A method and device for blade laser shot peening shape correction

A technology of laser peening and shape correction, which is applied to the laser peening and shape correction of blades and the field of laser peening shape correction, which can solve the problems of difficult to guarantee the accuracy of blades, difficult to accurately shape the shape, and easy to produce deformation, etc., to achieve improved effect, improve the fatigue life, and ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

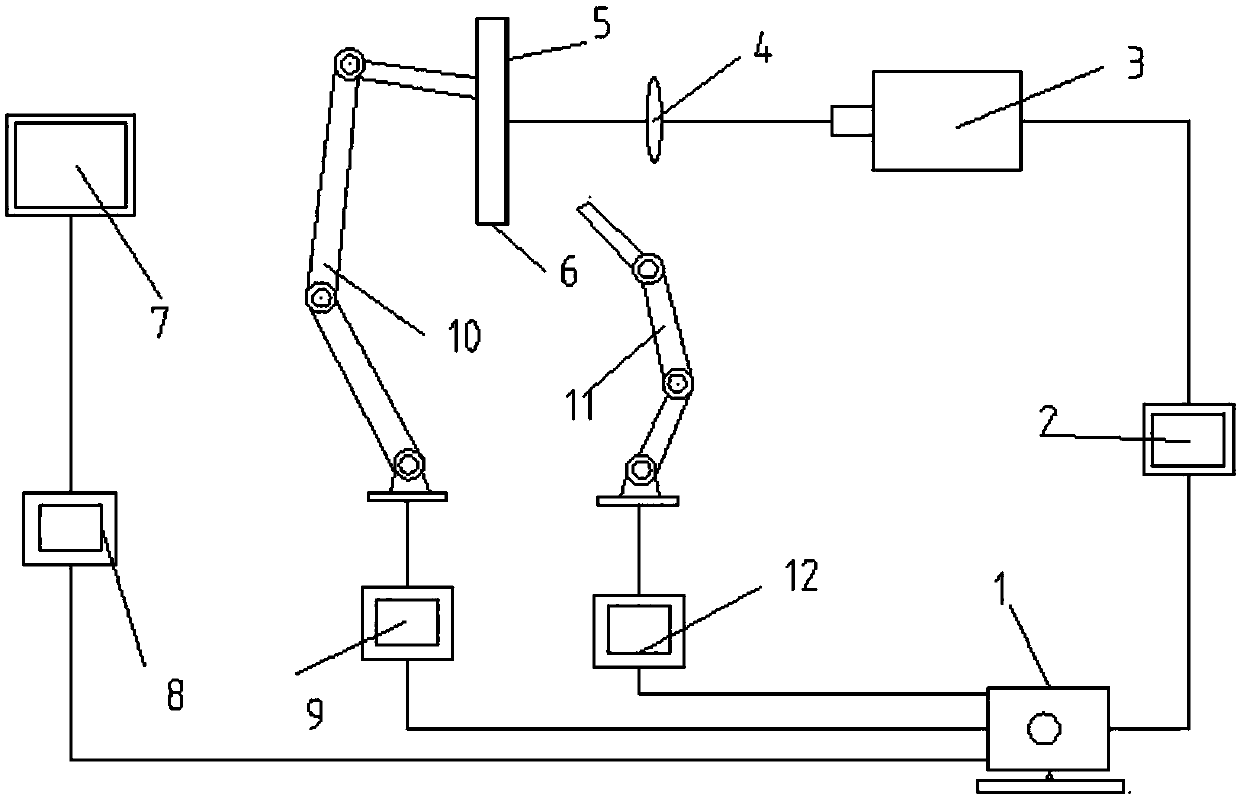

[0024] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The method for blade laser shot peening correcting shape of the present invention comprises the following steps:

