Patents

Literature

100results about How to "High hollowness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

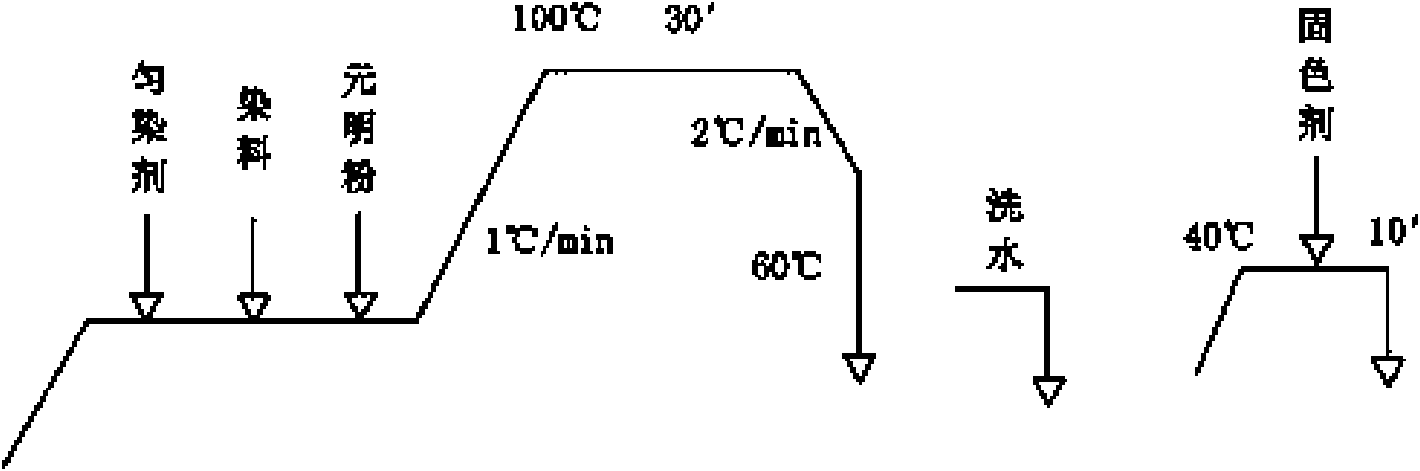

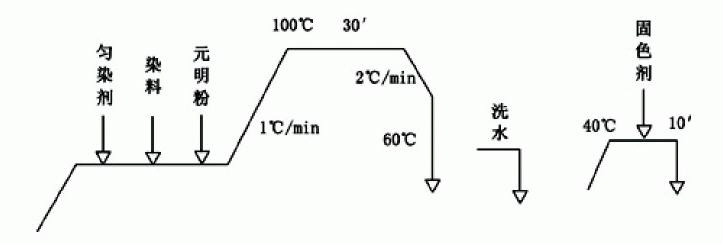

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

Hydrophilic hygroscopic and sweat-releasing polyester fiber and preparation method thereof

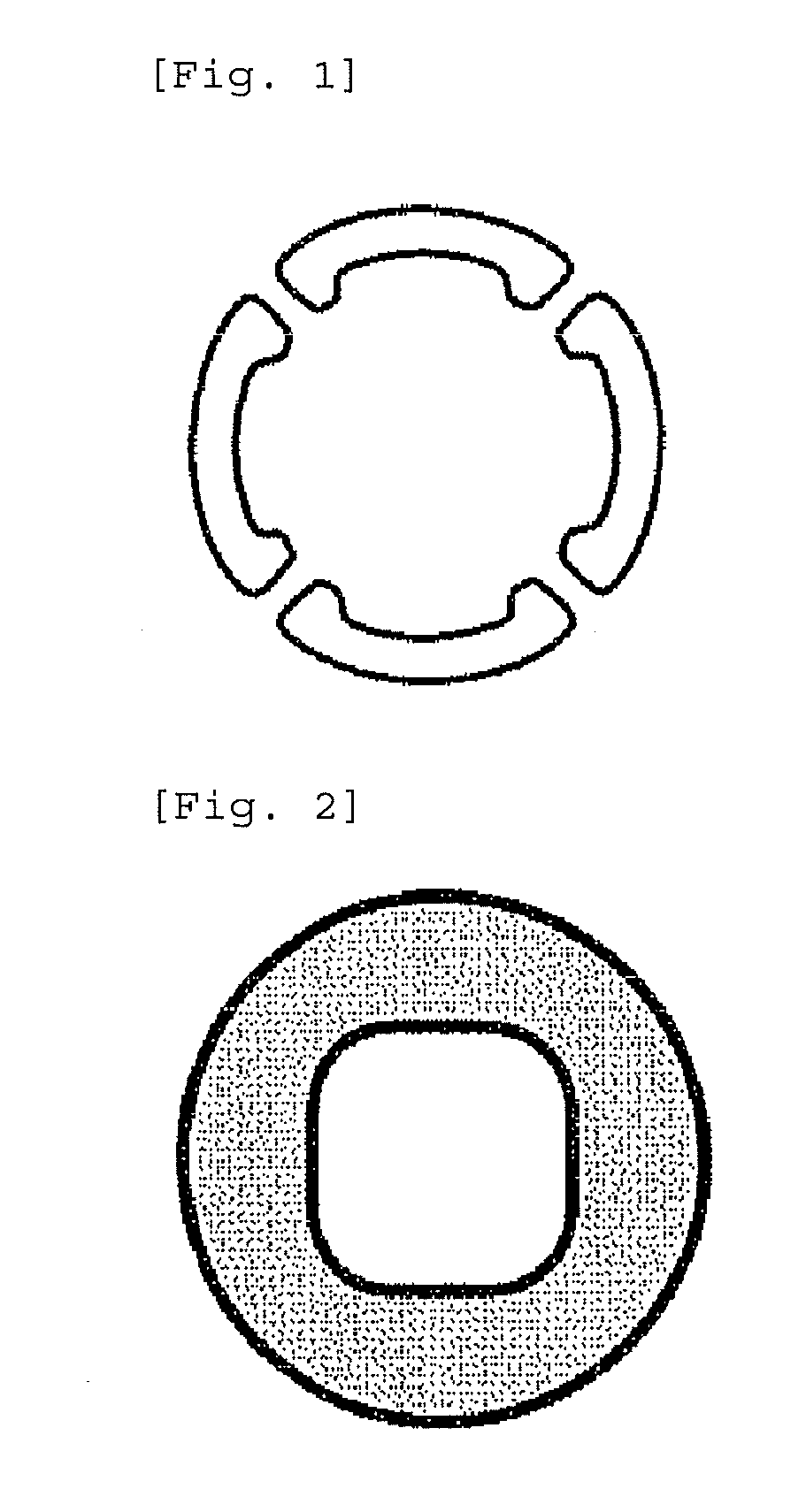

ActiveCN103320889ALarge specific surface areaHigh hollownessFibre typesMonocomponent polyesters artificial filamentChemistryWoven fabric

The invention discloses a hydrophilic hygroscopic and sweat-releasing polyester fiber and a preparation method of the hydrophilic hygroscopic and sweat-releasing polyester fiber. The method comprises the following steps of: slicing and respectively drying hydrophilic modification polyester, water-soluble polyester, and calcium carbonate powder-containing hydrophilic polyester master batch, mixing and melting according to certain mass percentage, extruding for spinning by a profile spinneret, and carrying out post-treatment to obtain polyester filament yarn or short fiber. Regardless of acid or alkali dyeing or processing environment, a great amount of micropores or grooves can be formed on the surface, better hydrophilic hygroscopic and sweat-releasing effects can be achieved, and the flexible and simple and convenient technique requirements can be reached; and the fiber can also obtain ultrahigh hygroscopic and sweat-releasing effects through superposition of dyeing or processing procedures. The profile hygroscopic and sweat-releasing fiber obtained by adopting the method is flexible in production technique no matter in pure or blended Dacron yarn weaved fabric, and achieves the changeability adjustability of the hygroscopic and sweat-releasing effects.

