Patents

Literature

475results about How to "Improve evenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile dyeing wastewater advanced treatment recycling technology

InactiveCN102145965AReduce chromaImproved BioprocessingMultistage water/sewage treatmentWater/sewage treatment by neutralisationTextile fiberChemical treatment

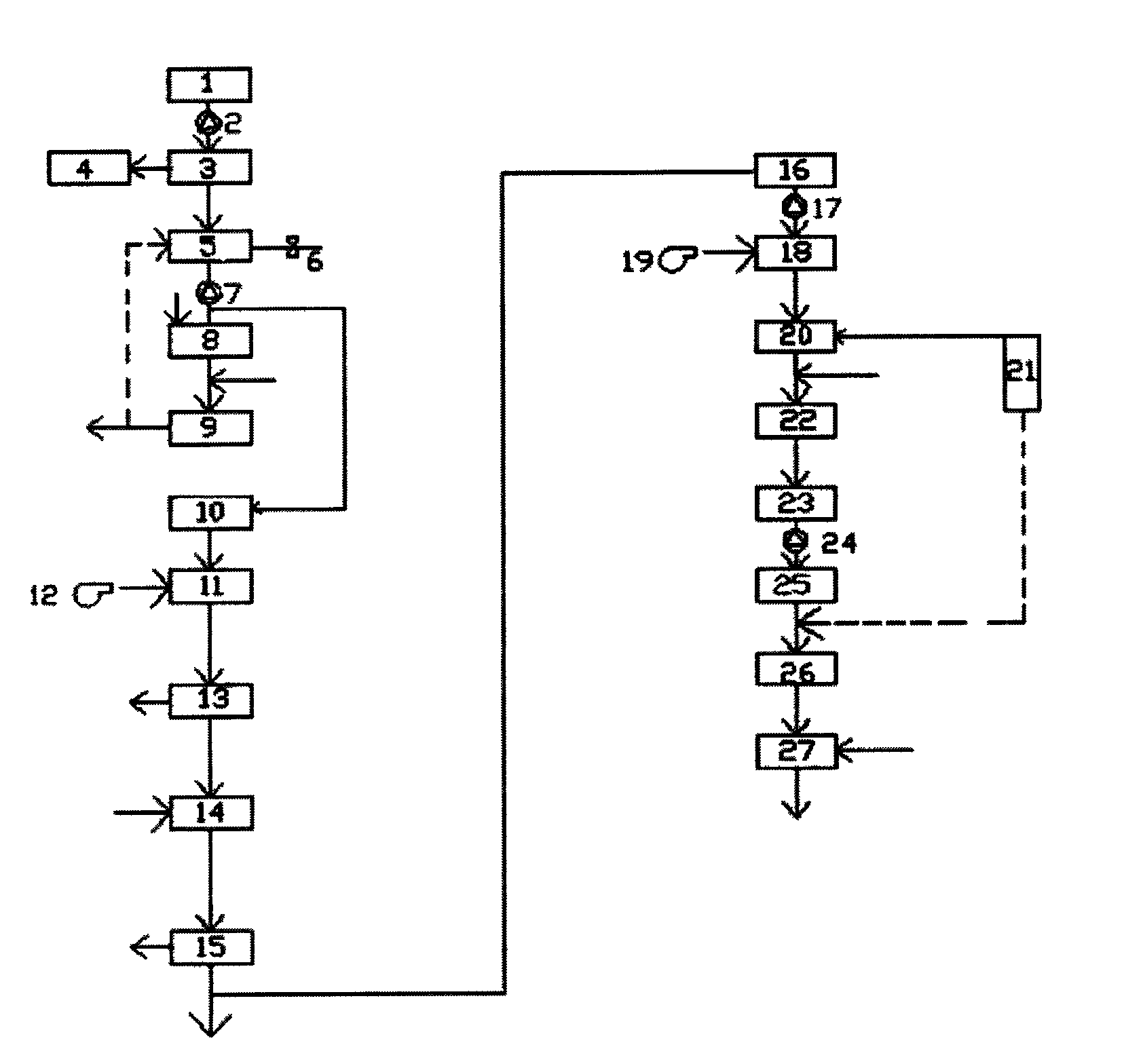

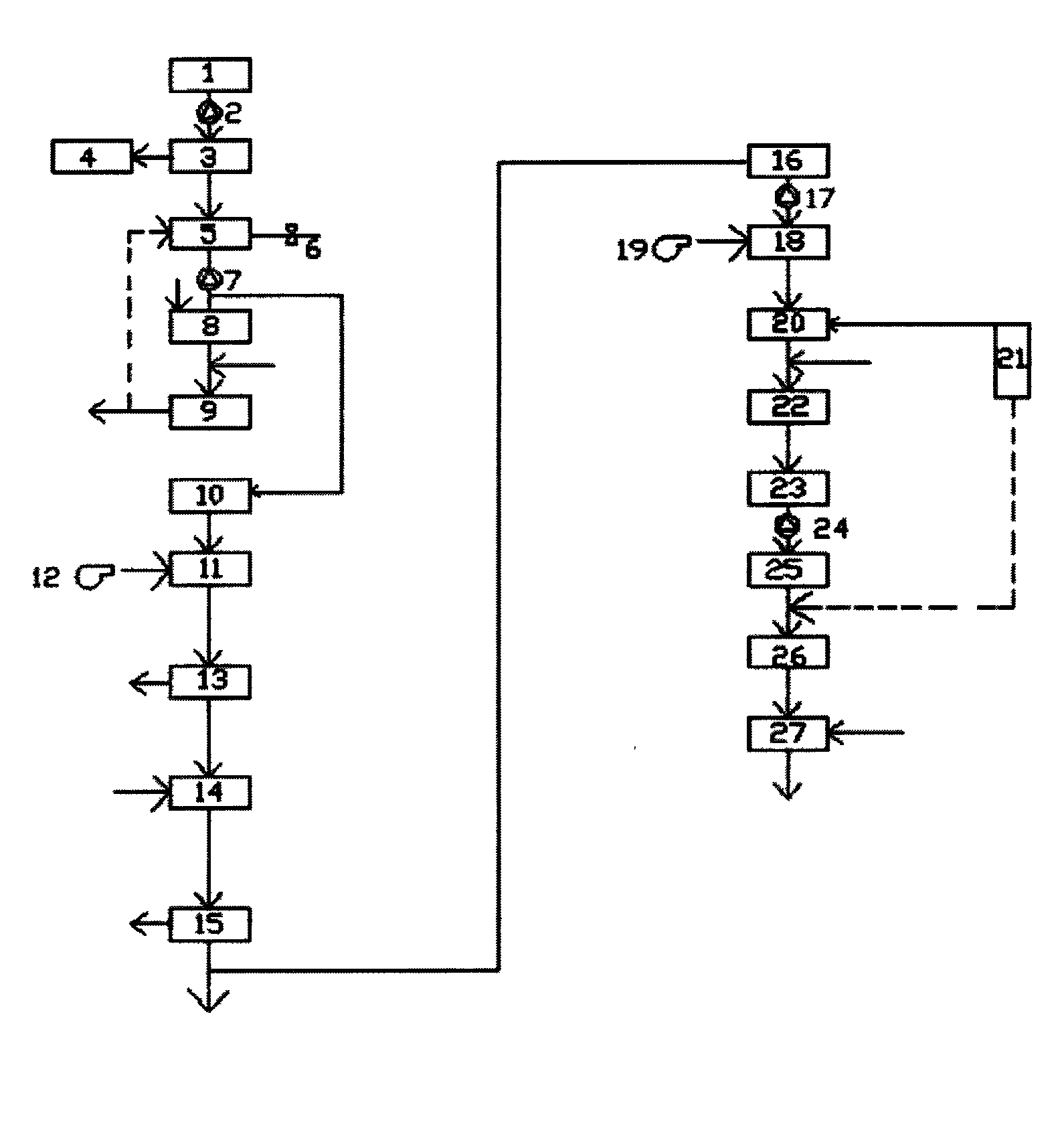

The invention discloses a textile dyeing wastewater advanced treatment recycling technology. The technology comprises the following steps: filtering to remove textile fibers; cooling; neutralizing, degrading organic matters and decomposing, replacing or degrading (cracking) the chormophoric groups of the organic matters to reduce the chroma of the wastewater; performing biochemical treatment with the biomembrane; precipitating to ensure that the precipitated sludge enters a sludge treatment system and the supernatant enters a flocculation pool; performing chemical treatment, namely adding a medicament in the flocculation pool to remove the suspended matter (SS), CODcr (chemical oxygen demand), BOD (biochemical oxygen demand) and chroma of the water; performing secondary precipitation to ensure that the free SS is precipitated and the wastewater is decolored further; separating to remove and degrade the chloride ions of the reuse water; performing secondary biochemical treatment to further reduce the concentrations of the SS, CODcr and BOD in wastewater; performing ozone oxidation treatment, decoloring, degrading organic matters; performing chemical treatment to remove insoluble dye materials and SS and reduce the COD and chroma; and performing secondary filtration, and forming an ozone / activated carbon system to ensure that the hydroxyl radicals of activated carbon are used and the organic reaction in wastewater is adopted to decolor and degrade organic matters. The invention overcomes the defects of the existing physical method, chemical method and chemical method treatment technologies; and the technology has been used in many enterprises, and the good treatment effects are obtained.

