Patents

Literature

657 results about "Thiocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiocyanate (also known as rhodanide) is the anion [SCN]⁻. It is the conjugate base of thiocyanic acid. Common derivatives include the colourless salts potassium thiocyanate and sodium thiocyanate. Organic compounds containing the functional group SCN are also called thiocyanates. Mercury(II) thiocyanate was formerly used in pyrotechnics.

Precursor source mixtures

A precursor source mixture useful for CVD or ALD of a film comprising: at least one precursor composed of an element selected from the group consisting of Li, Na, K, Rb, Cs, Fr, Be, Mg, Ti, Zr, Hf, Sc, Y, La, V, Nb, Ta, Cr, Mo, W, Mn, Re, Fe, Ru, Os, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Hg, B, Al, Ga, In, Tl, Si, Ge, Sn, Pb, As, P, Sb and Bi, to which is bound at least one ligand selected from the group consisting of hydride, alkyl, alkenyl, cycloalkenyl, aryl, alkyne, carbonyl, amido, imido, hydrazido, phosphido, nitrosyl, nitryl, nitrate, nitrile, halide, azide, alkoxy, siloxy, silyl, and halogenated, sulfonated or silyated derivatives thereof, which is dissolved, emulsified or suspended in an inert liquid selected from the group consisting of aliphatic hydrocarbons, aromatic hydrocarbons, alcohols, ethers, aldehydes, ketones, acids, phenols, esters, amines, alkylnitrile, halogenated hydrocarbons, silyated hydrocarbons, thioethers, amines, cyanates, isocyanates, thiocyanates, silicone oils, nitroalkyl, alkylnitrate, and mixtures thereof. The precursor source mixture may be a solution, emulsion or suspension and may consist of a mixture of solid, liquid and gas phases which are distributed throughout the mixture.

Owner:GLOBALFOUNDRIES INC

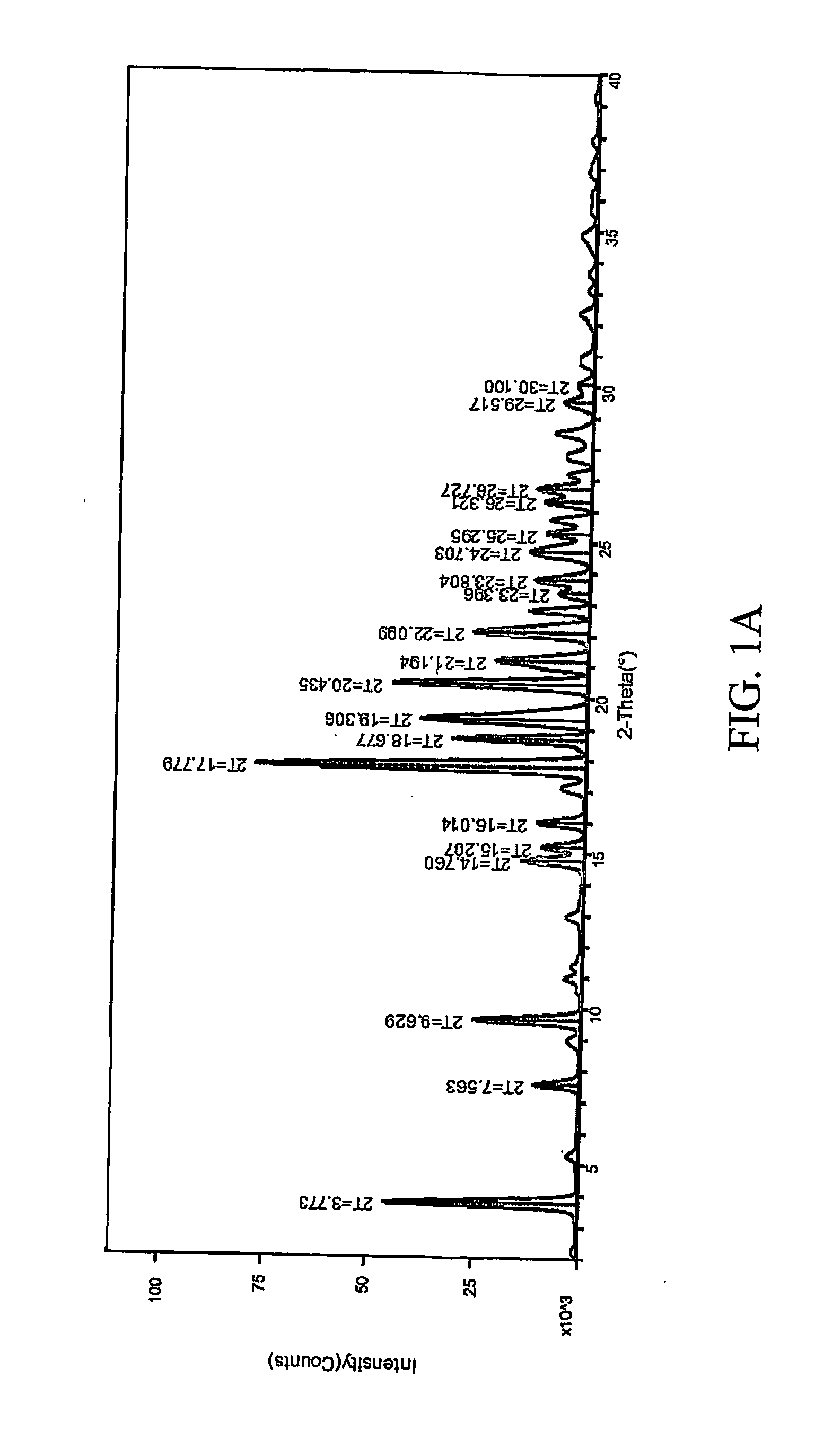

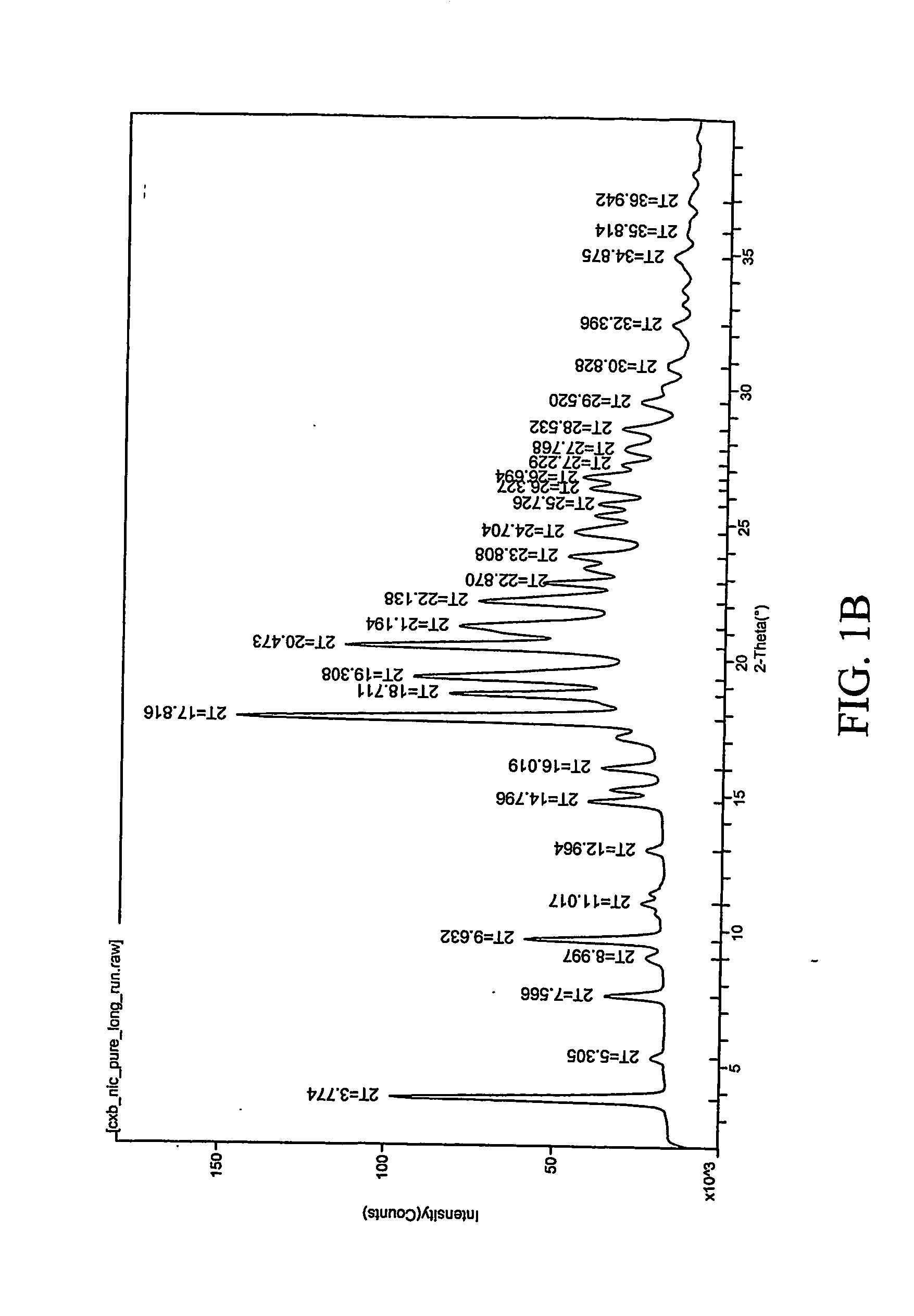

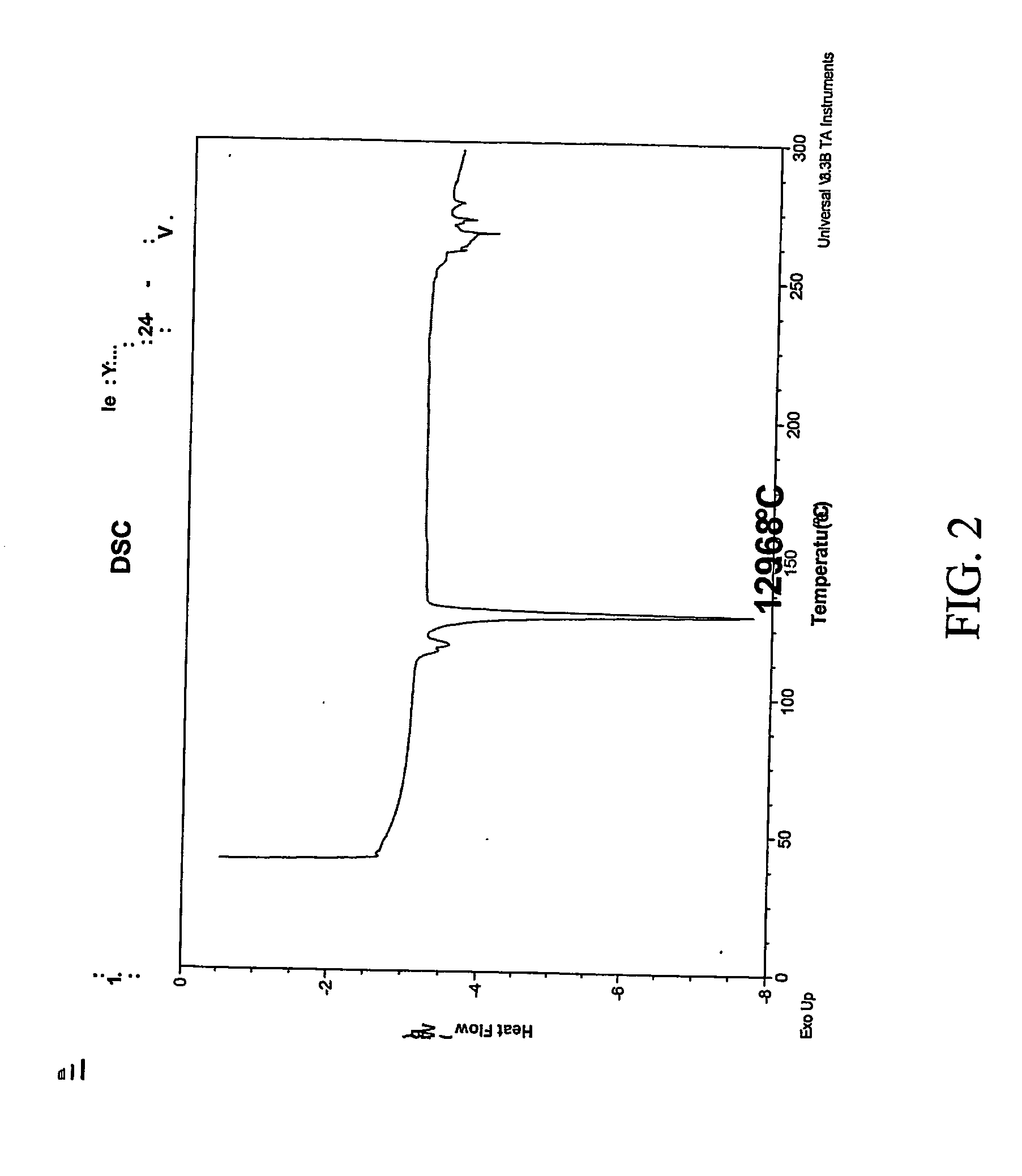

Pharmaceutical co-crystal compositions

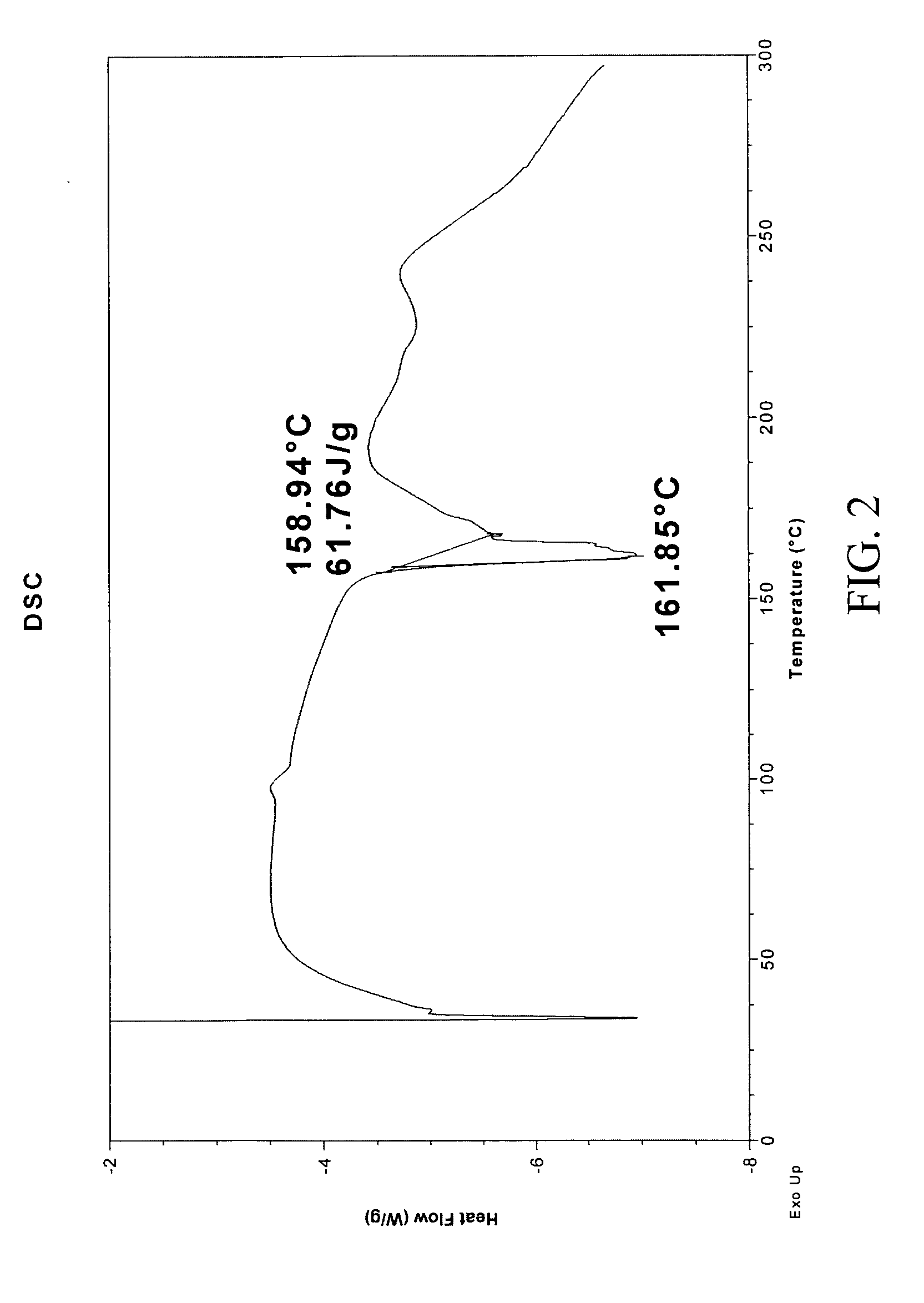

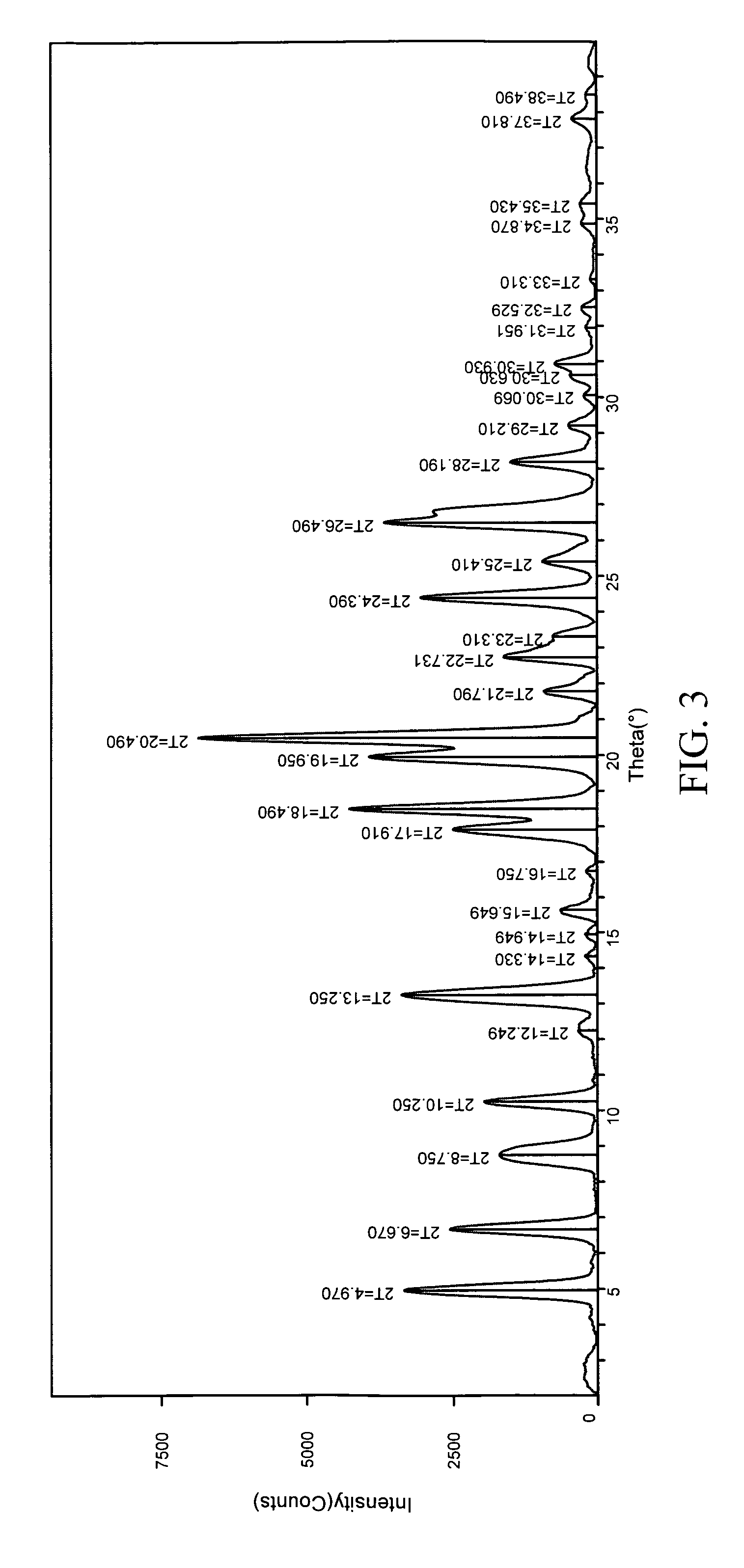

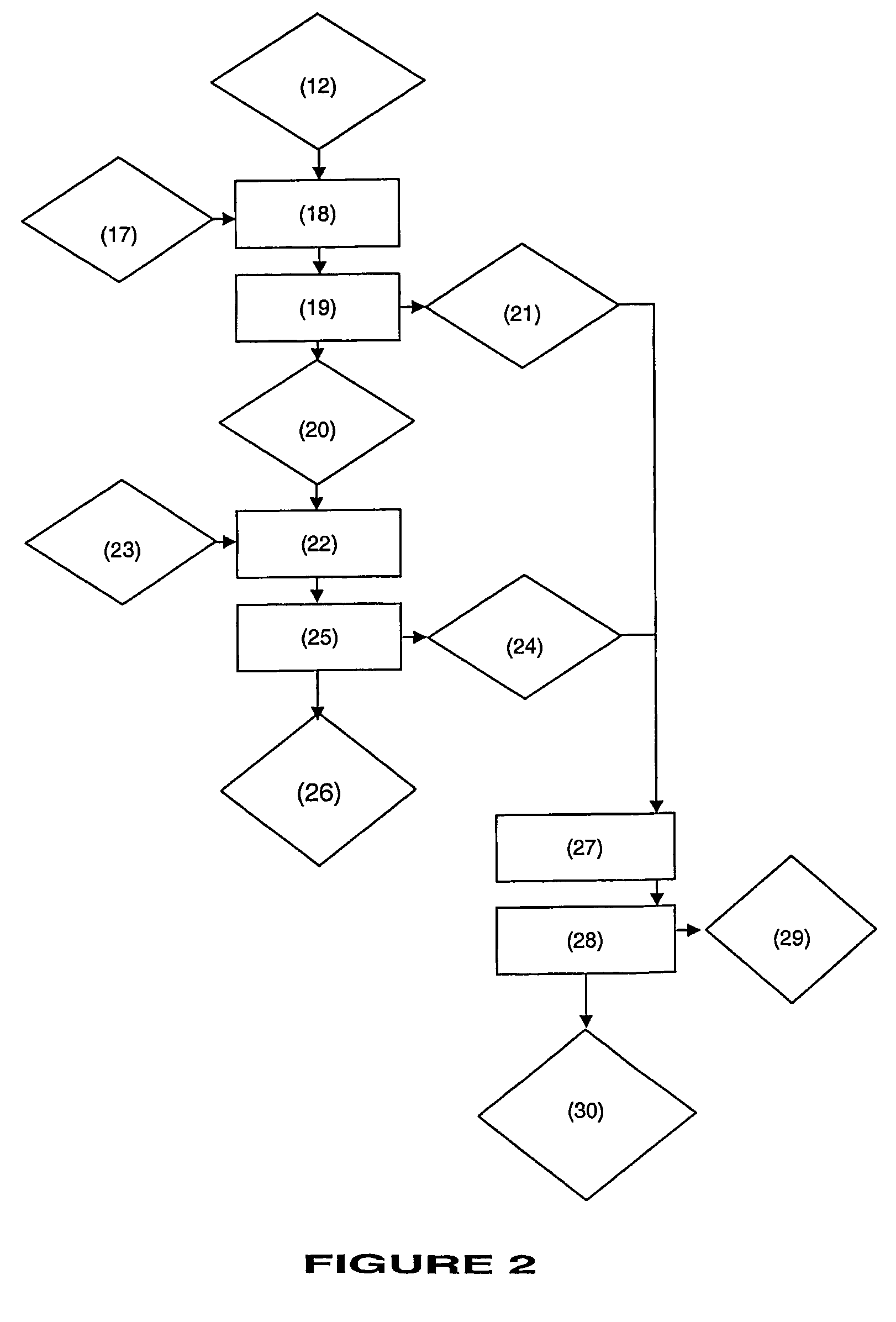

InactiveUS20070026078A1Improve solubilityLow hygroscopicityBiocidePowder deliveryThioketoneHydroxamic acid

