Patents

Literature

5167results about "Waste water treatment from quaries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

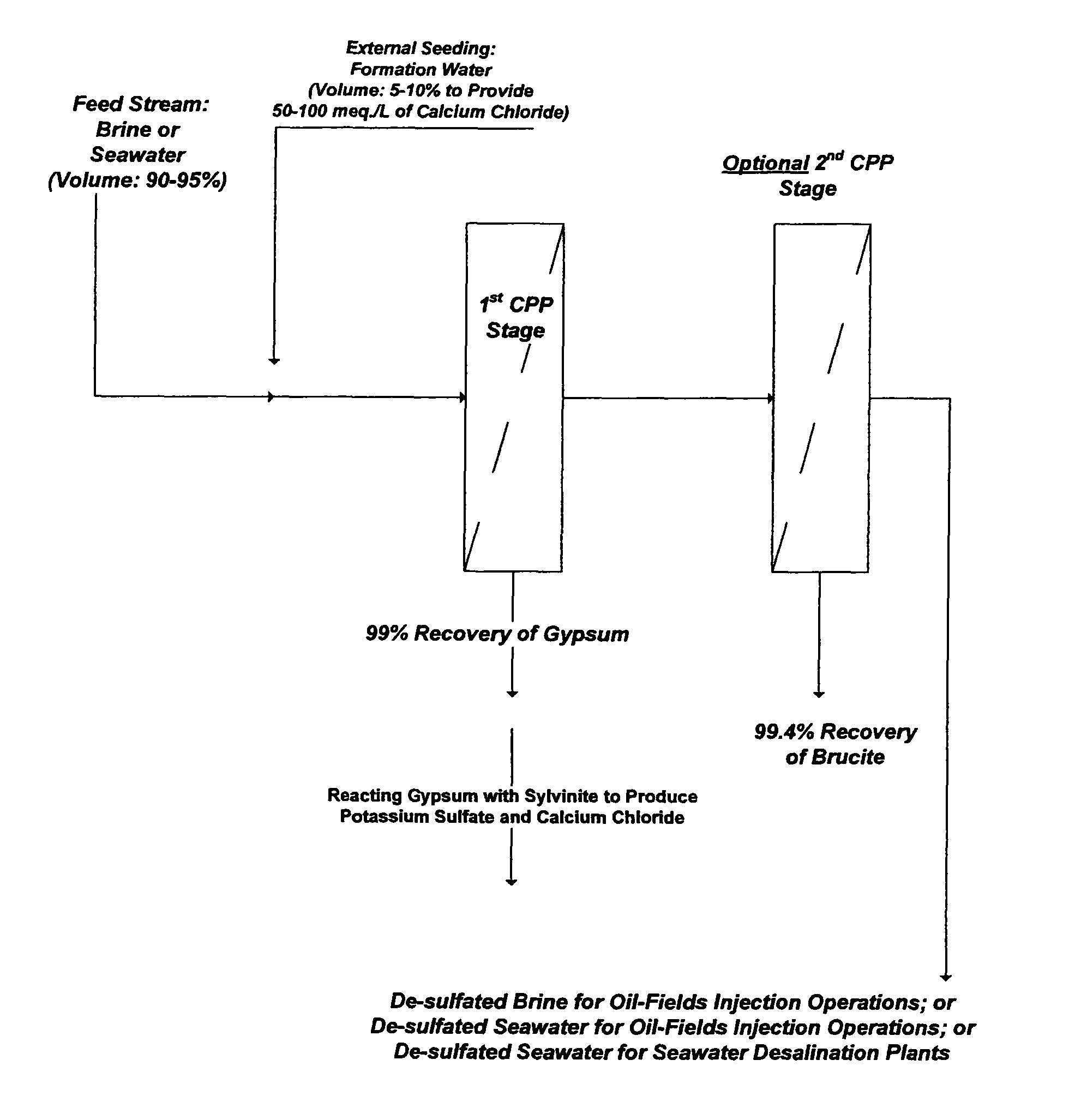

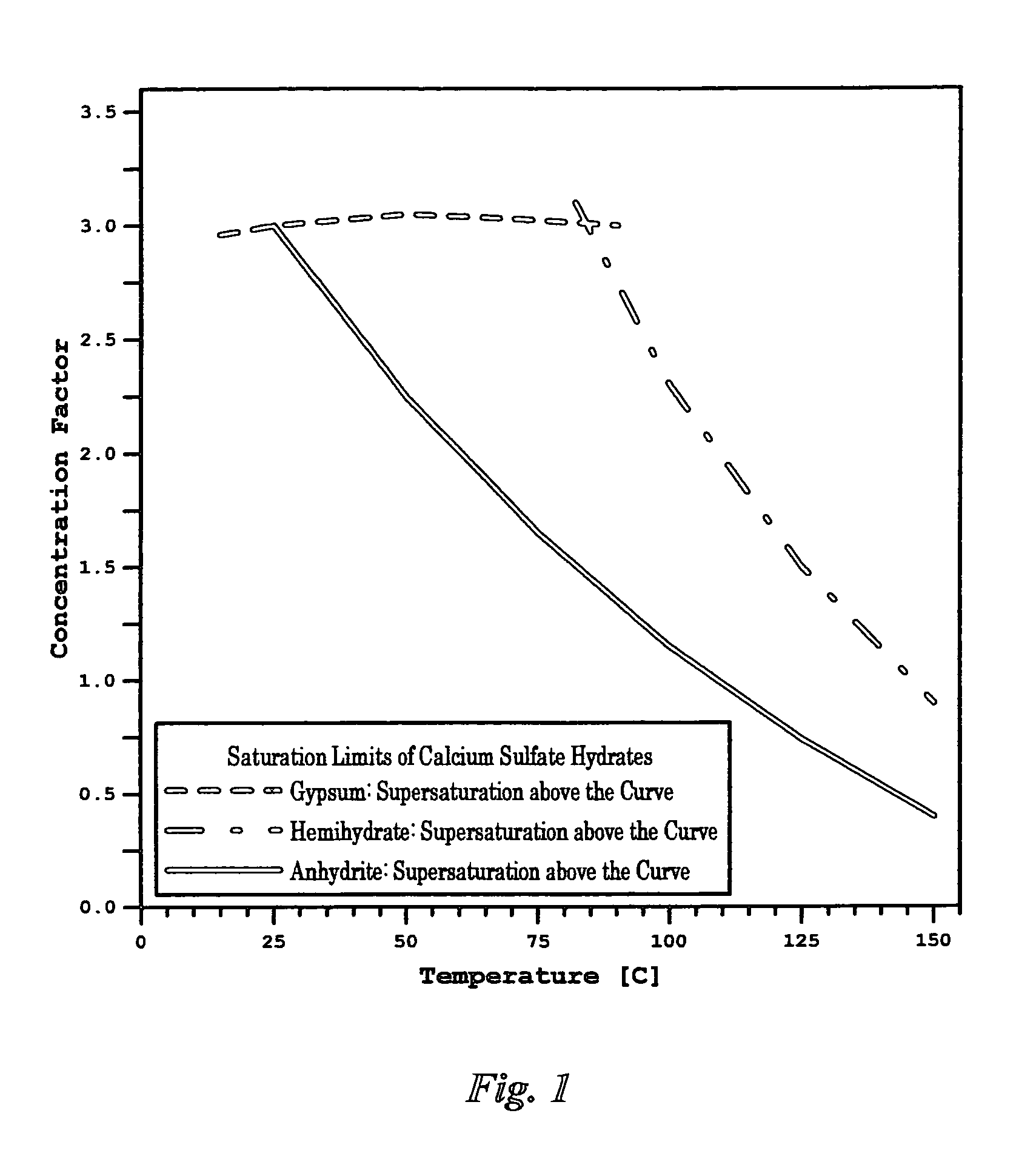

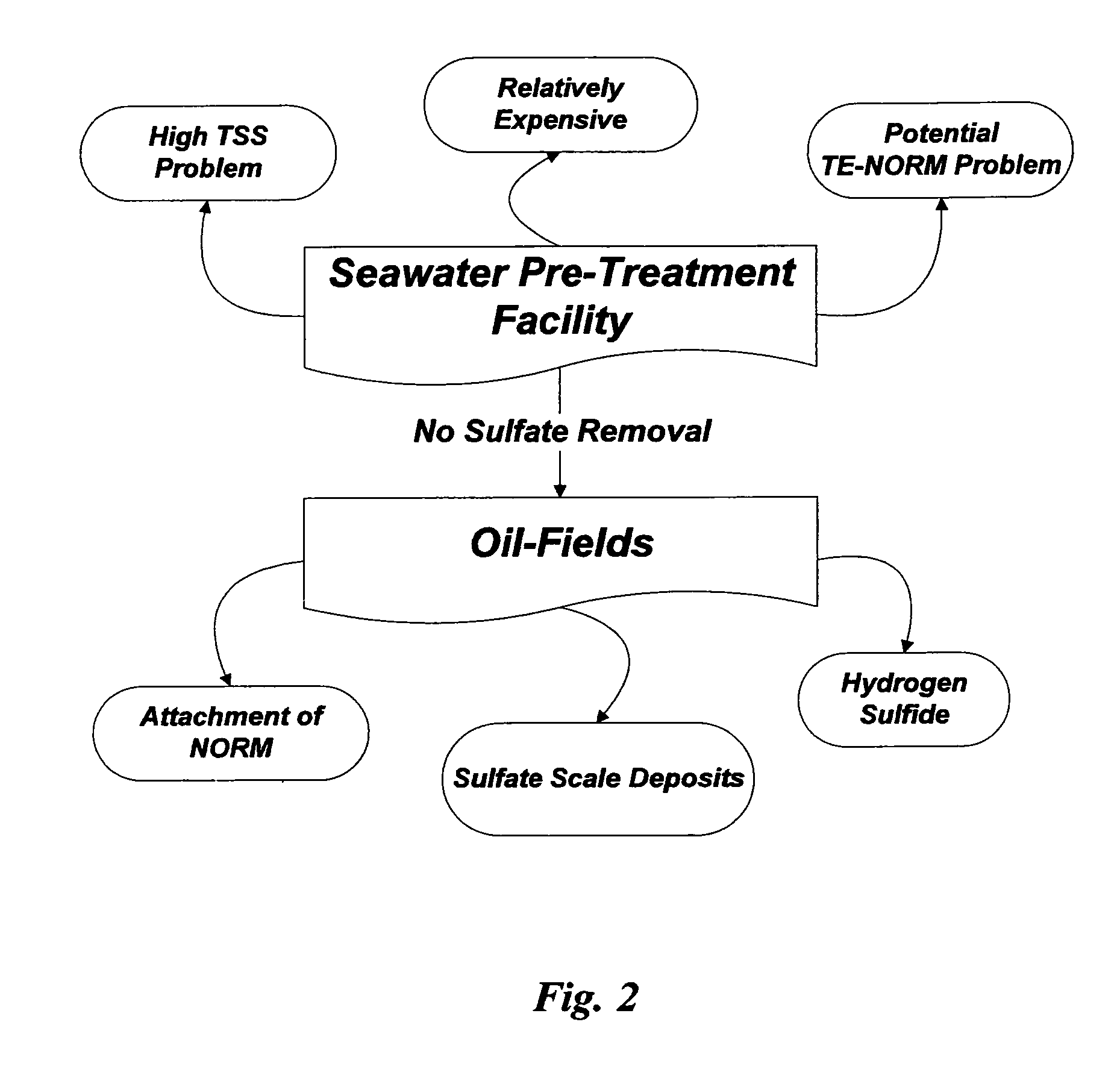

Methods to de-sulfate saline streams

ActiveUS7789159B1Avoid pollutionWaste water treatment from quariesSludge treatmentSaline waterInorganic materials

Methods are disclosed to de-sulfate saline streams such as seawater, brine from seawater desalination plants, and the like. The disclosed methods can also co-produce de-ionized water and inorganic materials from such de-sulfated saline streams.

