Patents

Literature

352 results about "Zirconium diboride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium diboride (ZrB₂) is a highly covalent refractory ceramic material with a hexagonal crystal structure. ZrB₂ is an ultra high temperature ceramic (UHTC) with a melting point of 3246 °C. This along with its relatively low density of ~6.09 g/cm³ (measured density may be higher due to hafnium impurities) and good high temperature strength makes it a candidate for high temperature aerospace applications such as hypersonic flight or rocket propulsion systems. It is an unusual ceramic, having relatively high thermal and electrical conductivities, properties it shares with isostructural titanium diboride and hafnium diboride.

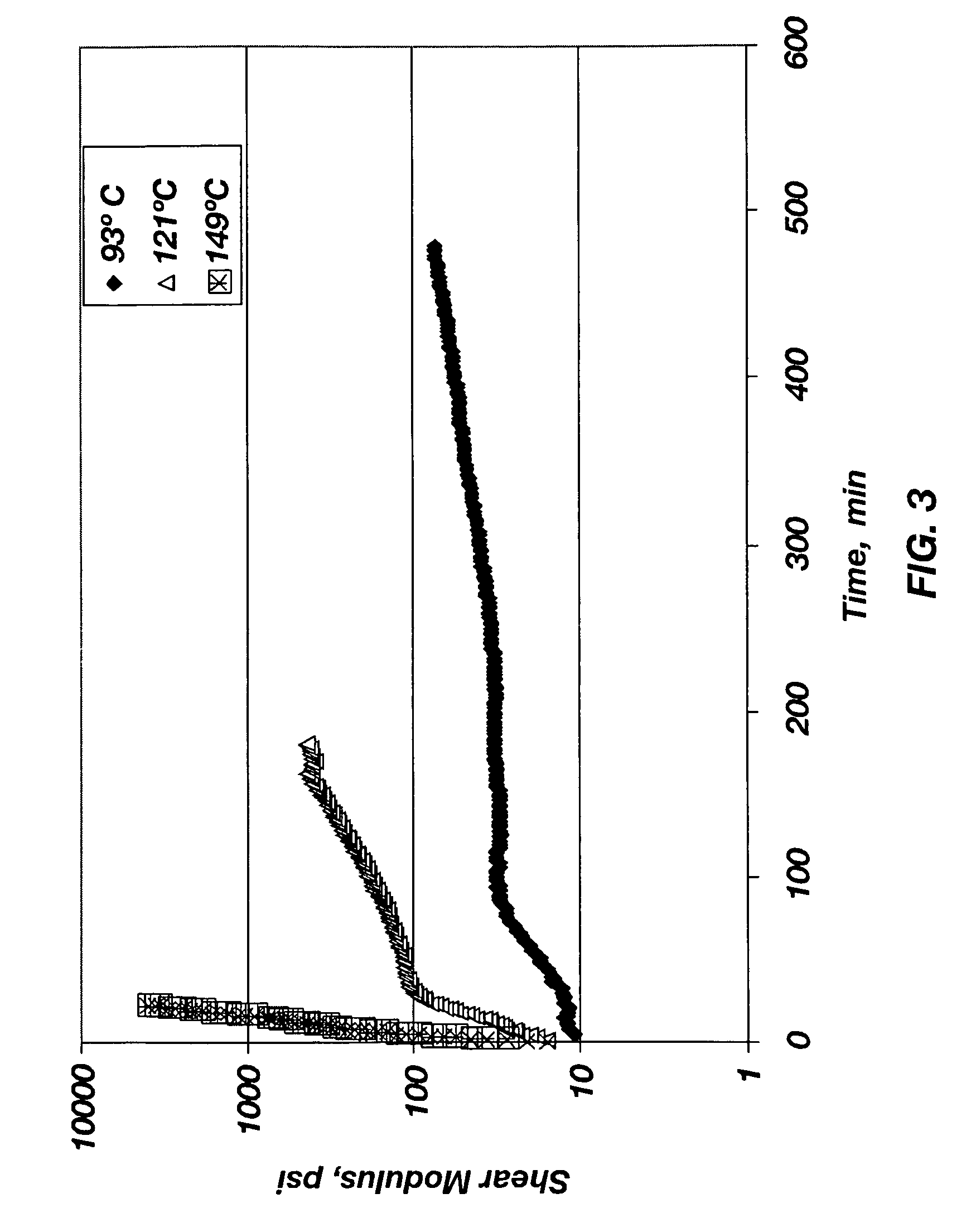

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

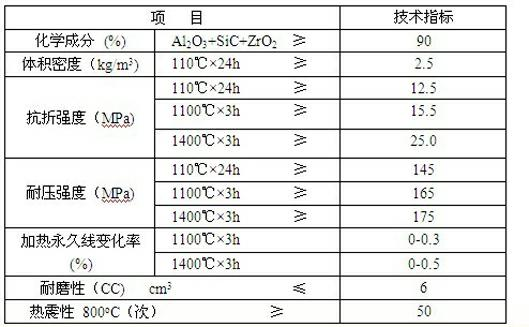

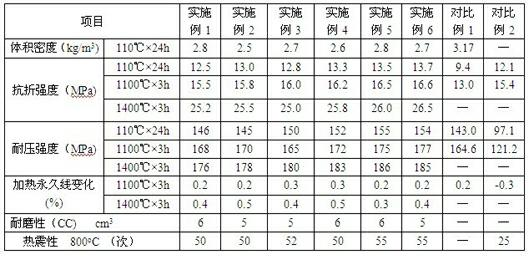

Special castable for kiln outlet

The invention discloses a special castable for a kiln outlet, which belongs to the field of refractory materials. According to the invention, the special castable comprises the following components in percentage by weight: 8-25% of silicon carbide, 10-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 1-5% of zirconium diboride, 1-5% of silicon nitride,5-15% of alumina micropowder, 3-6% of pure calcium aluminate cement, 0.5-1% of explosion-proof fiber and 0.06-0.2% of sodium tripolyphosphate, which is an additive. By using the special castable for the kiln outlet, disclosed by the invention, the phenomenon of poor wear resistance, block falling and the like in the kiln outlet can be effectively improved; the service life of the cement kiln outlet can be largely prolonged; and the special castable for the kiln outlet, disclosed by the invention, has the advantages of high temperature resistance, heat shock resistance, wear resistance, high strength, irreversible micro expansion and the like.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

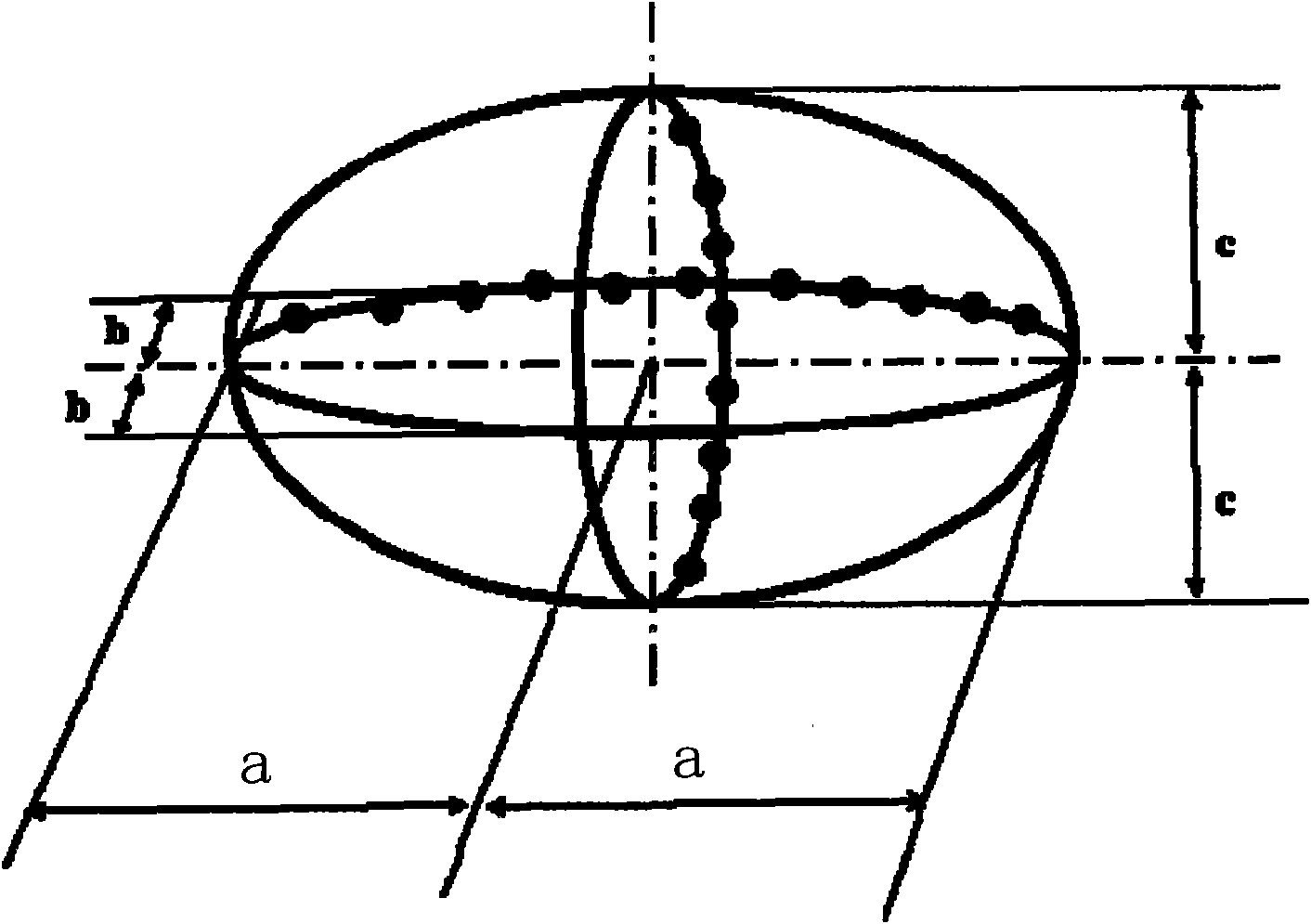

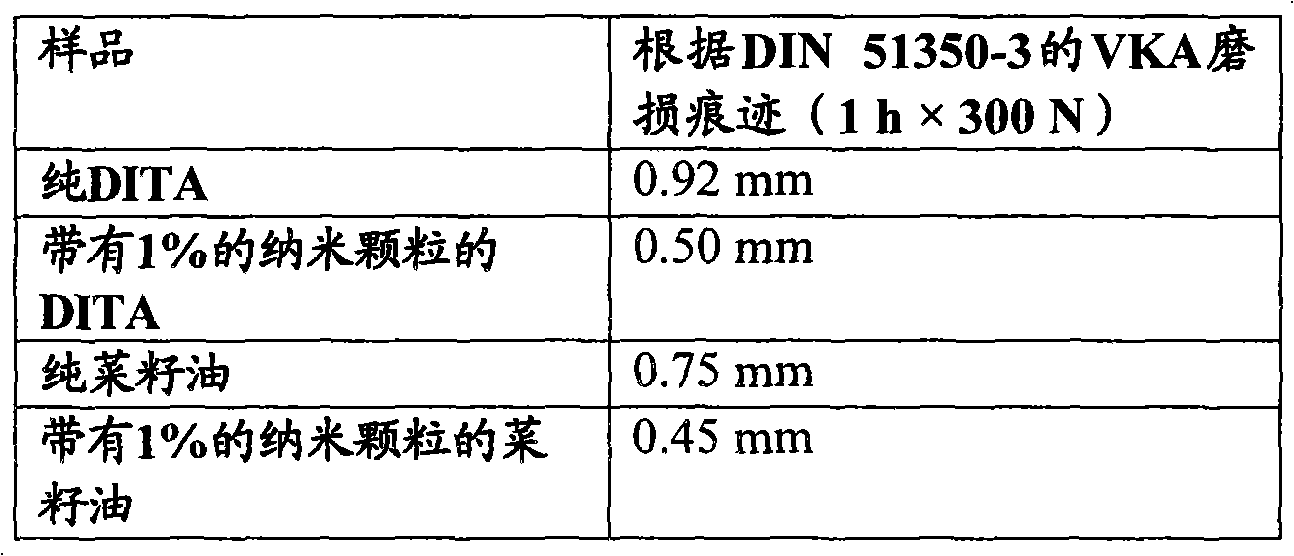

Additive for lubricant for improving the tribologic properties, a method for its production and application

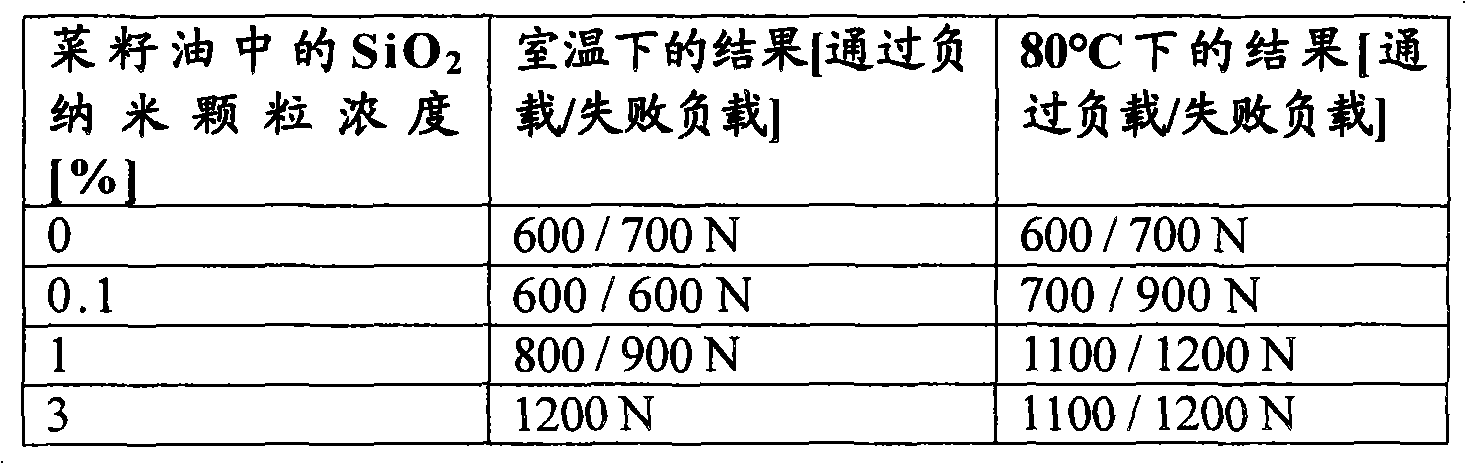

The present invention relates to novel lubricant additives for improving the tribological properties, novel lubricants containing these additives, processes for the preparation thereof and the use thereof. Lubricant comprises ceramic nanoparticles as additives comprising aluminum oxide, aluminum nitride, silicon dioxide, titanium dioxide, zirconium oxide, yttrium oxide, tungsten oxide, tantalum pentoxide, vanadium pentoxide, niobium pentoxide, cerium dioxide, boron carbide, aluminum titanate, boron nitride, molybdenum disilicide, silicon carbide, silicon nitride, titanium carbide, titanium nitride, zirconium diboride and / or clay minerals, and thermally stable carbonates and / or sulfates. The nanoparticles represent an ellipsoid with three semi-axes a, b and c, which are not equal to each other, or equal to each other. The ratio of a and b is 1-100, a and c is 1-1000, and b and c is 1:100.

