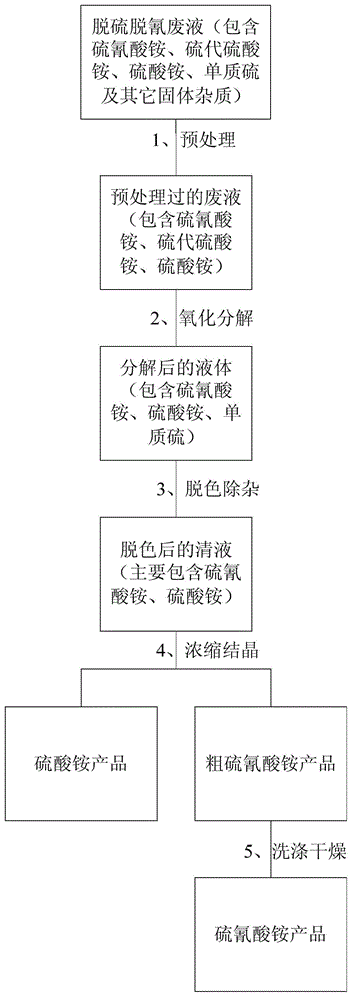

Method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization/decyanation waste liquor

A technology of ammonium thiocyanate and coking desulfurization, which is applied in the direction of thiocyanate and ammonium sulfate, can solve the problems of cost increase and complicated process, and achieve the effects of convenient operation, simple extraction method, and reduction of emissions and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Pretreatment of desulfurization and decyanation waste liquid

[0033] Take coke oven gas desulfurization and decyanation waste liquid 1100g [from Hebei Xuyang Coking Co., Ltd., wherein NH 4 SCN content 20.3wt%; (NH 4 ) 2 SO 4 Content 9.6wt%; (NH 4 ) 2 S 2 o 3 Content 0.6wt%], put it into the settling kettle and let it stand naturally for 10h. Filter to remove elemental sulfur and other solid impurities.

[0034] 2. Decomposition of ammonium thiosulfate

[0035] The desulfurization and decyanation waste liquid after preliminary filtration was placed in a decolorization kettle, and the air flow rate was 30ml / min. After stirring and heating at 85°C for 45 minutes, the measured pH value was 7.6.

[0036] 3. Decolorization and impurity removal

[0037] Then add 33g of activated carbon [purchased from Tianjin Guangfu Technology Development Co., Ltd.] into the decolorization kettle, decolorize at 60°C for 90min, and then filter.

[0038] 4. Concentrated crystalli...

Embodiment 2

[0043] 1. Pretreatment of desulfurization and decyanation waste liquid

[0044] The pretreatment of desulfurization and decyanation waste liquid was carried out in the same manner as in Example 1.

[0045] 2. Decomposition of ammonium thiosulfate

[0046] Except that the time of stirring and heating was 120 minutes instead of 45 minutes, the decomposition of ammonium thiosulfate was carried out in the same manner as in Example 1, and the measured pH value was 7.3.

[0047] 3. Decolorization and impurity removal

[0048] Decolorization and impurity removal were carried out in the same manner as in Example 1.

[0049] 4. Concentrated crystallization

[0050] Concentration crystallization was carried out in the same manner as in Example 1, wherein 105.5 g of ammonium sulfate product was obtained after crystallization at 48° C., wherein the ammonium sulfate content was 96.3 wt%, ammonium thiocyanate was 1.0 wt%, and the water content was 2.4 wt%. After crystallization at 15°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com