Preparation method of ultra-temperature oxidative damage resistant zirconium diboride-silicon carbide ceramic base composite material

The technology of silicon carbide ceramic base and zirconium diboride is applied in the field of preparation of ceramic matrix composite materials, which can solve the problems of poor stability of oxide layer, and achieve the effects of good oxidation resistance, simple and effective oxidation damage, and improvement of oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment 1: This embodiment is a method for preparing a zirconium diboride-silicon carbide ceramic matrix composite material resistant to ultra-high temperature oxidation damage, which is carried out in the following steps:

[0013] 1. Preparation of zirconium diboride-silicon carbide ceramic matrix composite material: weigh 70~90 parts of zirconium diboride powder and 30~10 parts of silicon carbide powder by weight, and carbonize the zirconium diboride powder The silicon powder is ball-milled and wet-mixed to obtain a slurry, and then the obtained slurry is dried by a rotary evaporator at a temperature of 50°C to 90°C for 1 hour to 4 hours to obtain a dried mixed powder. The obtained dried mixed powder is hot-pressed and sintered at a temperature of 1700°C~190°C under vacuum or inert gas atmosphere, the hot pressing pressure is 30MPa, the holding time is 20 minutes to 60 minutes, and it is naturally cooled to room temperature. Take out, that is, zirconium dibor...

specific Embodiment approach 2

[0021] Specific embodiment two: this embodiment is different from specific embodiment one in that: the particle size of the zirconium diboride powder described in step one is less than 10 microns; the particle size of the silicon carbide powder described in step one is less than 10 microns . Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the inert gas described in step one is argon. Others are the same as the first or second embodiment.

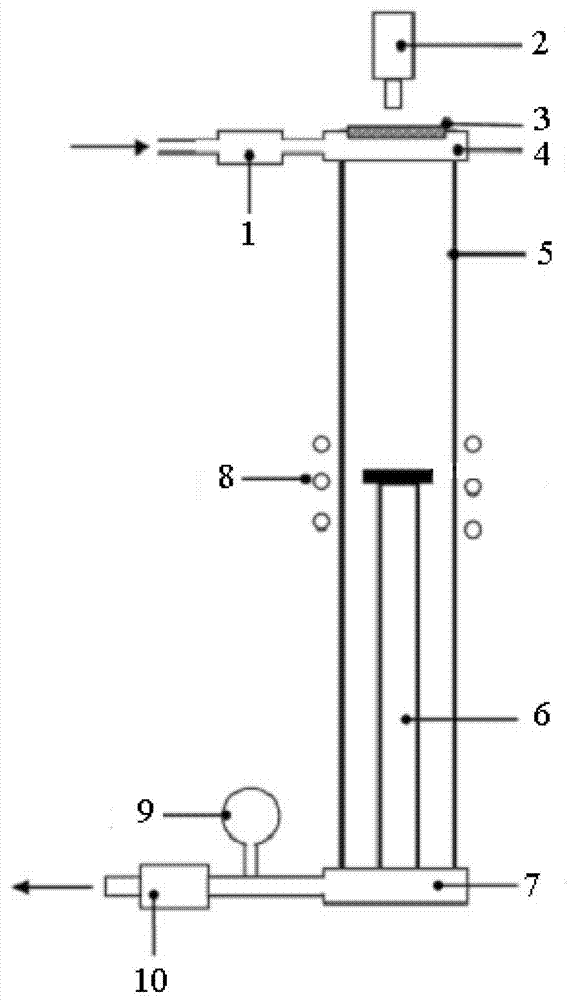

[0023] Specific implementation manner 4: combination figure 1 The difference between this embodiment and specific embodiments 1 to 3 is that the oxidation suppression treatment device described in step 2 includes a flow meter 1, an optical pyrometer 2, a calcium fluoride glass 3, a top cover 4, a quartz tube 5, Zirconia support 6, bottom cover 7, electromagnetic induction heating coil 8, pressure gauge 9 and vacuum pump 10; the flow meter 1 is connected to the air inlet of the top cover 4, and the calcium fluoride glass 3 is embedded in the top cover 4 enables light to penetrate from the inside of the quartz tube 5, the top cover 4 is hermetically connected to the upper end of the quartz tube 5, the bottom cover 7 is hermetically connected to the bottom end of the quartz tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com