Owner:李斌 +2

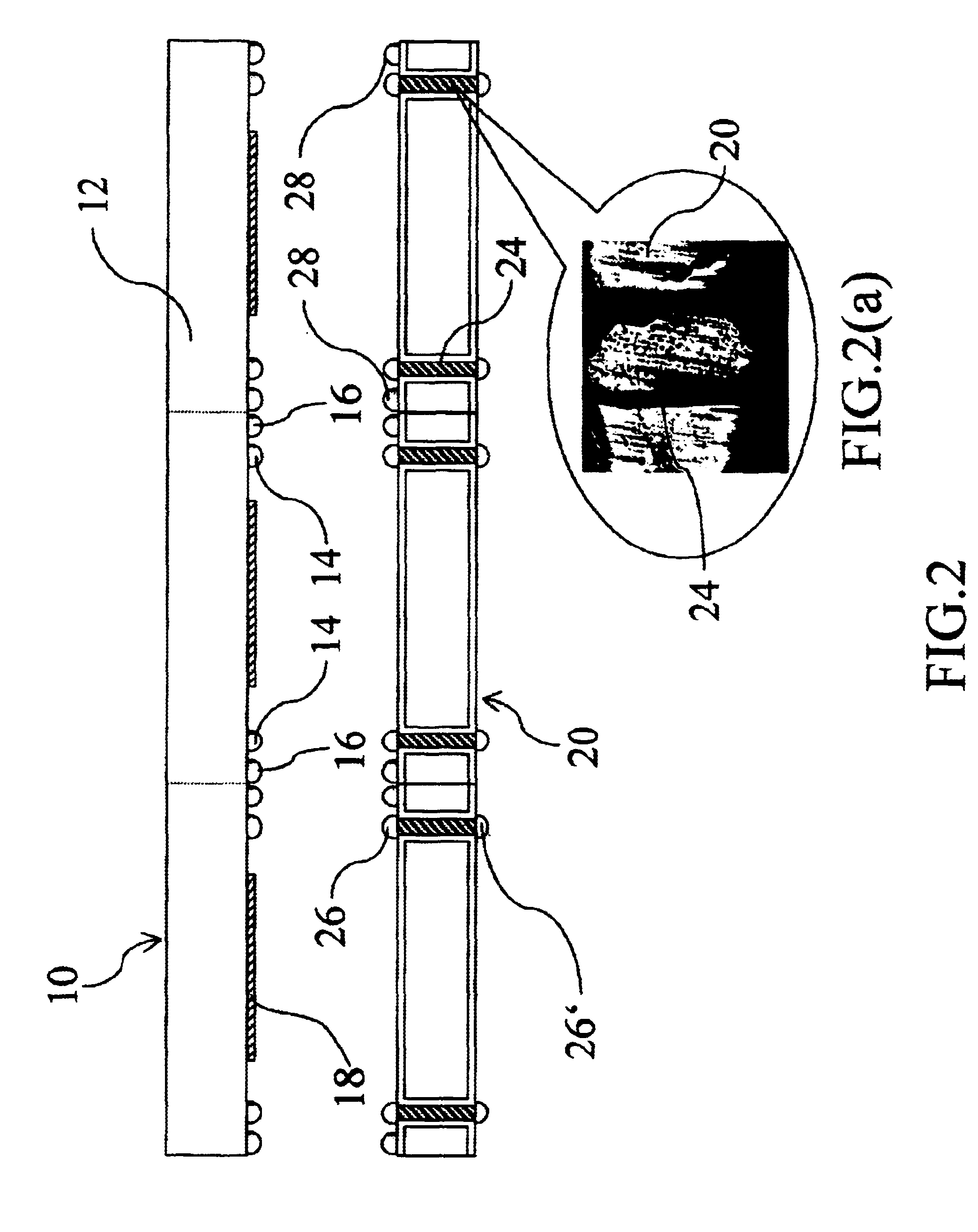

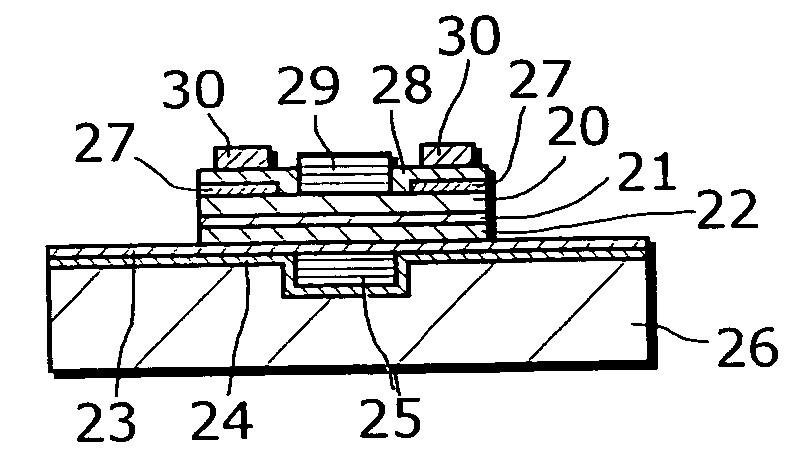

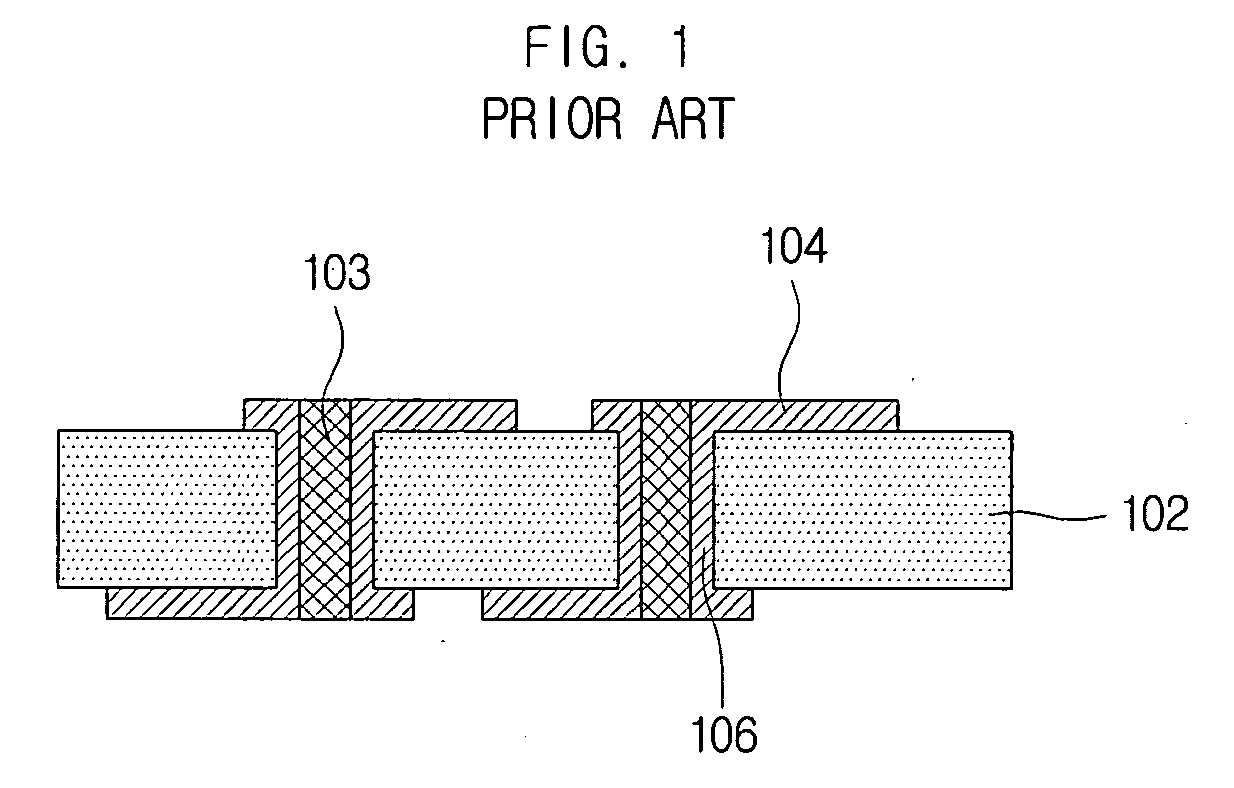

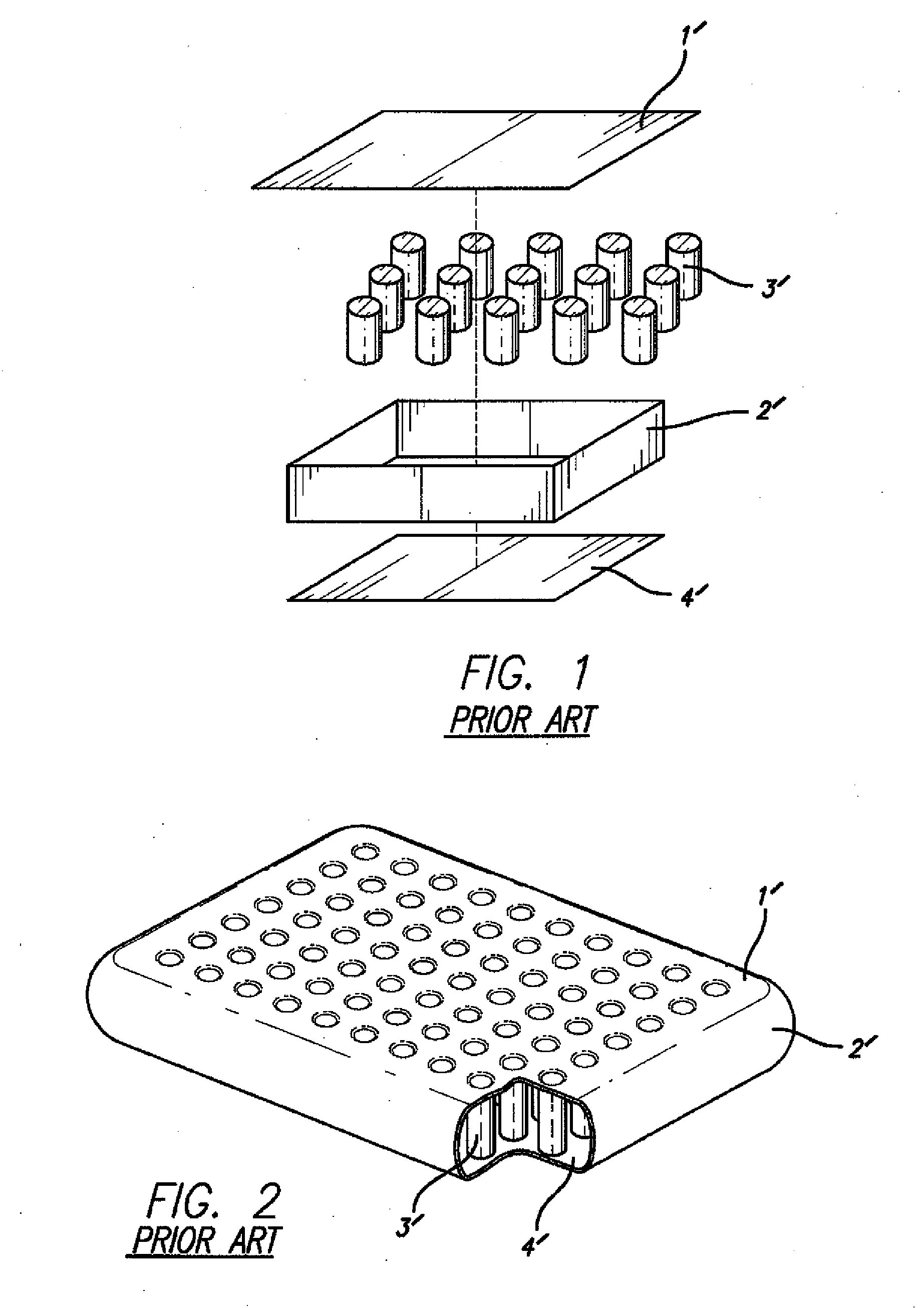

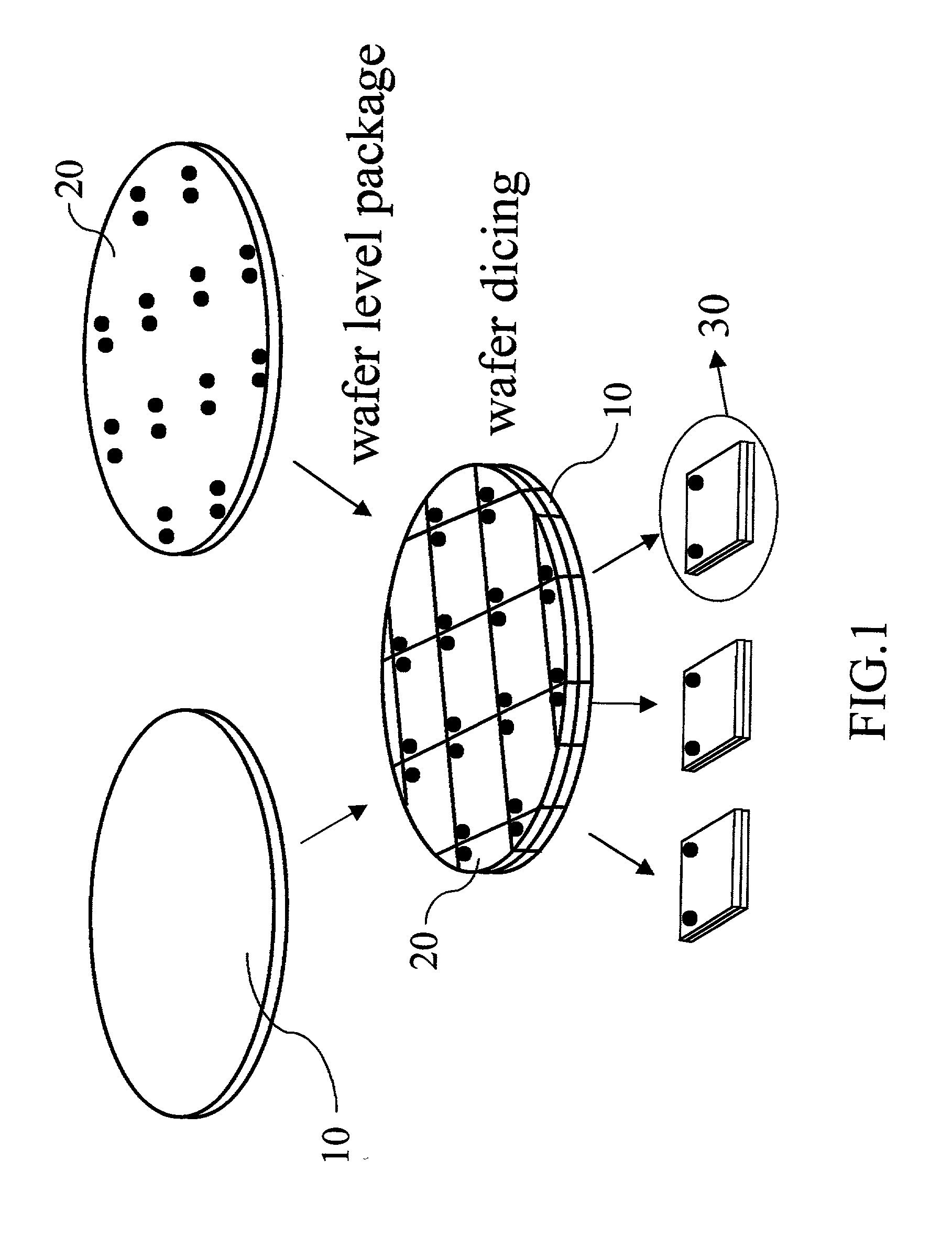

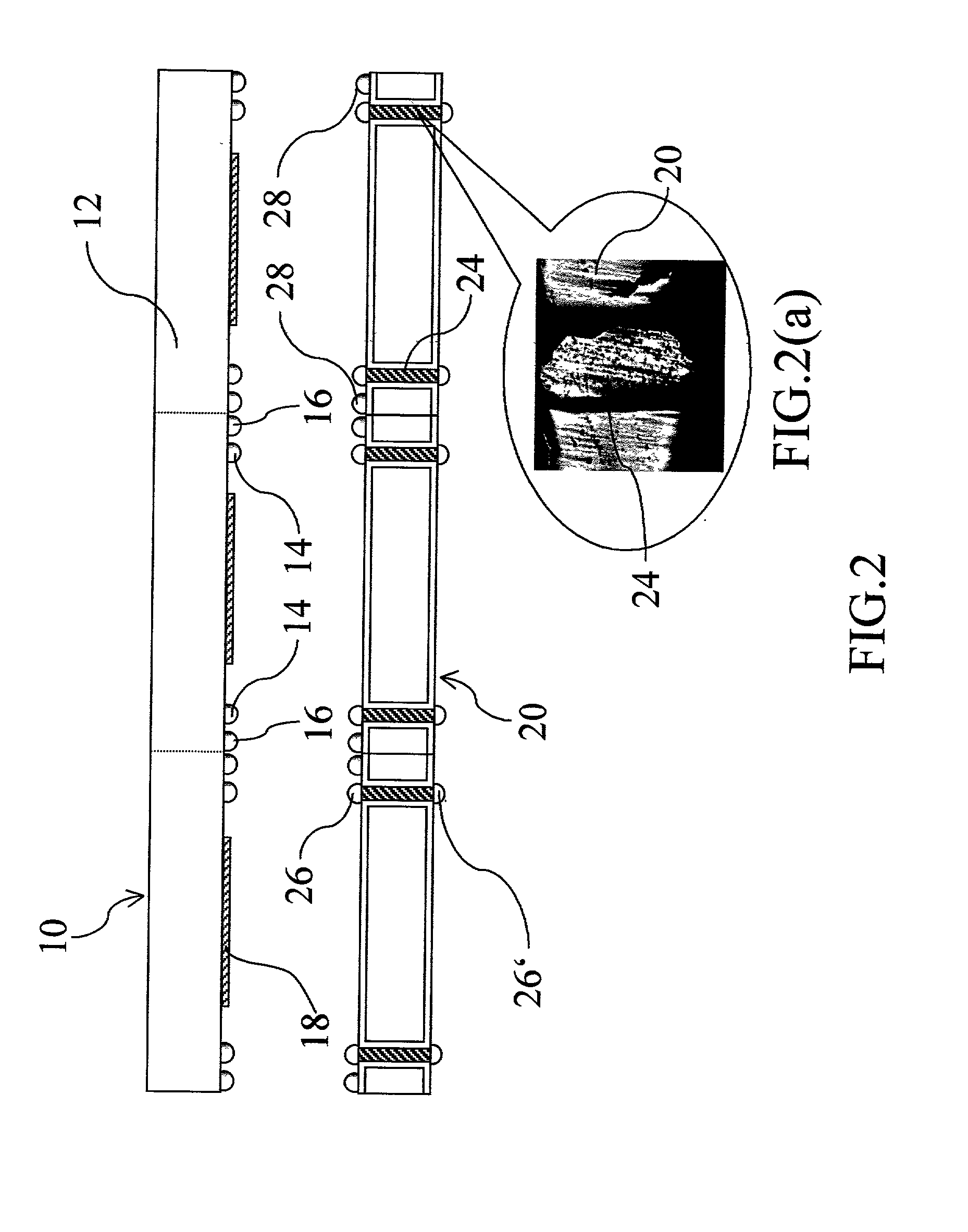

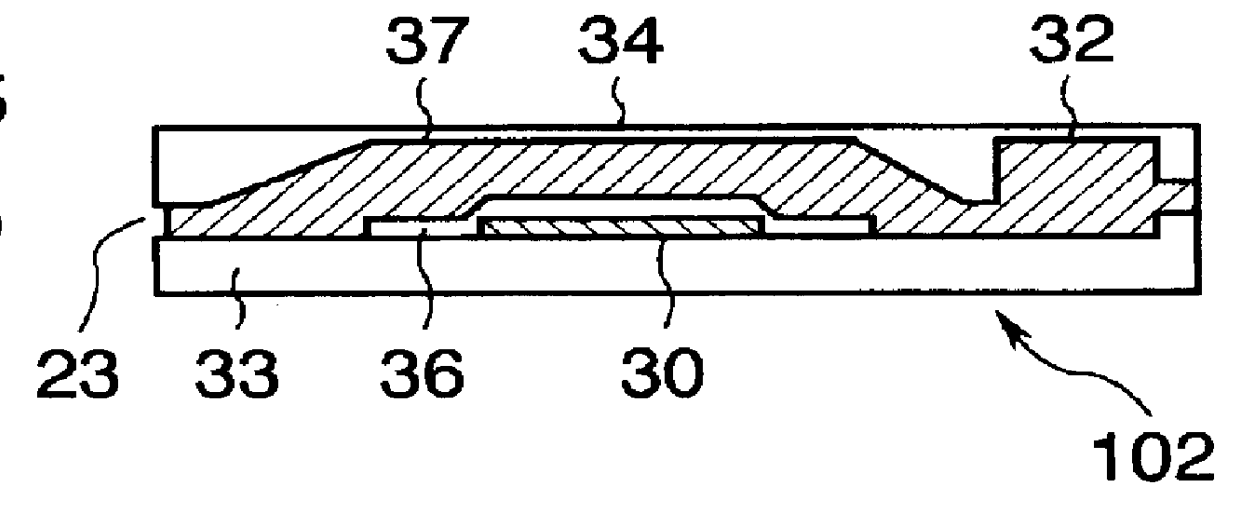

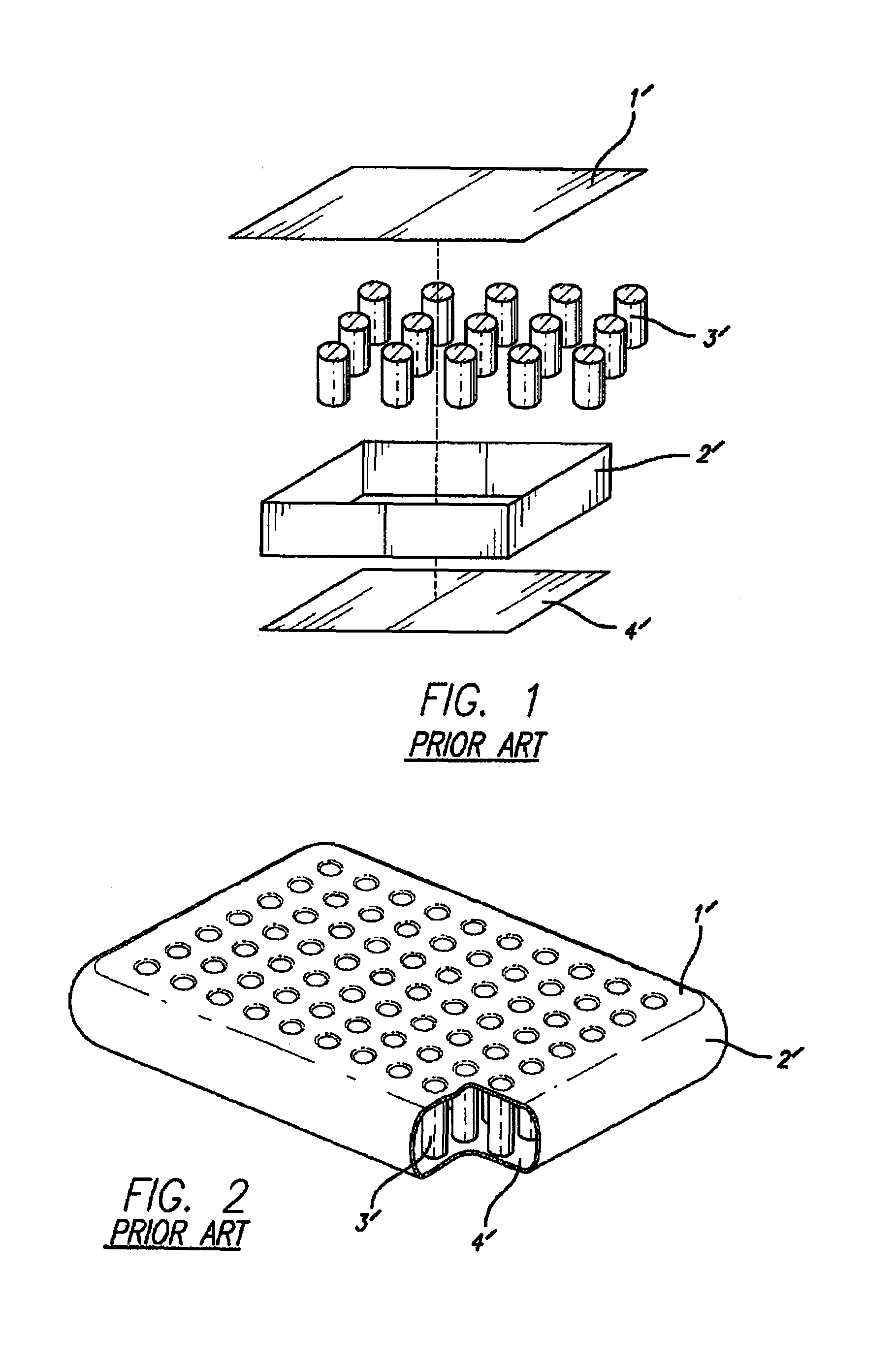

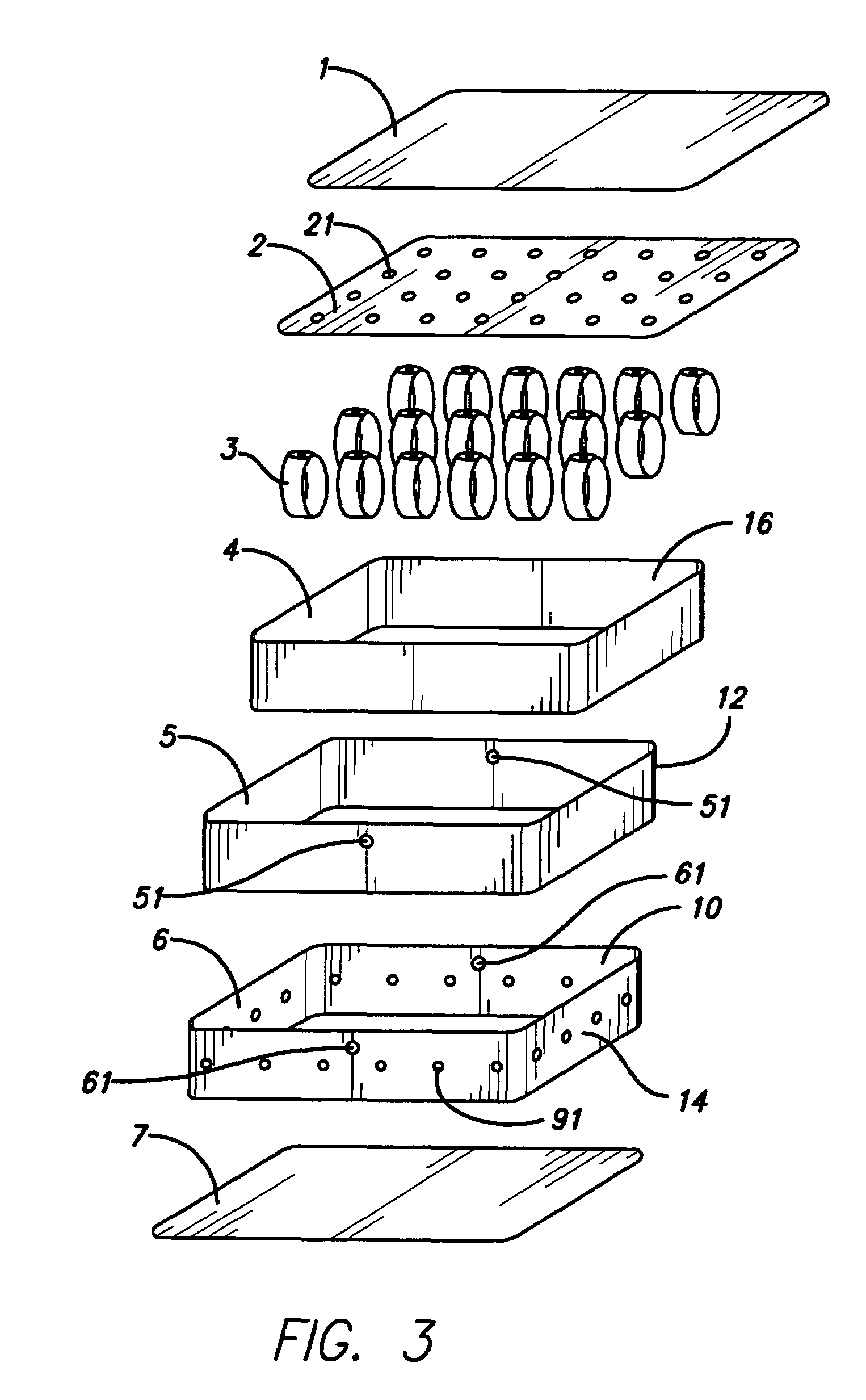

Wafer level packaging of micro electromechanical device

InactiveUS6710461B2Avoid damageImprove evennessDecorative surface effectsSemiconductor/solid-state device detailsElectrical conductorWafering

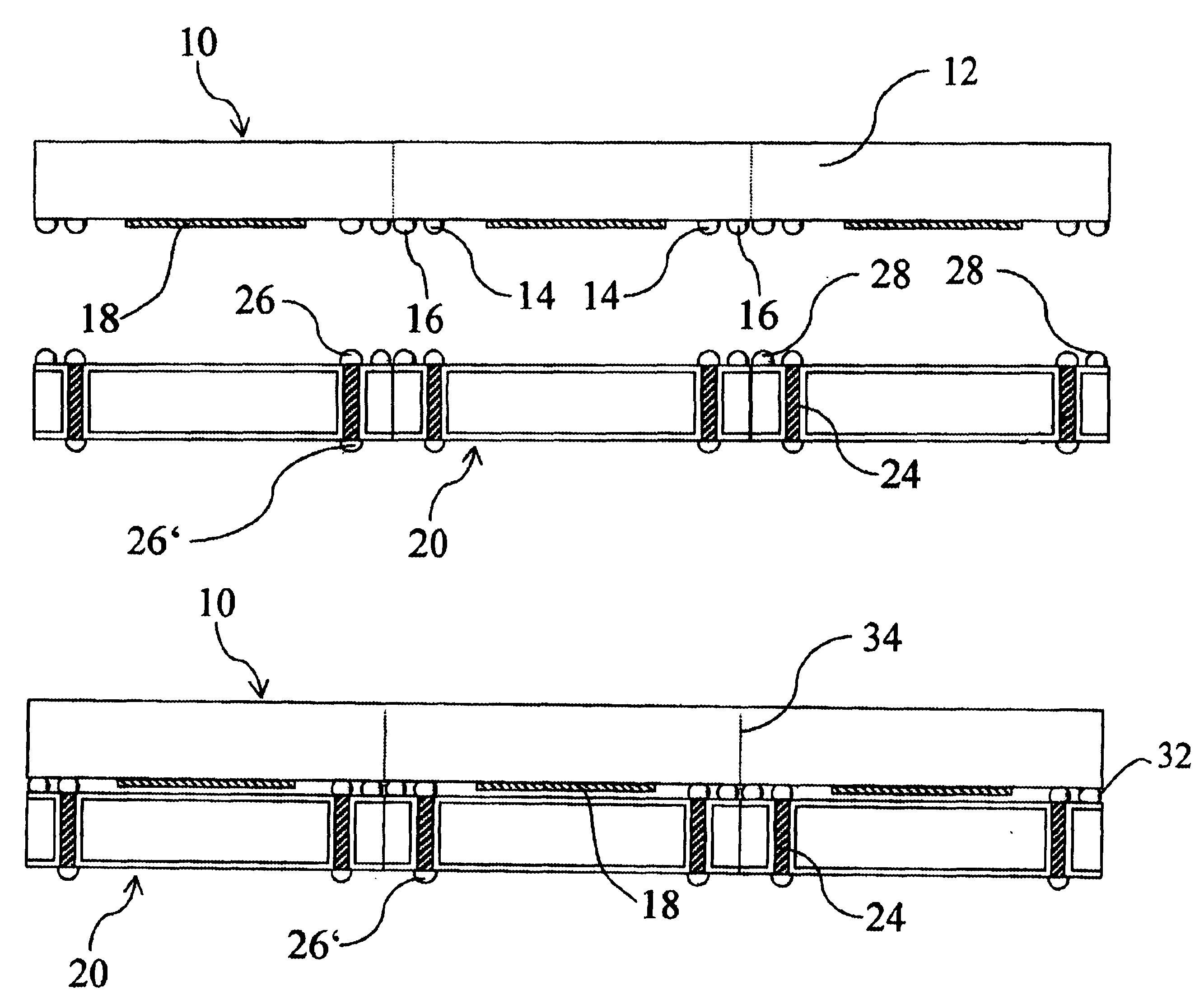

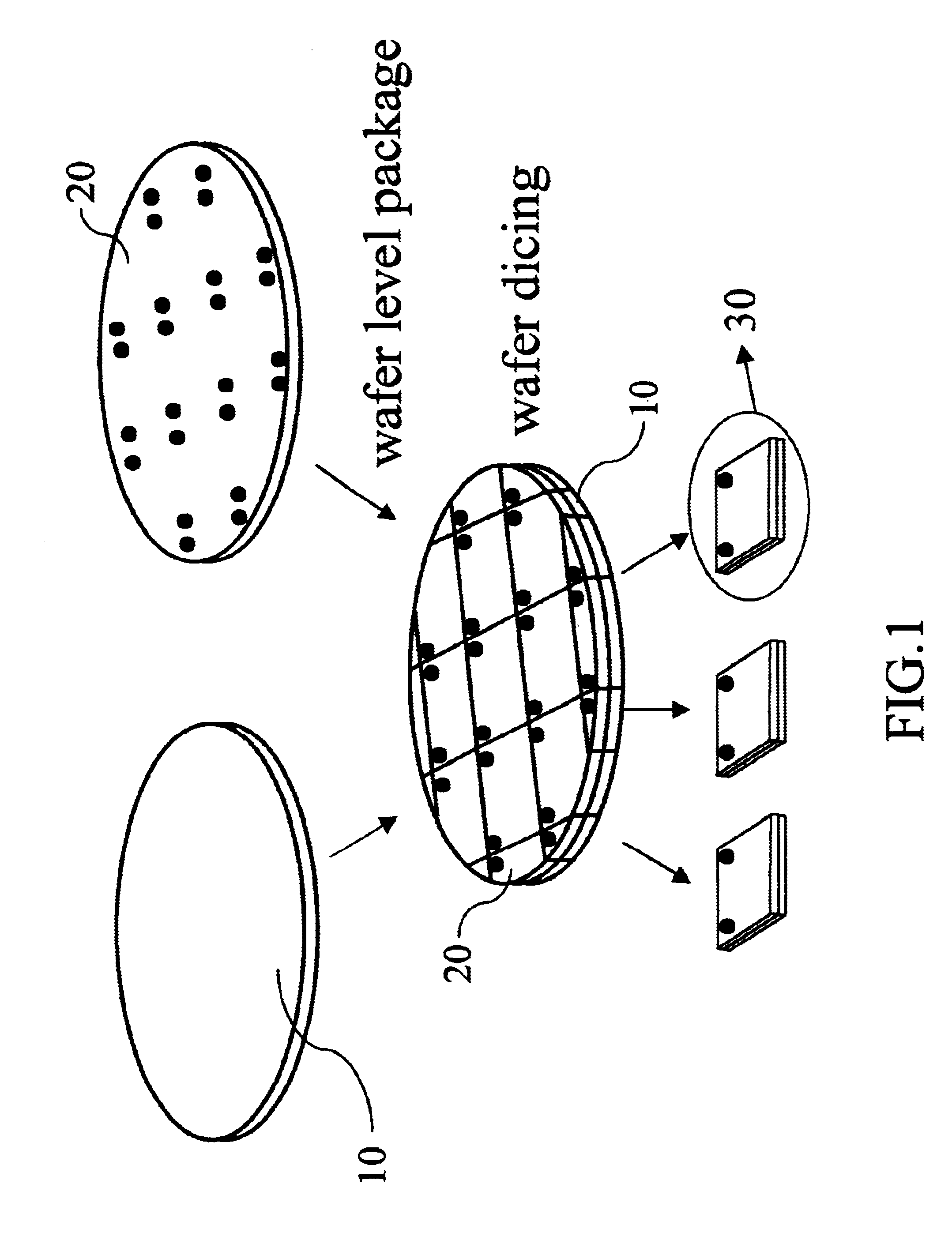

The present invention provides a wafer level package of micro electromechanical devices. The wafer level package of the present invention comprises a wafer having a plurality of micro electromechanical devices and a package wafer of the same size. A plurality of conductor plugs penetrate through the upper and lower surfaces of the package wafer. Solder bumps are formed on the conductor plugs to be adhered to predetermined solder bumps on the micro electromechanical device wafer so as to form a package device. The wafer level package of the present invention can prevent micro electromechanical devices from damage during the packaging procedure.