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

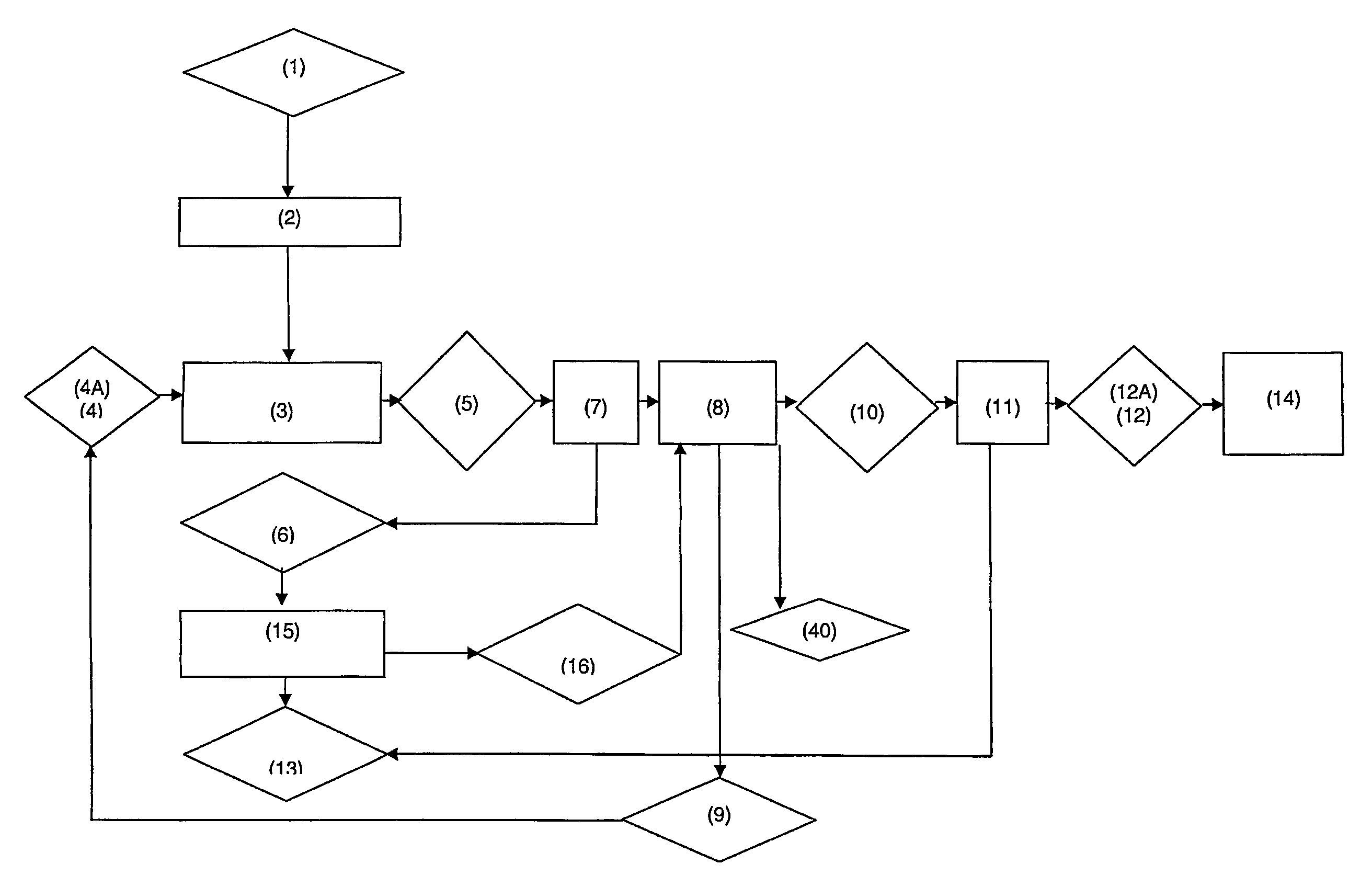

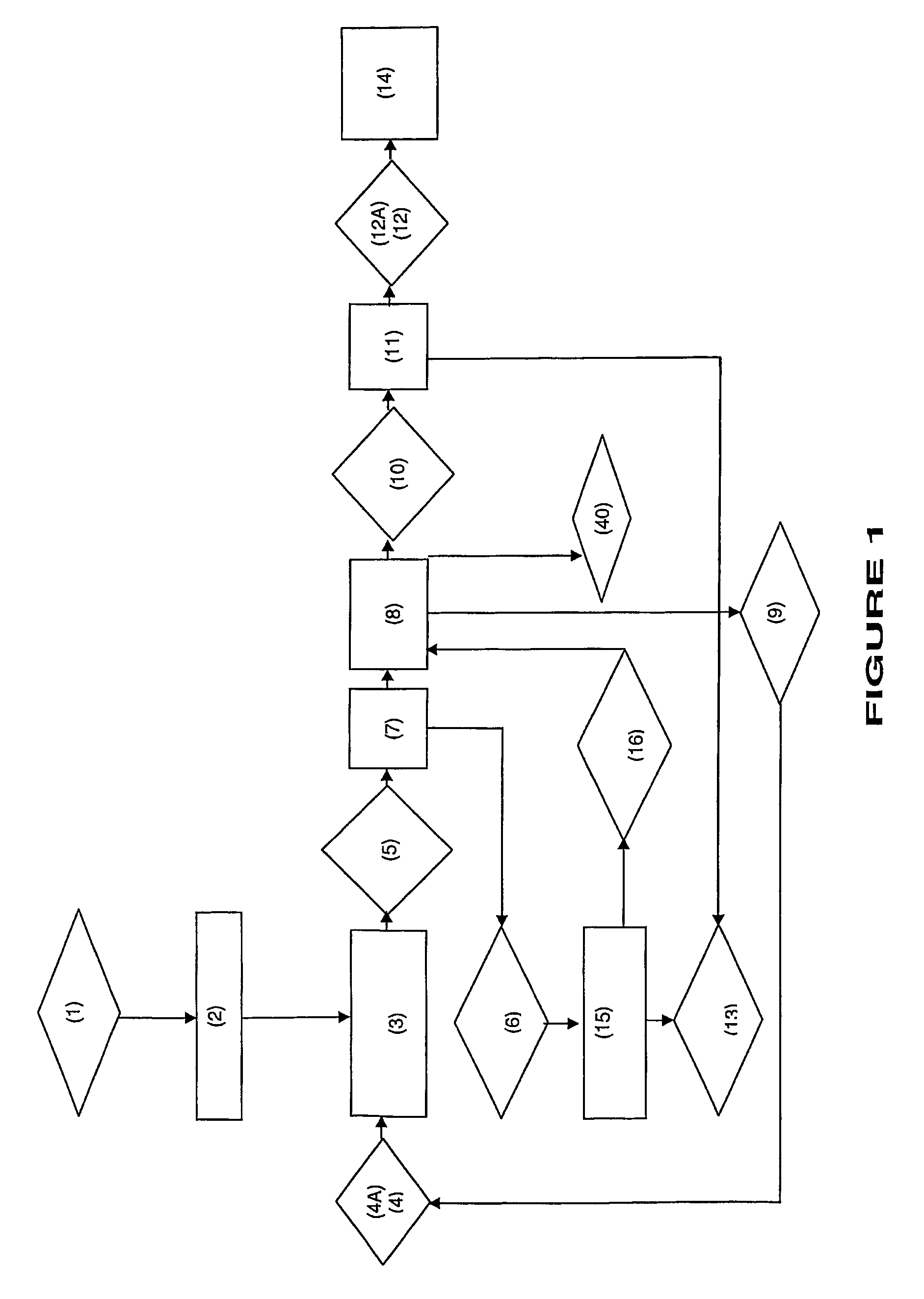

Method of producing an oil extract from seeds of plants via a binary azeotropic solvent mixture

The invention describes a method of producing extracts from the seeds of meadowfoam, brassicas and crambe plants. A number of subsidiary processes and steps are shown in order to extract differing fractions of oil. Products produced from the above method are also described including uses and methods of these products which include a variety of skin conditions including eczema, facial eczema, dermatitis, external ulcers, welts, rashes, insect bites, allergic reactions and other irritations, burns, wounds, psoriasis, acneiform eruptions, dryness, dry skin, irritation, skin atrophy, secondary infections and the like. The extracts are also described as being a useful compound for treatment of the symptoms of such skin conditions as described above. In particular the use and extraction of glucosinolate (GSL), thiocyanates (TCL) and isothiocyanates (ITCL) is described.

Owner:NEW ZEALAND BOTANICAL OILS

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

Pharmaceutical co-crystal compositions of drugs such as carbamazepine, celecoxib, olanzapine, itraconazole, topiramate, modafinil, 5-fluorouracil, hydrochlorothiazide, acetaminophen, aspirin, flurbiprofen, phenytoin and ibuprofen

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphinic acid, phosphonic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, imine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, S-heterocyclic ring, thiophene, N-heterocyclic ring, pyrrole, 0-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:UNIV OF SOUTH FLORIDA +3

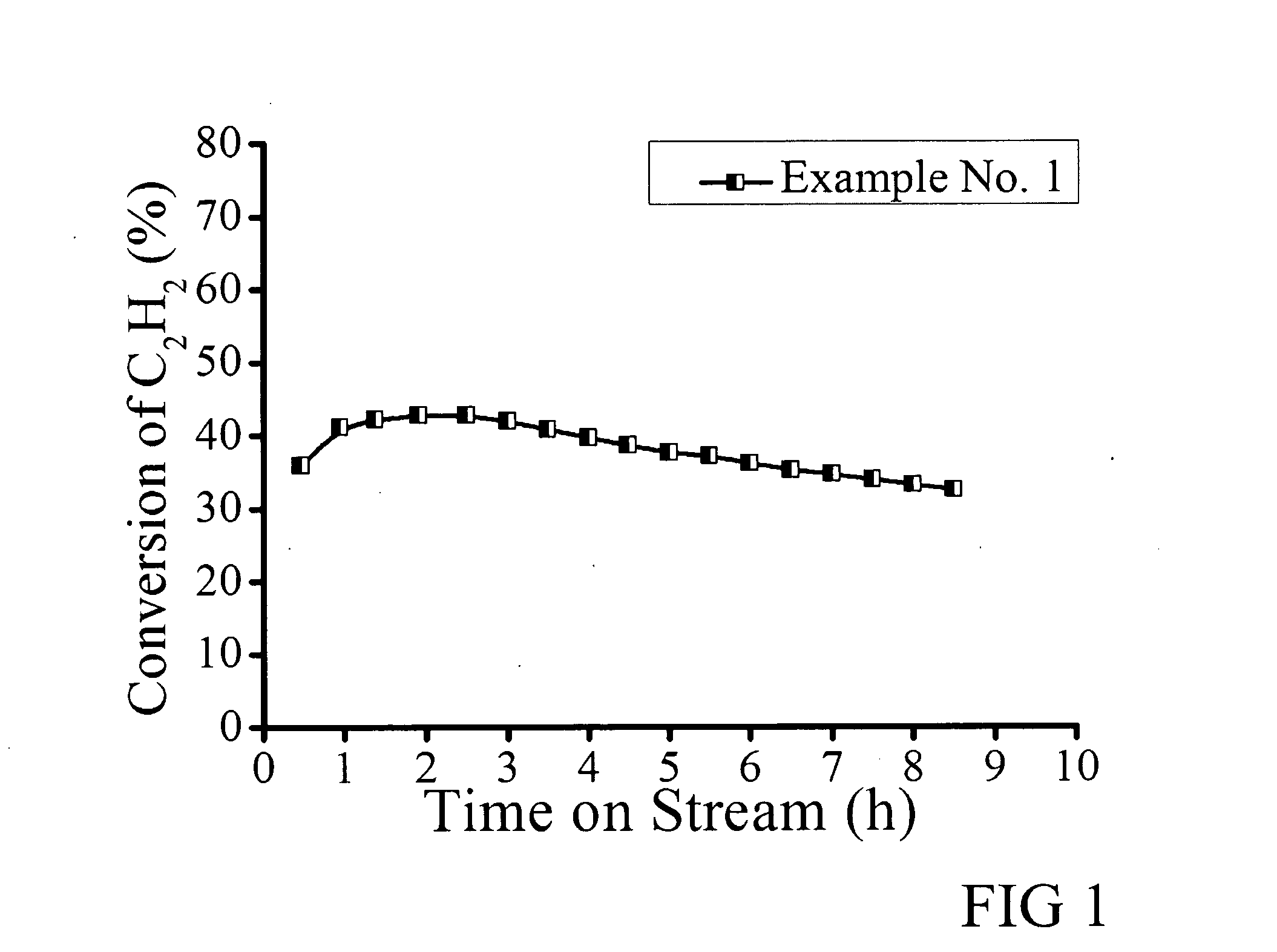

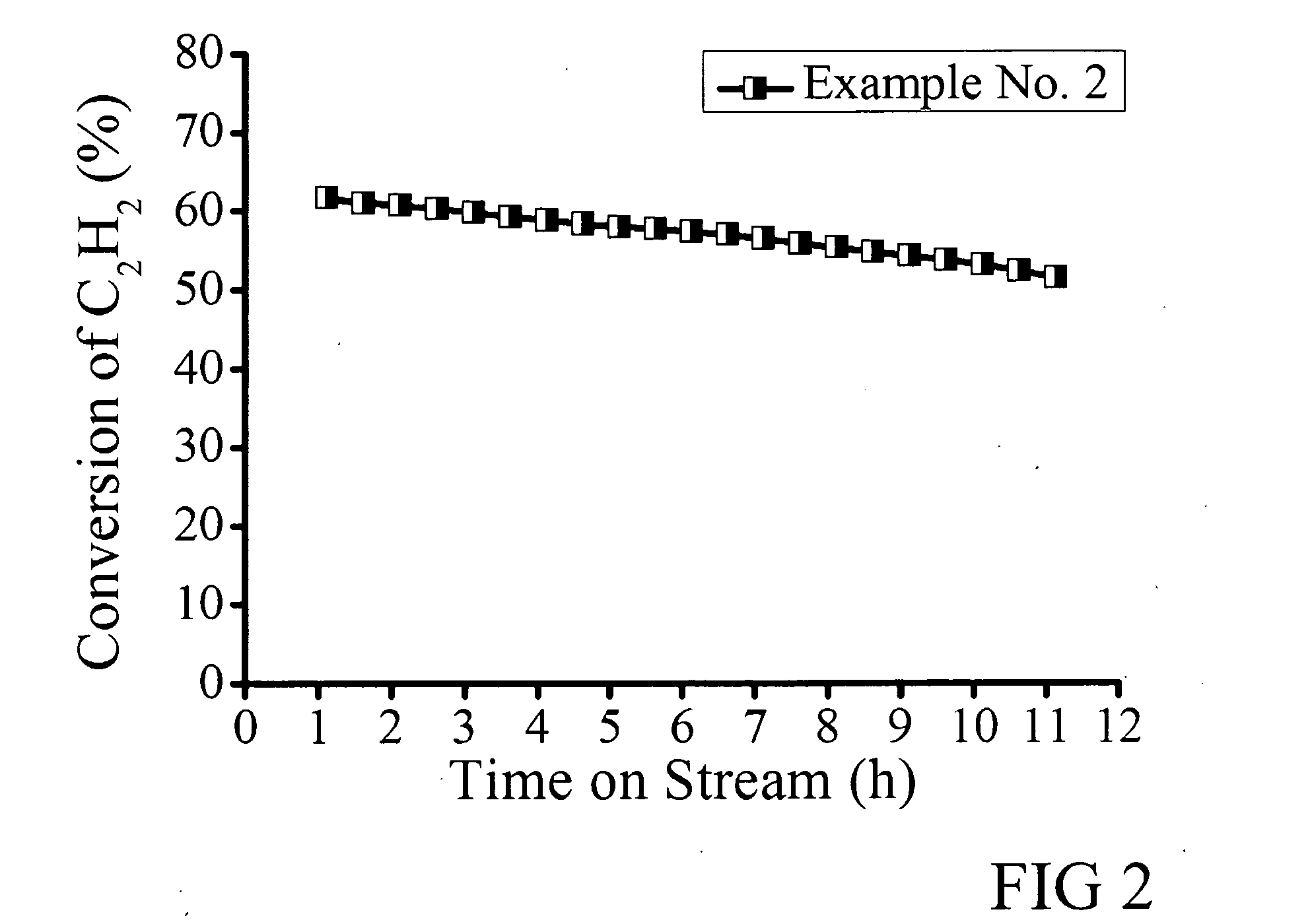

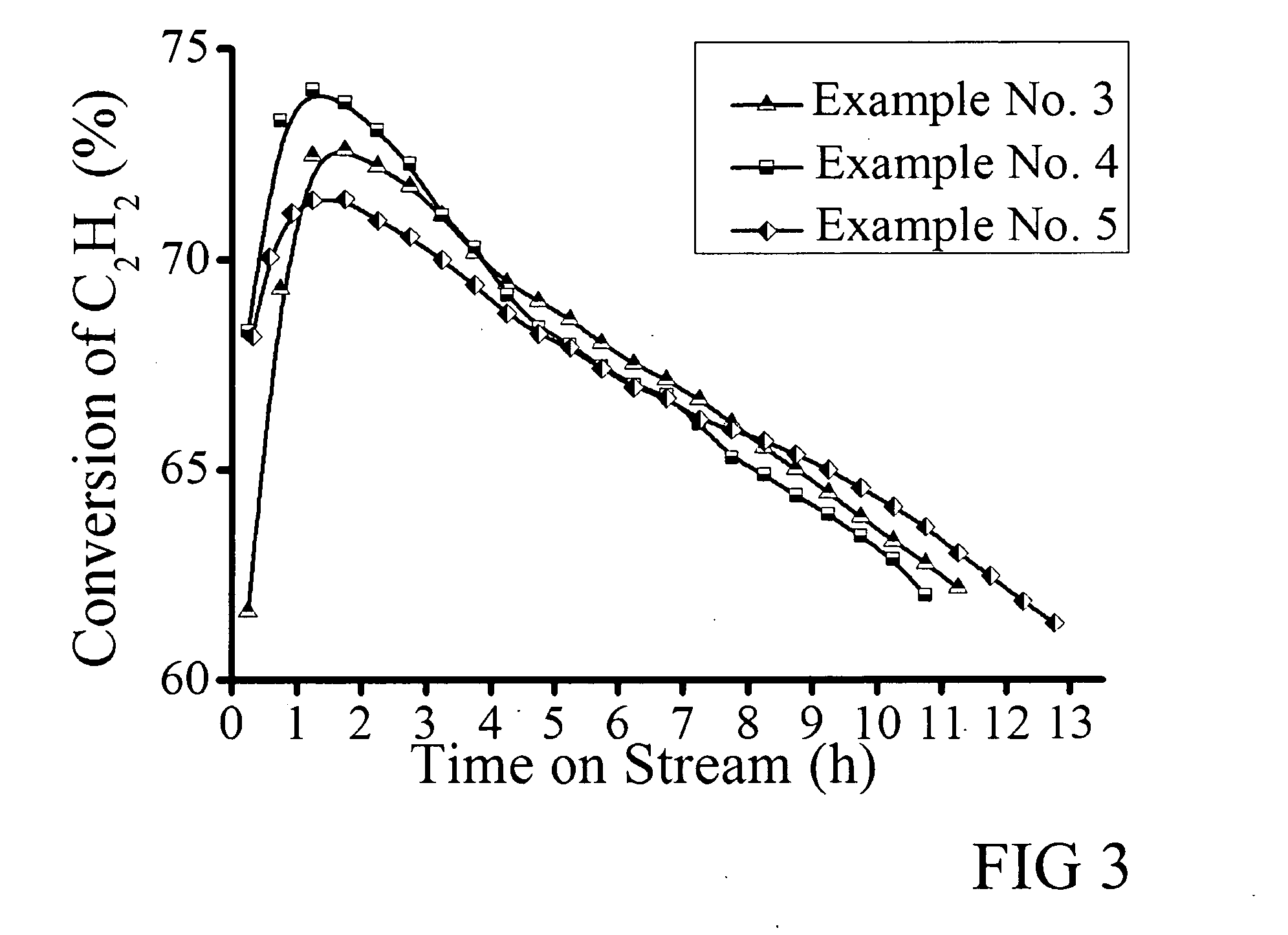

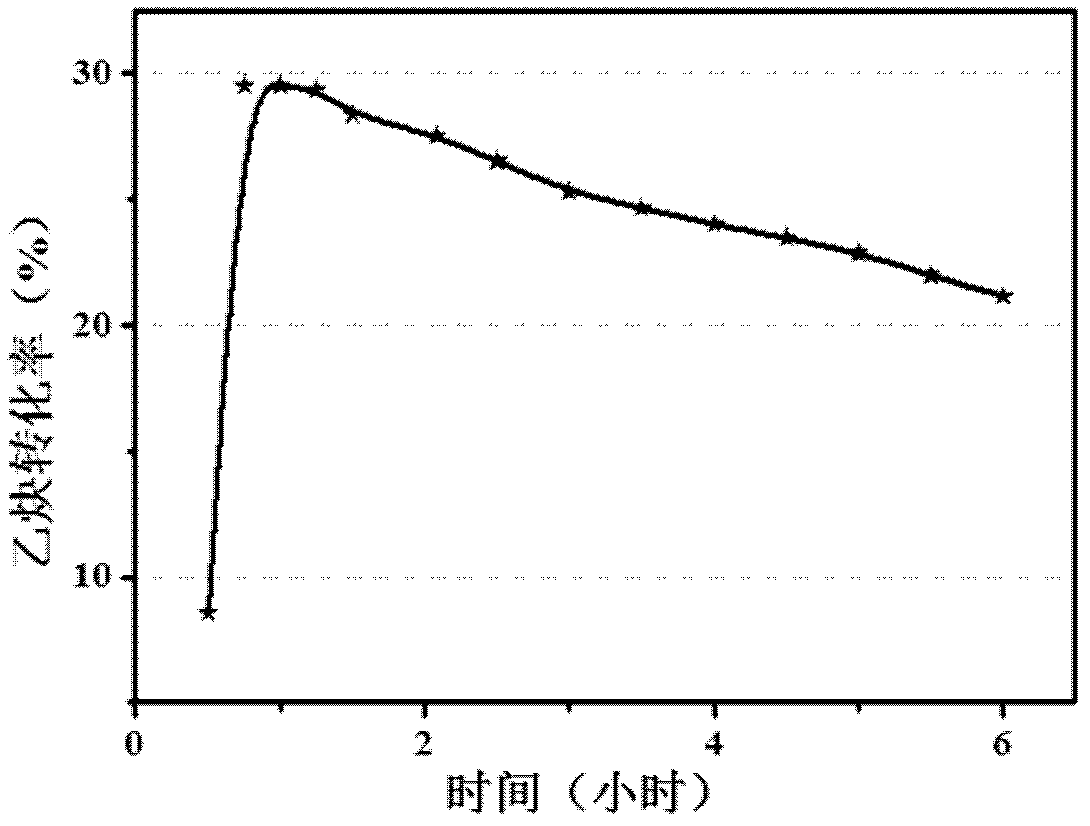

Gold-based catalysts for acetylene hydrochlorination

InactiveUS20140213437A1Molecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsHydrogenChemical compound

Powder catalysts that comprise particles of chemical compounds of Au and Cu deposited on acid-washed carbon-based supports are effective catalysts in ethyne hydrochlorination to produce vinyl chloride monomers (VCMs). They give a high selectivity and productivity of VCM and decreased amounts of the byproducts of chloroethane, dichloroethane and others. Thiocyanates are used as complexing agents to extend the catalyst lifetime. The activity of the catalyst is enhanced by doping nitrogen atoms into the support.

