Patents

Literature

3210results about "Electron beam welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

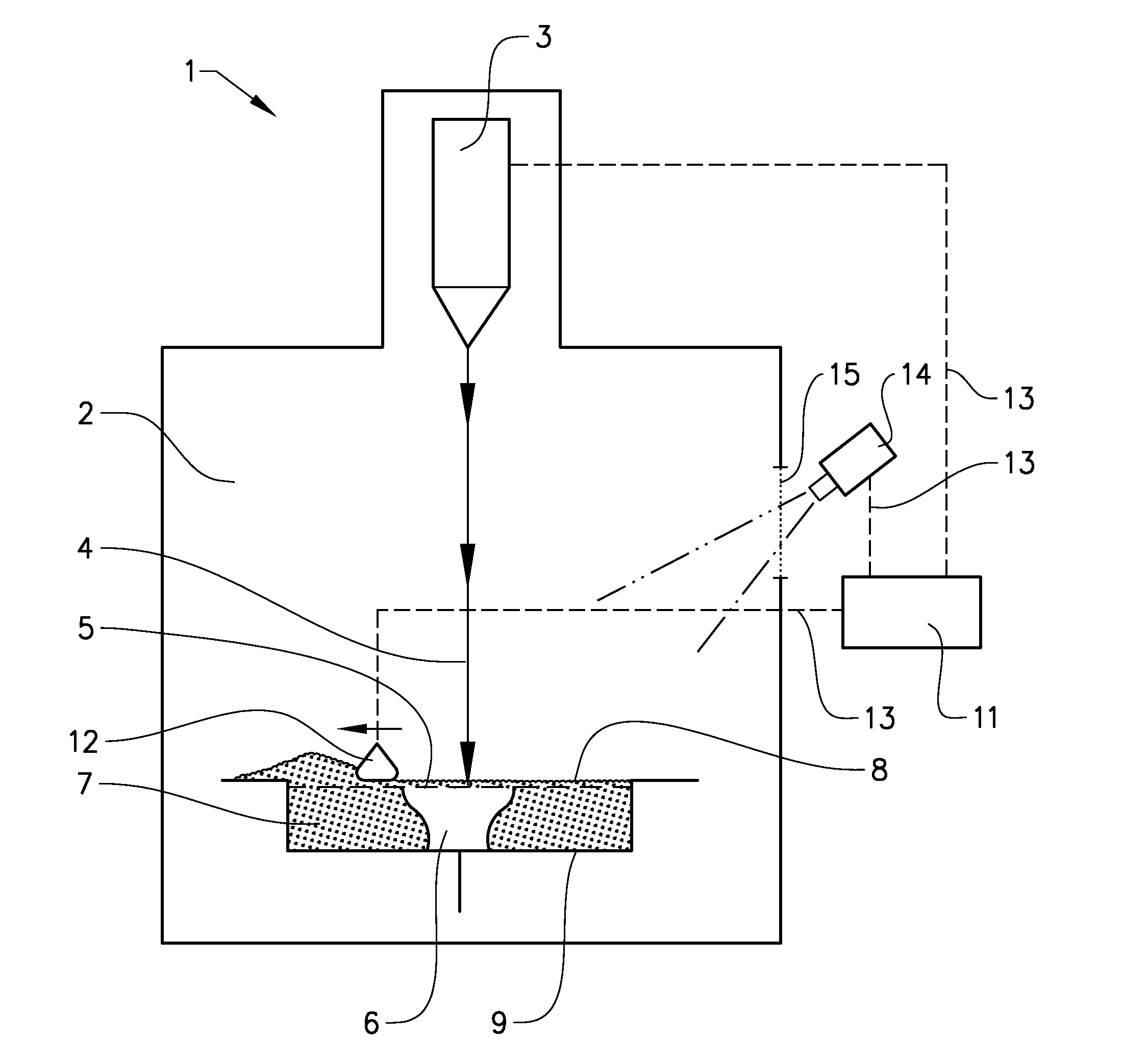

Electron beam layer manufacturing

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

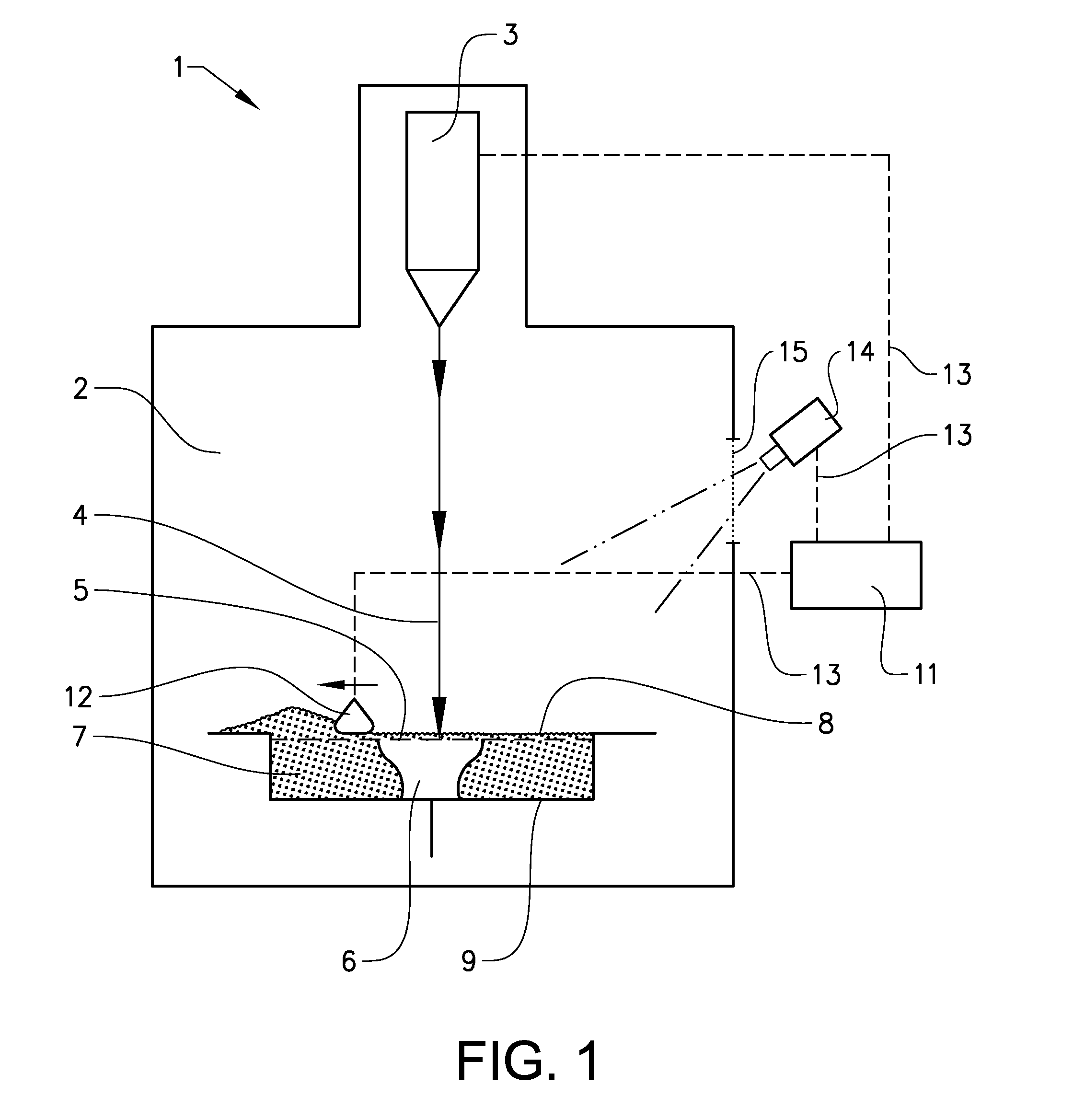

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

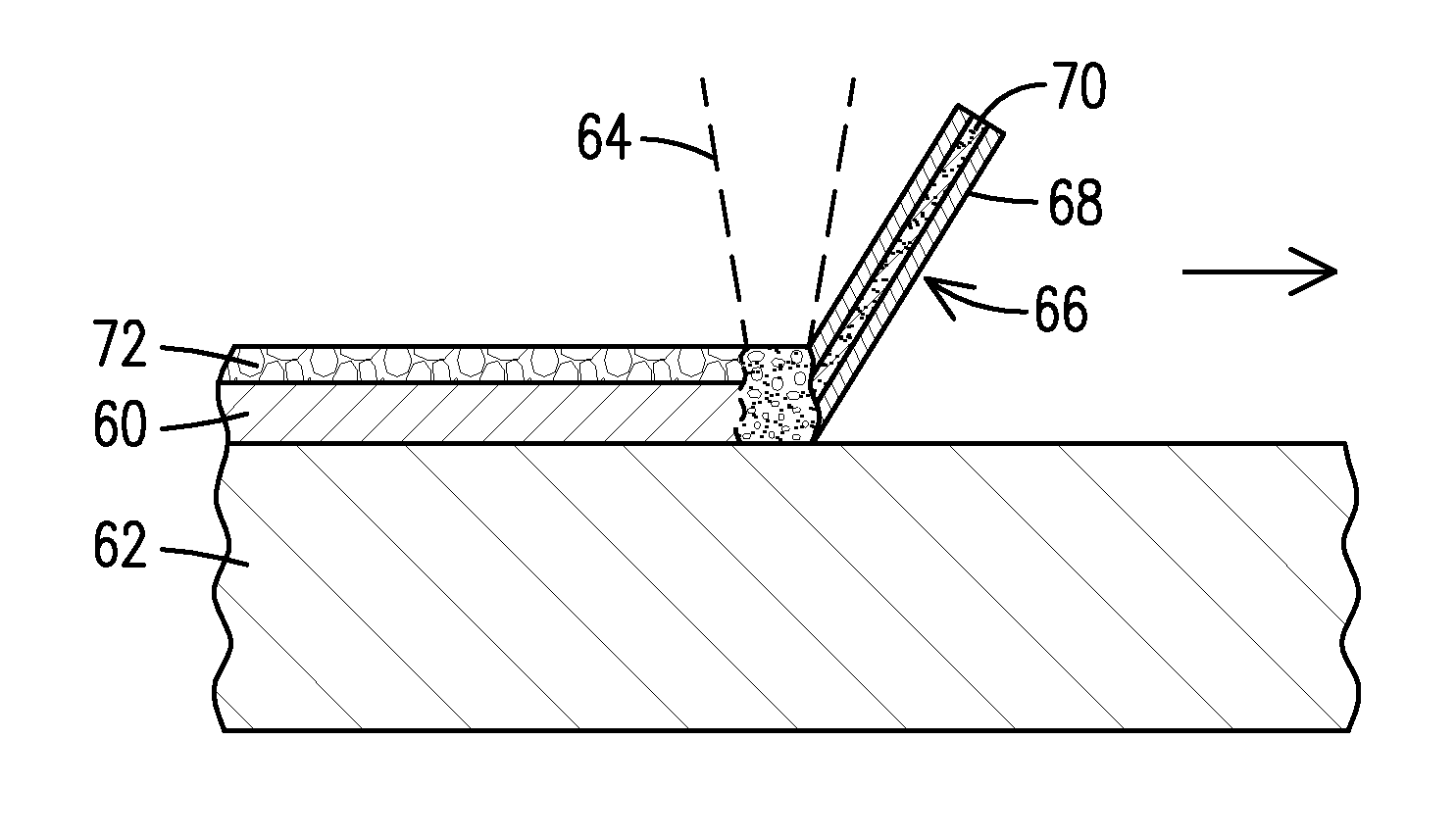

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

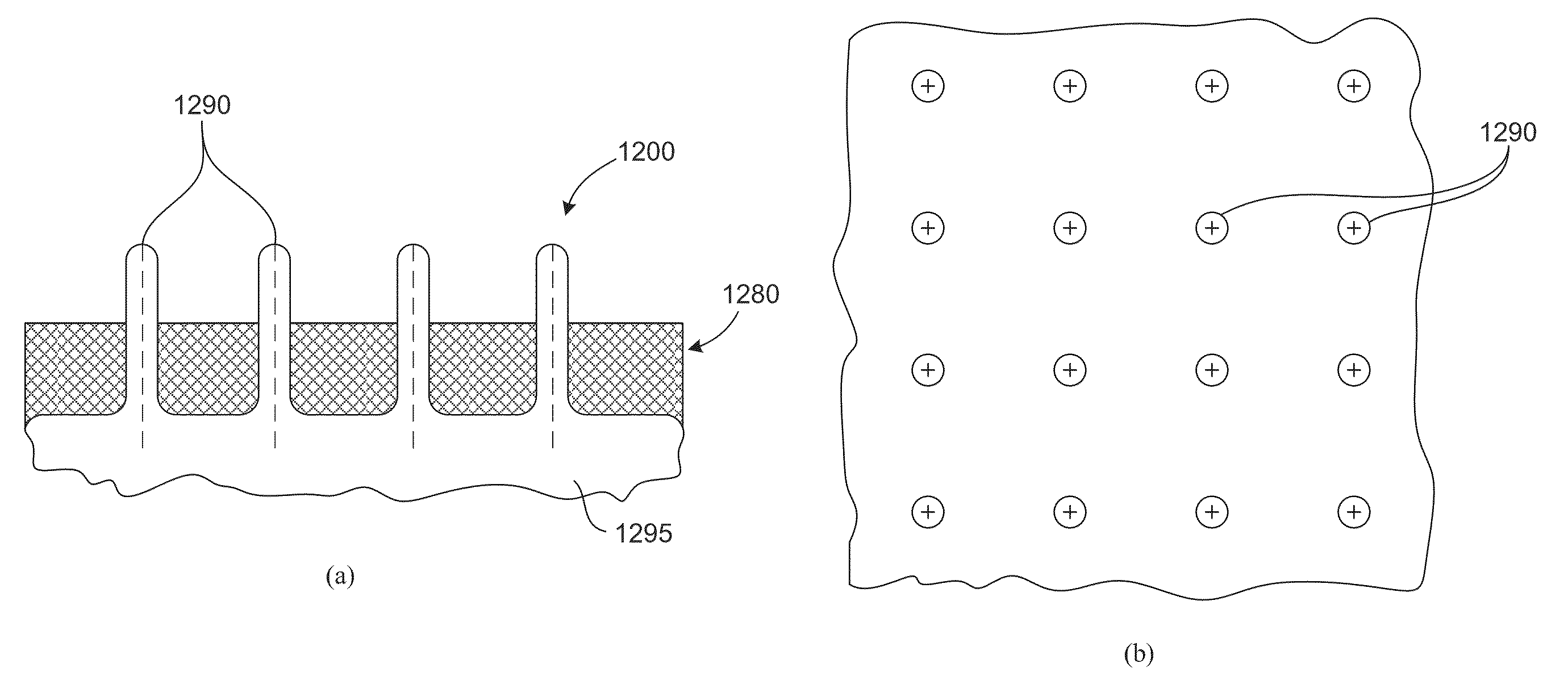

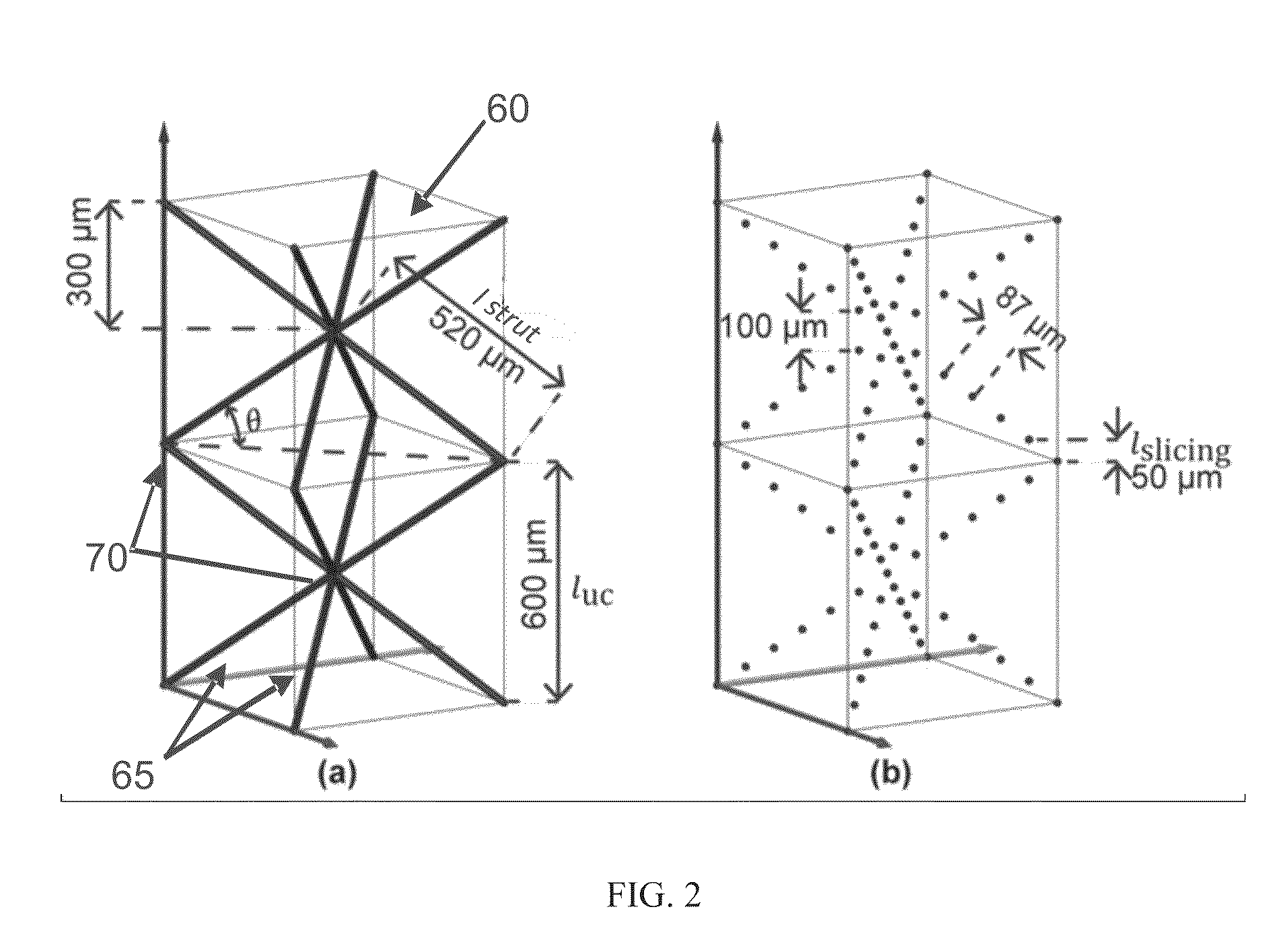

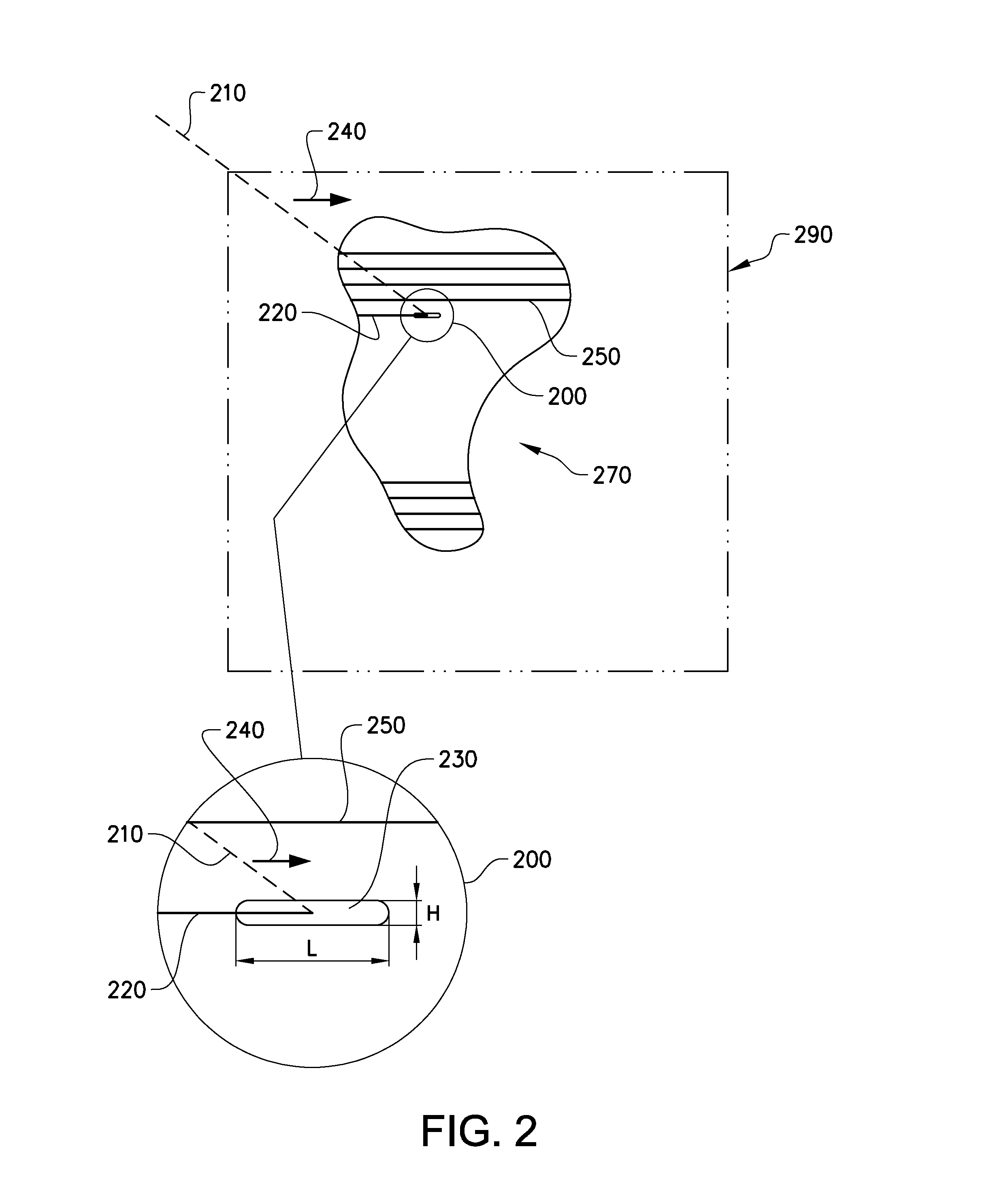

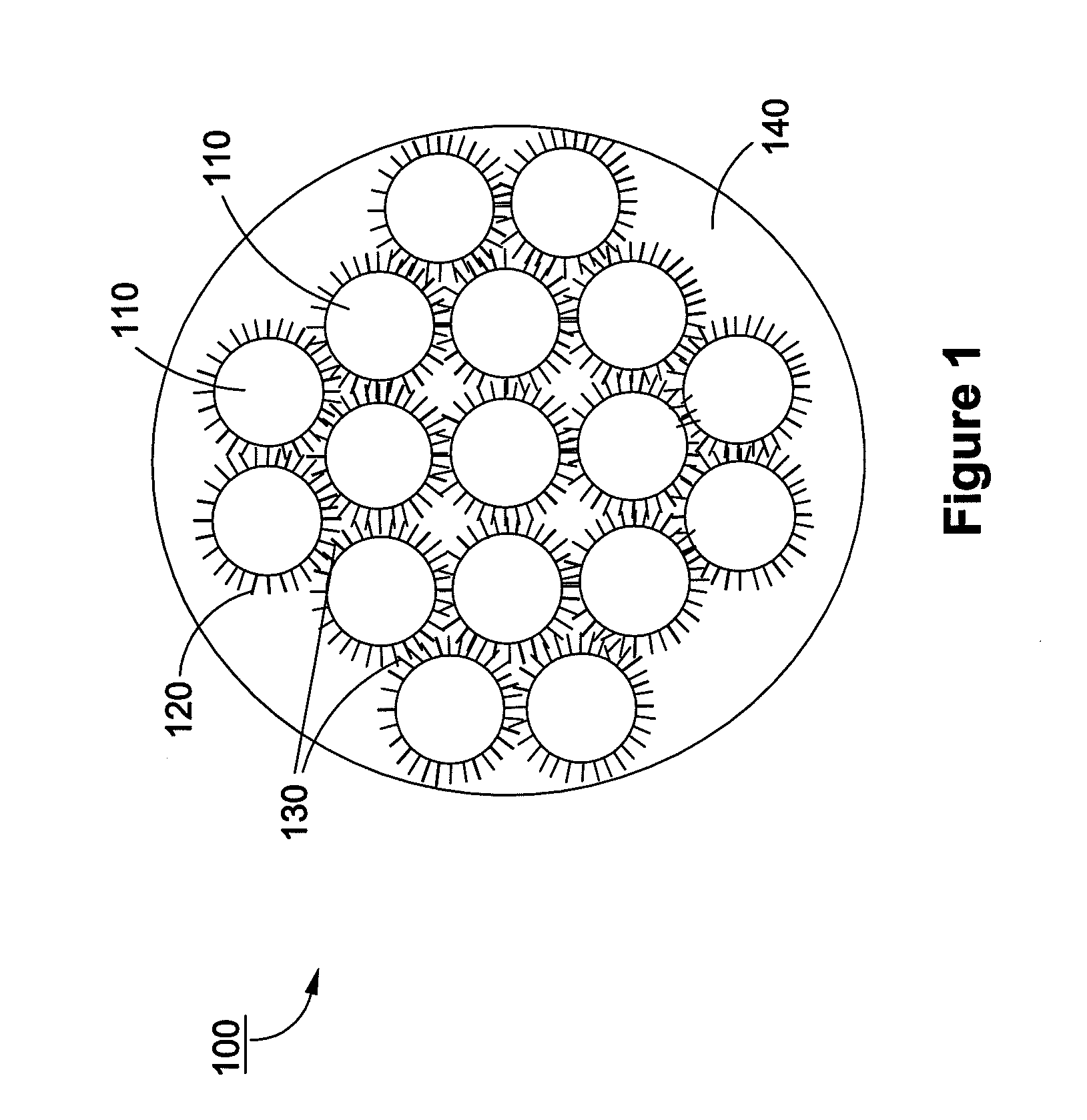

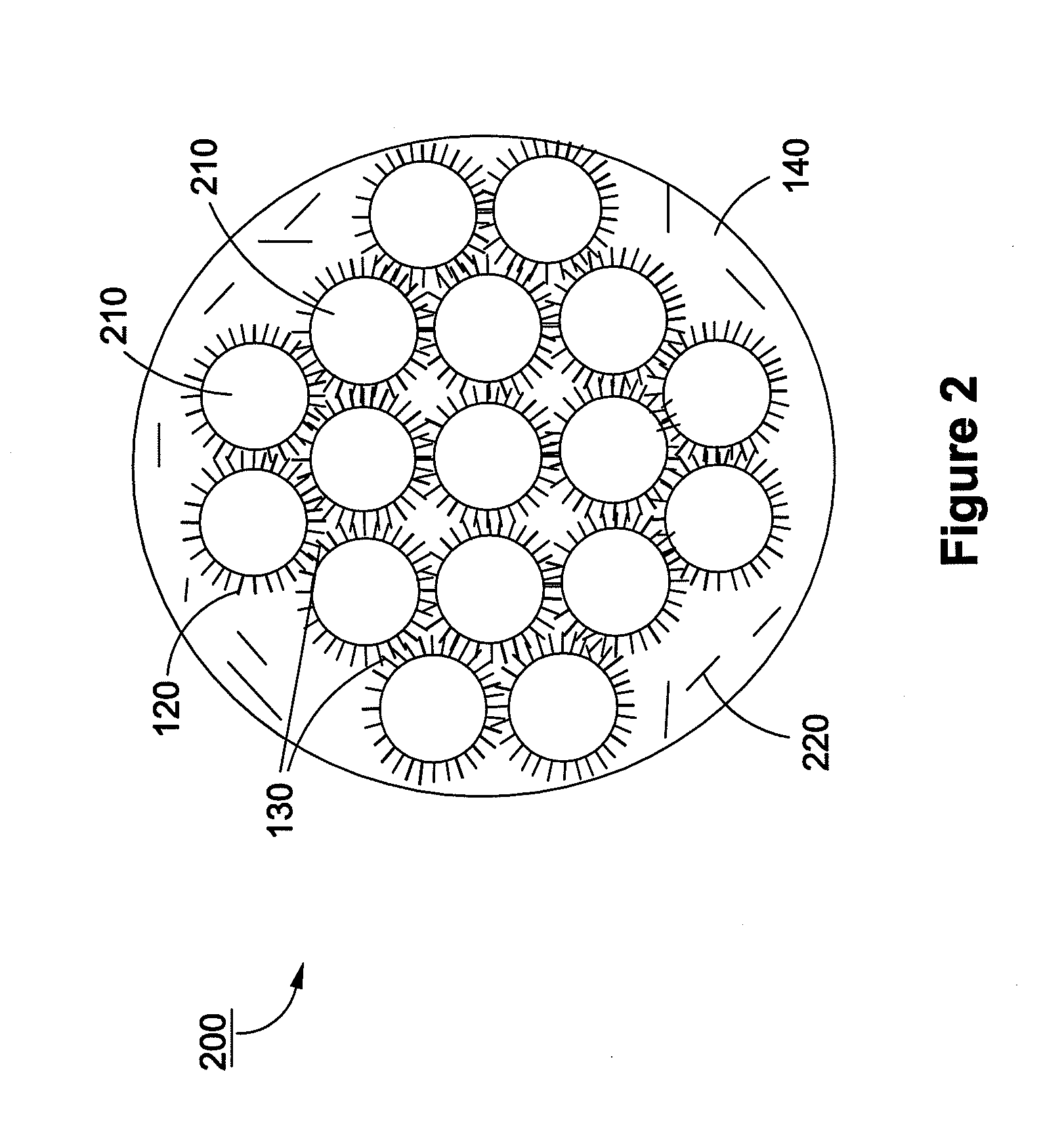

Surface modified unit cell lattice structures for optimized secure freeform fabrication

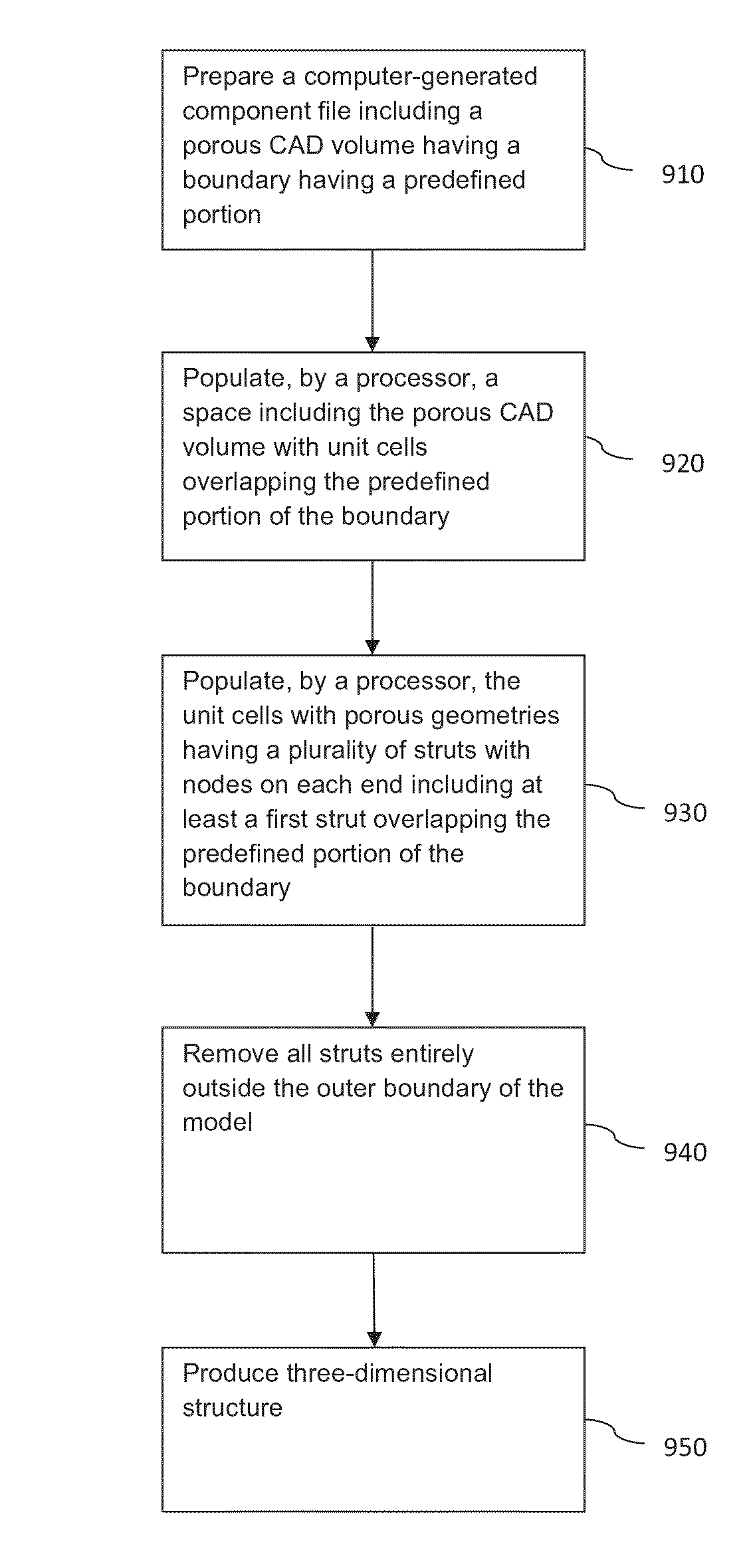

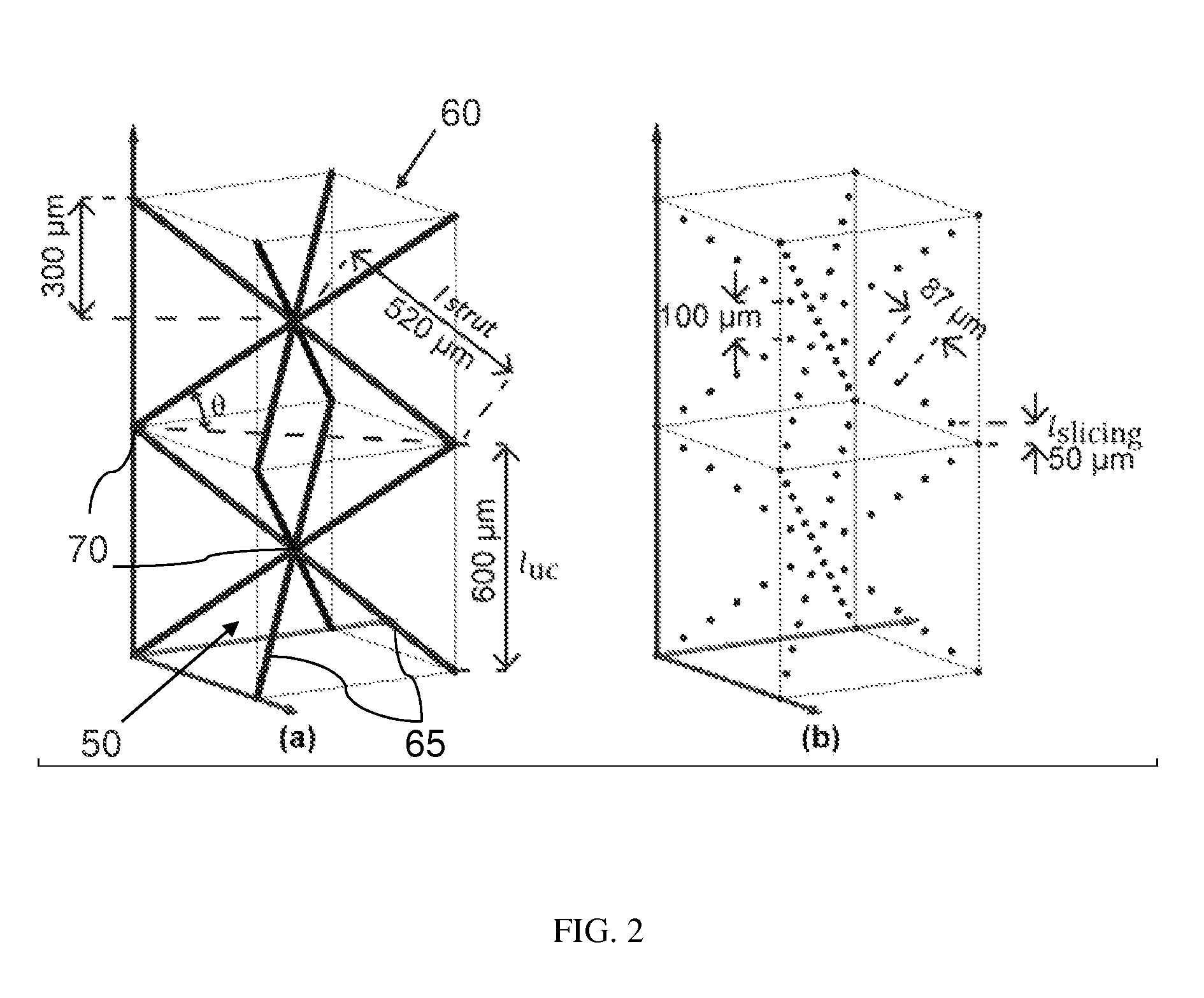

Aspects of the present disclosure relate generally to preparing models of three-dimensional structures. In particular, a model of a three-dimensional structure constructed of porous geometries is prepared. A component file including a porous CAD volume having a boundary is prepared. A space including the porous CAD volume is populated with unit cells. The unit cells are populated with porous geometries having a plurality of struts having nodes on each end. The space is populated with at least one elongated fixation element extending beyond the boundary to produce an interlocking feature enabling assembly or engagement with a mating structure.