Owner:XIANGQUN SCI & TECH

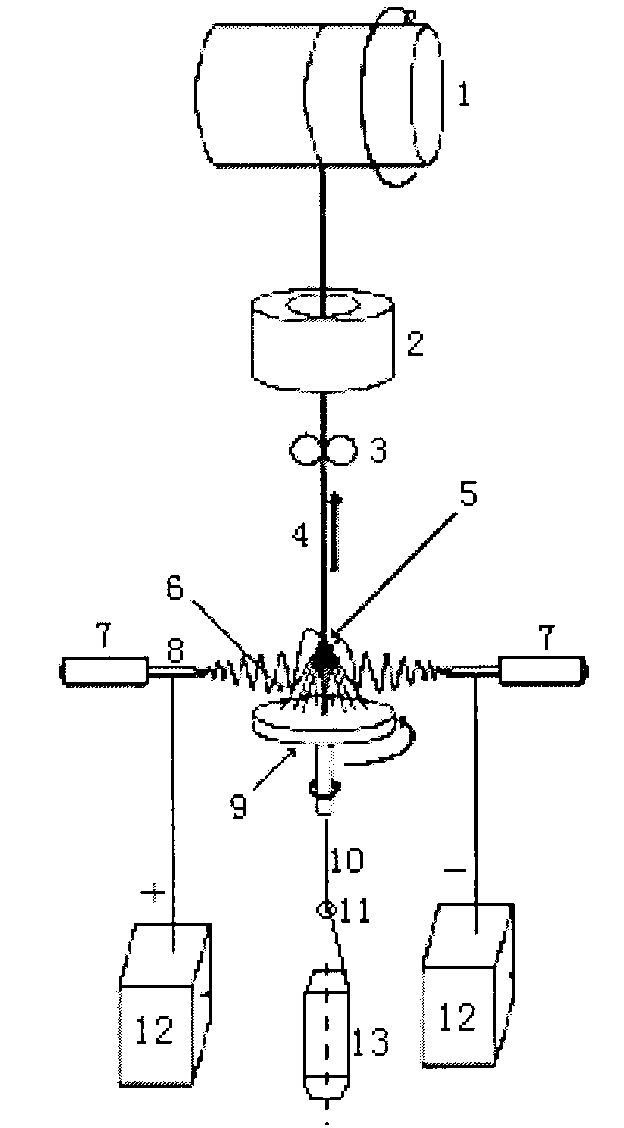

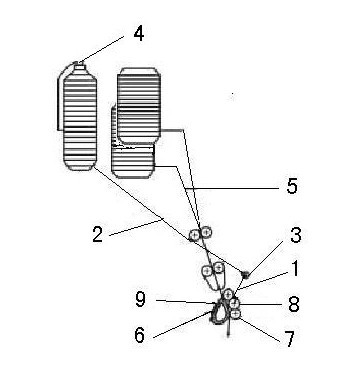

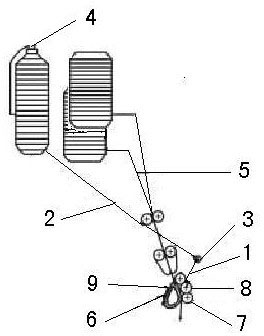

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

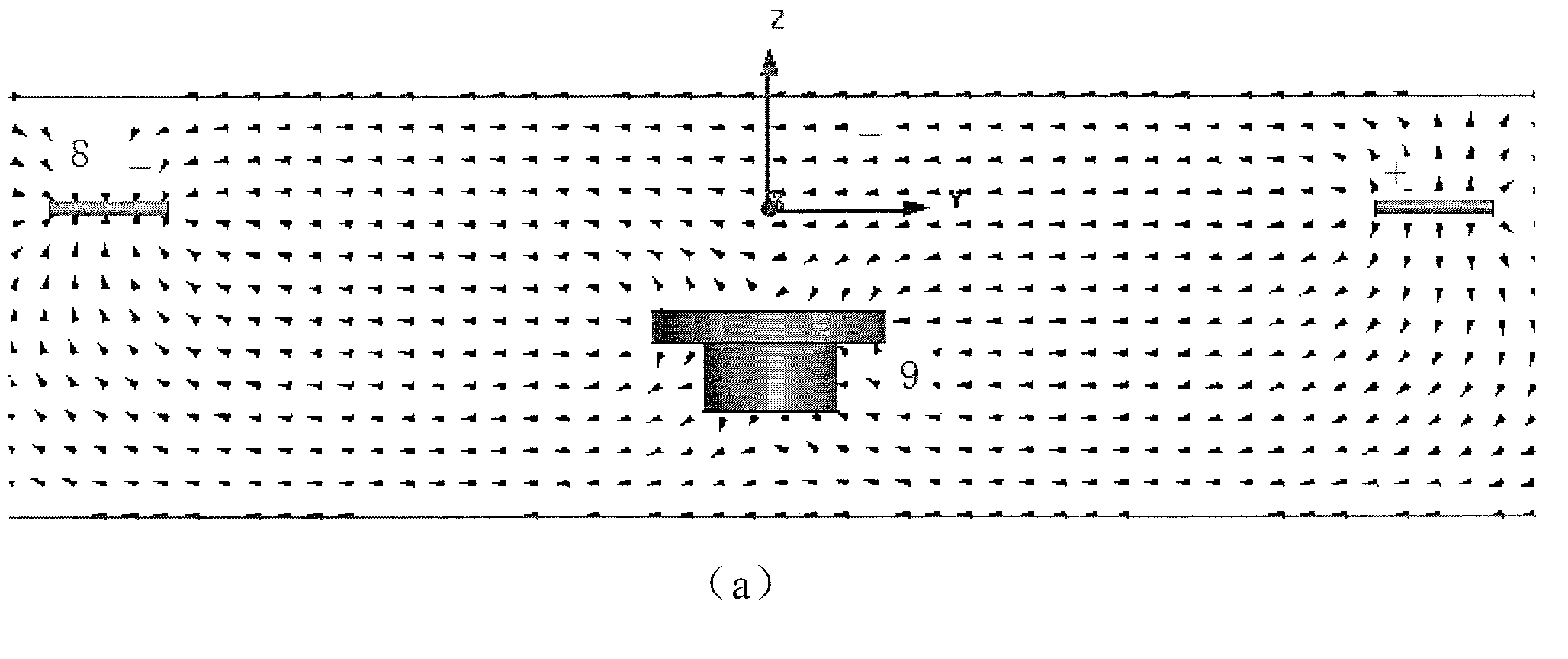

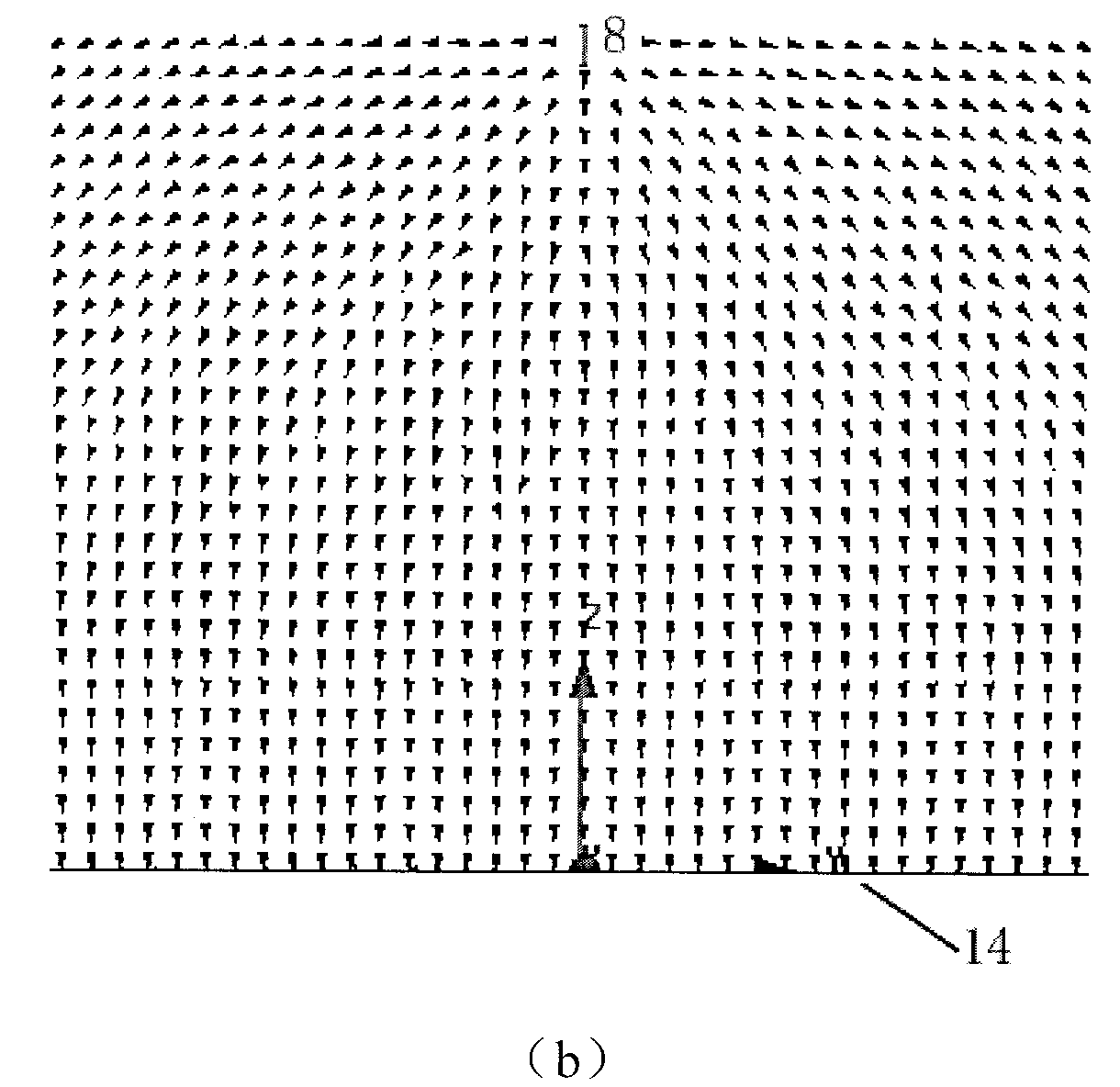

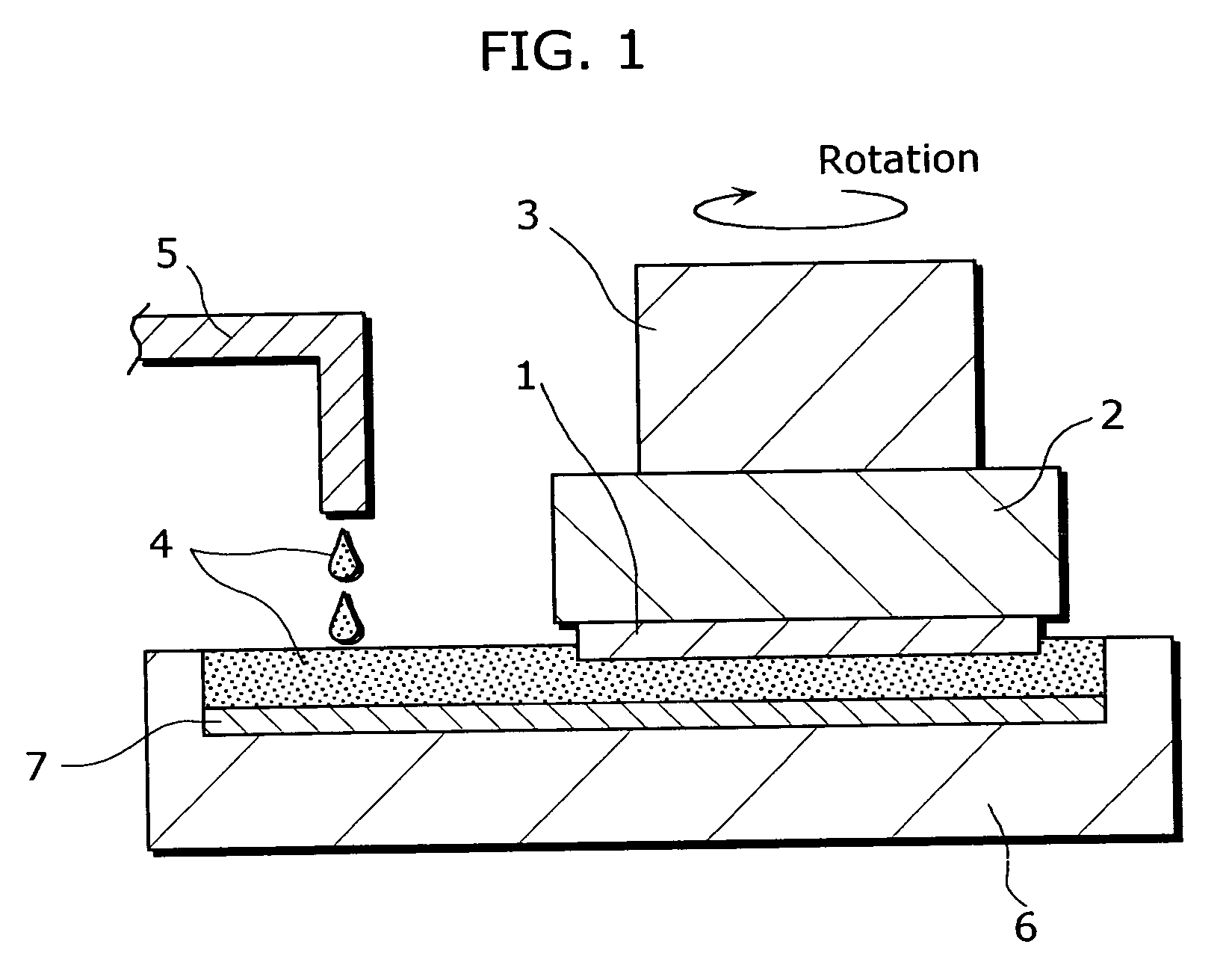

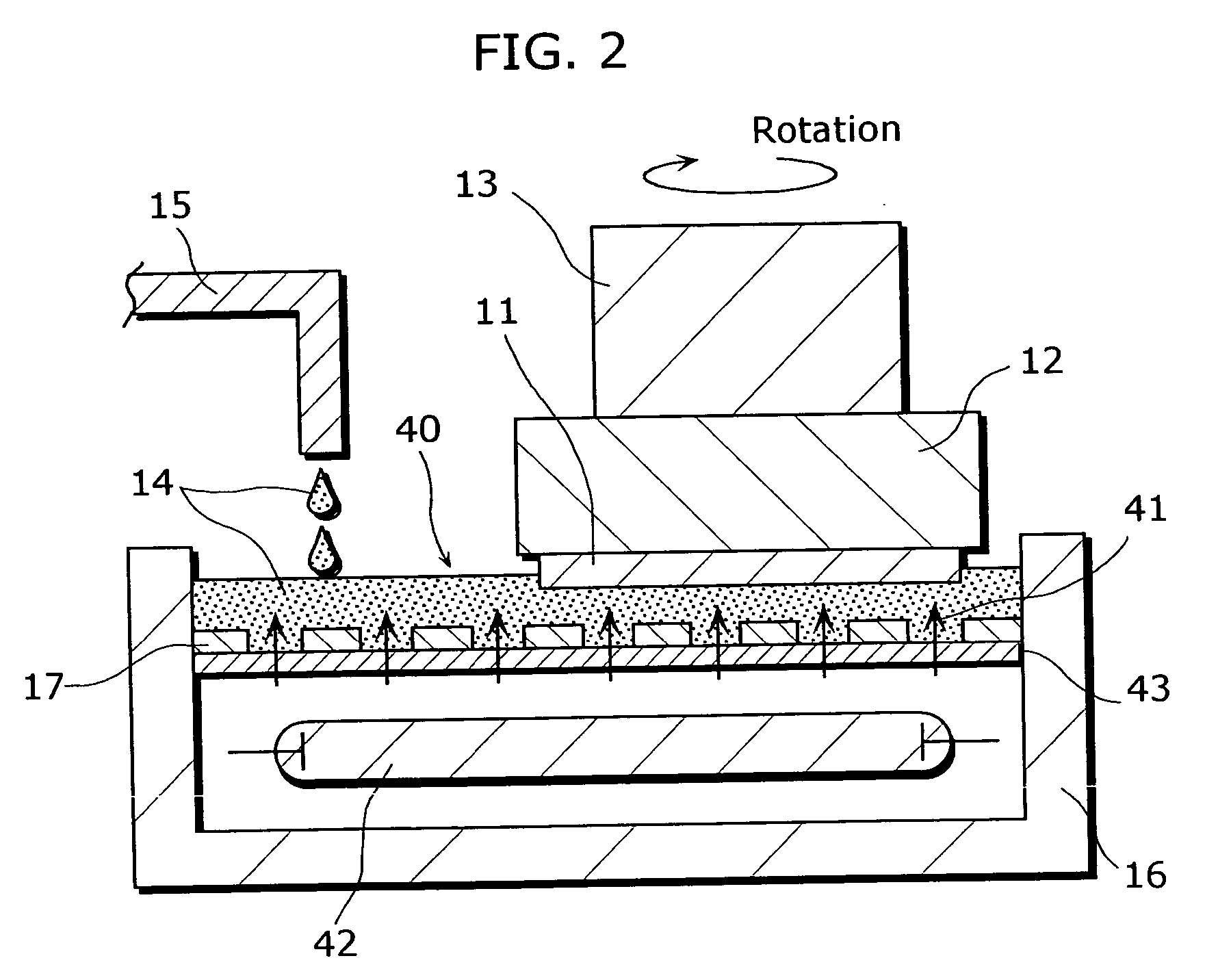

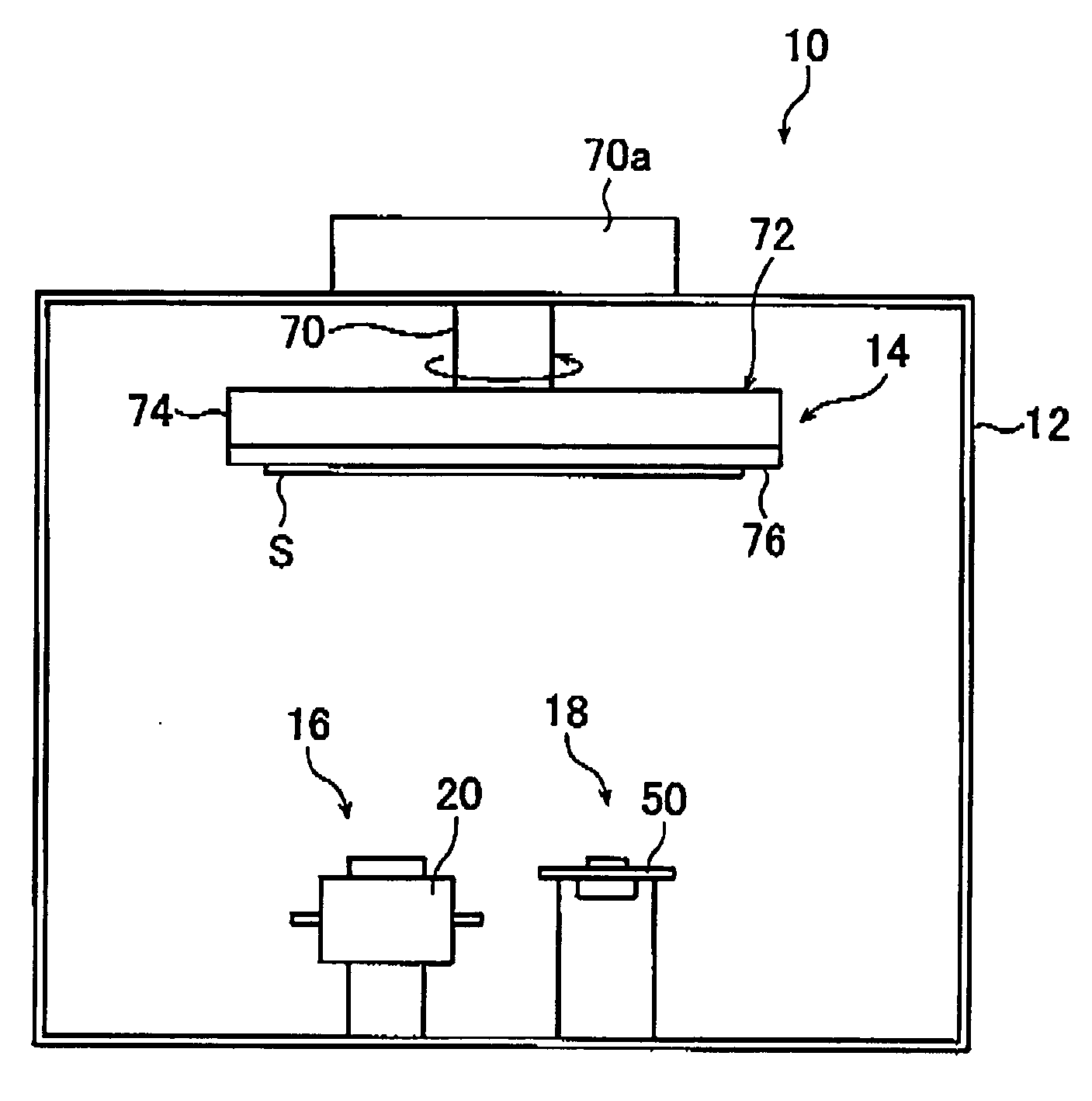

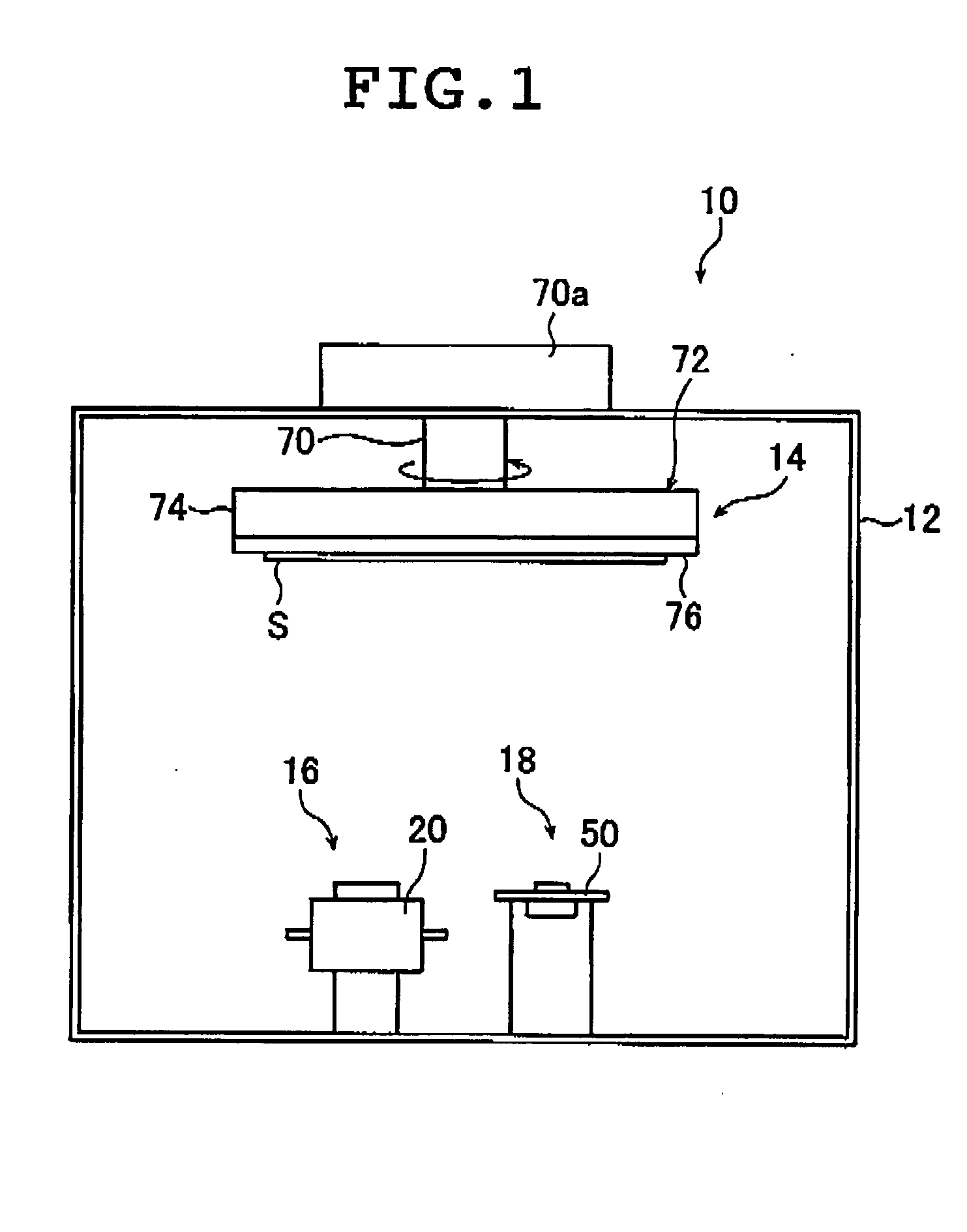

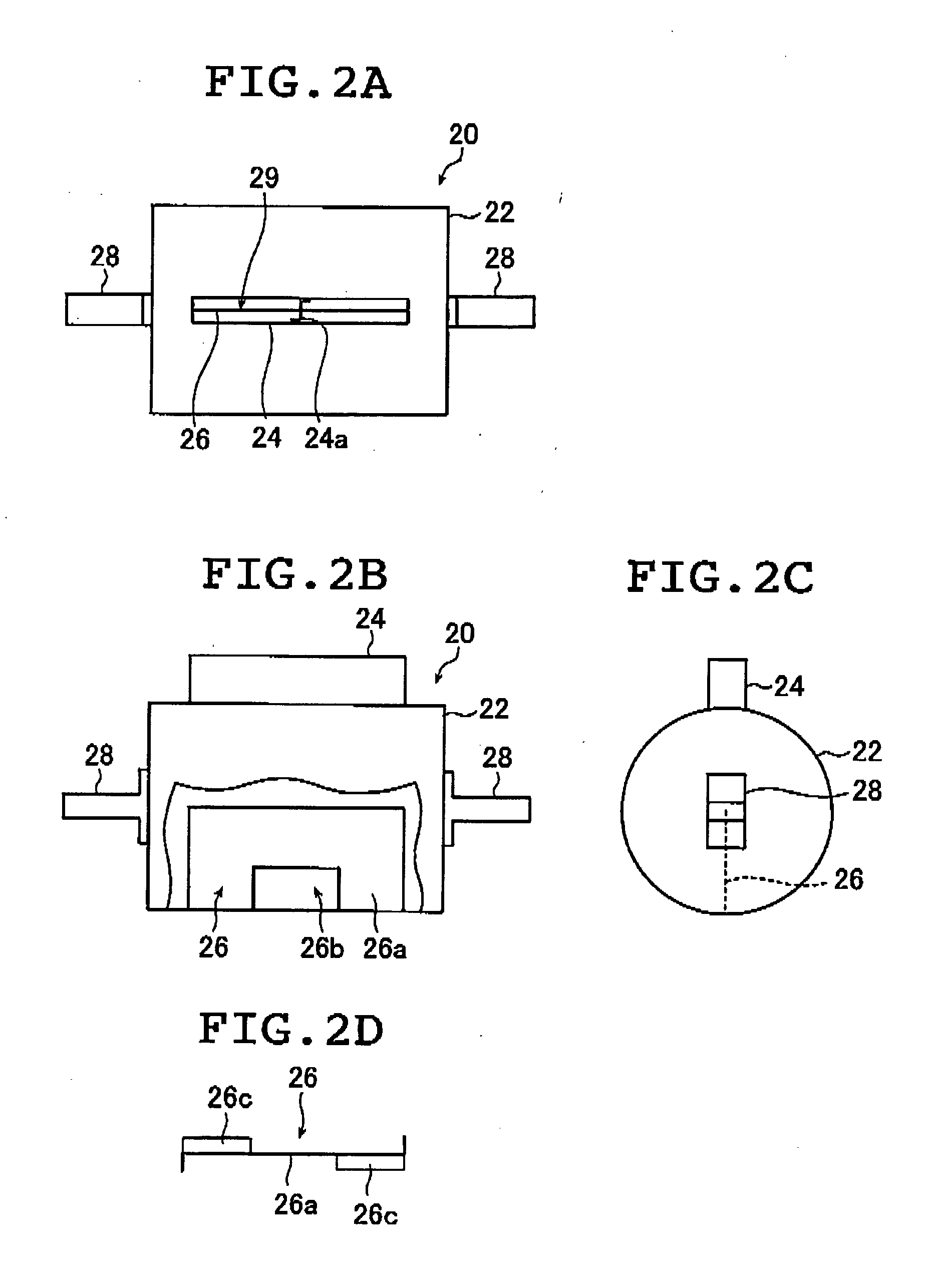

Surface treatment method and surface treatment device

InactiveUS20050269577A1Increase speedHigh evennessLaser detailsSemiconductor laser structural detailsUltraviolet lightsMetal particle

The present invention is conceived in order to accomplish an object of providing a surface treatment method and a surface treatment device that can planarize, at high speed, the surface of a nitride semiconductor with an excellent evenness. The surface treatment device includes an electrolyte supply port 15 for supplying a KOH electrolyte 14 containing fine metal particles and an abrasive, a storage container 40 having an opening on the top surface and is for storing the KOH electrolyte 14 supplied from the electrolyte supply port 15, a wafer holder 12 for fixing the GaN substrate 11 and bringing the surface of the GaN substrate 11 into contact with the KOH electrolyte 14 by impregnating the surface of the substrate into the KOH electrolyte 14 in the storage container 40 from above, a load 13 placed on the wafer holder 12, a device housing 16, a polishing pad 17 for polishing the surface of the GaN substrate 11 and an ultraviolet light source 42.

Owner:PANASONIC CORP

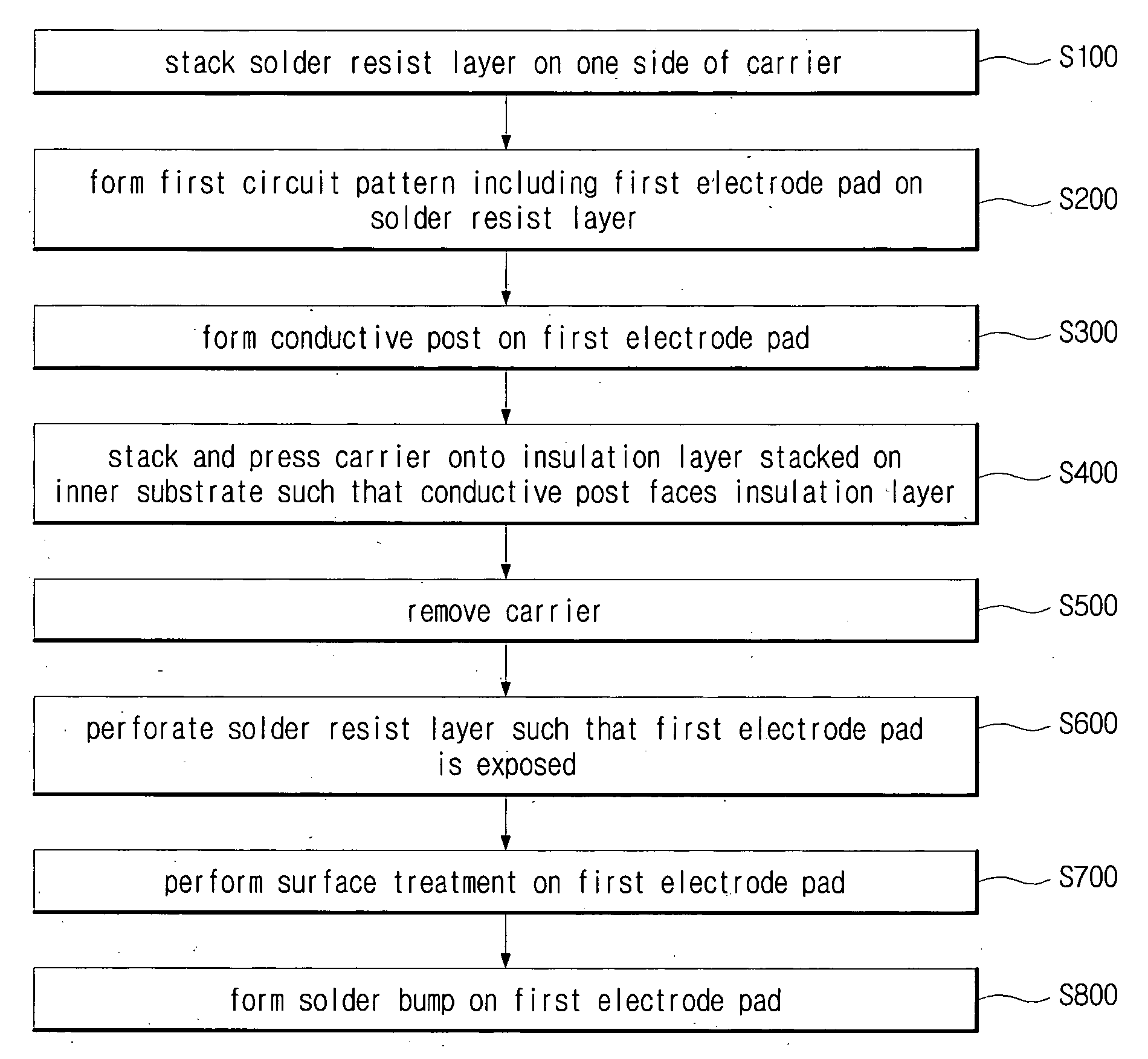

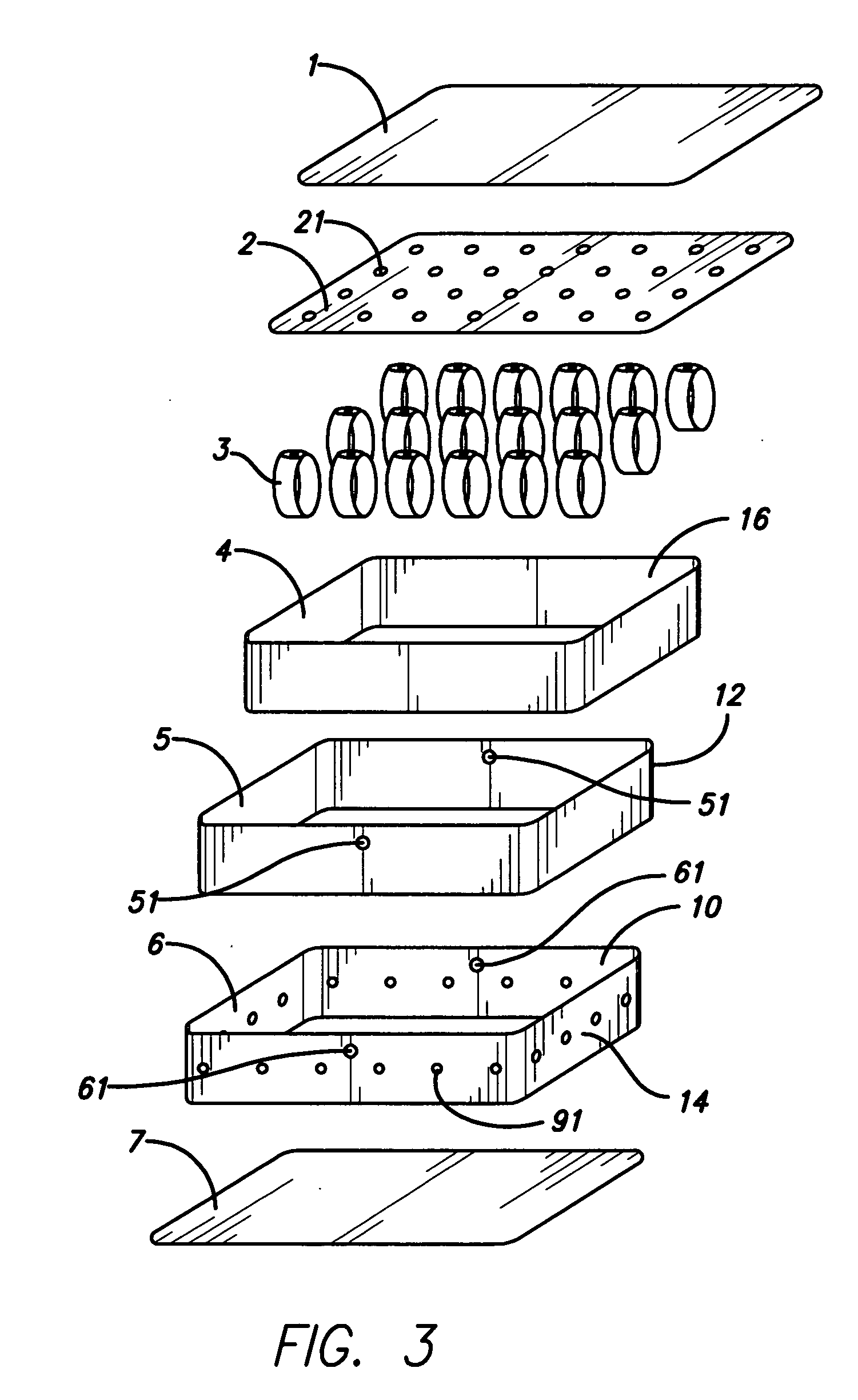

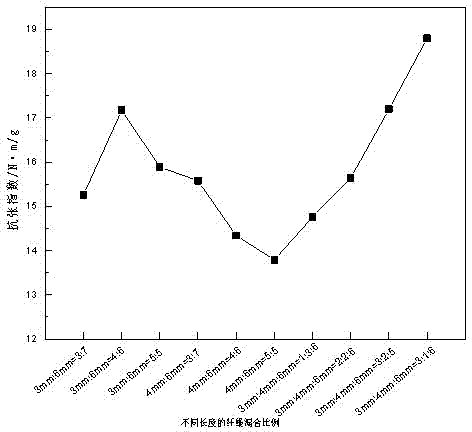

Printed circuit board and manufacturing method of the same

InactiveUS20090084595A1Increase freedomReduce thicknessPrinted circuit assemblingElectrically conductive connectionsResistInsulation layer

A method of manufacturing a printed circuit board includes stacking a solder resist layer on one side of a carrier; forming a first circuit pattern, which includes a first electrode pad, on the solder resist layer; forming a conductive post on the first electrode pad; stacking and pressing the carrier onto an insulation layer stacked in an inner substrate, such that the conductive post faces the insulation layer; and removing the carrier. As the conductive posts are pressed into the insulation layers to implement interlayer connections, certain drilling processes for forming via holes may be omitted, so that the degree of freedom can be increased in designing the circuits, and the circuits can be made to have greater densities. As the circuit patterns are buried in the insulation layers, the board can be made thinner, and the attachment areas can be increased, to allow greater adhesion.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