Owner:TSINGHUA UNIV

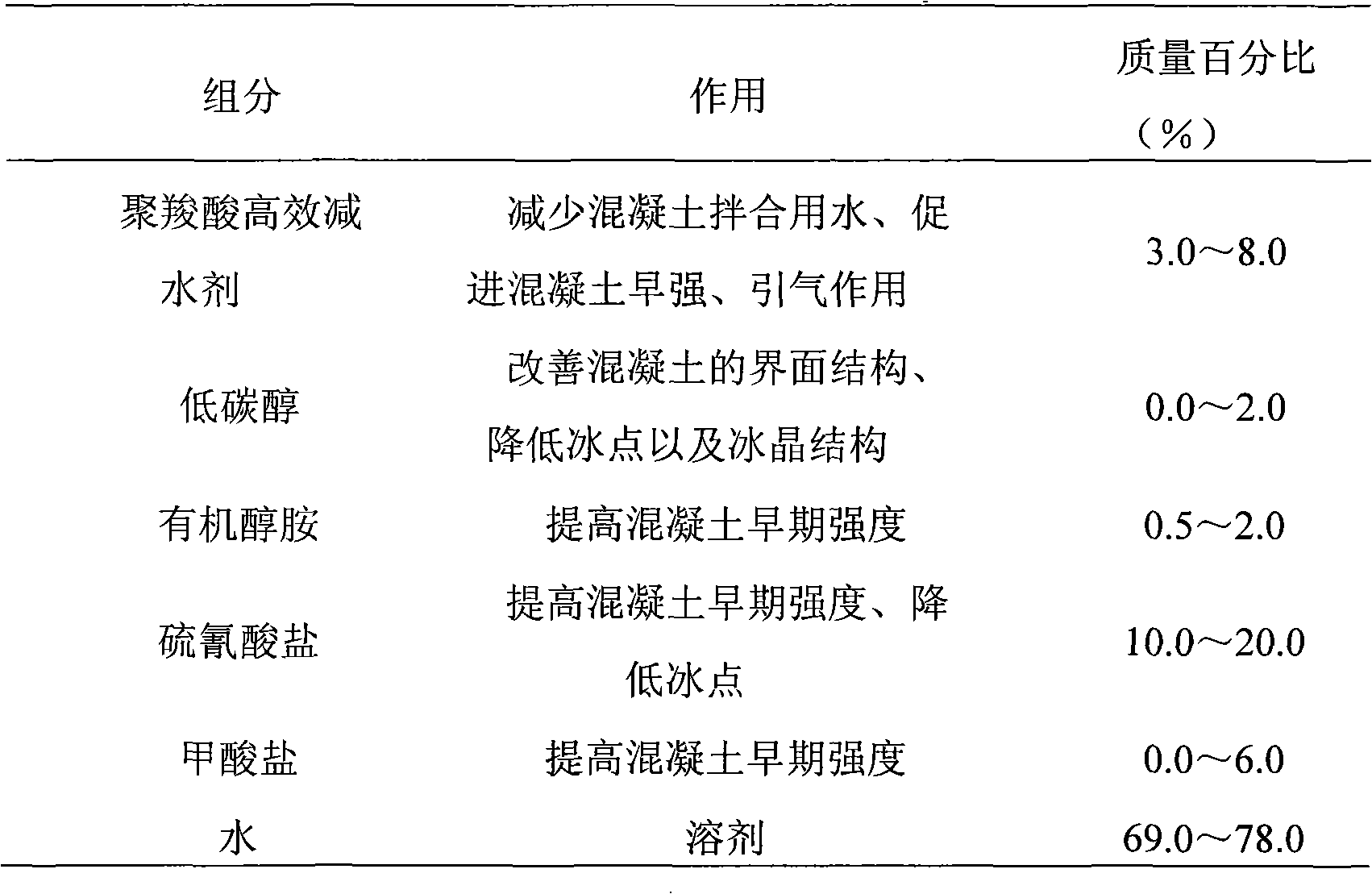

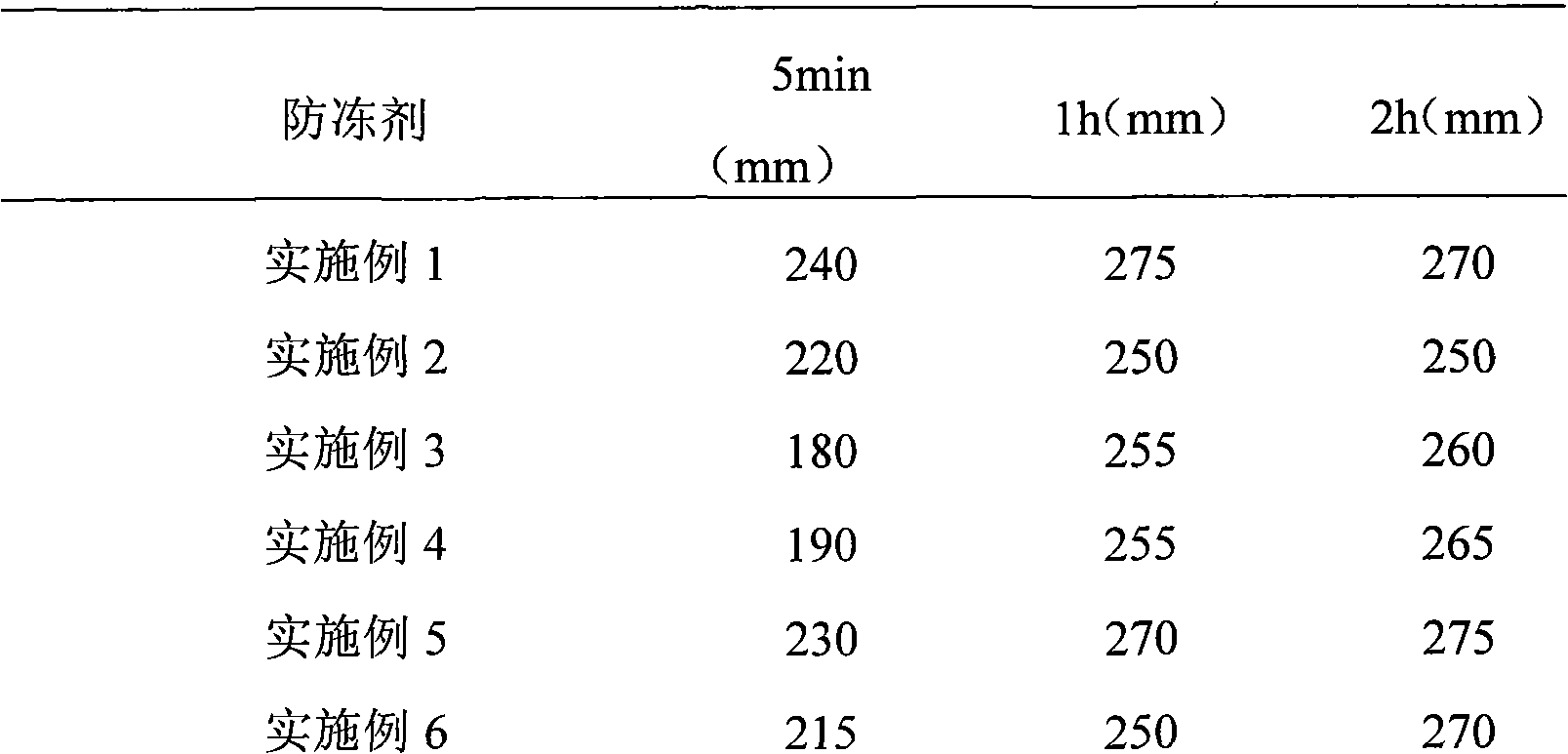

Polycarboxylic acids anti-freeze agent for cement concrete and method for preparing same

The invention relates to poly carboxylic acid system antifreeze applied to cement concrete and a preparation method thereof and belongs to the building material field. The antifreeze is prepared by the optimal combination of an efficient water reduce of poly carboxylic acid, organic alcohol amine, low-carbon alcohol, sulfocyanide and formate. The preferred proportion of the components is that the efficient water reducer to the organic alcohol amine to the low-carbon alcohol to the sulfocyanide to the calcium formate to water is equal to (3.0-8.0) to (0.5-2.0) to (0.0-2.0) to (10.0-20.0) to (0.0-6.0) to (65.0-75.0) (by mass percentage). Compared with the existing antifreeze, the antifreeze of the system has the advantages of high water reducing rate and comparatively good workability and quick growth of strength at negative temperature. The antifreeze has the advantages of low intermingled quantity in the cement concrete, good water solubility, low alkali content, high strength at the early stage and at the later stage of the cement concrete but no chlorine and is applicable to the preparation of various cement concrete at the negative temperature ranging from negative 5 DEG C to negative 20 DEG C in winter in the north area.

Owner:BEIJING UNIV OF TECH

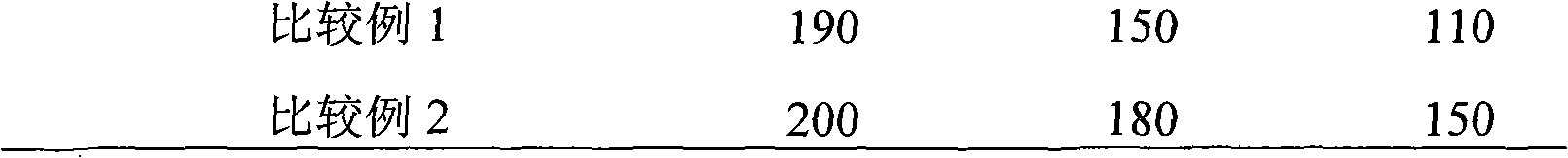

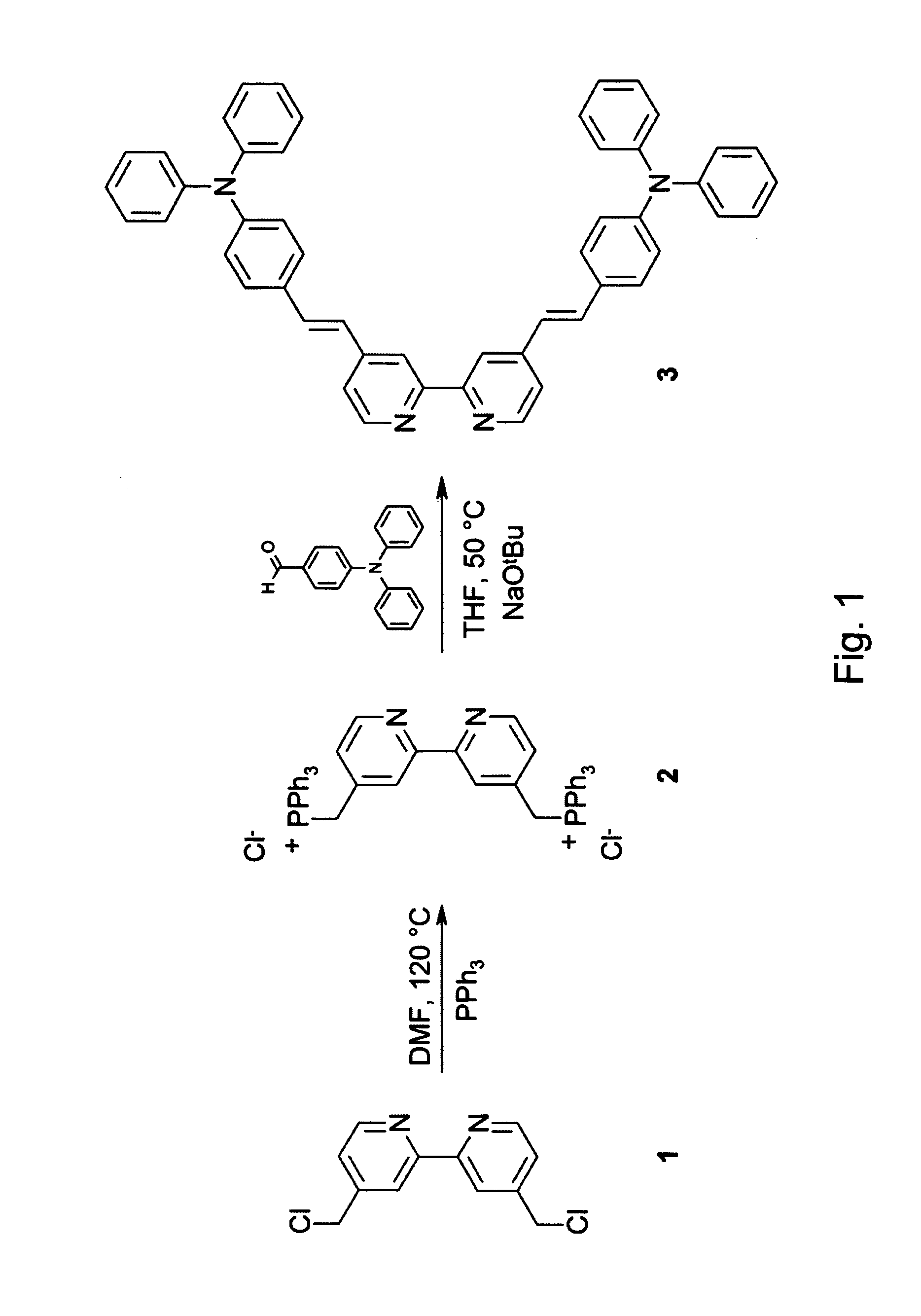

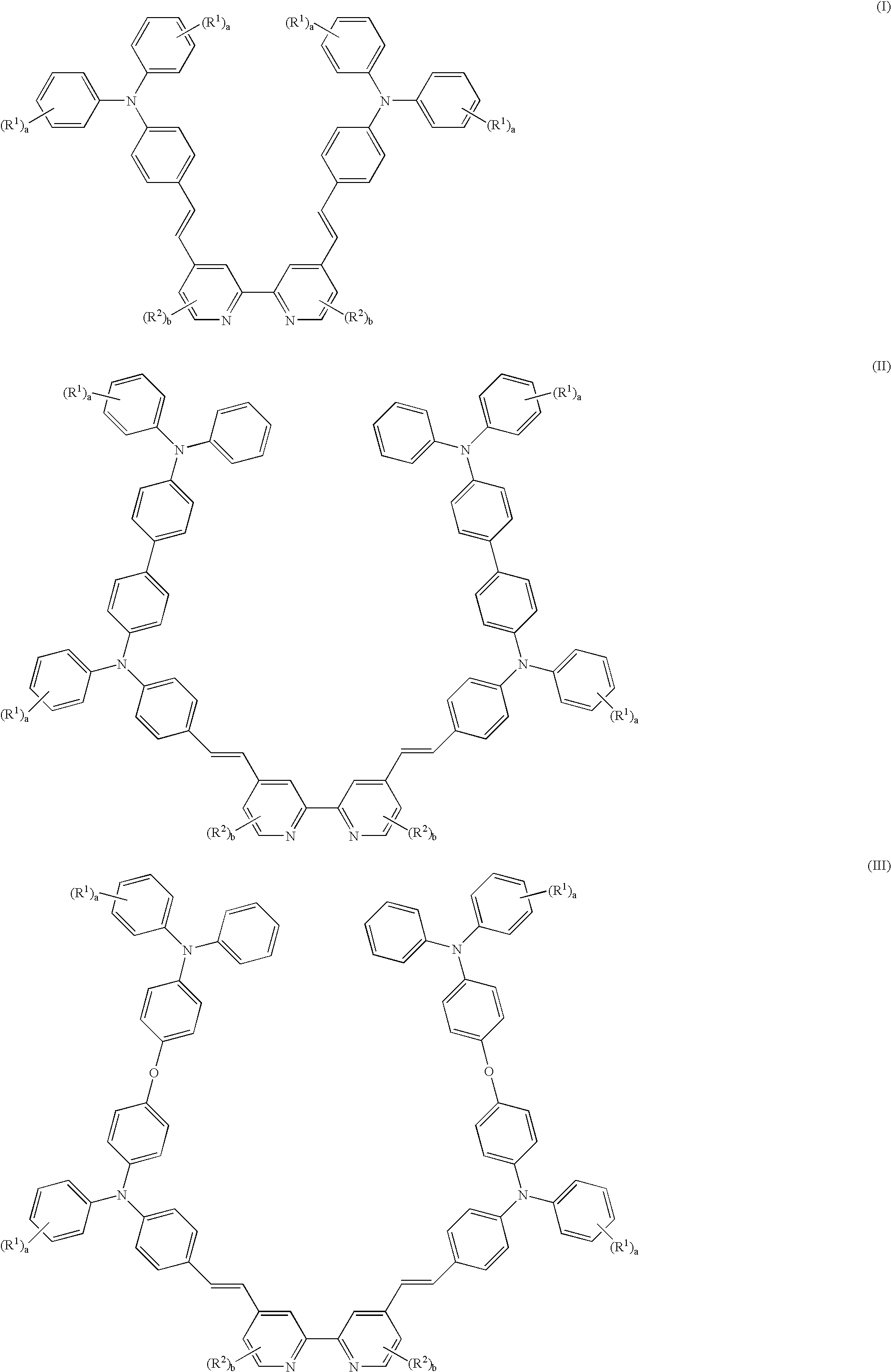

Metal complex compositions and use thereof in dye sensitized solar cells

InactiveUS20070017569A1Ruthenium organic compoundsElectrolytic capacitorsOxidation-Reduction AgentRedox

The present invention provides in one aspect a composition having at least one metal complex, such that the metal complex comprises at least one metal atom, at least one first organic ligand comprising at least one triarylamine group, at least one second ligand comprising at least one acidic group, and at least one thiocyanate or isothiocyanate ligand. This composition may be disposed on a semiconductor layer which is further disposed on an electrically conductive surface to provide a dye-sensitized electrode. The dye-sensitized electrode can be assembled together with a counter electrode and a redox electrolyte to provide a dye-sensitized solar cell.

Owner:GENERAL ELECTRIC CO

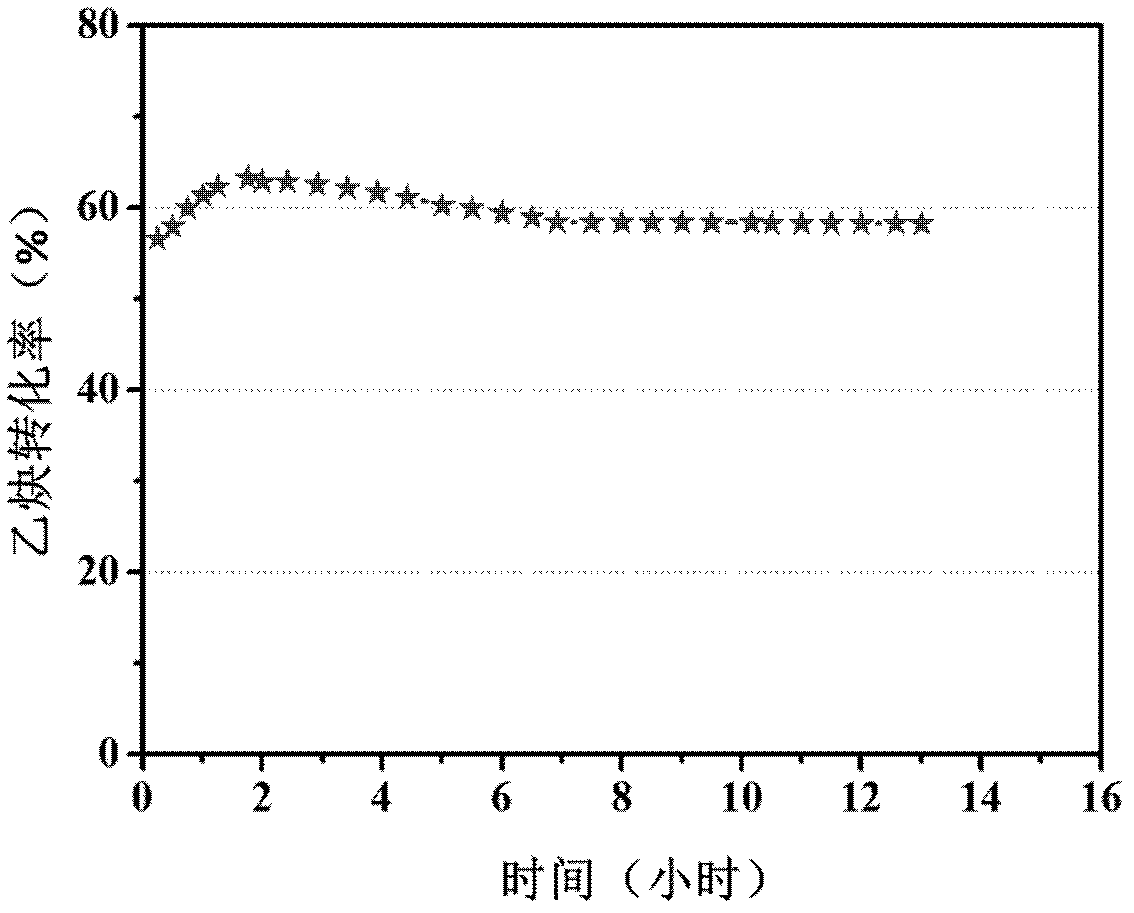

Gold complex catalyst for hydrochlorinating acetylene

ActiveCN102631947AImprove stabilityHigh activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsGold contentPotassium

The invention discloses a gold complex catalyst, and particularly relates to a non-mercury catalyst which is applicable to synthesizing vinyl chloride by acetylene hydrochlorination, and a preparation method of the non-mercury catalyst. The non-mercury catalyst comprises potassium aurate tetra-thiocyanate taken as a main active component, one or a combination of more than two of potassium chloride, copper chloride, cobalt chloride and zinc chloride taken as auxiliary active components, and carrier activated carbon, wherein gold complex accounts for 0.1-2.5% of the weight of the catalyst, and the auxiliary active components account for 0.05-15% of the total weight of the catalyst. According to the gold complex catalyst prepared by the invention, the gold content is lower, so that the cost of noble metal catalyst can be remarkably reduced; and the novel non-mercury catalyst is good in activity, high in stability and strong in selectivity. The gold complex catalyst has the advantages of being simple in production technology, short in production cycle and environment-friendly.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

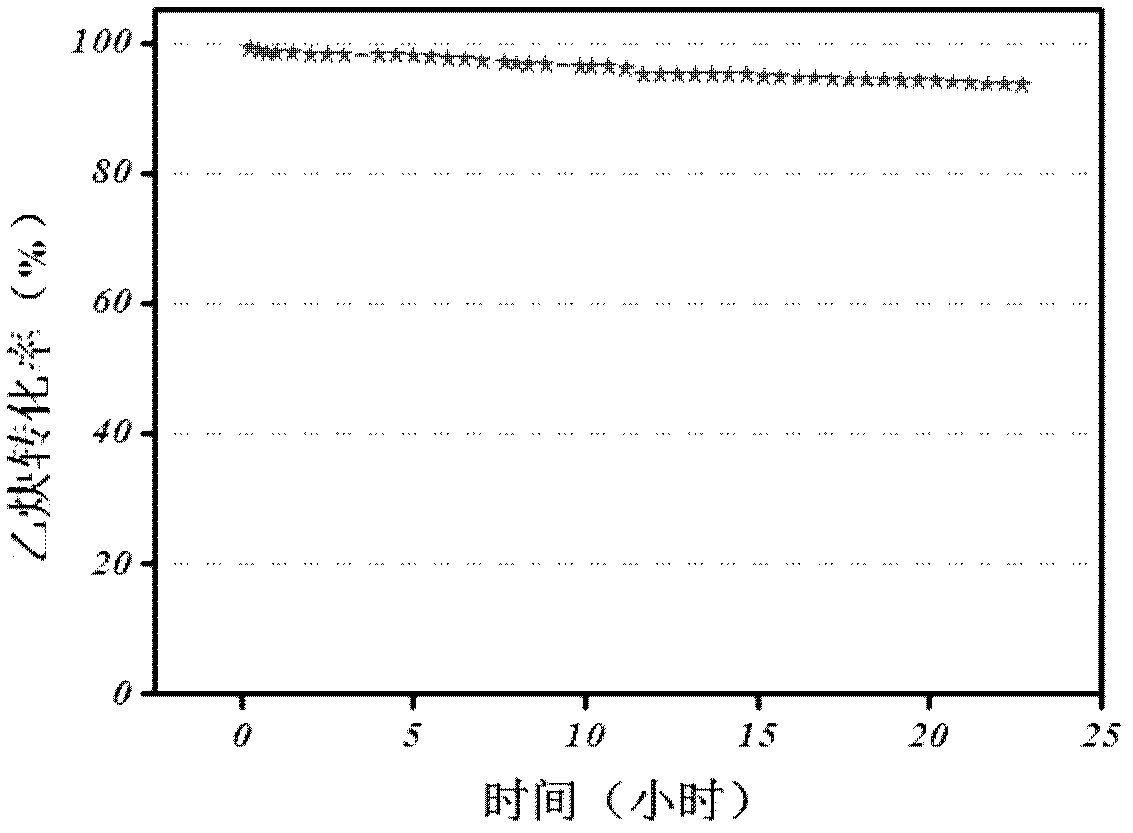

Composite metal salt catalyst for hydrochlorination reaction of acetylene

ActiveCN102631942AGuaranteed stabilityImprove stabilityPhysical/chemical process catalystsPreparation by halogen halide additionPotassiumCarbon nanotube

The invention discloses a composite metal salt catalyst for a hydrochlorination reaction of acetylene, belonging to the technical field of catalysts. The composite metal salt catalyst takes gold as active metal, and the reduction deactivation of the composite metal salt catalyst is reduced by reducing reduction potential of metal through a complexing action of a thiocyanate radical or a cyanate radical. Carbon deposition in a reaction process is restrained by introducing one or more of potassium, cerium and lanthanum elements. The composite metal salt catalyst is loaded on active carbon or carbon nanometer pipe with the specific surface area of not less than 100m<2>*g<-1>, wherein the mass fraction of a gold load is 0.05-0.50%, the mass fraction of a copper load is 0.1-5.0%, and the mass fraction of the potassium / cerium / lanthanum load is 0.1-5.0%. In a reaction for preparing vinyl chloride, composite salt of gold and copper has excellent activity, selectivity and stability; furthermore, one or two of cerium and lanthanum are added to a catalyst so as to be capable of effectively restraining the carbon deposition and catalyzing a hydrochlorination process of the acetylene in low cost and high efficiency.

