Patents

Literature

2311 results about "Pre cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-cooling refers to the rapid removal of field heat shortly after the harvest of a crop. Field heat can be defined as the difference in temperature between the temperature of the crop harvested and the optimal storage temperature of that product.

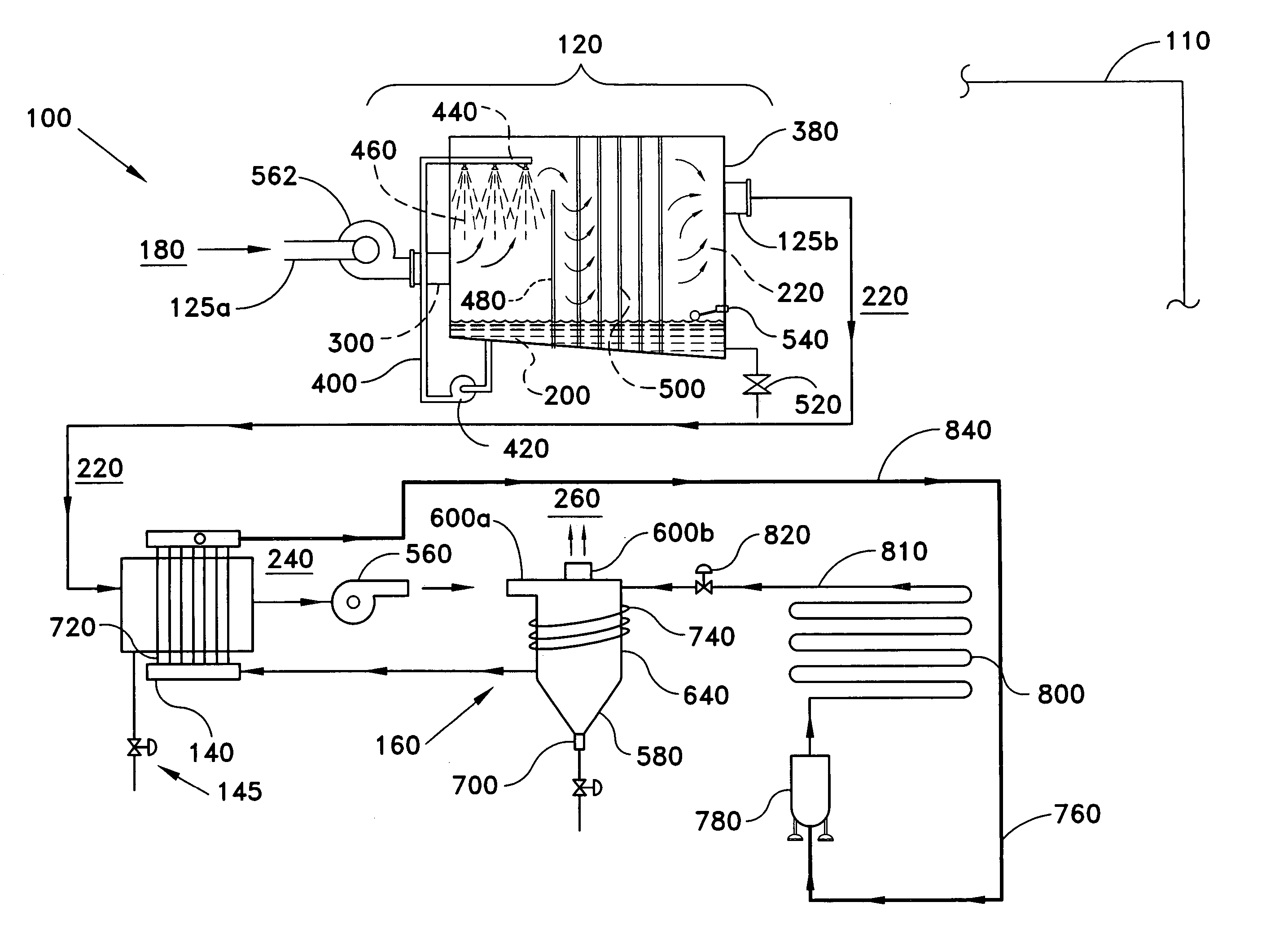

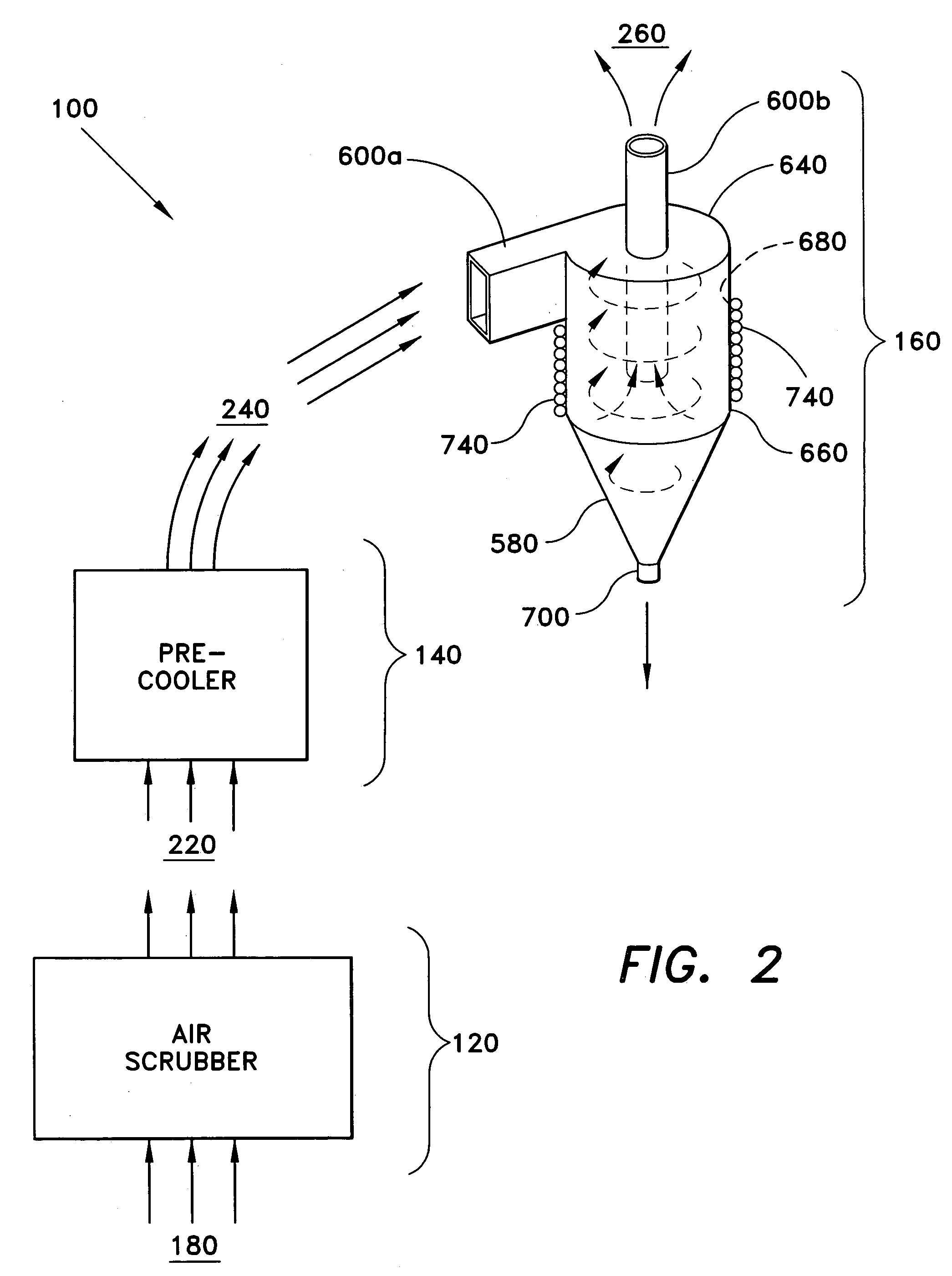

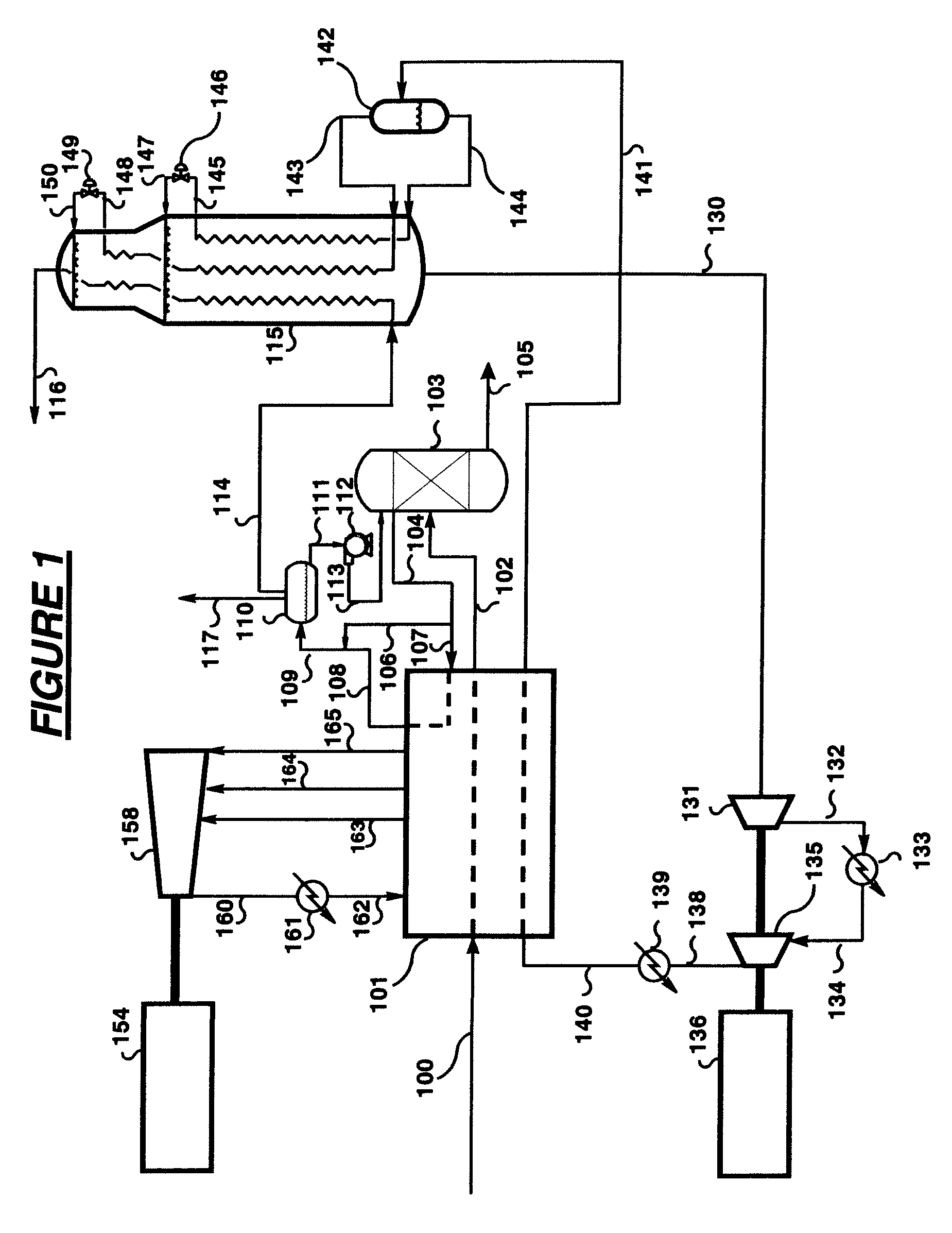

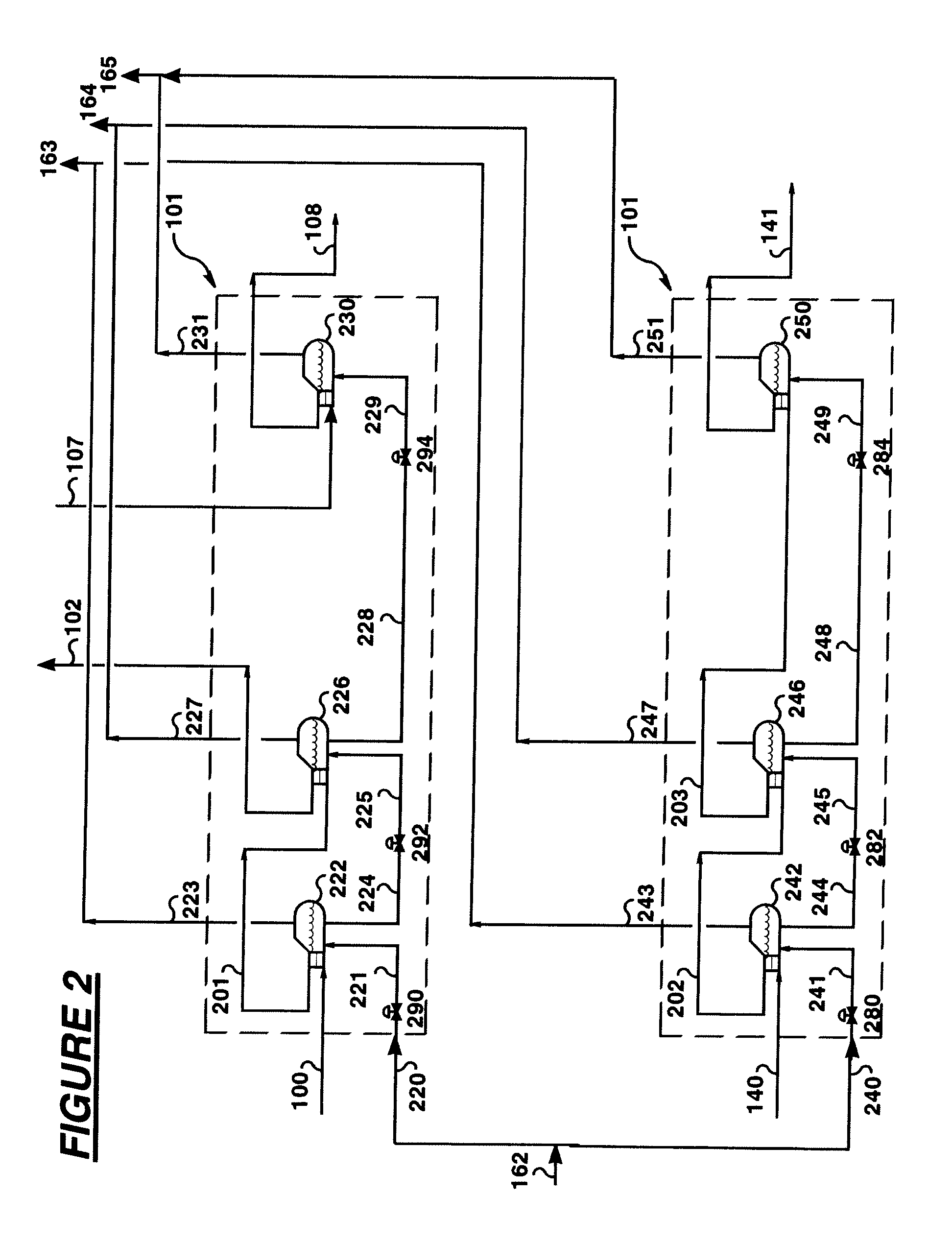

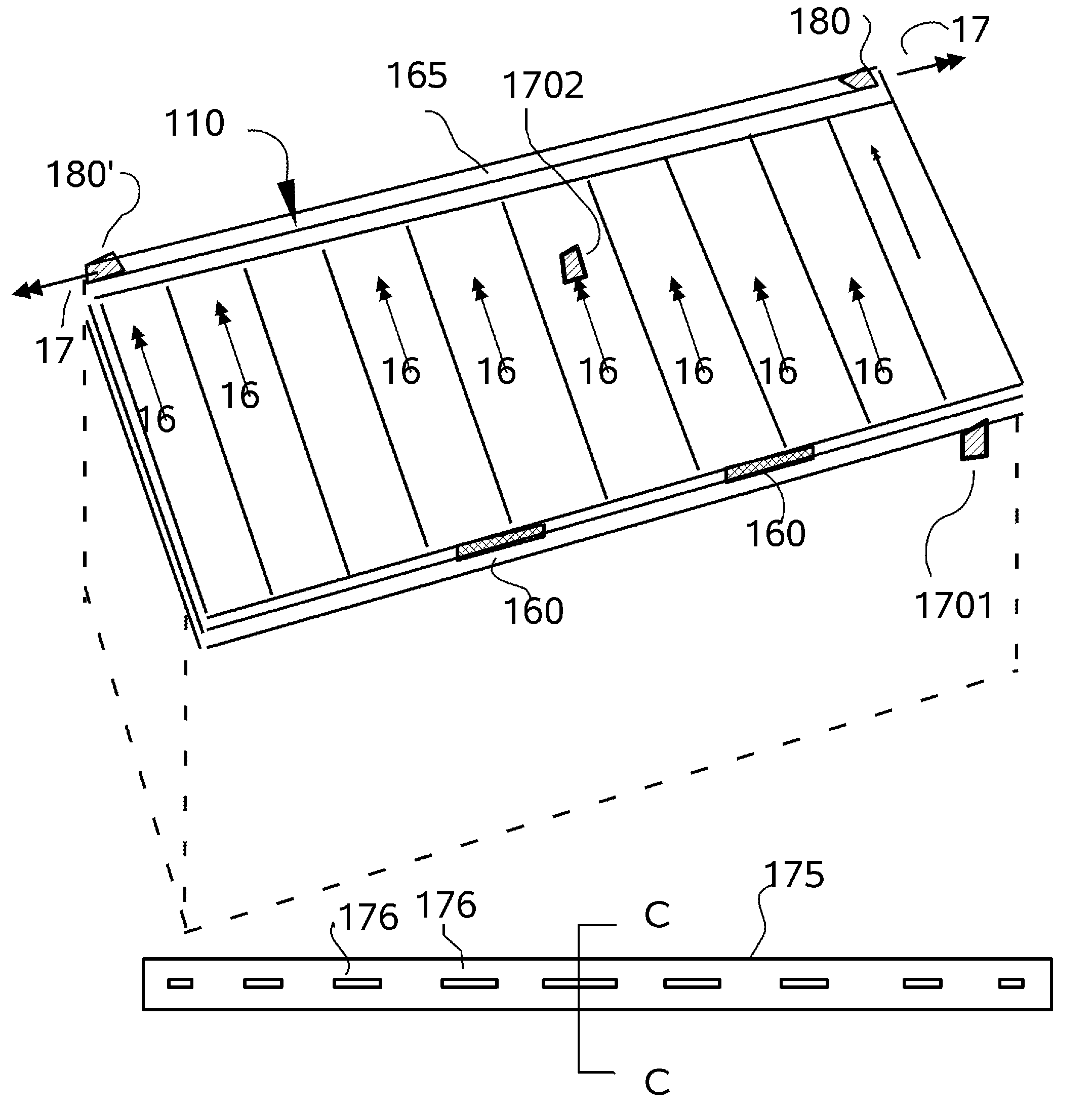

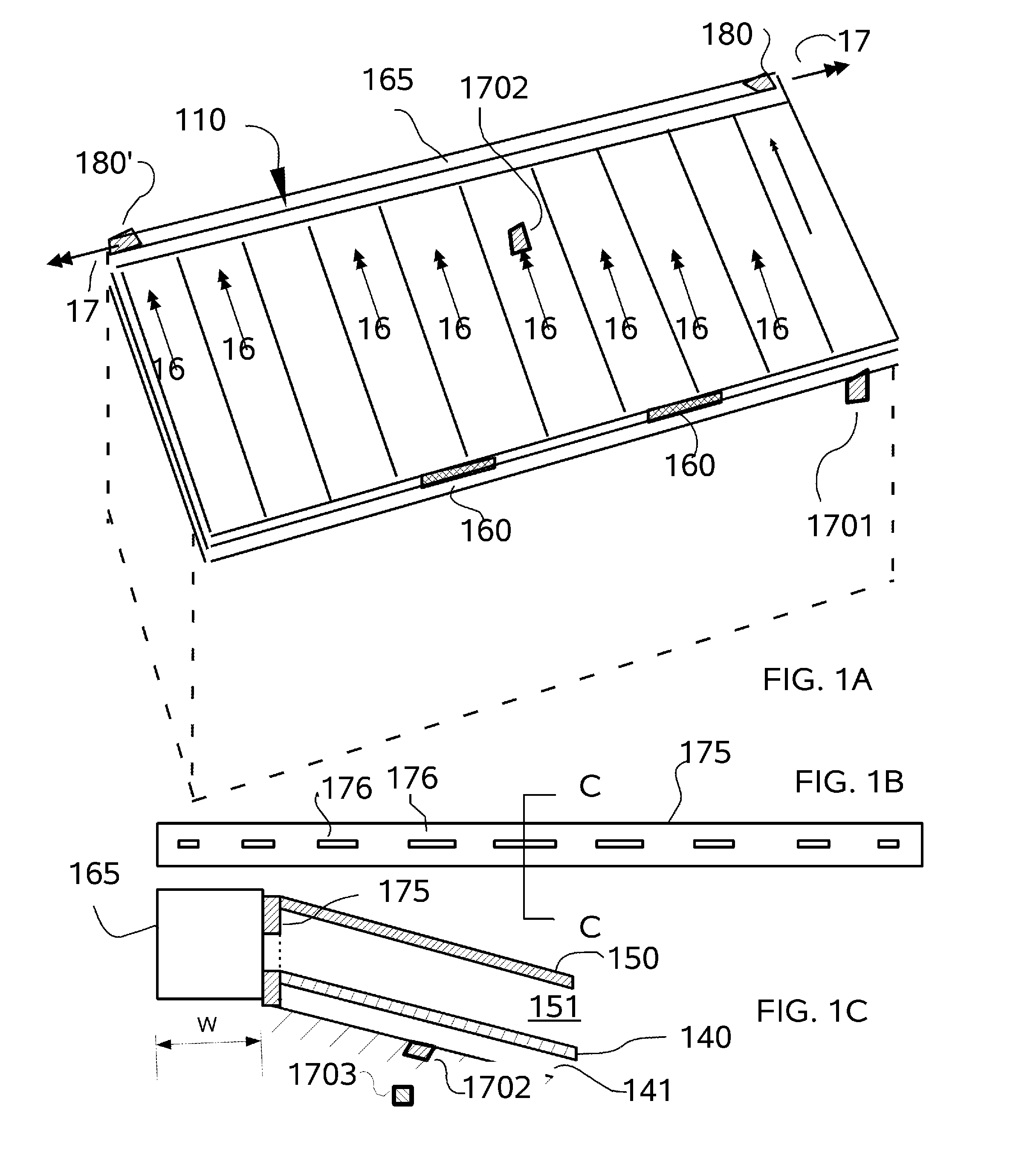

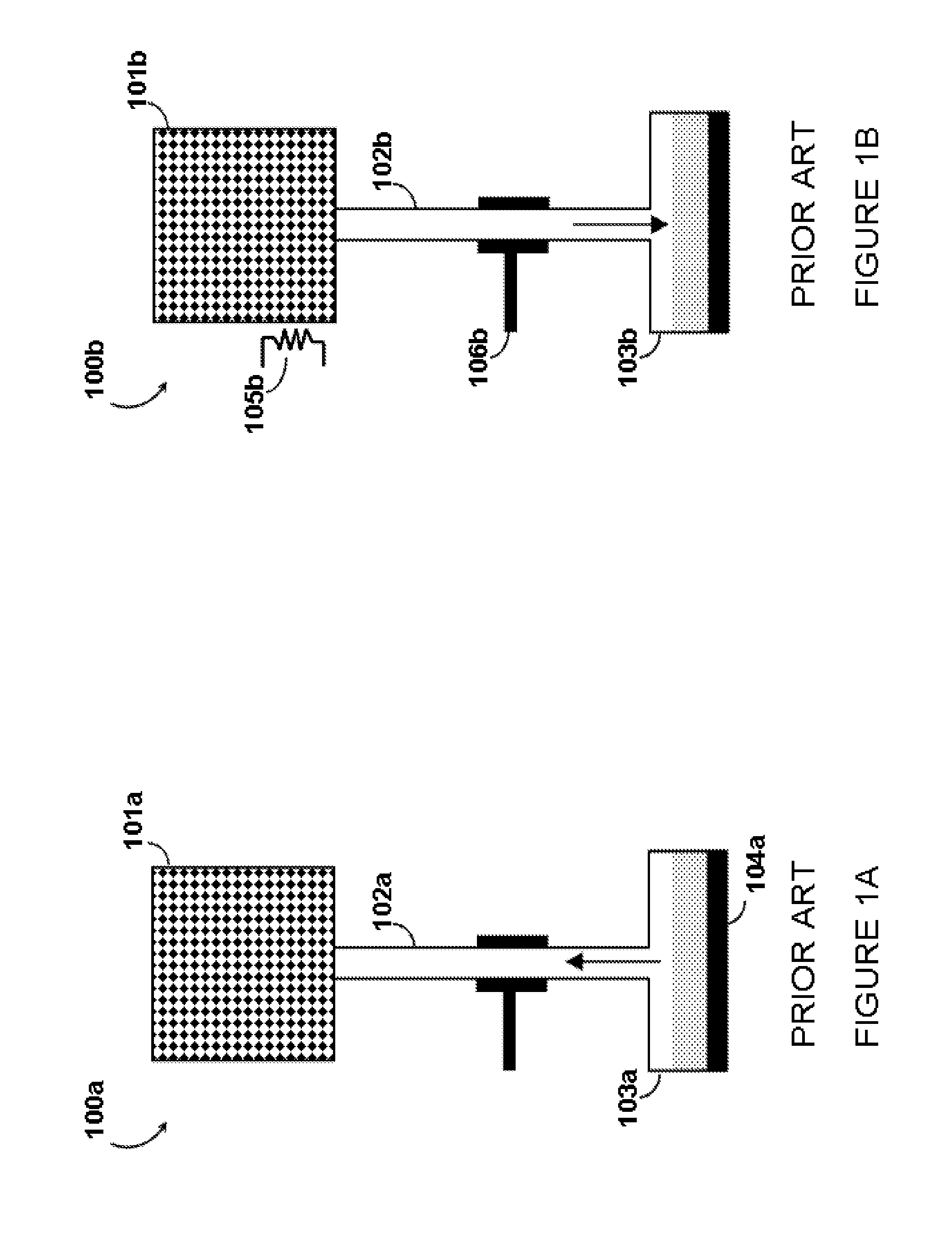

Method and apparatus of indirect-evaporation cooling

InactiveUS6497107B2Less energyHigh energy costFree-cooling systemsStationary conduit assembliesWorking fluidEvaporation