Owner:แลนด์เซสส์ ดอยช์แลนด์ จีเอ็มบีเอช

Thermal protective coating

ActiveUS20060156958A1Extended shelf lifeExcellent optical propertiesAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

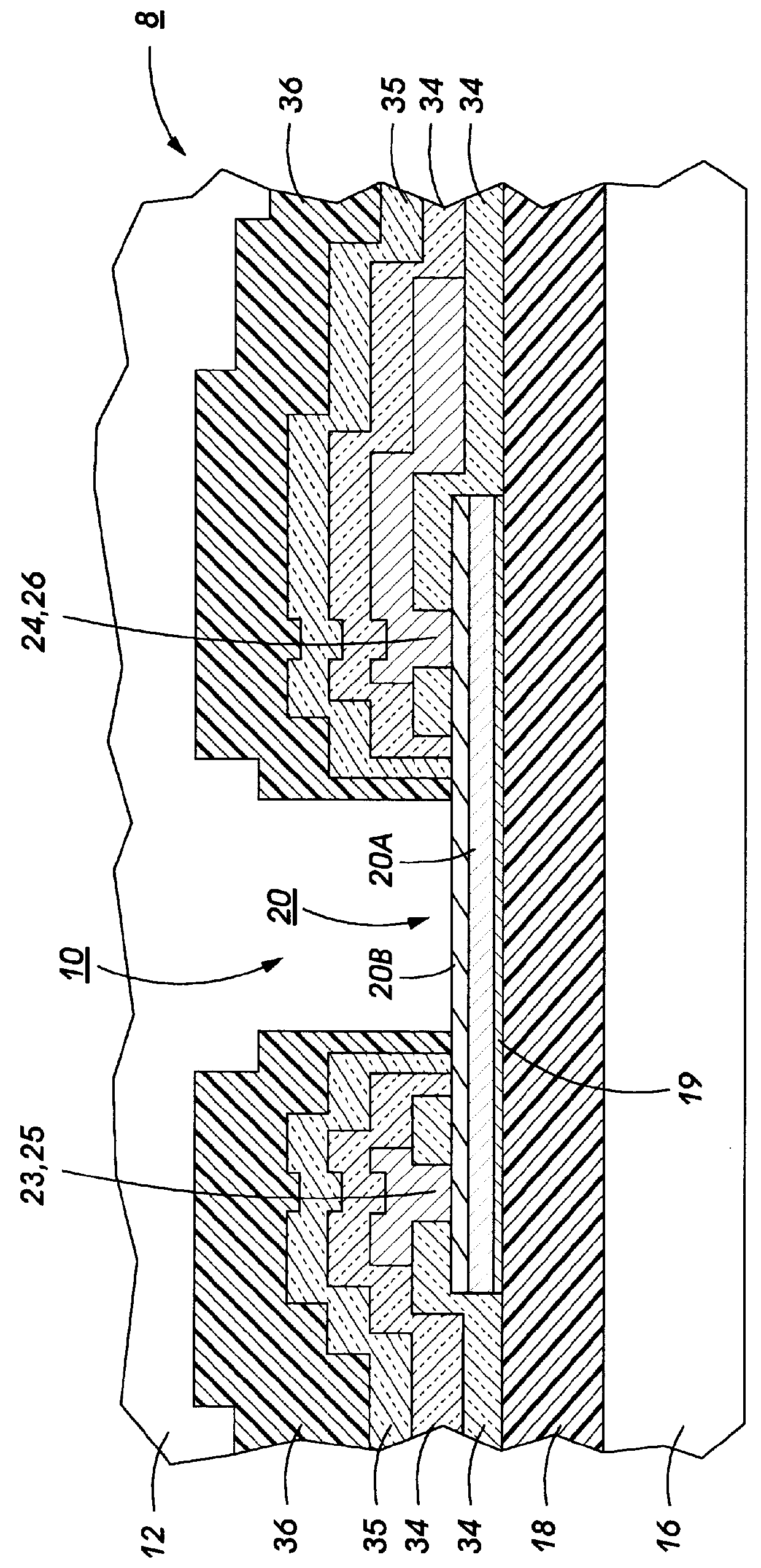

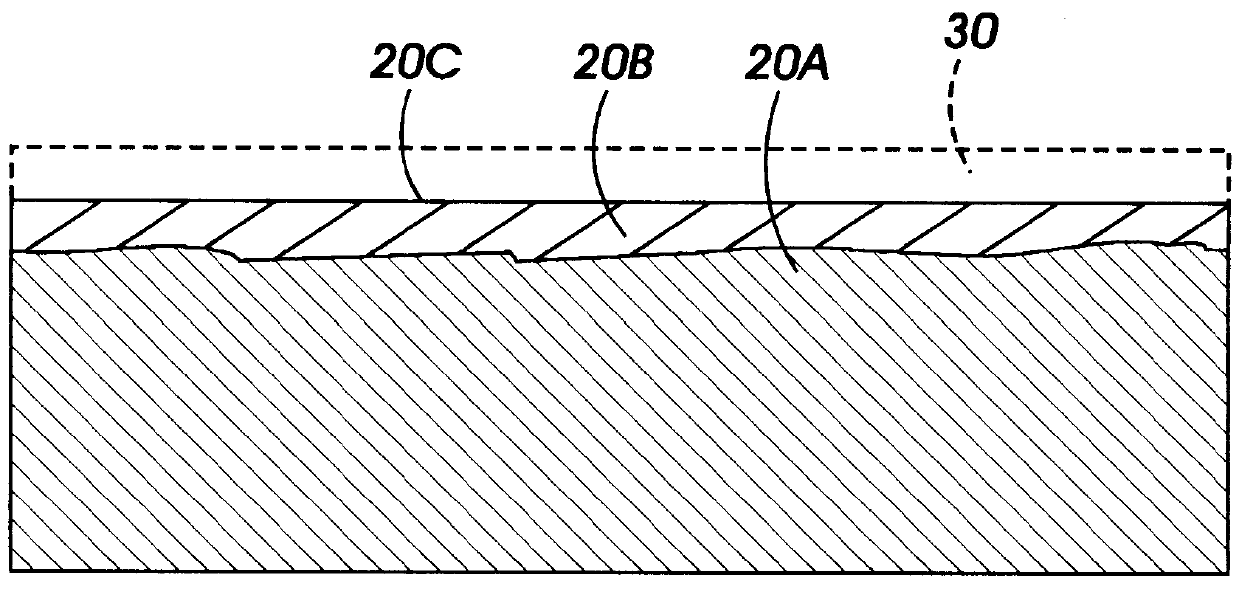

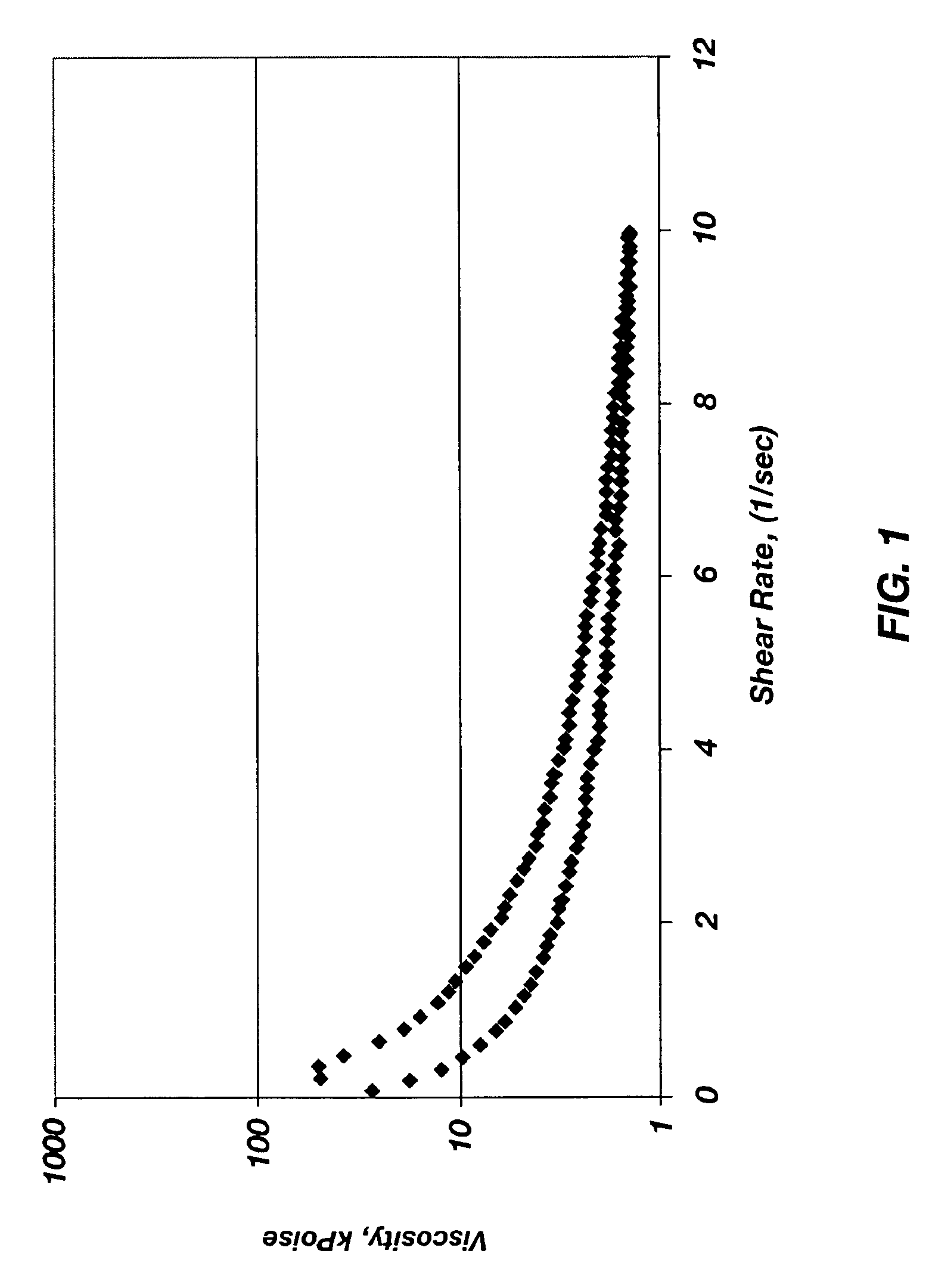

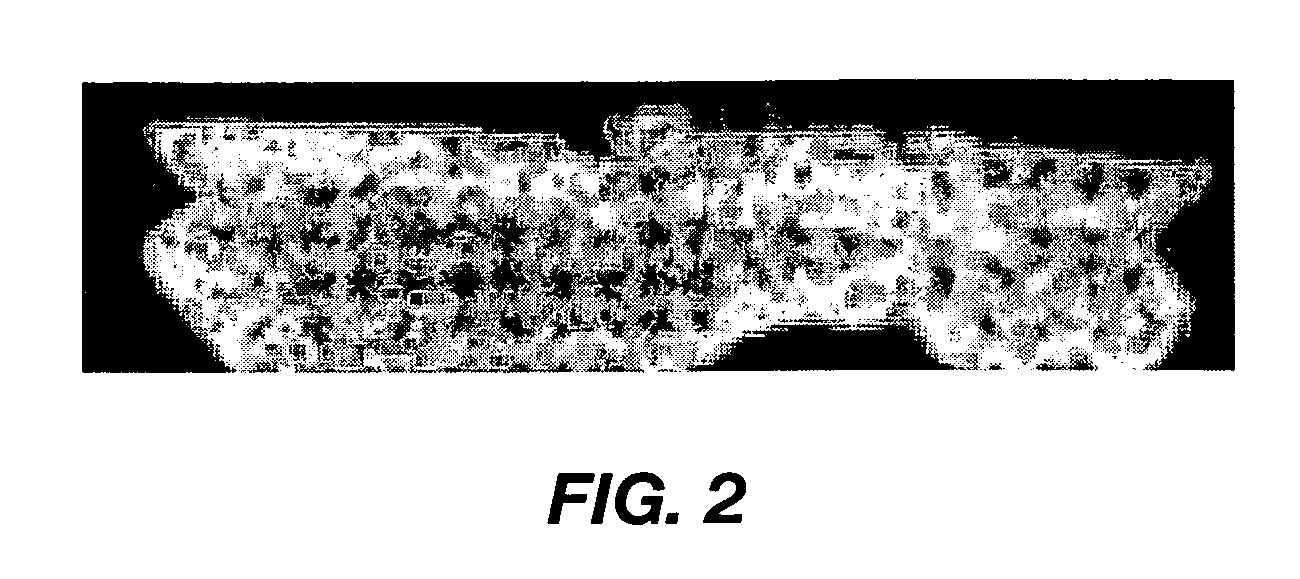

Method of making a printhead having reduced surface roughness

InactiveUS6013160AImproved drop ejection efficiencyDrop ejection efficiencyInking apparatusVacuum evaporation coatingElectrical resistance and conductanceSurface roughness

The nucleation efficiency of a thermal ink jet printhead is improved by providing a heater resistor with a thin planar oxide film formed over a conductive heater resistive layer. In a preferred embodiment, zirconium diboride is sputtered onto a silicon substrate surface to form a first, electrically conductive base portion of the resistor. At a predetermined time, during the sputtering process, oxygen is introduced to form a thin film of ZrB2Ox. The surface of this film is very smooth having a surface roughness of <5 nm RMS.

