Patents

Literature

876 results about "Sulphate Ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a sulphate (sulfate in US English) is a salt of sulphuric acid. The sulphate ion is a group of atoms with the formula SO4 and two negative charges. It consists of a central sulphur atom surrounded by four equivalent oxygen atoms. It occurs when sulfuric acid is deprotonated twice.

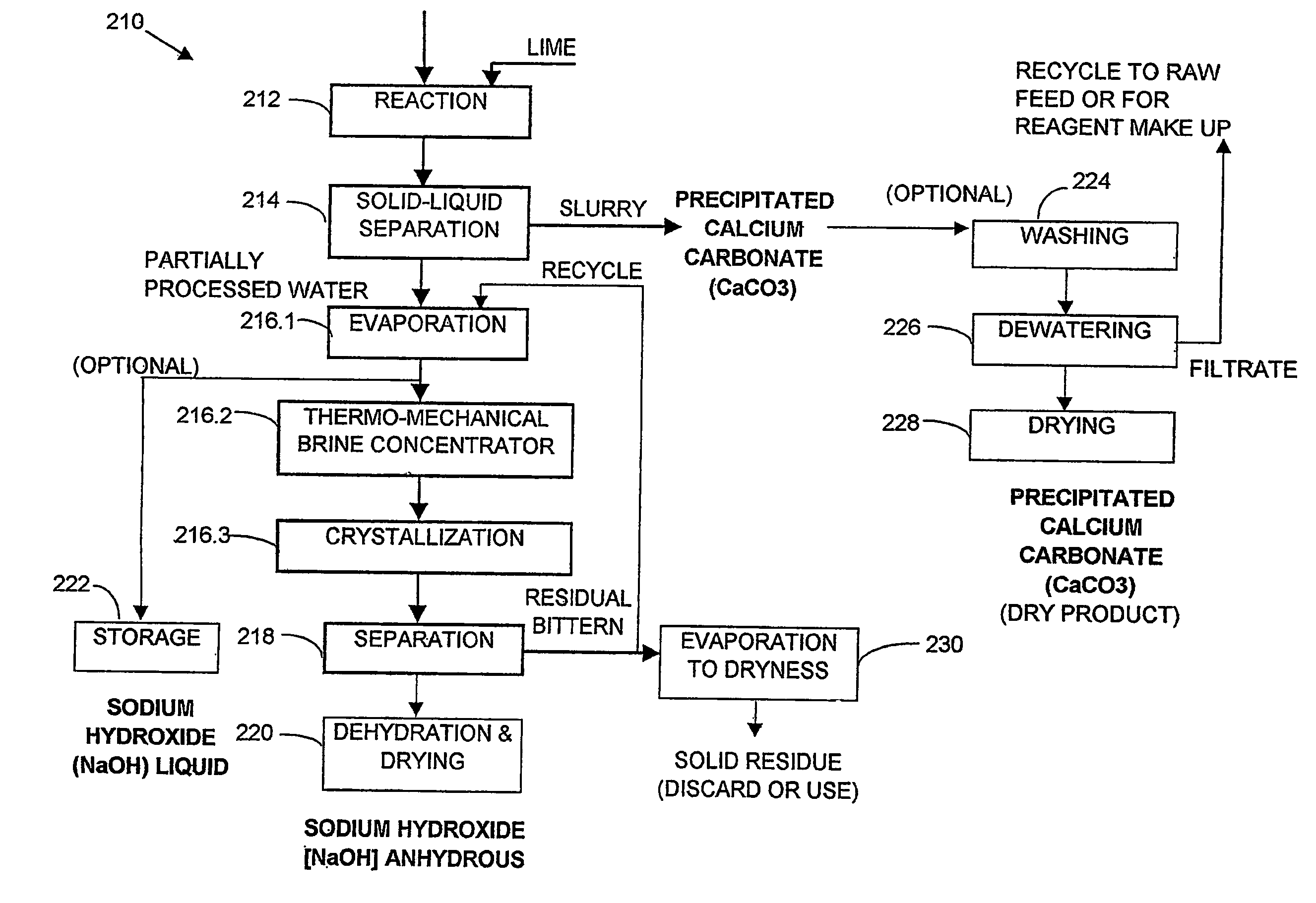

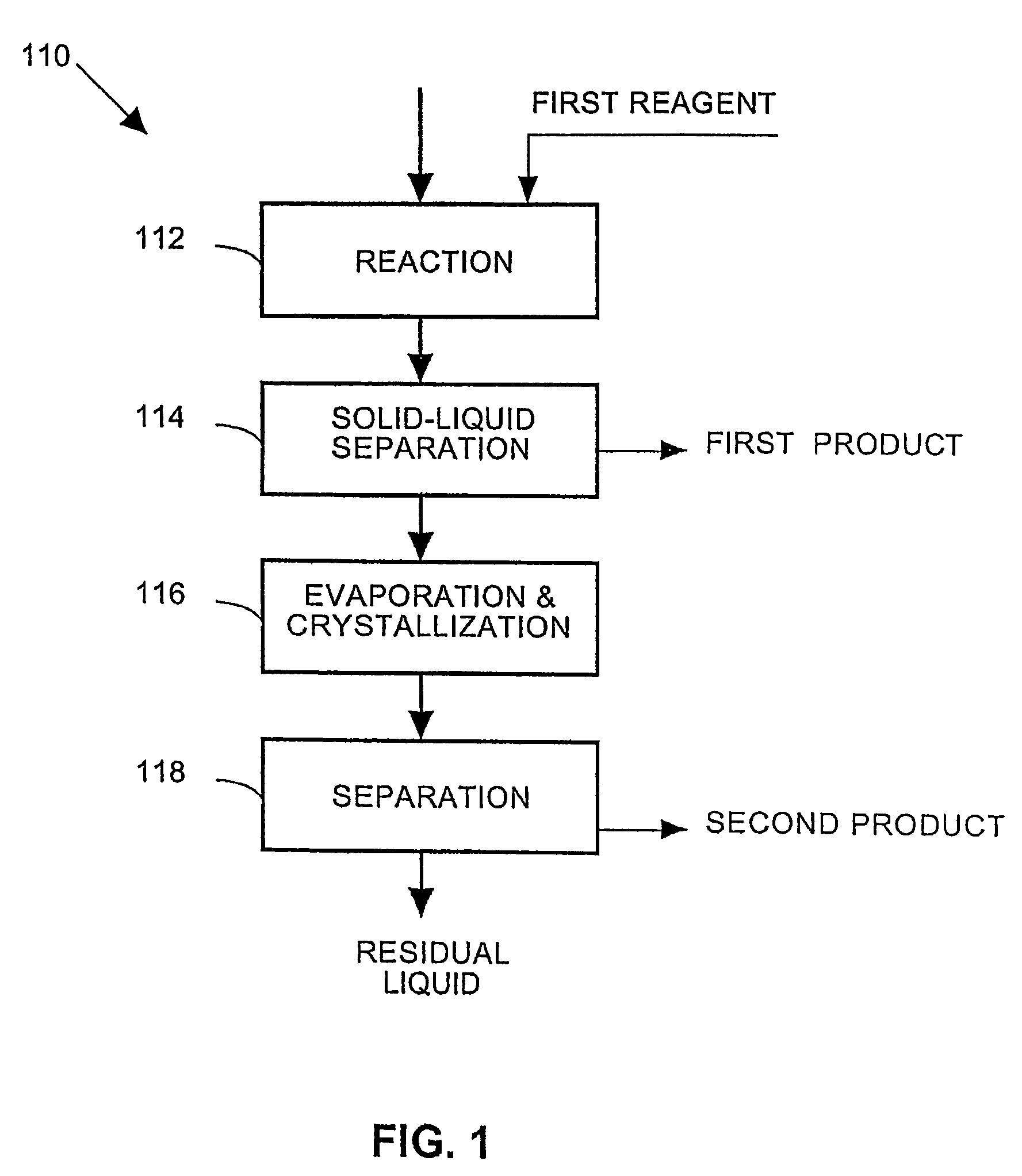

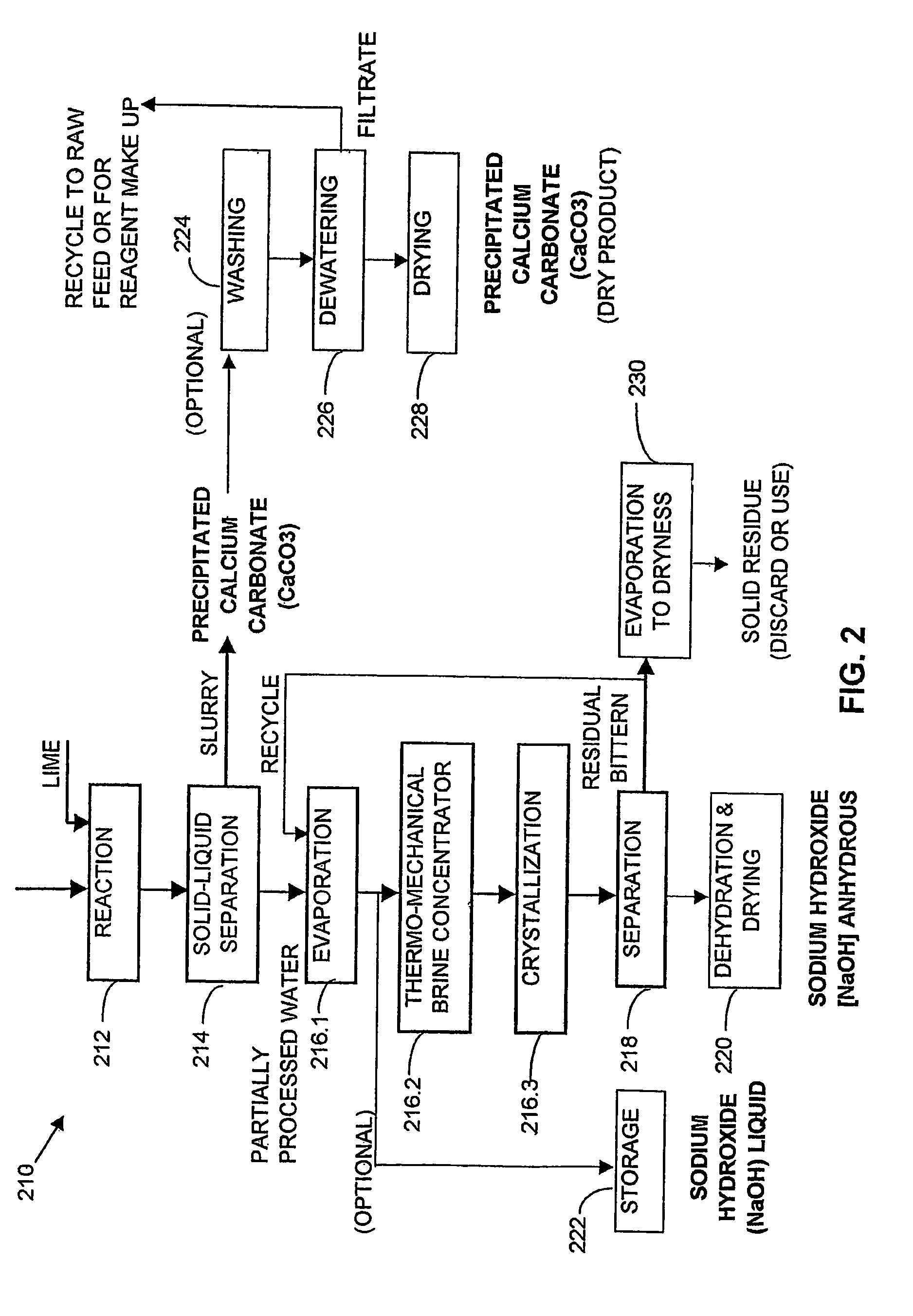

Process and apparatus for the treatment of saline water

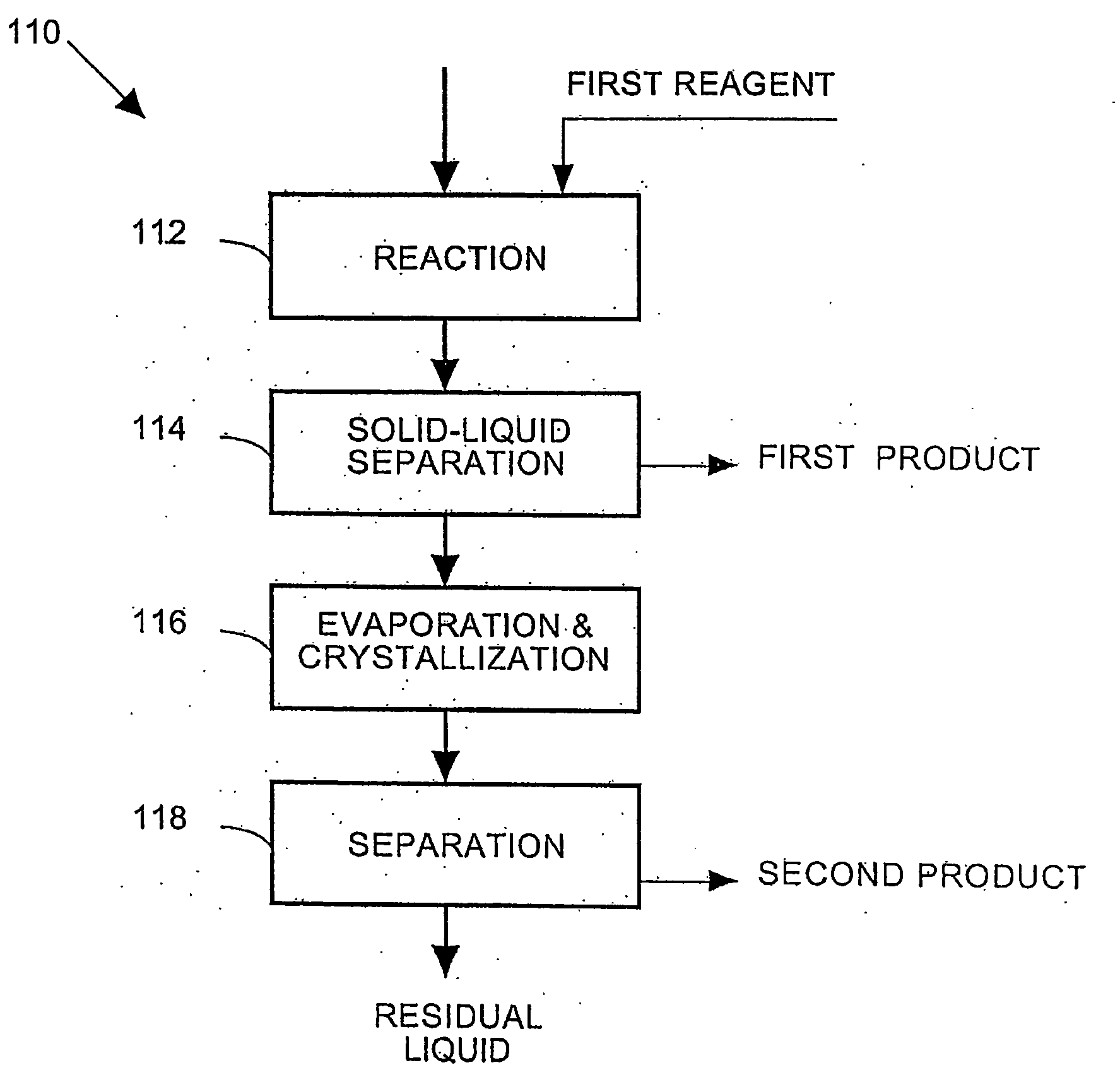

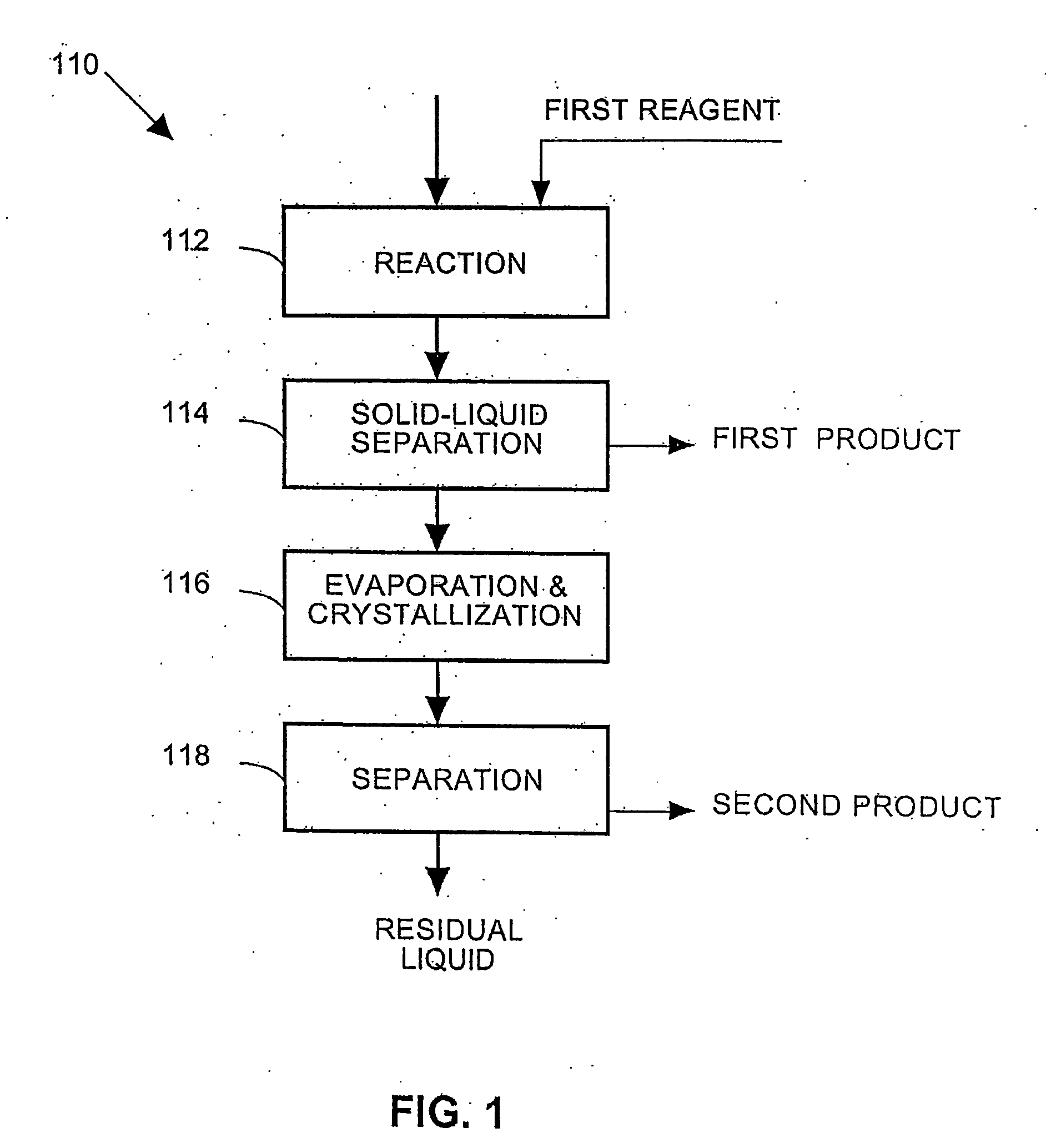

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

Liquid detergent composition for improved grease cleaning

InactiveUS20070275868A1Organic detergent compounding agentsSurface-active detergent compositionsSulphate IonSURFACTANT BLEND

