Patents

Literature

42results about How to "Sinter stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

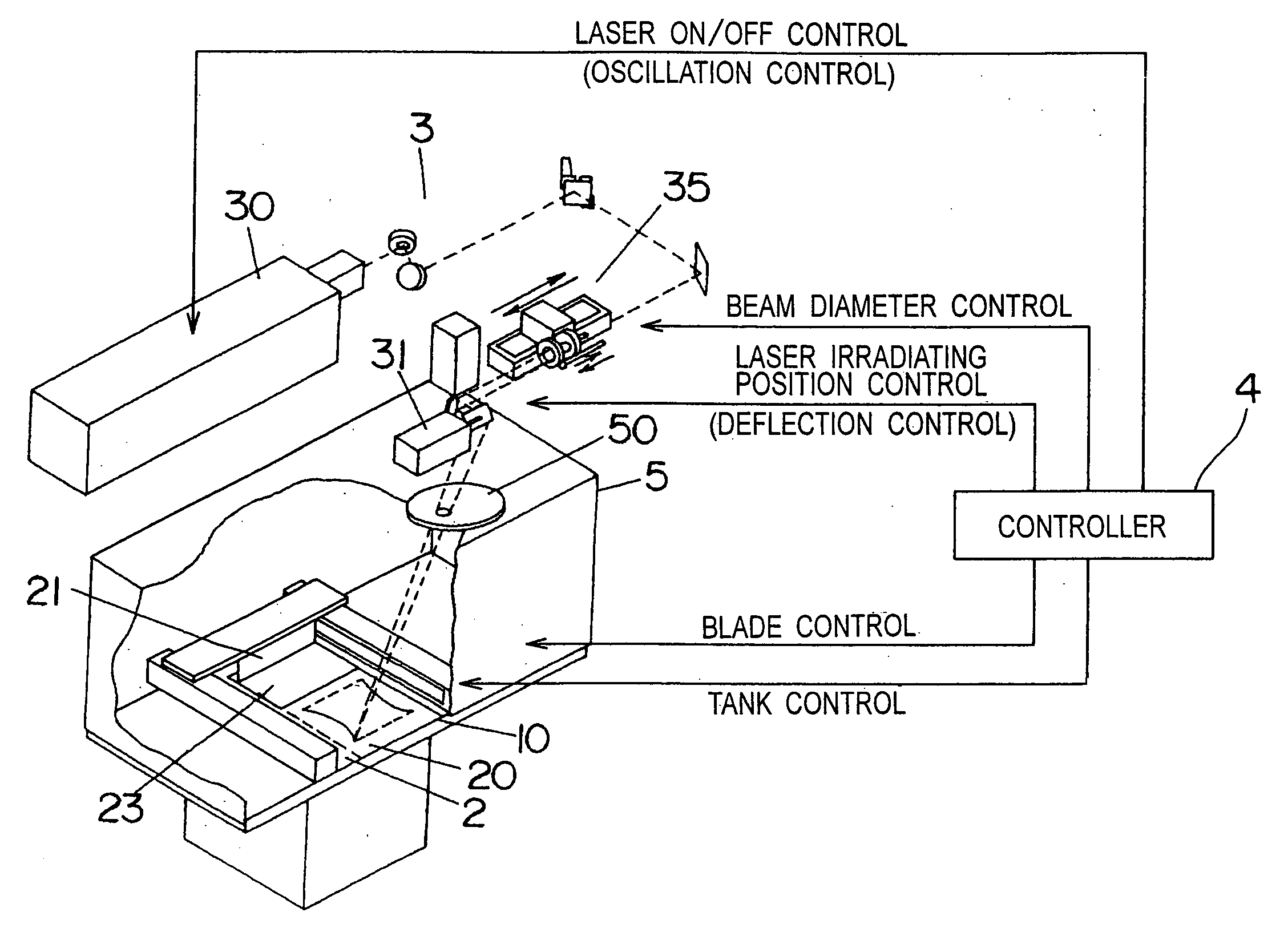

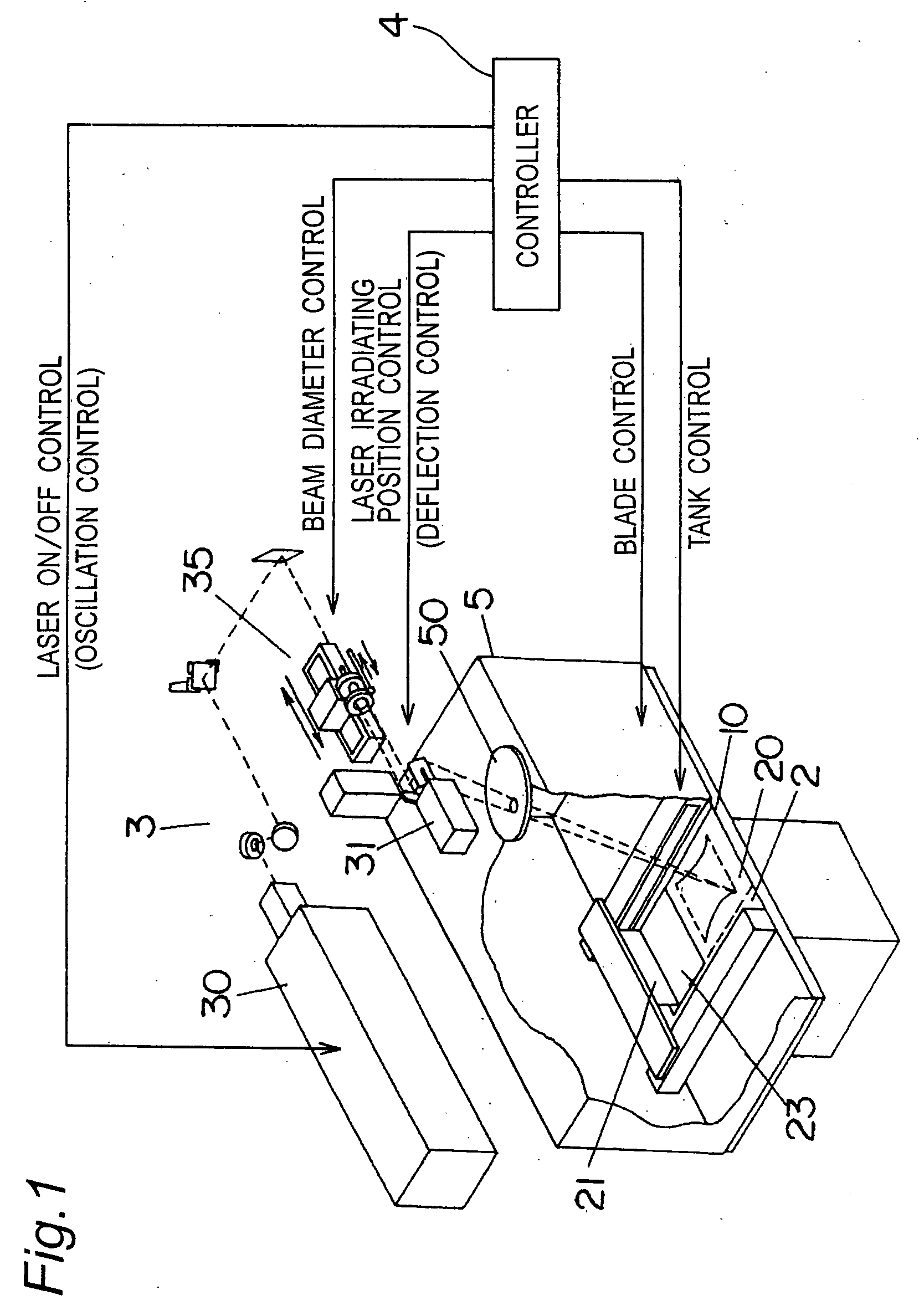

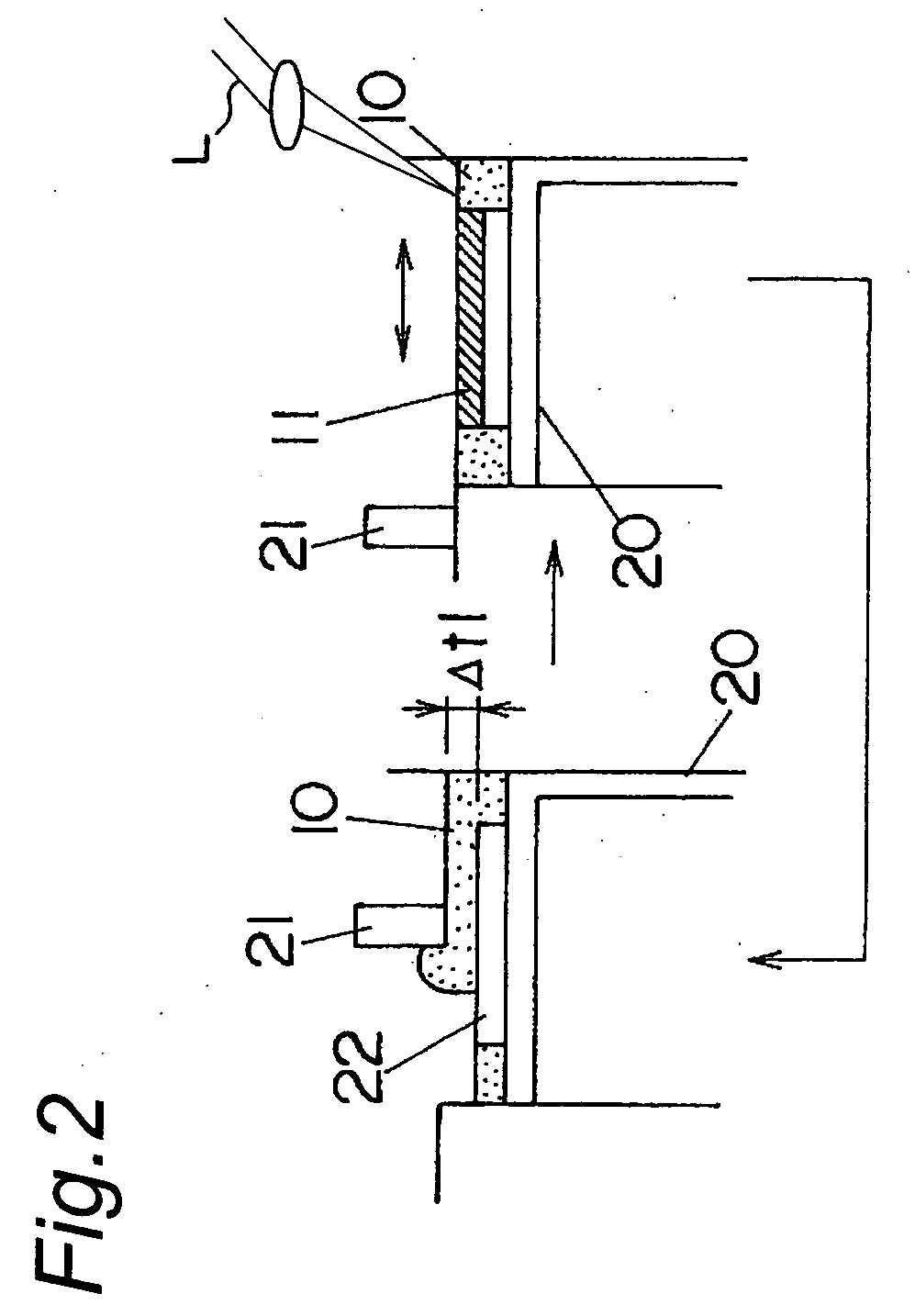

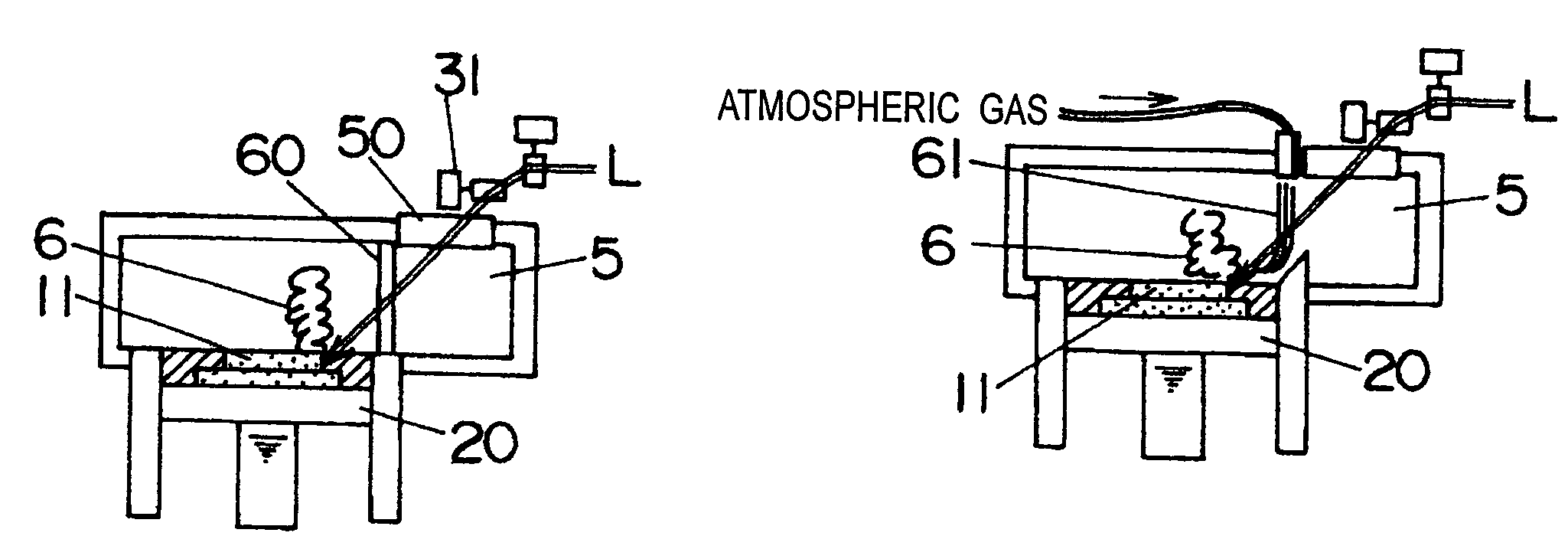

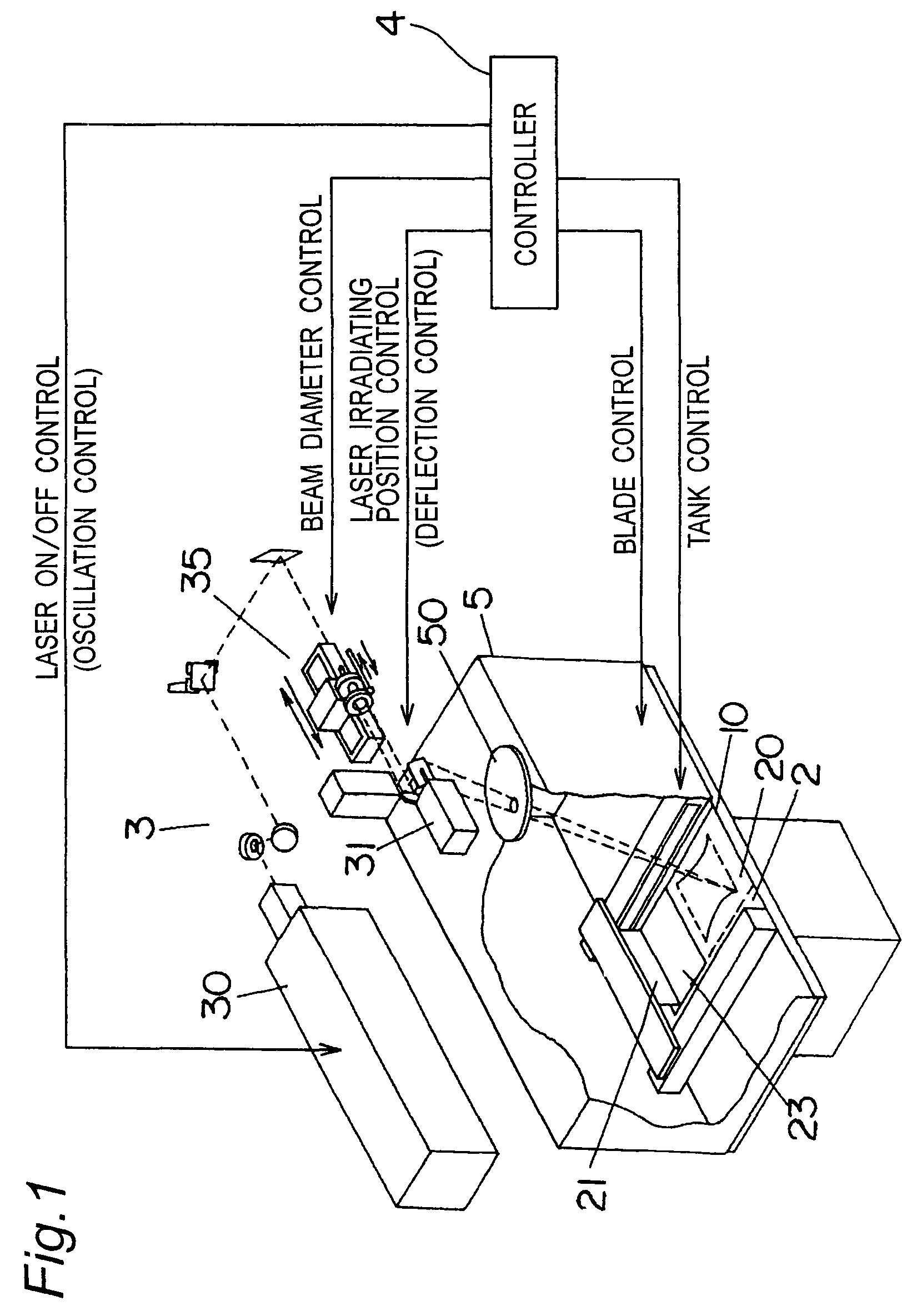

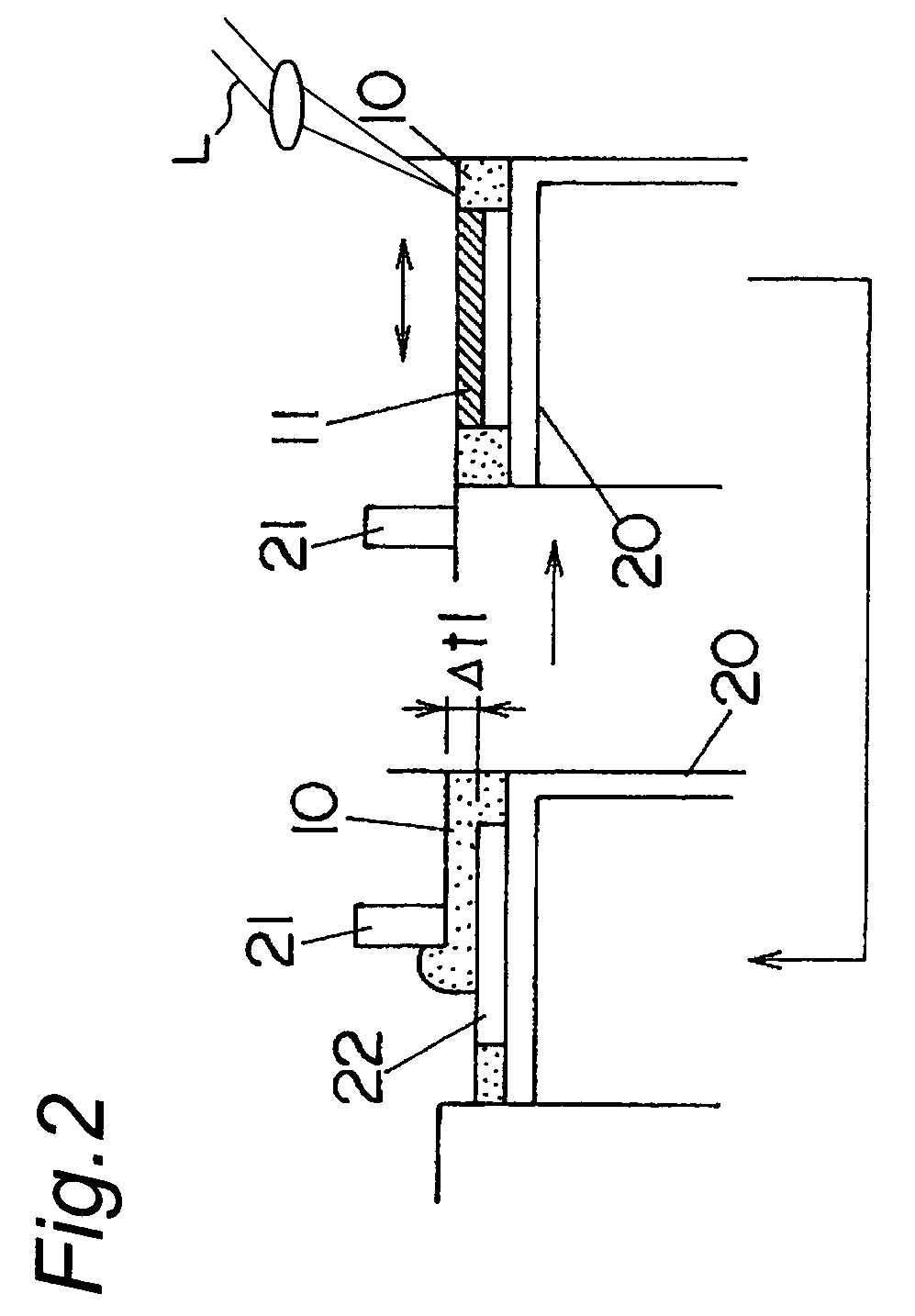

Three dimensional structure producing device and producing method

An apparatus for making a three-dimensional object includes a powdery layer-forming unit for forming a powdery layer on a table and an optical beam-irradiating unit for irradiating an optical beam on a predetermined region of the powdery layer to sinter the predetermined region. The optical beam-irradiating unit is disposed at a position spaced from immediately above an optical beam-irradiating range to obliquely irradiate the optical beam on the powdery layer. Because fumes generated by irradiating and heating the powdery layer with the optical beam rise towards a position immediately above them, the optical beam is irradiated from the position spaced from immediately above the optical beam-irradiating range, thereby reducing a cloud of the optical beam-irradiating unit that may be caused by the fumes.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Aluminum nitride sintered body and manufacturing method thereof

An aluminum nitride sintered body with high heat conductivity and high strength as well as a method of inexpensively manufacturing such an aluminum nitride sintered body at a low temperature are provided. The aluminum nitride sintered body is manufactured by adding a compound of at least one type of rare earth element (R) selected from La, Ce, Pr, Sm; and Eu, Y compound, Ca compound, and Al compound to an AlN powder and sintering the resulting mixture at a temperature of 1550° C. to 1750° C. The content of oxygen forming Al2O3 existing in an aluminate with rare earth element (R), Y and Ca and oxygen forming independently existing Al2O3 is calculated as 0.01 to 5.0% by weight, heat conductivity is 166 to 200 W / mK, and bending strength is at least 300 MPa.

