Patents

Literature

3869results about "Electric/magnetic/electromagnetic heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer solution for nanoimprint lithography to reduce imprint temperature and pressure

InactiveUS20040110856A1Reduce pressureReduce the temperatureNanostructure manufactureDecorative surface effectsCross-linkVitrification

A method of forming features on substrates by imprinting is provided. The method comprises: (a) forming a polymer solution comprising at least one polymer dissolved in at least one polymerizable monomer; and (b) depositing the polymer solution on a substrate to form a liquid film thereon; and then either: (c) curing the liquid film by causing the monomer(s) to polymerize and optionally cross-linking the polymer(s) to thereby form a polymer film, the polymer film having a glass transition temperature (Tg); and imprinting the polymer film with a mold having a desired pattern to form a corresponding negative pattern in the polymer film, or (d) imprinting the liquid film with the mold and curing it to form the polymer film. The temperature of imprinting is as little as 10° C. above the Tg, or even less if the film is in the liquid state. The pressure of the imprinting can be within the range of 100 to 500 psi.

Owner:HEWLETT PACKARD DEV CO LP

Solid free-form fabrication methods for the production of dental restorations

InactiveUS20050023710A1Improve bindingImpression capsCeramic shaping apparatusPolymer scienceFree form

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

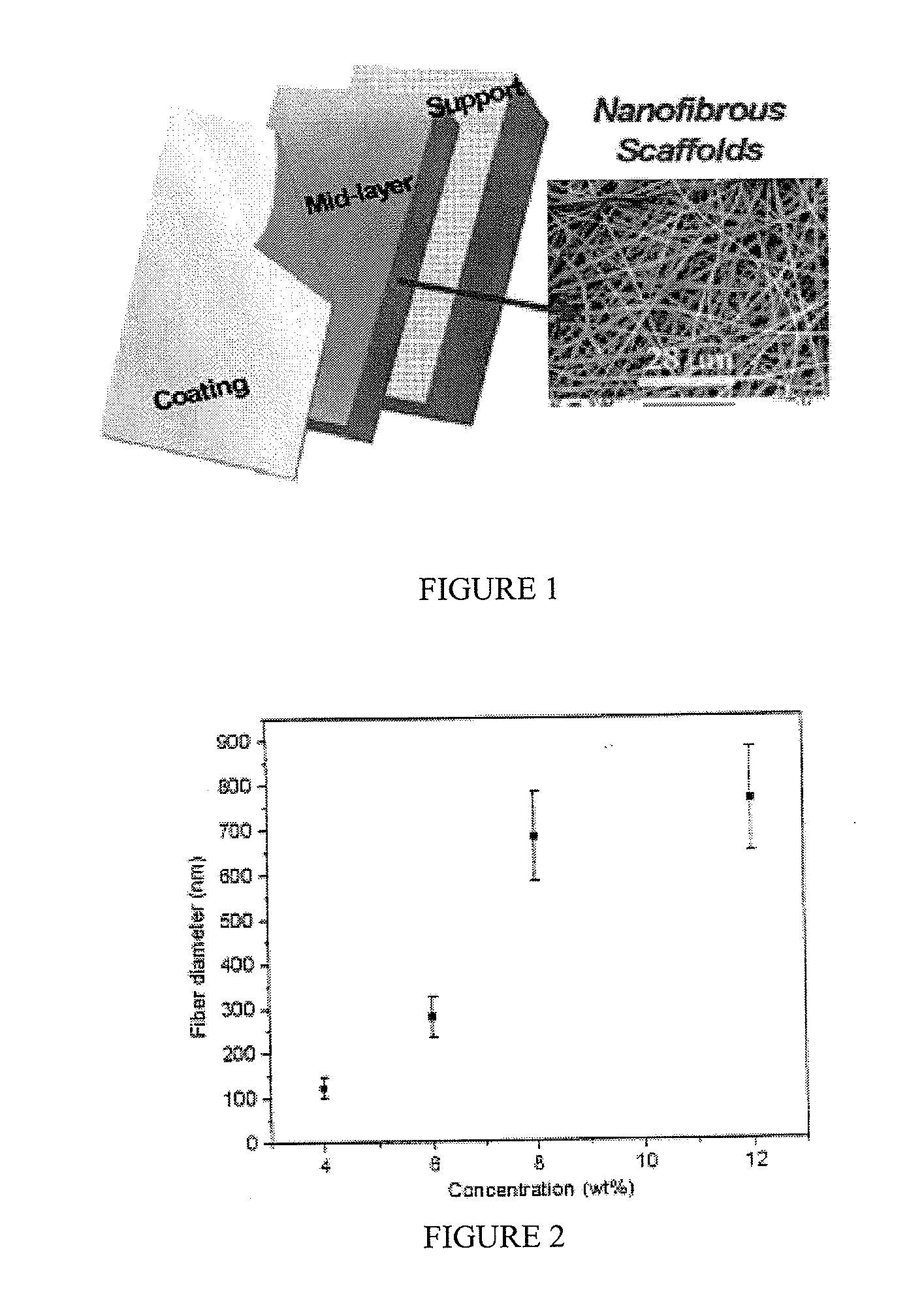

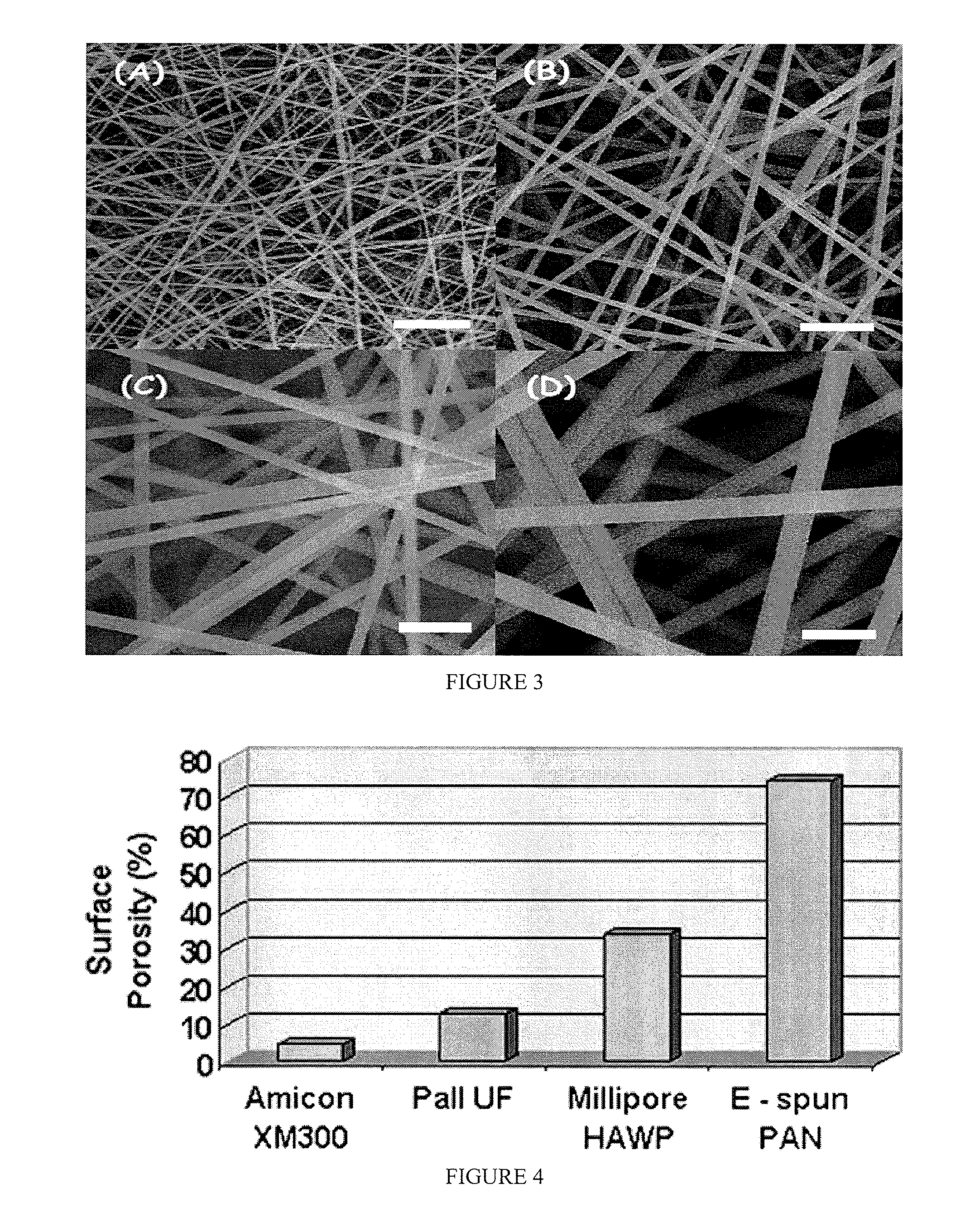

Articles Comprising a Fibrous Support

Articles comprising a fibrous support of nanofibers and an interfacially polymerized polymer layer disposed on a surface of the fibrous support are useful, e.g., as fluid separation membranes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

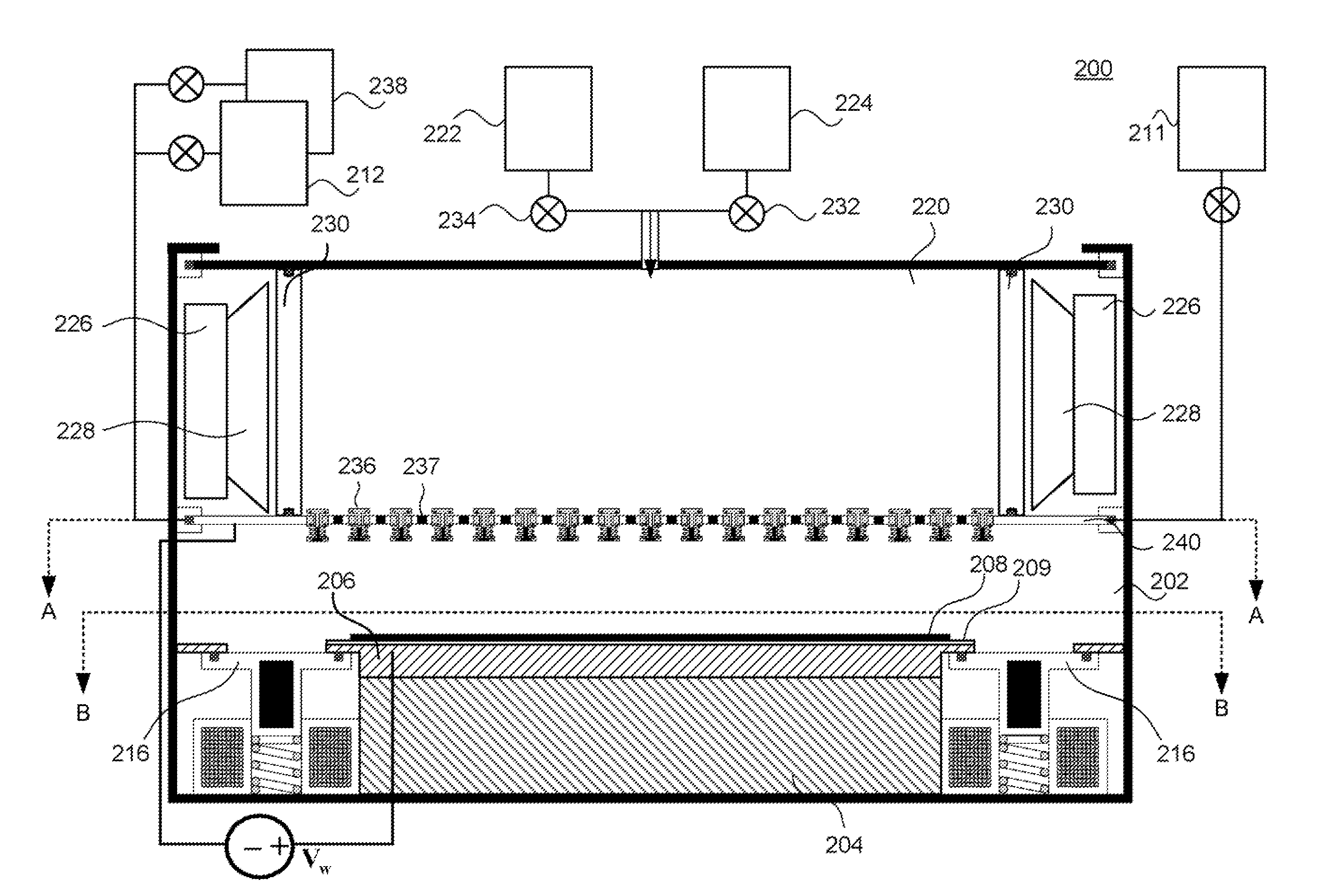

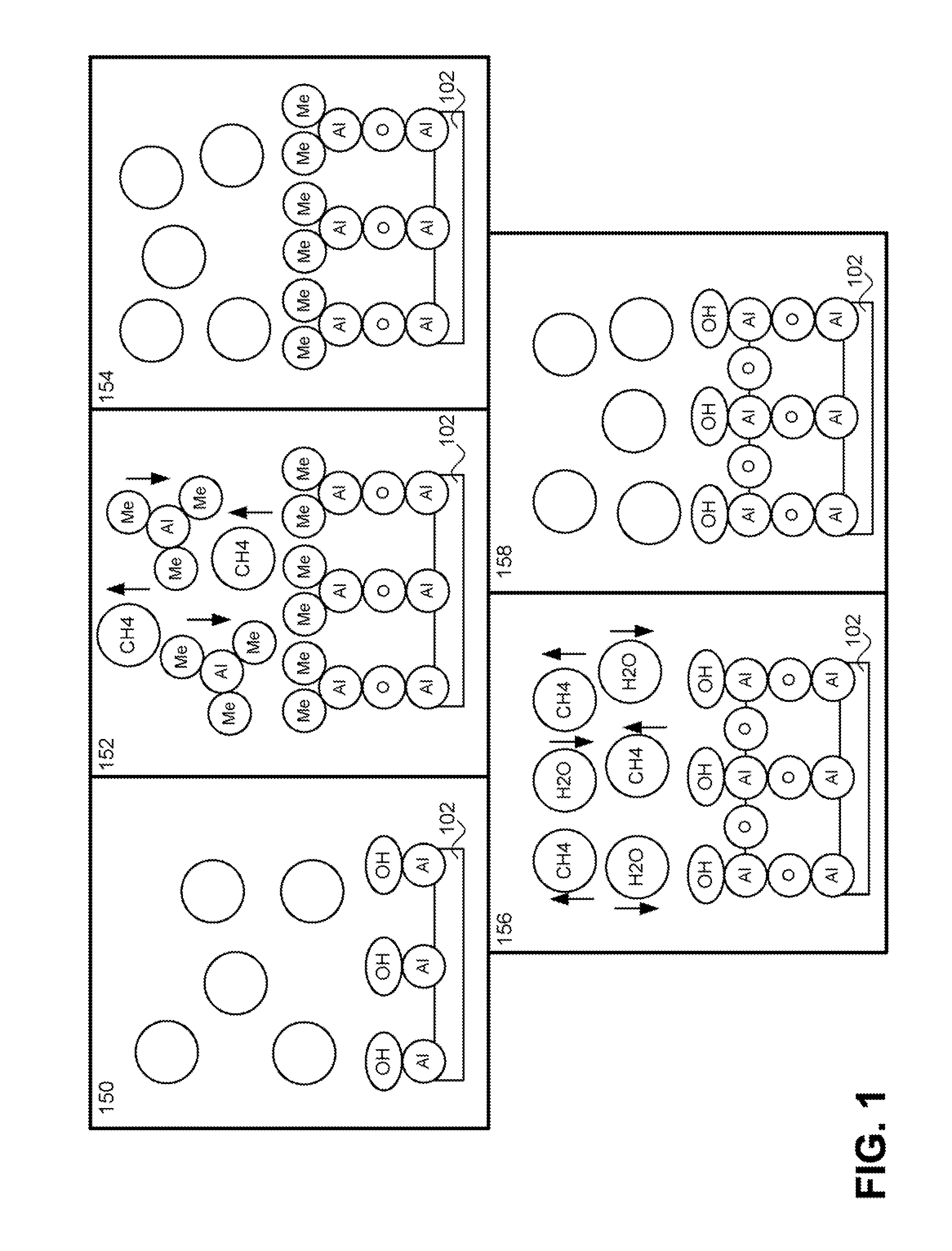

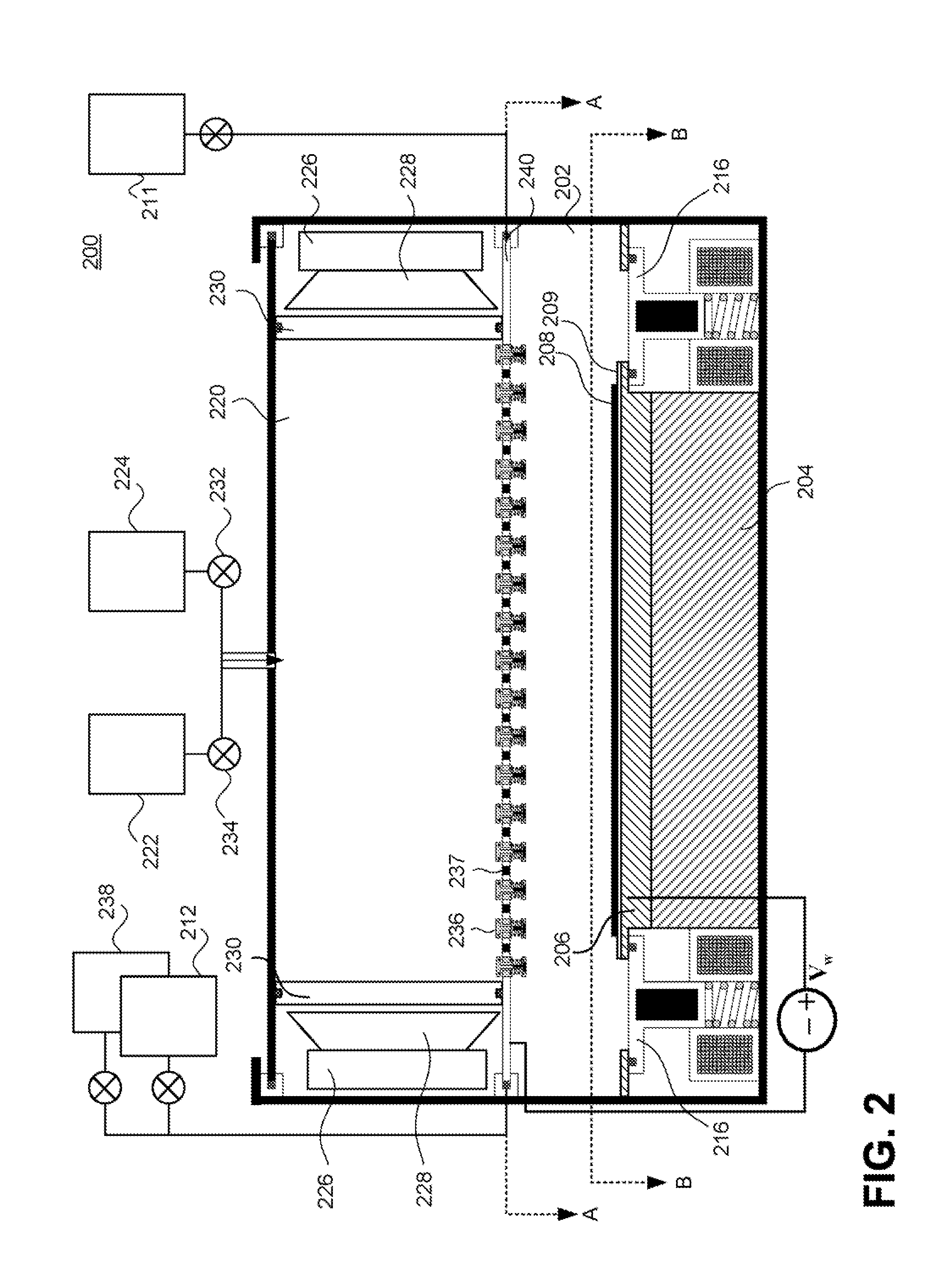

Flash Heating in Atomic Layer Deposition

InactiveUS20070281082A1Control performanceSave stepsSolid-state devicesPretreated surfacesMetallurgyAtomic layer deposition

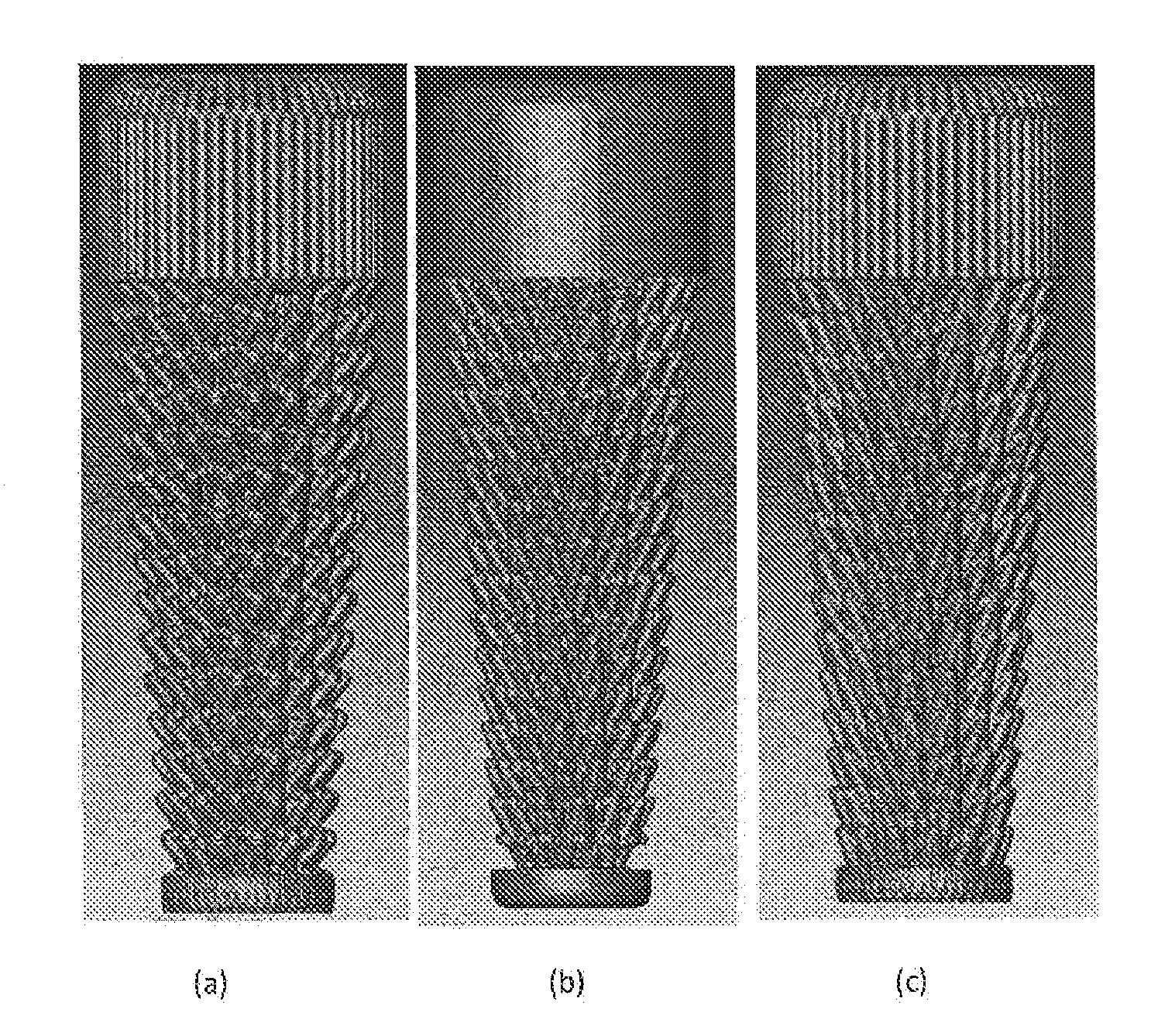

System and methods for flash heating of materials deposited using atomic layer deposition techniques are disclosed. By flash heating the surface of the deposited material after each or every few deposition cycles, contaminants such as un-reacted precursors and byproducts can be released from the deposited material. A higher quality material is deposited by reducing the incorporation of impurities. A flash heating source is capable of quickly raising the temperature of the surface of a deposited material without substantially raising the temperature of the bulk of the substrate on which the material is being deposited. Because the temperature of the bulk of the substrate is not significantly raised, the bulk acts like a heat sink to aid in cooling the surface after flash heating. In this manner, processing times are not significantly increased in order to allow the surface temperature to reach a suitably low temperature for deposition.

Owner:SANDISK TECH LLC

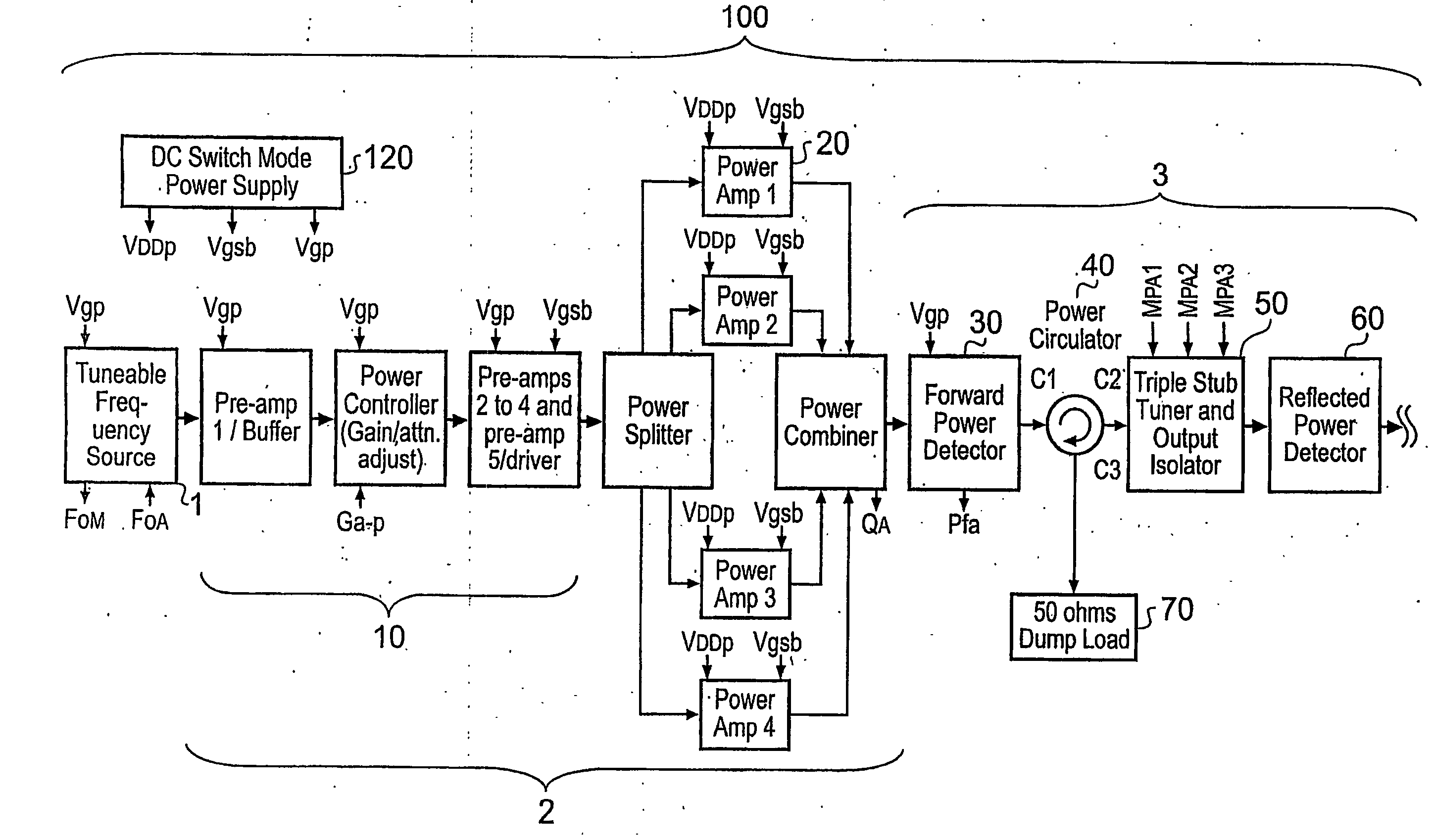

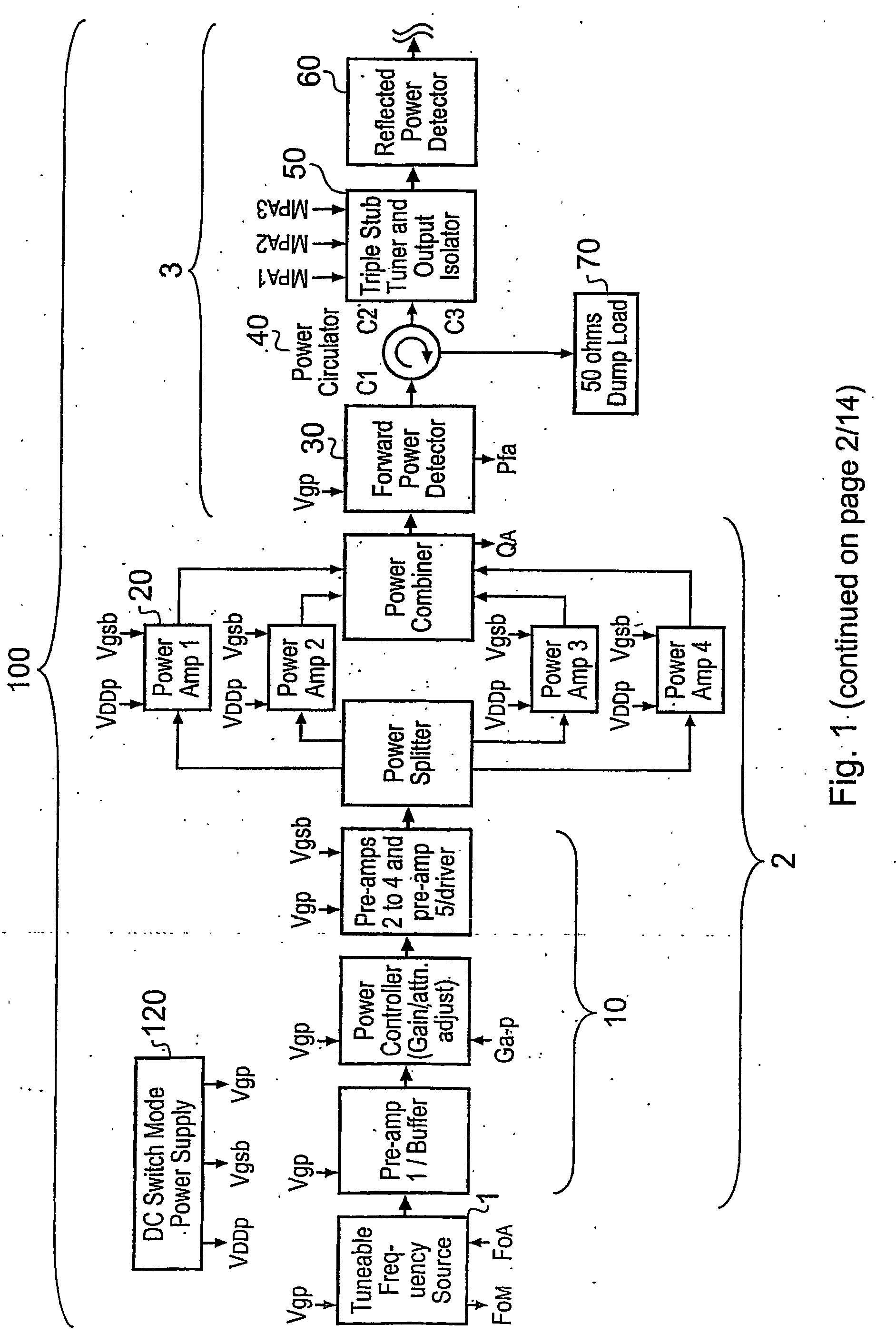

Tissue ablation apparatus and method of ablating tissue

InactiveUS20060155270A1Improve energy efficiencyQuantity minimizationSurgical instruments for heatingSurgical instruments using microwavesLocal oscillatorElectrical impedance

An apparatus and method for ablating tissue is disclosed. The apparatus comprises a source of microwave radiation (1), a probe (5) for directing the microwave radiation into tissue, one or more detectors for detecting the power and phase of the microwave radiation and an impedance adjuster (50) for adjusting impedance so as to minimize the amount of microwave radiation which reflected back through the probe. The detector or detectors use a local oscillator (230) to derive the phase information. A modulator for modulating the microwave radiation to a cutting frequency is also disclosed.