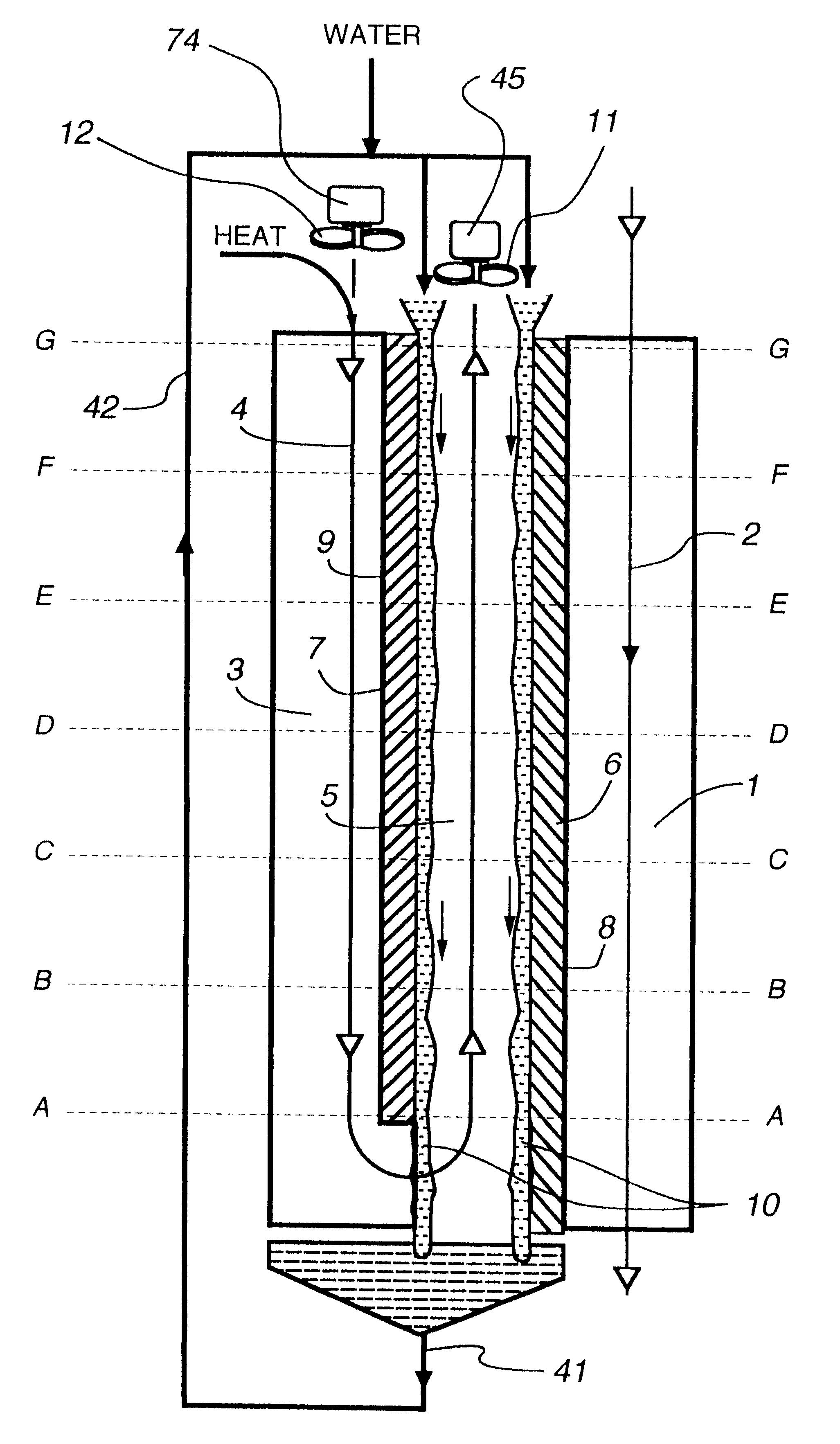

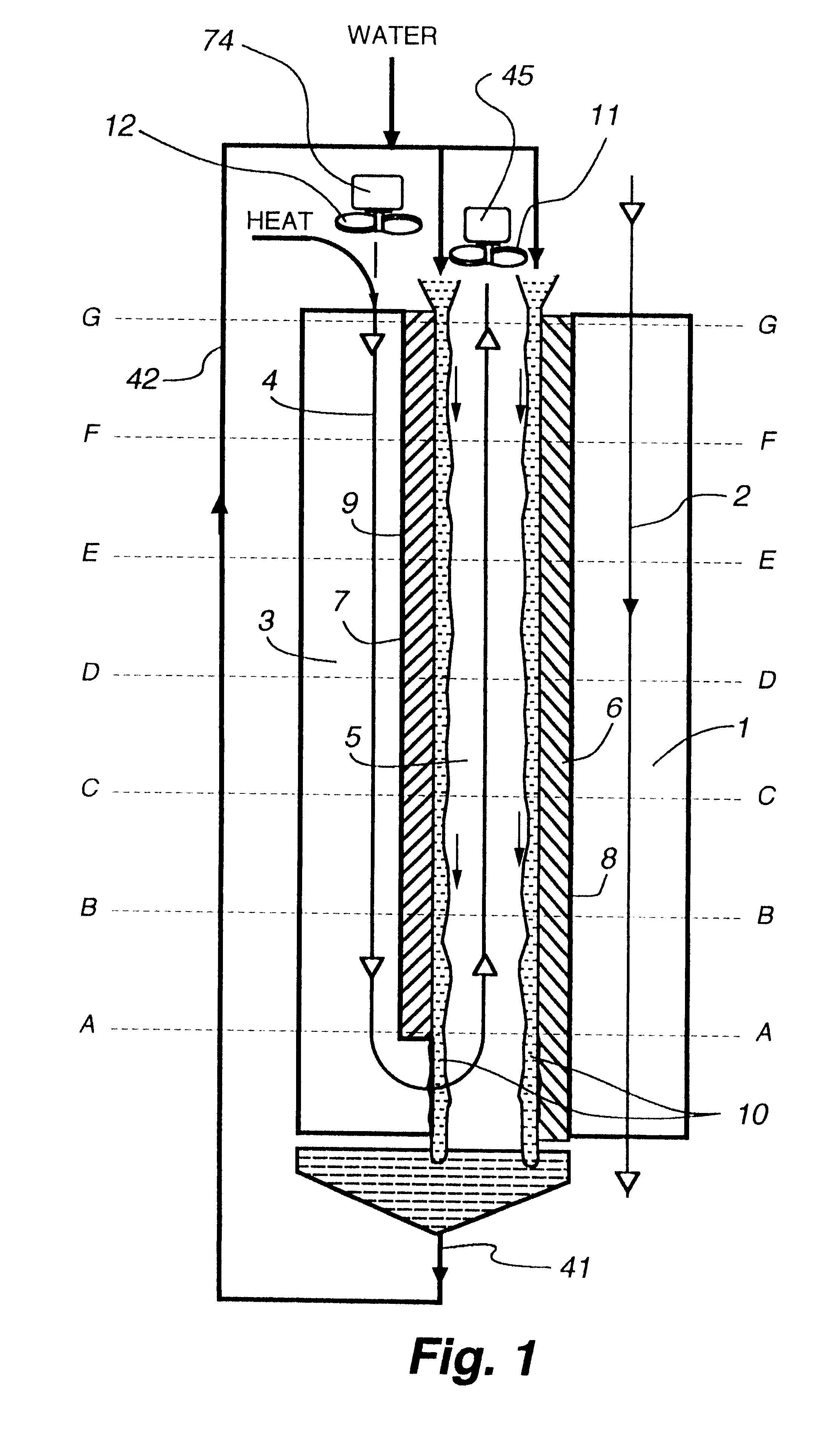

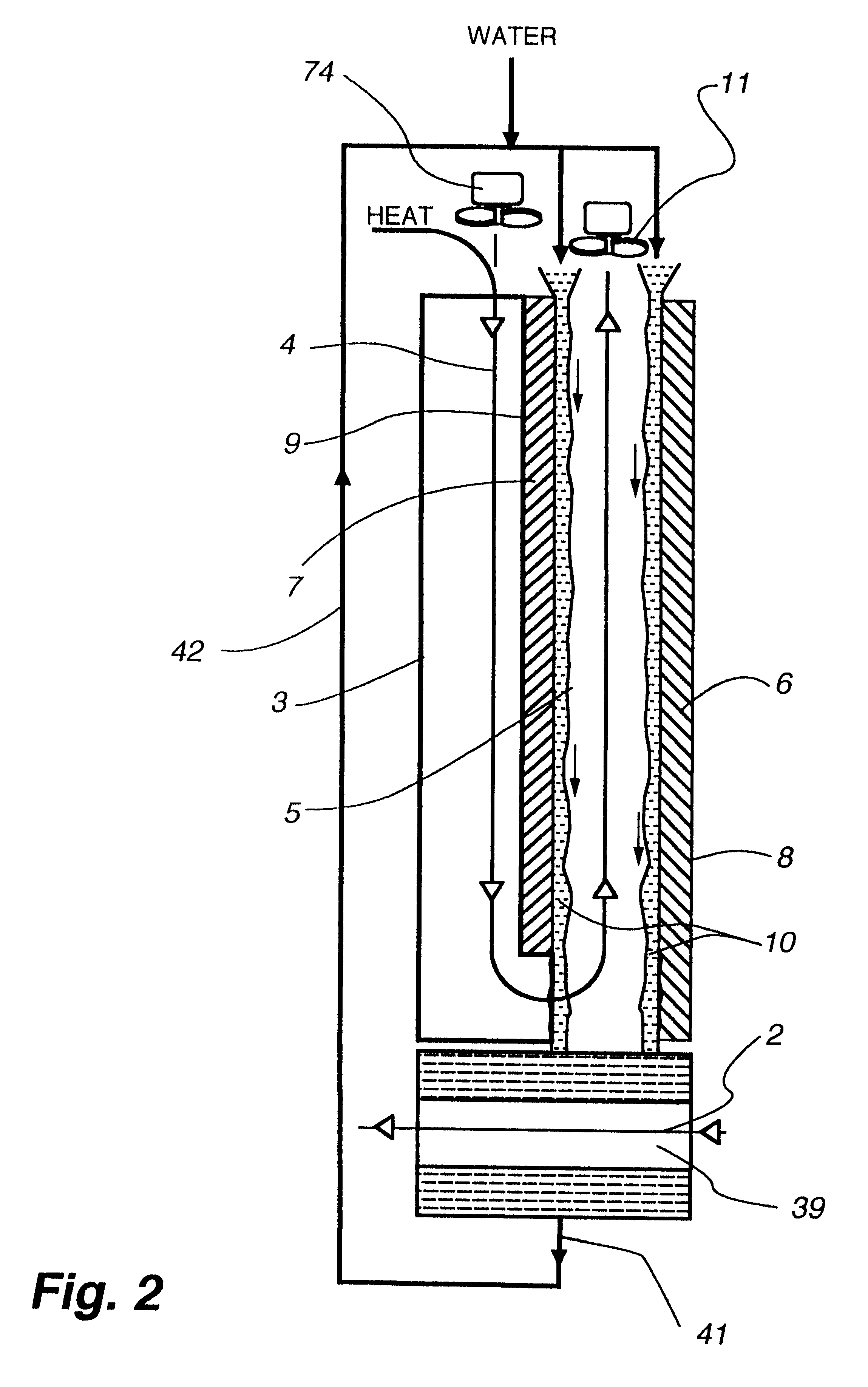

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:F F SEELEY NOMINEES

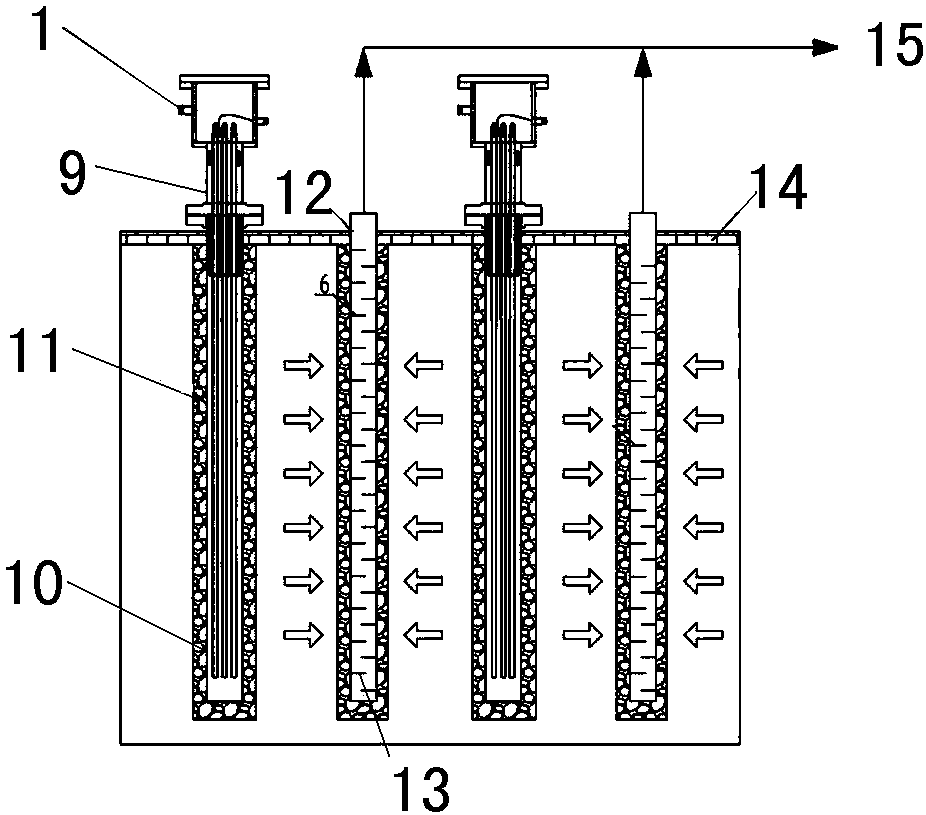

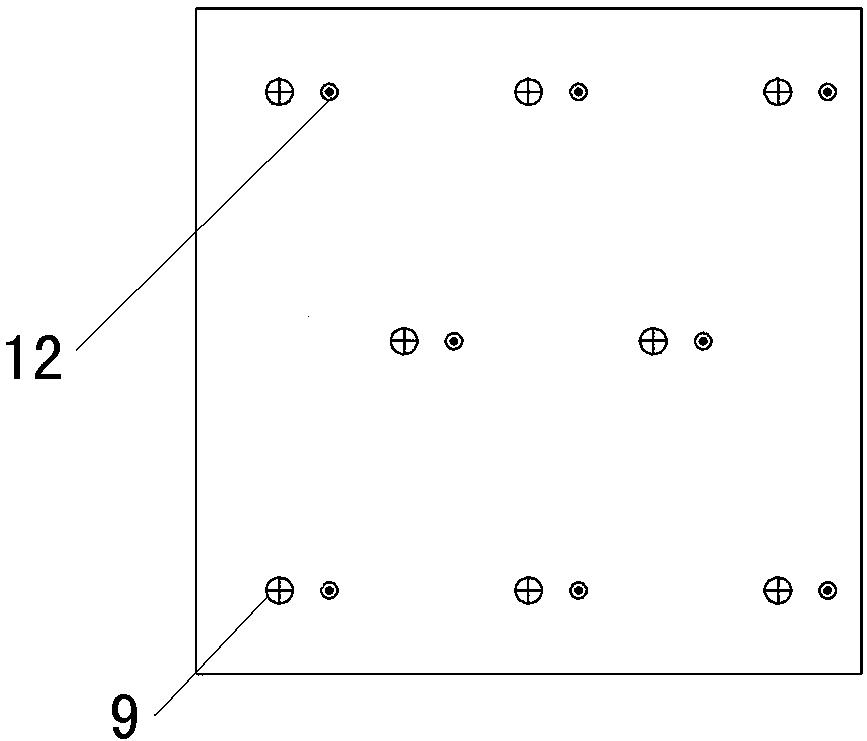

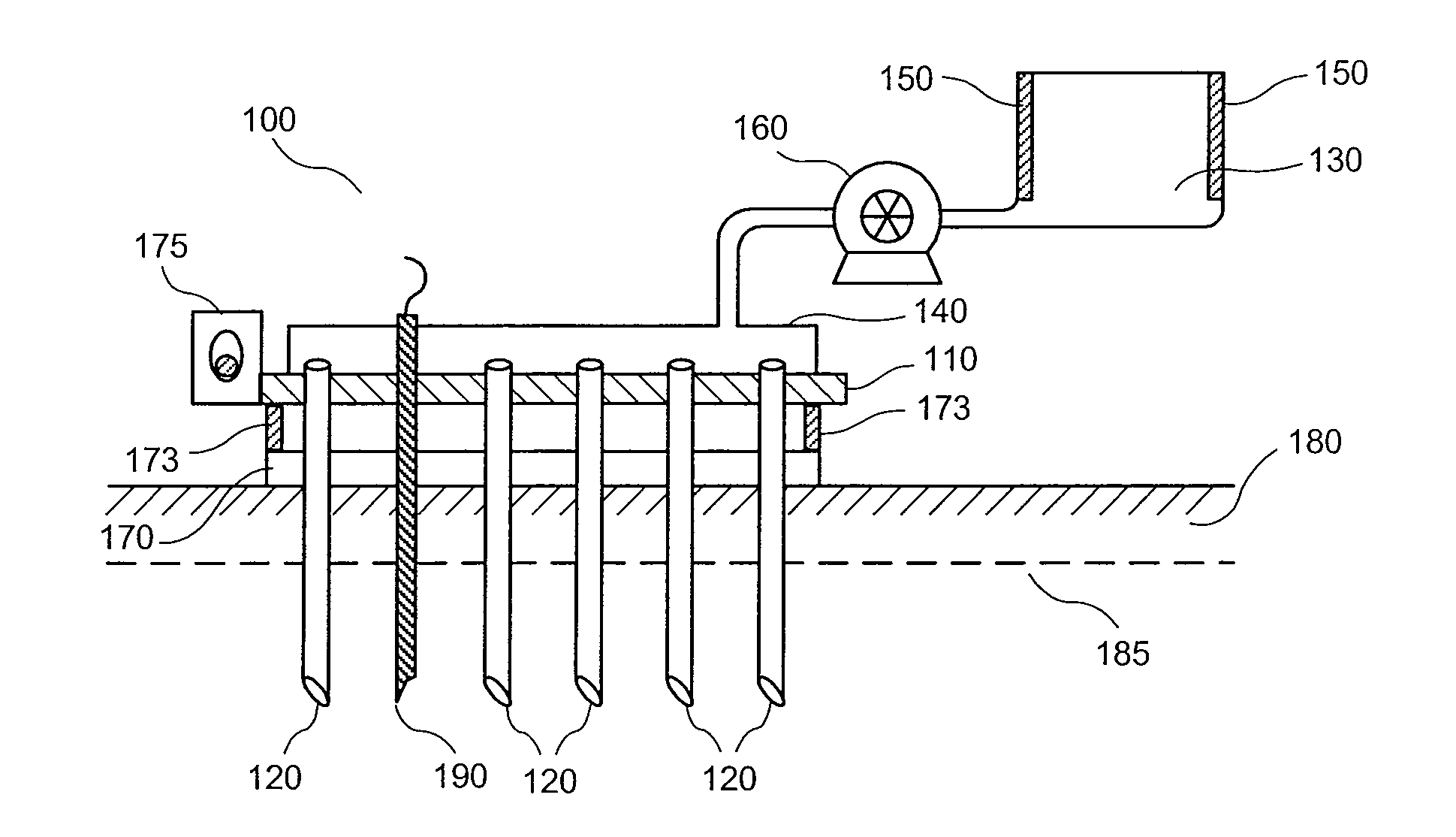

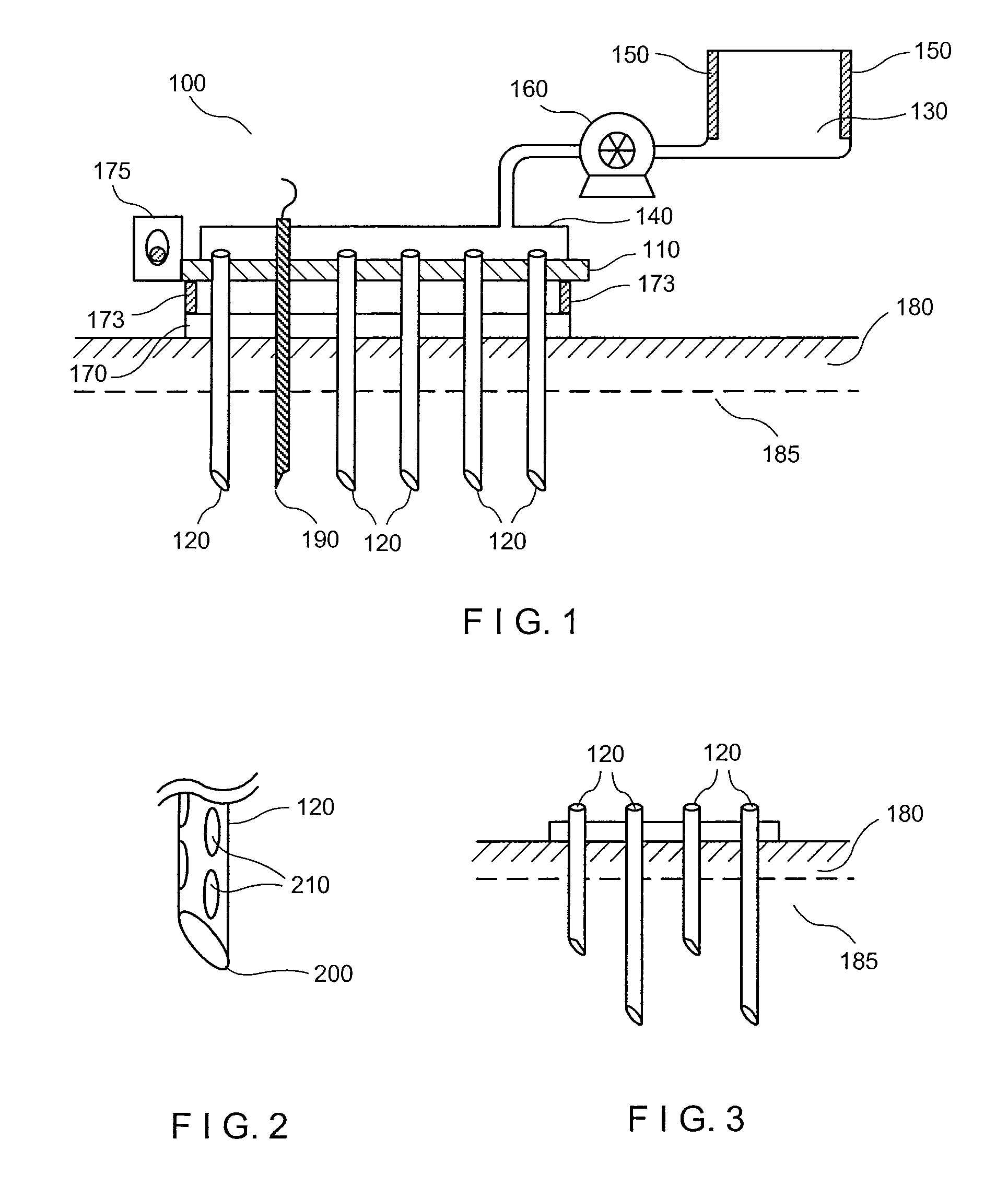

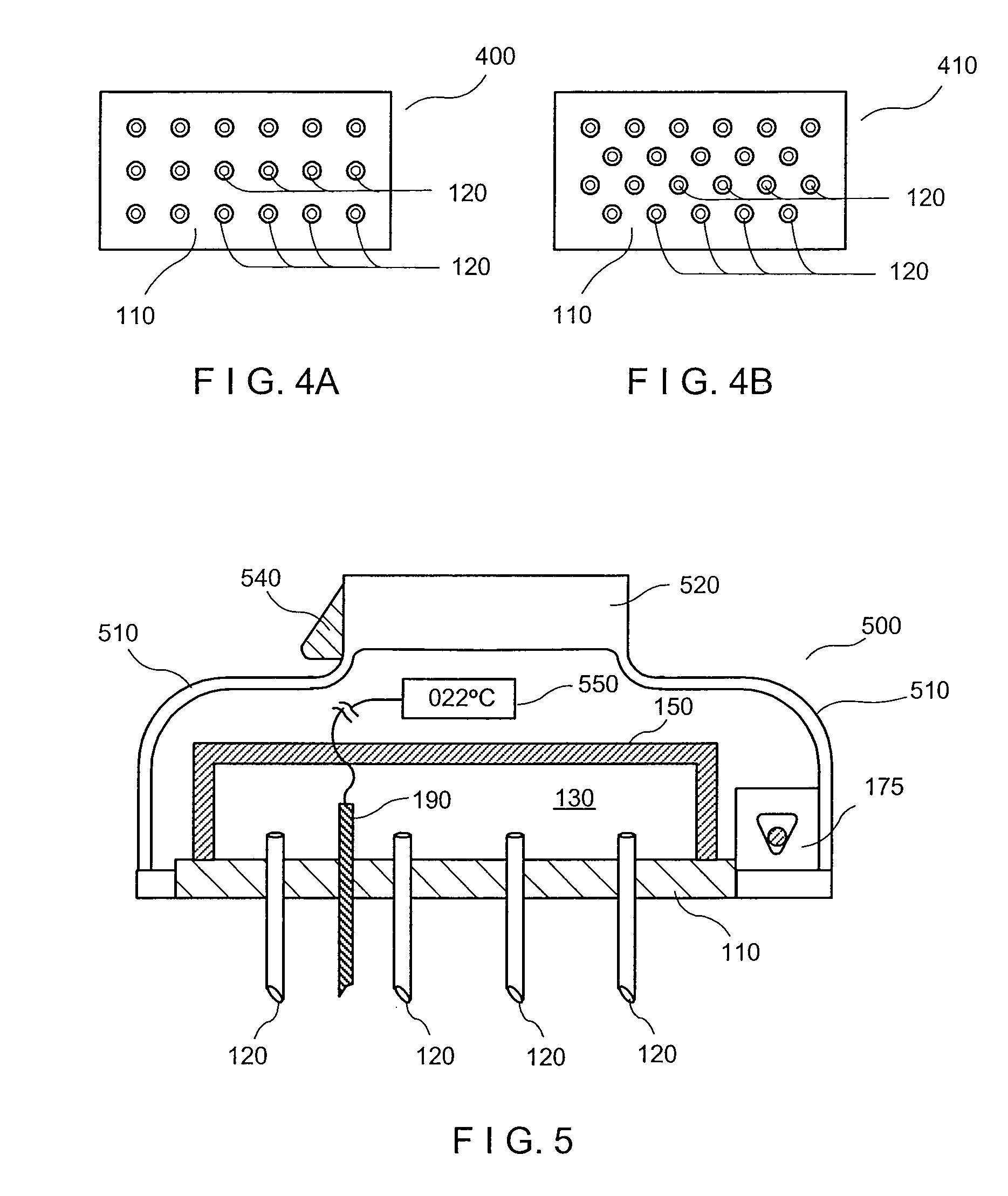

System for restoring organic contaminated soil through in-situ electrical heating and treatment method

ActiveCN108311535AUniversalPull out in timeCombination devicesContaminated soil reclamationTreatment effectSoil properties

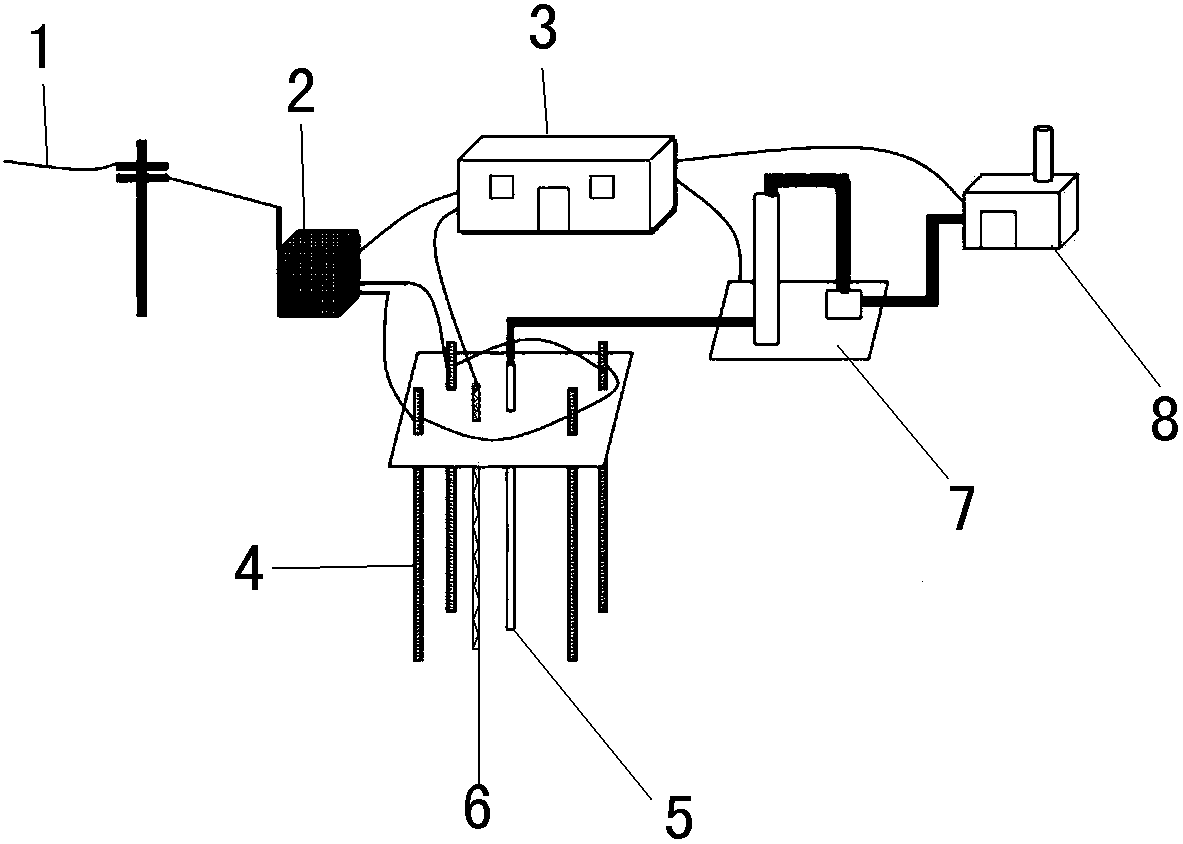

The invention provides a system for restoring organic contaminated soil through in-situ electrical heating. The system comprises an infrastructure technology, an electronic control system, a gas treatment system, a monitoring and data acquisition system and a repairing effect comprehensive assessment system. The infrastructure technology comprises heating well and extraction well construction, ground compaction and insulating layer construction technologies; heating wells are distributed on a contaminated site according to a triangle arrangement principle and a proximity principle, and the extraction well is arranged in the geometric center of the layout of the heating well; the gas treatment system is composed of a pre-cooling adsorption sledge, an extraction sledge and a treatment sledge, and is used for completing gas extraction and treatment and achieving the tail gas discharging requirement; and the repairing effect comprehensive assessment system evaluates the temperature risingeffect of the contaminated soil in the restoring process and the treatment effect of the contaminated soil. According to the system, the technological route is complete, the soil property applicability is wide, the heating temperature can reach 500 DEG C or above, and volatile and difficult-to-volatilize organic contaminant can be treated at the same time.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION +1

