Patents

Literature

155results about How to "Good moisture absorption and perspiration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moisture absorption perspiration-discharging dressing agent and its manufacturing technique and application

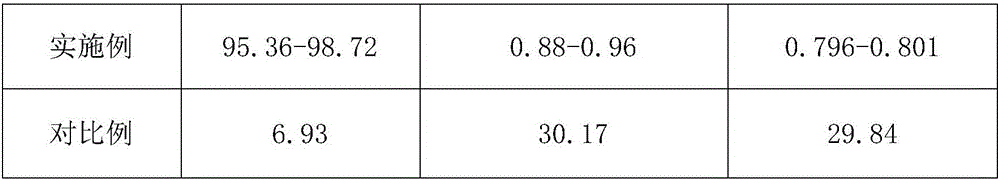

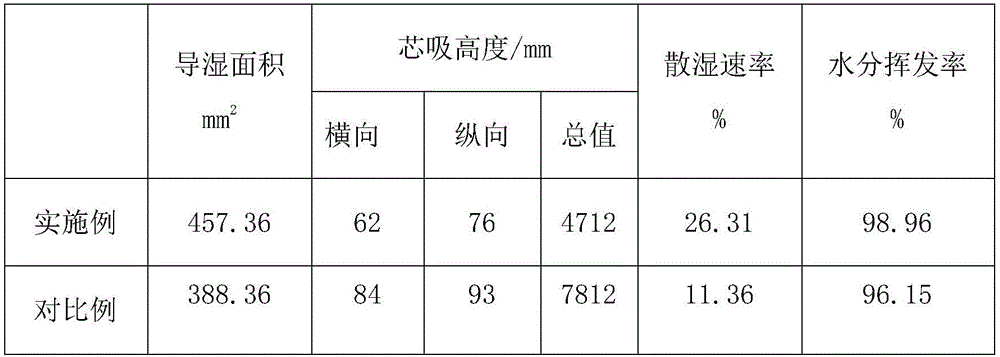

ActiveCN101265664AGood moisture absorption and perspirationGood modification effectFibre typesDyeing processFiberPolyester

The invention discloses the formula, the production process and the application of moisture absorbent and sweat conductive comfortable finishing agent which is used for modifying the polyester fiber to enable the polyester fiber to have moisture absorbent and sweat conductive capabilities. The formula of the moisture absorbent and sweat conductive comfortable finishing agent contains: polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate. The two-step continuous production process is adopted: in the first step of esterifying, polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate are put into a reaction vessel for esterification under the action of catalysts; and in the second step that the material produced after the esterification is transported to a polymerization kettle for polymerization under the actions of high temperature, vacuum, and catalysts, in order to generate polyester-polyether copolymer with high molecular weight to be 30000-50000, namely, the moisture absorbent and sweat conductive comfortable finishing agent. The moisture absorbent and sweat conductive comfortable finishing agent can be directly used or be used after being mixed with substances such as amino silicone oil and so on, and carry out chemical modification on the polyester fiber.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

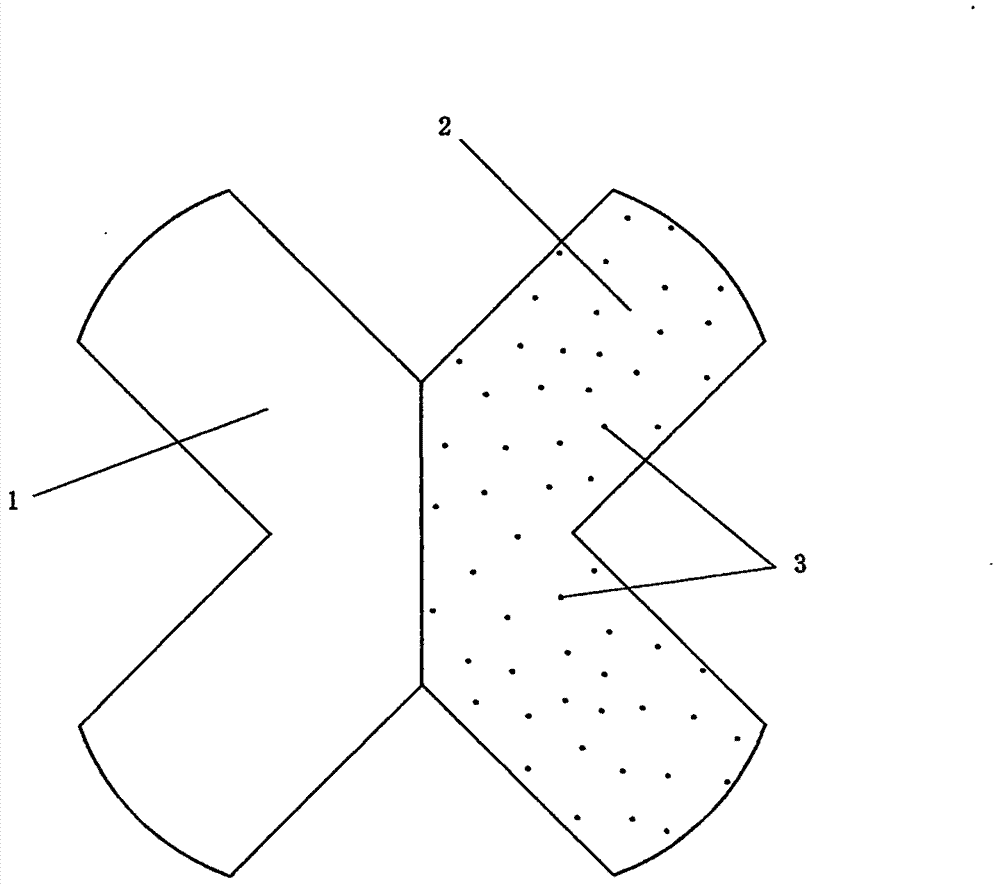

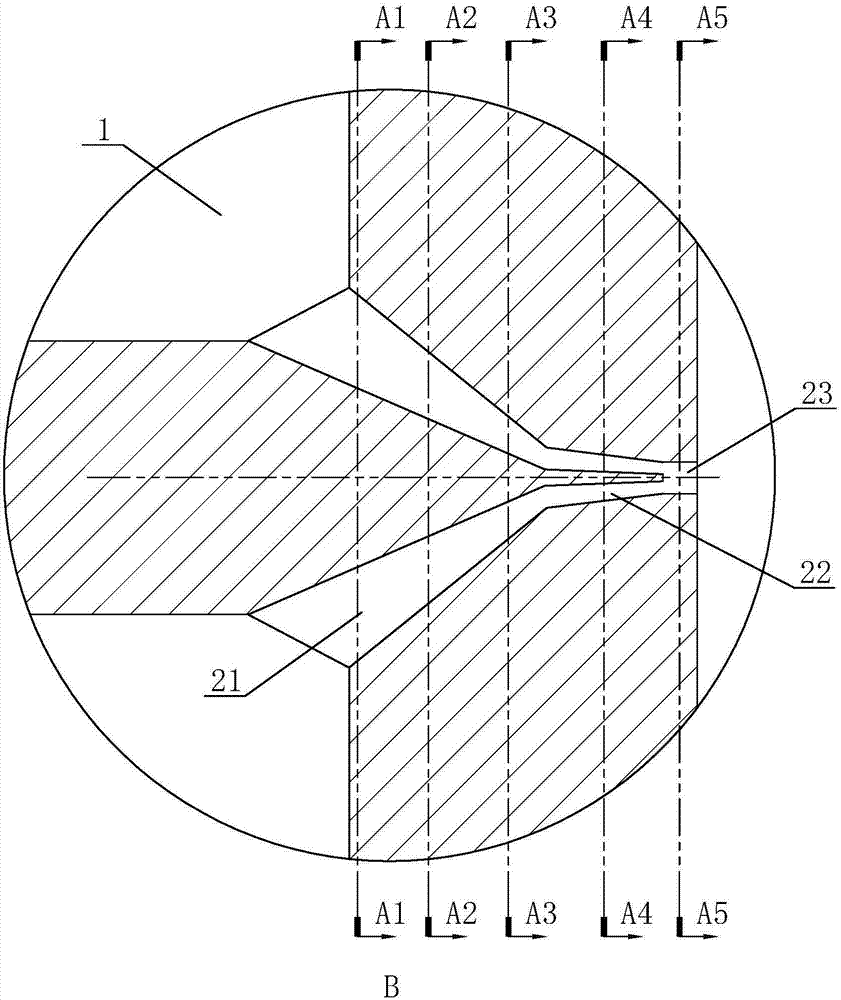

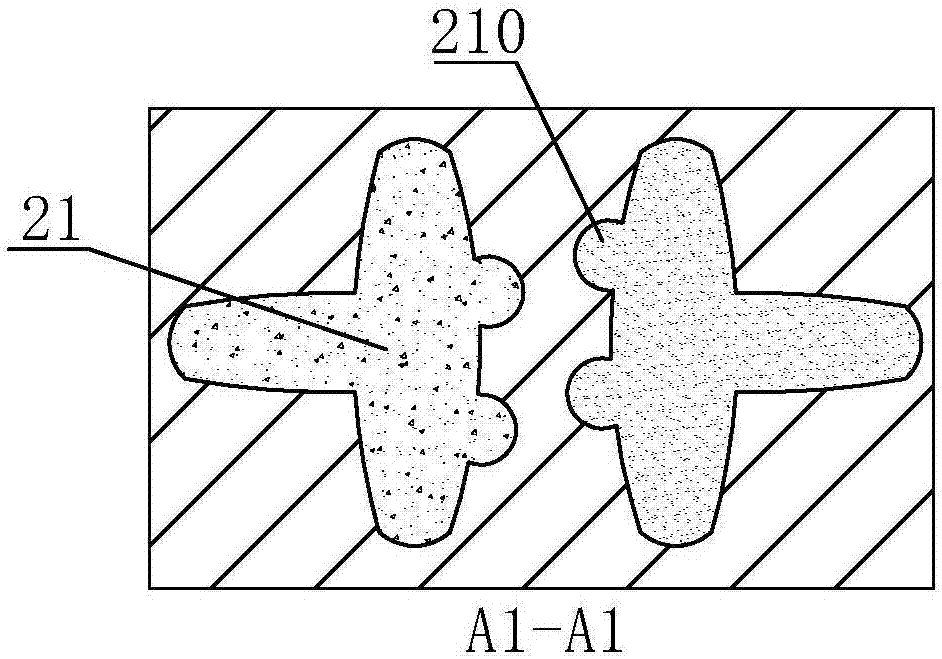

Antibacterial, moisture absorption and sweat releasing polyester composite elastic fiber

InactiveCN104726947AMultiple choiceSimple weaving processFilament/thread formingConjugated synthetic polymer artificial filamentsMoisture absorptionCompanion animal

The invention discloses a polyester composite elastic fiber with antibacterial, moisture absorption and sweat releasing function. The polyester composite elastic fiber has dual-component parallel composite structure and has cross-shaped cross section. Two components of the parallel composite fiber are respectively selected from one of PET, PBT, PTT and CO-PET and are different one another; antibacterial silver ions are added in at least one component. The fiber has natural curly spiral structure due to different shrinking percentage of the two components and has permanent elasticity; the elastic fiber has moisture absorption, sweat releasing and anti-bacterial function due to the fact that the cross-shaped cross section structure is adopted and the antibacterial agent is added. The fiber is widely applicable to the high-grade underwear, sportswear and swimwear and has the characteristics of being elastic, comfortable, breathable, fresh, bacteriostatic and healthy.