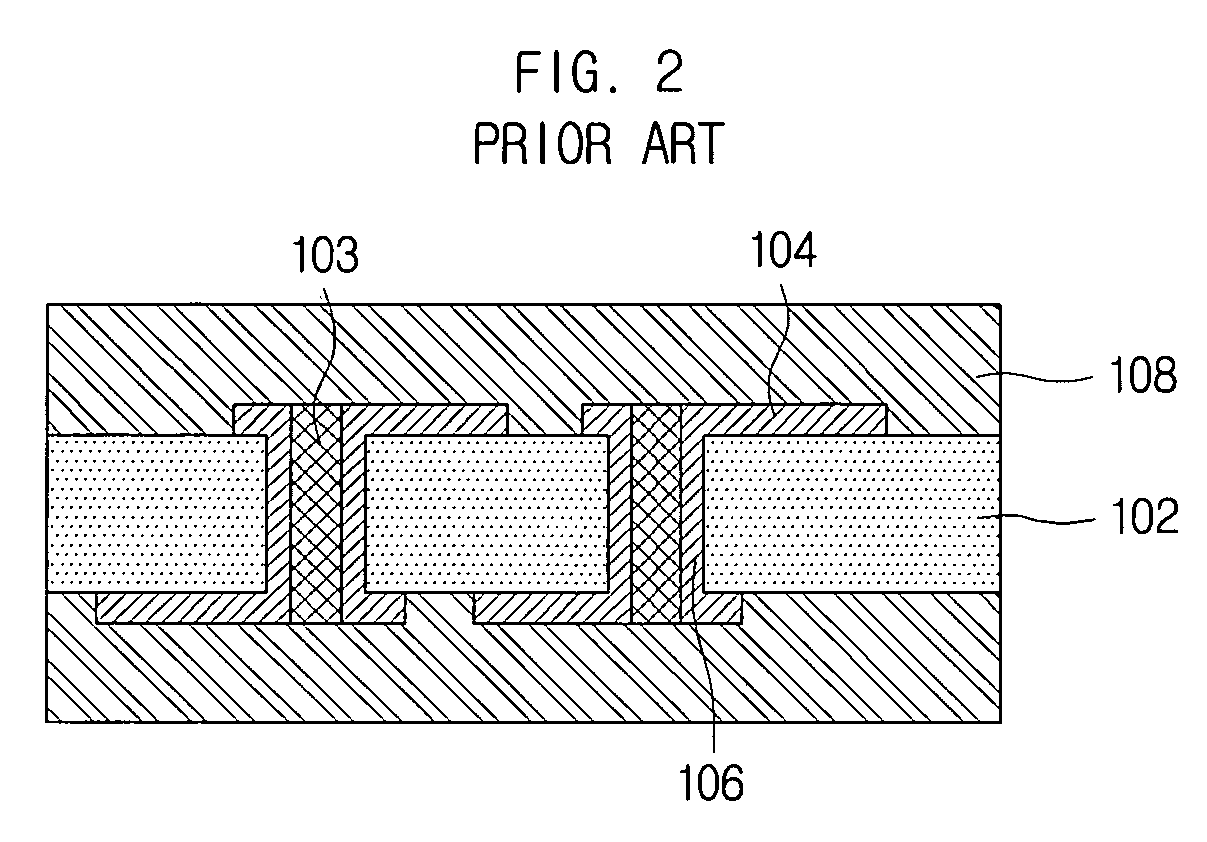

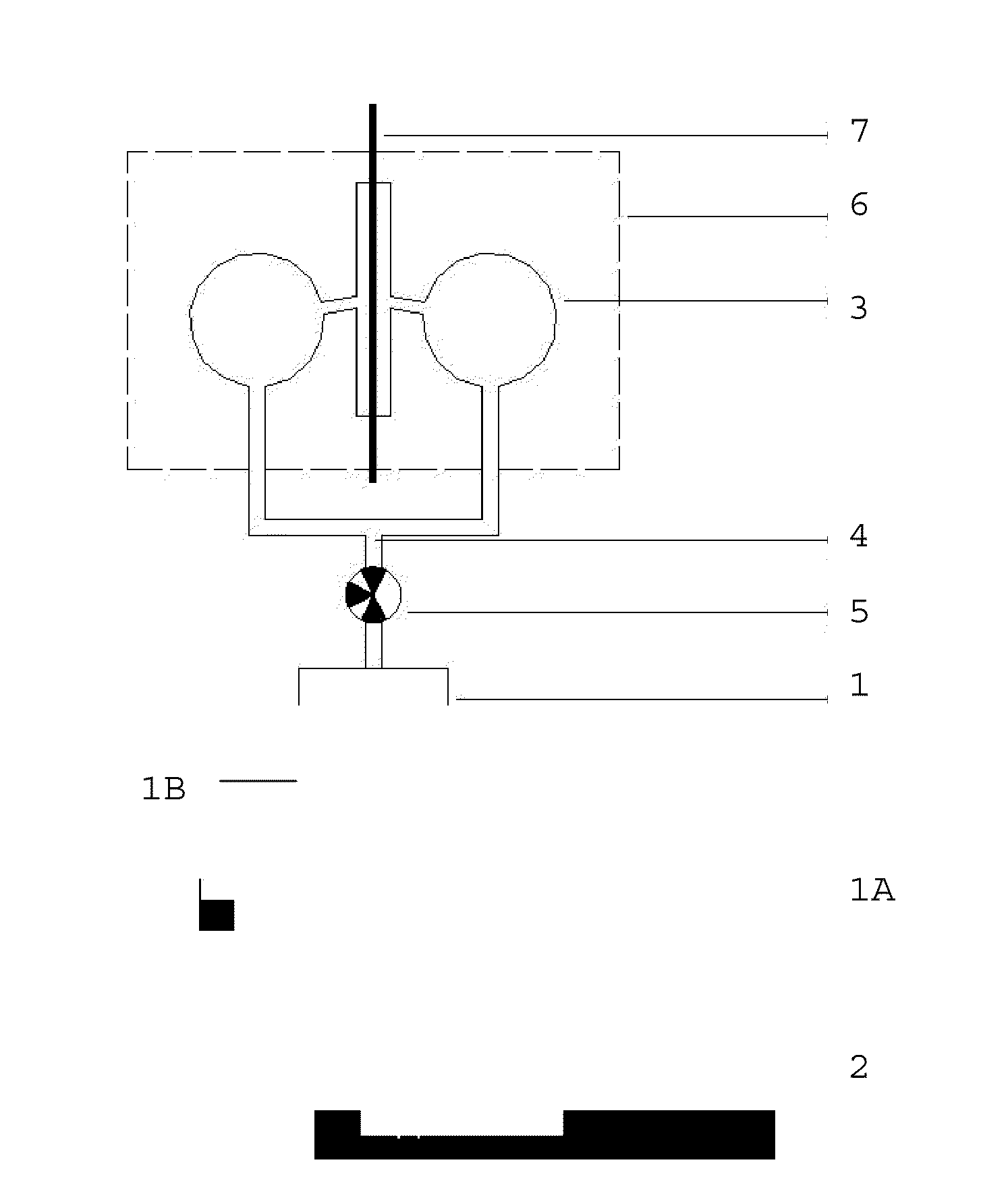

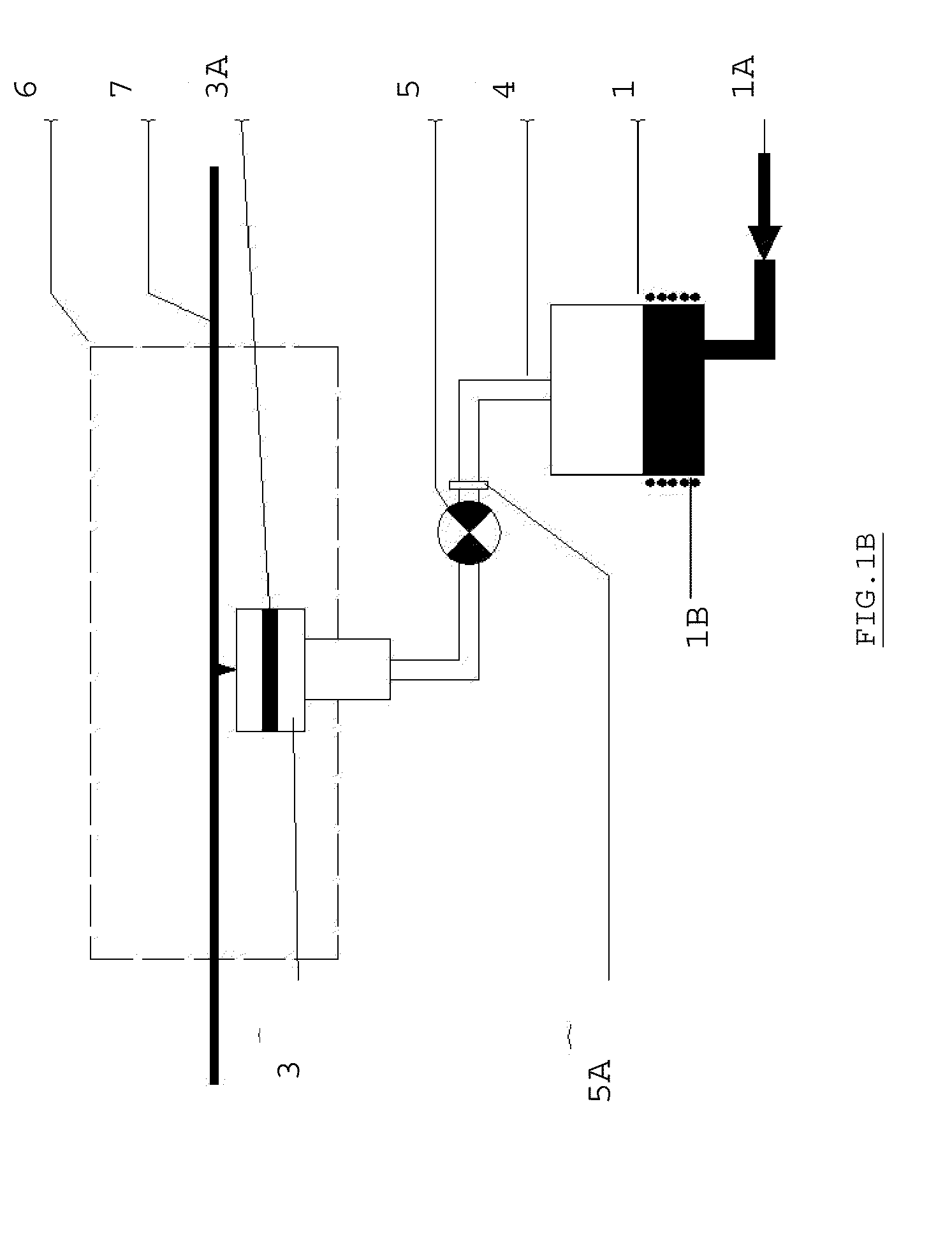

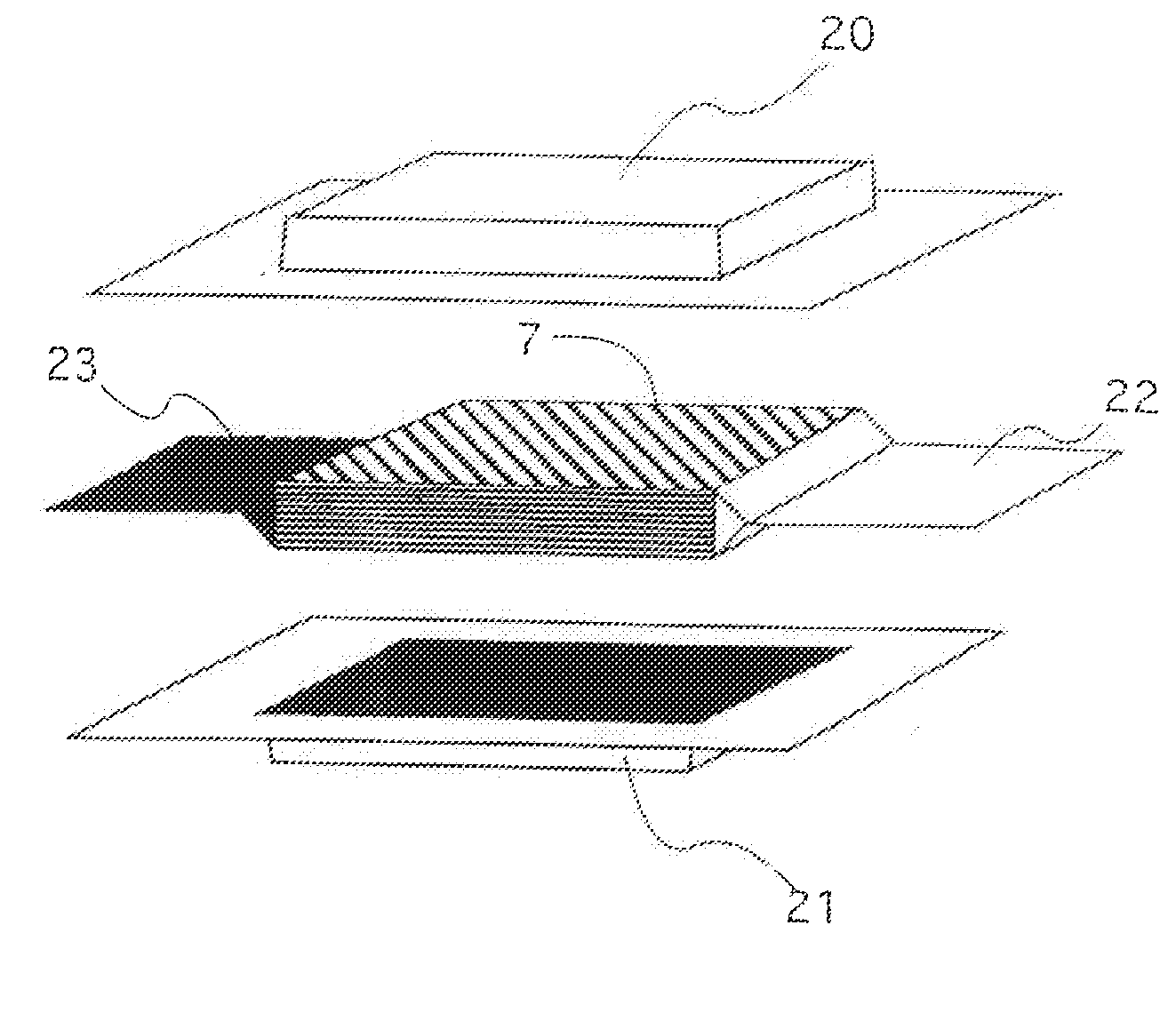

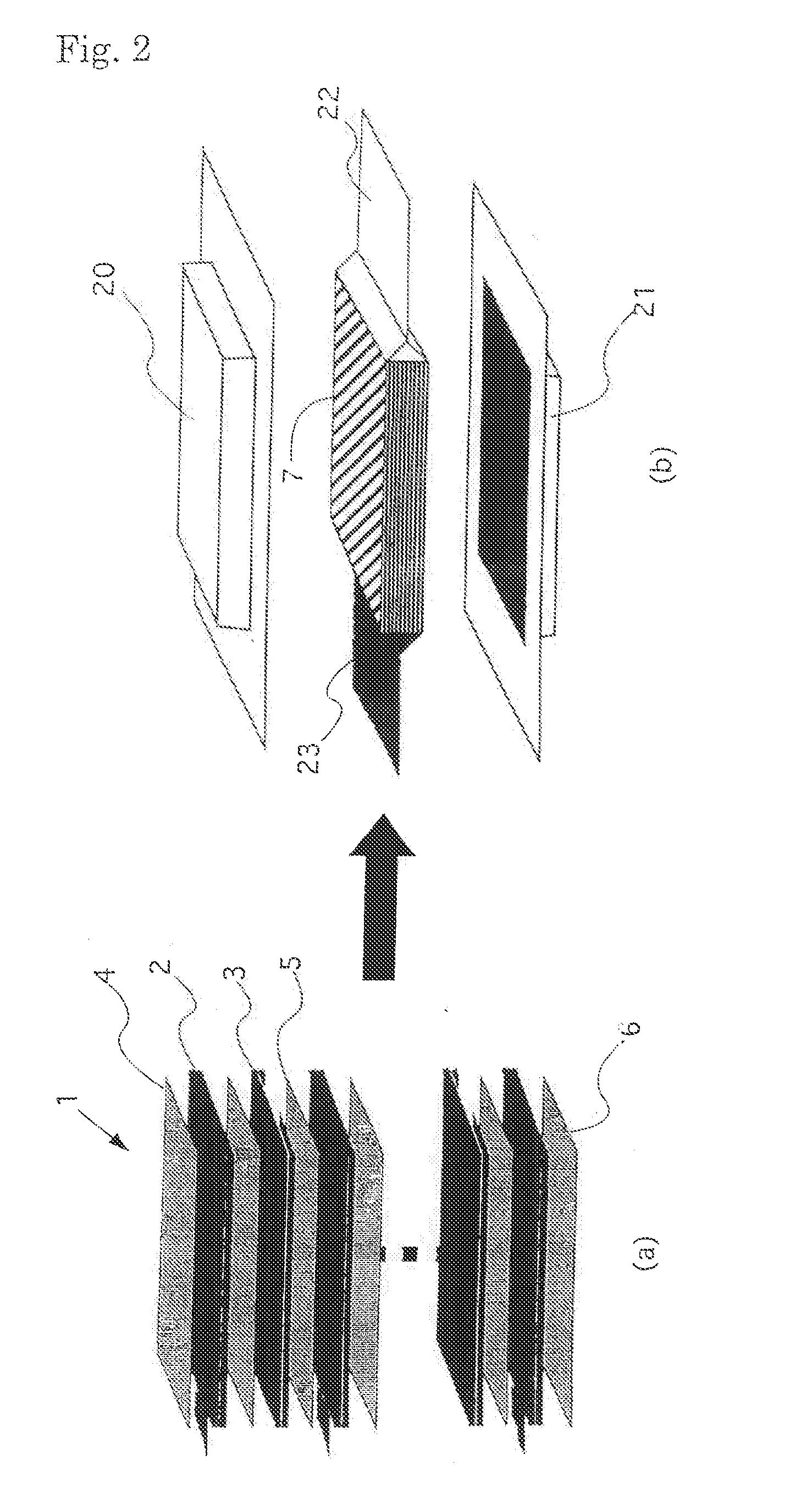

Industrial vapour generator for the deposition of an alloy coating onto a metal strip

ActiveUS20110000431A1Improve evennessEasy to superviseLiquid surface applicatorsVacuum evaporation coatingMetal stripsMetal coating

The invention relates to a vapour generator for the deposition of a metal coating onto a substrate (7), preferably a steel strip, that comprises a vacuum chamber (6) in the form of a housing including a vapour deposition head or ejector (3) in tight communication via a supply duct (4) with at least one crucible (1) containing the coating metal in a liquid form and located outside the vacuum chamber (6), characterised in that the ejector (3) includes a longitudinal slot for the vapour outlet acting as a sonic throat and extending on the entire width of the substrate (7), a filtration medium or a charge loss member (3A) made of a sintered material being provided in the ejector immediately before said slot on the vapour path in order to equalise the flow speed of the vapour exiting the ejector (3) through the sonic throat.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

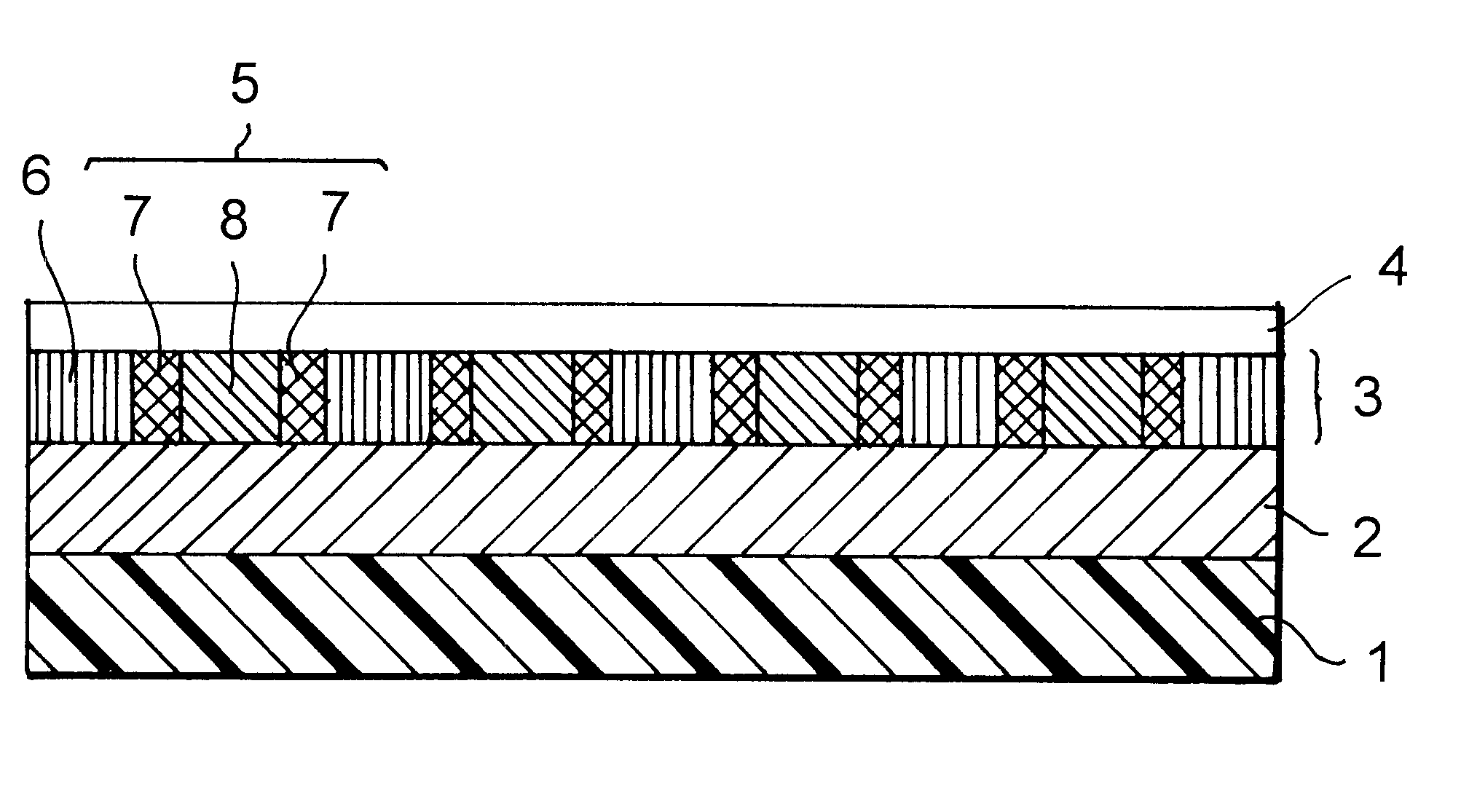

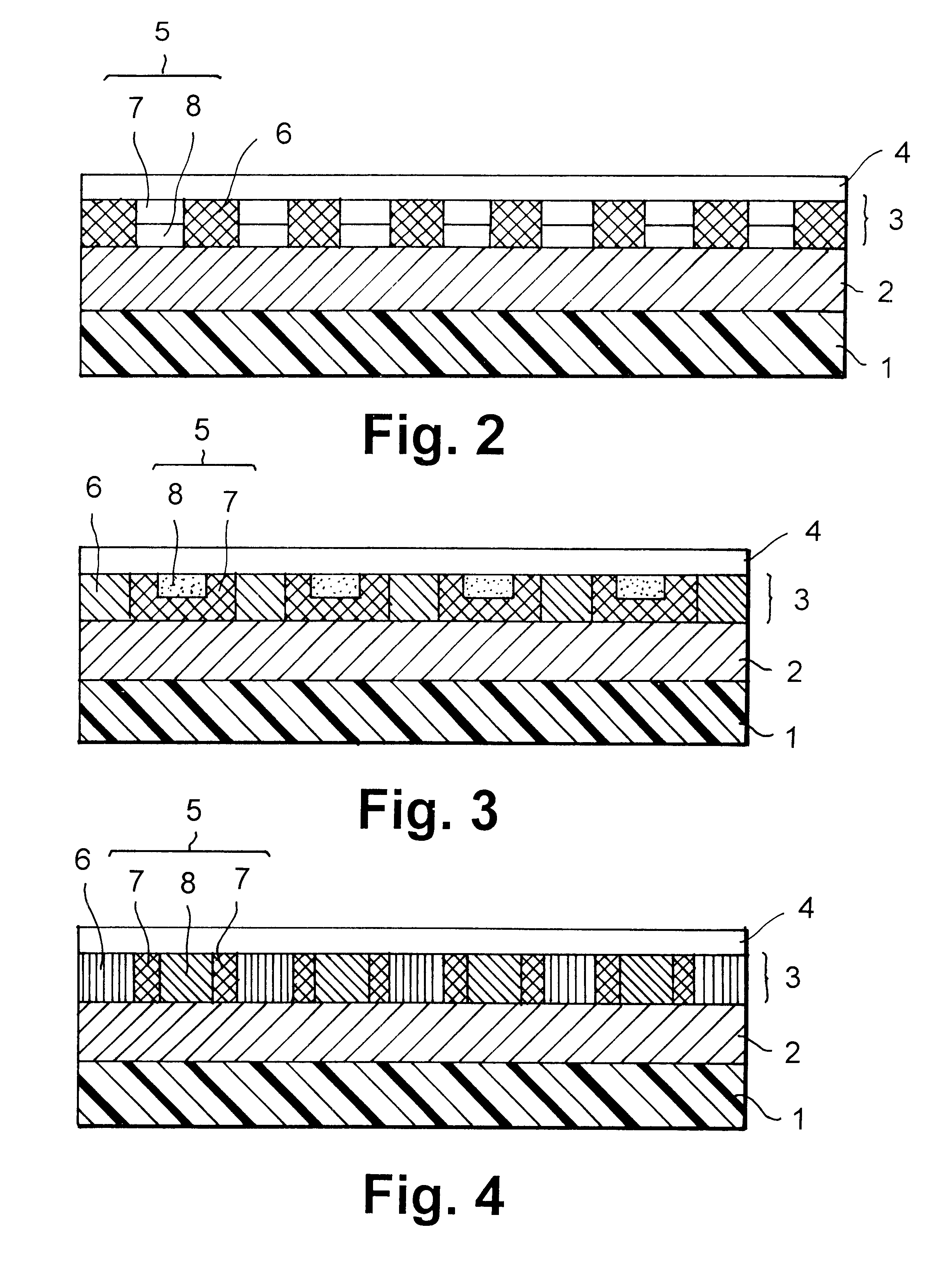

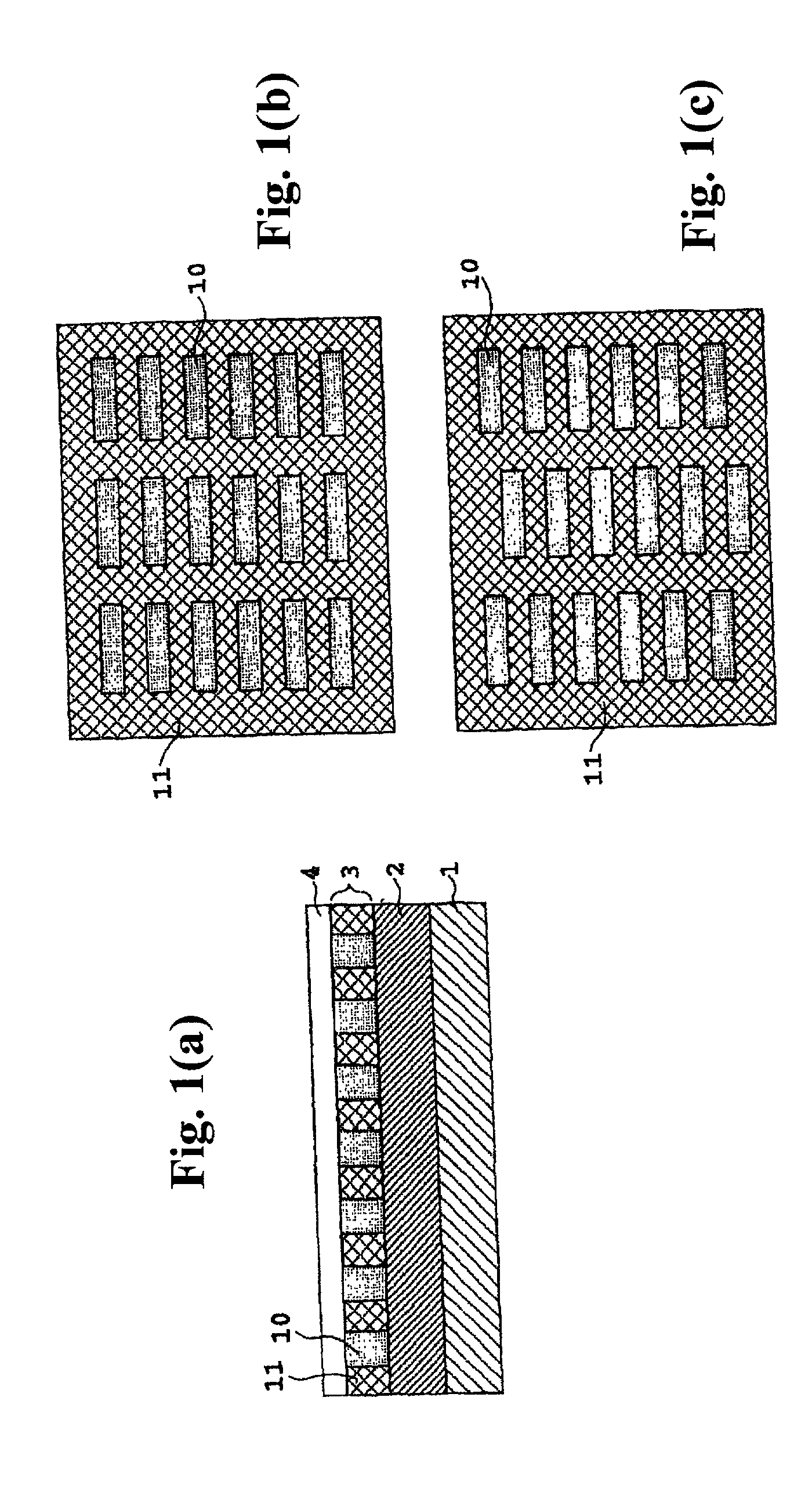

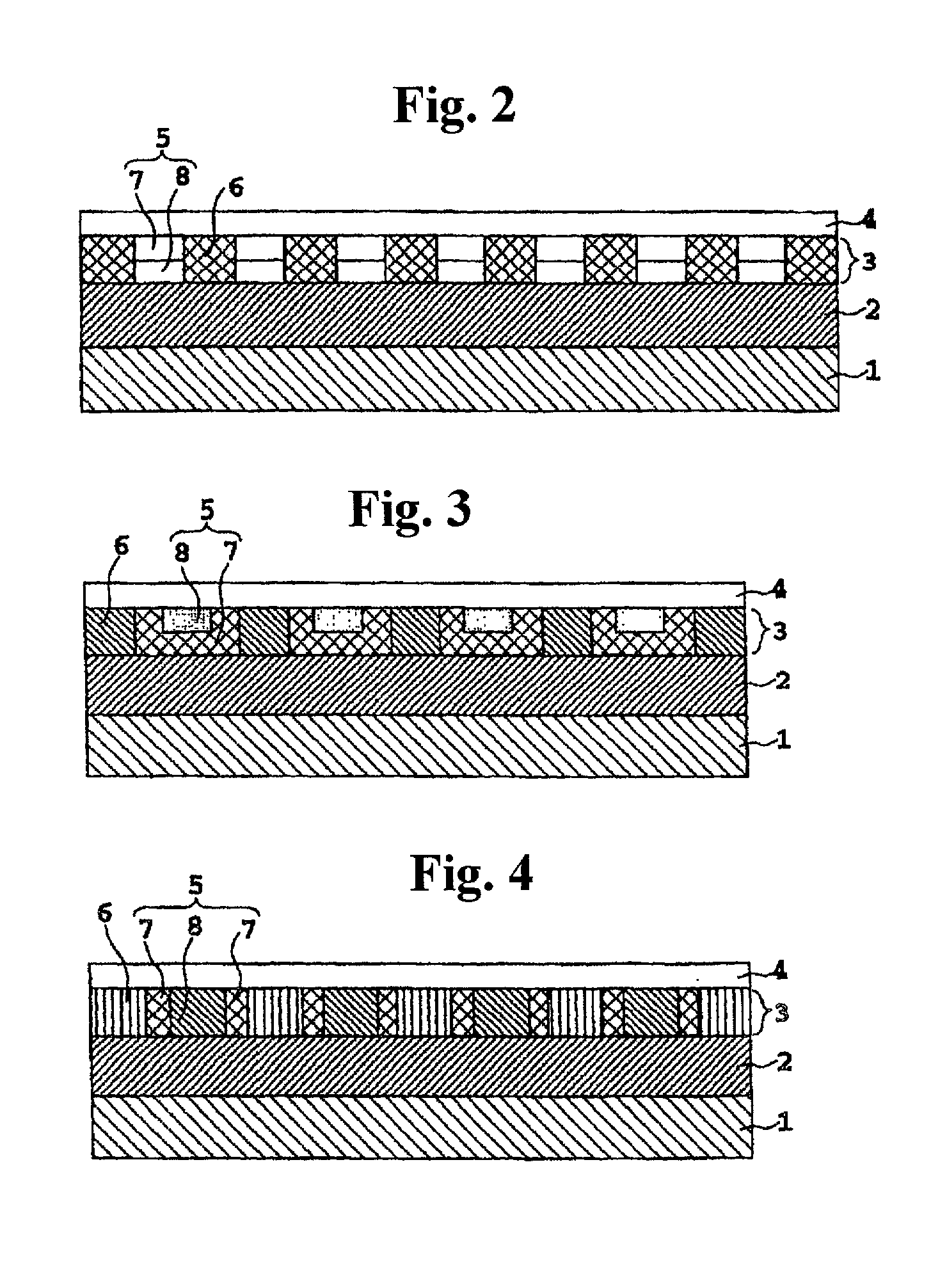

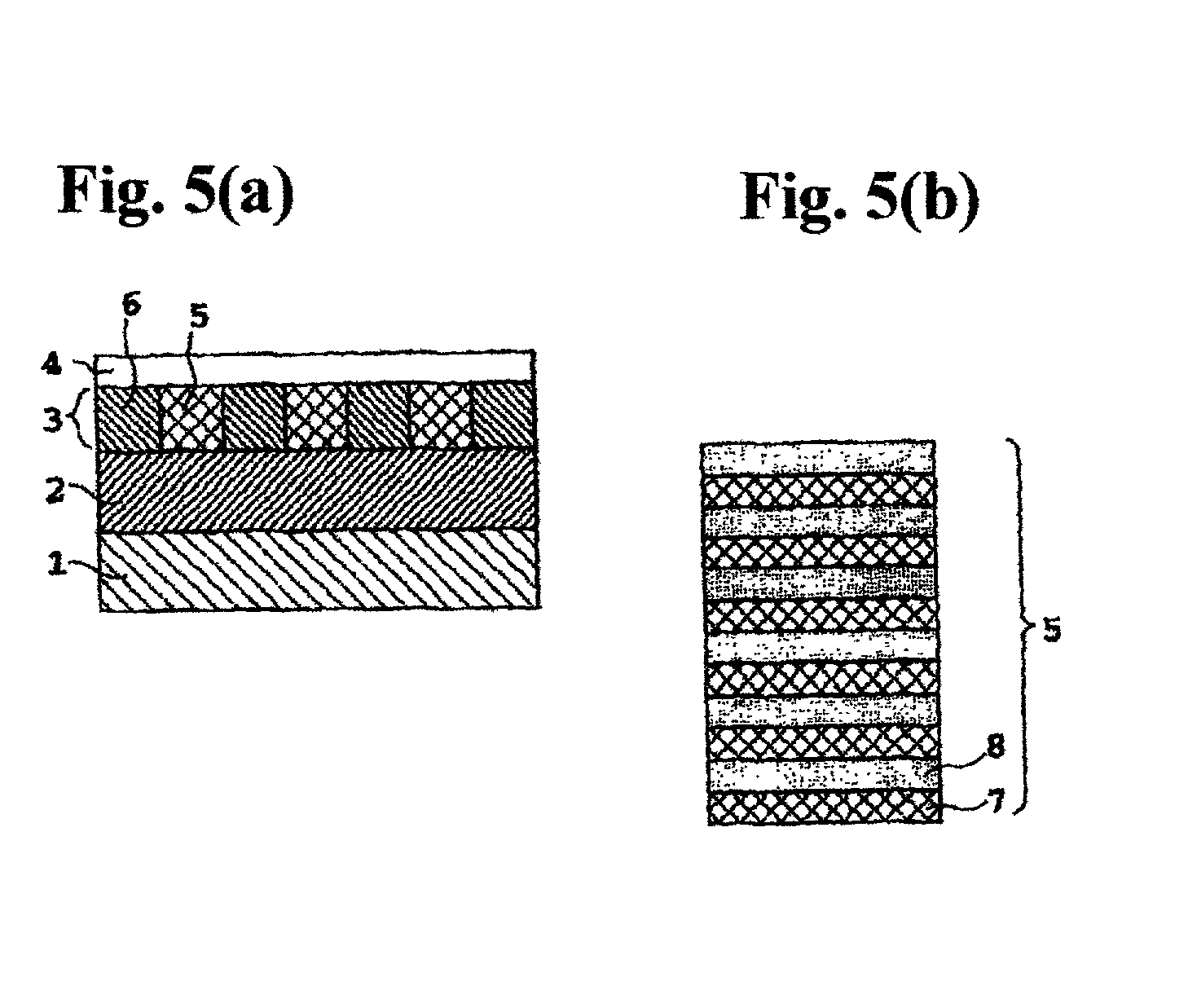

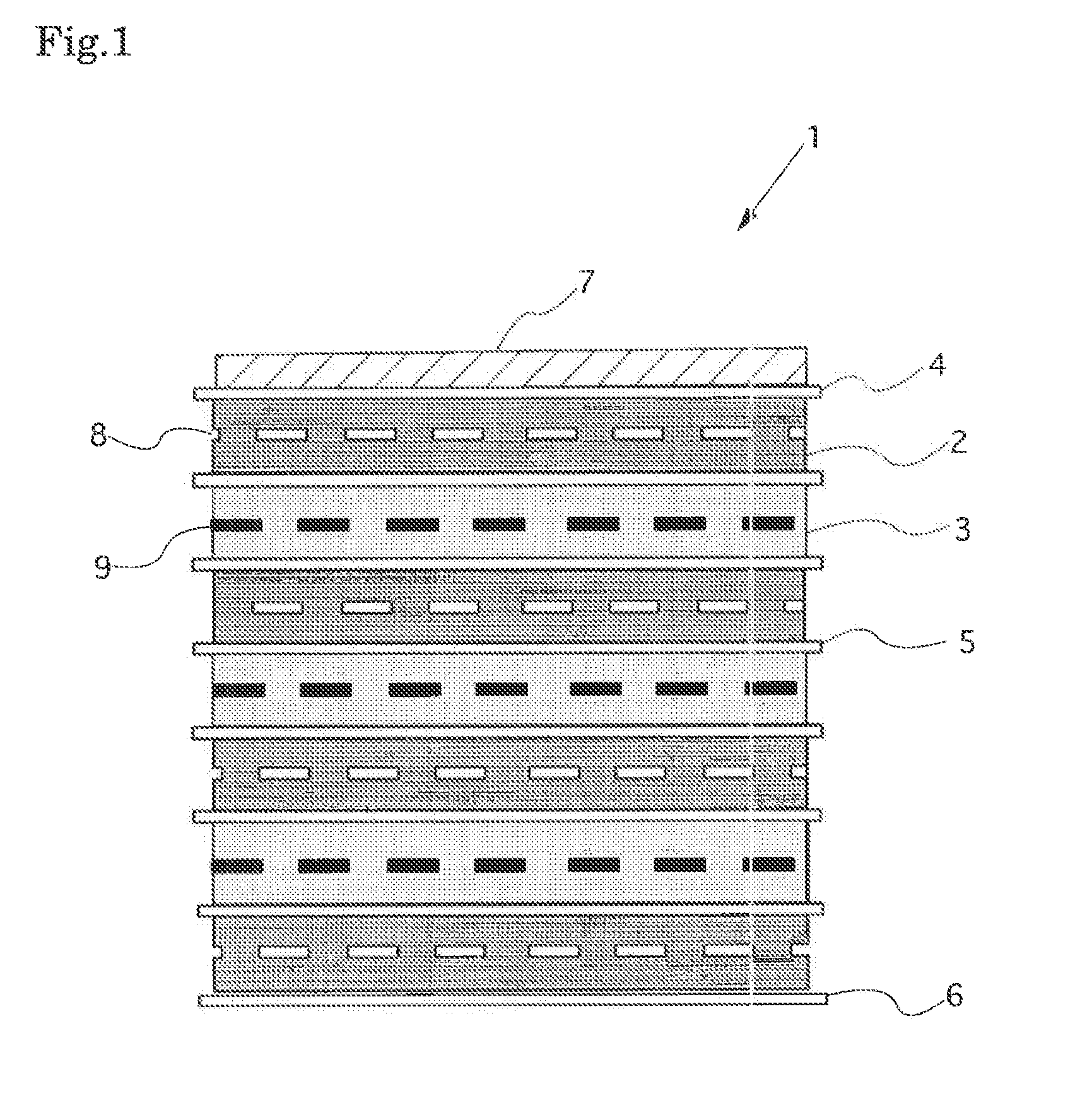

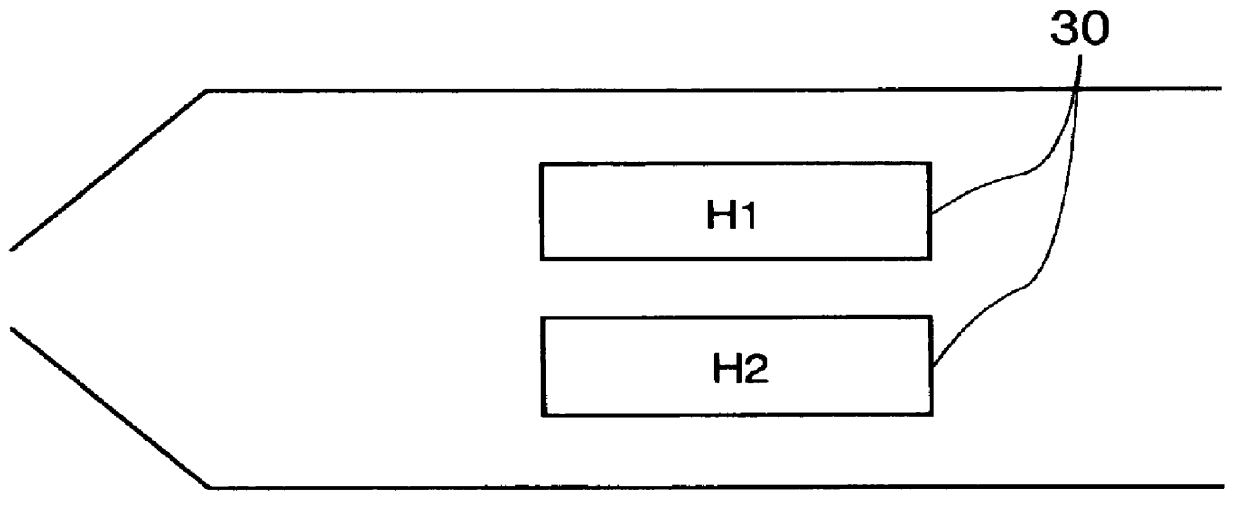

Magnetic recording medium

InactiveUS6579634B2Improve coercive forceImprove thermal stabilityMagnetic materials for record carriersLayered productsNon magneticMagnetic layer

A magnetic recording medium has a non-magnetic substrate, an under layer, a magnetic layer, and a protective layer in the recited order. The magnetic layer consists of a plurality of magnetic components embedded in a pattern in an isolating component. Each magnetic component includes at least one magnetic component of large coercive force and one of a magnetic component of small coercive force. The two components abut each other. In one embodiment the two components form one or more alternating layers. In another embodiment, one of the components has a recess in its upper surface which is filled with the other component. In still another embodiment, the two components are disposed side by side passing through the isolating component.