Owner:THE PROCTER & GAMBLE COMPANY

Method for scavenging mercury

Owner:RGT UNIV OF CALIFORNIA

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

Process for reclaiming catalyst for use in synthesis of acesulfame potassium

InactiveCN1883790ANo pollutionHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsSulphate IonPotassium

The invention discloses a process for recovering catalyst in synthesizing potassium acetylsulfanilate, which includes steps of: (1) neutralizing mixture containing triethylamine sulphate with base or basic salt, rising the temperature to 70-120 DEG C for distilling triethylamine. (2) removing water of triethylamine received in step (1) to obtain high purity triethylamine. In addition, acid could be added to the mixture of removing triethylamine in step (1) to neutralizing excess base, and gypsum is obtained by filtrating reactive liquid. The excellence of this method is that the process is simple, processing time is short, damage to the device is slight, having no contamination to environment, the retrieving triethylamine have high purity and can be used for synthesizing potassium acetylsulfanilate after removing water, and the byproduct such as gypsum also has some economic benefit

Owner:SUZHOU HOPE TECH

Low grade fluorite and barite flotation separation method

A low grade fluorite and barite flotation separation method uses waterglass as the inhibitor for silicious mineral and calcium carbonate mineral; uses oleic acid as the collector for fluorite and barite; and uses starch, sodium sulphate, hydrochloric acid and sodium hexametaphosphate as the inhibitor for barite mineral. The invention can perform flotation separation of low grade fluorite and barite effectively; under the condition that the given fluorite grade is 33.92%-40.41%, and the barite grade is 34.67%-35.33%, by mixing, flotation and separation, can achieves the fluorite concentrate with grade of above 95% and recovery rate of 75.5%-78.5%, and the barite concentrate with grade of 92.3%-93.27% and recovery rate of 75.2%-79.73%.

Owner:GUANGXI UNIV

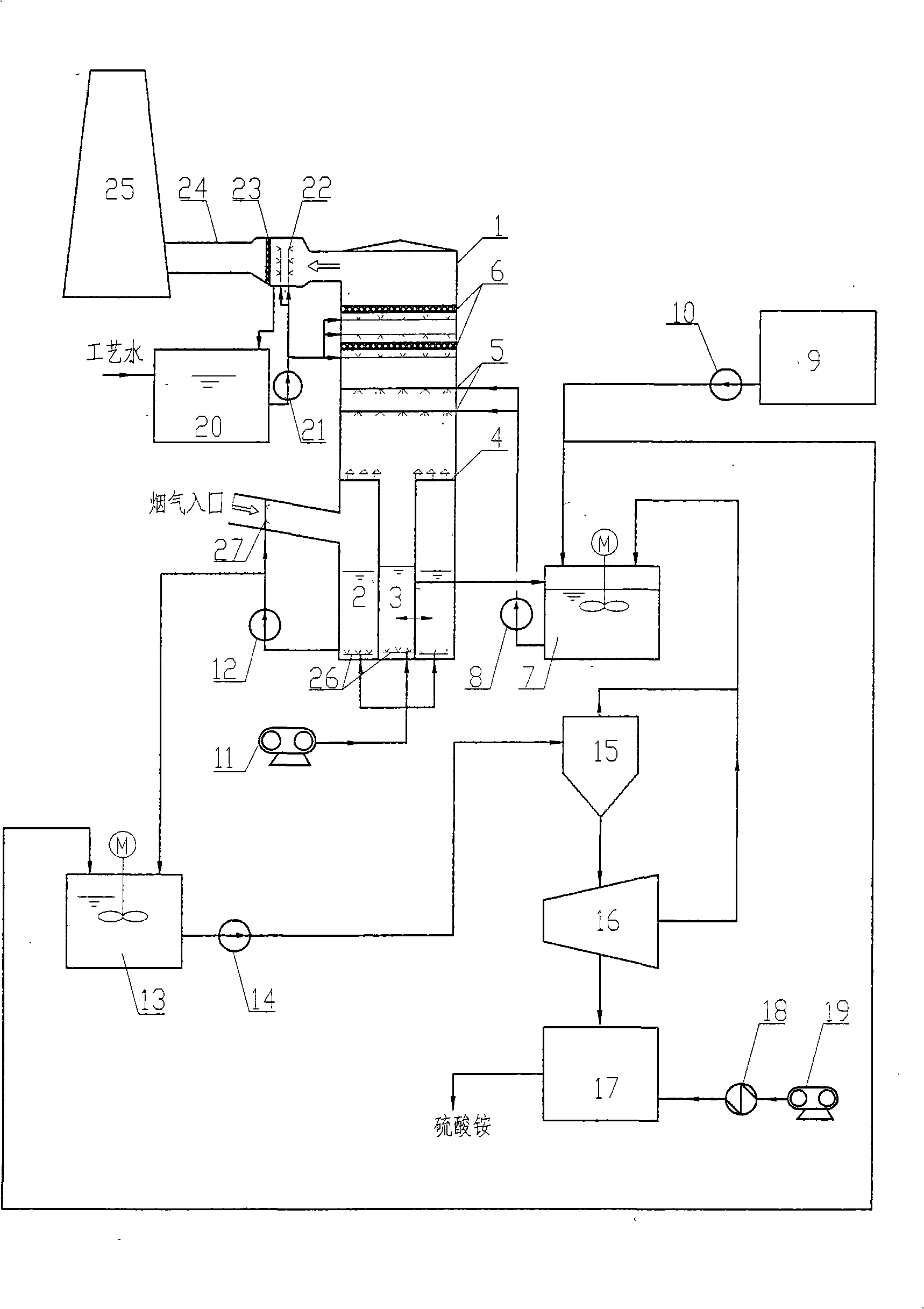

Segment-based ammonia flue gas desulfurization process and device thereof

InactiveCN101524620AHigh economic valueLow ammonia content in outlet flue gasDispersed particle separationProcess systemsPollution

A segment-based ammonia flue gas desulfurization process and a device thereof combine traditional absorption towers with a crystallization tower. A regeneration tank is arranged at the outside of the tower. The processes of absorption of SO2, sulfite oxidation, regeneration of desulfurization solution, crystallization of ammonium sulphate and ammonia volatilization are carried out respectively. The process system effectively improves the removal rate of SO2, improves the oxidation of the sulfite, strengthens the crystallization of the ammonium sulphate and reduces the escape of ammonia in outlet smoke. The standard discharge of the smoke can be realized after the smoke is processed by the system. The removal rate of SO2 is above 95 percent. The whole system process is simple and has no secondary pollution. And the by-product ammonium sulphate has high economic value and can be especially configured by enterprises with fixed ammonium sources.