Owner:SHANGHAI VITA SCI & TECH

Hydrophilic hygroscopic and sweat-releasing polyester fiber and preparation method thereof

ActiveCN103320889ALarge specific surface areaHigh hollownessFibre typesMonocomponent polyesters artificial filamentChemistryWoven fabric

The invention discloses a hydrophilic hygroscopic and sweat-releasing polyester fiber and a preparation method of the hydrophilic hygroscopic and sweat-releasing polyester fiber. The method comprises the following steps of: slicing and respectively drying hydrophilic modification polyester, water-soluble polyester, and calcium carbonate powder-containing hydrophilic polyester master batch, mixing and melting according to certain mass percentage, extruding for spinning by a profile spinneret, and carrying out post-treatment to obtain polyester filament yarn or short fiber. Regardless of acid or alkali dyeing or processing environment, a great amount of micropores or grooves can be formed on the surface, better hydrophilic hygroscopic and sweat-releasing effects can be achieved, and the flexible and simple and convenient technique requirements can be reached; and the fiber can also obtain ultrahigh hygroscopic and sweat-releasing effects through superposition of dyeing or processing procedures. The profile hygroscopic and sweat-releasing fiber obtained by adopting the method is flexible in production technique no matter in pure or blended Dacron yarn weaved fabric, and achieves the changeability adjustability of the hygroscopic and sweat-releasing effects.

Owner:SHANGHAI VITA SCI & TECH

Weaving process of hemp towel

InactiveCN101671905ARetain antibacterial health care performanceSoft and comfortableBiochemical fibre treatmentBleaching apparatusRadiation resistantPerspiration

The invention discloses a weaving process of a hemp towel, comprising the steps of cheese winding, warping, weaving and grey cloth post treatment. The rotating speed of a cheese winding grooved drum is 1,200+ / -5r / min; the concentration of caustic soda in desizing boiled bleaching liquor subjected to the grey cloth post treatment is 5ml / L; the concentration of FLOW preliminary treatment agent is 3ml / L; the concentration of hydrogen peroxide is 7.8ml / L; and the temperature of the desizing is 95 DEG C and the boiled bleaching is carried out for 50 minutes. The towel manufactured by the manufacturing process has few filoplume and easy degradation as well as excellent moisture absorbing perspiration performances, natural bacteriostasis and health-care performances reservation of hemp, favorablesoft and comfortable performances, excellent uvioresistant and radiation-resistant performance, high-temperature resistant performance and odor-absorbing and blowdown performances, and is new generation of natural environment-friendly products.

Owner:SUNVIM GROUP

Spinning method of spun-dyed hemp/cotton blended yarn

InactiveCN102021702AGood moisture absorption and perspirationSolve the problem that the length becomes shorter and the strength dropsYarnYarnCotton fibre

The invention discloses a spinning method of spun-dyed hemp / cotton blended yarn. The blended yarn is prepared by spinning the yarn which is formed by blending the dyed hemp fibre and cotton fibre at a ratio of (40-50):(50-60). The spinning method specifically comprises an opening picking process, a cotton carding process, a drawing process, a roving process and a spinning process, wherein the opening picking process is as follows: the dyed hemp fibre and the cotton fibre are manufactured into lap or cotton stream; and the cotton carding process is as follows: the lap or cotton layer is fed into a carding machine to be prepared into cotton strips, five-point gauge between a cylinder and a cover board is 0.22mm, 0.2mm, 0.18mm, 0.18mm, 0.2mm respectively, the rotation speed of the cylinder is 330-360r / min, and the speed of discharging strips is 65-75m / min. The blended yarn produced by the spinning method has bright color and has the advantages of good sterilization bacteriostasis and good wet-absorbing sweat-discharging property, and is a novel generation environment-friendly product.

Owner:SUNVIM GROUP

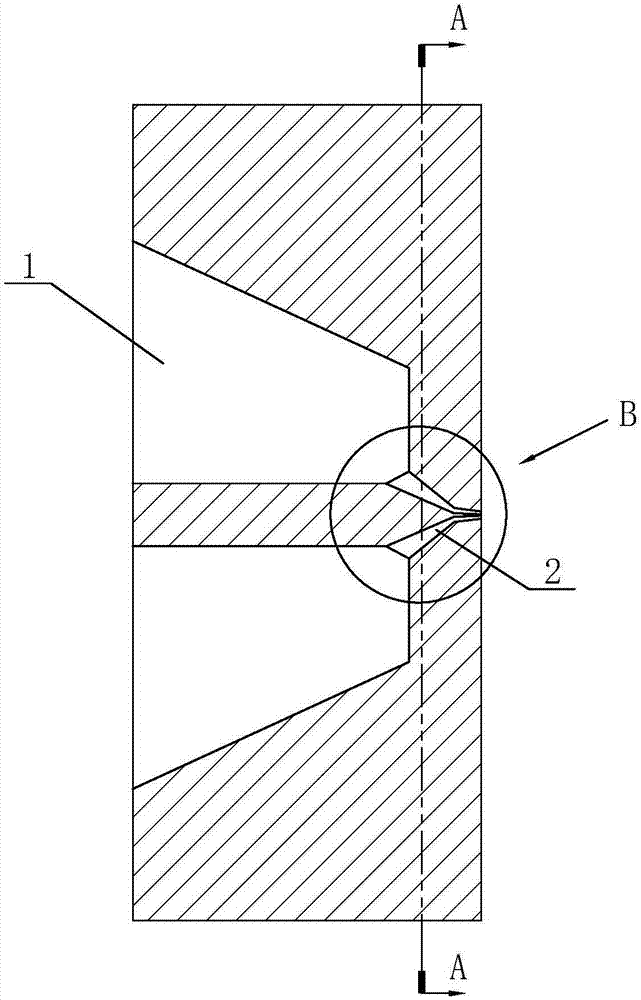

Preparation method of hollow polyester fiber with controllable hollowness

InactiveCN102453967AGood moisture wicking effectImprove hydrolysis efficiencyHollow filament manufactureMelt spinning methodsAbnormal shapedChemistry

The invention relates to a preparation method of hollow polyester fiber with controllable hollowness. In the method, two screw extruders are used for respectively feeding materials for a cover / core spinneret plate assembly, a cover layer which is made of polyester and water-solubility polyester and a core layer which is water-solubility polyester are melted in a certain proportion for composite spinning, and then postprocessing processes are carried out to prepare polyester staple fiber; and fabric made of the obtained fiber is treated with an alkaline solution to remove the water-solubility polyester from the core layer and the cover layer, and thus the fiber is of a hollow structure, and lots of micropores, trenches and through holes are formed on inner and outer surfaces of the fiber at the same time. Since hollow holes are formed after the core layer is removed through melting, deformation of hollow holes, caused by extrusion in a stretching process in the preparation of hollow fiber spun with a profile hole spinneret plate spinning method, can be avoided, and hollowness is reduced; and moreover, through the change of the proportion of raw materials for spinning, the polyester fiber with controllable hollowness being 5-75% is prepared.

Owner:SHANGHAI VITA SCI & TECH

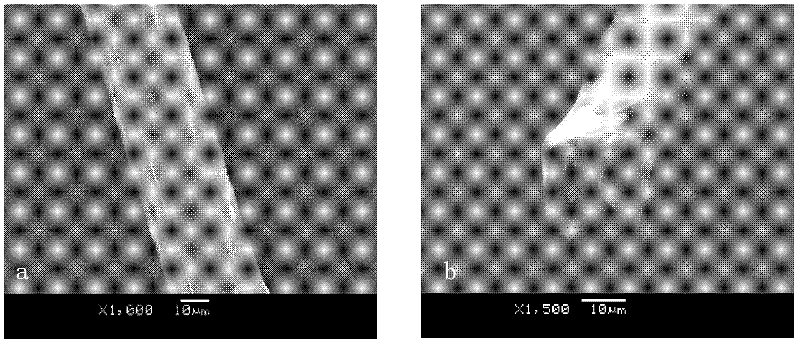

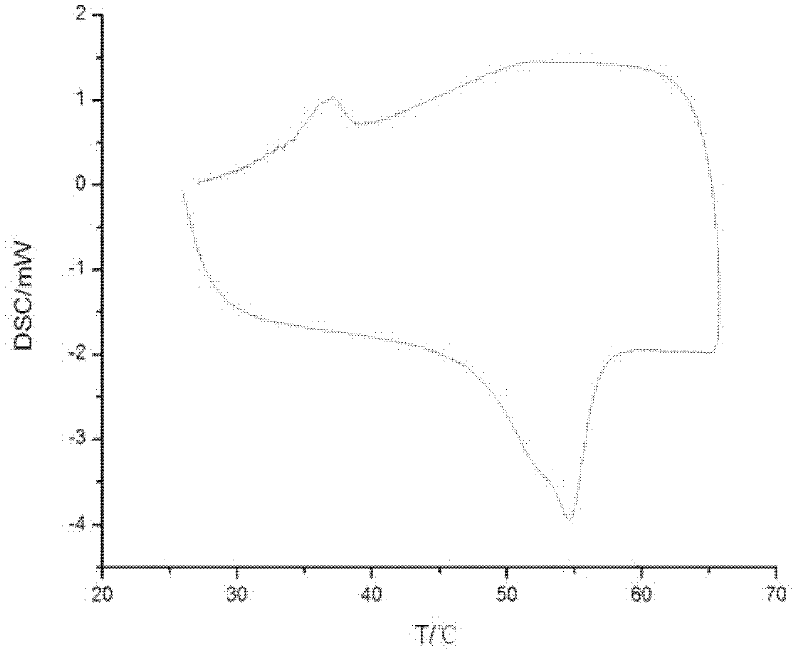

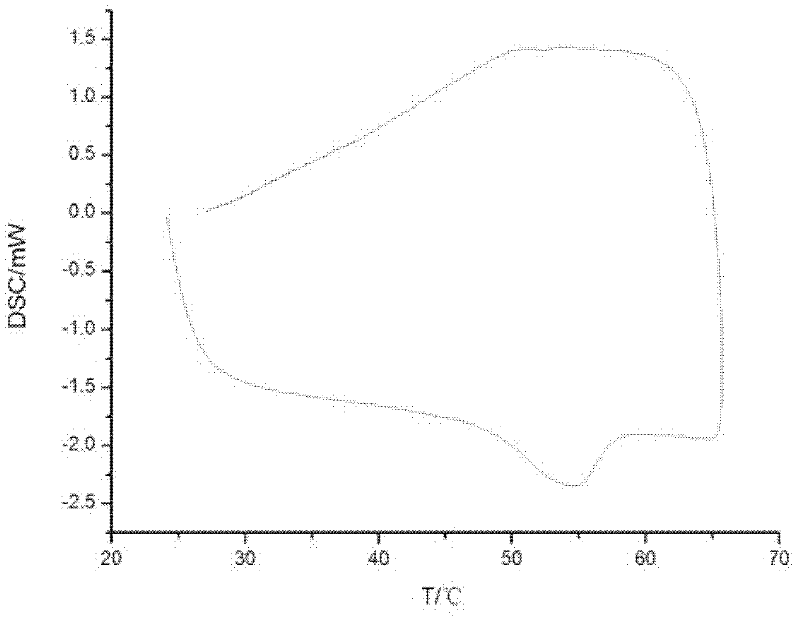

Multifunctional comfort fiber with functions of phase transition temperature regulation, moisture absorption and moisture wicking