Owner:HOWMEDICA OSTEONICS CORP +1

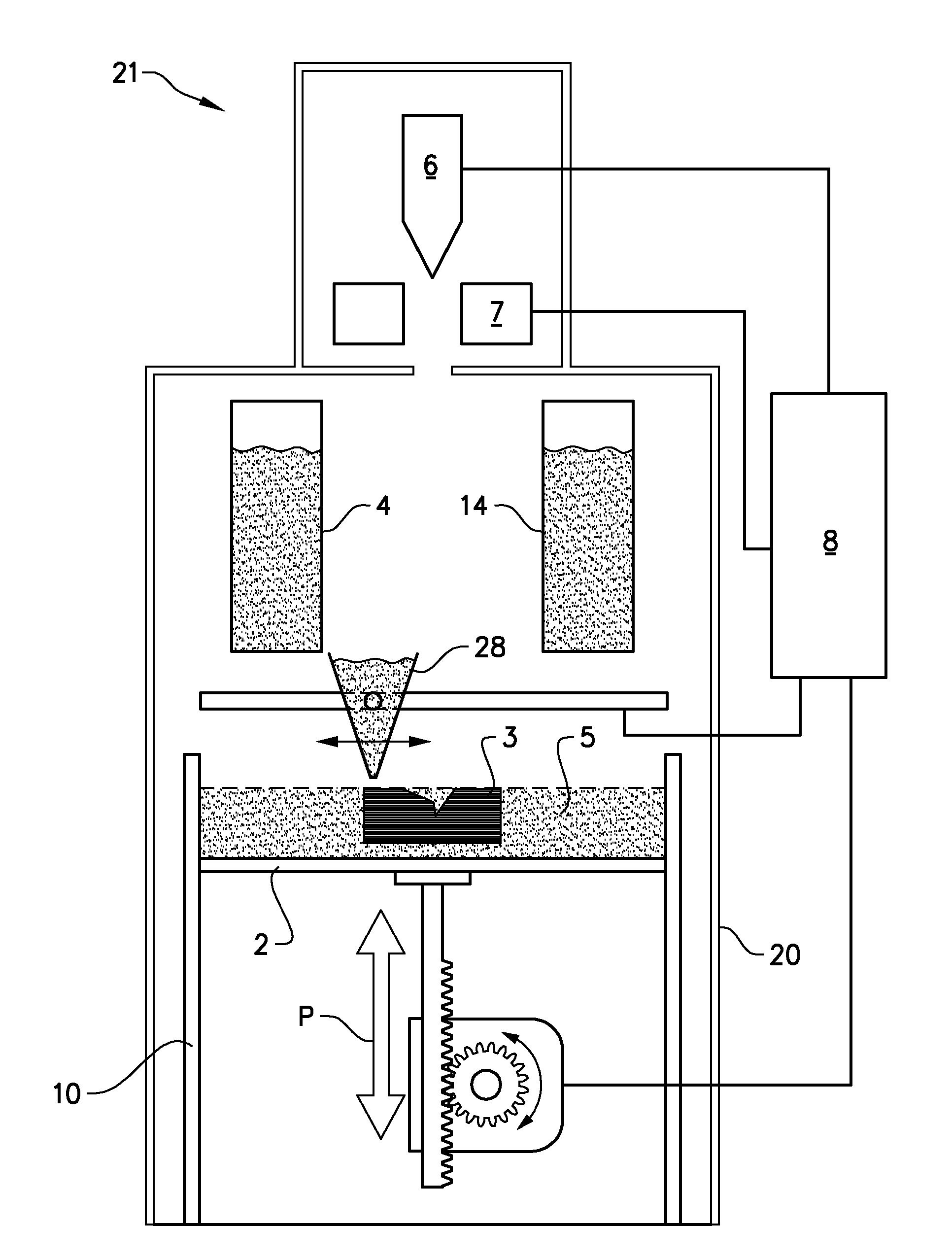

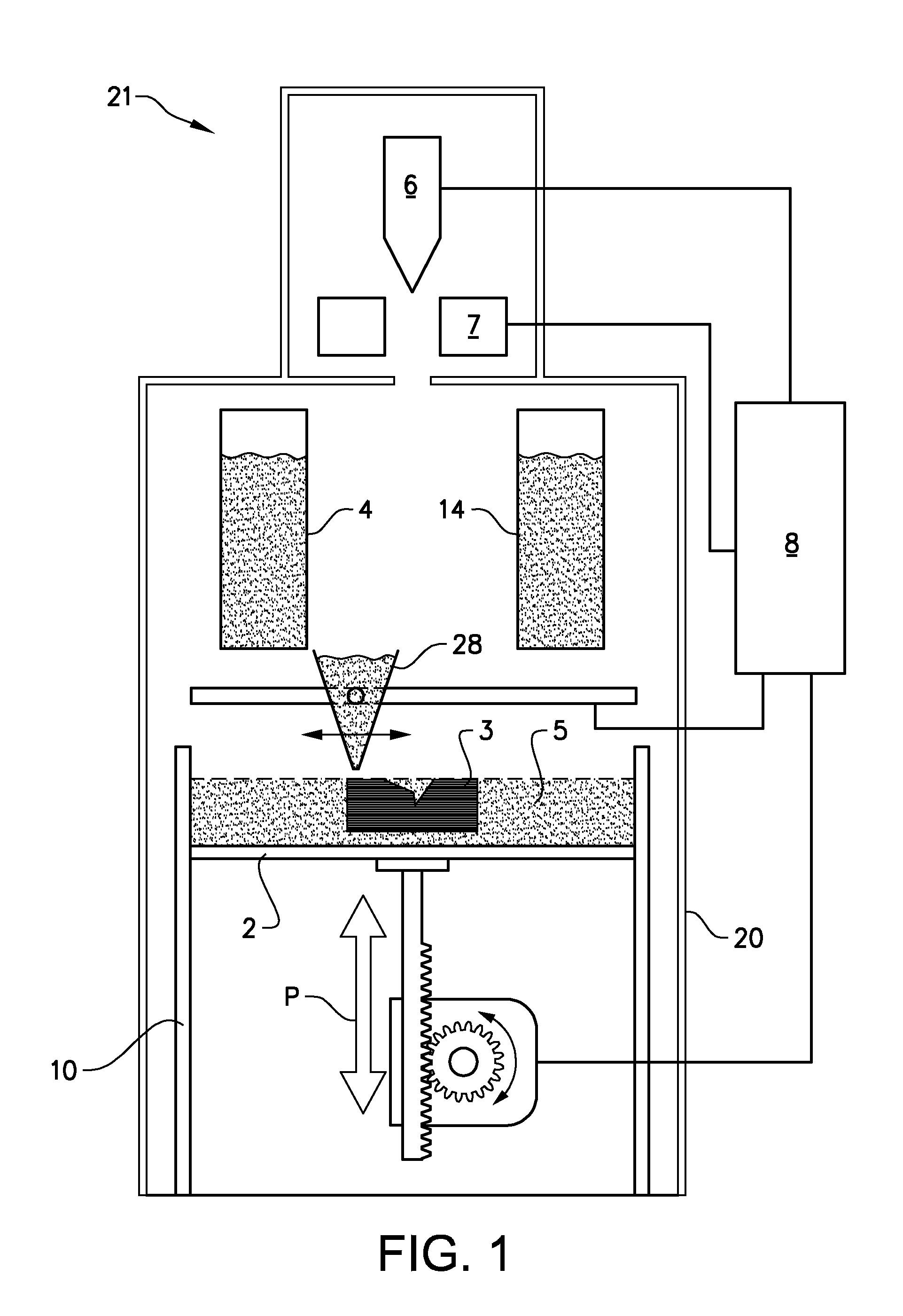

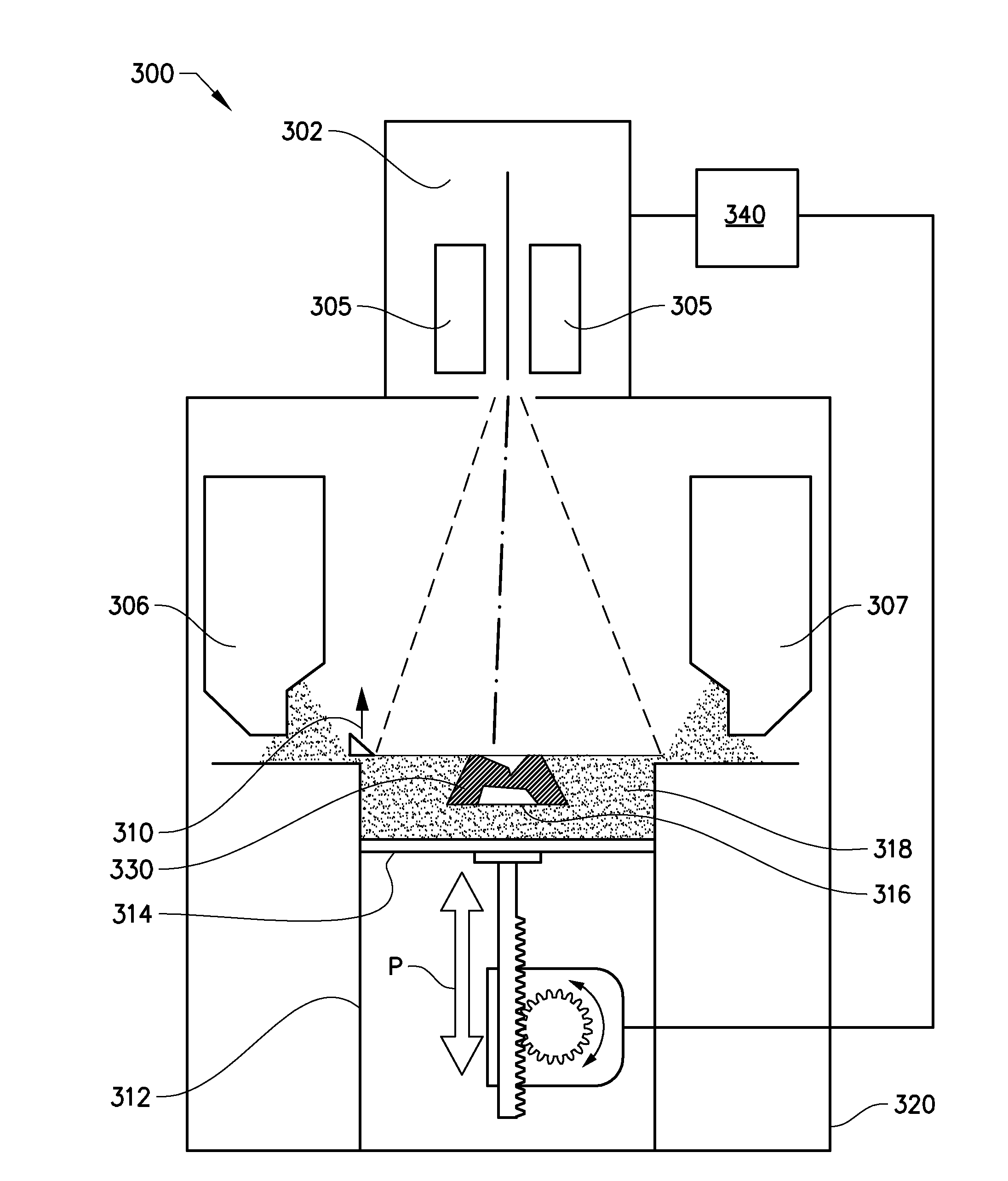

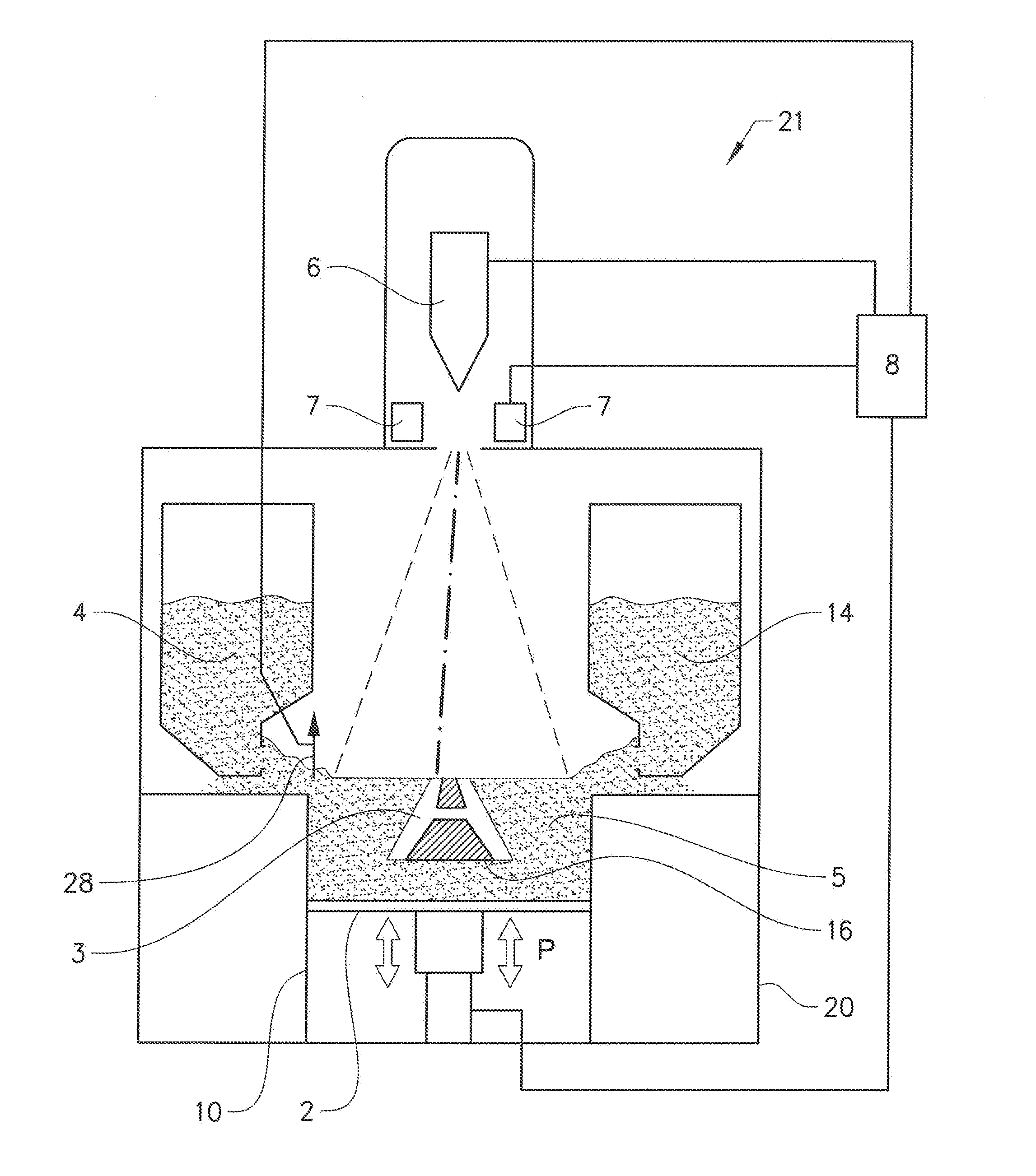

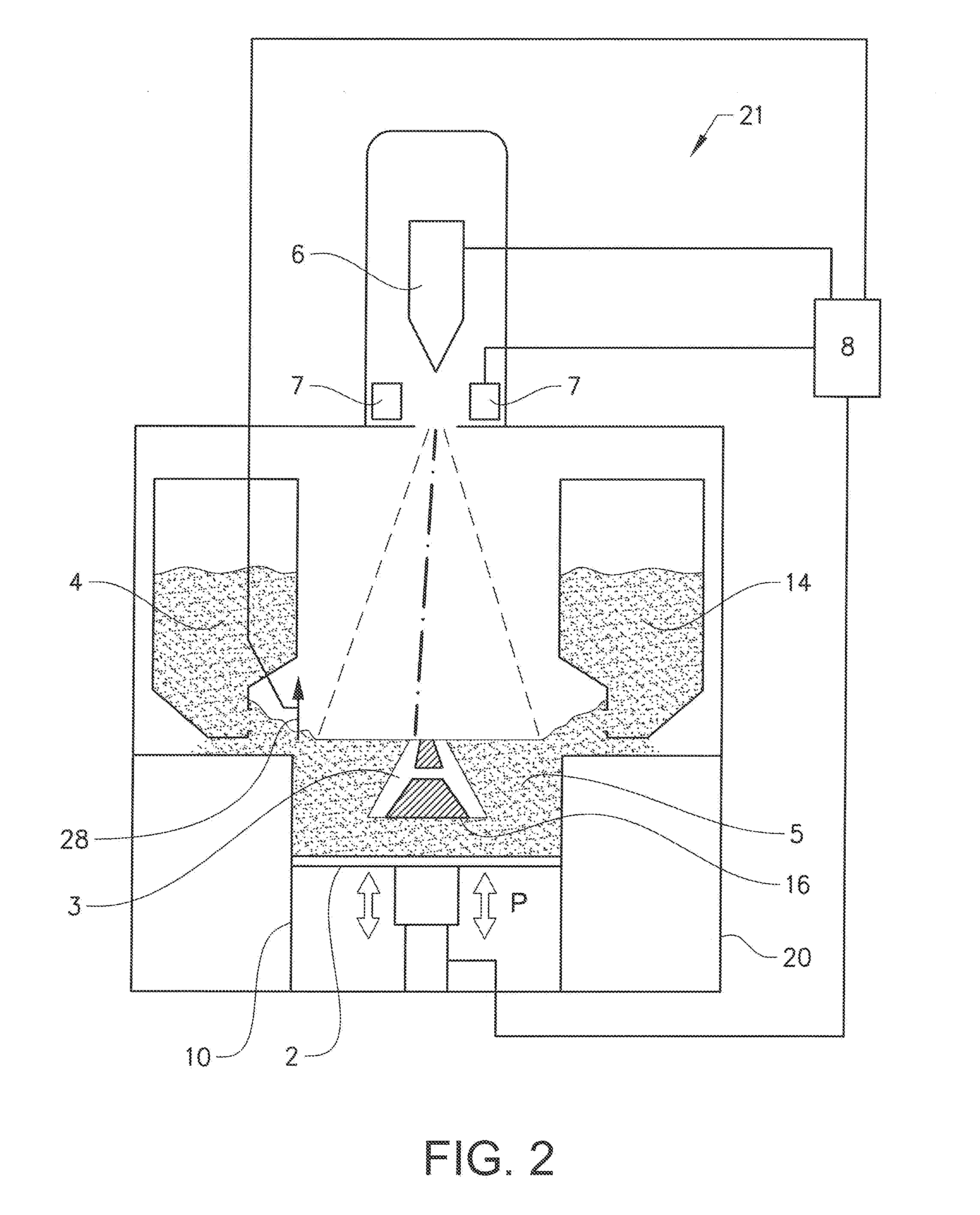

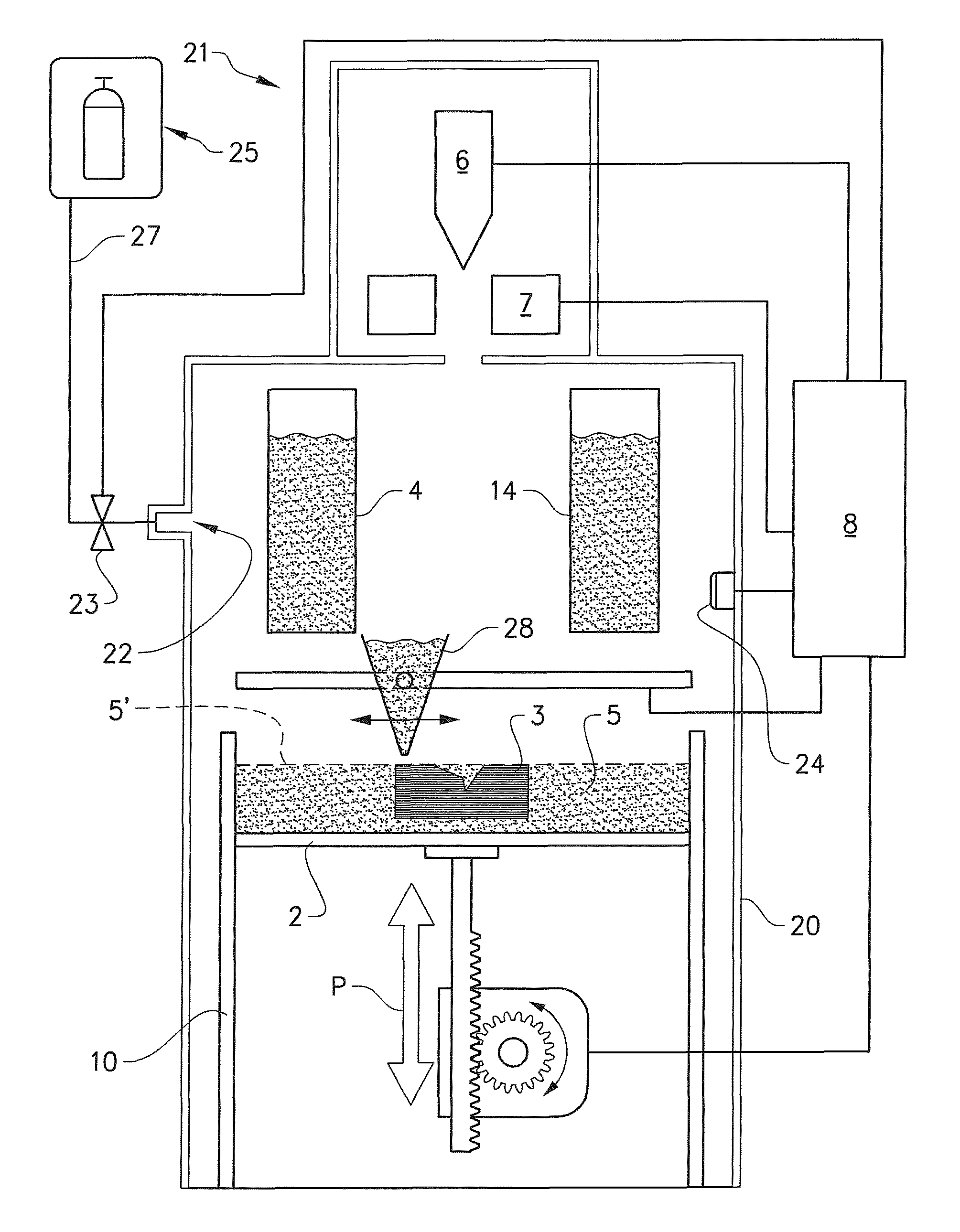

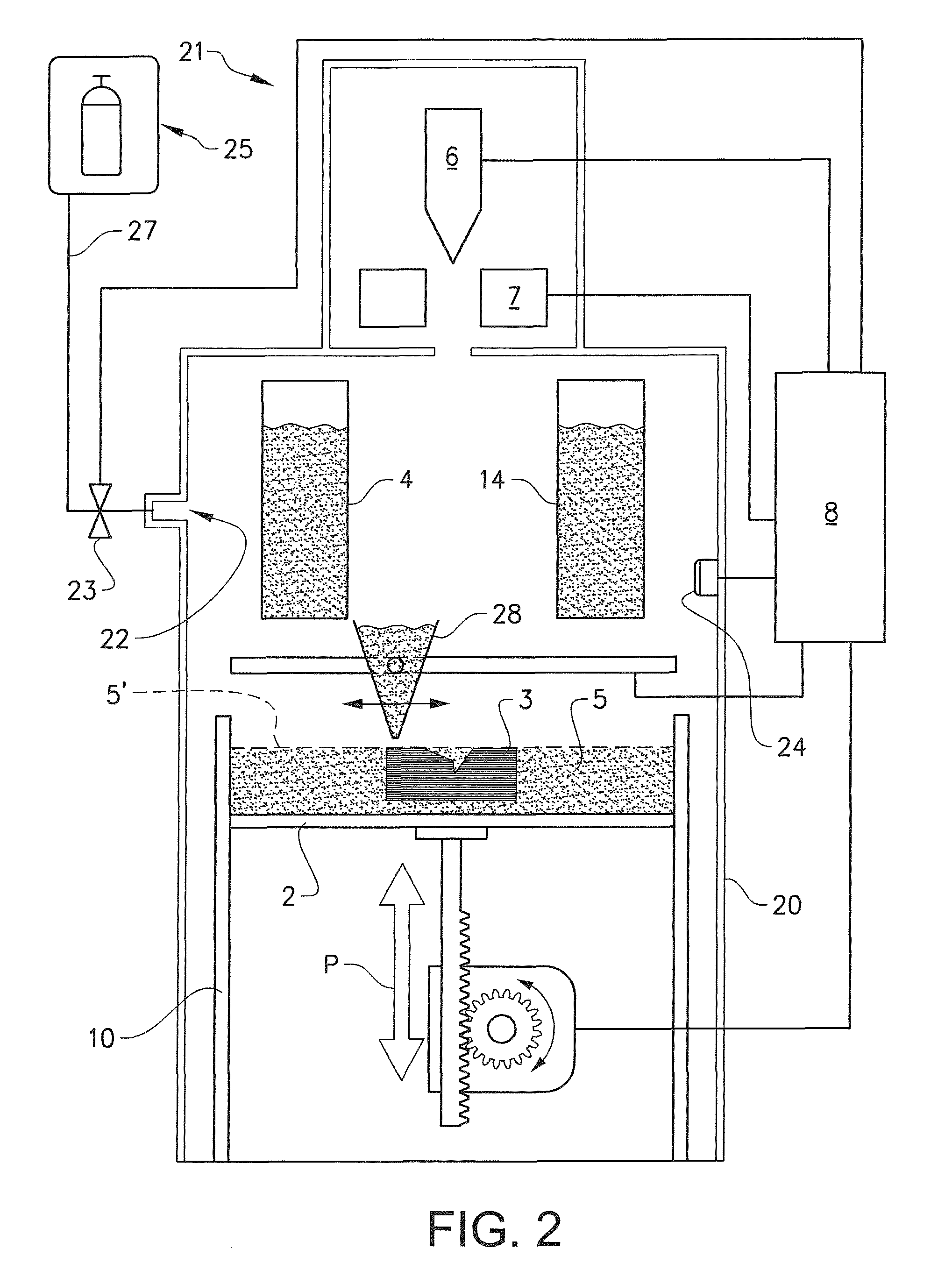

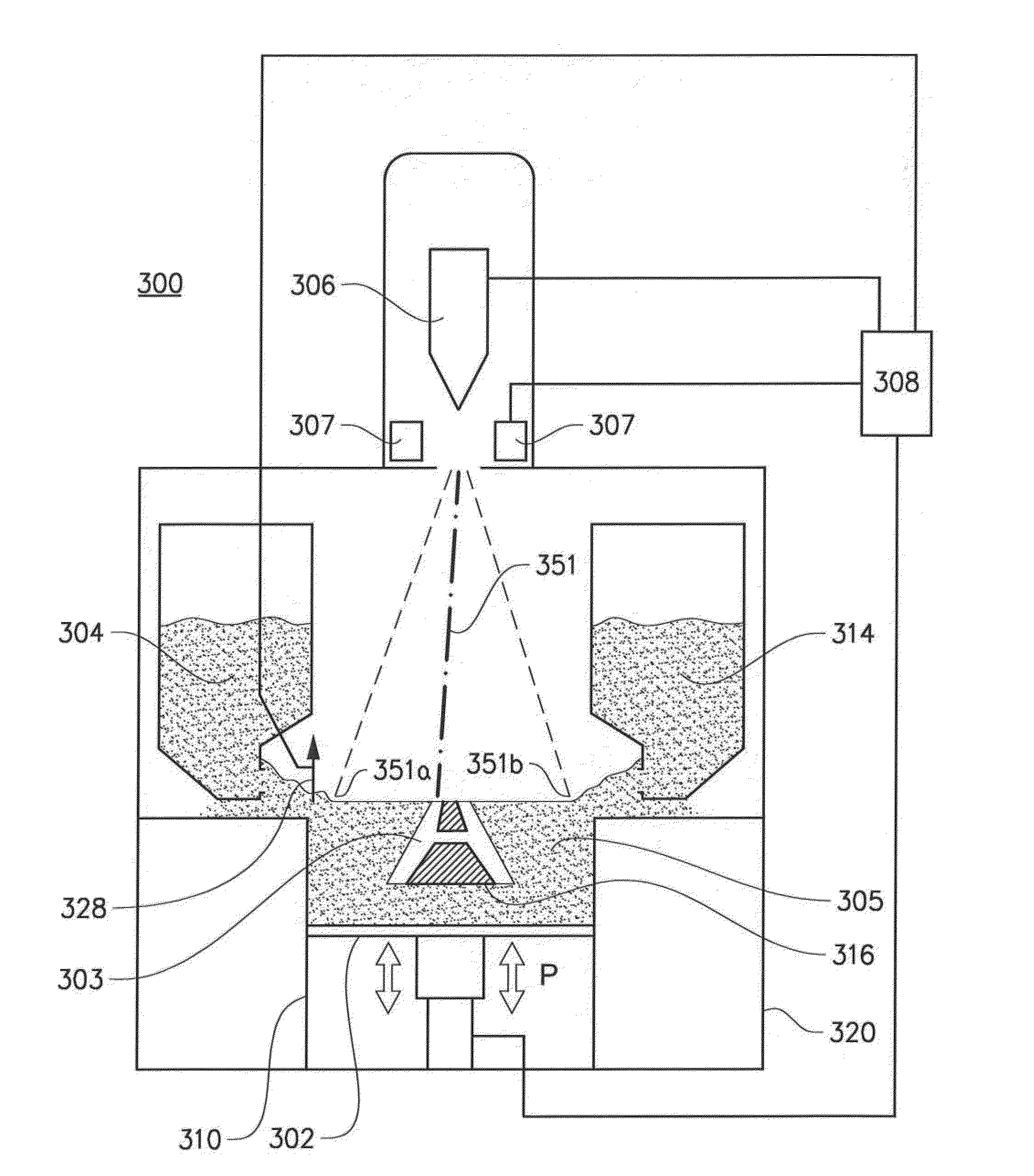

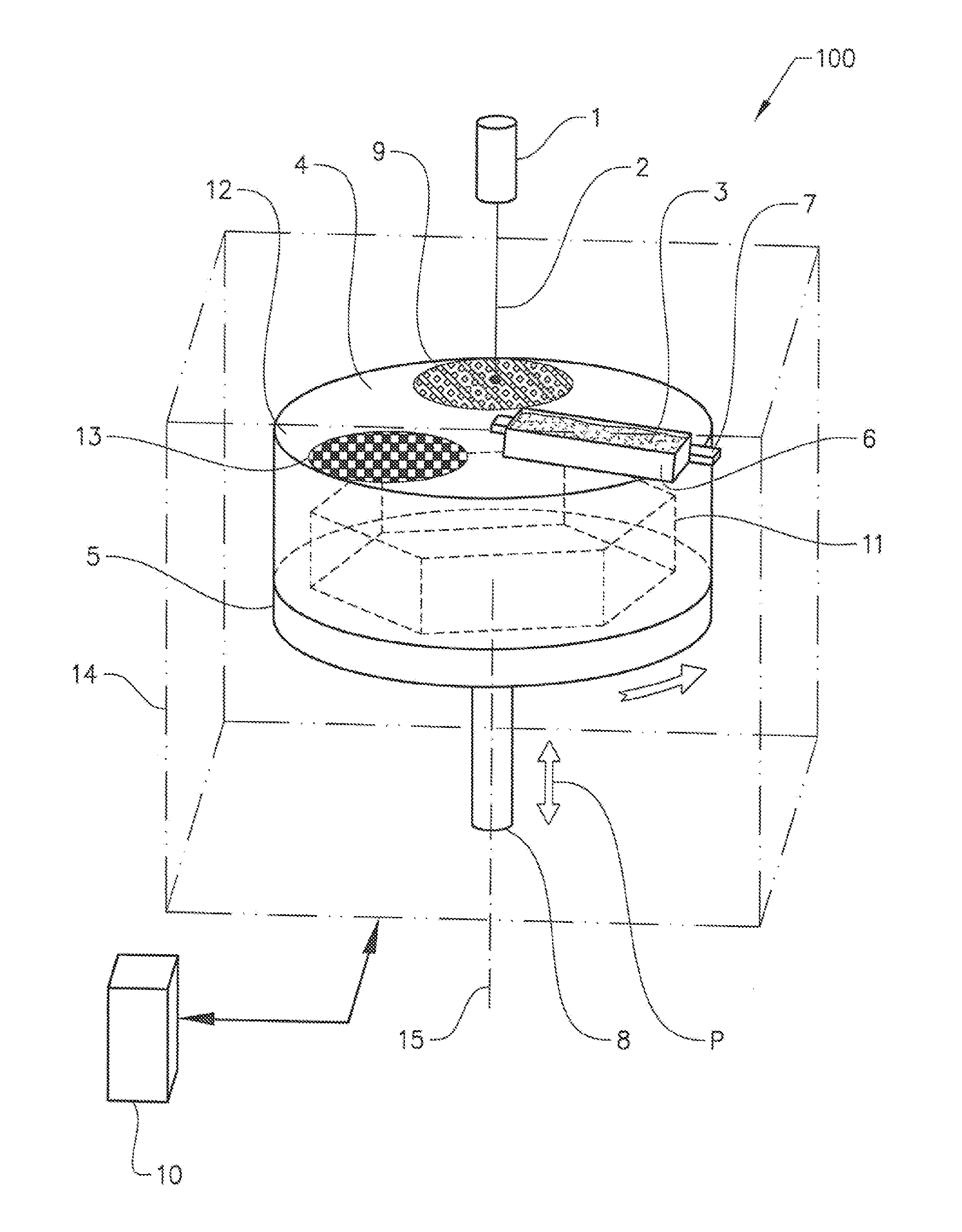

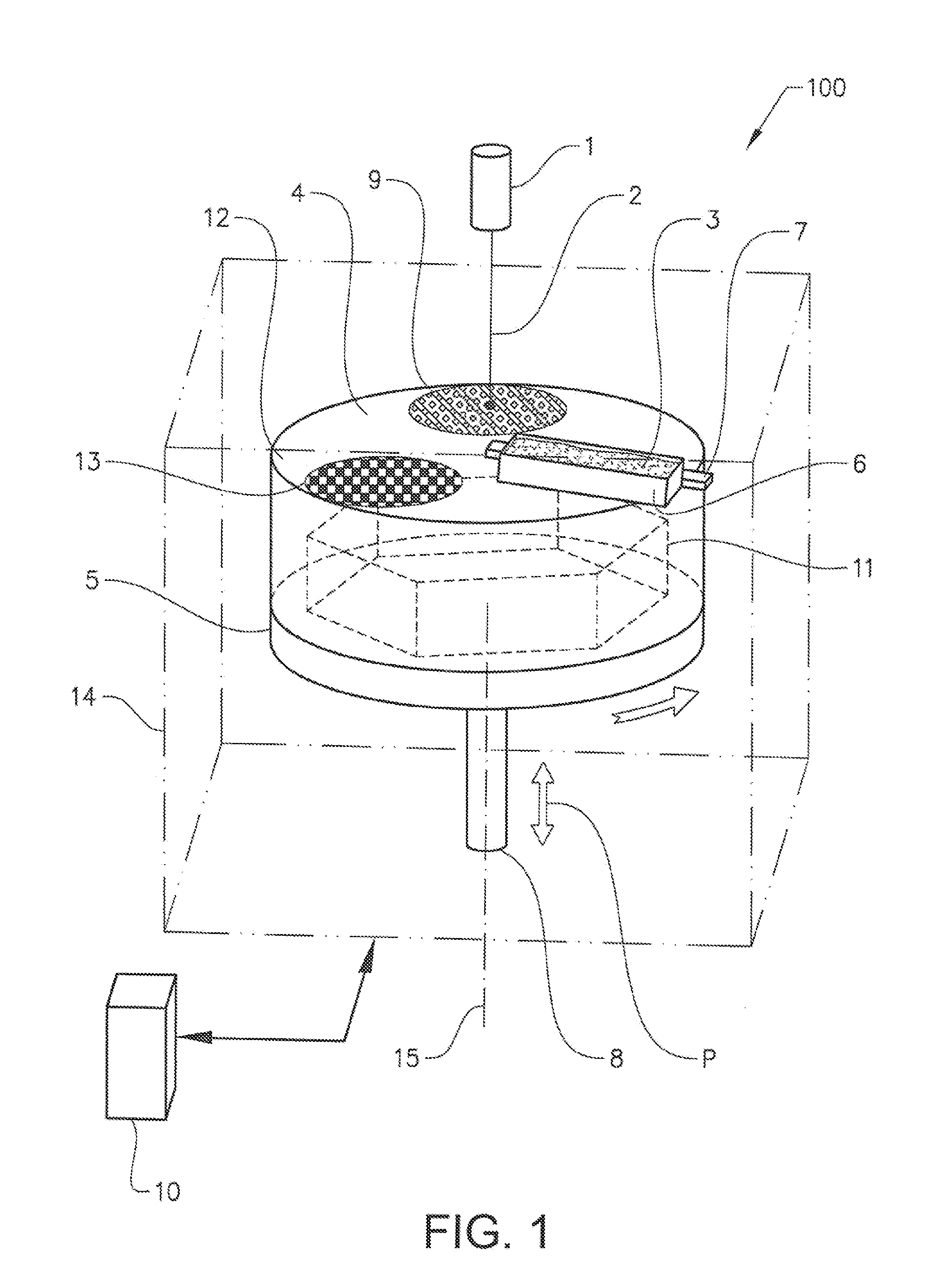

Powder distribution in additive manufacturing of three-dimensional articles

ActiveUS20150071809A1Additive manufacturing apparatusTransportation and packagingMetallurgyAdditive layer manufacturing

The present invention relates to a method for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table. Said method comprising the steps of: providing at least a first and second powder tank, providing a first type of powder in said first powder tank having a first particle size distribution, providing a second type of powder in said second powder tank having a second particle size distribution, providing a first sub-layer of said first type of powder on said work table, providing a second sub-layer of said second type of powder on top of said first layer of said first type of powder, fusing said first and second sub-layers simultaneously with a high energy beam from a high energy beam source for forming a first cross section of said three-dimensional article.

