Patents

Literature

5747 results about "Salt water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

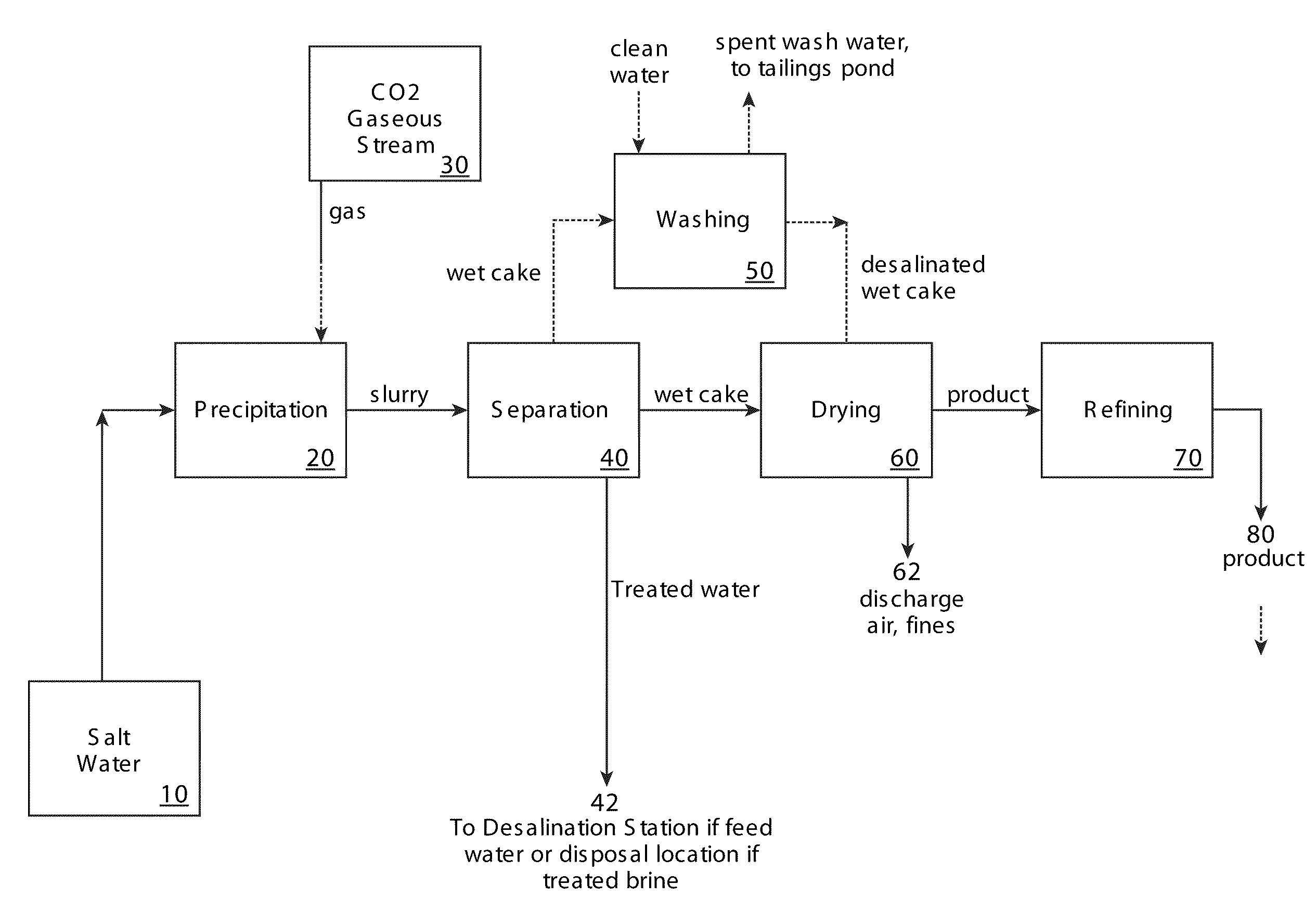

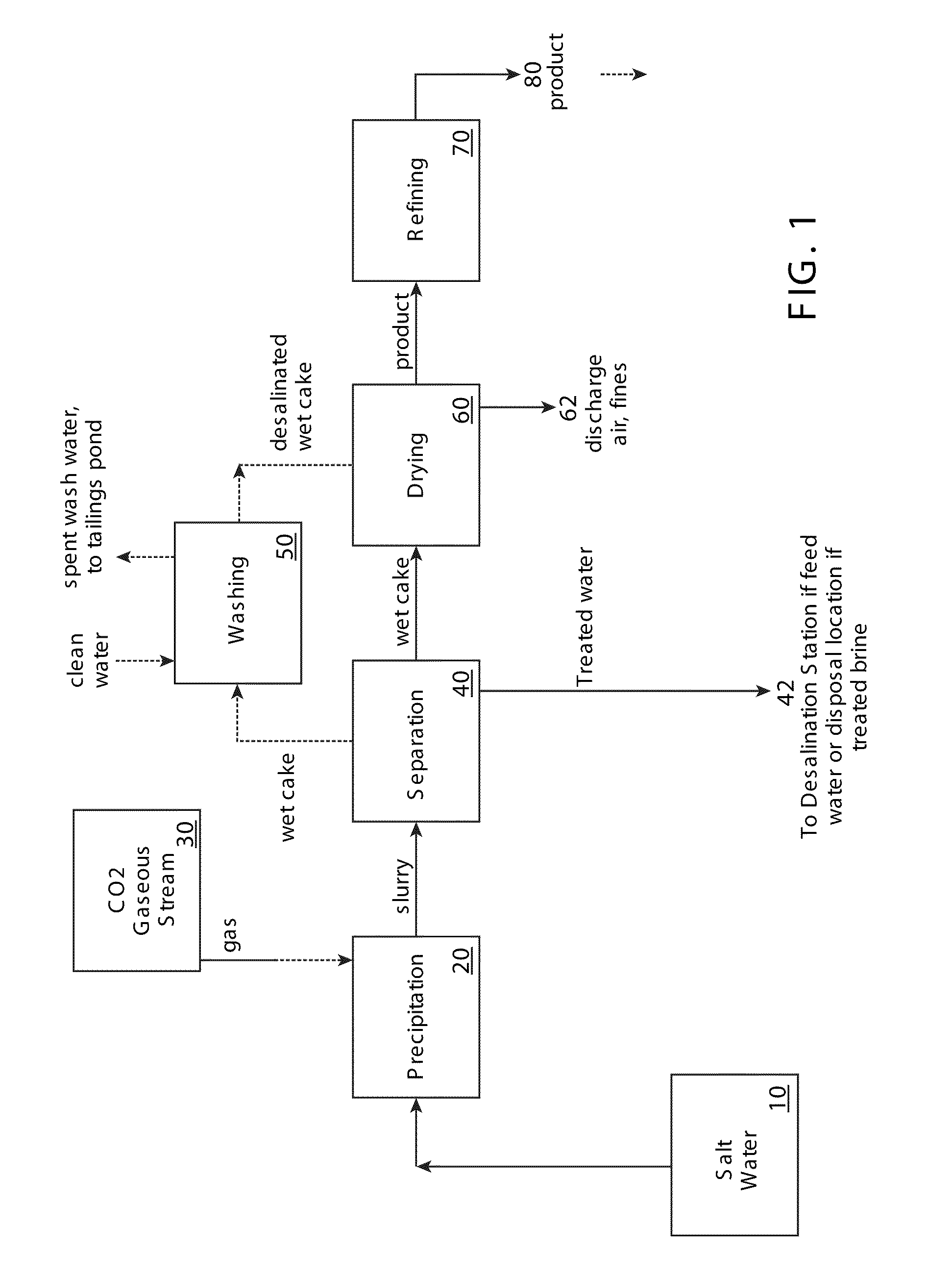

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20090001020A1Easy complianceImprove desalination efficiencyGeneral water supply conservationSeawater treatmentSaline waterDesalination

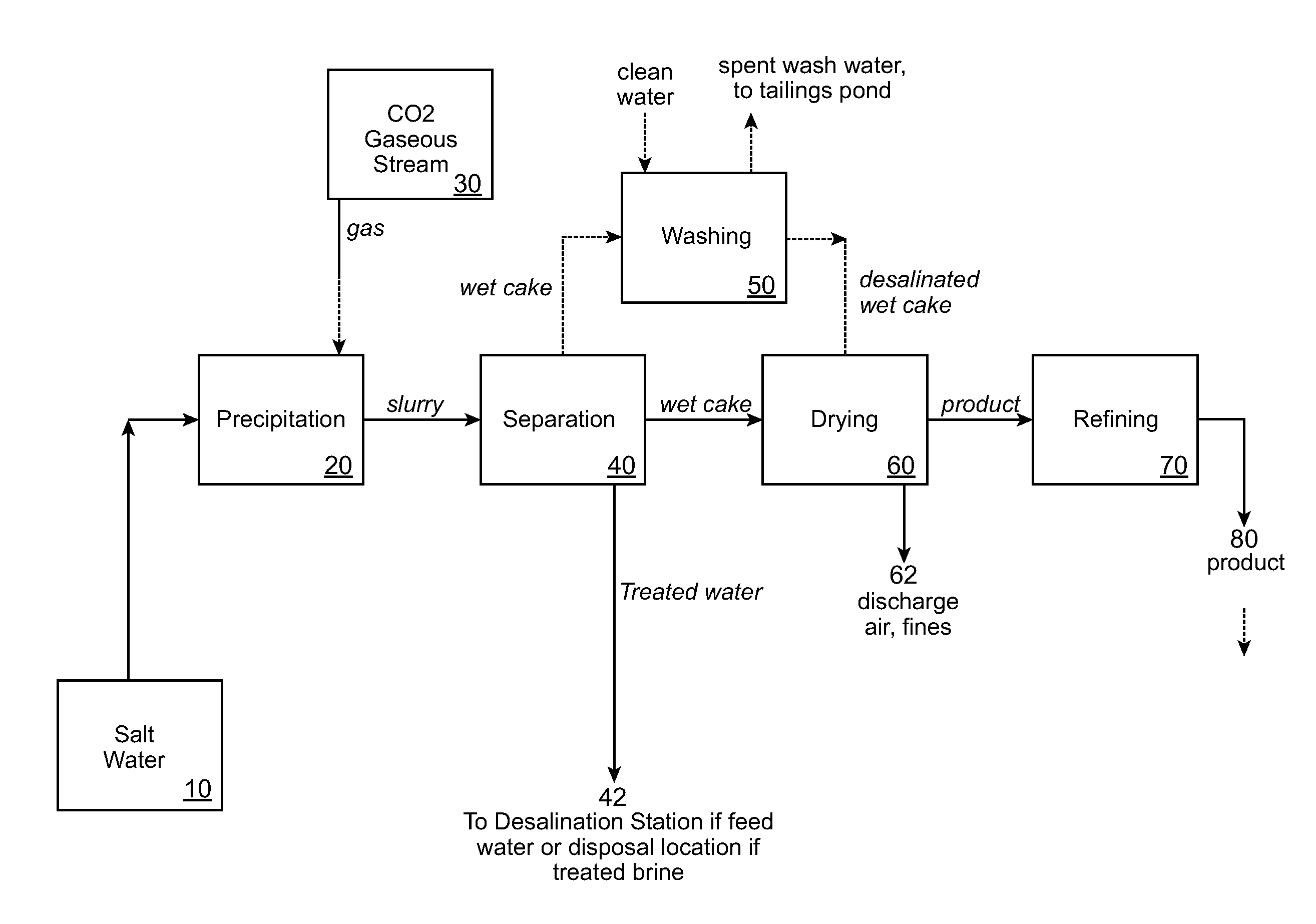

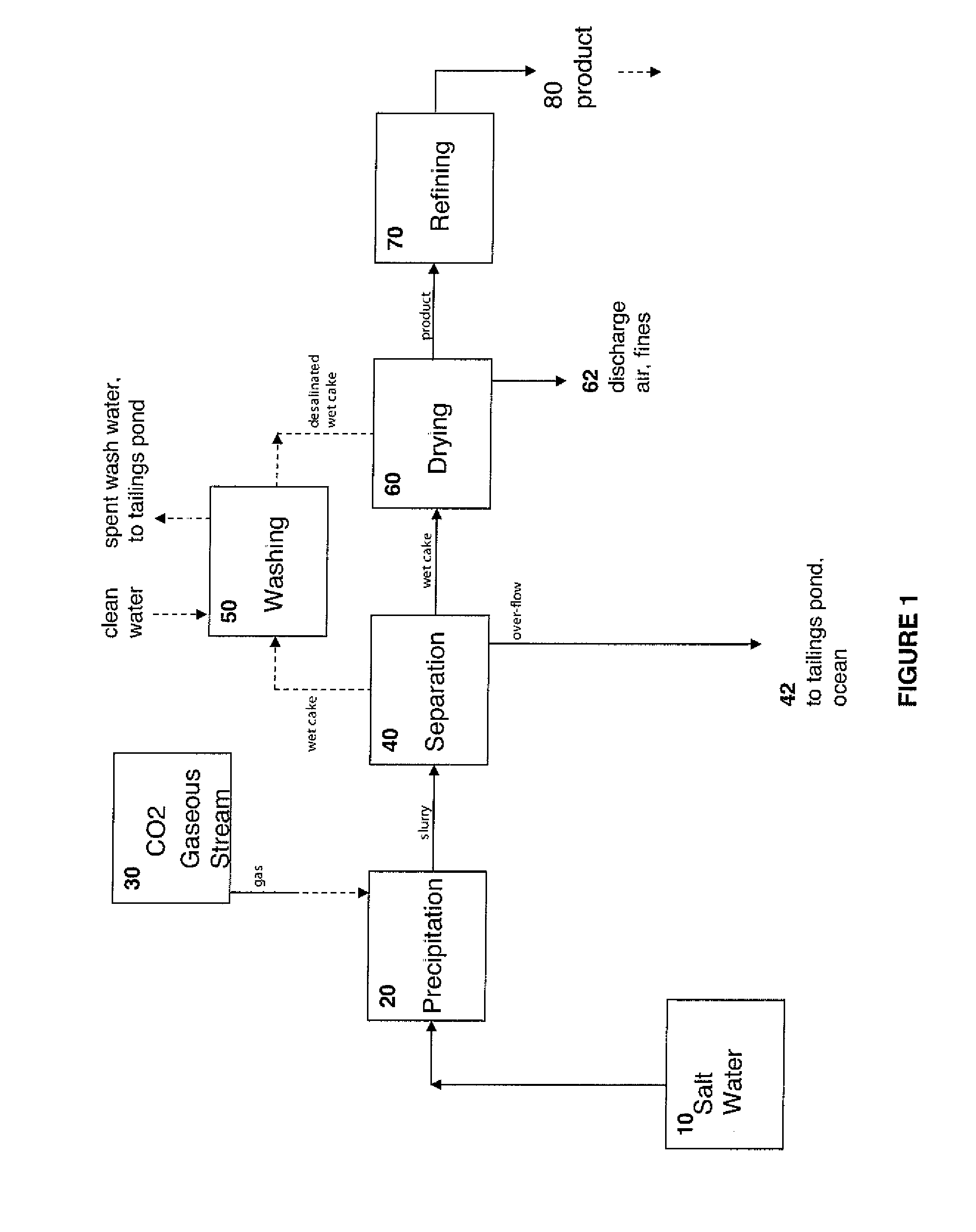

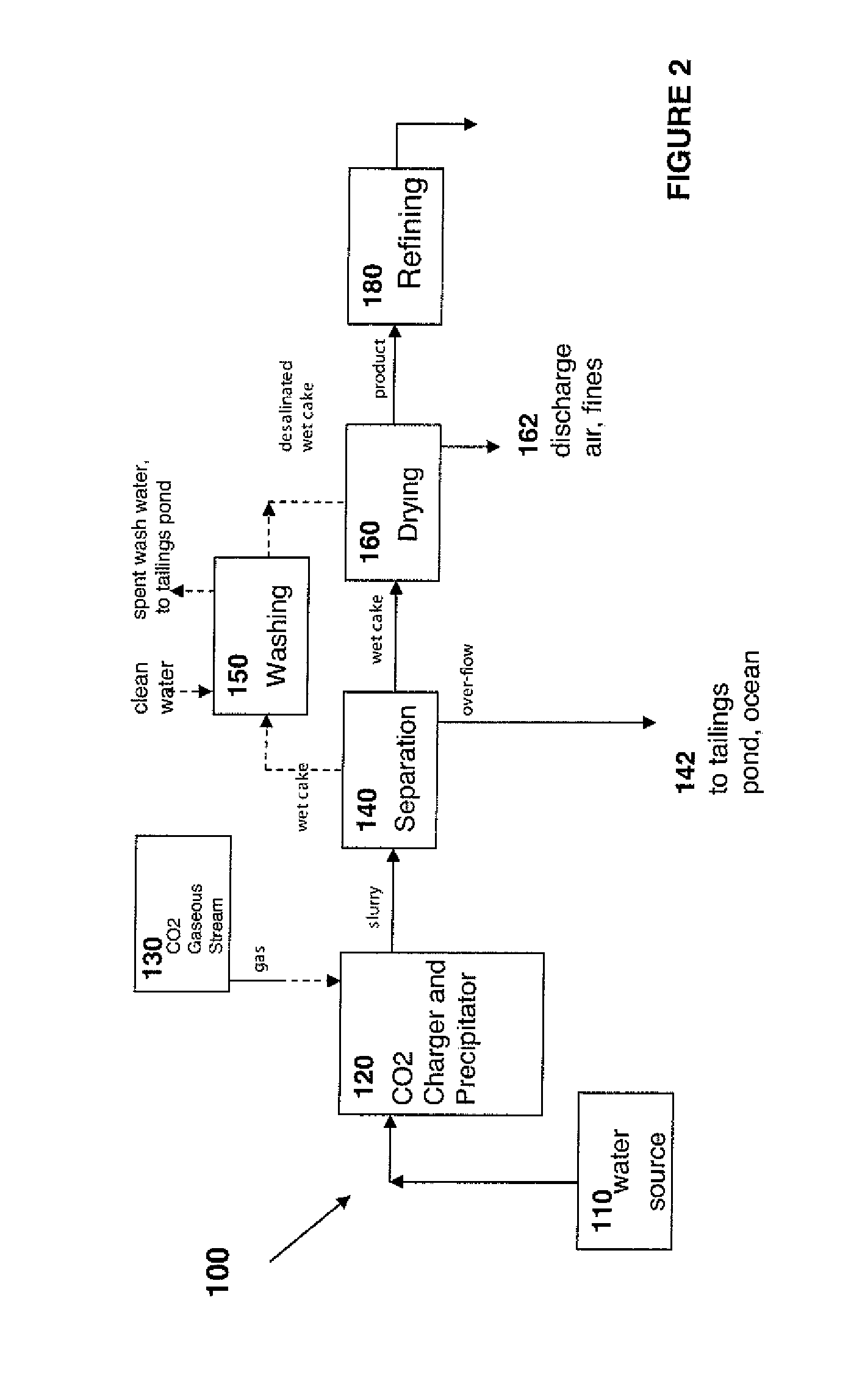

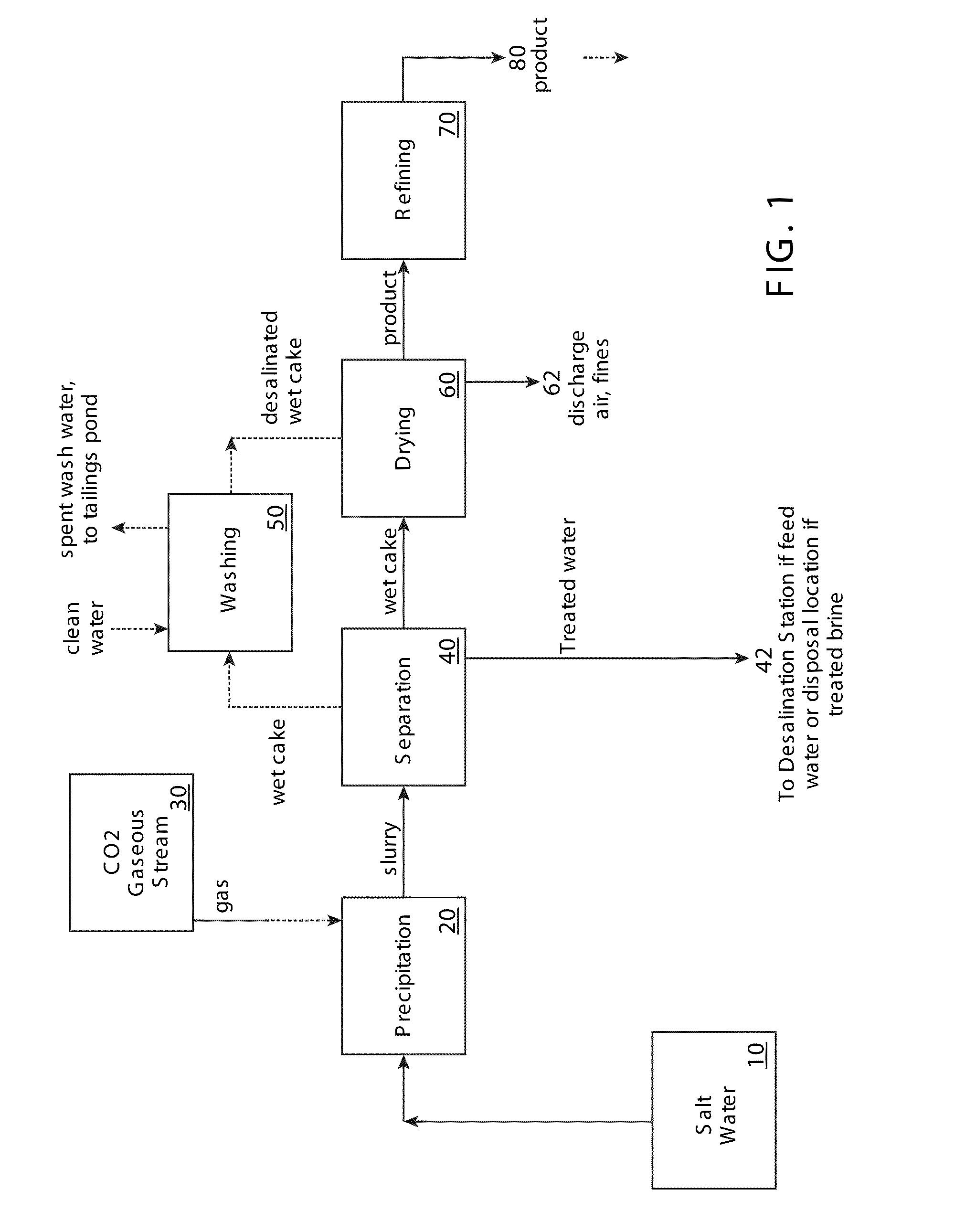

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

Oil-based settable spotting fluid

InactiveUS6524384B2Increase displacementHigh gel strengthDrilling compositionCoatingsEmulsionWater source

Oil-based settable spotting fluid compositions and methods of using the compositions are provided. The oil-based settable spotting fluid compositions are basically comprised of oil, an emulsifying surfactant for emulsifying the oil with water whereby an oil-external emulsion is formed, a de-emulsifying surfactant which in time de-emulsifies said oil-external emulsion when the emulsion is contacted with external water, a hydraulic settable component selected from the group consisting of ASTM Class C or the equivalent fly ash and ASTM Class F or the equivalent fly ash together with a source of calcium and water selected from the group consisting of fresh water and salt water.

Owner:HALLIBURTON ENERGY SERVICES INC

Oil-based settable spotting fluid

InactiveUS6315042B1Increase displacementHigh gel strengthFlushingDrilling compositionEmulsionWater source

Oil-based settable spotting fluid compositions and methods of using the compositions are provided. The oil-based settable spotting fluid compositions are basically comprised of oil, an emulsifying surfactant for emulsifying the oil with water whereby an oil-external emulsion is formed, a de-emulsifying surfactant which in time de-emulsifies said oil-external emulsion when the emulsion is contacted with external water, a hydraulic settable component selected from the group consisting of ASTM Class C or the equivalent fly ash and ASTM Class F or the equivalent fly ash together with a source of calcium and water selected from the group consisting of fresh water and salt water.

