Patents

Literature

232 results about "Laser peening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

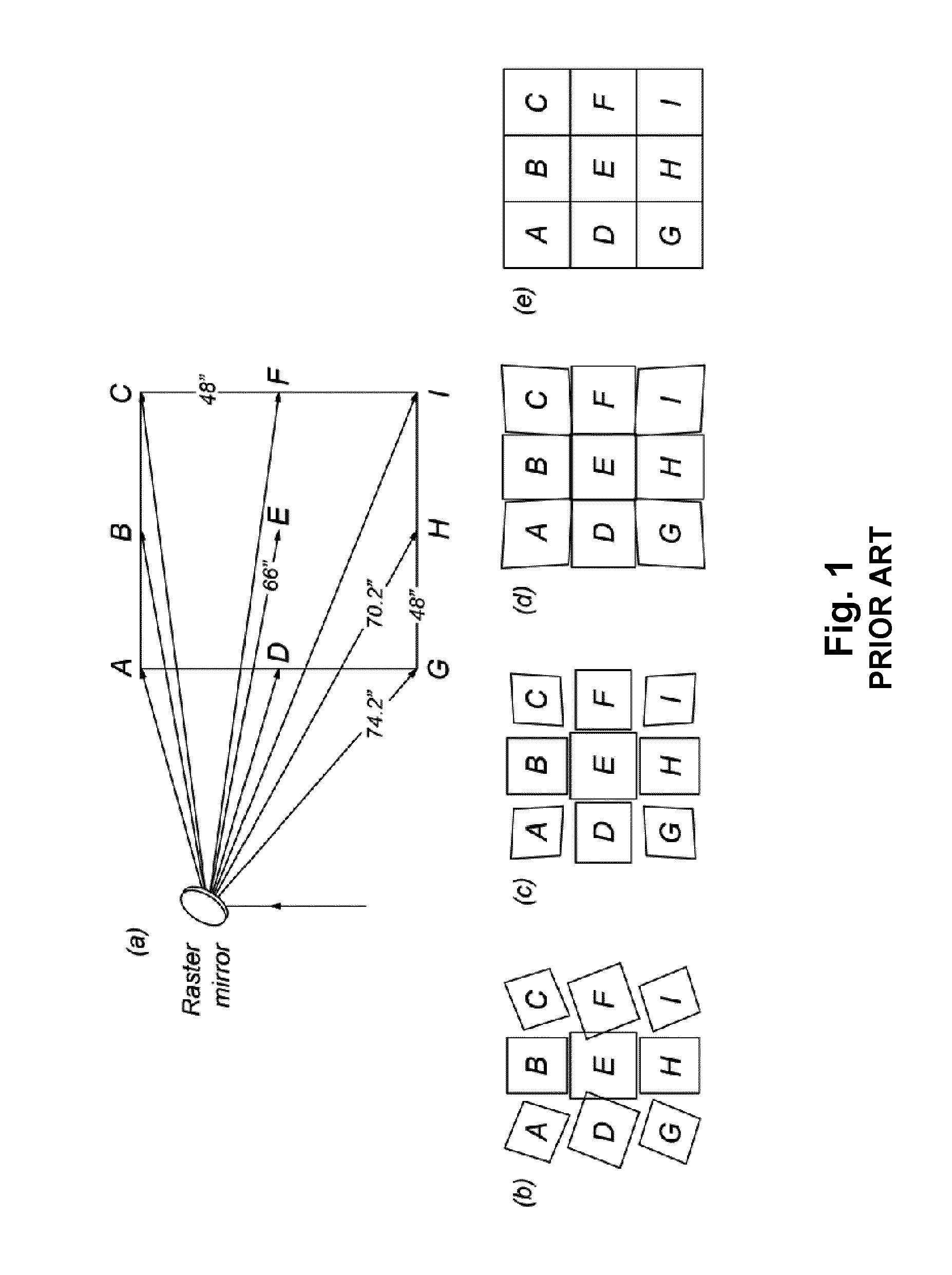

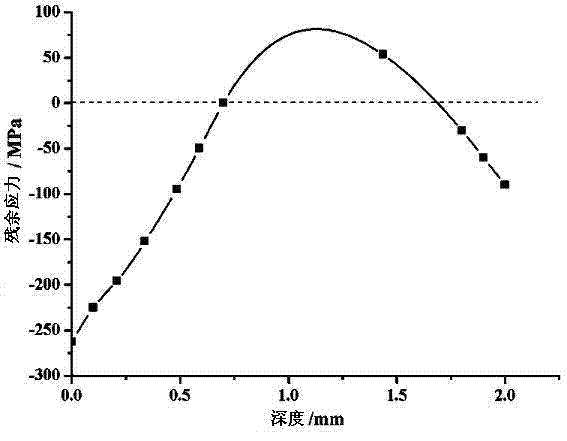

Laser peening (LP), or laser shock peening (LSP), is a surface engineering process used to impart beneficial residual stresses in materials. The deep, high magnitude compressive residual stresses induced by laser peening increase the resistance of materials to surface-related failures, such as fatigue, fretting fatigue and stress corrosion cracking. Laser shock peening can also be used to strengthen thin sections, harden surfaces, shape or straighten parts (known as laser peen forming), break up hard materials, compact powdered metals and for other applications where high pressure, short duration shock waves offer desirable processing results.