Owner:ARCAM AB

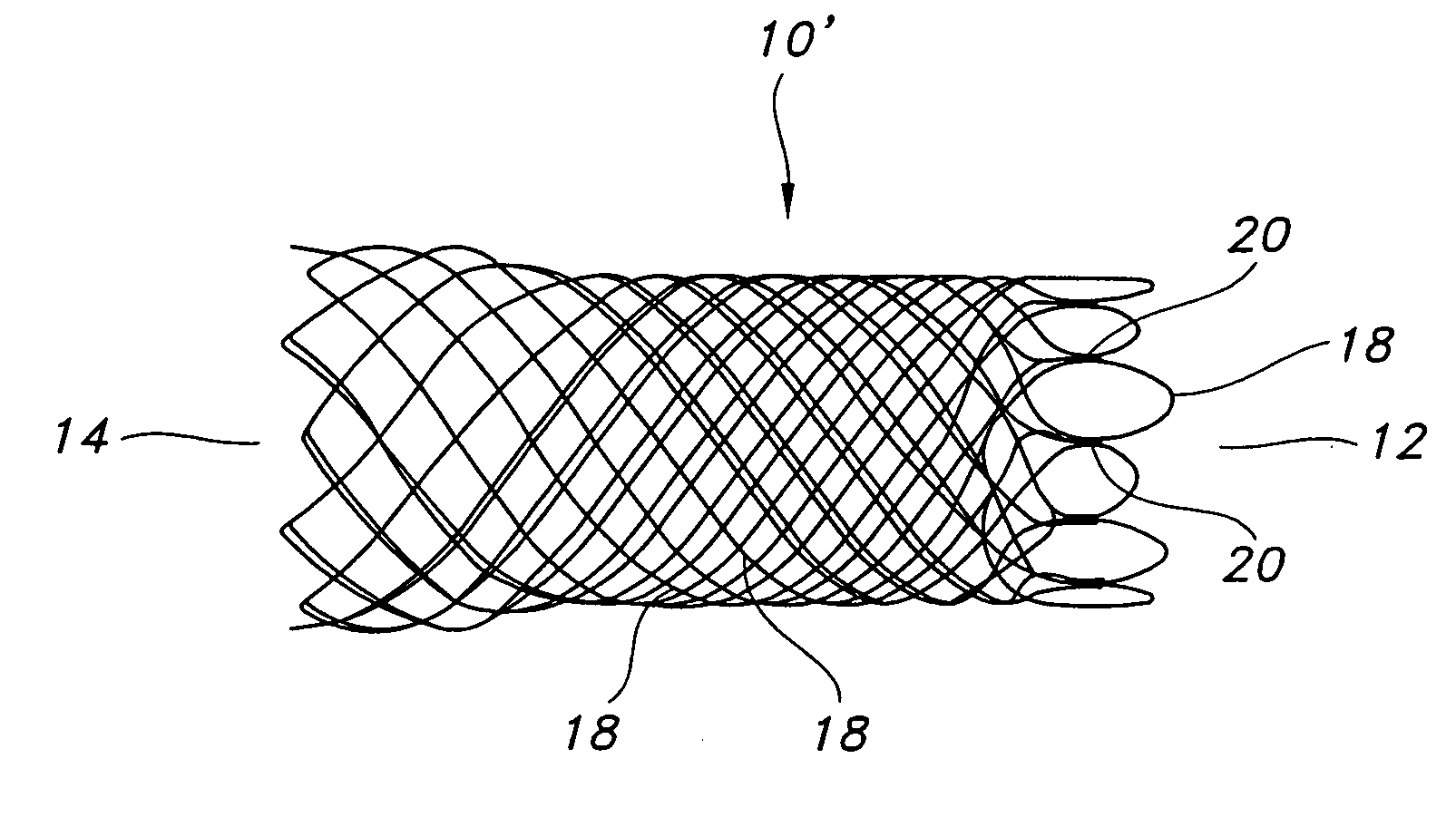

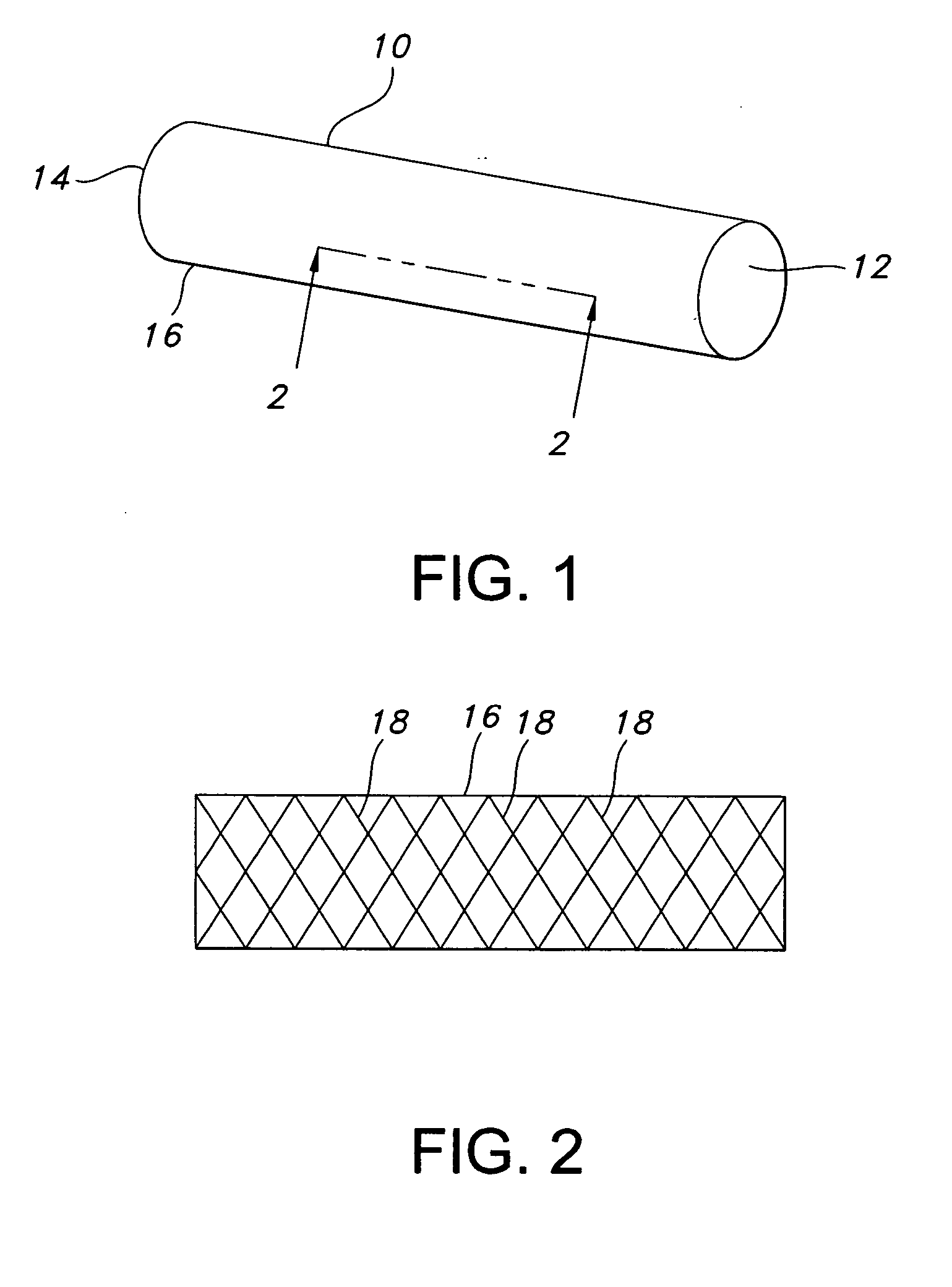

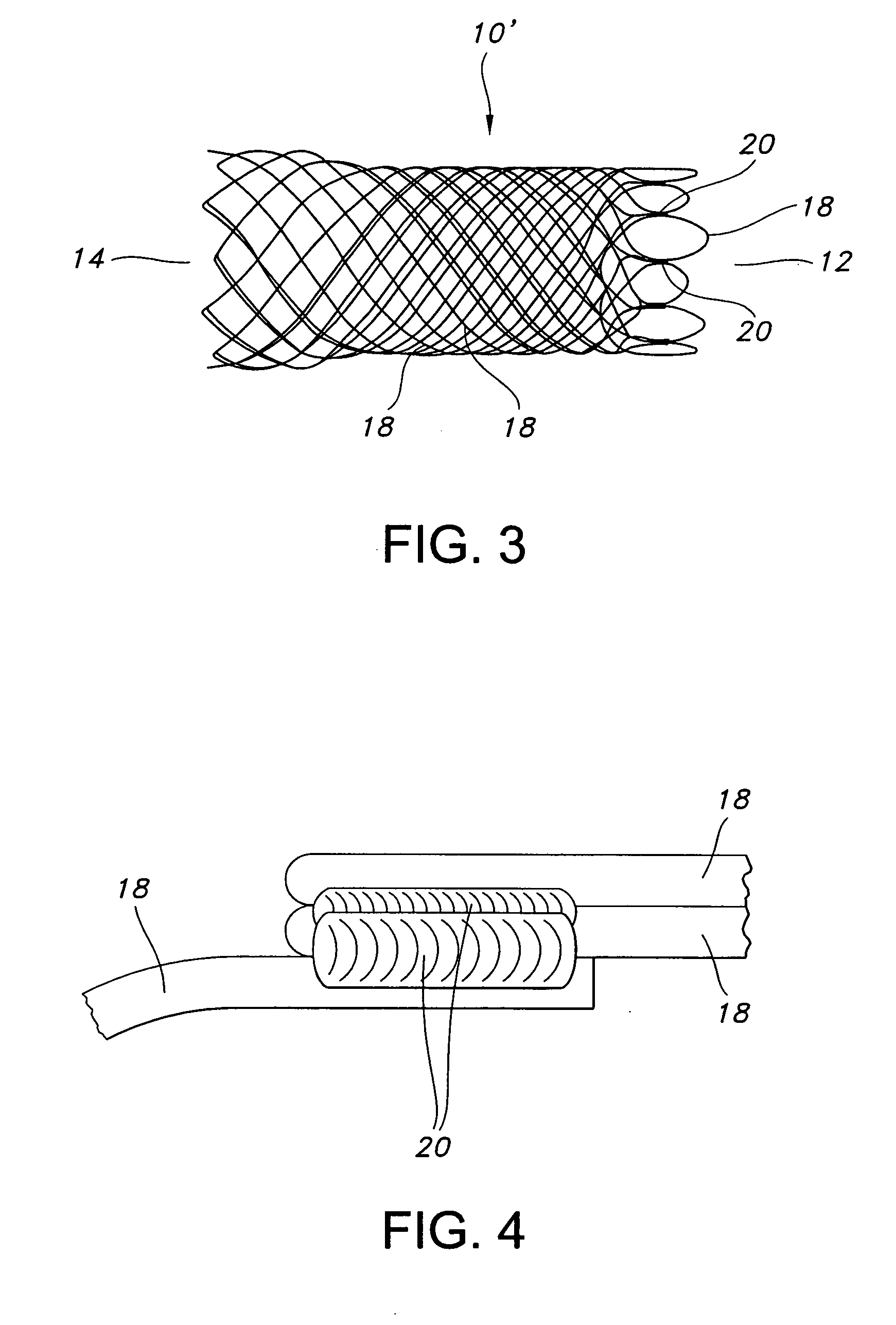

Method for reducing stent weld profiles and a stent having reduced weld

InactiveUS20050256563A1Easy to captureEasy to grabOrnamental textile articlesWelding/cutting auxillary devicesWire rodInsertion stent

A method for making an implantable stent includes the steps of (i) providing a plurality of elongate stent wires; (ii) forming said wires into a hollow tubular structure having opposed first and second open ends; (iii) terminating said wires at the second end; (iv) aligning the wires at the second end into a plurality of mated adjacent wires to define a plurality of abutting regions; (v) welding the mated adjacent wires to one and the other at the abutting regions to define a plurality of welds; and optionally (vi) chemically or electro-chemically removing a portion of the welds. The method may further include the steps of (a) extending at least one of the mated stent wires to provide an extended stent wire; (b) looping the extended stent wire so the extended end abuts a proximal pair of stent wires; and (c) welding the extended and looped wire to the proximal pair of wires. The step of looping may include the forming of the wire into a equilaterally arched loop having an apex, but not having other sharp bends.

Owner:BOSTON SCI SCIMED INC

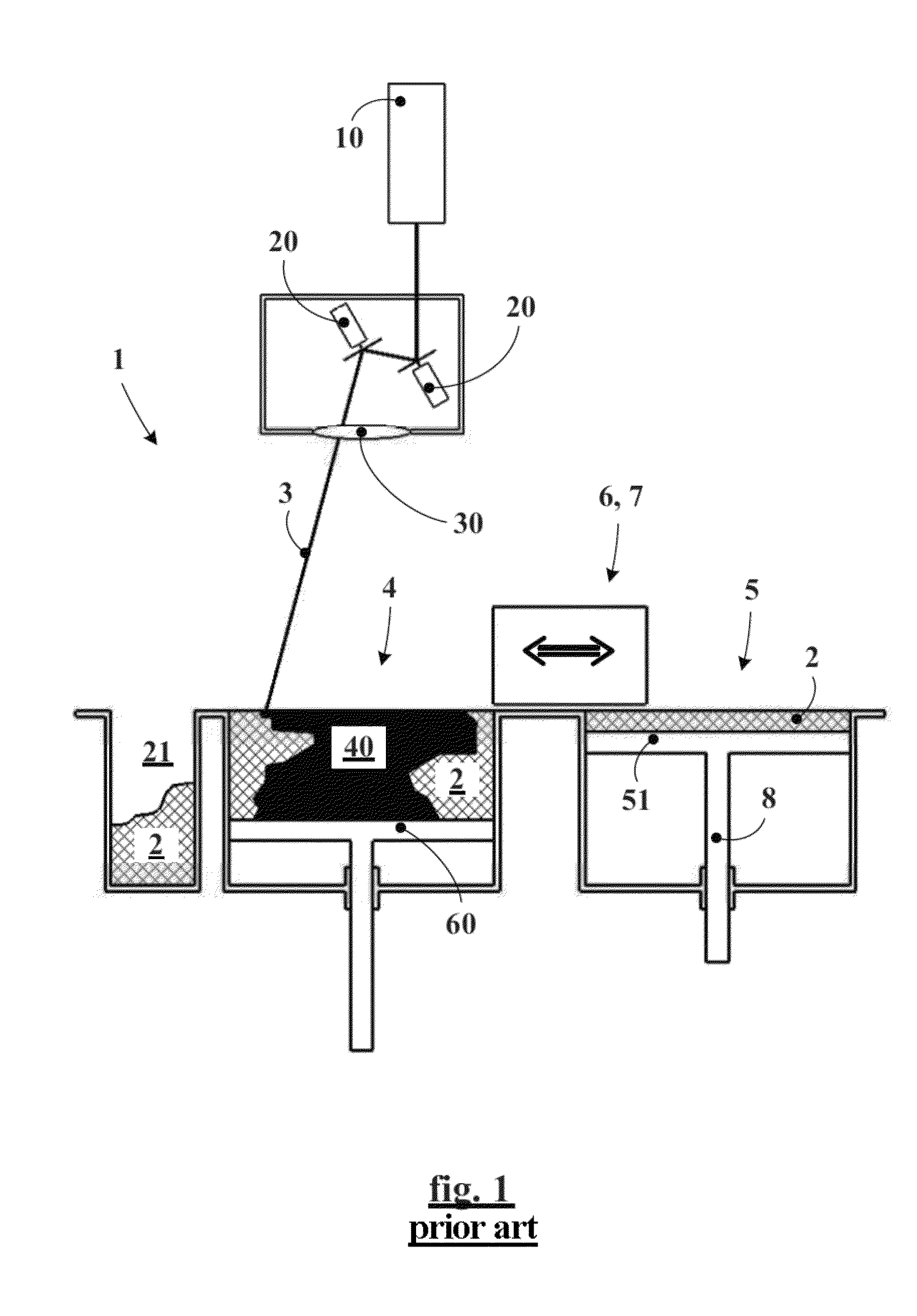

Method and apparatus for producing three-dimensional objects

ActiveUS20120100031A1Equally distributedAdditive manufacturing apparatusIncreasing energy efficiencyHigh energy beamMaterials science

Owner:ARCAM AB

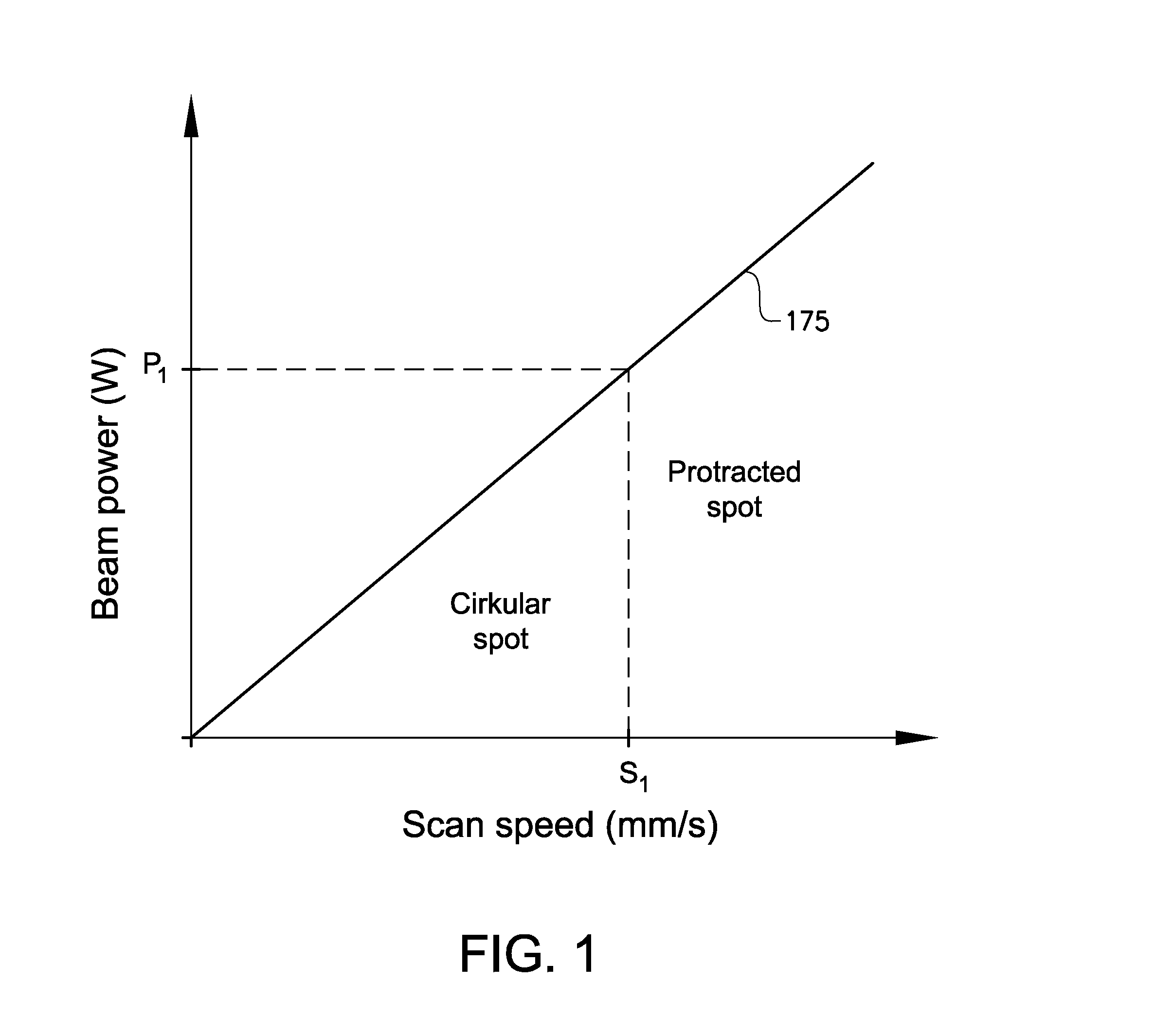

Method for fusing a workpiece

InactiveUS20150283613A1Increase powerSolve the slow scanning speedAdditive manufacturing apparatusAuxillary shaping apparatusEngineeringHigh energy beam

Various embodiments of the present invention relate to a method for welding a workpiece comprising the steps of: making a first weld at a first position on said workpiece with a high energy beam, deflecting the high energy beam with at least one deflection lens for making a second weld at a second position on said workpiece, focusing the high energy beam on said workpiece with at least one focusing lens, shaping the high energy beam on said workpiece with at least one astigmatism lens so that the shape of the high energy beam on said workpiece is longer in a direction parallel to a deflection direction of said high energy beam than in a direction perpendicular to said deflection direction of said high energy beam. The invention is also related to the use of an astigmatism lens and to a method for forming a three dimensional article.

Owner:ARCAM AB

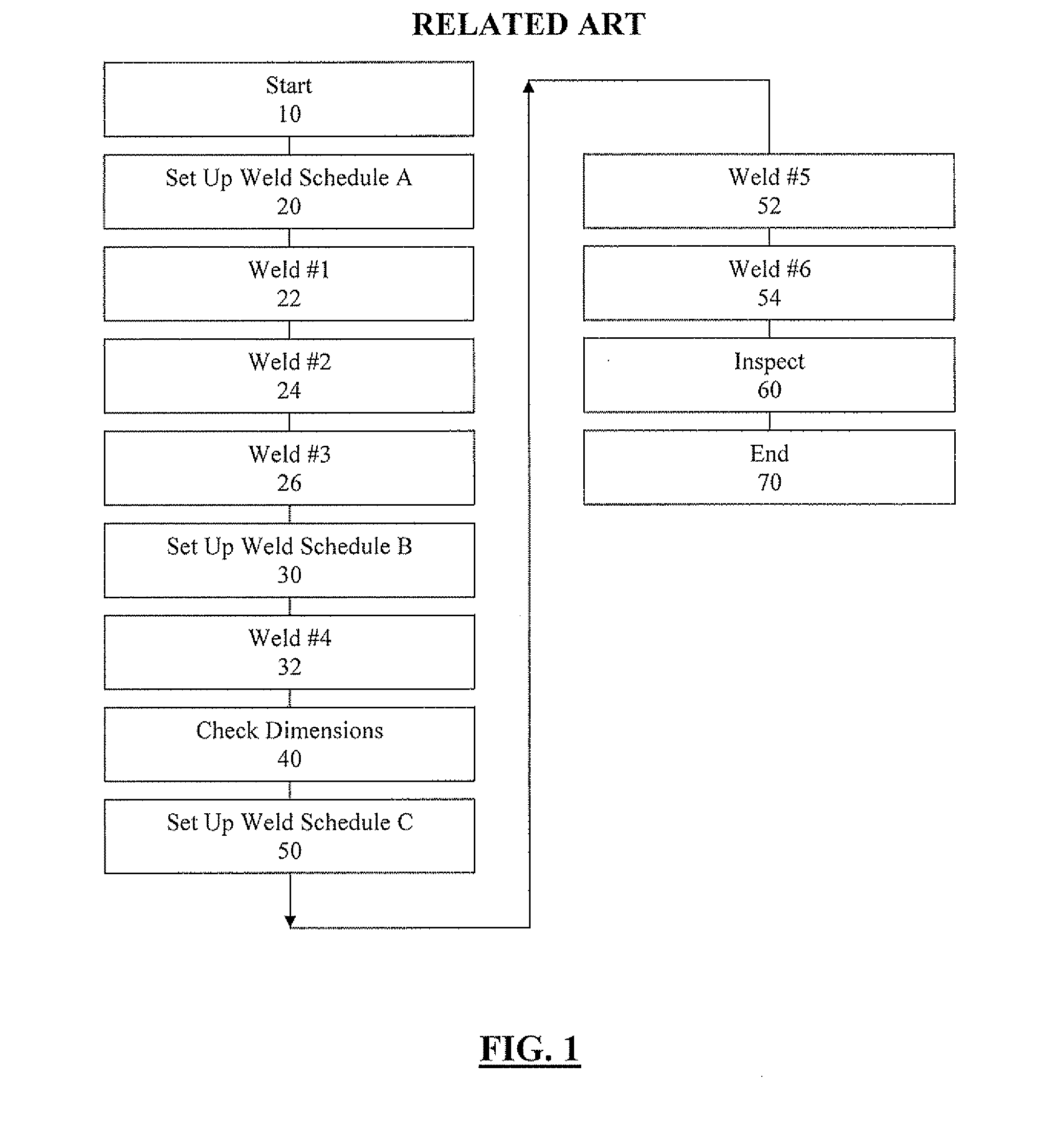

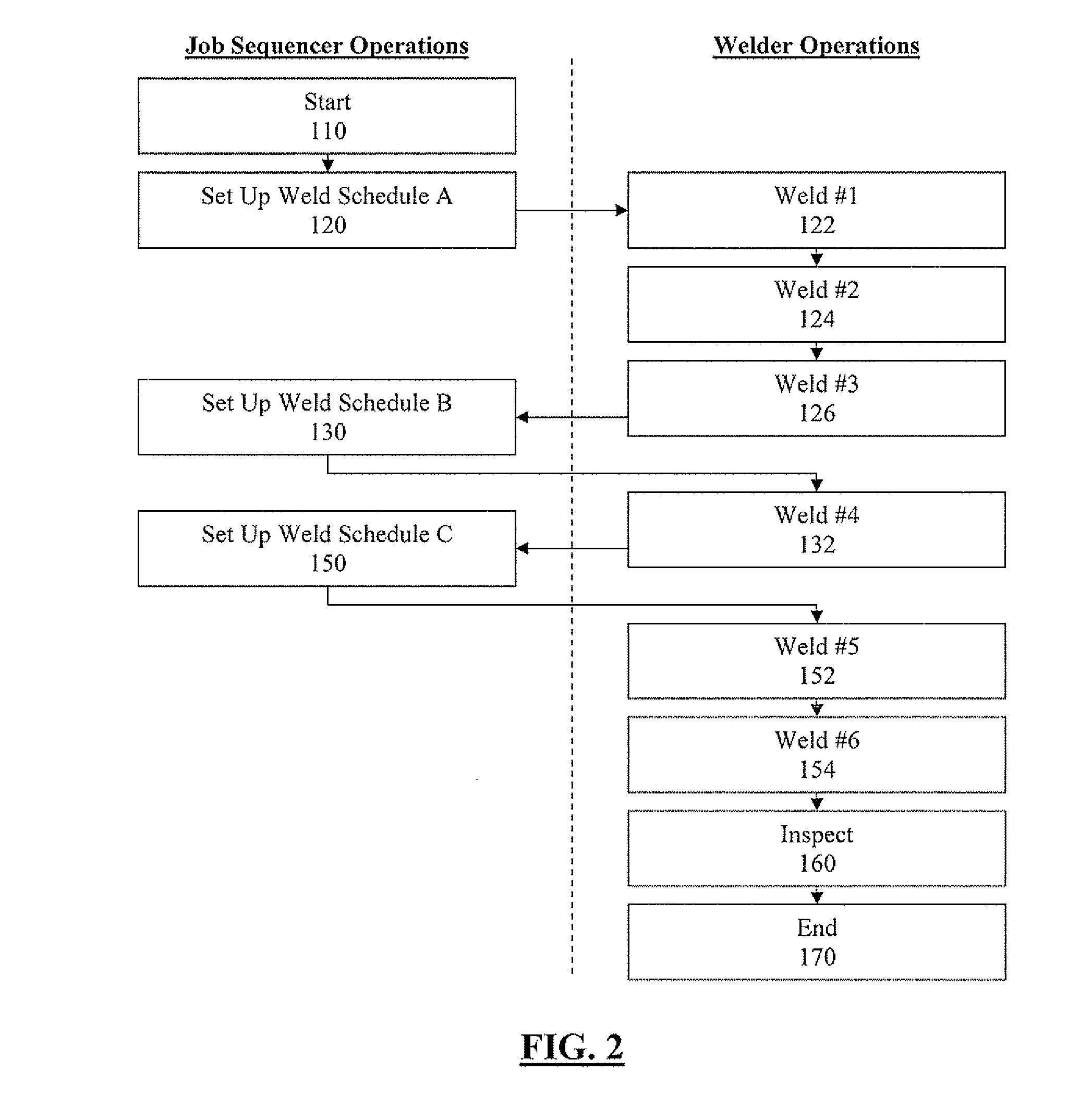

Welding Job Sequencer

A semi-automatic welding work cell, including a welding job sequencer that automatically selects a welding schedule for use by an operator in the semi-automatic welding work cell. The automatic selection may be by way of elapsed time, a detection of welding operations, a detection of the amount of welding wire supplied for the welding operation, or a detection of the amount of energy supplied for the welding operation.

Owner:LINCOLN GLOBAL INC

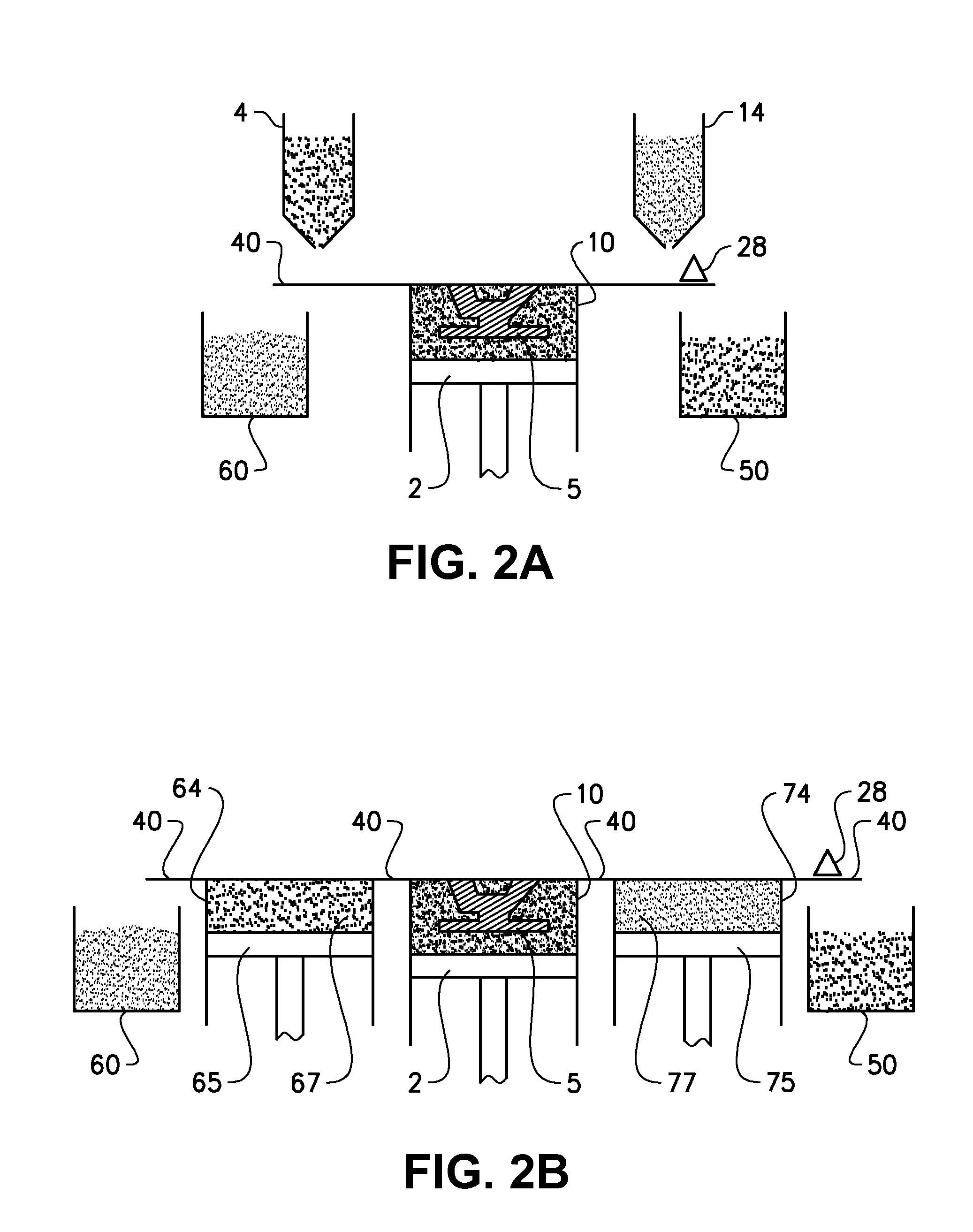

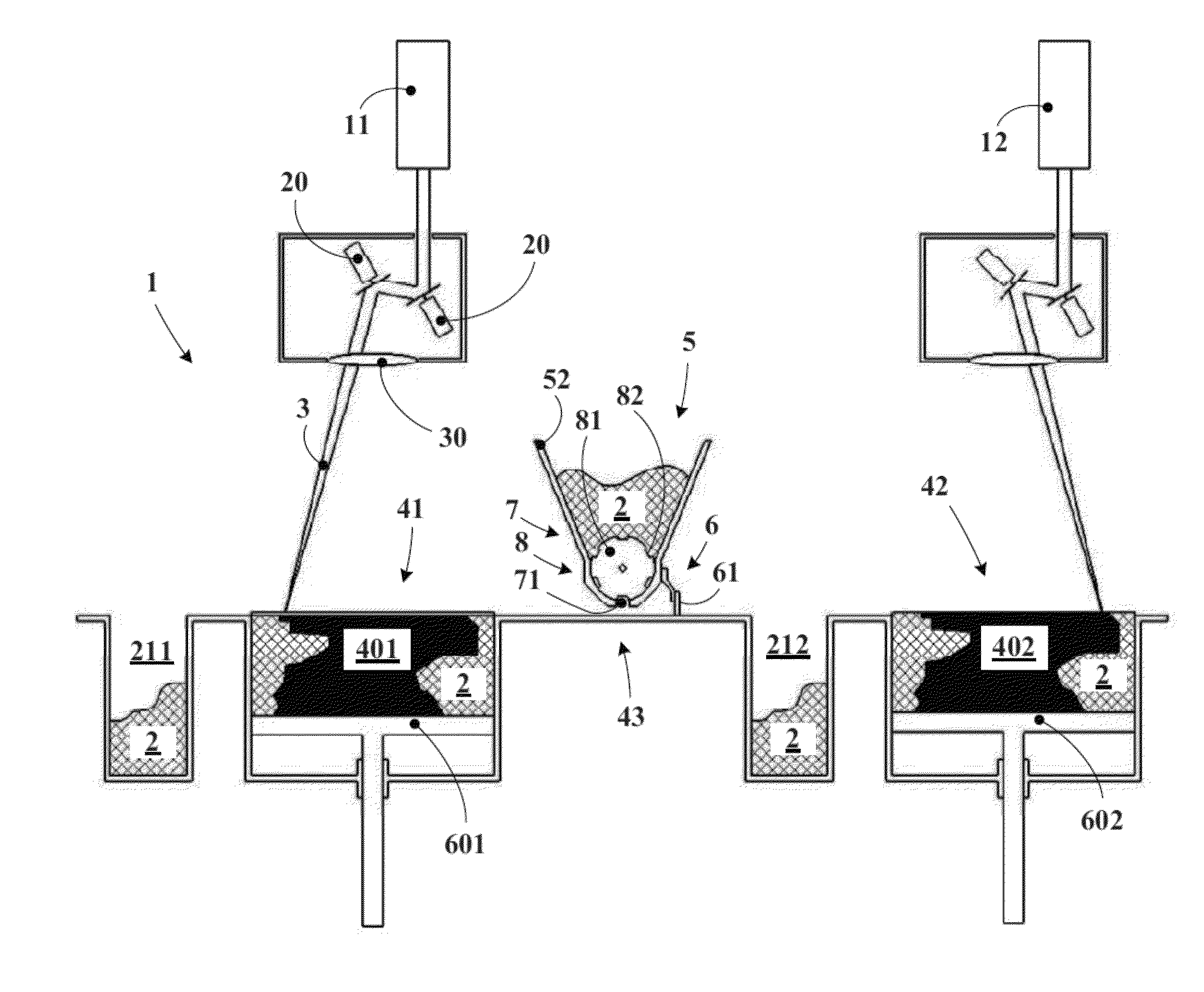

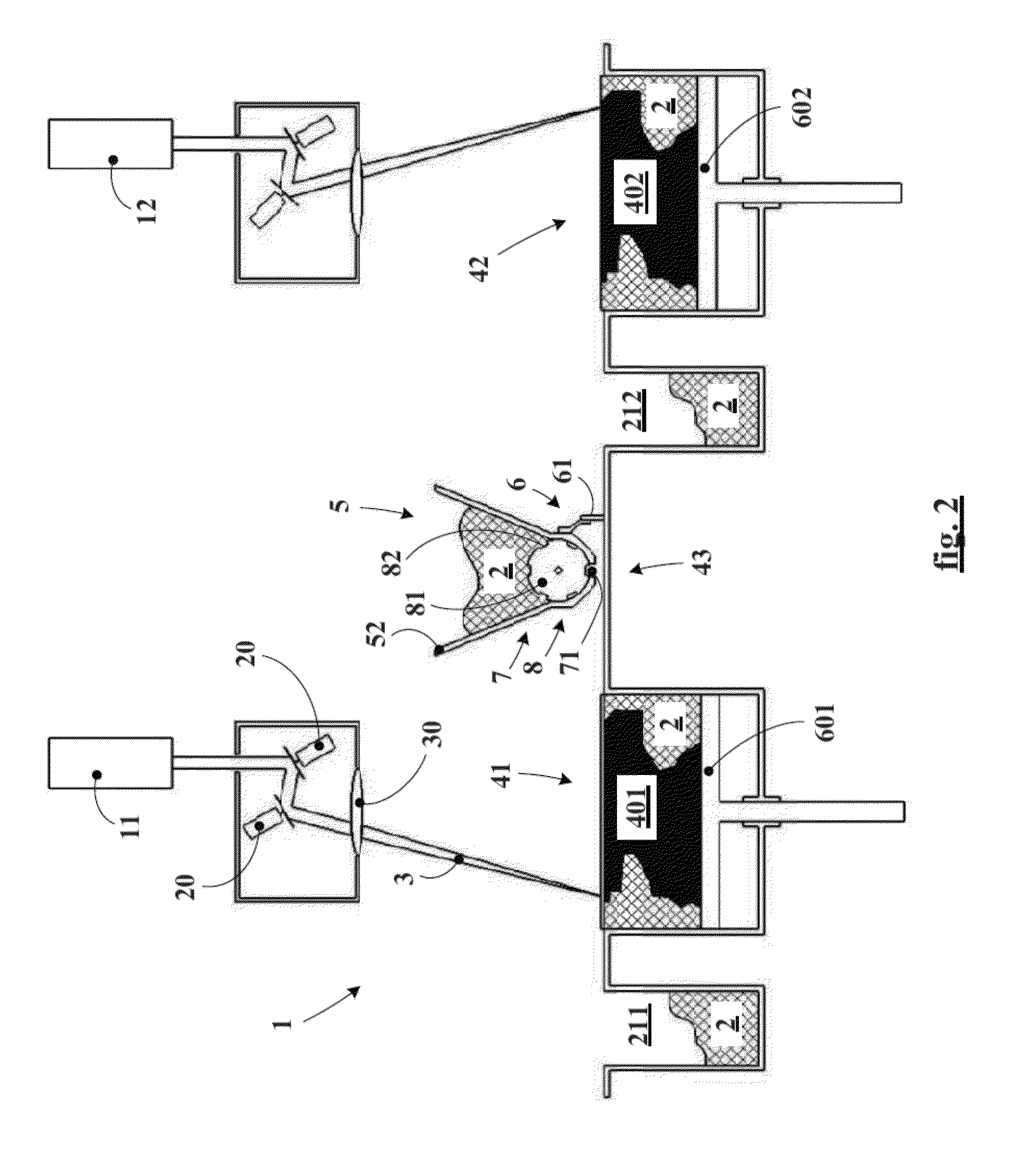

Machine and method for powder-based additive manufacturing

ActiveUS20150139849A1Additive manufacturing apparatusArc welding apparatusWork zoneAdditive layer manufacturing

acting on a powder layer in a working zone, containing a device for layering said powder, said device including:means for storing powder,means for distributing powder that travel over the working zone to distribute powder in a layer having a final thickness for additive manufacturing,feeding means that transfer powder from storage means to distributing means,metering means that control the quantity of powder transferred from storage means to distributing means,said machine being wherein:storage means are positioned higher than the working zone,feeding means utilize gravity,feeding means and the metering means move with the distributing means,the machine has two separate working zones and two separate working trays that move independently of one another,each of the working trays is associated with only one working zone, andthe layering device is common to both working zones.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

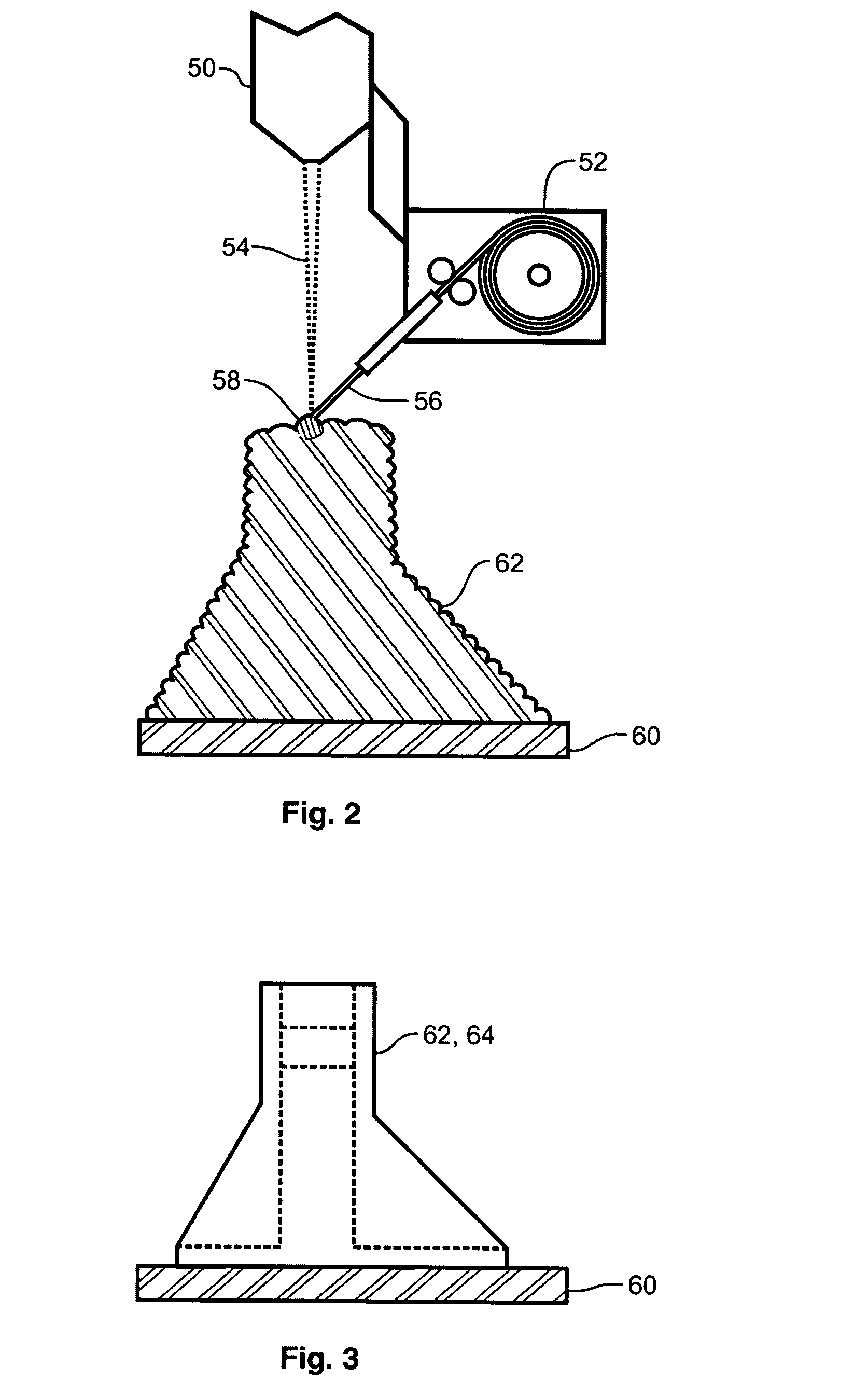

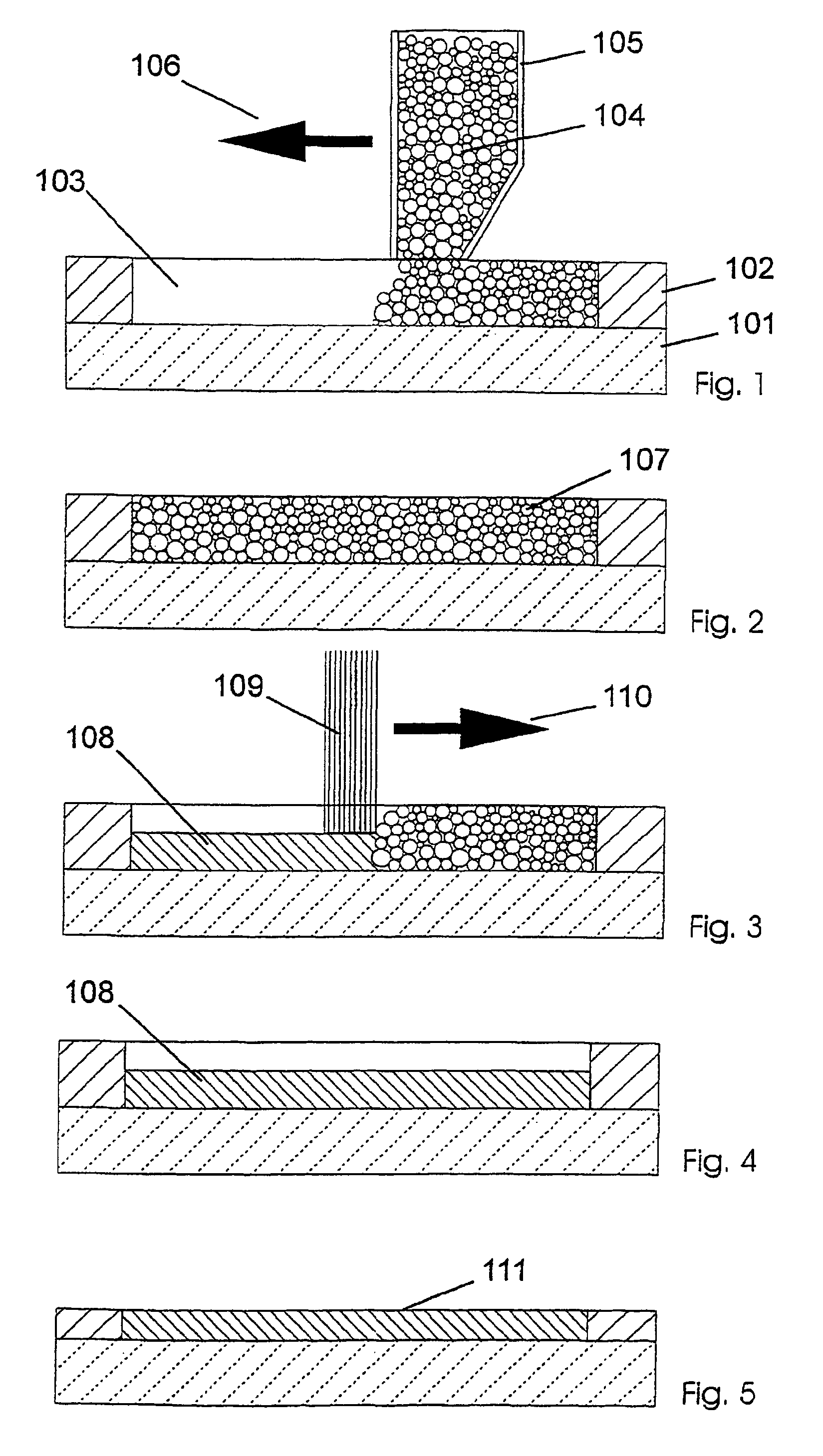

Solid freeform fabrication system and method

A system and method of solid freeform work piece fabrication through layered deposition of feedstock material on a mold structure. An energy beam and feedstock are fed to a feed point adjacent to a mold structure, thereby forming a molten puddle. The feed point is moved relative to the mold structure, thereby advancing the molten puddle of presently fed feedstock and rapidly solidifying previously fed feedstock. The feed point is sequentially advanced within a predetermined geometric volume containing at least a portion of the mold structure, thereby sequentially fusing the feedstock, by action of the advancing molten puddle, into a near net shape work piece built-up upon the mold structure.