Owner:BADER MANSOUR S

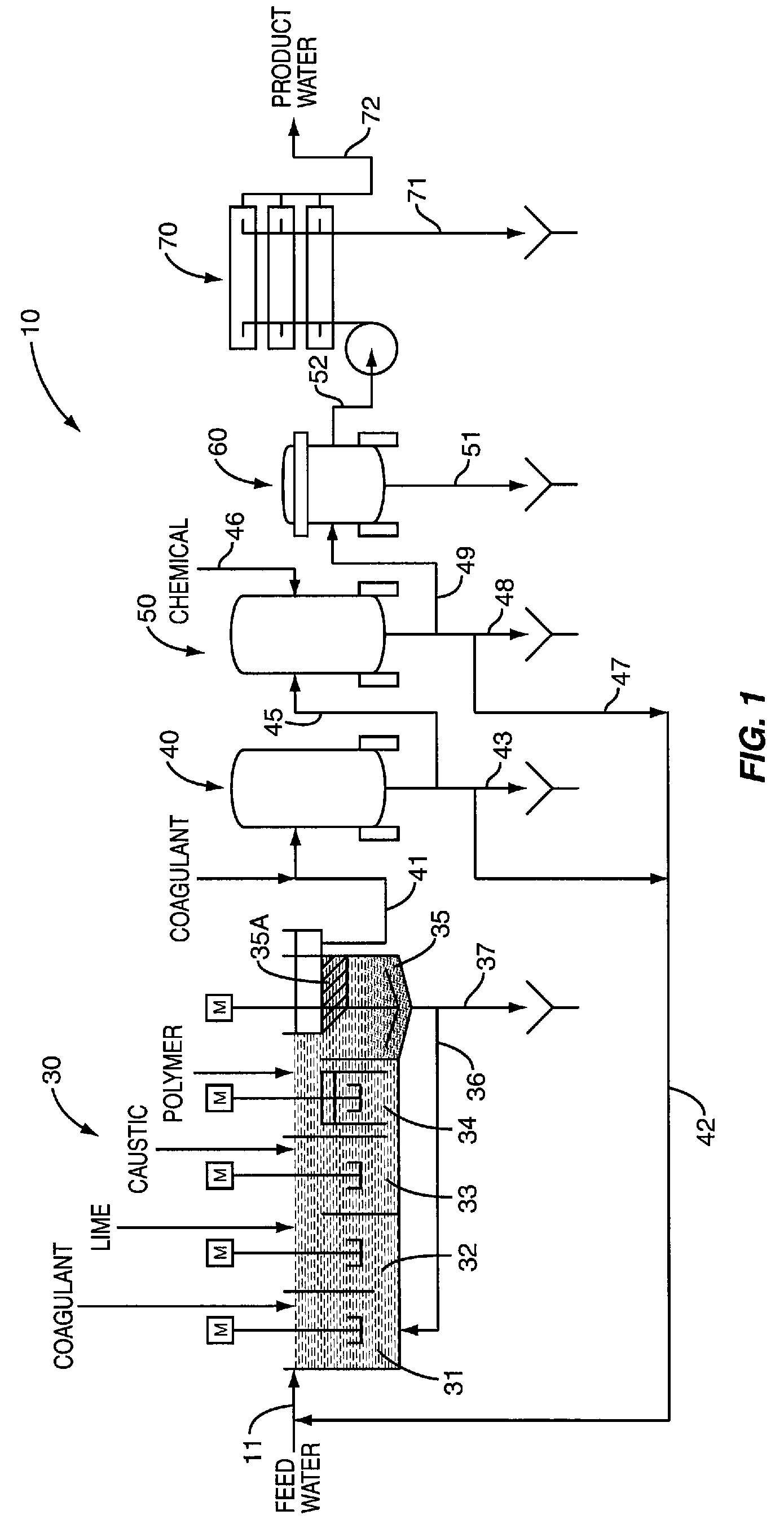

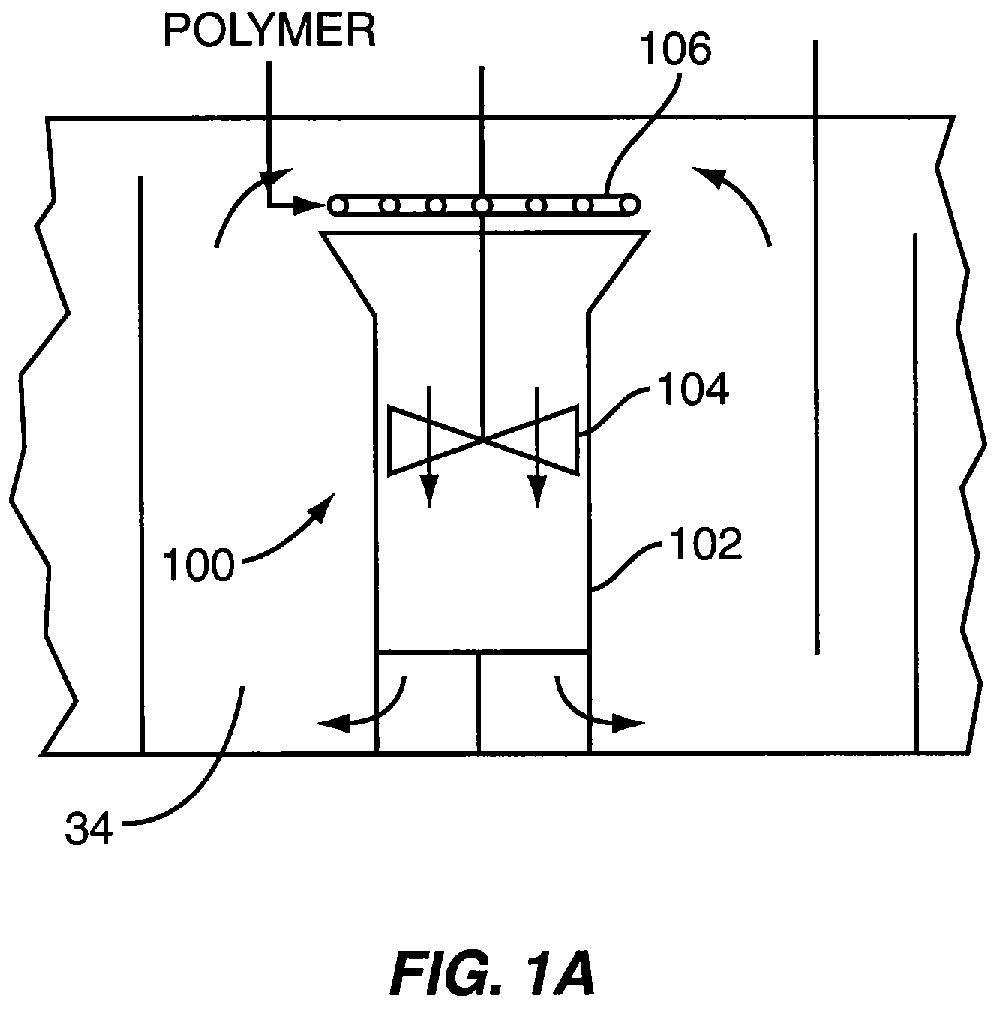

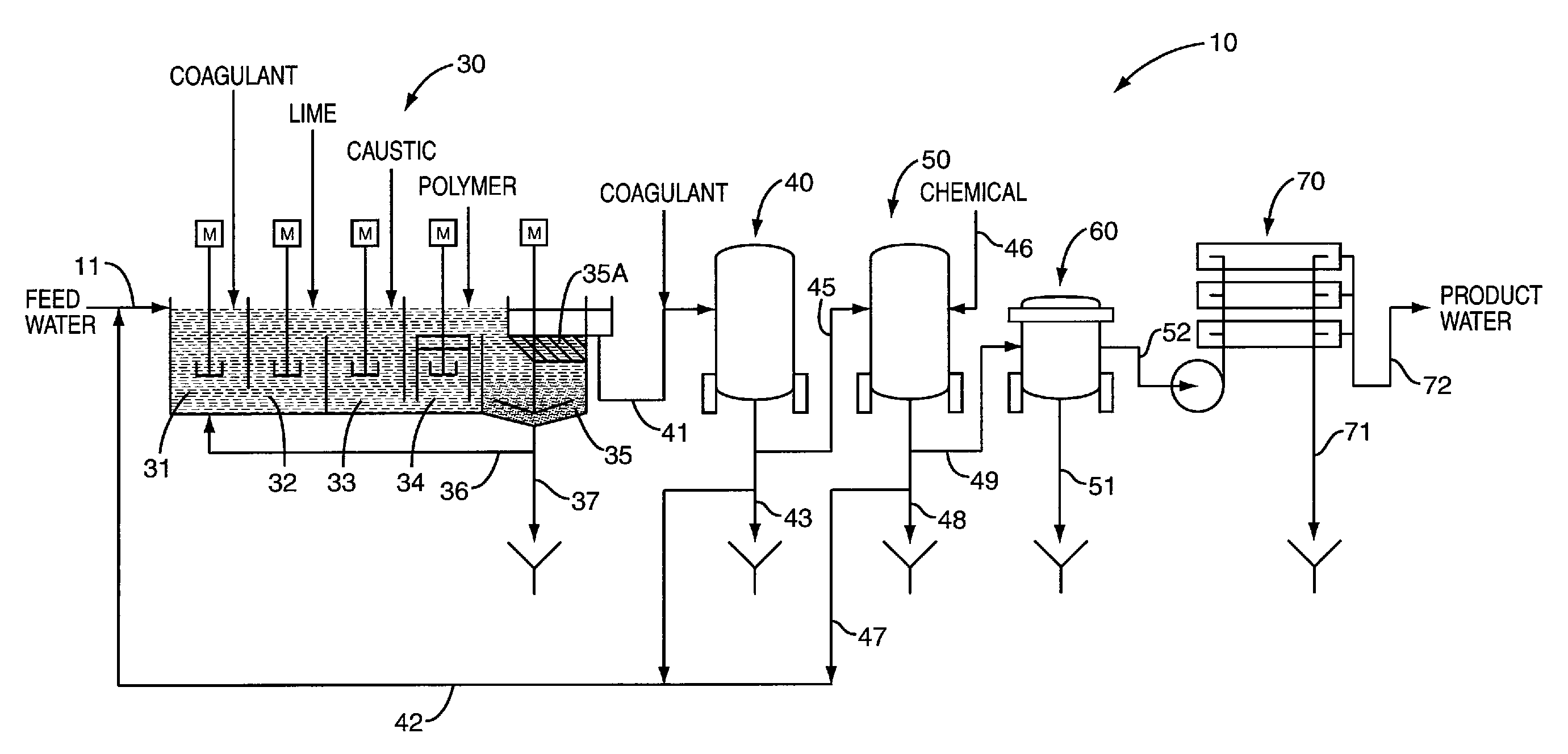

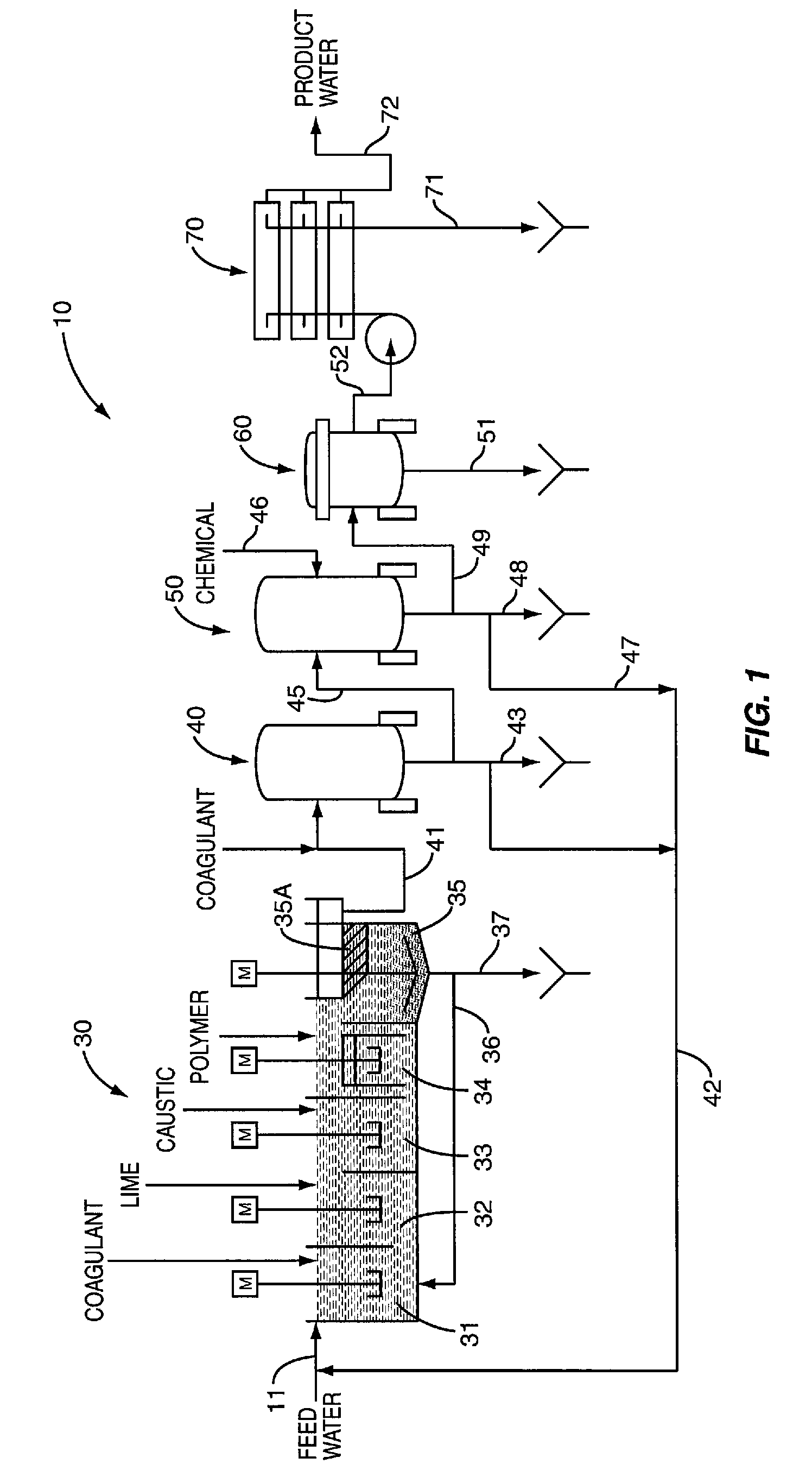

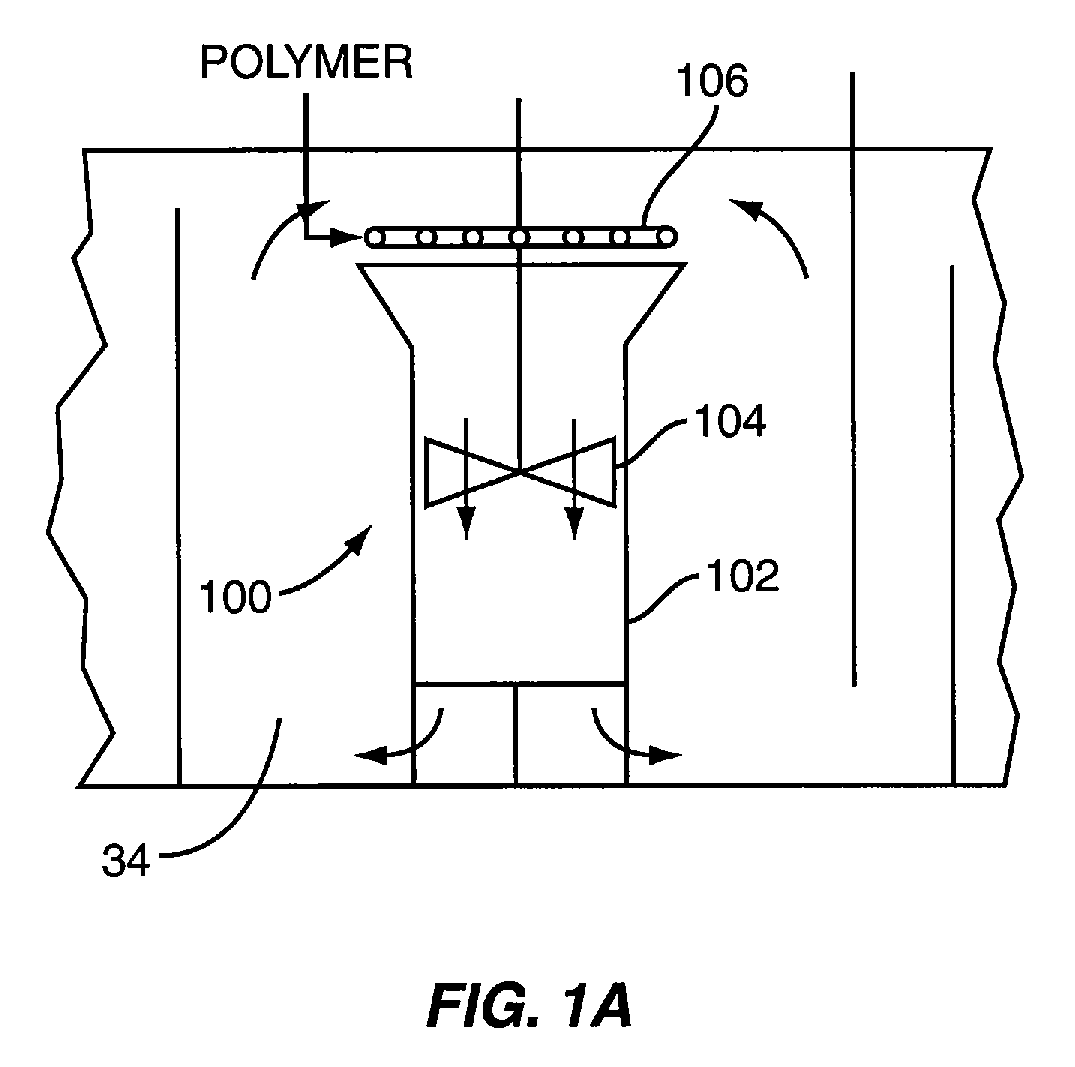

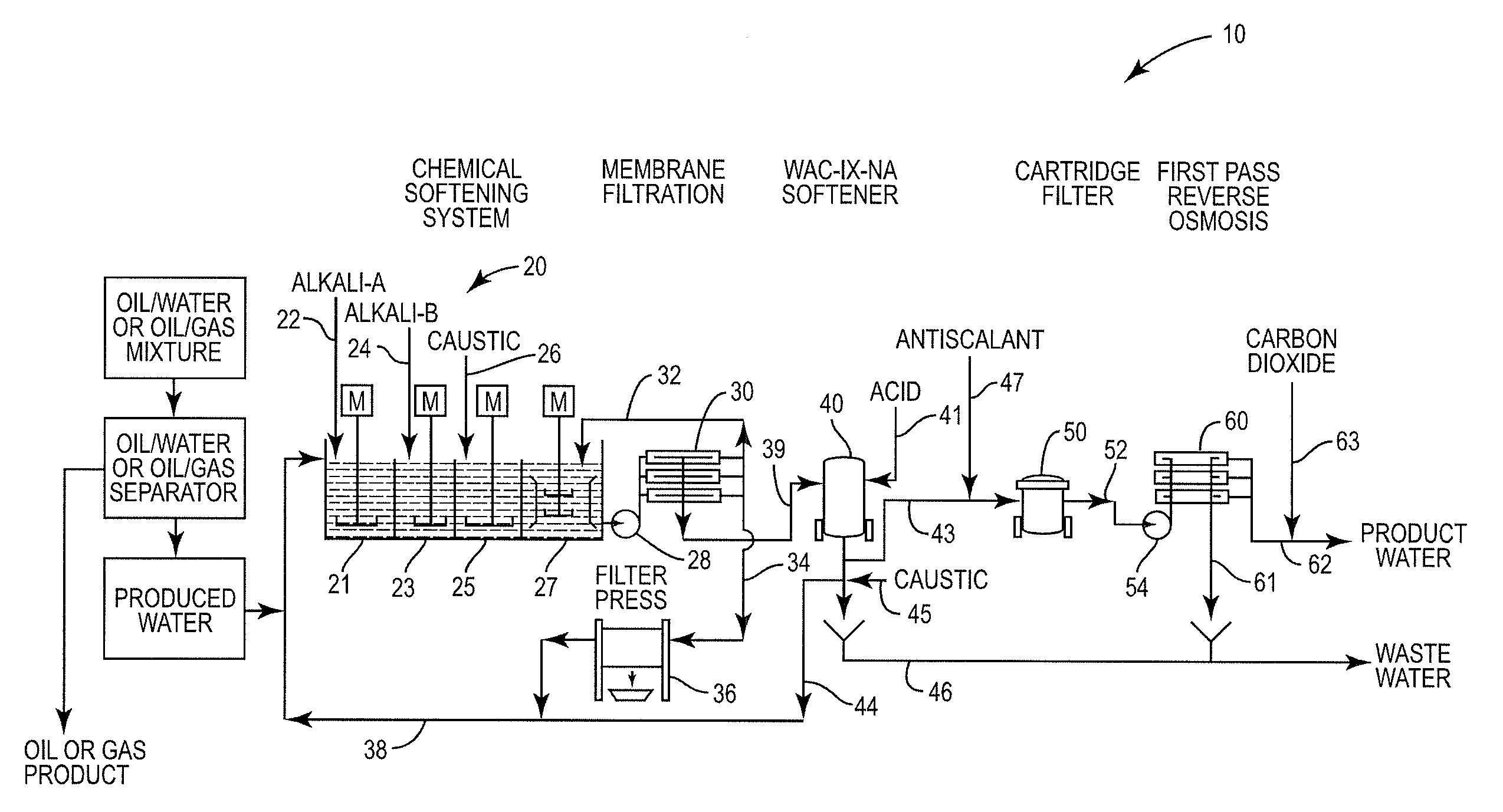

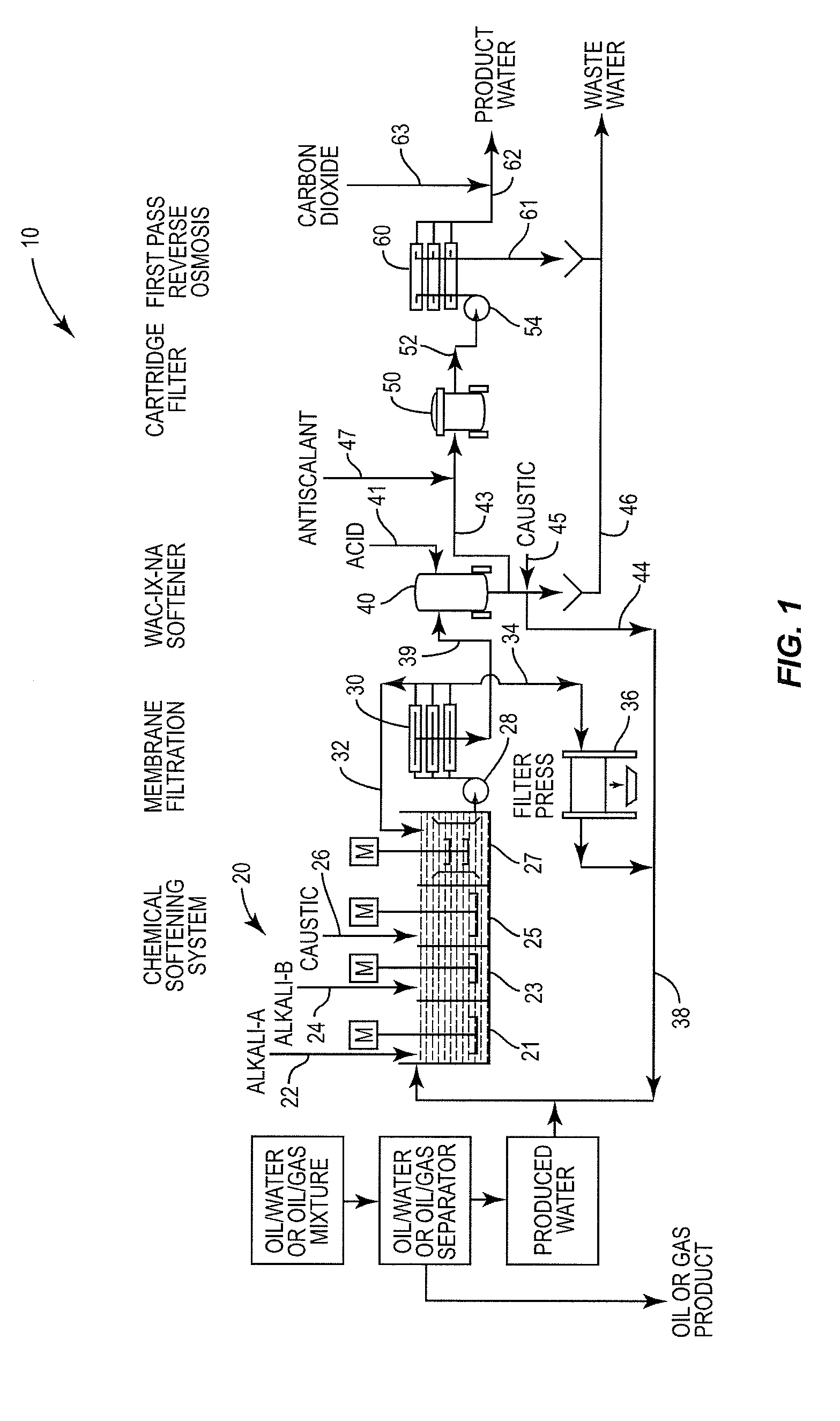

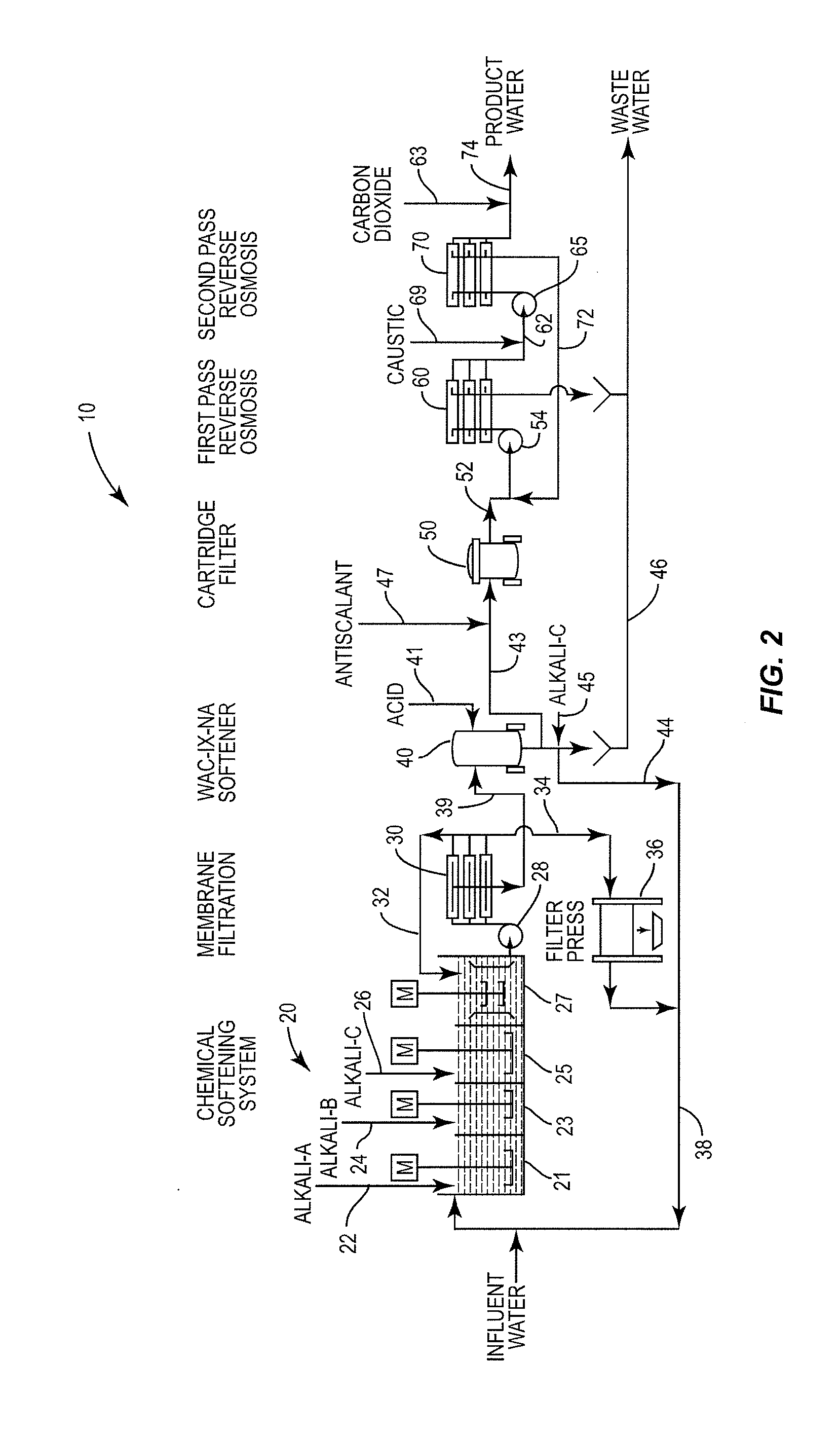

Method for treating wastewater or produced water

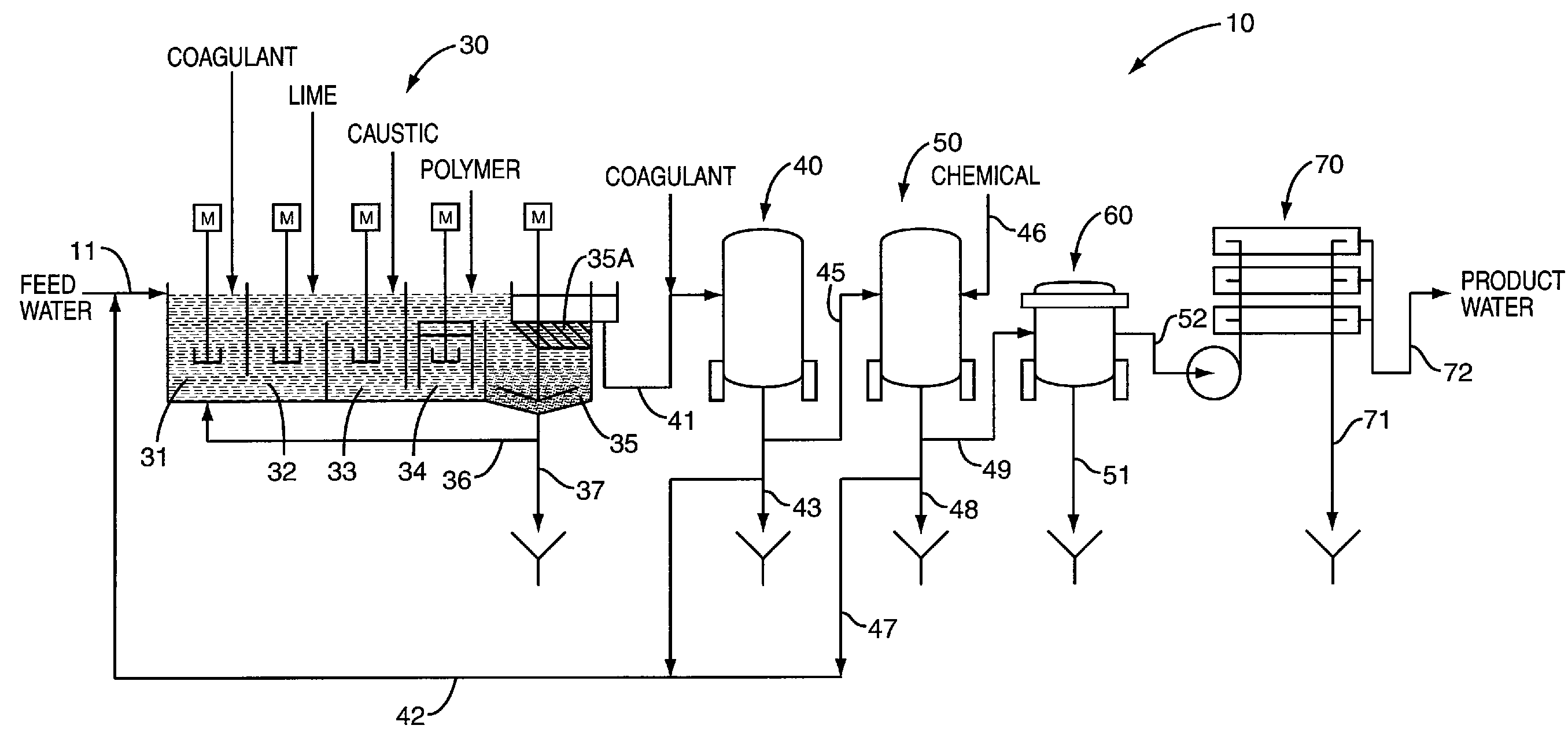

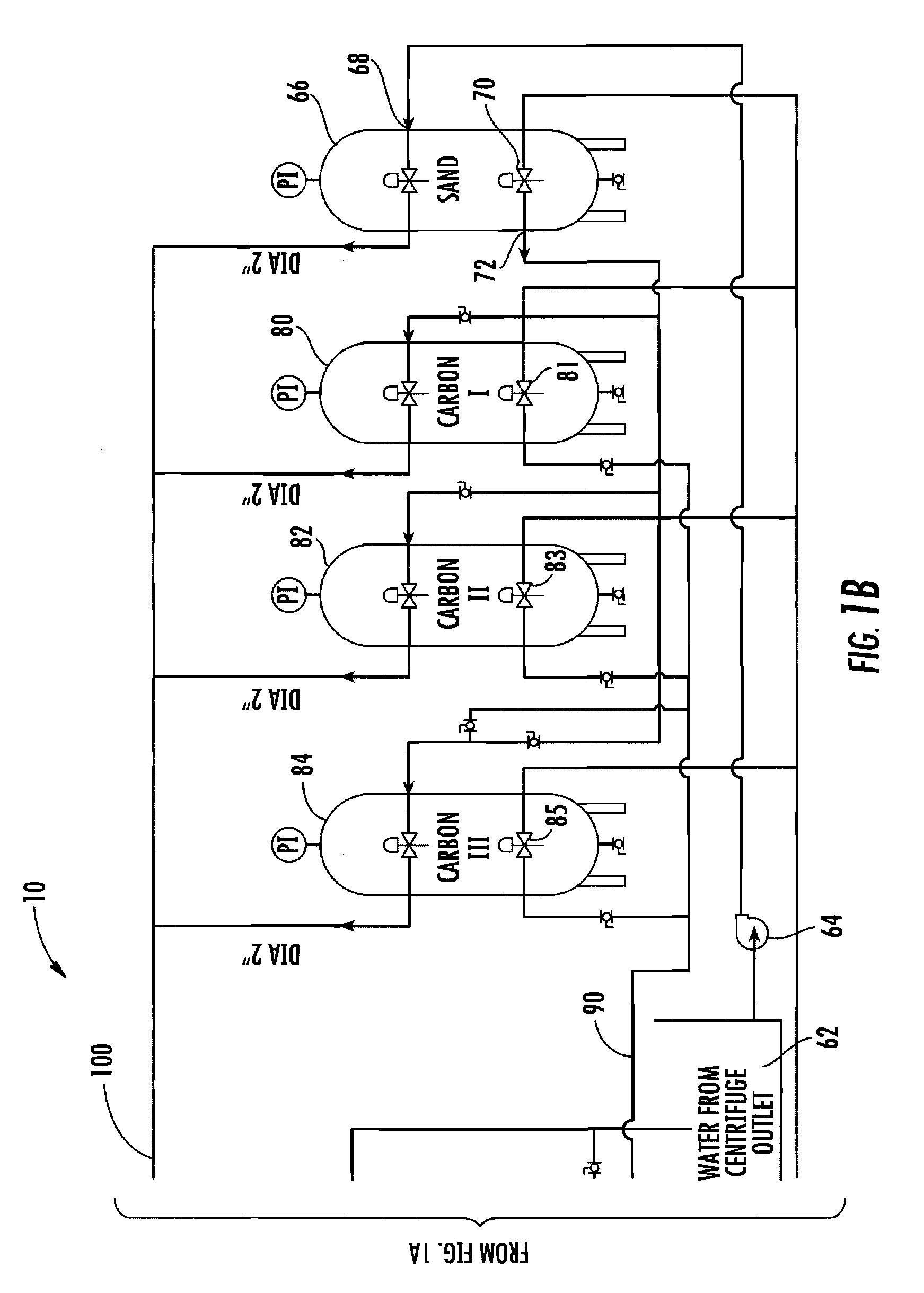

ActiveUS7815804B2Reduce hardnessReduce dissolved solidWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

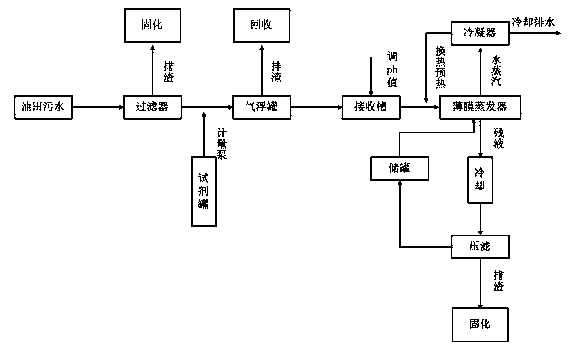

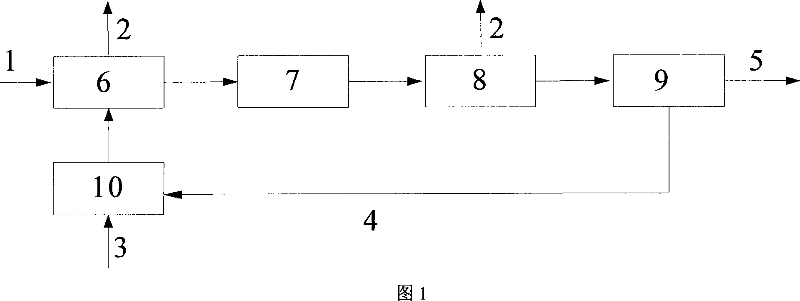

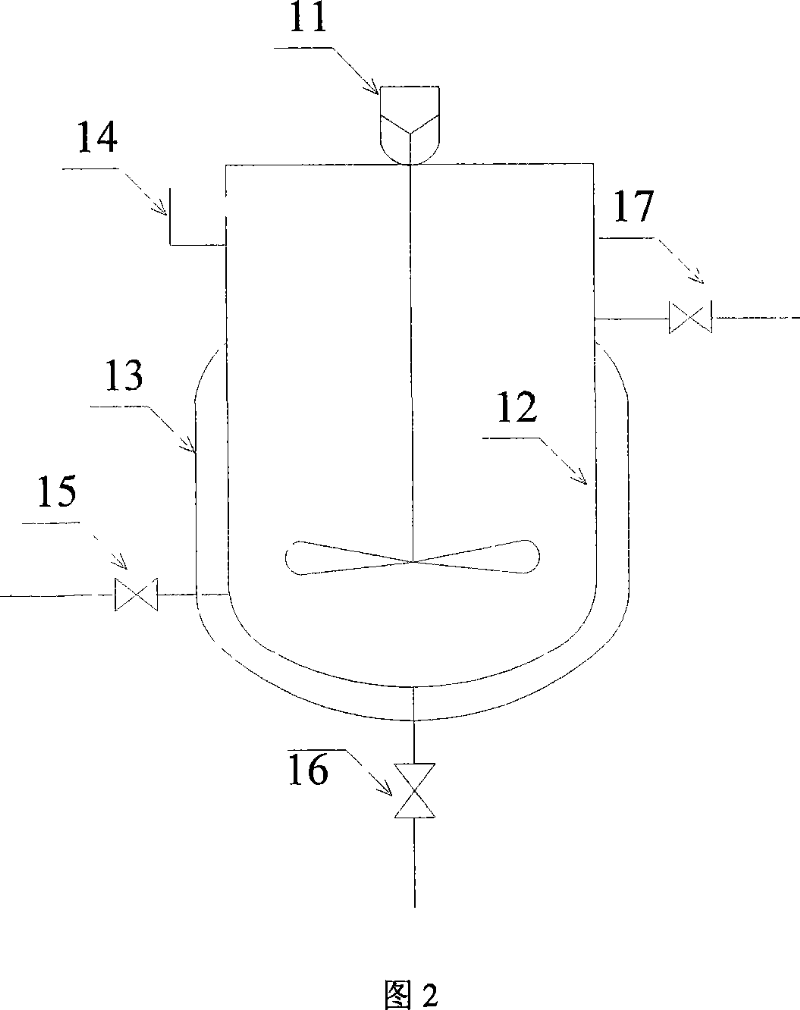

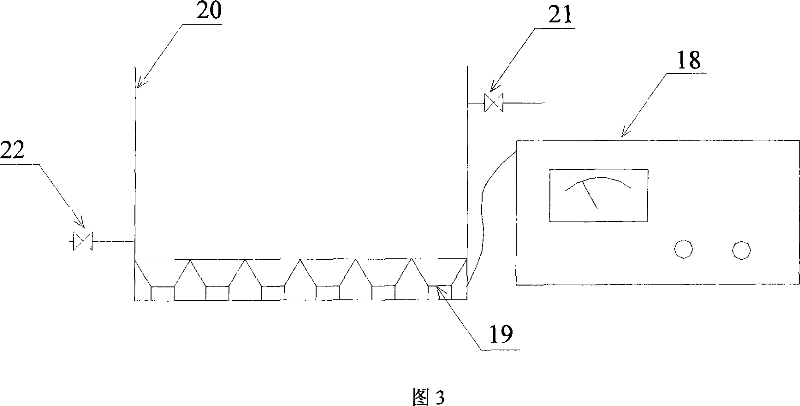

Processing method of sewage in oil fields by using film evaporator

InactiveCN103420532AReduce processing costsReduce consumptionWaste water treatment from quariesMultistage water/sewage treatmentSlagWastewater

The invention discloses a processing method of sewage in oil fields by using a film evaporator. The processing method is characterized by comprising following technology steps: filtering sewage with a filtering device, removing oil by the air-floating method, separating and condensing sewage by the thin-film evaporating method, and processing residual slag, is mainly used for evaporating processing of sewage in oil fields, and is capable of continuously processing oil-containing sewage. The liquid phase and solid phase after being processed can be discharged without causing pollution to the environment.

Owner:JEREH ENERGY SERVICES

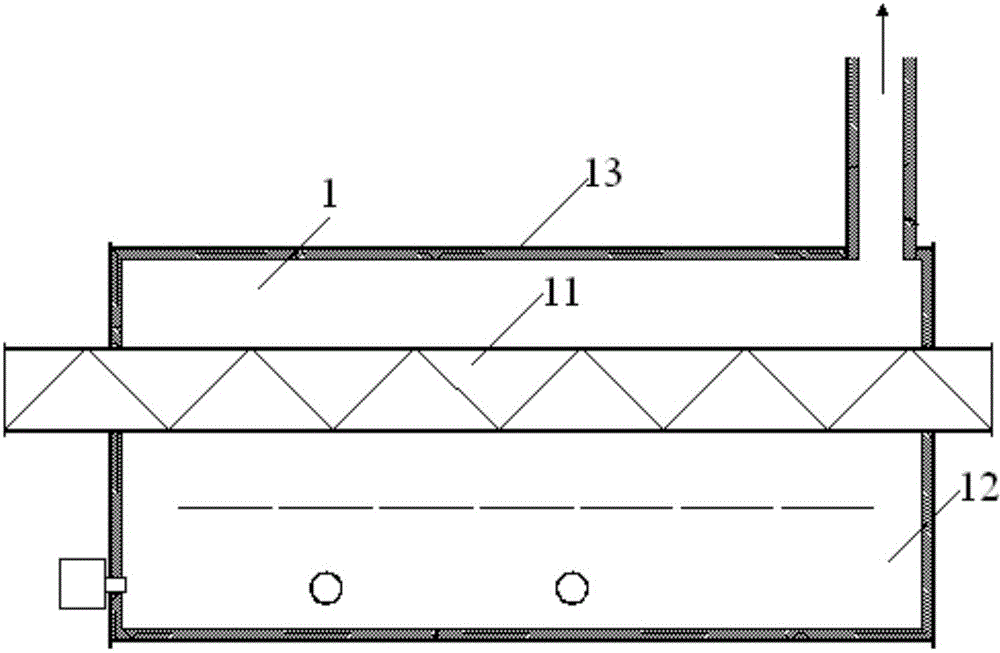

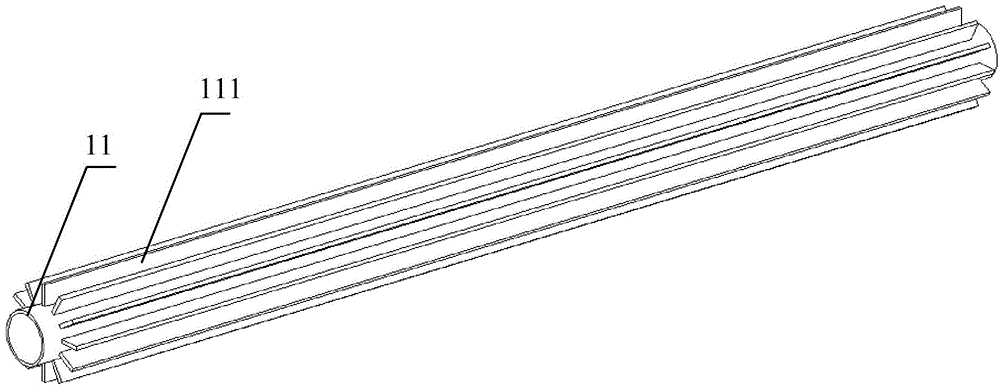

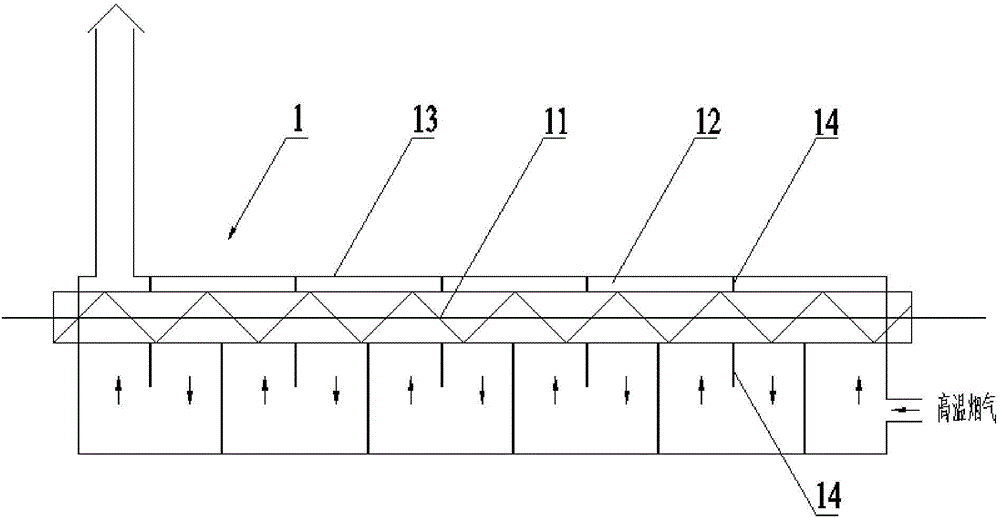

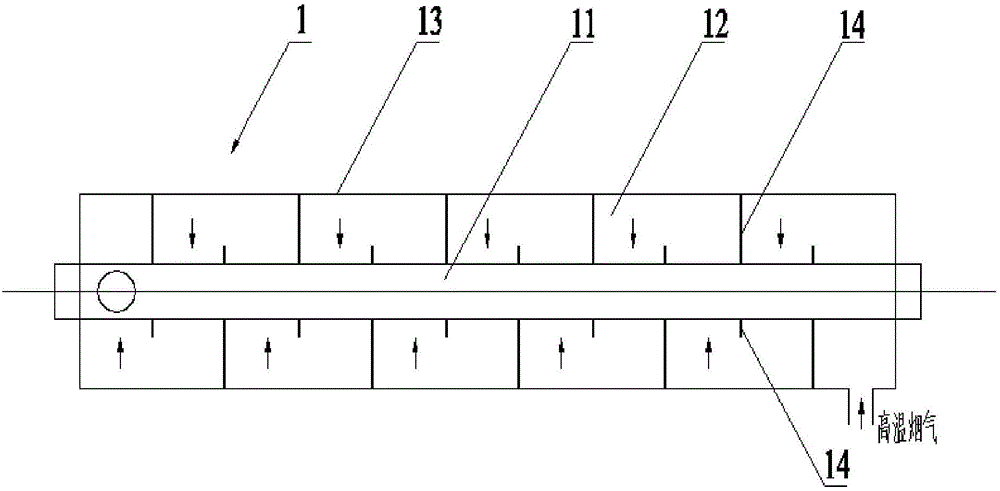

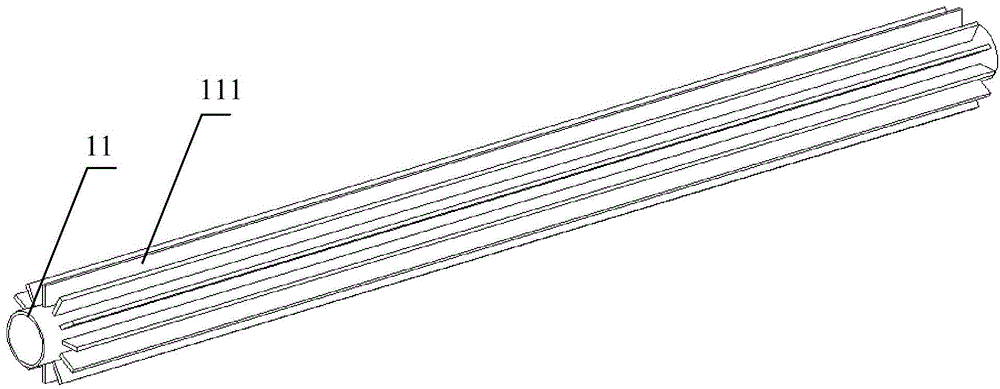

Thermal decomposition device of oil field waste

InactiveCN104402186AImprove heat transfer efficiencyIncrease the effective heat transfer areaWaste water treatment from quariesSpecific water treatment objectivesOil fieldEngineering

The invention discloses a thermal decomposition device of oil field wastes. The thermal decomposition device comprises a casing, wherein a flue and a heating cavity are formed inside the casing; the heating cavity is isolated from the flue; ribs are arranged on the casing with the heating cavity. Fume inside the flue flashes the casing with the heating cavity, so that the heat can be conducted; due to adoption of the ribs on the casing with the heating cavity, the heat exchange area is effectively increased when being compared with that of the prior art, and the heat exchange efficiency of the thermal decomposition device is improved.