Owner:XEROX CORP

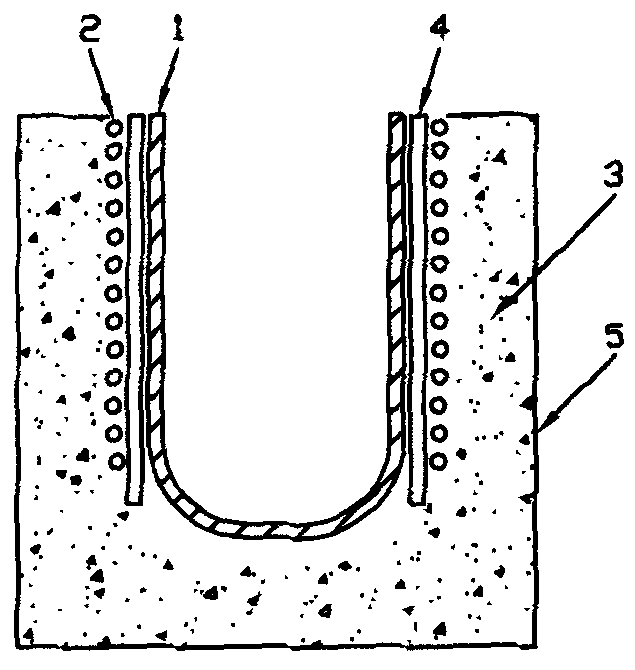

Preparation of high-temperature floamed ceramic

InactiveCN101323538AWide operating temperature rangeGuaranteed chemical stabilityCeramicwarePorosityContinuous use

The invention provides a preparation method of a high temperature foam ceramics, which is characterized in that: zirconium diboride-aluminum oxide composite ceramic powder is prepared into ceramic slurry, polyurethane foaming plastic with certain bore diameter and porosity is soaked into the ceramic slurry so that the ceramic slurry evenly adheres to the surface of the pores of the polyurethane foaming plastic to form a ceramic slurry layer, which are then prepared into a polyurethane foaming plastic ceramic blank, and then are subjected to drying, degreasing and sintering, and the high temperature foam ceramics is prepared. The invention adjusts the high temperature resisting performance of the high temperature foam ceramics prepared by adjusting the ratio of zirconium diboride and aluminum oxide, therefore, the high temperature foam ceramics can resist high temperature and greatly expand working temperature scope; the high temperature foam ceramics prepared by the method can resist high temperature and keep chemical stability under high temperature condition; therefore, in high temperature working environment, the high temperature foam ceramics can be used repeatedly or continuously for the performances of thermal-shock resistance, oxidation resistance, molten steel erosion resistance, and the like, when being used in the filtration of molten steel, showing good performance.

Owner:SHANDONG UNIV OF TECH

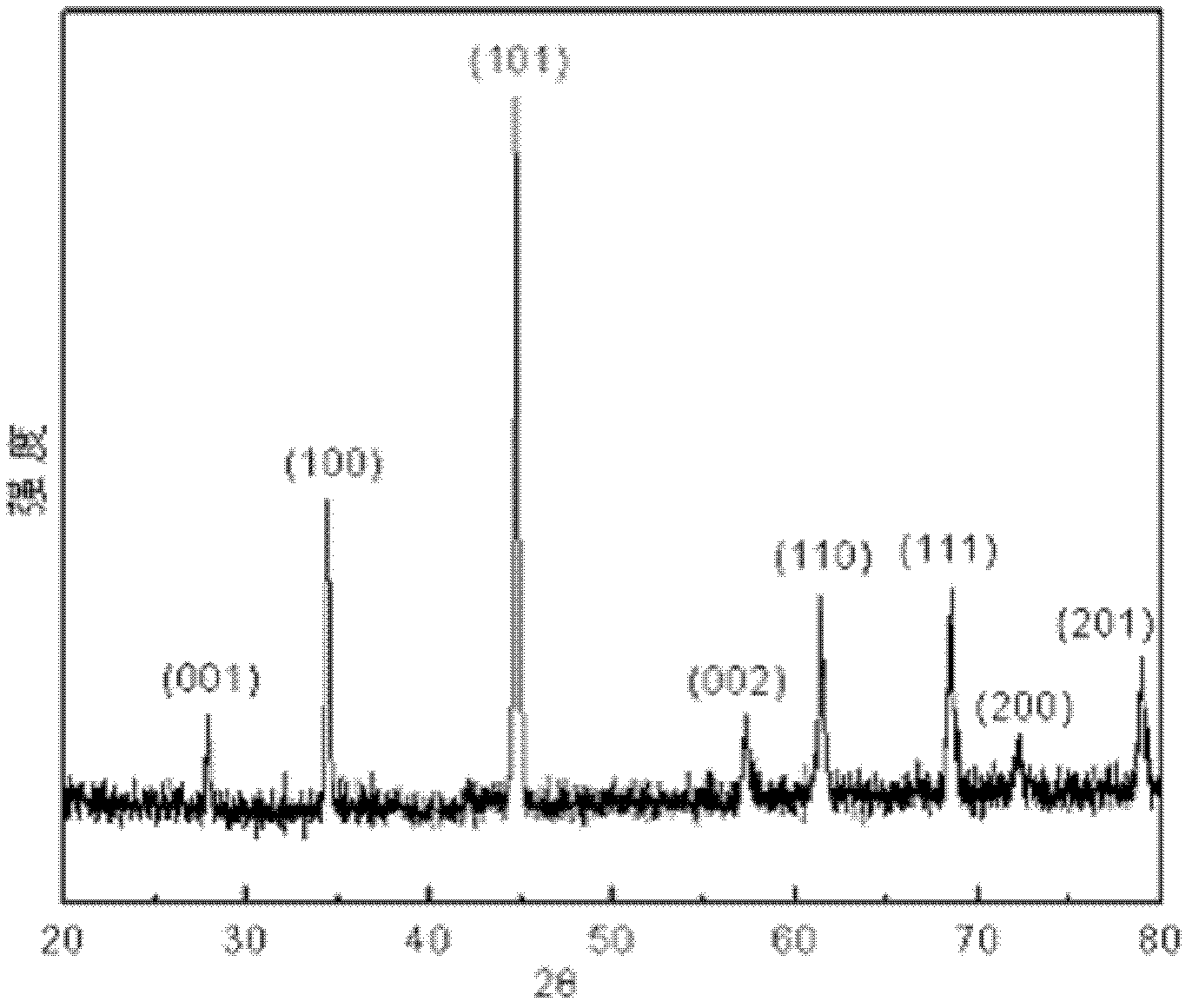

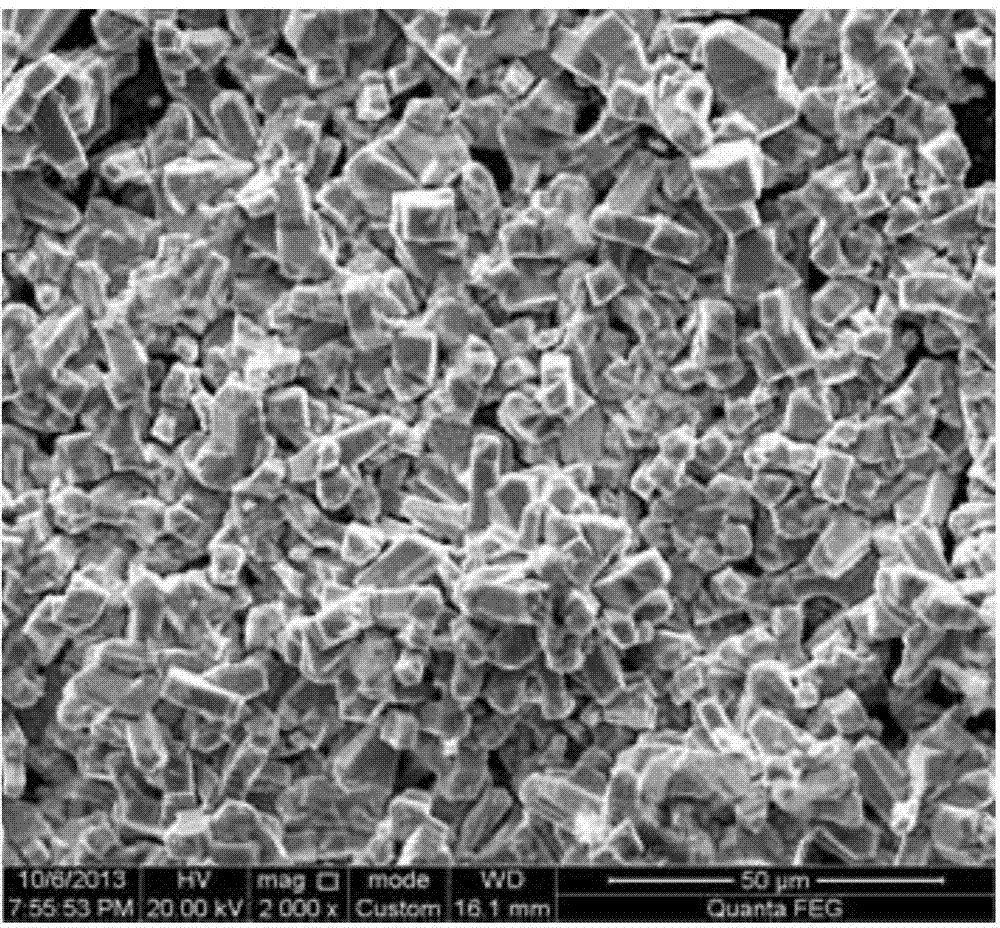

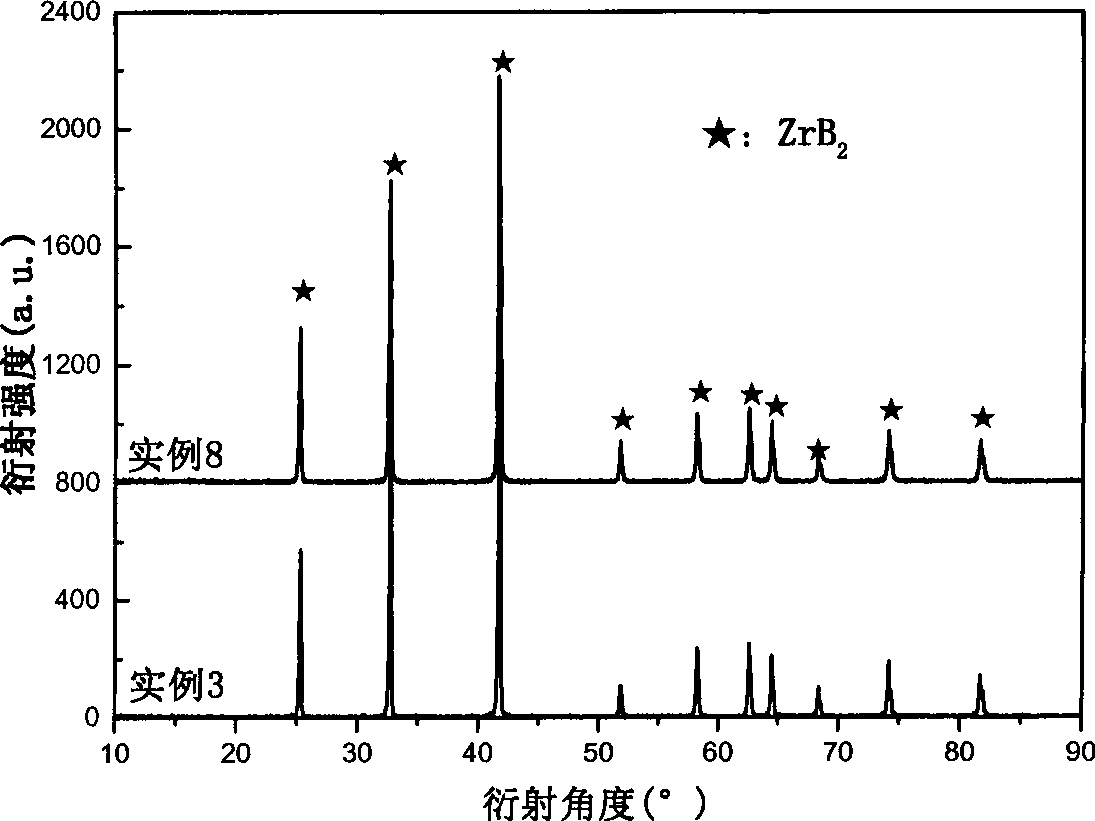

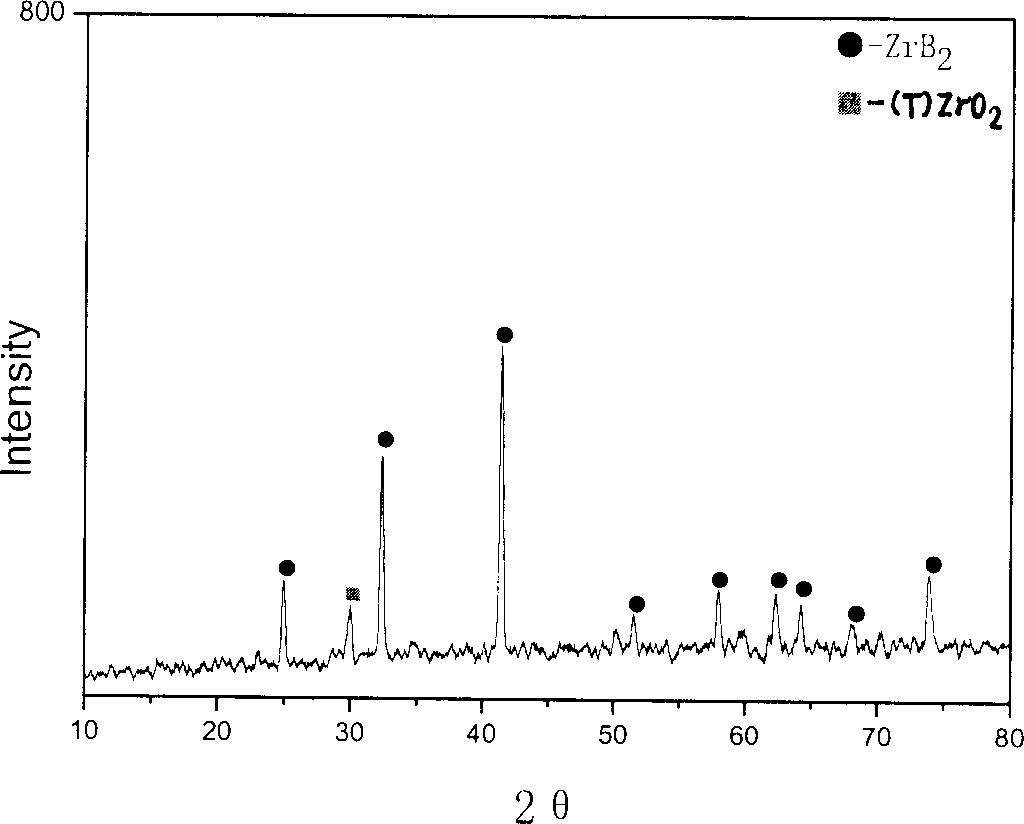

Preparation method of zirconium diboride ceramic with in-situ-introduced boron as additive

InactiveCN103011827AAvoid introducingGood for maintaining excellent performanceArgon atmosphereZirconium dioxide

The invention relates to the field of structural ceramic manufacturing, in particular to a preparation method of zirconium diboride ceramic with in-situ-introduced boron as an additive. The preparation method comprises the following steps: firstly, performing ball milling and mixing zirconium dioxide and elemental boron in a mol ratio of (1: 3.5)-(1: 4.5), and drying to obtain ZrO2 / B mixed powder; secondly, putting the ZrO2 / B mixed powder into a graphite crucible, and performing high-heat treatment at the air pressure of below 200Pa to obtain ZrB2 / B powder; and finally, sieving the obtained ZrB2 / B powder, performing isostatic pressing, putting the ZrB2 / B powder into the graphite crucible, performing pressureless sintering in an argon atmosphere, controlling the sintering temperature at 1800 -2100 DEG C, the heat-preserving time at 1-3 hours and the heating rate at 10-50 DEG C / min, and preserving heat for 0.5 hours at 1500-1700 DEG C to obtain the compact zirconium diboride ceramic. By the preparation method, a ball milling medium is not introduced, the impurity content is reduced, excellent performance of the zirconium diboride ceramic can be maintained easily, and the sintering compactness of the zirconium diboride ceramic is realized at a relatively low temperature (2000 DEG C).