Owner:FUJI ELECTRIC CO LTD

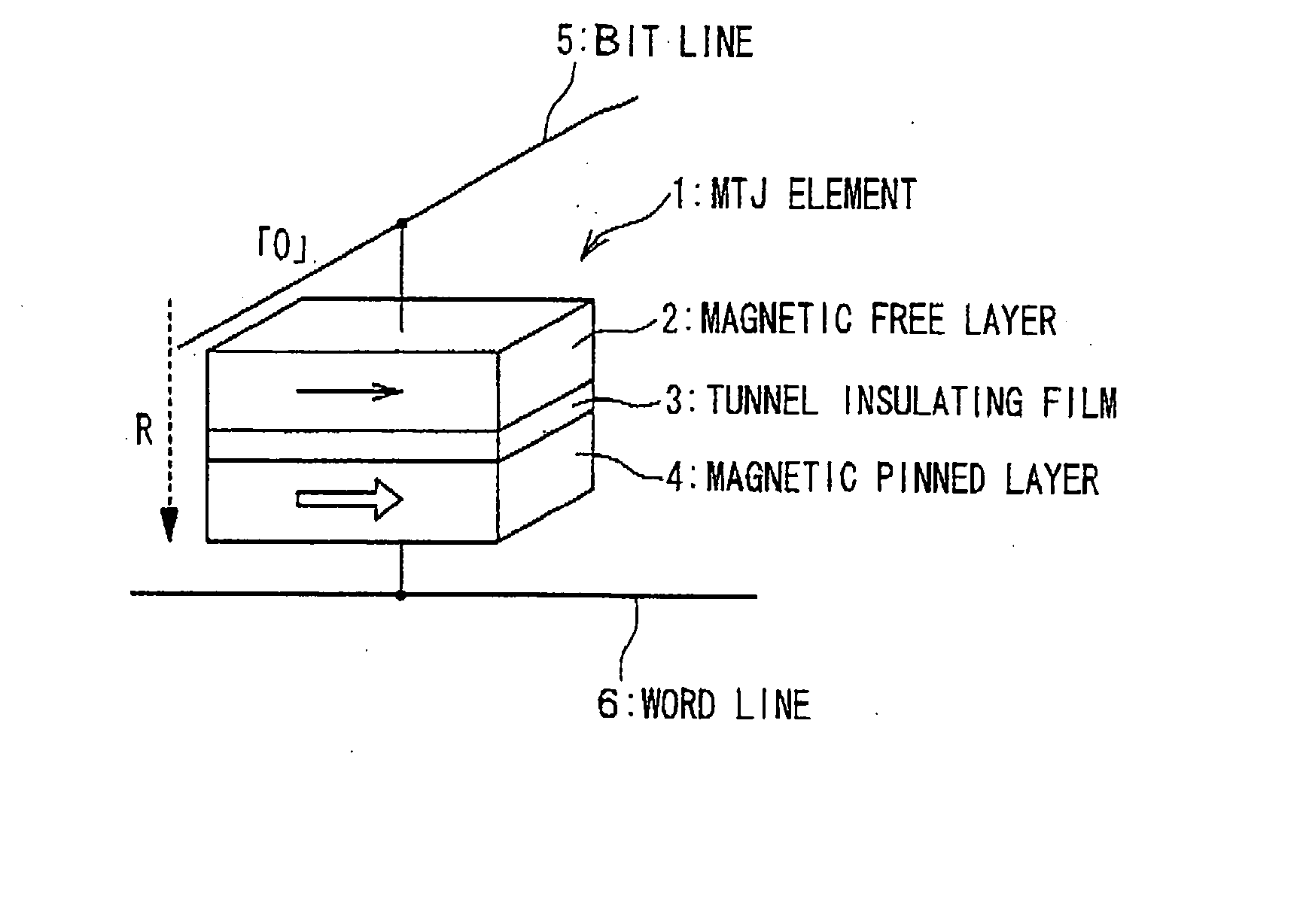

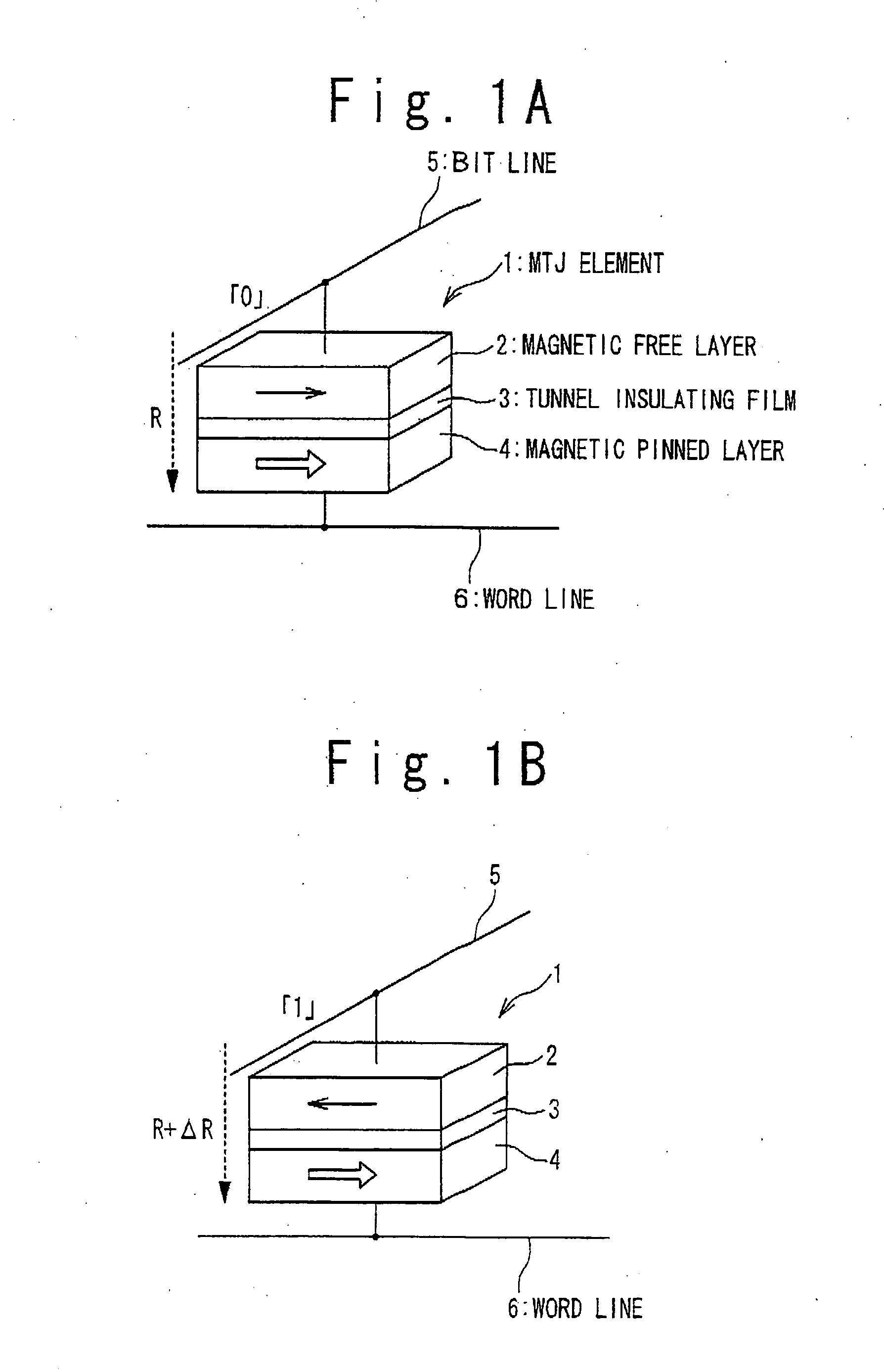

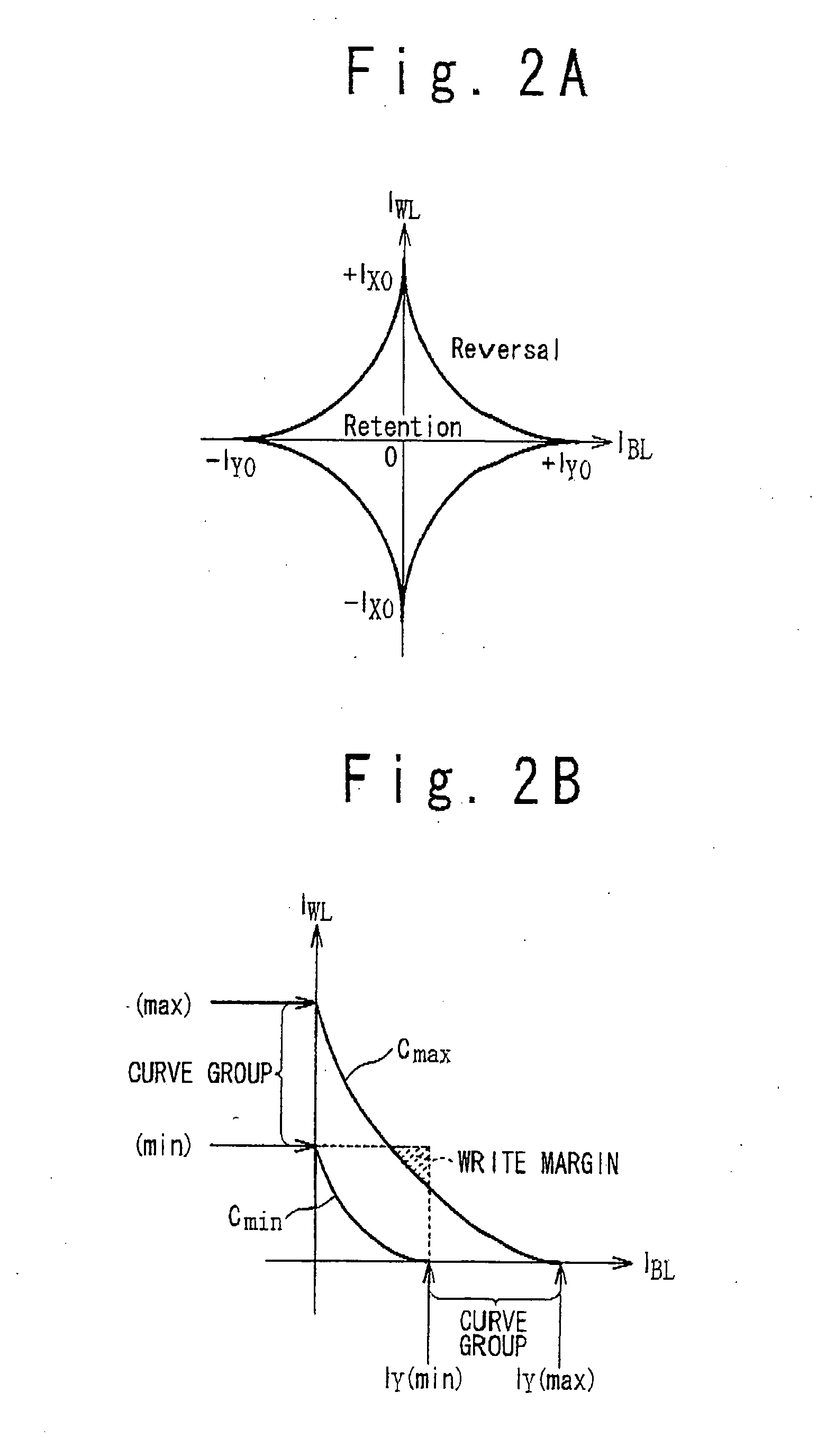

Ferromagnetic Film, Magneto-Resistance Element And Magnetic Random Access Memory

InactiveUS20080008908A1Reduce variationImprove operating profitNanomagnetismSynthetic resin layered productsElectrical resistance and conductanceRandom access memory

A ferromagnetic film according to the present invention includes ferromagnetic element and nonmagnetic element and has a first portion and a second portion. Concentration of the nonmagnetic element in the first portion is lower than an average concentration of the nonmagnetic element in the ferromagnetic film. On the other hand, concentration of the nonmagnetic element in the second portion is higher than the average concentration of the nonmagnetic element in the ferromagnetic film. The nonmagnetic element includes at least one element selected from the group consisting of Zr, Ti, Nb, Ta, Hf, Mo and W. The ferromagnetic film is applied to a magnetic free layer of a magneto-resistance element in an MRAM.