Owner:JEREH ENERGY SERVICES

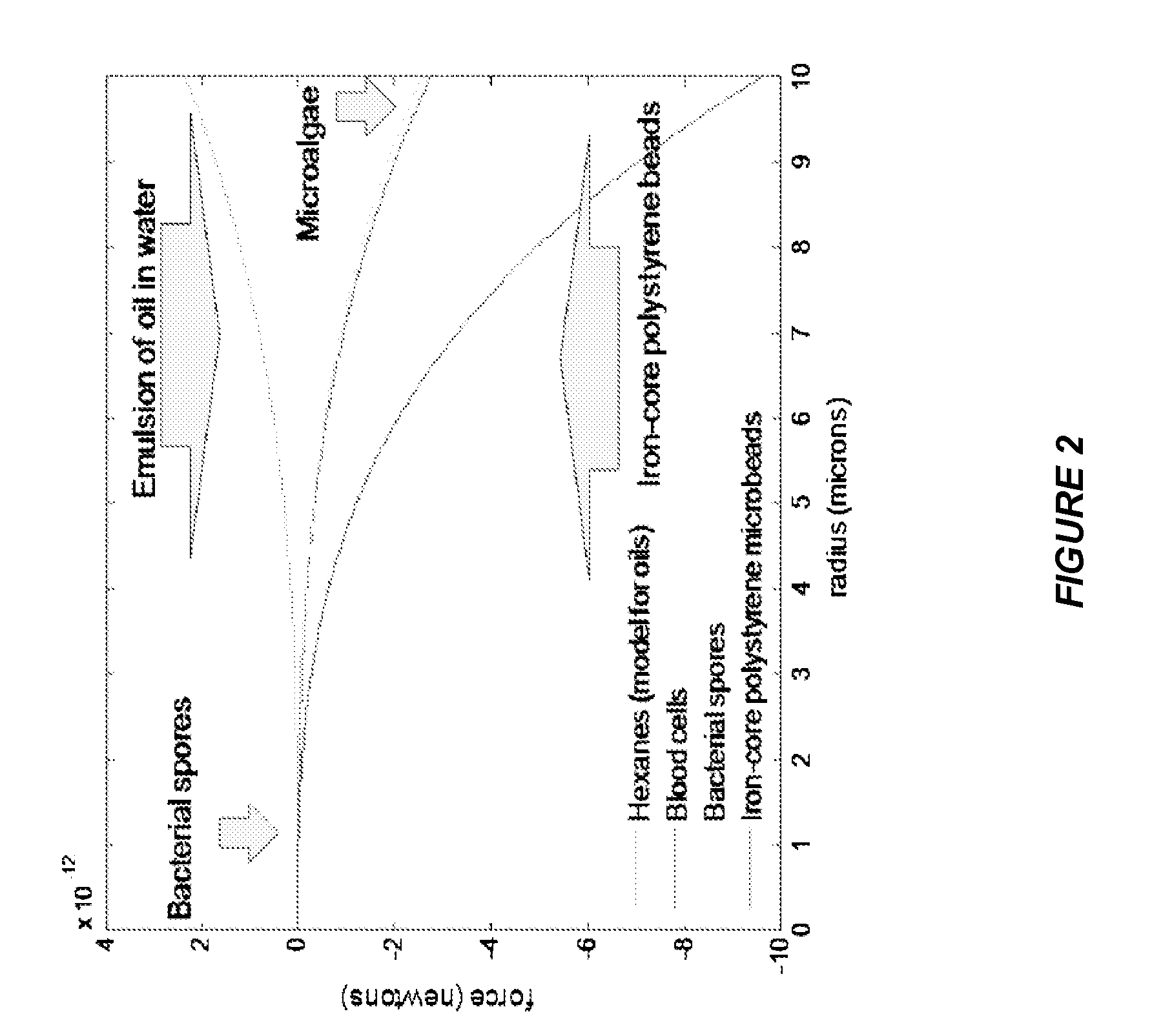

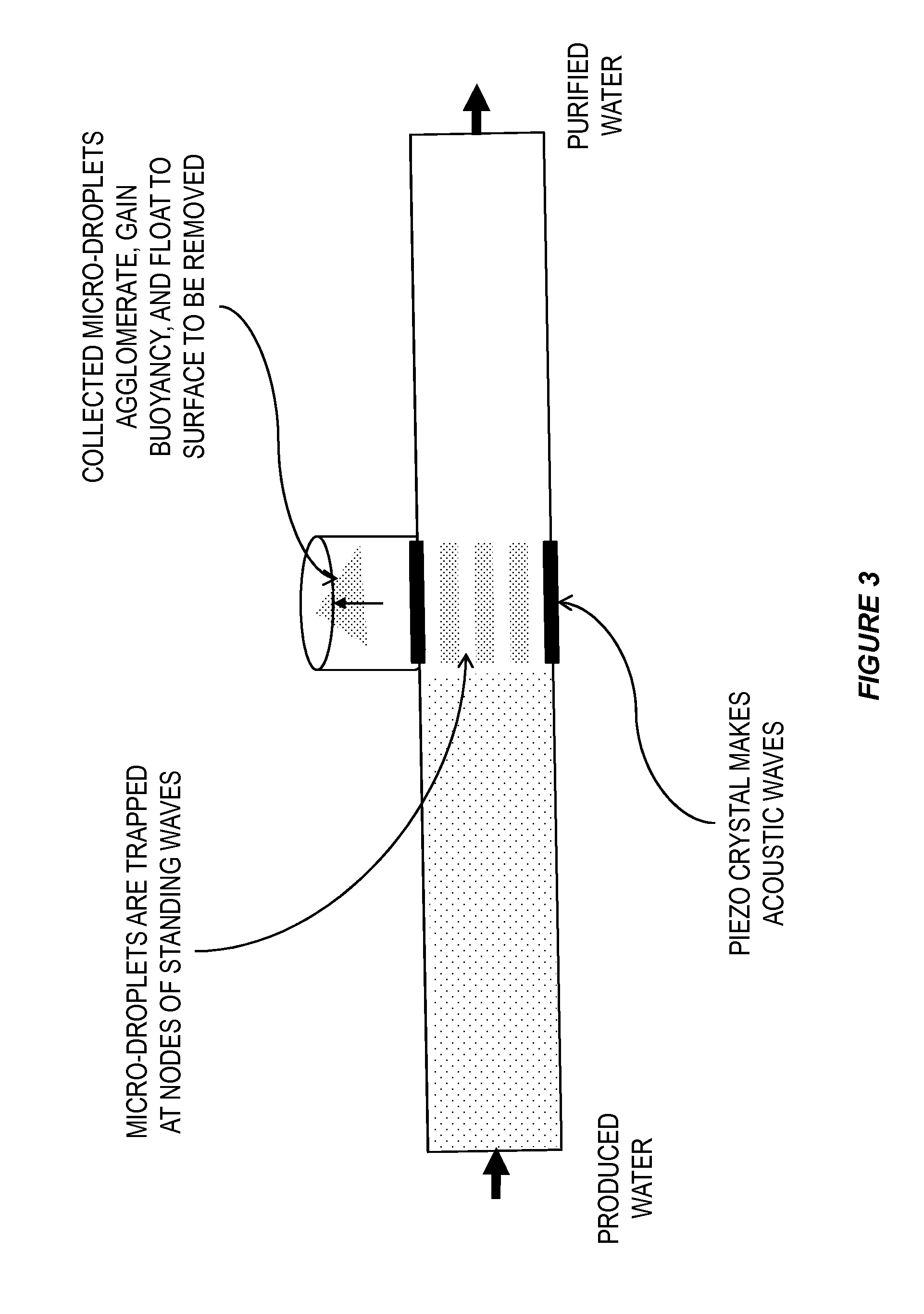

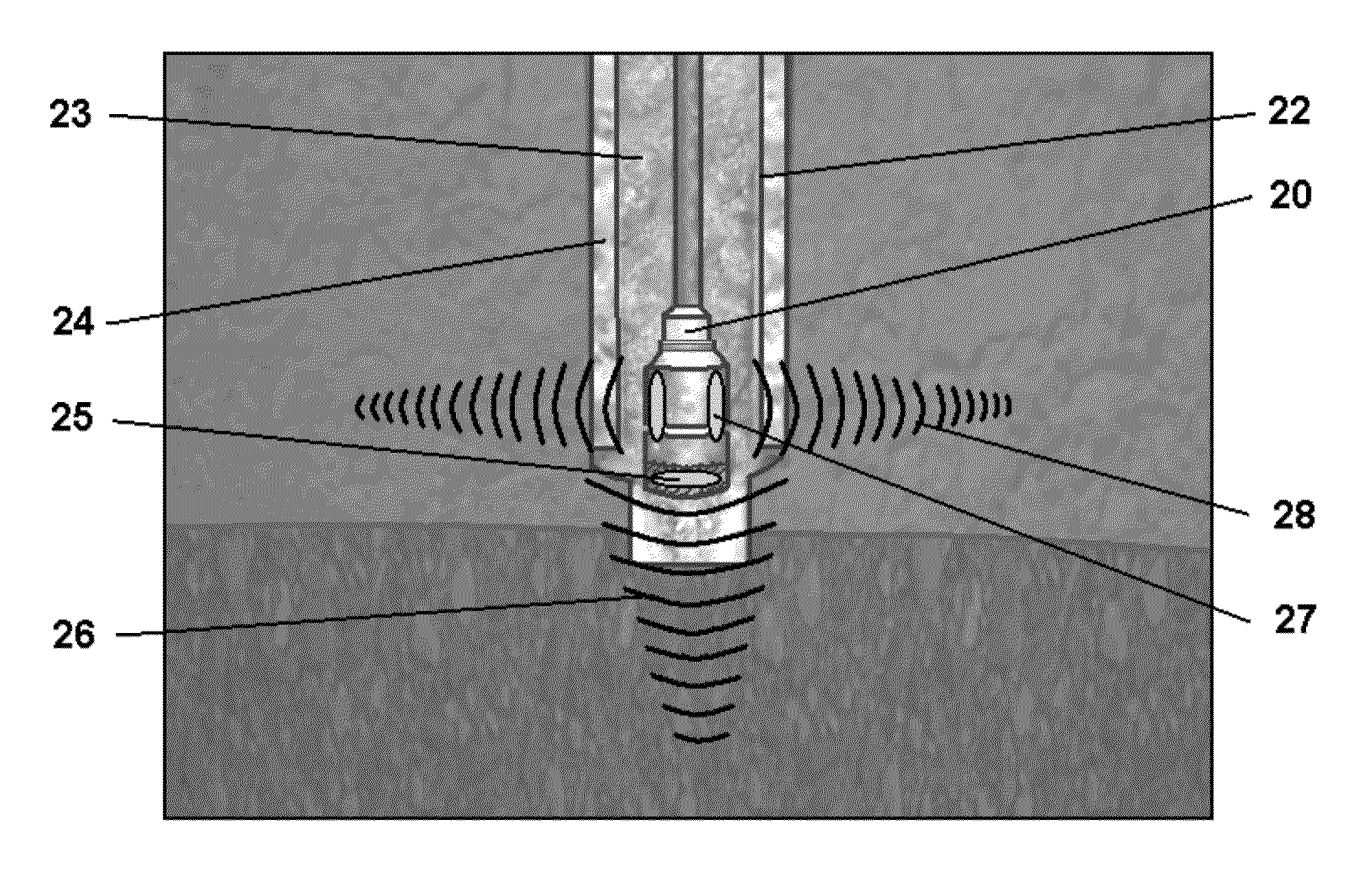

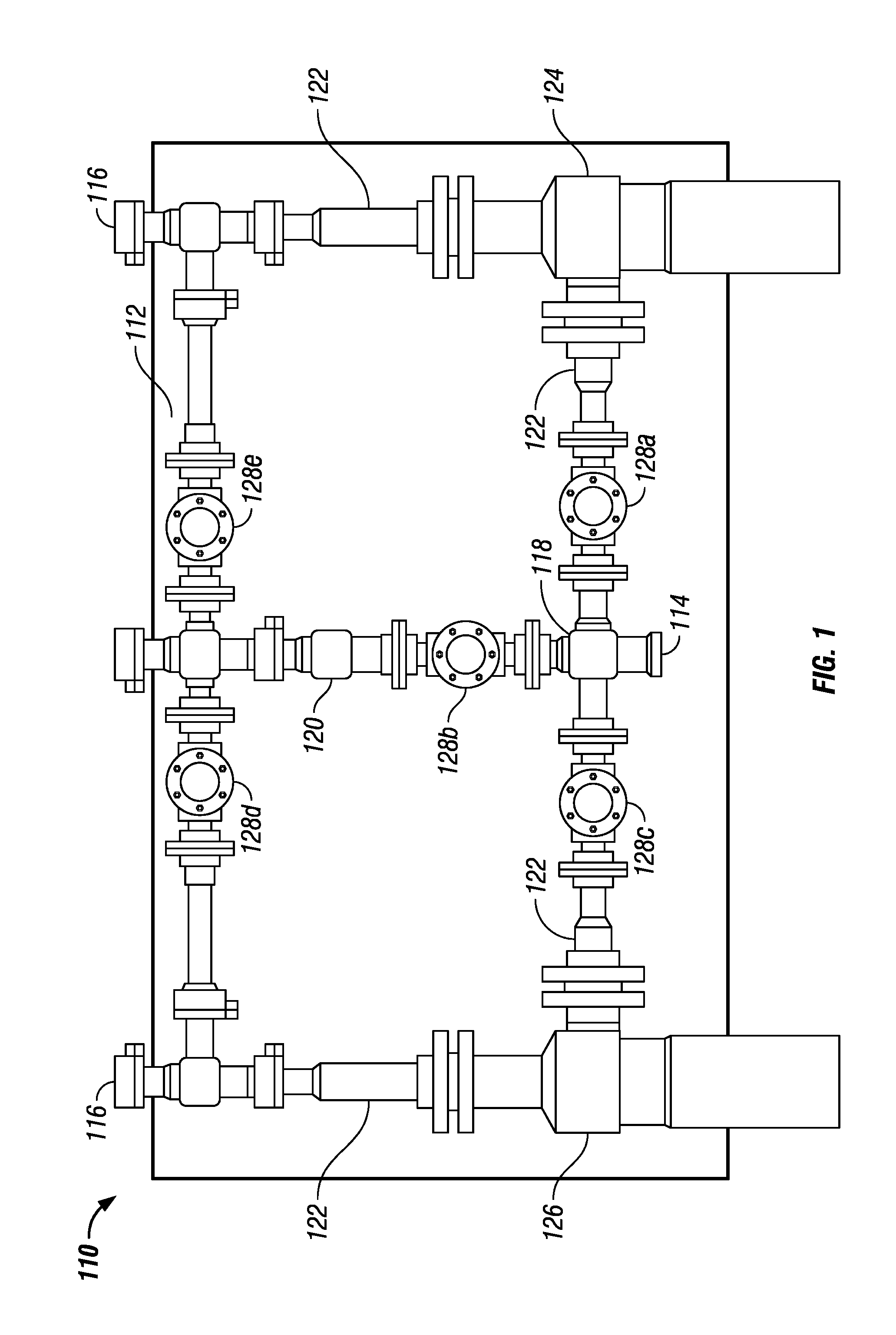

Ultrasound and Acoustophoresis Technology for Separation of Oil and Water, with Application to Produce Water

InactiveUS20110278218A1Maximize acoustic energy transferAvoid enteringWaste water treatment from quariesFatty/oily/floating substances removal devicesEmulsionResonance

Several prototype systems are described for separating oil and water from emulsions. The systems operate at ultrasonic resonance and are thus low power. Each system contains one or more acoustic transducers operating in the 100 kHz to 5 MHz range. Each system contains flow input for the emulsion and two or more flow outputs for the separated oil and water. Existing prototypes operate from 200 mL / min to >15 L / min. Each uses low power in the range of 1-5 W.

Owner:FLODESIGN SONICS

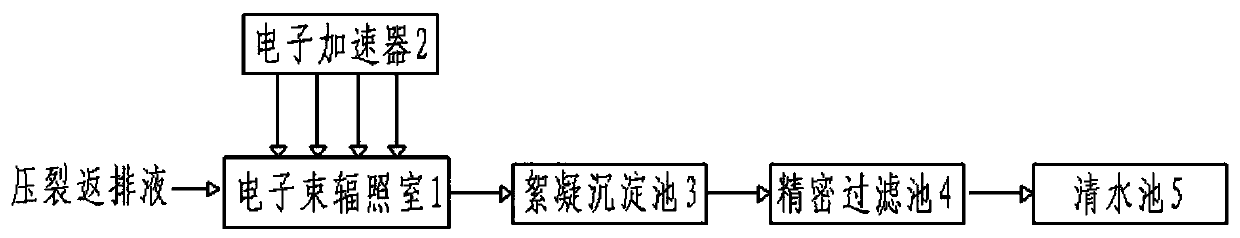

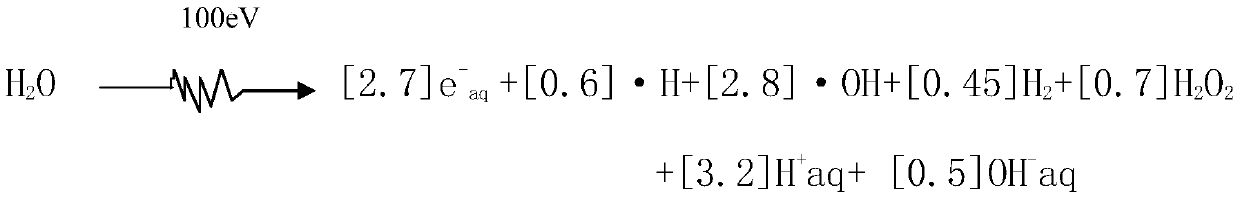

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

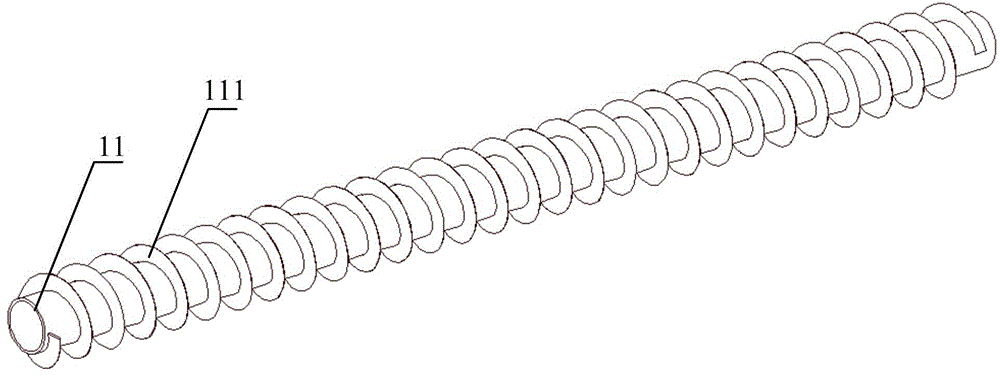

Thermal decomposition device of oil field waste

InactiveCN104402185AImprove heat transfer efficiencyEnhanced turbulence effectWaste water treatment from quariesSludge treatment by pyrolysisRetention timeOil field

The embodiment of the invention discloses a thermal decomposition device of oil field wastes. The thermal decomposition device comprises a casing, wherein a flue and a heating cavity are formed inside the casing; the heating cavity is isolated from the flue. The oil field waste thermal decomposition device is characterized in that a plurality of partitioning plates are arranged on the inner wall of the casing; the flue is of a snakelike structure through the adoption of the partitioning plates. Through the adoption of the partitioning plates on the inner wall of the casing of the thermal decomposition device disclosed by the invention, the flue inside the casing is of the snakelike structure, so that the flowing direction and the flowing speed of fume are changed, the turbulent flow effect is improved, the retention time is prolonged, and the heat exchange efficiency of the heating cavity and the fume is improved.

Owner:JEREH ENERGY SERVICES

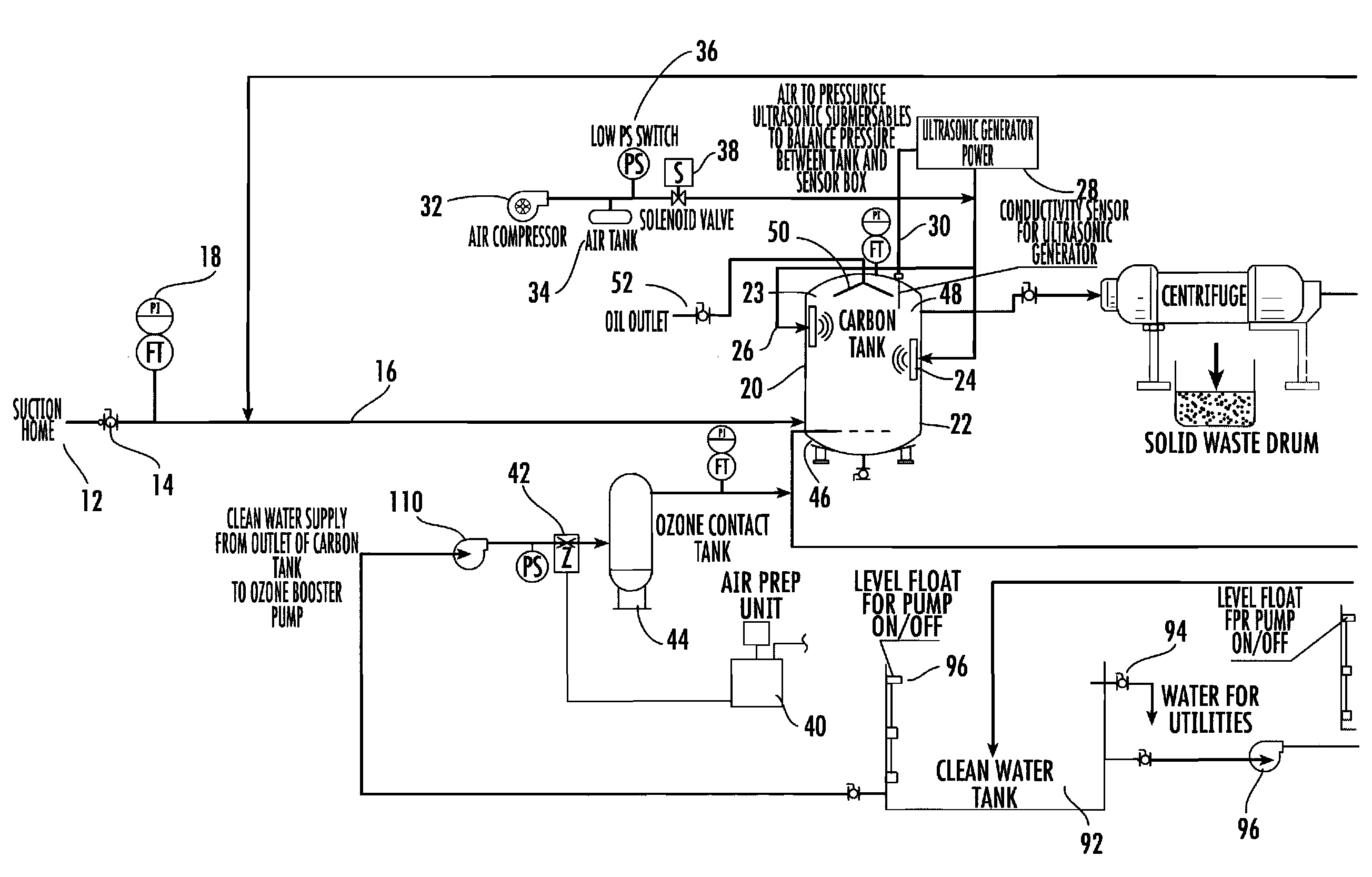

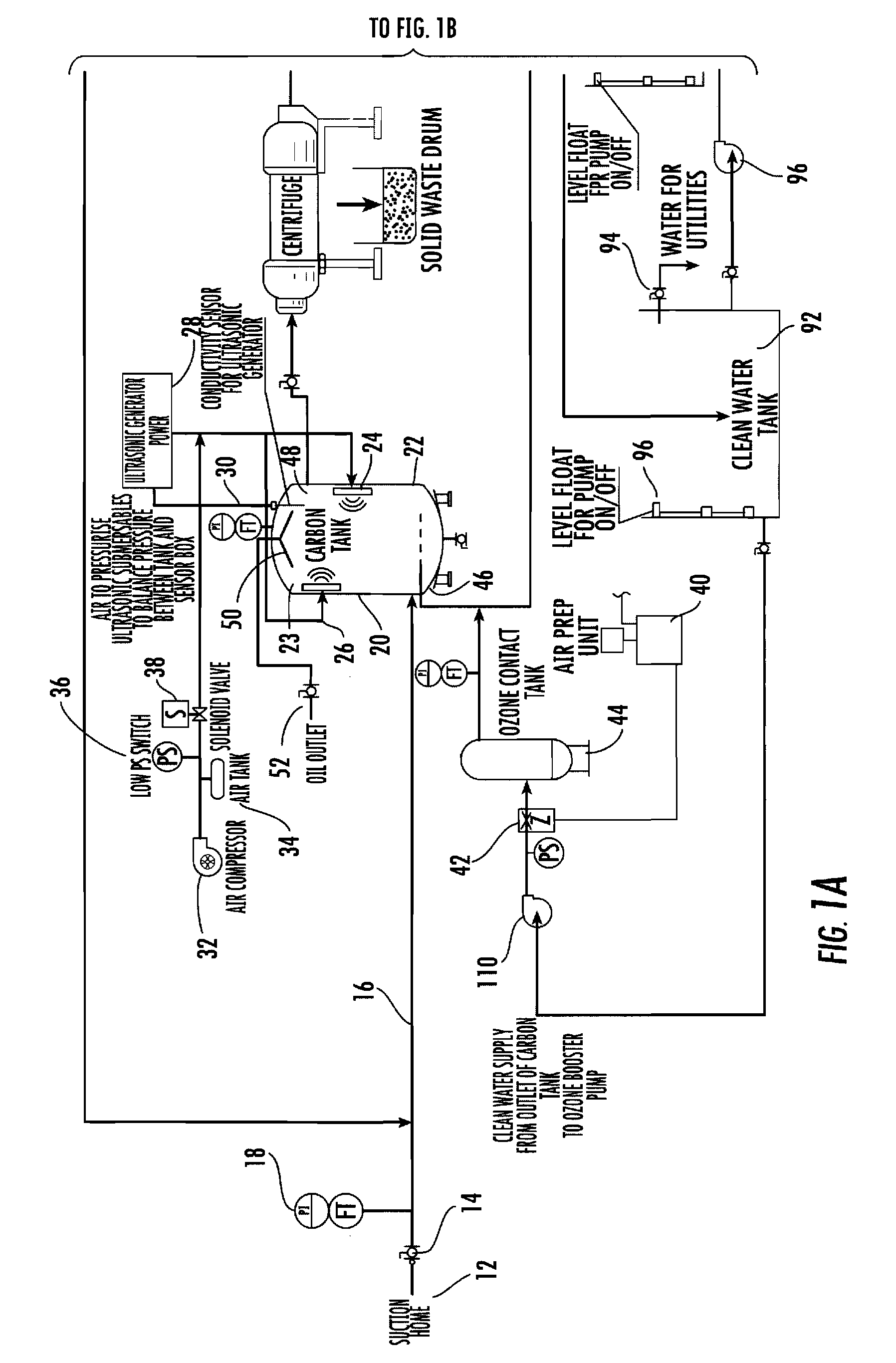

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090050572A1Low costCurrent expensiveWaste water treatment from quariesTreatment involving filtrationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

