Patents

Literature

202results about How to "Increase activation energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

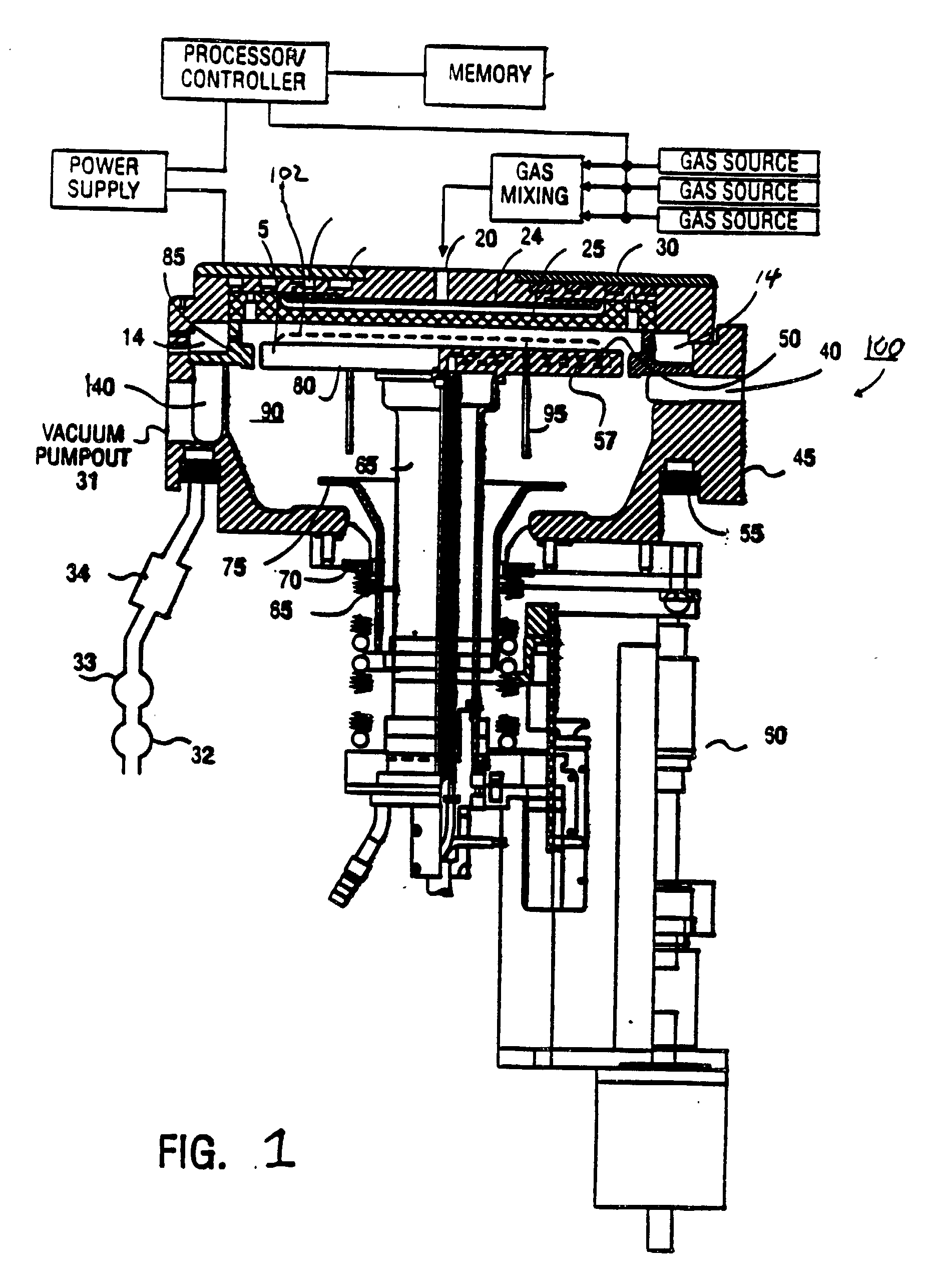

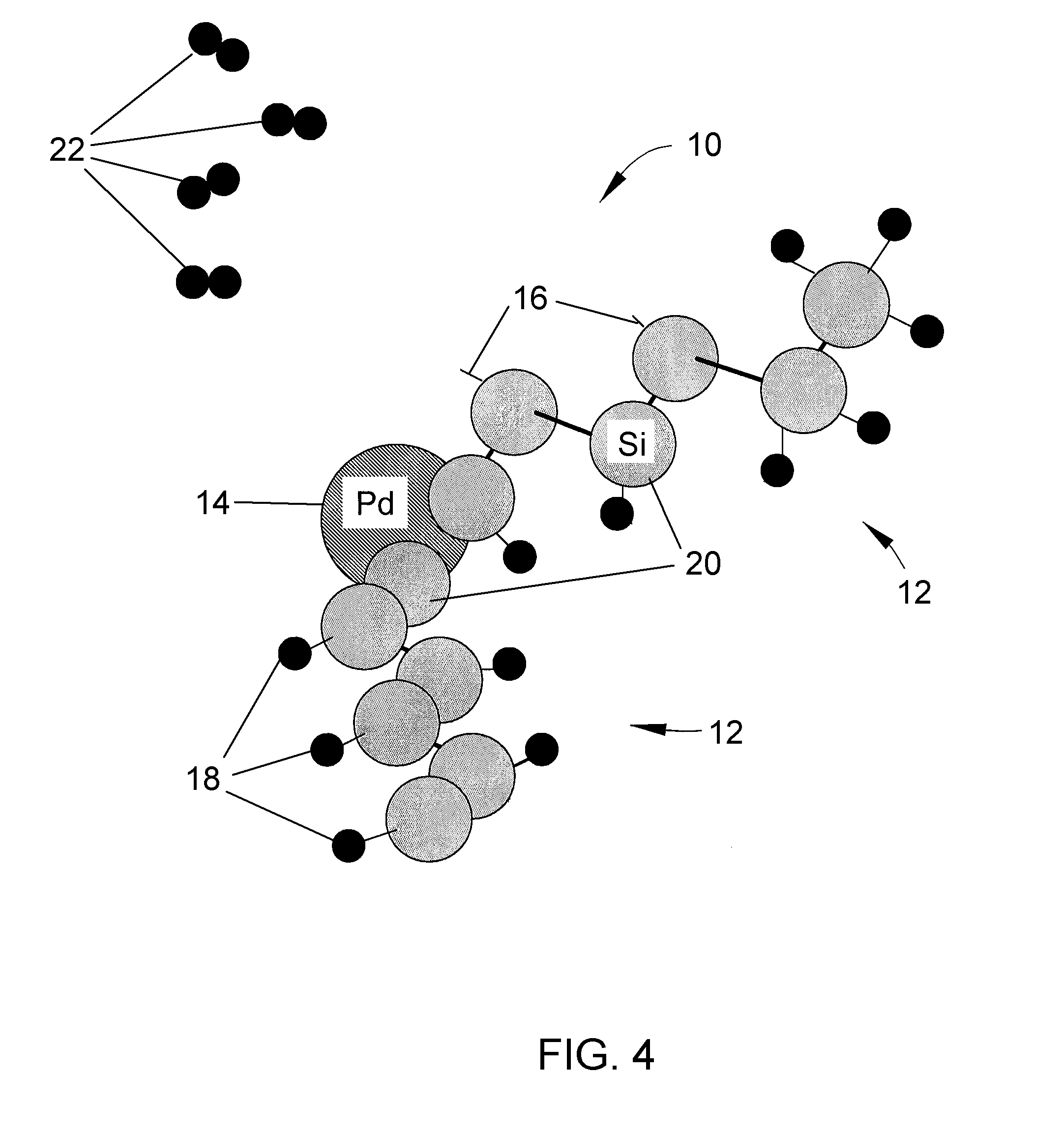

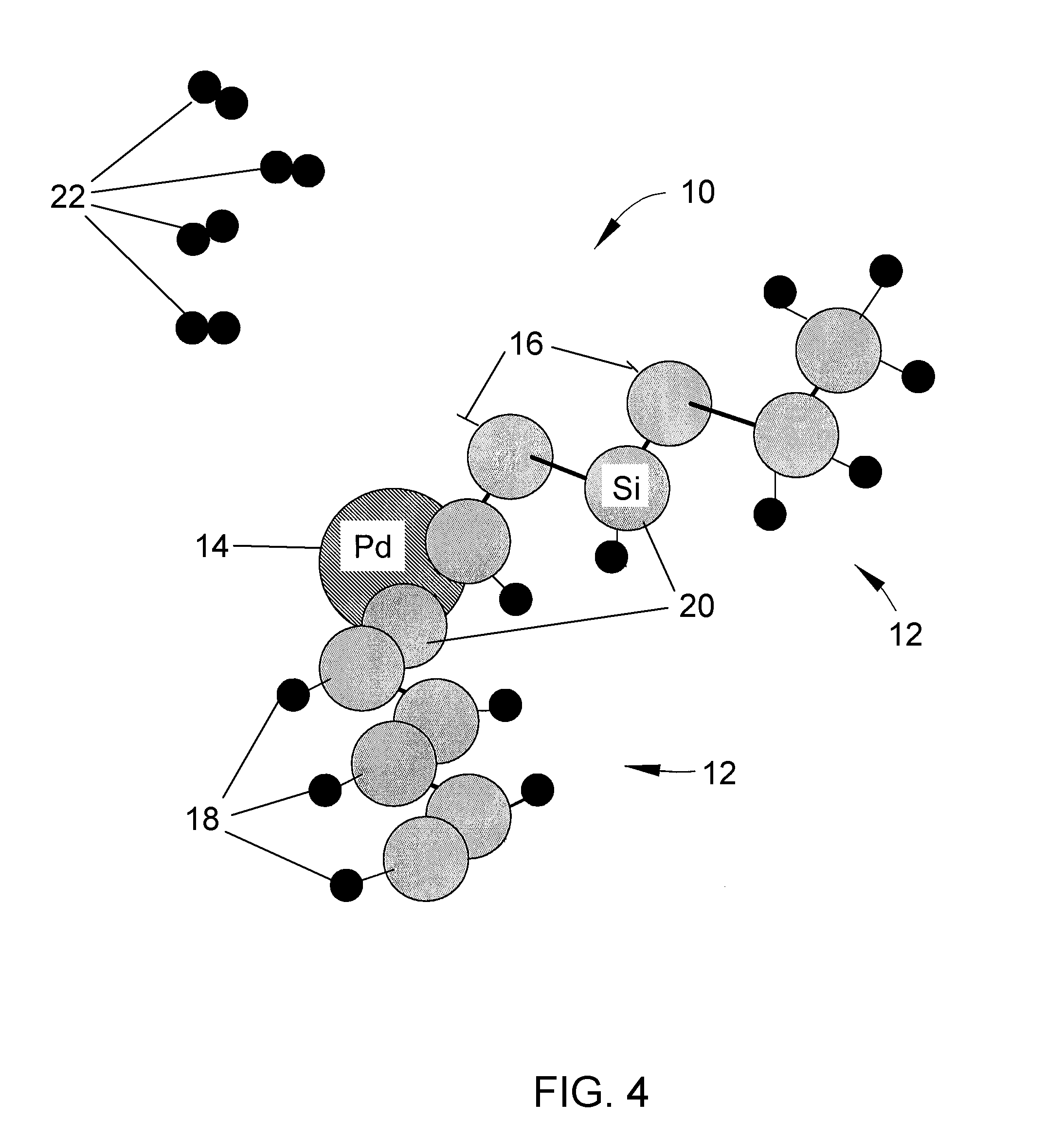

Method and apparatus for forming silicon containing films

InactiveUS20030124818A1Lower activation energyDecomposes faster and more efficientlyFrom solid stateSemiconductor/solid-state device manufacturingElectrical resistance and conductanceActivation energy

The present invention describes a method and apparatus for forming a uniform silicon containing film in a single wafer reactor. According to the present invention, a silicon containing film is deposited in a resistively heated single wafer chamber utilizing a process gas having a silicon source gas and which provides an activation energy less than 0.5 eV at a temperature between 750° C.-550° C.

Owner:APPLIED MATERIALS INC

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

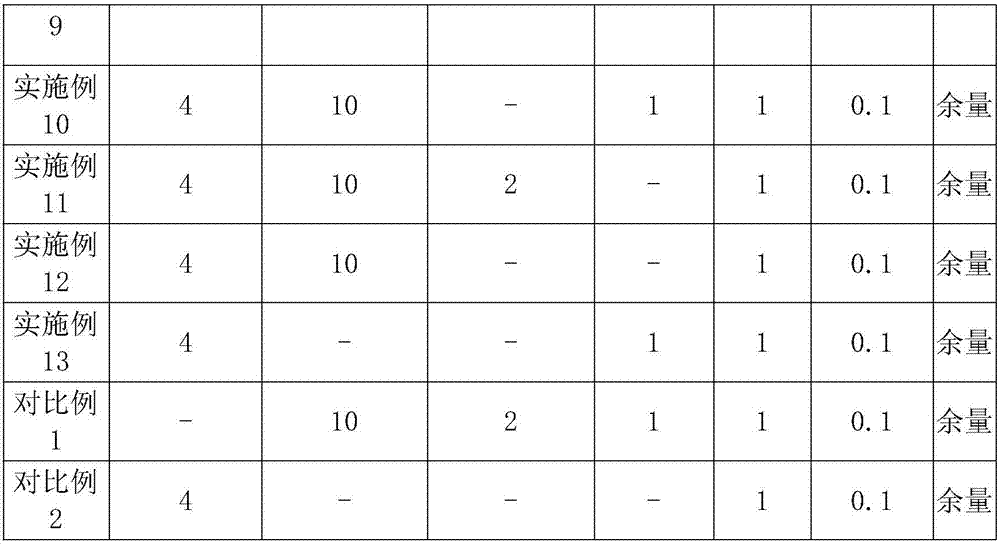

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

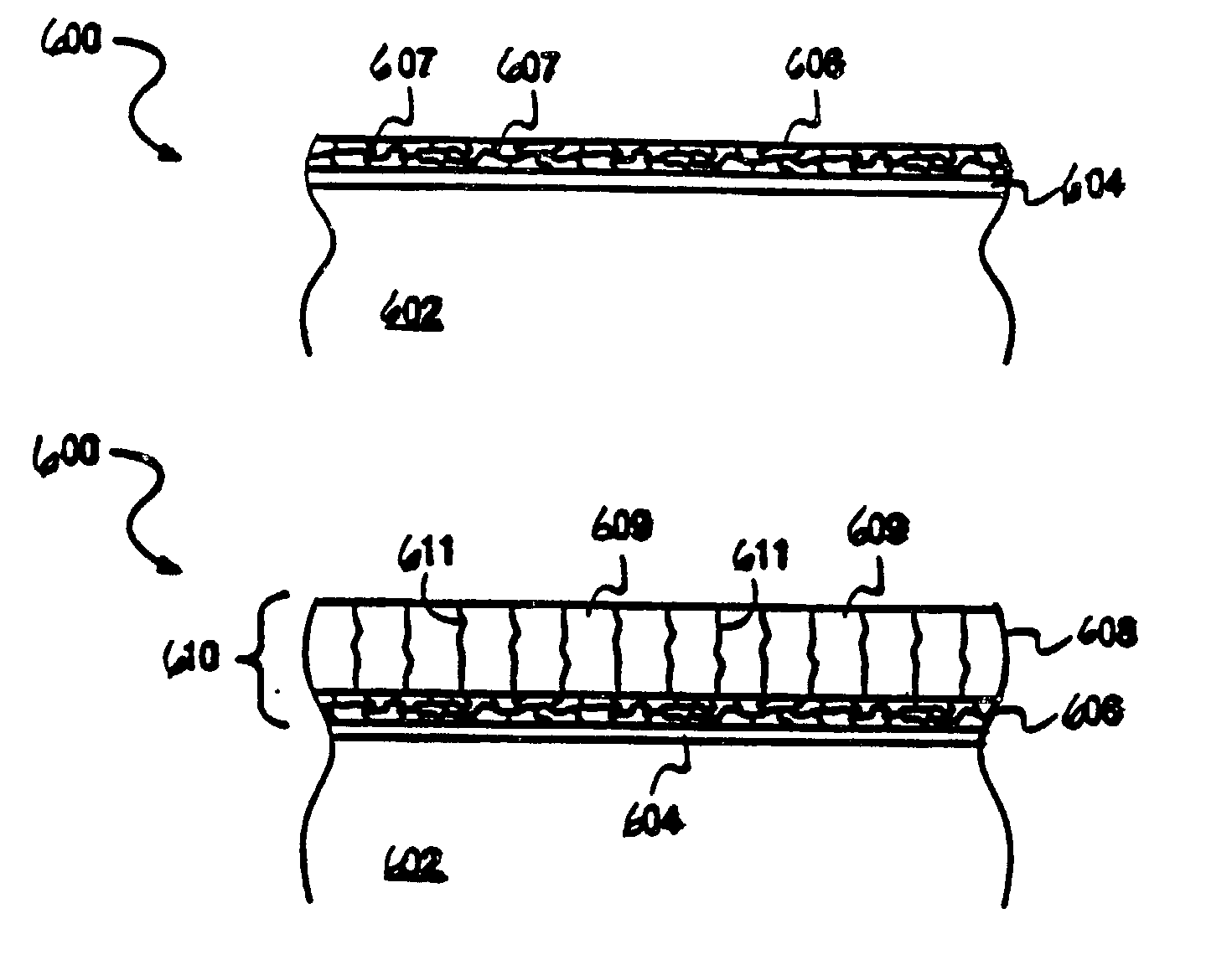

Biostable polyurethane products

InactiveUS20020072550A1Contributes strongly to stabilityEasy to prepareSurgeryCatheterCross-linkPolyol

