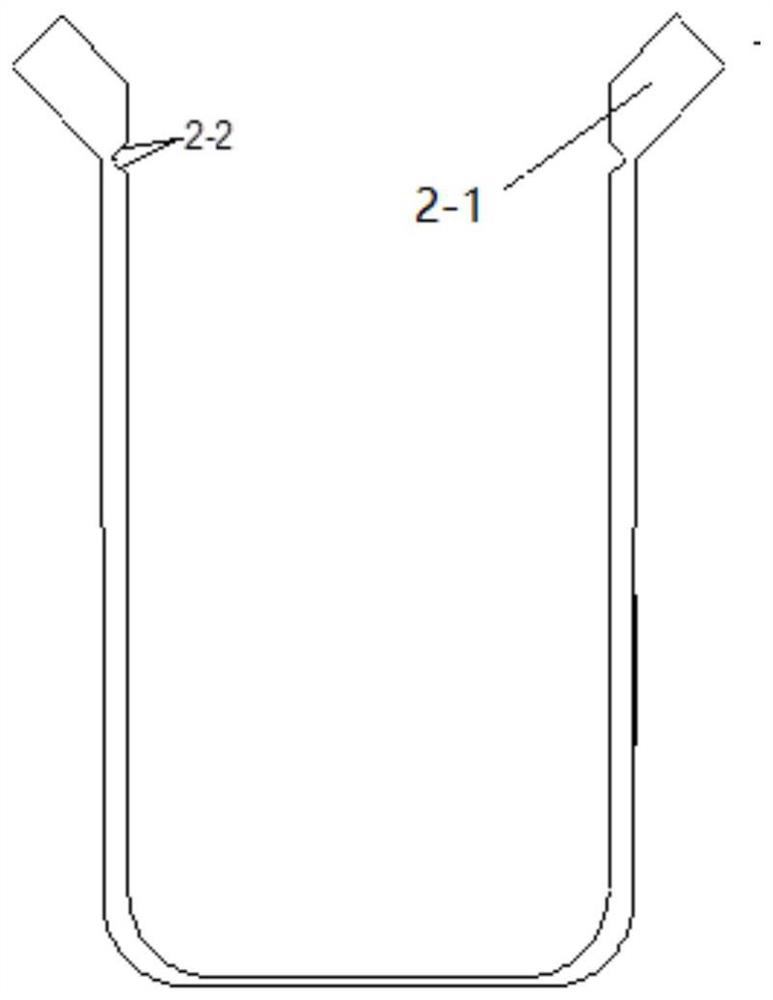

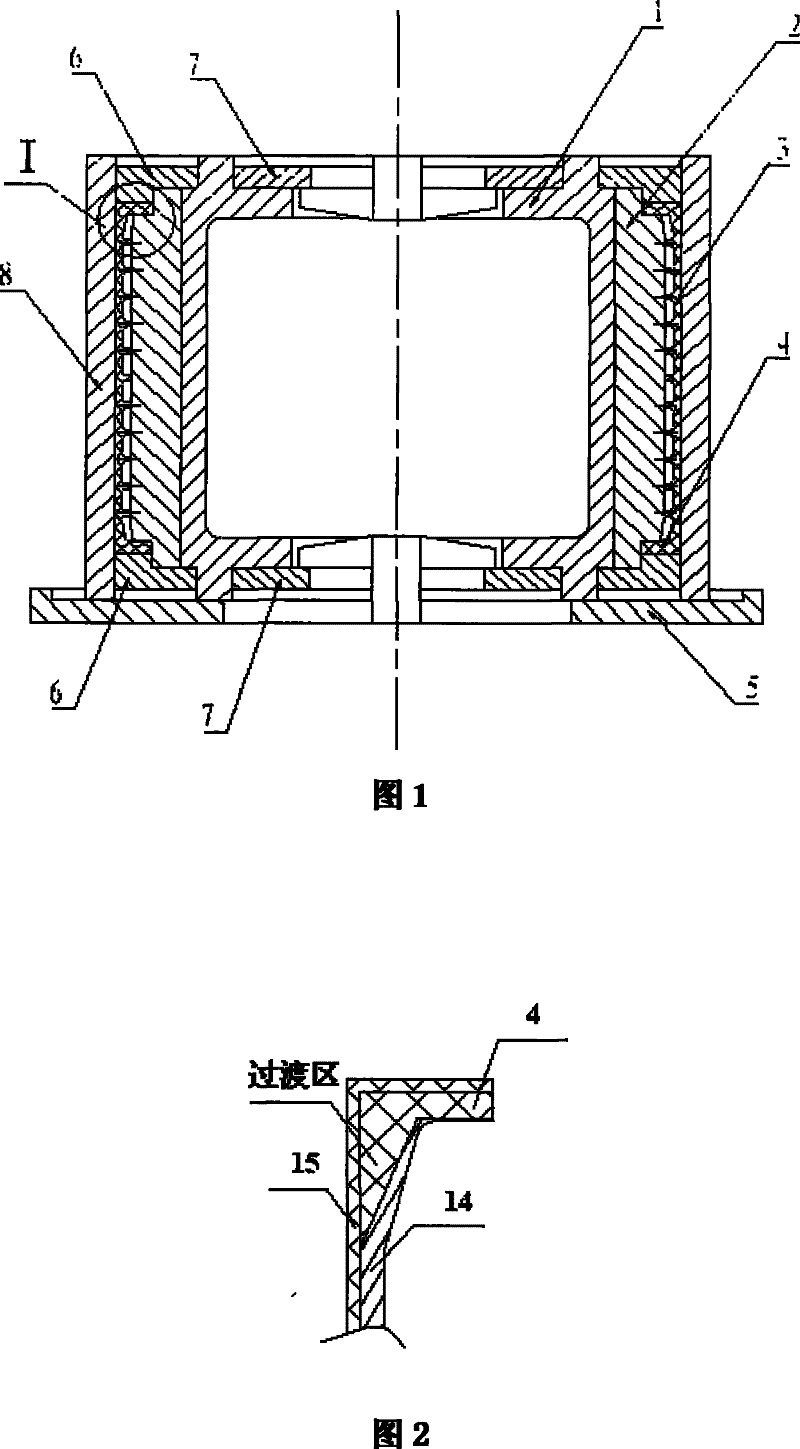

The invention relates to a winding die for molding an interior grid stiffened cylindrical shell structure part. The winding die comprises a body die, a core die and an outer die; evenly-arranged T-shaped grooves are formed in the two sides of the body die, the core die and the body die are assembled through T-shaped blocks, the outer die is arranged on the outer side of the core die and used for limiting the appearance of the molded part, end frame flanges facilitating turnup of the molded part are arranged at the two ends of the body die, and sealing heads are arranged on the outer side of the end frame flange. The using steps of the die comprises (1) cleaning and die assembling, (2) reinforcing rib winding, and vacuum bag hitting for pre-compaction; and (3) moving the die to a drying oven for curing, and demolding after curing is carried out. The winding die can be repeatedly used, grid reinforcing ribs of the molded product have the high size accuracy and position accuracy, the product quality consistency is good, and later period assembly of the product is facilitated.

Owner:HENGSHEN

Color pencil lead with high flexural strength and preparation method thereof

ActiveCN108129914AImprove erasabilityHigh flexural strengthPencil leadsNon-propelling pencilsFlexural strengthSolvent

The invention discloses a color pencil lead with high flexural strength and a preparation method thereof. The preparation method comprises blending 20-40 parts by mass of a thermosetting resin, 10-30parts by mass of a thermoplastic resin, 30-50 parts by mass of base raw materials, 10-20 parts by mass of pigment powder, 3-7 parts by mass of an enhancing filler and a solvent under heating, removinga part of the solvent, carrying out roller mixing at 100-120 DEG C until uniform dispersion, extruding the mixture through a bar extruding machine to obtain bars, extruding the bars to obtain pencilleads, and then cutting the pencil leads to obtain color pencil leads with high flexural strength. The preparation method can produce a color pencil lead with high flexural strength, high writing markscrubbability and bright color, has simple processes, realizes a low cost and has high efficiency. The method is suitable for direct large-scale production of color pencil leads with various specifications in the traditional large-scale production factory without new equipment.