Owner:HALLIBURTON ENERGY SERVICES INC

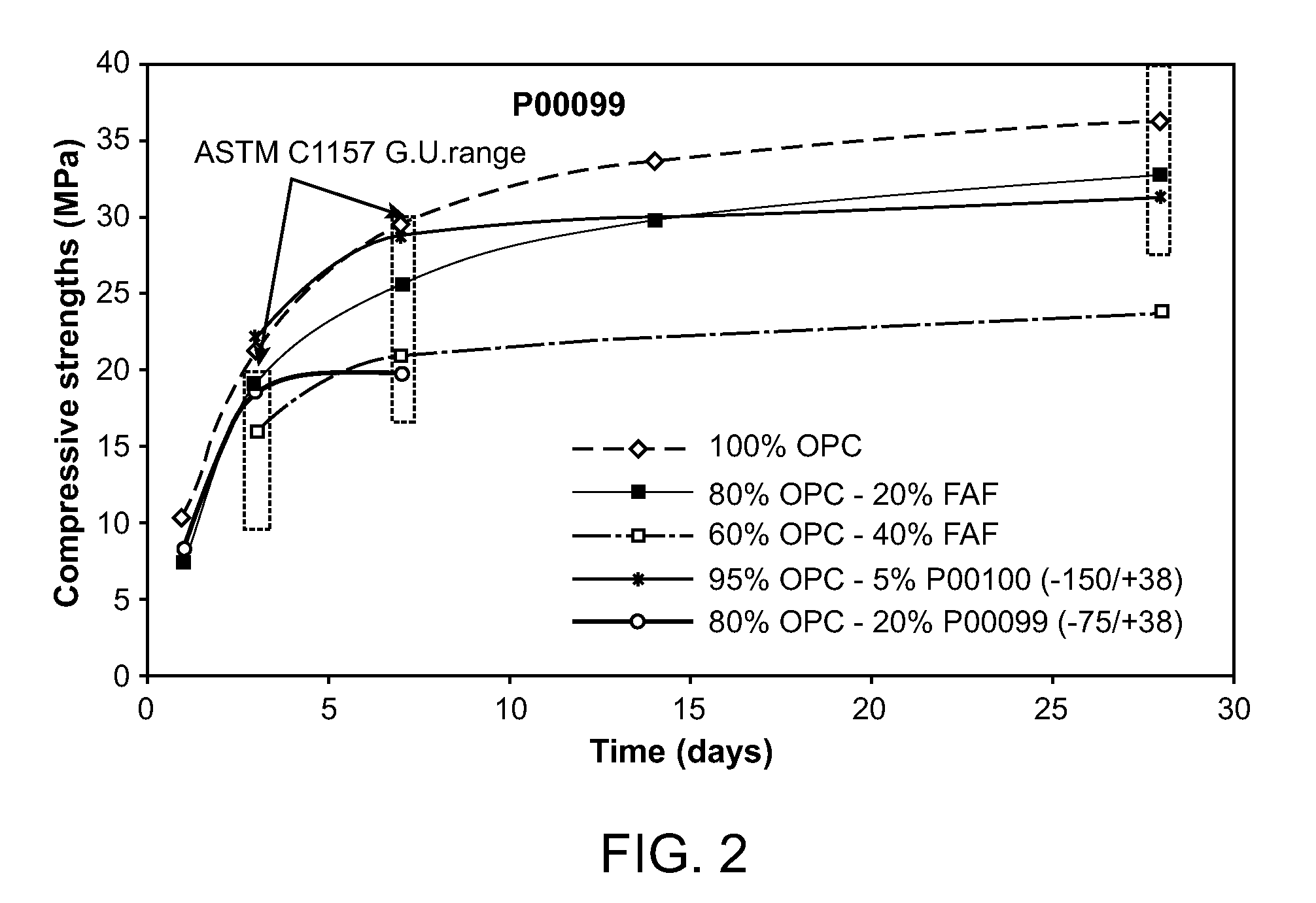

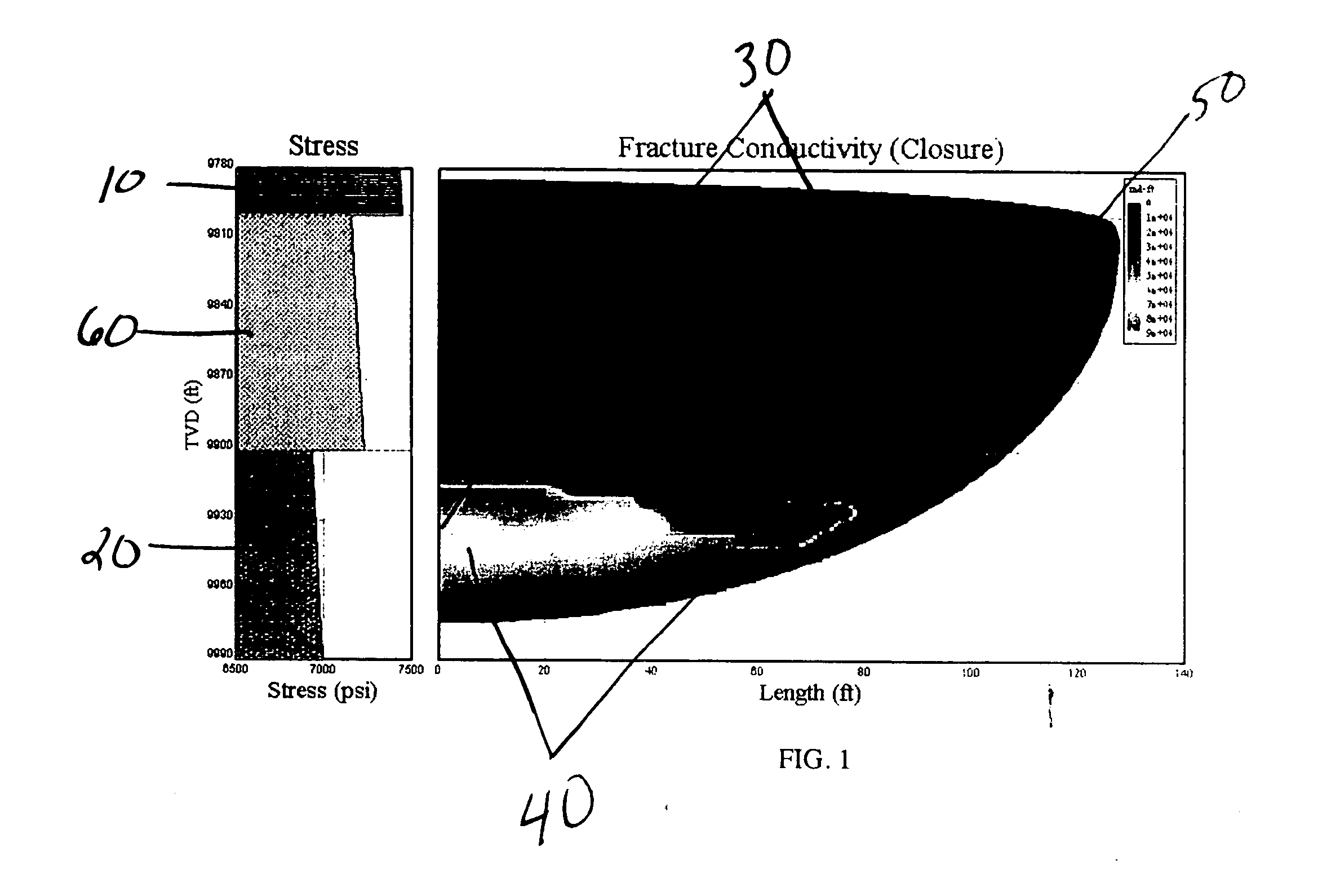

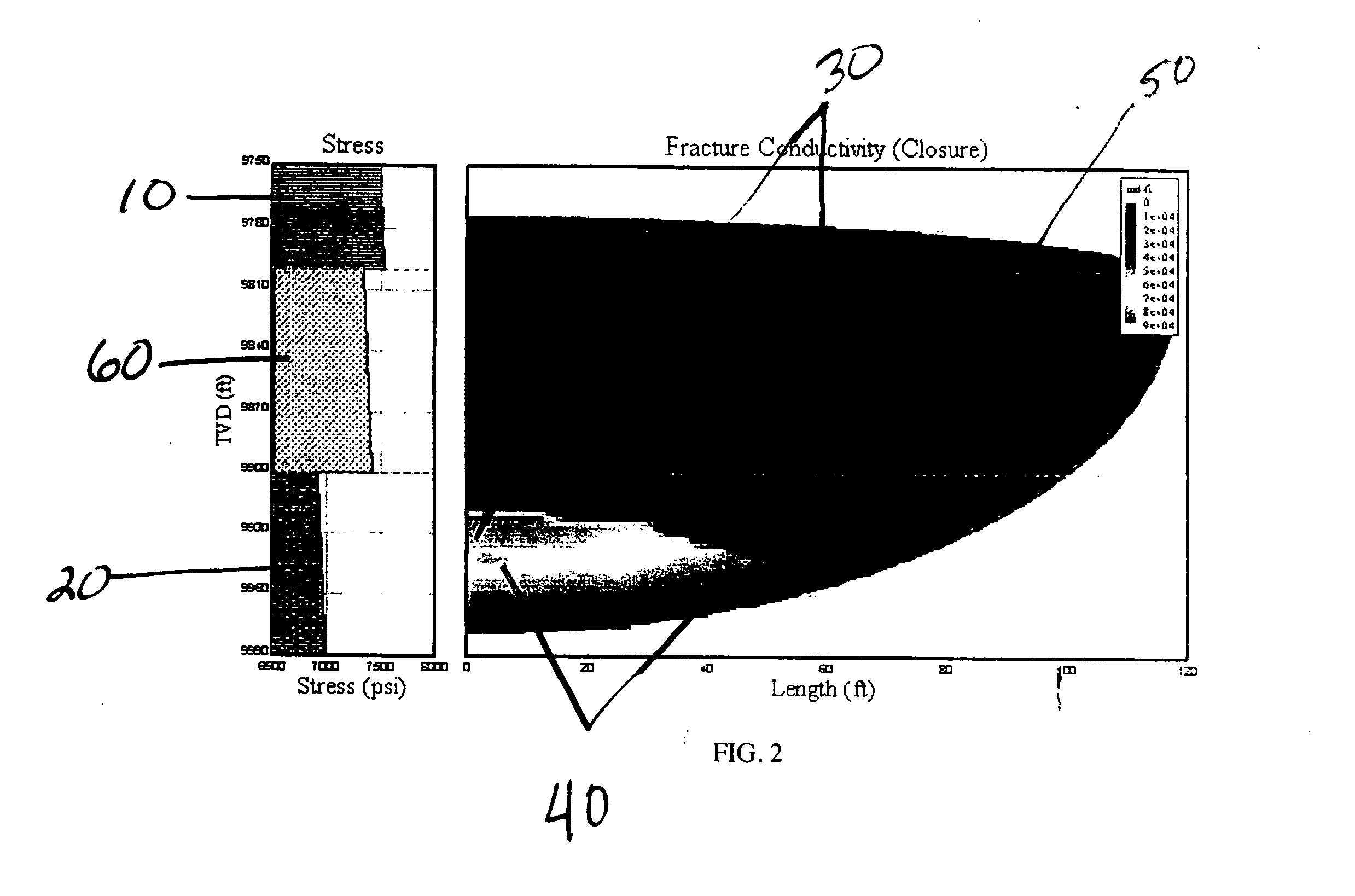

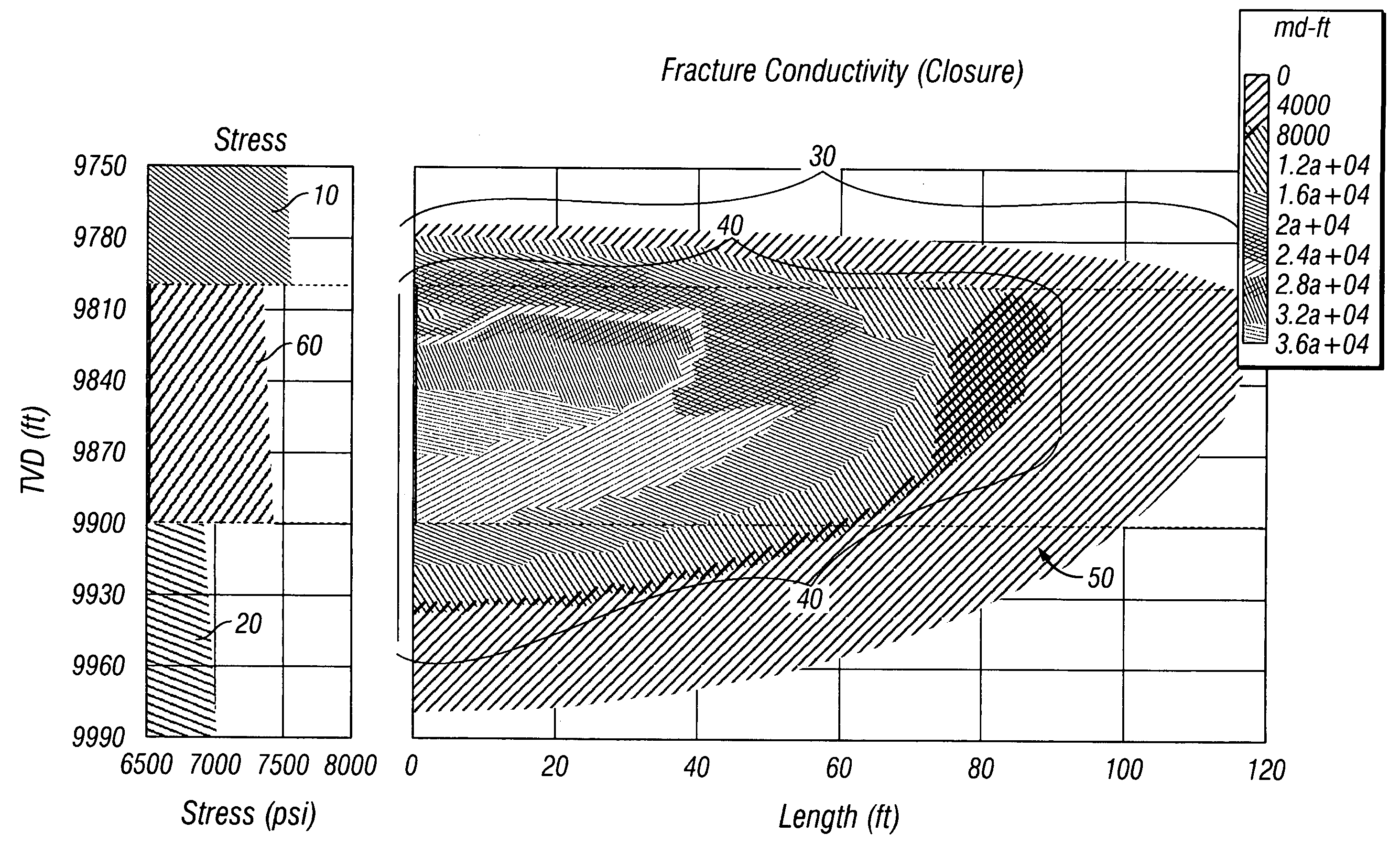

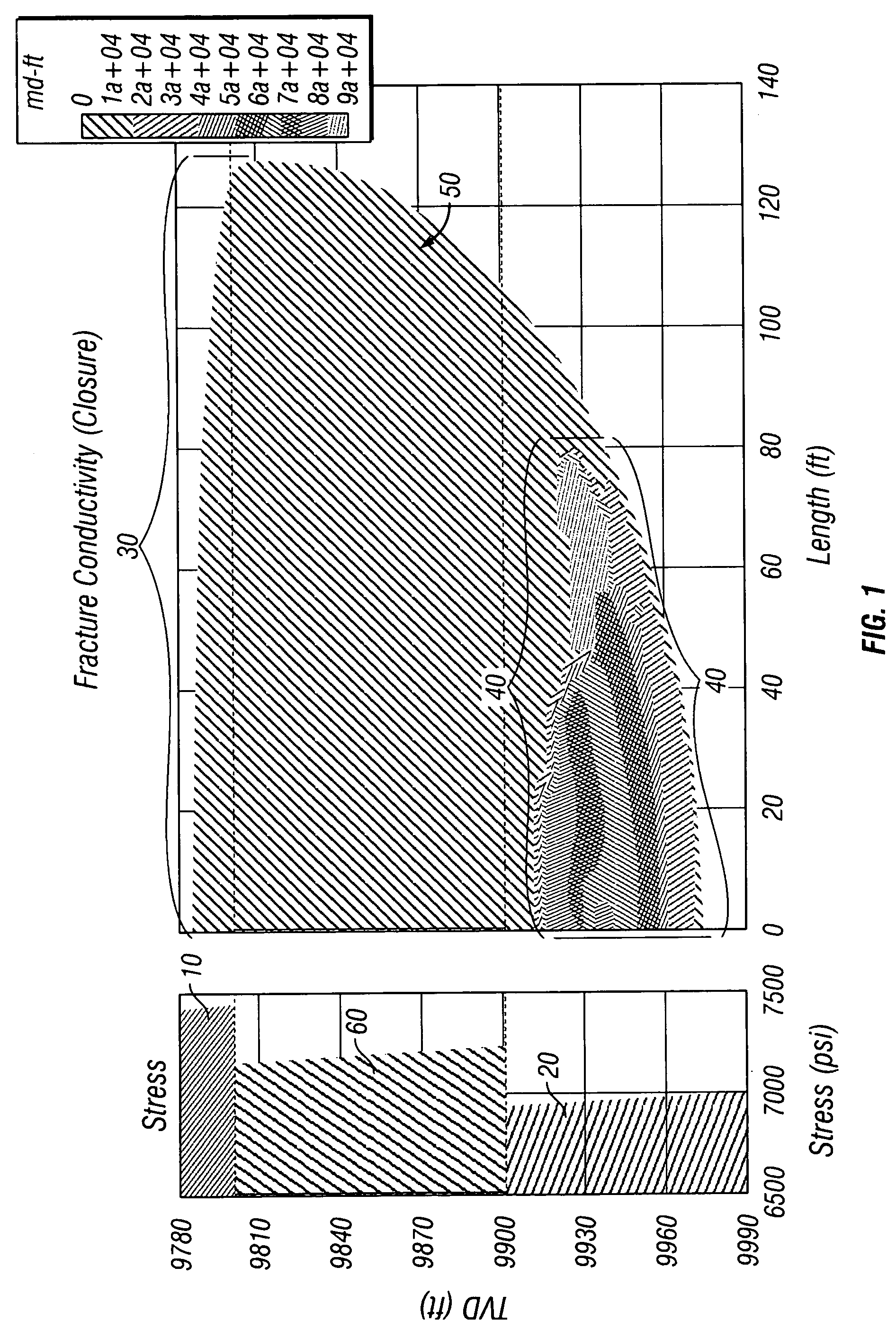

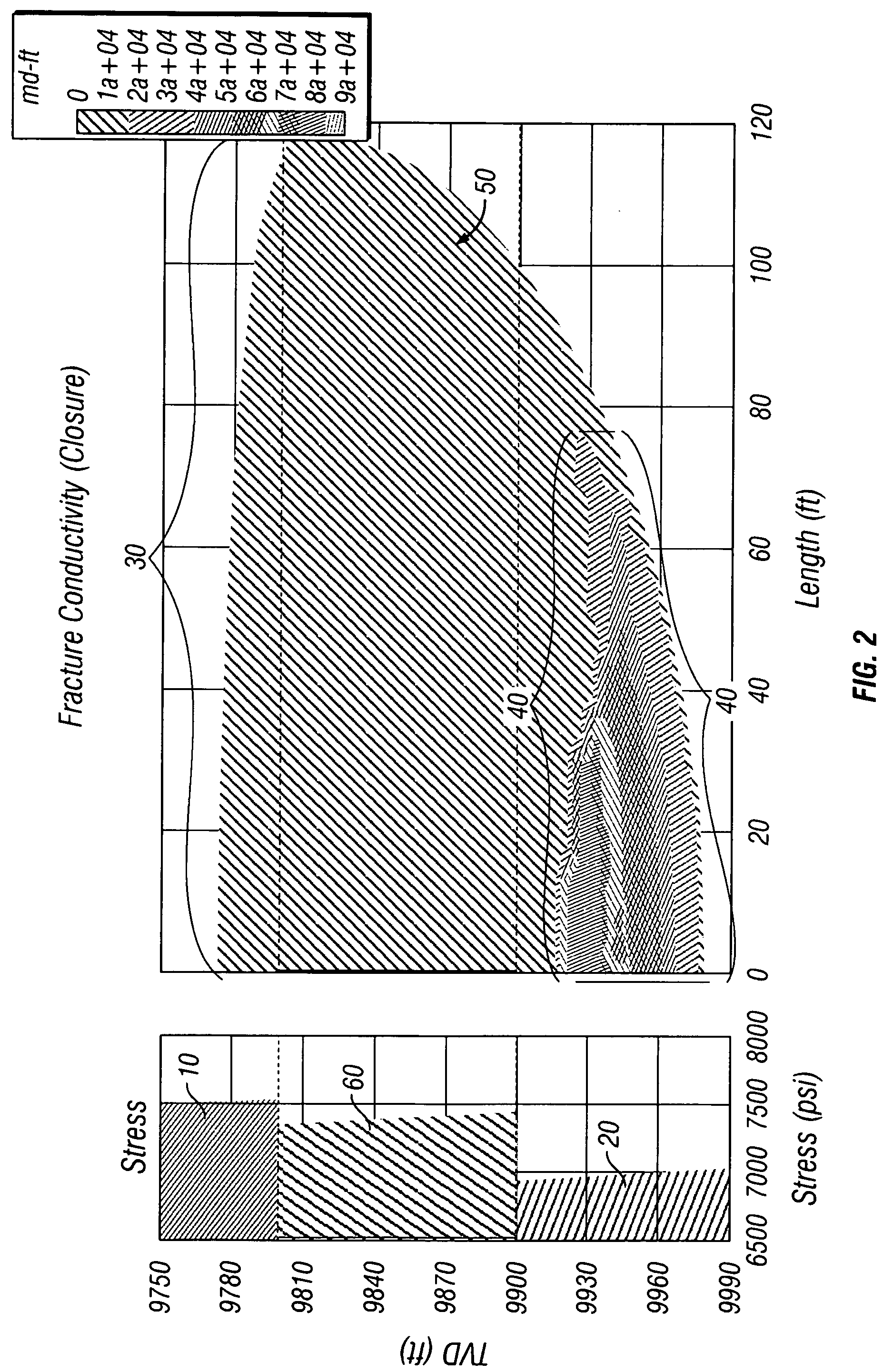

Method of hydraulic fracturing to reduce unwanted water production

ActiveUS20050016732A1Reduce conductivityFluid removalDrilling compositionGeomorphologyWater production

A method of hydraulically fracturing a hydrocarbon-bearing subterranean formation ensures that the conductivity of water inflow below the productive zone of the subterranean formation is reduced. The method consists of two principal steps. In the first step, a fracture in and below the productive zone of the formation is initiated by introducing into the subterranean formation a fluid, free of a proppant, such as salt water, fresh water, brine, liquid hydrocarbon, and / or nitrogen or other gases. The proppant-free fluid may further be weighted. In the second step, a proppant laden slurry is introduced into the subterranean formation which contains a relatively lightweight density proppant. Either the fluid density of the proppant-free fluid is greater than the fluid density of the proppant laden slurry or the viscosity of the proppant-free fluid is greater than the viscosity of the proppant laden slurry. The method limits undesirable fracture height growth in the hydrocarbon-bearing subterranean formation during the fracturing.

Owner:BAKER HUGHES INC

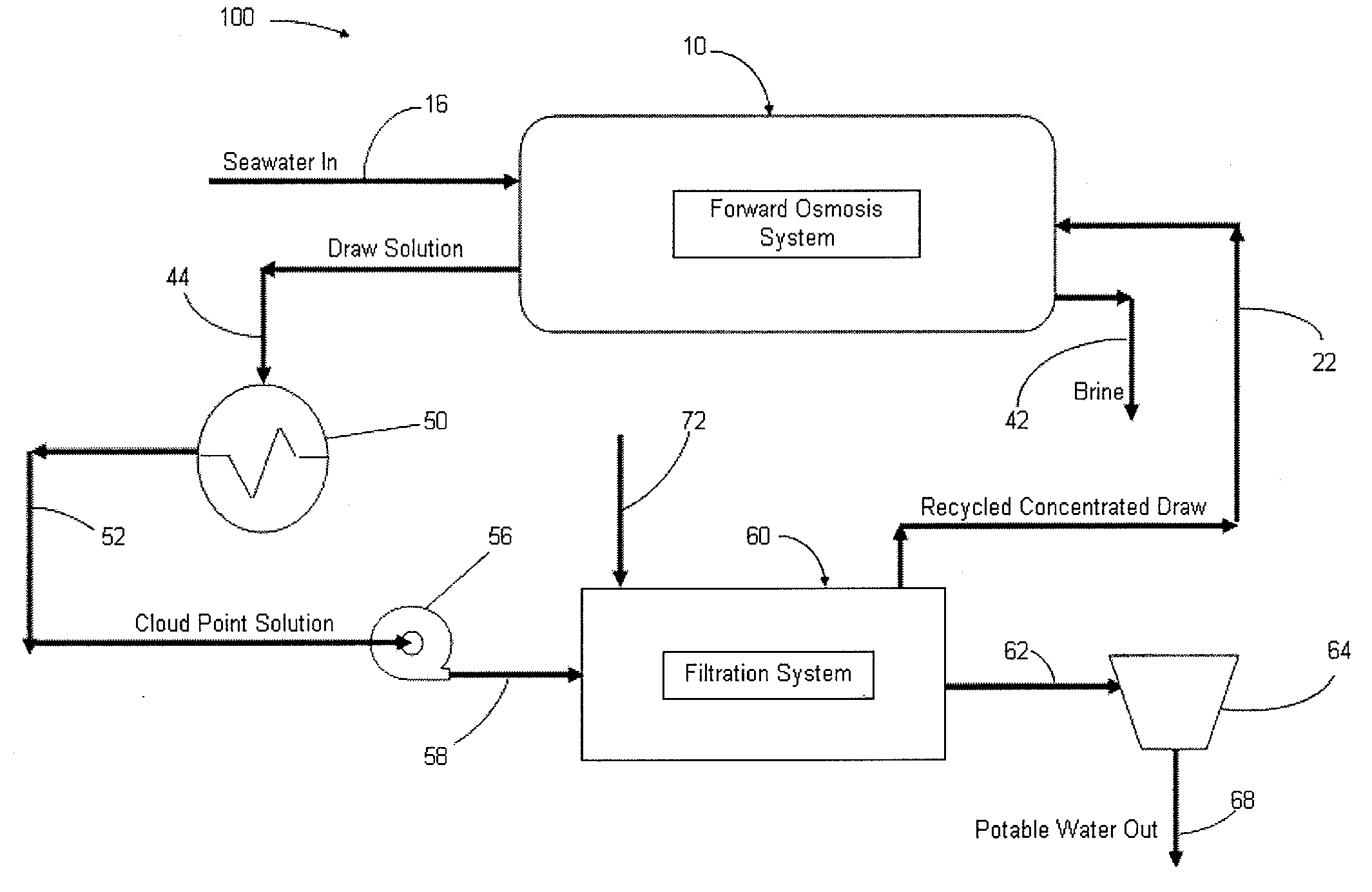

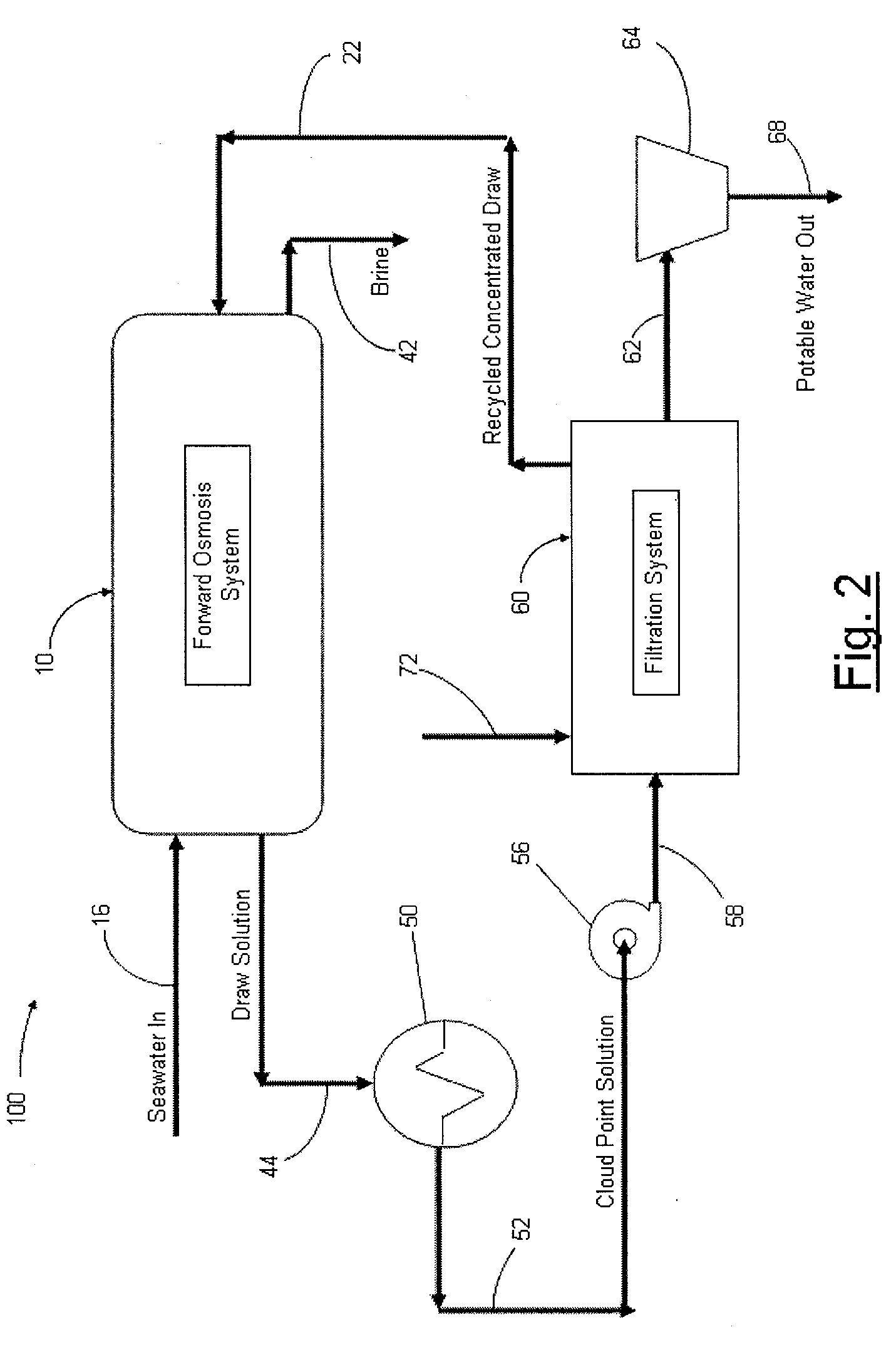

Systems and methods for forward osmosis fluid purification

ActiveUS20100155329A1Improve efficiencyFunction increaseGeneral water supply conservationSeawater treatmentSaline waterDesalination

A process for purification of fluids, for example, desalination of seawater or brackish water, using organic solutes in a concentrated water solution for use in a forward osmosis process, to extract fresh water out of salt water through the forward osmosis membrane, and subsequently separating the organic solutes out of the diluted forward osmosis permeate by cloud point extraction, thereby regenerating a concentrated organic solution for recycling to the forward osmosis process, and fresh water for potable water use.

Owner:JFEENG CORP

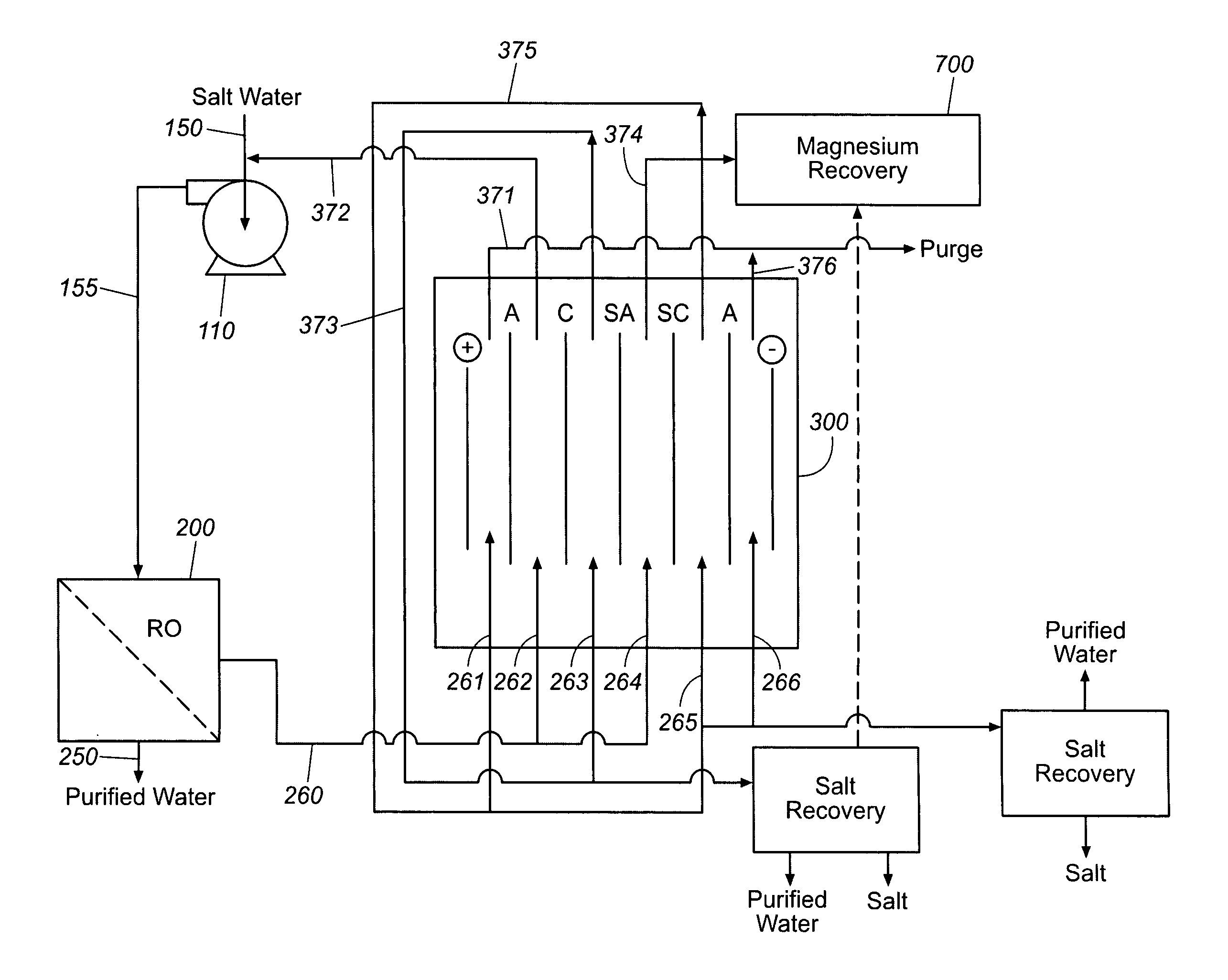

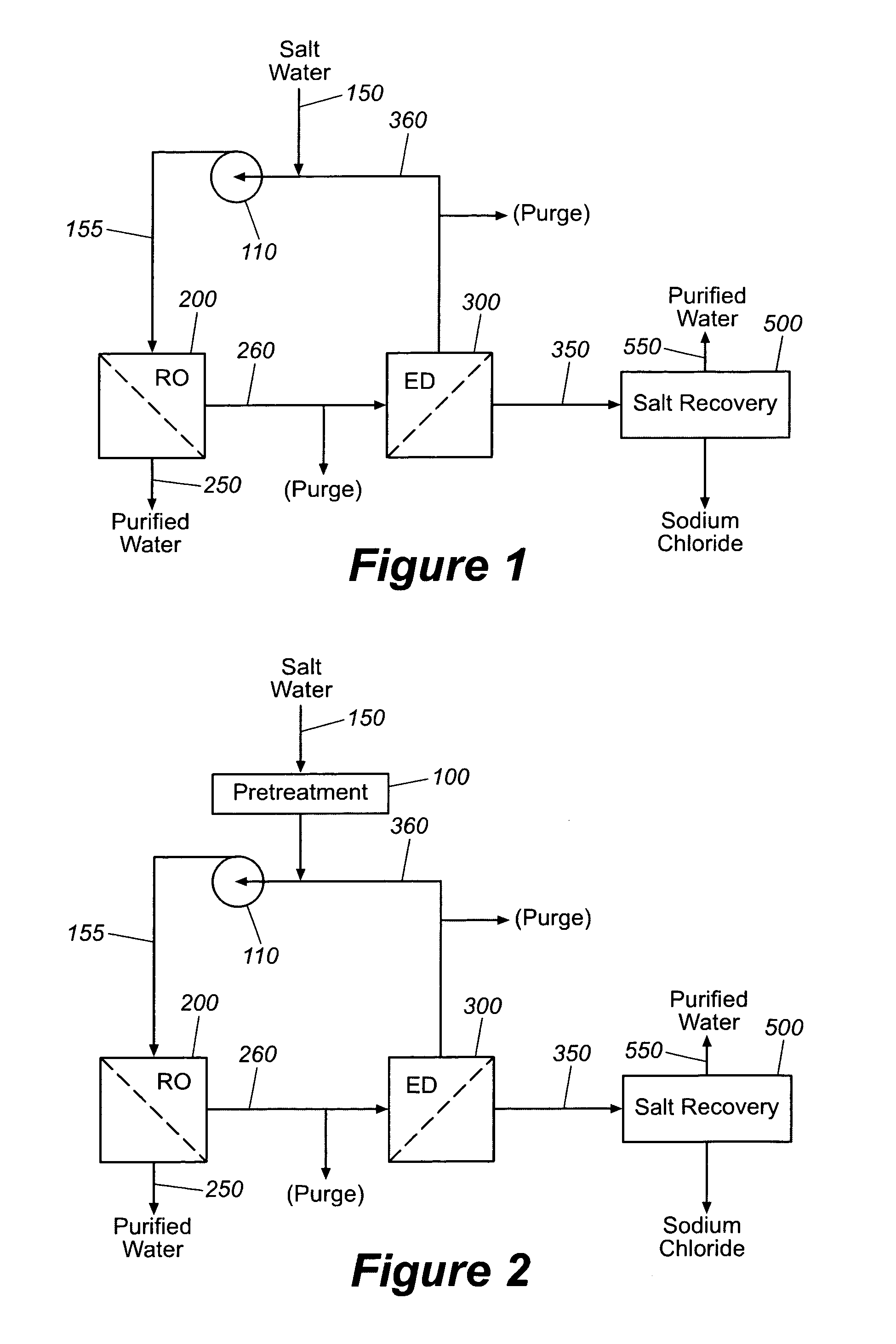

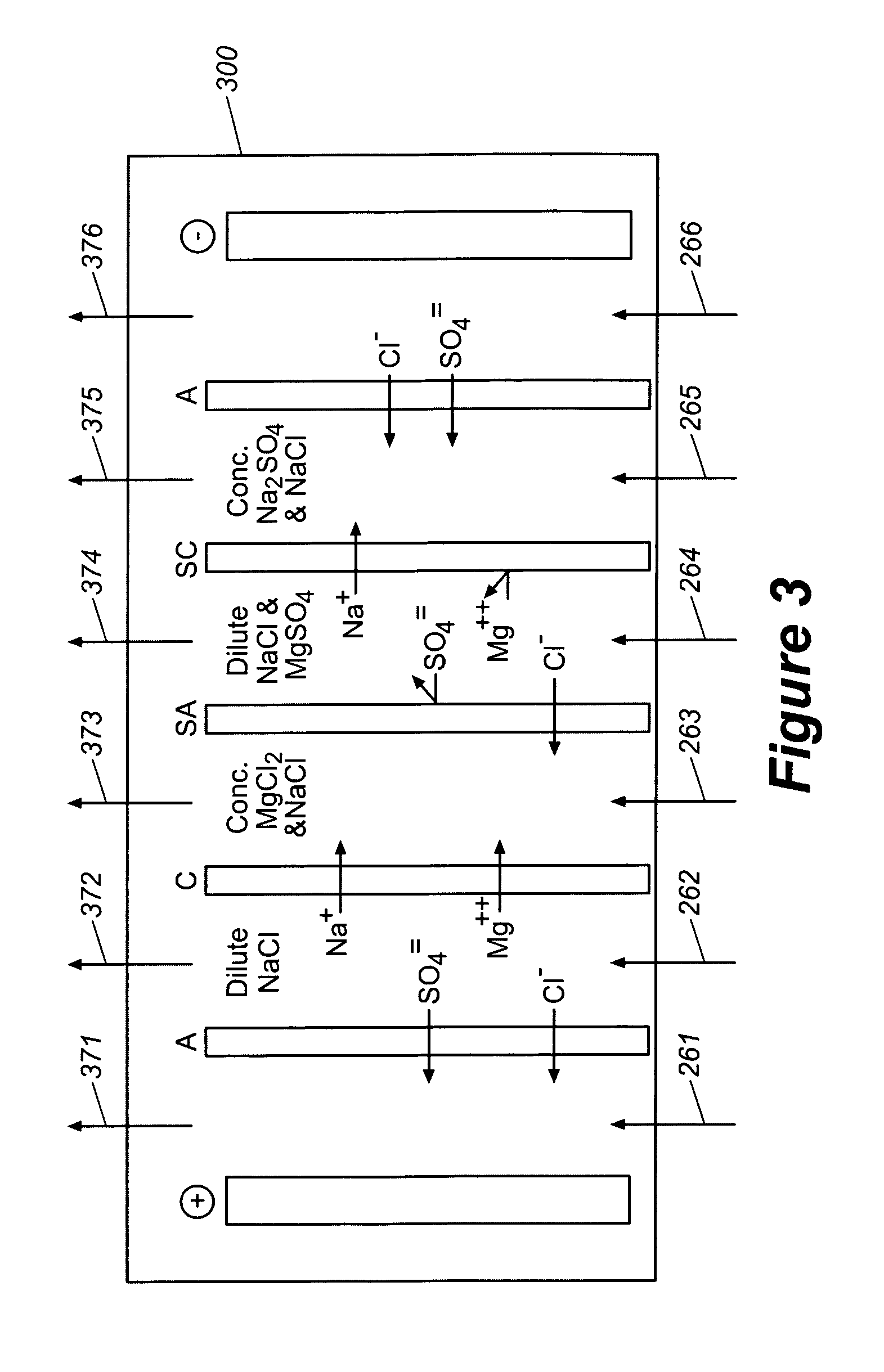

Production of purified water and high value chemicals from salt water

ActiveUS7083730B2Effective recoveryElectrolysis componentsSolvent extractionReverse osmosisHigh pressure

Sodium chloride and purified water are recovered by treating salt water that contains sodium chloride with an integrated reverse osmosis and electrodialysis system, which includes an efficiency-enhancing feature that is one or more of the following: the use of univalent anion and univalent cation selective membranes in the electrodialysis unit; the addition of a nanofiltration unit to process the diluate from the electrodialysis unit; or operation of the electrodialysis unit at an elevated pressure. Magnesium and bromine can optionally be produced when the salt water contains these materials.