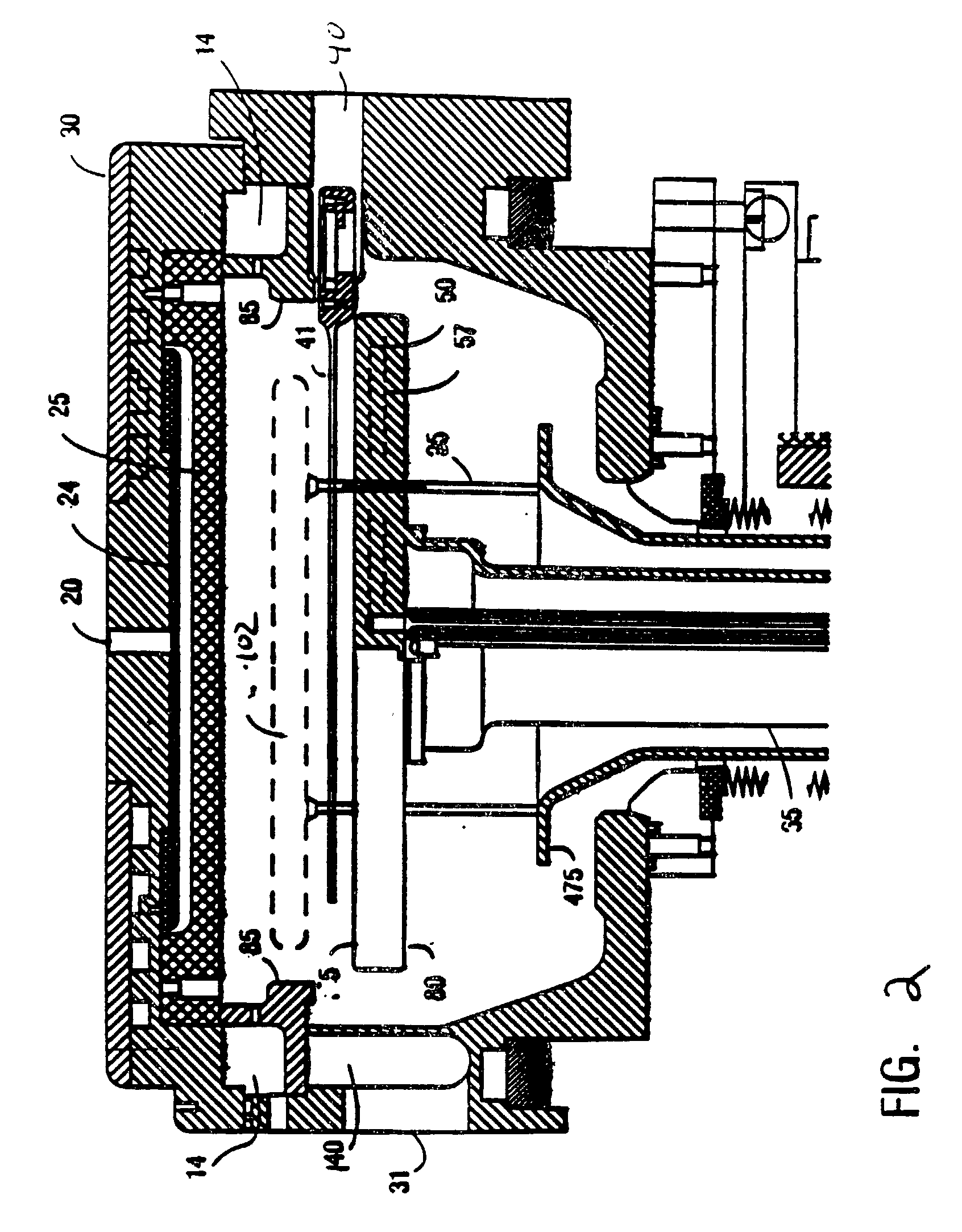

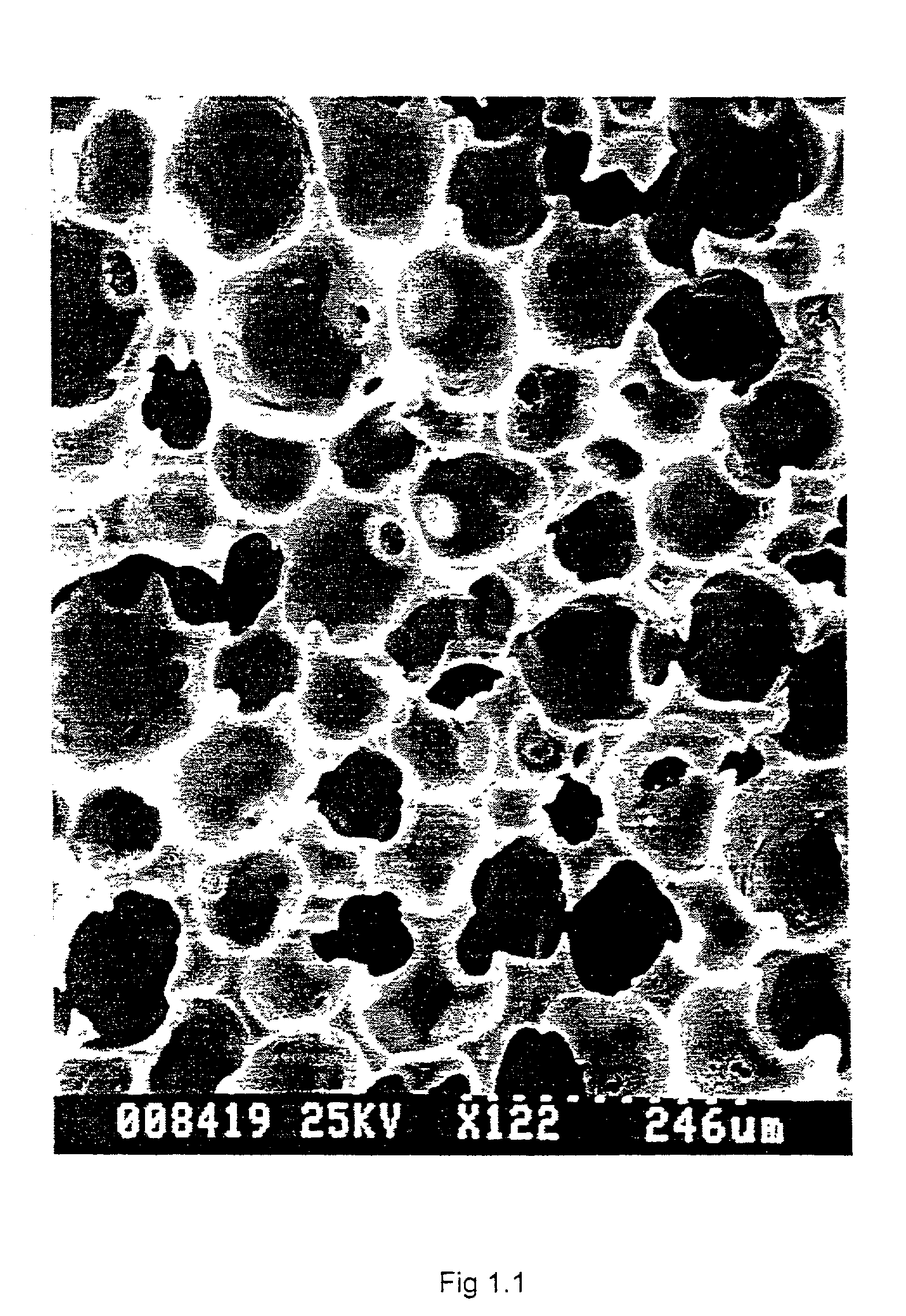

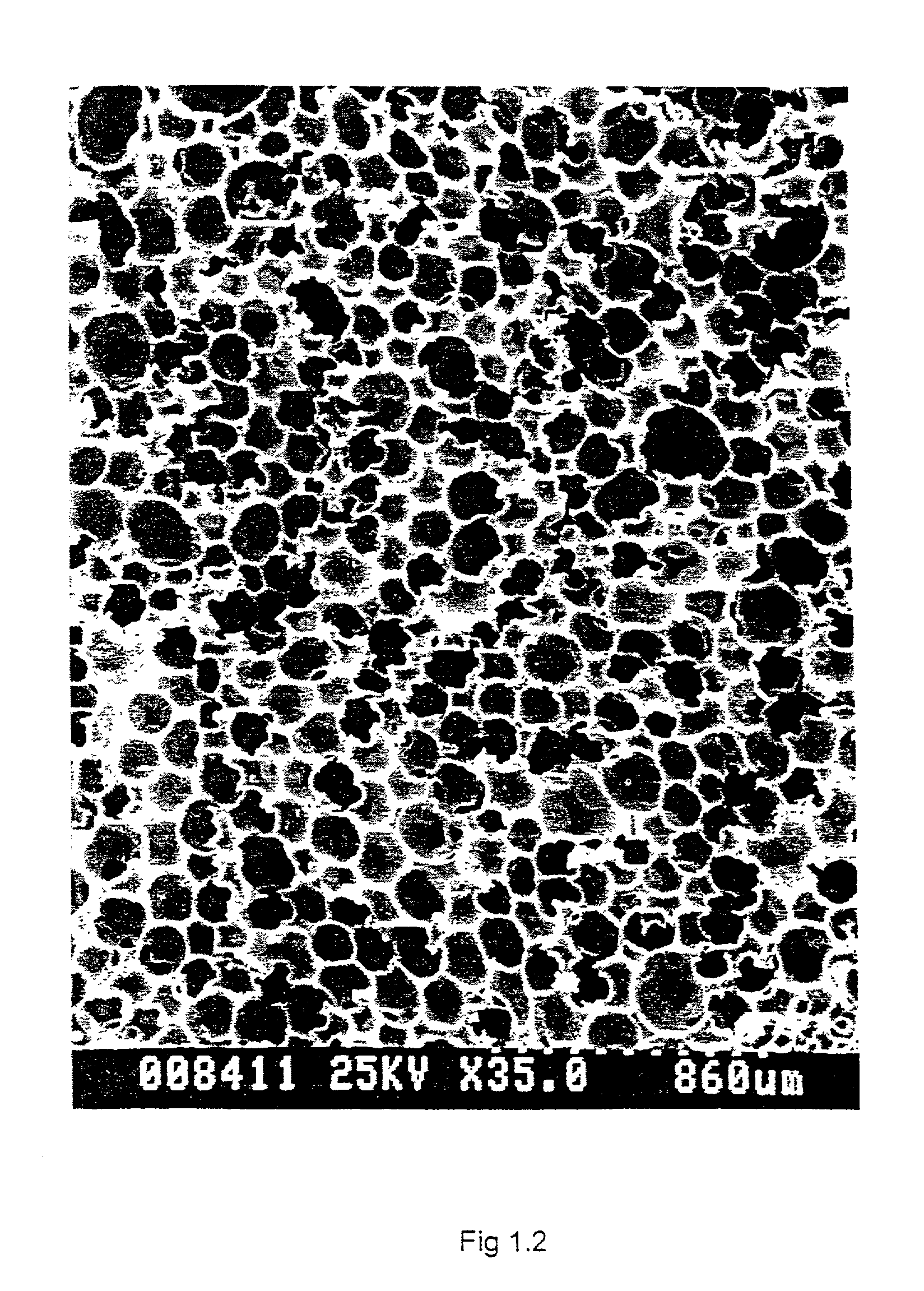

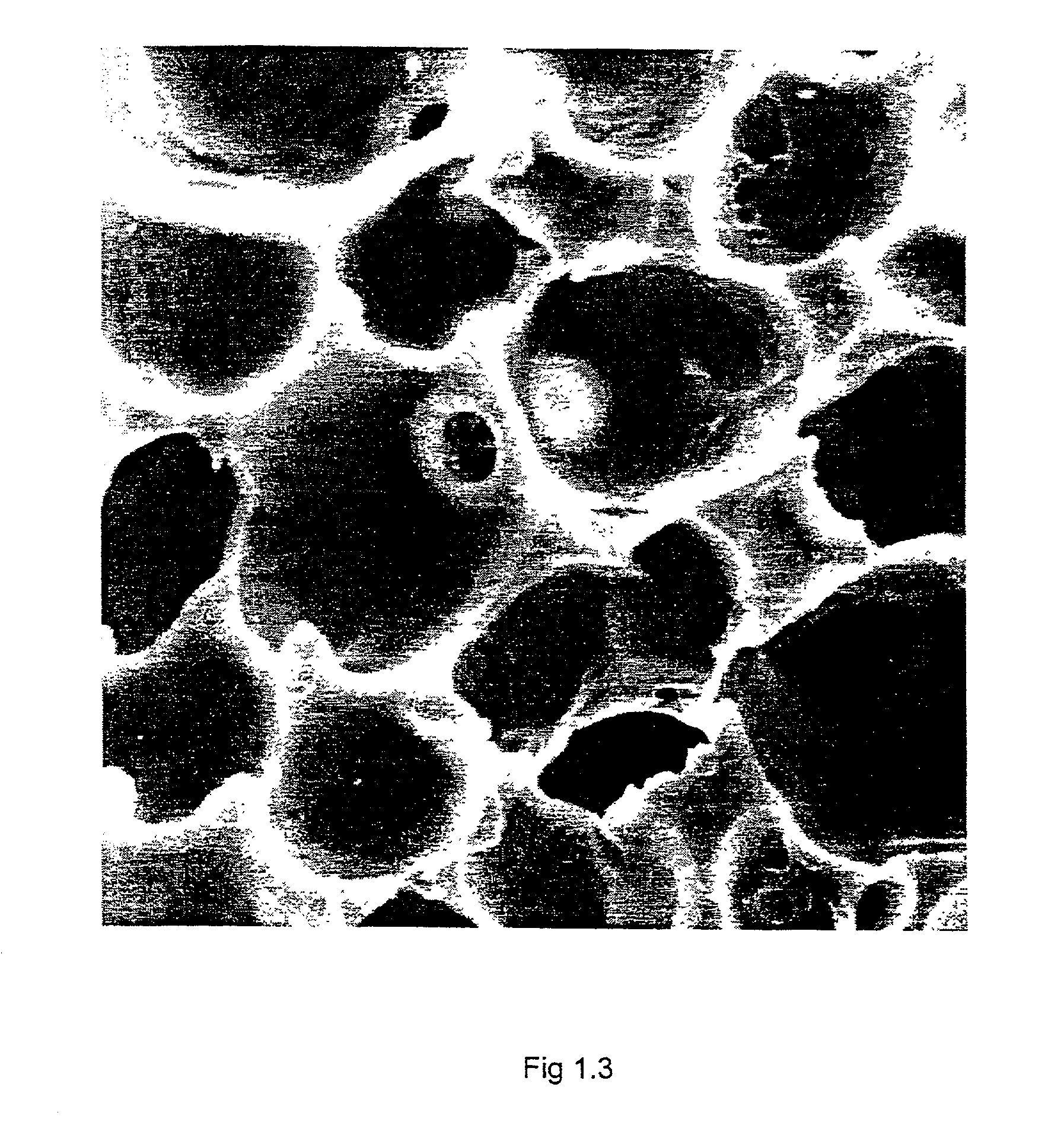

A biostable porous polyether or polycarbonate polyurethane implant is manufactured from diphenyl methane diisocyanate, difunctional polytetramethylene ether glycol or a polycarbonate polyol, a trimerisation catalyst, a chain extender, water, a cross-linking agent, a blowing and / or gelling catalyst and a surfactant. The porous biomaterial has isocyanurate linkages and avoid content in excess of 85%. The implant may be used as an occluder or a tissue bridge.

Owner:SALVIAC

Thermo-curable 3D printing photosensitive resin and preparation method thereof

ActiveCN106947034AIncrease activation energyHigh tensile strengthAdditive manufacturing apparatus3D object support structuresDecompositionHalf-life

The invention discloses a thermo-curable 3D printing photosensitive resin and a preparation method and an application thereof. The photosensitive resin includes, by weight, 50-70 parts of a prepolymer, 30-50 parts of a diluent, 1-5 parts of a photo-initiator and 0.5-5 parts of a thermal-initiator, wherein the decomposition temperature of the thermal-initiator is higher than or equal to 100 DEG C when the half-life period thereof is 1 h. After photo-curing 3D printing shaping, the 3D printing photosensitive resin can be subjected to curing by heating as a post-curing method with a stable constant temperature heating device, such as a drying box and the like, so that the 3D printing photosensitive resin develops application in a non-transparent sample, a sample having complex shape, an ultra-thick sample, a colored sample and the like, and enables the samples to have better mechanical performances.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

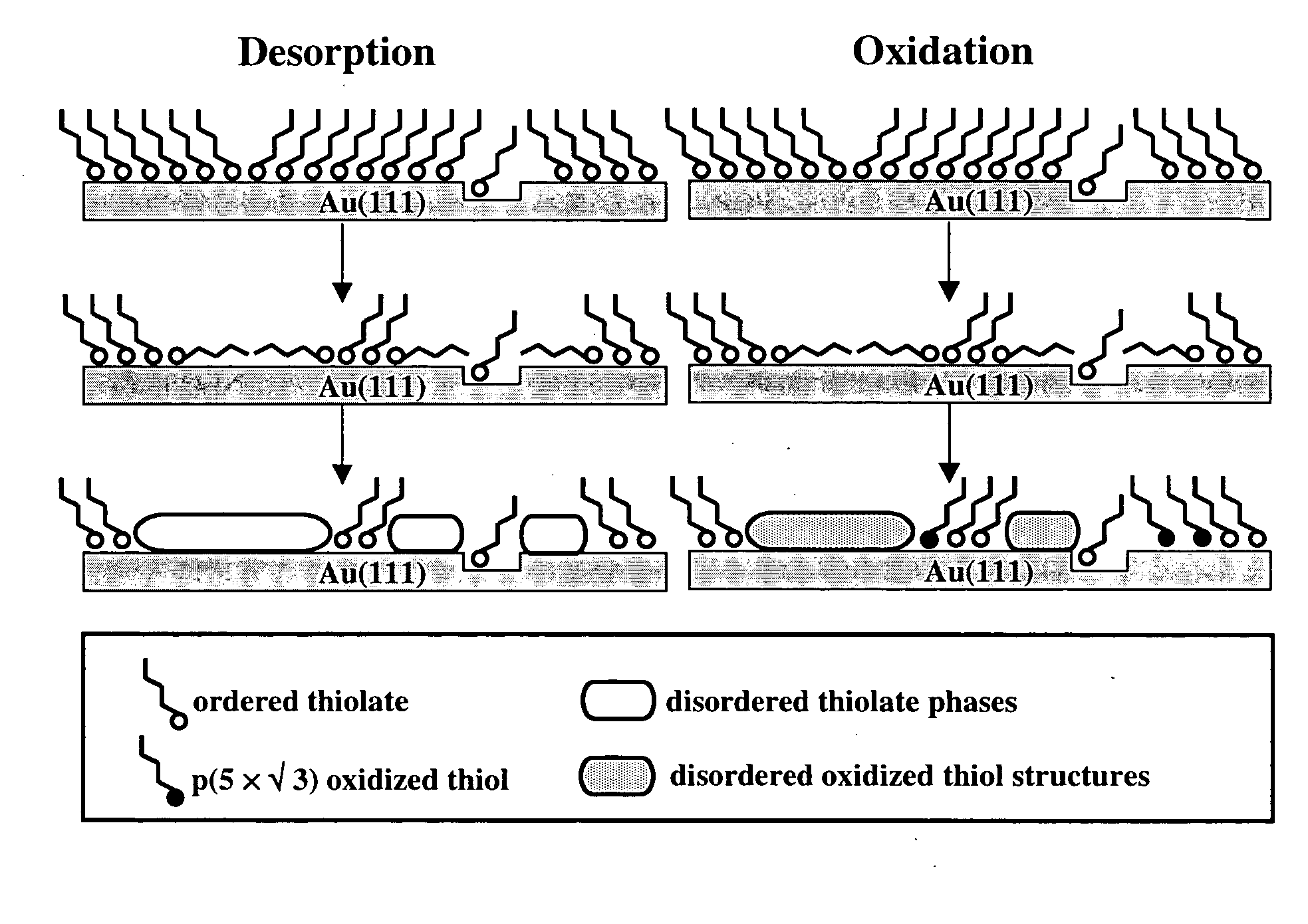

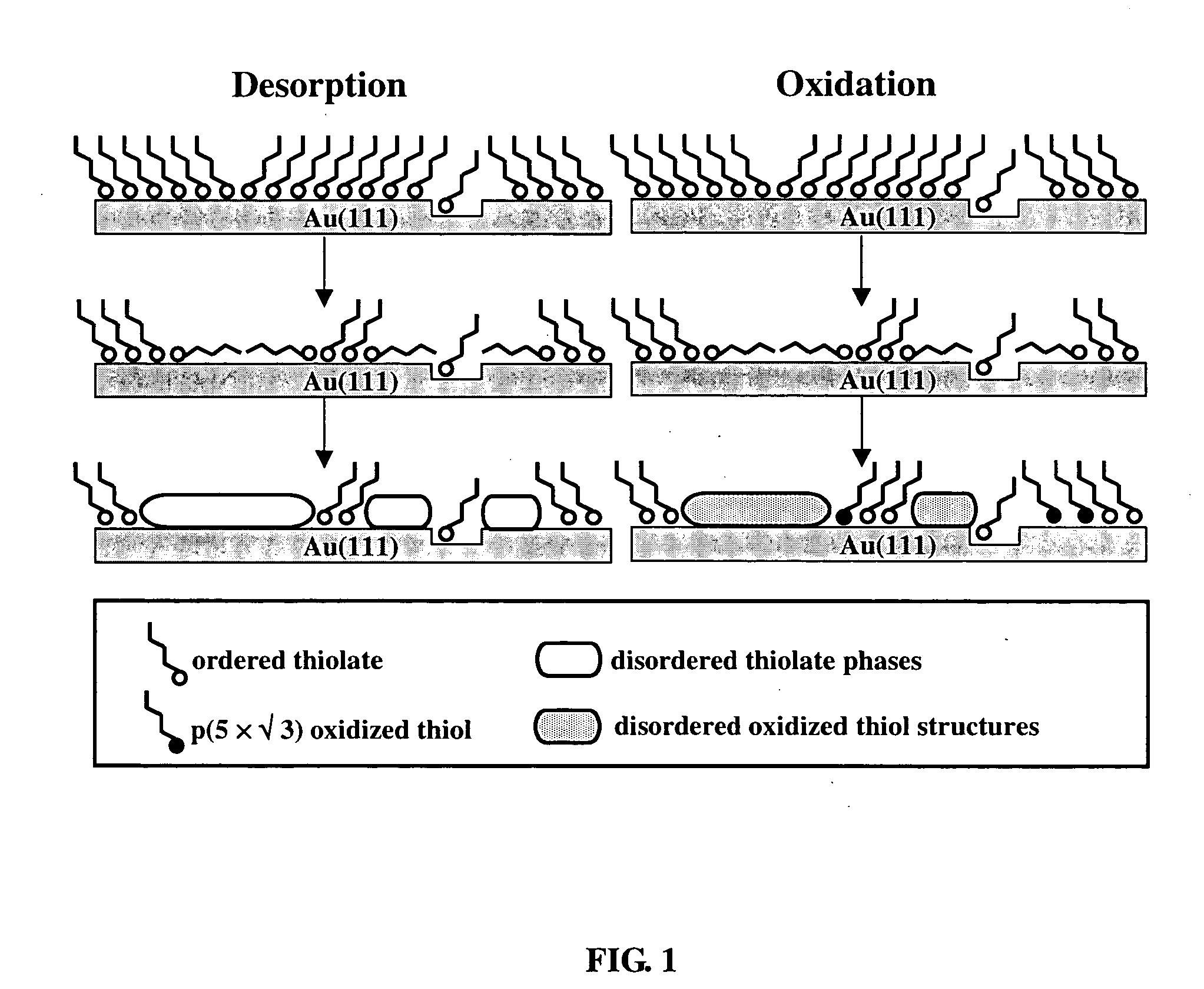

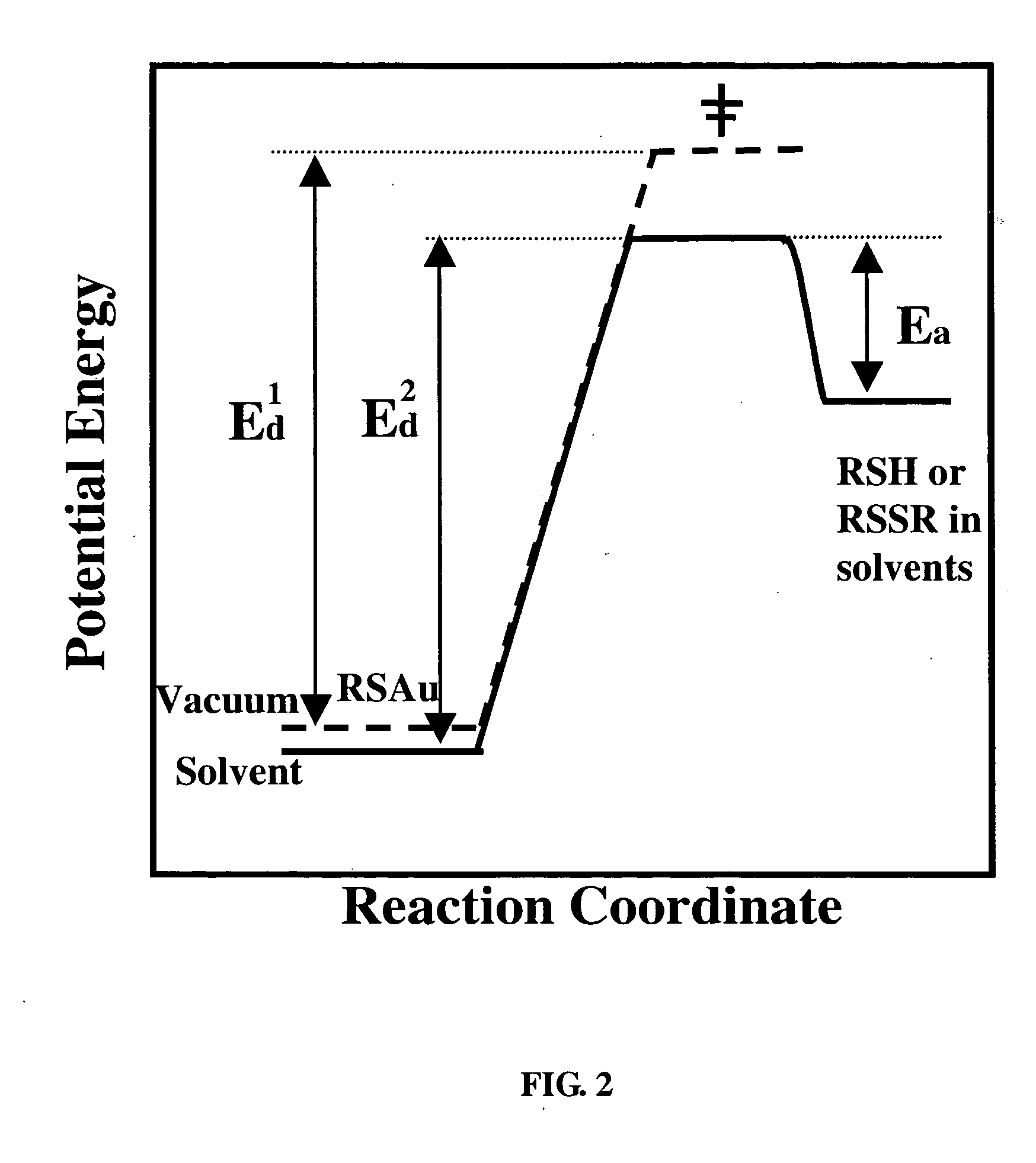

Stabilization of self-assembled monolayers

InactiveUS20050221081A1Ability to retard and preventRetard and prevent degradationMaterial nanotechnologyBiological material analysisResistAmphiphile

Self-assembled monolayers and other solid support / surface-layer systems are widely used as resists for nanofabrication because of its closely packed structure, low defect density, and uniform thickness. However these resists suffer the drawback of low stability in liquid due to desorption and / or oxidation induced desorption. Stabilized solid support / surface-layer systems and methods of preserving the integrity and structure of self-assembled monolayers on solid surfaces are provided. The method involves adding small amount of amphiphilic molecules, such as DMF and DMSO, into aqueous solutions as preserving media. These molecules adhere favorably to defect sites within monolayers and inhibit the initiation of both known degradation pathways: oxidation and desorption. Also provided are stabilized systems including the solid support / surface-layer system and stabilizing solution, as well as kits of stabilizing solutions for use with various systems.

Owner:RGT UNIV OF CALIFORNIA +1

Thermosensitive microencapsulation retarder for preventing and controlling spontaneous combustion of coal and preparing method of retarder

ActiveCN108729943AInhibition of spontaneous combustion reactionInhibition of oxidative cleavageDust removalFire preventionMolten stateSpontaneous combustion

The invention discloses a thermosensitive microencapsulation retarder for preventing and controlling spontaneous combustion of coal and a preparing method of the retarder. The retarder comprises corematerials and a wall material coating the core materials; the core materials are prepared from, by weight, 85-90% of catechin, 5-8% of ascorbic acid and 2-10% of anthocyanin, and the wall material ispolyethylene glycol. The preparing method comprises the steps of firstly, heating the wall material to be molten, grinding the core materials into fine powder, then adding the core materials into thewall material in the molten state in batch until the mass ratio of the wall material to the core materials reaches the standard, then adding a thickener and a cross-linking agent, after the materialsare fully mixed, slowly cooling a mixed system until a solid product is obtained, and finally, crushing and sieving the solid product to obtain the thermosensitive microencapsulation retarder. The retarder is rich in source of preparation raw materials, environmentally friendly, simple in preparing technology, low in cost, good in thermal stability, low in water-absorbing property and convenient to store, the retarding efficiency is improved, the retarding time is shortened, and the retarder helps to achieve efficient prevention and control of the spontaneous combustion of the coal.