Owner:烟台好前程文具有限公司

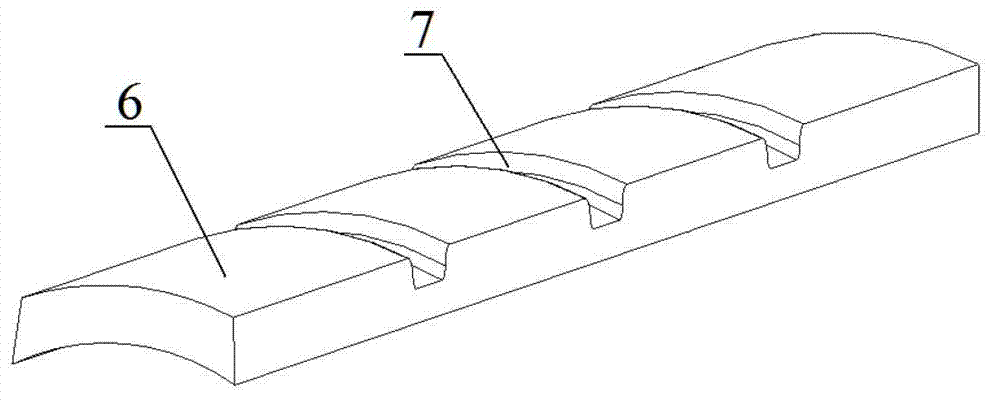

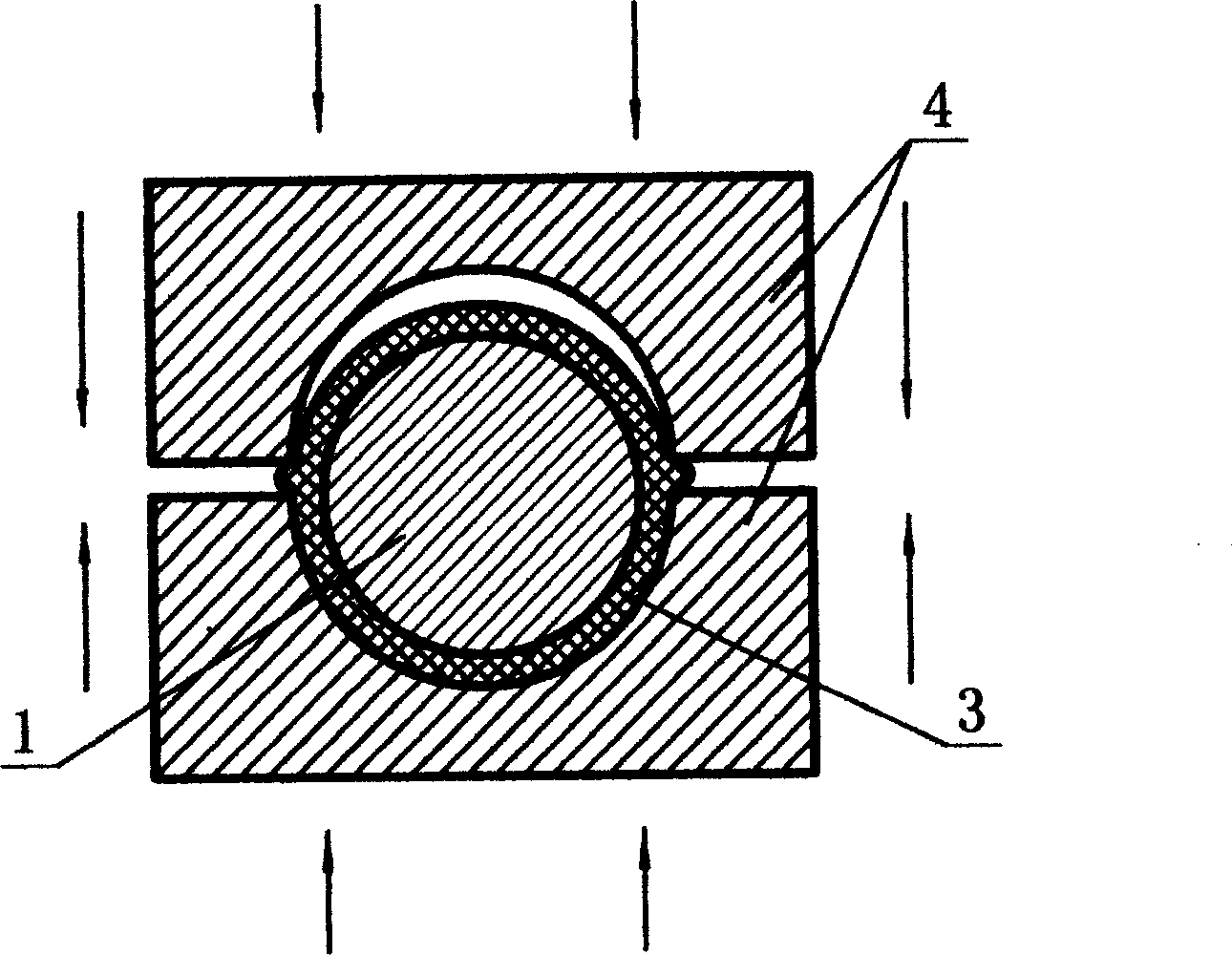

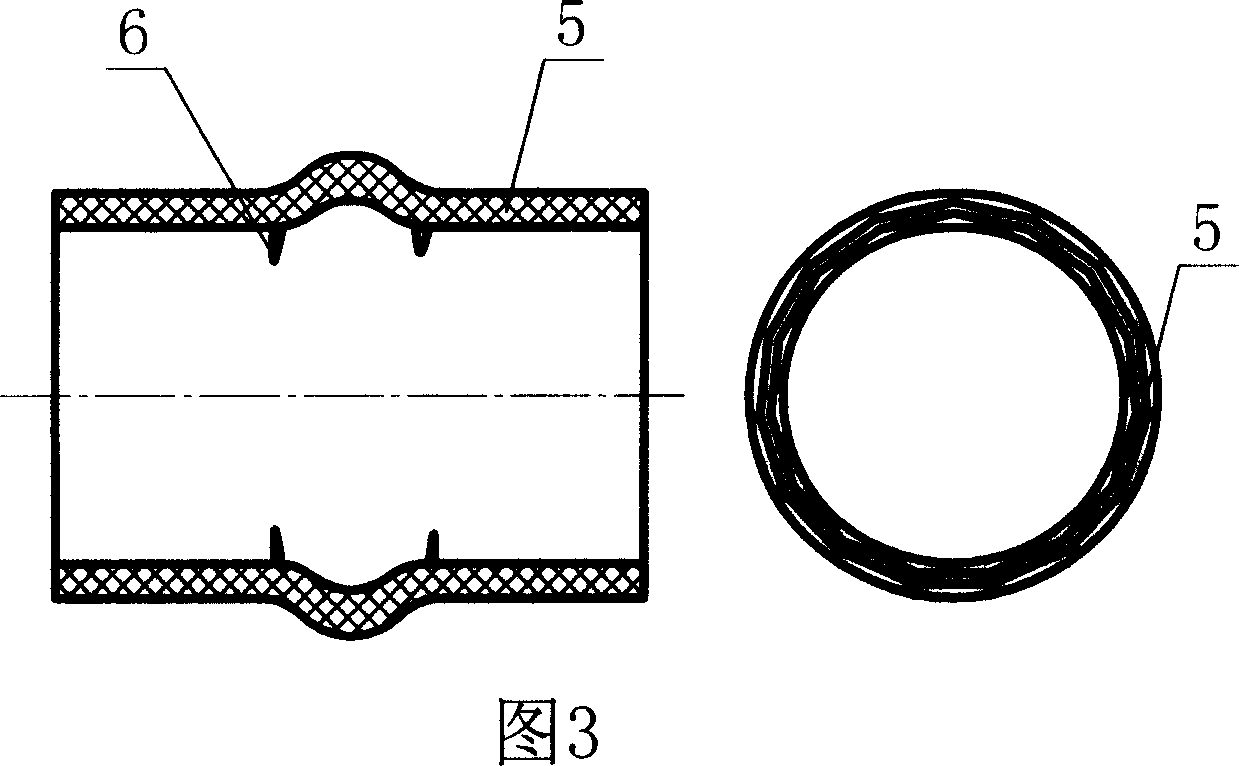

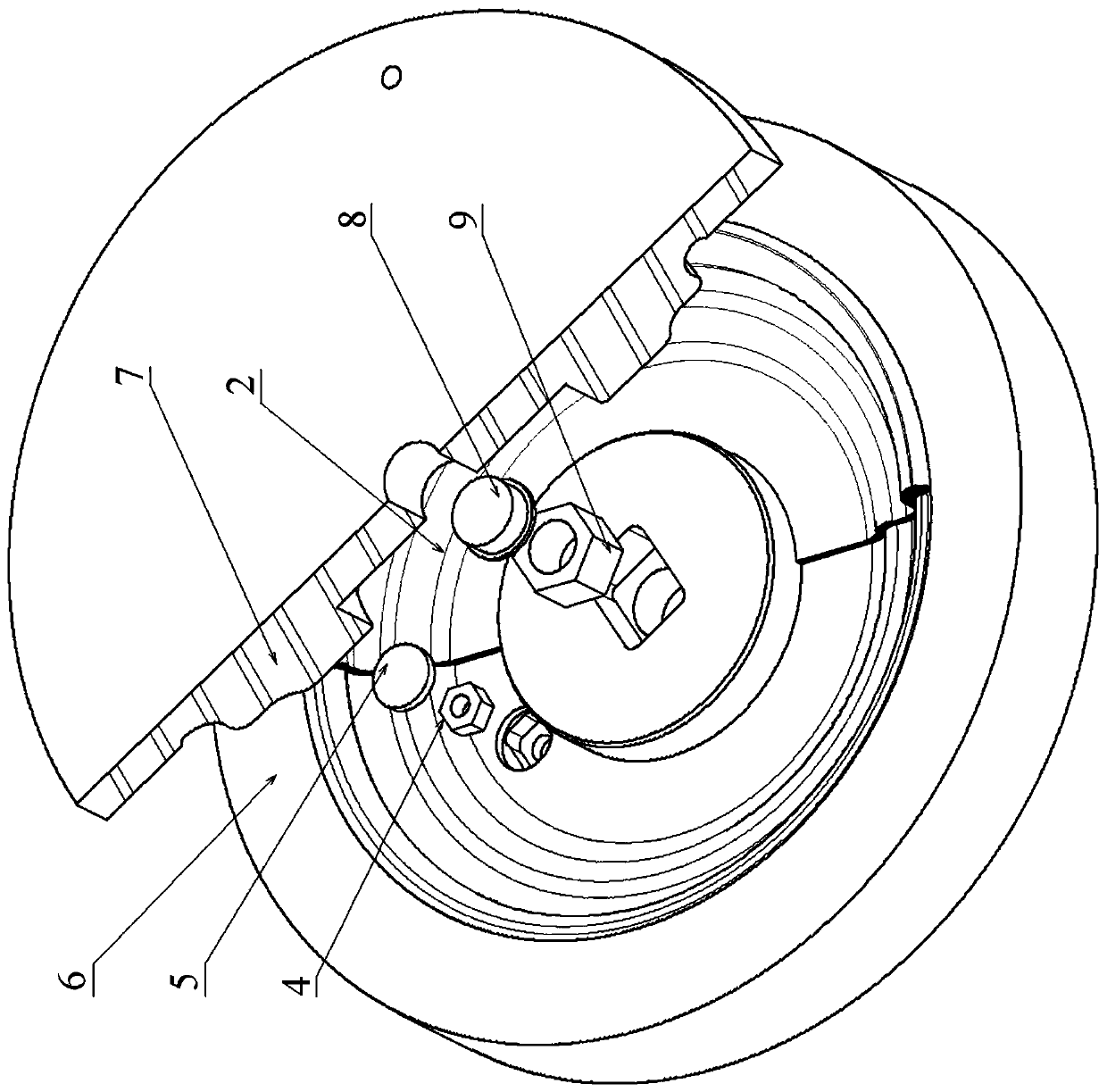

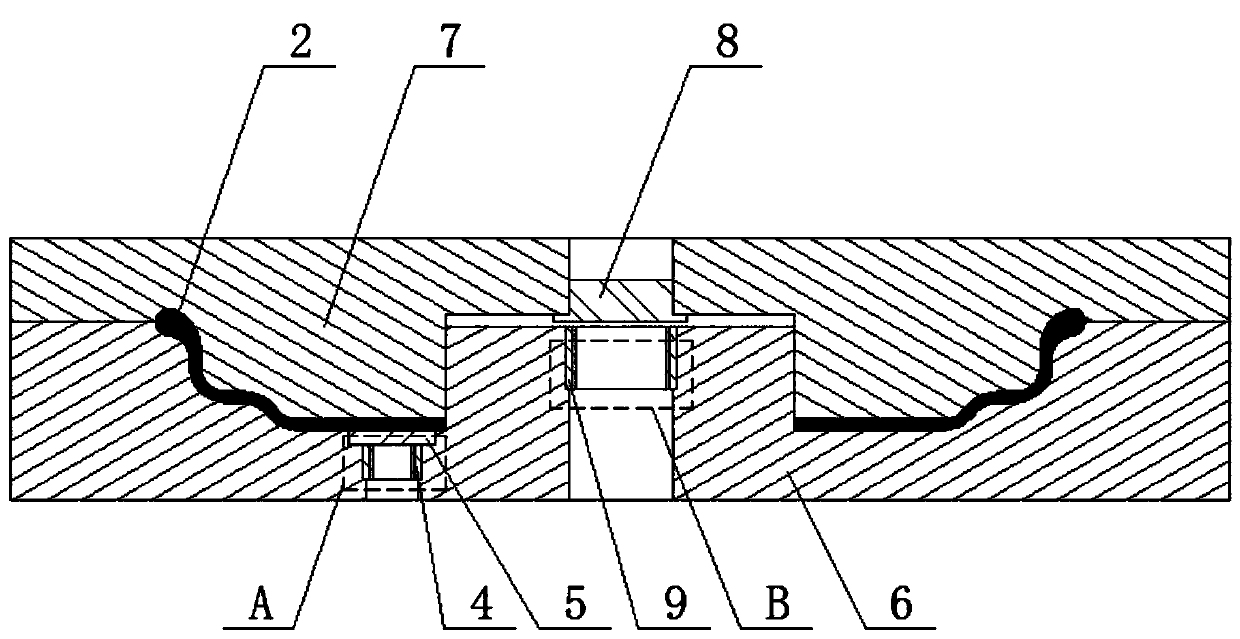

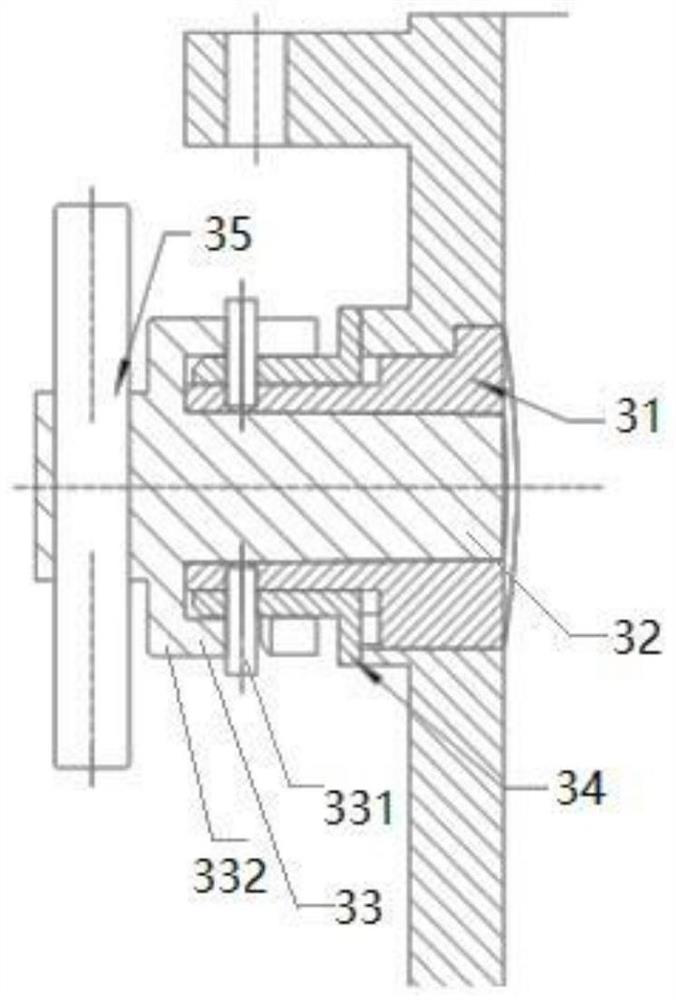

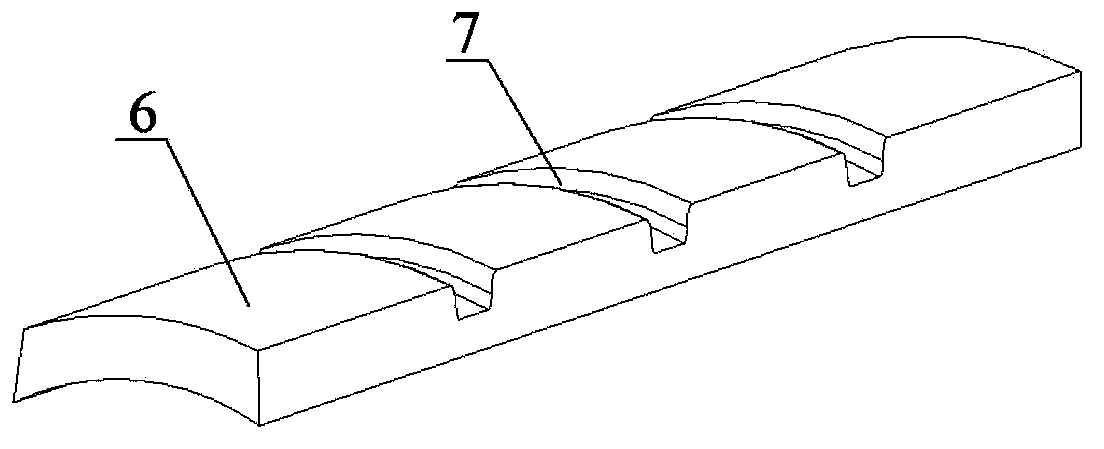

Core mold and shaping method for shaping strip annular internal reinforced rib rotary body thin-wall part

InactiveCN102764841APrevent movementHigh forming precisionForging/hammering/pressing machinesMetallic materialsUltimate tensile strength

The invention relates to a core mold and a shaping method for a shaping strip annular internal reinforced rib rotary body thin-wall part, wherein a base mold is composed of a base mold main body and a mold withdrawing end; a swallow tail groove and a positioning groove are formed on the base mold main body; a shape mold is wholly of an annular structure; the shape mold is uniformly divided into a plurality of split molds of same shapes; shaping arc grooves for annular internal reinforced ribs are formed on the shaping plane of the split molds; swallow tail tenons matched with the wallow tail groove and the positioning groove are formed on the inner surfaces of the split molds. By adopting the mode of combined core mold, the problem of hard demolding during the shaping process of the rotary body thin-wall part internal reinforced rib is solved. By virtue of the positioning on the base mold swallow tail groove, the movement of the shaping mold is prevented effectively; and the shaping precision of the rotary body thin-wall part internal reinforced rib is improved. The base mold, the shaping mold and the fixing pin of the core mold can be made of different metal materials according to respective strength requirements; only the mold needs to be replaced for rotary body thin-wall pieces of which the inner diameters are the same and the internal reinforcing ribs are different, so that the cost of the mold is reduced greatly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

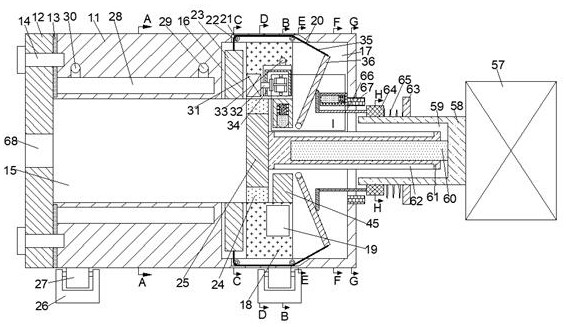

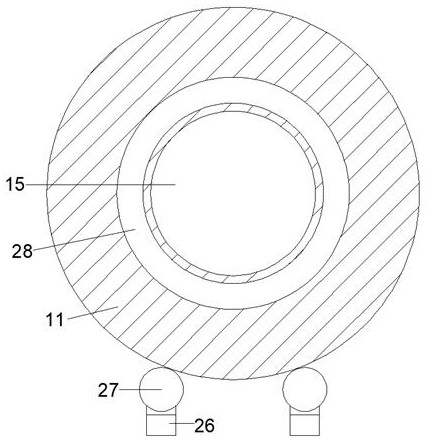

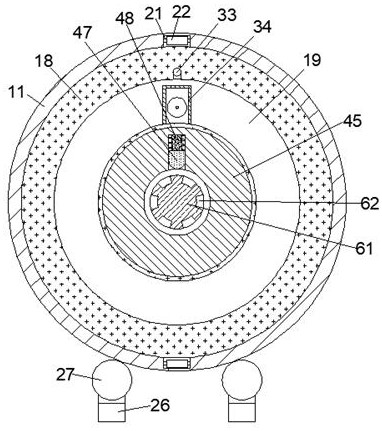

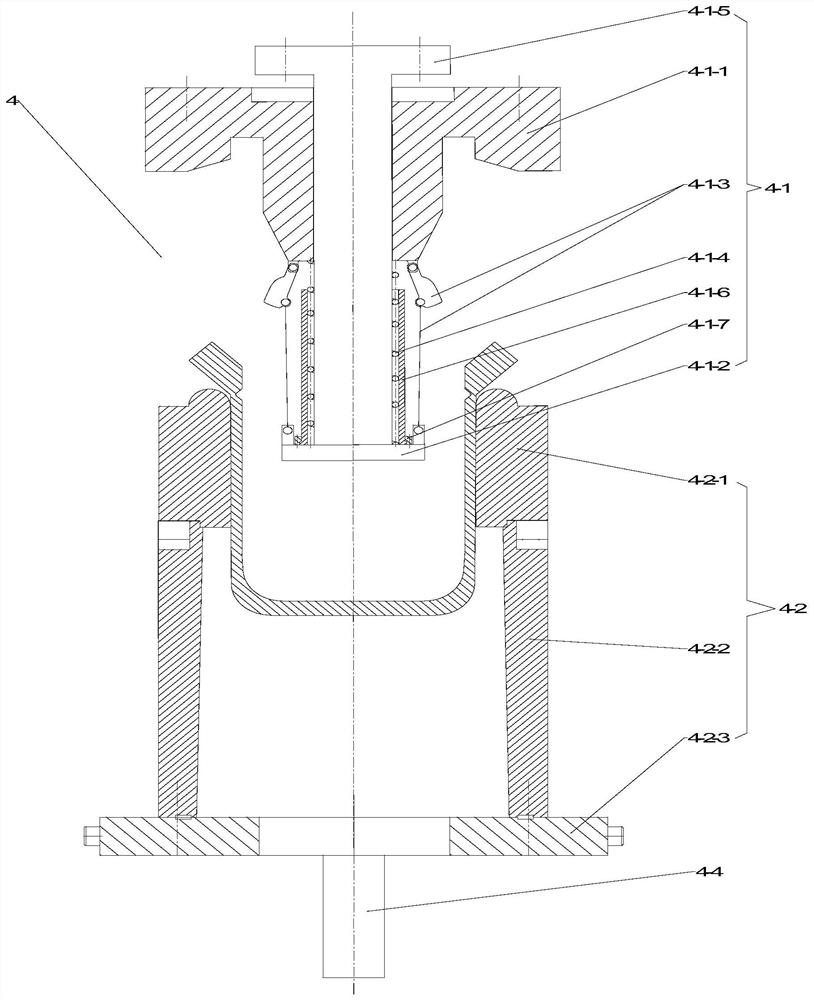

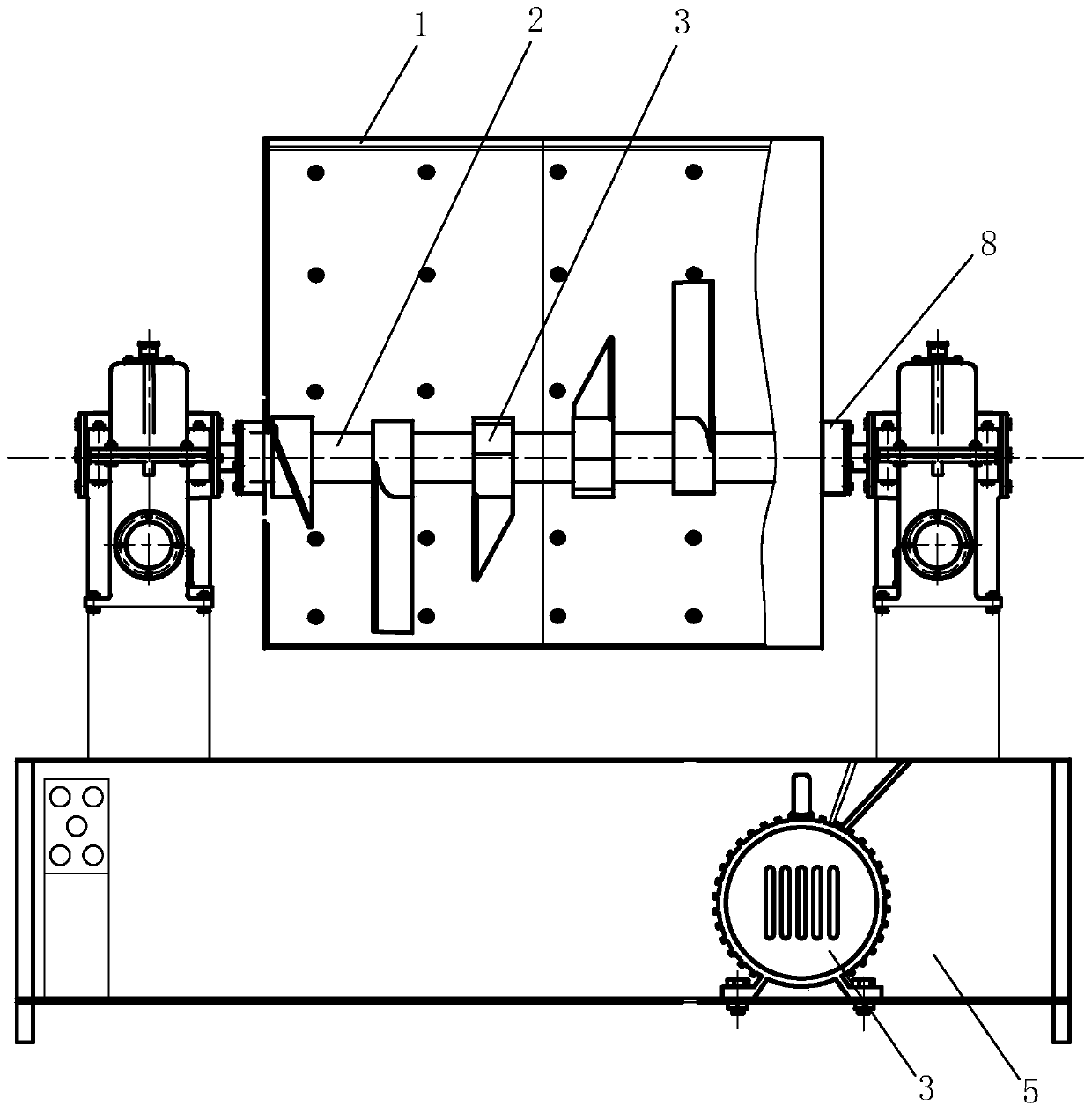

Centrifugal casting equipment capable of automatically coating paint

The invention discloses centrifugal casting equipment capable of automatically coating paint. The centrifugal casting equipment comprises a machine body, a detachable end cover is arranged at the leftend of the machine body, a feeding port communicating left and right is formed in the axis of the end cover, a working cavity is formed in the machine body, the feeding port communicates with the left side of the working cavity, a cooling water jacket is arranged on the side, away from the axis of the feeding port, of the working cavity, a closed door cavity communicating with the working cavityis formed in the right side of the cooling water jacket, and a closed door capable of moving in the direction away from or close to the axis of the working cavity is arranged in the closed door cavity. According to the centrifugal casting equipment, the problem that formed metal is difficult to demold is effectively solved by coating the inner wall surface of a metal liquid forming cavity with thedemolding coating, the metal liquid is rapidly cooled through water path circulation in the device, the overall casting time is effectively shortened, the casting efficiency is improved, and the product quality is improved.

Owner:HANGZHOU YABANG INTELLIGENT TECH CO LTD

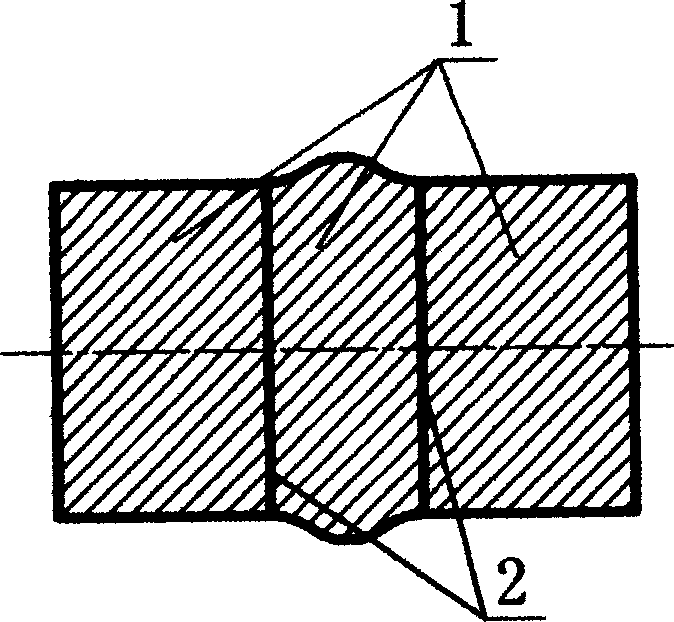

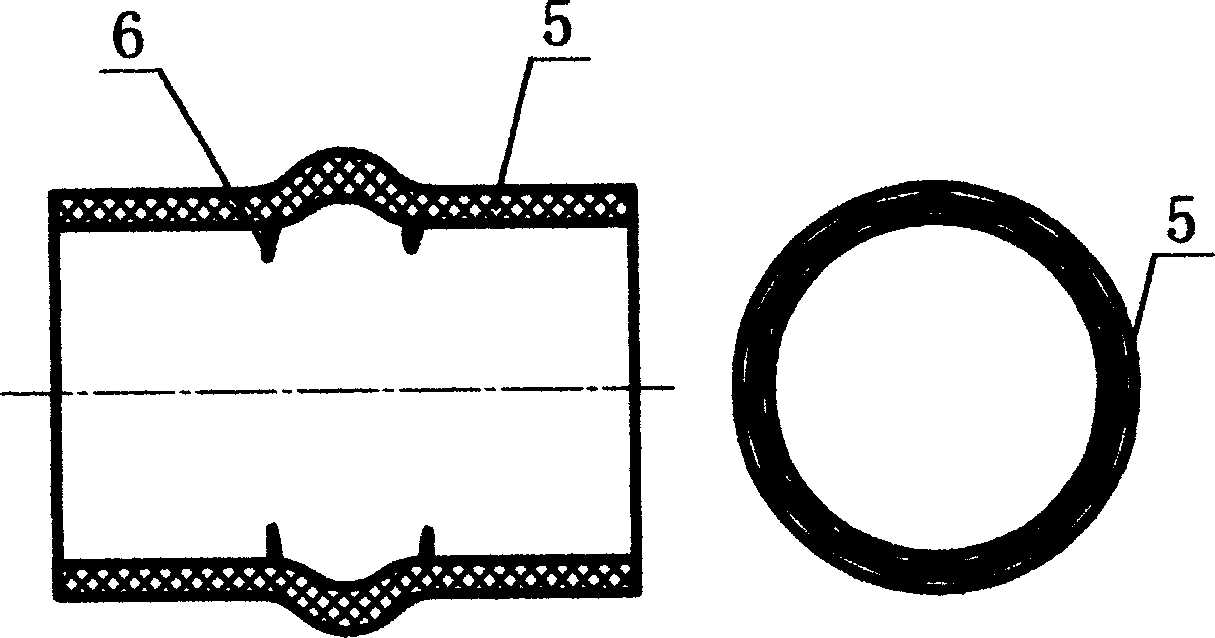

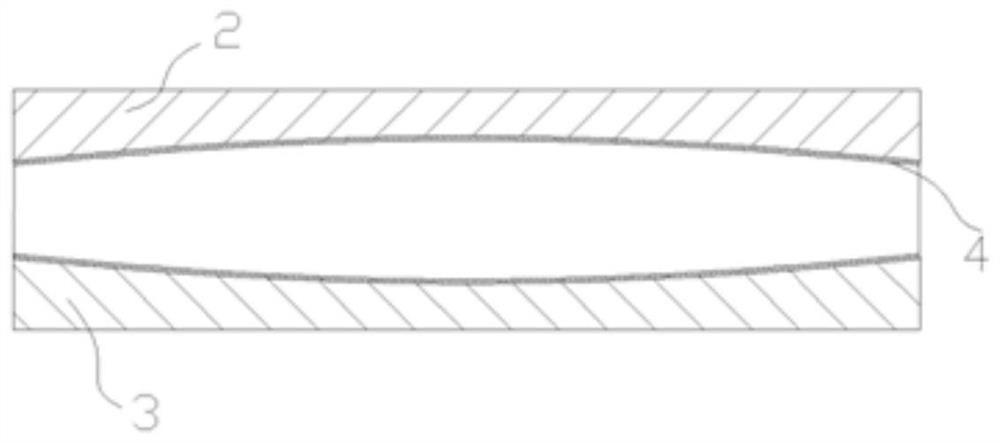

Tech, for producing sebific duct of silicon rubber and special mould core thereof

InactiveCN1792620ASolve easy extrusion fractureSolve difficult demouldingTubular articlesInternal pressureEngineering

A technology for preparing silicon rubber pipe includes such steps as directly forming the rubber pipe blank on the surface of a rubber bag suitable for the internal diameter of rubber pipe, putting them in the cavity of mould, closing the mould, applying pressure to internal space of rubber bag, sulfurizing, releasing internal pressure, and removing said rubber bag. Said rubber bag is just its dedicated moulding core.

Owner:刘建平

Tech, for producing sebific duct of silicon rubber and special mould core thereof

InactiveCN1302912CSolve difficult demouldingOrderly rowsTubular articlesInternal pressureEngineering

A technology for preparing silicon rubber pipe includes such steps as directly forming the rubber pipe blank on the surface of a rubber bag suitable for the internal diameter of rubber pipe, putting them in the cavity of mould, closing the mould, applying pressure to internal space of rubber bag, sulfurizing, releasing internal pressure, and removing said rubber bag. Said rubber bag is just its dedicated moulding core.