Owner:FUDAN UNIV

High purity ultra fine zirconium biboride powder and its preparation method

The present invention relates to a high-purity ultrafine zirconium diboride powder material and its preparation method. It is characterized by that the described powder material contains zirconium oxychloride, boron carbide powder and active carbon powder, their mole ratio is ZrOcl2:B4C:C=1:0.4-0.8:1.4-1.8. Its preparation method includes the following steps: firstly, mixing boron carbide powder, active carbon powder and water according to mixing ratio, regulating pH value to obtain mixed suspension; dissolving zirconium oxychloride in deionized water to obtain the zirconium oxychloride solution; mixing the above-mentioned suspension and zirconium oxychloride solution, adding ammonia water, making the zirconium oxychloride be fully hydrolyzed and precipitated; making suspension undergo the processes of solid-liquor separation, waster-washing, removing NH4+ and Cl-, drying and sieving; then placing the powder material into a vacuum furnace to make reaction synthesis, its synthesis temperature is 1500-1600 deg.C, heat-insulating for 0.5-4 h; grinding powder and sieving so as to obtain the invented powder material.

Owner:칭다오정왕철강수통제주식유한회사

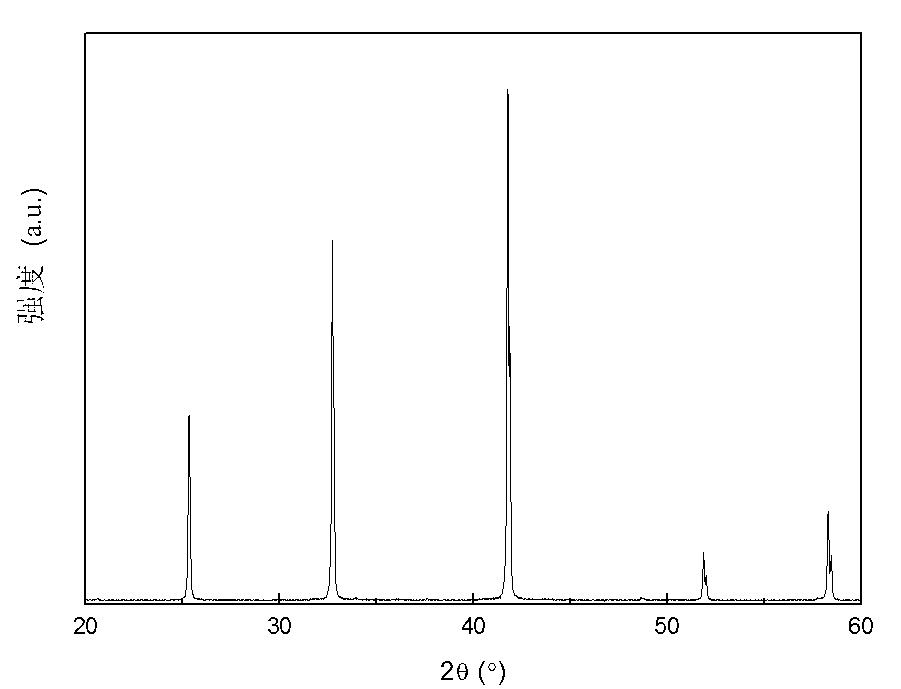

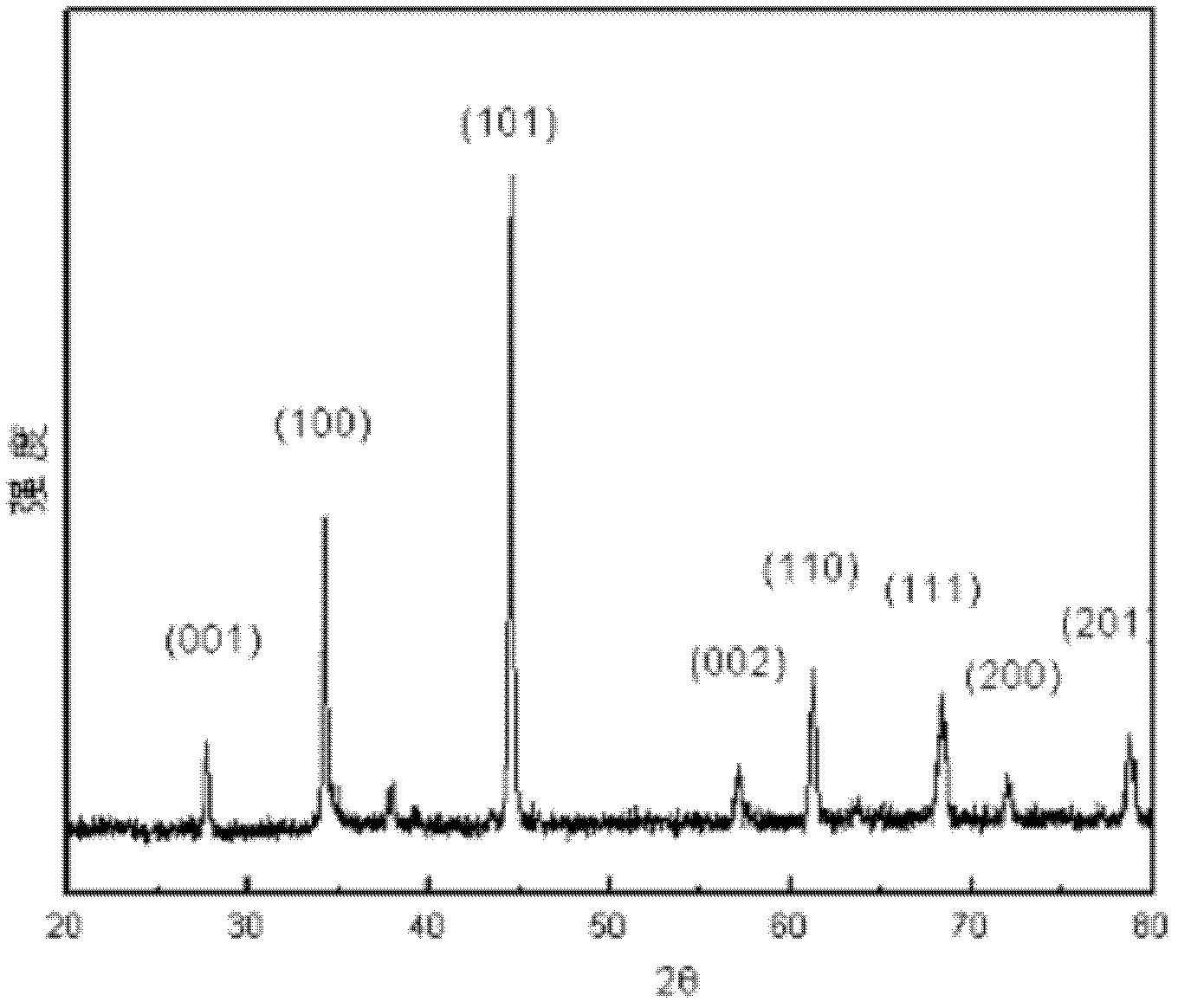

High-temperature high-pressure preparation method for titanium diboride

The invention relates to a high-temperature high-pressure preparation method for titanium diboride and belongs to the technical field of preparation for ultra-hard ceramic material. The method comprises the following steps of: taking titanium powder and boron powder as raw materials or titanium powder and carbon tetraborate powder as raw materials; preparing titanium diboride material by performing the processes of mixing materials, pressing into blocks, assembling, high-temperature high-pressure synthesis, cooling and releasing pressure; performing on a high-pressure device, after keeping temperature at 1300-2000K and pressure at 1.0-6.0GPa for 1-3 hours, cooling and releasing pressure, thereby obtaining TiB2 bulk sintered body. The method provided by the invention is simple and easily implemented; no fluxing agent is adopted; the pure-phase TiB2 material is prepared by changing the proportion of the raw materials and the compounding condition; a result of X-ray detection shows that the product is pure TiB2 phase and no other impure phase is introduced; and according to the TiB2 material prepared by taking B4C as the raw material, the residual C element is capable of enhancing the toughness of TiB2 or the C element is simply separated from TiB2.

Owner:JILIN UNIV

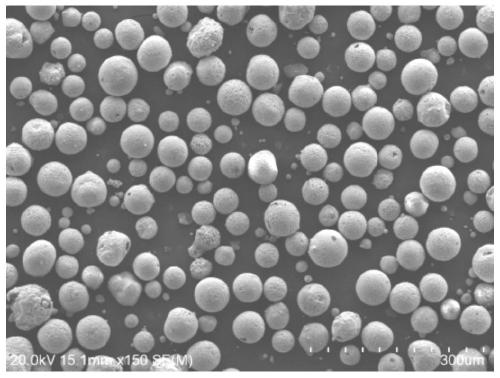

Method for preparing ablation-resistant coating

InactiveCN107021787AImprove liquidityImprove high temperature ablation resistanceCarbon compositesSlurry