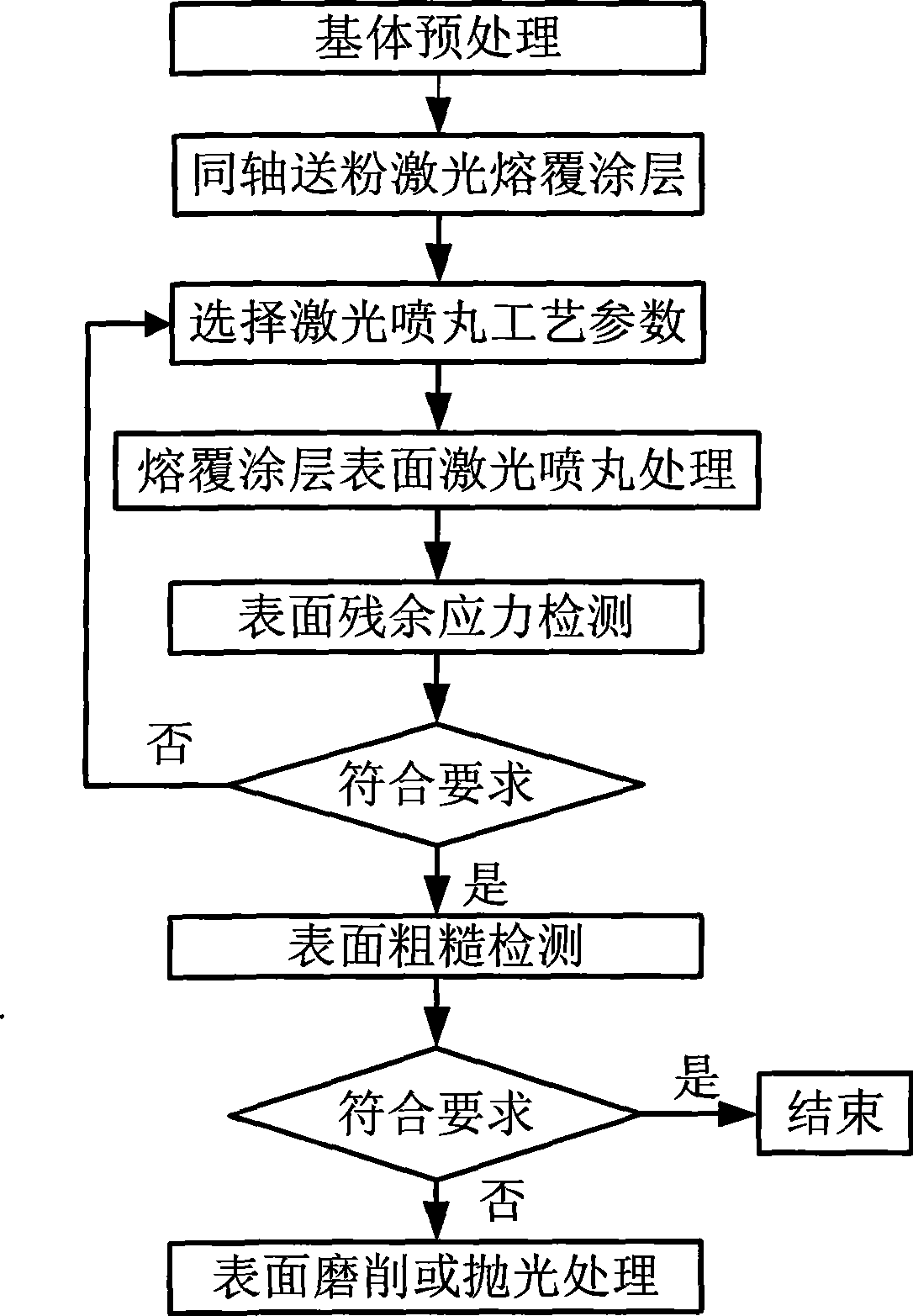

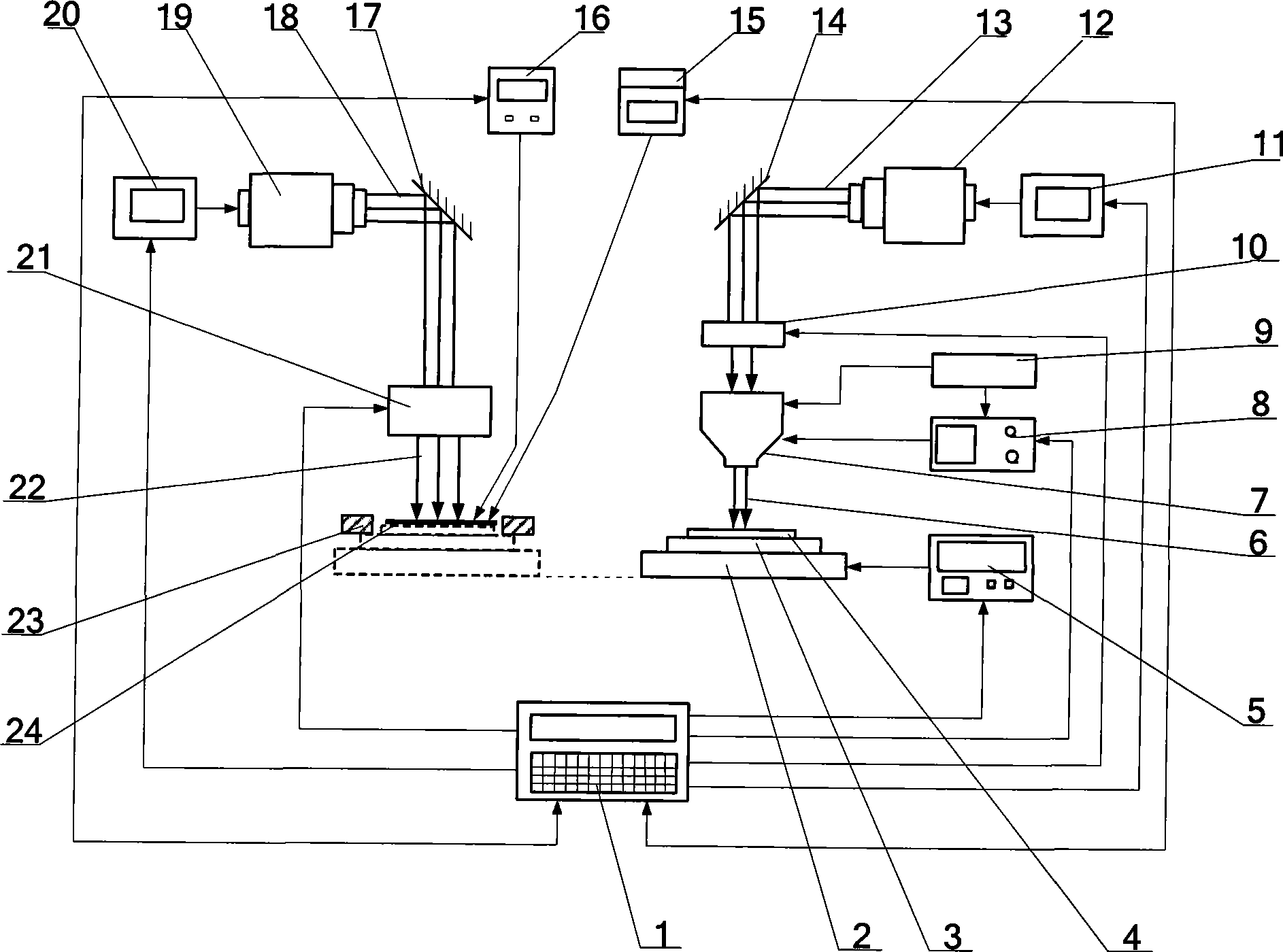

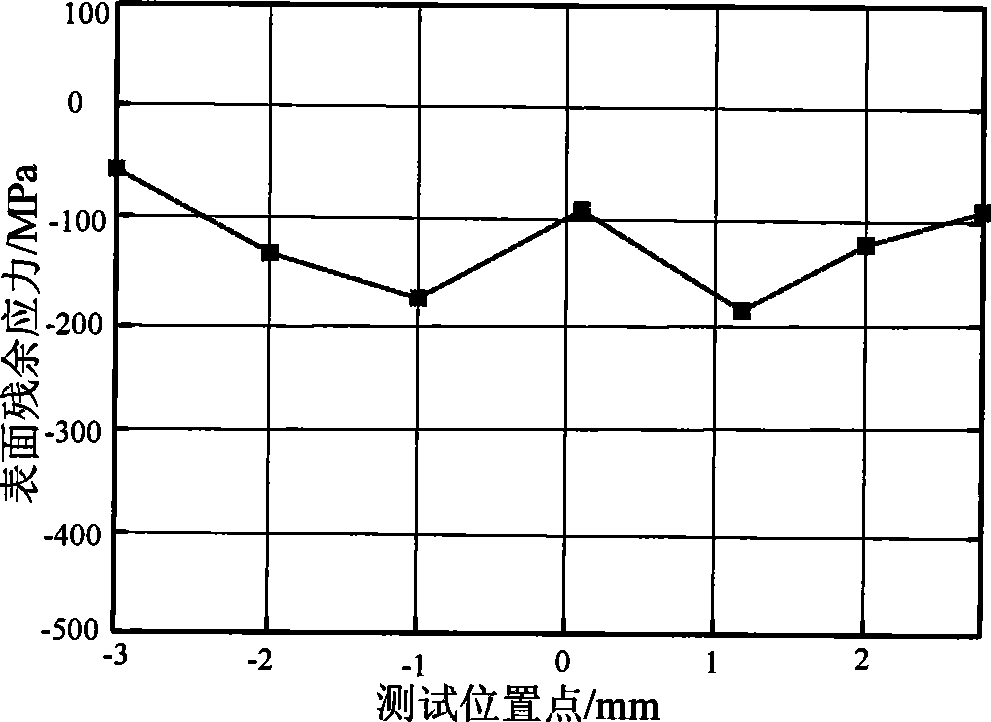

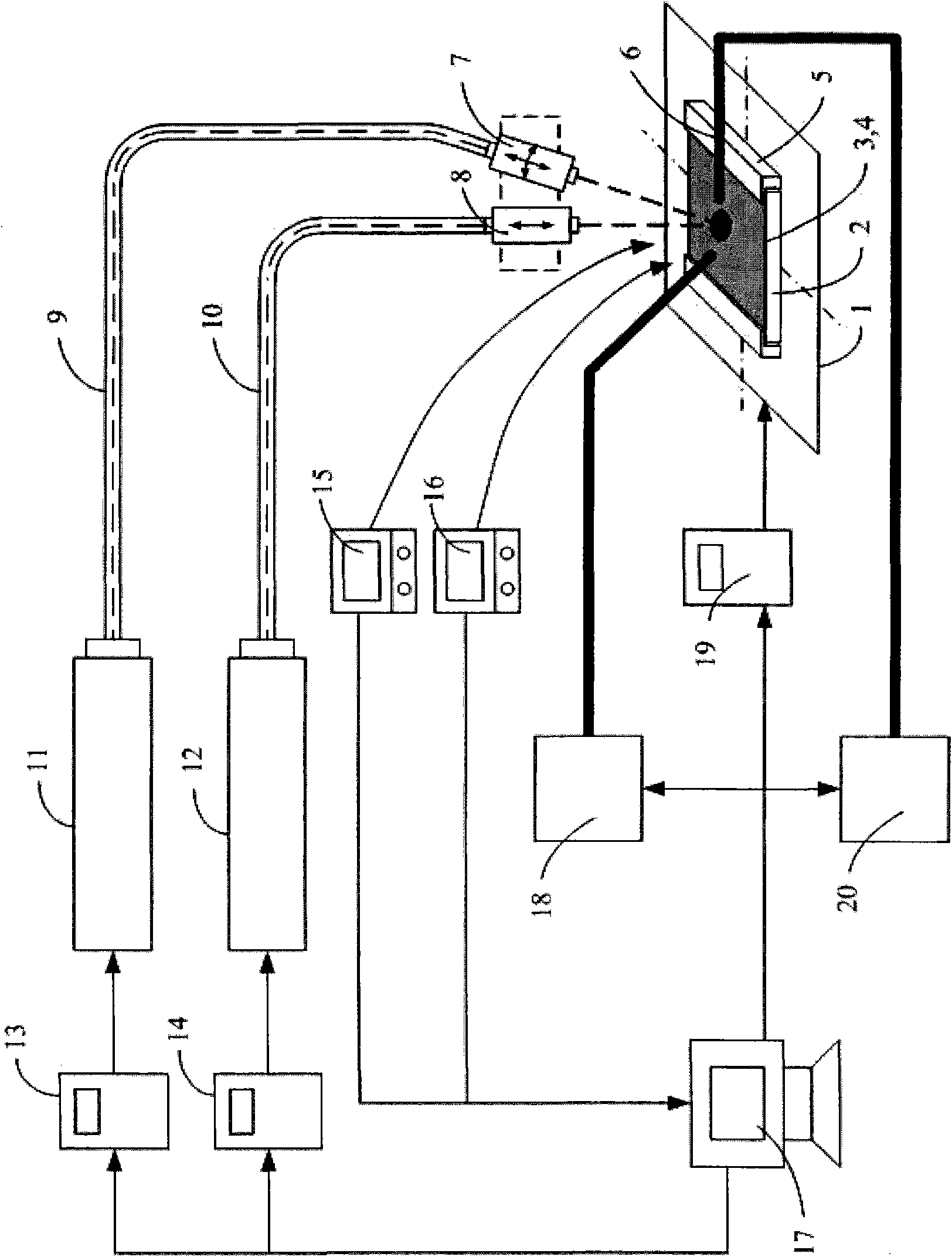

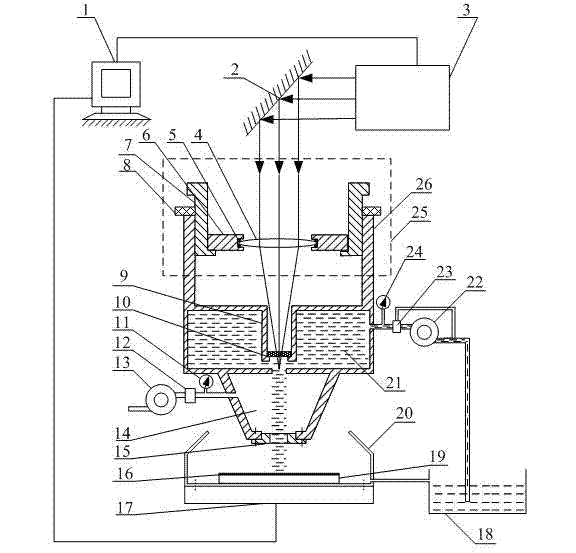

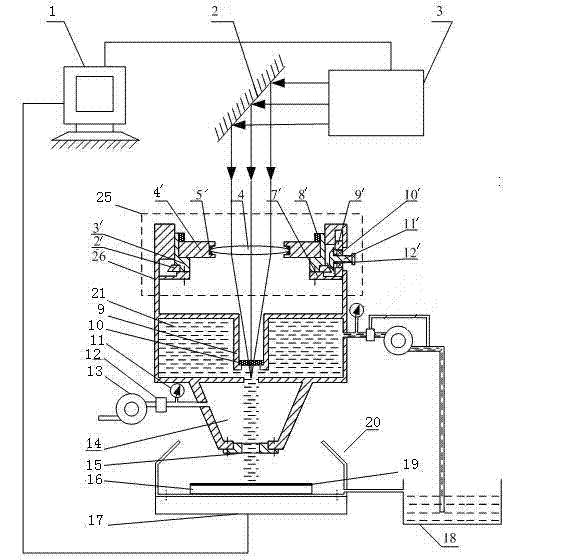

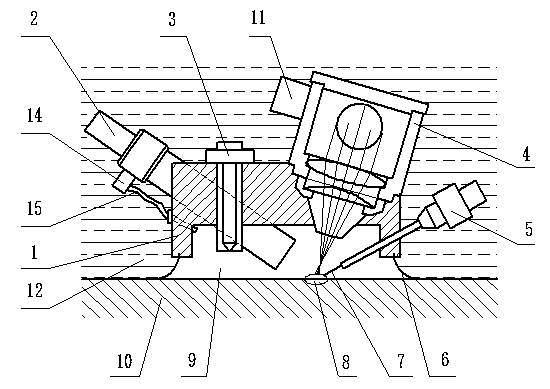

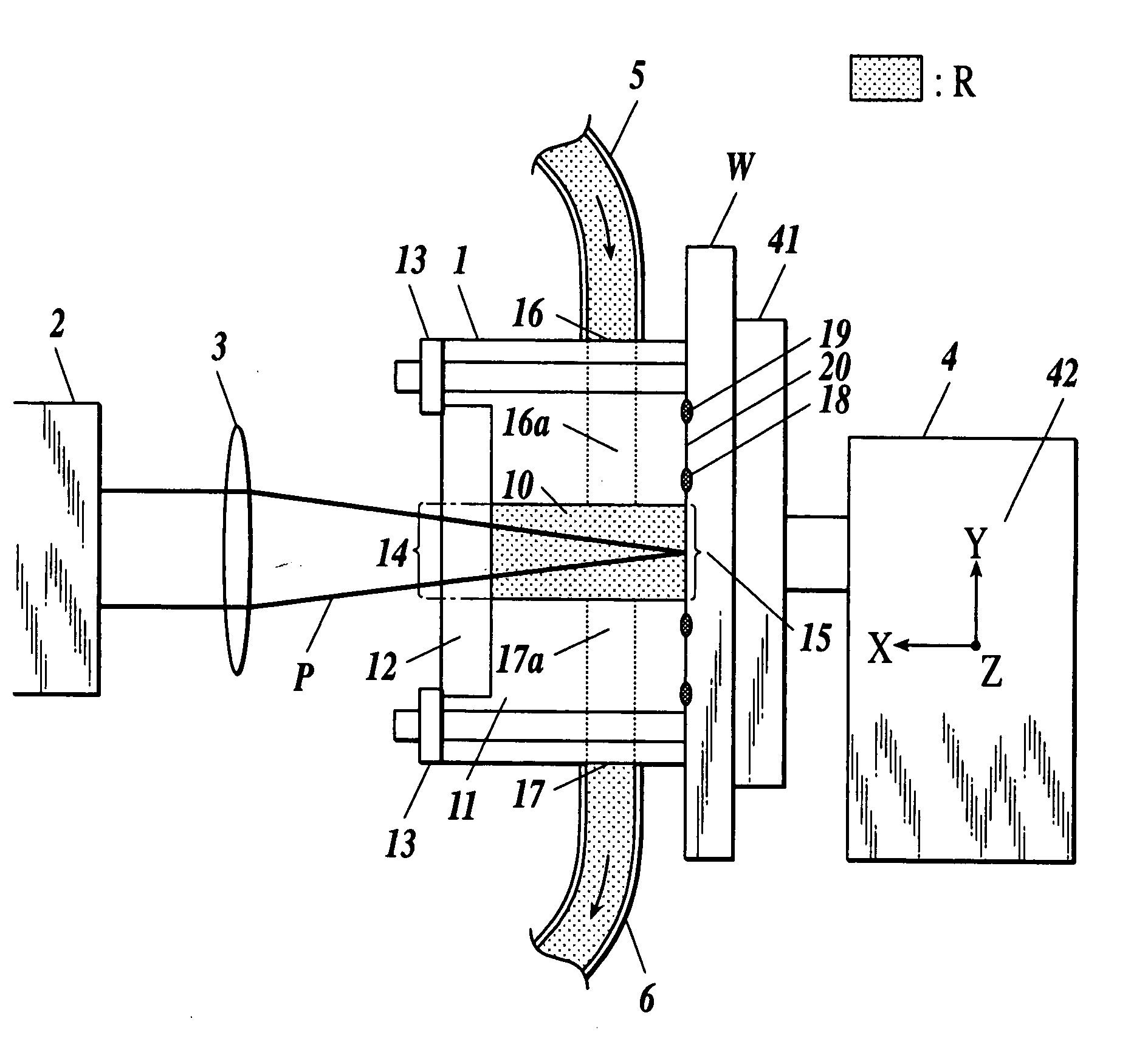

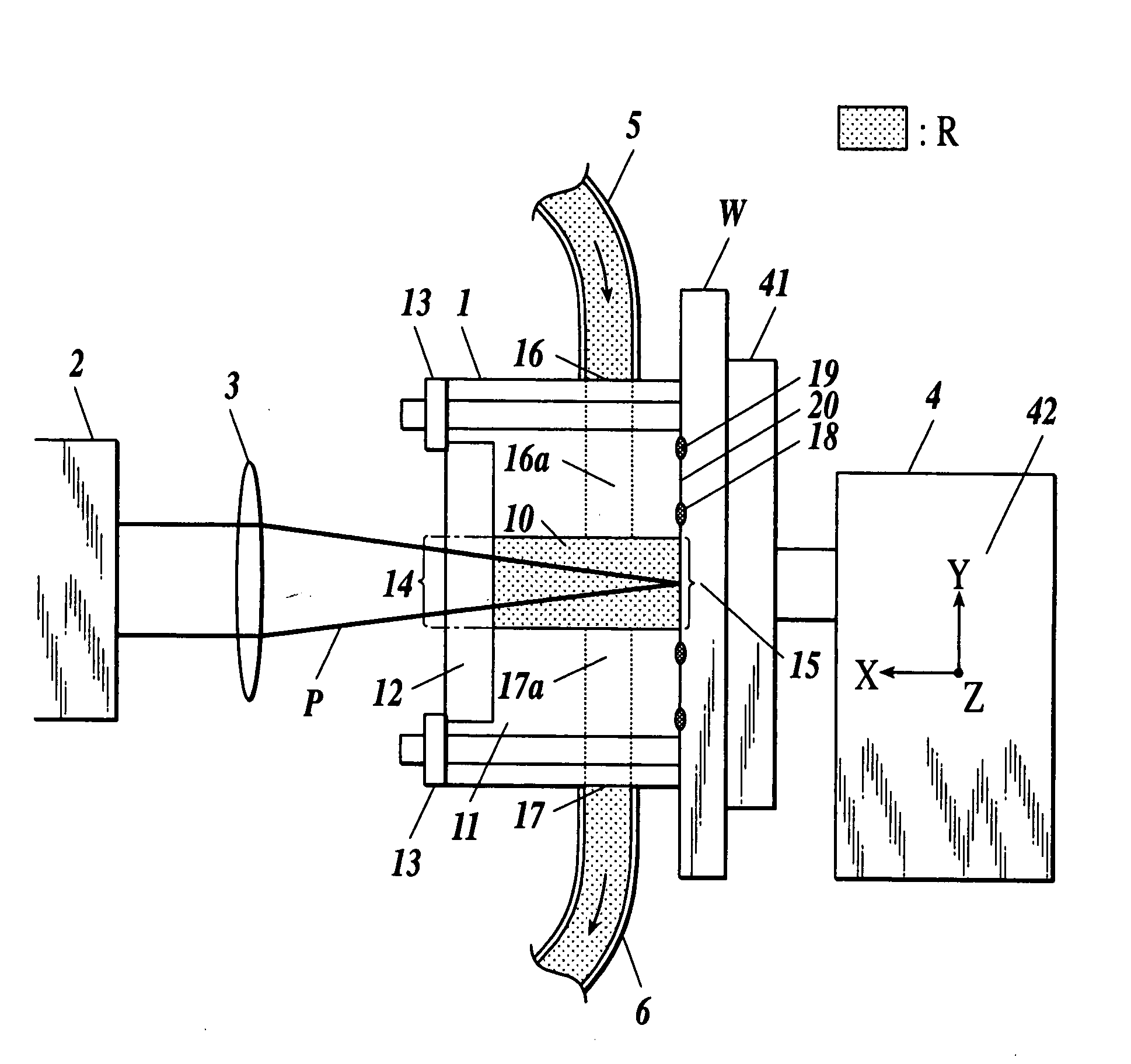

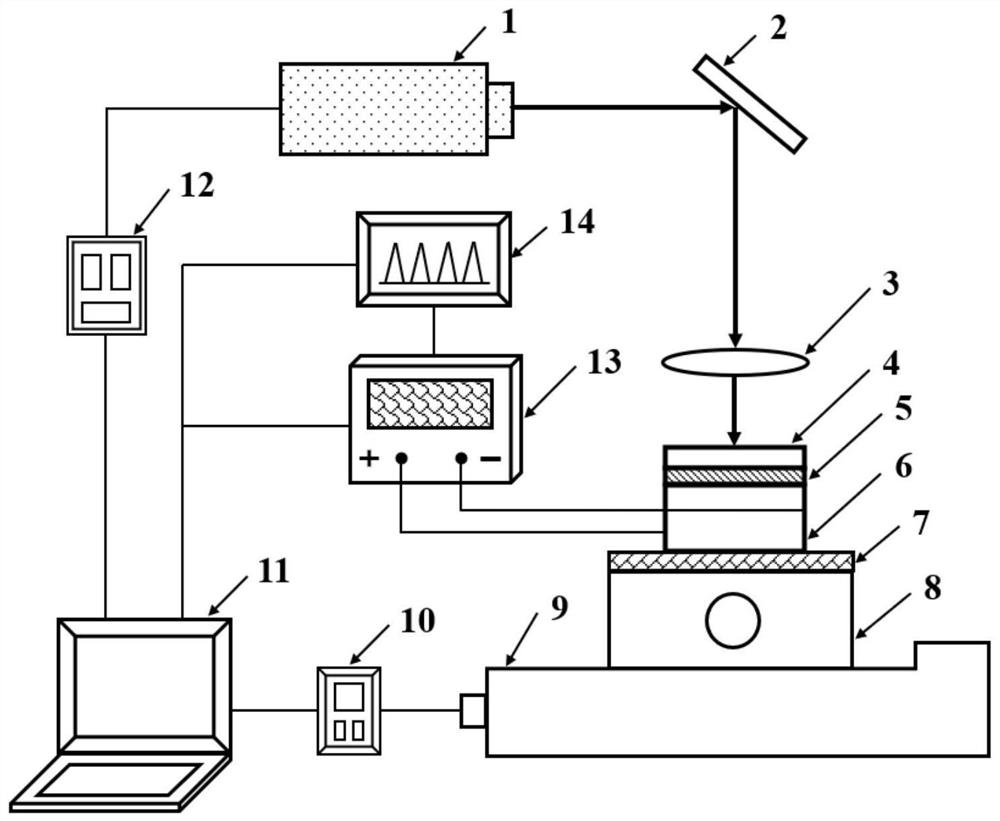

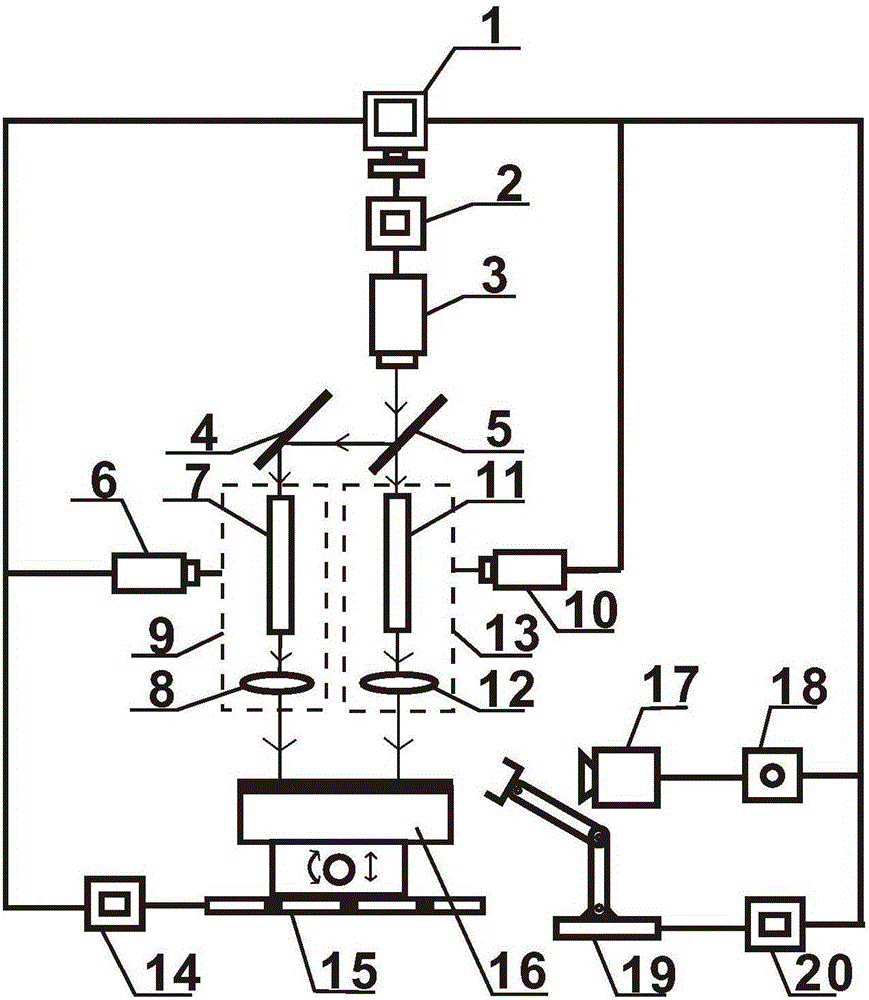

Method and device for strengthening surface modification by combination of laser cladding and laser peening

InactiveCN101392382AQuality improvementResidual stress distribution state changesMetallic material coating processesCoated surfaceSurface roughness

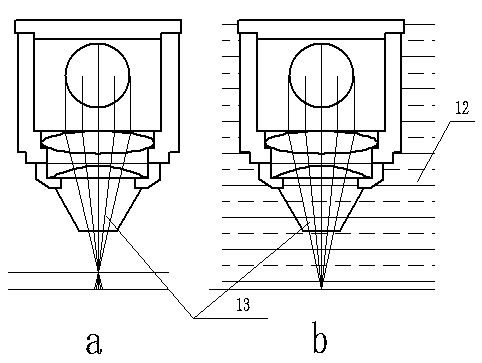

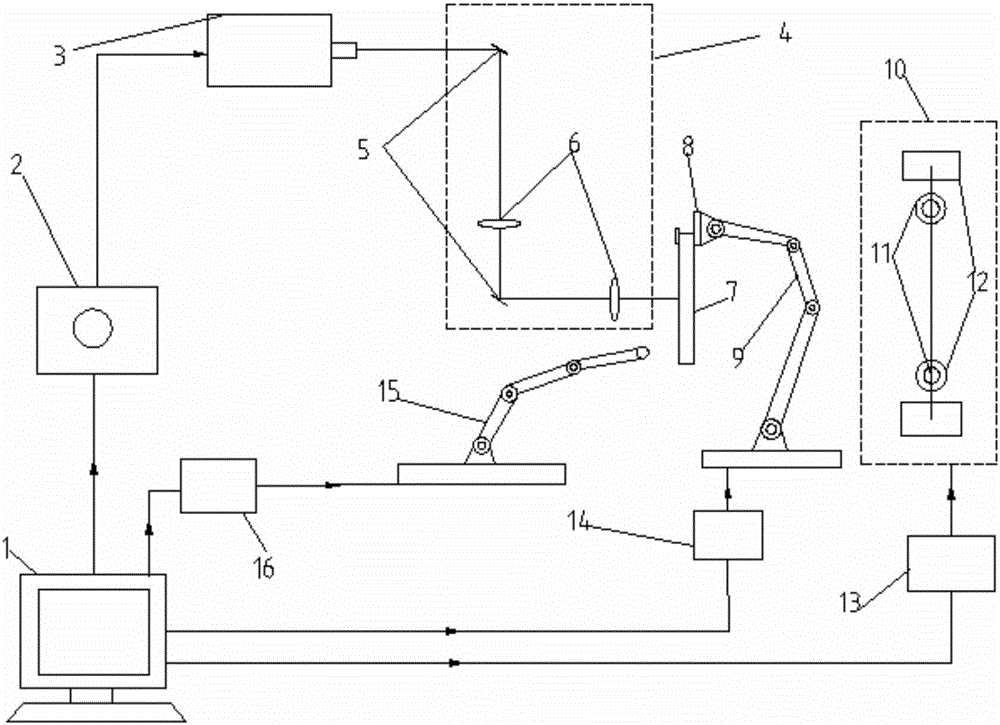

The invention provides a method for modifying a composite surface based on laser cladding and combining laser shock peening, and a device thereof. The method provided by the invention is characterized in that a coaxial and powder feeding type fast axial flow CO2 laser cladding unit clads a layer of coating on the surface of a substrate; then a neophane glass impulse laser shock peening unit is used for the shock peening on the surface of the cladded coating; a measurement feedback system is utilized to detect the surface roughness and the distribution state of residual stress of the cladded coating; the precise control over the surface roughness and the residual stress of the coating is realized by a central control and processing system so as to obtain a high quality surface-cladded coating with good performance. The device comprises the coaxial and powder feeding type laser cladding unit, the laser shock peening unit, a digital control working system, the measurement feedback system and the central control and processing system, and is under integrated control by a computer. The method and the device of the invention can reduce residual tensile stress and improve the quality of the cladded coating and prolong the service life thereof.