Owner:刘建平

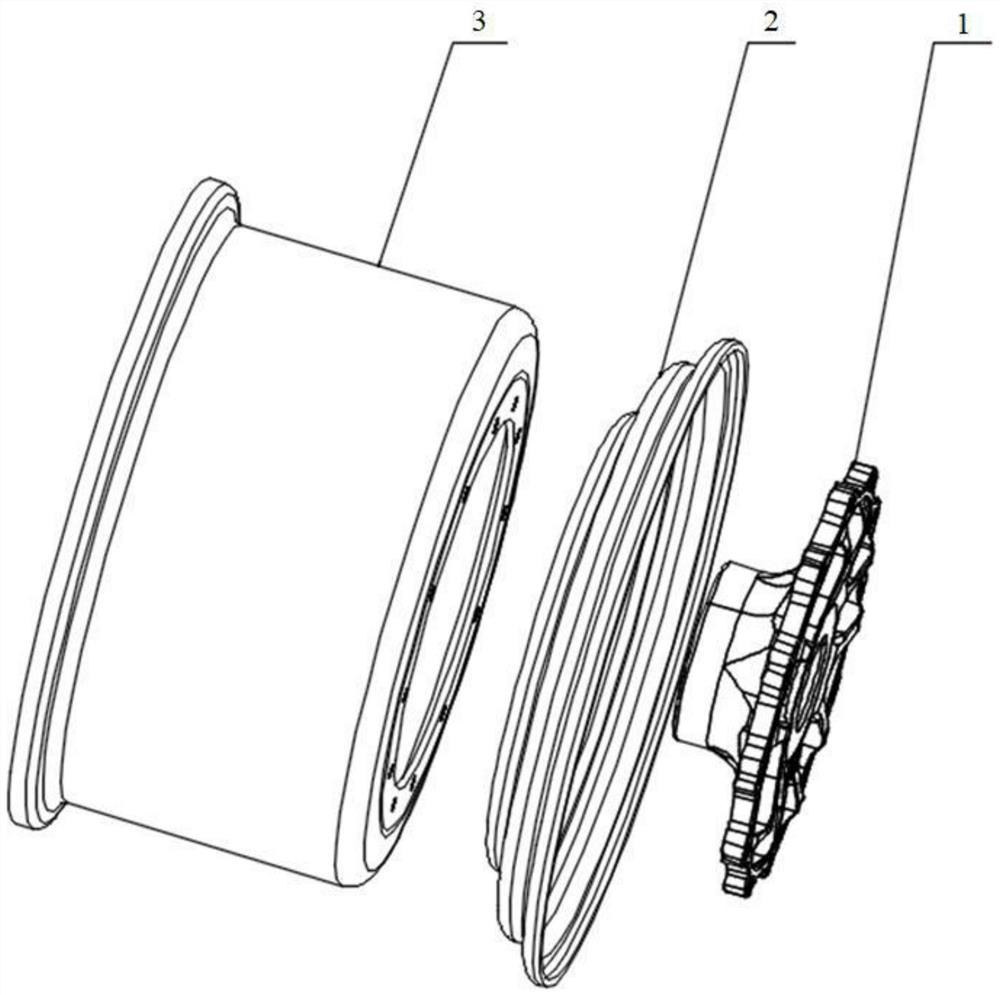

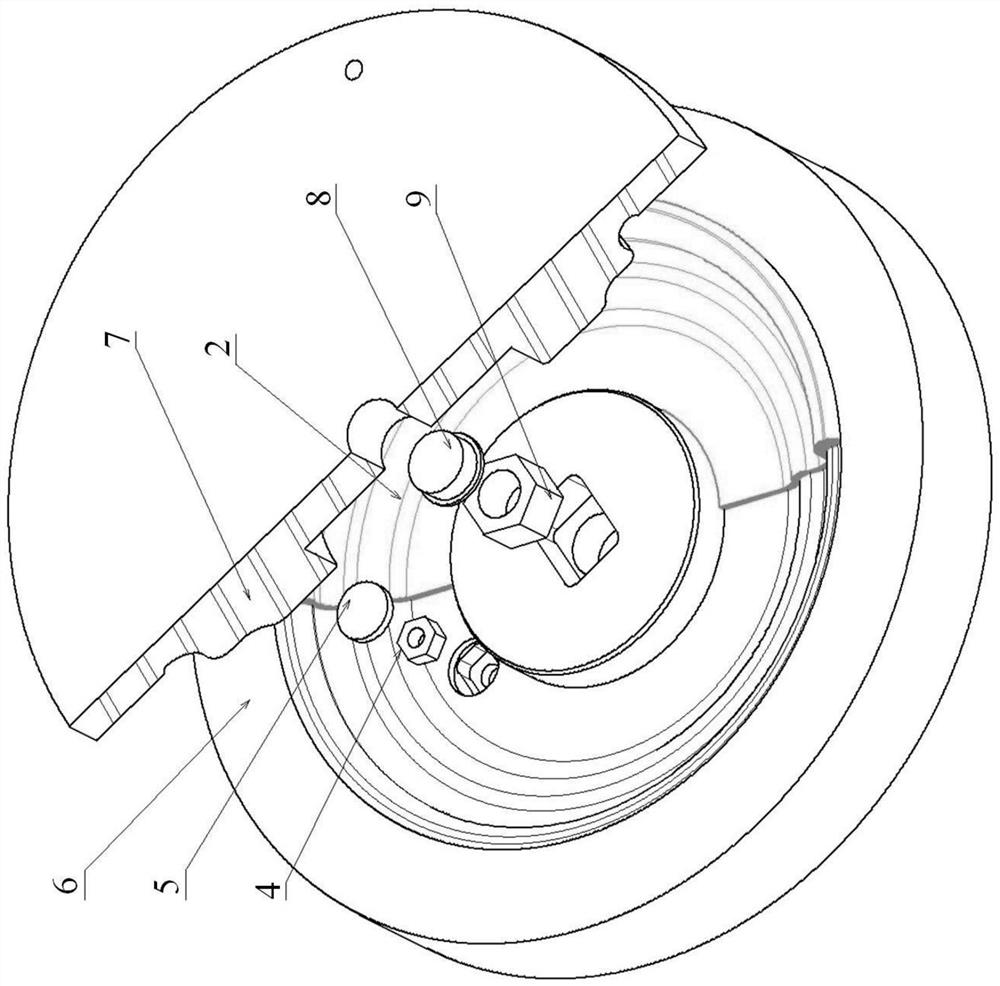

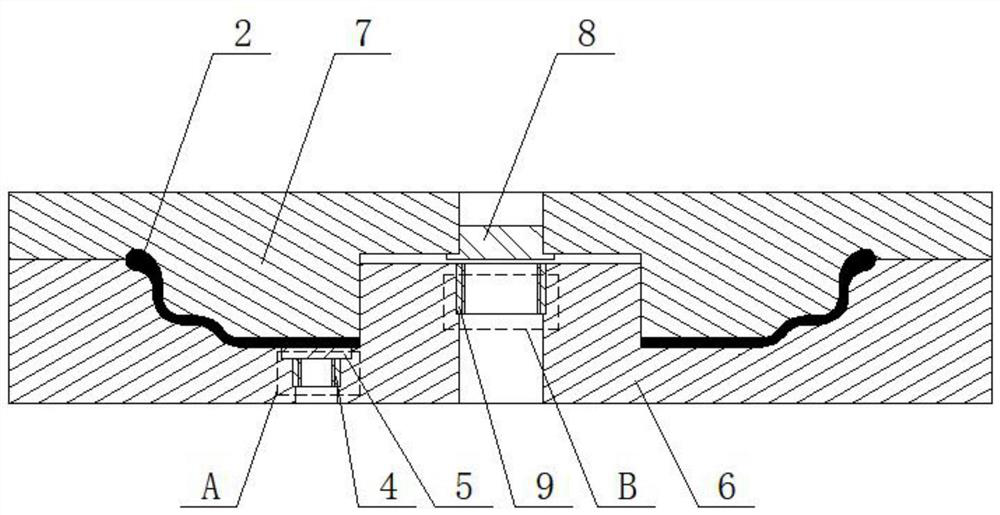

Carbon fiber three-piece combined rim and forming die thereof

The invention relates to a carbon fiber three-piece combined rim and a forming die thereof, and relates to the field of rims and forming dies thereof. The carbon fiber three-piece combined rim is characterized in that the inner end surface of an outer rim and the outer end surface of an inner rim are fixedly connected through high-strength adhesive to form a rim body, a central boss is arranged at the inner end of a spoke, the central boss of the spoke is arranged in a central cavity of the rim body, and the spoke is connected with the rim body in a locking mode. The forming die comprises an outer rim die set and an inner rim die set, when an upper die and a lower die of the outer rim die set are compounded, a cavity which is consistent with the contour shape of the outer rim to be manufactured is formed between the top surface of an annular boss of the upper die and the groove bottom surface of an annular inner groove of the lower die, and is used for forming the contour of the outer rim; and an inner core of a round pipe of the inner rim die set is arranged coaxial with a die cover and the inner core of the round cake, and carries out mutual insertion for positioning operation, and a round pipe outer die is arranged coaxial with the mold cover, and carries out mutual insertion for positioning operation. The forming die is used for forming the carbon fiber rim.

Owner:HARBIN INST OF TECH AT WEIHAI

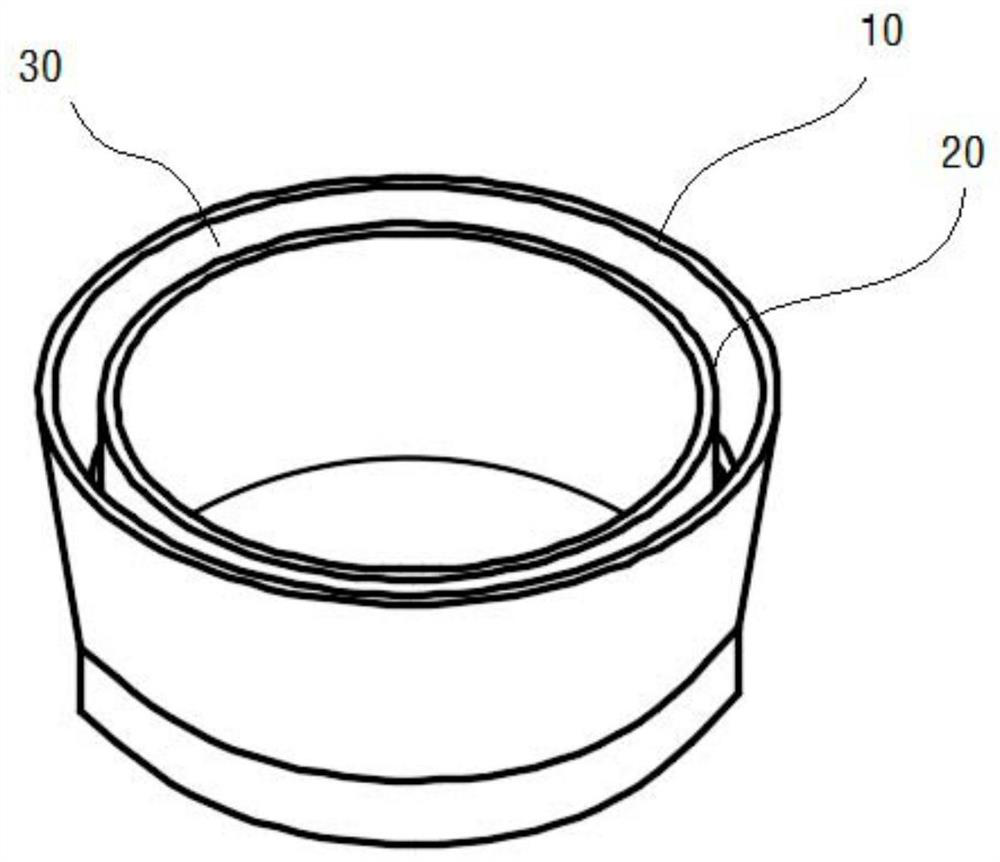

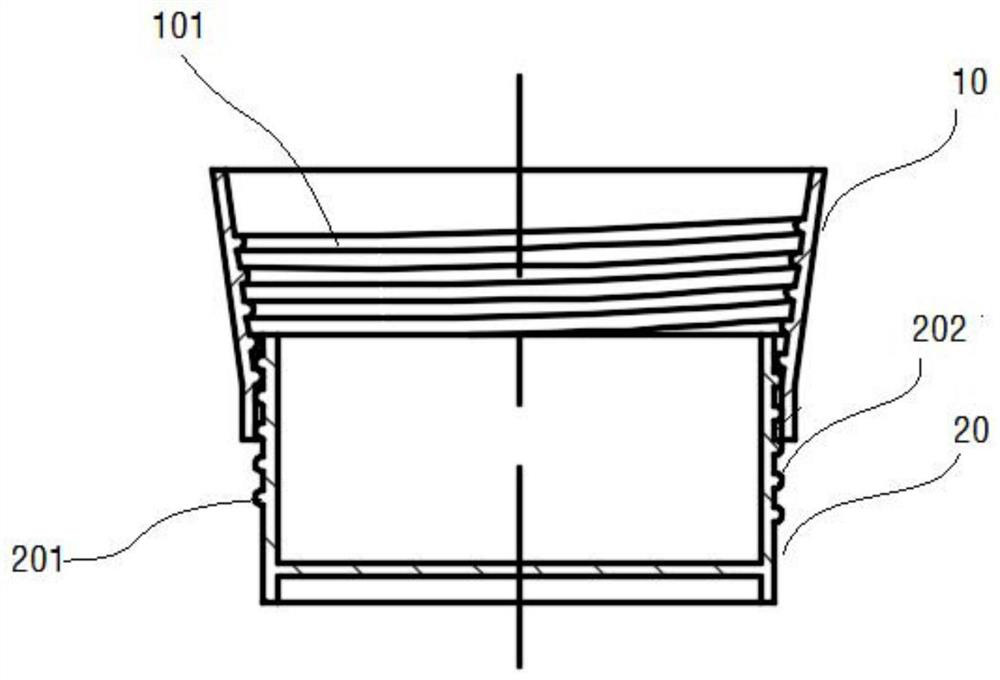

Polyurethane foam filled ring foaming mold

The invention provides a polyurethane foam filled ring foaming mold. The polyurethane foam filled ring foaming mold comprises a female mold, a male mold and an injection structure, wherein the femalemold comprises a left female mold and a right female mold, after the left female mold and the right female mold are assembled, a cavity is formed inside the left female mold and the right female mold,the left female mold and the right female mold are detachably connected, the male mold comprises an upper male mold and a lower male mold, after the upper male mold and the lower male mold are assembled, the upper male mold and the lower male mold cooperate with the cavity of the female mold to define a mold cavity, the mold cavity is suitable for formation of the polyurethane foam filled ring, and the injection structure is arranged on the female mold and suitable for injecting a polyurethane foam material into the mold cavity. According to the polyurethane foam filled ring foaming mold, thefemale mold and the male mold both can be smoothly detached, during demolding, it can be avoided that demolding directly acts on the product, it is avoided that prying, beating and other operation damage the product, and an injection opening can be rapidly sealed after the foam material forms for a certain extent; and the appearance of the product is smooth, and no redundant structure exists.