Owner:SOUTH CAROLINA UNIV OF

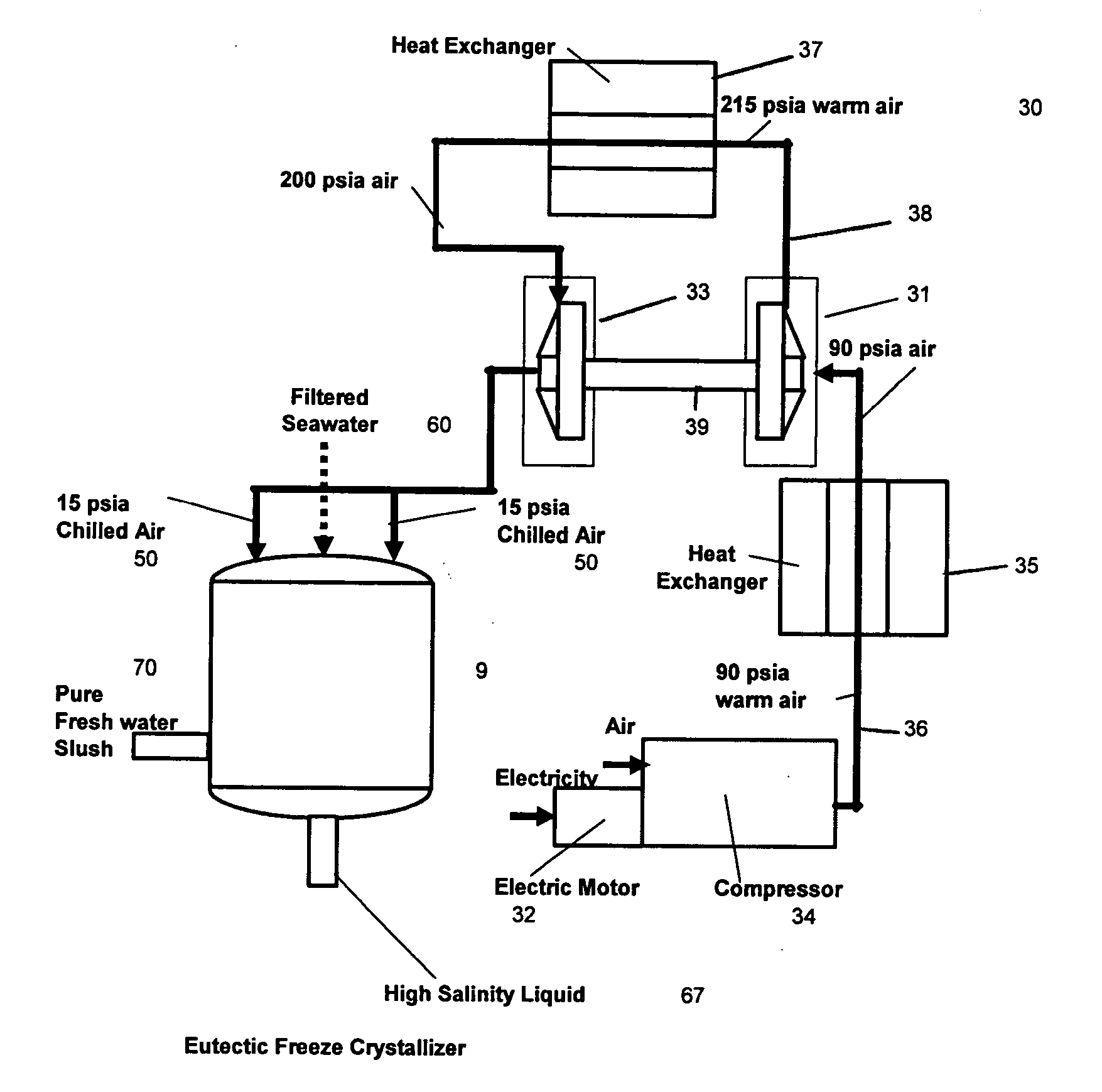

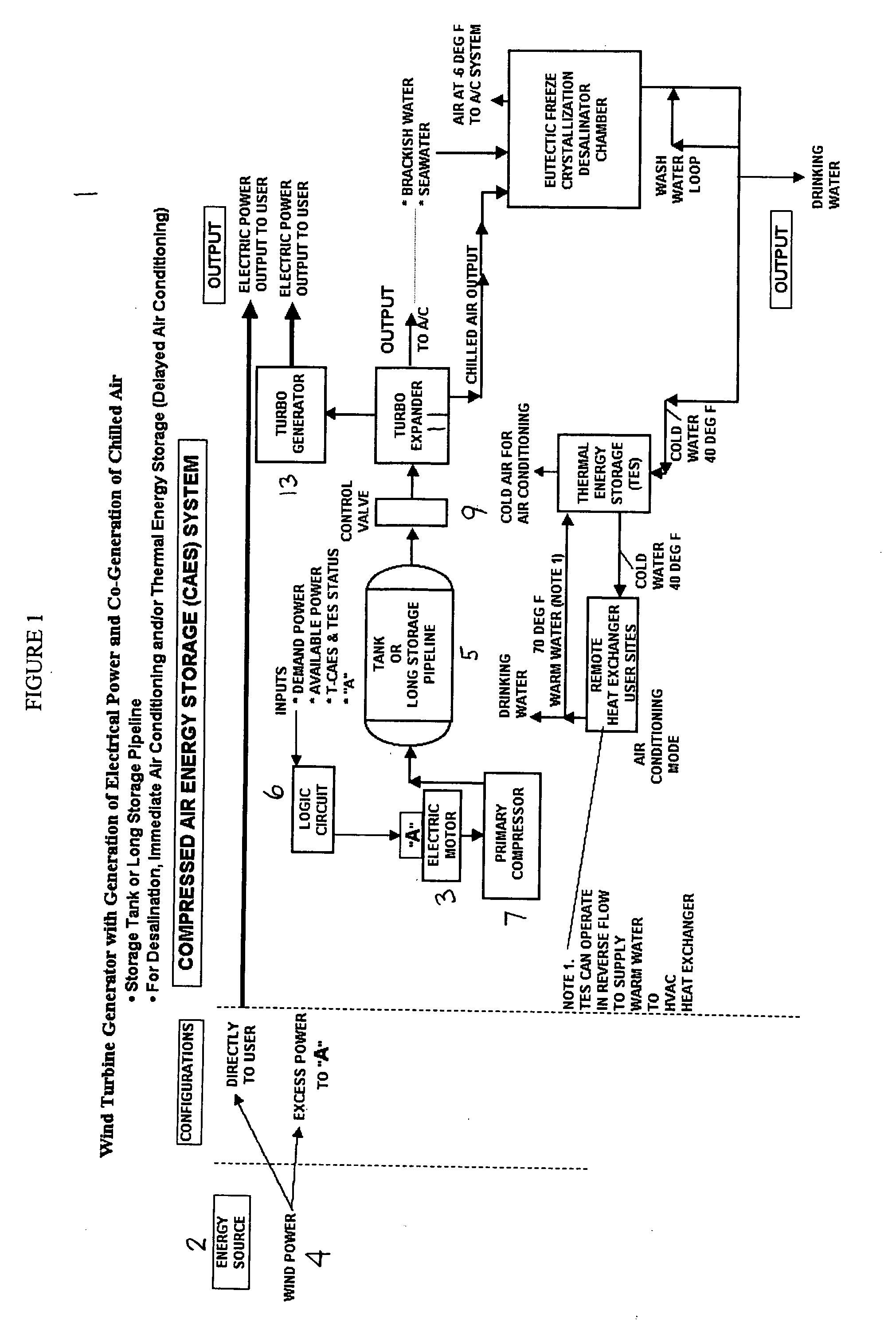

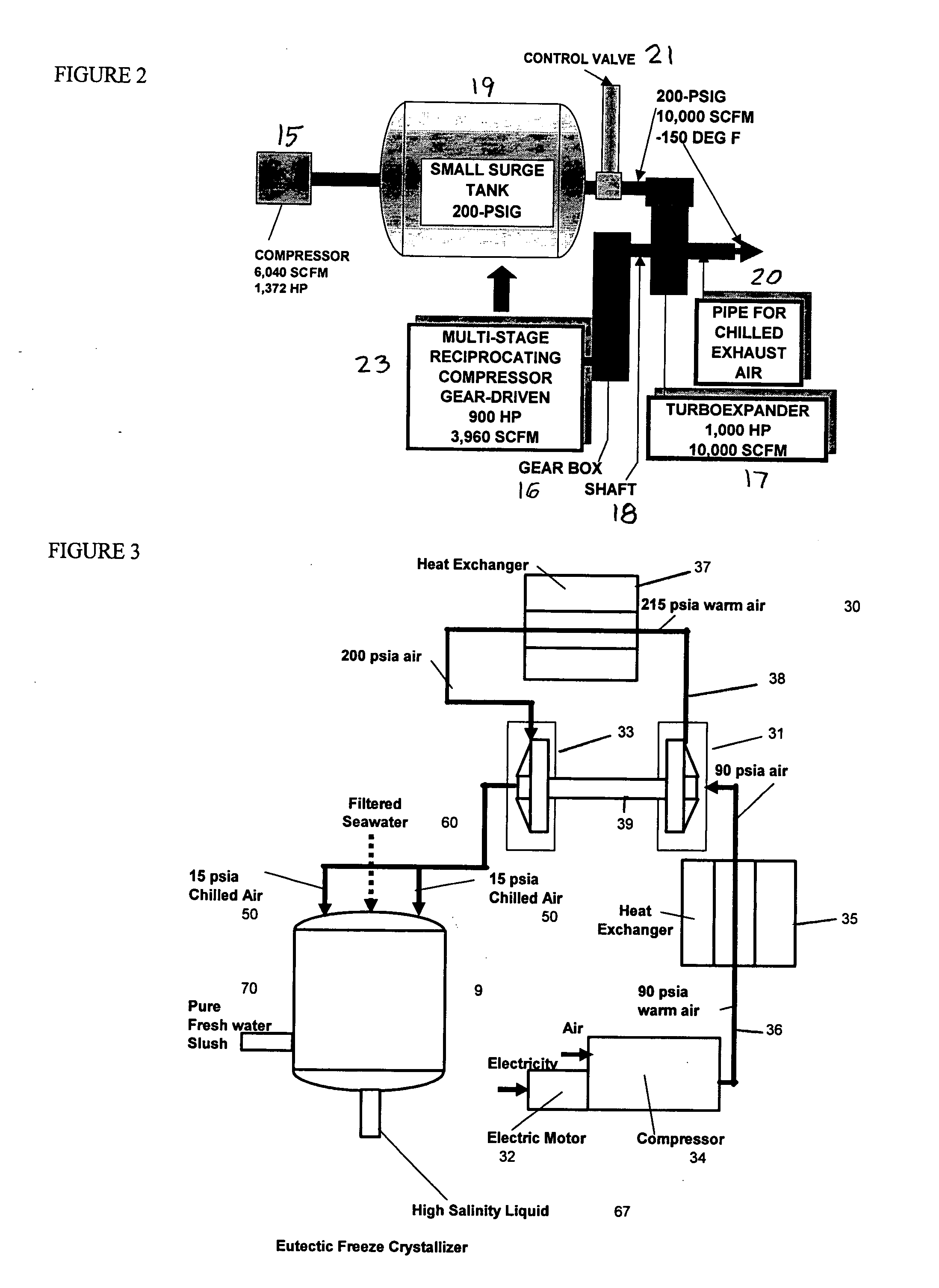

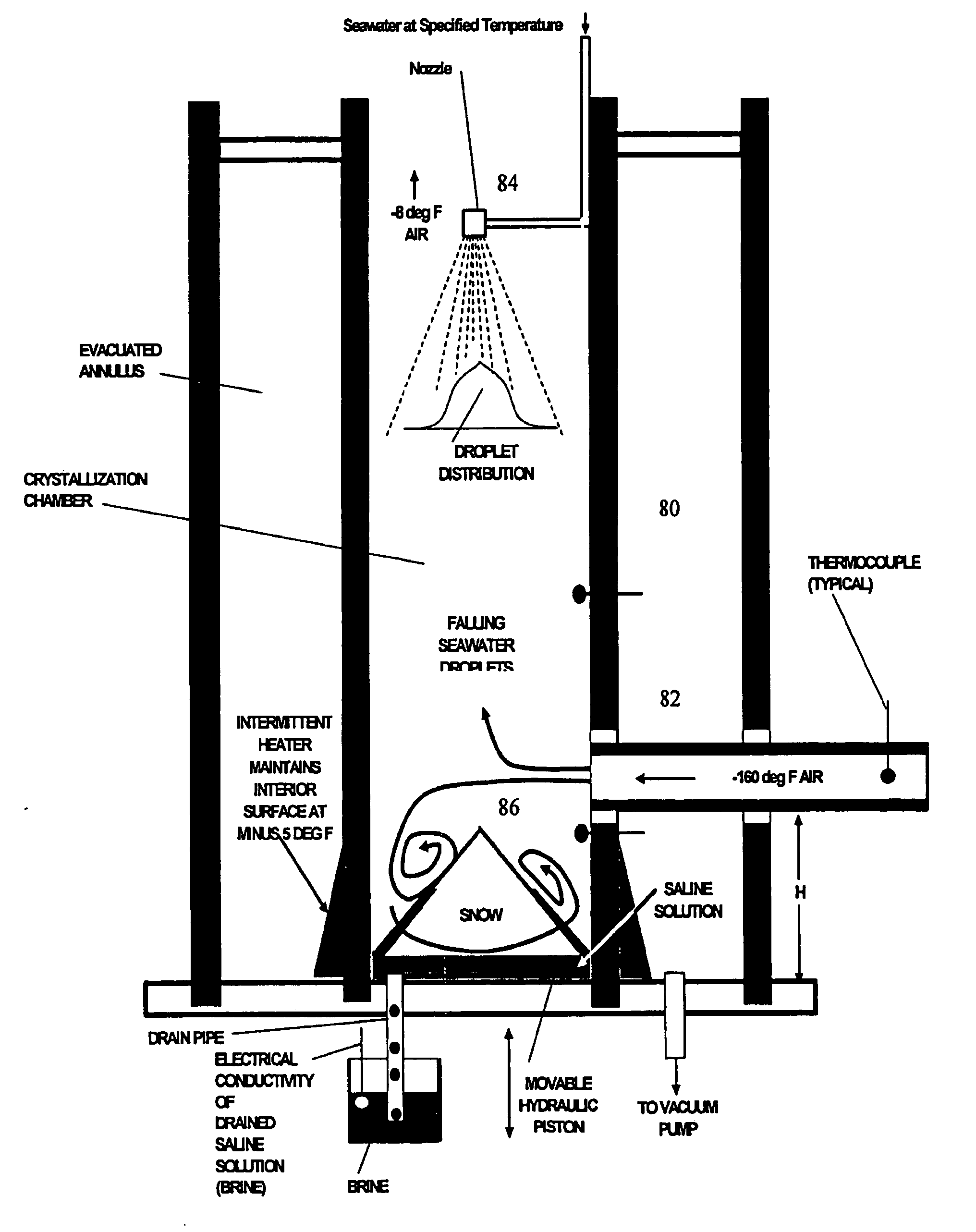

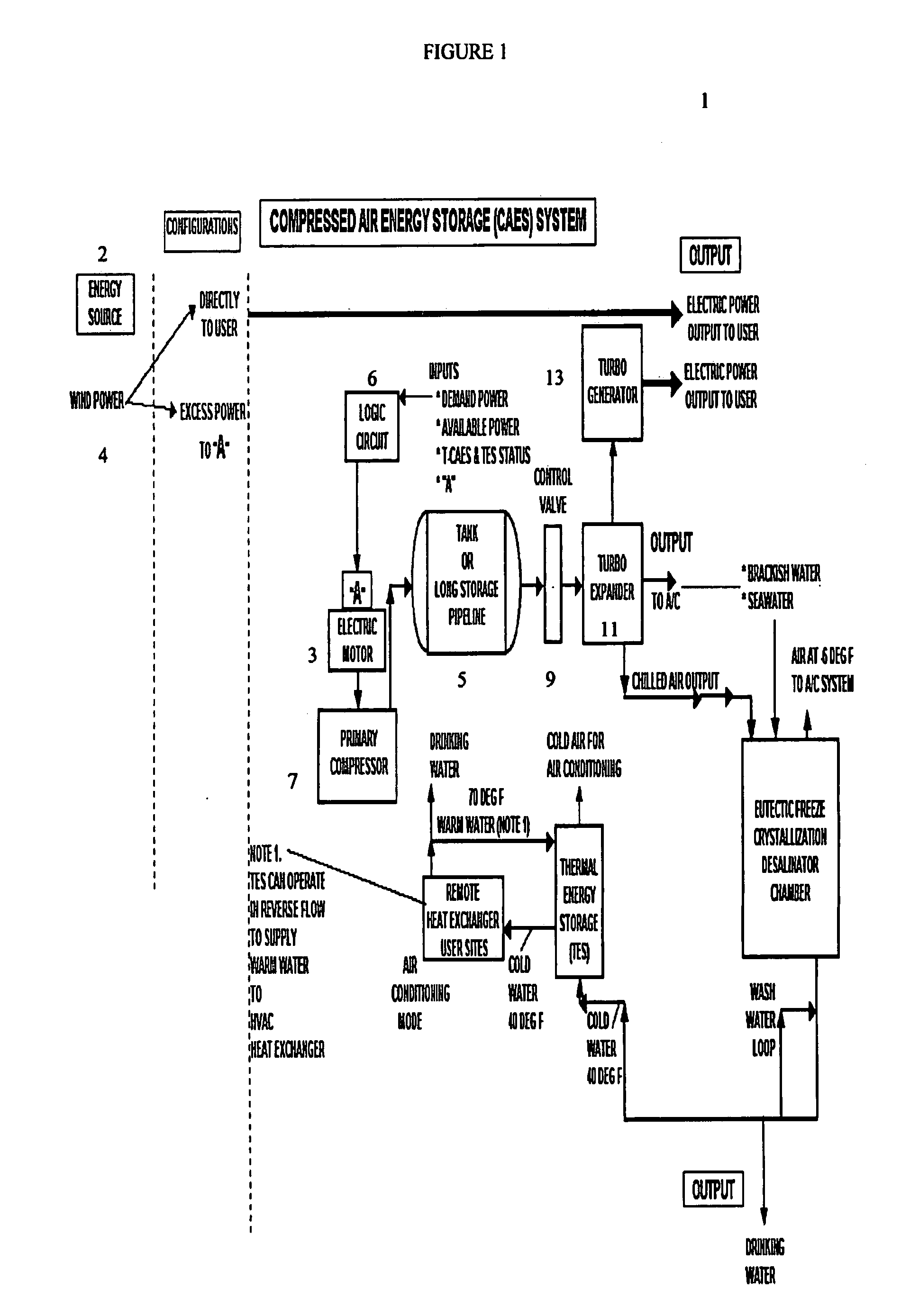

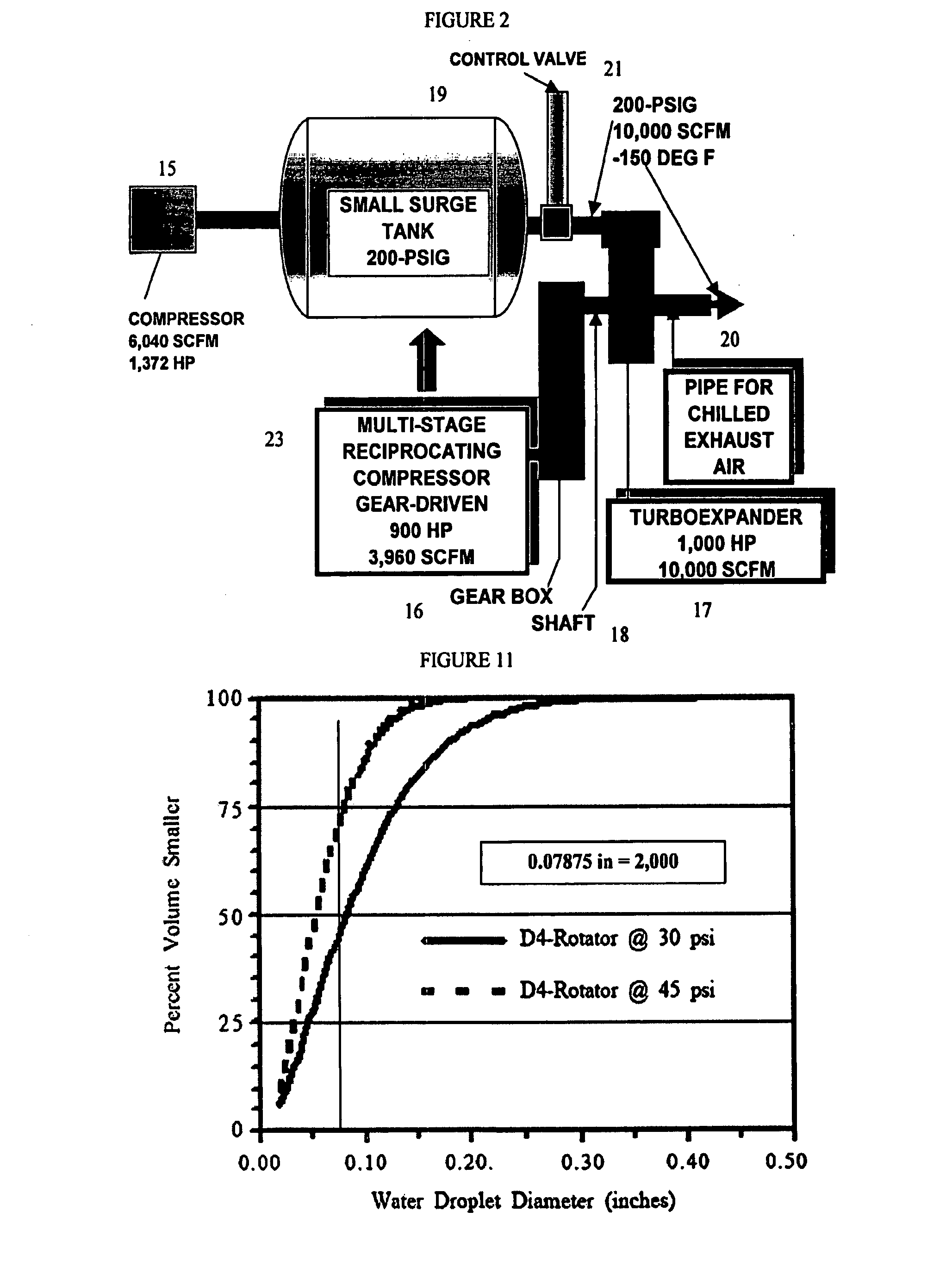

Desalination method and system using compressed air energy systems

InactiveUS20070295673A1Promote meltingFacilitate runoffWater treatment parameter controlWater cleaningSaline waterDesalination

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

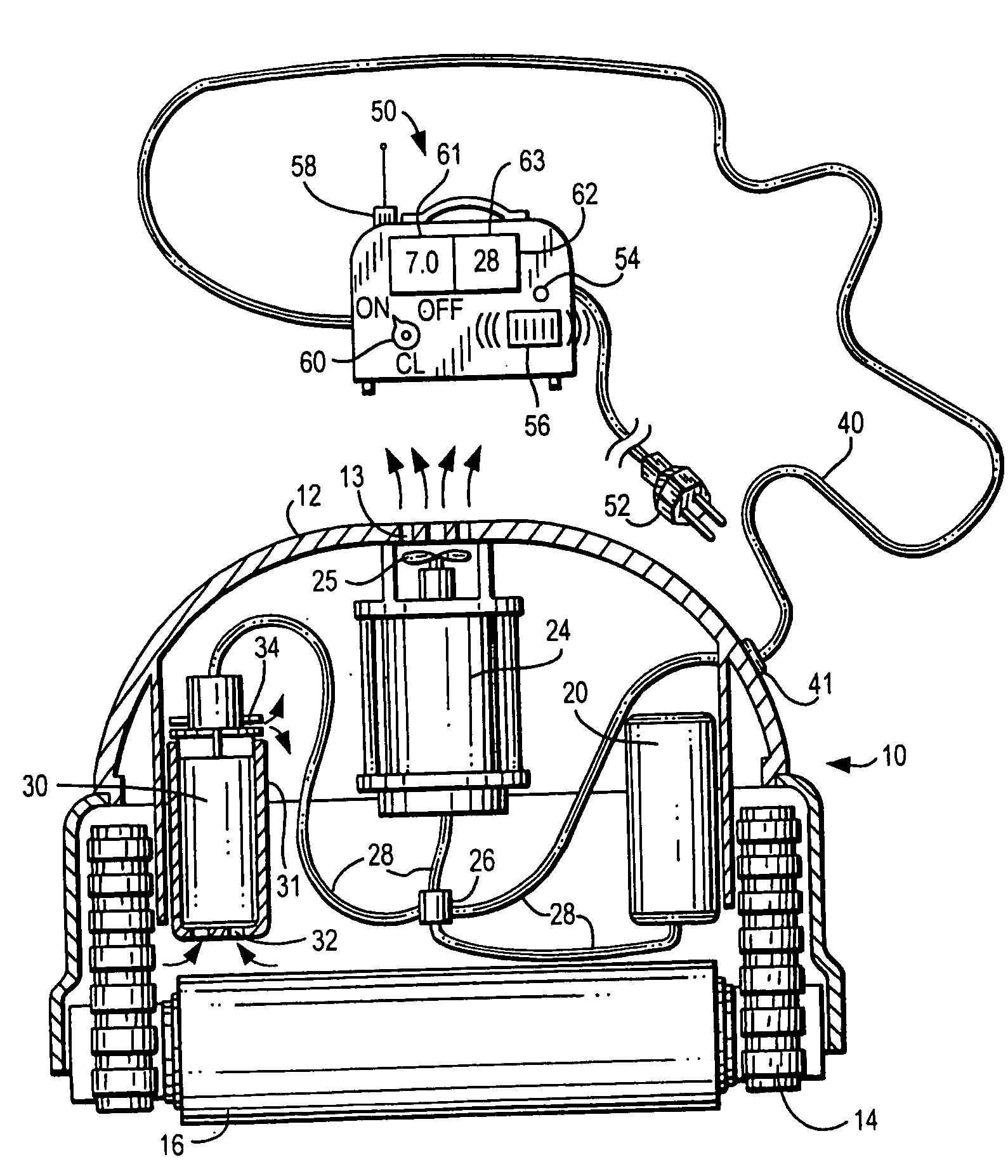

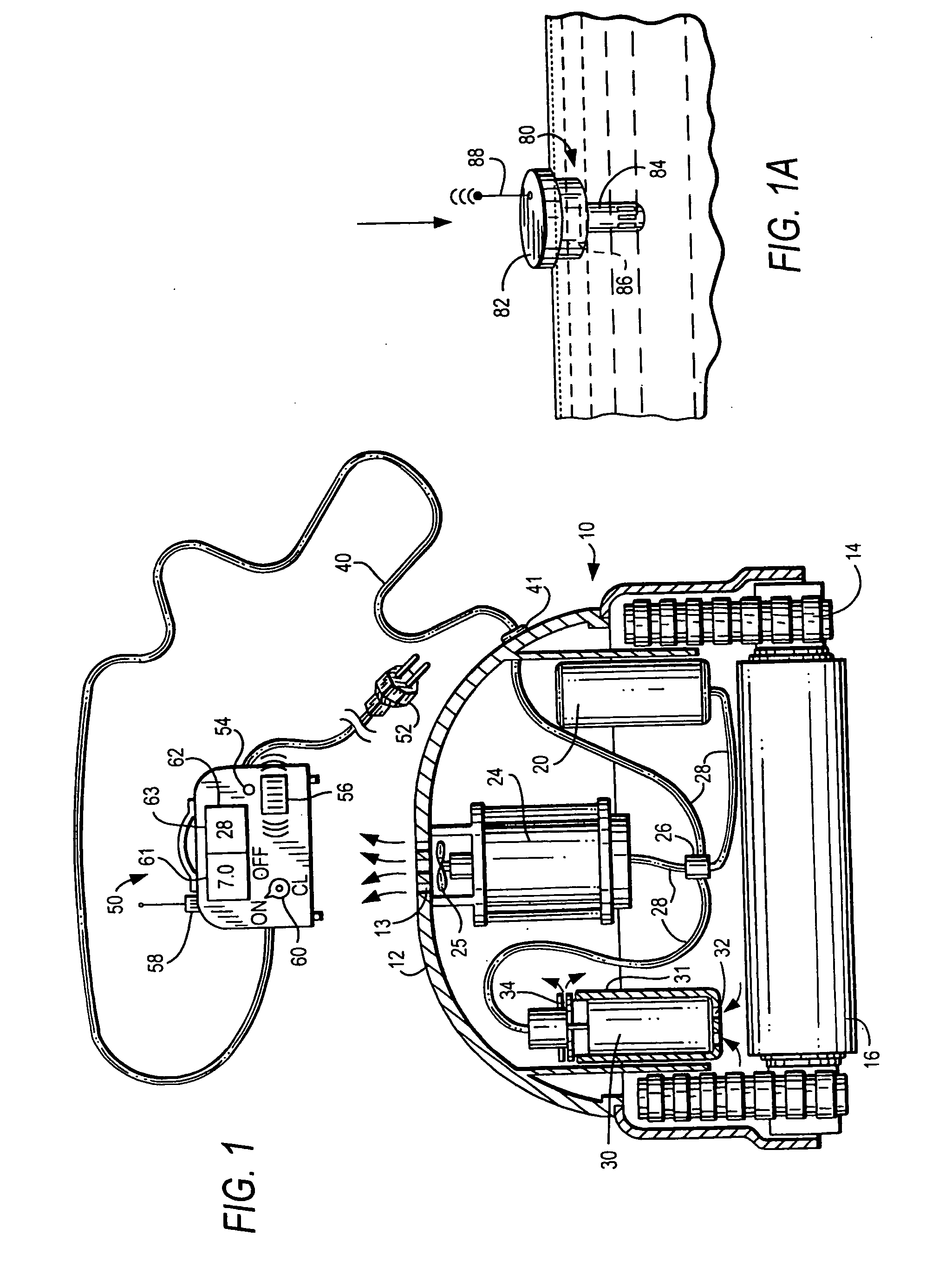

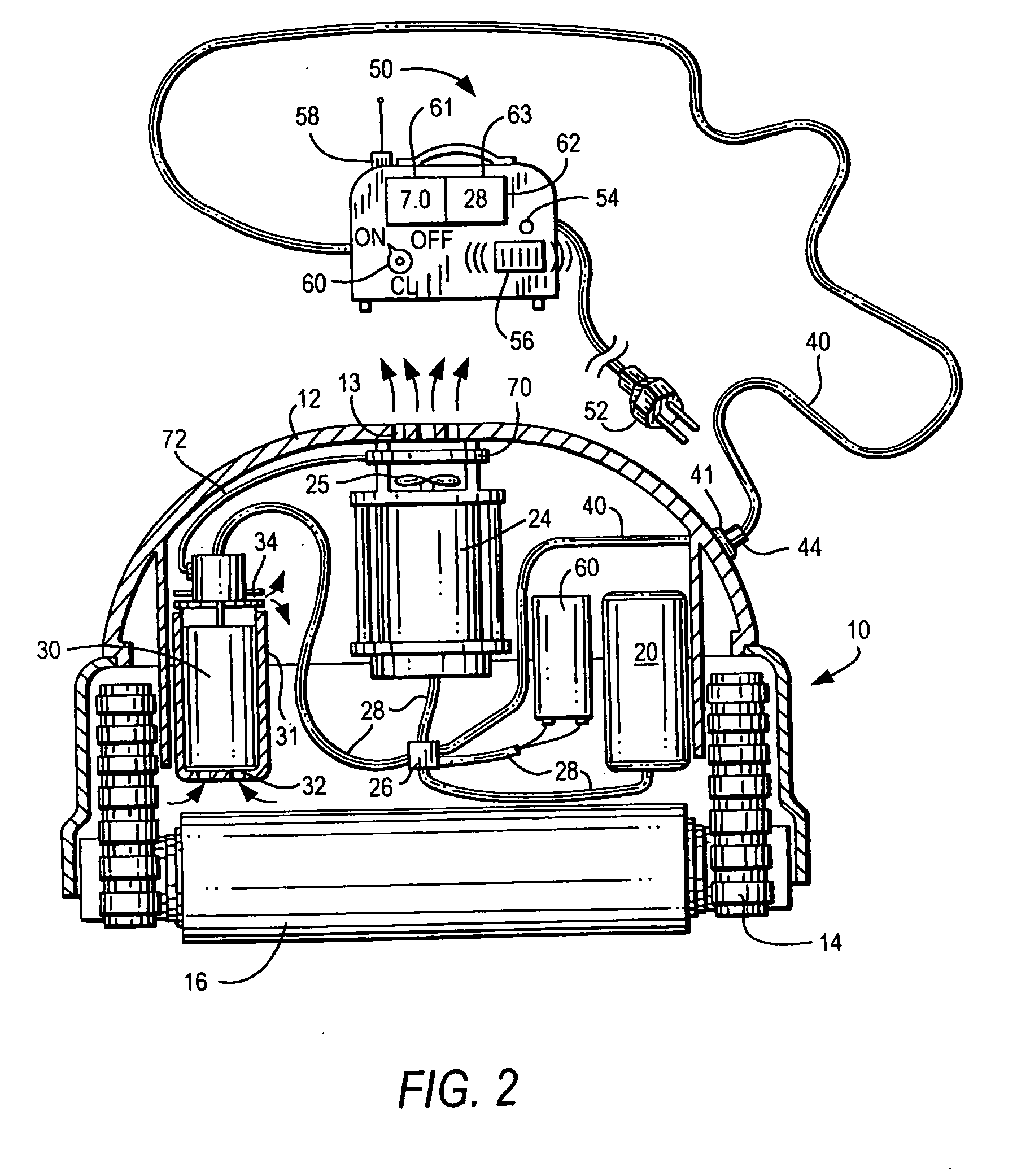

Method and appartus for operation of pool cleaner with integral chlorine generator

ActiveUS20090282627A1Efficiently and effectively distributesUniform concentrationCellsPhotography auxillary processesTime segmentElectrical battery

An automated self-propelled pool cleaner having a housing, a water pump for moving water through the housing, drive means for moving the pool cleaner over the surface of the salt water pool to be cleaned, and an integral electrochemical chlorine generator mounted in the housing, includes a processor / controller that is programmed to activate the chlorine generator, the pump and drive means in predetermined operational sequences that minimize wear and tear on the water pump and drive means, while at the same time distribute and maintain a safe level of sanitizing chlorine in the pool, to thereby obviate the need for an in-line chlorinator or other chemical additive treatments; an optional automated sensor device can be provided to activate a secondary maintenance program which enables the pool cleaner to operate over prolonged periods of time as the sole means for filtering and sanitizing the pool water. An electrochemical cell manual mounting system permits the cell to be secured in place for operation and manually removed for maintenance, repair or replacement by the user without special tools or training.

Owner:AQUA PRODS

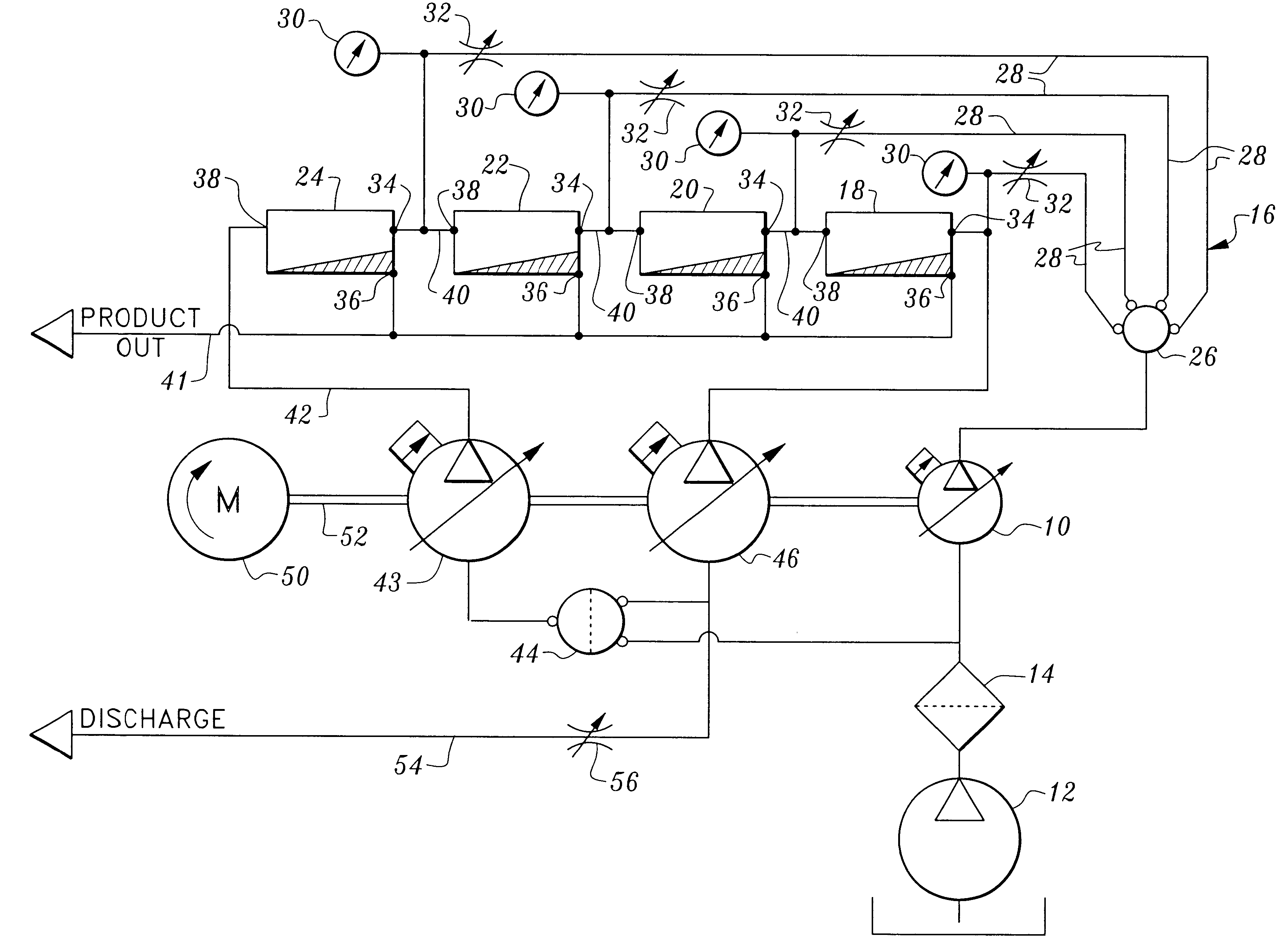

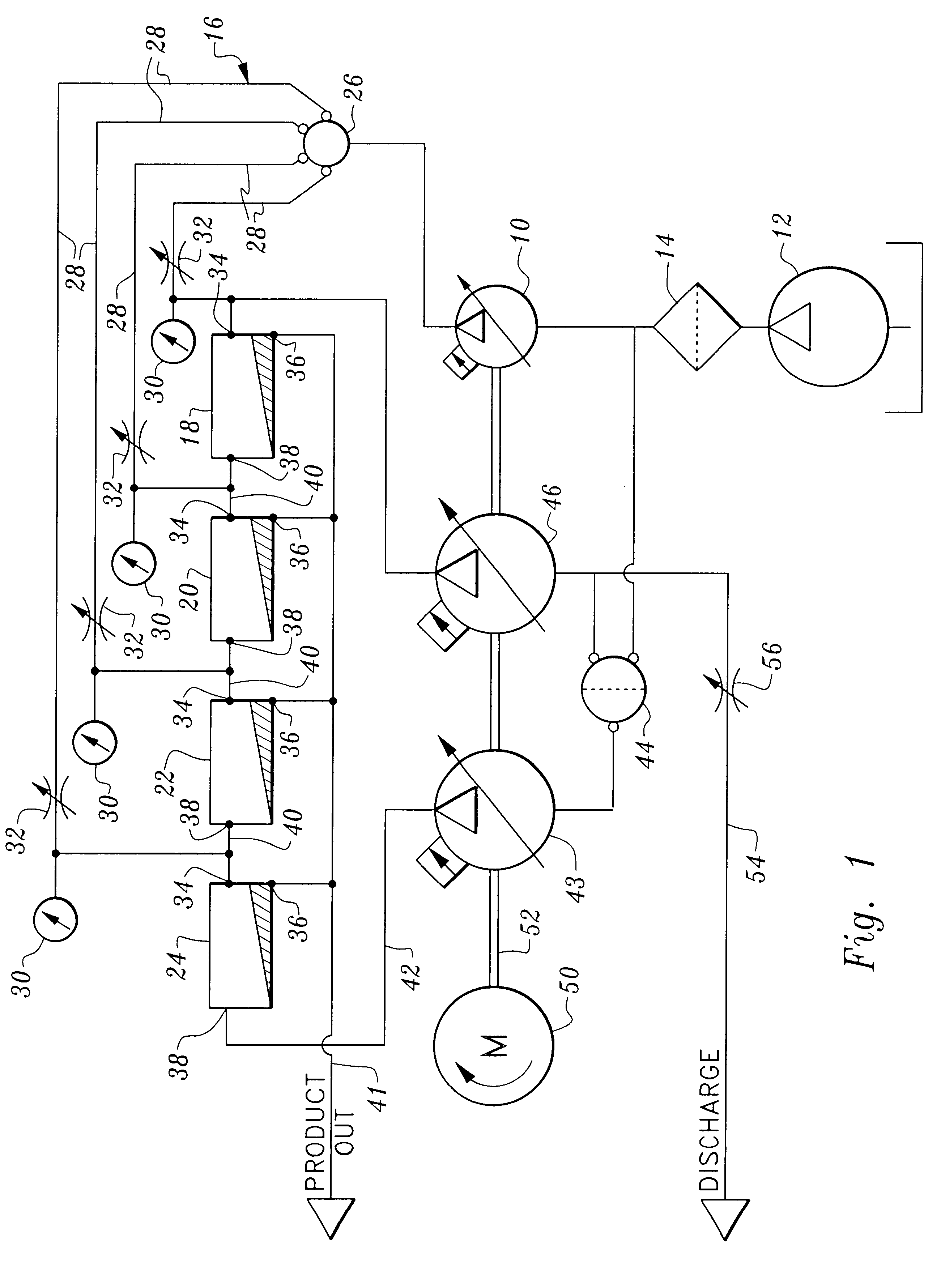

Reverse osmosis filtering apparatus with concentrate dilution

InactiveUS6299766B1HEPA filterLess energyDialysis systemsSedimentation separationReverse osmosisSalt water

Liquid filtering apparatus includes a plurality of reverse osmosis filters for receiving seriatim under pressure a mixture of feed liquid and recirculated concentrate. Feed liquid such as salt water is introduced into the inlet of each reverse osmosis filter to dilute the recirculated concentrate.