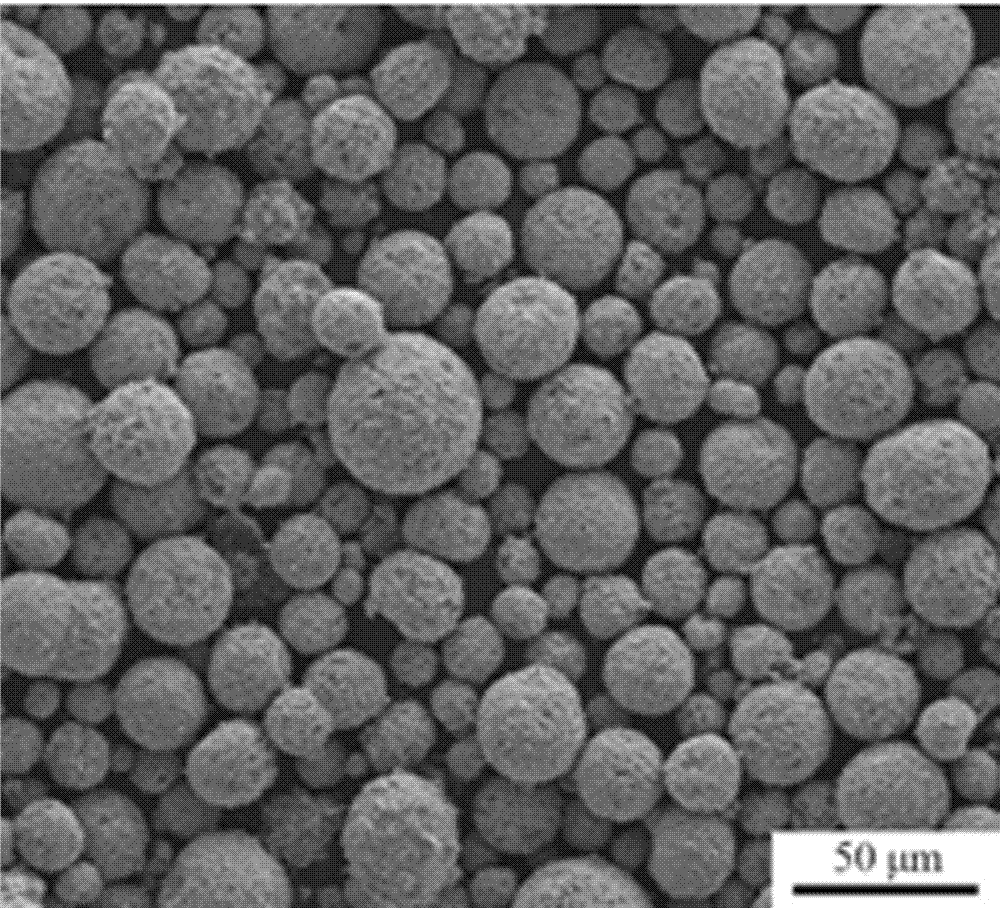

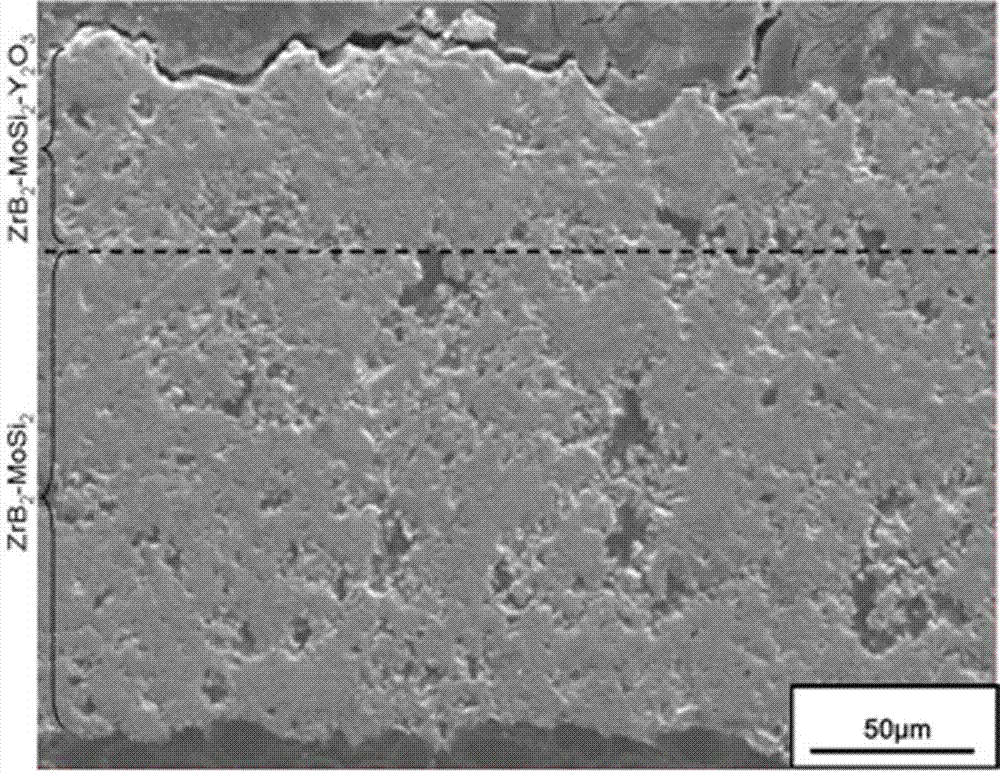

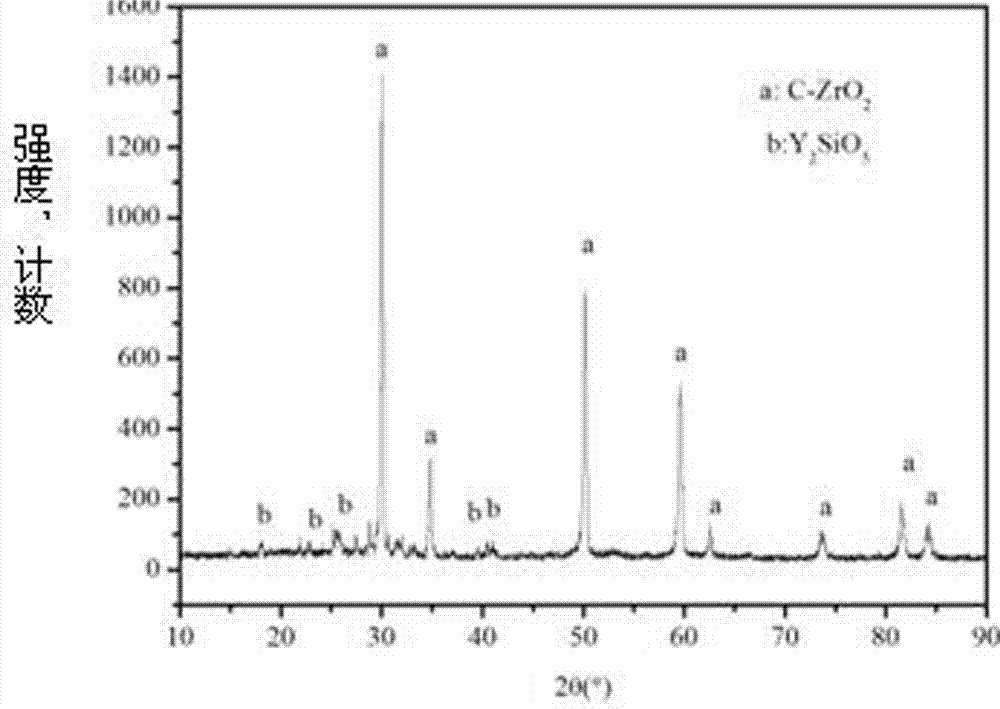

The invention relates to a method for preparing an ablation-resistant coating. The method comprises the following steps: mixing zirconium diboride and molybdenum disilicide or silicon carbide and yttrium oxide with the particle size of 1 to 3 microns, then, mixing the mixture with a binder so as to obtain a mixture, blending the mixture with deionized water, and then, carrying out ball milling, so as to obtain slurry; preparing spherical powder at the temperature of 110 DEG C to 130 DEG C; carrying out sintering for 1 to 2 hours at the temperature of 1,200 DEG C to 1,600 DEG C; carrying out sieving, so as to obtain zirconium diboride-molybdenum disilicide or silicon carbide-yttrium oxide powder for spraying; spraying a zirconium diboride-molybdenum disilicide or silicon carbide undercoat to the surface of a carbon / carbon composite material by a plasma spraying method, and then, spraying the zirconium diboride-molybdenum disilicide or silicon carbide-yttrium oxide powder to the undercoat by the same method, thereby preparing the ablation-resistant coating. The yttrium oxide modified zirconium diboride-molybdenum disilicide or silicon carbide coating prepared by the method can be used for remarkably improving the high-temperature ablation resistance of the carbon / carbon composite material.

Owner:GUANGDONG INST OF NEW MATERIALS

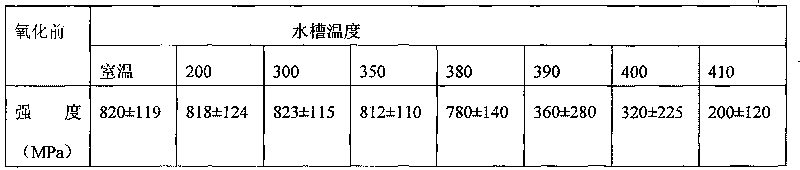

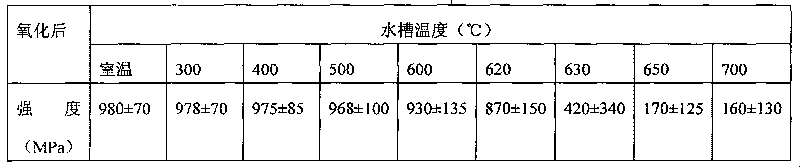

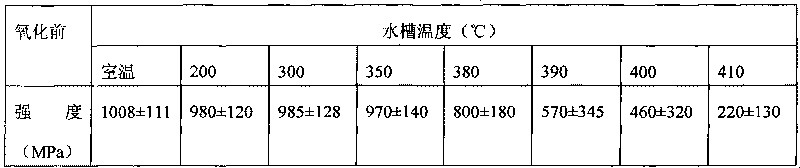

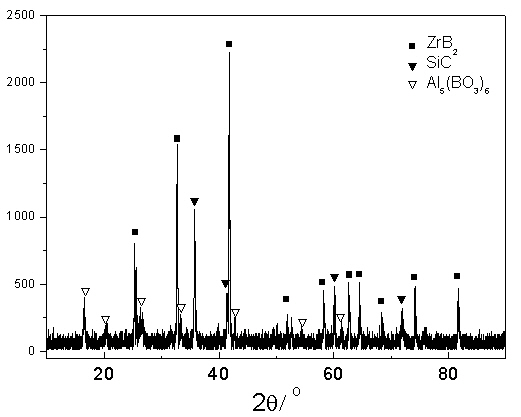

Method for improving heat shock resistance and strength of ZrB2-SiC superhigh temperature ceramic material

InactiveCN101747047AImprove thermal shock resistanceHigh strengthUltimate tensile strengthMechanical property

The invention discloses a method for improving the heat shock resistance and the strength of a ZrB2-SiC superhigh temperature ceramic material, which relates to a method for improving the heat shock resistance and the strength of a ceramic material and solves the problem that the traditional ZrB2-SiC based superhigh temperature ceramic material has poor heat shock resistance and strength. The method comprises the following steps: firstly, weighing raw materials; secondly, ball milling and dispersing; thirdly, drying; fourthly, sintering; fifthly, oxidizing; and sixthly, heating and maintaining the temperature, so the heat shock resistance and the strength of the ZrB2-SiC superhigh temperature ceramic material can be improved. The method effectively improves the heat shock resistance and the strength of the ZrB2-SiC superhigh temperature ceramic material; and compared with the traditional ZrB2-SiC based superhigh temperature ceramic material, the heat shock resistance is improved by about 50 percent and the mechanical property is improved by about 30 percent.

Owner:HARBIN INST OF TECH

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

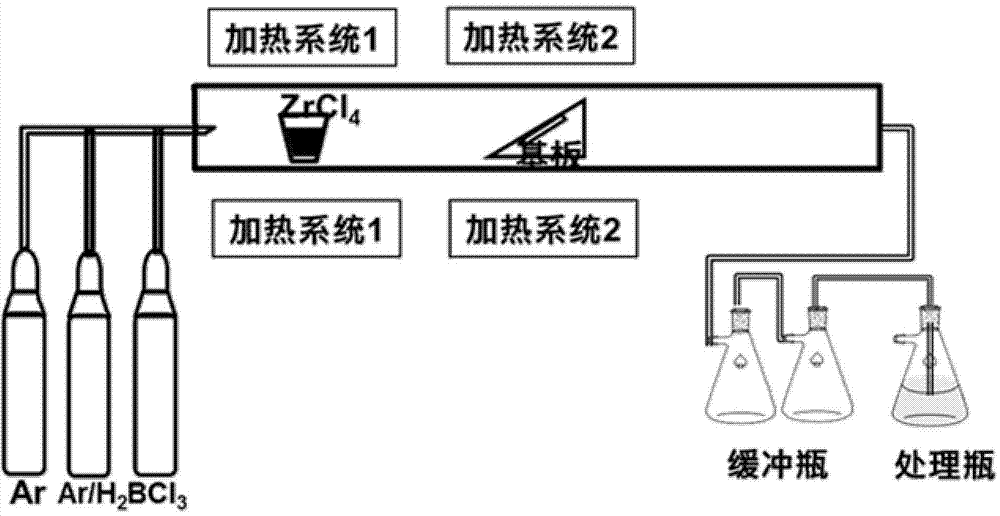

Method for preparing zirconium diboride coating

ActiveCN103757603AReduce concentrationPrevent oxidationChemical vapor deposition coatingTemperature controlCeramic coating

The invention discloses a method for preparing a zirconium diboride coating and relates to a method for preparing a ceramic coating. The invention aims to solve the problems that a gas circuit needs to be subjected to thermal insulation treatment and the requirement of a gas flowmeter is high by adopting a method for heating ZrCl4 to be higher than a sublimation temperature and introducing the ZrCl4 into a reaction chamber through the flowmeter in the process of preparing ZrB2 through a conventional chemical vapor deposition method. The preparation method comprises the following steps: by using a double-temperature-area heating mode, by taking ZrCl4, BCl3 and H2 as source gases, by taking Ar gas or N2 as carrier gas and protective gas, preparing the zirconium diboride coating by adopting the chemical vapor deposition method. According to the method in the invention, the gas circuit needs no special thermal insulation treatment, and the flow of the ZrCl4 can be controlled through a temperature control method. The method can be used for preparing zirconium diboride coating.

Owner:HARBIN INST OF TECH

Diffusion bonding method of zirconium diboride-silicon carbide composite material and metal alloy

The invention relates to a bonding method of a zirconium diboride-silicon carbide composite material and a metal alloy, particularly a diffusion bonding method of a zirconium diboride-silicon carbide composite material and a metal alloy. The invention aims to solve the problem of low strength of the active brazed joint of the existing zirconium diboride-silicon carbide composite material and metal alloy. The method comprises the following steps: 1. pretreating the zirconium diboride-silicon carbide composite material and the metal alloy; 2 pretreating a foam nickel middle layer; and 3. carrying out diffusion welding bonding. The method relieves the joint stress, and enhances the joint strength. The shear strength of the diffusion welding joint obtained by the method is 176.5-208.1MPa, andis enhanced by 76-197% as compared with the shear strength of the bonding joint by a brazing process. The invention can be used in the field of diffusion welding bonding.

Owner:HARBIN INST OF TECH

High-strength high-toughness zirconium diboride-silicon carbide-zirconia ceramic-based composite material and preparation method thereof

The invention relates to a high-strength high-toughness zirconium diboride-silicon carbide-zirconia ceramic-based composite material and a preparation method thereof, which relate to a ceramic-based composite material and a preparation method thereof and solve the problems of low fracture toughness and sintering difficulty of a ZrB2 ceramic-based composite material prepared by a traditional method. The material is made of zirconium diboride powder, silicon carbide powder and zirconium diboride fibers. The method comprises the following steps of: 1. weighing and wetly mixing raw materials to obtain slurry; 2. drying the slurry and then grinding to obtain a mixed powdery material; 3. sintering, cooling and taking out the mixed powdery material to obtain the ceramic-based composite material. In the invention, the ZrO2 fibers are introduced into a zirconium diboride-silicon carbide ultrahigh-temperature ceramic-material system to improve the brittleness and the thermal-shock resisting performance of an ultrahigh-temperature ceramic material and improve the use reliability of the material. The ceramic composite material prepared by the method provided by the invention is easy to sinter, the fracture toughness of the ceramic composite material is 5.69-6.82MPa.m1 / 2, and the bending strength is 700.86-723.15MPa.

Owner:HARBIN INST OF TECH

High-temperature-resistant cermet material and preparation method thereof

The invention belongs to the field of cermet materials, and discloses a high-temperature-resistant cermet material and a preparation method thereof. The high-temperature-resistant cermet material comprises 11-22 parts of nickel sesquioxide, 5-11 parts of magnesium oxide, 7-11 parts of zirconium diboride, 2-4 parts of thorium dioxide, 4-7 parts of bismuth oxide, 5-9 parts of zinc, 7-13 parts of copper, 2-4 parts of germanium and 12-17 parts of iron. The preparation method comprises the following steps: (1) quickly mixing metals and a ceramic material at high speed; (2) carrying out ball milling on the uniform mixture with a ball mill; (3) carrying out high-temperature press fitting on the cermet material subjected to ball milling in a hot-pressing furnace, heating the furnace to 720-780 DEG C, keeping the temperature, continuing heating the hot-pressing furnace to 1520-1610 DEG C, sintering, and cooling to obtain the high-temperature-resistant cermet material.