Owner:SUMITOMO ELECTRIC IND LTD

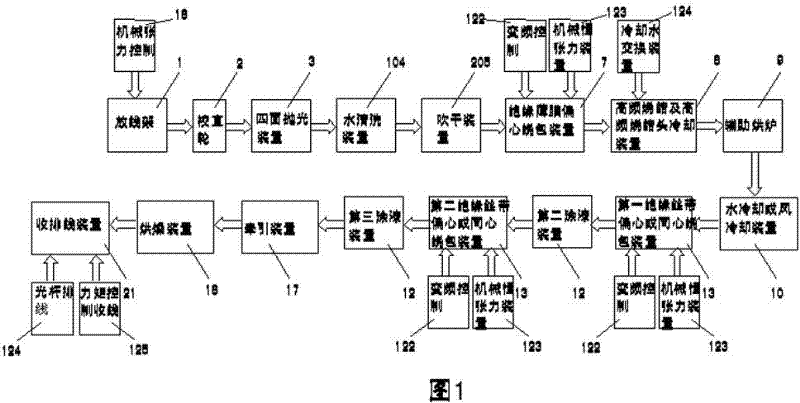

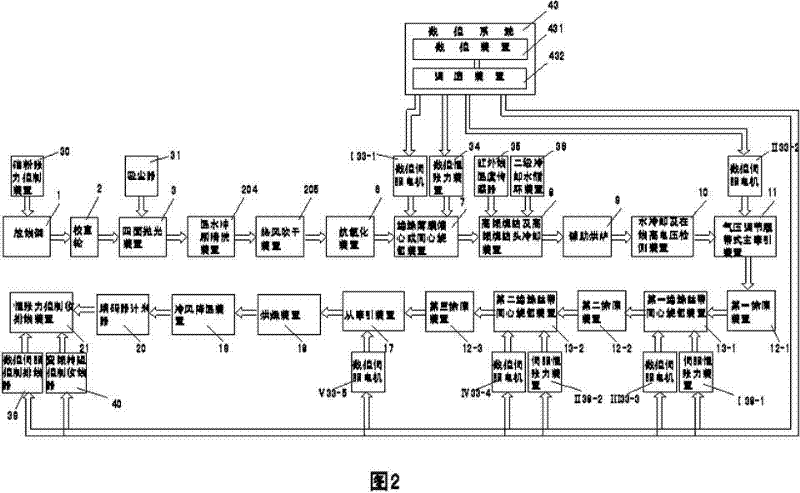

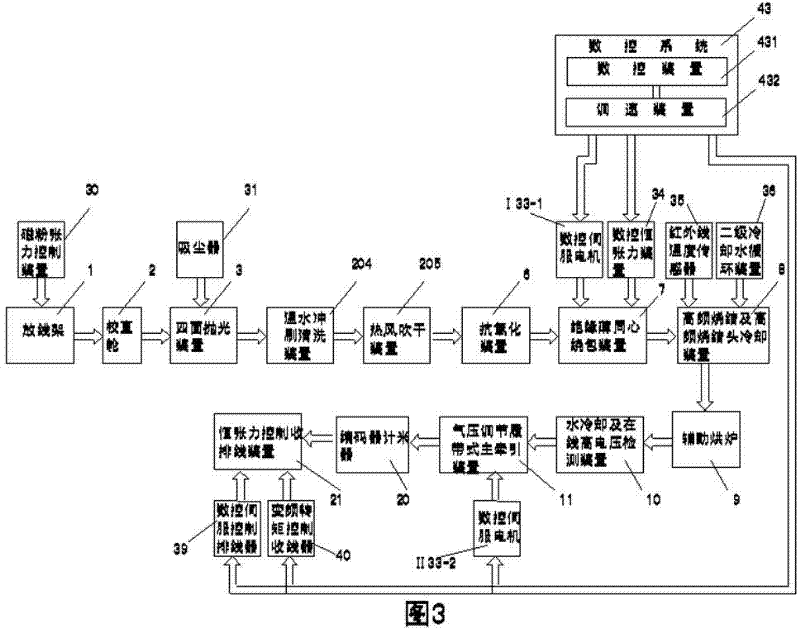

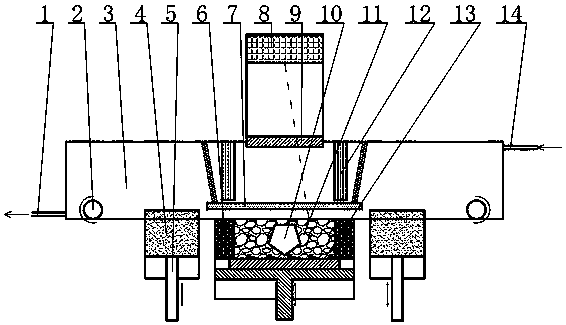

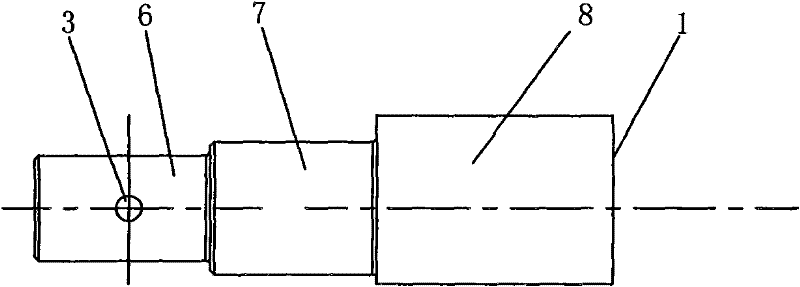

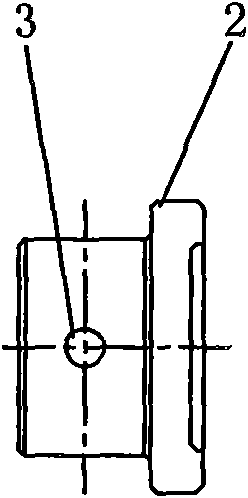

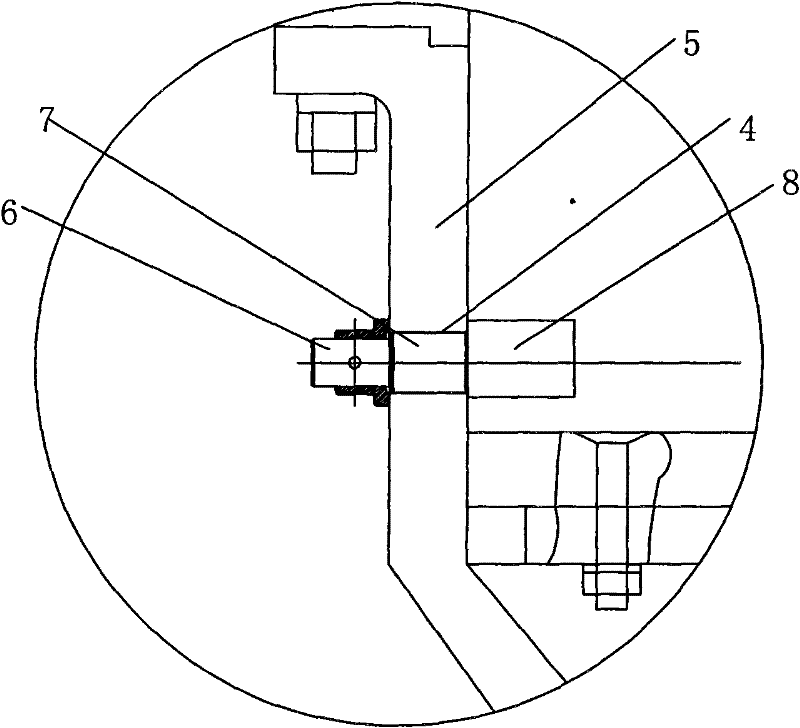

Numerical control multifunctional horizontal wrapping machine

ActiveCN102227091AImprove adhesionEasy to controlFilament handlingApplying solid insulationHigh frequencyBooster pump

The invention provides a numerical control multifunctional horizontal wrapping machine which comprises a constant tension line laying rack. The machine also comprises a straightening wheel, a four-side polishing device, a warm water washing cleaning device and a hot air blow-dry device which are installed on a first bench in order. The machine also comprises an insulation film eccentric or concentric wrapping device, a high frequency sintering and high frequency sintering head cooling device, an auxiliary oven and a water cooling and on-line high voltage detection device which are installed on a second bench in order. The machine also comprises a air pressure adjusting crawler type main draw gear, a first insulation ribbon eccentric wrapping device or concentric wrapping device, a second coating device, a second insulation ribbon eccentric wrapping device or concentric wrapping device, a third coating device, a draw gear, a drying device, and a wire arrangement collection device. The cleaning device is provided with a water heating device and a booster pump. An antioxidation device is provided between the hot air blow-dry device and the insulation film eccentric or concentric wrapping device. A constant tension device controlling film or filament disc material emptying on the wrapping head is a numerical control constant tension device. By using the numerical control multifunctional horizontal wrapping machine in the invention to wrap insulated wire, product quality and production efficiency of the insulated wire is raised.