Owner:SHANGHAI VITA SCI & TECH

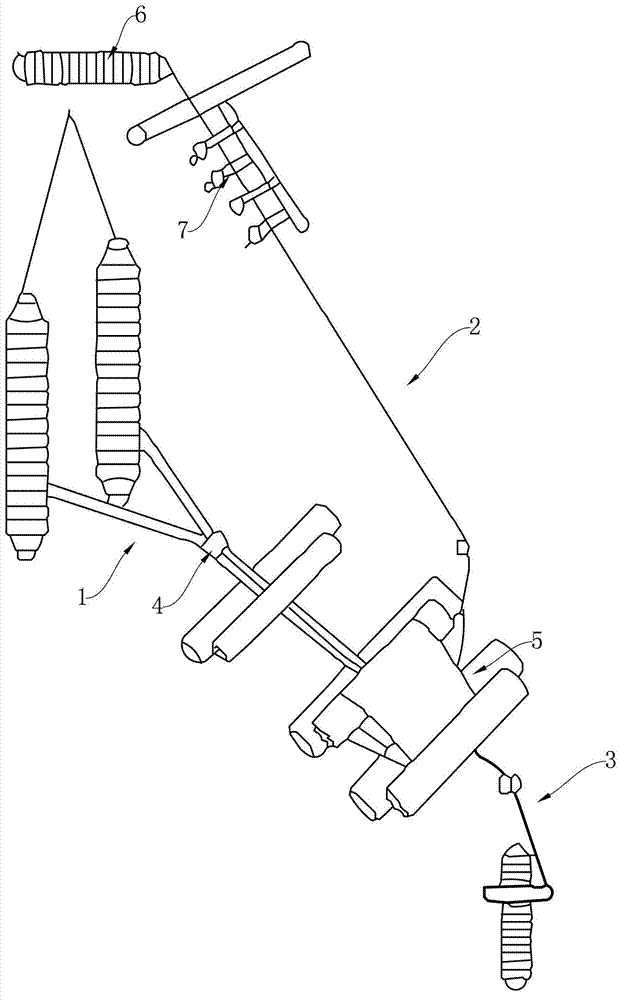

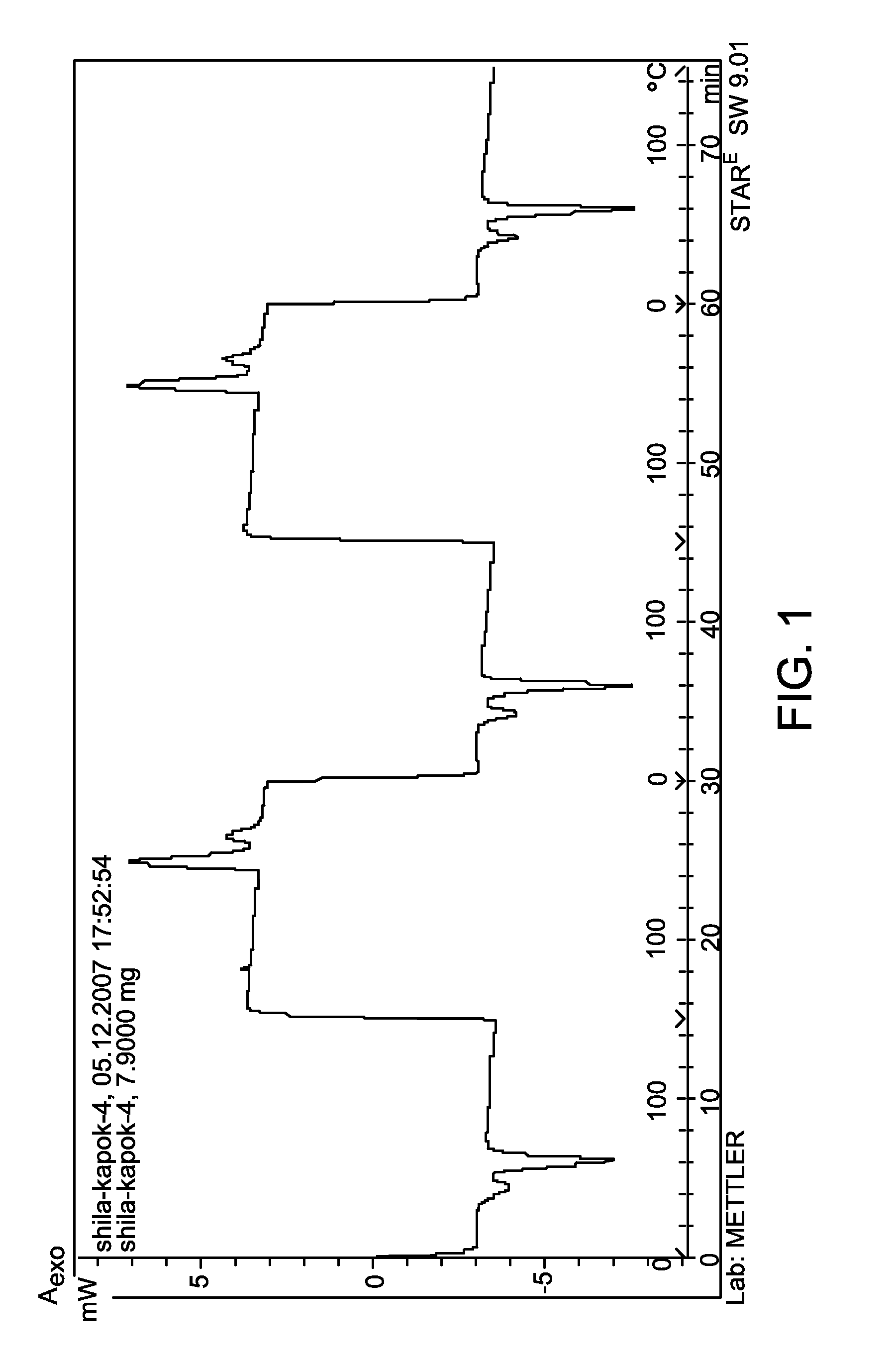

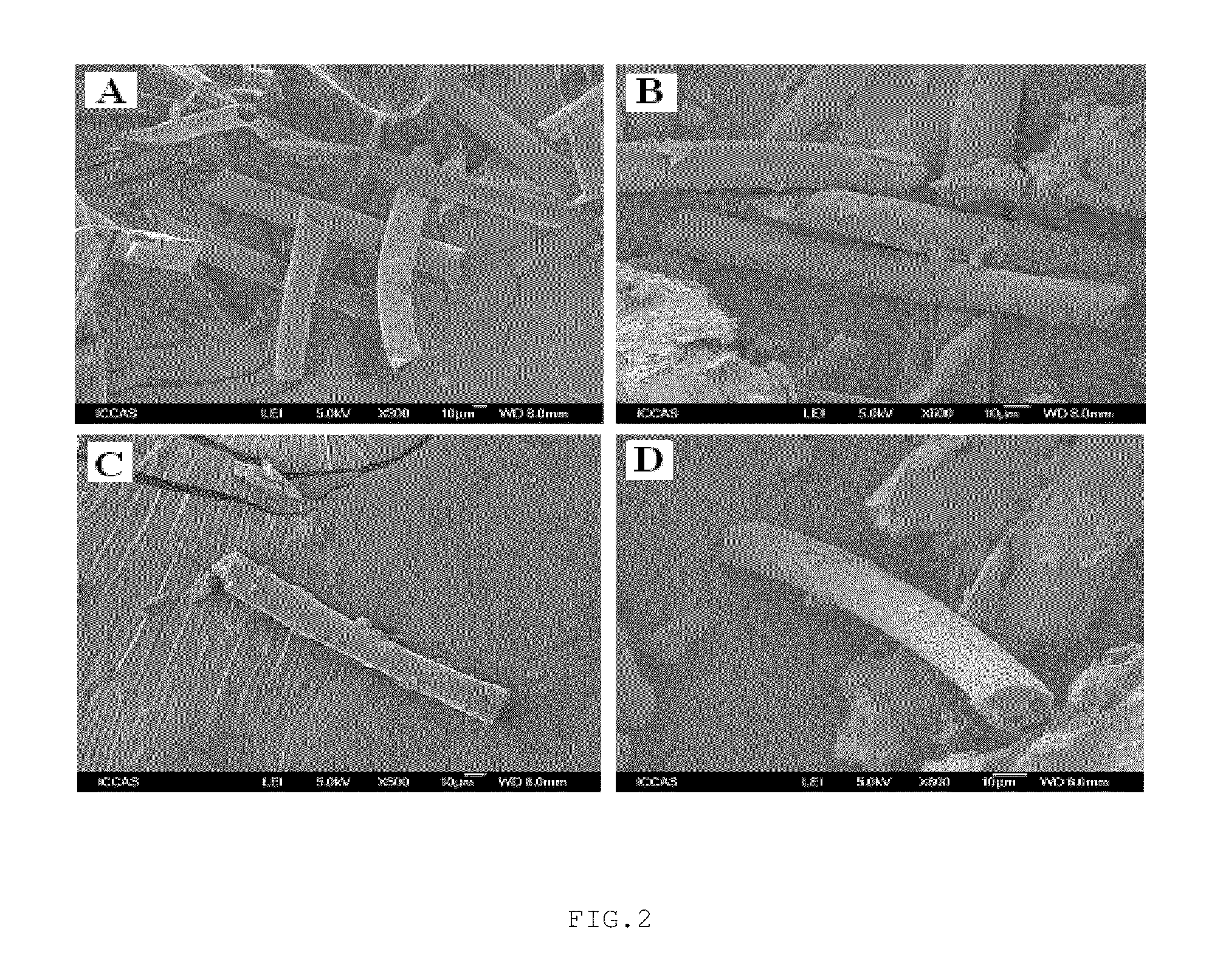

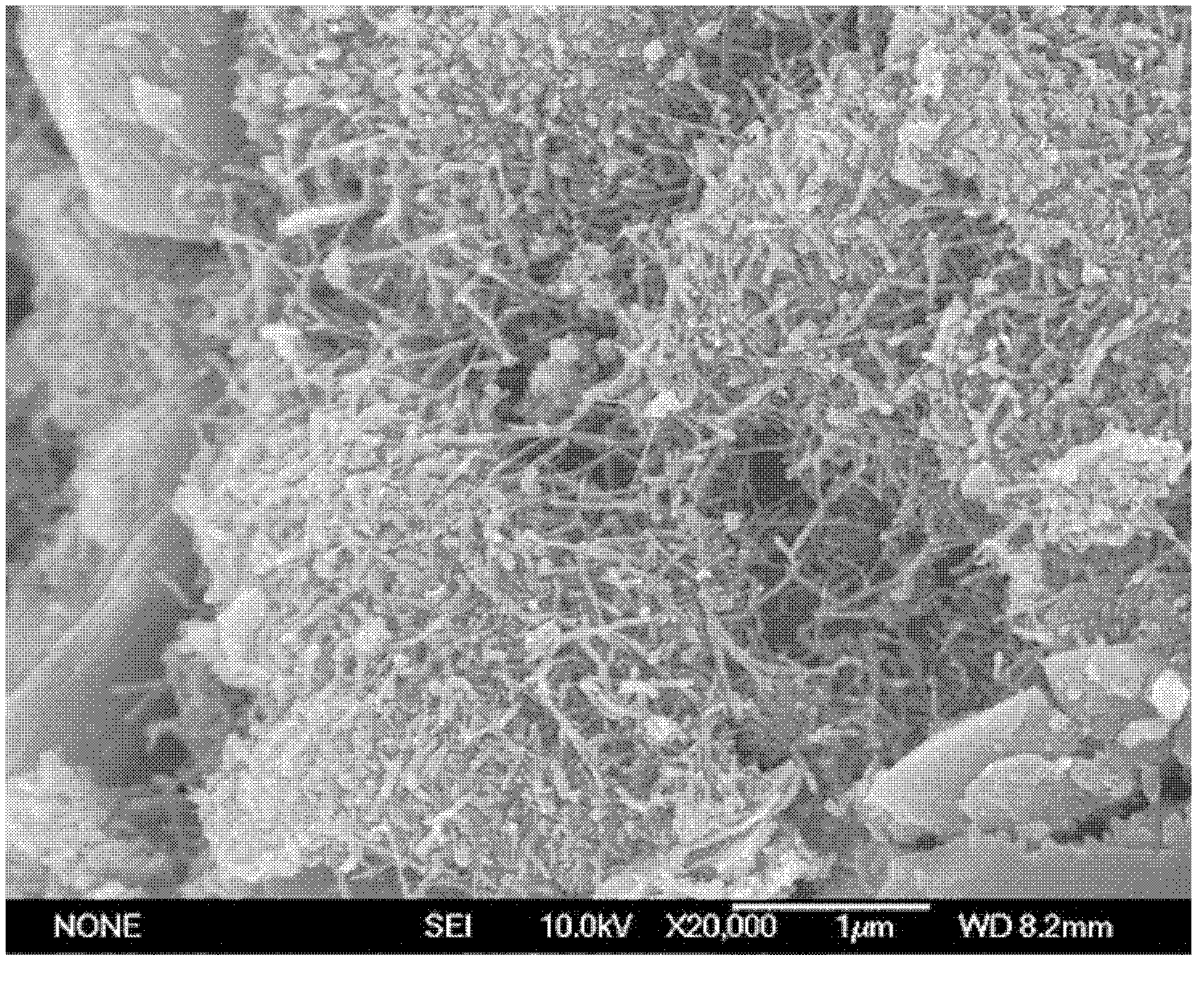

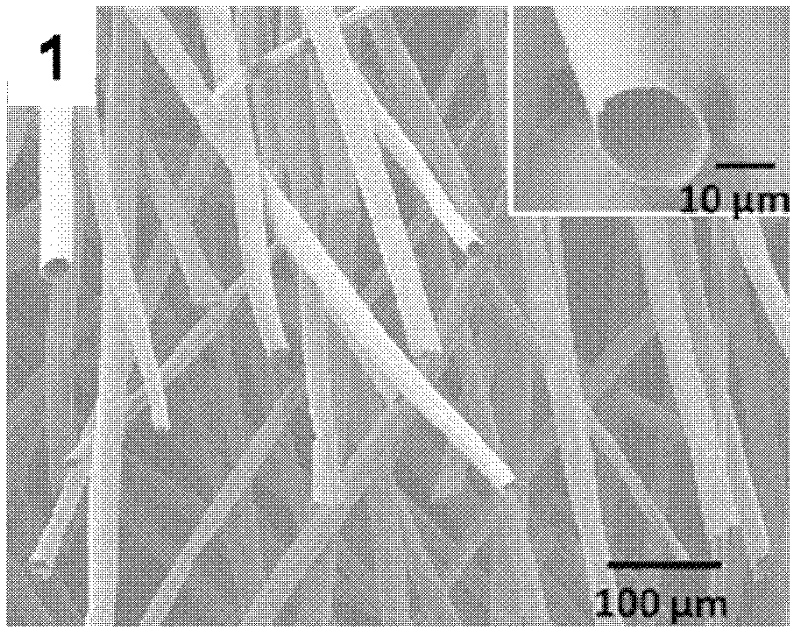

Natural microtubule encapsulated phase-change materials and preparation thereof

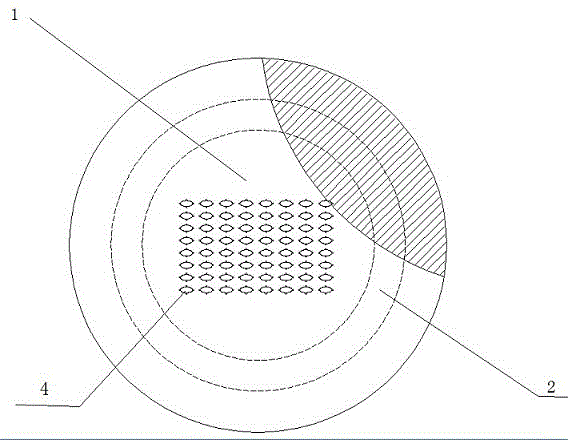

InactiveUS20100071882A1Cheap and easily available natural microfibersLarge specific surface areaHeat storage plantsMetal-working apparatusMicrotubulePolymer science

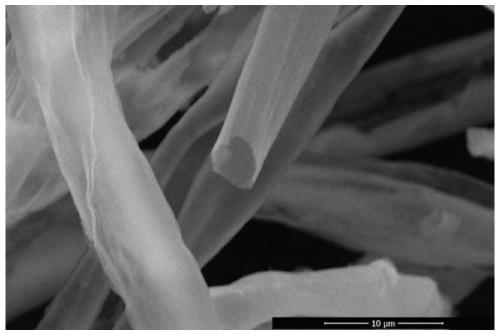

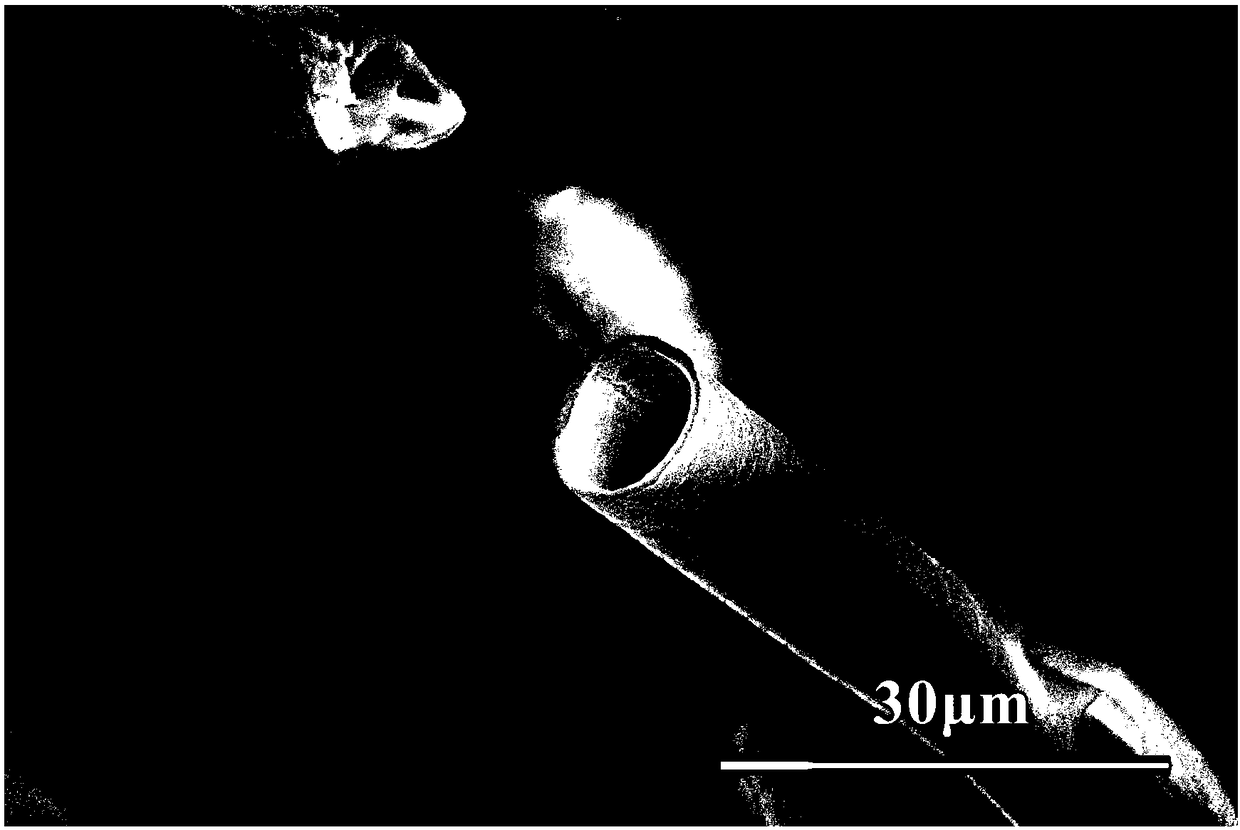

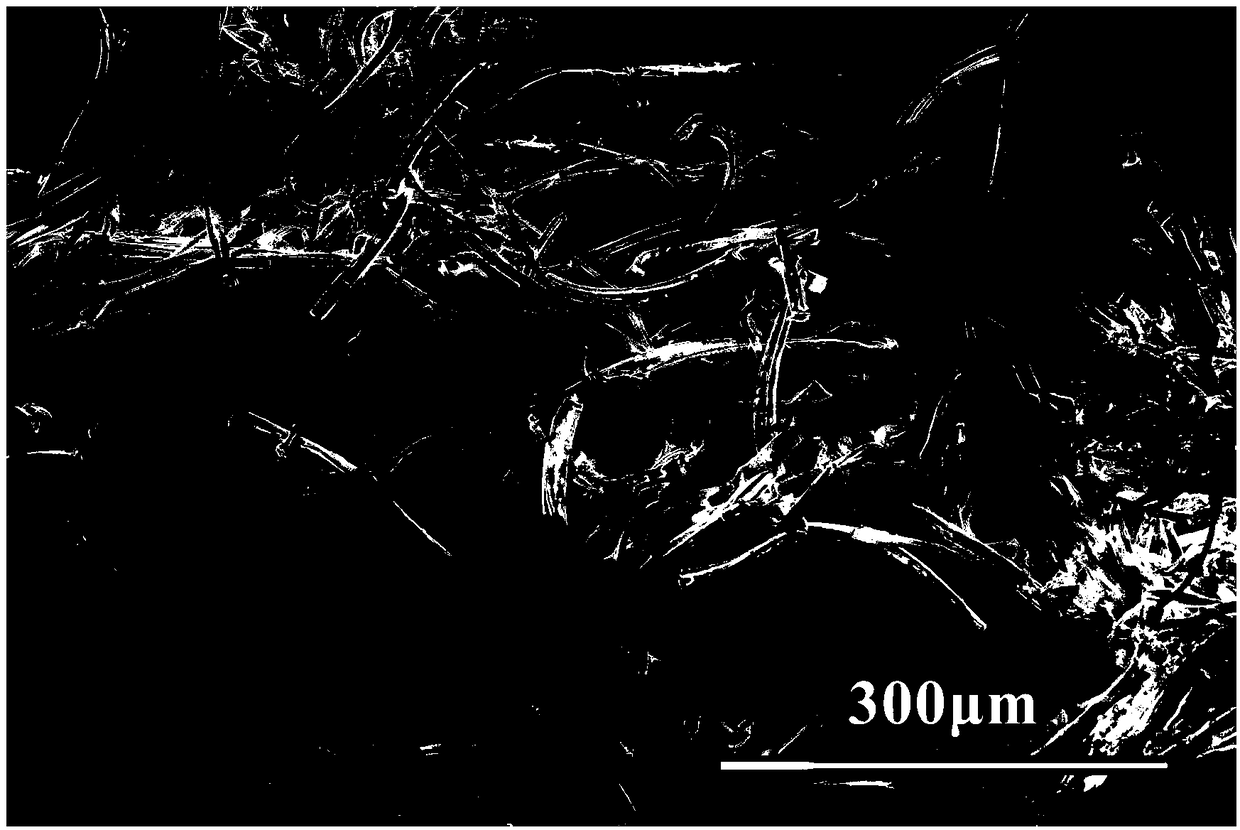

Microtubule encapsulated microcapsules of a phase-change material and preparation thereof are provided. The microcapsules of a phase-change material consist of a phase-change material, truncated microtubules, and a polymer. The truncated microtubules are formed by truncating hollow tubular natural fibers into fiber segments with a length of 0.1 mm-5 cm. The diameter of the hollow tubular natural fiber is 0.1-1000 μm. The phase-change material is encapsulated in the truncated microtubules and the truncated microtubules are covered with the polymer. The microtubules have high energy storage density due to high hollowness, and can transfer energy stably due to the closed structure, transfer heat rapidly due to the very fine micro-tubular structures, and may be used for a long term in view of the heat and chemical stability.