InactiveCN102443878AStrong moisture wickingGood heat resistanceMelt spinning methodsConjugated synthetic polymer artificial filamentsMultiple functionPolymer

The invention relates to multifunctional comfort fiber with functions of phase transition temperature regulation, moisture absorption and moisture wicking. According to the fiber, an interpenetrating network composite phase transition material is adopted as a heat storage and temperature regulation material, a fiber-forming polymer is adopted as a matrix, a pore-forming agent and a compatibilizer are added to prepare a spinning raw material, and a melt spinning process is adopted to prepare the multifunctional comfort fiber. The spinning raw material preparation method comprises: mixing the interpenetrating network composite phase transition material and the fiber-forming polymer according to a mass ratio of (95-60):(5-40), then adding the pore-forming agent and the compatibilizer, and uniformly mixing, wherein the mass of the pore-forming agent is 0-10% of the total mass of the interpenetrating network composite phase transition material and the fiber-forming polymer, the mass of the compatibilizer is 1-5% of the total mass of the interpenetrating network composite phase transition material and the fiber-forming polymer, the pore-forming agent is the PEG with the molecular weight of 1000-2000, the compatibilizer is one or a plurality of materials selected from PP-g-PEGA, PP-g-PEG, PET-g-PEGA, PEGA, montmorillonite, and the like. The phase transition temperature range of the multifunctional comfort fiber is 30-55 DEG C, the melting phase transition enthalpy is 5.24-29.12 J / g, the breaking strength is 3.0-3.5 cN / dex, and the thermal decomposition temperature is more than 400 DEG C.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Cotton COOLPLUS covering hygroscopic and sweat-releasing functional fabric as well as processing technique thereof

InactiveCN102080291AGood moisture absorption and perspirationComfortable to wearDyeing processWoven fabricsDyeingYarn

The invention relates to a cotton COOLPLUS covering hygroscopic and sweat-releasing functional fabric as well as a processing method thereof. The fabric warp adopts 70 / 30coolplus / JC 16.1tex*2, the fabric weft adopts 70 / 30coolplus / JC 21.4tex*2, and the fabric has the warp density of 368 / 10cm, the weft density of 208 / 10cm, the fabric width of 151cm and the texture of 3 / 2 twill.. The processing technique adopts a special processing method on spinning, weaving and dyeing processes. The invention has the advantages that covering yarn is formed by COOLPLUS fiber and cotton, and the fabric thereof has excellent hygroscopic and sweat-releasing effects and is comfortable to wear. The processing technique thereof has a special processing method and remarkably improves the quality and the grade of the product. The research and the development of the product and the breakthrough of the process thereof provide lessons for developing high-grade and individualized textile fabric, provide guidance for marketing and create favorable economic benefits for enterprises.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions

InactiveCN104413965AGood warmth functionGood warmth retentionProtective garmentSpecial outerwear garmentsFiberSurface layer

The invention discloses light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions. The light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions has a double-layer structure, the inner layer is composed of hollow far infrared warm keeping fiber, hydrophilic moisture absorbing and perspiring fiber and cotton or viscose in a blending mode, and the inner layer has warm keeping, moisture guiding and perspiring functions; the surface layer is composed of elastic fiber and cotton or viscose in a blending mode, and the surface layer has durable elasticity and moisture absorbing and quick drying functions; a regular air heat insulation cavity is formed between the surface layer and inner layer after being connected, and the heat storage and warm keeping performances are reinforced. The fabric is light and thin and has warm keeping, moisture guiding and quick drying effects, durable size stability and good hand feel; the light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions is especially suitable for underwear, warm clothing and the like.

Owner:毛志富

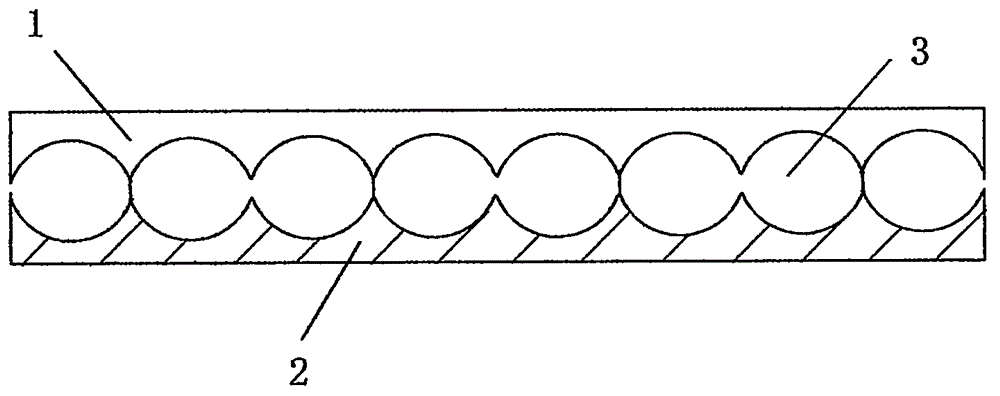

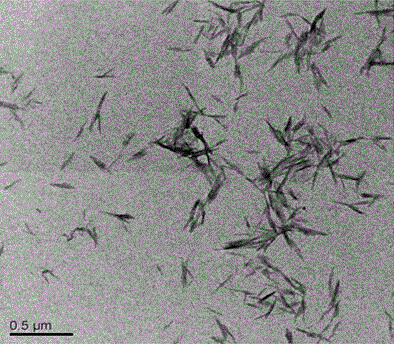

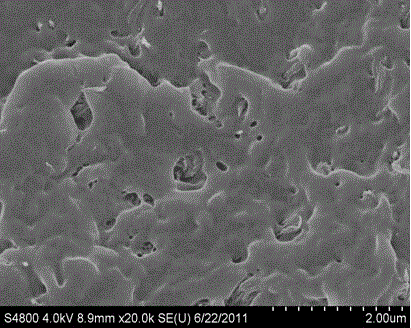

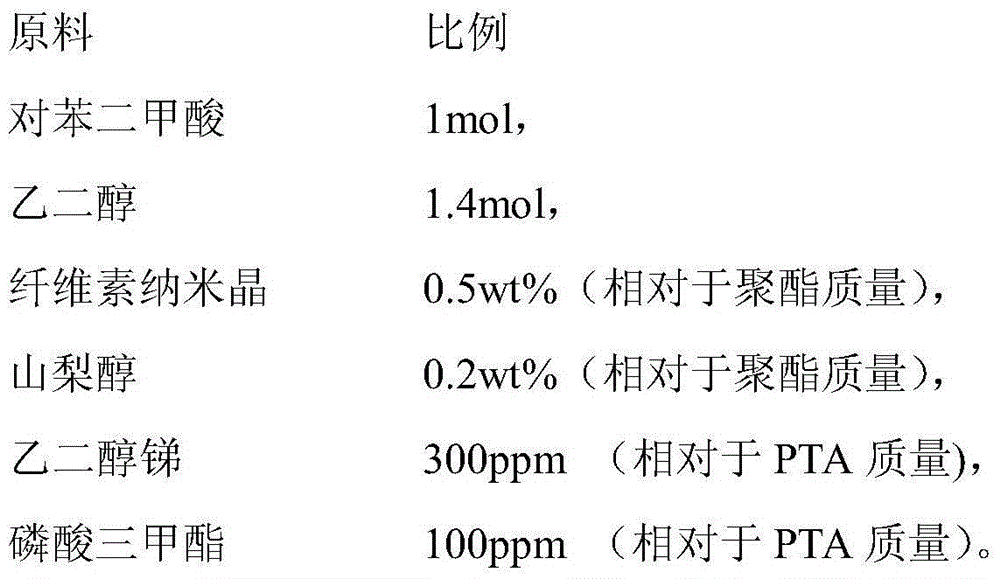

Hydrophilic polyester fiber modified by cellulose nanocrystal and preparation method thereof

ActiveCN104404647AImprove accessibilityGood dispersionMonocomponent polyesters artificial filamentArtifical filament manufactureCelluloseAlcohol

The invention relates to a hydrophilic polyester fiber modified by cellulose nanocrystal and a preparation method thereof and aims to solve a problem of a poor hydrophilicity of conventional polyester. The preparation method includes following steps: (1) mixing a cellulose nanocrystal aqueous suspension liquid and 75-85% by weight of ethylene glycol and removing water from a mixed liquid to prepare an ethylene glycol suspension liquid of the cellulose nanocrystal; (2) preparing a mixed slurry liquid from the ethylene glycol suspension liquid of the cellulose nanocrystal and terephthalic acid; (3) preparing a catalyst liquid form the balanced ethylene glycol and a catalyst; (4) mixing the mixed slurry liquid, the catalyst liquid and a thermal stabilizing agent, and performing a first esterification reaction in a reaction kettle with stirring and heating; (5) performing a secondary esterification reaction with addition of a polyhydroxy-alcohol; (6) performing vacuumizing condensation polymerization to obtain a hydrophilic polyester melt, and cooling and pelleting the melt to obtain a hydrophilic polyester chip; and (7) performing melt spinning to the hydrophilic polyester chip to prepare the hydrophilic polyester fiber.