Owner:GOLD CUP ELECTRIC APP CO LTD

Three dimensional structure producing device and producing method

An apparatus for making a three-dimensional object includes a powdery layer-forming unit for forming a powdery layer on a table and an optical beam-irradiating unit for irradiating an optical beam on a predetermined region of the powdery layer to sinter the predetermined region. The optical beam-irradiating unit is disposed at a position spaced from immediately above an optical beam-irradiating range to obliquely irradiate the optical beam on the powdery layer. Because fumes generated by irradiating and heating the powdery layer with the optical beam rise towards a position immediately above them, the optical beam is irradiated from the position spaced from immediately above the optical beam-irradiating range, thereby reducing a cloud of the optical beam-irradiating unit that may be caused by the fumes.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material prepared by a composite oxide and an additive. The composite oxide is represented by the following general formula: MLa4Ti3M'O15, whereinM is Ca, Ba or Mg, and M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the invention is prepared by the compound oxide represented by a specificgeneral formula and the additive and is a medium-dielectric-constant microwave dielectric ceramic; the microwave dielectric ceramic material satisfies the dielectric constant near 45 and is continuously adjustable, has an extremely high Q*f value and good sintering stability, and also can achieve continuous adjustment of temperature drift to meet various needs. Experimental results show that therelative dielectric constant [epsilon]r of the microwave dielectric ceramic material provided by the invention is 43.2-46.8, the quality factor Q*f value is more than or equal to 46200 GHz, and the sintering is stable; at the same time, the temperature drift adjusting range is from -8 to +13 ppm / DEG C and can be continuously adjustable to meet various needs, and the microwave dielectric ceramic material has excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

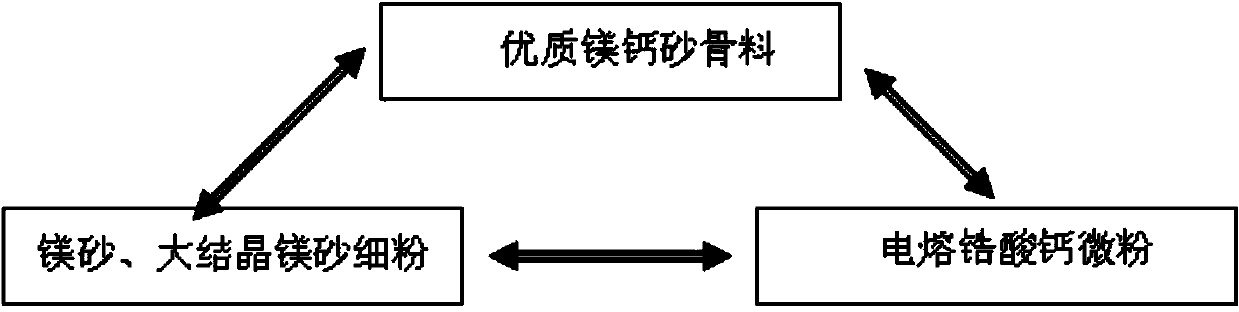

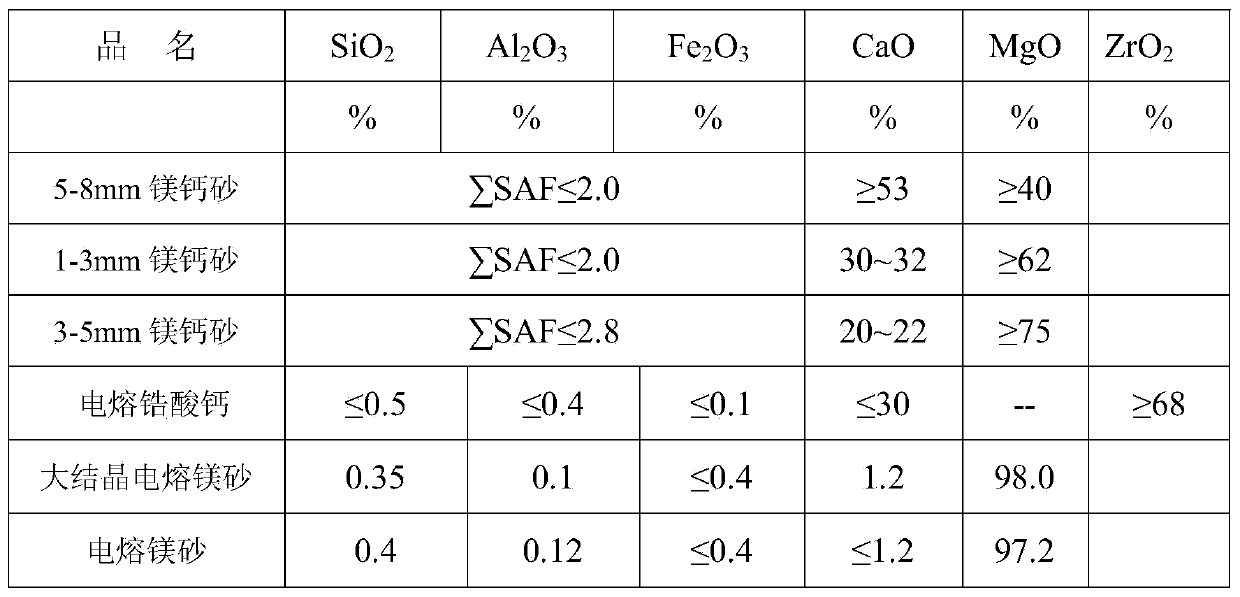

Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

The invention relates to a high-quality dolomite-periclase-calcium zirconate composite fireproof material suitable for smelting stainless steel, special steel AOD furnace and refining ladles. The adopted raw materials mainly comprise, by weight, 8-10% of magnesium calcium sand with a particle size of 5-8 mm, 9-18% of magnesium calcium sand with a particle size of 3-5 mm, 10-22% of magnesium calcium sand with a particle size of 1-3 mm, 5-10% of calcium zirconate with a particle size of 0.5-1 mm, 5-10% of magnesia with a particle size of 0.5-1 mm, 3-10% of 600 mesh electric melting calcium zirconate, 15-24% of magnesia with a particle size of less than or equal to 0.5 mm, 3-10% of 400 mesh 98 large crystal magnesia, 1-3% of a binding agent, and 1-2% of a sintering agent, wherein the raw materials are subjected to mixing, molding, sintering, finished product inspection, package and other steps to prepare the material.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Method of regulating and controlling air volume of sintering machine by using main ventilation valve and rotating speed in combined mode

The invention provides a method of regulating and controlling the air volume of a sintering machine by using a main ventilation valve and the rotating speed in a combined mode, and belongs to the field of metallurgical production. The opening degree of an inlet baffle of a draught fan is regulated to 14%-65%, and the rotating speed of the draught fan is regulated to 700-1000rpm. By means of the method, the temperature of sintering flue gas can be effectively stabilized, the frequency of abnormal vibration, caused by the excess temperature of the flue gas, of a main ventilation draught fan is reduced, and threats to operation of a flue gas desulfurization and denitrification system caused by the excess temperature of the flue gas can be reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

