Patents

Literature

45036results about How to "Increase contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

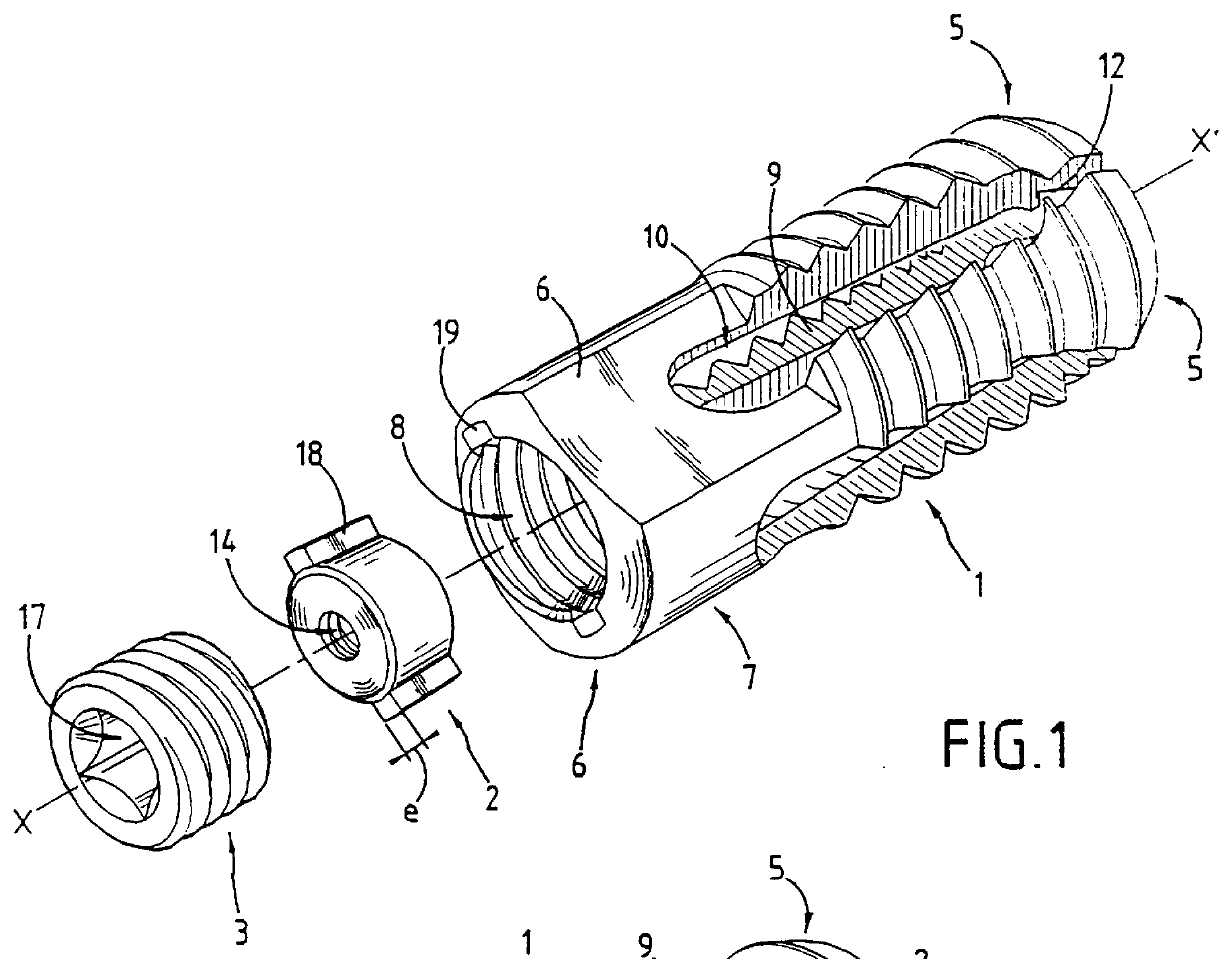

