Patents

Literature

53results about How to "Sintered to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

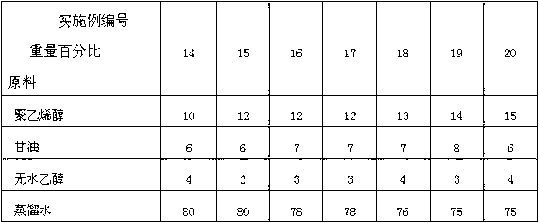

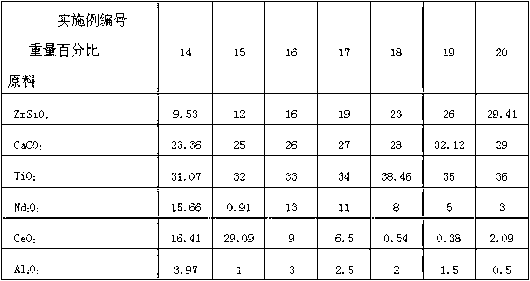

Method for preparing radioactive waste solidified body

InactiveCN102930915AImprove performanceEasy to excludeRadioactive decontaminationHigh densityPolyvinyl alcohol

The invention discloses a method for preparing a radioactive waste solidified body. The method is characterized by comprising the following steps of: finely grinding a raw material which comprises 9.53 to 29.41 weight percent of ZrSiO4, 23.36 to 32.12 weight percent of CaCO3, 31.07 to 38.46 weight percent of TiO2, 0 to 15.66 weight percent of Nd2O3, 0 to 29.09 weight percent of CeO2 and 0 to 3.97 weight percent of Al2O3; drying the raw material; and adding polyvinyl alcohol sol, granulating, screening, molding, discharging the sol, performing vacuum hot-pressing sintering, and thus obtaining the radioactive waste solidified body. By adoption of the method, the raw material is low in cost, a high-purity and high-density perovskite acorite and titanite combined mineral solidified body is prepared at low temperature by using a simple and practical hot-pressing sintering technology, and foundation is laid for engineering application to artificial rock solidification treatment of high-level waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

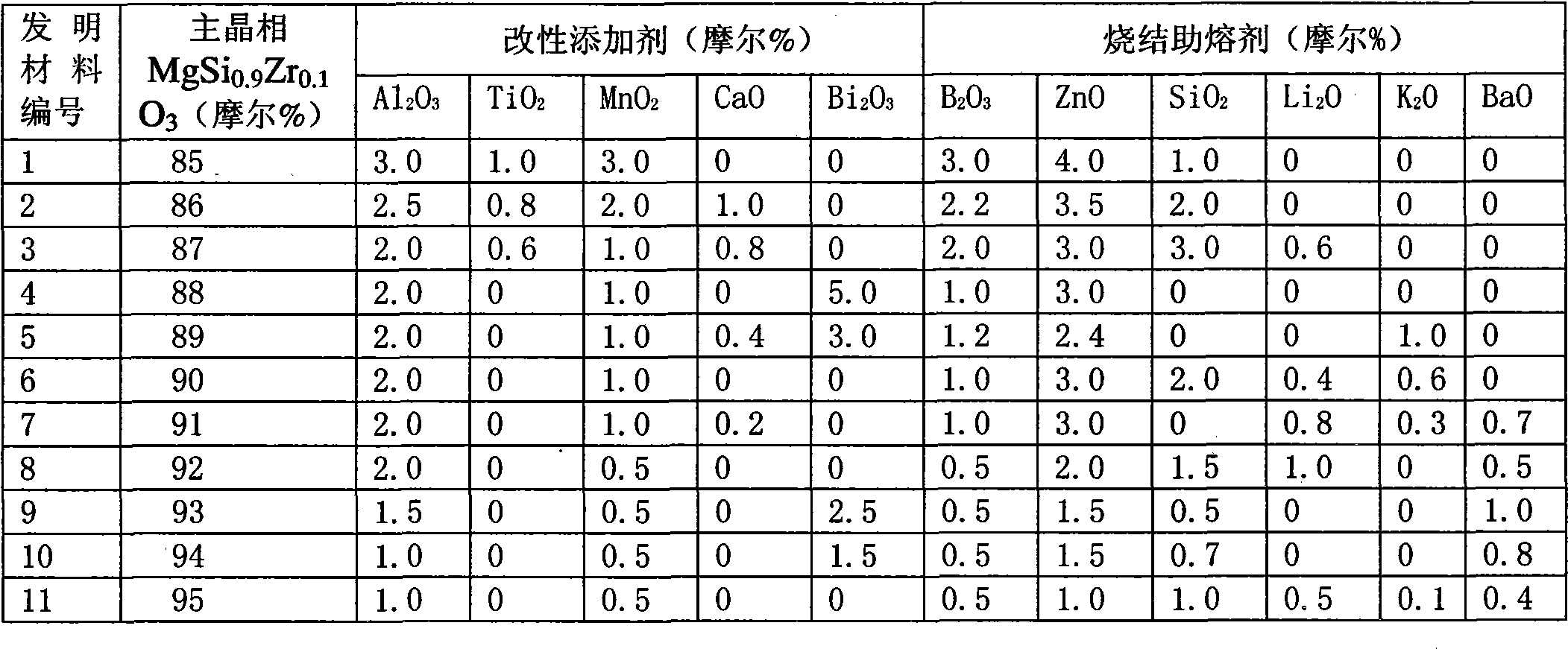

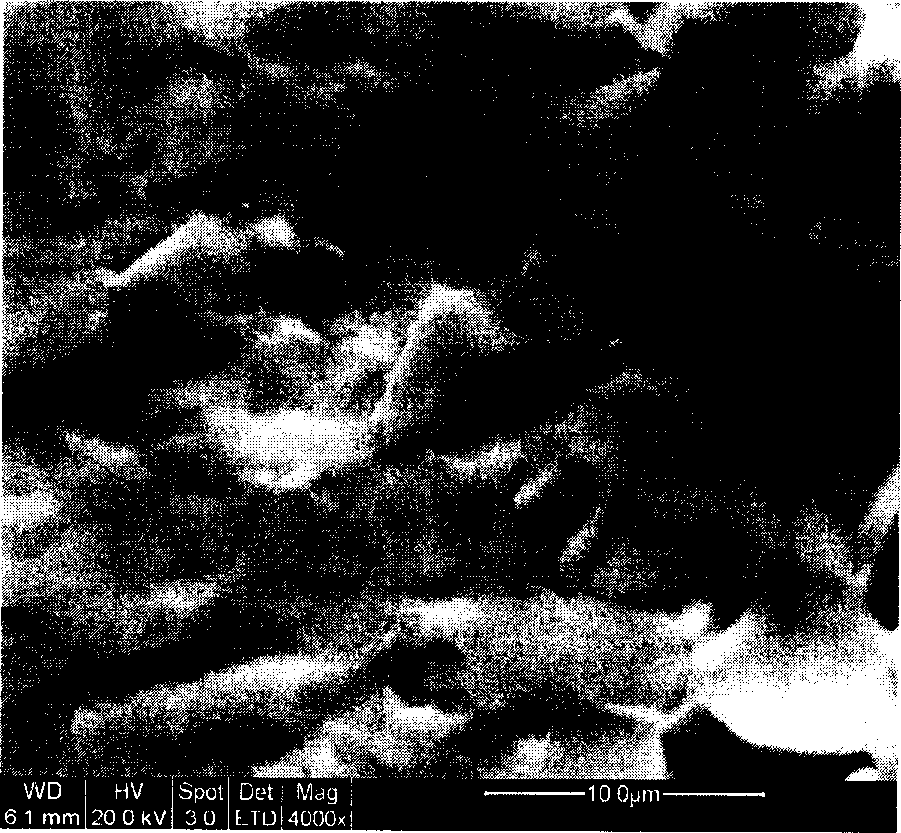

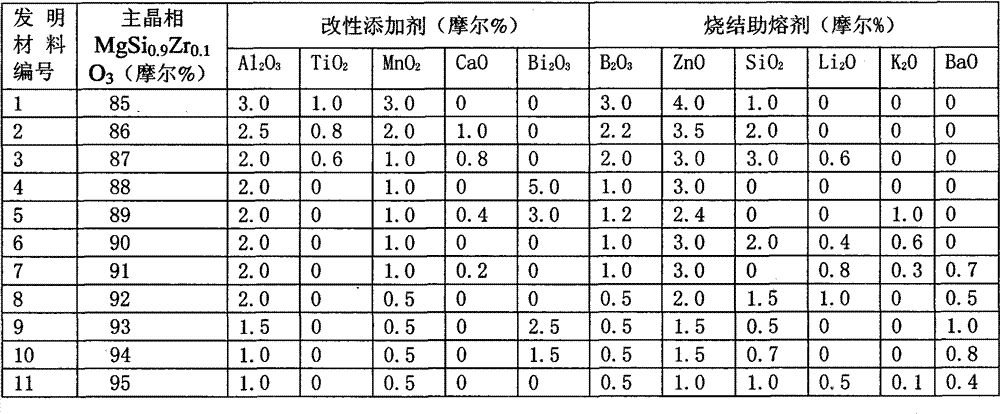

Ceramic dielectric material matched with nickel inner electrode and production method of capacitor produced by ceramic dielectric material

ActiveCN101786864ASolve the problem of co-firingResistantFixed capacitor dielectricStacked capacitorsCeramic capacitorReducing atmosphere

The invention discloses a ceramic dielectric material matched with a nickel inner electrode and a production method of a capacitor produced by the ceramic dielectric material. The ceramic dielectric material consists of a main crystal phase, a property-modifying additive and a sintered fluxing agent, wherein the main crystal phase is MgZrxSi(1-x)O3, and x is more than or equal to 0.05 and less than or equal to 0.15; the property-modifying additive is one or more of MnO2, Al2O3, CaO, Bi2O3 and TiO2; and the sintered fluxing agent is one or more of B2O3, SiO2, ZnO, Li2O, K2O and BaO. The ceramic dielectric material can meet the COG characteristic in the EIA standard, has good uniformity, uniform particle size distribution, high dispersibility, good molding technique and excellent dielectricproperty and meets the environmental requirement. When the material is used for making a multi-layer chip ceramic capacitor (MLCC), the material and the nickel electrode can be matched and sintered under the reducing atmosphere, the crystal particles of a ceramic body after sintering can grow uniformly and densely, the dielectric layer can be well matched with the inner electrode, and the productperformance is stable.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

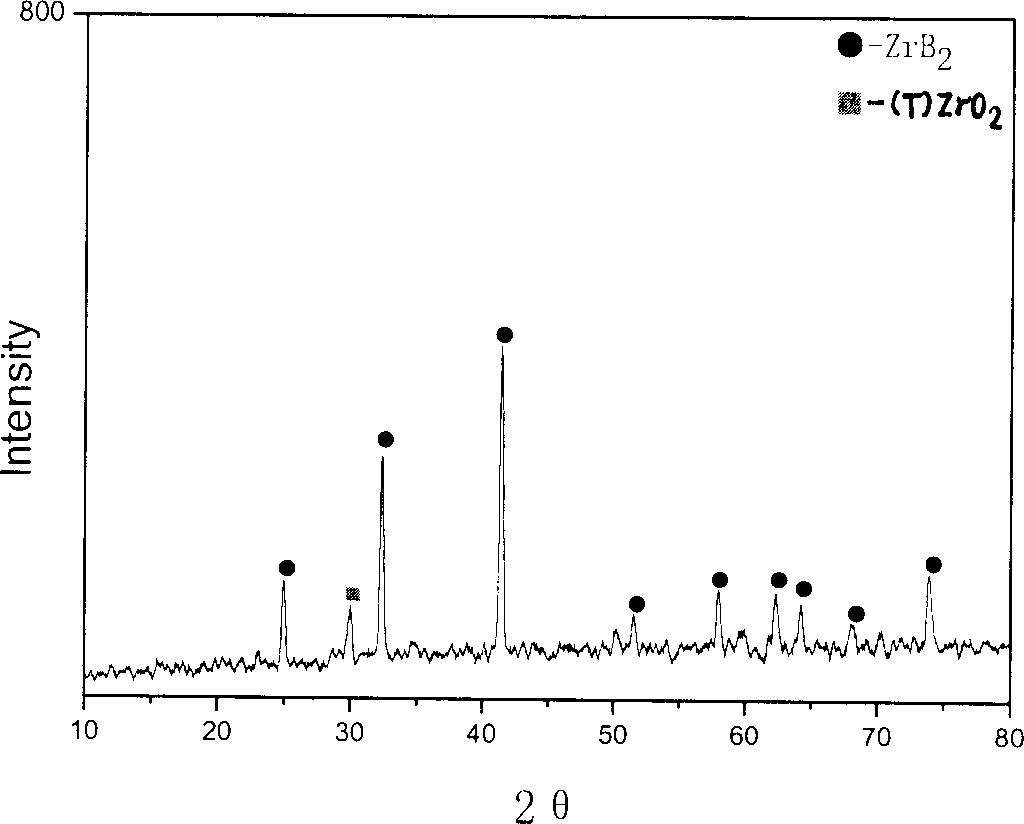

Process for preparing high-density zirconium diboride blocks by spark plasma sintering

InactiveCN1837044ASintered to achieveFast sinteringZirconium compoundsMetal boridesHigh densityAxial pressure

The invention refers to a method for preparation of zirconium diboride block material. The method is about a discharging plasma sinter high-integrity zirconium diboride block material, the character is lies in it includes steps as follows: directly posting coated format ZrB2 in graphite mould, and then putting mould in discharging plasma sintering furnace, applying axial pressure of 10- 50MPa, adopting vacuum condition or interia atmosphere which vacuum degree is less than 10Pa, sintering in sintered temperature of 1600- 2200Deg C, heating-up with rate of 50-500Deg C / min, heat preserving for 1-30min, cooling under 1300Deg C with cooling rate of 10-100Deg C / min, finally furnace cooling to room temperature, getting high degree of compactness zirconium diboride block material. The produced zirconium diboride block materials have high degree of compactness, hardness, high-temperature strength and oxidation resistance capability.