Owner:TSINGHUA UNIV +1

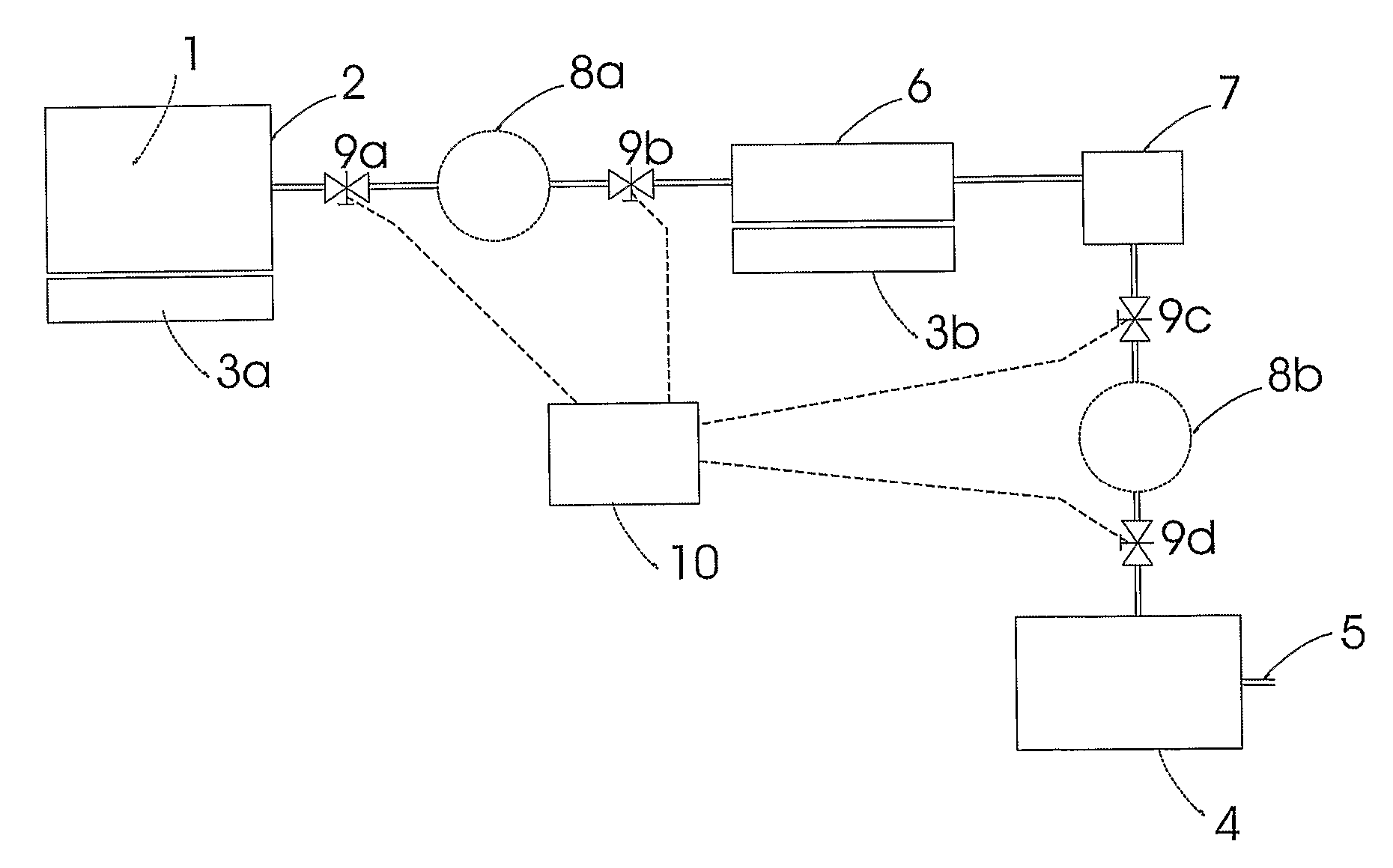

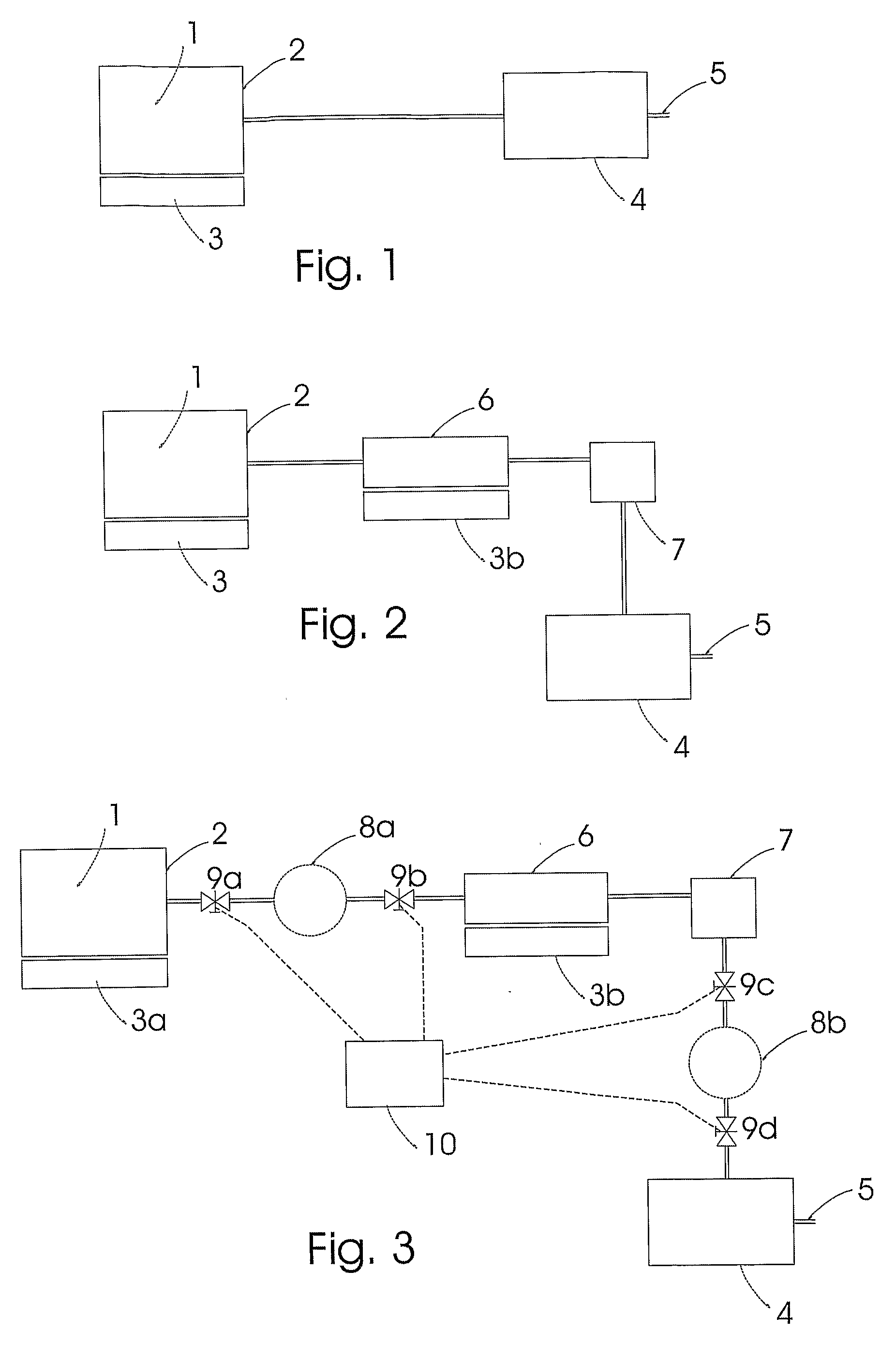

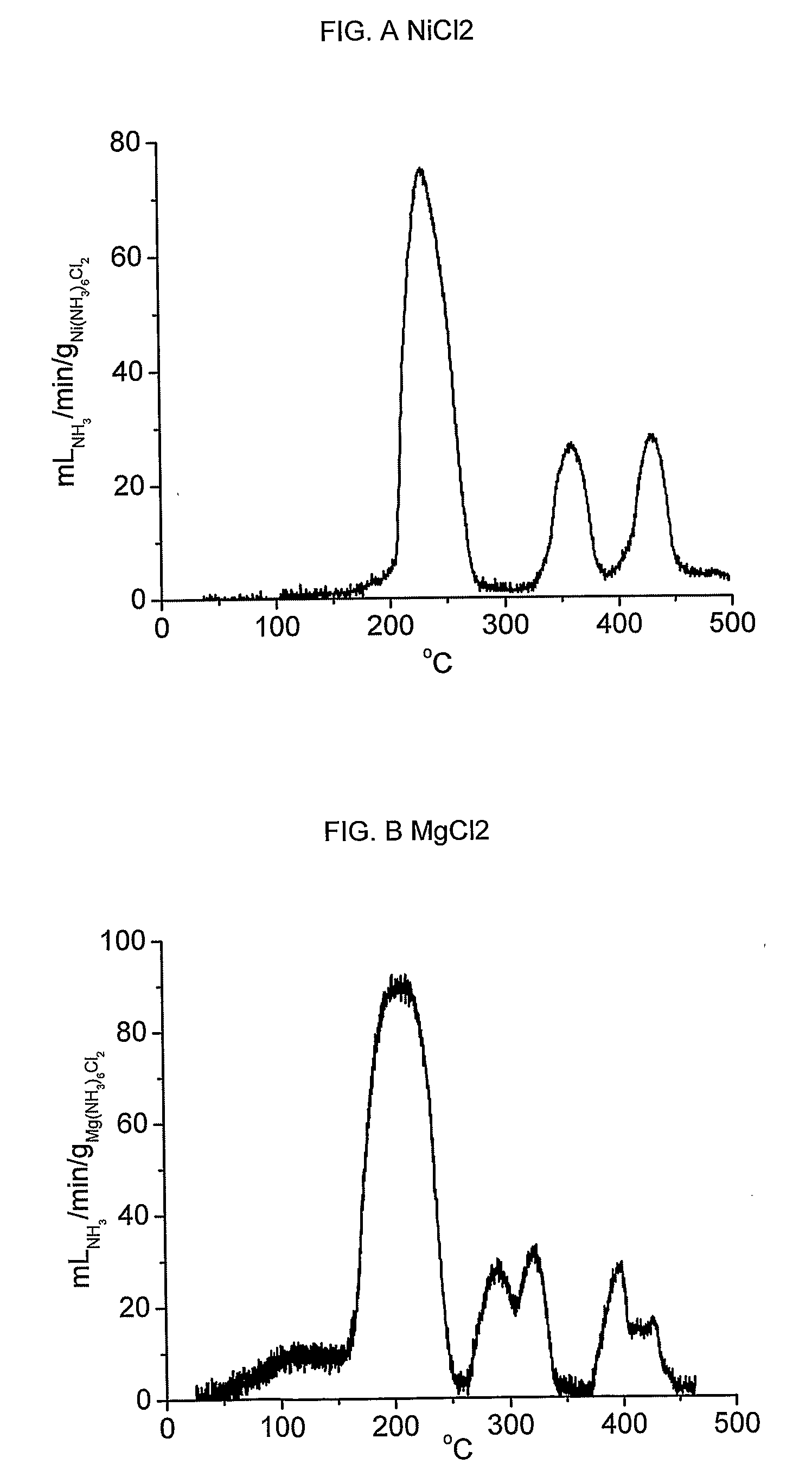

Use Of An Ammonia Storage Device In Production Of Energy

InactiveUS20070207351A1Reactant parameters controlMagnesium halidesAlkaline earth metalAmmonia storage

An electric power generating unit comprising (i) an ammonia storage device in the form of a container comprising an ammonia absorbing and releasing salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkali metals, alkaline earth metals, and transition metals such as Li, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu or Zn, X is one or more anions selected from fluoride, chloride, bromide, iodide, nitrate, thiocyanate, sulphate, molybdate, phosphate, and chlorate ions, a is the number of cations per salt molecule, Z is the number of anions per salt molecule, and n is the coordination number of 2 to 12. (ii) means for heating said container and ammonia absorbing and releasing salt for releasing ammonia gas and (iiia) a fuel cell for converting ammonia directly into electric power; or (iiib1) a reactor for dissociating ammonia into hydrogen and nitrogen and (iiib2) a fuel cell for converting hydrogen into electric power is useful for large stationary energy producing facilities, but also for use for is useful for large stationary energy producing facilities, but also for use for small rechargeable and / or replaceable power supply units for micro-fabricated or miniaturized ammonia decomposition reactors for use in mobile units and portable devices may be used for large energy producing facilities, and by use of small rechargeable and / or replaceable ammonia storage decomposition reactors, it is also possible to provide energy for mobile units and portable devices.

Owner:AMMINEX

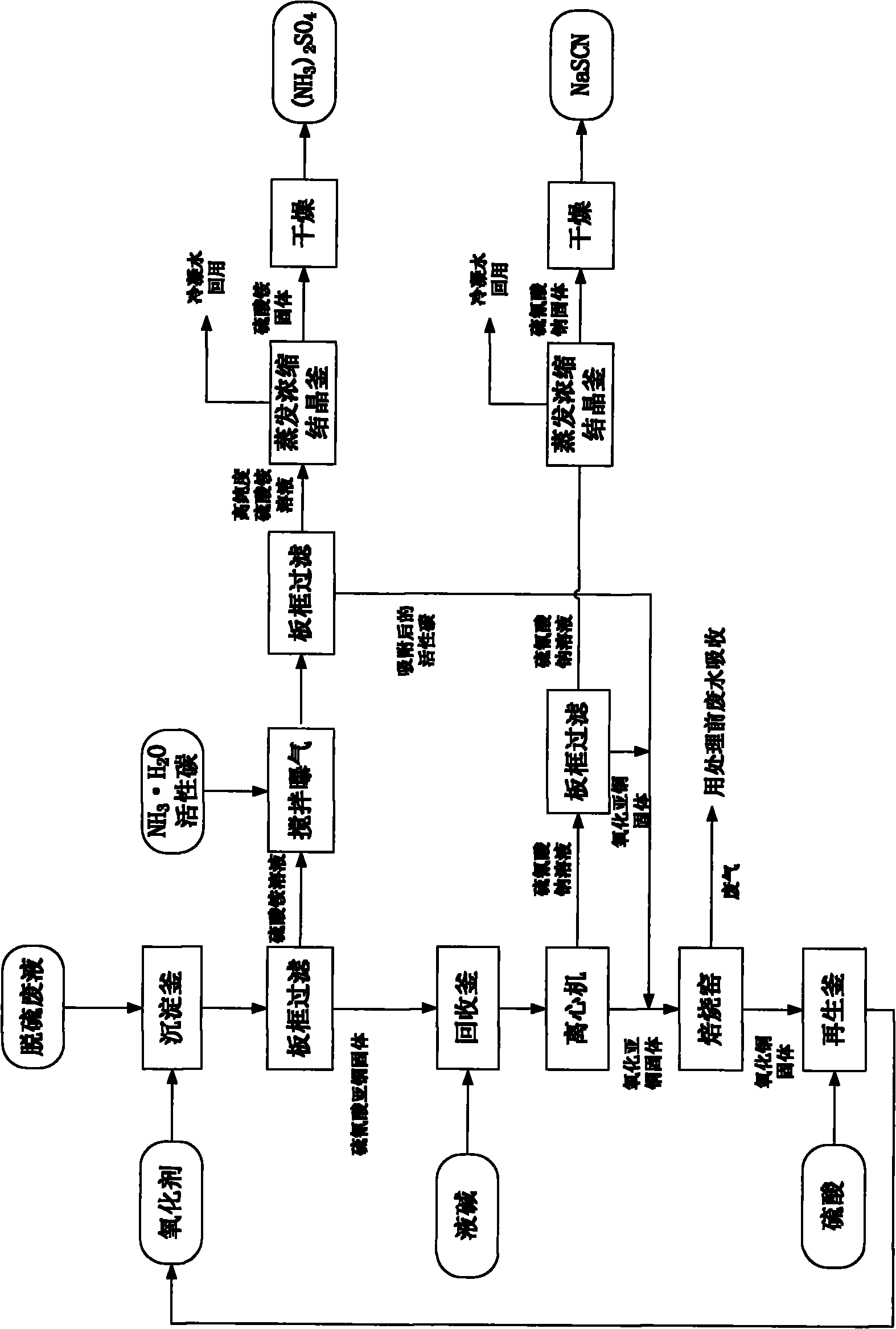

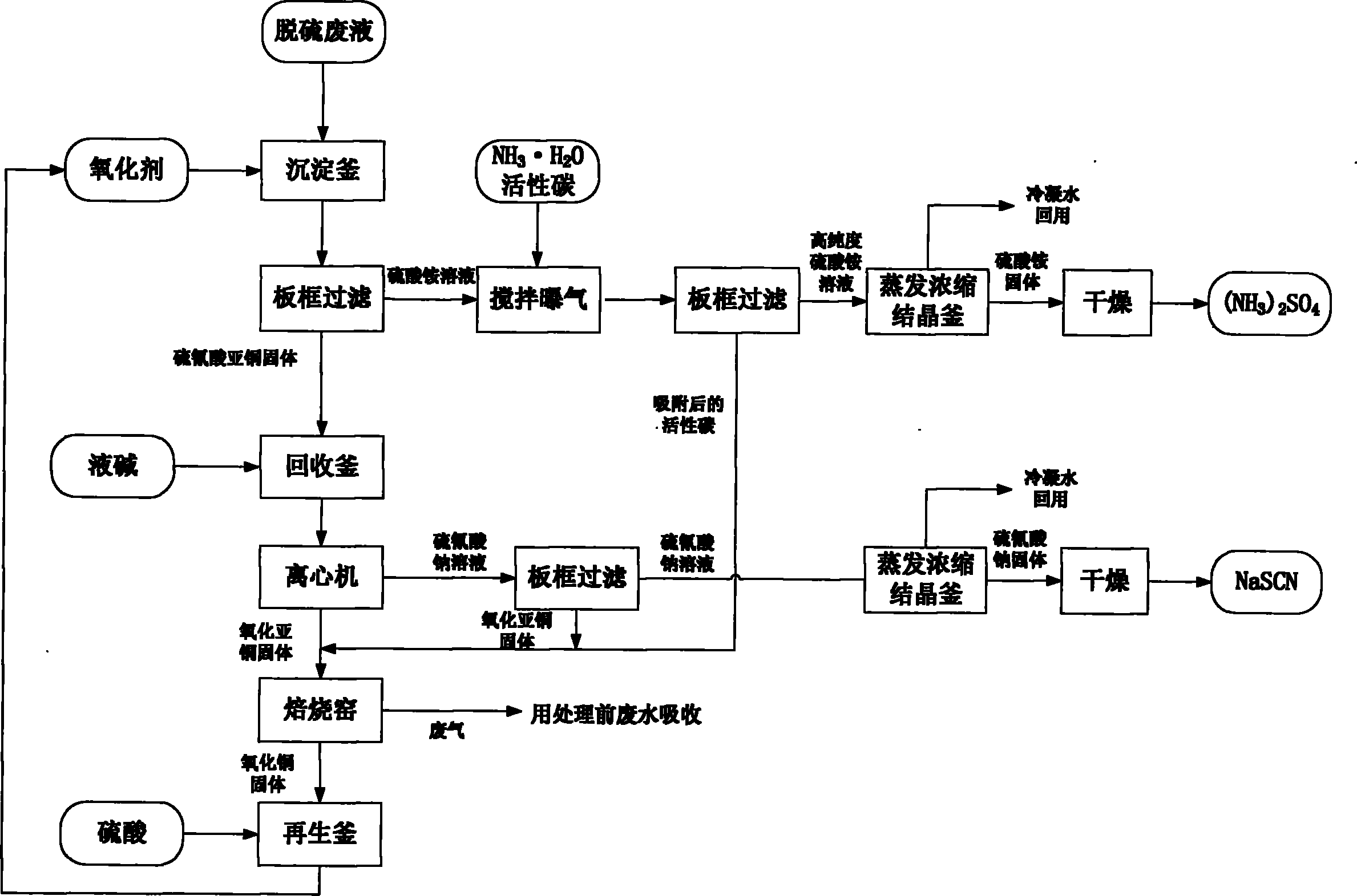

Method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in coking plant

ActiveCN101985359AReduce consumptionReduce lossesThiocyanic acidSulfate preparationActivated carbonSulfate

The invention relates to a method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in a coking plant, which comprises the following steps of: preparing saturated solution of copper sulfate, mixing the saturated solution with desulfuration waste liquor, and heating and stirring; performing solid-liquid separation to obtain a solid and sulfate liquid; adding aqueous alkali into the solid, heating at the temperature of between 50 and 98 DEG C, and stirring and reacting for 10 to 120 minutes; performing solid-liquid separation on slurry obtained by heating; concentrating the obtained liquid, and freezing for crystallizing and drying to obtain a high-purity thiocyanate product; calcining the obtained solid, adding solution of sulfuric acid, and stirring to produce the copper sulfate for circular use; adding activated carbon into the sulfate liquid, and aerating and oxidizing to purify sulfate; and concentrating the sulfate, and crystallizing and drying to obtain a high-purity sulfate product. The method solves the problem of pollution of the desulfuration waste liquor to the environment, and simultaneously, pollutants can become value products through the production of the high-purity thiocyanate product and the high-purity sulfate product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

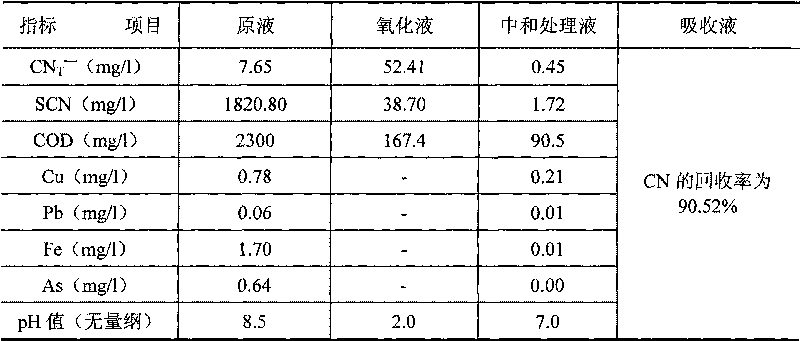

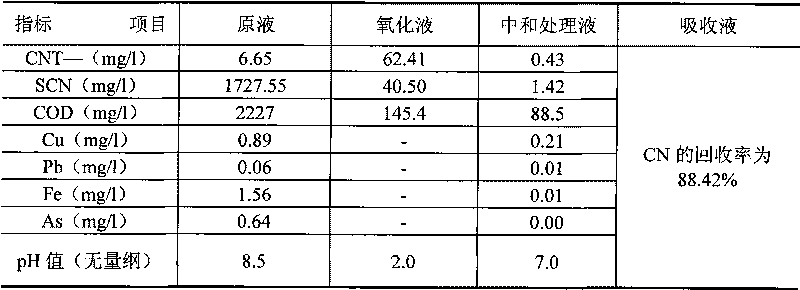

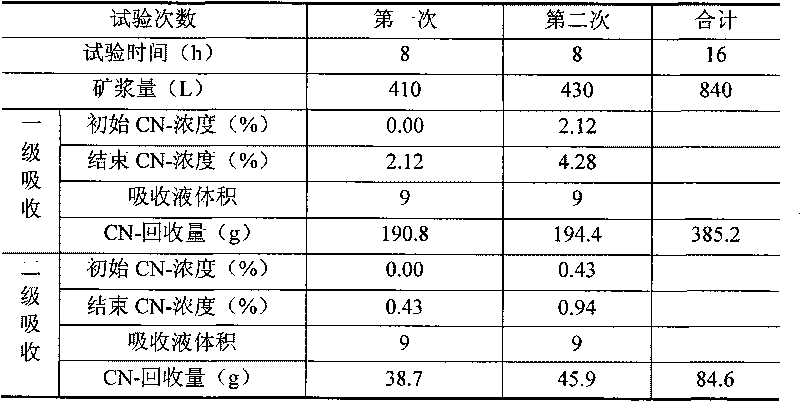

Recycling and harmless treatment method for cyaniding tailing slurry

ActiveCN101759274AIncrease contact areaToxicWaste water treatment from quariesWater contaminantsSlagGas phase

The invention discloses a recycling and harmless treatment method for cyaniding tailing slurry. In the method, the cyaniding tailing slurry containing cyanogen, thiocyanate, heavy metal and arsenic and liquid containing hydrogen peroxide are subjected to direct mixing treatment; the method utilizes high specific surface area of micro-fine granular ore to add the contact opportunity between the thiocyanate and the hydrogen peroxide and the contact area between gas phase and liquid phase through surface adsorption to accelerate a speed of oxidation-reduction reaction and an acidifying and stripping speed, utilizes metallic substances contained in slag to accelerate the reaction rate of the oxidation-reduction reaction without the addition of catalyst, and can reduce cost; meanwhile, in neutralization, Fe3+ in the slag is utilized to meet the requirement of arsenic precipitation without the addition of an arsenic precipitation reagent; when residual cyanides is removed from the hydrogen peroxide liquid, the hydrogen peroxide liquid and cyano complexes which are difficult to remove through the oxidation-reduction reaction form sediment so that the residual thiocyanate is further removed; the method can make the conversion rate of the thiocyanate in the ore slurry more than or equal to 88 percent; and compared with the treatment of filter pressing clear liquid of homogeneous ore slurry, the total reclaiming rate can be increased by over 20 percent.