Air purification system and method

Owner:LEE DAVID B

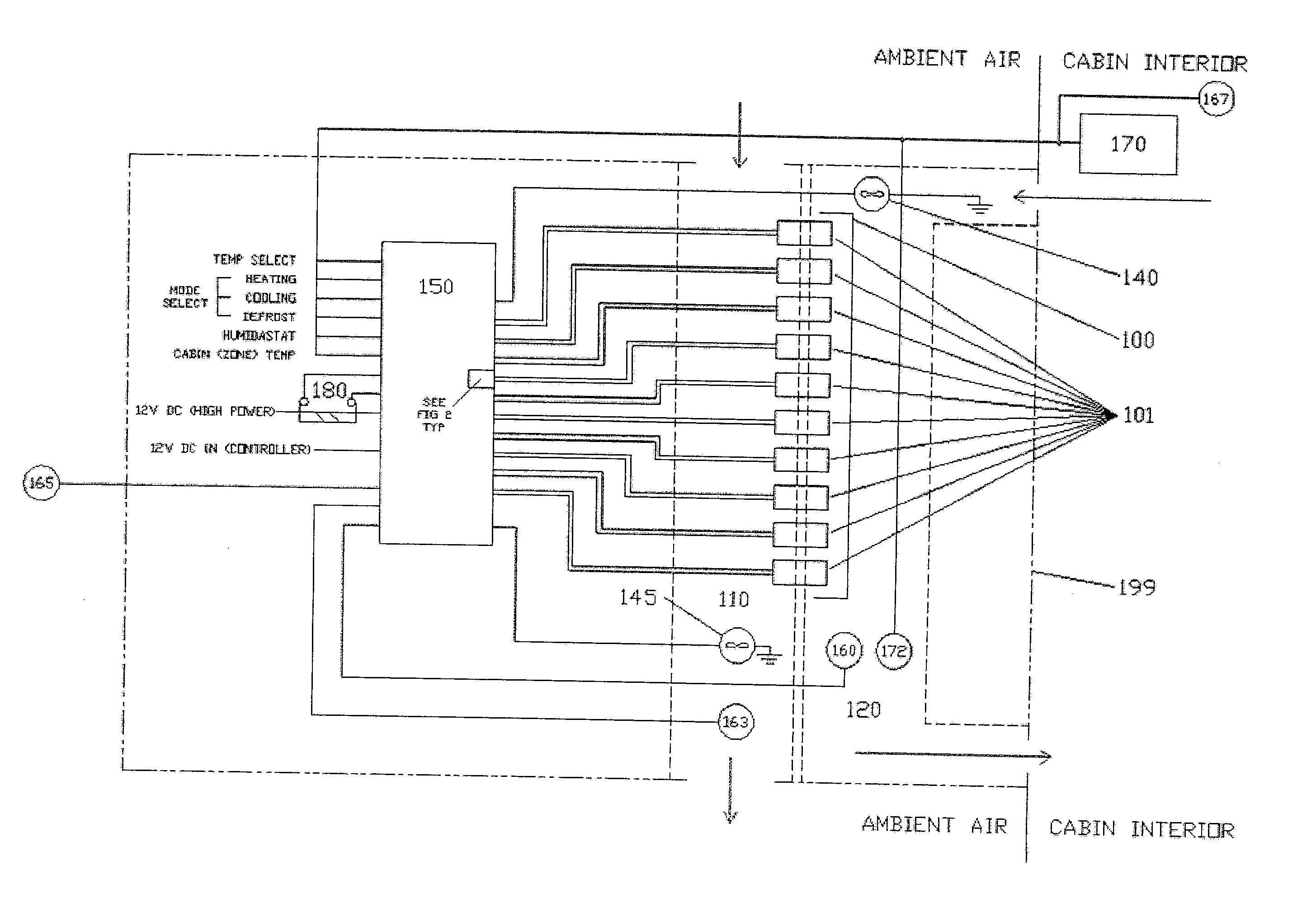

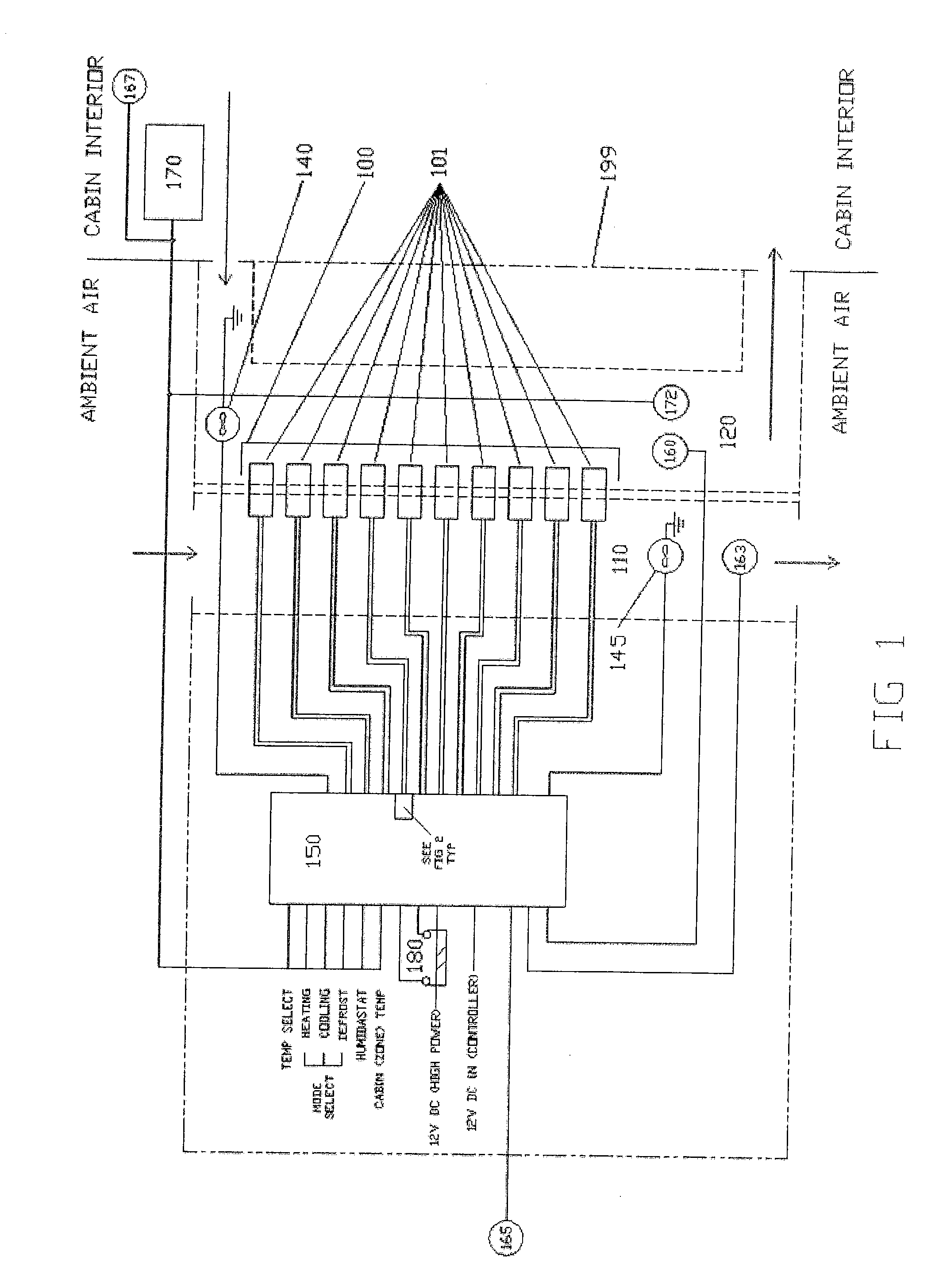

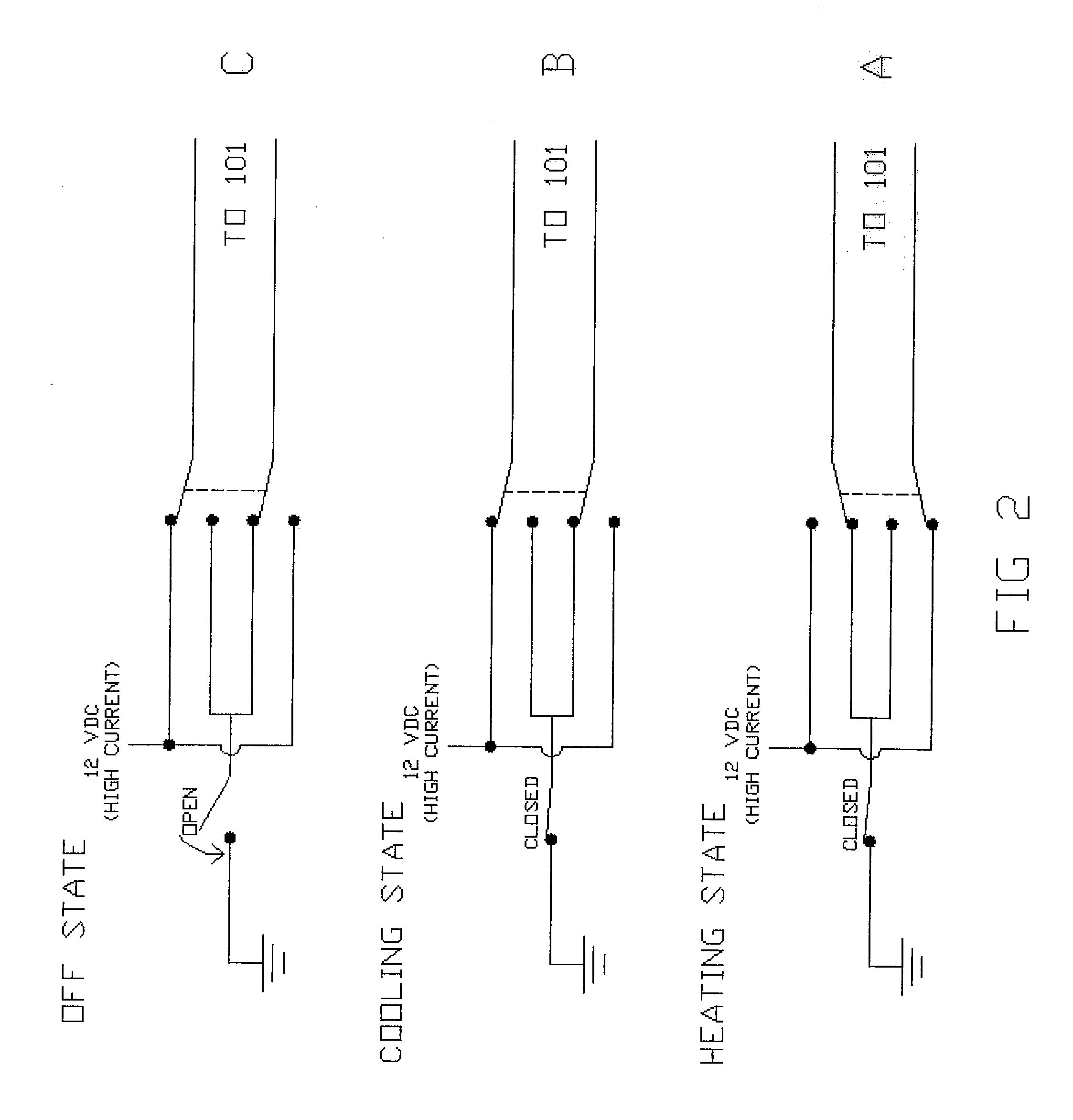

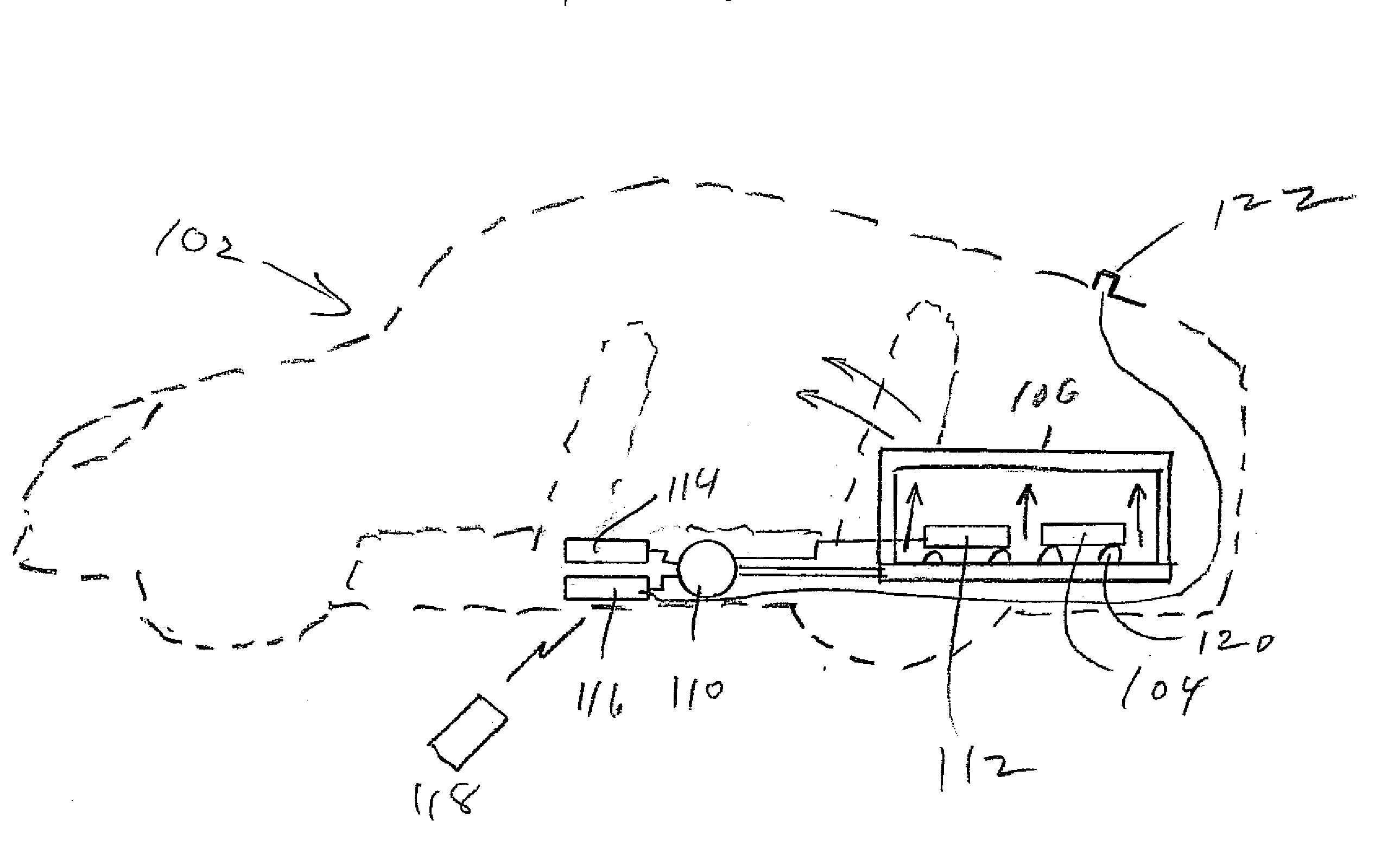

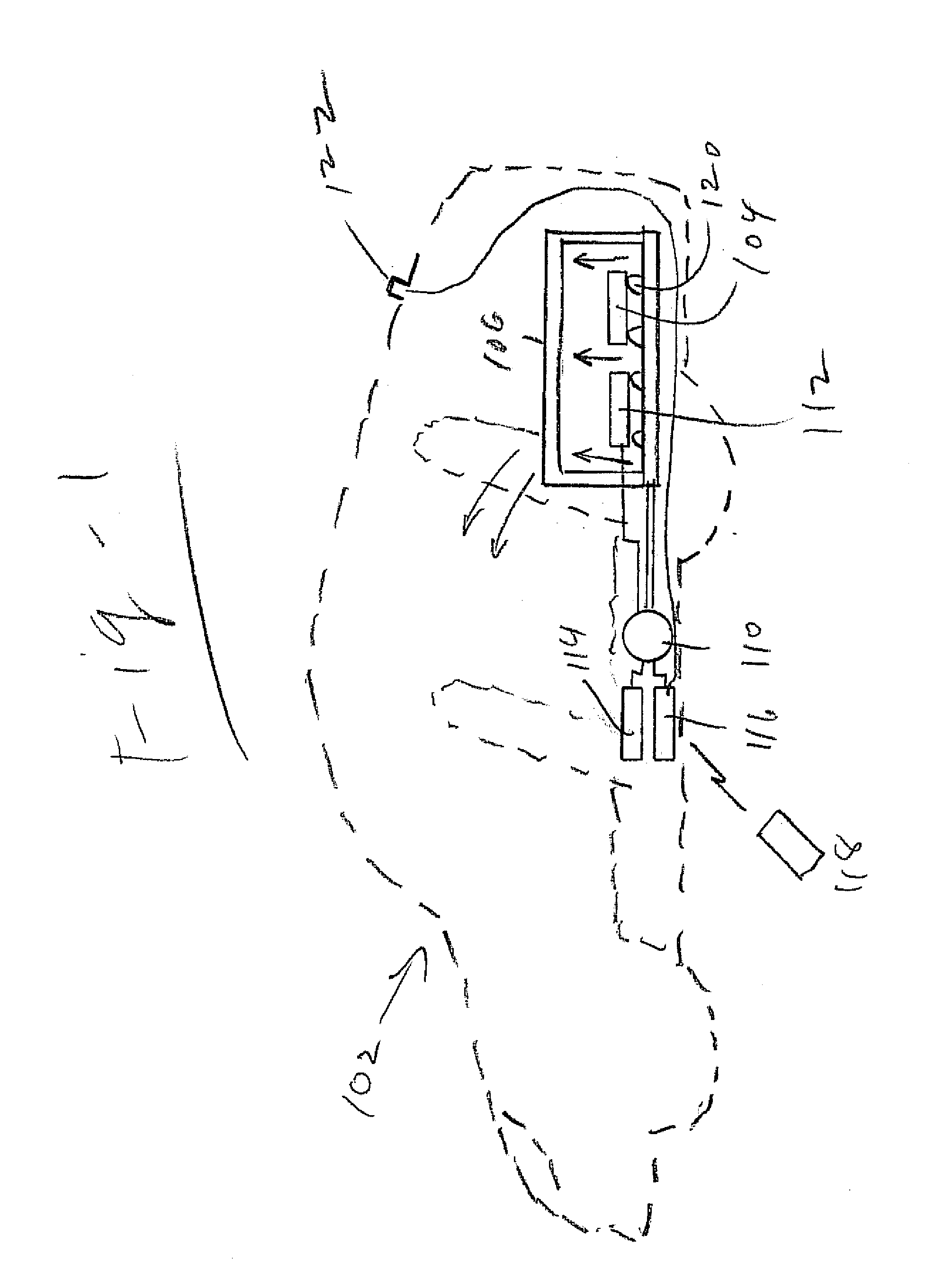

Regulating vehicle cabin environment and generating supplemental electrical current from waste heat

InactiveUS20070272290A1Reduce utilizationReduce weightInternal combustion piston enginesThermoelectric device with peltier/seeback effectNacelleElectrical devices

A method and system for environmental control and supplementary power generation in conventional and hybrid vehicle applications is presented. A thermoelectric heat pump function regulates vehicular interior temperature environments and uses the waste heat from a vehicles engine to power thermocouples and generate supplemental electrical current to power electrical devices. Thermocouples are used to gauge changes in temperature. The Peltier Effect is used to provide both primary cabin environmental control and supplementary power generation for motorized vehicle applications. Thermoelectric generators can be used for both primary internal climate control and supplementary power generation in the vehicular environment. Thermoelectric heat pumps' special characteristics are used to provide (a) primary cabin environment control including cooling, heating, dehumidifying, defrosting, pre-heating / pre-cooling and (b) supplemental DC power generation functions for conventional fossil fueled and / or biomass-fueled vehicles as well as emerging hybrid or all electric vehicle applications.

Owner:STATE OF FRANKLIN INNOVATIONS

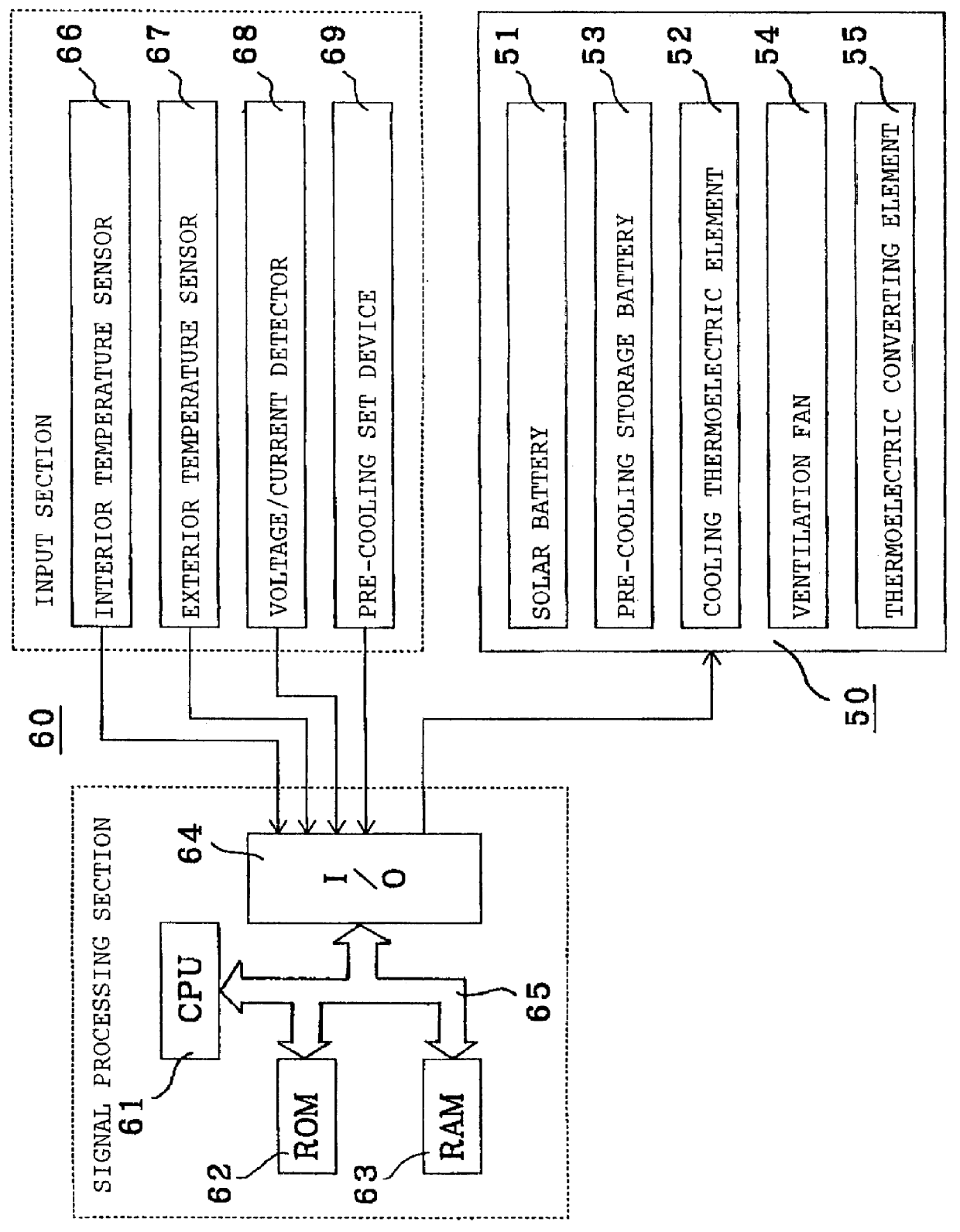

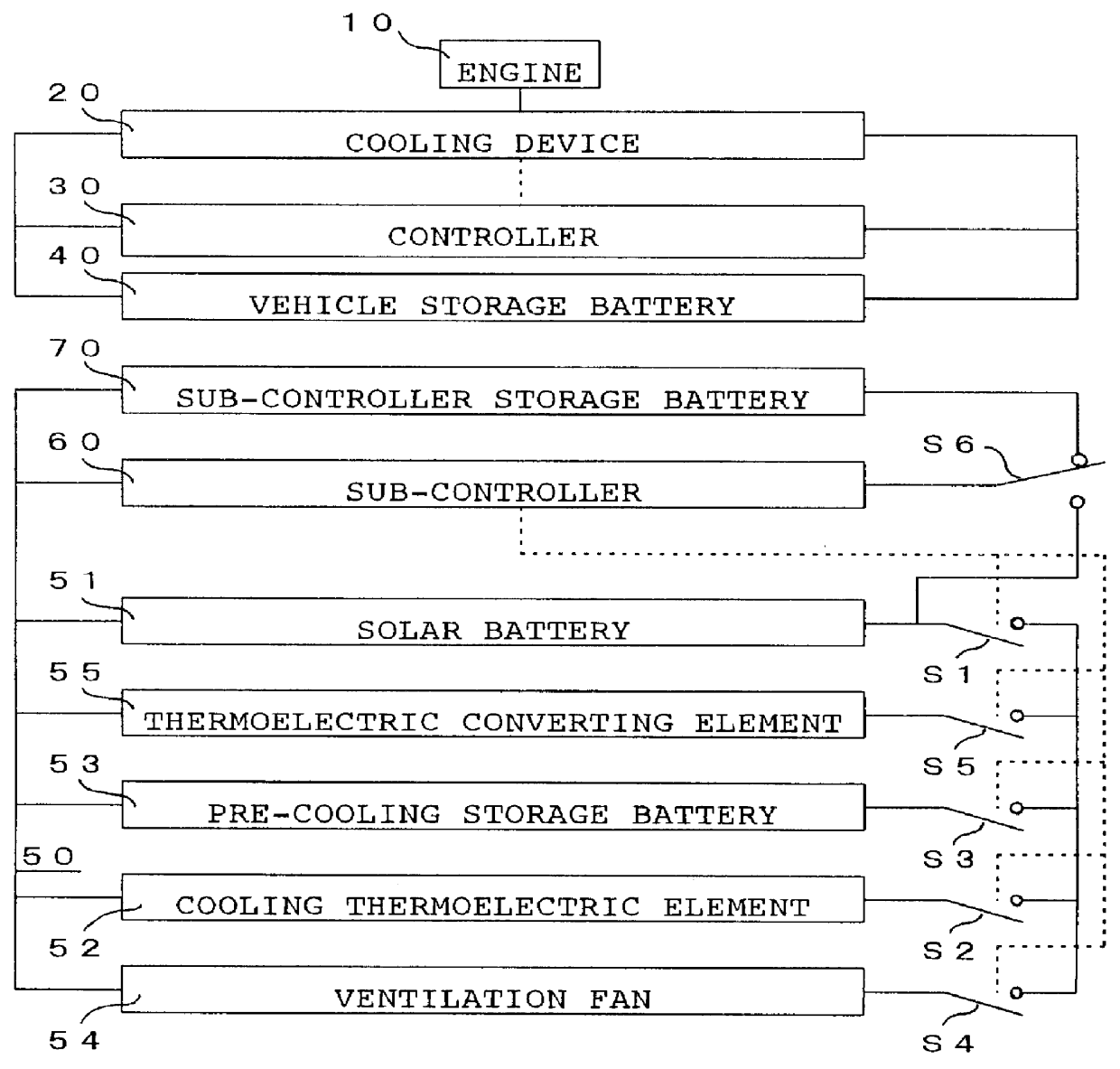

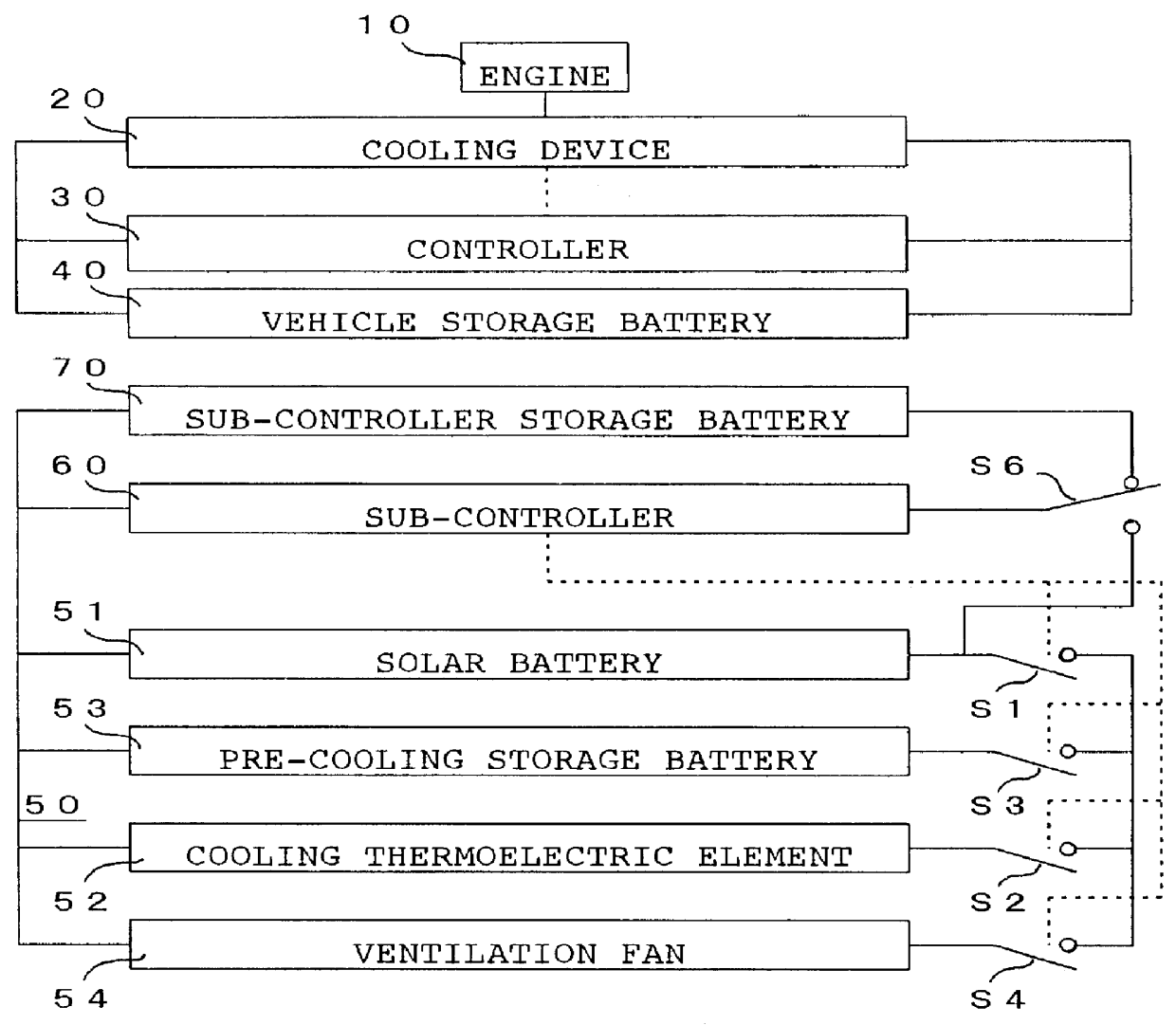

Automotive air-conditioning apparatus

InactiveUS6158225AImprove cooling effectEfficient use ofAir-treating devicesVehicle heating/cooling devicesAtmospheric temperatureSolar battery

To keep a temperature of an interior of an automotive vehicle at least at a level of an external atmospheric temperature even if the vehicle is parked with an engine being stopped for a long time, an automotive air-conditioning apparatus is composed of a cooling device 12 to be controlled by a controller 13, a pre-cooling device 20 for pre-cooling the interior of the vehicle, and a sub-controller 18 for controlling the pre-cooling device. The pre-cooling device is composed of a cooling thermoelectric element module 22, a ventilation fan 23, a solar battery 21 and a pre-cooling storage battery 24 charged by the solar battery. The sub-controller always operates the pre-cooling device 20 while the vehicle is stopped with the engine being stopped and starts the pre-cooling device 20, for example, one hour prior to a time when the vehicle starts to movement during parking for a long time in an interior parking lot or the like with the engine being stopped so that the temperature of the interior of the vehicle is kept at a temperature that does not so much exceed a set temperature, i.e., at least at the level of the external atmospheric temperature, until the engine is started.