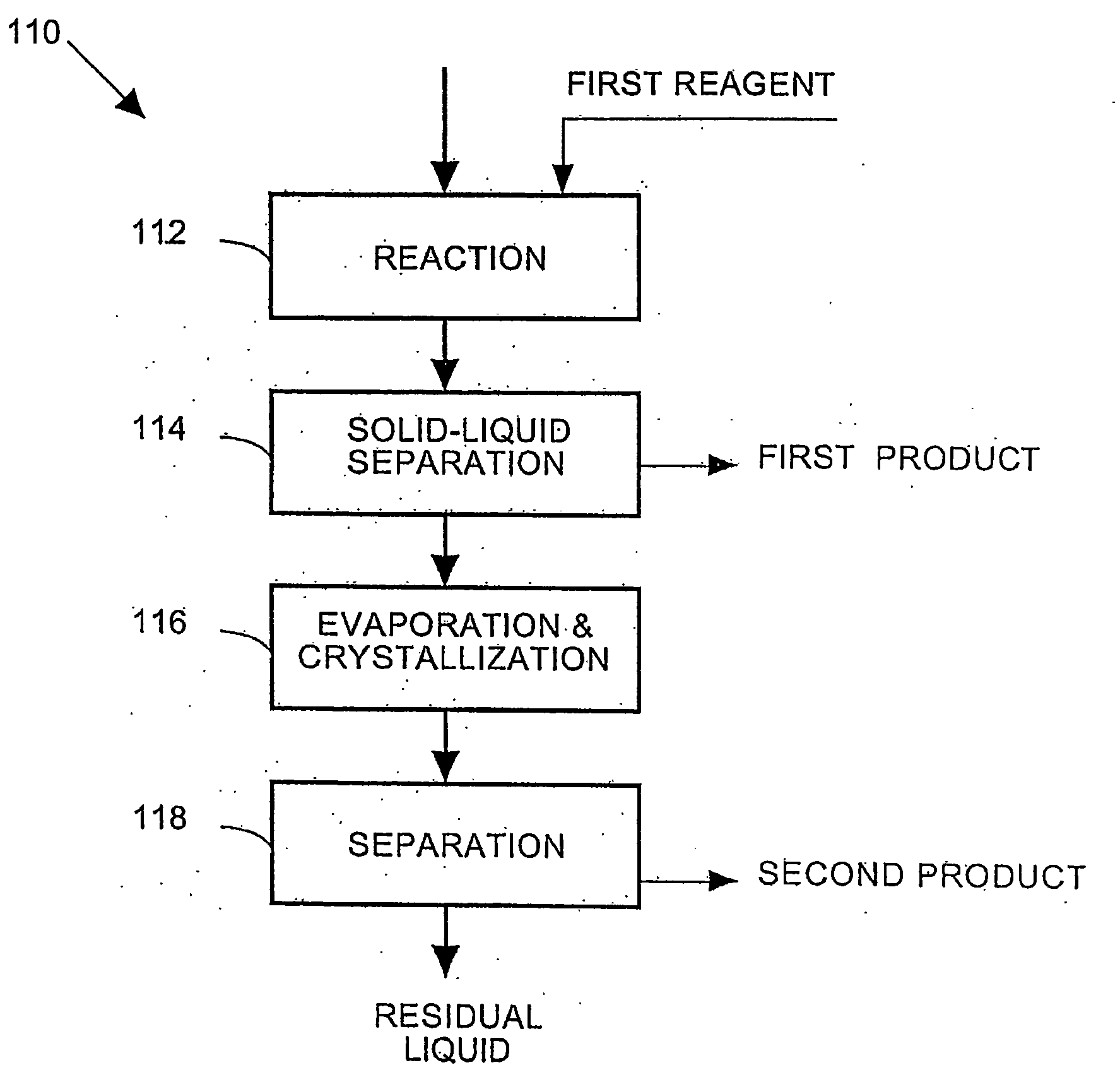

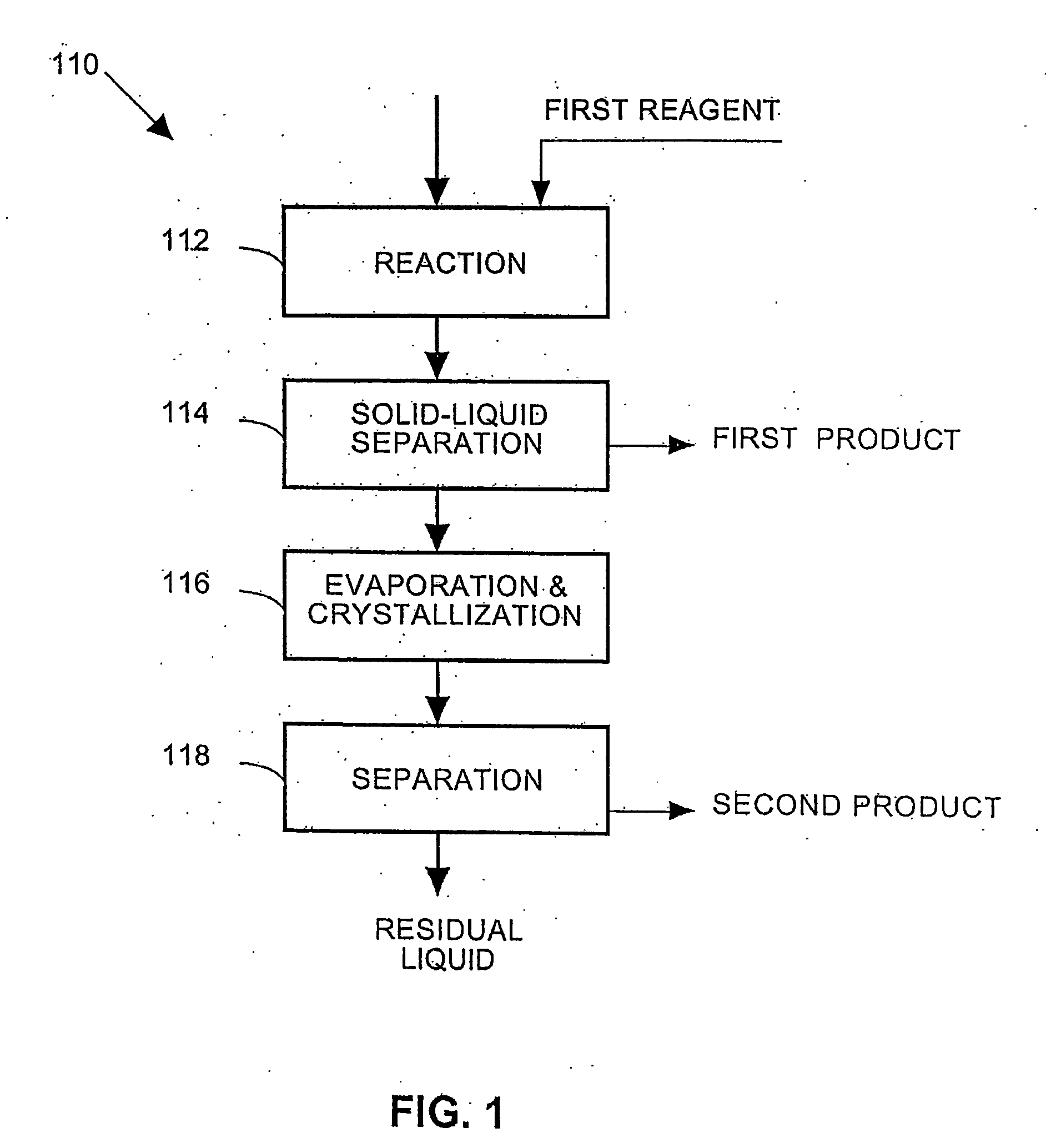

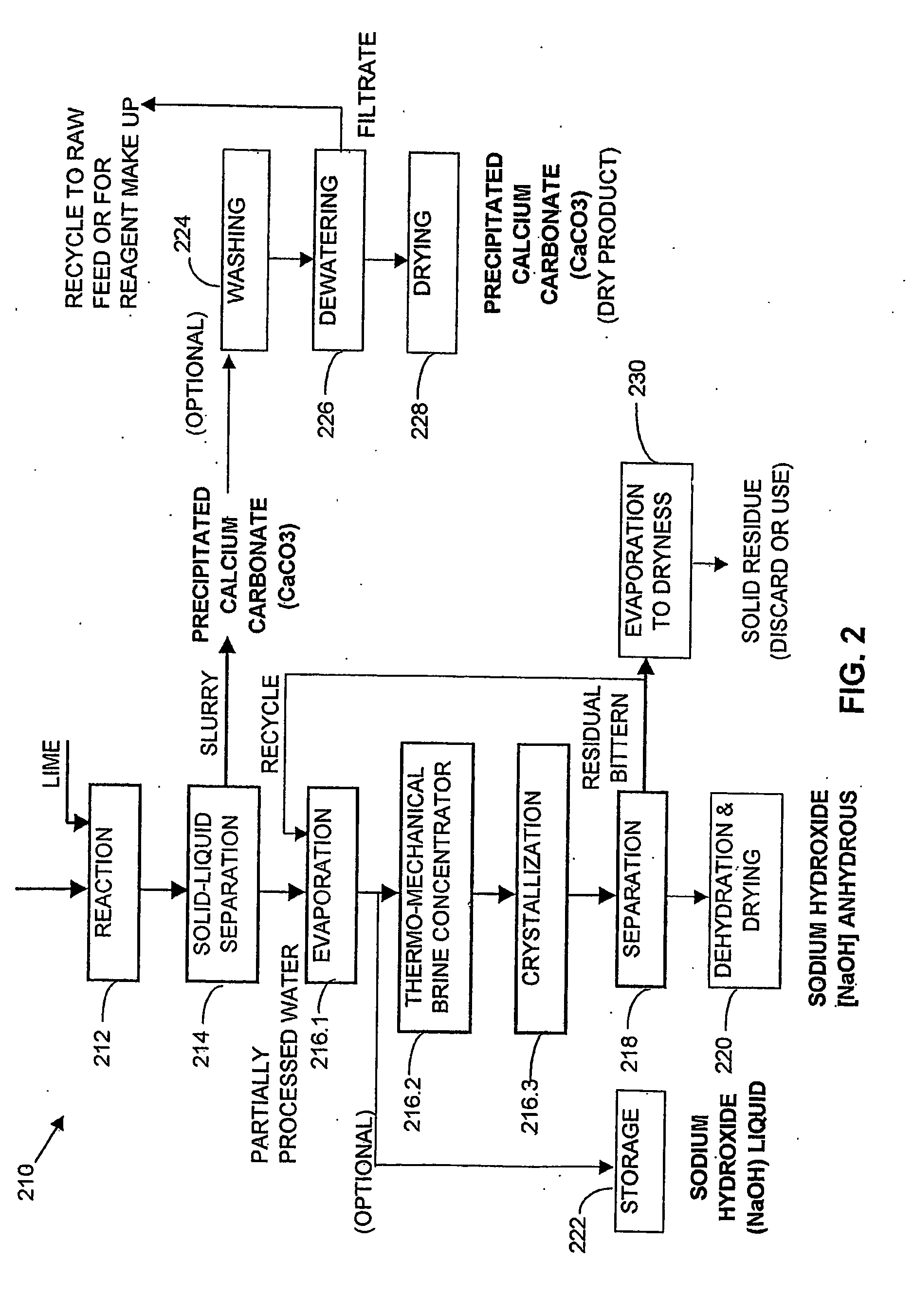

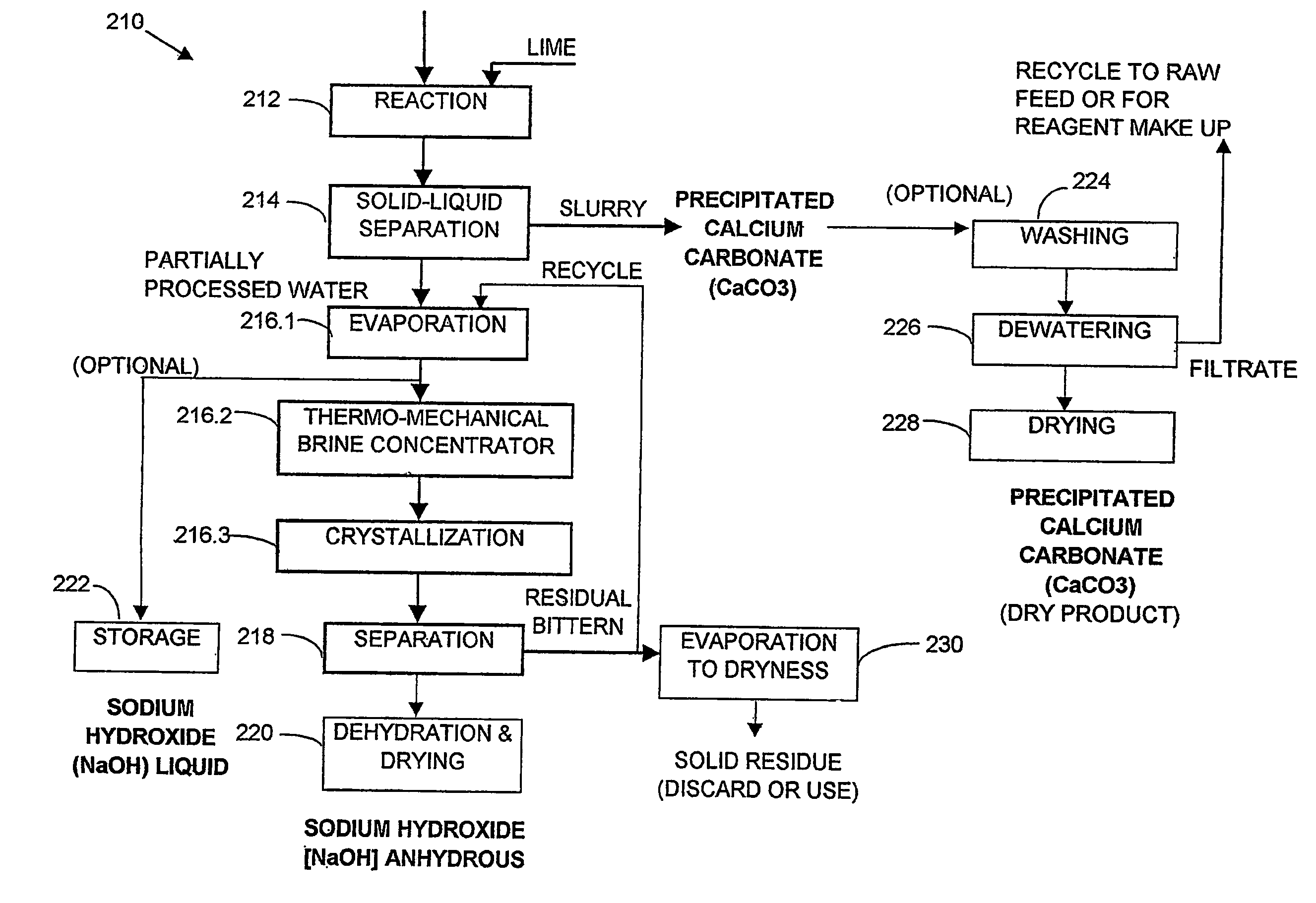

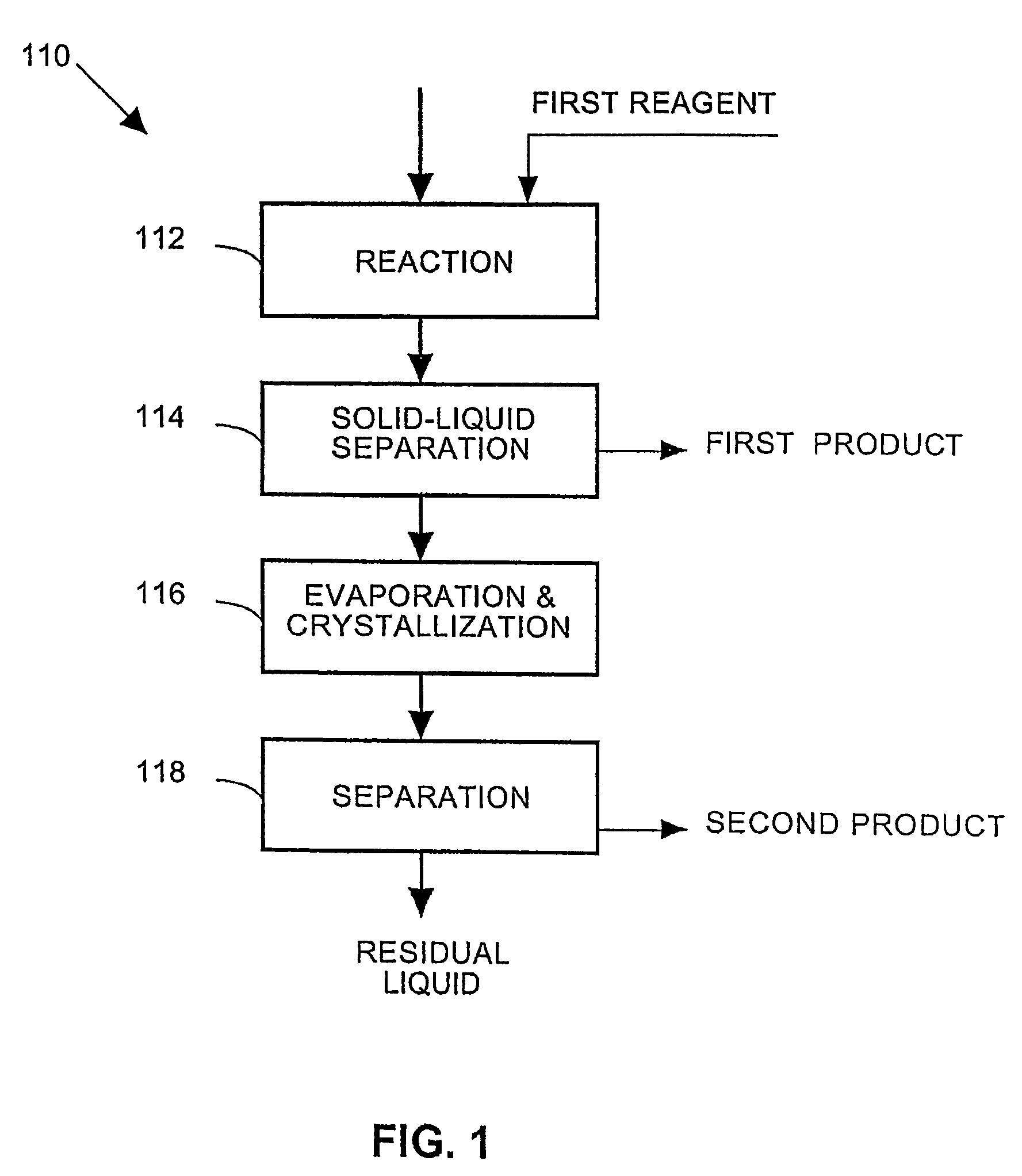

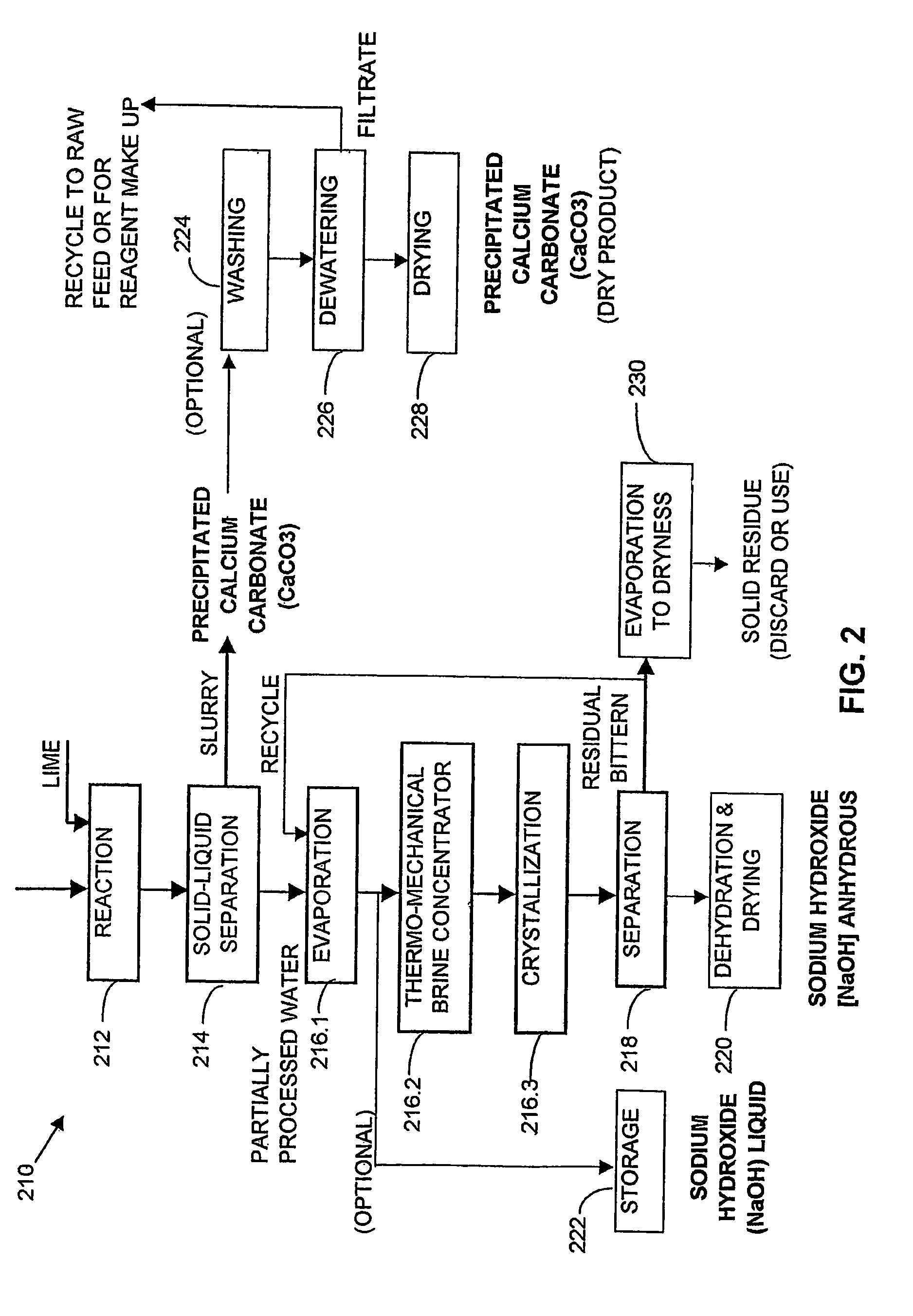

Process and apparatus for the treatment of saline water

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

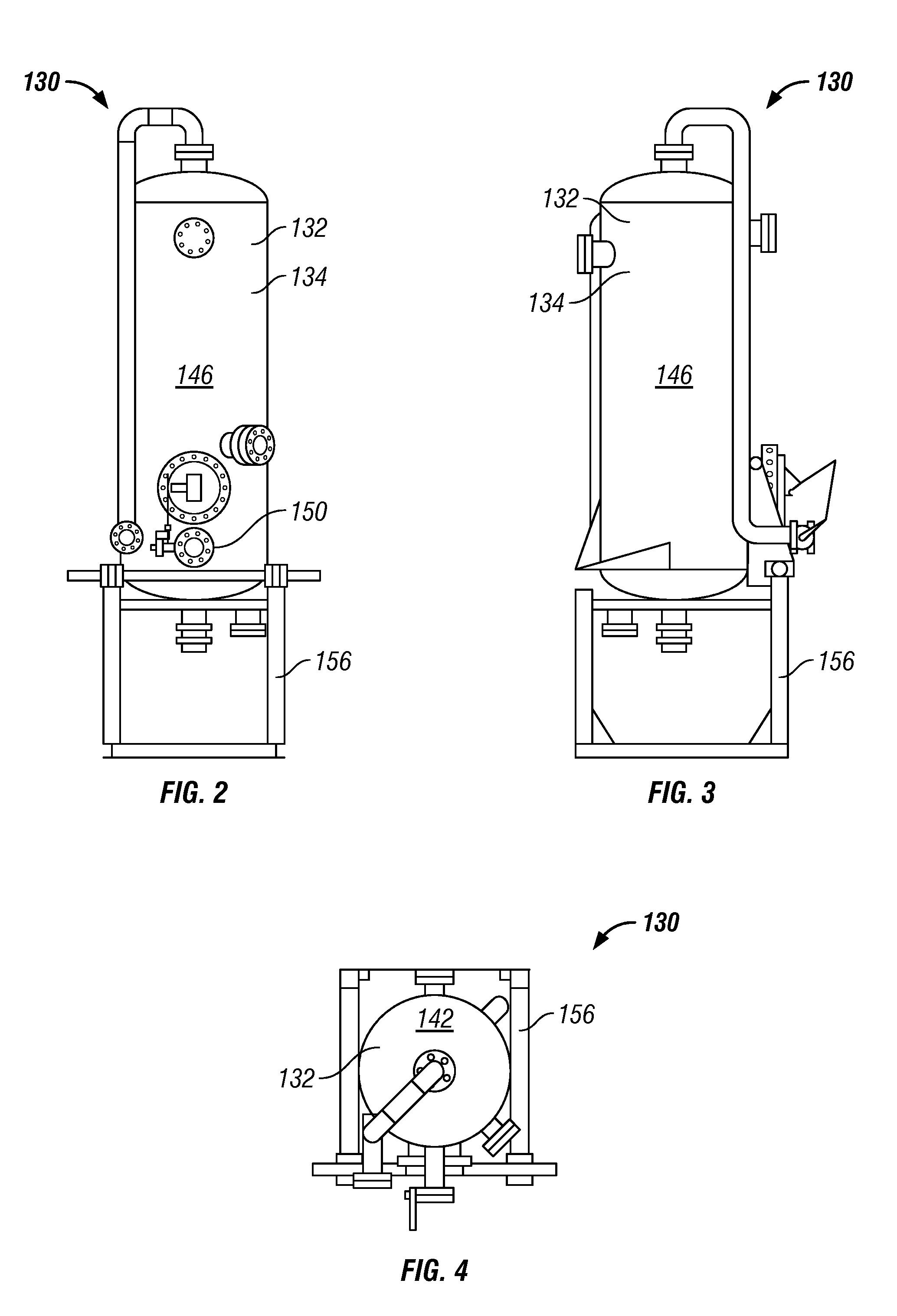

Method for Treating Wastewater or Produced Water

ActiveUS20080135478A1Reduce hardnessReduced silica concentrationWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

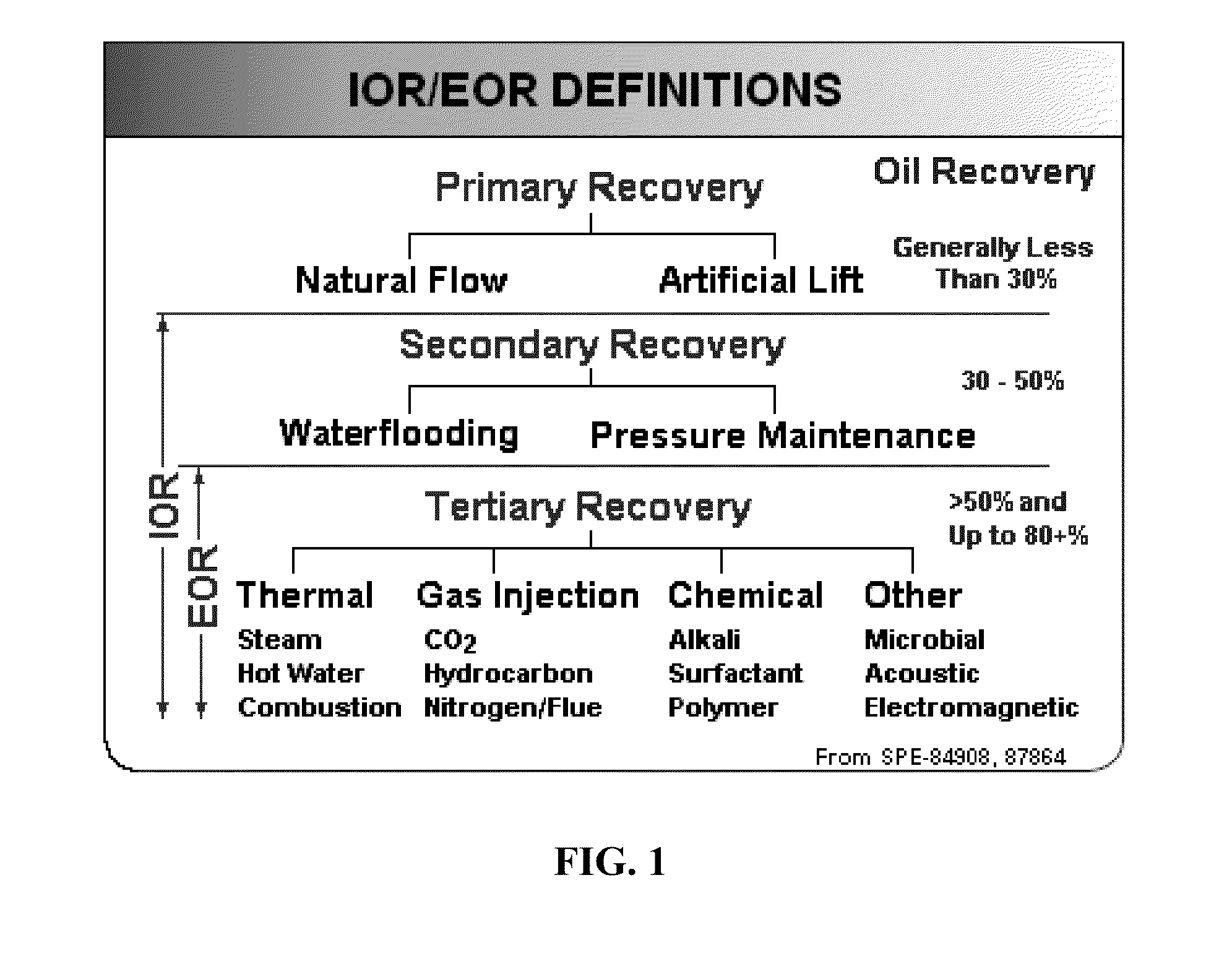

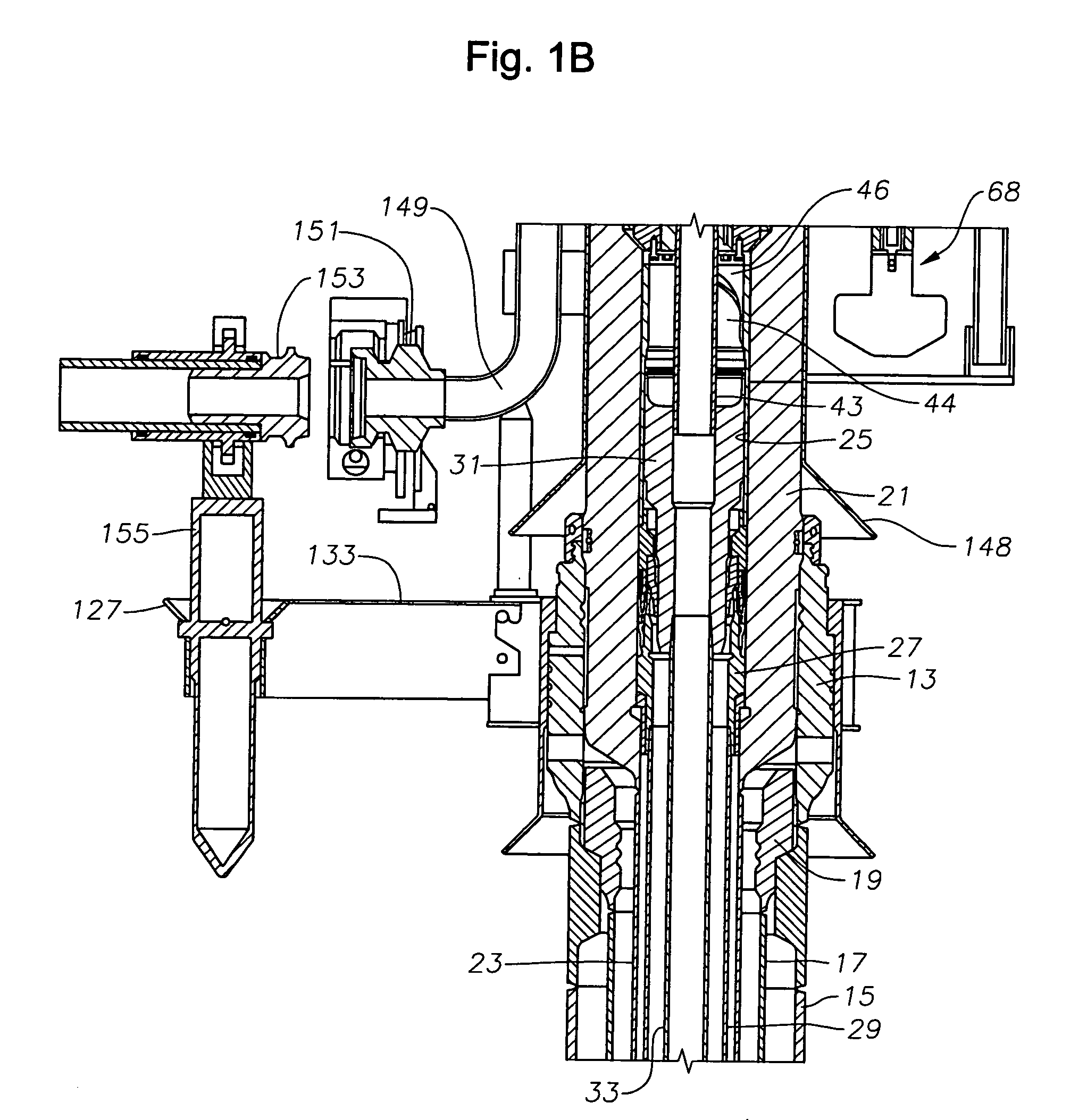

Apparatuses and methods for generating shock waves for use in the energy industry

ActiveUS20140305877A1Extend your lifeNeed can be fittedWaste water treatment from quariesFatty/oily/floating substances removal devicesShock waveFiber

Several methods and devices are provided herein to generate shock waves that are used in the oil industry for well drilling, hydrocarbon or gas exploitation, fracking process or improved oil recovery (IOR), enhanced oil recovery (EOR), cleaning of process waters, oil spills byproducts and oil pipes, which can be used as independent systems or as auxiliary systems concomitantly with other existing technologies. The different devices consist of generating shock waves utilizing either one or more laser sources, or a self-generated combustible gas supply, or a micro-explosive pellet, or piezocrystals, or a piezofiber composite structure.

Owner:SANUWAVE INC

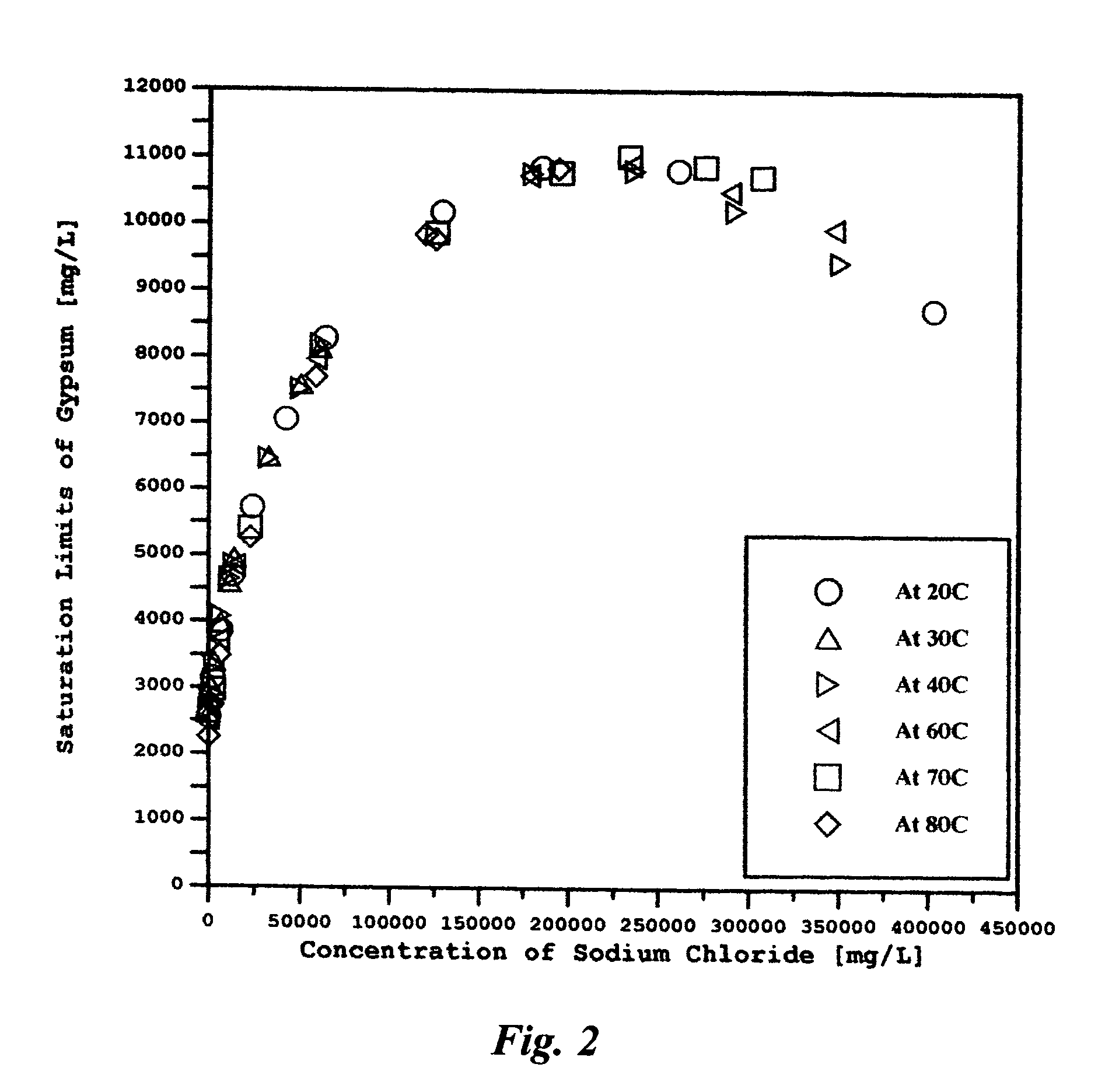

Methods to produce sulfate-free saline water and gypsum

ActiveUS7392848B1Avoid pollutionWaste water treatment from quariesSludge treatmentSaline waterSulfate

Methods are disclosed for the selective separation of sulfate from a saline stream such as seawater to produce nearly sulfate-free saline stream for oil-fields water injection operations. The separated sulfate in the form of gypsum from the treated saline stream can be used in different applications.

Owner:BADER MANSOUR S

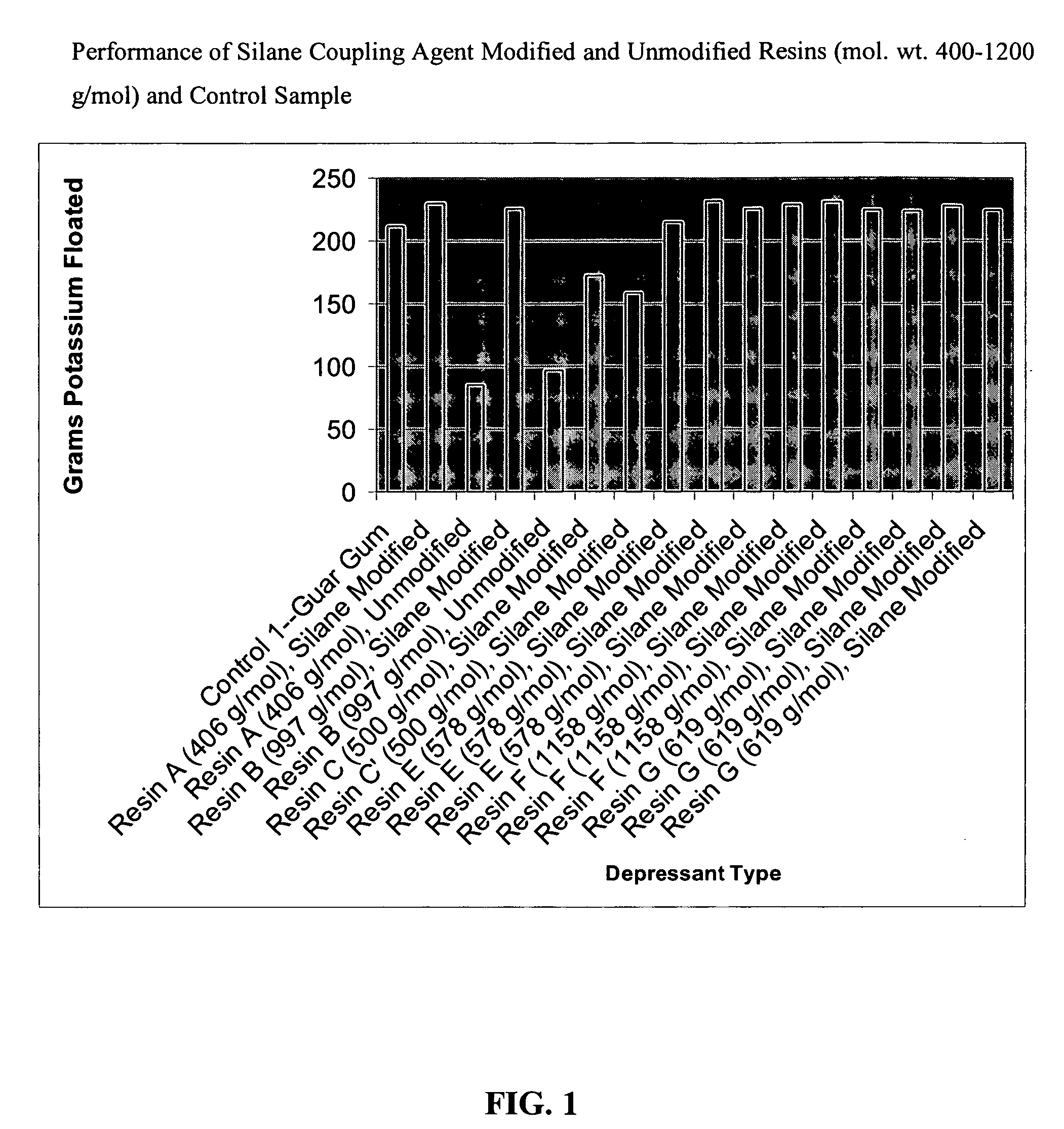

Modified amine-aldehyde resins and uses thereof in separation processes

InactiveUS20060151360A1Highly selective bindingWaste water treatment from quariesPigmenting treatmentIonAldehyde formation

Modified resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These modified resins are especially useful as froth flotation depressants in the beneficiation of many types of materials (e.g., mineral and metal ores), including the beneficiation of impure coal comprising clay impurities, as well as in the separation of valuable bitumen from solid contaminants such as sand. The modified resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water. The modified resins comprise a base resin that is modified with a coupling agent, which is highly selective for binding to solid contaminants and especially siliceous materials such as sand or clay.