Owner:HENN DAVID S

Method and apparatus for forming a three-dimensional article

ActiveUS20140314609A1Improve compactionIncrease flexibilityAdditive manufacturing apparatusElectric discharge tubesMetallurgyDistributor

An apparatus for forming at least one three-dimensional article by fusing parts of a powder bed layer-wise. The apparatus comprising a powder distributor and an energy beam for fusing the powder layer. Said powder distributor comprises a first part being an elongated rod provided movable at a predetermined distance above the powder bed and with its central axis in parallel with a top surface of said work table and second part being a metal foil having at least a first and a second opposite edge portions. Said metal foil is provided between said elongated rod and said work table, said first and second opposite edge portions are attached to said elongated rod so that a distance between said first and second edge portions is smaller than the distance between said first and second edge portions of said metal foil when said metal foil is in a flat position.

Owner:ARCAM AB

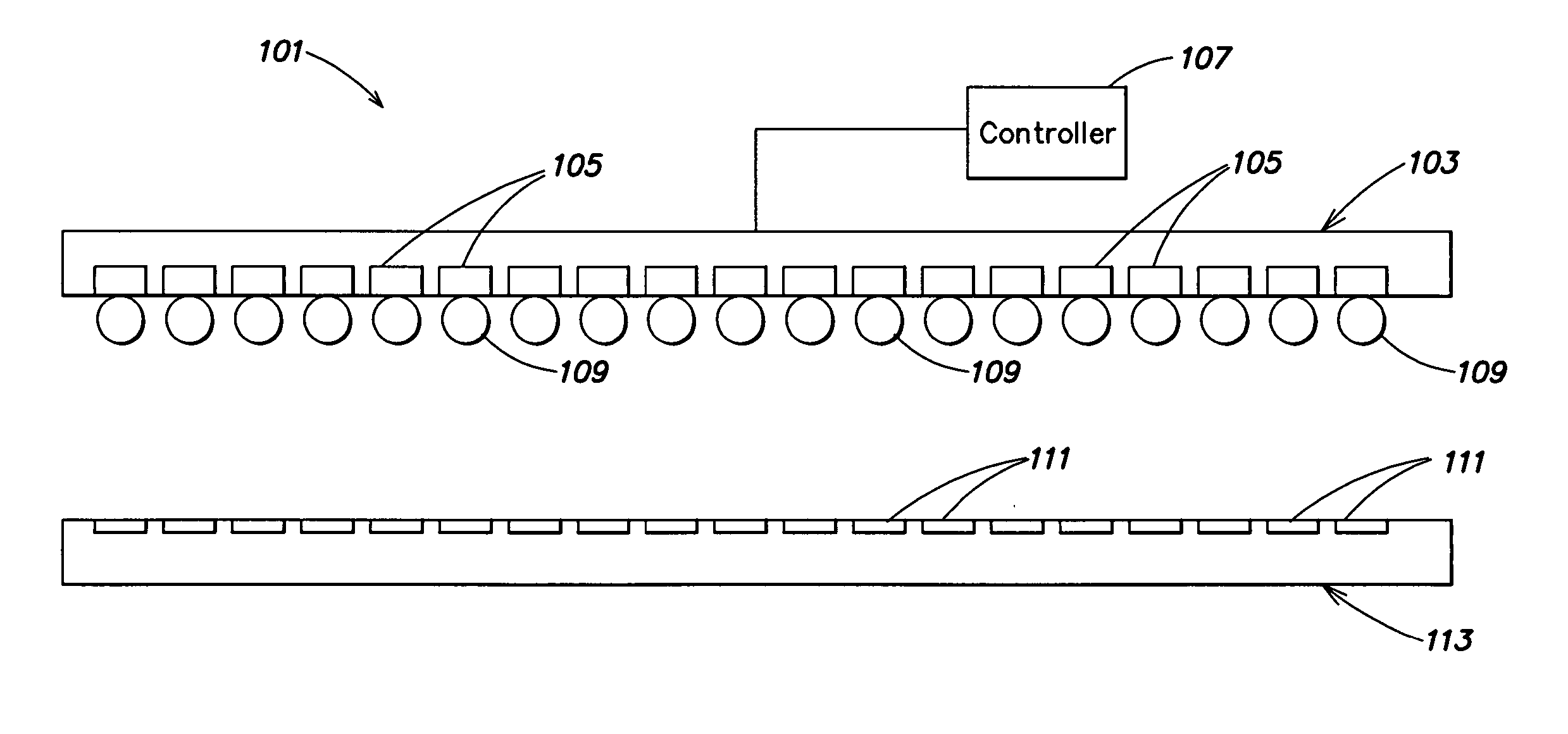

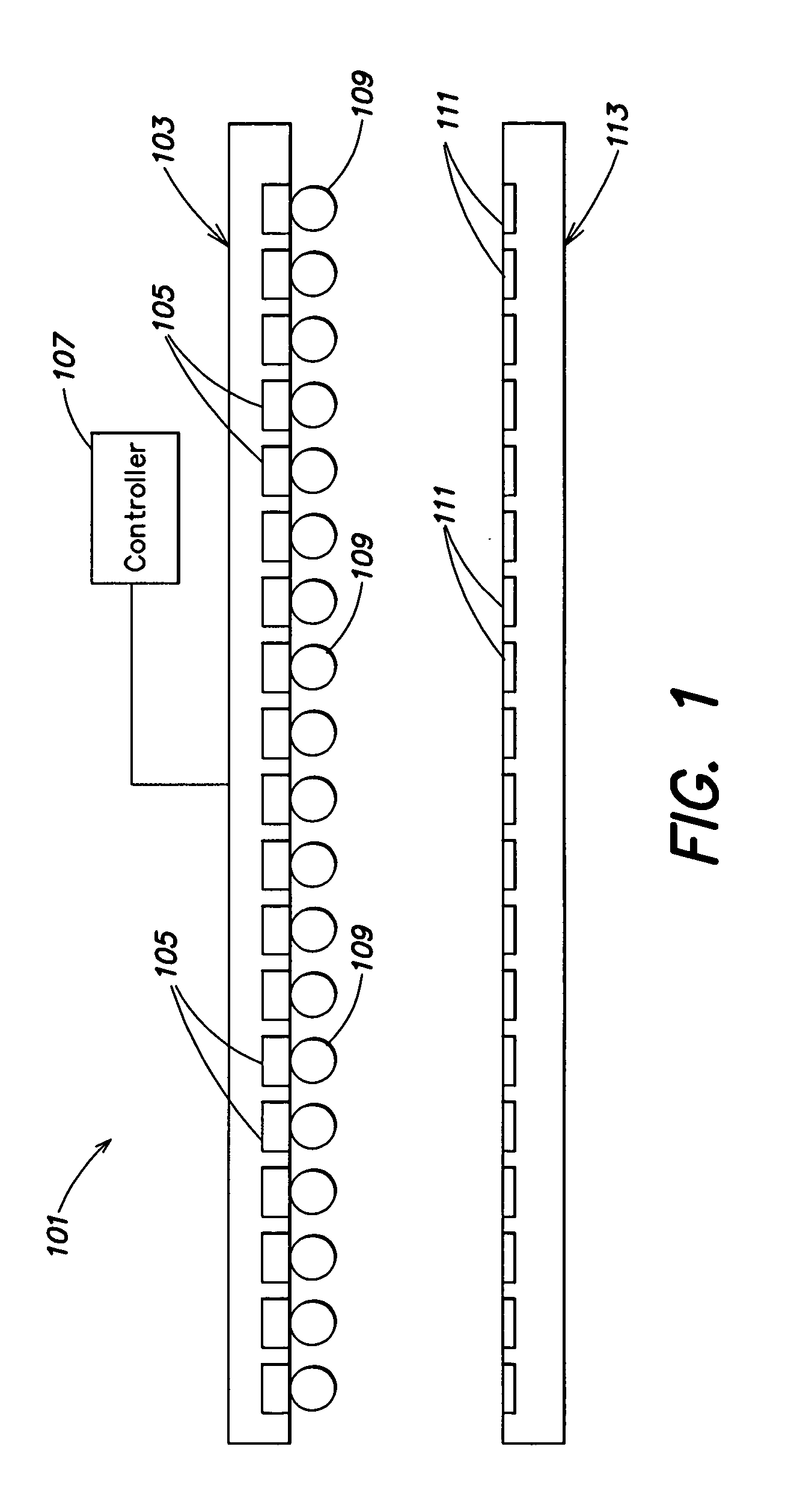

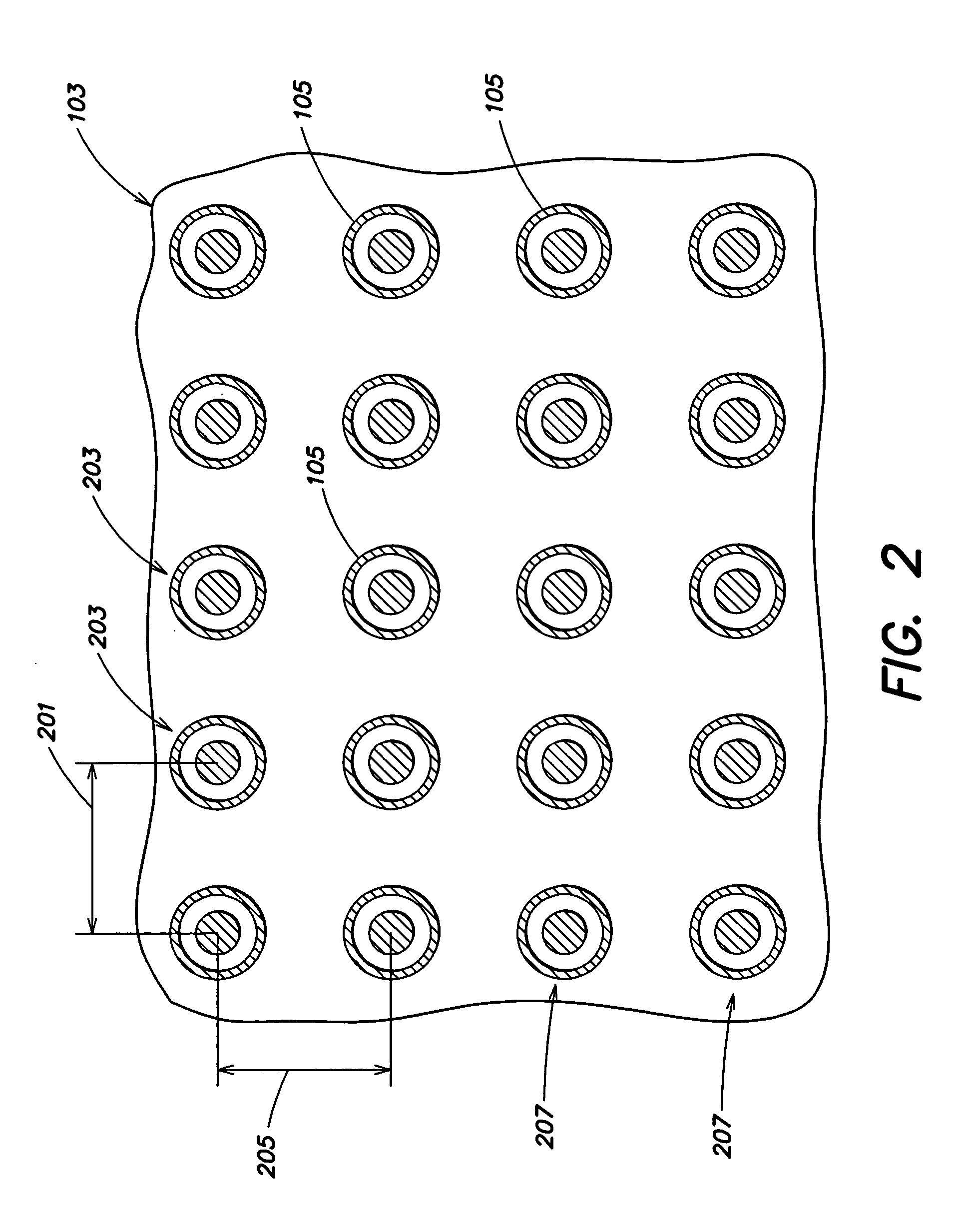

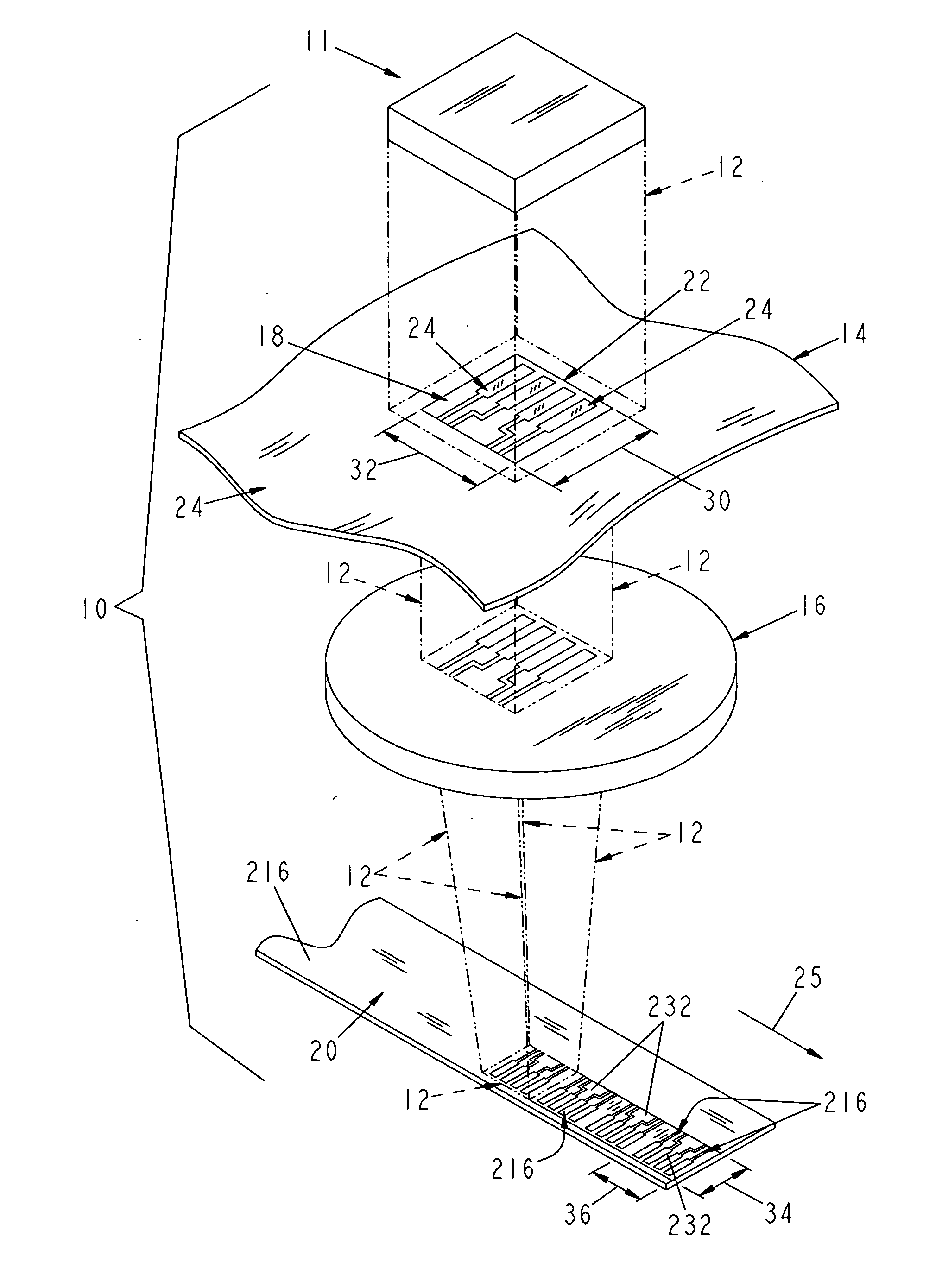

Methods and apparatus for transferring conductive pieces during semiconductor device fabrication

InactiveUS20050232728A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

In a first aspect, a programmable transfer device is provided for transferring conductive pieces to electrode pads of a target substrate. The programmable transfer device includes (1) a transfer substrate; and (2) a plurality of individually addressable electrodes formed on the transfer substrate. Each electrode is adapted to selectively attract and hold a conductive piece during transfer of the conductive piece to an electrode pad of a target substrate. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

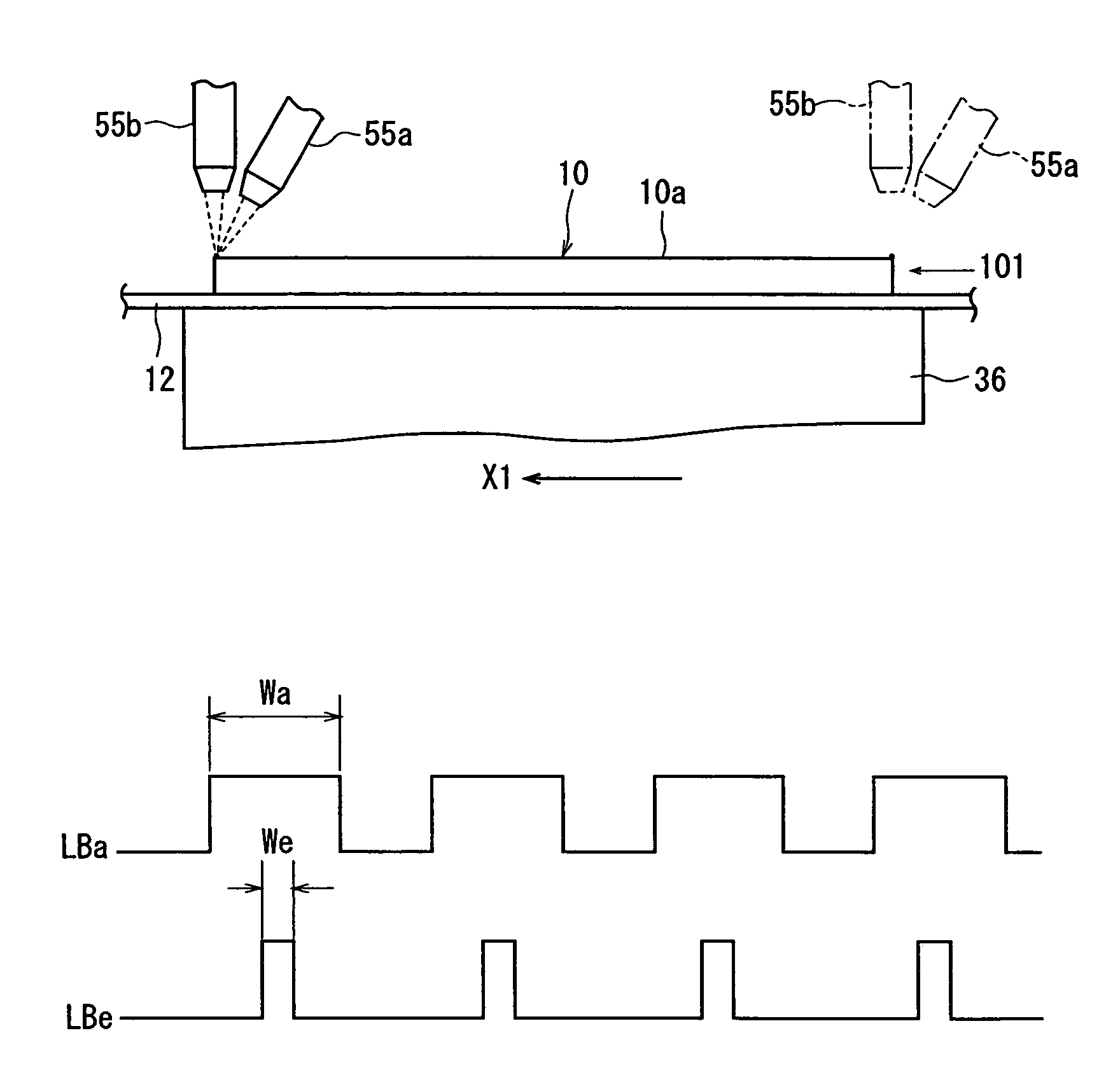

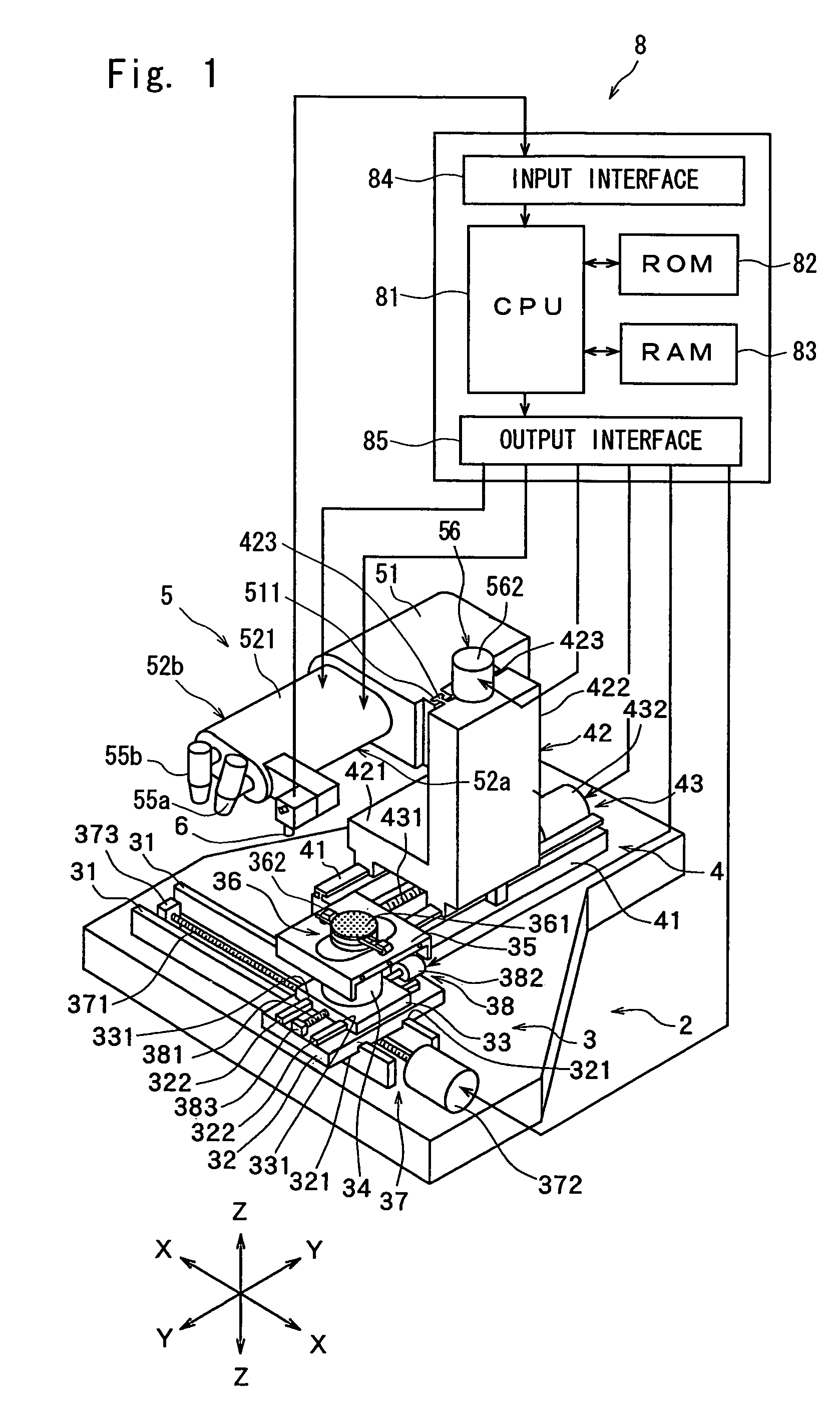

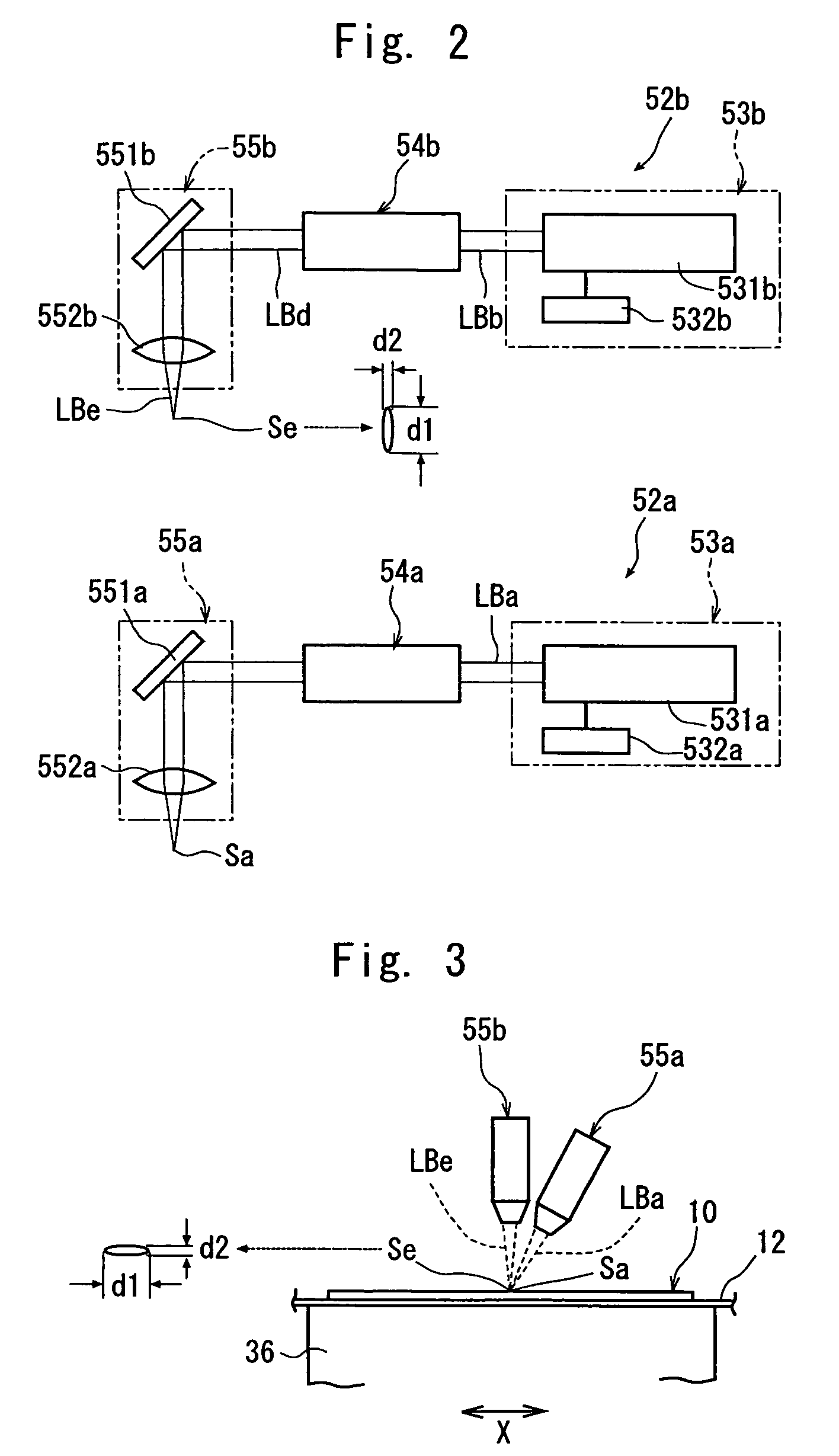

Laser processing apparatus

ActiveUS7473866B2Soften the processing area of the workpieceProcessing area is softenedPhotometrySemiconductor/solid-state device manufacturingLaser processingLight beam

A laser processing apparatus comprising a chuck table, laser beam irradiation means for irradiating a workpiece held on the chuck table with a laser beam, and processing feed means for processing-feeding the chuck table and the laser beam irradiation means relative to each other. The laser beam irradiation means includes first laser beam irradiation means for throwing a first pulsed laser beam having a wavelength in the intermediate-infrared radiation region, and second laser beam irradiation means for throwing a second pulsed laser beam having a wavelength in the ultraviolet radiation region. The first laser beam irradiation means and the second laser beam irradiation means are set such that at least a part, in the processing feed direction, of the focus spot of the second pulsed laser beam overlaps the focus spot of the first pulsed laser beam.

Owner:DISCO CORP

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS9079248B2High resolutionHigh pressure levelAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedImage resolution

Owner:ARCAM AB

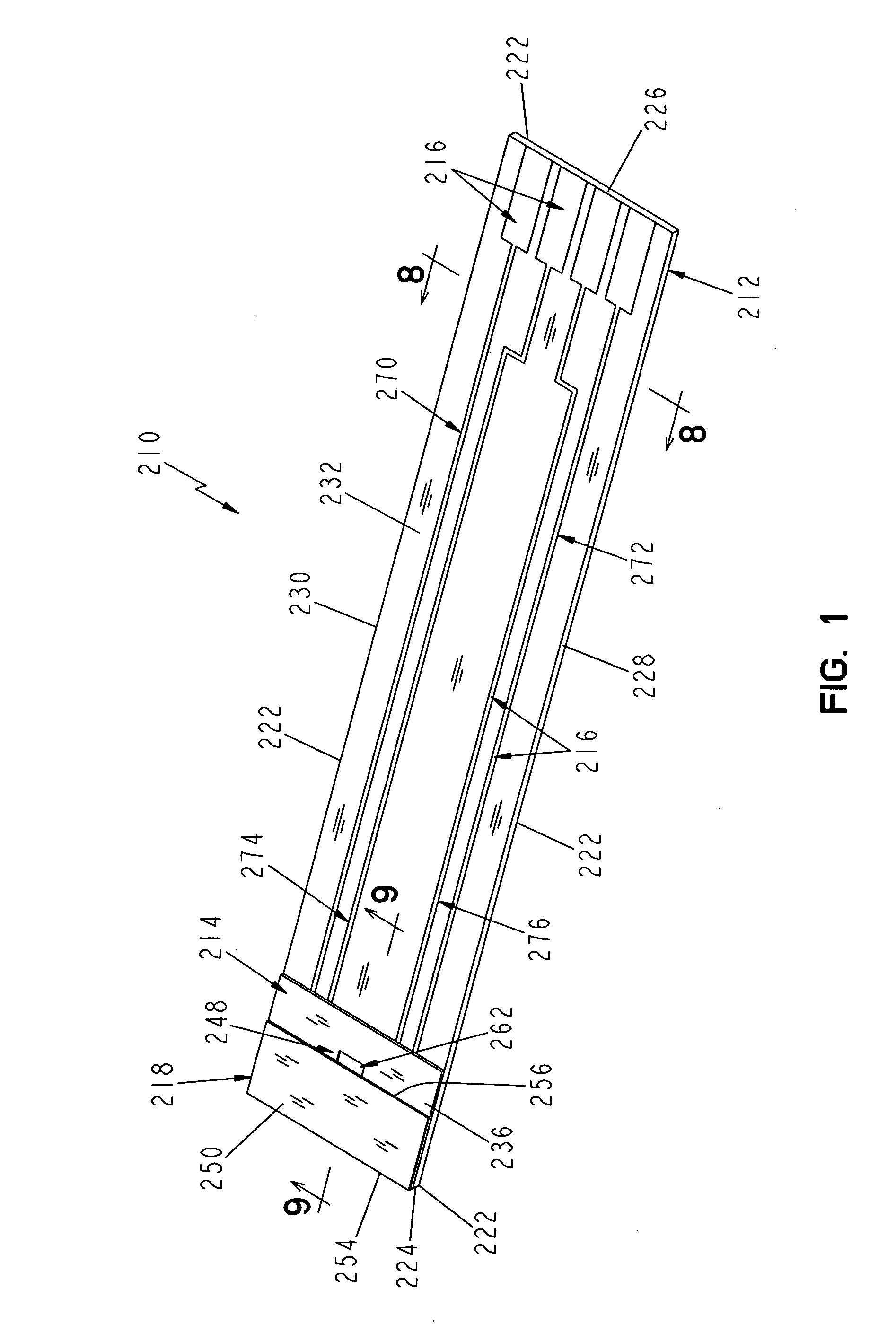

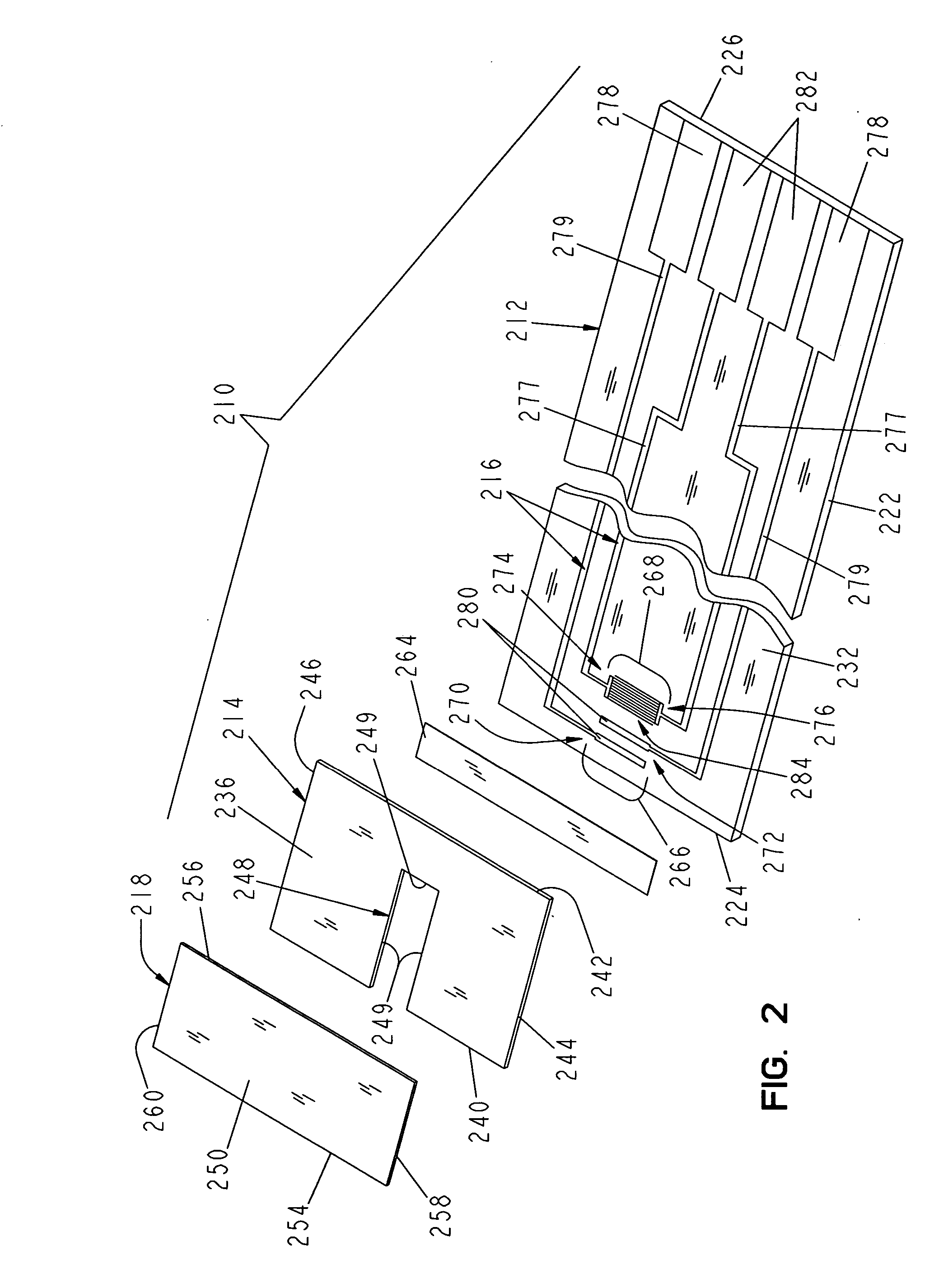

Method of making a biosensor

InactiveUS20060200982A1Line/current collector detailsMicrobiological testing/measurementConductive materialsEngineering

A method of making a biosensor is provided. The method includes providing an electrically conductive material on a base and partially removing the conductive material using laser ablation from the base so that less than 90% of the conductive material remains on the base and at least one electrode pattern is formed from the conductive material. The at least one electrode pattern has an edge extending between two points. A standard deviation of the edge from a line extending between two points is less than about 6 μm along the length of the edge.

Owner:ROCHE DIABETES CARE INC +1

Nanopore arrays and sequencing devices and methods thereof

Provided are devices comprising one or more nanoscale pores for use in, inter alia, analyzing various biological molecules. Also provided are methods for the fabrication of nanoscale pores in solid-state substrates, methods for functionalizing nanopores in solid-state substrates, and methods for sequencing polymers using devices containing nanoscale pores.