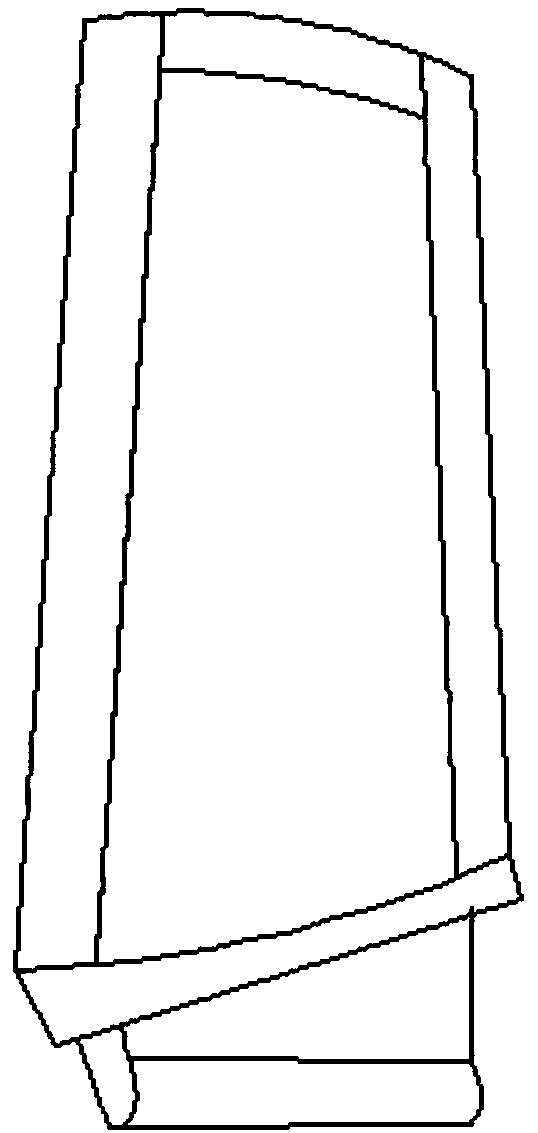

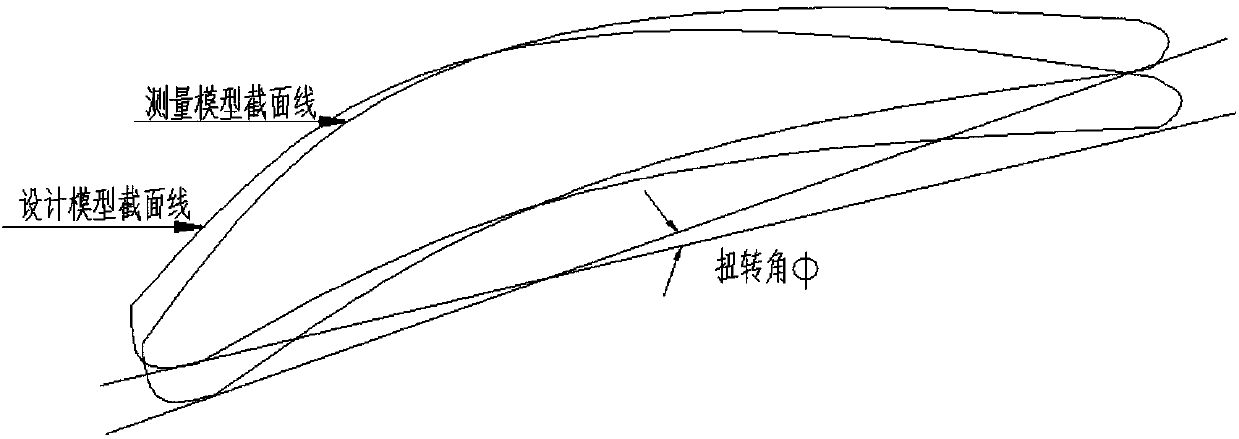

[0026] Step 1: Carry out three-dimensional scanning of the blade (6) with the help of a three-dimensional profile scanner (7), coordinate the three-dimensional results obtained from the actual test with the three-dimensional CAD model of the product, and calculate the distortion error and curvature error, which are respectively in accordance with the allowable The error is compared, and then the position and the amount of shape correction of laser shot peening are determined, and transmitted to the computer control system (1) through the data acquisition system (8);

[0027] Step 2: establish the one-to-one correspondence between the laser peening parameters and the blade twist ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com