Owner:INGEVITY SOUTH CAROLINA

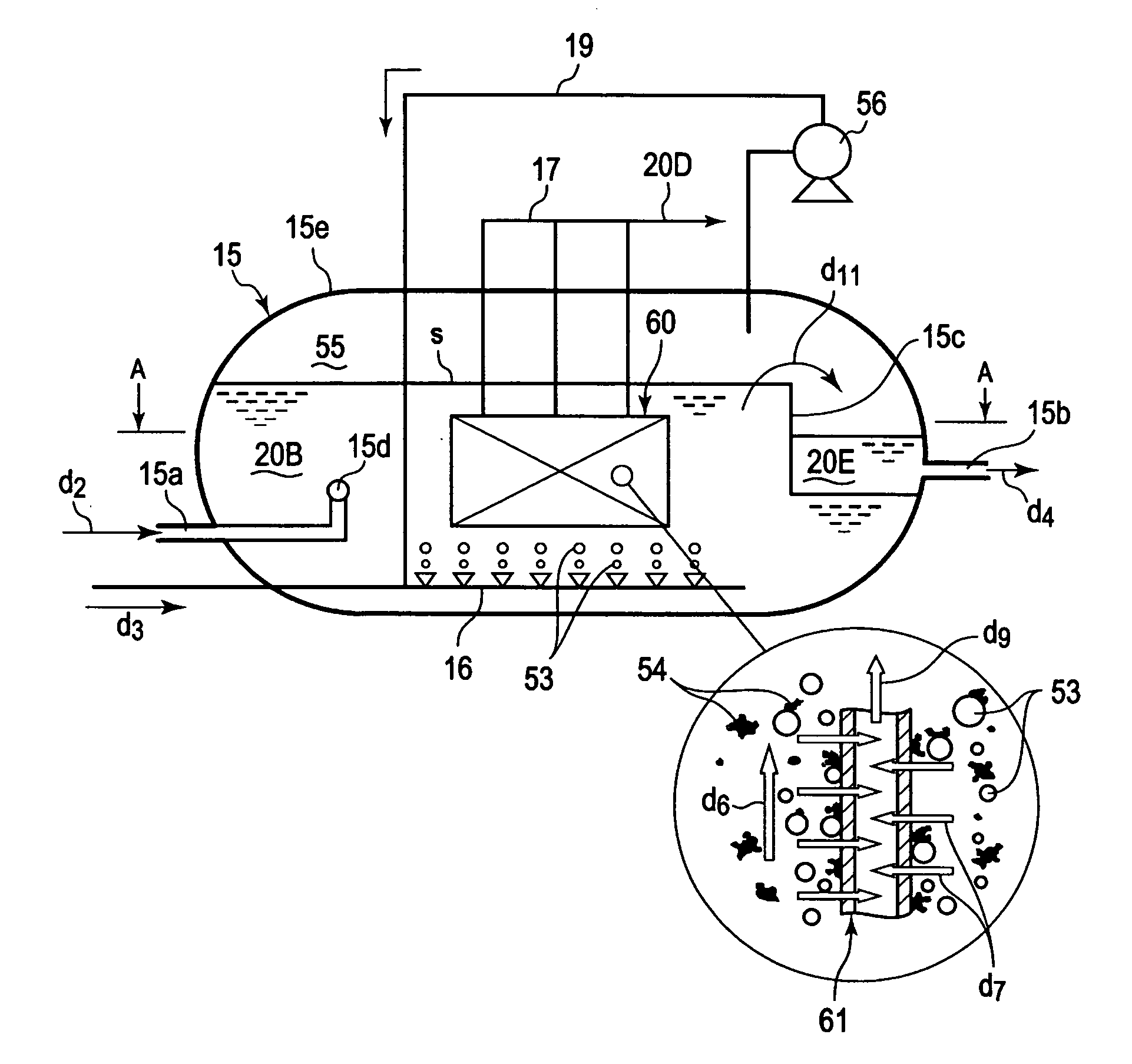

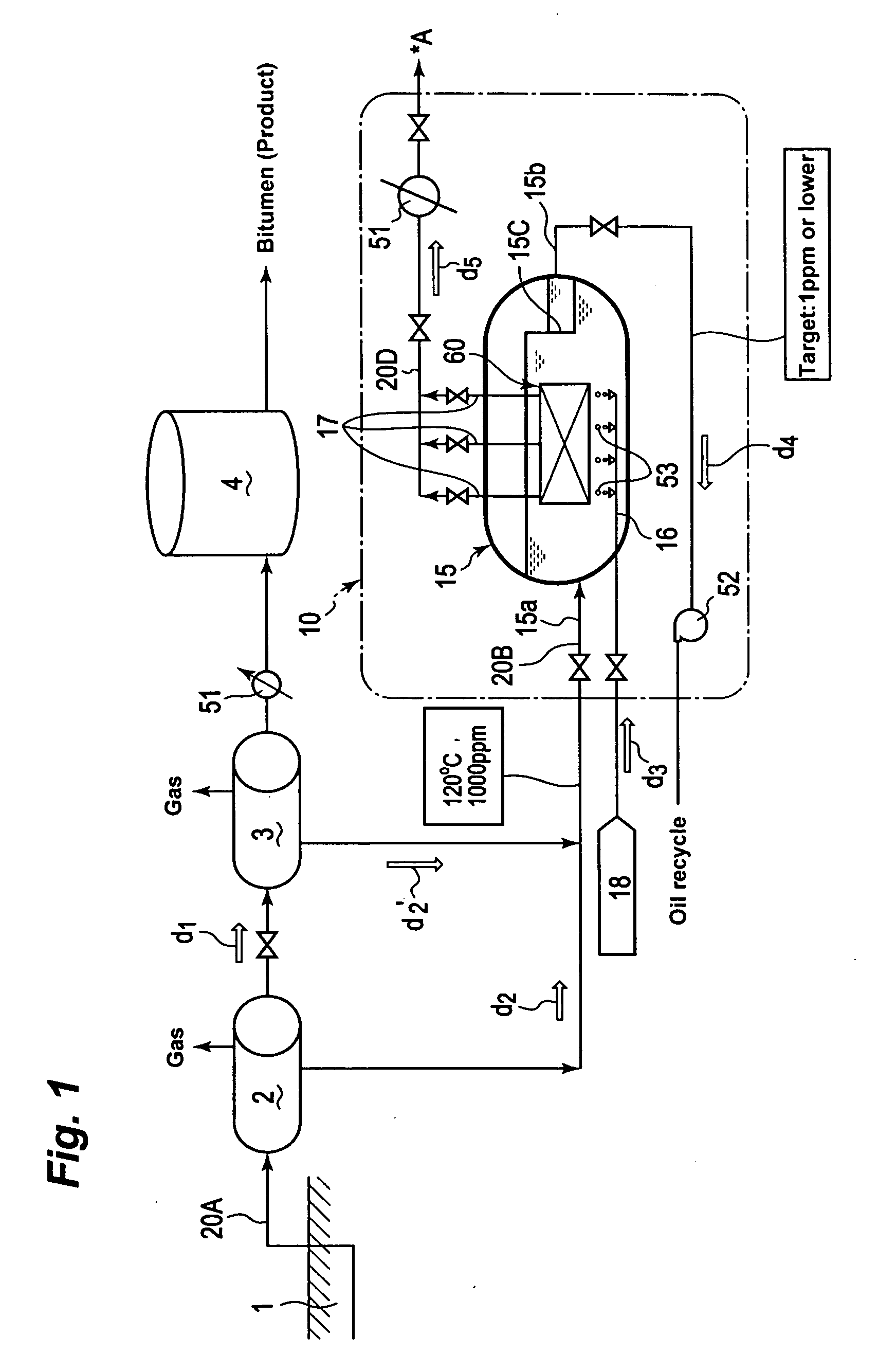

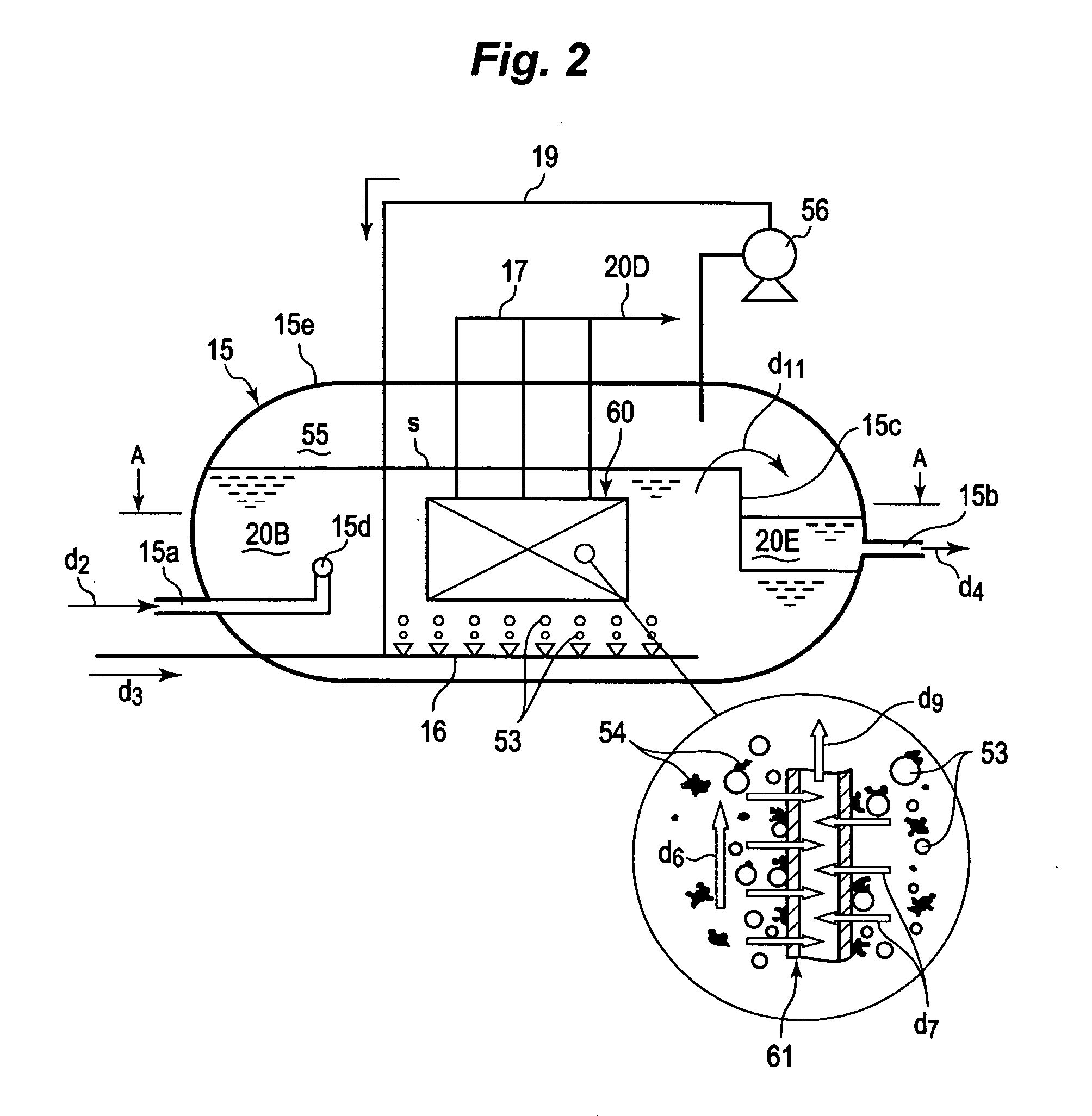

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

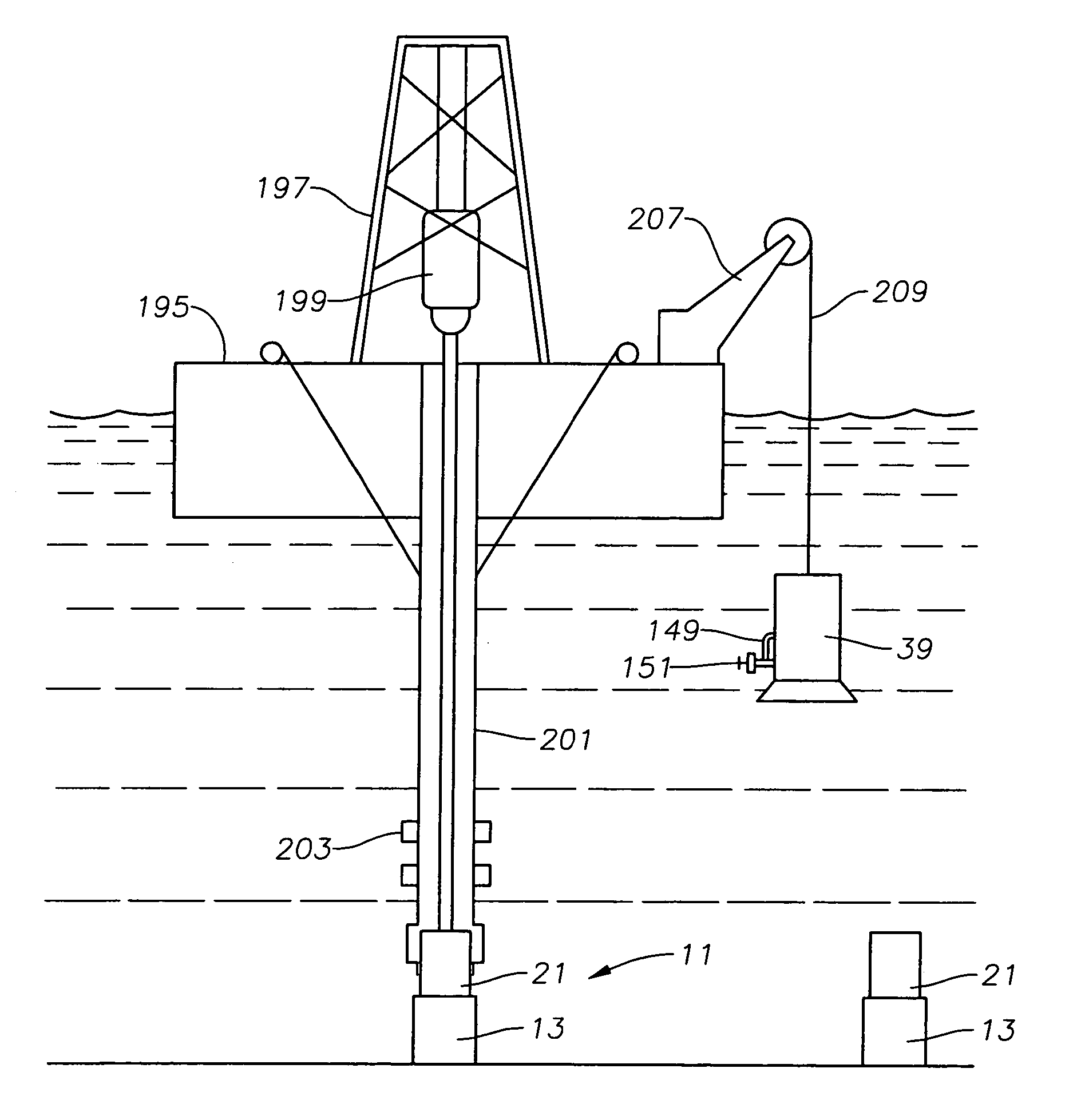

Drilling and producing deep water subsea wells

InactiveUS6968902B2Efficient separationMinimize flow disturbanceWaste water treatment from quariesLiquid separation auxillary apparatusOcean bottomWell drilling

Subsea wells are drilled and completed with an offshore floating platform in a manner that allows simultaneous work on more than one well. A first well is drilled and cased. Then a tubing hanger is run through a drilling riser and landed in the wellhead housing. Then, with the same floating platform, the drilling riser is disconnected and moved to a second well. While performing operations on the second well, the operator lowers a production tree from the floating platform on a lift line, and connects it to the first wellhead housing. An ROV assisted subsea plug removal tool is used for plug removal and setting operations. Seabed separation is configured upstream of a production choke valve.

Owner:VETCO GRAY

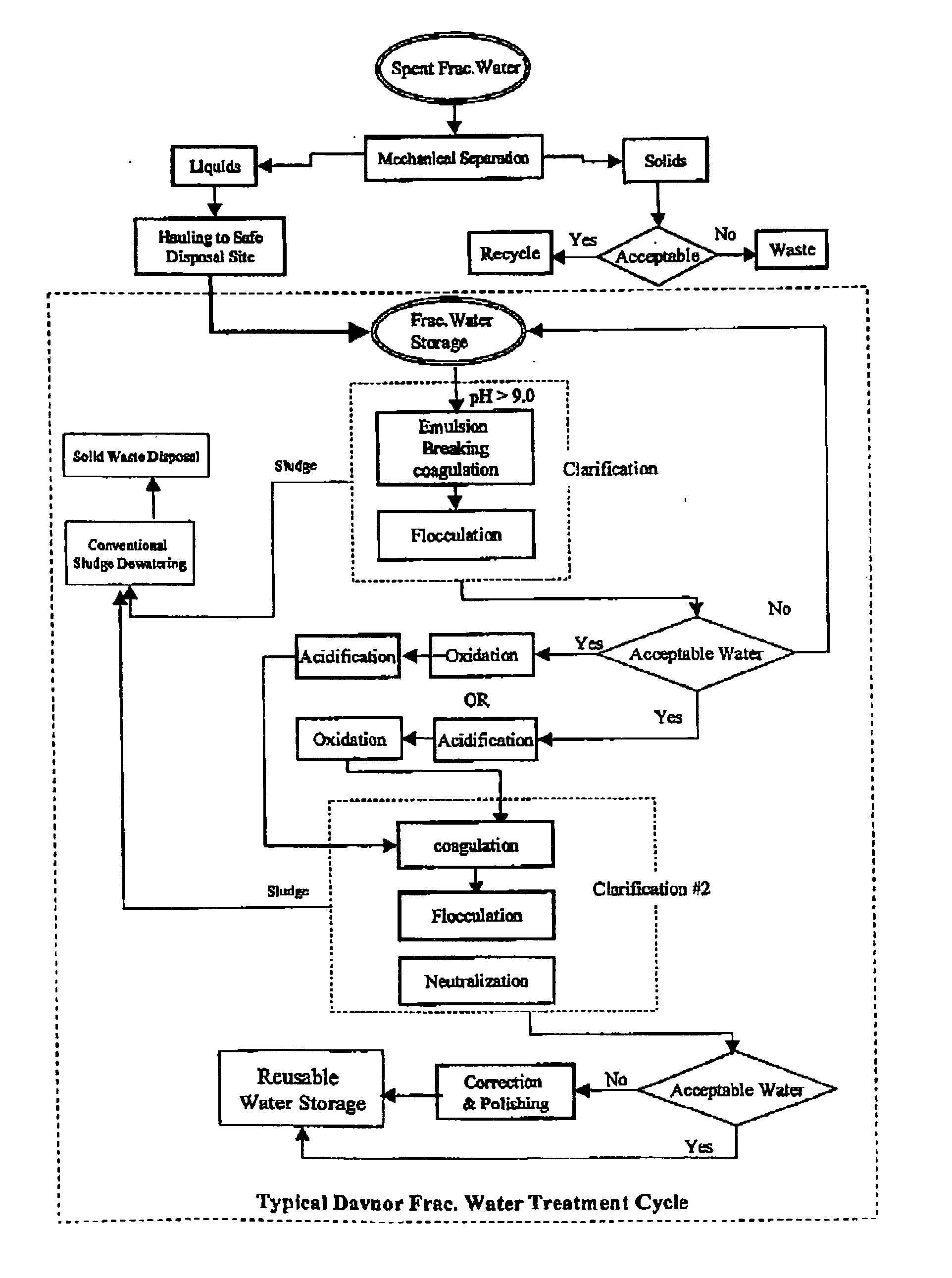

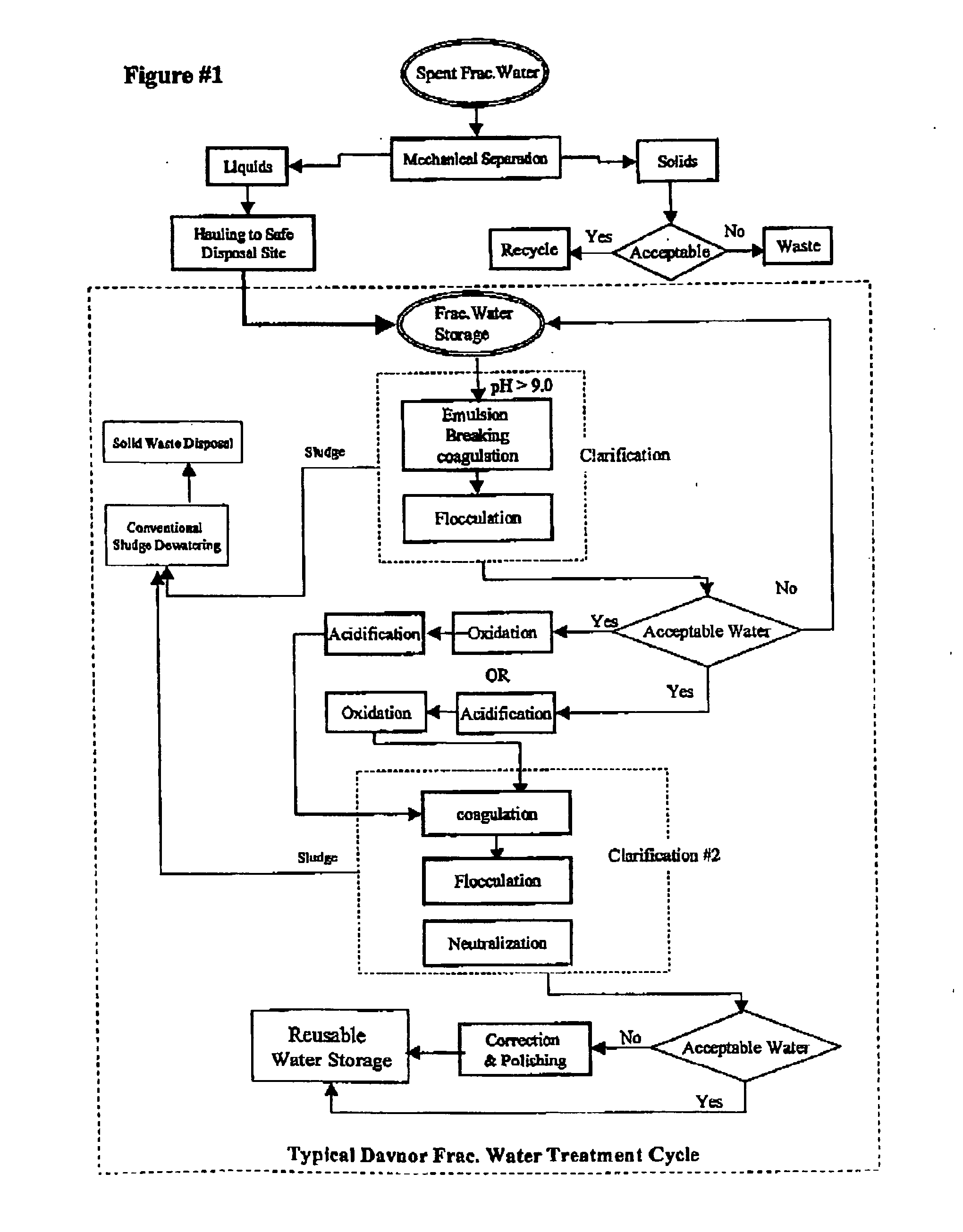

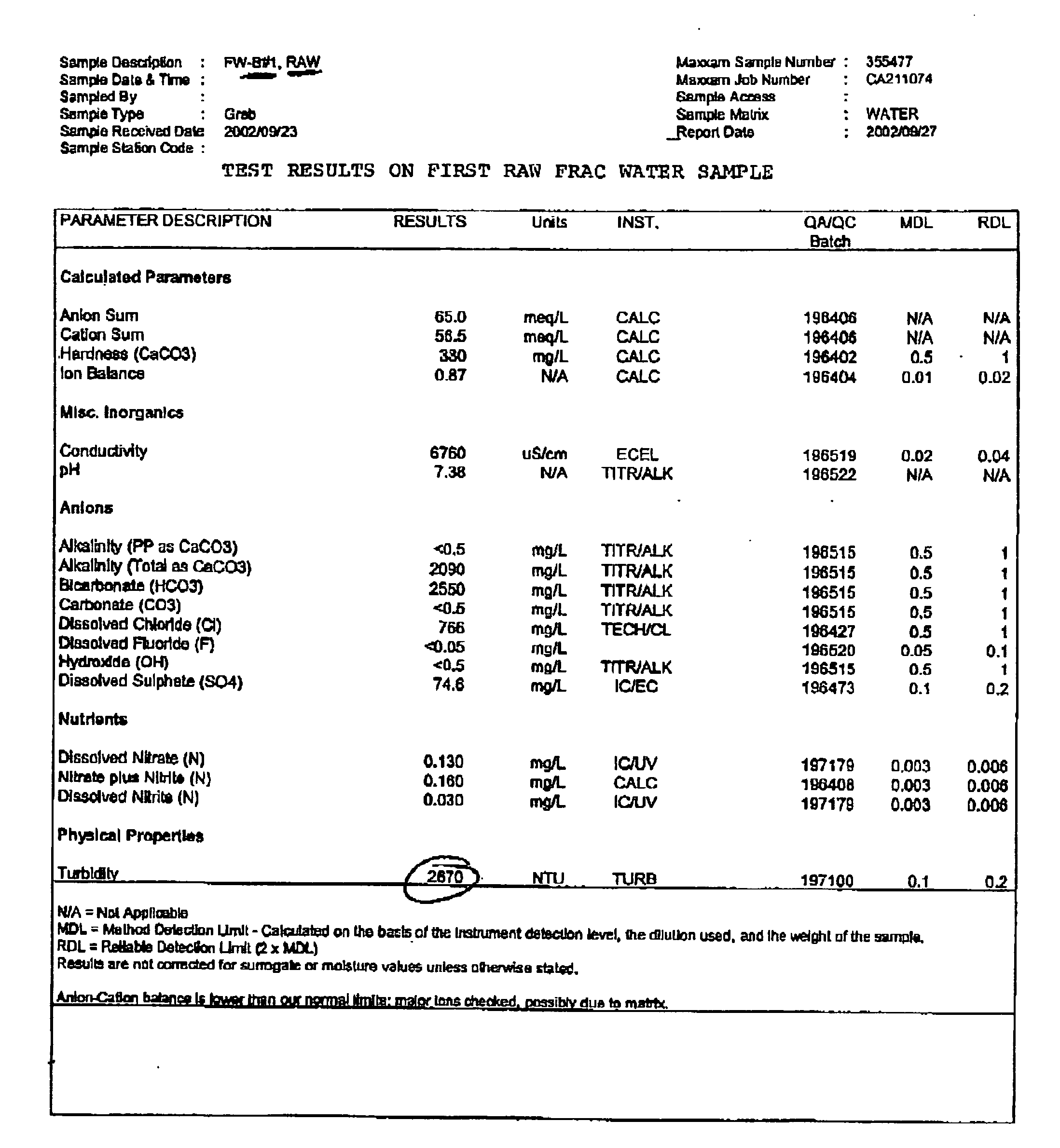

Oil and gas well fracturing (frac) water treatment process

InactiveUS20050098504A1Reduced pHRaise the pHWaste water treatment from quariesDewatering/demulsification with chemical meansFracturing fluidOxidizing agent

This invention relates to a novel process for treating and removing undesirable impurities from oil and gas well fracturing fluid. A method for treating fracturing water comprising: (a) passing contaminated fracturing water containing solids and liquid through a mechanical separator to remove solids from the liquid; (b) treating the fracturing water liquid with an alkaline agent to increase the pH of the liquid to a level of above 9; (c)) adding a coagulant to the fracturing water to form an agglomerate and separating the agglomerate from the fracturing water; (d) reducing the pH of the fracturing water of step (c)) to a level of less than about 5.5; and (e) adding an oxidizing agent to the fracturing water of step (d) to oxidize oxidizable impurities in the fracturing water.