Owner:SEIKO INSTR INC

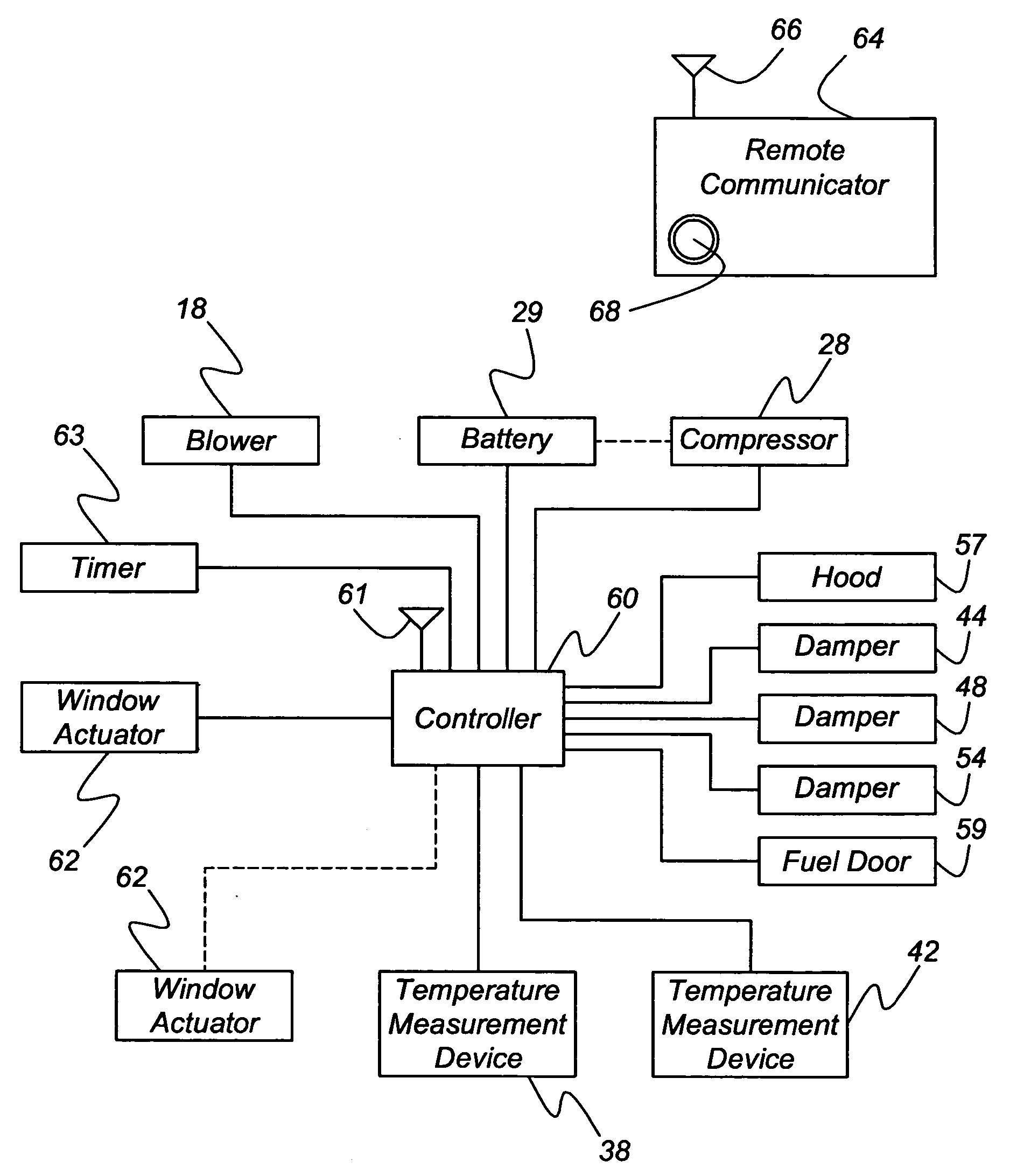

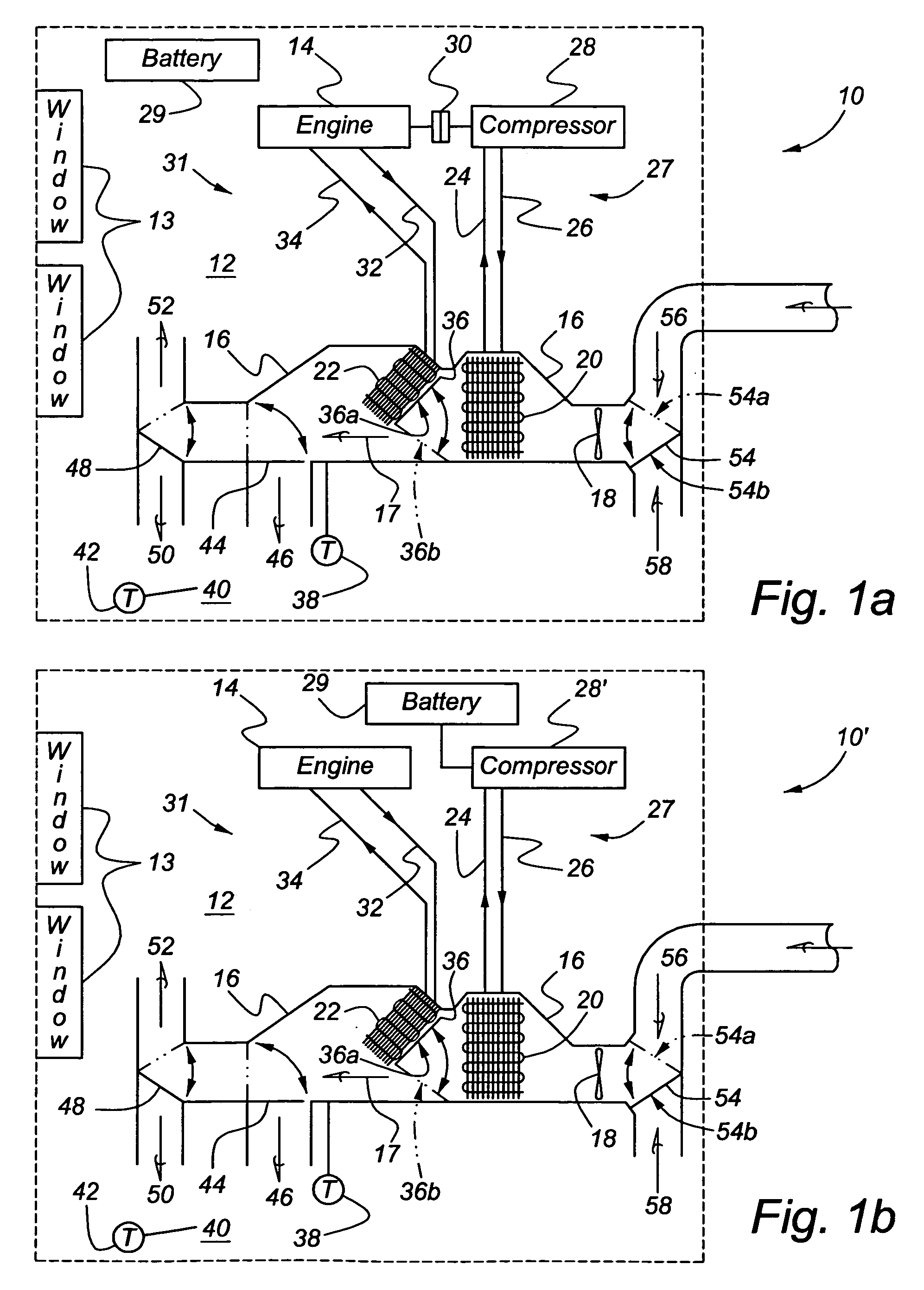

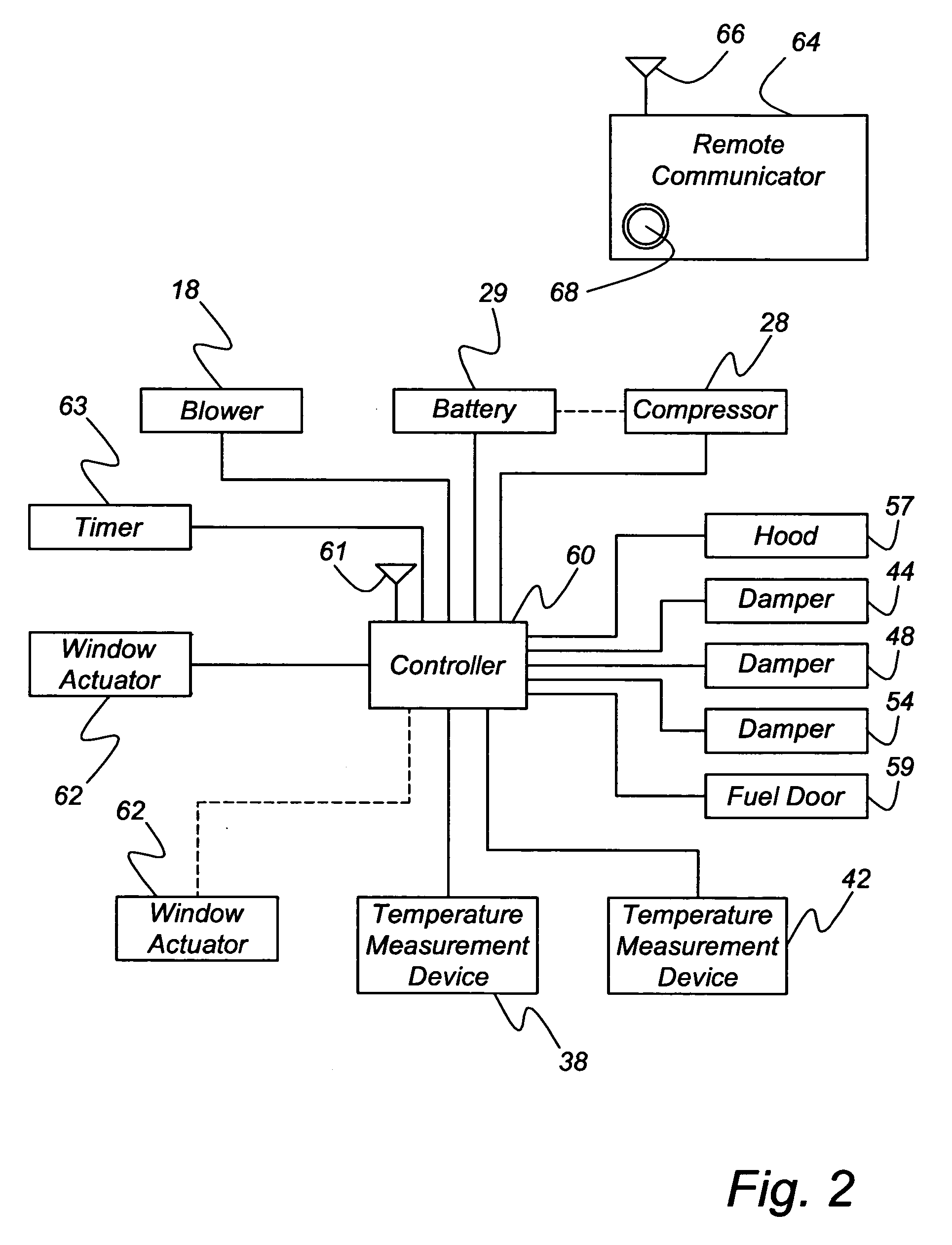

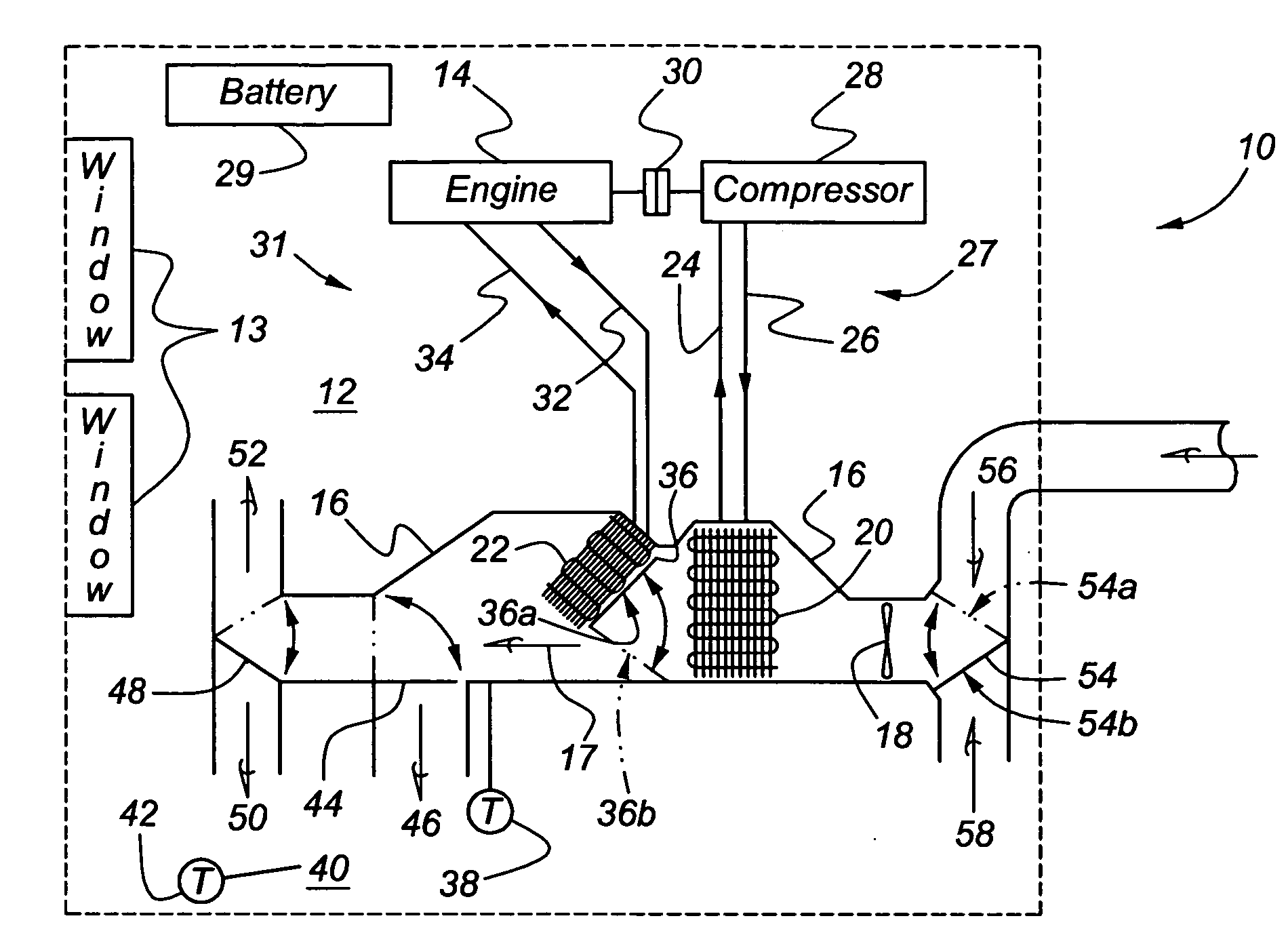

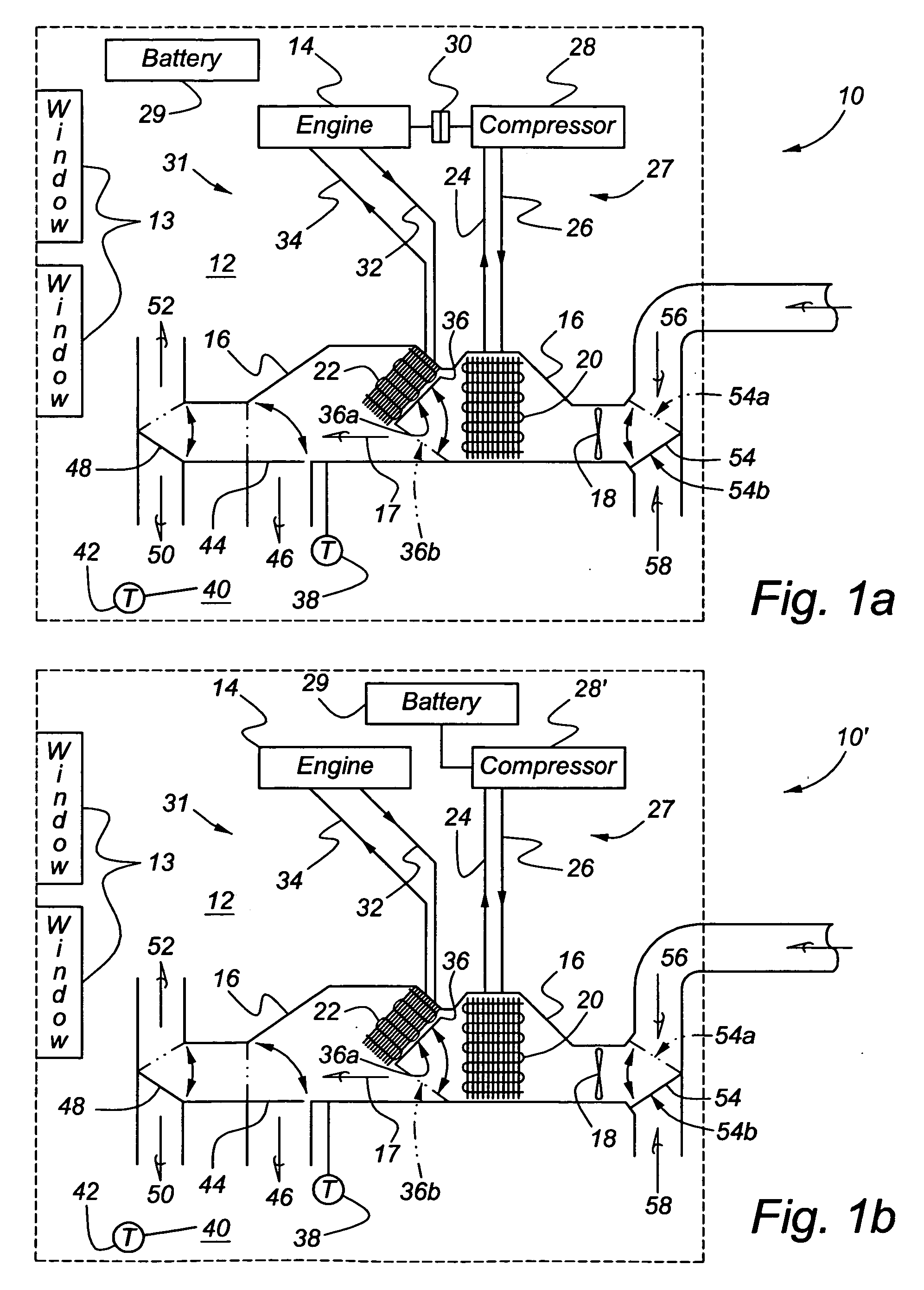

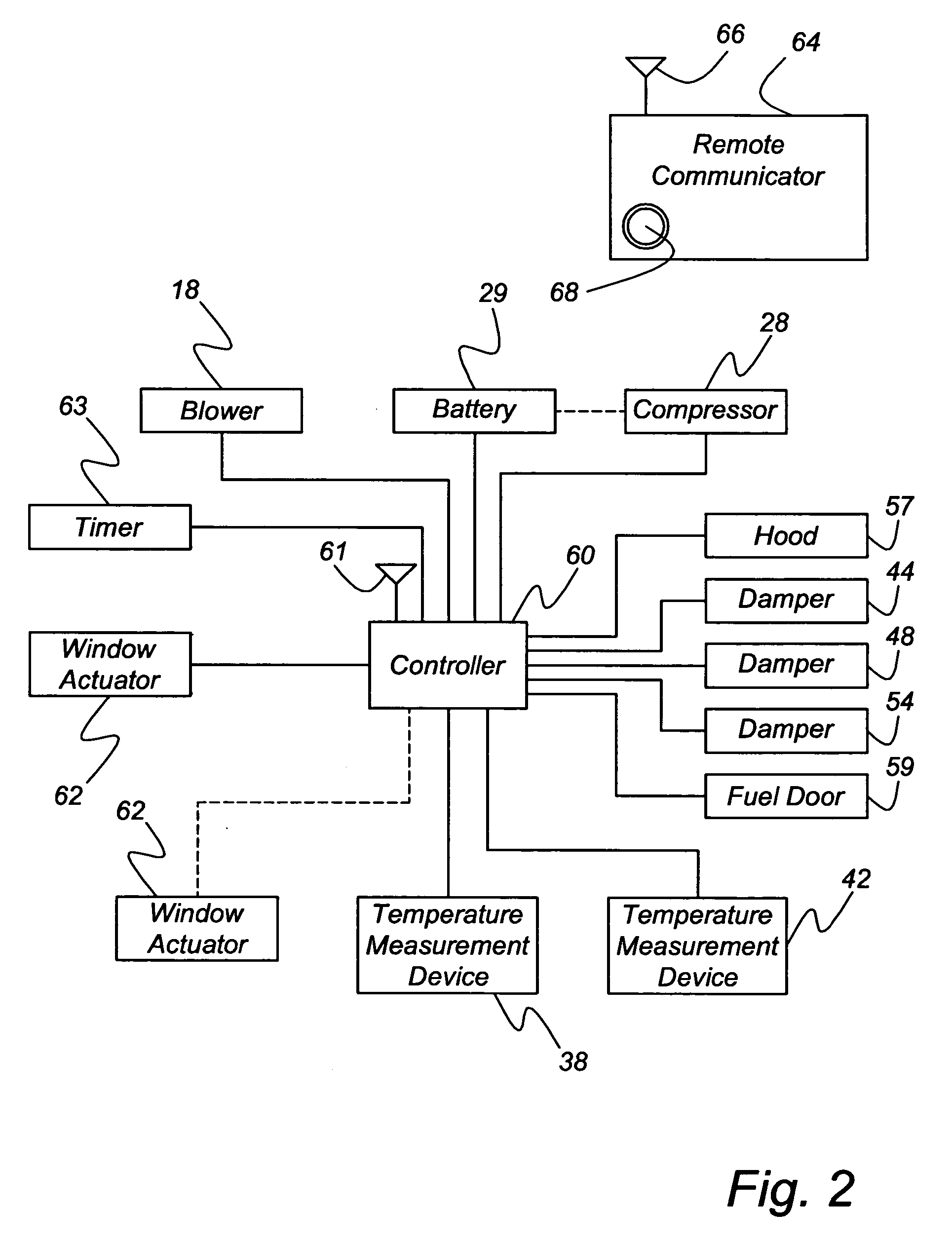

Method for pre-cooling automotive vehicle passenger compartment

InactiveUS7441414B2Air-treating devicesCompression machines with non-reversible cycleMobile vehicleMotorized vehicle

The present invention concerns a method for pre-cooling the passenger compartment of an automotive vehicle. The vehicle includes at least one electrically actuatable window and a HVAC system having at least a controller, a blower, a passenger compartment temperature sensor, and a HVAC ducting leading to the passenger compartment. The controller and the blower are connected to a vehicle battery. The method includes determining the passenger compartment temperature and comparing the temperature to a first predetermined value; cycling an blower inlet to an outside air intake position and operating the blower to provide pressurized air to the passenger compartment if the passenger compartment temperature is greater than the first predetermined value; opening the vehicle windows; comparing the passenger compartment temperature to a second predetermined value; and stopping operation of the blower when the passenger compartment temperature drops below the second predetermined value.

Owner:GM GLOBAL TECH OPERATIONS LLC

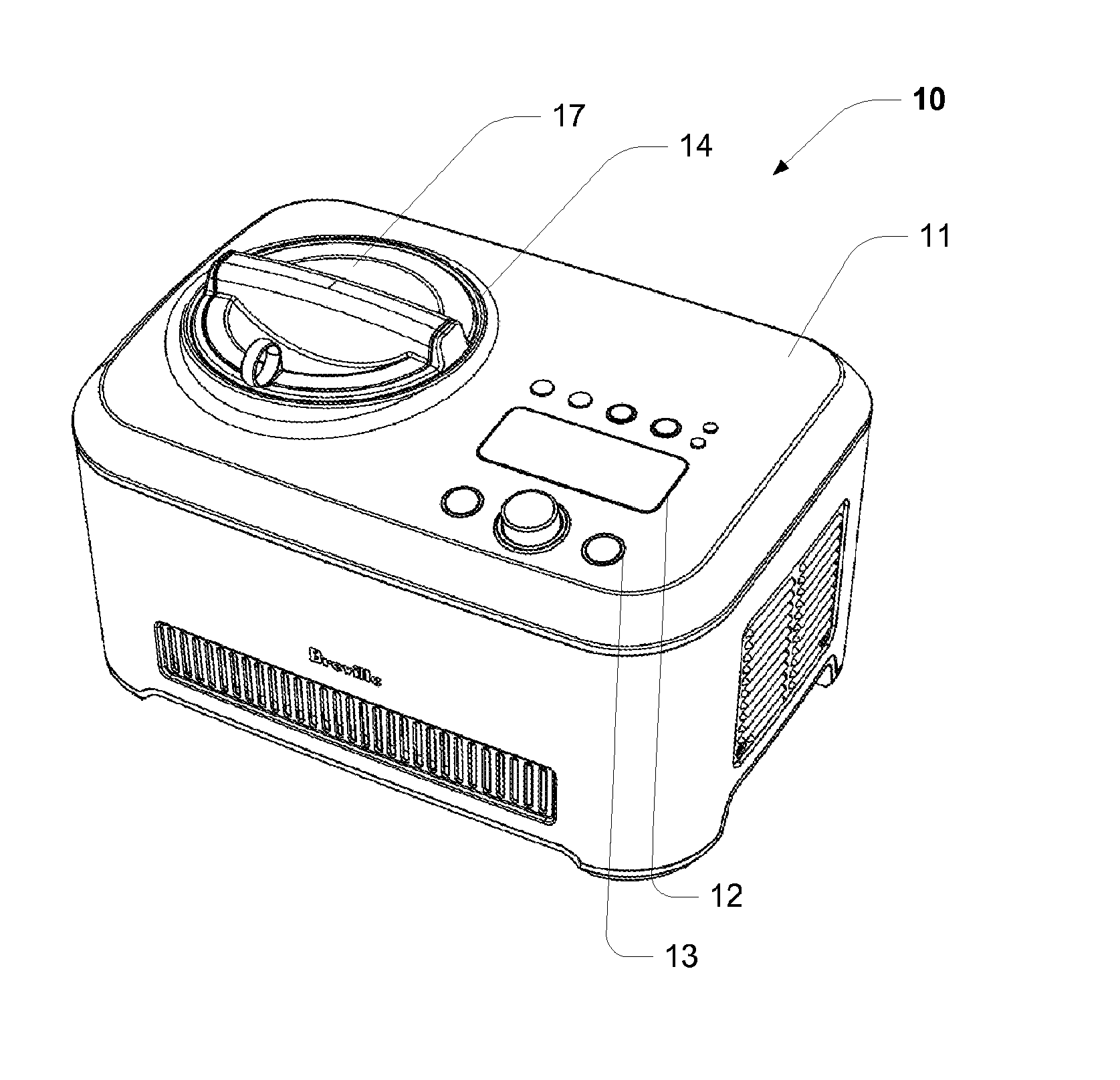

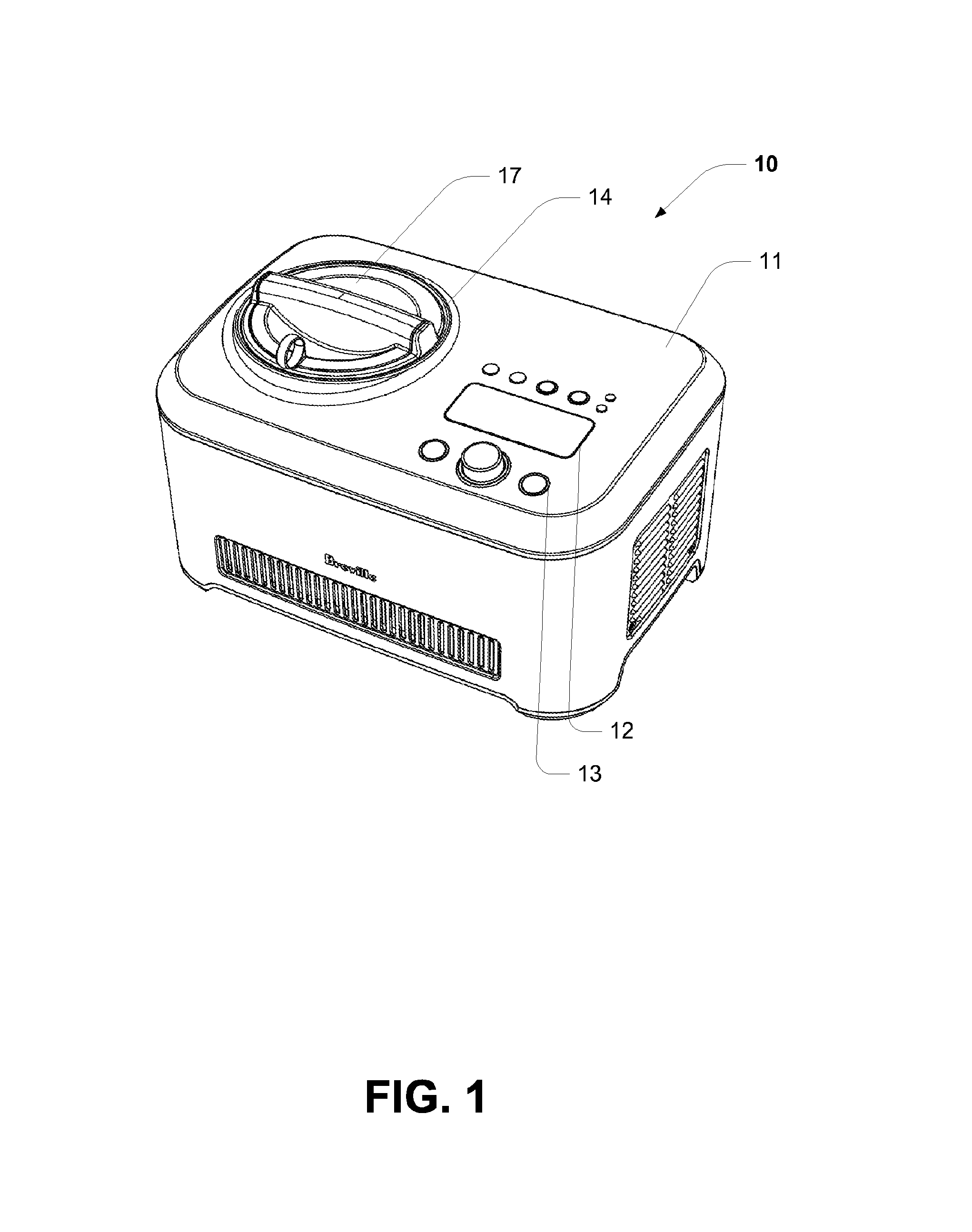

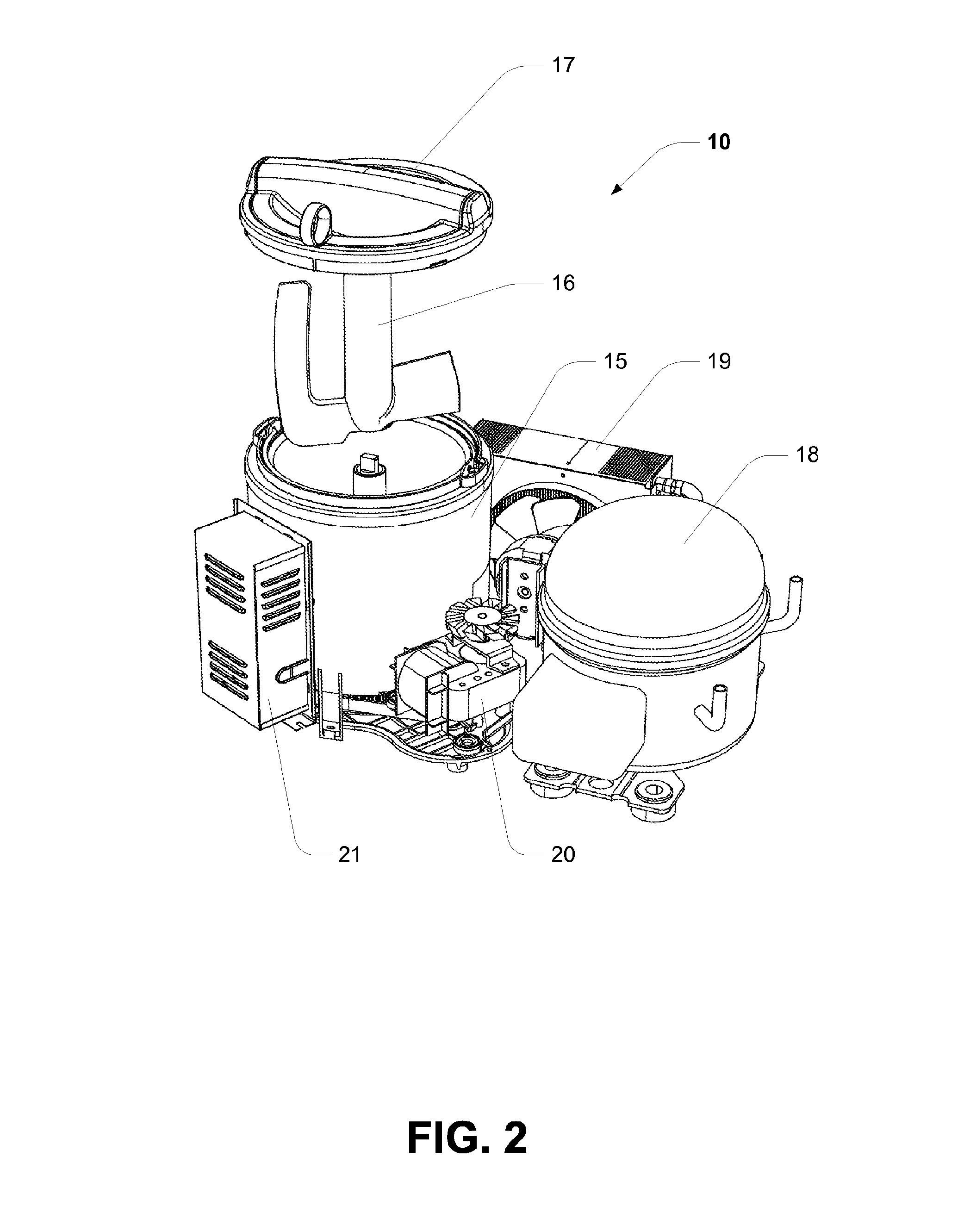

Ice Cream Maker

An ice-cream maker comprising: a body having a rotatable paddle; a cooling chamber supported by the body for receiving an ice-cream mixture, the paddle being adapted to move through the ice-cream mixture; a sensor module for detecting a hardness measure of the ice-cream mixture; a processor module coupled to the sensor module for receiving a signal indicative of the hardness measure, the processor module being adapted to control the operation of the paddle. After the ice-cream mixture has reached a selected hardness, the processor module periodically operates paddle to churn the mixture to substantially maintain the mixture at the selected hardness. Before introduction of the mixture, the processor module can operate a cooling element to pre-cool the cooling chamber.

Owner:BREVILLE HLDG PTY LTD

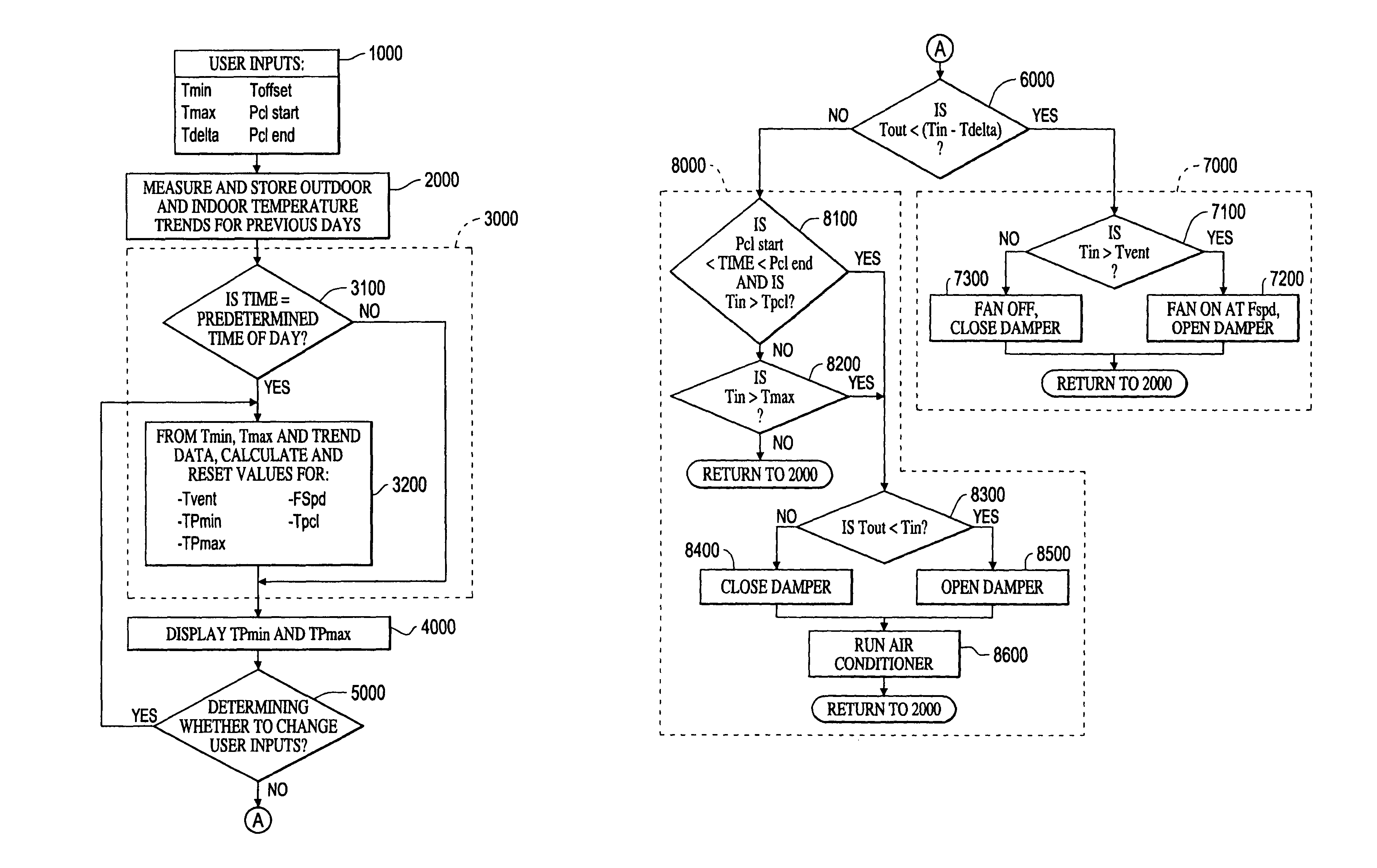

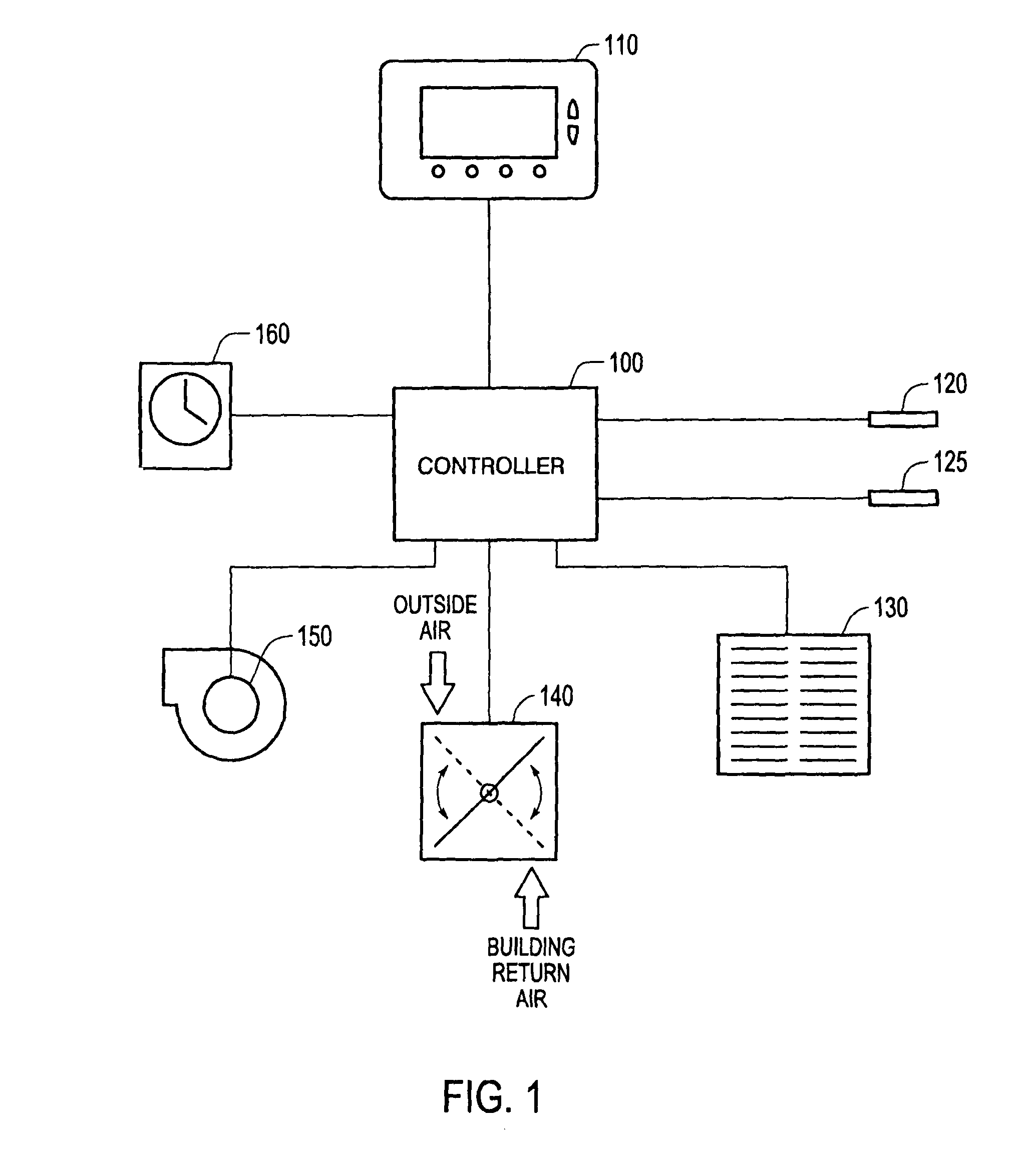

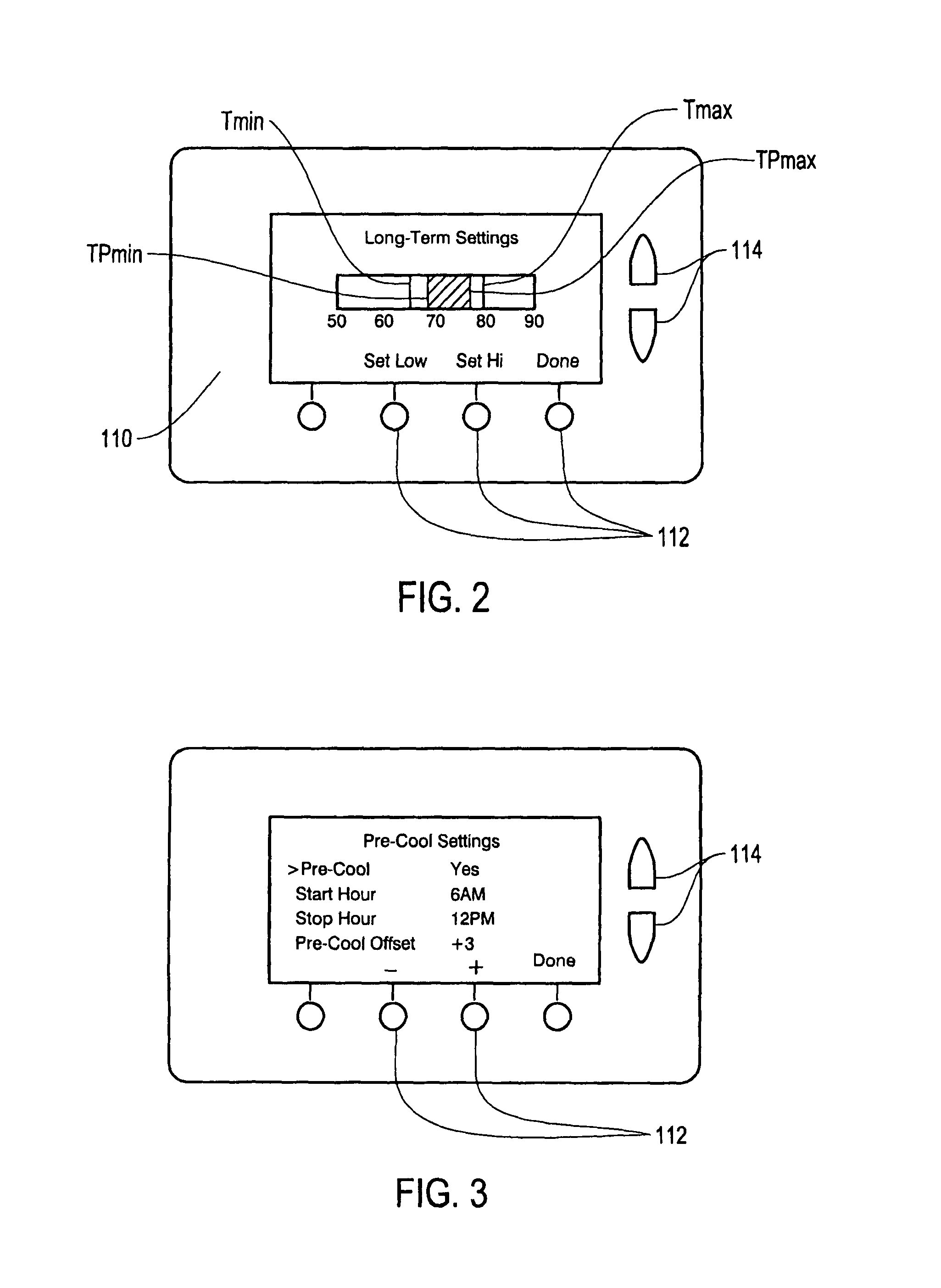

System and method for pre-cooling of buildings

ActiveUS7992630B2Reduce energy costsMinimize energy consumptionAir-treating devicesMechanical apparatusUser inputEngineering

A method for nighttime pre-cooling of a building comprising inputting one or more user settings, lowering the indoor temperature reading of the building during nighttime by operating an outside air ventilation system followed, if necessary, by a vapor compression cooling system. The method provides for nighttime pre-cooling of a building that maintains indoor temperatures within a comfort range based on the user input settings, calculated operational settings, and predictions of indoor and outdoor temperature trends for a future period of time such as the next day.