Owner:山西晋丰节能环保工程设计有限公司 +1

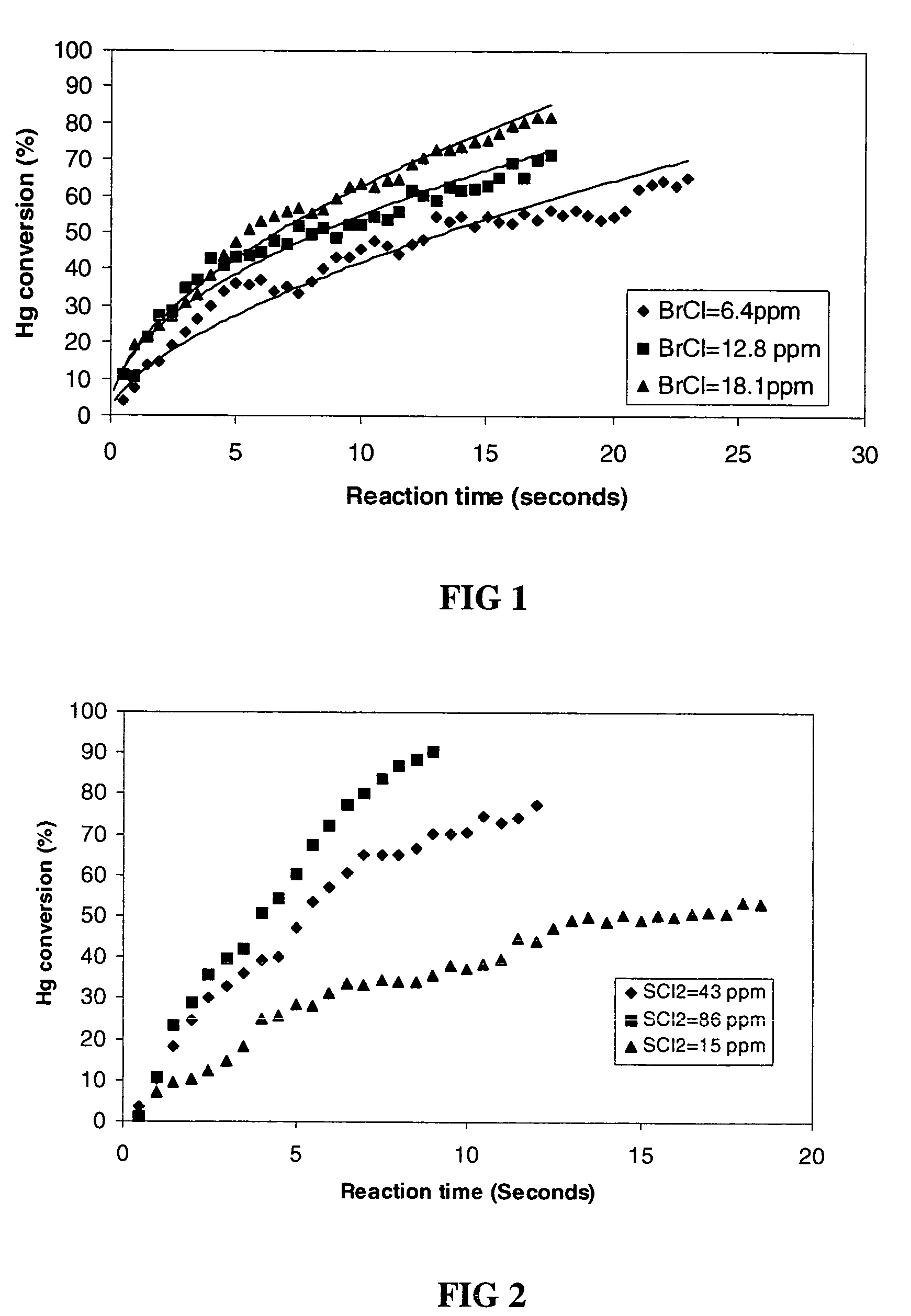

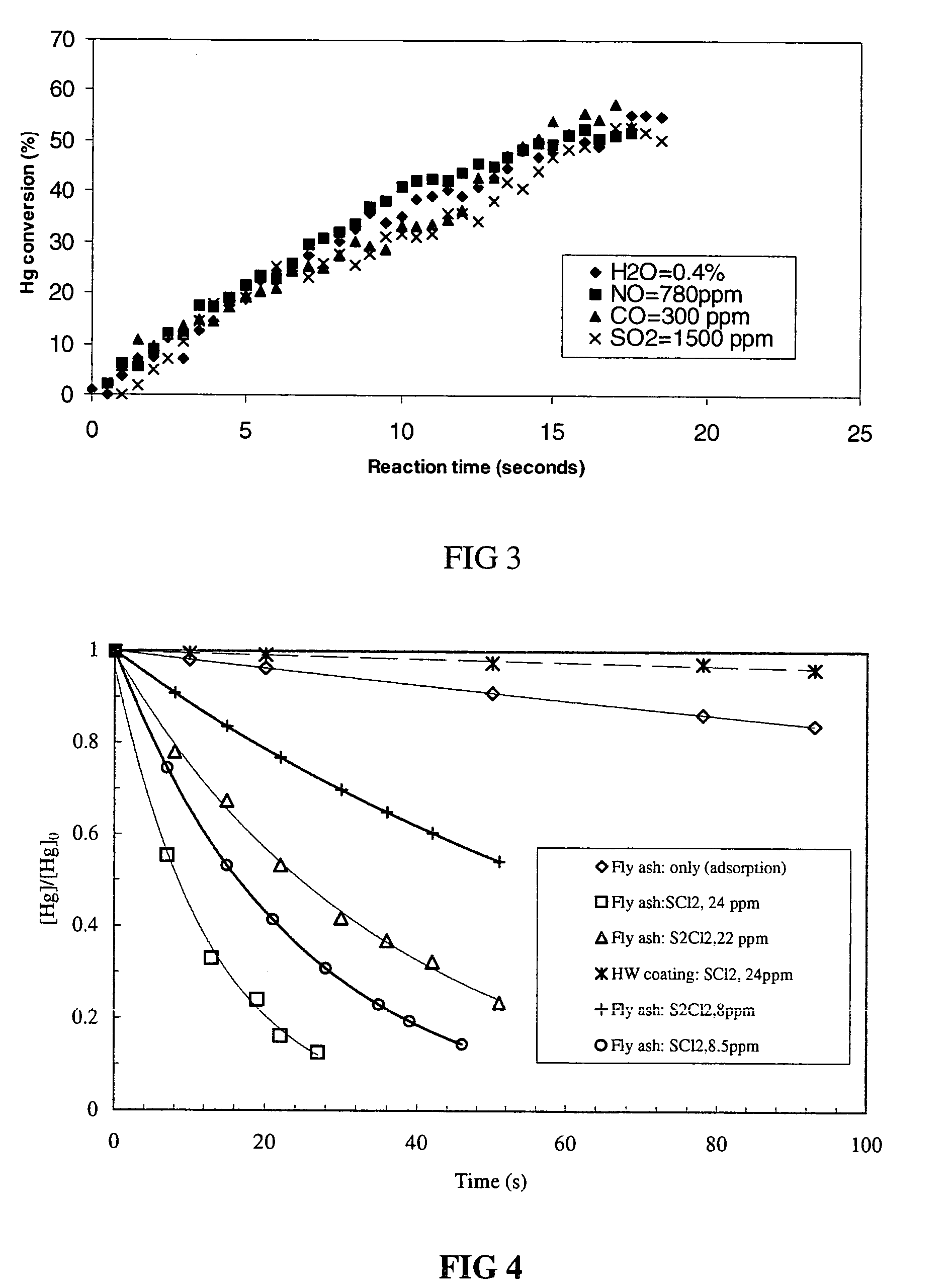

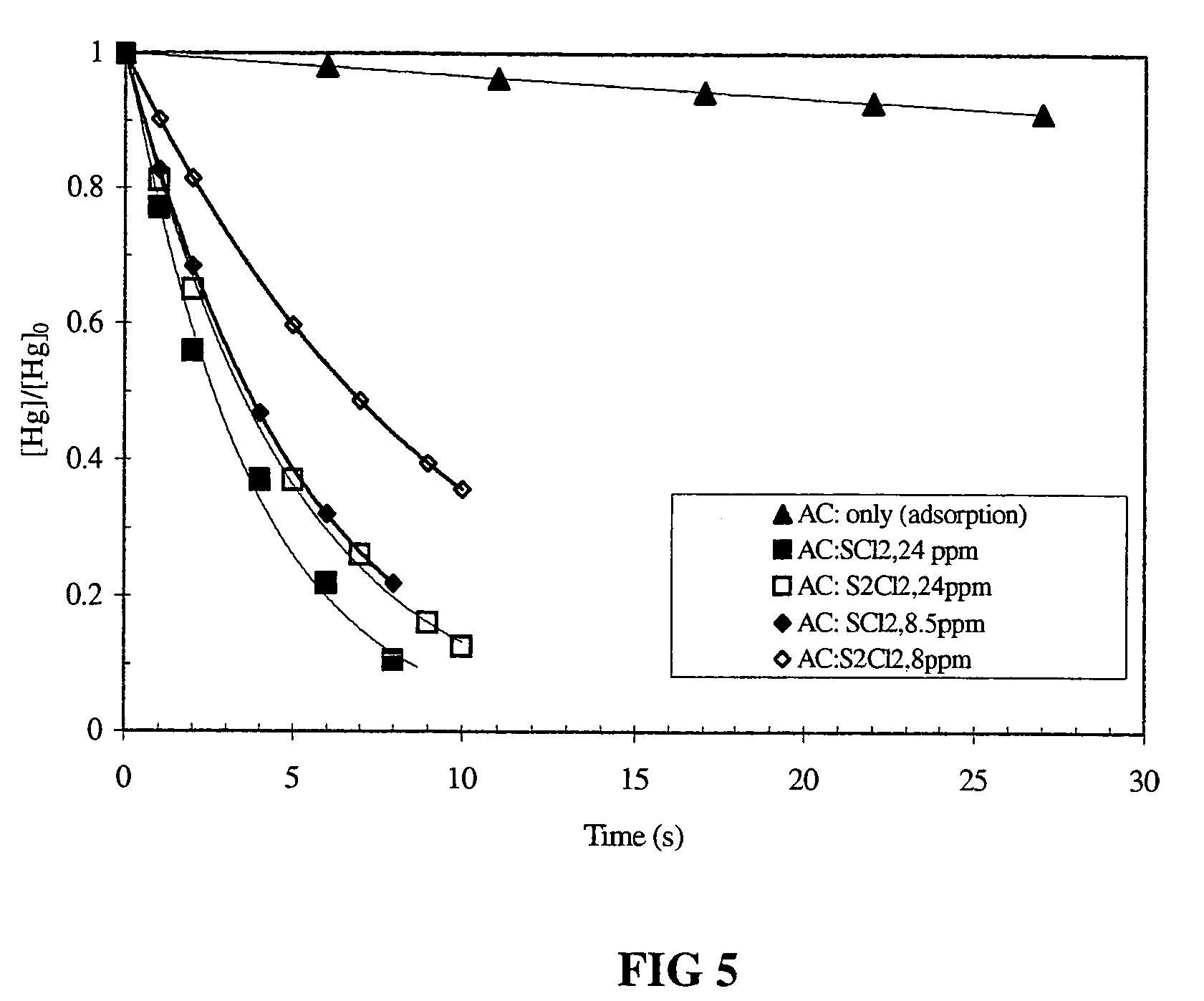

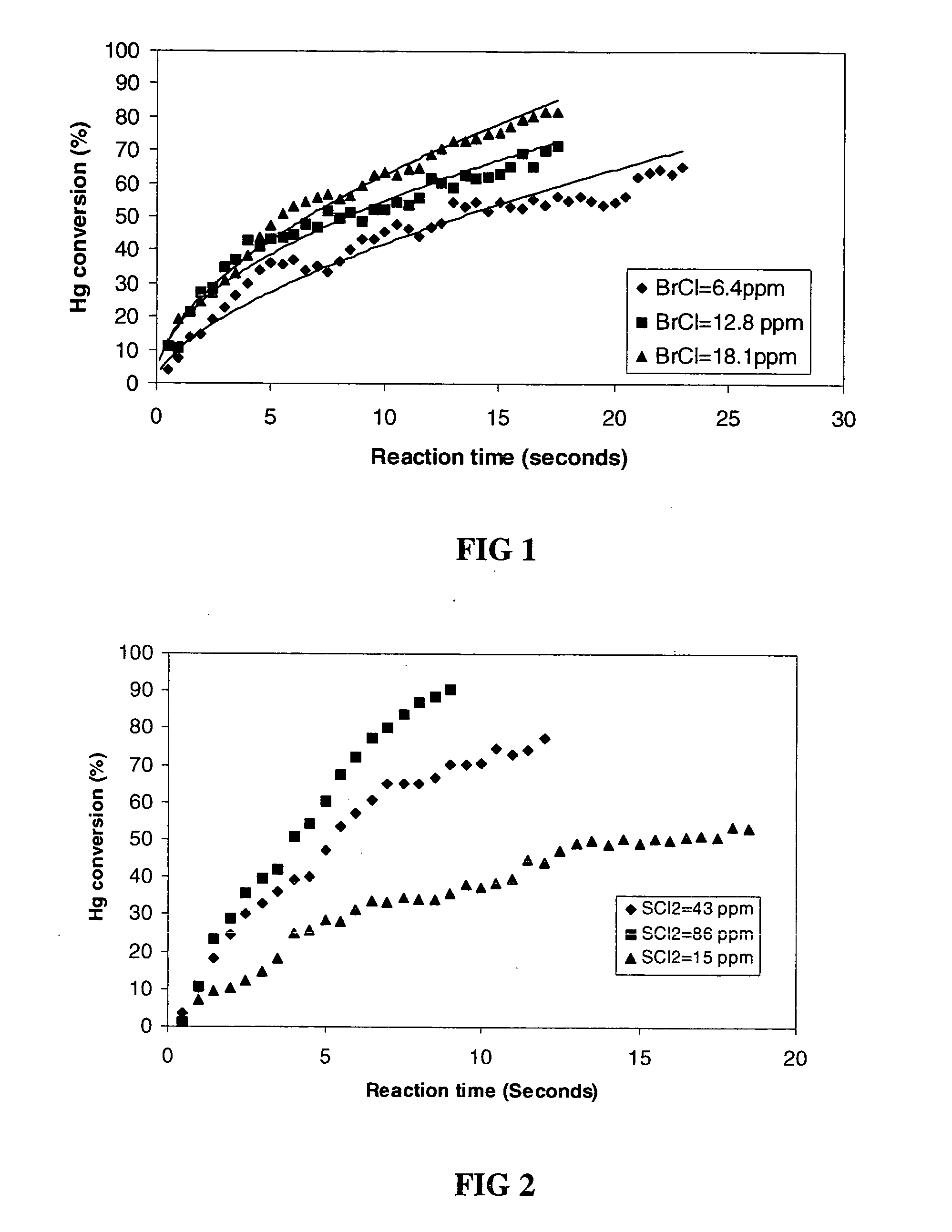

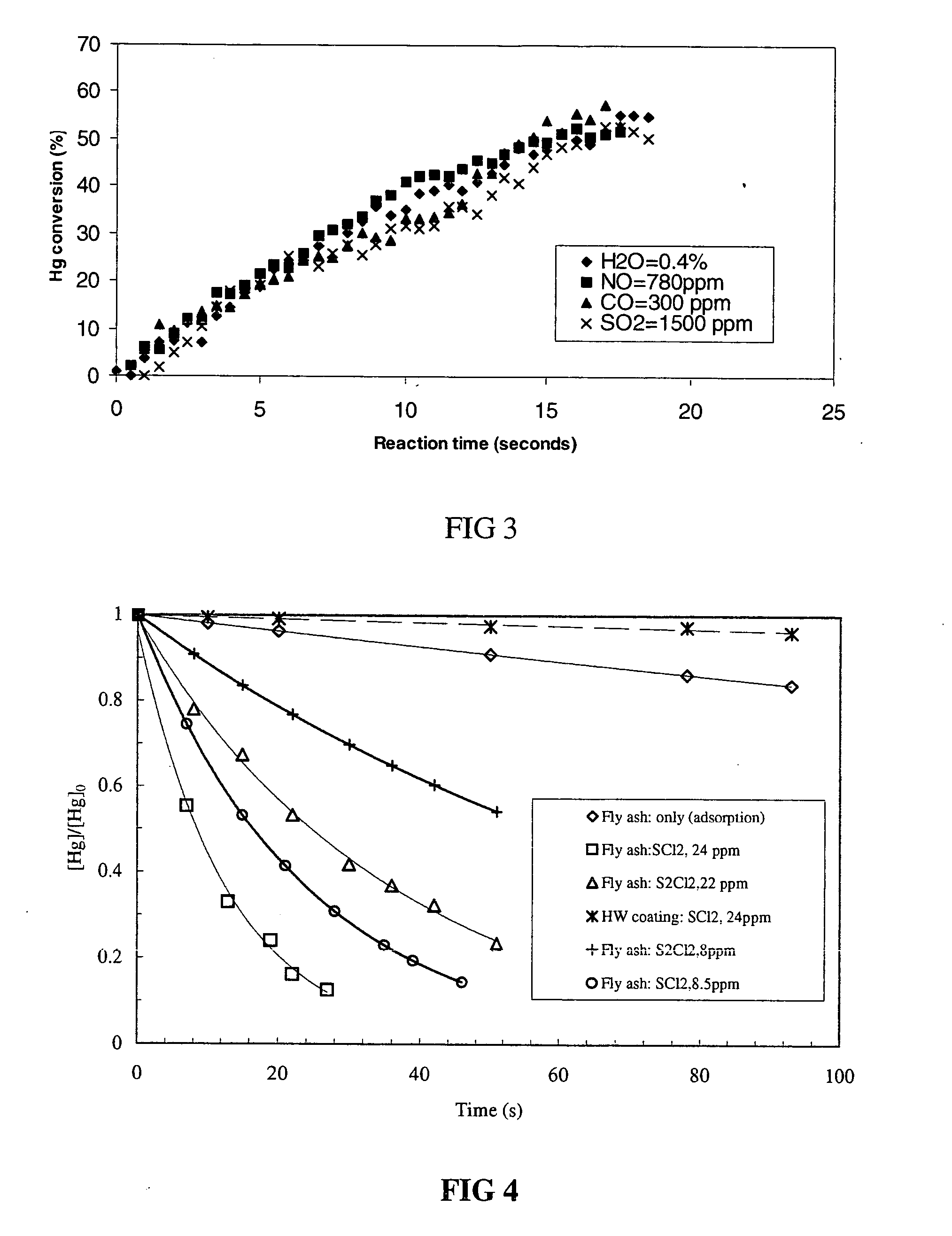

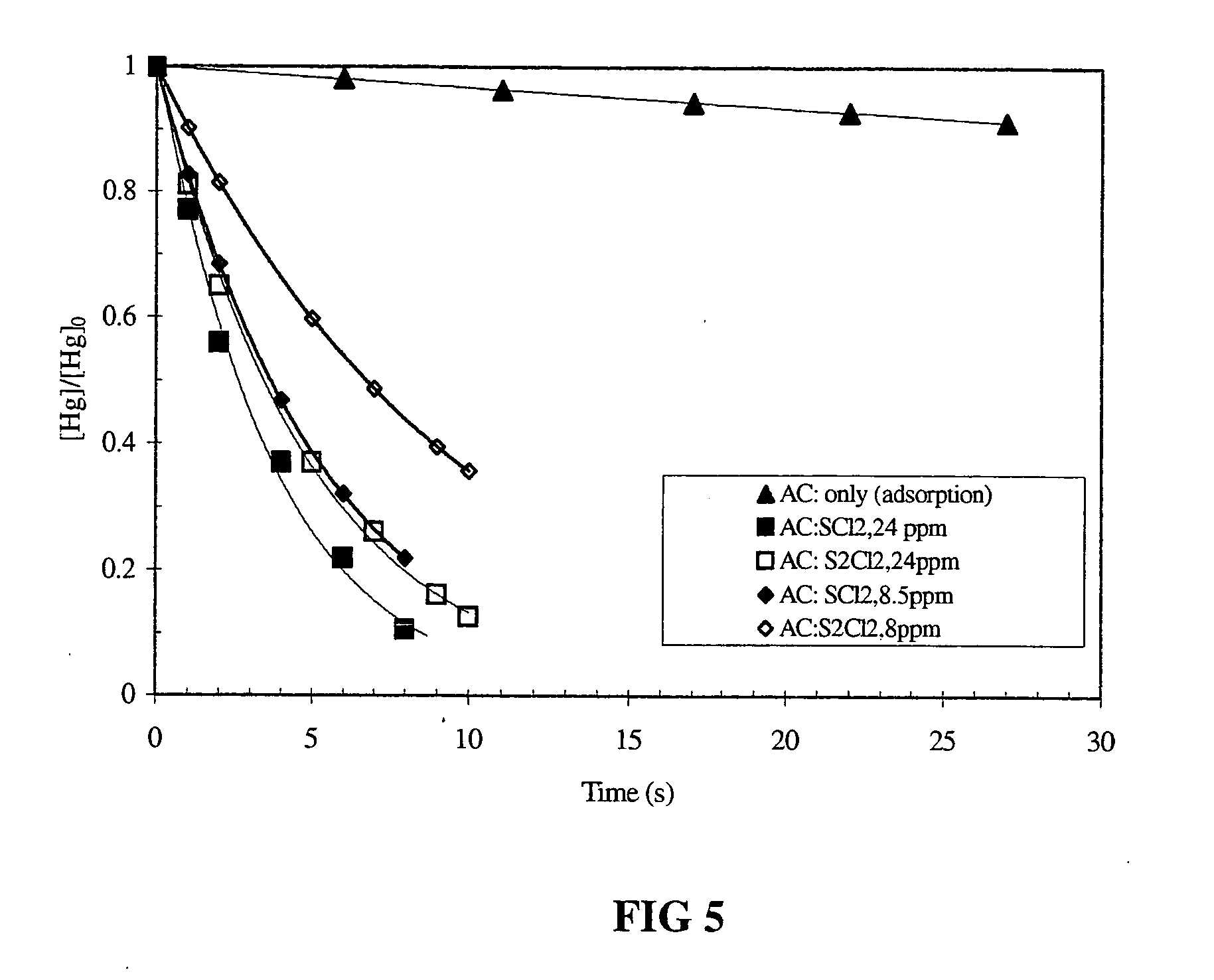

Method for scavenging mercury

Disclosed herein is a method for removing mercury from a gas stream comprising contacting the gas stream with a getter composition comprising bromine, bromochloride, sulphur bromide, sulphur dichloride or sulphur monochloride and mixtures thereof. In one preferred embodiment the getter composition is adsorbed onto a sorbent. The sorbent may be selected from the group consisting of flyash, limestone, lime, calcium sulphate, calcium sulfite, activated carbon, charcoal, silicate, alumina and mixtures thereof. Preferred is flyash, activated carbon and silica.

Owner:RGT UNIV OF CALIFORNIA

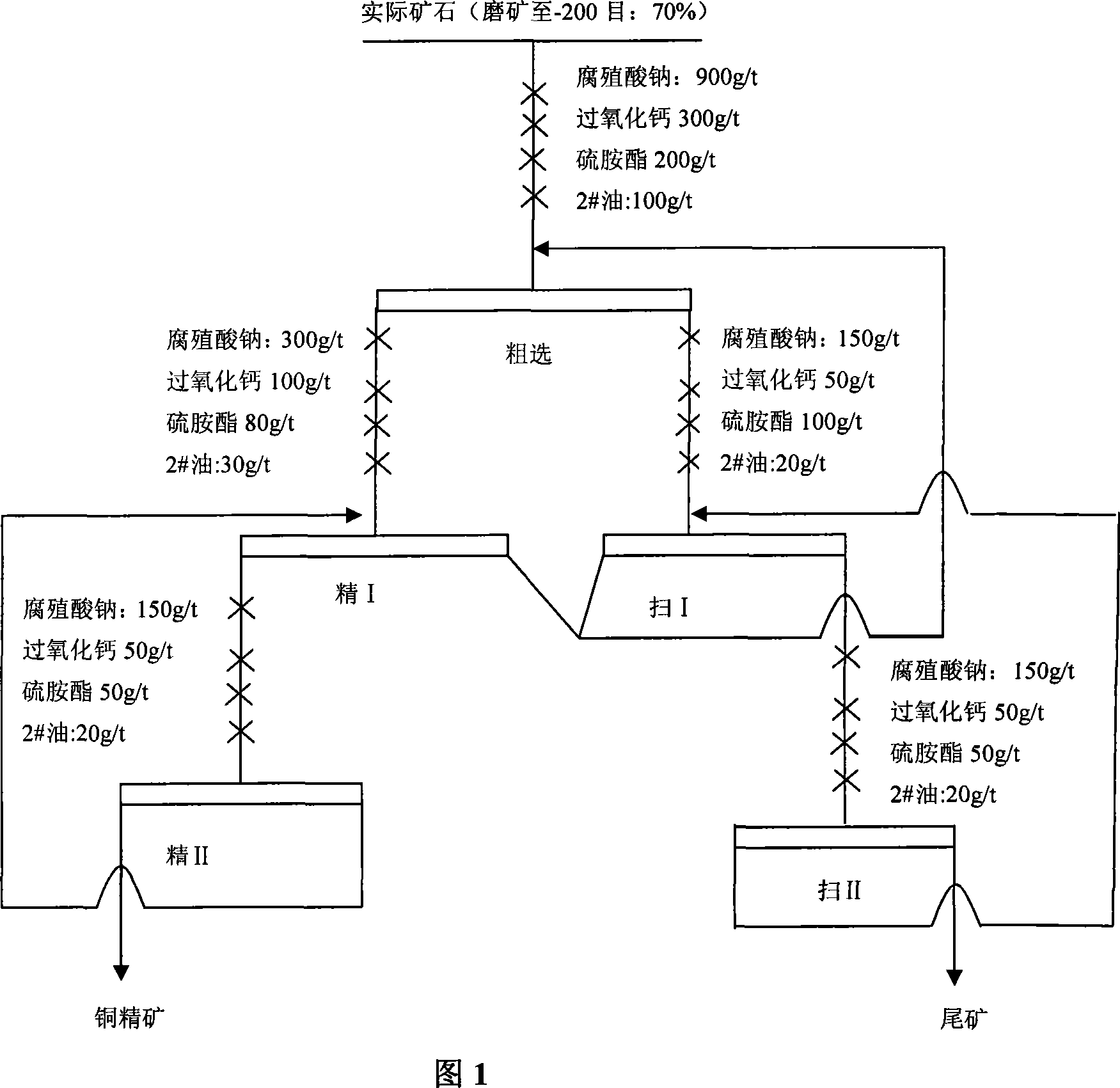

Highly effective composite restrainer of ferro-sulphur ore in complex vulcanizing ore and method of use thereof

The invention relates to a high-efficient combined inhabitor for pyrite in complex sulfide ores and the application method of the inhabitor. The inhabitor comprises calcium superoxide and HA-Na. The inhabitor of the invention can inhibit complex vulcanized iron-bearing minerals selectively, has better inhibition properties for magnetic pyrite, pyrite and arsonopyrite, and is an inhabitor of high selectivity. Compared with the prior inhibitors such as lime, cyanide, bichrome, potassium permanganate, sodium sulfide, sulphite, zinc sulphate and trisodium phosphate, the invention has the advantages of lower use level, good effects, no pollution, and other advantages.