Owner:WUHAN UNIV OF TECH

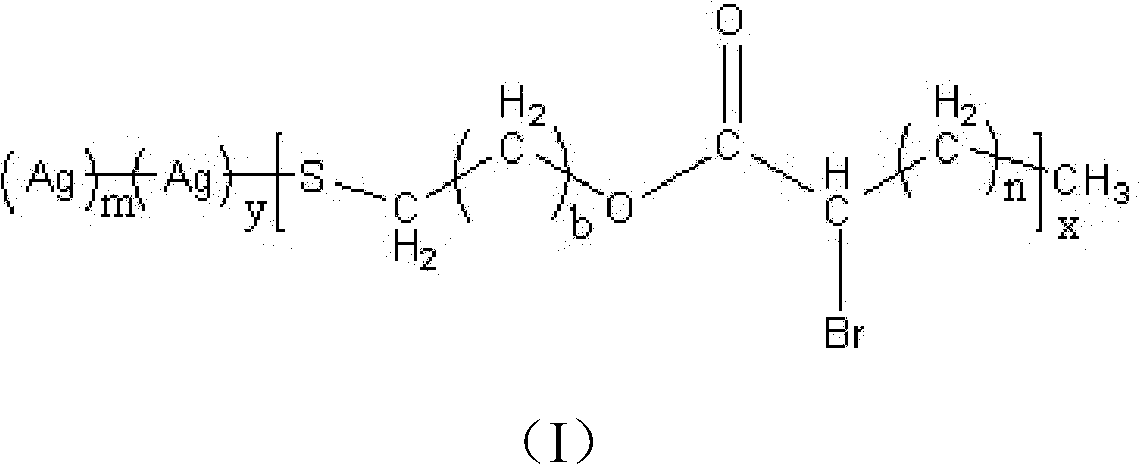

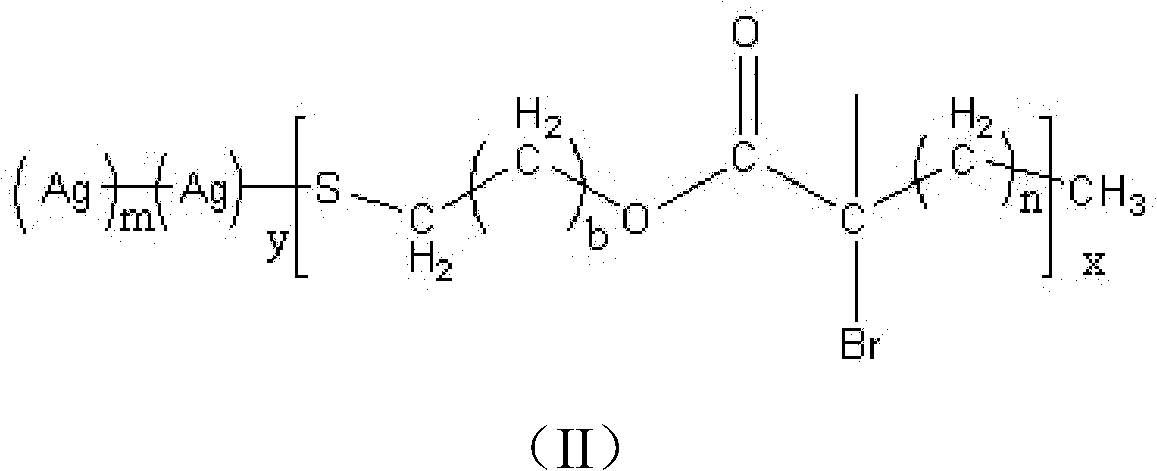

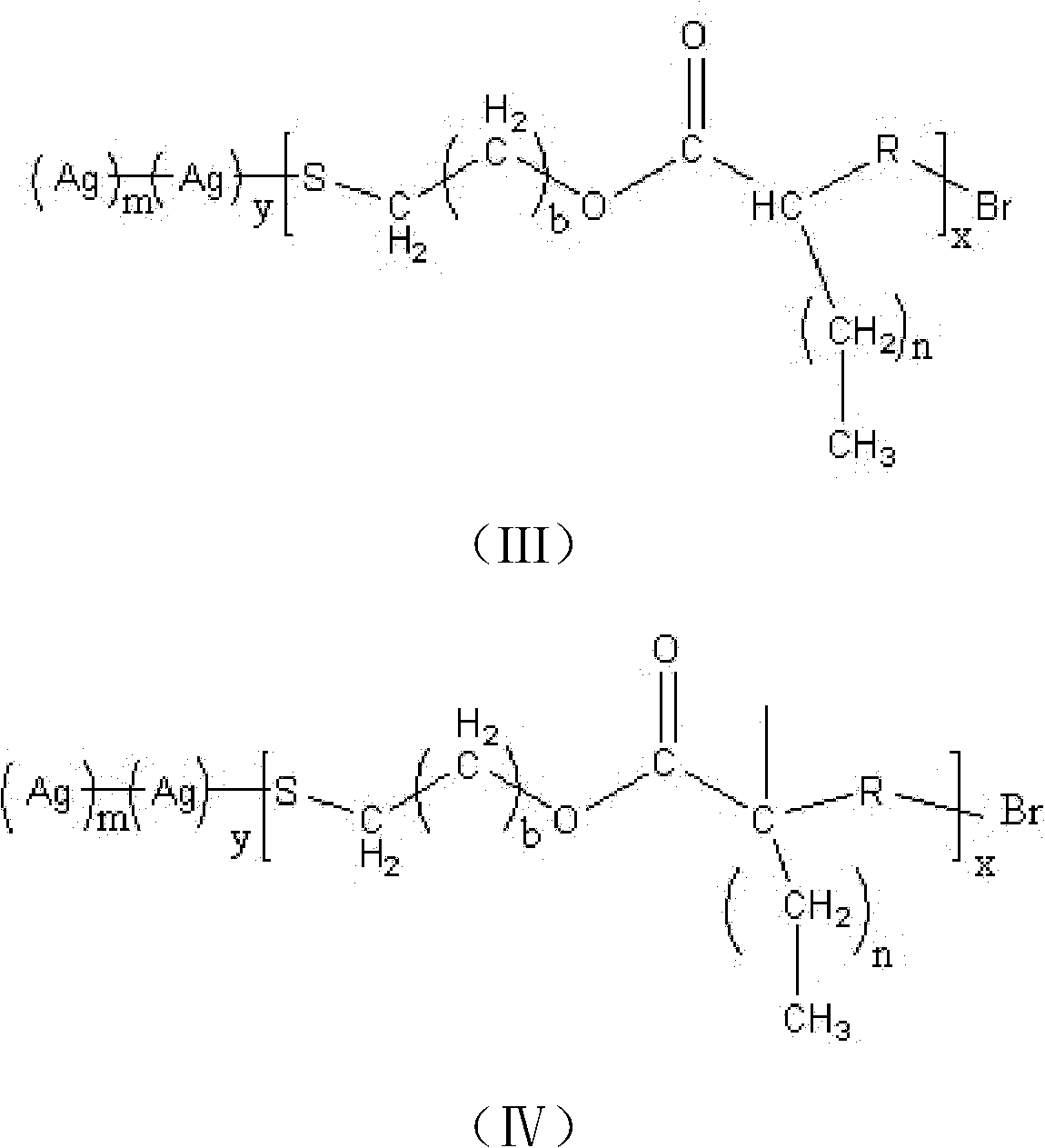

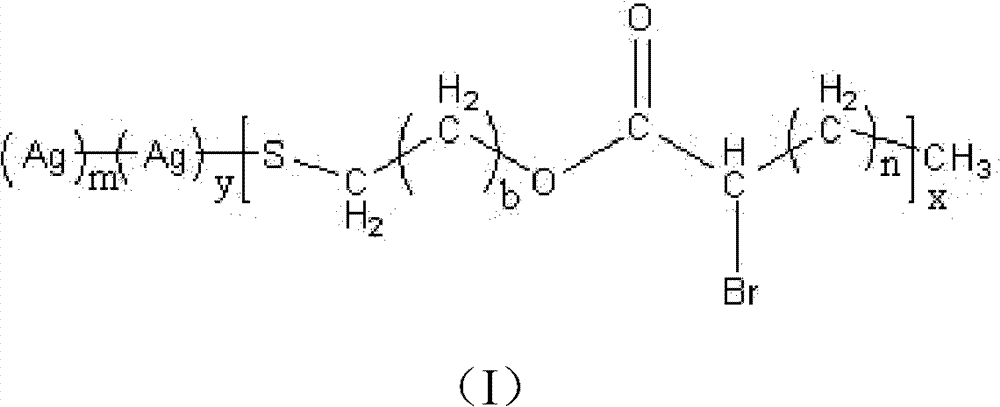

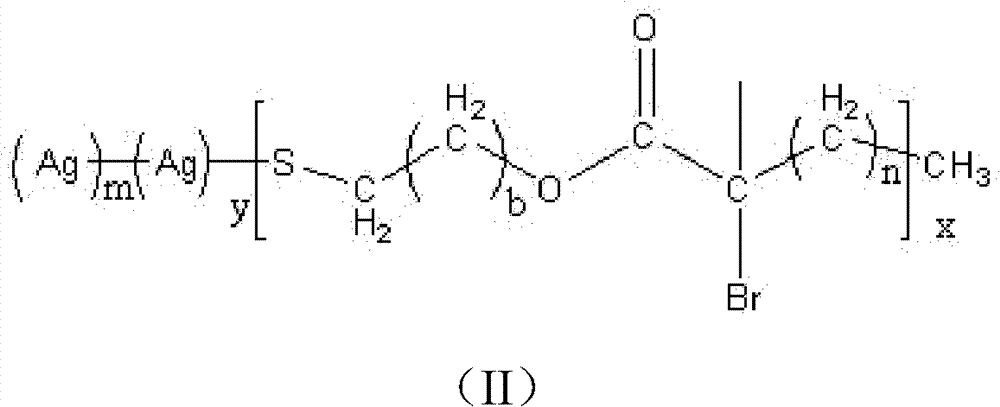

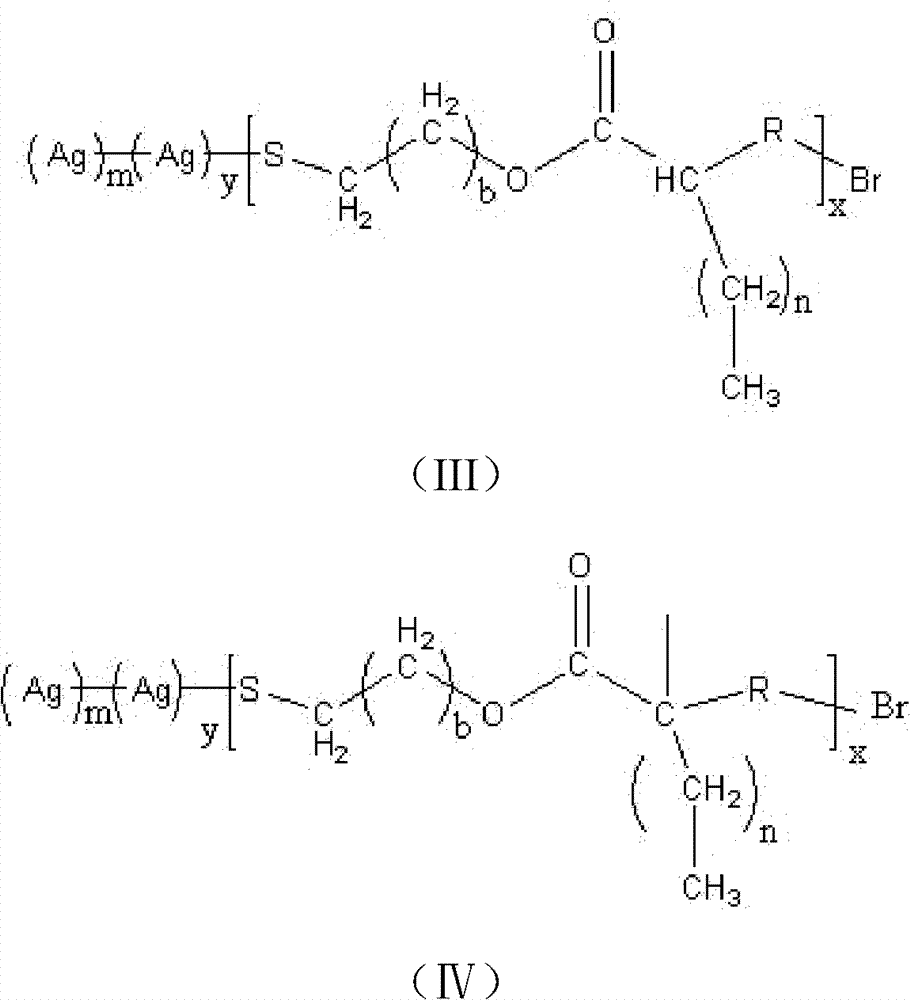

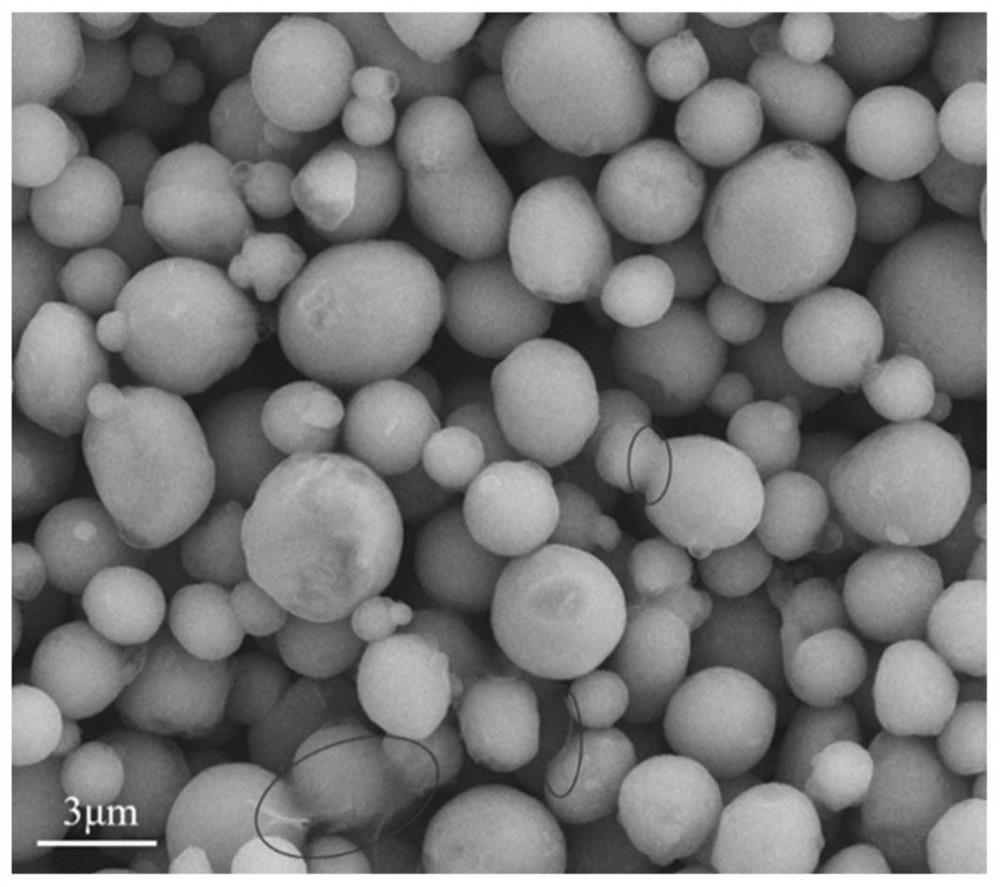

High-dispersion silver powder and solar battery electrode conductive silver paste

InactiveCN102139368ALow percolation valueReduce fill rateSemiconductor devicesSilver pasteElectrical battery

The invention discloses high-dispersion silver powder and solar battery electrode conductive silver paste, wherein the conductive silver paste is prepared from the following components in mass percentage: 53-61.8% of high-dispersion silver powder in claim 1, 21.5-31% of glass cement and 15-17.6% of organic carrier. The high-dispersion silver powder provided by the invention has very good dispersity and by means of the conductive silver paste prepared by the high-dispersion silver powder, the usage amount of the silver powder is reduced and the conductive efficiency is improved in the mean time; in addition, the conductive silver paste provided by the invention is clean and environmental-friendly and is suitable for popularization and application. By means of the high-dispersion silver powder and the solar battery electrode conductive silver paste which are provided by the invention, the defects of poor dispersity of the conventional silver powder and large usage amount of the silver powder of the conventional conductive silver paste are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

High-power LED (Light-Emitting Diode) heat dissipation ceramic substrate

The invention belongs to the technical field of ceramic substrates, and particularly relates to a high-power LED (Light-Emitting Diode) heat dissipation ceramic substrate. The ceramic substrate comprises the following materials in percentage by mass: 70-80 percent of alumina powder, 3-8 percent of melamine, 3-6 percent of hydroxymethyl cellulose, 6-10 percent of deionized water and 5-10 percent of composite sintering aid, wherein the composite sintering aid comprises the following materials in percentage by mass: 40-60 percent of silicon powder, 5-10 percent of aluminum powder, 20-30 percent of kaolin powder and 10-30 percent of calcium fluoride. The ceramic substrate has the advantages of high heat conductivity coefficient, excellent heat resistance, high bending strength and avoidance of the phenomena of bending, wrapping and the like. Through adoption of an appropriate sintering method and selection of an appropriate sintering aid, denseness of an alumina ceramic sintered body is realized, and the heat conductivity of alumina ceramics is increased greatly.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Method for producing pre-reducing composite sinter

The invention relates to a production method of pre-reductional composite sinter. The method mixes two kinds of charging high alkalinity sinter and acid pellet together and adds coal dust to the material for acid pellet. Then the uniform mixture of high alkalinity sinter and acid pellet is sintered in sintering machine to produce charging for pre-reduction blast furnace. The produced charging of the invention has higher grade and concise blast furnace operation.