Owner:佛山市三水华纳陶瓷有限公司

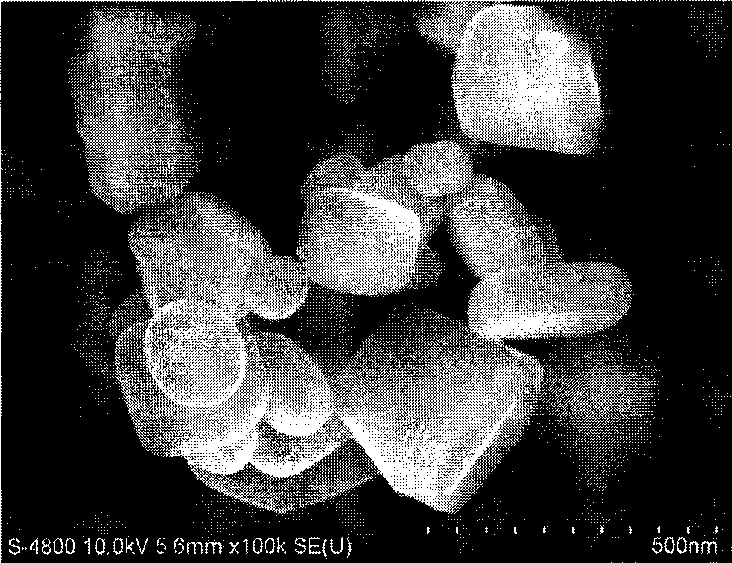

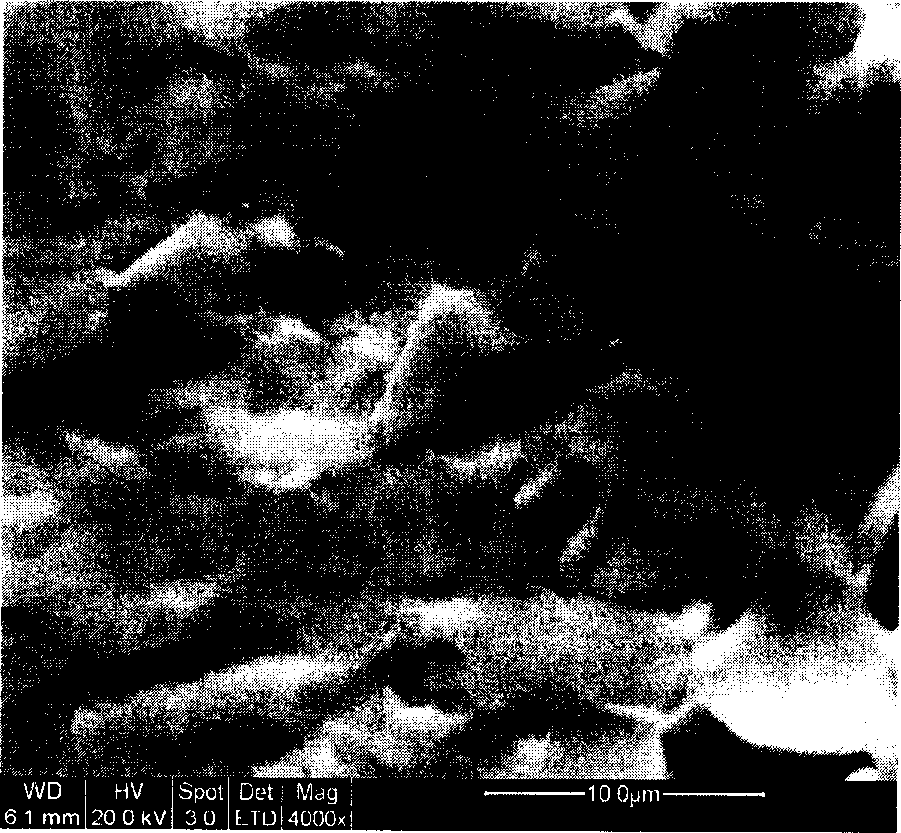

Preparation of nano zirconium diboride ceramic powder

InactiveCN101486577ASynthesis temperature is lowGuaranteed normal productionMetal boridesChemical treatmentCoprecipitation

The invention relates to a preparation method for nano zirconium diboride ceramic powder, which is characterized by comprising the following steps: 1) selecting materials: selecting according to a mol ratio of 1 : 3 to 1 : 5 between Zr and amorphous boron powder in soluble zirconium salt; 2) selecting one of the two methods as follows: a) using a coprecipitation method for gel forming to obtain xerogel; b) using a sol-gel method for gel forming to form the xerogel; 3) preparing precursor powder; 4) synthesizing quickly: arranging the materials into a large current reaction synthesizer; the inside of a black lead reactor is protected by vacuum or insert gases; applying a large current directly on the black lead reactor, quickly heating to 800 and 1500 DEG C at the temperature rising speed of 50 to 500 DEG C / min, preserving the temperature for 0 to 60 minutes to obtain a powder sample; and 5) chemical processing for obtaining the nano zirconium diboride ceramic powder. The method has the characteristics of quick synthesizing speed and high efficiency; the purity of the obtained nano zirconium diboride ceramic powder is high (equal to or more than 95 percent); and the grain diameters of the obtained nano zirconium diboride ceramic powder are uniform and thin(the average grain diameter is equal to or less than 300nm).

Owner:WUHAN UNIV OF TECH

Method for preparing zirconium boride/silicon carbide composite powder with low cost

The invention belongs to the technical field of ceramic materials and particularly relates to a method for preparing zirconium boride / silicon carbide composite powder with low cost, which comprises the steps of: taking raw materials of ZrSiO4, B4C and C according to the proportion of 1:0.5-0.65:4.5-5.85; mixing and then ball-milling for 4-8h; making the ball-milled powder react for 0.5-1h at a temperature of 1,500-1,600 DEG C under the protection of inert gas; and then ball-milling again to obtain the zirconium boride / silicon carbide composite powder. The invention has low cost and simple production equipment, can be used for synthesizing the zirconium boride / silicon carbide composite powder on a large scale, is simple and easy to implement, and is suitable for industrialized application and popularization.

Owner:ZHENGZHOU UNIV

Metal treatment to eliminate hot tear defects in low silicon aluminum alloys

An aluminum alloy and a method of casting. At least one of zirconium, scandium, a nucleating agent selected from the group consisting of metal carbides, aluminides and borides, and rare earth elements are added to the alloy while in the molten state such that upon solidification, the cast alloy exhibits improved hot tear resistance. In a particular form, the nucleating agent may be titanium diboride for grain refining. Other agents that can be used for grain refining include scandium, zirconium, silicon, silver and one or more rare earth elements. In the case of rare earth elements, mischmetal may be used as a precursor. Combinations of titanium diboride and at least one other agent are especially effective in reducing the incidence of hot tearing in products cast from the modified aluminum alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC

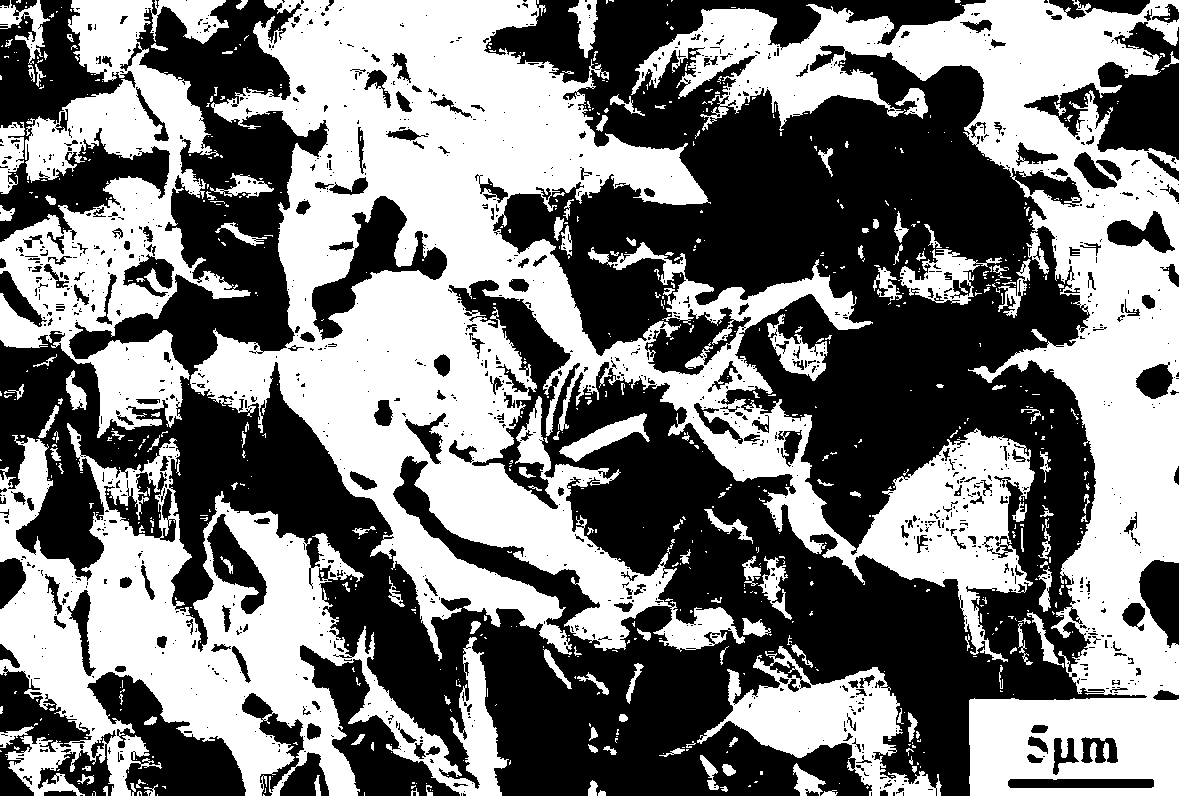

Aluminium oxide and zirconium diboride reinforced aluminum matrix in-situ composite and preparation method thereof

InactiveCN103276389AImprove high temperature wear resistanceHigh hardnessMetallic material coating processesChemical reactionAluminium matrix

The invention relates to an aluminium oxide and zirconium diboride reinforced aluminum matrix in-situ composite and a preparation method thereof. A ZrO2 particle and a B or B2O3 particle are mixed and ball-milled, the mixed particle formed after ball-milling is added into a matrix, a particle filling area of the matrix is processed through stirring friction, the rotating speed, the travel speed, the downward-pressing quantity, the inclination angle, the processing times of a stirring tool are 600-3000 r / min, 30-60 mm / min, 0.05-0.6 mm, 0-3 degrees, and 3-8 respectively, and during the processing process, ZrO2 and B or B2O3 particle is in chemical reaction with the aluminium matrix jointly to finally obtain the aluminium oxide and zirconium diboride reinforced aluminum matrix in-situ composite. In the aluminium matrix composite, the AL2O3 and ZrB2 particle subjected to in-situ synthesis have higher hardness and thermal stability, so that the composite has higher high-temperature-resistance abrasion performance.

Owner:SHANDONG UNIV

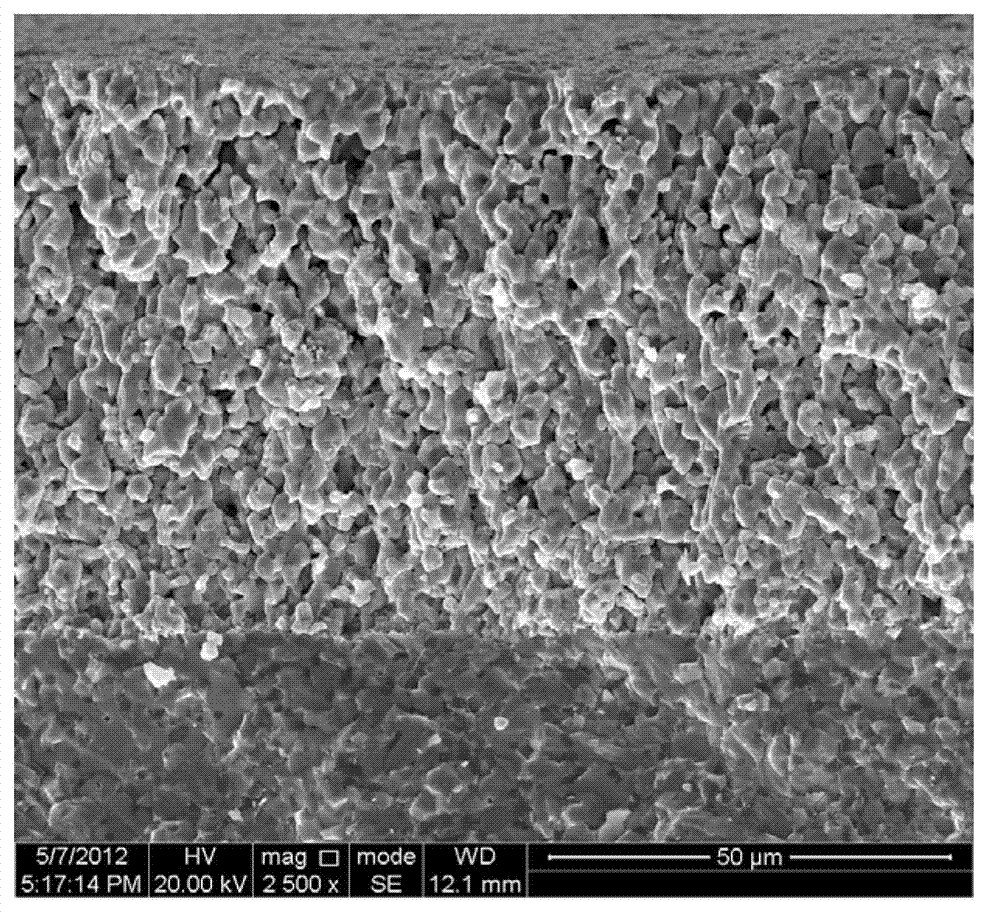

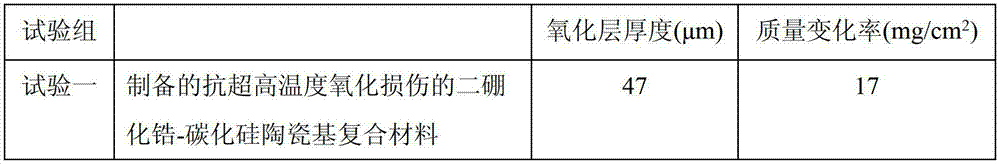

Preparation method of ultra-temperature oxidative damage resistant zirconium diboride-silicon carbide ceramic base composite material

ActiveCN103172382AReduce oxidation rateImprove antioxidant capacityCeramic matrix compositeOxidative damage

The invention relates to a preparation method of an ultra-temperature oxidative damage resistant zirconium diboride-silicon carbide ceramic base composite material, and relates to a preparation method of an ultra-temperature oxidative damage resistant ceramic base composite material. The preparation method aims to solve the problem of poor oxide layer stability of the traditional zirconium diboride-silicon carbide ceramic base composite material at a superhigh temperature (more than 1700 DEG C). The preparation method comprises the following steps of: 1, preparing the zirconium diboride-silicon carbide ceramic base composite material; and 2, carrying out oxidization inhibition processing to obtain the superhigh temperature oxidative damage resistant zirconium diboride-silicon carbide ceramic base composite material. The preparation method disclosed by the invention can be used for preparing the superhigh temperature oxidative damage resistant zirconium diboride-silicon carbide ceramic base composite material.