Owner:CHANGCHUN GOLD RES INST +1

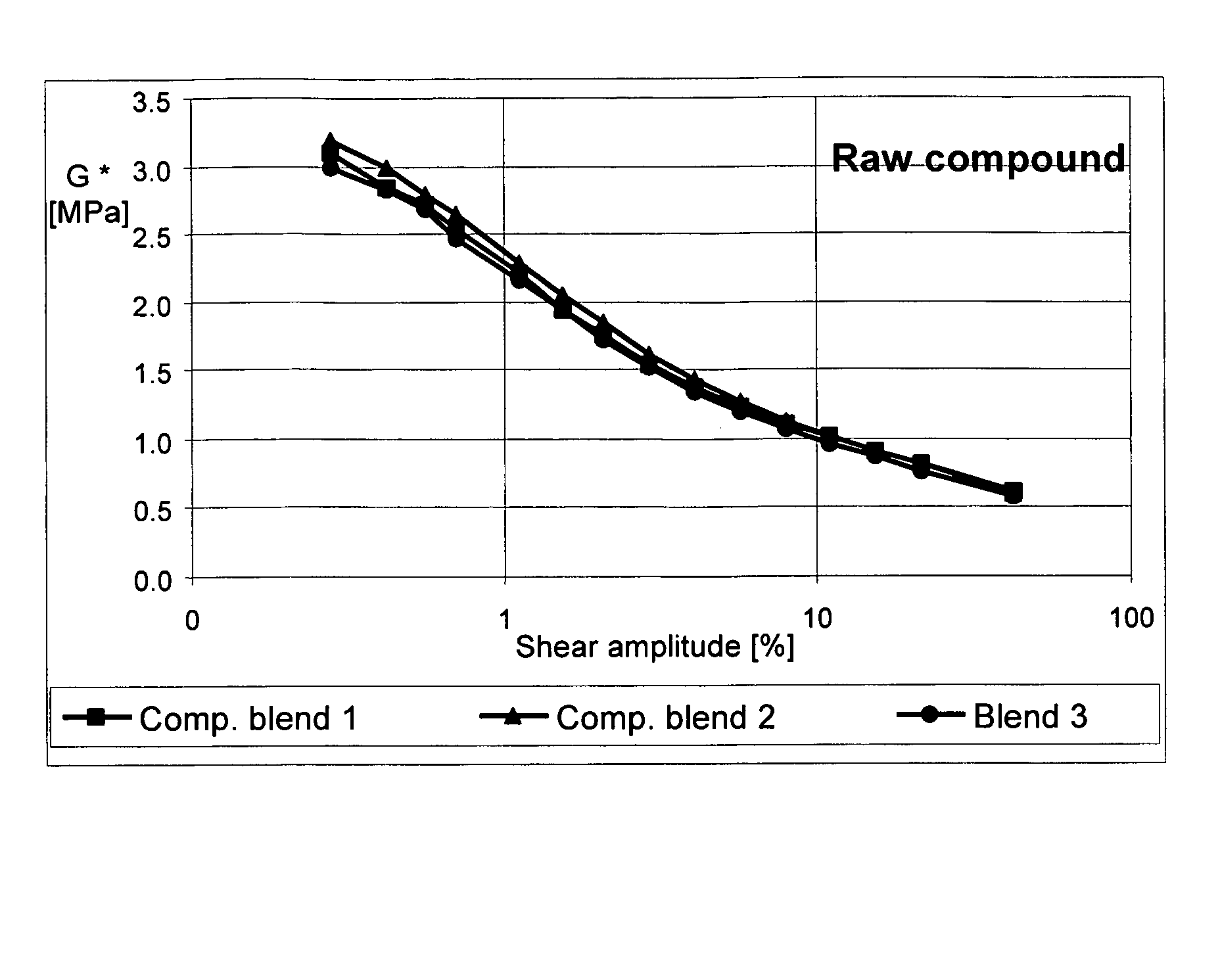

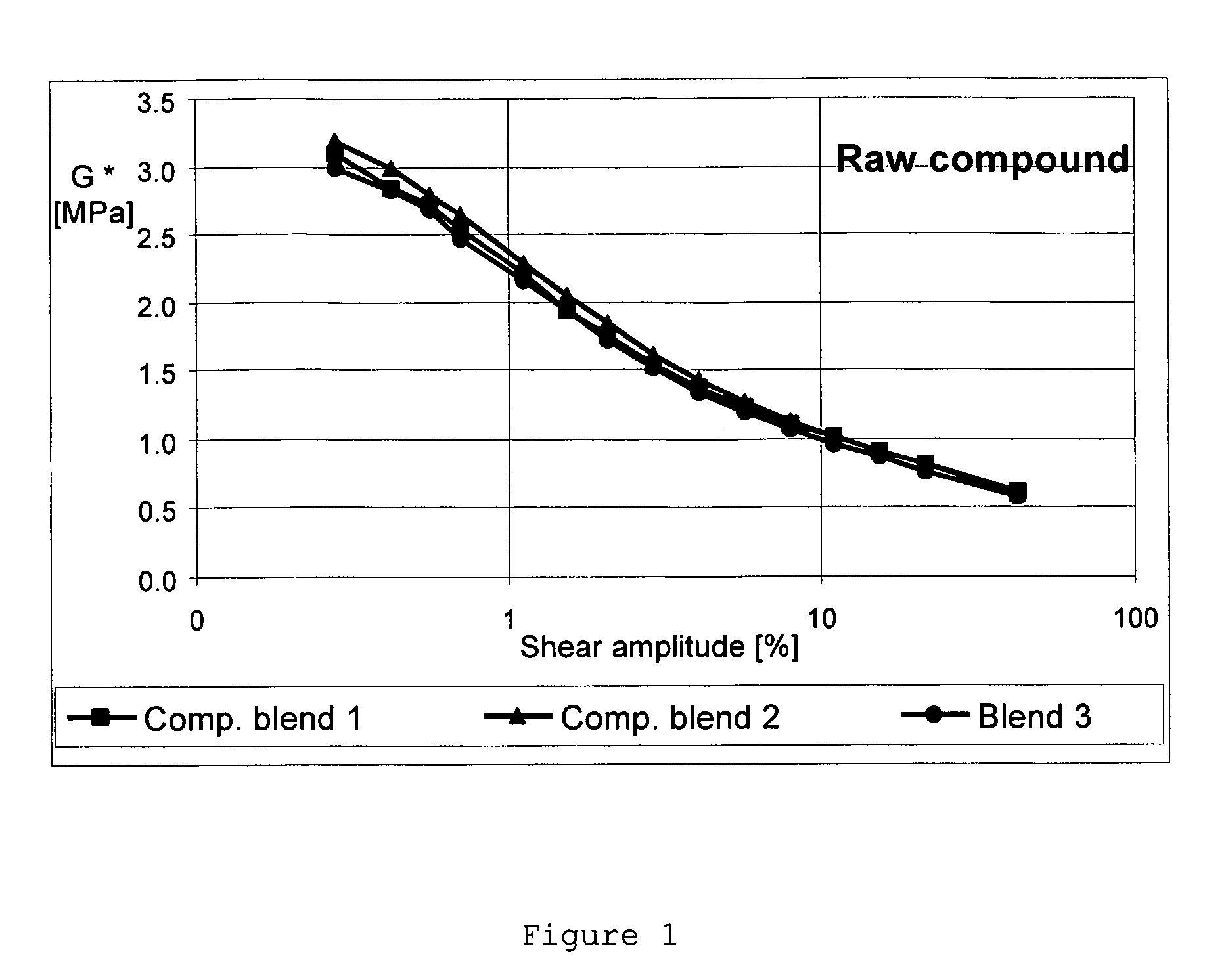

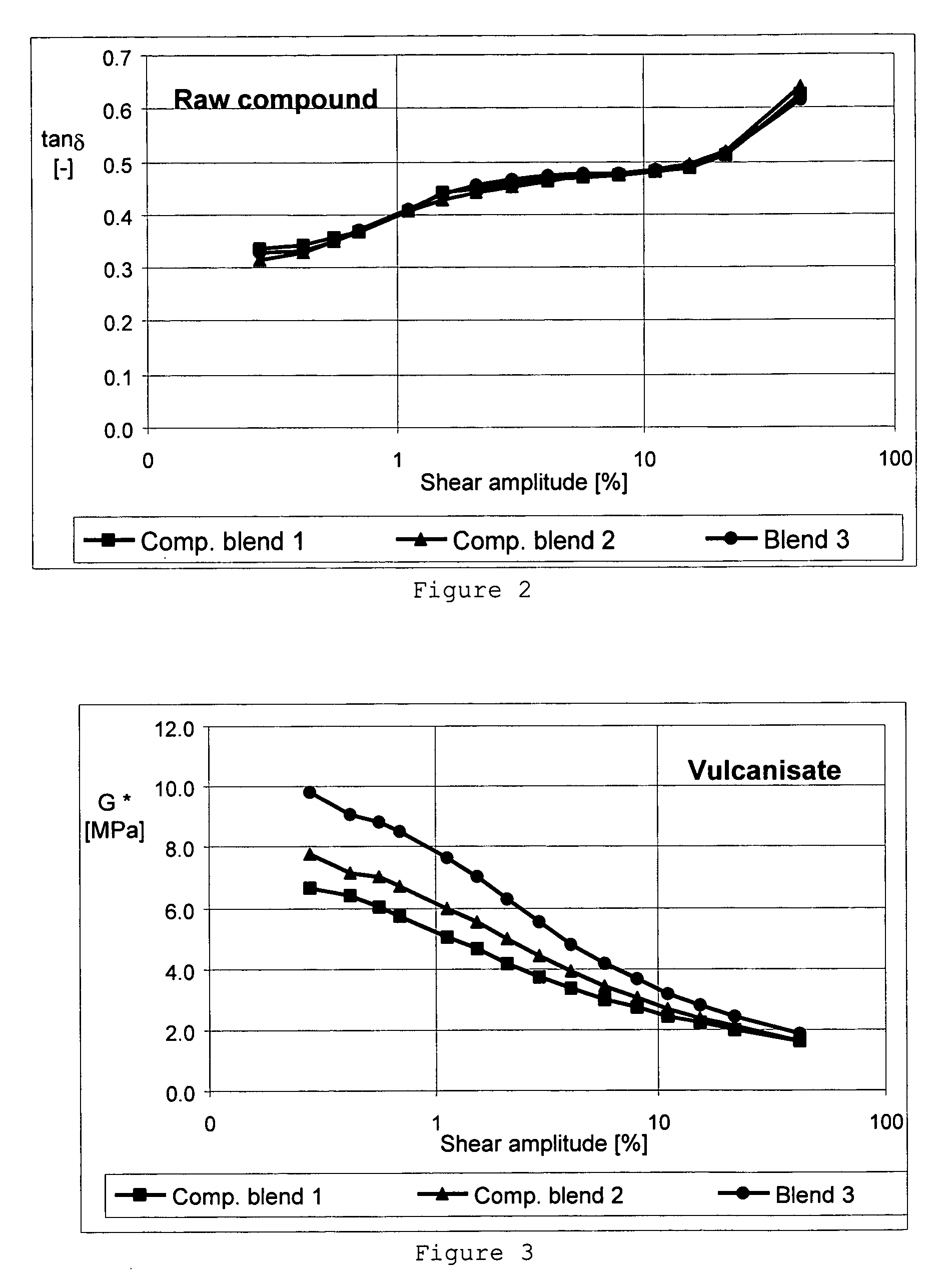

Carbon black

ActiveUS7300964B2Improve dynamic rigidityReduce hysteresisOrganic chemistryOther chemical processesOrganic groupOrganic compound

Carbon black having organic groups, the organic group containing a thiocyanate group. Also described is a process for the production of the carbon black, wherein carbon black is reacted with organic compounds containing a C—C double or triple bond, which is not part of an aromatic system, whose C—C double or triple bond is activated by at least one substituent, and the organic compound contains at least one thiocyanate group. The carbon black according to the invention can be used in rubber compounds.

Owner:UBS AG

Method for extracting aurum from difficult-to-handle sulphide ore aurum concentrate by two-segment pressurization leaching method

InactiveCN101876005ADoes not affect the leaching rateReduce consumptionProcess efficiency improvementIron sulfateSlag

The invention relates to a method for extracting aurum from difficult-to-handle sulphide ore aurum concentrate by two-segment pressurization leaching method comprising two segments of pressurization oxidation preprocessing and pressurization oxidation aurum leaching. The method comprises the steps of: firstly, pressurizing and oxidizing base metal sulfide such as iron sulfide with sulfuric acid-iron sulfate, wherein most S2- and S22- are oxidized into elemental sulfur; and secondly, pressurizing and leaching the preprocessed slag with thiocyanate so that aurum is selectively dissolved in the solution in the form of aurum-thiocyanic acid compound. Therefore, the pre-oxidation slag can be directly leached without neutralization, the technical process is short, the aurum recovery rate is high, the cost is low and pollution of low-concentration SO2 smoke gas, As2O3 smoke dust, and the like is avoided.

Owner:CENT SOUTH UNIV

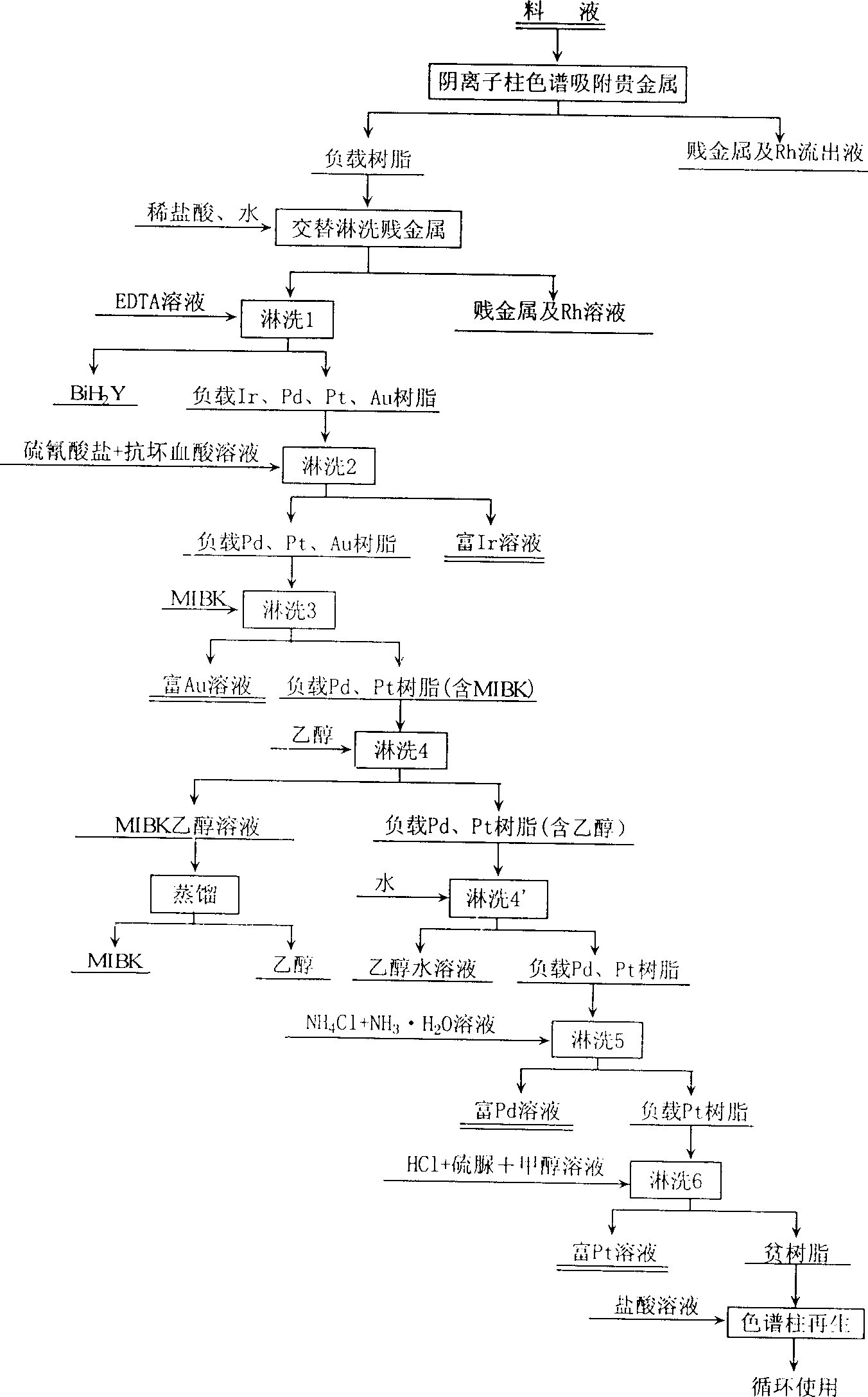

Method for separating platinum palladium iraurita

InactiveCN1400322AAchieve mutual separationEasy to separateProcess efficiency improvementIridiumThiourea

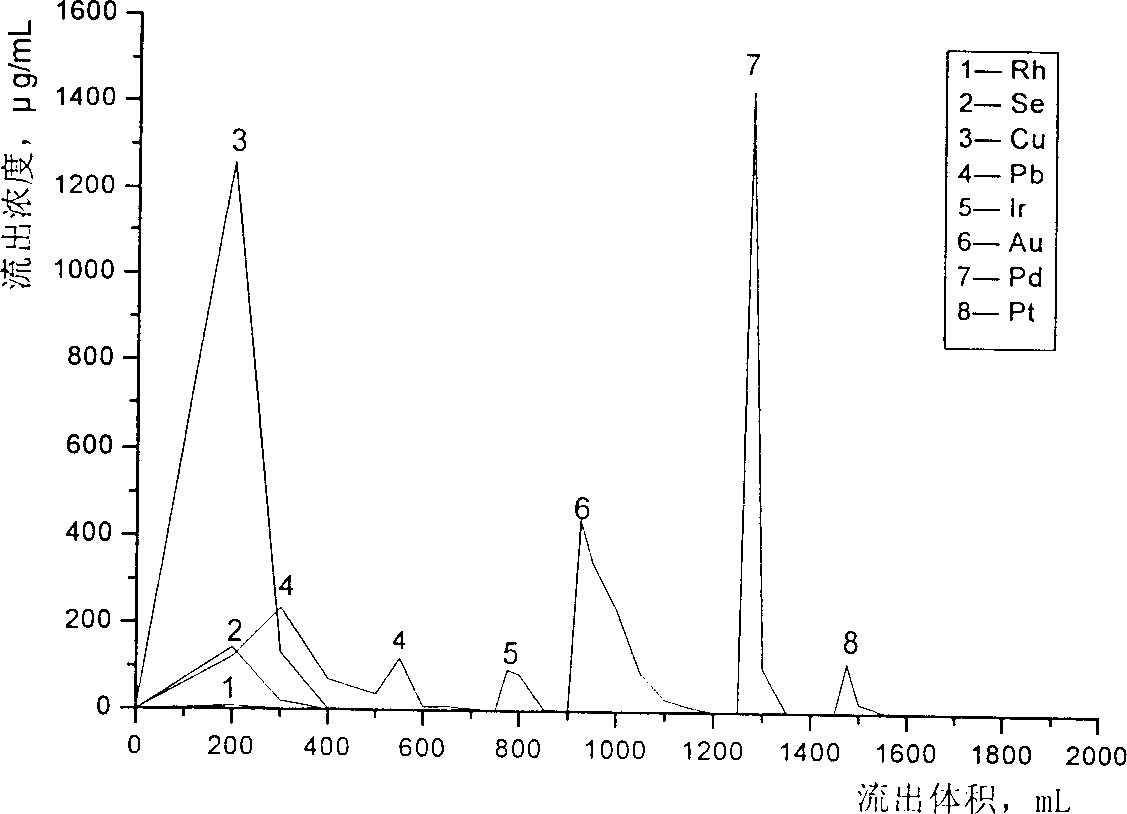

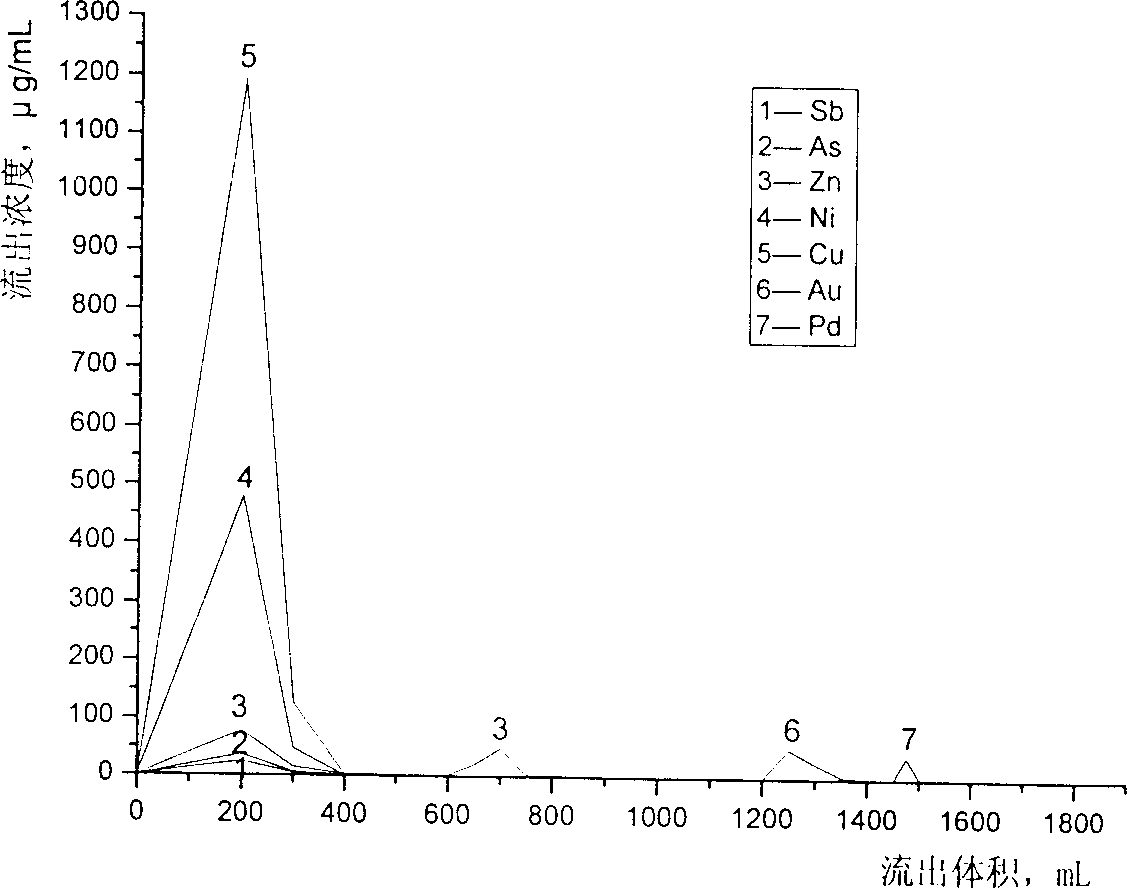

The present invention uses weak base phenylethylene series trialkylamine type anion-exchange resin as fixed phase and uses hydrochloric acid medium as mobile phone to implement coarse separation of platinum, palladium, iridium and gold from base metal, adopts dilute hydrochrolic acid, water and EDTA to elute base metal, and utilizes sulfocyanate+ascorbic acid solution, hydrochloric acid equilibrated methyl isobutanedione, NH4Cl+NH3.H2O solution and HCl+thiourea+thiourea+methyl alcohol solution to selectively shower-wash iridium, gold, palladium and platinum, and its chromatographic column canbe regenerated by using hydrochloric acid. Its resolution is good, the baseline separation can be obtained, and their recoveries are above 95%.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas

InactiveCN101597073AHigh purityHigh selectivityChemical industryThiocyanic acidLiquid wasteSodium thiocyanate

The invention discloses a method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas, and belongs to the technical field of utilization of desulphurization waste liquid of the coke oven gas. The method comprises the following steps: using the desulphurization waste liquid of the coke oven gas as a raw material, firstly, filtering the waste liquid in vacuum, using tributyl phosphate to extract thiocyanate radicals in the waste liquid, then using sodium hydroxide solution to back-extract the extract, and finally concentrating and crystallizing the extract, and washing and drying the crystals to obtain sodium thiocyanate crystals. The method uses the desulphurization waste liquid of the coke oven gas to prepare a sodium thiocyanate product with the purity as high as 93 to 95 percent so as to change waste into valuable and makes full use of waste resources; and the method is simple, saves energy, has no three-waste discharge, is favorable for environmental protection, has low production cost and good economic benefit, and develops a new path for the utilization of the desulphurization waste liquid resources of the coke oven gas. The sodium thiocyanate product prepared by the method can be widely applied in the industries of medicaments, textile, printing and dyeing, pesticide, chemistry and the like.

