Patents

Literature

1627results about How to "Good modification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for constructing functionalized surface and interface by polydopamine coating layer

ActiveCN103736156AHigh densityGood modification effectPharmaceutical containersMedical packagingChemistrySurface modification

The invention discloses a method for constructing a functionalized surface and interface by a polydopamine coating layer. The method comprises the following steps: (1) dipping a to-be-modified base material into a dopamine aqueous solution, and automatically forming the polydopamine coating layer on the material surface; (2) preparing an active ester group-containing functionalized polymer; and (3) carrying out an amidation reaction of the active ester group-containing functionalized polymer with the polydopamine coating layer, and carrying out bonding fixation of the functionalized polymer on the material surface, so as to achieve functional modification of the material surface. The method takes the dopamine crosslinking layer having superstrong adhesion performance as a transition layer, is almost suitable for surface modification of any base material, also can overcome a problem that the artificially synthesized functionalized polymer is limited by the dopamine content, and constructs a biomimetic surface having stronger stability.

Owner:NORTHWEST UNIV

Moisture absorption perspiration-discharging dressing agent and its manufacturing technique and application

ActiveCN101265664AGood moisture absorption and perspirationGood modification effectFibre typesDyeing processFiberPolyester

The invention discloses the formula, the production process and the application of moisture absorbent and sweat conductive comfortable finishing agent which is used for modifying the polyester fiber to enable the polyester fiber to have moisture absorbent and sweat conductive capabilities. The formula of the moisture absorbent and sweat conductive comfortable finishing agent contains: polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate. The two-step continuous production process is adopted: in the first step of esterifying, polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate are put into a reaction vessel for esterification under the action of catalysts; and in the second step that the material produced after the esterification is transported to a polymerization kettle for polymerization under the actions of high temperature, vacuum, and catalysts, in order to generate polyester-polyether copolymer with high molecular weight to be 30000-50000, namely, the moisture absorbent and sweat conductive comfortable finishing agent. The moisture absorbent and sweat conductive comfortable finishing agent can be directly used or be used after being mixed with substances such as amino silicone oil and so on, and carry out chemical modification on the polyester fiber.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

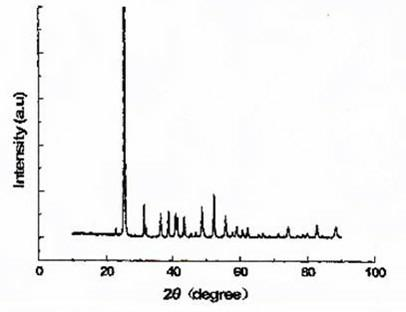

Method for preparing modified calcium sulfate whisker by using desulfurization gypsum

ActiveCN101994153AGood compatibilitySolve the problem of prone to hydration leading to whisker breakagePolycrystalline material growthFrom normal temperature solutionsSulfateMicrometer

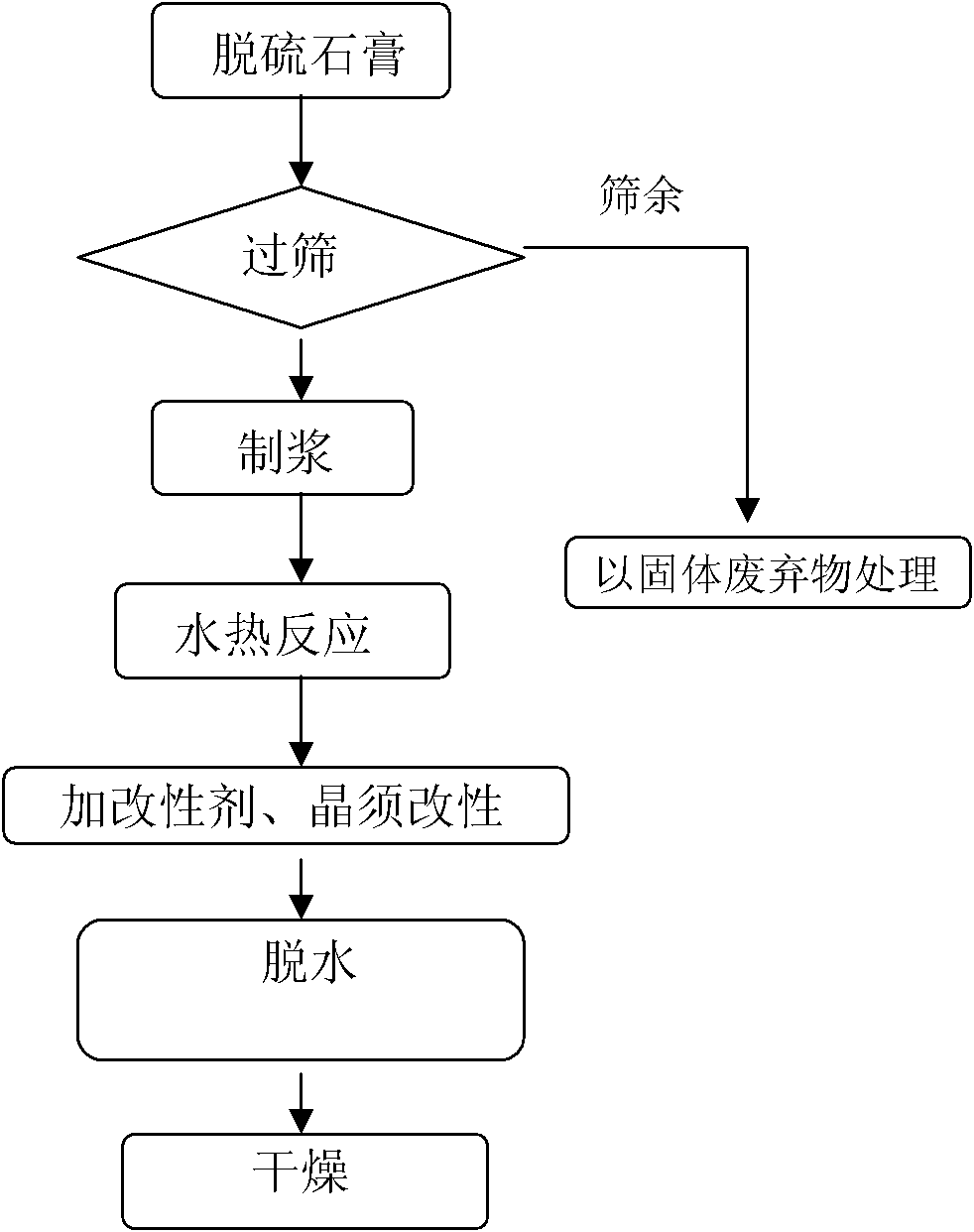

The invention discloses a method for preparing a modified calcium sulfate whisker by using desulfurization gypsum, comprising the following steps of sieving, pulping, performing hydro-thermal reaction and whisker surface modification, dewatering and drying, wherein the reaction temperature ranges from 107 DEG C to 180 DEG C, the concentration of desulfurization gypsum and water is 5-33wt% and the drying temperature ranges from 100 DEG C to 300 DEG C, and a modifier which is 0.05-5% of the weight of desulfurization gypsum in the calcium sulfate whisker suspension formed in hydro-thermal reaction. The invention solves the problem that CaSO4.0.5H2O whisker is easy to hydrate in the drying process tocause fracture of the whisker and enhances the compatibility of the calcium sulfate whisker and the high polymer materials. The prepared modified calcium sulfate whisker has a diameter of 0.5-6 micrometers, a length of 30-300 micrometers and a diameter ratio of 15-115 and the contact angle of water on the surface of the modified calcium sulfate whisker ranges from 12 to 140 degrees. The invention has the advantages of good modified effect, simple process, low production cost, the use of the non-toxic modifier and environmental-friendly preparation process.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

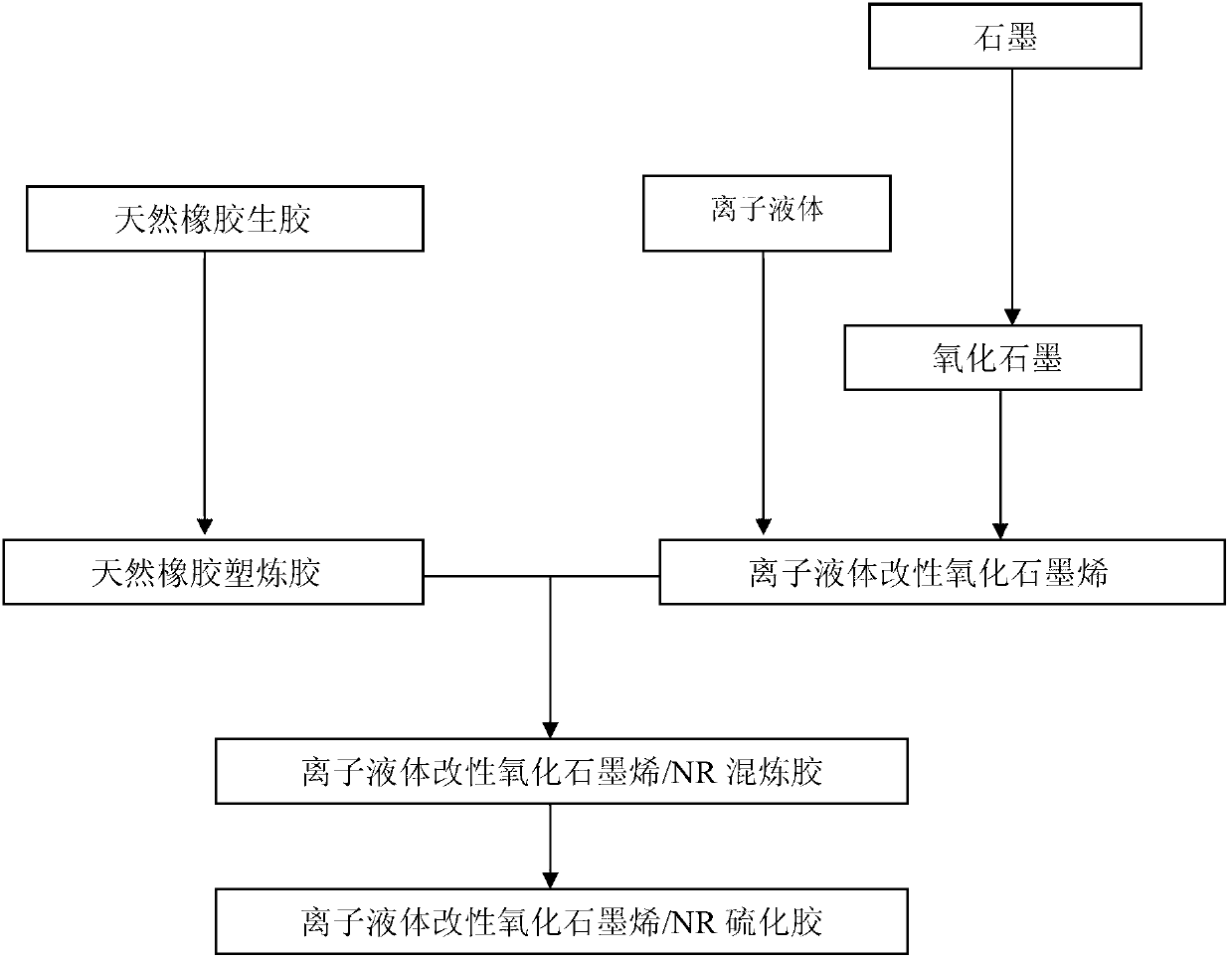

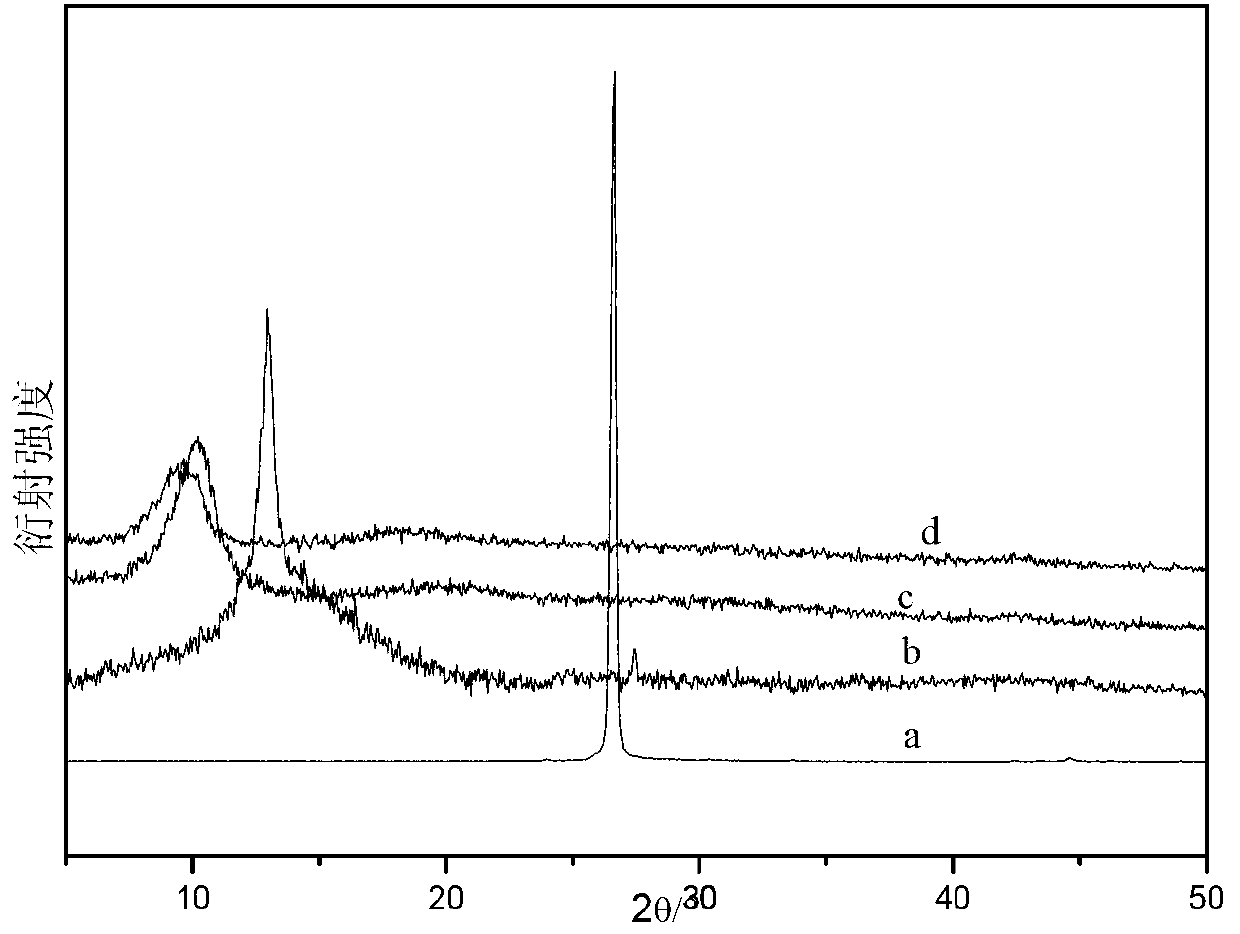

Ionic liquid modified graphene oxide/natural rubber vulcanized rubber and preparation method thereof

The invention relates to ionic liquid modified natural rubber vulcanized rubber containing graphene oxide. Graphene oxide is modified by use of ionic liquid through a solid grinding method, the modified graphene oxide and natural rubber are mechanically mixed in an open mill or internal mixer, and the formulas such as zinc oxide, stearic acid, an anti-aging agent, an accelerant, a vulcanizing agent, carbon black and the like are added at the same time to obtain natural rubber compound containing ionic liquid modified graphene oxide; and the ionic liquid modified graphene oxide / natural rubber vulcanized rubber provided by the invention can be obtained through vulcanization processing. According to the invention, modified graphene oxide is prepared by use of ionic liquid through the solid grinding method. Under the synergistic effect of the ionic liquid modified graphene oxide and carbon black, the heat conduction coefficient and the mechanical performance of the vulcanized rubber can be improved at the same time. The invention provides a preparation method of novel modified graphene oxide / natural rubber vulcanized rubber with simple technology and excellent performance.