Owner:ANGANG STEEL CO LTD

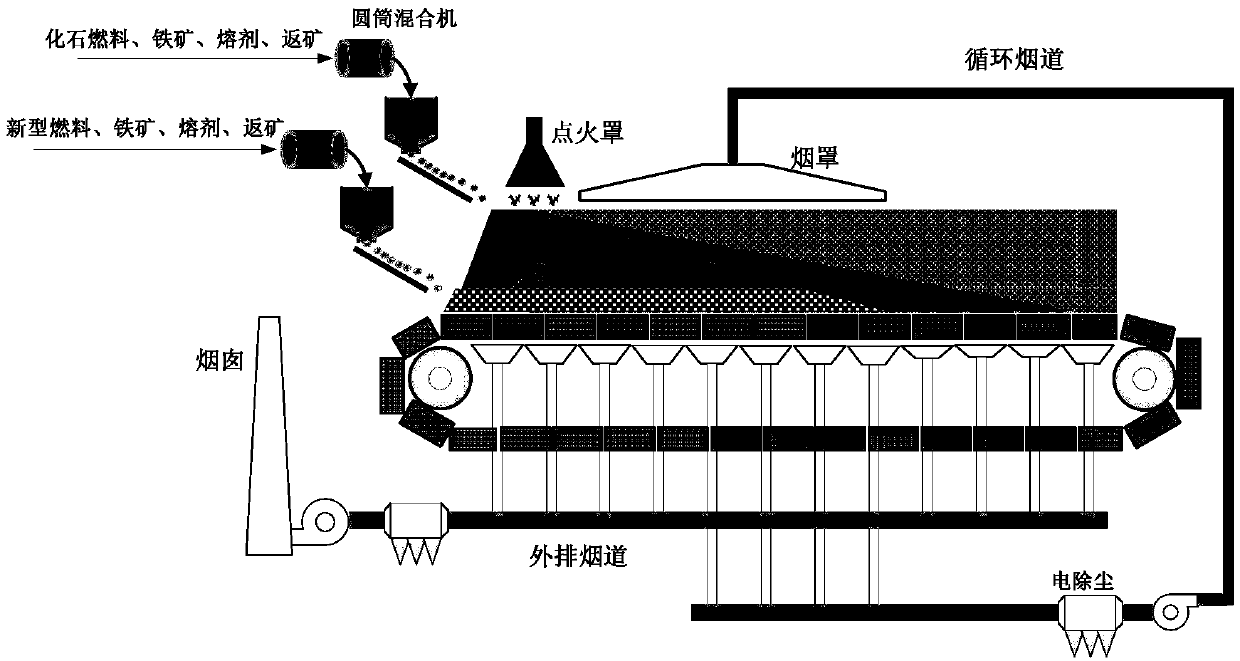

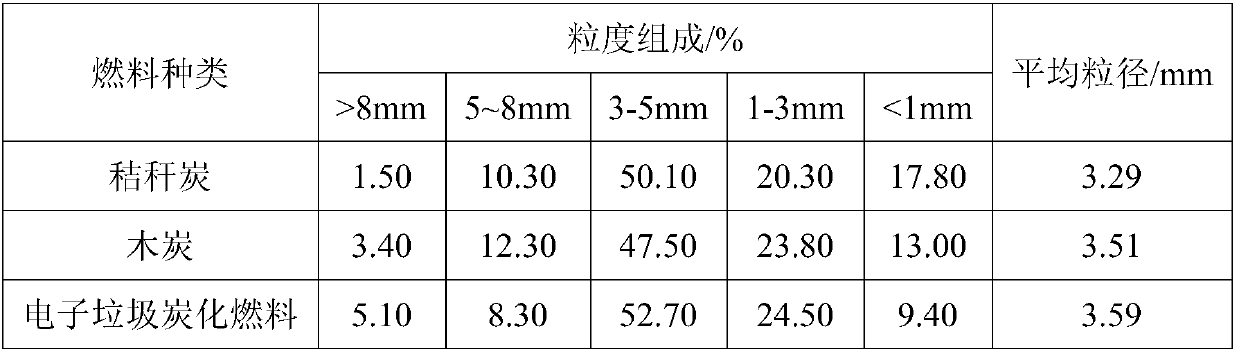

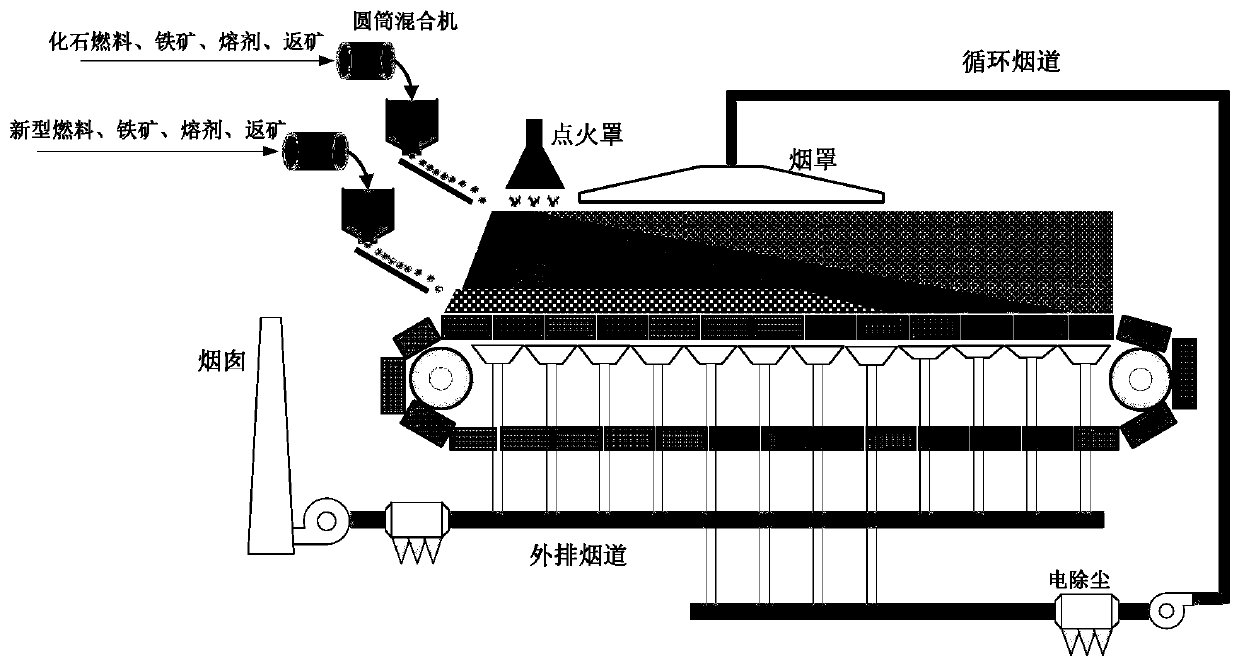

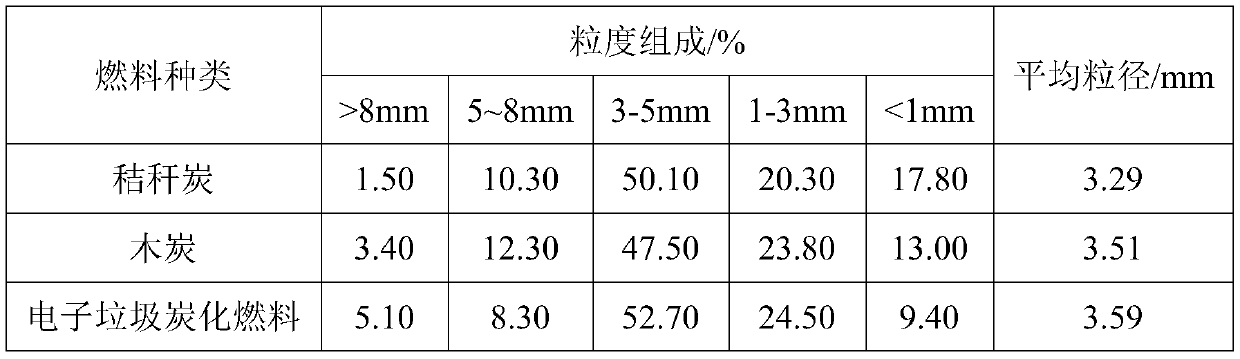

Low-carbon and low-NOx sintering method based on reasonable distribution of fuel

ActiveCN109628733AImprove less heat storageImprove the problem of insufficient heat supplyFlue gasNitrogen

The invention discloses a low-carbon and low-NOx sintering method based on reasonable distribution of fuel. According to the low-carbon and low-NOx sintering method based on reasonable distribution offuel, a lower fuel layer is mainly fed with new fuel which is high in burning speed, relatively low in heat value and low in nitrogen content, an upper fuel layer is fed with fossil fuel which is lowin burning speed and high in heat value, flue gas with high in CO content in an intermediate air bellow of a sintering machine is circulated to a sintered material surface at the same time, and latent heat of the flue gas is fully utilized for further supplementing heat to the upper fuel layer. According to the low-carbon and low-NOx sintering method based on reasonable distribution of fuel, thecharacteristics that the sintering speed changes from low to high from the upper fuel layer to the lower fuel layer, and heat storage changes from low to high, the difference between the burning speedof the new fuel and the fossil fuel, and the difference between the heat value of the new fuel and the fossil fuel are effectively coupled, the CO latent heat in the fuel gas is efficiently utilized,and at the same time of increasing sintering yield and improving quality indexes, solid fuel consumption of each ton of sinter is reduced by 2kgce to 4 kgce, CO emission is reduced by 30% to 50%, NOxemission is reduced by 40% to 60%, and low-carbon and low-NOx sintering is implemented.