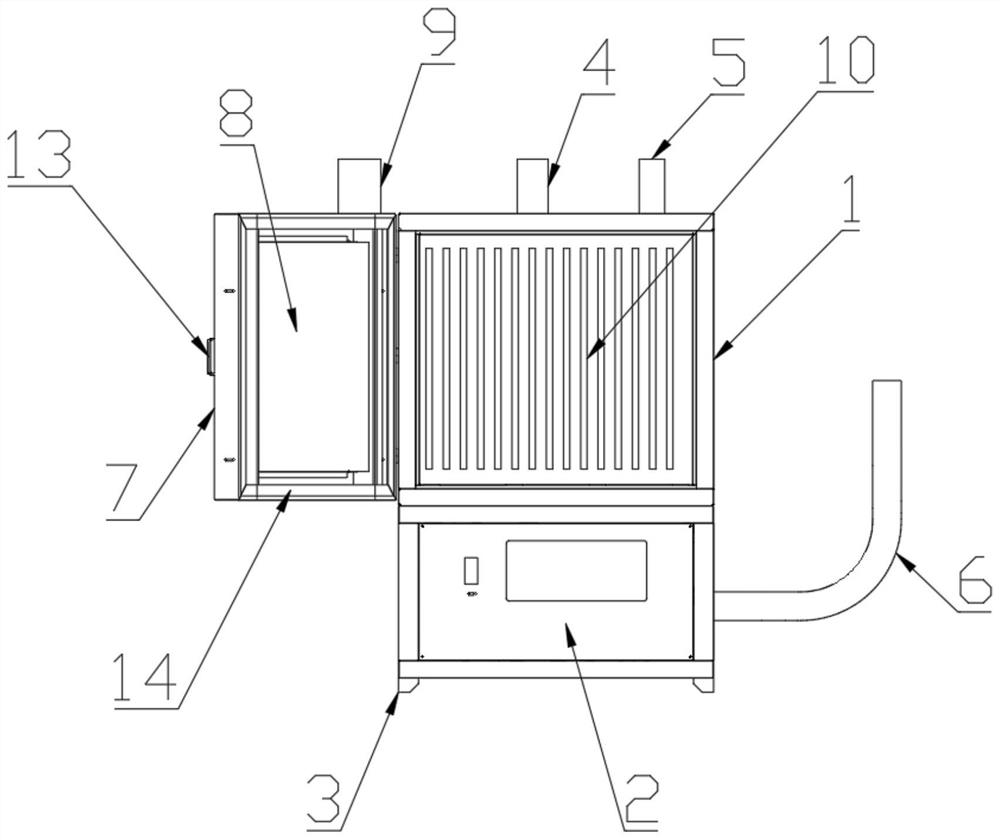

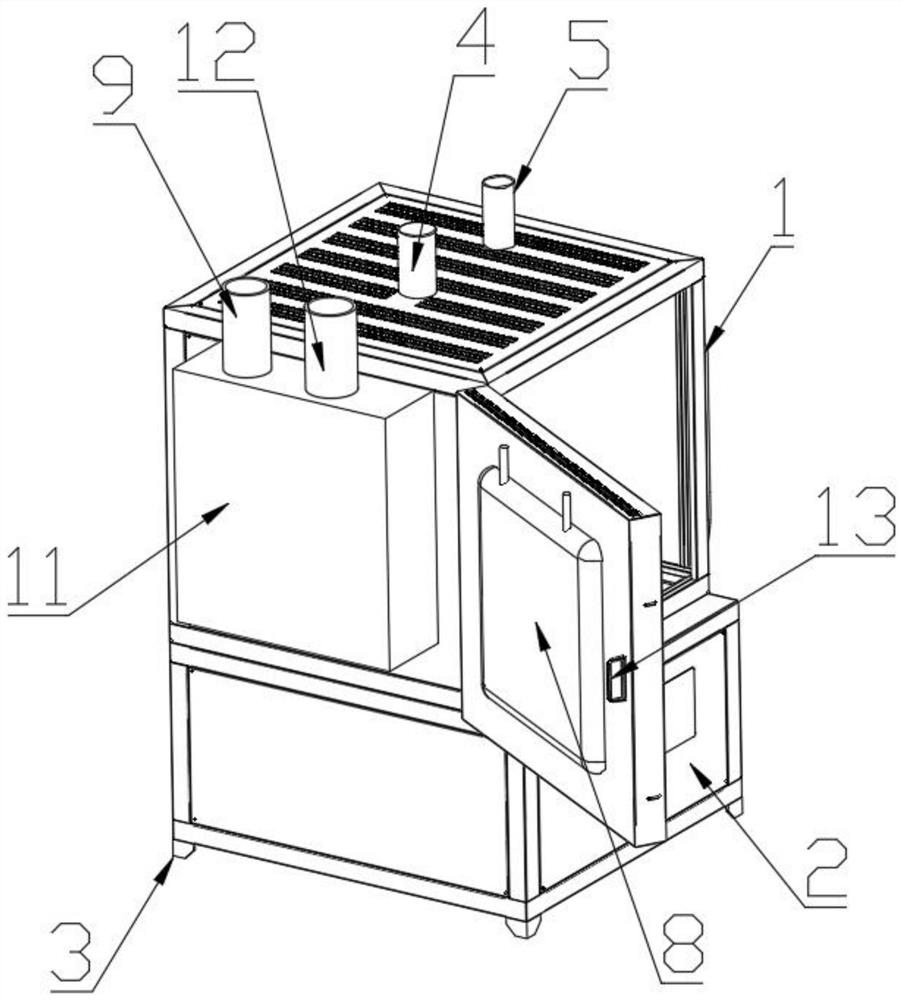

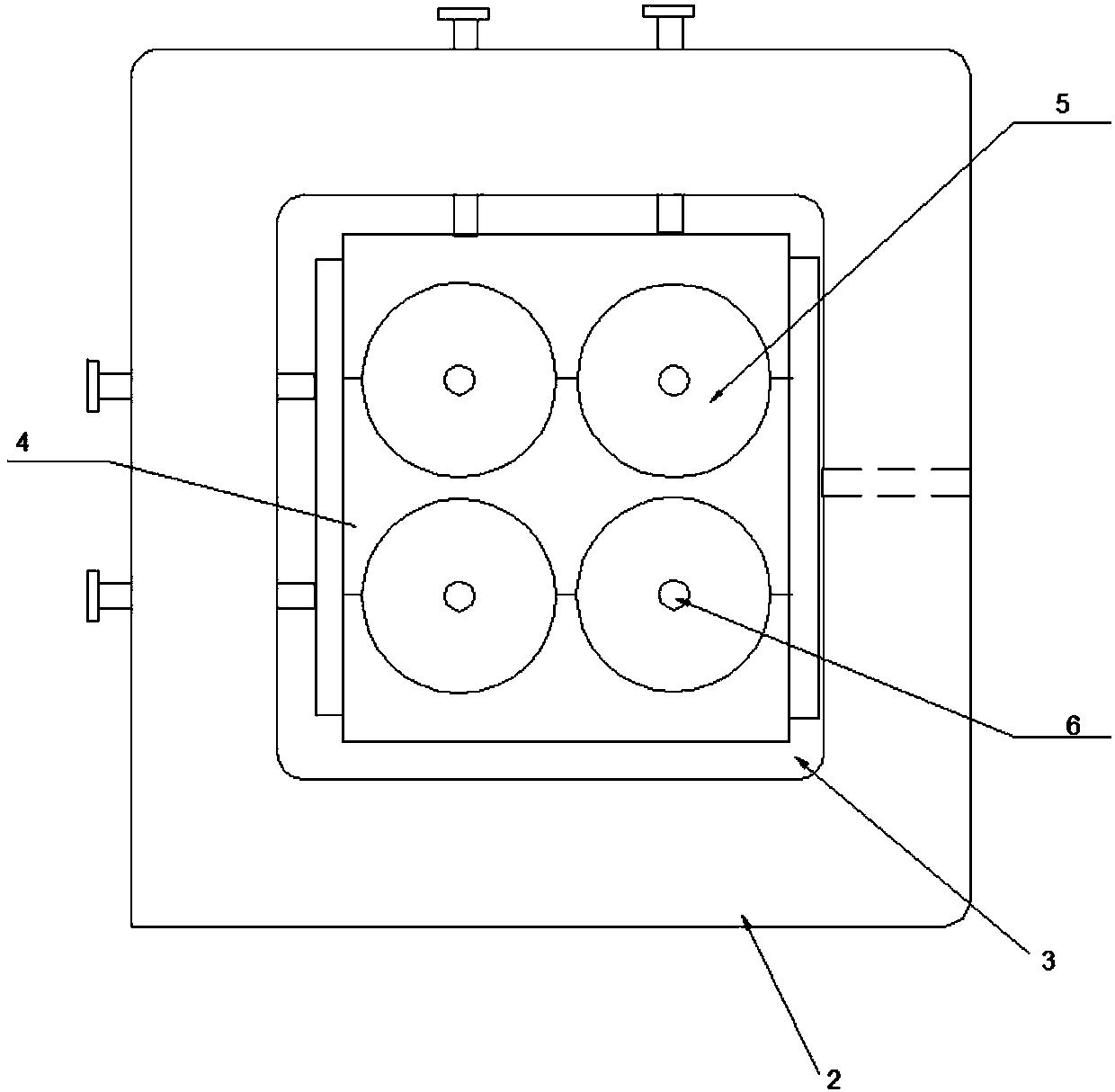

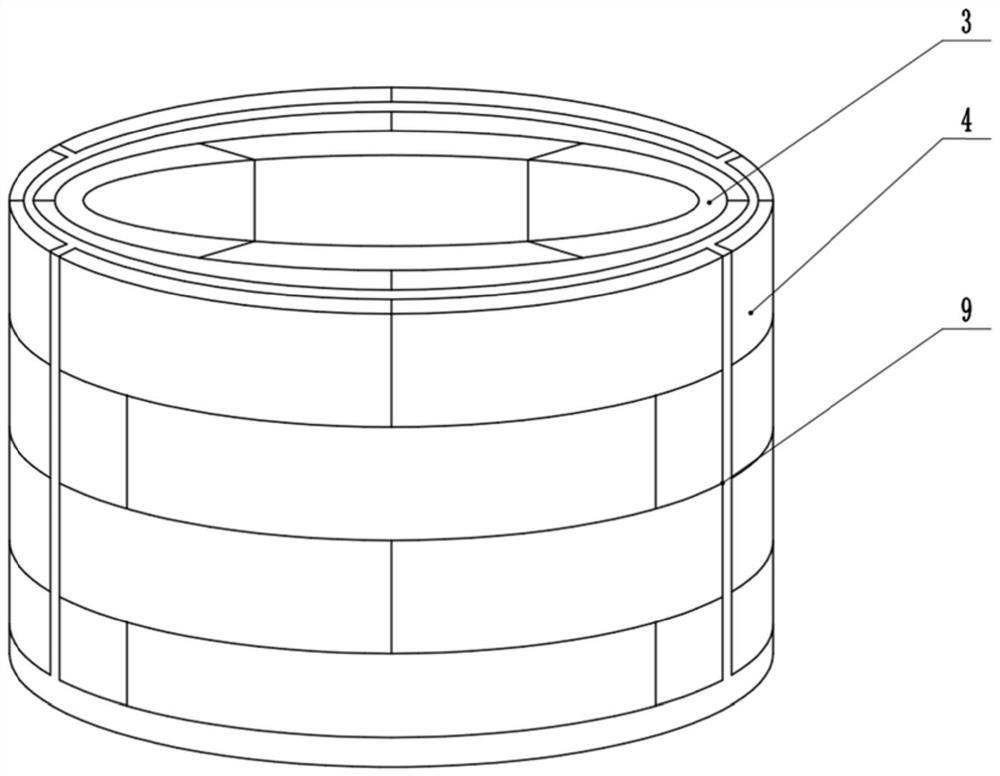

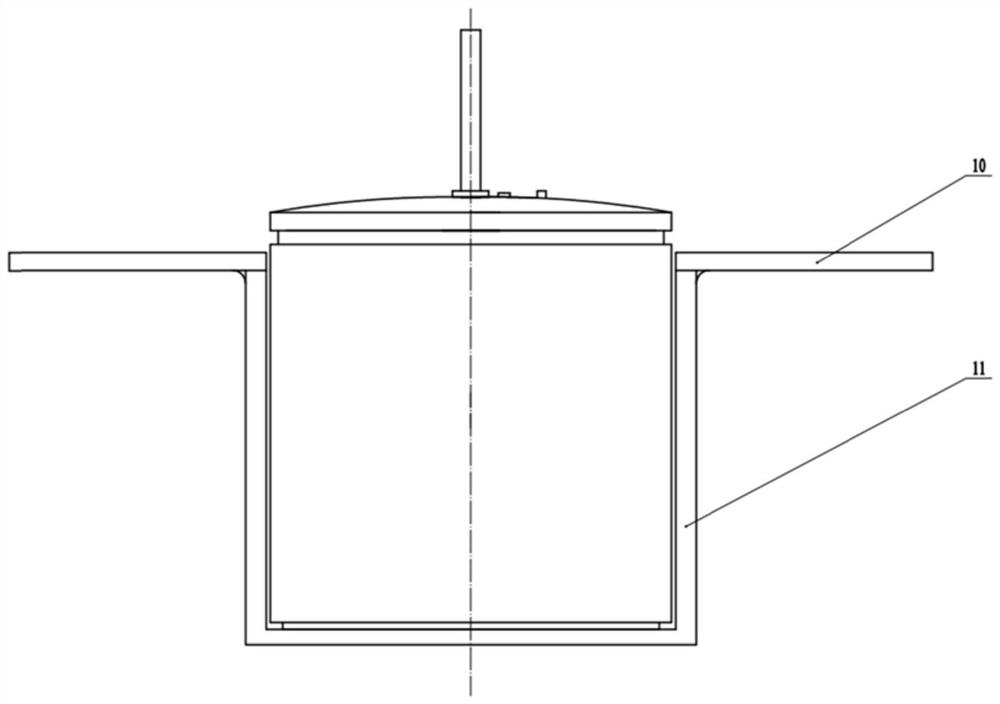

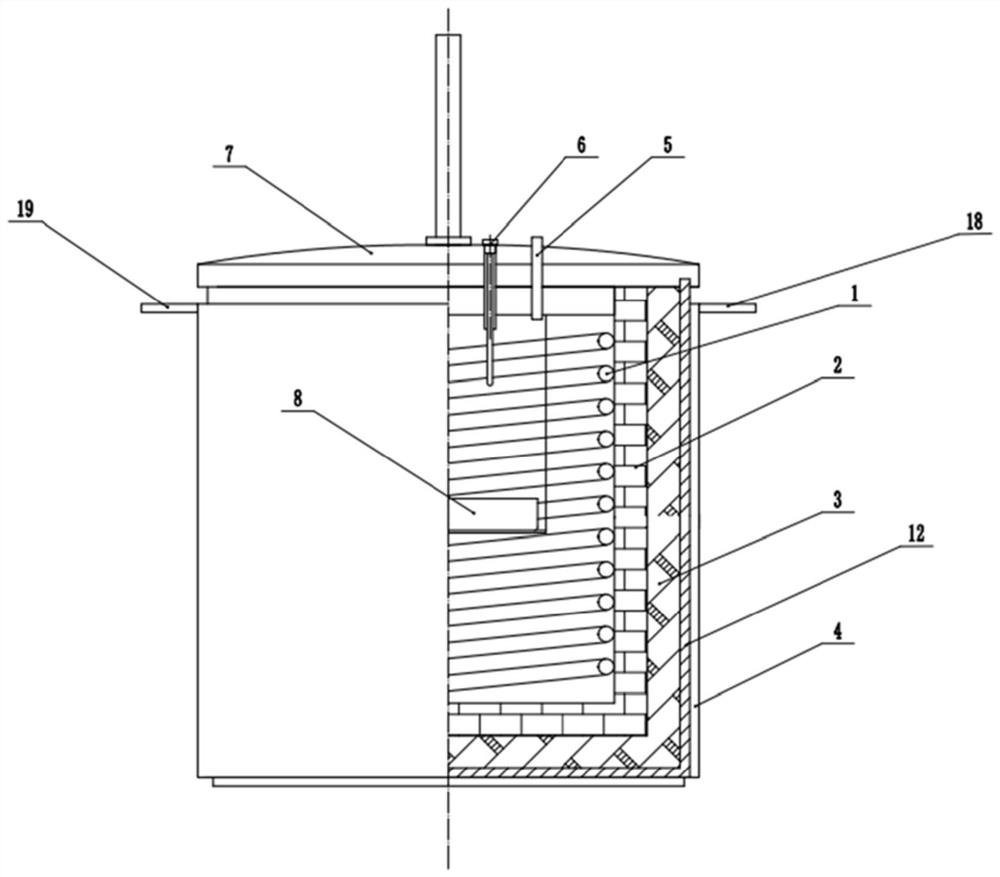

Atmosphere box type sintering furnace for producing mobile phone back plate

InactiveCN112097523AEfficient sinteringSinter stableMaintainance of heating chambersFurnace typesFlue gasTester device

The invention discloses an atmosphere box type sintering furnace for producing a mobile phone back plate. The atmosphere box type sintering furnace comprises a furnace body, a filter box, an extraction opening, an atmosphere opening, a furnace door, a tail gas treatment box and a temperature controller, wherein a heat preservation material is arranged inside the furnace body, a degreasing pipe isinstalled on the side face of the filter box, the degreasing pipe is connected with a draught fan, the extraction opening communicates with the furnace body, the furnace body can be vacuumized beforesintering, the atmosphere opening is connected with a storage tank, nitrogen can be introduced into the furnace body, a cooling box is installed in the furnace door, the tail gas treatment box is installed on the side surface of the furnace body and can be used for filtering and treating flue gas during colloid discharging and sintering, a smoke outlet and an explosion-proof pipe are installed atan outlet of the tail gas treatment box, the explosion-proof pipe is controlled by an air pressure tester to be opened and closed, and the temperature controller is controlled by a PLC element and isconnected with a power supply and a heating device through wires to control the temperature inside the furnace body. According to the atmosphere box type sintering furnace for producing the mobile phone back plate, the colloid discharging and sintering are integrally processed, so that the production efficiency is improved, the labor force is reduced, and the mobile phone backboard ceramic is efficiently and stably sintered.

Owner:YANCHENG INST OF TECH

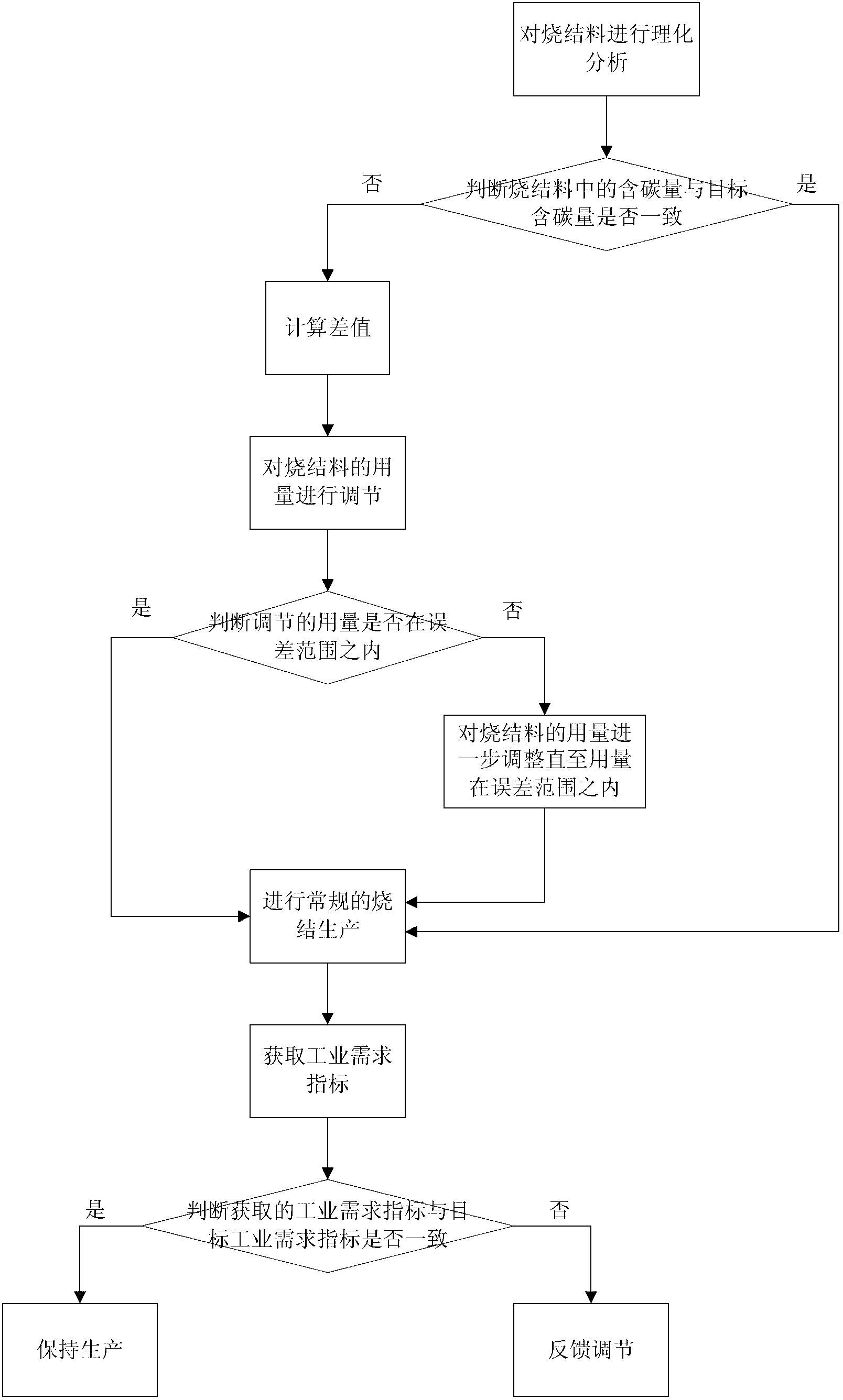

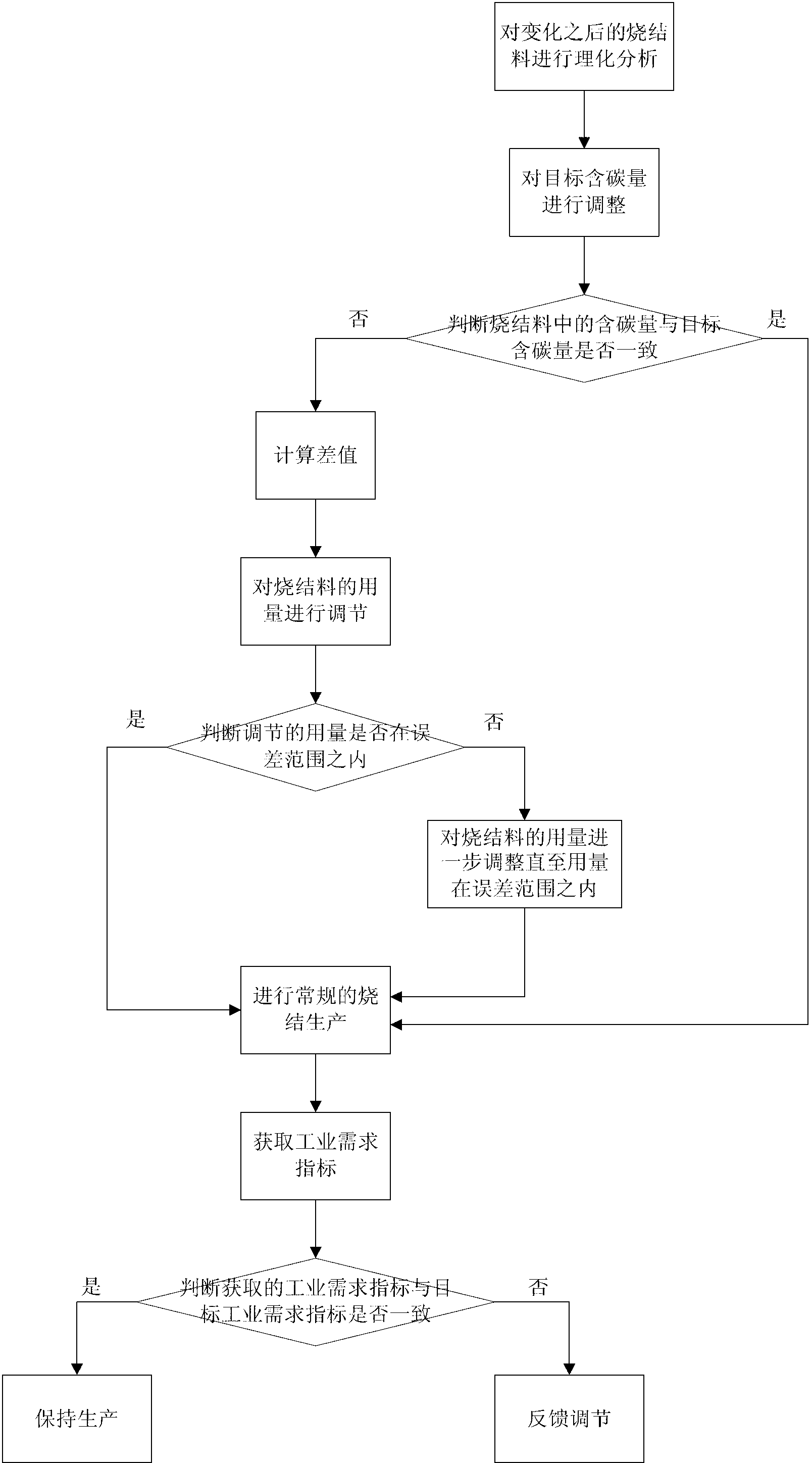

Control method for carbon content of sintered material

ActiveCN103234351ASolving the problem of carbon fluctuationsReduce fuel consumptionFurnace typesUltimate tensile strengthFeedback regulation

The invention relates to the technical field of control methods and discloses a control method for a carbon content of a sintered material. The control method comprises the steps of comparing the carbon content of the sintered material obtained by analysis with a preset target carbon content; if the carbon content of the sintered material does not conform to the target carbon content, adjusting the usage amount of the sintered material until the carbon content of the sintered material conforms to the target carbon content and then performing conventional sintered production; performing feedback regulation on the target carbon content according to industrial demand indexes after the conventional sintered production, and continuing performing comparison regulation on the carbon content of the sintered material according to the target carbon content fed back. According to the control method, stability of the carbon content of the sintered material is guaranteed, the problem of fluctuation of the carbon content of the sintered material is effectively solved, the sintering production process is stable, and the aims of optimizing the sintering process, improving sintering efficiency and quality of sintered ore and reducing solid burn-up and post labor intensity are achieved.

Owner:首钢股份公司迁安钢铁公司

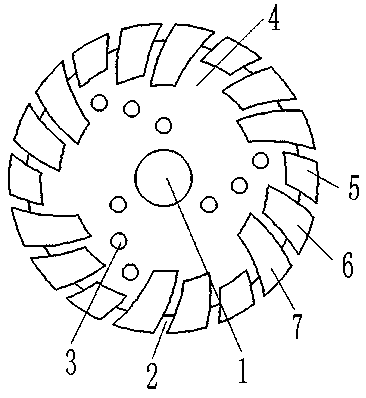

Diamond saw blade and preparation method

PendingCN111070423AIncrease stiffnessExtended service lifeTransportation and packagingMetal-working apparatusTool bitEngineering

The invention discloses a diamond saw blade and a preparation method. The diamond saw blade includes a disc matrix. A plurality of cutting units are evenly arranged along the outer circumference of the matrix. The center of the matrix is provided with an axle hole. The cutting units are in the same shape, and each cutting unit includes at least two diamond cutter heads. The cross section of each diamond cutter head is U-shaped, and each diamond cutter head is mounted at the edge of the matrix in a crossing mode. The outermost side of each diamond cutter head is distributed in a circle and theinnermost side of each diamond cutter head overlaps with the upper and lower surfaces of the matrix. Through structure improvement, the stiffness of the matrix and the service life of the saw blade are improved, further, the interface bonding between diamond particles and a metal blank body is improved, thus the utilization rate of the diamond particle in the diamond saw blade is increased, so thecutting efficiency and service life are increased, and finally the high-efficiency and low-cost diamond saw blade is obtained.