Owner:NANJING UNIV OF SCI & TECH

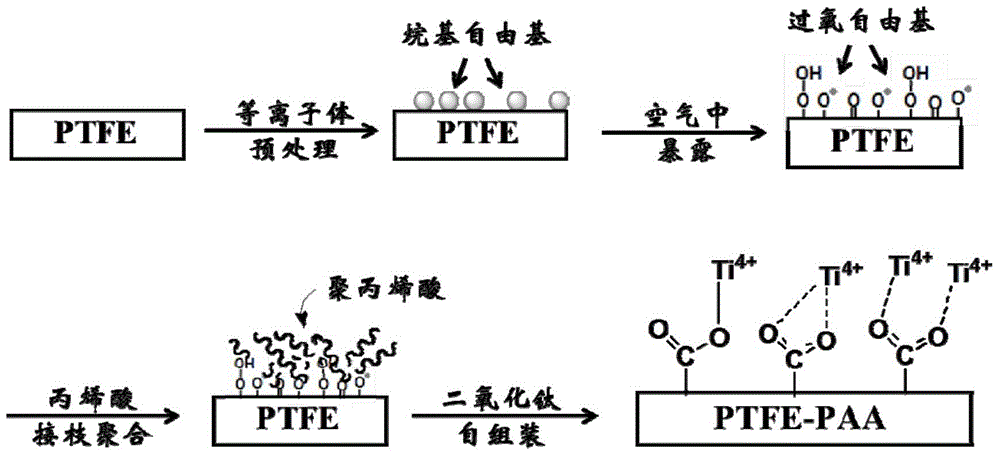

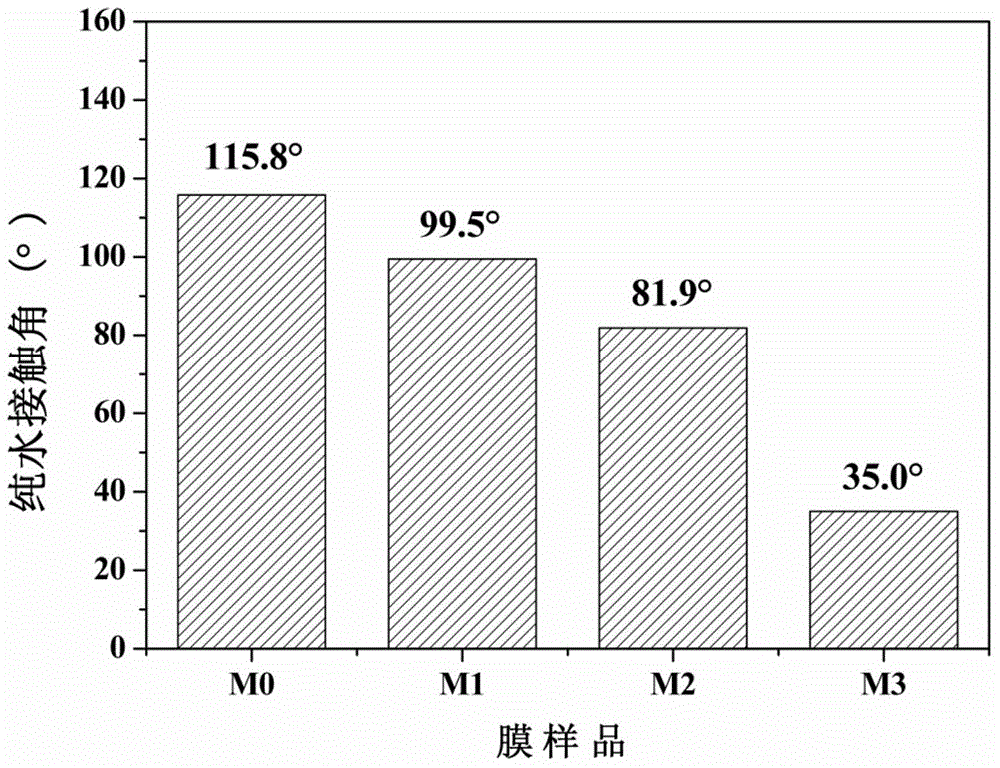

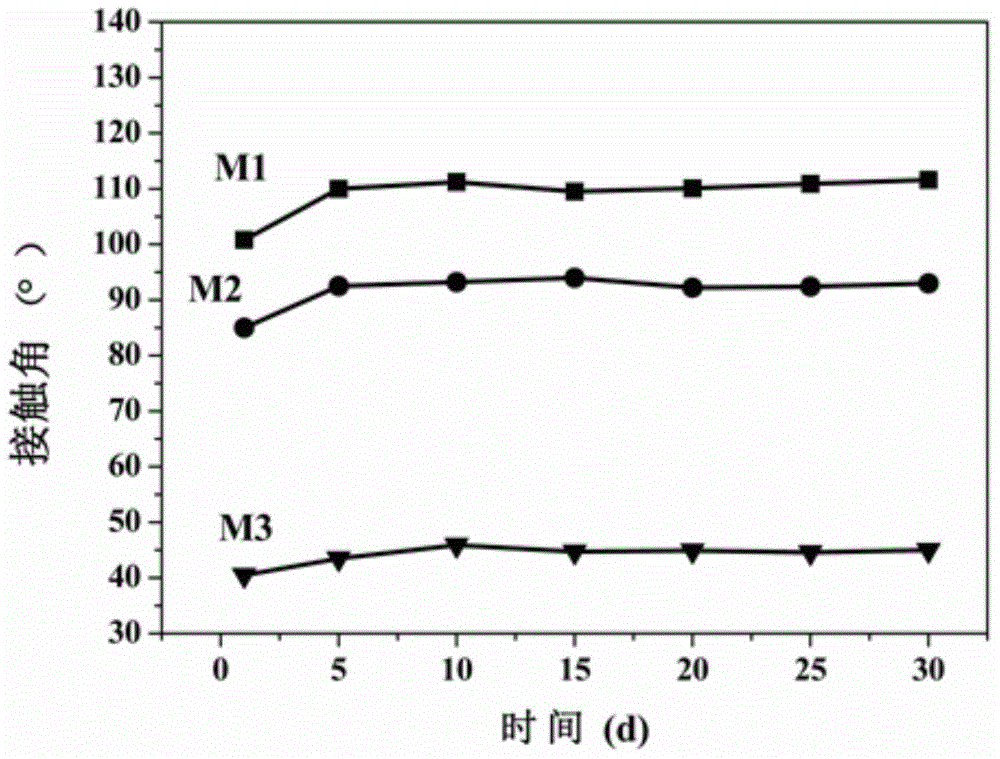

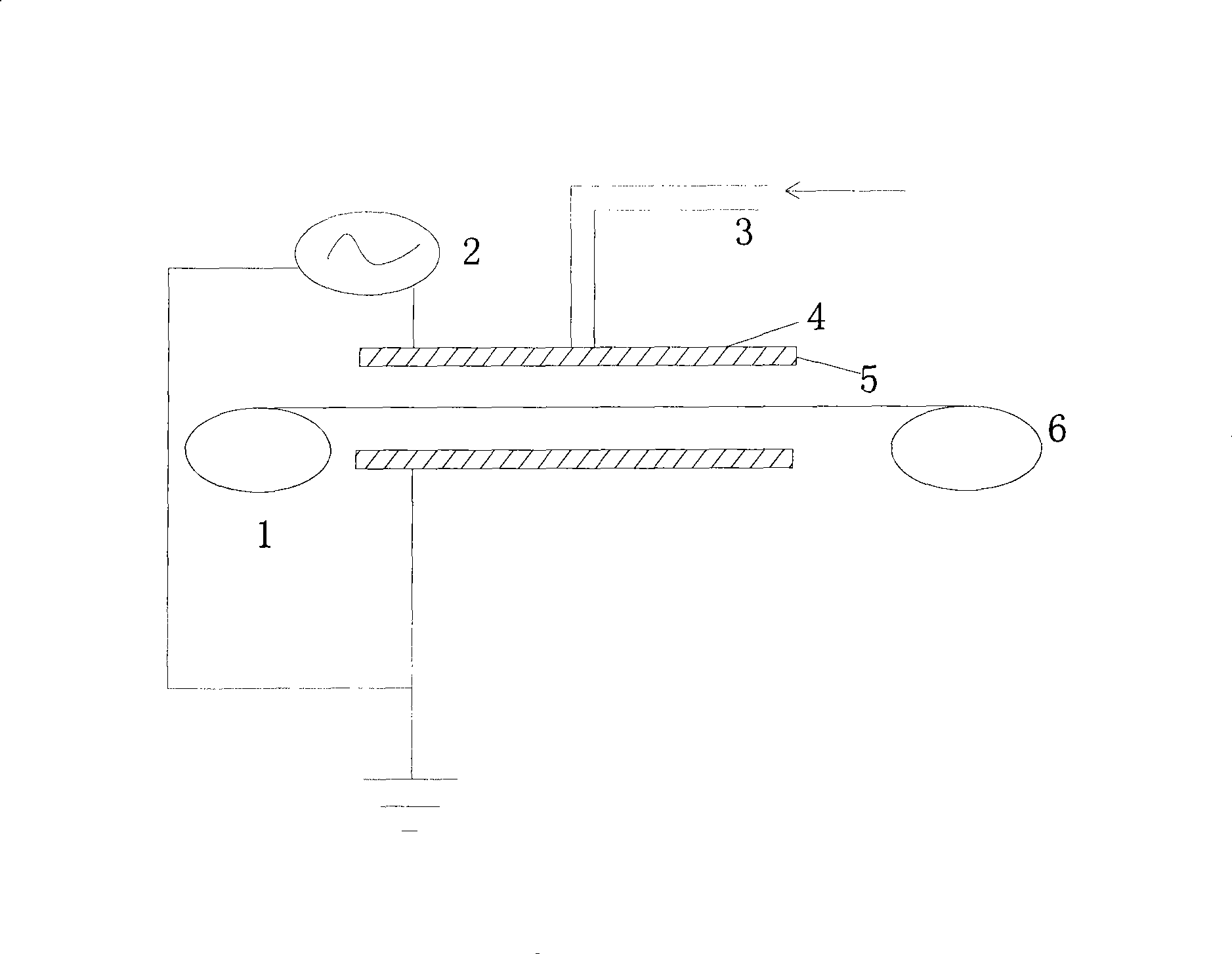

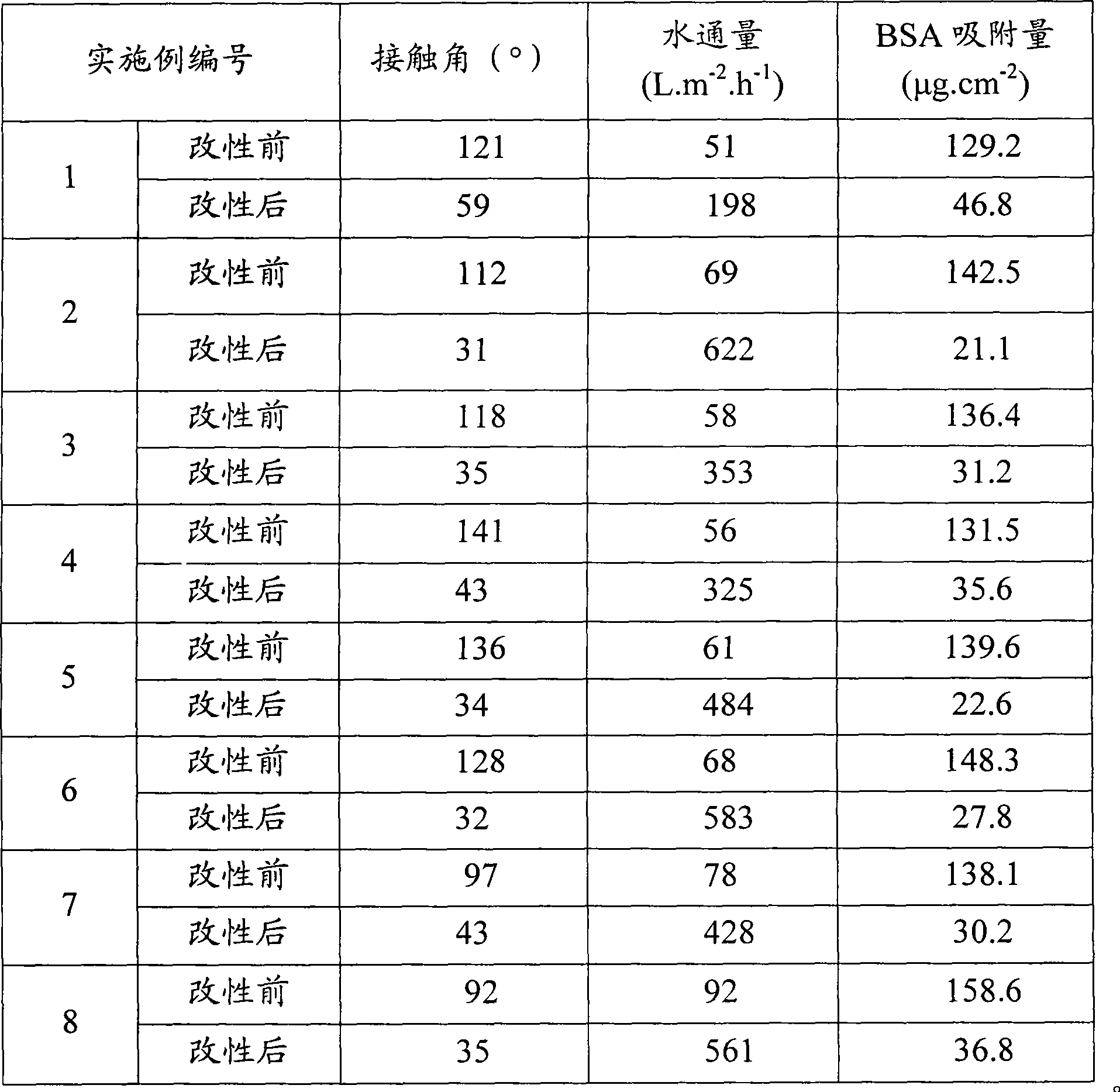

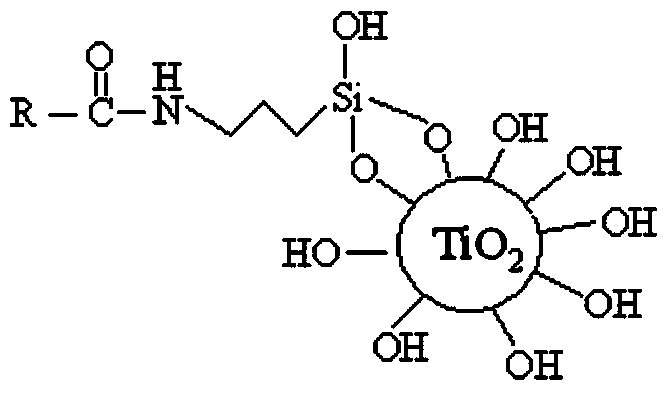

Hydrophilic modification method for polytetrafluoroethylene membrane

ActiveCN104998562AImprove featuresImprove filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGlass sheetVacuum drying

The inveniton provides a hydrophilic modification method for a polytetrafluoroethylene membrane. The method comprises the following steps: step 1, subjecting the polytetrafluoroethylene membrane to plasma treatment under a nitrogen atmosphere, and allowing the surface of the polytetrafluoroethylene membrane to generate relatively-stable free radicals and active sites; step 2, placing the polytetrafluoroethylene membrane into an acylic acid solution and carrying out static impregnation for a period of time, then taking the polytetrafluoroethylene membrane out of the solution and then placing the polytetrafluoroethylene membrane between two glase plates, and carrying out thermochemical polymerization in a vacuum drying oven so as to obtain the polytetrafluoroethylene membrane with the surface grafted with polyacrylic acid; and step 3, subjecting the polytetrafluoroethylene membrane to static impregnation in a titanium dioxide sol for a period of time, and allowing titanium dioxide to be assembled onto the surface of the polytetrafluoroethylene membrane through the coordination effect of metal titanium-ion Ti4+ and a carboxyl group on the polyacrylic acid so as to obtain a hydrophilic modified polytetrafluoroethylene membrane. The hydrophilic modified polytetrafluoroethylene membrane prepared by using the method in the invention retains excellent properties of a conventional polytetrafluoroethylene membrane and greatly improves filter performance, hydrophilic property, pollution resistant property and photocatalytic property of the polytetrafluoroethylene membrane.