Owner:NIGHTBREEZE

High-strength transparent cellulose material and preparation method thereof

ActiveCN101880410AGood mechanical propertiesImprove thermal stabilityMonocomponent cellulose artificial filamentSpinning solutions preparationSupercritical dryingCellulose

The invention discloses a transparent high-strength fiber material. The preparation method comprises the following steps that: cellulose is dissolved in NaOH-urea aqueous solution or LiOH-urea aqueous solution which is pre-cooled at low temperature to obtain a cellulose solution, and different thicknesses of cellulose hydrogels are prepared by the cellulose solution; water in the cellulose hydrogel is replaced into an organic solvent to obtain a cellulose organic gel; the cellulose hydrogel or the cellulose organic gel is subject to supercritical drying, ambient pressure drying or freeze drying to remove a liquid medium so as to obtain a cellulose aerogel; and the cellulose hydrogel, the organic gel or the aerogel are autoclaved at a temperature of 30-200 DEG C under the pressure of 10-160Mpa to obtain the high-strength transparent cellulose material. The cellulose material prepared by the invention has excellent mechanical properties, thermal stability and optical permeability.

Owner:WUHAN UNIV

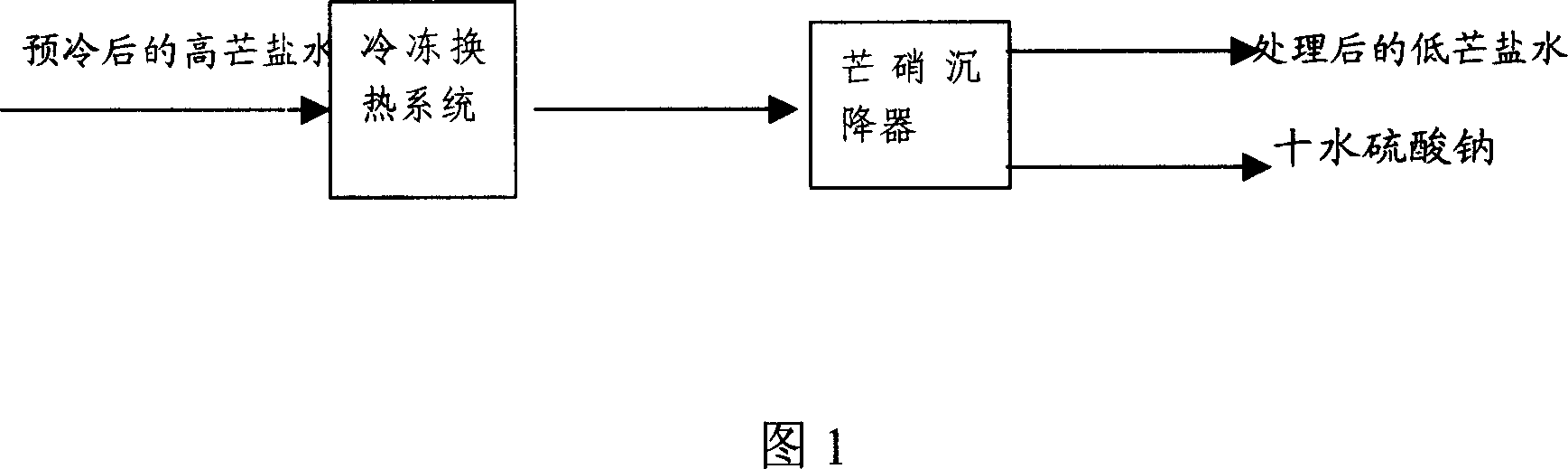

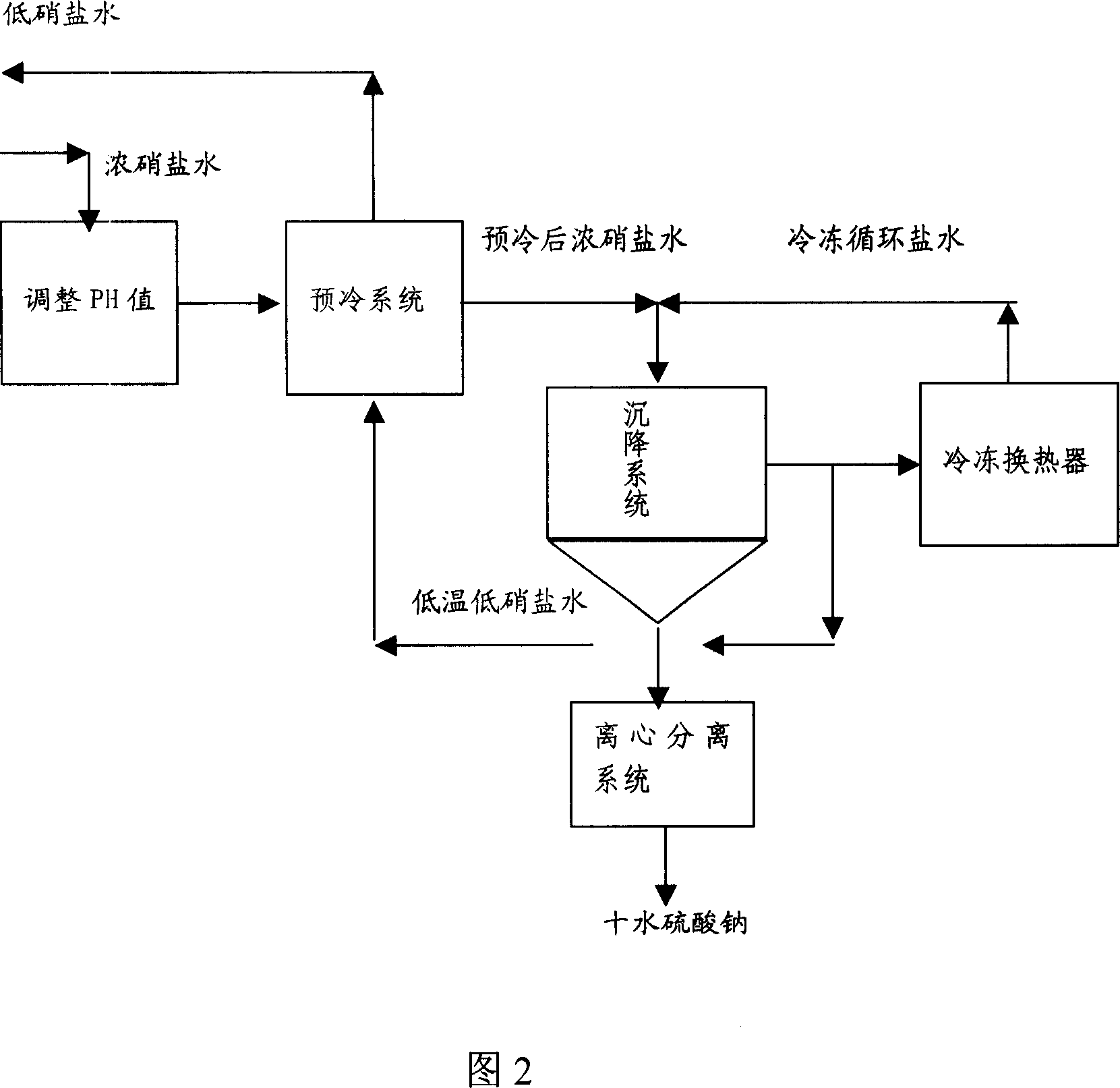

Method freezing separating mirabilite by brine solution

The invention discloses a method of cold separating mirabilite in salt water solution, which comprises the following steps: (1) adjusting pH value of armed salt cake solution as alkalify; (2) proceeding pre-cool in the precooling system; (3) mixing with low-temperature low-nitrate water of incorporating salt cake with lower temperature through demirabilite treatment; controlling temperature at -10-0 deg.c; proceeding solid-liquid separation in salt cake settler; getting ten water sodium sulfate crystal and low nitrate water; (4) lowering temperature of part low nitrate water through freezing heat exchanger; recycling as low temperature nitrate water of step (3); discharging the other part of low nitrate water as byproduct.

Owner:山东布莱恩化工技术有限公司

Method to heat or cool vehicle battery and passenger compartments

InactiveUS20080179040A1Improve economyLong rangeBatteries circuit arrangementsSolar heat devicesRemote controlCombined use

A battery heater / cooler increases mileage, comfort and / or safety in a conventional, electric or hybrid electric vehicle. An enclosure around the battery or batteries includes an inlet for heated or cooled air or liquid and an outlet to facilitate the transfer of heated or cooled air into a passenger compartment. A second battery unit may be used in conjunction with a timer or a remote controlled device to pre-heat or pre-cool itself and the primary battery or batteries and / or passenger compartment before commute times.

Owner:REDEVEX

Method and apparatus for cooling biological tissue

InactiveUS20110224761A1Prevent adverse side effectsLocalized coolingMedical devicesSurgical instruments for coolingMedicineReady to use

Exemplary embodiments of apparatus and method for tissue cooling using a plurality of hollow needles to deliver a cooled fluid into the tissue can be provided. For example, a volume and / or temperature of the fluid can be controlled to cool the tissue to a particular temperature or to within a predetermined temperature range. A tissue surface overlying the tissue to be cooled can be pre-cooled using conventional cooling techniques to increase the efficacy of the exemplary procedure. The exemplary method and apparatus can be used, e.g., to disrupt or damage fatty tissue that may then be reabsorbed by the body.

Owner:THE GENERAL HOSPITAL CORP

Pre-Cooled Liquefaction Process

A system and method for liquefying a natural gas stream, the method including the steps of providing a dehydrated natural gas stream for liquefaction, pre-cooling the dehydrated natural gas stream in a pre-cooling apparatus, where the pre-cooling is performed by using a pre-coolant that consists essentially of a hydroflorocarbon (HFC) refrigerant, further cooling the pre-cooled dehydrated natural gas stream in a main heat exchanger through indirect heat exchange against a vaporized hydrocarbon mixed refrigerant coolant to produce a liquefied natural gas product stream, where the mixed refrigerant coolant comprises ethane, methane, nitrogen, and less than or equal to 3 mol % of propane.

Owner:AIR PROD & CHEM INC

Thermogenic Augmentation System

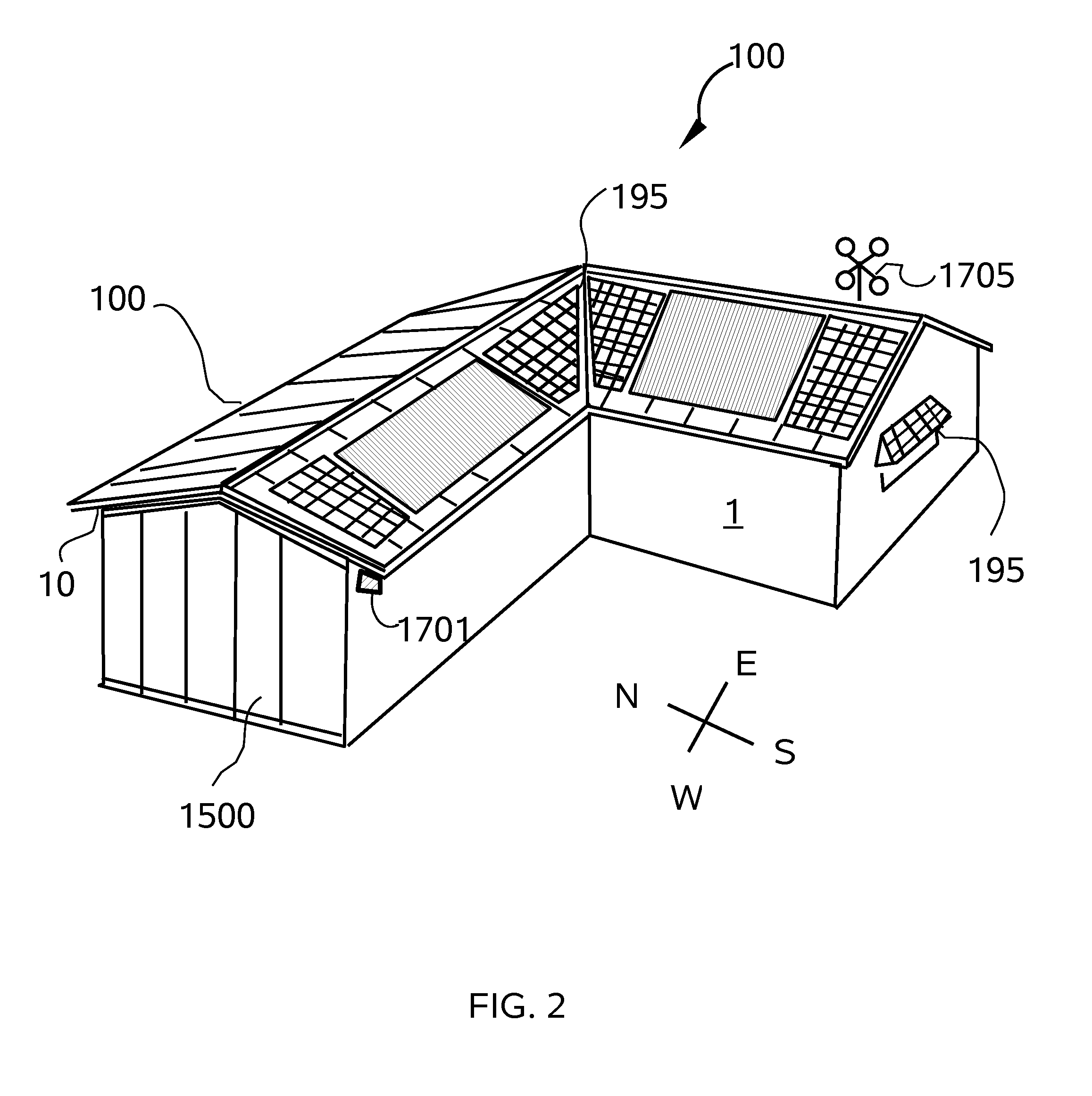

ActiveUS20120149291A1Reduce electricalReduce other power consumption/generationMechanical apparatusSpace heating and ventilation safety systemsNatural convectionRadiant barrier

A dual air cavity roof has a continuous upper cavity which is cooled by fans, while the lower cavity is generally sealed. Preferably the cavities are separated by a radiant barrier. The fans are preferably powered by one or more photovoltaic cells that are also disposed on the roof. The roof can be pre-cooled with cooler night air and fans only activated when necessary to remove heat from the solar load on the upper cavity. When it is desirable to remove heat, the fan speed is optimized in each zone of the roof to enhance the natural convective flow to the optimum level. A radiant barrier can also cover the roof substrate, which is optionally an existing roof that is in need of repair. The roof structure is preferably assembled in parallel modules using insulating support brackets that support the outer surface and the barrier that separates the upper and lower cavity.

Owner:RODERICK DAVID

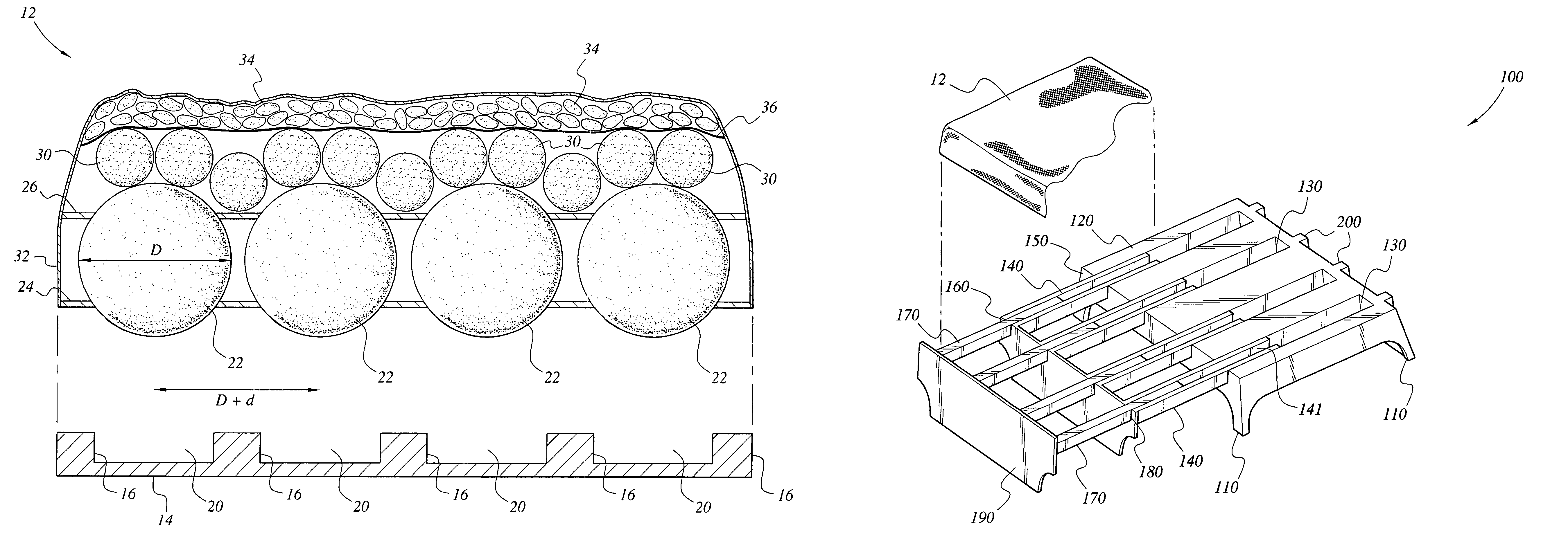

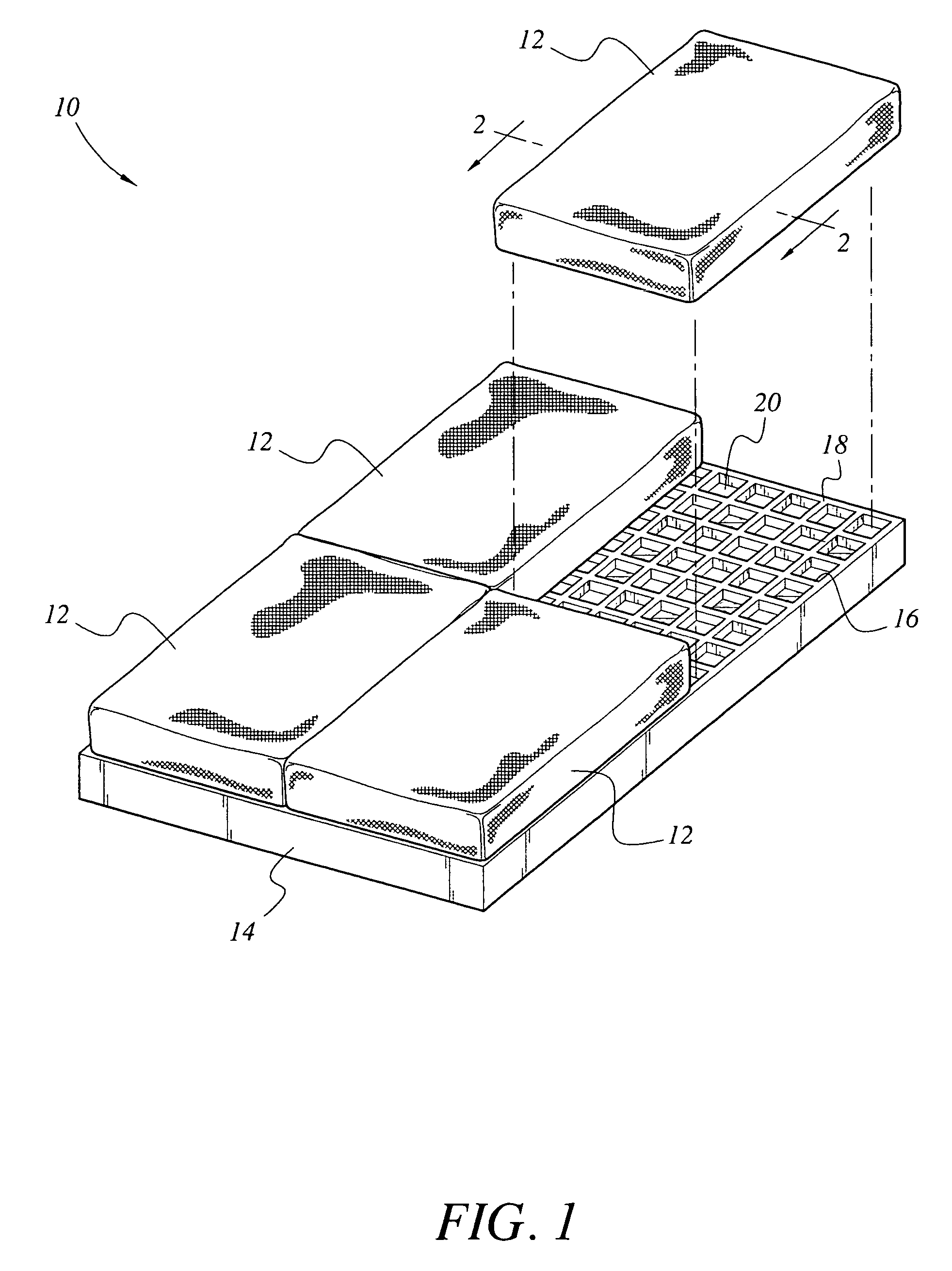

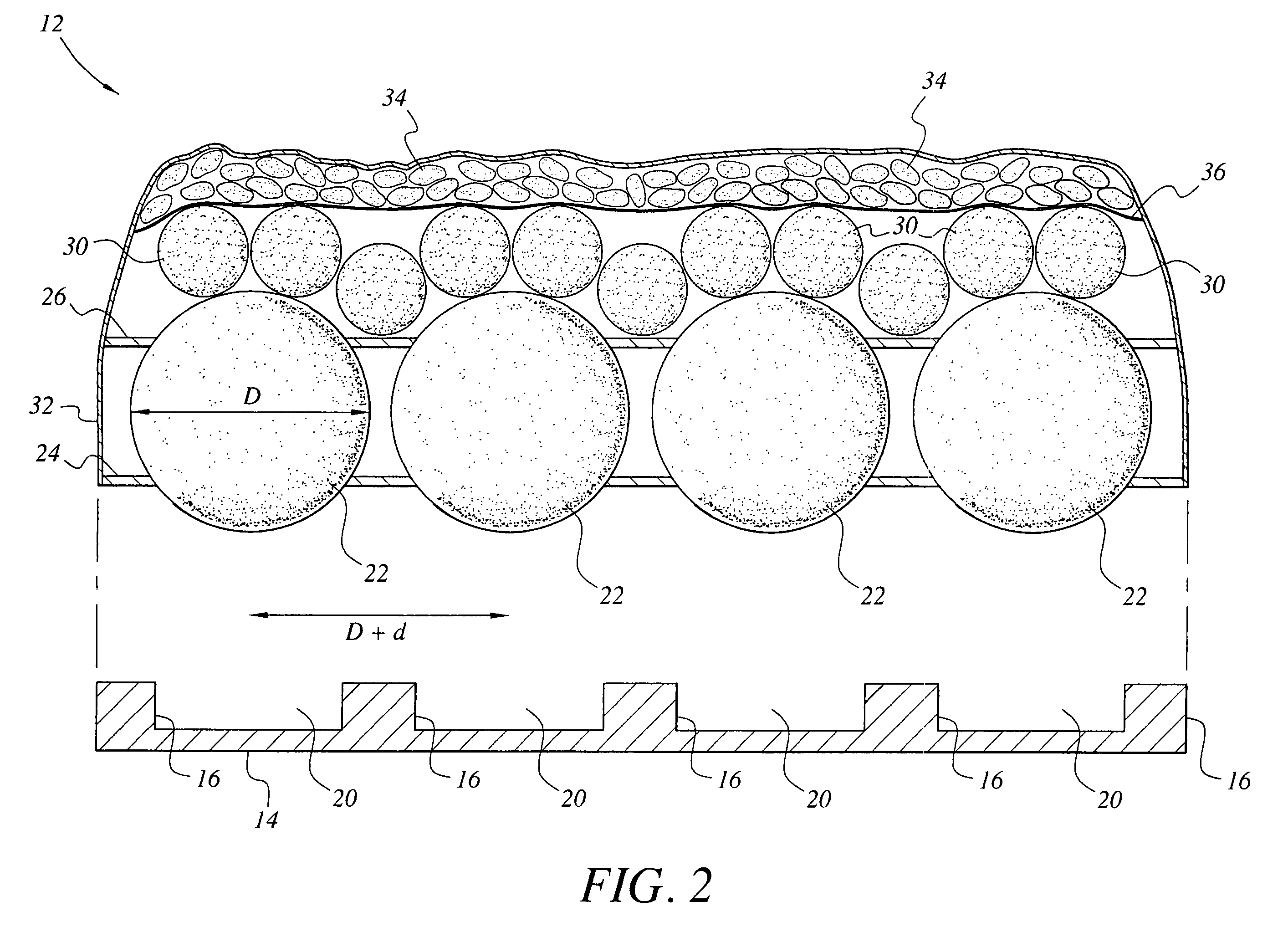

Sectional non-slip mattress and support frame therefor

The sectional non-slip mattress includes a support frame defining a plurality of compartments and at least one cushion having a plurality of ball bearings received within a cushion housing. Each compartment receives a corresponding ball bearing, thus preventing horizontal movement of the cushion with respect to the support frame. The ball bearings form a first material layer and a second material layer is formed from a set of elastic beads. A third material layer is formed from a plurality of gel-filled capsules and the three material layers are all housed within a fabric cushion housing, which is permeable to air. An additional air supply may be provided for driving pre-cooled or pre-heated air through the cushion.

Owner:LITVAK VERA

Lithium hydrate and carbamide composition solvent for dissolving cellulous fiber and its use

InactiveCN1546556AHigh strengthWide range of usesMonocomponent cellulose artificial filamentSpinning solutions preparationAcid waterLithium hydroxide

The invention relates to a dissolvent for cellulose dissolution through freezing-unfreezing method or direct dissolution method, and process for preparing the regenerated cellulose fibers and films by utilizing the dissolvent, wherein the dissolvent is the water solution of lithium hydroxide and urea whose compositions are 3.0-7.0wt% of lithium hydroxide, 4.0-30.0.0wt% of urea, the rest is water. The water solution of lithium hydroxide and urea can directly dissolve cellulose through freezing-unfreezing method or by pre-cooling the dissolvent in advance to -10 deg. C - -4 deg. C. It can be used to obtain high dissolvability transparent concentrated cellulose solution. By using the concentrated cellulose solution and through 3-5wt% diluted acid water solution coagulation, regeneration, regenerated cellulose films and fibers can be prepared.