Owner:ETERNAL MATERIALS CO LTD

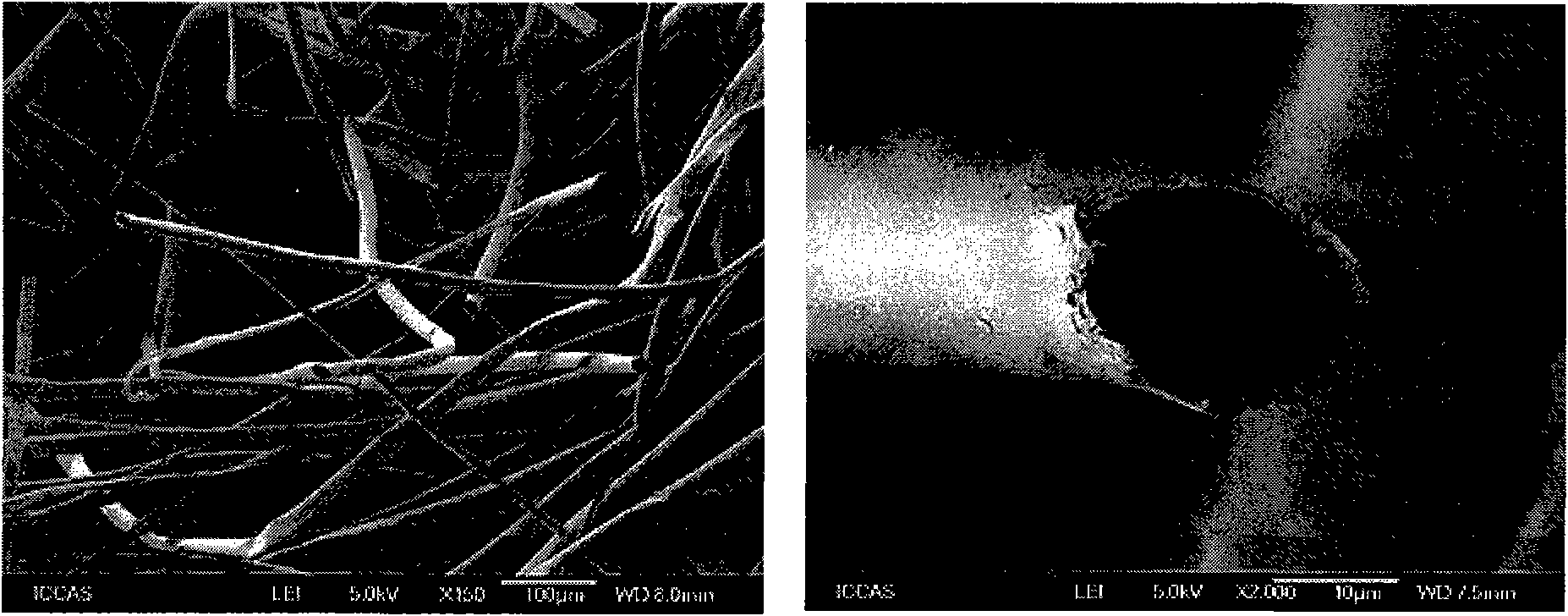

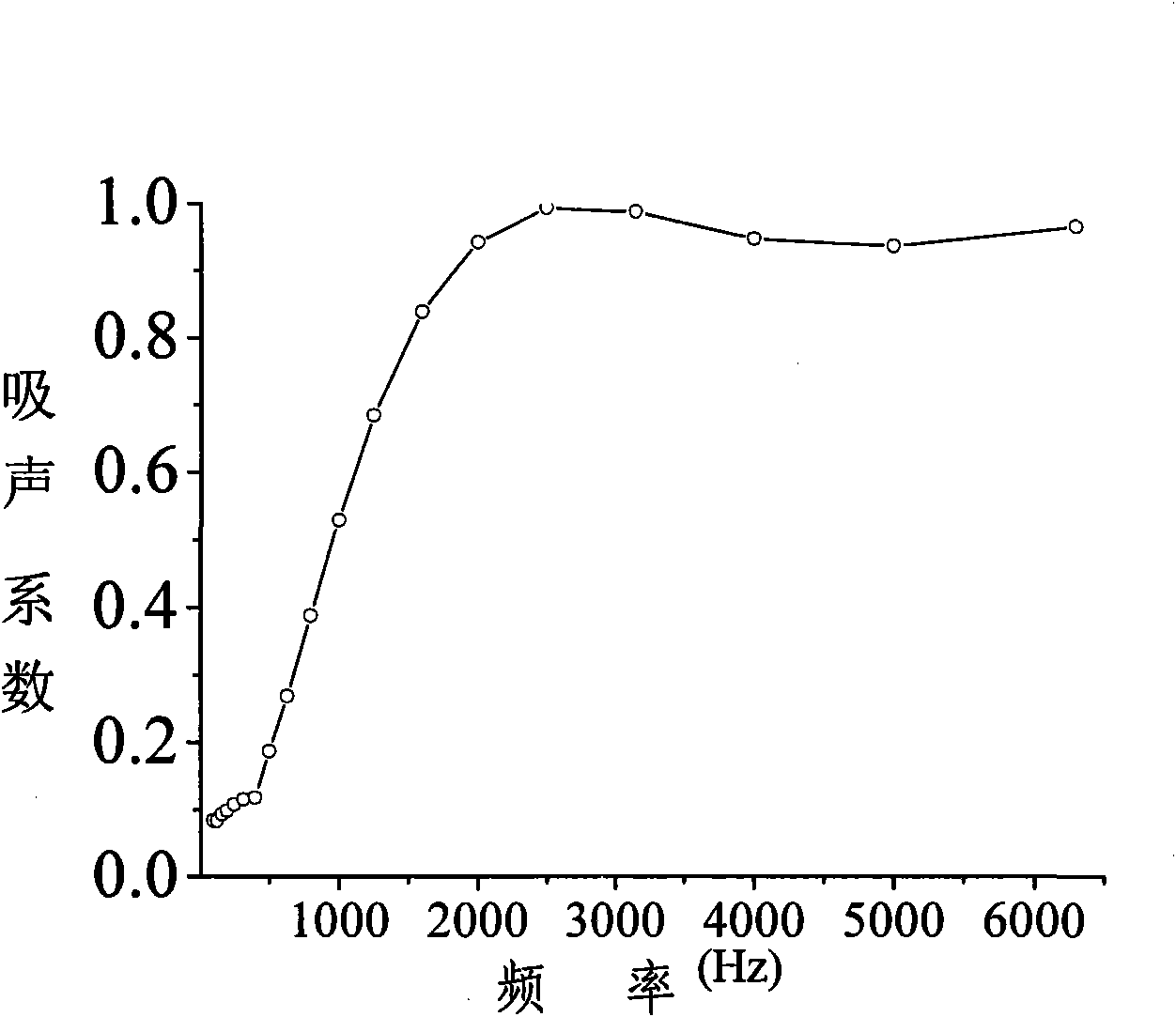

Sound absorption and noise reduction material and application thereof

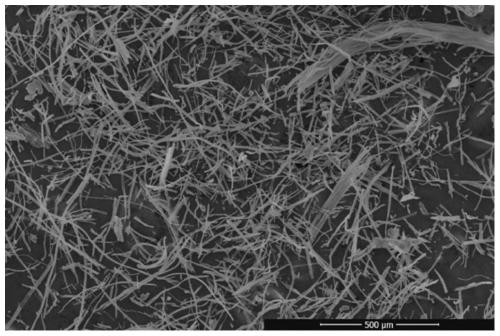

InactiveCN101593515AUnique anti-mildewGood sound absorption and noise reduction effectSound producing devicesSocial benefitsKapok fiber

The invention discloses a sound absorption and noise reduction material and application thereof in preparation of sound absorption and noise reduction products. The sound absorption and noise reduction material provided by the invention mainly comprises natural kapok and can also comprise natural organic fiber, inorganic fiber and synthetic fiber. The total content by mass percentage of the natural organic fiber, inorganic fiber and synthetic fiber is 0-95% of the sound absorption and noise reduction material. As the kapok fiber has the characteristics of high degree of hollowness, dampproof and mothproof, low price and easy availability, the kapok fiber can be made into sound absorption and noise reduction products such as kapok sound absorption batting filling material, kapok acoustic felt, kapok sound absorption non-woven fabrics and the like, the sound absorption and noise reduction has favourable effect, simple preparation technology, low cost, thus having great economic benefit and social benefit.

Owner:INST OF CHEM CHINESE ACAD OF SCI

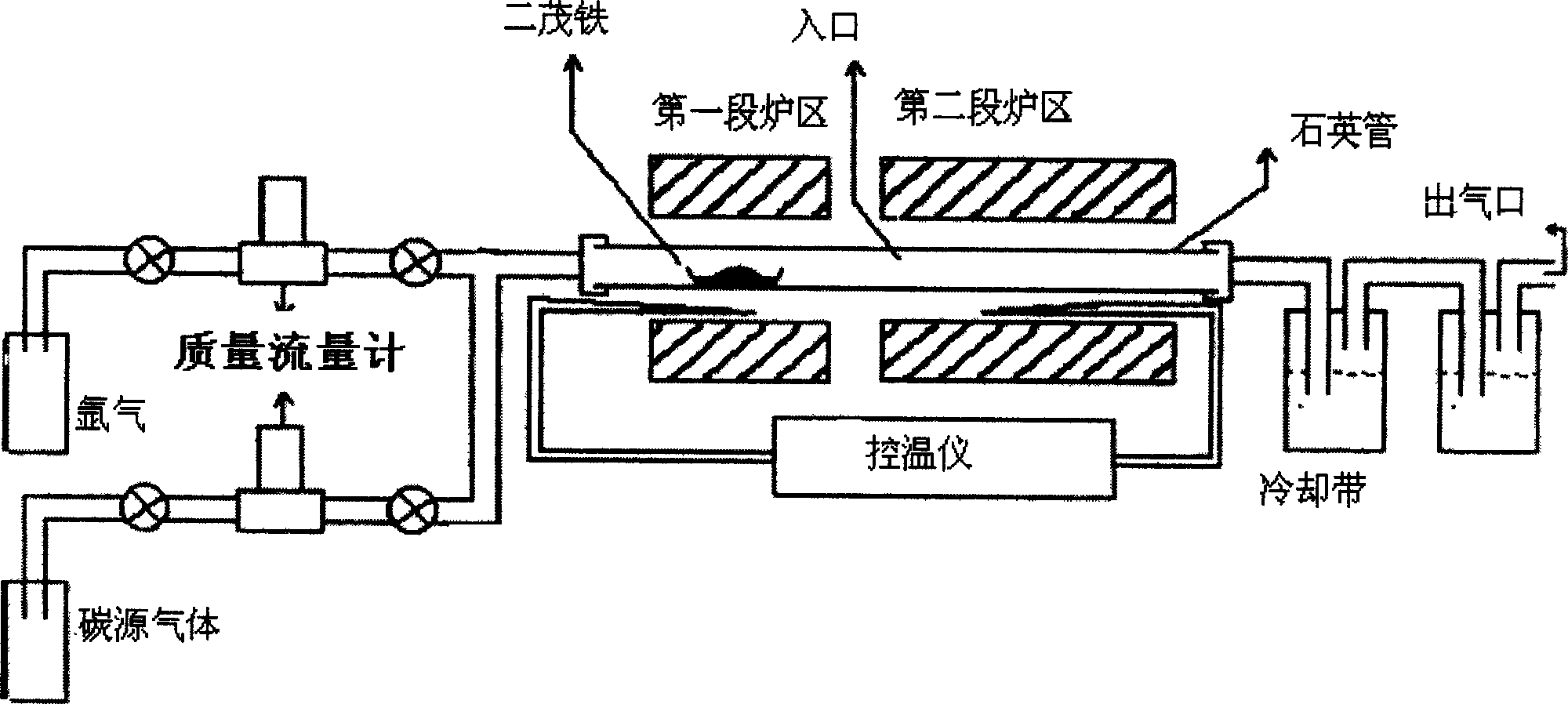

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

Kapok spunlace non-woven fabric, preparation method thereof and product of kapok spunlace non-woven fabric

InactiveCN107916499ABreathableWarm and antibacterialNon-woven fabricsMaterials preparationForeign matter

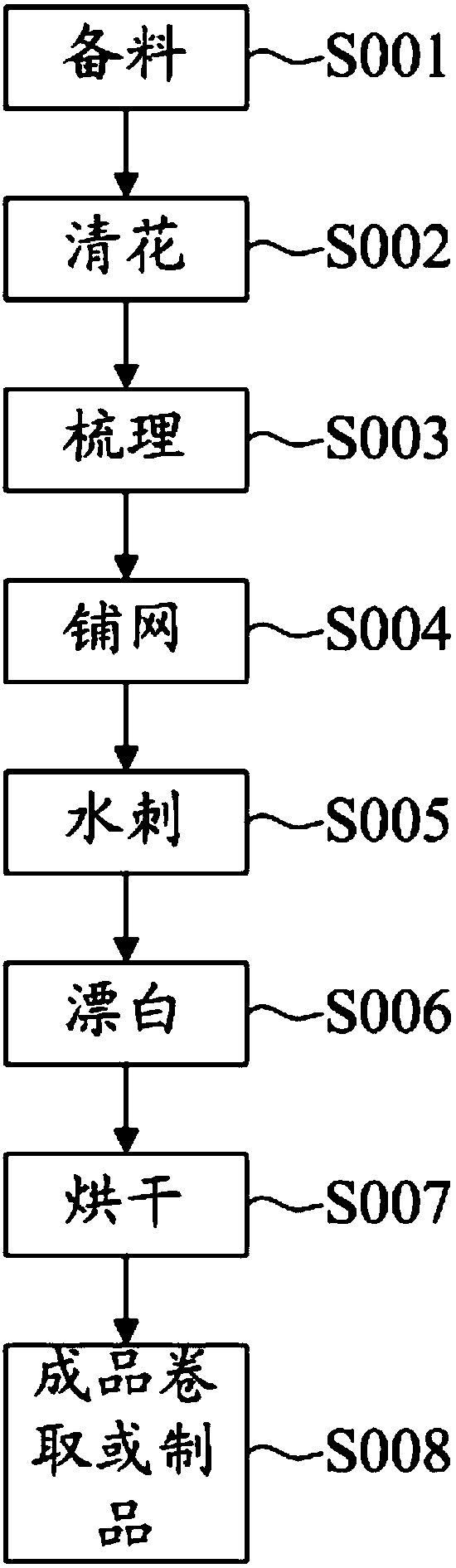

The invention discloses a kapok spunlace non-woven fabric, a preparation method thereof and a product of the kapok spunlace non-woven fabric. The preparation method of the kapok spunlace non-woven fabric comprises the following steps: material preparation: independently preparing kapok fibers, or uniformly mixing the kapok fibers with one or more of other natural fibers and chemical fibers to obtain mixed fibers; blowing: removing impurities from the prepared kapok fibers or mixed fibers, and sieving out foreign matters; carding: opening the blown kapok fibers or mixed fibers into single fibers at first, and then smoothly combing the single fibers; carrying out lapping; carrying out spunlace; carrying out bleaching; carrying out drying; and rolling a finished product or obtaining a product. Because the kapok fibers have characteristics of lightness and softness, breathability, high wet permeability, high degree of hollowness, anti-bacterial property, mothproof property and mildew proofproperty. The kapok spunlace non-woven fabric is prepared by the spunlace non-woven process, chemical auxiliaries are not added in a whole fabric forming process, and therefore, the prepared kapok spunlace non-woven fabric has the advantages of warming and bacteria inhibition, lightness, softness and comfort, dryness and breathability and the like.