Owner:深圳市新纳捷科技有限公司

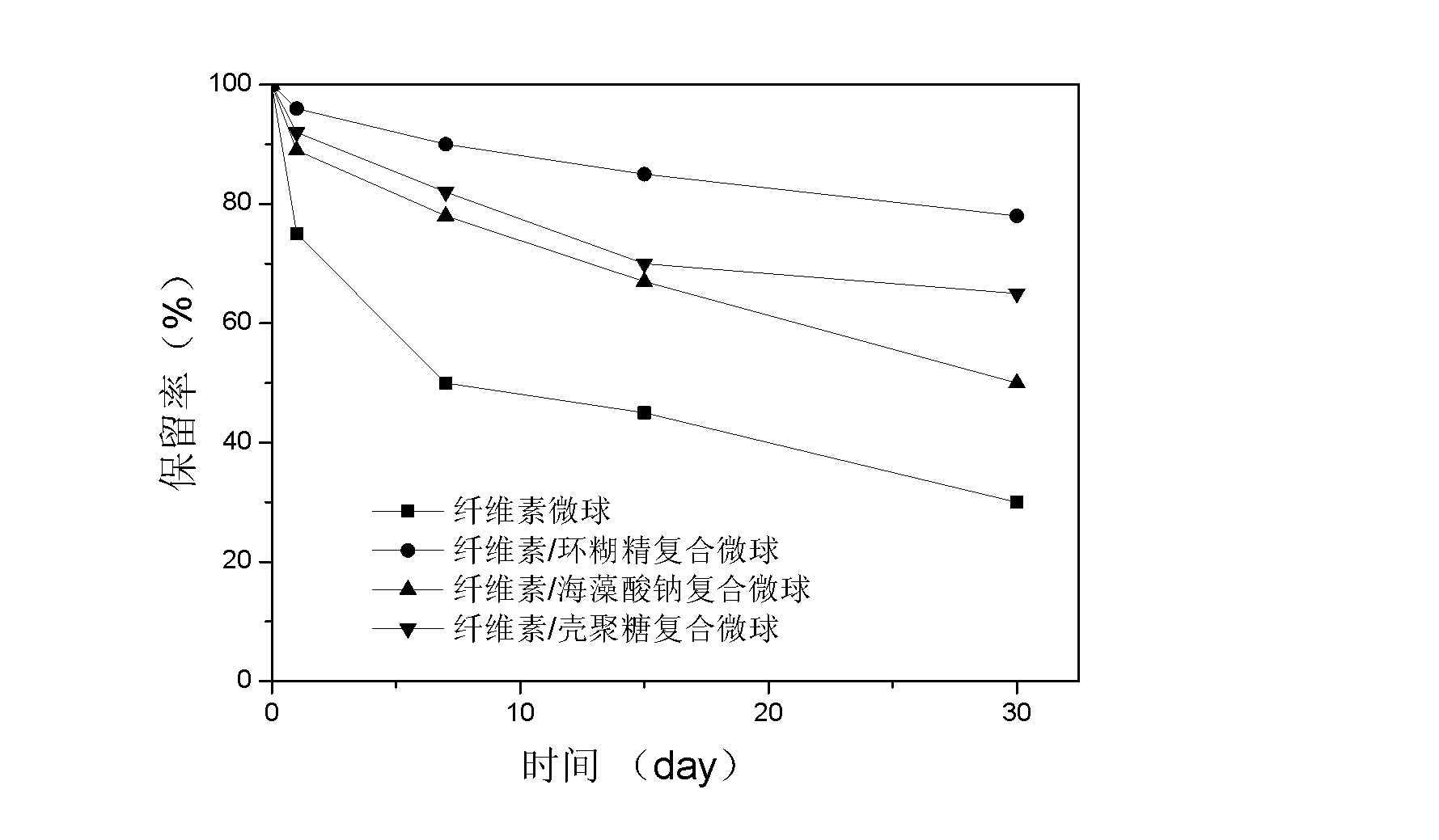

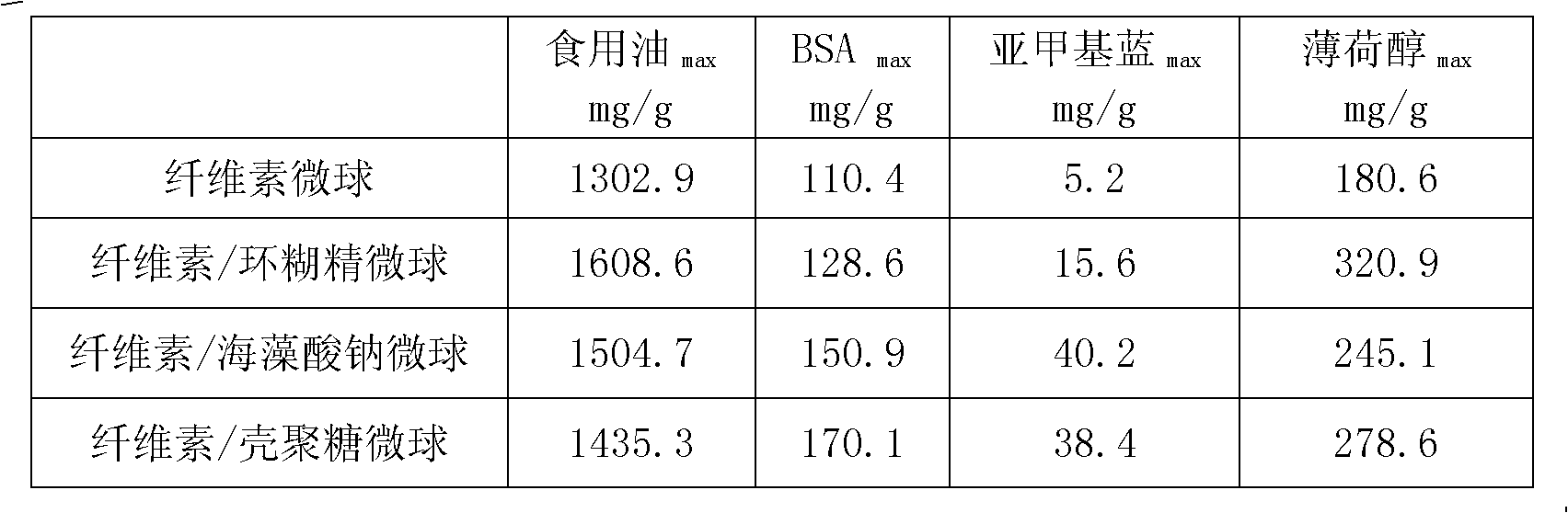

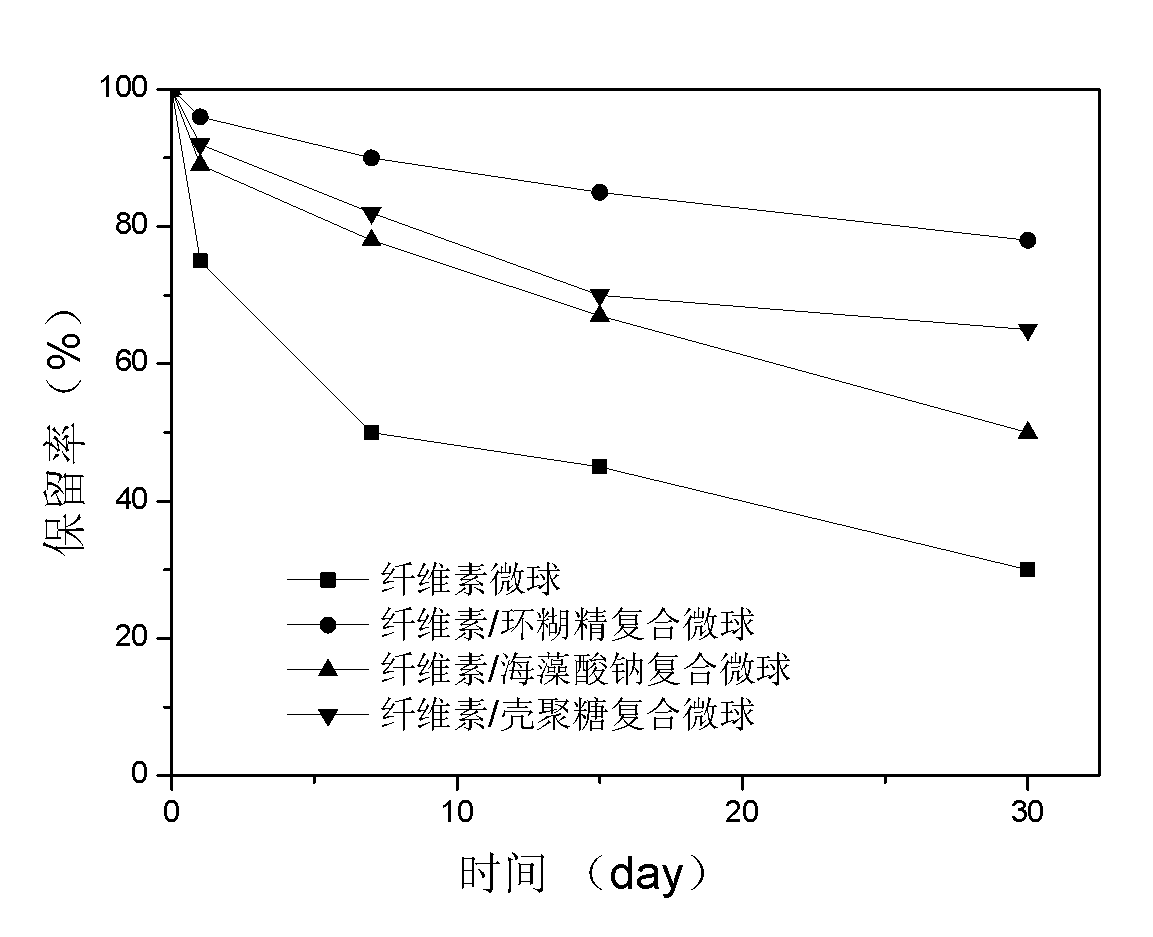

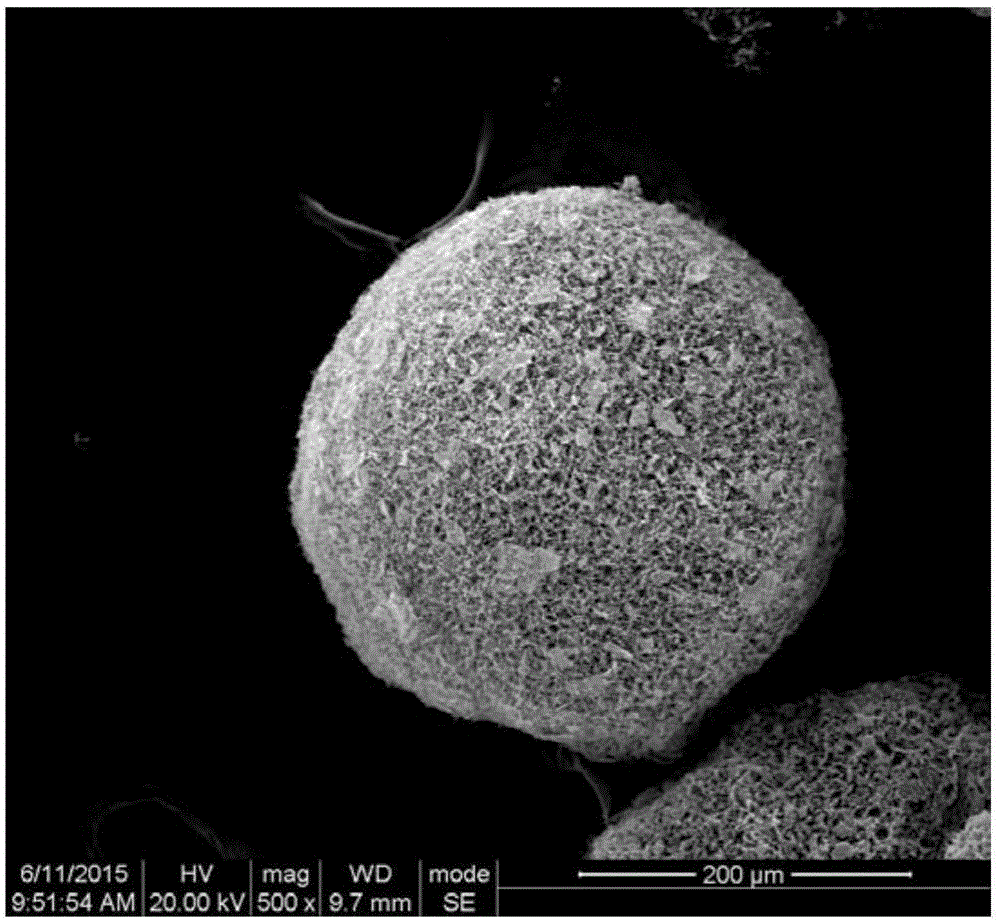

Cellulose composite microsphere and preparation method thereof

InactiveCN102553545ALarge specific surface areaHigh porosityOther chemical processesAlkali metal oxides/hydroxidesSolventUrea

The invention discloses a cellulose composite microsphere, a preparation method thereof and application. The particle size of the cellulose composite microsphere is 1mum-1200mum, the specific surface area of the cellulose composite microsphere is 100m<2> / g-500m<2> / g, and the aperture of the cellulose composite microsphere is 200nm-900nm. The preparation method comprises the following steps of: preparing a mixture solution of cellulose and a composite material by using the cellulose as a matrix, a polymer material as composite material and a water solution of alkali / urea or alkali / thiourea as a solvent, and obtaining the cellulose composite microsphere through sol-gel phase transition and cross-linking agent cross linkage. The advantages of cellulose microsphere are reserved by the cellulose composite microsphere, and due to the adding of the composite material, new functional groups are simultaneously added for the surface of the microsphere and further decoration and modification are facilitated. An organic solvent used in the preparation method disclosed by the invention can be reused, the whole preparation technology is simple, low in time consuming, undemanding for equipment and convenient for industrial production, and the prepared cellulose composite microsphere has a good flow property and mechanical property and a wide application.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

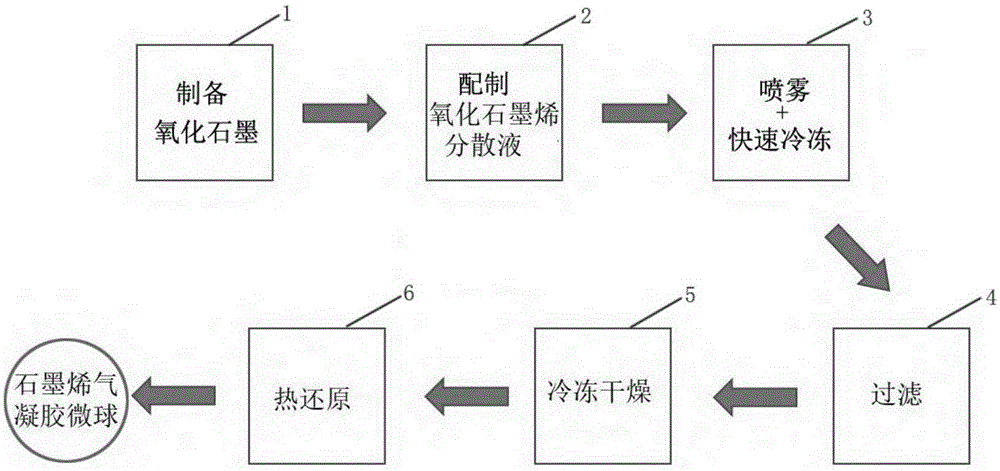

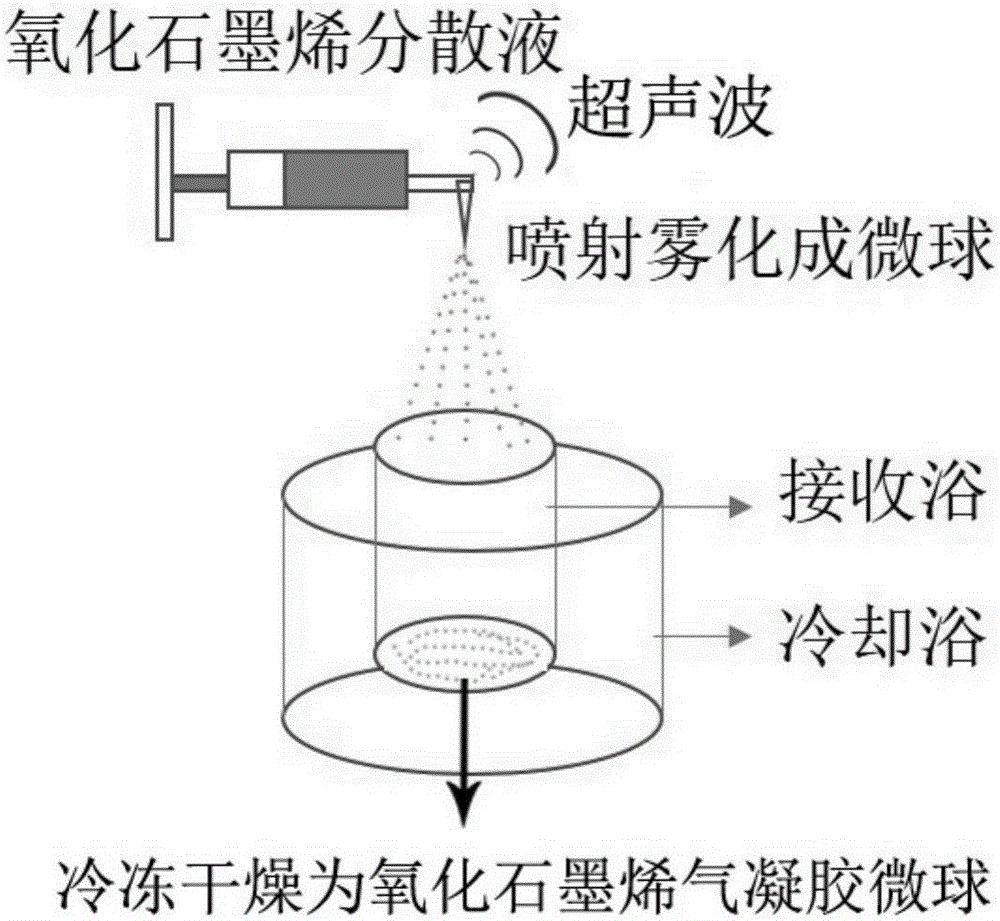

Graphene aerogel microspheres and preparation method and application thereof

ActiveCN105195067AParticle size controllableLarge specific surface areaIon-exchange process apparatusWater cleaningFreeze-dryingMicrosphere

The invention discloses graphene aerogel microspheres and a preparation method and application thereof. The preparation method is characterized in that 1, graphite oxide is prepared; 2, graphene oxide aqueous dispersion is prepared; 3, the graphene oxide aqueous dispersion is atomized through a spraying method into graphene oxide liquid drop microspheres, and meanwhile the microspheres are collected through receiving liquid in a cooling bath; 4, the receiving liquid is filtered to obtain graphene oxide ice microspheres, and then freeze drying is performed on the microspheres to obtain graphene oxide aerogel microspheres; 5, the graphene oxide aerogel microspheres are subjected to thermal reduction to obtain the graphene aerogel microspheres. The preparation method is simple and convenient to implement, no environmental pollution is generated, and the obtained graphene aerogel microspheres are uniform in size and large in specific area, are of a stable center-divergence multi-porous-channel network structure and are used for adsorbing environmental pollutants.