Owner:CENT SOUTH UNIV

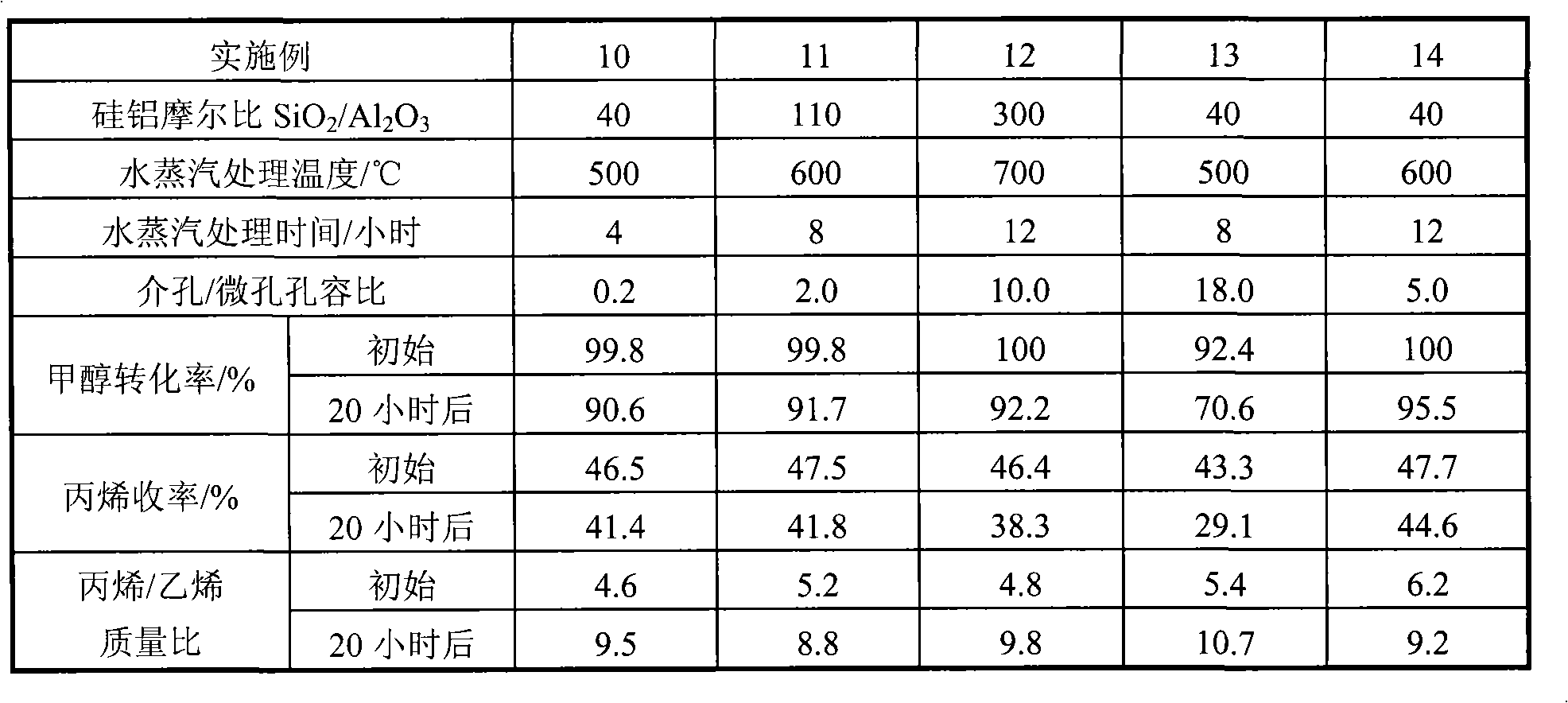

ZSM-5 mesoporous molecular sieve catalyst for preparing propylene from methanol and preparation thereof

ActiveCN101279282AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMaleopimaric acidAmmonium nitrate

The present invention relates to a ZSM-5 mesoporous molecular sieve catalyst used for manufacturing propylene by methanol and a preparation method thereof, which mainly solves the problems of low propylene selectivity, low propylene / ethylene mass ratio as well as poor thermal stability of molecular sieve and poor water thermal stability in the prior art. The present invention adopts the technical proposal of adopting ZSM-5 mesoporous molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 20 to 100 percent as well as at least one caking agent selected from SiO2, clay and Al2O3 to extrude, tablet or spray into shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol or acetic acid under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid or maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

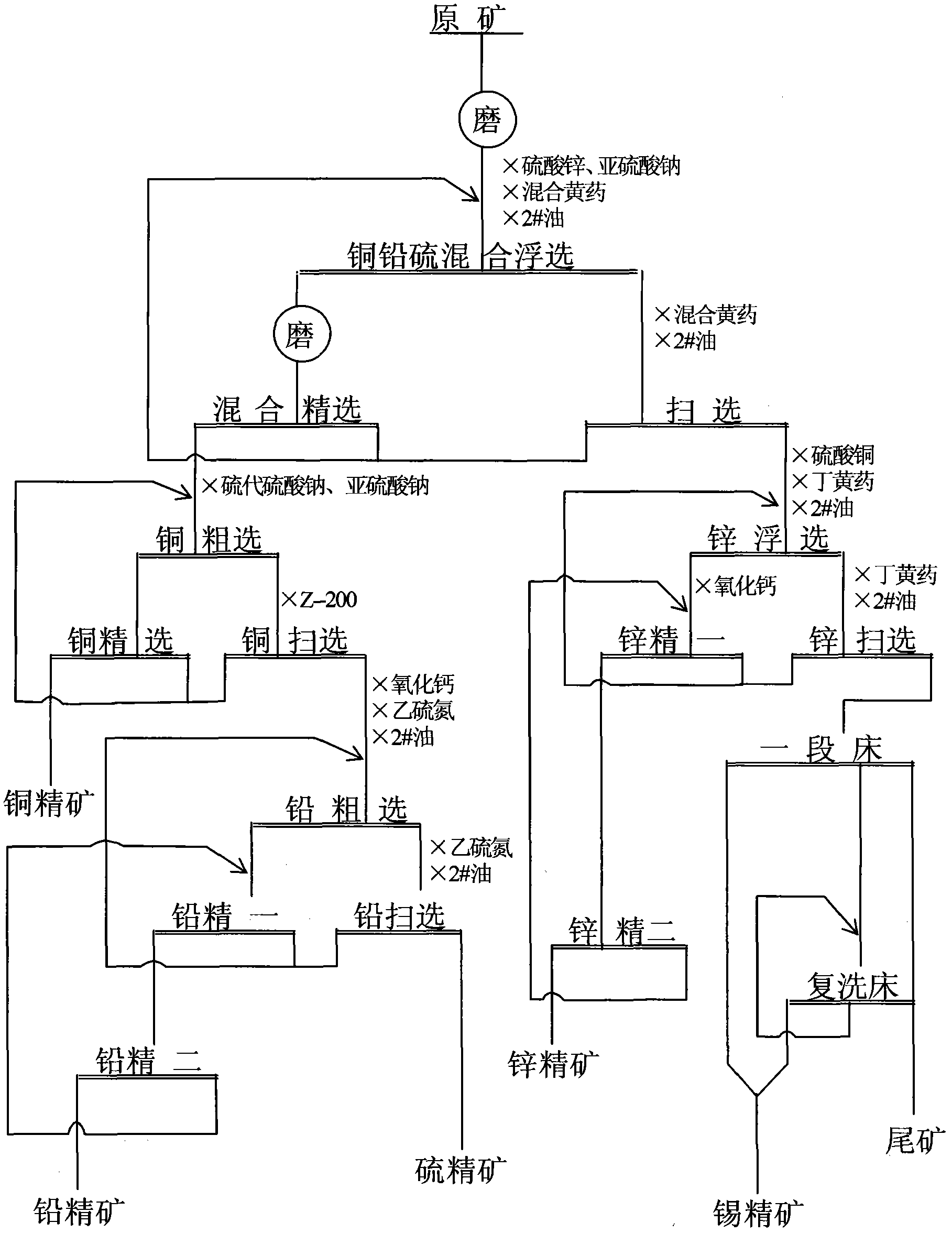

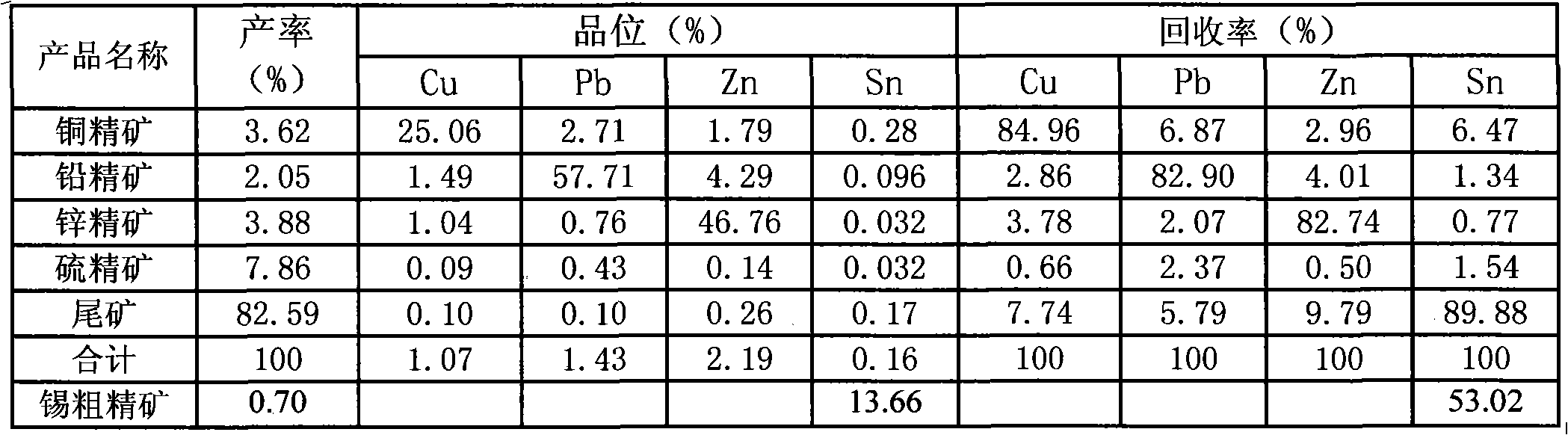

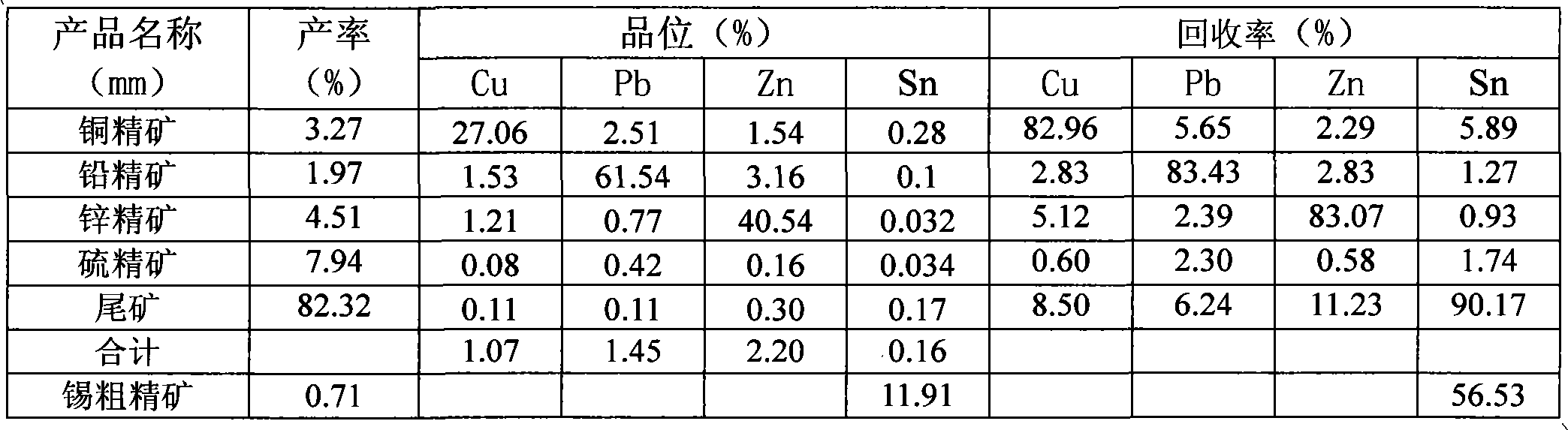

Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

The invention relates to a beneficiation method, in particular to a beneficiation method for separating the polymetallic sulphide ore containing copper, lead, zinc and tin. The method comprises the following steps: (1) carrying out ore grinding on the raw ore before carrying out bulk flotation on copper, lead and sulphur, using diethyl mixed with xanthate as collecting agent of copper and lead mineral, using zinc sulphate and sodium sulfite as inhibitor of zinc mineral; (2) carrying out phase-2 ore grinding and selection; (3) separating copper, lead and sulphur, using sodium sulfite and sodium thiosulfate as the inhibitor of the lead and sulphur mineral, using Z-200 as collecting agent for separation and scavenging and then carrying out lead flotation after the separation and scavenging; (4) carrying out zin flotation on the bulk flotation tailings; and (5) finally, carrying out reselection on the zinc flotation tailings to recover tin. The metalliferous mineral of the invention has the advantages of good separating effect, high metal recovery rate, more complete comprehensive recovery of useful minerals, low cost of medicament, simple method, easy operation and energy conservation.

Owner:云南锡业研究院有限公司研究设计院

Preparation method of modified activated carbon adsorption desulfurizing agent

InactiveCN101804325AHigh selectivityHigh desulfurization depthOther chemical processesHydrocarbon oils refiningCeriumFuel oil

The invention relates to a preparation method of a modified activated carbon adsorption desulfurizing agent. Cocoa nut activated charcoal serves as a carrier; oxidant, such as concentrated nitric acid, concentrated sulfuric acid or ammonium sulphate and the like, is added for modification; active components, such as copper, silver, nipple, cerium and the like are loaded; the metallic oxide content of active components accounts for 1-20 wt% of activated carbon; the mixture is dried to obtain desulfurizing agent. Compared with the prior art, the preparation method has the characteristics of large sulfur adsorption capacity, high desulfurization precision, convenient reproduction and the like, and can be widely applied to producing ultra clean fuel oil in the petrochemical industry field.

Owner:SHANGHAI RES INST OF CHEM IND

Antistatic polyester film and antistatic film laminate

InactiveUS6103368AIncrease resistanceIncrease productivityRecord carriersMagnetic materials for record carriersCarbon numberPolyester

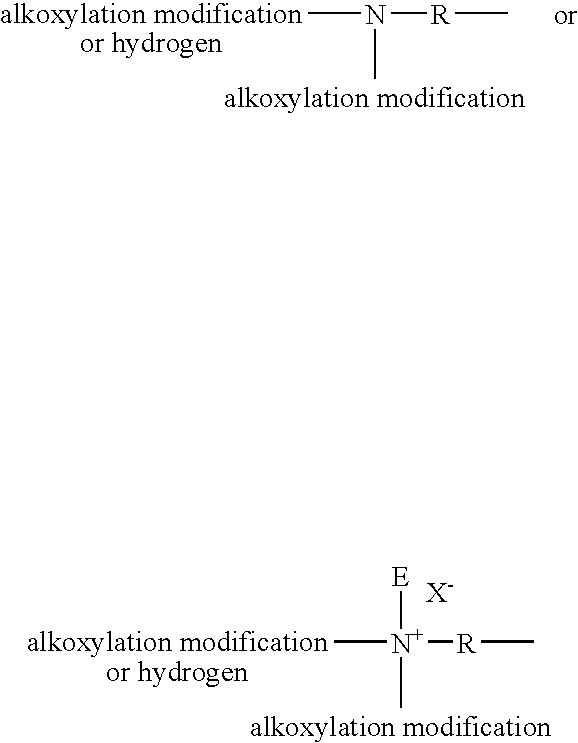

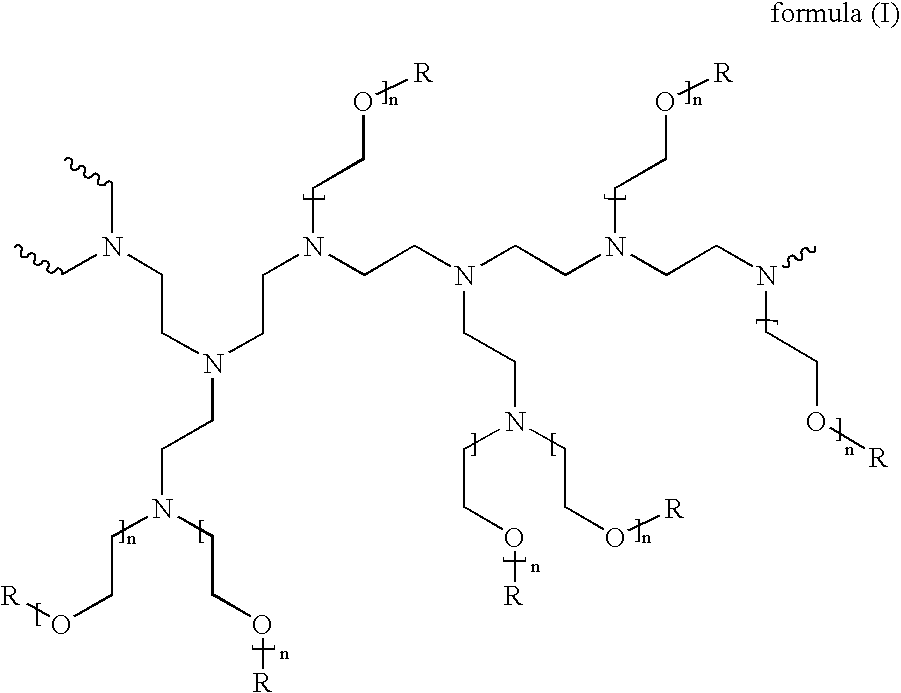

PCT No. PCT / JP97 / 02341 Sec. 371 Date Feb. 27, 1998 Sec. 102(e) Date Feb. 27, 1998 PCT Filed Jul. 7, 1997 PCT Pub. No. WO98 / 02308 PCT Pub. Date Jan. 22, 1998The present invention provides an antistatic polyester film having an antistatic layer formed of an antistatic agent (A) composed mainly of a polymer having a recurring unit of a structure expressed by the following formula (I) on at least one surface of a polyester film wherein R1 and R2 are each H or CH3, R3 is an alkylene group having a carbon number of 2 to 10, R4 and R5 are each a saturated hydrocarbon group having a carbon number of 1 to 5, R6 is an alkylene group having a carbon number of 2 to 5, n is a number of 0 to 40, m is a number of 1 to 40, and Y- is a halogen ion, a mono- or polyhalogenated alkyl ion, nitrate ion, sulfate ion, an alkylsulfate ion, sulfonate ion or an alkylsulfonate ion.