Owner:WINNER MEDICAL CO LTD +1

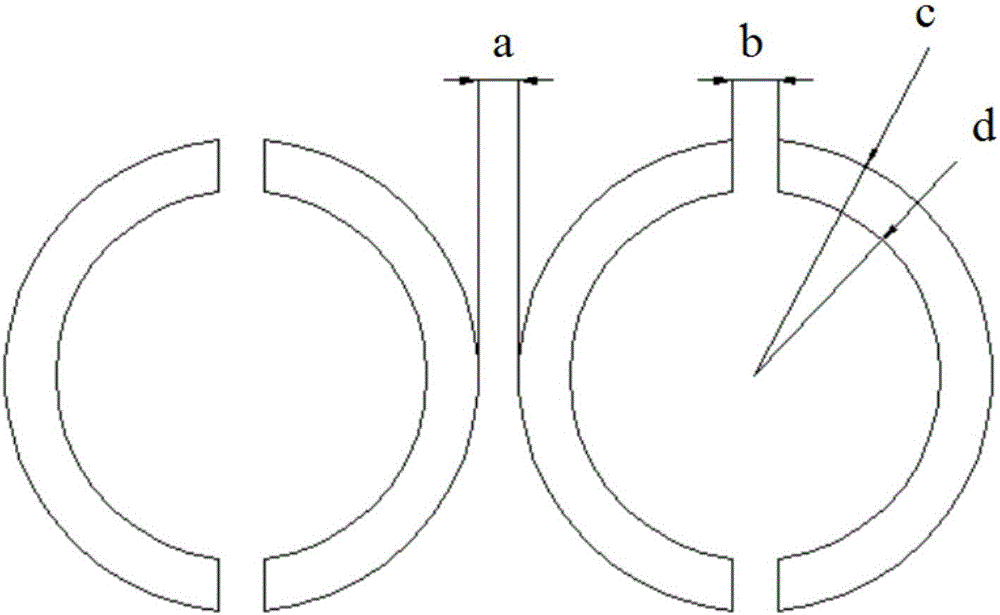

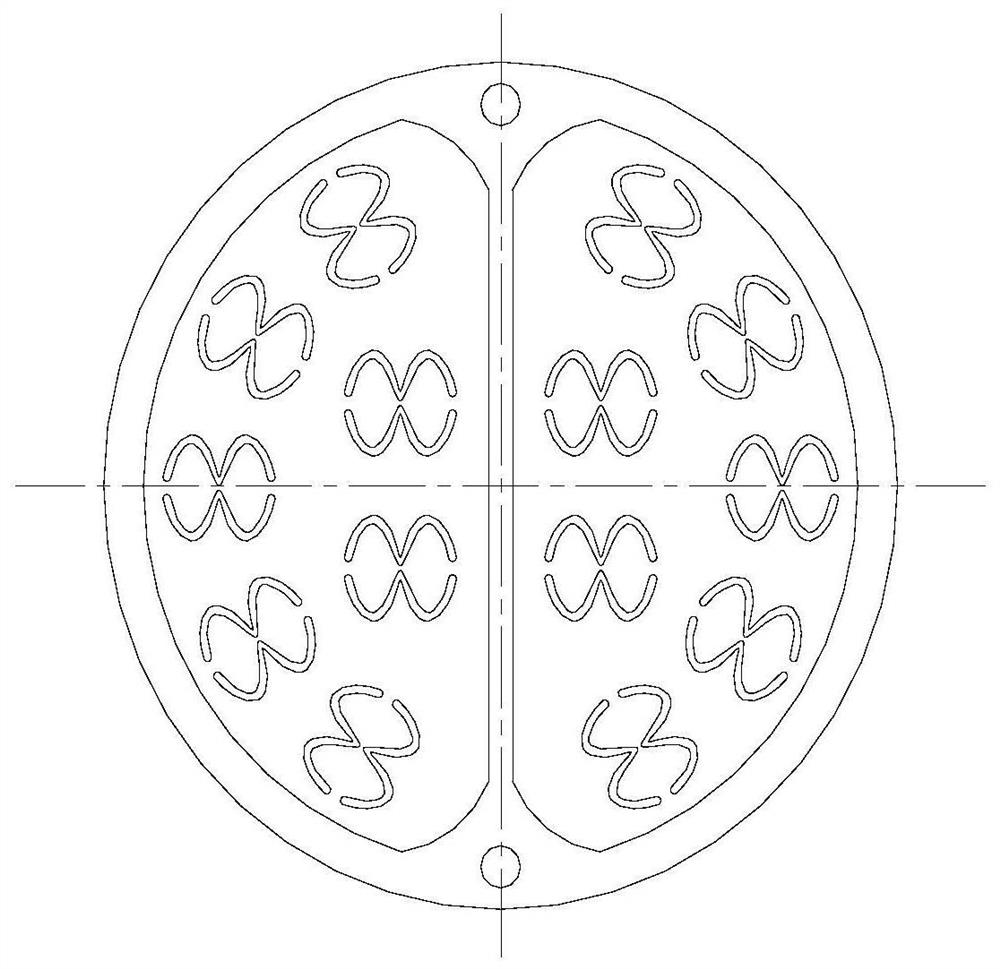

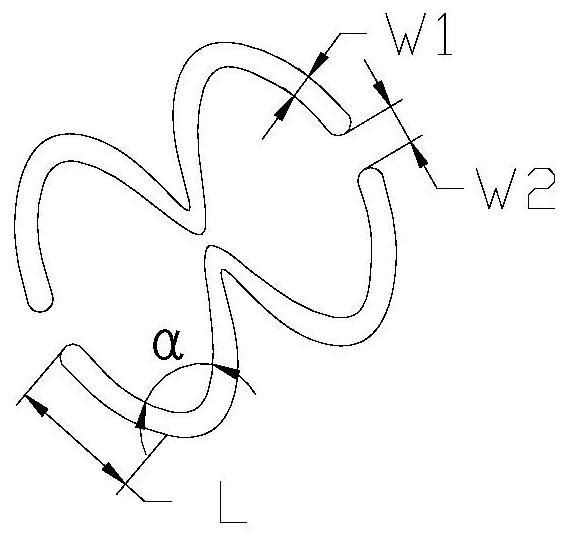

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

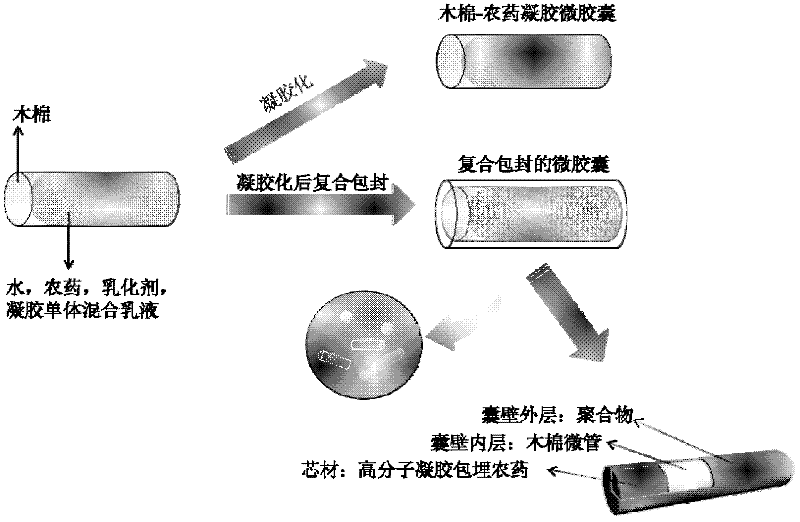

Pesticide microcapsule and preparation method thereof

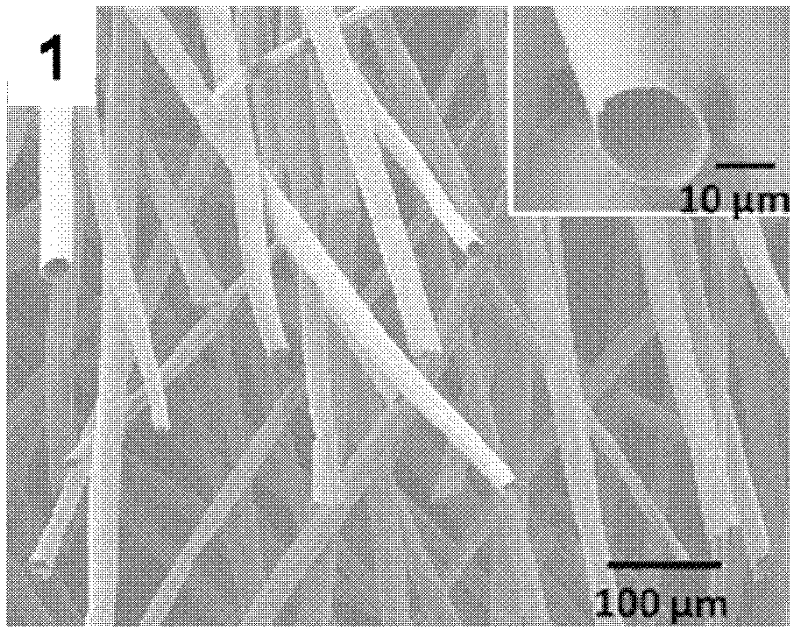

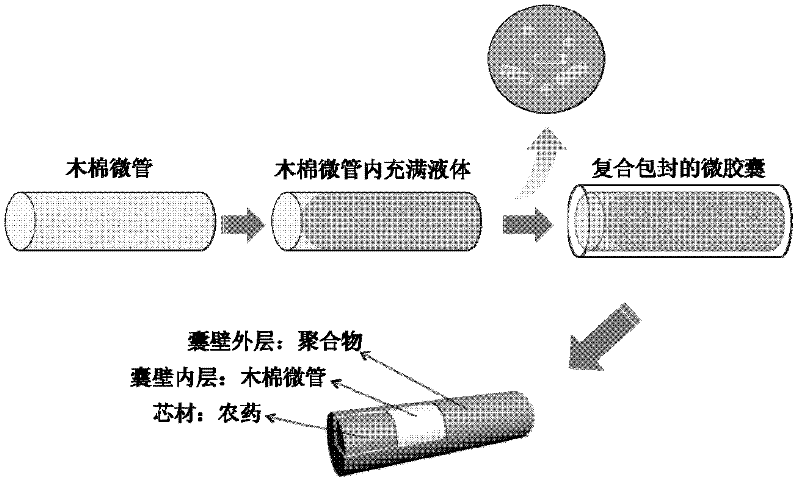

ActiveCN102388864AHigh hollownessIncrease encapsulationBiocideAnimal repellantsPesticides/herbicidesNatural fiber

The invention discloses a pesticide microcapsule and a preparation method thereof. The pesticide microcapsule consists of a capsule core and a capsule wall; and the capsule core is pesticide and the capsule wall is a compound capsule wall which is formed by encapsulating natural fibers by high polymer materials. The preparation method comprises the following steps of: 1) dispersing natural fibers in liquid pesticide, and soaking to ensure that liquid pesticide is filled in microtubules of natural fibers; 2) and encapsulating the natural fibers in which pesticide is filled in the step 1) by using the high polymer materials to obtain the pesticide microcapsule. The cotton fibers which are adopted in the method have natural plant microtubules which have high hollowness, are environment-friendly, and low in price and can be obtained easily, and have the characteristics of high encapsulation capacity, low cost, sustained release and the like when used for the pesticide microcapsule.

Owner:INST OF CHEM CHINESE ACAD OF SCI

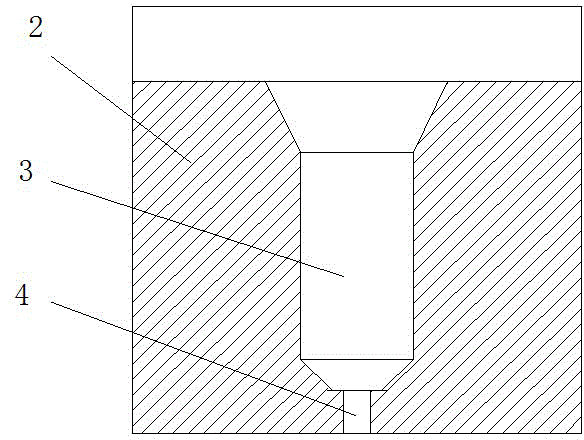

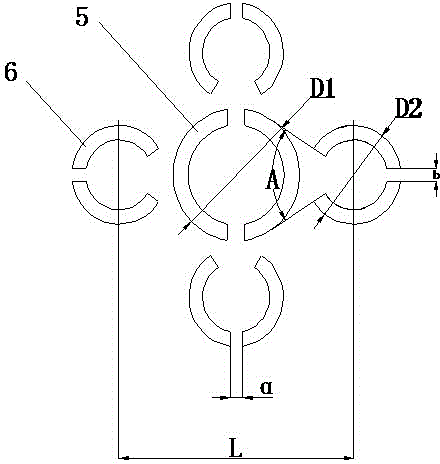

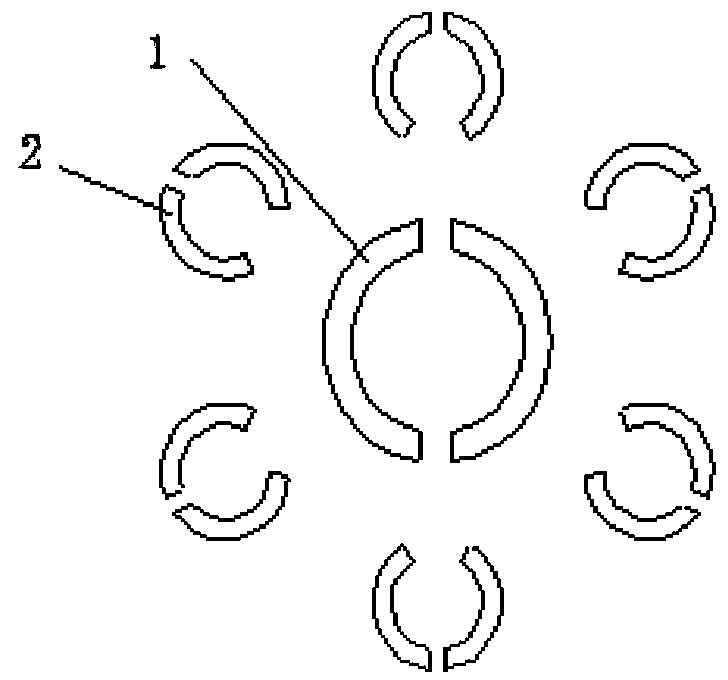

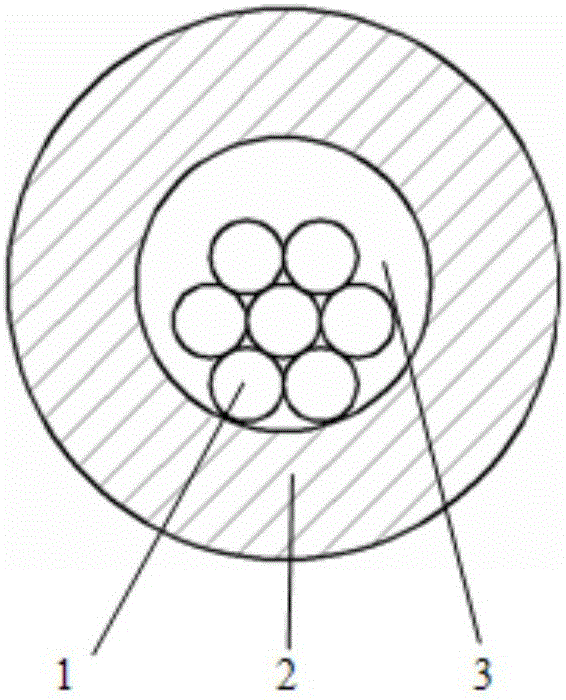

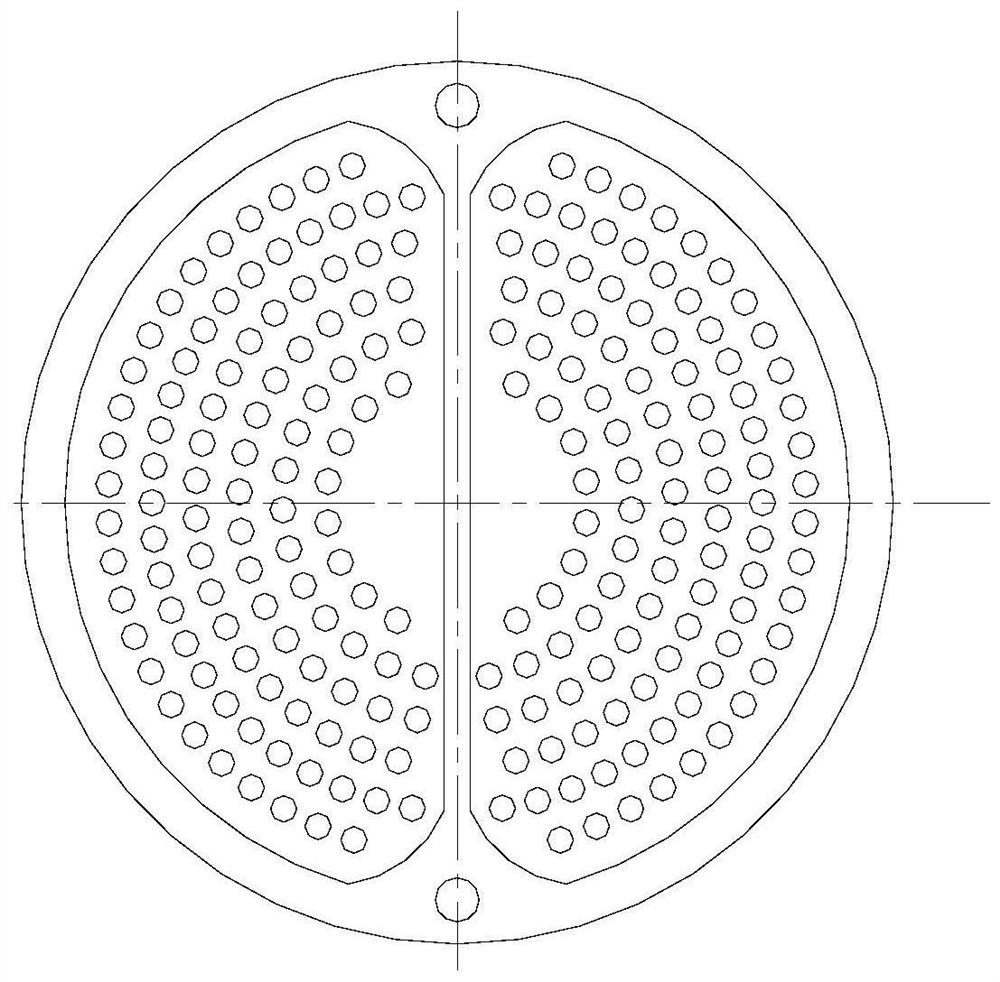

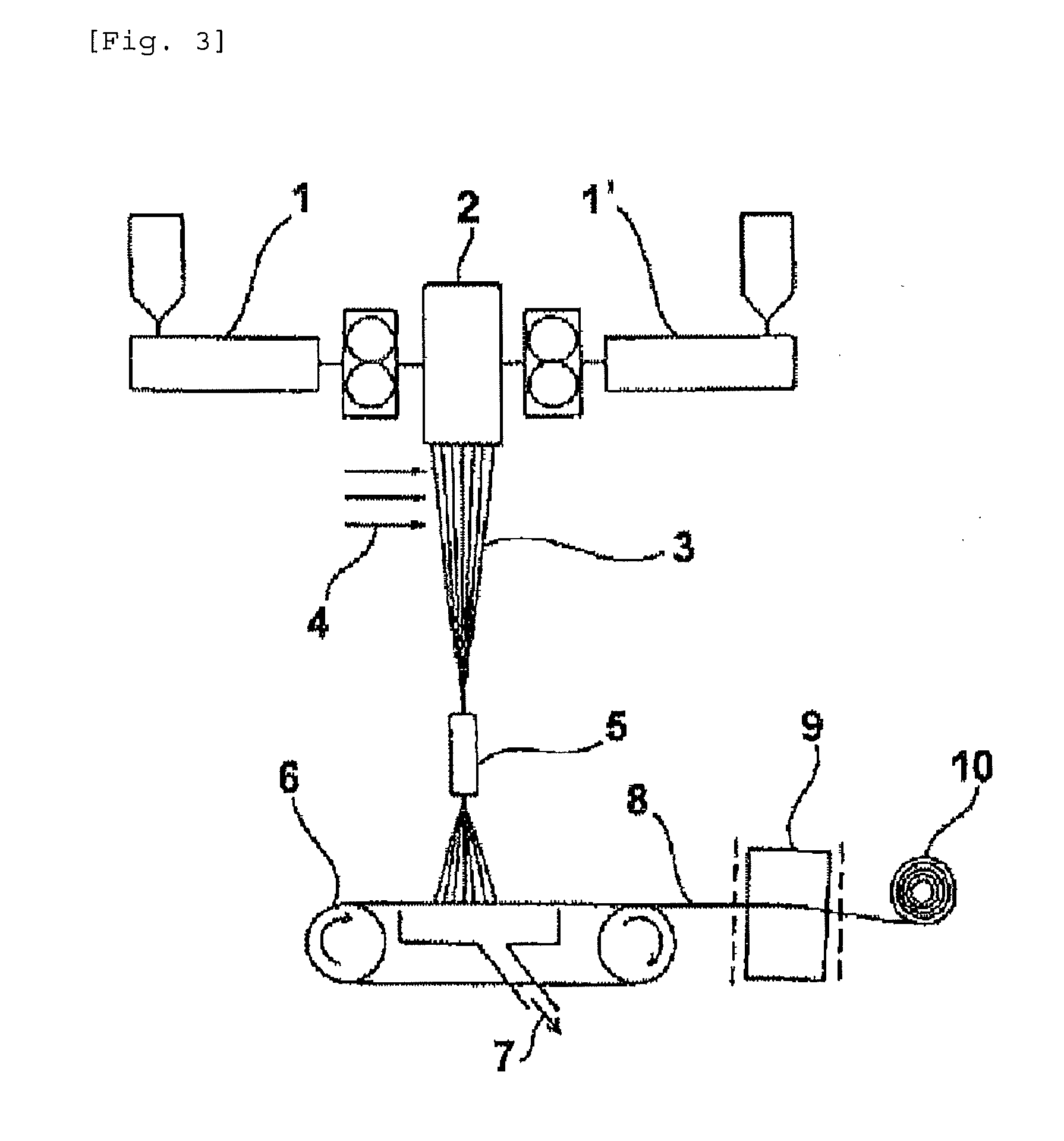

Method for spinning cross-shaped multi-hole hollow short fibers with recycle polyester bottle chip

InactiveCN104088026AEasy to shapeOptimization parametersFilament forming substance formingHollow filament manufacturePolyesterPolymer science

Provided is a method for spinning cross-shaped multi-hole hollow short fibers with a recycle polyester bottle chip. The recycle polyester bottle chip is dried by a vacuum drum and then is subjected to melt spinning. The recycle polyester bottle chip enters a spinning box body by screw squeezing and is sprayed out from spinneret orifices of a cross-shaped multi-hole hollow spinneret plate, nascent fibers are obtained, then the processes such as cross air blow cooling forming, winding, bundling, drafting, curling, oiling, relaxation heat setting and cutting are carried out, and the cross-shaped multi-hole hollow short fibers with the fineness of 6.67-14.44 dtex are obtained. The spinneret orifices are formed in the cross-shaped multi-hole hollow spinneret plate, the spinneret orifices are distributed in an array mode, spinneret orifice inlets are guiding holes, and spinneret orifice outlets are spinneret capillary pores. A center arc hole group and four outer periphery arc hole groups are formed in the spinneret capillary pores. The four outer periphery arc hole groups and the center arc hole group form a cross-shaped structure. A spinning technology is improved, the spinneret plate is designed in an innovative mode, and the prepared cross-shaped multi-hole hollow short fibers have the advantages of being high in hollowness degree, good in rebound resilience, large in specific surface area, soft in hand feel, good in moisture absorbing and breathing performance and the like.