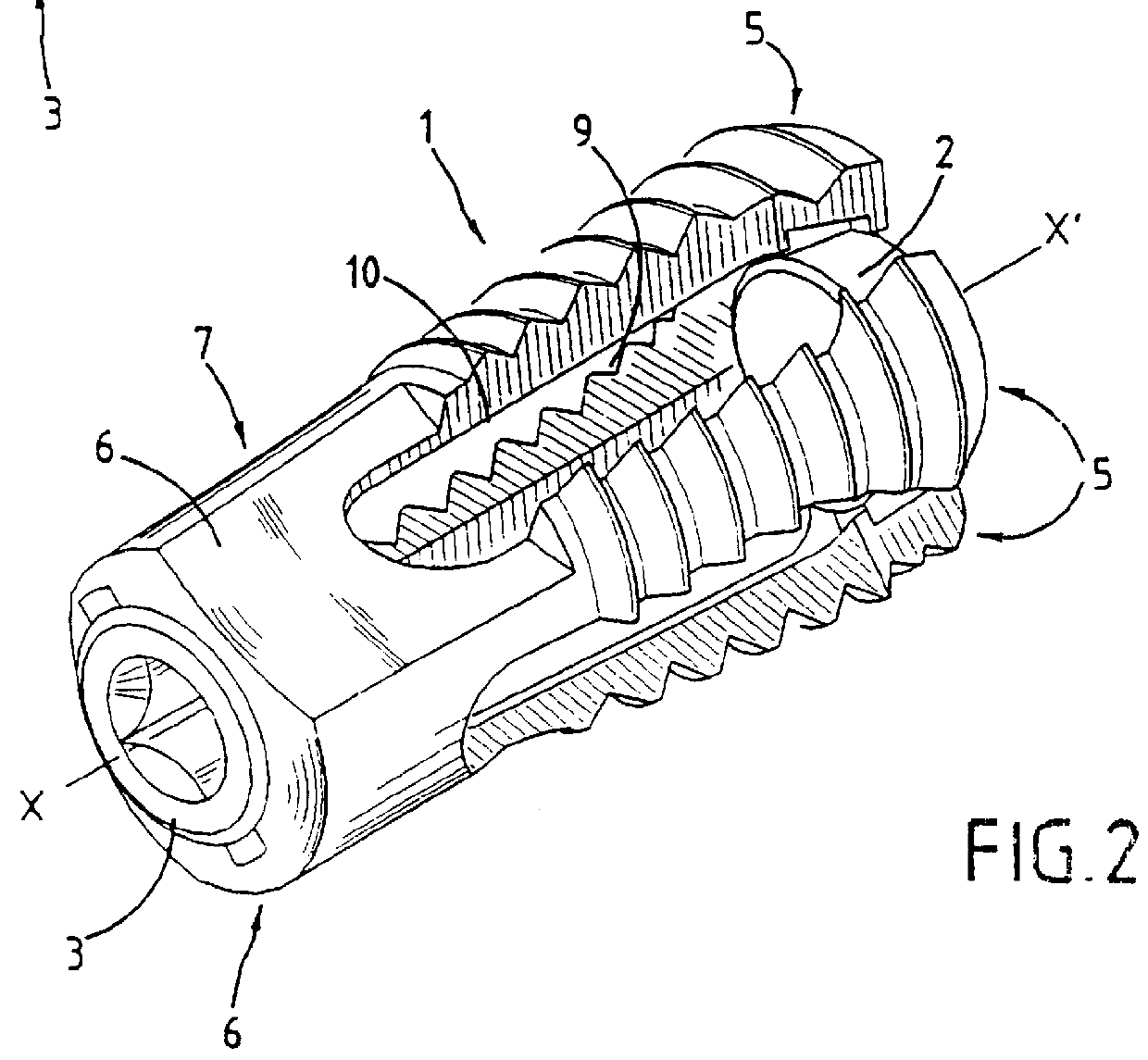

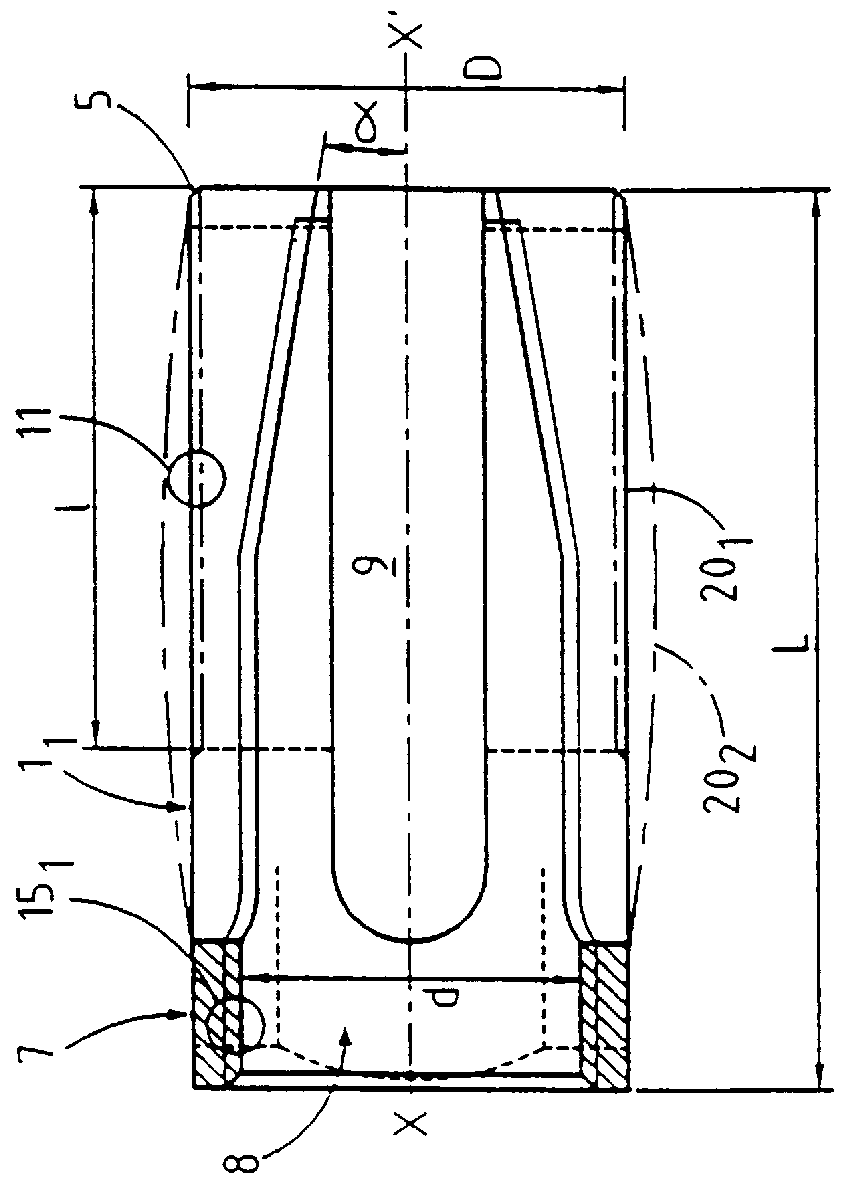

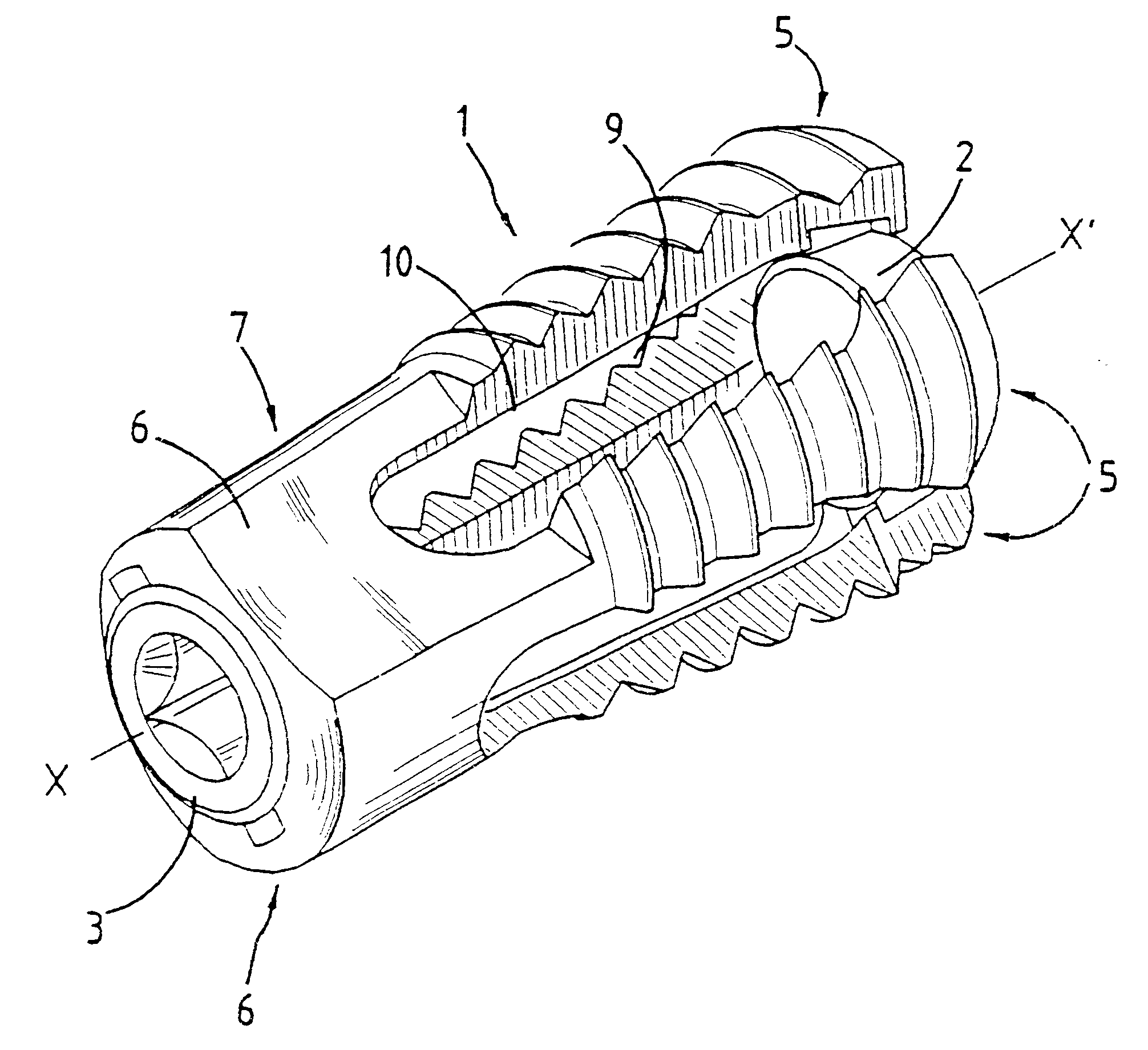

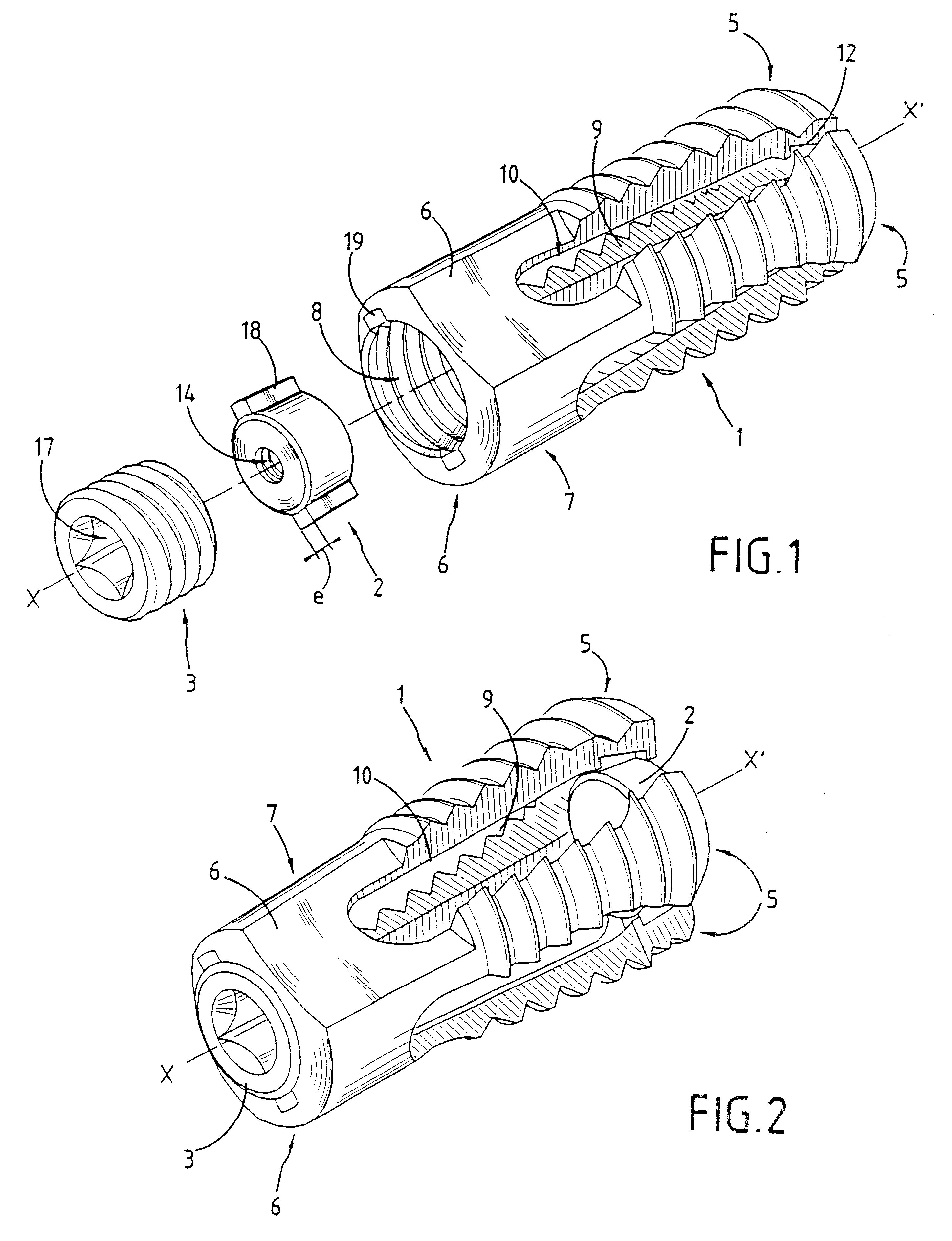