Owner:嘉兴逸鹏化纤有限公司

Tussah silk interwoven mat and weaving process method

ActiveCN102512042AElegant and luxurious appearancePromote circulationWoven fabricsBed-coversFiberMassage

The invention provides a tussah silk interwoven mat and a weaving process method. The tussah silk interwoven mat is prepared by interweaving 125dtex / 2-250dtex / 2 tussah silk twisted warp and 107.62dtex / 2-168.6dtex / 2 combed cotton thrown weft, wherein the weave structure is 2 / 2 herringbone twill, the warp density is 200-260 / 10cm, and the weft density is 180-220 / 10cm. The product has jewelry luster,elegant and luxurious appearance, has good moisture absorption and sweat discharge effects, is cool in summer and warm in winter, and has multiple health-care functions of resisting acarids, preventing mildews and bacteria, nourishing skin, promoting blood circulation, improving sleep quality, not generating static electricity and the like. The linear product of the herringbone twill structure and high fiber twist has protruded surface texture points, clear grains, obvious concave-convex effect, solid, elastic, stiff and elegant effects and no creping. When the mat is used, point contact between the human body skin and the surface of the mat is formed, thus the air permeability and massage-effect comfortability are effectively increased. In the weaving process, fine weft yarn twist is preferable, thus the product has good interweaving performance; and in the post-treatment process, pre-shrinking treatment is adopted, thus the fabric has excellent dimensional stability and has no deformation after being washed.

Owner:辽宁柞蚕丝绸科学研究院有限责任公司

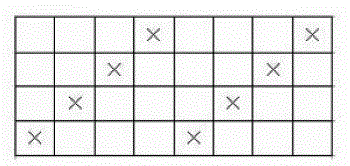

Moisture absorption and perspiration antistatic fabric

InactiveCN101413168AGood hygroscopicityLower specific resistanceWoven fabricsFiberMoisture absorption

The invention discloses an antistatic fabric for moisture absorption and sweat elimination, which is formed by interweaving warps and wefts. The fabric has rib weave consisting of back weave and face weave, wherein odd warps are back warps which are interwoven with the wefts to form the back weave, even warps are face warps which are interwoven with the wefts to form the face weave, the back warps are common fiber back warps, the face warps are superfine fiber face warps, and the fabrics are embedded into conductive yarns at intervals in the warp direction and in the weft direction respectively. The invention provides the antistatic fabric for the moisture absorption and the sweat elimination, which has good effects on moisture absorption and sweat elimination, good antistatic effect, and comfort.

Owner:苏州新纶超净技术有限公司 +1

Weaving process for flax and fiber fabric blended home textile products

InactiveCN104746213ALess hairyEasy to degradeBiochemical fibre treatmentSingeingWinding machineGreen environment

The invention discloses a weaving process for flax and fiber fabric blended home textile products. Flax fibers, cotton fibers and pearl fibers are spun into blended yarns, and the blended yarns serve as warp yarns and weft yarns which are woven into the flax and fiber fabric blended home textile products. The weaving process includes the steps: winding; warping; drawing-in; refining; singeing; drying; weaving. Warps and wefts are firstly made into twisting cheeses by a winding machine, the rotating speed of a groove drum in winding is 600+ / -5r / min, the warps and the wefts on the twisting cheeses are made into a warp beam through a warping machine according to the requirements of a warping process, a direct-reverse singeing process is adopted, and softening agents are used for drying. The flax and fiber fabric blended home textile products produced by the weaving process are less in hairiness and easily degraded, have excellent moisture absorbing and sweat releasing performances, reserve natural antibacterial healthcare functions, fine soft and comfortable performances, excellent ultraviolet resistance, radiation-proof and antibacterial performances, outstanding high temperature resistance and unique odor absorption and sewage disposal performances of flax, are soft and comfortable in hand feeling as compared with other flax products, and are new-generation green environment-friendly products.

Owner:NANTONG YOUKAI TEXTILE TECH

A kind of moisture-absorbing and sweat-wicking weft elastic yarn card fabric

InactiveCN102268767AImprove breathabilityGood moisture absorption and perspirationWoven fabricsYarnPolyesterFiber

The invention provides a moisture-absorbing and sweat-wicking weft-elastic fabric. The fabric is woven from warp yarns and weft yarns. Cashmere / cashmere / moisture-wicking polyester fiber = 40 / 10 / 50, the weft yarn is blended with long-staple cotton, cashmere, moisture-wicking polyester fiber, and spandex yarn, and the blending ratio is long-staple cotton / sheep Fleece / wicking polyester / spandex = 32 / 10 / 50 / 8. This kind of moisture-absorbing and sweat-wicking weft-elastic yarn card fabric achieves excellent moisture-wicking and sweat-wicking effects through a reasonable ratio of moisture-wicking polyester fibers to long-staple cotton and cashmere, with good air permeability and good wearing comfort. It is very suitable for making sportswear and casual wear fabrics.

Owner:SHANDONG LICHANG TEXTILE TECH

Sportswear shell fabric and production method thereof

ActiveCN105876949AGuaranteed finishing effectLow costGarment special featuresBiochemical fibre treatmentPolyesterFiber

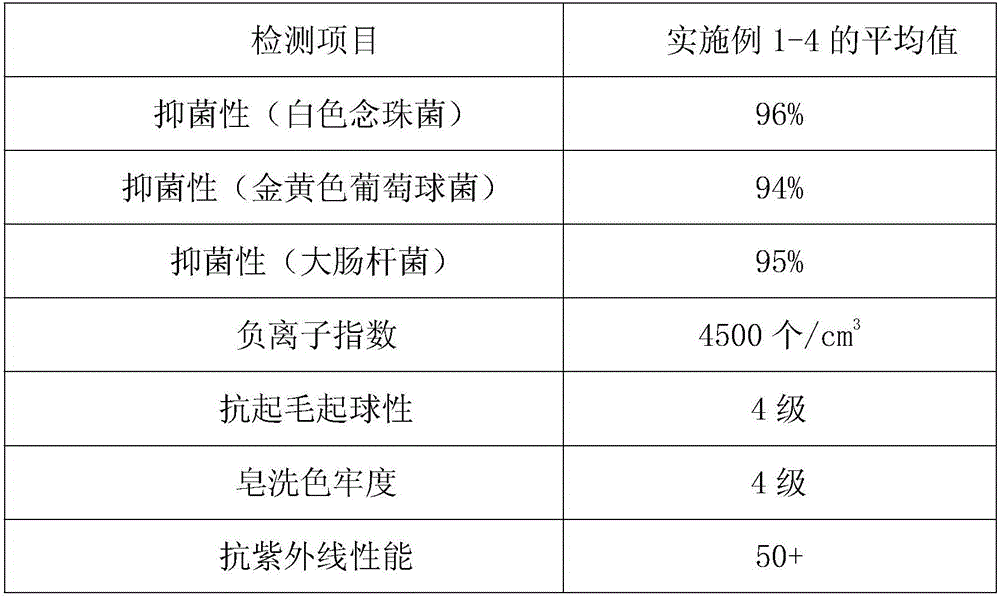

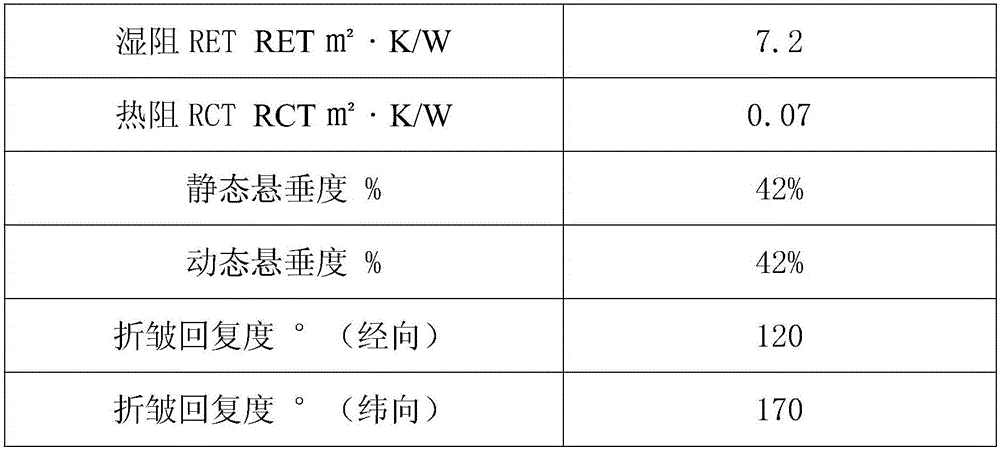

The invention discloses sportswear shell fabric and a production method thereof. The sportswear shell fabric and the production method thereof have the advantages that superfine polyester fibers, Coolplus fibers and profiled polyester fibers are selected, so that the shell fabric has good uvioresistant performance and moisture absorption and sweat release performance; blend fibers have excellent drapability, so that the shell fabric has attractive appearance and high quality; the Coolplus fibers are subjected to pearl powder ultrasonic treatment, nanoparticles of pearl powder enter tiny grooves of the fibers, and accordingly, the finally woven blend fibers have the effect of skin care, ultraviolet resistance and the like; after the Coolplus fibers are subjected to antibacterial treating and anion finishing, antibacterial treating and anion finishing of the blend fibers are not needed, overall effect is guaranteed, and cost is reduced.

