A Forming Method of Cylinder Workpiece with Transverse Internal Ribs

A technology of body workpieces and workpieces, which is applied in the field of forming cylindrical workpieces with transverse inner ribs, can solve the problems of high machining cost, large machining allowance and high cost, improve performance and production efficiency, and prevent material breakage. , the effect of reducing shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions and specific implementation methods of the present invention will be described in detail below.

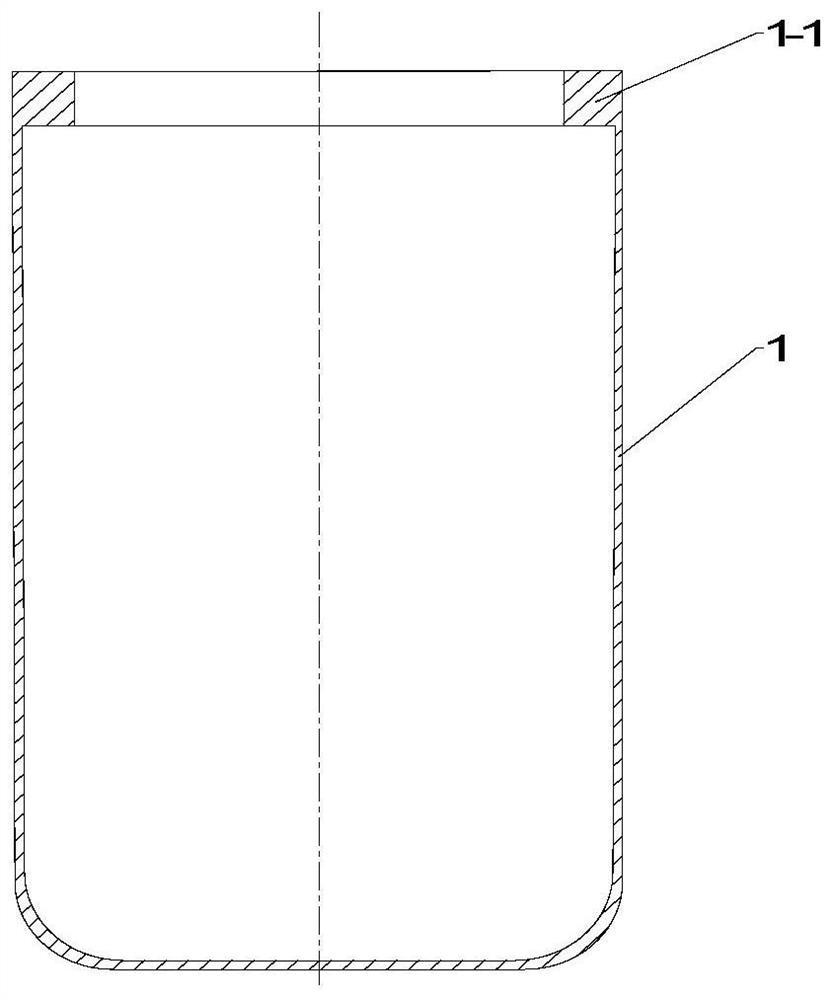

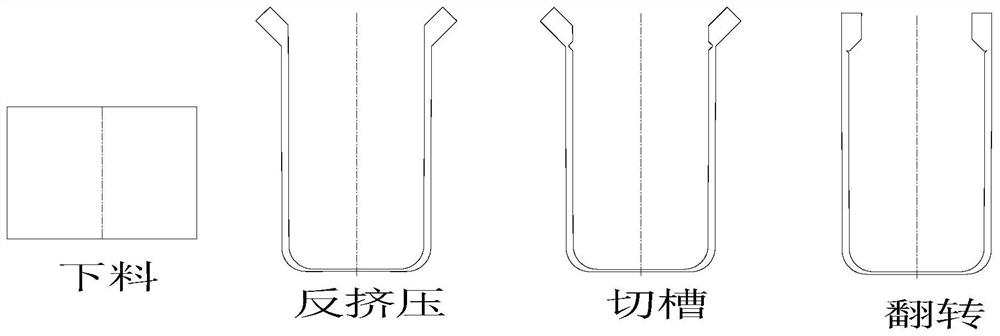

[0046] Such as figure 2 As shown, the schematic diagram of the forming process flow of the present invention; a method for forming a cylindrical workpiece with transverse inner ribs of the present invention adopts blanking + upsetting + back extrusion process, and its characteristics are: it also adopts grooving, turning The process, each process is as follows:

[0047] (1) Blanking and upsetting: the conventional blanking is the blank 2, and the blank is put into the reverse extrusion die for extrusion and upsetting;

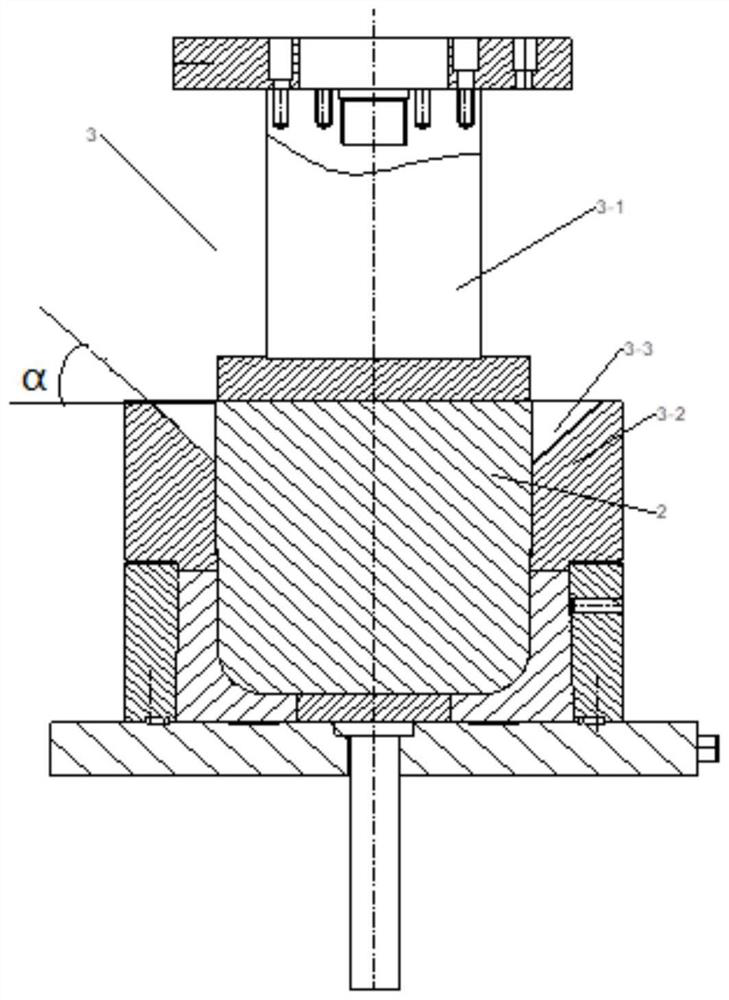

[0048] (2) Back-extrusion: the blank is extruded in the back-extrusion die; image 3 Shown; Used back extrusion die 3, comprises back extrusion punch 3-1, back extrusion die 3-2, between back extrusion die 3-3; Described back extrusion die gap It is the space for the billet to overflow upward to form the inner rib of the blank; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com