Owner:JIANGSU UNIV

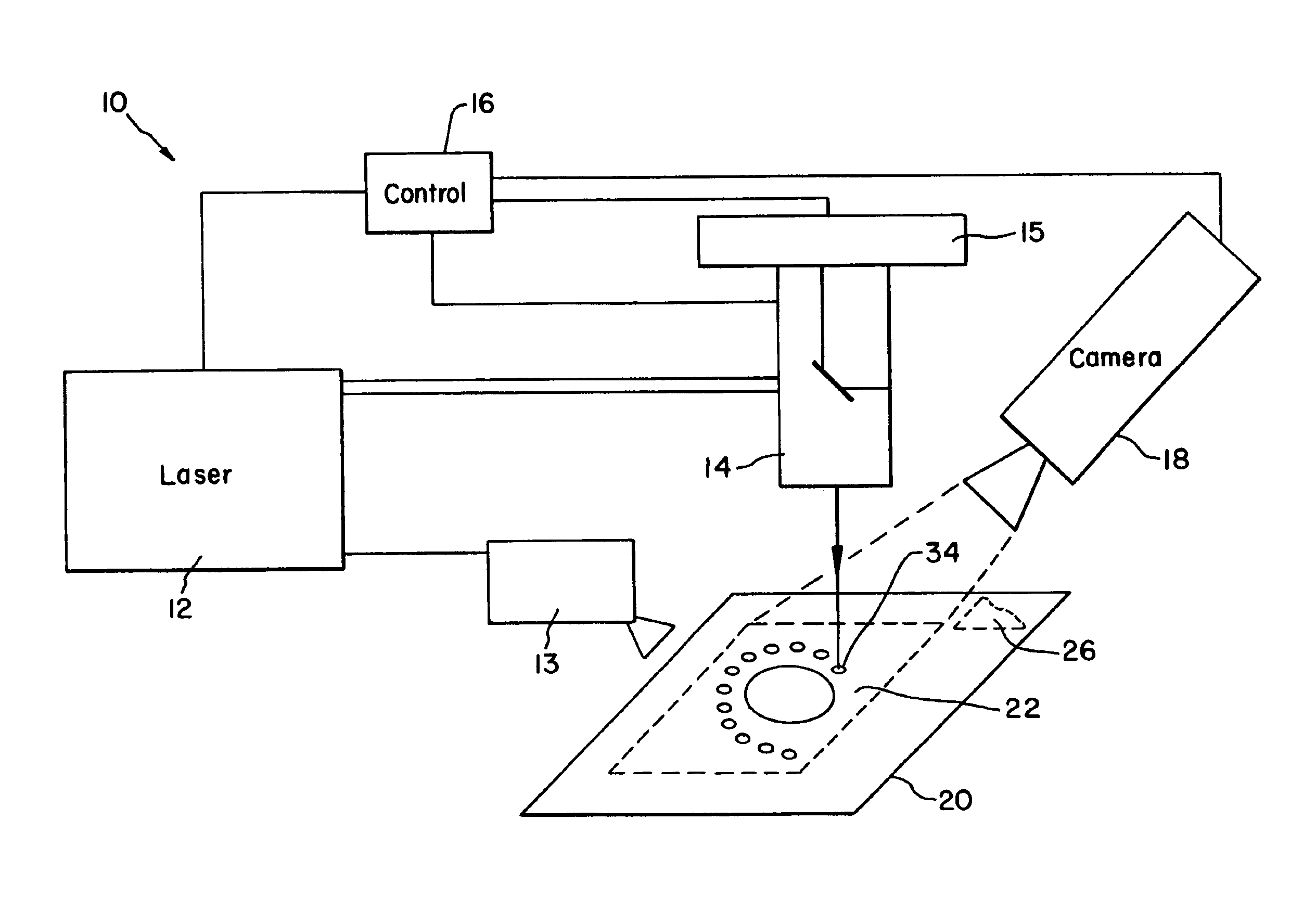

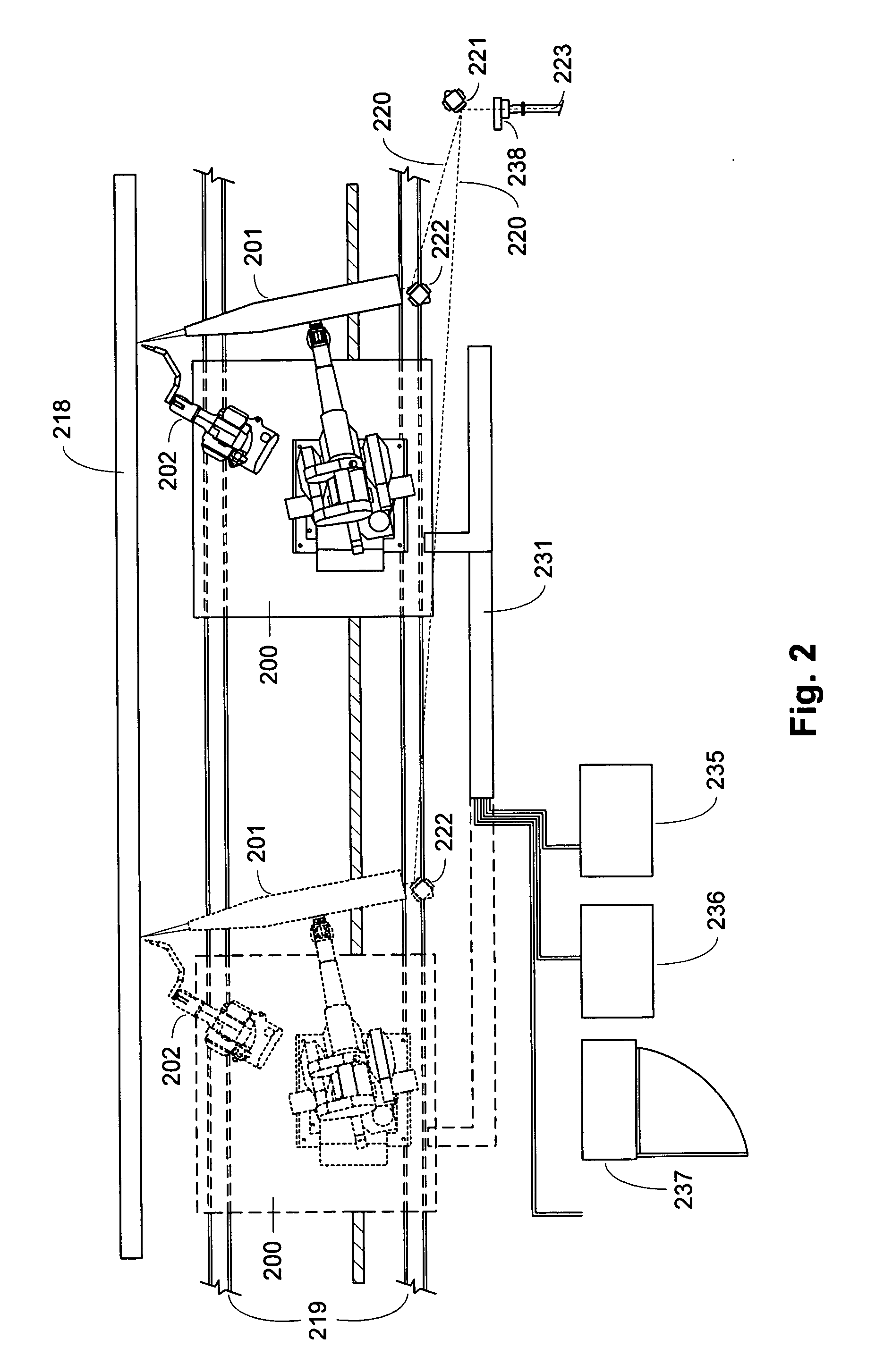

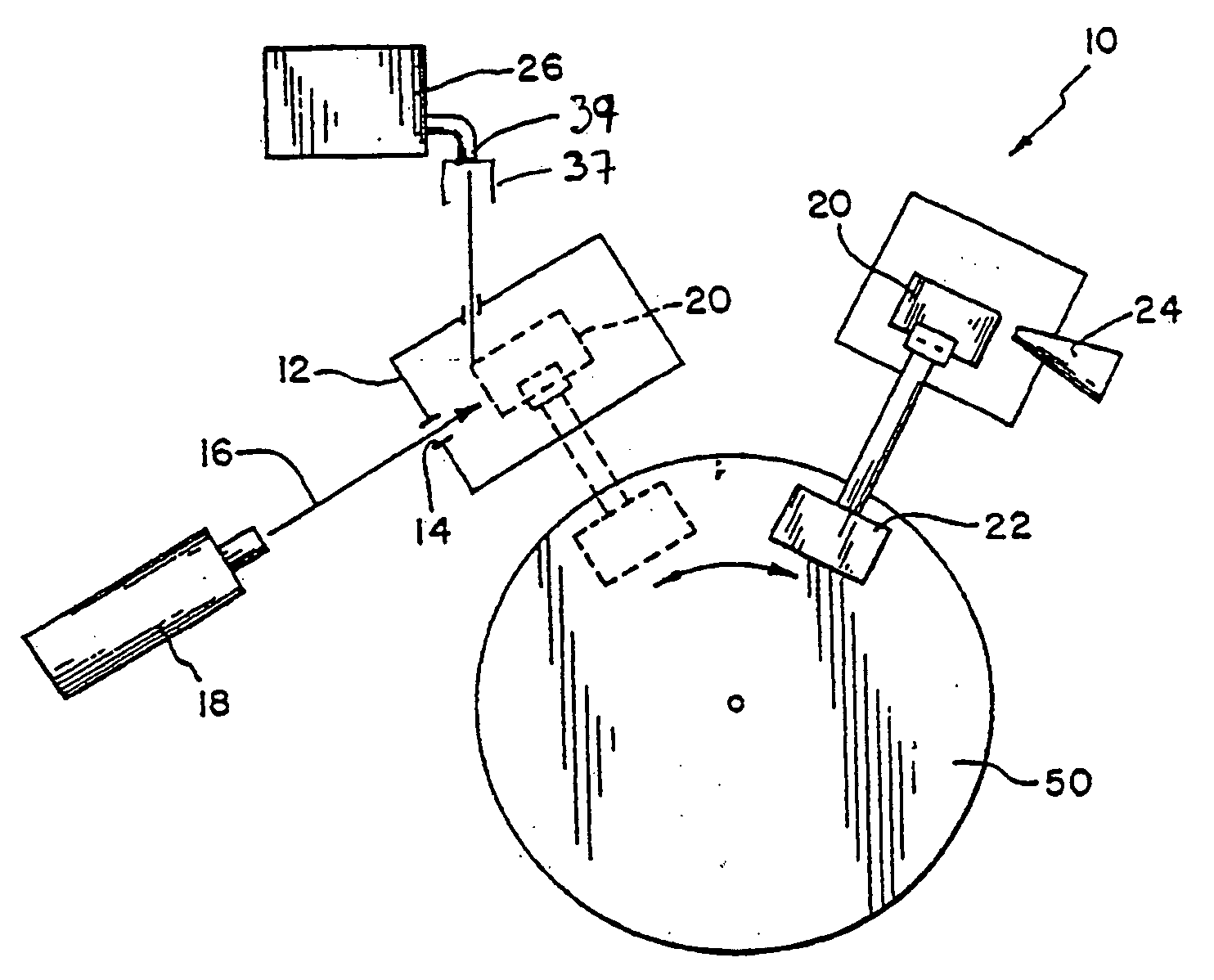

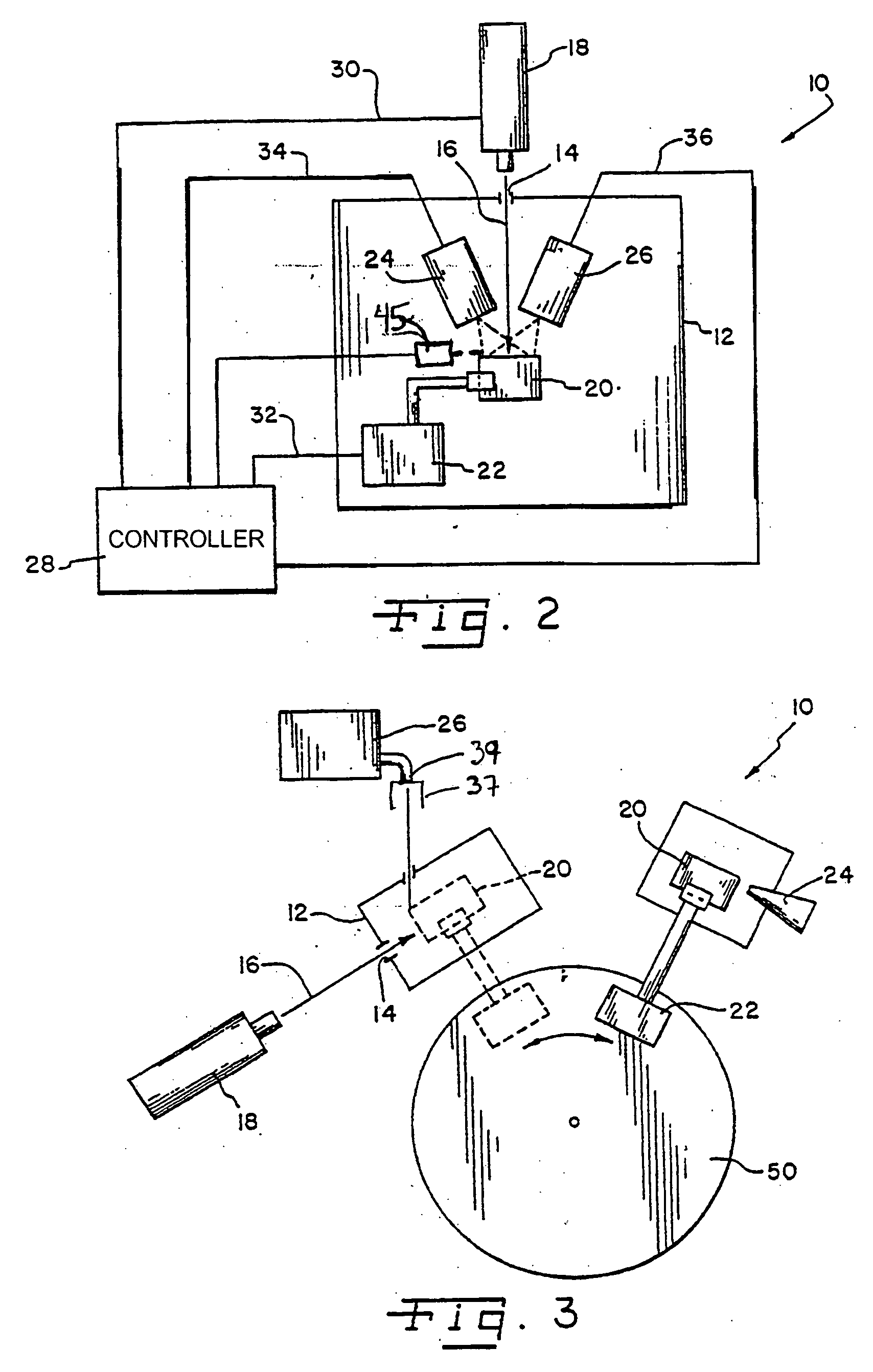

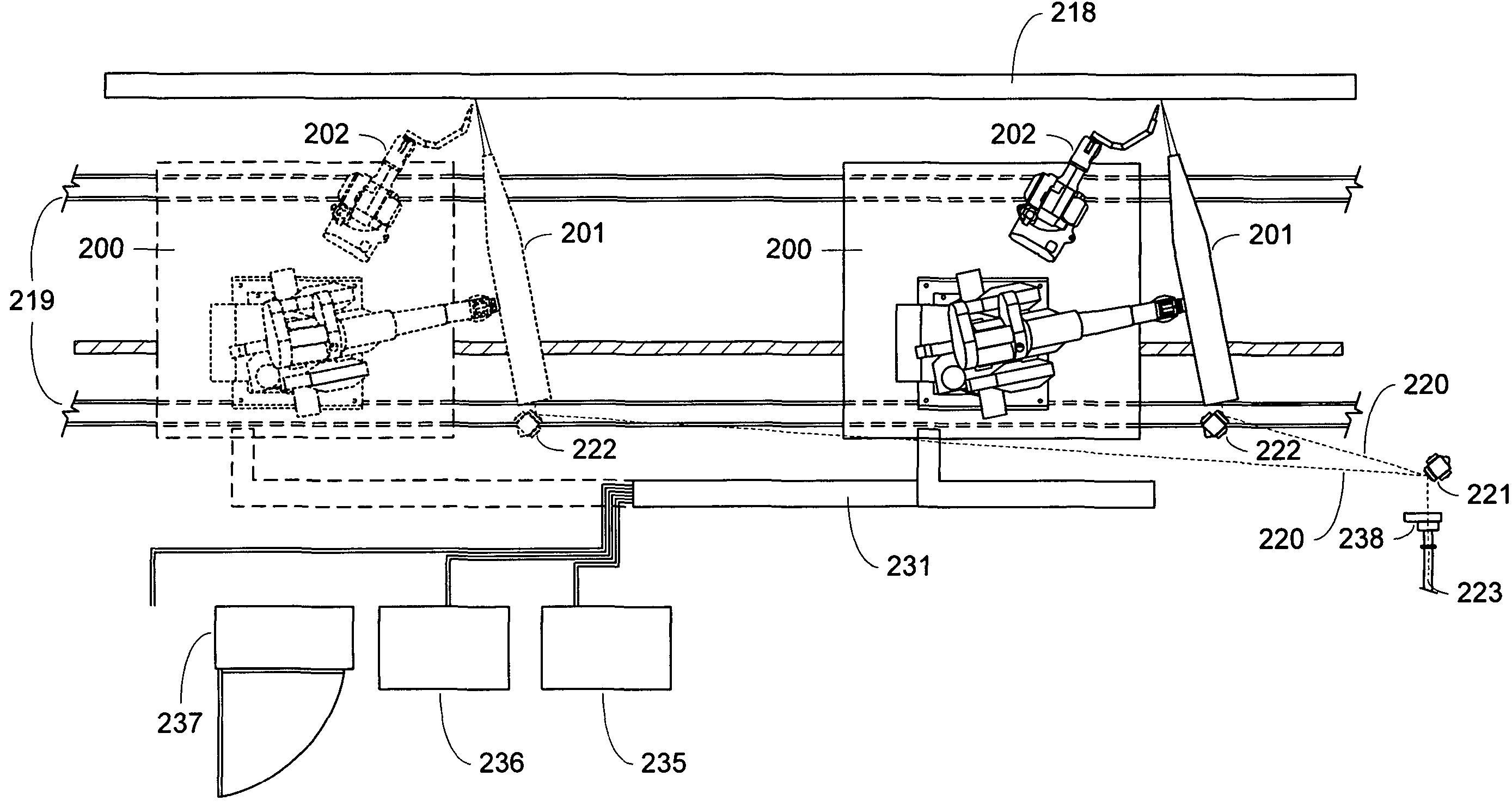

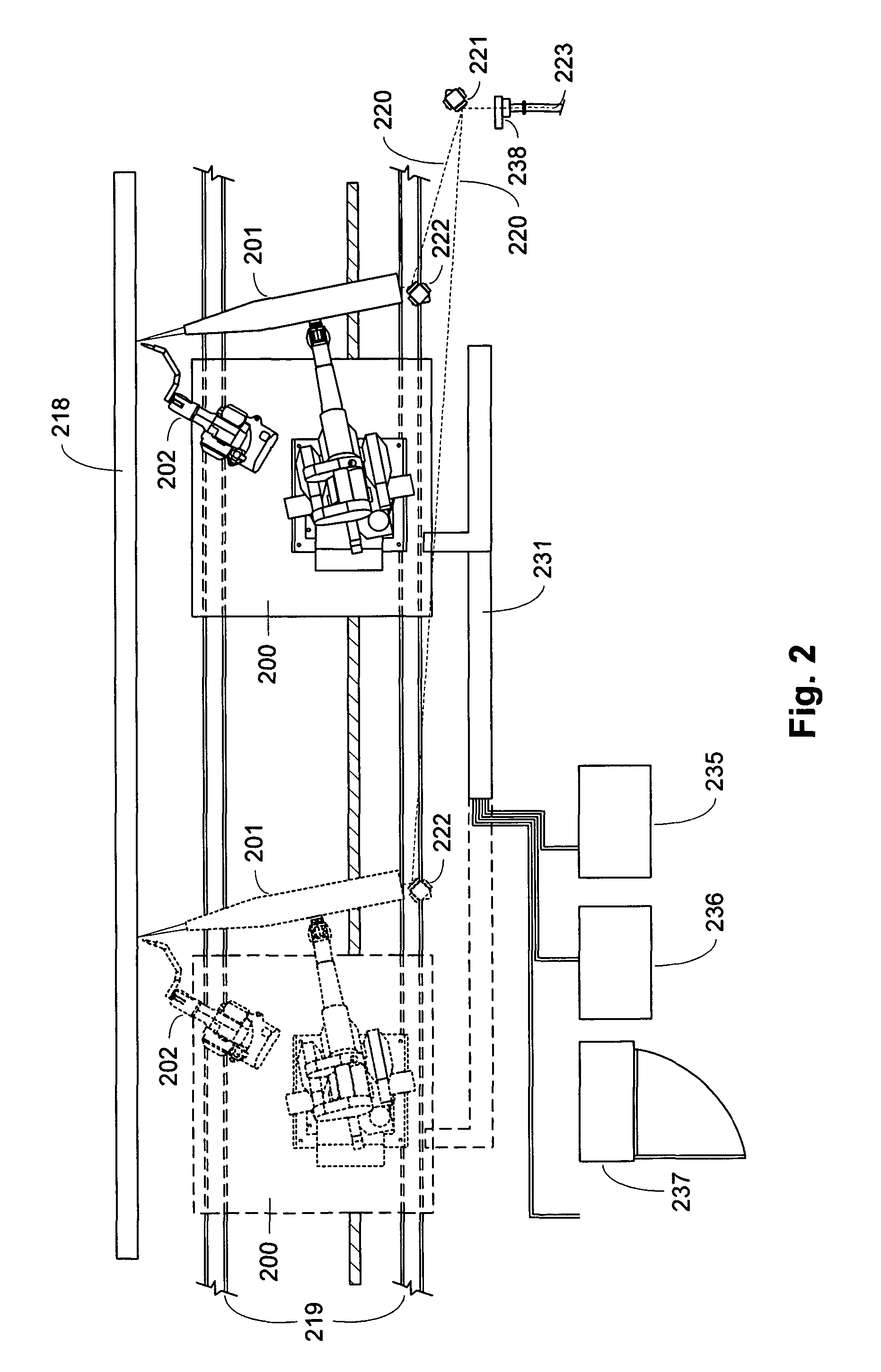

Automated positioning of mobile laser peening head

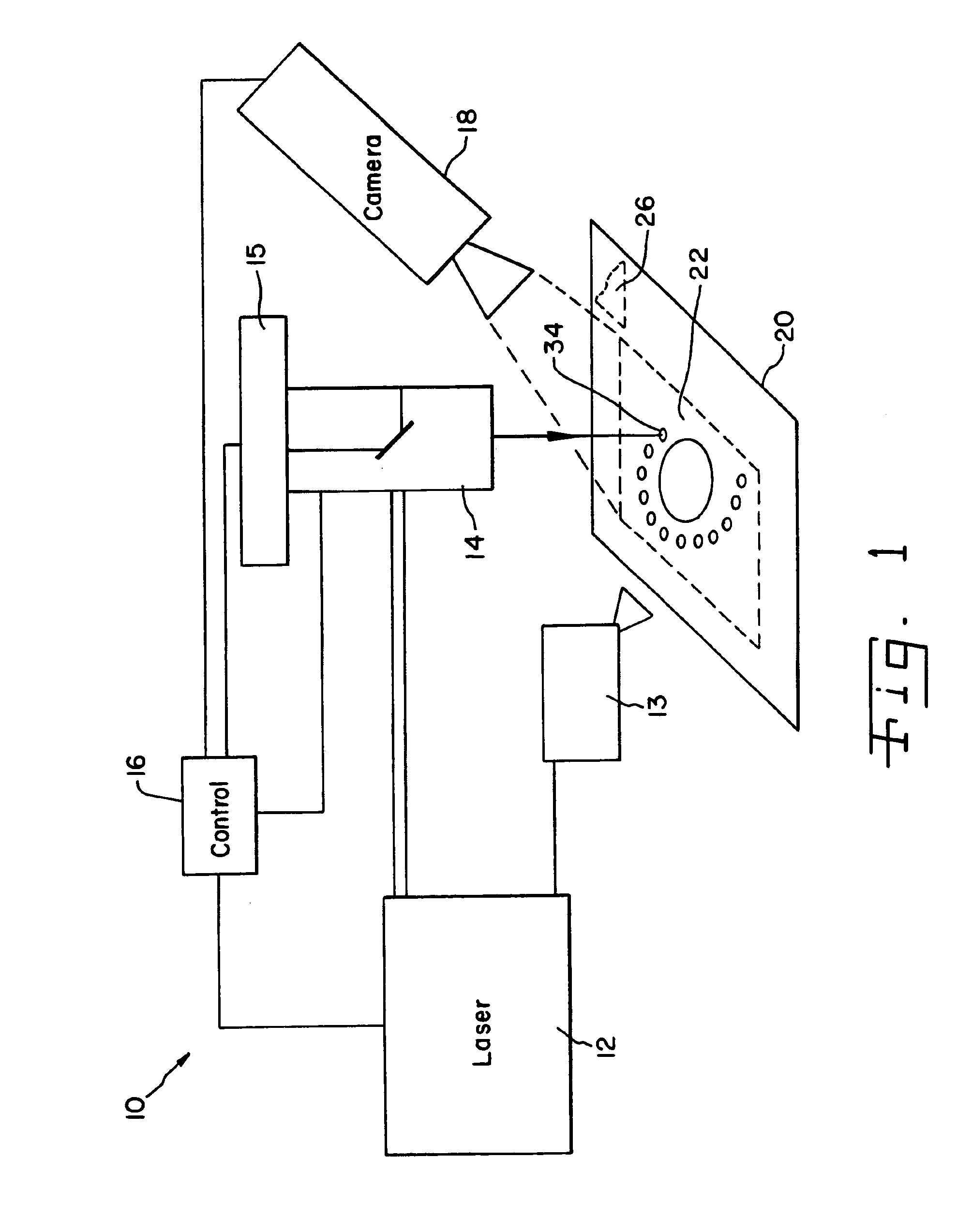

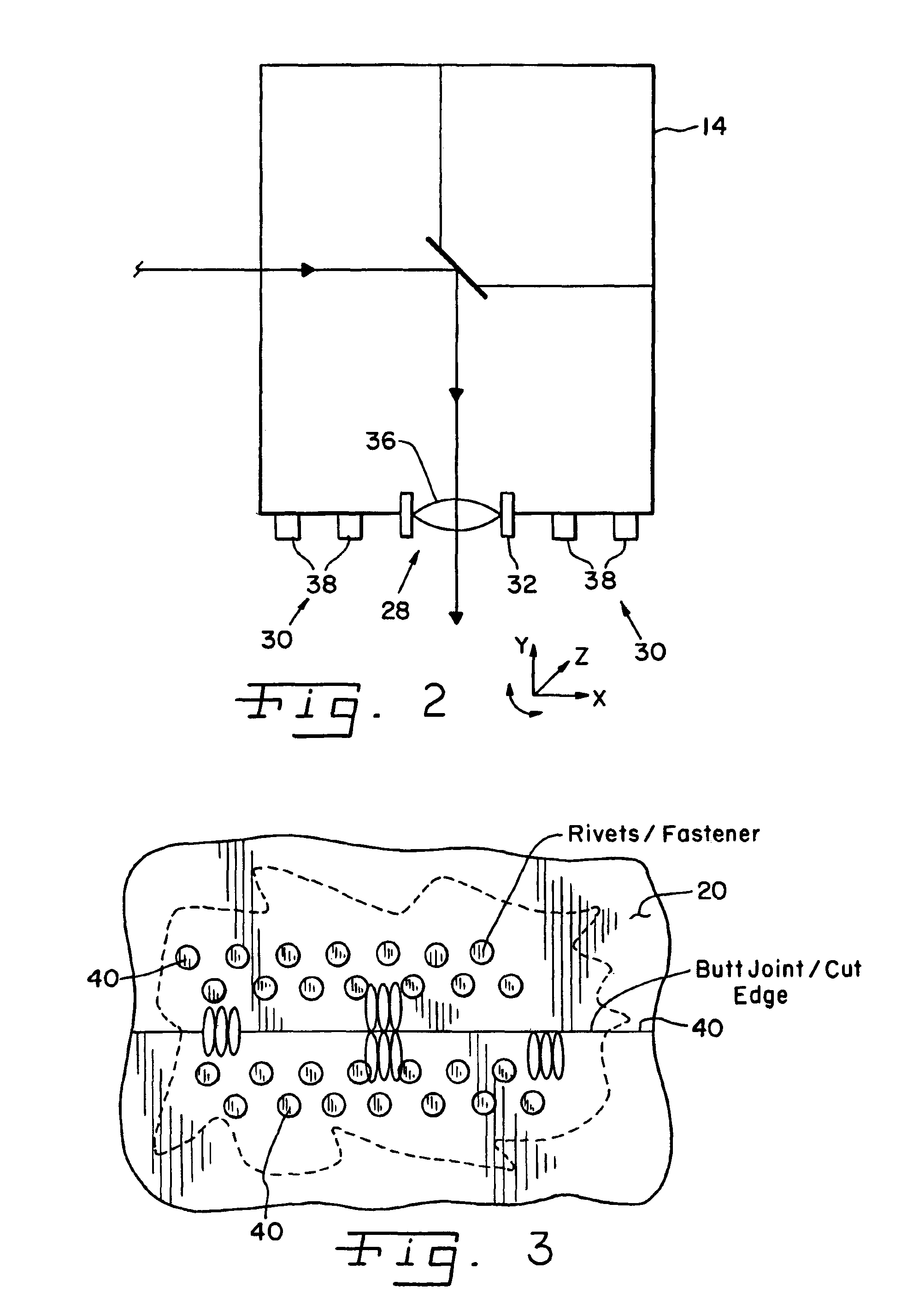

InactiveUS6867390B2Increase the areaFacilitates immediate verificationOptically investigating flaws/contaminationAircraft components testingSpatial positioningLaser peening

The present invention enables the processing head to locate itself precisely on the surface of the structure being processed, and to then reposition itself correctly for the next laser spot. Further, the present invention will complete processing a laser peened area, the area including a multiplicity of spots arranged in a specific pattern, and correctly laser peen each spot in the area under control of a controller including control linkages with the laser.The invention further provides an automated laser peening processing head encompassing spatial position sensing and locating means, as well as programmed spatial positioning, application of overlay materials, verification of proper overlay condition and positioning, and notification of the laser to pulse the surface of the structure.