Owner:东莞众越电子饰品有限公司

Multi-component weft triple fabric and weaving process thereof

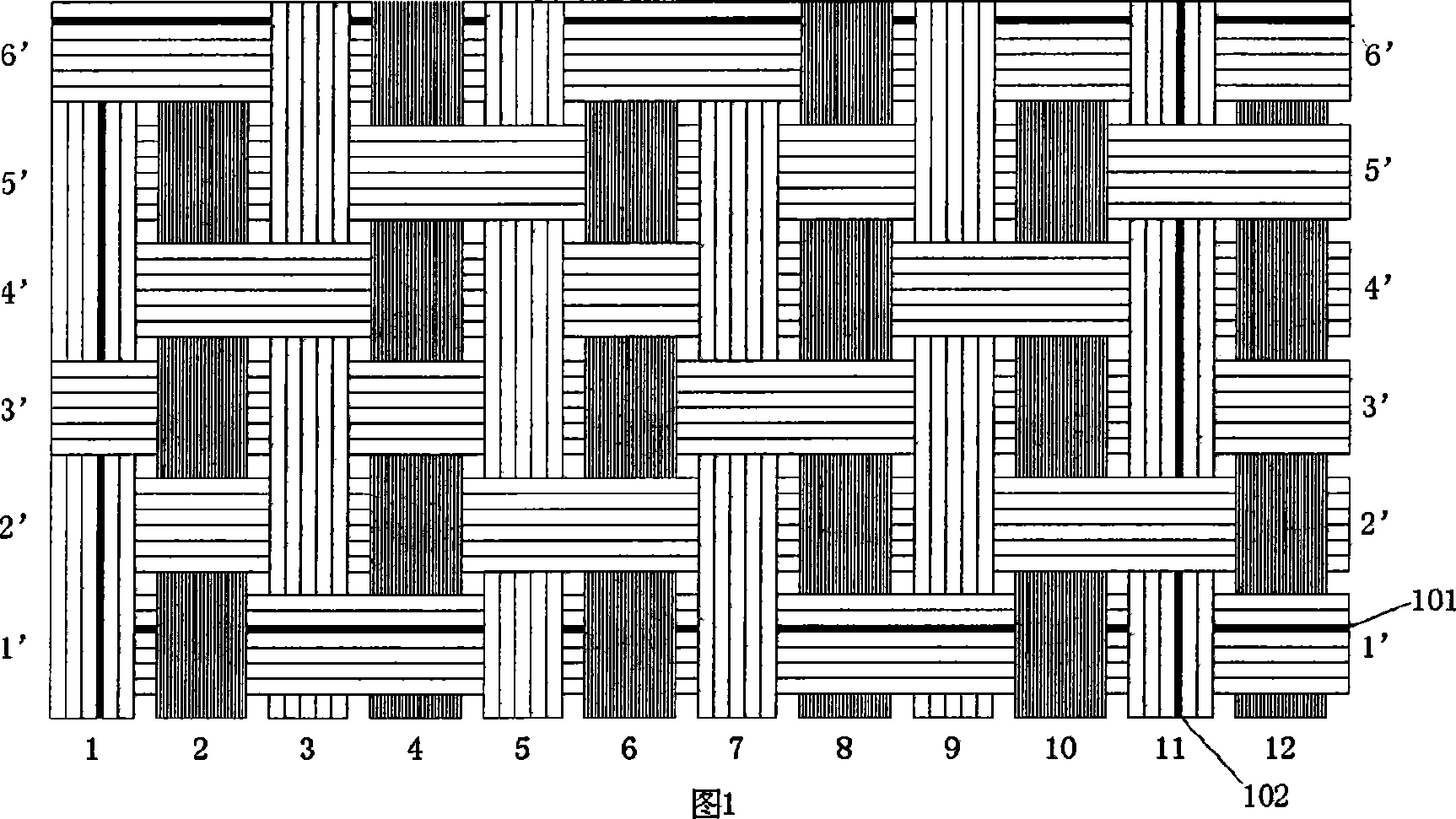

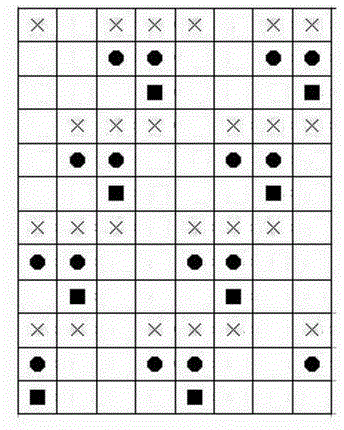

InactiveCN105568473AStrong moisture wickingImprove antistatic performanceLoomsWarping machinesWear resistantEngineering

Provided are a multi-component weft triple fabric and a weaving process thereof. The fabric is formed y five components of cotton, Coolmax modified polyester fibers, China-hemp, conductive fibers, and polyester filament yarns. Four kinds of yarns are used, and warps are combed cotton / Coolmax modified polyester fibers, and weft yarns are combed cotton / Coolmax modified polyester fibers, terylene low-elastic interlaced yarns, combed cotton / China-hemp and terylene, and conductive fibers. Fabric weave structure is a weft triple structure. The front surface is combed cotton / Coolmax modified polyester fiber warps and wefts, the middle layer is the terylene low-elastic interlaced yarns, and the back surface is the combed cotton / China-hemp blended yarns. The face weave is cross grain, the intermediate weave is cross grain, and the inner weave is cross grain. The fabric is cool and crisp in hand feeling, novel in style, and is firm and wear-resistant. The fabric has good moisture absorption and sweat releasing property, and is comfortable in wearing. The fabric has good healthcare and functionality, and is especially suitable for professional uniform in spring and autumn.

Owner:JIHUA 3542 TEXTILE CO LTD

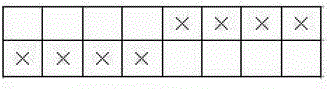

Warp and weft thread water absorben perspiring shell fabric

InactiveCN101067256AGood moisture absorption and perspirationWoven fabricsUndergarmentsFiberEngineering

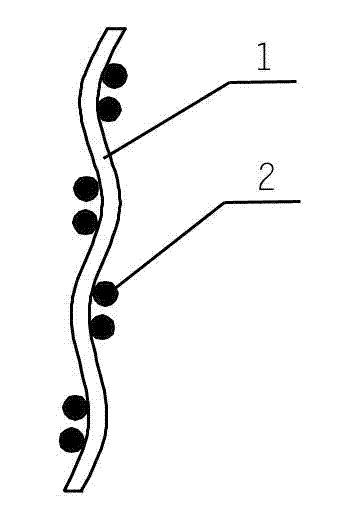

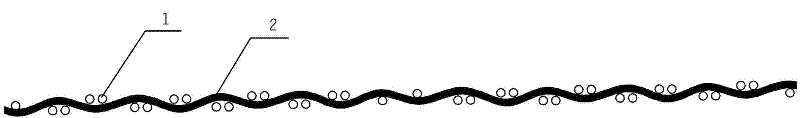

The present invention provides one kind of moisture absorbing and sweat exhausting fiber fabric. The moisture absorbing and sweat exhausting fiber fabric is woven with both hydrophilic and hydrophobic monofilament fibers. It includes two layers, one warp layer and one weft layer, and possesses excellent moisture absorbing performance and excellent sweat exhausting performance.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

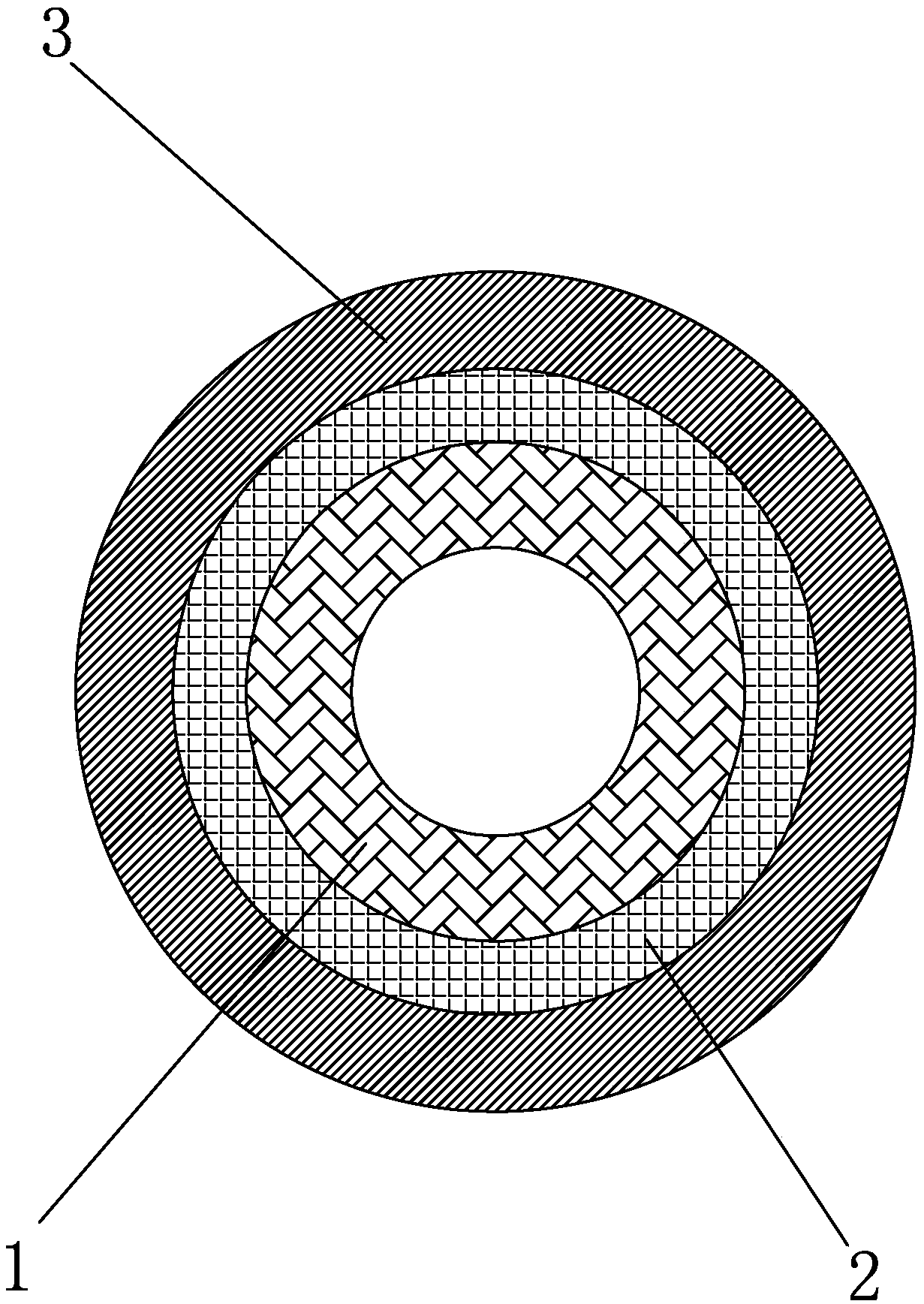

Hollow soft antibacterial yarn

PendingCN109183225AImprove breathabilityGood air permeability, good antibacterial and deodorizing propertiesYarnYarnCarbon fibers

The invention discloses a hollow soft antibacterial yarn. The yarn includes a yarn body, wherein the yarn body is of a sheath core structure, the yarn body is a hollow yarn, an inner portion is a hollow core, the yarn body sequentially includes a bamboo charcoal fiber layer, a coffee carbon fiber layer and a colored cotton fiber layer from the inside to the outside in the radial direction of the yarn body, the hollow core of the yarn body is formed through hydrolysis of a core yarn made of the water-soluble vinylon fiber, the bamboo charcoal fiber layer is formed by spirally winding raw bamboofibers, the bamboo charcoal fiber layer is internally filled with silver nano particles, the coffee carbon fiber layer is formed through spirally covering the coffee carbon fiber outside the bamboo charcoal fiber layer, and the colored cotton fiber layer is formed by spirally covering the colored cotton fiber outside the coffee carbon fiber layer. The yarn is advantaged in that the hollow yarn structure is utilized, the bamboo charcoal fiber layer and the coffee carbon fiber layer are arranged internally, and the yarn is super soft and super fluffy, has good warmth keeping effect, breathability, good antibacterial and deodorizing performance, the bright color and no dye need and can realize environmental protection and energy saving.