Owner:CENT SOUTH UNIV

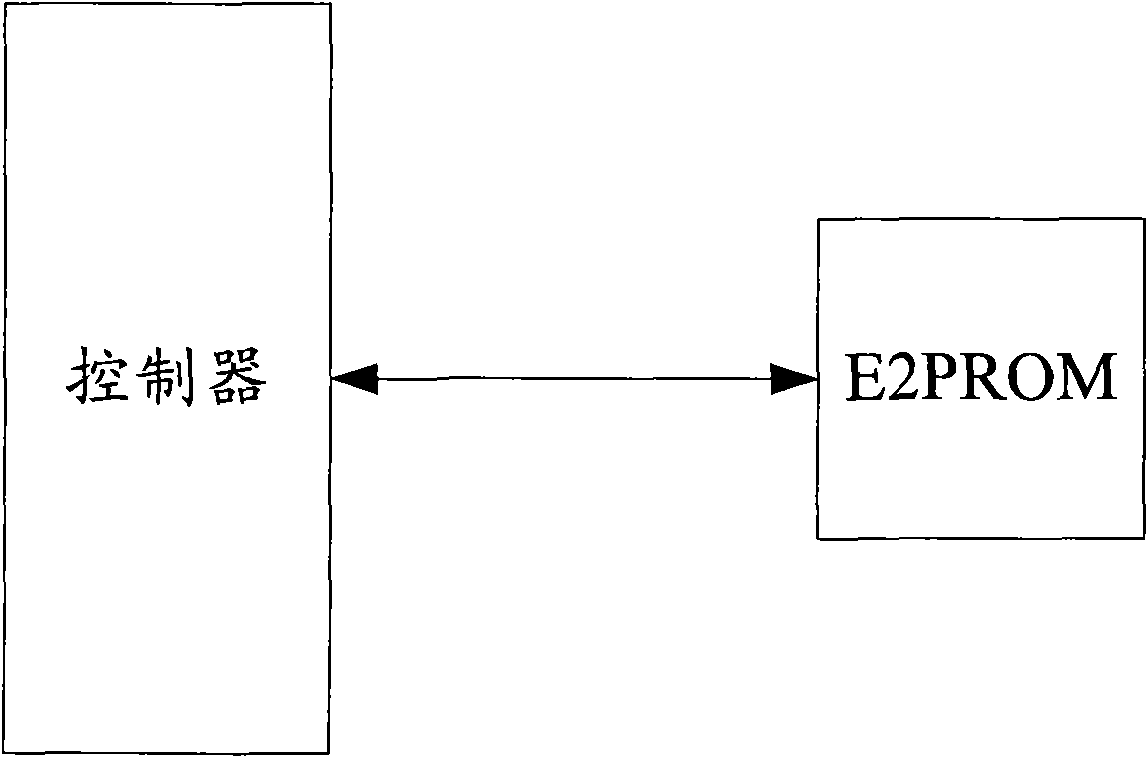

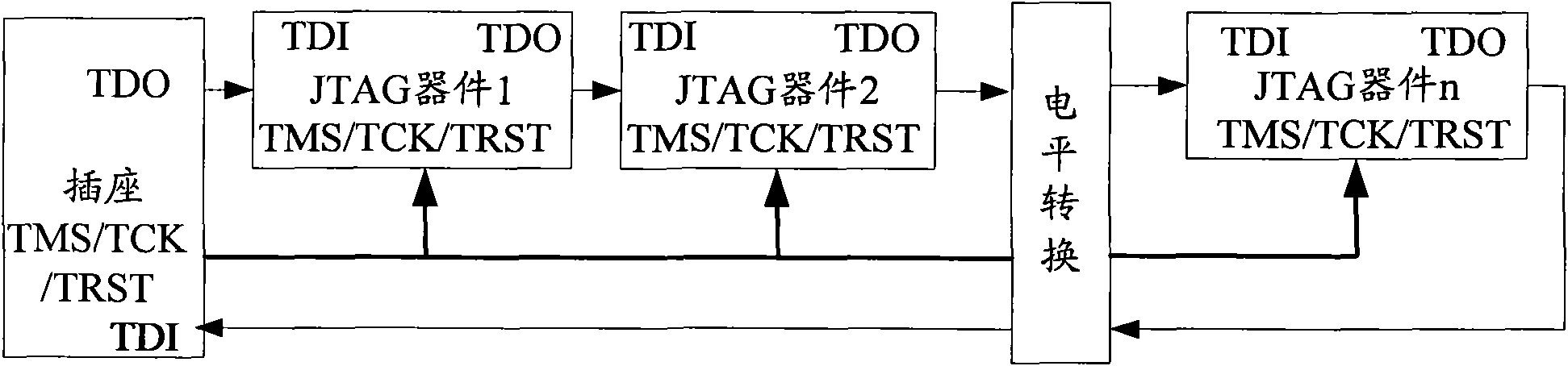

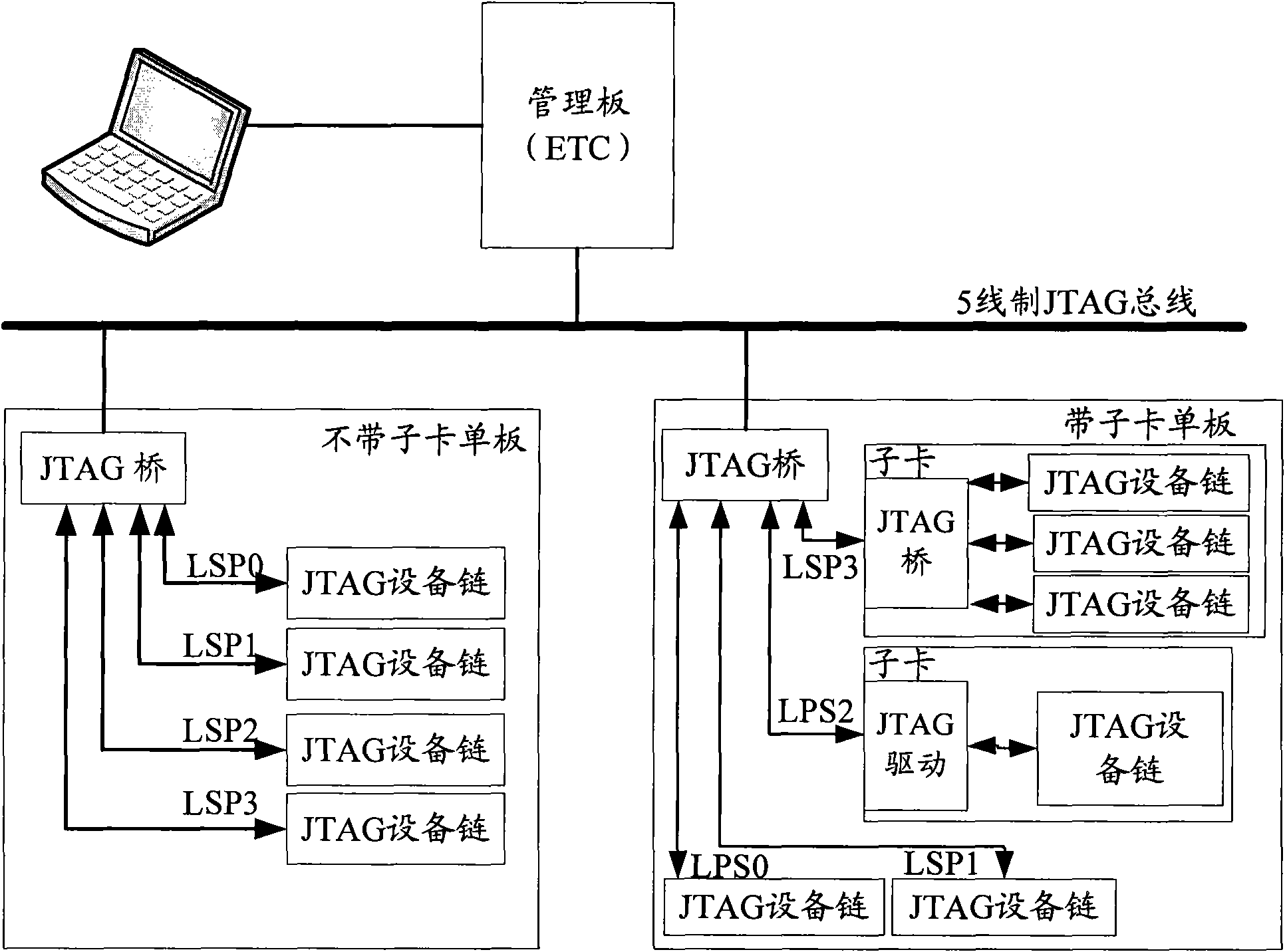

Agglomeration method and device of configurable firmware

InactiveCN101551769AOvercome the problem of high error rateReduce failureError detection/correctionProgram loading/initiatingSingle plateBoundary scan

The invention provides an agglomeration method and device configurable firmware, wherein the collocating method comprises: obtaining the subchain information to be agglomerated based on a single-plate identification ID by a controller ETC, wherein the subchain information at least comprises the corresponding connection relationship between a device pin and a configurable firmware; based on the subchain information, a boundary scanning unit BSC in the ETC control device pin simulating the interface time sequence of the configurable firmware and realizing the agglomeration of the configurable firmware based on the simulated interface time sequence. The agglomeration method and device can solve the problem that the error ratio is higher due to the single-plate configurable firmware solidified using a manual agglomeration tool, furthermore the error in the action of the system is reduced.

Owner:ZTE CORP

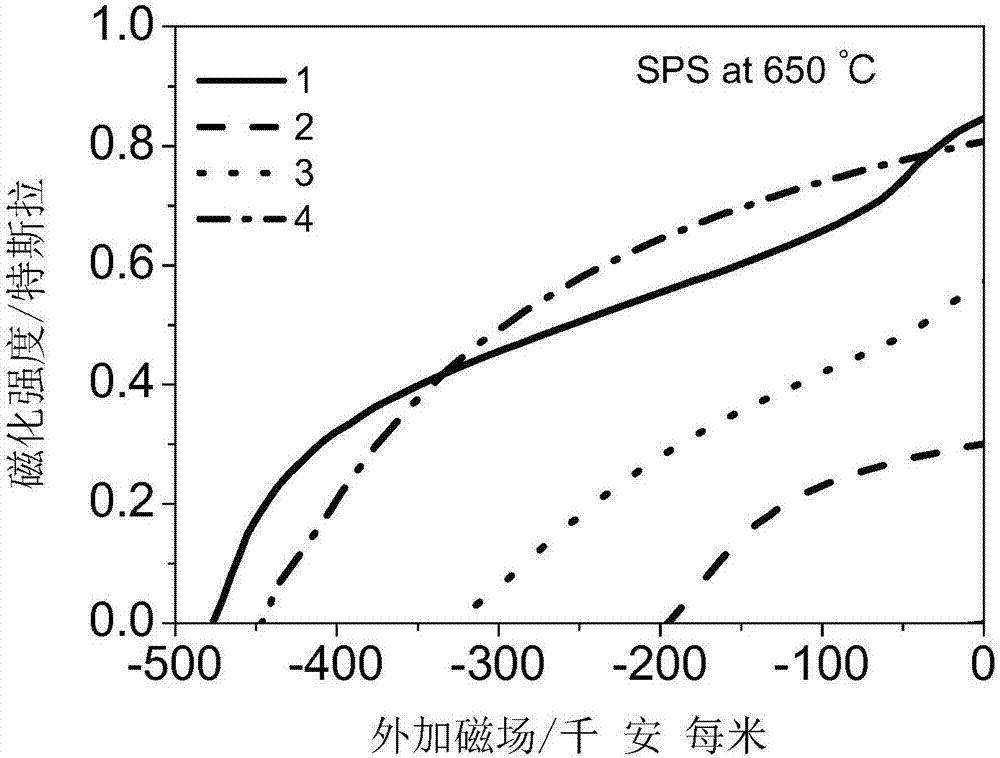

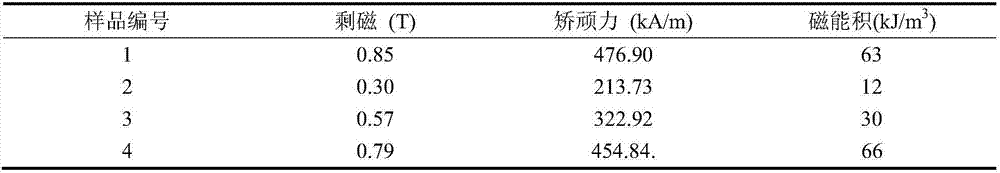

Dual-alloy nanocrystal rare earth permanent magnet and preparation method therefor

ActiveCN107424695ALow costReduce material costsInorganic material magnetismInductances/transformers/magnets manufactureSquare degreeThermal deformation

The invention discloses a dual-alloy nanocrystal rare earth permanent magnet and a preparation method therefor. The preparation method comprises the following steps of (1) preparing rapidly quenched ARE-Fe-B magnetic powder, wherein the content of ARE is greater than or equal to 12%, and ARE is selected from one or more than two kinds of mixed rare earths of La, Ce and Y; and preparing rapidly quenched PRE-Fe-B magnetic powder, wherein the content of Fe is greater than or equal to 82%, and PRE is rare earth Nd and / or Pr; and (2) performing mixing on the above-mentioned two kinds of magnetic powder, and carrying out discharge plasma sintering to obtain the isotropous nanocrystal rare earth permanent magnet. By taking the low-cost rare-earth-rich alloy and earth-earth-less iron-rich nanometer composite alloy as the raw materials of the magnetic powder, the material cost of the magnet is lowered; the sintering performance and the thermal deformation performance of the ally are improved; by virtue of the discharge plasma sintering technology, quite high fusion between the two kinds of magnetic powder with relatively high performance difference is realized, so that a magnetic hysteresis loop with single-alloy magnet characteristic is obtained; and in addition, by improving the square degree of the loop, the magnetic performance optimization is realized.

Owner:金磁海纳新材料科技(南通)有限公司

Nitride ceramic material microwave sintering method

The invention discloses a nitride ceramic material microwave sintering method. According to the invention, a nitride ceramic blank is placed between graphite plates, and microwave sintering is carried out under a protective atmosphere in a microwave sintering device. A microwave frequency value range is 2.45GHz, a microwave sintering temperature is 500-3000 DEG C, and a temperature maintaining time is 0-50h. The protective atmosphere is composed of nitrogen gas or argon gas or a mixed gas of nitrogen and hydrogen. The pressure is normal pressure. Different from traditional convection, conduction or radiation heating method, according to the invention, heat is produced through the coupling of a special band of microwave and the basic structure of the material. With the medium loss of the material, the material is heated with an integral heating manner. The method has the advantages of low sintering temperature, short temperature maintaining time, low energy consumption, and the like. The sintered material has good performances and considerable economic benefit.

Owner:HENGYANG KAIXIN SPECIAL MATERIAL TECH CO LTD

Aluminum nitride ceramic low-temperature sintering aid system

The present invention relates to an aluminum nitride ceramic low-temperature sintering aid system, which comprises a component A and a component B, wherein the component A is at least one selected from TiO2, ZrO2 and HfO2, and the component B is at least one selected from V2O5, Nb2O5 and Ta2O5. Compared to the scheme reported in the current literatures, the sintering aid scheme of the present invention has the following advantages that the densification process of the material can be achieved within the short time, the process is simple and reliable, and the high thermal conductivity can be obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

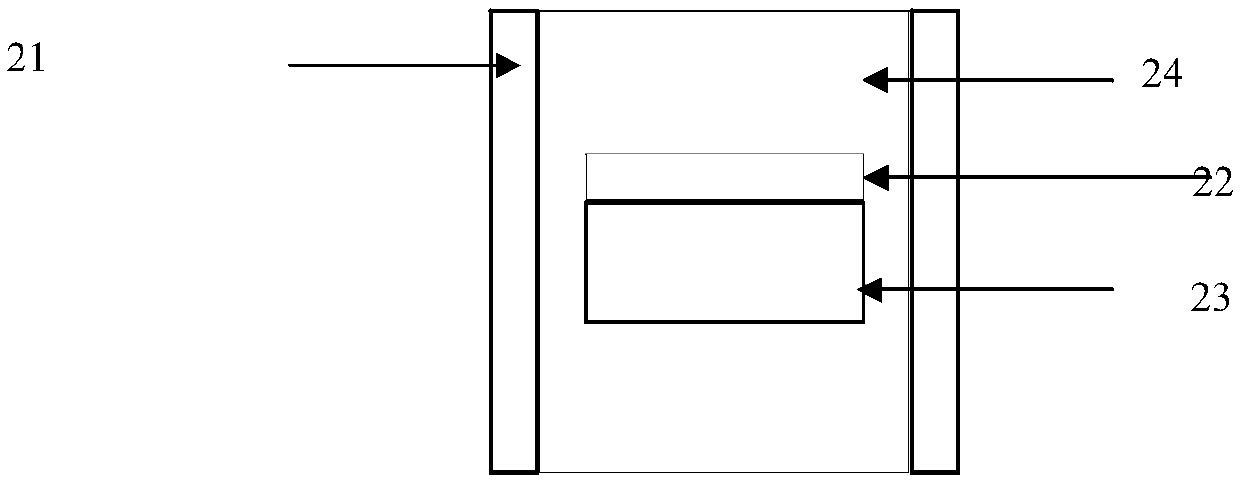

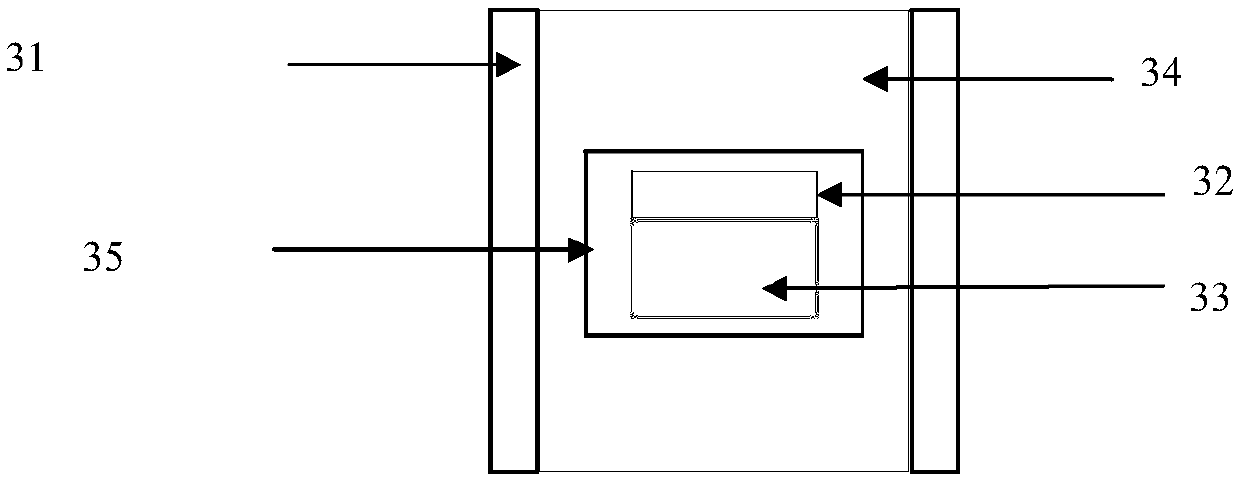

Growth type polycrystalline diamond sintered assembly and application thereof

InactiveCN104014281ASintered to achieveEasy to controlUltra-high pressure processesPolycrystalline diamondMetal binding

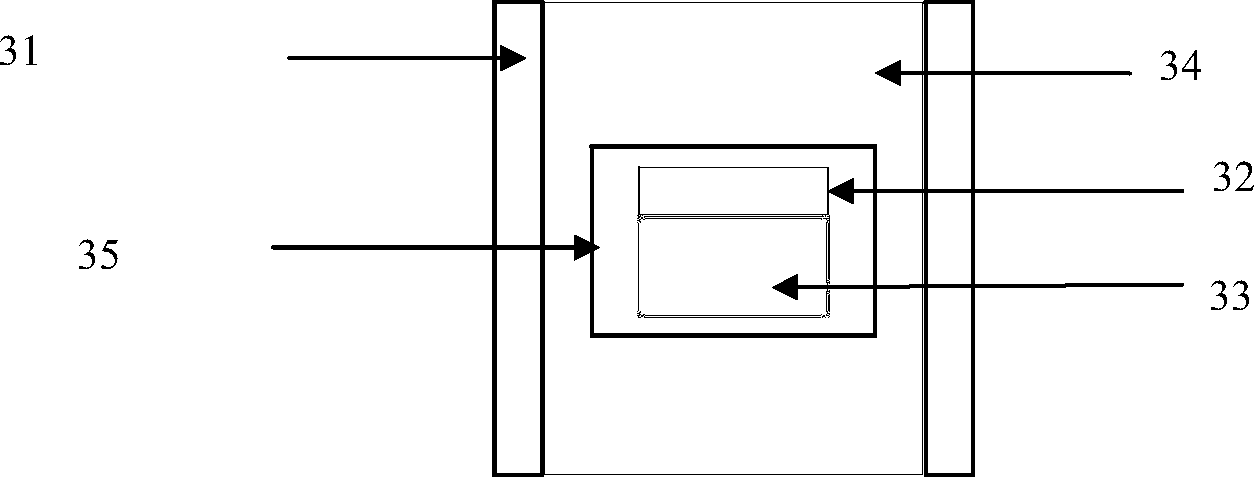

The invention provides a growth type polycrystalline diamond sintered assembly and an application thereof. The polycrystalline diamond sintered assembly comprises a heating pipe, an insulating pipe, a melt infiltration cavity, a metal binding agent and diamond powder, wherein the heating pipe is positioned on the outermost layer of the sintered assembly; the insulating pipe is positioned in the heating pipe and is clung to the heating pipe; a first hollow cavity is formed in the insulating pipe; the melt infiltration cavity is formed in the first hollow cavity, and a second hollow cavity is formed in the melt infiltration cavity; the second hollow cavity is filled with the metal binding agent and the diamond powder.