Owner:CHINA UNIV OF MINING & TECH

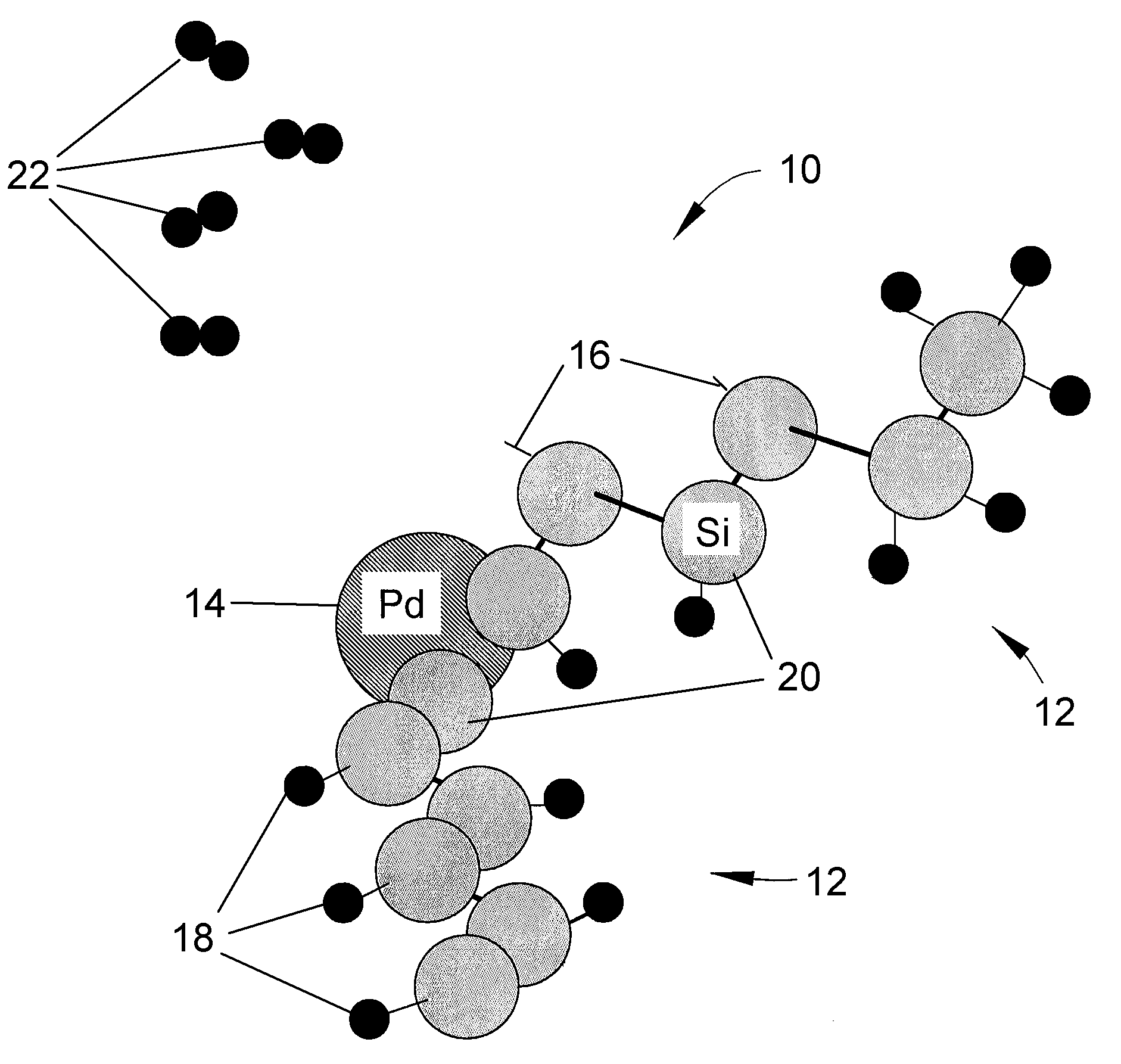

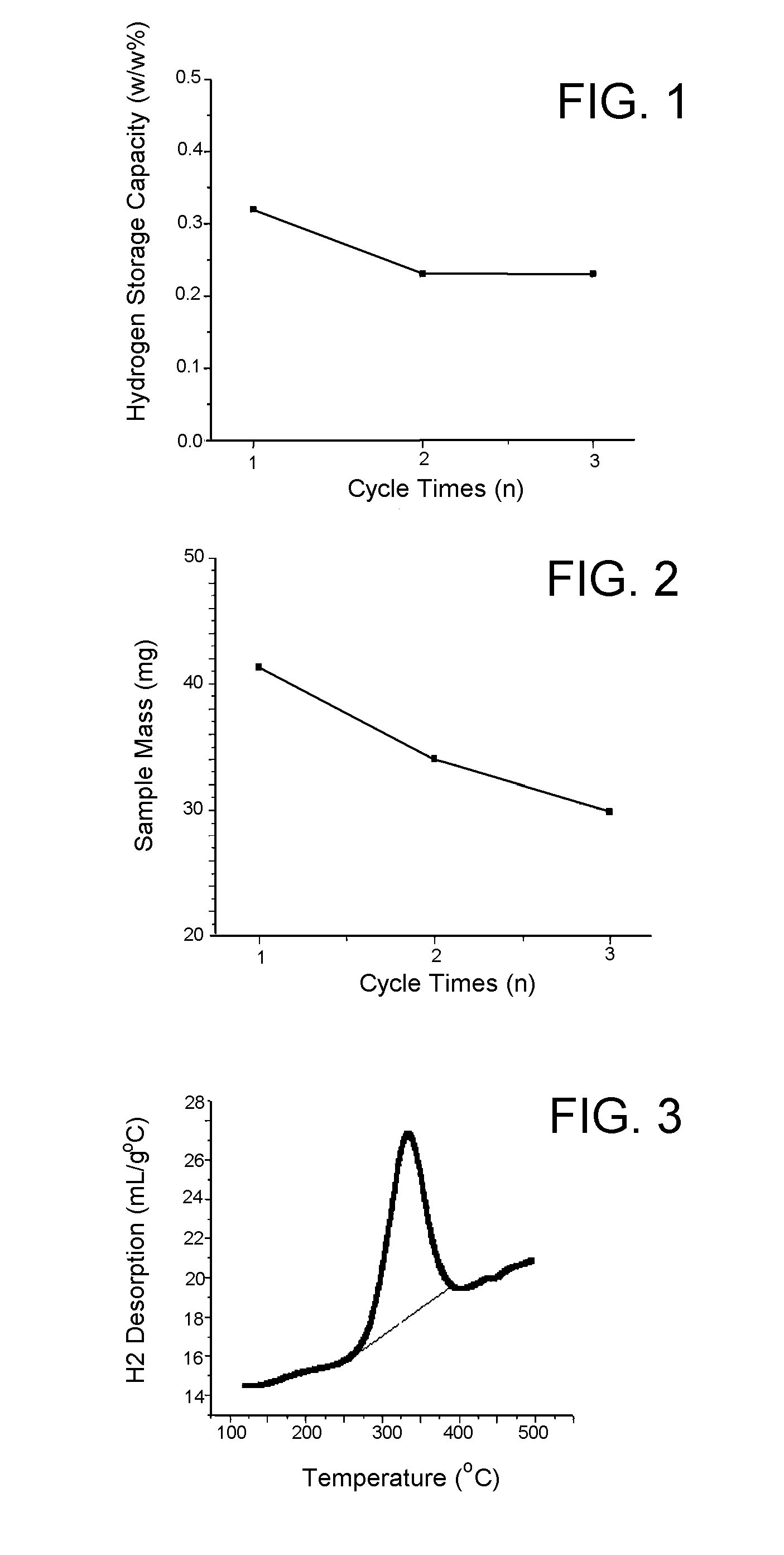

Solid-state hydrogen storage media and catalytic hydrogen recharging thereof

ActiveUS20080274873A1Low costIncrease activation energyMolecular sieve catalystsReversible hydrogen uptakeBond energyHydrogen atom

A solid-state hydrogen storage material and process for making the material more thoroughly rechargeable. The process entails forming a porous matrix material to contain atoms of a first element and hydrogen atoms, in which the atoms of the first element are capable of bonding with more than one hydrogen atom per atom of the first element, and the atoms of the first element are molecularly arranged within the porous matrix material so that different atoms of the first element are bonded to different numbers of hydrogen atoms at correspondingly different levels of bonding energy. At least some of the hydrogen atoms bonded to the atoms of the first element at the lowest bond energies are then removed without removing hydrogen atoms bonded at higher bond energies, after which atoms of a second element are bonded to those atoms of the first element from which hydrogen atoms were removed.

Owner:INDIANA UNIV RES & TECH CORP

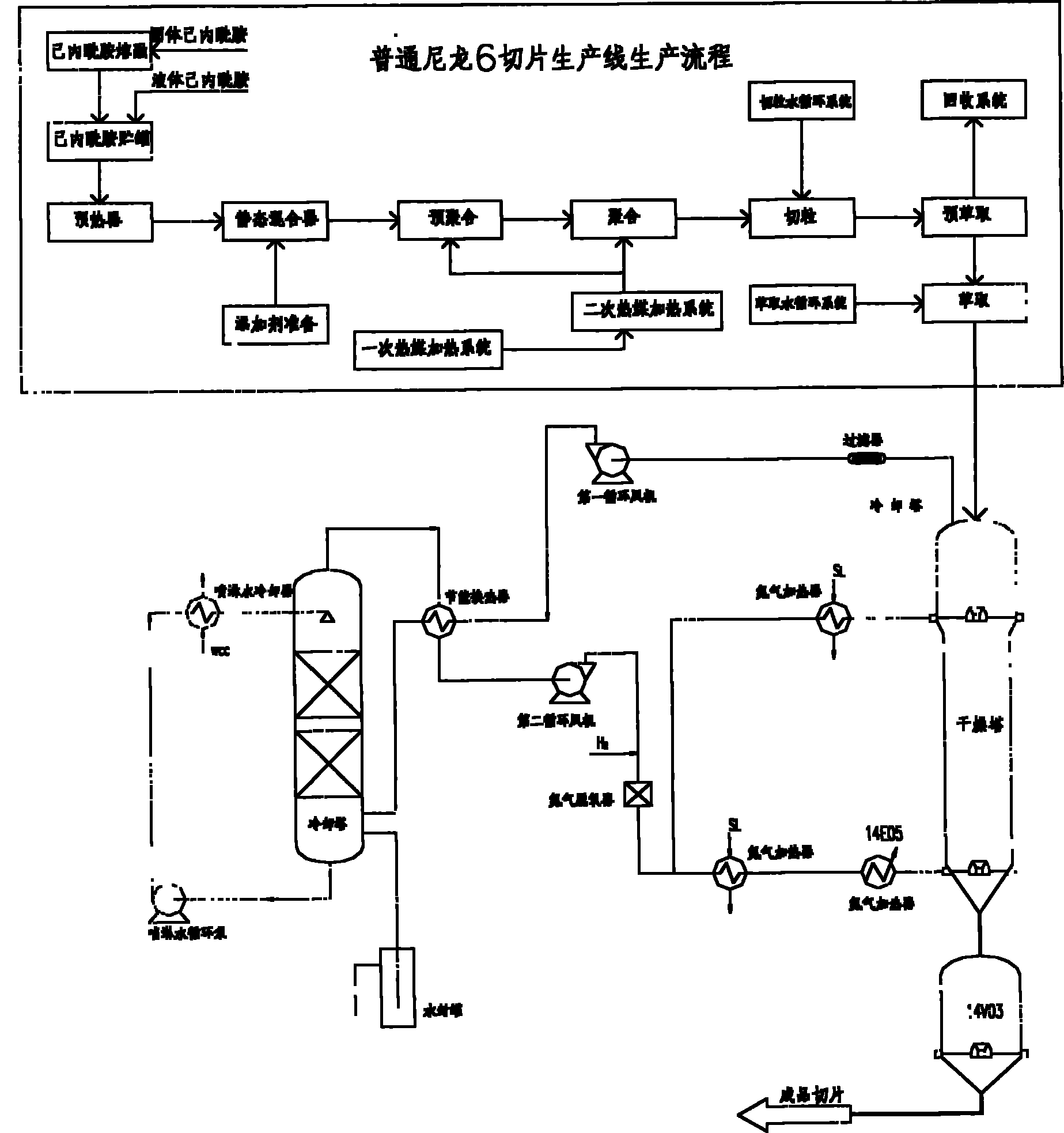

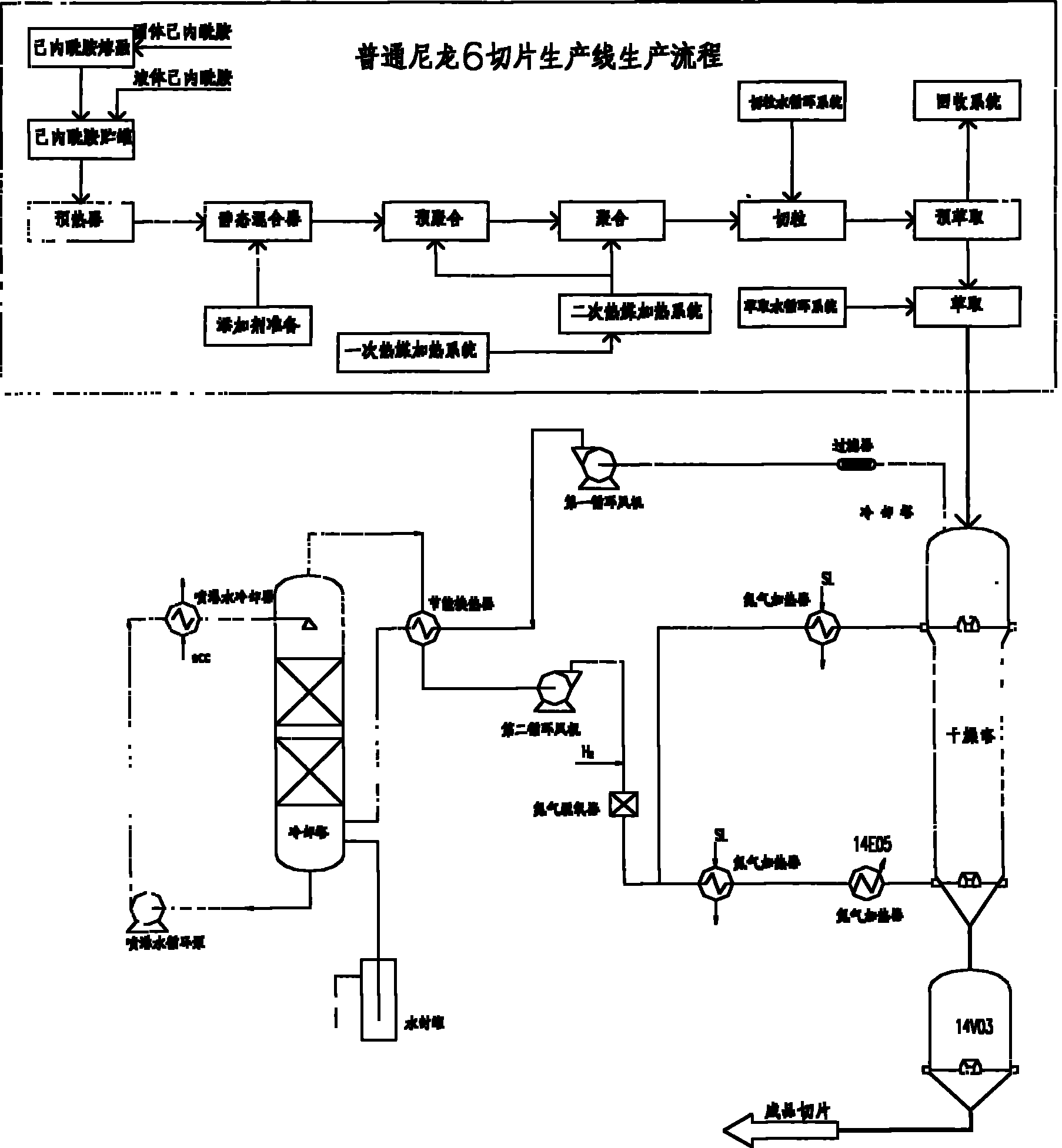

Process for producing high-viscosity chips by applying solid-phase viscosifying technology

ActiveCN102060992AIncrease risk resistanceMature production processChemical industryNylon 6Process engineering

The invention relates to a process for producing high-viscosity chips by applying a solid-phase viscosifying technology, comprising the following steps of: obtaining extracted nylon 6 chips according to a conventional production process of spinning nylon 6 chips, and introducing into a drying tower; leading the chips to flow in the drying tower from top to bottom in a plunger-type mode and fully contact with nitrogen gas, wherein the hot nitrogen gas for drying is introduced into the drying tower from the bottom and the middle of the tower in a two-current mode; keeping the chips stay in the drying tower for about 24 hours; and delivering the dried chips to a chip cooling bin after the flow is controlled by a metering delivering valve, and delivering the chips to a finished product bin through a gas-flow conveying device after the chips are cooled to reach a qualified temperature under the circulation cooling of cold nitrogen gas flow.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

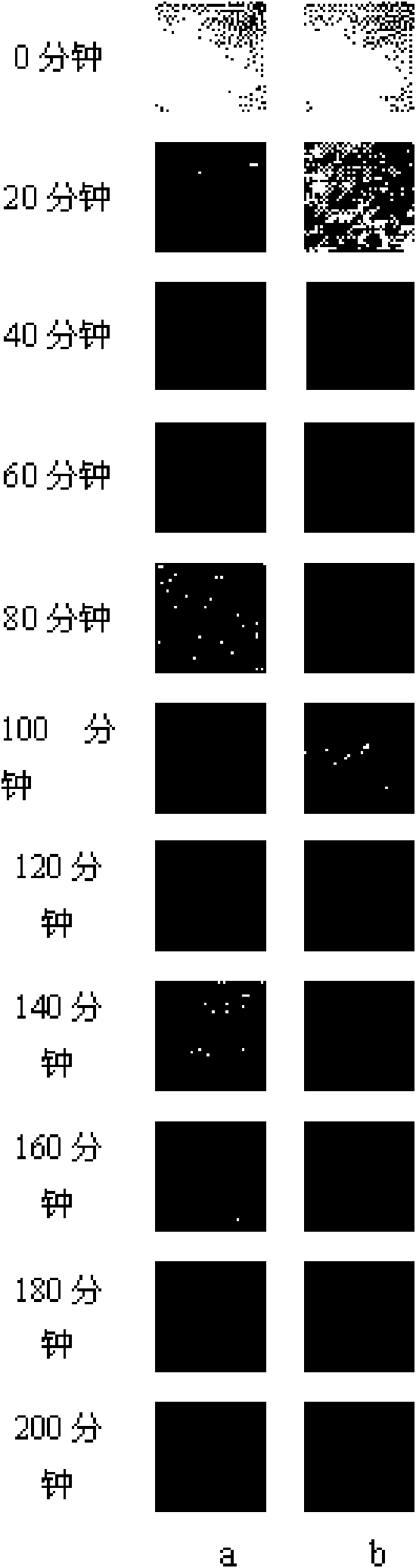

PVC compound heat stabilizer prepared from magnesium/aluminum rare-earth hydrotalcite and application thereof

The invention relates to a PVC compound heat stabilizer prepared from magnesium / aluminum rare-earth hydrotalcite and application thereof. The compound heat stabilizer is obtained through the optimal combination between the magnesium / aluminum rare-earth hydrotalcite and calcium soap and zinc soap in a certain amount in a certain ratio, wherein, the compatibility between the magnesium / aluminum rare-earth hydrotalcite and the PVC is improved by the titanate wet modification on the magnesium / aluminum rare-earth hydrotalcite; since the rare-earth elements in the magnesium / aluminum rare-earth hydrotalcite have various track structures, the magnesium / aluminum rare-earth hydrotalcite can be coordinated with the active chlorine on the PVC, and the dehydrochlorination reaction is effectively prevented; in addition, the magnesium / aluminum rare-earth hydrotalcite can absorb and neutralize hydrochloric acid (HCl), thereby eliminating the catalytic reaction against the degradation. The invention overcomes the disadvantages of toxicity, high cost, poor pigmentation, shorter heat stabilizing time, complicated preparation process and the like in the conventional heat stabilizer and adds the heat stabilizer prepared through the combination between the modified magnesium / aluminum rare-earth hydrotalcite and the calcium / zinc heat stabilizer to PVC for the first time; and according to the results of static heat-ageing tests, the heat stabilizing time of the compound heat stabilizer obtained through the optimal combination is over 200min.