Owner:LSP TECH INC

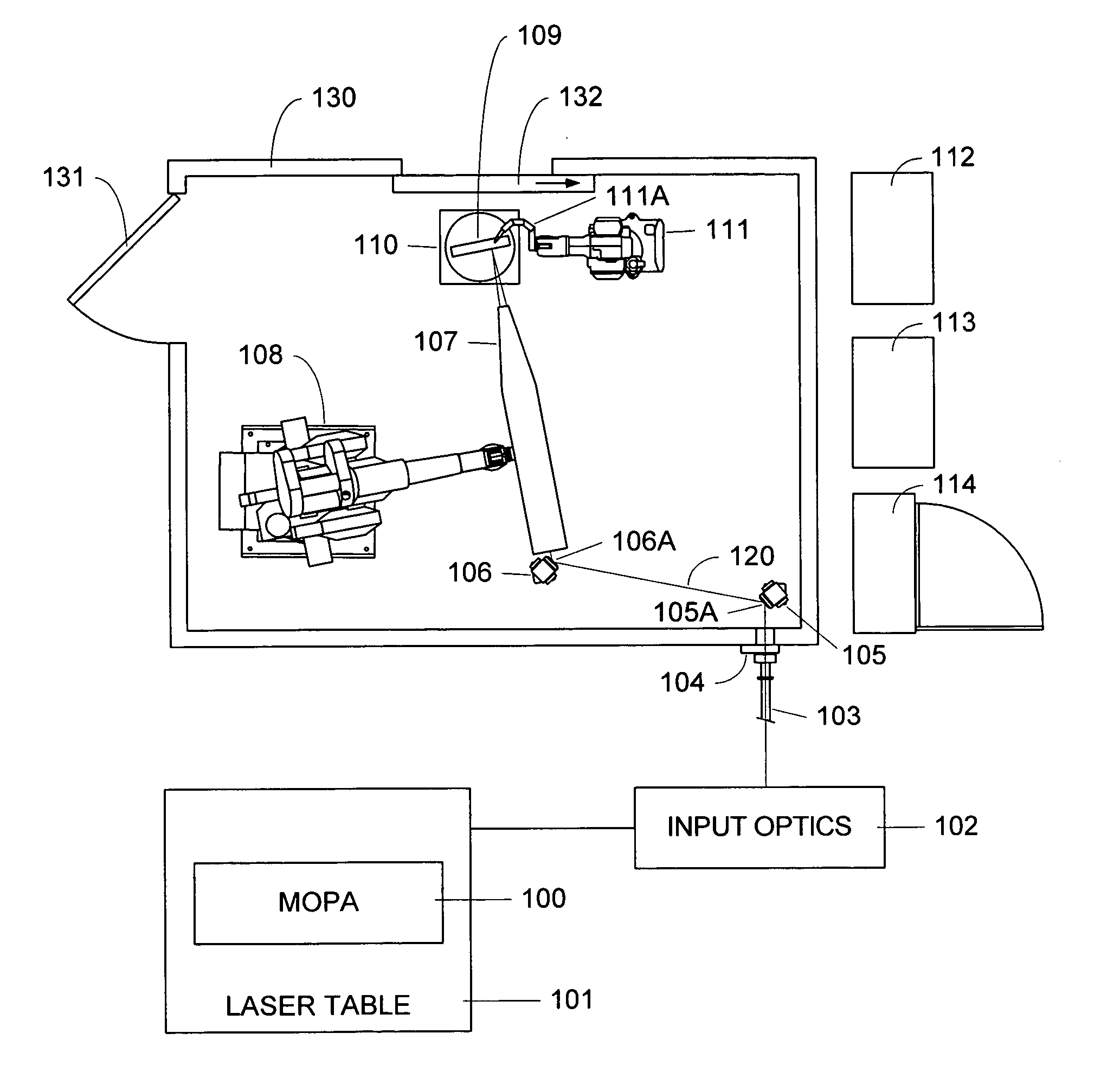

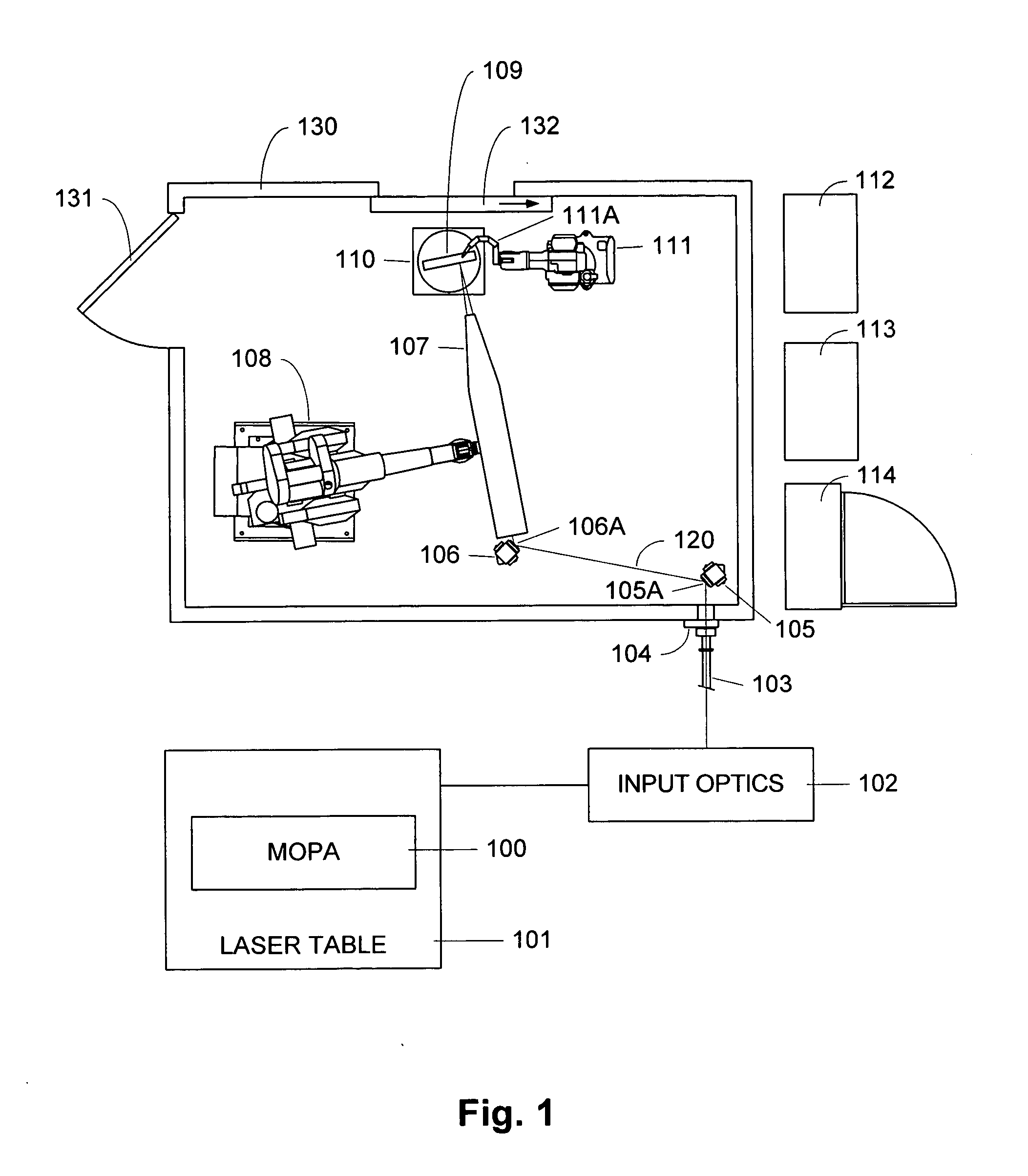

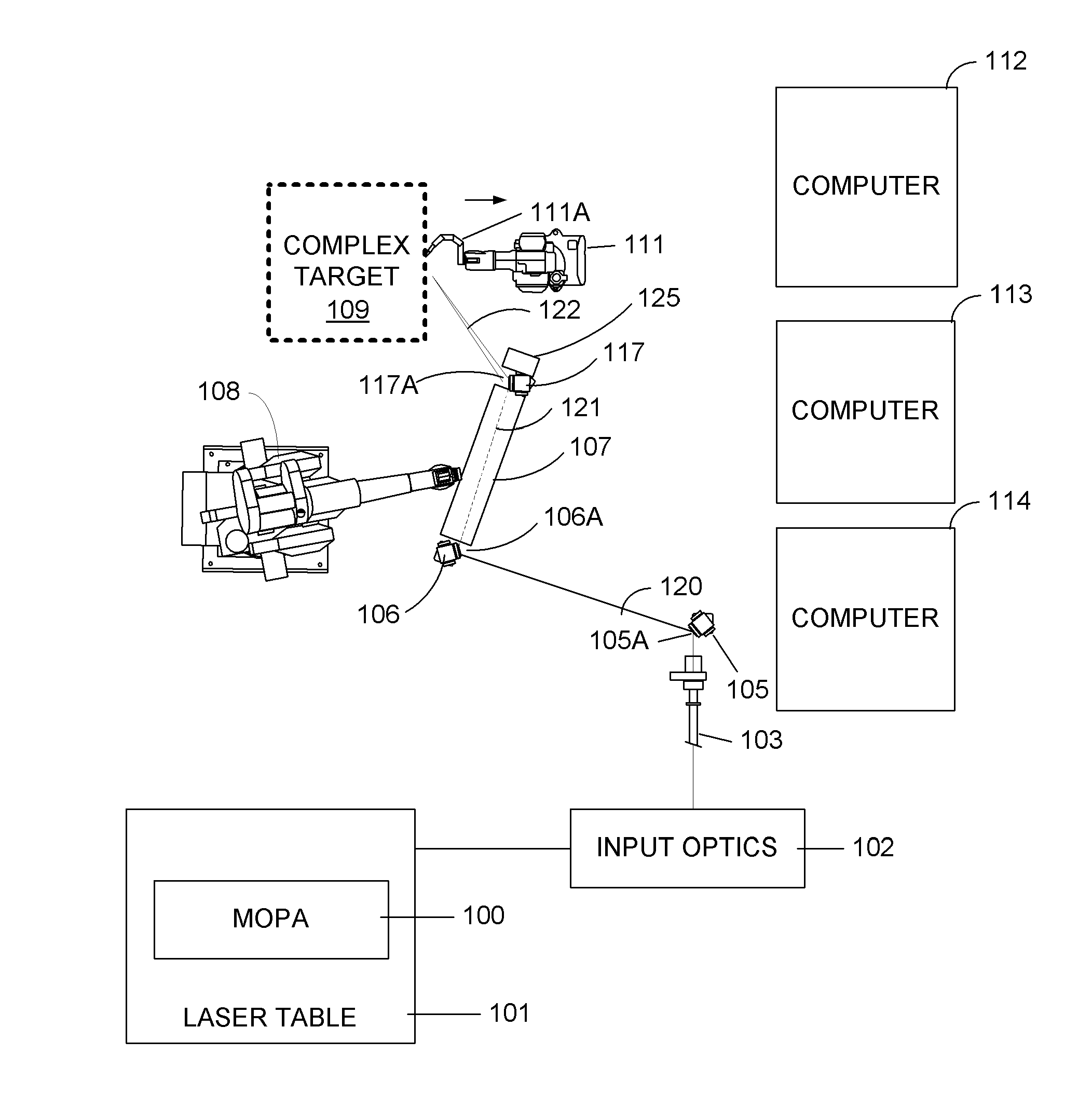

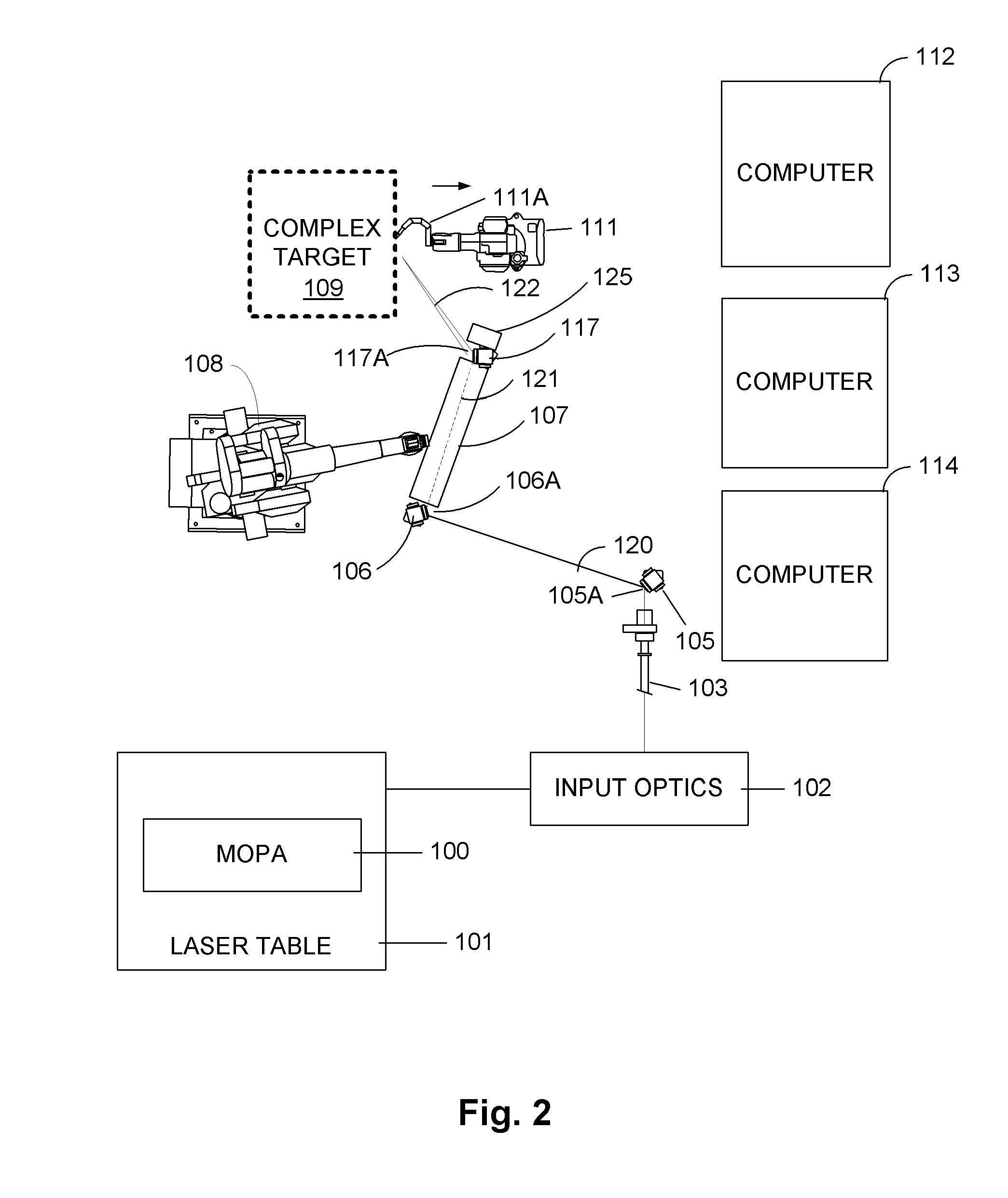

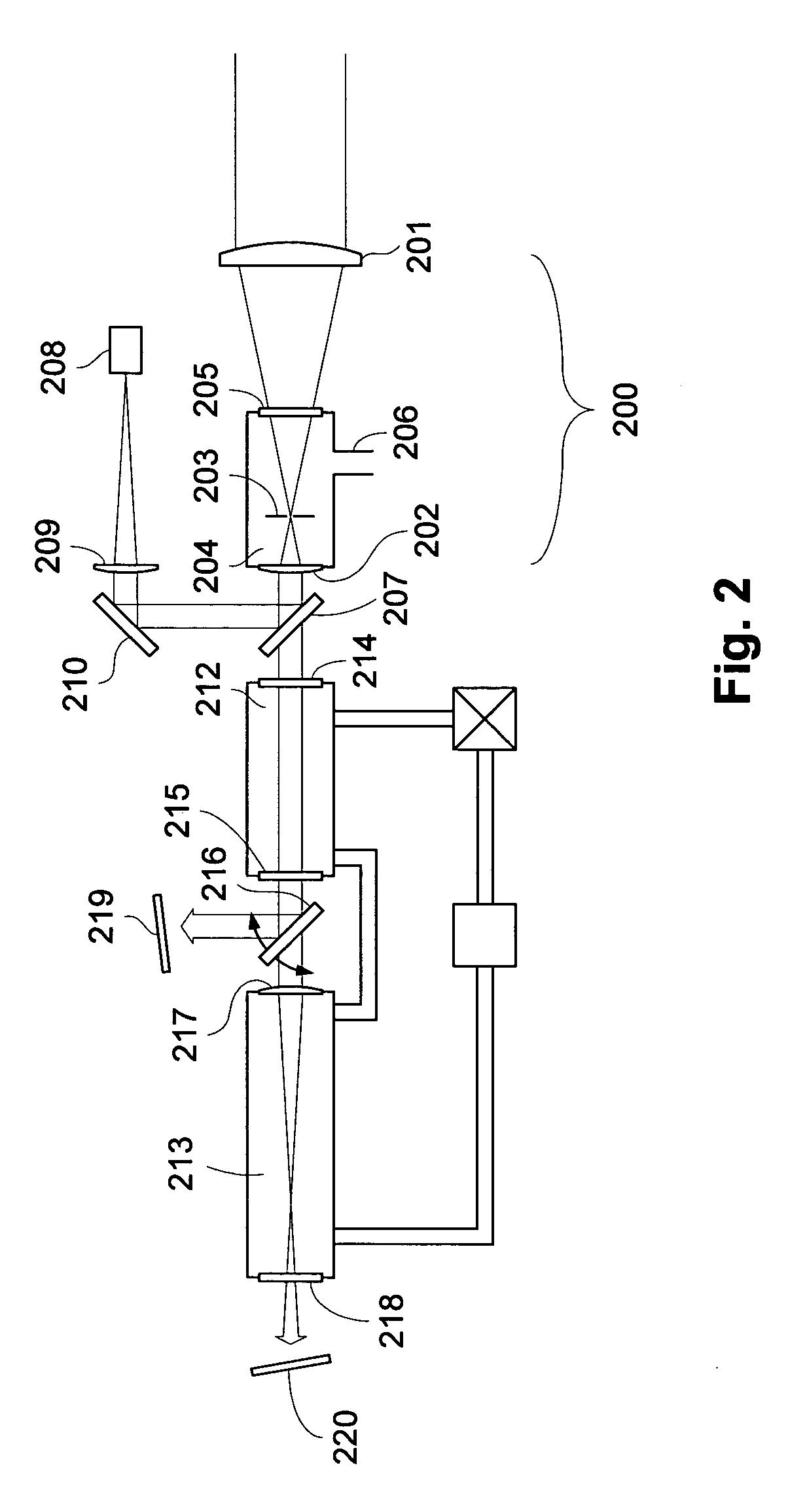

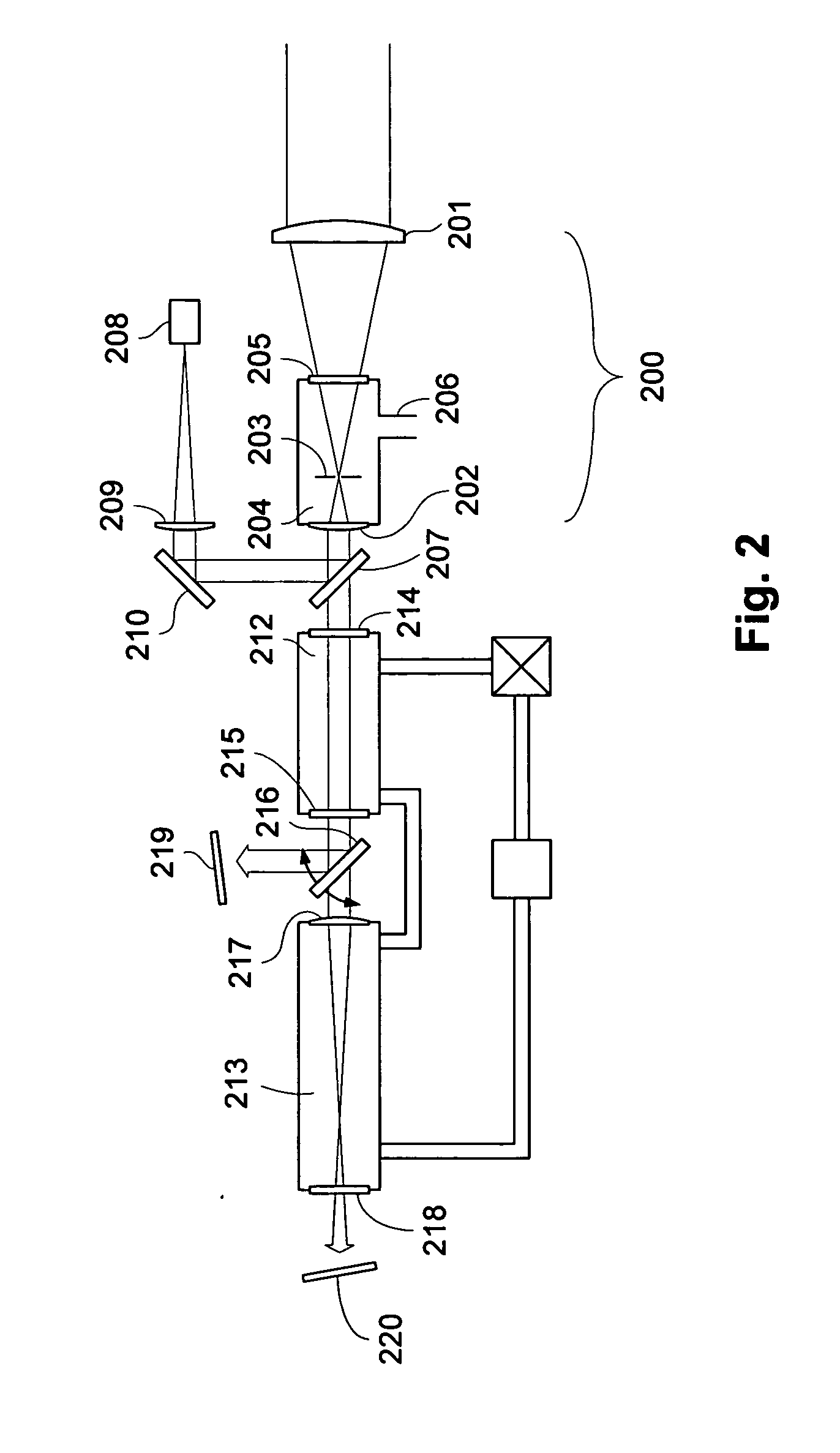

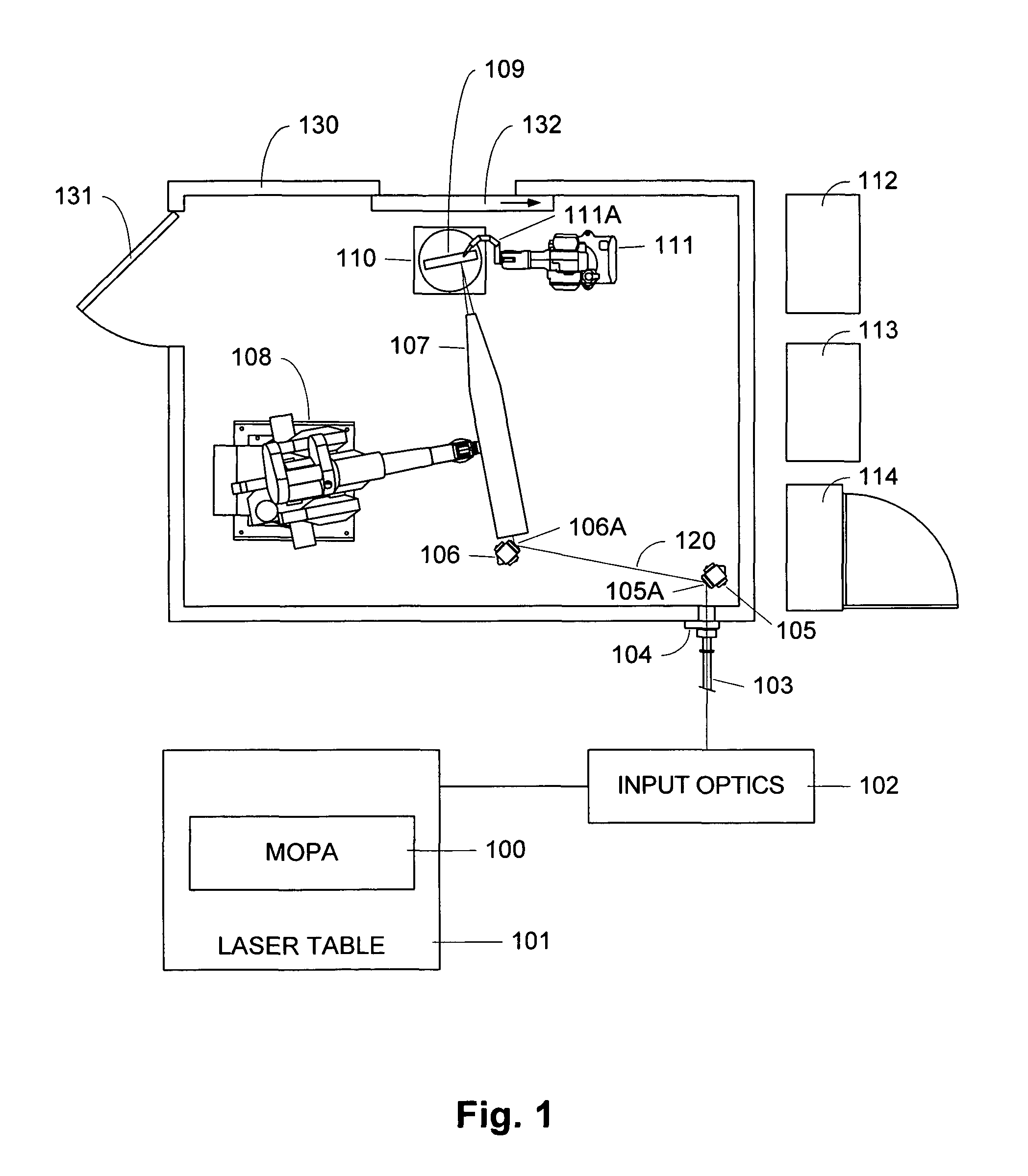

Active beam delivery system for laser peening and laser peening method

ActiveUS20060102609A1Minimizes holding fixtureMinimizes work piece moving complexityWelding/cutting auxillary devicesAuxillary welding devicesAngle of incidenceVariable length

A laser peening method and system allows the work piece to be fixed, while moving and directing the laser beam. A laser energy delivery system includes a relay imaging system. Input optics arranged to receive the laser energy, a transmitting mirror having adjustable angle of incidence relative to the input optics, and a robot mounted processing head including an optical assembly are configured to direct laser energy toward the movable target image plane. The laser energy follows an optical path including an essentially straight segment from the transmitting mirror to the receiving mirror, having a variable length and a variable angle relative to the input optics. Diagnostics on the processing head facilitate operation.

Owner:METAL IMPROVEMENT CO INC

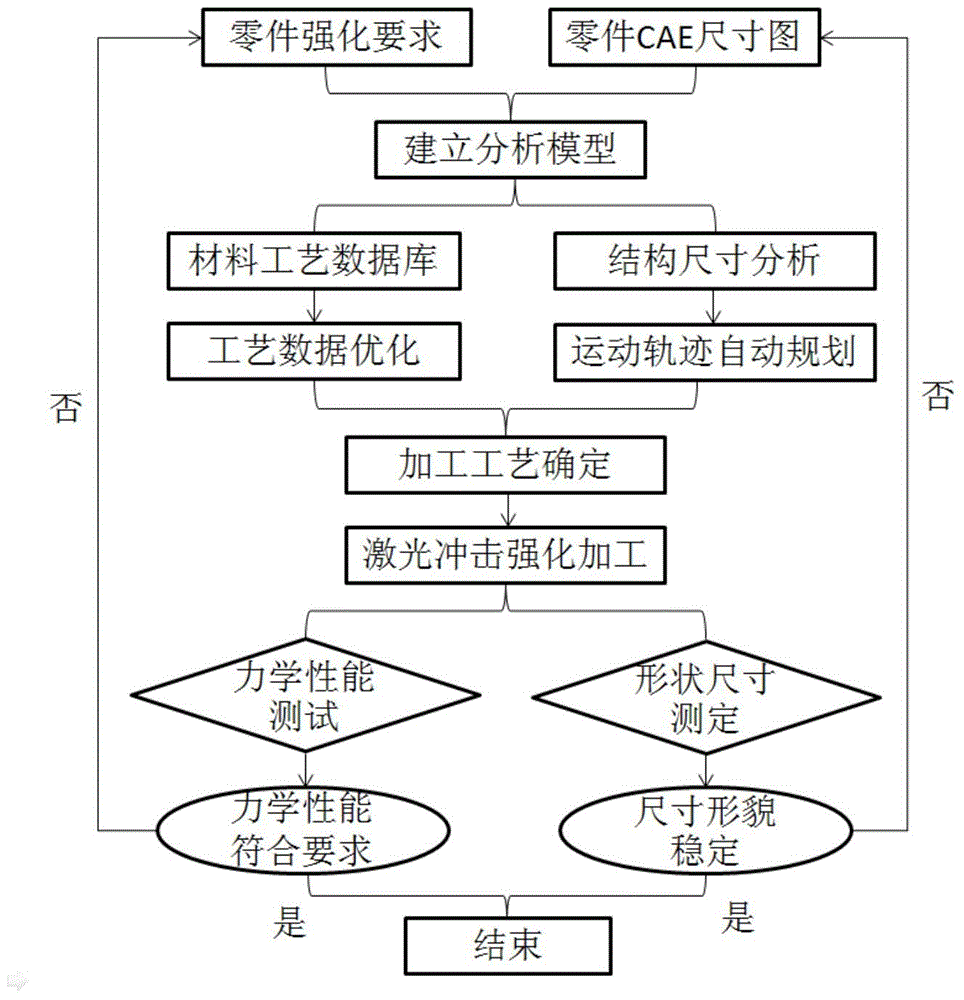

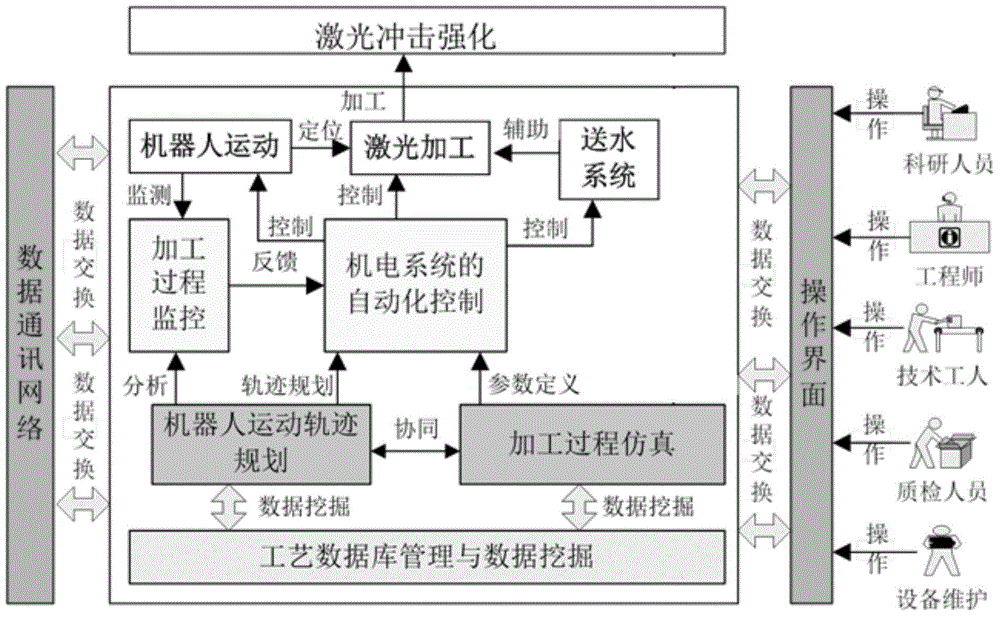

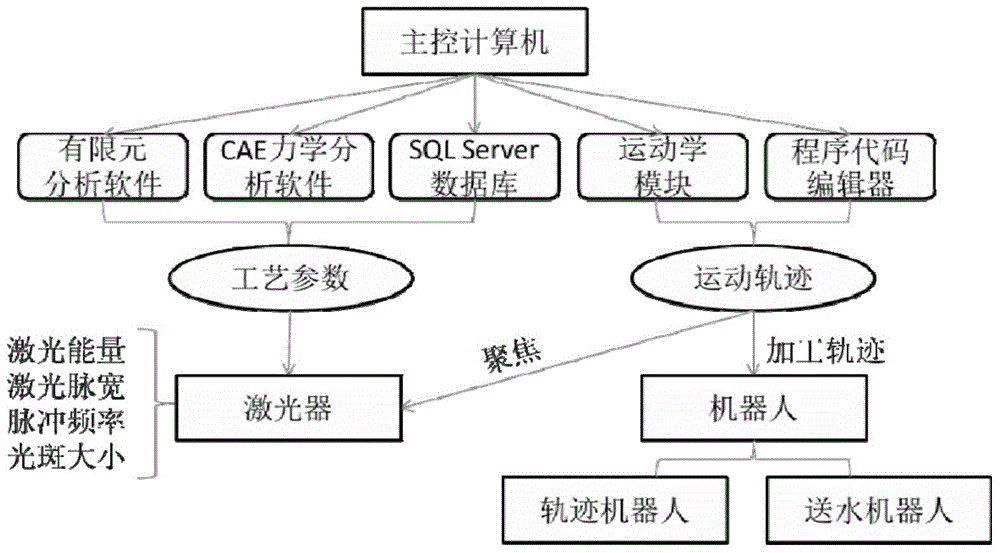

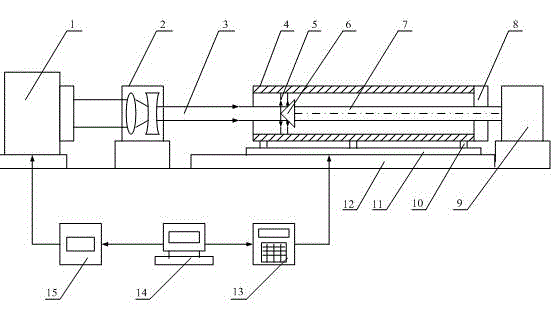

System and method for automatic control over laser shock peening

InactiveCN105385839AAchievement of laser shock strengtheningRealization of automatic open distributed control of laser shock strengthening equipmentForeign matterShock wave

The invention relates to a method for automatic control over laser shock peening. The method comprises the following steps that a part analysis model is built in mechanical analysis software according to the machining requirement, and residual stress distribution is obtained; residual stress distribution is guided into CAE analysis software, and a machining motion track acting on the surface of a part is automatically generated; meanwhile, technological parameters corresponding to a laser shock wave pressure set value are selected by an industrial personal computer according to the relation between laser shock wave pressure and laser peening technological parameters; the machining motion track and the technological parameters are guided into the mechanical analysis software for simulation so as to obtain a strain value after machining simulation; and if the strain value is within the set range, the technological parameters are sent to a laser device through the industrial personal computer, the machining motion track is sent to a robot, and automatic laser machining is achieved. By means of the method, laser shock peening of an integral blade disc can be achieved, quantitative precise control over residual stress is achieved, the service life of the integral blade disc is effectively prolonged, and the foreign matter damage resisting capacity of the integral blade disc is effectively improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

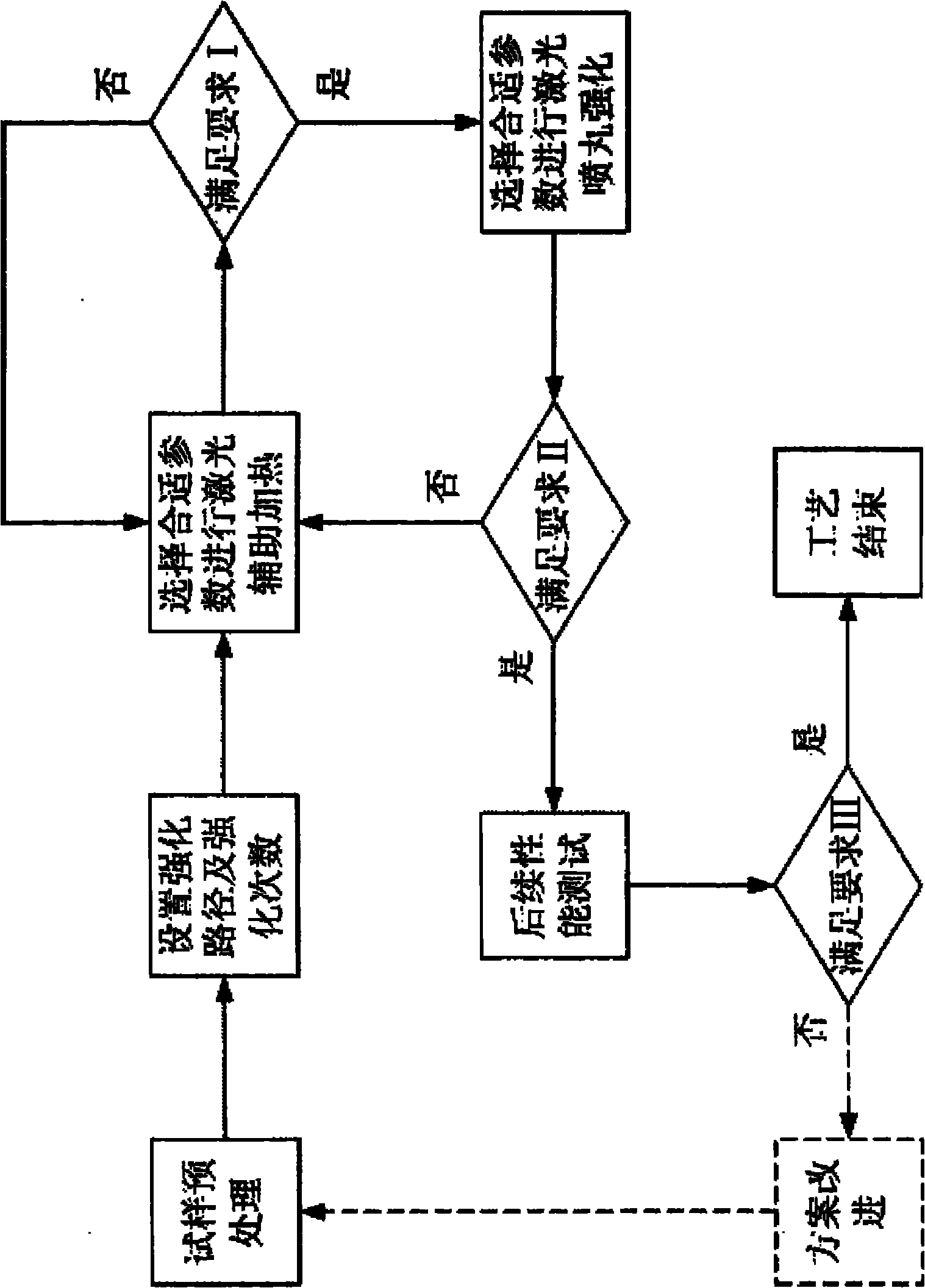

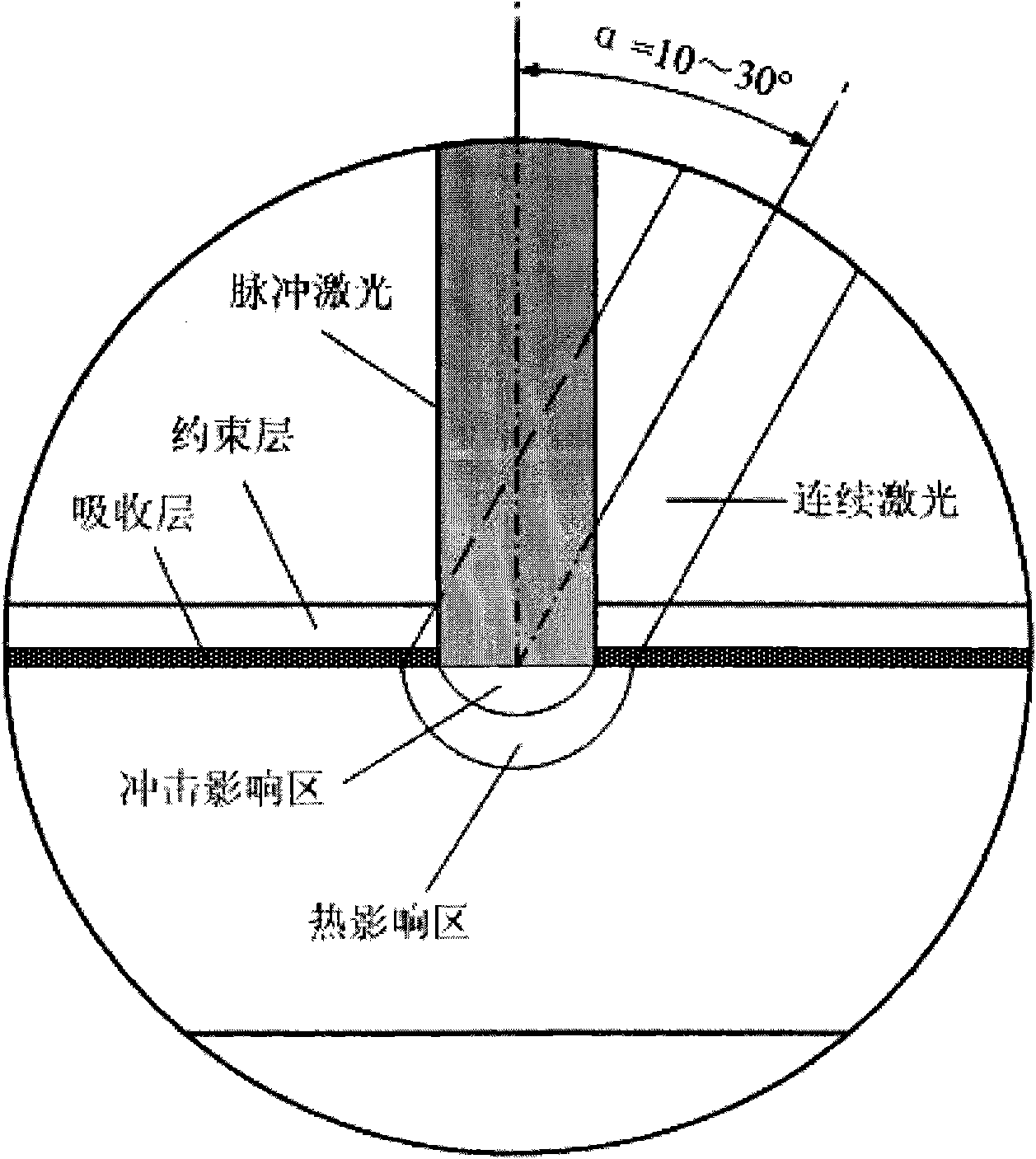

Device and method for laser shot blasting reinforcement of hard and brittle material

The invention discloses a device and a method for laser shot blasting reinforcement of a hard and brittle material, and relates to the field of mechanical manufacture of hard and brittle material processing and laser application. The device comprises a laser aid heating system, a laser shot blasting reinforcement system, a workpiece clamp system, a computer numerical control system, a measurement feedback system and a protective gas circulating system. The method comprises a laser aid heating stage and a laser shot blasting reinforcement stage, namely performing aid heating treatment on the area to be reinforced by adopting high-power continuous laser, wherein for most metal materials, the plastic performance is improved along with the rise of temperature; and after the temperature of the heating area reaches a predetermined heating temperature, implementing laser shot blasting reinforcement treatment by adopting high-power pulse laser. The device and the method can implement the laser shot blasting reinforcement on the hard and brittle material so as to broaden the application range of the laser shot blasting reinforcement technology, and meanwhile compound the advantages of continuous laser and pulse laser so as to broaden the application field and the application prospect of laser manufacture.

Owner:JIANGSU UNIV

Flexible beam delivery system for high power laser systems

ActiveUS20110253690A1Photometry using reference valueLaser beam welding apparatusHigh power lasersLight beam

A beam delivery technology for high power laser systems, like laser peening systems, for work pieces which may have compound curvatures, includes placing an optical assembly having a receiving optic, beam formatting optics and a scanner mounted thereon, in a position to receive laser pulses from a laser source and within an operating range of the process area. Polarized laser pulses are delivered to the receiving optic while the position of the optical assembly remains unchanged. The pulses proceed through the beam formatting optics to the scanner, and are direct to respective impact areas having nominal shapes and locations on the work piece. The scanning process includes for each laser pulse, setting direction, divergence, polarization, rotation and aspect ratio of the laser pulses output from the scanner, to control the polarization, shape and location on respective impact areas.

Owner:METAL IMPROVEMENT

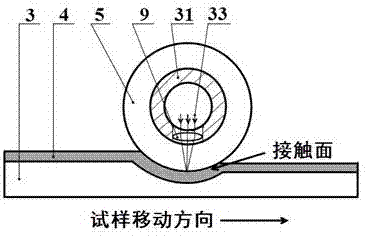

Method and device of shot peening for surface of metal component by means of light-water complex

ActiveCN102925646AImprove impact performanceLarge amplitude of residual compressive stressLaser processingHigh energy

The invention relates to the technical field of laser processing, and discloses a method and a device of shot peening for the surface of a metal component by means of a light-water complex. According to the method and the device of the shot peening for the surface of the metal component by means of the light-water complex, laser beams of high energy density and deionized water with certain pressure are utilized for coupling, and the light-water complex obtained after the coupling is utilized for the shot peening for the surface of the metal component. Through the shot peening with the light-water complex, the problem that shot peening effect is not ideal due to the fact that a water constraining layer is uneven in thickness and high in flexibility is solved, the deionized water with the certain pressure has certain momentum, the constraining effect of the deionized water can be similar to rigid constraint, and therefore the constraining effect is better. At the same time, after the shot peening, the shock pressure of the deionized water and the laser induced shock pressure are superposed, and therefore residual compressive stress amplitude generated on the surface of the material is enabled to be significantly improved, the residual compressive stress field is distributed more evenly, the surface material is high in nanocrystallization, and mechanical properties of the material are effectively improved.