Owner:北京玻钢院复合材料有限公司

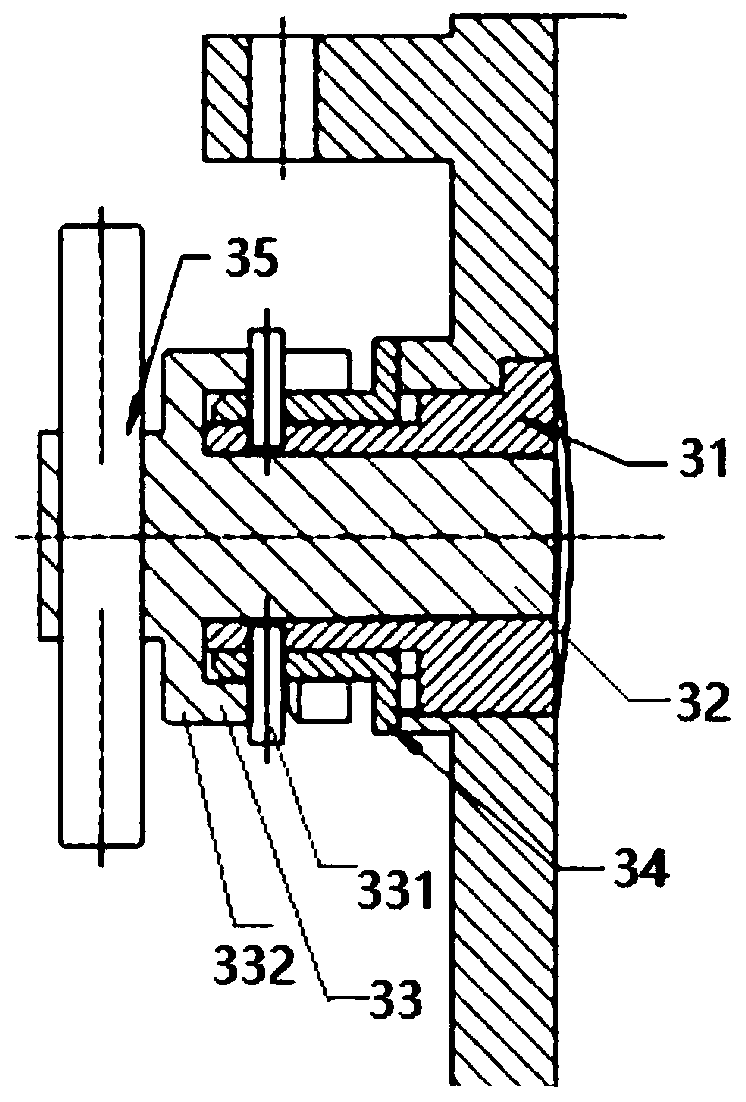

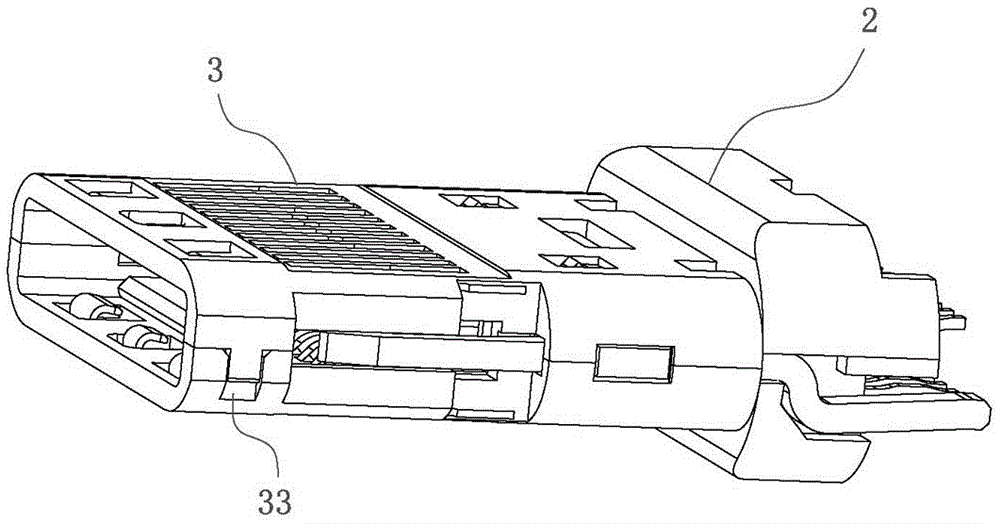

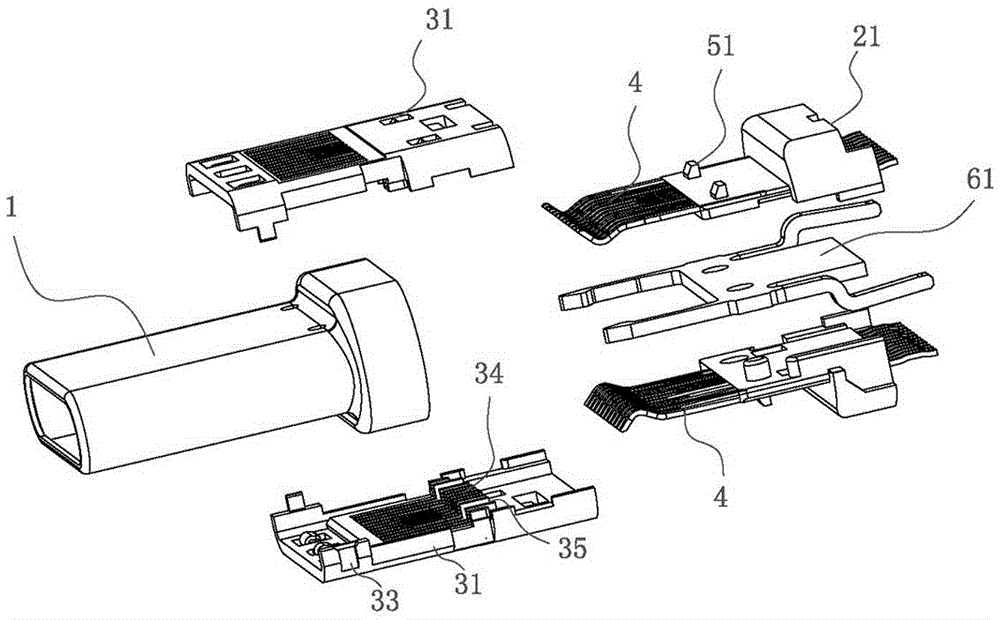

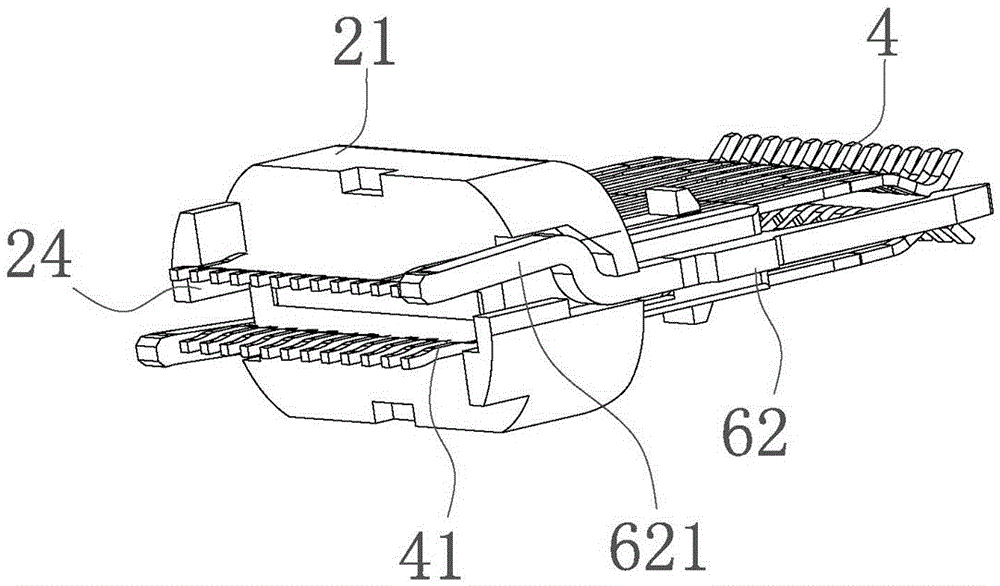

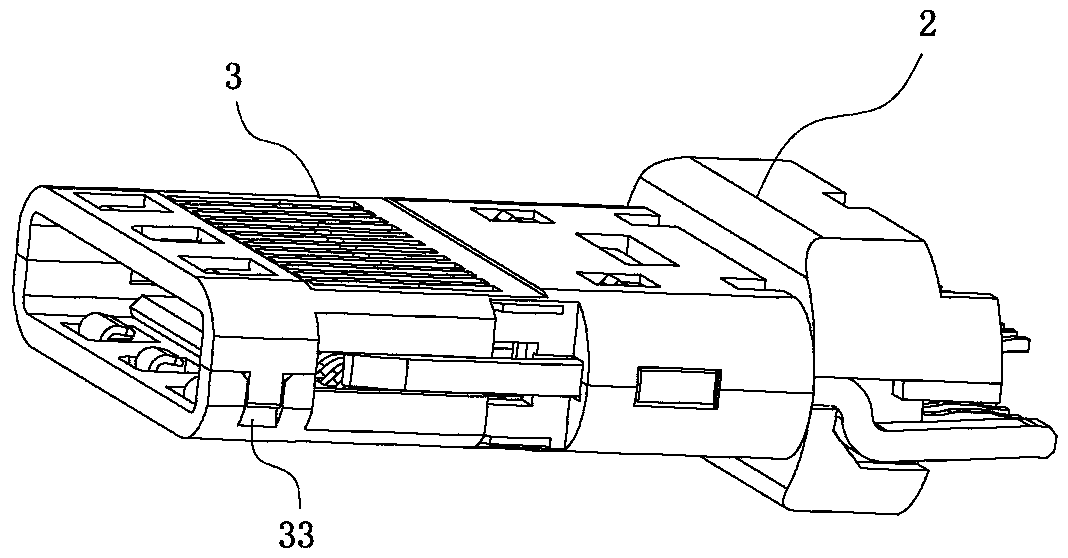

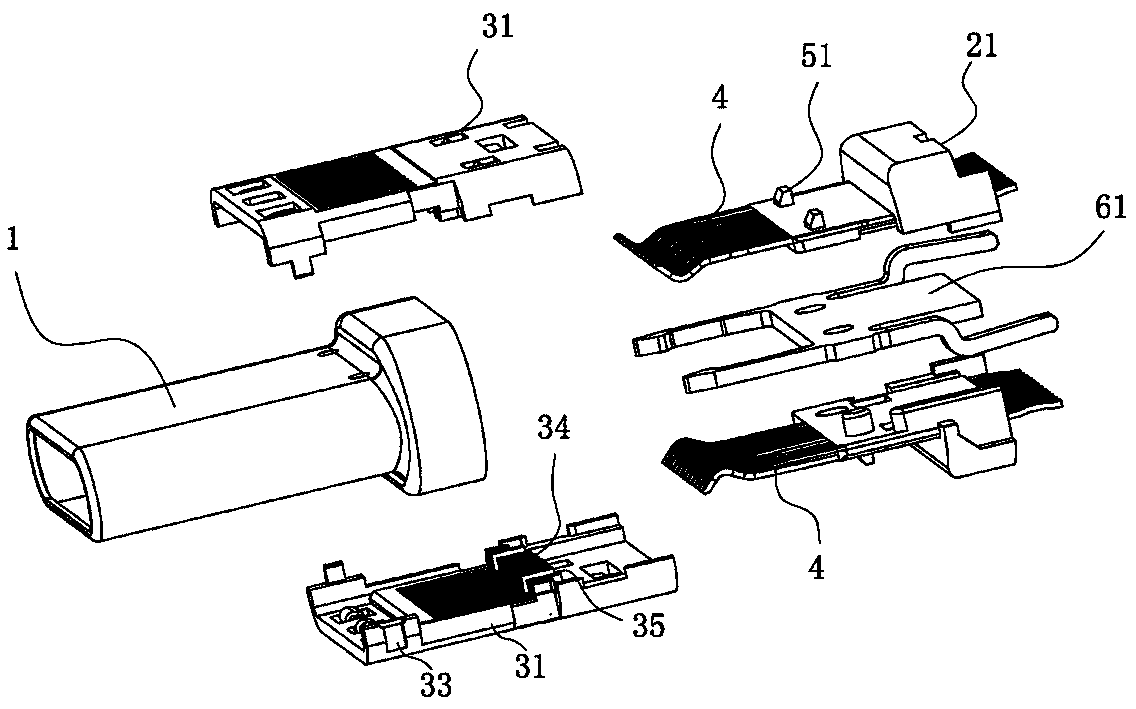

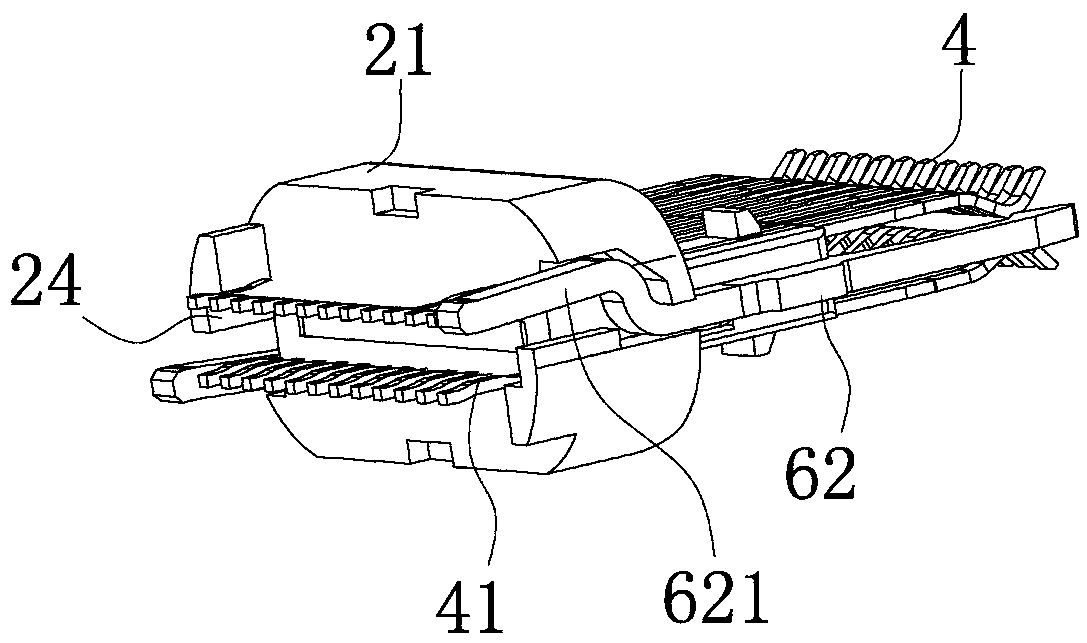

Connector production method and connector structure

ActiveCN105826793ASimple structureCompact structureContact member cases/bases manufactureContact member assembly/disassemblyStructural engineeringInjection moulding

The present invention provides a connector production method. When production, a row of terminals are subjected to injection moulding to form a rear rubber core unit, the rear rubber core unit is fixedly connected with a front rubber core unit to form a connector unit, and any two connector units are assembled together to form the main body of the whole connector. The terminals and the rear rubber core unit are steadily fixed, so that the problem is solved that a traditional injection moulding rear rubber core module group is difficult to demould, it is ensured that the terminals are tidily arranged at the rear rubber core unit, and the requirement is satisfied that the connector is compactly and firmly assembled. The present invention further provides a connector structure, and the connector structure is cooperated with the production method provided by the invention. The rear rubber core module group is formed by two rear rubber core units with the same structure through buckling, and the front rubber core module group is formed by two front rubber core units with the same structure through buckling, and the rear rubber core units and the front rubber core units are produced on a large scale, then any two rear rubber core units and any two front rubber core units can be combined.

Owner:韶关胜蓝电子科技有限公司

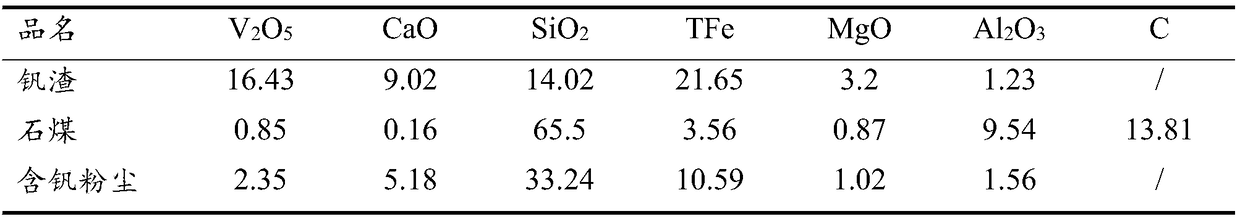

Method for roasting vanadium-containing raw materials to prepare vanadium-containing clinker

The invention relates to a method for roasting vanadium-containing raw materials to prepare vanadium-containing clinker. The method comprises the following steps: a. uniformly mixing vanadium slag, stone coal and caustic soda in a certain percentage by weight to prepare the raw materials; b. pressing the raw materials prepared in the step a under the pressure intensity of 15-20MPa to prepare pellets; c. charging the prepared pellets into a drying kiln and drying; d. preheating the dried pellets through a preheating rotary kiln, and then roasting the pellets through a roasting rotary kiln; ande. rapidly cooling the roasted pellets to prepare the vanadium-containing pellet clinker. According to the method disclosed by the invention, the pellets are prepared from the mixed materials, and thestone coal is added into the pellets, so that a series of problems of material entrainment due to powder bonding is effectively solved; and meanwhile, the problems of material bonding due to a too high heat release amount in a roasting process for the vanadium slag, and insufficient heat due to independent roasting for the stone coal, are also greatly solved. Carbon in the stone coal plays a lubrication role; and meanwhile, a two-stage roasting manner is adopted, so that the conversion rate for the vanadium-containing raw materials is increased.

Owner:PANZHIHUA HENGHONG IRON PELLETS CO LTD

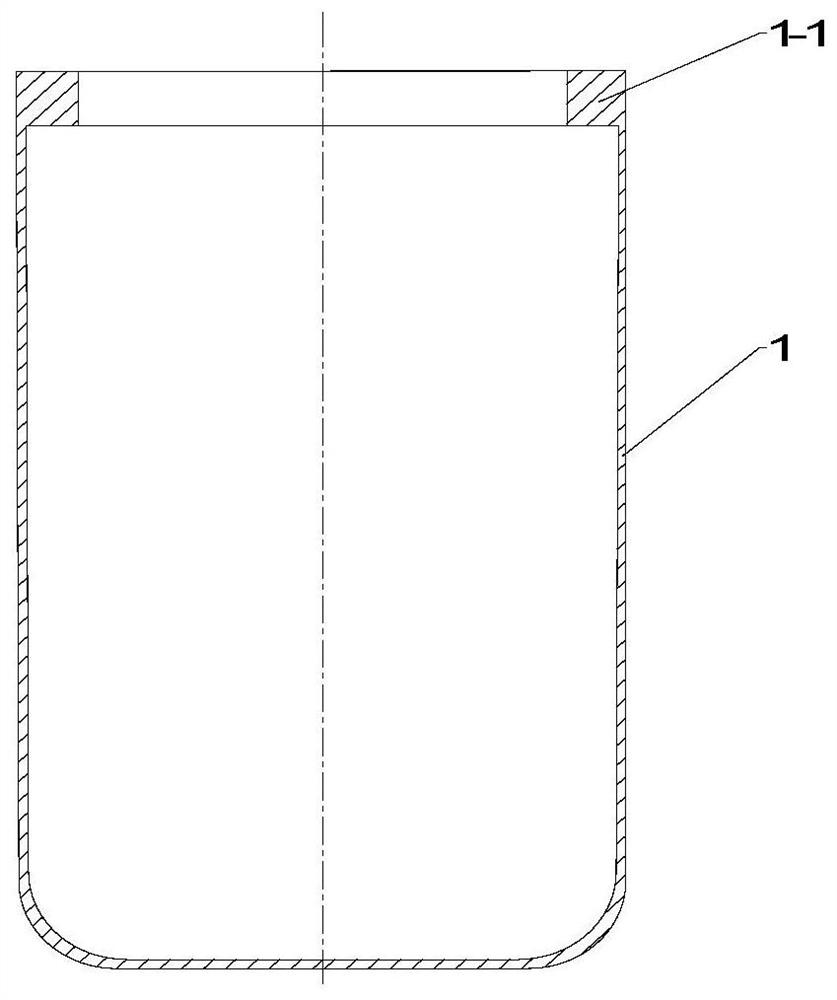

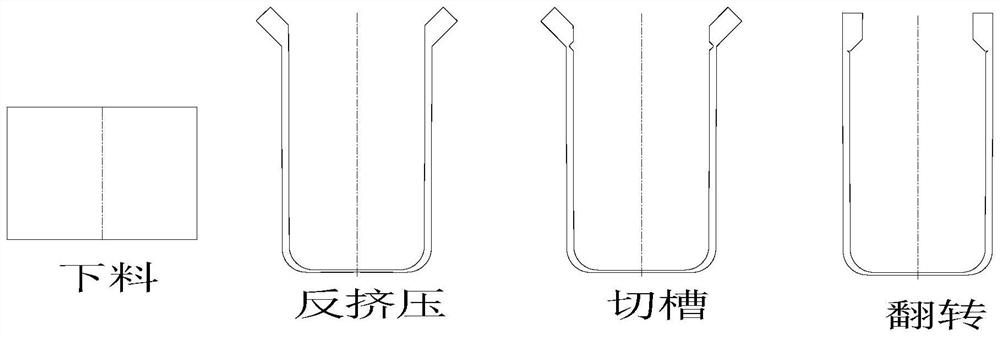

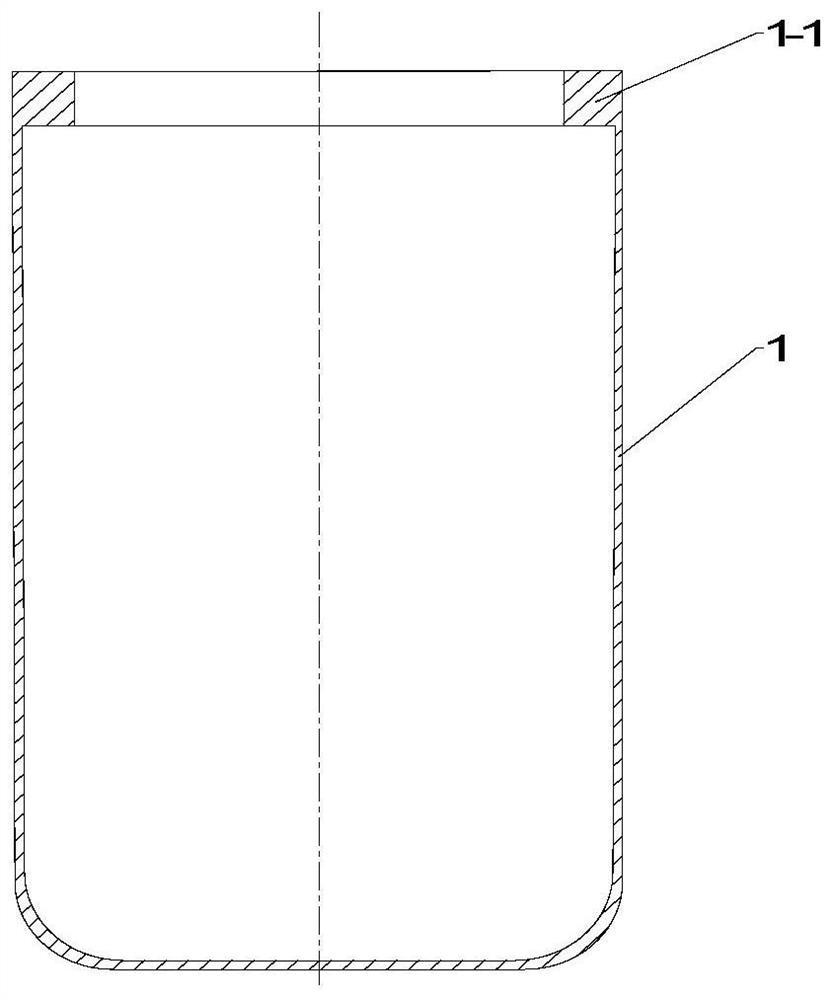

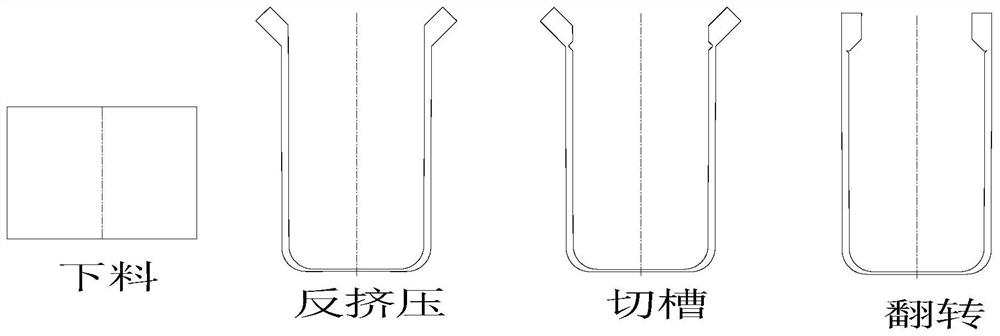

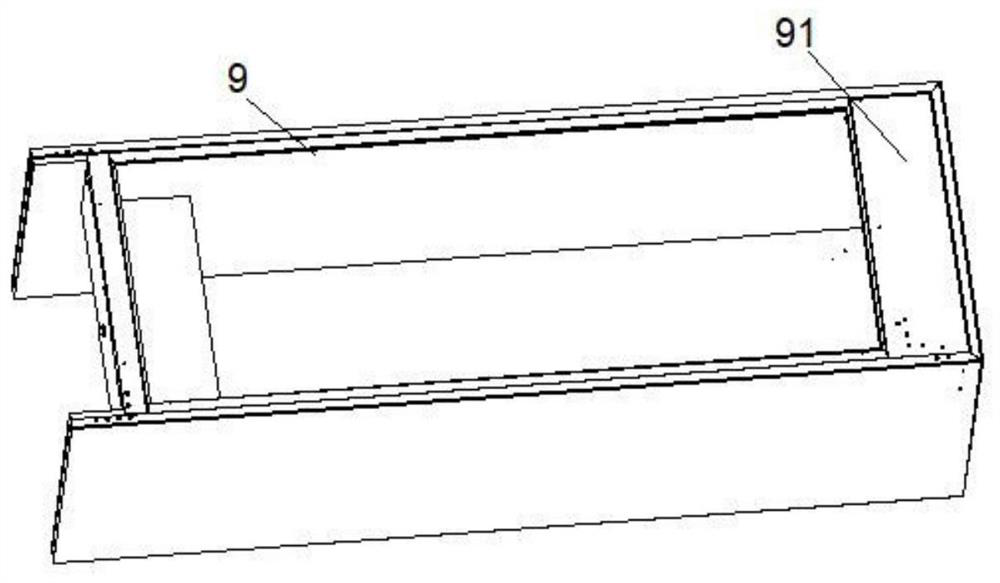

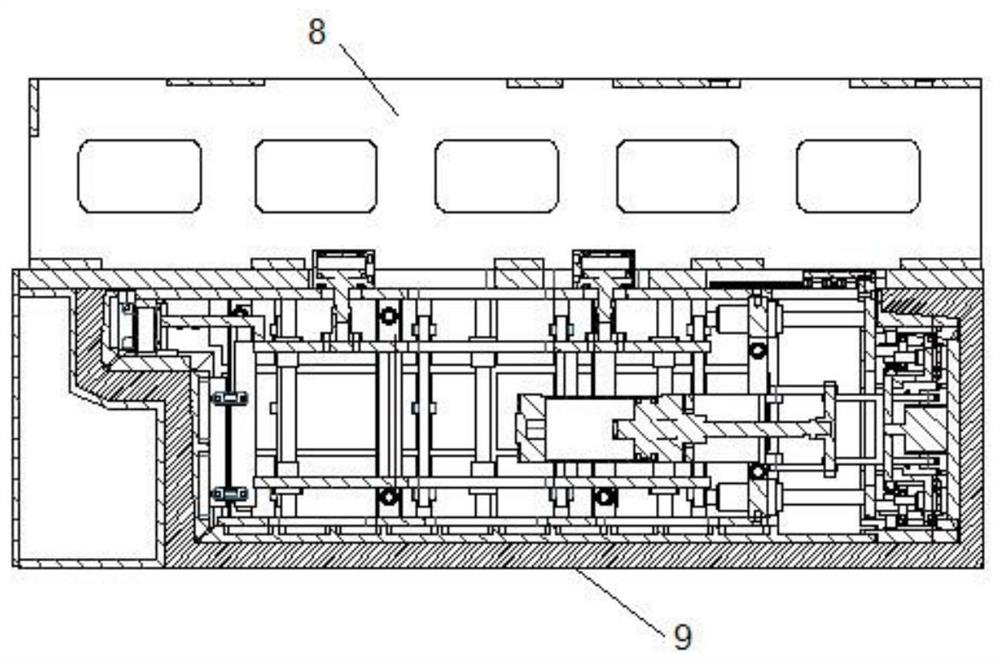

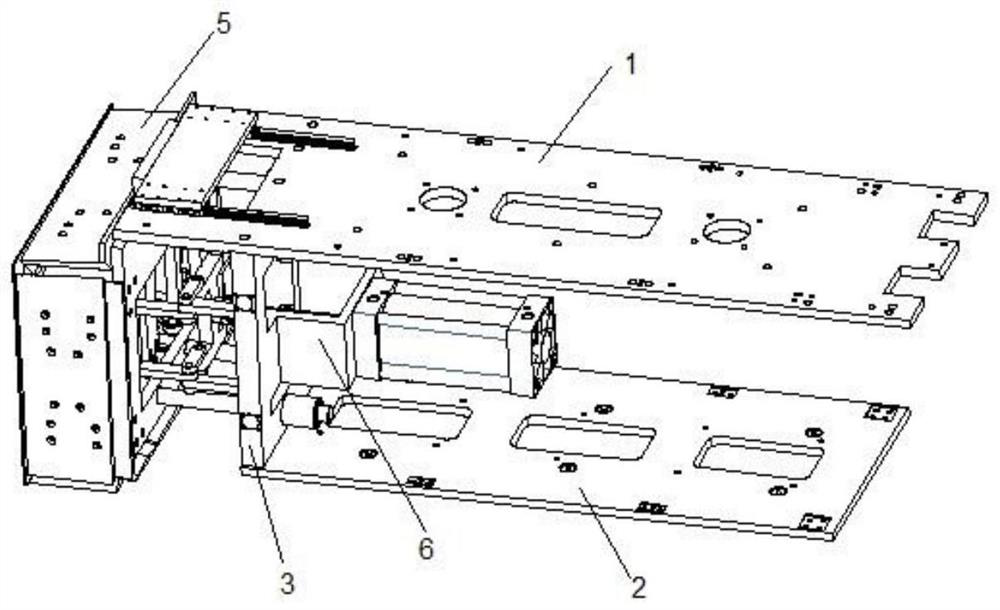

Forming method of cylinder workpiece with transverse inner rib

ActiveCN113182474ASolve difficult demouldingAvoid breakingShaping toolsExtrusion diesShear stressEngineering