Owner:CHONGQING UNIV

Cellulose solvent compositions and methods of making and employing same

InactiveUS6827773B2Duplicating/marking methodsMonocomponent cellulose artificial filamentEthylenediamineCellulose

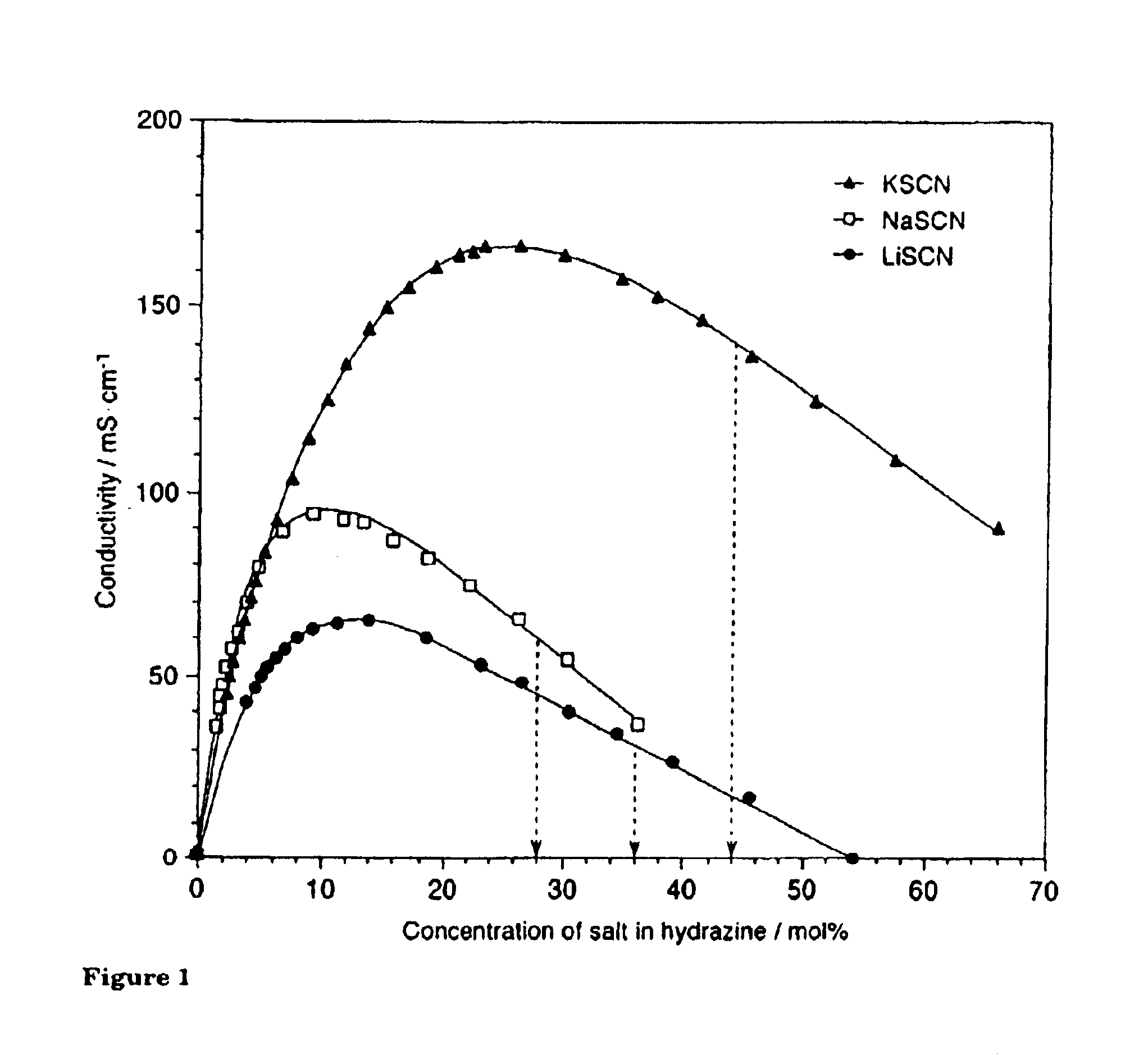

Cellulose solvents, cellulose compositions, and methods of making and using the same. For example, a cellulose composition including cellulose dissolved in the following solvent: an amine-based composition, provided however, the amine-based composition is not ammonia; and a salt selected from the group including a thiocyanate salt, a halide salt, and a nitrate salt. Representative amine-based compositions include hydrazine, hydrazine hydrate, and ethylenediamine.

Owner:NORTH CAROLINA STATE UNIV

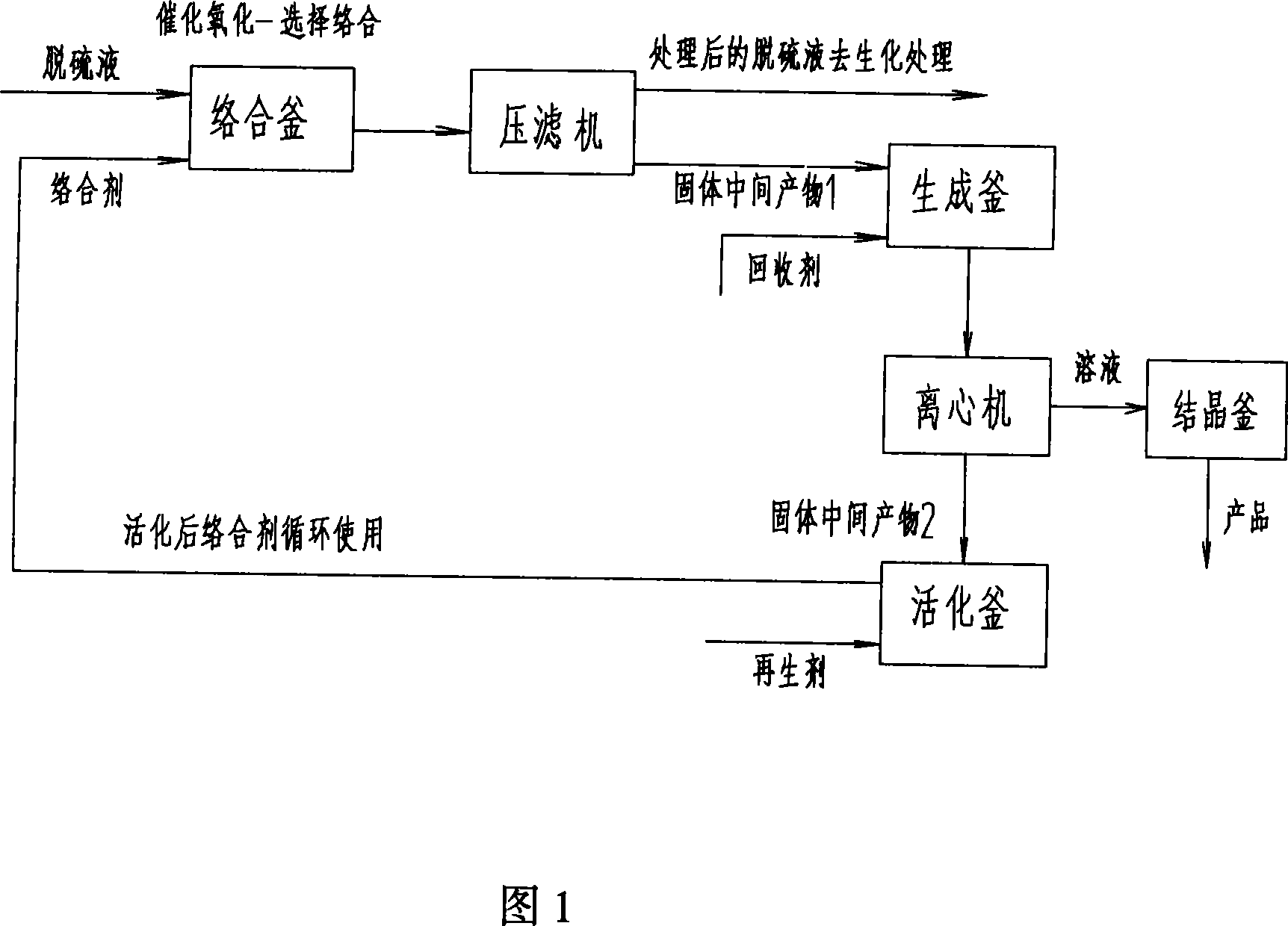

Process technique for discharged doctor solution of HPF desulfurization system of coke-oven plant

InactiveCN101219340AAvoid pollutionLow running costDispersed particle separationLiquid wasteSocial benefits

The invention relates to a processing technique for discharging desulfurization solution of a coke-oven plant HPF desulfurization system, which pertains to the waste fluid process technical field and is used for solving the problems of reducing COD content in the desulfurization solution and recycling a plurality of thiocyanate products. Particularly, the method comprises the procedures that: A. catalytic oxidation-selection of complexing; B. filter pressing or centrifugal separation; C. product generation; D. regeneration of complexing agents. The method of the invention is characterized in that: 1. using SCN<-> in the desulfurization solution produces chemical products such as NaSCN, KSCN, etc.; 2. the processed COD is reduced from 140000mg / L to 15000mg / L; 3. the invention has relatively small technical investment and simple operation; 4. the complexing agents can be recycled, thus having low operating cost and obvious economic benefits. The invention has novel research thought and reasonable technique, and conforms to a concept of circular economy and has quite good economic and social benefits.

Owner:HEBEI IRON AND STEEL

Method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater

ActiveCN102424401AMeet the requirements of green circular economyEasy to handleThiocyanic acidPersulfateThiocyanate

The invention discloses a method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater. The method comprises the steps of: adding persulfate or sulfuric acid to polyamine salt wastewater for reacting with ammonium thiosulfate so as to generate ammonium sulfate and ammonium sulfite, and further oxidizing into ammonium sulfate and sulfur, thus the wastewater is changed into a two-component mixed liquid which contains ammonium thiocyanate and ammonium sulfate and is easy to separate by crystallization from a three-component mixed liquid, and high-efficiency separation is realized. The purity of the obtained ammonium thiocyanate crystal can reach 99%.

Owner:江苏燎原环保科技股份有限公司

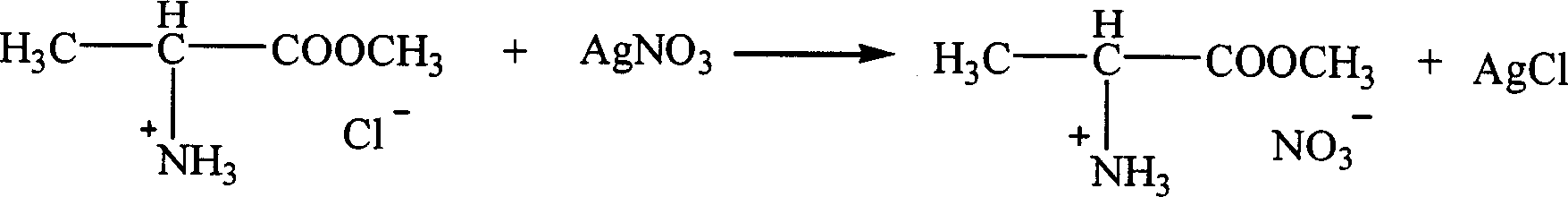

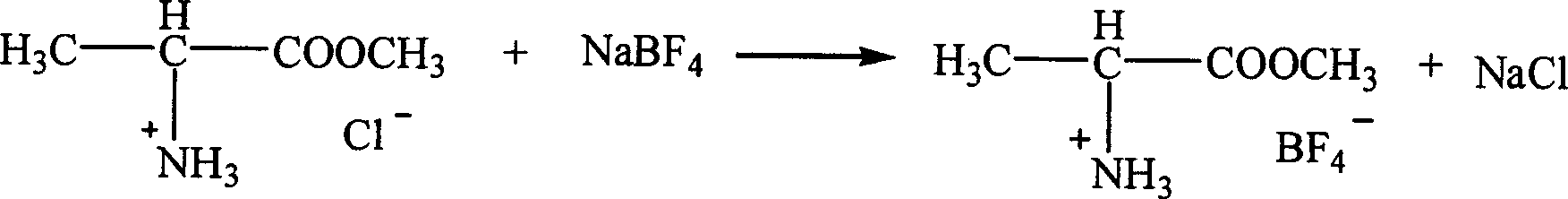

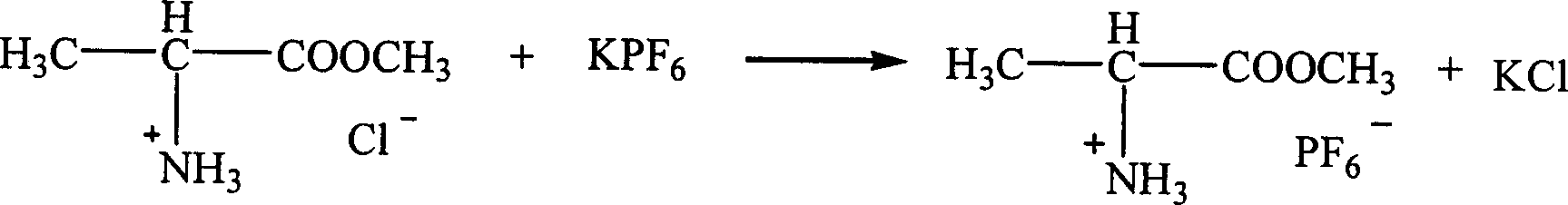

Ion liquid of amino acid ester cation and its preparation method

InactiveCN1621152AEasy to getLow priceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroborateAmino acid

The present invention is ion liquid of amino acid ester cation and its preparation process, and belongs to the field of new chemical material and its preparation technology. The ion liquid of amino acid ester cation is prepared with amino acid ester hydrochloride and through the substitution reaction with nitrate, tetrafluoroborate, hexafluorophosphate, bistrifluoromesyl imine salt or thiocyanate or the direct addition reaction with aluminum trichloride, ferric trichloride or zinc chloride, and the separation. The ion liquid thus prepared has the characteristic of chiral matter except the ion liquid characteristics, has low cost, simple preparation process and no pollution. The present invention is suitable for industrial production and is expected to become important green chemical material.

Owner:PEKING UNIV

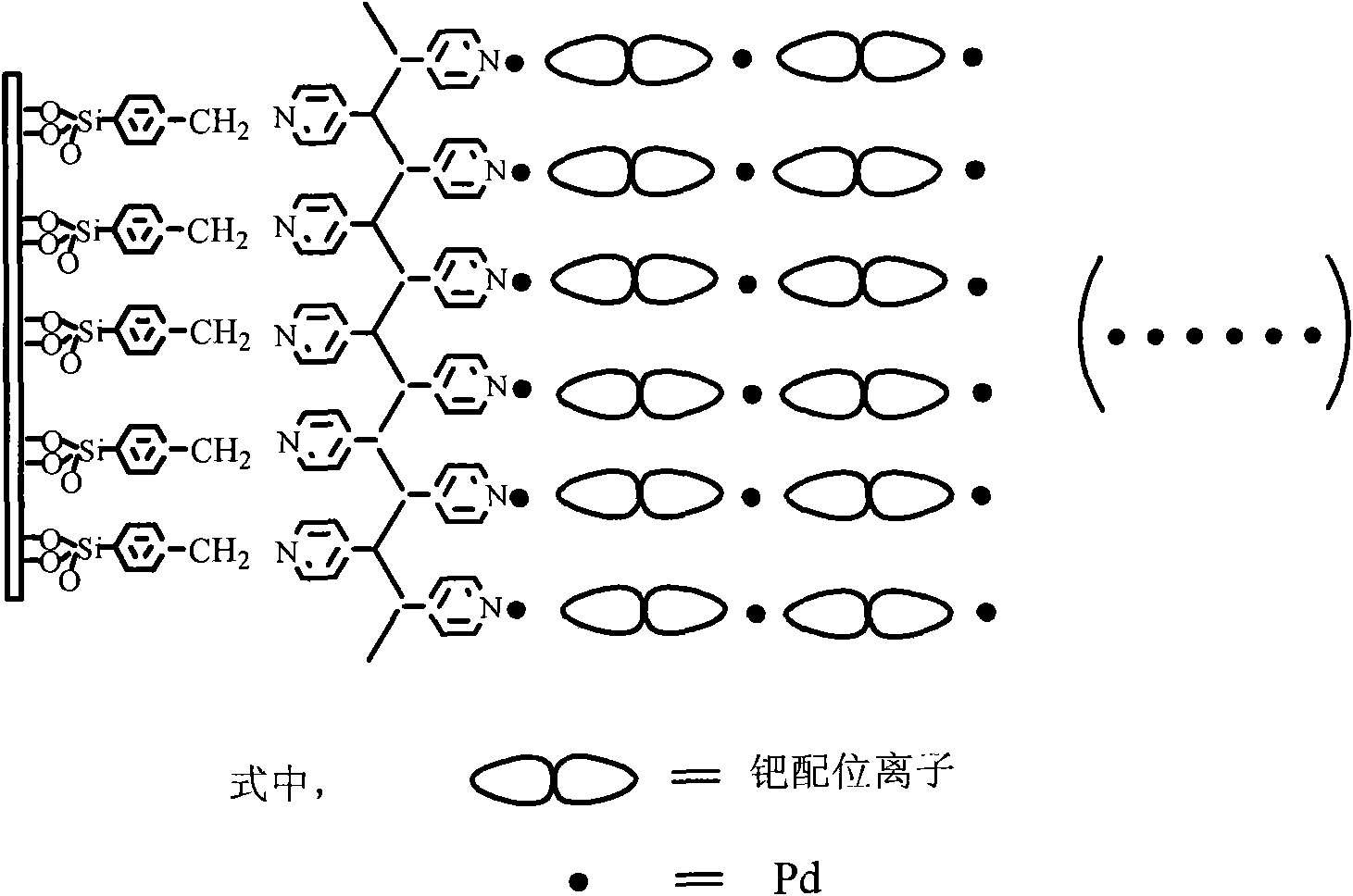

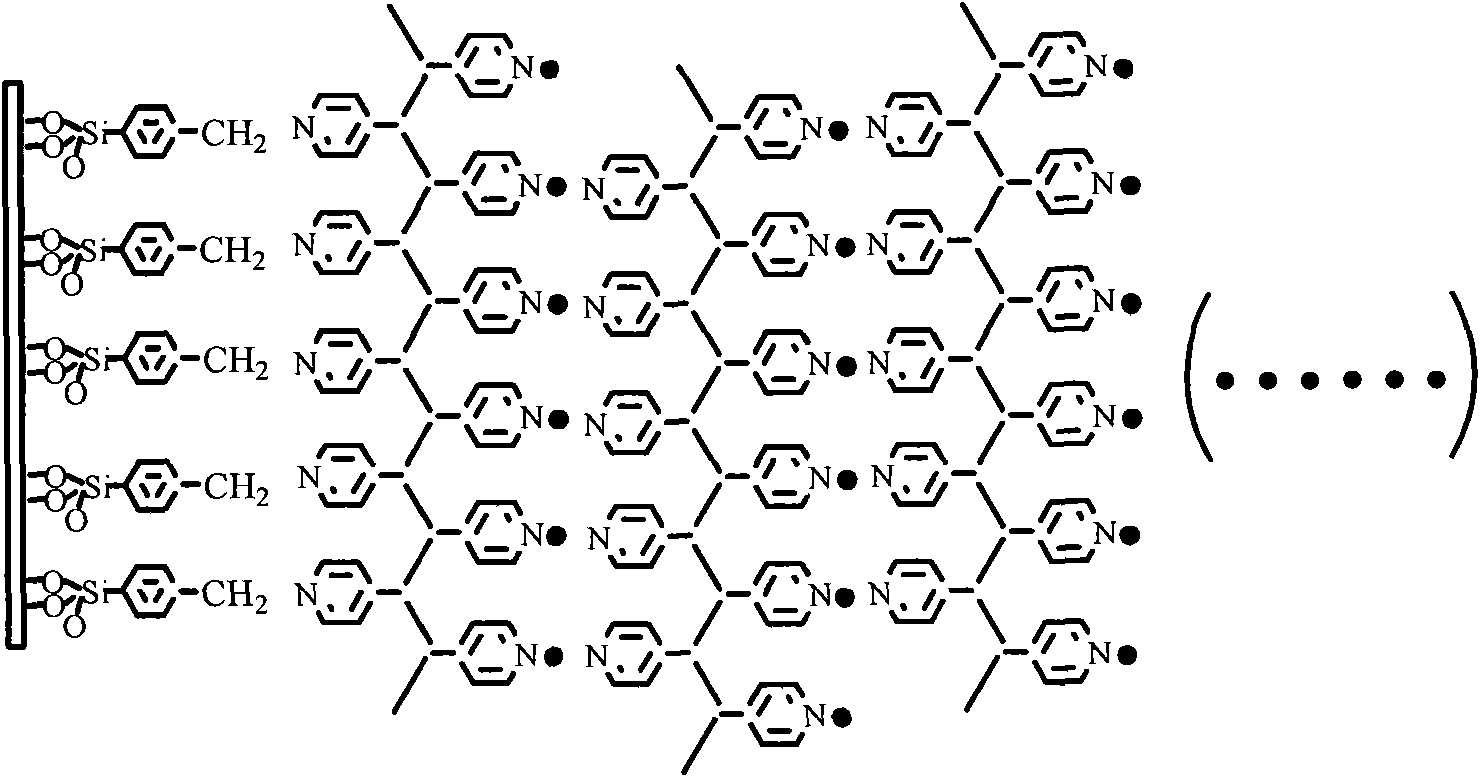

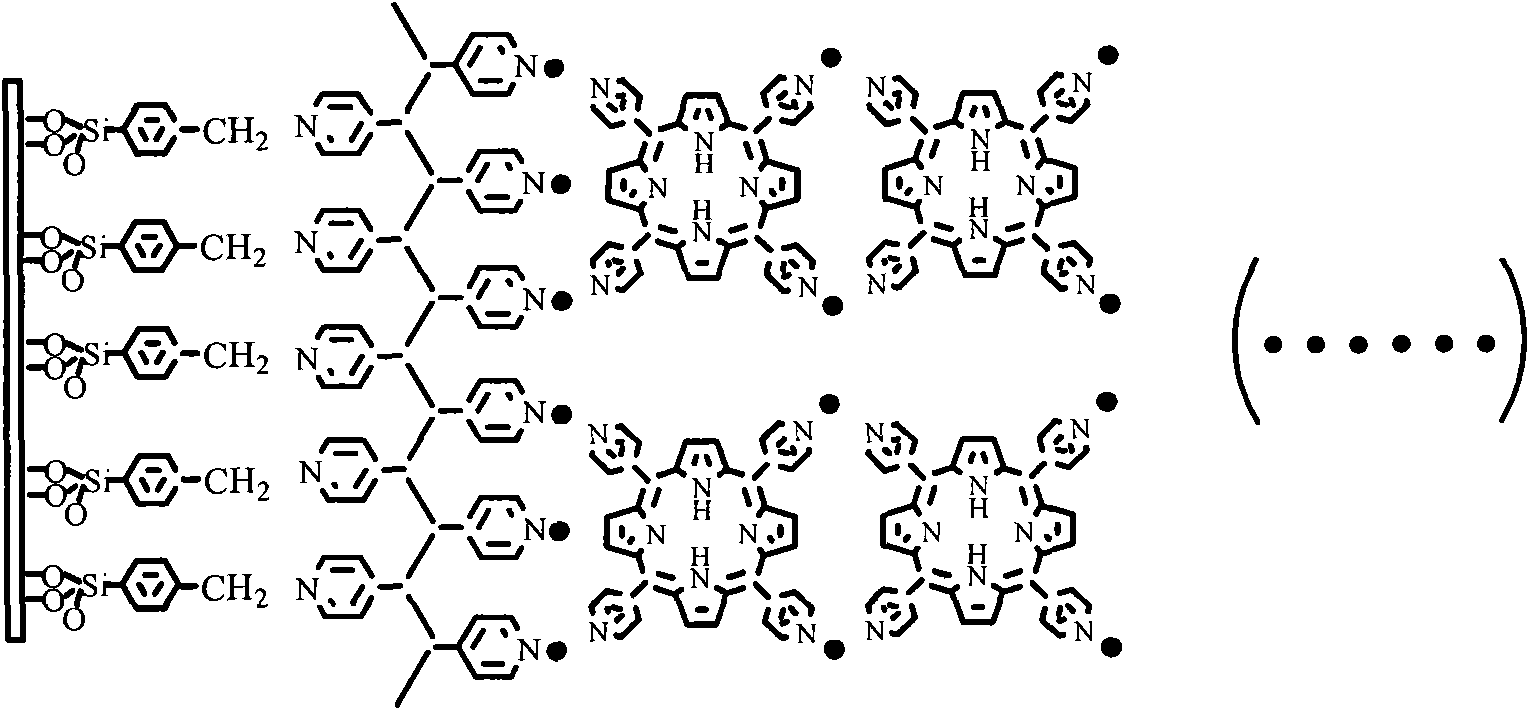

Palladium coordination polymer molecule aggregate catalysis material as well as preparation method and application thereof