Owner:JILIN UNIV

Preparation process of ceramic base plate for high-power LED (light emitting diode) heat radiation

The invention belongs to the technical field of a ceramic base plate, and particularly relates to a preparation process of a ceramic base plate for high-power LED (light emitting diode) heat radiation. The preparation process comprises the following steps of 1, preparing composite sintering auxiliary agents; 2, preparing ceramic slurry; 3, forming ceramics. The preparation process has the following beneficial effects that 1, the heat conduction coefficient of the ceramic base plate is great, the heat-resistant performance is excellent; the bending-resistant intensity is high, and phenomena such as bending and tilting are avoided; 2, a proper sintering method is used, and the proper sintering auxiliary agents are selected, so that the compactness of alumina ceramic sintering bodies is realized, and the heat conductivity of the alumina ceramics is greatly improved; 3, low-melting point phases can be formed by the sintering auxiliary agents, the liquid-phase sintering can be realized, the sintering temperature is lowered, and the blank compactness is promoted; 4, melamine in a recipe can produce aluminum nitride and carbonitride at high temperature, and the hardness and the lustrousness of the surface of the ceramic base plate are improved.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

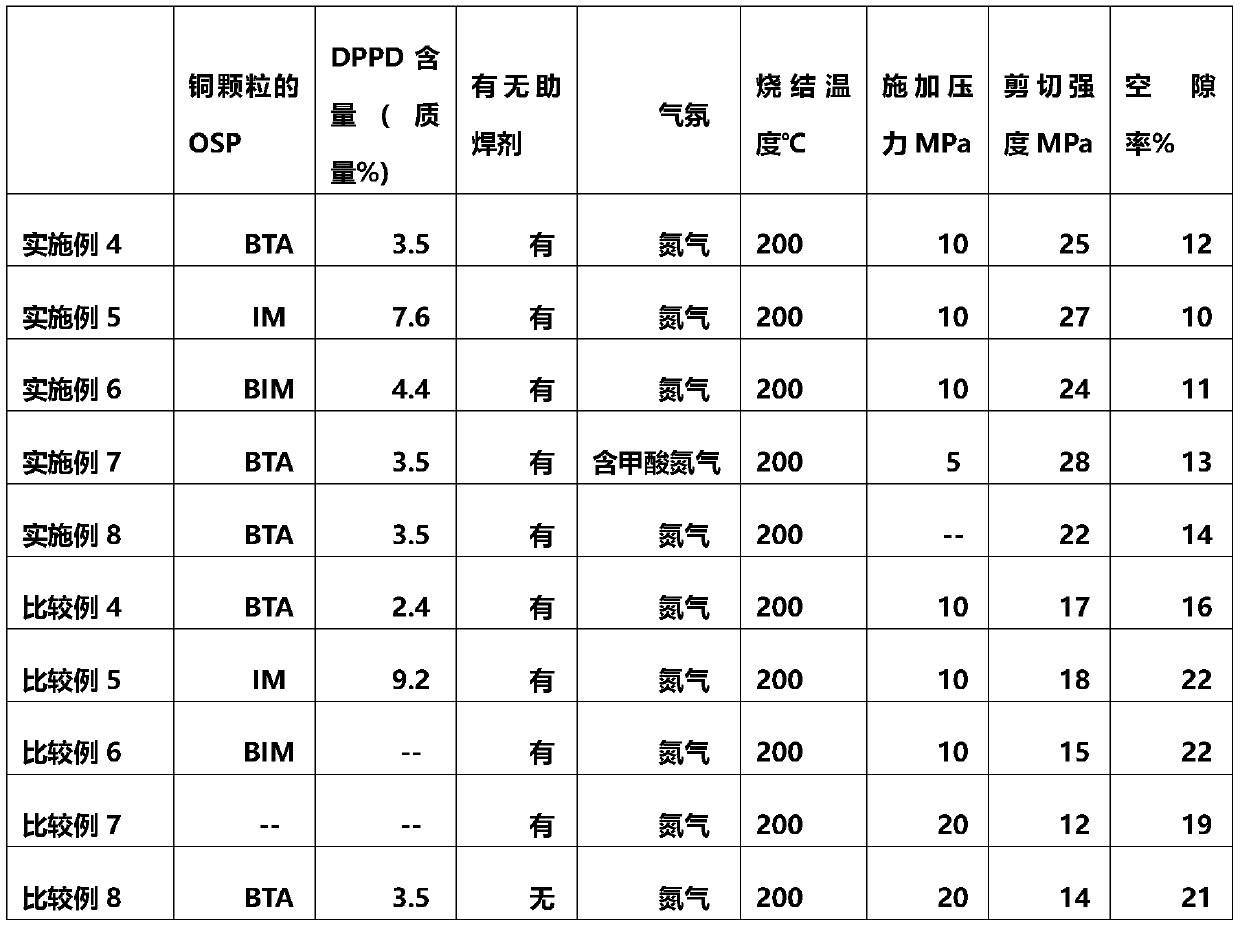

Copper particle with surface subjected to antioxidant protection, low-temperature sintered copper paste and sintering process using low-temperature sintered copper paste

ActiveCN110181041ASintered to achieveAchieve solidificationTransportation and packagingSemiconductor/solid-state device detailsBenzeneBenzotriazole

The invention relates to a copper particle with a surface subjected to antioxidant protection, a low-temperature sintered copper paste, and a sintering process using the low-temperature sintered copper paste. According to the copper particle with the surface subjected to antioxidant protection, the surface of the copper particle is modified by an organic solderable protective agent, wherein the organic solderable protective agent contains a certain proportion of diphenyl-p-phenylenediamine. The organic solderable protective agent may be at least one of benzotriazole, imidazole, and benzimidazole.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

High-dispersion silver powder and solar battery electrode conductive silver paste

InactiveCN102139368BLow percolation valueReduce fill rateSemiconductor devicesSilver pasteElectrical battery

The invention discloses high-dispersion silver powder and solar battery electrode conductive silver paste, wherein the conductive silver paste is prepared from the following components in mass percentage: 53-61.8% of high-dispersion silver powder in claim 1, 21.5-31% of glass cement and 15-17.6% of organic carrier. The high-dispersion silver powder provided by the invention has very good dispersity and by means of the conductive silver paste prepared by the high-dispersion silver powder, the usage amount of the silver powder is reduced and the conductive efficiency is improved in the mean time; in addition, the conductive silver paste provided by the invention is clean and environmental-friendly and is suitable for popularization and application. By means of the high-dispersion silver powder and the solar battery electrode conductive silver paste which are provided by the invention, the defects of poor dispersity of the conventional silver powder and large usage amount of the silver powder of the conventional conductive silver paste are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

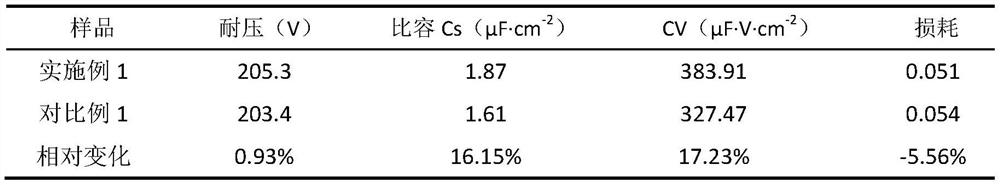

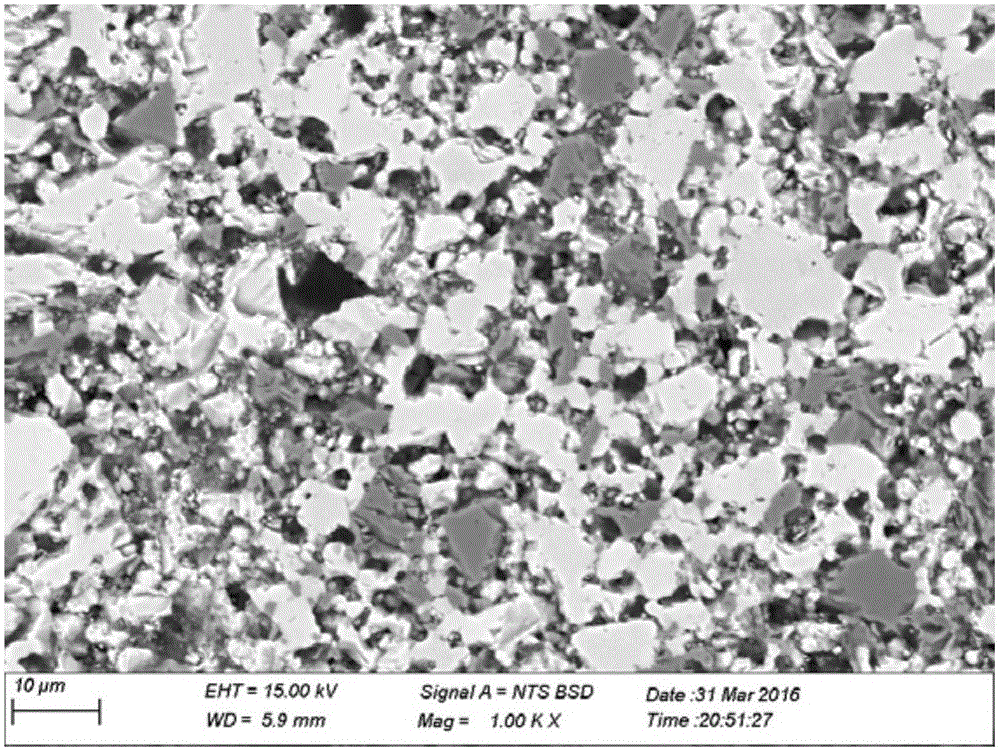

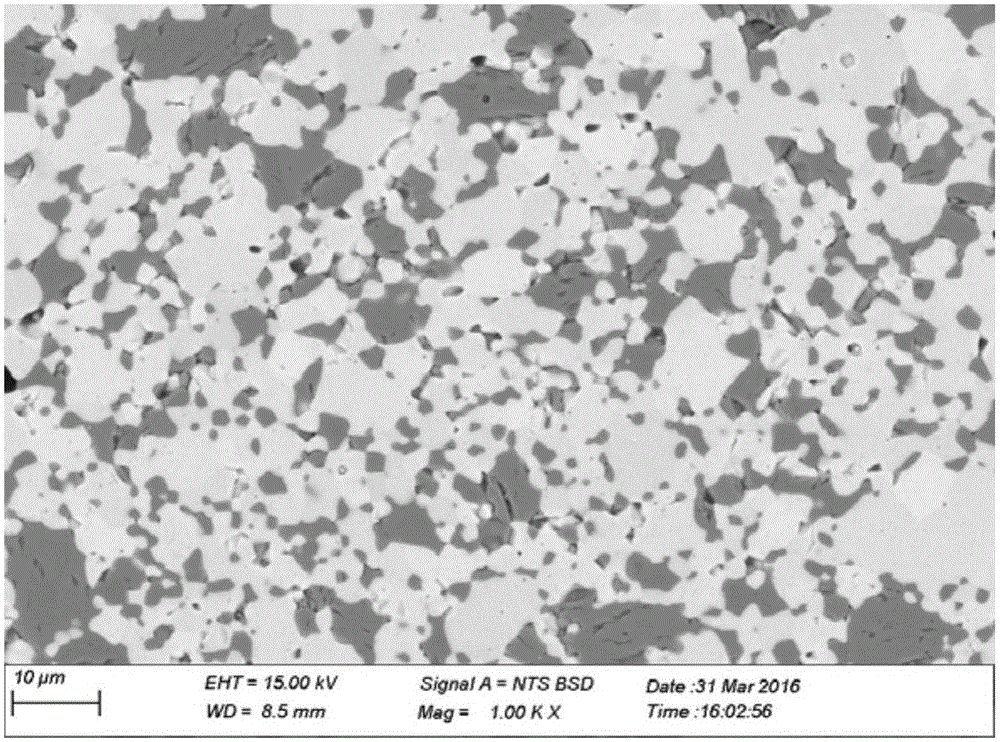

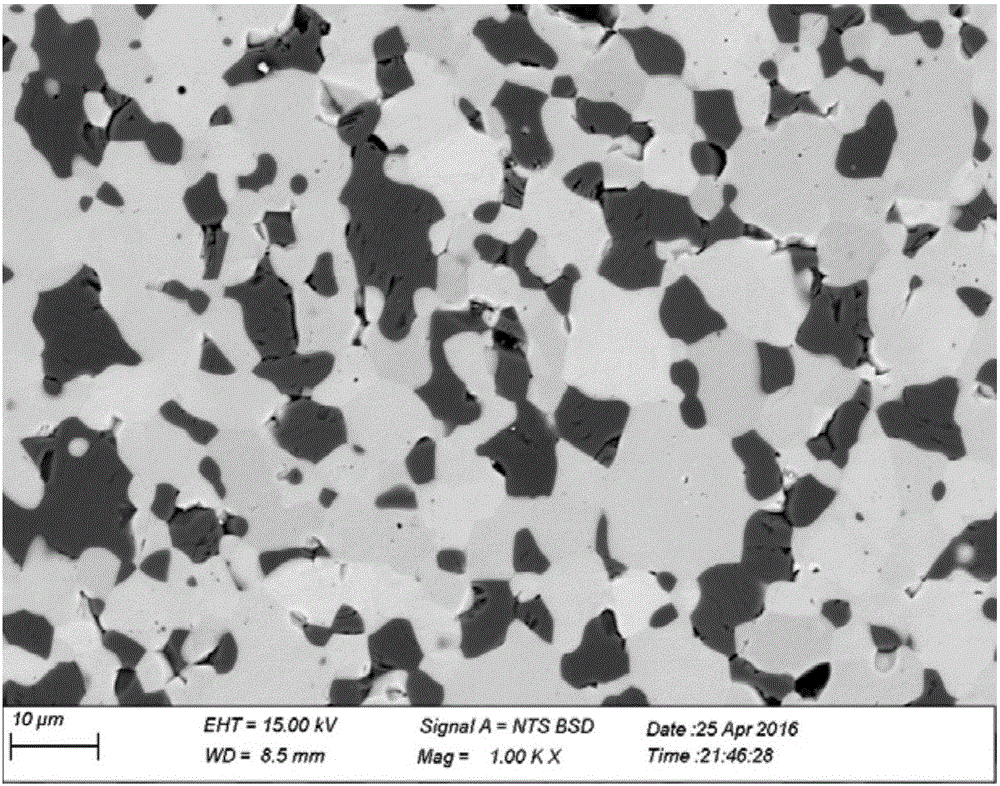

Graphene coated aluminum powder sintering type electrolytic capacitor anode foil and preparation method thereof

ActiveCN113593910AIncrease contactLarge specific surface areaElectrolytic capacitor manufactureAl powderElectrolysis

The invention discloses a preparation method of a graphene coated aluminum powder sintering type electrolytic capacitor anode foil, which comprises the following steps of uniformly mixing spherical aluminum powder, an adhesive and a solvent to form aluminum powder slurry, adding graphene or graphene dispersion liquid into the aluminum powder slurry to obtain mixed slurry, coating an aluminum foil with the mixed slurry to obtain an initial slurry-coated aluminum foil, sintering the initial slurry-coated aluminum foil in inert gas, and acquiring the graphene-coated aluminum powder sintering type porous electrode foil, and performing anodic oxidation treatment on the graphene-coated aluminum powder sintering type porous electrode foil to obtain the graphene-coated aluminum powder sintering type electrolytic capacitor anode foil. The aluminum powder is subjected to graphene coating treatment, graphene serving as a two-dimensional material has the characteristic of ultrahigh specific surface area, contact between the aluminum powder is facilitated by adding the graphene in the sintering process, so that the sintering performance is improved, and the graphene / Al2O3 composite structure has a high dielectric constant.