Owner:CENT SOUTH UNIV

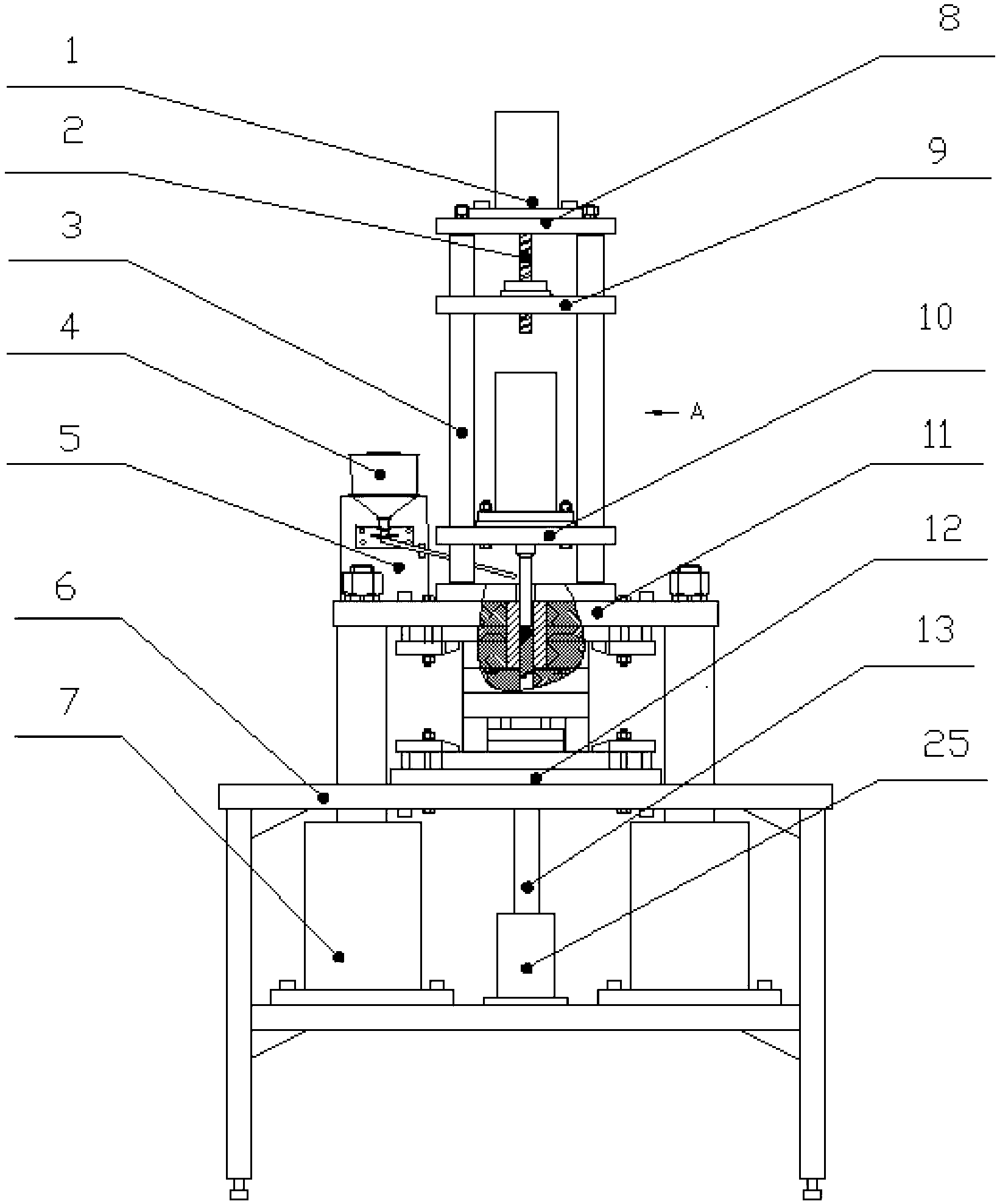

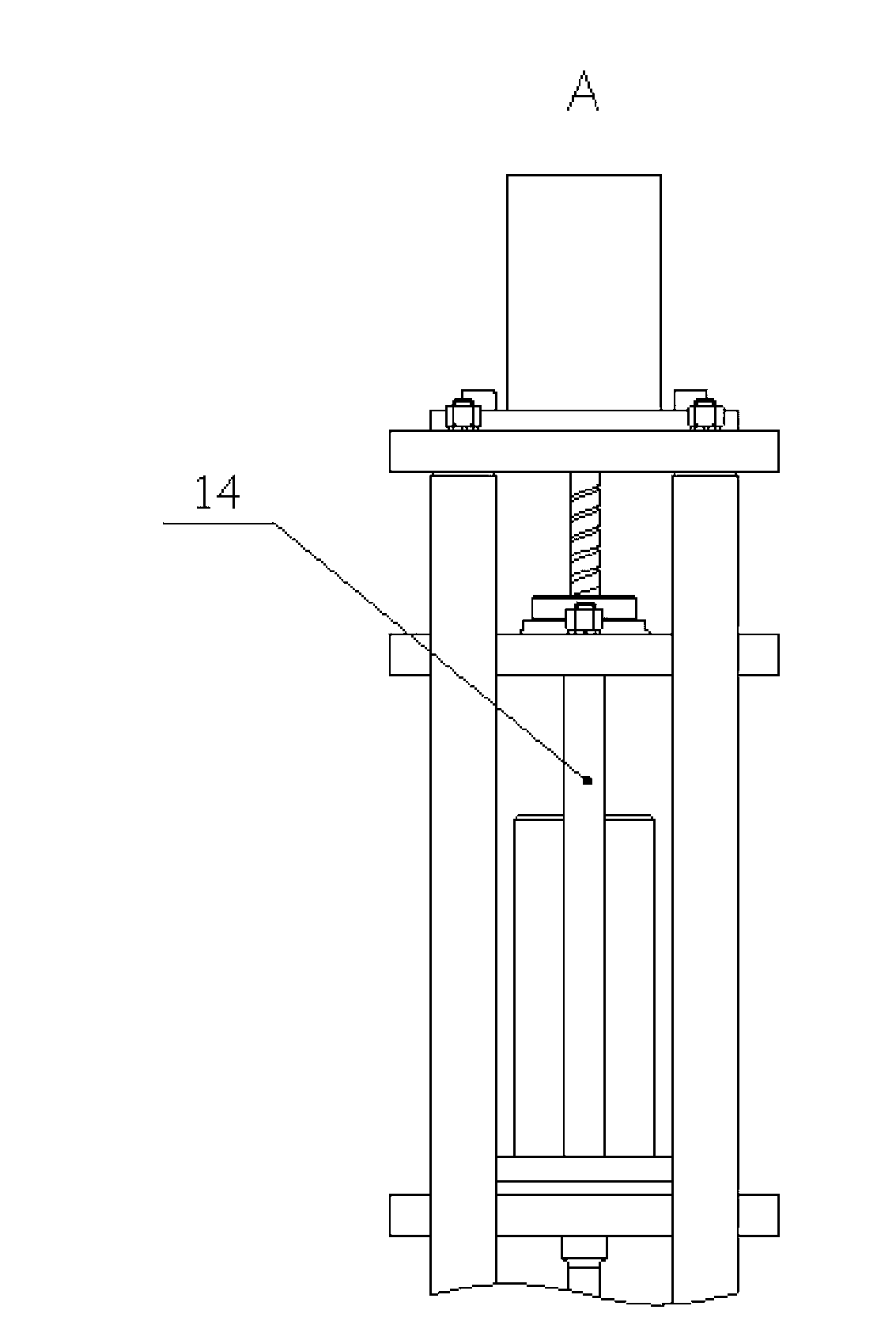

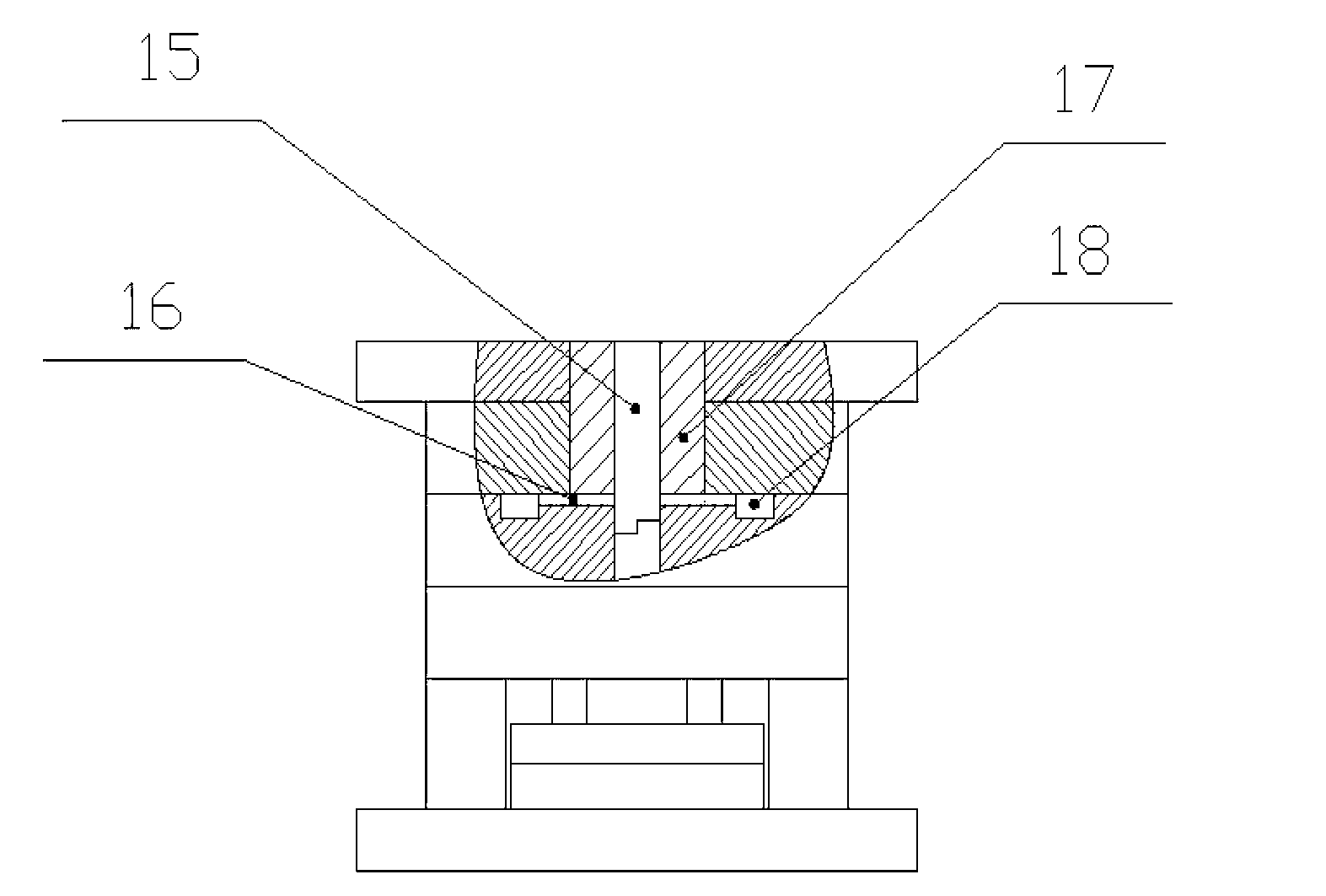

Screw-free ultrasonic microinjection molding device for molten and plasticized polymer and molding method

The invention discloses a screw-free ultrasonic microinjection molding device for a molten and plasticized polymer and a molding method. An injection part comprises an injection motor, a lead screw, an injection push plate and a connecting rod; an ultrasonic vibration system comprises an ultrasonic generator, an energy converter, an amplitude-change pole and a tool head; an injection module is provided with a plasticizing hole, a sub-runner and a mould cavity; a feeding system comprises a hopper and a support; and a mould closing and ejecting system comprises a mould closing hydraulic cylinder, an ejecting hydraulic cylinder, an upper mould fixing plate, a lower mould fixing plate and an ejector rod. A solid polymer is molten into a liquid under the action of frication thermogenesis and viscoelasticity thermogenesis applied into the polymer particle process through ultrasonic vibration, and meanwhile, ultrasonic waves play a cavitation role in the polymer liquid, so that the apparent viscosity is reduced, the phenomenon of short shot or insufficient filling in the machining process is overcome, the injection molding of a small plastic device can be well realized, the energy consumption is reduced, the difficulty in controlling the process is lowered, the economic efficiency of the device is increased, and the production cost is reduced.

Owner:CENT SOUTH UNIV

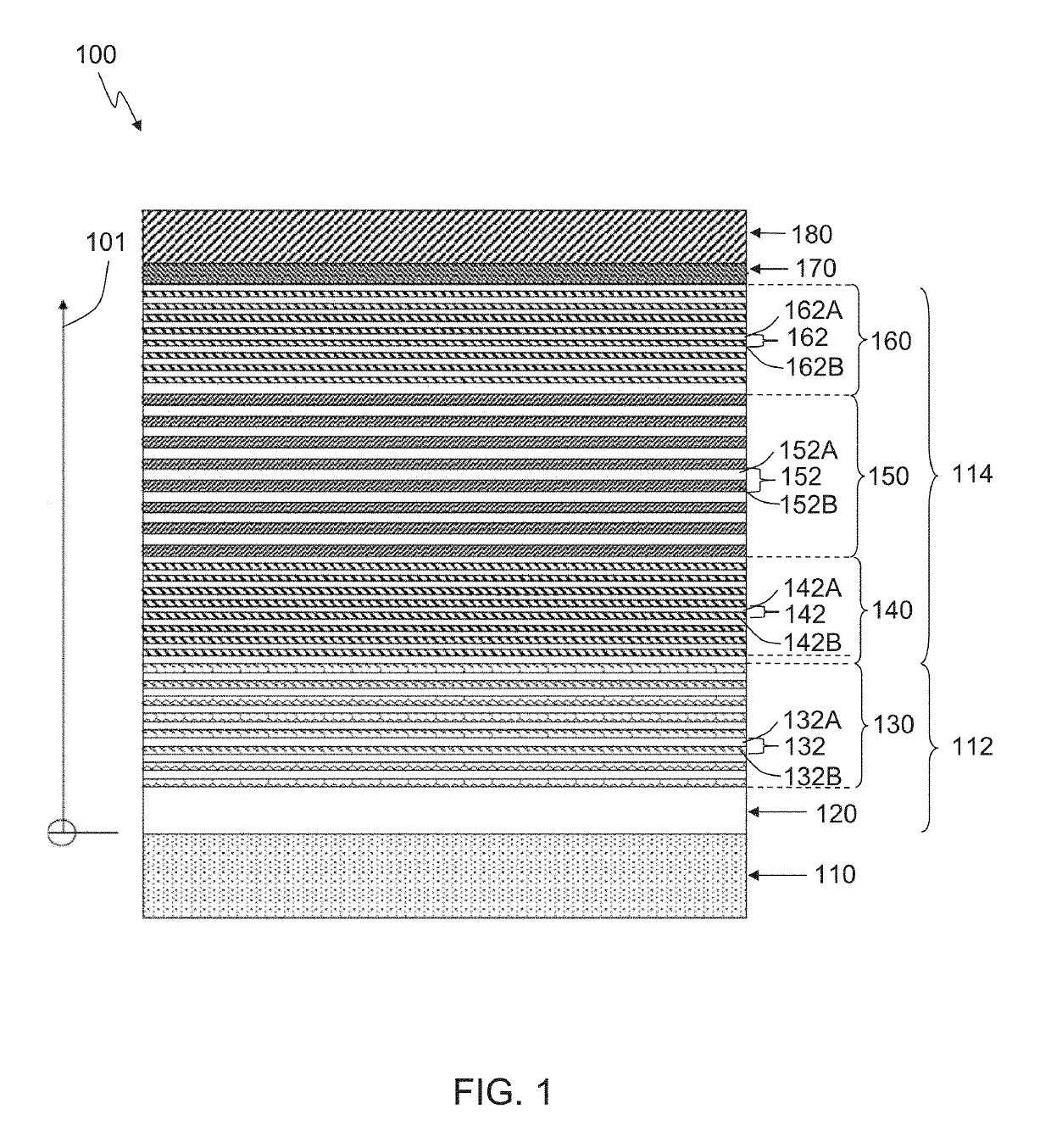

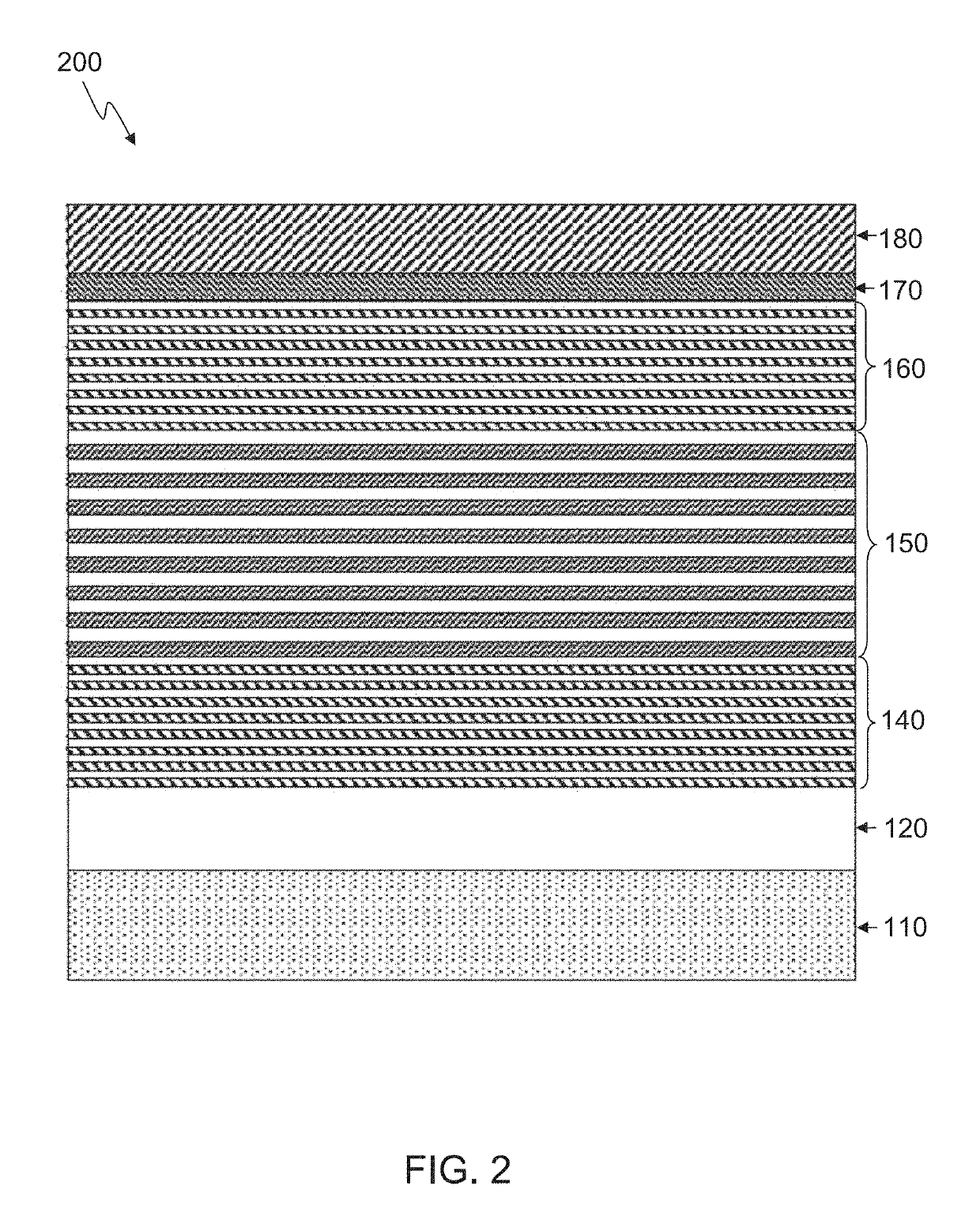

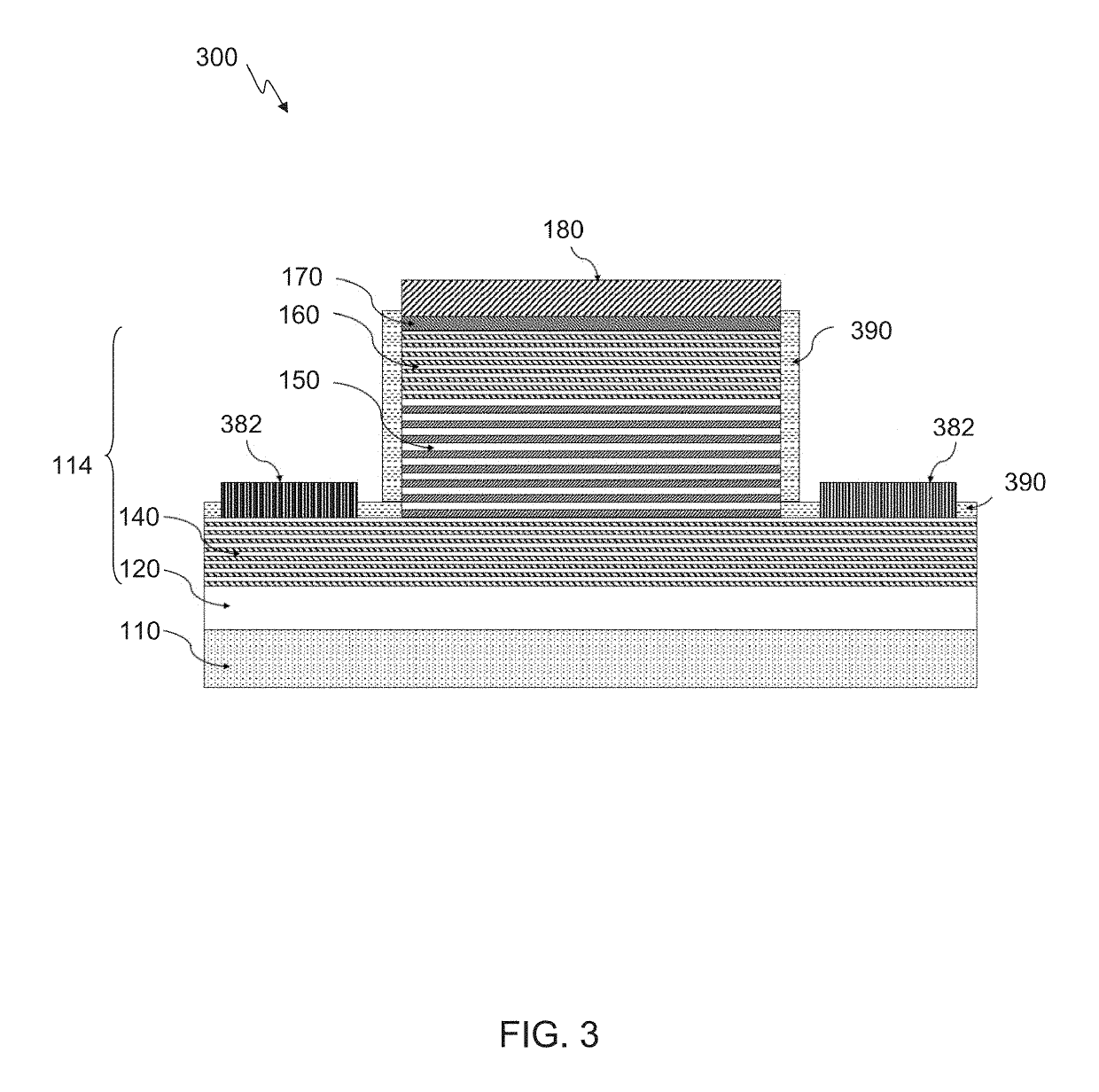

Optoelectronic device

ActiveUS10475956B2Improve the out coupling of the optical energy generatedIncrease activation energySolid-state devicesDiodeSemiconductor structureSingle crystal

An optoelectronic device comprising a semiconductor structure includes a p-type active region and an n-type active region. The semiconductor structure is comprised solely of one or more superlattices, where each superlattice is comprised of a plurality of unit cells. Each unit cell comprises at least two distinct substantially single crystal layers.

Owner:SILANNA UV TECH PTE LTD

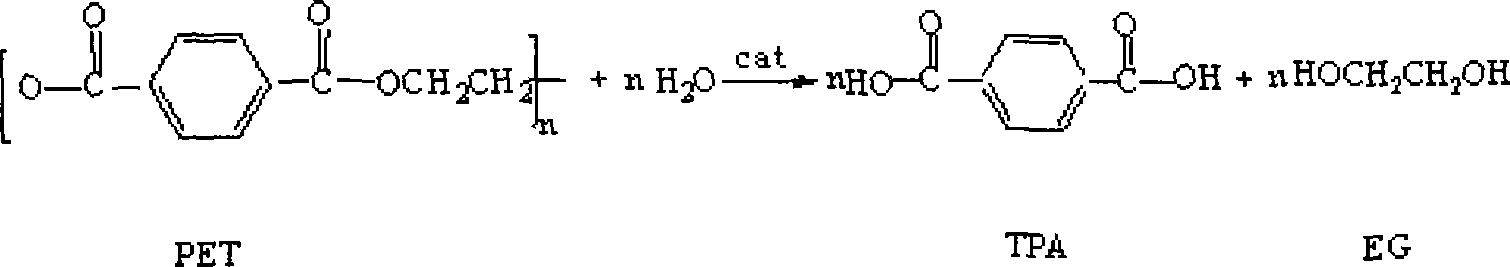

Catalytic depolymerization process of poly-glycol telephthalate unde microwave irradiation

InactiveCN101066904AHeating up fastIncrease activation energyOxygen-containing compound preparationOrganic compound preparationDepolymerizationIron oxide

The present invention is one kind of environment friendly catalytic depolymerization process of polyglycol telephthalate under microwave irradiation with mild reaction condition. The present invention features that in the presence of metal oxide as catalyst, polyglycol telephthalate and water as reaction medium in certain weight ratio are reacted at 100-200 deg.c temperature and 0-1.3 MPa pressure under microwave irradiation, so that polyglycol telephthalate is depolymerized into telephthalic acid and glycol. The metal oxide catalyst may be zinc oxide, magnesium oxide, manganese dioxide, ferric oxide or their mixture.