The invention relates to a forming method of a cylinder workpiece with a transverse inner rib. According to the forming method, the procedures of blanking, upsetting and backward extrusion are adopted, and the forming method is characterized in that the procedures of grooving and overturning, overturning a blank inner rib die and the like are adopted; a male die of the overturning blank inner rib die comprises a male die correcting ring, a male die pressing plate, a connecting rod mechanism, a spring, a pressing rod, a limiting pipe and a pressing ring; and a female die comprises an inner overturning female die body, an inner overturning female die body supporting ring and a lower die plate. The problems that a cylindrical part with a large body and a small opening is extruded, and demolding is difficult are solved, a female die opening is designed to be a large-arc-shaped fillet, the shearing stress generated when a thick-wall annular rib at the upper end of a backward extrusion cylinder workpiece is overturned is reduced, material breakage during overturning is prevented, and the quality of the outer surface of an extrusion cylinder is improved; and materials are saved, efficiency is high, and the forming method is suitable for batch production.

Owner:ZHONGBEI UNIV

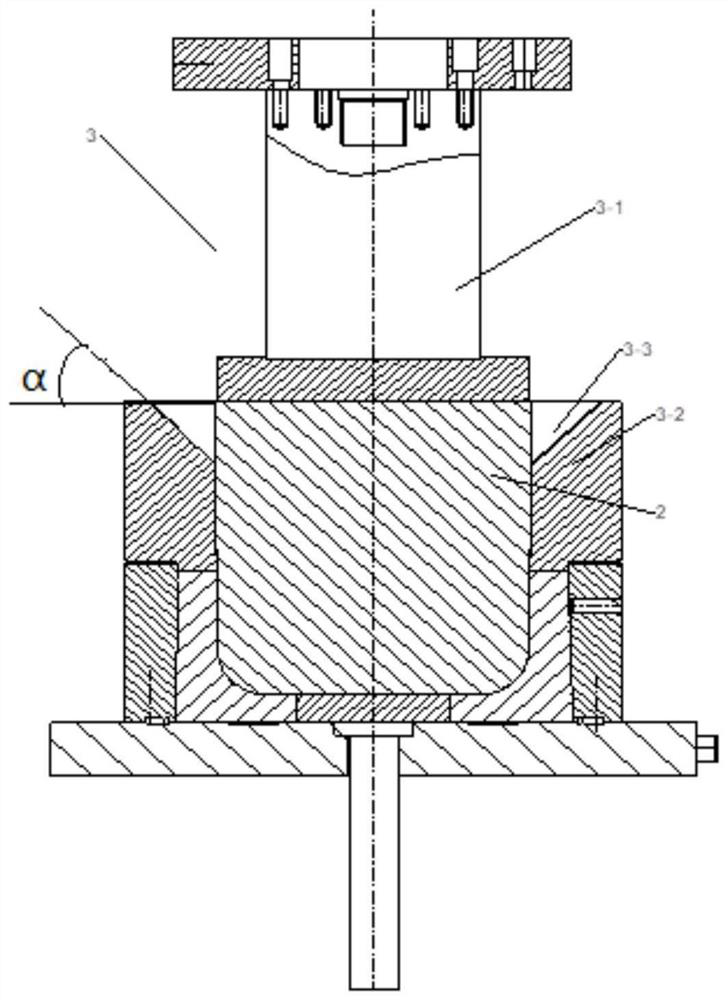

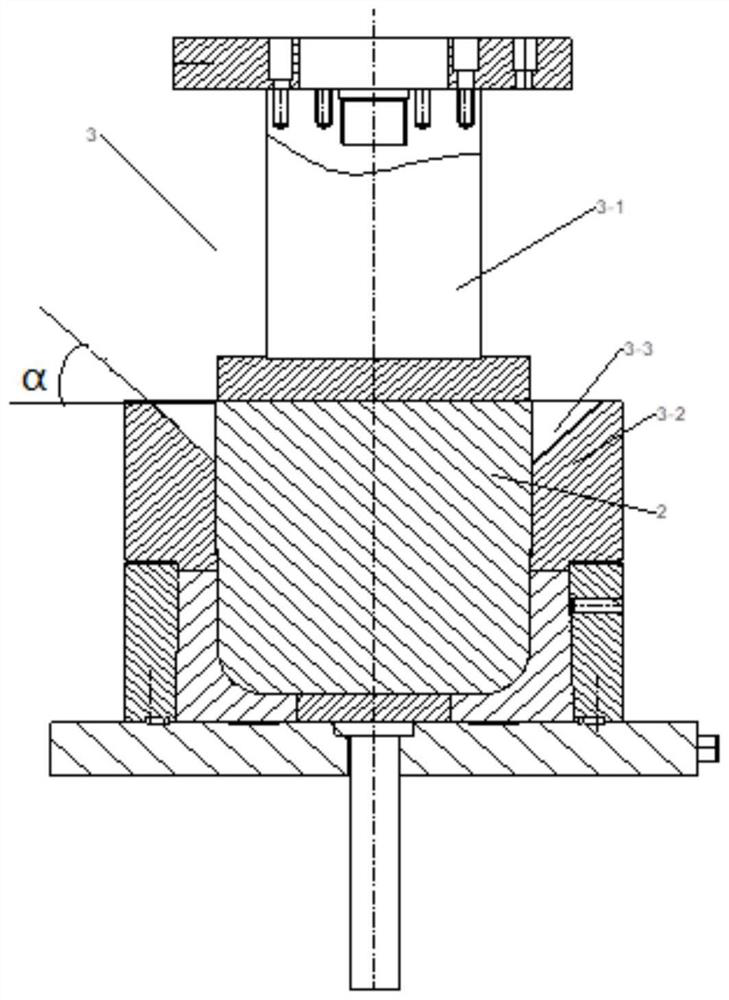

Blank inner rib overturning die for cylinder workpiece with transverse inner ribs

ActiveCN113275460ASolve difficult demouldingAvoid breakingShaping toolsEjection devicesStructural engineeringLever pressing

The invention relates to a blank inner rib overturning die for a cylinder workpiece with transverse inner ribs. The blank inner rib overturning die comprises a male die, a female die and a lower ejector rod. The blank inner rib overturning die is characterized in that the male die comprises a male die correcting ring, a male die pressing plate, a connecting rod mechanism, a spring, a pressing rod, a limiting pipe and a pressing ring; the male die pressing plate is fixedly connected to the lower end of the pressing rod, the male die correcting ring is arranged on the pressing rod in a sleeving manner, and the connecting rod mechanism is connected with the male die correcting ring and the male die pressing plate; the spring is arranged in the limiting pipe, and the spring and the limiting pipe are arranged on the pressing rod between the male die pressing plate and the male die correcting ring together in a sleeving manner, and are fixed on the male die pressing plate through the pressing ring; the female die comprises an inner overturning female die body, an inner overturning female die body supporting ring and a lower die plate; and the overturning female die is connected to the inner overturning female die supporting ring, and the inner overturning female die supporting ring is fixed to the lower die plate. According to the blank inner rib overturning die, the problem of difficult demolding due to extrusion of the large-and-small-opening cylinder workpiece are solved, the shearing stress during overturning is reduced, material breakage during overturning is prevented, and the extrusion quality of the outer surface of a cylinder is improved.

Owner:ZHONGBEI UNIV

Two-end closing tubular composite material component forming method

InactiveCN111688237AReduce manufacturing costReduce manufacturing difficultyTubular articlesThermoplasticGlass transition

The invention relates to a two-end closing tubular composite material component forming method. According to the forming method, a tubular meltability die is formed in a cavity of an auxiliary die formed through tubular combination of an upper die and a lower die, and the outer profile of the cavity of the auxiliary die is the same with the inner profile of a tubular composite material component.The two-end closing tubular composite material component is prepared through the tubular meltability die, after the tubular composite material component is formed, heating is conducted to make the tubular meltability die softened, and then demoulding is finished. Demoulding is achieved through the glass transition temperature difference of the tubular meltability die and the tubular composite material component, usage of a metal combined die is avoided, the die manufacturing cost and manufacturing difficulty are reduced, thermoplastic plastics used in the meltability die have the characteristic of being recyclable, repeated usage can be achieved, and the method has the characteristics of being simple and convenient to operate, low in cost and the like.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

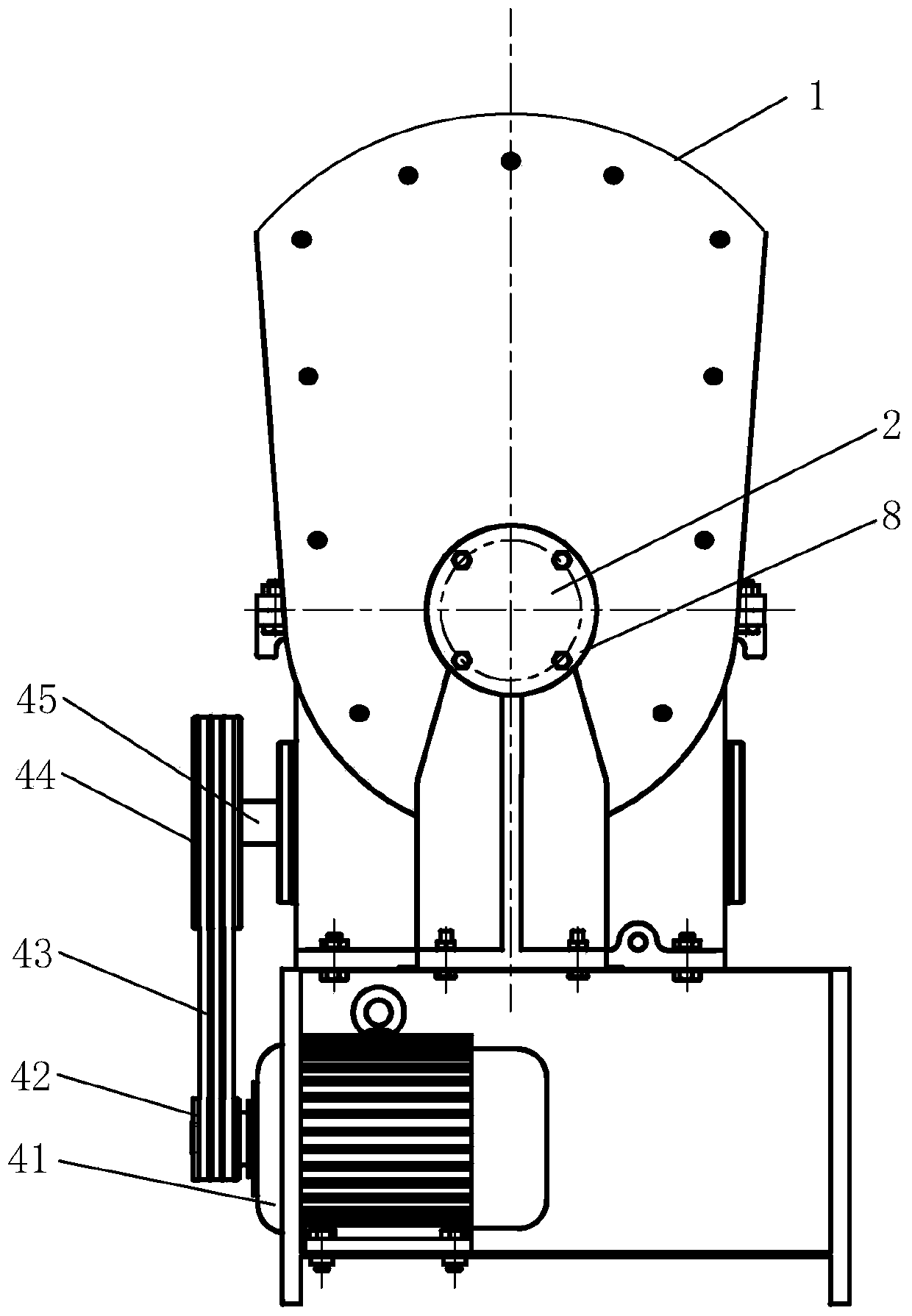

Stirring equipment for producing epoxy resin-bonded mastic

PendingCN111330477AEasy to cleanEasy to demouldTransportation and packagingRotary stirring mixersEpoxyResin adhesive

The invention discloses stirring equipment for producing resin-bonded mastic, and belongs to the technical field of industrial stirring equipment. The stirring equipment comprises a shell, a stirringshaft, stirring blades and a power device, wherein the stirring shaft, the stirring blades and the power device are arranged in the shell, the power device is connected with the stirring shaft and drives the stirring shaft to rotate, the stirring blades are installed on the stirring shaft, easy-to-demold layers are arranged on the surface layers of the stirring shaft and the stirring blades, and asmooth film layer is arranged on the inner wall of the shell. According to the invention, the stirring shaft and the stirring blades are provided with the easy-to-demold layers, and the inner wall ofthe shell is provided with the smooth film layer, so that the resin-bonded mastic is not bonded, the resin-bonded mastic is easy to demold, and the used stirring equipment is easy to clean; and the easy-to-demold layer adopted by the invention is a heat shrinkable film which is low in price, long in service life, simple in operation process and extremely suitable for production.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

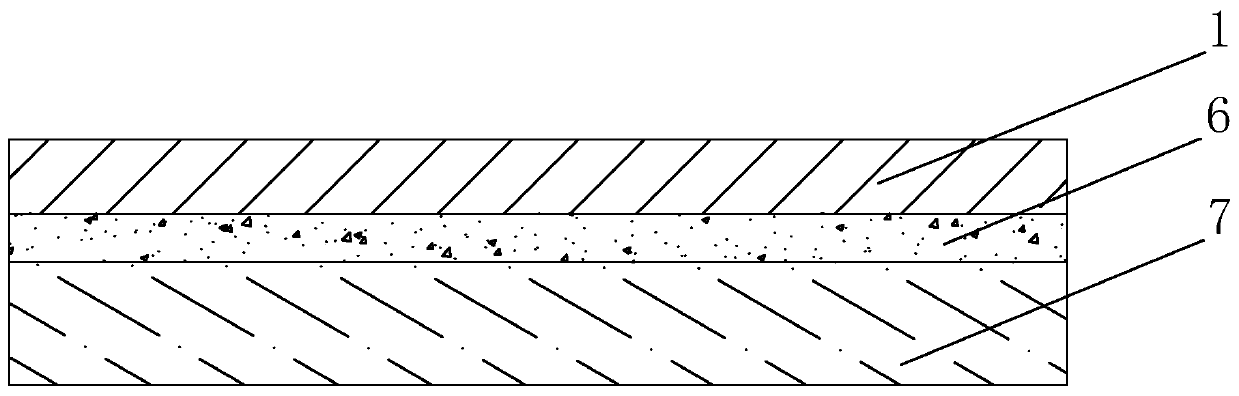

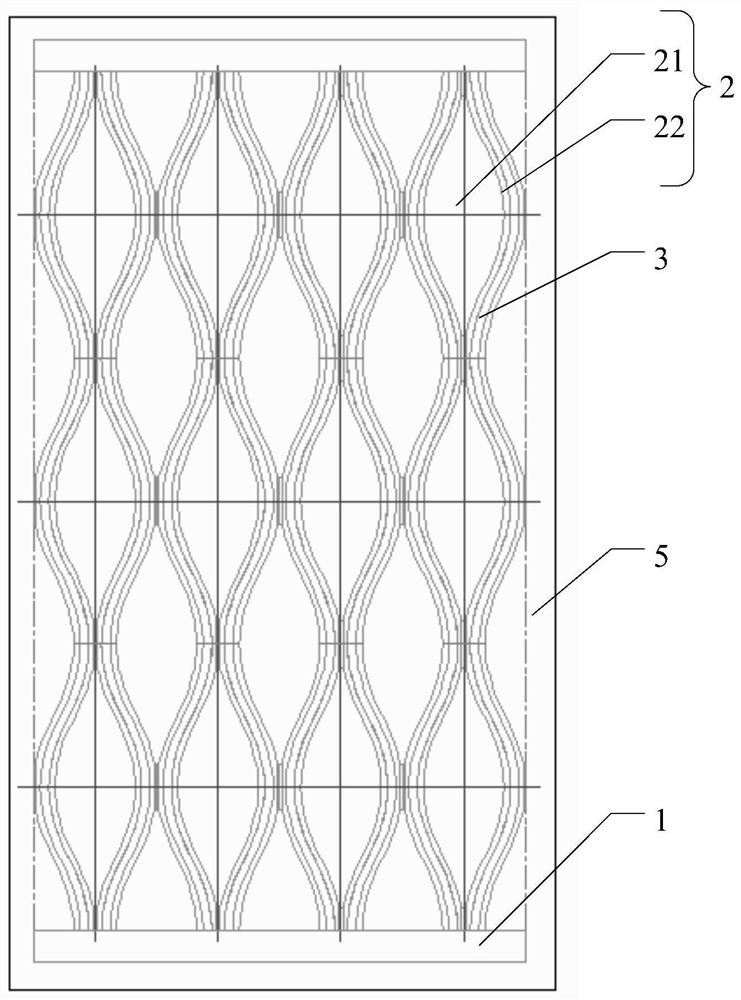

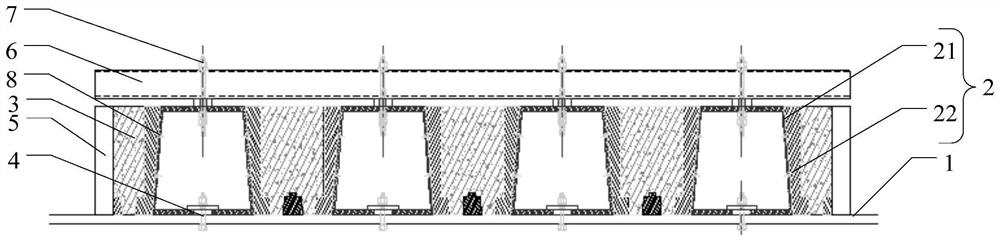

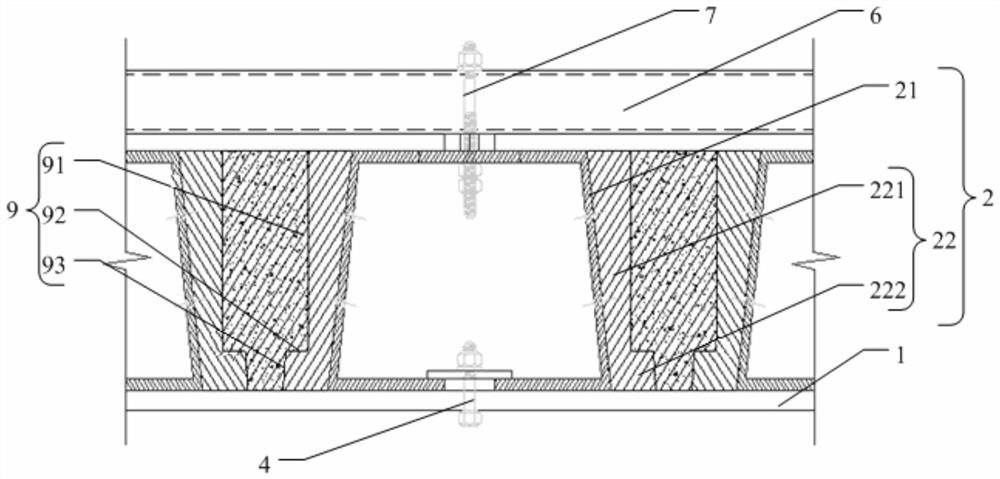

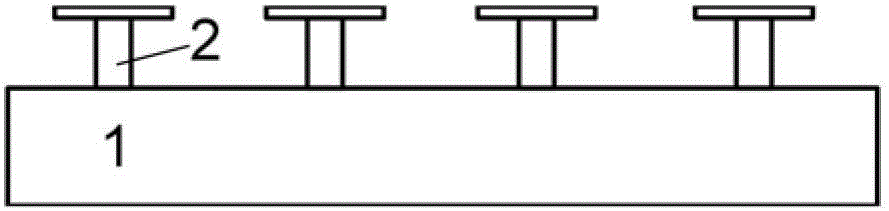

Forming mold and construction method for prefabricated hollowed-out concrete member

InactiveCN113059661ASolve difficult demouldingSolve problems such as component breakageMouldsMould fastening meansPre stressConstruction engineering

The invention provides a forming mold for a prefabricated hollowed-out concrete member. The forming mold comprises a working platform and a forming structure located on the working platform, wherein the forming structure comprises a plurality of modules, each module comprises an inner core column, the side face of each inner core column is wrapped with an outer mold wrapping layer, and the adjacent modules are spaced to form prefabricated concrete pouring cavities. The invention further provides a construction method for the prefabricated hollowed-out concrete member. According to the forming mold and the construction method for the prefabricated hollowed-out concrete member, the problems that an existing mold for preparing an oversized hollowed-out concrete member is extremely difficult to demold or the member is fractured due to the conditions of complex rib distribution, non-prestress and the like formed by a curved hollowed-out shape of the member can be solved, and the prepared concrete member is high in dimensional precision and low in manufacturing cost.