Owner:TRUSTEES OF BOSTON UNIV

Cnt-based resistive heating for deicing composite structures

ActiveUS20110024409A1Prevent freezingInhibition formationMaterial nanotechnologyLayered productsFiberCarbon nanotube

A composite structure includes a matrix material and a carbon nanotube (CNT)-infused fiber material that includes a plurality of carbon nanotubes (CNTs) infused to a fiber material. The CNT-infused fiber material is disposed throughout a portion of the matrix material. The composite structure is adapted for application of a current through the CNT-infused fiber material to provide heating of the composite structure. A heating element includes a CNT-infused fiber material includes a plurality of CNTs infused to a fiber material. The CNT-infused fiber material is of sufficient proportions to provide heating to a structure in need thereof.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

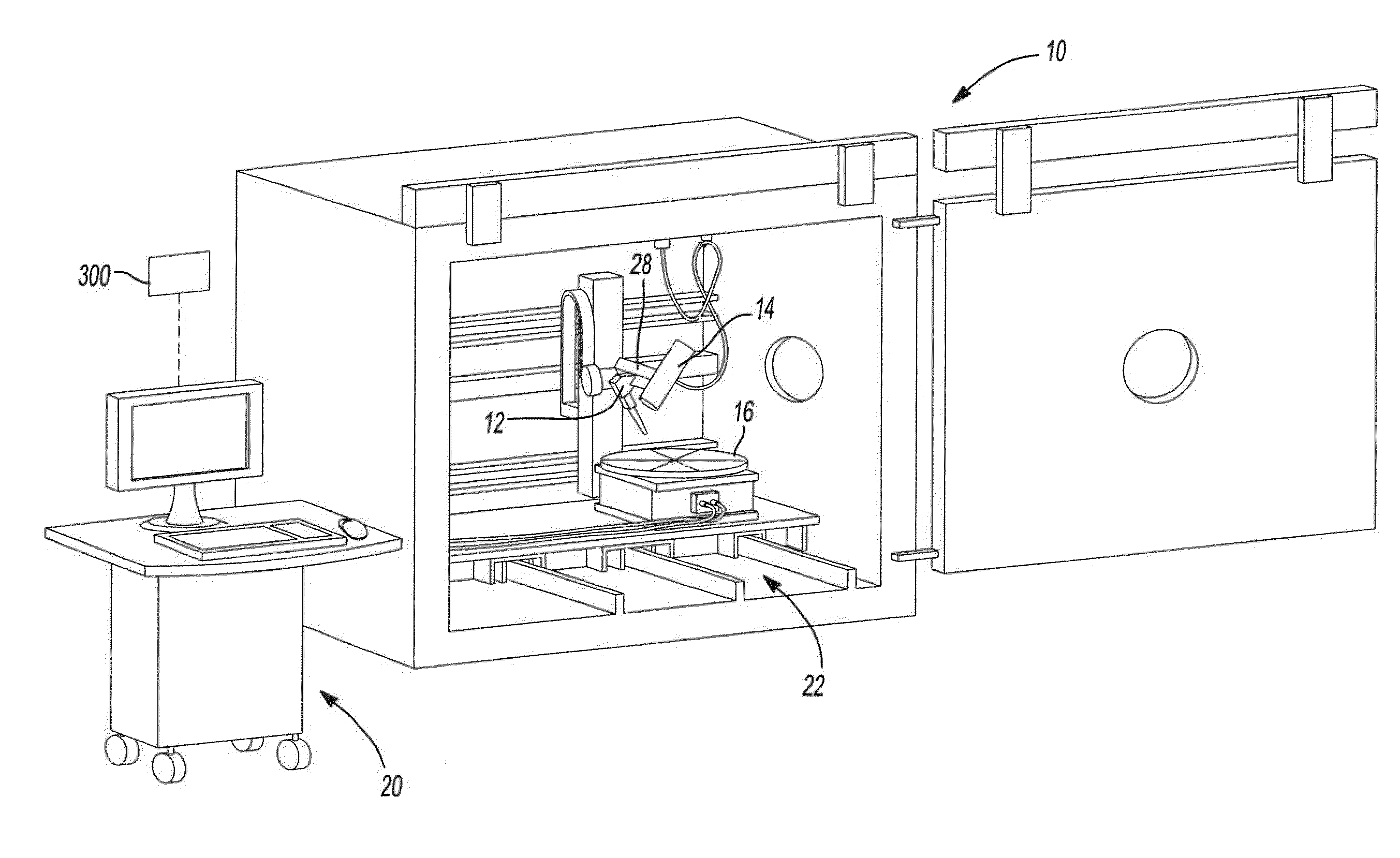

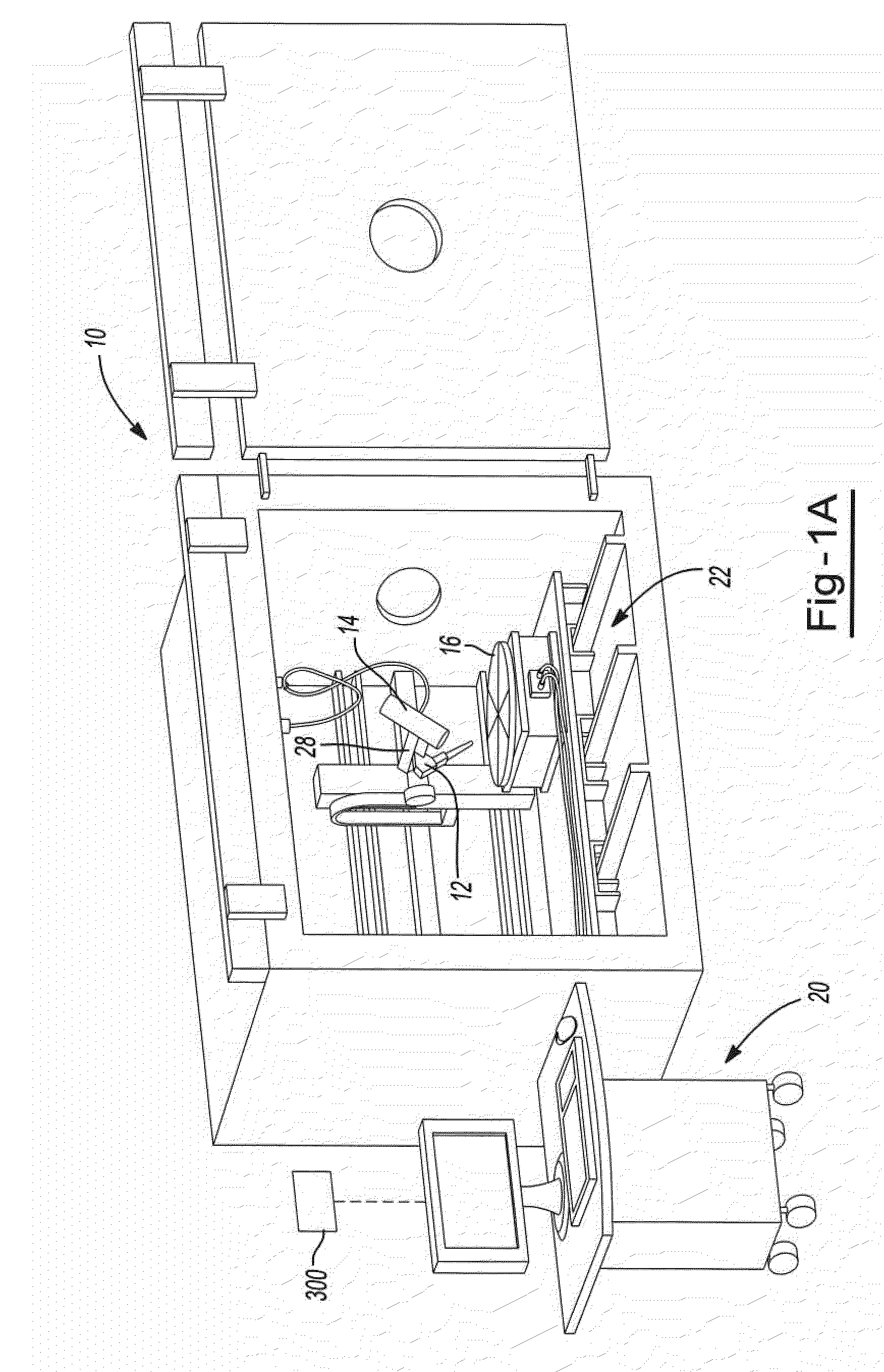

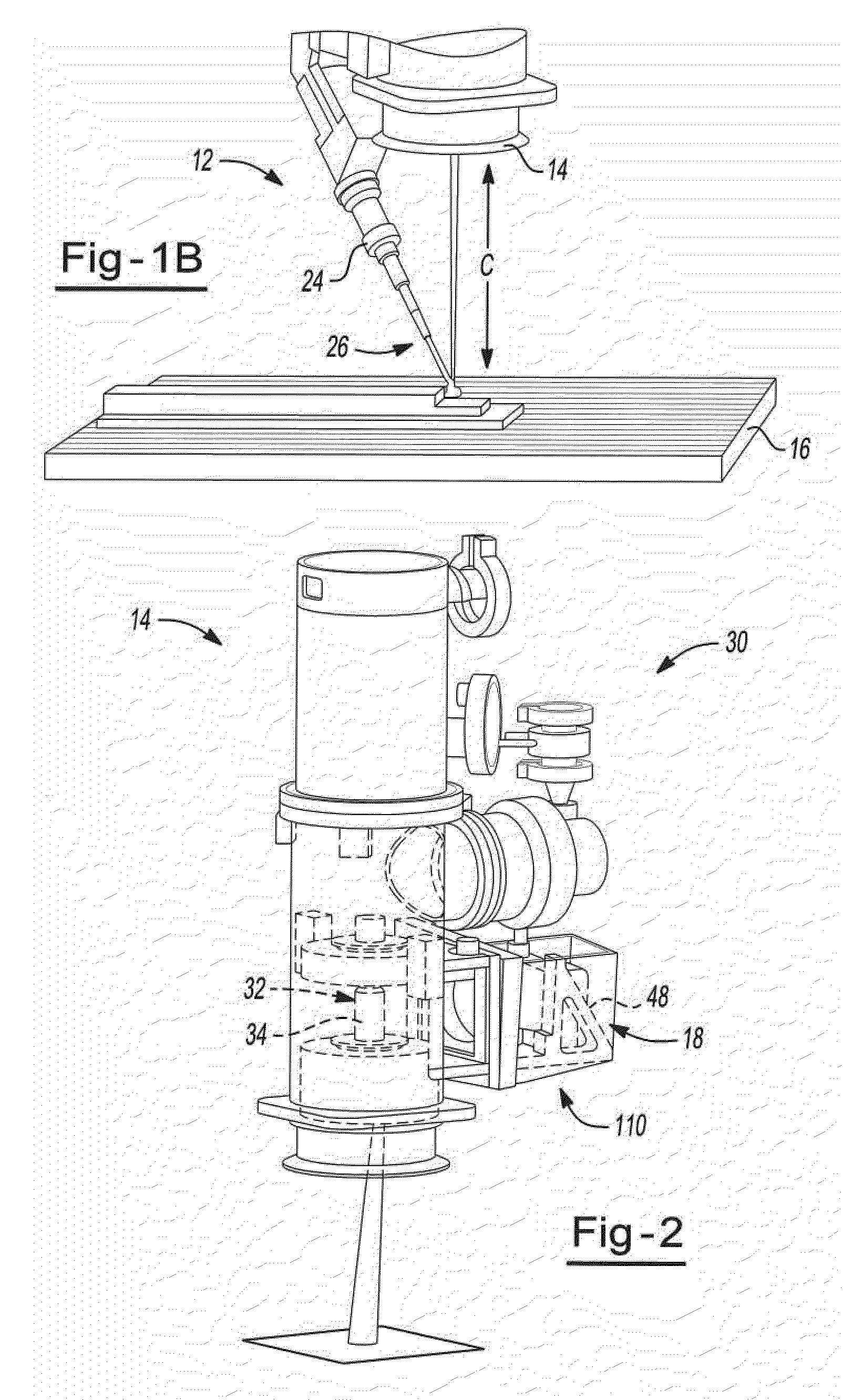

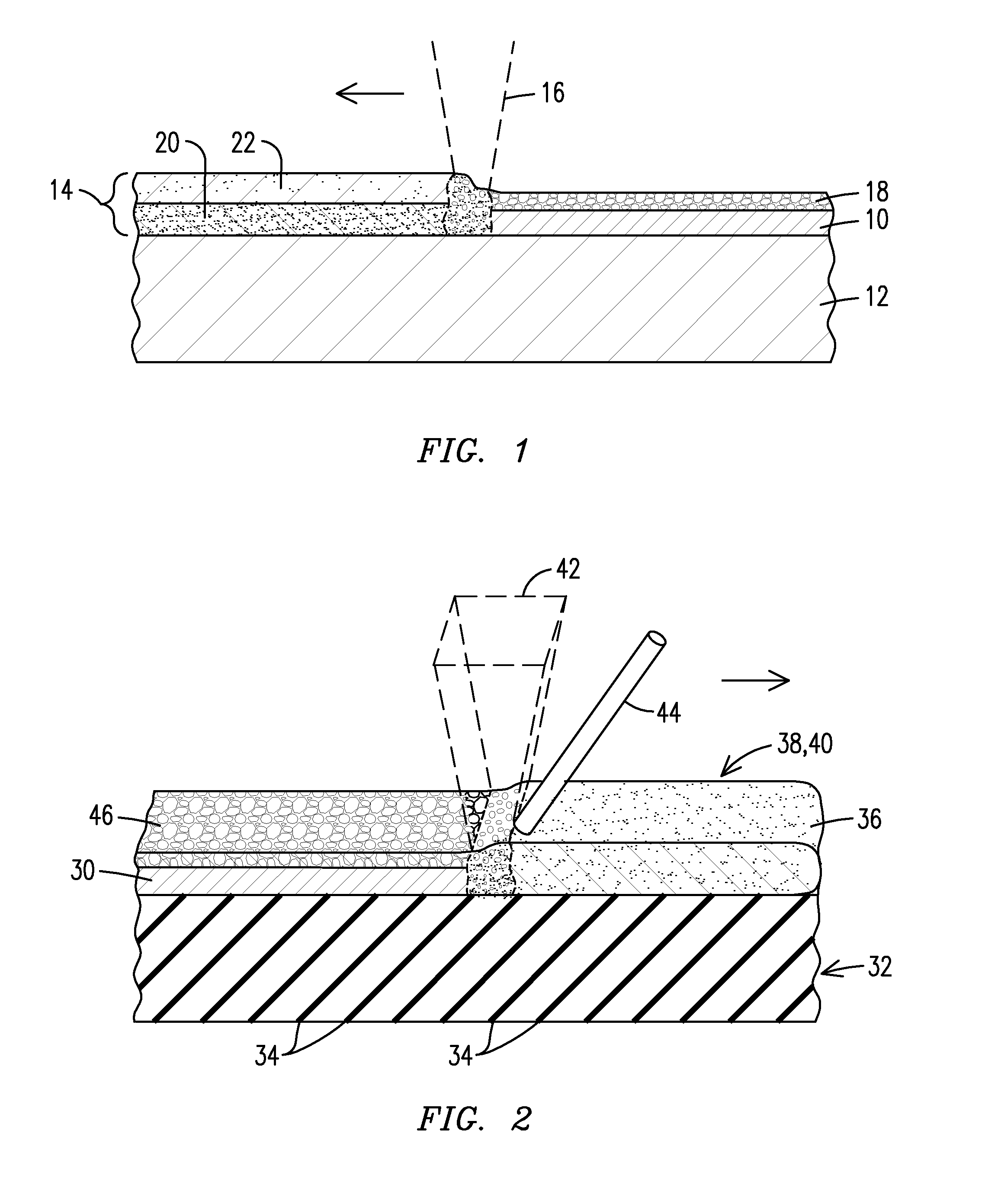

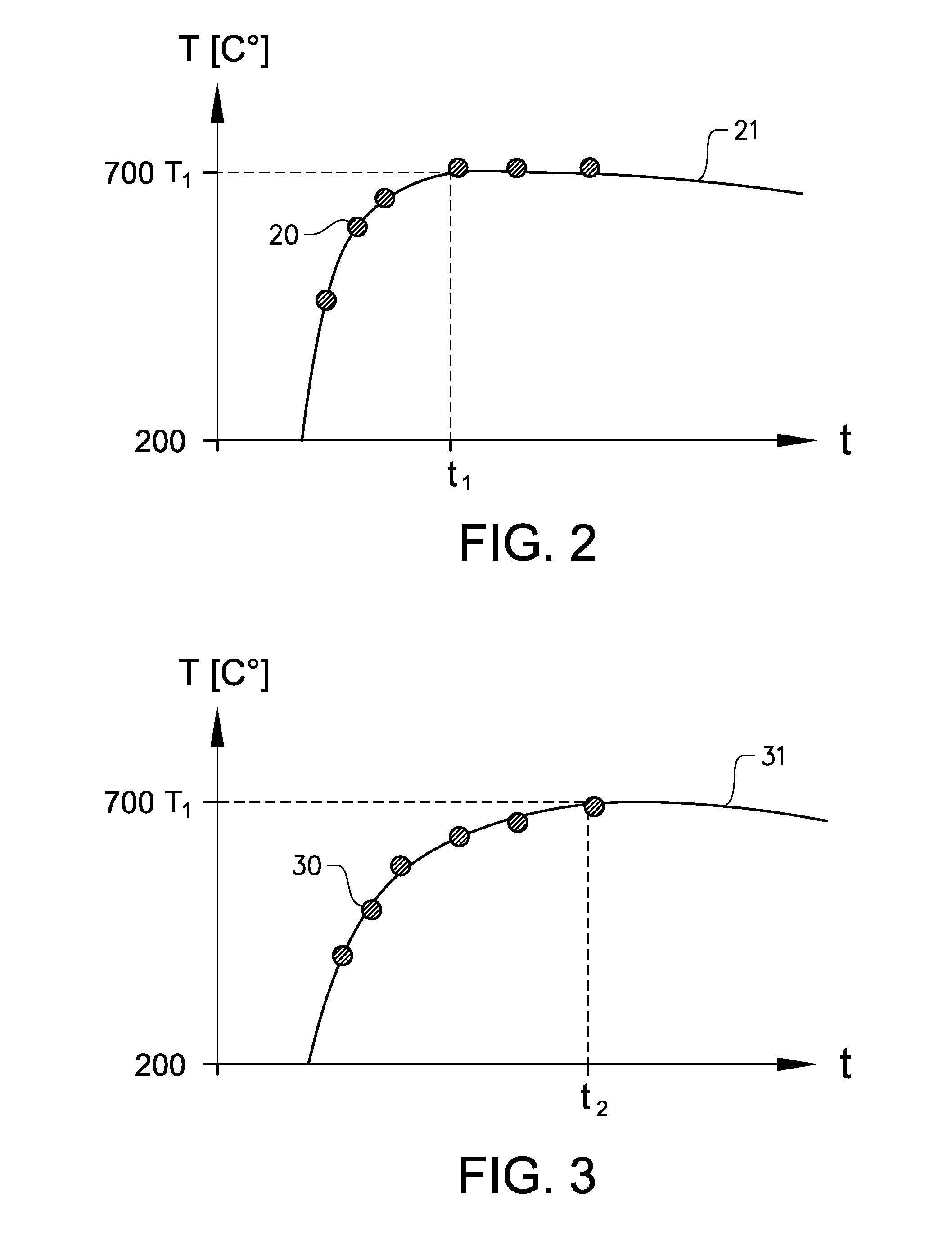

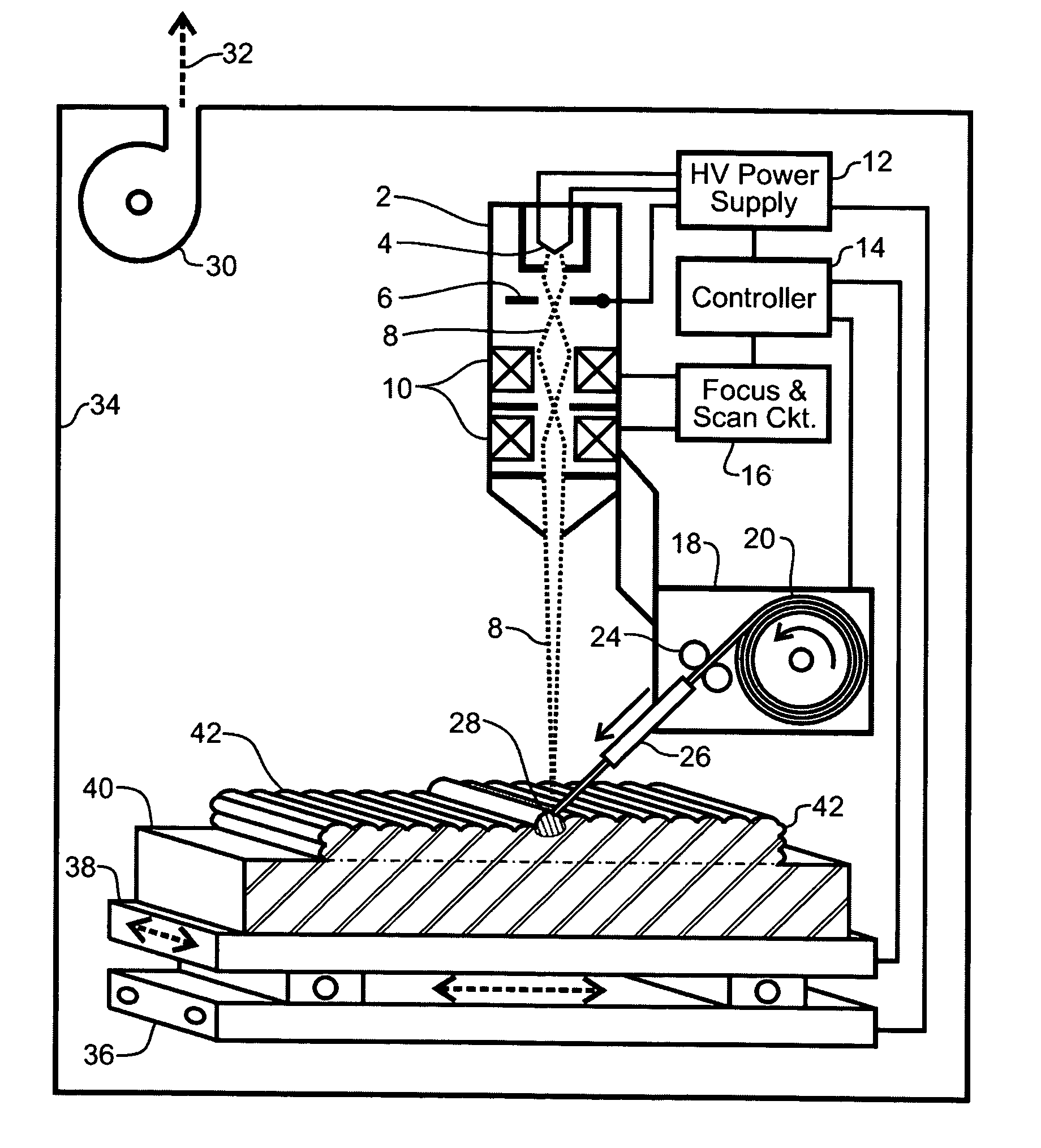

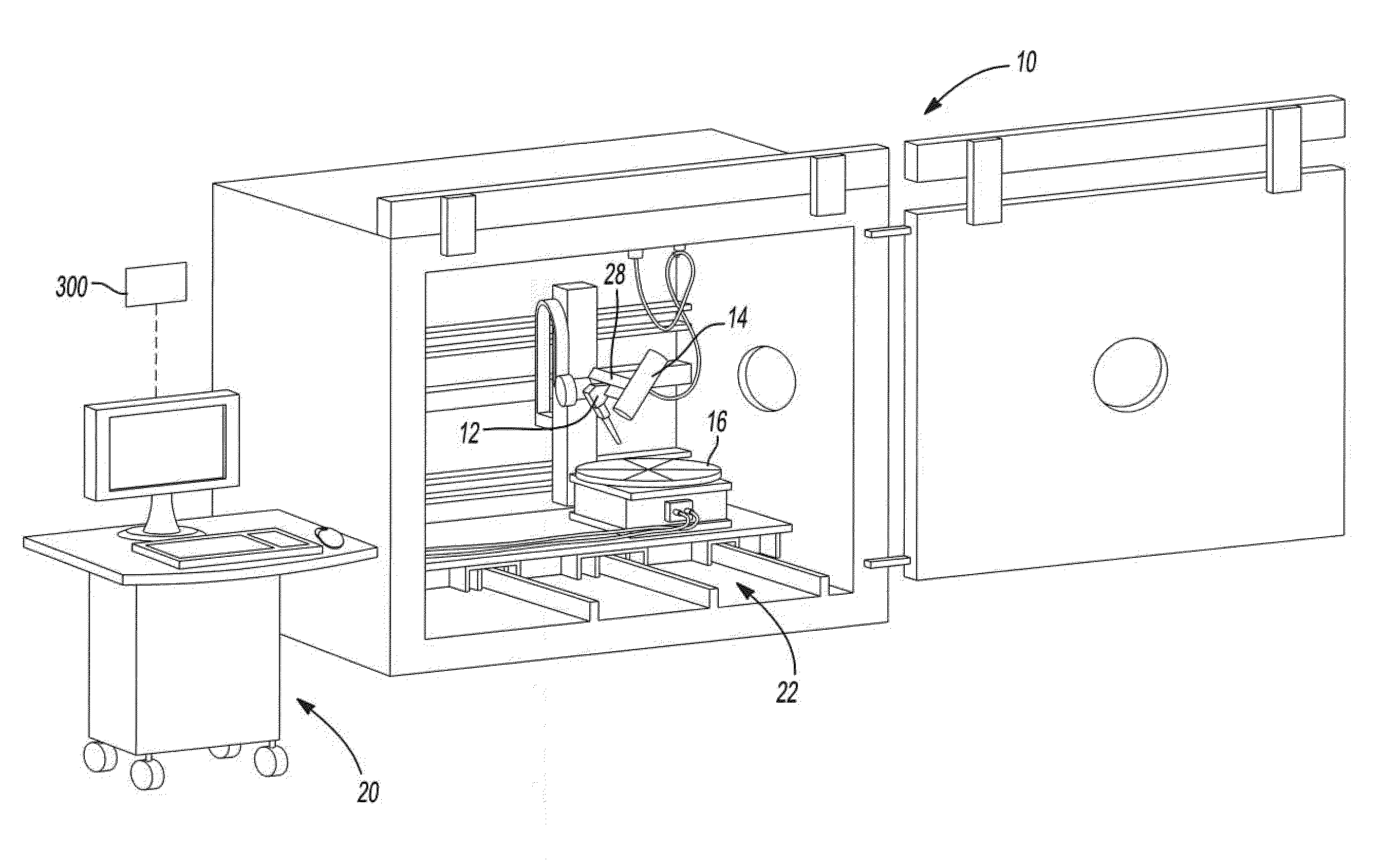

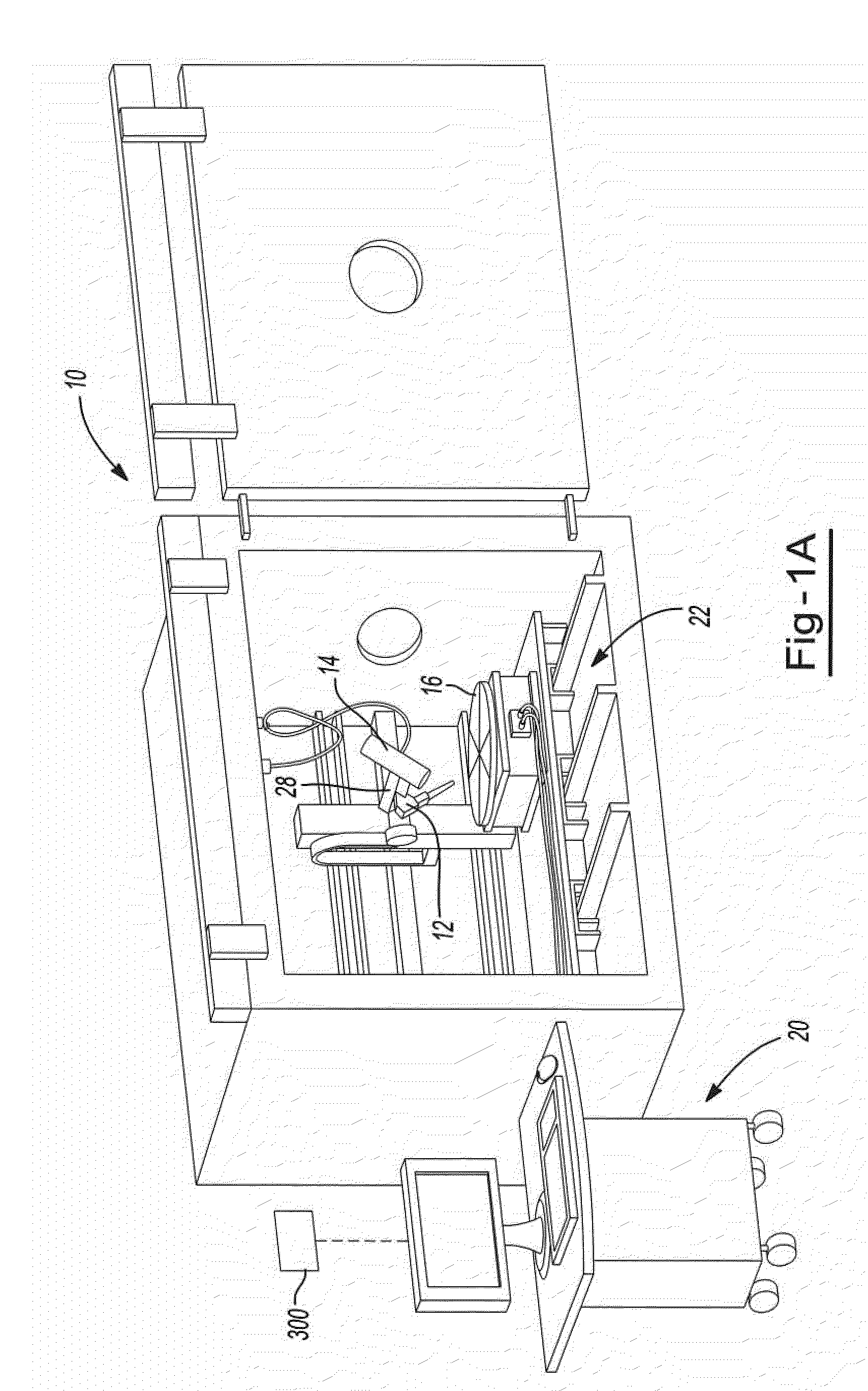

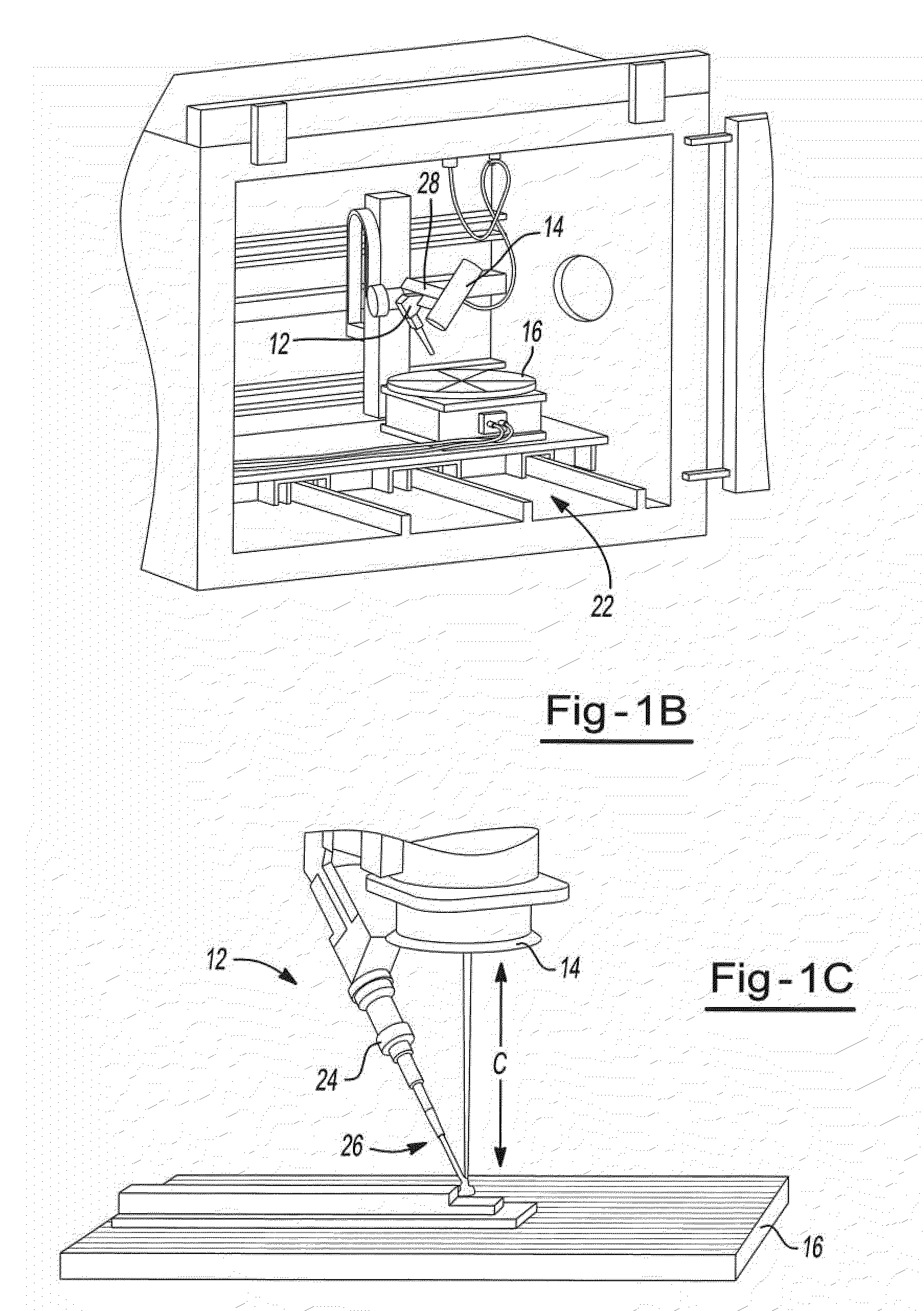

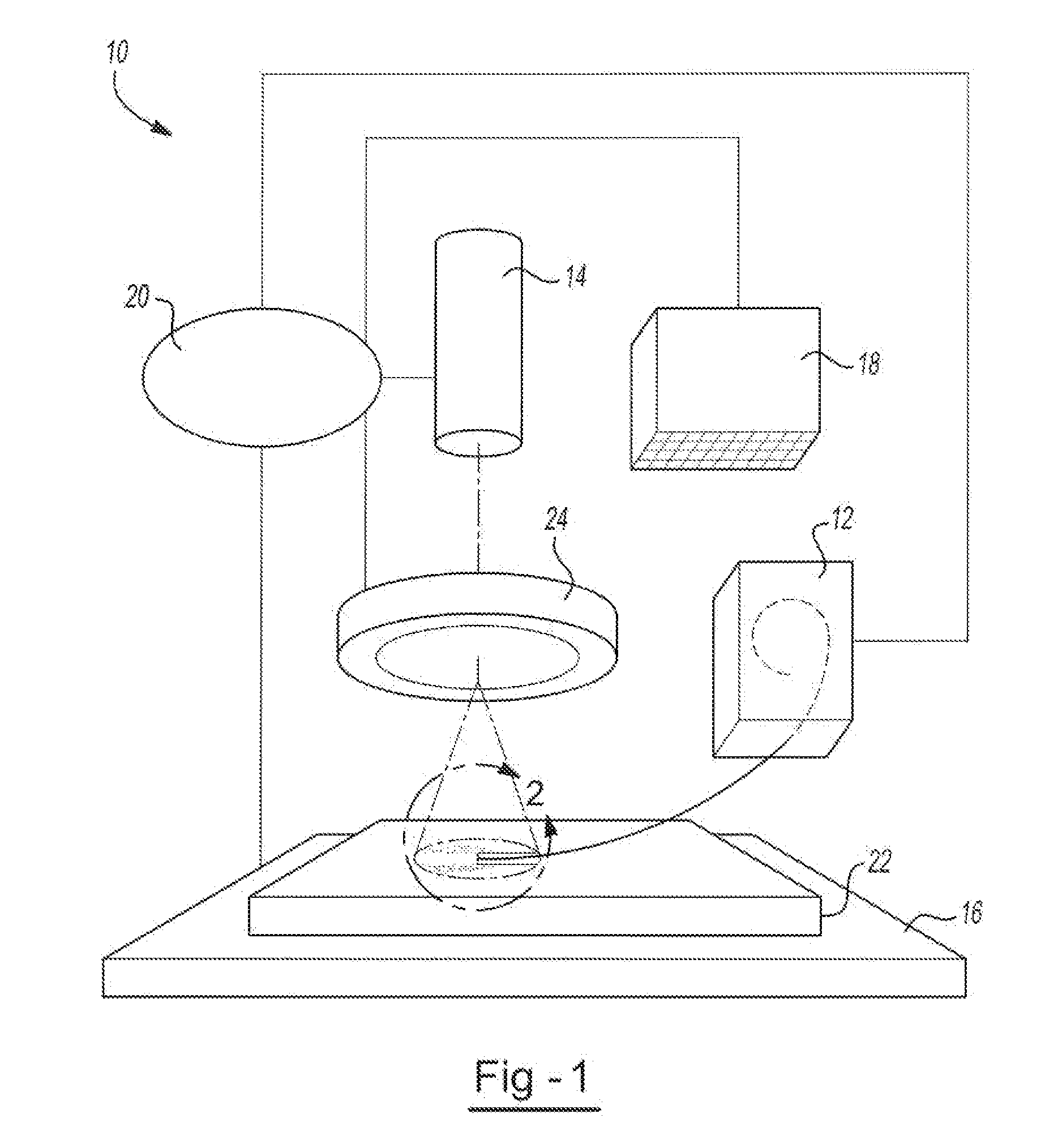

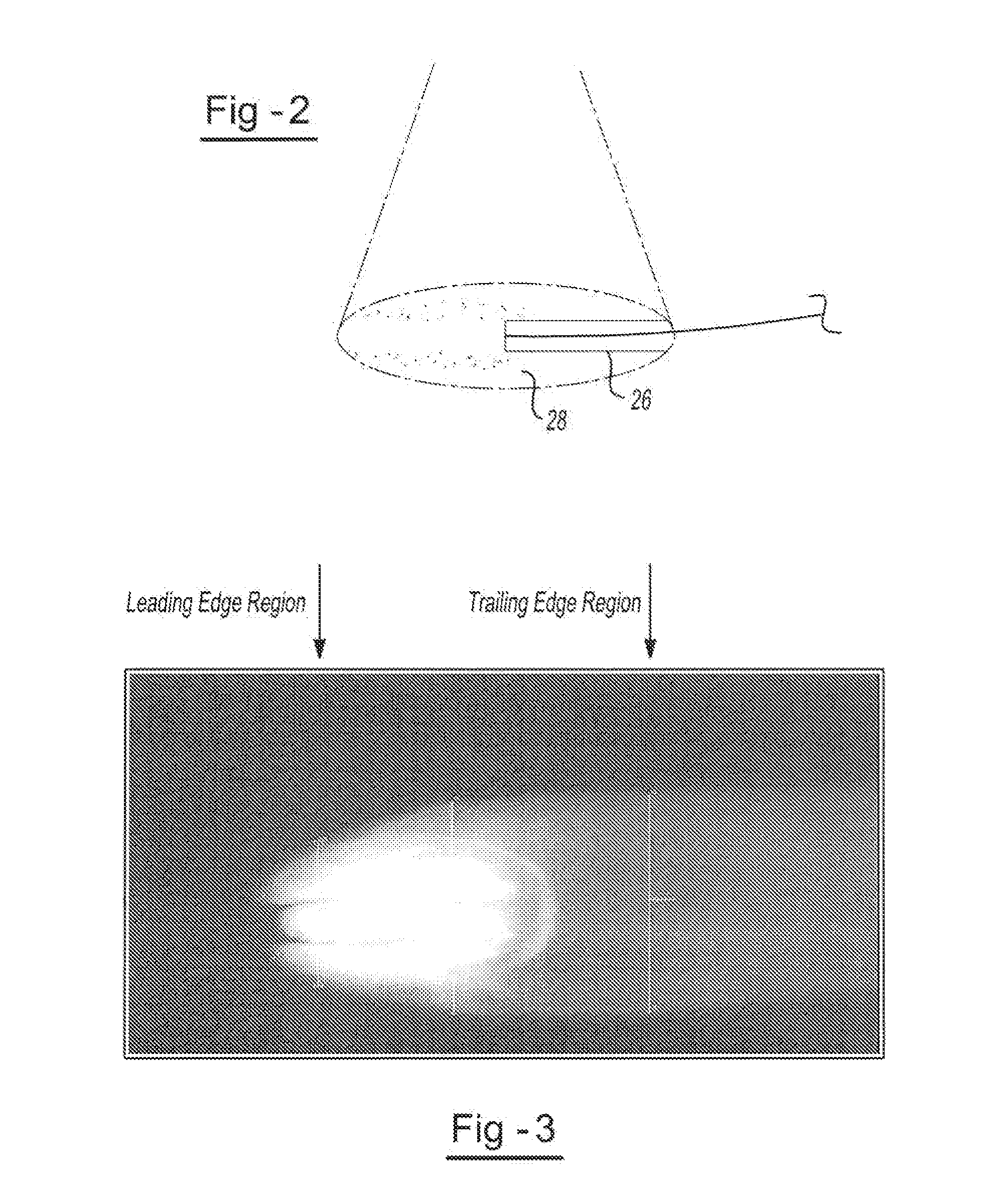

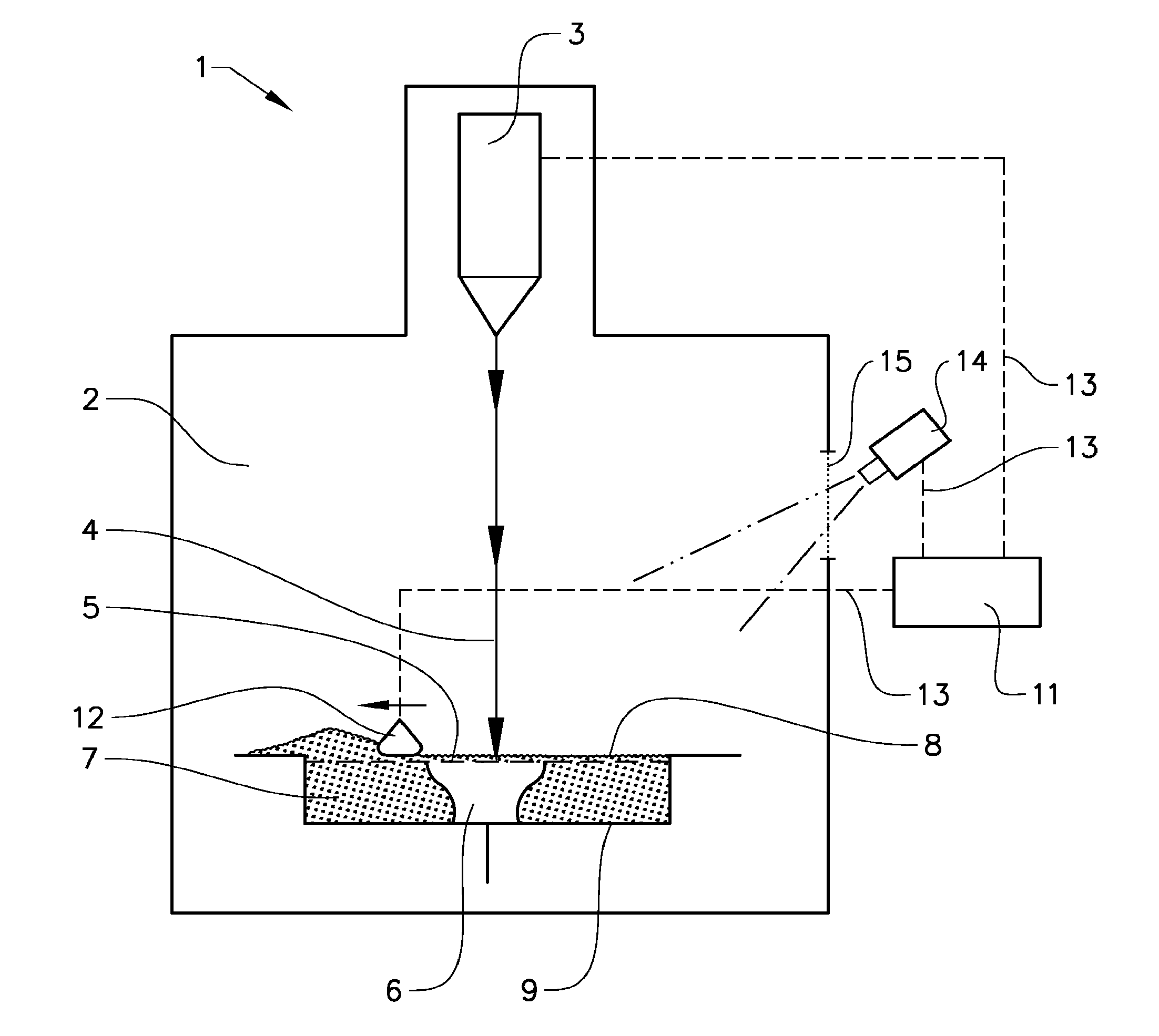

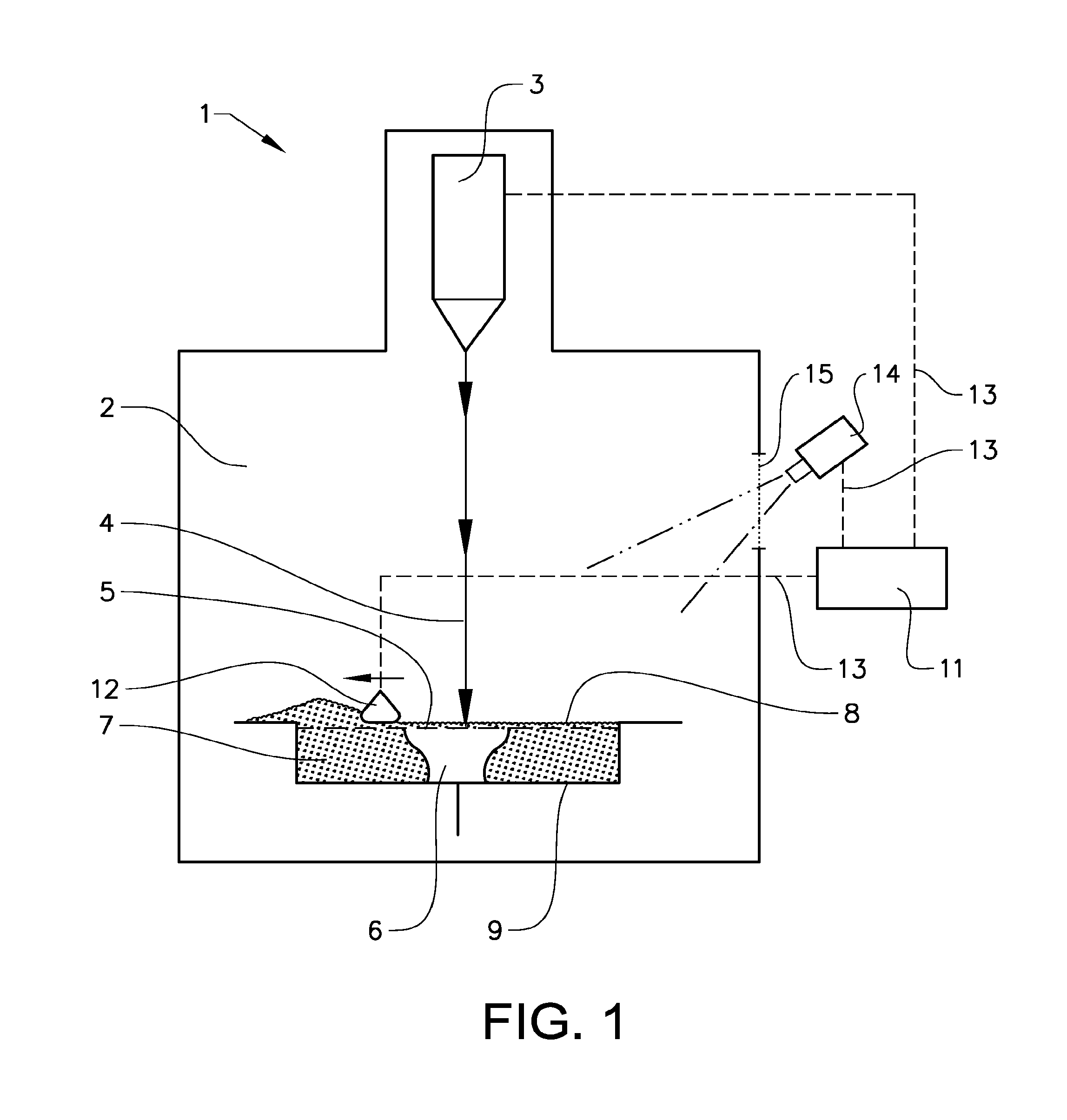

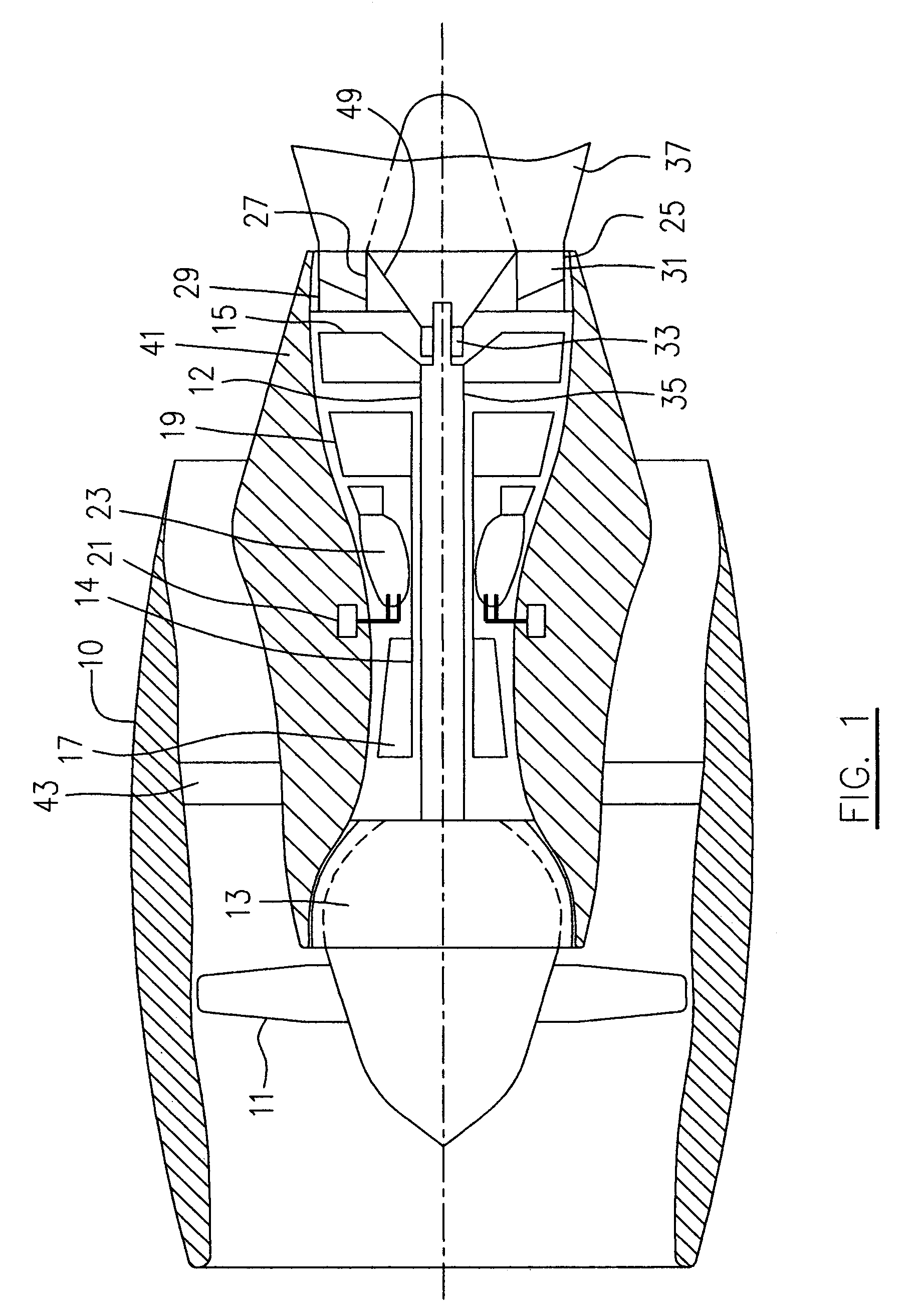

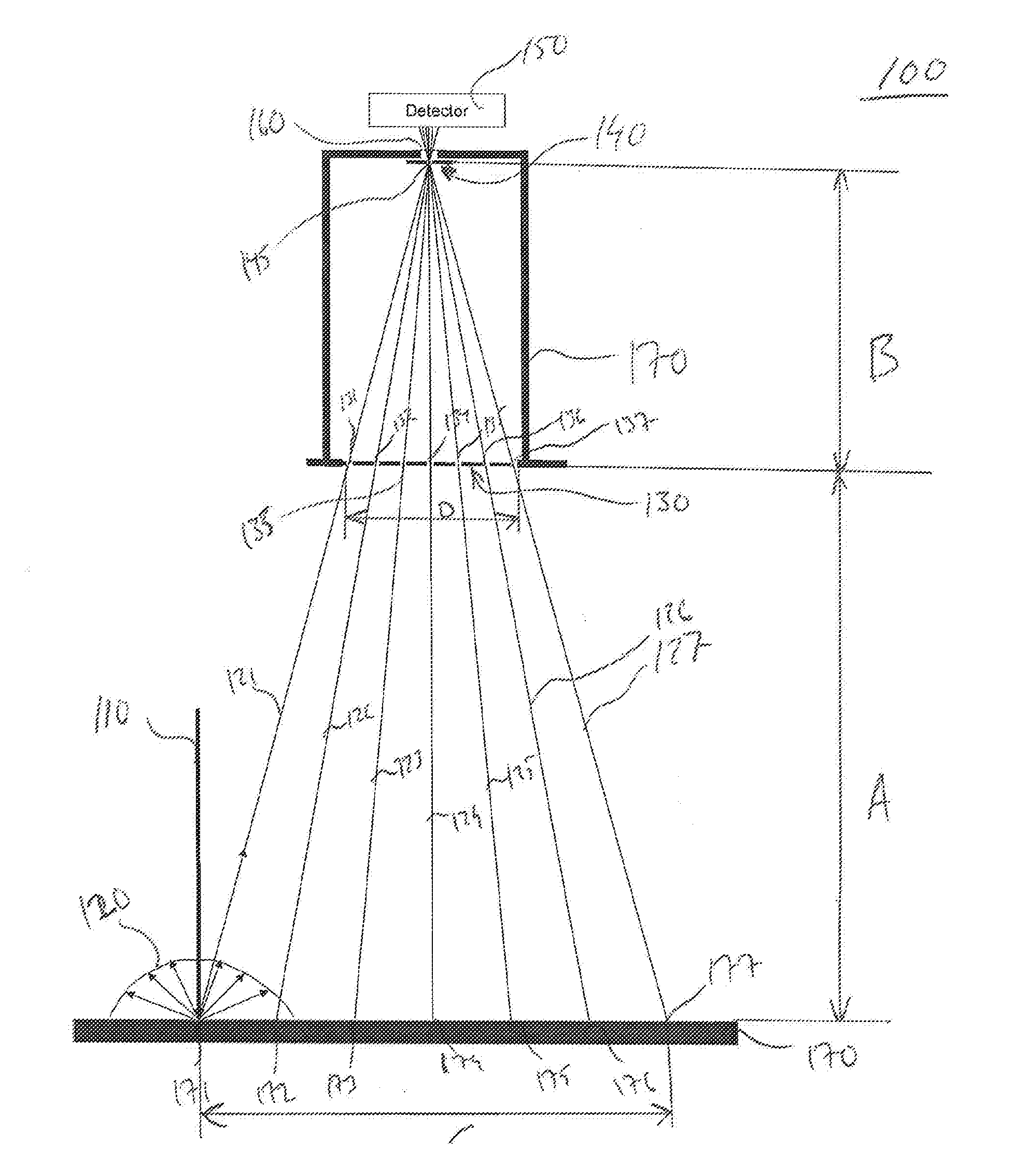

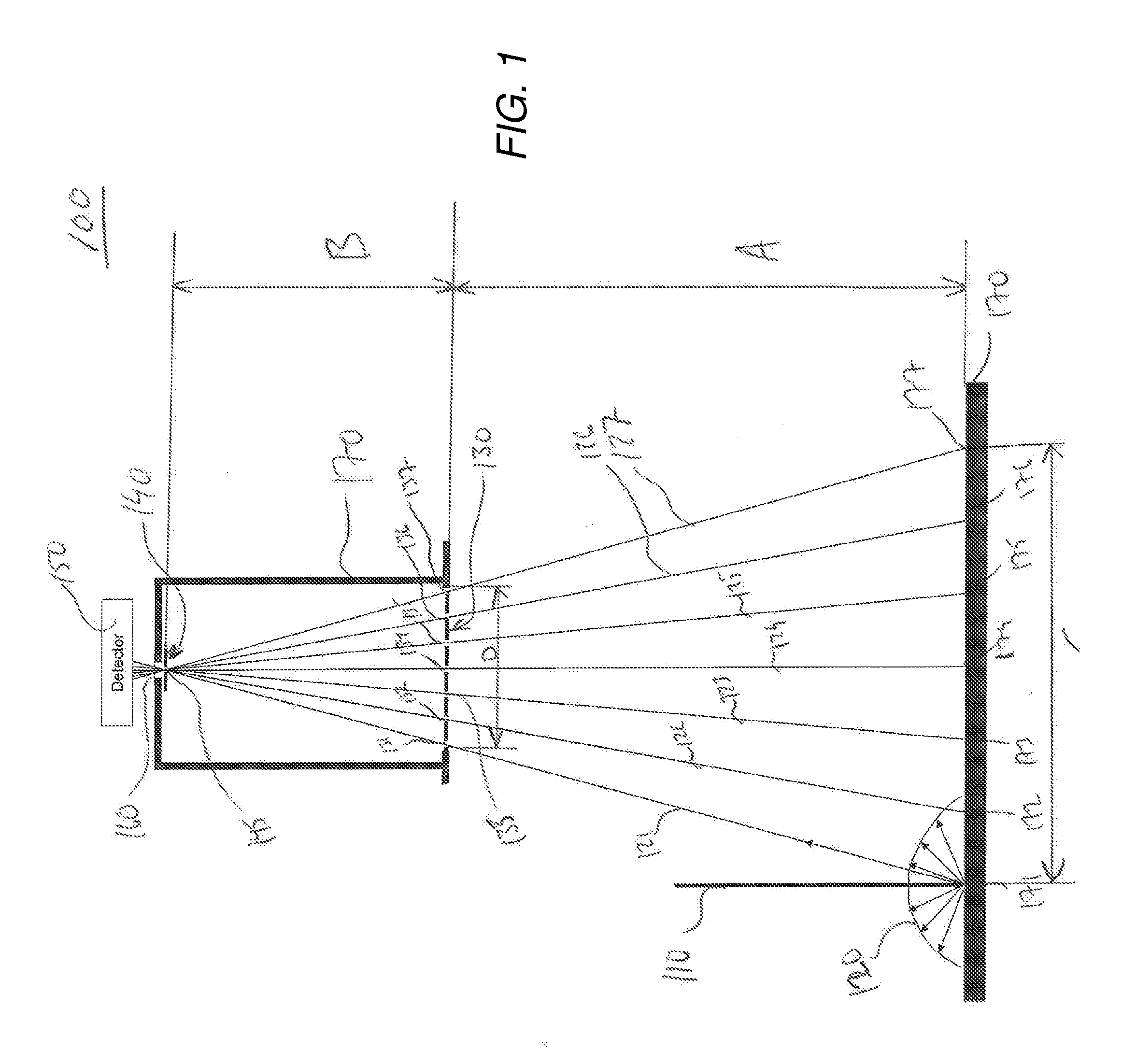

Electron beam layer manufacturing using scanning electron monitored closed loop control