Owner:TEIJIN LTD

Compound amino acid injecta, and preparation method and detection method thereof

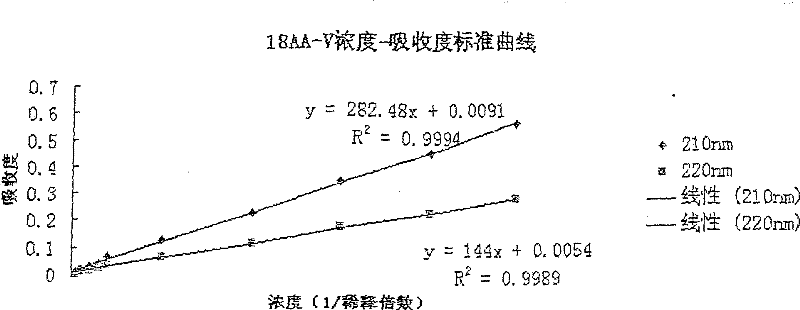

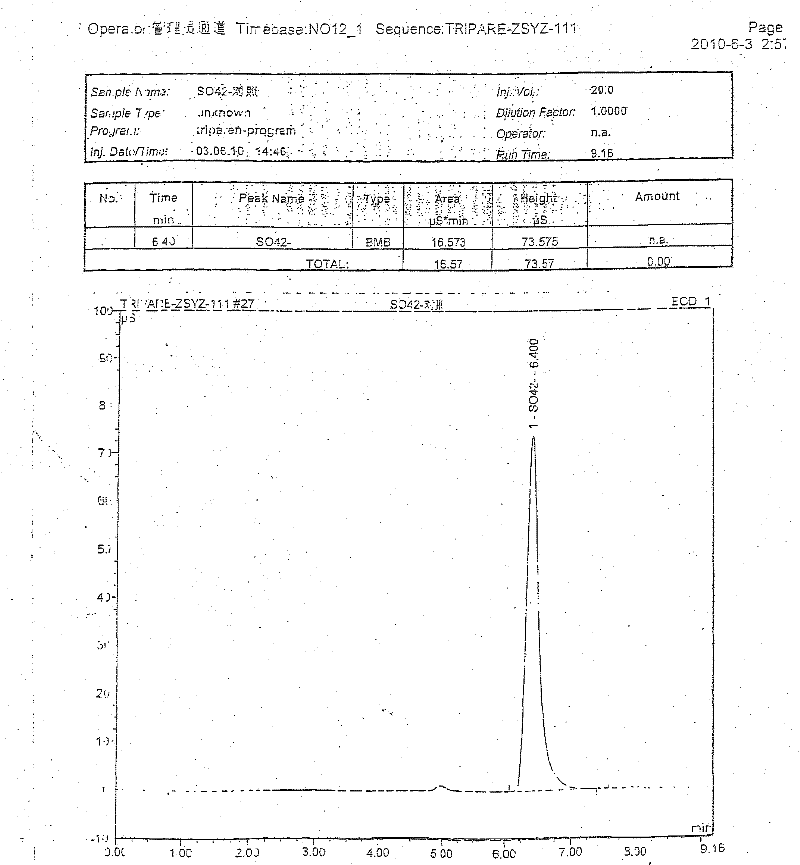

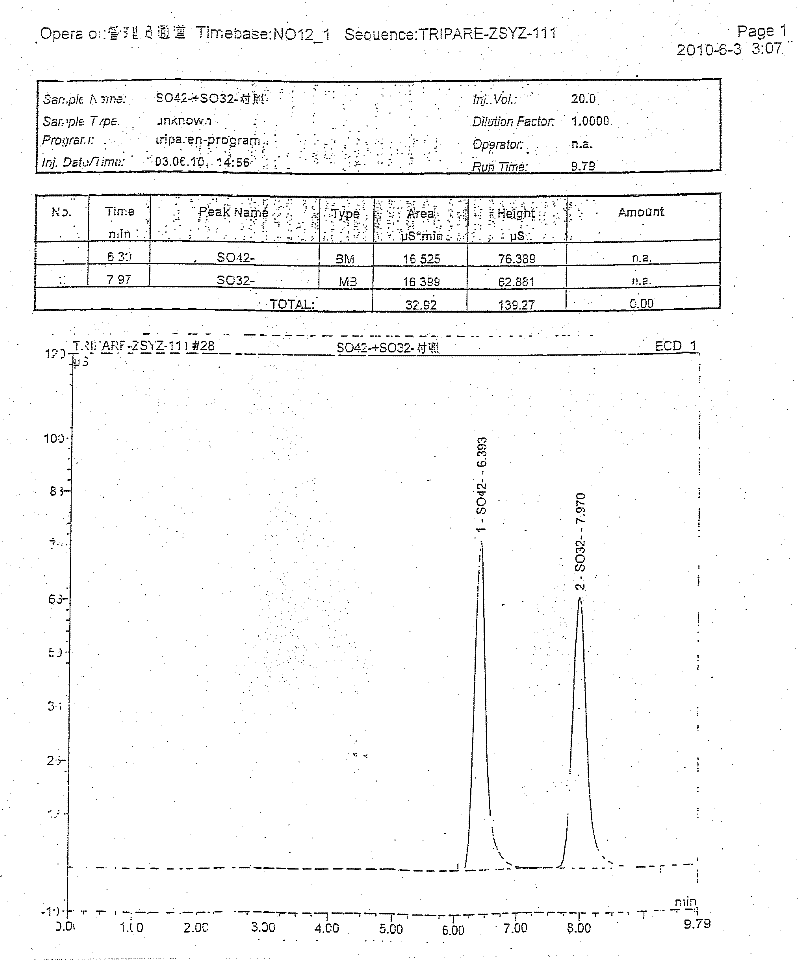

ActiveCN102440989AAccurate measurementExact reproductionOrganic active ingredientsMetabolism disorderIon chromatographySulfate radicals

The invention discloses compound amino acid injecta, which contains arginine hydrochloride, histidine monohydrochloride, leucine, isoleucine, lysine hydrochloride and the like; meanwhile, the invention further discloses a preparation method of the compound amino acid injecta (18AA); in the event of ensuring the product quality, the compound amino acid injecta has the characteristics of saving energy and enhancing efficacy; by means of repetitive verification on precision, detection limit, quantitation limit, linear range and the like, a simple, convenient, rapid and reliable method with cleaning verification is ensured; furthermore, the residual quantity of antioxygen, namely sodium hydrogensulfite, in the compound amino acid injecta and sulphate ion generated by degrading sodium hydrogensulfite are detected according to an ion chromatography principle, thus, the amount of the antioxygen charged in the raw material proportioning can be accurately measured, and the stability of the raw material proportioning process is judged according to the measurement result; and a detection method of the compound amino acid injecta provided by the invention is an online derivative amino acid content measuring method, the speed is rapid, and the method is applied to large-scale detection.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Maintenance-free lead-acid storage battery and preparation method thereof

The invention particularly relates to a maintenance-free lead-acid storage battery and a preparation method thereof. The lead-acid storage battery is prepared from the following anode lead plaster materials: 100kg of lead powder, 1 to 10kg of red lead, 0.02 to 0.15kg of short fiber, 0.02 to 0.15kg of teflon, 0.01 to 0.2kg of stannous mono-sulphate, 0.01 to 0.2kg of antimonous oxide, 6 to 14 weight percent of deionized water, and 5 to 12 weight percent of dilute sulphuric acid, and the following cathode lead plaster materials: 100kg of lead powder, 0.02 to 0.15kg of short fiber, 0.05 to 0.4kg of acetylene black, 0.1 to 1kg of barium sulfate, 0.05 to 0.4kg of lignin, 0.05 to 0.4kg of humic acid, 6 to 14 weight percent of deionized water, and 5 to 12 weight percent of dilute sulphuric acid. The storage battery provided by the invention has good heavy-load discharge performance.

Owner:骆驼集团新疆蓄电池有限公司

High-capacity formation lead paste and preparation method thereof

InactiveCN102931410AIncrease capacityExtended service lifeLead-acid accumulator electrodesFiberPolyester

The invention discloses a high-capacity formation lead paste. An anode lead paste comprises the raw materials of lead powder, deionized water, dilute sulphuric acid and anode auxiliary materials, and particularly comprises 100 parts by weight of lead powder, 6.6-7.4 parts by weight of dilute sulphuric acid, 10-11 parts by weight of deionized water, 3-5 parts by weight of red lead, 0.1-0.3 part by weight of aquadag, 0.08-025 part by weight of stannous mono-sulphate, 0.03-0.05 part by weight of bismuth trioxide, 0.03-0.05 part by weight of antimonous oxide and 0.06-0.1 part by weight of polyester staple fiber; and a cathode lead paste comprises the raw materials of lead powder, deionized water, dilute sulphuric acid and cathode auxiliary materials, and particularly comprises 100 parts by weight of lead powder, 6.5-8.5 parts by weight of dilute sulphuric acid, 9-10 parts by weight of deionized water, 0.5-0.8 part by weight of barium sulfate, 0.15-0.25 part by weight of acetylene carbon black, 0.30-0.40 part by weight of humic acid and 0.06-0.1 part by weight of polyester staple fiber. The invention also discloses a preparation method of the high-capacity formation lead paste.

Owner:CHAOWEI POWER CO LTD

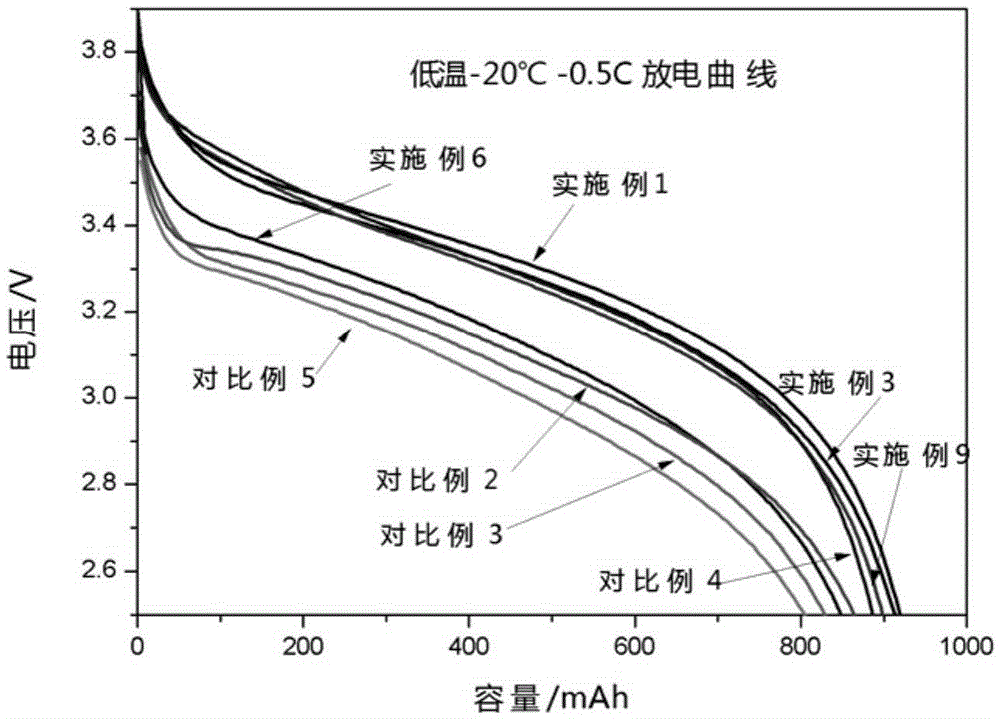

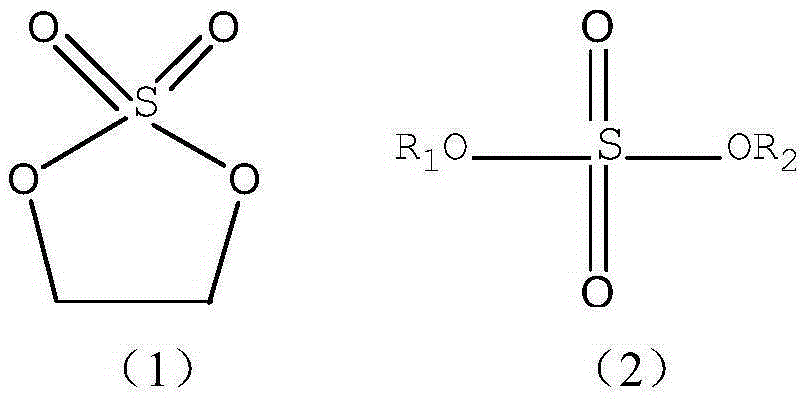

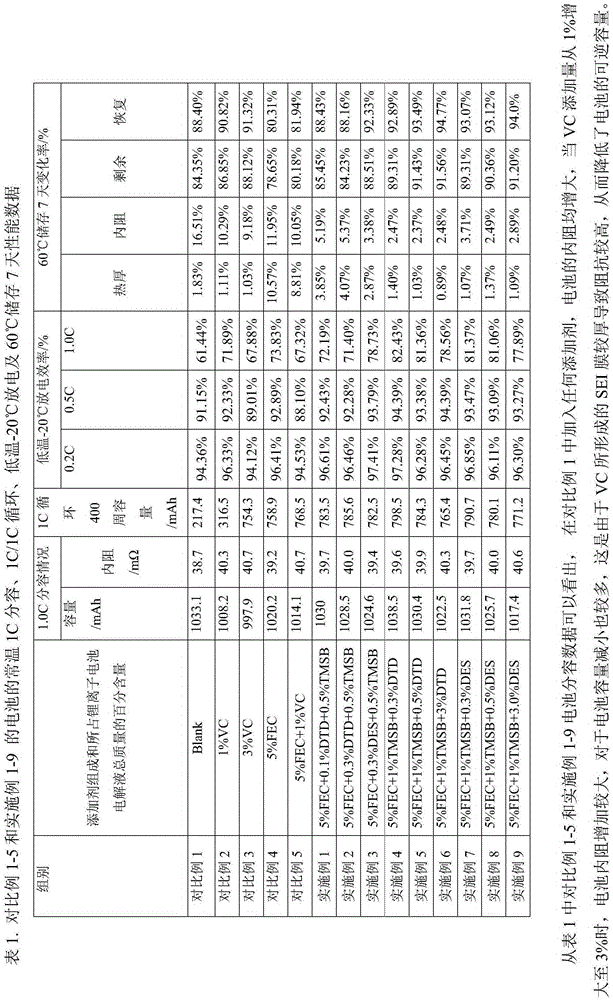

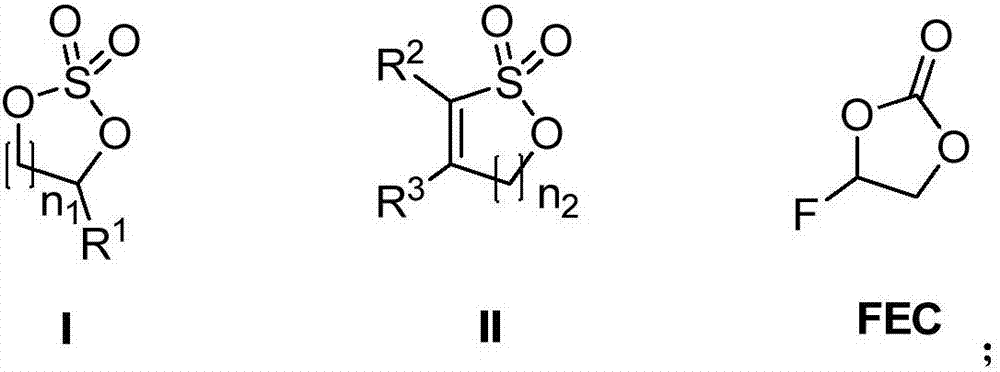

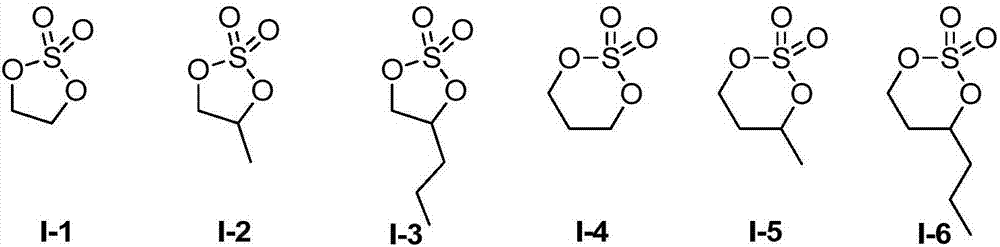

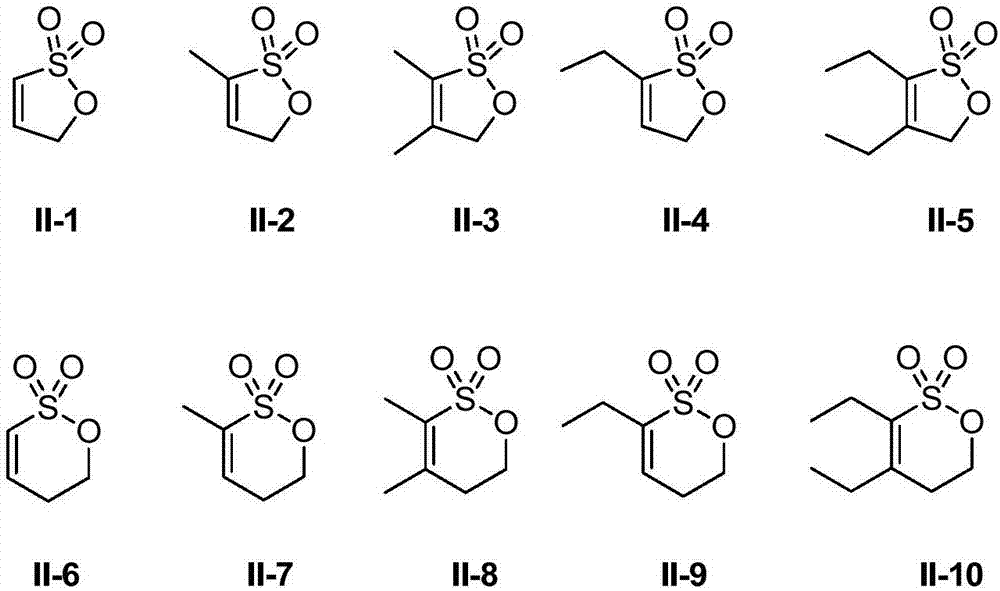

Electrolyte suitable for silicon-carbon negative electrode lithium ion battery and silicon-carbon negative electrode lithium ion battery

ActiveCN105375066AImprove cycle performanceGood high and low temperature performanceSecondary cellsOrganic solventTrimethylsilyl