Owner:JIANGSU FEILIN FIBER TECH

Method for manufacturing natural antibacterial warming knitted fabric with kapok bamboo charcoal

The invention discloses a method for manufacturing natural antibacterial warming knitted fabric with kapok bamboo charcoal, which comprises the following steps of: (1) weaving: knitting kapok fabrics and bamboo charcoal polyester fibers to knitted gray cloth with a double-sided composite structure; (2) pre-treatment; (3) aerosol dyeing; (4) squeezing slack drying; and (5) post-finishing. By using the natural warming property of the kapok fabrics with high hollowness degree and high-strength adsorption of the bamboo charcoal, the prepared fabric has the characteristics of natural hollow warming, mouldproofing and moth-proofing, deodorization, bacteriostasis, washing resistance, sunproofing and the like, is easy for washing and maintenance, can release negative ions, and is suitable for clothes products on casuals, sports, health-care textiles, underwears and the like.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

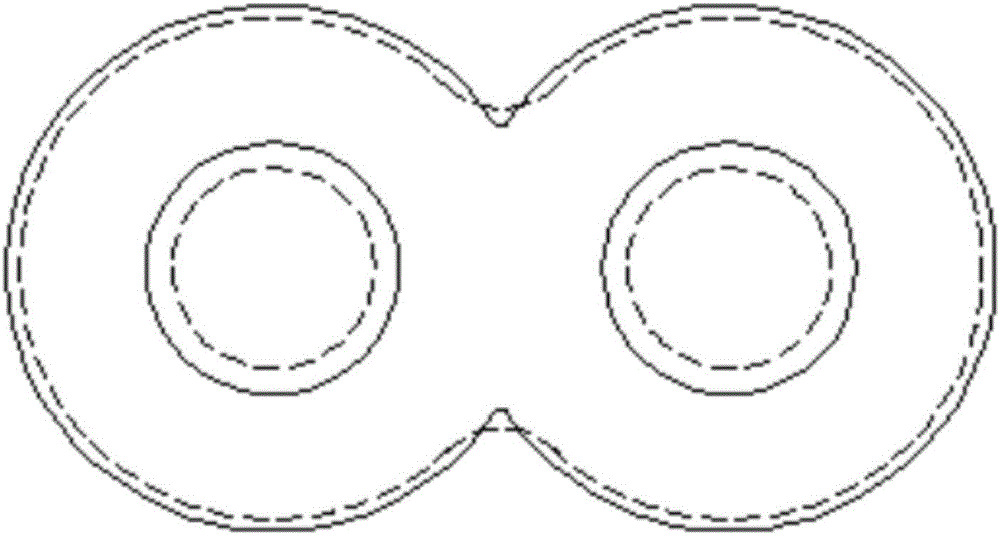

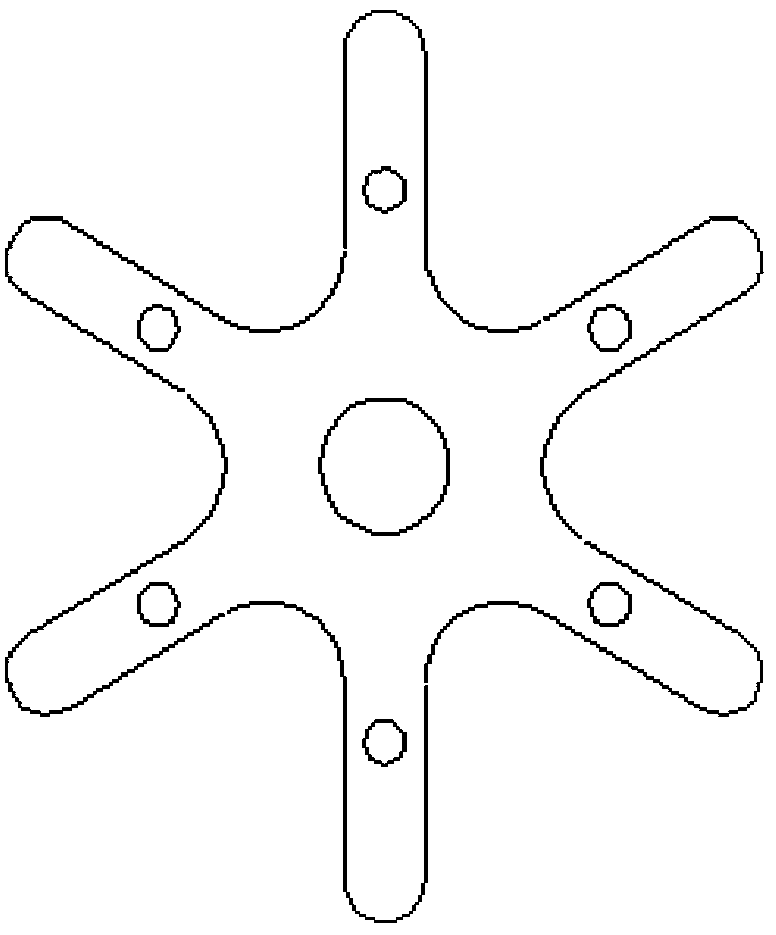

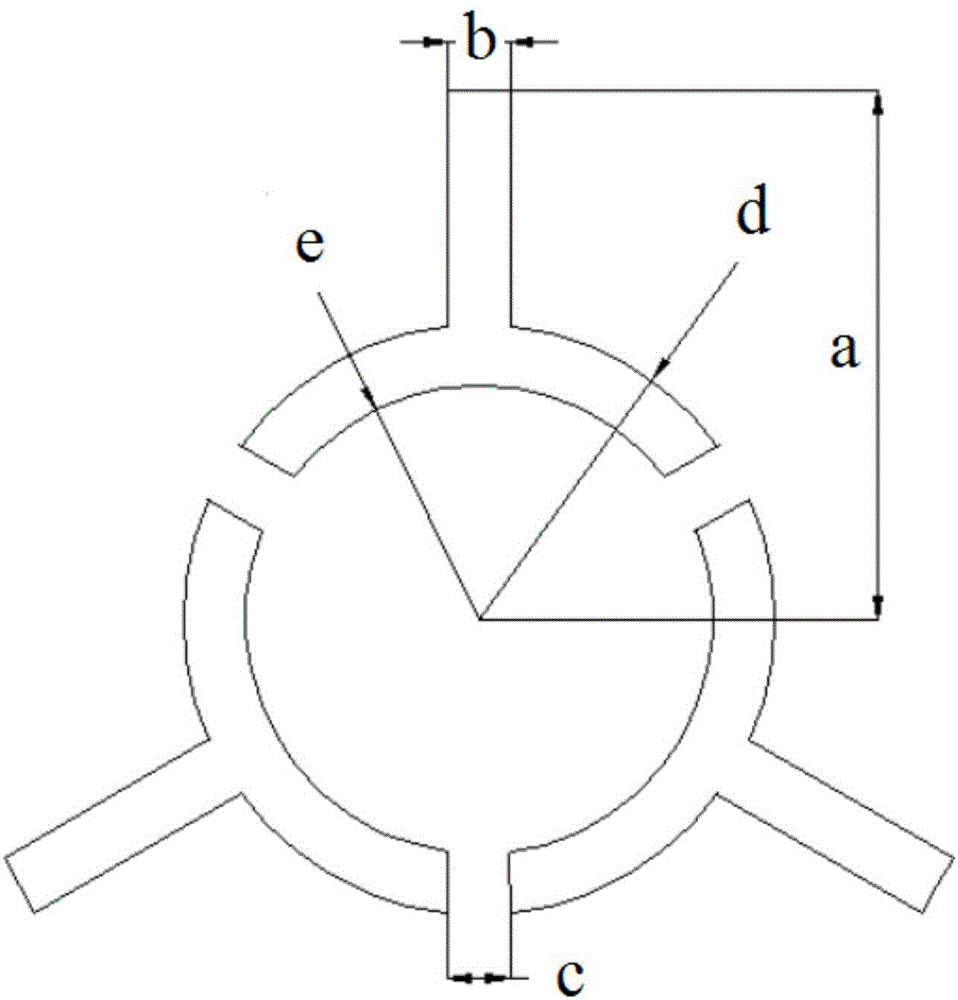

Preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes

ActiveCN104389036AEasy to shapeHigh degree of abnormalityHollow filament manufactureArtificial filament heat treatmentPolyesterPolymer science

The invention provides a preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes. The preparation method comprises the following steps: performing melt spinning on the renewable polyester bottle flakes after vacuum drum drying, enabling the renewable polyester bottle flakes to enter a spinning box body through screw extrusion, spinning out of spinneret orifices of a six-leaf porous hollow spinneret plate to obtain nascent fibers, cooling and forming through circulating air blowing, winding, bundling, drafting, crimping, oiling, loosening and heat setting, and cutting to obtain the six-leaf porous hollow staple fibers, wherein the spinneret orifices are formed in the six-leaf porous hollow spinneret plate and are arranged in arrays; inlets of the spinneret orifices are guide holes, and outlets of the spinneret orifices are spinning capillary holes; each spinning capillary hole comprises one central arc-shaped hole group and six peripheral arc-shaped hole groups; the six peripheral arc-shaped hole groups and the central arc-shaped hole group form a six-leaf structure. Through improvement of a spinning process and innovative design of the spinneret plate, the prepared six-leaf porous hollow staple fibers have the characteristics of high hollow degree, high rebound resilience, large specific surface area, good moisture-absorbing and breathable effect and the like.

Owner:江苏省科学技术情报研究所

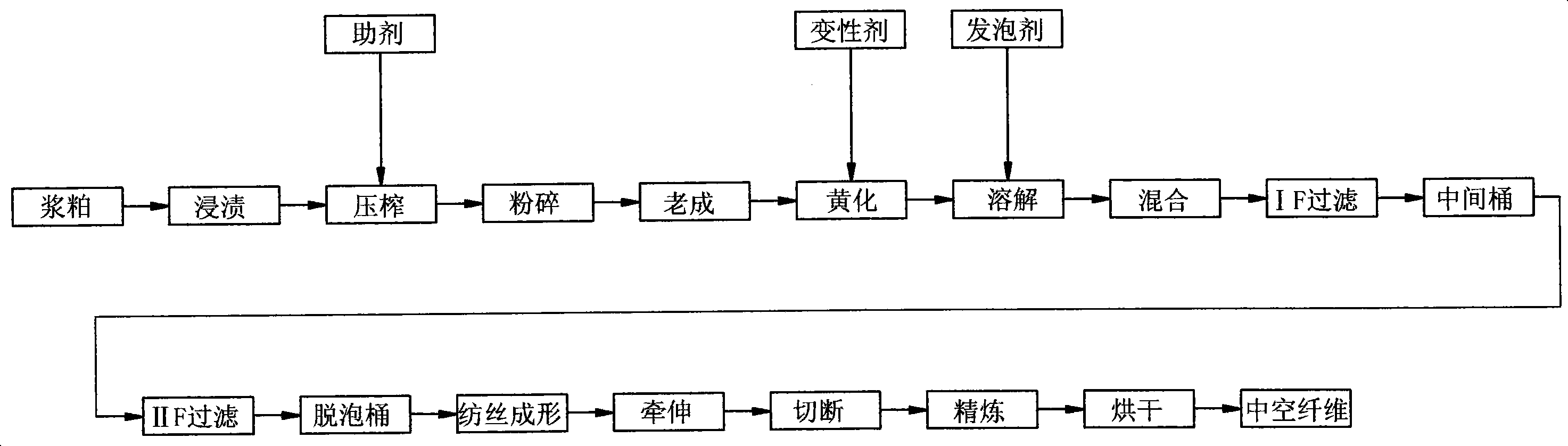

Manufacturing method of high performance hollow cellulose fibre

ActiveCN101089256AEasy to operateHigh hollownessHollow filament manufactureArtificial filaments from viscoseFoaming agentFiltration

Owner:潍坊欣龙生物材料有限公司

Pesticide microcapsule and preparation method thereof

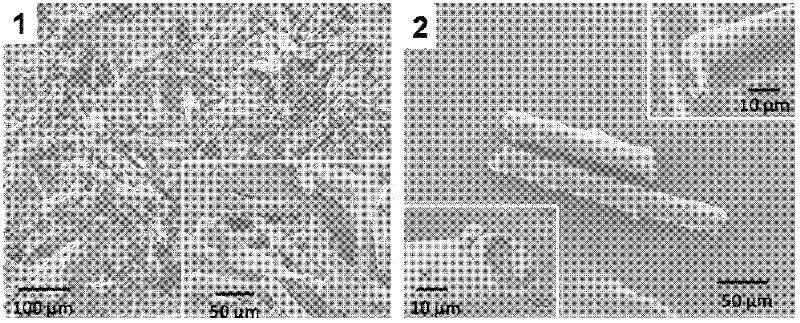

InactiveCN102379286AHigh hollownessIncrease encapsulationBiocideAnimal repellantsHollow fibreEmulsion

The invention discloses a pesticide herbicide microcapsule and a preparation method thereof. The pesticide microcapsule comprises a capsule core and a capsule wall. The capsule core is a high-molecular gel embedded with pesticide; and the capsule wall is natural fibre or a composite capsule wall with a high-molecular material cladded the natural fibre. The preparation method is as below: 1) mixing the pesticide, an emulsifier, water and gel monomer to prepare an emulsion; 2) dispersing the natural fibre in the emulsion and immersing to fill microtubules of the natural fibre with emulsion; 3) filtering and collecting natural fibre full of emulsion, carrying out gelating or crosslinking solidification on the gel monomers in the emulsion to form gel and obtaining the pesticide microcapsule. When preparing the composite capsule wall, hollow fiber needs to be further cladded by the high-molecular material. The bombax cotton employed by the invention is an environment friendly cheap and easily available natural plant microtubule with large degree of hollowness and has characteristics of high packaging amount, low cost ad slow release, etc., when used as the pesticide microcapsule.

Owner:INST OF CHEM CHINESE ACAD OF SCI

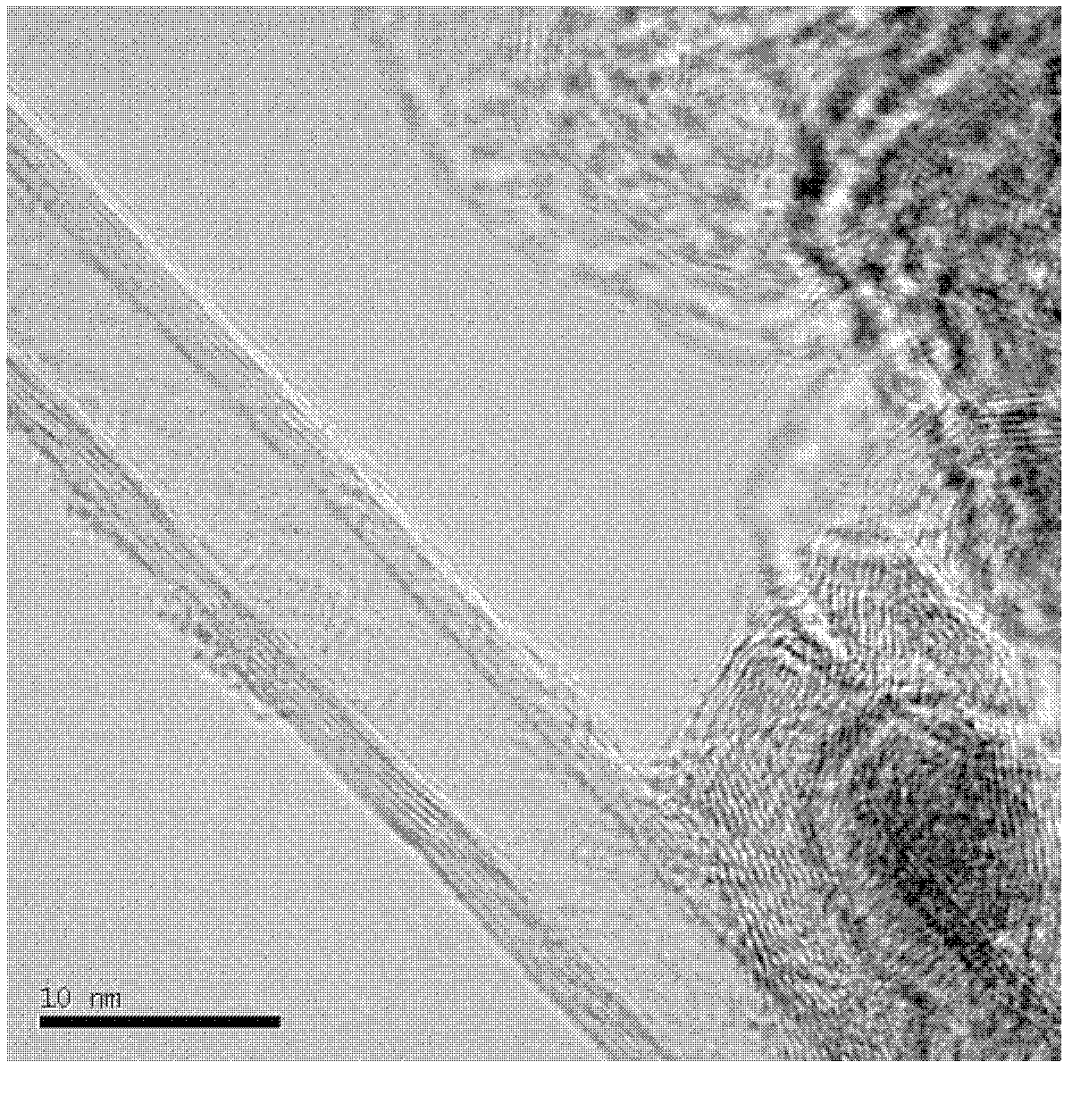

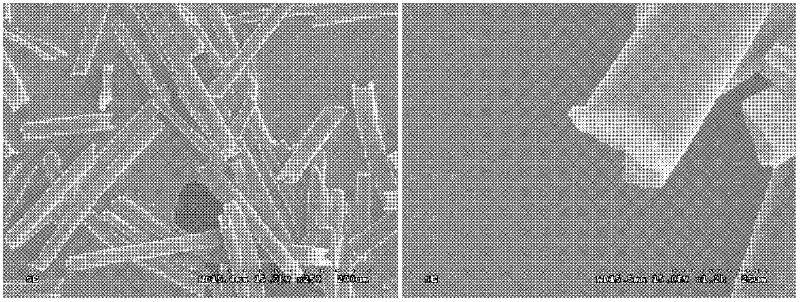

Method of in-situ filling symbiotic iron nanometer wire on thin wall nanometer pipe

InactiveCN1868868AThe preparation process is simple and controllableLow degree of graphitizationNanostructure manufactureNanowireOrganic solvent

A process for preparing the in-situ symbiotic thin-wall carbon nano-tubes and iron nanowires filled in said nanotube includes such steps as dissolving ferrocene in Cl contained organic solvent, filling Ar gas in air-tight quartz tube, heating, controlling the temp at the end of capillary tube inserted in said quartz tube to be 250-300 deg.C, filling H2, pumping said solution in reactor, reaction, stopping to fill H2, and cooling.