ActiveUS20110114839A1Speed up the processQuick buildAdditive manufacturing apparatusMaterial analysis using wave/particle radiationClosed loopTrailing edge

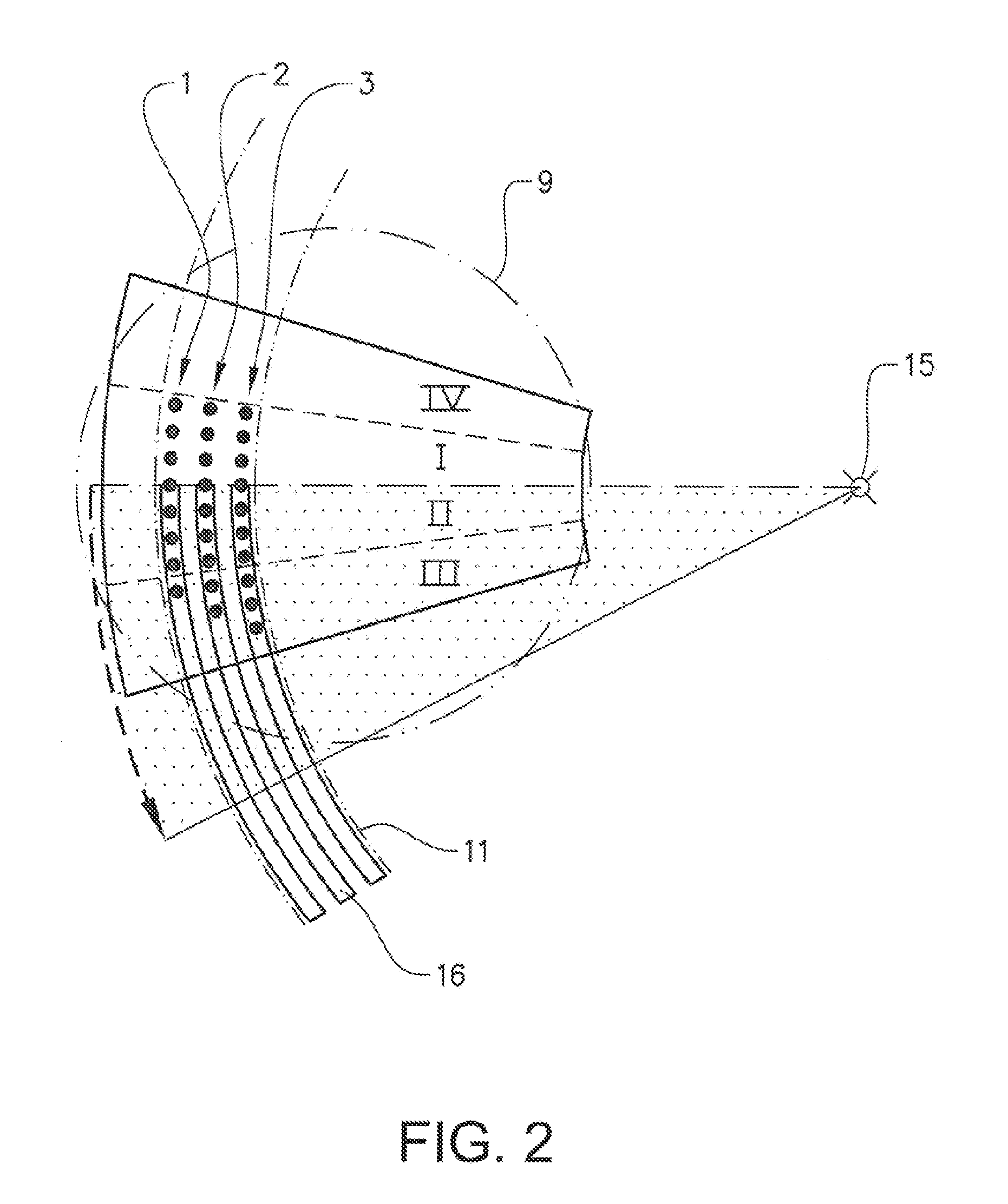

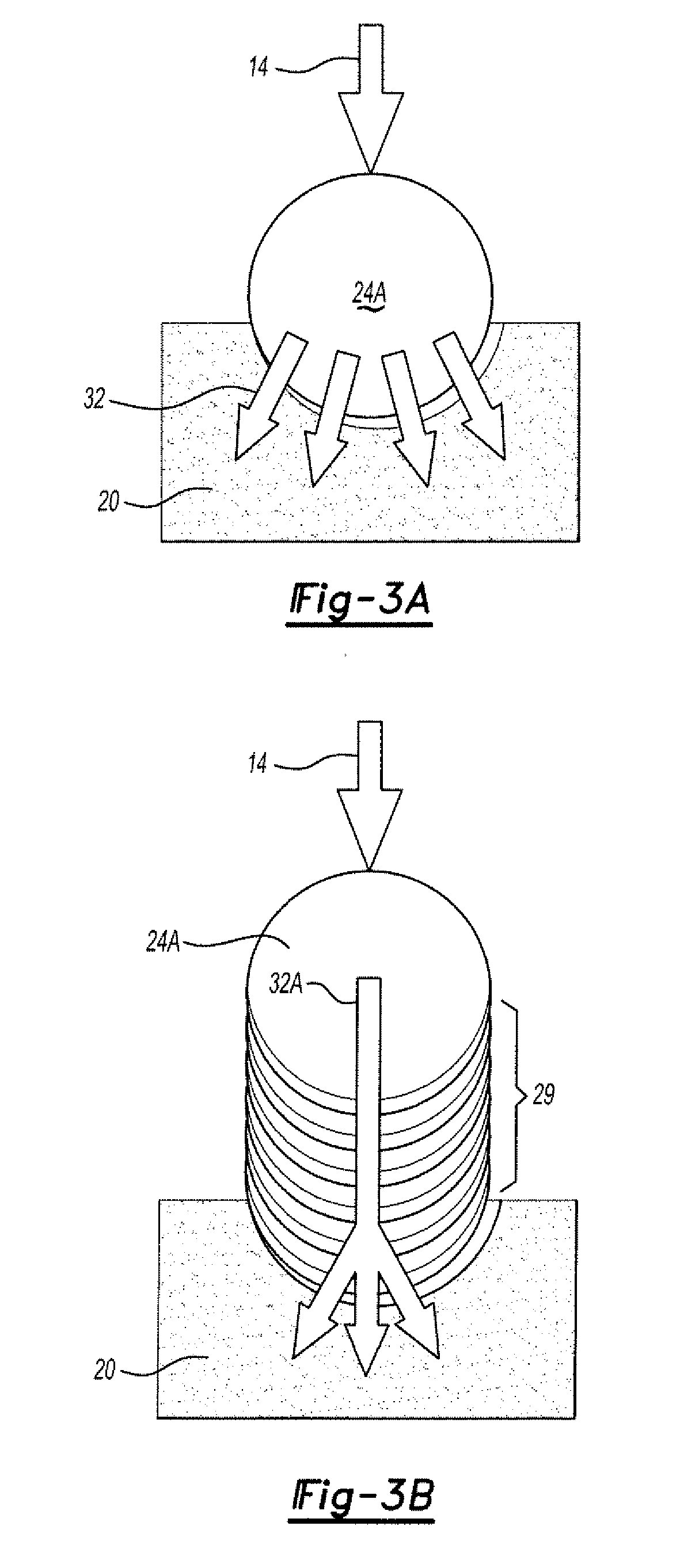

A process (and apparatus for performing the process) for layer manufacturing a three-dimensional work piece comprising the steps of; feeding raw material in a solid state to a first predetermined location; exposing the raw material to an electron beam to liquefy the raw material; depositing the raw material onto a substrate as a molten pool deposit, the deposit having a forward edge region in an x-y plane with a forward edge region width and a trailing edge region in the x-y plane with a trailing edge region width, under at least one first processing condition; monitoring the molten pool deposit for at least one preselected condition using detecting of scatter from a scanning electron beam contemporaneously with the depositing step; solidifying the molten pool deposit; automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step; and repeating steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional work piece.

Owner:SCIAKY SA

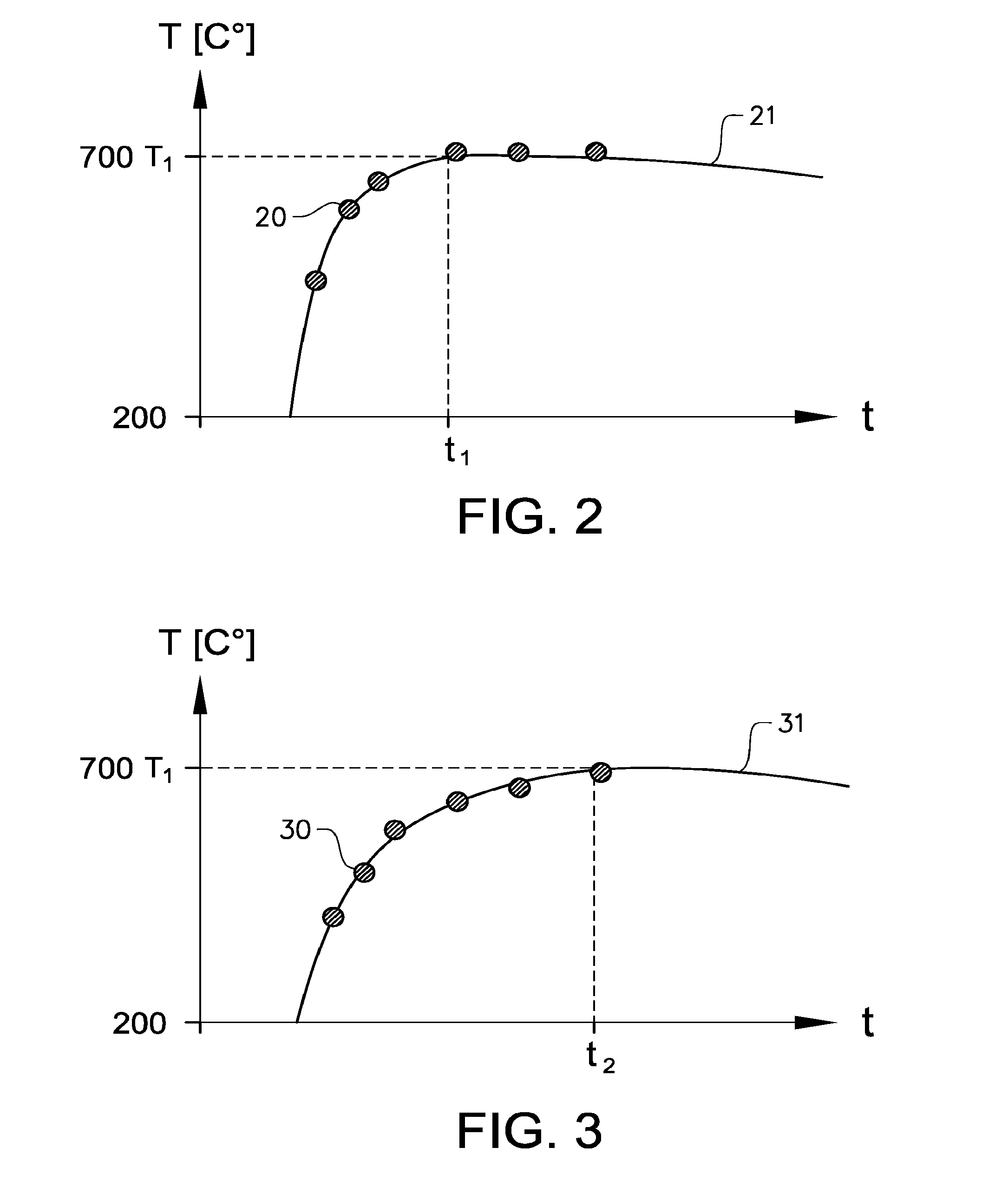

Mass production of tridimensional articles made of intermetallic compounds

ActiveUS20080014457A1The material is lowReduce oxidationTurbinesAdditive manufacturing apparatusCompound aChemical compound

A process for mass production of three-dimensional articles made of intermetallic compounds based on titanium and aluminium by an electron beam melting technology. The articles are produced in successive sections from powders of the intermetallic compound with which the articles are to be produced. For each section, melting of the powders preceded by a preheating step is performed.