Owner:MEDICAL DEVICE INNOVATIONS

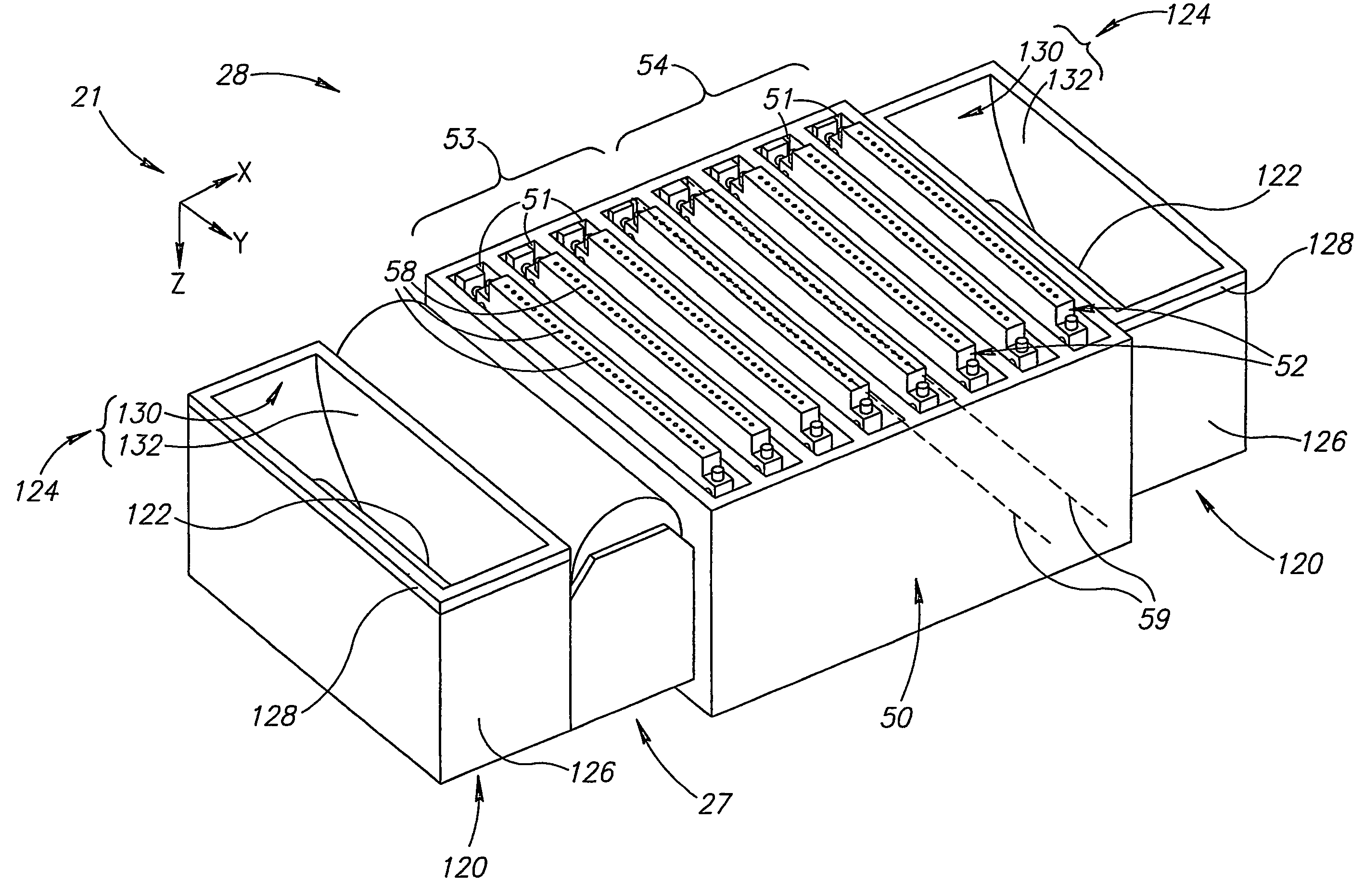

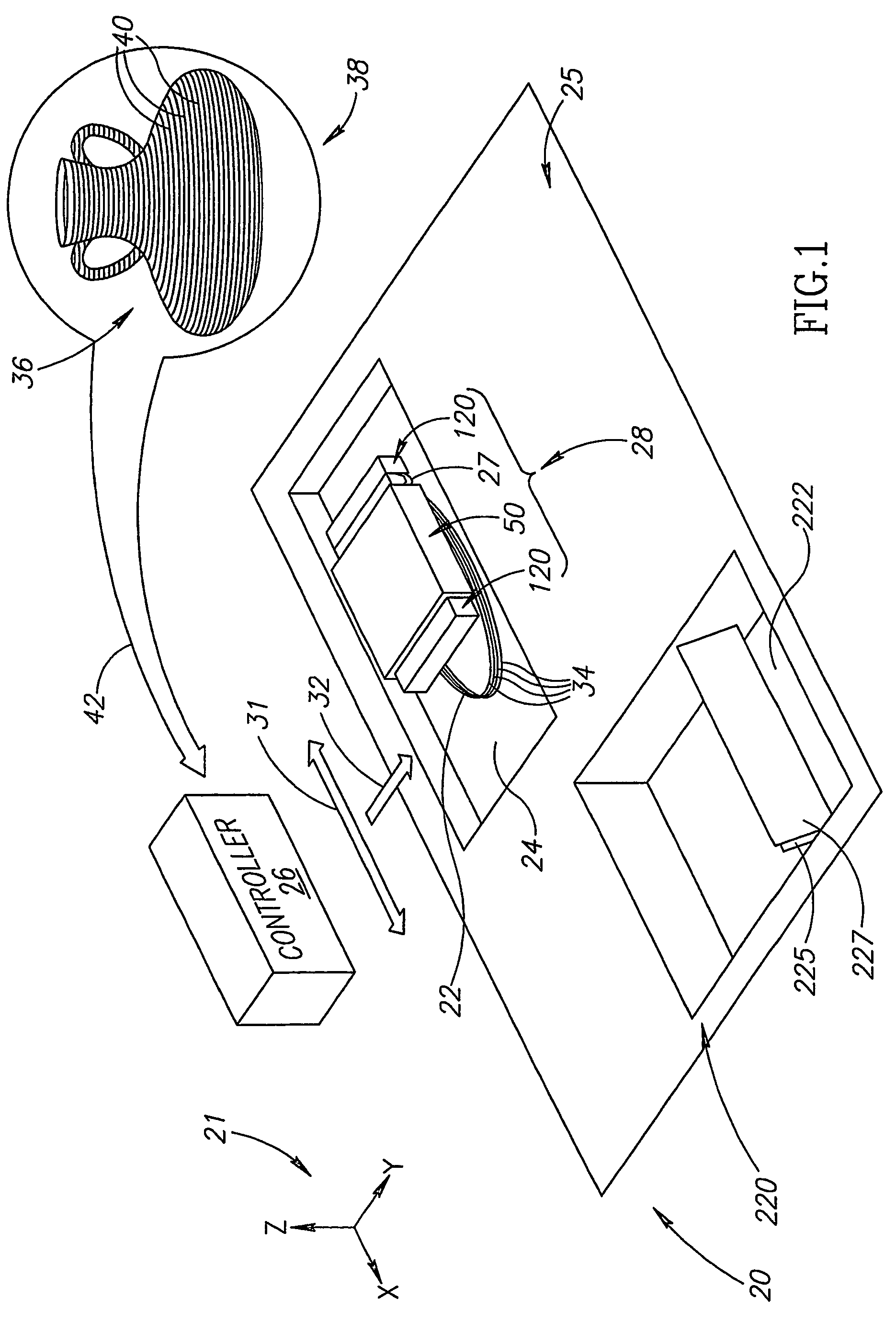

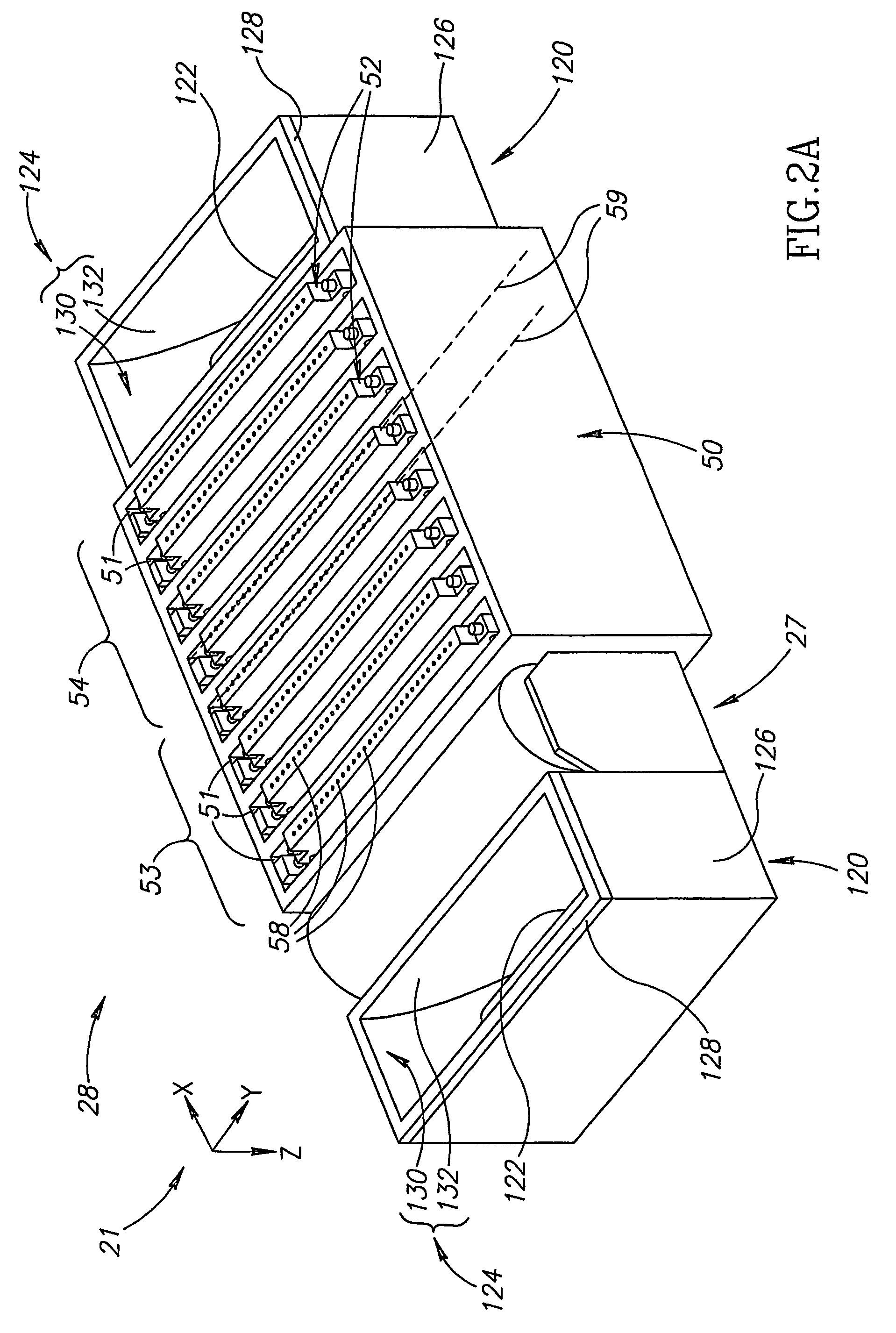

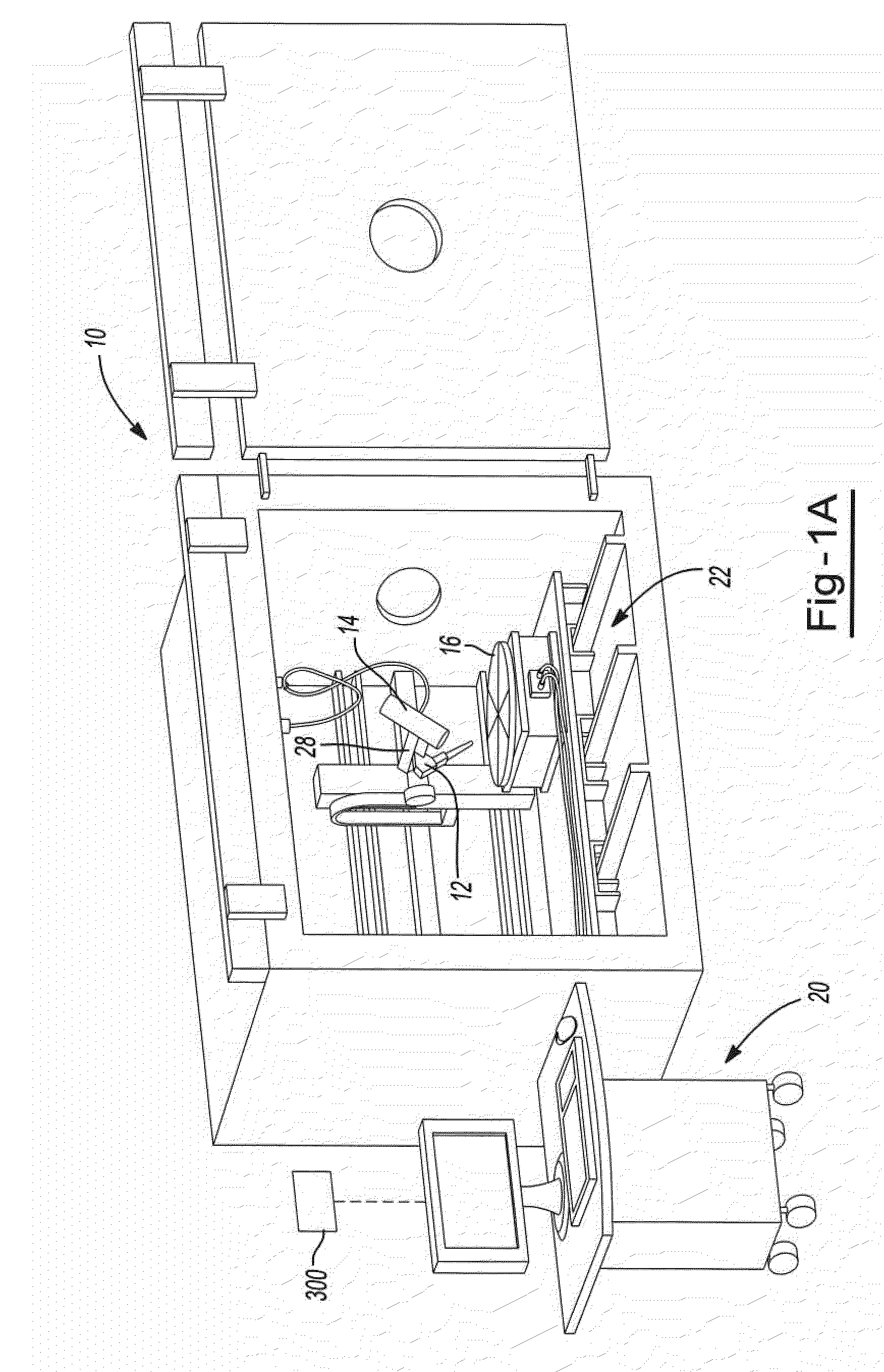

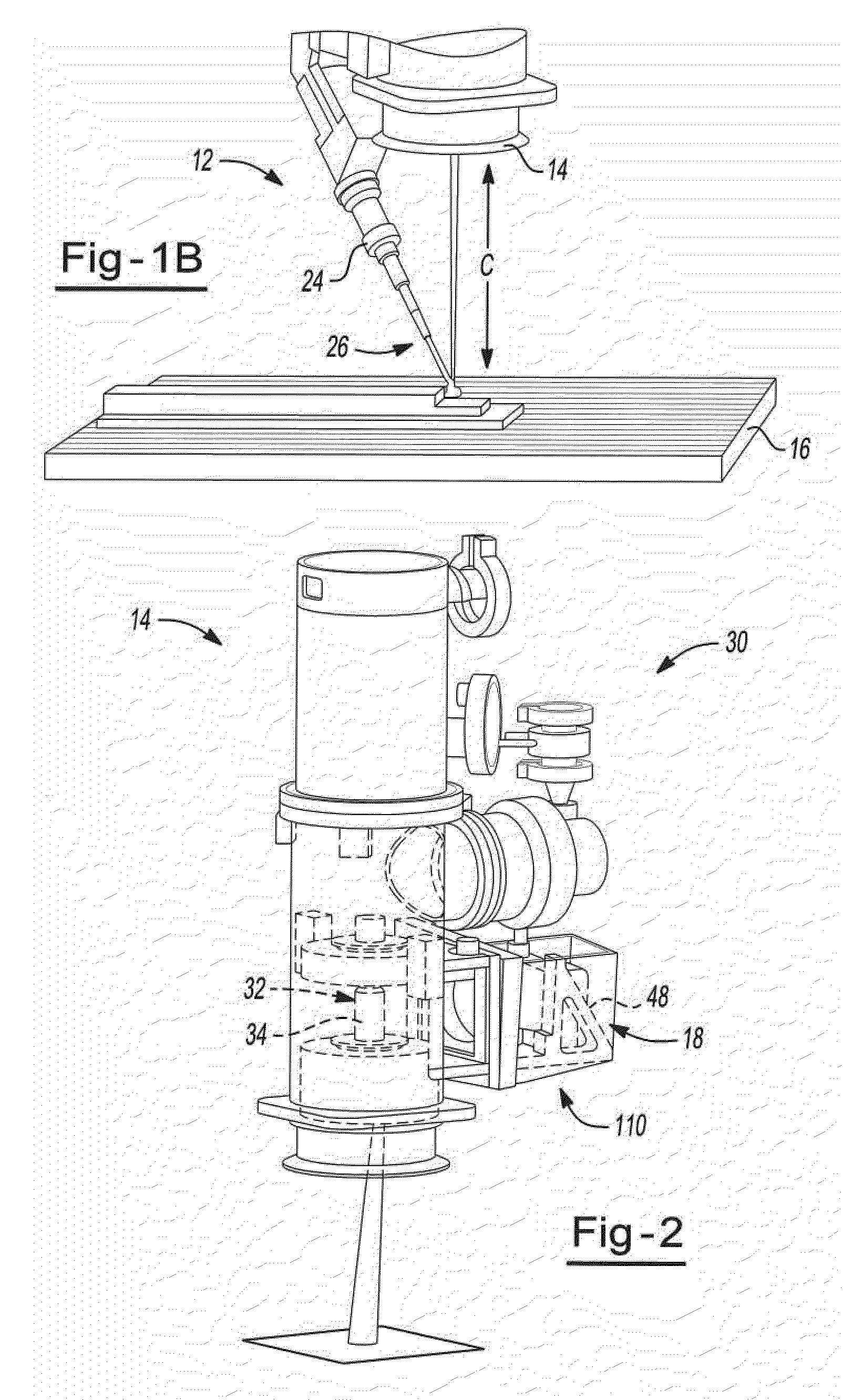

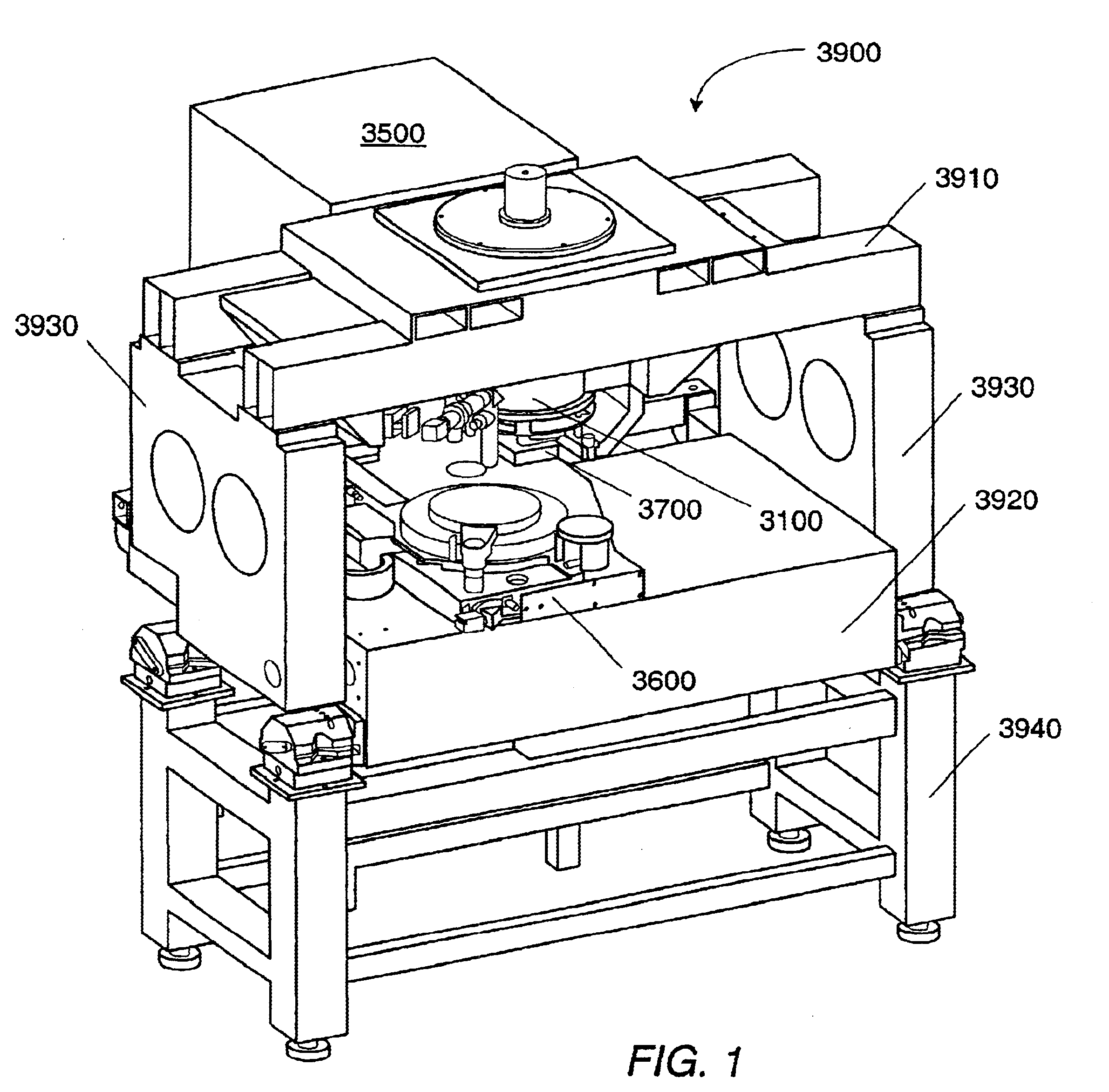

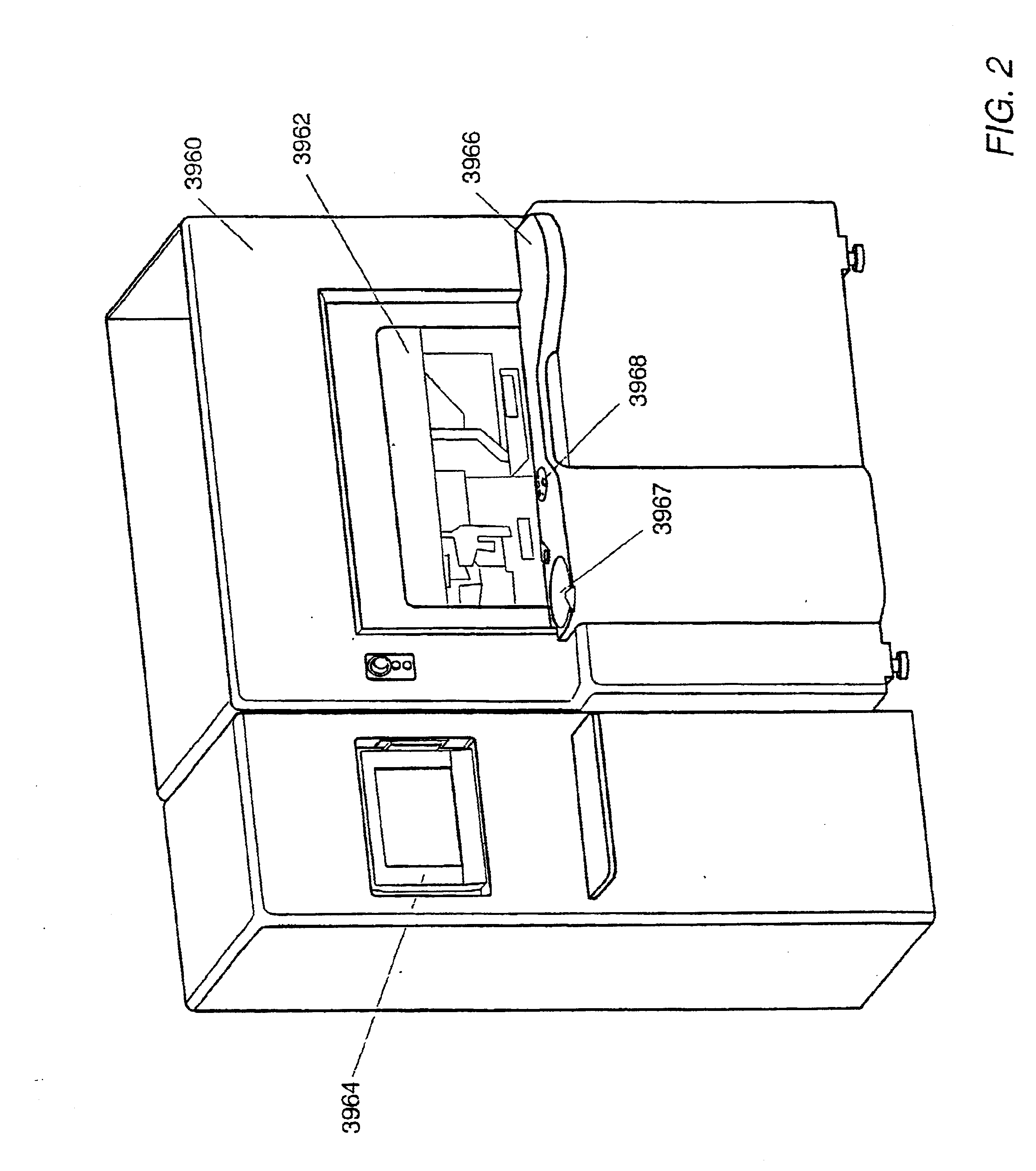

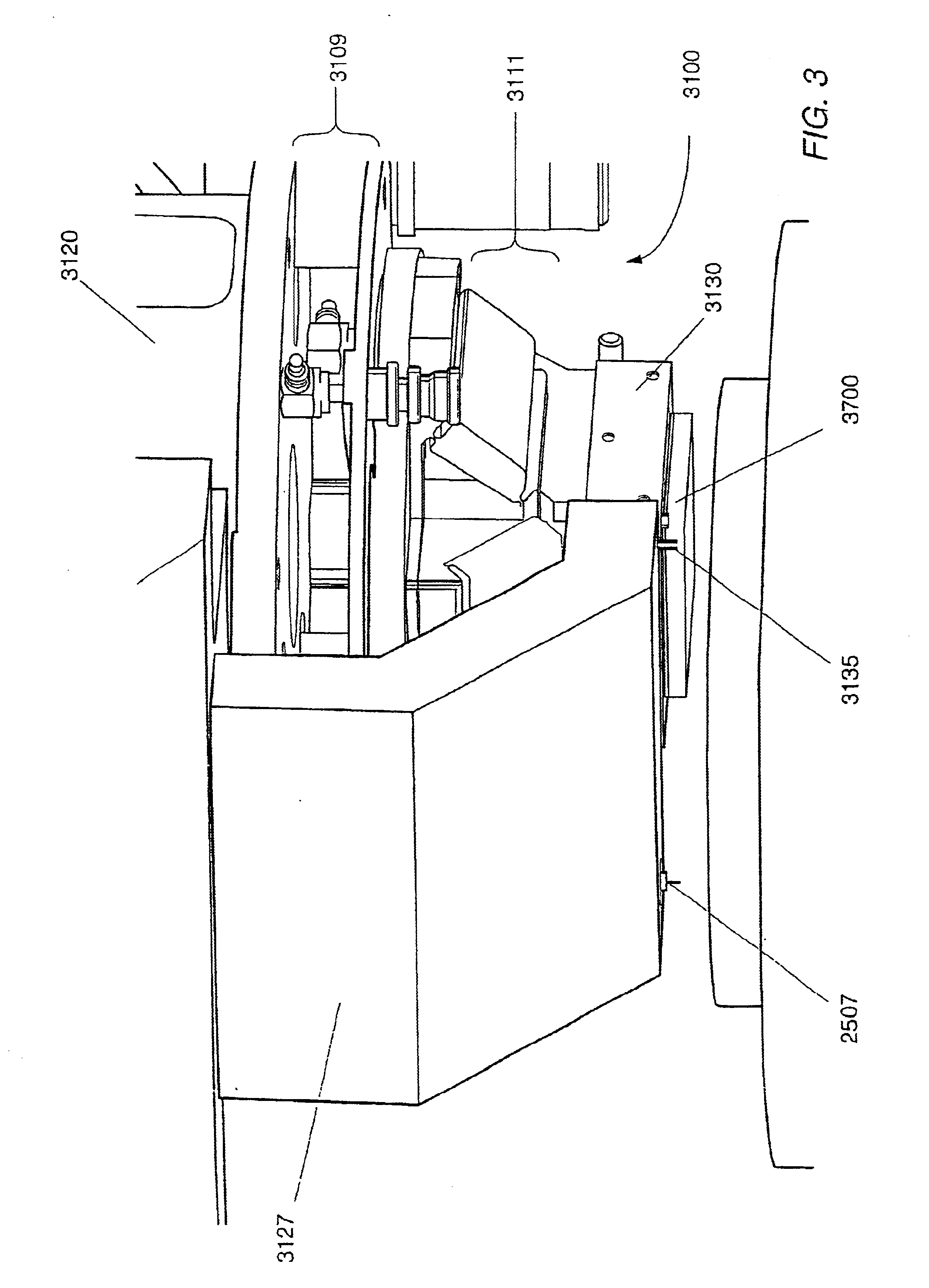

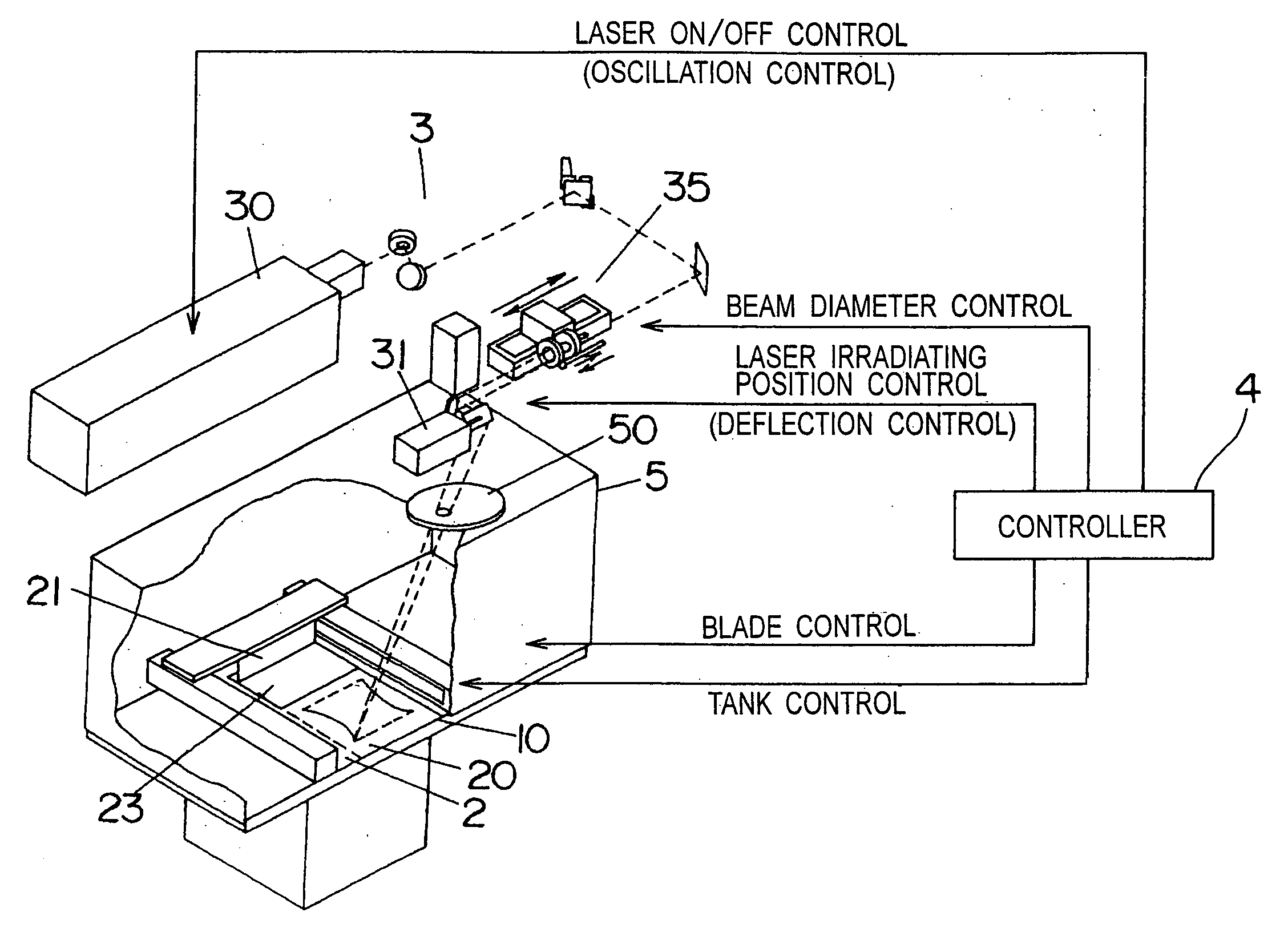

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

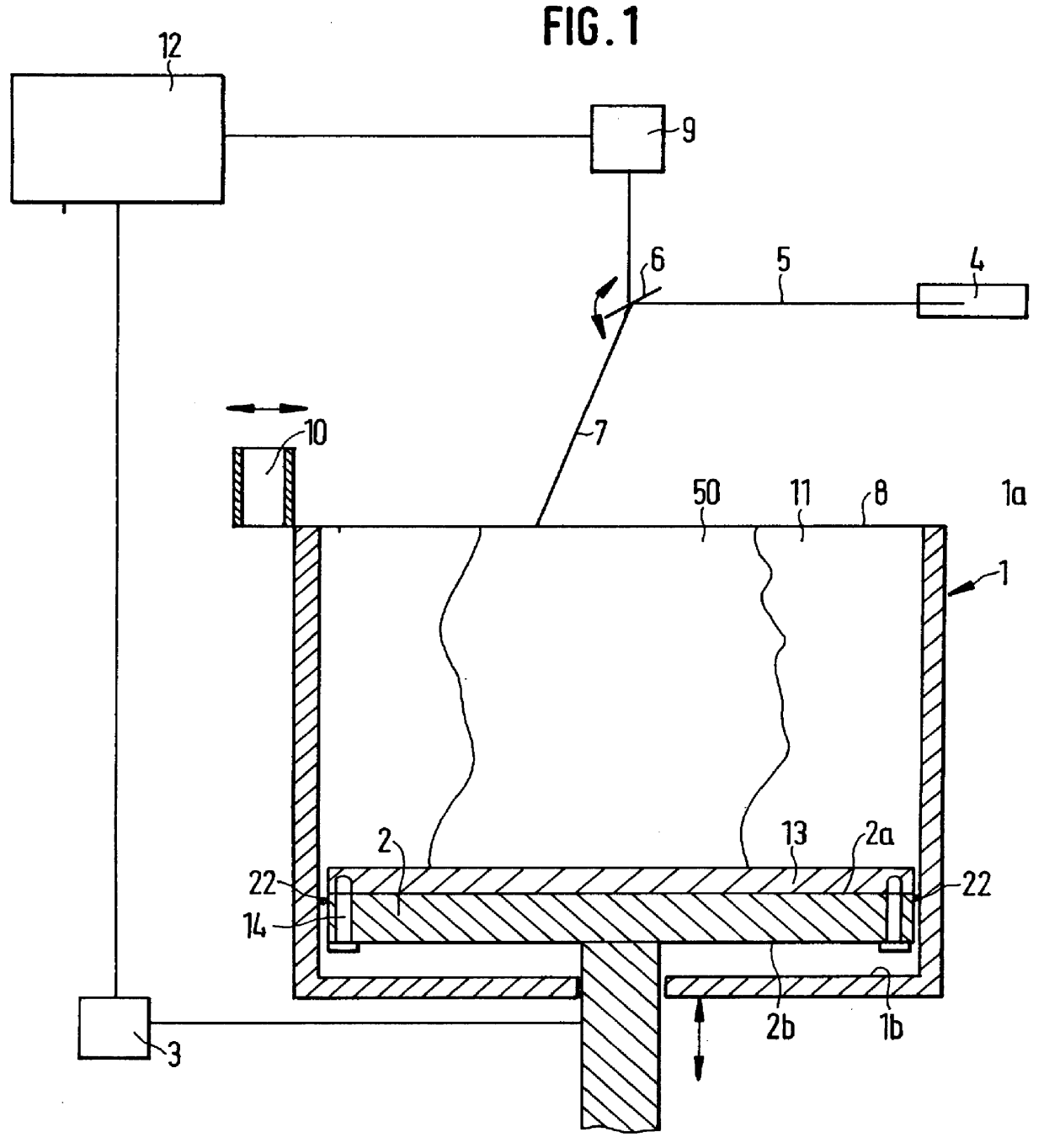

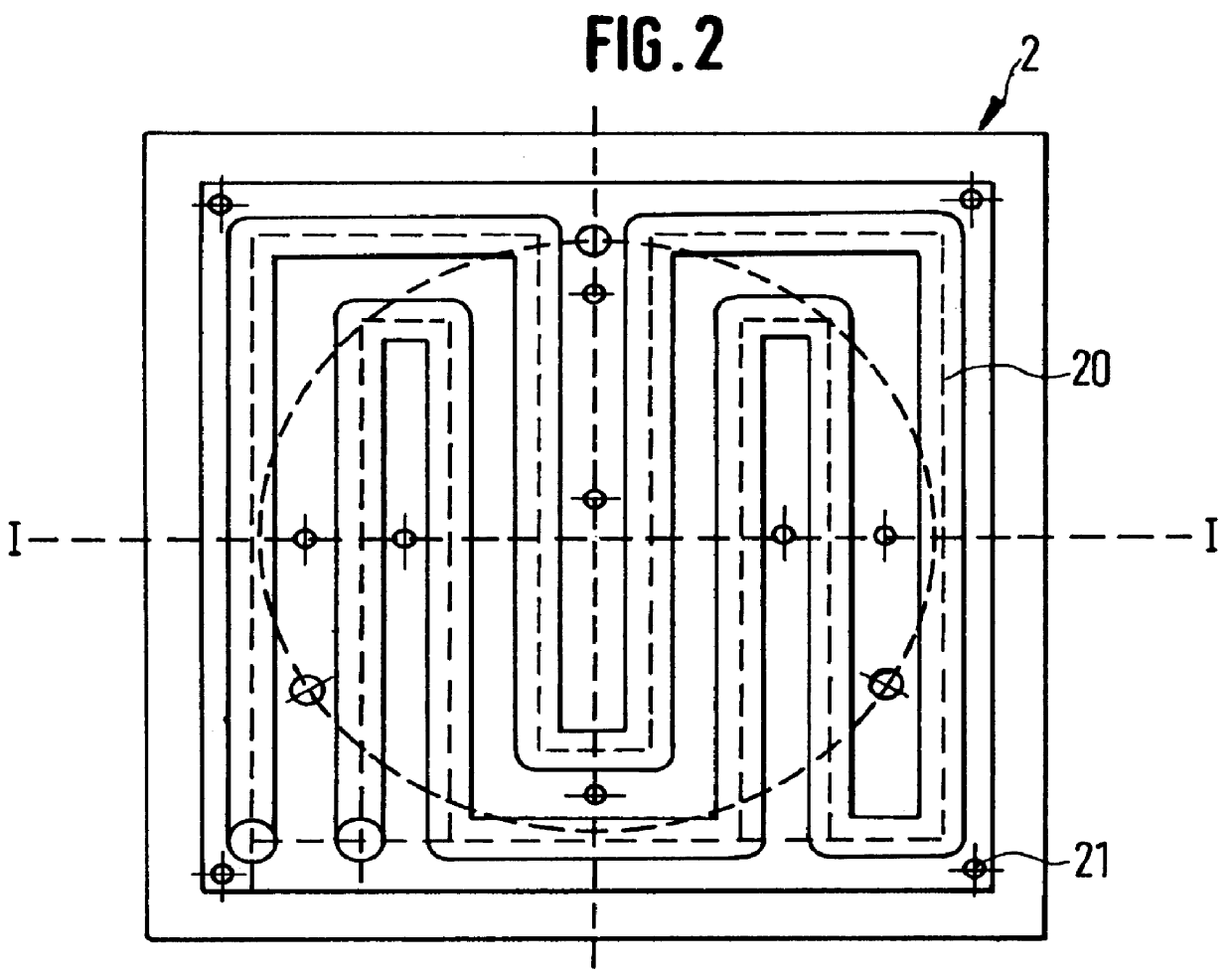

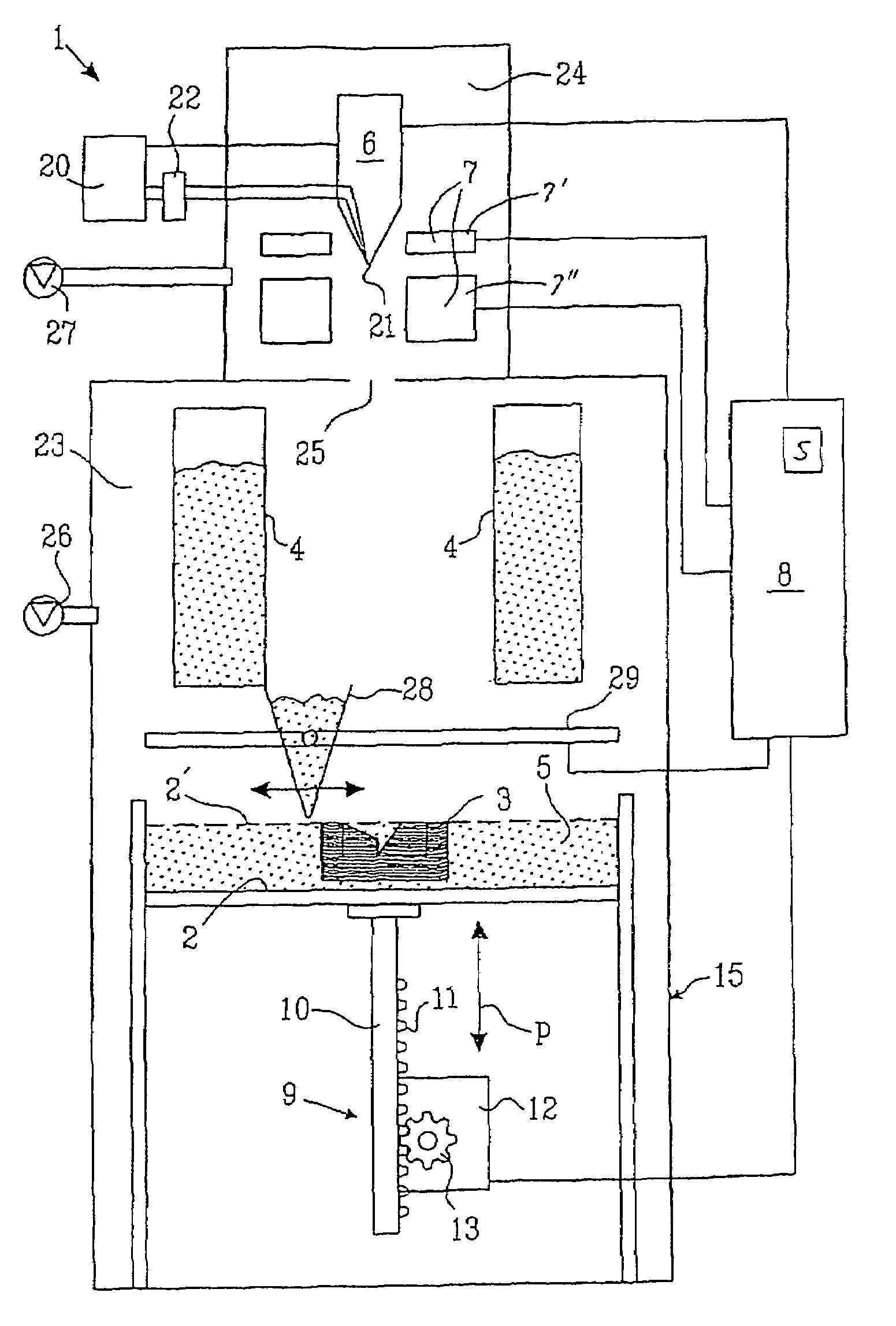

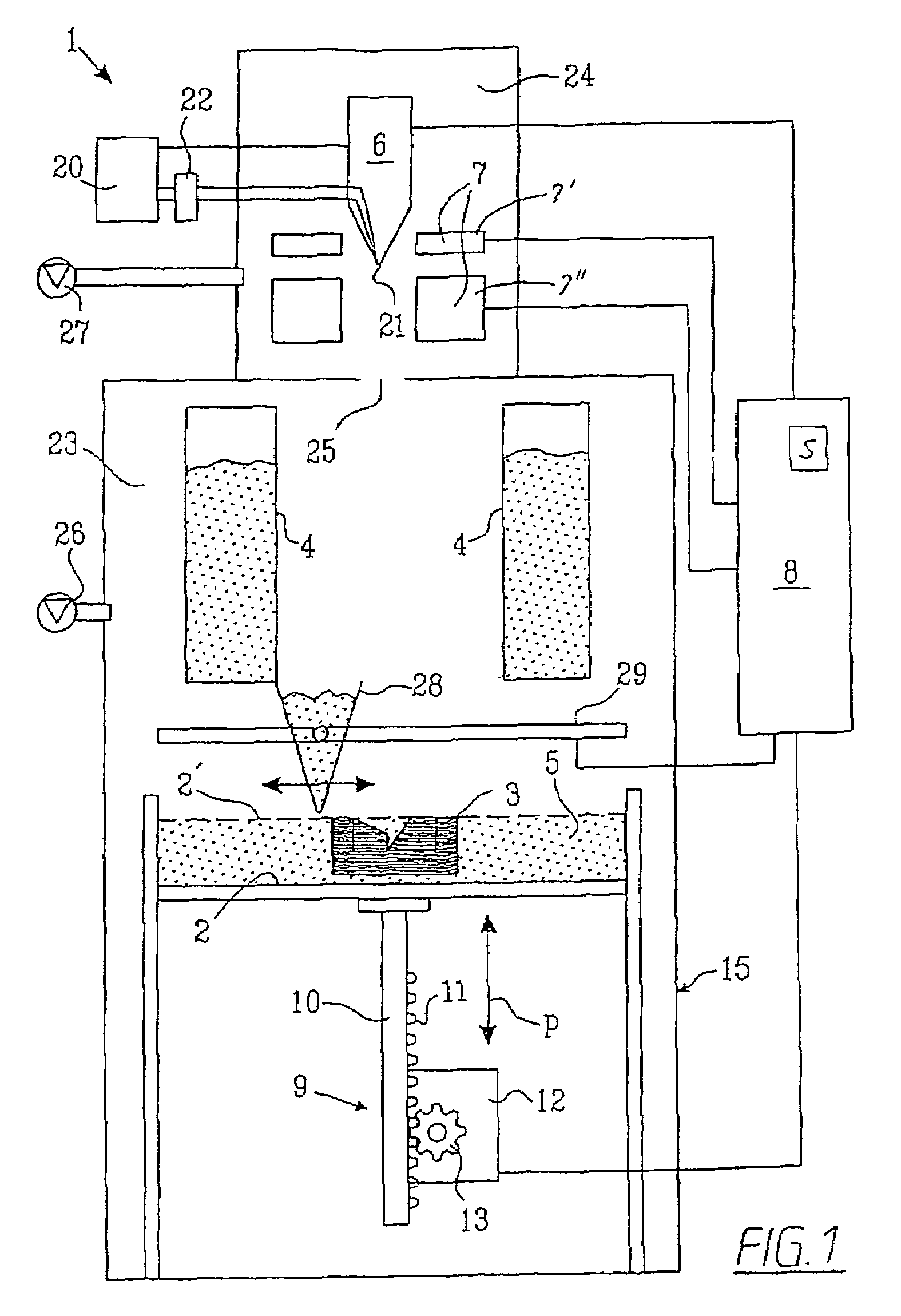

Method for producing a three-dimensional object

InactiveUS6042774AShorten production timeAdditive manufacturing apparatus3D object support structuresIrradiationMaterials science

A method of producing an object by successive solidification of layers of a powder material is disclosed. The method provides a preformed base plate having a metal plate with a solidified layer of a powder material formed thereon. Then, successive layers of said powder material are applied and solidified on the solidified layer of the base plate to form the object. In further detail, the method for produces a three-dimensional by providing a support and a preformed base plate having an upper surface for supporting the object. The base plate is removably attached to the support. Means are provided for adjusting the elevation of said upper surface. A layer of the powder material is applied to the upper surface of the base plate. The powder material is solidified at points corresponding to a cross-section of the object by irradiation with electromagnetic or particle radiation. Then, the applying and solidifying steps are repeated for completing the object.