Owner:XI AN JIAOTONG UNIV

Method for preparing eutectic composite LaB6-VB2 through spark plasma sintering technology

The invention discloses a method for preparing LaB by spark plasma sintering technology. 6 -VB 2 The method for eutectic composite material is characterized in that: first according to the mass percentage of eutectic phase diagram, LaB 6 Powder and VB 2 The powder is mixed evenly by high-energy ball milling, then pre-pressed, and finally sintered in a spark plasma sintering furnace to obtain LaB 6 -VB 2 Eutectic composites. LaB prepared by spark plasma sintering technology in the present invention 6 -VB 2 The eutectic composite material has a high density of 97%.

Owner:HEFEI UNIV OF TECH

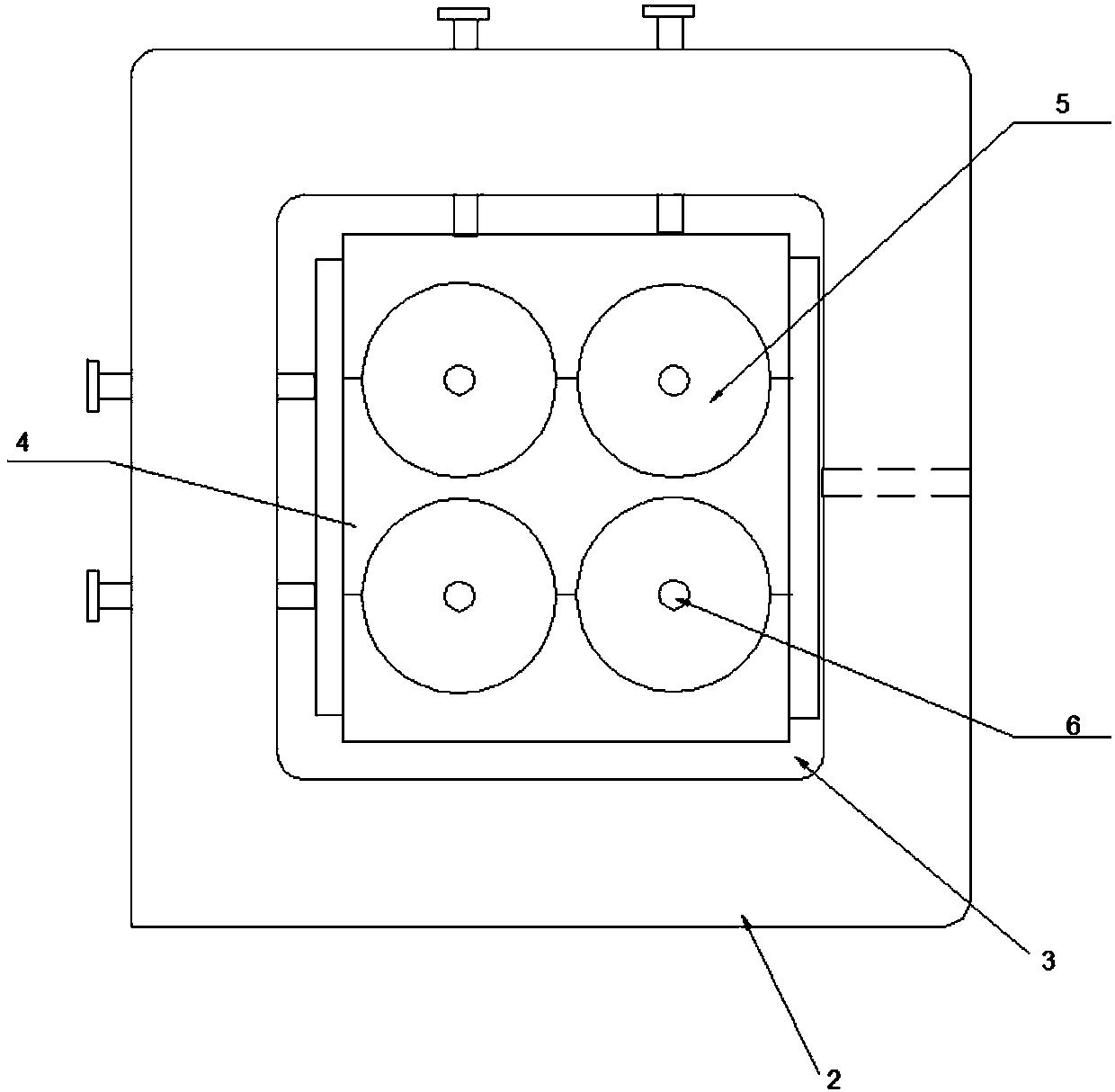

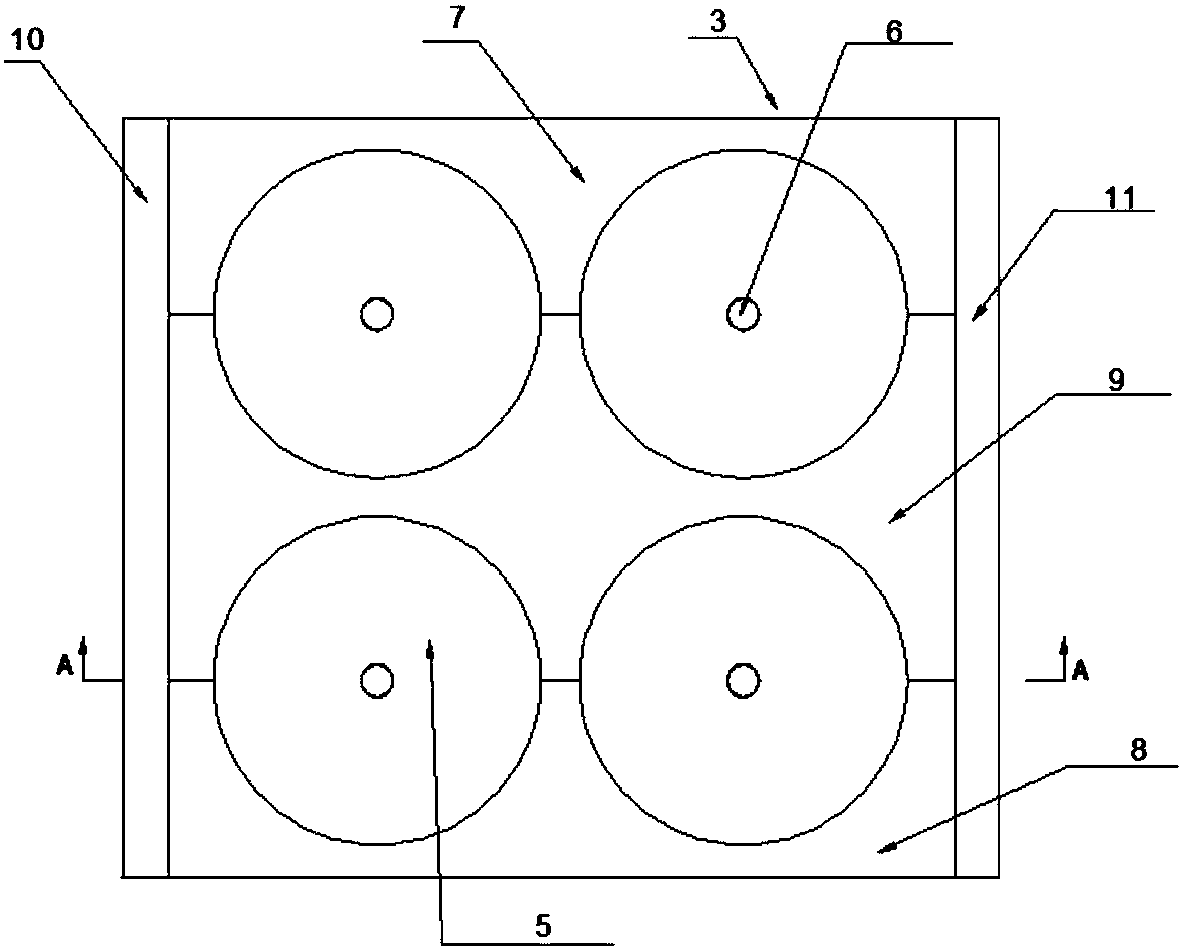

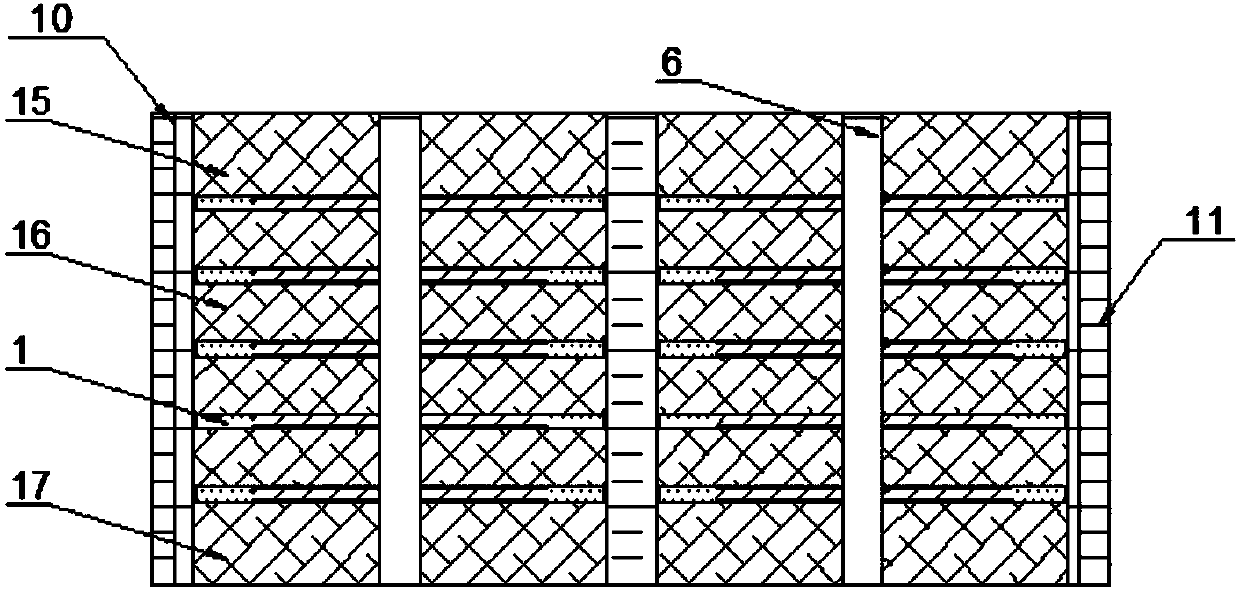

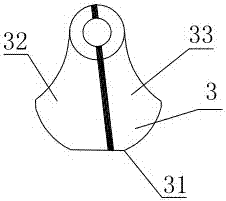

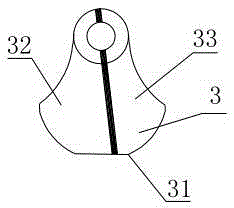

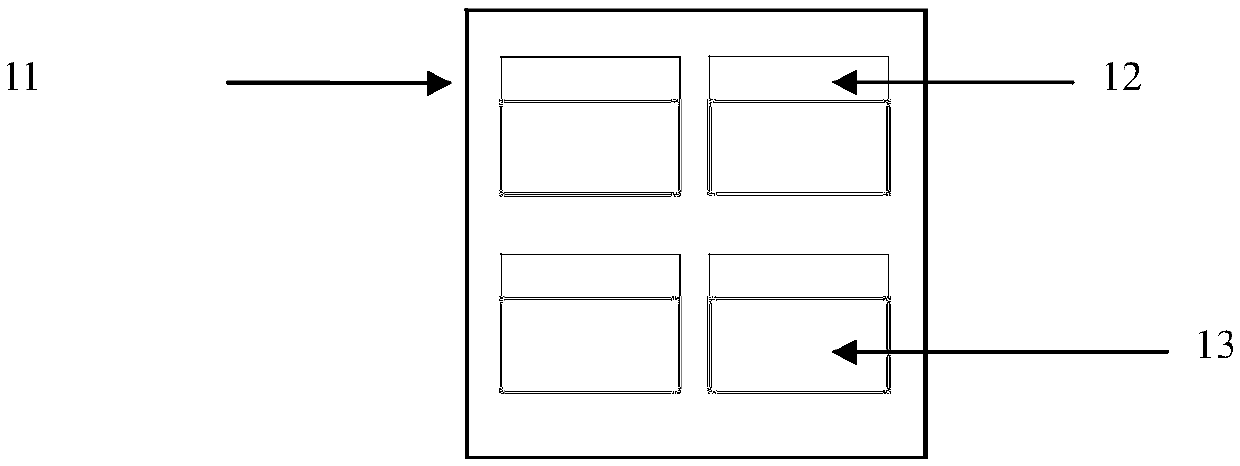

Hot-pressing mold for small-sized engraving saw blades

PendingCN108097960AQuality improvementAvoid interactionTurbinesOther manufacturing equipments/toolsStone carvingGraphite

The invention discloses a hot-pressing mold for small-sized carving saw blades. The hot-pressing die comprises the carving saw blades, a mold frame assembly and a hot-pressing mold assembly used in cooperation with the mold frame assembly; and the hot-pressing mold assembly comprises a baffle plate assembly, separation plate assemblies and center rods, wherein the baffle plate assembly is made ofa high-strength graphite material, and the separation plate assemblies and the center rods are used in cooperation with the baffle plate assembly. According to the hot-pressing mold, the mold frame assembly with the carving saw blades and made of the high-strength graphite material, the hot-pressing mold assemblies and the center rods are assembled together, and are put into a vacuum hot-pressingsintering machine to be subjected hot-pressing sintering so that high-pressure sintering of the stone carving saw blades can be realized, and therefore single sintering time is shortened, the production speed is increased, and the product quality is improved.