Owner:GE AVIO

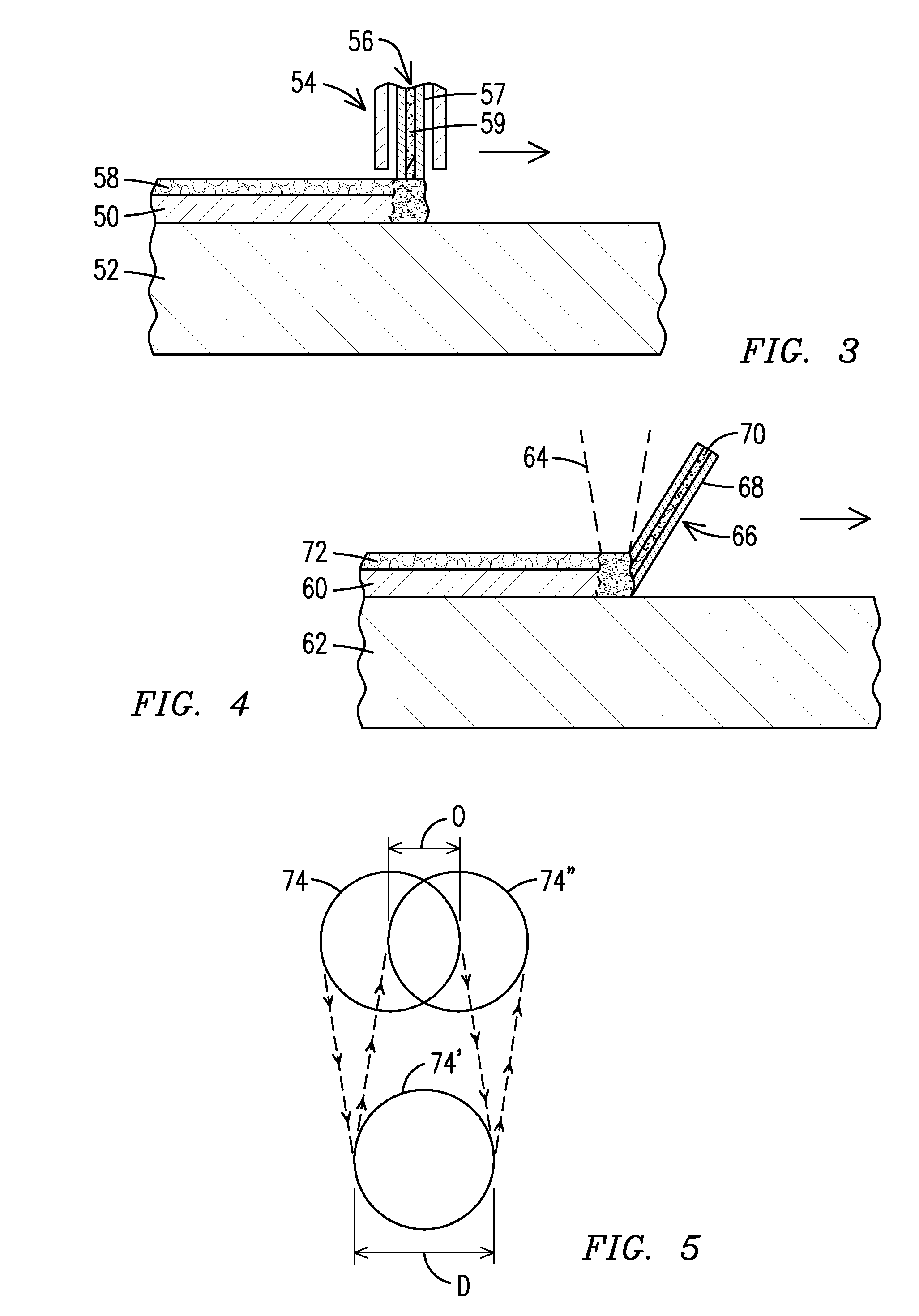

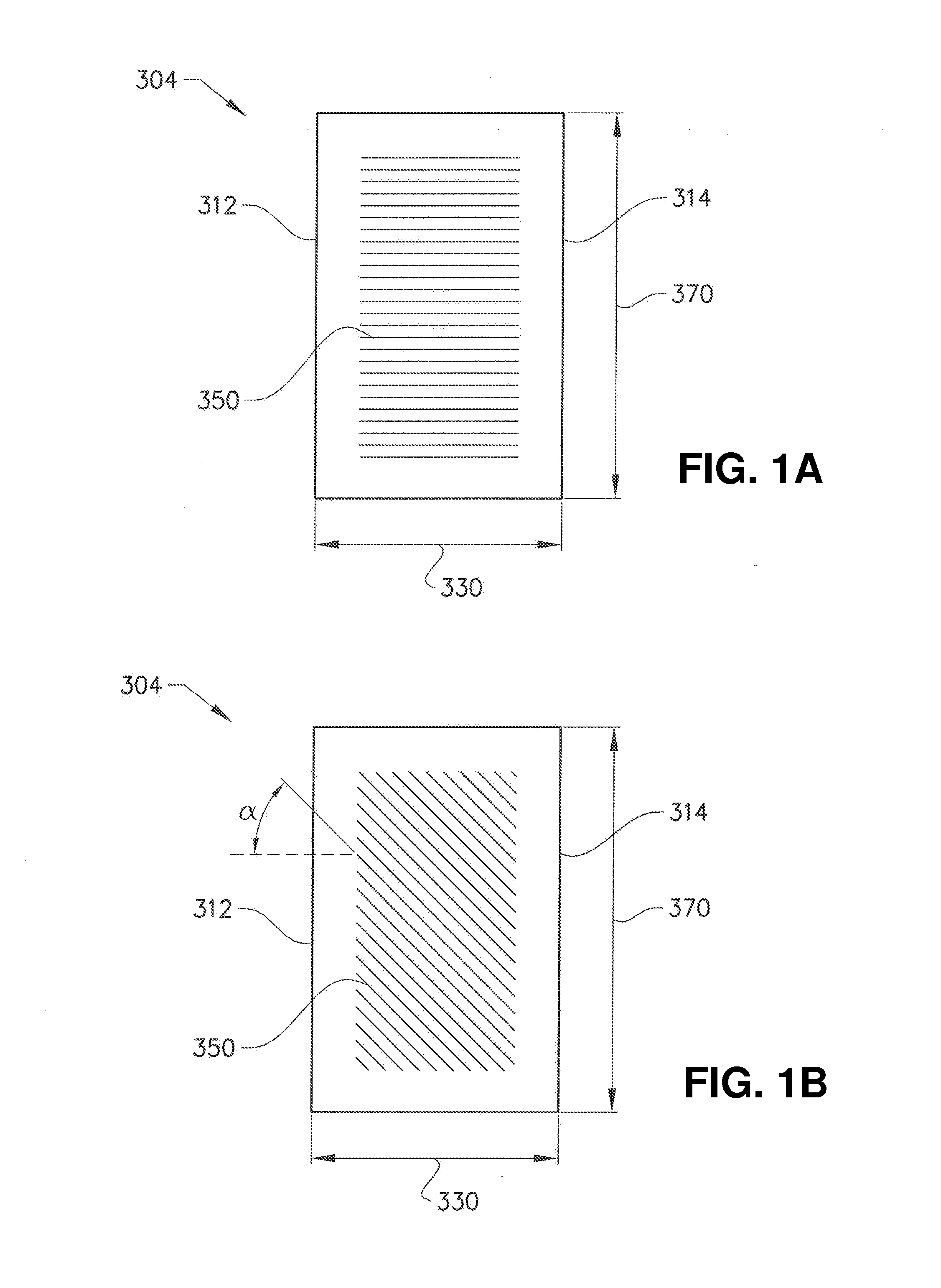

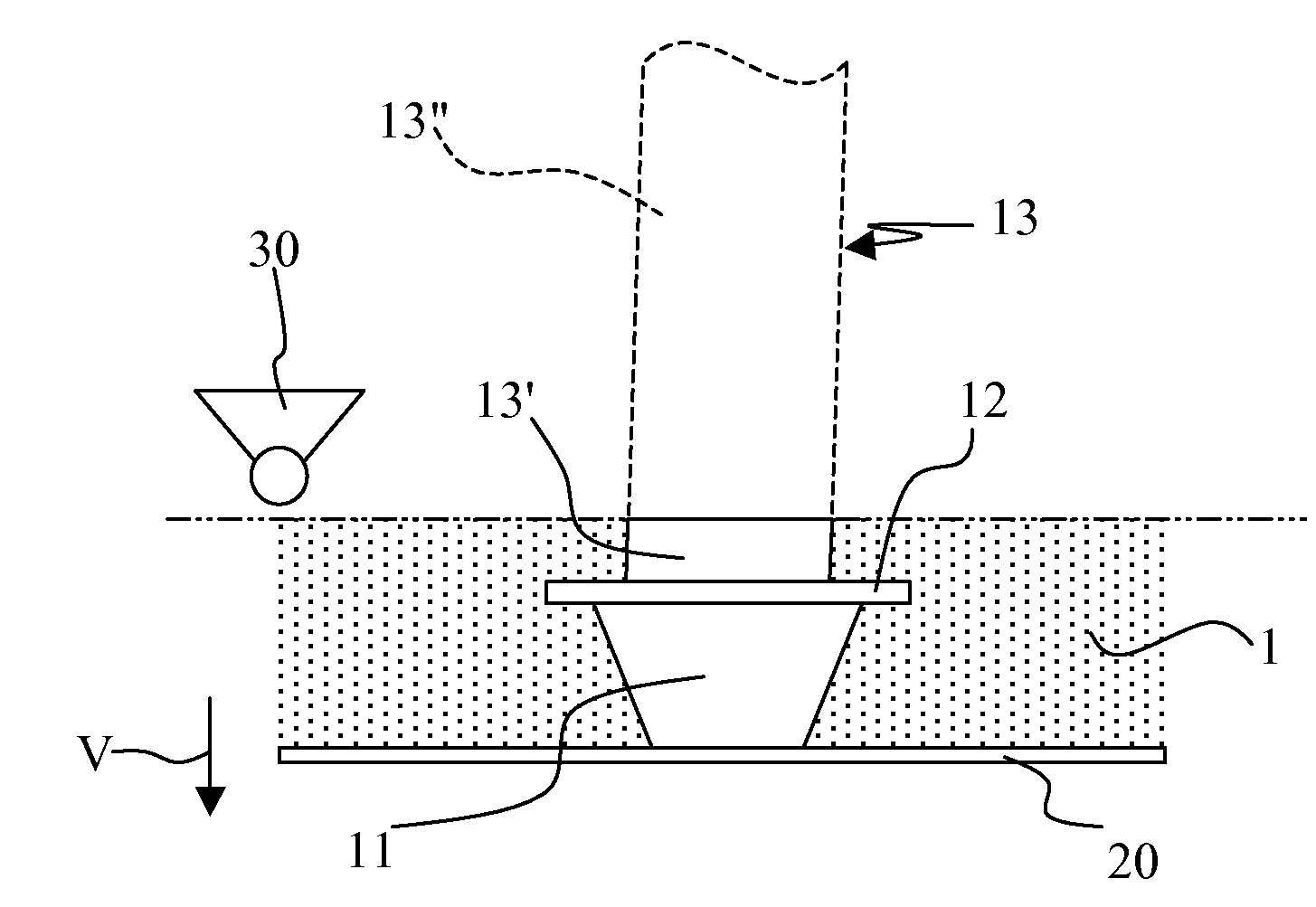

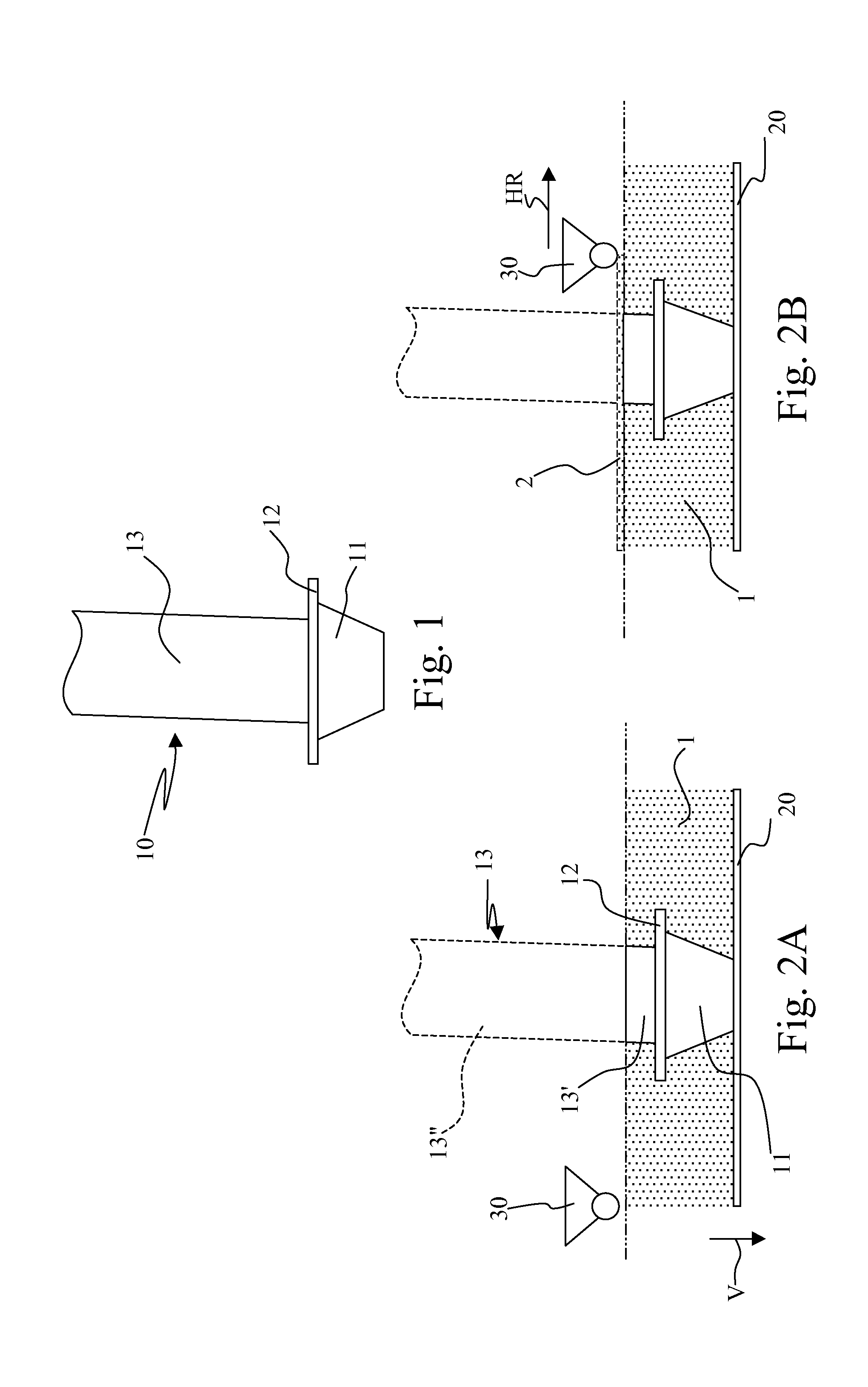

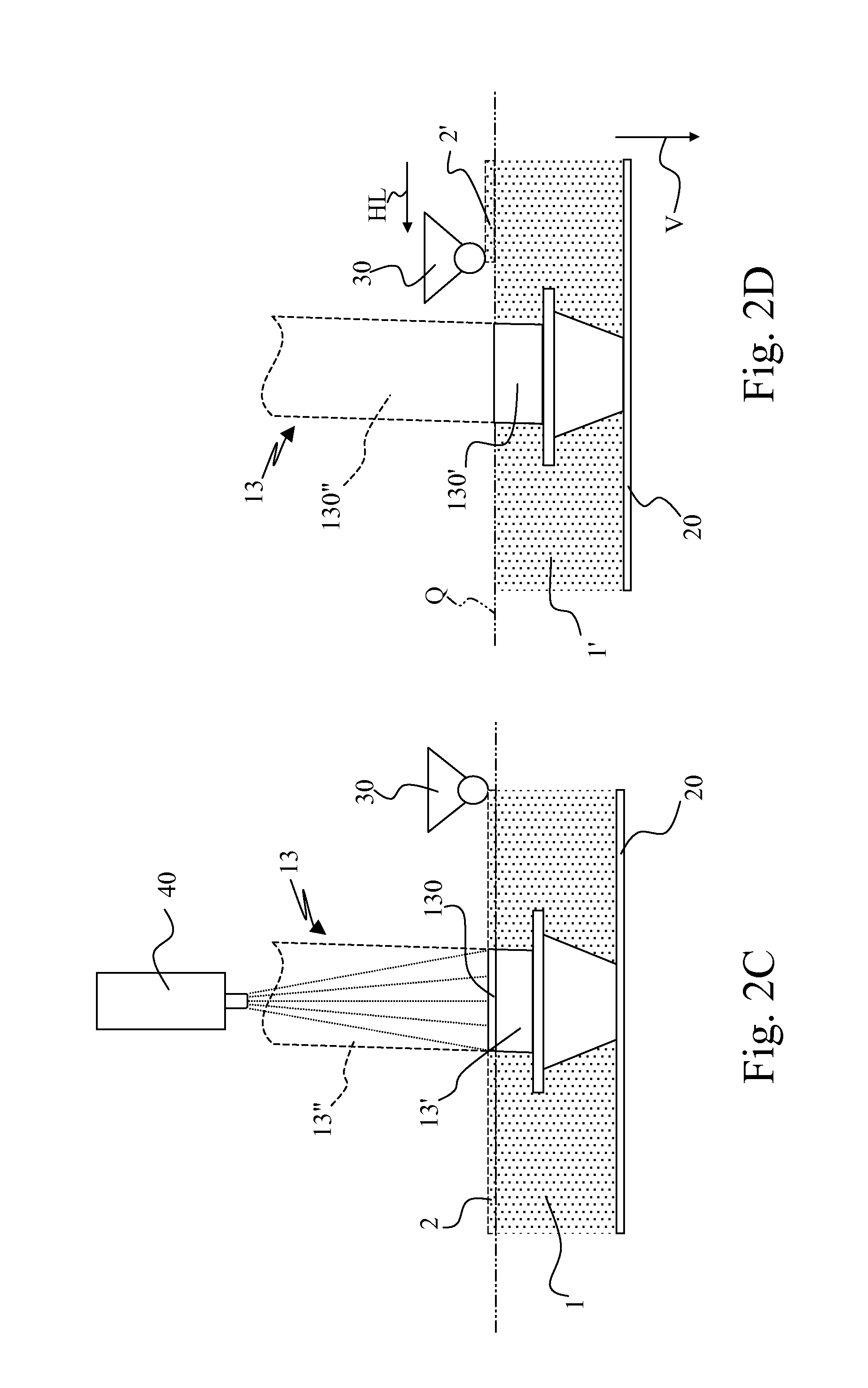

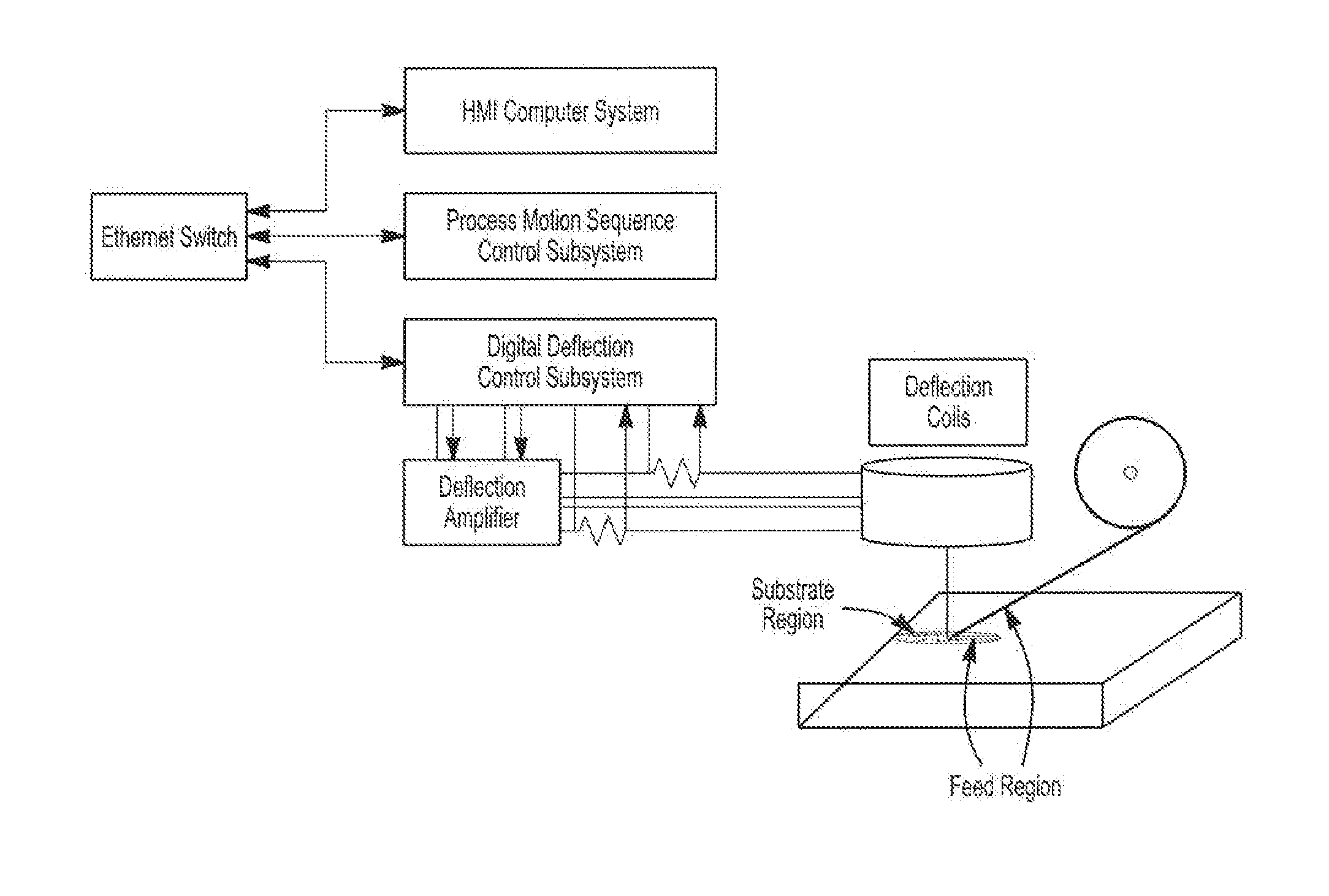

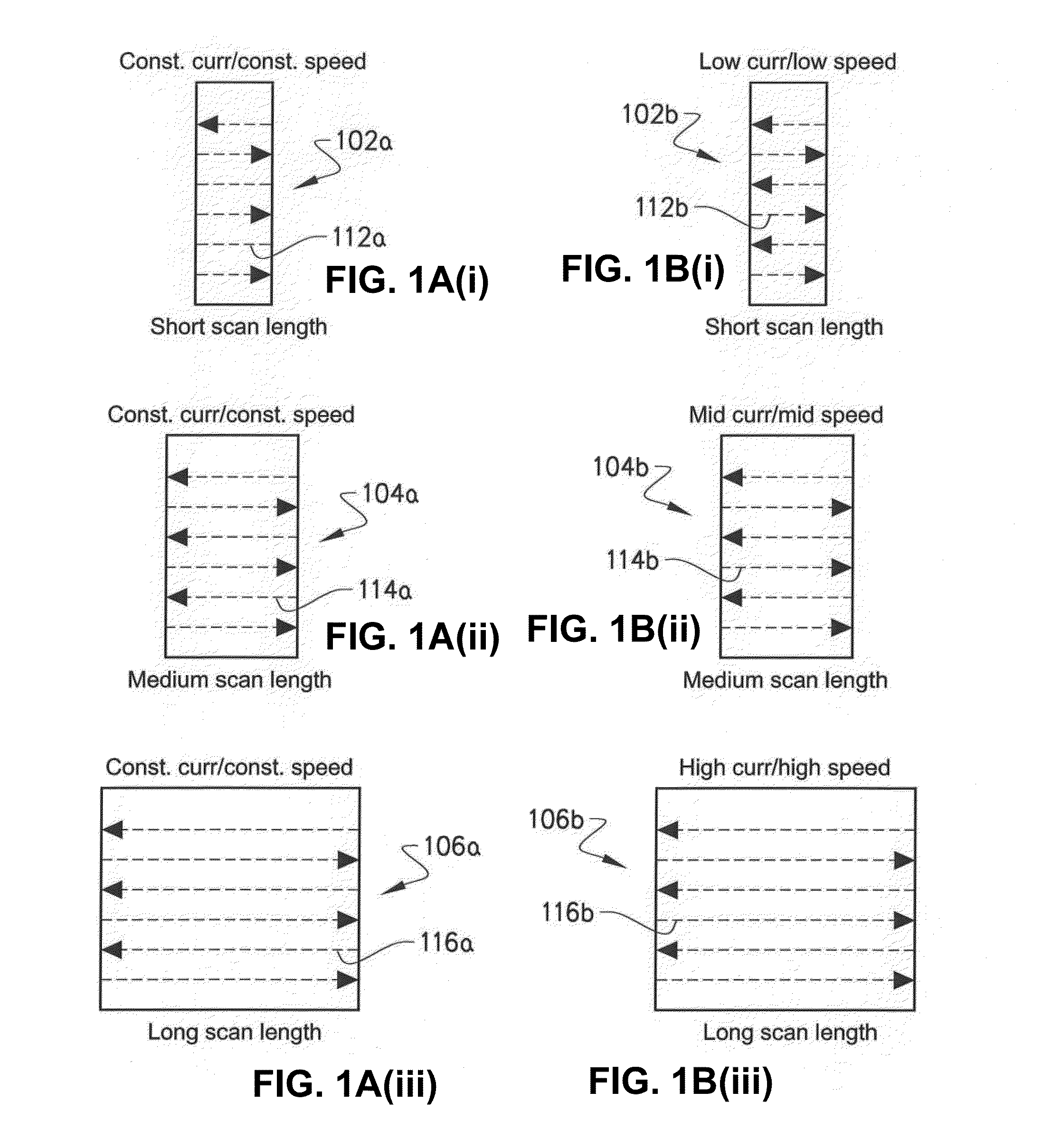

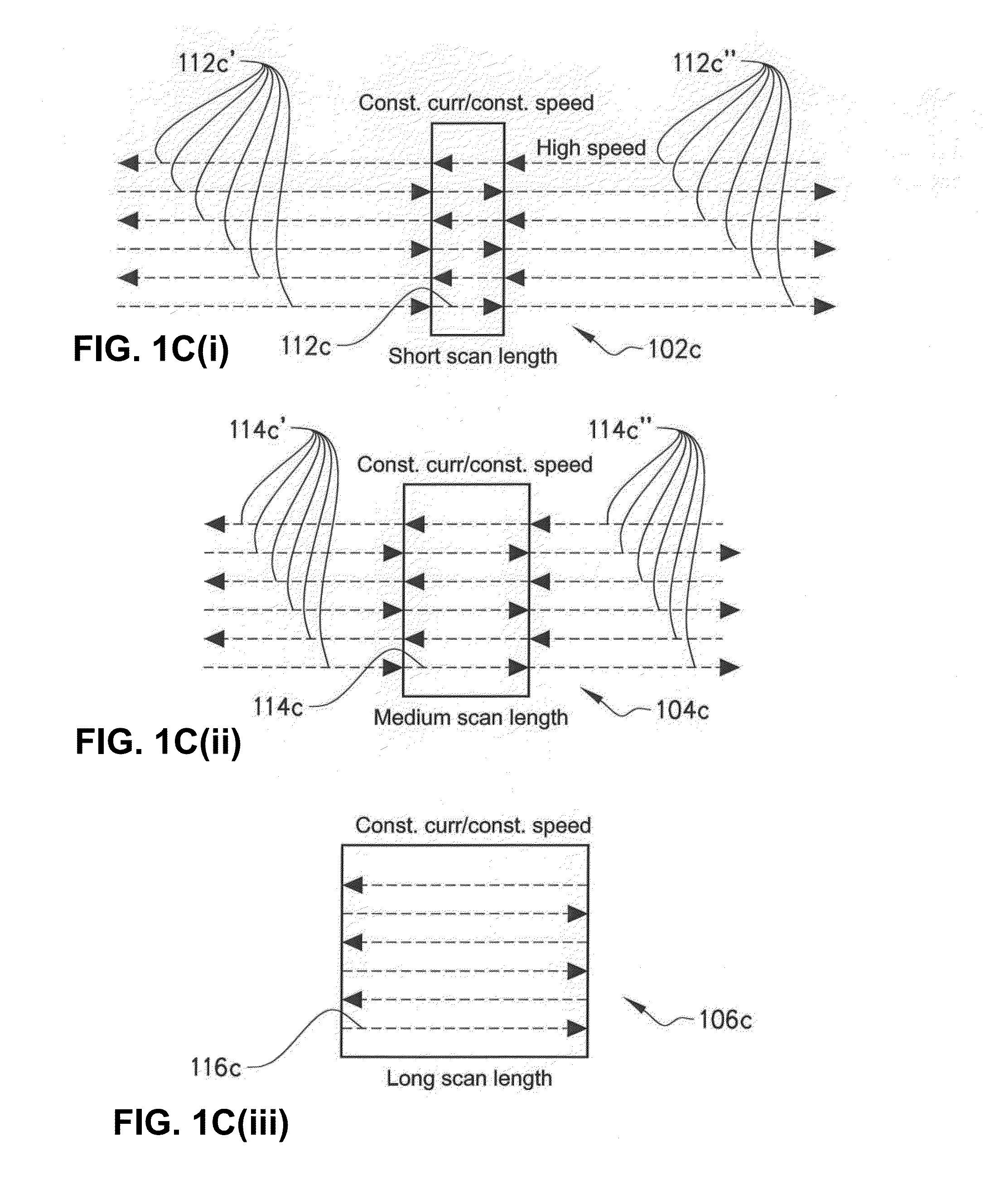

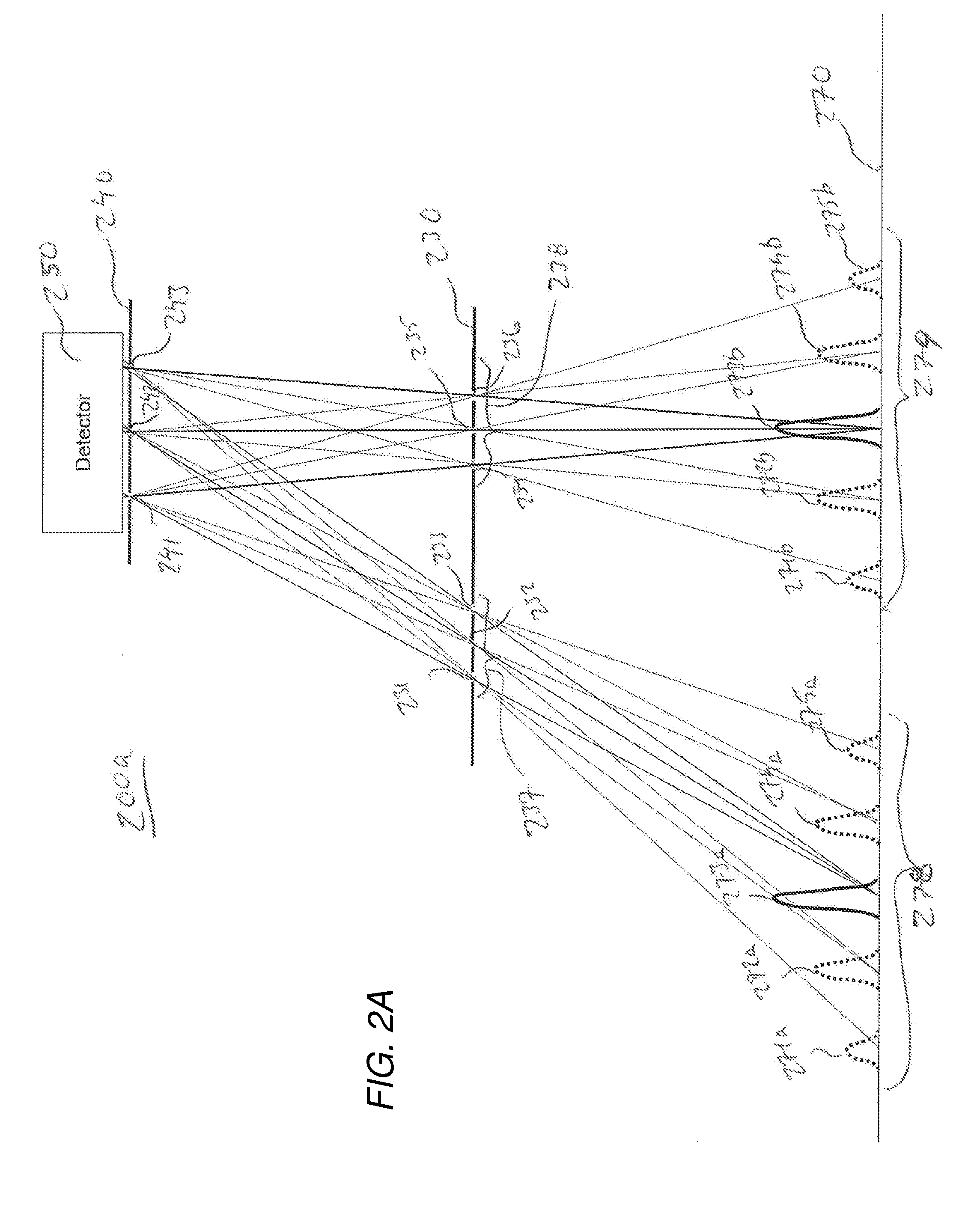

Raster methodology, apparatus and system for electron beam layer manufacturing using closed loop control

ActiveUS20110240607A1Constant feed rateConstant frame rateLiquid surface applicatorsAdditive manufacturing apparatusGratingClosed loop

A method for layer-by-layer manufacturing of a three-dimensional metallic work piece, comprising the steps of: delivering a metallic feed material in a substantially solid state into a feed region; emitting an electron beam having one or more predetermined electrical currents; translating the electron beam through a first predetermined raster pattern frame in an x-y plane that includes: a plurality of points within the feed region sufficient so that the metallic feed material is subjected to a melting beam power density level sufficient to cause melting of the metallic feed material and formation of a molten pool deposit; and a plurality of points in a substrate region that is outside of the feed region, sufficient so that the plurality of points outside the feed region is subjected to a substrate beam power density level that is different from (e.g., lower than) the melting beam power density level; monitoring a condition of one or both of the feed region or the substrate region substantially in real time for the occurrence of any deviation from a predetermined condition; upon detecting of any deviation, translating the electron beam through at least one second predetermined raster pattern frame in the x-y plane that maintains the melting beam power density level substantially the same as the first predetermined raster pattern frame, but alters the substrate beam power density level in a manner so that the monitored condition returns to the predetermined condition; and repeating the above steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional layered metallic work piece. The teachings herein also contemplate an apparatus that includes an electronic control device that performs any of the methods herein, as well as articles made according to such methods.

Owner:SCIAKY SA

Method for additive manufacturing

ActiveUS20150174695A1Easy to controlImprove ductilityAdditive manufacturing apparatusIncreasing energy efficiencyScan lineBeam source

The invention relates to a method for forming a three-dimensional article through successive fusion of locations of a powder bed. The method comprising: providing a model of said three-dimensional article; applying a powder layer on a work table; determining a maximum scan length of an energy beam; directing said energy beam from a first energy beam source over said work table with constant energy causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, wherein locations with a shorter scan length than said maximum scan length is provided with a time sink before and / or after said scan line so that the time period between each two adjacent scan lines is constant throughout the manufacture of said three-dimensional article.

Owner:ARCAM AB

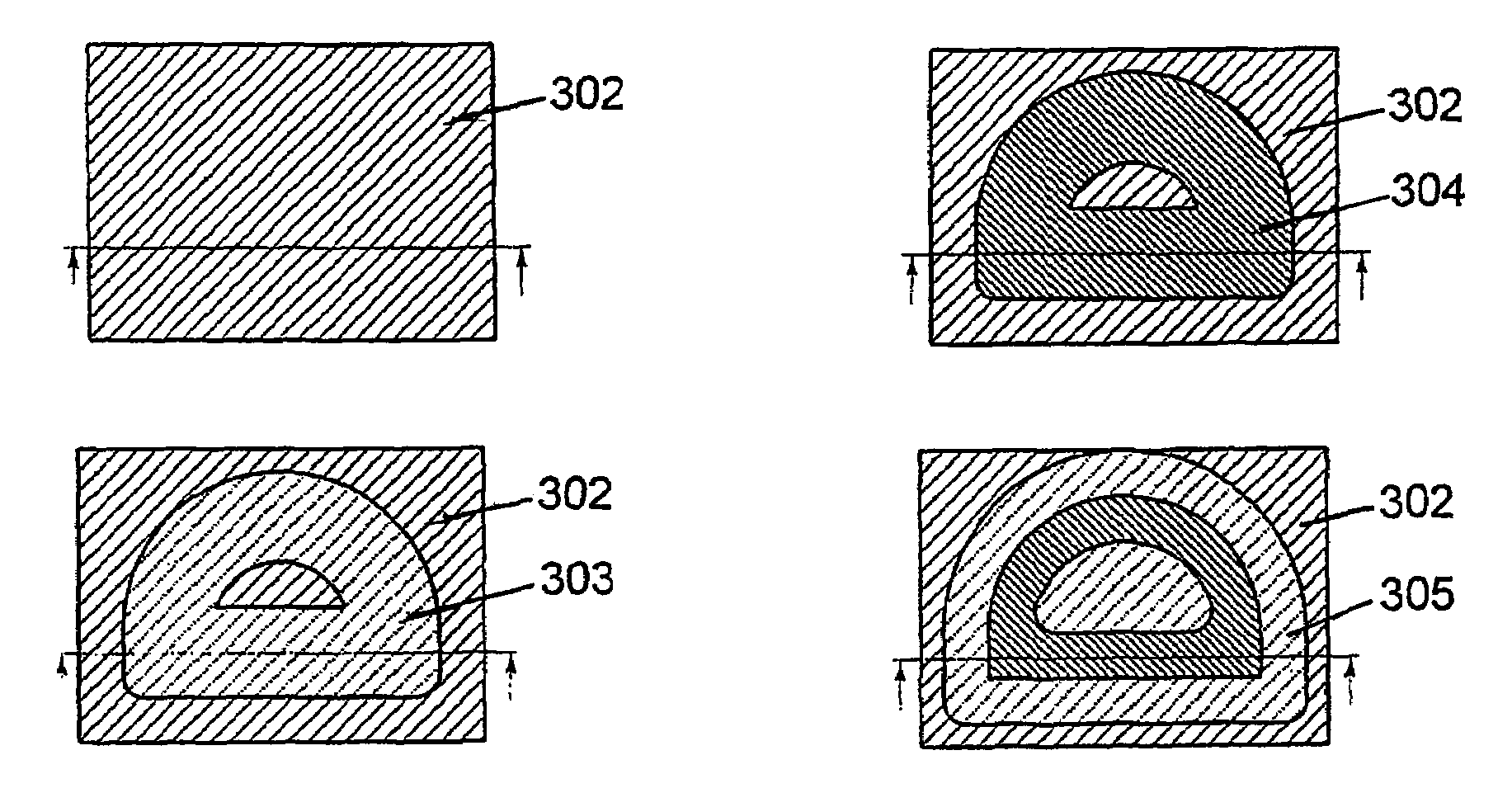

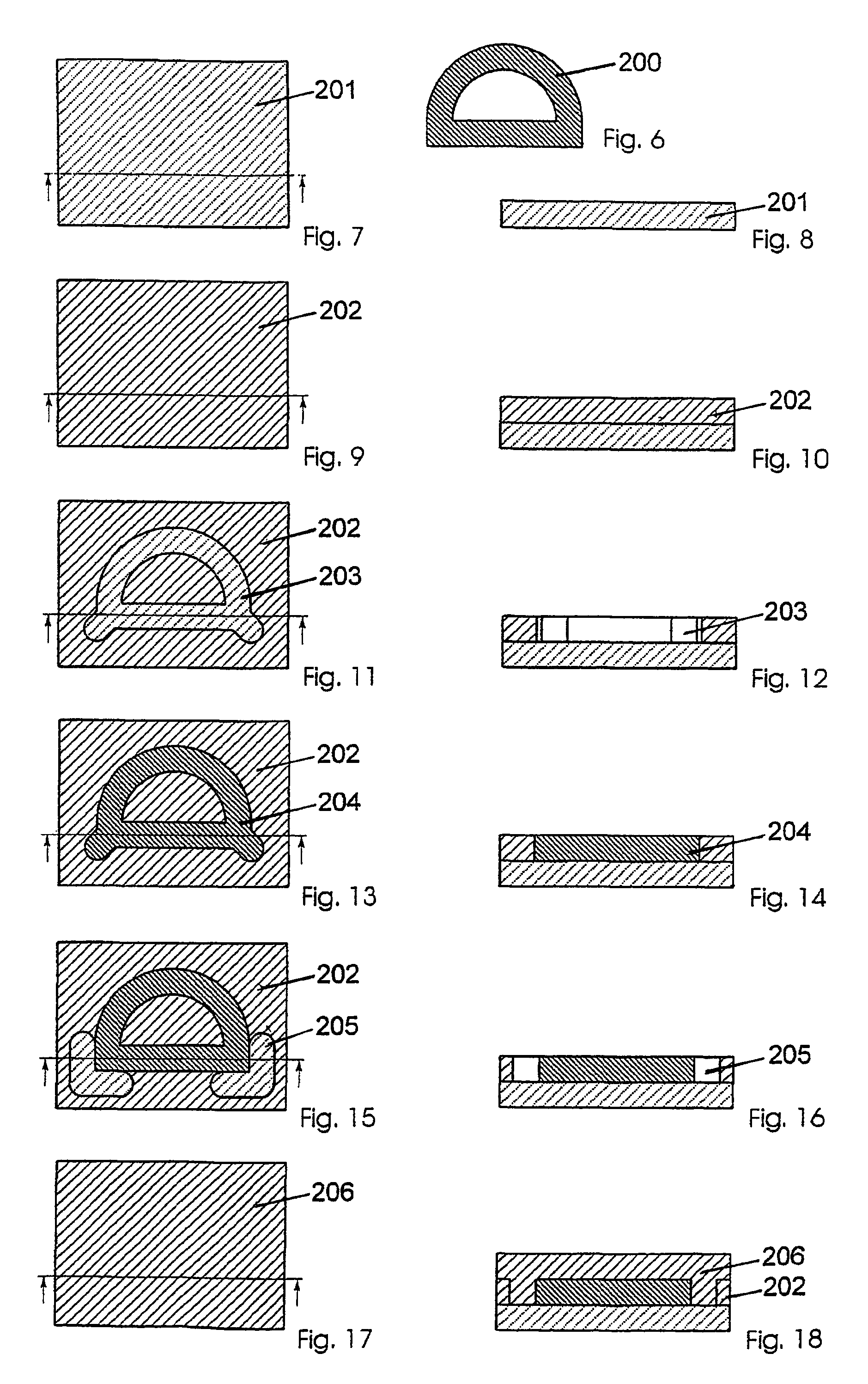

Method for producing a part and device for carrying out this method

InactiveUS7003864B2Faster machinabilityReduced tool wearMouldsWood working apparatusEngineeringRapid prototyping

The present invention relates to a method for producing a part (108, 200, 300), comprising the following steps:a) applying a first flat layer consisting of a support material (102, 202, 302), to a construction platform (101, 201, 301),b) introducing at least one recess (103, 203, 303) into the support material (102, 202, 302),c) filling the recess (103, 203, 303) with a construction material (104, 204, 304),d) applying a further layer of support material (102, 202, 302),e) repeating steps b) through d) until completion of the part (108, 200, 300), andf) removing the support material (102, 202, 302).This method is to provide a manufacturing method and a device that combine the advantages of the layerwise construction (rapid prototyping) with the advantages of machining (e.g. high-speed cutting) and particularly permit the production of sharp-edged contours.Furthermore, the present invention relates to a device for carrying out the method.

Owner:HERMLE MASCHENBAU

Method and apparatus for producing three-dimensional objects

ActiveUS20160303687A1Equally distributedAdditive manufacturing apparatusIncreasing energy efficiencyLight beamMechanical engineering

Owner:ARCAM AB

Surface modified unit cell lattice structures for optimized secure freeform fabrication

Aspects of the present disclosure relate generally to preparing models of three-dimensional structures. In particular, a model of a three-dimensional structure constructed of porous geometries is prepared. A component file including a porous CAD volume having a boundary is prepared. A space including the porous CAD volume is populated with unit cells. The unit cells are populated with porous geometries having a plurality of struts having nodes on each end. The space is populated with at least one elongated fixation element extending beyond the boundary to produce an interlocking feature enabling assembly or engagement with a mating structure.

Owner:HOWMEDICA OSTEONICS CORP +1

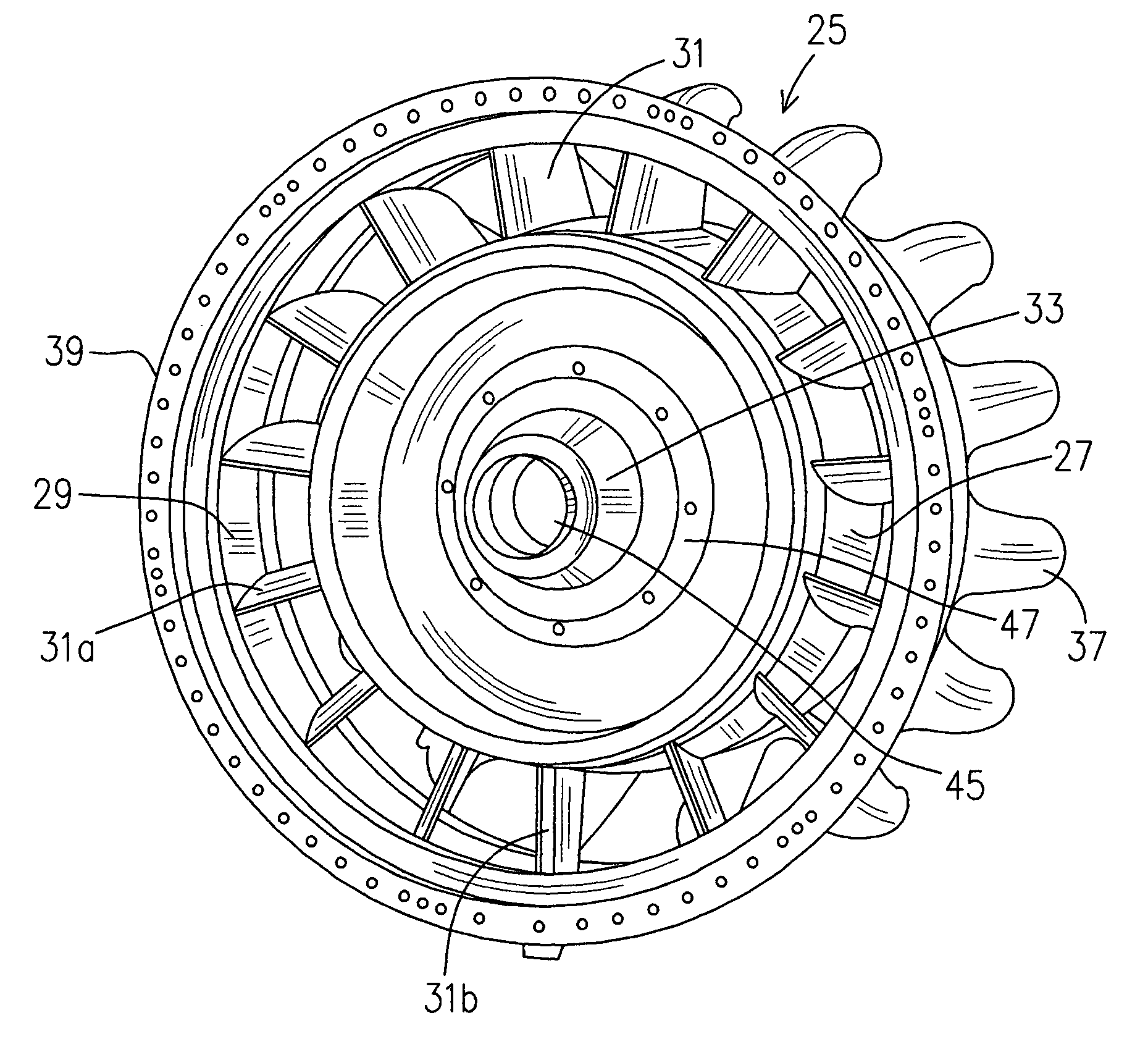

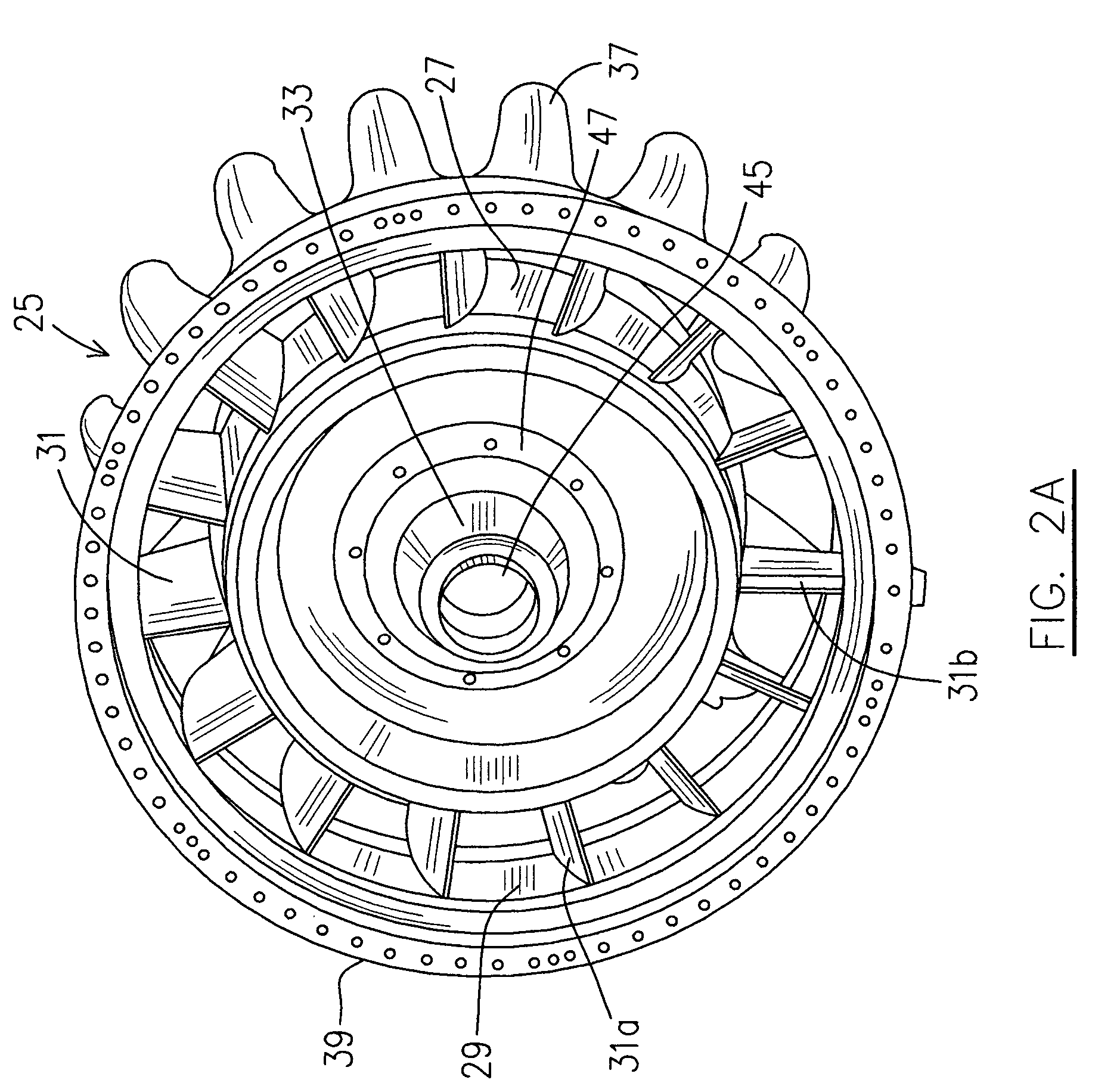

Turbine exhaust case and method of making

A structural turbine exhaust case of a gas turbine engine, comprises inner and outer case portions; a bearing housing connected to the inner case portion for supporting a main spool of the gas turbine engine; and a plurality of airfoils extending between the inner and outer case portions, airfoils structurally connecting the inner case portion to the outer case portion.