Owner:苏州璟珮新材料科技有限公司

Hygroscopic and sweat releasing knitted fabric with shape memory function and processing method thereof

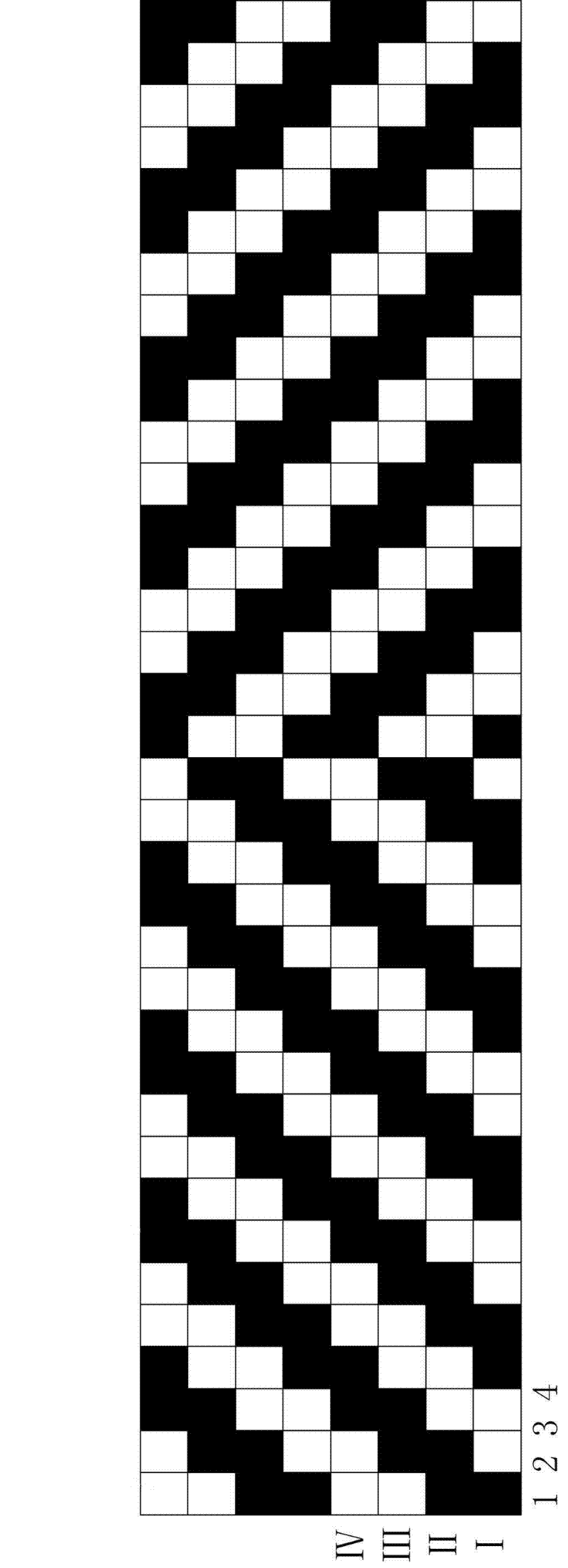

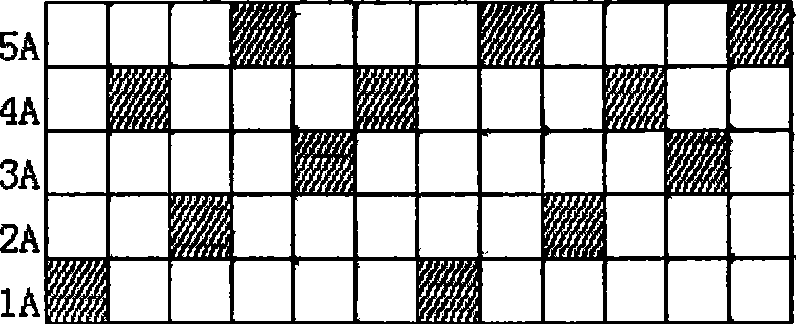

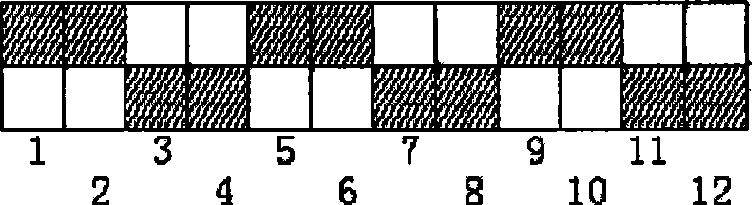

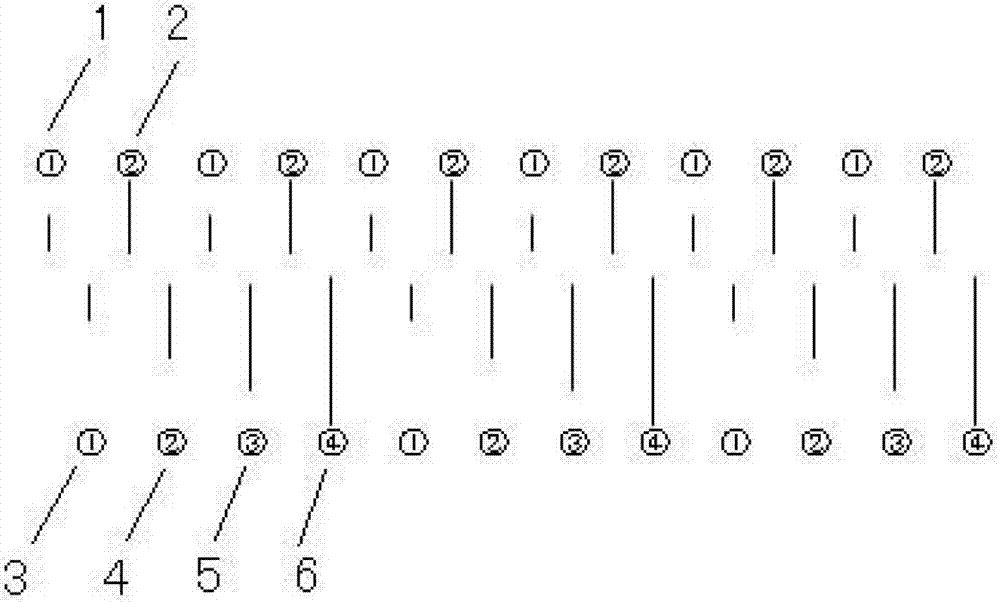

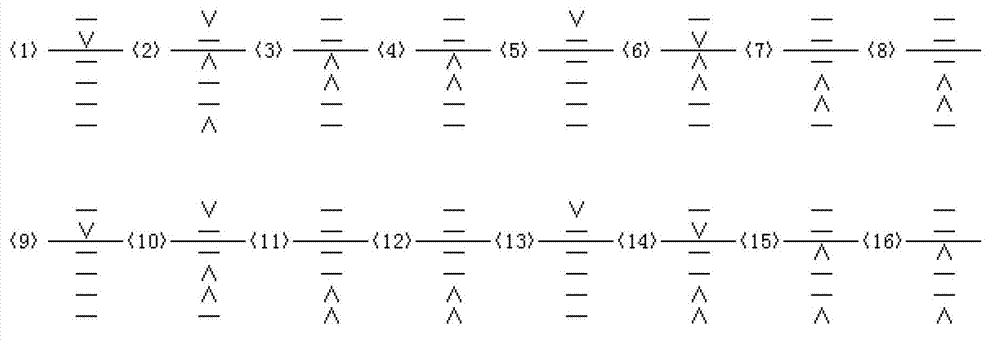

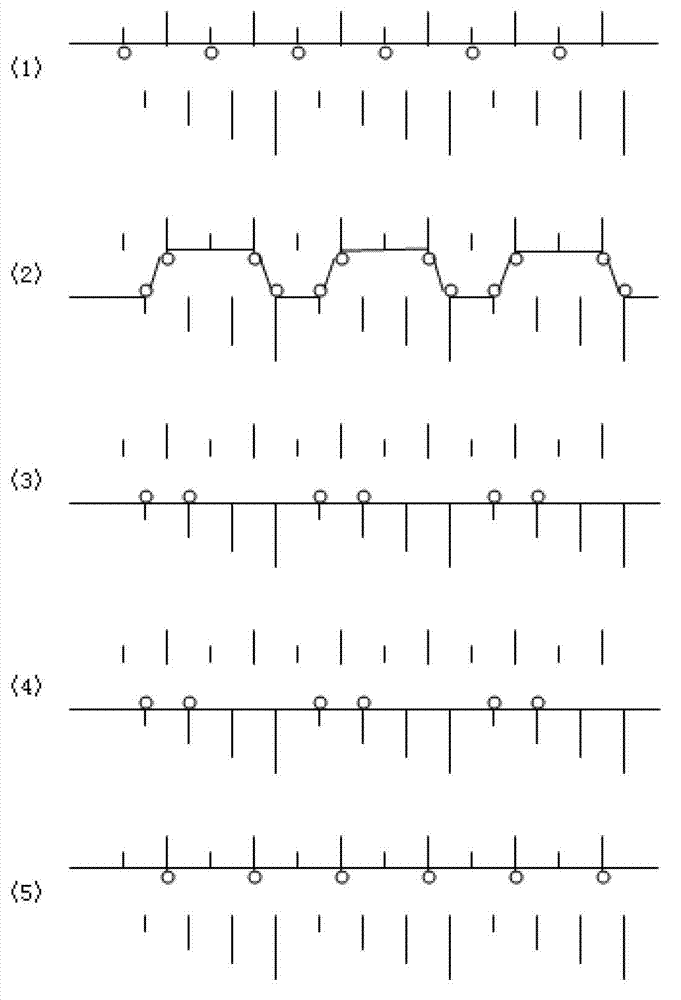

The invention discloses hygroscopic and sweat releasing knitted fabric with a shape memory function and a processing method thereof. The fabric comprises a dual-face dual-layer twill cloth structure, wherein a face, that is to say, an outer layer is a cotton bale shape memory function covering yarn, and an opposite face, that is to say, an inner layer is a shape memory polyester fiber. The processing method of the fabric comprises the following steps: the outer-layer structure is selected from the cotton bale shape memory function covering yarn, and the inner-layer structure is selected from the shape memory polyester fiber, knitting is carried out on a dual-face knitted circular knitting machine, and ribs are opposite: two upper needles with one low needle and one high needle are arranged, and four lower needles 1 2 3 4 are arranged; and a knitting process is a cycle including 16 paths. The fabric has a shape memory function and good hygroscopic and sweat releasing performance of a cotton natural fiber. Clothes made by the fabric is not supported by external force, so that any shapes can be independent kept and any drapes can be represented, after lightly whisking by a hand, the smooth state is completely restored without any folds, and the shape is kept and the fabric has permanence.