Owner:PERMAR CLARK

System and method for using carbon dioxide sequestered from seawater in the remineralization of process water

ActiveUS7771599B1Reduce scaleReduce inorganicLiquid degasificationGeneral water supply conservationSaline waterAlkalinity

Disclosed is an improved method for the remineralization of process water in a desalination system. The method sequesters carbon dioxide gas (CO2) from seawater or concentrate (brine) of desalination process via a gas transfer membrane. The sequestered carbon dioxide gas (CO2) is thereafter used in the production of soluble calcium bicarbonate (Ca(HCO3)2). The calcium bicarbonate (Ca(HCO3)2) adds hardness and alkalinity to the resulting process water.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

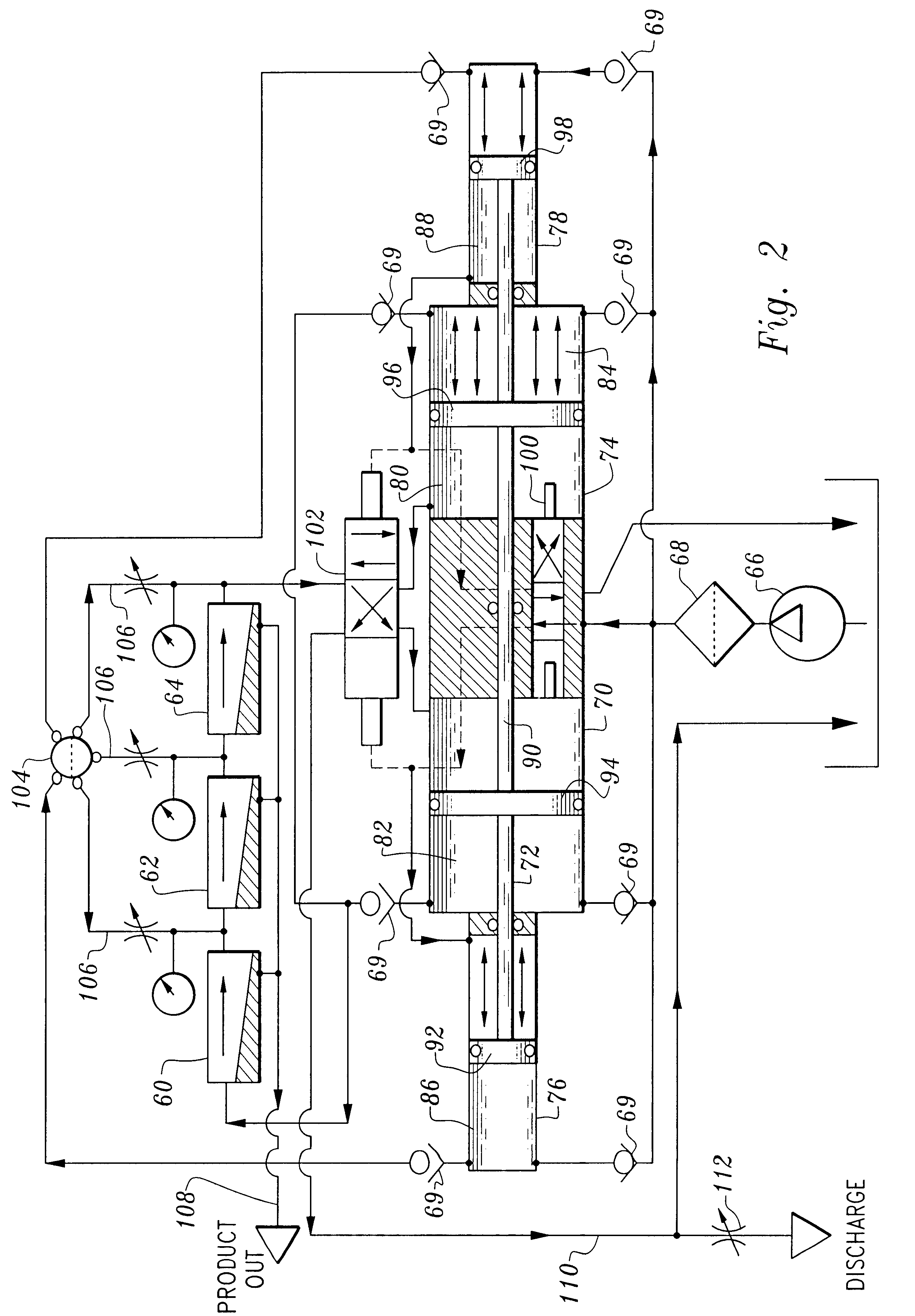

Desalination Method and System Using Compressed Air Energy Systems

InactiveUS20100037653A1Facilitate runoffClean the ice massGeneral water supply conservationSeawater treatmentDesalinationSalt water

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

Method of hydraulic fracturing to reduce unwanted water production

ActiveUS7207386B2Limit undesirable height growthFluid removalDrilling compositionSaline waterGeomorphology

A method of hydraulically fracturing a hydrocarbon-bearing subterranean formation ensures that the conductivity of water inflow below the productive zone of the subterranean formation is reduced. The method consists of two principal steps. In the first step, a fracture in and below the productive zone of the formation is initiated by introducing into the subterranean formation a fluid, free of a proppant, such as salt water, fresh water, brine, liquid hydrocarbon, and / or nitrogen or other gases. The proppant-free fluid may further be weighted. In the second step, a proppant laden slurry is introduced into the subterranean formation which contains a relatively lightweight density proppant. Either the fluid density of the proppant-free fluid is greater than the fluid density of the proppant laden slurry or the viscosity of the proppant-free fluid is greater than the viscosity of the proppant laden slurry. The method limits undesirable fracture height growth in the hydrocarbon-bearing subterranean formation during the fracturing.

Owner:BAKER HUGHES HLDG LLC

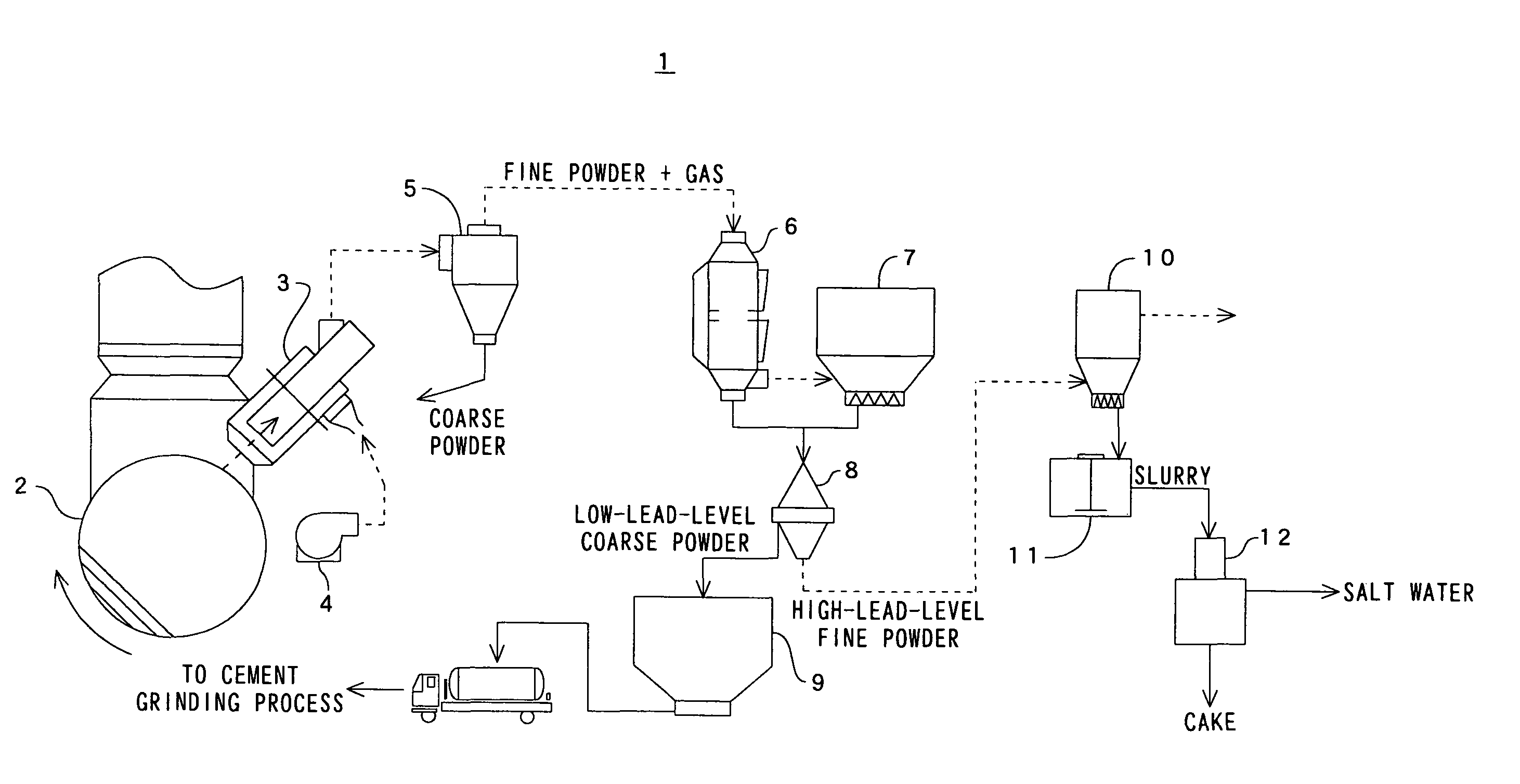

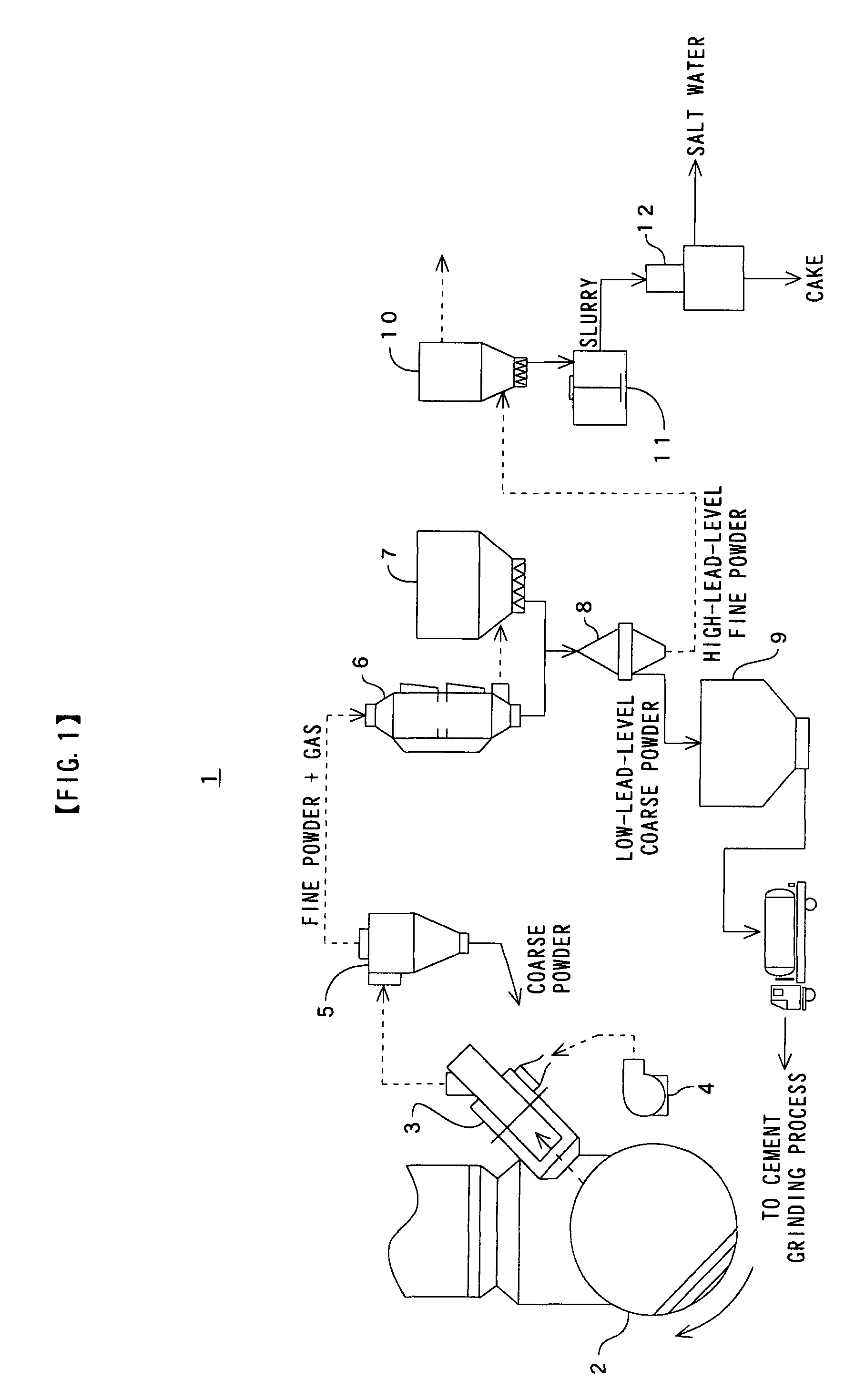

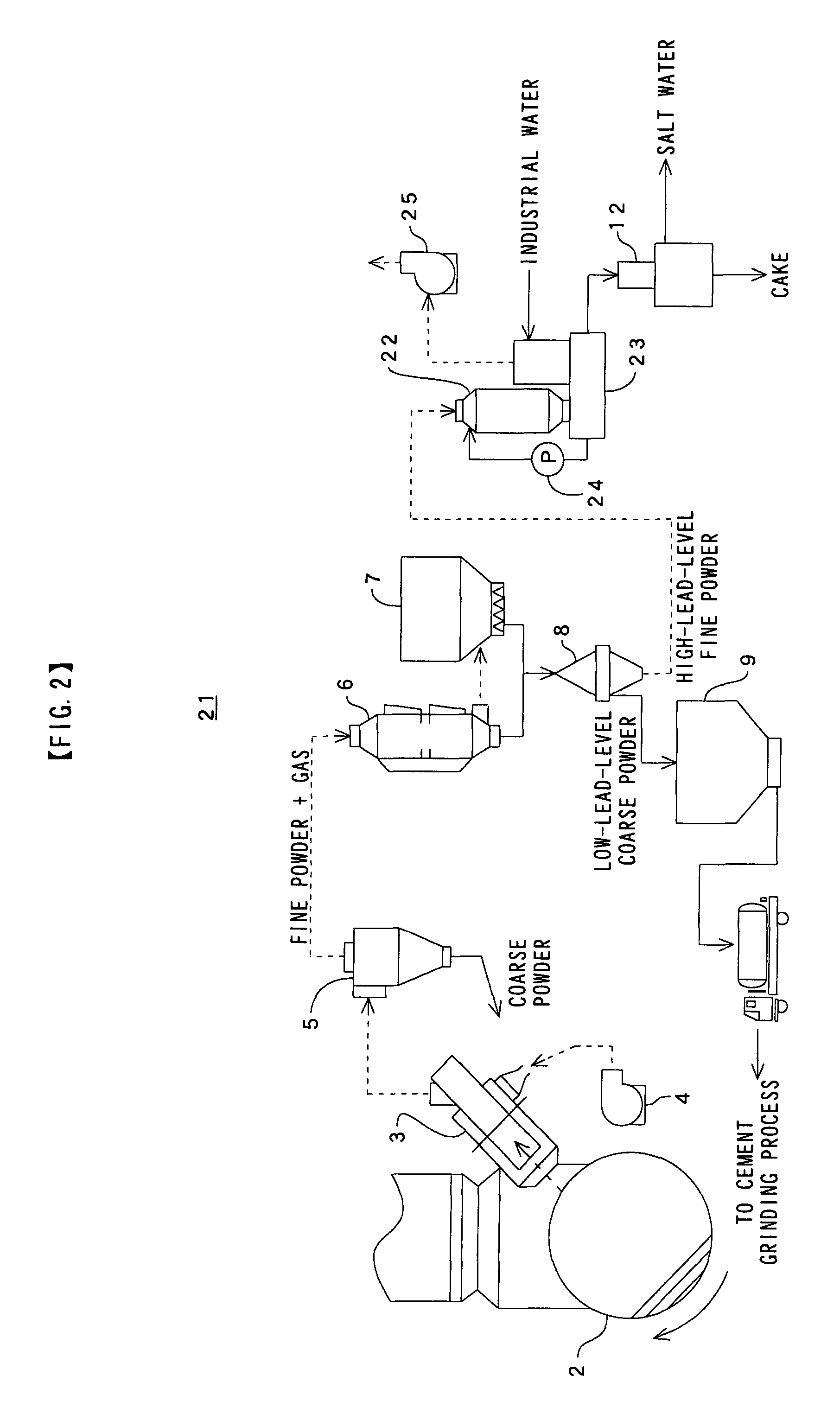

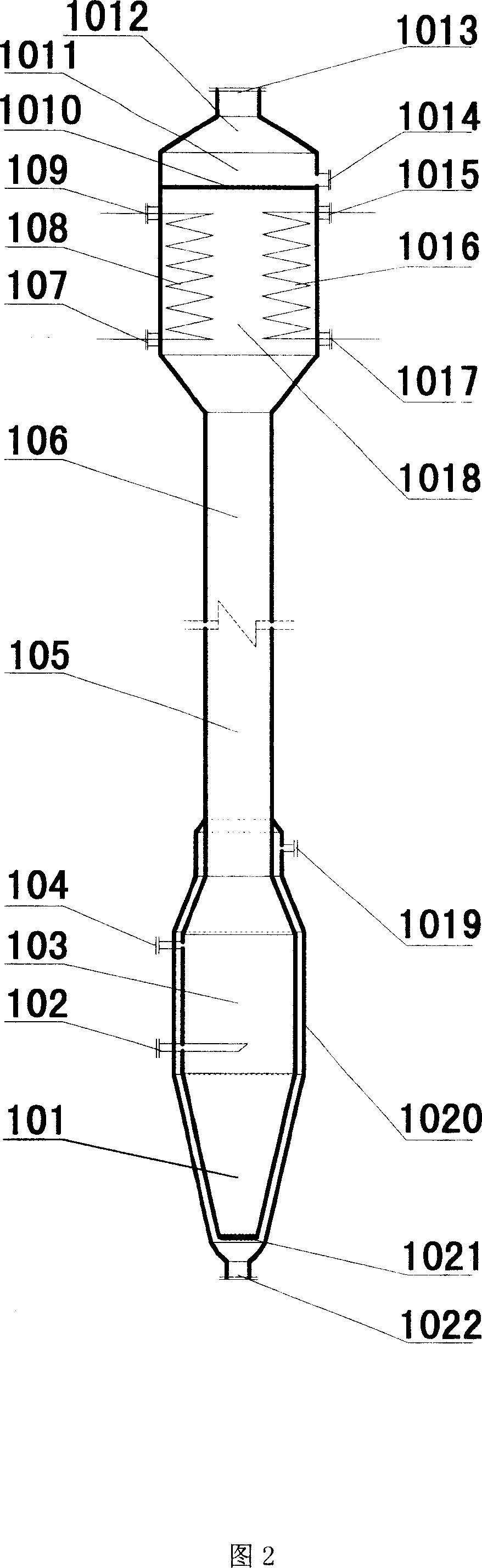

System and method for treating dust contained in extracted cement kiln combustion gas

ActiveUS7749311B2Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

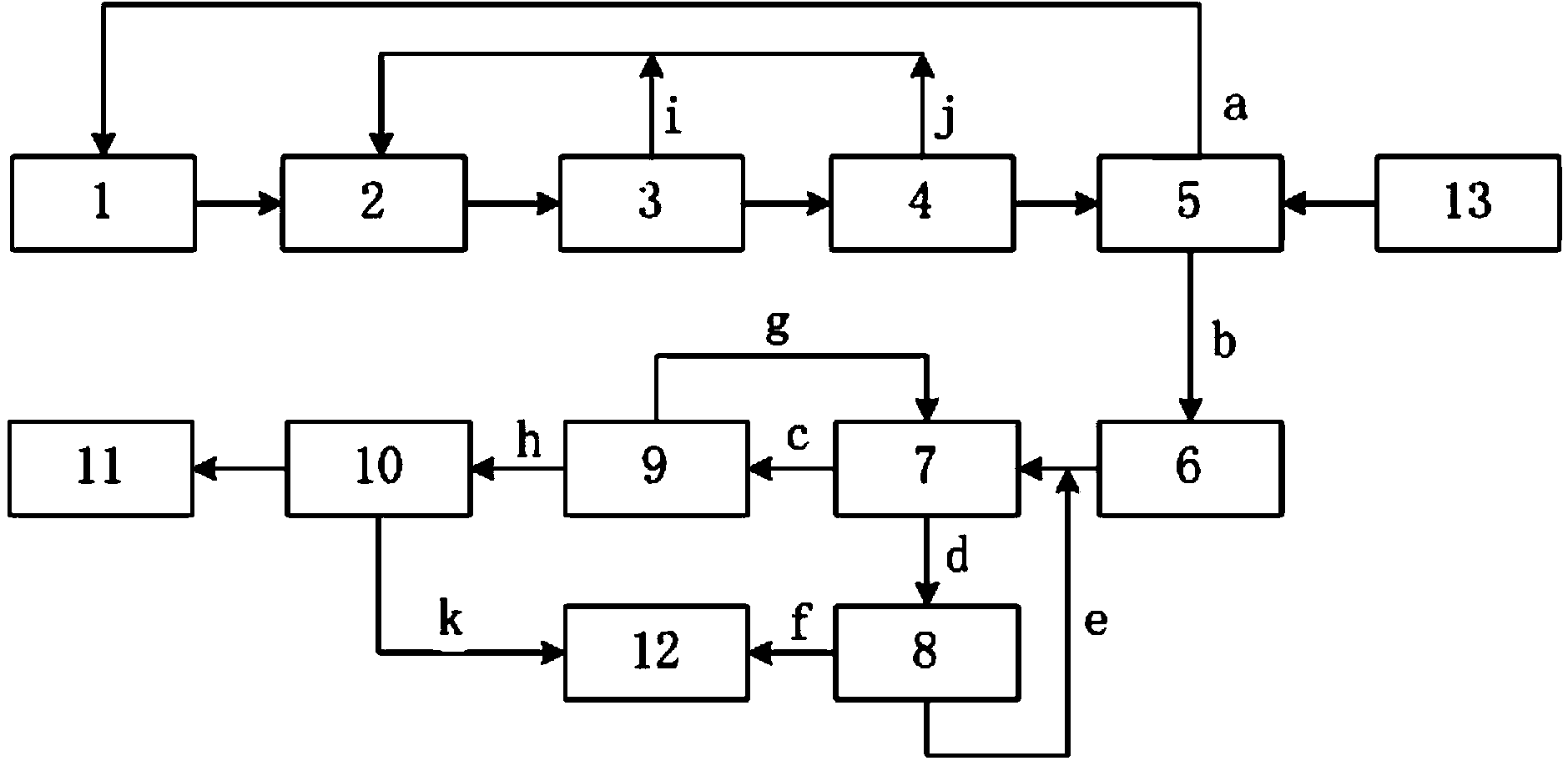

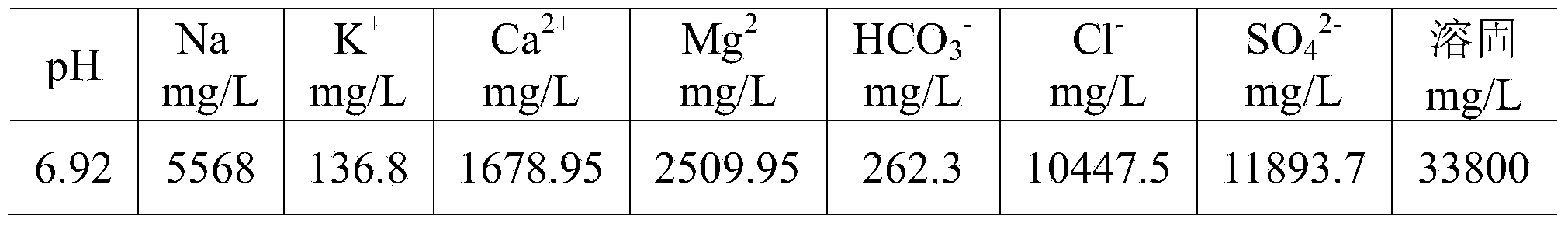

Desulfurization waste water recycling and zero discharge system and method

InactiveCN103979729ALimit concentrationEfficient separationMultistage water/sewage treatmentWater dischargeWastewater

The invention relates to a desulfurization waste water recycling and zero discharge system and method. The desulfurization waste water recycling and zero discharge system comprises a desulfurization tower, a filter and a nanofiltration device which are sequentially connected, wherein a scale inhibitor dosing device is arranged at the inlet of the nanofiltration device, the concentrated water outlet of the nanofiltration device is connected with the desulfurization tower, the fresh water outlet of the nanofiltration device is connected with a saline water concentrating device, the fresh water outlet of the saline water concentrating device is connected with a fresh water tank, the concentrated water outlet of the salt water concentrating device is connected with a crystallizer, and the condensed water outlet of the crystallizer is connected with the fresh water tank; a drying encapsulating machine is arranged at the solid outlet of the crystallizer. The desulfurization waste water recycling and zero discharge system has the advantages that desulfurization waste water discharged from the desulfurization tower is filtered and then is fed into the nanofiltration device, nanofiltration concentrated water returns to the desulfurization tower, nanofiltration fresh water is treated by virtue of the salt water concentrating device and then is crystallized by virtue of the crystallizer, the obtained fresh water is recycled in the fresh water tank, and salt is separated out, dried into crystallized salt and transported outside after being encapsulated, so that zero discharge of the desulfurization waste water is realized, quality of the recycled fresh water is improved, and a chemical agent and operating cost are saved.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION +2

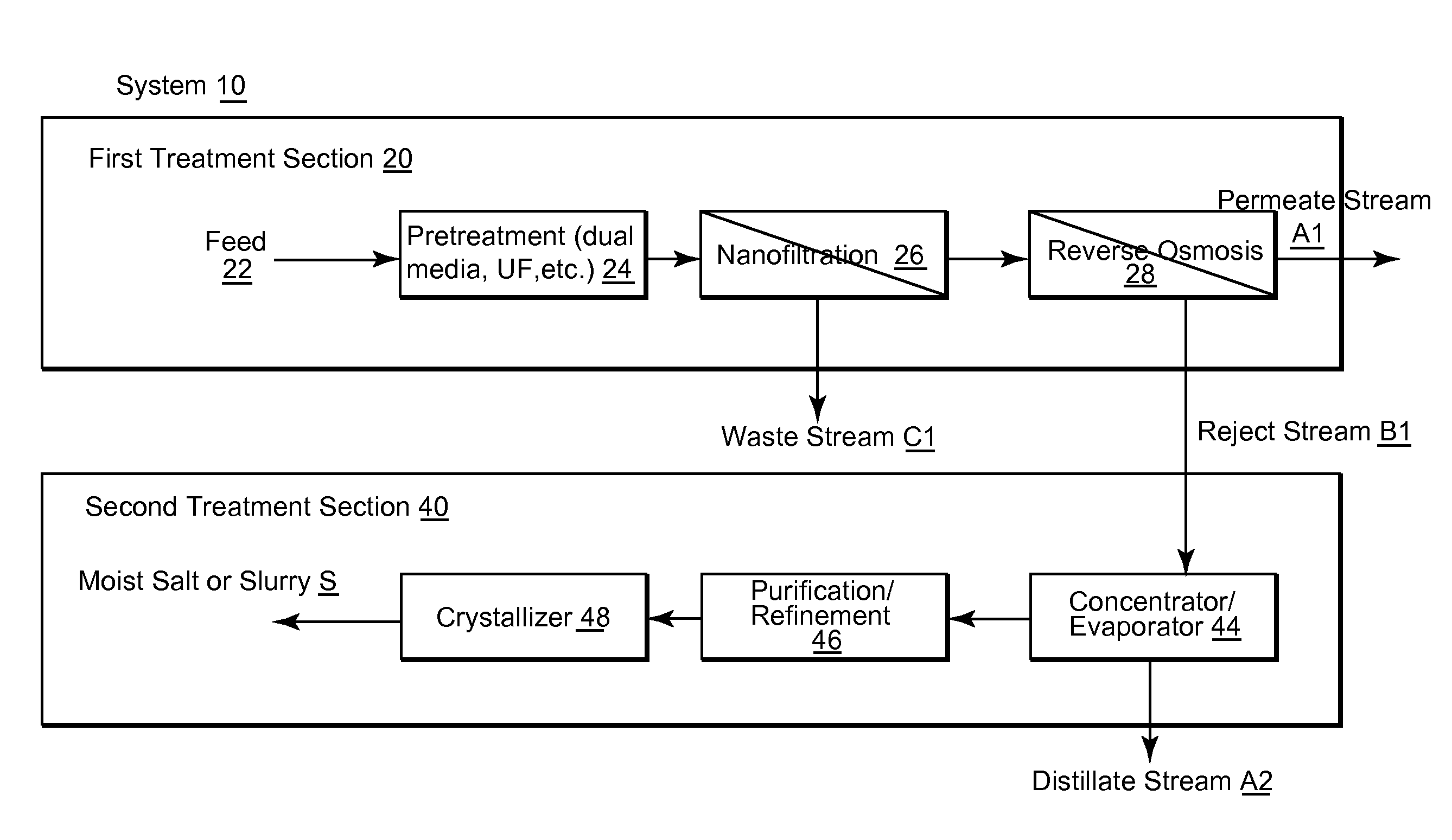

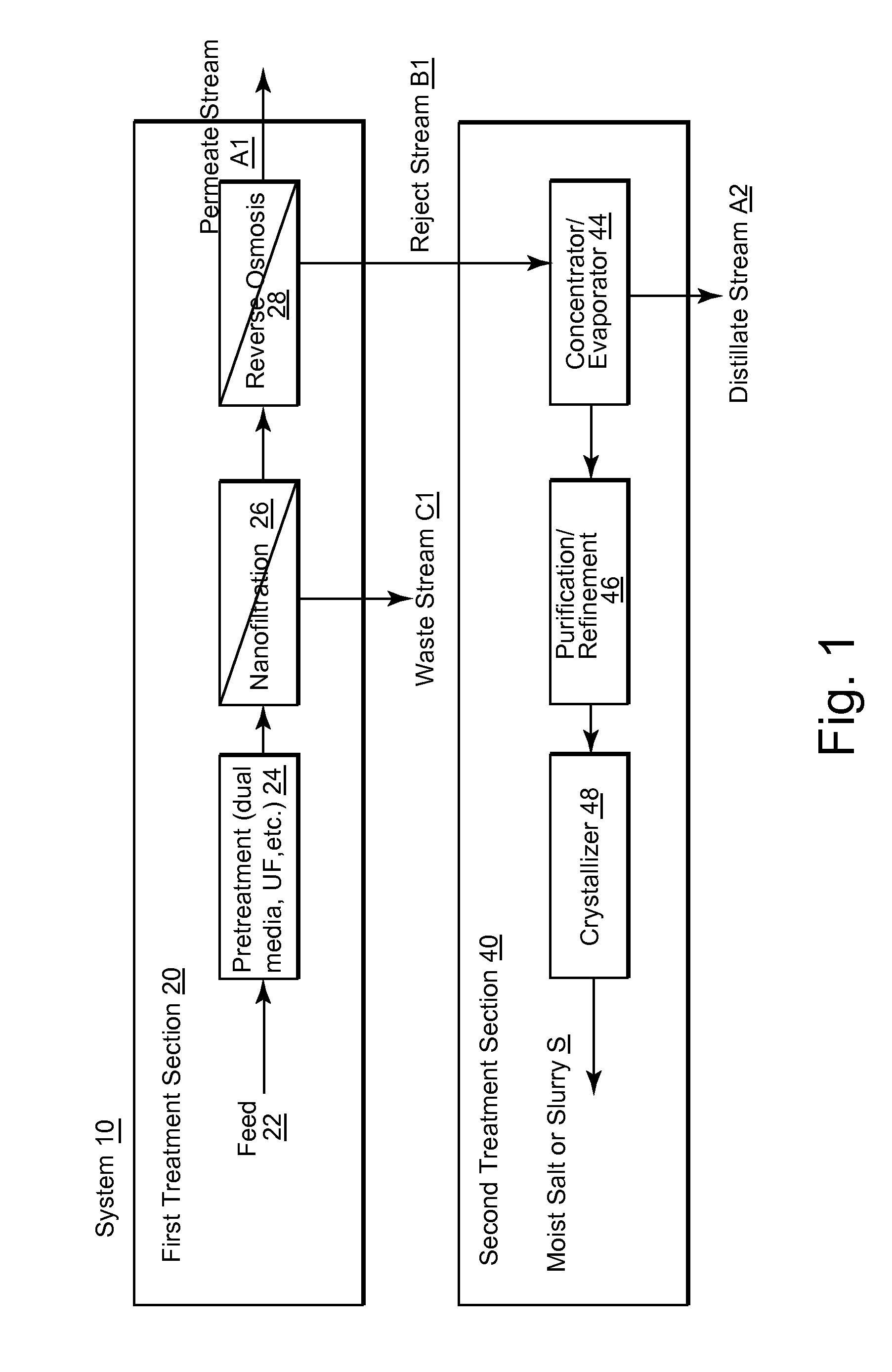

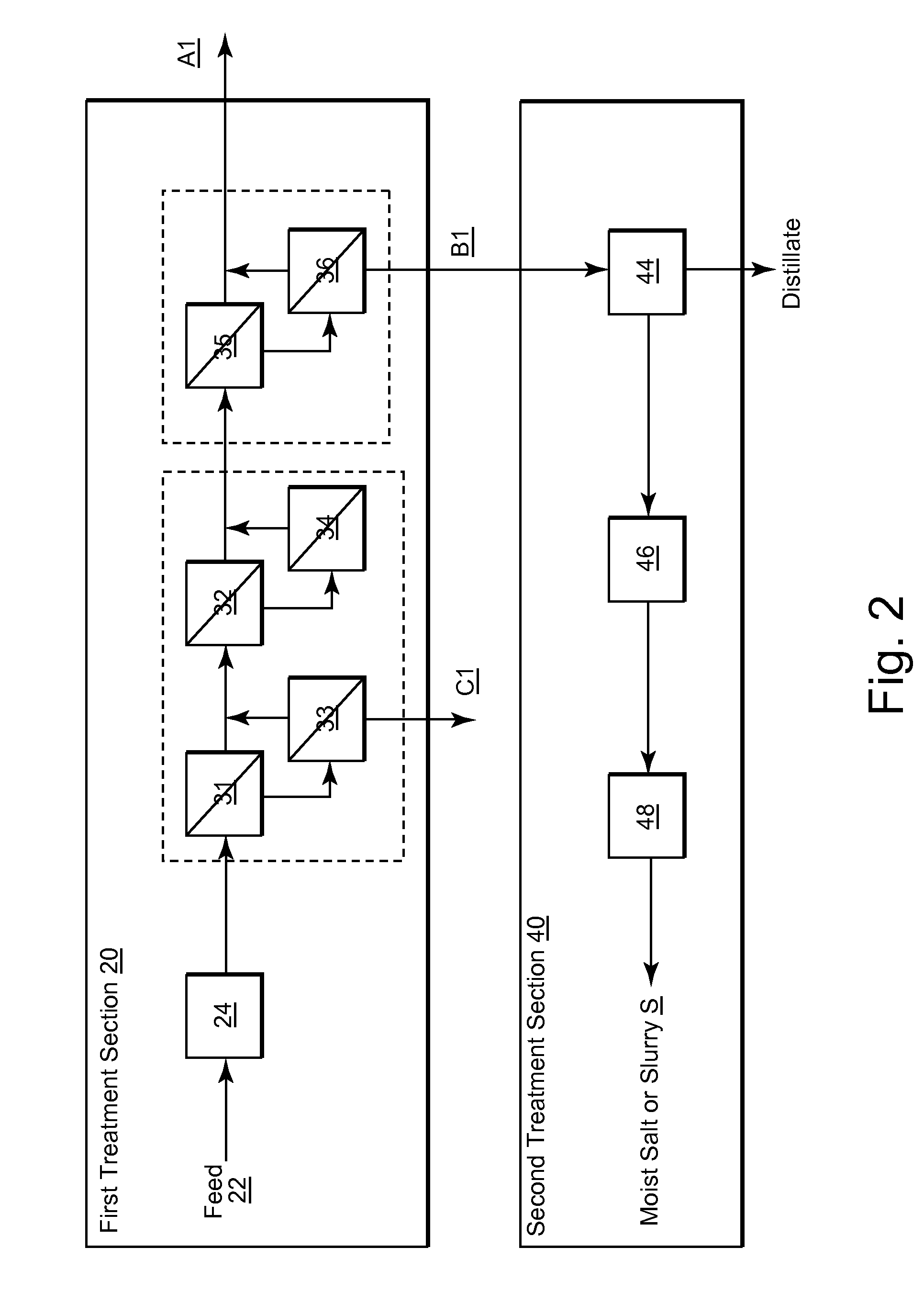

Water desalination plant and system for the production of pure water and salt

InactiveUS20120160753A1Enhanced commercial NaCl productionGeneral water supply conservationSeawater treatmentSaline waterWater desalination

A desalination plant for treating a sea water or brackish water feed is provided. The desalination plant includes a first treatment section to effectively remove scaling species, the first treatment section including nanofiltration section, the nanofiltration section including at least two stages and at least two passes; and a reverse osmosis section that operates at high recovery to produce a purified permeate stream and a selectively NaCl salt-enriched reject stream as a saline output.