Owner:河南涵信金刚石工具有限公司

Method for synthesis of binary metal composite oxide by microwave sintering

InactiveCN104402059AReduce the temperatureSintered to achieveZirconium compoundsChemical industryBrickMicrowave sintering

A method for synthesis of a binary metal composite oxide by microwave sintering relates to a method for synthesis of the metal oxides, the method is as follows: internal heating of the reaction system is performed by use of the properties that activated carbon mixed in a reactant can absorb microwave, and high temperature solid state reaction can be completed at relatively lower temperature and in shorter time. The method is suitable for the realization of microwave sintering reaction between a non-microwave-absorption metal oxide and a weak-microwave-absorption metal oxide. A proper amount of activated carbon is added into a mixture of the non-microwave-absorption metal oxide and the weak-microwave-absorption metal oxide which are weighed in stoichiometric ratio, the activated carbon, the non-microwave-absorption metal oxide and the weak-microwave-absorption metal oxide are fully mixed, and the mixture is pressed into a cylinder to be burned. The cylinder to be burned is put into a heat insulating support made of magnesium oxide refractory bricks, then sent into a microwave oven for sintering to obtain a sintered product. The sintered product is thermally treated in air and dipped and washed by hot water, and then is dried to obtain the target complex oxide. The method is applicable to all kinds of metal oxides with thermal stability, and is energy-saving, and relatively mild in conditions.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

A kind of bulletproof ceramic sheet and preparation method thereof

ActiveCN104329988BPromote sinteringEnhanced interface bindingPersonal protection gearMulliteLamellar structure

The invention relates to a bulletproof ceramic chip and a preparation method thereof, wherein the first layer, the third layer and the fifth layer of the bulletproof ceramic chip are prepared from the following components: 82-99% of Al2O3 + 9-0.5% of Y2O3 + 9-0.5% of MgO in terms of mass percent; the second layer and the fourth layer of the bulletproof ceramic chip are prepared from the following components: 70-95% of SiC + 5-30% of Si in terms of mass percent; a thickness ratio of an Al2O3 layer to an SiC layer of the sintered bulletproof ceramic chip with a composite sandwich structure is 10-20:1; the bulletproof ceramic chip can be used as a hard bulletproof material for a human body and an armor. According to the preparation method, an oxidation product SiO2 of Si is used for wrapping the surface of SiC micro powder, so that the oxidization of the SiC micro powder is prevented, and the bulletproof ceramic chip with a layer structure is obtained; SiO2 is reacted with Al2O3, so that a mullite phase is formed, the effective combination between the Al2O3 layer and an SiC+Si layer is promoted, and therefore the ceramic chip transfers energy in the process of suffering from impacts.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP

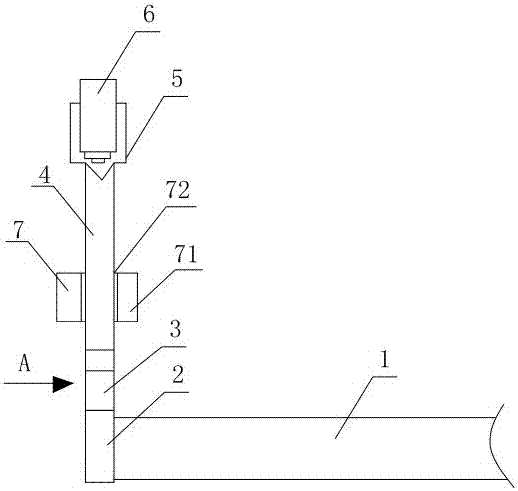

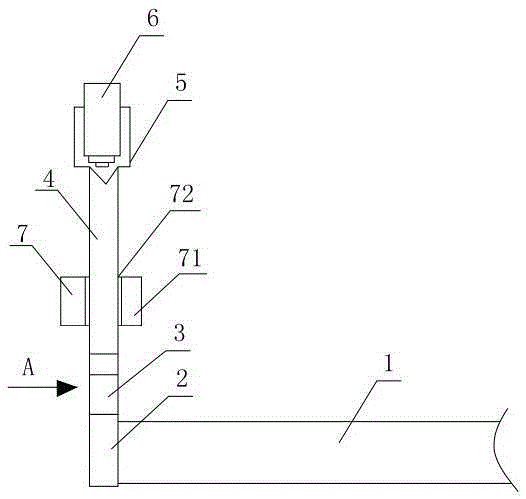

Bottom sintering automatic device for glass bottle making machine

ActiveCN105293876BIncreasing the thicknessSintered to achieveGlass reforming apparatusGlass productionSteering wheelDrive shaft

The invention discloses an automatic device for sintering the bottom of a glass bottle making machine, which comprises a cam, a vertical shaft and a clamping device sequentially connected to the steering wheel of the main drive shaft, the cam and the steering wheel engage and rotate, and the vertical shaft is fixed on the clamping device And it cooperates with the cam to move up and down, the glass bottle to be processed is placed in the clamping device; the surface of the cam in contact with the steering wheel includes at least one flat section, and the flat section corresponds to the sintering position of the glass bottle. The glass bottle bottom automatic sintering device of the present invention is provided with at least one plane section on the cam, so that when the cam rotates to the sintering position, it can stay for a rotating plane section, thereby achieving the purpose of increasing the time for sintering the bottom of the bottle and realizing the bottom of the bottle. The increase in thickness finally achieves the enhancement of its freezing resistance, reduces its product rate and manufacturing cost, and improves its quality and service life.

Owner:双峰格雷斯海姆医药玻璃(丹阳)有限公司

A method of low temperature inkjet printing nano metal pattern

ActiveCN106274110BGuaranteed uniformityImprove uniformityDuplicating/marking methodsInksMetal particleEngineering

The invention is suitable for the field of printing electronics, and provides a method for low-temperature ink-jet printing of a nano-metal pattern. The method comprises the following steps: carrying out ink-jet printing on a substrate by using ink under a negative pressure condition to obtain an ink-jet printed pattern, wherein the ink includes a main body solvent A and a Marangoni initiation solvent B; placing the ink-jet printed pattern in vacuum environment, and carrying out primary drying treatment, wherein the pressure P2 of the vacuum environment and the saturated vapor pressure PB of the Marangoni initiation solvent B meet a formula of P2 - PB >= 1000 Pa; adjusting the relative vacuum degree to -0.08 ~ -0.1 MPa, and carrying out secondary drying treatment, wherein the temperature T2 of the vacuum drying treatment is smaller than the sintering temperature Ts of nano-metal particles in the ink; sintering the vacuum-dried ink-jet printed pattern in vacuum environment; and annealing the sintered ink-jet printed pattern in the vacuum environment.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Ceramic dielectric material matched with nickel inner electrode and production method of capacitor produced by ceramic dielectric material

ActiveCN101786864BSolve the problem of co-firingResistantFixed capacitor dielectricStacked capacitorsDielectricCeramic capacitor

A high-frequency and low-dielectric-constant ceramic dielectric material matched with nicket internal electrode and a method for producing capacitor using same. The ceramic dielectric material consists of main crystalline phase, modifying additive and sintering flux. The main crystalline phase is MgZrxSi(1−x)O3, wherein 0.05≰x≰0.15. The modifying additive is one or more of MnO2, Al2O3, CaO, Bi2O3 and TiO2, and the sintering flux is one or more of B2O3, SiO2, ZnO, Li2O, K2O and BaO. The ceramic dielectric material has good uniformity, and excellent dielectric properties, meets the requirements of COG characteristics in EIA standard, and meets the environmental requirements. The ceramic dielectric material can be sintered under the reducing atmosphere and can be matched with nickel electrodes. The chip multilayer ceramic capacitor made of the ceramic dielectric material and nickel internal electrodes has stable performance.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

A low-carbon and low-nox sintering method based on reasonable fuel distribution

The invention discloses a low-carbon and low-NOx sintering method based on reasonable distribution of fuel. According to the low-carbon and low-NOx sintering method based on reasonable distribution offuel, a lower fuel layer is mainly fed with new fuel which is high in burning speed, relatively low in heat value and low in nitrogen content, an upper fuel layer is fed with fossil fuel which is lowin burning speed and high in heat value, flue gas with high in CO content in an intermediate air bellow of a sintering machine is circulated to a sintered material surface at the same time, and latent heat of the flue gas is fully utilized for further supplementing heat to the upper fuel layer. According to the low-carbon and low-NOx sintering method based on reasonable distribution of fuel, thecharacteristics that the sintering speed changes from low to high from the upper fuel layer to the lower fuel layer, and heat storage changes from low to high, the difference between the burning speedof the new fuel and the fossil fuel, and the difference between the heat value of the new fuel and the fossil fuel are effectively coupled, the CO latent heat in the fuel gas is efficiently utilized,and at the same time of increasing sintering yield and improving quality indexes, solid fuel consumption of each ton of sinter is reduced by 2kgce to 4 kgce, CO emission is reduced by 30% to 50%, NOxemission is reduced by 40% to 60%, and low-carbon and low-NOx sintering is implemented.

Owner:CENT SOUTH UNIV

Automatic bottle bottom sintering device of glass bottle making machine

ActiveCN105293876AIncreasing the thicknessSintered to achieveGlass reforming apparatusGlass productionSteering wheelDrive shaft

The invention discloses an automatic bottle bottom sintering device of a glass bottle making machine. The automatic bottle bottom sintering device comprises a cam, a vertical shaft and a clamping device which are successively arranged on and connected with a steering wheel of a main transmission shaft, wherein the cam and the steering wheel rotate in an engaged way, the vertical shaft is fixed on the clamping device and cooperated with the cam to realize up-and-down movement, and a to-be-processed glass bottle is placed in the clamping device. The surface where the cam contacts with the steering wheel comprises at least one plane section which corresponds to a sintering position of the glass bottle. According to the invention, at least one plane section is arranged on the cam of the automatic glass bottle bottom sintering device, so the cam can retain for a time period of rotation of the plane section when the cam rotates to the sintering position; thus, time for sintering of bottle bottom is prolonged, the thickness of the bottle bottom is increased, refrigeration resistance of the glass bottle is eventually enhanced, the defective rate and manufacturing cost of the glass bottle are reduced, and the quality and service life of the glass bottle are improved.

Owner:双峰格雷斯海姆医药玻璃(丹阳)有限公司

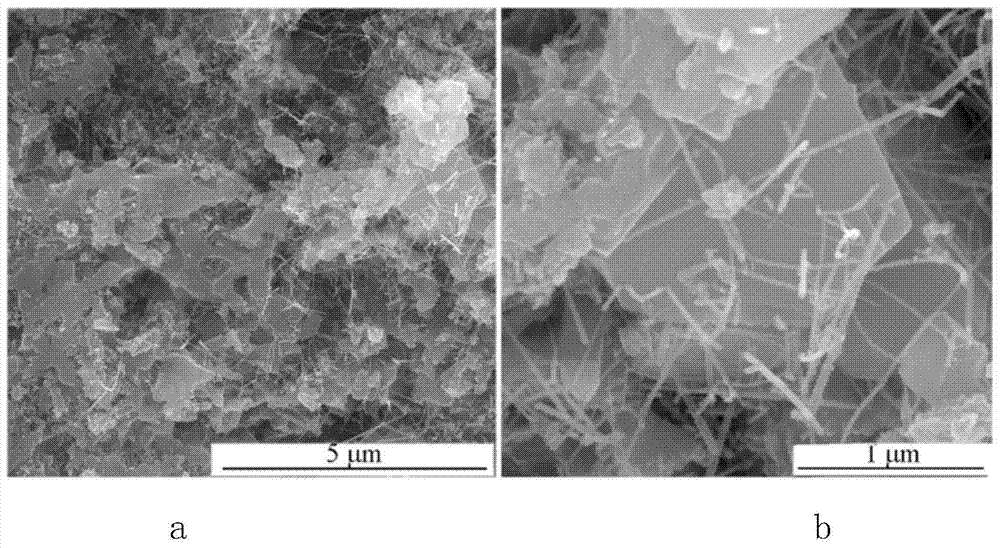

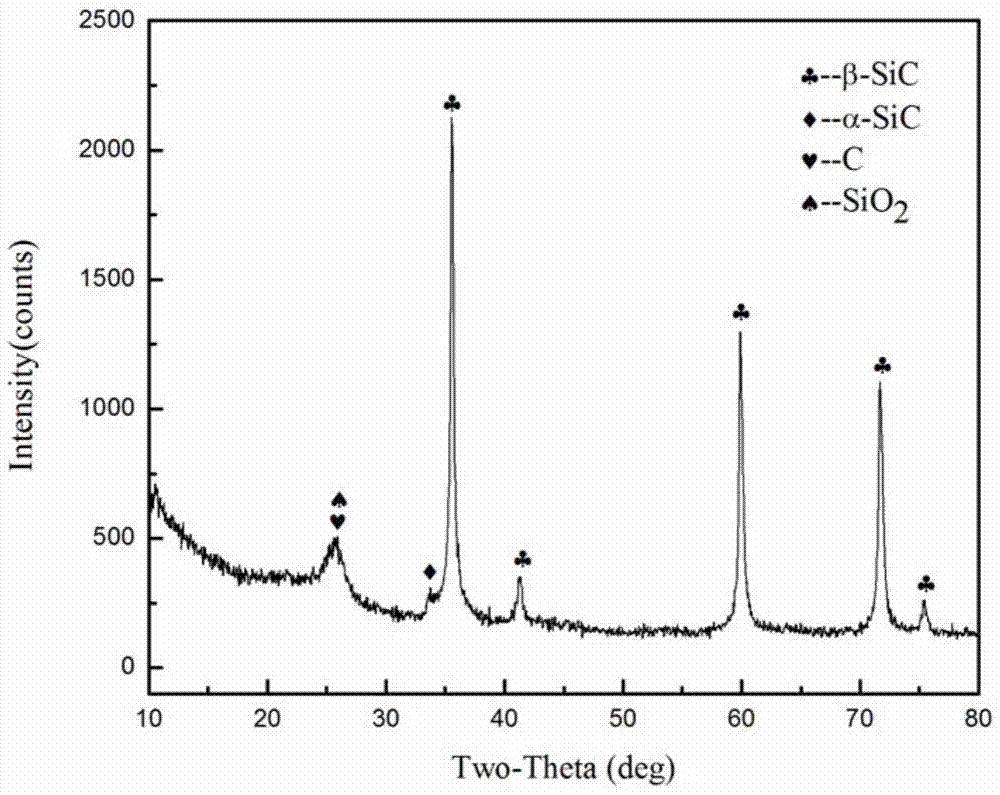

Method for preparing porous silicon carbide ceramics by reaction sintering and micro-oxidation treatment

The invention discloses a method for preparing porous silicon carbide ceramics by reaction sintering and micro-oxidation treatment. First, a certain amount of mesocarbon microspheres and silicon powder are wet ball-milled to obtain mixed powder, and then dry-pressed at room temperature to prepare a green body. , and finally sintered at high temperature under micro-oxidation treatment to obtain porous silicon carbide ceramics. Under the micro-oxidation treatment, a large number of silicon carbide whiskers were generated in situ; at the same time, SiO 2 The glassy phase promotes sintering and forms sintering necks between SiC particles. The invention has simple operation and high production efficiency, and the porous silicon carbide ceramic prepared by the method has uniform pore size distribution and high bending strength, and the strength reaches 176 MPa when the porosity is 32%.

Owner:江西源瓷科技有限公司

A kind of high temperature resistant special ceramics containing cerium oxide and its preparation method

The invention discloses a high-temperature-resistant special ceramic for a sparking nozzle of an oil-fired machine and a preparation method thereof. The special ceramic is composed of the following raw materials in parts by weight: 30-40 parts of andalusite, 22-28 parts of volcanic rock, 10-15 parts of diatomite, 15-25 parts of aluminium oxide, 3-6 parts of tantalum carbide, 2-4 parts of cerous sulfide, 6-12 parts of titanium oxide, 5-10 parts of magnesium oxide, 4-8 parts of zirconium oxide, 3-5 parts of polyvinylpyrrolidone, 2.5-4.5 parts of sodium hydroxypropyl oxidized starch succinate, 4-6 parts of sorbitan trioleate, 3-5 parts of coconut oil monoethanolamide, 2-4 parts of dispersing agent NNO, and proper amount of deionized water. A bowl mill is employed for preparing an ultrafine powder, addition of proper amount of titanium oxide and magnesium oxide helps to reduce the sintering temperature of a blank and save energy, and addition of proper amount of tantalum carbide and cerous sulfide helps to reduce the possibility of the ceramic nozzle being oxidized in a high-temperature environment. experiment measuring results show that the ceramic nozzle is resistant to a high temperature up to 2500 DEG C and has the density larger than 4.0 g / cm<3>, and the nozzle has the service life larger than 10000 h.