Owner:SICHUAN UNIV

Enzymatic hydrolysis lignin epoxide resin and preparation thereof

The invention provides an enzymolysis lignin epoxy resin and a preparation method thereof. The raw materials include: an enzymolysis lignin-dianhydride prepolymer, a glycidol ether, a catalyst, a curing agent and a filler. The preparation method comprises the following steps that: under the action of the catalyst, an etherification of a hydroxyl group contained in the enzymolysis lignin or a derivative of the enzymolysis lignin and dianhydride is carried to synthesize a prepolymer of enzymolysis lignin-dianhydride; then the prepolymer reacts with the glycidol ether and undergoes etherification and ring closing reaction to obtain an enzymolysis lignin--polyester type epoxy resin. The enzymolysis lignin adopted by the method is natural macromolecular material extracted from the residues which is produced in the preparation of alcohol through the fermentation of wood chips, bamboo and stalk, thereby not only effectively utilizing biological resources, but also replacing petrochemical raw materials. The enzymolysis lignin epoxy resin which can be used as a modifier for engineering materials, adhesives, paints and macromolecular materials has a broad application prospect.

Owner:重庆辉泰化工销售有限公司

Hydrophilic modification method of polymer microporous film

InactiveCN101439265ANot easy to cause pollutionEasy to achieve continuous modificationSemi-permeable membranesPolymer scienceMonomer

The invention discloses a method of atmospheric dielectric barrier discharge plasma to carry out polymer microporous membrane hydrophilic modification. The method comprises the following steps: (1) the polymer microporous membrane is cleaned clearly, dried and then arranged into the solution of an organic monomer for dipping; after the surface of the microporous membrane absorbs the organic monomer, the microporous membrane is taken out and aired; (2) the polymer microporous membrane treated by the step (1) is arranged between the two discharge electrodes of the dielectric barrier discharge to carry out atmospheric dielectric barrier discharge plasma treatment; (3) the polymer microporous membrane treated by step (2) is cleaned and then dried. The method has the characteristics of simple technique, convenient operation, quick processing speed, good and durable processing effect, low cost, being not easy to cause environment pollution, energy saving, and the like.

Owner:ZHEJIANG UNIV

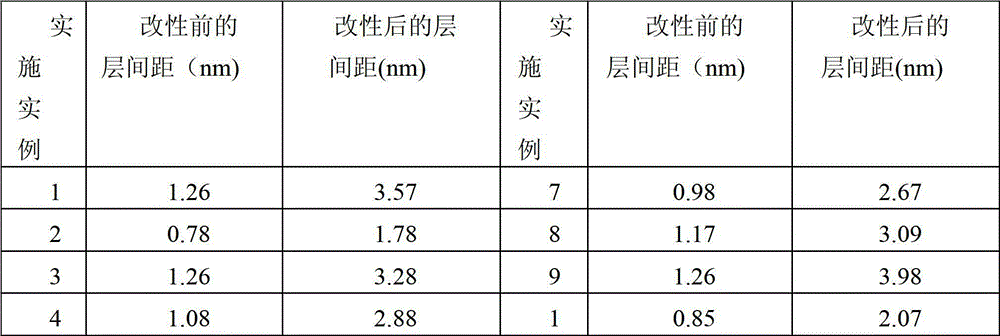

Preparation process of modified china-clay for inserted layer

The invention relates to a method of preparing intercalation modified kaoline, firstly dispersing the kaoline in an intercalation agent solution to form uniform suspension serum, then making ultrasonic treatment, and finally separating, washing, drying and grinding to obtain the products, where the ultrasonic treatment: placing the suspension serum in a ultrasonic reactor, using 30-60 deg. water as medium, regulating ultrasonic frequency to 15-40 KHz, and making mixing ultrasonic treatment for 3-4 hours. It is a method of saving energy sources and benefiting environmental protection, and has high intercalation efficiency, the need time is short, on conditions of relaxative operation and environment, it can make the intercalation ratio up to above 90%.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

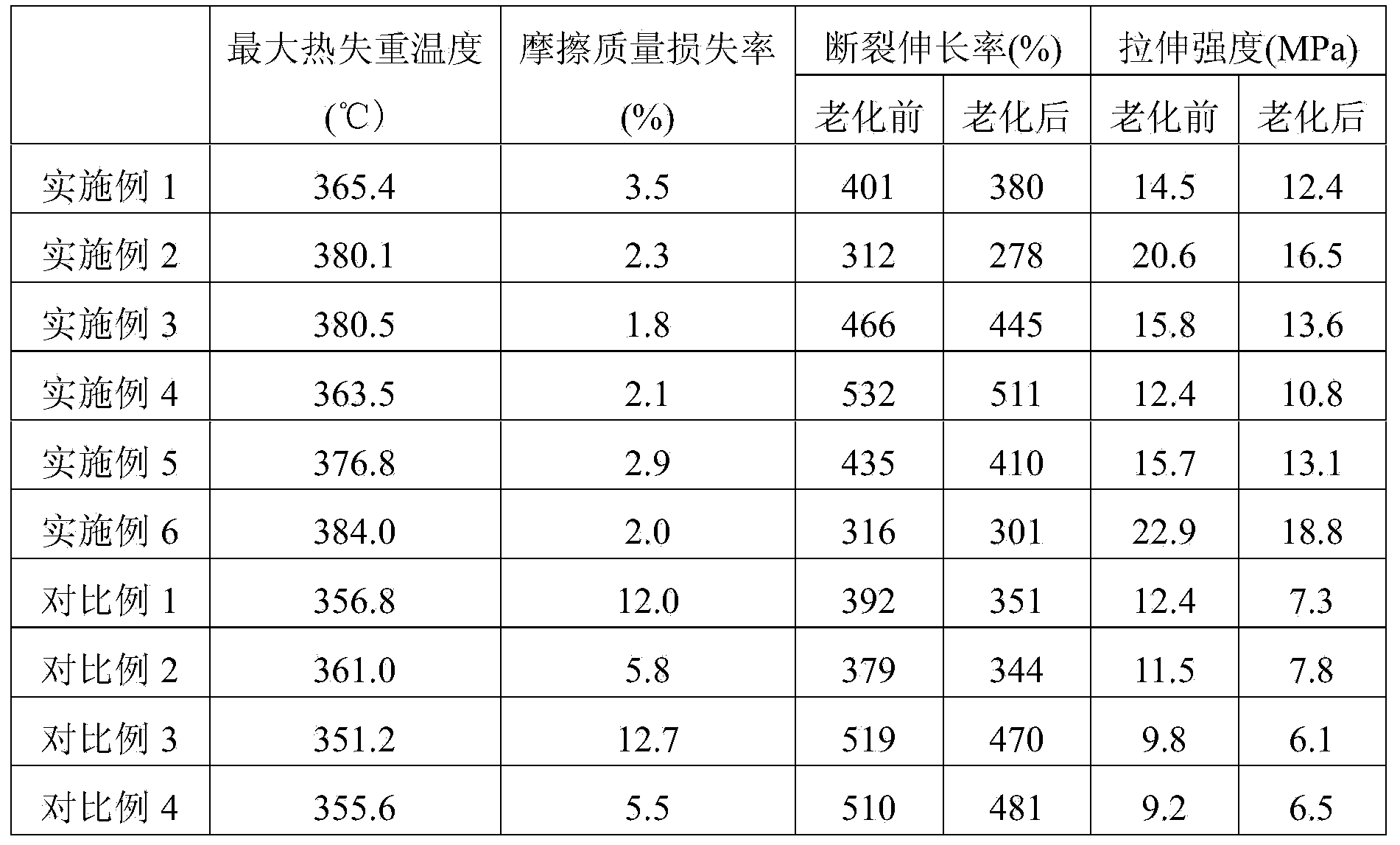

Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

ActiveCN104403548AGood thermal propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention belongs to the technical field of water-based polyurethane paints, and discloses a water-based polyurethane paint containing a polyether glycol / nano TiO2 hybrid material, and a preparation method and application thereof. The paint comprises the following components in parts by mass: 25-75 parts of polyether glycol / nano titanium dioxide hybrid material, 15-65 parts of diisocyanate, 100 parts of polyether glycol, 8-16 parts of polyhydroxy-carboxylic acid, 0.05-0.5 part of organo-metallic catalyst, 0.5-10 parts of crosslinking agent, 6.2-12.4 parts of neutralizer, 1-8 parts of chain extender and 0.2-2.0 parts of defoaming agent. The paint enhances the compatibility between the nano titanium dioxide and polyurethane base, has the advantages of favorable thermal properties, favorable mechanical properties, favorable wear resistance and excellent ultraviolet resistance, and can be widely used in the fields of architectural paints, automobile paints, wood paints, electrodeposition paints, paper conditioning paints, glass fiber paints, electrophoretic paints and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and preparation method thereof

ActiveCN102746784AExcellent performanceGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryWetting

The invention discloses an energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and a preparation method thereof. The functional coating is prepared from the following raw materials: an aqueous polyurethane dispersion, a flame retardant, a flame-retardant antismoke agent, a hollow glass bead, a wetting dispersant, an anti-settling agent, a thickening agent, water, a leveling agent and a de-foaming agent, has the functions of heat preservation, flame retarding, water prevention and corrosion resistance and the like, is unlikely to become yellow when in use, is safe and reliable, is excellent in performance, is good in compatibility with pigment dyestuff, is unlikely to damage the coated surface, is easy to modify, is nontoxic, is safe to use, does not pollute environment and is suitable for the fields of inner and outer wall coating, pipeline coating, wood furniture coating, decoration coating, chemical corrosion-proof coating and the like.

Owner:江苏瑞丰科技实业有限公司

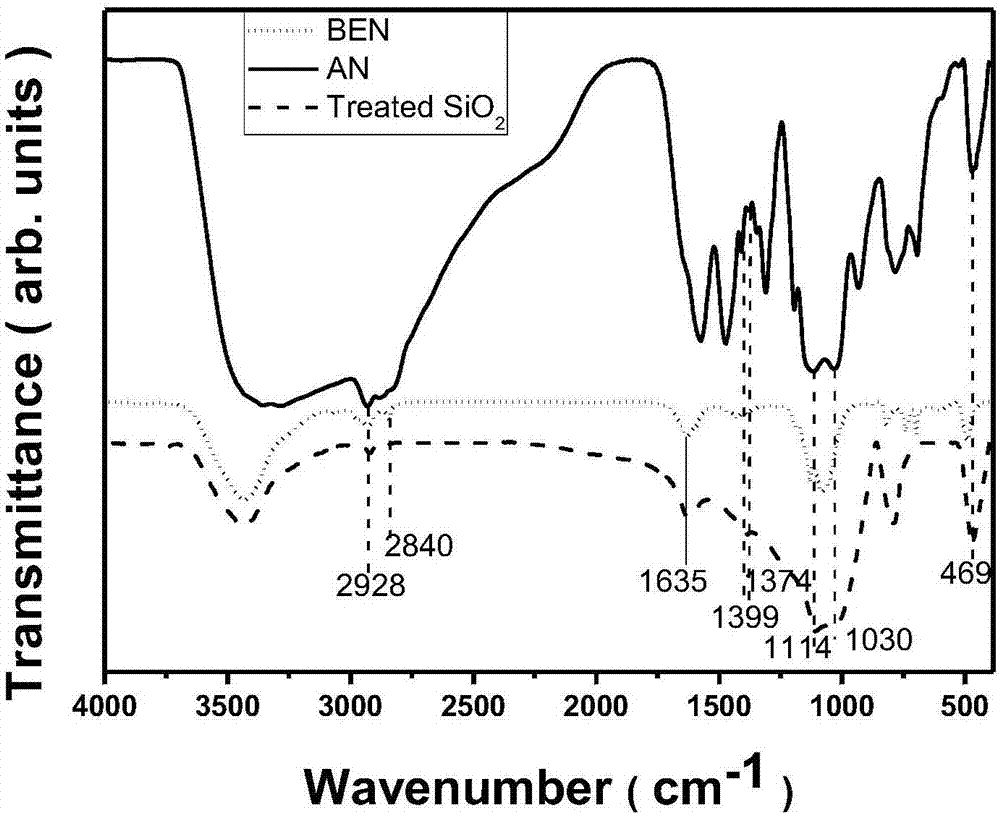

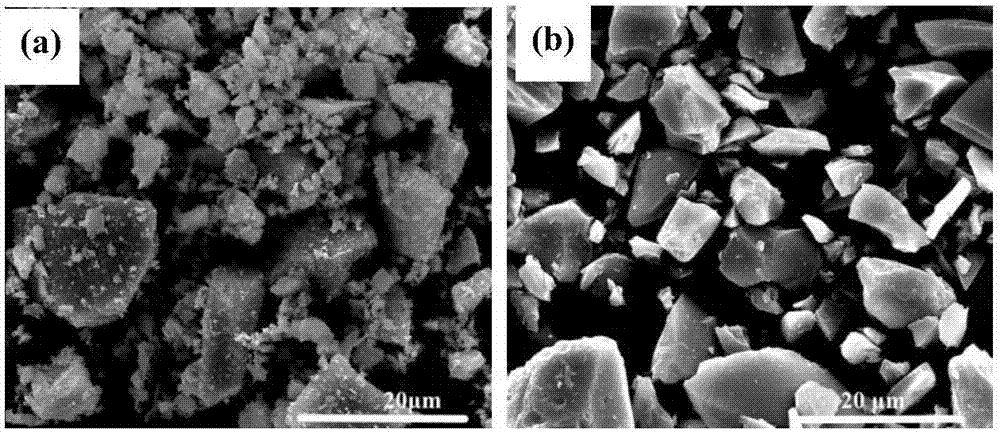

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate is disclosed. The method includes 1) adding silicon dioxide ceramic powder into a liquid mixture of hydrogen peroxide and concentrated hydrochloric acid after the silicon dioxide ceramic powder is dried, and heating the mixture to 50-70 DEG C to obtain a suspension; 2) subjecting the suspension to suction filtration and drying a product in a vacuum environment; 3) adding the silicon dioxide ceramic powder obtained in the step 2) into a solution mixture of deionized water and absolute alcohol, adjusting the pH value to be 3-5, weighing a coupling agent the weight of which is 1.0-2.5% of the weight of the silicon dioxide ceramic powder, performing ball milling, and fully mixing the mixture to obtain a material mixture; 4) filtering and drying the material mixture to obtain modified silicon dioxide ceramic powder; 5) ball-milling and mixing the modified silicon dioxide powder, chopped glass fibers and polytetrafluoroethylene, and then performing demulsification to obtain dough; and 6) subjecting the dough to molding and hot-pressed sintering. The ceramic-filled material prepared by the method has a low dielectric constant (with epsilon being equal to 2.94), ultralow dielectric loss (with tg[delta] being less than 0.0008, 10 GHz), low water absorption (less than 0.02%) and a small thermal expansion coefficient (less than 20 ppm / DEG C).

Owner:汕头超声覆铜板科技有限公司

Preparation method of polypropylene nano composite material

ActiveCN102086280AGood modification effectImprove interface strengthHeat deflection temperatureMasterbatch

The application of the invention discloses a preparation method of a polypropylene nano composite material, which comprises the following steps of: (1) proportionally fusing and blending inorganic nano particles and maleic anhydride grafted polypropylene on an internal mixer, an open mill or a screw extruder to obtain a reinforcing agent master batch; (2) proportionally fusing and blending a beta crystal type nucleating agent and the maleic anhydride grafted polypropylene on the internal mixer, the open mill or the screw extruder to obtain a flexibilizer master batch; and (3) proportionally diluting and dispersing the reinforcing agent master batch and the flexibilizer master batch in a polypropylene high-polymer substrate, and carrying out injection molding to obtain the polypropylene nano composite material. With the preparation method, the technical problem that the nano particles and the nucleating agent agglomerate in the polypropylene substrate is well solved; when the flexibility of the modified polypropylene material is greatly improved, strength, rigidity, heat deflection temperature and other parameters are also improved to a certain extent, and simultaneously the density of the material is hardly increased so that a series of high-strength, high-flexibility and high-heat resistance modified polypropylene materials can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing silicon-aluminum aerogel by using fly ash as raw material through normal pressure drying

The invention discloses a method for preparing silicon-aluminum aerogel by using fly ash as a raw material through normal pressure drying, which comprises the following steps of: mixing, grinding and calcining the fly ash and sodium carbonate to enable acidic oxides and amphoteric oxides in the fly ash to react with the sodium carbonate, then dissolving a sintered material with hydrochloric acid, and carrying out suction filtration to obtain a filtrate, i.e. silicon-aluminum sol; settling and aging the silicon-aluminum sol to form silicon-aluminum gel; soaking with circulating water to remove chloride ions; soaking with an ethanol solvent instead of water; soaking with an organosilicon compound as a surface hydrophobic agent for surface hydrophobic treatment; and preparing the silicon-aluminum aerogel through normal pressure drying. The invention uses the industrial waste fly ash as the raw material to replace an organosilicon source with high price and a certain toxicity, and uses normal pressure drying to replace supercritical drying, so the safety performance is greatly enhanced, the production cost is greatly lowered; and the method has simple process and convenient operation and is suitable for large-scale production. The prepared silicon-aluminum aerogel can be widely applied to the fields of heat insulating materials and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and preparation method thereof

InactiveCN103351618AGood modification effectImprove antistatic performanceZinc borateAntistatic agent

The invention relates to an antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and a preparation method thereof. The fire-retardant master batch is composed of following components in parts by weight: 25 to 50 parts of PA, 15 to 30 parts of alkyl phosphinate fire-retardant, 15 to 30 parts of melamine polyphosphate fire retardant, 8 to 15 parts of zinc borate fire retardant, 4 to 6 parts of CTI improver, 1 to 1.5 parts of antistatic agent, 3 to 8 parts of flexibilizer, 0.5 to 1 part of coupling agent, 0.7 to 1.5 parts of lubricant, and 0.3 to 1 part of anti-oxidant. The sum of the weight ratio of components mentioned above is 100 wt%. The fire-retardant master batch is used to produce fire-retardant enhanced and modified nylon, meets standards of the United States underwriters laboratories (UL)-941.6mm and a higher V-0 grade, simultaneously achieves that glowing wire temperature (GWIT) is equal to or larger than 750 DEG C and the CTI value is equal to or larger than 600 V, also has a antistatic performance, meets European Union RoHS, International Electrotechnical Commission (IEC) halogen-free and Reach rule requirements, is easy to use and excellent in comprehensive performance, and does not affect color matching.

