Loose block combined thermoforming flanging mold and its application method

A flanging mold and thermoforming technology, which is applied in the field of precision sheet metal processing, can solve the problems of difficult demoulding, difficult demoulding of air inlet, and difficult forming, so as to achieve easy demoulding, solve difficult flanging, and reduce weld bead Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

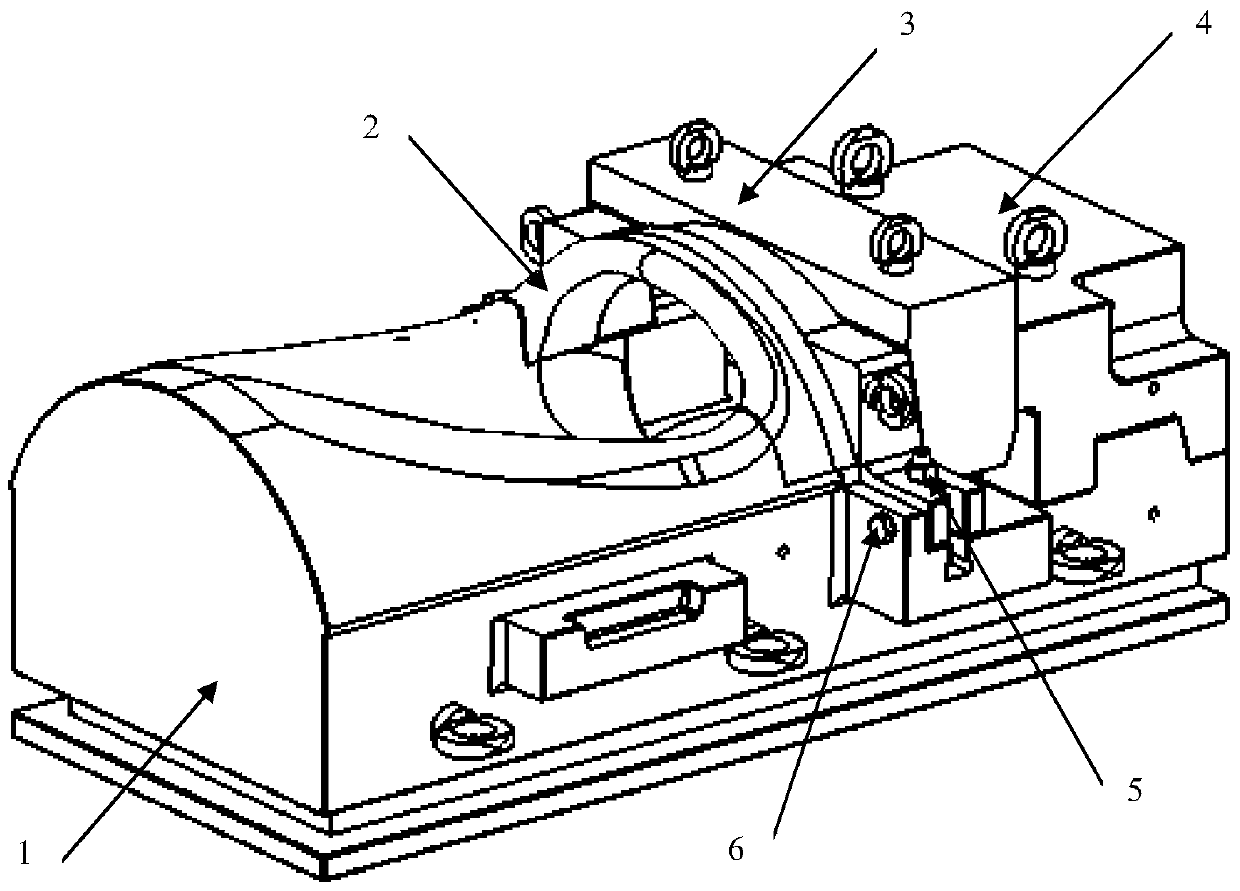

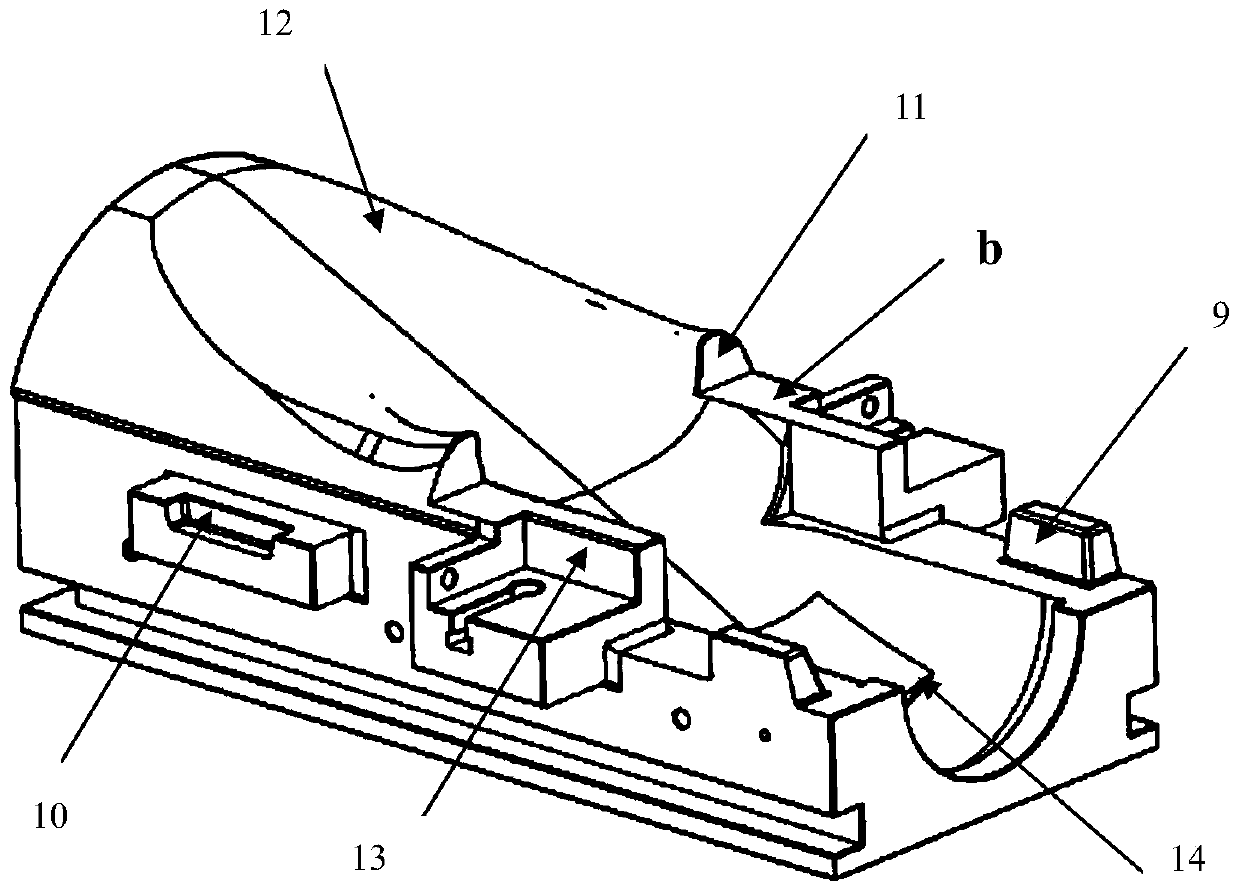

[0041] The loose block combined thermoforming flanging die is generally divided into an upper die and a lower die with movable limit blocks.

[0042] It mainly includes lower mold body 1, lip movable limit block 2, wedge block 3, positioning pressing block 4, fasteners for pressing 5, fasteners for tensioning 6, upper mold body 7, installed on the upper mold body Scribe on pin 8.