Owner:铜陵市华冉科技服务有限公司

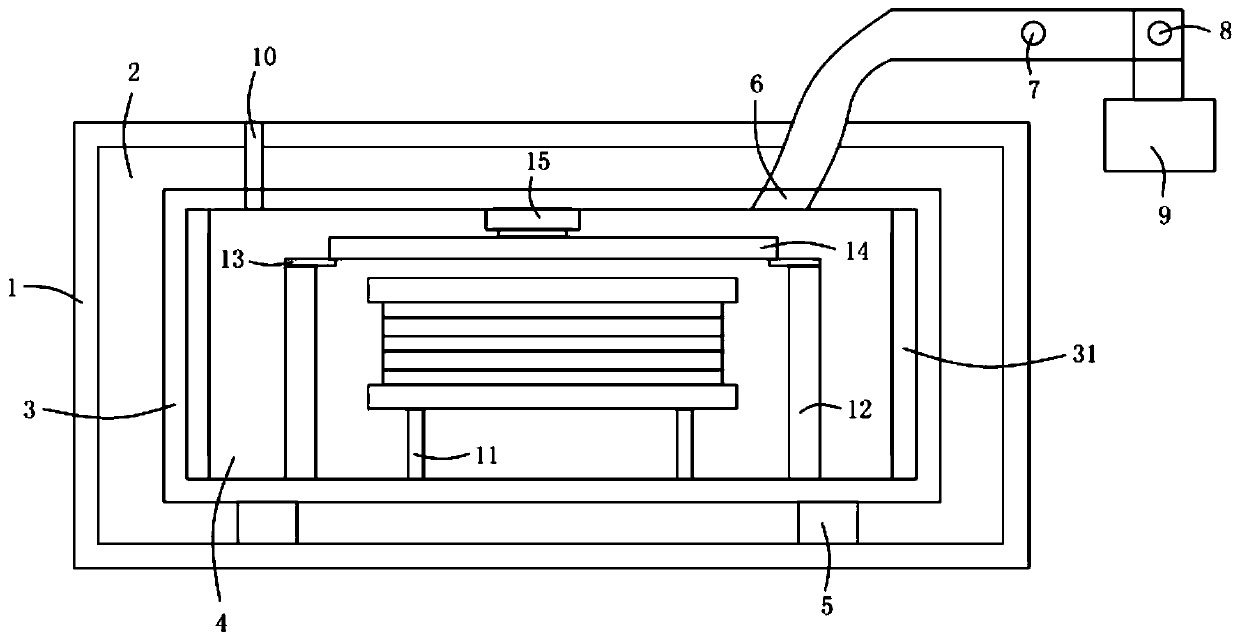

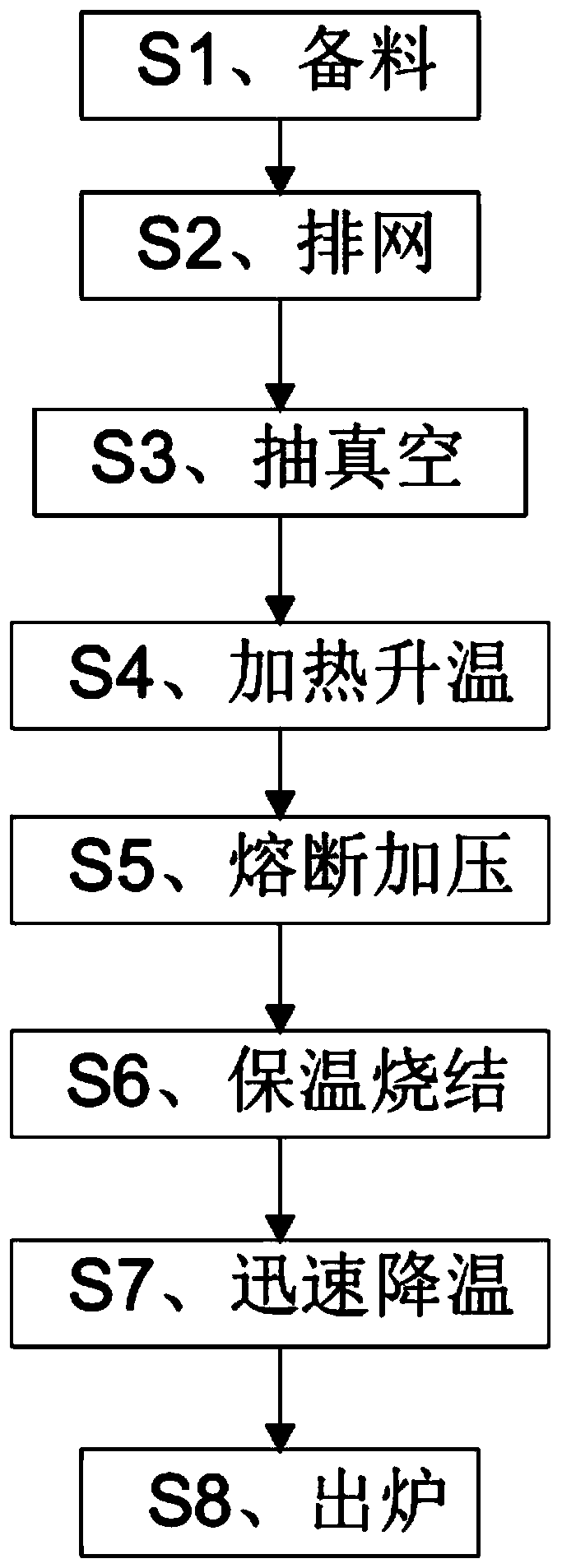

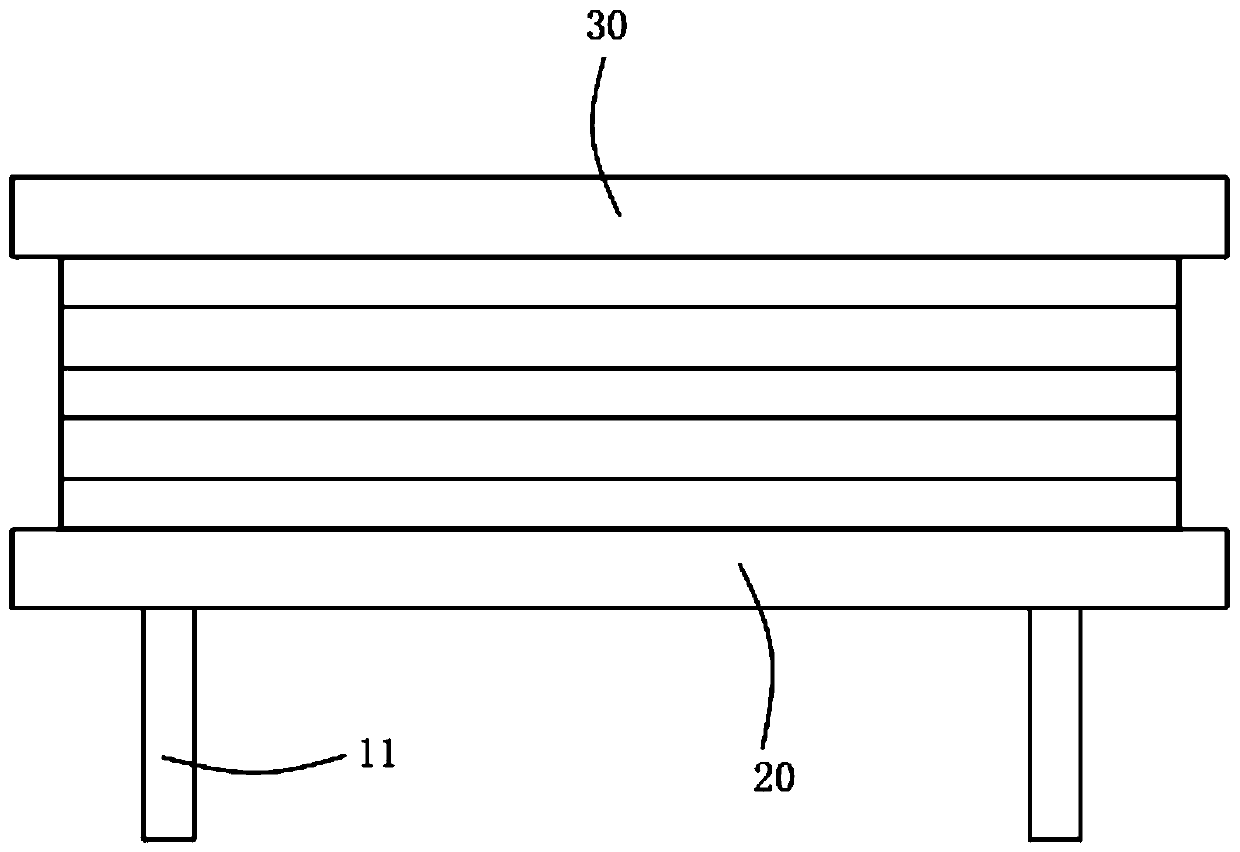

A wire mesh sintering furnace and a method of using the furnace for wire mesh sintering

ActiveCN108469175BSintered to achieveAvoid settingMuffle furnacesRetort furnacesMaterials preparationVacuum pumping

The invention discloses a screen mesh sintering furnace. The screen mesh sintering furnace comprises a furnace body. The furnace body comprises an outer furnace wall and an inner furnace wall. One endof an installation rod is connected with a gray cast iron fast-melting rod. The gray cast iron fast-melting rod is made of low-melting-point gray cast iron. The low-melting-point gray cast iron comprises, by mass, 4.0% to 4.5% of carbon, 2.0% to 2.8% of silicon, 1.5% to 2.0% of manganese, 0.5% to 1.3% of sulfur, and the balance pure iron. The invention further discloses a method for using the screen mesh sintering furnace to carry out screen mesh sintering. The method comprises the following steps of first, material preparation; second, screen arrangement; third, vacuum pumping; fourth, temperature rising by heating; fifth, fusing pressurization; sixth, heat preservation sintering; seventh, quick temperature lowering; and eighth, discharging from the furnace. With the screen mesh sintering furnace, sintering of screen meshes is implemented better, a hydraulic ejector rod is omitted, and no sealing treatment is needed. With the screen mesh sintering method, the temperature of heating sintering is effectively lowered, the sintering time can be effectively shortened, and a better screen mesh sintering effect can be achieved.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

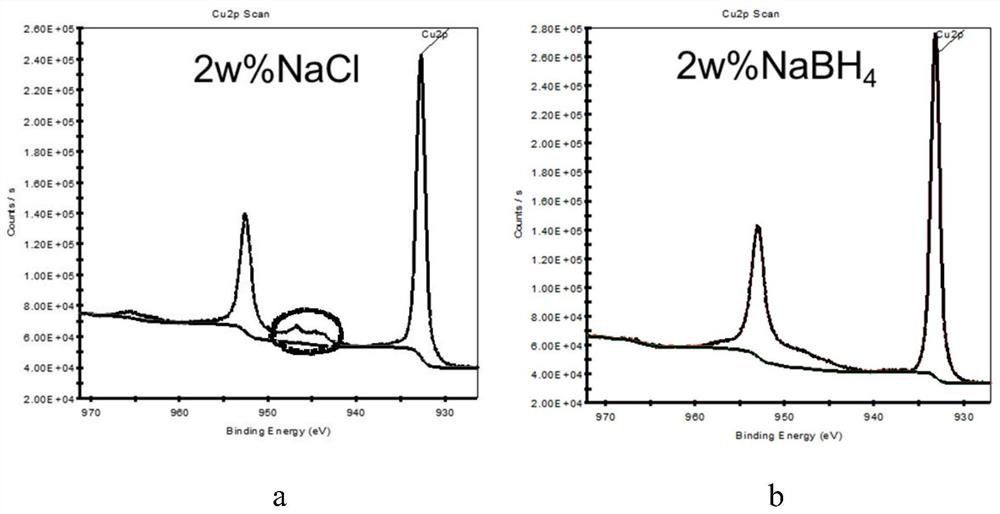

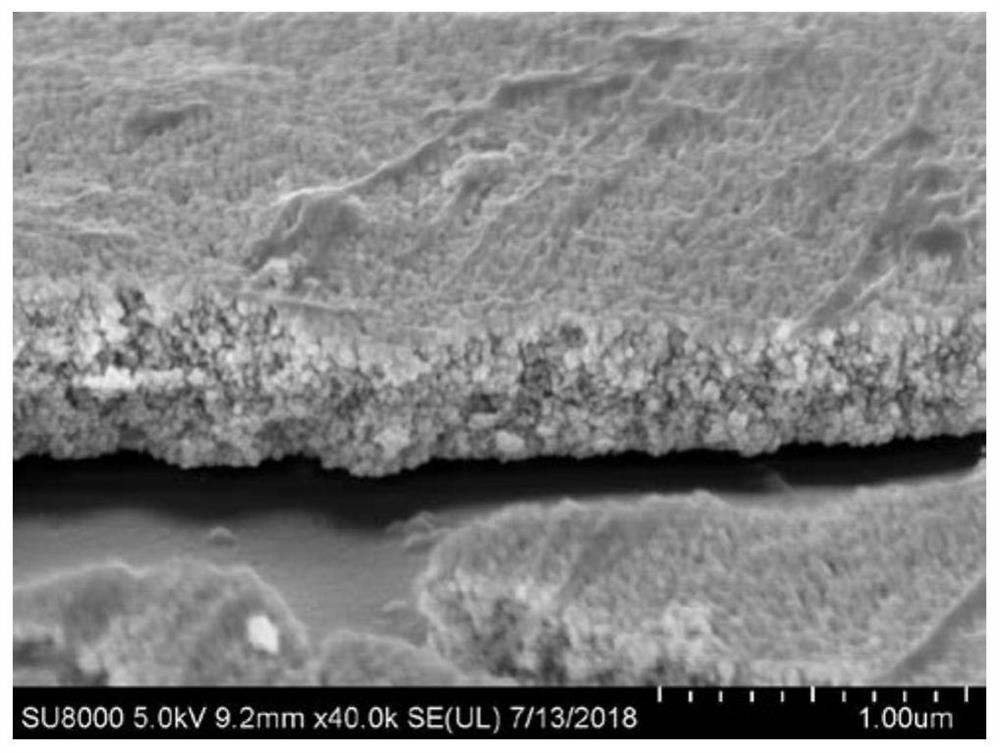

A kind of room temperature sintering method of nano-silver clad copper conductive ink

The invention discloses a room temperature sintering method of nano silver-coated copper conductive ink, belonging to the field of conductive ink. The method comprises the following steps: a, printingink on a flexible film substrate with a printer, a film coating machine, or the like or coating a flexible film substrate with ink with a printer, a film coating machine, or the like; b, soaking thefilm of the step a in 0-50 v% of an alcohol amine solution for 0-1h, and then conducting washing for 2-4 times with a hydrophilic solvent, and conducting wiping to be dry; c, repeating the steps a andb for repeat printing or coating to achieve the required print layer thickness; and d, soaking the film of the step c in 0-40w% of a reducing agent solution for 0-30 min, then conducting washing withwater for 2-4 times, and conducting wiping to be dry. The metal thin layer prepared by the chemical sintering method has low resistivity, the sintering of the nanometer copper-coated silver ink in room temperature air is realized, and the method can be used for various heat-sensitive and flexible substrates.

Owner:TSINGHUA UNIV

A growth type polycrystalline diamond sintered component and its application

InactiveCN104014281BSintered to achieveEasy to controlUltra-high pressure processesPolycrystalline diamondMetal binding

The invention provides a growth type polycrystalline diamond sintered assembly and an application thereof. The polycrystalline diamond sintered assembly comprises a heating pipe, an insulating pipe, a melt infiltration cavity, a metal binding agent and diamond powder, wherein the heating pipe is positioned on the outermost layer of the sintered assembly; the insulating pipe is positioned in the heating pipe and is clung to the heating pipe; a first hollow cavity is formed in the insulating pipe; the melt infiltration cavity is formed in the first hollow cavity, and a second hollow cavity is formed in the melt infiltration cavity; the second hollow cavity is filled with the metal binding agent and the diamond powder.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com