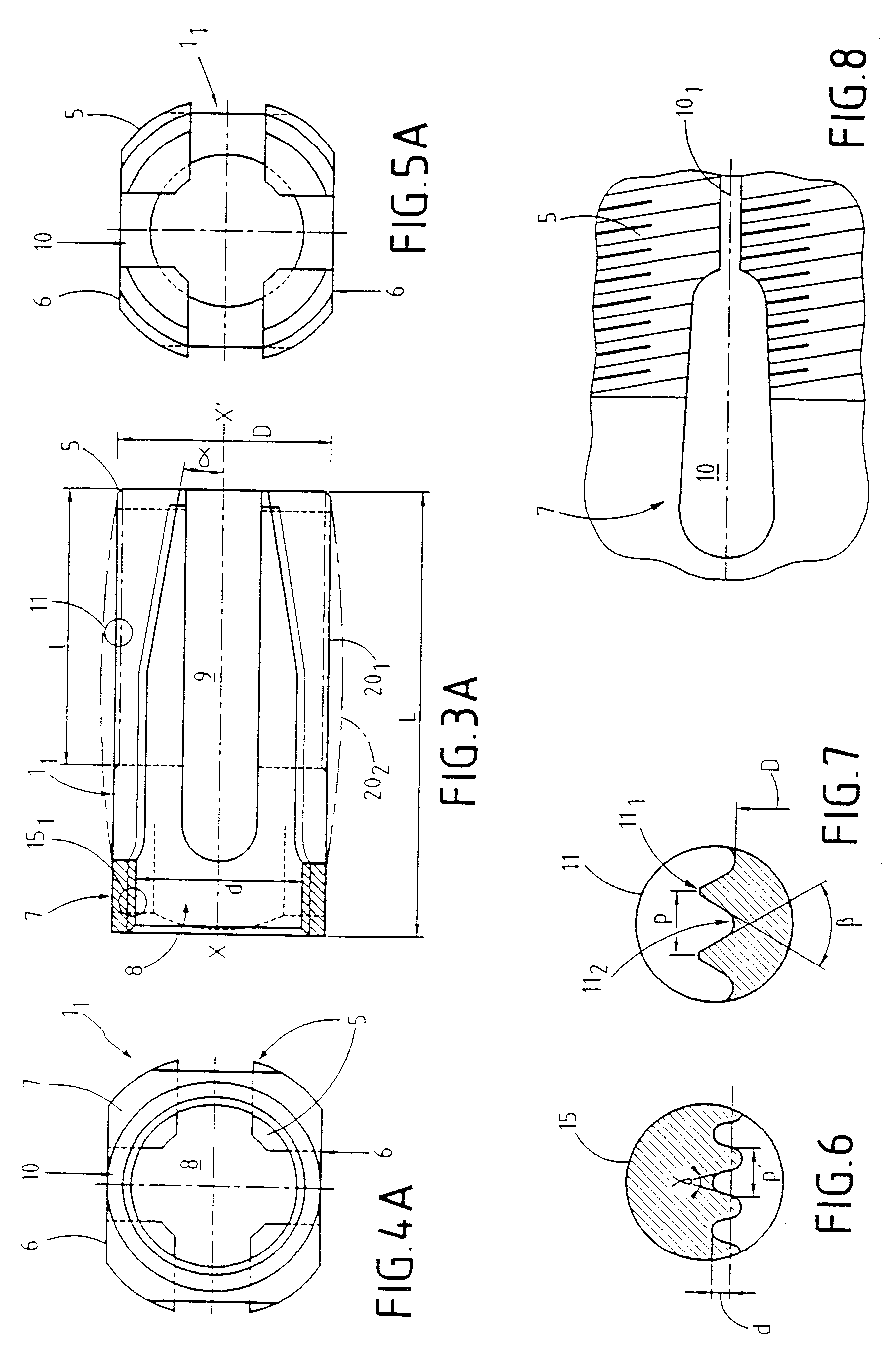

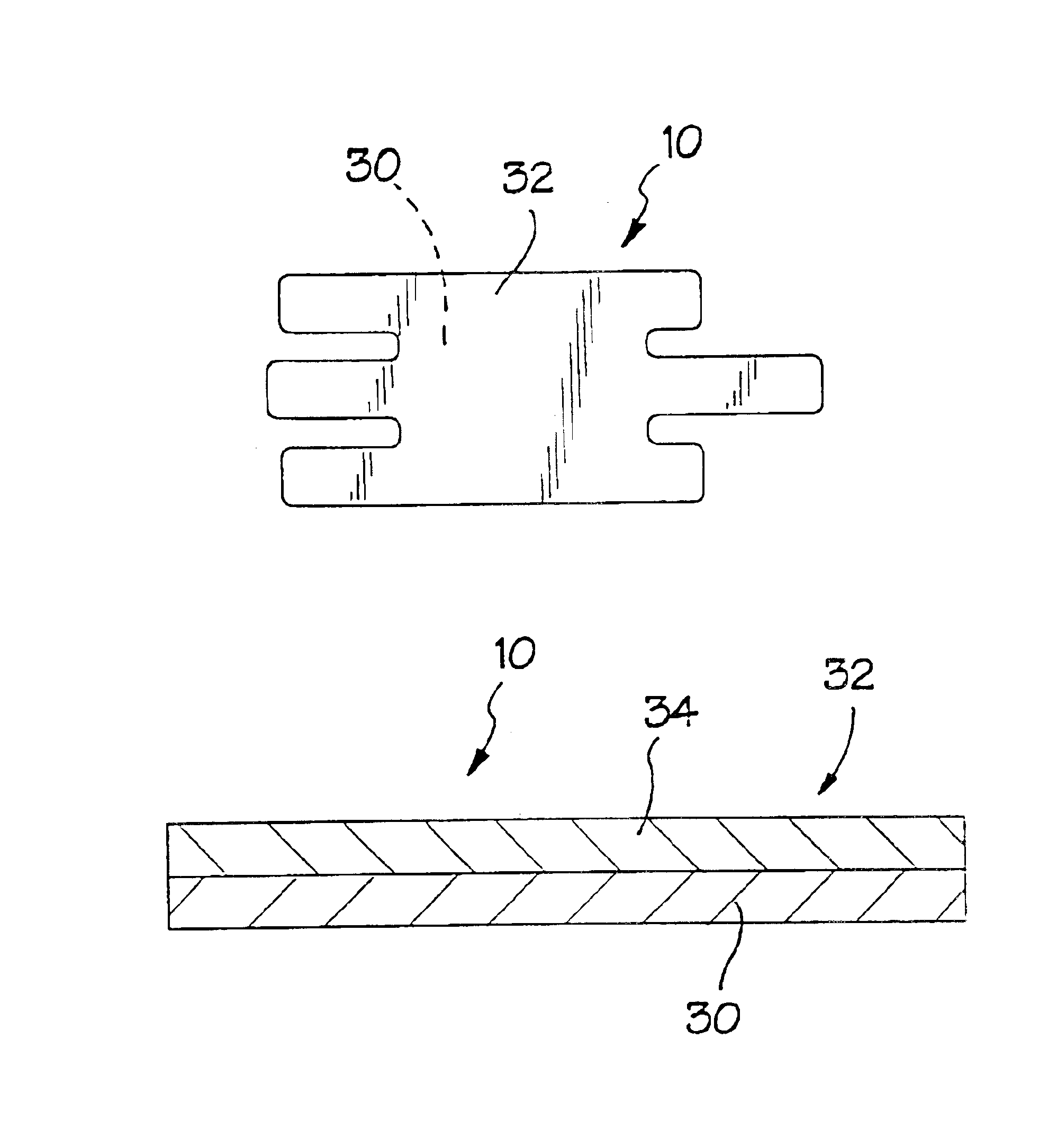

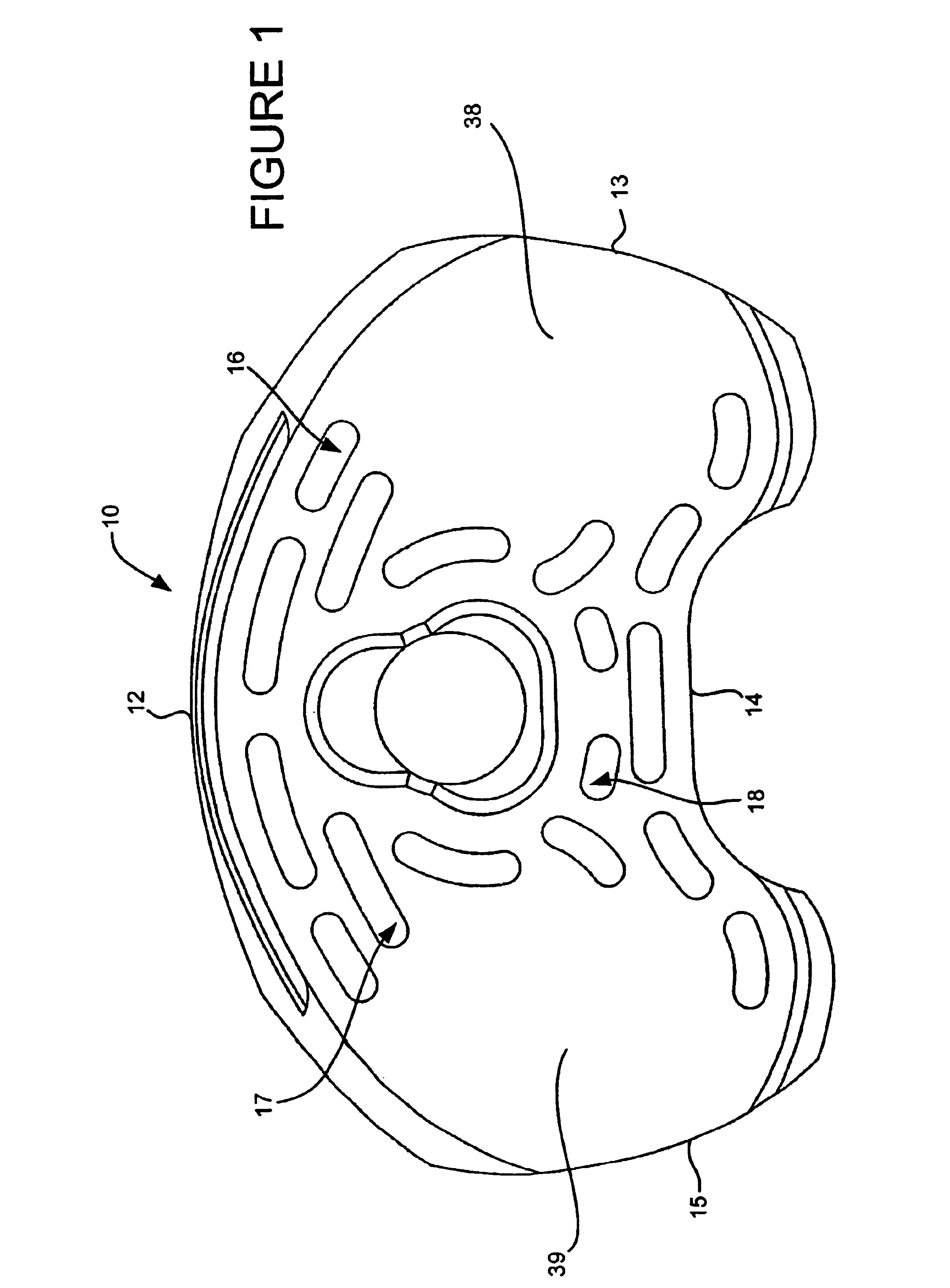

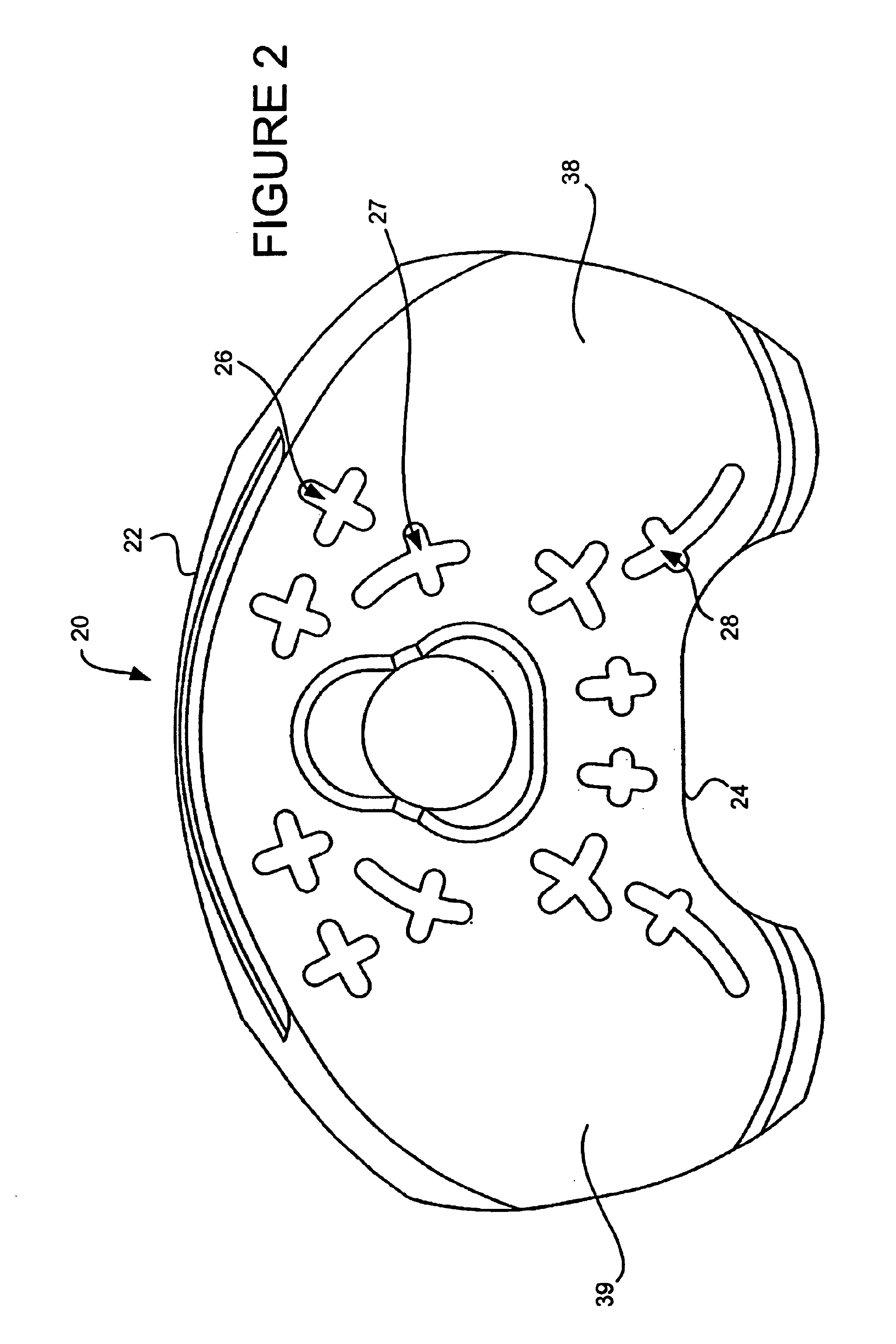

Expandable osteosynthesis cage

InactiveUS6129763AGood jamLarge inside volumeBone implantJoint implantsSpinal columnBiomedical engineering