Owner:江苏乐泰超硬材料有限公司

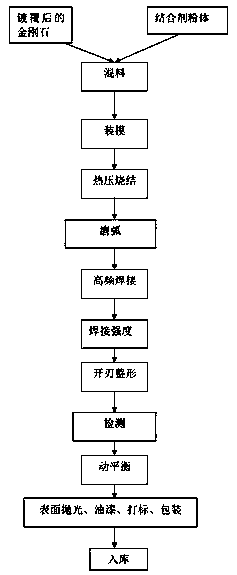

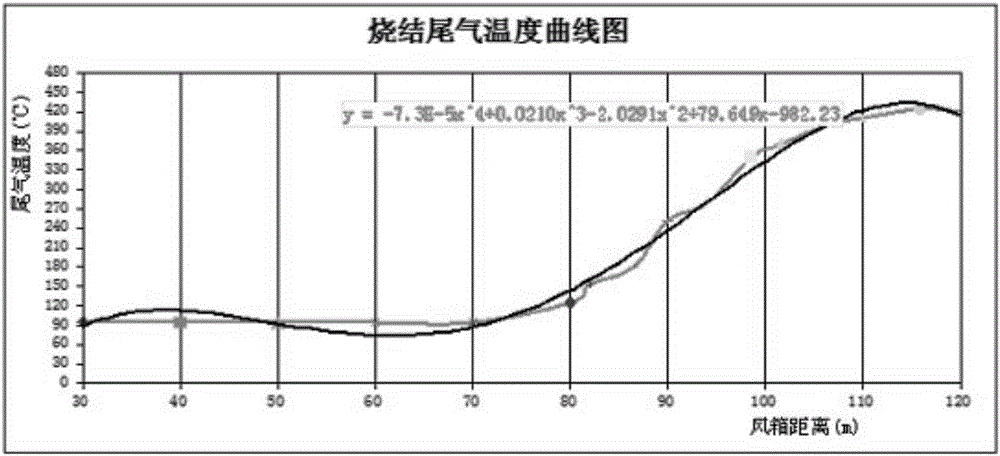

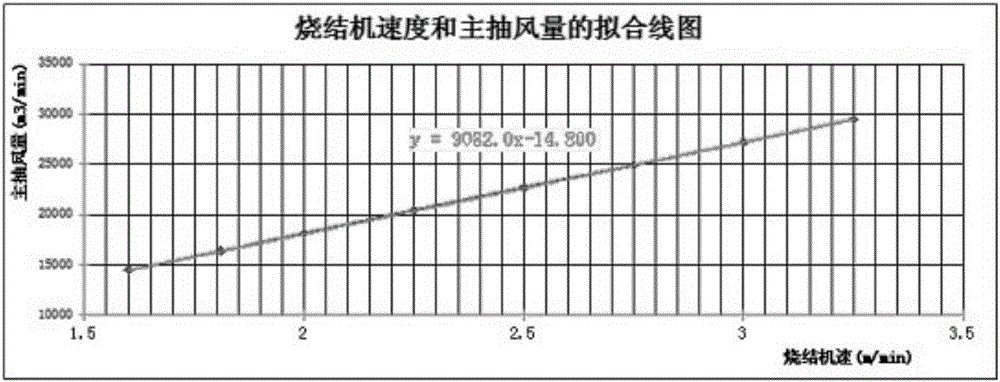

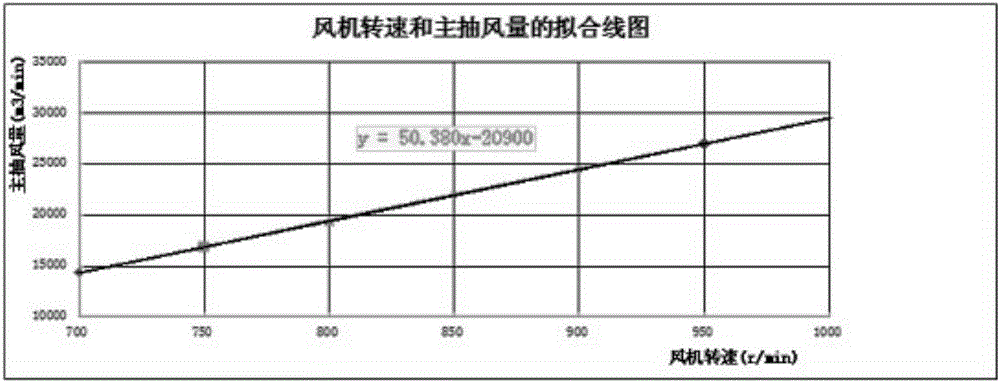

Frequency conversion and energy conservation control method for main suction fan of sintering machine

InactiveCN105674745AAvoid operational biasSinter stableFurnace typesControl devices for furnacesFrequency conversionControl theory

The invention provides a frequency conversion energy-saving control method for the main exhaust fan of a sintering machine, which includes the following steps: S1: according to the collected temperature, fit the function relationship curve between the temperature of the bellows and the position of the bellows; S2: get the function curve according to the function curve Sintering end point BTP and temperature rise point BRP calculated at time; S3: S3: Determine whether the change of the temperature rise point BRP exceeds the stable range, if not, go to step S4; S4: Calculate according to the sintering end point BTP obtained in step S2 Determine the current vertical sintering speed; calculate and determine the ideal vertical sintering speed with the second-to-last or third-to-last bellows as the sintering end point; S4: Compare the current vertical sintering speed with the ideal vertical sintering speed to determine whether adjustment is required, If adjustment is required, calculate and determine the adjustment value of the corresponding vertical sintering speed; S5: Determine the adjustment value of the speed of the main exhaust fan according to the adjustment value of the vertical sintering speed determined in step S4, and then adjust the speed of the main exhaust fan.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

Wastewater treatment catalyst and preparation method thereof

InactiveCN102000579BGuaranteed puritySinter stableCatalyst activation/preparationNature of treatment waterImpurityElemental iron

The invention relates to a wastewater treatment catalyst and a preparation method thereof. The wastewater treatment catalyst comprises the following raw materials in percentage by mass: 15 percent of elemental iron, 4.5 percent of bivalent iron oxide, 17.5 percent of trivalent iron oxide, 30 percent of magnesium oxide, 2.7 percent of nickel, 1.4 percent of zinc and 28.9 percent of yellow mud. Theinvention has the advantages that the sintering stability of added metal materials and metal oxide materials is ensured by utilizing the inherent viscosity of the yellow mud, and the yellow mud does not contain impurities of metals and metal oxides per se, therefore, the purity of a sintering result is ensured; various metals and metal oxides have good uniformity and dispersibility in a process of repeated sintering; and the yellow mud volatilizes per se in the sintering process to form gaps, and therefore, catalyst particles have good hydrophilicity and dispersion rate.

Owner:江苏沃土环境科技有限公司

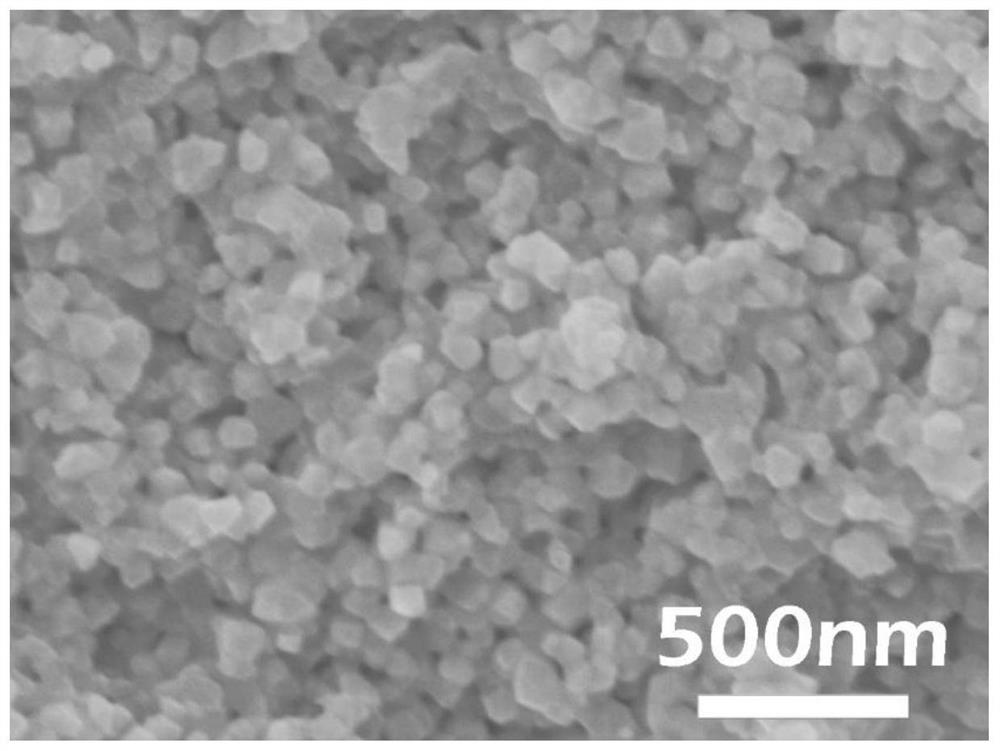

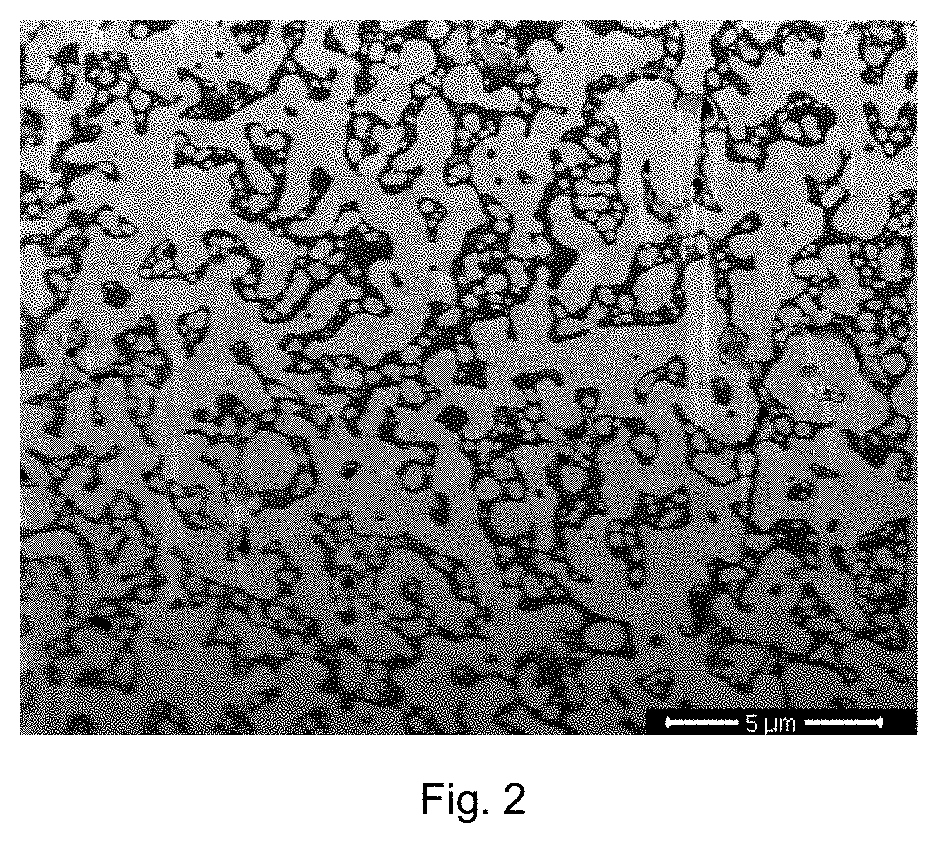

Zirconium oxide ceramic material and preparation method and application thereof

The invention relates to the technical field of ceramic materials, in particular to a zirconium oxide ceramic material and a preparation method and application thereof. The preparation method provided by the invention comprises the following steps of mixing zirconium oxide, an oxide stabilizer, an organic dispersant, a polymer stabilizer and water, and homogenizing to obtain a homogeneous mixed solution, pre-sintering the homogeneous mixed solution to obtain a pre-sintered green body, and finally sintering the pre-sintered green body to obtain the zirconium oxide ceramic material, wherein the pre-sintering temperature ranges from 600 DEG C to 1000 DEG C; and the temperature of the final sintering is 1200 to 1400 DEG C. The zirconium oxide ceramic material prepared by the preparation method has high volume percentage content of tetragonal phase zirconium oxide and stably exists in the presence of water vapor; and the tetragonal zirconium oxide is small in grain size and high in bending strength.