Owner:JIANGSU UNIV

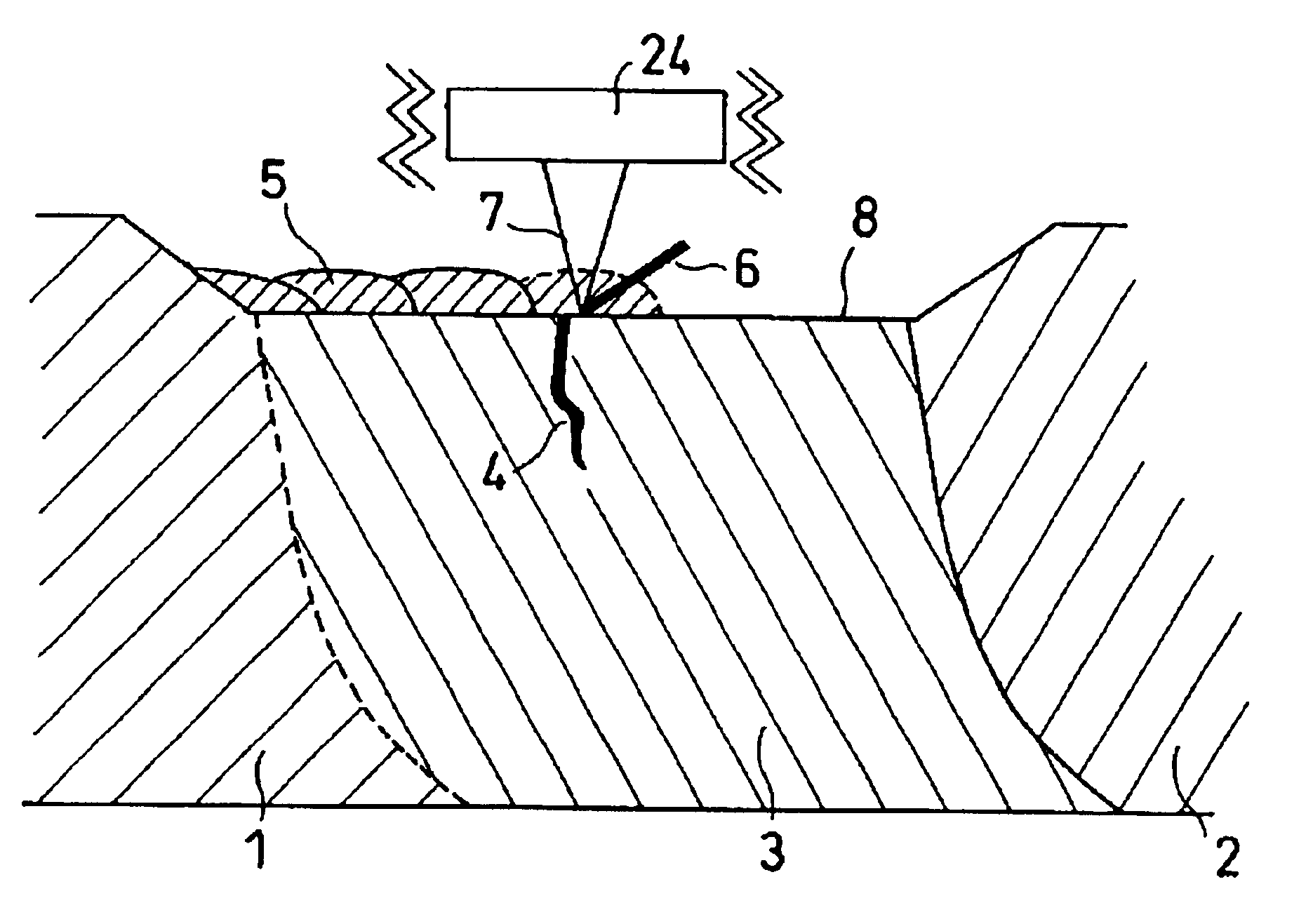

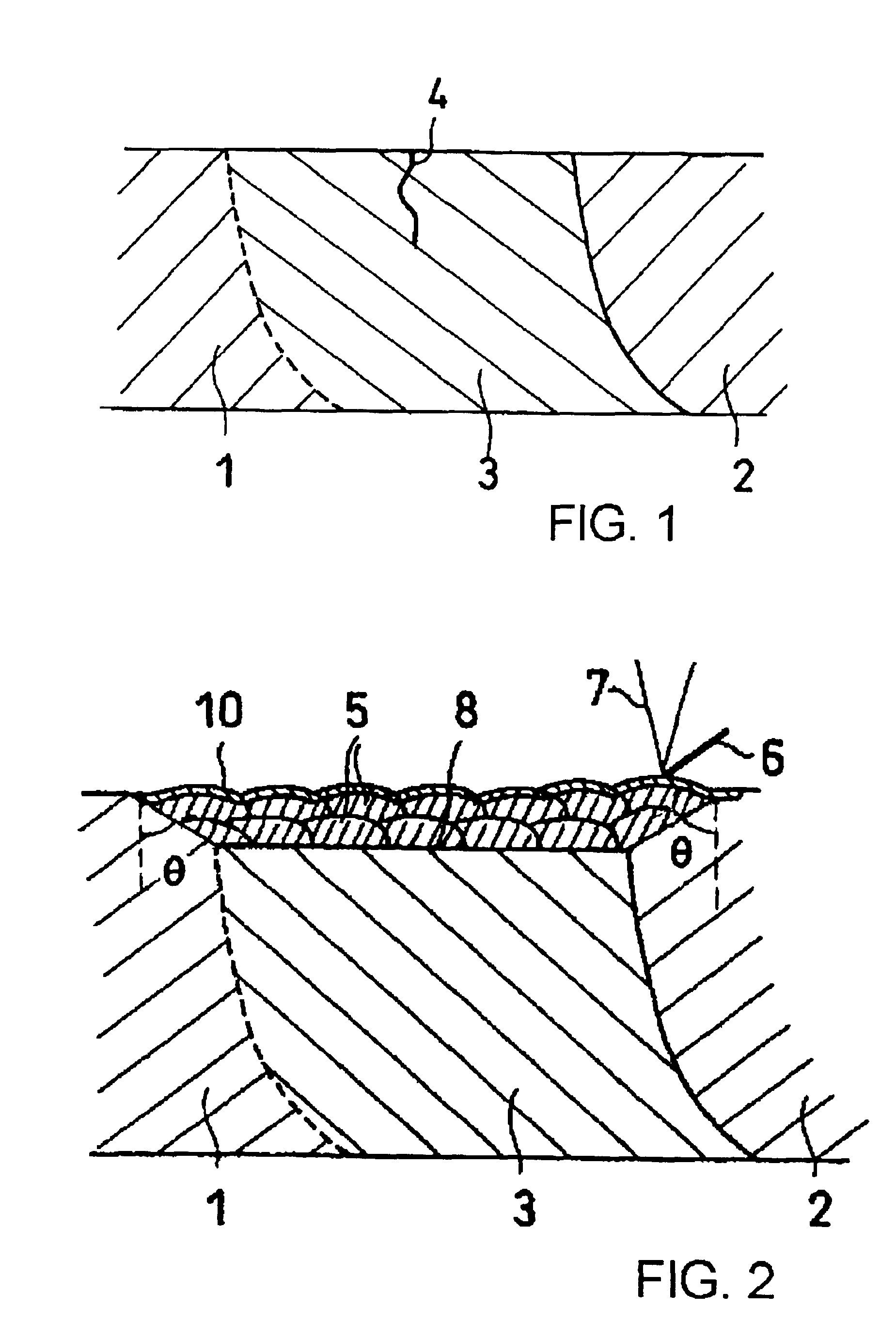

Repair method for structure and repair welding apparatus

InactiveUS7022938B2Prevent relapseReducing tensile residual stressBuilding repairsArc welding apparatusLaser peeningEngineering

A repair method for a structure having an open flaw in a welding heat affected portion, including, removing at least a part of the open flaw and thereby forming a concave portion in the welding heat affected portion, forming build-up weld layers so as to fill the concave portion, treating a surface of the build-up layers to reduce tensile residual stress by means of at least one of laser peening, shot blasting and water jet machining. Also disclosed is an apparatus suitable for carrying out the repair method.

Owner:KK TOSHIBA

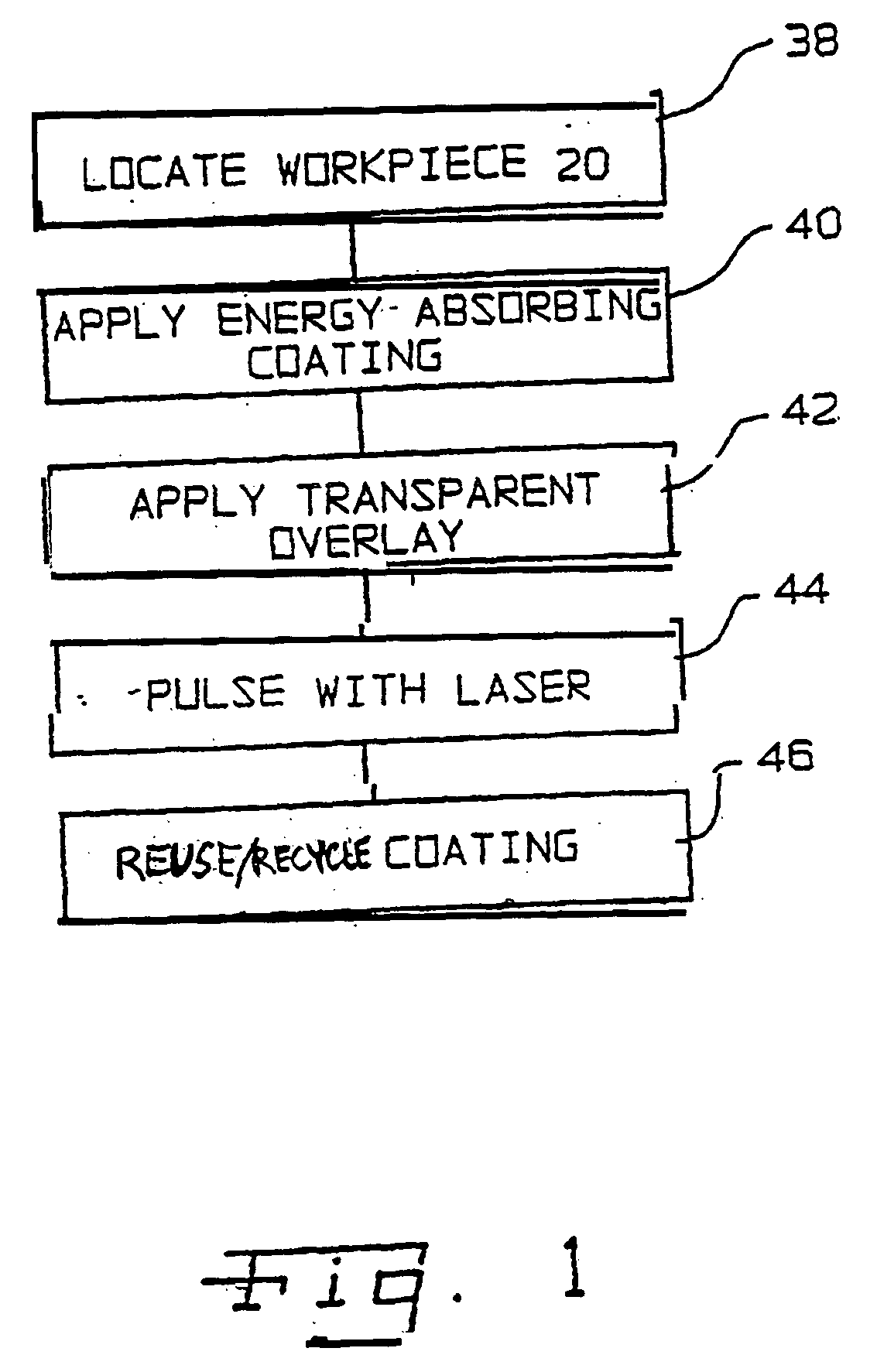

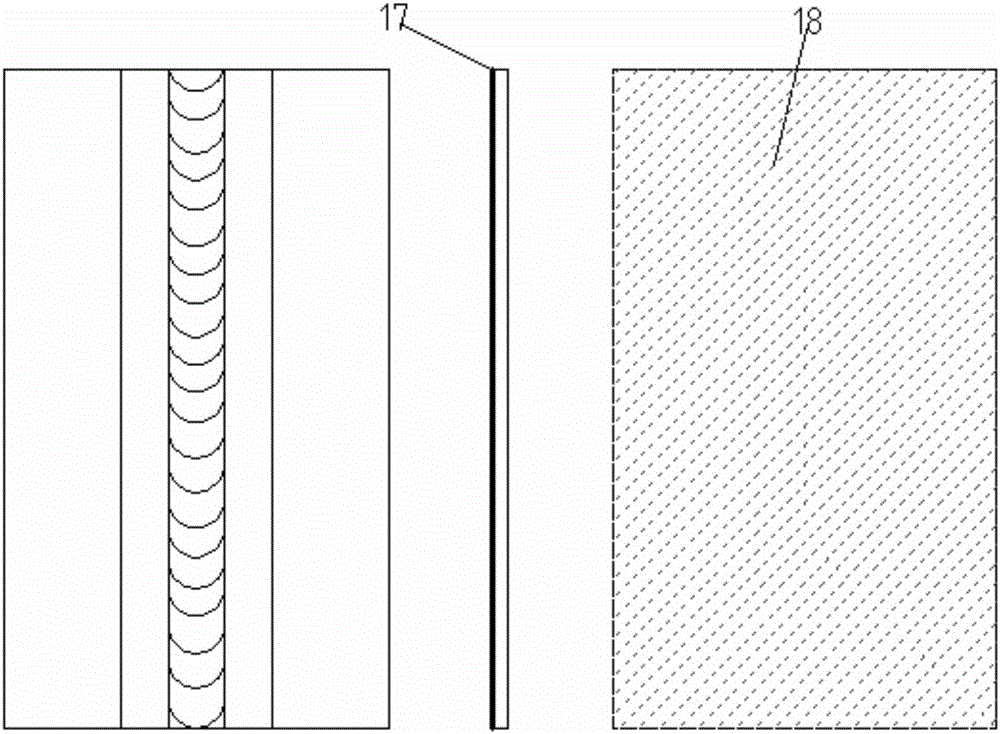

Laser peening process and apparatus using a liquid erosion-resistant opaque overlay coating

InactiveUS20050045607A1Allow useIncrease displacementLaser beam welding apparatusDissolutionLaser peening

The invention relates to a method and apparatus for improving properties of a solid material by providing shockwaves there through. Laser shock processing is used to provide the shockwaves. The method includes applying a liquid energy-absorbing overlay, which is resistant to erosion and dissolution by the transparent water overlay and which is resistant to drying to a portion of the surface of the solid material and then applying a transparent overlay to the coated portion of the solid material. A pulse of coherent laser energy is directed to the coated portion of the solid material to create a shockwave. Advantageously, at least a portion of the unspent energy-absorbing overlay can be reused in situ at a further laser treatment location and / or recovered for later use.

Owner:LSP TECH INC

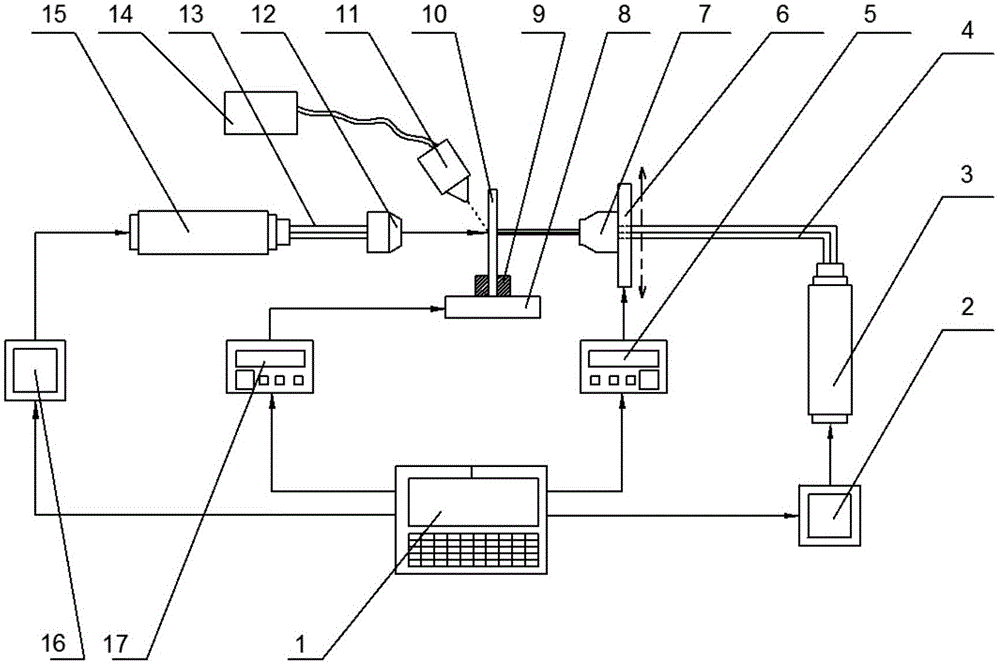

Combination device capable of achieving underwater laser welding and laser shot blasting

InactiveCN103521919AReduce volumeAdaptableLaser beam welding apparatusLasing wavelengthLaser peening

The invention discloses a combination device capable of achieving underwater laser welding and laser shot blasting. A laser welding-shot blasting component, an ultrasound detecting device, a water-argon inlet and a welding strip filling device are mounted on the same sealing cover which is placed underwater. Two functions of laser welding and laser shot blasting are achieved, and laser ultrasound detecting can be directly carried out on a workpiece after processing. By setting different laser wavelengths and sealing cover cavity inner environments, different functions can be used. During laser welding, a sealing cover cavity is filled with argon through the water-argon inlet. During laser shot blasting, the sealing cover cavity is filled with water through the water-argon inlet. The combination device is ingenious in structure, easy to operate, strong in adaptability, high in machining efficiency, capable of being used for alternating or continuous working of underwater welding and laser shot blasting and especially suitable for working under a special environment and defect repairing under the situation that the face where a defect exists is small in area.

Owner:JIANGSU UNIV

Articles having improved residual stress profile characteristics produced by laser shock peening

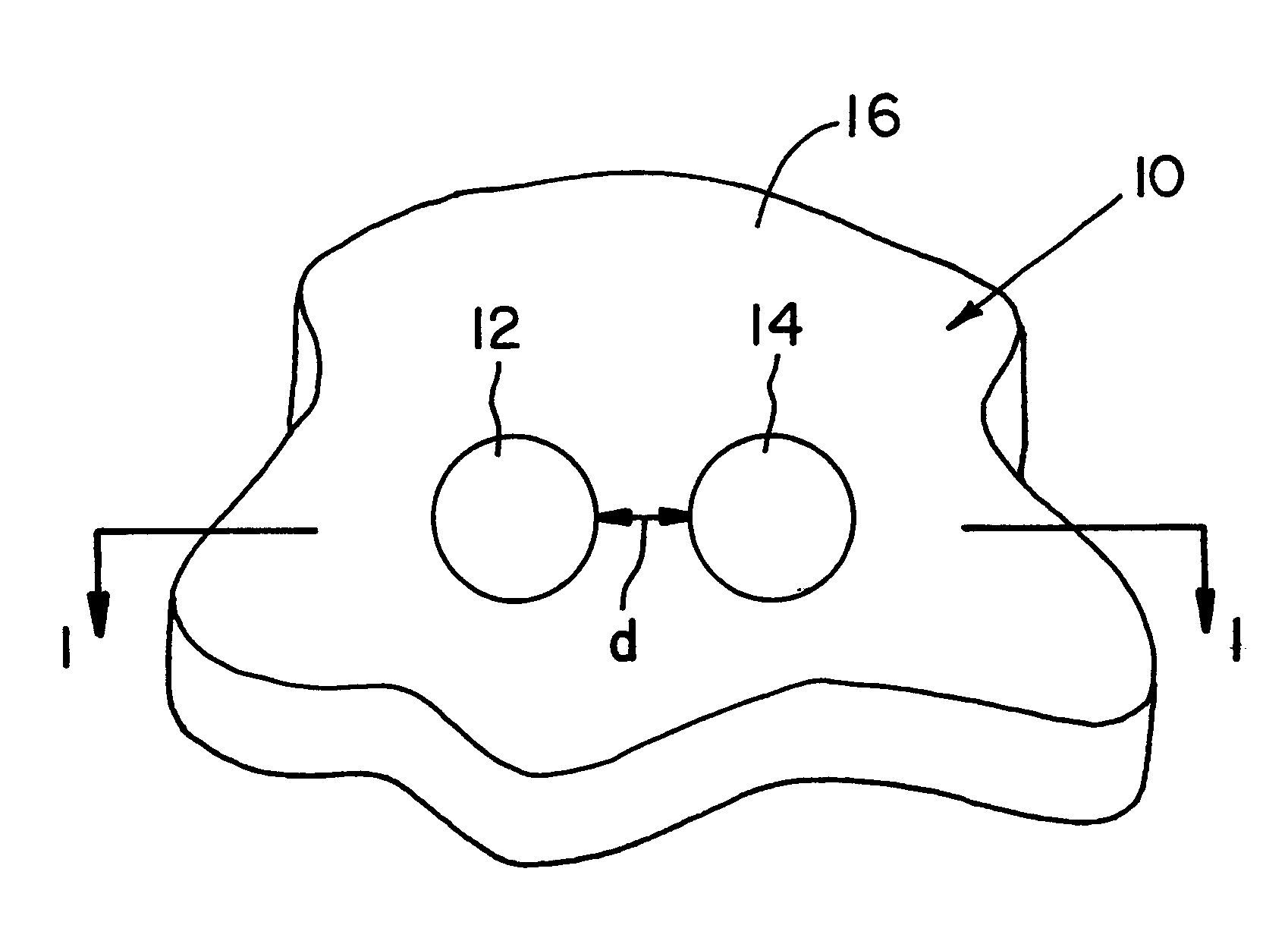

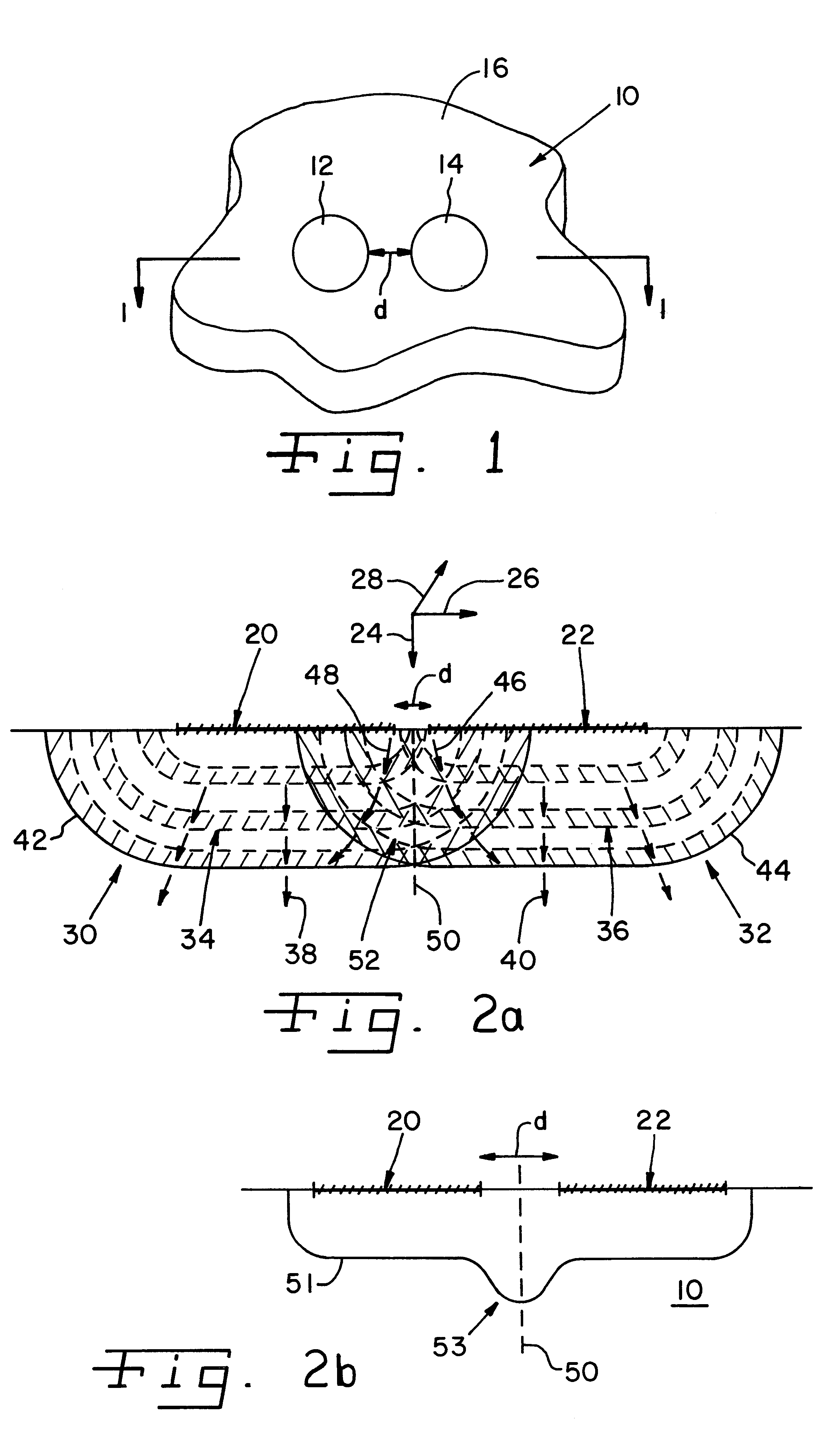

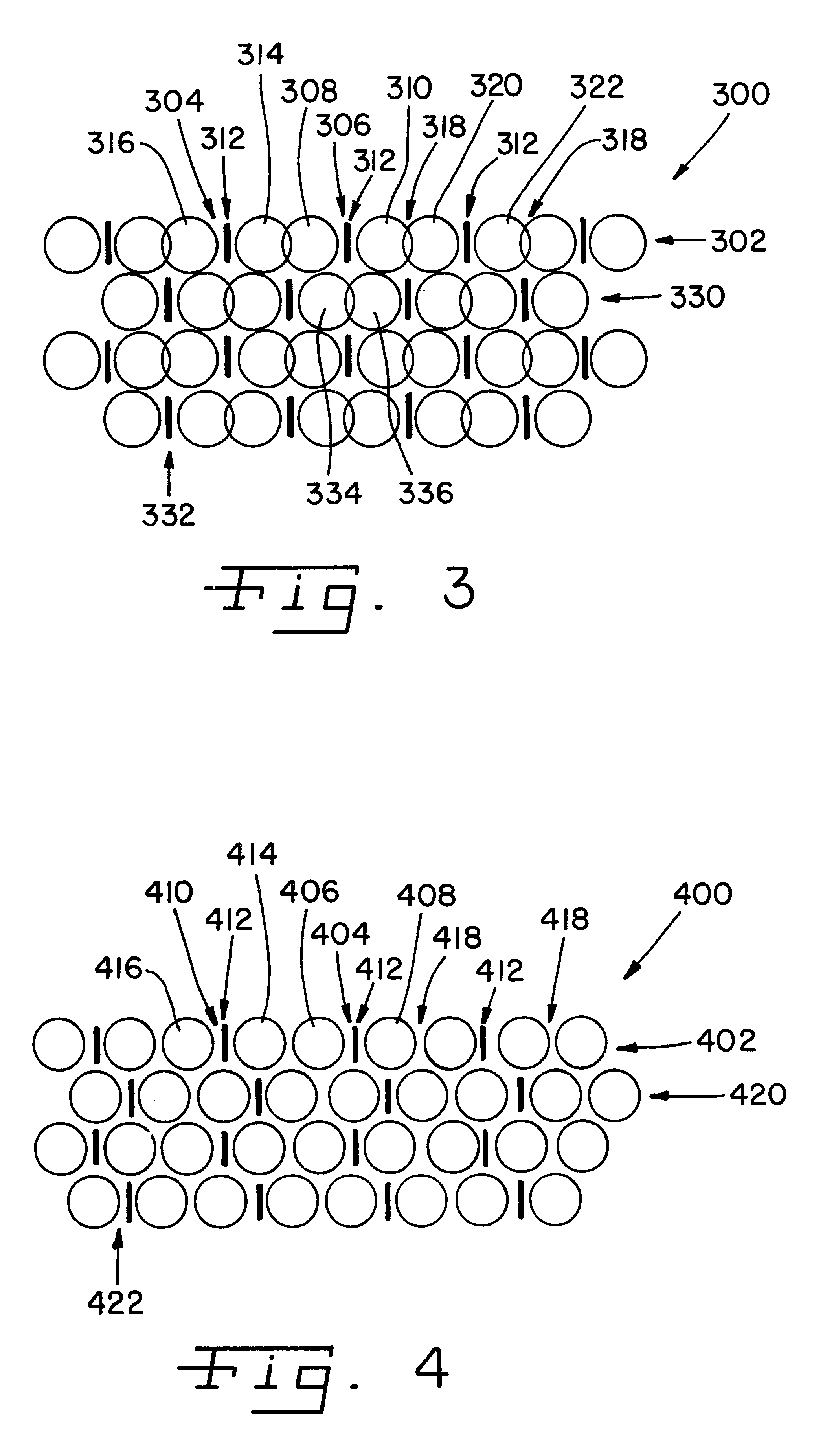

InactiveUS6752593B2Increase penetration depthControl of depthPropellersReaction enginesOptoelectronicsLaser peening

Articles produced by laser shock processing exhibit various compressive residual stress distribution profiles. A gas turbine engine airfoil includes an asymmetrical stress profile formed through the thickness of its thin section. The articles include plural laser shock peened surfaces and plural regions having deep compressive residual stresses imparted by laser shock peening extending into the article from the laser peened surfaces. One article includes at least one set of simultaneously formed, adjacent non-overlapping laser shock peened surfaces. Another article includes at least one set of opposing laser shock peened surfaces formed at different times at opposite sides of the article. Another article includes at least one set of opposing laser shock peened surfaces formed simultaneously at opposite sides of the article using laser beams having different pulse lengths. Another article includes at least one set of laterally offset laser shock peened surfaces simultaneously formed at opposite sides of the article.