Owner:DAVNOR WATER TREATMENT TECH

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

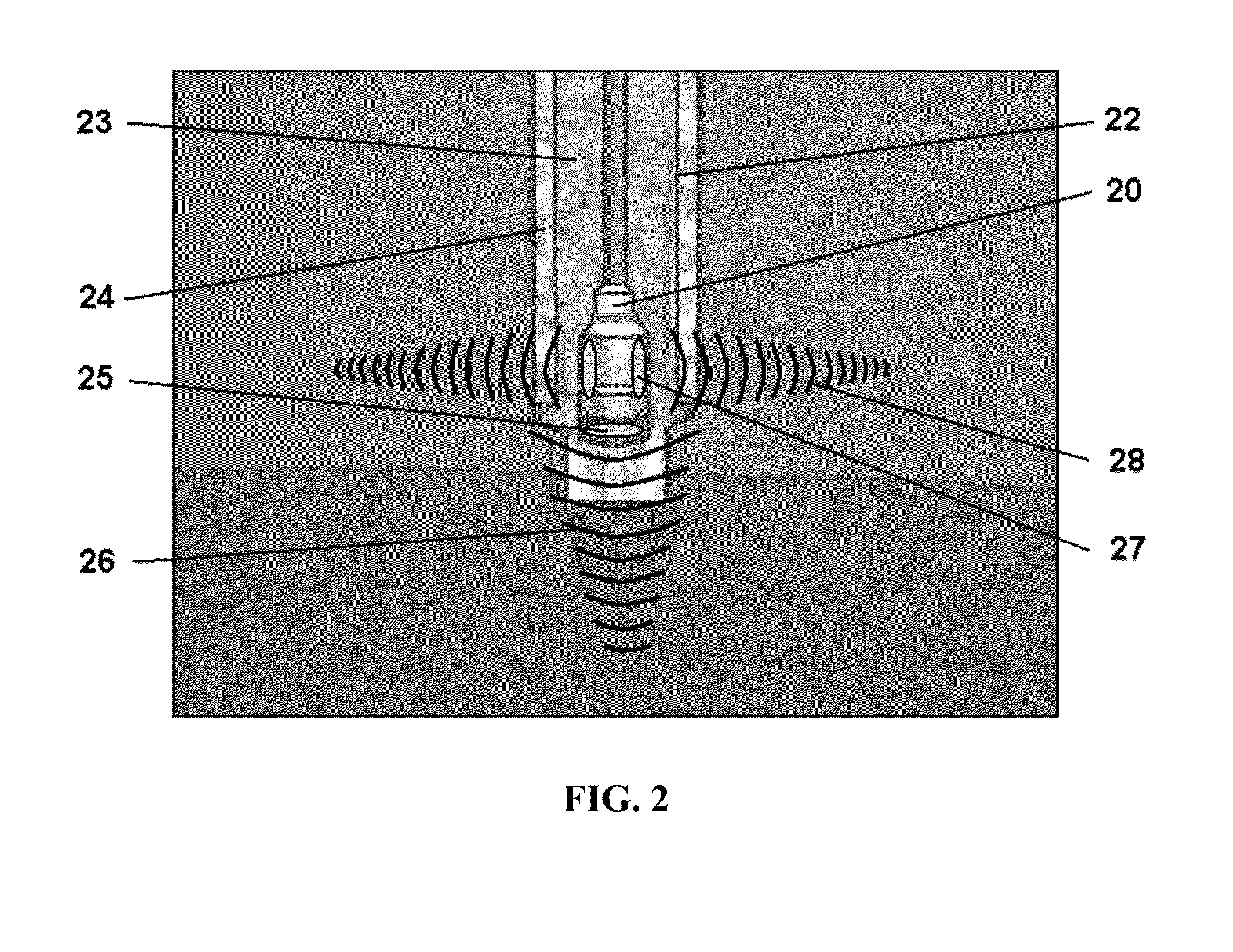

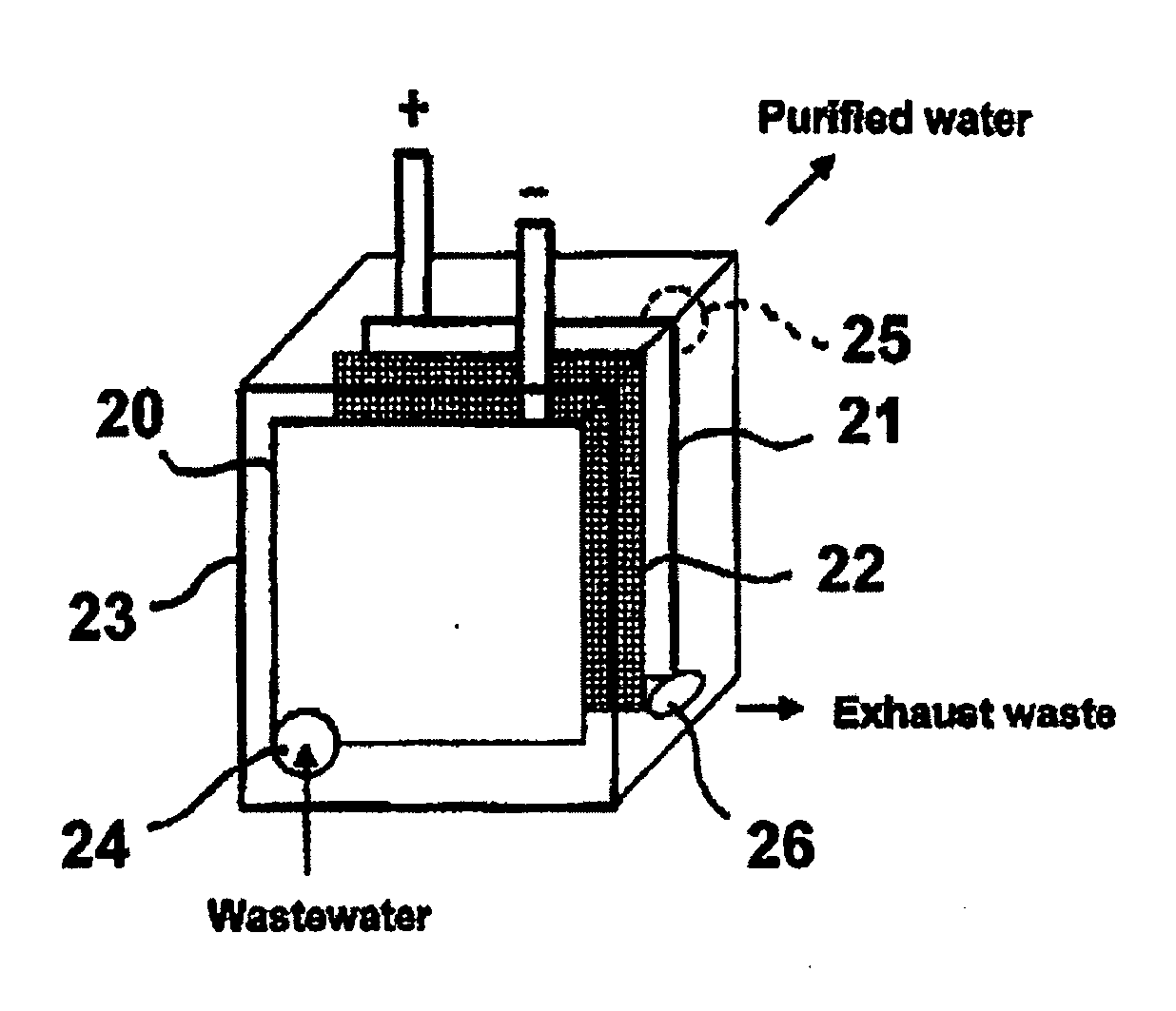

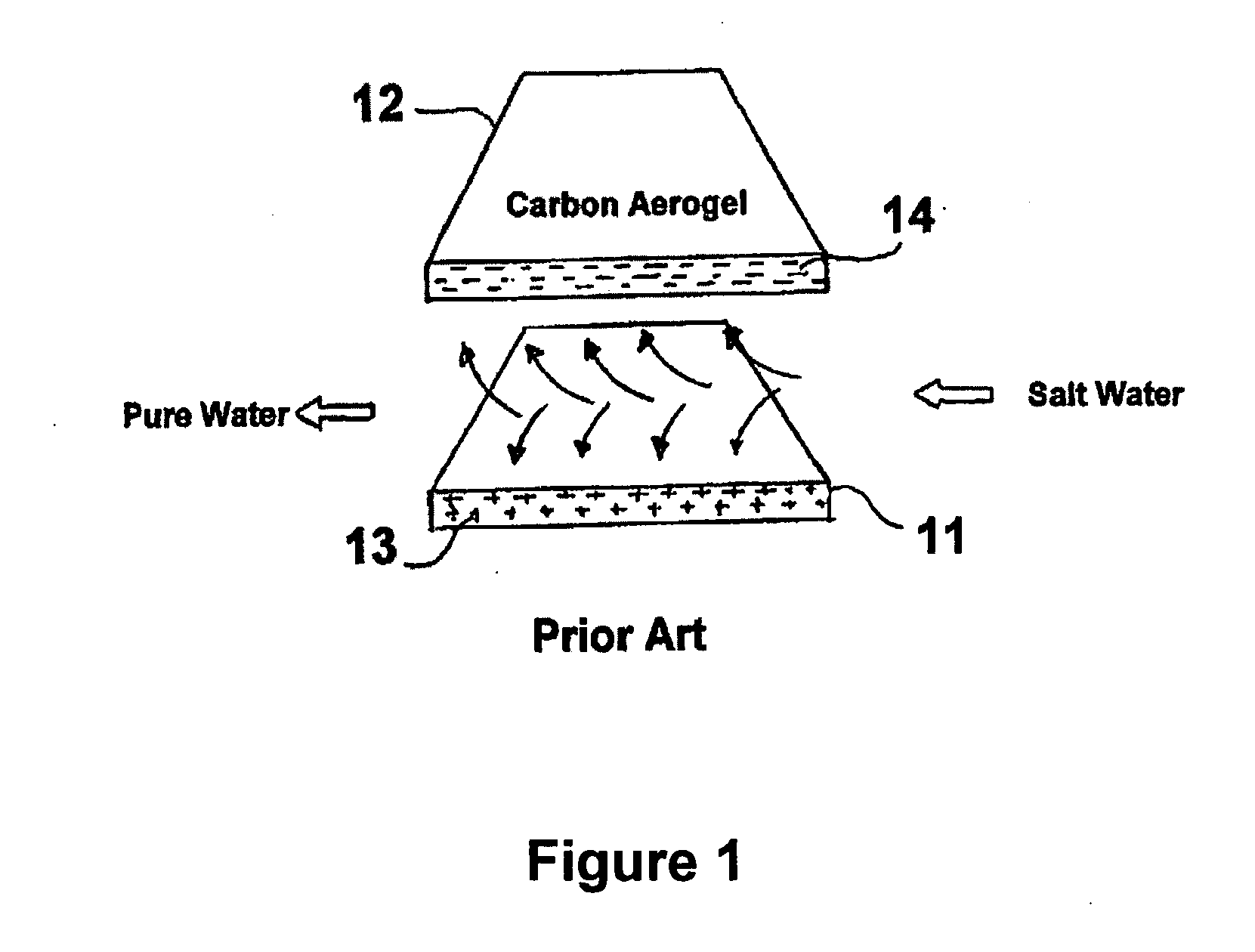

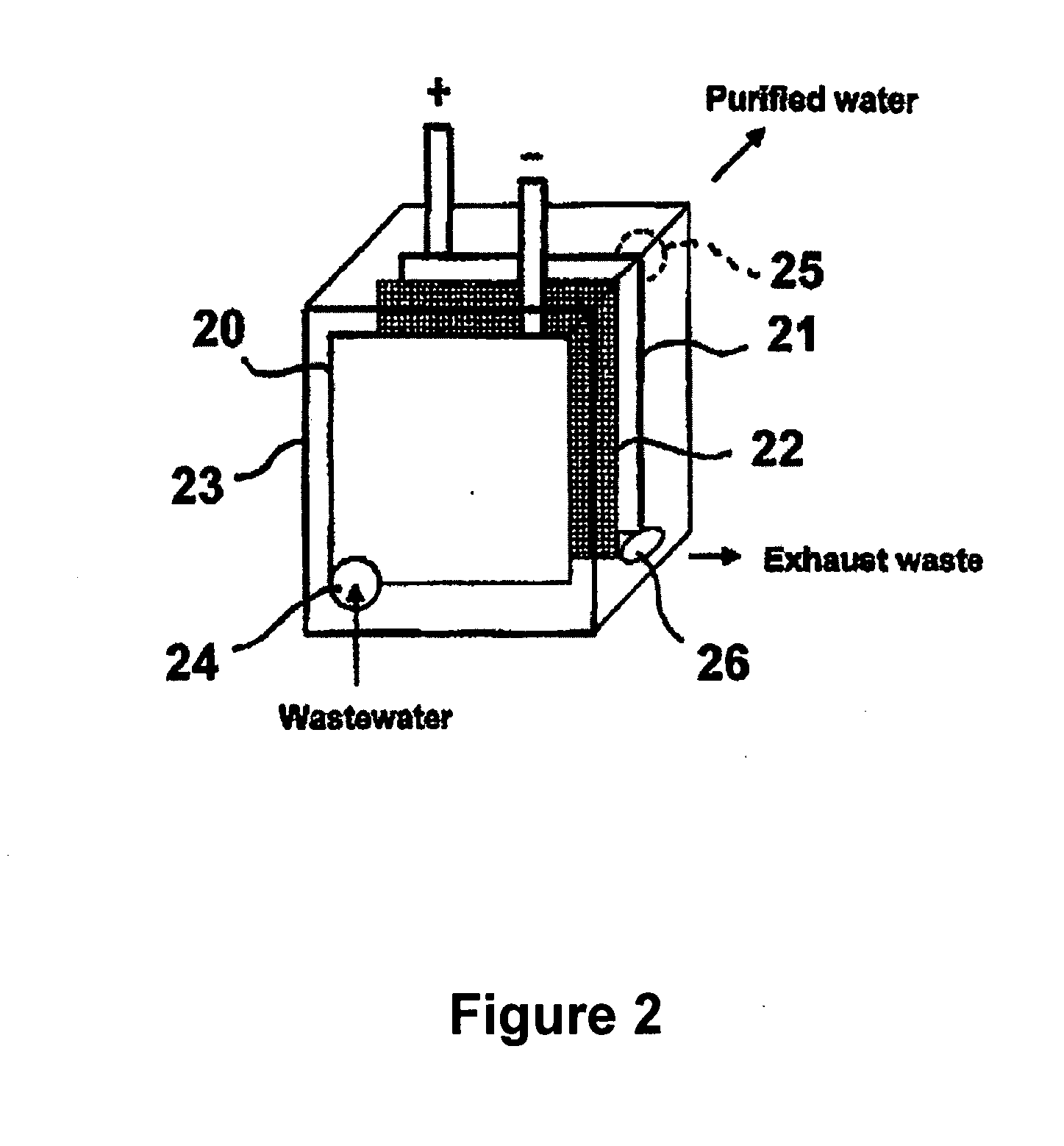

Multifunctional filtration and water purification systems

InactiveUS20080073288A1Waste water treatment from quariesElectrolysis componentsCross-linkFiltration

A water purification system having a porous anode electrode (21) and a porous cathode electrode (20), each of which is made of graphite, at least one metal oxide, and an ion-exchange, cross-linked, polarizable polymer, and optionally comprises microchannels. Disposed between the electrodes is a non-electron conductive, fluid permeable separator element (22), whereby wastewater is able to flow from one electrode to the other electrode. The electrodes and separator may be disposed within a housing (23) having a wastewater inlet opening (24), and exhaust waste outlet opening (26) and a purified water outlet opening (25). In this way, components of the system are easily replaced should the need arise.

Owner:QUOS

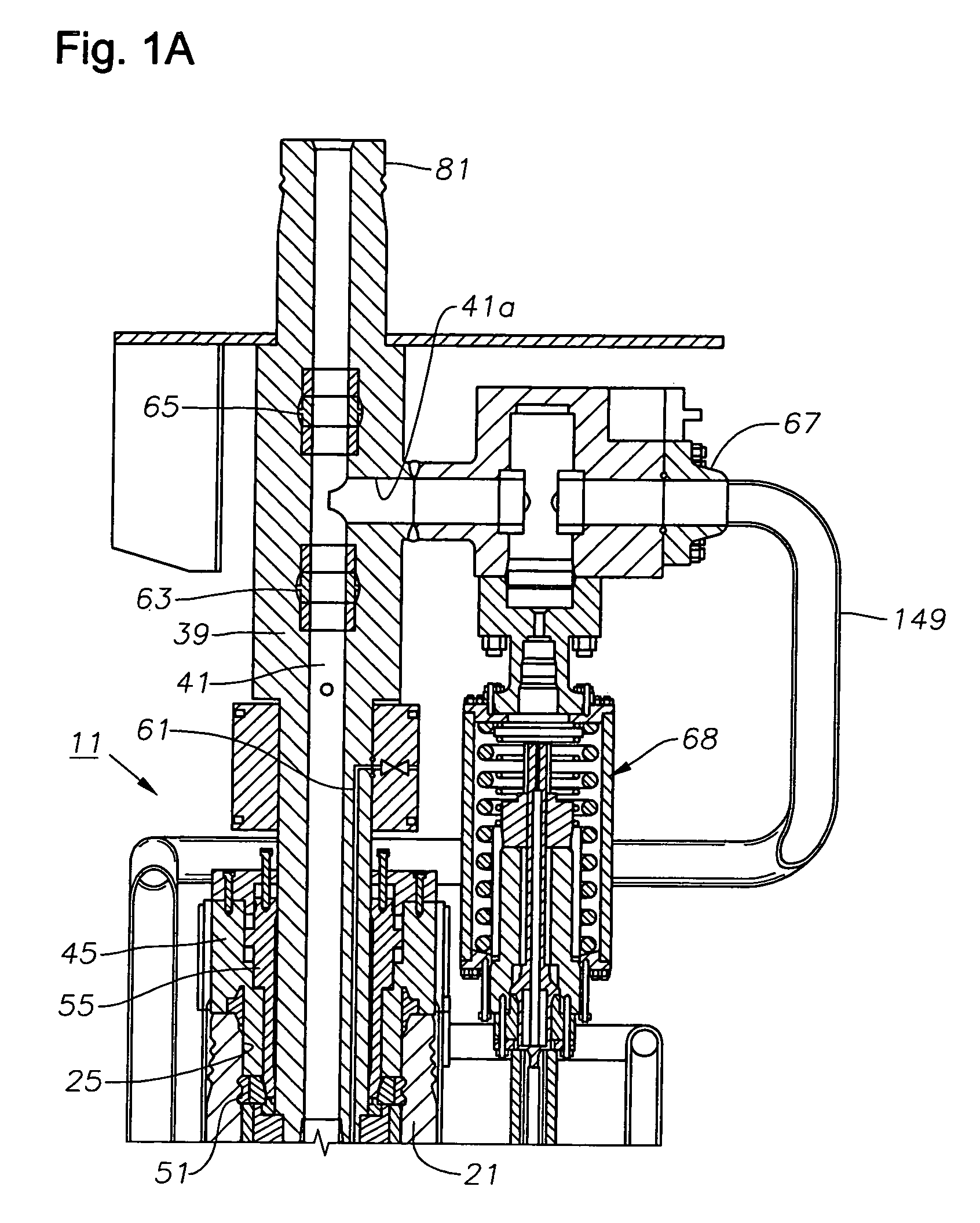

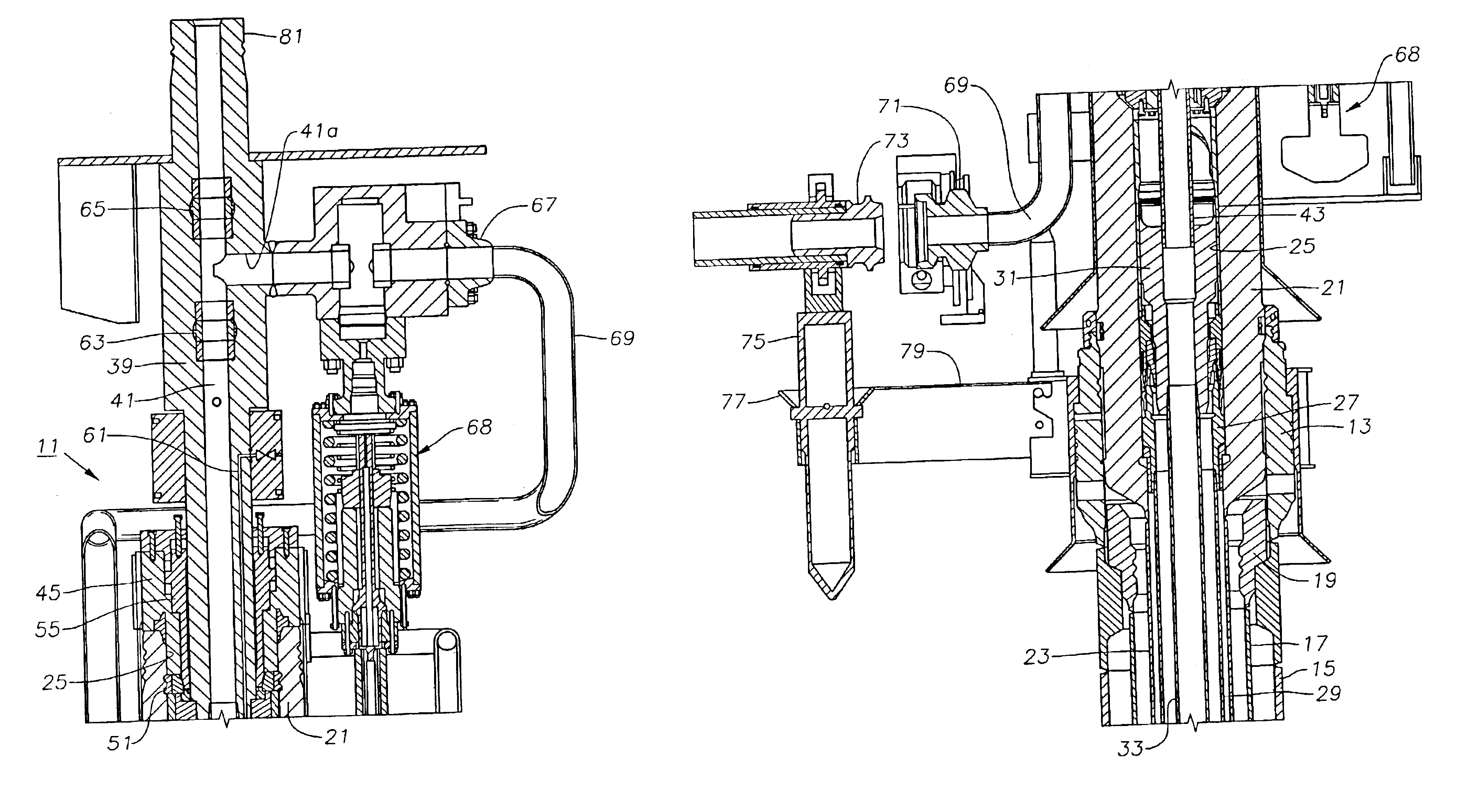

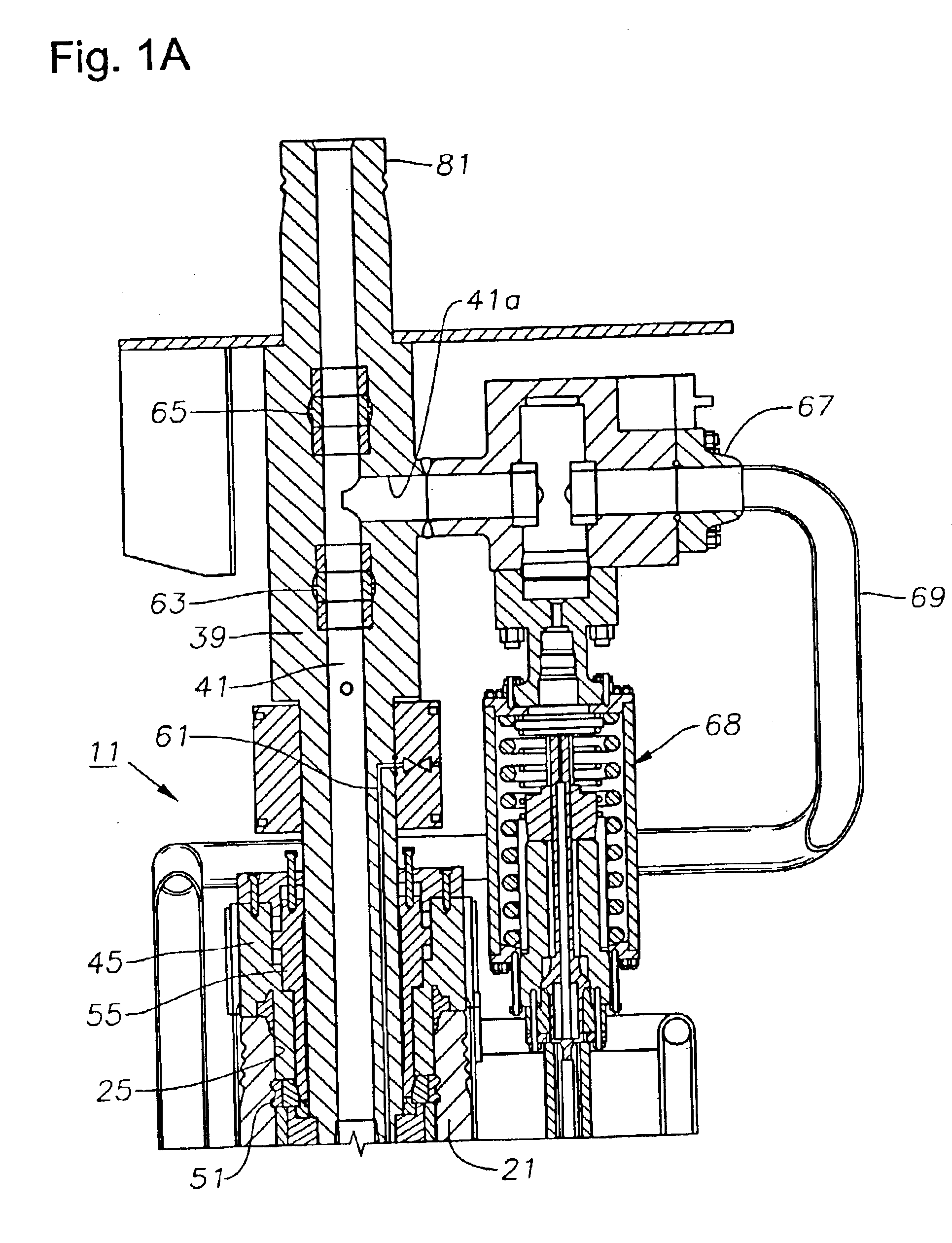

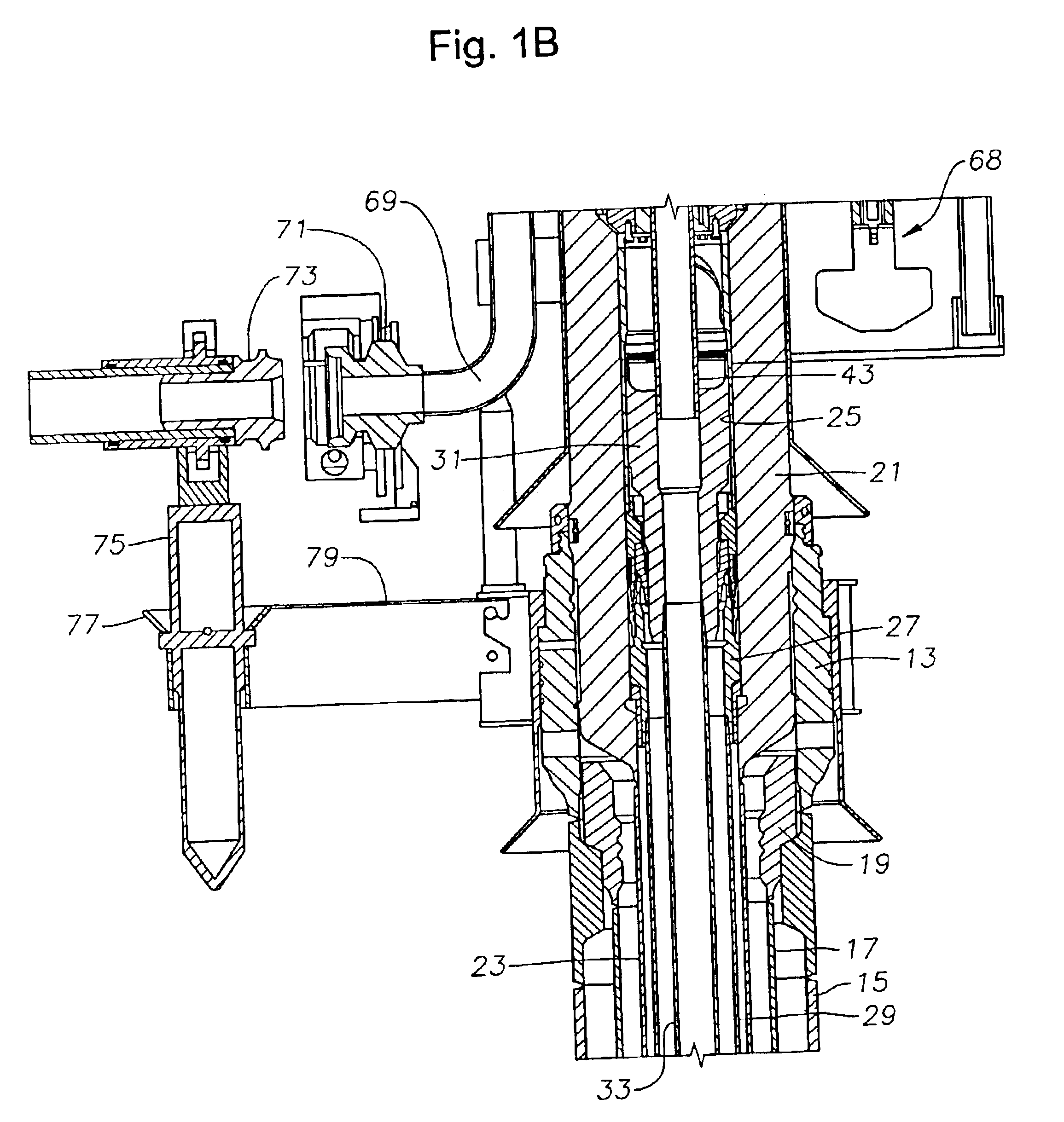

Tubing annulus valve

InactiveUS6840323B2Increased durabilityGuaranteed uptimeWaste water treatment from quariesDrilling rodsOcean bottomTubing hanger

A subsea wellhead assembly has a tubing hanger with a tubing annulus passage and a production passage. A metal-sealing shuttle valve is mounted in the tubing hanger for blocking upward flow through the tubing annulus passage. The shuttle valve has a retention mechanism that prevents the shuttle from moving to the open position when fluid pressure is applied from above. The retention mechanism is released by the running tool after testing has been completed, causing the shuttle to close. The tree has an engaging member that can be stroked downward into the tubing hanger annulus passage to move the shuttle valve to the open position for communicating with the annulus.

Owner:VETCO GRAY

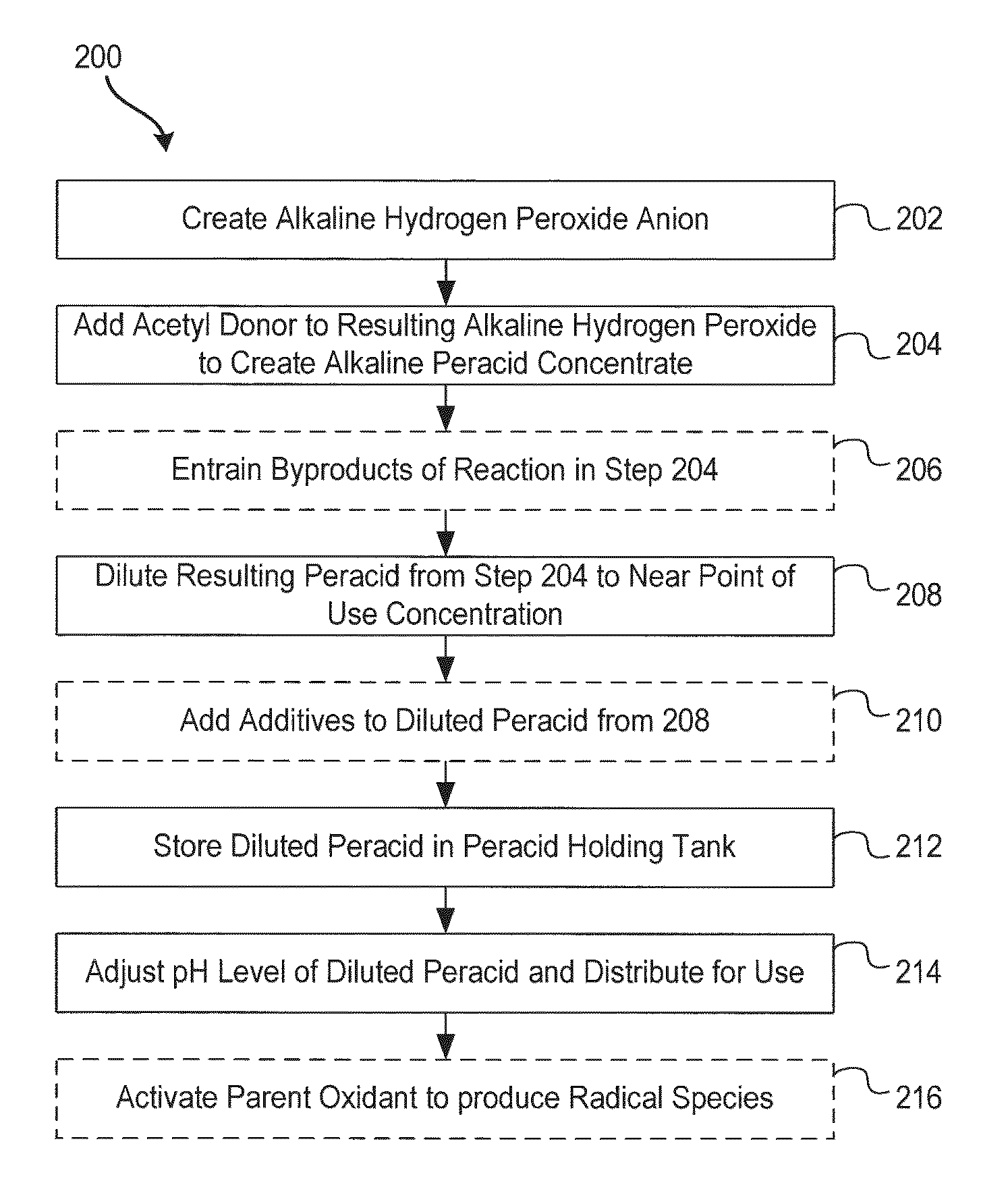

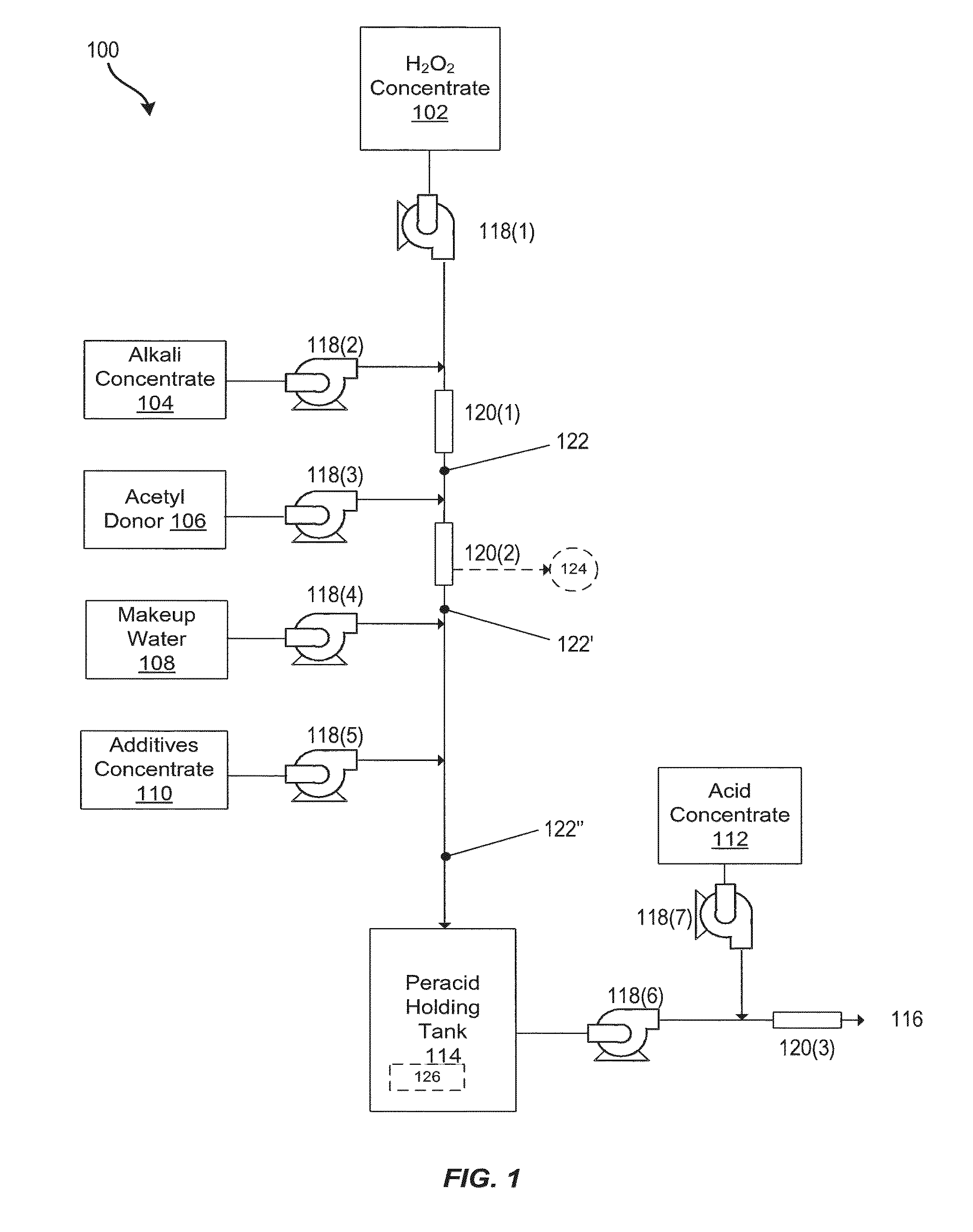

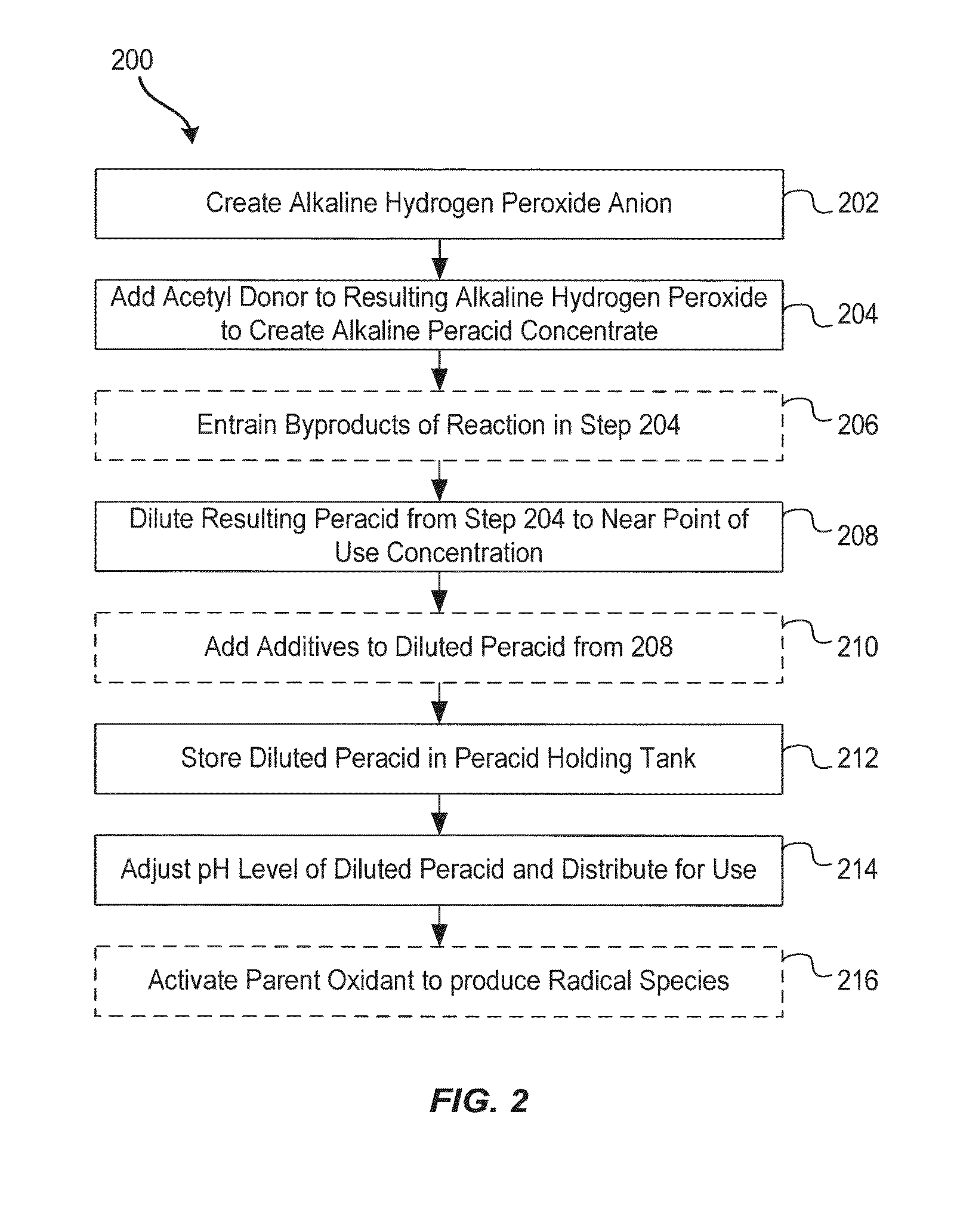

System and method for generation of point of use reactive oxygen species

Systems and methods for generating reactive oxygen species formulations useful in various oxidation applications. Exemplary formulations include singlet oxygen or superoxide and can also contain hydroxyl radicals or hydroperoxy radicals, among others. Formulations can contain other reactive species, including other radicals. Exemplary formulations containing peracids are activated to generate singlet oxygen. Exemplary formulations include those containing a mixture of superoxide and hydrogen peroxide. Exemplary formulations include those in which one or more components of the formulation are generated electrochemically. Formulations of the invention containing reactive oxygen species can be further activated to generate reactive oxygen species using activation chosen from a Fenton or Fenton-like catalyst, ultrasound, ultraviolet radiation or thermal activation. Exemplary applications of the formulations of the invention among others include: cleaning in place applications, water treatment, soil decontamination and flushing of well casings and water distribution pipes.