Owner:上海鼎中新材料有限公司

A Forming Method of Cylinder Workpiece with Transverse Internal Ribs

ActiveCN113182474BSolve difficult demouldingAvoid breakingShaping toolsExtrusion diesPunch pressShear stress

The invention relates to a method for forming a cylindrical workpiece with transverse internal ribs. The forming method adopts the process of blanking + upsetting + reverse extrusion, and is characterized in that it adopts the processes of grooving, turning over, and turning over the inside of the blank. Rib molds, etc.; among them: the punch of the inner rib mold of the flip blank includes a punch correction ring, a punch plate, a connecting rod mechanism, a spring, a pressure rod, a limit tube, and a pressure ring; the die includes an inner flip die, an inner flip Die support ring and lower template; the invention solves the problem of difficult demoulding when extruding cylindrical parts with large or small mouths. The shear stress of the thick-walled ring rib at the upper end prevents the material from breaking during the overturn and improves the quality of the outer surface of the extruded cylinder; it saves material and has high efficiency, and is suitable for mass production.

Owner:ZHONGBEI UNIV

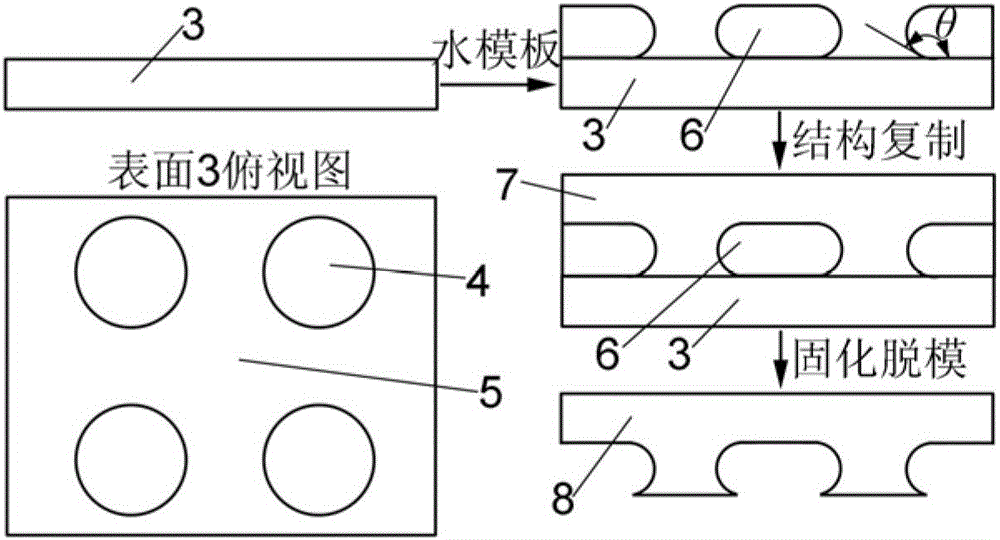

A liquid-assisted forming method for preparing superoleophobic surfaces

InactiveCN103030105BReusableSolve difficult demouldingMicrostructural devicesPolymer scienceReplica molding

The invention relates to the technical field of functional surface preparation, in particular to a liquid assisted forming method for preparing a superoleophobic surface. The method is suitable for preparing a polymer superoleophobic surface, particularly for preparing the superoleophobic surface under simple and easy conditions. The method comprises the steps that assisted forming liquid is injected into a treated flat surface with preferential wettability; the liquid and the flat surface serve as a template; and the preparation of a secondary groove structure is achieved by a replica molding method. Equipment required by the liquid assisted forming method is simple, the preparation of the superoleophobic surface can be achieved under the simple and easy conditions, the preparation cost is low, and batch preparation is easy.

Owner:JIANGSU UNIV

A polyurethane foam filled ring foaming mold

The invention provides a polyurethane foam filled ring foaming mold, comprising: a female mold, including a left female mold and a right female mold, the left female mold and the right female mold are combined to form a mold cavity inside, and the left female mold and the right female mold are detachable connection; the male mold, including the upper male mold and the lower male mold, the upper male mold and the lower male mold are combined to form a mold cavity with the cavity of the female mold, and the mold cavity is suitable for polyurethane foam filling ring molding; the injection structure is designed On the female mold, it is suitable for injecting polyurethane foam into the mold cavity. The polyurethane foam filled ring foaming mould, male and female molds can be removed smoothly, and can avoid direct action on the product during demoulding, avoiding prying, knocking and other operations that cause damage to the product. Rapid plugging, smooth product shape, no redundant structure.

Owner:北京玻钢院复合材料有限公司

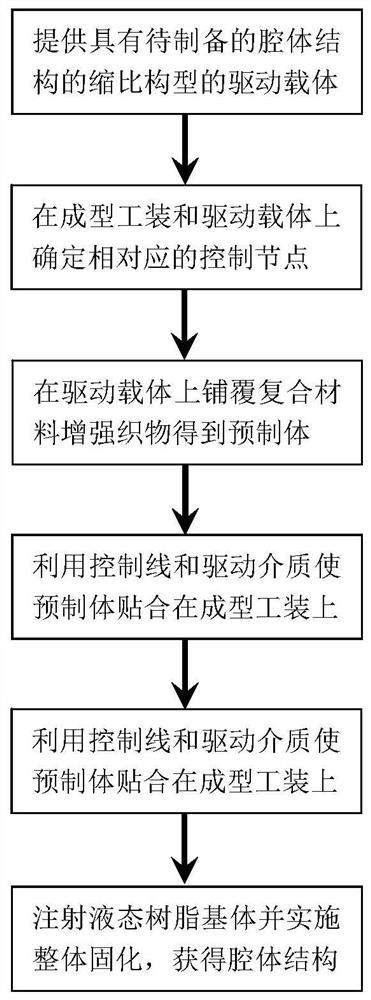

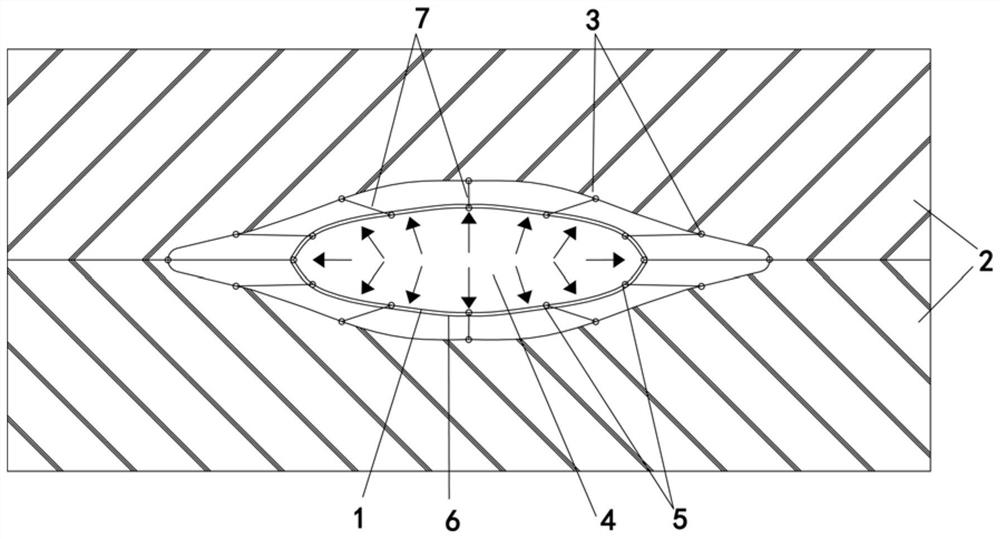

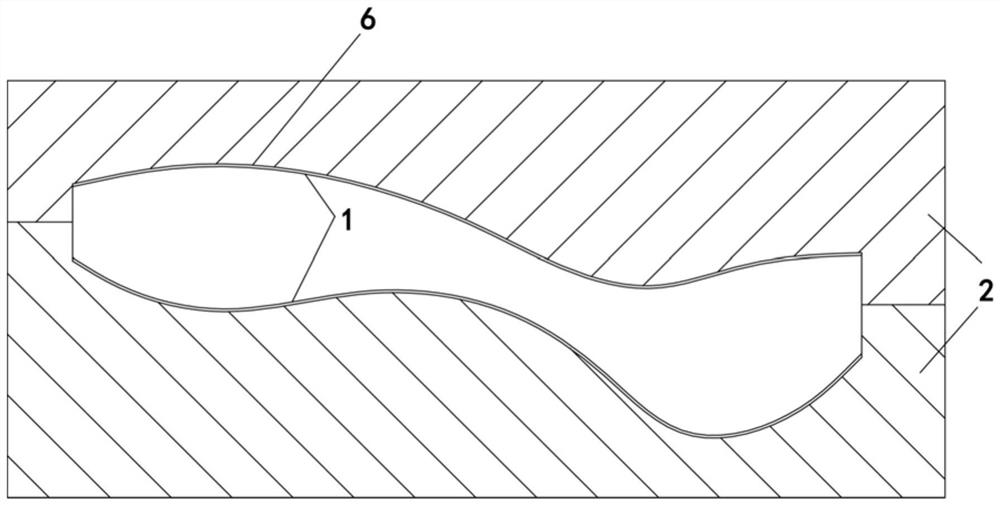

A cavity structure and its preparation method

The invention relates to a cavity structure and a preparation method for the same. The method comprises the steps that a drive carrier with a geometrical similarity is provided; corresponding controlnodes are disposed on a formed fixture and the drive carrier respectively; a composite reinforced fabric is paved and fixed on the drive carrier to form a prefabricated body; the prefabricated body isadhered on the formed fixture by a fluid drive medium; and a liquid state matrix is injected and solidified, so the cavity structure can be obtained. The invention also provides the cavity structuremade with the method. The method provided by the invention is extensively applicable and especially applicable to complicated thin-wall cavity structures with abrupt cross-section changes and great changes of main axis curvatures of cavities; problems in traditional technologies such as difficulty in paving and demoulding can be solved; the formed fixture is simple and does not have many requirements for equipment, and the duration is short; and the fabricated cavity structure has a good appearance and high accuracy, is free of layering and loosening and is highly overall and reliable.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