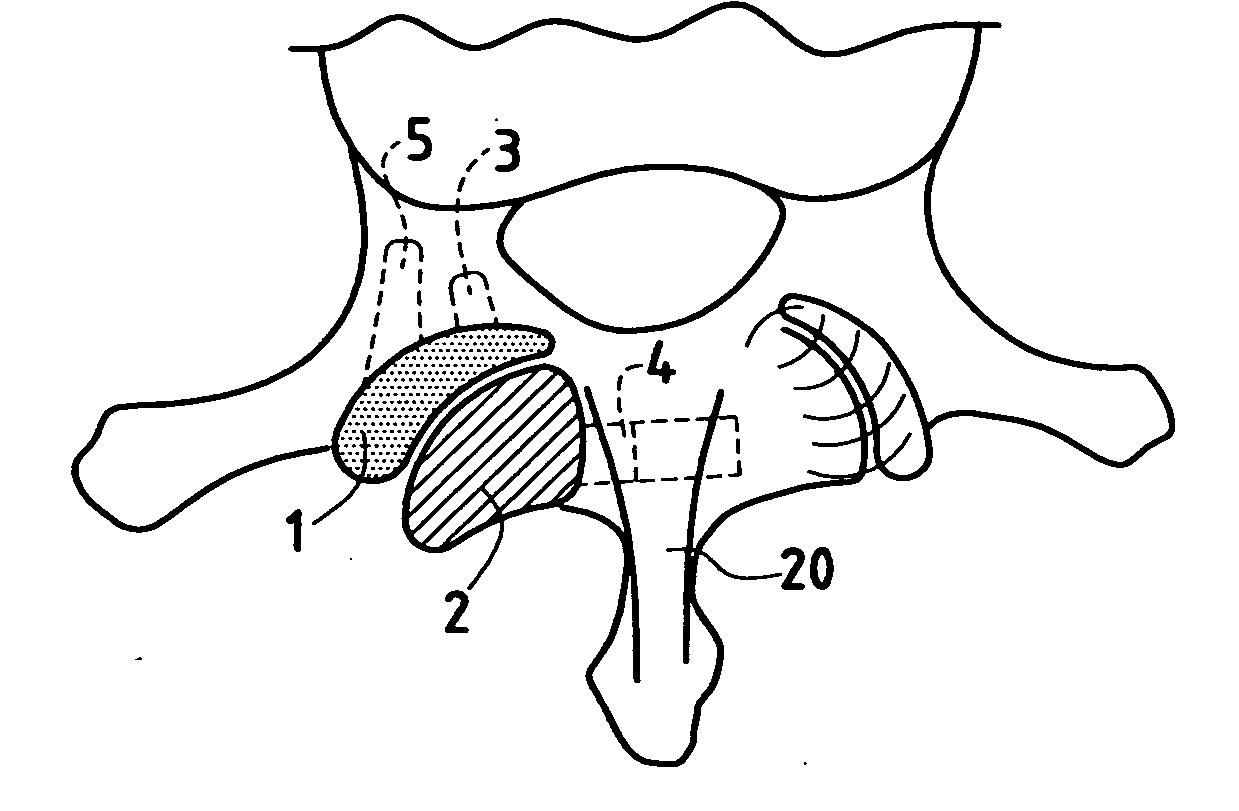

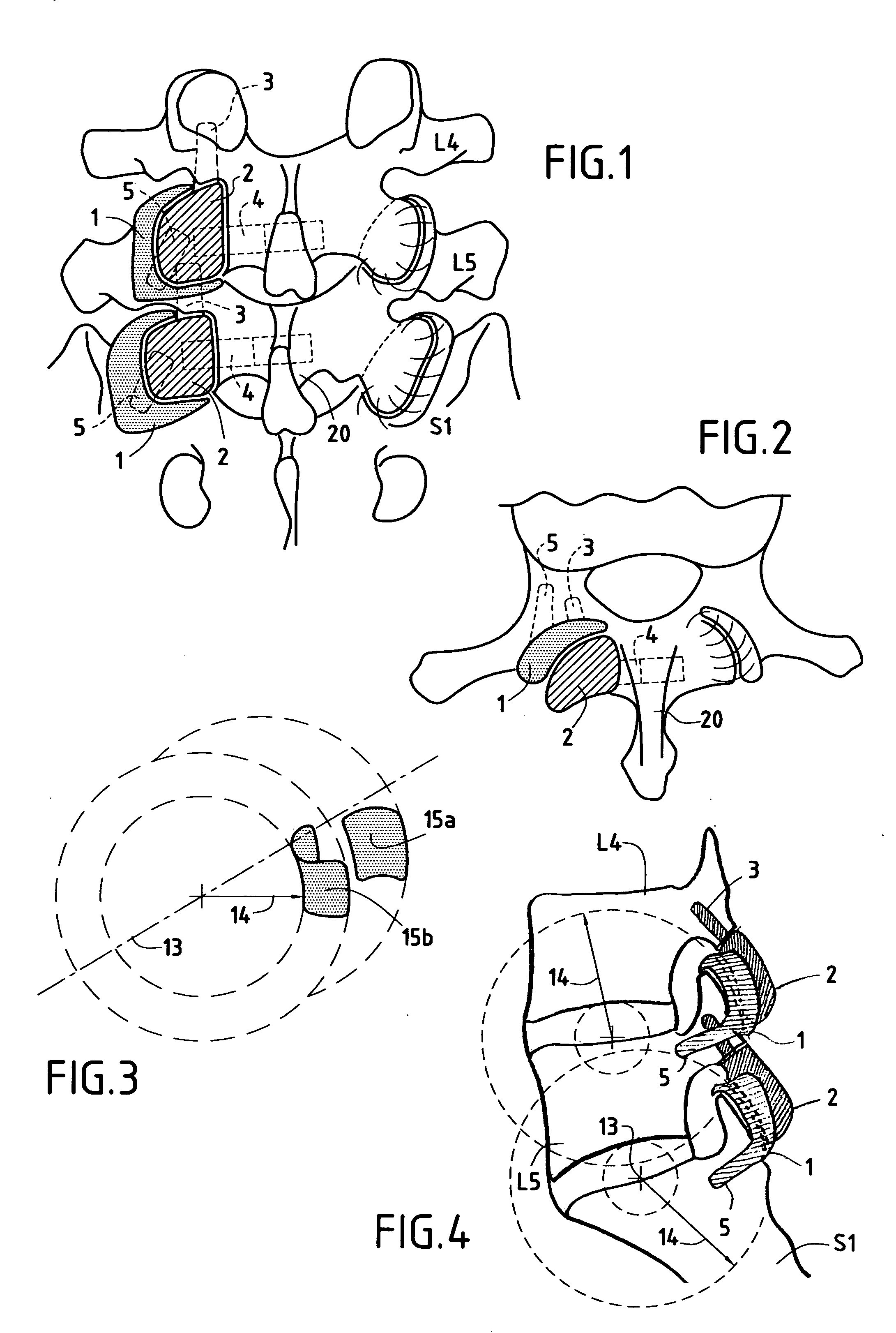

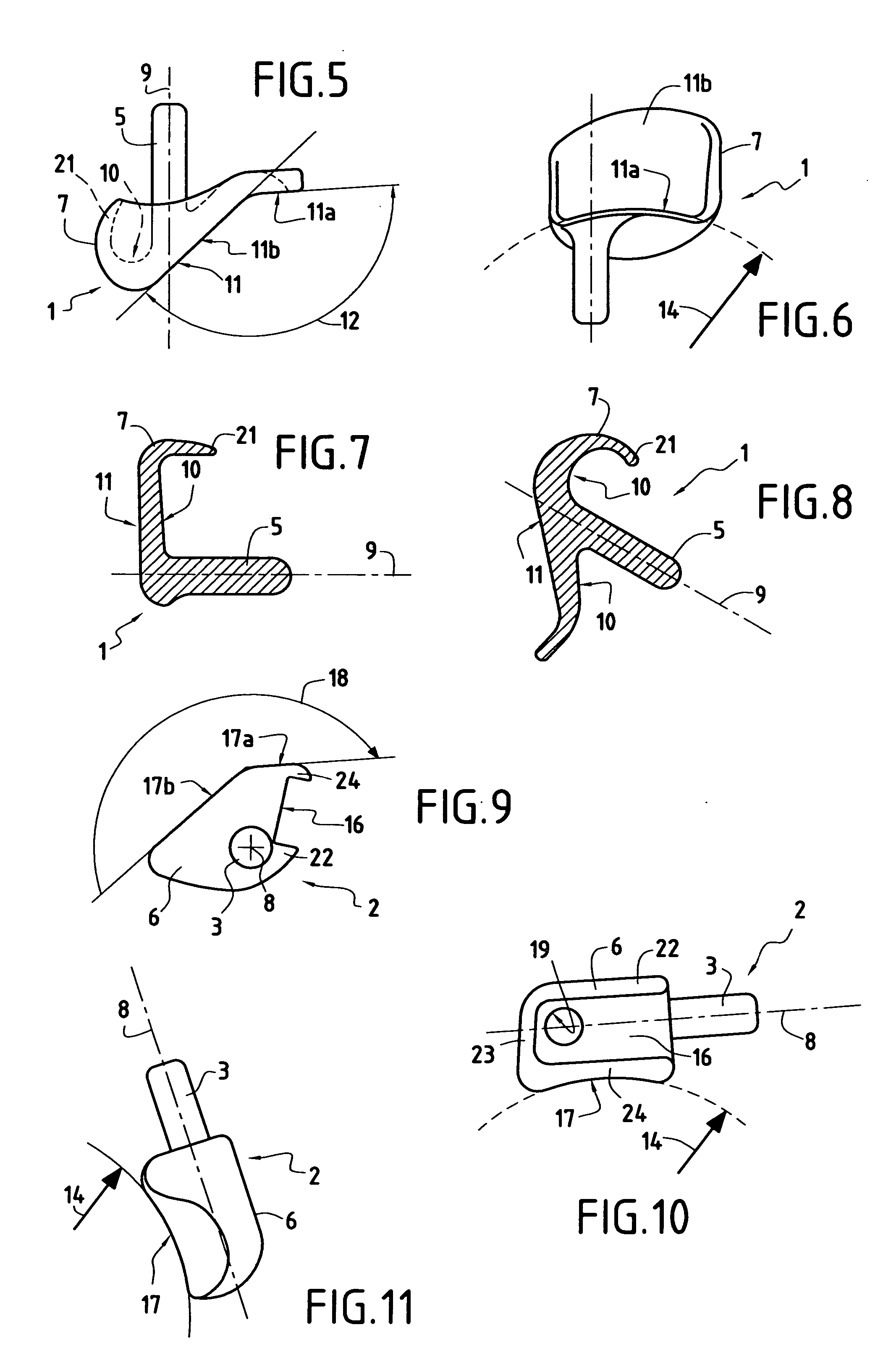

PCT No. PCT / FR97 / 01617 Sec. 371 Date Jul. 28, 1998 Sec. 102(e) Date Jul. 28, 1998 PCT Filed Sep. 12, 1997 PCT Pub. No. WO98 / 10722 PCT Pub. Date Mar. 19, 1998An expandable osteosynthesis implant has branches (5) each connected at one end to a seat (7) which is pierced by an orifice (8), suitable for being slid from a posterior direction between the facing faces of two consecutive vertebrae in order to hold them a given distance apart and restore stability of the spinal column. According to the invention, the branches (5) and the seat (7) define a hollow cage (1) which, in a "rest" position, has an outside general shape that is a cylinder of circular section, and a portion at least of the inside volume (9) of the cage (1) towards the distal ends of the branches (5) is in the form of a circular truncated cone whose large base is towards the seat (7), which implant has at least three branches (5) and, inside the inside volume (9) at least one spacer (2) suitable for passing through the orifice (8) and the large base of the truncated cone.