Owner:WENZHOU UNIVERSITY

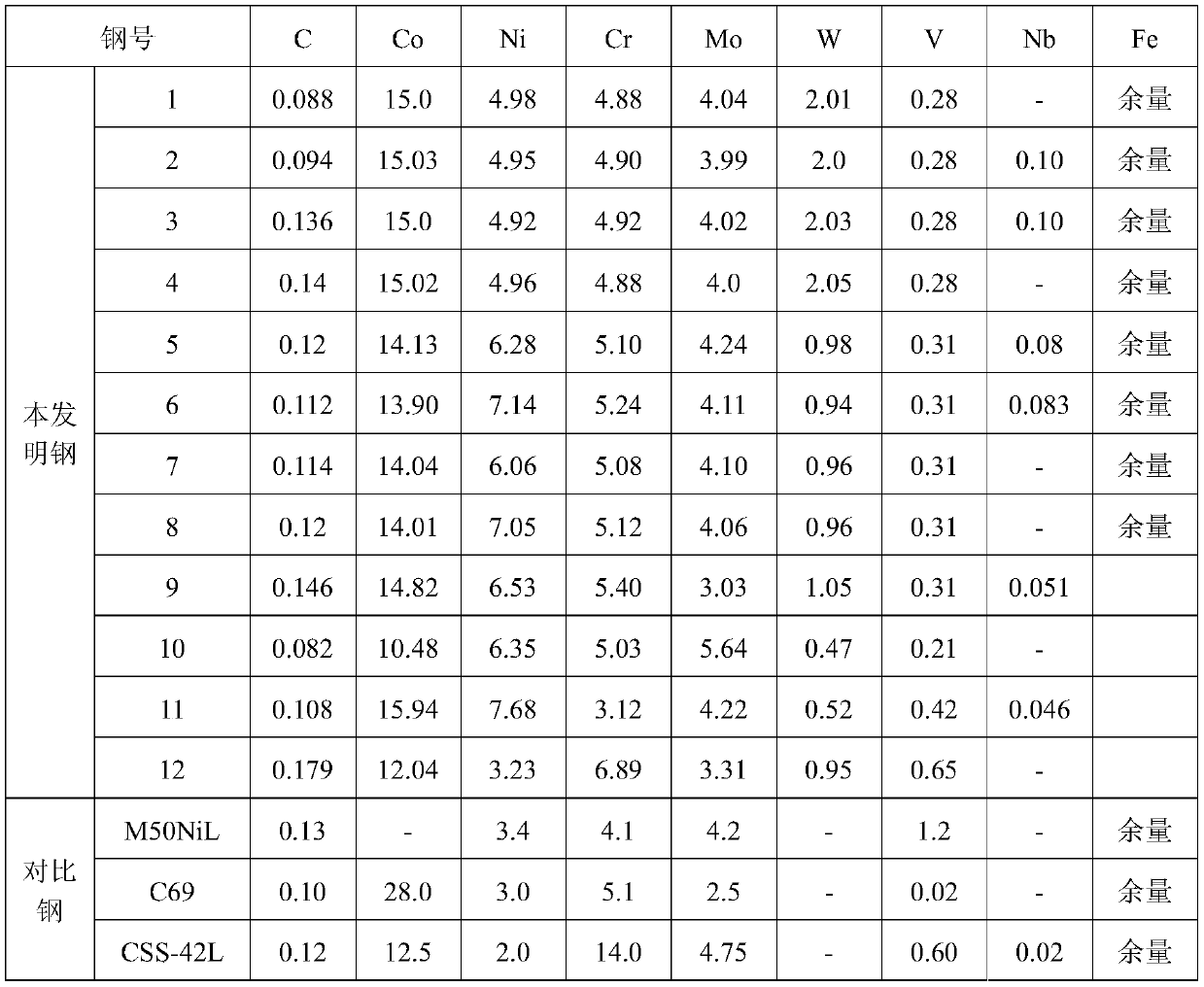

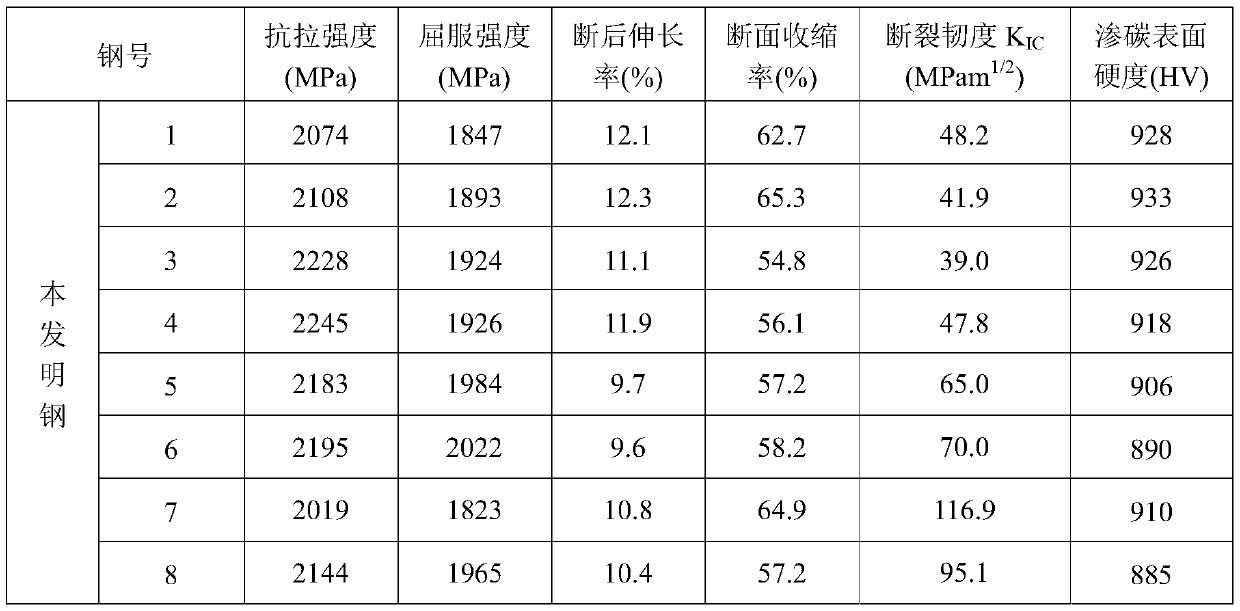

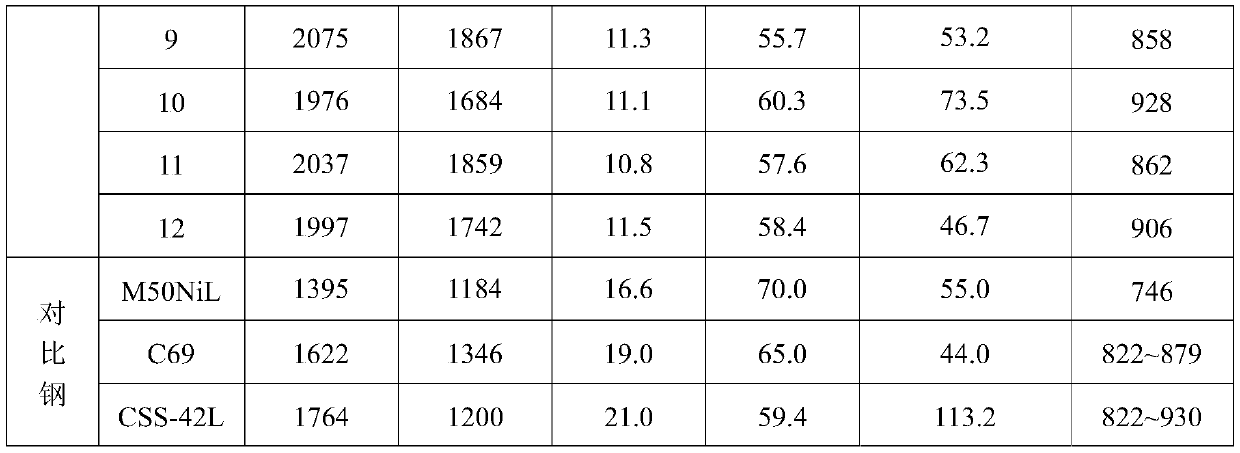

Ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and preparation method thereof

ActiveCN110423955AHigh tensile strengthImprove plasticitySolid state diffusion coatingCarburizingVacuum arc remelting

The invention belongs to the technical field of materials, and relates to an ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and a preparation method thereof. The chemical composition of the steel comprises the following chemical components of, in percentage by mass, 0.08-0.18% of C, 10.0-16.0% of Co, 3.0-8.0% of Ni, 3.0-7.0% of Cr, 3.0-6.0% of Mo, 0.5-2.0%of W, 0.2-1.0% of V, 0-0.1% of Nb, and the balance Fe and impurity elements. According to the method, vacuum induction melting, vacuum induction melting and vacuum arc remelting or vacuum induction melting and electroslag remelting are adopted for smelting. Steel ingots are diffusion annealed and forged into steel products. Steel samples are subjected to preliminary heat treatment, carburization and final heat treatment, the tensile strength of the steel is not less than 1900 MP a, the yield strength is not less than 1600 MP a, and the carburized surface hardness is not less than 850 HV (equivalent to 66 HRC). The method has the advantages that compared with the prior art, the method has higher tensile strength, yield strength and relatively good plasticity, toughness and heat resistance,has excellent surface carburization super-hardening performance and fatigue performance, and achieves good matching of the core super-toughening and surface super-hardening.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High creep resistance rareearth contained tin base leadless soldering-flux and preparation method thereof

InactiveCN1385280AReduced creep resistanceRestricted movementWelding/cutting media/materialsSoldering mediaLithium chlorideSoldering

The present invention relates to a high creep resistance rare earth containing tin base leadless brazing filler metal and its preparation method. Said material contains (wt%) 2-5% of Ag, 0.2-1% of Cu, 0.025-1.0% of commercially-available Ce base mixed rare earth and the rest is Sn. Its preparation method includes the following steps: melting mixed salt of potassium chloride and lithium chloride with weight ratio of 1-1.6:0.8-1.2, pouring it on the Sn, after the Sn is melted, adding the weighed Ag and Cu into Sn solution to melt Ag and Cu, then using bell jar whose wall has hole to press the Ce base rare earth into the above-mentioned mixed salt and Sn-Ag-Cu alloy, turning bell jar, heat-insulating for 1-2 hr., stirring, standing still, setting and removing mixed salt from surface so as toobtain the invented brazing fill metal.

Owner:YIYUAN ELECTRONICS TECH

System, methods and materials for storing and retrieving hydrogen

ActiveUS20110236790A1Cost reductionLow costReversible hydrogen uptakeFuel cell auxillariesChemistryBond energy

A system for storing and retrieving elemental hydrogen. The system includes a housing, a hydrogen storage element enclosed within the housing and having a solid-state hydrogen storage material, and a control system for regulating storage of hydrogen into and retrieval of hydrogen from the storage material. At least a portion of the storage material is a porous matrix material having atoms of a first element capable of bonding with more than one hydrogen atom per atom of the first element, and atoms of a second element capable of molecularly bonding to atoms of the first element and hydrogen. Different atoms of the first element have bond sites available for different numbers of hydrogen atoms at different levels of bonding energy. The atoms of the second element are bonded to those atoms of the first element having bond sites for more than one hydrogen atom.

Owner:GREEN FORTRESS ENG INC

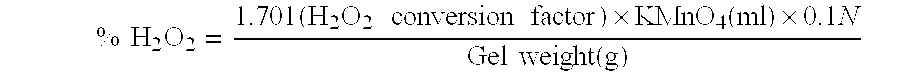

Dental Bleaching Gel Composition Containing Vegetative Enzymes

InactiveUS20090220919A1Improve defectsImprove energy absorptionCosmetic preparationsGum massageDecompositionNuclear chemistry

This invention is related to a kind of teeth bleaching formulation containing the vegetative enzymes extracted from plant tubers with extensively applications in cosmetic dentistry. The enzymes are susceptible to promote the decomposition (dissociation) of peroxide compounds, thus the intermediate hydroxyl free radicals are generated to turn the unpleasant stained tooth into light or colorless appearance effectively. The composition of a whitening gel may comprising 2˜50 wt % of hydrogen peroxide, 0.003˜3 wt % vegetative enzyme extract, and transferring to alkalinity approximately pH 8˜13 to achieve the high efficiency dental bleaching usage.

Owner:YANG JEN CHANG +4

Metal surface passivating treatment fluid

InactiveCN104087924AReduced responseChange interface structureMetallic material coating processesEnvironmental resistancePhosphoric acid

The invention discloses a metal surface passivating treatment fluid which is characterized by comprising the following components in percentage by mass: 80-120g / l of magnesium fluoride, 5-7g / l of sodium tripolyphosphate, 20-30g / l of sodium fluosilicate, 40-50g / l of hydrochloric acid, 30-40g / l of nitric acid, 80-120g / l of phosphoric acid, 3-4g / l of sulfuric acid, 16-22g / l of calcium nitrate and the balance of water. The metal surface passivating treatment fluid disclosed by the invention is simple and practical in formula and safe, environment-friendly and pollution-free by containing no chromate, forms an oxygen or oxygen-containing particle absorption layer when reacted with a metal surface and achieves the passivation by enhancing the activation energy of electrode reaction and reducing the reaction capacity of the metal surface by changing the interface structure of metal and a solution due to the absorption of oxygen on the metal surface.

Owner:ANHUI TONGRUN AUTO ACCESSORY

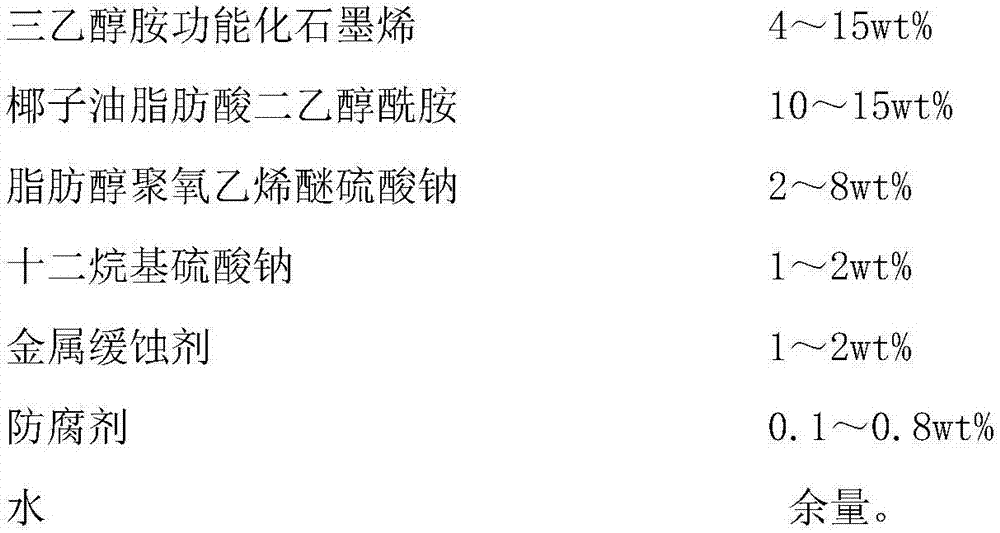

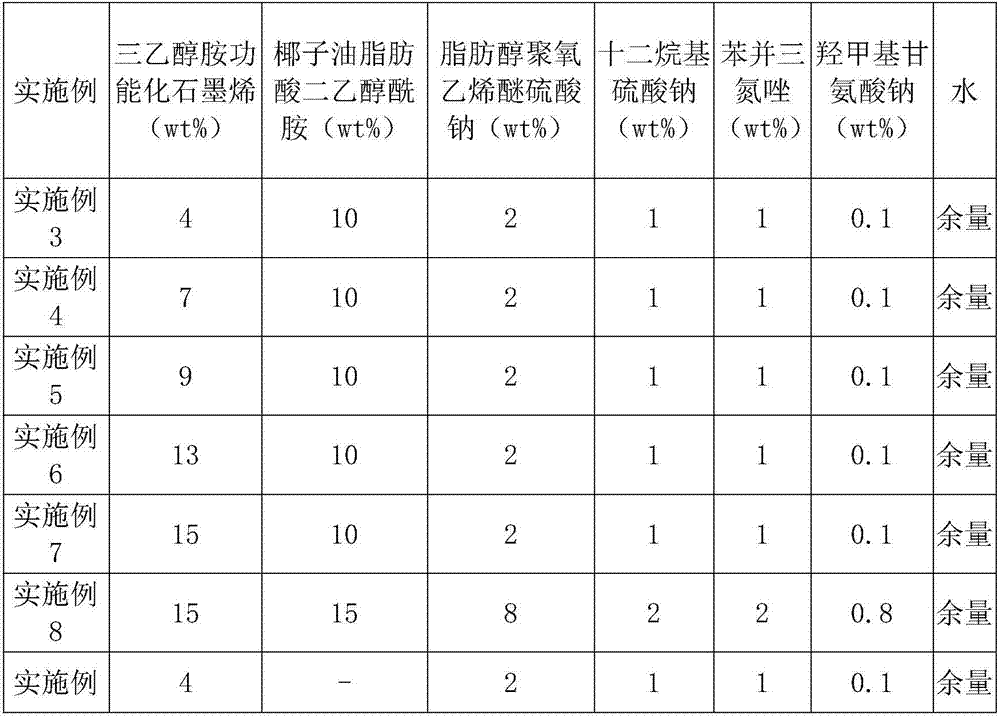

Metal cleaning agent added with functional modified graphene and preparing method of metal cleaning agent

The invention relates to a metal cleaning agent, and discloses a metal cleaning agent added with functional modified graphene and a preparing method of the metal cleaning agent. The metal cleaning agent is composed of 4-15wt% of triethanolamine functional graphene, 13-25wt% of surfactant, 1-2wt% of metal corrosion inhibitor, 0.1-0.8wt% preservative and the balance water. According to the metal cleaning agent, the triethanolamine functional graphene is creatively used to be added into the metal cleaning agent, triethanolamine of the triethanolamine functional graphene and the graphene are bonded as covalent bond, and the surface of the metal cleaning agent contains a large amount of tertiary amine nitrogen and hydroxyl active functional groups; and amino ionic liquid functional graphene achieves graphene modification through the non-covalent interaction between imidazole rings and graphite rings, the graphene has the super large specific surface area, the strong complexing effect is achieved after the grapheme and the triethanolamine are functionalized, so that the strong adsorption capacity is achieved, the hydrophilic and lipophilicity of the triethanolamine are retained, the strong adsorption capacity also can be achieved, and the metal cleaning agent is used without matching of an additional complexing agent.

Owner:郴州国盛新材科技有限公司

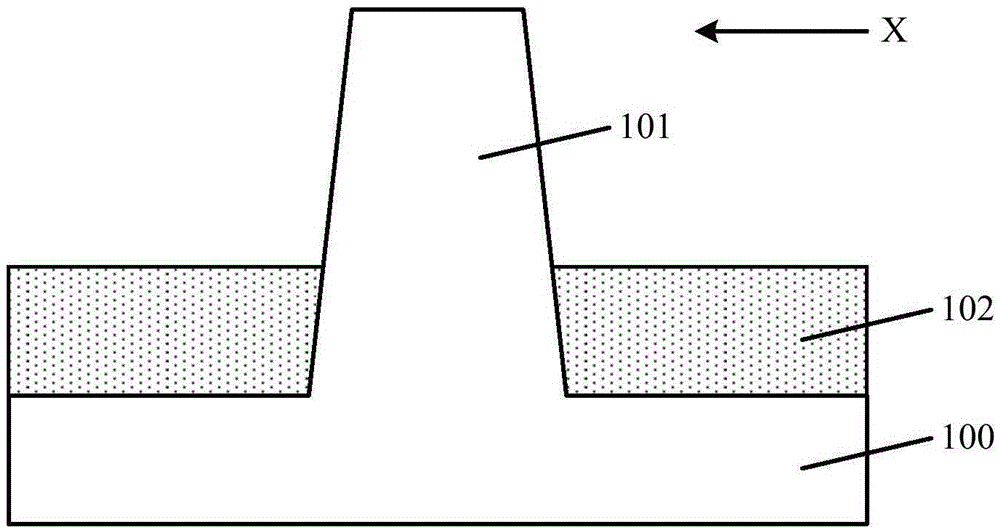

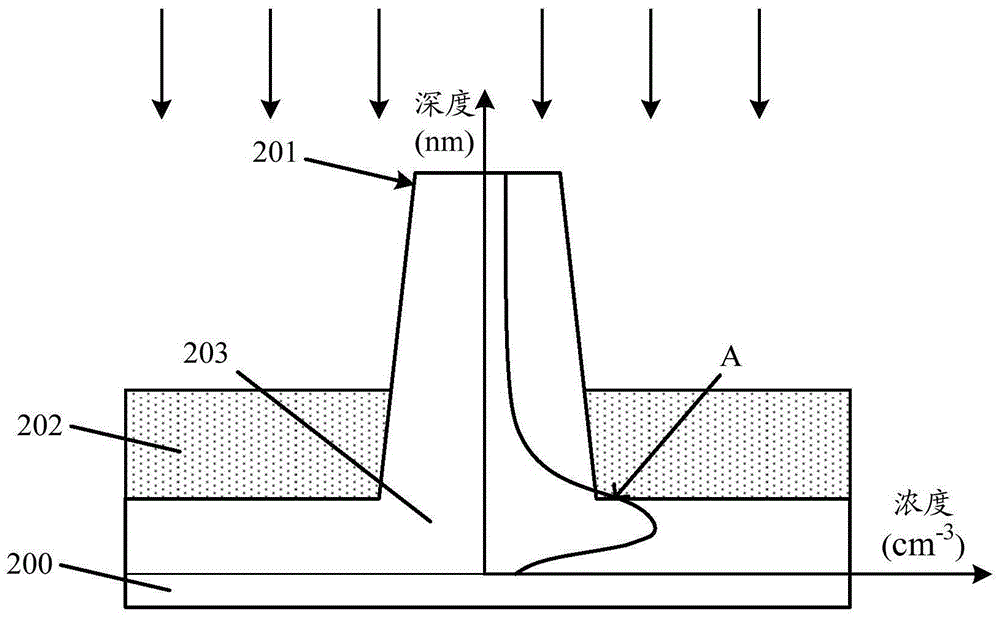

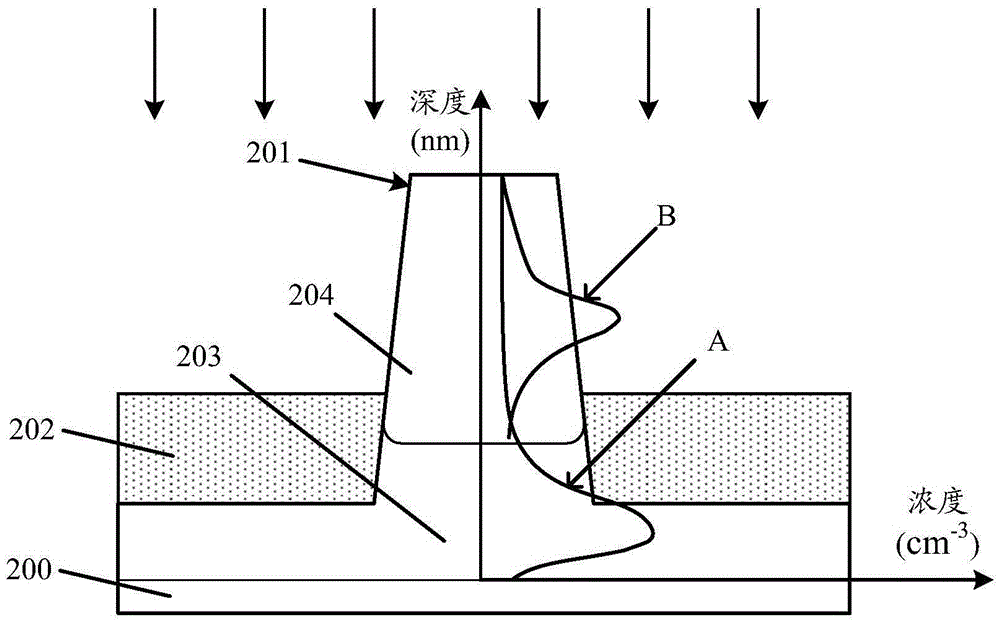

Semiconductor structure forming method

ActiveCN106449405AInhibited DiffusionSuppression of short channel effectsSemiconductor/solid-state device manufacturingSemiconductor devicesCarbon ionSemiconductor structure