Owner:EOS ELECTRO OPTICAL SYST

Atomic layer deposition apparatus using neutral beam and method of depositing atomic layer using the same

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

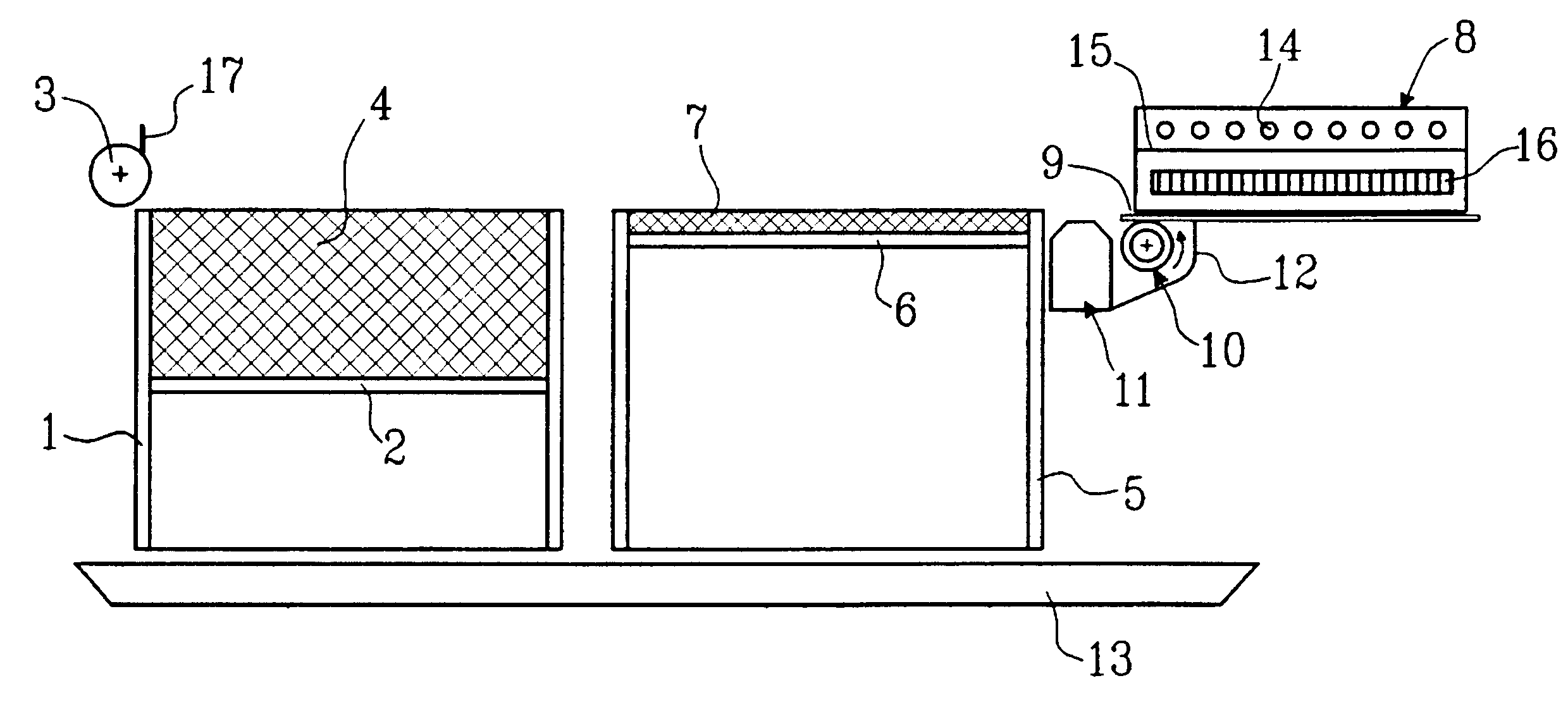

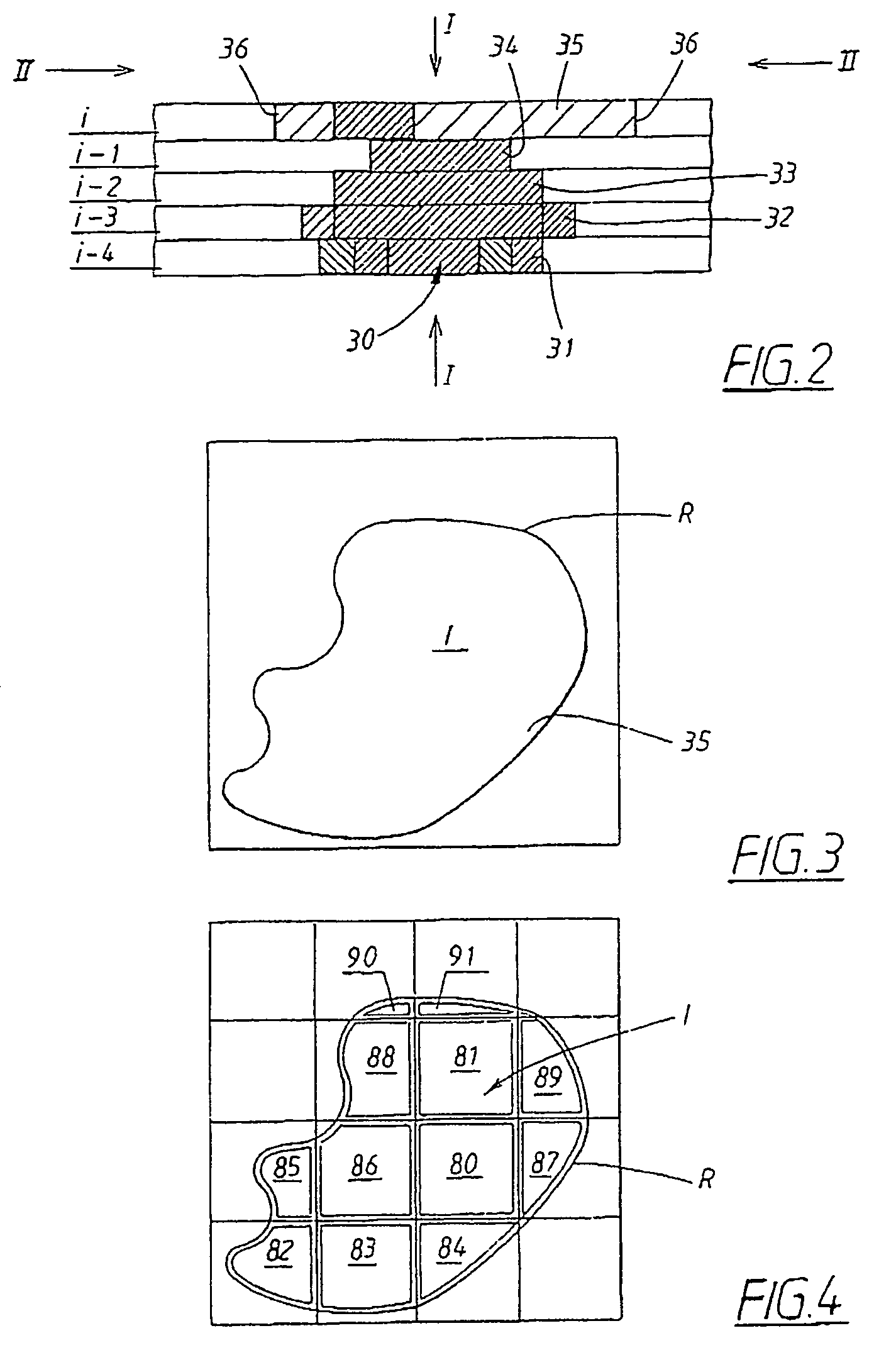

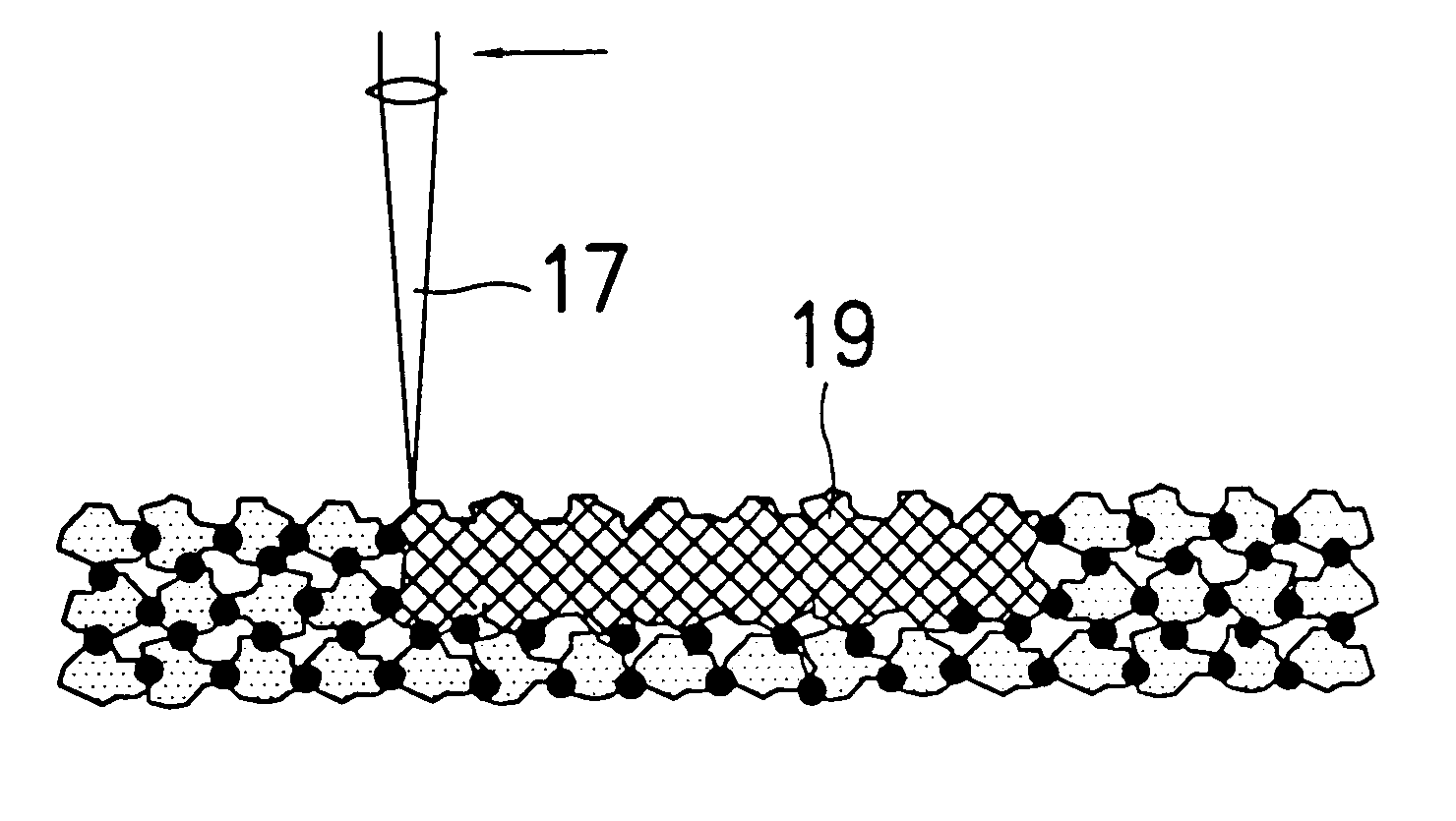

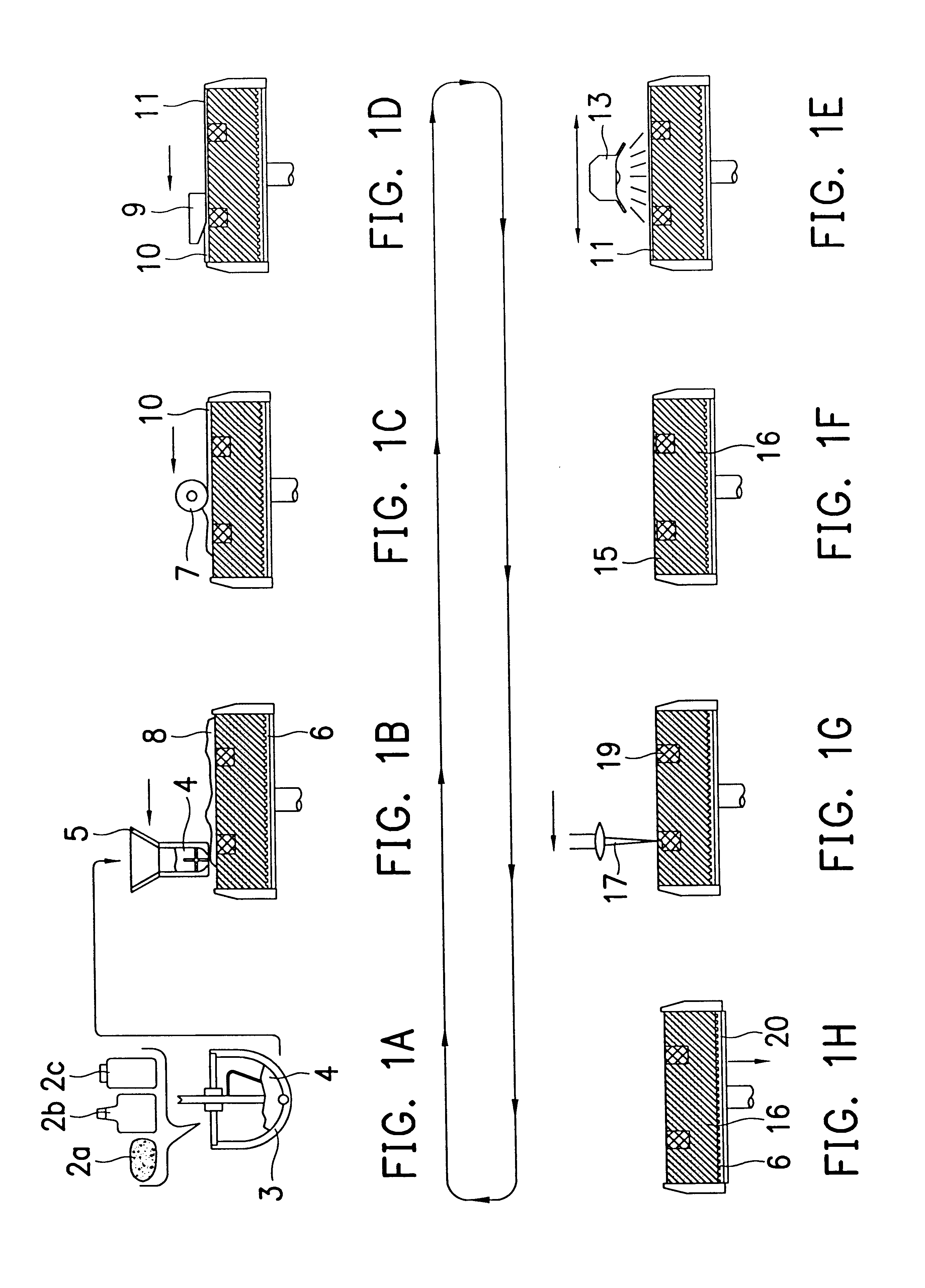

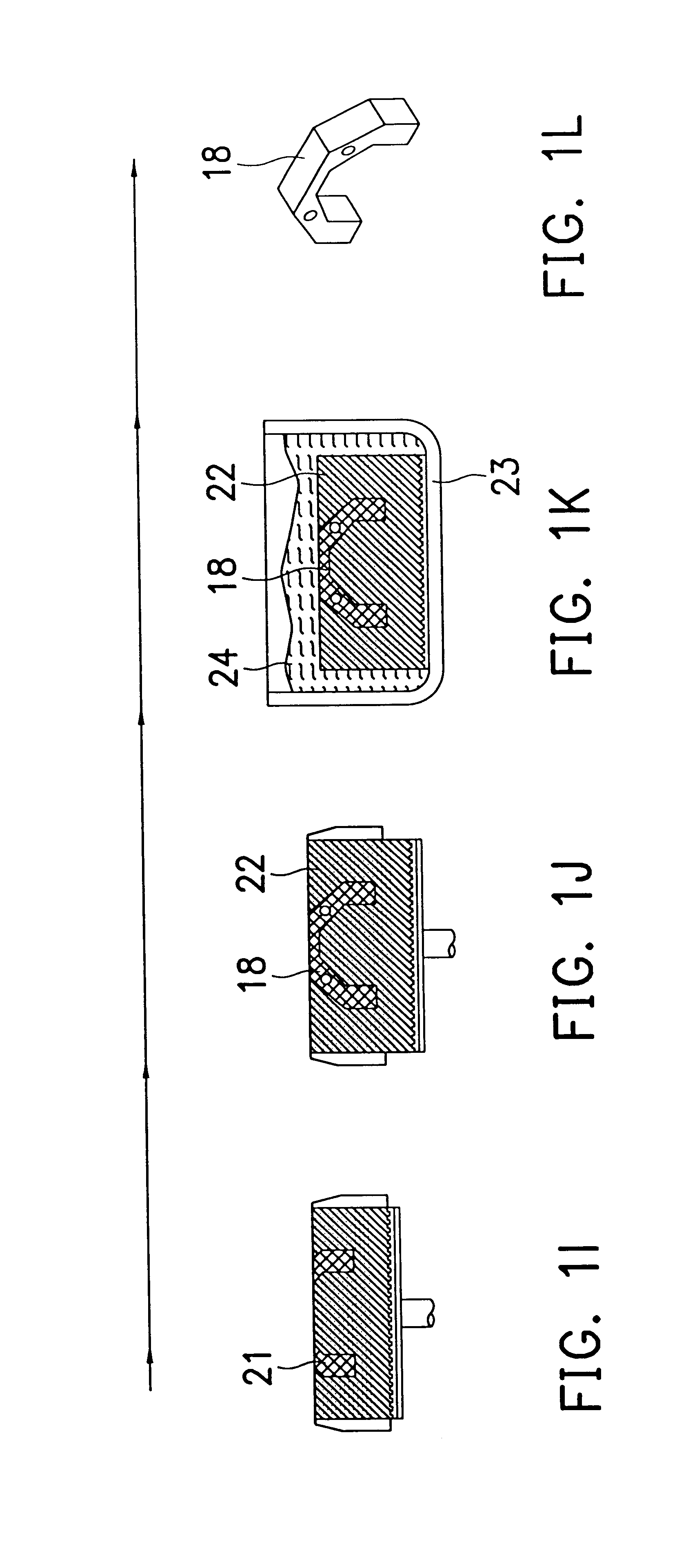

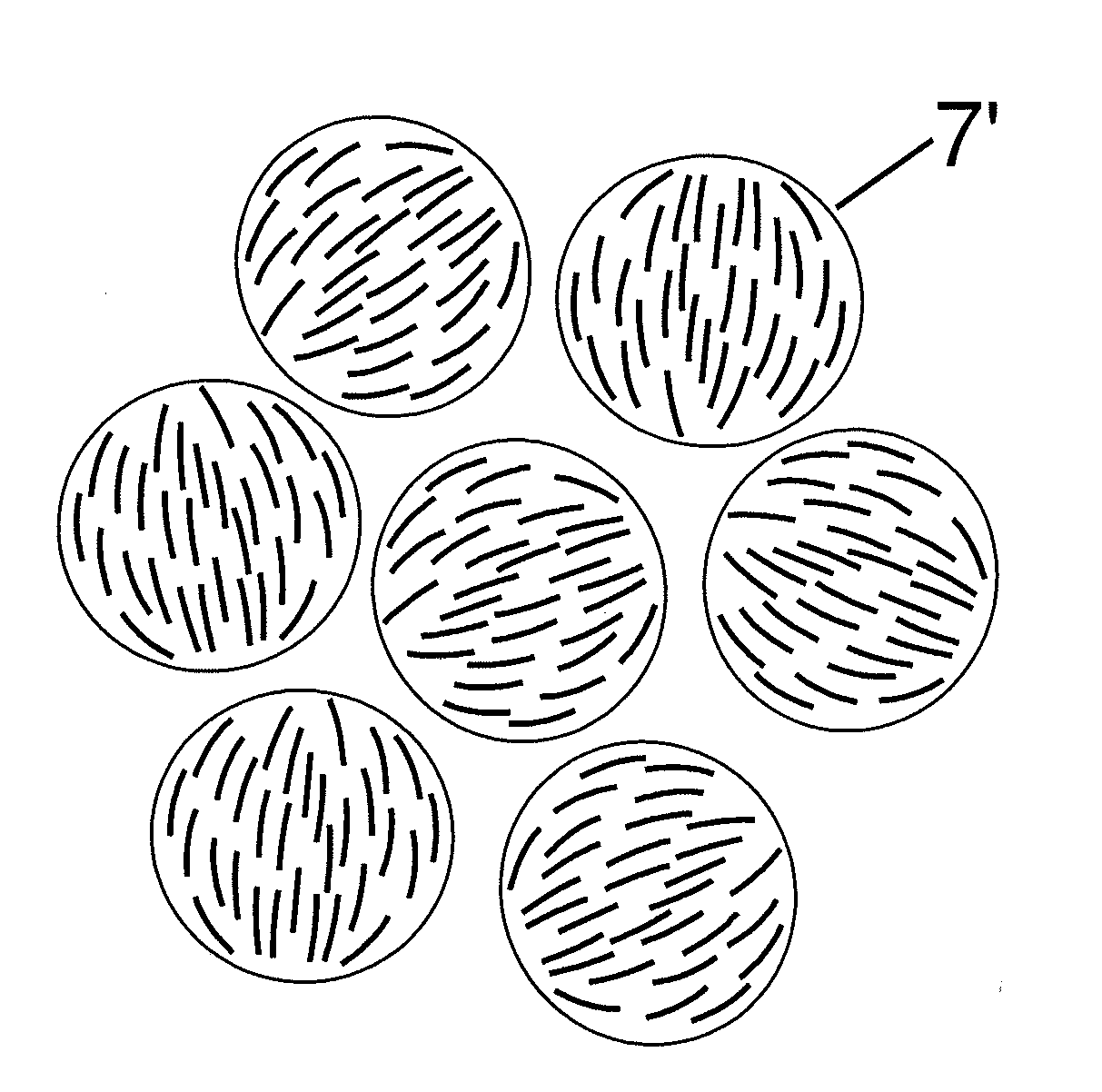

Method and device for manufacturing three-dimensional bodies

A method for producing three-dimensional bodies of a large number of mutually connected layers of a particle-shaped material such as a powder, and where the information of the appearance of each layer is achieved from a computer's CAD-unit or similar. An essentially even particle layer (7) of building material is applied on a support base (6) and on a masking device (9) is arranged a masking pattern in accordance with the information from the CAD-unit, which masking device is led over said particle layer and close to it. A radiation producer (8) is arranged or is led over the masking device (9), whereby the particles which are not covered by the masking pattern are exposed for radiation and thereby are attached to each other. The masking pattern is removed from the masking device and new sequences in accordance with the above are carried through until the three-dimensional body (19) is produced.