Owner:TSINGHUA UNIV

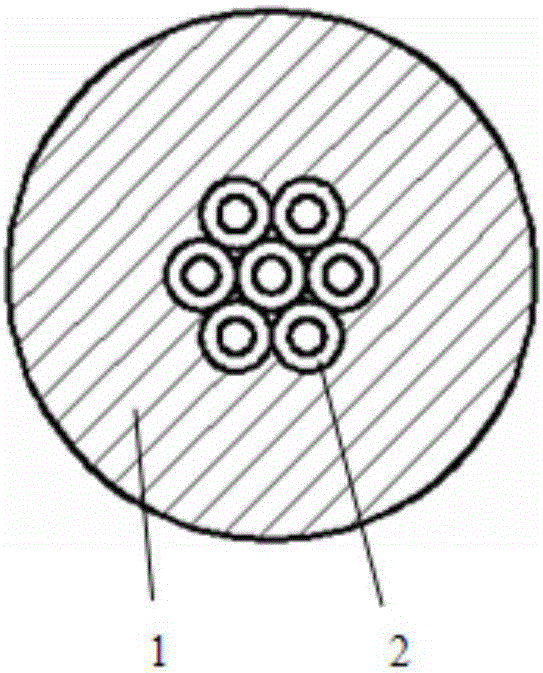

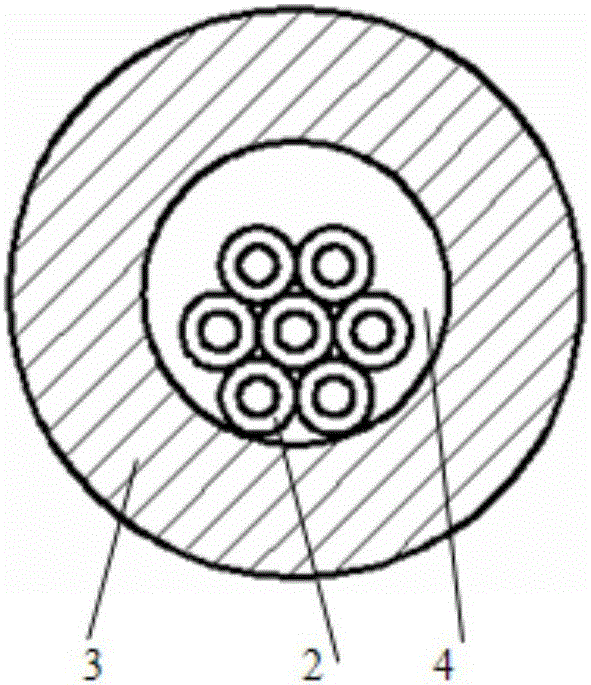

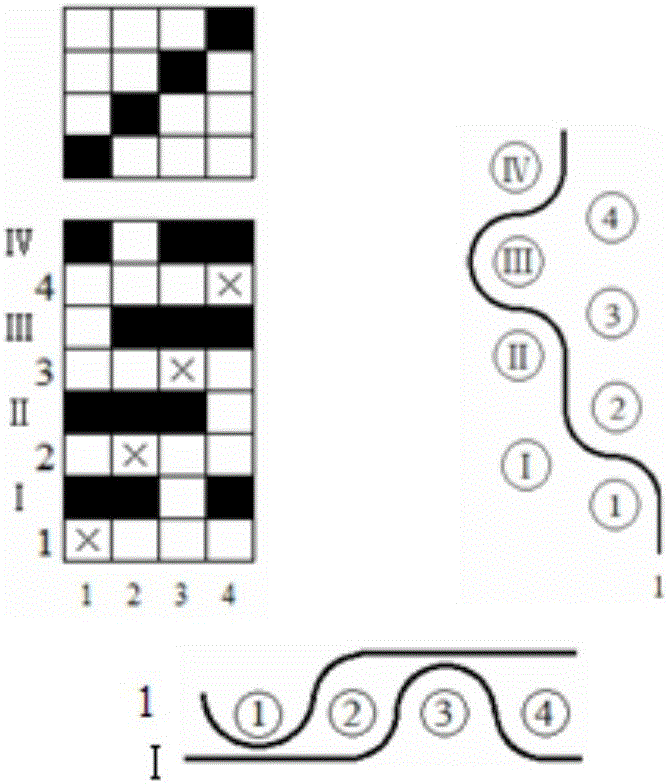

Yarn spinning method of heat-accumulation and heating fiber blended and bulked double-layered-structure yarns

The invention discloses a yarn spinning method of heat-accumulation and heating fiber blended and bulked double-layered-structure yarns. The yarn spinning method comprises the following steps: selection of raw materials and a blending ratio; a blended yarn spinning process; a yarn spinning process; a vinylon dissolving process. The formation of hollow parts of the double-layered-structure yarns actually comprises two aspects that in one aspect, the hollow parts are formed through dissolving water-soluble vinylon with hot water; in the other aspect, in a hot water treatment process, an irreversible heat shrinkage rate generated by high shrinkage acrylic fibers is more than a heat shrinkage rate generated by outer wrapping short fibers, so that the bulkiness and the hollow degree are also increased on the basis of previous hollow parts.

Owner:徐州银宇纺织有限公司

Multilobal hollow polyester fiber FDY (fully drawn yarn) and preparation method thereof

ActiveCN106835334AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureMonocomponent polyesters artificial filamentFiberYarn

The invention belongs to the field of polyester spinning, and relates to a multilobal hollow polyester fiber FDY (fully drawn yarn) and a preparation method thereof. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s; a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a rigid structure chain segment, the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02 to 0.05) to 1, the extrusion swelling ratio of the spinning melt is 1.20 to 1.31, and the post-filtering pressure is 80 to 120kg / cm<2> during spinning. The prepared multilobal hollow polyester fiber FDY has higher hollow degree and a better shape preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Method for manufacturing hollow micro-fine terylene denier fiber

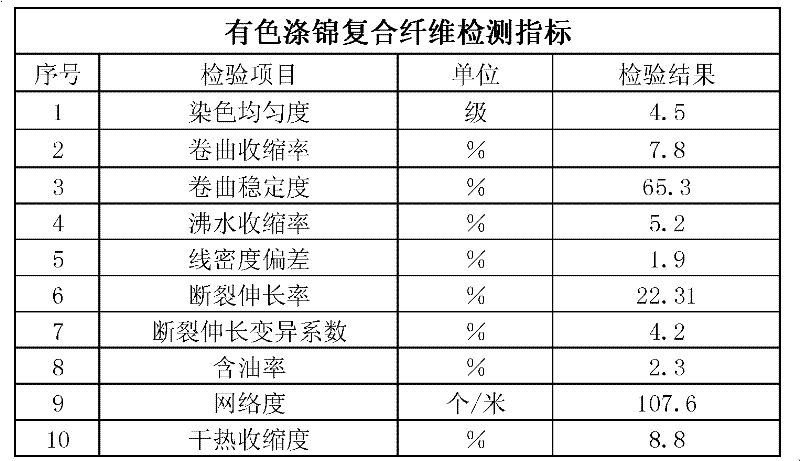

ActiveCN102517719AHigh hollownessIncrease coverageHollow filament manufactureFilament/thread formingState of artFiber

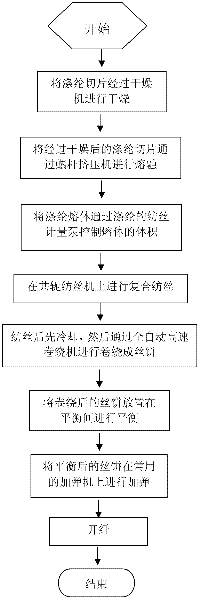

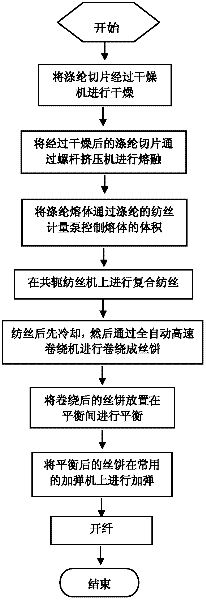

The invention discloses a manufacturing process for a hollow micro-fine terylene denier fiber. The process is characterized by comprising the following steps of: a) preparing a raw material, i.e. sliced terylene; b) drying the sliced terylene through a cystallization dryer; c) injecting the dried sliced terylene into a screw extruder to be fused; d) controlling the volume of a melt through a spinning oil metering pump and a spinning metering pump; e) spinning on a spinning machine, and after spinning, coiling the silk into silk cakes through a fully-automatic high-speed coiler; f) balancing the silk cakes in a balance room to be balanced; and g) elasticizing the silk cakes on an elasticizer. Compared with the prior art, the process realizes the fiber of which the denier per filament is less than 0.5dpf.

Owner:NINGBO SANBANG MICROFIBER

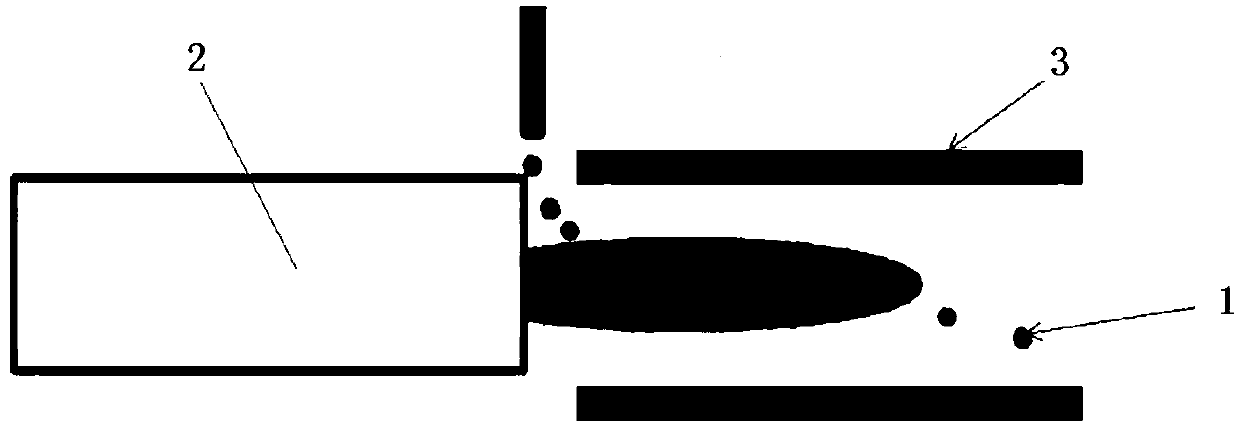

Preparation method of thin-shell structure zirconia powder for thermal spraying

The invention discloses a preparation method of thin-shell structure zirconia powder for thermal spraying, which includes steps of step 1, preparing porous zirconia powder with grain diameter of 20-106 mu m by spraying and prilling, and calcining the prepared powder at 800-1000 DEG C; preserving temperature for 1-5 hours; step 2, delivering the calcined powder to a plasma spray gun to nodulize. The method is characterized in that a heat insulation zone is arranged in the zone along 10-500 mm of axial direction of a flame flow and 10-50 mm in a radial direction of a spray gun outlet, and the temperature in the heat insulation zone is not less than the melt point of the zirconia powder; step 3, collecting the cooled powder at outside of the heat insulation zone. Through arranging the lengthof the control zone, the hollow degree of the powder can be controlled, thus the powder with different hollow degrees can be acquired. For adopting the heat insulation method, additional heating device is not required to add. Therefore, the method is simple and feasible, and low in cost.

Owner:苏州炻原新材料科技有限公司

Blended yarn of acrylic fiber, kapok fiber and cuprammonuium

InactiveCN102851815AIn line with the trend of environmentally friendly clothingBrightly dyedYarnCuprammonium rayonYarn

The invention provides a blended yarn of acrylic fiber, kapok fiber and cuprammonuium, which comprises the components in parts by weight: 45-55 parts of acrylic fiber, 25-35 parts of kapok fiber and 15-25 parts of cuprammonuium. The blended yarn of the acrylic fiber, the kapok fiber and the cuprammonuium is complementary in characteristics and exerts the advantages of the acrylic fiber, the kapok fiber and the cuprammonuium.