Owner:LSP TECH INC

Weldability of alloys with directionally-solidified grain structure

ActiveUS20060157165A1Improve solderabilityFurnace typesElectron beam welding apparatusSand blastingStrain energy

A method of welding alloys having directionally-solidified grain structure. The methods improve the weldability of these alloys by creating a localized region of fine grain structure, wherein the welding occurs in these localized regions. The localized regions are formed by applying strain energy using a variety of different methods, such as by hammer peening, laser peening or sand blasting. Then, a heat treatment step may be used to create recrystallized grains having the fine grain structure. The region of fine grain structure provides better weldability.

Owner:SIEMENS ENERGY INC

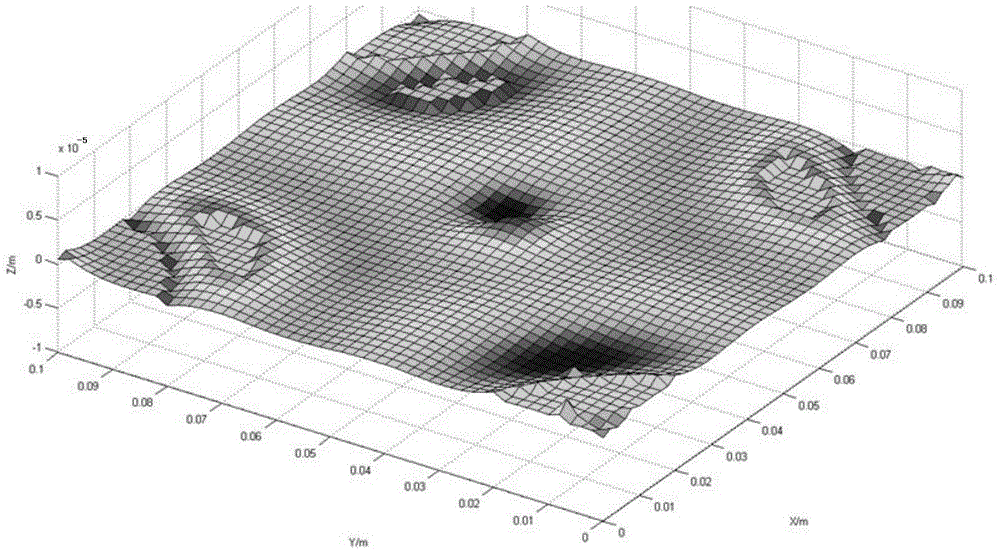

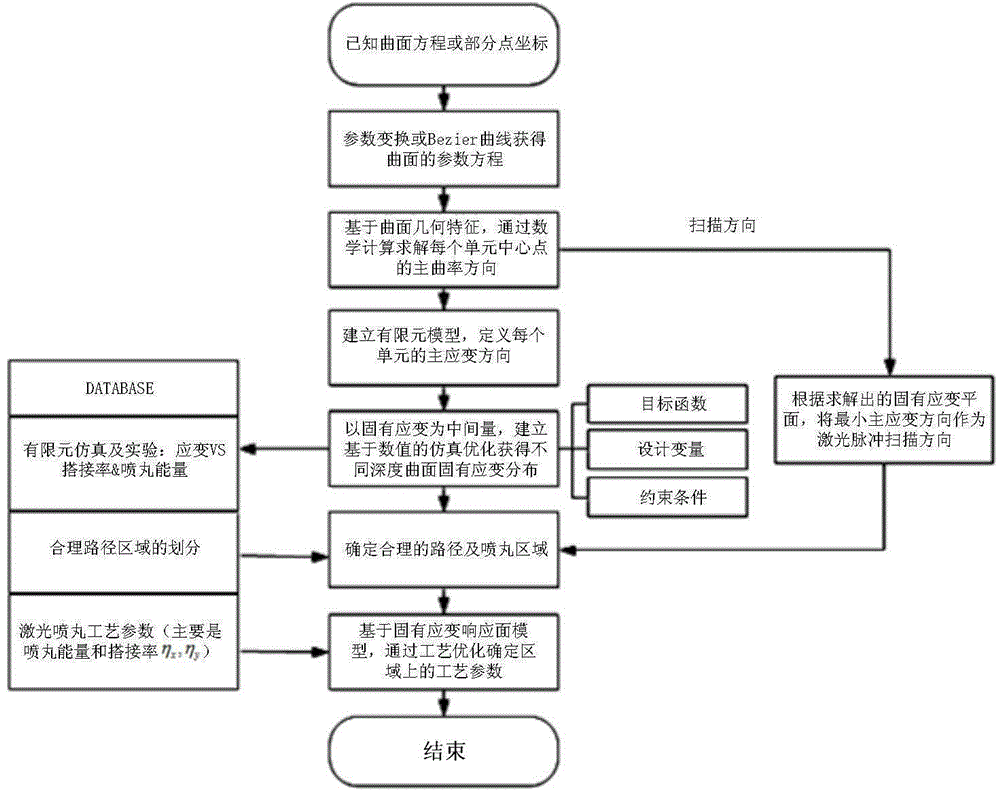

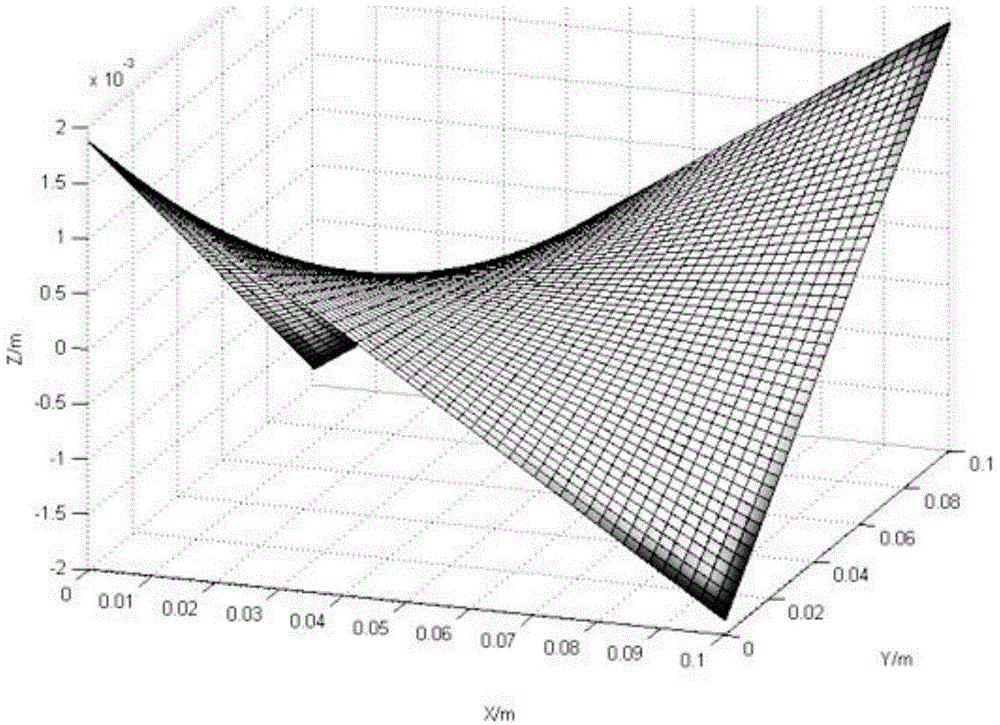

Method for determining laser peening forming process parameter of complex curved-surface-shaped workpiece

ActiveCN104899345AImprove fatigue resistanceAccelerated corrosionSpecial data processing applicationsElement modelStrain response

The invention provides a method for determining a laser peening forming process parameter of a complex curved-surface-shaped workpiece. The method comprises the following steps: according to a curved surface parameter equation of the workpiece, carrying out geometrical characteristic analysis on the curved surface of the workpiece to calculate a main strain direction so as to obtain a laser pulse scanning direction in laser peening forming; establishing a workpiece bending deformation finite element model which takes depth-direction inherent strain distribution as a deformation source, and optimizing an inherent strain field to obtain the inherent strain distribution of different positions of the workpiece along the depth direction, wherein an inherent strain direction is the main strain direction; and according to inherent strain response surface models under different laser peening forming process parameters and the inherent strain of different positions of the workpiece along the depth direction, optimizing the laser peening forming process parameters, and obtaining an optimal laser peening forming process parameter corresponding to different inherent strain fields on the surface of the workpiece. A non-elastic deformation problem can be converted into an elastic deformation problem to improve the efficiency and the precision of finite element simulation.

Owner:SHANGHAI JIAO TONG UNIV

Laser peening apparatus

ActiveUS20080105666A1Avoid pollutionClean and saving and convenientLaser beam welding apparatusEngineeringLaser peening

Owner:SUBARU CORP +1

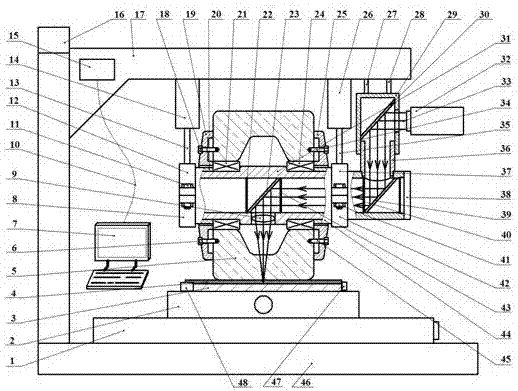

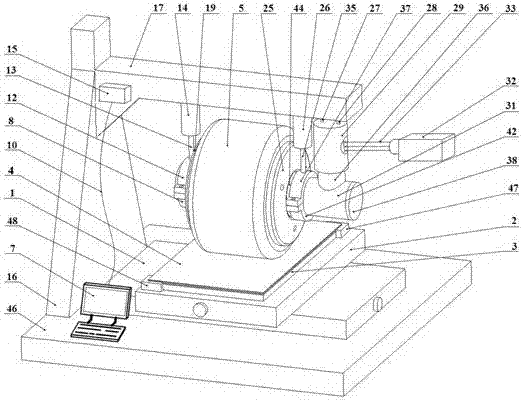

Laser peening composite rolling strengthening surface modification method and device

The invention discloses a laser peening composite rolling strengthening surface modification method and device. The device comprises a control system, a movable platform, a hydraulic system, a rolling system, a laser and a light path system. According to the device and the method, the hydraulic system is controlled through a computer so as to enable a transparent rolling wheel to roll the surface of a workpiece with a preset load so that the surface of the workpiece can get initial deformation, meanwhile, a light path adjusting system controls the light emitting direction of a short pulse laser beam with the high-peak power density so as to enable the laser beam to vertically irradiate the surface of the workpiece pasted with an aluminum foil through the transparent rolling wheel, an instantaneous plasma shock wave is induced to act on a surface material so as to generate plastic deformation with ultrahigh strain rate, and therefore laser peening and rolling composite strengthening of the workpiece can be achieved. The device and the method have the advantages that the gain effects of laser peening and rolling strengthening can be seamlessly combined, and meanwhile, good surface quality and uniform residual stress distribution can be ensured.

Owner:JIANGSU UNIV

Method and device for laser peening correction size precision online control for welded metal plate

ActiveCN106216842AAdjust the impact in timeTimely adjustment of the school pathLaser beam welding apparatusWelding residual stressOptoelectronics

The invention provides a method and device for laser peening correction size precision online control for a welded metal plate. A laser machine emits a laser beam, the laser beam is transmitted to a workpiece welding area through a light path system, a water limiting layer covers the welding area, and a limiting layer is formed. Under the action of laser pulse, impulse waves are formed on the welding surface, residual compressive stress is generated in the welded metal plate, and the residual compressive stress is eliminated. Efficiency of laser penning is high, a deep residual compressive stress layer can be generated, size correcting efficiency is high, the size correcting makes the surface and a certain depth range of a peening area of a welded piece to be subjected to plastic deformation, the straightening purpose is achieved, and meanwhile, fatigue strength of a welded joint is improved. According to the method and device for the laser peening correction size precision online control for the welded metal plate, precise size correcting can be conducted on the welded piece, working efficiency is high, controllability is good, and the range of application is wide.

Owner:GUANGDONG UNIV OF TECH

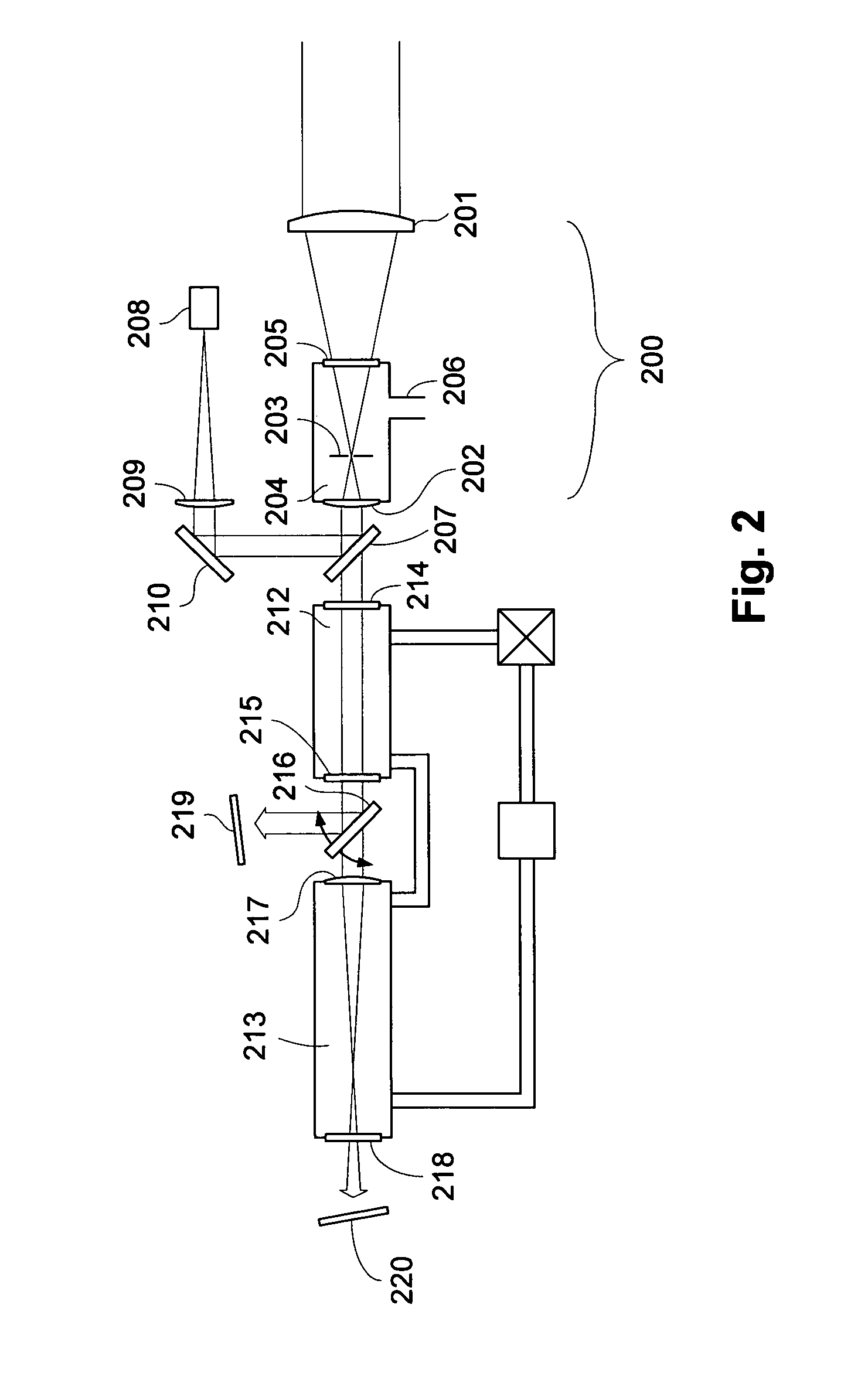

Target isolation system, high power laser and laser peening method and system using same

ActiveUS20050092722A1Fluence levels at the impact areas of the blocked beams are reducedAvoid damageLaser arrangementsLaser beam welding apparatusHigh power lasersLight beam

A system for applying a laser beam to work pieces, includes a laser system producing a high power output beam. Target delivery optics are arranged to deliver the output beam to a target work piece. A relay telescope having a telescope focal point is placed in the beam path between the laser system and the target delivery optics. The relay telescope relays an image between an image location near the output of the laser system and an image location near the target delivery optics. A baffle is placed at the telescope focal point between the target delivery optics and the laser system to block reflections from the target in the target delivery optics from returning to the laser system and causing damage.

Owner:METAL IMPROVEMENT CO INC +1

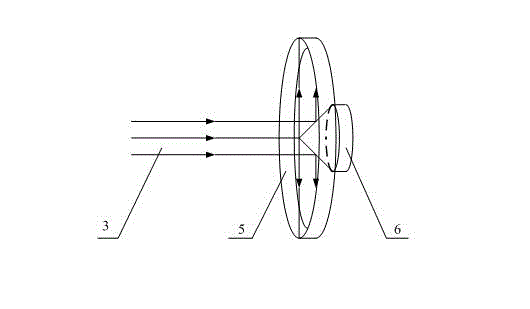

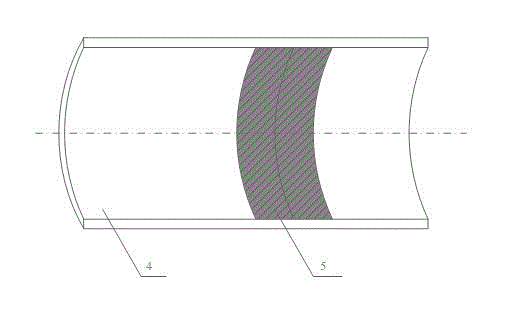

Method and device for strengthening inner wall of middle-small diameter long tube through laser shot blasting

ActiveCN102912088AImprove efficiencyUniform effectFurnace typesHeat treatment furnacesShock waveBand shape

The invention relates to a method and device for strengthening inner wall of a middle-small diameter long tube through laser shot blasting. The method is characterized by comprising the steps of coating a reflecting film on the surface of a 90-degree taper reflector, reflecting a round laser beam into an annular shape through the taper reflector, and pasting a layer of flexible coated film on the inner wall of an enhanced tube to be strengthened. The central line of the laser beam, the central axis of the tube and the central axis of the 90-degree taper reflector are on the same line and parallel to a guide rail. The annular laser reflected by the reflector vertically irradiates the flexible coating film on the inner wall to produce plasma shock wave acting on the inner wall of the tube so as to form a residual compressive stress layer on the inner wall of the tube, so that the rigidity, corrosion resistance, wearability, fatigue strength and other performances of the inner wall of the tube are improved. The taper reflector moves from one end to the other end of the tube to realize a continuous strengthening process of the whole tube wall. The method and the device disclosed by the invention not only can be applied to tubes with middle-small diameters in a certain range, and continuous laser shot blasting can be realized for tubes with relatively longer length.

Owner:JIANGSU UNIV

Method for modifying high-toughness surfaces of metal materials

The invention discloses a method for modifying the high-toughness surfaces of metal materials, relating to a surface modification technique for materials. The method comprises the following main steps: 1) pretreating the surface of a metal material; 2) carrying out laser shot blasting treatment on the pretreated surface of the material; 3) carrying out magnetic field nitriding on the surface subjected to laser shot blasting treatment; 4) carrying out magnetic field quenching on the surface subjected to nitriding; 5) carrying out low-energy laser shot blasting treatment on the surface subjected to magnetic field quenching; 6) carrying out magnetic field quenching again on the surface subjected to low-energy laser shot blasting treatment, so that a flat high-toughness surface is obtained. According to the invention, the grain structure of a surface can be effectively refined, the thickness of a nitriding layer can be increased, the nitriding time can be shortened, the brittleness of the nitriding layer can be reduced, and the toughness of the surface can be improved. The method disclosed by the invention is simple in technological process, easy in operation, high in efficiency, and suitable for mass production in a large scale.

Owner:常熟市通顺纺织有限责任公司

Method and device for strengthening metal material through pulse current coupled laser peening

The invention discloses a method and device for strengthening a metal material through pulse current coupling laser peening, and belongs to the technical field of metal material strengthening. The method comprises the following steps of (a) pretreating the surface of the metal material; (b) determining optimal electric pulse treatment process parameters of a test sample; (c) testing the test sample by utilizing a Hopkinson pressure bar to obtain the dynamic yield strength of the metal material in the electric pulse treatment process; (d) solving the Hugoniot elastic limit of the metal material, and further obtaining the optimal laser power density of the test sample; and (e) in the electric pulse treatment process, performing laser peening strengthening treatment on the test sample by a Nd:YAG solid laser in the optimal laser power density range at the same time. Through the coupling effect of electroplastic deformation caused by electric pulses and ultrahigh-strain-rate plastic deformation induced by laser peening, the amplitude and depth of residual compressive stress are improved, and more excellent comprehensive mechanical properties are obtained.

Owner:CHANGZHOU UNIV

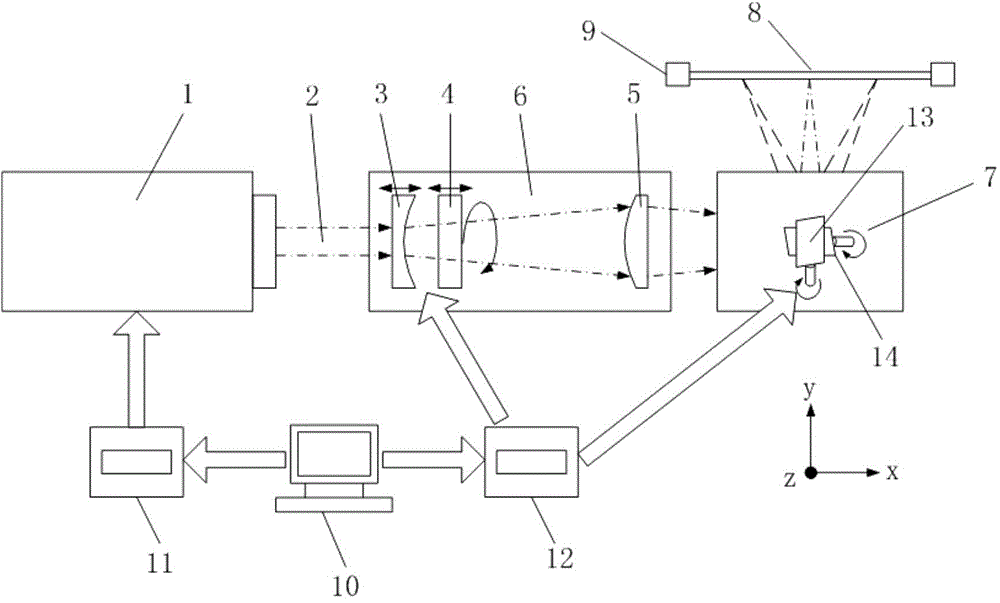

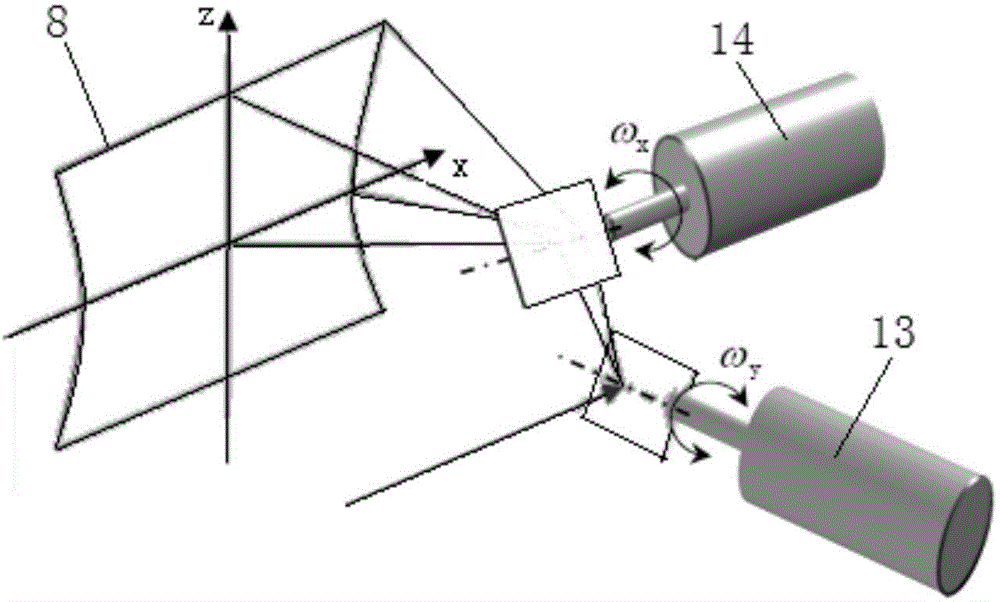

Method and device for thermal-assisted laser peen forming

InactiveCN105033462AImprove surface qualityNo obvious mechanical damageMetal working apparatusLaser beam welding apparatusOptoelectronicsLaser peening

The invention provides a device for thermal-assisted laser peen forming. The device comprises a shot peening laser and a light path part thereof, a heating laser and a light path part thereof, a workpiece clamp control part, a water spraying part and a central control processor part. The central control processor part is connected with the shot peening laser and the light path part thereof, the heating laser and the light path part thereof and the workpiece clamp control part. The shot peening laser and the light path part thereof and the heating laser and the light path part thereof are located on the front face and the back face of a workpiece respectively. The invention further provides a method, adopting the device, for thermal-assisted laser peen forming. According to the device and method, laser-aided heating and laser shot peening are carried out on the two sides of the workpiece respectively at the same time. Due to the fact that part of shot peening area is heated, energy is effectively utilized, and processed materials have good surface property and high-temperature stability; the processing and manufacturing purpose of high-strength high-property plates is effectively achieved, and the requirement of the industry for processing and manufacturing of the materials is met.