Owner:SPEED PART RP

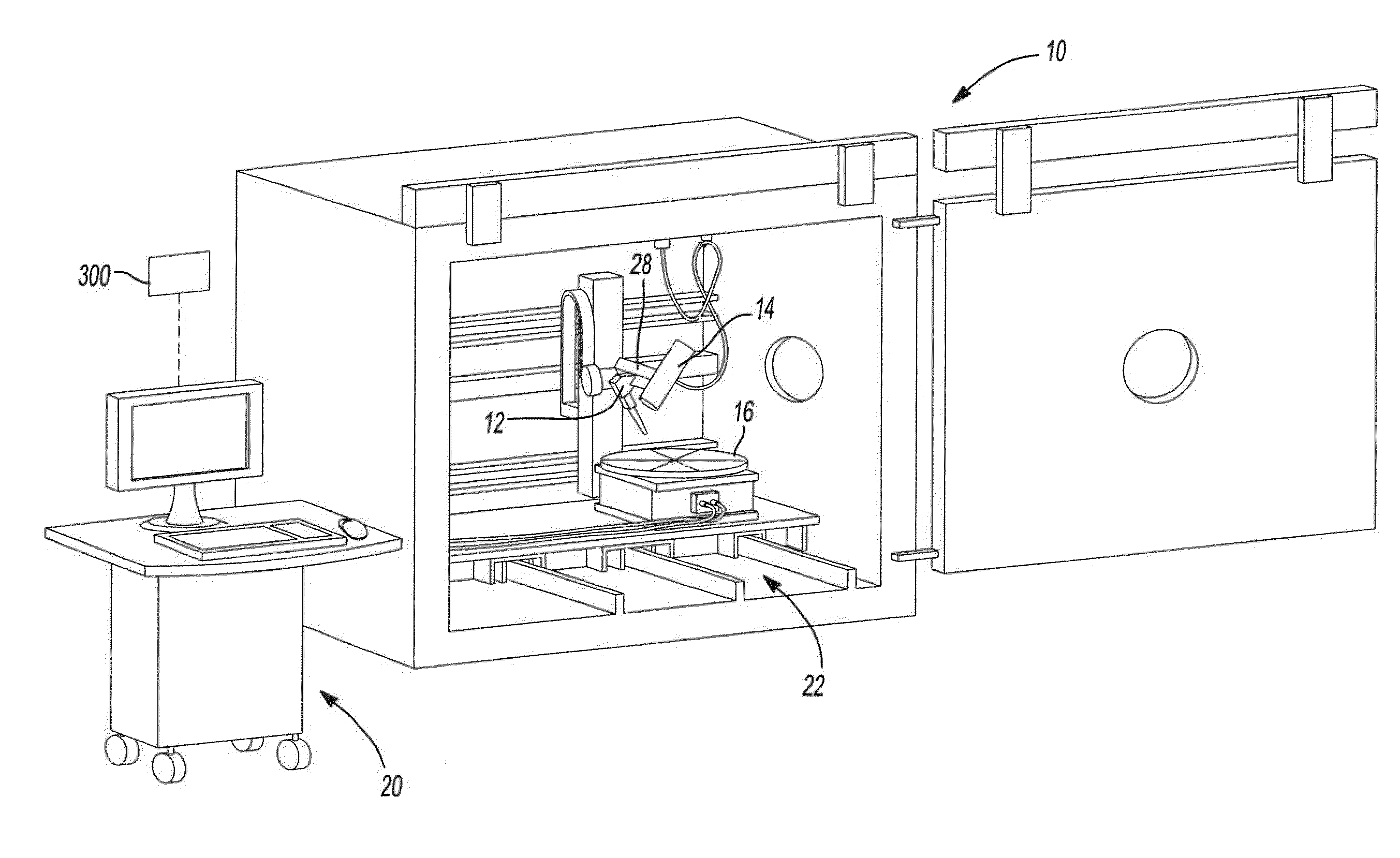

Electron beam layer manufacturing

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

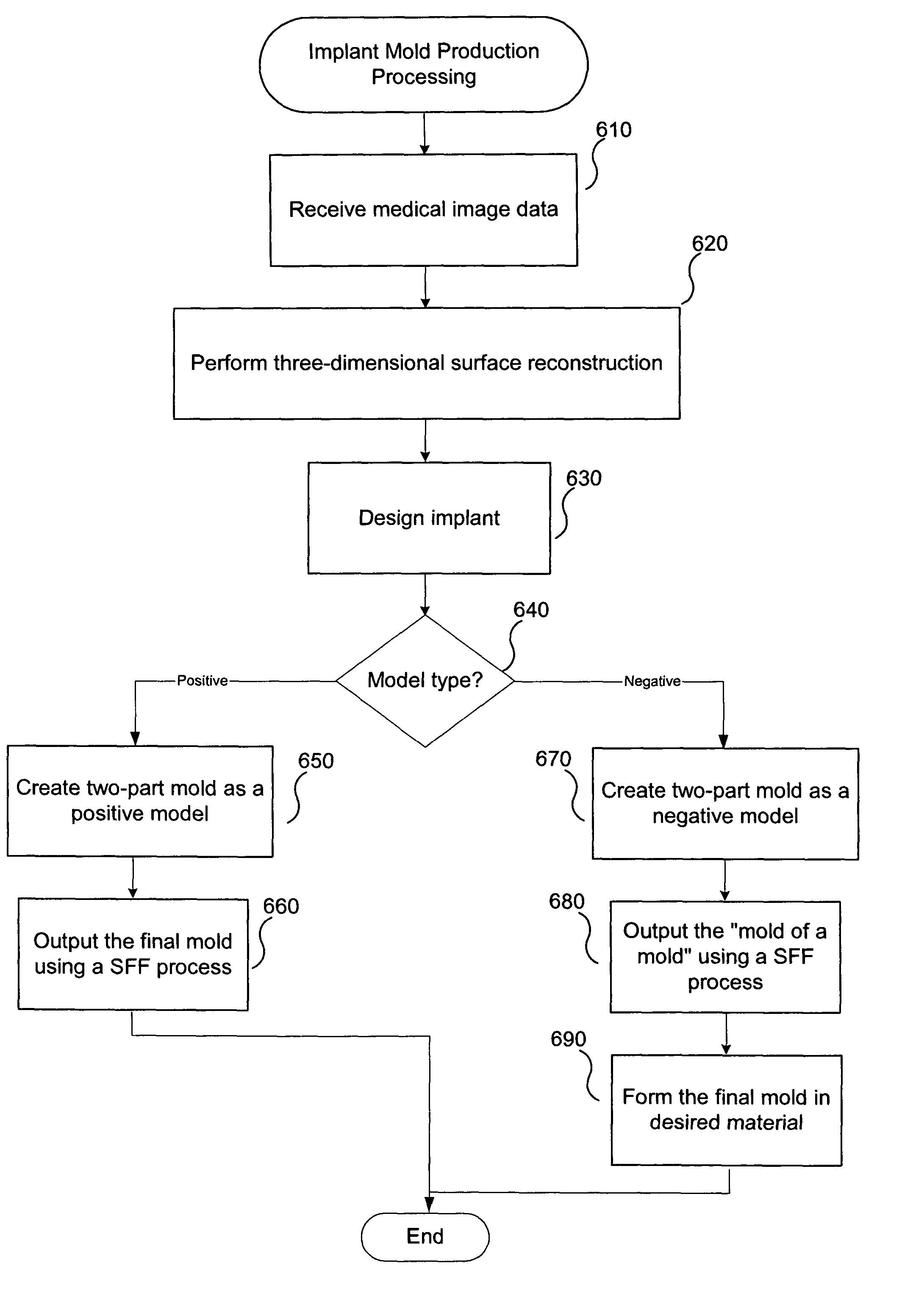

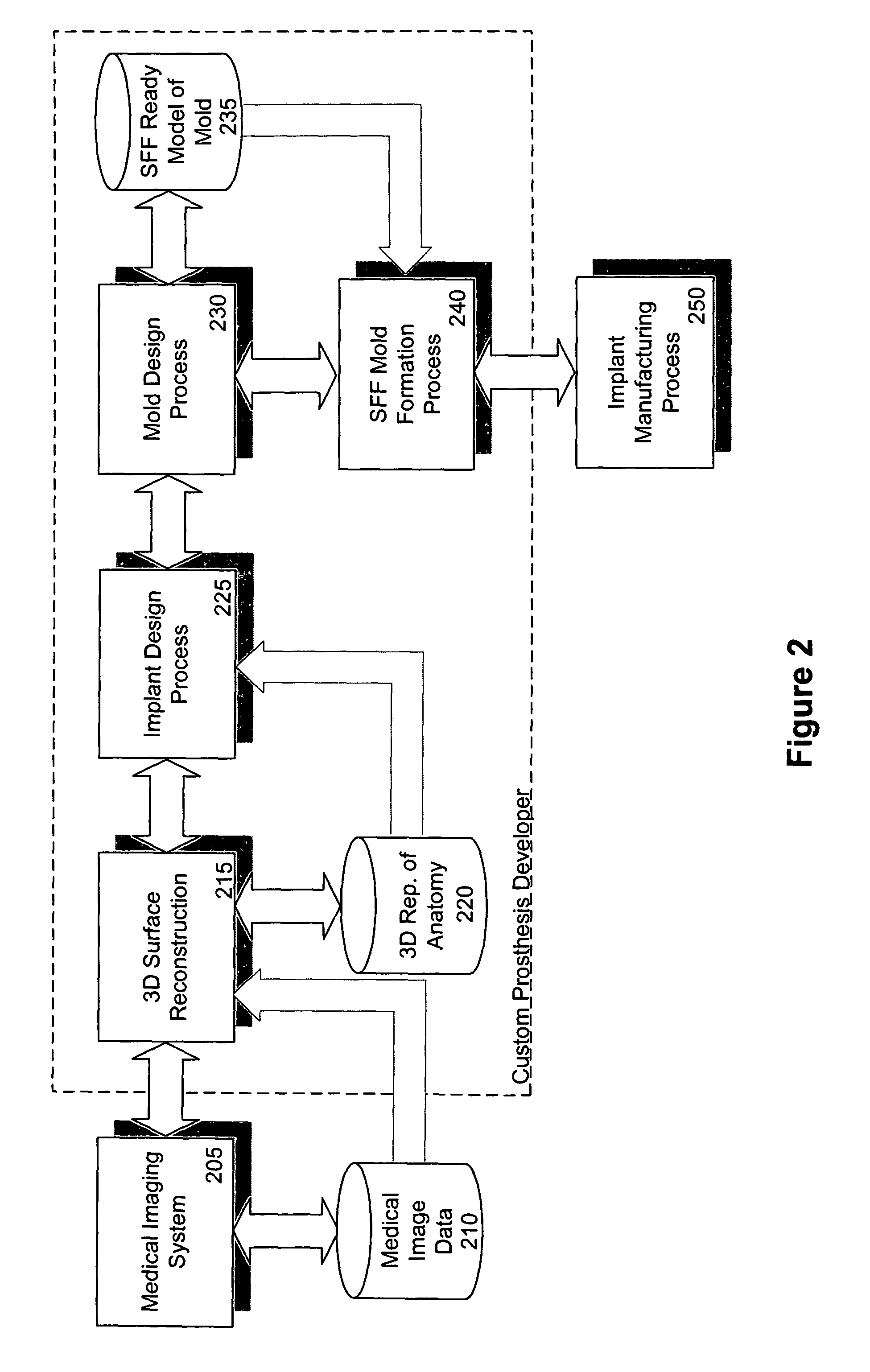

Method for design and production of a custom-fit prosthesis

Systems and methods are provided for designing and producing a custom-fit prosthesis. According to one embodiment, a mold is produced from which a custom-fit implant may be directly or indirectly manufactured. Medical image data representing surrounding portions of a patient's anatomy to be repaired by surgical implantation of the custom-fit implant are received. Then, three-dimensional surface reconstruction is performed based on the medical image data. Next, the custom-fit implant is designed based on the three-dimensional surface reconstruction and a positive or negative representation of a two-part mold is created with a void in the shape of the custom-fit implant by subtracting a representation of the custom-fit implant from a representation of a mold. Finally, the two-part mold is output from which the custom-fit implant may be directly manufactured; or an implant is directly output. Alternatively, an intermediate mold is created from which a two-part mold may be directly manufactured.

Owner:3D SYST INC

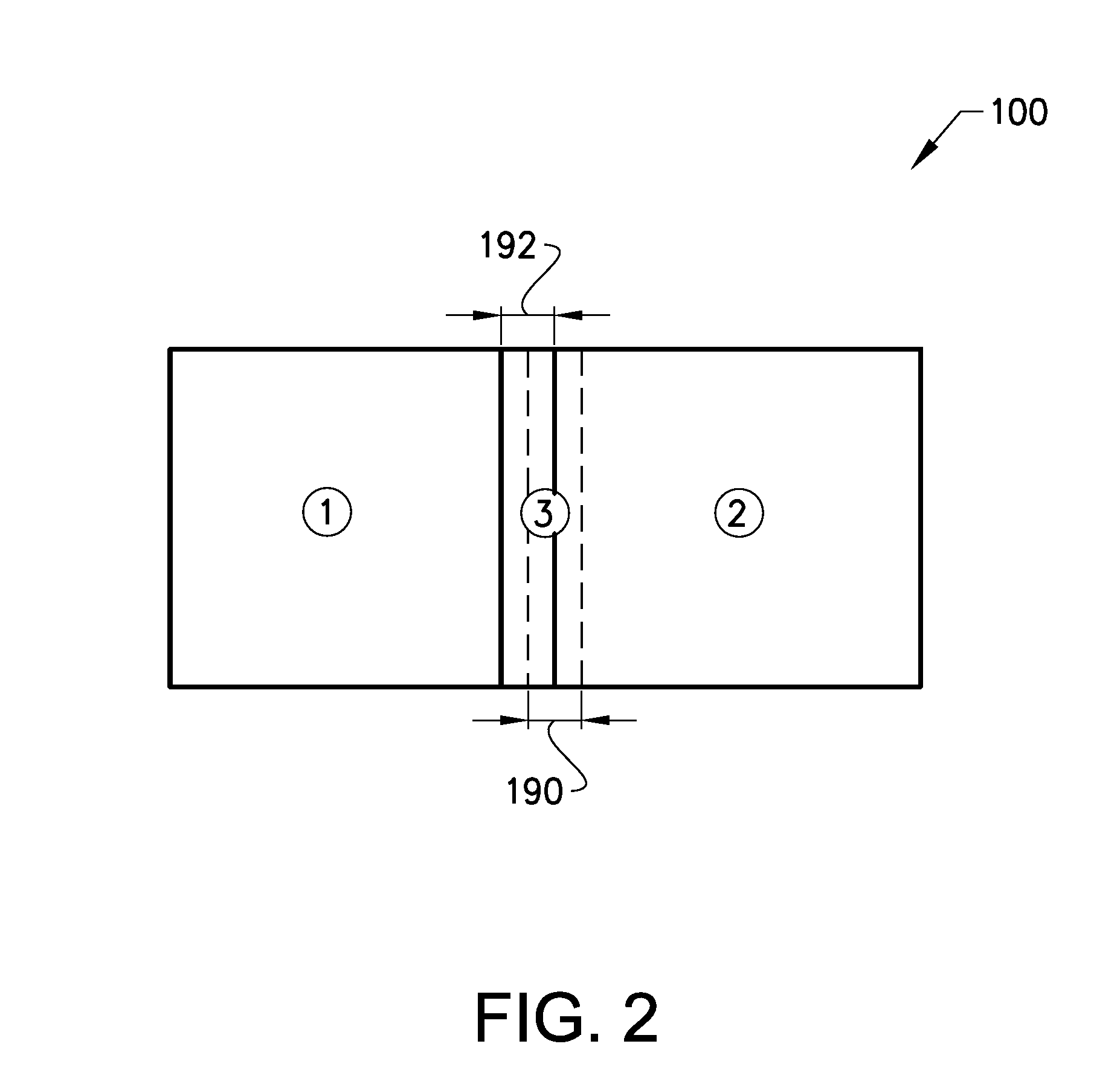

Alignment methods for imprint lithography

InactiveUS6916584B2Enhance lithography processLow viscosity liquidNanoinformaticsSemiconductor/solid-state device manufacturingEngineeringRotational alignment

Described are methods for patterning a substrate by imprint lithography. Imprint lithography is a process in which a liquid is dispensed onto a substrate. A template is brought into contact with the liquid and the liquid is cured. The cured liquid includes an imprint of any patterns formed in the template. Alignment of the template with the substrate is performed prior to curing the liquid. Alignment of the template with the substrate includes rotational alignment of the template with respect to the substrate.

Owner:CANON KK

Jettable compositions

ActiveUS20050171237A1Prevent long-term corrosionReaction is slowAdditive manufacturing apparatusLiquid surface applicatorsMeth-Oligomer

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabiliser for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

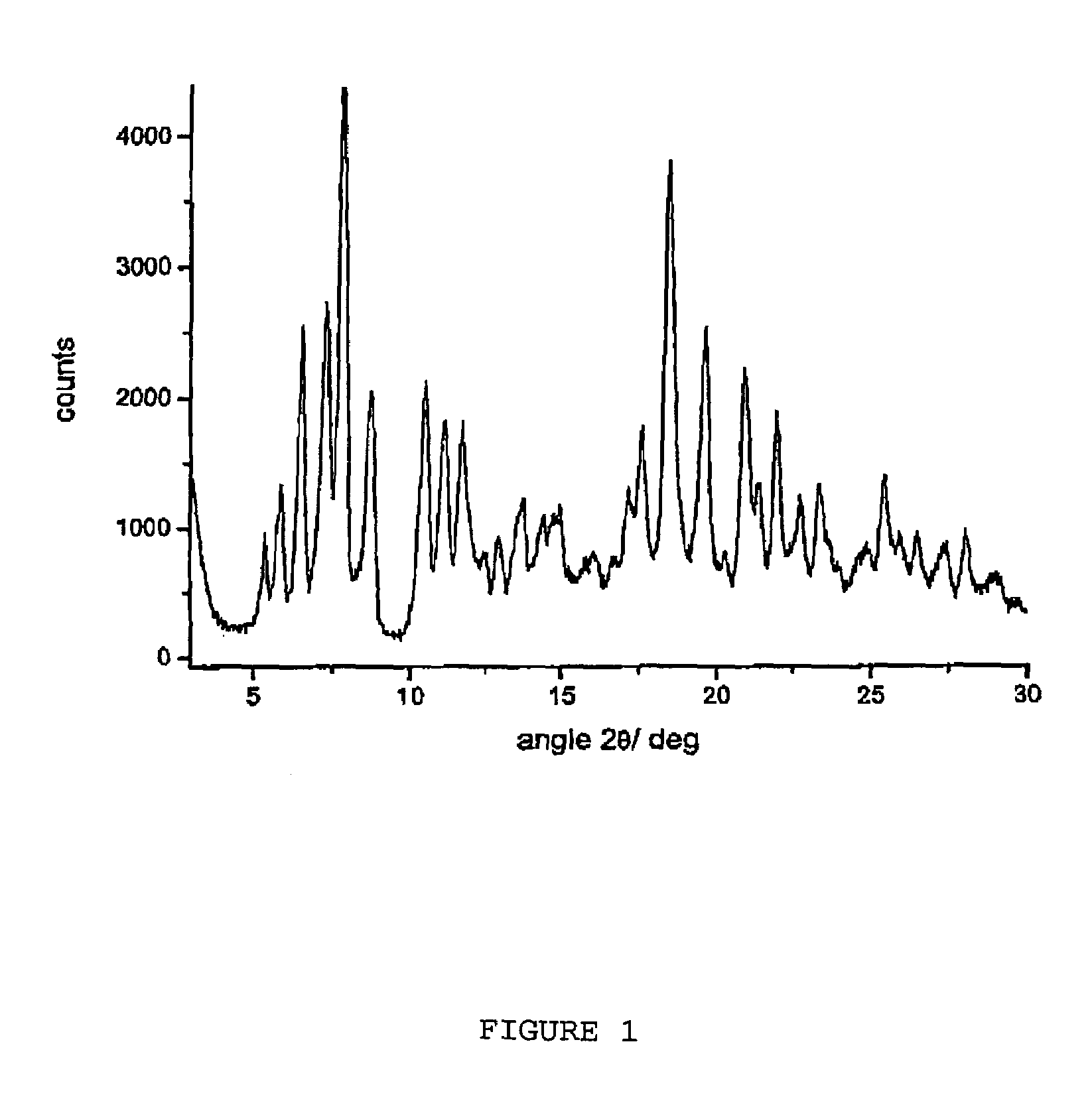

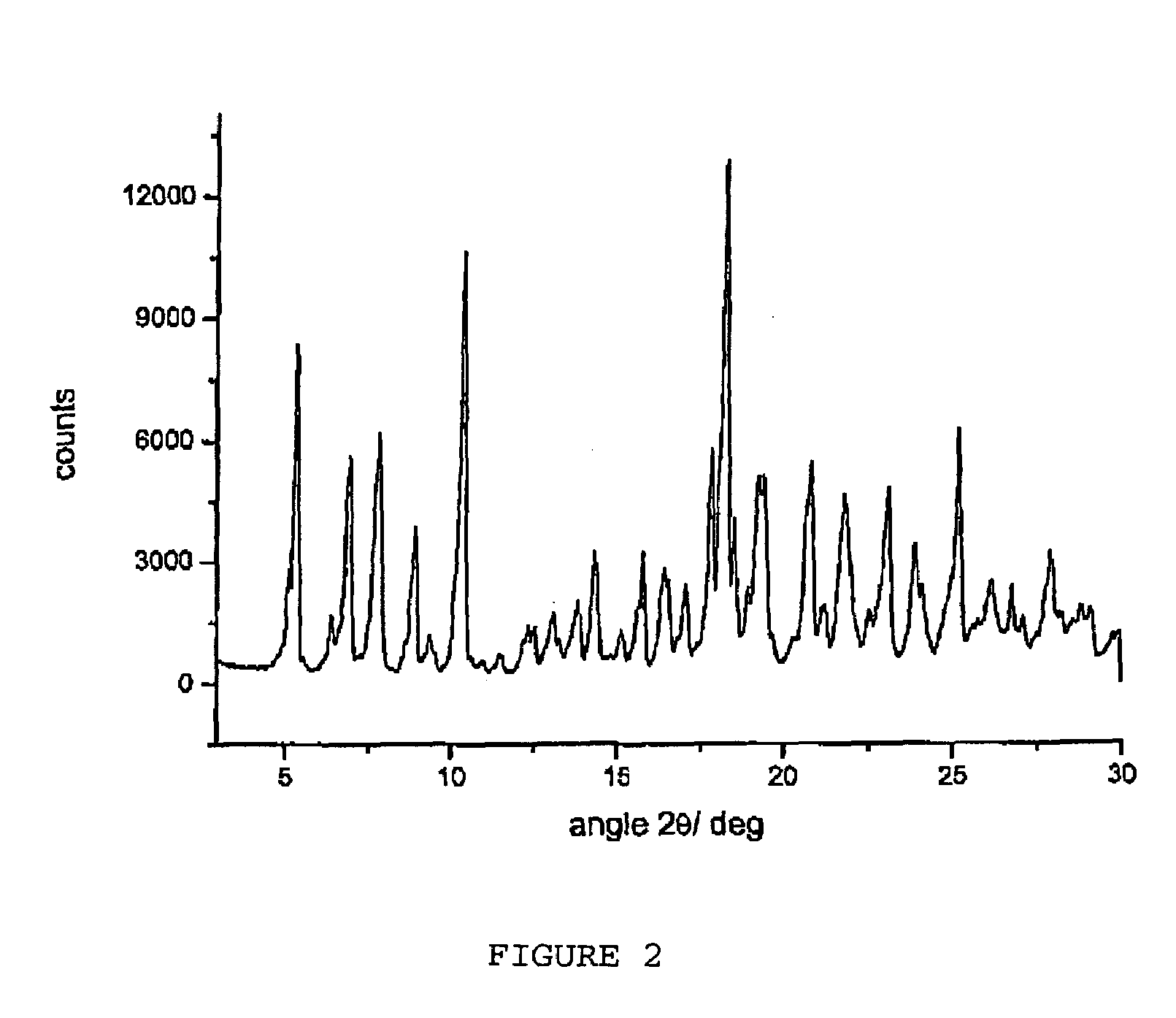

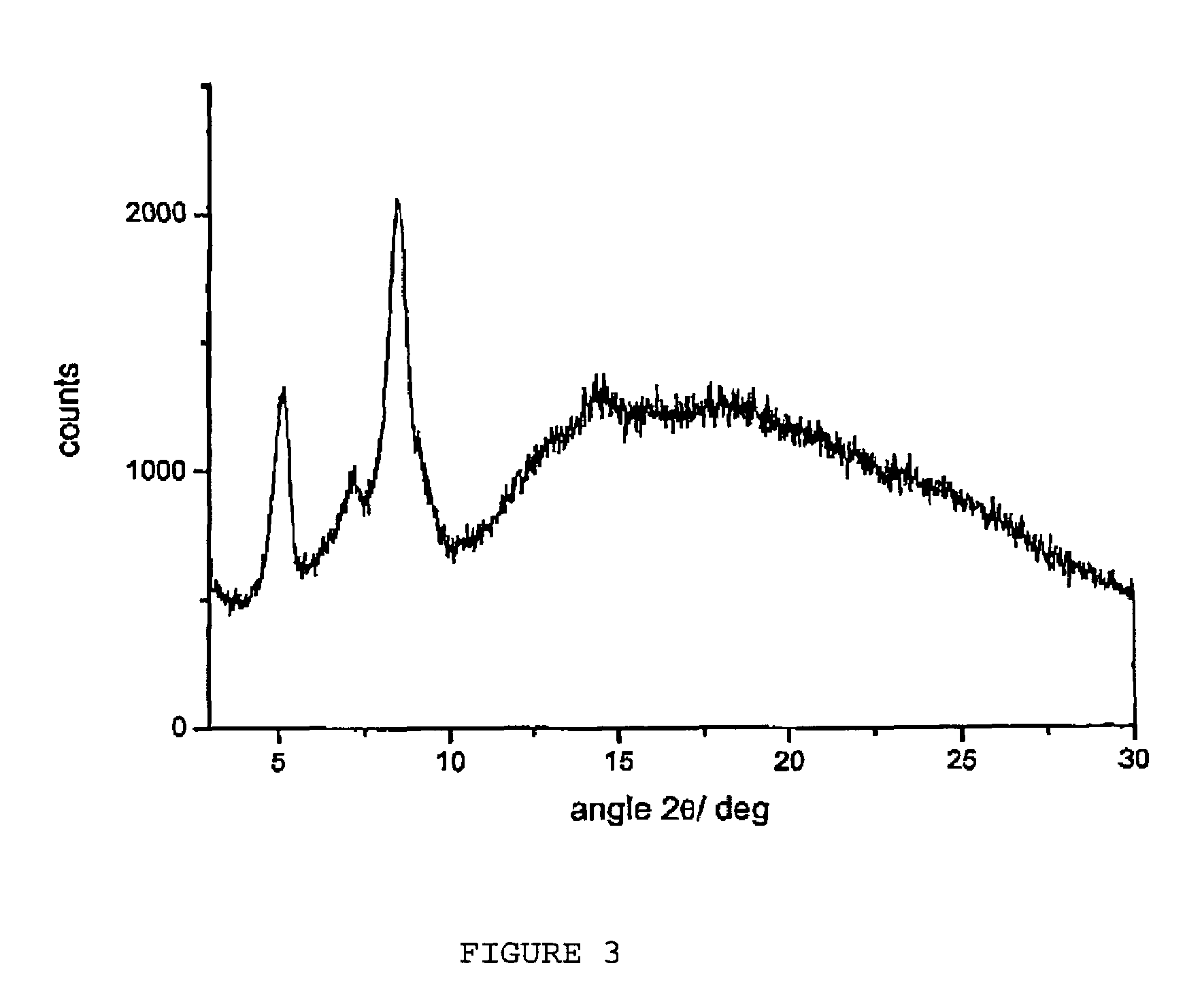

Polymorphous forms of rifaximin, processes for their production and use thereof in medicinal preparations

Crystalline polymorphous forms of the rifaximin (INN) antibiotic named rifaximin α and rifaximin β, and a poorly crystalline form named rifaximin γ have been discovered. These forms are useful in the production of medicinal preparations for oral and topical use and can be obtained by means of a crystallization process carried out by hot-dissolving the raw rifaximin in ethyl alcohol and by causing the crystallization of the product by the addition of water at a determinate temperature and for a determinate period of time. The crystallization is followed by drying carried out under controlled conditions until a specific water content is reached in the end product.