Owner:WUHAN UNIV

Method and apparatus for operating an internal combustion engine

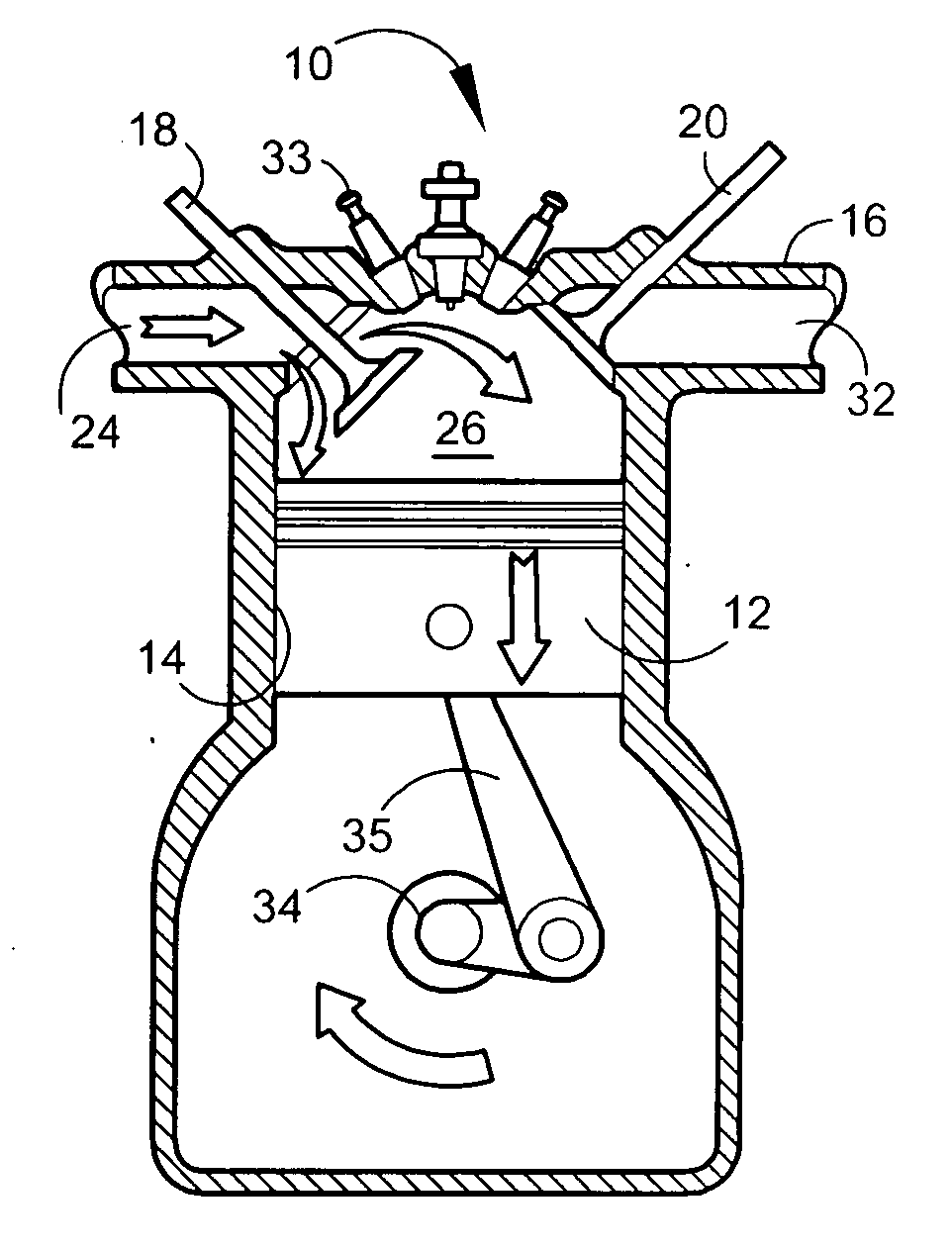

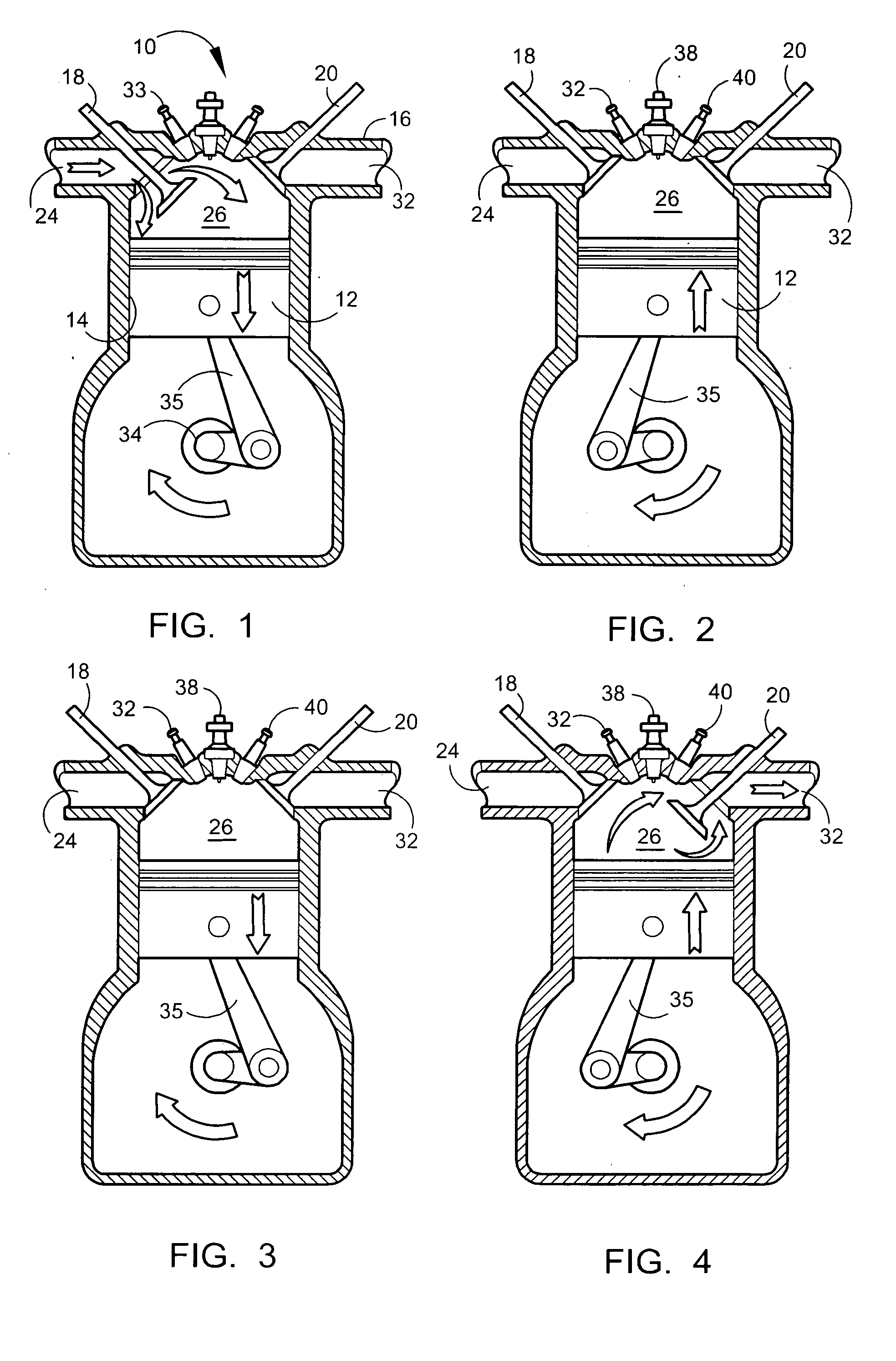

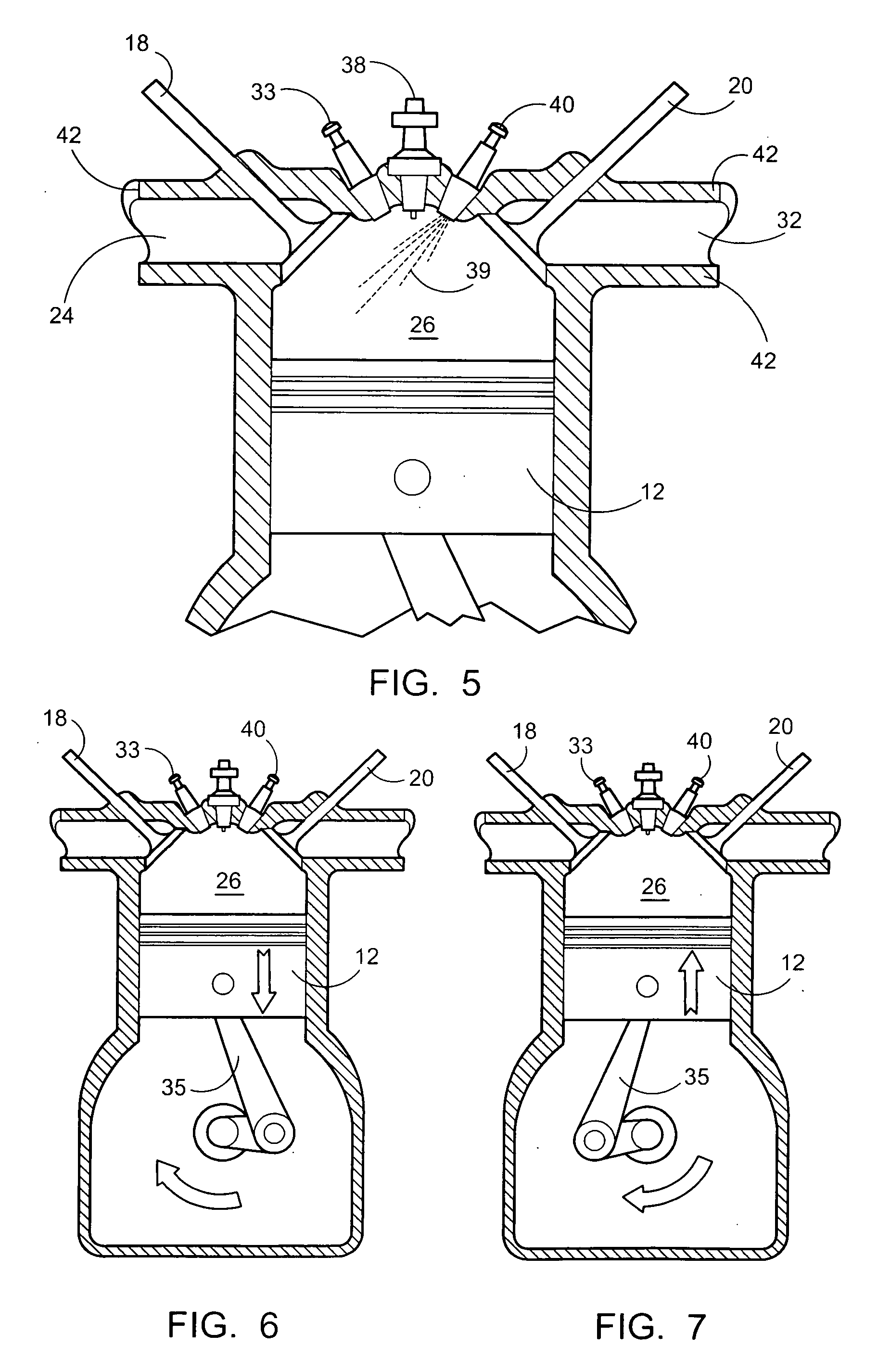

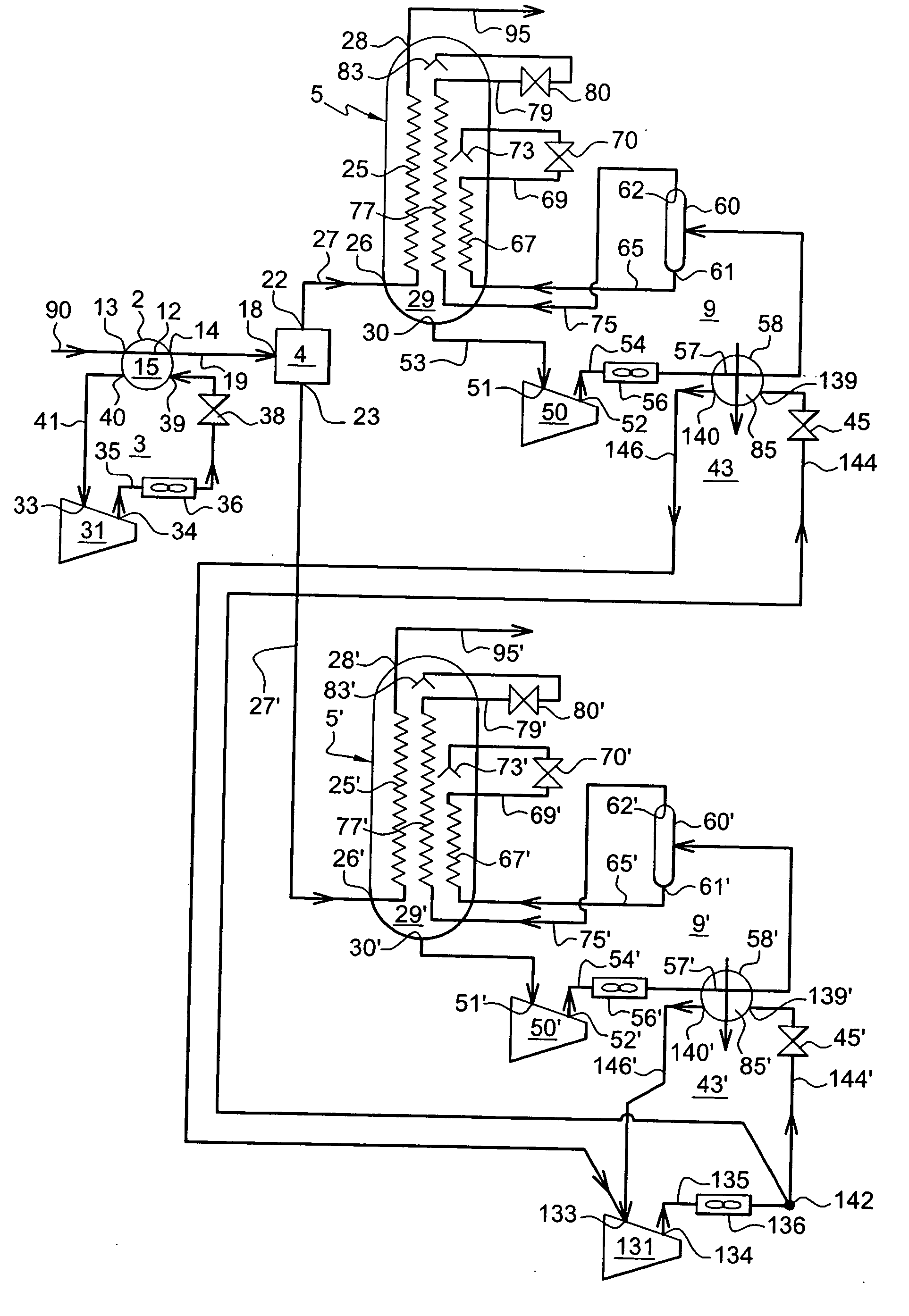

InactiveUS20070022977A1Improve engine efficiencyIncrease powerNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberSystem requirements

An internal combustion engine and method of operation employing timed injection of water into the combustion chamber for one or a combination of recapturing waste heat, cooling the engine, and lowering Nox emissions of the engine. The water injection subsequent to the power stroke of the engine employs residual heat and heat conducted from surfaces of the combustion chamber, to form steam to drive a second power stroke. The water injection can also be employed to pre-cool the combustion chamber to avoid formation of Nox gases during fuel combustion and by recapturing residual and conductive heat from the combustion chamber the engine is cooled thereby minimizing or eliminating exterior cooling system requirements.

Owner:CROWER H BRUCE

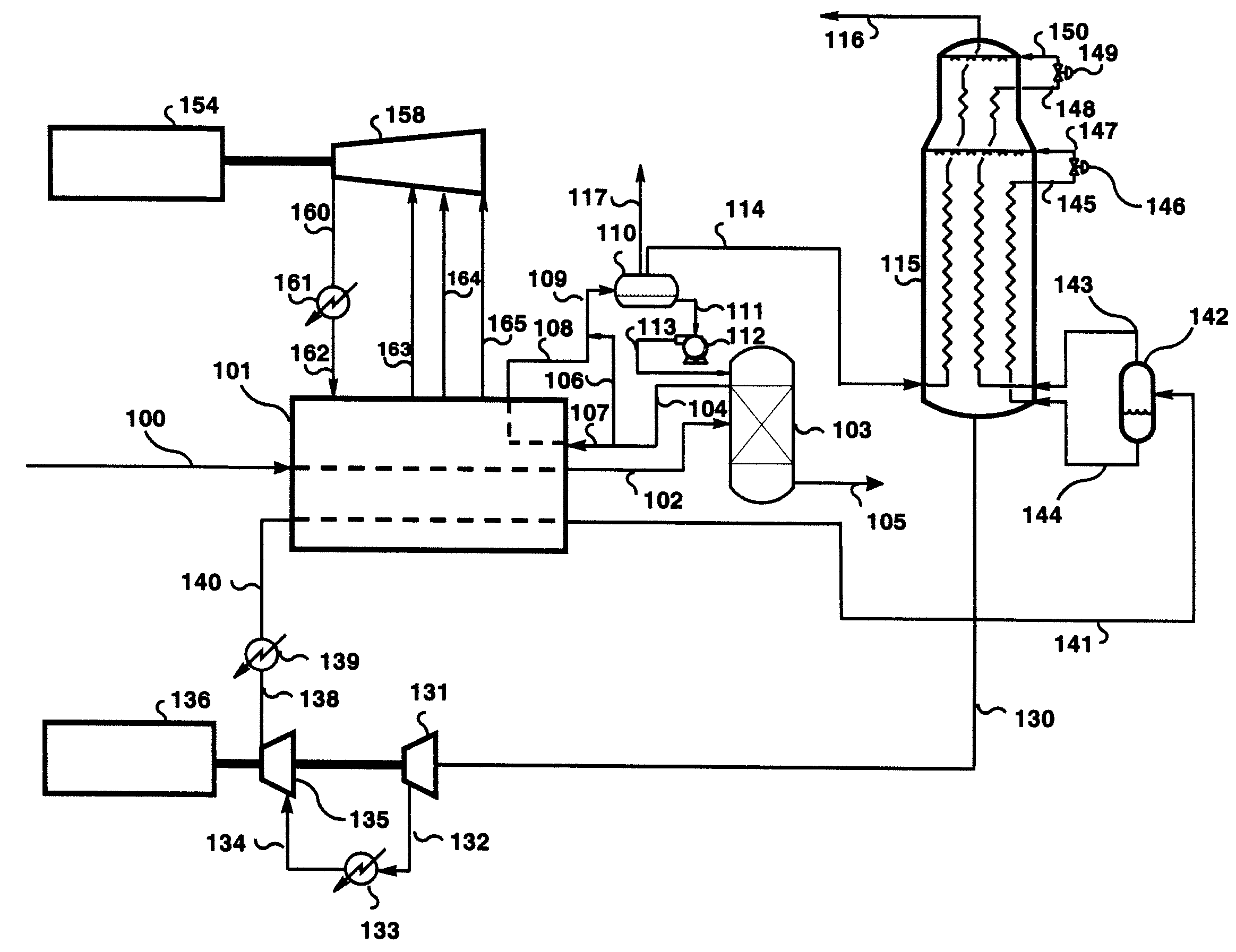

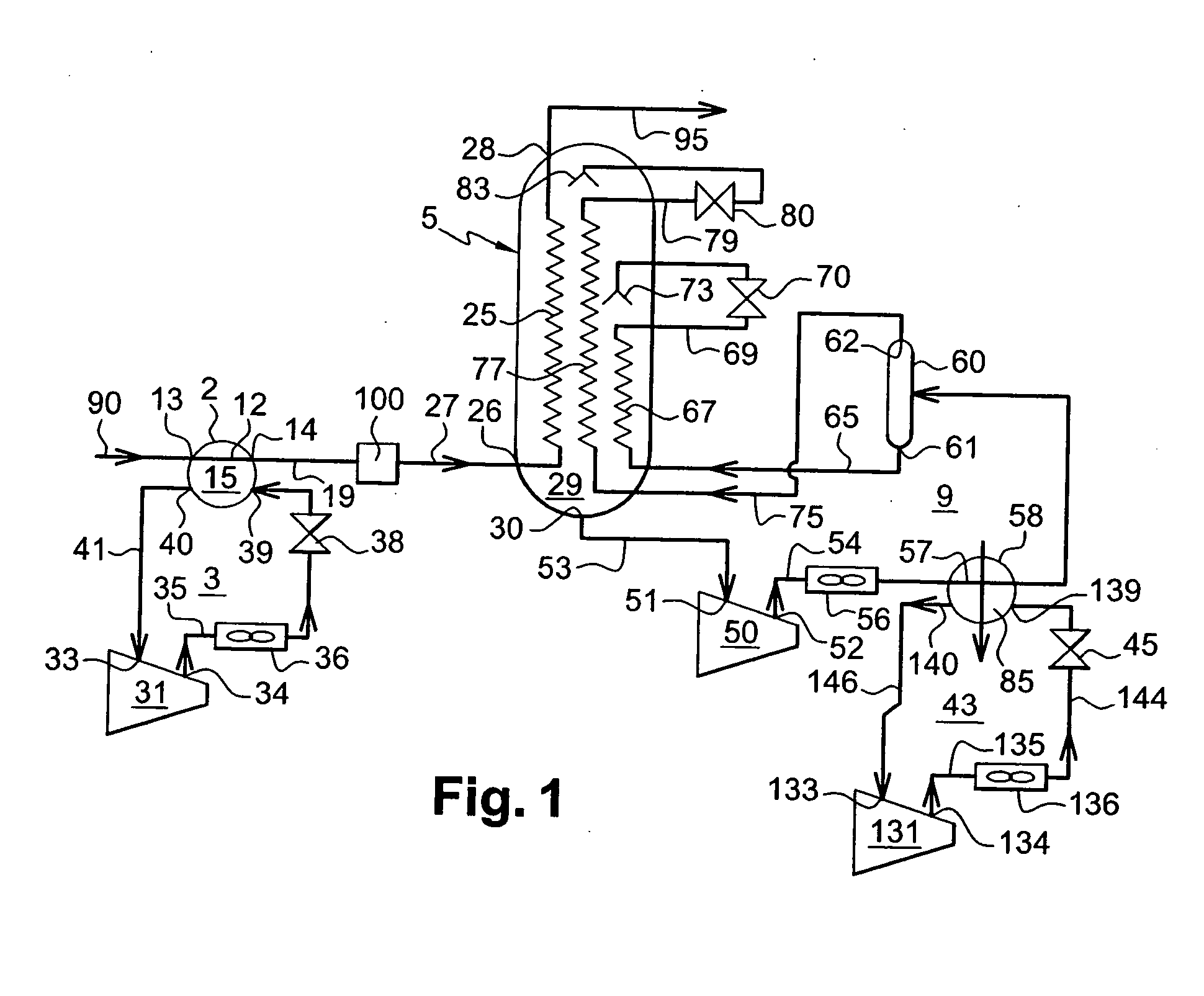

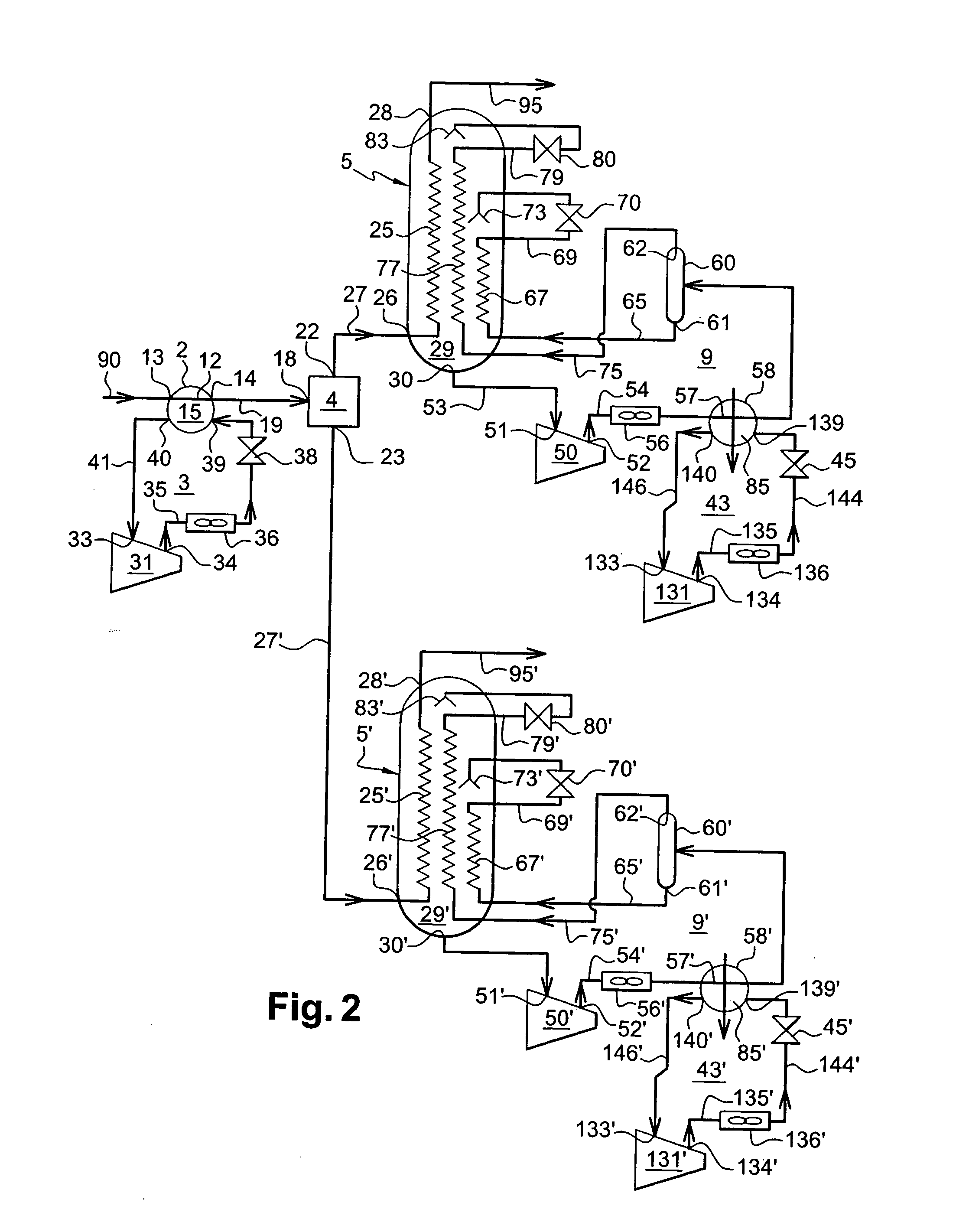

Plant and process for liquefying natural gas

The invention relates to novel plant and process for producing liquefied natural gas. The plant of the invention is of the type that comprises one natural gas pre-cooling heat exchanger having an inlet for natural gas and an outlet for cooled natural gas, optionally a distributor having an inlet connected to the outlet for cooled natural gas and having one or more outlets, and one or more main heat exchangers each comprising a first hot side having one inlet connected to one outlet of the distributor and an outlet for liquefied natural gas, which plant further comprises a pre-cooling refrigerant circuit for removing heat from the natural gas in the natural gas pre-cooling heat exchanger, and one or more main refrigerant circuits for removing heat from natural gas flowing through the first hot side of the corresponding main heat exchanger. The invention is based on the use of separate pre-cooling circuits: one for the pre-cooling of the natural gas and one for the pre-cooling of the main refrigerant.

Owner:TOTAL PUTEAUX FR

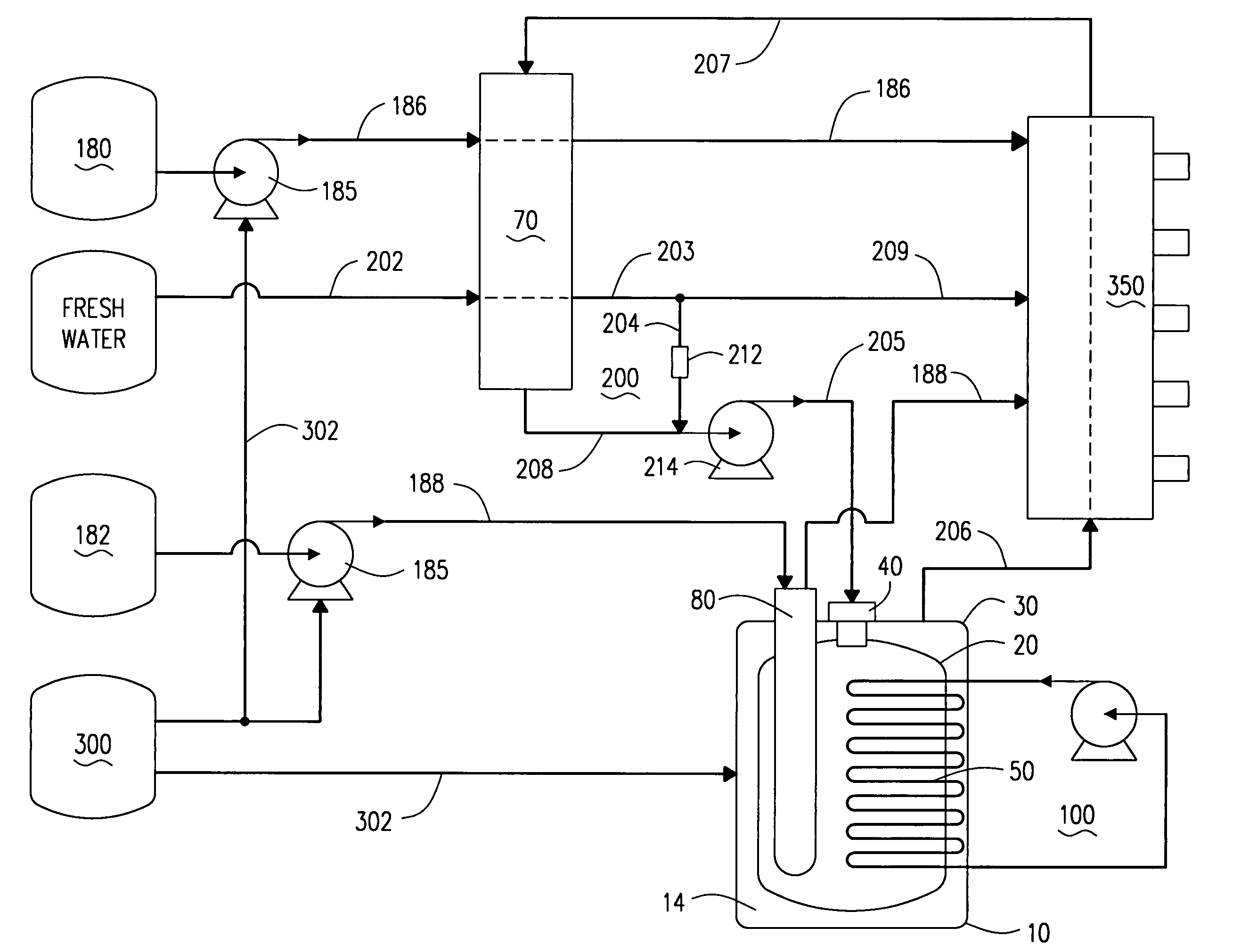

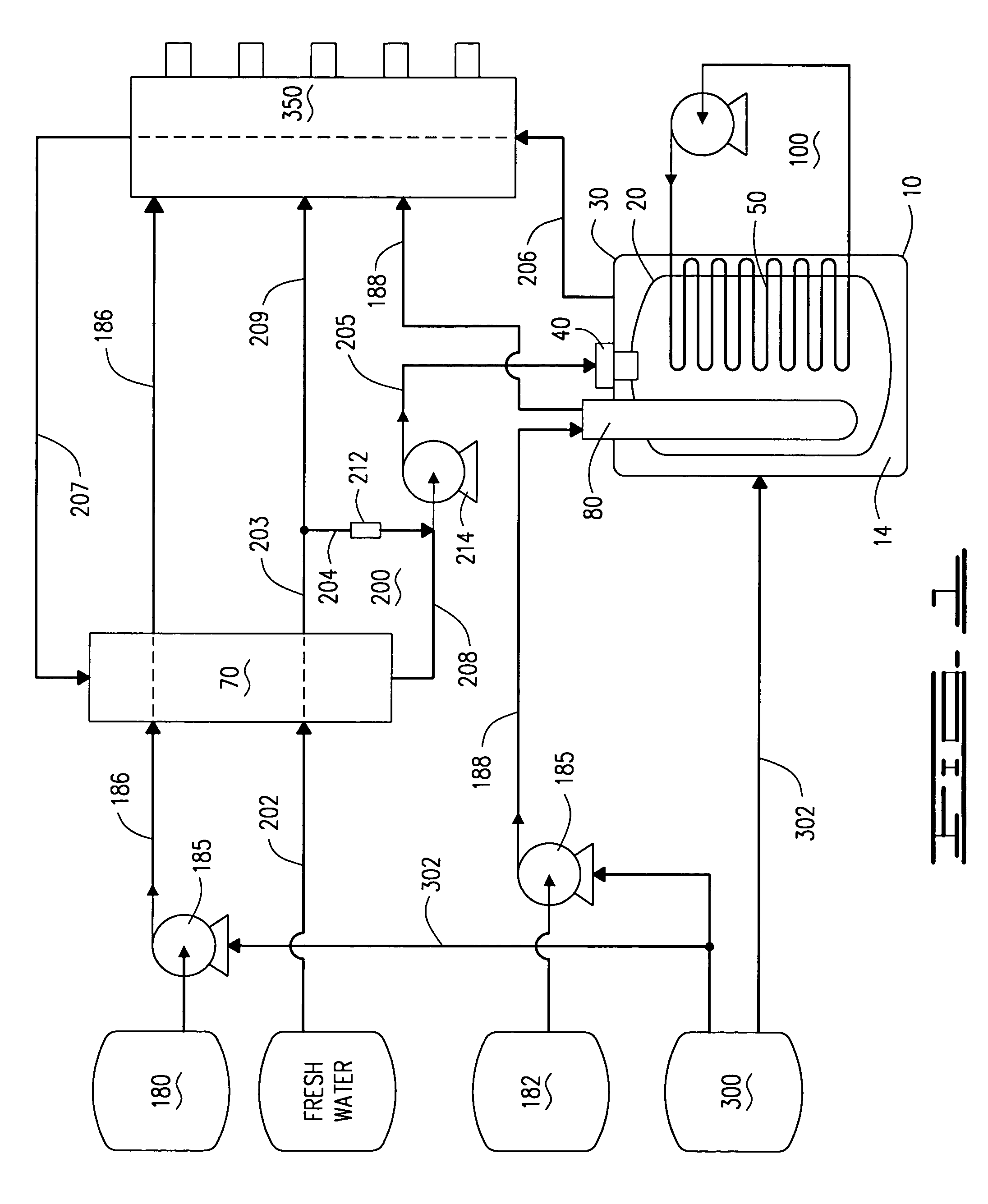

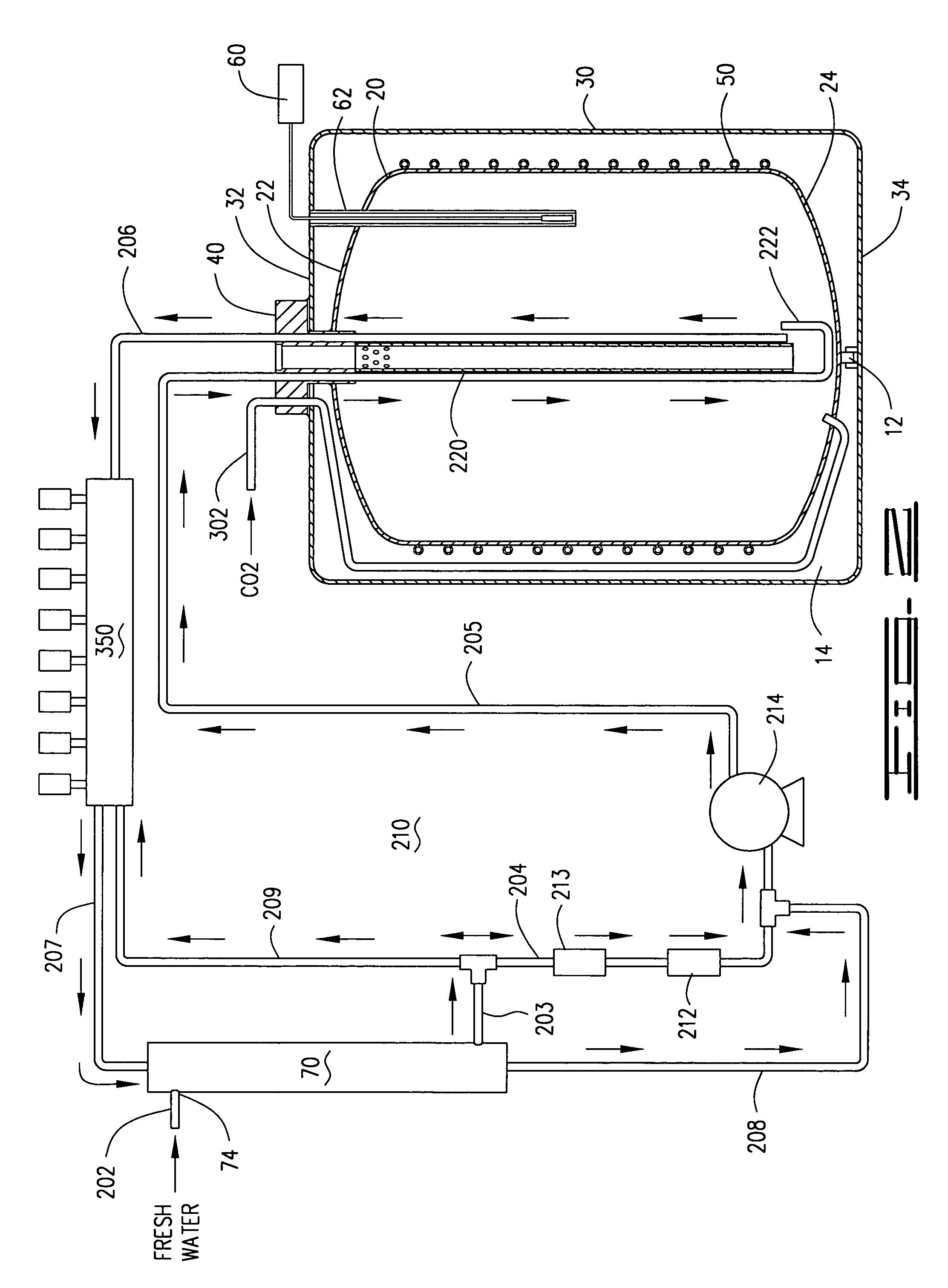

Apparatus for delivering carbonated liquid at a temperature near or below the freezing point of water

InactiveUS6981387B1Less likely to melt iceEasy to processDomestic cooling apparatusFlow mixersFresh waterEngineering

A double tank refrigerated carbonated beverage dispensing apparatus for blending fresh water and carbon dioxide to produce a carbonated liquid delivered to a faucet bank for dispensing mixed soft drinks at a temperature at or below the freezing point of water, includes a double tank carbonator having in inner tank contained within an outer tank, insulated by a void between the two tank, the void having refrigeration coils connected to a refrigeration circulation system. The apparatus includes a soda water circulating system, a heat exchange unit for pre-cooling water and beverage syrup lines, syrup coils adapted to the double tank carbonator for chilling some beverage syrup lines, temperature sensors for regulating temperature of the carbonated water and fluid level probes to regulate the amount of water delivered to the double tank carbonator.