Owner:SHANGHAI JIALE

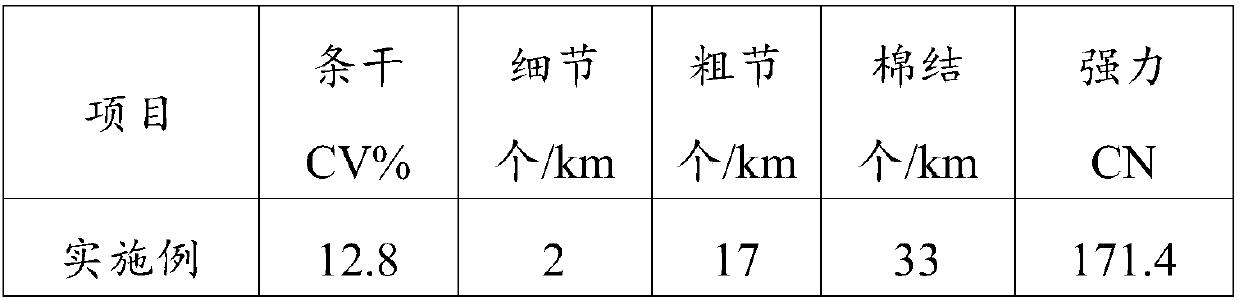

Compact spinning yarn produced through polylactic acid fiber and combed fine stable cotton blending and production method and application of compact spinning yarn

The invention belongs to the technical field of textile, and particularly relates to compact spinning yarn produced through polylactic acid fiber and combed fine stable cotton blending and a production method and application of the compact spinning yarn. According to the production method, polylactic acid fiber and combed fine stable cotton serve as raw materials, and the compact spinning yarn with the number being 40 is obtained through the processes of blowing, carding, combing, drawing, roving, spinning and spooling. According to the production method, parameters of all the processes are qualified definitely so as to make the polylactic acid fiber and the combed fine stable cotton blended smoothly to obtain the compact spinning yarn with the number being 4; fabric produced through the compact spinning yarn is good in gloss and skin adaptability and smooth and delicate in hand feeling, the fabric has the excellent drapability and flexibility, the natural antimicrobial and moisture absorption and sweat releasing properties are excellent, the elastic recovery is good, and the compact spinning yarn can be used for making underwear and sportswear.

Owner:JIHUA 3509 TEXTILE

A sweat-absorbent polyester fiber pantyhose

ActiveCN109123821AEvenly dispersedAvoid secondary reunionsElectroconductive/antistatic filament manufactureWeft knittingPerspirationPolyester

The invention discloses a sweat-absorbent polyester fiber pantyhose including a pantyhose body. The pantyhose body is formed by interlacing a lining yarn and a veil. The lining yarn is made of a blended viscose fiber and a moisture wicking polyester fiber, and the veil is spandex, in terms of weight percent, the composition of each fiber raw material of the pantyhose body is: 12 to 13% of spandex,8 to 9% of modified viscose fiber, and 78 to 80% of moisture-absorbing and perspiration polyester fiber. The sweat-absorbent polyester fiber pantyhose has better moisture absorption and perspirationperformance, and has washing resistance, antibacterial, anti-ultraviolet, anti-static and other functions.

Owner:YIWU ZHISHANG SOCKS

Production process of antibacterial blended fiber towels

InactiveCN105231933AGuaranteed water absorptionSoft touchSolvent-treatmentDomestic applicationsYarnFiber

The invention relates to a production process of antibacterial blended fiber towels. Bamboo fiber, cotton fiber and Modal fiber are made into blended yarns, the blended yarns are subjected to warping, the warped blended yarns are subjected to sizing, the sized blended yarns are spun into gray fabric, the gray fabric is flushed to remove water-soluble threads, the gray fabric is boiled and bleached and is dyed, the dyed gray fabric is dried with a drying appliance, the dried gray fabric is cut and sewn to form blended fiber towels, and the blended fiber towels are subjected to antibacterial finishing using an antibacterial finishing agent. According to the production process, antibacterial finishing is carried out, thus germ growth can be prevented effectively and towel fabric is protected from contamination by microorganisms; features such as water retention and softness are retained, the towel fabric has excellent moisture-absorbing and sweat transfer performances, outstanding high temperature resistance and outstanding stink-absorbing and foul-eliminating performances and is green and long in service life, a processing technique is simple, and production efficiency is high.

Owner:陈剑

Sweat discharge naked feeling triple antibacterial underpants and manufacturing method thereof

ActiveCN109938419AAchieve leapfrog upgradesExquisite technologyWeft knittingVegetal fibresFiberMoisture absorption

The invention discloses sweat discharge naked feeling triple antibacterial underpants and a manufacturing method thereof. The manufacturing method of the sweat discharge naked feeling triple antibacterial underpants comprises the following steps: (1) preparing an antibacterial finishing liquid; (2) carrying out lining antibacterial finishing; and (3) cutting and sewing a large body fabric, a rubber rib and an antibacterial lining into underpants by using a common method, thereby obtaining the sweat discharge naked feeling triple antibacterial underpants. By adopting the sweat discharge naked feeling triple antibacterial underpants and the manufacturing method thereof, the lining is made of an X-STATIC and bamdal fiber and is further subjected to antibacterial finishing, a naked feeling fabric is adopted as the large body fabric, the obtained sweat discharge naked feeling triple antibacterial underpants are good in moisture absorption and sweat discharge, soft and breathable, high in yellowing resistance, high in washing resistance, remarkable in antibacterial property after multiple times of washing and comfortable to wear, and the remarkable and long-lasting antibacterial propertyis beneficial to human body health.