Owner:ALFASIGMA SPA

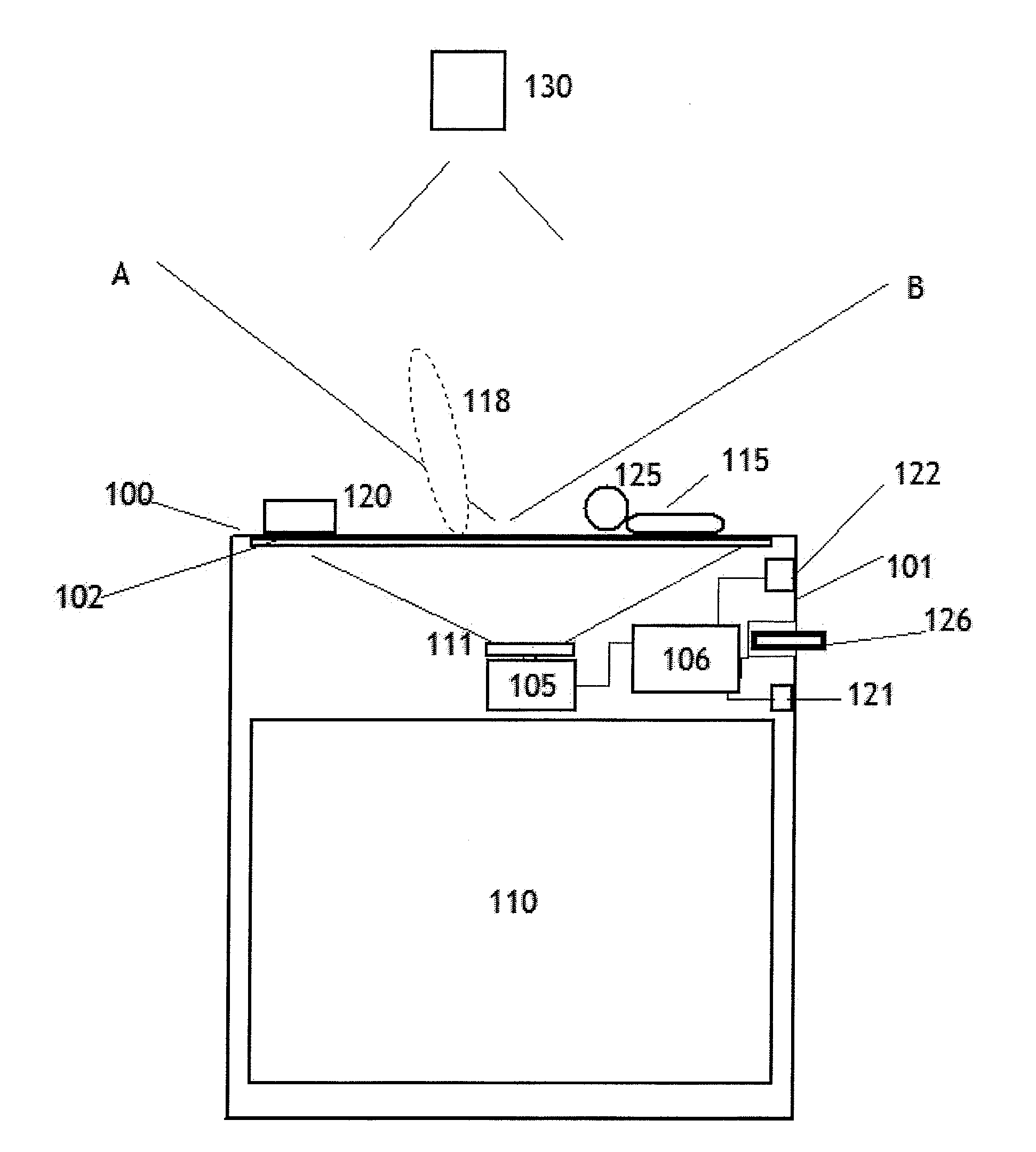

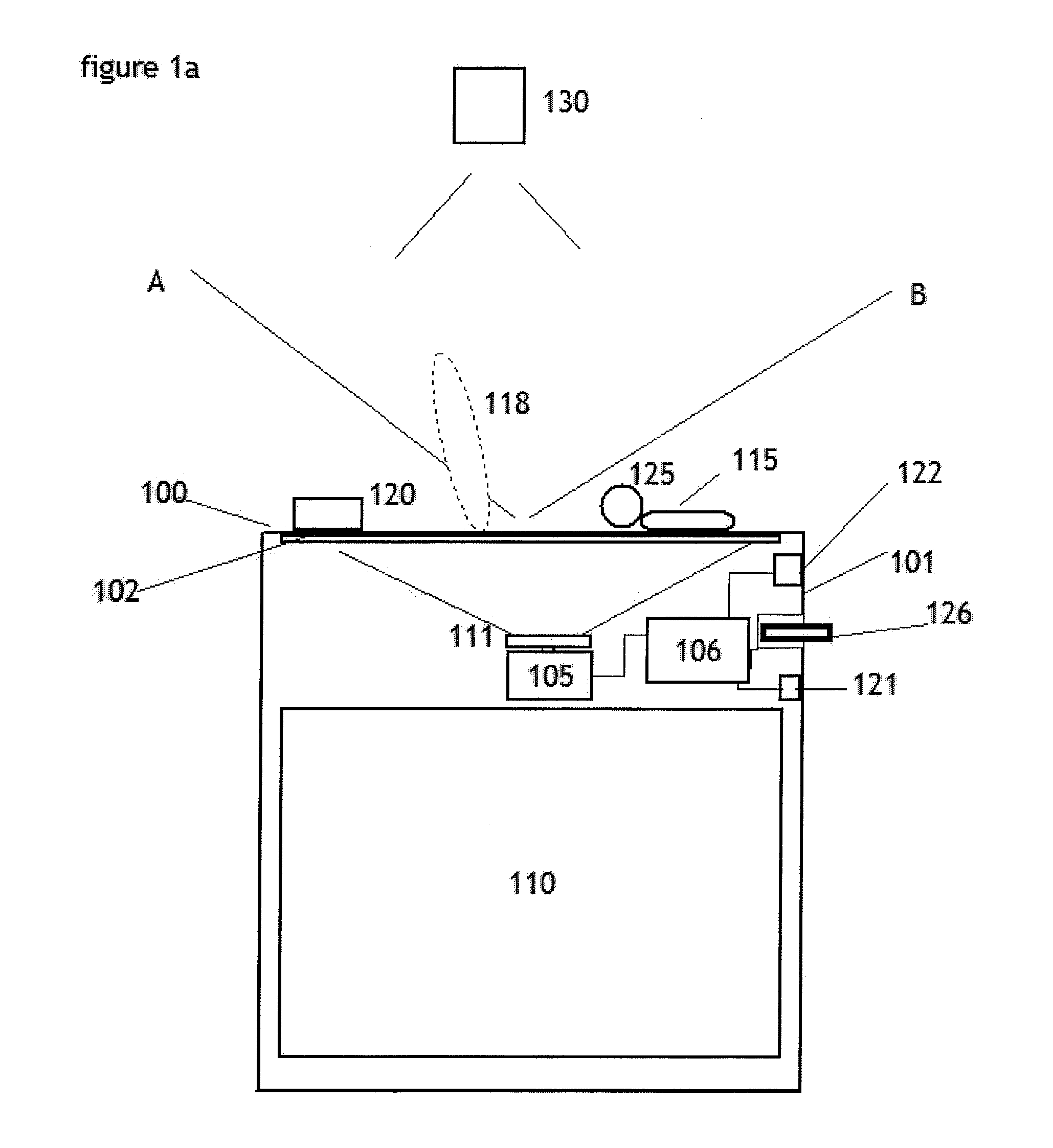

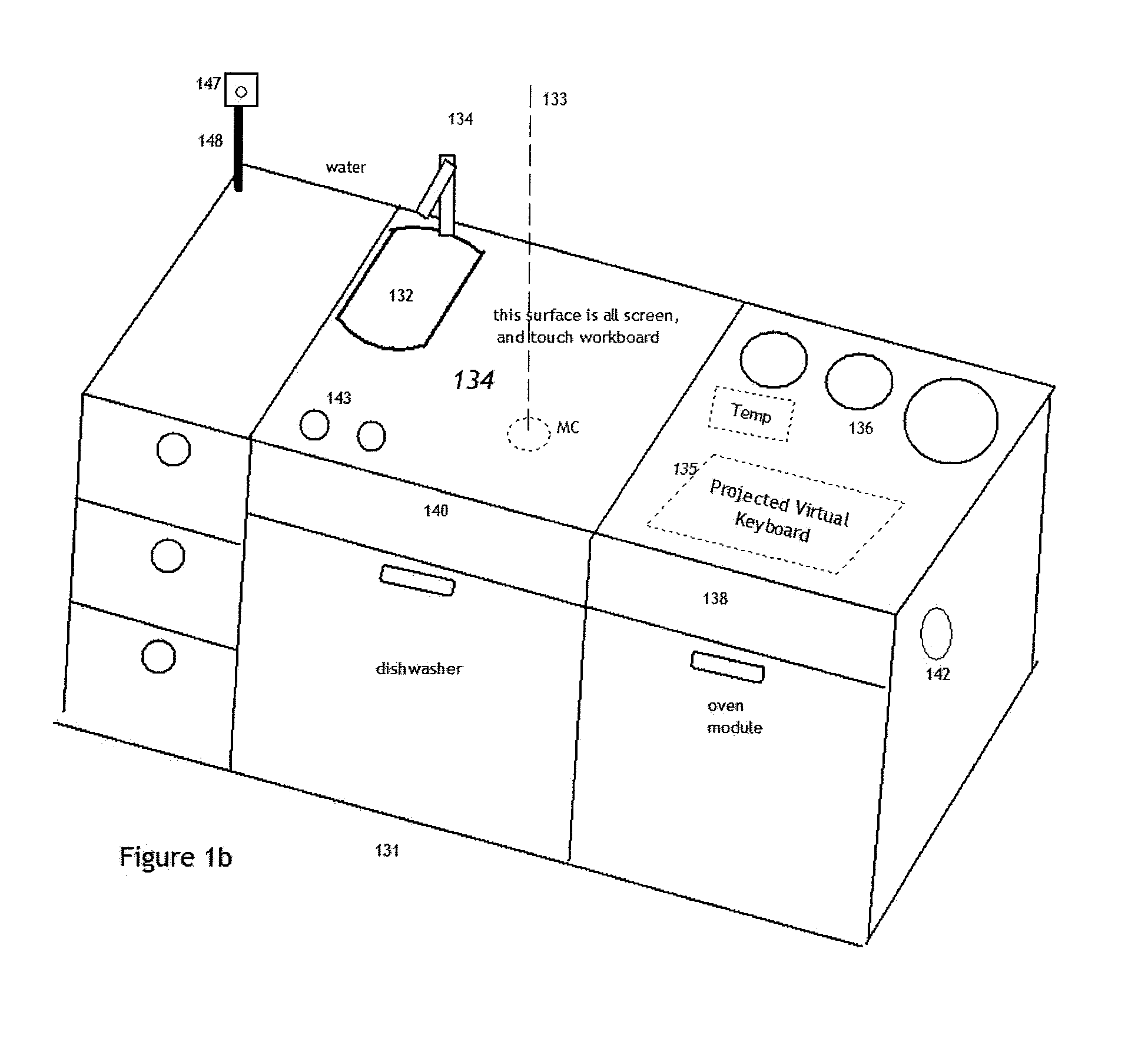

Control of appliances, kitchen and home

InactiveUS20100182136A1Ease kitchenEase house workProgramme controlWashing controlling processesOlder peopleThe Internet

The disclosed invention is generally in the field of control of appliances in the home, and in their networking and connectivity also with audio systems and internet sources and the integration of these elements in a connected manner. Preferred apparatus generally employs a video projection system and one or more TV cameras. Embodiments of the invention may be used to enhance the social interaction and enjoyment of persons in the kitchen and reduce the work of food preparation. The invention may be used in many rooms of the house, and contribute to the well being of seniors and others living therein.

Owner:PRYOR TIMOTHY

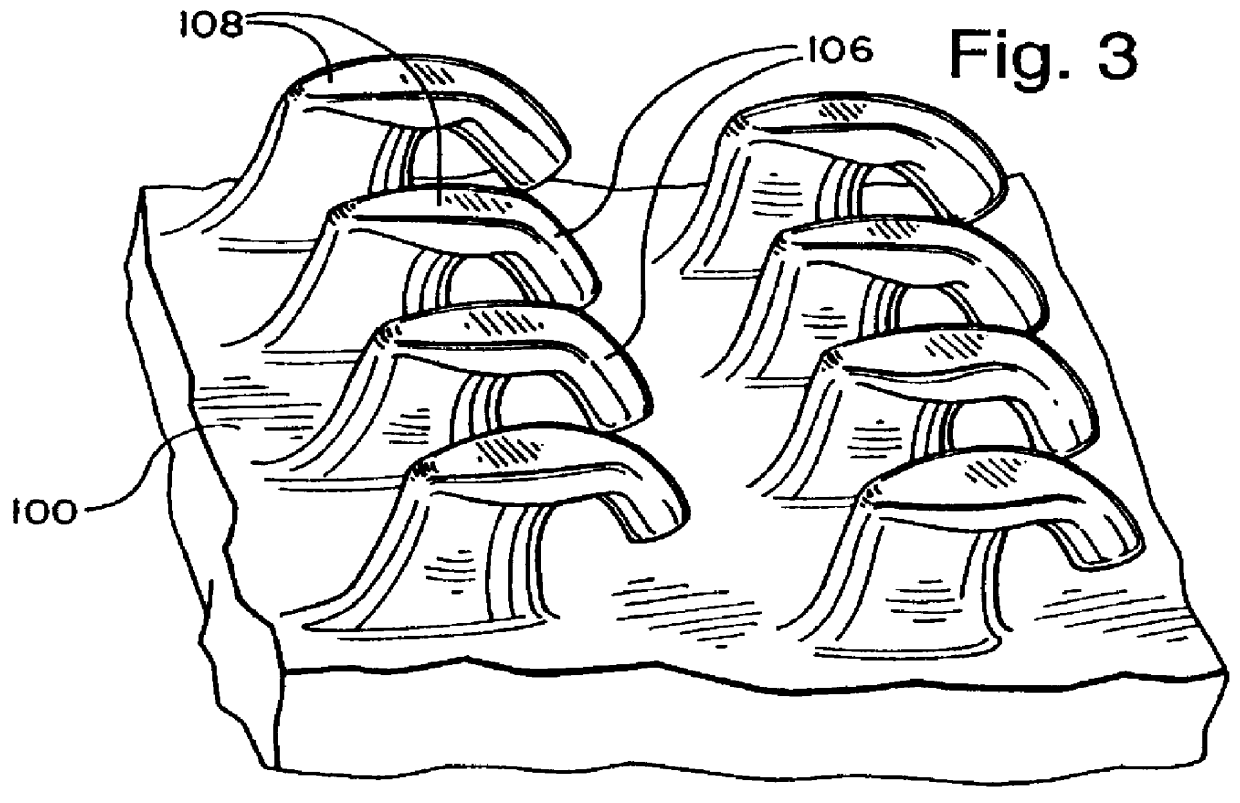

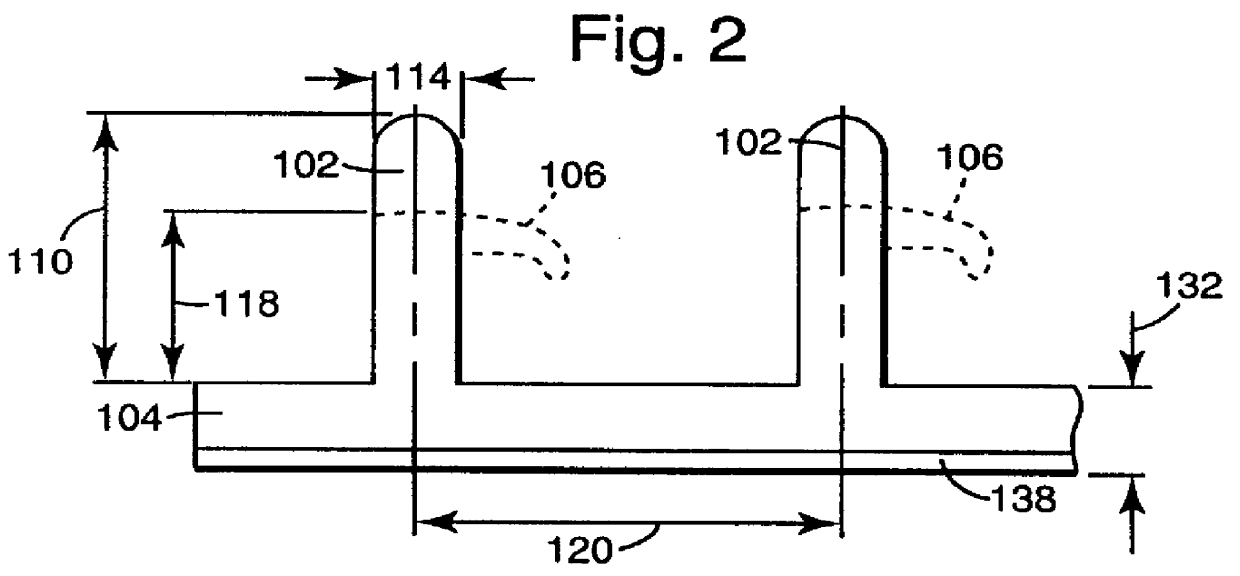

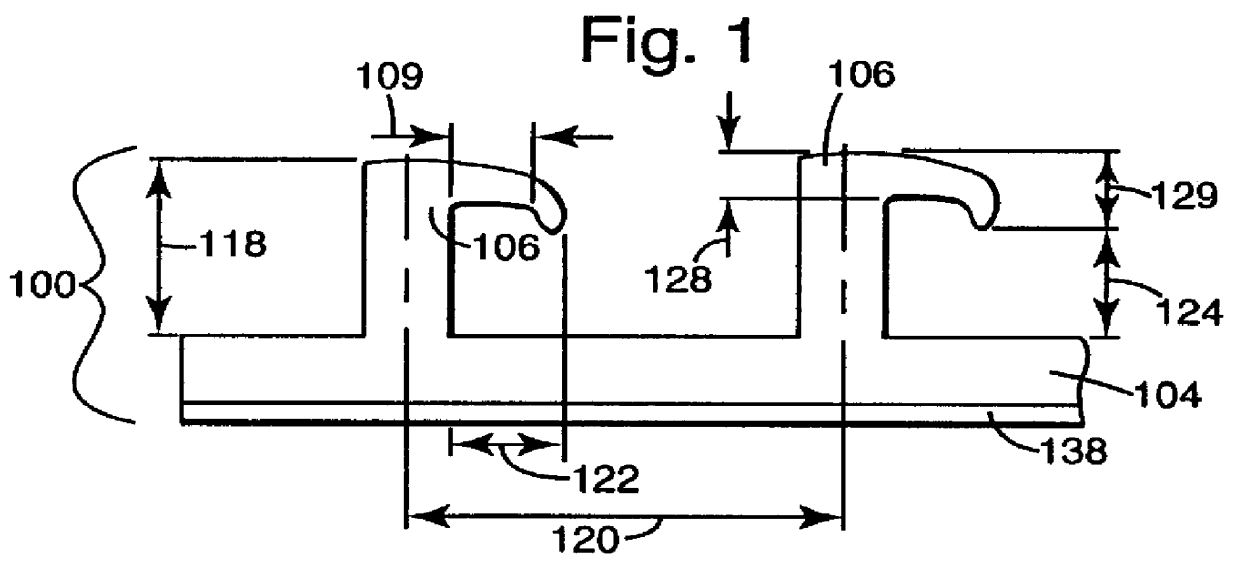

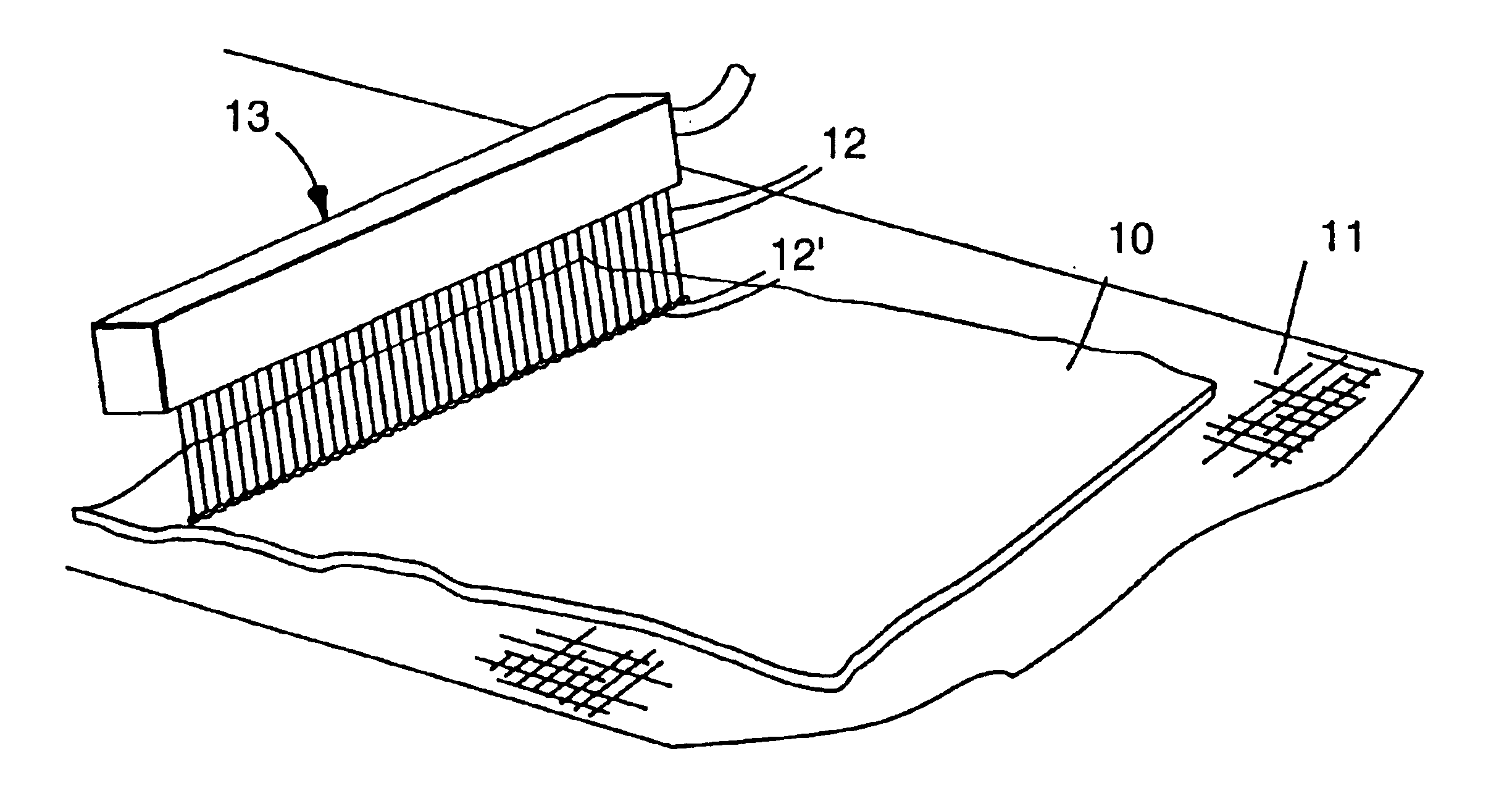

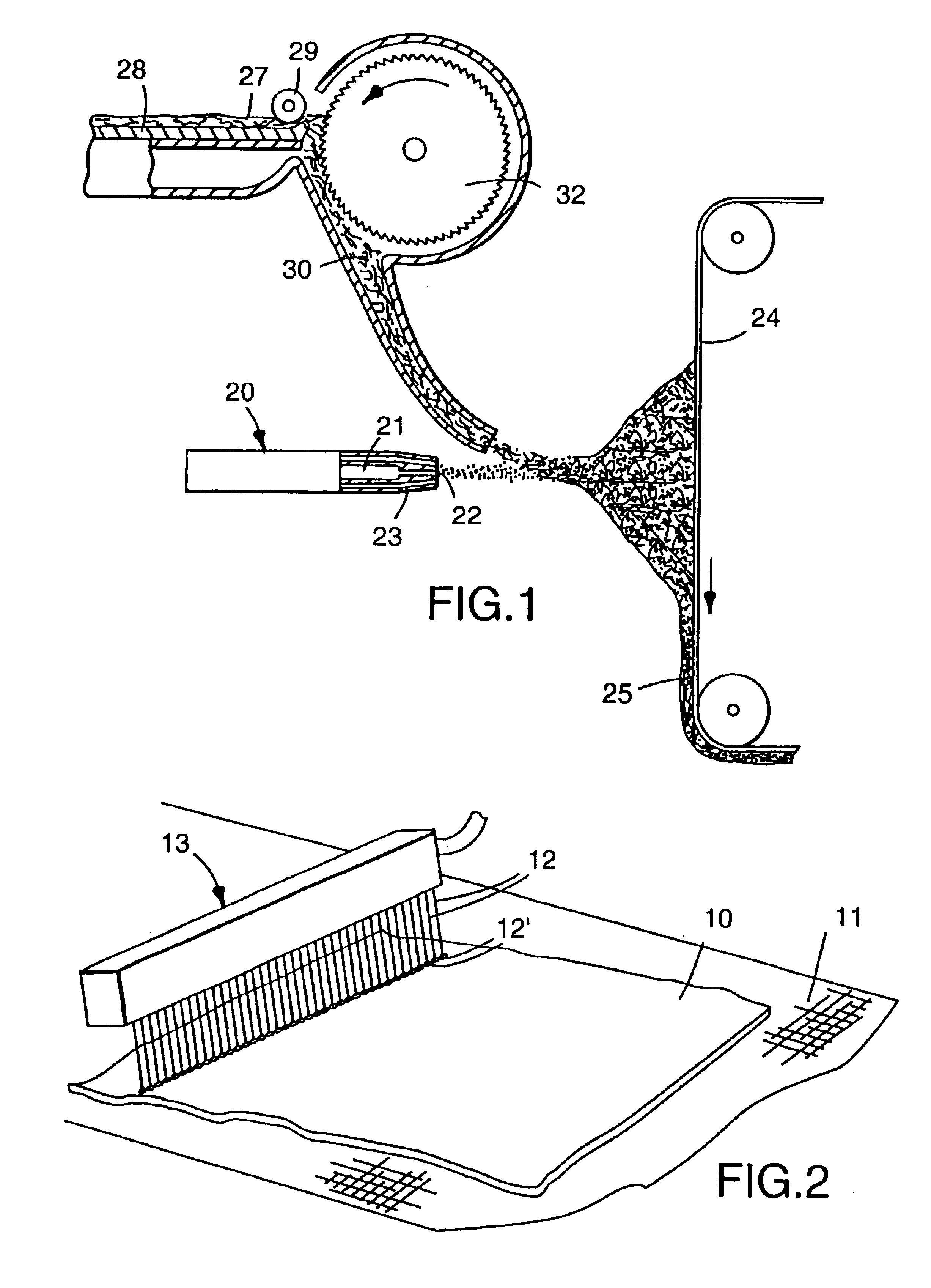

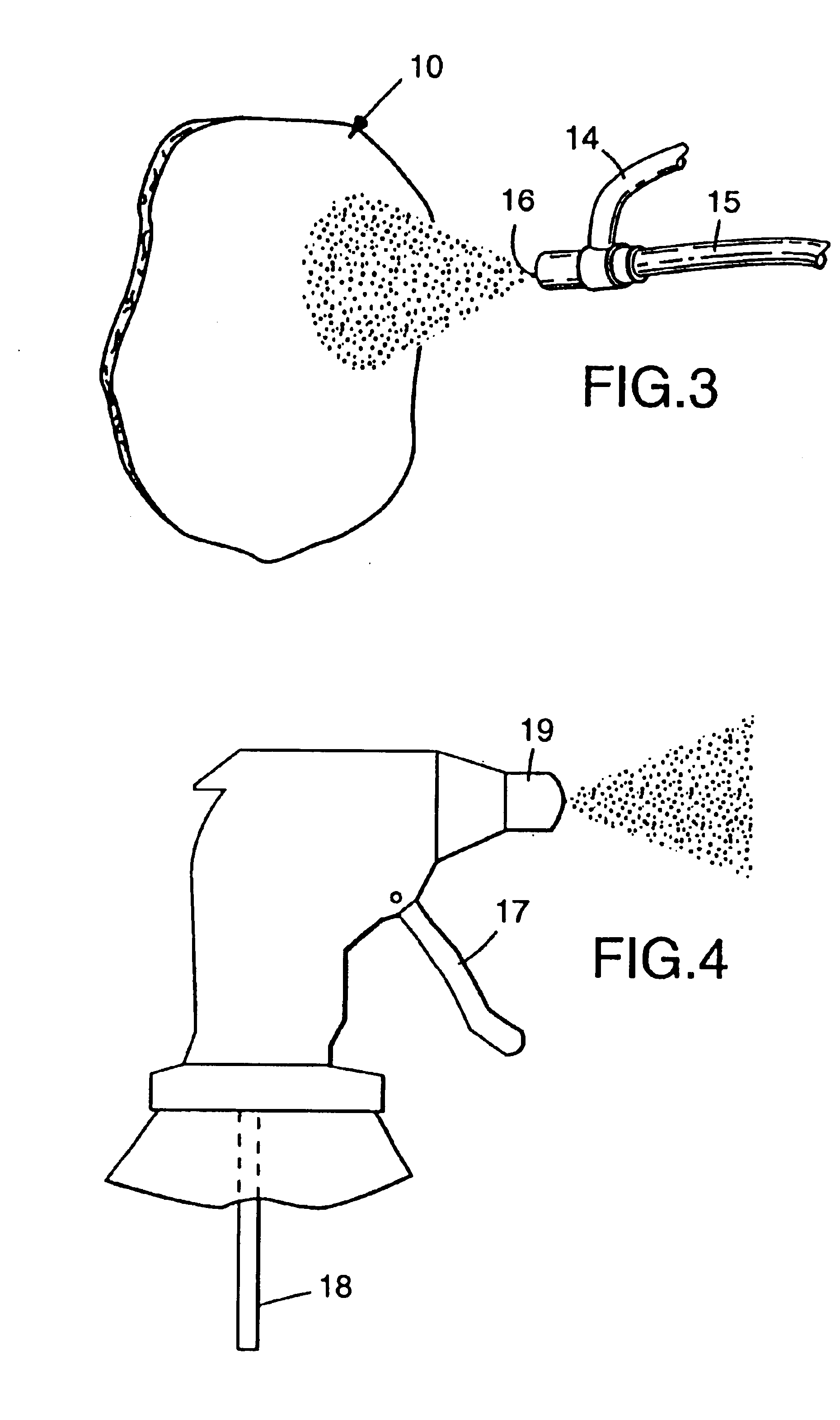

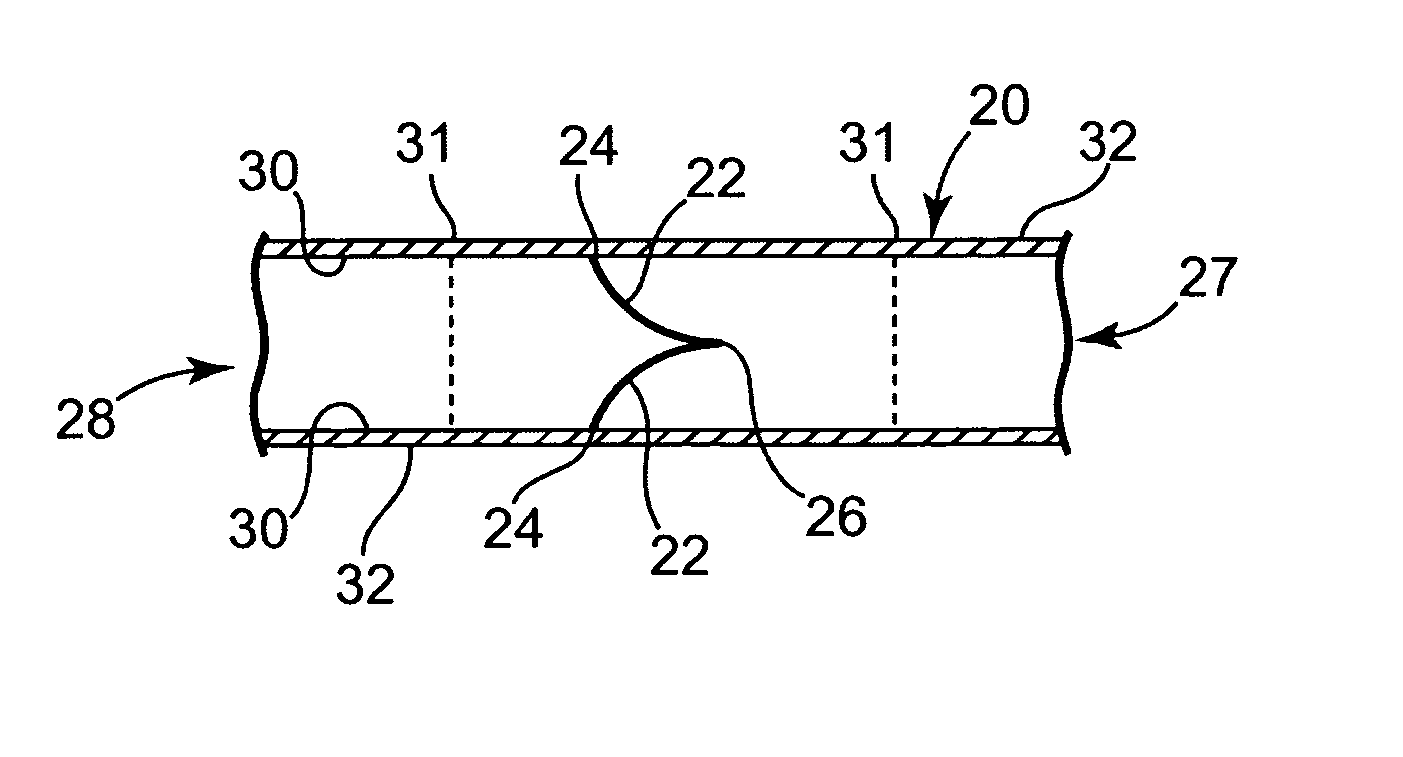

J hook-type hook strip for a mechanical fastener

A method of making a hook strip having J-shaped hooks that can be used as a mechanical fastener. The method includes using an initial substrate of material formed as an array of upstanding precursor stems having distal tips at their ends opposite a backing. In addition, a heat source adapted for heating and a mechanism for deforming stem tips is provided. The substrate is positioned relative to the heat source such that a portion of the upstanding stems on the array is heated. Subsequently, the substrate is moved to a position relative to the mechanism for deforming to create a hook strip of J-shaped hooks from the heated portion of the upstanding stems. In addition, an article of manufacture, made in accordance with the method, is provided which includes a hook portion of a hook-and-loop type of mechanical fastener.

Owner:3M CO

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

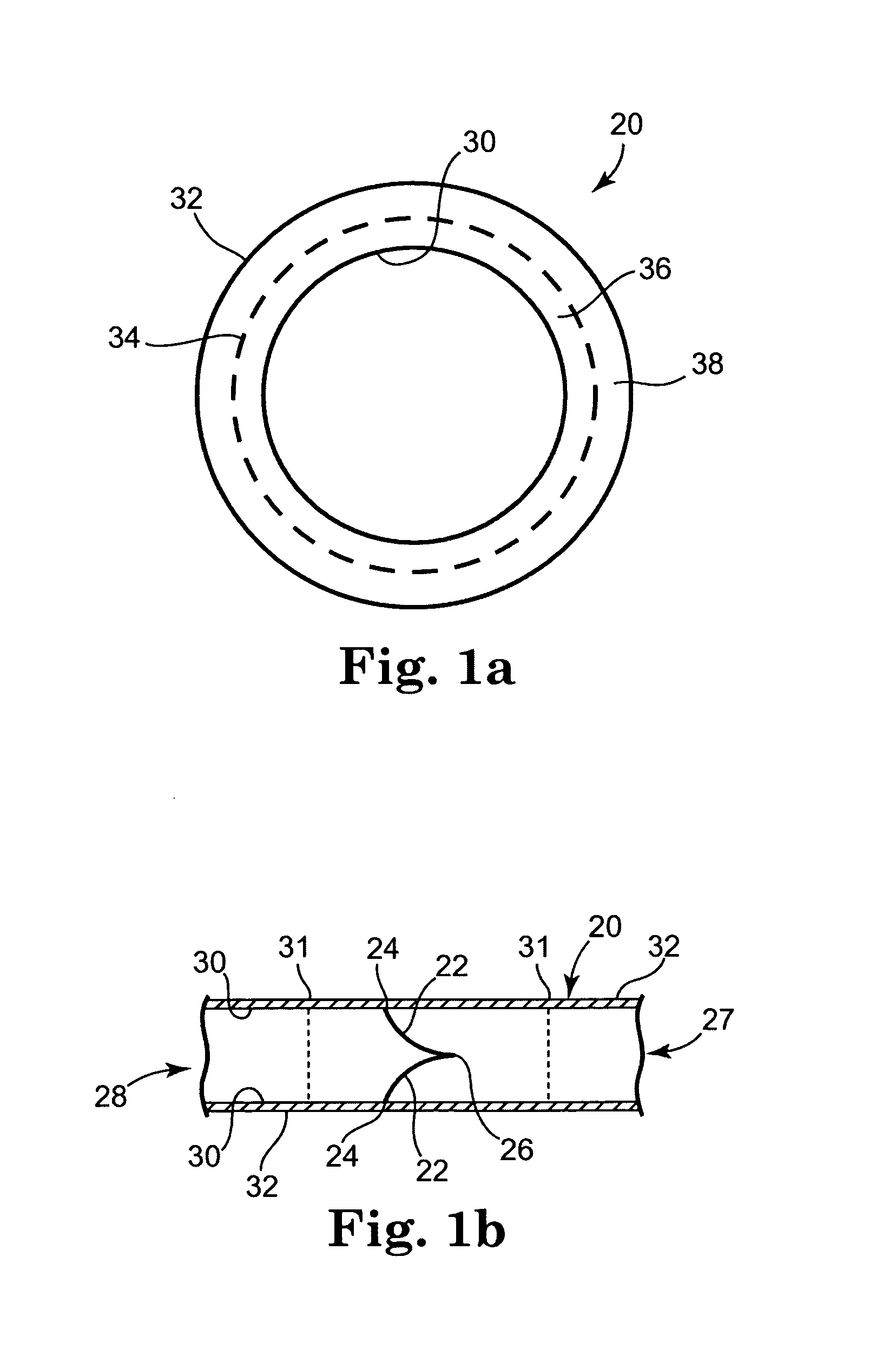

Composite heart valve apparatus manufactured using techniques involving laser machining of tissue

ActiveUS20070073392A1Modifies tissue much fasterLow scrap rateTubular organ implantsVenous valvesVeinLaser processing

Methodology for using laser machining techniques to modify a tissue for use in a medical device. In a representative mode of practice, relatively low energy laser machining is used to thin down at least a portion of a valved jugular vein. The thinned down vein may then be sutured to, or otherwise integrated with, a corresponding stent to make a percutaneous heart valve.