Owner:NEC CORP +1

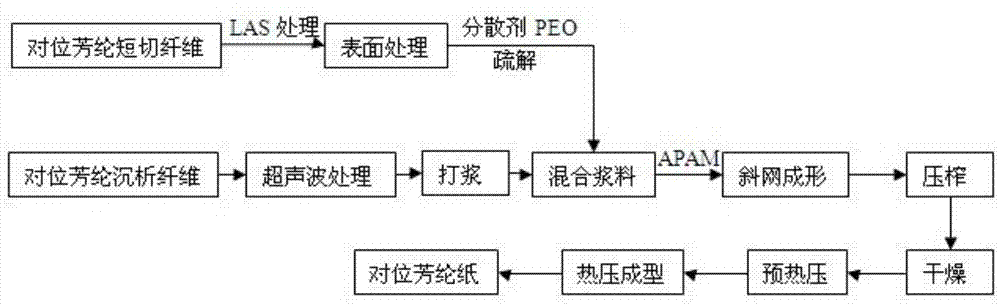

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

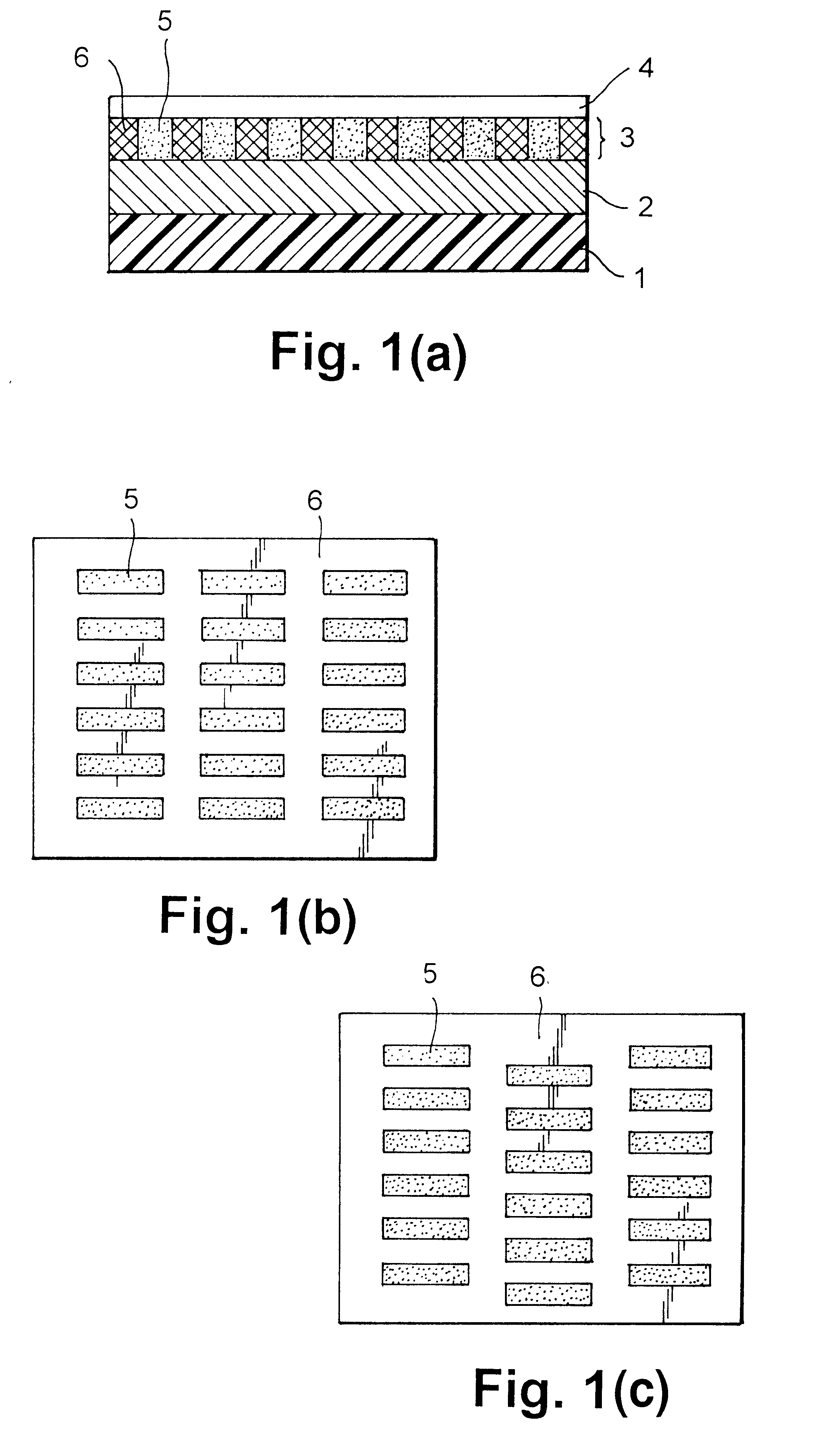

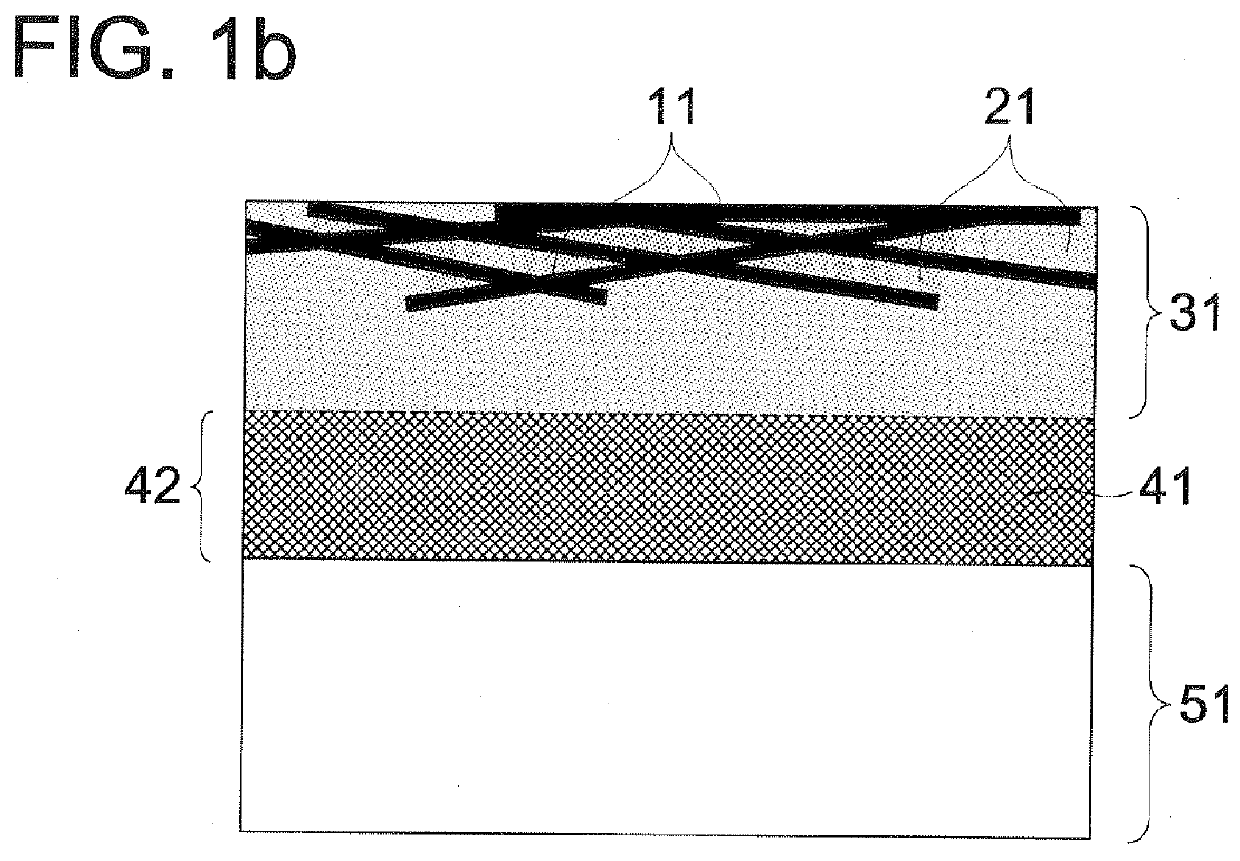

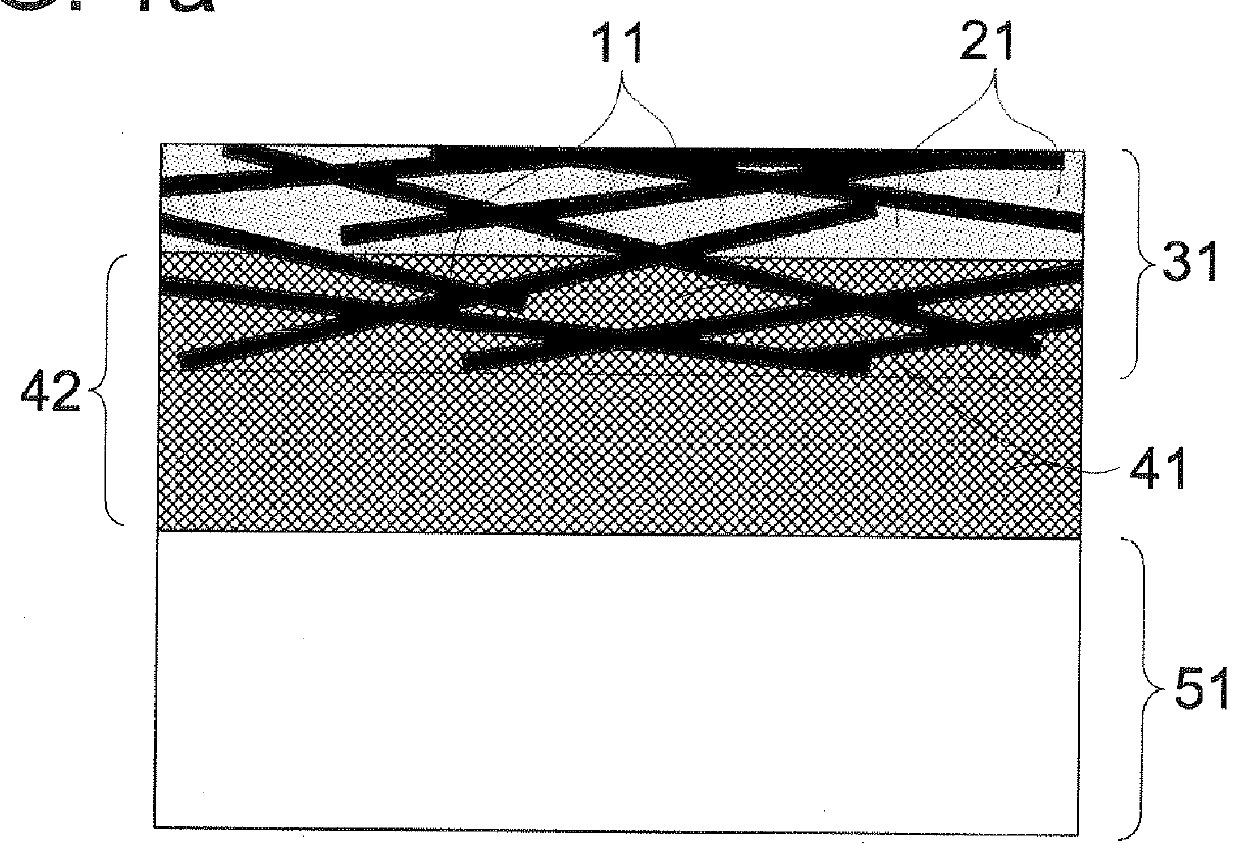

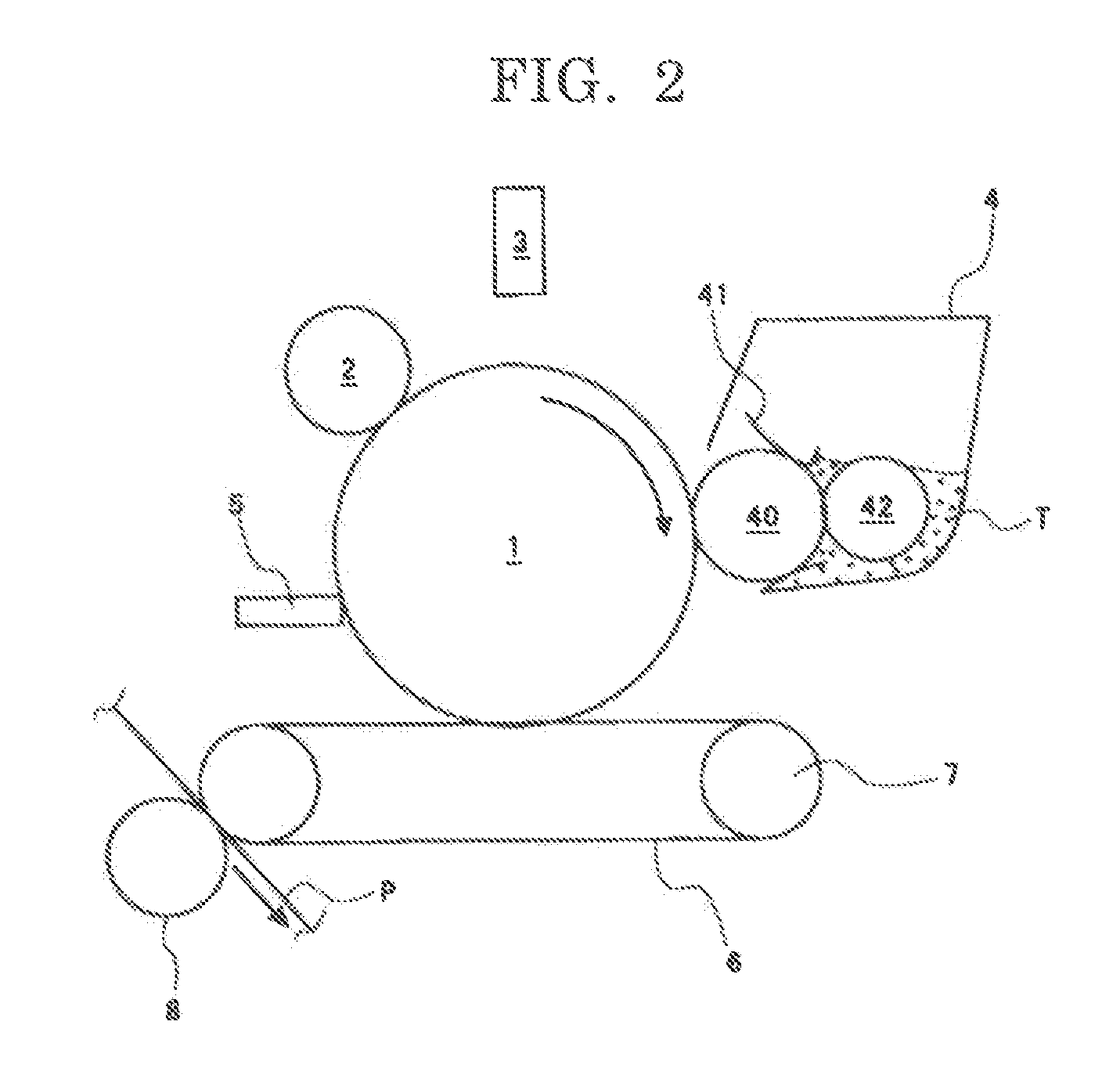

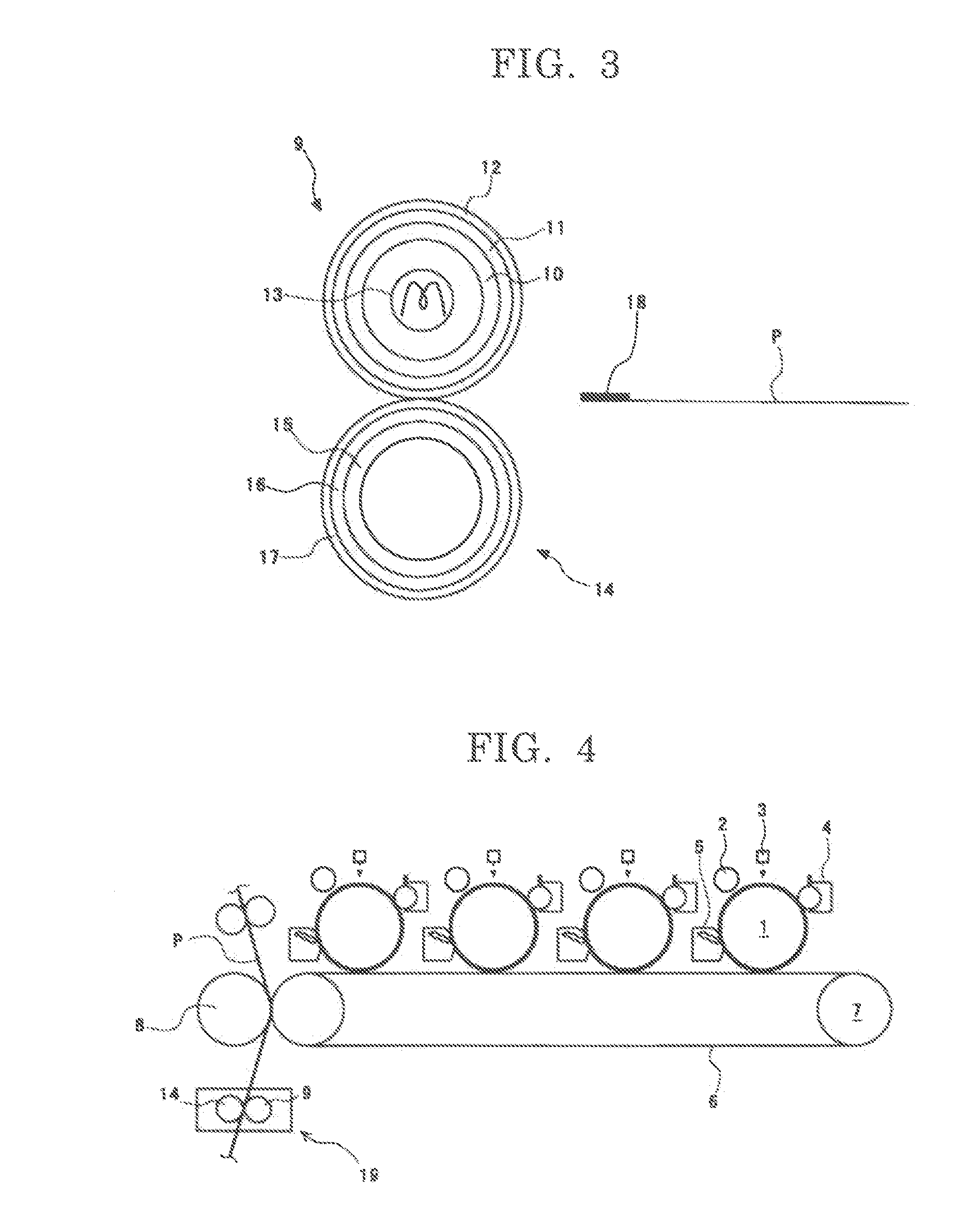

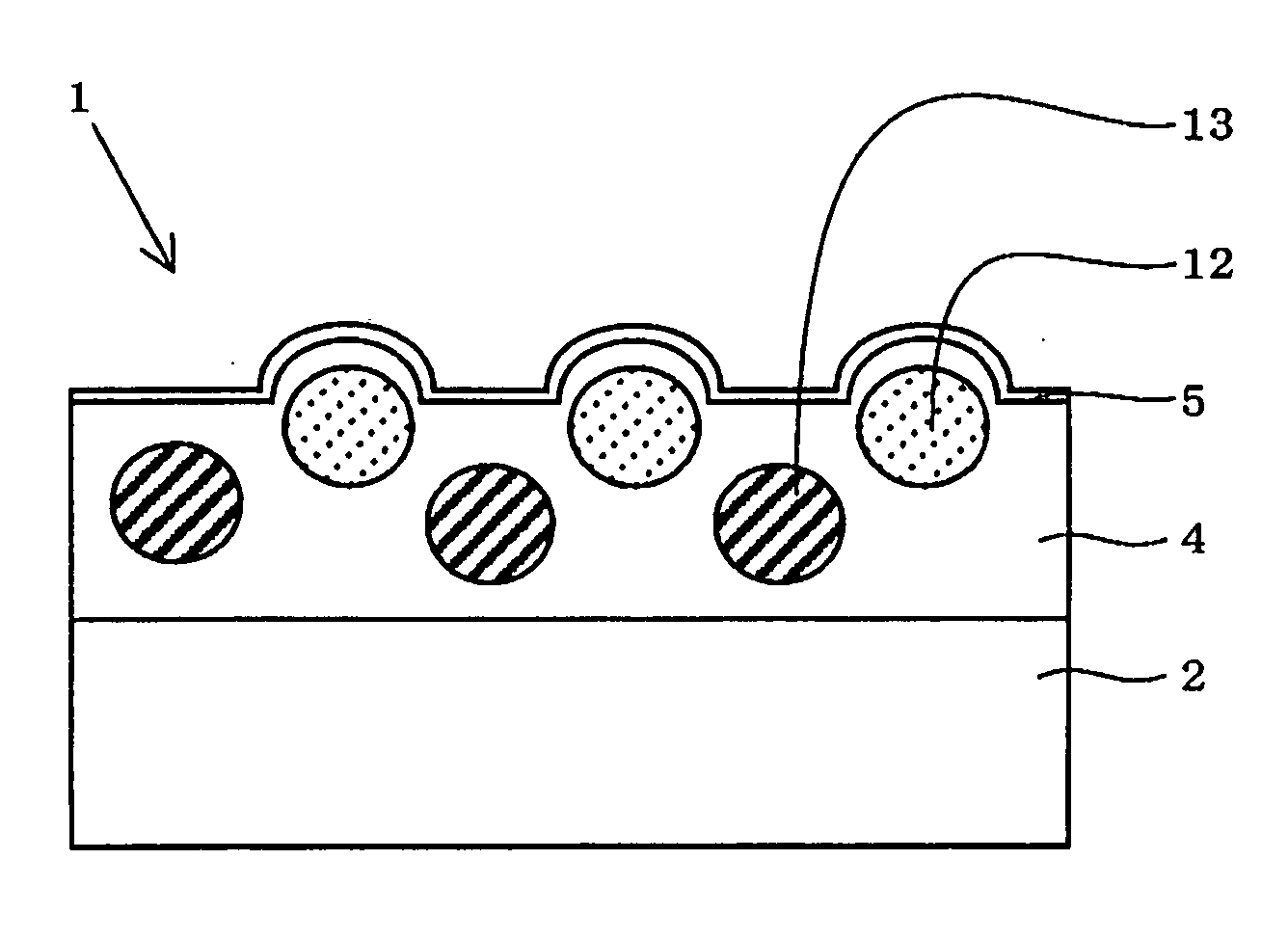

Transparent electrode and production method of same

ActiveUS8198796B2Improve surface smoothnessExcellent in lightweight and flexibilityFinal product manufactureSolid-state devicesFiberOptical transparency

Disclosed are: a transparent electrode with excellent optical transparency, electrical conductivity, and surface smoothness and is capable of providing lightness in weight and flexibility, comprising a transparent conductive layer on a transparent substrate, wherein the transparent conductive layer contains a conductive fiber and a transparent conductive material, the surface of the transparent conductive layer is composed of the conductive fiber and the transparent conductive material, and the smoothness (Ry) of the surface of the transparent conductive layer is greater than or equal to 1 nm and less than or equal to 50 nm; and a production method of same, and the present invention may provide a light emitting element with excellent uniformity of light emission.

Owner:RESONAC CORPORATION

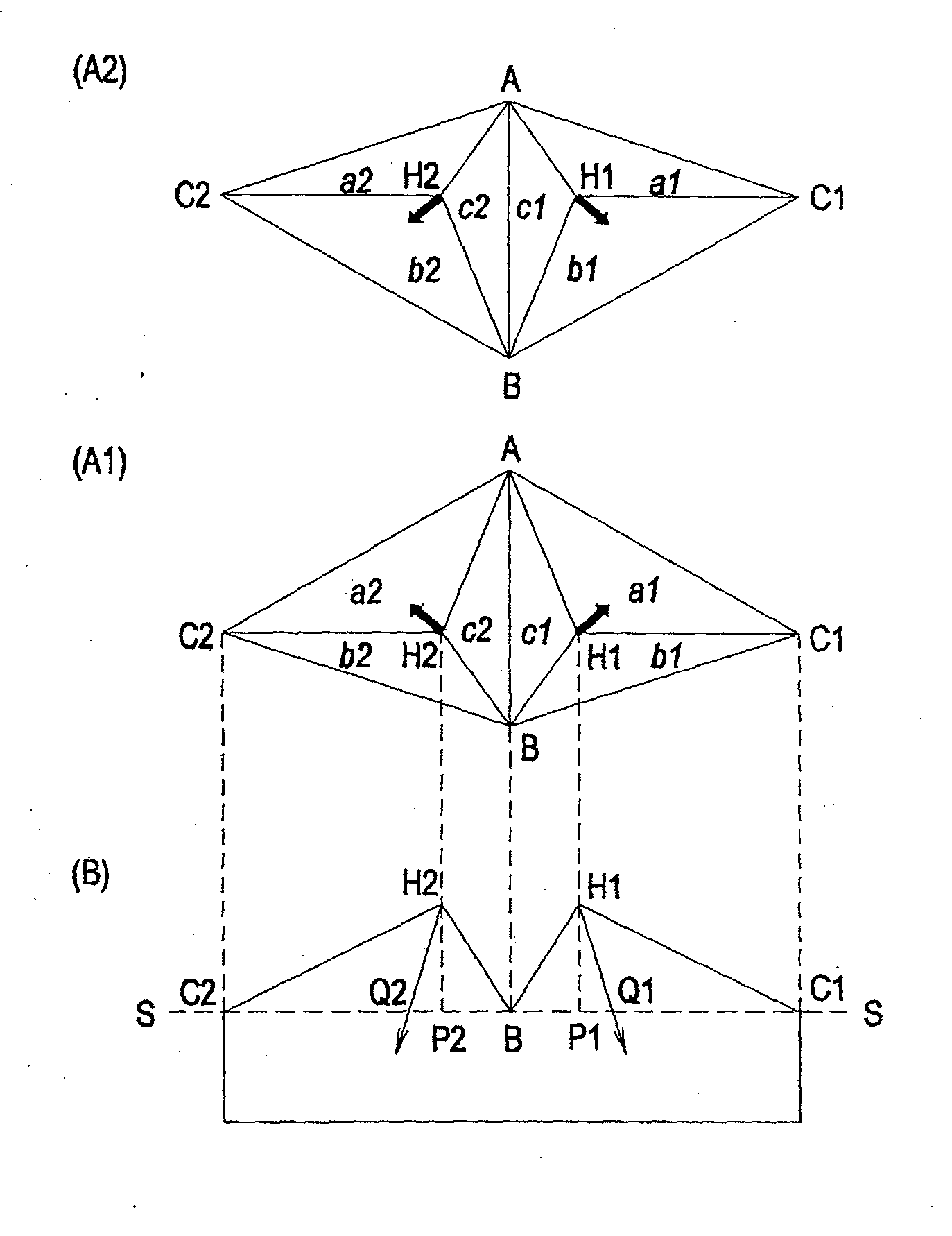

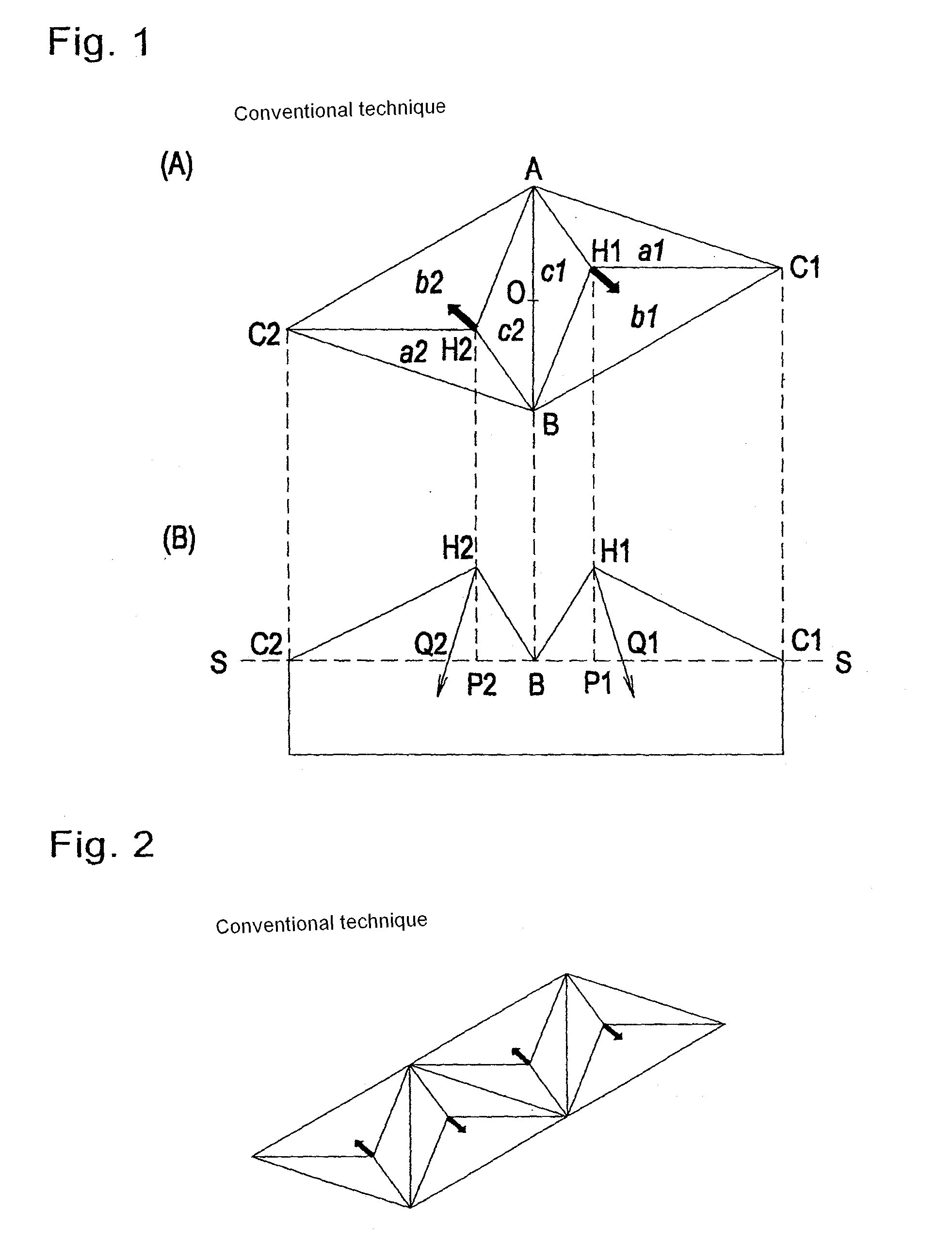

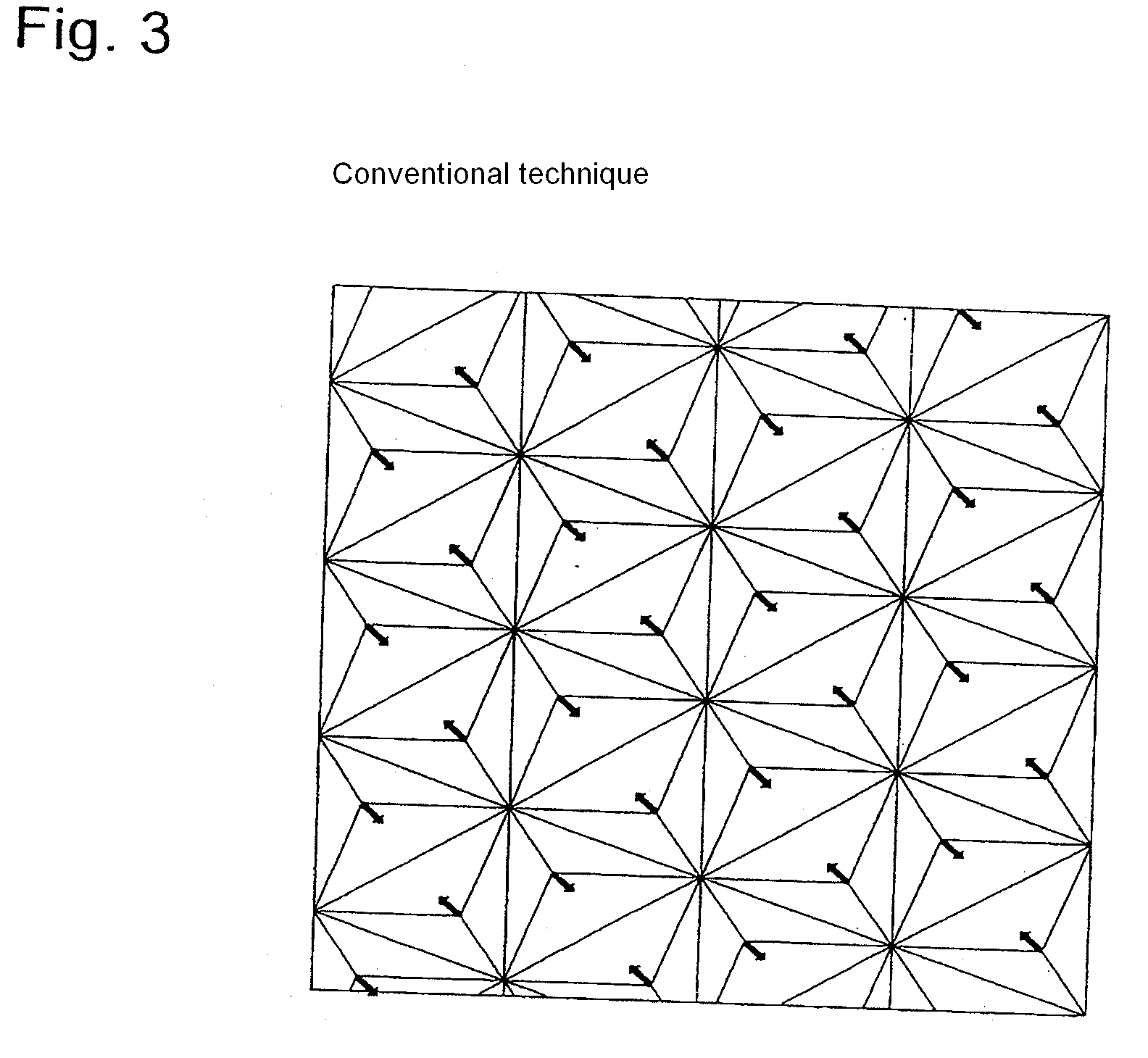

Triangular pyramid type cube corner retroreflection article, and its manufacturing method

ActiveUS20110013281A1Improve angularity angularity angularityGood for observationLamination ancillary operationsLaminationEngineeringMechanical engineering

The present invention relates to a triangular pyramidal cube corner retroreflective article and a producing method thereof. In the triangular pyramidal cube corner retroreflective article, a triangular pyramidal cube corner retroreflective element pair group is disposed in a closest-packed fashion on a common plane defined by three base lines, and the each of retroreflective elements in a pair having one base line (A-B) shared by the retroreflective elements in the pair. The triangular pyramidal cube corner retroreflective article includes a first element pair group, in which two interior angles (α=∠BAC and β=∠ABC) formed by the shared base line of the element pair and two other base lines are different from each other and the element pair is line-symmetrically disposed in relation to the shared base line (A-B); and a second element pair group, in which the element pair is congruent to a line-symmetrical shape to the first element pair in relation to a line segment connecting vertexes of the base planes.

Owner:NIPPON CARBIDE KOGYO KK

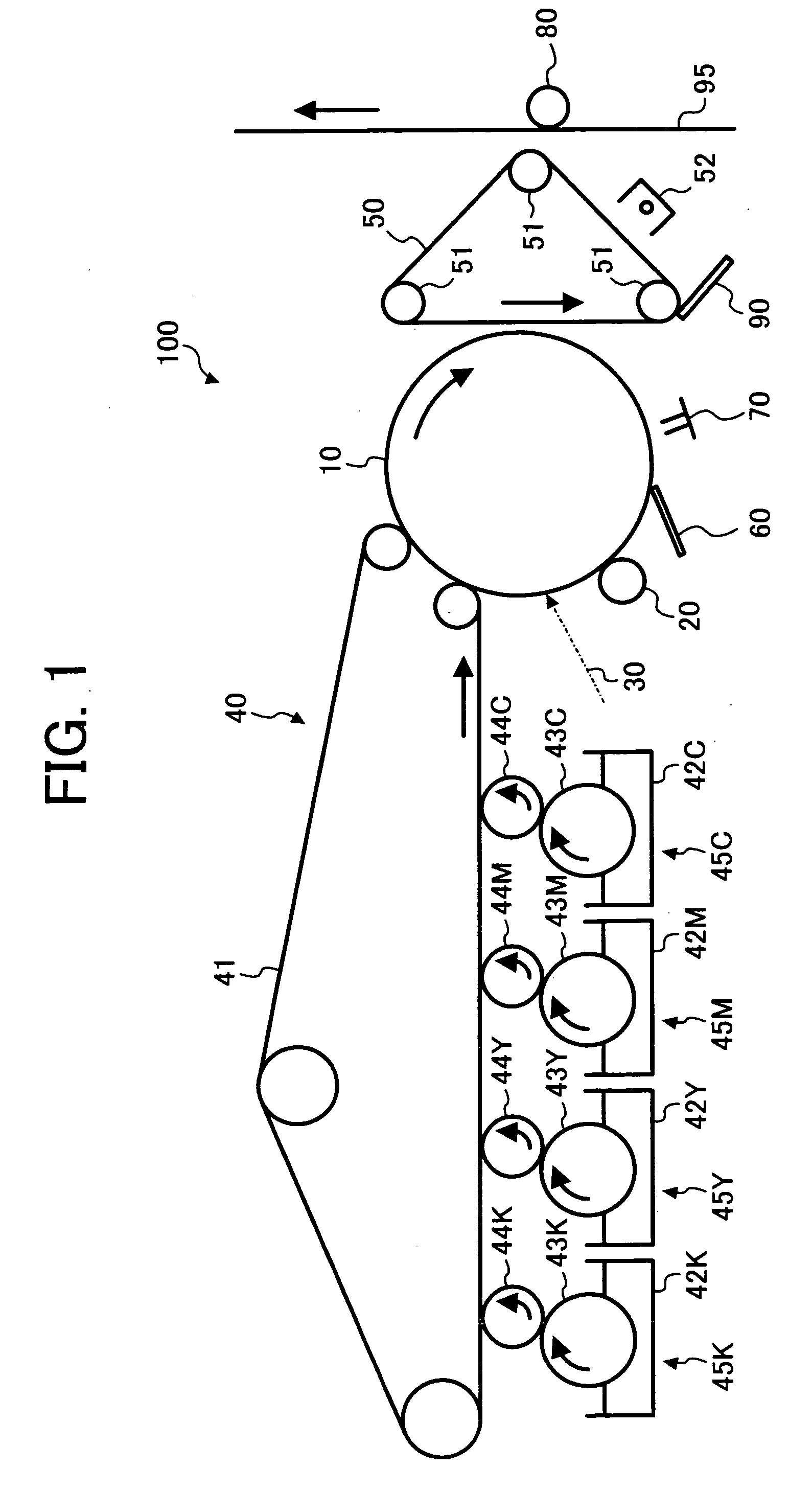

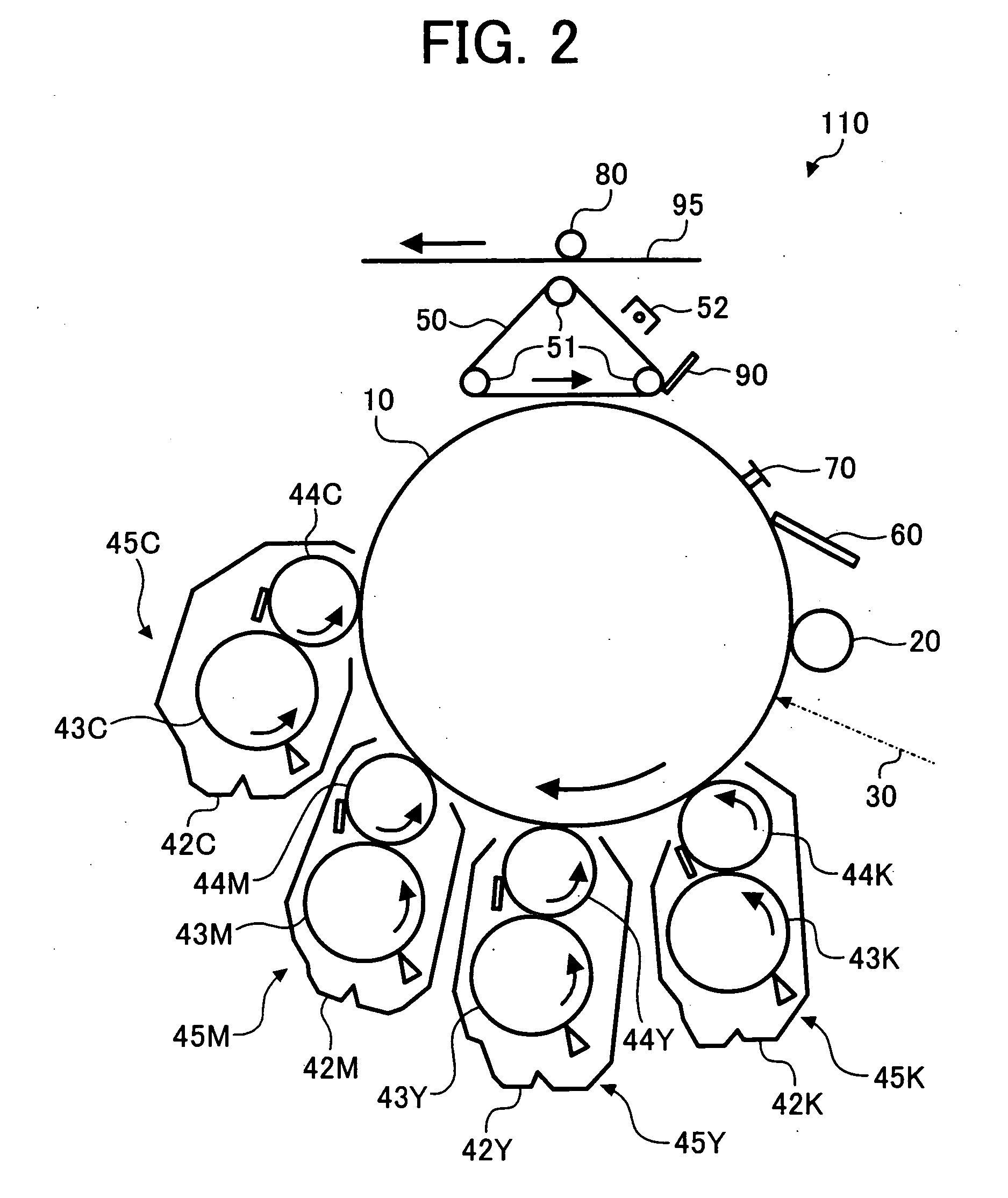

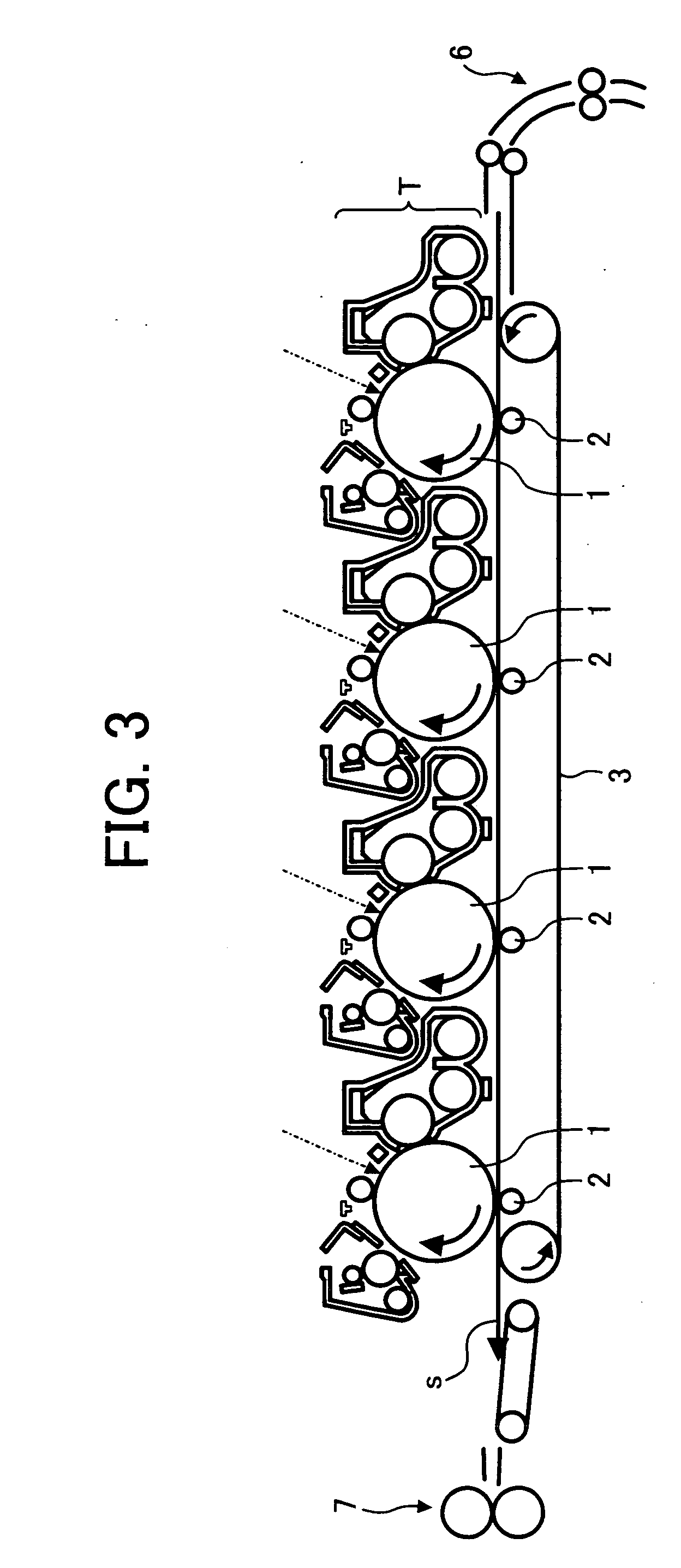

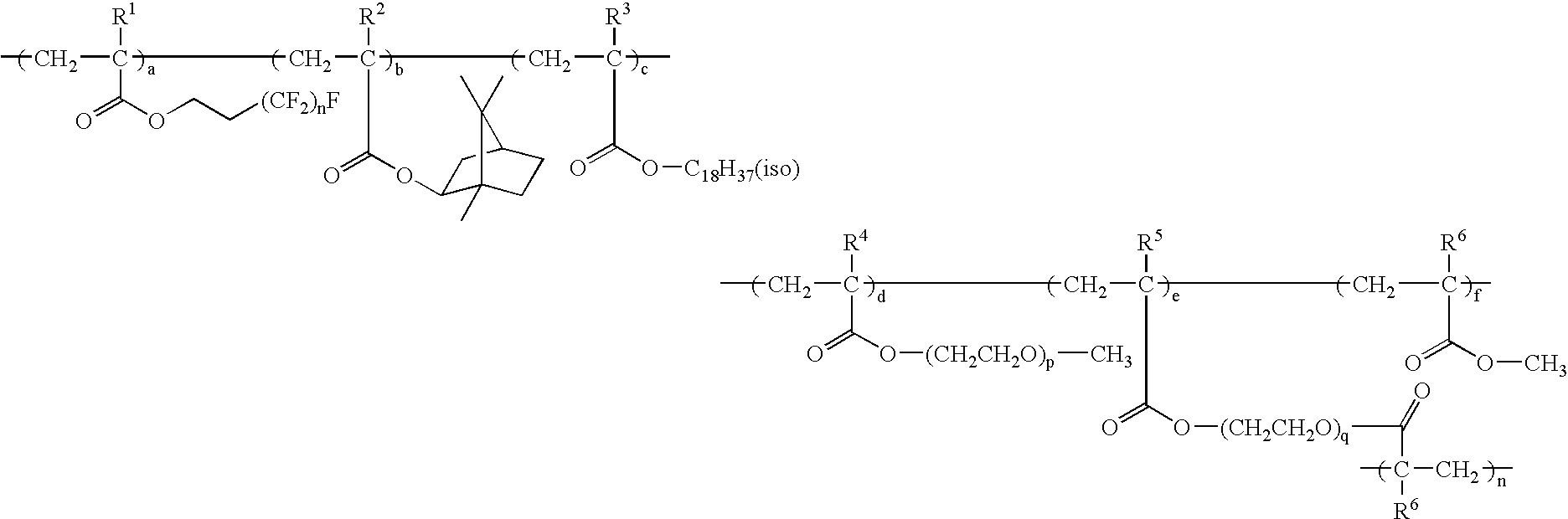

Toner, developer including the toner, and image forming method, image forming apparatus and process cartridge using the toner

ActiveUS20060024604A1Quality improvementHigh image densityElectrographic process apparatusDevelopersPolymer sciencePolymer chemistry

A toner including a binder resin and a colorant, wherein a pellet of the toner which is prepared by applying a pressure of 15 kg / cm2 to the toner has a tensile strength of from 900 Pa to 10,000 Pa, and wherein the toner has a methanol wettability of from 25 to 65% by volume, wherein the methanol wettability is measured by a method in which the toner is dispersed in a mixture solvent of water and methanol, and methanol is added to the toner dispersion while checking the transparency of the dispersion to determine a transparency fall starting point, wherein the methanol wettability is defined as {Vm / (Vm+Vw)}×100, wherein Vm represents a total volume (ml) of methanol in the dispersion at the transparency dropping point, and Vw represents the total volume of the pure water added.