Owner:GUANGDONG WAYLAM ENG PLASTICS

Elastic plastics blended antioxidation modified bituminous water-proof coiled material

InactiveCN1354203AGood low temperature flexibilityImprove high temperature resistanceOther chemical processesBuilding insulationsBituminous waterproofingThermoplastic elastomer

The present invention relates to a modified water-proofing asphalt roll material (called SA roll material for short), and is characterized by that in the raw material formula of asphalt 4-15% of thermoplastic elastomer polystyrene-butadiene-styrene block copolymer (SBS), 3-12% of atactic polypropylene (APP), 1-8% of light shielding agent, 0.05-3% of antioxidant, 0.05-3% of light stabilizer and 0.05-3% of UV absorbing agent. Said water-proofing roll material possesses low-temp. resistance, high-temp. resistance. UV-resisting property and good ageing resistance.

Owner:CHONGQING CITY NEW TYPE WATER PROOFING MATERIAL

Enzymatic hydrolysis lignin epoxy resin material formula and its preparation method

The invention provides a raw materials formula of enzymolysis lignin epoxy resin and its fabrication method. The formula includes enzymolysis lignin or its derivatives, bisphenol A-type compound, epichlorohydrin or its mixture with organic solvent, catalyst, curing agent, and filler. The preparation method includes adding enzymolysis lignin or its derivatives into epichlorohydrin solution or its mixture with organic solvent, stirring and adding catalyst, curing agent or the mixture of curing agent and filler, heating and reacting completely, vacuum-distilling to remove the excessive epichlorohydrin or organic solvent to obtain brown solid insoluble in water, washing, and drying to obtain enzymolysis lignin epoxy resin. The adopted enzymolysis lignin is the natural polymer material extracted from wood, bamboo and straw, which not only effectively use the biological resources, but also can replace petrochemical raw materials. The prepared enzymolysis lignin epoxy resin can be used for engineering materials, adhesives, coating or polymer materials modifier, which has a broad application prospect.

Owner:重庆辉泰化工销售有限公司

Residual oil hydrogenation catalyst and preparation method and use thereof

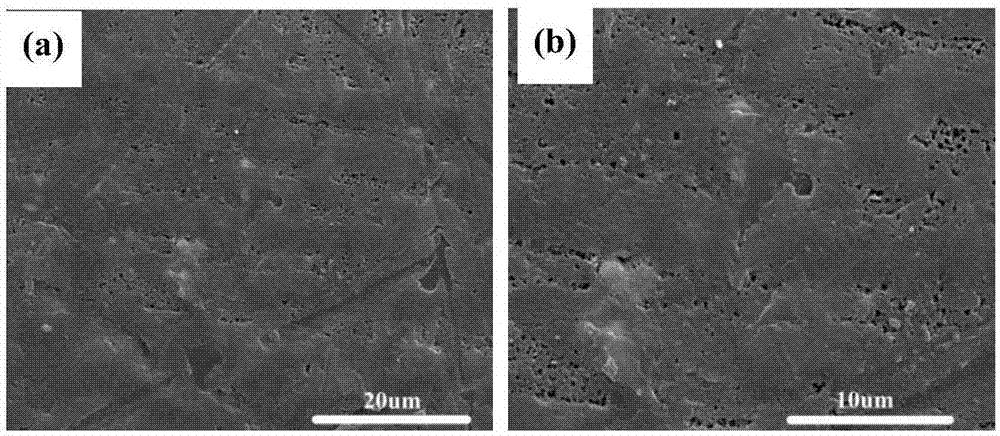

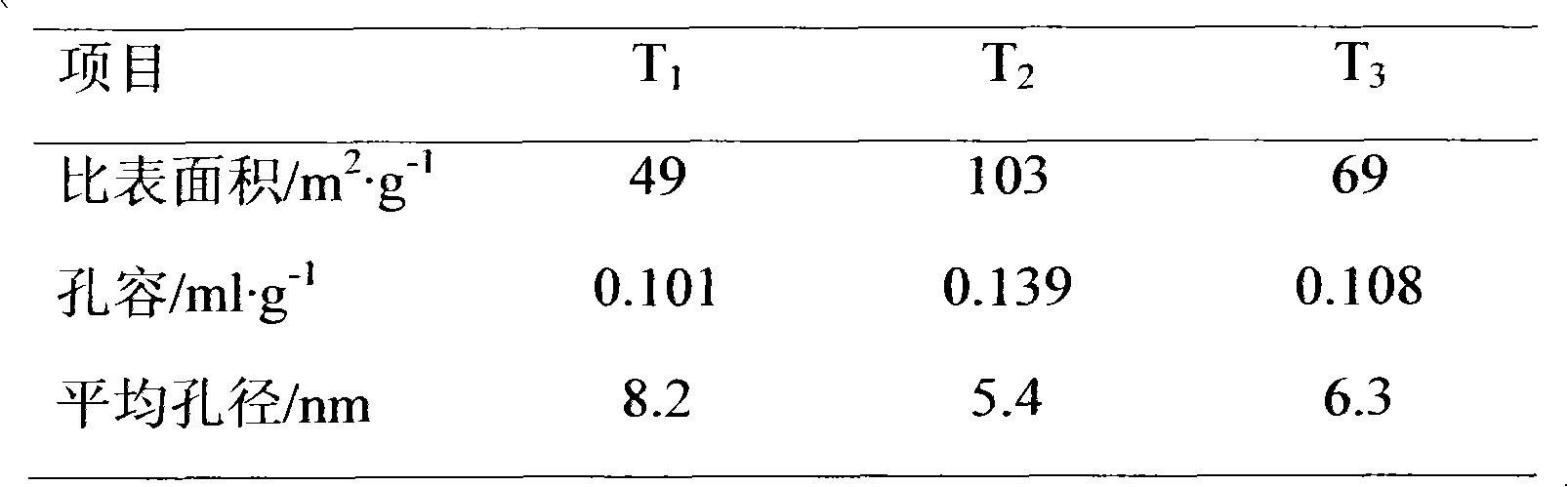

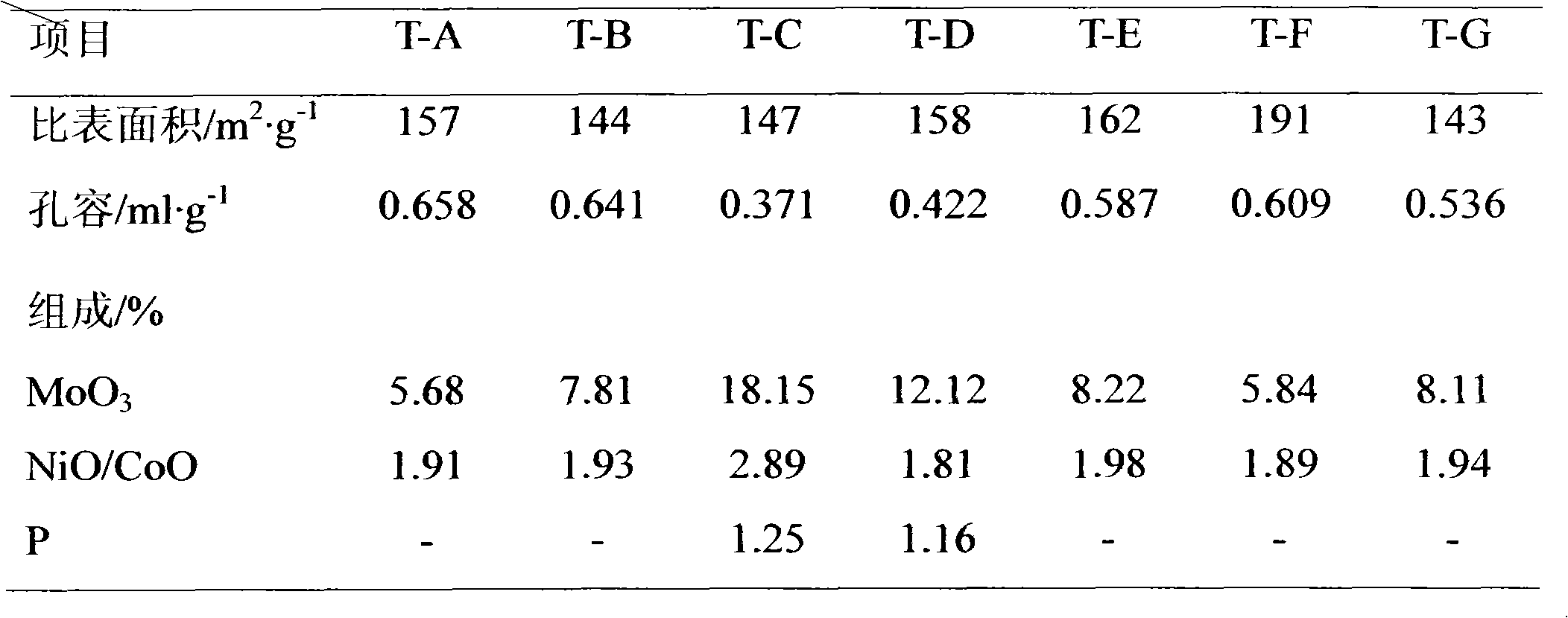

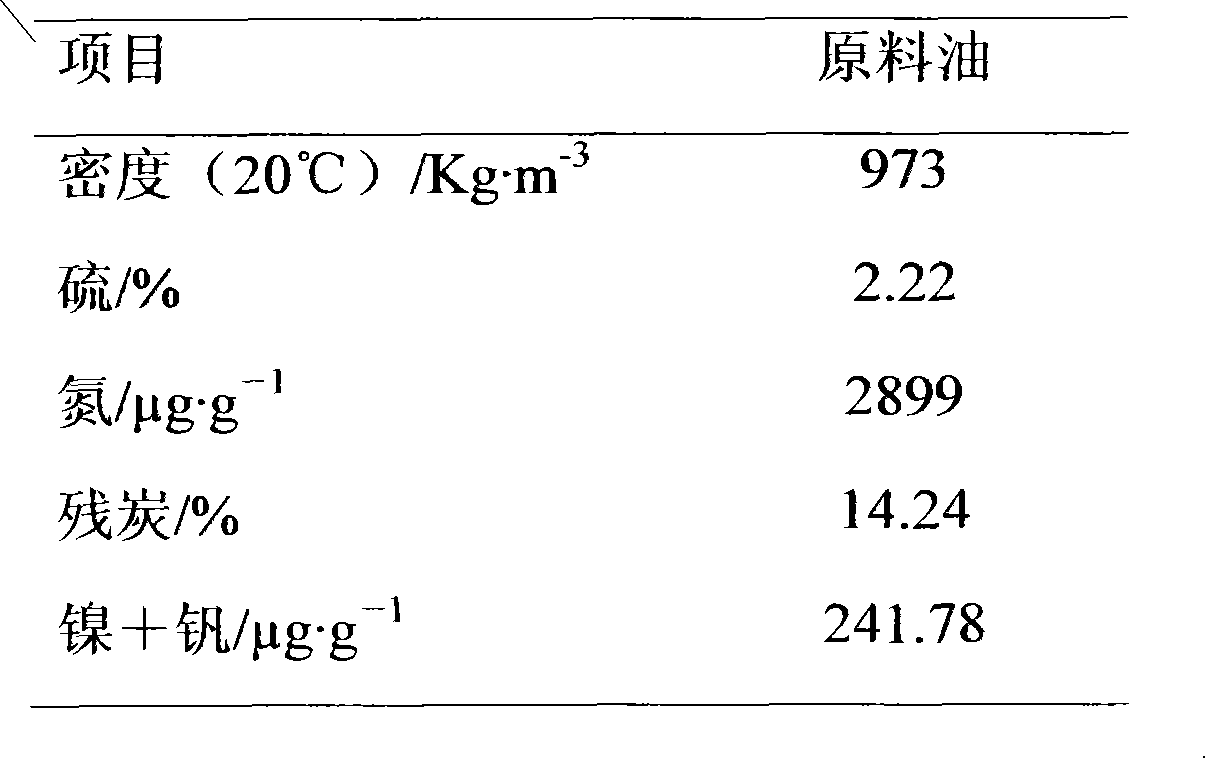

ActiveCN101491764AIncrease acidityImprove cracking capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationStrong acids

The invention relates to a residual oil hydrogenation catalyst, a preparation method and application thereof. The residual oil hydrogenation catalyst contains modified kaolin; the process for modifying the kaolin mainly comprises the steps of roasting and treating raw kaolin, and then treating the raw kaolin with mixed acid of strong acid and weak acid; and the modified kaolin has larger aperture and proper surface property, and is properly used as a carrier material of the residual oil hydrogenation catalyst. The residual oil hydrogenation catalyst adopts an impregnation method to load active metal components of VIB and VIII families; and the prepared catalyst can be applied in the field of hydrogenation demetallization, hydrogenation desulfurization, hydrogenation conversion, and the like of heavy oil or residual oil, and has good using performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

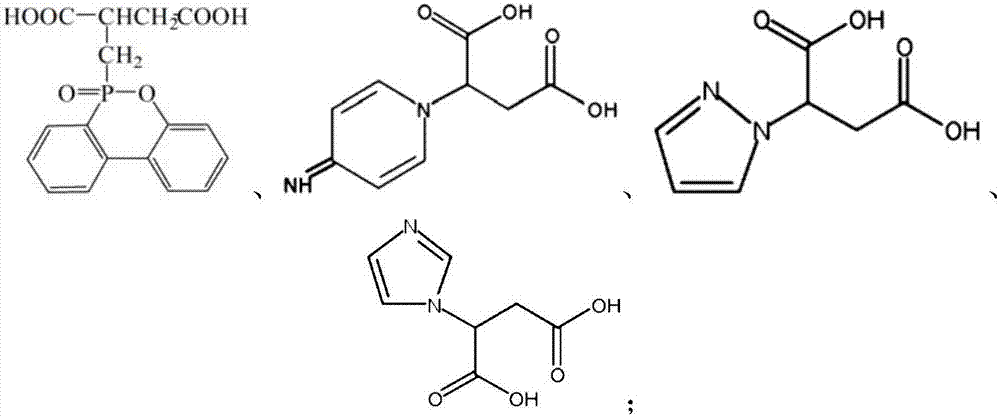

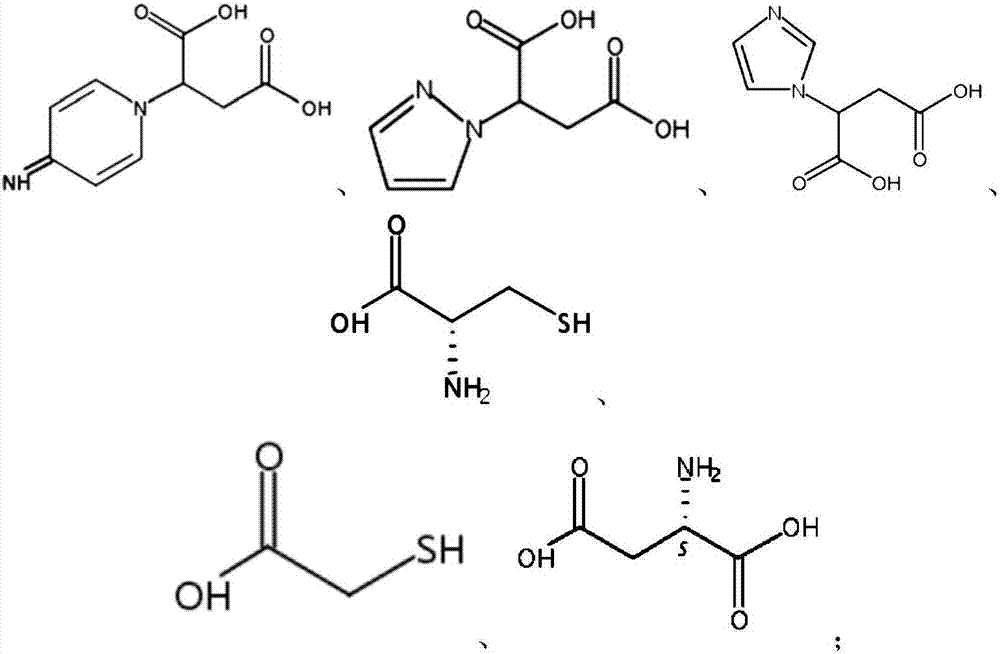

1,3-propanediol and preparation method thereof

ActiveCN106866740AHigh molecular weightGood compatibilityGroup 5/15 element organic compoundsEnd-groupPhosphate

The invention relates to 1,3-propanediol and a preparation method thereof. Firstly, through the melt esterification reaction between dibasic acid and pentaerythritol, DAPER with the terminal group being carboxyl is prepared; then, DADA with the terminal group containing carboxyl is prepared through the melt condensation reaction between the double-functional-group organic acid containing functional elements and dihydric alcohol; the double functional groups in the double-functional-group organic acid containing functional elements are selected from phosphate, carboxylic group and hydrosulphonyl; the functional elements are one kind of materials from P, S and N, or the combination of S and N; finally, the DAPER is added into the DADA to prepare the final product through the esterification reaction between the DAPER and the DADA. The defects of storage and use difficulty, single purpose due to simple structure, environment pollution in the preparation process and the like of the conventional liquid type 1,3-propanediol are overcome. The finally prepared 1,3-propanediol is solid materials with the high molecular weight; the terminal group of the molecule is a reaction active group; 8.14 to 18.32 weight percent of functional elements are contained inside the terminal group of the molecule; the advantages of high thermal stability, wide purposes and the like are realized.