Owner:MEDTRONIC INC

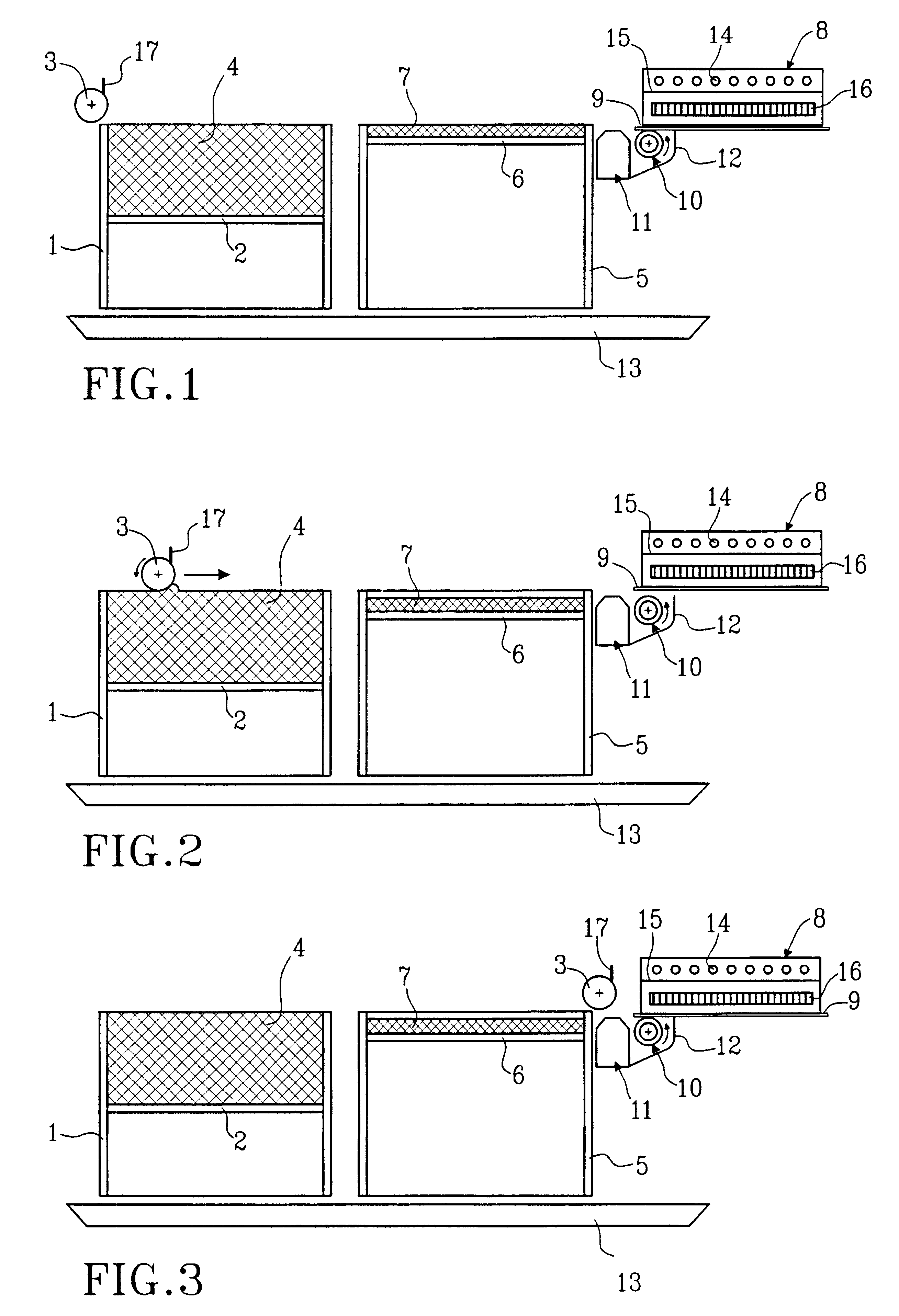

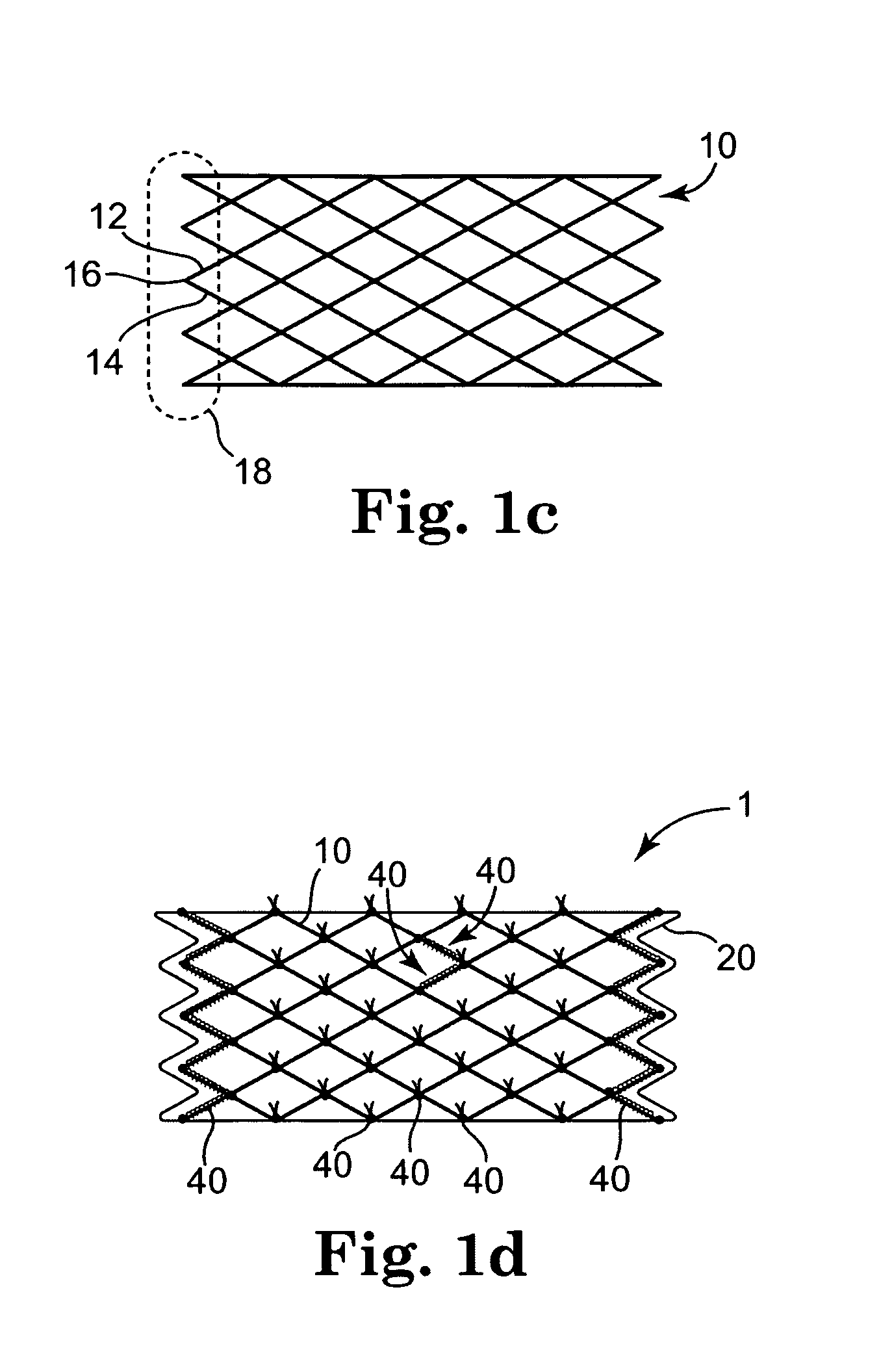

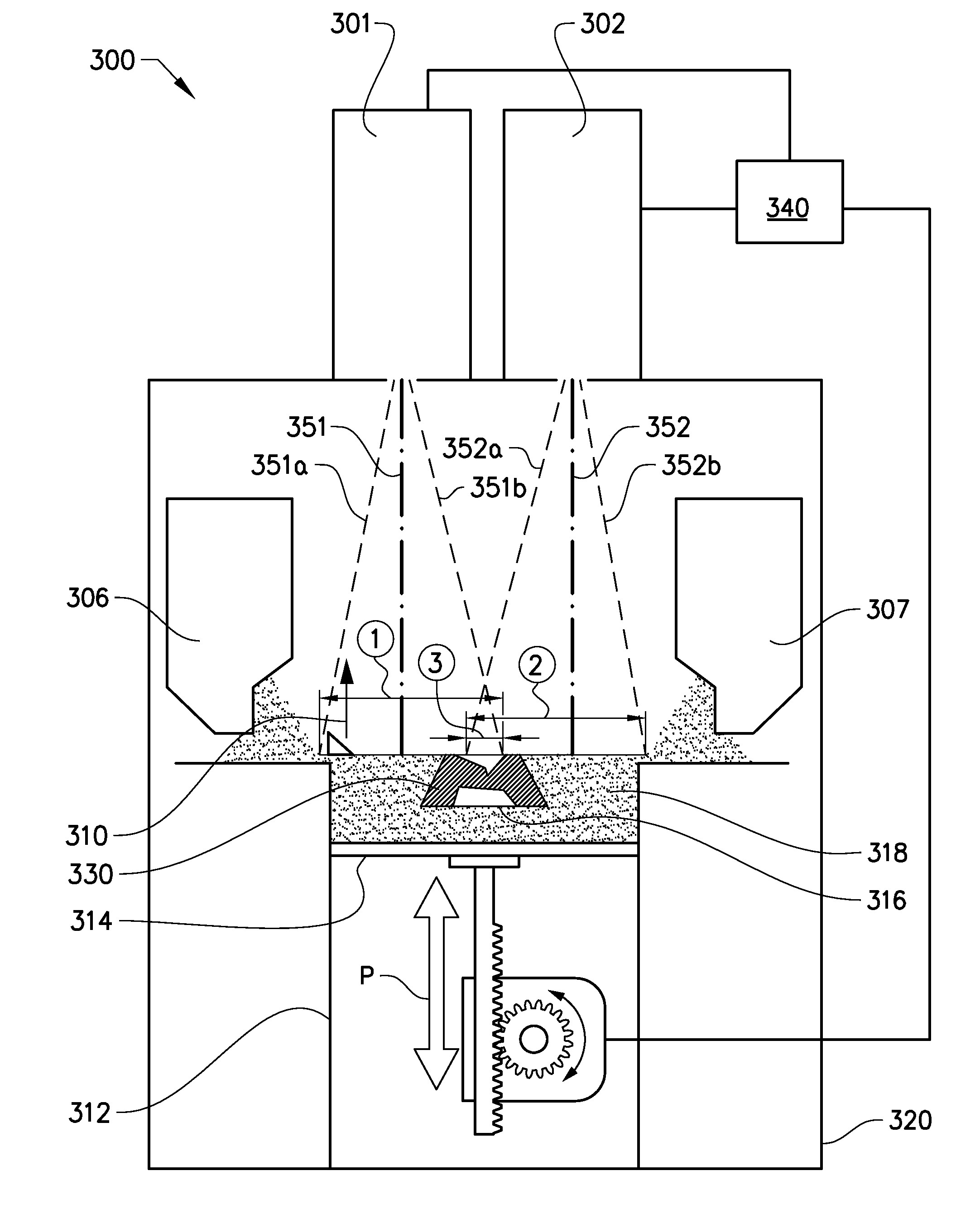

Method and apparatus for additive manufacturing

ActiveUS20140348691A1Large build volumeSacrificing qualityAdditive manufacturing apparatusAuxillary shaping apparatusBeam sourceEngineering

A method for forming a three-dimensional article through successive fusion of parts of a powder bed, which parts corresponds to successive cross sections of the three-dimensional article, said method comprising the steps of: providing a model of said three dimensional article, providing a first powder layer on a work table, directing a first energy beam from a first energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, directing a second energy beam from a second energy beam source over said work table causing said first powder layer to fuse in second selected locations according to said model to form the first cross section of said three-dimensional article, wherein said first and second locations of said first powder layer are at least partially overlapping each other.

Owner:ARCAM AB

Arrangement and method for producing a three-dimensional product

Arrangement for producing a three-dimensional product, which arrangement comprises a work table on which said three-dimensional product is to be built up, a powder dispenser which is arranged so as to distribute a thin layer of powder on the work table for forming a powder bed, a radiation gun for delivering energy to the powder, fusing together of the powder then taking place, means for guiding the beam emitted by the radiation gun over said powder bed for forming a cross section of said three-dimensional product by fusing together parts of said powder bed, and a control computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build up the three-dimensional product, where the control computer is intended to control said means for guiding the radiation gun over the powder bed according to an operating scheme forming a cross section of said three-dimensional body, said three-dimensional product being formed by successive fusing together of successively formed cross sections from by the powder dispenser, and method for producing three-dimensional product using such an arrangement.

Owner:ARCAM AB

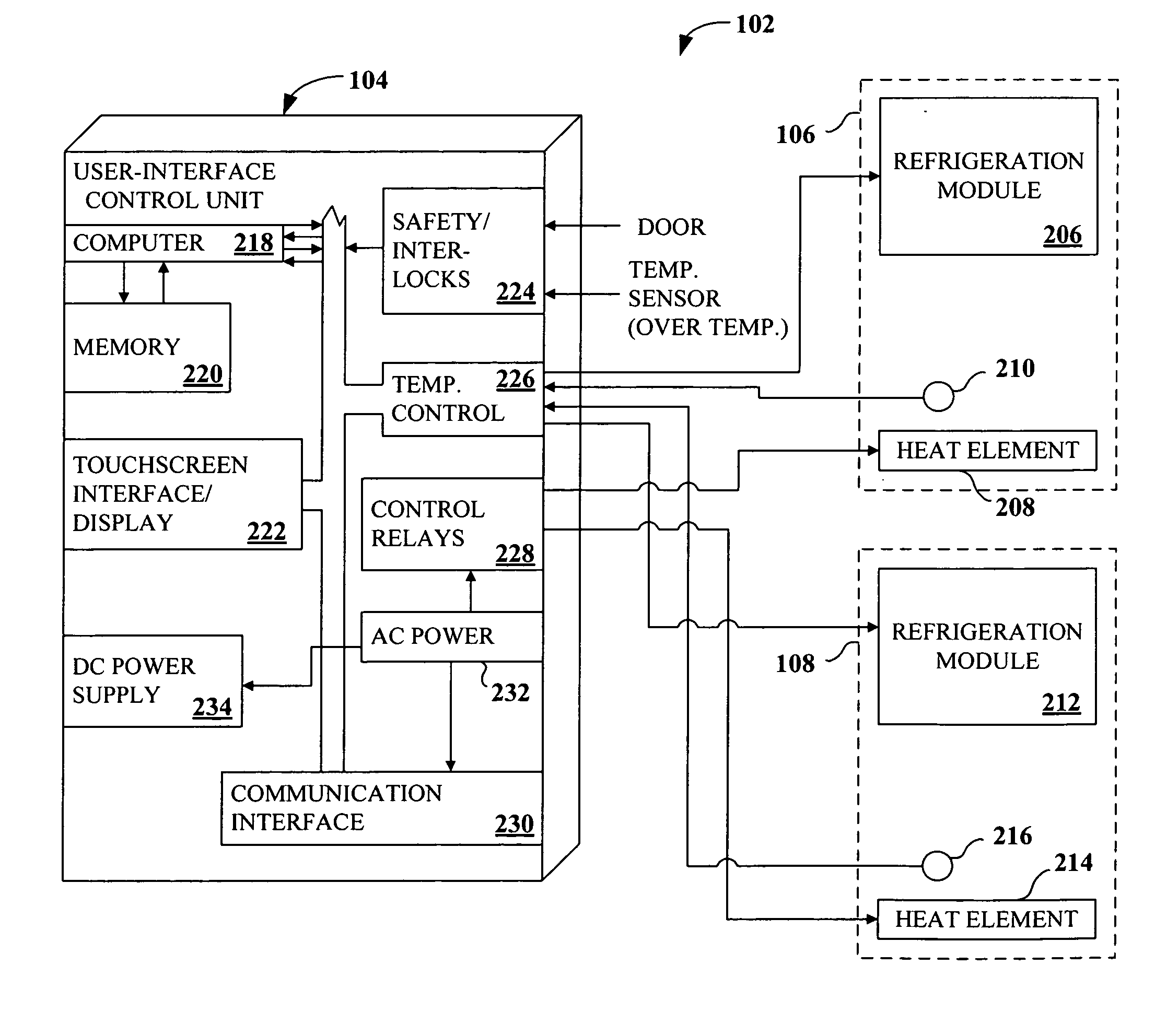

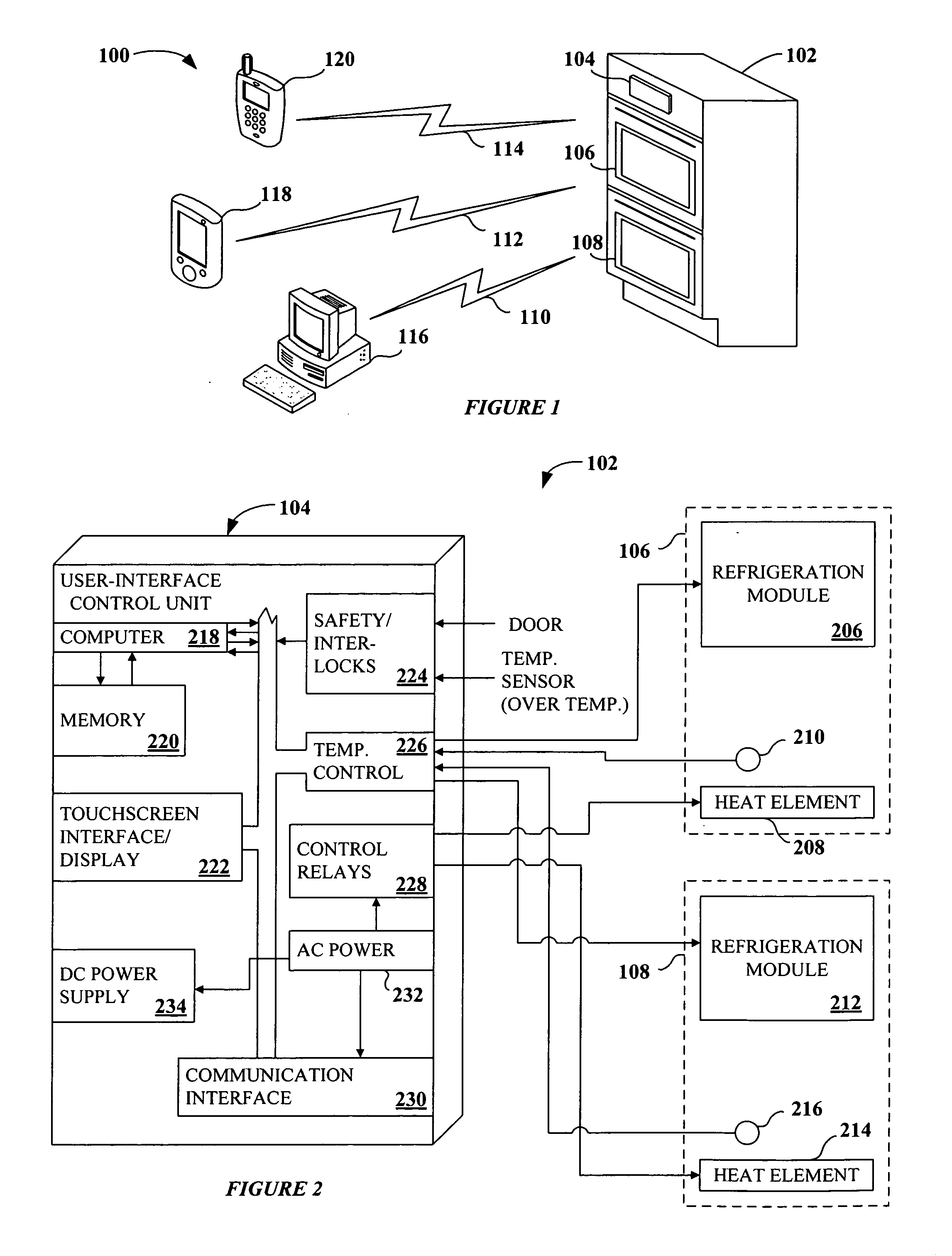

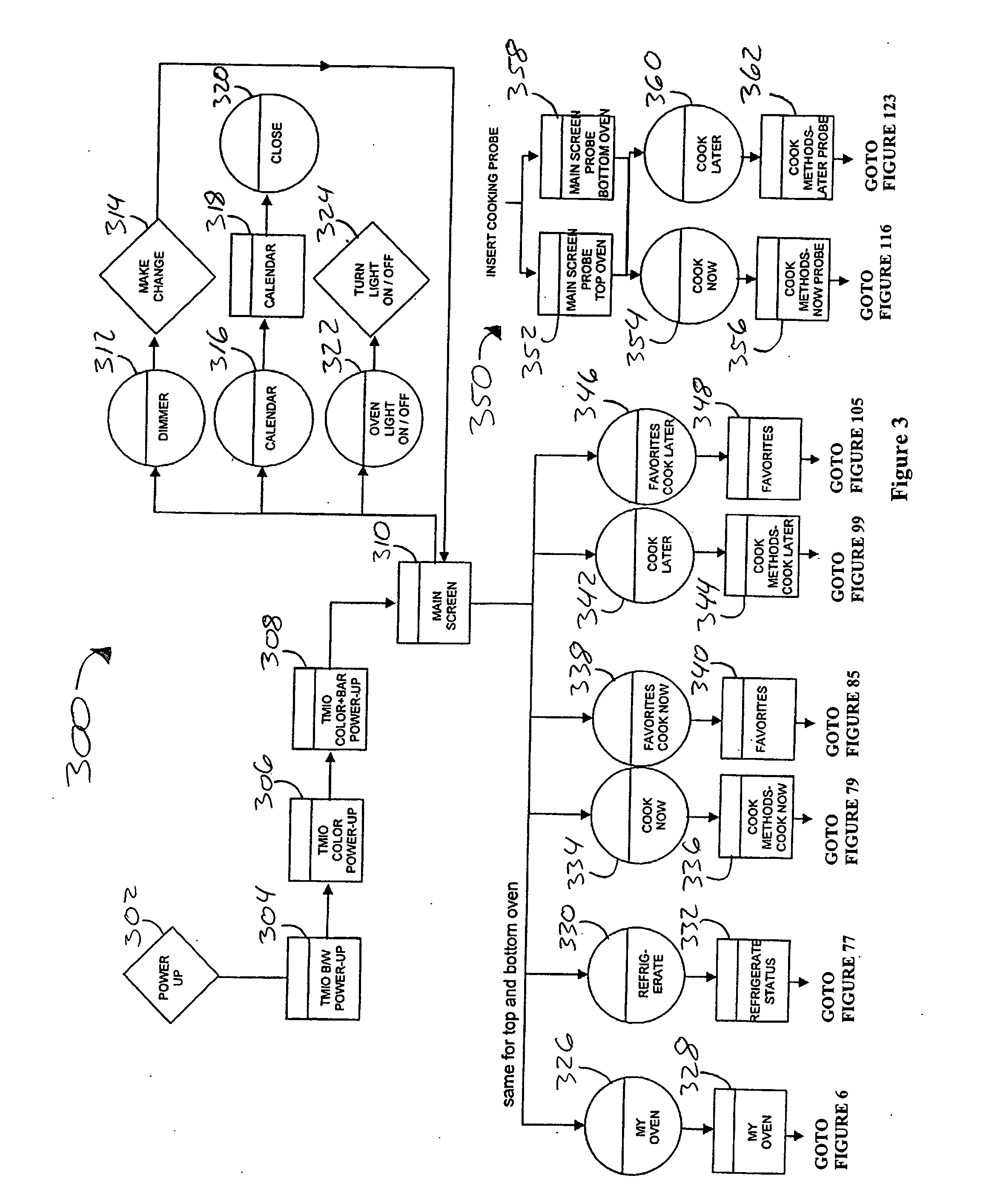

Method and control interface for food preparation on a cooking appliance

InactiveUS20070158335A1Domestic stoves or rangesBoiling over preventionGraphical user interfaceThe Internet

A graphical user interface adapted to enable a user to direct and control a cooking appliance. The graphical user interface generally enables a plurality of cooking appliance operations through associated layers of screens, such as a refrigerate operation, a cook now operation, a cook later operation, etc., and a plurality of cook settings, such as a bake setting, a roast setting, a broil setting, a warm setting, a convection bake setting, a convection roast setting, a convection broil setting, a convection defrost setting, etc. The graphical user interface is adapted to be integrated with and accessible through one or more of the cooking appliance, a handheld device, an Internet-accessible computer, etc.

Owner:VIKING RANGE

Method for rapid forming of a ceramic work piece

InactiveUS6217816B1Rapid productionPrevent dislocationAdditive manufacturing apparatusFeeding arrangmentsHeat fusionLaser beams

An inorganic binder and a dissolving agent are put into ceramic powder. They are mixed to form a plastic green mixture. Then the said mixture is formed into a thin green layer. Preferably, this thin green layer will be preheated and dried such that the thin green layer will be hardened due to the bonding effect of the inorganic binder. A portion of the thin green layer exposed under a directed high-energy beam is sintered, preferably by a laser beam, to cause ceramic molecules to bond together locally due to heat fusion. By controlling the scanning path of the high-energy beam, a two-dimensional thin cross section of the ceramic part in arbitrary form can be produced. A second thin ceramic layer can be built onto the first thin ceramic layer and bonded to it by the same method. After multiple repetitions of this procedure a three dimensional ceramic part can be fabricated layer upon layer. The green portion, which is not scanned by the high-energy beam, will be removed with suitable method. A ceramic part can be rapidly produced in this way.

Owner:NAT SCI COUNCIL

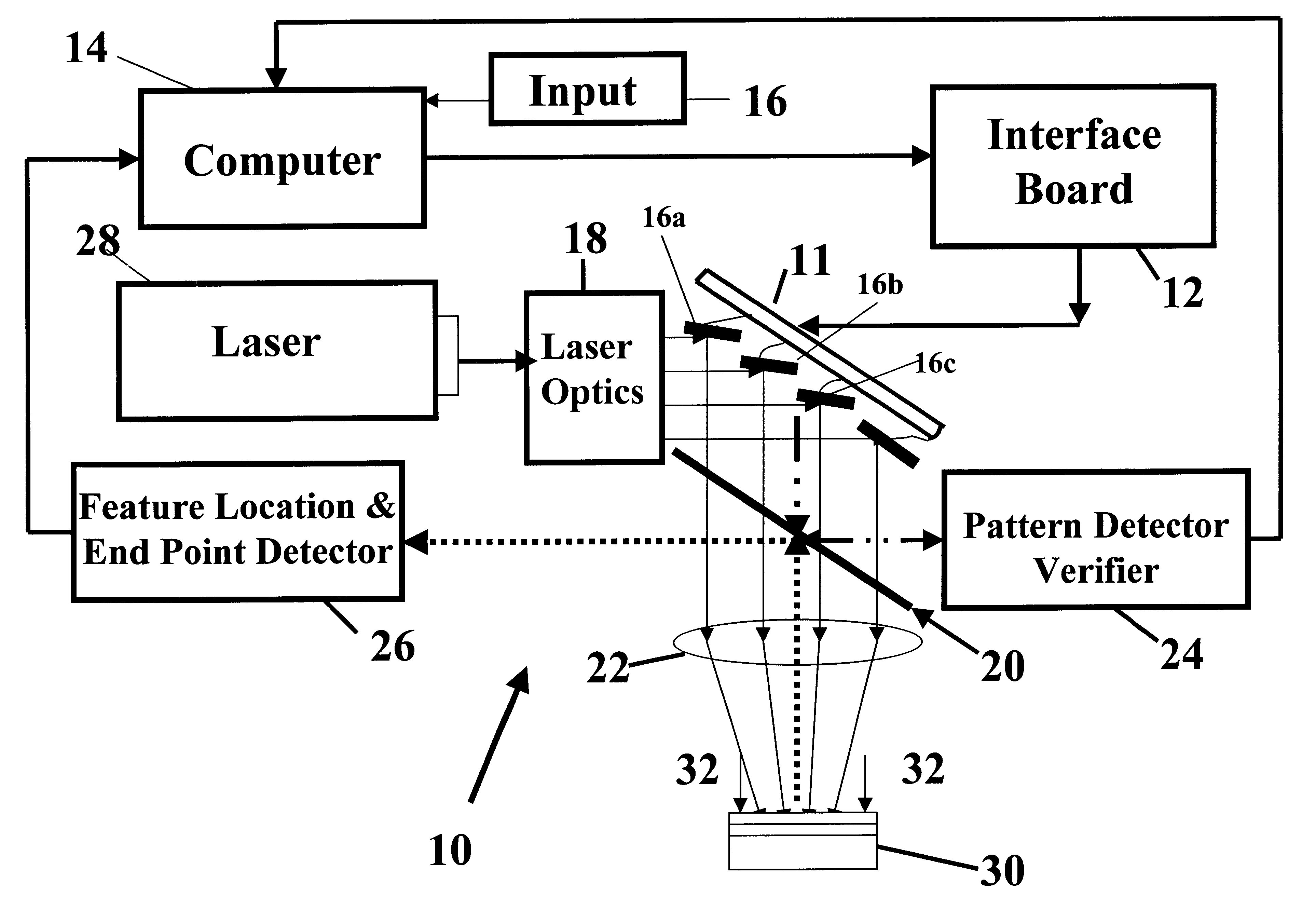

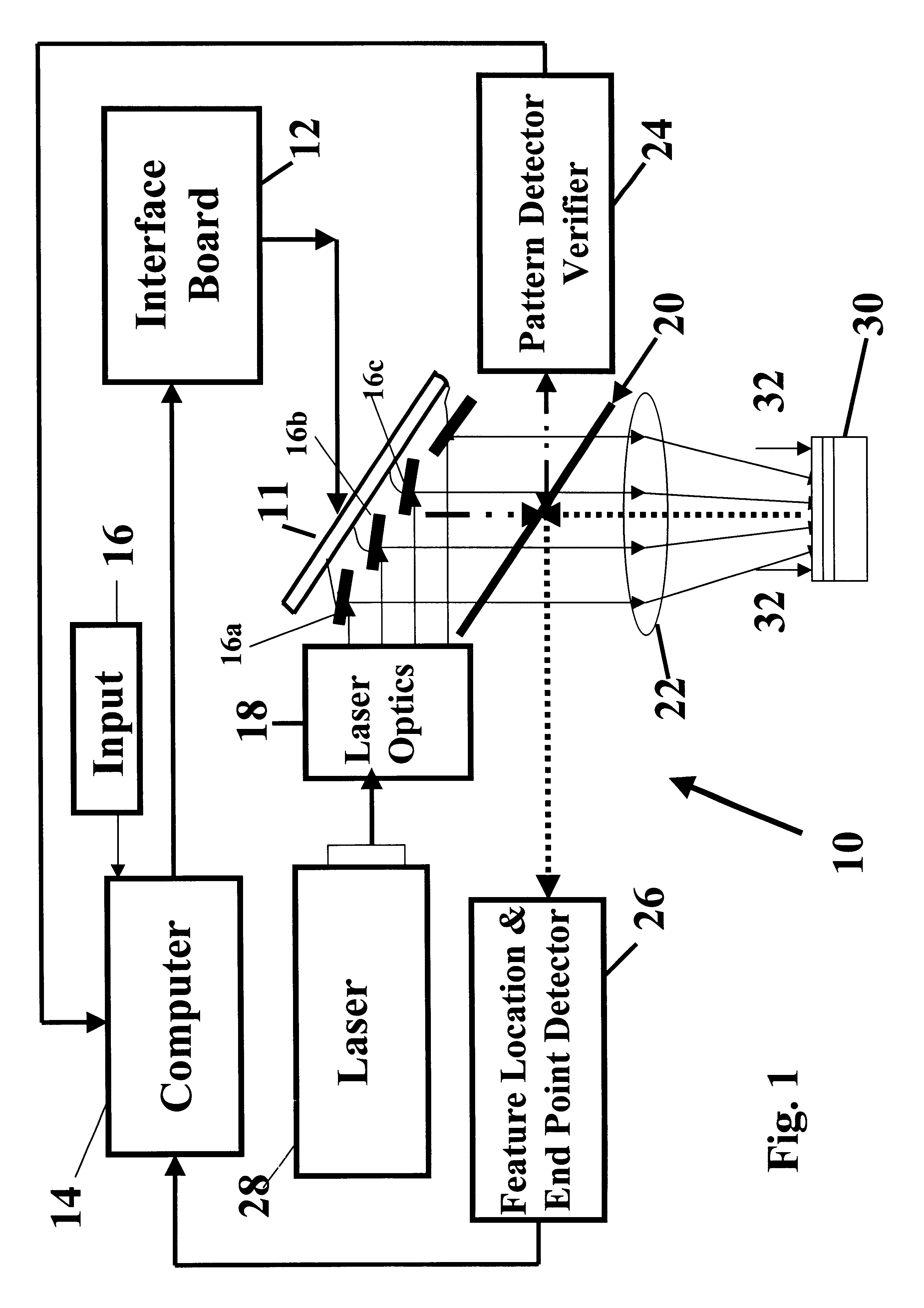

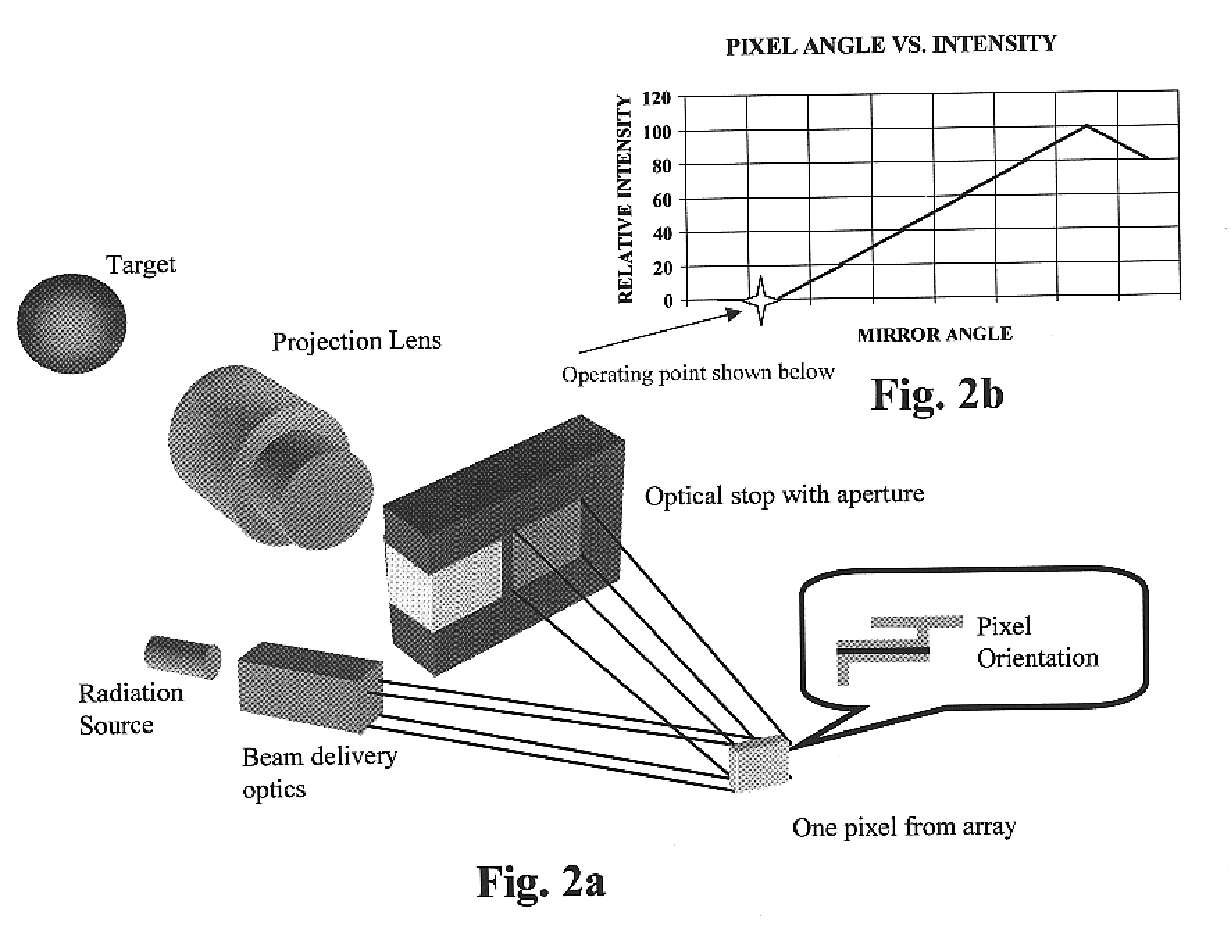

Maskless laser beam patterning ablation of multilayered structures with continuous monitoring of ablation

A maskless patterning apparatus allows for laser beam ablation of one or more layers of material while not etching an underlying different material layer. A micromirror array produces the desired complex pattern on the workpiece and a continuous feature and end point detection system provides location and material parameter changes to accurately control the pattern position and depth of etching. End point detection includes monitoring energy reflected from a specially prepared replica of the material to be ablated, whose thickness and consistency match the active workpiece area. The process terminates when the proper amount of material is removed.