Owner:上海小蓝象服装有限公司

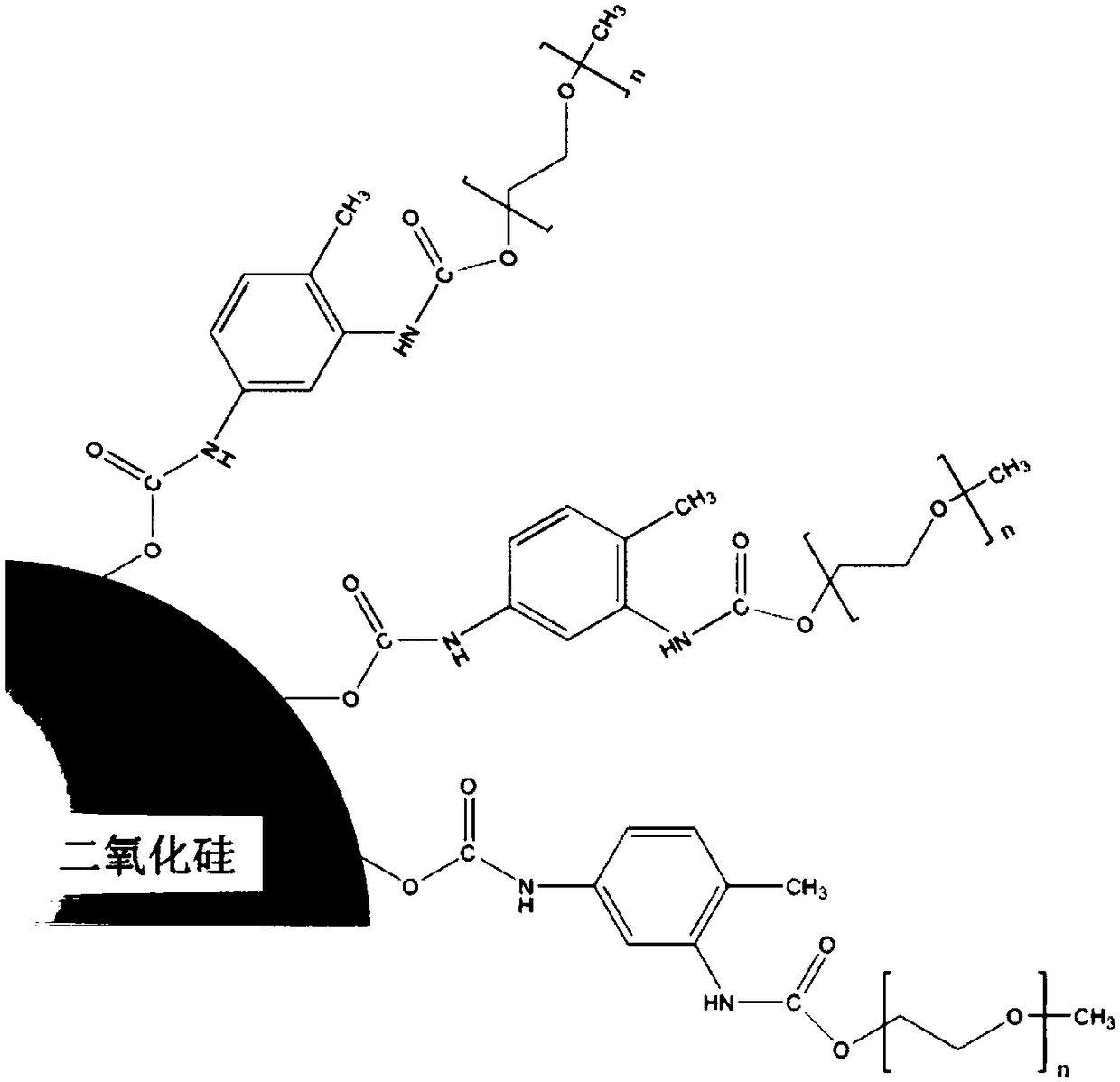

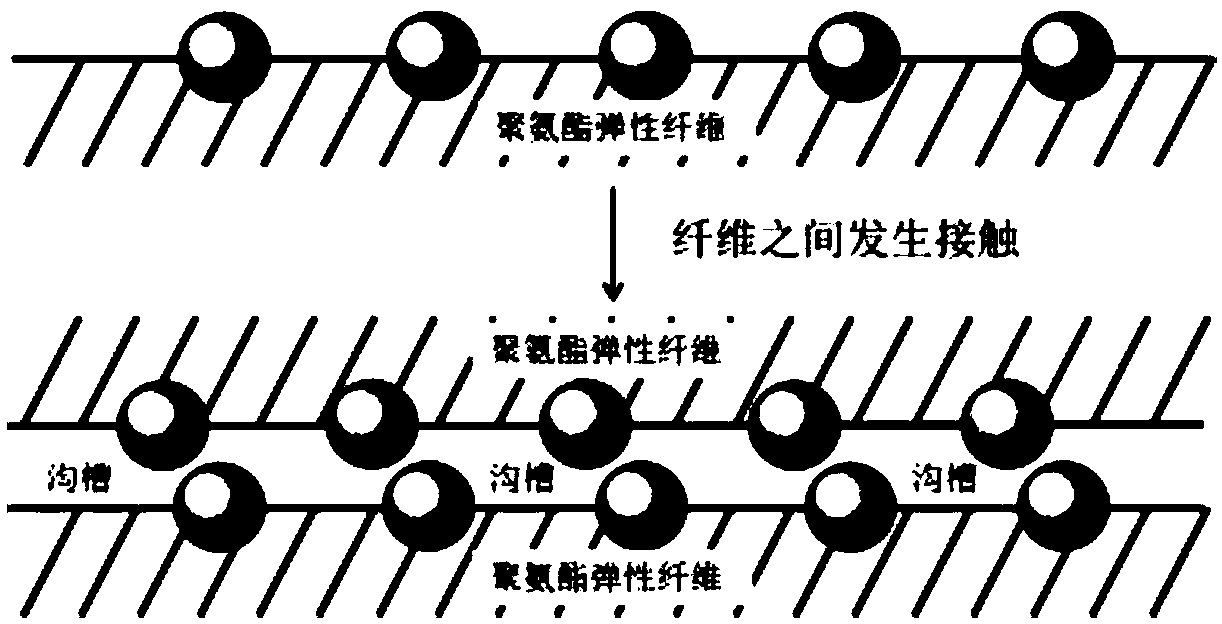

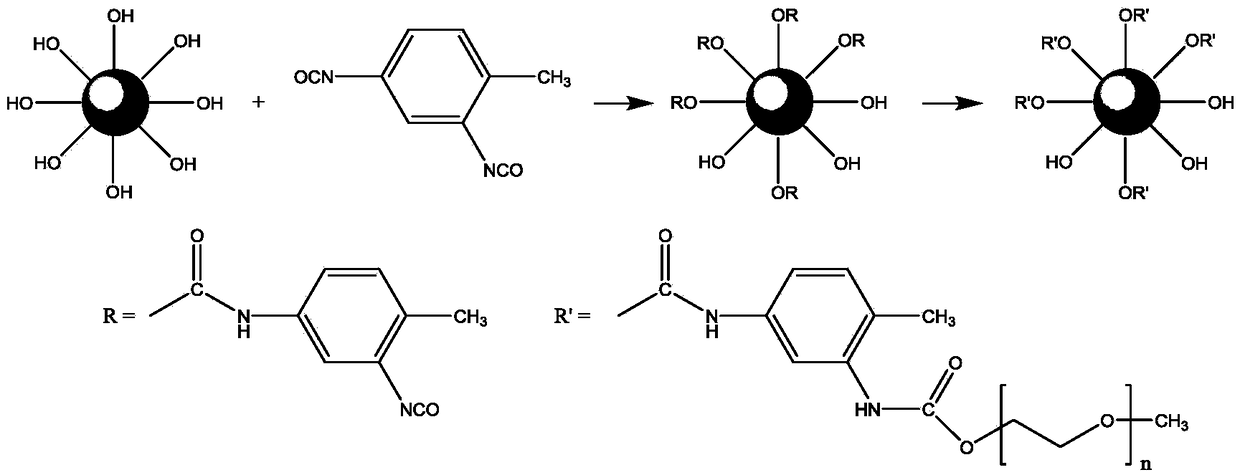

Method for preparing moisture absorption and sweat releasing polyurethane elastic fibers having skin core structure

ActiveCN108977929AGood moisture absorption and perspirationParticle size controllableFilament/thread formingConjugated synthetic polymer artificial filamentsYarnSilica particle

The invention discloses a method for preparing moisture absorption and sweat releasing polyurethane elastic fibers having a skin core structure. The method comprises the following steps: (1) preparinga N,N-dimethylacetamide dispersion solution of hydrophilic silicon dioxide particles; (2) preparing an N,N-dimethylacetamide solution of polyurethane-polyurea, and curing to obtain a sandwich layer spinning liquid; (3) adding conventional additives and the N,N-dimethylacetamide dispersion solution of hydrophilic silicon dioxide particles into part of the polyurethane-polyurea solution, diluting with N,N-dimethylacetamide, and curing to obtain a skin layer spinning fluid; and (4) performing spin-stretching on the sandwich layer spinning liquid through a spinning plate, drying at high temperature through a first corridor to preparing sandwich layer polyethene elastic fiber yarns, coating the skin layer spinning fluid to the surface of the polyurethane elastic fiber yarns through a specificstructure coating device, and performing high-temperature drying, oiling and winding through a second channel to obtain the moisture absorption and sweat releasing polyurethane elastic fibers.

Owner:ZHEJIANG HUAFENG SPANDEX

Production technology of novel antibacterial home textile fabric

The invention discloses a production technology of a novel antibacterial home textile fabric. The novel antibacterial home textile fabric is produced through interweaving of warp and weft; the patternis one of taffeta, satin and jacquard, the warp is blended yarn of graphene chinlon / viscose, and the weft is blended yarn of coconut carbon / combed cotton and wrap yarn of sliver fiber / honeycomb dacron; graphene in the graphene chinlon is added before spinning, and the adding proportion is 1-2%; the blended yarn of coconut carbon / combed cotton and the wrap yarn of sliver fiber / honeycomb dacron aresubjected to wefting insertion by the specified picking proportion of 3:1 or 4:1 to complete weaving; 2-4% of silane coupling agent is used for preprocessing the sliver fiber, obtained sliver layersare good in homogeneity and high in binding force, the coating crystal structure is complete, and the depth is 1-2 micrometers. The technology is simple, the novel home textile fabric is smooth, soft,skin-friendly, comfortable, antibacterial and warm, is not likely to pill, has good hygroscopicity and air permeability, and meets the needs of families, hotels and other consumers.

Owner:IANGSU COLLEGE OF ENG & TECH

Ultra-light warm-keeping fabric

InactiveCN103898663ALow densityGood warmth retentionWoven fabricsProtective garmentPulp and paper industryUltra fine

The invention discloses an ultra-light warm-keeping fabric. The ultra-light warm-keeping fabric comprises warp and weft. The ultra-light warm-keeping fabric is formed by interweaving the warp and the weft and comprises, by weight, 49 percent to 53 percent of the warp and 47 percent to 51 percent of the weft. The warp is formed by blending ultra-fine denier polypropylene fiber and bamboo fiber, and the weft is formed by blending ultra-fine denier polypropylene fiber and cotton fiber. Through the method, the ultra-fine denier polypropylene fiber is mainly adopted for the ultra-light warm-keeping fabric, and thus the ultra-light warm-keeping fabric has the advantages of being small in density and good in warm keeping performance. Moreover, the moisture absorbing and sweat releasing performance is excellent, the ultra-light warm-keeping fabric is suitable for being made into clothes worn in winter, and the ultra-light warm-keeping fabric is light and comfortable.

Owner:APPROACH SUZHOU GARMENT

Method for preparing moisture absorption and sweat releasing anti-UV finishing agent for pure cotton fabrics

InactiveCN105734967APromote swellingPlay a protective effectLight resistant fibresGrip property fibresWrinkle skinBreaking strength

The invention discloses a method for preparing a moisture absorption and sweat releasing anti-UV finishing agent for pure cotton fabrics, belongs to the technical field of textiles and chemicals. The preparation method of the invention is green, environment-friendly, healthy and efficient; a prepared finishing agent solution is mild and non-irritant, and can be directly used for finishing fabrics; the finishing agent of the invention is used for finishing the pure cotton fabrics in a padding-steaming manner, gives the pure cotton fabrics excellent UV resistance after finishing while ensuring that the pure cotton fabrics have excellent moisture absorption and sweat releasing properties and good washing resistance and are suitable for wearing when working and living outdoors in hot seasons, also has less influence on the pure cotton fabrics after finishing while essentially remaining the whiteness, breaking strength and wrinkle recovery angle unchanged in comparison with unfinished cotton fabrics, can satisfy people's favorite to the pure cotton fabrics, and has a good market promotional value.

Owner:SUZHOU INSILK CO LTD

Preparation method of moisture-absorbing sweat-releasing PLA/PET side-by-side compound fiber

ActiveCN107955982AGood moisture wicking effectPromote absorptionFilament forming substance formingMelt spinning methodsFiberWater baths

The invention provides a preparation method of a moisture-absorbing sweat-releasing PLA / PET side-by-side compound fiber. PLA slices and PET slices are separately subjected to three-segment type dryingand screw-rod melting, enter a spinning box body and are compounded side by side at a spinneret plate, a side-by-side compound fiber from the spinneret plate is cooled by wind blowing, oiled, wound,dragged, contained and then subjected to oil-immersed water bath stretching, steam stretching, oiled cooling and hot shaping, and the moisture-absorbing sweat-releasing PLA / PET side-by-side compound fiber is obtained; the mass ratio of PLA to PET is 80:20-50:50. The PLA / PET side-by-side compound fiber is excellent in moisture absorbing and sweat releasing performance and suitable for the field ofapparel fabric, in particular to the field of sports apparel fabric.

Owner:南通华盛高聚物科技股份有限公司

Bio-based nylon fabric, and preparation method and product thereof

PendingCN110983566AImprove tensile strengthImprove mechanical propertiesWeft knittingWarp knittingCelluloseCarboxymethyl cellulose

The invention discloses a bio-based nylon fabric, and a preparation method and a product thereof. The bio-based nylon fabric is prepared from 80 to 90 parts of bio-based nylon fiber, 12 to 15 parts ofcotton fiber and 6 to 9 parts of polyfluortetraethylene fiber in parts by weight through a knitting or weaving process; and the bio-based nylon fiber is prepared from the following raw materials in parts by weight: 80 to 90 parts of bio-based poly pentamethylene diamine adipate, 14 to 18 parts of poly pentamethylene diamine adipate, 5 to 7 parts of carboxymethyl cellulose, 6 to 8 parts of sepiolite powder, 4 to 6 parts of fumed silica and 4 to 5 parts of a dispersing agent. The bio-based nylon fabric has the advantages that the tensile strength is strong; the mechanical property is good; highdurability is ensured; the service life is long; the moisture permeation rate is high, the moisture permeability is high, and good moisture absorption and perspiration effects are achieved during wearing, so that the wearing feeling is comfortable; and the air permeability is high, and the air-permeable performance is good, so that the wearing feeling is comfortable .

Owner:卡尔美体育用品有限公司

Method for spinning yarns for home textile by adopting air jet vortex spinning and method for weaving home textile shell fabric by using the yarns

ActiveCN102168328ALess hairyGood moisture absorption and perspirationBleaching apparatusContinuous wound-up machinesYarnEngineering

The invention discloses a method for spinning yarns for home textile by adopting air jet vortex spinning. The method for spinning yarns is characterized in that the yarns are cotton yarns of 18-40tex and technological parameters are as follows: nozzle pressure P is equal to 0.3-0.4Mpa, spindle distance is equal to18-20mm, and spinning speed is equal to 300-320m / min. The invention also discloses a method for weaving home textile shell fabric by using the yarns which are obtained by the air jet vortex spinning method, and the shell fabric is woven from the yarns which are formed by air jet vortex spinning and are taken as weft and warn yarns. Concretely, the method for weaving home textile shell fabric includes the technological steps of package rewinding, warping and weaving, wherein the rotation speed of a groove drum is 550-650r / min in the technological step of package rewinding. The home textile product prepared by the methods of the invention has less filoplume, good moisture wicking property and soft comfort, and excellent ultraviolet resistance, radiation protection and antibacterium property, and is a new-generation environment-friendly product.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com