Owner:中新棠国业(江苏)科技有限公司

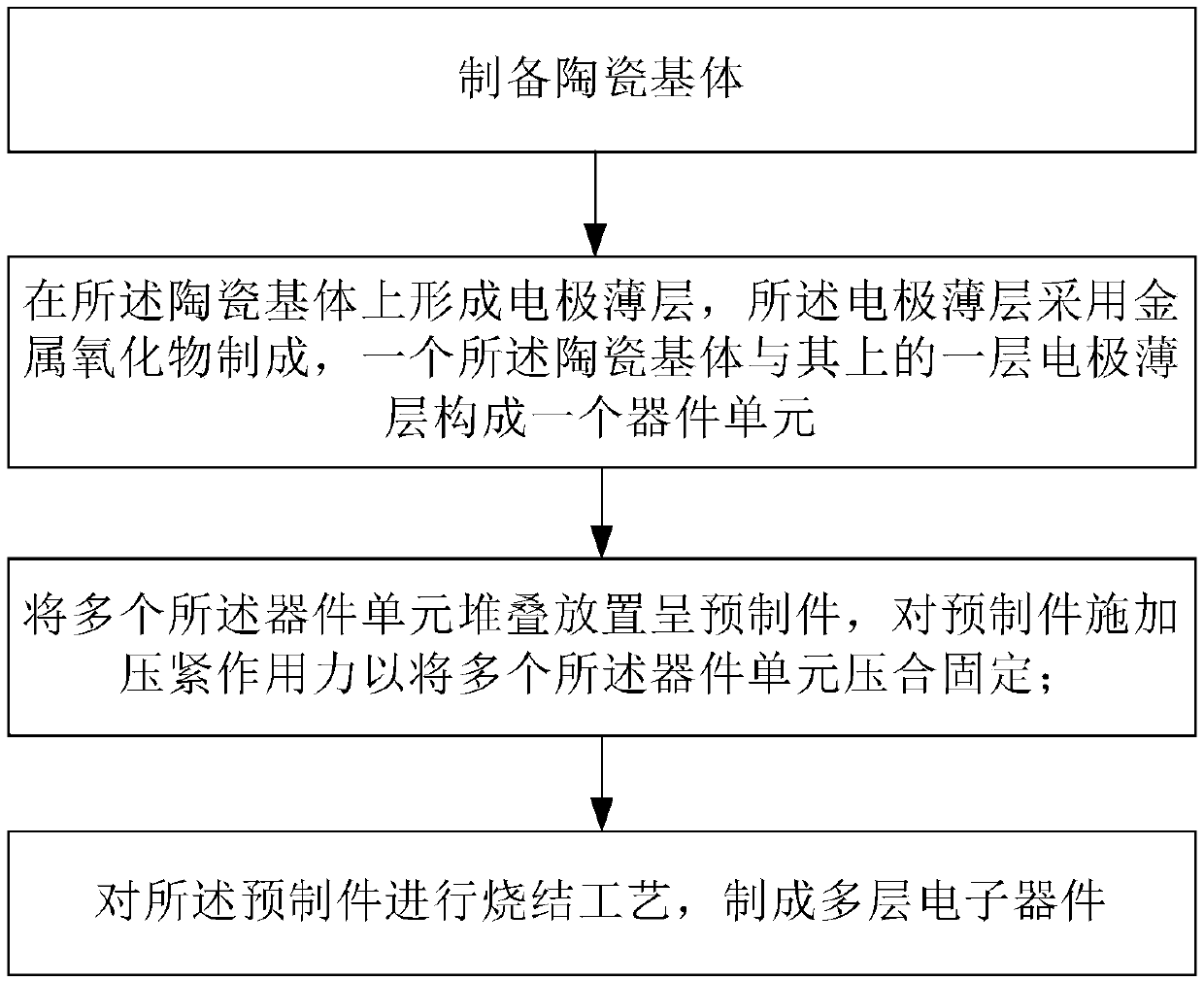

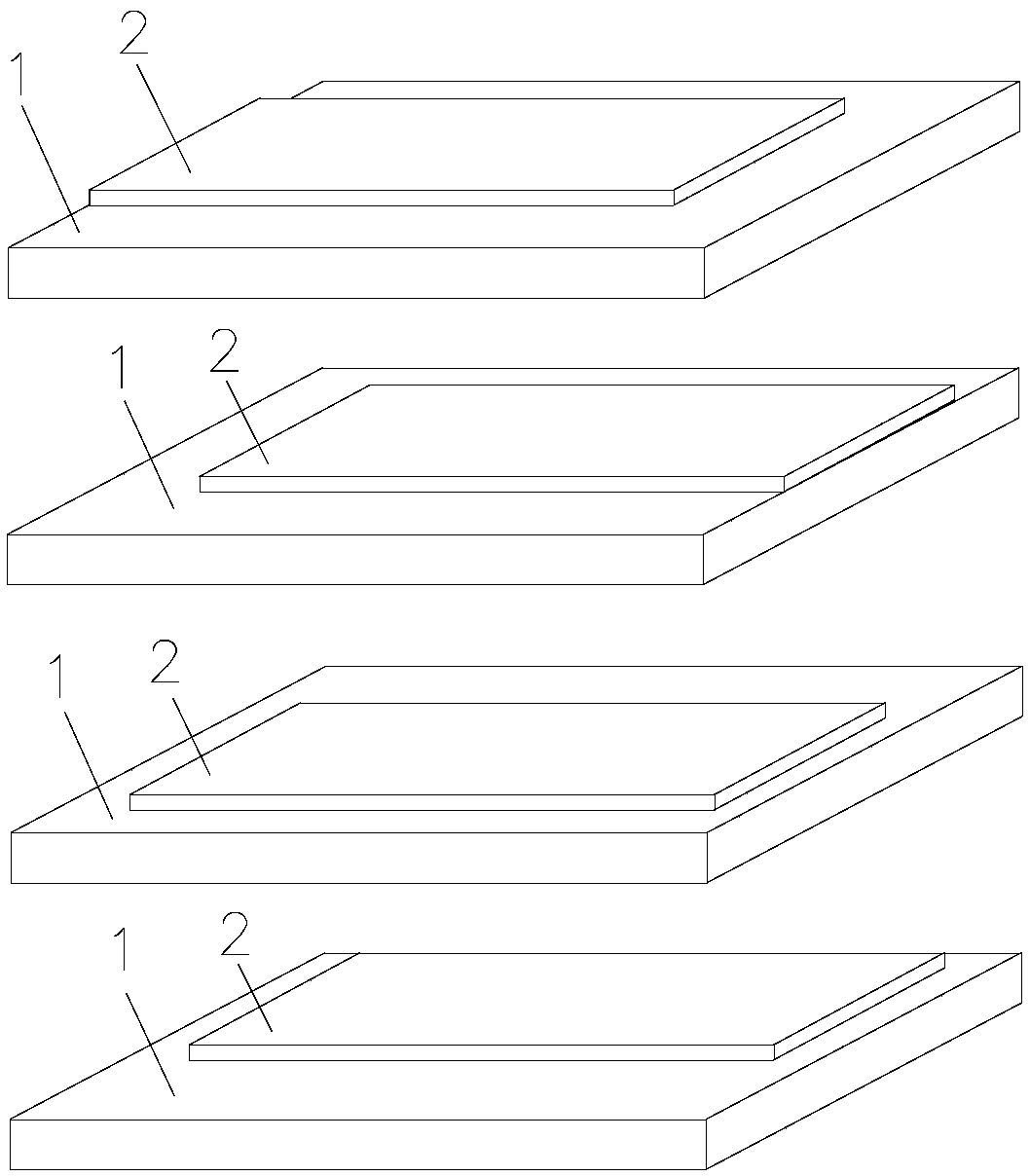

Method for preparing multilayer electronic device and multilayer electronic device

InactiveCN109671566ASinter stableFixed capacitor electrodesFixed capacitor dielectricThin layerMachining process

The invention discloses a method for preparing a multilayer electronic device and a multilayer electronic device. The preparation method comprises the steps of: preparing a ceramic substrate; formingan electrode thin layer on the ceramic substrate, wherein the electrode thin layer is made of metallic oxide, and one ceramic substrate and one electrode thin layer on the ceramic substrate form one device unit; putting a plurality of device units to a preformed unit in a stack mode, and applying pressing force to the preformed unit to laminate and fix the device units; and performing the sintering process to the preformed unit to prepare the multilayer electronic device. The problem is solved that the electrode thin layer is easily volatilized during processing.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

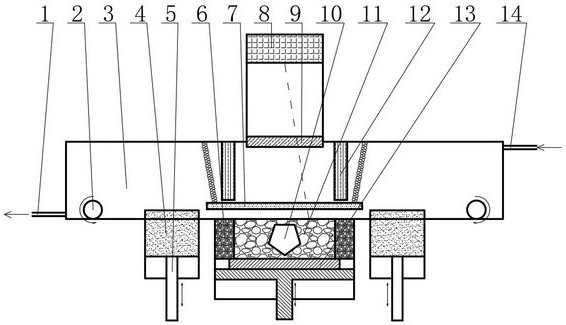

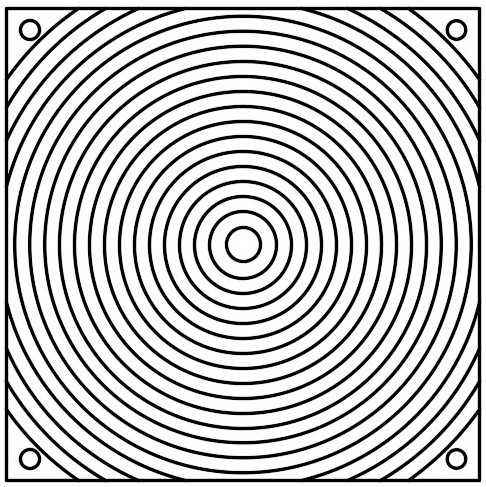

Soaking fault-prevention selective laser sintering device and manufacturing method thereof

ActiveCN111361149AImprove uniformityUniform structureManufacturing heating elementsManufacturing environment conditioningSelective laser sinteringLine width

The invention discloses a soaking fault-prevention selective laser sintering device and a manufacturing method thereof. The selective laser sintering device is composed of a machine base, a laser scanning device, a printing working cavity, a feeding device and a forming cavity; preheating devices which are uniformly distributed are arranged in an area, which does not affect a laser channel, in theprinting working cavity and located over the position of the forming cavity, and a soaking block is fixed at the position, corresponding to the forming cavity, of the inner surface of the machine base; and a soaking light-transmitting plate which is made of solar ultra-white rolled glass and is 1-2 mm in thickness is suspended in a middle area below the preheating device and above the position ofthe forming cavity, and optical disk grains constructed by a plurality of groups of circular and incomplete circular convex grains with the line width of 180-195 microns, the line height of 5-7 microns and the line spacing of 5 mm are etched on the upper surface of the soaking light-transmitting plate at equal intervals. During 3D printing, preheating is uniform, sintering formability is good, the performance of a sintered finished product is uniform, a sintering fault is avoided, and the structure of the sintered finished product is stable.

Owner:贵州森远增材制造科技有限公司

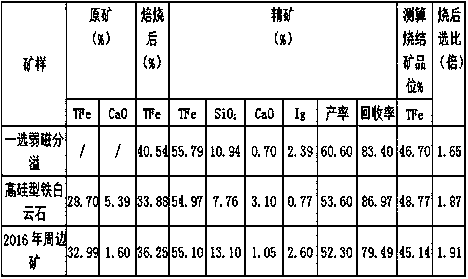

Ore blending method for blending ferrodolomite into low-magnetism crude iron ore

The invention discloses an ore blending method for blending ferrodolomite into low-magnetism crude iron ore. The method specifically comprises the following steps: acquiring data of an iron ore resource to be mined as a plan; setting the level and calcium oxide content target of iron output from the iron ore; building ore blending models of iron ore and ferrodolomite; and outputting the ore blending quantity of ferrodolomite. The method has the advantages that ferrodolomite is reasonably blended into the low-magnetism crude iron core according to the ore-dressing study and the practice result; the reasonable ore blending quantity and the output ore quality are calculated; the ferrodolomite in an own mine can be recovered. Therefore, the resource utilization level can be improved; the production cost of ore mining, ore dressing and sintering can be synchronously decreased; the reasonable ferrodolomite blending quantity and the output ore quality can be calculated, so that the resource utilization efficiency can be improved, and the ore mining cost can be decreased; the service life of a mine can be prolonged, and the waste stone output can be reduced; the ore dressing and sintering processes are stable; the ore dressing ratio can be reduced during ore dressing, and the lime consumption in sintering can be decreased, thus reducing the cost of ore dressing and sintering systems.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

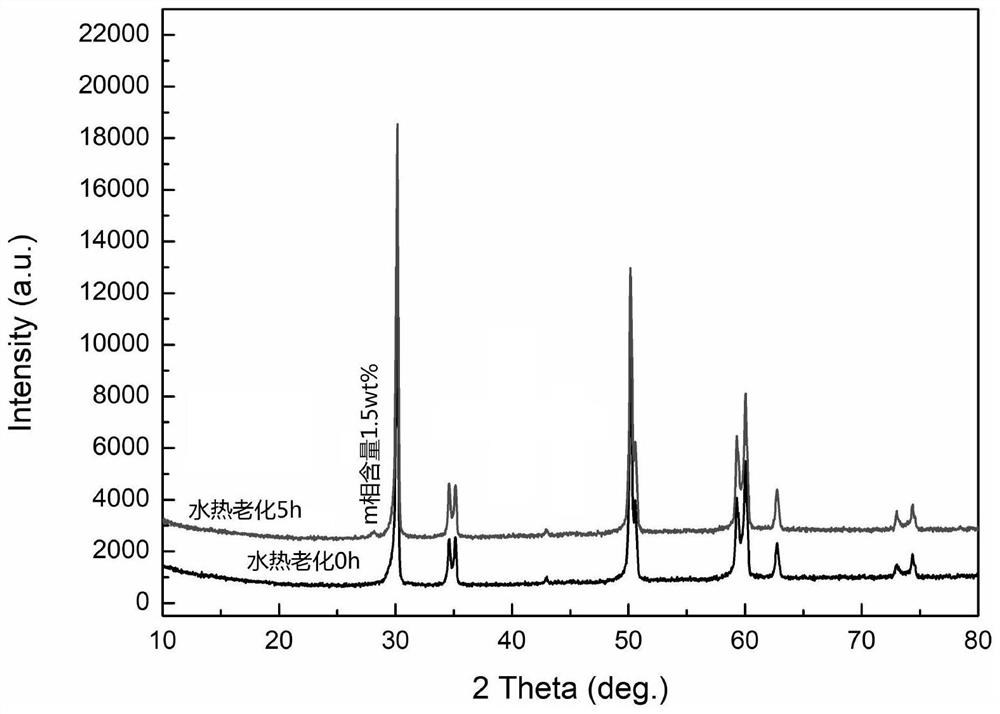

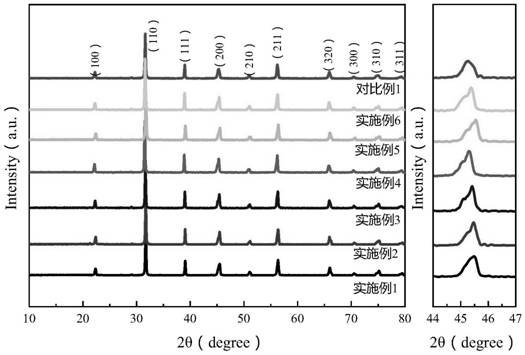

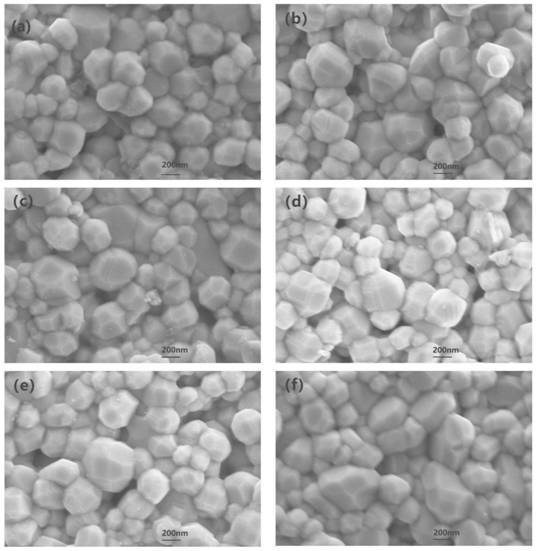

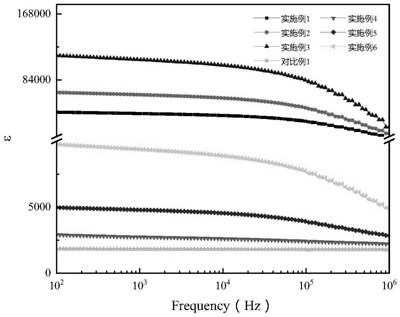

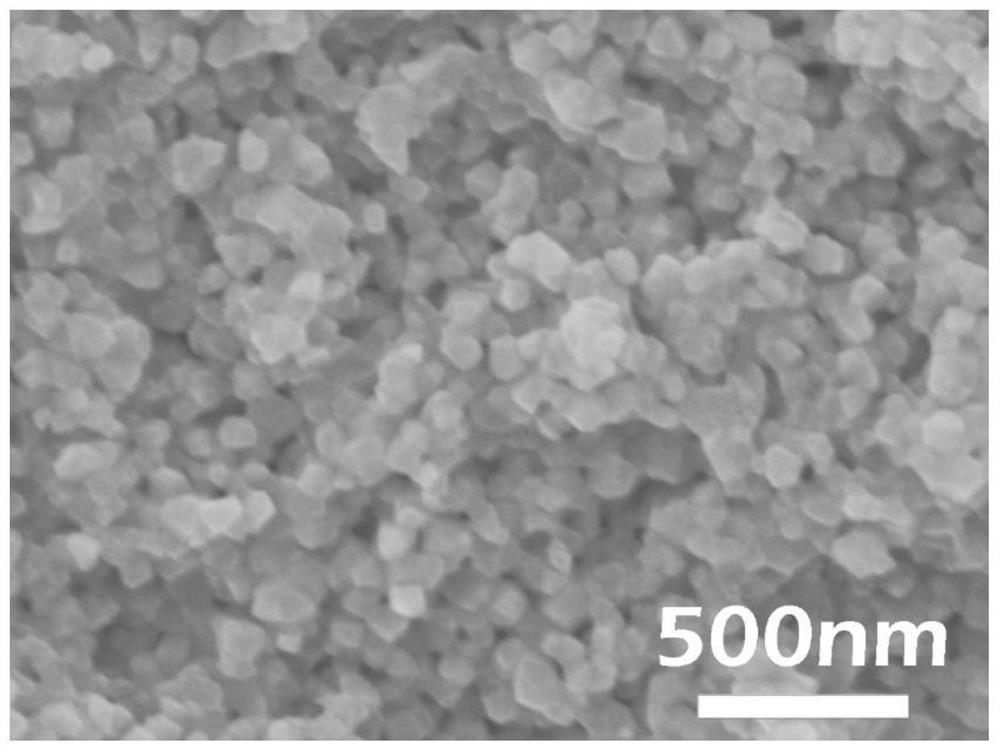

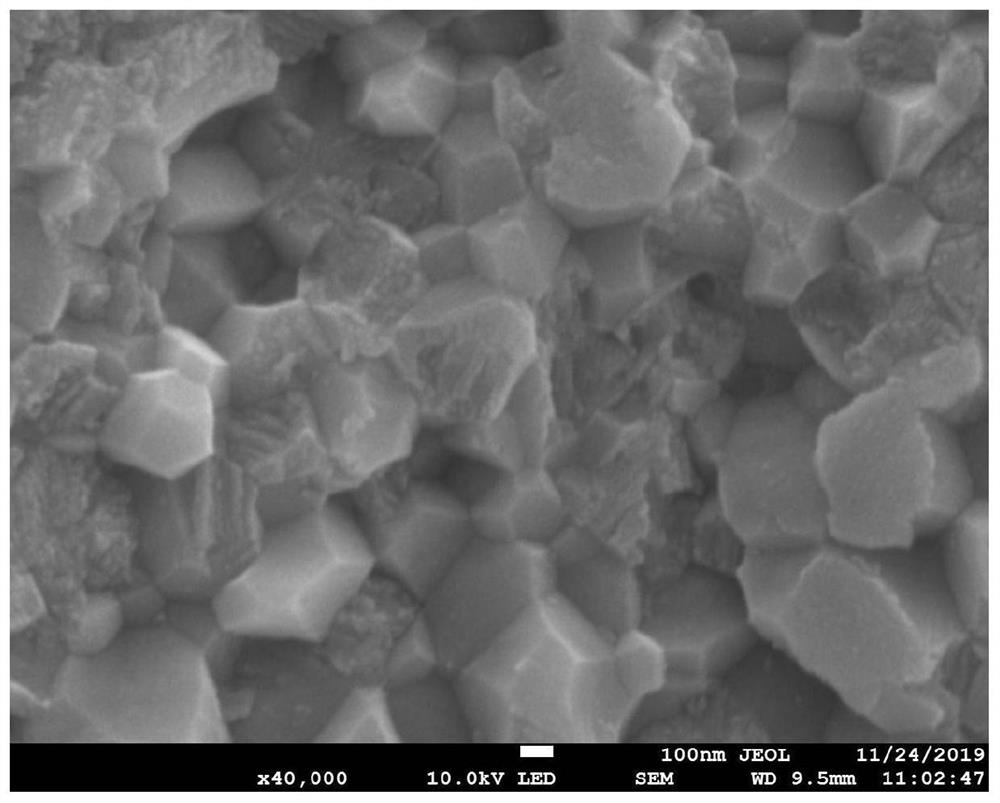

BaTiO3-based fine-grain ceramic with giant dielectric constant, low loss and high resistivity and preparation method of BaTiO3-based fine-grain ceramic