Owner:WESTAR PHOTONICS

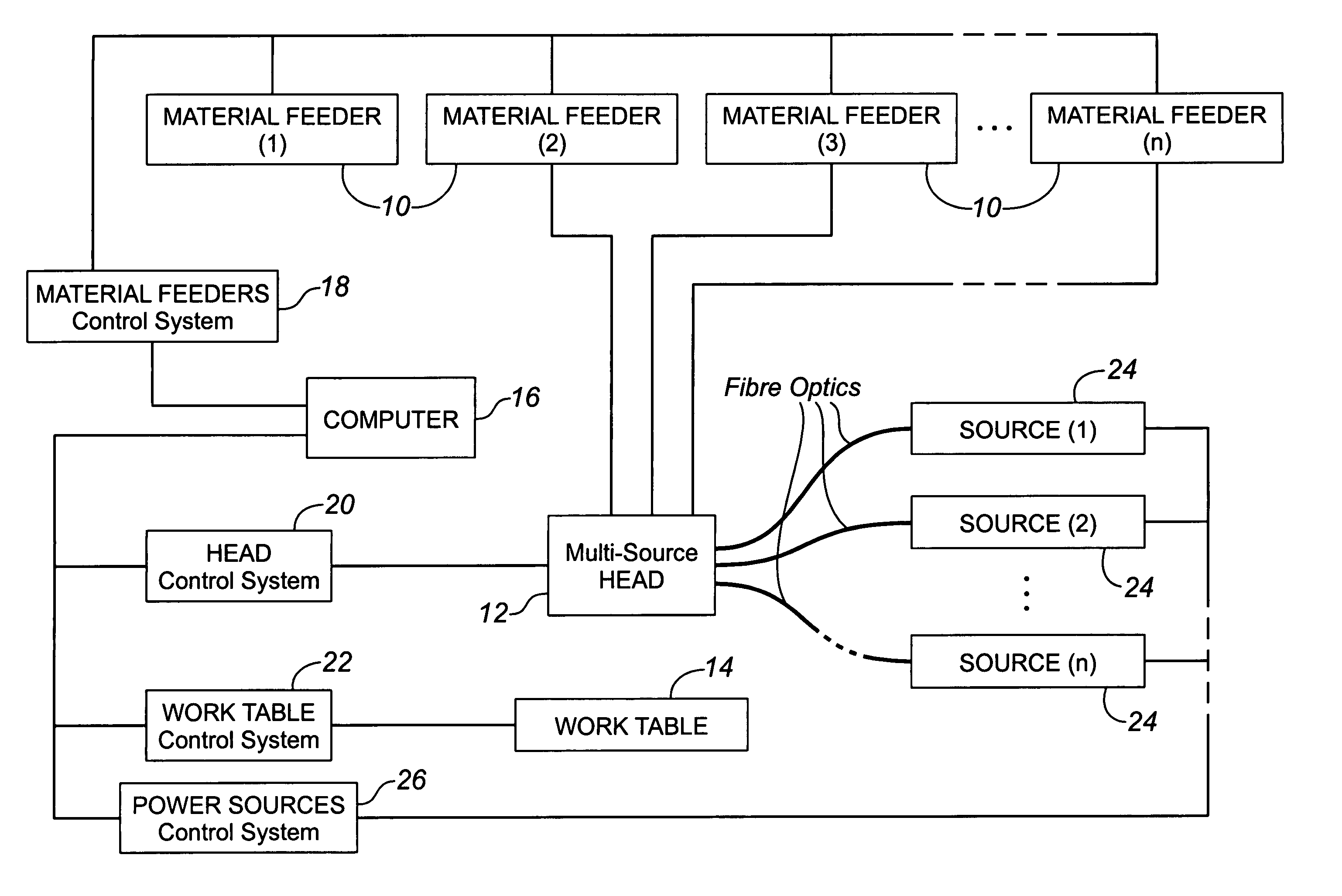

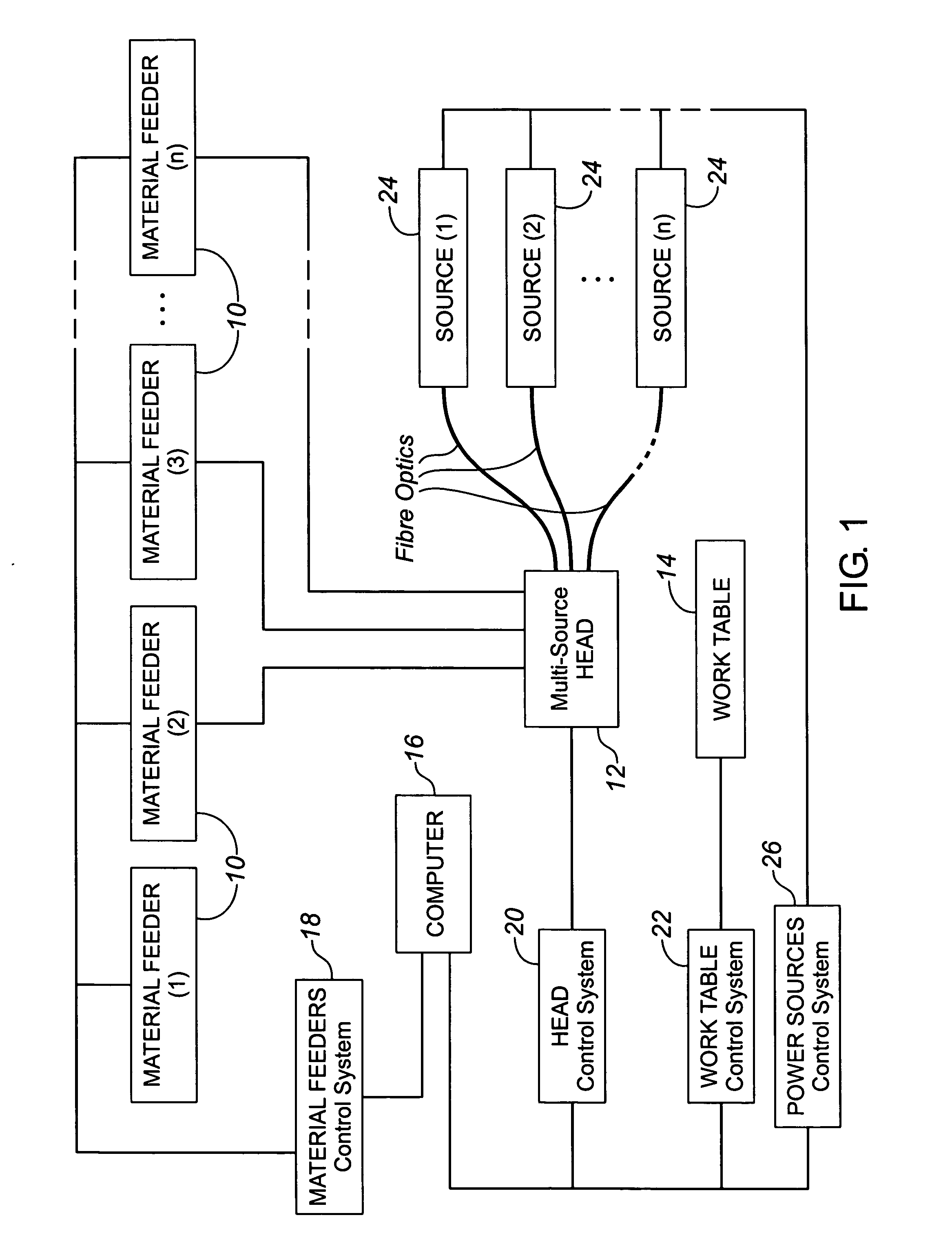

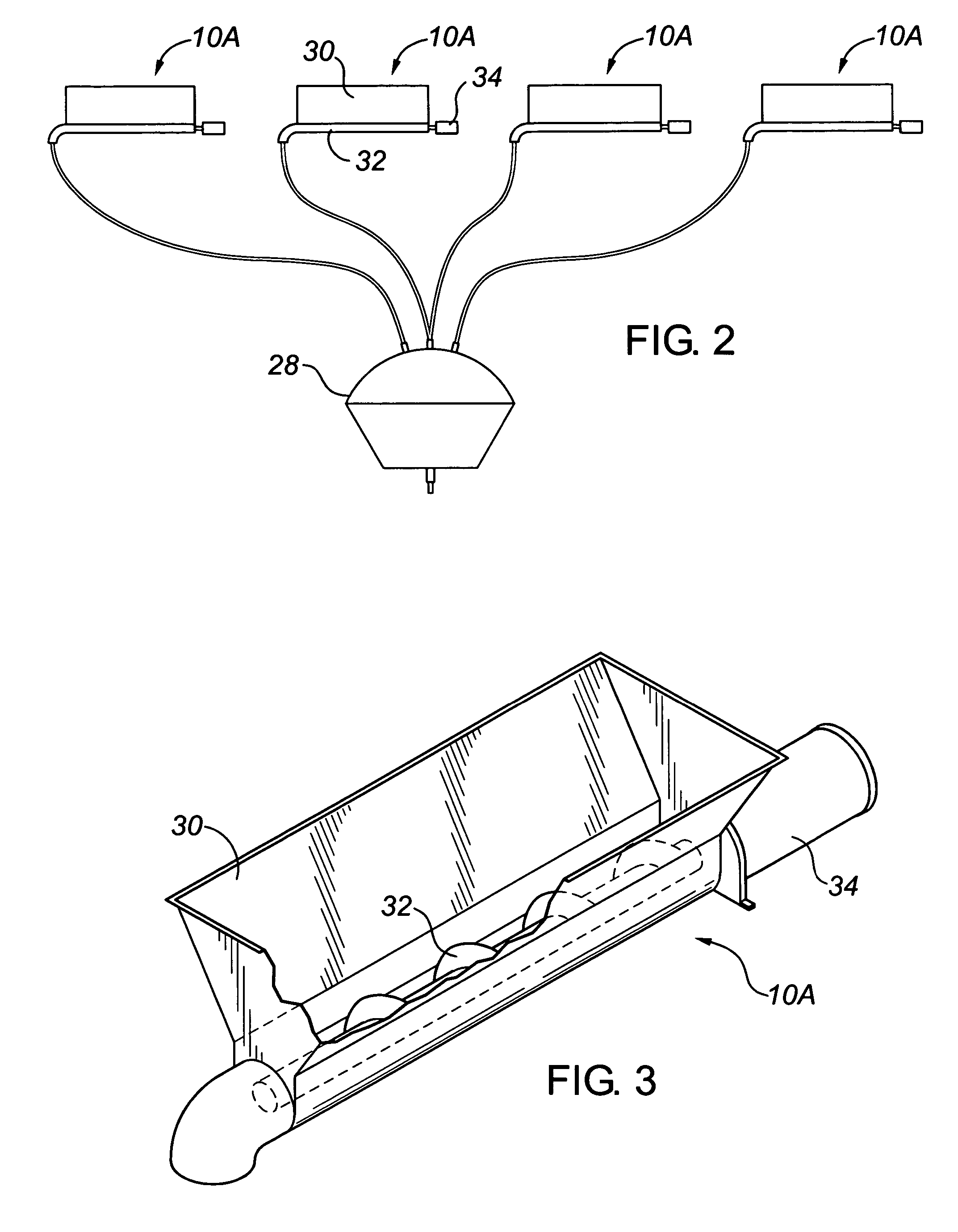

Multisource and multimaterial freeform fabrication

InactiveUS20050104257A1Liquid surface applicatorsMechanical working/deformationControl systemEngineering

An apparatus for forming freeform solid articles includes a head unit having a plurality of arc-shaped support arms. The support arms mount material feeders and power sources which are directed at a work table. The material feeders, power sources and movement of the head unit and work table are controlled by a computerized control system.

Owner:UNIV TECH INT

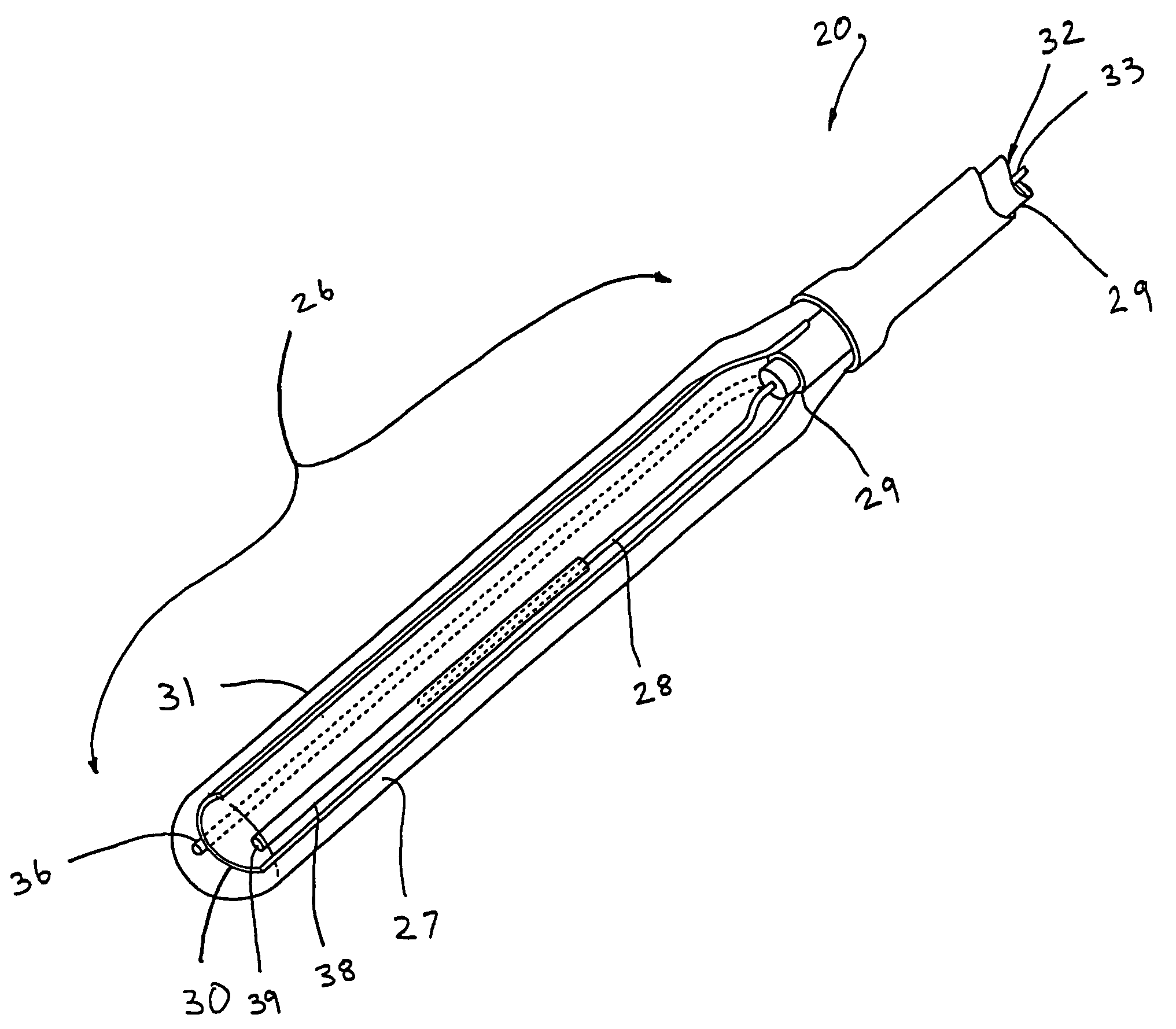

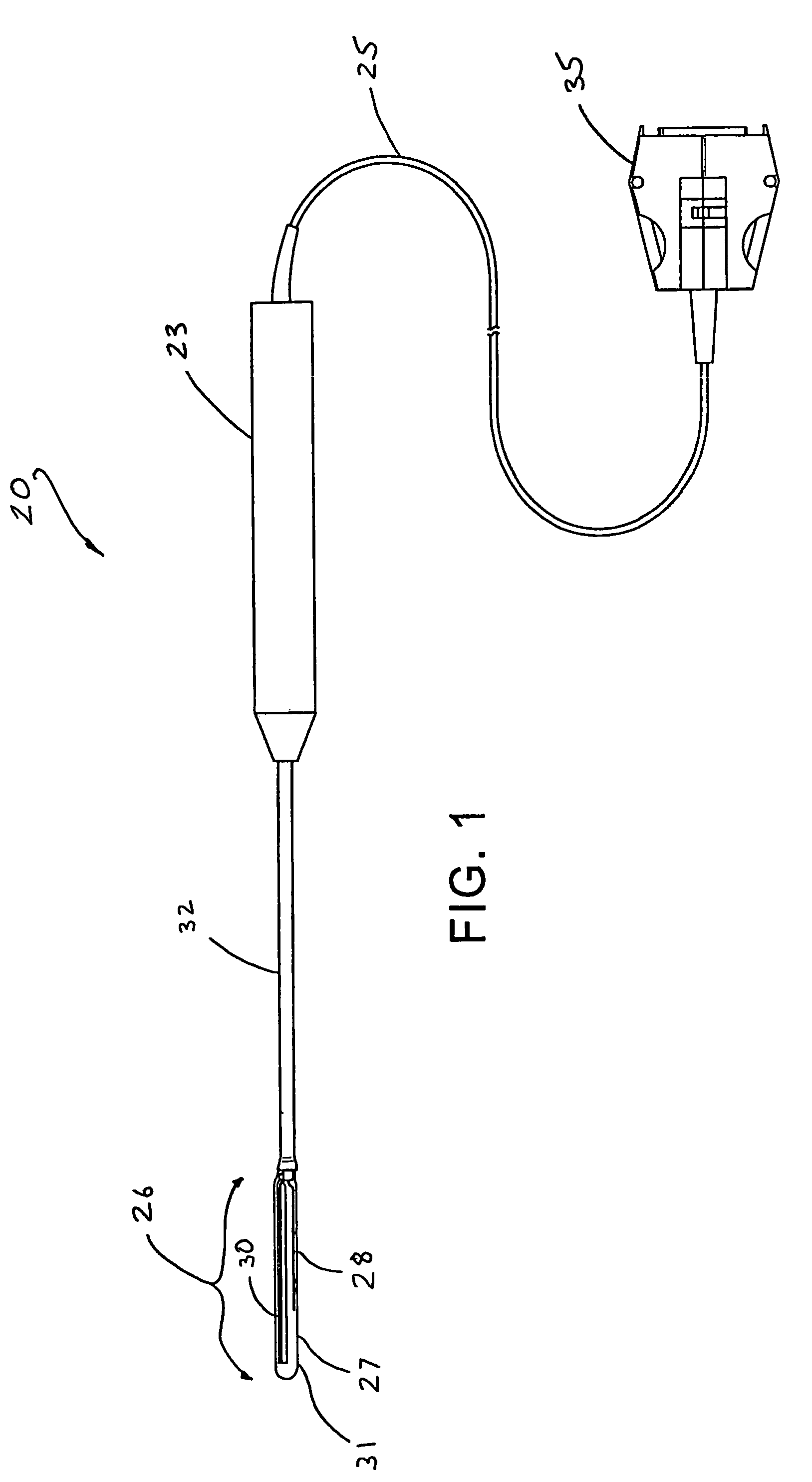

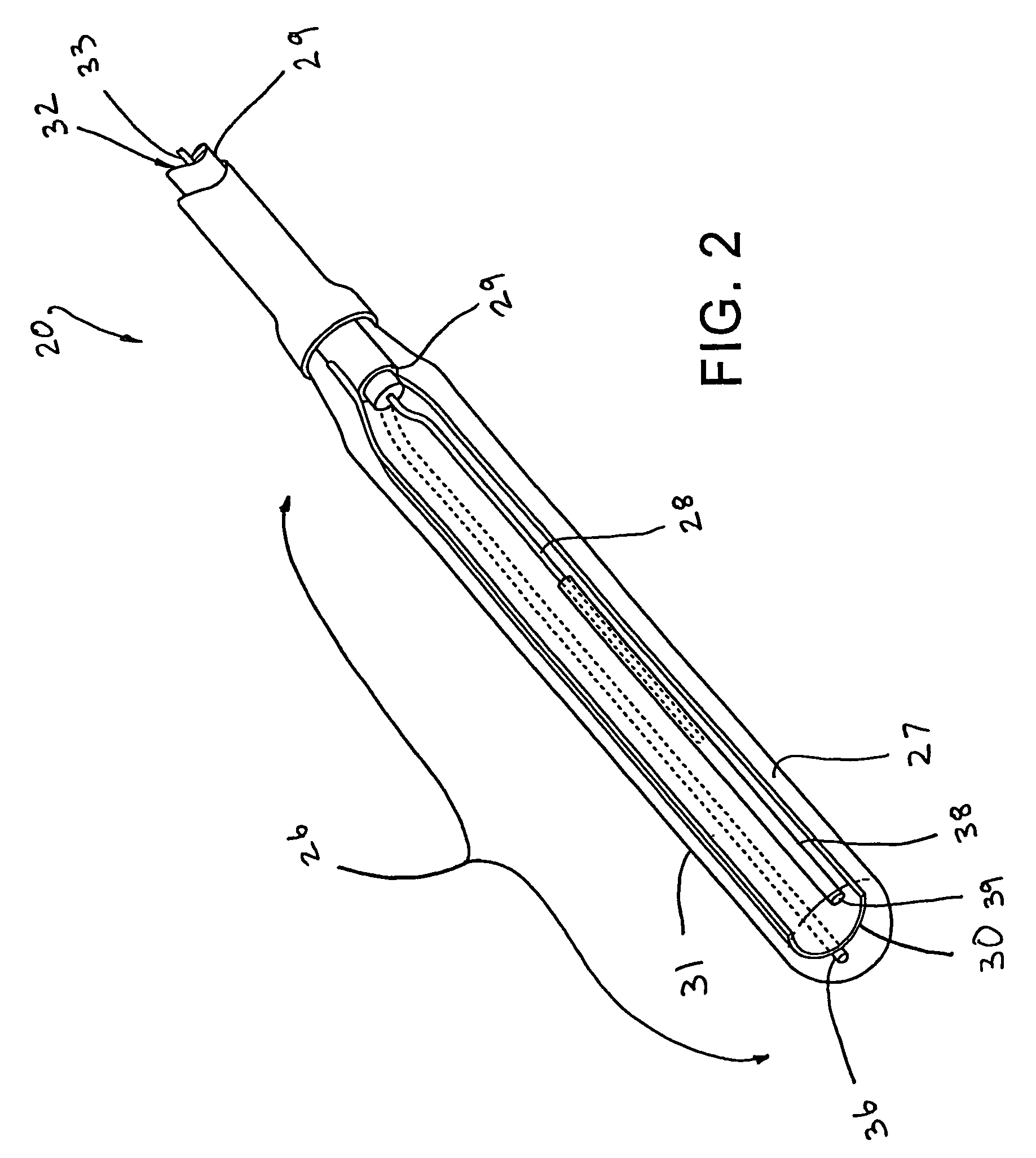

Flexible ablation instrument

A flexible microwave antenna assembly for a surgical ablation instrument capable of conforming to a tissue surface for ablation thereof. The ablation instrument includes a transmission line having a proximal portion suitable for connection to an electromagnetic energy source. The antenna assembly includes a flexible antenna coupled to the transmission line for radially generating an electric field sufficiently strong to cause tissue ablation. A flexible shield device is coupled to the antenna to substantially shield a surrounding area of the antenna from the electric field radially generated therefrom while permitting a majority of the field to be directed generally in a predetermined direction. A flexible insulator is disposed between the shield device and the antenna which defines a window portion enabling the transmission of the directed electric field in the predetermined direction. The antenna, the shield device and the insulator are formed for selective manipulative bending thereof, as a unit, to one of a plurality of contact positions to generally conform the window portion to the biological tissue surface to be ablated.

Owner:MAQUET CARDIOVASCULAR LLC +1

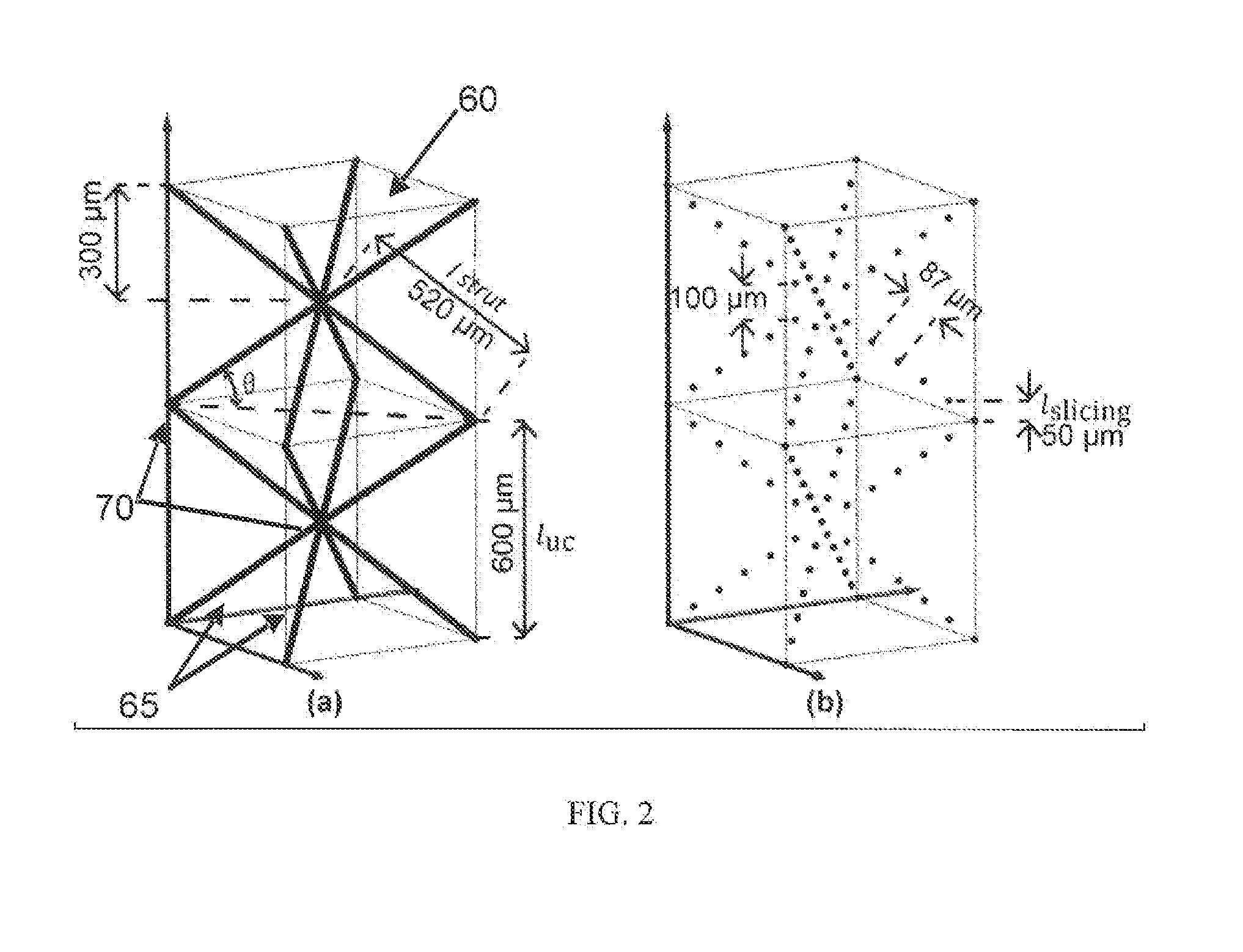

Surface modified unit cell lattice structures for optimized secure freeform fabrication

ActiveUS20130264749A1Additive manufacturing apparatusComputer aided designStructural engineeringMechanical engineering

Owner:HOWMEDICA OSTEONICS CORP +1

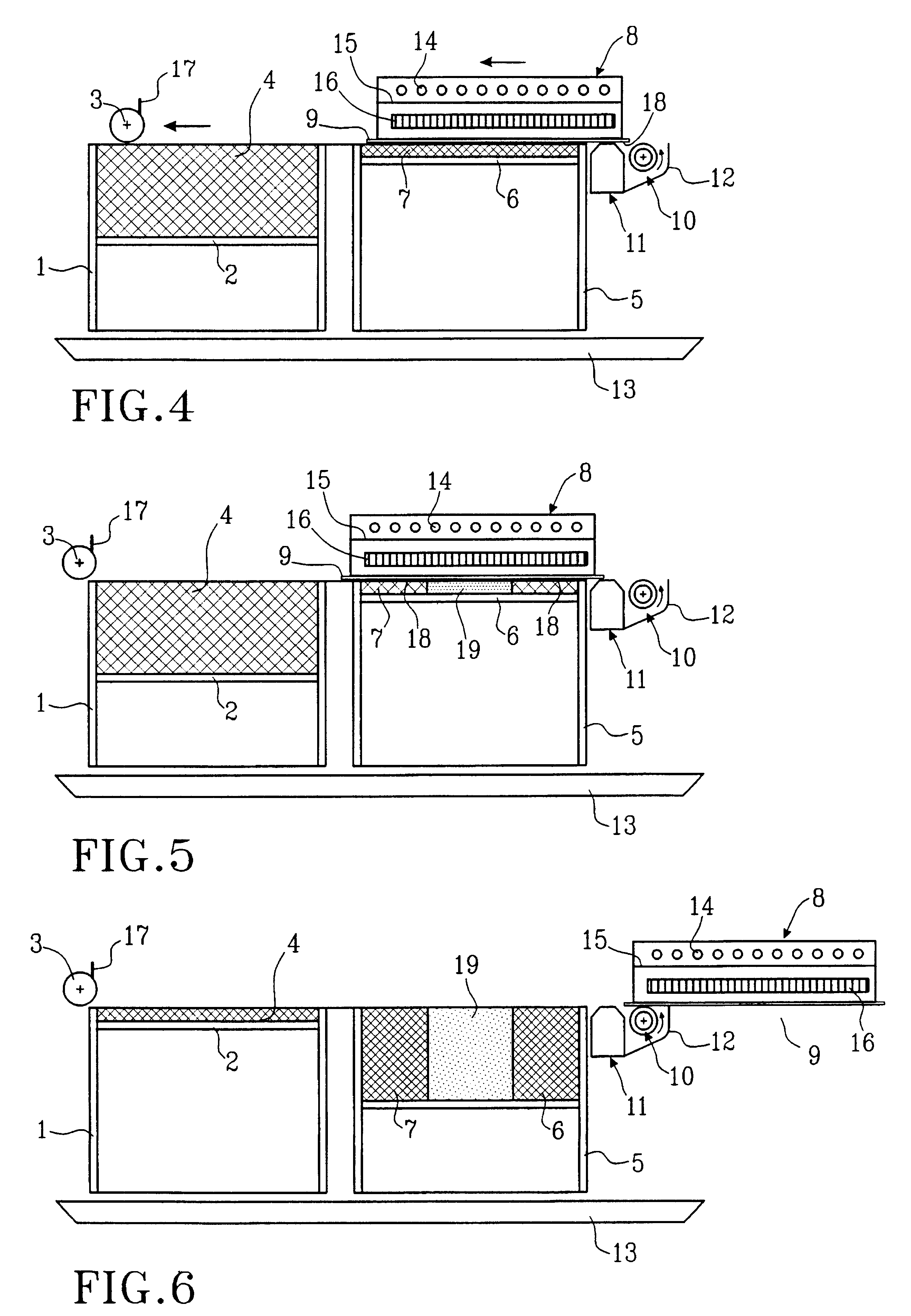

Device and arrangement for producing a three-dimensional object

InactiveUS7537722B2Reduce biasReduce riskAdditive manufacturing apparatusAuxillary shaping apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

Three dimensional structure producing device and producing method

An apparatus for making a three-dimensional object includes a powdery layer-forming unit for forming a powdery layer on a table and an optical beam-irradiating unit for irradiating an optical beam on a predetermined region of the powdery layer to sinter the predetermined region. The optical beam-irradiating unit is disposed at a position spaced from immediately above an optical beam-irradiating range to obliquely irradiate the optical beam on the powdery layer. Because fumes generated by irradiating and heating the powdery layer with the optical beam rise towards a position immediately above them, the optical beam is irradiated from the position spaced from immediately above the optical beam-irradiating range, thereby reducing a cloud of the optical beam-irradiating unit that may be caused by the fumes.