The invention relates to the technical field of lithium ion batteries, in particular to an electrolyte suitable for a silicon-carbon negative electrode lithium ion battery and the silicon-carbon negative electrode lithium ion battery. The electrolyte suitable for the lithium ion battery is prepared from a non-aqueous organic solvent, lithium salt and additives. The additives comprise fluoroethylene carbonate, tris(trimethylsilyl) borate and a sulphate compound with the formula (1) or the formula (2). Compared with the prior art, under the synergistic effect of the three additives in combined use, the capability of changing and controlling SEI composition and stability is achieved, the overall impedance of a formed SEI film is small, and the components and the structure of the SEI film are stable, so that the reversible capacity of the silicon-carbon negative electrode lithium ion battery is greatly increased, the actual discharge capability of the silicon-carbon negative electrode lithium ion battery is greatly improved, then the battery has good cycle performance and good high-and-low temperature performance, and it is guaranteed that the battery can be used within a wide ambient temperature range.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

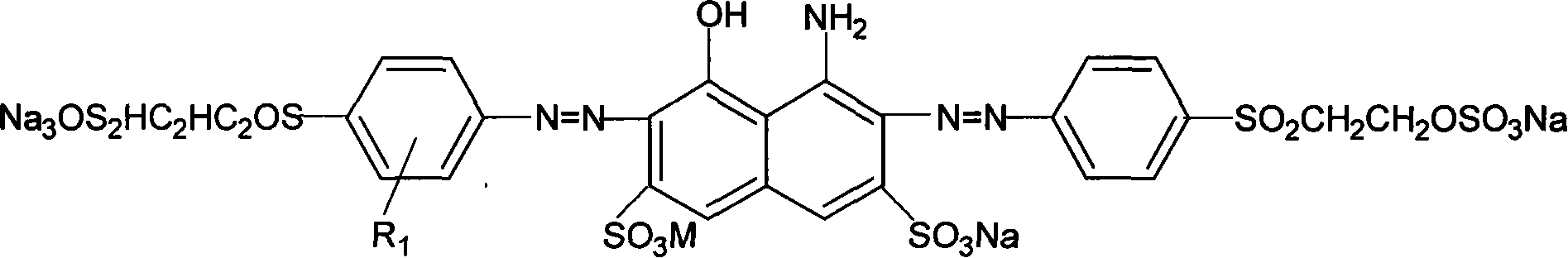

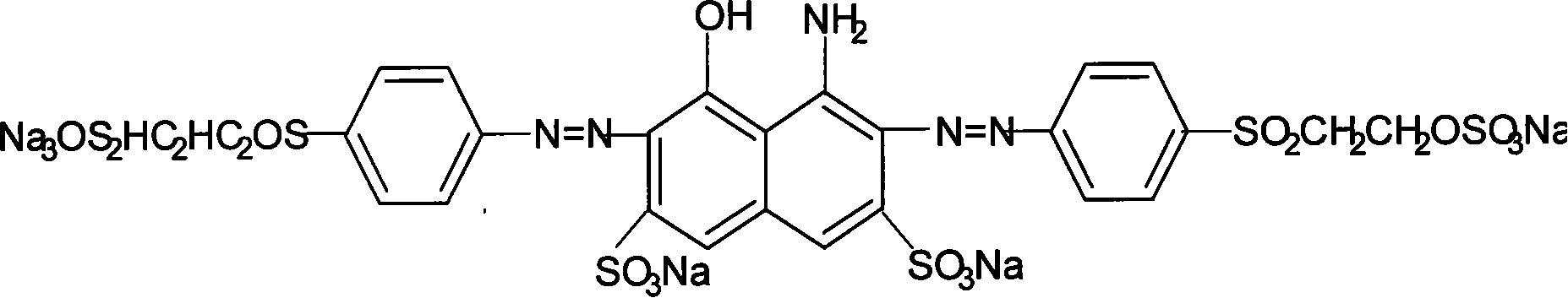

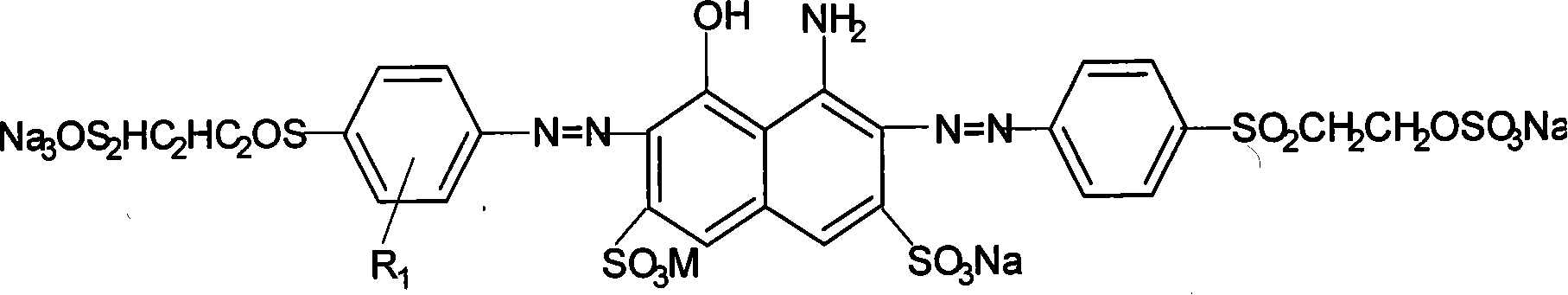

Reactive dark blue RGB diazo dyes and preparation method thereof

Reactive navy blue RGB azo dye and a preparation process thereof are disclosed, and the structural formula showed as right formula, wherein R1=H, SO3H, OCH3, CH3, C2H5, OC2H5, and M=Na, K. The compound is prepared through coupling H acid with diazonium salt of sulphate ethyl sulphone aniline compound which comprises sulfonic acid group or methyl group, methoxyl group, ethyl group and ethoxyl group. The dye is suitable to be used on the dying, direct printing and discharge of cotton fiber, and has the advantages of evenly coloring, bright color, excellent fastness, favorable lifting power, high color yield and extreme high fixation yield.

Owner:赵卫国

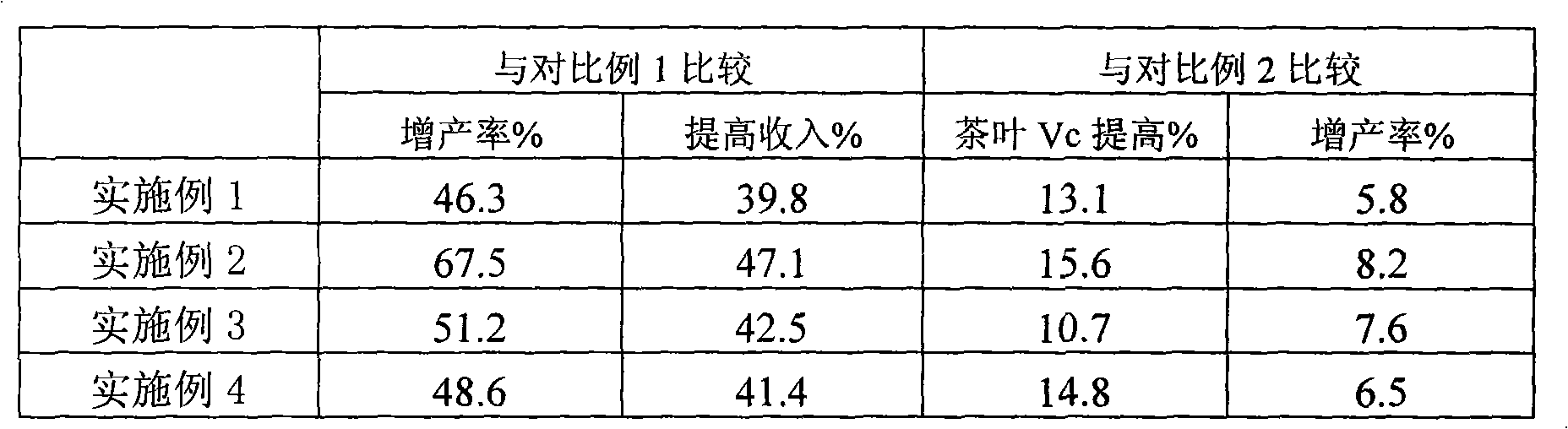

Organic and inorganic compound fertilizer specially used for tea tree and preparation method thereof

InactiveCN101607843AReasonable ratio of nutrientsUniform supplyBiocideBio-organic fraction processingMicrobial agentSlag

The invention relates to an organic and inorganic compound fertilizer specially used for tea trees and a preparation method thereof. The organic and inorganic compound fertilizer is prepared from the following raw materials by weight portion: 40-70 portions of fermented organic fertilizer, 3-15 portions of carbamide, 10-30 portions of ammonium sulfate, 5-25 portions of diammonium phosphate and 5-15 portions of potassium sulphate, wherein the fermented organic fertilizer is prepared by taking 45-65 portions of furfural residues, 20-35 portions of fuming slag and 10-20 portions of weathered coal as raw materials and adding 1-2 portions of microbial fermentation agent EM compound microbial agents to be accumulated and fermented and then dried until the moisture content is 25-35 percent. The organic and inorganic compound fertilizer specially used for the tea trees has long-time fertilizer effect, thereby increasing the fertilizing times; and in addition, the organic and inorganic compound fertilizer specially used for the tea trees has reasonable nutrient proportion, thereby enhancing the tea-leaf yield.

Owner:SHANDONG GUANGDA FERTILIZER INDAL TECHCO

Coated fertilizer for fruit trees and mfg. method

InactiveCN1834069AIncrease profitImprove productivitySuperphosphatesUrea compound fertilisersParaffin waxMagnesium phosphate