Owner:VORA NISHITH +4

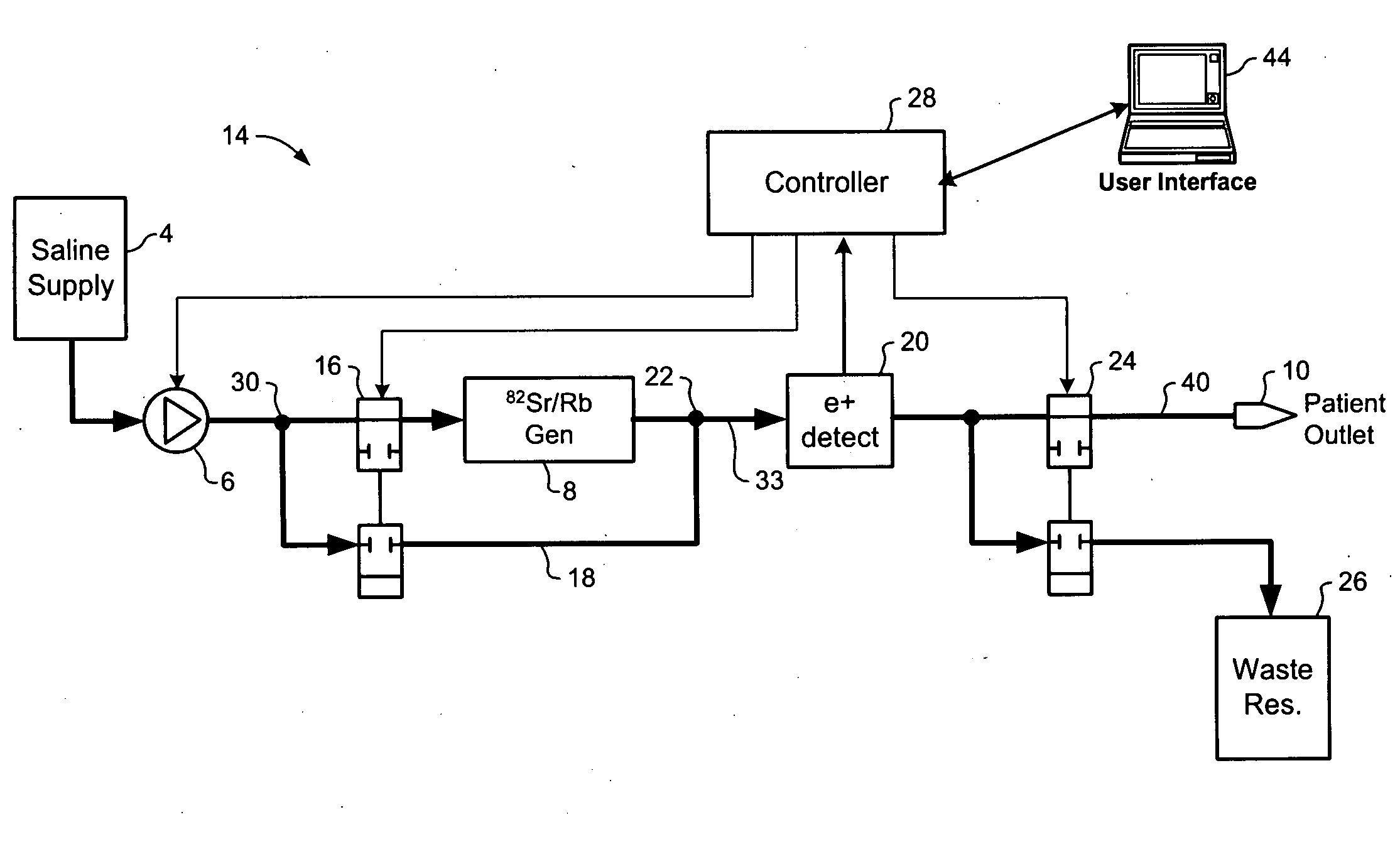

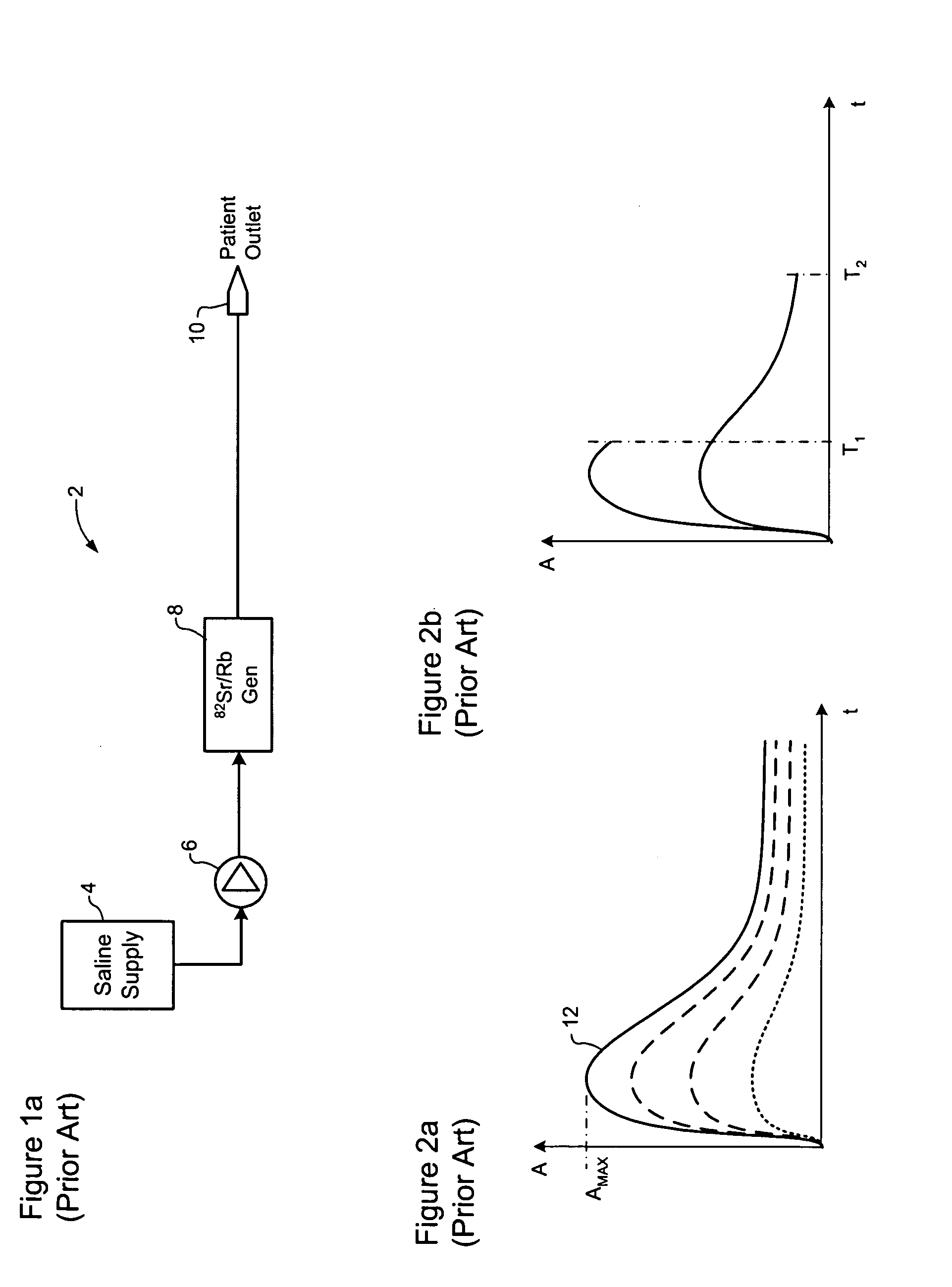

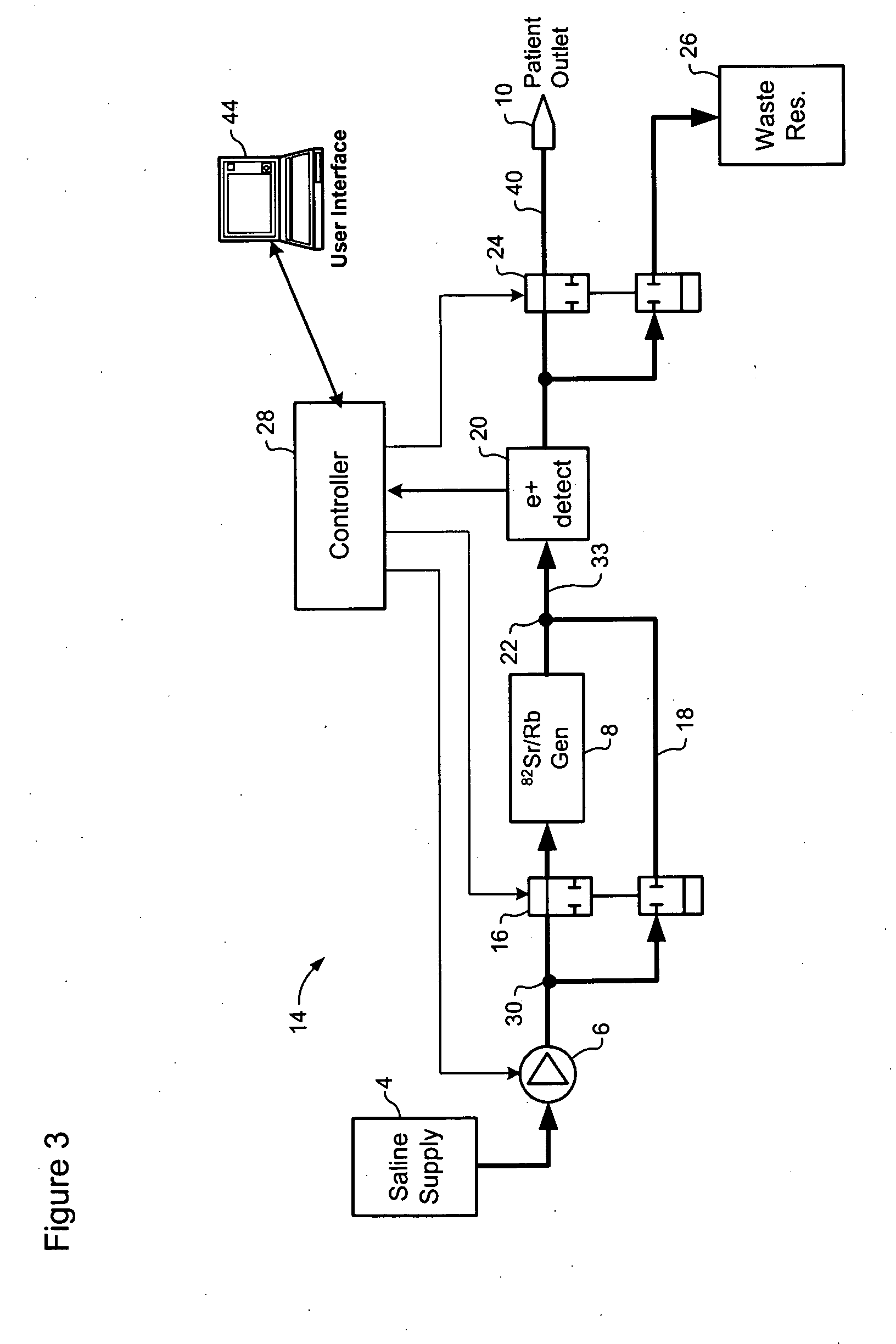

Rubidium elution system control

A method of controlling an 82Sr / 82Rb elution system having a generator valve for proportioning a flow of saline solution between an 82Sr / 82Rb generator and a bypass line coupled to an outlet of the generator such that saline solution traversing the bypass line will merge with eluted saline solution emerging from the generator to provide an active saline solution. During each elution run, a plurality of successive concentration parameter values are obtained at predetermined intervals. Each concentration parameter value is indicative of a respective instantaneous activity concentration of the active saline solution. Respective error values between each concentration parameter value and a target activity concentration value of the elution run are computed. Error data based on a plurality of the computed error values is accumulated. Between successive elution runs, at least one performance parameter of the elution system is adjusted based on the accumulated error data.

Owner:OTTAWA HEART INST RES

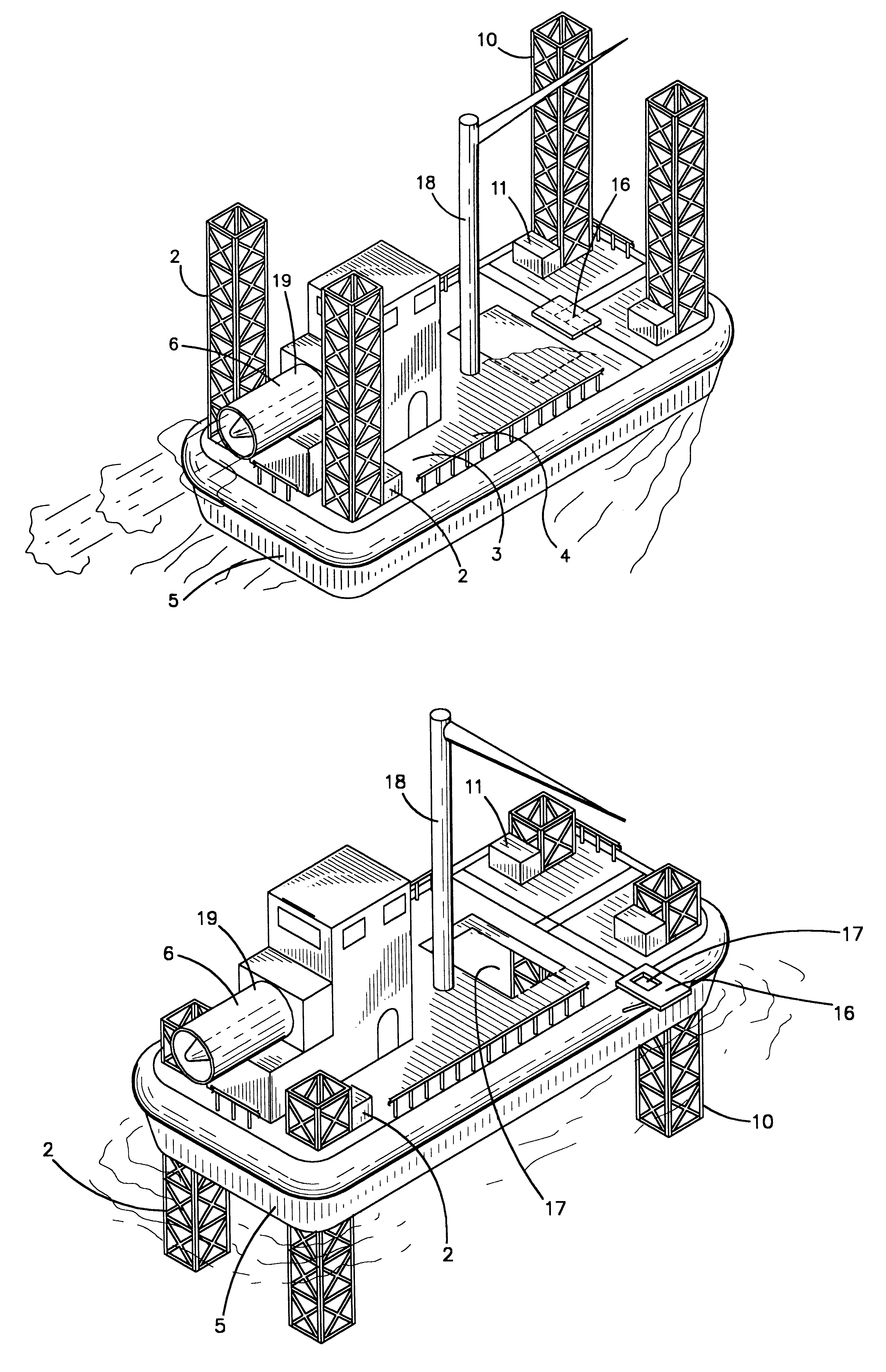

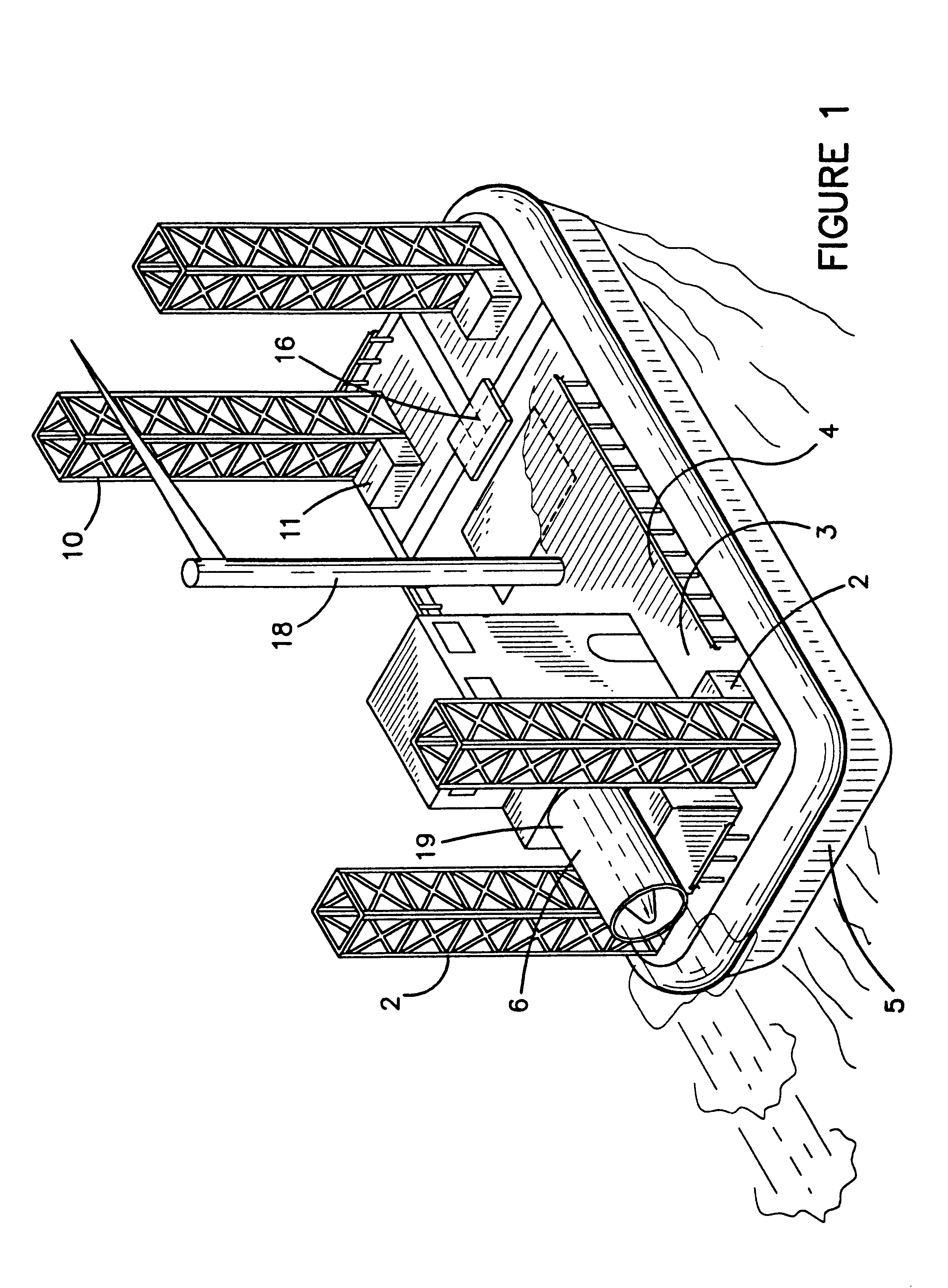

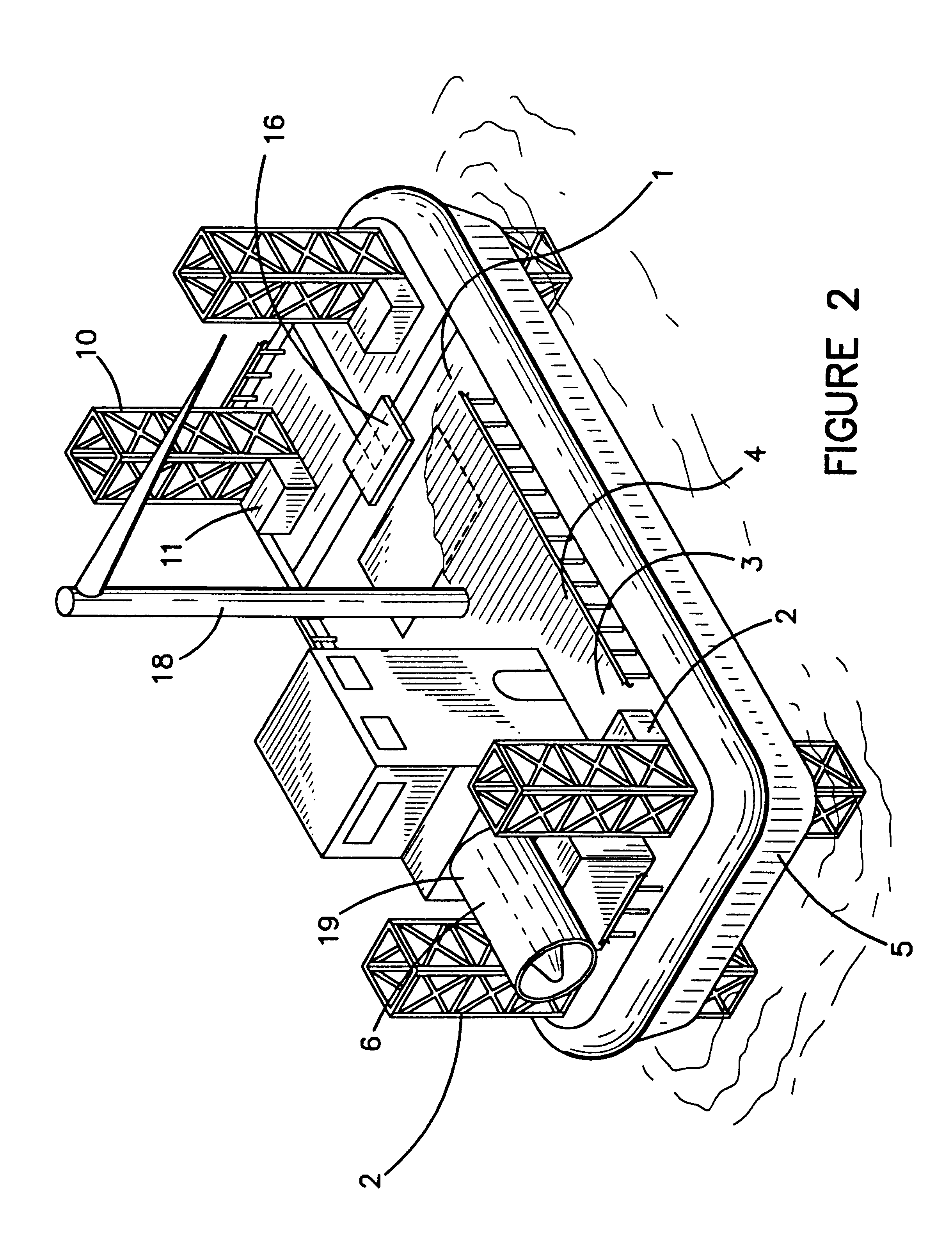

Hovercraft work platform

A jack up work platform is recited. The work platform comprises a hovercraft vessel outfitted with several jack up legs. The hovercraft can traverse environmentally sensitive terrain such a brackish and freshwater marshes without the need to dig canals that may cause or exacerbate salt water intrusion. Once the drilling or exploration site is reached, the jack up legs may be lowered, lifting the work platform above the surface. Once the vessel is secured on the legs, it may be used like a conventional oil field work platform for drilling, exploration, or construction jobs for which other work platforms or vessels are typically used. The deck of the hovercraft may serve as the work platform or the deck may be provided with a cantilevered work platform extension. The hovercraft will preferably be provided with typical oil field heavy machinery such as a crane for assembly of the legs, and drill stem as well as for work on other structures.

Owner:MILLER GEORGE AUSTIN

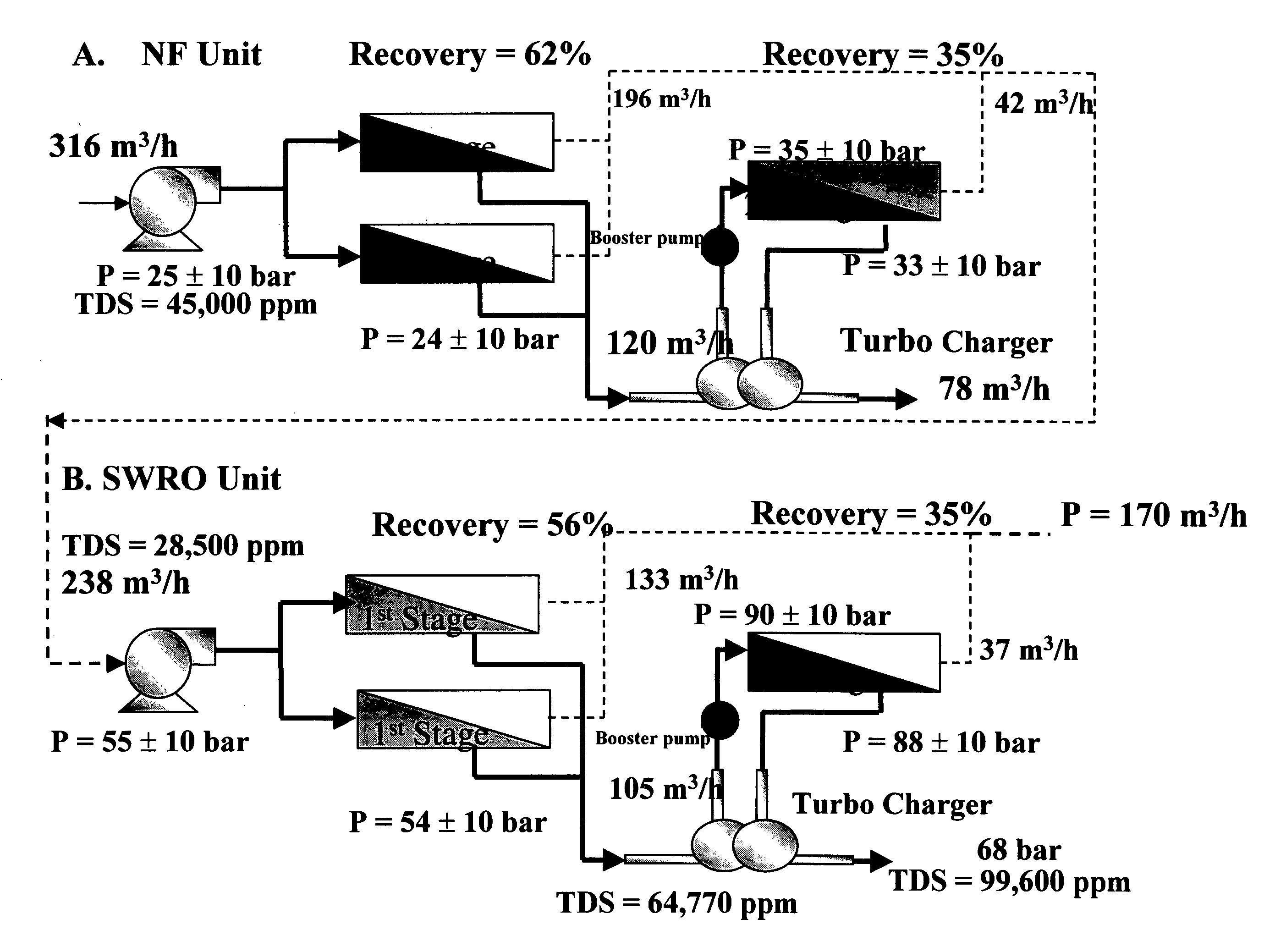

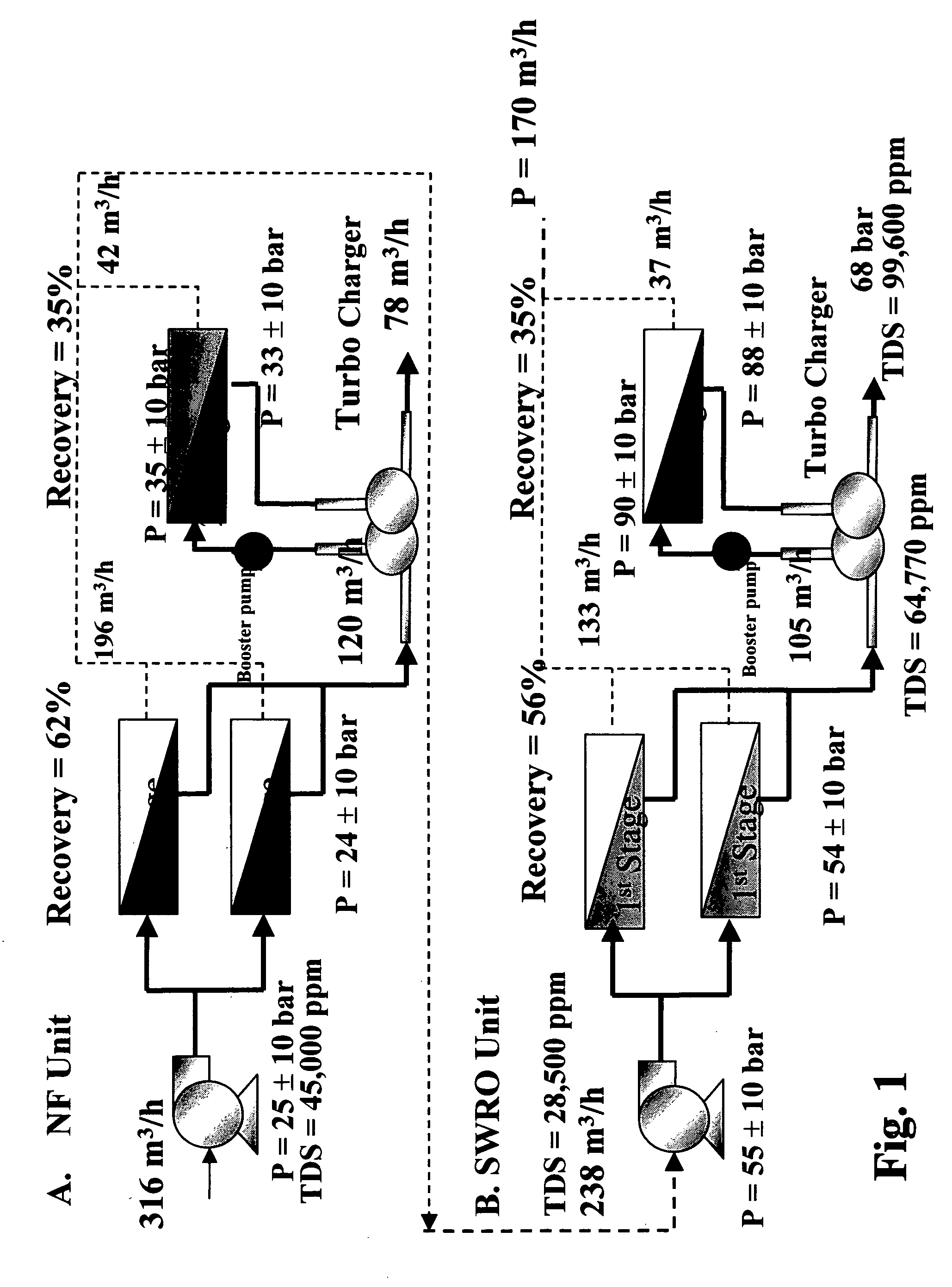

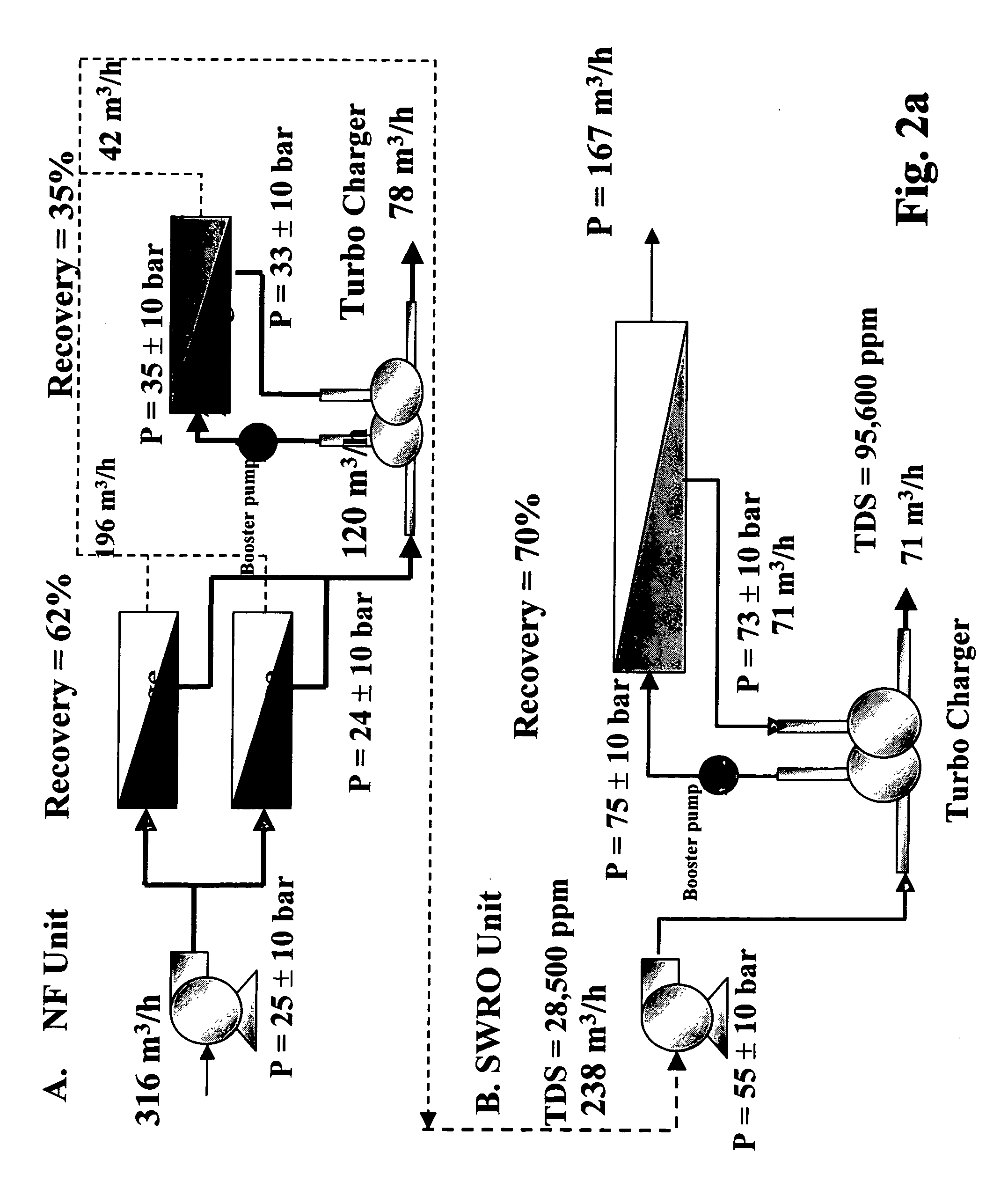

Fully integrated NF-thermal seawater desalination process and equipment

InactiveUS20060157410A1High yieldEffectively and efficiently dealGeneral water supply conservationReverse osmosisDistillationEngineering