Owner:DONGHUA UNIV +1

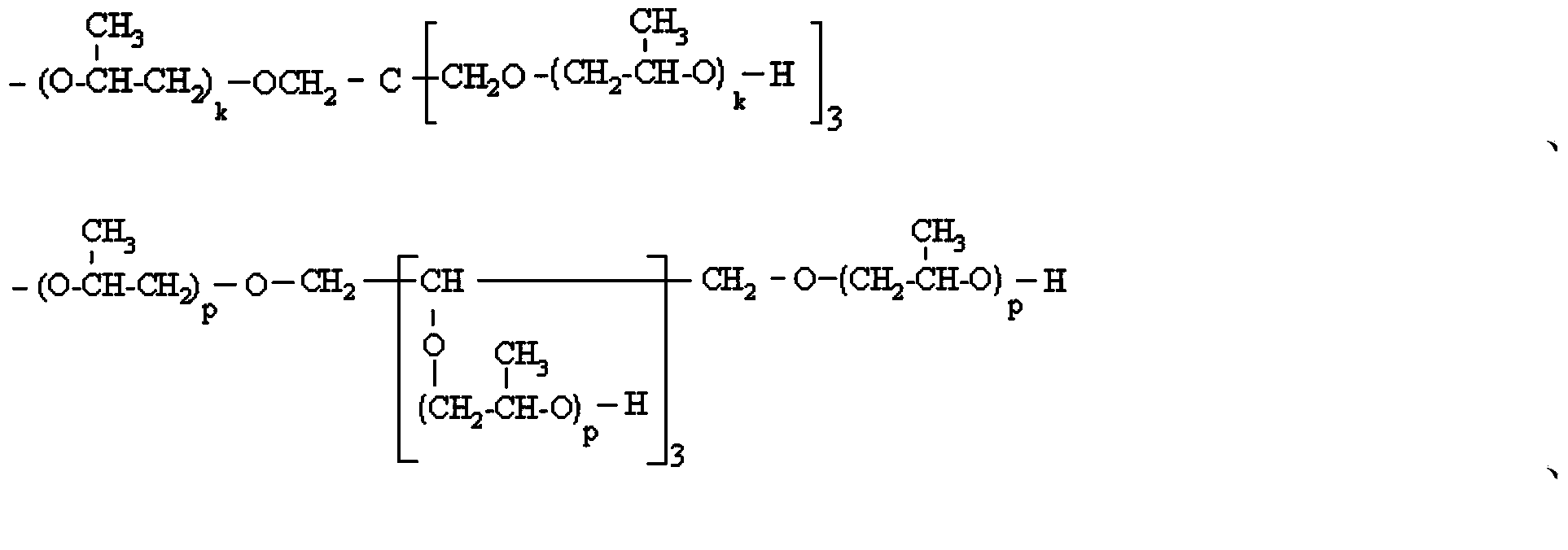

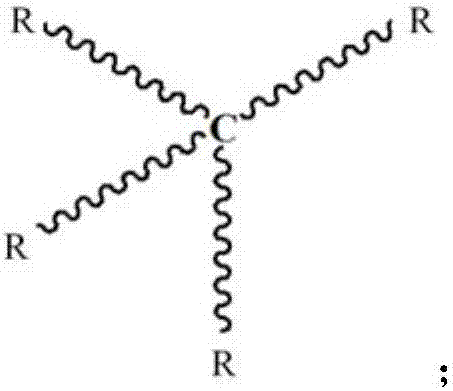

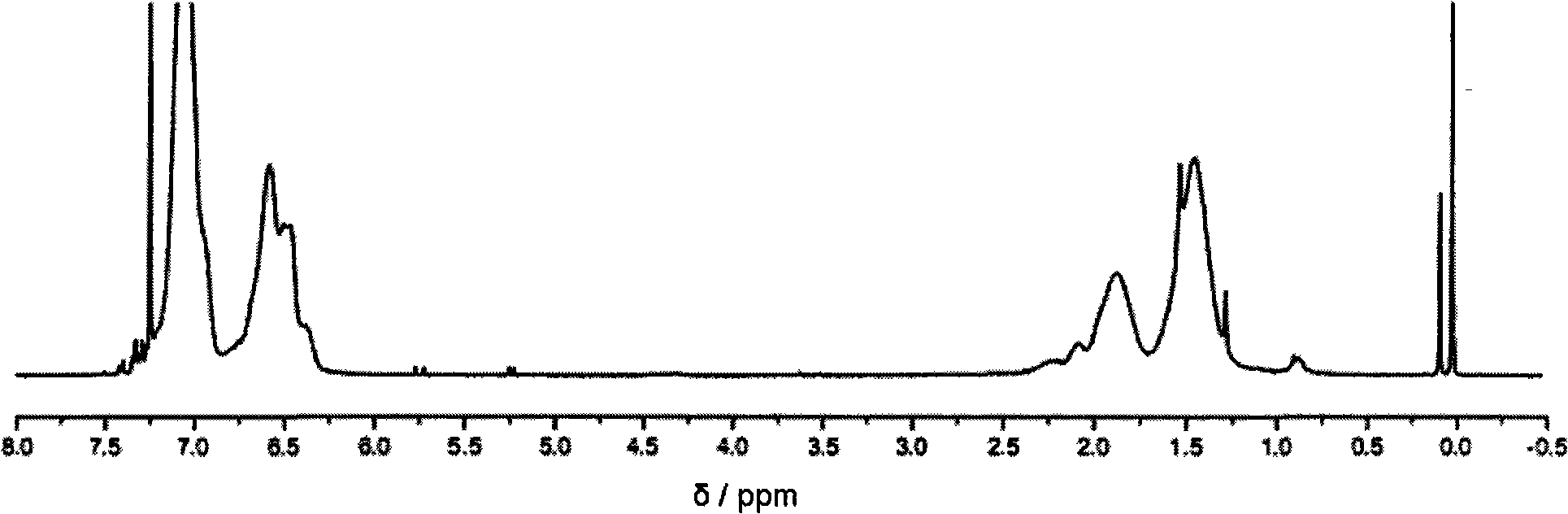

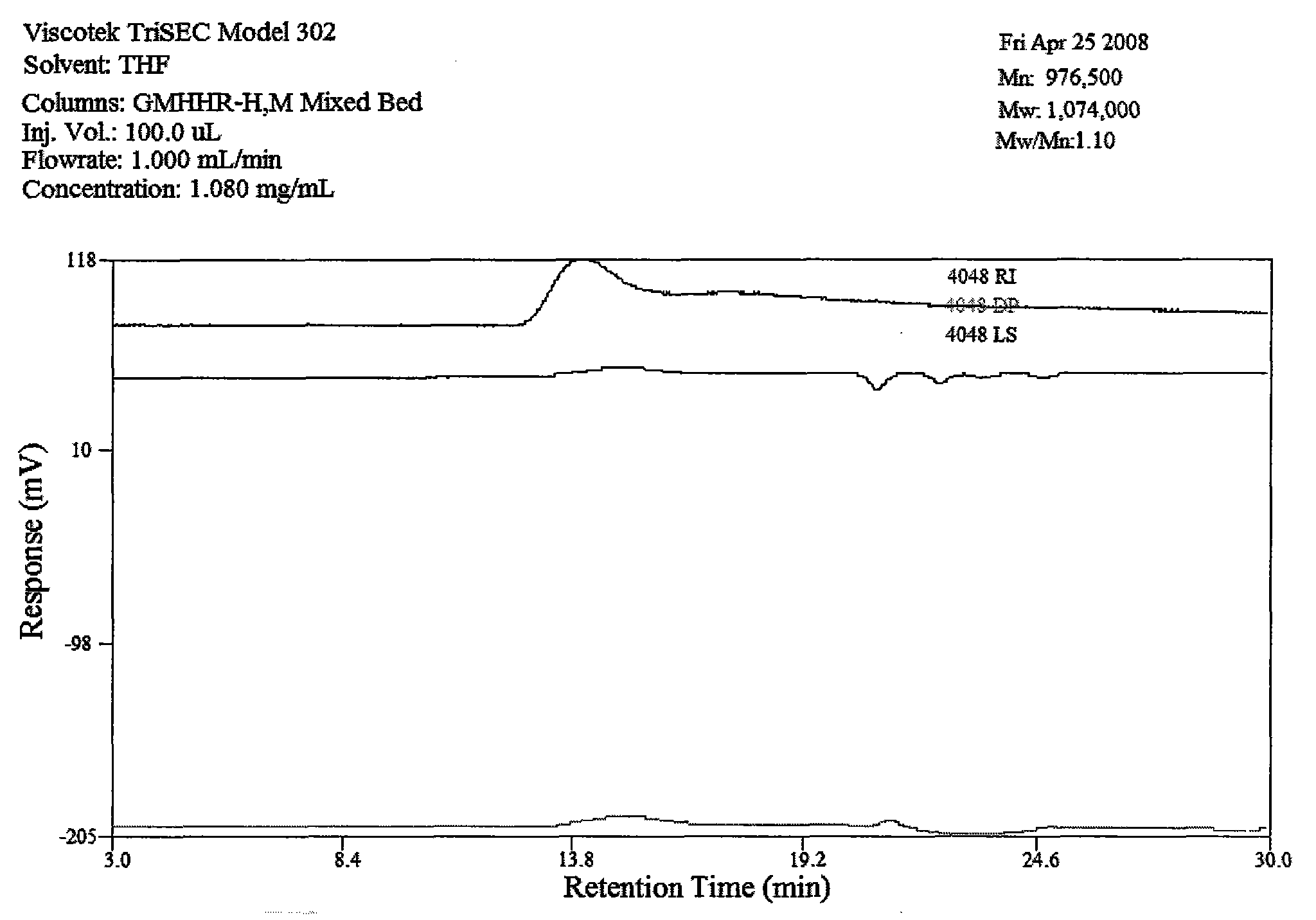

Multi-arm star-type polymer and preparation method thereof

The invention discloses a multi-arm star-type polymer and a preparation method thereof. The method synthesizes the multi-arm star-type polymer by a method with the following two steps of step one: taking a complex formed by a polydentate nitrogen-contained compound and a transitional metal halide as a catalytic system so as to catalyze the polymerization of atom transfer free radicals and self-condensing vinyl of a monomer, thus preparing and obtaining the halogen atom-contained hyperbranched polystyrene macromolecular initiator taken as the star-type polymer core; and step two: taking the complex formed by the the polydentate nitrogen-contained compound and the transitional metal halide as the catalytic system and taking the prepared halogen atom-contained hyperbranched polystyrene macromolecular as the initiator to initiate the polymerization of the atom transfer free radicals of the monomer, thus preparing and obtaining the multi-arm star-type polymer with controllable core structure, core size, core property, arm number, arm length and arm property and adjustable molecular weight within wider range.