Owner:OSTEOIMPLANT TECH

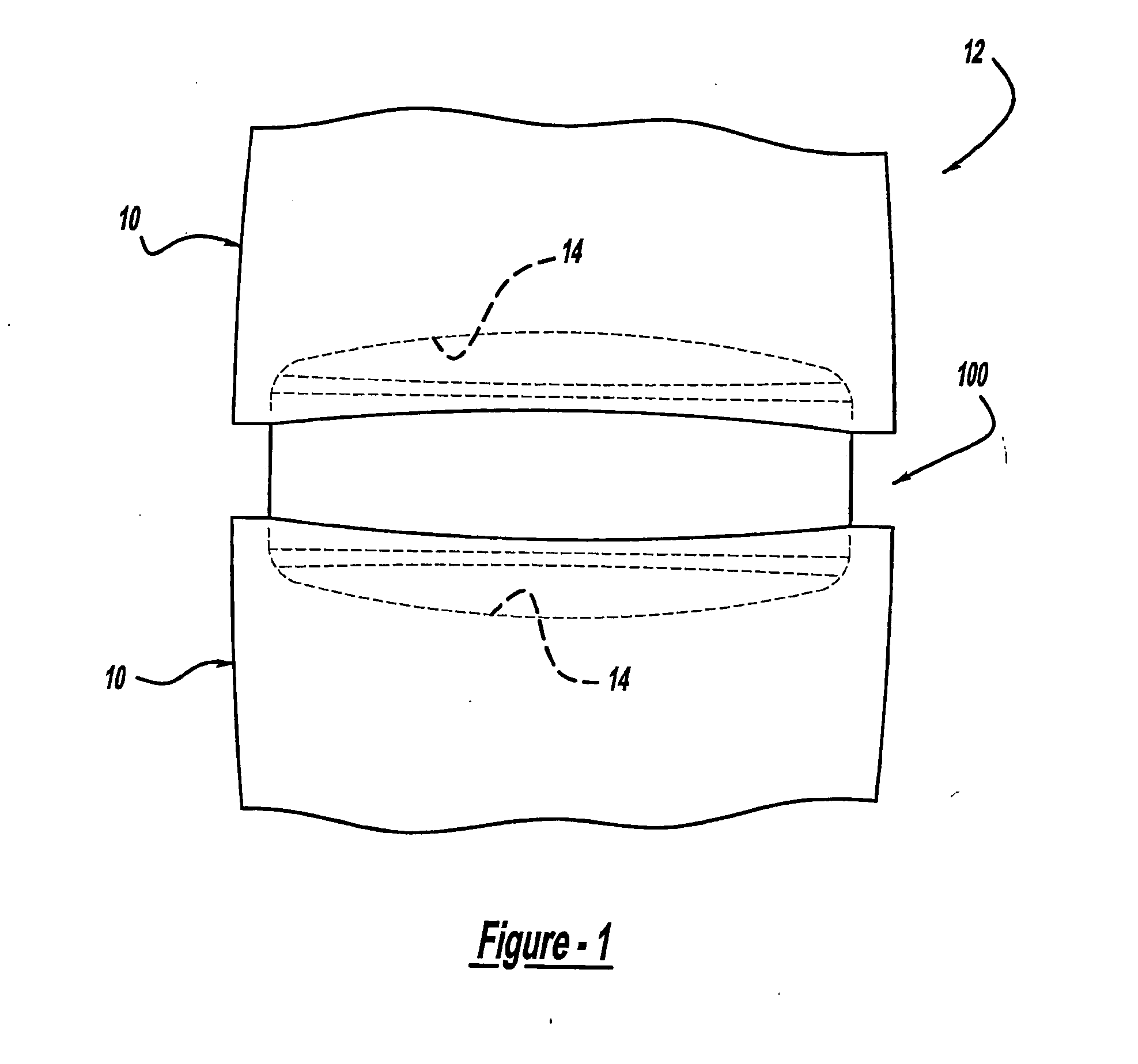

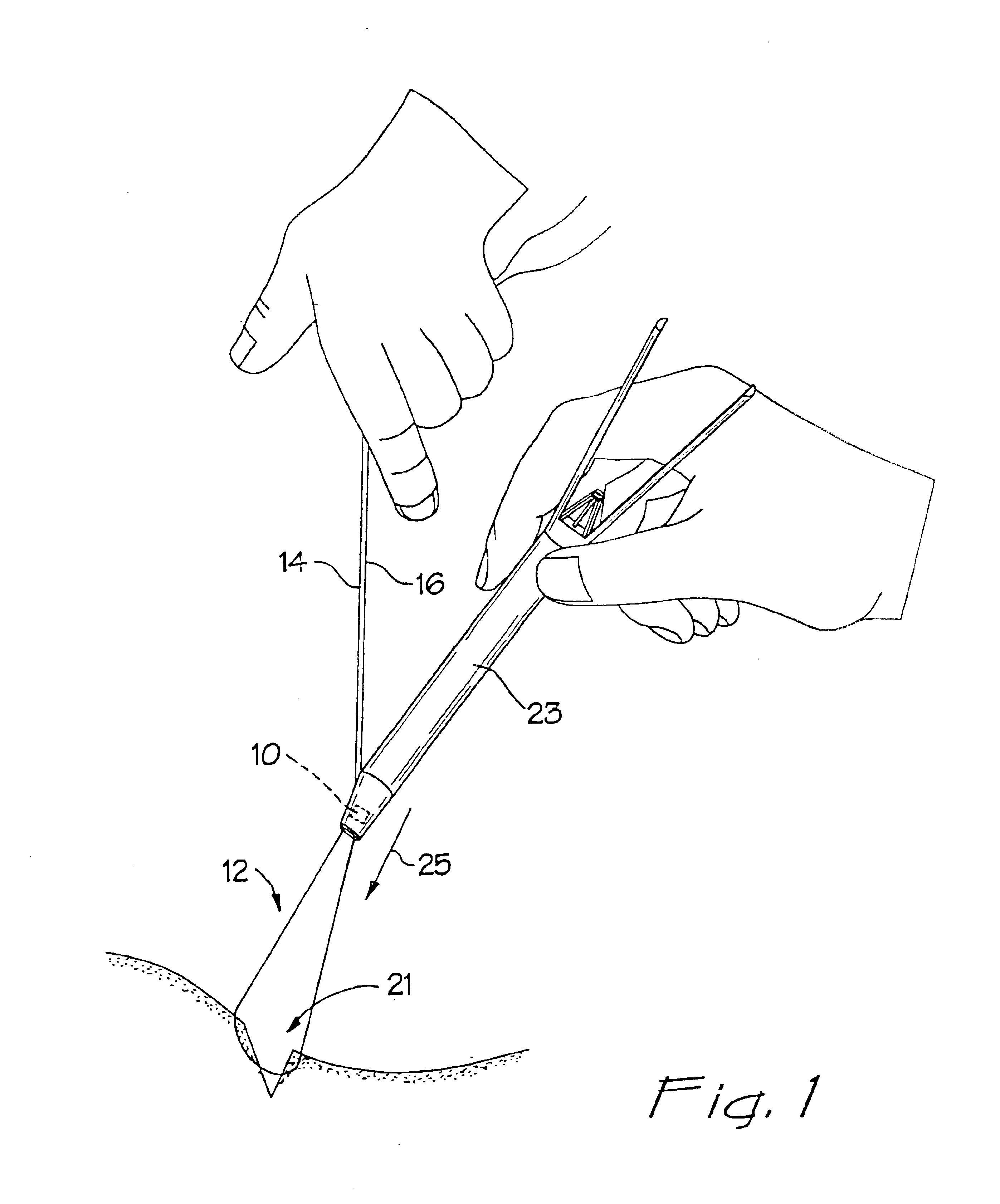

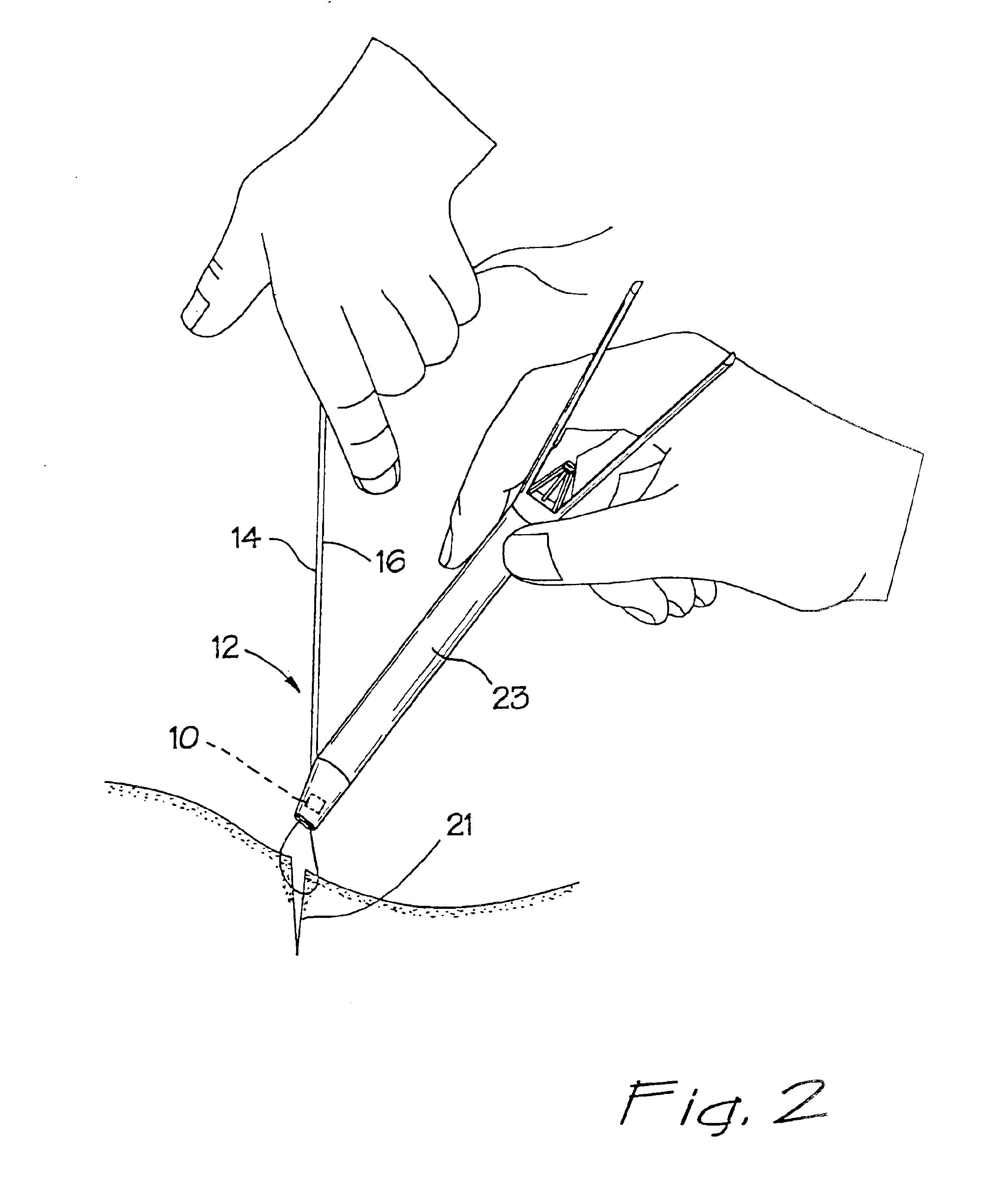

Method of providing proper vertebral spacing

InactiveUS6371989B1Easy to anchorInhibit migrationBone implantJoint implantsSpinal columnBiomedical engineering

An expandable osteosynthesis implant has branches (5) each connected at one end to a seat (7) which is pierced by an orifice (8), suitable for being slid from a posterior direction between the facing faces of two consecutive vertebrae in order to hold them a given distance apart and restore stability of the spinal column. According