An optimal thermal seawater desalination process is disclosed, which combines two or more substantially different water pretreatment processes in a unique manner and in a special configuration, hereto unknown to prior desalination arts, to produce a high yield of high quality fresh water, including potable water. In this process a two stage NF membrane pretreatment unit (NF2) with an energy recovery turbo charger (TC) device in between the stages or equipped with an energy recovery pressure exchanger (PX) is synergistically combined with at least one thermal desalination unit to form a dual hybrid of NF2-Thermal (FIG. 4 ), or alternatively the two stage NF2 unit is synergistically combined with a two stage SWRO unit (SWRO2) with an energy recovery TC in between the stages or combined with one stage SWRO (SWRO1) equipped with an energy recovery TC or PX system and the reject from the SWRO2 or SWRO1 unit is made make-up to a thermal unit to form a tri-hybrid of NF2-SWRO2 reject-Thermal (FIG. 5 ). In both the cases of di- or trihybrids the thermal unit is equivalent to a multistage flash distillation (MSFD) or multieffect distillation (MED) or vapor compression distillation (VCD) or thermal reheat (RH) evaporator. Typically a process of this invention using the two stage NF2 initial pretreatment step will perform a semi-desalination step by reducing feed TDS by about 35 to 50%, but most important, especially to the thermal seawater desalination process, it removes the water recovery limiting, scale forming hardness ions of Ca++ and Mg++ by better than 80% and their covalent anions of sulfate to better than 95% and bicarbonate to about 65%. The removal of scale forming hardness ions, especially SO4=, and bicarbonates allowed for the operation of thermal unit in the above hybrids at top brine temperature (TBT) much greater than its present TBT limit by the singular conventional process of 120° C. for MSFD and operation of MED or VCD or RH unit at TBT much higher than their present TBT limit of 65-70° C., with many advantages gained by this process over prior art sweater desalination processes. The process of this invention exceeds all prior thermal seawater desalination arts in efficiency, including water yield, product water recovery ratio and unit water cost as well as in energy consumption per unit product which is equivalent or less than other efficient prior art seawater thermal desalination processes. By this process, an NF product recovery ratio of 75 and 80% or better is achieved from the high salinity Gulf sea (TDS≈45,000 ppm) and about an equal product recovery ratio is also obtained from the SWRO or thermal unit when it is operated on NF product for a total water recovery ratio in excess of 52% for seawater

Owner:SALINE WATER CONVERSION CORP SWCC

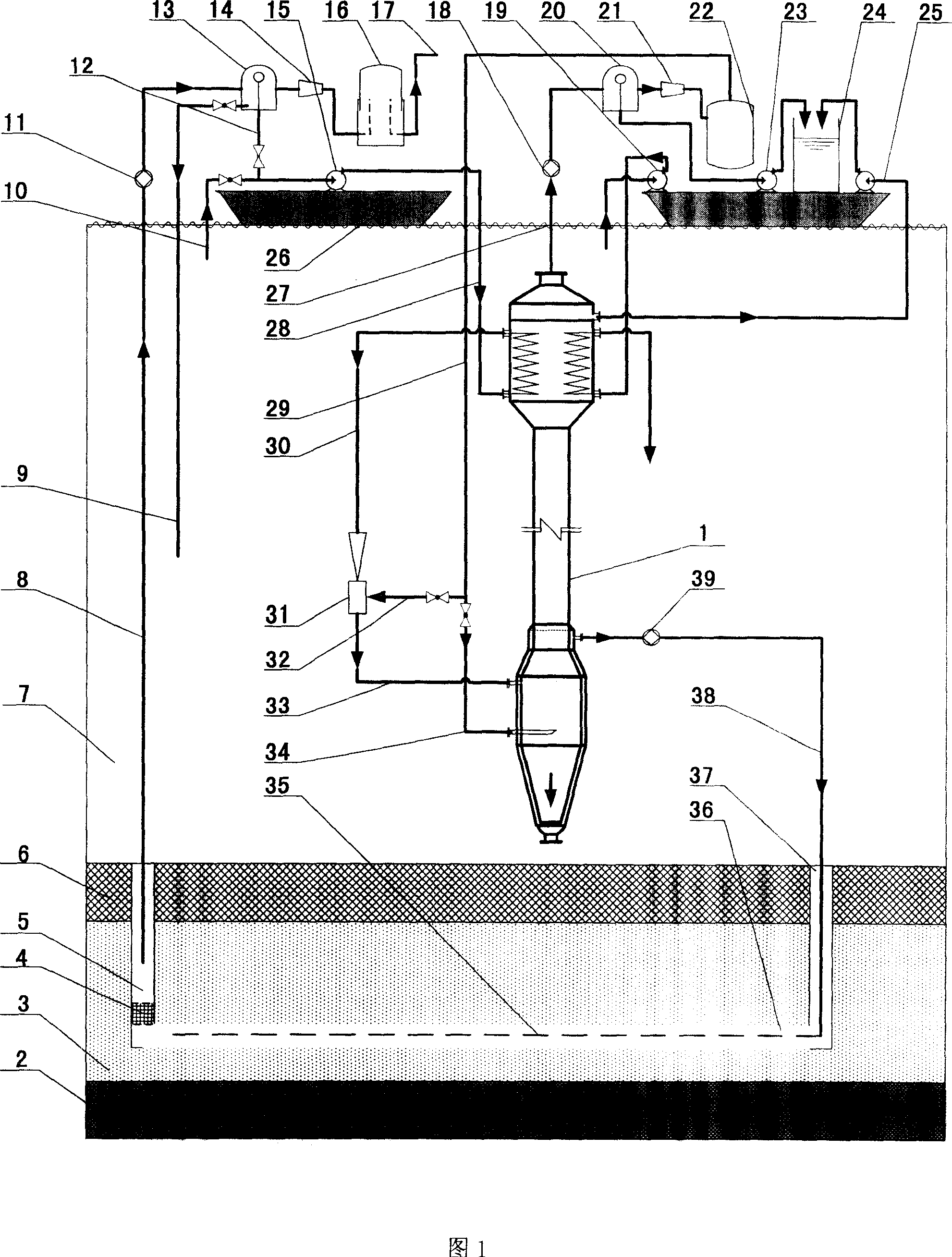

Method for exploiting natural gas hydrates and device thereof

ActiveCN101016841AImprove energy efficiencySimplify mining processConstructionsMineral miningSaline waterSalt water

The invention discloses a method for developing natural gas hydrate, which comprises that building developing well, horizontal well and collecting well, building floating platform and natural gas hydrate developer on sea, building sea concentration heater, preparing hot salt water, decomposing natural gas hydrate and collecting natural gas. And the inventive device comprises a sea floating platform, a developing well, a collecting well, a horizontal well, a hydrate recycling system, a fresh water groove, a hot salt water tube, a hot salt water pump, and a seawater concentrating heater. The invention has simple process, low energy consumption and low cost, without pollution.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Desalination methods and systems that include carbonate compound precipitation

InactiveUS20100154679A1Easy complianceImprove desalination efficiencyAuxillariesGeneral water supply conservationSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbon dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:CALERA CORP

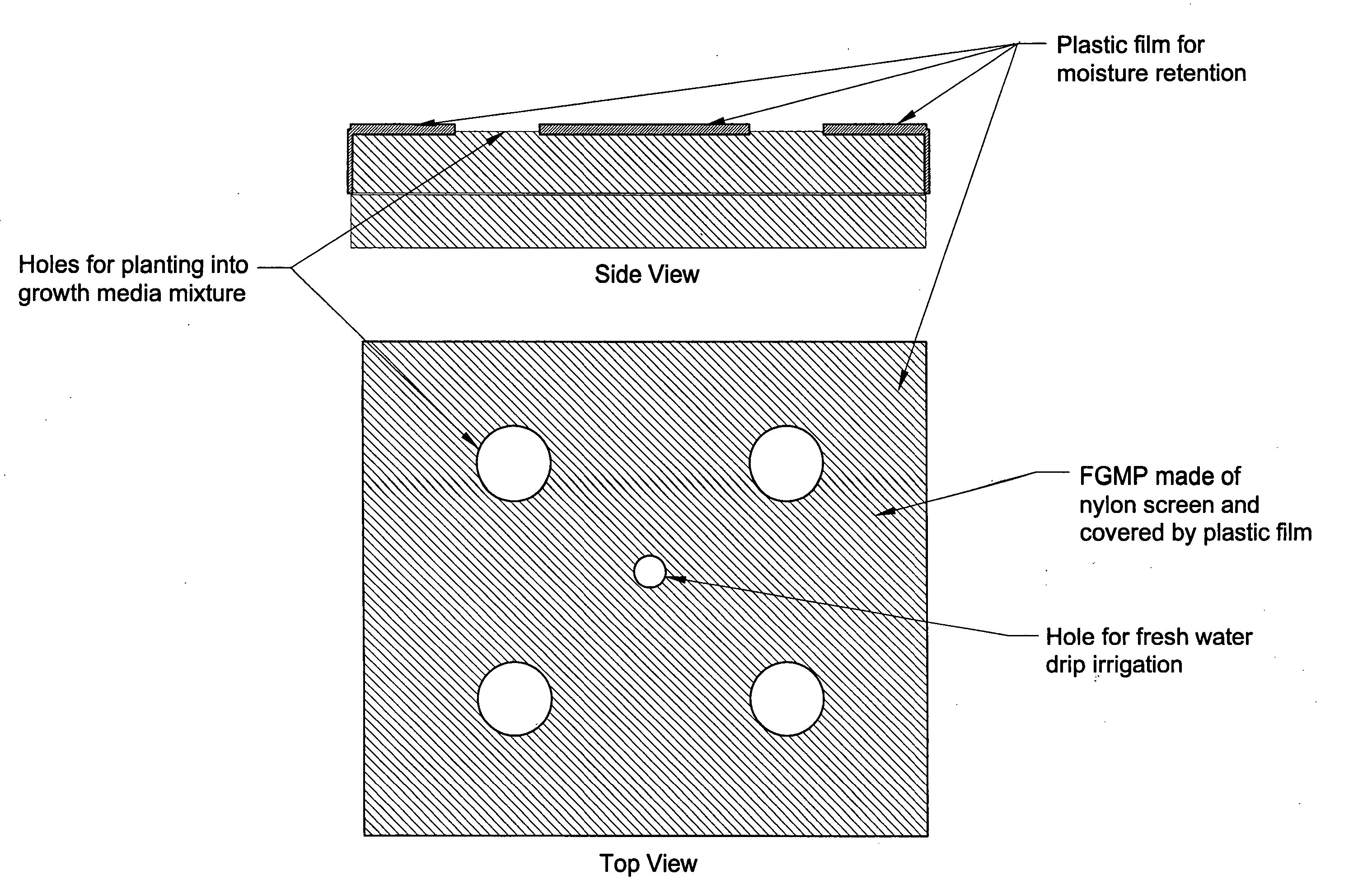

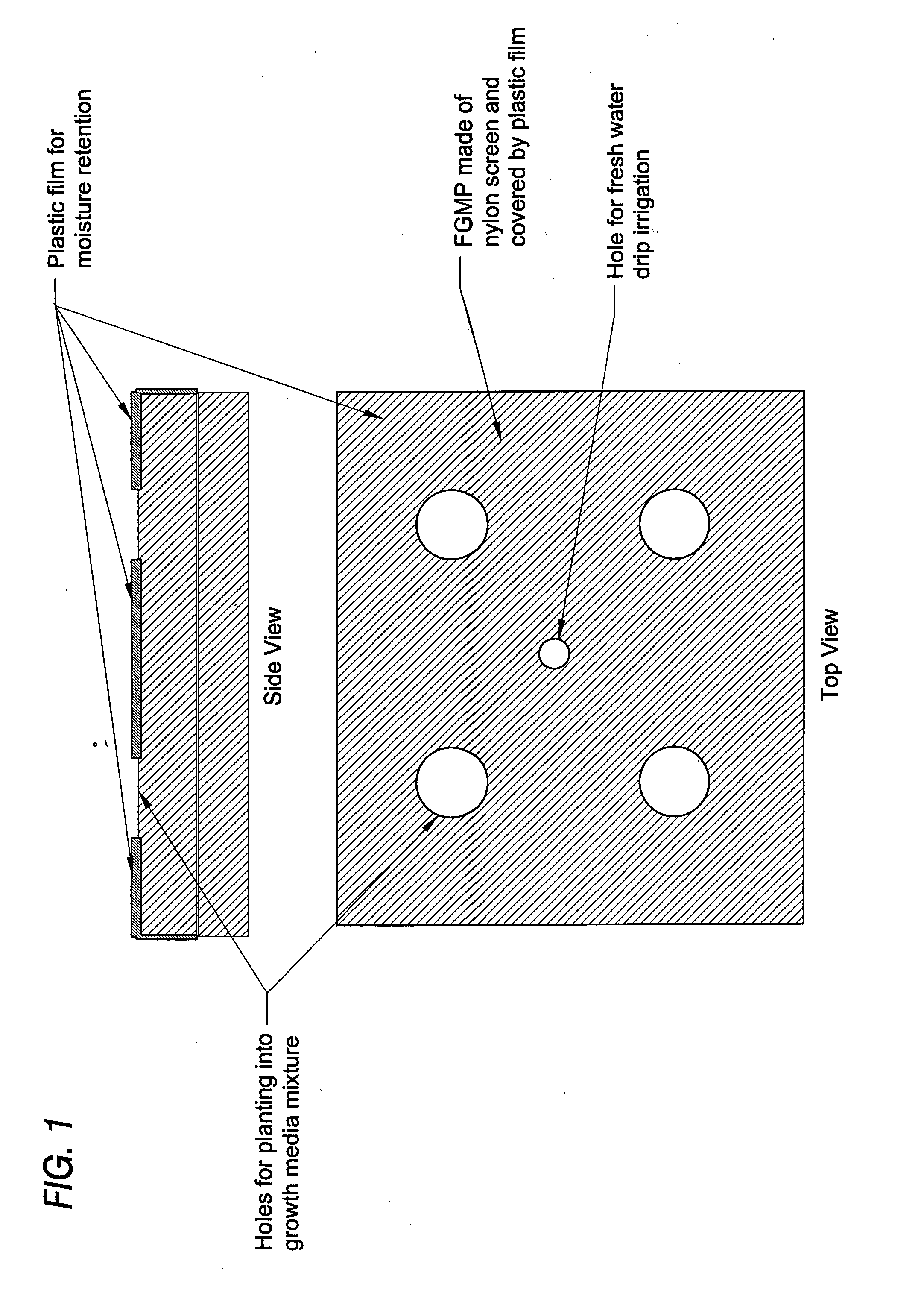

Floating plant cultivation platform and method for growing terrestrial plants in saline water of various salinities for multiple purposes

InactiveUS20050044788A1Efficient managementMinimal requirementSeed and root treatmentClimate change adaptationShootCell culture media

The cultivation of terrestrial plants in brackish water or seawater is carried out with this invention. A light-weight, floating growth medium package (FGMP) or, alternatively, a sheet of suitable material is used to support the growth of terrestrial plants floating on water bodies of various salinity, including 100% seawater in marine environments. The FGMP units can be linked together and confined in a floating, rigid or flexible framework to form a floating seawater cultivation platform (FSCP). Using the method, plants were able to grow and thrive on the FSCP floating on 100% seawater in a sustainable manner. Halophytic akulikuli (Sesuvium portulacastrum L.) can regenerate its shoot and root in seawater. Thus, the discovery will enable us to practice marine agriculture, or agriculture on the sea. The FSCP can be used for wide range of purposes, from environmental protection to landscaping to crop production.

Owner:UNIV OF HAWAII

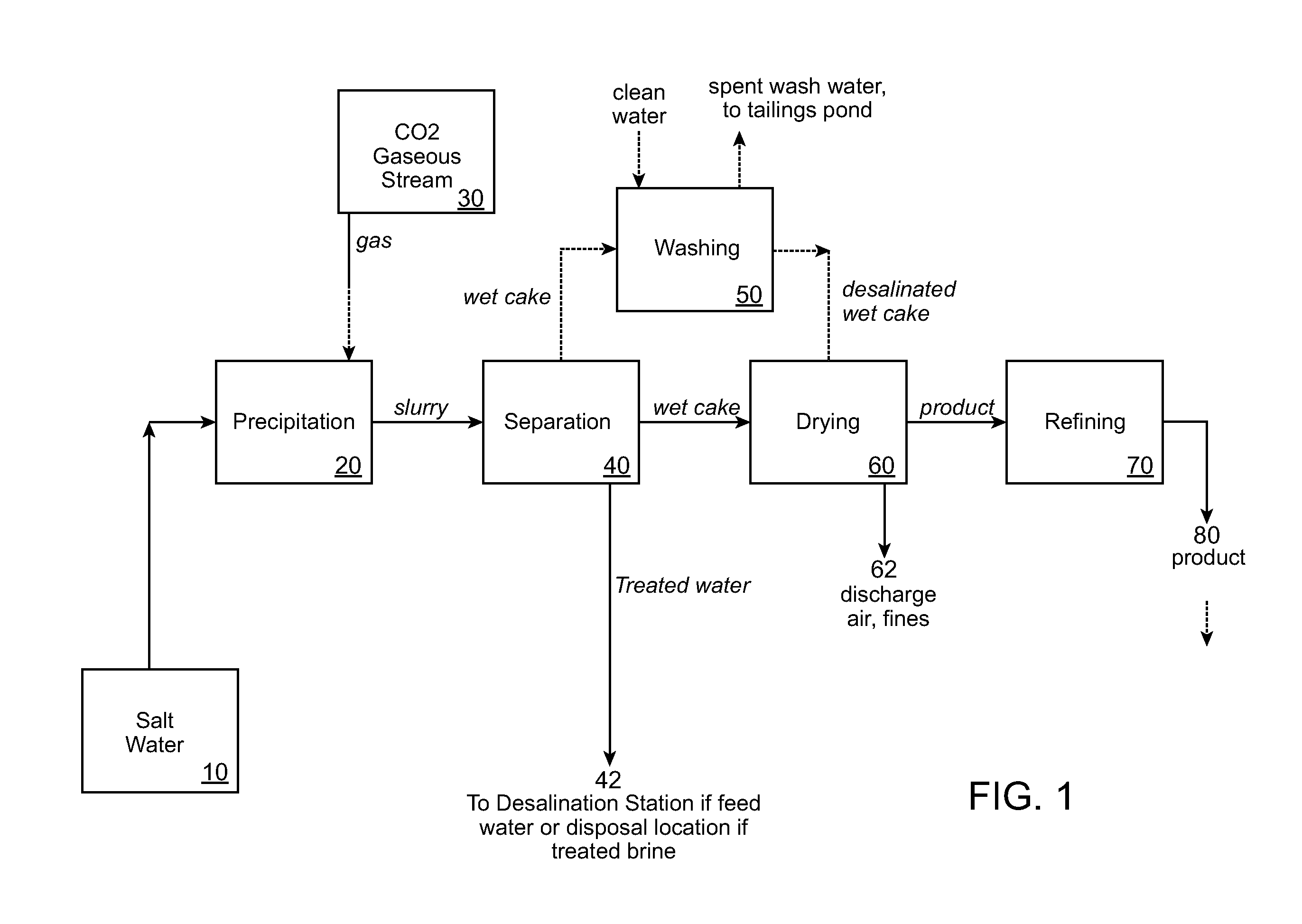

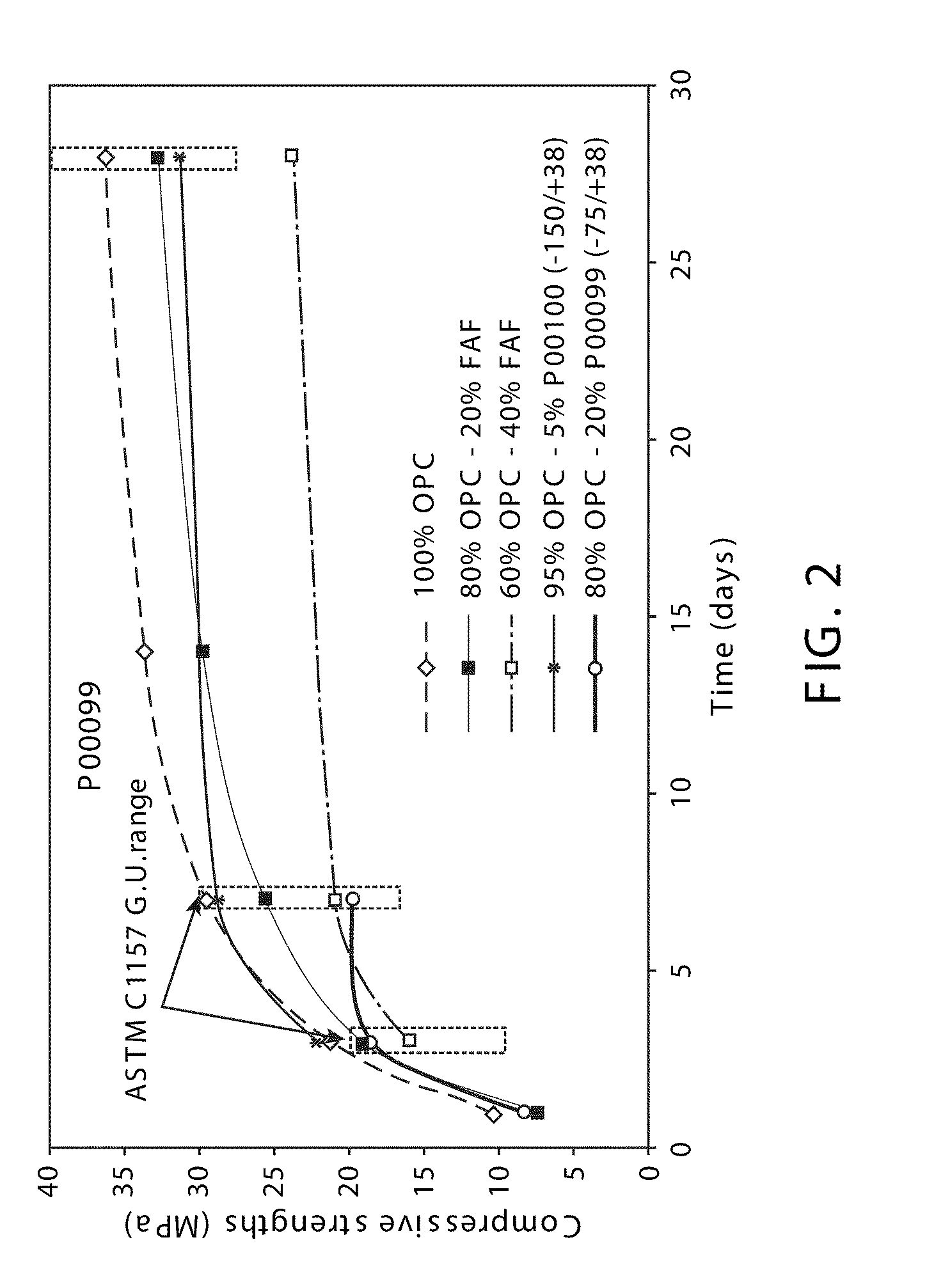

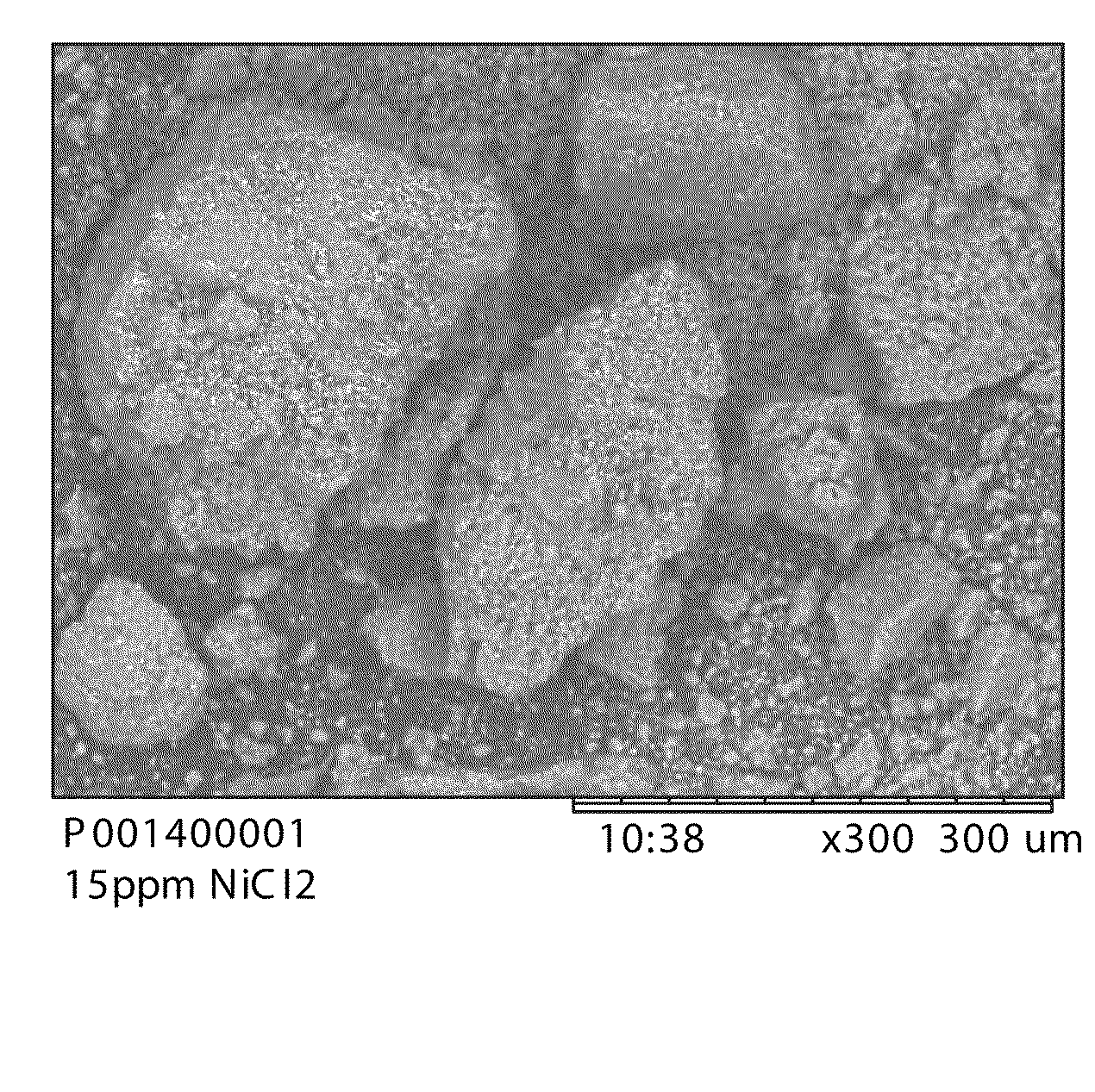

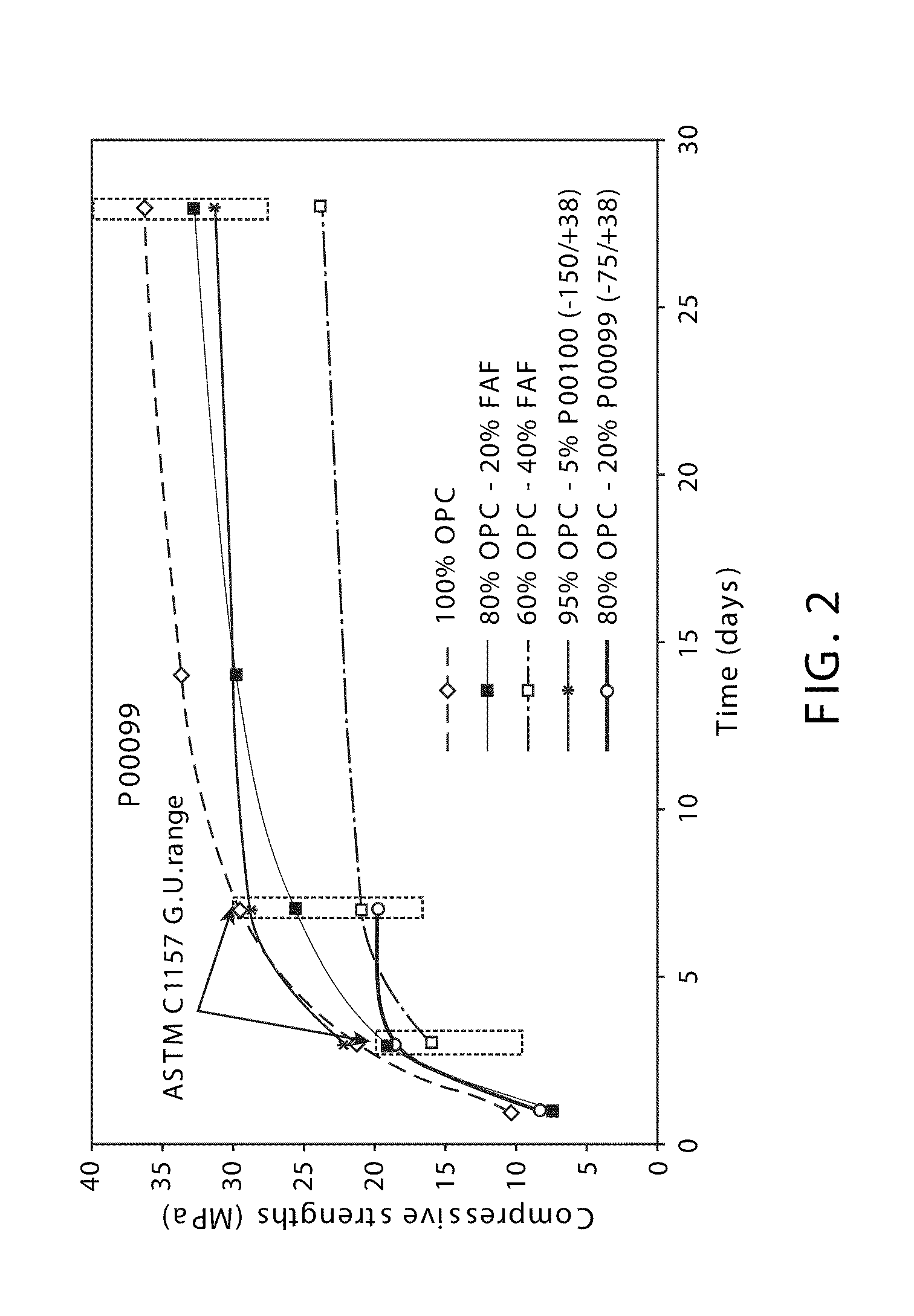

Hydraulic Cements Comprising Carbonate Compound Compositions

ActiveUS20100132591A1Energy based wastewater treatmentCarbonate/bicarbonate preparationSalt waterCarbonate

Hydraulic cement compositions that include a carbonate compound composition, e.g., a salt-water derived carbonate compound composition containing crystalline and / or amorphous carbonate compounds, are provided. Also provided are methods of making and using the hydraulic cements, as well as settable compositions, such as concretes and mortars, prepared therefrom. The cements and compositions produced therefrom find use in a variety of applications, including use in a variety of building materials and building applications.

Owner:ARELAC INC

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20100158786A1Easy complianceImprove desalination efficiencyCalcium/strontium/barium carbonatesAuxillariesSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