Owner:INST OF CHEM CHINESE ACAD OF SCI

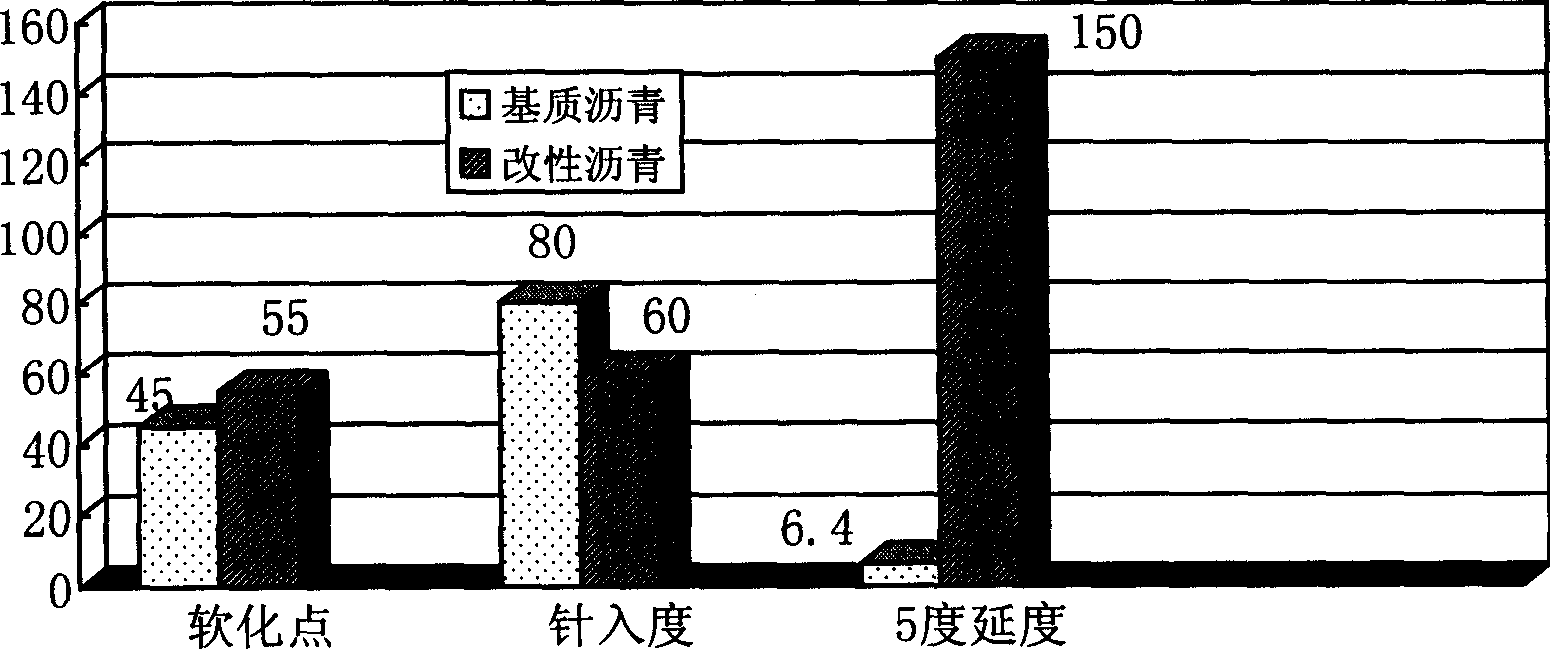

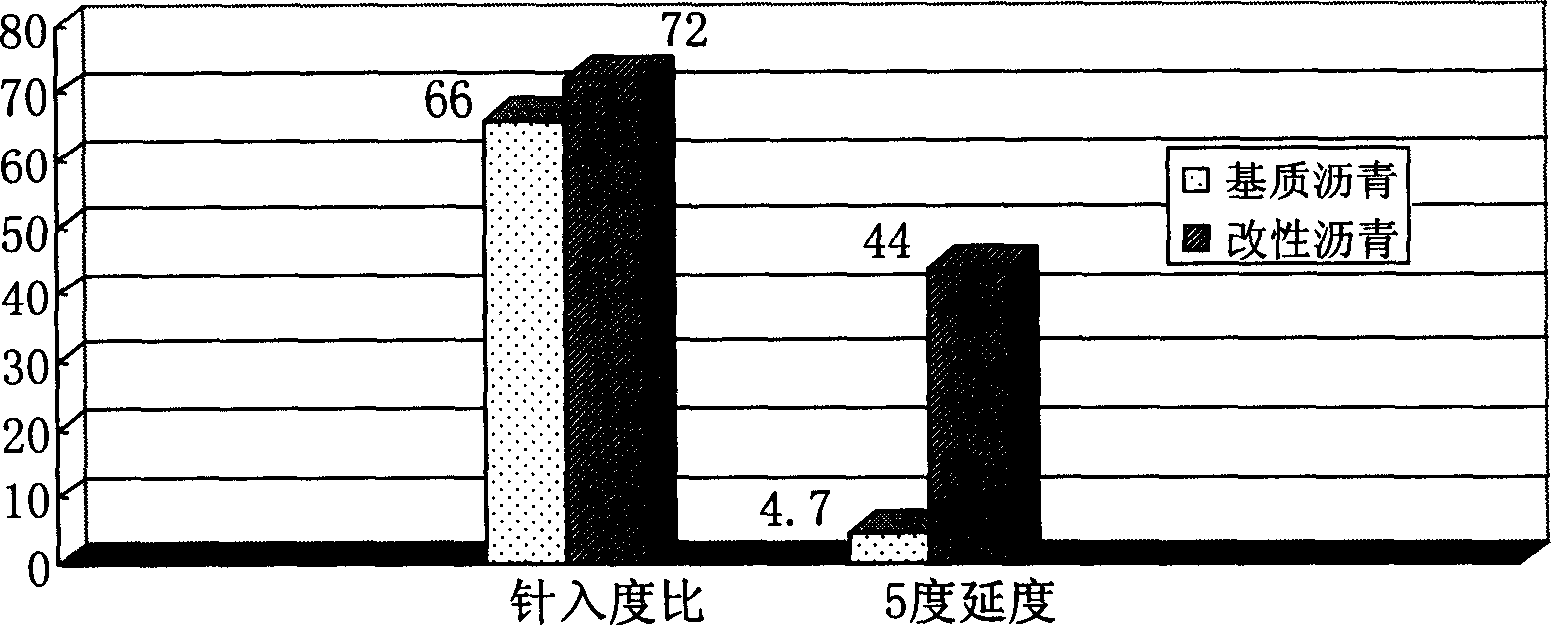

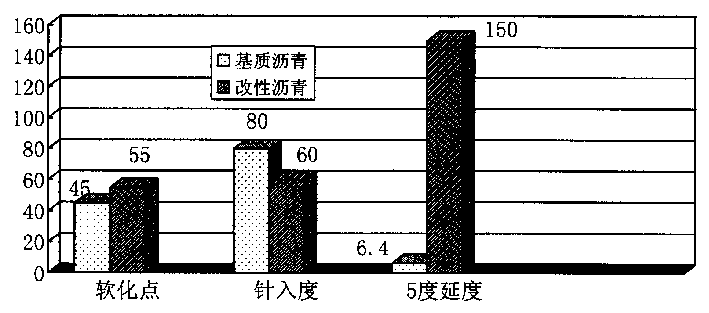

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

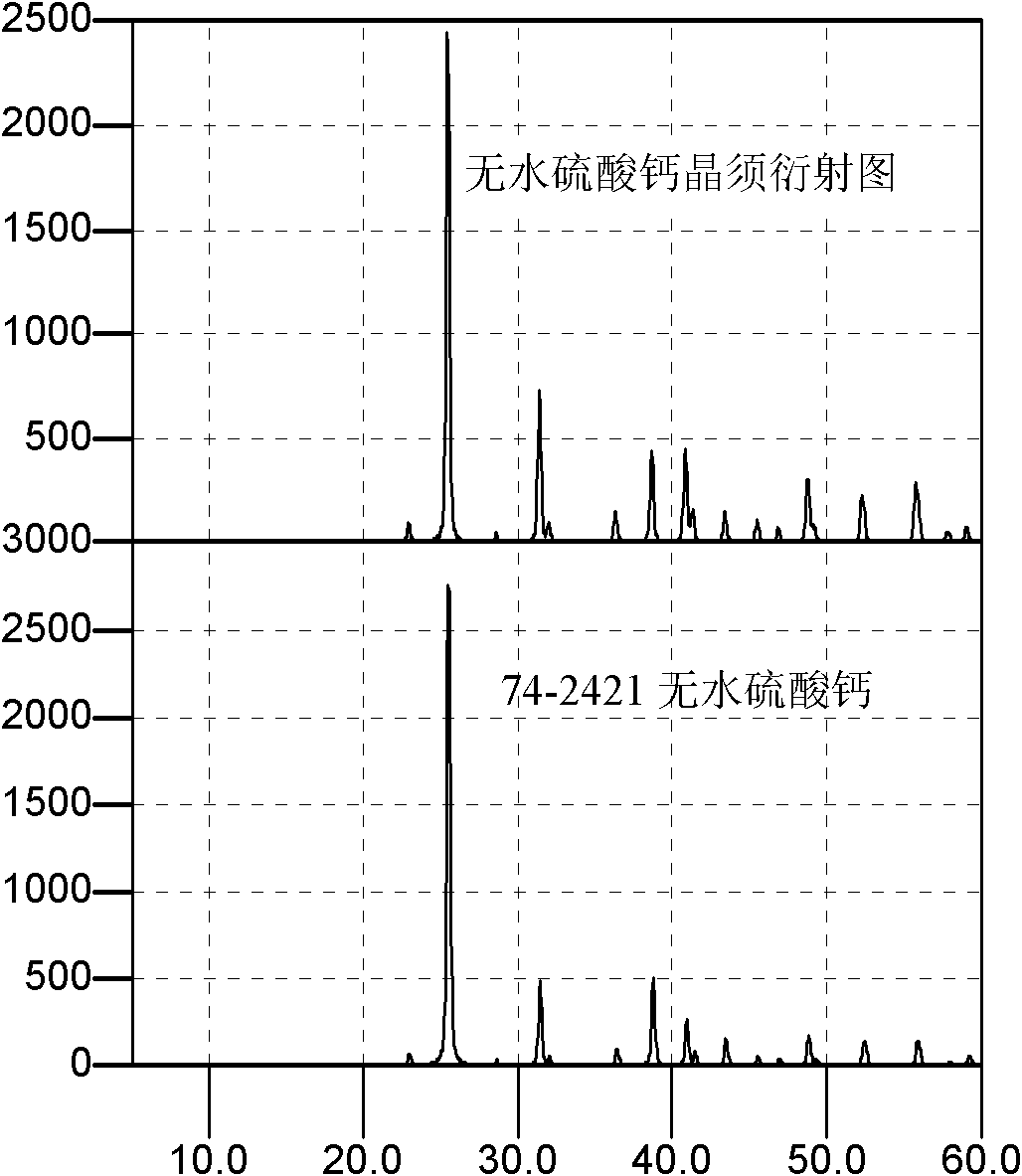

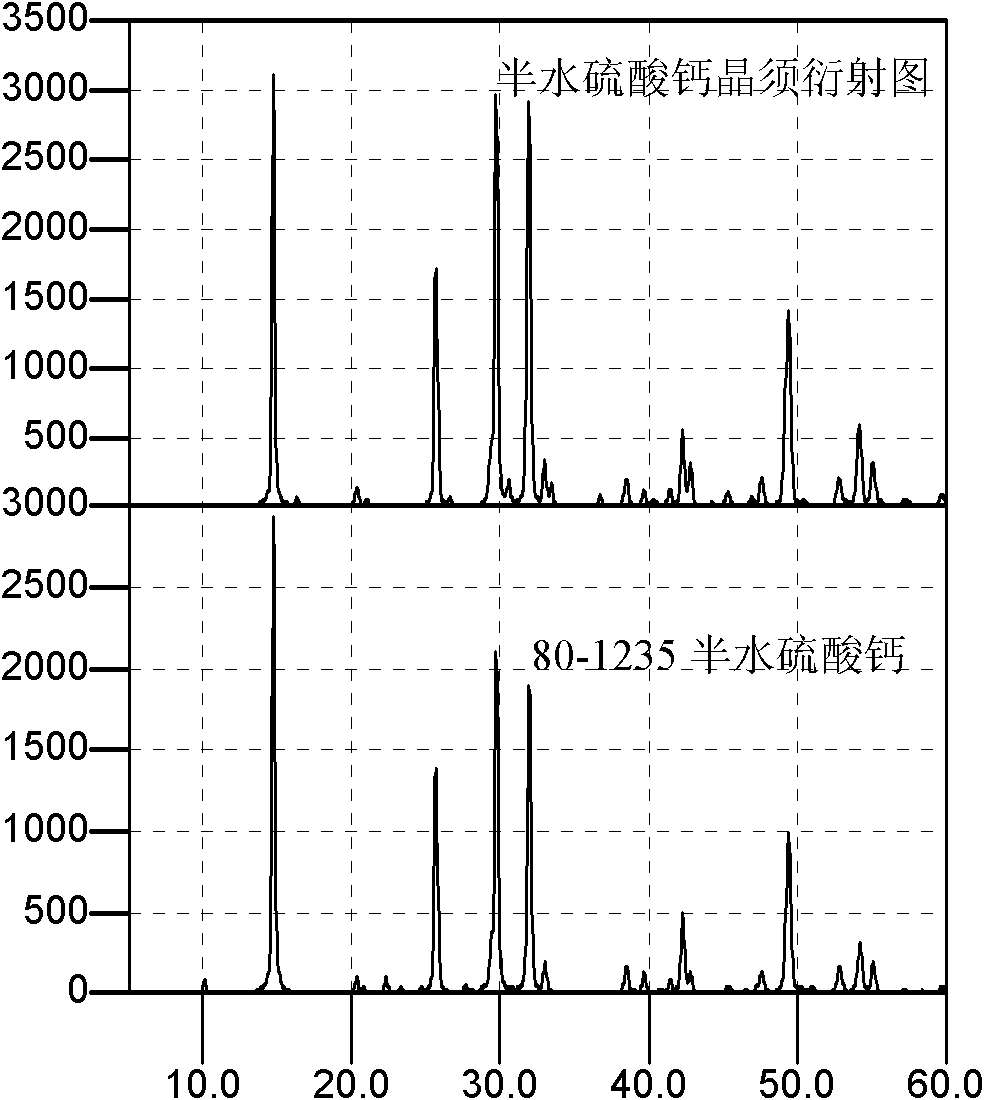

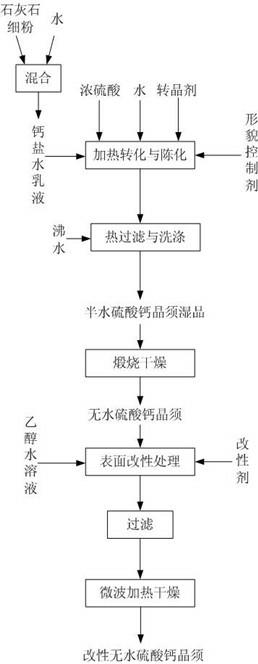

Production method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers

InactiveCN102534773ASimple processThorough responsePolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateCalcium EDTA

The invention discloses a preparation method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The method comprises the following steps that: firstly, limestone powder is added into stirred water to be prepared into calcium salt aqueous emulsion; then, sulfuric acid and crystal modifiers are sequentially added into the stirred water to be prepared into sulfuric acid water solution; next, the calcium salt aqueous emulsion containing 1 mol part of Ca<2+> is added into the sulfuric acid water solution containing 2 mol parts of SO4<2-> with the temperature reaching 100 to 110 DEG C, then, morphology control agents are added, the materials are subjected to stirring and aging for 2 to 3.5 hours under the temperature condition being 110 to 120 DEG C, leaching and washing are carried out, and calcium sulfate hemihydrate crystal whisker wet products are obtained; the calcination drying finally is carried out under the temperature condition higher than 200 DEG C to obtain the anhydrous calcium sulfate crystal whiskers; and then, the surface modification treatment is carried out to finally obtain the high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The preparation method has the advantages that the product quality is high, the cost is low, the preparation process is short, the reaction condition is mild, and in addition, green and environmental-friendly effects can be realized.

Owner:四川万润非金属矿物材料有限公司

Preparation method of high-thermal-conductivity low-leakage phase-change composite

InactiveCN104371666AHigh phase change heat storage capacityLow phase change heat storage capacityHeat-exchange elementsMass ratioLow leakage

The invention discloses a preparation method of a high-thermal-conductivity low-leakage phase-change composite. The method includes: taking a phase-change material and thermal-conductive filler in the mass ratio of 0.1%-1% for melt mixing at the temperature above the melt temperature of the phase-change material for 10min, and taking out the mixture for cooling prior to breaking into granules to obtain modified filler; taking the phase-change material and a support material in the mass ratio of 0.1%-10% for melting at the temperature above the melting temperature of the support material and the phase-change material for 20min, and taking out the molten materials for cooling prior to breaking the materials into granules to obtain a modified support material; adding the modified thermal-conductive filler and the modified support material in the proportion of 1:9-9:1 into the phase-change material counting for 40-50% of total mass for melting the the temperature above the melting temperature of the support material and the phase-change material for 30min prior to obtaining a mixed composite; pouring the mixed composite into a preheated mould, applying certain pressure to the mould, maintaining the pressure for 20min, and performing cooling and demoulding to obtain the high-thermal-conductivity low-leakage phase-change composite. Compared with the prior art, the preparation method has the advantages of simplicity, low cost and chip and available raw materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

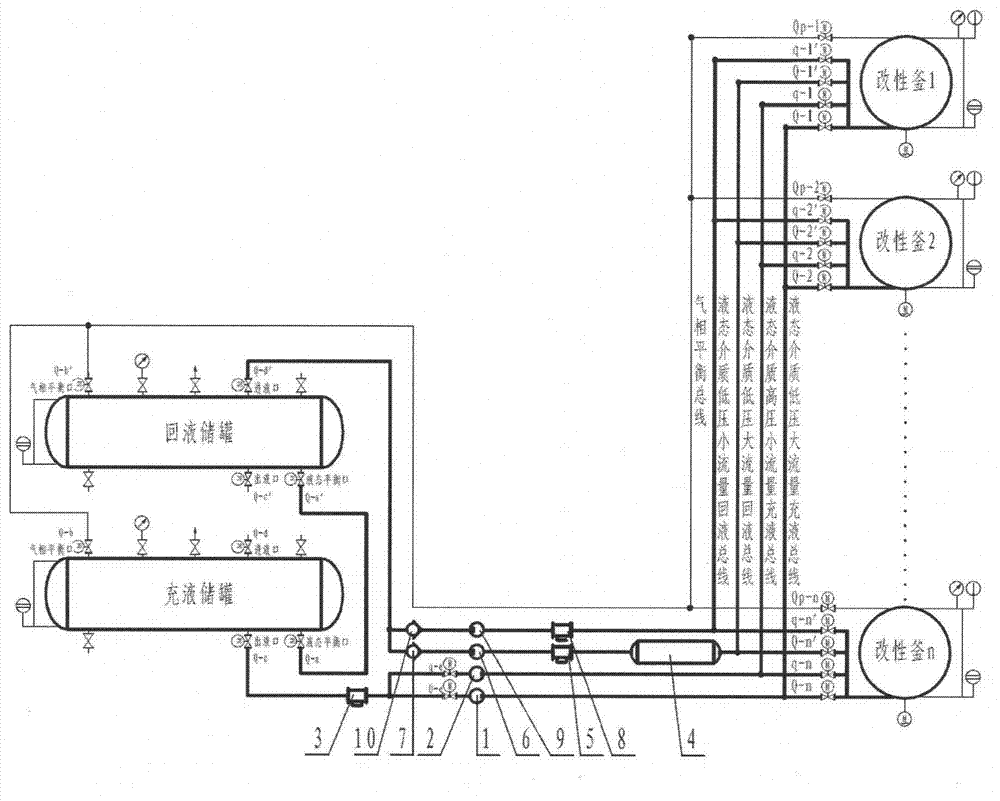

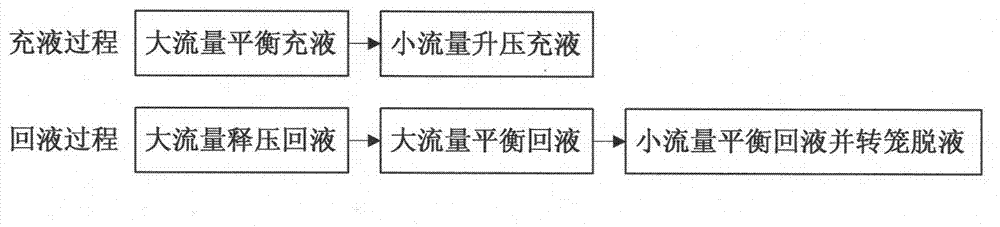

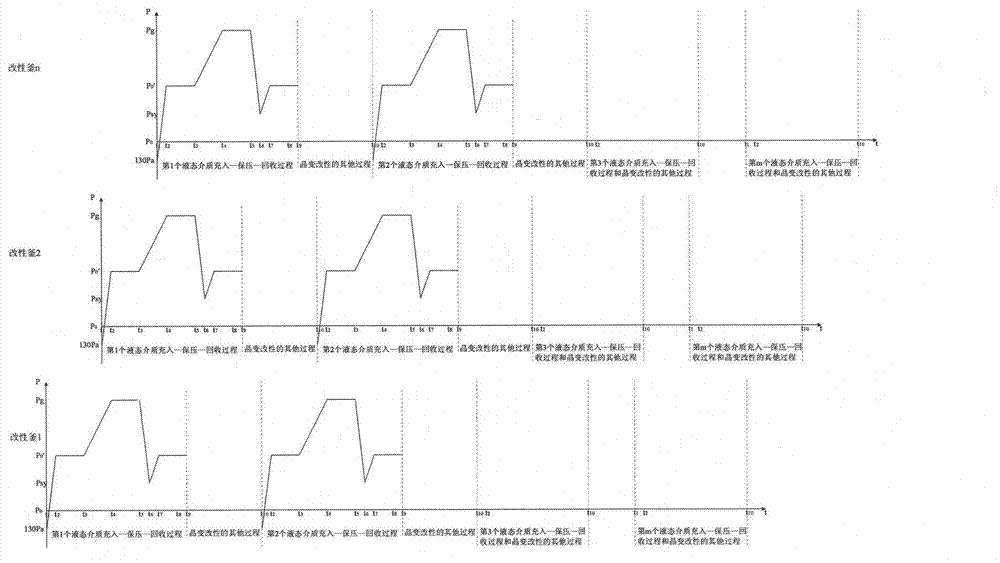

Natural fiber crystal variation modified liquid medium filling and recovery system and method based on paralleled multiple buses and multiple modified kettles

InactiveCN103161046AImprove equipment utilization and production efficiencyReduce equipment cost and production costTextile treatment machine arrangementsTraffic volumeNatural fiber

The invention provides a natural fiber crystal variation modified liquid medium filling and recovery system based on paralleled multiple buses and multiple modified kettles. The natural fiber crystal variation modified liquid medium filling and recovery system based on the paralleled multiple buses and multiple modified kettles comprises a liquid medium low-pressure mass flow liquid-filling bus, a liquid medium high-pressure small flow liquid-filling bus, a liquid medium low-pressure mass flow liquid-return bus, a liquid medium low-pressure small flow liquid-filling bus, a gas phase balance bus, and n modified kettles which are in parallel connection on the buses, and n >=1. The invention further provides a natural fiber crystal variation modified liquid medium filling and recovery method based on the paralleled multiple buses and multiple modified kettles. The liquid-filling process comprises mass flow balance liquid filling and small flow pressure boosting liquid filling, and the liquid return process comprises mass flow pressure relief liquid return, mass flow balance liquid return, small flow balance liquid return, and cage shift liquid exhaustion. The natural fiber crystal variation modified liquid medium filling and recovery system and the method based on paralleled multiple buses and multiple modified kettles are good in modified effect, small in system energy consumption, and high in production efficiency.