Owner:郑升杰

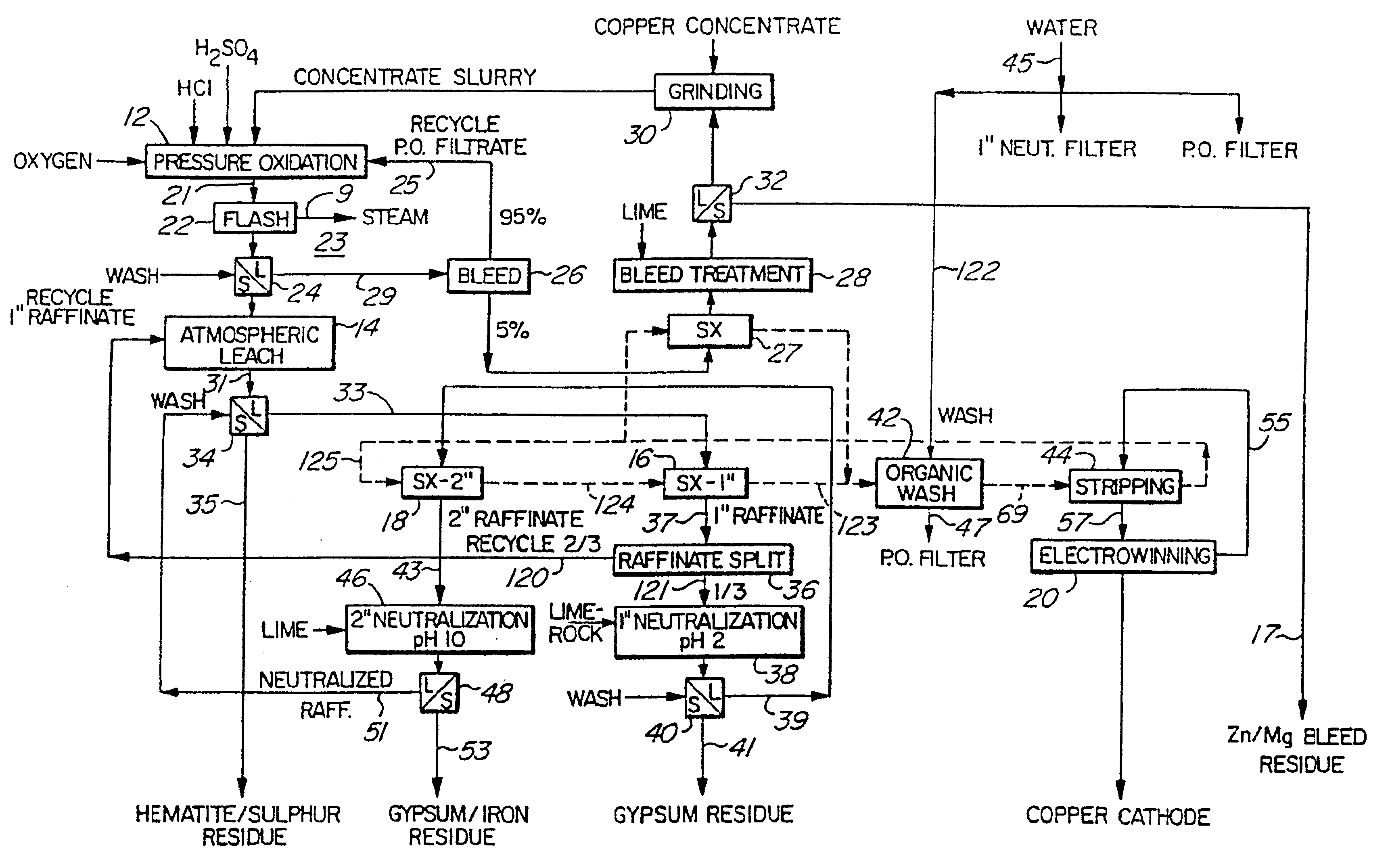

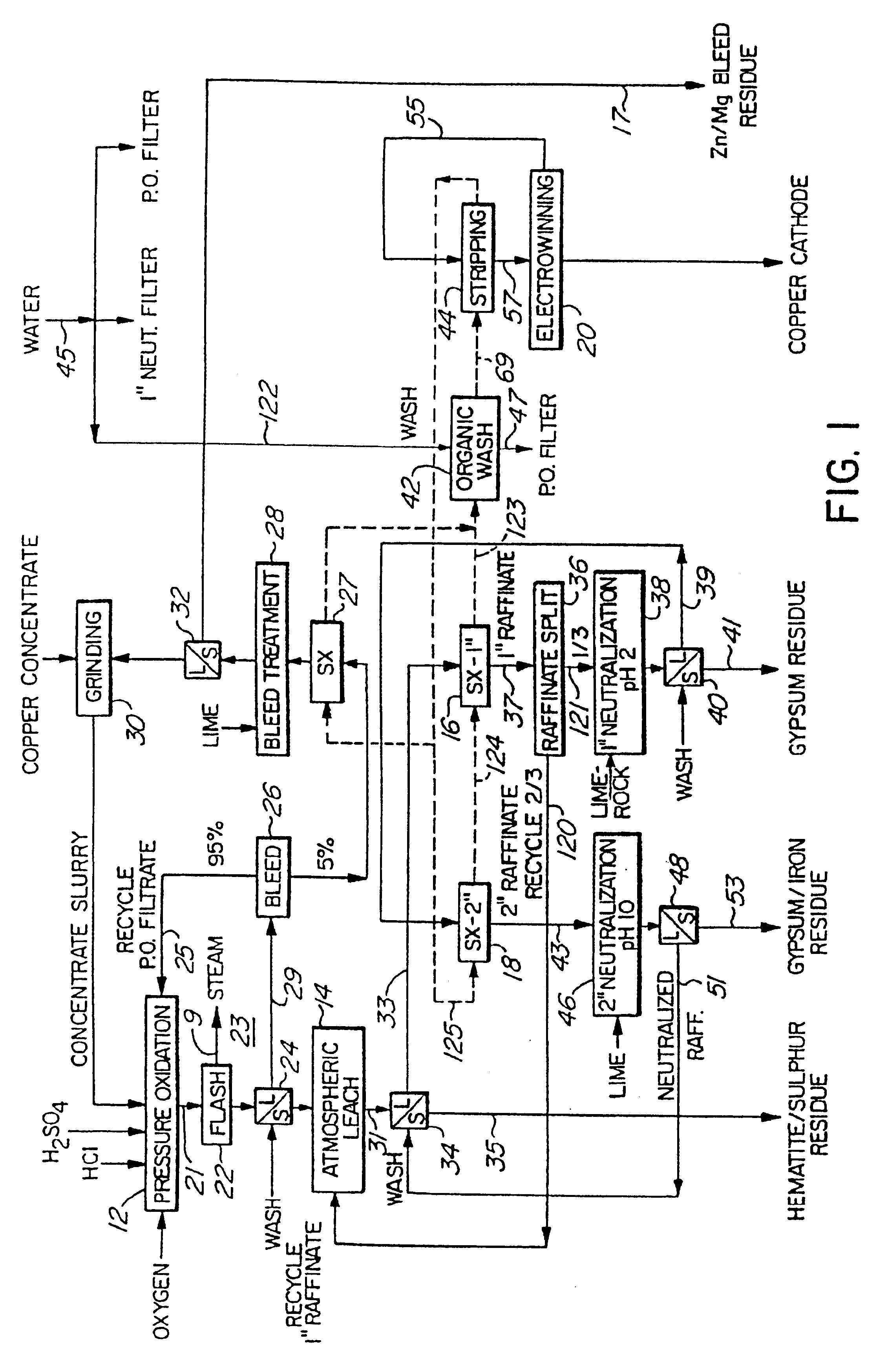

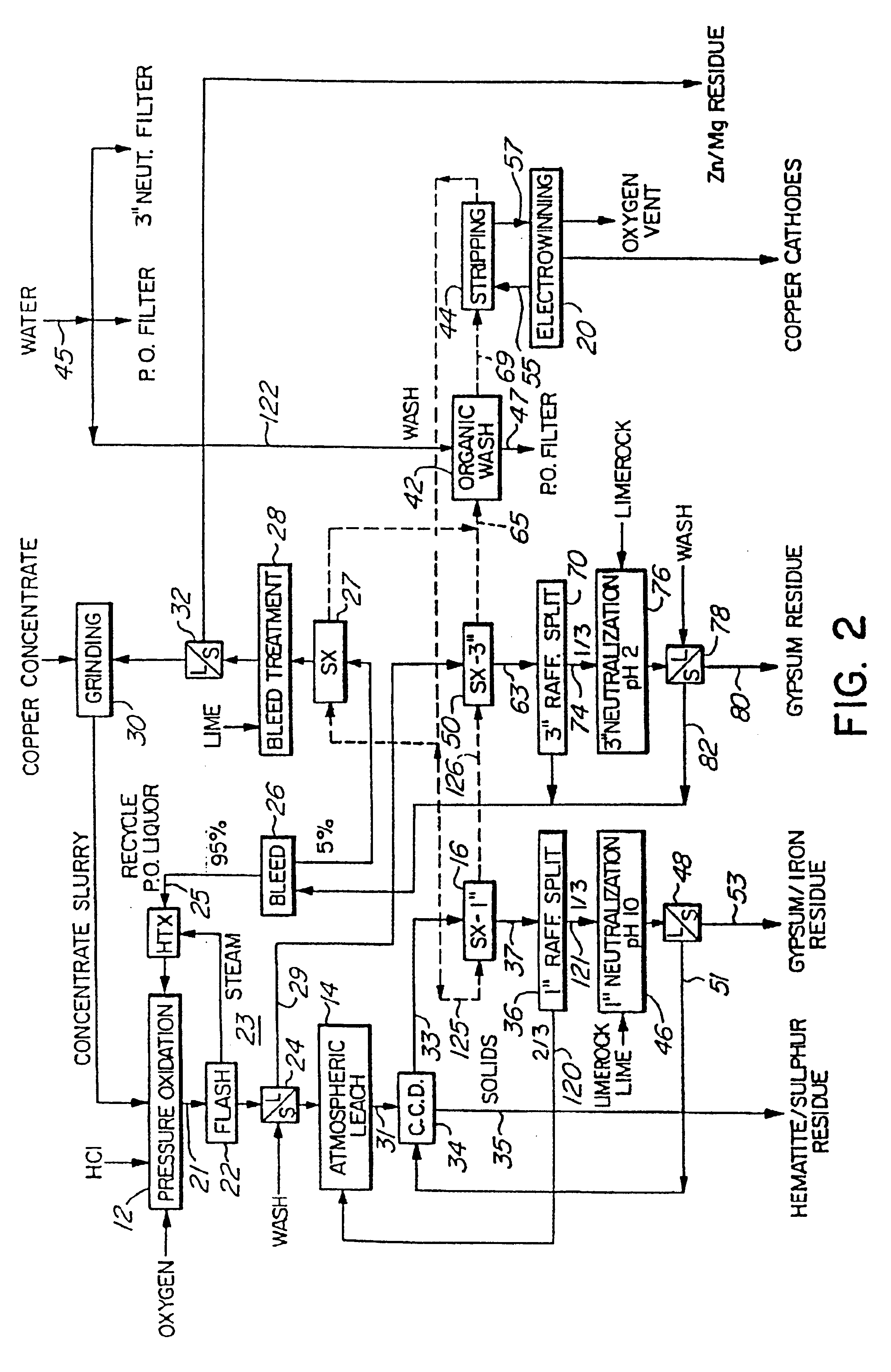

Chloride assisted hydrometallurgical extraction of metal

A process for the extraction of a metal from an ore or concentrate comprises subjecting the ore or concentrate to pressure oxidation in the presence of oxygen and an acidic solution containing halogen ions and a source of bisulphate or sulphate ions, such as H2SO4. The metals which can be extracted by the process comprises copper as well as non-cuprous metals such as zinc, nickel and cobalt. During pressure oxidation the metal may be precipitated as an insoluble basic salt, such as basic copper sulphate, or substantially completely solubilized and precipitated later as the basic metal salt.

Owner:CESL LIMITED

Method for preparing folic acid

The invention relates to a preparation method of folic acid. The process steps are as follows: firstly, the intermediate product N-p-aminobenzoyl glutamic acid is prepared by using p-nitrobenzoyl chloride and sodium glutamate; Guanidine and sodium methoxide were used to prepare the intermediate product 6-hydroxy-2,4,5-triaminopyrimidine sulfate; finally, the above two intermediate products were used to prepare crude folic acid, which was purified to obtain pure folic acid. The beneficial effects of the invention are that the production cost is greatly reduced, the product efficiency is improved, and the pollution to the environment is reduced.

Owner:潘福星

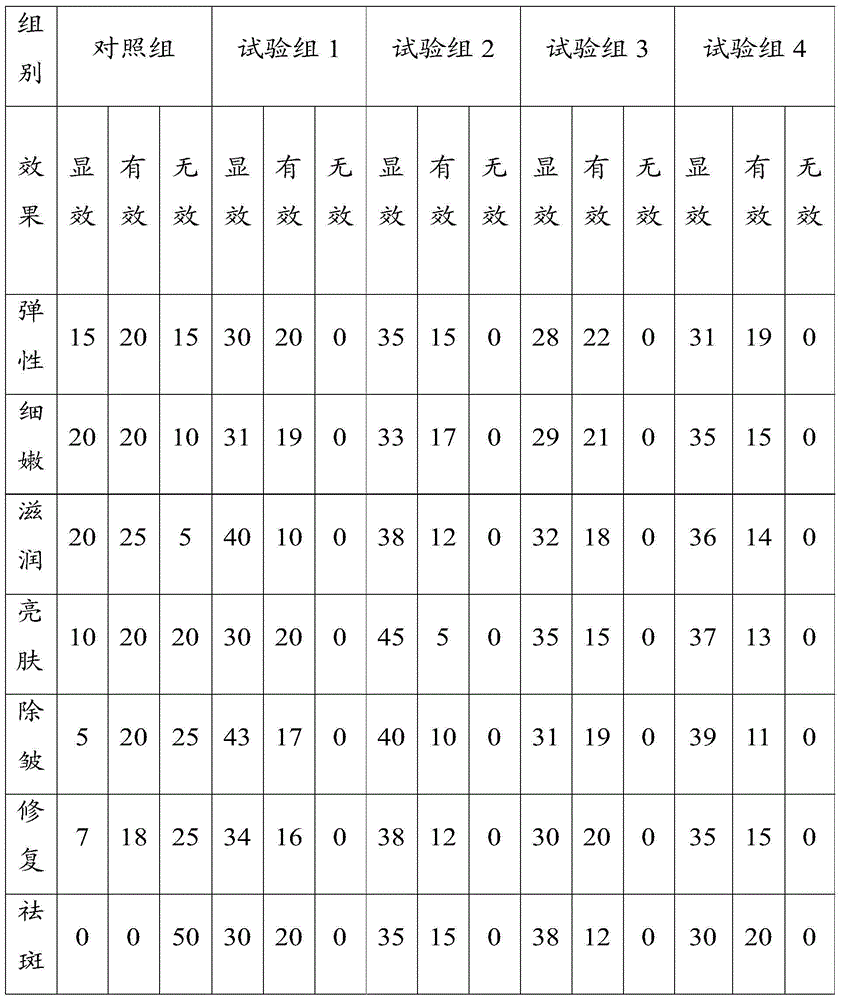

Origin fermentation method and origin fermentation product prepared by same

ActiveCN104152514AShort fermentation timeSimple stepsCosmetic preparationsToilet preparationsAdditive ingredientUltrafiltration

The invention relates to the field of biological fermentation and in particular relates to an origin fermentation method and an origin fermentation product prepared by the same. The origin fermentation method comprises the following steps: acquiring fresh leaves, pulping and crushing to obtain a leaf slurry; placing the leaf slurry into a fermentation tank, adding sterilized ammonium sulphate, ammonium dihydrogen phosphate, ammonium hydrogen carbonate and an aqueous solution of corn steep liquor dry powder into a fermentation tank so as to be fermented; carrying out cell breakage, ultrafiltration, low-temperature drying and concentrating on a fermentation product, and packaging, so that the origin fermentation product is obtained. The origin fermentation method provided by the invention has the advantages that fresh leaves are crushed, bacteria and enzymes carried by the leaves are directly utilized for carrying out fermentation, no organic solvent, saccharifying enzyme or yeast is added in a fermentation process, the fermentation time is short, main ingredients of the obtained origin fermentation product are active substances beneficial to skin, such as micromolecule plant proteins, plant growth factors, plant activity auxin and part of cell growth factors, and the quality of the obtained origin fermentation product is high.

Owner:北京翰若生物科技有限公司

Composite porous activated carbon flue gas adsorbent and preparation method thereof

InactiveCN104437371AImprove toughnessHigh strengthOther chemical processesDispersed particle separationPorositySodium metasilicate

The invention discloses a composite porous activated carbon flue gas adsorbent which is characterized by comprising the following raw materials in parts by weight: 98-105 parts of shell activated carbon, 36-40 parts of diatomite, 2-3 parts of sodium metasilicate, 2-3 parts of rosin, 2-3 parts of VAE emulsion, 2-3 parts of polyvinyl alcohol, 1-2 parts of sodium alcohol ether sulphate, 1-2 parts of sodium citrate, 1-2 parts of gypsum residue, 2.5-3.5 parts of pulverized fuel ash, 4-5 parts of edible corn starch, 2-3 parts of lanthanum nitrate, 9-12 parts of glass fiber powder, 4-6 parts of adsorption aids and a proper amount of water. The composite porous activated carbon flue gas adsorbent disclosed by the invention is reasonable in formula, viscous matters such as polyvinyl alcohol and edible corn starch are added, the toughness and strength of the activated carbon are improved, and the service life is prolonged; and due to the addition of the adsorption aids, the adsorbent has special porosity, the contact time between gas and the adsorbent is prolonged, and the effects of inhibiting bacteria and purifying the air are achieved. Therefore, the adsorption efficiency is high, the production process is simple, and the adsorbent is suitable for industrial dry desulfurization, automobile exhaust desulfurization and daily air purification.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

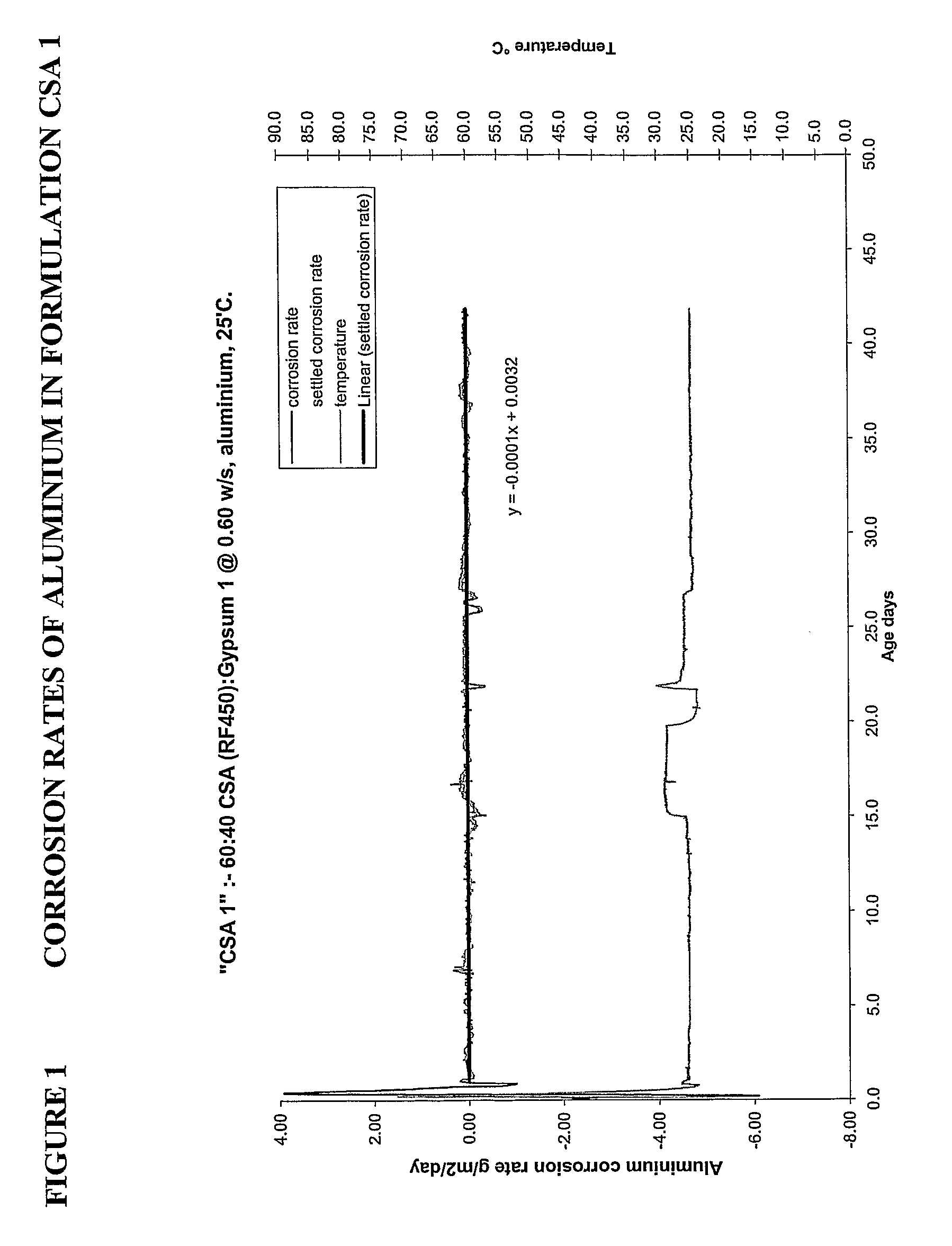

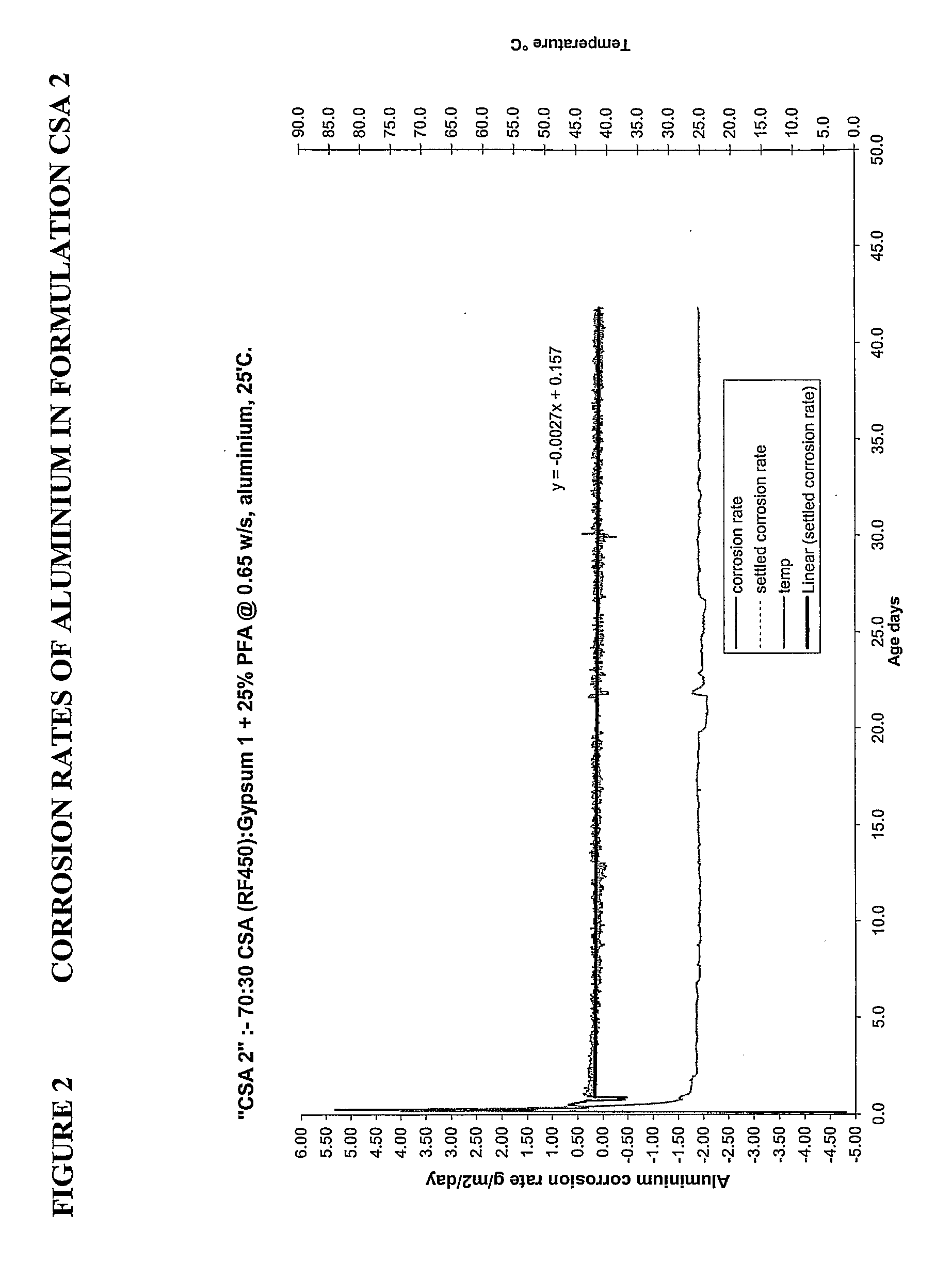

Encapsulation Medium

InactiveUS20080134943A1Improve liquidityReduced early corrosion rateSludge treatmentSolid waste managementAlkaline earth metalSulphate Ion

The invention provides a cementitious composition comprising at least one sulphoaluminate cement which comprises a sulphoaluminate salt of an alkaline earth metal, the cementitious composition being essentially free of other cementitious components. Preferably the at least one sulphoaluminate salt of an alkaline earth metal comprises calcium sulphoaluminate and the cementitious composition additionally comprises at least one further salt of an alkaline earth metal, preferably calcium sulphate. The invention also provides a method for the encapsulation of materials, the method comprising treating the materials with the said at least one cementitious composition. Preferably, the materials which are encapsulated according to the method of the invention comprise waste materials generated in the nuclear processing industry comprising amphoteric reactive metals.

Owner:NUCLEAR DECOMMISSIONING AUTHORITY

Test method of sulphate content of desulfurization gypsum

InactiveCN101625300ASimple methodFast analysisWeighing by removing componentCooking & bakingWater content

The invention provides a test method of the sulphate content of desulfurization gypsum, comprising the following steps: 3-5 grams of gypsum samples are taken to be heated and dried for 30-60 minutes in a baking oven with the temperature of 42-48 DEG C and then placed into a drier to be cooled to room temperature and weighed by a 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W (g) of the gypsum samples is recorded; the gypsum samples are placed back to the baking oven to be heated and dried for 30-60 minutes under the temperature of 350-370 DEG C and then placed into the drier to be cooled to the room temperature and weighed by the 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W1 (g) of the gypsum samples is recorded; the computation of the crystallization water content of the gypsum samples is as follows: the crystallization water content X(%)=(W-W1)*100 / W, and the computation of the sulphate content of the gypsum samples is as follows: the sulphate content is indicated by calcium sulphate dehydrate content, CaSO4.2H2O(%)=X*100 / 20.9275. The method is simple, convenient and fast; and in addition, compared with the prior art, the invention greatly enhances the analysis speed, simplifies the analysis steps and decreases the experimental apparatus.