Owner:SHANGHAI JIAO TONG UNIV

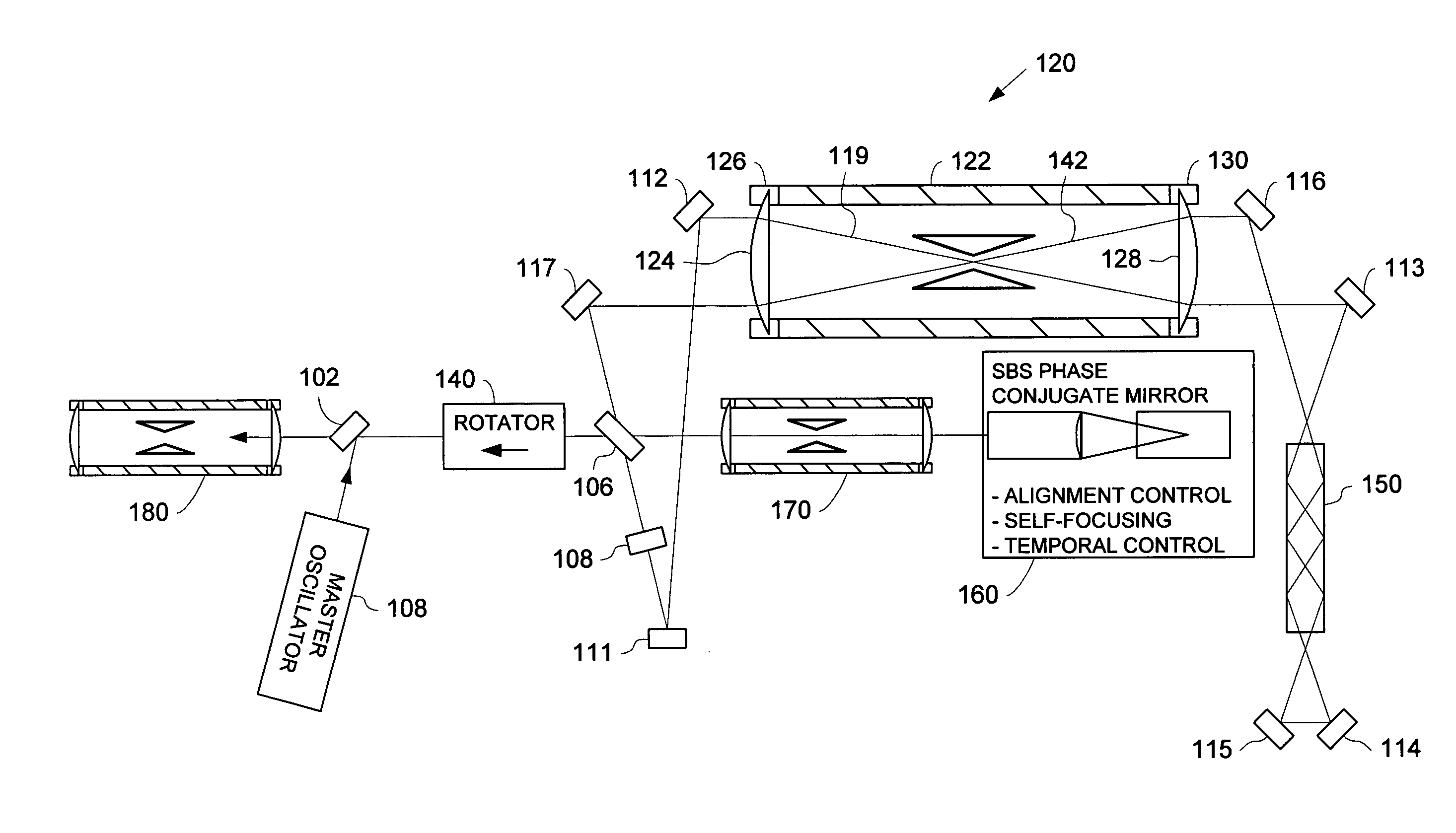

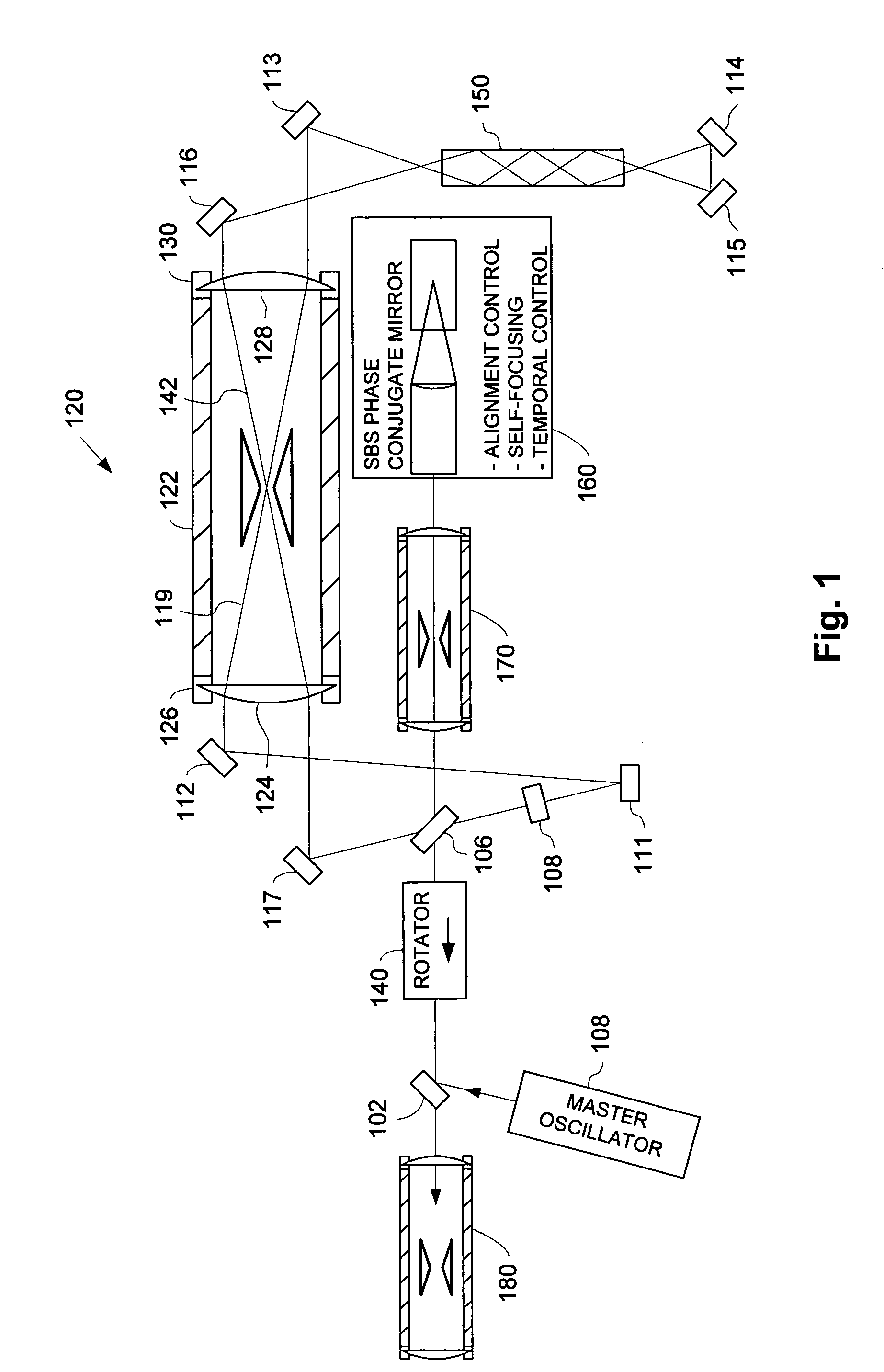

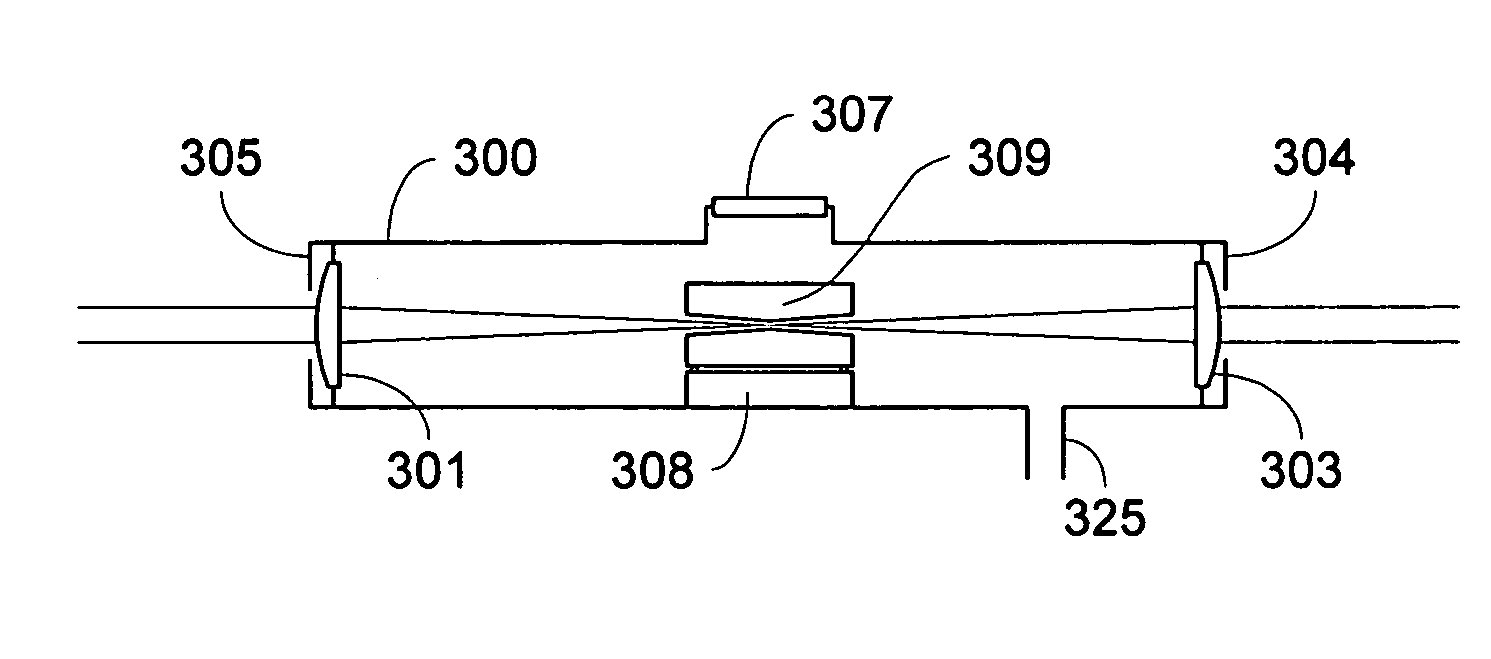

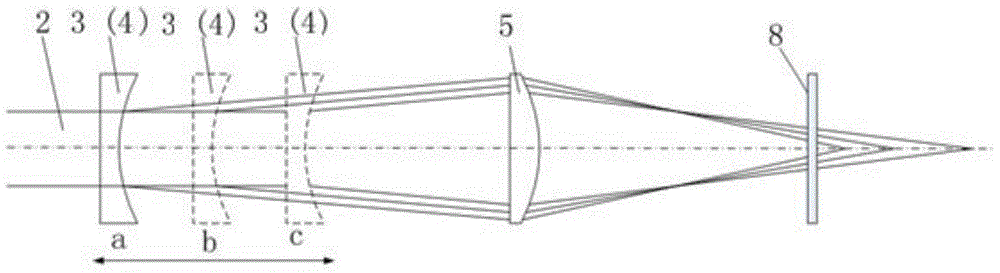

Relay telescope, high power laser alignment system, and laser peening method and system using same

ActiveUS20050094250A1Avoid damageFluence levels at the impact areas of the blocked beams are reducedLaser using scattering effectsOptical resonator shape and constructionAngle of incidenceHigh power lasers

A laser system includes an optical path having an intracavity relay telescope with a telescope focal point for imaging an output of the gain medium between an image location at or near the gain medium and an image location at or near an output coupler for the laser system. A kinematic mount is provided within a vacuum chamber, and adapted to secure beam baffles near the telescope focal point. An access port on the vacuum chamber is adapted for allowing insertion and removal of the beam baffles. A first baffle formed using an alignment pinhole aperture is used during alignment of the laser system. A second tapered baffle replaces the alignment aperture during operation and acts as a far-field baffle in which off angle beams strike the baffle a grazing angle of incidence, reducing fluence levels at the impact areas.

Owner:METAL IMPROVEMENT CO INC +1

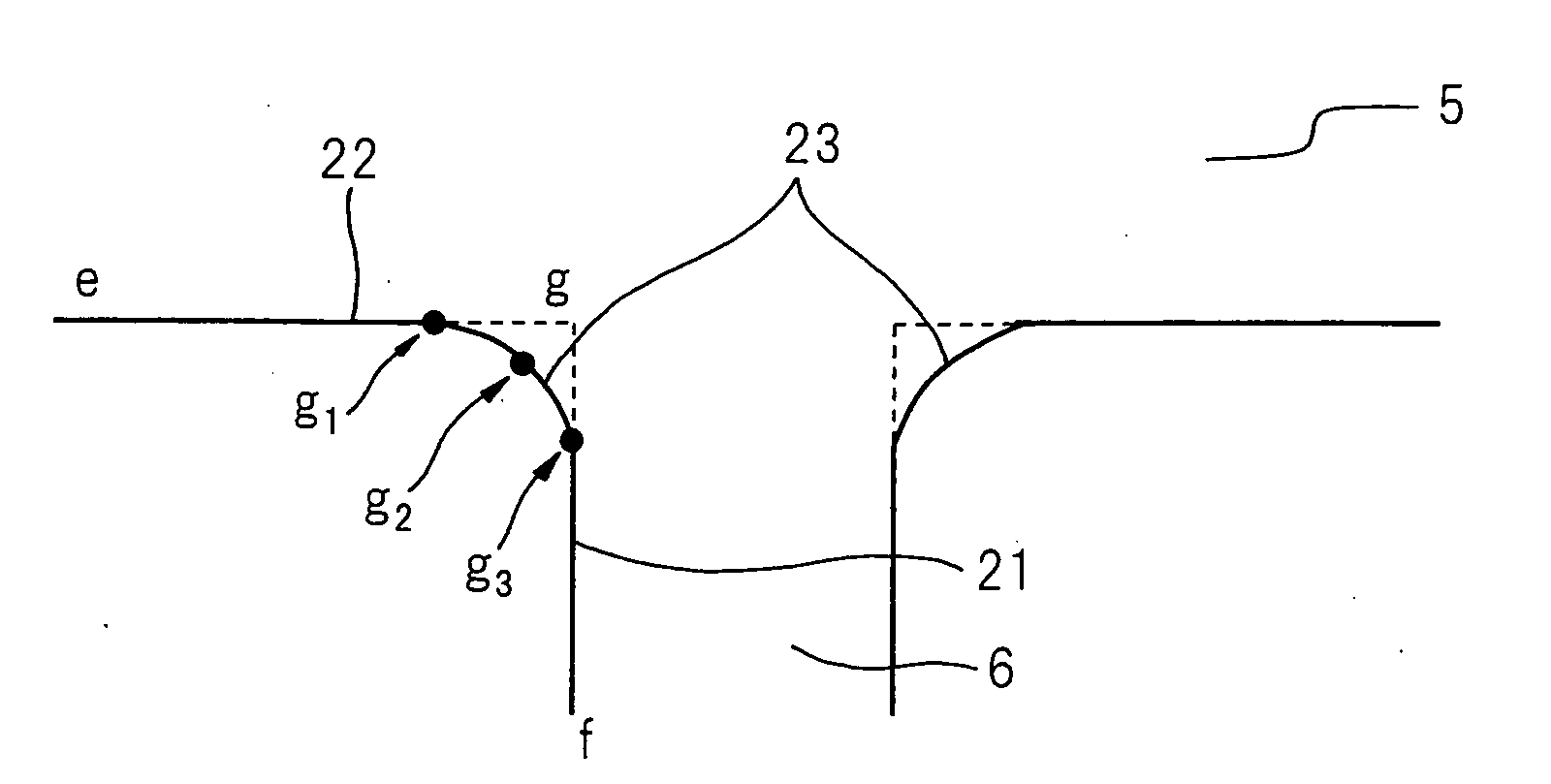

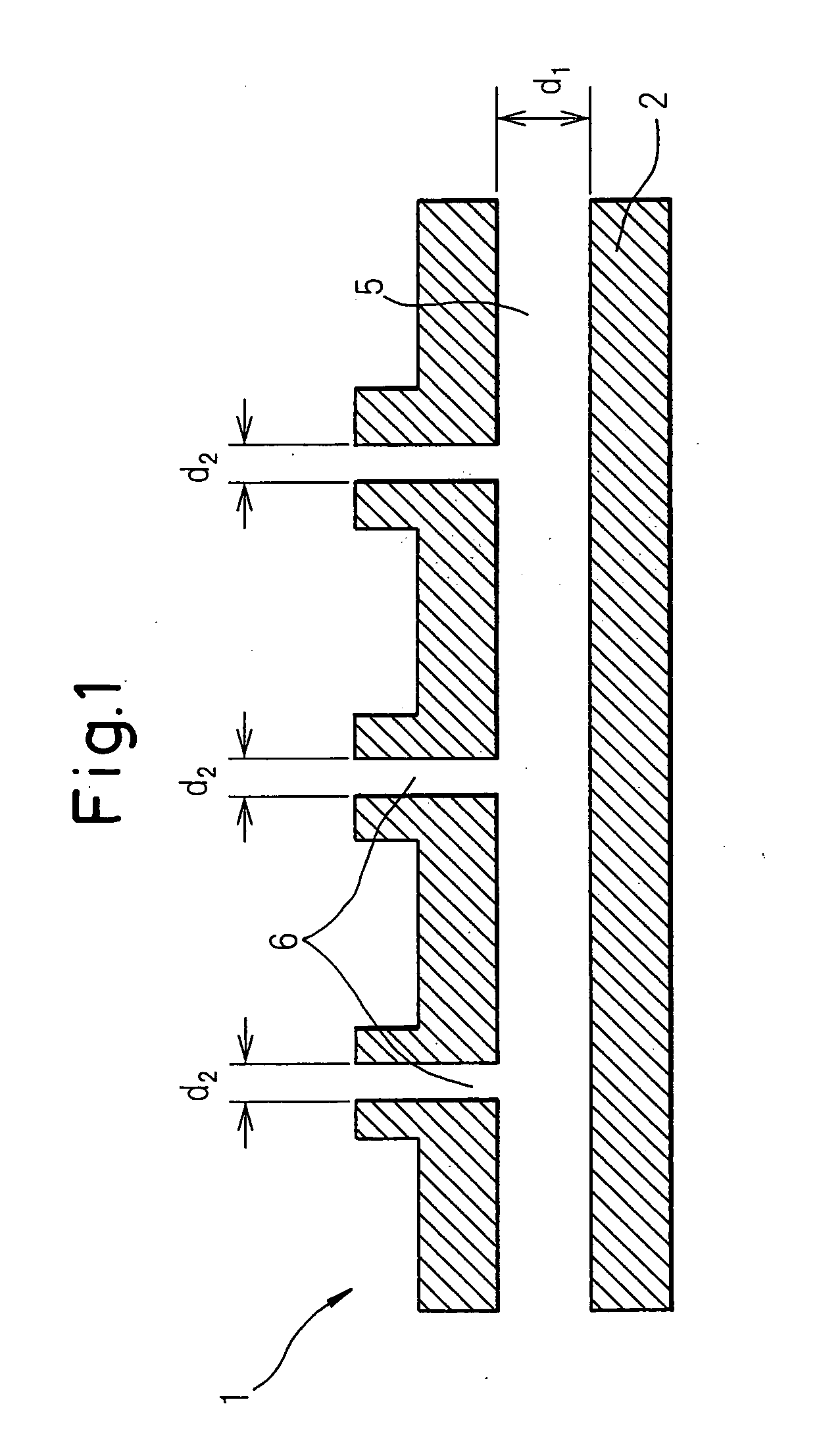

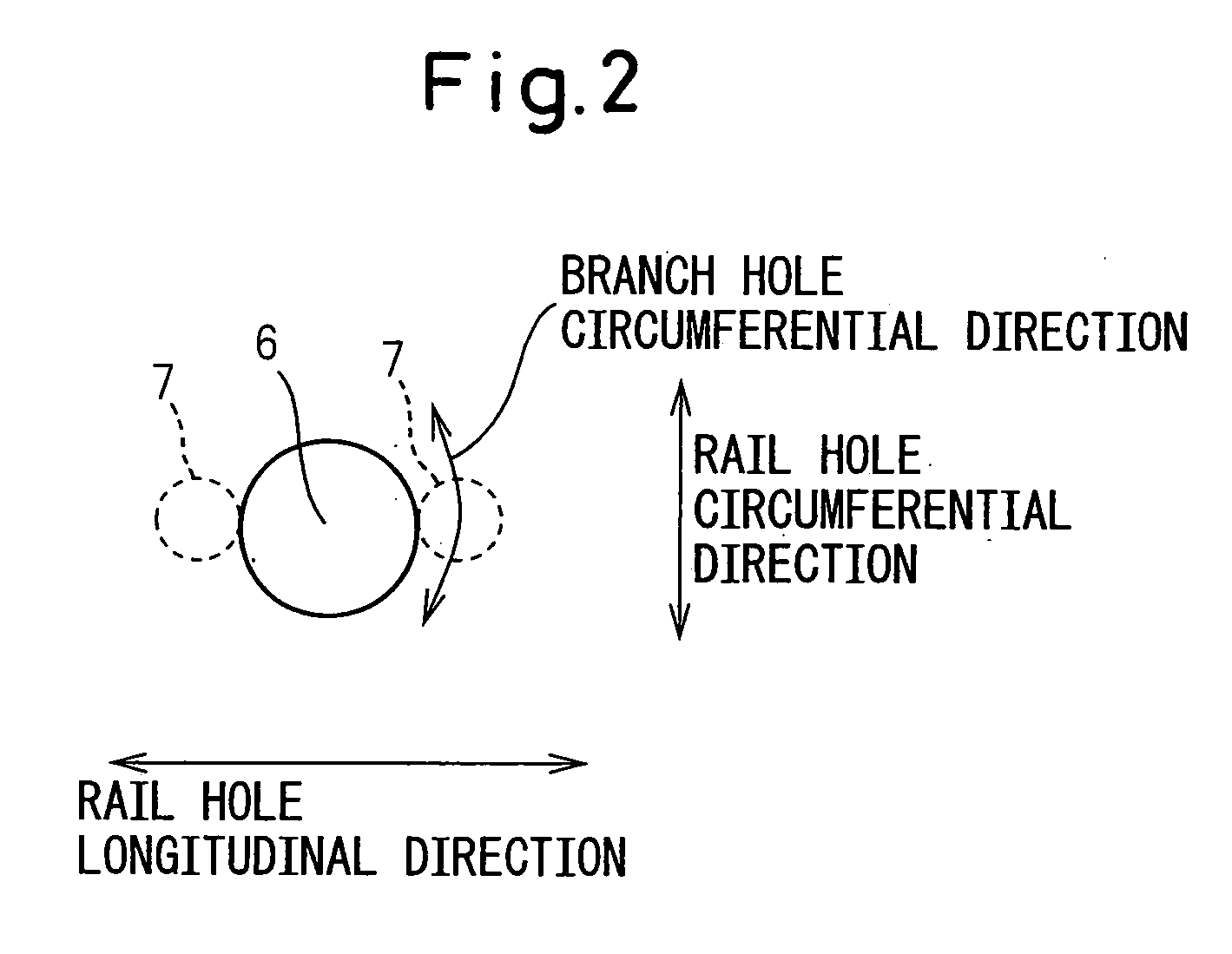

Method producing common rail locally reinforced common rail

InactiveUS20100055490A1Easy to processReduced strengthExhaust apparatusExtrusion containersSurface layerCommon rail

This invention relates to a method producing a common rail excellent in fatigue strength from an inexpensive steel which uses as the material of the common rail a steel for high-strength liquid phase diffusion bonding having good toughness and fatigue strength, which steel contains, in mass %, C: 0.01 to 0.3%, Si: 0.01 to 0.5%, Mn: 0.01 to 3.0%, Cr: 1.0 to 12.0% and Mo: 0.1 to 2.0%, further contains, in mass %, V: 0.01 to 1.0%, B: 0.0003 to 0.01%, Ti: 0.01 to 0.05% and N: 0.001 to 0.01%, has P content limited to 0.03% or less, S content to 0.01% or less and O content to 0.01% or less, further has total content of grain boundary segregated embrittling elements As, Sn, Sb, Pb and Zn limited to 0.015% or less, and a balance of unavoidable impurities and Fe. The steel is used for liquid phase diffusion bonding. The production method uses a pulsed laser beam to perform laser-peening in the presence of a transparent liquid with respect to the vicinity of the boundary between the inner surface 21 of each branch hole 6 and the inner surface 22 of the rail hole 5, located at an opening peripheral zone of the branch hole 6. The surface layer of steel of the opening peripheral zone is thereafter removed.

Owner:NIPPON STEEL CORP

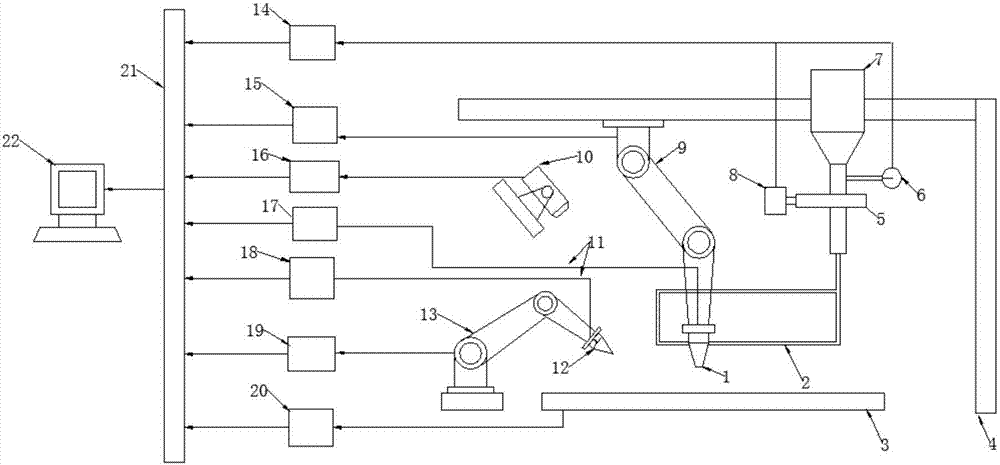

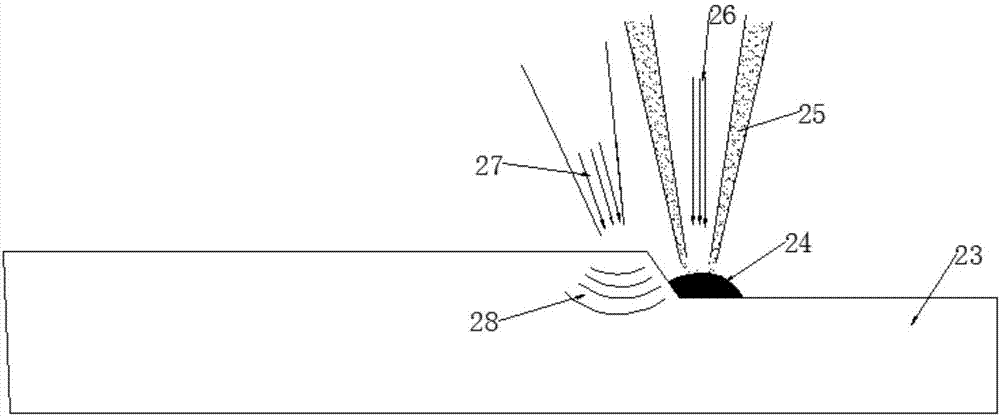

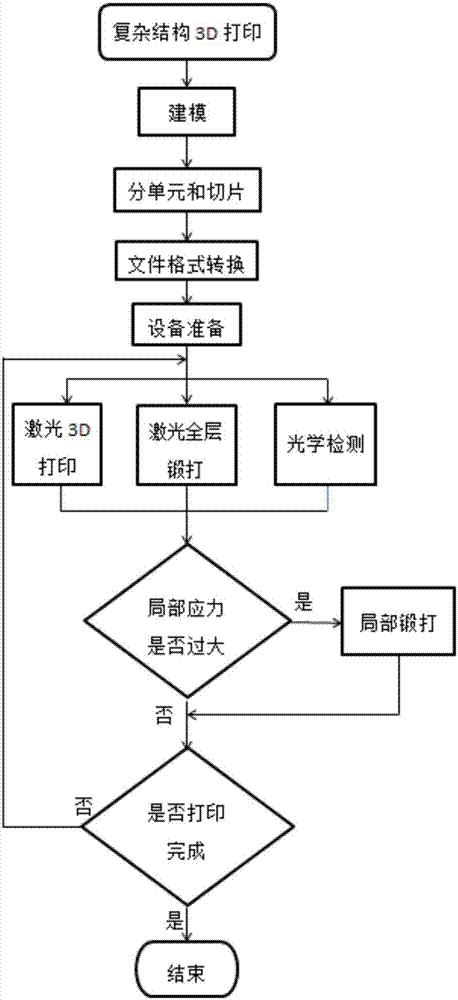

Additive manufacturing method and system for complex structure

InactiveCN107138728AWarpage ControlHigh mechanical strengthAdditive manufacturing apparatusIncreasing energy efficiencyElectricitySpray nozzle

The invention discloses an additive manufacturing system for a complex structure. The additive manufacturing system comprises a workbench, a 3D printing device, a laser forging device and a master control device. The 3D printing device comprises a powder supplying nozzle, a 3D printing mechanical arm used for driving the powder supplying nozzle to move relative to the workbench and a laser generator connected with the powder supplying nozzle. The laser forging device comprises a shot blasting nozzle, a laser shot blasting mechanical arm used for driving the shot blasting nozzle to move relative to the workbench and a pulse laser generator connected with the shot blasting nozzle. The master control device is electrically connected with the 3D printing device and the laser forging device to control moving of the 3D printing mechanical arm and the laser shot blasting mechanical arm. The invention further discloses an additive manufacturing method for the complex structure. By applying the additive manufacturing system and method, the mechanical strength of a part subjected to double-laser printing and forging is greatly improved, and the mechanical comprehensive performance is improved. Thus, the part structure can be further optimized, the structure is improved, the size is reduced, and finally, weight losing is achieved.

Owner:GUANGDONG UNIV OF TECH

Path planning device of laser shot blasting strengthened hook surface and path planning method for device

The invention discloses a path planning device of a laser shot blasting strengthened hook surface. The path planning device comprises a high energy pulse laser, a positioning laser, a CCD displayer, a correction block, a correction reflection film and a mechanical arm. The positioning laser and the CCD displayer are symmetrically arranged on the two sides, the correction block is provided with a correction plane, the correction reflection film is attached to the correction plane, the mechanical arm clamps and can freely adjust the correction block or a workpiece, and a visible laser beam is reflected to the CCD displayer. The invention further discloses a path planning method for the laser shot blasting strengthened hook surface. The parallel visible laser beam, the reflection film and the CCD displayer serve as positioning tools; the steps of distancing, positioning calibrating, tracing point positioning, coordinate recording, fitting of the coordinates into a trajectory path and the like are included; the device and method are adopted to conveniently and rapidly achieve running path planning of the hook surface in laser shot blasting strengthening, the method and device can be used for laser shot blasting strengthening of aircraft engine blades and steam turbine blades, the working position of the hook surface can be precisely located, the laser utilization rate is greatly improved, and power and density consistency in the strengthening process is ensured.