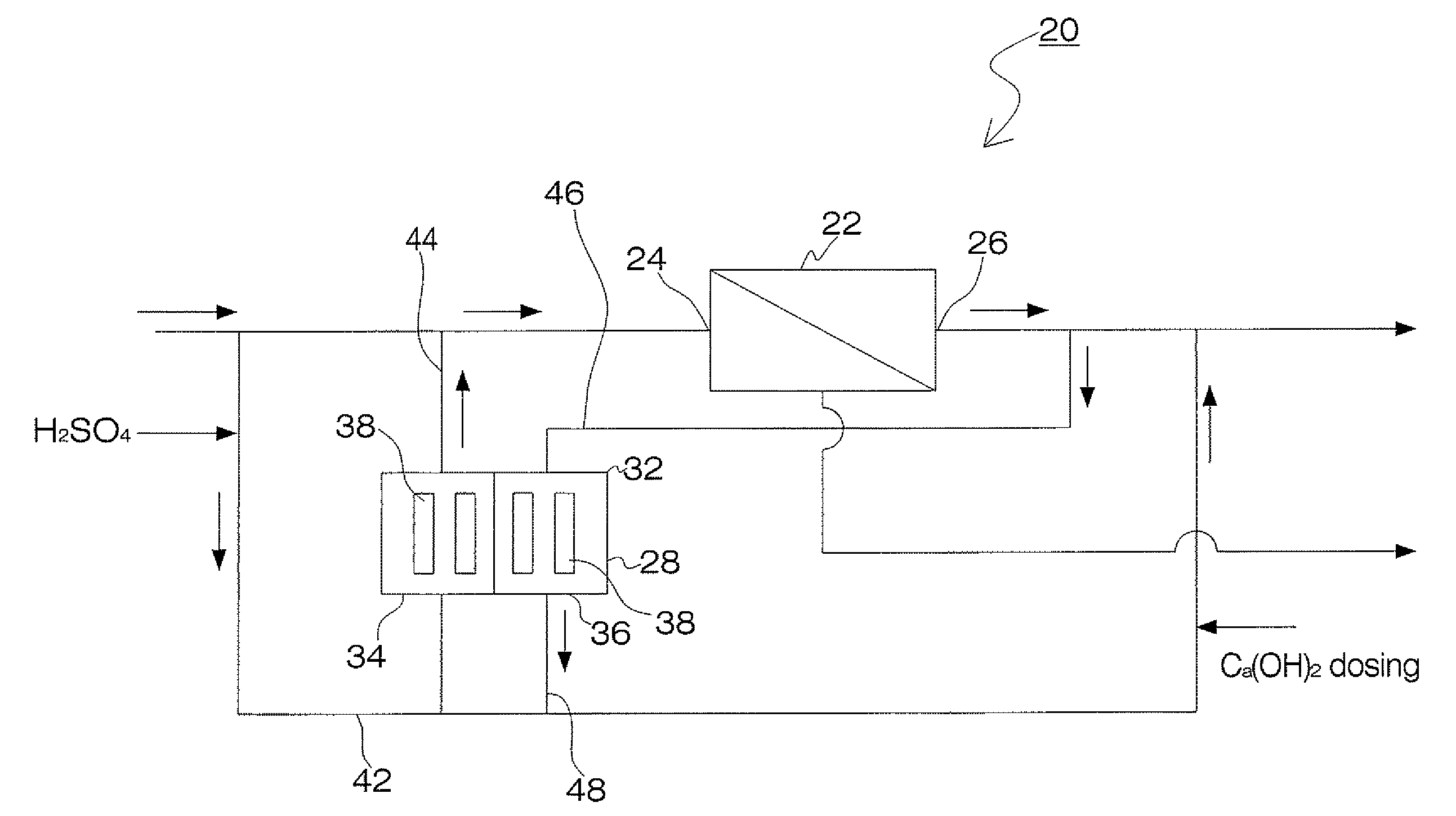

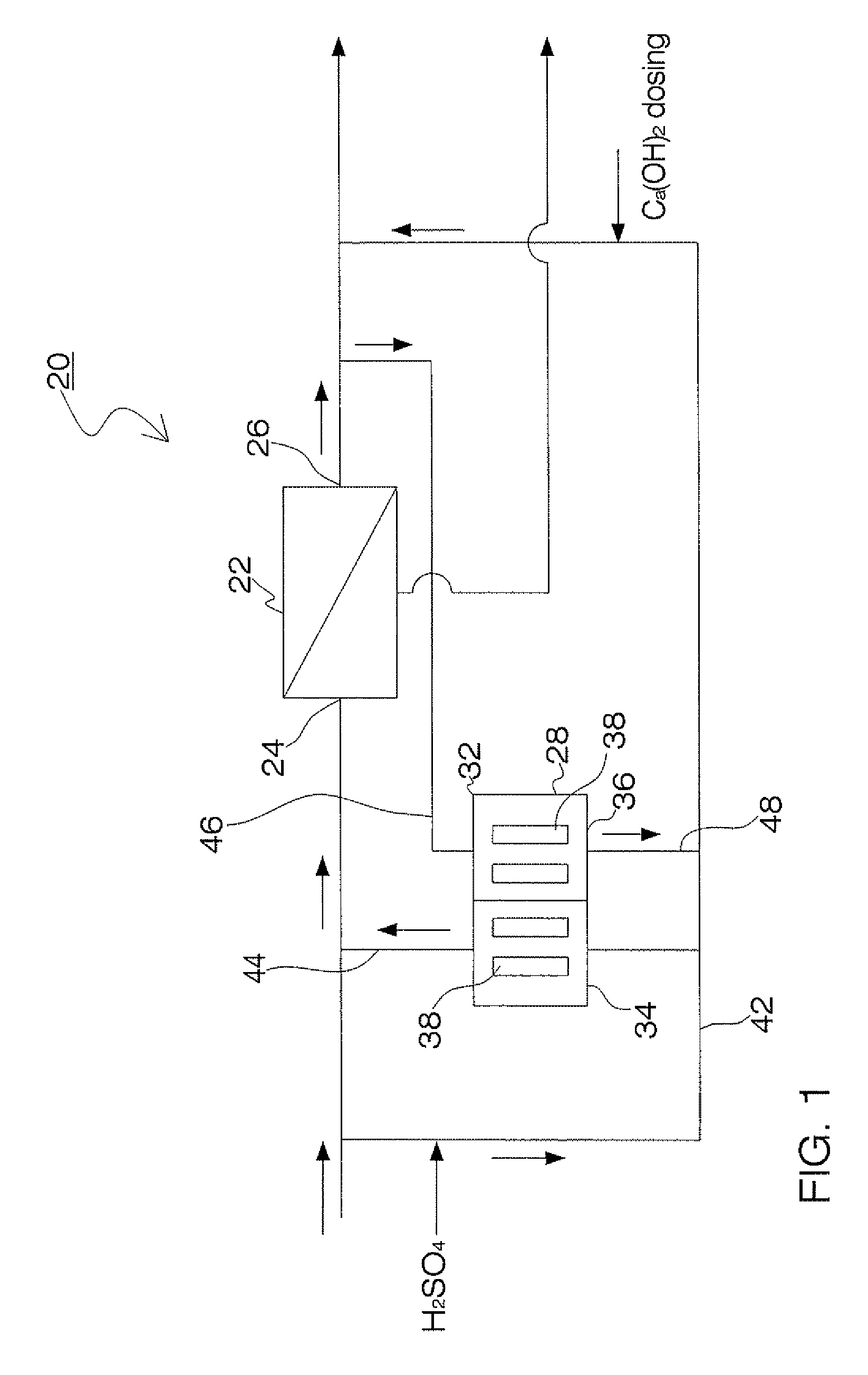

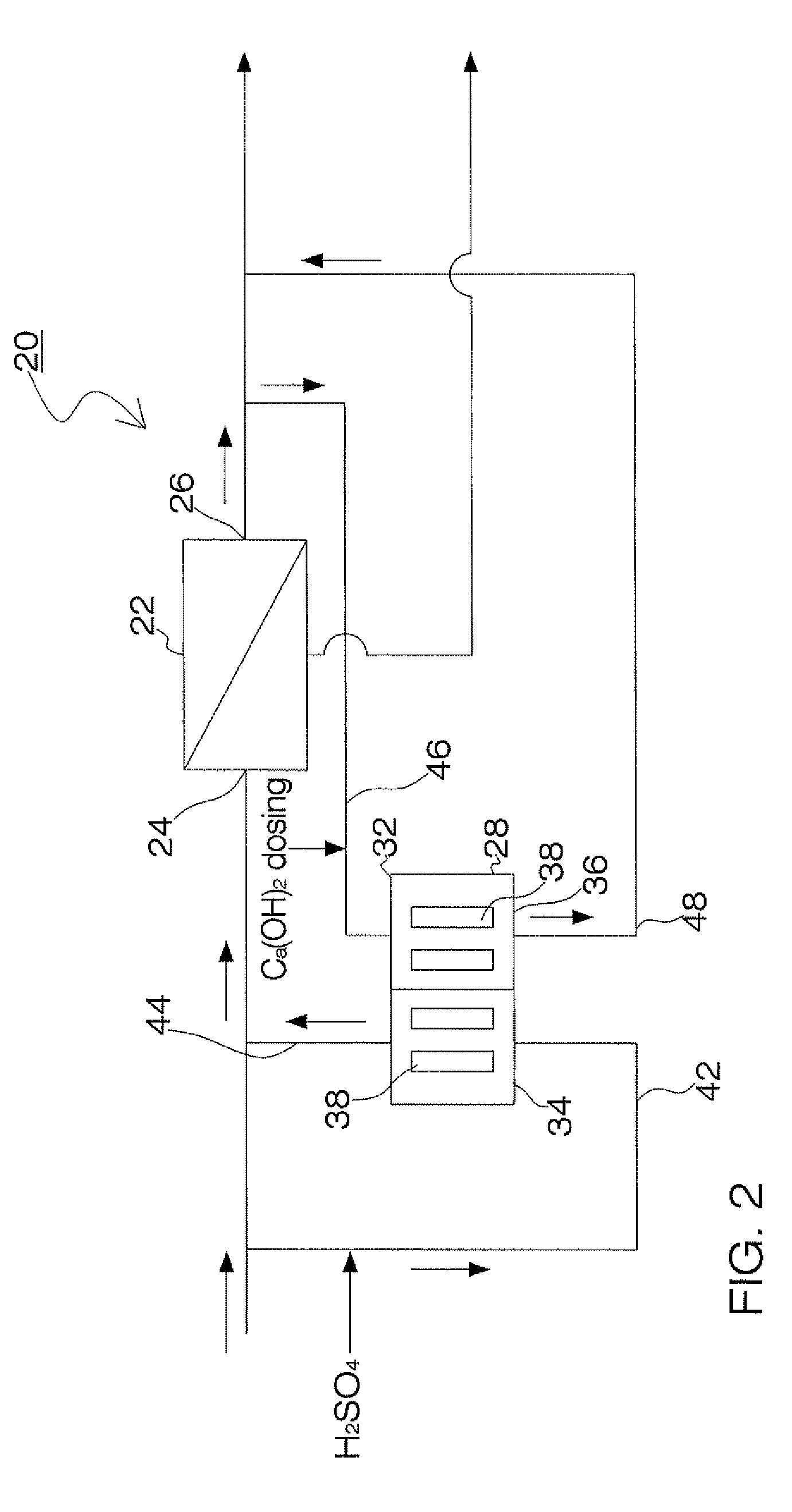

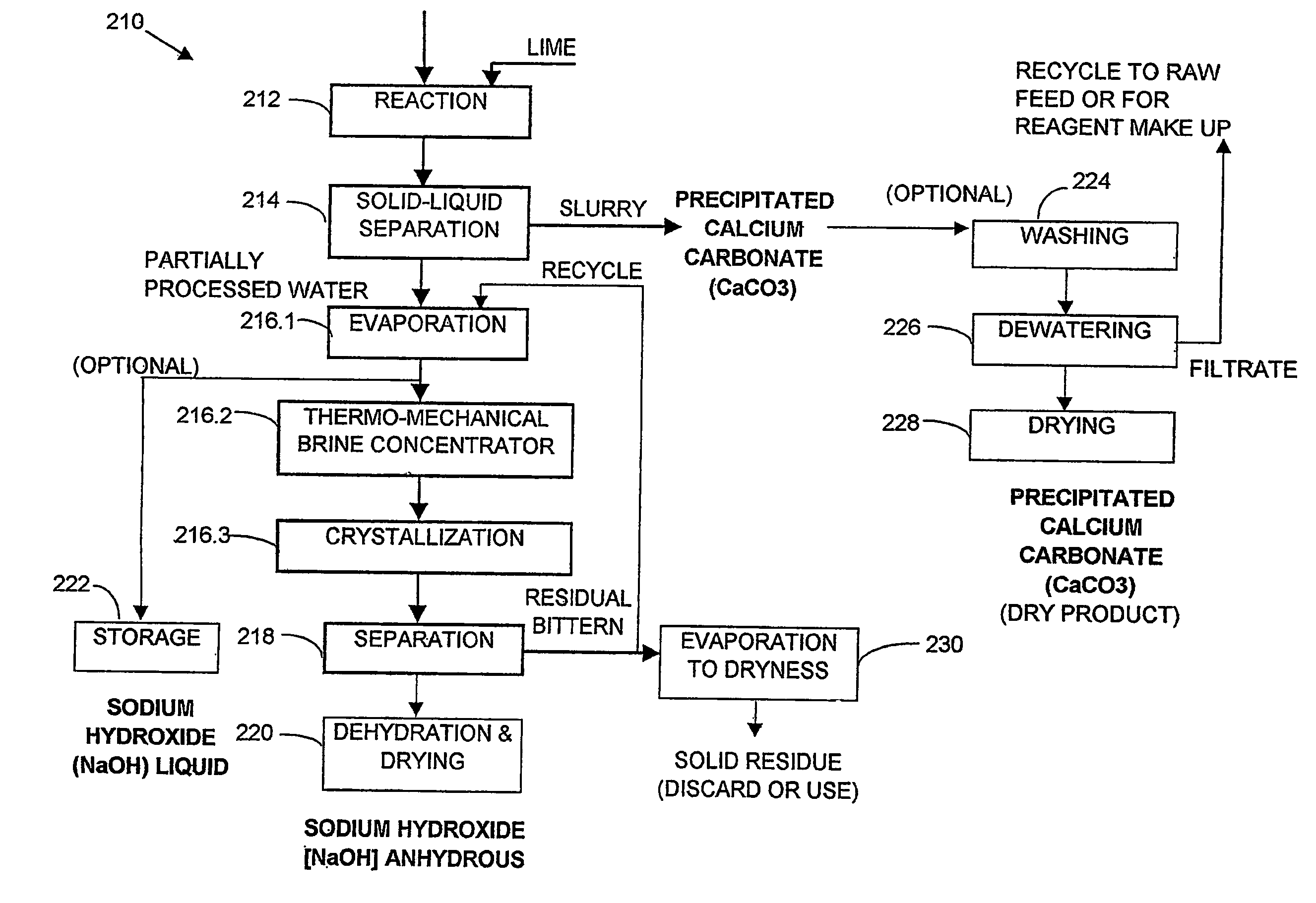

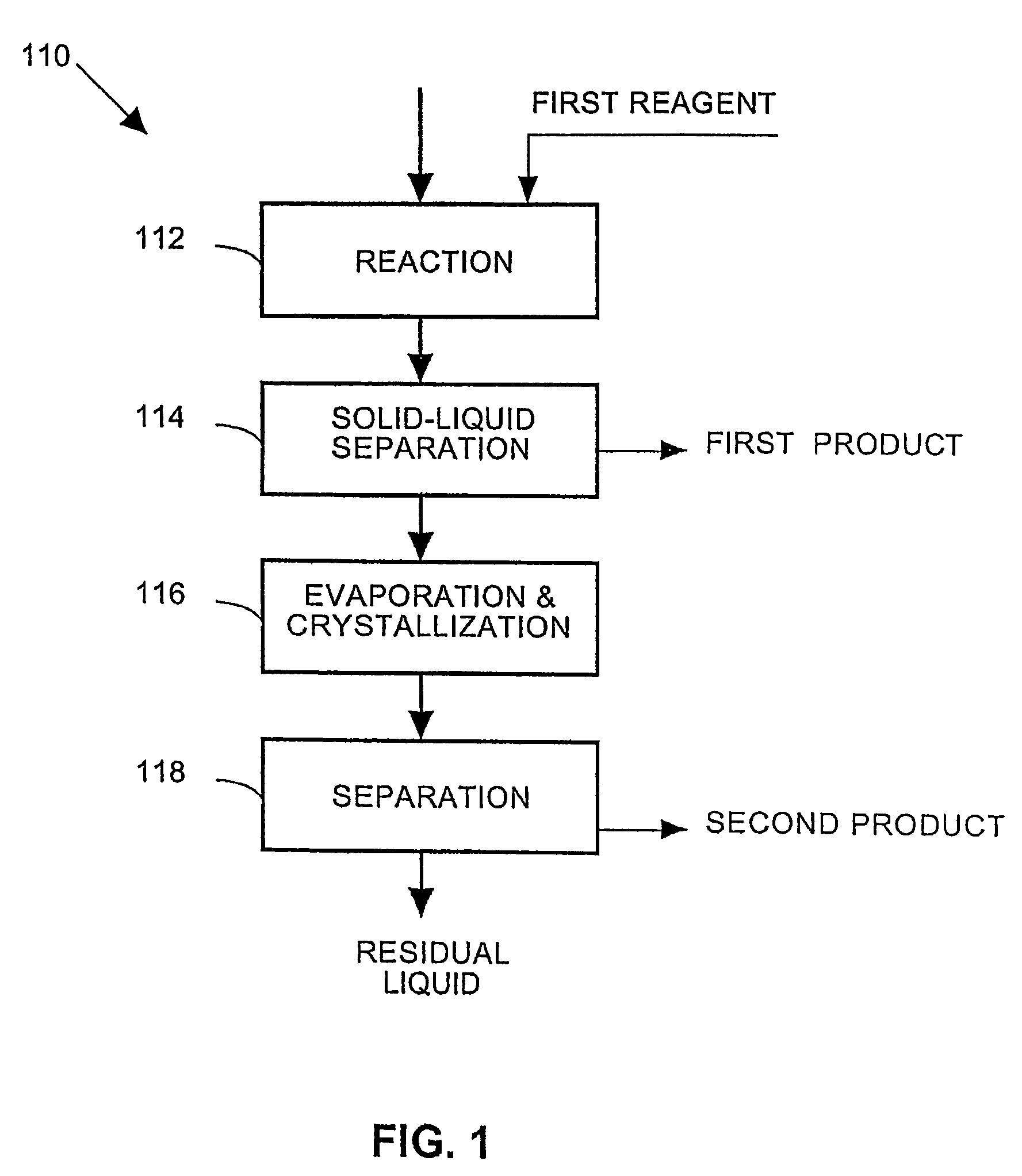

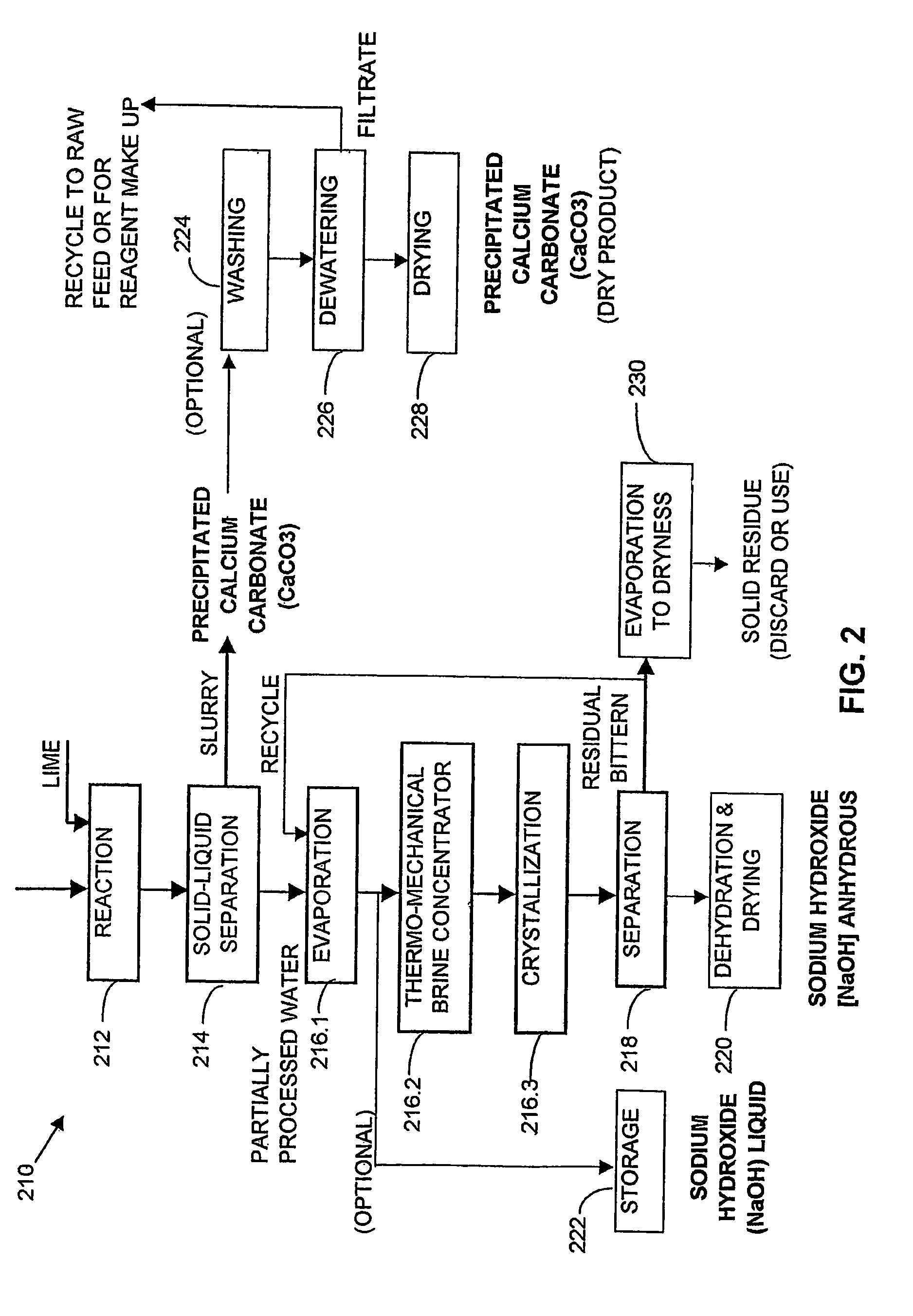

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

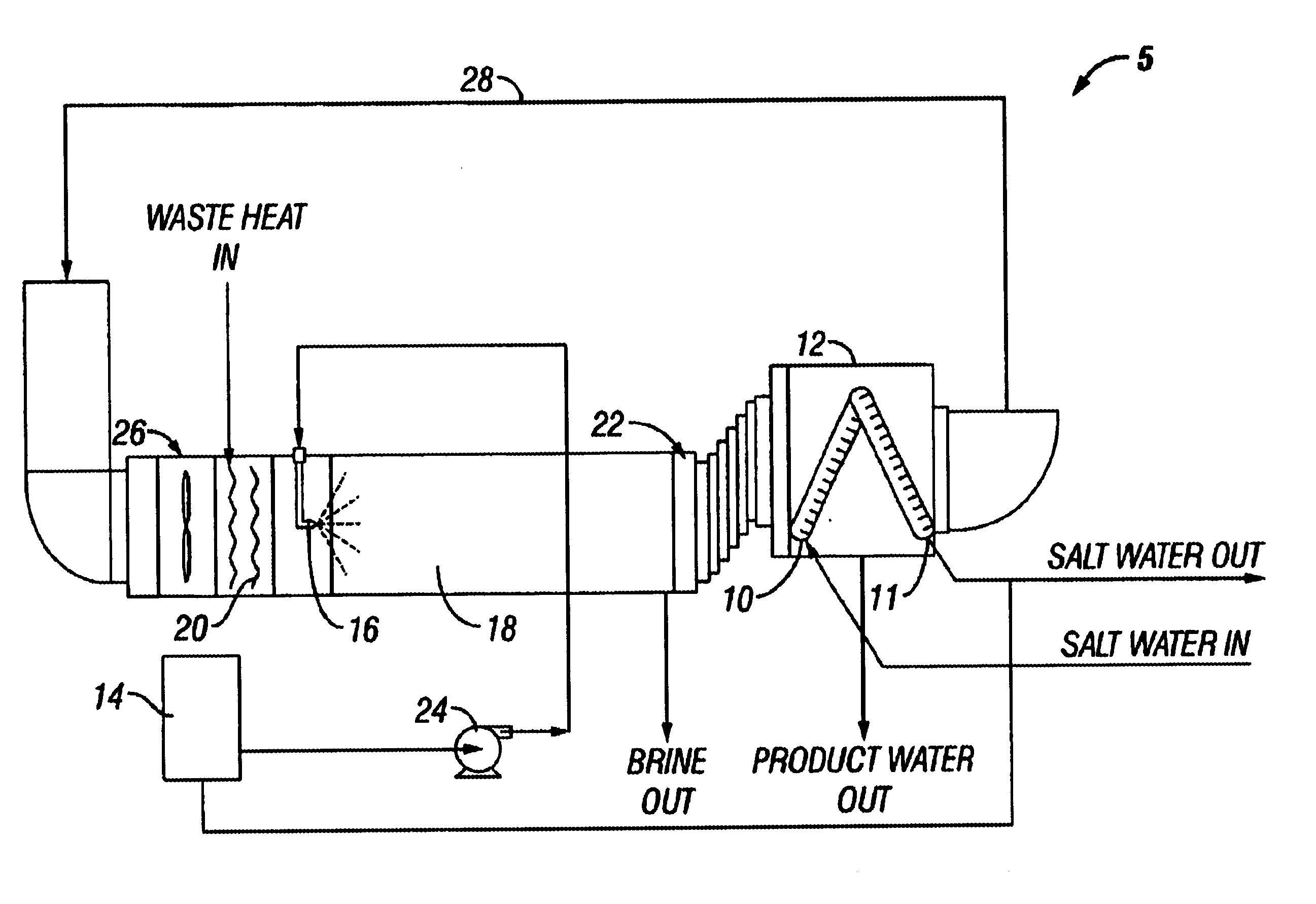

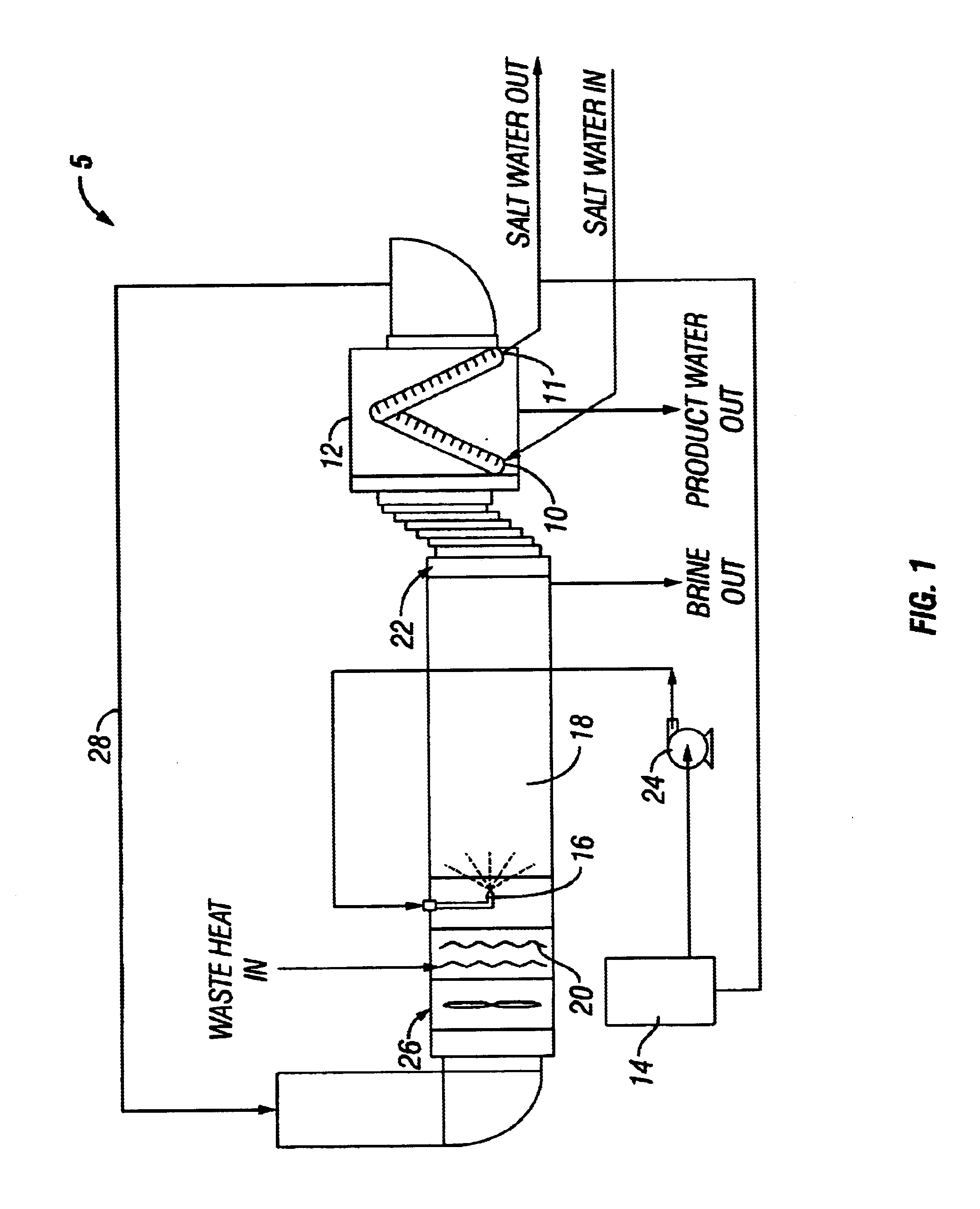

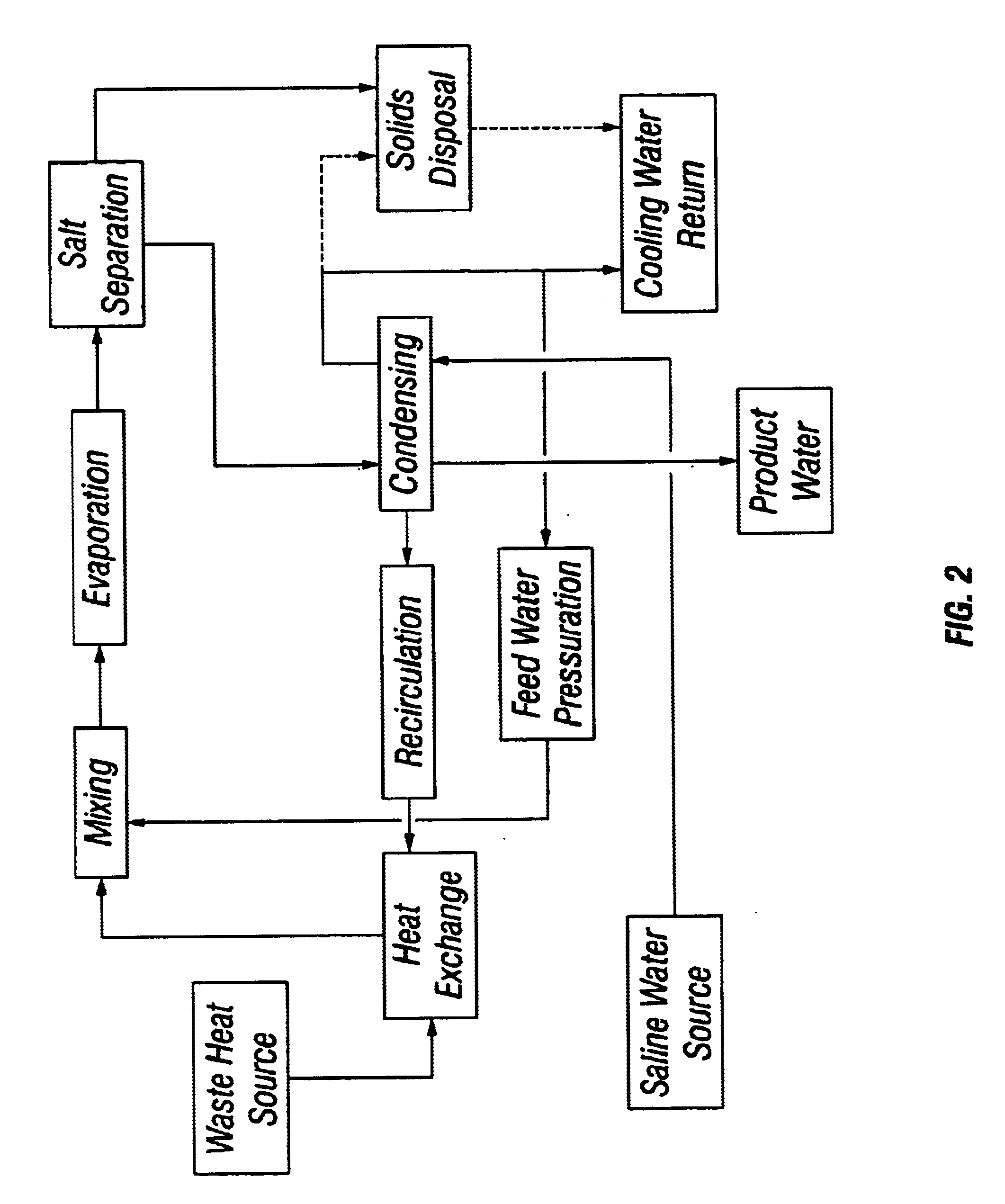

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

Method of Increasing Lubricity of Brine-based Drilling Fluids and Completion Brines

ActiveUS20100016180A1Increase completionImprove the lubrication effectFluid removalFlushingSolubilityVegetable oil

The lubricity of a drilling fluid or a completion fluid may be increased by incorporating into the fluid a water-soluble or water-dispersible salt of a sulfonated (sulfated) vegetable oil or a derivative thereof, such as a sulfonated (sulfated) castor oil. Suitable derivatives include the sodium, potassium, calcium, magnesium or ammonium salt. A non-ionic or anionic surfactant which is capable of enhancing the solubility of the salt may further be incorporated into the drilling fluid or completion fluid.

Owner:BAKER HUGHES INC

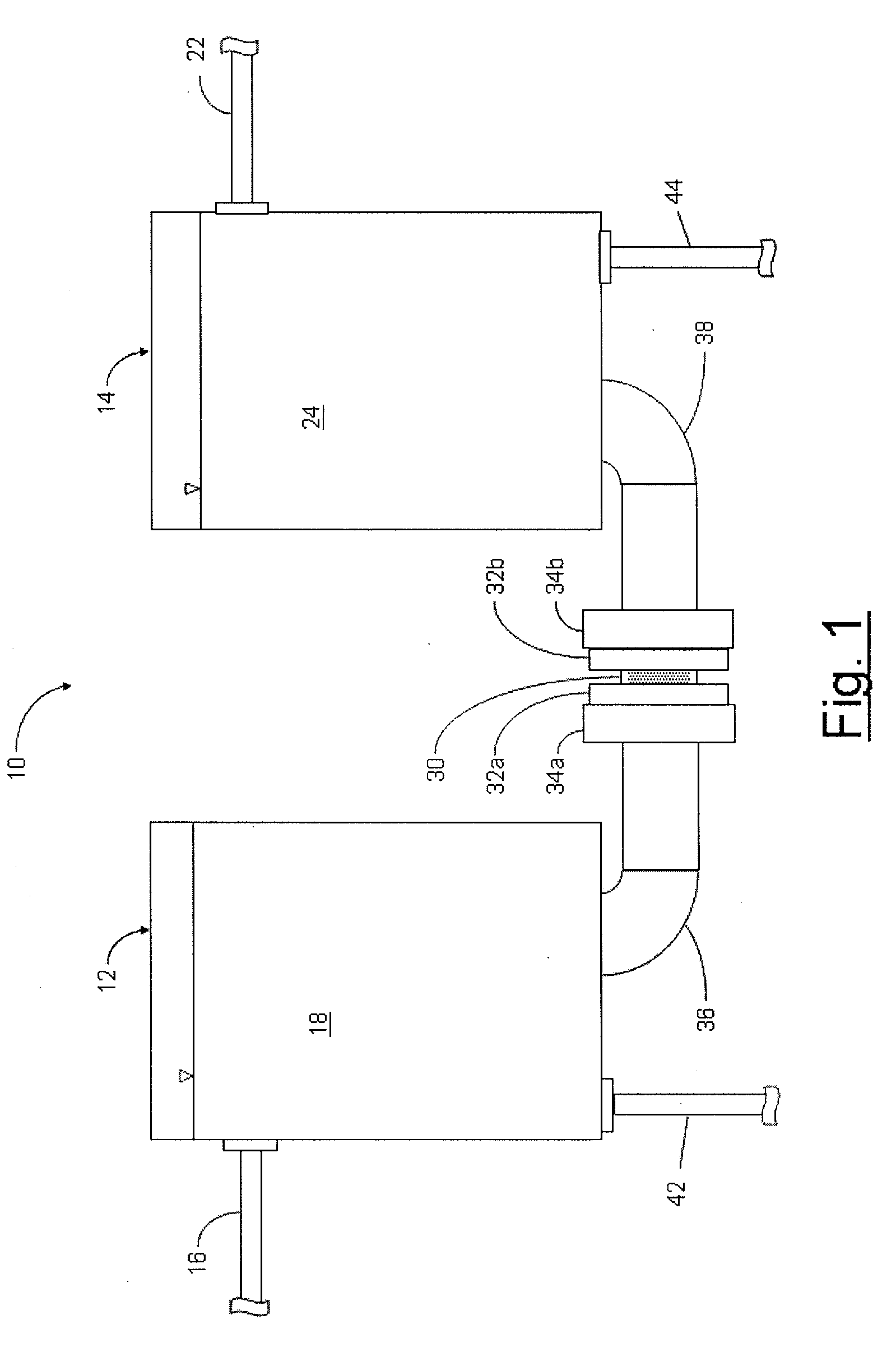

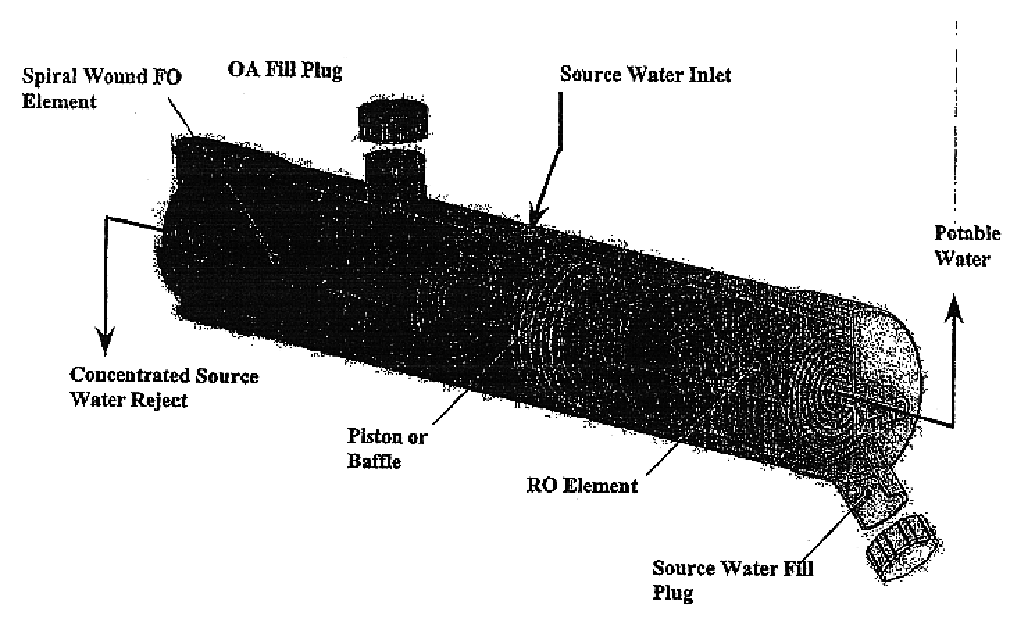

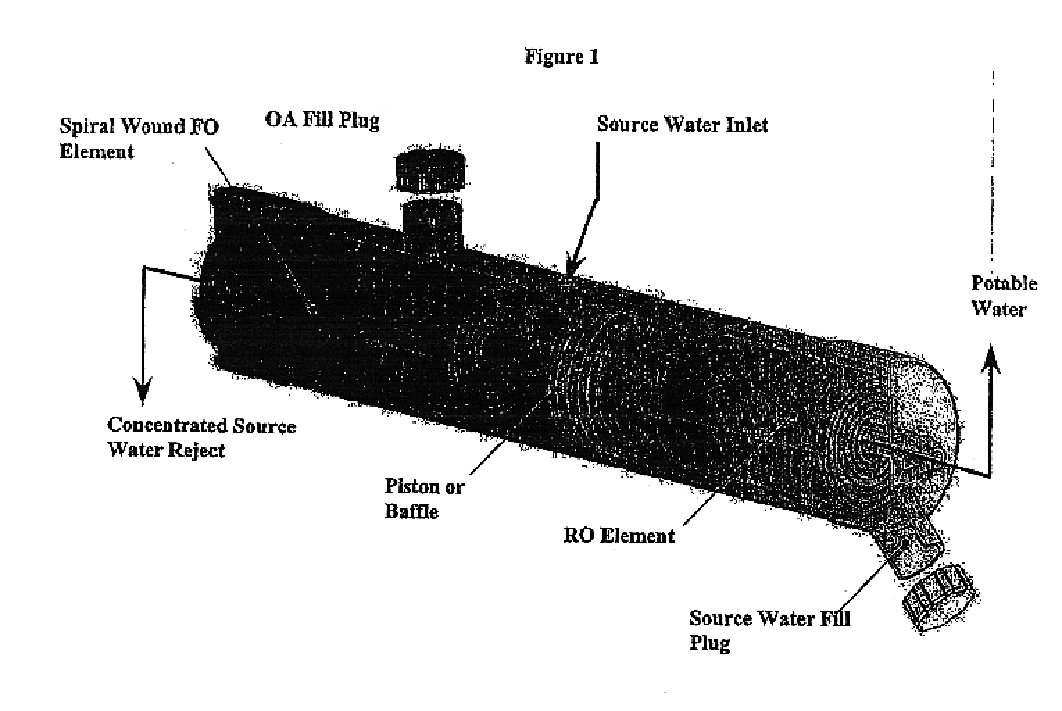

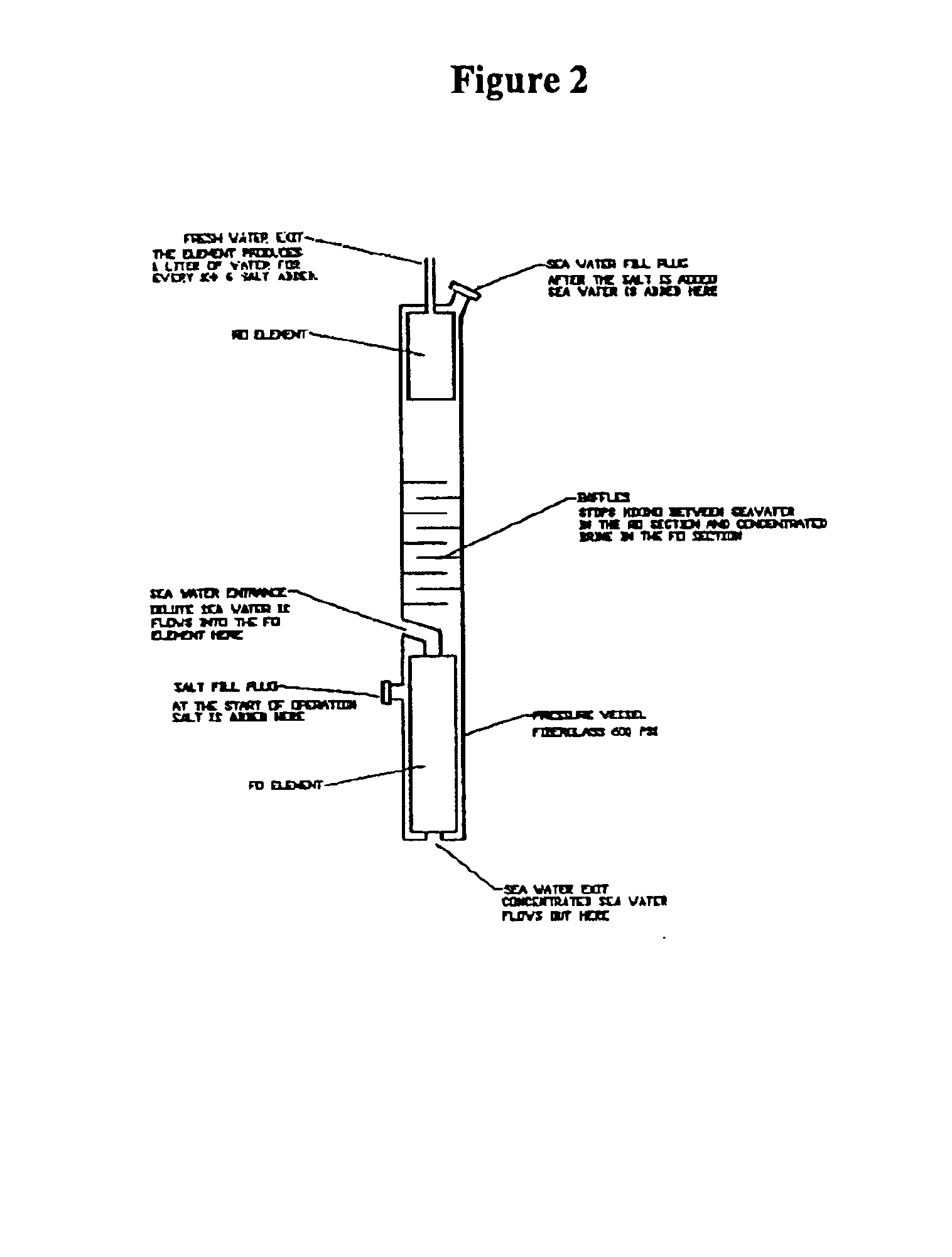

Forward osmosis pressurized device and process for generating potable water

There is disclosed a process and device for Forward Osmosis (FO) Pressurized Device (FOPD) in general and one hydraulically coupled to a reverse osmosis (RO device for a FOPRO (Forward Osmosis Pressurized Reverse Osmosis). Specifically, there is disclosed a passive device (that is, not needed energy input) for using forward osmosis to generate significant hydraulic pressure that can be used to drive a reverse osmosis process, wherein the reverse osmosis process (not needed external energy to run pumps) can separate salt from salt water to generate potable water from water with high salt content (such as sea water, urine, sweat, brackish water and the like).