Owner:RICOH KK

Preparation process for manufacturing insulated paper by para position fiber and meta position fiber

InactiveCN1884692AImprove evennessGood flexibilityPlastic/resin/waxes insulatorsSynthetic cellulose fibresManufacturing technologyPulp and paper industry

The invention discloses a manufacturing technology of copy-allocating insulated paper of para and meta aramid fiber, which comprises the following steps: adopting para-aramid chopped fiber and meta aramid pulp fiber to dispense insulated paper according to certain proportion; dispersing the fiber through PEC or congenic adjuvant; improving paper evenness and flexibility; proceeding heat pressing for para aramid fiber to modify physical strength and insulating property.

Owner:SHAANXI UNIV OF SCI & TECH

Magnetic recording medium

InactiveUS20010006744A1Eliminate Magnetic InterferenceStabilizes magnetizationMagnetic materials for record carriersLayered productsNon magneticMagnetic layer

A magnetic recording medium has a non-magnetic substrate, an under layer, a magnetic layer, and a protective layer in the recited order. The magnetic layer consists of a plurality of magnetic components embedded in a pattern in an isolating component. Each magnetic component includes at least one magnetic component of large coercive force and one of a magnetic component of small coercive force. The two components abut each other. In one embodiment the two components form one or more alternating layers. In another embodiment, one of the components has a recess in its upper surface which is filled with the other component. In still another embodiment, the two components are disposed side by side passing through the isolating component.

Owner:FUJI ELECTRIC CO LTD

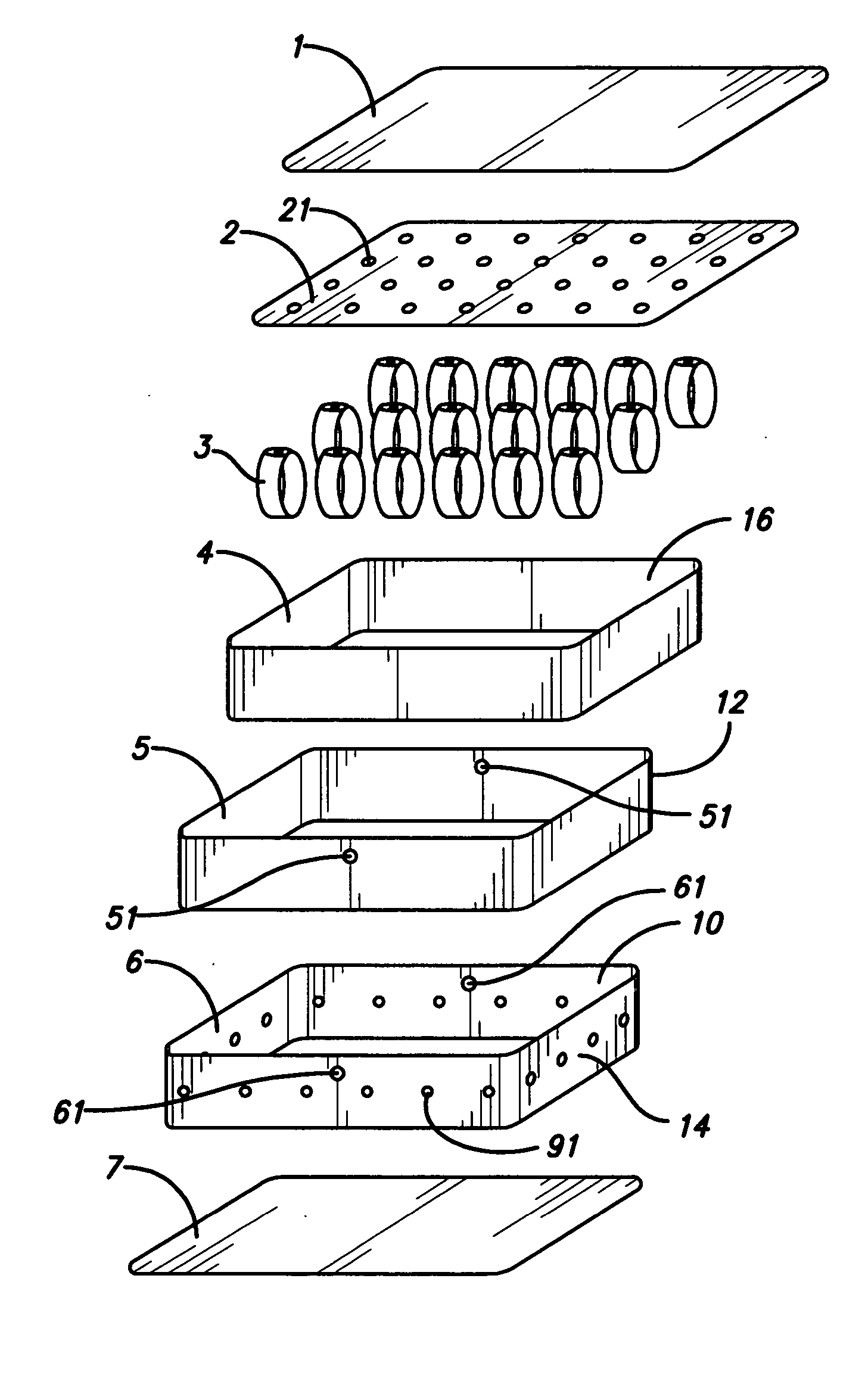

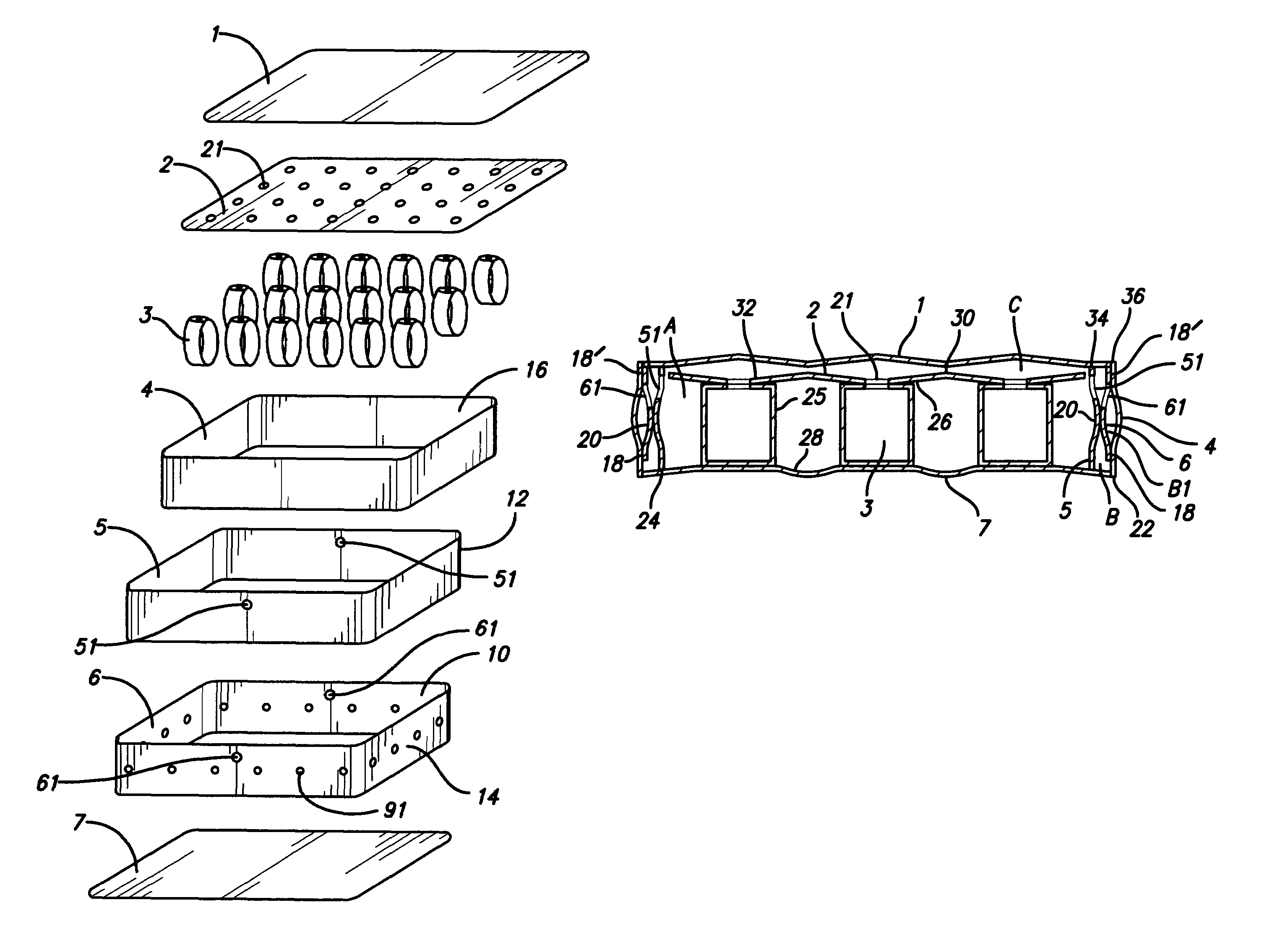

Air-inflated mattress

ActiveUS20070283499A1Improve evenness and out lookImprove evennessStuffed mattressesSpring mattressesAir mattressEngineering

An air-inflated mattress, comprising a top layer, an outer shroud band, a plurality of anchor separators and a bottom layer, wherein said shroud band connects the top and bottom layers together to form an inflatable bladder; further comprising a middle layer below said top layer sealed to the top layer. The mattress may also comprise a middle shroud band and an inner shroud band, a plurality of joint spots welded on the bottom side of the top layer, alternatively arranged with anchor separators and a plurality of joint spots welded between the shrouds and means to pass air between the bladder and a plurality of half-sealed sub-chambers created by the joint welds, which slows the spreading speed of the air to the bladder and the chambers, so that the air mattress is even and level and the supporting strength of the air mattress is greatly improved.

Owner:INTEX RECREATION

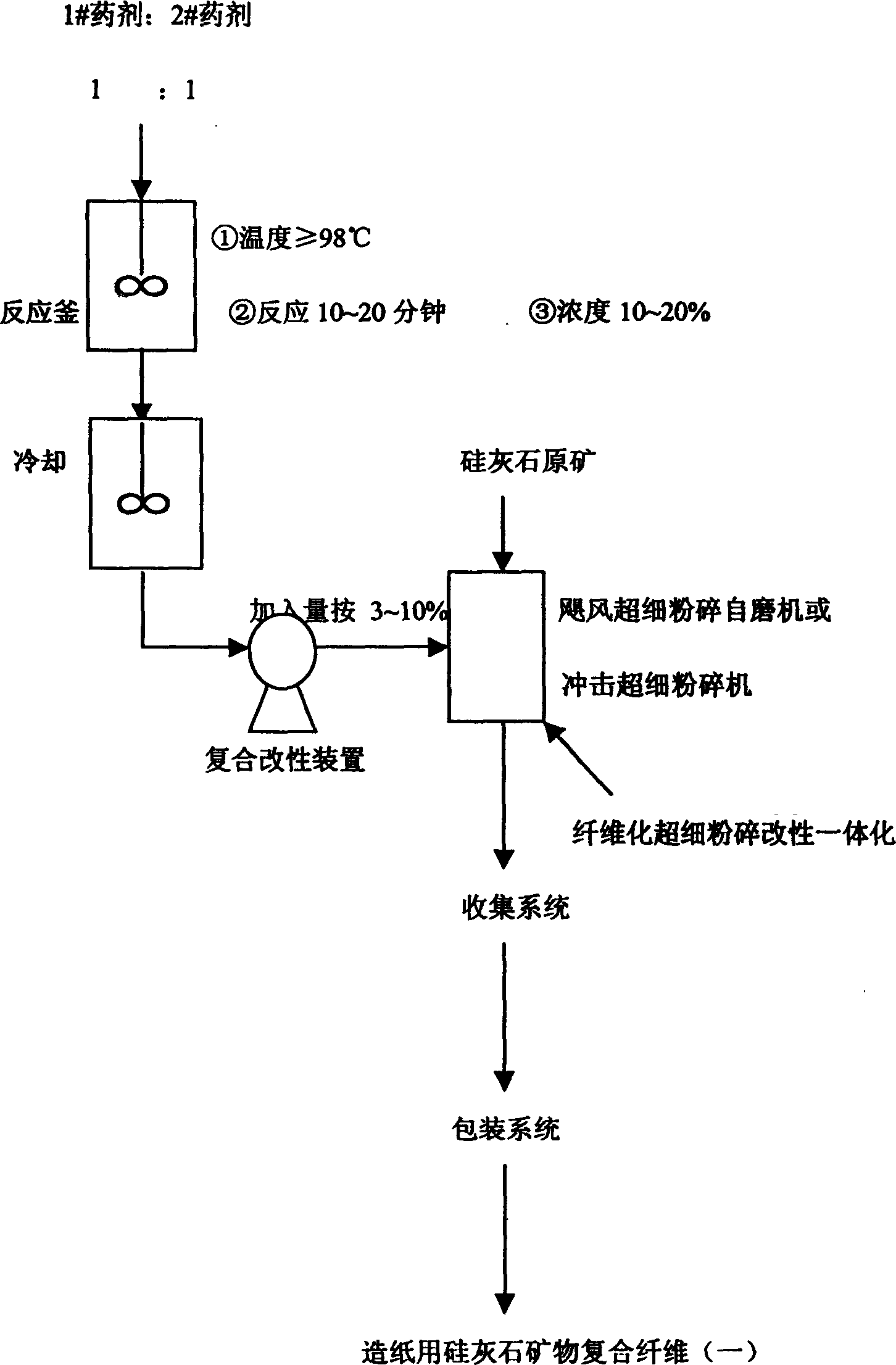

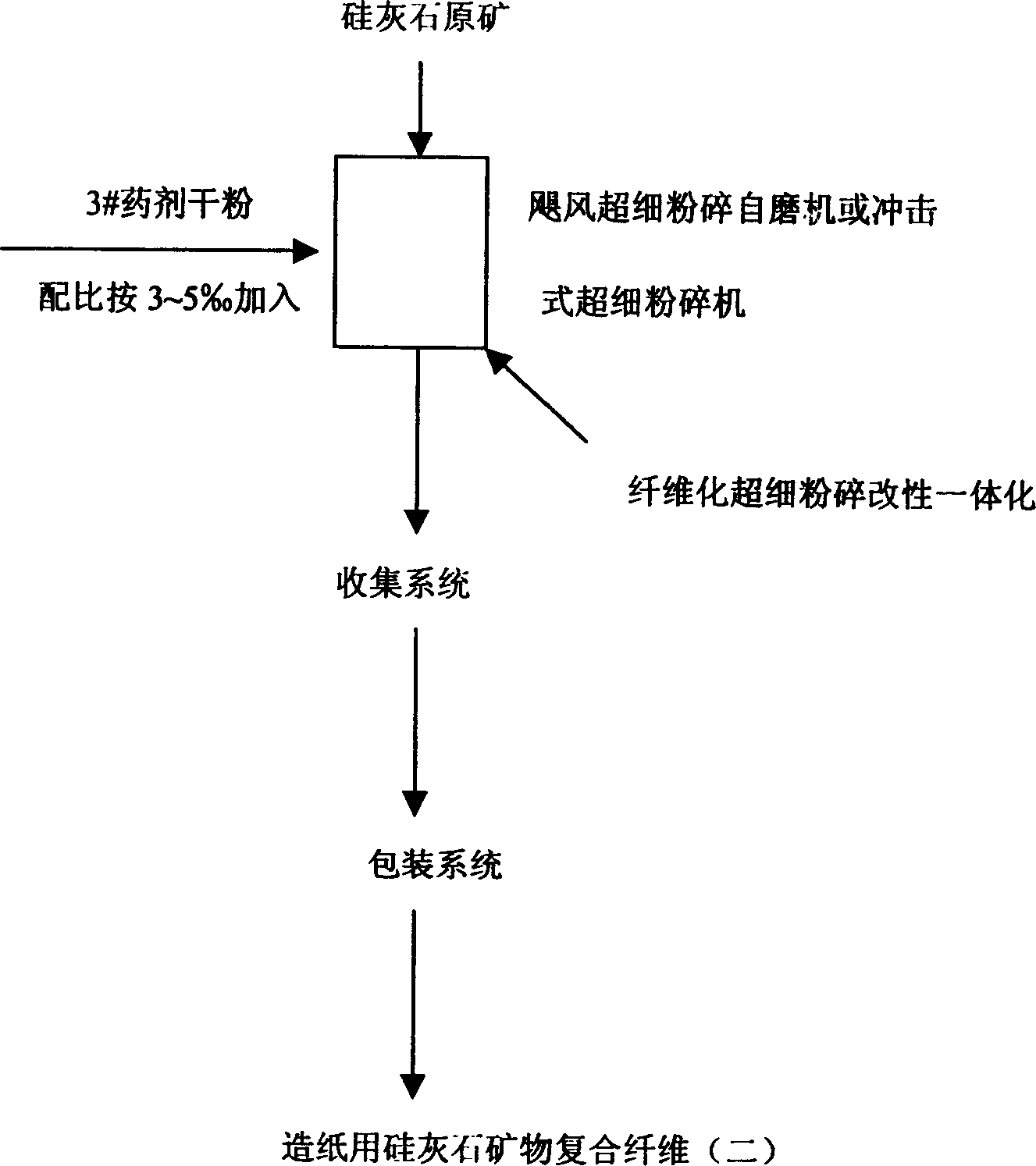

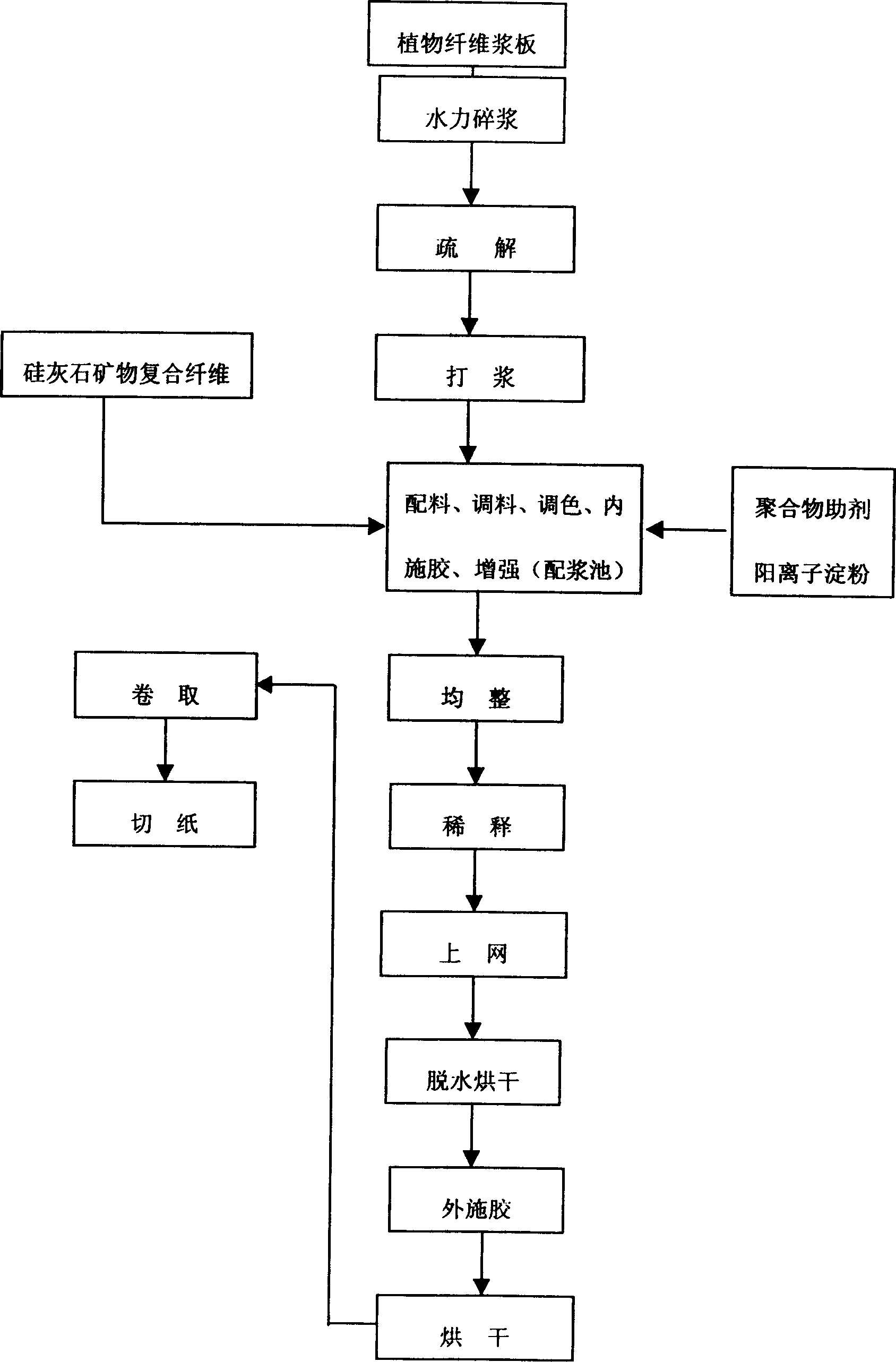

Modified wollastonite mineral composite fibre for making paper and its paper-making process

The present invention provides a modified wollastonite mineral composite fibre for making paper and its paper-making method. It includes the following steps: breaking wollastonite raw ore to obtain the thin-long fibre whose grain size is 5-20 micrometer and the ratio of mid-diameter:length=1:6-30, and according to the ratio of alkali or salt of aluminium: alkali or salt of sodium=1:1 adding modification agent whose added quantity is 3-10% of wollastonite mineral composite fibre weight so as to obtain the wollastonite mineral composite fibre covered with modification agent. In the course of preparing pulp in paper-making process 5-50% of modified wollastonite mineral composite fibre and 50-95% of plant fibre and paper-making auxiliary material are added, it can reduce production cost.

Owner:云南省非金属矿产应用研究所

Toner, image forming apparatus, and process cartridge

ActiveUS20110053071A1Excellent releasing ability and charging ability and durabilityFacilitated releaseElectrographic process apparatusDevelopersHydrogen atomPolyester resin

To provide a toner comprising: a binder resin, a colorant, and a releasing agent, wherein the toner has a core shell structure, and wherein the core contains at least one resin selected from the group consisting of a hybrid resin and a polyester resin, where the hybrid resin is a resin in which a polyester resin and a vinyl resin are chemically bonded to each other, and the shell contains a resin prepared by polymerizing at least a styrene monomer and an ester monomer represented by the following General Formula (1):where, ‘n’ is 2 or 3, ‘X’ is any of 0 to 9, R1 is a hydrogen atom, or an alkyl group, and R2 is a hydrogen atom, an alkyl group, or a phenyl group.

Owner:RICOH KK

Production method of tight sirospun yarn of combed crystal cotton

InactiveCN102493064AHairiness value reductionImprove evennessContinuous wound-up machinesYarnCotton fibreCombing

The invention relates to a production method of tight sirospun yarn of combed crystal cotton. The production method comprises the following sequential working procedures: combed cotton preparation; opening, cleaning and blending of combed cotton and crystal cotton; cotton combing; drawing; roving; mixing of sirospun yarn of nylon filament; and winding. According to the invention, crystal cotton fiber is blended with the combed cotton fiber, the tight sirospun yarn of the nylon filament is added during the spinning working procedure, and a double-rough-yarn feeding device and a tight spinning device are additionally installed on a traditional ring spinning frame, so that two threads of rough yarn are simultaneously fed to a drafting region, a certain spacing is reserved between drafted fiber strands, and the drafted fiber strands are gathered, converged and twisted at the downstream of the roller chop to obtain yarn. Under the action that the fiber strand twisting triangular region is canceled due to bundling action and two threads of fiber strands are combined, the filoplume value of single yarn is obviously reduced, the yarn evenness is significantly improved, the fracture strength is greatly increased and better resultant yarn quality is obtained; and functional yarn with high strength, high hygroscopicity, cleanness, high elasticity and bacteriostatic characteristic is produced by the equipment.

Owner:DANYANG DANSHENG TEXTILE

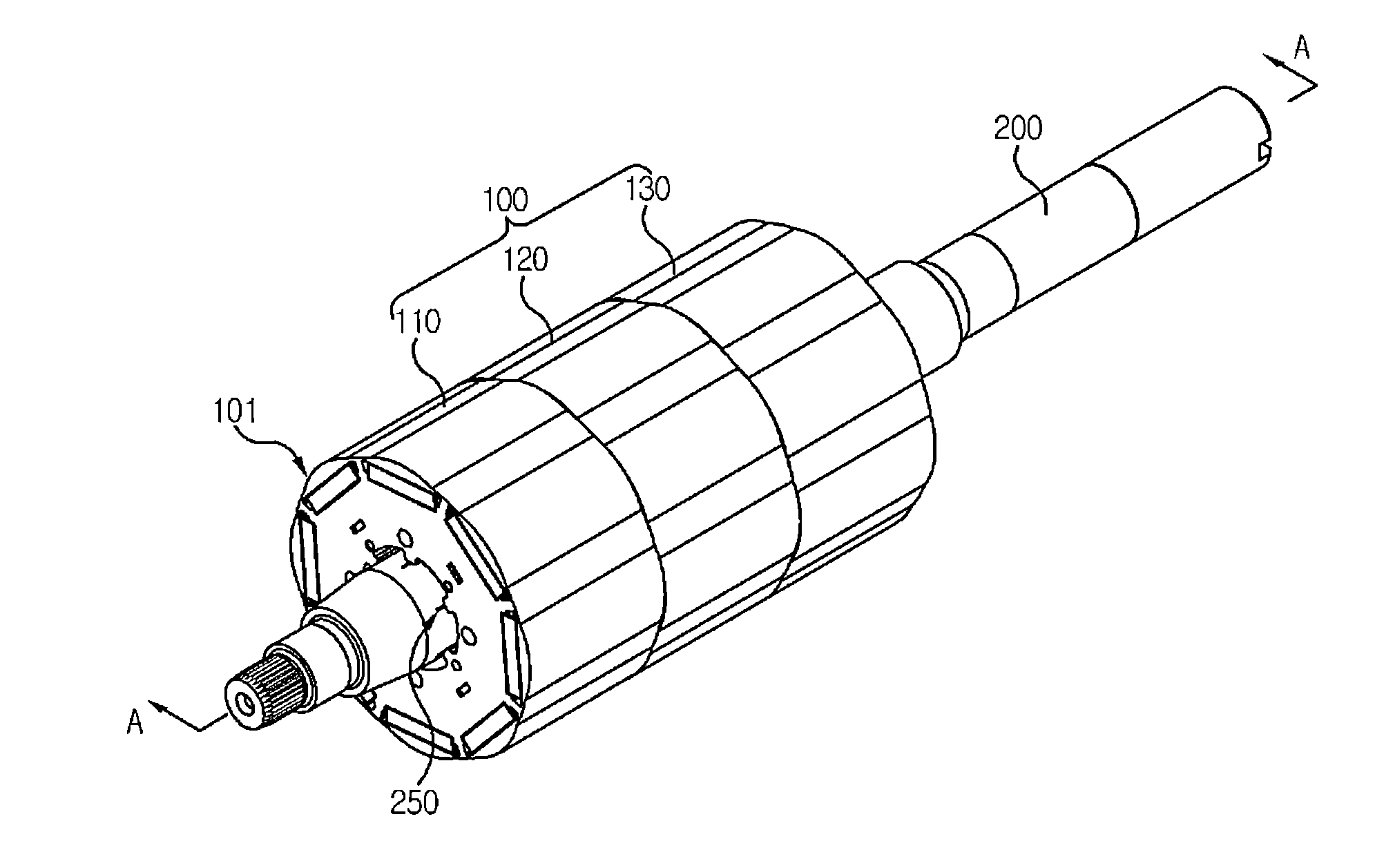

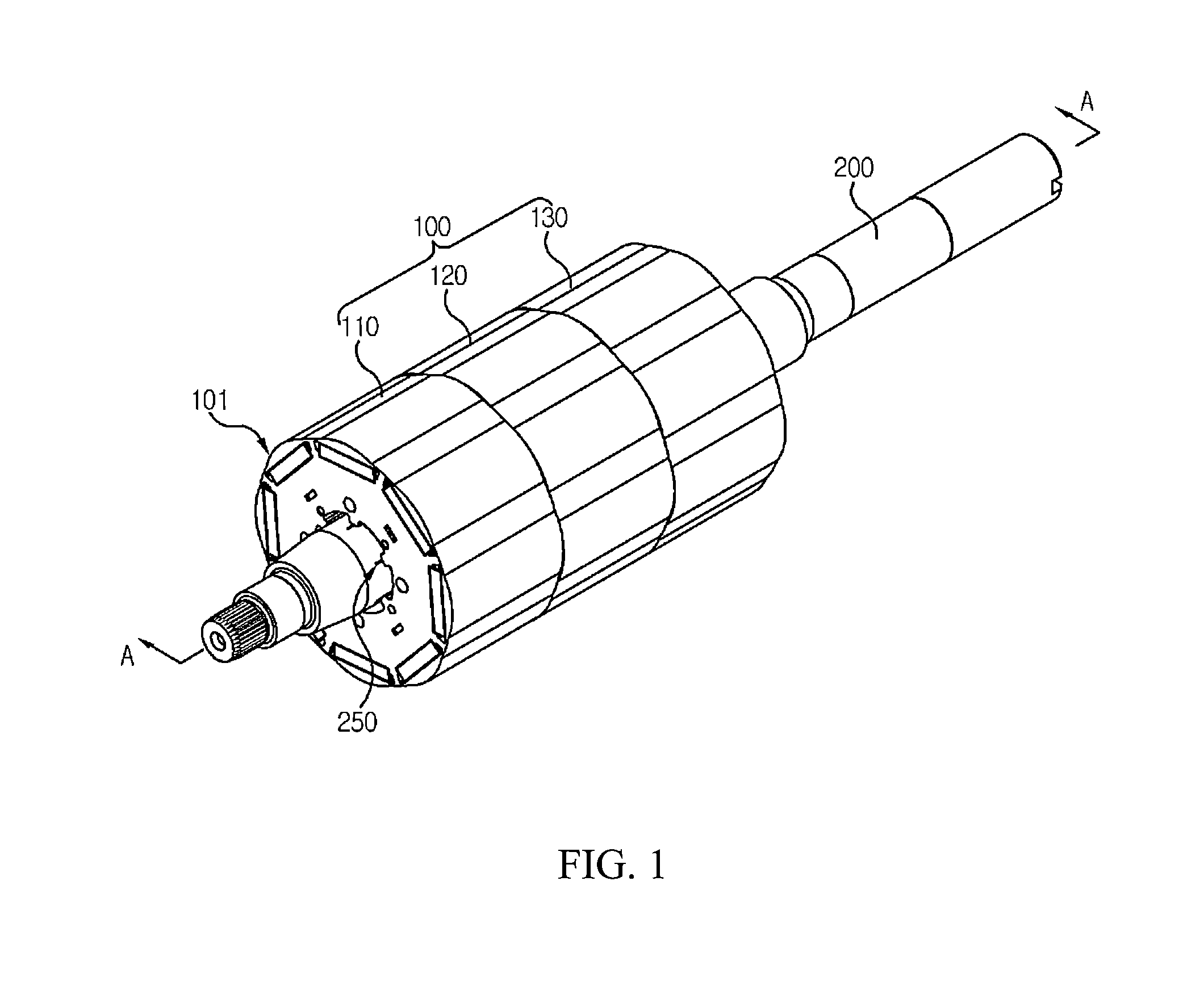

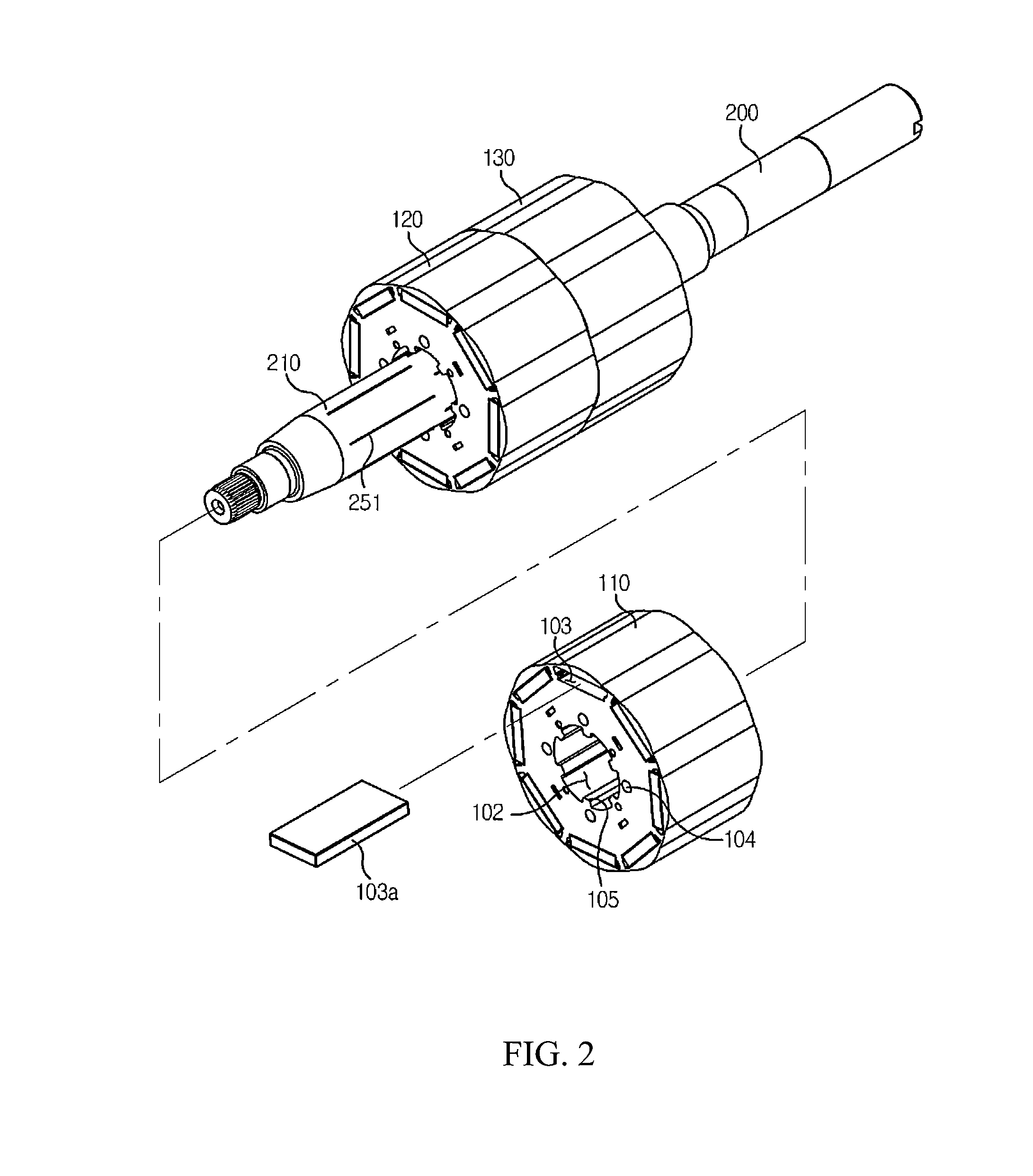

Rotor Core For Motor

ActiveUS20130020898A1Good effectImprove accuracyMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsEngineeringMagnet

Provided is a rotor core of a motor, the rotor core, the rotor core including: a thin disk-shaped rotor core member; a shaft hole penetratively formed in a center of the rotor core member; a shaft press-fitted into the shaft hole; a plurality of magnet insertion holes penetratively formed at a position near to a periphery of the rotor core member for inserted coupling by a magnet; a plurality of teeth protrusively formed at an inner circumferential surface of the shaft hole, and a skived portion protrusively formed at a position corresponding to the plurality of teeth of the shaft, wherein the rotor core members are stacked each at a predetermined height, and the shaft is press-fitted into the shaft hole.

