Hot-pressing mold for small-sized engraving saw blades

A technology of hot-pressing molds and small specifications, which is applied to other manufacturing equipment/tools, mechanical equipment, turbines, etc. It can solve the problems of low accuracy of the appearance and size of saw blades, high-pressure sintering, and long sintering time, etc., so as to shorten the sintering time , improve quality, and avoid the effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

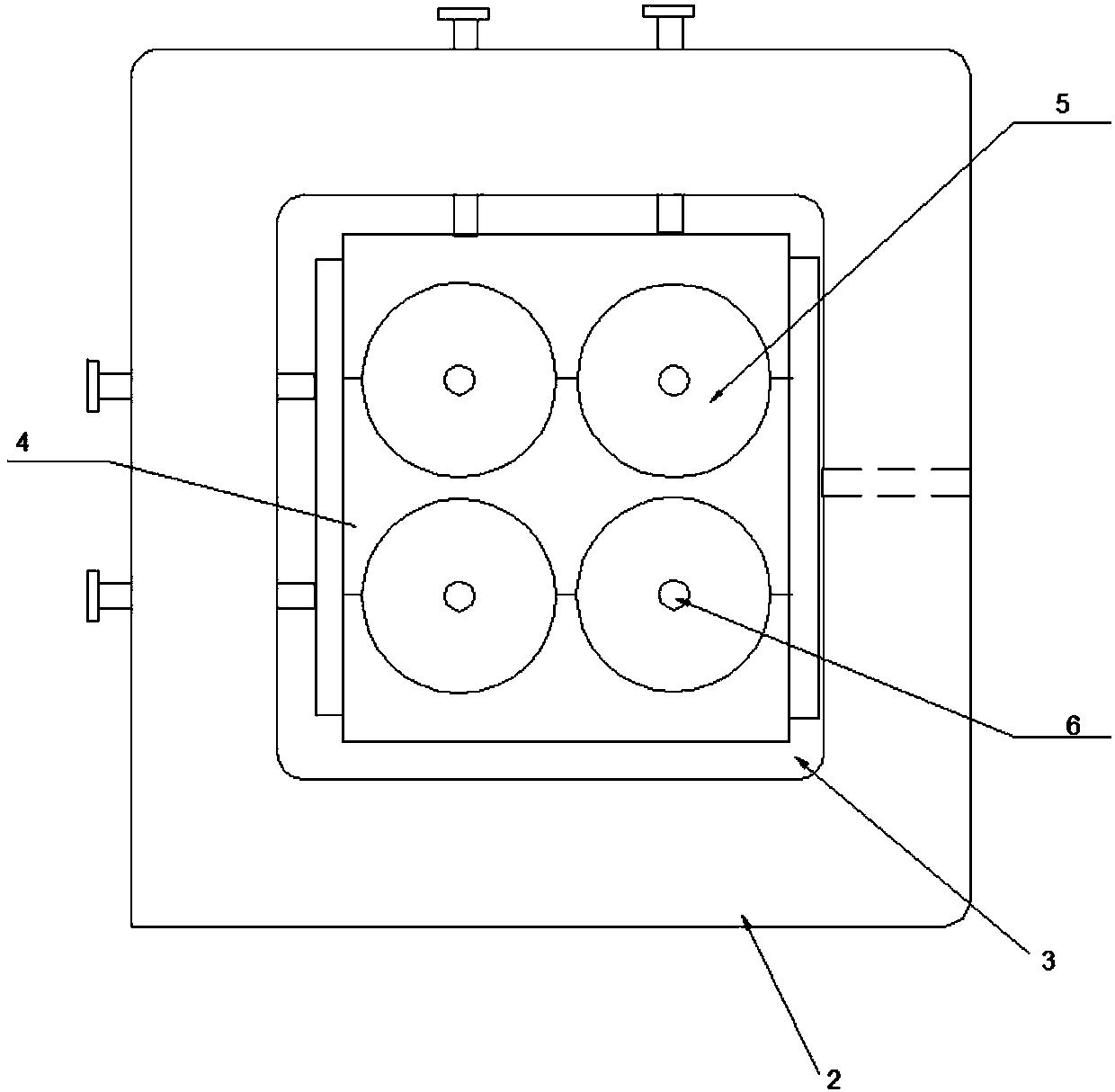

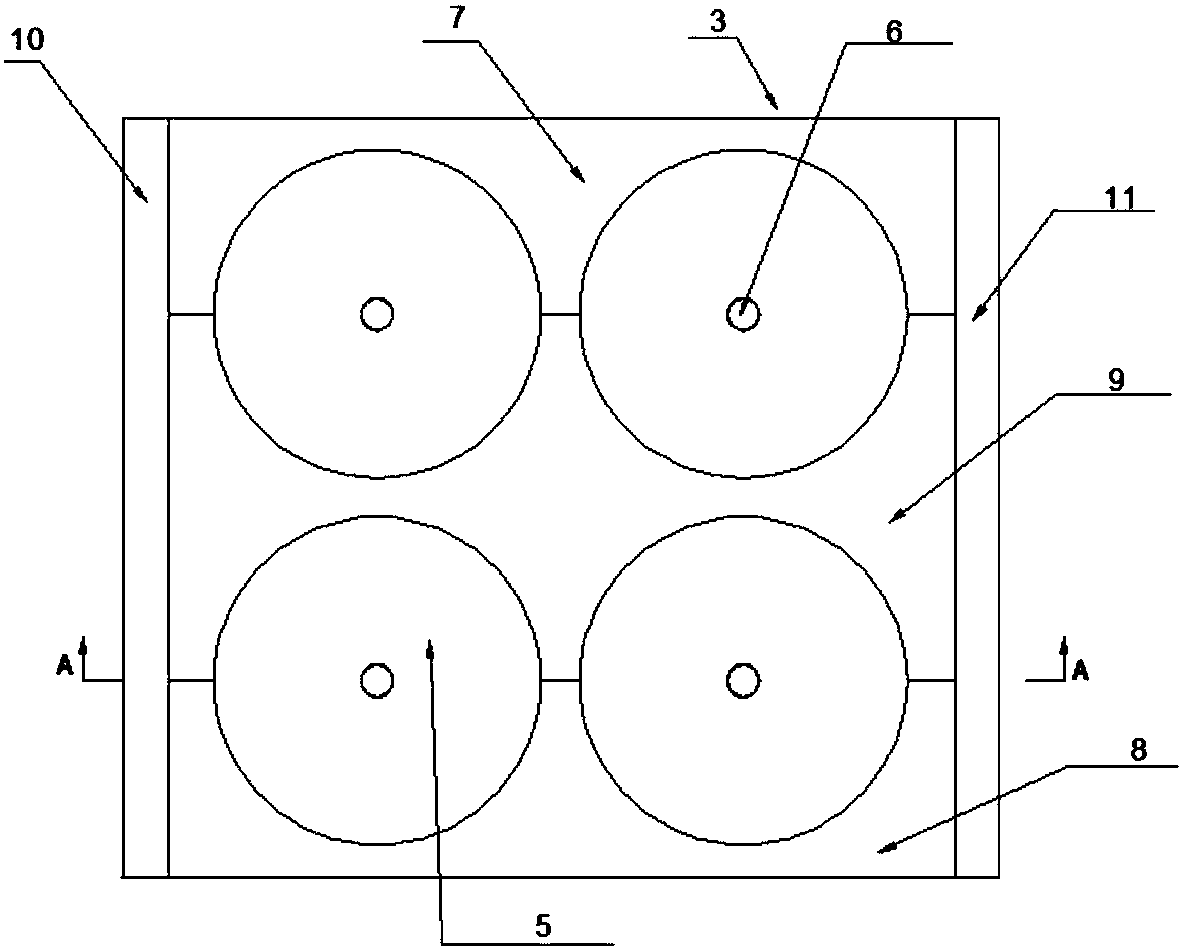

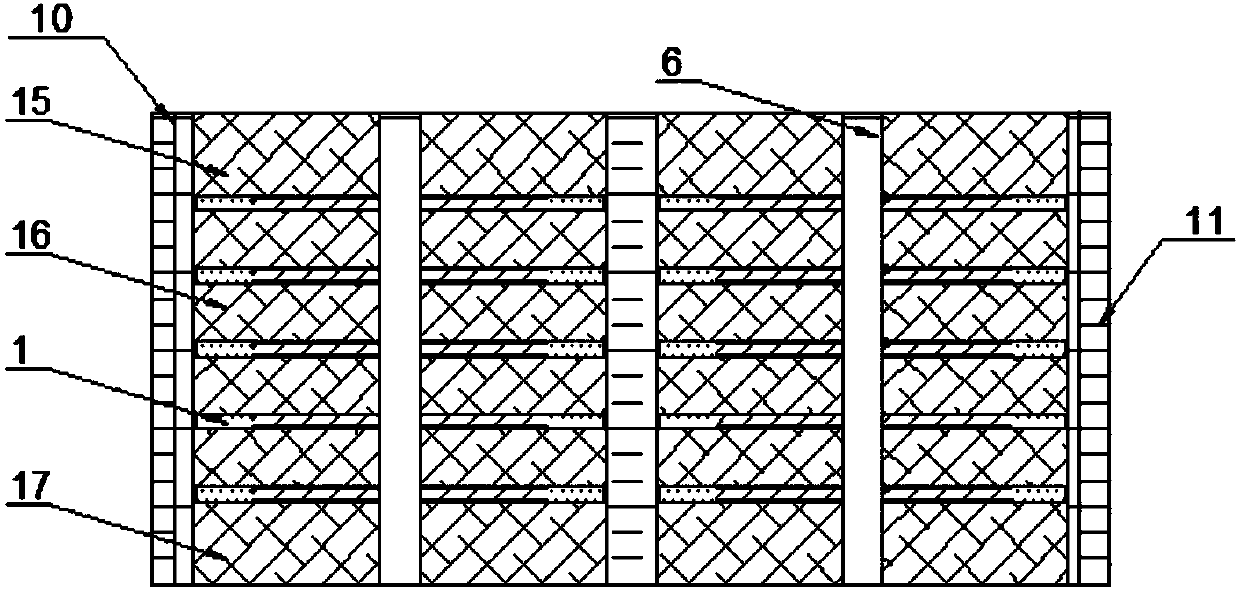

[0039] The technical scheme adopted in the present invention is as follows: a small-sized engraving saw blade hot-pressing mold, including an engraving saw blade 1, a mold frame assembly 2, and a hot-pressing