Owner:JIANGSU TONGHAI THREAD

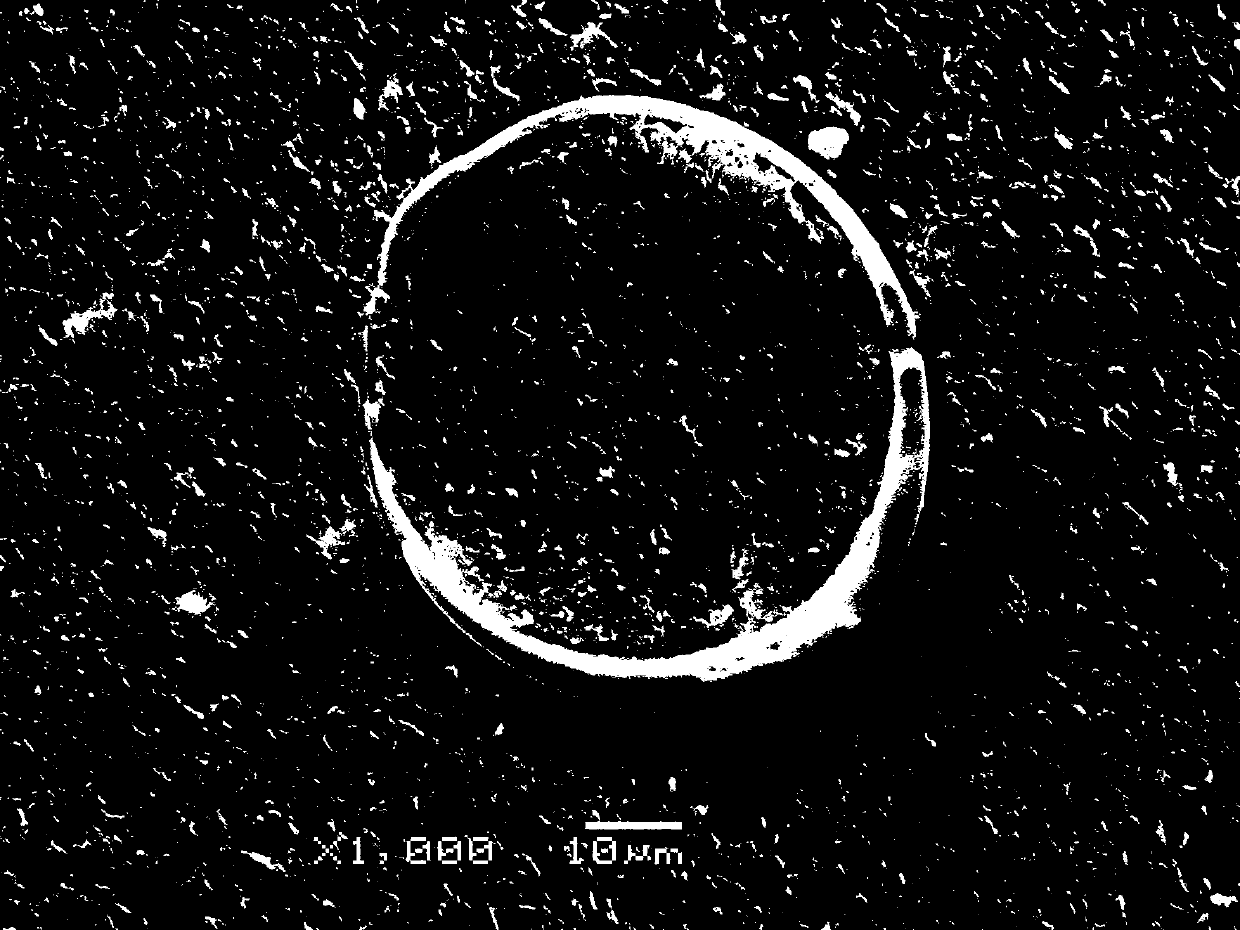

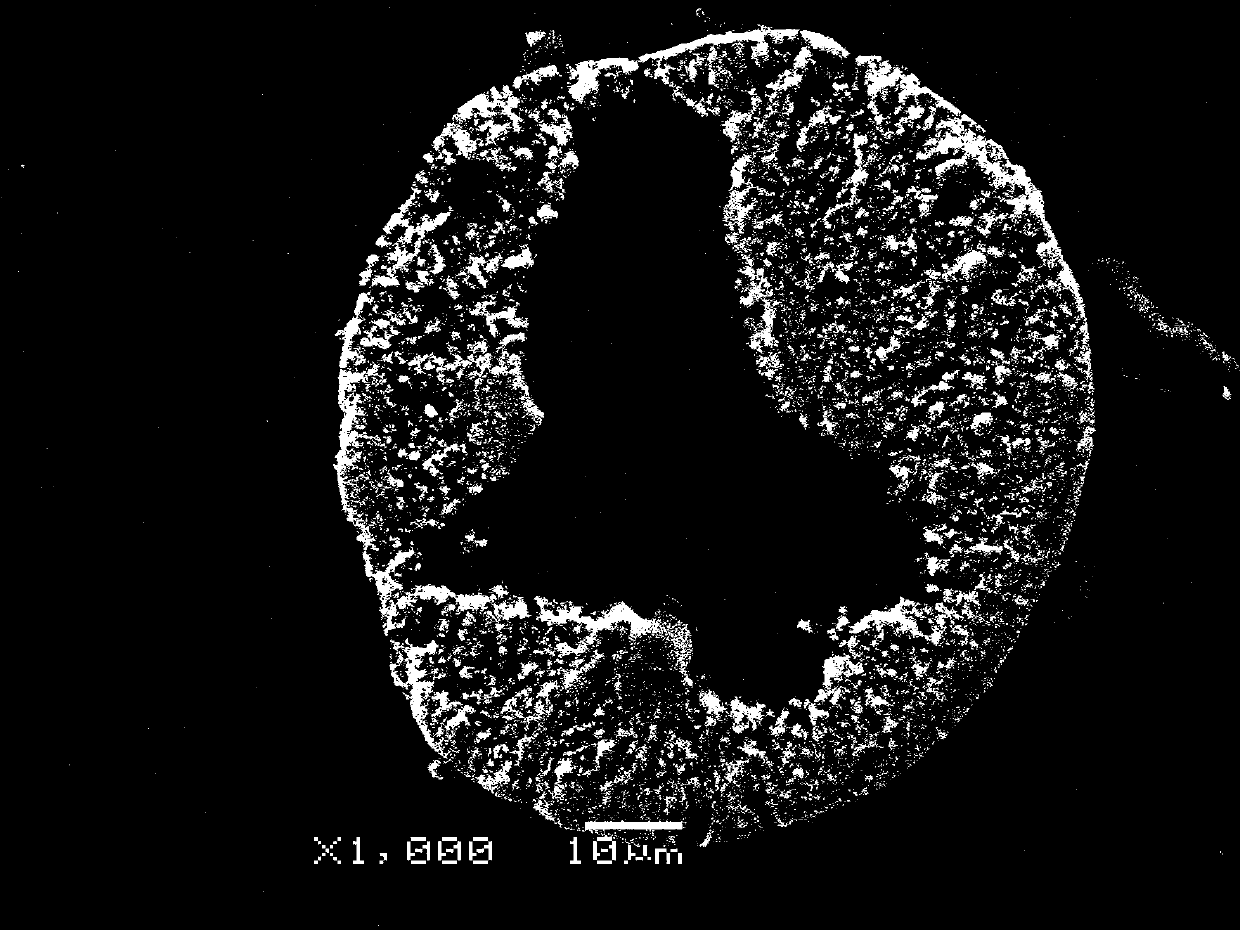

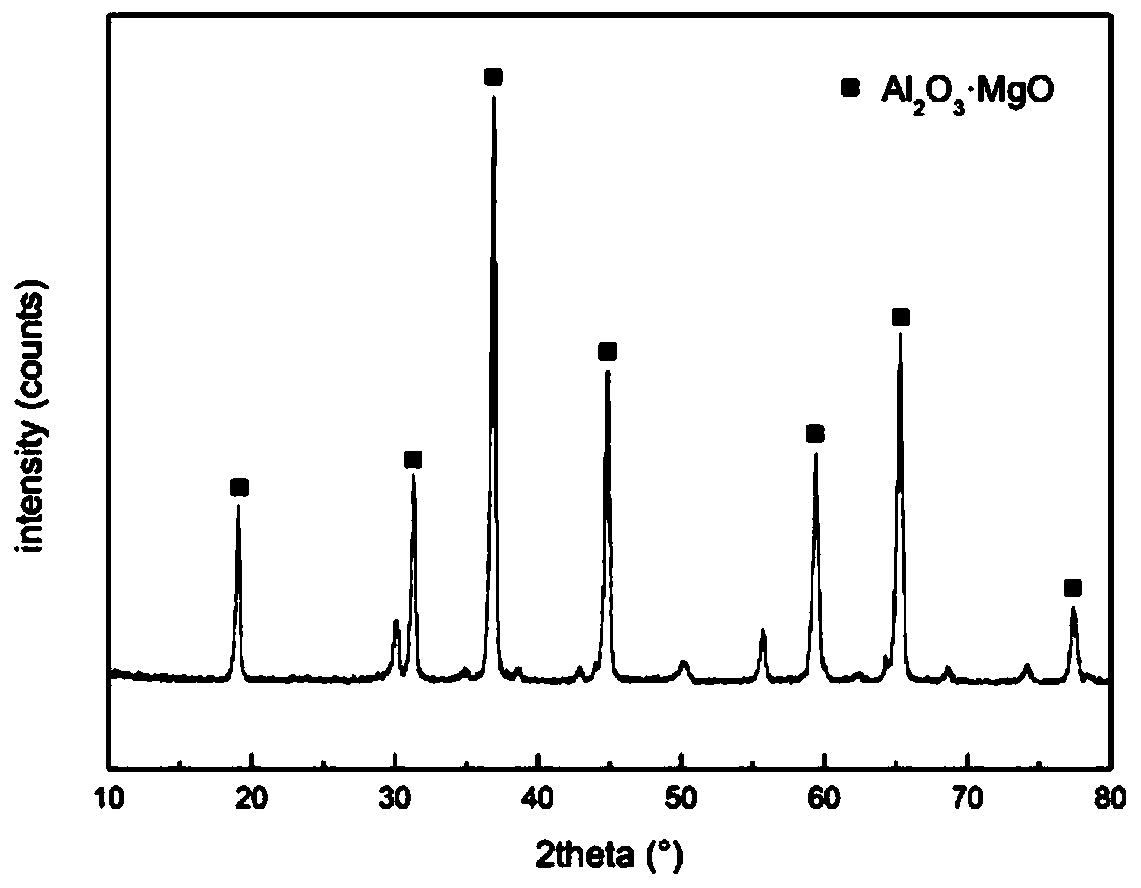

Method for preparing hollow magnesium aluminate spinel ceramic fiber by using reed fibers

ActiveCN109704750ANot easy to stickImprove continuityInorganic material artificial filamentsAluminium chlorideFiber

The invention discloses a method for preparing a hollow magnesium aluminate spinel ceramic fiber by using reed fibers. According to the method, natural reed is used as a template and an ethanol watersolution is used as a dipping solvent, the natural reed is dipped in a mixed ethanol water solution of aluminum salt and magnesium salt, drying is carried out, and then sintering is carried out in anoxygen atmosphere at a high temperature. In the sintering process, aluminum chloride and magnesium chloride react to generate aluminum oxide and magnesium oxide; reed fibers are decomposed; finally the reed which serves as a template is disappeared; the generated aluminum oxide and magnesium oxide form a stable magnesium-aluminum spinel structure; and the hollow structure of the reed template is retained. The prepared magnesium-aluminum spinel fiber is of a hollow tubular structure, has good toughness and high hollowness and bulkiness, and has good thermal shock stability, chemical erosion resistance and wear resistance. Solid phases are separated from each other by gas existing in the hollow fibers, so that the heat transfer rate is reduced, heat conductivity of the ceramic material is reduced, and the heat insulation property of the ceramic material is good.

Owner:NANJING UNIV OF SCI & TECH

Hollow regenerated cellulose fiber and manufacturing method thereof

ActiveCN103088455ALow costIncrease productivityArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentPolymer scienceCellulose fiber

The invention relates to a manufacturing method of a hollow regenerated cellulose fiber. The manufacturing method comprises the following steps of: preparing a spinning viscose solution through working procedures of soaking, squeezing, grinding, aging, yellowing, dissolving, filtering and defoaming on cellulose pulp, then spinning, in the dissolving step out of the working procedures for the preparation of the spinning viscose solution, adding one or mixture of water-soluble vinylon, a denaturing agent and a crosslinking agent, and then spinning to prepare the hollow regenerated cellulose fiber, wherein the fineness of the hollow regenerated cellulose fiber is 2.22-3.33 dtex, the dry strength of the hollow regenerated cellulose fiber is 2.2-2.6 cN / dtex, the wet strength of the hollow regenerated cellulose fiber is 1.2-2.0 cN / dtex, the degree of hollowness of the hollow regenerated cellulose fiber is greater than or equal to 70%, and the dry elongation is 10-20%. The manufacturing method is simple to operate, does not need special processing technology or equipment, does not release gas in a spinning process, and solves the problems such as reduction of the end breakage rate in spinning. The produced hollow fiber not only has high degree of hollowness, but also cannot collapse or deform due to after finishing and machining.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Production method of heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping woven fabric

ActiveCN106087183AIncrease warmthHigh hollownessSingeingDry-cleaning apparatus for textilesEngineeringLayered structure

The invention discloses a production method of a heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping woven fabric. The production method comprises the following steps: selecting fiber raw materials; selecting specifications of yarns; designing the heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping woven fabric; carrying out a production process flow of the woven fabric. The heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping woven fabric disclosed by the invention has a triple warm-keeping function of heat-accumulation and heating fibers, inner hollows parts of double-layered-structure yarns, double-faced fabrics and the like; if chemical fiber filaments used as core yarns have hollow parts, the warm-keeping woven fabric has a quadruple warm-keeping function of the heat-accumulation and heating fibers, the inner hollows parts of the double-layered-structure yarns, the hollow chemical fiber filaments, the double-faced fabrics and the like, so that the warm-keeping effect of the woven fabric is extremely improved under the condition that the thickness is not increased.

Owner:江苏世纪纺织有限公司

Spinning method for thermal storage heating fiber blended core-spun double-layer structure yarn

ActiveCN107059205AImprove the mixing effectHigh bulkinessWoven fabricsYarnShrinkage rateWater soluble

The invention discloses a spinning method for thermal storage heating fiber blended core-spun double-layer structure yarn. The method comprises the following steps of selection of raw materials and a blending ratio; a mix spinning process; a spinning process; and a vinylon dissolution process. According to the method provided by the invention, a hollow part of the double-layer structure yarn is formed by two ways: on the one hand, water-soluble vinylon is removed by being dissolved with hot water, and on the other hand, a hot-shrinkage rate generated by chemical fiber filament serving as core yarn is more than that generated by outsourced staple fiber during a hot water treatment process, and thus bulkiness and degree of hollowness are also added on the basis of the original hollow part.

Owner:徐州银丰纺织有限公司

Preparation method of palm fibril core and palm fibril core

InactiveCN103862759AGood antibacterial effectSoft touchSynthetic resin layered productsVegetal fibresEngineeringAntibacterial activity

The invention provides a preparation method of a palm fibril core and the palm fibril core. The preparation method comprises the following steps: dissolving sodium hydroxide with the minimum mass fraction of 1.0% and hydrogen peroxide with the minimum mass fraction of 2.0% in water; putting palm fibers according to a bath ratio of 1:(20-50); treating the palm fibers to prepare palm fibrils with the relatively high degree of hollowness, so that the water absorption capacity of a fiber material is improved. Bump mapping is spread all over the surface of the fiber material, so that the moisture absorption rate is increased, and the fiber material has the good gas permeability; the palm fibers have the natural light fragrance and the certain antibacterial activity; the prepared palm fibril core has the average fiber diameter of about 10 microns, and is more slender than fibers taken as an absorption core at present, so that the palm fibril core is relatively soft and relatively comfortable and has the good hand feeling, the raw materials of palm are relatively narrow in application range and low in cost, and resources can be fully utilized.

Owner:SUZHOU UNIV

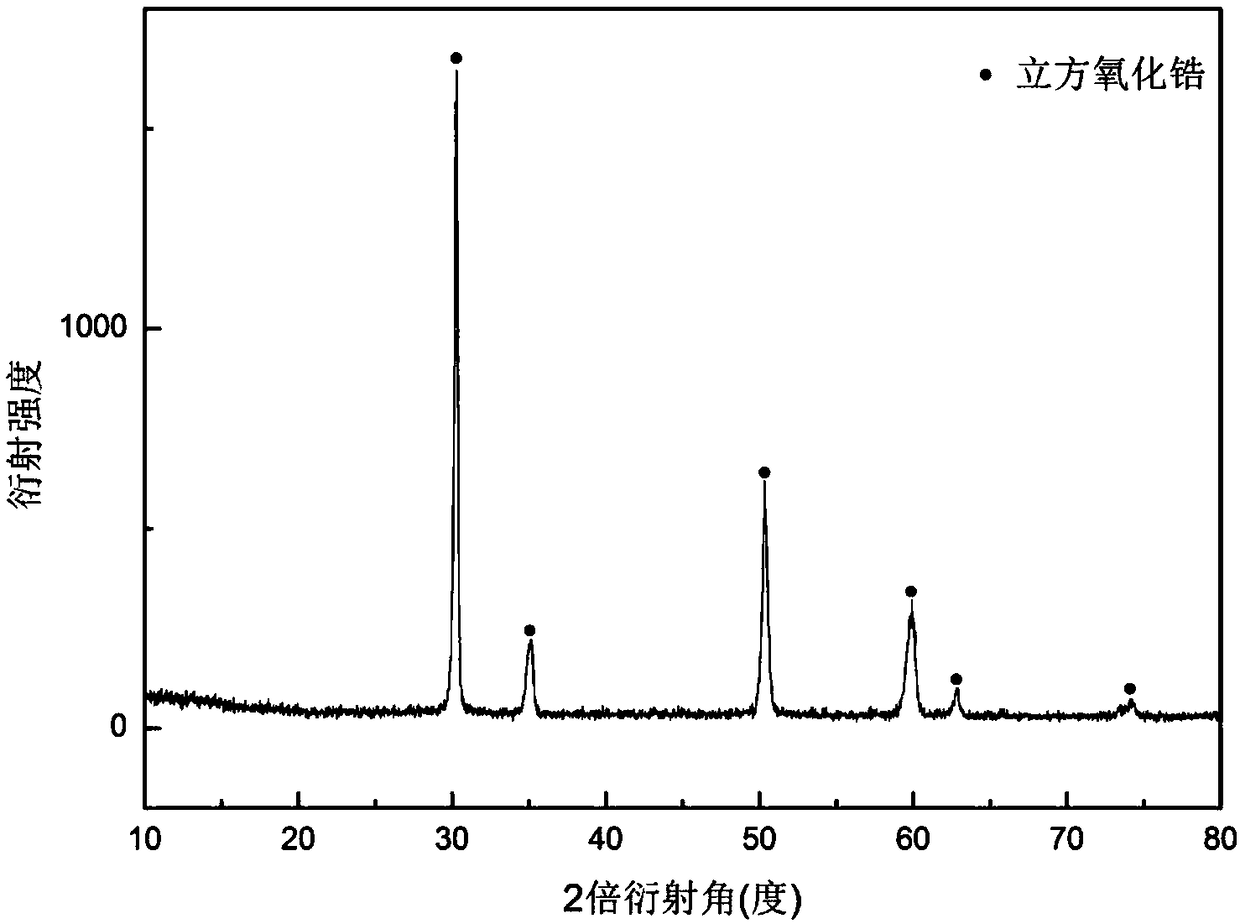

Method for obtaining hollow zirconia fiber by microwave sintering of Metaplexis japonica (Thunb.) Makino. fiber

InactiveCN108517584AImprove continuityHigh hollownessInorganic material artificial filamentsFiberHeat flow

The invention discloses a method for obtaining hollow zirconia fiber by microwave sintering of Metaplexis japonica (Thunb.) Makino. fiber, comprising the following steps: mixing zircon salt, a stabilizing agent and a microwave sintering aid in proportion and dissolving the mixture in a 50% (by volume) of an ethanol aqueous solution, immersing Metaplexis japonica (Thunb.) Makino. fiber in the solution for a certain period of time and taking the Metaplexis japonica (Thunb.) Makino. fiber out and drying; and placing the dried Metaplexis japonica (Thunb.) Makino. fiber into a microwave oven and carrying out aerobic sintering so as to obtain the hollow zirconia fiber. The prepared zirconia fiber is in a hollow tube shape. The structure can help limit transfer of a hot fluid in a fiber product,and heat insulation performance can be greatly raised. The zirconia fiber prepared from Metaplexis japonica (Thunb.) Makino. template has good toughness. There is a certain gap between fibers, and thefiber has high degree of hollowness. In comparison with a traditional microwave sintering mode, the invention has the following advantages: heating rate of microwave sintering of zirconia is raised by the addition of the microwave sintering aid, the microwave sintering apparatus is simplified, the disadvantage that zirconia has poor wave absorbing capacity at low temperature and heating is slow is overcome, sintering time is shortened and energy consumption is lowered, and efficiency is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

Inorganic hollow powder, process for producing the inorganic hollow powder, and composition comprising the inorganic hollow powder

Inorganic hollow powder is provided having a high purity, an enhanced fineness and a high hollowness. Specifically, inorganic hollow powder is provided having an average particle diameter of 1 to 5 μm, the maximum particle diameter of 20 μm or less, a particle size distribution standard deviation of 3 μm or less, and an average hollowness of 35 to 70 vol %. The inorganic hollow powder is obtained, for instance, by supplying, via an inorganic feed material powder supply pipe at a discharge rate of 80 m / s or more, inorganic raw material powder having a specific surface area of 500 m2 / g or more and an average particle diameter of 7 μm or less, into a flame formed by a burner comprising at least a triple pipe portion sequentially arranged with, in order from outside, a combustion supporting gas supply pipe, a combustible gas supply pipe and the inorganic feed material powder supply pipe. The present inorganic hollow powder is useful when blended in rubber and / or resin, for instance, for lowering the dielectric constant in multilayer printed boards, wiring covering materials, semiconductor encapsulating materials and the like.