The invention provides a semiconductor structure forming method which comprises the following steps: providing a substrate with a well region, wherein a first type of ions are disposed in the well region; using a first anti-punch-through-injection process to inject the first type of ion into the well region wherein the depth of the first anti- punch-through injection process is less than the distance from the bottom of the well region to the top surface of the substrate, forming an anti-punch-through region in the well region; using a second anti- punch-through-injection process to inject carbon ions into the well region to form a carbon doped region in the well region wherein the doped concentration of the carbon ions is greater than that of the first type of ion in the anti-punch-through region and the carbon doped region surrounds the anti-punch-through region; and using a third anti-punch-through-injection process to inject nitrogen ions into the well region wherein the third anti-punch-through-injection depth is less than those of the first anti- punch-through -injection and the second anti-punch-through-injection, forming a nitrogen doped region between the anti- punch-through regions and the top part of the substrate. According to the semiconductor structure forming method, it is possible to improve the performances of a semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

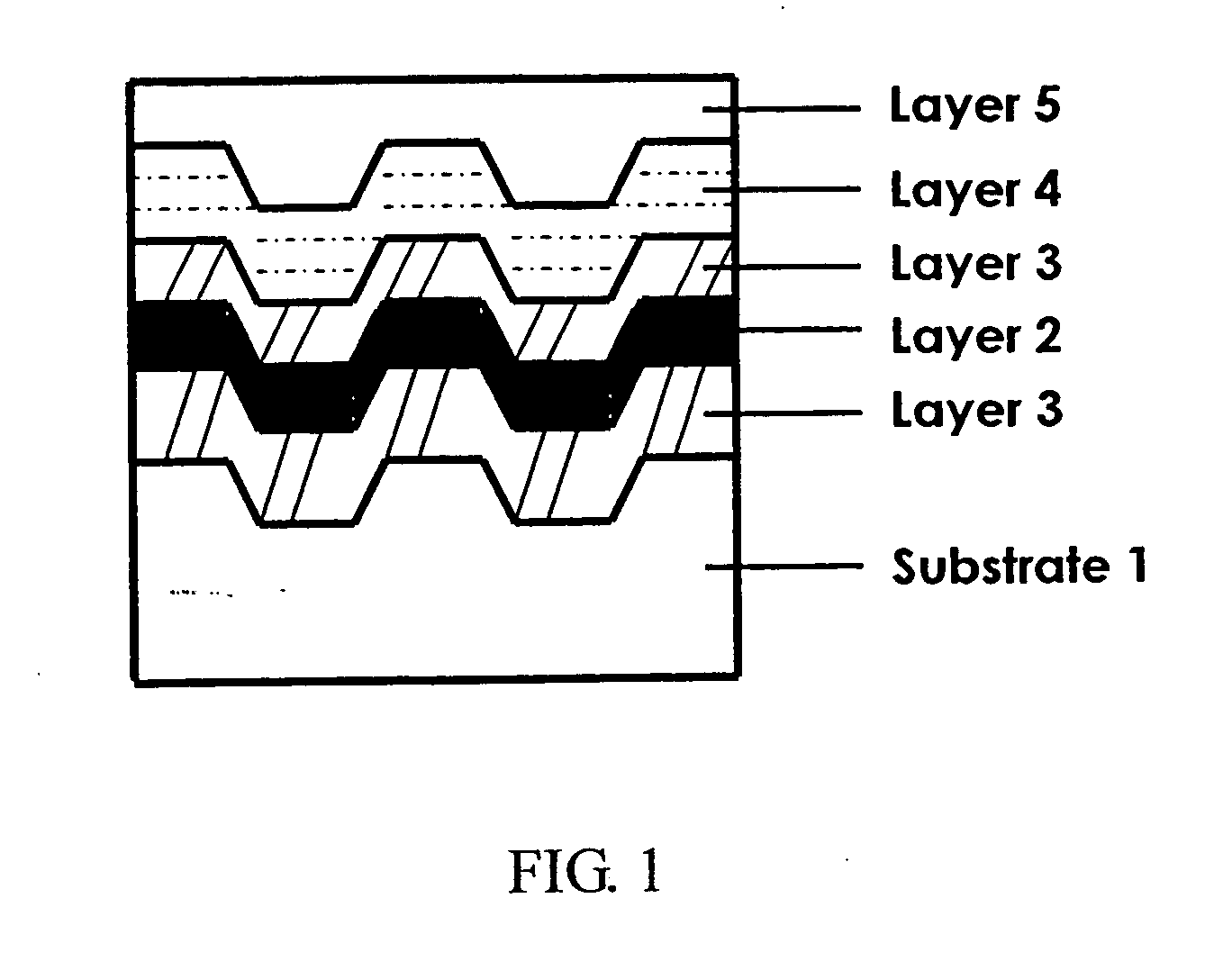

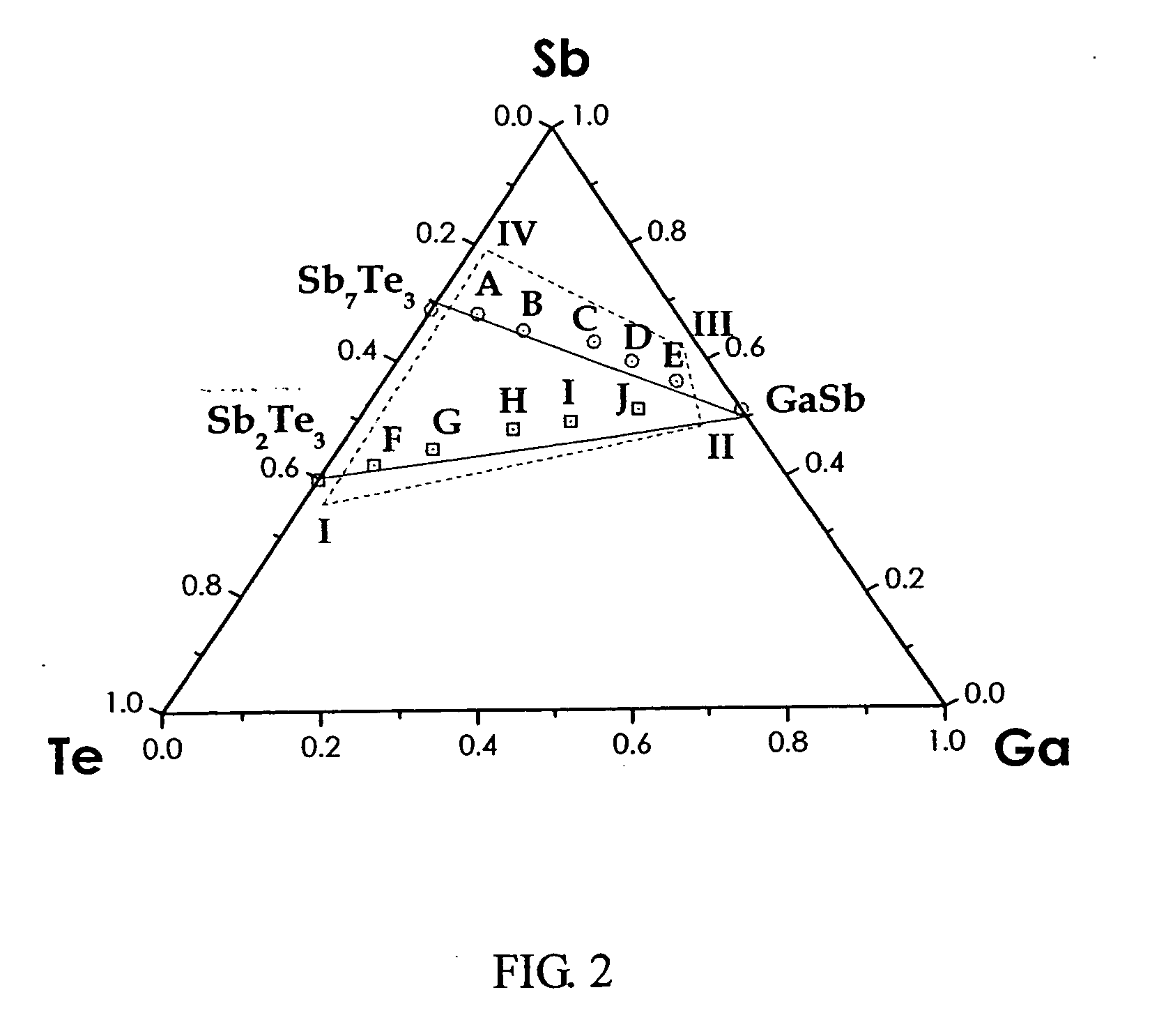

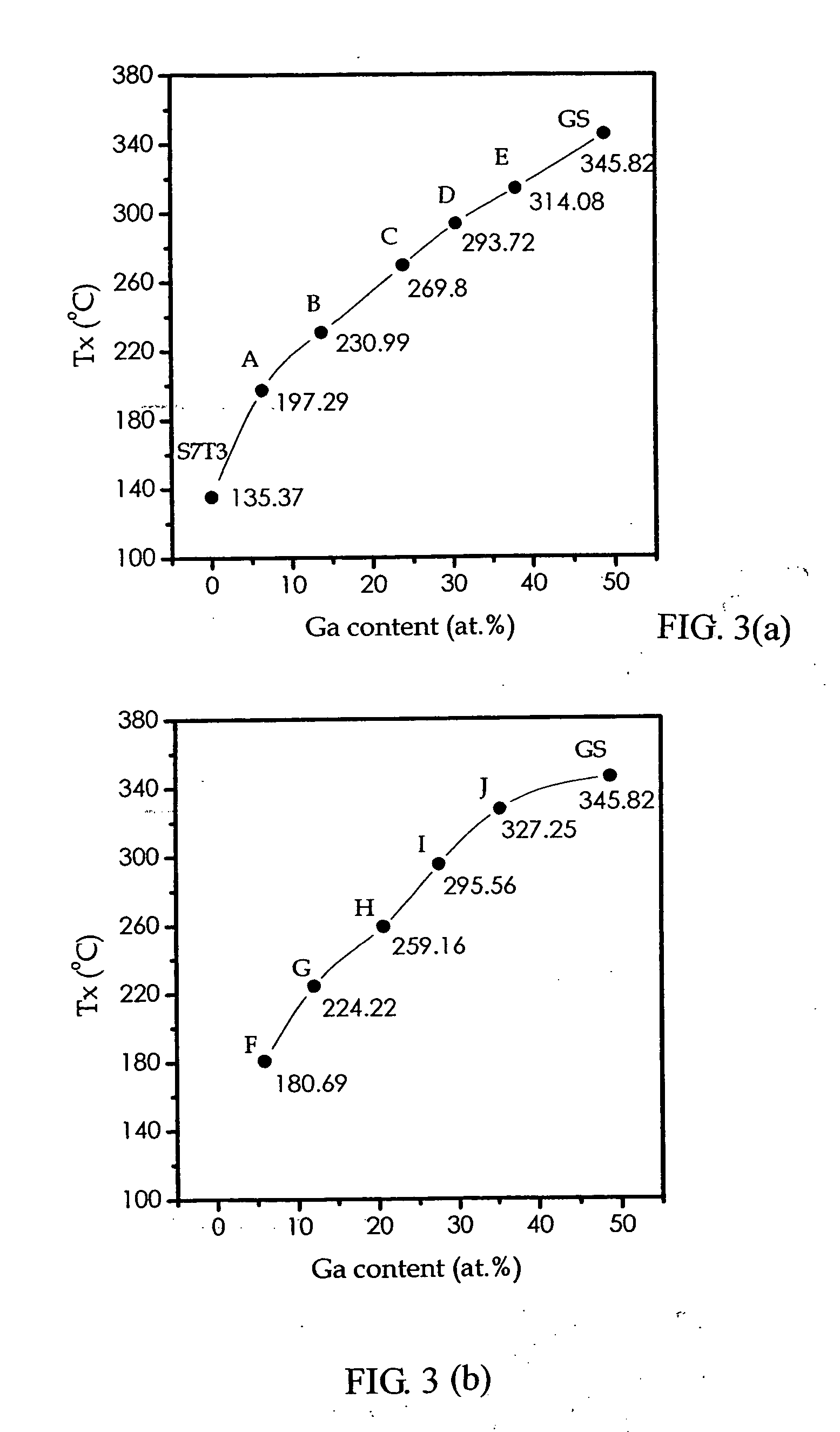

Phase-change recording media based on the Ga-Sb-Te system for ultra-high density optical recording

ActiveUS20050136209A1Improve data transfer rateIncrease rotation speedLayered productsPhotomechanical apparatusHigh rateCrystallization kinetics

This invention discloses a novel rewritable phase-change recording medium for optical data storage, which is based on the GaSbTe ternary alloy system. The designed compositions reside on the Sb7Te3—GaSb and Sb2Te3—GaSb pseudo-binary tielines, and the claimed region can be expressed by the formula (SbxTe100-x)1-z(GaySb100-y)z, 35≦x≦80, 40≦y≦50, 0.05≦z≦0.9. The crystallized phase of the GaSbTe films is a single phase after laser annealing, and the crystal structure is hexagonal with continuous variation in lattice constants. The lattice parameters, a is from 4.255 Å to 4.313 Å and c is from 11.200 Å to 11.657 Å, corresponding to the c / a ratio 2.60 to 2.73. The crystallization kinetics shows increased crystallization temperature (181 to 327° C.) and activation energy (2.8 to 6.5 eV) with increasing GaSb content. The Sb7Te3-rich compositions in the GaSbTe recording media are characteristic of enhanced recrystallization, while those with increasing GaSb content are indicative of higher rate of crystal growth and better erasability. The compositions around Ga2Sb5Te3 exhibit the features of nearly complete erasure and stable cycling performance.

Owner:TSUNG SHUNE CHIN +1

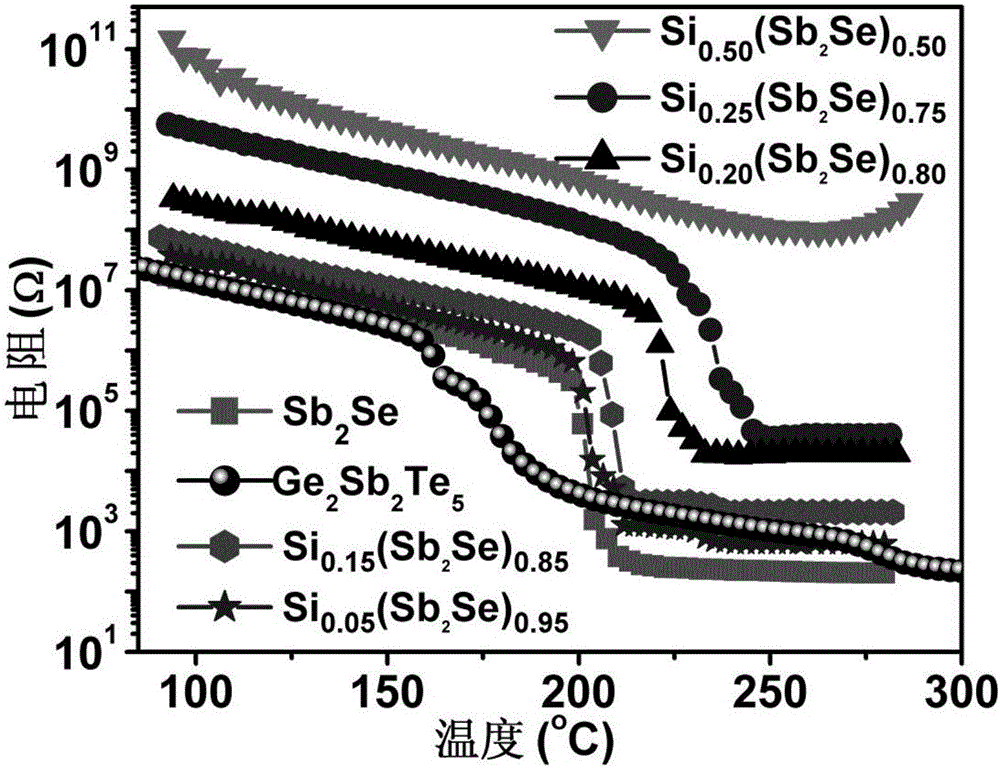

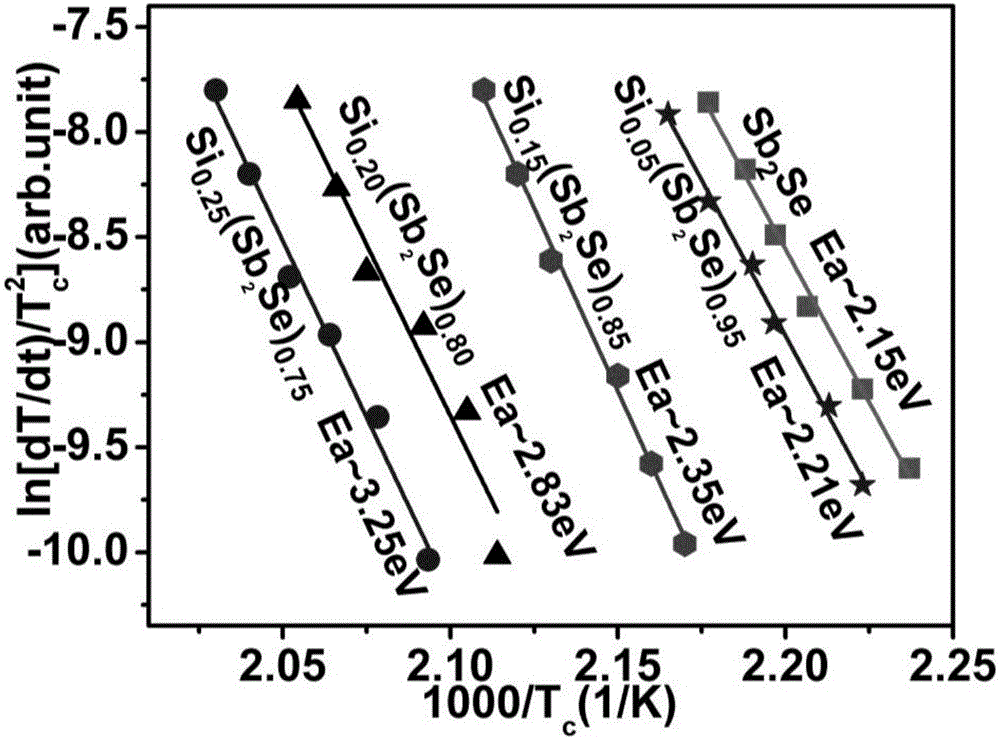

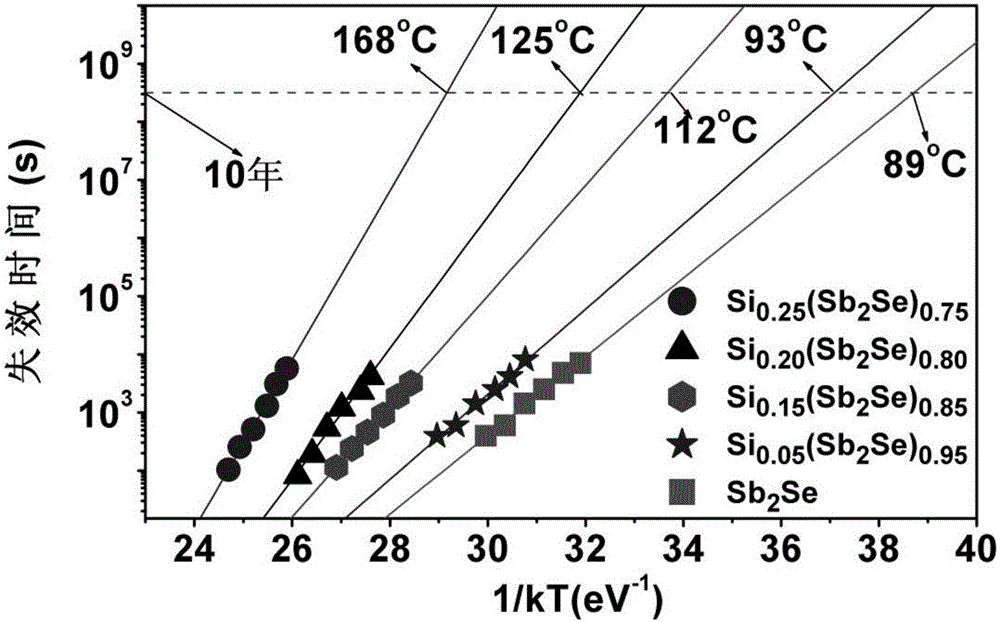

Si-Sb-Se nano phase-change thin film material and preparation method and application thereof

InactiveCN106374043AImprove thermal stabilityFast phase changeElectrical apparatusVacuum evaporation coatingChemical compositionSemiconductor materials

The invention belongs to the field of semiconductor materials, and discloses an Si-Sb-Se nano phase-change thin film material. A general formula of a chemical composition of the phase-change thin film material is Si<x>(Sb<2>Se)<1-x>, wherein x is smaller than 0.50 and greater than or equal to 0.05; the proportion of an ingredient Si in the Si<x>(Sb<2>Se)<1-x> is controlled through the diameters of stacked Si sheets; and the Si-Sb-Se nano phase-change thin film material is formed by deposition through a room-temperature high-vacuum magnetron sputtering method. The Si-Sb-Se nano phase-change thin film material provided by the invention does not contain a Te element and belongs to an environment-friendly material; and meanwhile, Si-Sb-Se also has ultra-high thermal stability, relatively low power consumption and a high phase change speed, is an ideal phase-change storage material and has a relatively good market application prospect.