mold assembly 3 used in conjunction with the mold frame assembly 2, the hot-pressing mold assembly 3 includes a baffle assembly 4 made of high-strength graphite material, a baffle assembly 5 used in conjunction with the baffle assembly 4, and a central rod 6. The baffle assembly 4 includes a first side baffle 7 and a second side The baffle 8, at least one middle baffle 9, the front baffle 10 and the rear baffle 11, each side of the first side baffle 7 and the second side baffle 8 is provided with at least two symmetrical The first groove 12, the two sides of the middle baffle plate 9 are respectively provided with the second groove 13 corresponding to the first groove 12, the corresponding first groove 12 and the second groove 13 It is combined into a housing cavity 14 fo...

Embodiment 2

[0042] On the basis of Example 1, the shortest distance between adjacent first grooves 12 is 4-8 mm, and the distance between each adjacent second groove 13 is 4-8 mm. The shortest distance between the first groove 12 and the other side of the first side baffle 7 is 4-9 mm. This avoids a reduction in the quality of the engraving saw blade 1 due to mutual influence between the engraving saw blades 1 during the sintering process.

Embodiment 3

[0044] On the basis of Example 2, the shortest distance between adjacent first grooves 12 is 6 mm, and the distance between each adjacent second groove 13 is 6 mm. The shortest distance between the groove 12 and the other side of the first side baffle 7 is 7mm. The quality of the engraving saw blade 1 sintered out like this is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com