Owner:GUANGDONG UNIV OF TECH

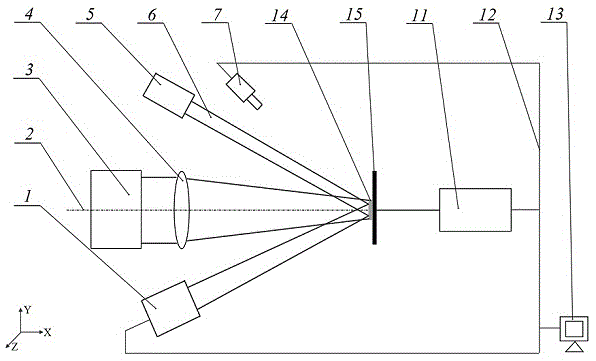

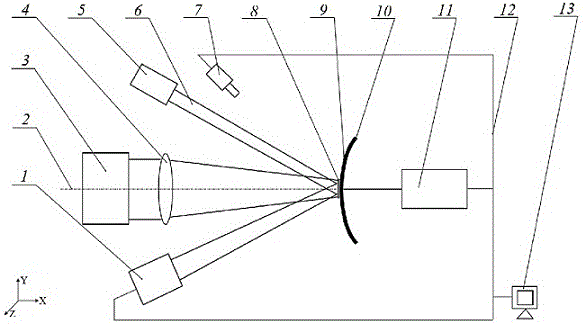

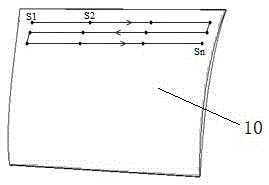

Light path device and method for laser peening forming of large workpiece

The invention discloses a light path device and method for laser peening forming of a large workpiece. The light path device comprises a laser device, a dynamic focusing and shape righting system, a scanning galvanometer system, the formed workpiece, a computer, a laser control card and a movement control card. The laser control card is connected with the laser device and is used for controlling starting of the laser device and various parameters of laser. The movement control card is connected with the dynamic focusing and shape righting system and the scanning galvanometer system. Both the laser control card and the movement control card are controlled by the computer. The dynamic focusing and shape righting system and the scanning galvanometer system are controlled by the computer to make corresponding movement after a specific shot blasting path is given, the shape of the section and the focusing position of a high-energy pulse laser beam are changed after the high-energy pulse laser beam emitted by the laser device passes through the dynamic focusing and shape righting system, and then the high-energy pulse laser beam points to a specific emergent direction after passing through the scanning galvanometer system, so that scanning and shot blasting on the large workpiece by laser are achieved through continuous movement of the dynamic focusing and shape righting system and the scanning galvanometer system.

Owner:SHANGHAI JIAO TONG UNIV

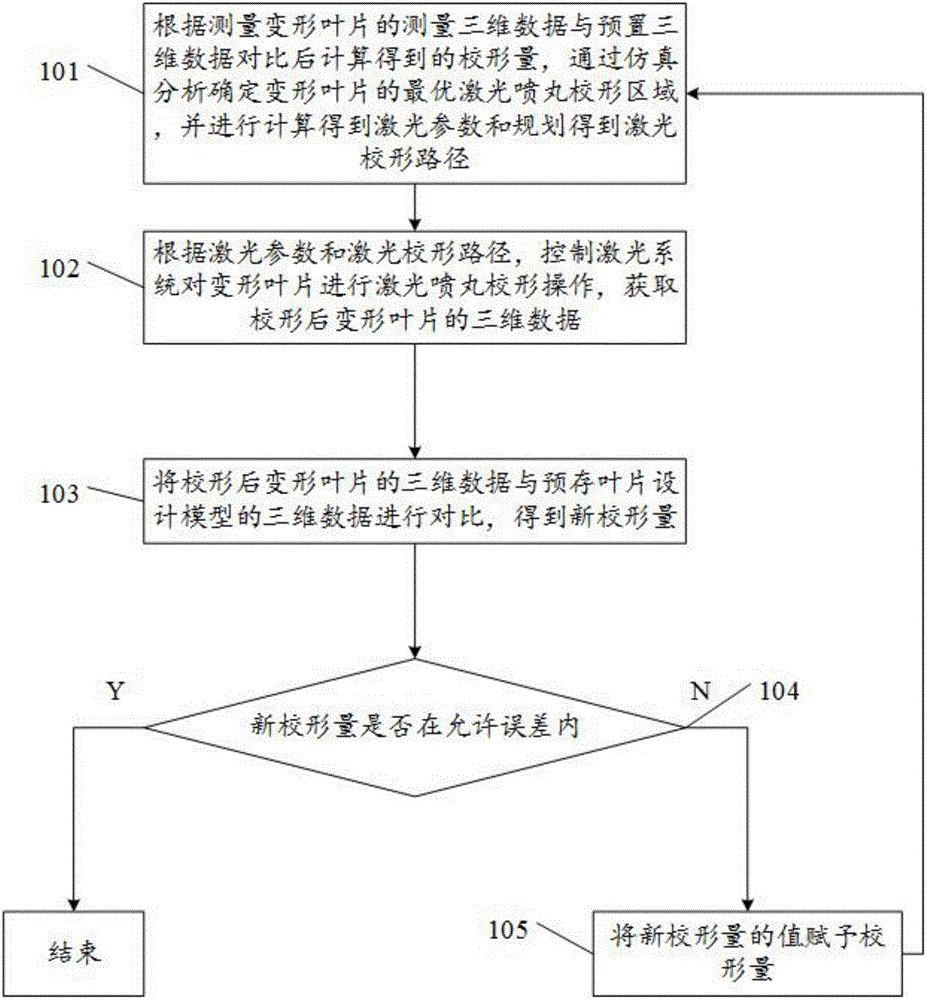

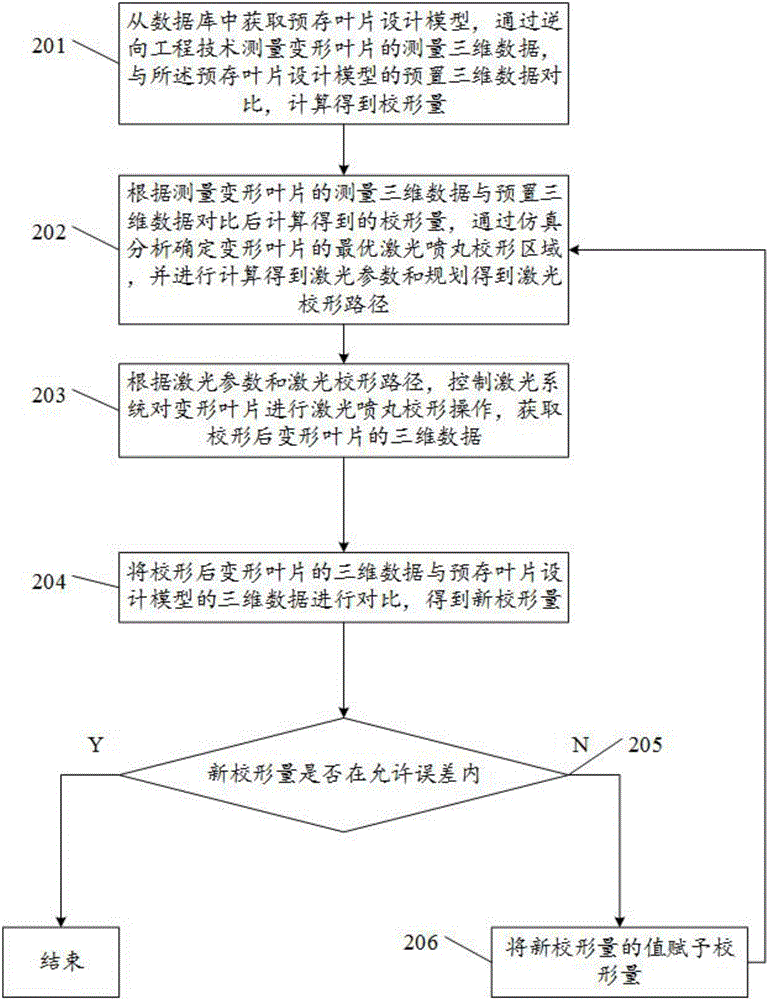

Laser peening straightening method and device for deformed blade

ActiveCN106312323AImprove resistance to fatigue damageImprove corrosion resistanceLaser beam welding apparatusFatigue damageLaser peening

The embodiment of the invention discloses a laser peening straightening method and device for a deformed blade. Straightening is performed from the two ends of a straightening path through two laser beams, so that half of the straightening time can be saved, and the working efficiency can be improved; laser peening straightening can generate residual compressive stress in the blade to improve the fatigue damage prevention capability and the corrosion resistance of the blade, as well as the strength of the blade; and the blade deformation control process is simple and reliable, low in cost and easy to realize automation, conforms to the demand for precision manufacture of aircraft parts and is particularly suitable for precision straightening of the deformed blade with an out-of-tolerance torsion angle.

Owner:GUANGDONG UNIV OF TECH

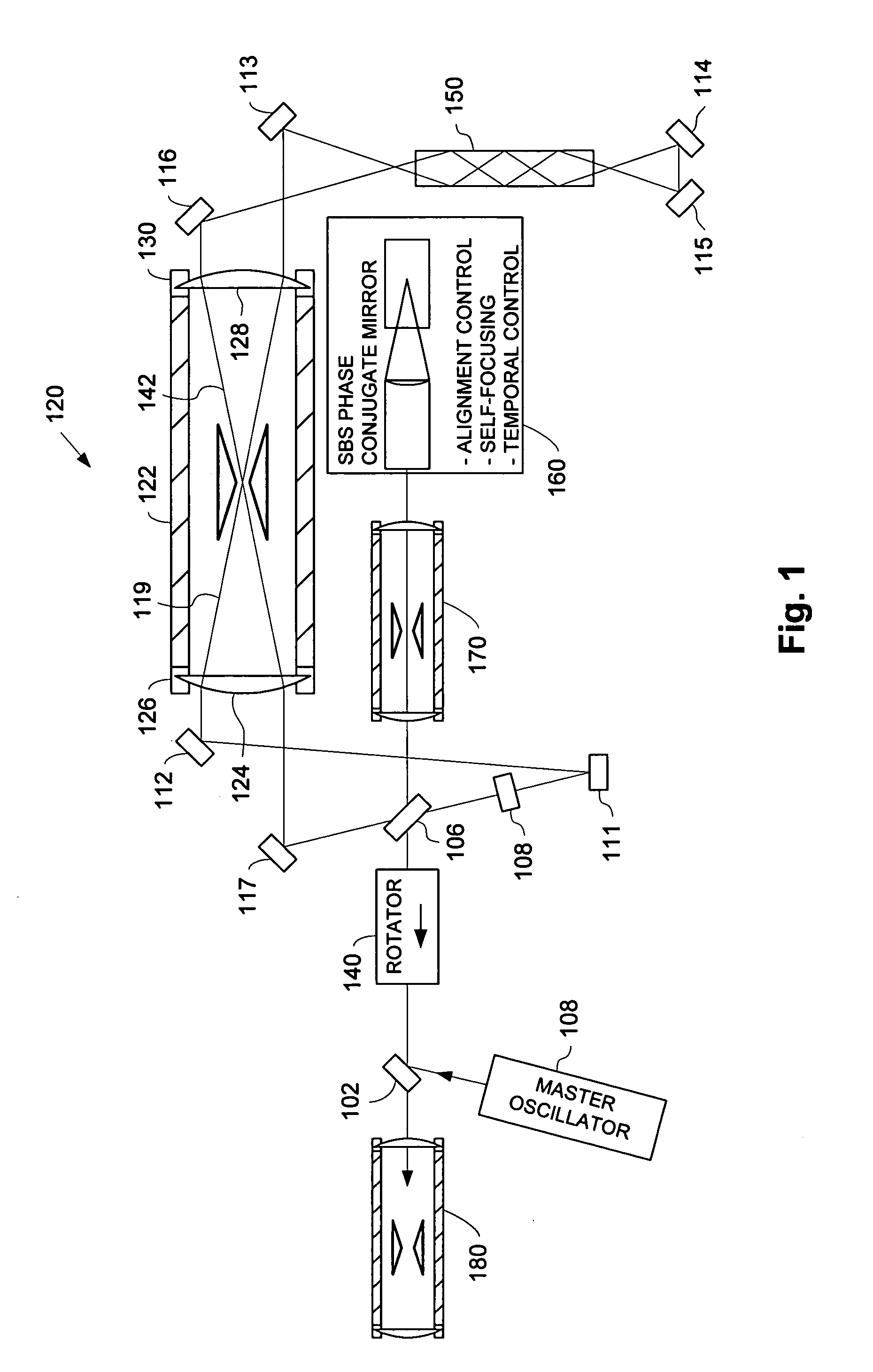

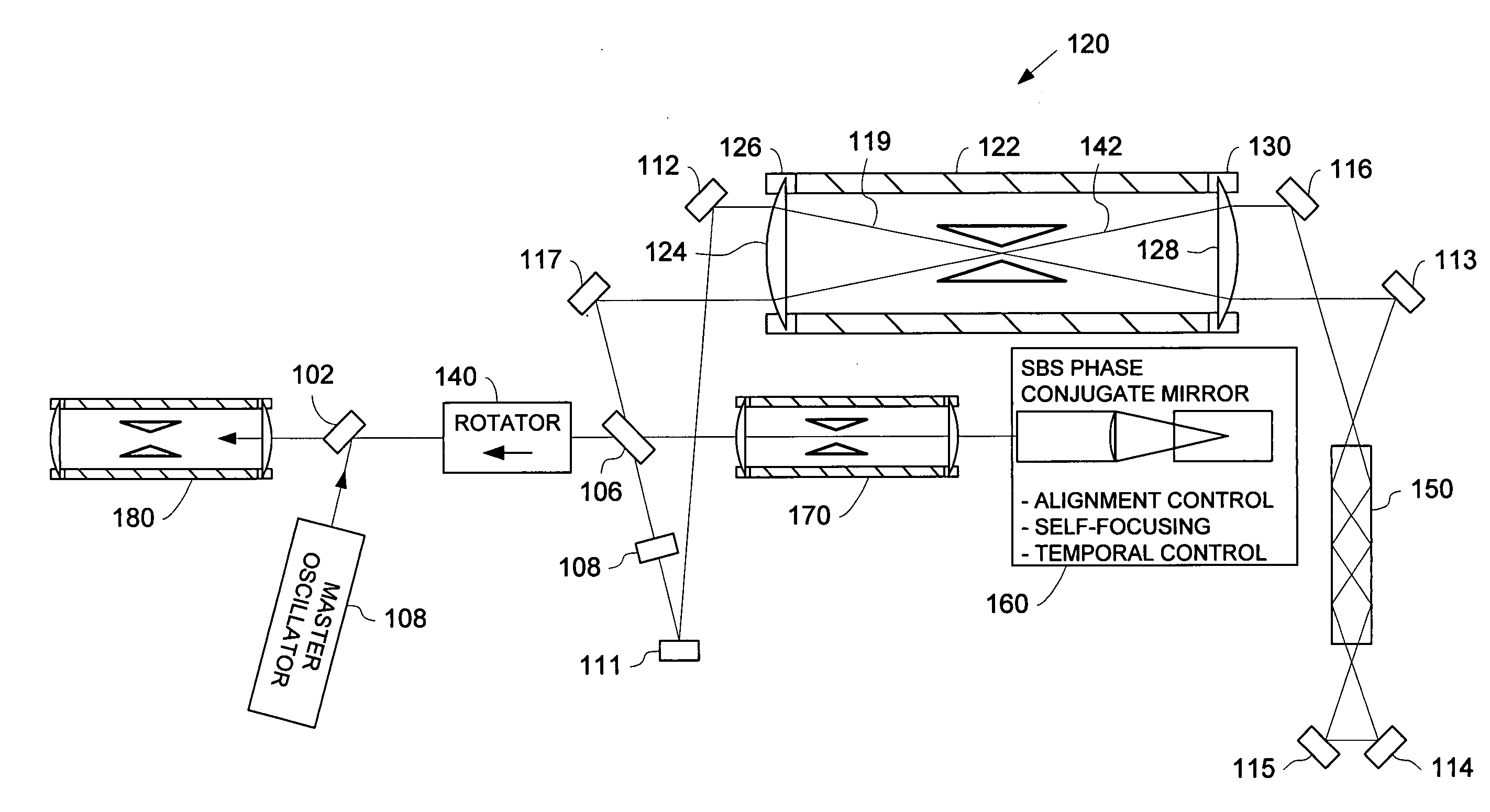

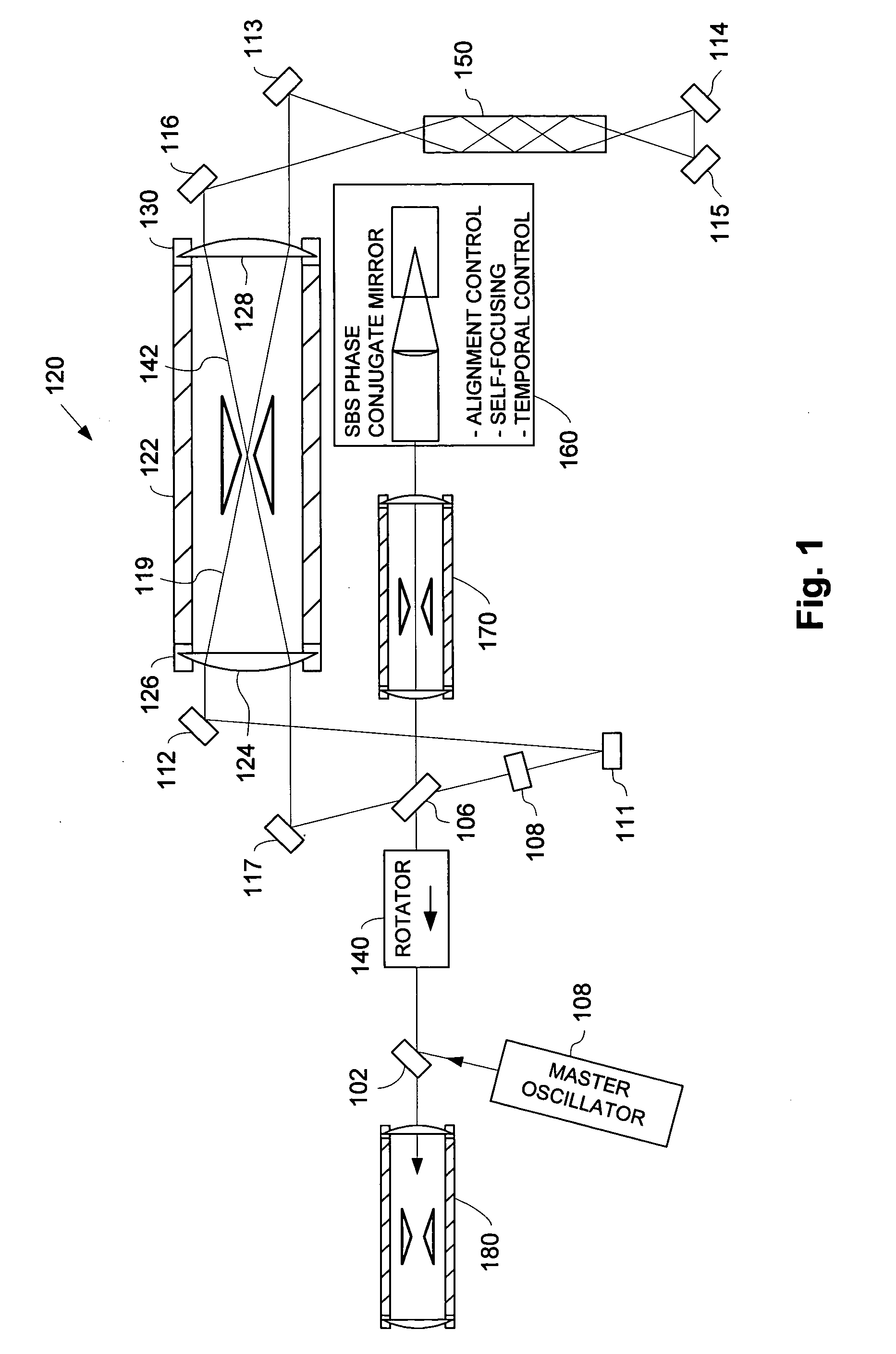

Stimulated brillouin scattering mirror system, high power laser and laser peening method and system using same

ActiveUS20050094256A1Fluence levels at the impact areas of the blocked beams are reducedAvoid damageLaser using scattering effectsOptical resonator shape and constructionBeam splitterHigh power lasers

A laser system, such as a master oscillator / power amplifier system, comprises a gain medium and a stimulated Brillouin scattering SBS mirror system. The SBS mirror system includes an in situ filtered SBS medium that comprises a compound having a small negative non-linear index of refraction, such as a perfluoro compound. An SBS relay telescope having a telescope focal point includes a baffle at the telescope focal point which blocks off angle beams. A beam splitter is placed between the SBS mirror system and the SBS relay telescope, directing a fraction of the beam to an alternate beam path for an alignment fiducial. The SBS mirror system has a collimated SBS cell and a focused SBS cell. An adjustable attenuator is placed between the collimated SBS cell and the focused SBS cell, by which pulse width of the reflected beam can be adjusted.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

Active beam delivery system for laser peening and laser peening method

ActiveUS7750266B2Minimize complexityLow costWelding/cutting auxillary devicesAuxillary welding devicesAngle of incidenceVariable length

A laser peening method and system allows the work piece to be fixed, while moving and directing the laser beam. A laser energy delivery system includes a relay imaging system. Input optics arranged to receive the laser energy, a transmitting mirror having adjustable angle of incidence relative to the input optics, and a robot mounted processing head including an optical assembly are configured to direct laser energy toward the movable target image plane. The laser energy follows an optical path including an essentially straight segment from the transmitting mirror to the receiving mirror, having a variable length and a variable angle relative to the input optics. Diagnostics on the processing head facilitate operation.

Owner:METAL IMPROVEMENT CO INC

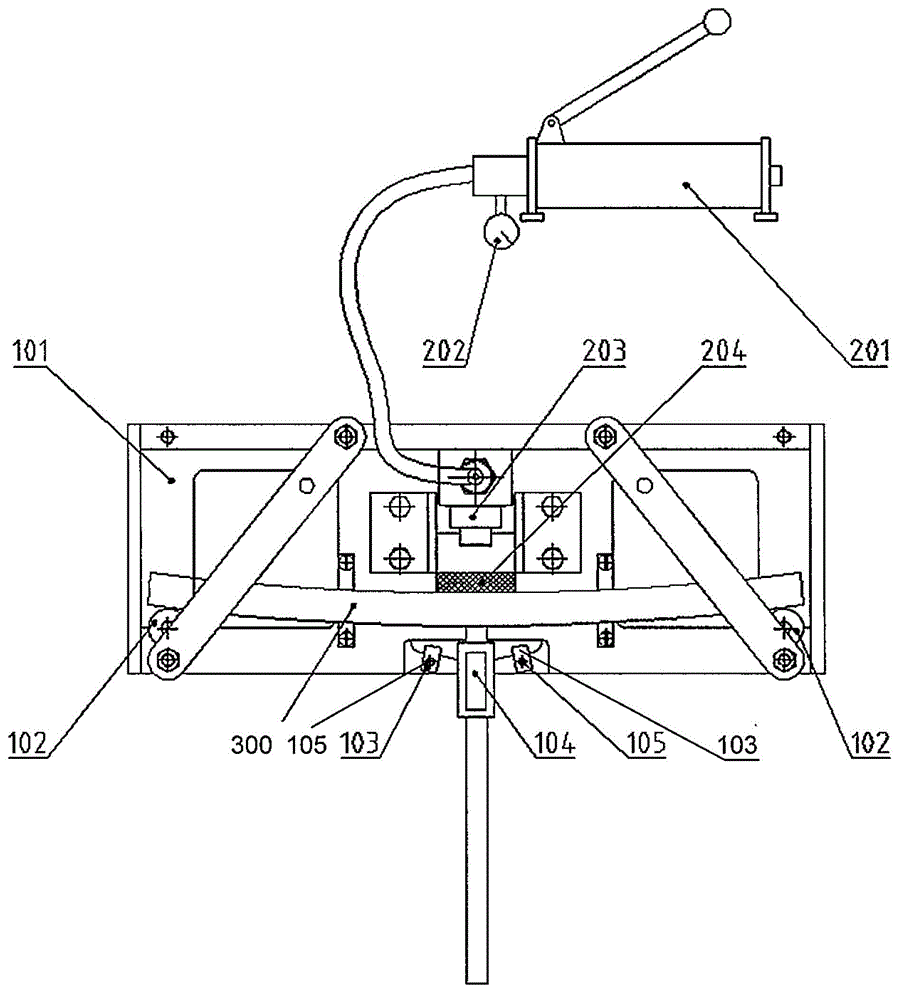

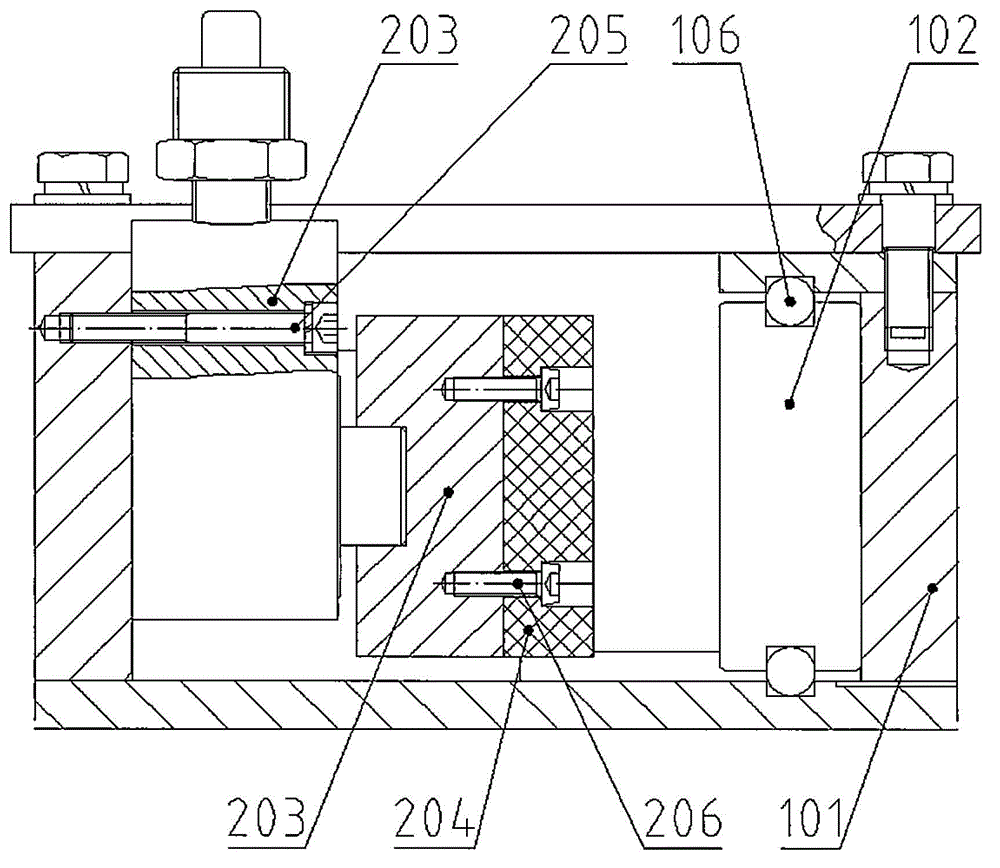

Pre-stressing clamp for laser peening formation of workpiece

InactiveCN103143597AControlled prestressControllable elasticityMetal-working feeding devicesPositioning devicesPre deformationPre stress

The invention discloses a pre-stressing clamp, which comprises a framework, two support spherical columns, a hydraulic jack, a soft padding block, a hydraulic driving pump, an oil pressure gauge and a length measuring component; wherein the hydraulic jack is fixed onto the framework to enable a piston rod of the hydraulic jack to be basically and vertically positioned in the center between the two support spherical columns, so that a workpiece is pressed and abutted between the piston rod of the hydraulic jack and the two support spherical columns; the soft padding block is arranged between the piston rod of the hydraulic jack and the workpiece; the hydraulic driving pump is connected onto the hydraulic jack to drive the hydraulic jack; the oil pressure gauge is connected onto the hydraulic driving pump to display a driving oil pressure of the hydraulic driving pump; and the length measuring component is fixed onto the framework and is positioned in the center between the two support spherical columns to measure a vertical deformation amount of the workpiece under action of the hydraulic jack. When the pre-stressing clamp is used for carrying out laser peening formation on a metal board, controllable and continuously changeable pre-stressing force can be implemented on the workpiece, so that the workpiece is enabled to produce controllable pre-stressing force and a flexible pre-deformation amount before peening formation, and the processing quality of the workpiece after peening formation can be remarkably improved.

Owner:SHANGHAI AIRCRAFT MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com