Owner:HARBIN INST OF TECH

Preparation method of multi-component-doping modified zirconium diboride-silicon carbide coating

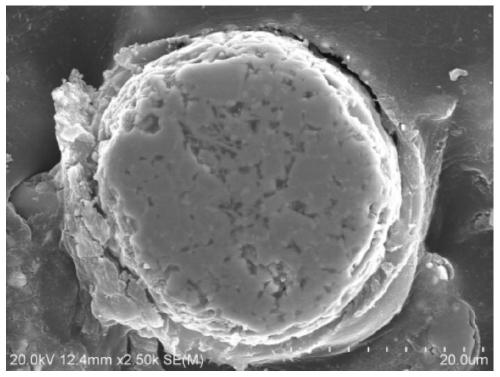

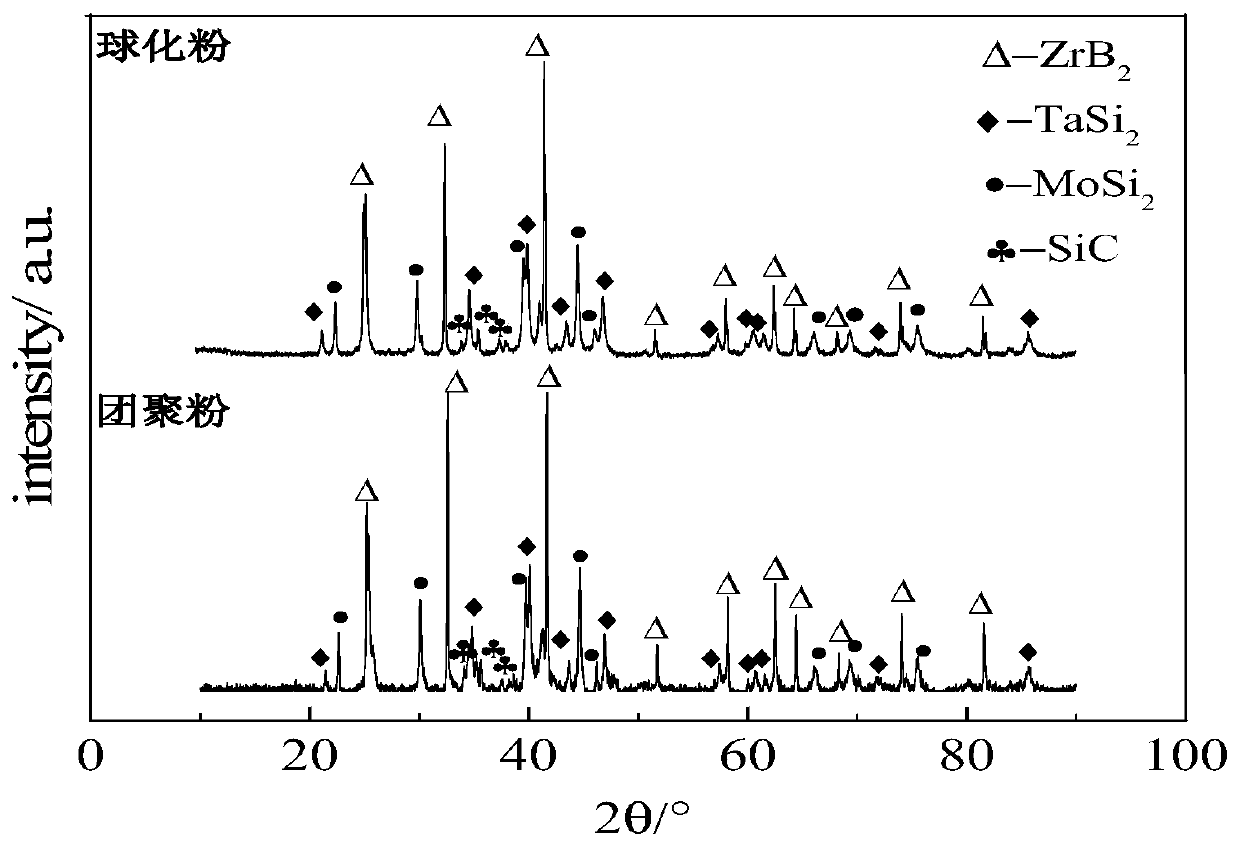

ActiveCN110396003AImprove densification performanceImprove high temperature resistanceZirconium hydrideInduction plasma technology

The invention relates to a preparation method of a multi-component-doping modified zirconium diboride-silicon carbide coating, and belongs to the technical field of composite powder and coating preparation. The method comprises the following steps: preparing ZrB2-SiC agglomerated powder doped with MoSi2 and TaSi2 through spray granulation and induction plasma spheroidization, and forming a coatingon a substrate by adopting an atmospheric plasma spraying process. By doping MoSi2 and TaSi2 at the same time, firstly, the two components serve as low-melting-point phases to fill pores and cracks in the powder, so that the compactness of the coating is improved; secondly, the two components serve as high-emissivity components to effectively radiate out heat in the coating, so that the high-temperature resistance of the coating is improved. The coating has good temperature resistance, infrared radiation performance, oxidation resistance, scouring resistance and thermal shock resistance. Thecoating can bear 300s oxyacetylene ablation examination at the surface temperature of 2000 DEG C and breaks through the technical bottleneck of 1800 DEG C.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

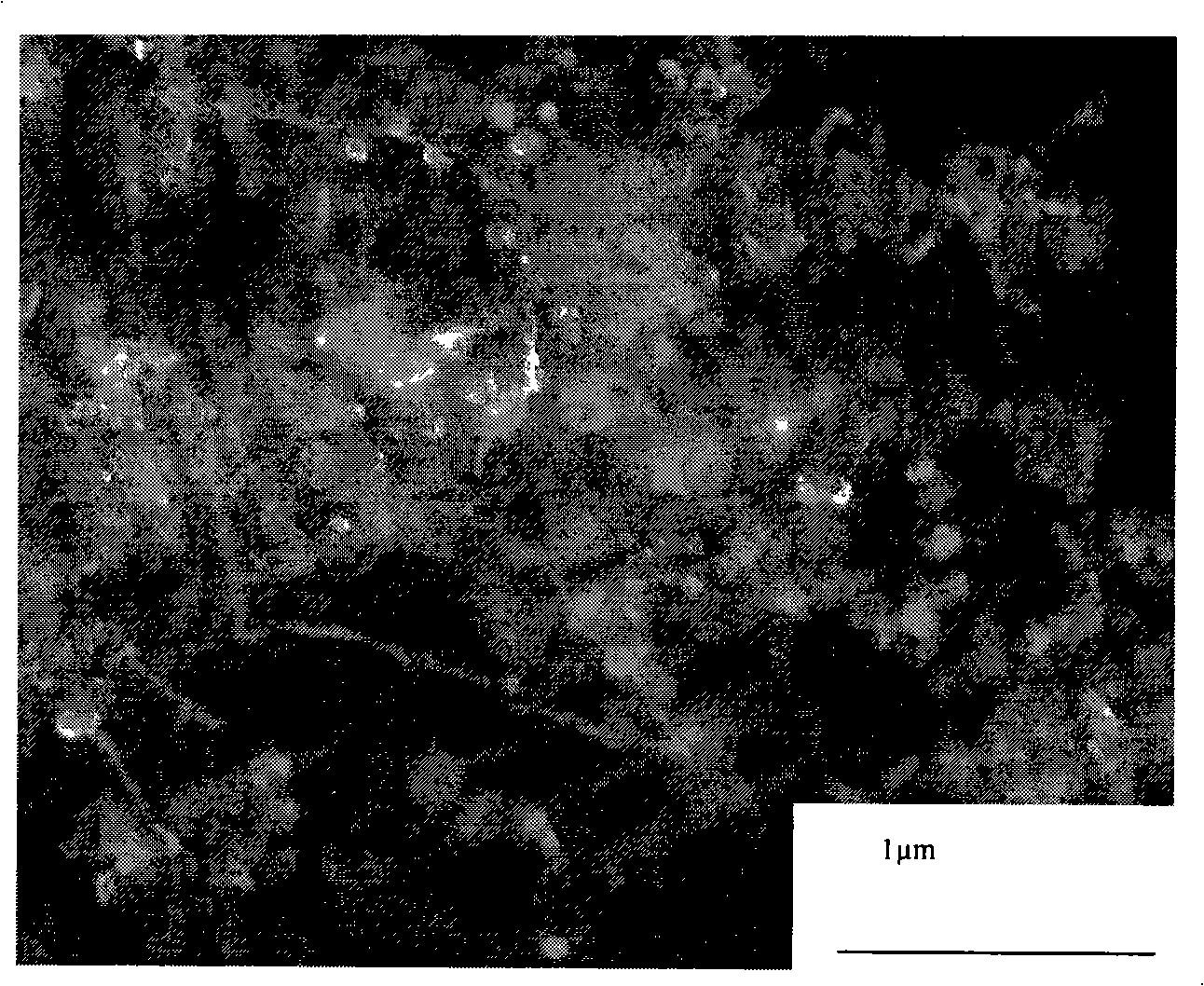

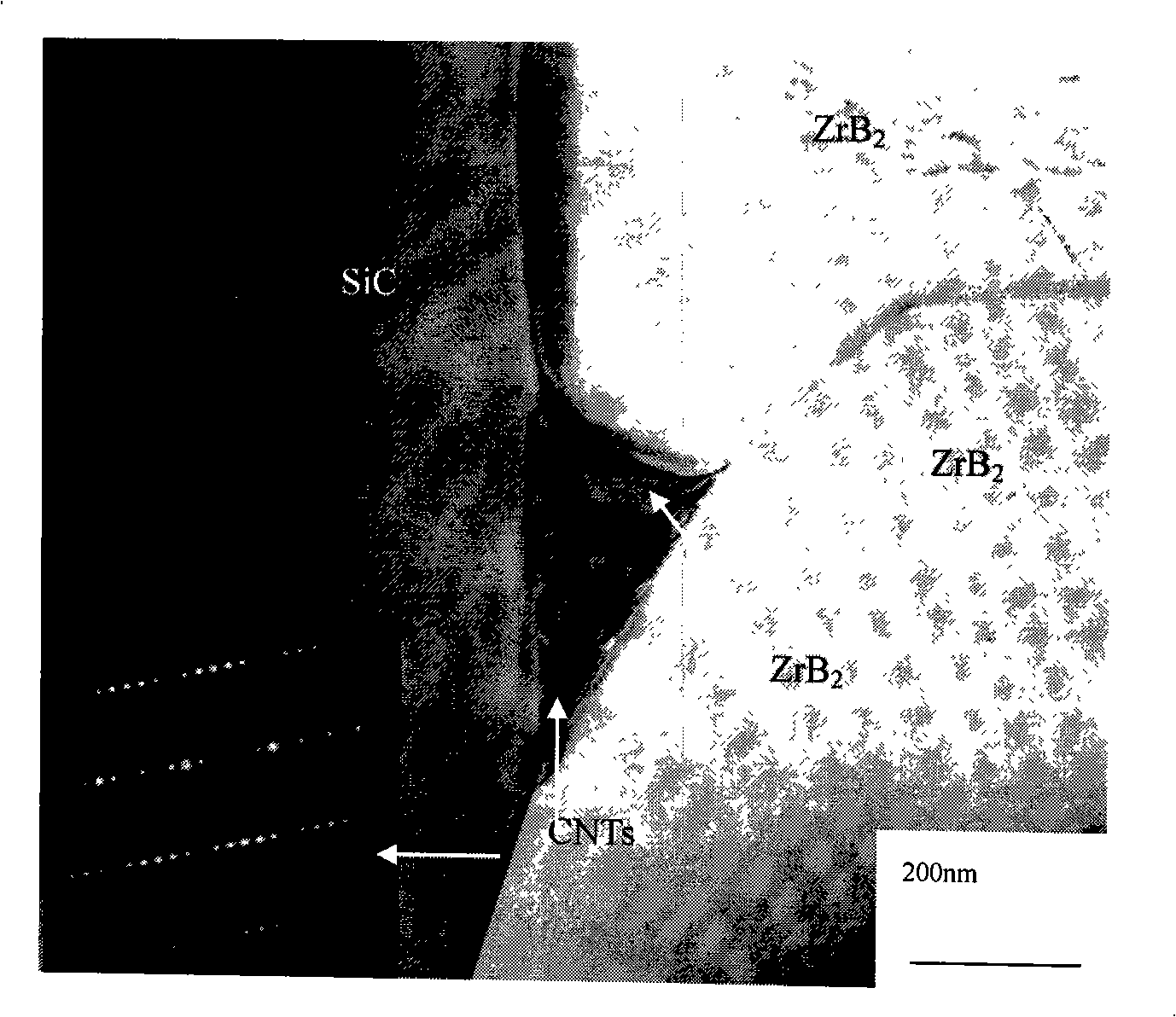

Carbon nano-tube zirconium boride-carborundum based material and preparation method thereof

A carbon nano-tube zirconium boride-silicon carbide composite and a method for the products thereof relate to a zirconium boride-silicon carbide composite and a method for the products thereof. The invention solves the problem that the prior zirconium boride - silicon carbide composite is fragile, low-intensity and poor in sintering performance. The inventive product is mainly prepared by zirconium boride, silicon carbide and carbon nano-tube. The preparation method of the invention includes: dispersing carbon nano-tubes ultrasonically in dispersing agents; adding zirconium boride and silicon carbide; then ball milling and dispersing, drying, grinding; putting the mixed powder into a graphite die coated with release agent for hot pressing. The inventive composite material has a relative density of 98.1%-99.8%, a fracture toughness increased by 19%-44% than that of zirconium boride - silicon carbide base, a bending strength increased by 13 per cent-85 per cent than that of zirconium diboride - silicon carbide base and a sintering temperature reduced to 1800 DEG C.