Owner:HYDRATION SYST

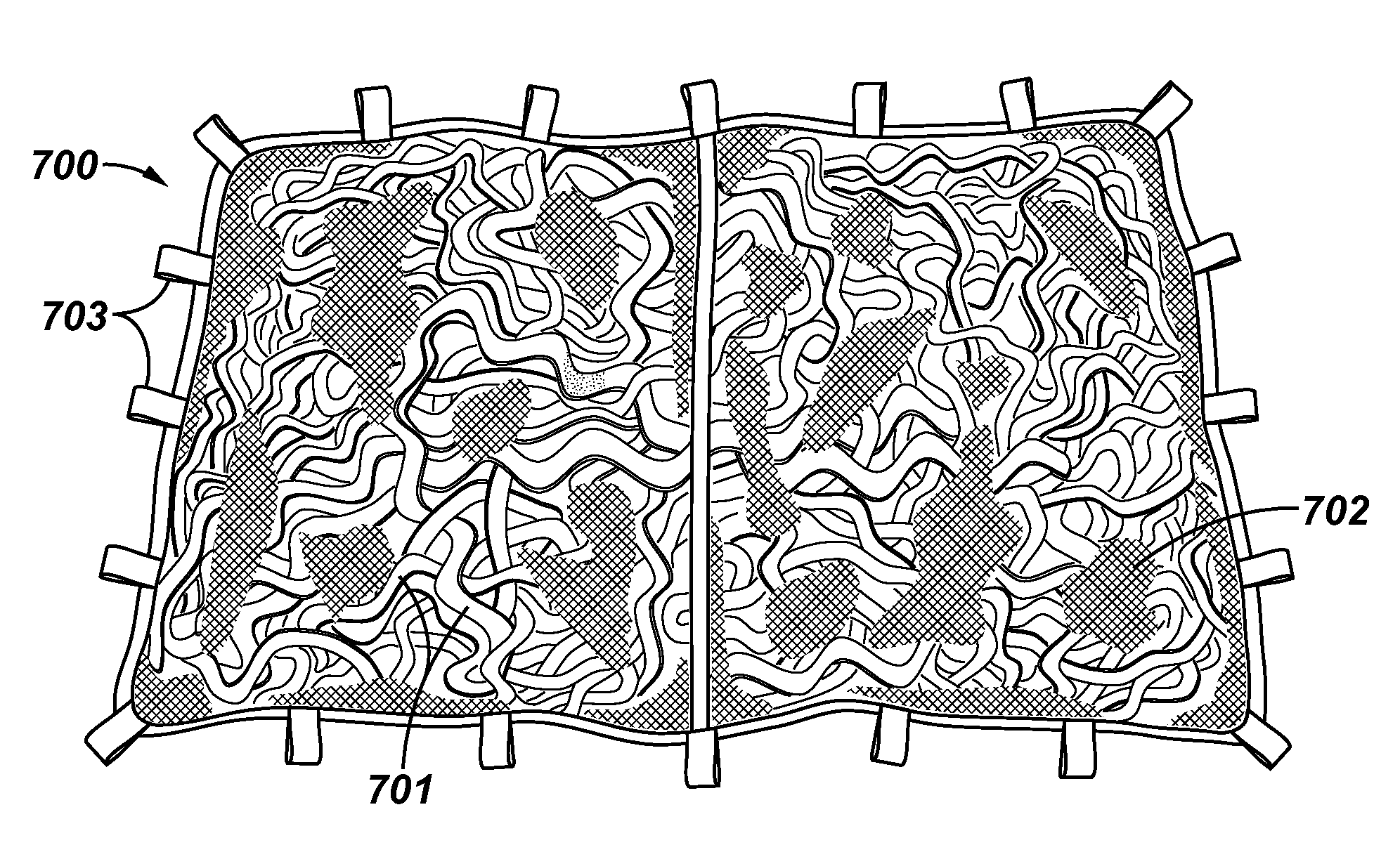

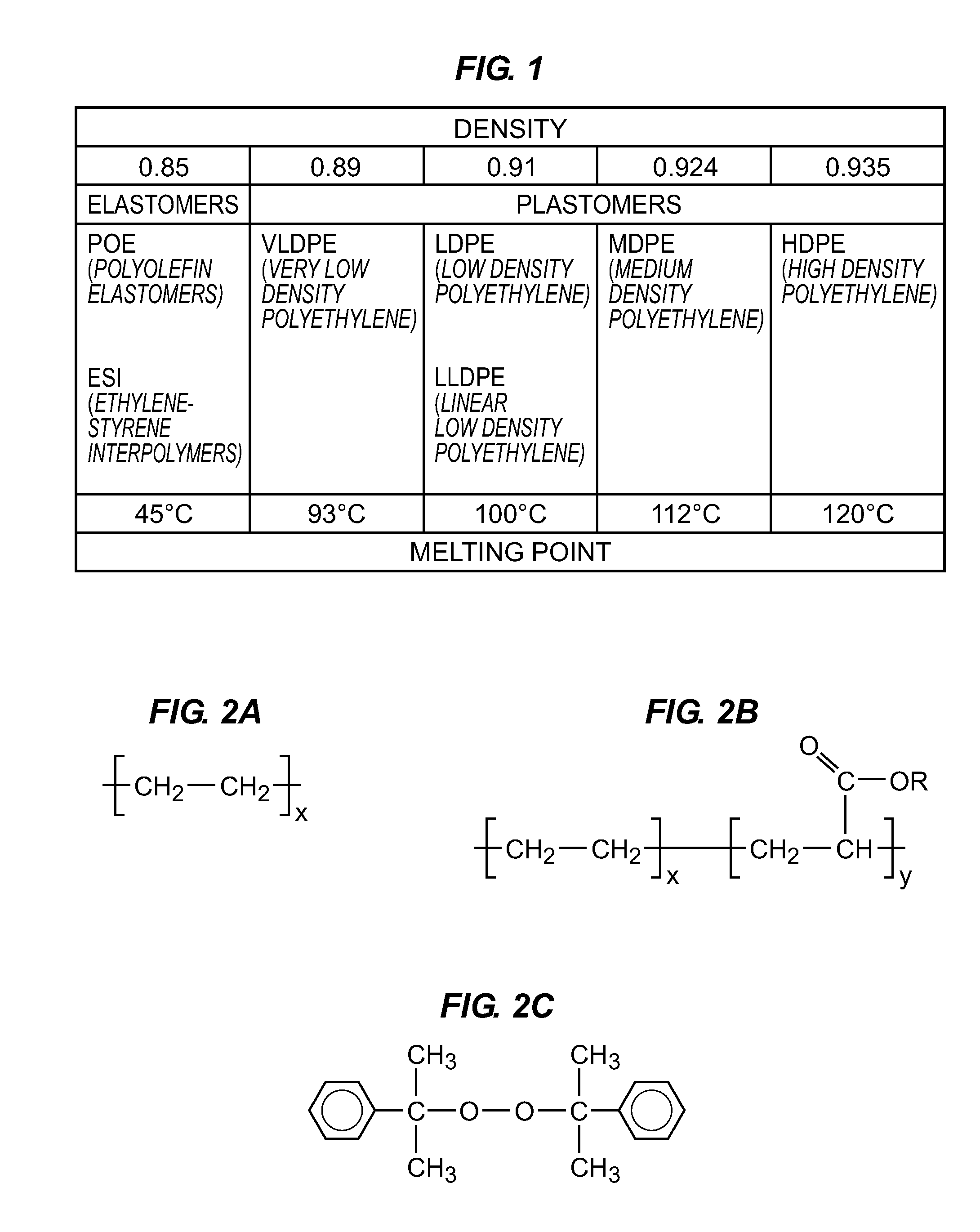

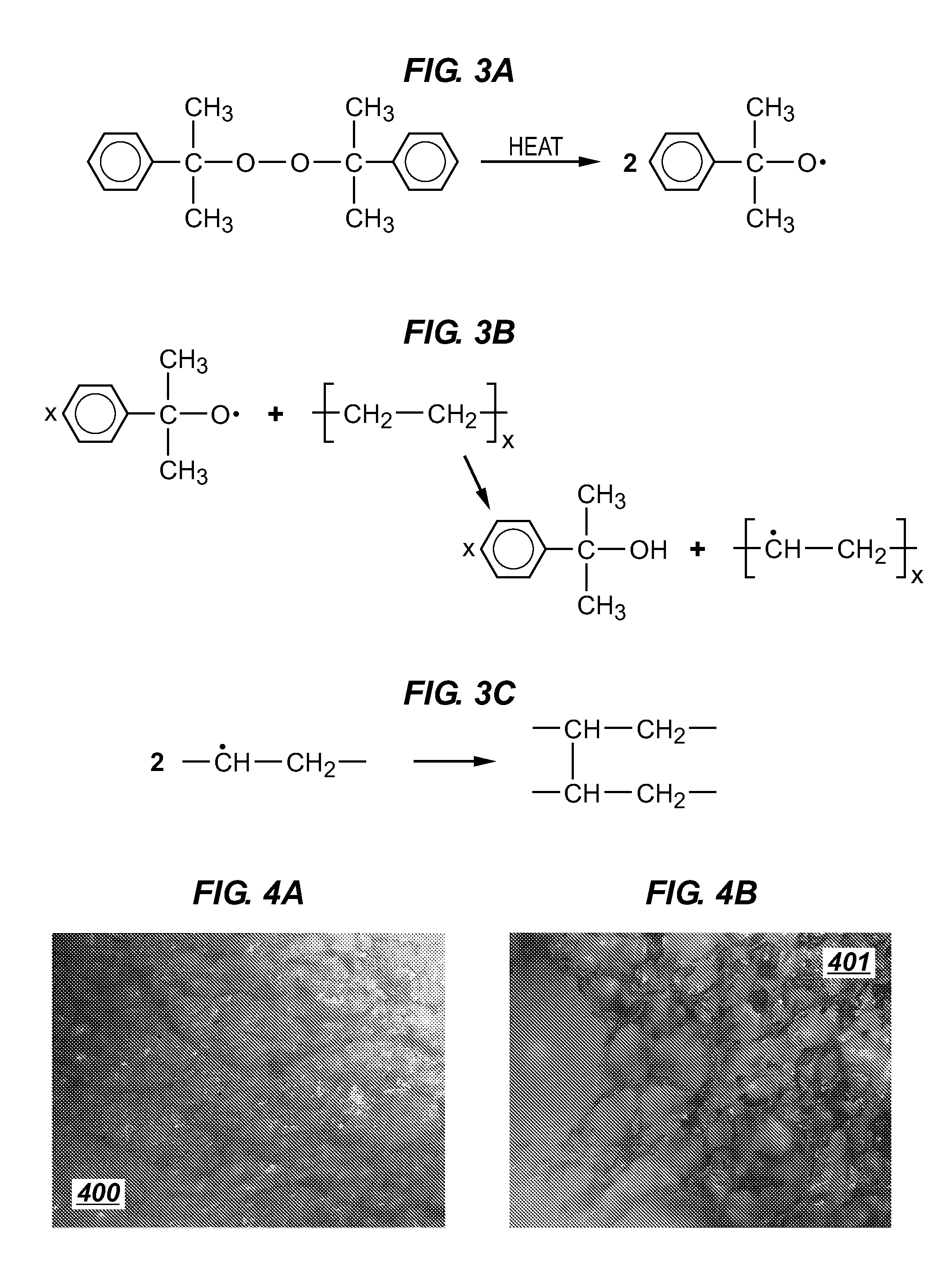

Foam compositions for selective recovery of oil spills and other applications

InactiveUS20110287929A1Improve oil absorption capacityOther chemical processesSeawater treatmentSaline waterSalt water

A polymer composition for use in the removal and recovery of oil slicks or spills floating on the surfaces of bodies of water or present on land, such as beaches comprising a foam of a blend of polyethylene and an ethylene-alkyl acrylate copolymer and a process for using such foams in the selective removal of oil from fresh water or salt water and the recovery of the absorbed oils from the foams is disclosed. The polymer composition is also for use in other applications in which absorption of liquids is desired.

Owner:OPFLEX TECH

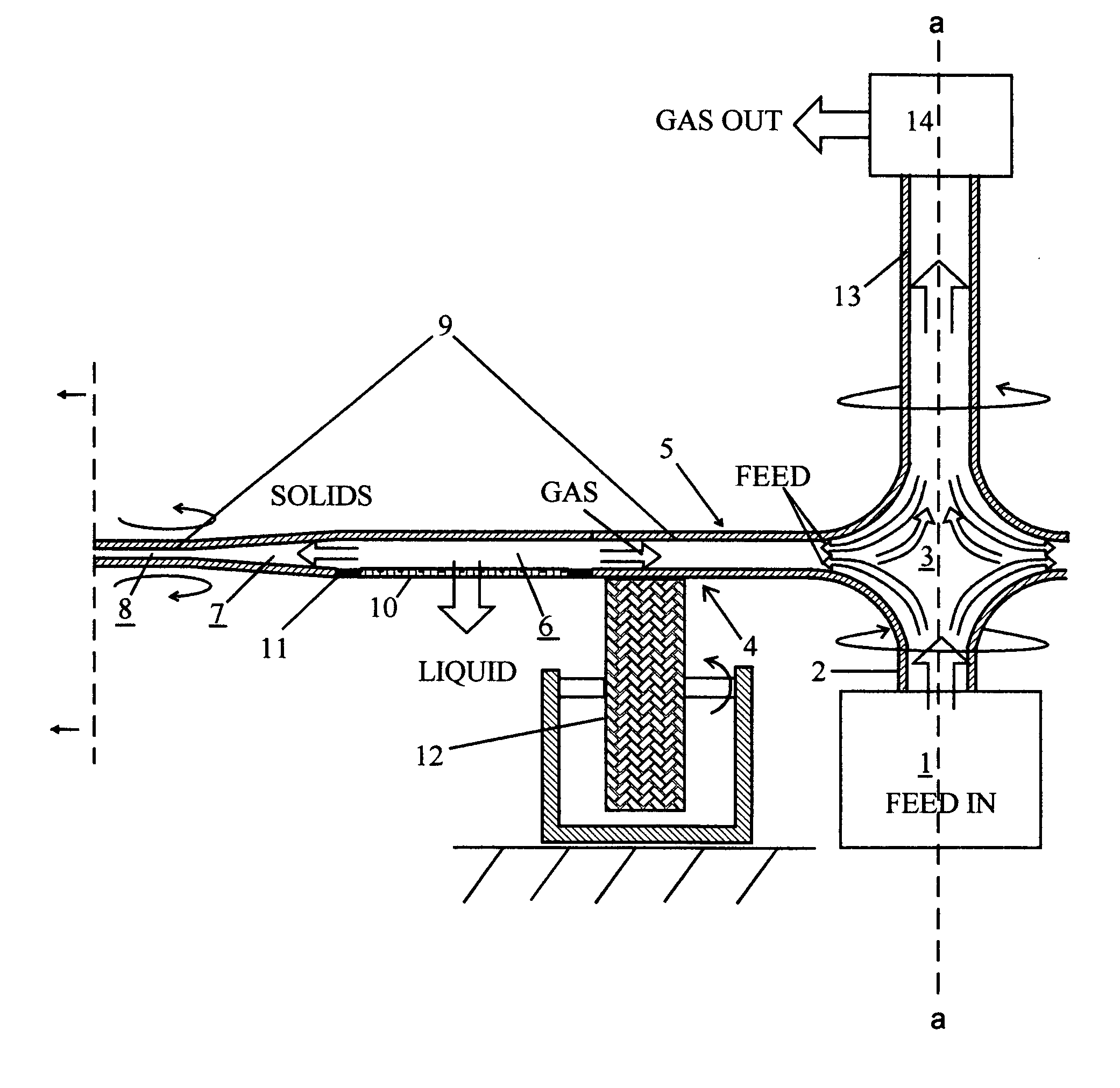

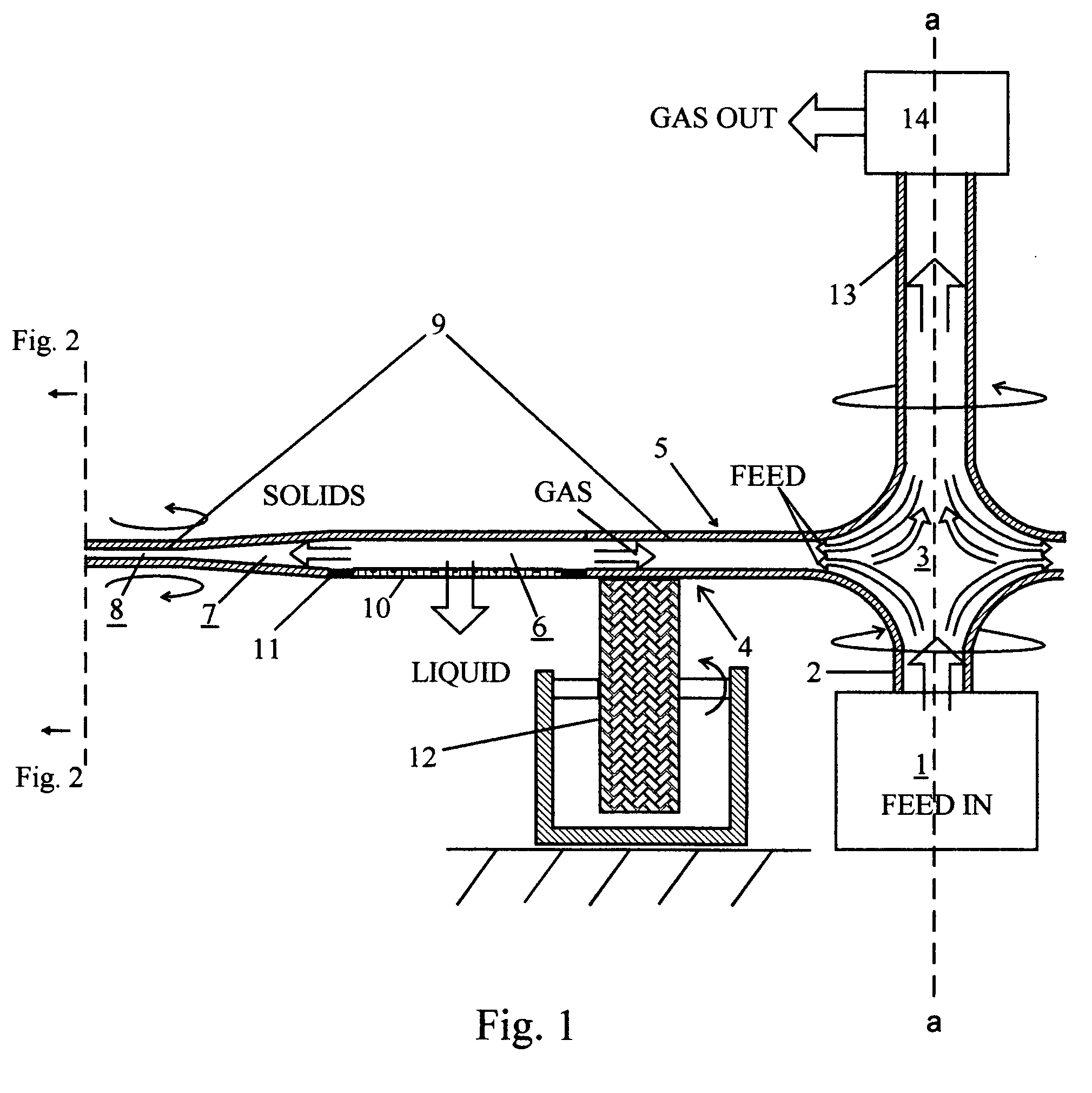

Rotary annular crossflow filter, degasser, and sludge thickener

ActiveUS20090159523A1Accelerate scrubbing reactionAvoid emissionsLiquid degasificationSludge treatmentHigh energySludge

A rotating annular crossflow filter shears radially outward flowing axial feed between counter-rotating coaxial centrifugal impellers. A radial impedance of flow at the impeller periphery slows the radially outward flow and increases residence time of feed between the impellers. Shear lift ejects solids from the boundary layer at the filter surface, and ejected solids collect by centrifugation at the impeller periphery, where they thicken into a sludge and are extruded. Gases, oils, floating solids, and fractions having a specific gravity less than water evolve into radial vortices and are sucked radially inward and out from between the impellers by an axial pump. Three way phase separation proceeds continuously in one pass through a simple mechanical device having a long residence time for feed in the processing zone.Opposing rugose portions of counter-rotating impeller surfaces cause audio frequency pressure pulses. At the impeller periphery, the pressure pulses milk liquid out of sludge. At the portion of the radial passage prior to the filter, pressure pulses evolve gases and degassed cavitation bubbles inactivate microbes. Degassing of the high energy forced periodic cavitation bubbles between the impellers removes the cushion of noncondensibles which would otherwise absorb energy on compression, therefore implosion becomes extremely violent and a barrage of high pressure pulses and ultraviolet light pulses inactivates microbes.Applications include field water purification, municipal and industrial wastewater degassing and sludge thickening, swimming pool filtration, effluent dewatering, wine and beverage degassing and clarification, fruit crushing, olive oil dewatering, produced brine and drilling mud processing, manure slurry dewatering and degassing, and recovery of solvents and fine suspended solids from fluid mixtures such as wastewater from machining operations.

Owner:VORSANA INC

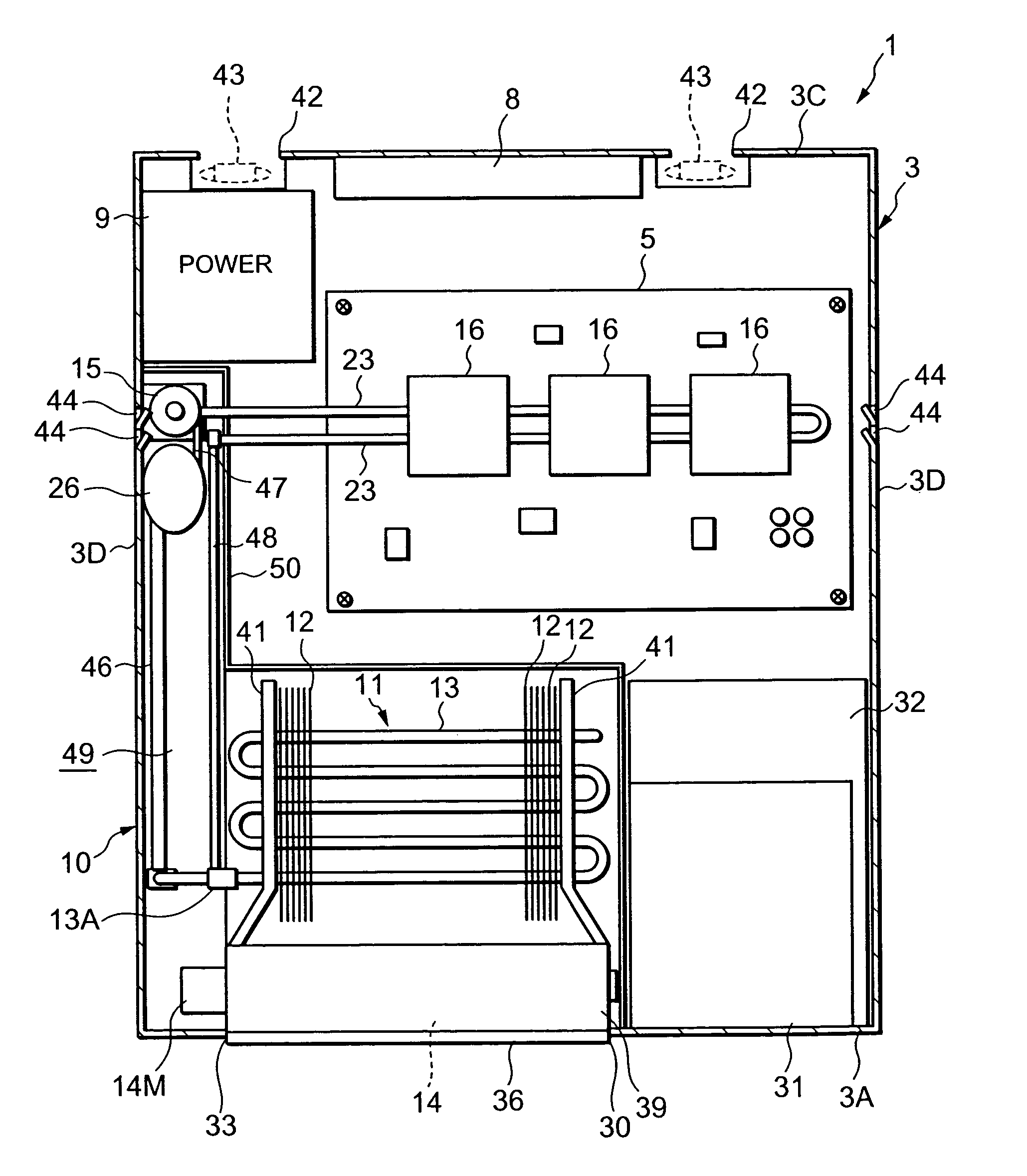

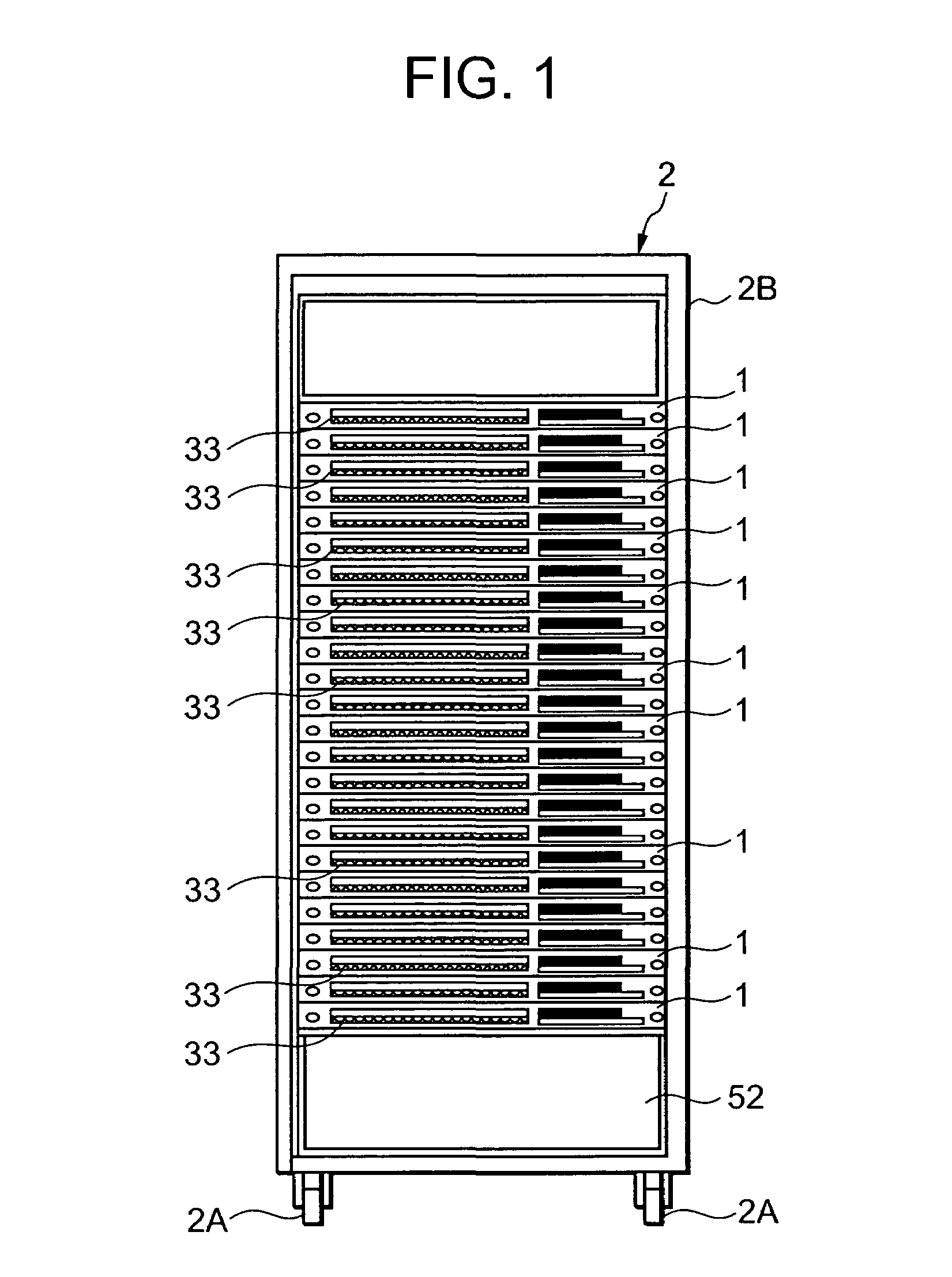

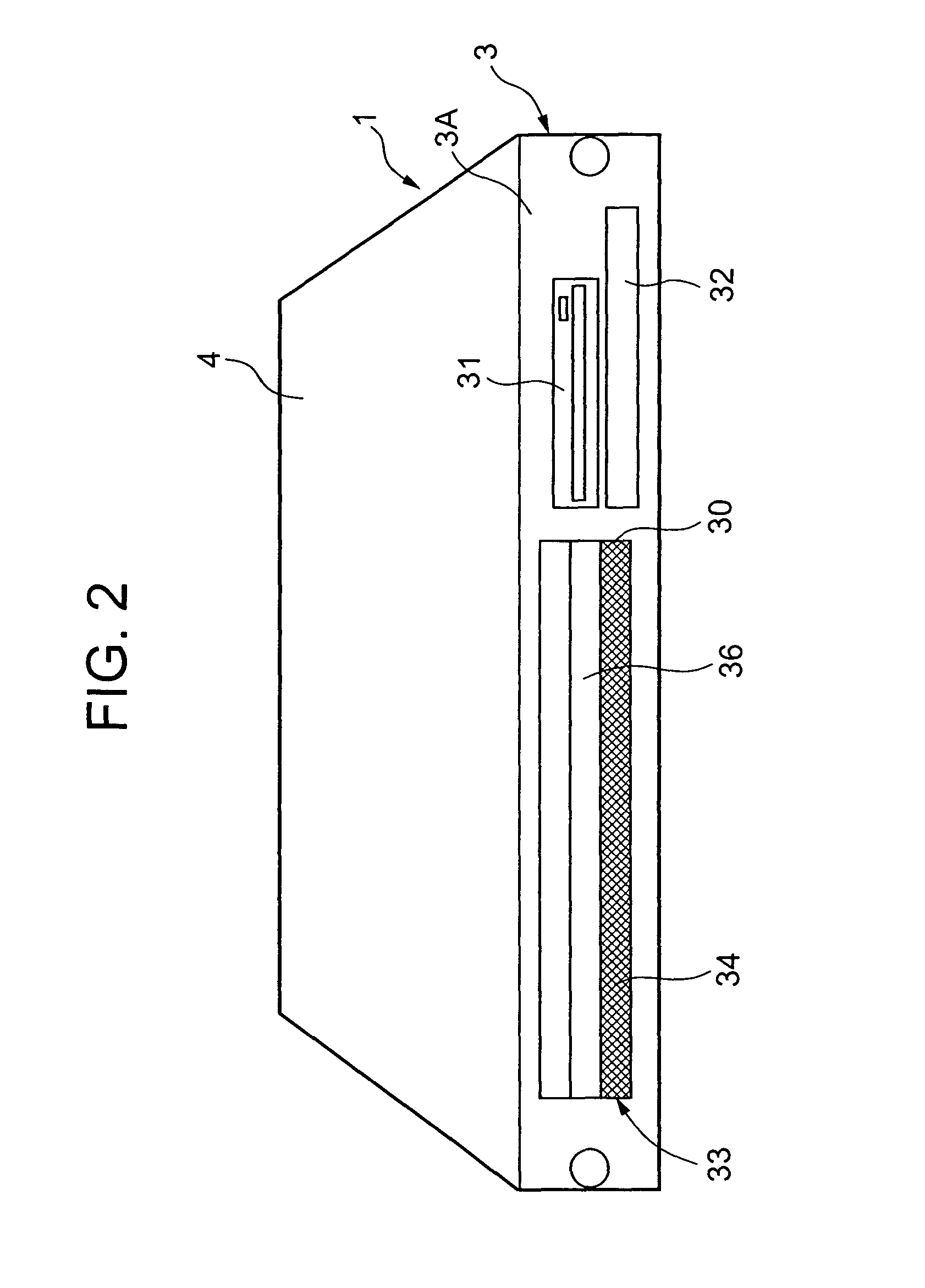

Electronic device

InactiveUS6967842B2Improve cooling effectSolid-state devicesIndirect heat exchangersIntegrated circuitSalt water

An electronic device capable of efficiently cooling an integrated circuit element provided in such a way as to enable a heat exchange on a cold plate. The electronic device contains a circuit board mounted with an integrated circuit element requiring measures against heat generation in a single case, comprising: a cold plate mounted on the integrated circuit element in such a way as to enable a heat transfer from the integrated circuit element; a heat exchanger for cooling brine heated by the cold plate by circulating the brine; a fan casing forming an air way from a blower fan at an opening on a surface of the case to the heat exchanger; a reserve tank and a pump provided in order in a brine flow from the heat exchanger to the cold plate; and a linear brine passage formed in the cold plate and having at least one pair of back and forth channels.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com