The invention provides a BaTiO3-based fine-grain ceramic with a giant dielectric constant, low loss and high resistivity. The BaTiO3-based fine-grain ceramic is prepared from the following raw materials in parts by mole and MAS: 100 parts of BaTiO3; 0.2 to 2 parts of Ln2O3; 0.2 to 2 parts of MnO2; 0.05 to 2 parts of MgO; the Ln2O3 is one or more of Y2O3, H2O3, Dy2O3 and Sm2O3, and the Ln2O3 is one or more of Y2O3, H2O3, Dy2O3 and Sm2O3; the content of the MAS accounts for 0.5 wt%-3 wt% of the BaTiO3. Compared with the prior art, the BaTiO3-based fine-grain ceramic with the giant dielectric constant, the low loss and the high resistivity provided by the invention adopts components with specific contents, so that relatively good overall interaction is realized, and the obtained product overcomes the problems of relatively low dielectric constant, overlarge crystal grains, low resistivity and the like of most dielectric ceramic materials; the method has great potential in application to the field of MLCC; the ceramic prepared by the invention shows excellent performance: relative dielectric constant gt; 104, the dielectric loss is 0.01-0.05, and the resistivity is gt; 109 omega.cm, the crystal grains are fine (the grain size is 1t; the material belongs to an environment-friendly electronic material, and can meet the practical application requirements of a miniaturized and light multilayer ceramic capacitor (MLCC).

Owner:福建贝思科电子材料股份有限公司

A selective laser sintering device for soaking heat and preventing faults and its manufacturing method

ActiveCN111361149BImprove uniformityUniform structureManufacturing heating elementsManufacturing environment conditioningSelective laser sinteringLaser scanning

The invention discloses a selective laser sintering device for soaking heat and preventing faults and a manufacturing method thereof. The area that affects the laser channel and the position directly above the molding cavity are equipped with a uniformly distributed preheating device, and a soaking block is fixed on the inner surface of the machine base corresponding to the position of the molding cavity; between the lower part of the preheating device and the position above the molding cavity In the area, there is also a heat soaking light-transmitting panel made of solar ultra-clear rolled glass with a thickness of 1mm-2mm. A disc pattern formed by multiple sets of circular and incomplete circular reliefs with a pitch of 5mm. The invention has uniform preheating during 3D printing, good sintering formability, uniform performance of sintered products, no faults in sintering, and stable structure of sintered products.

Owner:贵州森远增材制造科技有限公司

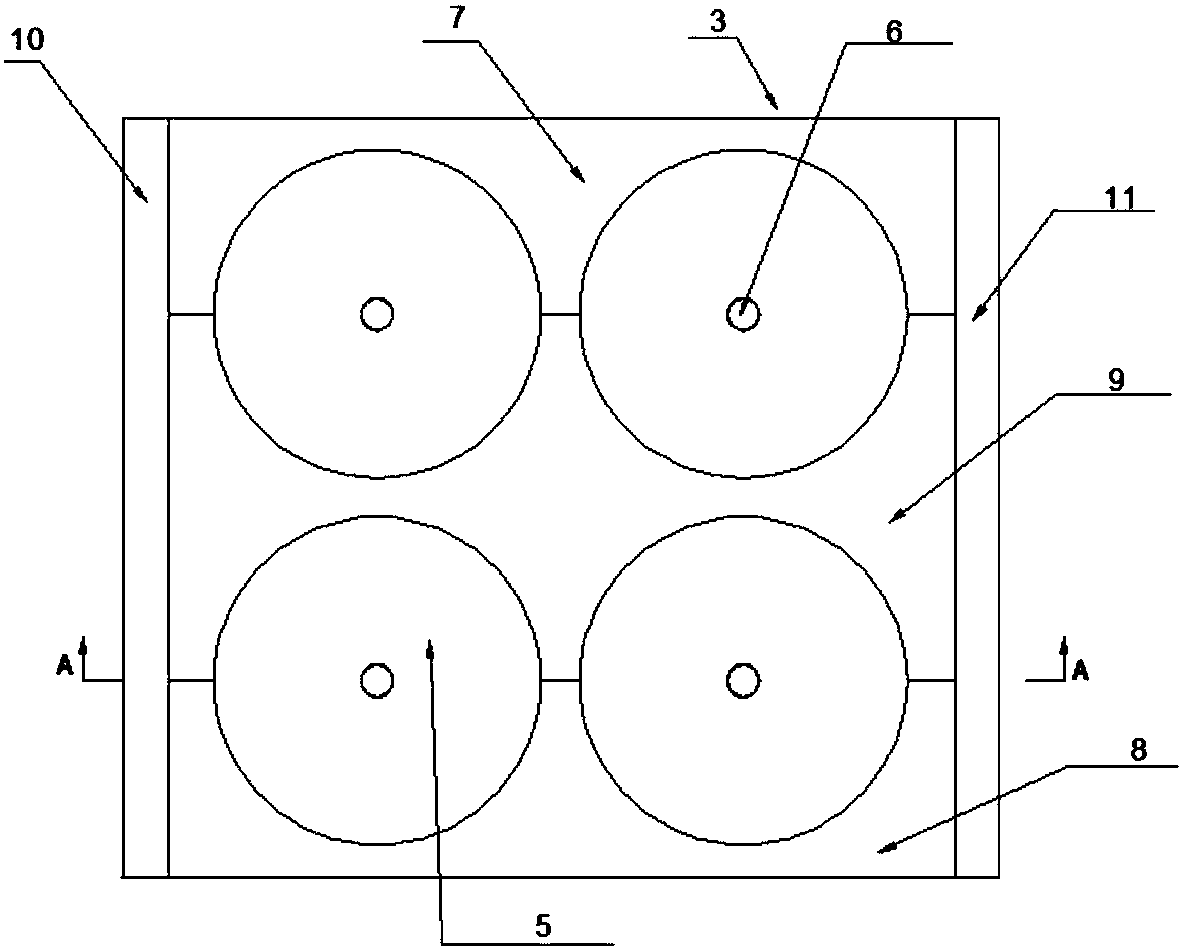

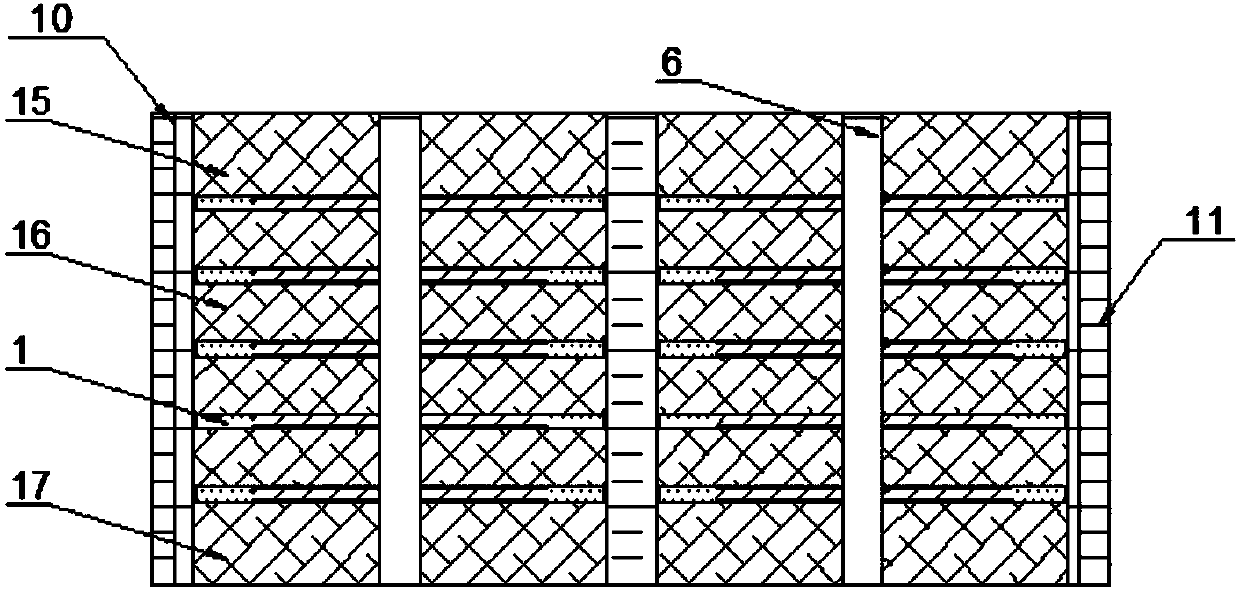

Hot-pressing mold for small-sized engraving saw blades

PendingCN108097960AQuality improvementAvoid interactionTurbinesOther manufacturing equipments/toolsStone carvingGraphite

The invention discloses a hot-pressing mold for small-sized carving saw blades. The hot-pressing die comprises the carving saw blades, a mold frame assembly and a hot-pressing mold assembly used in cooperation with the mold frame assembly; and the hot-pressing mold assembly comprises a baffle plate assembly, separation plate assemblies and center rods, wherein the baffle plate assembly is made ofa high-strength graphite material, and the separation plate assemblies and the center rods are used in cooperation with the baffle plate assembly. According to the hot-pressing mold, the mold frame assembly with the carving saw blades and made of the high-strength graphite material, the hot-pressing mold assemblies and the center rods are assembled together, and are put into a vacuum hot-pressingsintering machine to be subjected hot-pressing sintering so that high-pressure sintering of the stone carving saw blades can be realized, and therefore single sintering time is shortened, the production speed is increased, and the product quality is improved.

Owner:河南涵信金刚石工具有限公司

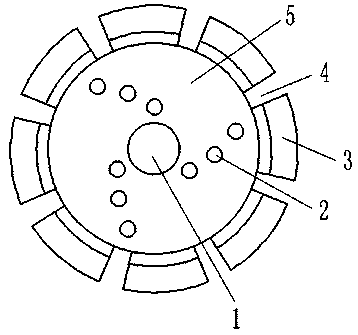

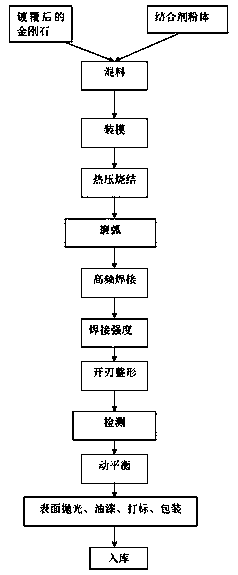

Composite diamond tool bit, manufacturing method of composite diamond tool bit, diamond saw blade and manufacturing method of diamond saw blade

PendingCN111070424AReduce manufacturing costIncrease profitStone-like material working toolsComposite materialTool bit

The invention discloses a composite diamond tool bit, a manufacturing method of the composite diamond tool bit, a diamond saw blade and a manufacturing method of the diamond saw blade. The diamond sawblade comprises a disc-shape base, wherein a shaft hole is formed in the center of the base; a plurality of composite diamond tool bits are uniformly arranged along the periphery of the base; chip removal grooves are formed between the composite diamond tool bits; each composite diamond tool bit comprises a metal matrix and a plurality of diamond particles; the outside of each diamond particle iscoated with a tungsten layer; the outside of each tungsten layer is coated with a nickel layer; and each diamond particle coated with the nickel layer at the outermost layer is inlayed in the metal matrix. The tungsten layers and the nickel layers improve the interface bonding between the diamond particles and the metal matrixes so as to increase the utilization rate of the diamond particles in the diamond saw blade, therefore, the cutting efficiency of the diamond saw blade is improved, the service life of the diamond saw blade is prolonged, and it is ensured that the diamond particles are sintered firmly in the metal matrixes and are not prone to falling off.

Owner:江苏乐泰超硬材料有限公司

Petrochemical wastewater treatment method

InactiveCN106745959ASinter stableImprove uniformityWater treatment parameter controlMultistage water/sewage treatmentOxidation reductionPetrochemical wastewater

The invention discloses a petrochemical wastewater treatment method. The petrochemical wastewater treatment method comprises the following steps: 1) discharging sewage into a treatment tank and adjusting the pH (Potential of Hydrogen) value in the treatment tank to 5.5-6.0; 2) adding copper sulfate and a catalyst and adjusting the pH value to 3.6-6.0 again, wherein in each 5L of the sewage, 0.5g of the copper sulfate is added; 3) adding an oxidant into the treatment tank and controlling the electric potential of an oxidation-reduction reaction to be 200mV-220mV; 4) stirring for 1h to enable the sewage to be in sufficient contact with the oxidant and a catalyst and reacting to obtain a mixed solution A; 5) adjusting the pH value of the mixed solution A to 8.0 to 9.0 and adding polyacrylamide; sufficiently mixing to obtain a mixed solution B, wherein in each 5L of the sewage, 1mg-2mg of the polyacrylamide is added; 6) stirring the mixed solution B at a constant speed for 5min and sufficiently coagulating and reacting; and after standing and precipitating, taking supernatant as treated effluent. The petrochemical wastewater treatment method disclosed by the invention has the advantages of good catalysis effect, high purification effect, low production cost and wide applicable range.

Owner:NANNING HEIJING INFORMATION TECH CO LTD

A kind of microwave dielectric ceramic material and preparation method thereof

ActiveCN108821768BContinuously adjustable dielectric constantHigh Q*f valueDielectricDielectric permittivity

The invention provides a microwave dielectric ceramic material, which is prepared from composite oxides and additives; the composite oxide has the general formula shown in the following formula: MLa 4 Ti 3 M'O 15 ; Wherein, M is Ca, Ba or Mg; M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the present invention is prepared from a composite oxide of a specific general formula and additives, and is a microwave dielectric ceramic with a medium dielectric constant; the microwave dielectric ceramic material satisfies a dielectric constant near 45 and It is continuously adjustable, and has a very high Q*f value and good sintering stability. At the same time, it can realize continuous adjustment of temperature drift to meet various needs. The experimental results show that the relative permittivity ε of the microwave dielectric ceramic material provided by the invention r 43.2~46.8, quality factor Q*f value ≥46200GHz, and sintering is stable; at the same time, the temperature drift adjustment range is ‑8~+13ppm / ℃, and can be continuously adjusted to meet various needs. It has very excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