Owner:CLEAN CHEM

Method for recycling of oil based drilling fluid contaminated with water and water contaminated with oil based drilling fluid

InactiveUS6881349B2Waste water treatment from quariesDewatering/demulsification with chemical meansDemulsifierAlkyl polyglycoside

A mobile apparatus and method for recycling an invert emulsion based drilling fluid, in which the invert emulsion based drilling fluid includes an oleaginous component and an aqueous component. The apparatus includes an emulsion breaking tank, a water treatment tank, a filter press, and hydrocarbon filters. The method includes: mixing said invert emulsion drilling fluid with a emulsion breaker, wherein the emulsion breaker is a mixture of an alkyl glucoside and an alkane sulfonate; and separating the oleaginous component of the invert emulsion drilling fluid from the aqueous component of the invert emulsion drilling fluid. The method preferably utilizes an emulsion breaker that is a combination of an anionic surfactant, a nonionic surfactant and an alkyl polyglycoside surfactant.

Owner:MI

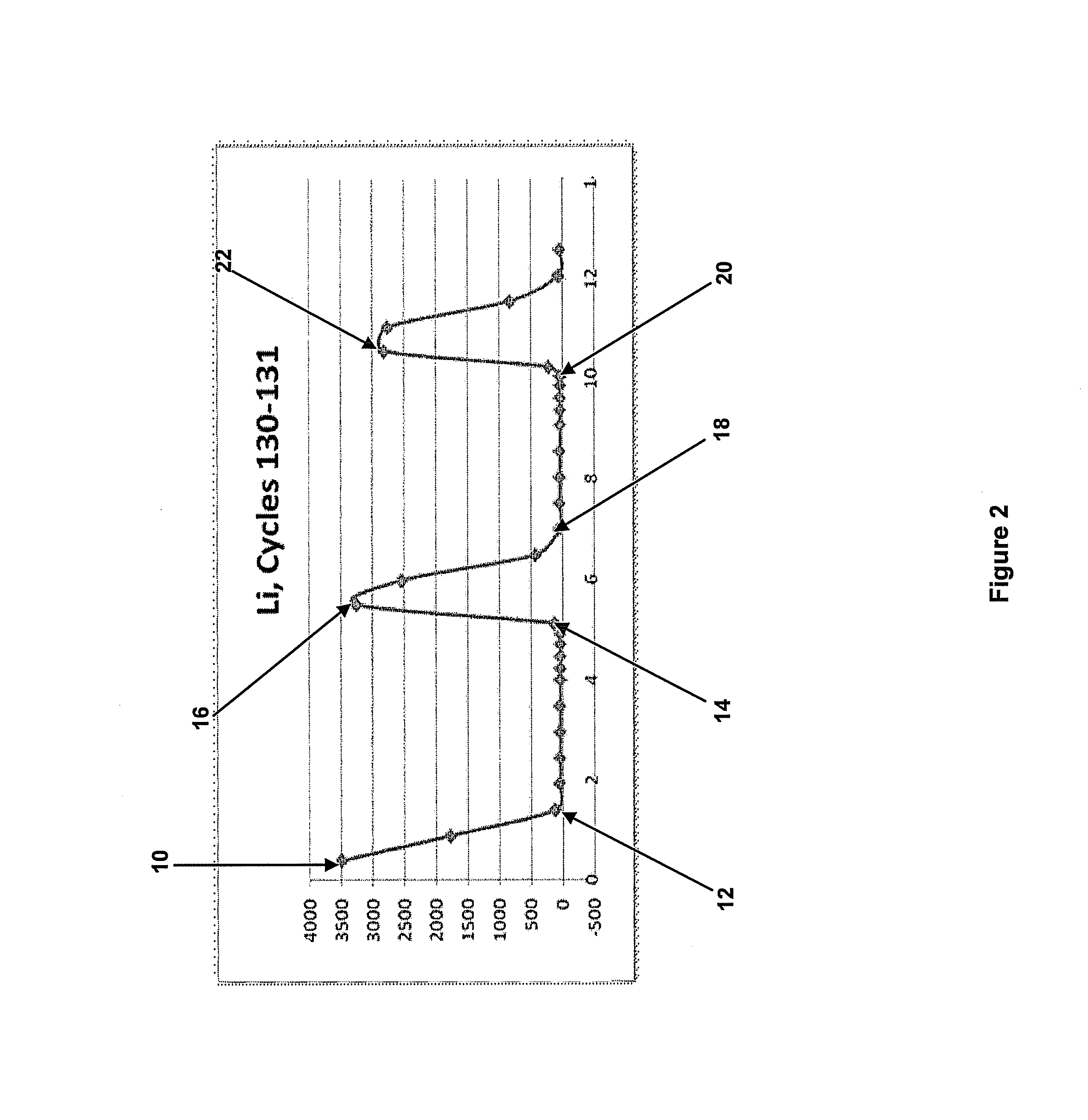

Sorbent for lithium extraction

ActiveUS8753594B1Increase ionic strengthWaste water treatment from quariesAluminium compoundsSorbentLithium aluminate

This invention relates to a method for preparing a lithium aluminate intercalate (LAI) matrix solid and methods for the selective extraction and recovery of lithium from lithium containing solutions, including brines. The method for preparing the LAI matrix solid includes reacting aluminum hydroxide and a lithium salt for form the lithium aluminate intercalate, which can then be mixed with up to about 20% by weight of a polymer to form the LAI matrix.

Owner:TERRALITHIUM LLC

Processes for water treatment

InactiveUS7077963B2Low costEconomical and efficientWaste water treatment from quariesSolid waste disposalSufficient timeMagnesium ion

The invention provides compositions comprising bauxite refinery residues that have been reacted with sufficient calcium and magnesium ions that they have a reaction pH of less than 10.5, and one or more water treating additives. The invention also provides processes for treatment of water containing dissolved inorganic substances involving stepwise treatment of the water in which the reacted bauxite refinery residues are added after the addition of a pH-raising additive. The invention also provides processes for treatment of water containing dissolved inorganic substances in which the reacted bauxite refinery residues are added stepwise, with one or more water treating additives also being added in at least one of the steps. The invention also provides a process for the neutralisation of bauxite refinery residue by reacting it with a base amount and a treating amount of calcium ions and a base amount and a treating amount of magnesium ions for a time sufficient to produce an at least partially-neutralized residue exhibiting a reaction pH of less than 10.5.

Owner:NAUVEAU TECH INVESTMENTS

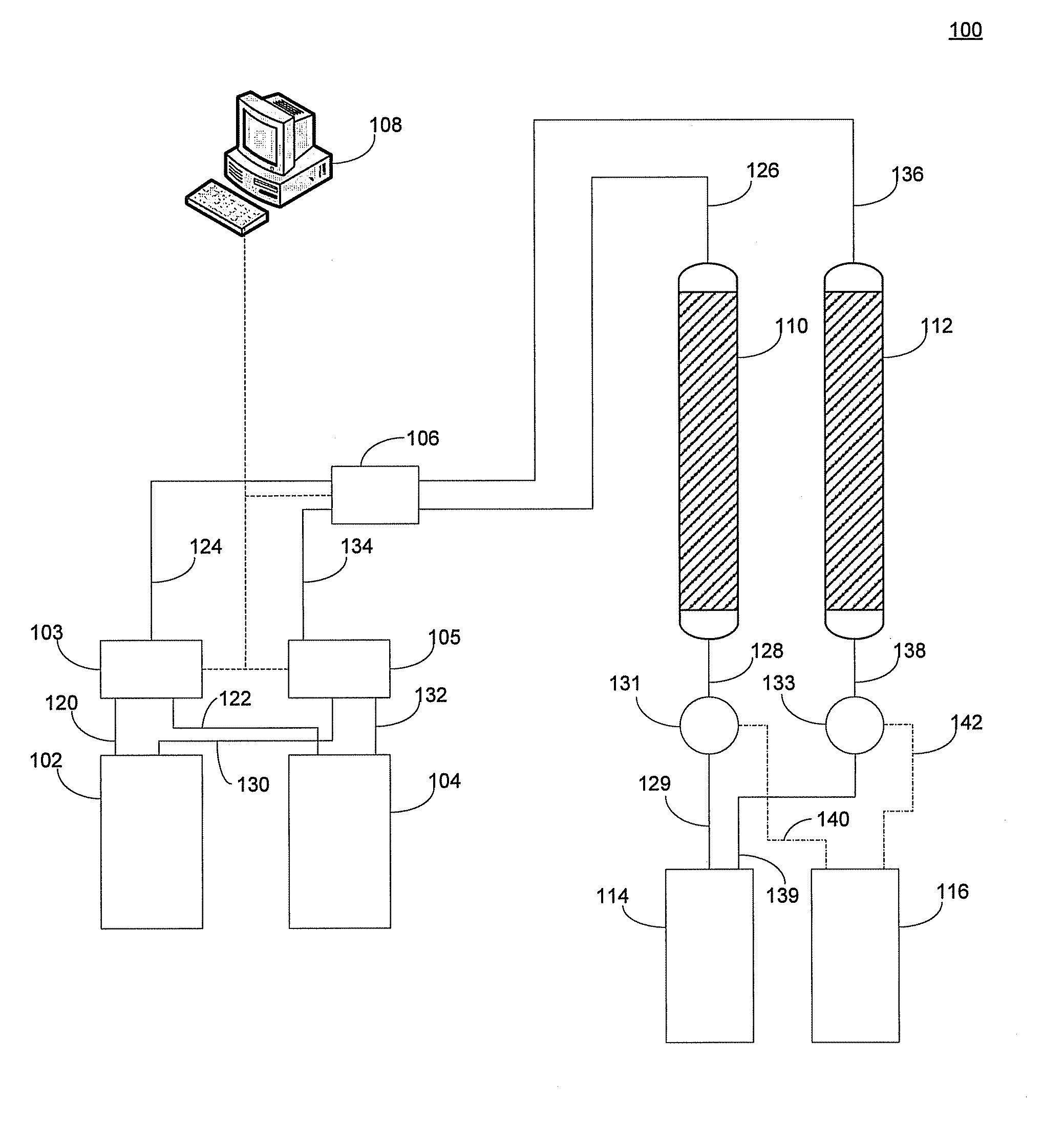

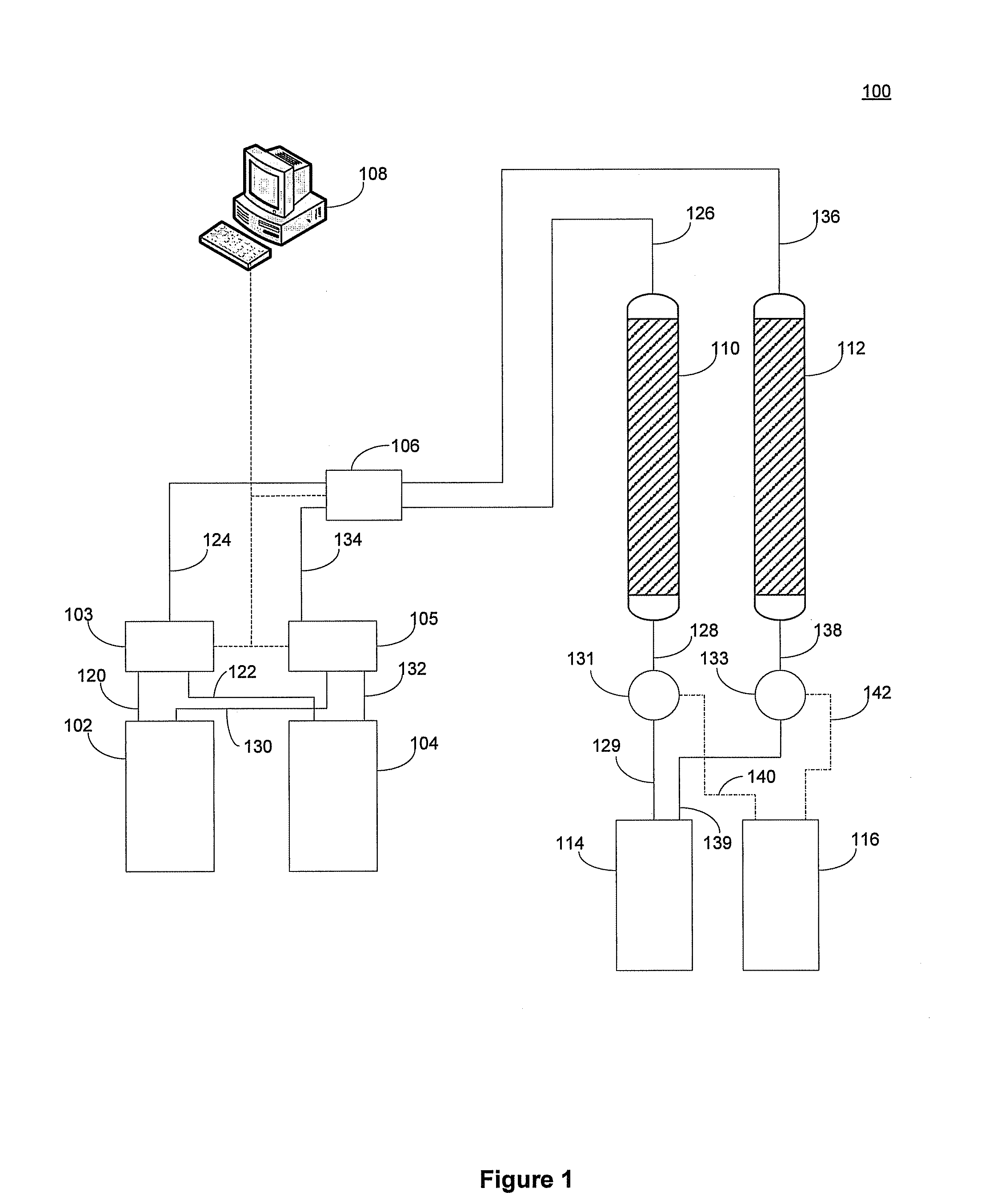

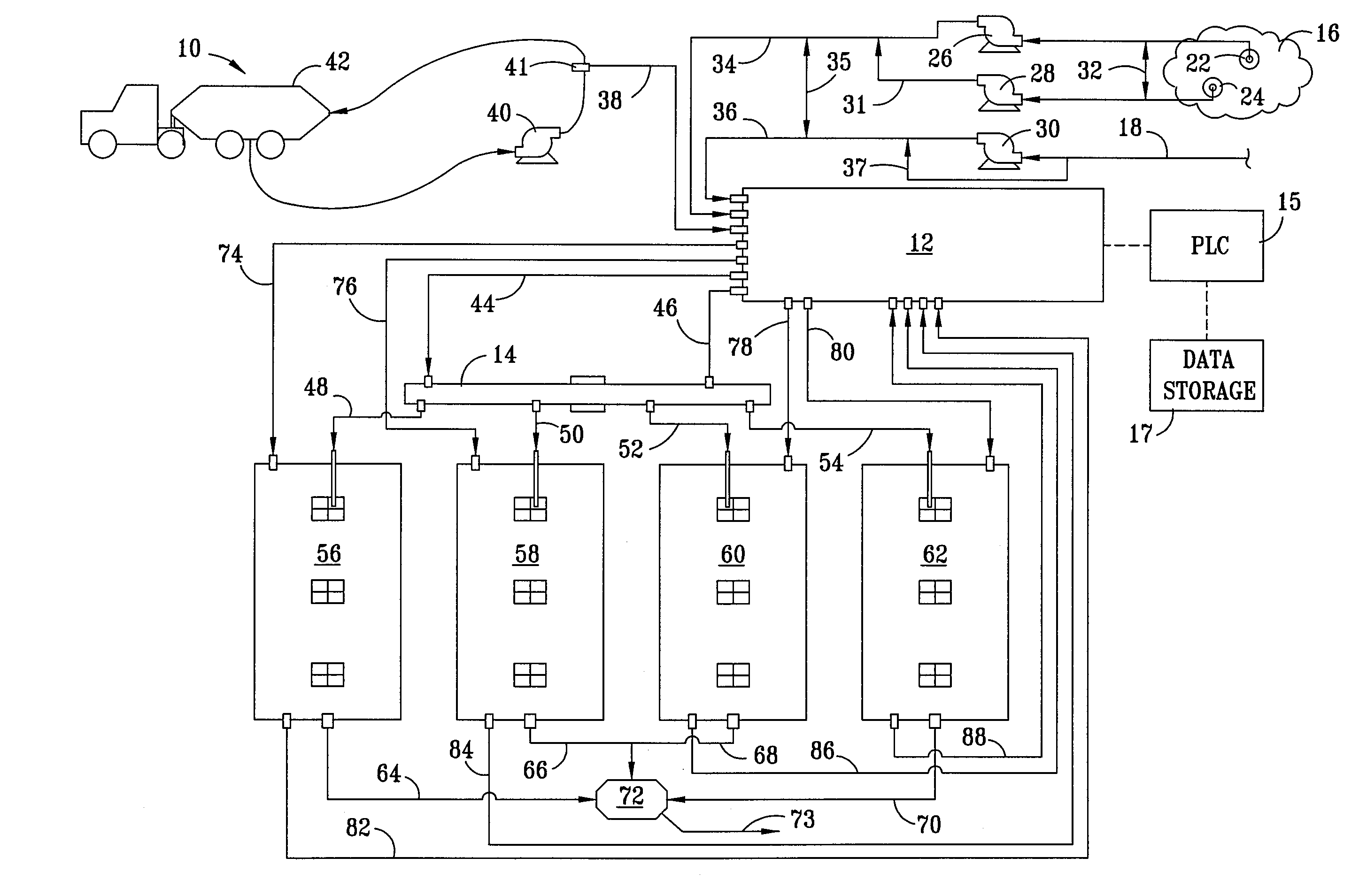

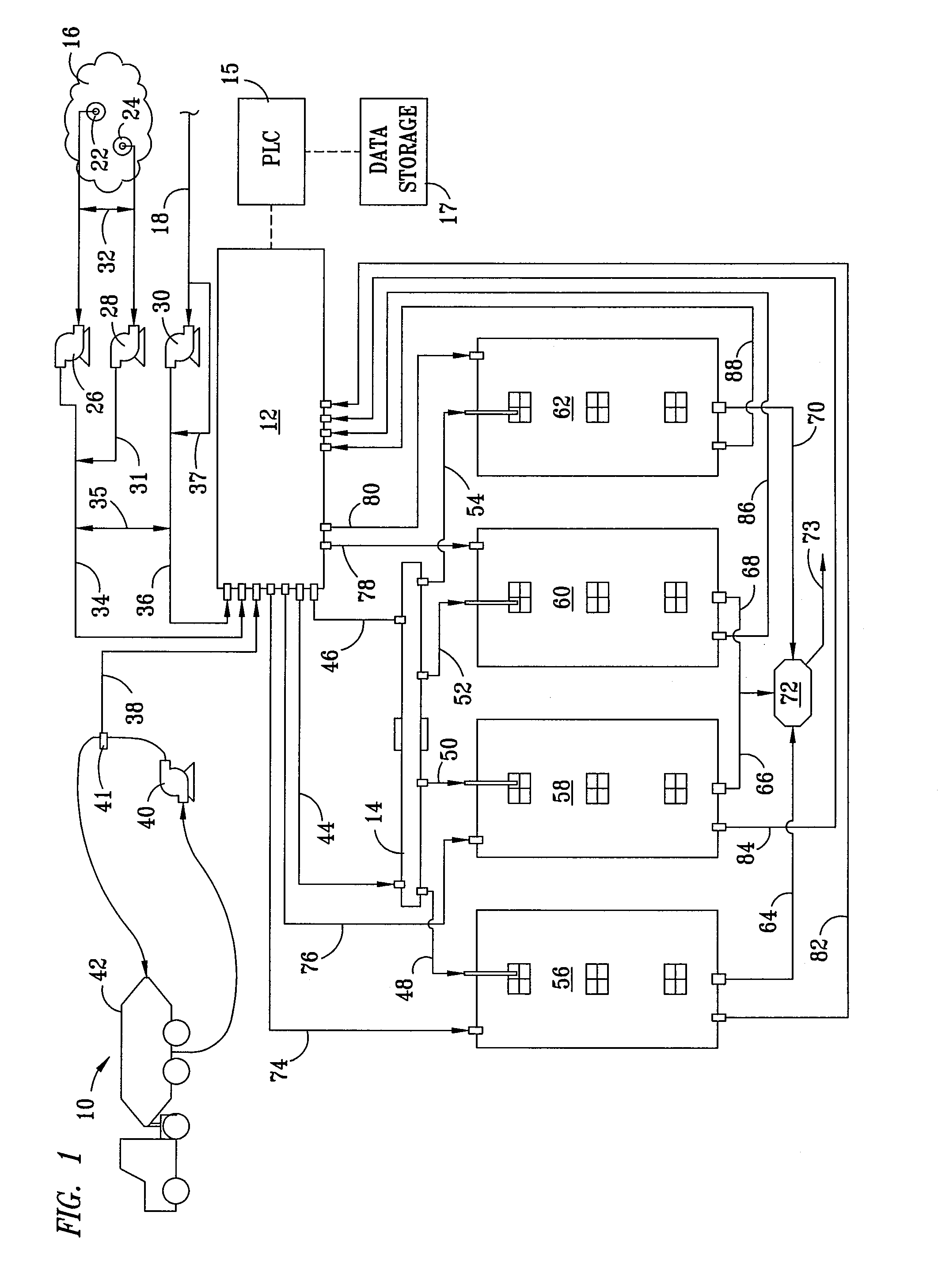

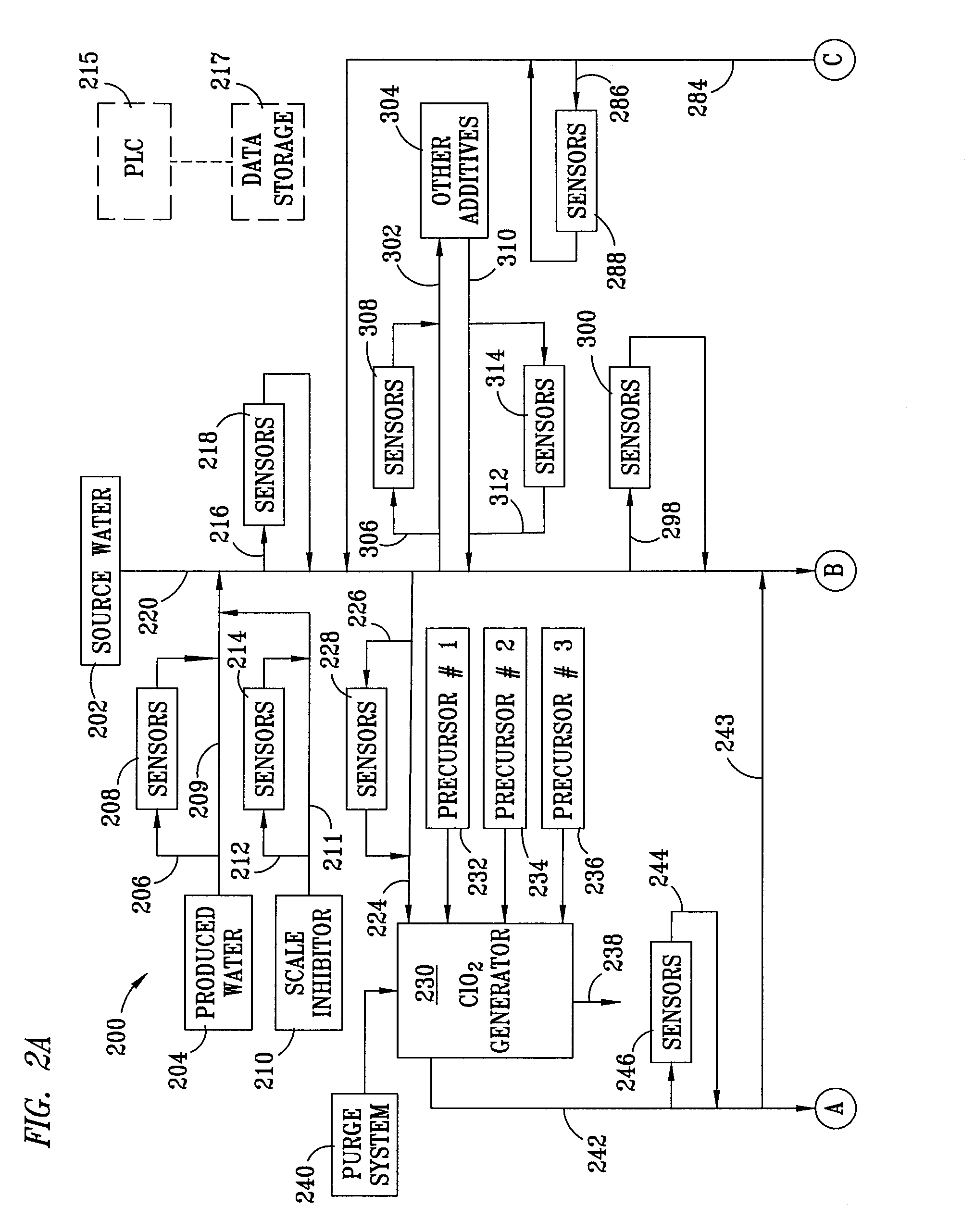

Portable Water Treatment System and Apparatus

InactiveUS20110132815A1Effective treatmentQuickly and reliably adjusting and controllingWaste water treatment from quariesIon-exchanger regenerationWater treatment systemDisinfectant

A portable water treatment system and apparatus is disclosed that can effectively and efficiently treat aqueous fluids by quickly and reliably adjusting and controlling the free residual level of disinfectants, contaminants or additives through the addition of one or more treating agents such as oxidizing chemicals and / or other special-purpose additives, and that can continuously store, log, retrieve and report the related fluid composition data and other operating parameters on a real-time basis at either the use site or a remote location. A preferred use for the subject system and apparatus is managing the chemistry of disinfectant, contaminant and / or additive levels in aqueous fluids used in hydraulic fracturing operations, and controlling the free residual levels of the disinfectant or contaminants within the fluids, including fluids maintained in frac tanks during temporary cessation of a hydraulic fracturing operation.

Owner:ECOCYCLE SERVICES LLC +1

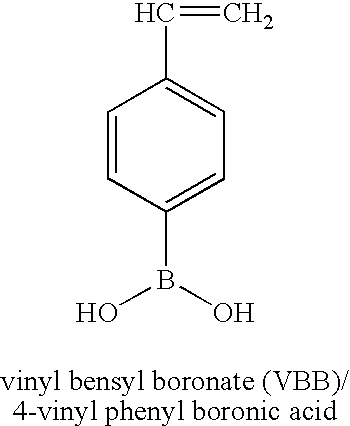

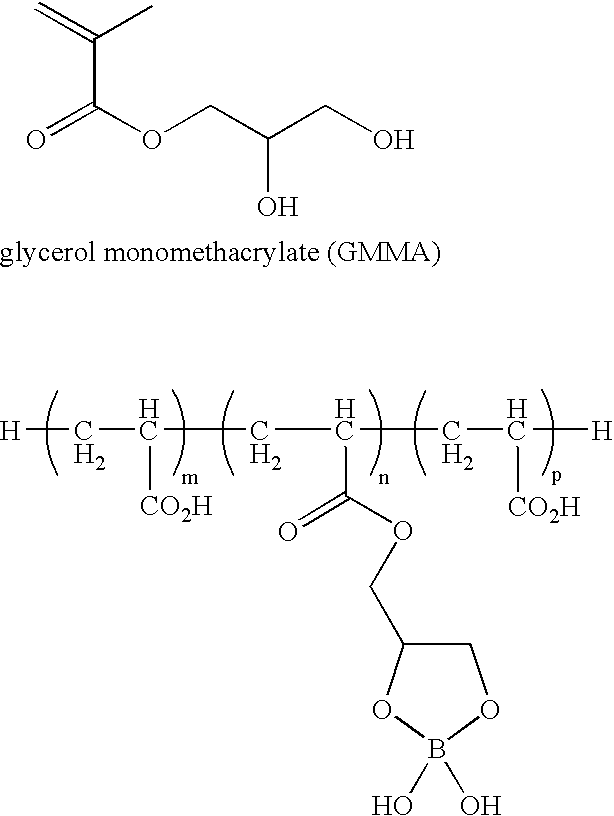

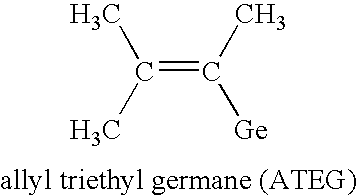

Stimulating Oilfields Using Different Scale-Inhibitors

Oilfields are stimulated by injecting an inflow stream of a fluid into an oil producing well linked to the oilfield, displacing the oil and recovering an outflow stream of fluid comprising the oil, wherein at least two streams are injected into at least two production zones of an oil well or are injected into at least two different oil producing wells from which at least two outflow streams from the two zones or wells are combined before recovering, with a scale inhibitor having detectable moieties being introduced into the oilfield(s) and / or into the fluid, and wherein two different scale inhibitors are used, dedicated to the two zones or wells, said different scale inhibitors having different detectable moieties that can be distinguished by analysis.