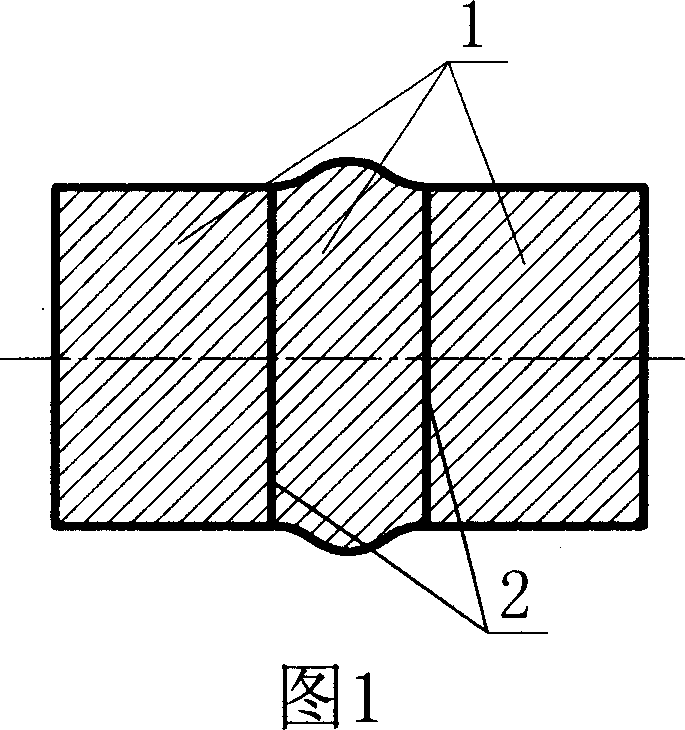

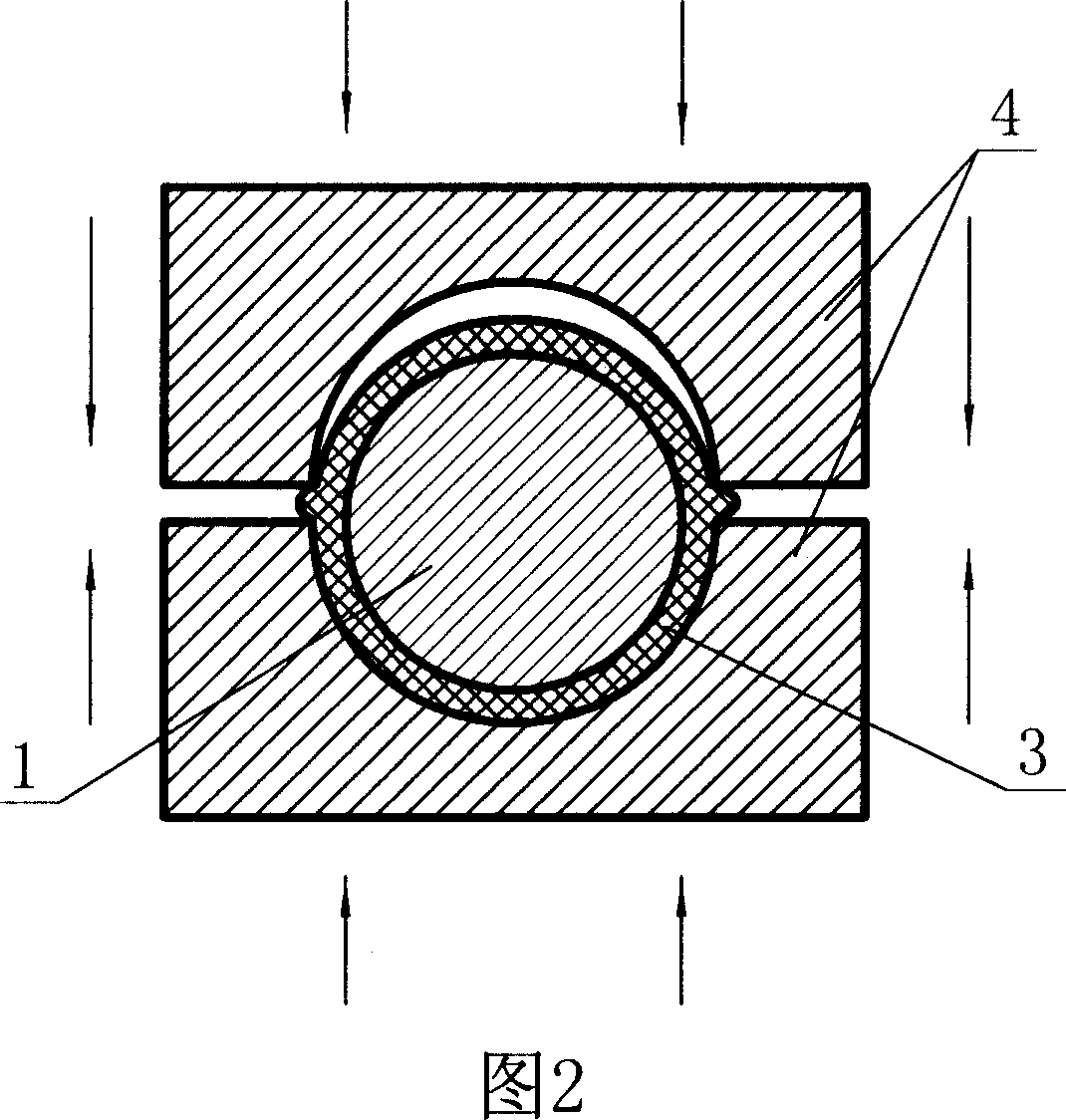

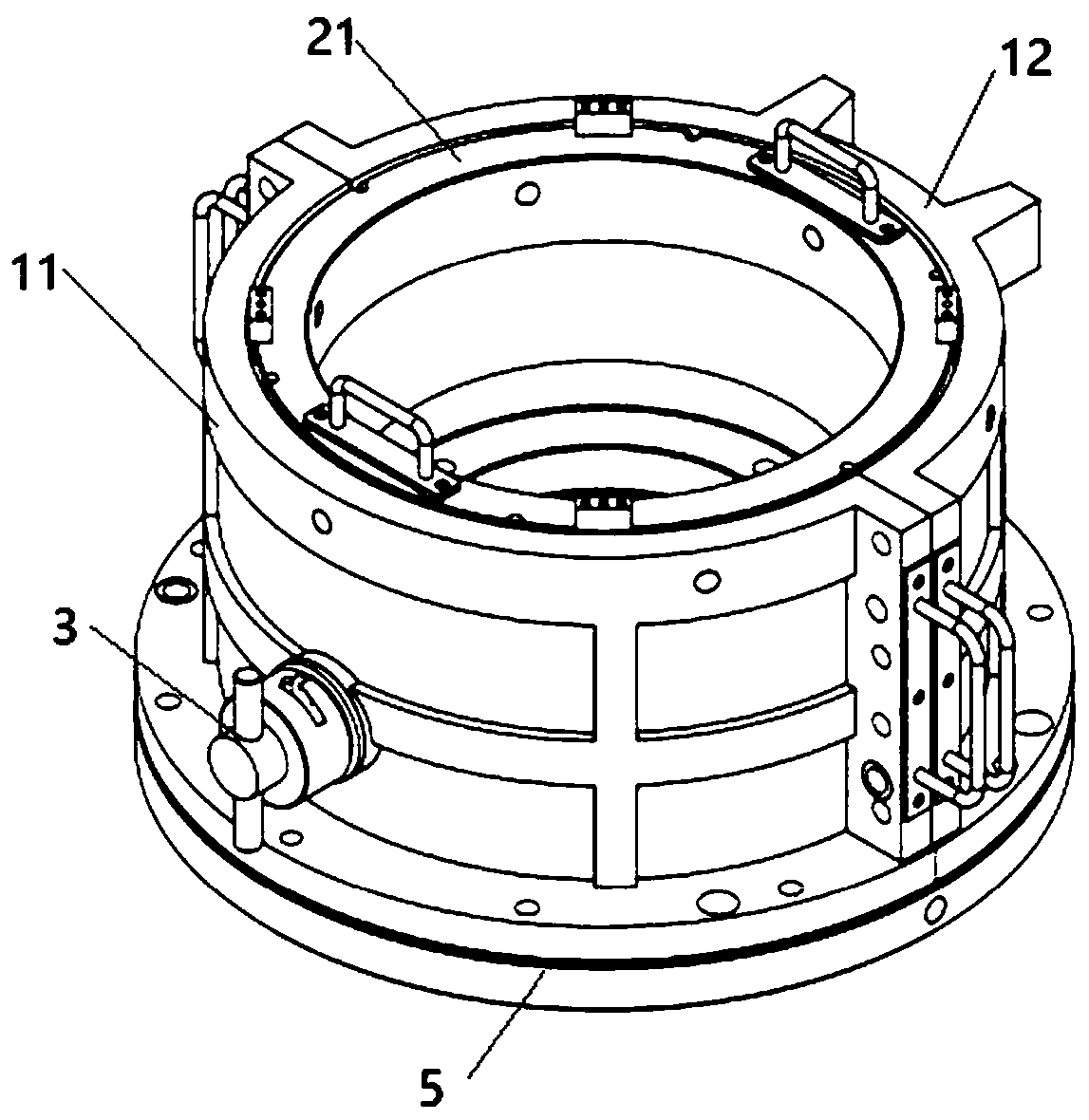

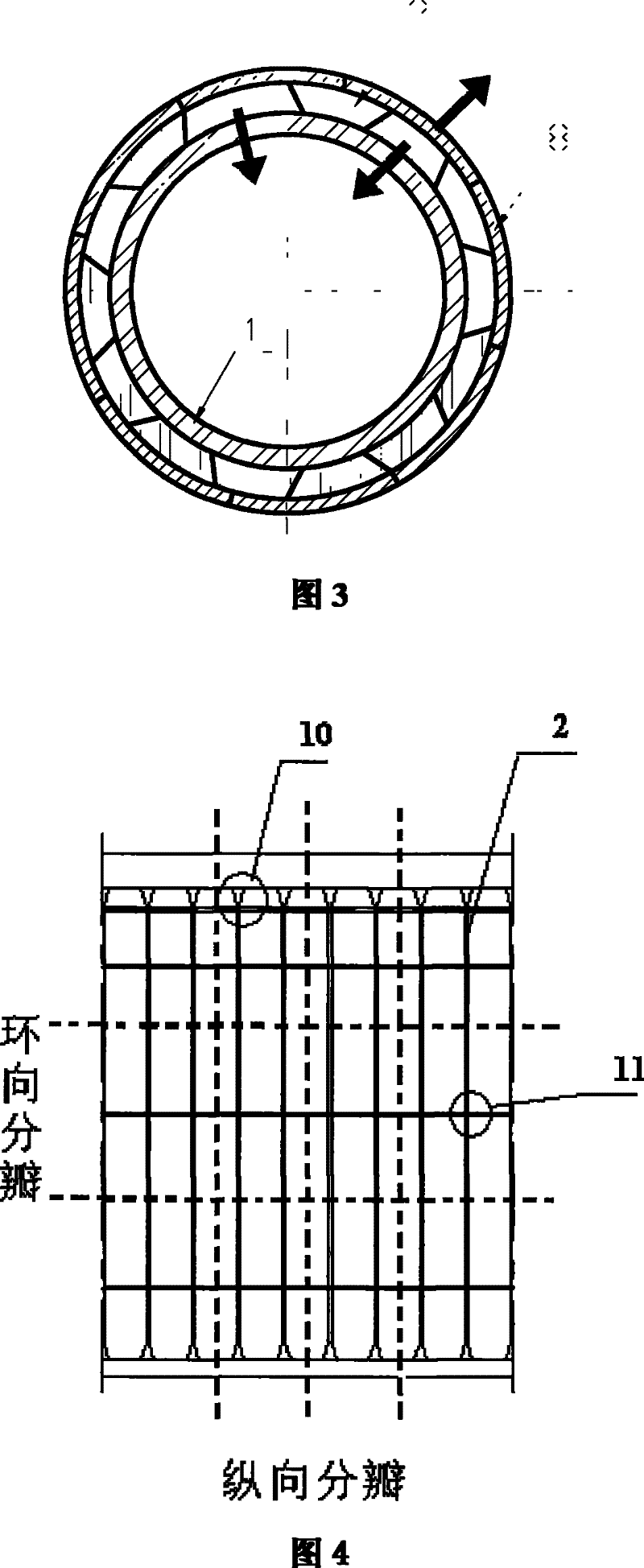

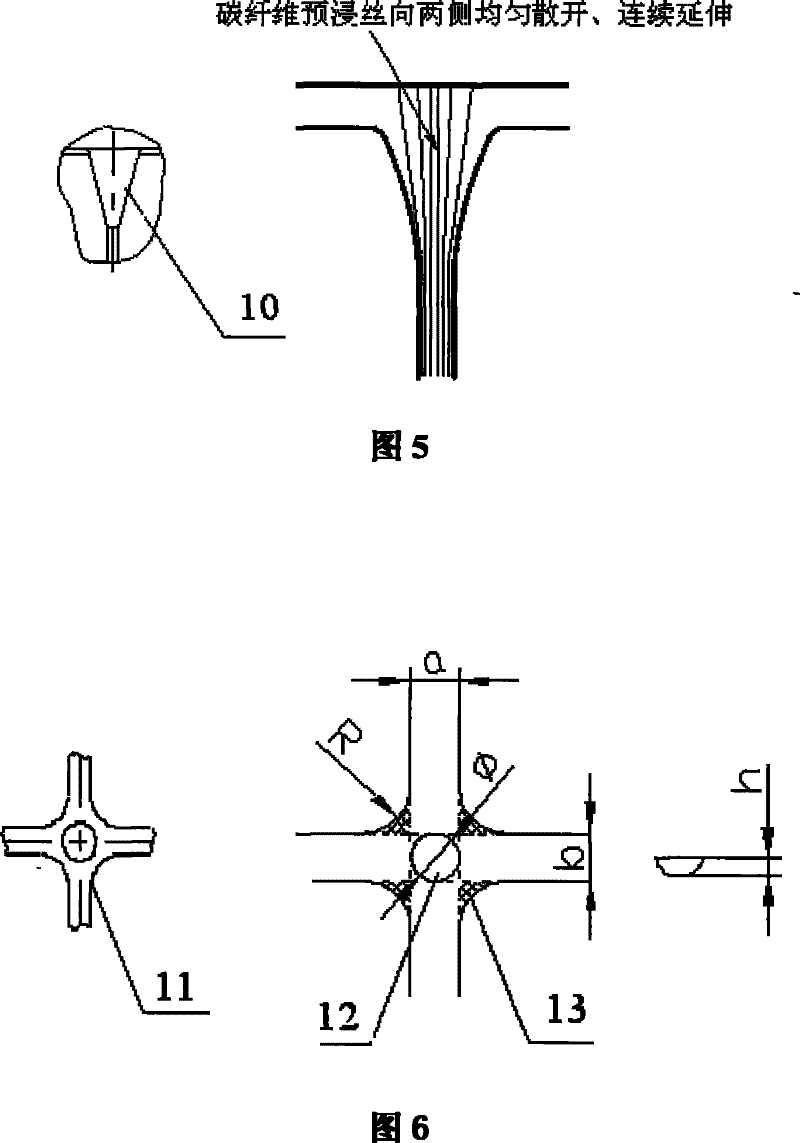

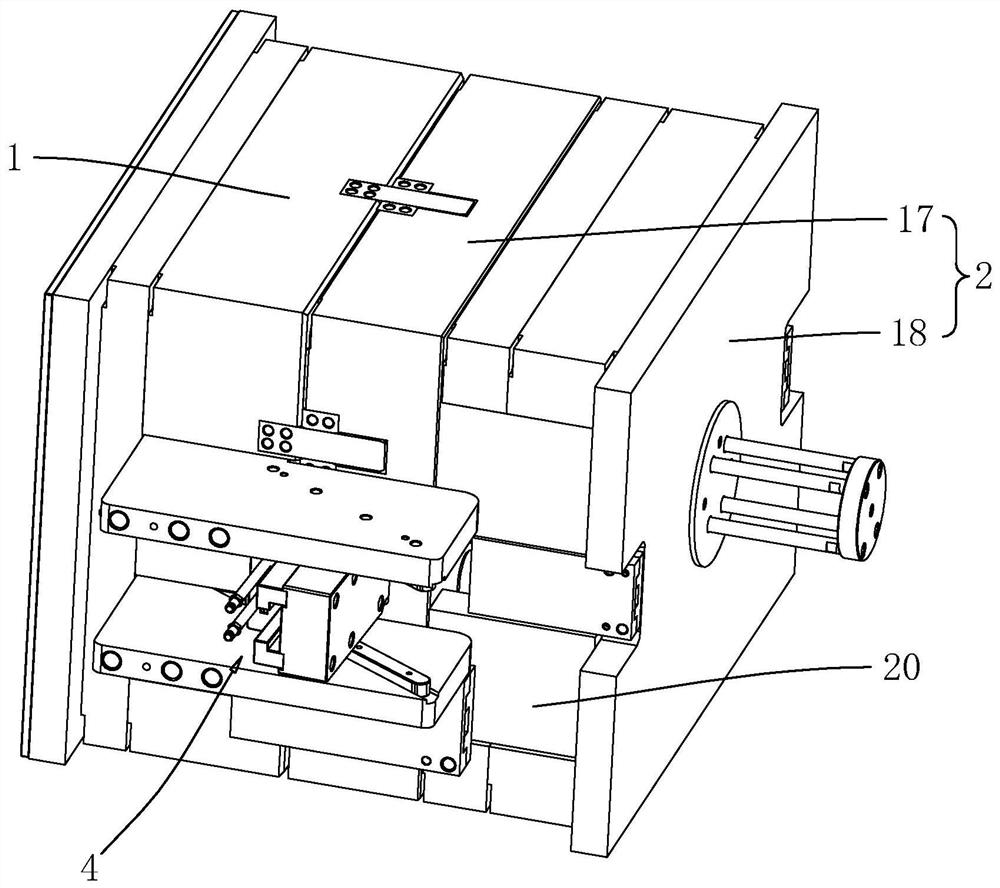

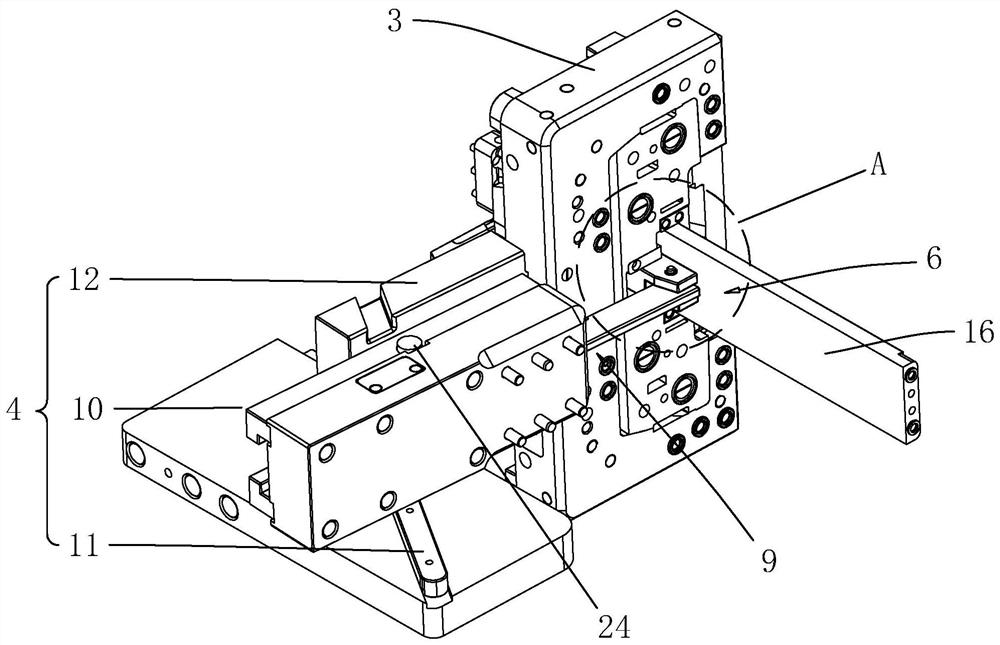

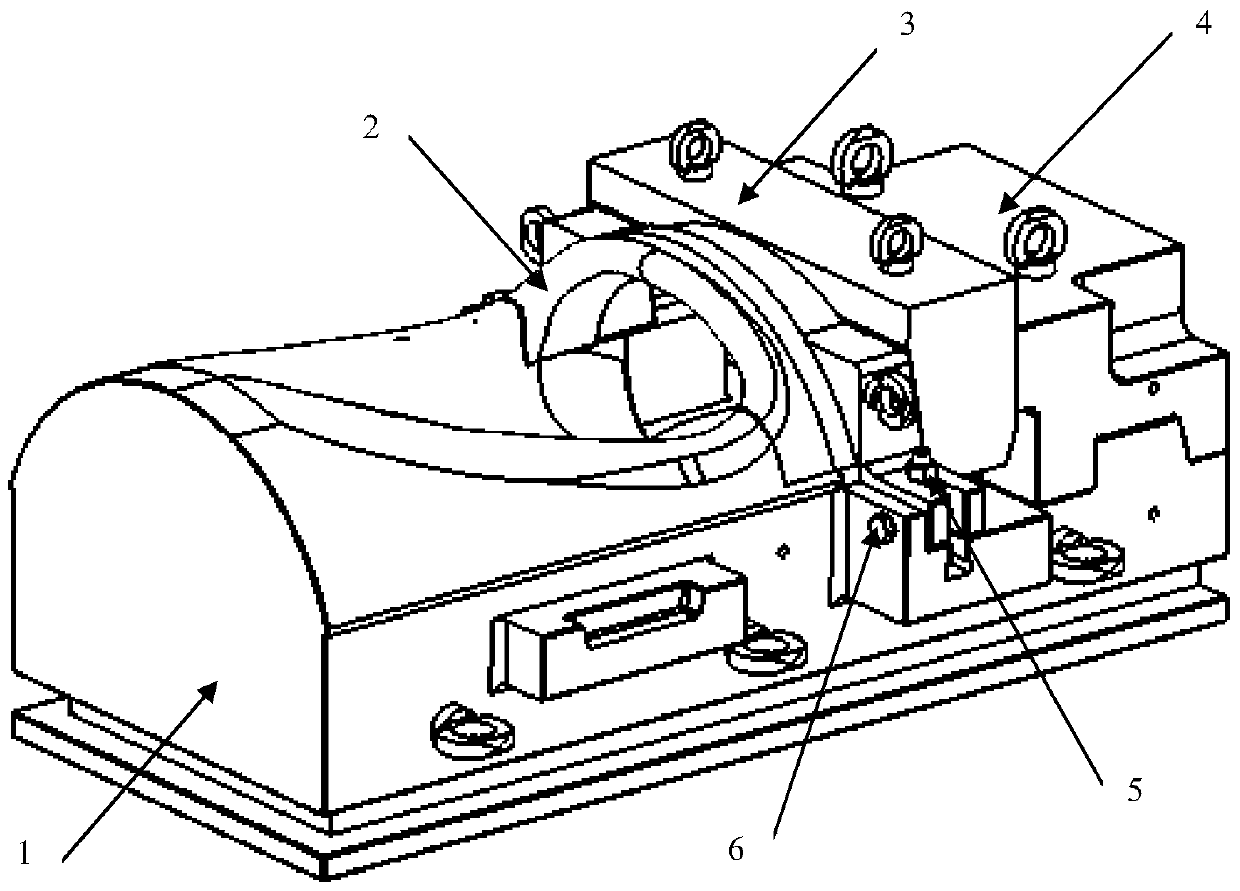

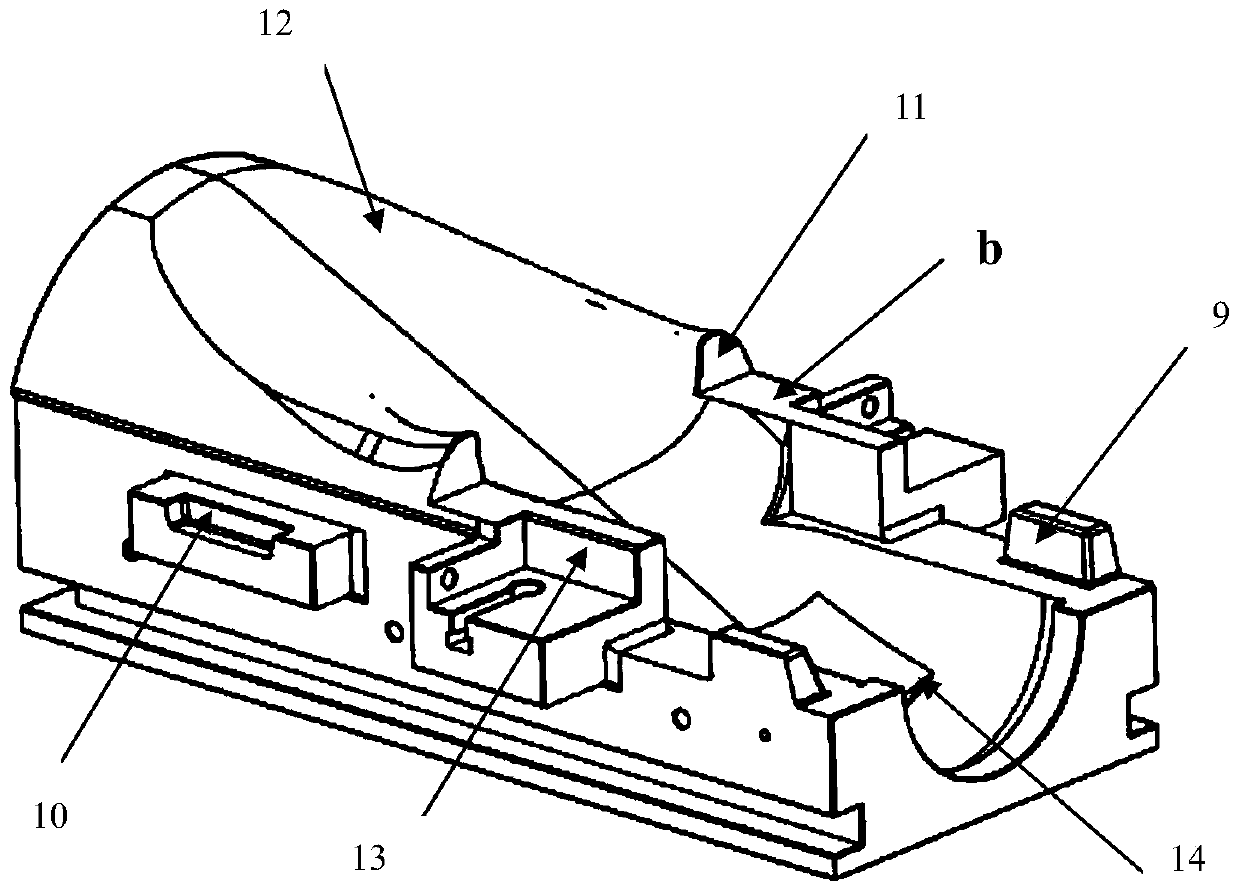

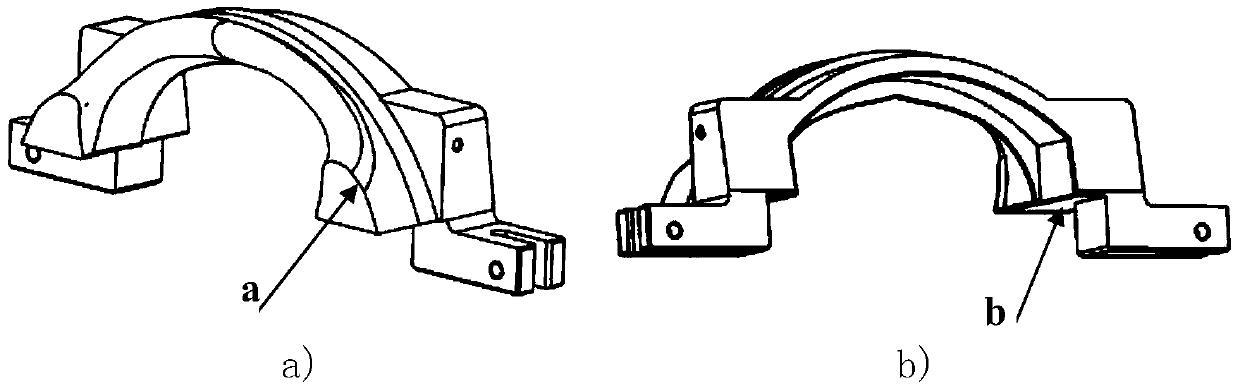

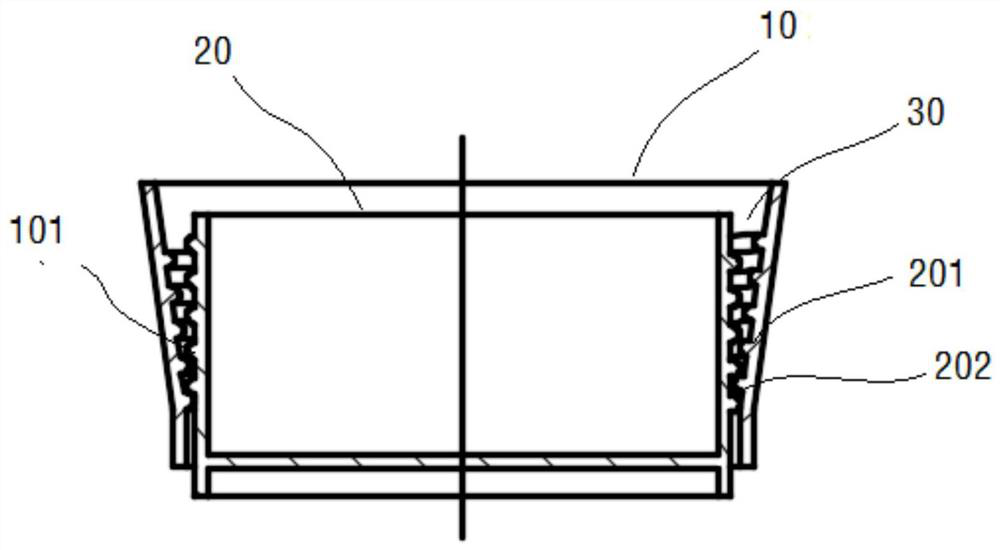

Carbon fiber reinforcement resin base composite material lattice structural-component conforming die and method

ActiveCN101450533BSolve the problem of continuous intersectionSolve the difficulty of demouldingCarbon fibersResin-Based Composite

The invention relates to a mould and a method for molding a carbon fiber reinforced resin-based composite material grid structural piece. The mould for molding the carbon fiber reinforced resin-based composite material grid structural piece consists of a main body mould, a splitting grid male mould and a splitting grid female mould sequentially from an inner layer to an outer layer; and two end frame pressure loops are arranged on the upper part and the lower part of the main body mould and the splitting grid male mould respectively. The mould can be repeatedly used for a plurality of times; a grid reinforced rib of a molded product has higher dimension precision and position precision; and the quality of the product has good consistency. The method for molding the carbon fiber reinforcedresin-based composite material grid structural piece is wholly co-cured and molded, is favorable for ensuring the consistency of the whole performance and quality of the composite material grid structural product so that the structure has good rigidity and bearing capacity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

A colored pencil lead with high flexural strength and preparation method thereof

ActiveCN108129914BImprove erasabilityImprove flexural strengthPencil leadsNon-propelling pencilsPolymer scienceFlexural strength

The invention discloses a color pencil lead with high flexural strength and a preparation method thereof. The preparation method comprises blending 20-40 parts by mass of a thermosetting resin, 10-30parts by mass of a thermoplastic resin, 30-50 parts by mass of base raw materials, 10-20 parts by mass of pigment powder, 3-7 parts by mass of an enhancing filler and a solvent under heating, removinga part of the solvent, carrying out roller mixing at 100-120 DEG C until uniform dispersion, extruding the mixture through a bar extruding machine to obtain bars, extruding the bars to obtain pencilleads, and then cutting the pencil leads to obtain color pencil leads with high flexural strength. The preparation method can produce a color pencil lead with high flexural strength, high writing markscrubbability and bright color, has simple processes, realizes a low cost and has high efficiency. The method is suitable for direct large-scale production of color pencil leads with various specifications in the traditional large-scale production factory without new equipment.