Owner:DENKA CO LTD

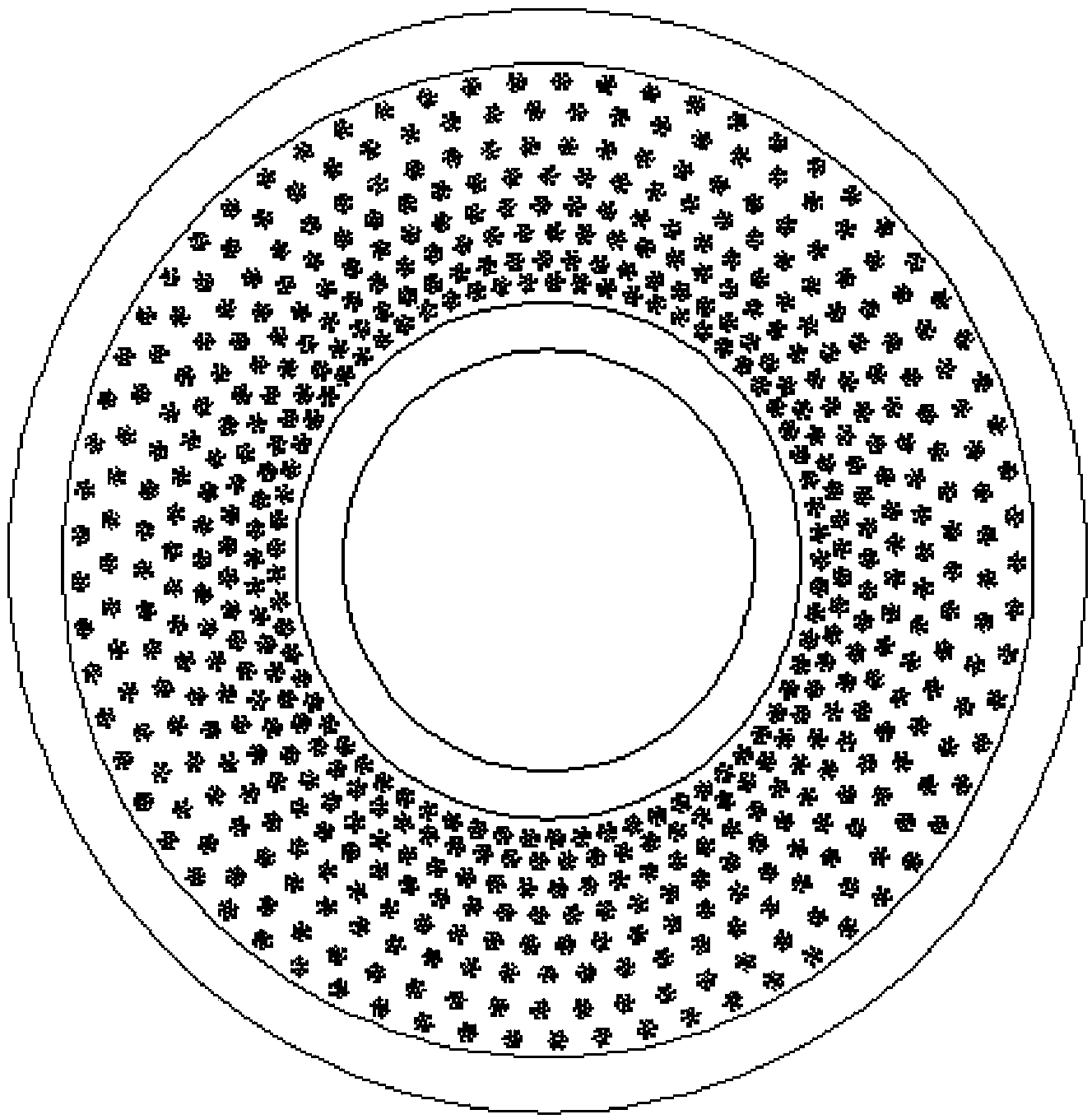

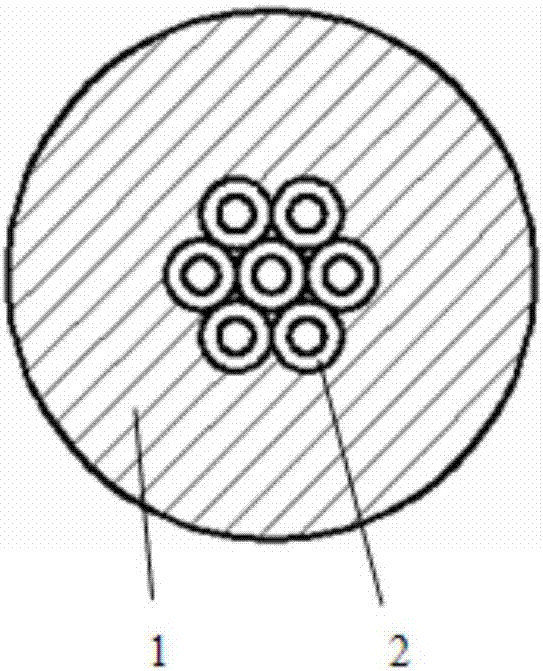

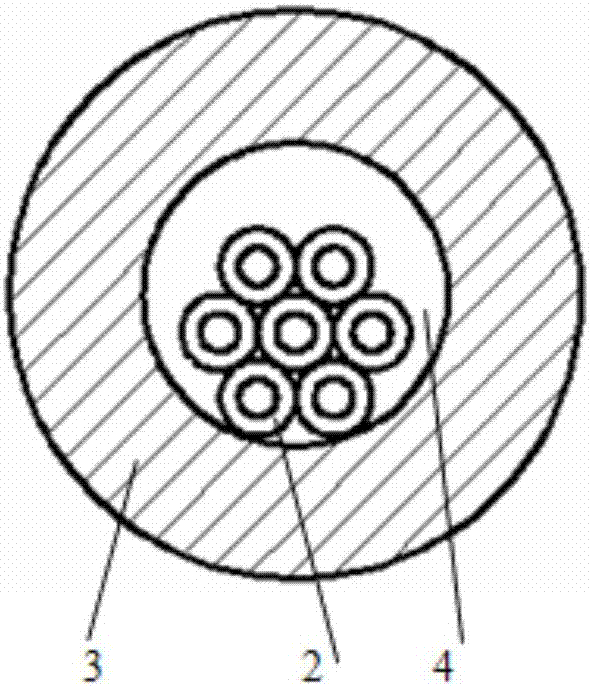

Porous moisture-permeable warm-keeping antistatic polyester fiber and preparation method thereof

ActiveCN112663153AAvoid deformationImprove evennessElectroconductive/antistatic filament manufactureHollow filament manufacturePolyesterFiber

The invention relates to a porous moisture-permeable warm-keeping antistatic polyester fiber and a preparation method thereof. The porous moisture-permeable warm-keeping antistatic polyester fiber is prepared from antistatic modified polyester, and a process flow of the preparation method comprises a spinning DIO assembly filtering process and a cooling process; a spinning DIO assembly is a double-channel device; the cooling process comprises the following steps: extruding antistatic modified polyester melt from spinneret orifices in a spinneret plate, passing through a slow cooling area, firstly entering a filter element in a circular blowing box to be subjected to circular blowing cooling, and then carrying out side blowing cooling; a filter element in the through blowing box is formed by sequentially sleeving an outer cylinder, a secondary outer cylinder, a secondary inner cylinder and an inner cylinder; the upper end and the lower end between the outer cylinder and the inner cylinder are sealed through high-temperature-resistant silica gel pads with caps, and the outer cylinder and the secondary outer cylinder are fixed through a plurality of stainless steel supporting strips; two perforated plates which are parallel to each other and perpendicular to the surface of the spinneret plate are arranged in the filter element in the circular blowing box, and the two perforated plates are used for separating tows extruded from two areas on the spinneret plate; and finally, the prepared fiber is relatively high in hollowness and relatively good in yarn evenness.

Owner:JIANGSU DELI CHEM FIBER CO LTD

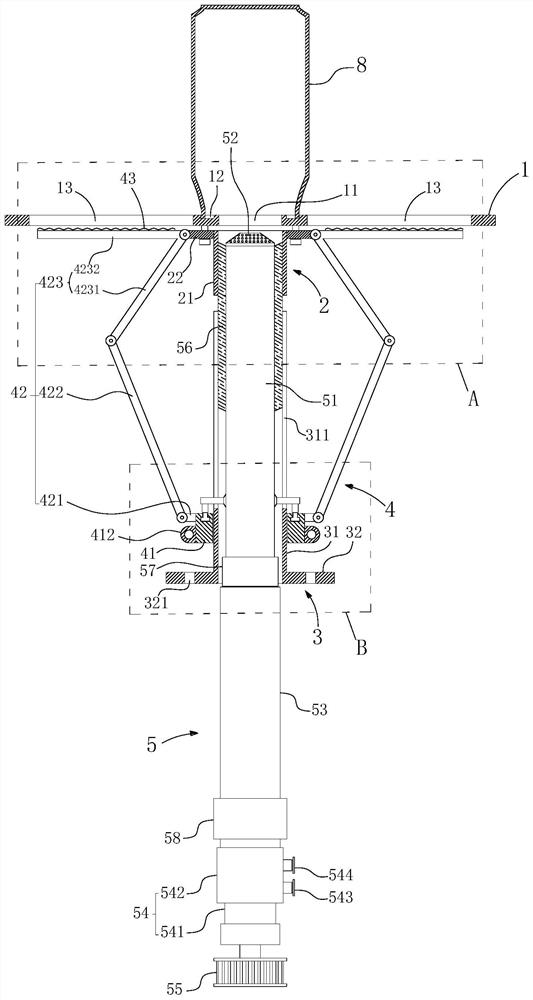

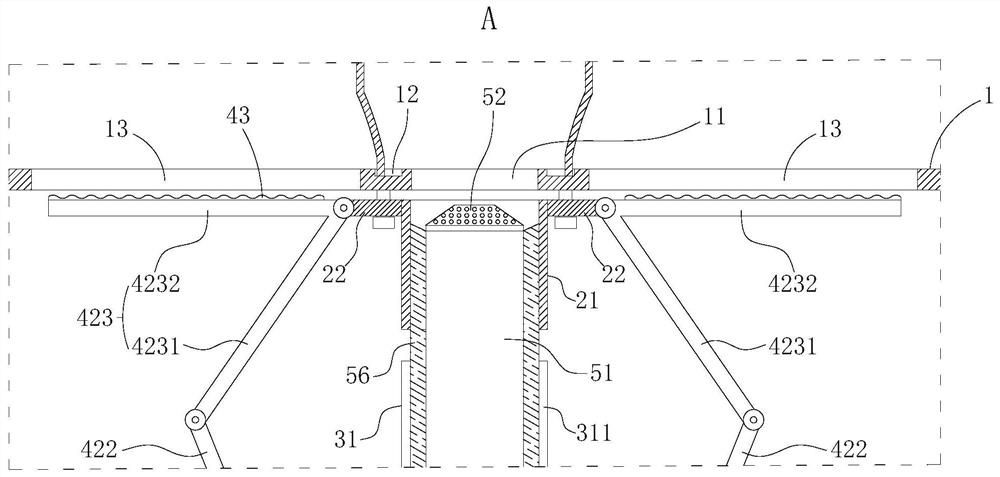

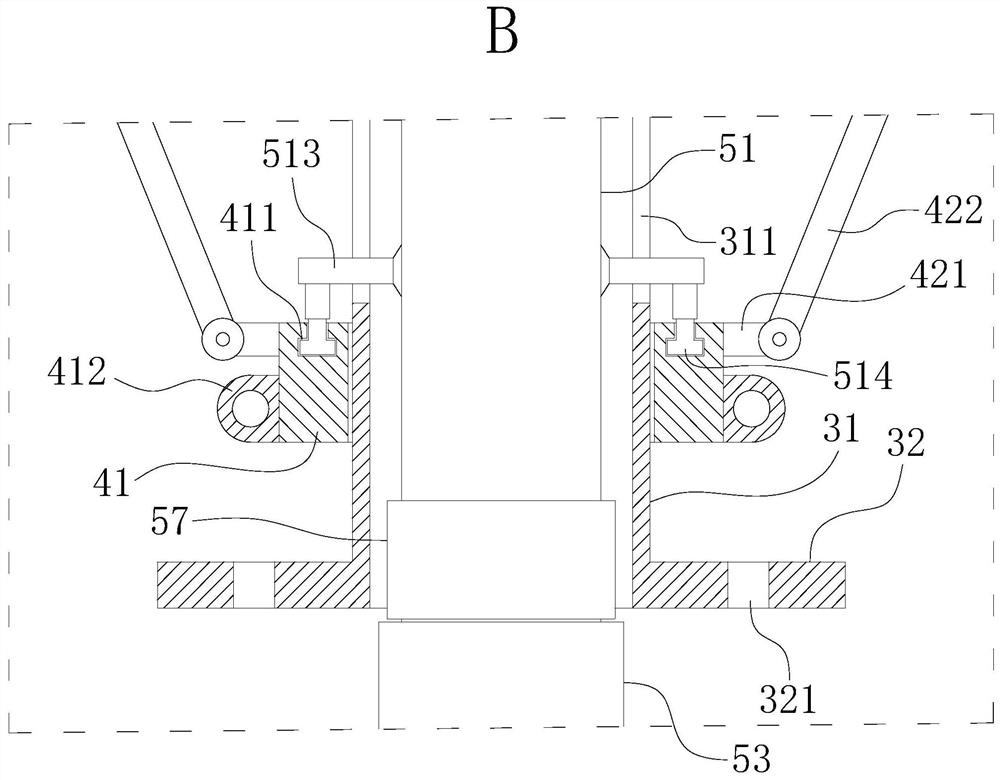

Glass bottle cleaning device

ActiveCN112122280AGood flexibilityHigh hollownessHollow article cleaningStructural engineeringBottle

The invention discloses a glass bottle cleaning device. The glass bottle cleaning device comprises a working table, a first fixing sleeve, a second fixing sleeve, a clamping mechanism, and an inner cavity cleaning mechanism. The first fixing sleeve is fixed below the working table; the second fixing sleeve is arranged below the first fixing sleeve at an interval; the clamping mechanism comprises asliding sleeve, two sets of connecting rod mechanisms and two clamping plates; the sliding sleeve can slide along the second fixing sleeve; the two sets of connecting rod mechanisms are located on two sides of the sliding sleeve respectively and can perform corresponding actions along with movement of the sliding sleeve; the two clamping plates are respectively arranged on the two sets of connecting rod mechanisms and can be driven by the connecting rod mechanisms so as to clamp a glass bottle above the working table; the inner cavity cleaning mechanism comprises a cleaning pipe, an umbrella-shaped nozzle, a telescopic pipe, a gas-liquid transmission sliding ring and a belt wheel; the cleaning pipe can be driven by the sliding sleeve so as to extend into the glass bottle; bristles are arranged on the outer wall of the cleaning pipe; the umbrella-shaped nozzle is installed at the top of the cleaning pipe; and the telescopic pipe, the gas-liquid transmission sliding ring and the belt wheel are sequentially installed below the cleaning pipe. The glass bottle cleaning device provided by the invention can replace an existing manual glass bottle inner cavity cleaning mode, and help enterprises to improve cleaning efficiency and save cost.

Owner:SHANDONG JINGYAO GLASS GRP

Continuous fiber nonwoven fabric

InactiveUS20110136402A1High fiber strengthHigh hollownessFilament/thread formingMonocomponent polypropylene artificial filamentPolymer scienceNonwoven fabric

The invention has an object of providing a continuous fiber nonwoven fabric including a hollow fiber having excellent strength, in particular mono-filament strength, and having high hollowness even when formed to a fine filament.A continuous fiber nonwoven fabric includes a hollow fiber including a propylene polymer having a ratio of the Z average molecular weight (Mz) and the weight average molecular weight (Mw), (Mz / Mw), in the range of 1.5 to 1.9, and in a preferred embodiment having a ratio of the weight average molecular weight (Mw) and the number average molecular weight (Mn), (Mw / Mn), in the range of 2.0 to 2.9.

Owner:MITSUI CHEM INC

Kawo kawo fiber and cotton fiber blended down-proof and anti-mite fabric and weaving method for same

The invention provides a kawo kawo fiber and cotton fiber blended down-proof and anti-mite fabric and a weaving method for the same and relates to the technical field of textile production. The kawo kawo fiber and cotton fiber blended down-proof and anti-mite fabric is weaved via warp yarns and weft yarns. The warp yarns and the weft yarns are blended via kawo kawo fibers and cotton fibers; the weight percentage of the kawo kawo fibers is 20% to 30%; the weight percentage of the cotton fibers is 80% to 70%; the number of the warp yarns is 14.5tex; the number of the weft yarns is 9.7tex; and the fabric is in a plain weave structure. The weaving method comprises the following steps of a spooling procedure, a warping procedure, a slashing procedure, a denting procedure, a weaving procedure and a finishing procedure. Blended yarns formed by the kawo kawo fibers and the cotton fibers at a rational ratio are employed and weaved to form bedding article fabric with natural down-proof and anti-mite effects as well as great downproofness and great moisture absorbing and ventilating performance; the textile structure is tight, plain and fine and has smooth hand feeling and gloss; the fabric is ventilating and downproof and anti-mite as well as firm and abrasion-resistant; and great comfortableness and warming effect can be achieved.

Owner:JIHUA 3542 TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com