InactiveCN101607213AEasy to makeEasy to separateOrganic reductionOrganic compound preparationPorphyrinSolid substrate

The invention relates to a palladium coordination polymer molecule aggregate catalysis material as well as a preparation method and an application thereof. The catalysis material is a coordination polymer molecule aggregate catalysis material formed by self-assembling on the surface of a solid substrate, the precursor of the catalysis material comprises palladium coordination ion as well as pyridine containing multidentate ligand or high molecular ligand, wherein the palladium coordination ion is selected from one of tetrachloro combined palladium acid radical, dichloro-2, 2'-dipyridine palladous, and dichloroacetamide palladous, and the pyridine containing multidentate ligand or high molecular ligand is selected from one of 4, 4'-combined pyridine, 2, 4, 6- collidine triazine, metal or hollow tetra pyridyl porphyrin, trans-1, 2- collidine ethylene, combined dipyridylzinc thiocyanate and polyethylene pyridine. LB film preparation technology or layered assembly method is adopted for organism selective ethylenic bond organic hydrogenation reaction, thus having high catalysis efficiency, easy realization in separation of catalyst and reactant and product, convenient operation and low cost.

Owner:FUDAN UNIV

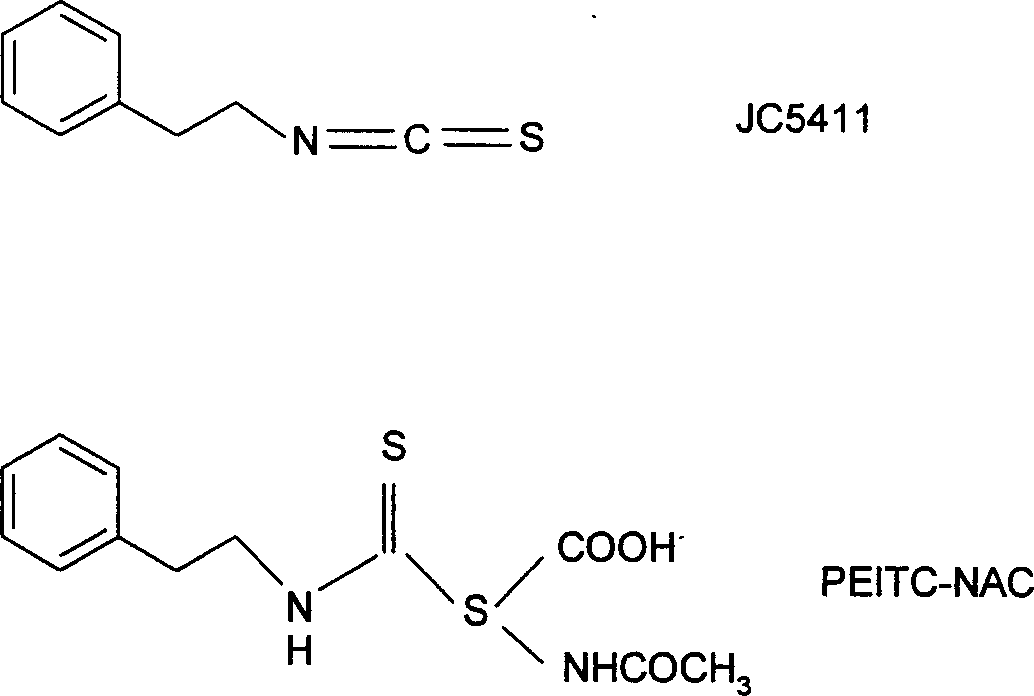

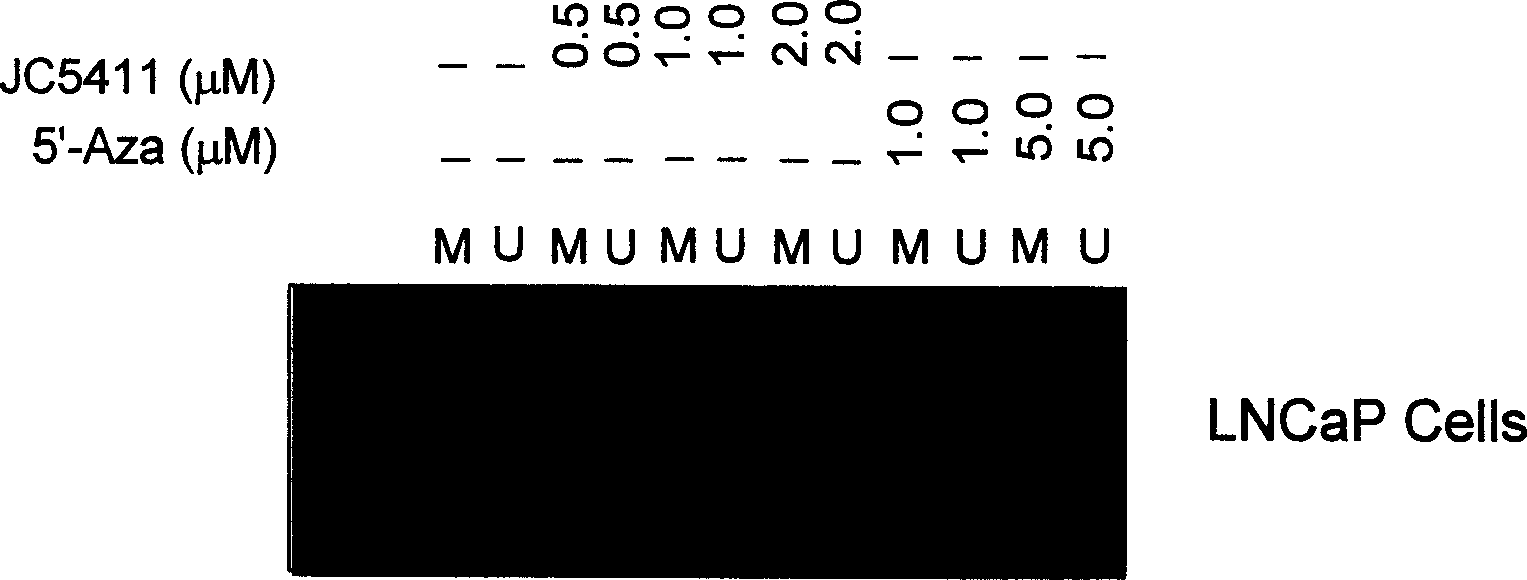

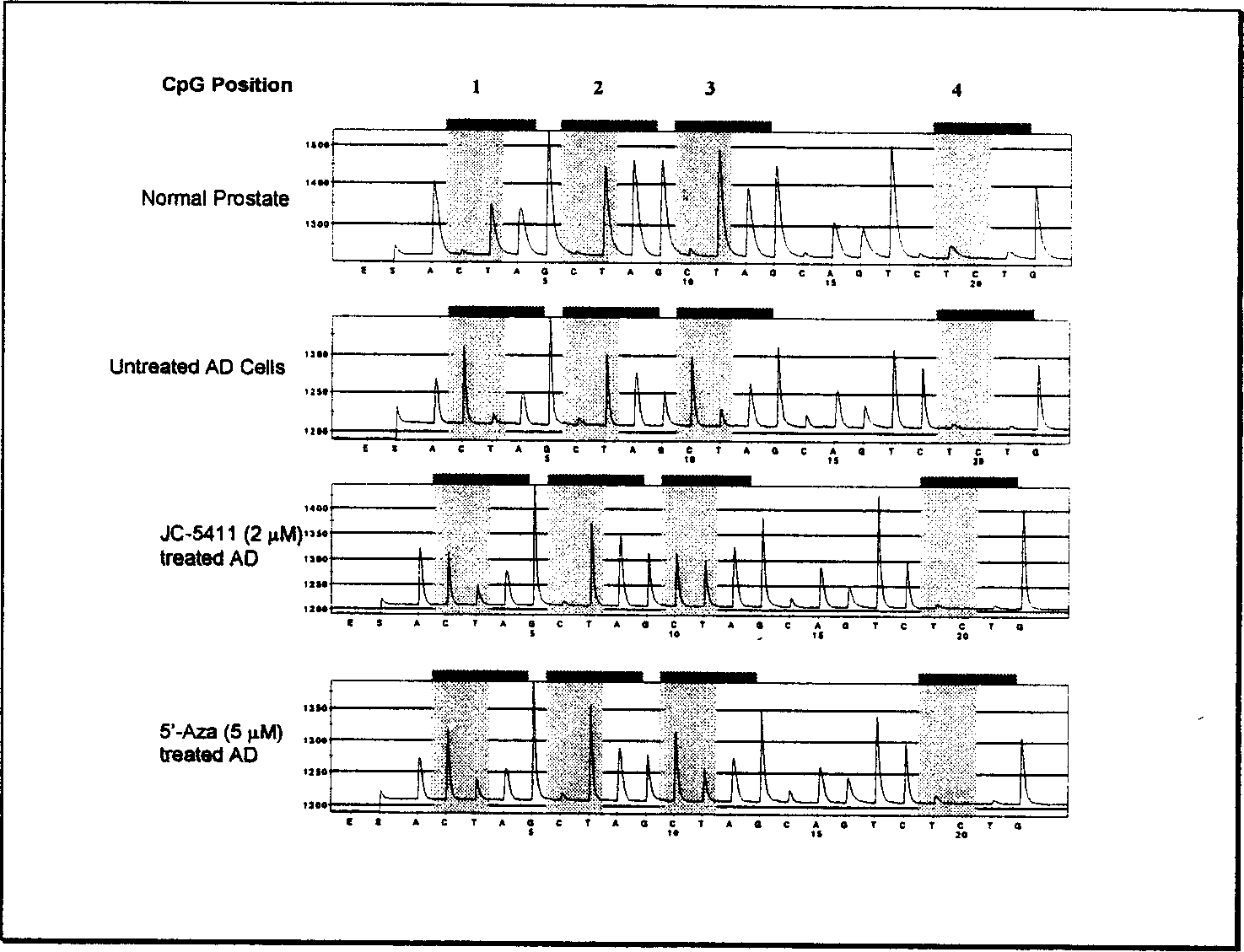

Natural and synthetic isothiocyanate kind compound and its application in treating and preventing cancer

The invention relates to naturally or artificially synthesized iso-thiocyanates i.e. JC-5411 compounds and their use in treating and preventing malignant tumor, wherein the compounds can directly suppress the methylation of the gene promoter / 5-UTR area CpG DNA, directly inhibit the reactivity of histone deacethylases (HADC), selectively promote histone acetylation and methylation, then further recover the expression of genes with important functions that are shut abnormally in cancer cells, thus control the malignant proliferation of cancer cells.

Owner:JC (WUXI) CO INC

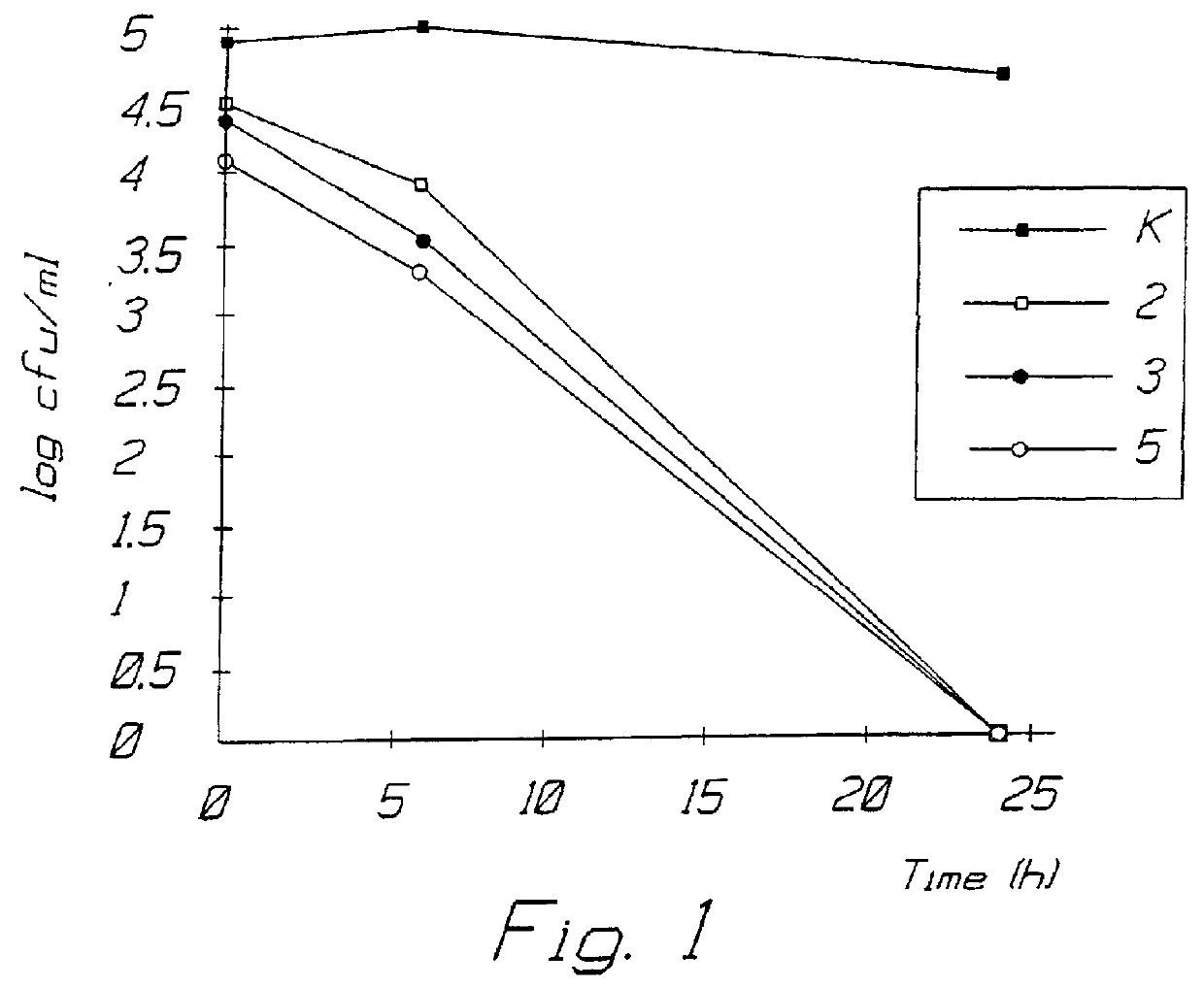

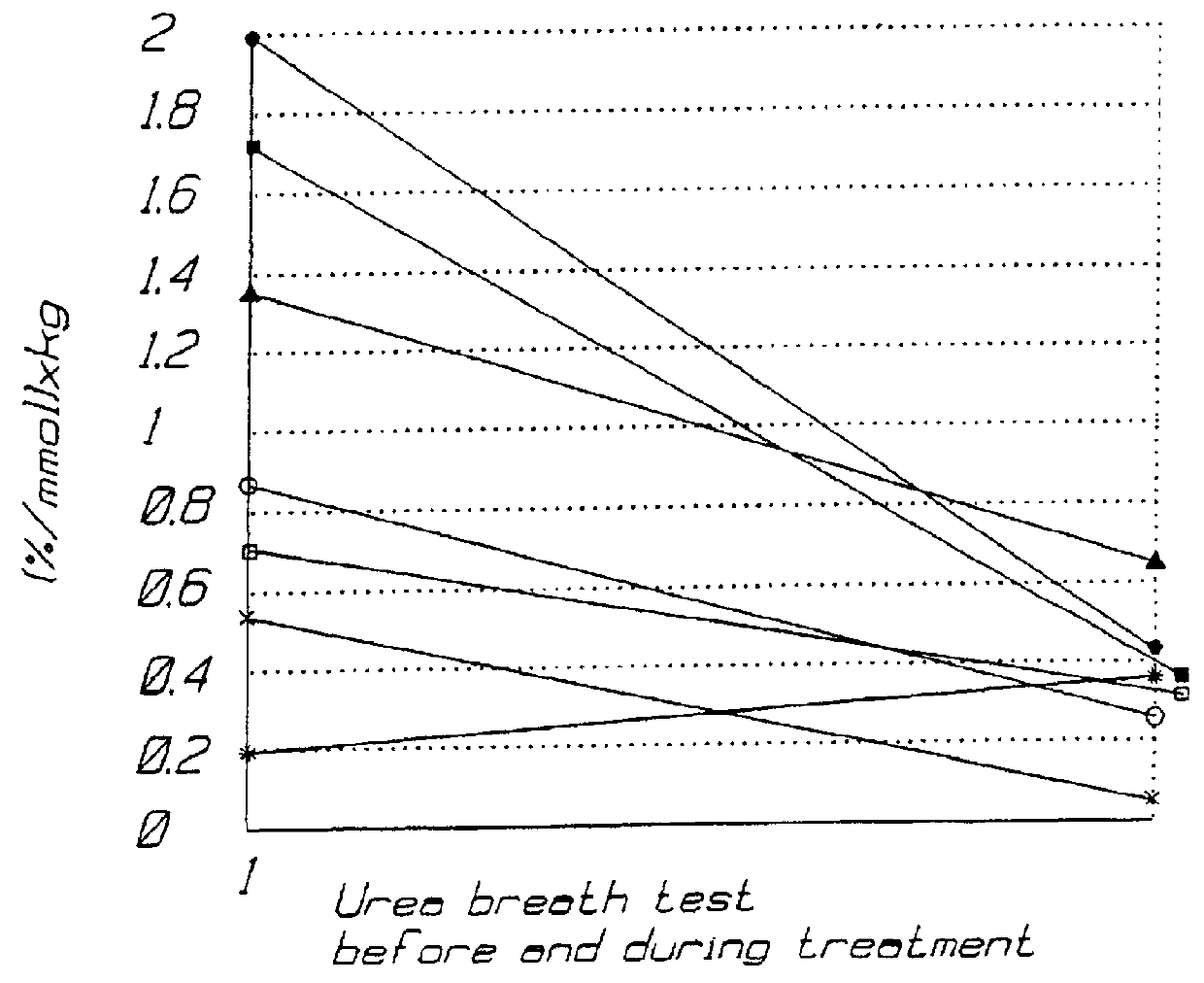

Use of lactoperoxidase, a peroxide donor and thiocyanate for the manufacture of a medicament for treating Helicobacter pylori infection

InactiveUS6149908AHigh frequencyKeep for a long timeAntibacterial agentsMilk preparationMedicineIn vivo

PCT No. PCT / SE97 / 00098 Sec. 371 Date Jul. 22, 1998 Sec. 102(e) Date Jul. 22, 1998 PCT Filed Jan. 22, 1997 PCT Pub. No. WO97 / 26908 PCT Pub. Date Jul. 31, 1997Use of an antibacterial system comprising lactoperoxidase and a peroxide donor for preparing a preparation for prophylactic or therapeutic treatment "in vivo" of an infection caused by the bacteria Helicobacter pylori existing in the stomach, which preparation is completed by the presence of thiocyanate in an antibacterial level, and eventually in the presence of lactoferrin. A daily dose for human treatment is 1.2-1.6 grams of the system taken 3 times a day.

Owner:MJOLKKANNAN FORVALTNING

Crosslinkable Vinyl Fluoride Copolymer Coated Film and Process for Making Same

ActiveUS20080156367A1Film/foil adhesivesSynthetic resin layered productsPhosphoric Acid EstersIodide

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD +1

Process for Removing Nickel and Vanadium From Hydrocarbons

Nickel and / or vanadium can be removed or transferred from a hydrocarbon phase to a water phase using an Extractant Composition selected from an isocyanate, a thiocyanate, a cyanides, mercaptides, nitrites, and mixtures thereof. The Extractant Composition may also include at least one mineral acid, a solvent, and other additives. The invention permits transfer of vanadium and nickel from a hydrocarbon into an aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil.