Owner:LG INNOTEK CO LTD

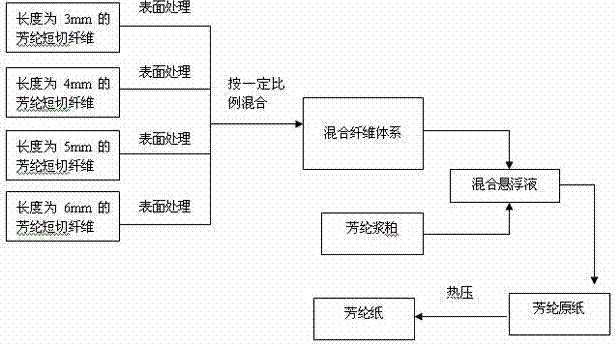

Preparation method of mixed fiber system aramid paper

ActiveCN103485234AReduce the ratioPrevent flocculationSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceAramid

The invention discloses a preparation method of mixed fiber system aramid paper. The mixed fiber system aramid paper comprises the following components in parts by mass: (1) 30-50 parts of aramid chopped fiber with different average lengths, which is compounded by the aramid chopped fiber with the lengths of 3mm, 4mm, 5mm and 6mm; and (2) 50-70 parts of aramid pulp. The preparation method of the aramid paper comprises the following steps: (1) performing surface treatment on the aramid chopped fiber with the different lengths; (2) mixing the aramid chopped fiber with the different lengths according to different proportions to obtain a mixed aramid chopped fiber system; (3) mixing the aramid chopped fiber system with the aramid pulp; (4) preparing wet-formed aramid raw paper; and (5) performing hot-pressing on the aramid raw paper. The preparation method disclosed by the invention can solve the problems of fiber flocculation, poor evenness of the formed paper and poor paper strength in an existing aramid preparation process.

Owner:SHAANXI UNIV OF SCI & TECH

Wafer level packaging of micro electromechanical device

InactiveUS20030227094A1Avoid damageImprove evennessDecorative surface effectsSemiconductor/solid-state device detailsElectrical conductorEngineering

The present invention provides a wafer level package of micro electromechanical devices. The wafer level package of the present invention comprises a wafer having a plurality of micro electromechanical devices and a package wafer of the same size. A plurality of conductor plugs penetrate through the upper and lower surfaces of the package wafer. Solder bumps are formed on the conductor plugs to be adhered to predetermined solder bumps on the micro electromechanical device wafer so as to form a package device. The wafer level package of the present invention can prevent micro electromechanical devices from damage during the packaging procedure.

Owner:XIANGQUN SCI & TECH

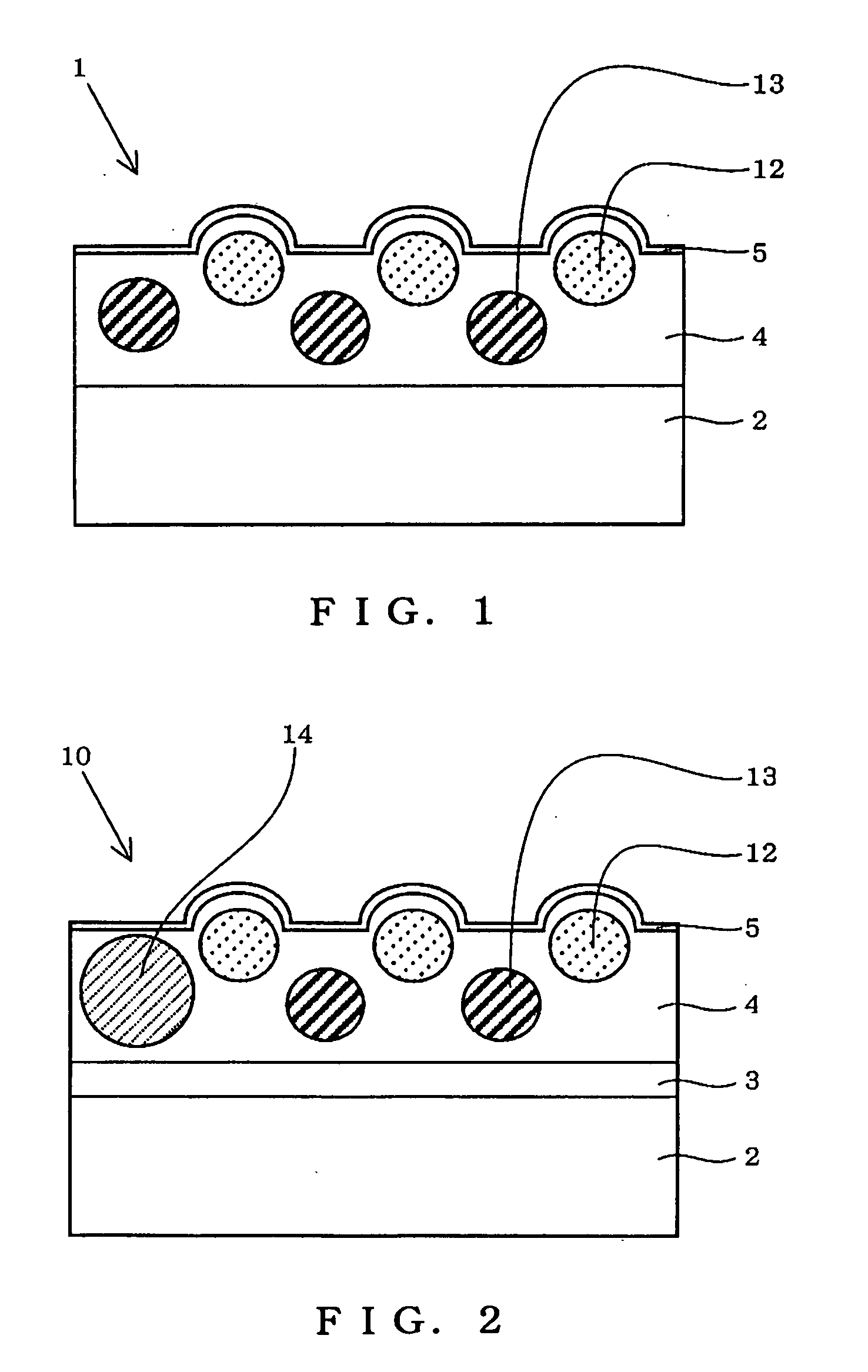

Coated electrode and organic electrolyte capacitor

ActiveUS20100027193A1Improve conductivityHigh strengthHybrid capacitor electrolytesHybrid capacitor electrodesApparent densityLithium

A coated electrode includes a current collector of an etched aluminum foil having a thickness of 20 to 45 μm, an apparent density of 2.00 to 2.54 g / cm3, an air permeability of 20 to 120 s and a number of through-holes penetrating therethrough from the front surface to the back surface, and an electrode layer formed by applying a coating material including, as an active material, a substance capable of reversibly carrying lithium ions and anions on to the current collector. The coated electrode is industrially producible, high in conductivity and strength, and excellent in evenness. A capacitor, for example, can make use of the electrode.

Owner:MUSASHI ENERGY SOLUTIONS CO LTD

Anti-dazzling film

The present invention discloses an anti-dazzling film that can be provided by high-speed coating and can meet market demands for an increased area and homogeneous properties and lowered cost while enjoying satisfactory scratch resistance. The present invention provides the anti-dazzling film comprises a triacetylcellulose film and an anti-dazzling layer provided on the triacetylcellulose film. The anti-dazzling layer comprises: a light transparent resin comprising an acrylic resin; plastic light transparent fine particles; and a leveling agent comprising a copolymer comprising (meth)acrylic acid repeating units containing at least one perfluoroalkyl group having 8 or more carbon atoms and (meth)acrylic acid repeating units having at least one bornane ring. A low-refractive index layer is provided on the anti-dazzling film to constitute an antireflection film.

Owner:DAI NIPPON PRINTING CO LTD +1

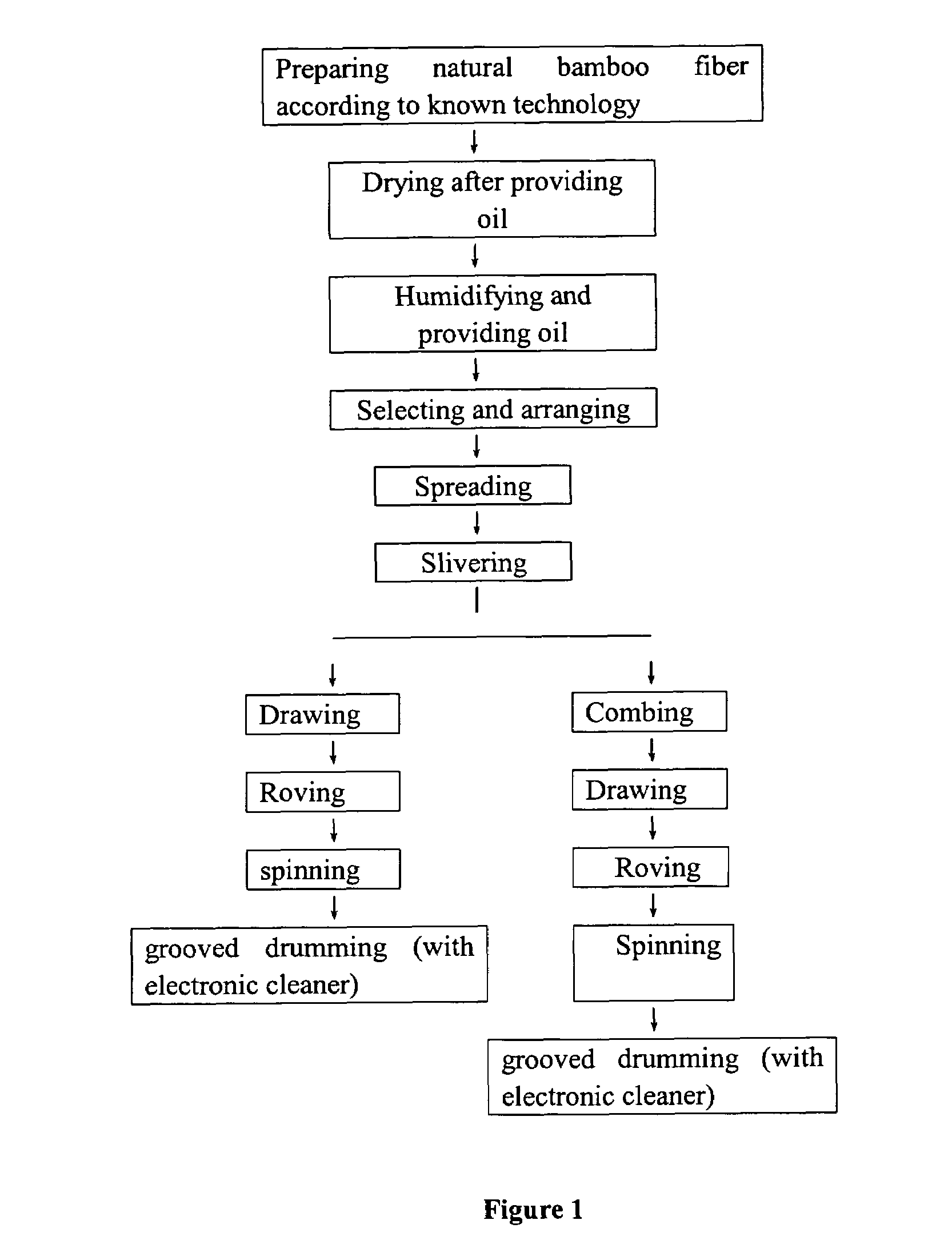

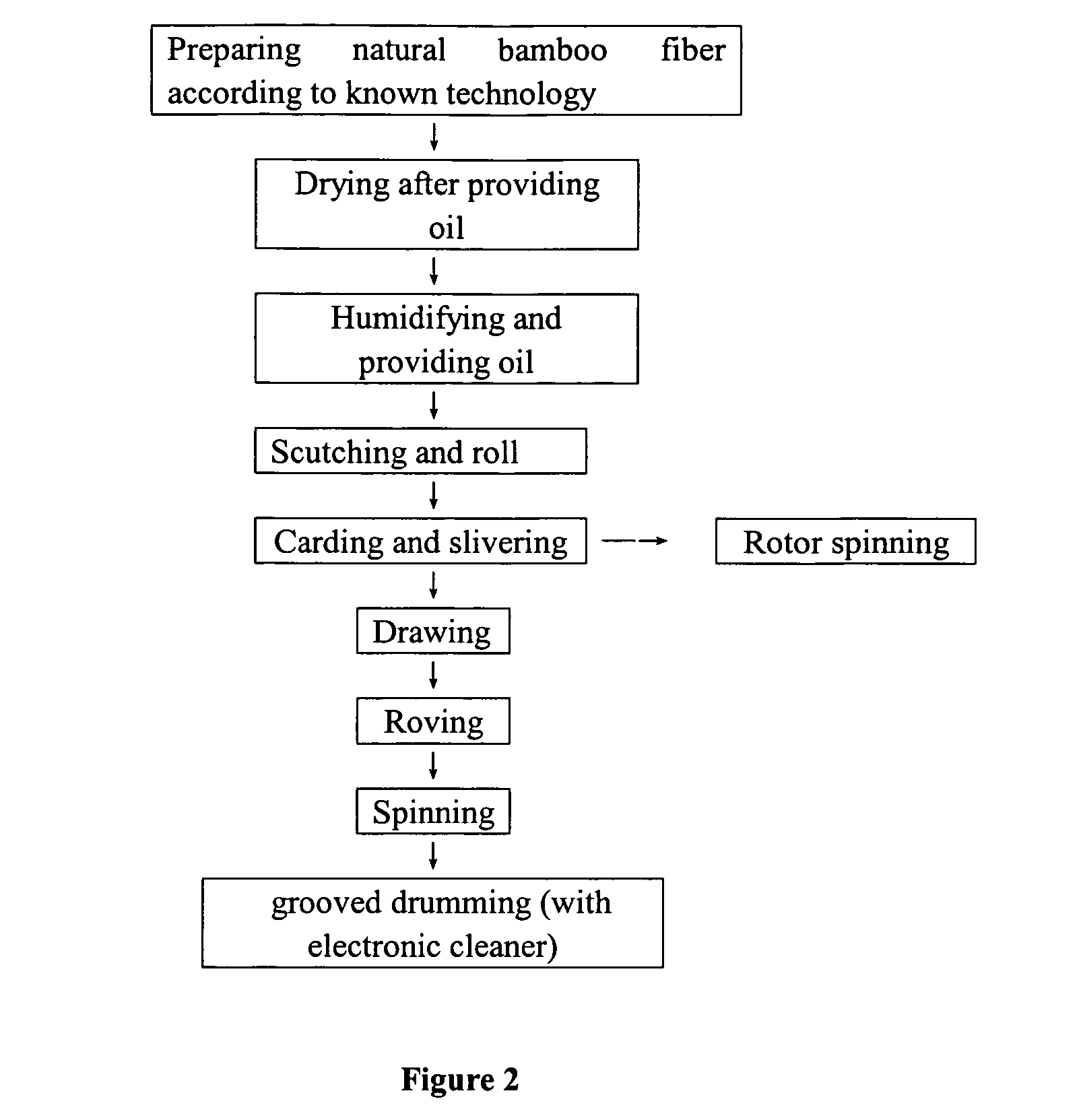

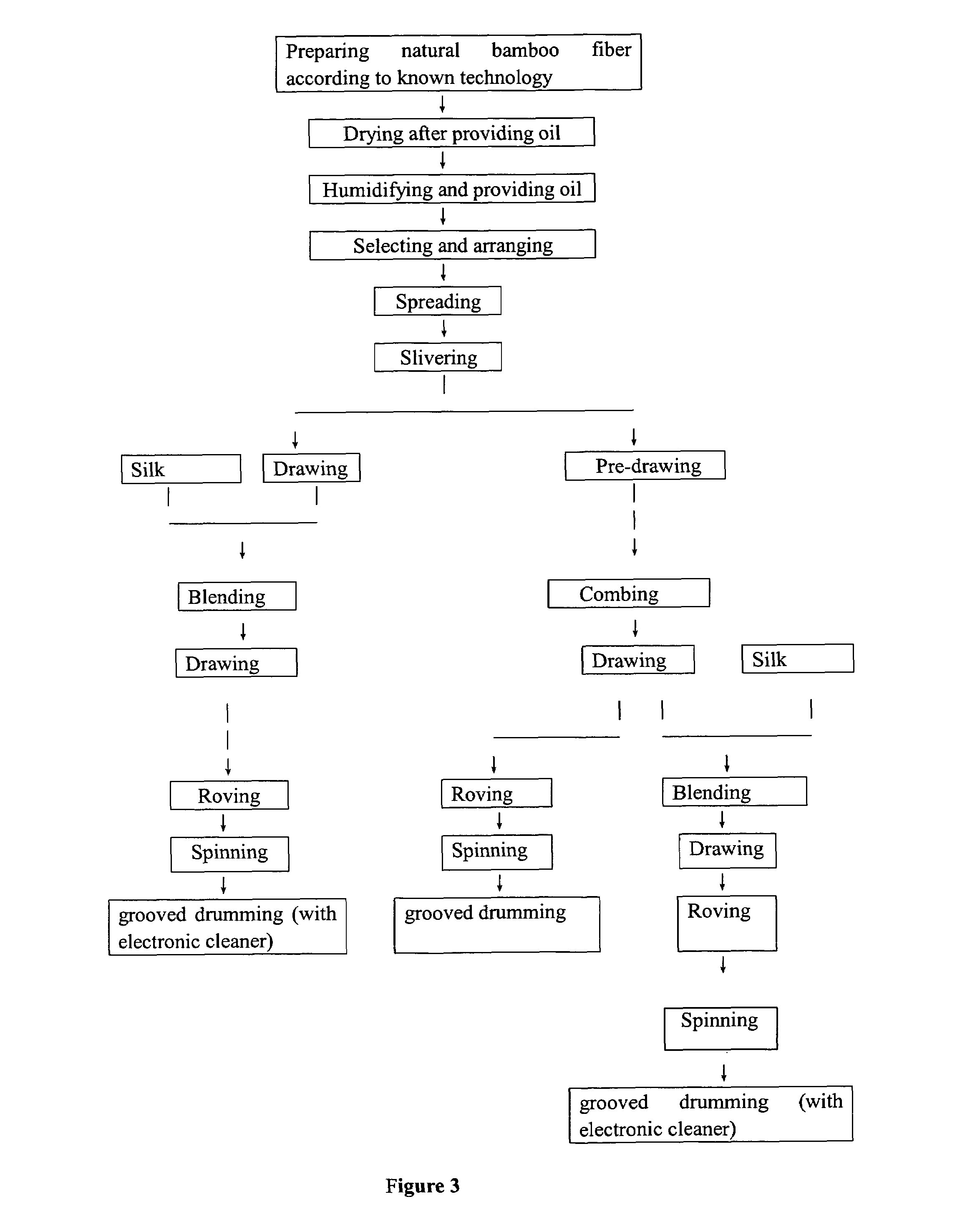

Yarn comprising bamboo fiber and the processing method thereof

ActiveUS7313906B2Avoid large quantitiesSmall tensionYarnFibre treatment to obtain bast fibreFiberYarn

Owner:ZHUZHOU CEDAR RAMIE INDAL

Vacuum evaporation crucible and phosphor sheet manufacturing apparatus using the same

InactiveUS20050103273A1Stable formation of freeImprove evennessX-ray/infra-red processesVacuum evaporation coatingPhosphorCrucible

A crucible for vacuum evaporation includes a crucible main body accommodating a film forming material and generating heat through energization and a convection member secured in position inside the crucible main body and forcibly changing the direction of natural convection of the molten material. Other crucible includes the crucible main body and a cover member closing the material accommodating portion of the main body and equipped with a vapor outlet port, the main body and the cover member being firmly connected to each other. A phosphor sheet manufacturing apparatus uses those crucibles.

Owner:FUJIFILM HLDG CORP +1

Ink-jet recording process, ink-jet recording apparatus and image formed article

InactiveUS6158856AAvoid it happening againImprove evennessMeasurement apparatus componentsPrintingEngineeringMechanical engineering

Disclosed herein is an ink-jet recording process for forming an image by applying an ink to a recording medium in accordance with an ink-jet recording system, comprising the steps of: (A) applying an ink containing a coloring material to the recording medium in accordance with the ink-jet recording system; and (B) applying a liquid composition different from the ink to an ink-applying region of the recording medium in accordance with the ink-jet recording system, wherein the liquid composition is applied in an amount less than 50% by volume of the amount of the ink to be applied to the ink-applying area.

Owner:CANON KK

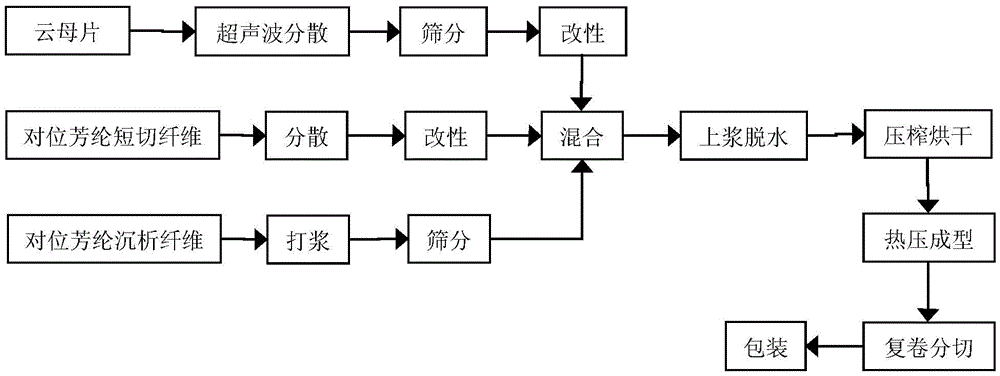

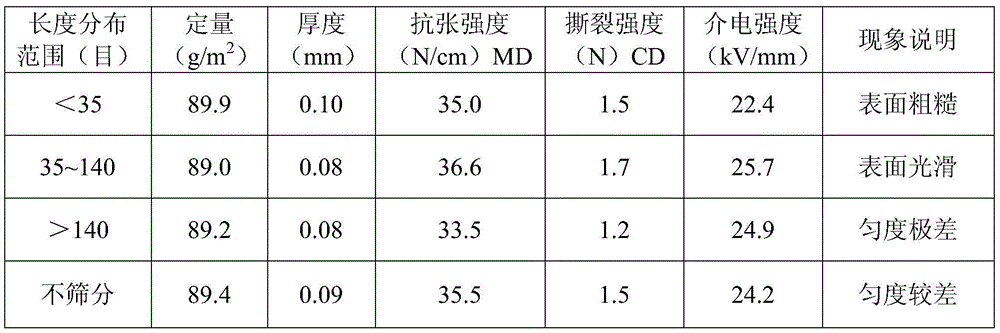

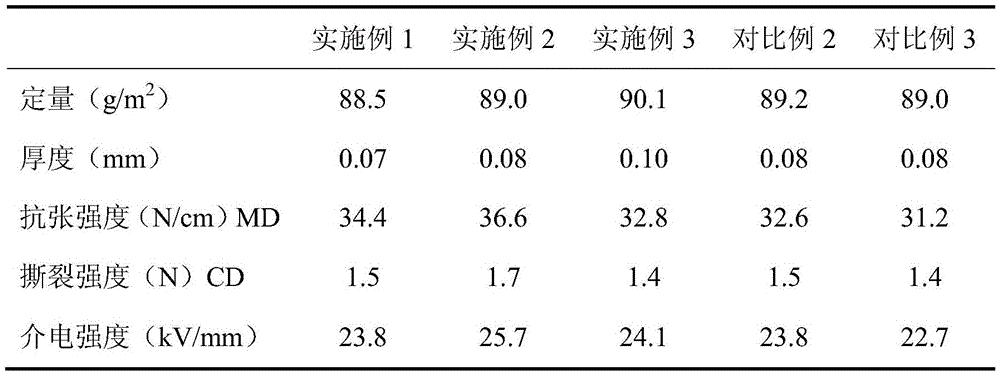

Preparation method of p-aramid fiber-mica paper

ActiveCN105544286AHigh strengthImprove evennessInorganic fibres/flakesPhysical paper treatmentDielectric breakdown strengthSlurry

The invention relates to a preparation method of a p-aramid fiber-mica paper. The preparation method comprises defibering and dispersing silane coupling agent-modified p-aramid chopped fibers to obtain slurry A, carrying out screening on the p-aramid fibrids with a beating degree of 40-65 degrees SR to obtain slurry B, modifying mica plates through an ionic starch solution to obtain modified mica plates, mixing the slurry A, the slurry B and the modified mica plates to obtain uniform mixed slurry, wherein the uniform mixed slurry comprises, by mass, 10-20% of p-aramid chopped fibers, 20-40% of the p-aramid fibrids and 40-70% of the mica plates, carrying out sizing, dehydration and formation on the mixed slurry, carrying out squeezing and drying and carrying out hot press molding to obtain the p-aramid fiber-mica paper. The p-aramid fiber-mica paper obtained through fiber screening and modification, wet method paper making and hot pressing molding has good evenness, excellent mechanical strength, excellent dielectric breakdown strength and high temperature resistance stability.

Owner:YANTAI METASTAR SPECIAL PAPER

Air-inflated mattress

ActiveUS7406735B2Fine surfaceIncrease contact areaStuffed mattressesSpring mattressesInter layerEngineering

Owner:INTEX RECREATION

Adhesive composition and sheet for forming semiconductor wafer-protective film

InactiveUS20110223420A1High yieldEasily formSemiconductor/solid-state device detailsSolid-state devicesSolventChemistry

There is disclosed an adhesive composition containing: (A) 100 parts by mass of a phenoxy resin; (B) 5 to 200 parts by mass of an epoxy resin; (C) 1 to 20 parts by mass of an alkoxysilane-partial hydrolytic condensate which is a partial hydrolytic condensate of alkoxysilane including one kind or two or more kinds of alkoxysilane represented by the following general formulae (1) and (2), wherein the weight average molecular weight is 300 or more and 30,000 or less and an amount of residual alkoxy is 2 wt % or more and 50 wt % or less; (D) a curing catalyst for an epoxy resin; (E) an inorganic filler; and (F) a polar solvent having a boiling point of 80° C. to 180° C. and a surface tension of 20 to 30 dyne / cm at 25° C. There can be a sheet for forming a semiconductor wafer-protective film and an adhesive composition capable of forming a protective film excellent in evenness, cutting characteristics and adhesiveness.

Owner:SHIN ETSU CHEM CO LTD

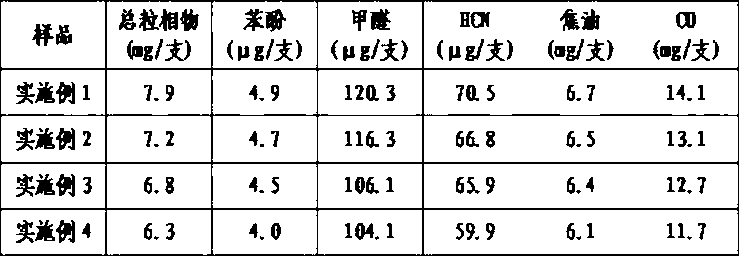

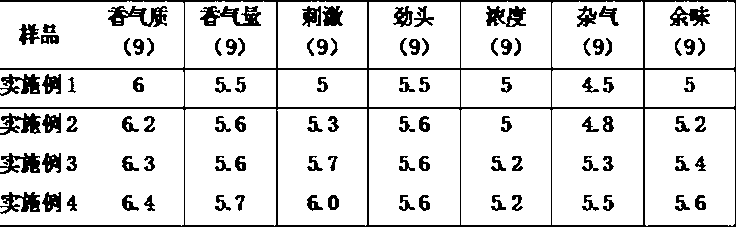

Method of manufacturing reconstituted tobacco through high-quality functional paper-making process

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com