Owner:PRATT & WHITNEY CANADA CORP

Slicing method

InactiveUS20160167303A1Increase the lengthSynchronization is simpleManufacturing platforms/substratesArc welding apparatusRotational axisBeam source

A method for forming at least one three-dimensional article through successive fusion of parts of a powder bed, which parts correspond to successive portions of the three-dimensional article, said method comprising the steps of: providing at least one model of said three-dimensional article, wherein said model of said three-dimensional article is described in a 2-dimensional angular coordinate system; applying a powder layer on a support structure; directing at least one energy beam from at least one energy beam source over said powder layer causing said powder layer to fuse in first selected locations according to said model to form a first portion of said three-dimensional article, providing a first portion of said powder layer simultaneous as fusing a second portion of said powder layer, wherein said second portion of the powder layer is fused along a line perpendicular to a rotational axis of said support structure.

Owner:ARCAM AB

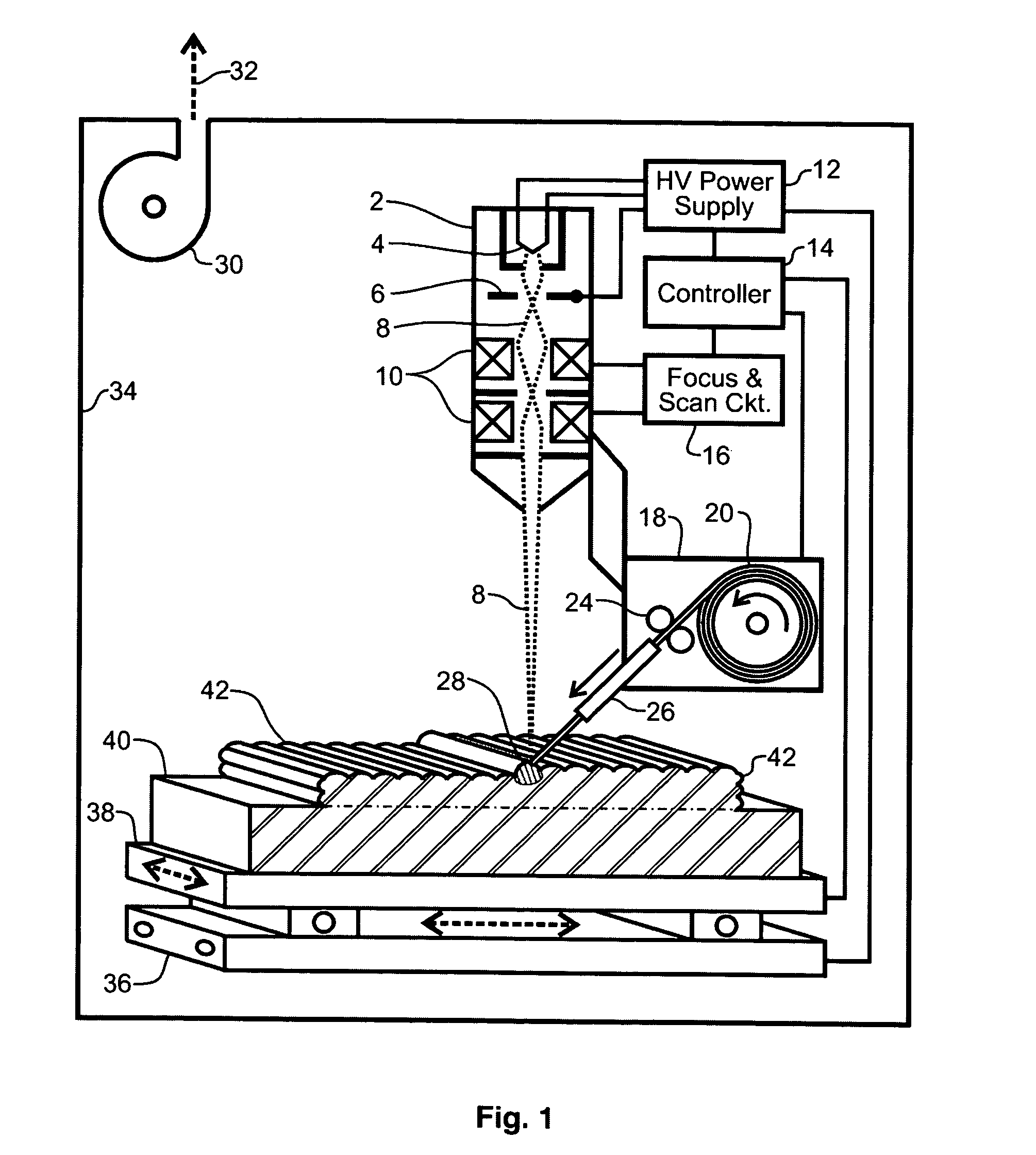

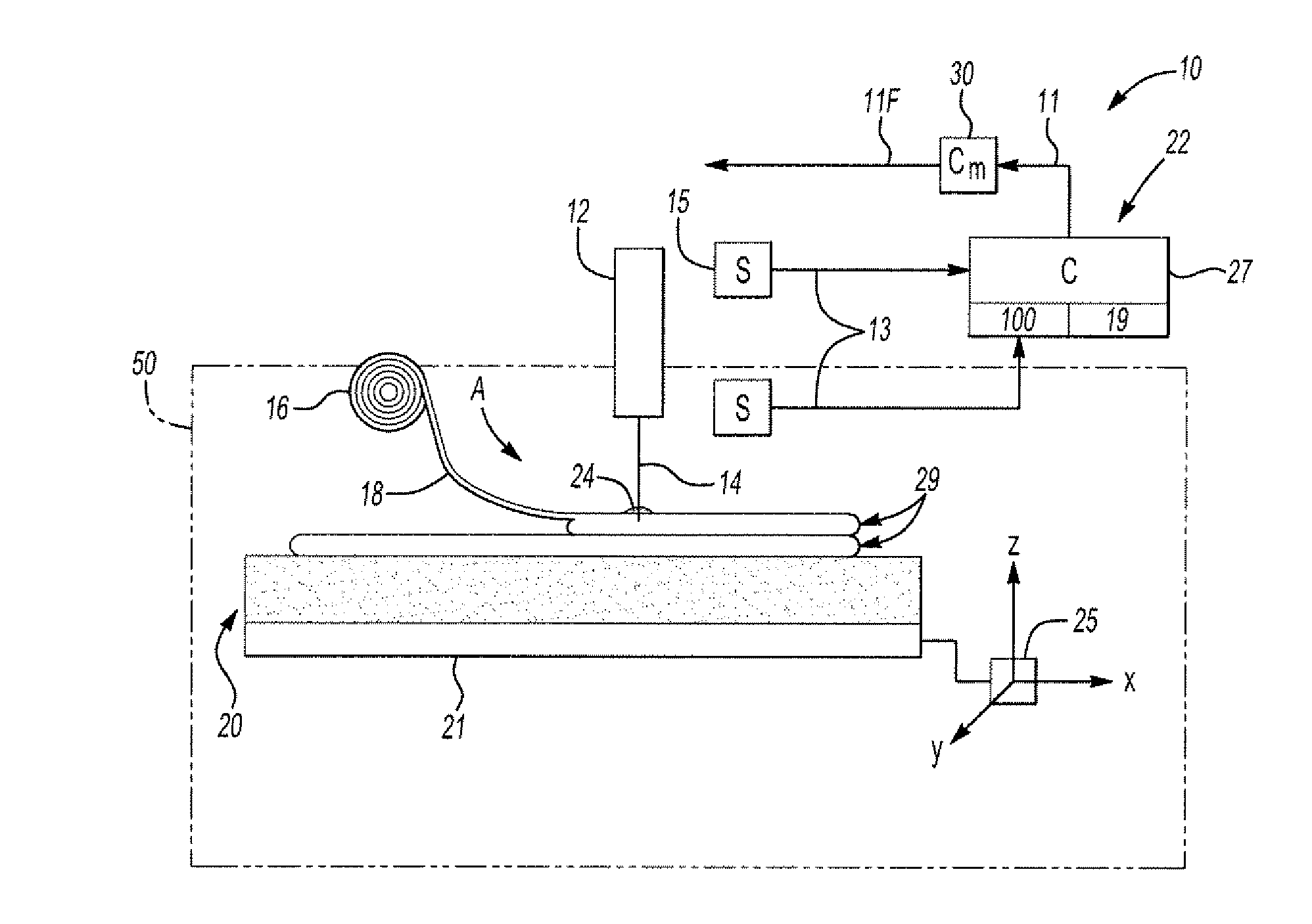

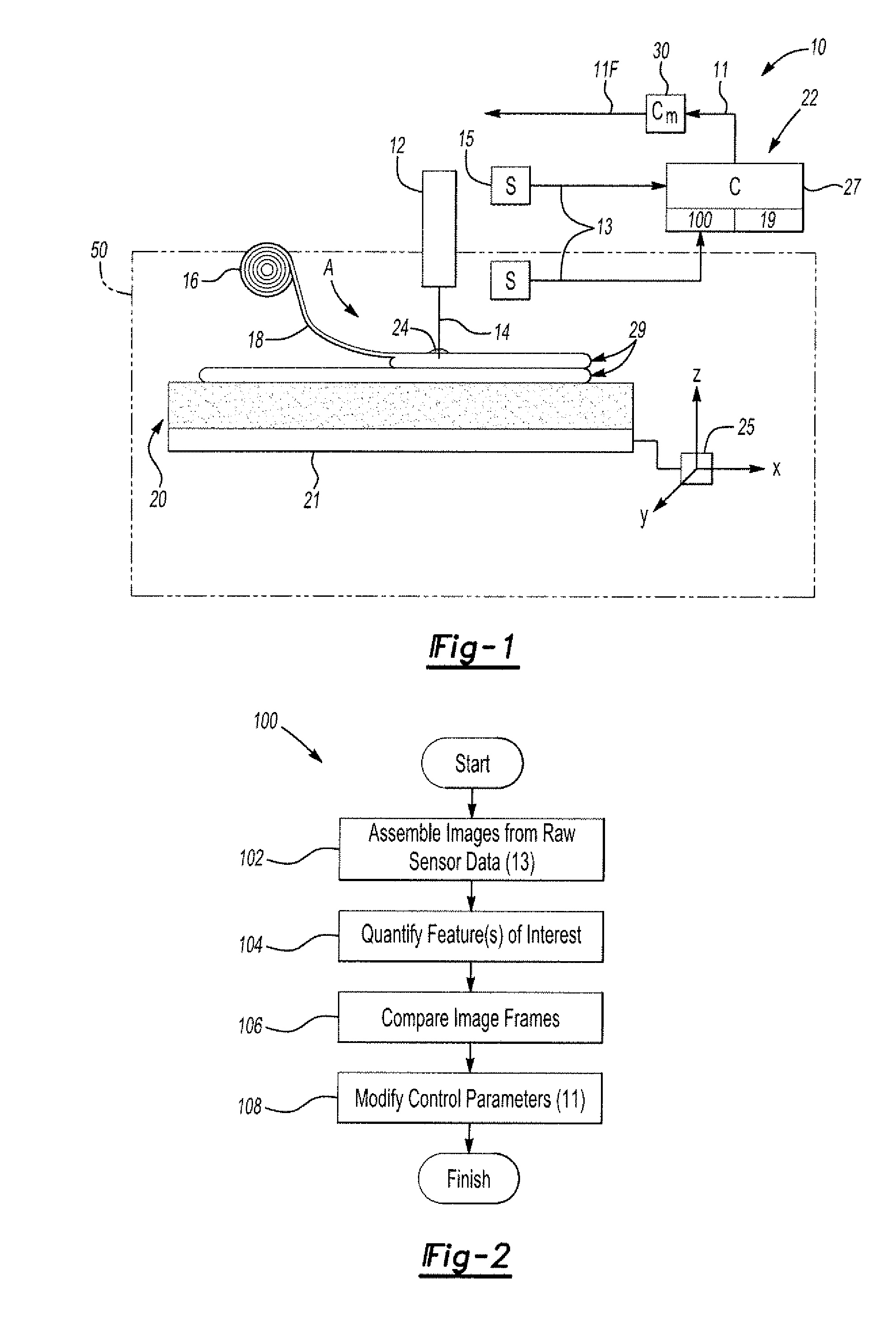

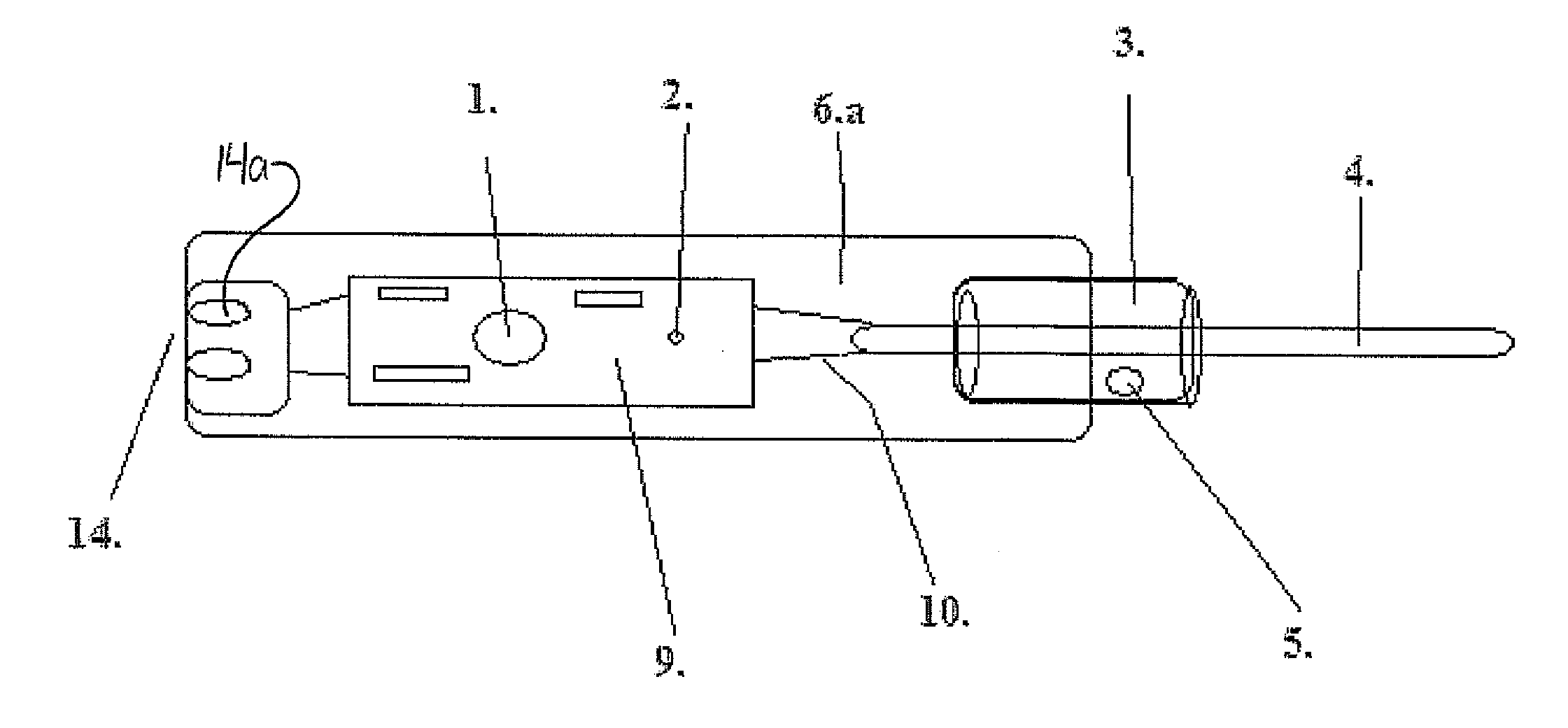

Closed-Loop Process Control for Electron Beam Freeform Fabrication and Deposition Processes

InactiveUS20100260410A1Electric discharge tubesCharacter and pattern recognitionClosed loopEngineering

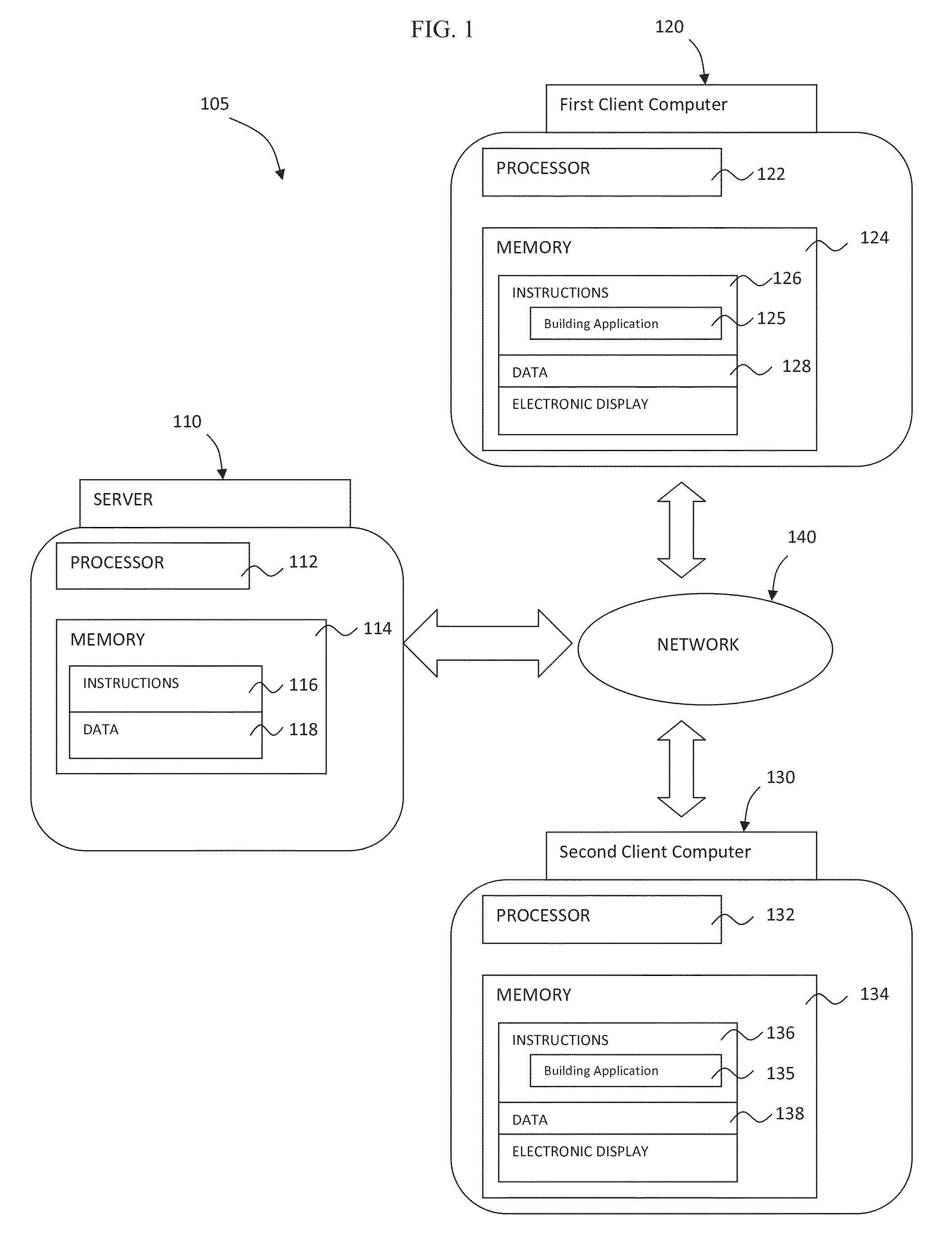

A closed-loop control method for an electron beam freeform fabrication (EBF3) process includes detecting a feature of interest during the process using a sensor(s), continuously evaluating the feature of interest to determine, in real time, a change occurring therein, and automatically modifying control parameters to control the EBF3 process. An apparatus provides closed-loop control method of the process, and includes an electron gun for generating an electron beam, a wire feeder for feeding a wire toward a substrate, wherein the wire is melted and progressively deposited in layers onto the substrate, a sensor(s), and a host machine. The sensor(s) measure the feature of interest during the process, and the host machine continuously evaluates the feature of interest to determine, in real time, a change occurring therein. The host machine automatically modifies control parameters to the EBF3 apparatus to control the EBF3 process in a closed-loop manner.

Owner:NASA

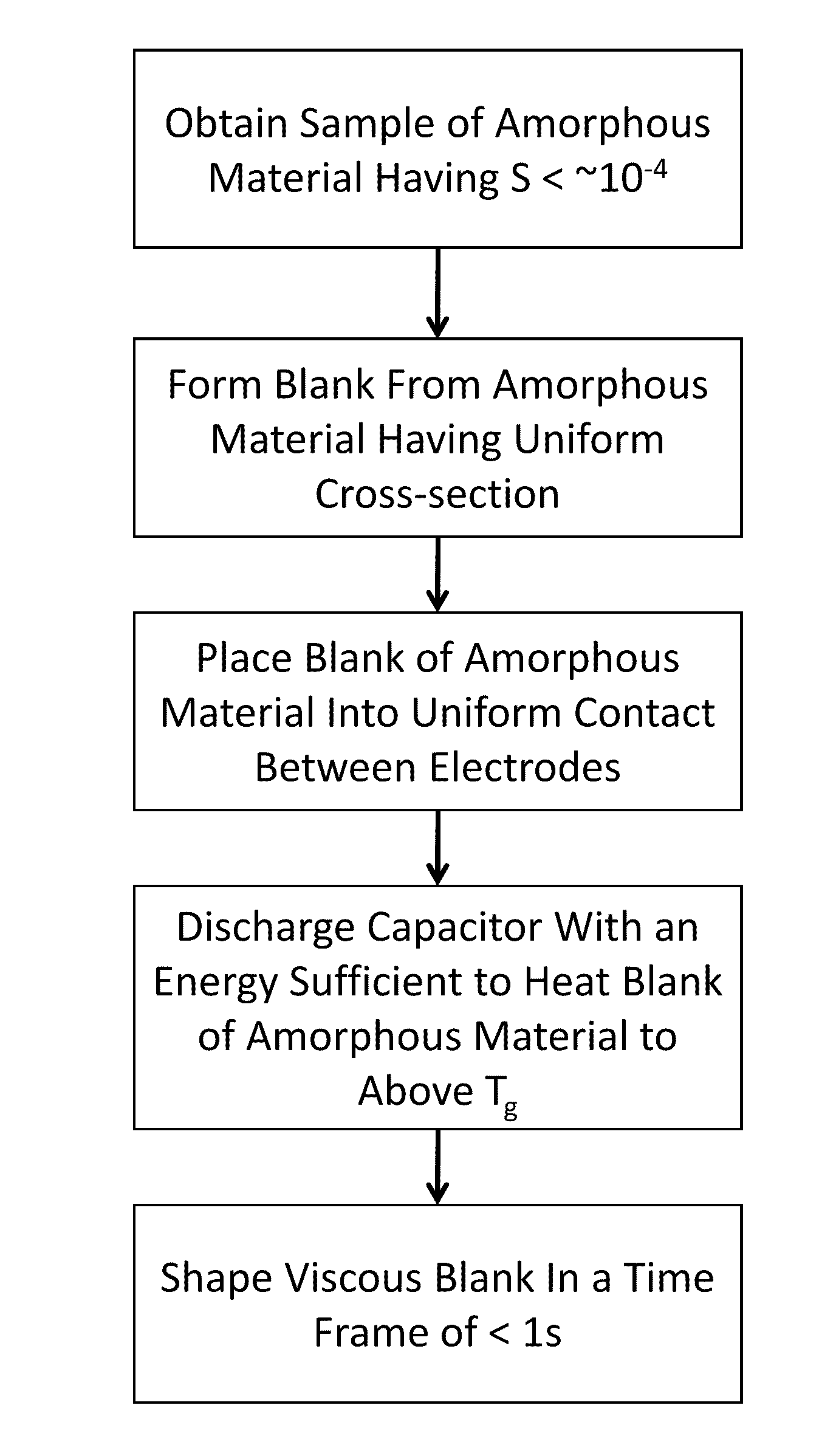

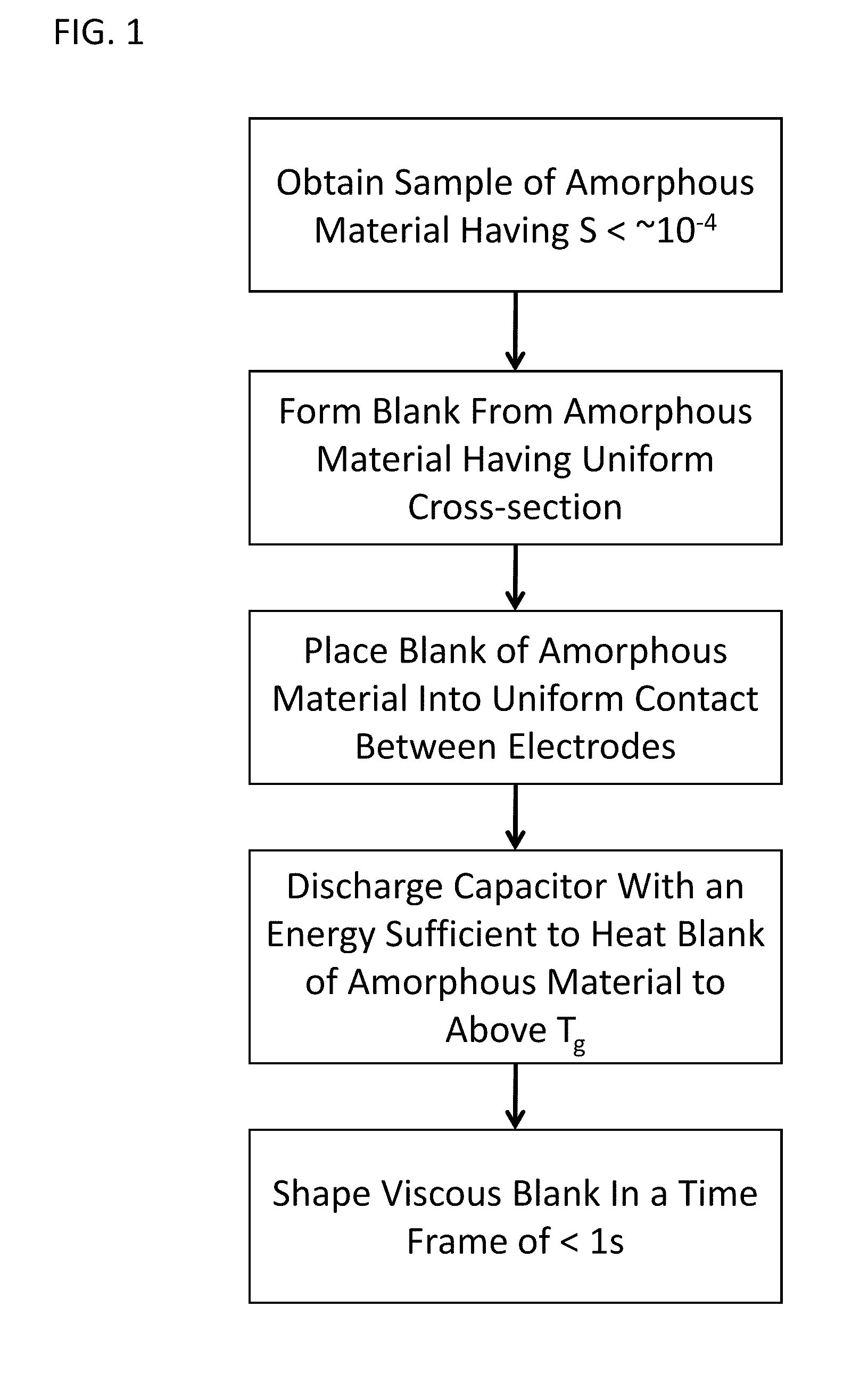

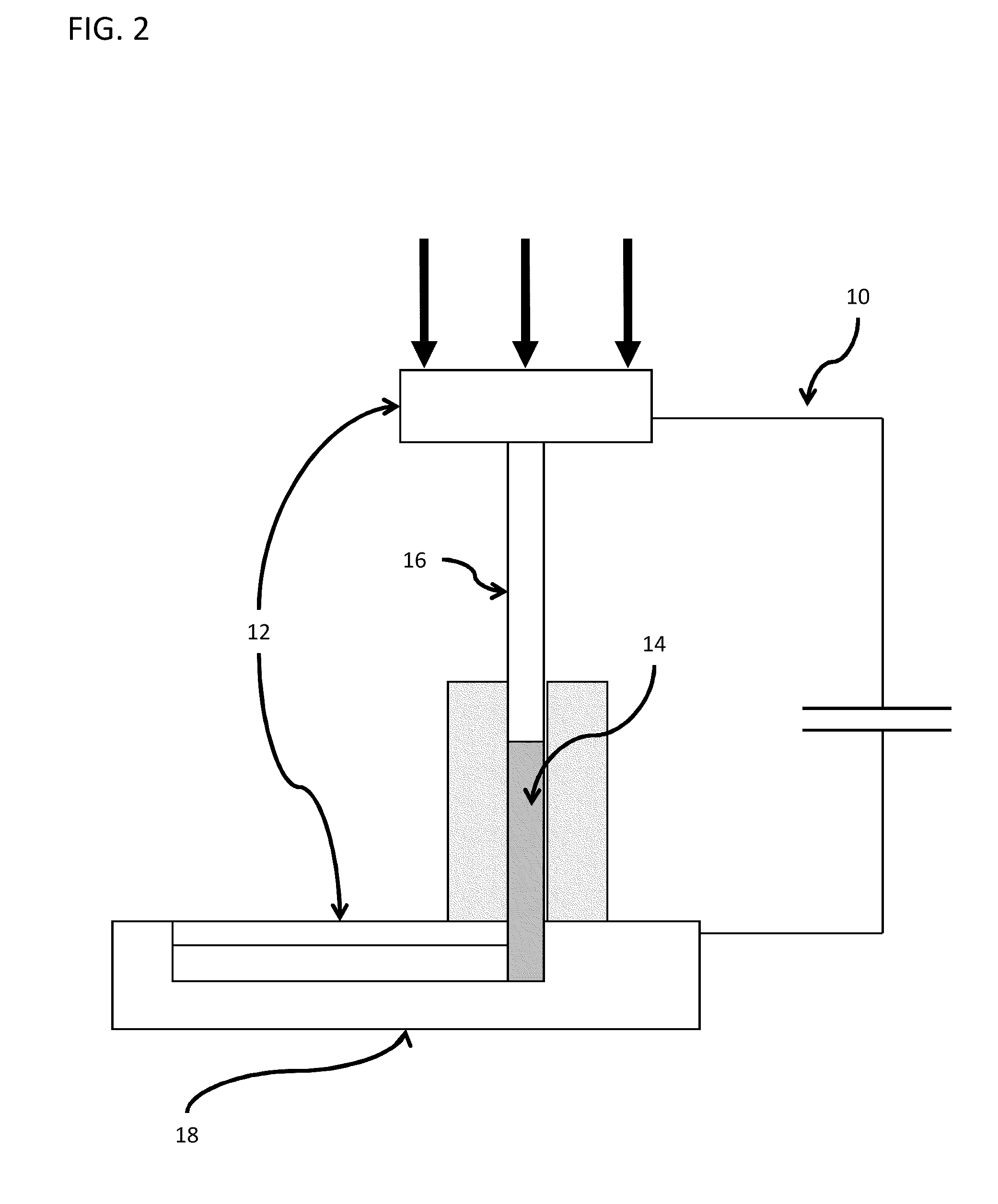

Forming of metallic glass by rapid capacitor discharge

ActiveUS20090236017A1Avoid failureAvoid thermal transport and development of thermalDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

Method and device for characterizing an electron beam

ActiveUS20160211116A1Solve the lack of spaceEasy to manufactureAdditive manufacturing apparatusElectric discharge tubesGratingX-ray

A device for detecting X-rays radiated out of a substrate surface, said device comprising at least one X-ray detector, a resolver grating and a modulator grating, said resolver grating with at least one opening facing towards said X-ray detector is arranged in front of said X-ray detector. Said modulator grating is provided between said resolver grating and said substrate at a predetermined distance from said resolver grating and said substrate, where said modulator grating having a plurality of openings in at least a first direction, wherein said x-rays from said surface is spatially modulated with said modulator grating and resolver grating.

Owner:ARCAM AB

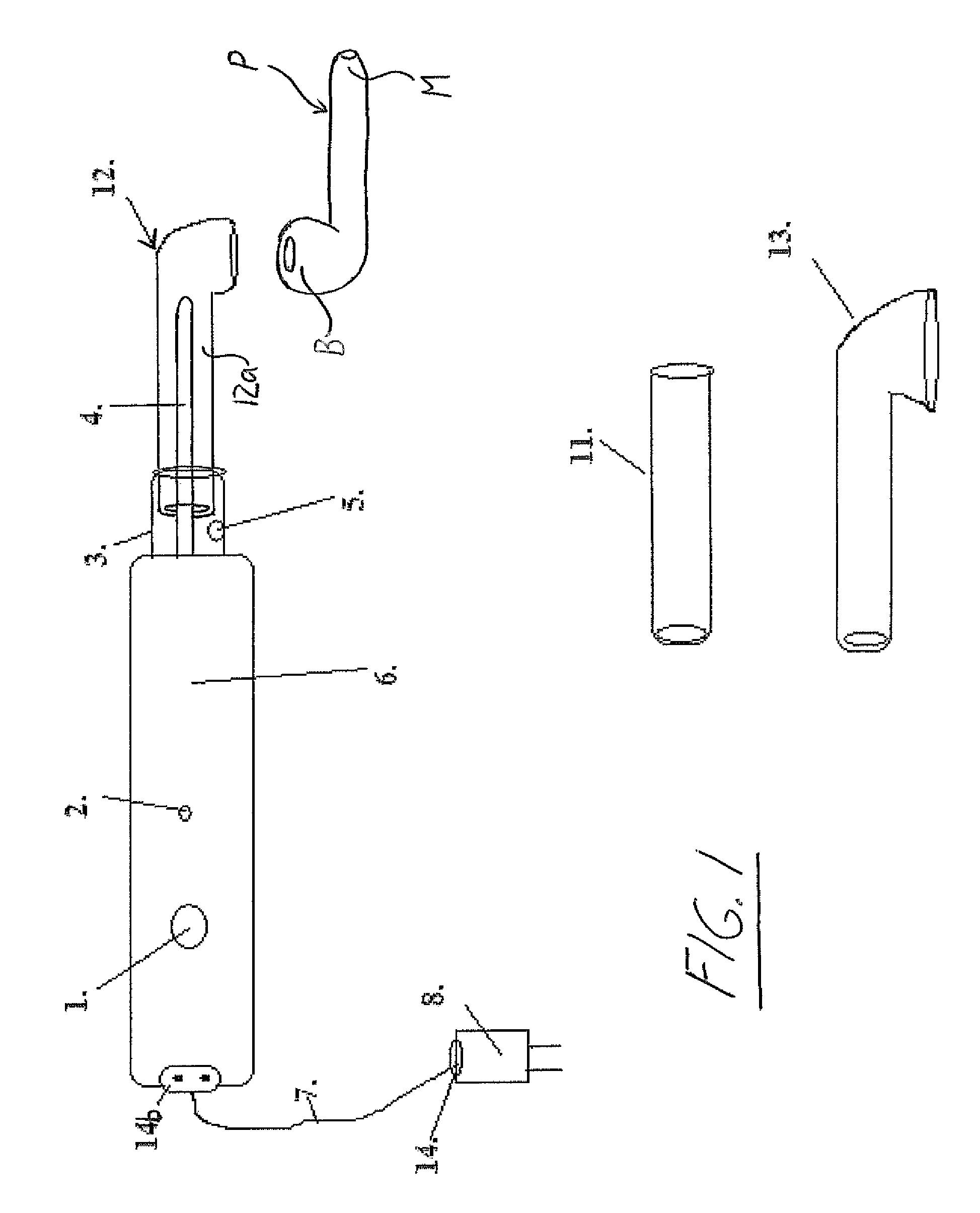

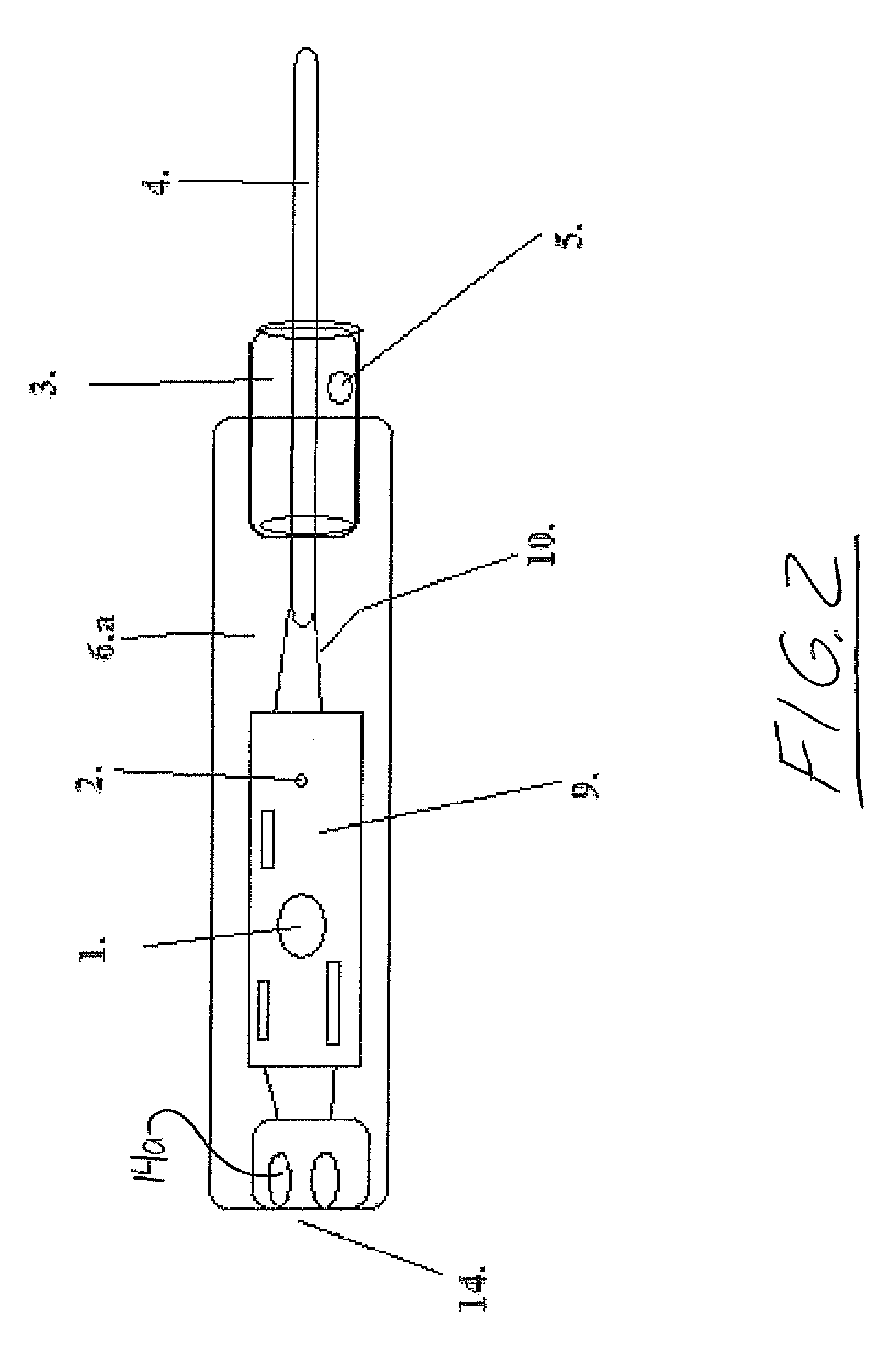

Apparatus and Method for Vaporizing Volatile Material

A volatile material vaporizing apparatus features a heating element and heating element controls supported in separate housings to avoid exposure of the controls to heat produced by the heating element. Another embodiment features an elongate heating element supported entirely within a housing having an open end sized to fit over the bowl of an existing smoking device so that drawing air through the smoking device induces airflow into an inlet opening of the housing, along the heating element disposed therein, and onward to the smoking device. In another embodiment, a housing includes a plug portion slidable into a cigarette lighter socket of a vehicle to establish connection with electrical contacts therein. A heating chamber opposite the plug portion is in fluid communication with a heating element in the housing, and an inlet opening allows airflow into the housing for flow along the heating element into the heating chamber.

Owner:SELENSKI TIM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com