Owner:BAKER HUGHES INC

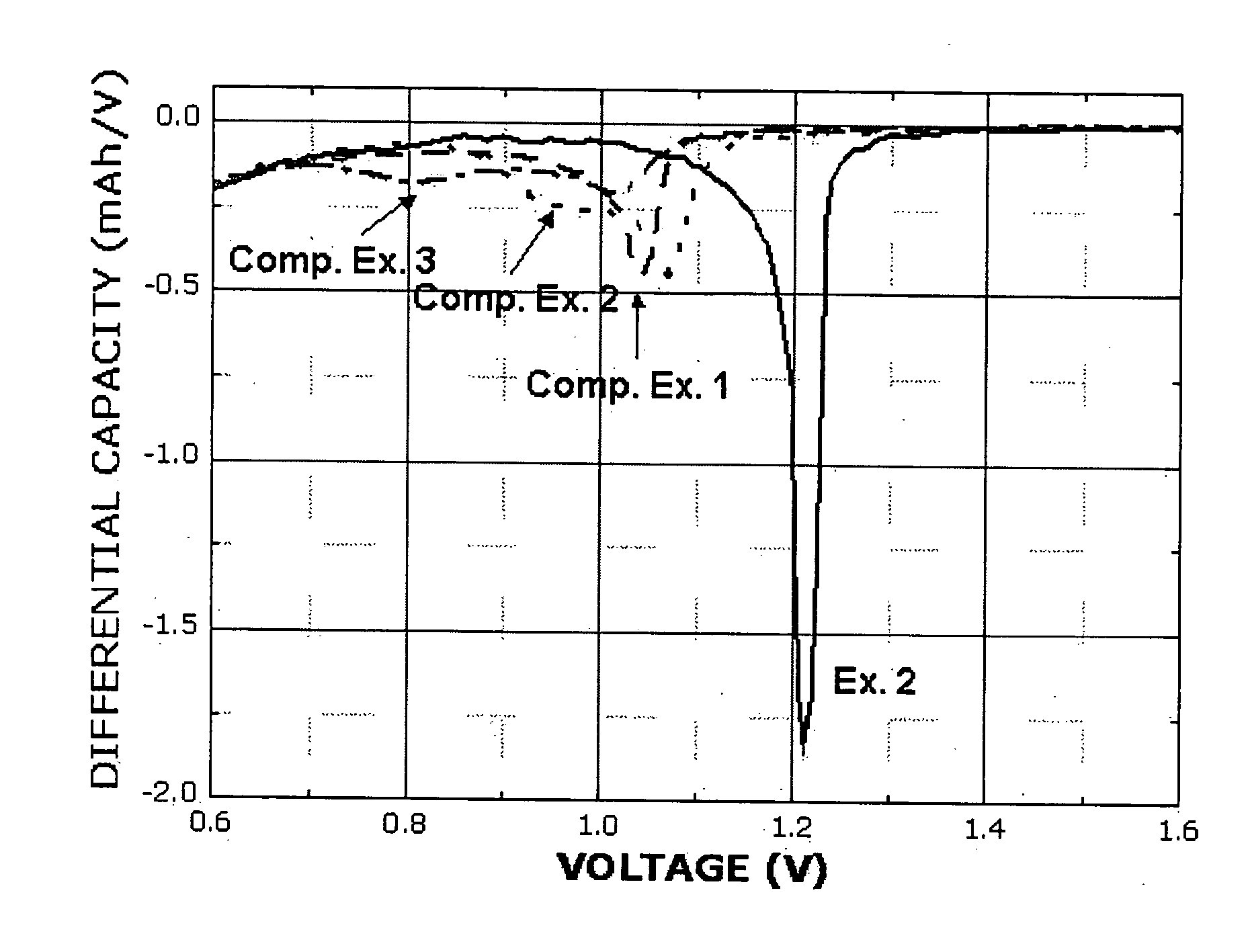

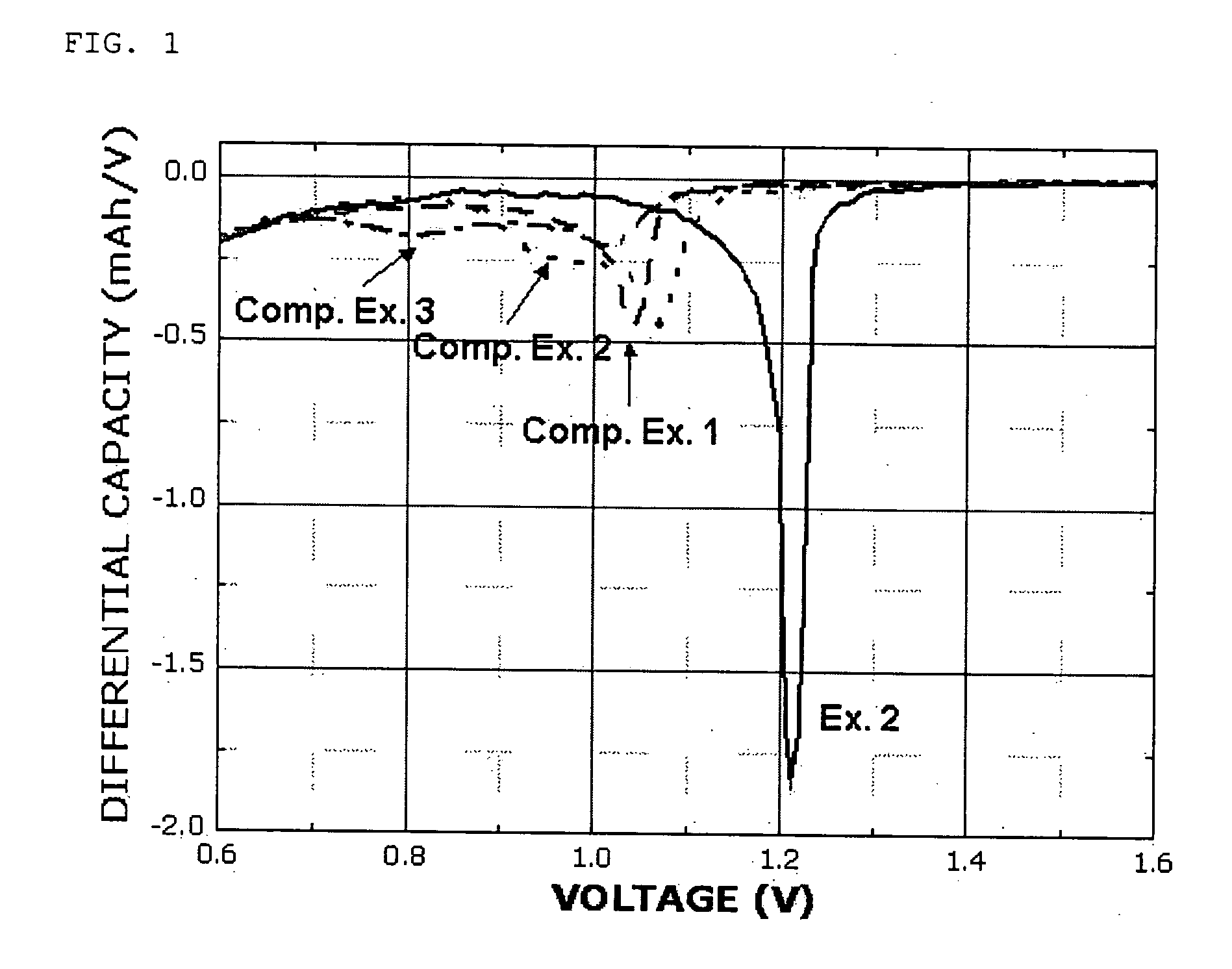

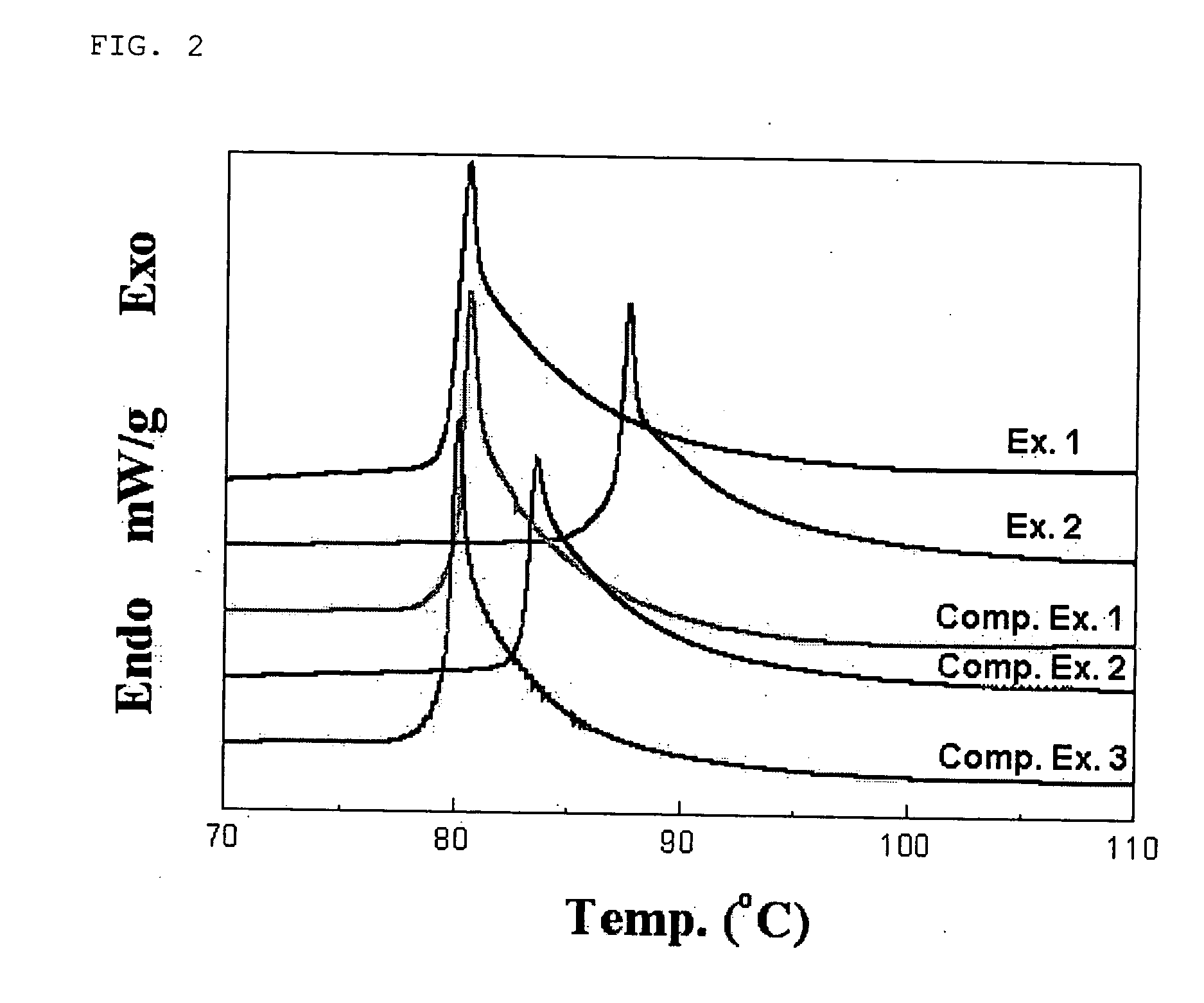

Additives for non-aqueous electrolytes and electrochemical device using the same

ActiveUS20070059588A1Quality improvementExcellent characteristicsCell electrodesConductive materialSulfonateChemical reaction

Disclosed is an electrolyte for batteries, which comprises: (a) an electrolyte salt; (b) an electrolyte solvent; and (c) a sulfonate-based compound containing at least one electron withdrawing group (EWG) selected from the group consisting of a cyano group (—CN), an isocyanate group (—NCO), a thiocyanate group (—SCN) and an isothiocyanate group (—NCS). An electrode comprising the sulfonate-based compound or a chemical reaction product thereof, partially or totally formed on the surface thereof, and an electrochemical device comprising the electrolyte and / or the electrode are also disclosed. The electrochemical device using the sulfonate-based compound containing a cyano group, an isocyanate group, a thiocyanate group and / or an isothiocyanate group as an additive for electrolytes can provide significantly improved high-temperature lifespan characteristics.

Owner:LG ENERGY SOLUTION LTD

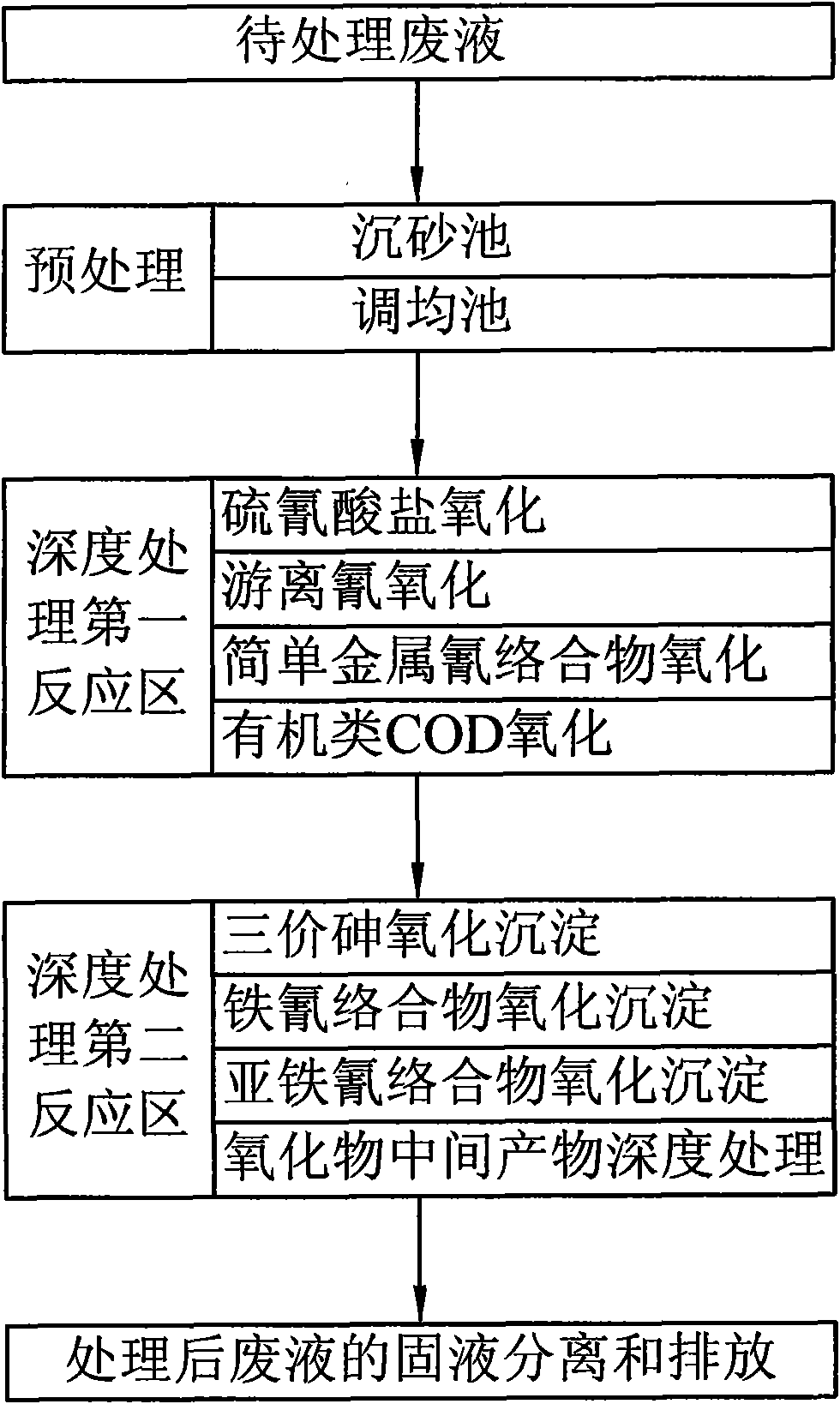

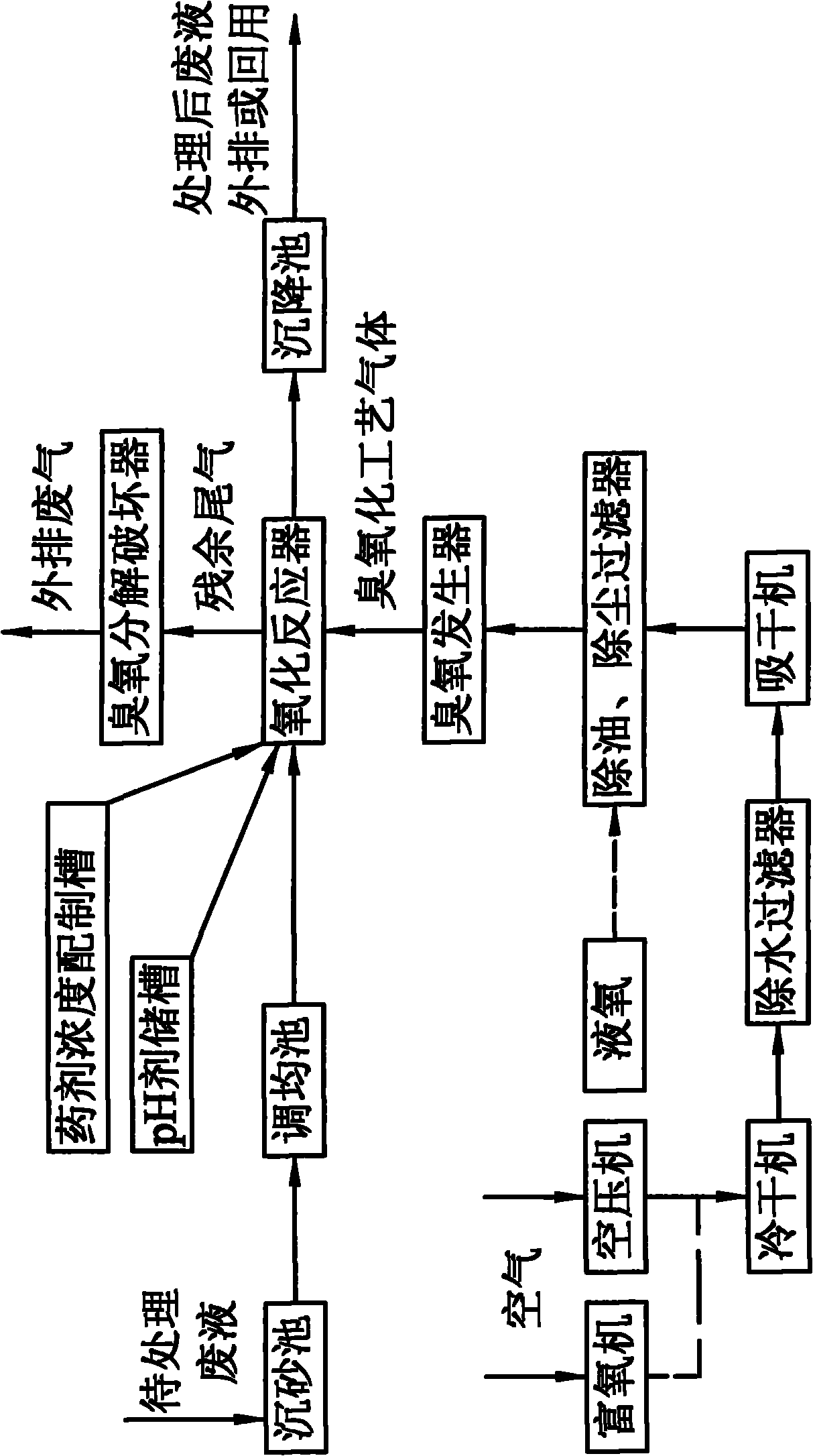

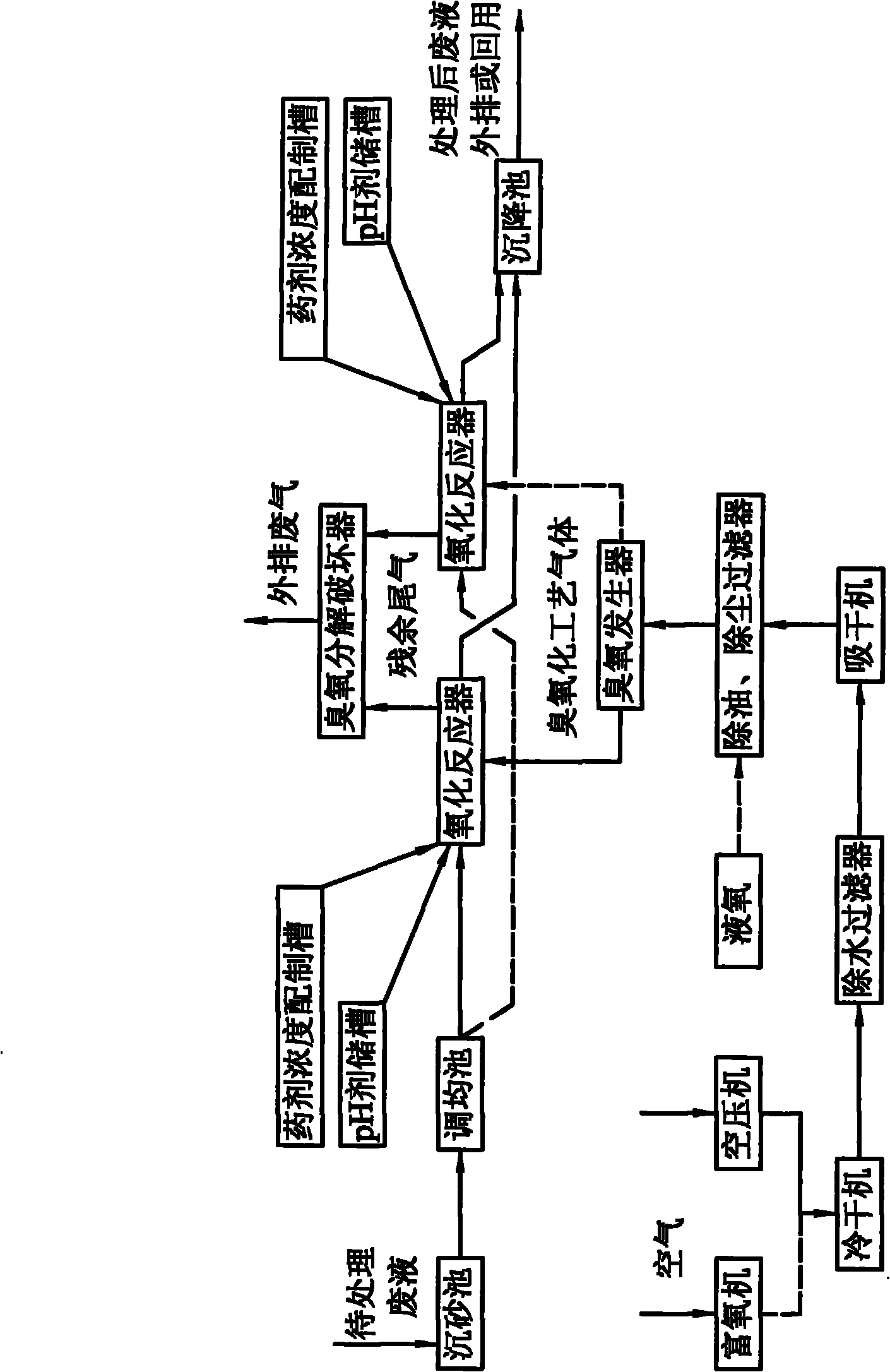

Method for removing cyanide, thiocyanate, COD and arsenic in waste liquid

ActiveCN102070264ALow costReduce complexityWater contaminantsMultistage water/sewage treatmentLiquid wasteThiocyanate

The invention discloses a method for removing cyanide, thiocyanate, COD and arsenic in waste liquid, comprising the following steps: the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid are deeply treated by utilizing ozonized gas, a mode with continuous treatment and direct discharge can be adopted, also a mode with batch treatment and intermittent discharge can be adopted, and the implementation process of the method is easy to control; in the range of the pH value with sectioned control, the generation concentration and mass velocity of ozone do not need to be required strictly, the problem that single technology can not treat the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid deeply can be solved, the cost and the operation complexity of technological equipment are reduced, and the environmental pollution is reduced; solid suspensions (SS) in the treated waste liquid is removed by settlement, and clear liquor is directly discharged outwards or returned to the upstream technology for repeated use; the contents of pollutants in the treated waste liquid are stable, the total content of the cyanide is less than 0.2mg / L(waste water); the content of the thiocyanate is less than 5mg / L(waste water); the total content of the COD is less than 30mg / L; the total content of the arsenic is less than 0.5mg / L(waste water), and no secondary pollutants are generated in the reaction process.

Owner:CHANGCHUN GOLD RES INST +1

Process for manufacturing N-alkoxy(or aryloxy)carbonyl isothiocyanate derivatives using N,N-dialkylarylamine as catalyst

InactiveUS6066754AHigh purityHigh yieldCarbamic acid derivatives preparationOrganic compound preparationOrganic solventChloroformate

The present invention provides a process for making N-alkoxy(or aryloxy)carbonyl isothiocyanate derivatives by reacting a chloroformate with a thiocyanate, in the presence of an organic solvent and a catalytic amount of a N,N-dialkylarylamine, to produce a N-alkoxy(or aryloxy)carbonyl isothiocyanate intermediate product, wherein the intermediate product is converted to a N-alkoxy(or aryloxy)carbonyl isothiocyanate derivative in high yield and purity.

Owner:BAYER CORP

Repair method for mercury-polluted soil

InactiveCN105414166AImprove adsorption capacityAchieve the purpose of repairContaminated soil reclamationSodium BentonitePhytoremediation

The invention discloses a repair method for mercury-polluted soil. The repair method comprises the following steps: ploughing up surface soil with a depth of 25-30 centimetres away from ground surface, of the mercury-polluted soil, air-drying, grinding and sieving to obtain pre-treated surface soil; forming a passivator from 40-55 parts of bentonite, 5-15 parts of hydroxyapatite, 3-8 parts of ammonium thiosulphate and 8-16 parts of calcium hydroxide in parts by mass; adequately and uniformly mixing the passivator with the treated surface soil according to an added amount which is 2-5% of the mass of the surface soil, of the passivator, standing for 10-20 days until mercury with a content of 70% in the surface soil is fixed, and completing passivator repair; and levelling the surface soil, planting Indian mustard, dissolving calcium thiocyanate in water and uniformly spraying the solution into the peripheral soil of the root systems of Indian mustard during the vigorous growth period of Indian mustard, and finally harvesting Indian mustard. The repair method disclosed by the invention is simple to operate, low in cost, short in remediation period, and suitable for application of repair for large-area mercury-polluted soil plants.

Owner:陕西清扬环境科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com