Owner:烟台好前程文具有限公司

Injection mold with channel inner arc-shaped chamfer demolding mechanism

ActiveCN113001910ASolve difficult demouldingEasy to controlClassical mechanicsStructural engineering

The invention discloses an injection mold with a channel inner arc-shaped chamfer demolding mechanism, and relates to the technical field of injection molds. According to the technical solution, the injection mold with the channel inner arc chamfer demolding mechanism comprises a left mold and a right mold, mold cores are fixedly installed on the left mold and the right mold correspondingly, a side core pulling mechanism is arranged between the left mold and the right mold, a front core pulling mechanism and a chamfer demolding mechanism are installed on the right mold, the front core pulling mechanism and the chamfering demolding mechanism are sequentially separated from the same end of a workpiece during demolding, the side core pulling mechanism is separated from the other end of the workpiece, the chamfering demolding mechanism comprises hinge pieces hinged to the mold cores, curved surfaces matching with injection molding to form arc-shaped chamfers is arranged on the hinge pieces, and the side, away from the curved surfaces, of the hinge pieces are attached to the front core pulling mechanism, and the right mold is further provided with a linkage assembly for linking the hinging pieces and the side core pulling mechanism during demolding. The injection mold is reasonable in structure, and the problem that the demolding is difficult due to the fact that the demolding space is limited is effectively solved.

Owner:上海铭嵌模塑科技有限公司

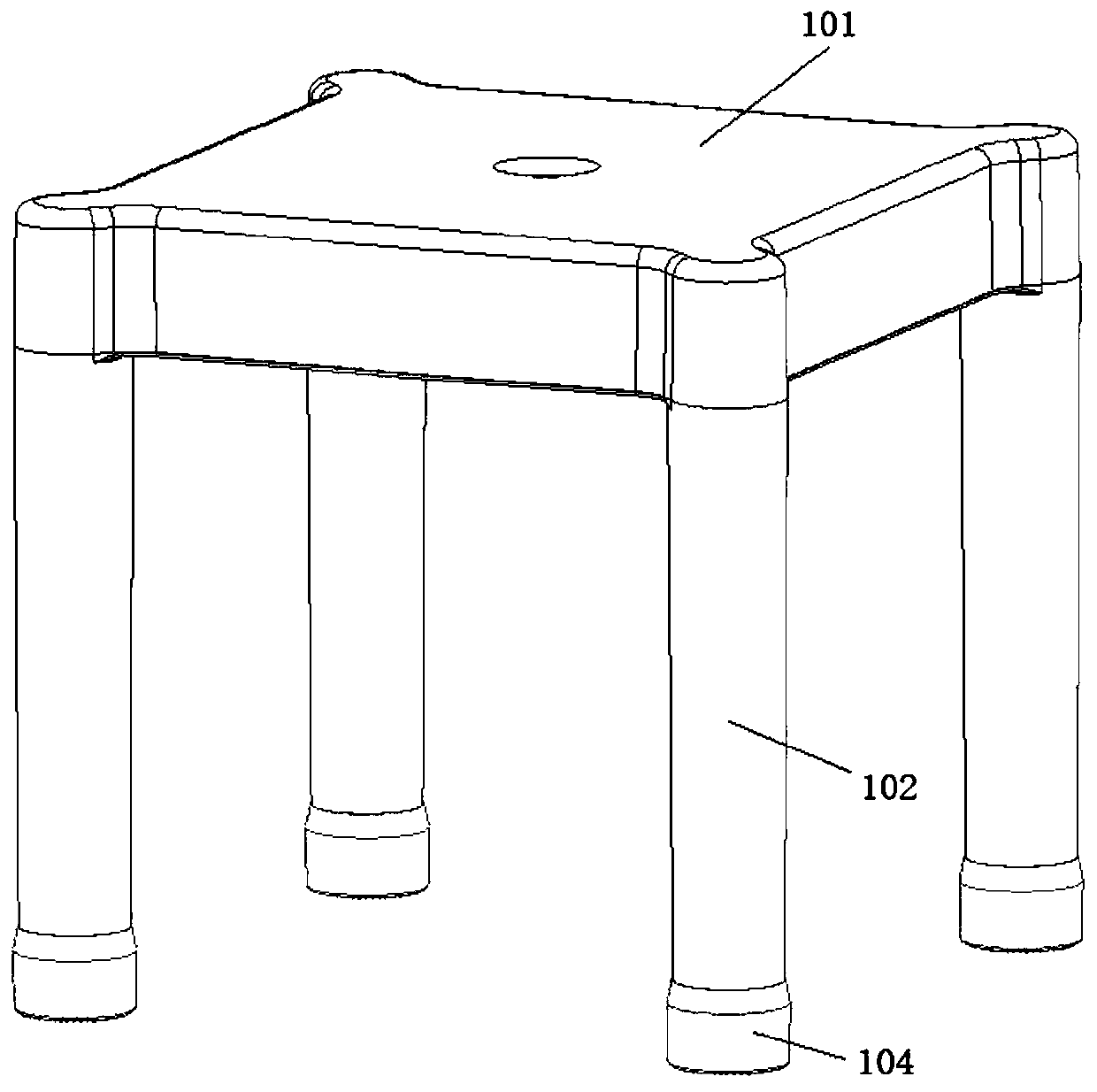

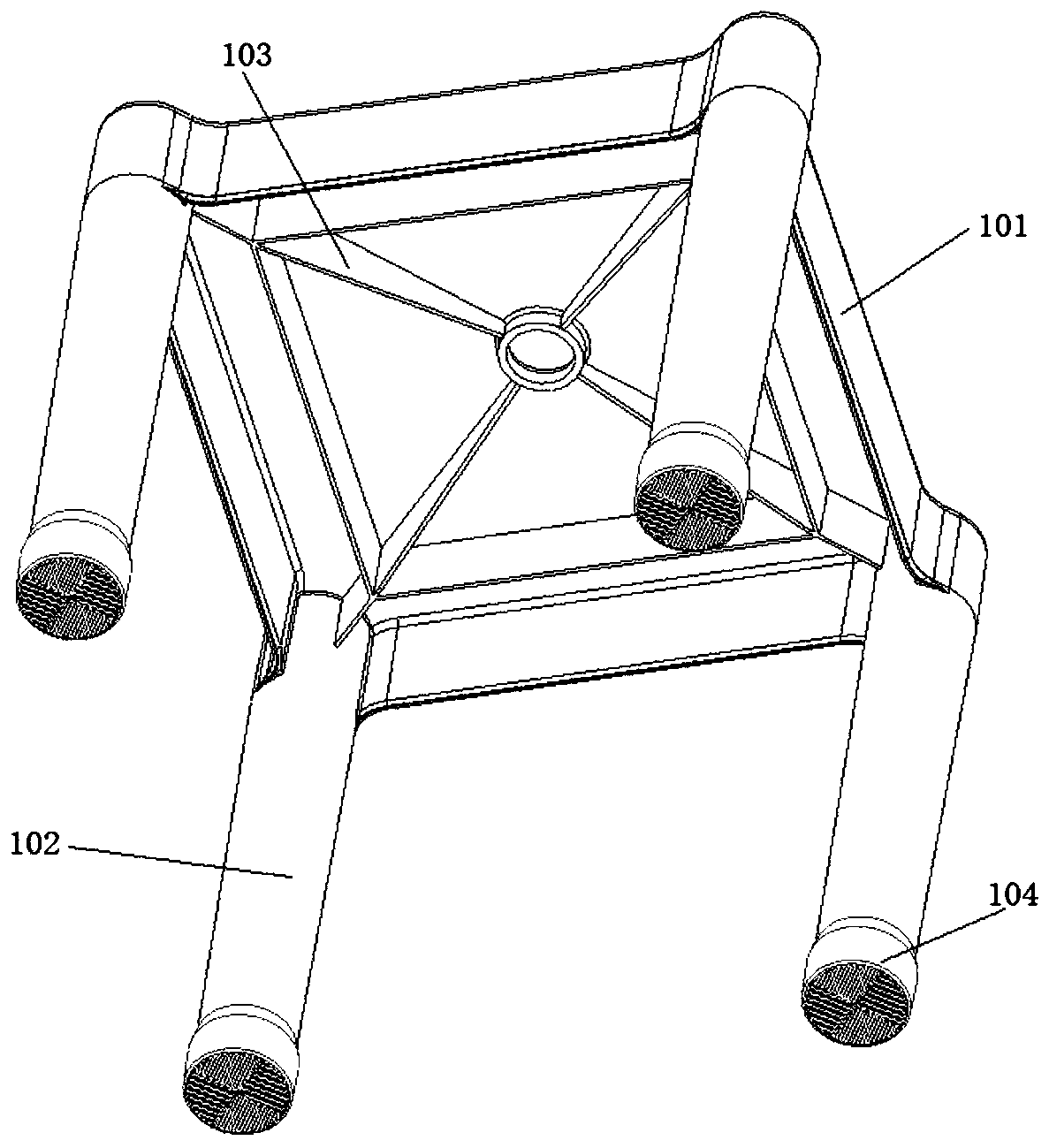

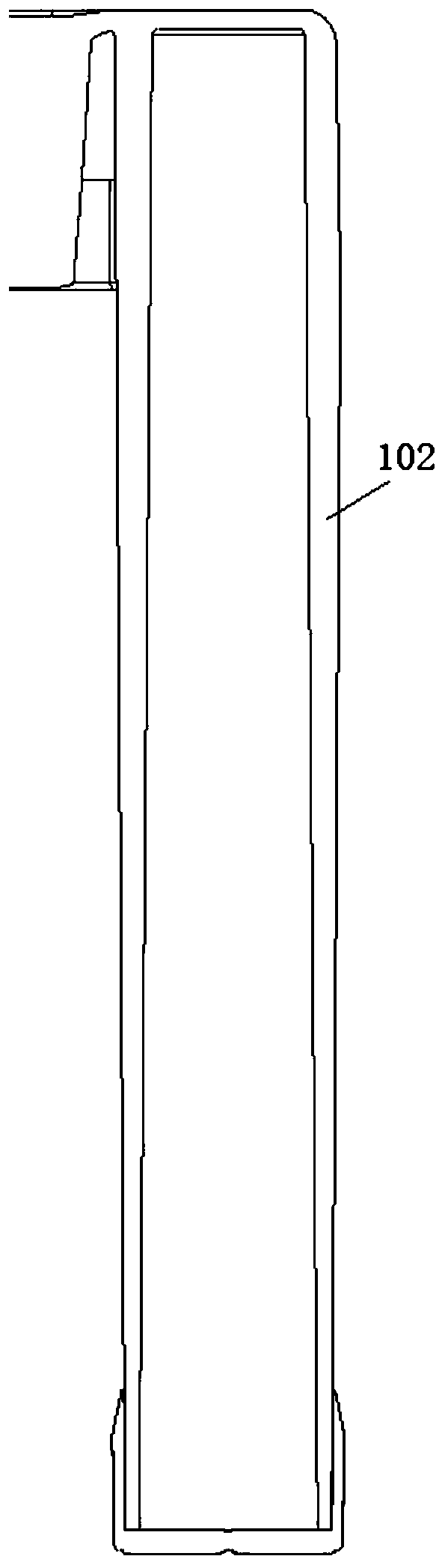

Chair, die for machining chair and machining process of die

InactiveCN111374464AReduce manufacturing costReduce labor costsStoolsAdjustable chairsInjection mouldingMachining process

The invention discloses a chair, and the chair comprises a chair surface, chair legs and reinforcing ribs; the chair surface, the chair legs and the reinforcing ribs are formed through one-time injection molding; the chair legs are perpendicular to the chair surface, and the reinforcing ribs are located at the bottom of the chair surface and used for connecting the chair surface and the chair legs. A chair machining process comprises the following machining steps: S1, pouring plastic used for machining a chair into a pouring gate of a mold, and after a cavity of the mold is filled with the plastic, performing cooling forming; S2, opening the front mold, pushing an ejector plate through an ejector rod hole, enabling an ejector pin and an ejector sleeve on the ejector plate to synchronouslymove upwards, pushing the chair out of a cavity, realizing demolding, and compressing a spring; S3, after the chair is demolded, enabling the spring to rebound, so that the ejection plate, the ejectorpin and the ejection sleeve are reset, and one-time injection molding is completed. The chair produced by the invention overcomes various defects of a plastic chair formed by combining metal tubes and plastics; meanwhile, the design that the chair legs are perpendicular to the chair surface enables the bearing of the plastic chair to reach the maximum value, the production process is simple, anda large amount of cost is saved.

Owner:魏典财

A kind of production method of connector and its structure

ActiveCN105826793BSimple structureCompact structureContact member cases/bases manufactureContact member assembly/disassemblyEngineeringInjection moulding

The present invention provides a connector production method. When production, a row of terminals are subjected to injection moulding to form a rear rubber core unit, the rear rubber core unit is fixedly connected with a front rubber core unit to form a connector unit, and any two connector units are assembled together to form the main body of the whole connector. The terminals and the rear rubber core unit are steadily fixed, so that the problem is solved that a traditional injection moulding rear rubber core module group is difficult to demould, it is ensured that the terminals are tidily arranged at the rear rubber core unit, and the requirement is satisfied that the connector is compactly and firmly assembled. The present invention further provides a connector structure, and the connector structure is cooperated with the production method provided by the invention. The rear rubber core module group is formed by two rear rubber core units with the same structure through buckling, and the front rubber core module group is formed by two front rubber core units with the same structure through buckling, and the rear rubber core units and the front rubber core units are produced on a large scale, then any two rear rubber core units and any two front rubber core units can be combined.

Owner:韶关胜蓝电子科技有限公司

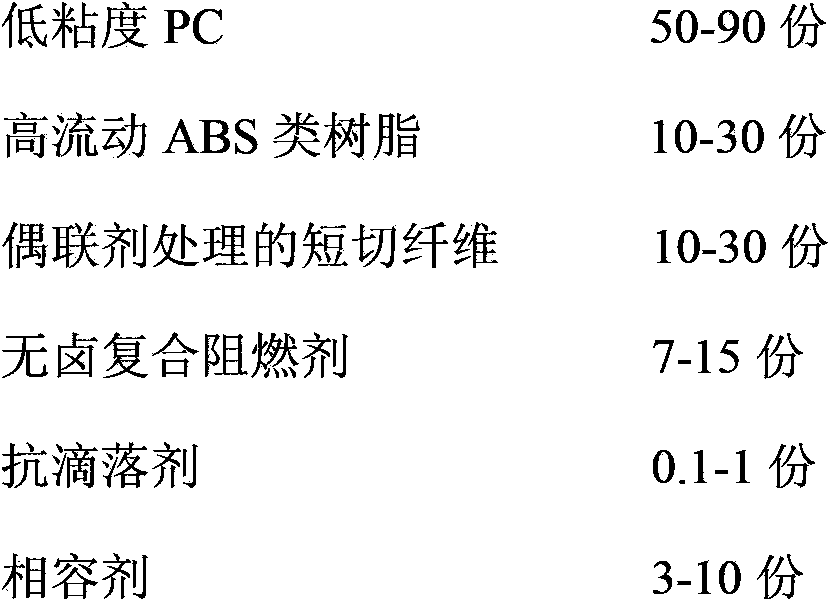

Flame-retardant glass fiber reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

ActiveCN103013089BReduced flame retardancyMeet the requirements of environmental standardsFiberAlkali free

The invention relates to a flame-retardant glass fiber reinforced PC (Polycarbonate) / ABS (Acrylonitrile Butadiene Styrene) composite material and a preparation method thereof. The preparation method comprises the steps of: respectively and fully drying low-viscosity PC, high-flow ABS resin, chopped fibers treated by using silane coupling agent, a halogen-free composite flame retardant, an anti-dripping agent, a black color base and a processing agent; fully mixing other raw materials except for the alkali-free chopped fibers treated by using the silane coupling agent in a high-speed mixer according to a proportion; then feeding the raw material into a double-screw extruder; laterally adding the alkali-free chopped fibers treated by using the silane coupling agent; and mixing, extruding, drawing, cooling, grain-sized dicing, and drying to obtain a finished injection molding raw material. The preparation method of the flame-retardant glass fiber reinforced PC / ABS composite material, disclosed by the invention, keeps certain impact intensity and rational MFR (Melt Flow Rate), thermal distortion temperature, vicat softening point and the like of the material while obtaining high intensity, high rigidity and flame retardant properties by selecting an assistant and proportions of the raw materials reasonably and adding the fibers as well as the flame retardant.

Owner:SHANDONG UNIV +1

Loose block combined thermoforming flanging mold and its application method

ActiveCN104289602BRealize the correctionReduce the number of weld passesShaping toolsMetal-working feeding devicesInlet channelEngineering

The invention discloses a movable block combined type hot forming turnup mold and a use method, and belongs to the field of machining of precision sheet metal. The movable block combined type hot forming turnup mold comprises a lower mold body, an upper mold body, a wedge, a positioning pressing block, a scribed pin and a movable lip limit block, and the external profile of an air inlet channel serves as a standard. Turnup formation and hot shaping are carried out on the aluminum alloy thin-wall air inlet channel with a complex turnup structure through the hot forming technology, the air inlet channel is accurately positioned through the movable limit block in the mold, and the problem that turnup of a lip of the air inlet channel is difficult is solved. A part can be taken out by taking down the movable limit block after being formed, and the problem that demolding is difficult after turnup of the air inlet channel is conducted is solved. The movable block combined type hot forming turnup mold is suitable for precision formation of air inlet channels which are made of aluminum alloy and the like and provided with the complex turnup structure.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

A retractable and outwardly retractable expansion and contraction mechanism for a freezer

ActiveCN111571908BSolve difficult demouldingReduce labor intensityDomestic articlesStructural engineeringMechanical engineering

Owner:CHUZHOU HONGDA MOLD MFG

A molding die for a carbon fiber three-piece combined rim

A molding die for a carbon fiber three-piece composite wheel rim, and the invention relates to the field of wheel rim molding dies. A carbon fiber three-piece combined rim. The inner end surface of the outer rim and the outer end surface of the inner rim are fixedly connected by high-strength glue to form a rim body. The inner end of the spoke is provided with a central boss, and the central boss of the spoke It is arranged in the central cavity of the rim body, and the spokes are locked and connected with the rim body. The forming mold includes an outer rim mold set and an inner rim mold set. When the upper mold and the lower mold of the outer rim mold set are closed, the top surface of the annular boss of the upper mold and the bottom surface of the annular inner groove of the lower mold A cavity that is consistent with the contour shape of the outer rim to be made is formed between them to form the outer rim contour; the inner core of the inner rim mold set, the mold cover and the inner core of the round cake are coaxially arranged and inserted into each other for positioning , the outer mold of the circular tube, the mold cover and the mold bottom are coaxially arranged and inserted into each other for positioning. The invention is used for forming carbon fiber rims.

Owner:HARBIN INST OF TECH AT WEIHAI

Core mold and shaping method for shaping strip annular internal reinforced rib rotary body thin-wall part

InactiveCN102764841BPrevent movementHigh forming precisionForging/hammering/pressing machinesMetallic materialsUltimate tensile strength

The invention relates to a core mold and a shaping method for a shaping strip annular internal reinforced rib rotary body thin-wall part, wherein a base mold is composed of a base mold main body and a mold withdrawing end; a swallow tail groove and a positioning groove are formed on the base mold main body; a shape mold is wholly of an annular structure; the shape mold is uniformly divided into a plurality of split molds of same shapes; shaping arc grooves for annular internal reinforced ribs are formed on the shaping plane of the split molds; swallow tail tenons matched with the wallow tail groove and the positioning groove are formed on the inner surfaces of the split molds. By adopting the mode of combined core mold, the problem of hard demolding during the shaping process of the rotary body thin-wall part internal reinforced rib is solved. By virtue of the positioning on the base mold swallow tail groove, the movement of the shaping mold is prevented effectively; and the shaping precision of the rotary body thin-wall part internal reinforced rib is improved. The base mold, the shaping mold and the fixing pin of the core mold can be made of different metal materials according to respective strength requirements; only the mold needs to be replaced for rotary body thin-wall pieces of which the inner diameters are the same and the internal reinforcing ribs are different, so that the cost of the mold is reduced greatly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

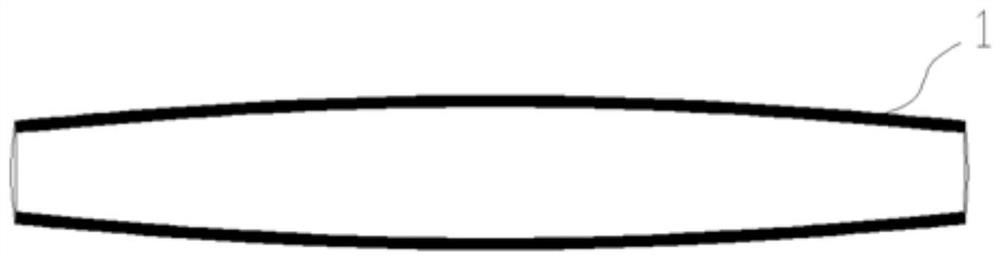

Paper bucket volume variable structure and spiral method thereof

InactiveCN112173358AReduce storage costsReduce shipping costsVariable capacity containersInterior spaceEngineering

Owner:WING FAT (HENAN) MOLDED FIBER TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com