Owner:MATSUSHITA ELECTRIC WORKS LTD

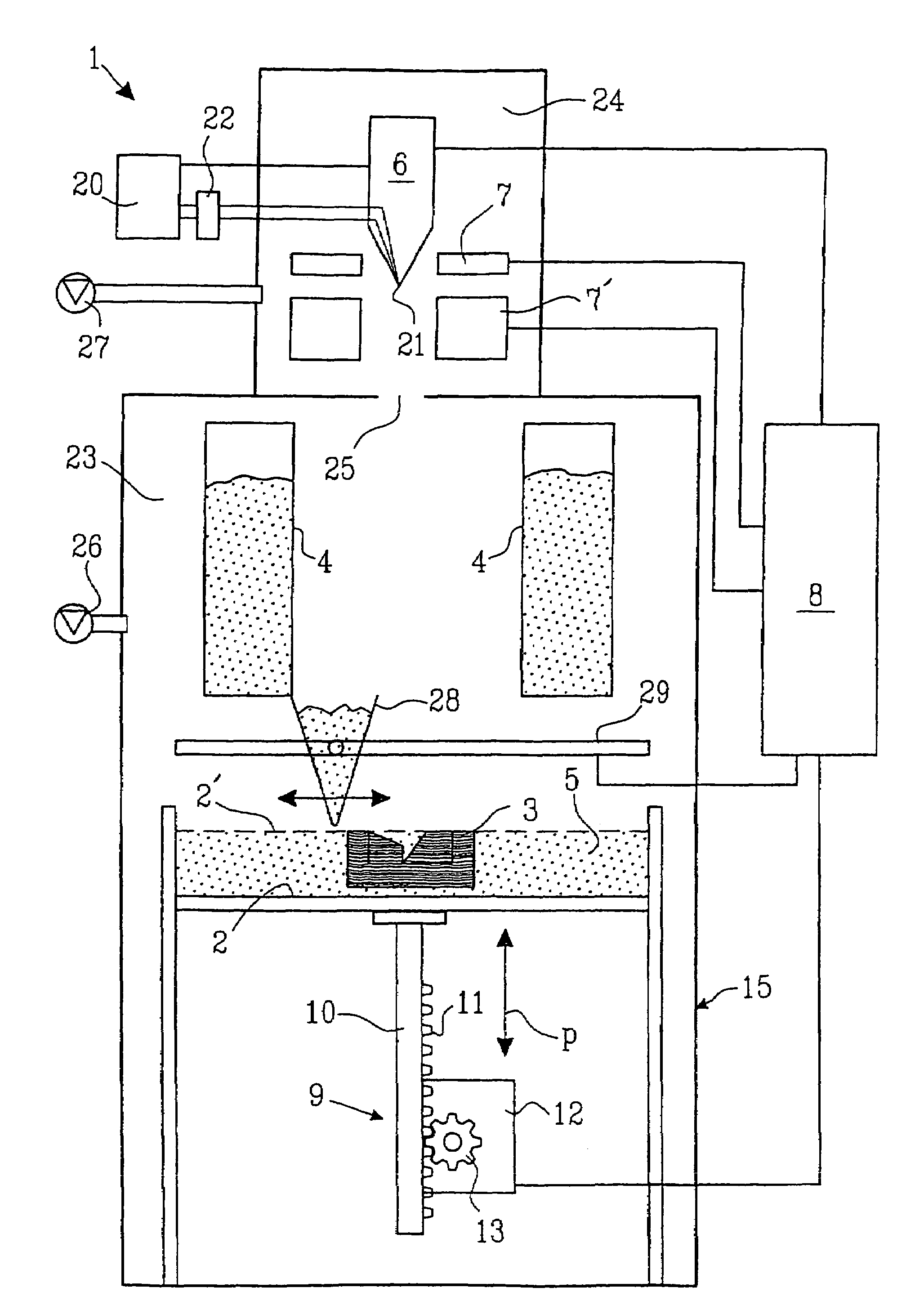

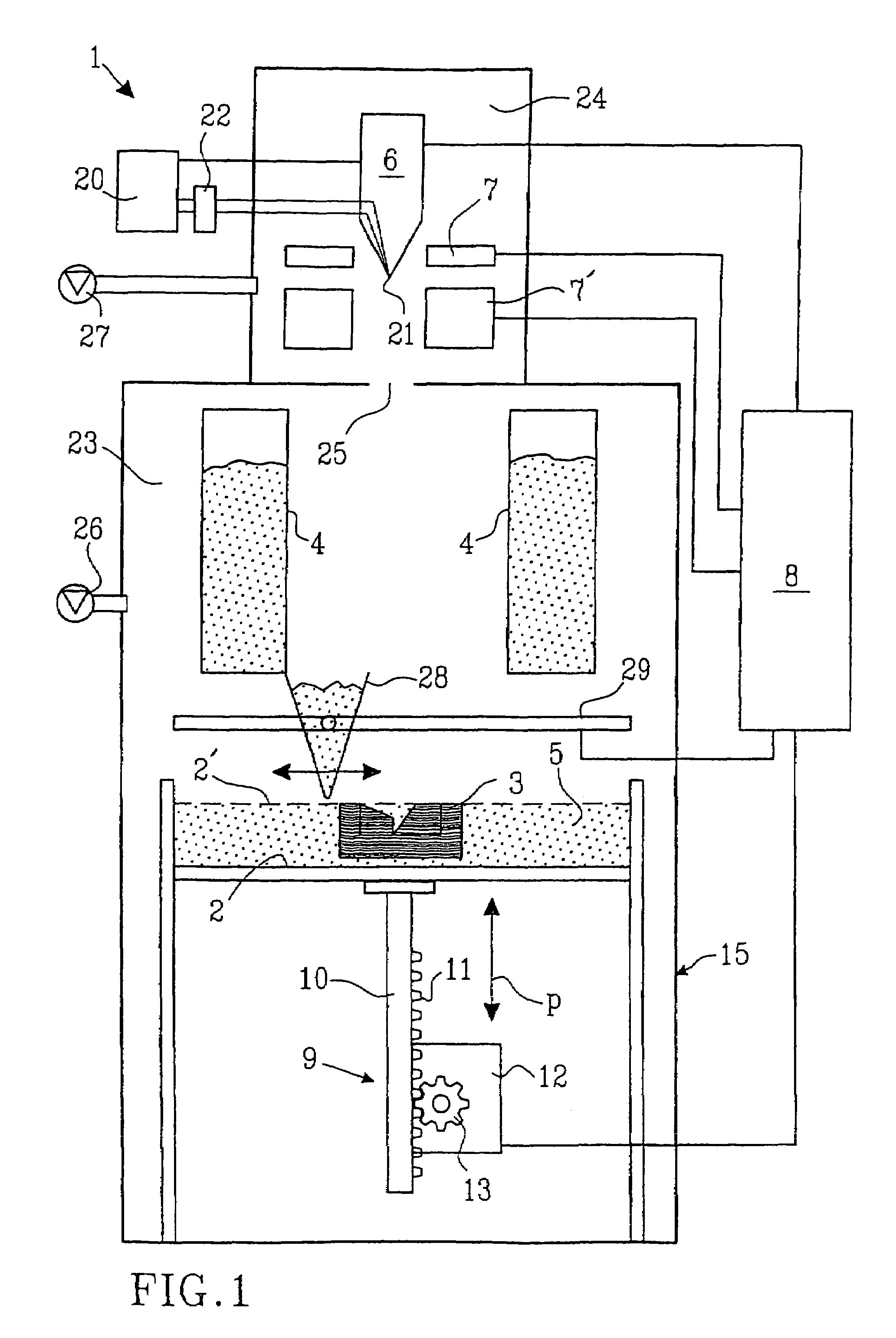

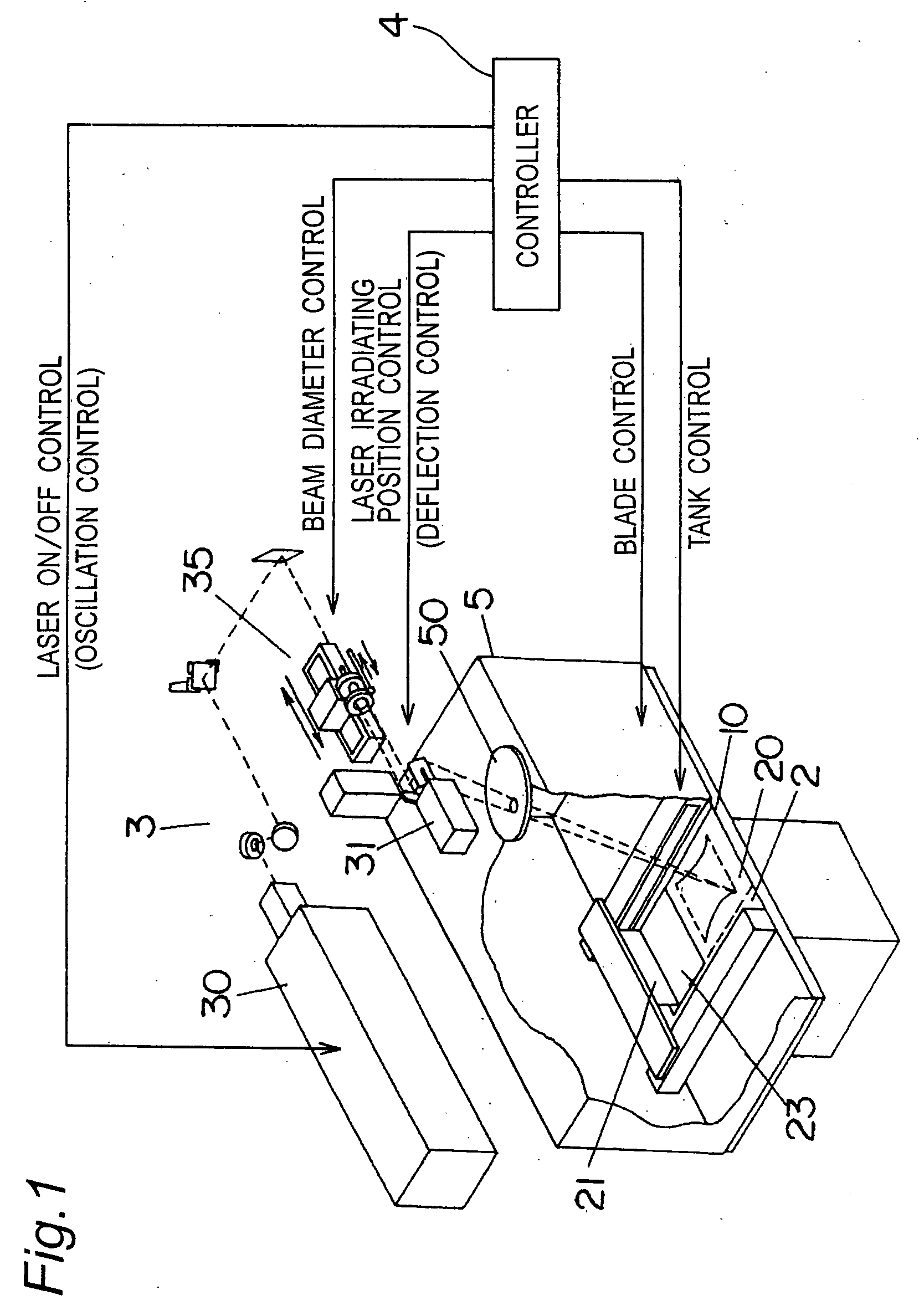

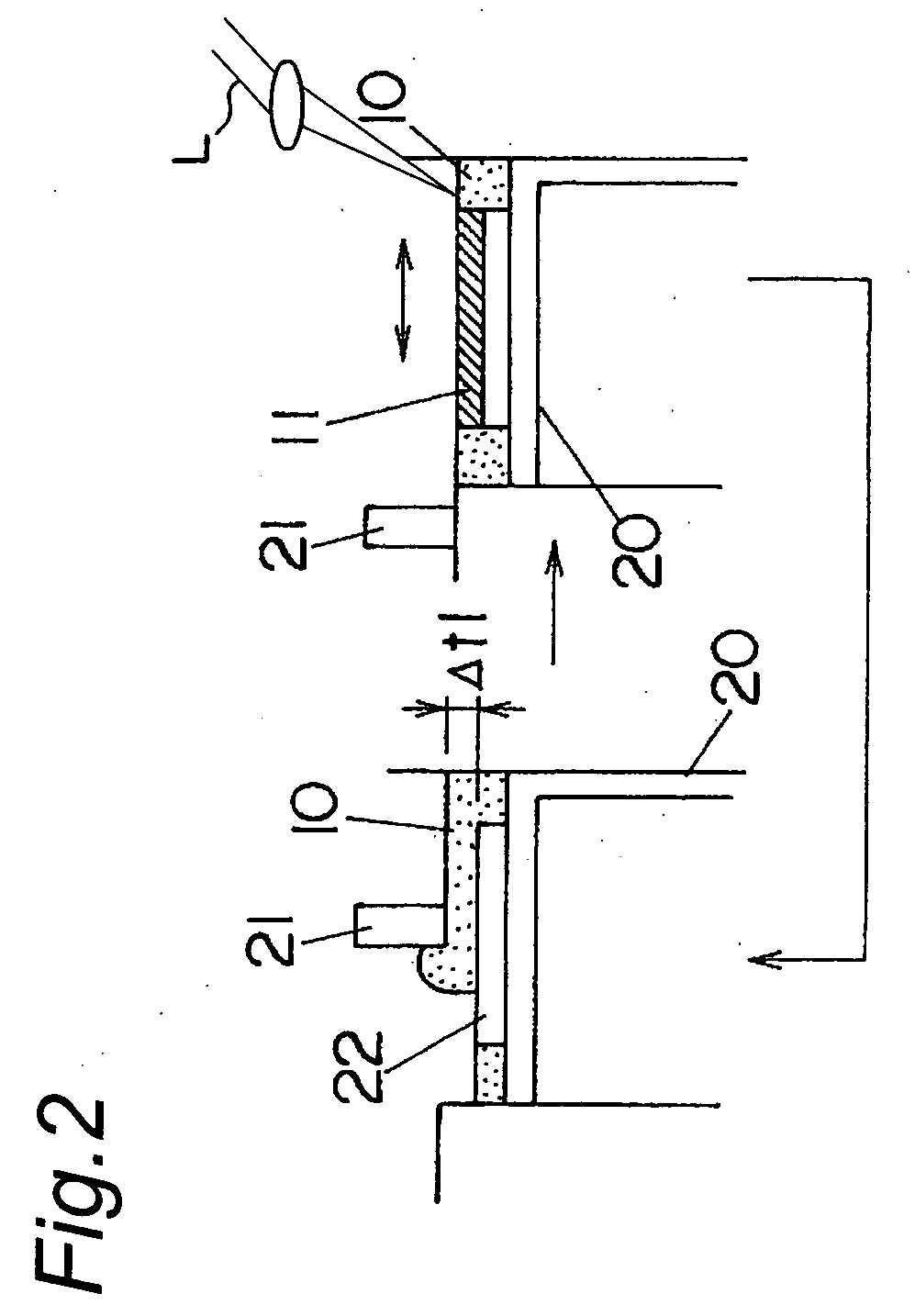

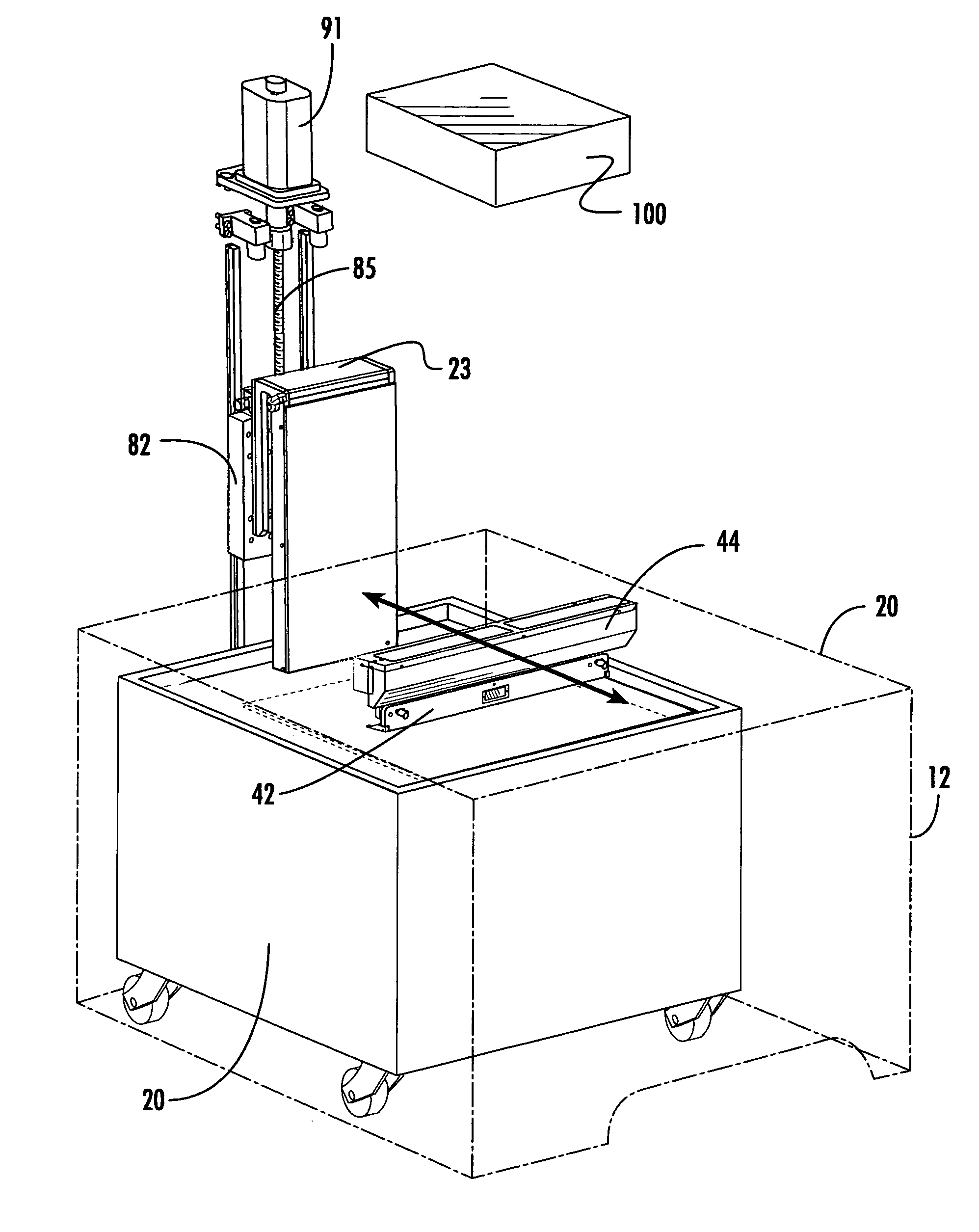

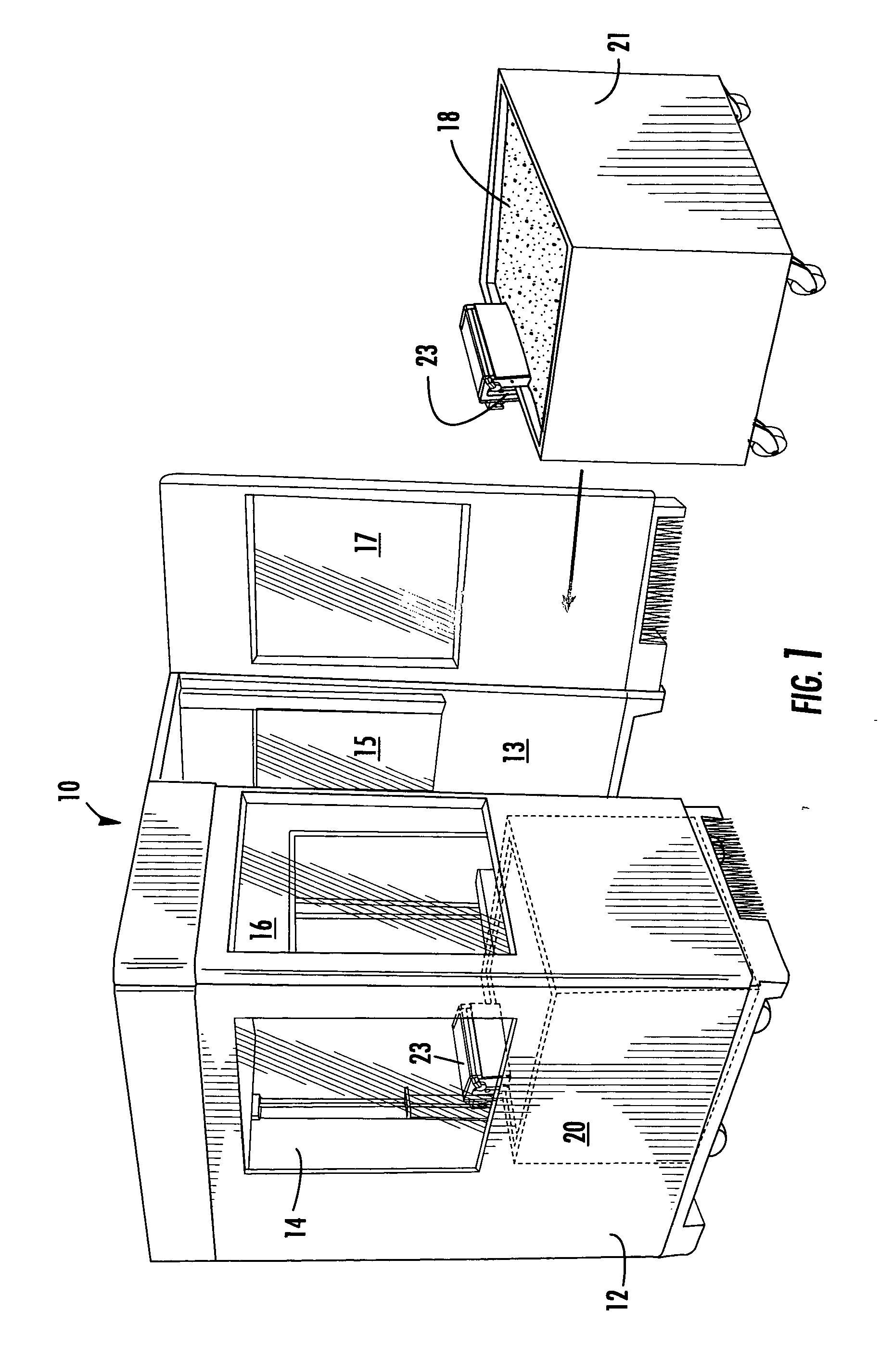

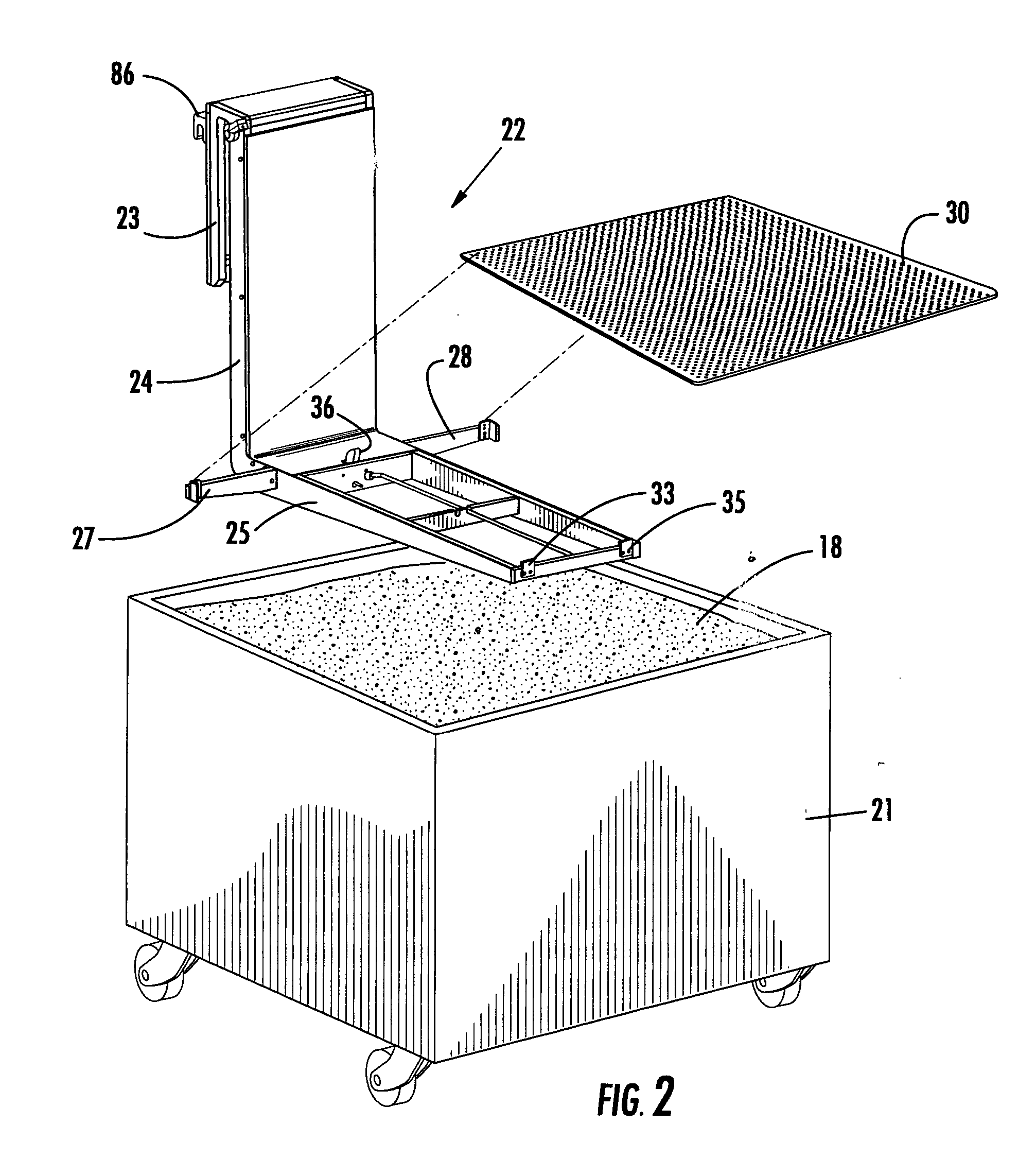

Rapid prototyping and manufacturing system and method

ActiveUS20070074659A1Simplify obtaining precisionFast preparationConfectioneryPretreated surfacesEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

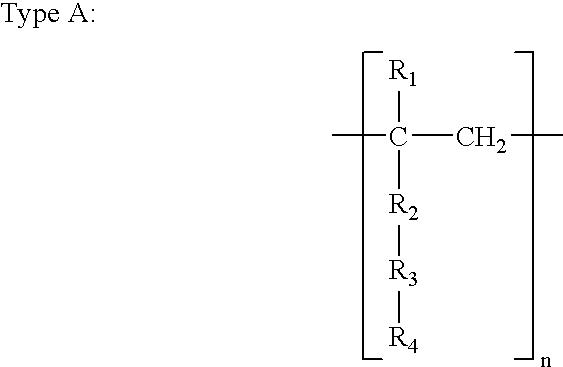

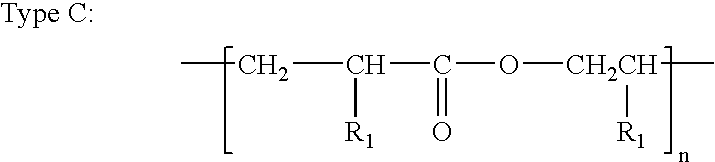

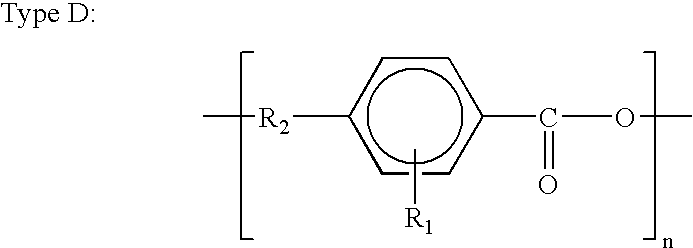

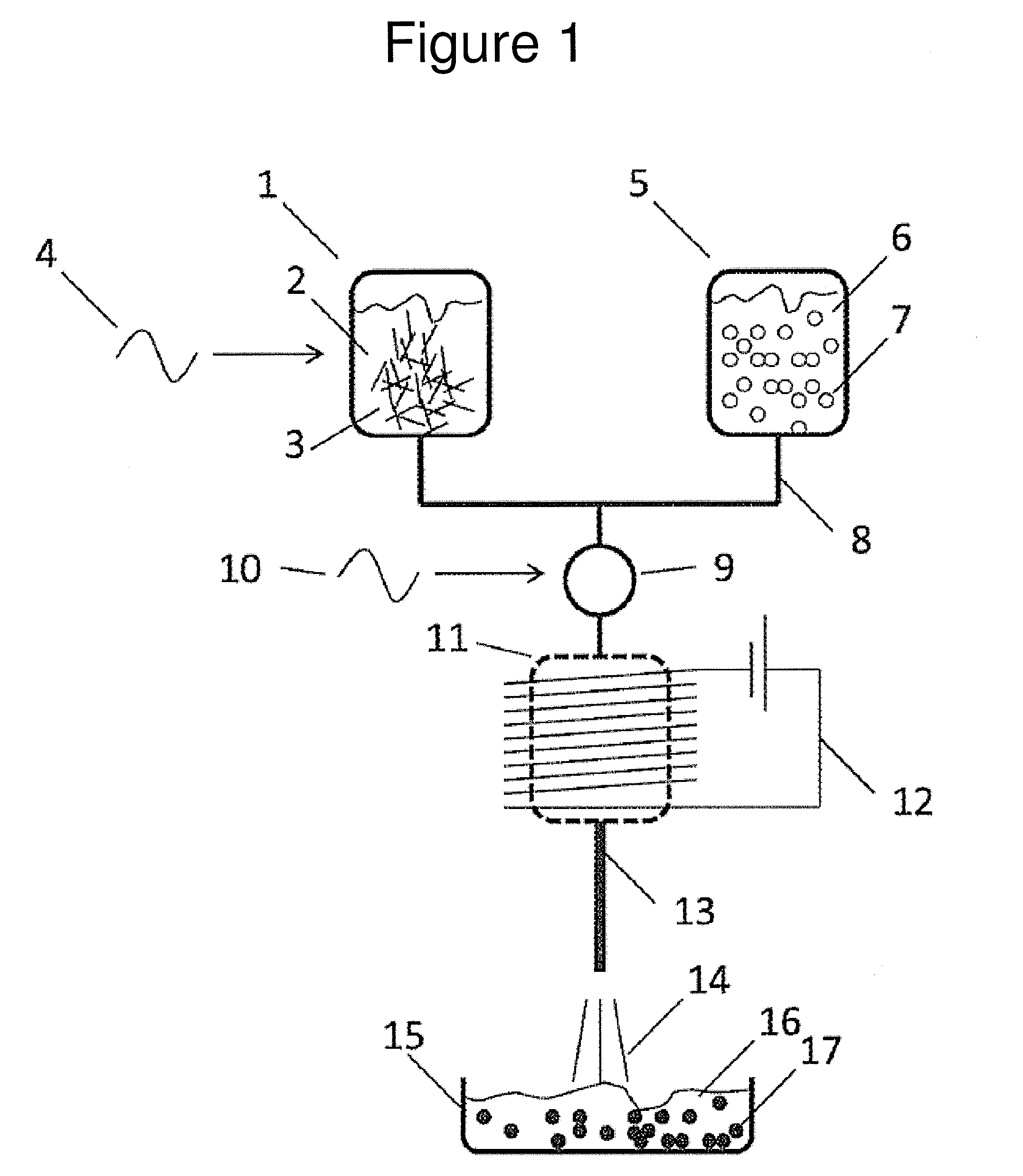

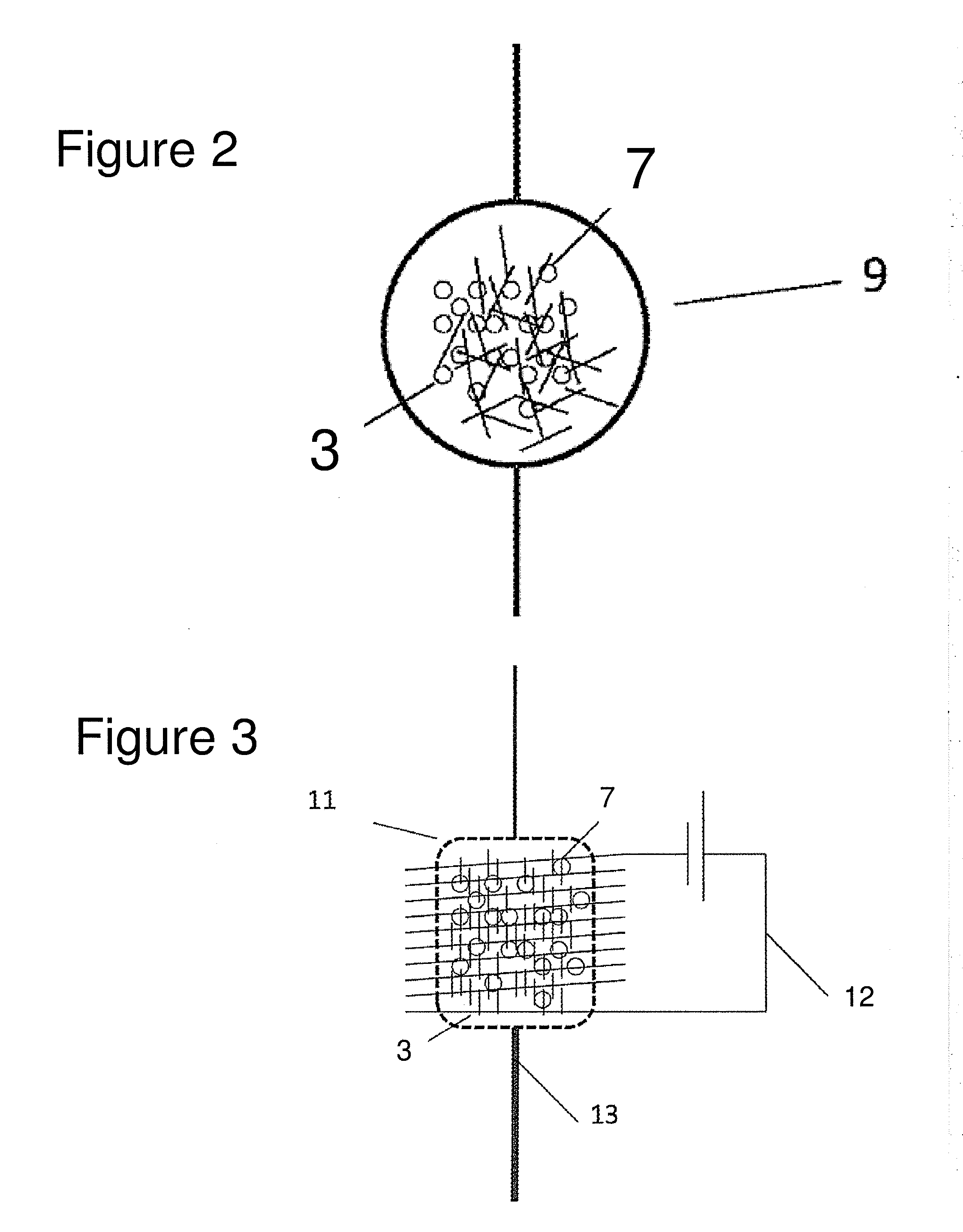

Thermoplastic polymer powder

ActiveUS20130337265A1Material nanotechnologySynthetic resin layered productsElectromagnetic fieldPolymer chemistry

A method of modifying a thermoplastic polymer powder. A suspension of thermoplastic polymer powder and reinforcement elements in a liquid is heated within a reaction chamber so that the thermoplastic polymer powder becomes softened and the reinforcement elements migrate into the softened thermoplastic polymer powder to form modified thermoplastic polymer powder. The modified thermoplastic polymer powder is then separated from the liquid. The reinforcement elements have an electromagnetic moment and are subjected to an electromagnetic field as the suspension is heated. The interaction of the electromagnetic field with the electromagnetic moment of the reinforcement elements causes the reinforcement elements to become aligned with the electromagnetic field before they migrate into the powder.

Owner:EURON AERONAUTIC DEFENCE & SPACE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com