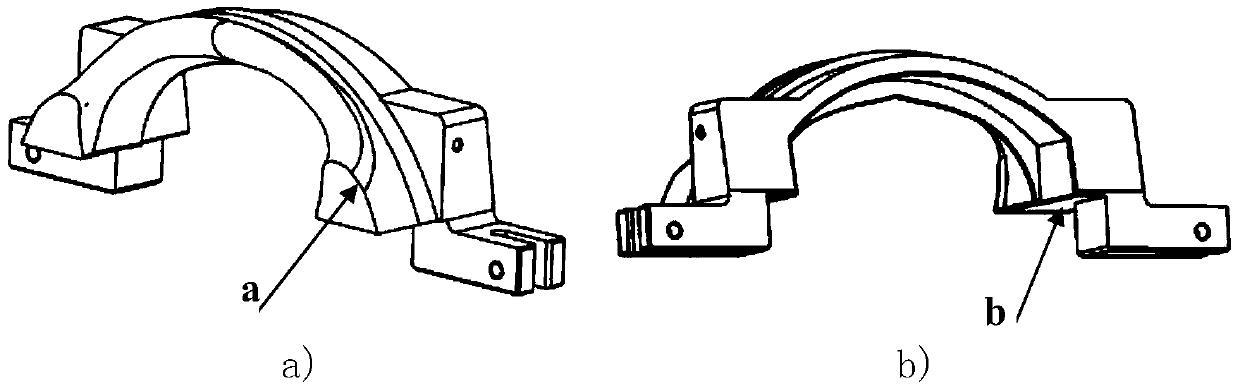

[0043] Such as figure 1 As shown, the lower mold is composed of the lower mold body 1, the lip movable limit block 2, the wedge block 3, the positioning briquetting block 4, the fastener 5 for pressing, and the fastener 6 for tensioning. The lip movable limit block 2 can form a complete air intake lip profile with the lower mold body after being assembled on the lower mold body 1, and can be used as the flanging corresponding to the core surface of the upper mold body when the air inlet flanging is used. Datum plane, to ensure the flanging size. The inner surface of the lip movable limit block 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com