Owner:MORGAN LOUIS A

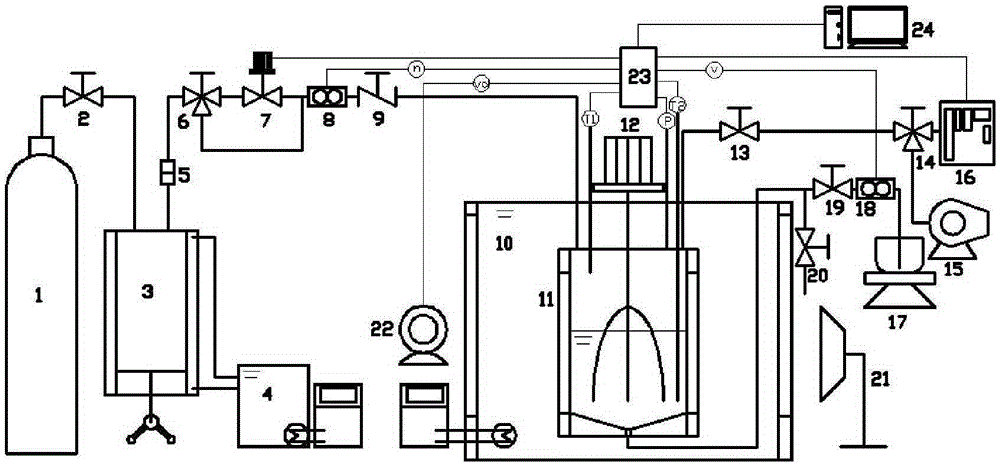

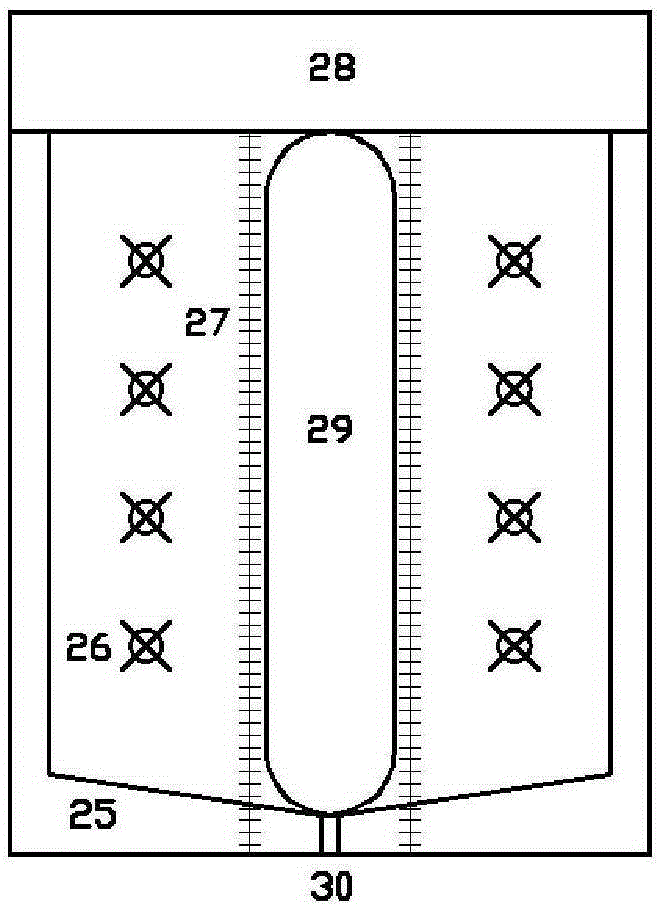

Visual gas hydrate dynamic experimental device

InactiveCN105301205AEasy dischargeEasy to operateChemical/physical/physico-chemical stationary reactorsFeed devicesGrowth phaseTemperature control

The invention provides a visual gas hydrate dynamic experimental device. The visual gas hydrate dynamic experimental device comprises a visual electromagnetic stirring reaction still, a voltage stabilizing pre-cooling gas supplying unit, an gas exhaust unit, a liquid charging / discharging unit, a temperature control unit and a data collecting and processing unit, wherein the visual electromagnetic stirring reaction still is used for mixing experimental gas and experimental liquid in the reaction still for reaction to form and decompose hydrate; the voltage stabilizing pre-cooling gas supplying unit and the gas exhaust unit are used for supplying pre-cooling experimental gas for the visual electromagnetic stirring reaction still and discharging gas; the liquid charging / discharging unit is used for injecting the experimental liquid to the visual electromagnetic stirring reaction still or discharging the experimental liquid; the temperature control unit is used for controlling the temperature change of the visual electromagnetic stirring reaction still; the data collecting and processing unit is used for collecting, processing, saving and analyzing kinetic parameters during a hydrate formation and decomposition process. According to the visual gas hydrate dynamic experimental device, numerous defects of a common hydrate dynamic experimental device are overcome, the kinetic properties in a nucleation phase and a growth phase of gas hydrate can be accurately determined, and the experimental device is simple, economical and convenient to operate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

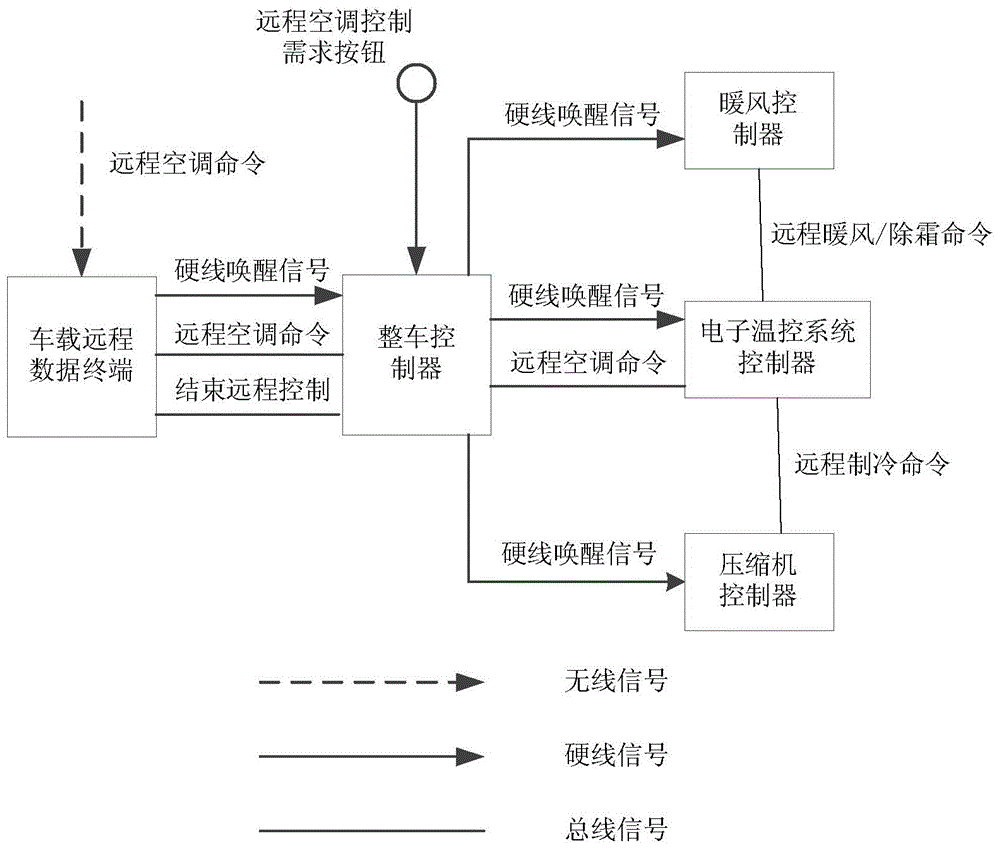

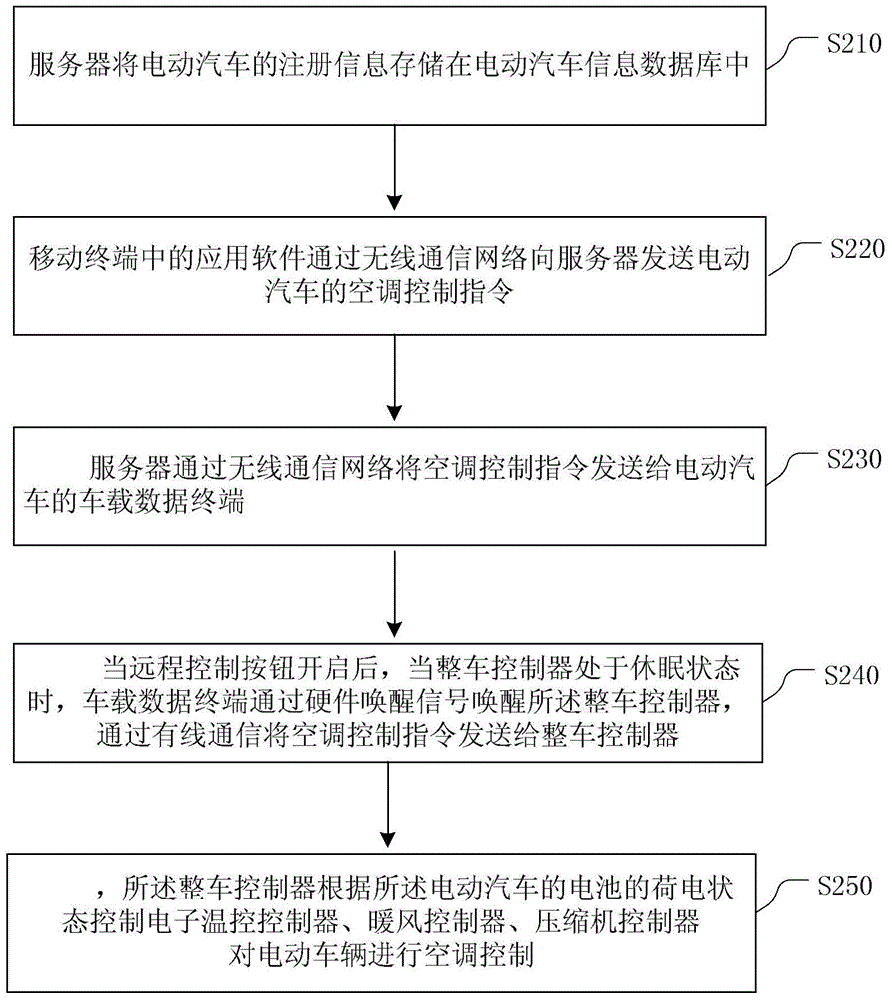

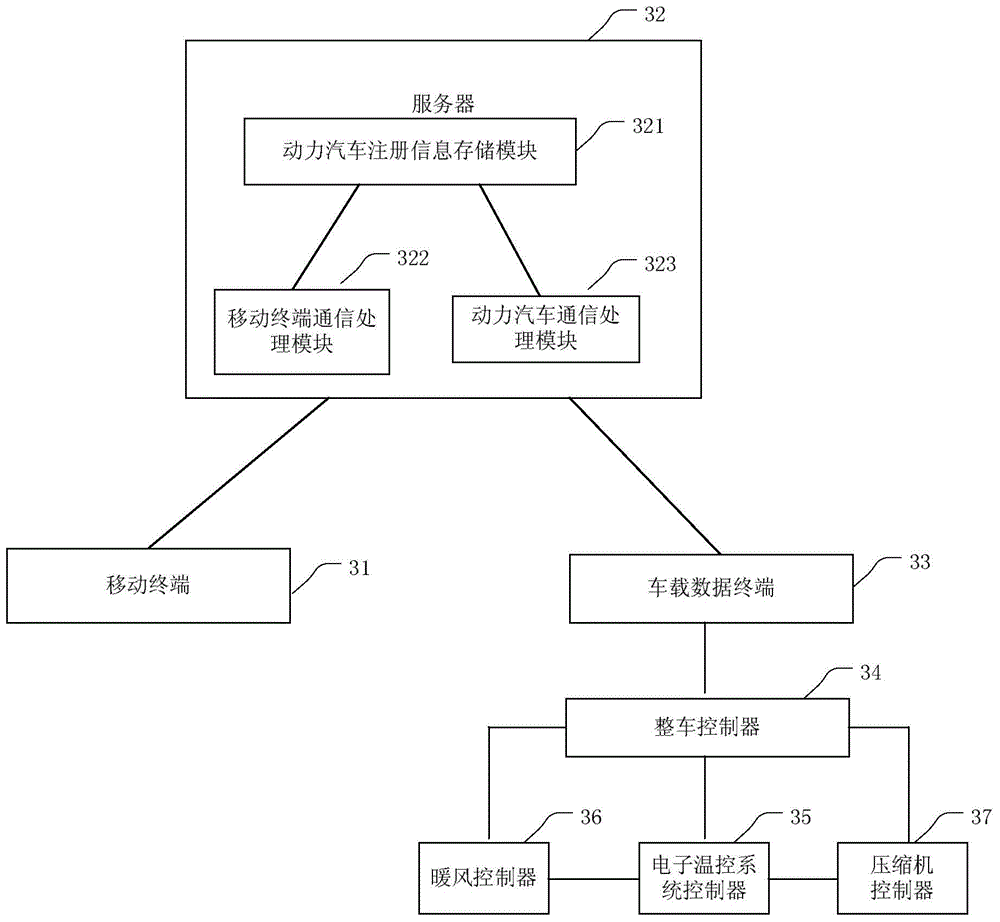

Method and system for performing remote air conditioning control on electric vehicle

ActiveCN104597787AImprove driving experienceElectric vehicle charging technologyProgramme control in sequence/logic controllersData terminalWired communication

The embodiment of the invention provides a method and a device for performing remote air conditioning control on an electric vehicle. The method comprises the following steps: an application software in a mobile terminal sends an air conditioning control order of the electric vehicle to a server through a wireless communication network, and the server sends the air conditioning control order to a vehicle-mounted data terminal of the electric vehicle through the wireless communication network; the vehicle-mounted data terminal sends the air conditioning control order to a whole vehicle controller of the electric vehicle through wired communication, and the whole vehicle controller controls an electronic temperature controller to perform air conditioning control on the electric vehicle according to a charge state of the electric vehicle. According to the embodiment adopted by the invention, the application software in the mobile terminal can be combined with the server to remotely and flexibly control starting and ending of an air conditioning control process of the electric vehicle, so that a user can pre-cool or pre-heat a cab before going out, and the driving experience of the electric vehicle is improved.

Owner:BEIJING ELECTRIC VEHICLE

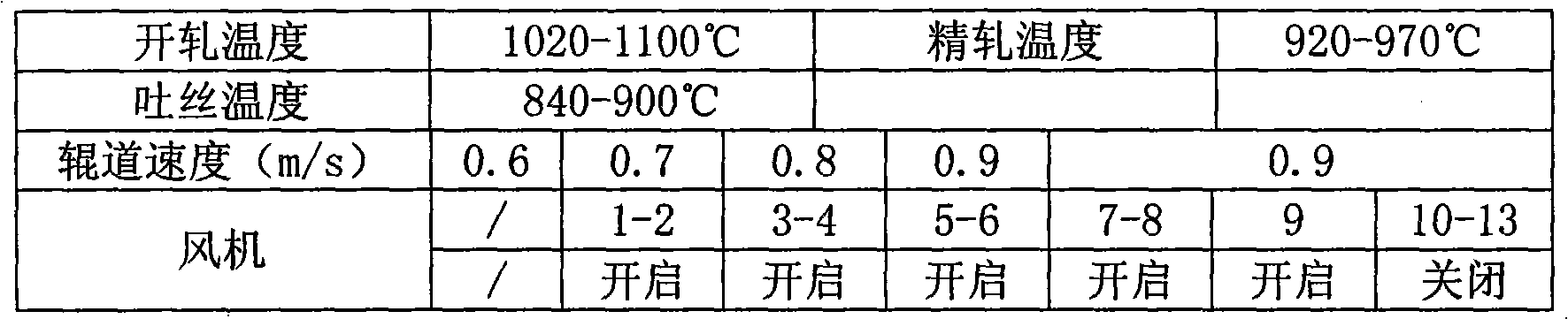

Micro alloying SWRH87B hot rolled wire rod and manufacturing method thereof

InactiveCN101597713AQuality improvementEasy to useTemperature control deviceManufacturing convertersTemperature controlWire rod

The invention provides a micro alloying SWRH87B hot rolled wire rod and a manufacturing method thereof, belonging to the technical field of hot rolled wire rod. In the invention, Cr and V micro alloying are adopted; double slag process high drawing carbon operation is used in a converter; end-point carbon is controlled at 0.40-0.60%, the steel tapping temperature is 1580-1620 DEG C, and the slag-blocked tapping is used; low nitrogen carburant is used for recarburization; Si-Ca-Ba is used for deoxidation; 600-800kg synthetic slag is added into each converter; oxygen activity is controlled below 10ppm by entering into an LF refining station, and the refined finishing slag sum of FeO and MnO is no more than 3%; inclusion modification treatment is carried out on the Ca-Si line; a billet in the size of 160mm*160mm is used, a casting mould is used for coordinating with final electromagnetic stirring (F-EMS); continuous casting machine whole protection, constant drawing speed casting and proper secondary cooling system are adopted; the initial rolling temperature is controlled at 1020-1150 DEG C which is conductive to welding the drawholes and increasing the probability of the drawholes welding; the water pre-cooling and phase transformation strengthening cooling technology is used to control the texture and the performance. The invention has the advantages that the aging time of the wire rod before the follow-up processing is shortened, the tensile strength thereof after aging time is larger than 1280MPa, and the area reduction rate is larger than 25%.

Owner:SHOUGANG CORPORATION

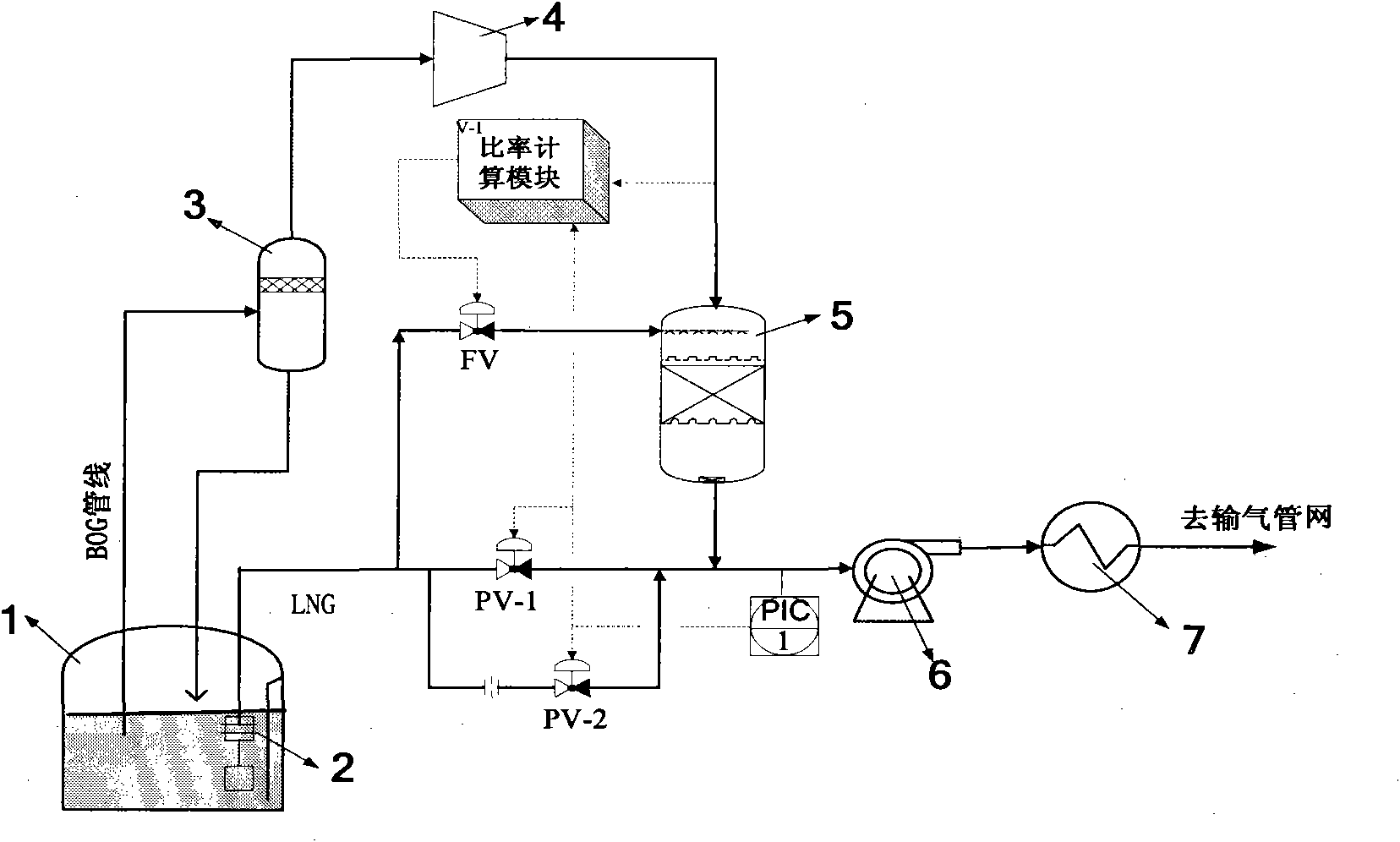

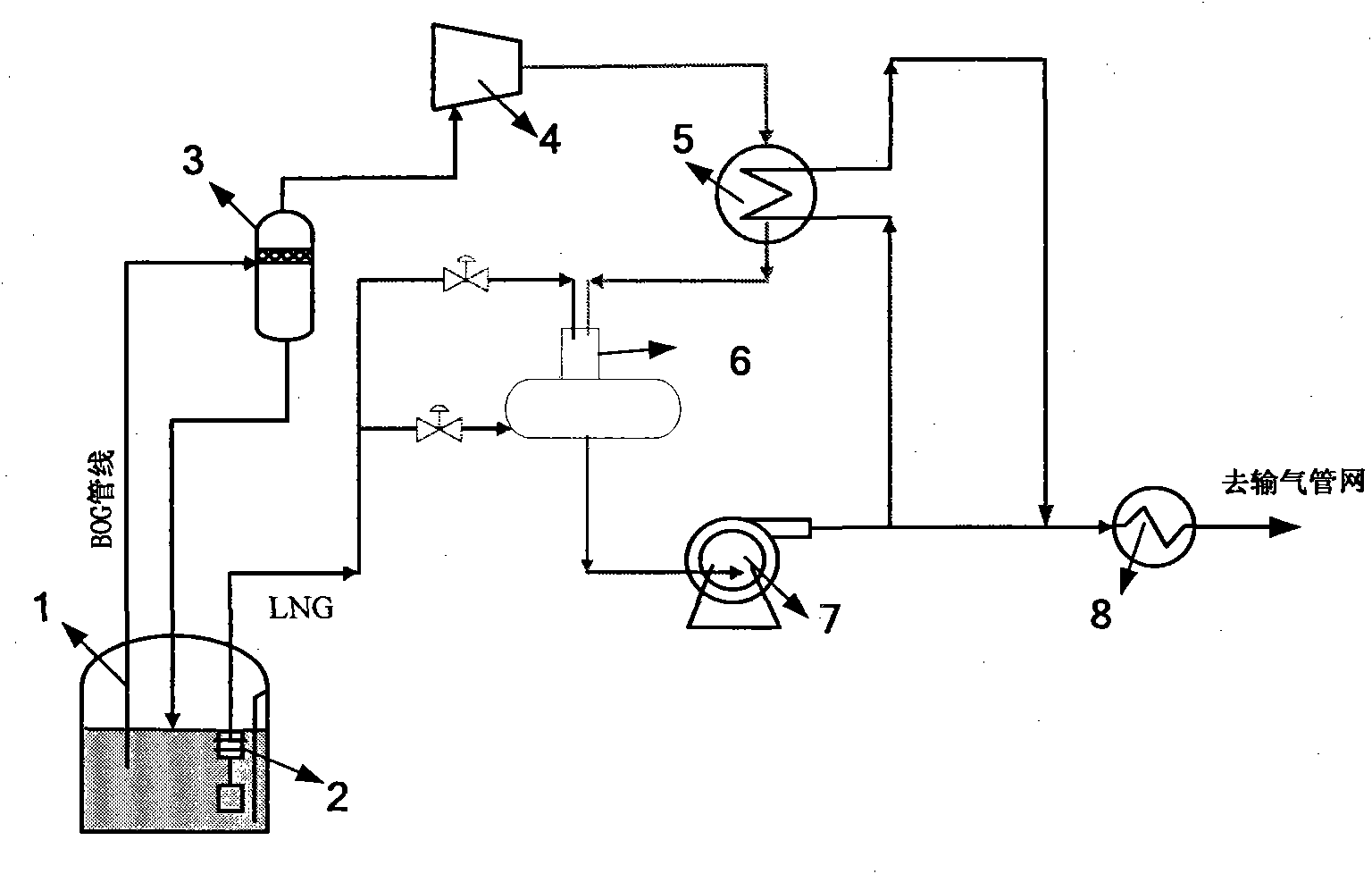

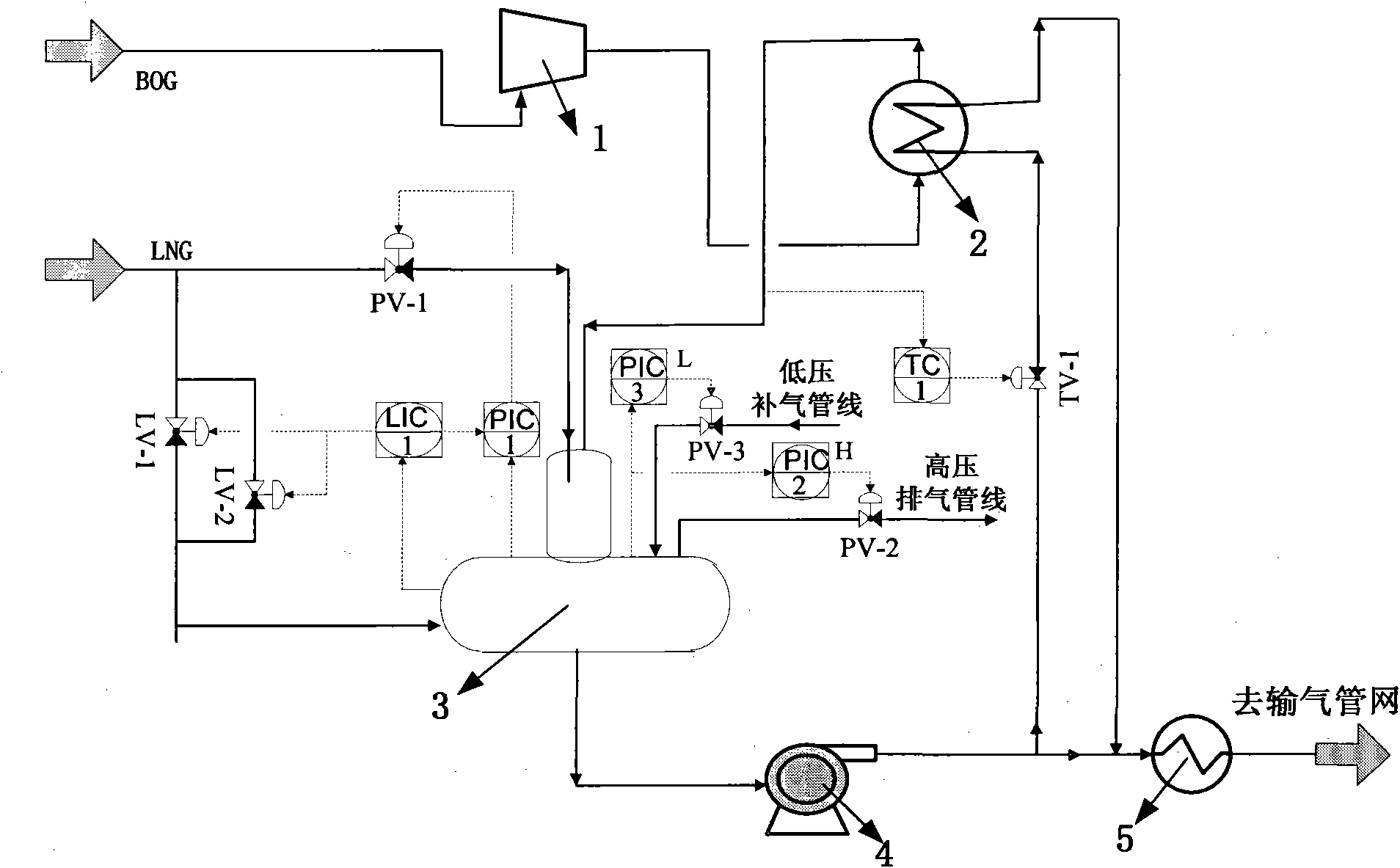

Re-condensation reclaiming system for evaporated gas of liquefied natural gas receiving station and reclaiming method thereof

ActiveCN101881549AReduce energy consumptionAdaptableSolidificationLiquefactionSuper coolingGas compressor

The invention discloses a re-condensation reclaiming system and a re-condensation reclaiming method for evaporated gas of a liquefied natural gas receiving station. The system comprises an evaporated gas compressor, an evaporated gas pre-cooling heat exchanger and a re-condenser, wherein the re-condenser consists of a vertical condensing tower and a high-pressure pump buffer tank; and the vertical condensing tower is positioned above the high-pressure pump buffer tank. The bottom of the high-pressure pump buffer tank is provided with a brace, and a crossed vortex breaker is arranged in the brace. The reclaiming method comprises the following steps of: (1) compressing the evaporated gas, (2) pre-cooling the evaporated gas, (3) condensing and super-cooling the evaporated gas and (4) conveying secondary pressure of LNG. The design of the buffer tank improves the running stability of a high-pressure pump; the re-condenser operates and controls the system more stably and simply; and the system and the method reduce the energy consumption, and have good adaptability to gas conveying load fluctuation.