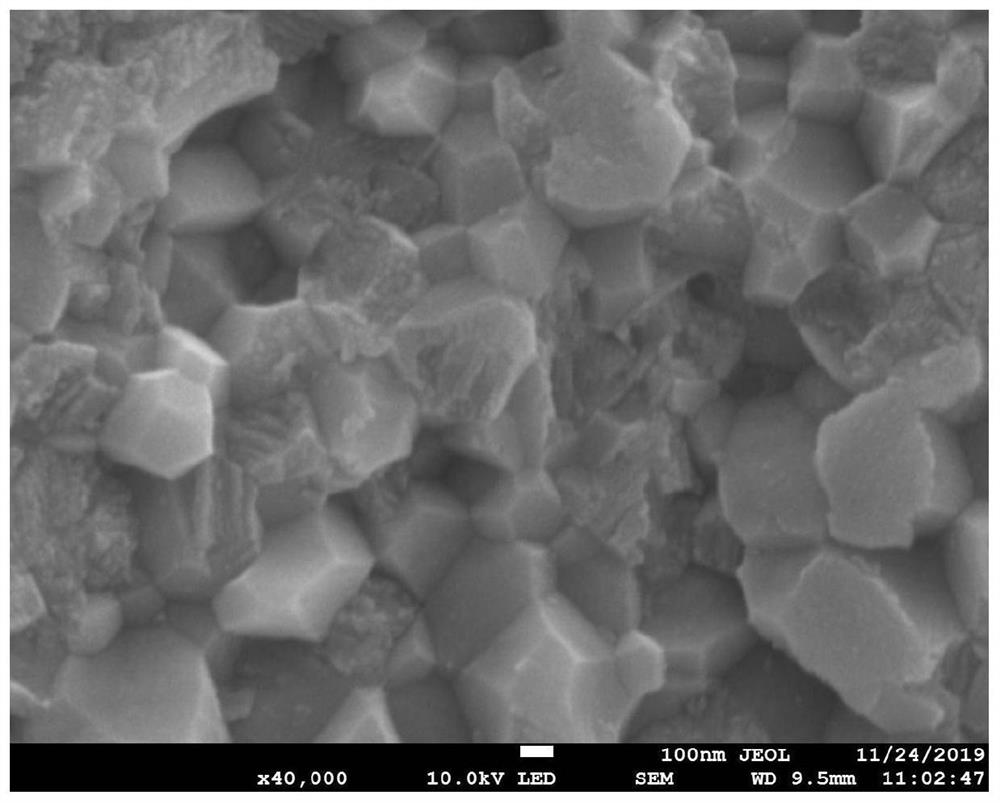

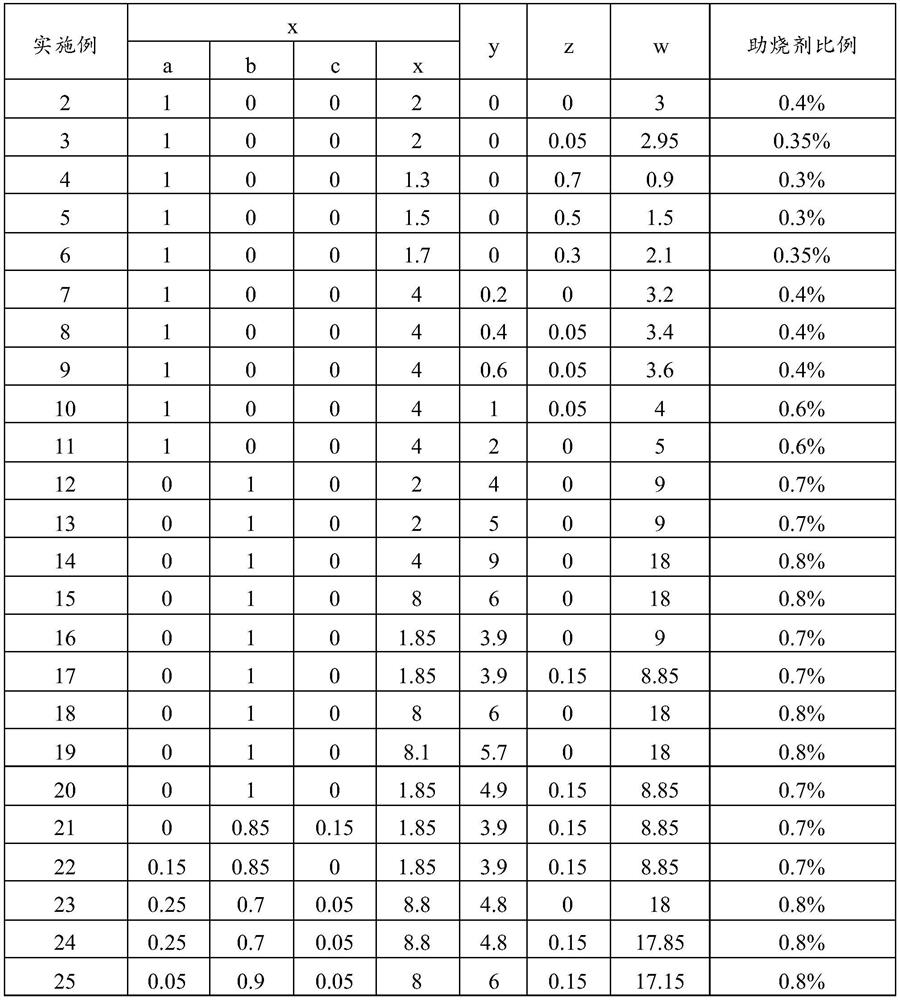

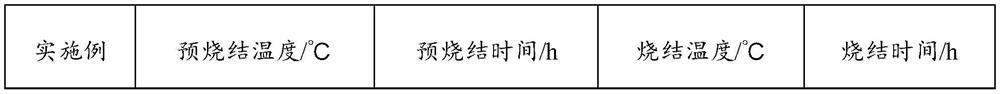

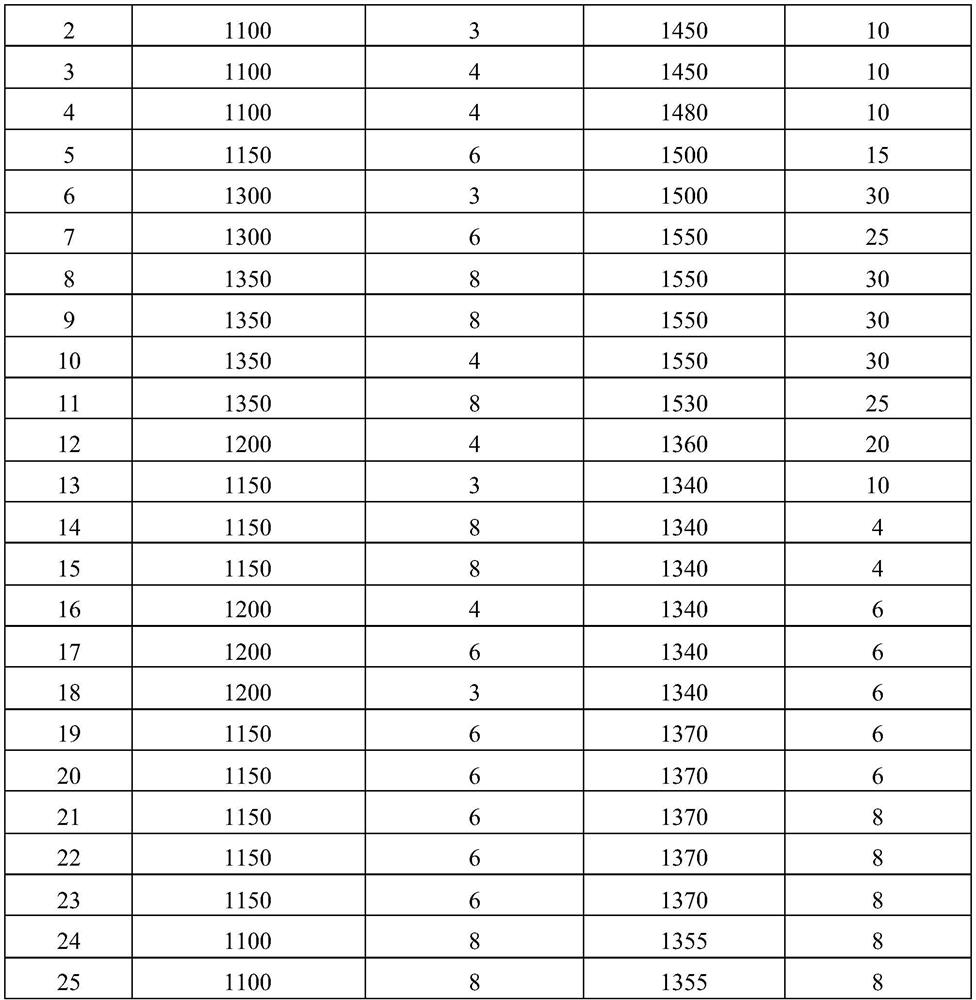

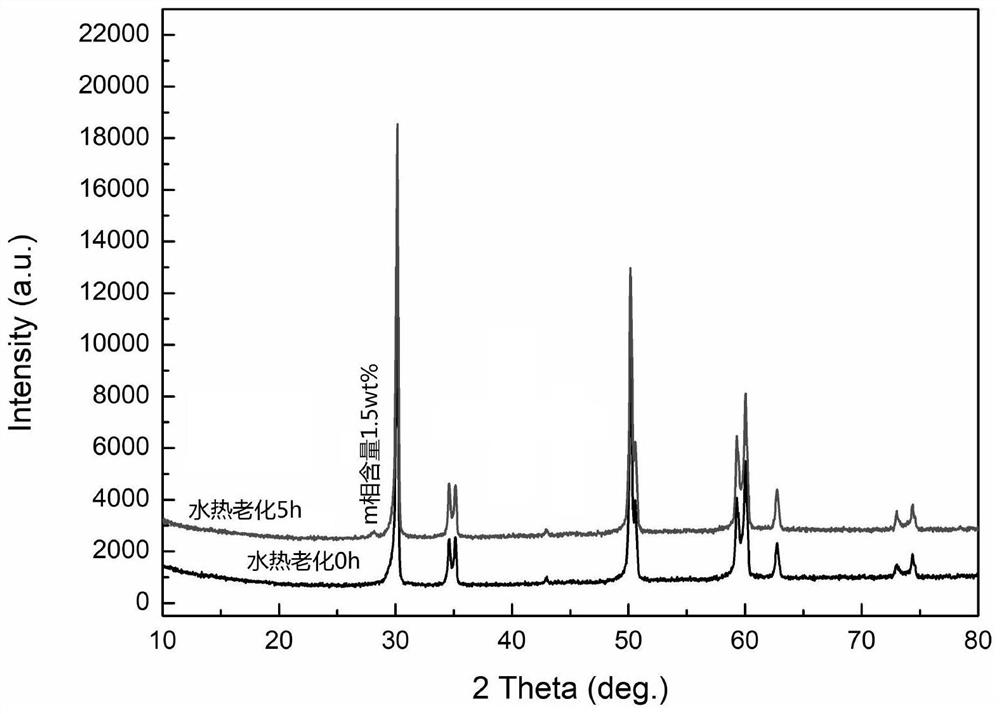

A kind of nanometer microwave dielectric ceramic material and preparation method thereof

The invention provides a nano-microwave dielectric ceramic material prepared from a mixture comprising a composite oxide and a sintering aid; the composite oxide has a general formula shown in formula (I): xLn 2 o 3 ‑yBaO‑zAl 2 o 3 ‑wTiO 2 ; In formula (I), 0<x≤10, 0≤y≤10, 0≤z≤1, 0<w≤20. Compared with the prior art, the nano-microwave dielectric ceramic material provided by the present invention takes the composite oxide of the above-mentioned specific general formula as the main component, and its crystal structure changes from the perovskite structure as the ratio of x, y, z, and w changes. Transforming to the composite perovskite structure and then to the black bronze structure, the BaO‑Ln 2 o 3 -TiO 2 (Ln: La\Sm\Nd) system microwave dielectric ceramic material is effectively improved; the nano-microwave dielectric ceramic material also has a high dielectric constant, extremely low dielectric loss and good sintering stability, and at the same time resonant The frequency temperature coefficient is adjustable, and it has very broad application prospects in the field of microwave communication.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Silver sintering composition containing copper alloy for metal bonding

PendingUS20220319733A1Good adhesion and sintering strengthSinter stableTransportation and packagingSemiconductor/solid-state device detailsMetal substrateMetallic substrate

Owner:HENKEL KGAA

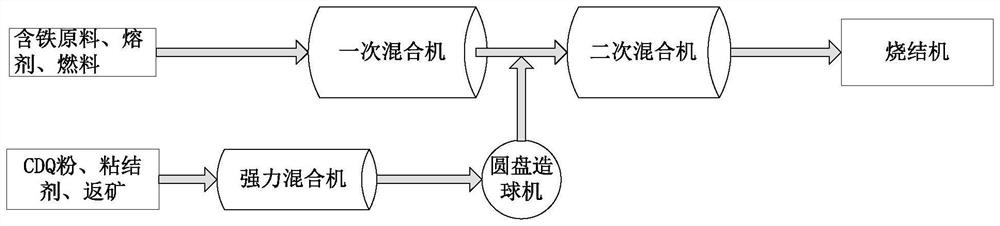

A sintering method using cdq powder for sintering

The invention discloses a sintering method using CDQ powder for sintering, belonging to the technical field of sintering pellets in the metallurgical industry. ~ 0.5 proportion of ingredients, and sent to a strong mixer for material mixing, and then sent to a disc pelletizer to make pellets with the returned ore particles as the core, and the pellets were sent to the sintering production after the primary mixer. On the mixing belt, it is sent to the secondary mixer for mixing and granulation, and then sent to the sintering machine for distribution, ignition and sintering, and the CDQ powder is directly consolidated on the returned ore particles through the binder. It is wrapped by other materials, which improves the granulation effect of the sintering mixture and overcomes the adverse effects of the direct ingredients of CDQ powder participating in the sintering production.

Owner:武汉钢铁有限公司

A kind of zirconia ceramic material and its preparation method and application

The invention relates to the technical field of ceramic materials, in particular to a zirconia ceramic material and a preparation method and application thereof. The preparation method provided by the present invention includes the following steps: after mixing zirconia, oxide stabilizer, organic dispersant, polymer stabilizer and water, performing homogenization treatment to obtain a homogeneous mixed solution; Pre-sintering is performed to obtain a pre-sintered body; final sintering is performed on the pre-sintered body to obtain the zirconia ceramic material; the temperature of the pre-sintering is 600-1000°C; the temperature of the final sintering is 1200- 1400℃. The zirconia ceramic material prepared by the preparation method has a high volume percentage of tetragonal zirconia and can exist stably in the presence of water vapor; and the tetragonal zirconia has small grain size and high bending strength.

Owner:中新棠国业(江苏)科技有限公司

Sewage treatment method

InactiveCN106477776ASinter stableImprove uniformityMultistage water/sewage treatmentWater/sewage treatment by oxidationSewageSewage treatment

The invention discloses a sewage treatment method, comprising the steps of 1, the sewage, catalyst, and a first oxidizing agent being mixed and treated, the treating temperature being 50-80 DEG C, the treating time being 1-3 hours; 2, the first round treated sewage being solid-liquid separated, and the PH value being adjusted to 8-10; 3, the separated liquid under a pressure of 0.2-1.6 MPa, being heated to 110-150 DEG C, adding a second oxidizing agent, the reacting time being 1-5 hours: 4, the second round treated sewage being solid-liquid separated; the catalyst has excellent water hydrophilicity and dispersion ratio, increases catalyst effect, the treated sewage achieves industrial discharge standard, the sewage treatment result is good.

Owner:NANNING HEIJING INFORMATION TECH CO LTD

A kind of microwave dielectric ceramic material and preparation method thereof

ActiveCN108383519BLow dielectric constantHigh Q*f valueCeramicsDielectric ceramicsDielectric permittivity

The invention provides a microwave dielectric ceramic material, which is prepared from composite oxides and additives; the general formula of the composite oxides is xMg 1.2 Zn 0.8 SiO 4 -yMg 0.65 Zn 0.35 al 2 o 4 ; Wherein, x+y=1, 0.4≤x≤0.9, 0.1≤y≤0.6. Compared with the prior art, the microwave dielectric ceramic material provided by the present invention is prepared from a composite oxide of a specific general formula and additives, and realizes the microwave dielectric ceramic material Mg 2 SiO 4 Effective improvement; the microwave dielectric ceramic material also has a low dielectric constant, a very high Q*f value and good sintering stability, and can realize continuous adjustment of temperature drift to meet various needs. The experimental results show that the relative permittivity ε of the microwave dielectric ceramic material provided by the invention r It is 7~8, the quality factor Q*f value is ≥180000GHz, the temperature drift adjustment range is -10~+6ppm / ℃, and the sintering is stable, which has very excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Seal device used for pin hole of bar grate block

InactiveCN101571352BPlay a sealing rolePrevent air leakageMolten spray coatingFurnace typesEngineeringMechanical engineering

Owner:济南宏升益德科技发展有限公司

plutonium dioxide raw material pretreatment device for mox

ActiveCN109721111BEffective protectionImprove protectionTransuranic element compoundsNuclear energy generationThermal insulationRefractory

A plutonium dioxide pretreatment device for MOX, including a resistance furnace body, the resistance furnace body is respectively an electric heating element, a refractory material, an insulating material, a furnace shell, and a cooling water jacket from the inside to the outside; the electric heating element is fixed on the refractory material through The bricks are fixed around the furnace cavity of the resistance furnace, and the electrodes of the electric heating element are placed above the furnace body; the refractory and heat preservation materials are used to fix the earth bricks as a whole through a stainless steel frame, and there are hooks on it; the furnace cover of the resistance furnace is located on the upper part of the resistance furnace body , the resistance furnace cover is connected to the storage platform through a rope, and a movable quartz boat is placed on the storage platform to place pretreated raw materials. The storage platform can be lifted and lowered with the resistance furnace cover; , used to pass dry air; the resistance furnace cover is welded with stainless steel cooling water pipes; the armored thermocouple penetrates into the furnace body through the hole on the resistance furnace cover.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com