Owner:HEBEI ELECTRIC POWER RES INST

Electrolyte of sodium ion battery, and preparation method and application of electrolyte

ActiveCN106920988AImprove high temperature storageImprove cycle performanceFinal product manufactureElectrolyte accumulators manufactureHigh temperature storageDischarge rate

The invention discloses an electrolyte of a sodium ion battery, and a preparation method and an application of the electrolyte. The electrolyte of the sodium ion battery comprises sodium salt, non-aqueous organic solvents and additives, wherein the additives are a sulphate type compound as shown in the formula I, a sultone type compound as shown in the formula II and fluoroethylene carbonate (FEC); the non-aqueous organic solvents are carbonic ester or carbonic ester and carboxylic ester; and the carbonic ester is cyclic carbonate and / or chain carbonate. According to the electrolyte of the sodium ion battery disclosed by the invention, the cyclic sulphate type compound is initially used as the additive to be applied to the field of the sodium ion battery; and the sodium ion battery prepared from the electrolyte of the sodium ion battery disclosed by the invention has excellent high-temperature storage performance, high-temperature cycling performance and low-temperature discharging rate capability.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

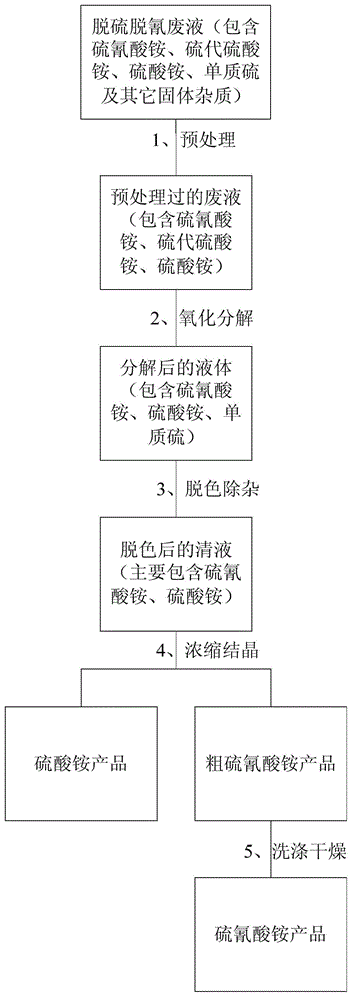

Method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization/decyanation waste liquor

InactiveCN102976361AEfficient decompositionHigh purityThiocyanic acidAmmonium sulfatesPollutionAmmonium sulfate

The invention provides a method for recycling ammonium salt from chemical waste liquor generated in the desulfurization / decyanation process of coke oven gas, and particularly, the invention provides a method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization / decyanation waste liquor. The purities of ammonium thiocyanate and ammonium sulphate produced by using the method disclosed by the invention are greatly improved in comparison with those of products produced by contrasted embodiments. According to the method disclosed by the invention, high-purity products can be prepared under the condition of only carrying out one-time step-by-step concentration, so that the wastewater discharge amount is reduced and the environment pollution of coking plants is alleviated; and high-purity and high-added-value chemical raw materials are recycled, thereby increasing the economic benefits of enterprises.

Owner:BEIJING RISUN TECH CO LTD

Fucosan sulphate, preparation method thereof, and application of fucosan sulphate in preparing anti-influenza virus medicine

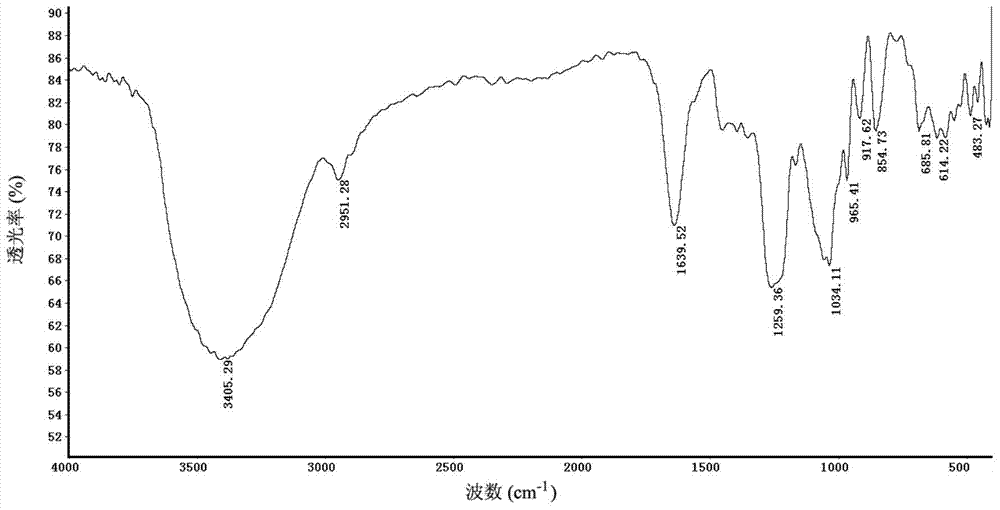

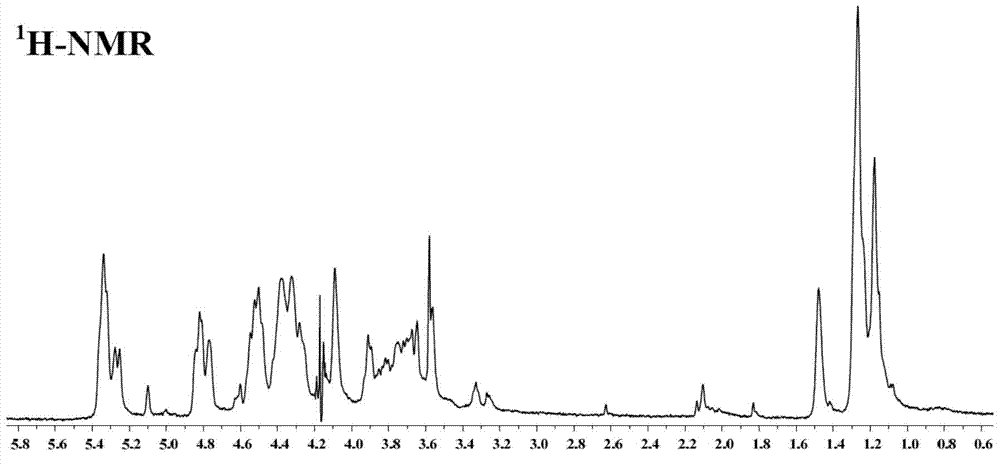

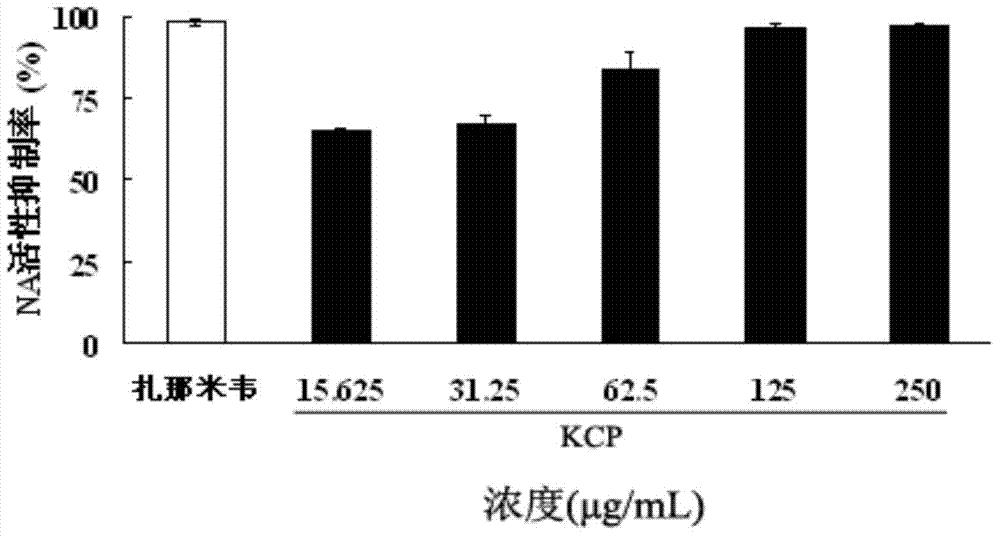

The invention belongs to the field of marine medicines, and relates to a fucosan sulphate, a preparation method thereof and application of the fucosan sulphate in preparing an anti-influenza virus medicine. Polysaccharide with a main chain taking alpha-1,2-D-mannose and beta-1,4-D-glucuronic acid as repetitive units, and with a branched chain of alpha-1,3-L-fucosan sulphate is obtained by virtue of hot-water extraction, calcium chloride precipitation and DEAE-Cellulose chromatographic column purification. The fucosan sulphate prepared by the invention is high in inhibition effect on the influenza virus neuraminidase activities of A H1N1, H5N1 and H3N2, and obvious in protection effect on the dog kidney epithelial cells infected by A H1N1. The fucosan sulphate provided by the invention has the advantages of being rich in raw material source, simple in preparation process, easy to industrialize, high in product water solubility, high in stability, free from toxic and side effects, and the like, and has the prospect of being developed to the anti-influenza virus medicine.

Owner:威海人生药业有限公司

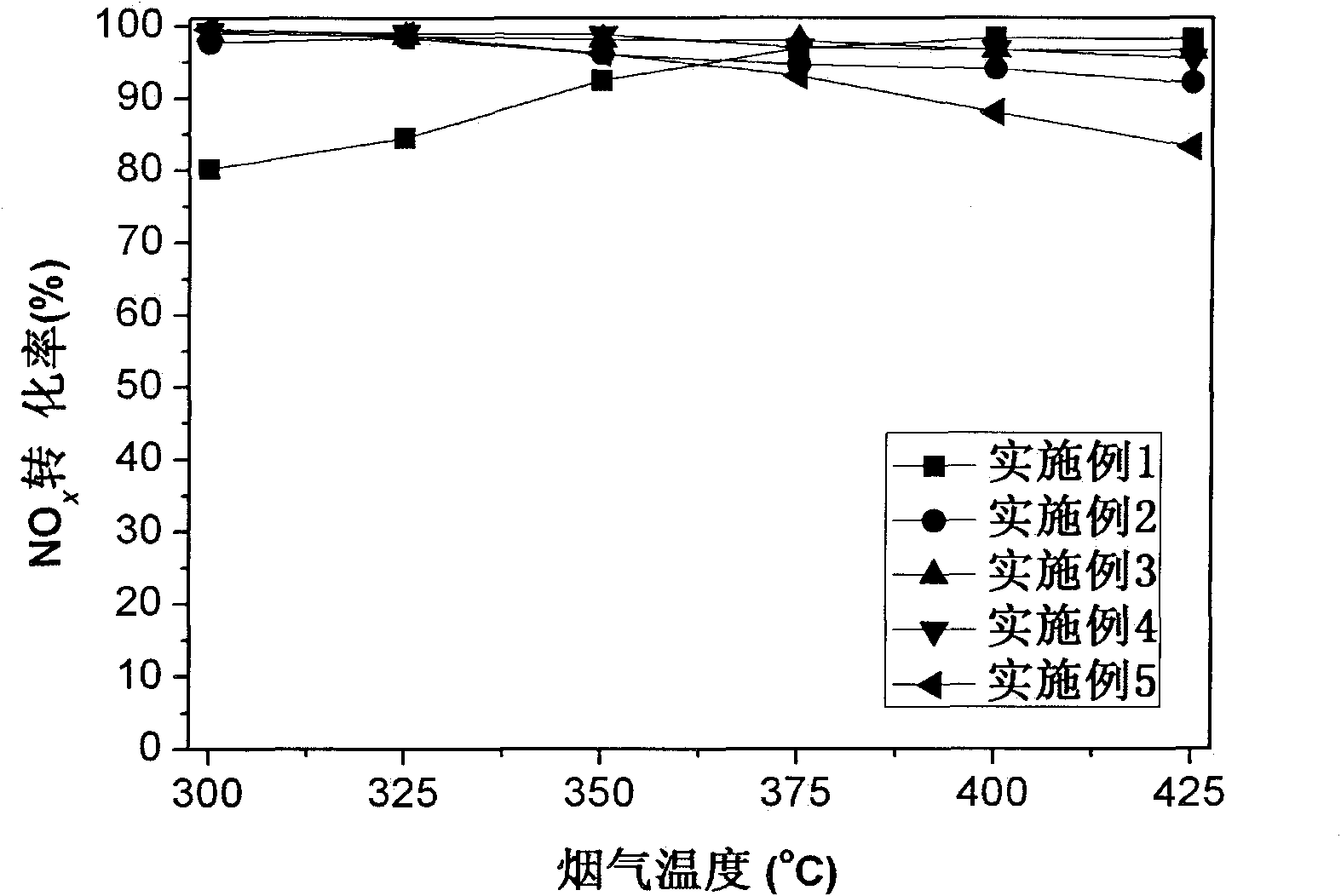

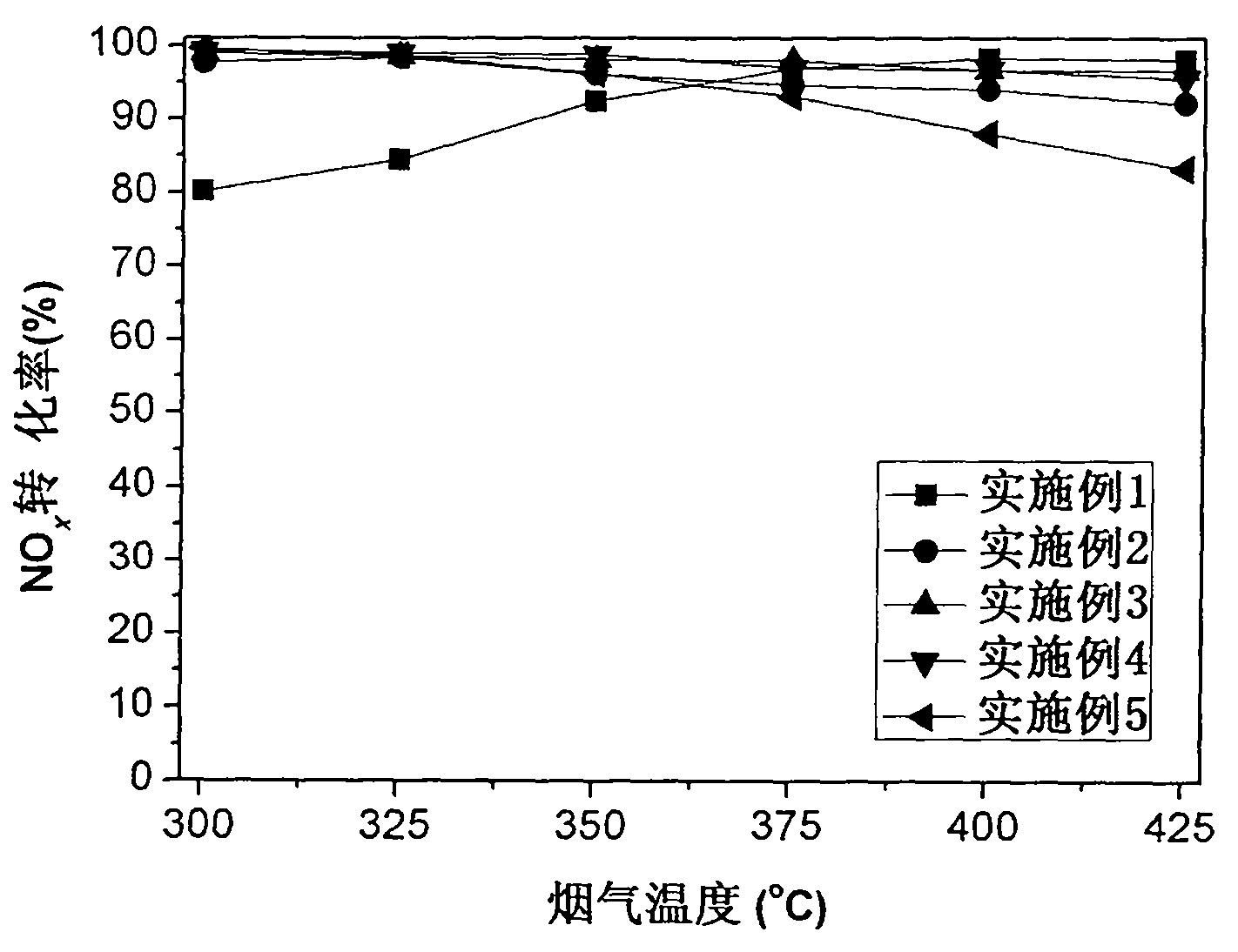

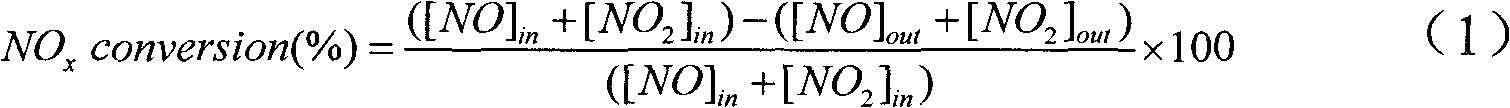

Composite oxidant SCR (Selective Catalytic Reduction) denitrating catalyst, preparation method and applications thereof

ActiveCN101829573ANon-toxicHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulphate IonHigh activity

The invention discloses a composite oxidant SCR (Selective Catalytic Reduction) denitrating catalyst for warm fume in boilers, a preparation method and application thereof. The catalyst comprises the components of transition metal element M and Ti element. As counted by the oxidant, the amount of the transition metal element M accounts for 6.8-20wt% of the total weight of the catalyst. As counted by TiO2, the amount of Ti accounts for 80-93.2wt% of the total weight of the catalyst. Compared with the widely used commercial catalyst, the catalyst decreases the cost by more than 20%, does not contain W, Mo, V and Ce, and has the advantages of low cost, no toxicity, high activity, good sulphate resisting property and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com