Owner:佛山市天然气高压管网有限公司

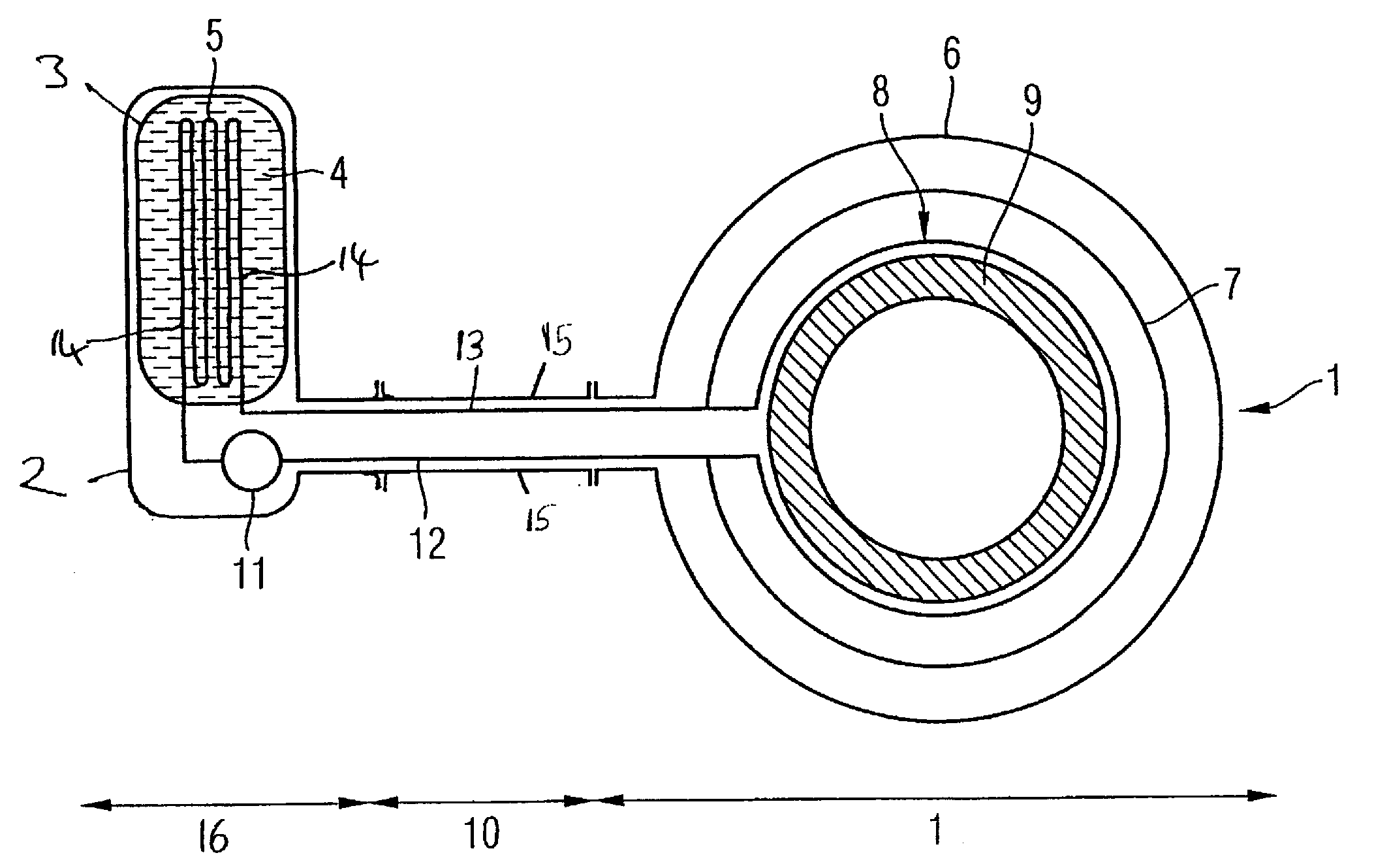

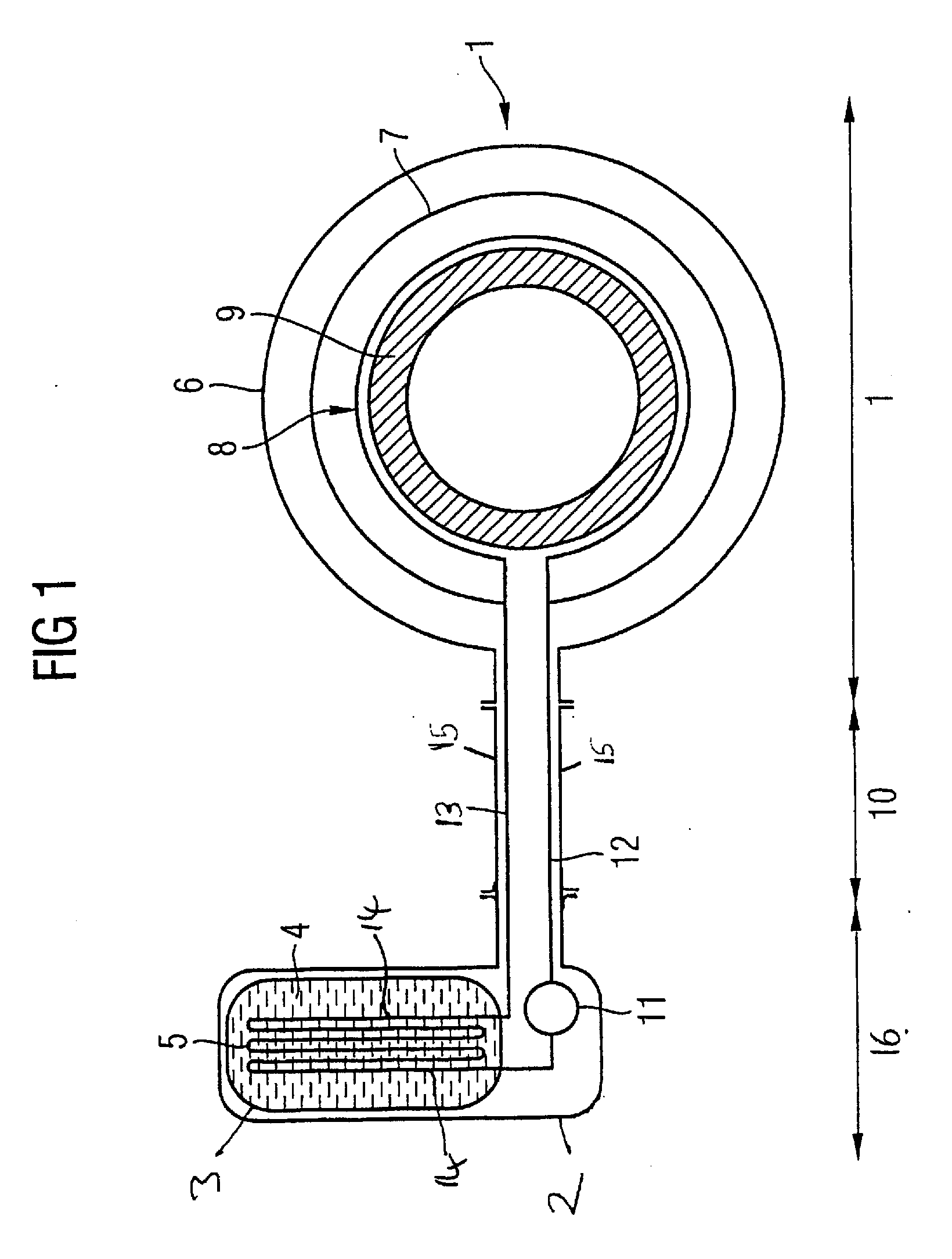

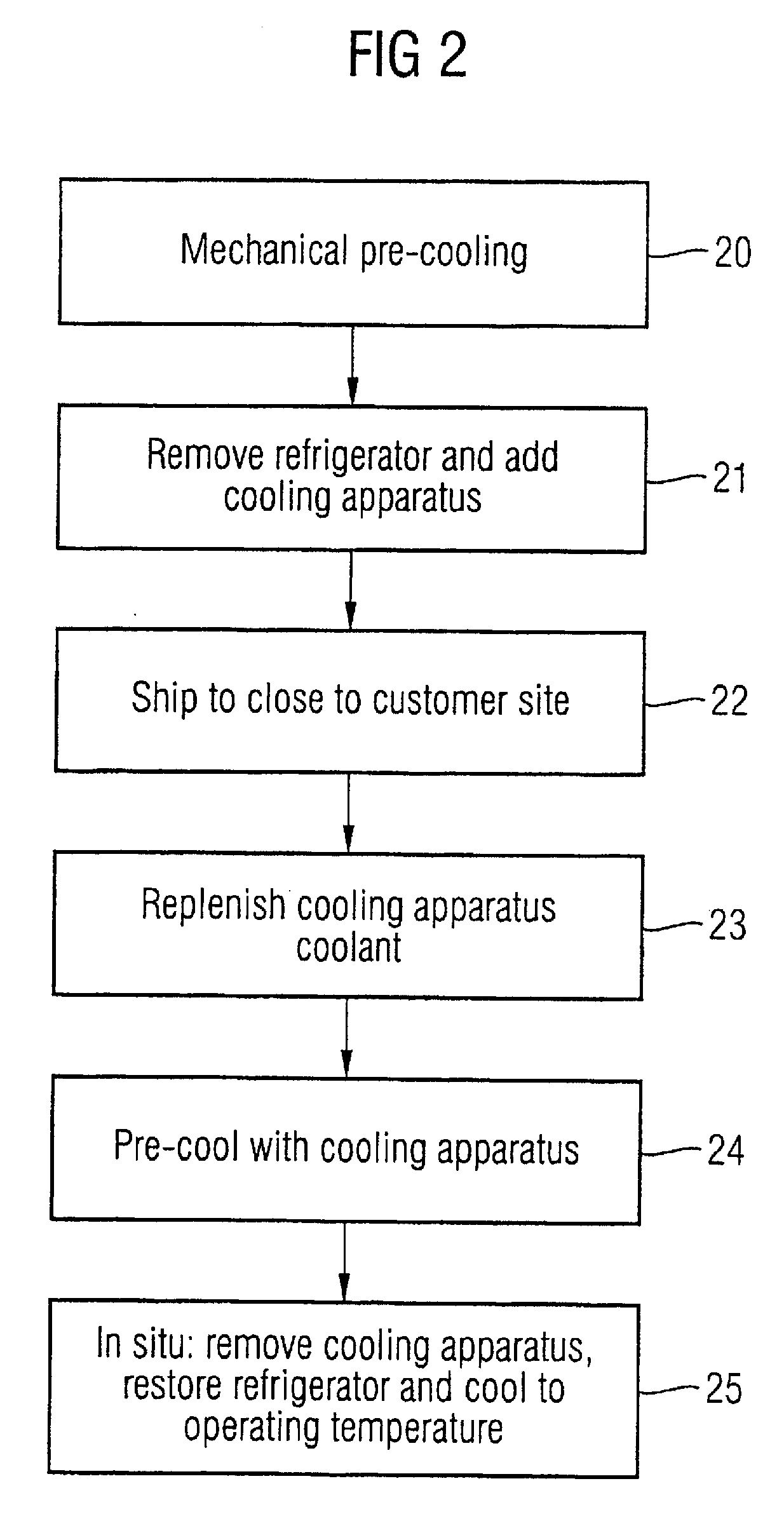

Method and apparatus for maintaining a superconducting system at a predetermined temperature during transit

A superconductor system cooling apparatus, the apparatus comprising a casing, a solid coolant and a cooling circuit; wherein the cooling circuit comprises a heat exchanger, and a connector to couple the heat exchanger to a pre-cool loop of the superconductor system; wherein the cooling circuit further comprises a heat exchange medium to transfer heat between the solid coolant and the superconducting system.

Owner:SIEMENS PLC

Method for pre-cooling automotive vehicle passenger compartment

InactiveUS20060075766A1Rapid coolingAir-treating devicesCompression machines with non-reversible cycleElectricityMotorized vehicle

The present invention concerns a method for pre-cooling the passenger compartment of an automotive vehicle. The vehicle includes at least one electrically actuatable window and a HVAC system having at least a controller, a blower, a passenger compartment temperature sensor, and a HVAC ducting leading to the passenger compartment. The controller and the blower are connected to a vehicle battery. The method includes determining the passenger compartment temperature and comparing the temperature to a first predetermined value; cycling an blower inlet to an outside air intake position and operating the blower to provide pressurized air to the passenger compartment if the passenger compartment temperature is greater than the first predetermined value; opening the vehicle windows; comparing the passenger compartment temperature to a second predetermined value; and stopping operation of the blower when the passenger compartment temperature drops below the second predetermined value.

Owner:GM GLOBAL TECH OPERATIONS LLC

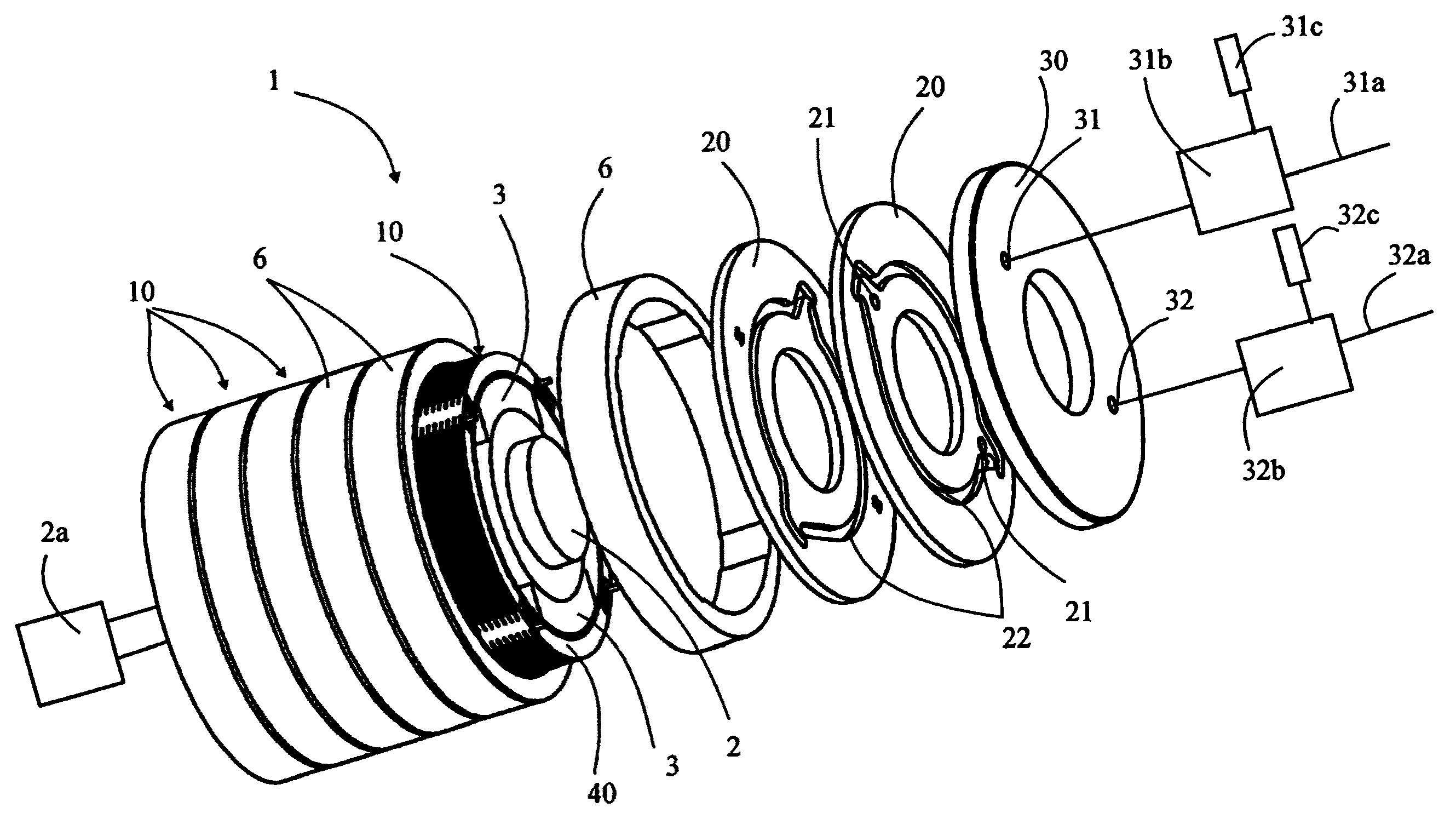

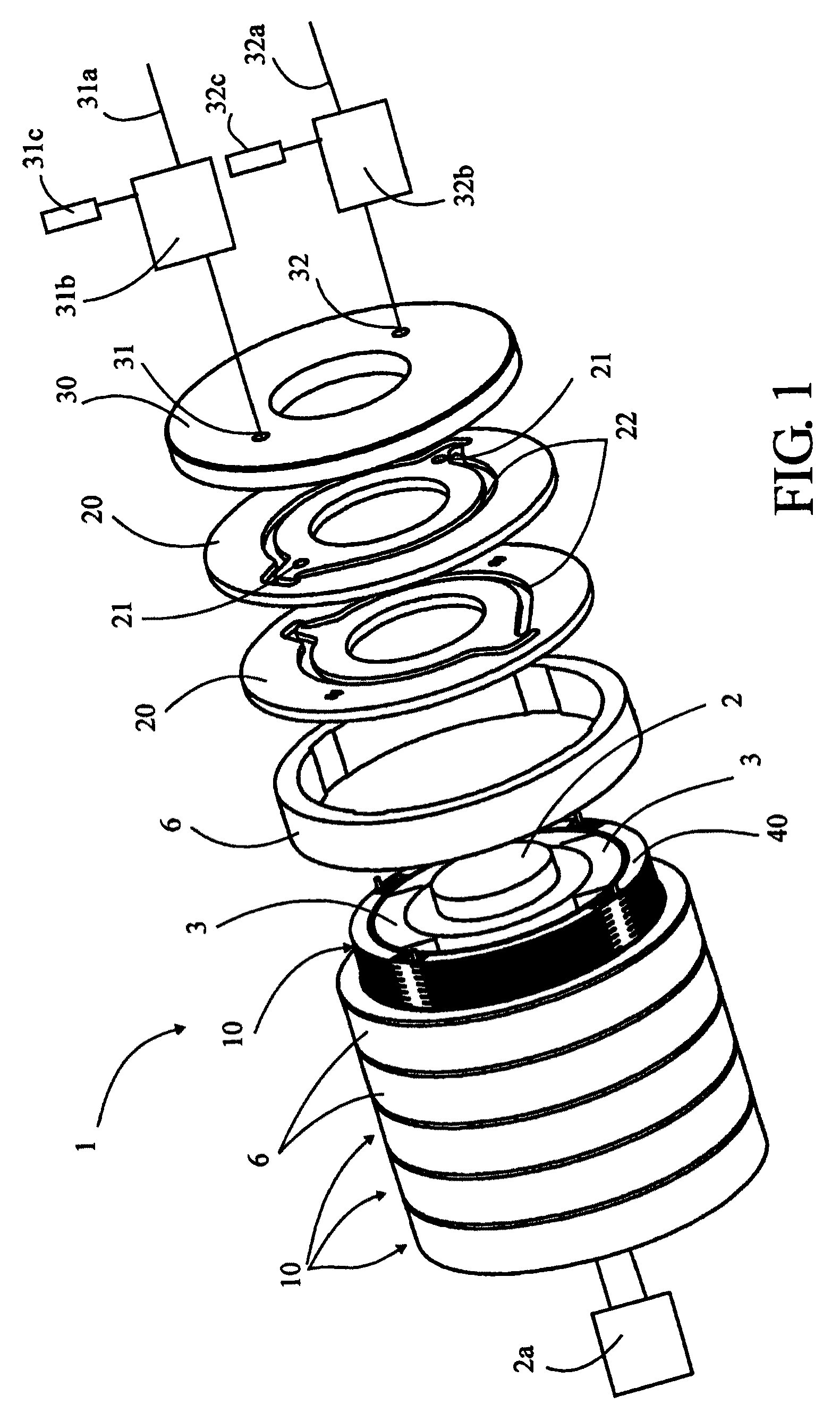

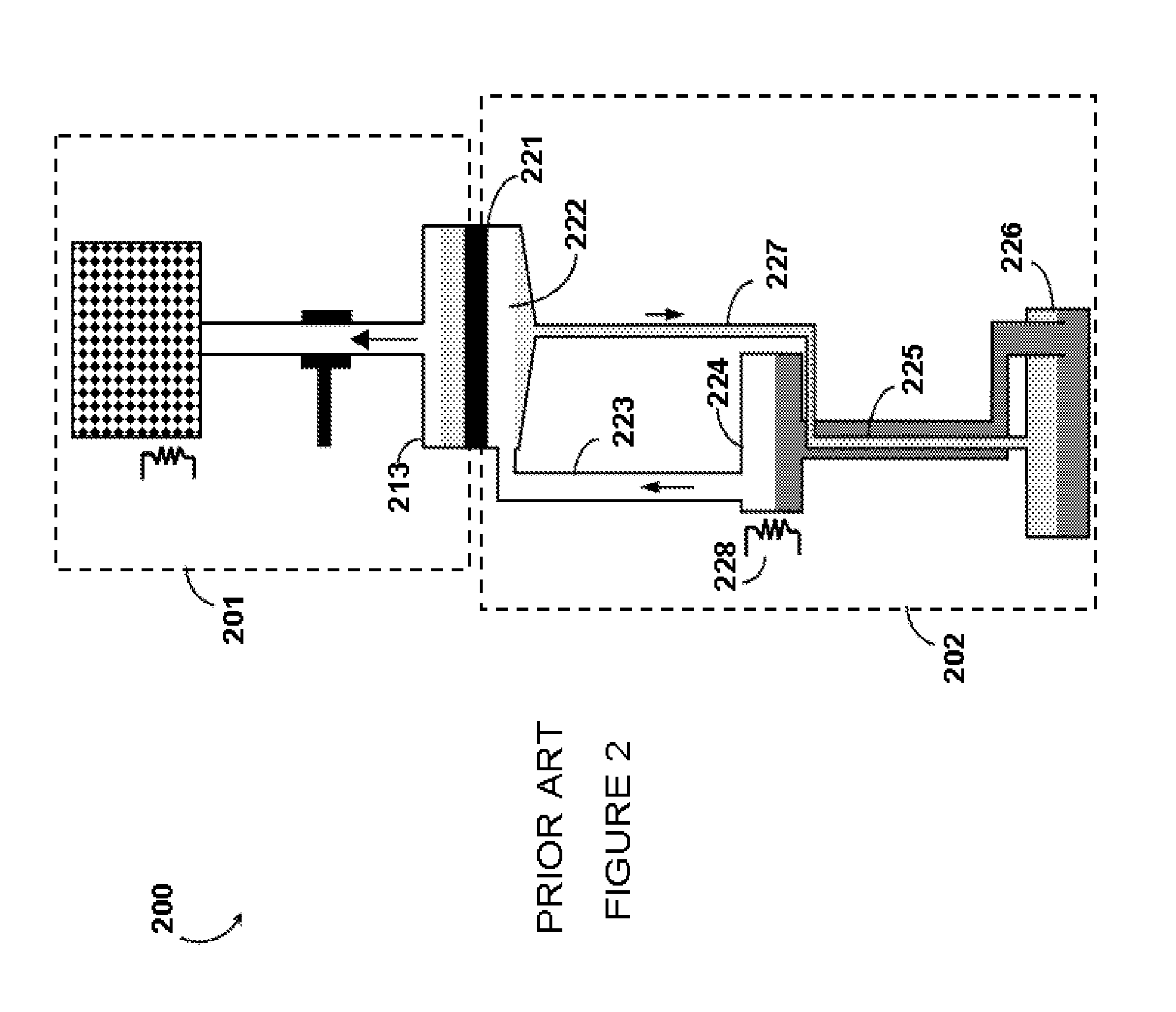

Process and apparatus to increase the temperature gradient in a thermal generator using magneto-calorific material

InactiveUS8904806B2Improve energy efficiencyEasy to buildEnergy efficient heating/coolingMachines using electric/magnetic effectsEngineeringAir conditioning

A method and an apparatus for increasing the temperature gradient of a magneto-calorific thermal generator comprising magneto-calorific elements subjected to a magnetic field variation. At least one of a pre-heating and pre-cooling of the magneto-calorific elements (60) is carried out to modify the initial temperature before and / or during the magnetic field variation before reaching the maximum and / or minimum field value. The method and apparatus may be employed in heating, tempering, air conditioning, refrigeration and other industrial or domestic applications.

Owner:COOLTECH APPL SAS

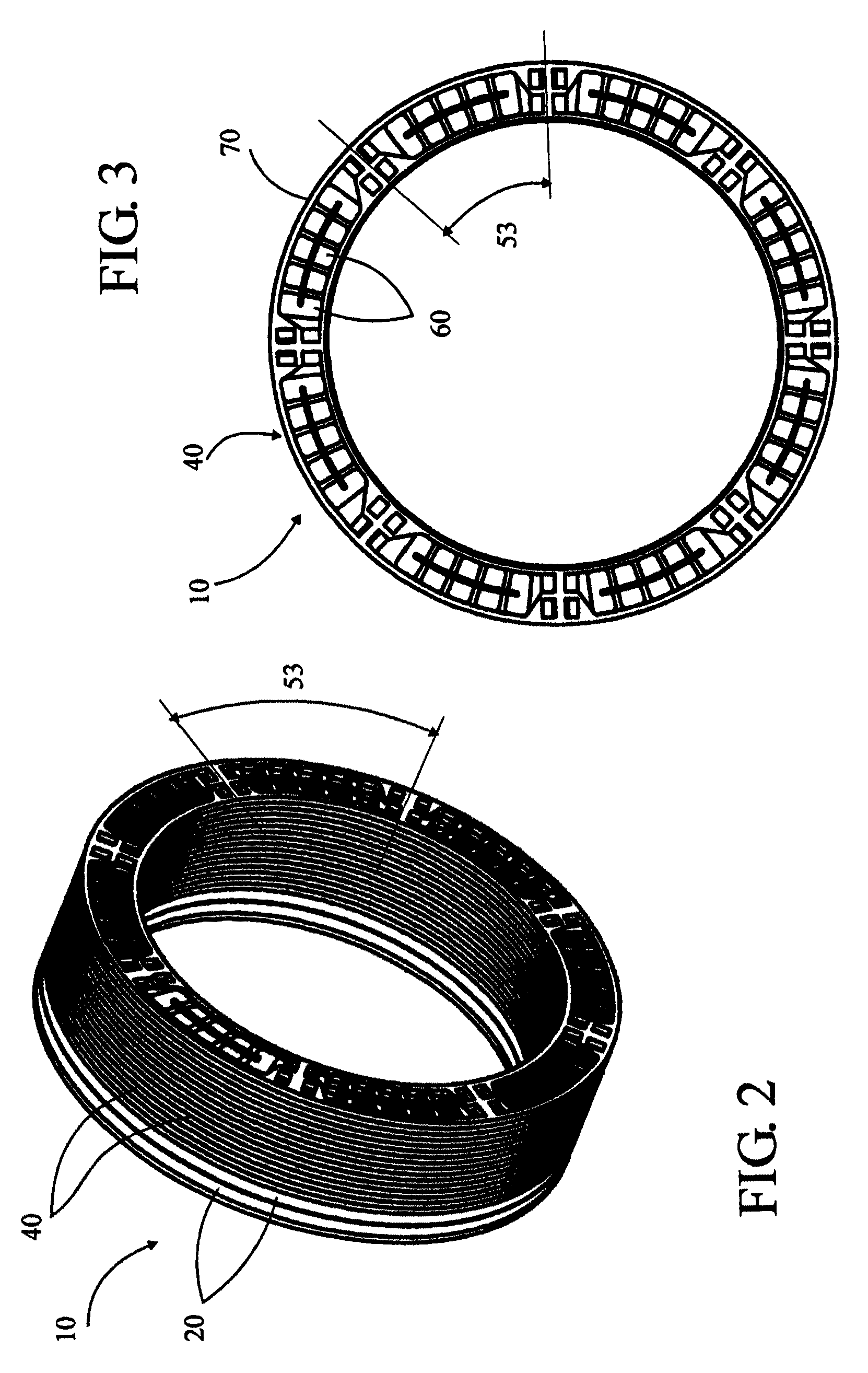

System and method for rapid hydrogen filling

InactiveCN103244825AImprove securityReduce temperature risePipeline systemsContainer filling under pressureGas cylinderHigh pressure hydrogen

The invention provides a system and a method capable of achieving balanced pressure-reducing rapid hydrogen filling by three storage tanks with hydrogen of any sources. The system comprises a hydrogen compression device, hydrogen storage devices and a hydrogen filling device. Hydrogen prepared by any methods is compressed via the hydrogen compression device and then is stored in the high-pressure hydrogen storage devices, and a hydrogen outlet of each hydrogen storage device is directly connected to a hydrogen dispenser or an industrial hydrogen cylinder filling system. A set of pressure-reducing balanced filling system is shared during automobile hydrogen (hydrogen for the energy purpose) filling and cylinder filling (industrial hydrogen). A pressure-reducing valve is not arranged in the system, so that pipe resistance of the system is lower, and filling rate is higher. Besides, a pre-cooling device is added to the system, so that temperature rise of a filling container is lower.

Owner:BEIJING JONTON HYDROGEN TECH

Systems, methods, and apparatus for cryogenic refrigeration

ActiveUS20100281885A1Efficient evacuationDigital data processing detailsCompression machinesDilution refrigeratorEvaporation

Cryogenic refrigeration employs a pulse tube cryo-cooler and a dilution refrigerator to provide very low temperature cooling, for example, to cool superconducting processors. Continuous cryogenic cycle refrigeration may be achieved using multiple adsorption pumps. Various improvements may include multiple distinct thermal-linking points, evaporation pots with cooling structures, and / or one or more gas-gap heat switches which may be integral to an adsorption pump. A reservoir volume may provide pressure relief when the system is warmed above cryogenic temperature, reducing the mass of the system. Additional heat exchangers and / or separate paths for condensation and evaporation may be provided. Multi-channel connectors may be used, and / or connectors formed of a regenerative material with a high specific heat capacity at cryogenic temperature. Flexible PCBs may provide thermal links to components that embody temperature gradients. Various components may be pre-cooled, for example via a switchable thermalization system.

Owner:D WAVE SYSTEMS INC

Composite vegetable powder products and method for preparing the same

InactiveCN101095493ACompatibility is reasonablePreserve nutritional valueFruits/vegetable preservation by freezing/coolingFood preparationFlavorPre cooling

The invention relates to a kind of compound vegetable powder and the production method. The comprised components and their weight proportion are as follows: cabbage powder 20-85%, west orchid powder 0-50%, and other vegetable powder of cruciferae 0-30%. The method comprises following steps: picking raw material, selecting, pre-cooling, washing, blanching, cooling, cutting to sheet or block, freezing, subliming drying, hydrolyzing drying, grinding, matching, vacuum packing. The product is characterized by reasonable matching, flavor for absorption, health-care effect. The process is reasonable and the nutrition and biological activity in vegetable are retained at maximum degree because of the vacuum freezing technique.

Owner:SHANGHAI RIYI AGRI TECH

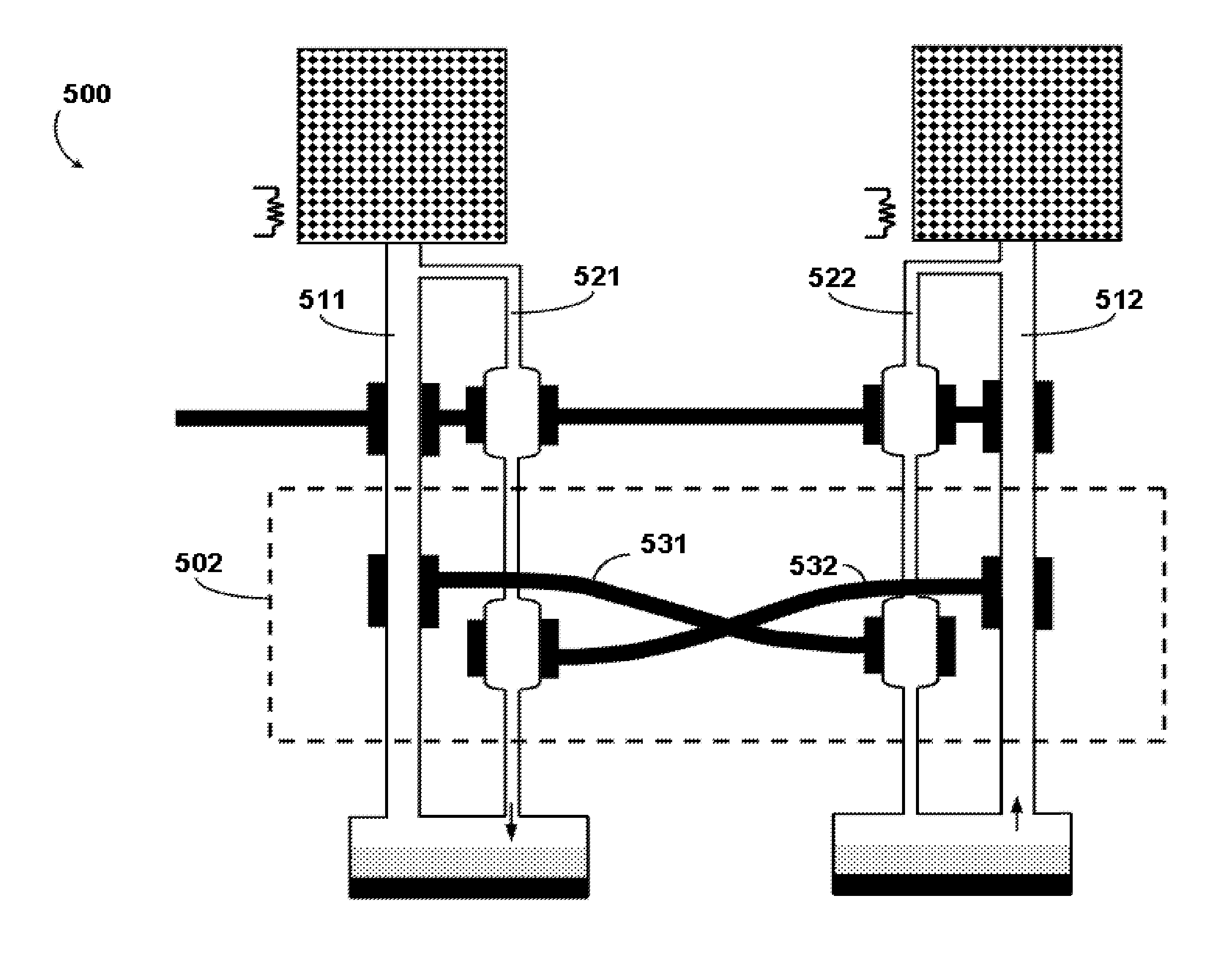

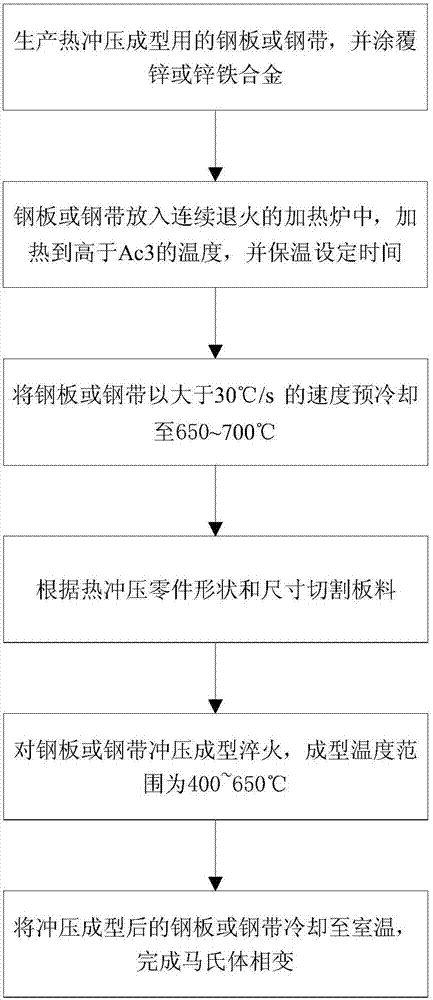

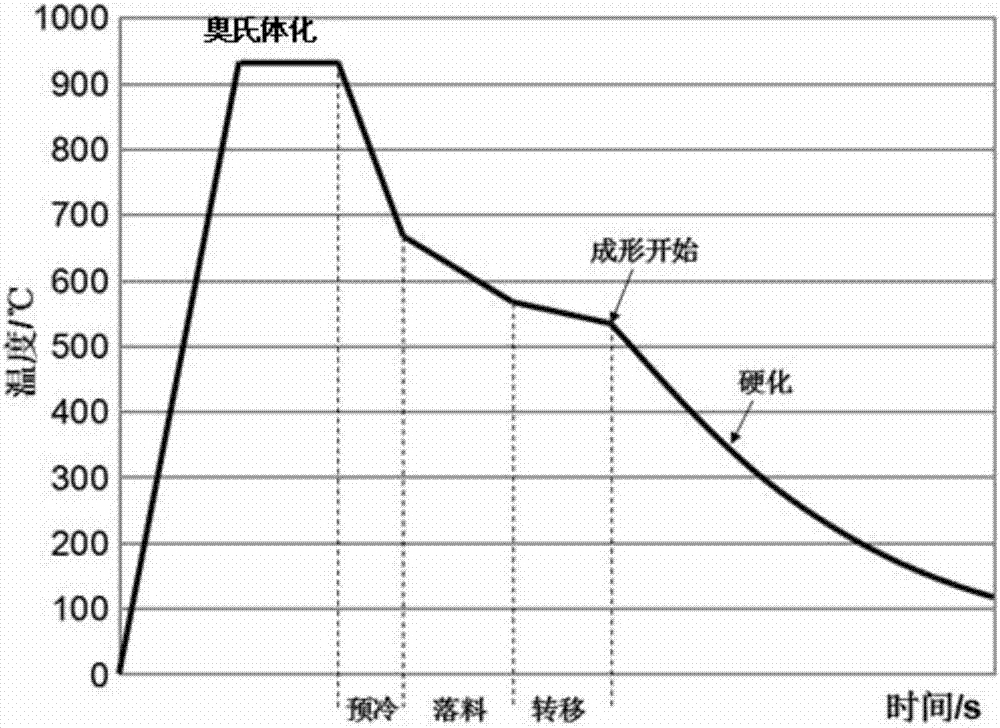

Hot-stamping forming method for zinc plating steel plate or steel strip

ActiveCN107127238ALow heating temperatureShort holding timeShaping toolsHot-dipping/immersion processesHot stampingSheet steel

The invention relates to a hot-stamping forming method for a zinc plating steel plate or a steel strip. According to the hot-stamping forming method, the steel plate or the steel strip is conveyed into a vertical heating annealing furnace, the temperature is kept for a certain time, the steel plate is completely austenitized, a pre-cooling device is used when the steel plate leaves the annealing furnace, the steel plate is cooled to 650-700 DEG C at the cooling rate higher than 30 DEG C / s, then blanking is performed according to the part shape and size, then the steel plate is quickly transferred into a mold for hot-stamping forming, the steel plate is hardened at the speed higher than 30 DEG C / s, and the hot-stamping forming temperature is kept between 400 DEG C and 650 DEG C. Base plate cracks caused by partial stress and liquid metal embrittlement (LME) can be avoided, and the method is used for solving the problem that the base plate cracks cannot be avoided for existing zinc-based hot-stamping formed steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com