Owner:RHODIA CHEM SA

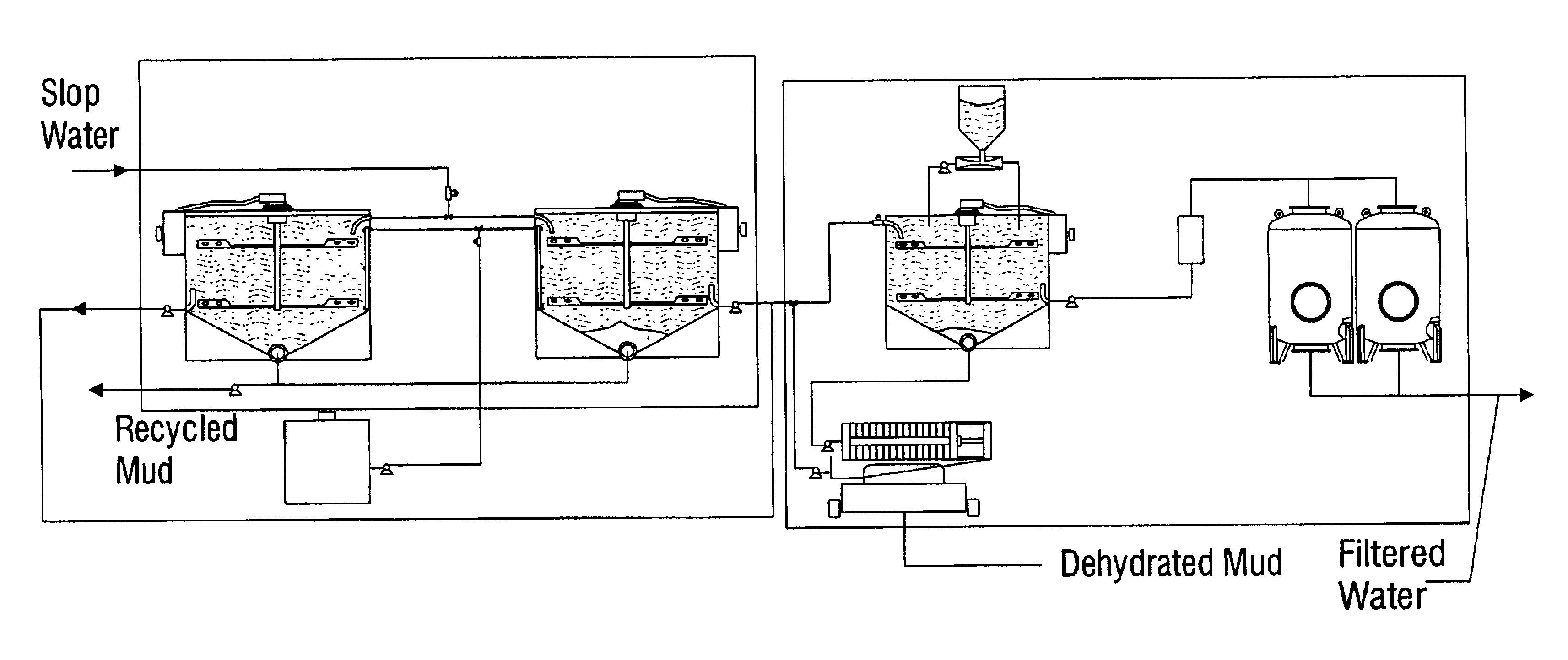

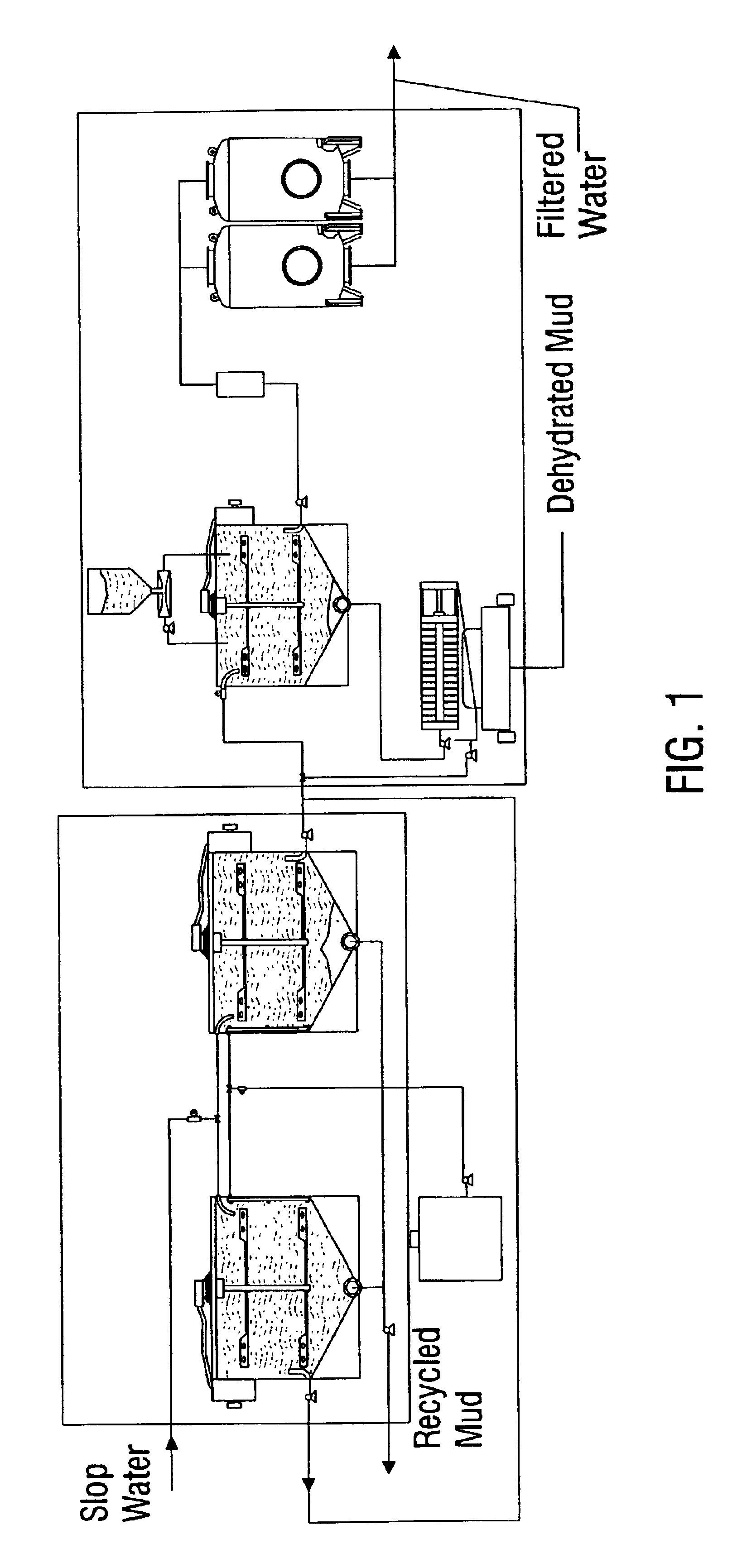

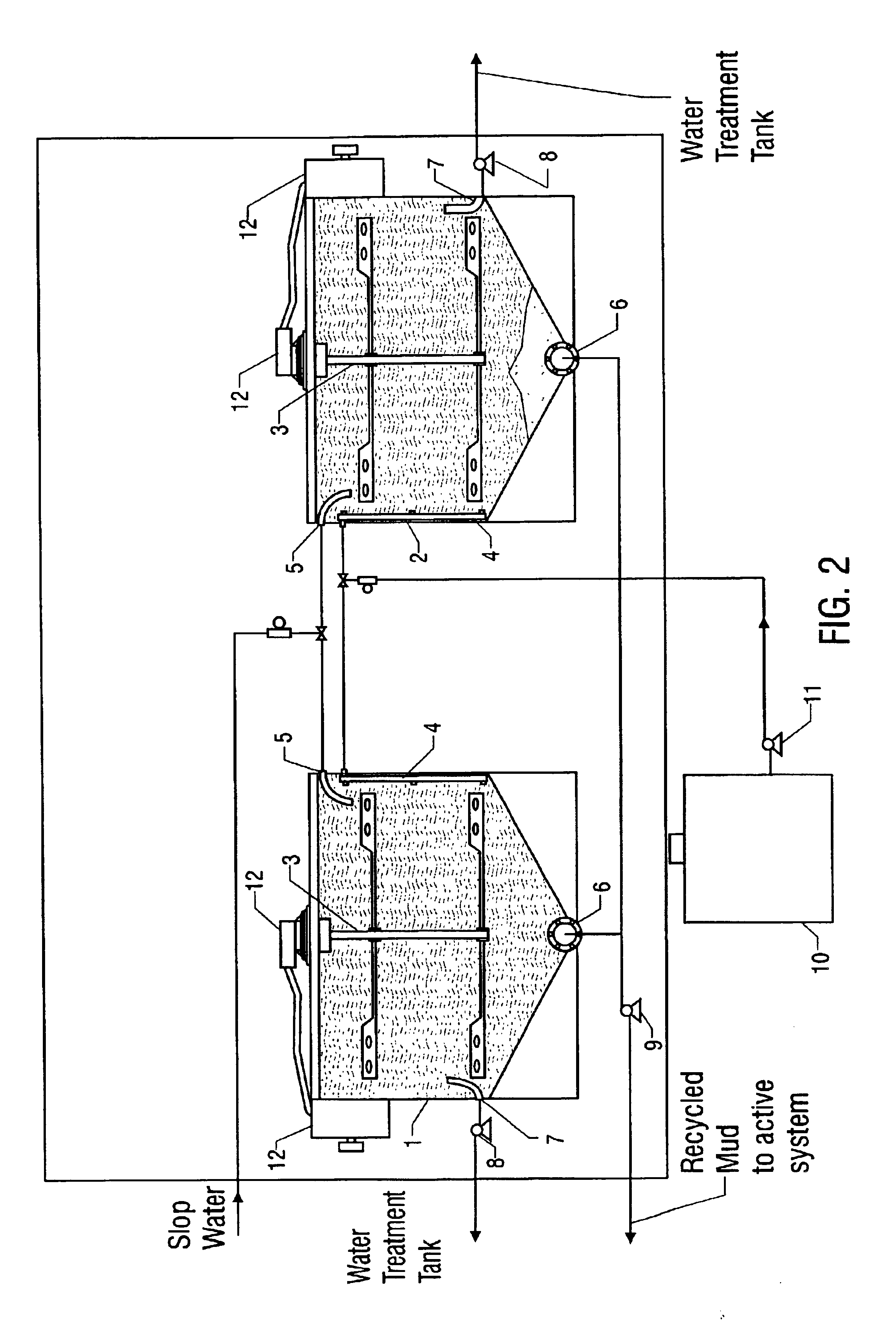

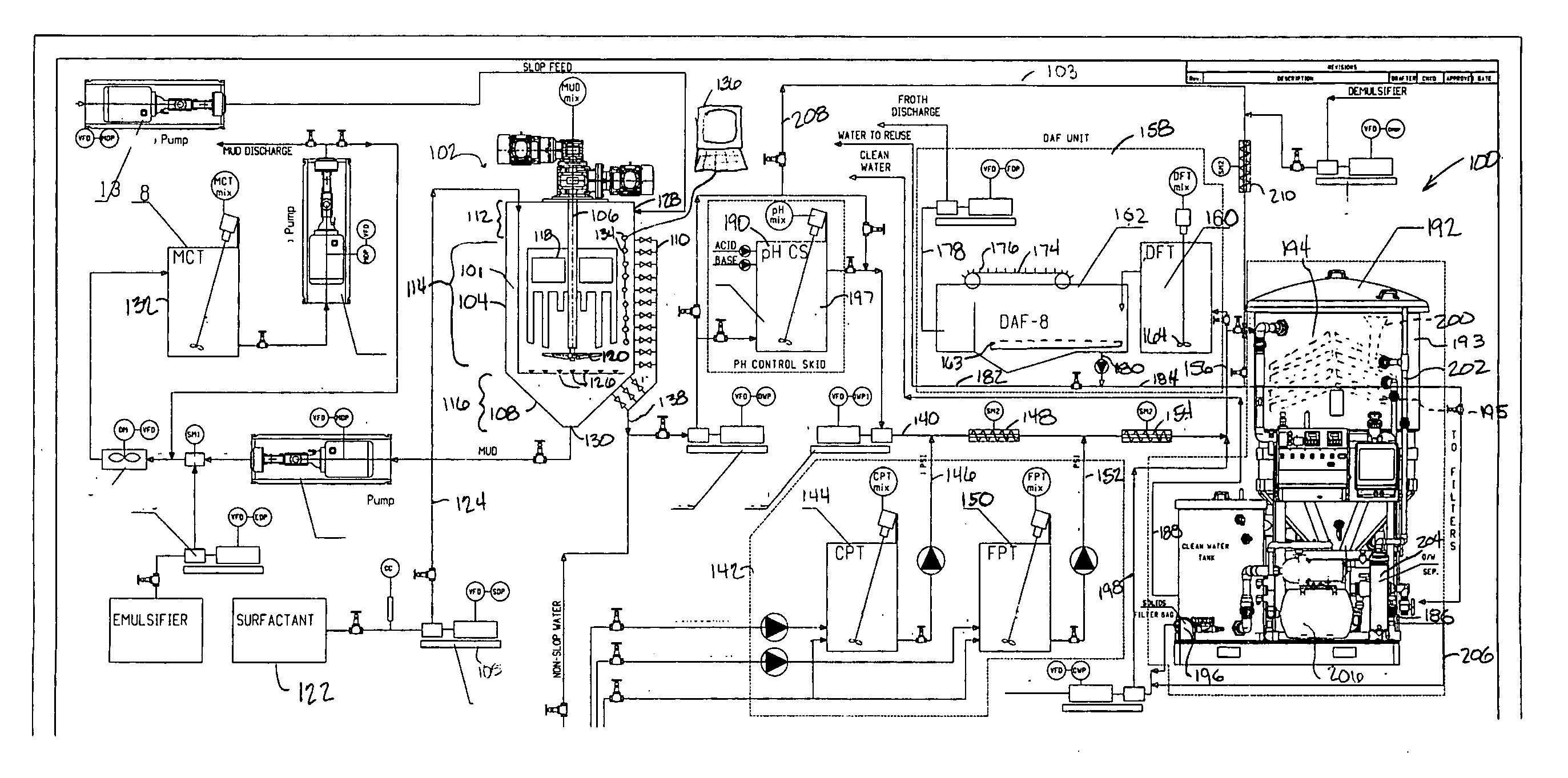

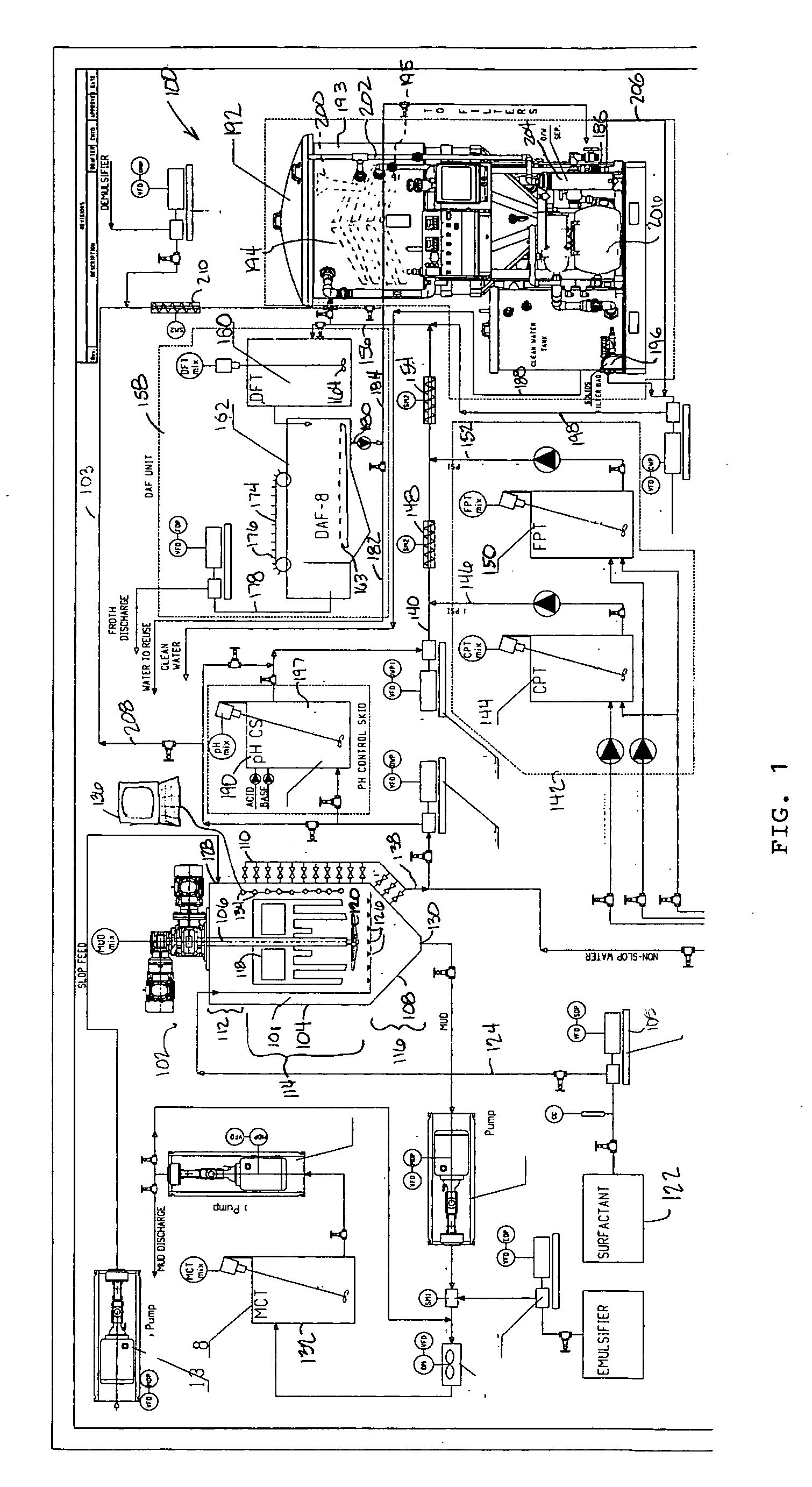

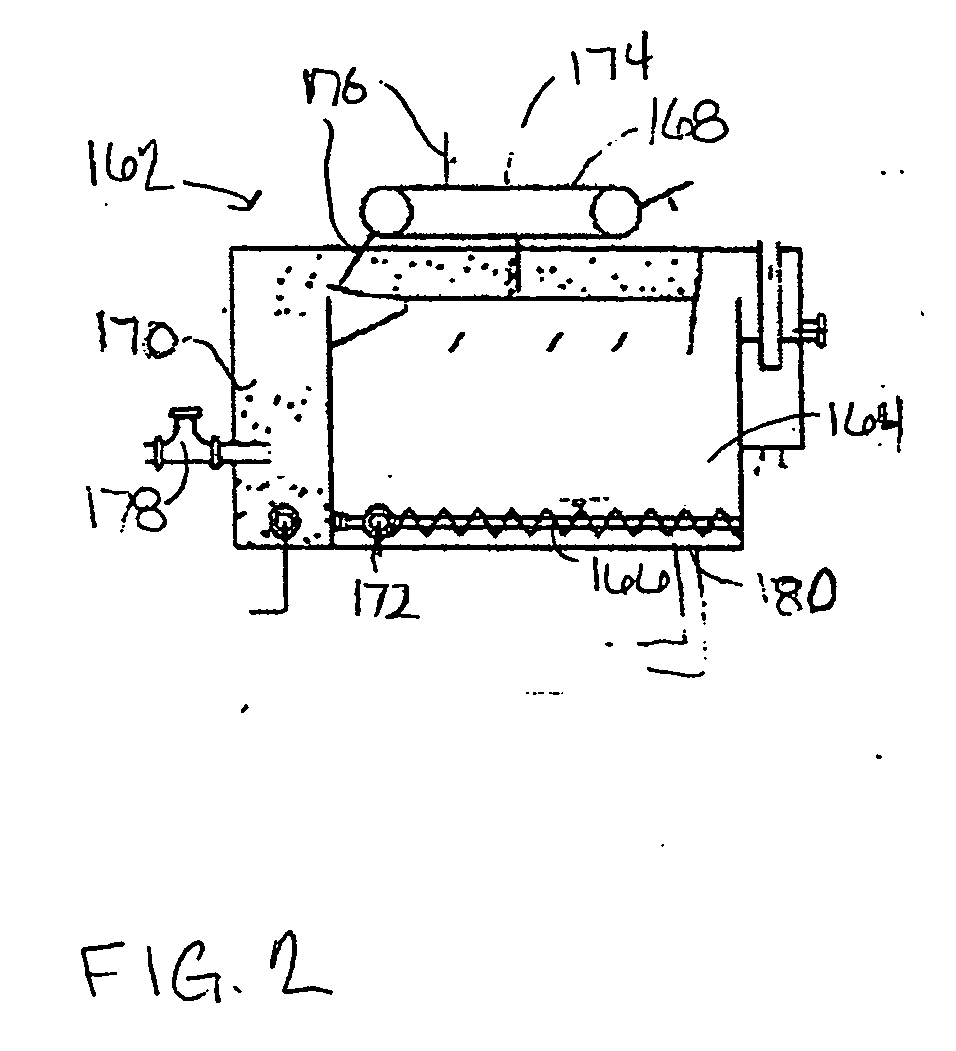

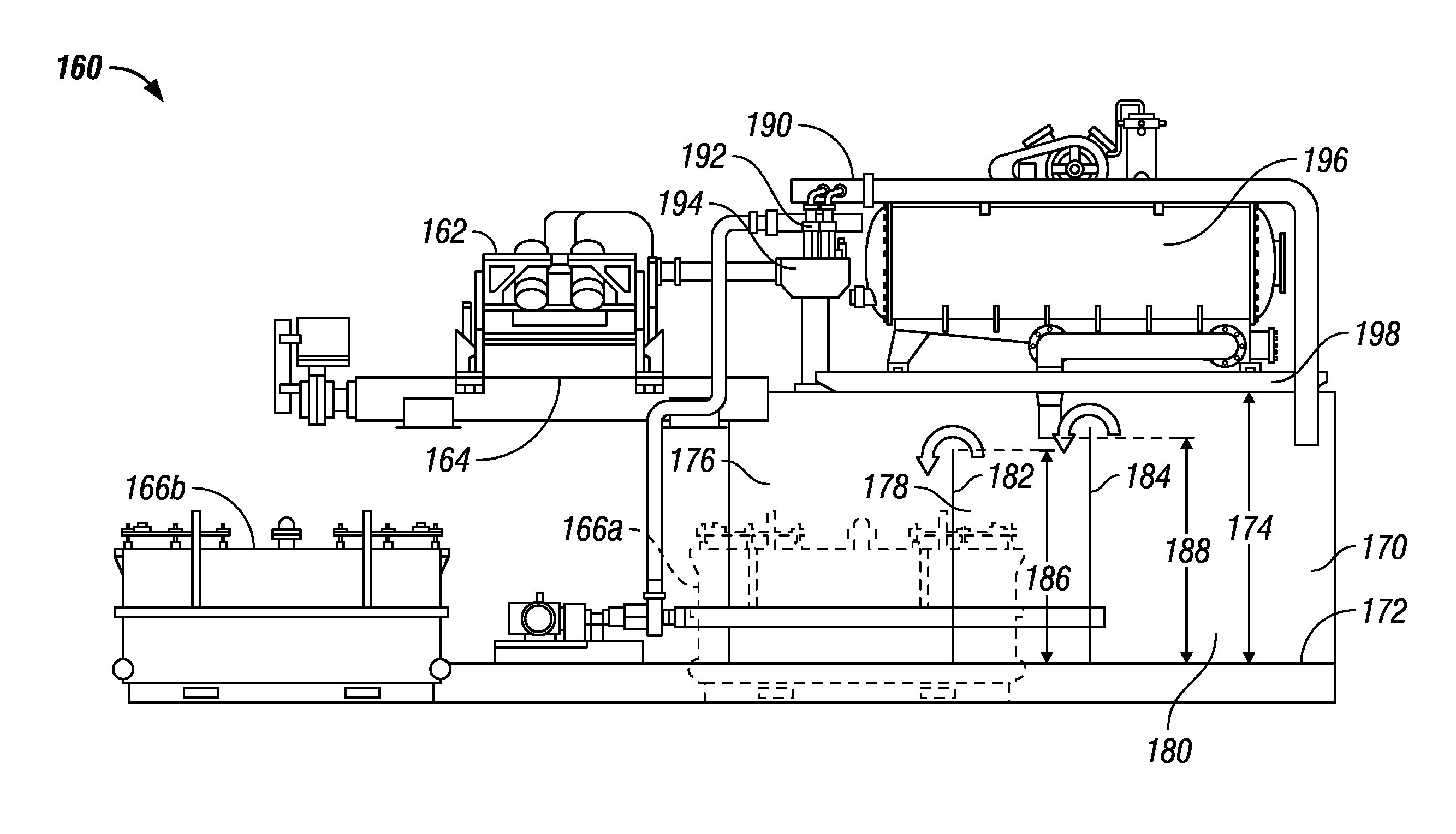

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS20060186056A1Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

Oil-removing treatment process of oil-containing sludge

InactiveCN101037286ABreak the adhesionIncreased efficiency of thermally eluted oilWaste water treatment from quariesSludge treatmentSludgeOil field

The invention provides a method of treating oiliness sludge in oil field or refinery, which is economical, quick, and large-scaled in use. The method applies thermally washing oiliness sludge by a hyperacoustic washing apparatus with a low frequency and a highpower, then assisting to air flotation, in order to effectively recycle the dirty oil in sludge. The whole art is provided with four treating units of a warm-up conditioning, a hyperacoustic irradiation, an aerating flotation, and gravity settling. It does not have any medicament, so is without a secondary pollution. The invention recycles cleaning liquid.

Owner:NANJING UNIV OF TECH

Modular pressure control and drilling waste management apparatus for subterranean borehole operations

ActiveUS7207399B2Waste water treatment from quariesWater/sewage treatment with mechanical oscillationsDegasserDisposal waste

Owner:MI

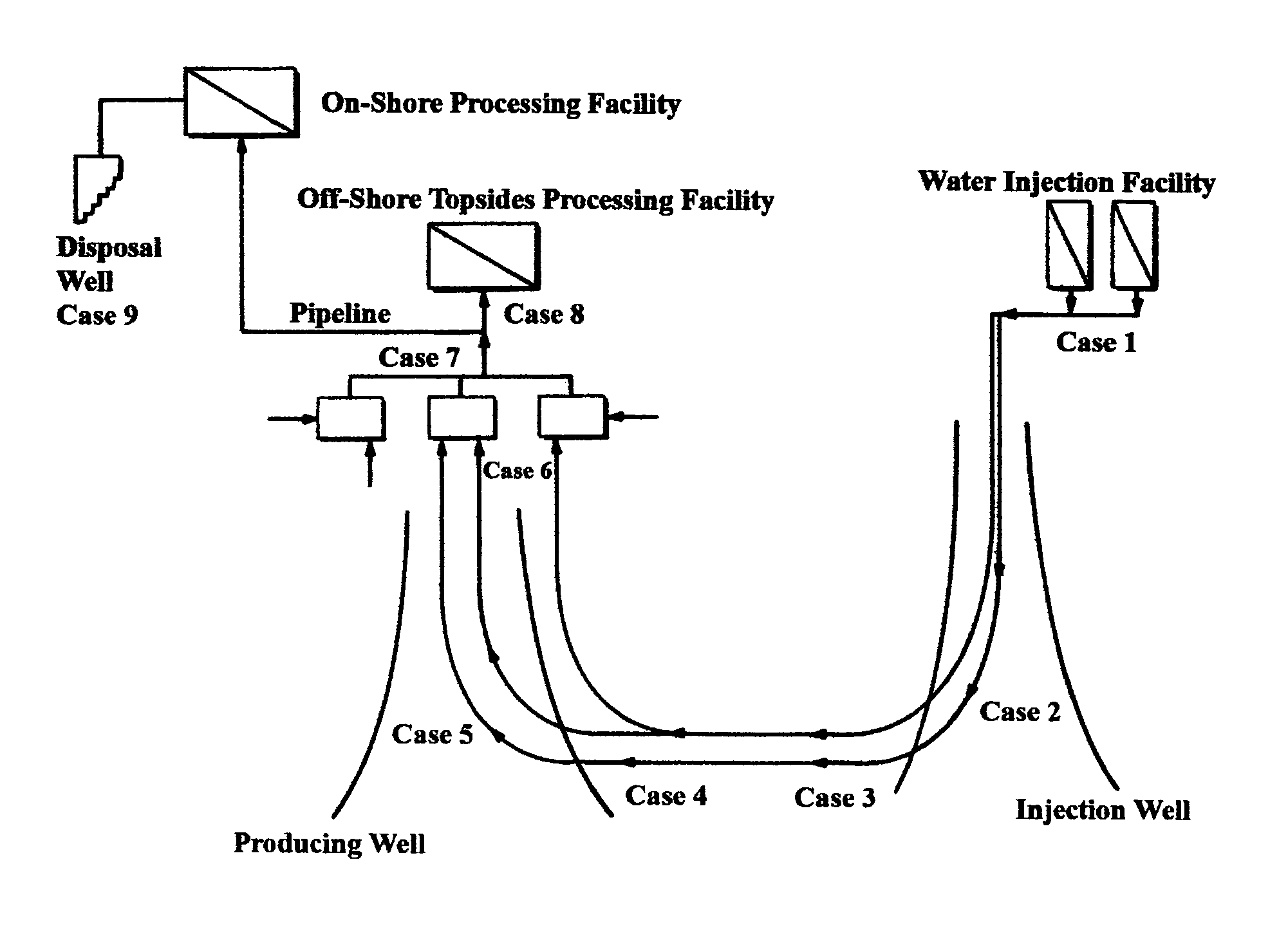

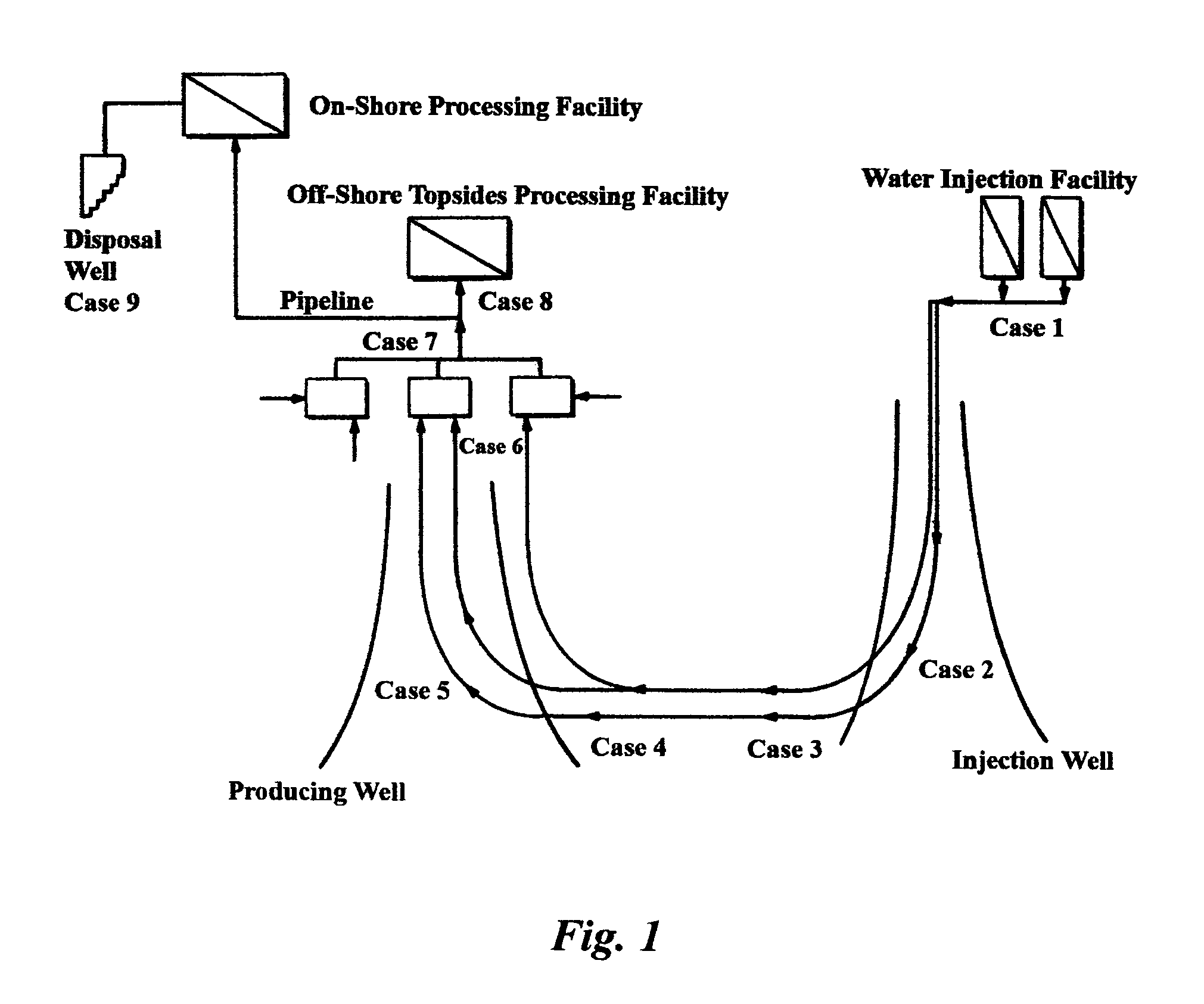

Method of Recovering Oil or Gas and Treating the Resulting Produced Water

ActiveUS20120255904A1Reduce hardnessWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Water purification method

InactiveUS20140175015A1Conveniently and efficiently purifyingInexpensivelyWaste water treatment from quariesWaste water treatment from ceramic industriesPurification methodsSorbent

A water purification method comprising adding a purification agent to water having a contaminant concentration of 1 μg / L to 10 g / L, the purification agent containing an adsorbent having an average particle size of 100 nm to 500 μm, an iron-based flocculant, and an alkaline substance; causing the adsorbent to adsorb at least a part of the contaminants in water; settling the adsorbent with the adsorbed contaminants by the iron-based flocculant; and removing the sediment from water, wherein the purification agent is added in an amount of 0.01 g to 20 g per liter of water, can purify contaminated water conveniently and efficiently.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com