Owner:JIANGSU UNIV OF TECH

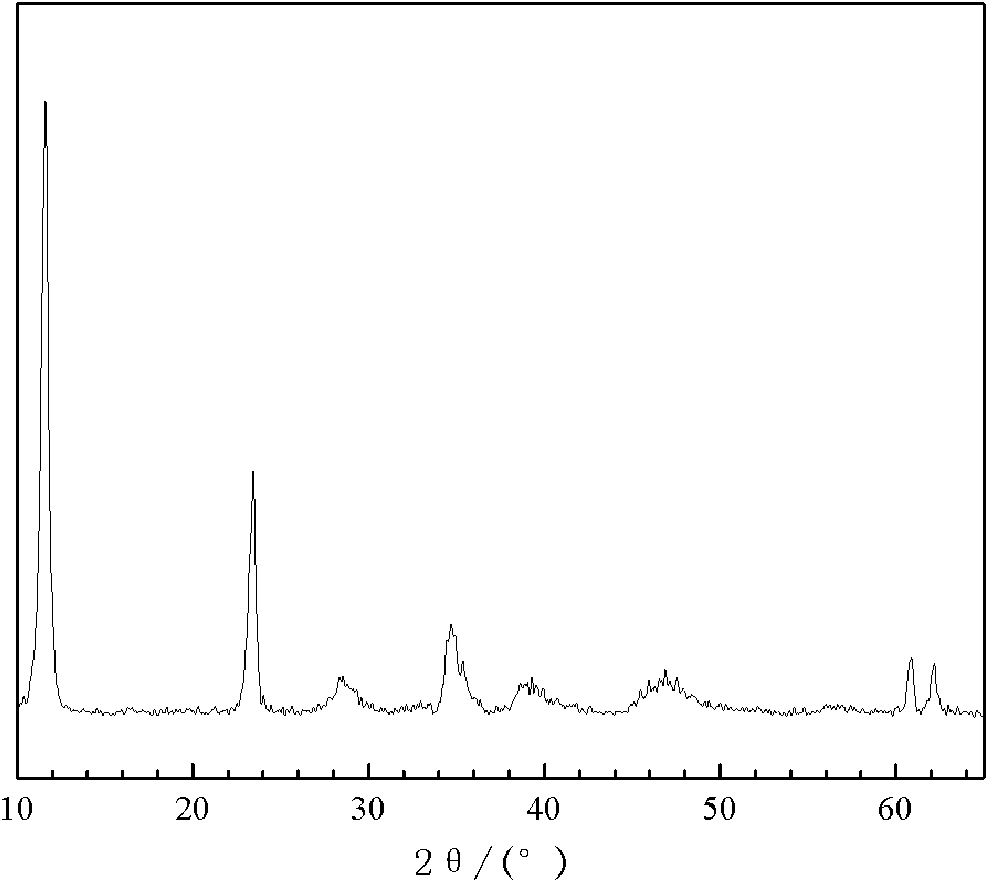

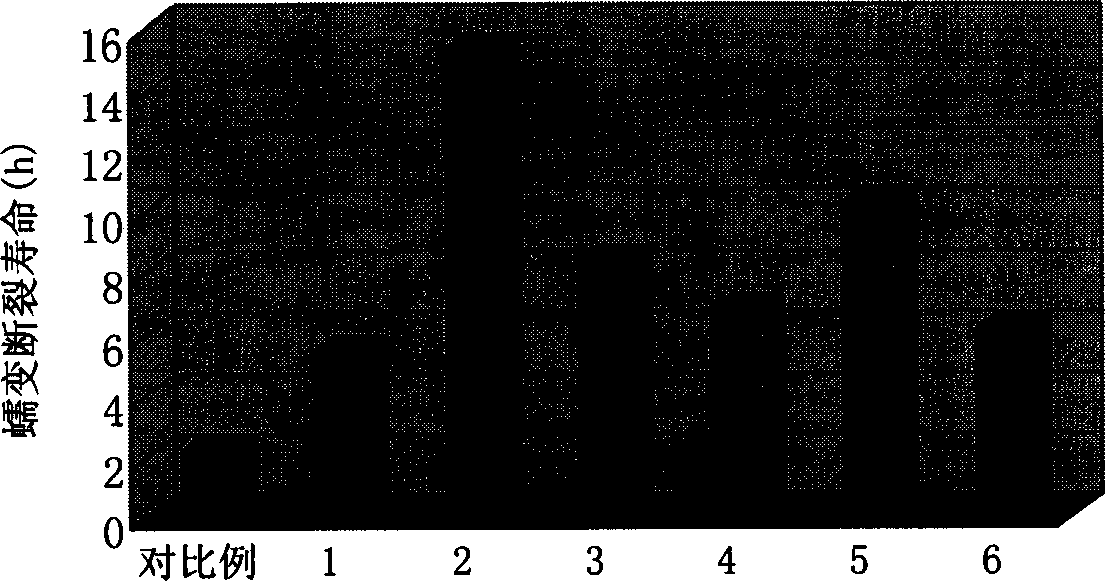

Preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylate

ActiveCN101973943AIncrease activation energyIncrease contact areaOrganic chemistryAlcoholSubstitution reaction

The invention provides a preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylat, which comprises the steps of: sequentially calcining and grinding a basic catalyst and then heating for activating to obtain an activated catalyst; carrying out a substitution reaction on 3,3-dimethoxy-2-(2-hydroxyphenyl) methyl propionate and 4,6-dichloropyrimidine in the presence of the activated catalyst, and then carrying out a dealcohol reaction on the 2-[2-(6-pyrimidine-4-yloxy) phenyl]-3,3-dimethoxy methyl propionate obtained from the substitution reaction to obtain the (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylat. In the method, the basic catalyst is activated, which improves the catalysis efficiency of the catalyst and increases the conversion rate of the raw materials in the same reaction time, thus the product yield of the substitution reaction is improved, and the product yield of the dealcohol reaction is enhanced.

Owner:CHONGQING UNISPLENDOUR CHEM

Self-priming coil coating composition and method

InactiveUS20040204538A1Fast curingHigh degreeColloidal chemistry detailsPigment compositionPVA - Polyvinyl alcohol

The invention discloses self-priming coating composition based on a vinyl terpolymer, a monomeric or oligomeric alkoxy amino resin cross linker and a multi component combination of two or more co-resins selected from (a) oligomeric saturated polyester resin, (b) oligomeric unsaturated polyester resin dissolved in an unsaturated monomer with a free radical initiator (c) oligomeric bifunctional phenolic resole resin and (d) oligomeric epoxy resin (e) low molecular weight polyurethane resin and (f) short to medium oil alkyd resin, wherein said vinyl terpolymer is predominantly polyvinyl formal with polyvinyl alcohol and polyvinyl acetate as two other co-polymers. The composition can be applied as a clear coat or as a pigmented composition with addition of pigment on ferrous and non-ferrous metallic substrate and is particularly suitable for continuous coil coating lines for both dark and light colour metal coatings. The invention also concerns method of coating ferrous and non-ferrous metallic substrate by applying the said coating composition on a degreased but untreated surface and coated articles so produced.

Owner:ROTOMAC ELECTRICALS PVT

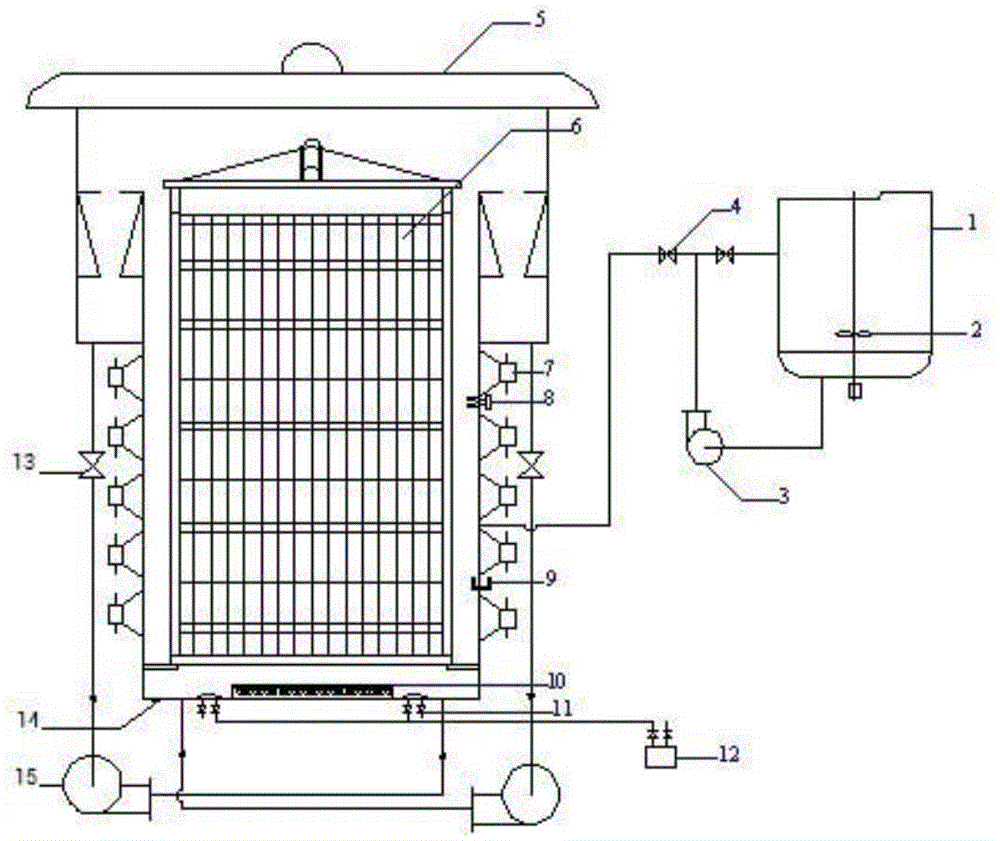

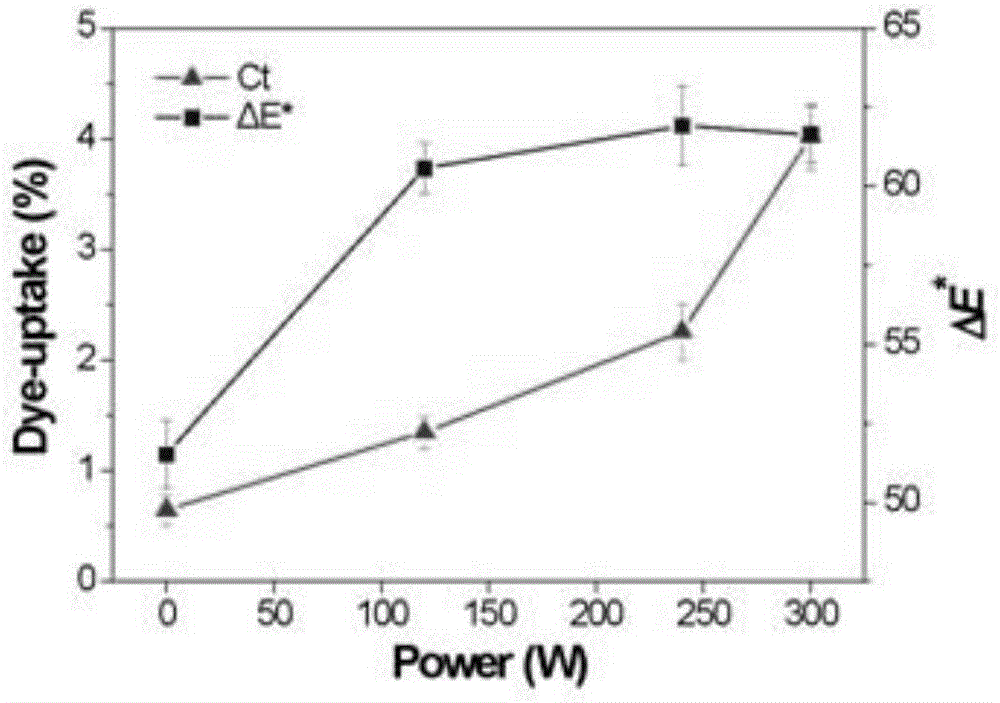

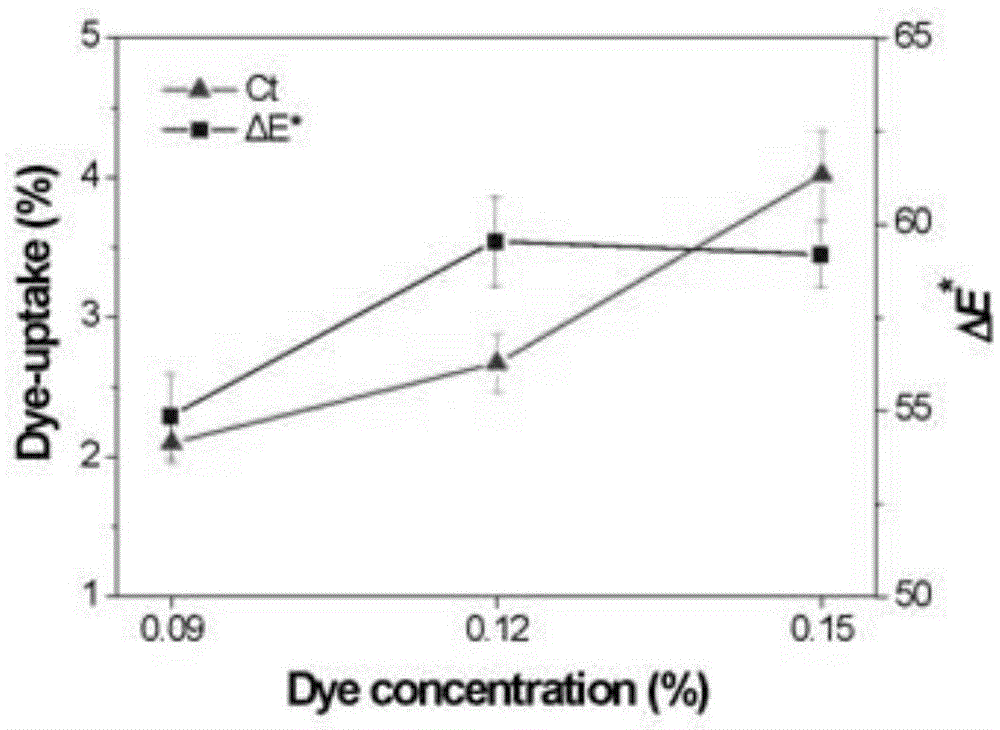

Ultrasonic-assisted wood veneer dyeing method

InactiveCN104369243AImprove dyeing efficiencyEasy to operateWood treatment detailsWood veneerUltrasonic assisted

The invention discloses an ultrasonic-assisted wood veneer dyeing method. The method includes the steps of wood pretreatment; placing pretreated wood veneers into a dye vat and injecting dye liquor into the dye vat; opening a circulating system to enable the dye liquor to flow circularly in the dye vat, opening a heating system after the dye liquor circulates stably, opening an ultrasonic assisting system after the dye liquor reaches the set temperature, and subjecting the wood veneers to ultrasonic treatment. The ultrasonic-assisted wood veneer dyeing method has the advantages that ultrasonic treatment and wood veneer dyeing are conducted simultaneously, dyeing efficiency is high, and pressure equipment is not required; by means of ultrasonic treatment, new fluid passageways in wood are broken through, new dye molecule sorption sites are provided, dye liquor activation energy is improved, wood permeability can be improved, dye dye-uptake rate can be increased, dyeing time is shortened, dyeing temperature is lowered, dyeing effects are enhanced, and the method is applicable to thick veneers and is energy saving and efficient.

Owner:BEIJING FORESTRY UNIVERSITY

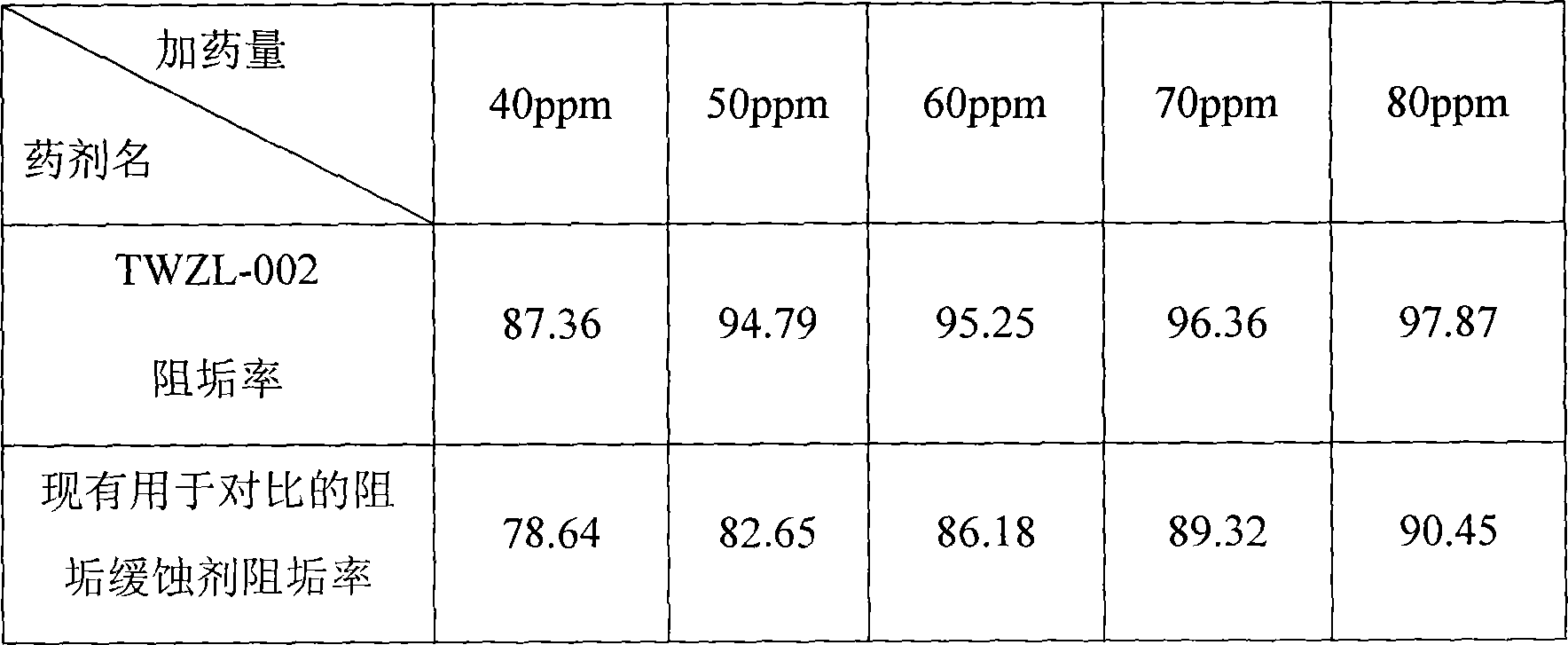

Dirty-proof inhibition composition for reclaimed water circulation sewage and preparation method and application

InactiveCN101117257AInhibition formationImprove adsorption capacityScale removal and water softeningWater qualityCarboxylic acid

The invention relates to a corrosion and deposit inhibiting combination for intermediate water sewage system, a fabrication and application method to be concerned, the corrosion and deposit inhibiting combination comprises an organic phosphonate, carboxylic acid multipolymer, zince sulfate and water; the corrosion and deposite inhibiting combination of the invention is fabricated by carboxylic acid multipolymer and other compounds, which can effectively prevent the formation of calcium carbonate in cool circulating water, and also has a favorable performance on preventing the formation of calcium phosphate scale, as the result shows, the corrosion and deposit inhibiting combination has an outstanding corrosion inhibiting effect, the corrosion velocity of carbon steel is only 0.05mm / a which is far smaller than 0.125mm / a equivalent to the national standard, the invention is applicable to a wide arrange of water quality fluctuation, and can provide with an outstanding corrosion and deposit inhibiting performance, the medicament consumption is small, only 40 to 60mg / l of the corrosion and deposit inhibiting combination in the invention can be used for capability of meeting the requirement on corrosion and deposit inhibiting, an industrial water consumption and an economic expense are tremendously saved, the economic benefit and the social benefit are favorable.

Owner:北京能泰高科环保技术有限公司

Fracturing process in oil and water well by means of biological enzyme preparation

InactiveCN1766283AImprove work efficiencyDoesn't take into account the reverse dischargeFluid removalWater wetFracturing fluid

The invention discloses an oil field oil-water well fracturing craft method of biological enzyme agent, which is characterized by the following: building the mixed biological enzyme agent and water or biological acid or antisludging agent or liquid nitrogen as fracturing fluid; forcing the fracturing fluid into the oil well or water well through the fracturing vehicle; pressing the fracturing fluid into the crack; opening the well after 72 hours. The biological enzyme agent penetrates the hole throat then enters into the microscopic hole gap, which attaches the rock surface and denudes the raw oil to improve the earth penetration factor. The method improves the water wet effect and washes the spalling oil film, which improves the recovery factor of raw oil.

Owner:SUNCOO PETROLEUM TECH

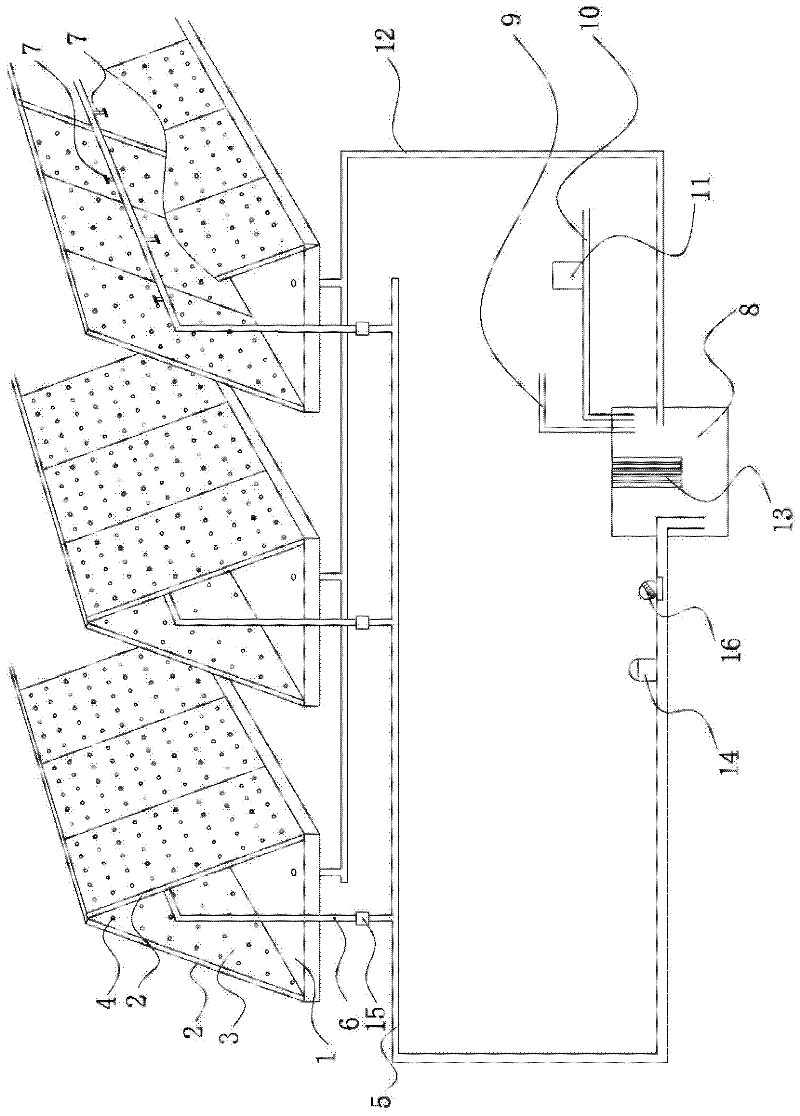

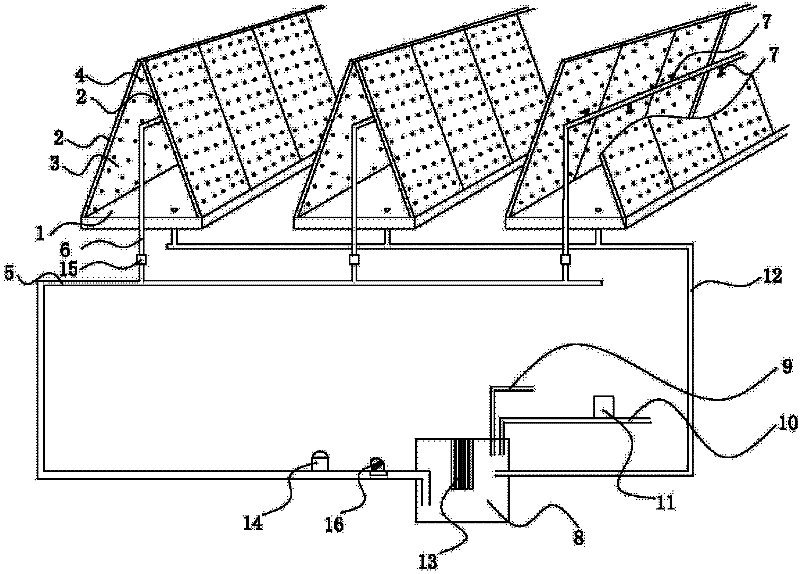

High-efficiency high-yield production method of mycorrhizal fungi

InactiveCN102229893AImprove the immunityNo pollutionFungiMicroorganism based processesMicroorganismNutrient solution

The invention provides a high-efficiency high-yield production method of mycorrhizal fungi, integrates multiple technical characteristics of biological nutrient fluids, tower-shaped plate-type three-dimensional cultivation racks and electrostatic field treatment of host plant seeds, and achieves the effect of high-efficiency high-yield production of mycorrhizal fungi. In the whole production process, the utilization of tower-shaped plates maximizes the use of space and increases the planting area. Considering the nutrient fluid preparation, instead of the conventional inorganic nutrient fluids, organic nutrient fluids which are prepared by fermenting formulated ingredients with microorganisms are adopted and sprayed to the root systems of plants, and the residual fluids are returned to a nutrient fluid tank to achieve the recycling of the nutrient fluids. The purpose of zero discharge is achieved by the symbiosis of microorganisms and plants.