Owner:HARBIN INST OF TECH

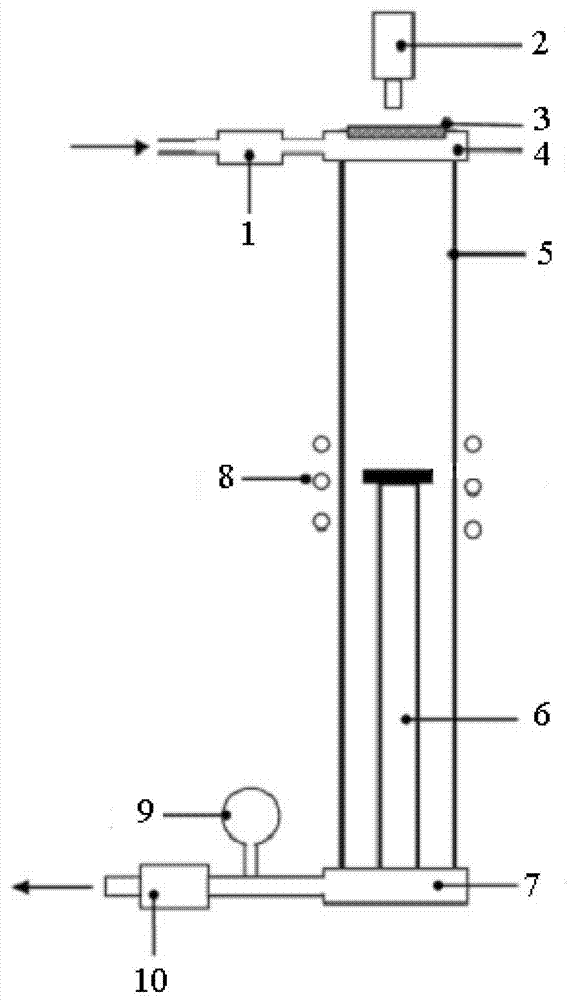

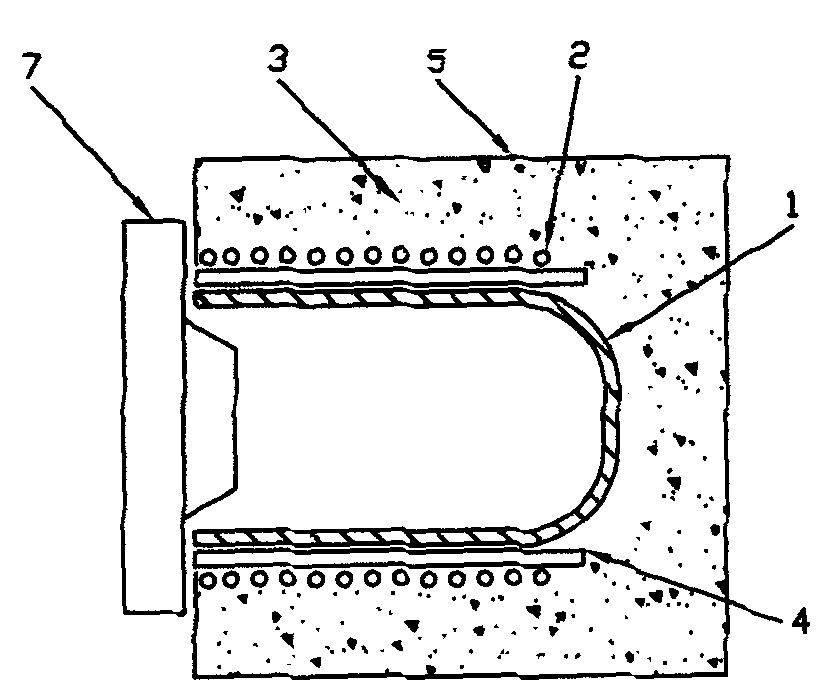

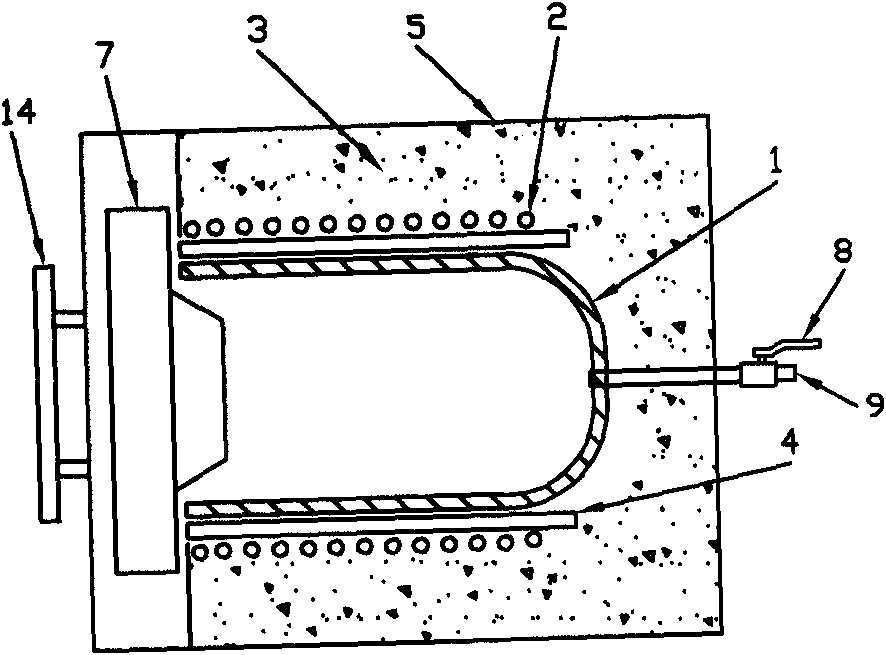

Ultrahigh temperature heating furnace

InactiveCN101788225AHigh melting pointHigh temperature ceramic materials are a class of high melting pointMuffle furnacesRetort furnacesComposite ceramicTransformer

The invention discloses an ultrahigh temperature heating furnace which comprises a transformer, a controller, a furnace body, an inductor, a heat-preserving insulating material, a hearth, an infrared thermometer and a circulating water cooling device, wherein the heat-preserving insulating material is arranged in the furnace body, the infrared thermometer is arranged at one side of the furnace body, the transformer, the controller and the inductor are cooled through circulating water, the hearth is made of a zirconium diboride composite ceramic material, the inductor is positioned at the periphery of the hearth, and the heat-preserving insulating material is arranged between the inductor and the hearth. In the invention, when an alternating current power supply is input into an induction coil, an alternating electromagnetic field is formed in the inductor mainly through an induction heating principle. When the magnetic flux of the alternating electromagnetic field passes through the hearth made of the ZrB2 composite ceramic material, an eddy current can be generated, a large amount of heat can be generated by the hearth made of the ZrB2 composite ceramic material, and the hearth can heat. A high temperature environment is formed in the hearth and used for sintering under an oxidizing atmosphere and a vacuum atmosphere.

Owner:LUOYANG SIGMA FURNACE

High-temperature-resistant and cracking-resistant cable material and preparation method thereof

InactiveCN103351516AImprove high temperature performanceIncrease softnessPlastic/resin/waxes insulatorsSlagMechanical property

The invention provides a high-temperature-resistant and cracking-resistant cable material and a preparation method thereof. The cable material is characterized by comprising the following raw materials by weight parts: 3-4 parts of stearic acid polyoxyethylene ester, 4-5 parts of nano-clay brick slag powder, 2-3 parts of vanadium diboride, 1-2 parts of zirconium diboride, 64-66 parts of linear low-density polyethylene, 12-14 parts of impact-resistant polystyrene, 6-8 parts of ABS, 2-3 parts of dibutyltin dilaurate, 2-3 parts of cyanuric acid zinc, 1-2 parts of zinc oxide, 2-3 parts of zine stearate, 3-4 parts of a silane coupling agent KH560, 42-46 parts of bauxite, 12-15 parts of bentonite, 1-2 parts of an accelerator DM, 1-2 parts of an antioxidant OD, 2-3 parts of a titanate coupling agent TMC-TTS, 3-4 parts of 2-ethyl methacrylate, 12-14 parts of carbon black N 220, 22-25 parts of carbon black N 660, 3-4 parts of beryllia and 6-8 parts of modified diatomite. According to the invention, the impact-resistant polystyrene is relatively good in high-temperature performance and thus can improve heatproof level of products, with the heatproof level being 150 DEG C. Furthermore, mechanical properties are improved, cracking problems are eliminated, and a flexibility of the cable material is high.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

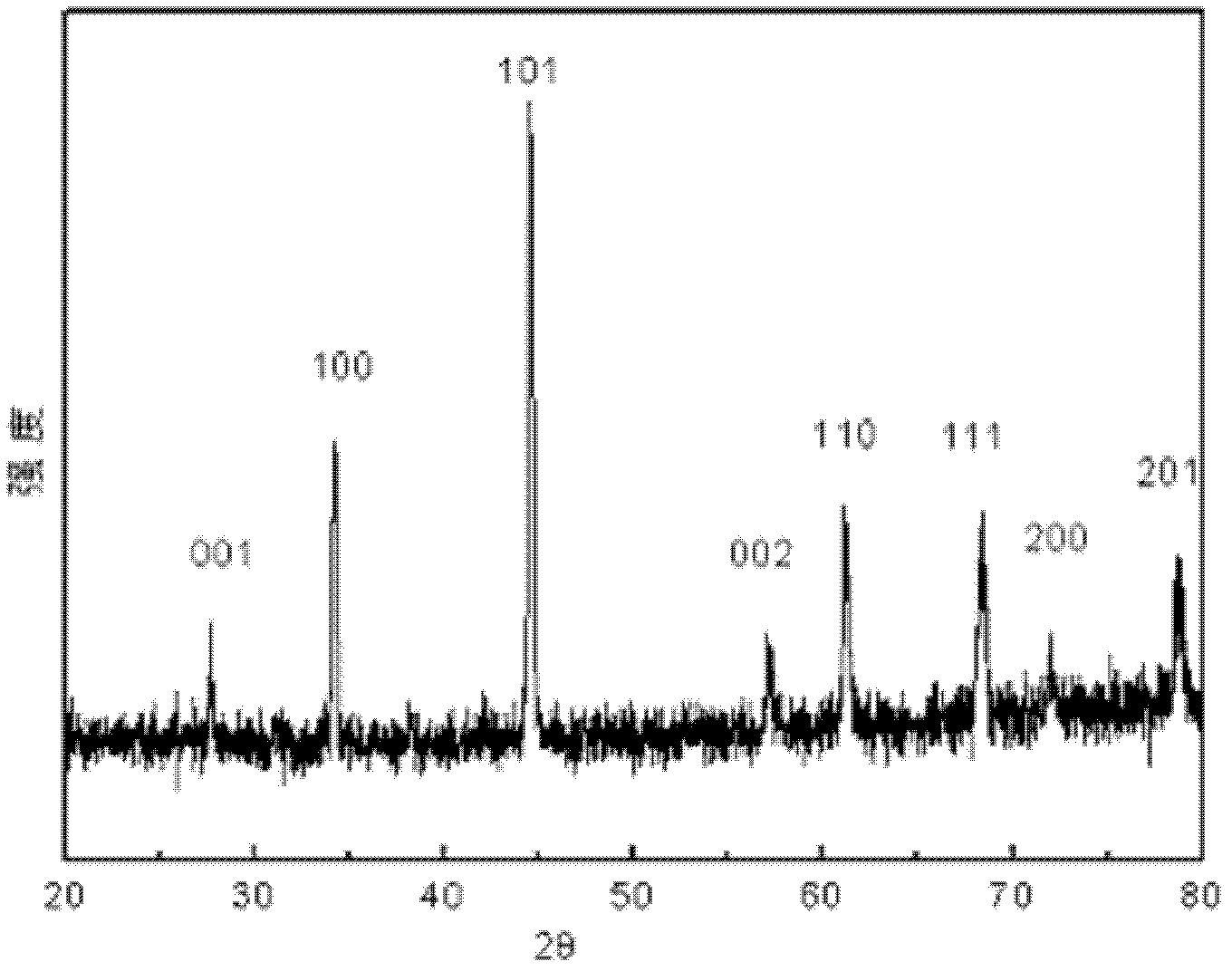

Process for preparing high-density zirconium diboride blocks by spark plasma sintering

InactiveCN1837044ASintered to achieveFast sinteringZirconium compoundsMetal boridesHigh densityAxial pressure

The invention refers to a method for preparation of zirconium diboride block material. The method is about a discharging plasma sinter high-integrity zirconium diboride block material, the character is lies in it includes steps as follows: directly posting coated format ZrB2 in graphite mould, and then putting mould in discharging plasma sintering furnace, applying axial pressure of 10- 50MPa, adopting vacuum condition or interia atmosphere which vacuum degree is less than 10Pa, sintering in sintered temperature of 1600- 2200Deg C, heating-up with rate of 50-500Deg C / min, heat preserving for 1-30min, cooling under 1300Deg C with cooling rate of 10-100Deg C / min, finally furnace cooling to room temperature, getting high degree of compactness zirconium diboride block material. The produced zirconium diboride block materials have high degree of compactness, hardness, high-temperature strength and oxidation resistance capability.

Owner:WUHAN UNIV OF TECH

Composition for making submerged nozzle

The invention relates to a composition used to make submerged nozzles, which comprises a composition used to make a main body and a composition used to make a slag line part, wherein the composition used to make the main body consists of feldspar, corundum, silicon carbide, graphite and phenolic resin and the composition used to make the slag line part consists of zirconia, zirconium boride, graphite and phenolic resin. The combination mode between atoms of the composition used to make the main body can form a structure of carbon-carbon bond and porcelain composition, so as to improve the strength of the composition; zirconium diboride in the composition used to make the slag line part can improve corrosion resistance; and simultaneously, two materials adopted according to different parts can reduce cost in manufacturing.

Owner:BENGANG STEEL PLATES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com