Owner:DONGHUA UNIV +1

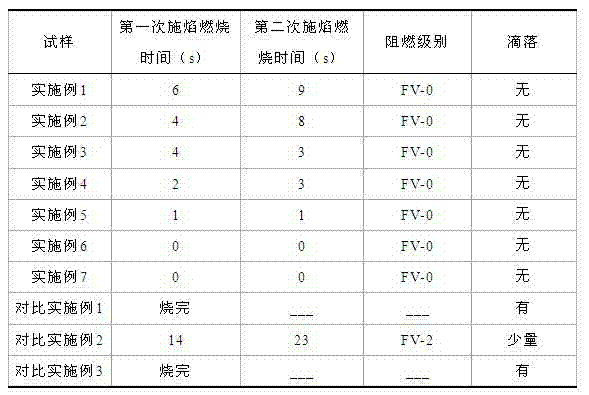

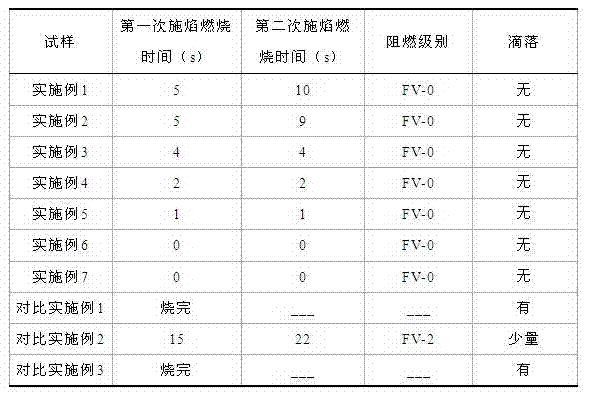

Preparation method for solvent-based lignin-cyanamide derivative flame retardant

The invention relates to a preparation method for a solvent-based lignin-cyanamide derivative flame retardant. The method is characterized in that: after being subjected to a hydroxymethylation reaction, solvent-based lignin is subjected to a condensation polymerization with cyanamide and urea to prepare the solvent-based lignin-cyanamide derivative flame retardant. The solvent-based lignin-cyanamide derivative flame retardant has characteristics of high performance, halogen free, low cost, simple preparation method, and good flame-retardant effect, and can be widely applicable for the modified fields of polymers such as rubber, plastic and the like, and has good economic benefit and social benefit.

Owner:FUZHOU UNIVERSITY

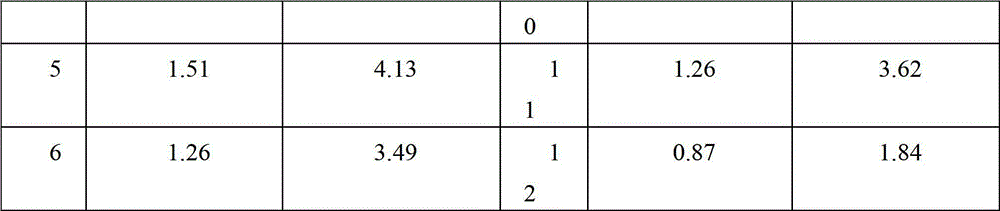

Compound modification method for clay

The invention relates to a compound modification method for clay, which comprises the following steps: dissolving 0.5-2g of silane coupling agent in a certain amount of alcohol-water mixture, and stirring for a certain time on a magnetic stirrer; adding a certain amount of clay into a stirring furnace, performing high-speed stirring at a certain temperature, and meanwhile, adding the alcohol-water mixture into the clay within a certain time; after the alcohol-water mixture is added, continuing to stir for 0.5 hour, pouring out, and performing heat treatment at 80-200 DEG C for 1-3 hours; and mixing the product obtained in the previous step with a certain amount of long-chain alkyl ammonium salt water solution, adding a small amount of acetic acid to regulate the pH value to 2-5, stirring at a certain temperature for a certain time, repeatedly performing vacuum filtration 2-5 times, and performing heat treatment at 80-200 DEG C for 2-5 hours. Secondary modification takes full advantages of the synergic modification effects of the silane coupling agent and the long-chain alkyl ammonium salt, enlarges the molecular layer interval of the clay, increases the affinity of the clay to polymer and widens the application range of the clay.

Owner:南通南京大学材料工程技术研究院

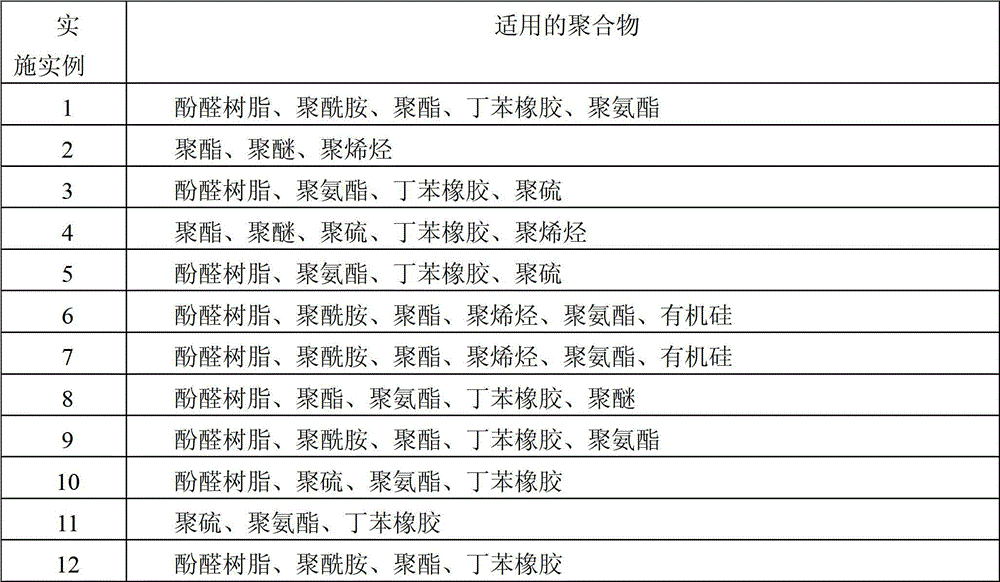

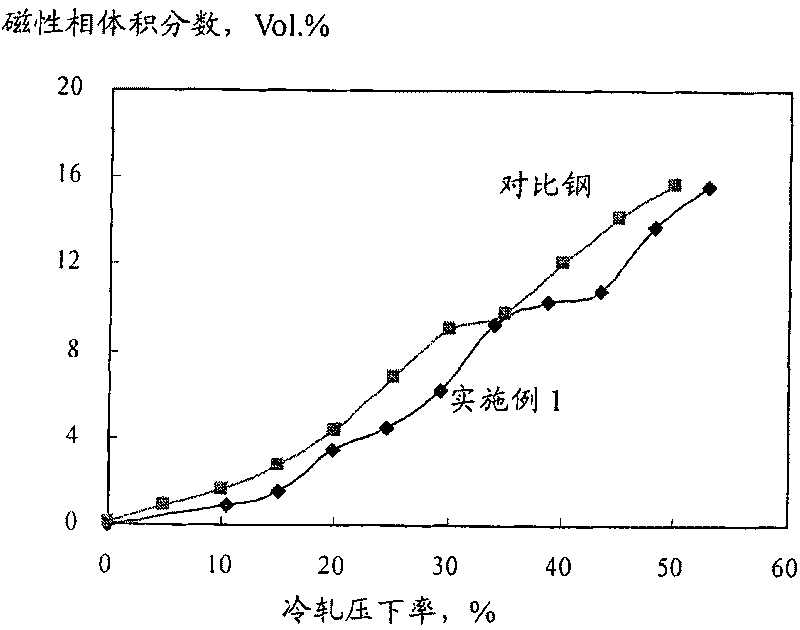

Low-nickel austenitic stainless steel and manufacturing method thereof

The invention relates to a low-nickel austenitic stainless steel, which comprises the following chemical components by weight percent: no less than 0.05% and no more than 0.15% of C, less than 1.00% of Si, more than 9.00% and less than 10.00% of Mn, no less than 14.00% and no more than 16.00% of Cr, no less than 0.50% and less than 1.00%, more than 0.15% and no more than 0.25% of N, more than 1.50% and no more than 2.00% of Cu, no less than 10*10<-4>% and no more than 30*10<-4>% of B, no less than 1*10<-4> and no more than 50*10<-4>% of Ca, less than 0.030% of P, no less than 0.020% of S and the balance of Fe and inevitable impurities. For the stainless steel, heat processing performance of materials is improved through B alloying treatment on premise of further reducing the content of precious metal of nickel, and the purity of the liquid steel is enhanced through Ca treatment. The formability of stainless steel is enhanced through the reasonable alloy system design and a micro-alloy treatment method, the defects of sand buckle, sand holes, and the like are avoided in the forming process, the delayed rupture phenomenon is lightened, and the application scope of the festival nickel austenitic stainless steel is further broadened.

Owner:BAOSHAN IRON & STEEL CO LTD

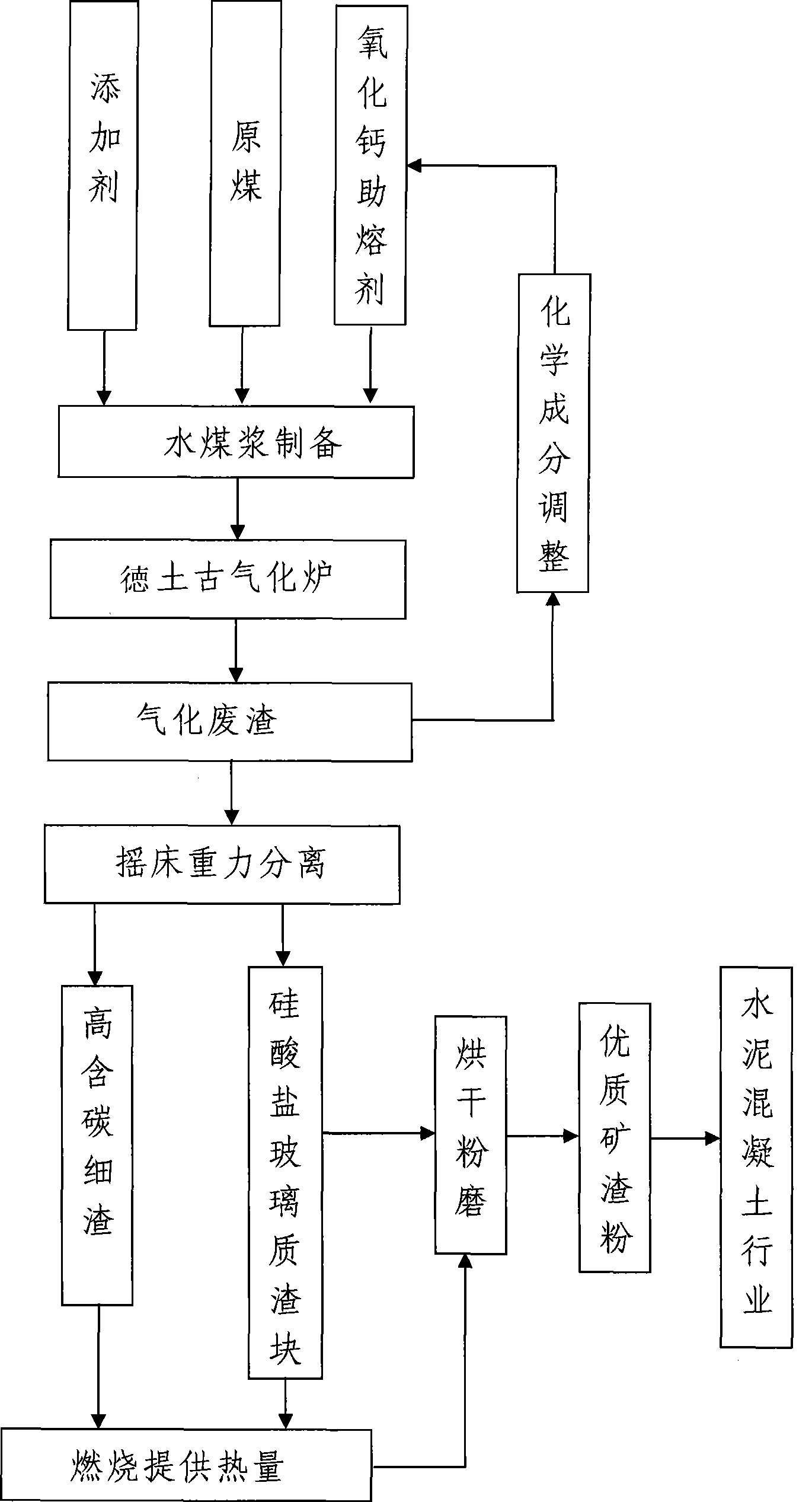

Comprehensive utilization method of coal water slurry gasified waste residue on Texaco gasifier

InactiveCN101456689AGood modification effectTake advantage ofSolid waste managementCement productionHigh carbonSlag

The invention provides a comprehensive utilization method for gasified waste residue of Texaco furnace water coal slurry, which is characterized in that enough fluxing agent is added during preparation and gasification of the water coal slurry; without changing a Texaco gasification process, the alkali coefficient of the generated waste residue is larger than 1.0, and then high carbon-containing granules and silicate glass slag blocks are separated by a gravity separation method; the waste residue is dried during grinding of the silicate glass slag blocks by using the heat value of the high carbon-containing granules; and finally obtaining the high-activity slag powder used for the cement or concrete industry, wherein the specific surface area of the slag powder is larger than 350m<2> / kg, and the moisture content is less than 1 weight percent, so the aim of effectively utilizing the gasified waste residue of the Texaco furnace water coal slurry is achieved. The method has the advantages of simple process, high utilization rate of the waste residue, and good economic benefit.

Owner:CHANGAN UNIV

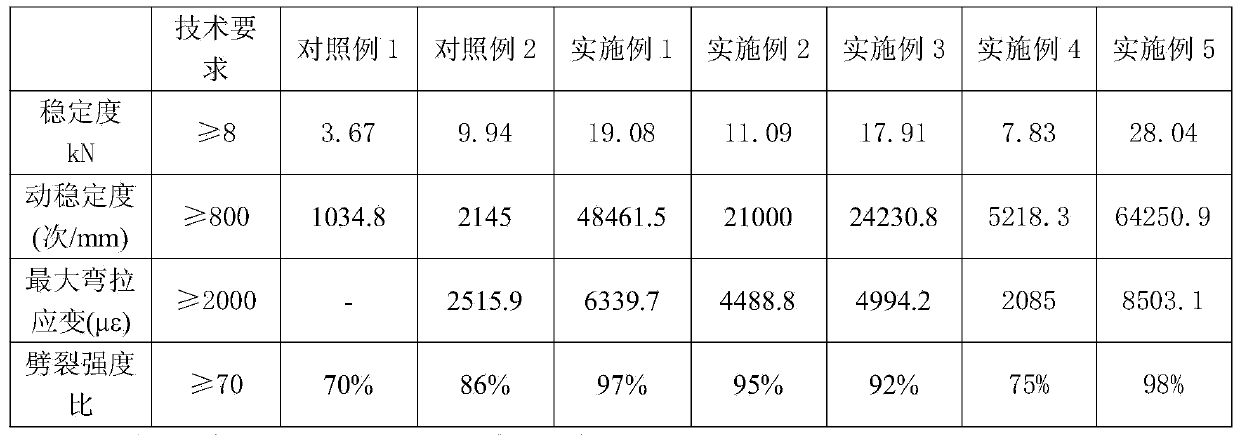

Waterborne polyurethane emulsified asphalt concrete as well as preparation method and application thereof

The invention discloses a waterborne polyurethane emulsified asphalt concrete which is prepared from the following raw materials: mineral aggregates, emulsified asphalt and waterborne polyurethane emulsion, wherein the weight ratio of the mineral aggregates, the emulsified asphalt and the waterborne polyurethane emulsion is 100:(1-20):(7-20). The invention also discloses a preparation method of the waterborne polyurethane emulsified asphalt concrete, and the preparation method comprises the following steps: mixing the waterborne polyurethane emulsion with the emulsified asphalt, and uniformly stirring, so that waterborne polyurethane modified emulsified asphalt is obtained; adding the waterborne polyurethane modified emulsified asphalt into the mineral aggregates, uniformly stirring, and carrying out maintenance on the obtained product; or uniformly stirring the mineral aggregates, the emulsified asphalt, and the waterborne polyurethane emulsion, and carrying out maintenance on the obtained product. The prepared waterborne polyurethane emulsified asphalt concrete not only has the advantages of cold-mixed asphaltic concrete, but also has excellent mechanical properties and stability; the waterborne polyurethane emulsified asphalt concrete is excellent in pavement performance, and can be used for greatly prolonging the service life of pavements; and the maintenance time is short, and the traffic can be implemented in 1-3 days, therefore, the waterborne polyurethane emulsified asphalt concrete can be applied to the preparation of asphalt concrete paving materials, asphalt pavement repair materials, slurry seals for maintenance and asphalt mortar for micro-surfacing and high-speed railways.

Owner:山东大山绿道工程科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com