Owner:刘方一

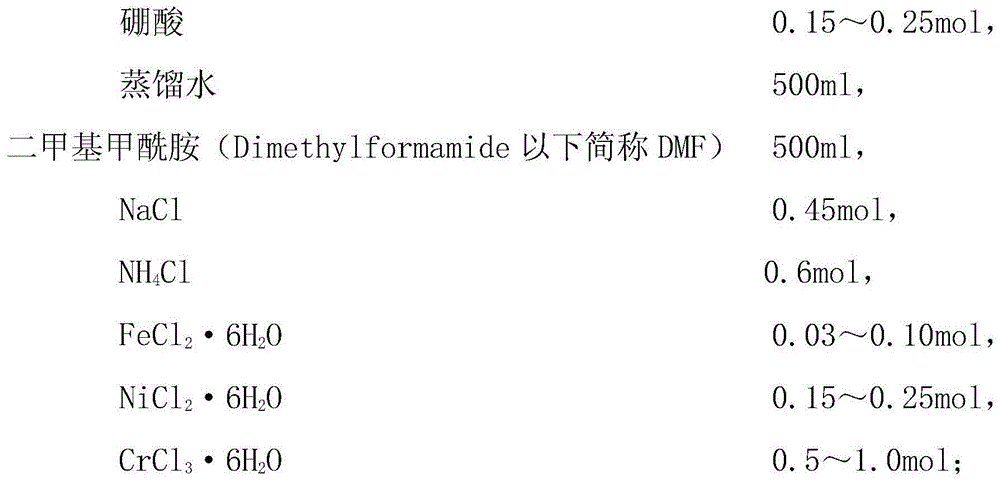

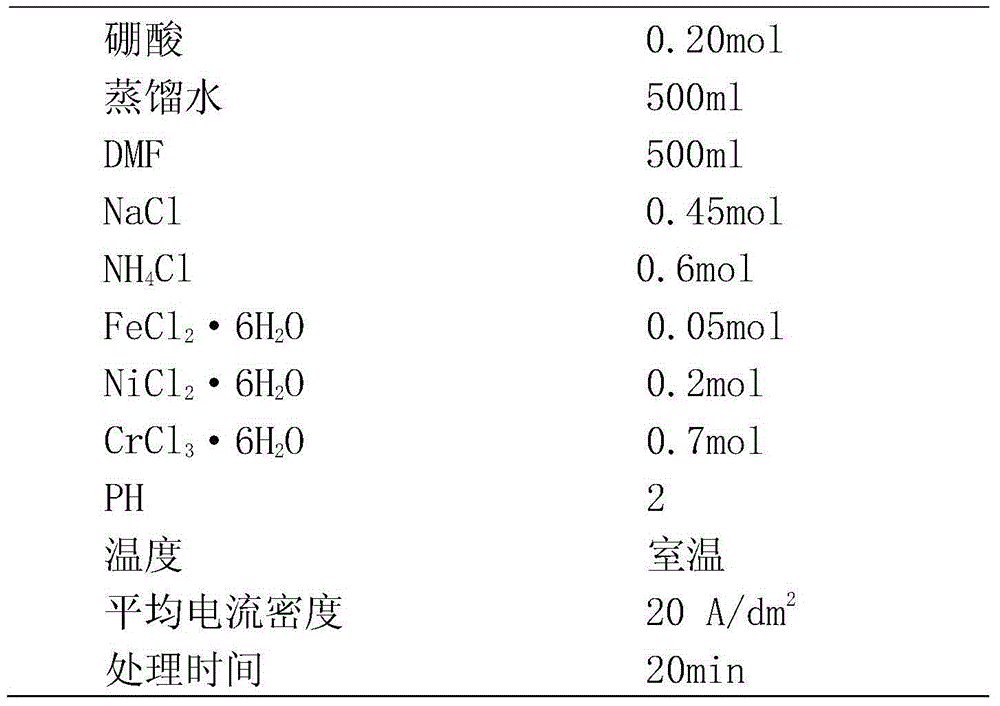

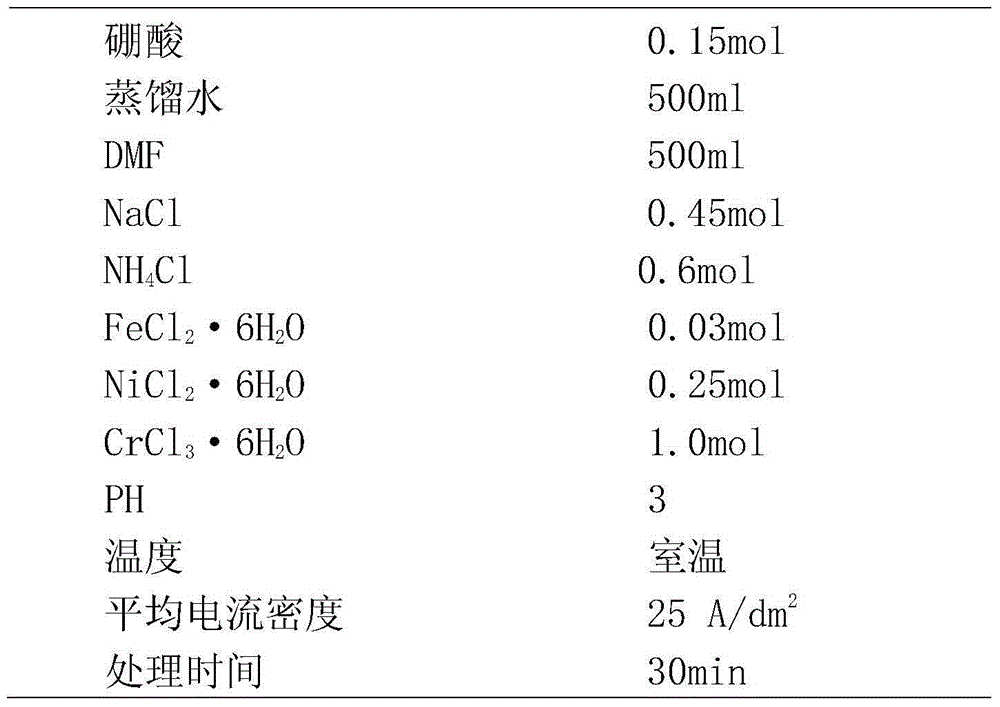

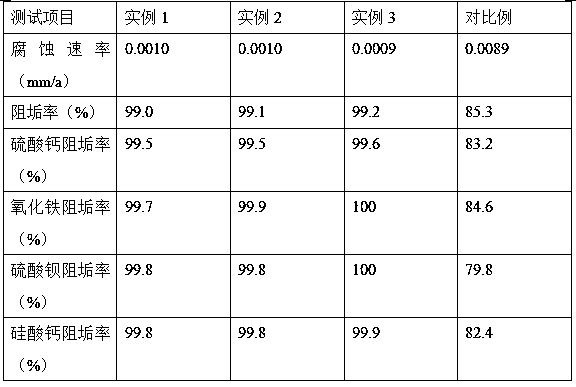

Low-temperature anti-corrosion gas nitriding method for metal workpiece and metal workpiece

ActiveCN104911533AImprove corrosion resistanceWill not deformSolid state diffusion coatingMicro nanoAlternating current

The invention relates to a low-temperature anti-corrosion gas nitriding method for a metal workpiece and the metal workpiece. According to the method, the metal workpiece is put in configured electrolyte, a common electro-deposition is utilized for carrying out pulse or alternating current treatment on the surface of the metal workpiece to form a micro-nano structural layer containing Ni<2+> and Cr<3+> on the surface of the metal workpiece under the effect of an electric field, grains on the surface of the workpiece are refined, and the activation energy is enhanced; by virtue of introduced Ni<2+> and Cr<3+>, nitriding can be promoted, the low-temperature nitriding is realized, and the corrosion resistance of the workpiece is improved; without recourse to a dense nitride layer (white bright layer), the danger caused by brittleness is solved, and the corrosion resistance of the workpiece is improved. In conclusion, by virtue of electro-deposition pretreatment provided by virtue of the method, the metal workpiece is not deformed, meanwhile, the nitriding temperature can be effectively decreased, the nitriding period can be shortened, the electro-deposition pretreatment is applicable to parts with complex shapes and precise parts, and the energy is saved.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation technology of modified fly ash

InactiveCN107913688AIncrease activation energyGood modification effectOther chemical processesAlkali metal oxides/hydroxidesPlasma treatmentGrinding mill

The invention discloses a preparation technology of modified fly ash. According to key points of the technical scheme of the invention, the preparation technology comprises the following preparation steps: firstly, mixing flue gas desulfurization gypsum and fly ash, and grinding by virtue of a ball grinding mill, thus obtaining a mixed material; secondly, carrying out low temperature plasma treatment on the mixed material; thirdly, adding a modifier into the mixed material subjected to the plasma treatment in the step two, uniformly mixing, adding water, preparing into slurry, artificially stirring for 2-5 minutes, then adding into a cement paste mixer, automatically stirring, preparing into a 10cm*10cm*40cm blank after stirring is completed, placing into a drying oven at the temperature of 50 DEG C, and drying, thus obtaining the finished product. The operation of blending and grinding the flue gas desulfurization gypsum and fly ash can increase activation energy of the fly ash, and then an operation of carrying out low temperature plasma treatment on a blended material can further increase activation energy of the mixed material, so that modification effect in a modifying operation process is excellent.

Owner:天津海得润滋建材有限公司

Preparation method of scale and corrosion inhibitor

InactiveCN108911189AImprove hydrophilic abilityChange state of chargeScale removal and water softeningIon exchangeElectronegativity

The invention discloses a preparation method of a scale and corrosion inhibitor, which belongs to the technical field of preparation of water treatment chemicals. Nano cellulose prepared by utilizingneedle wood leaves is used as an adsorption carrier of corrosion inhibitor. The parent corrosion inhibitor prepared by the invention is Mannich base, by virtue of quaternization, the parent corrosioninhibitor adopts nitrogen atoms with larger electronegativity as a center polar group, the polar group is extremely high in hydrophilic performance, the concentration of the metal ions which are easyin forming scales such as calcium and magnesium can be reduced, the surface of a chelated adsorption material is coated with oxidized nano cellulose to form a nano filter membrane, the metal ions canbe efficiently adsorbed, the corrosion of saline-alkaline water for a salt discharging concealed pipe can be reduced, and when the added graphene oxide is oxidized, the graphene lamina is swelled, sothat a gap between two layers can be enlarged, the ion exchange is likely to occur for the metal ions in the saline-alkaline water, and the scale and corrosion inhibitor provided by the invention is high in capability for adsorbing and controlling the metal ions in the saline-alkaline water, and wide in application prospect.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

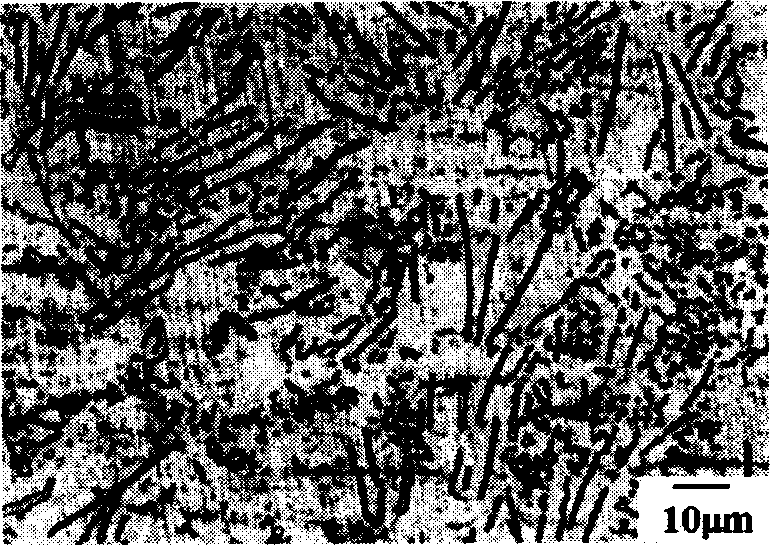

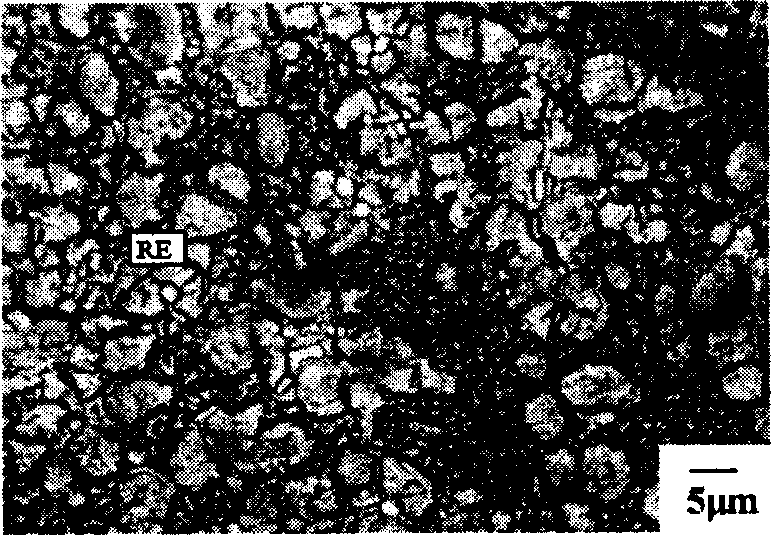

![Preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylate Preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylate](https://images-eureka.patsnap.com/patent_img/0ea06784-2c0e-47f0-bed0-9cf30fece34d/BSA00000290632400011.PNG)

![Preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylate Preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylate](https://images-eureka.patsnap.com/patent_img/0ea06784-2c0e-47f0-bed0-9cf30fece34d/BSA00000290632400051.PNG)

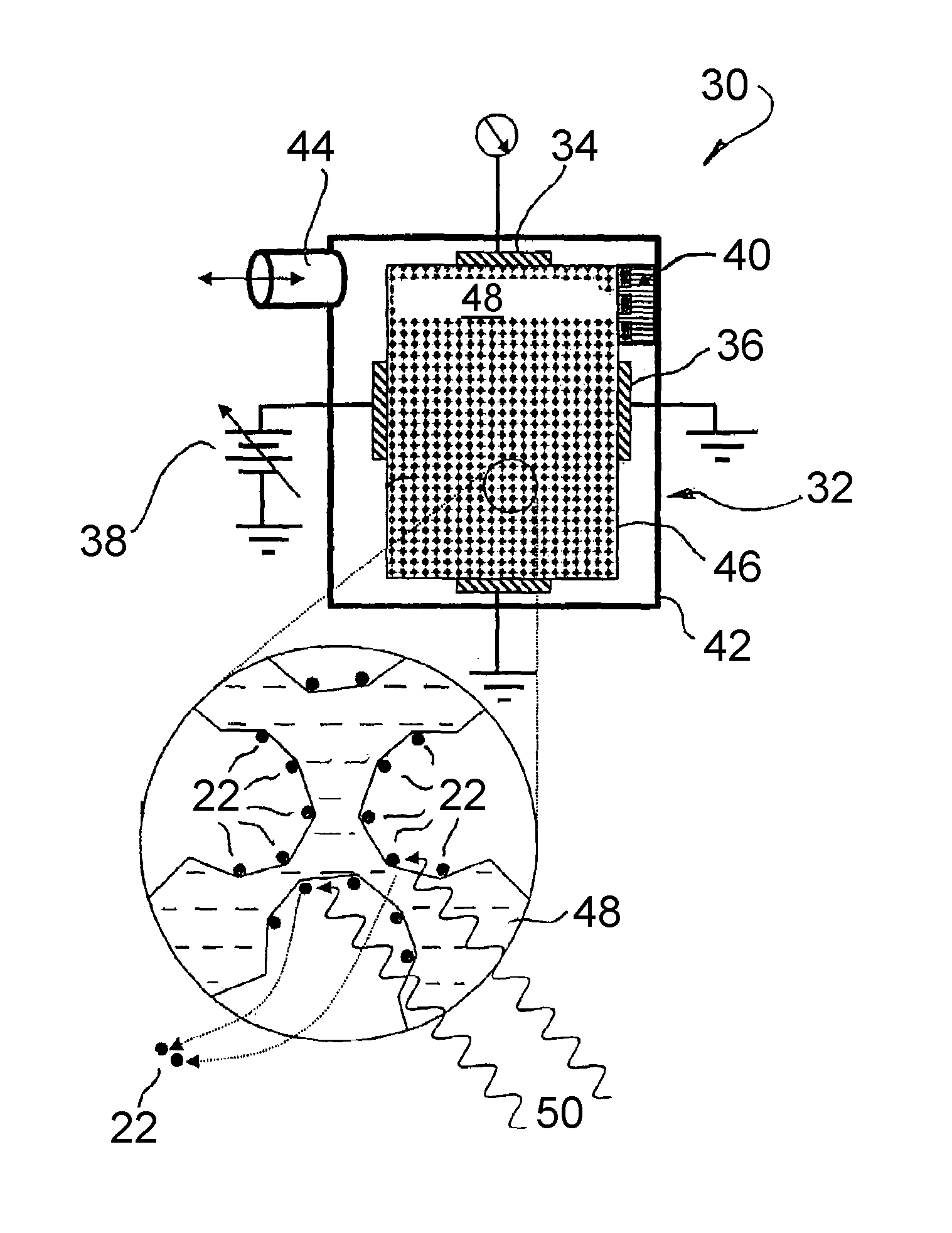

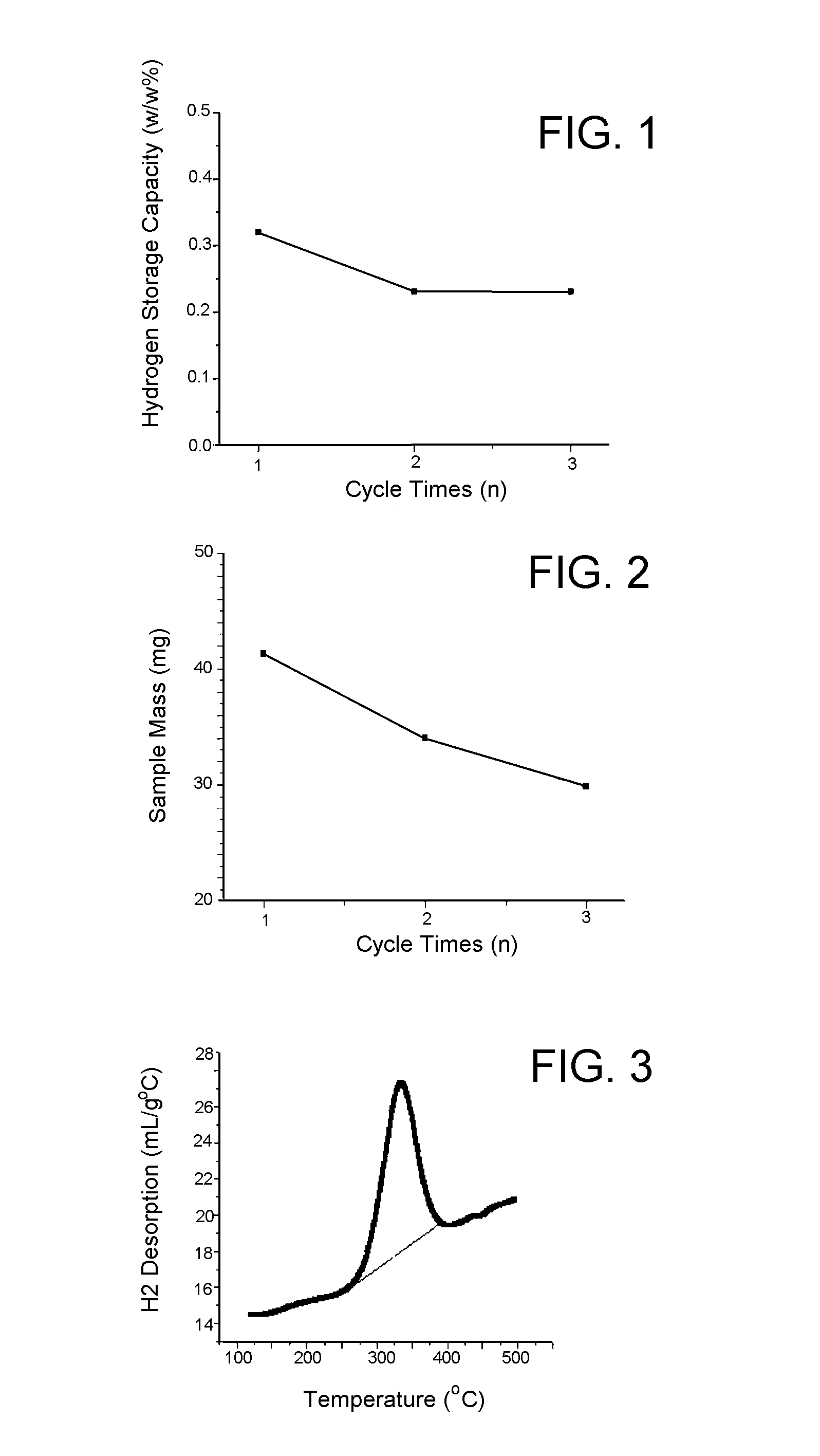

![Preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylate Preparation method of (E)-2-[2-(6-pyrimidine-4-yloxy) phenyl]-3-methoxyacrylate](https://images-eureka.patsnap.com/patent_img/0ea06784-2c0e-47f0-bed0-9cf30fece34d/BSA00000290632400052.PNG)