to the invention, the branches (5) and the seat (7) define a hollow cage (1) which, in a "rest" position, has an outside general shape that is a cylinder of circular section, and a portion at least of the inside volume (9) of the cage (1) towards the distal ends of the branches (5) is in the form of a circular truncated cone whose large base is towards the seat (7), which implant has at least three branches (5) and, inside the inside volume (9) at least one spacer (2) suitable for passing through the orifice (8) and the large base of the truncated cone.

Owner:OSTEOIMPLANT TECH

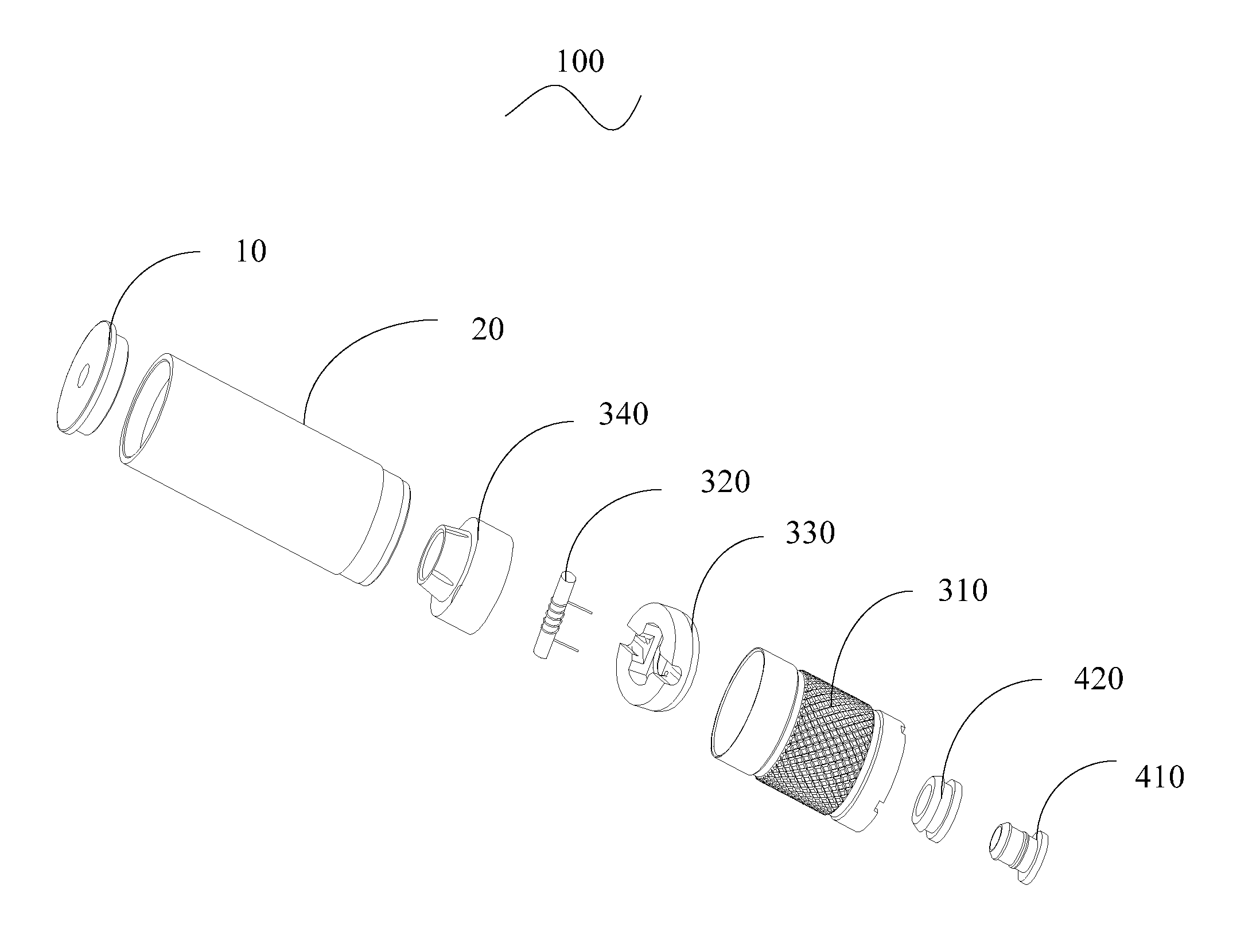

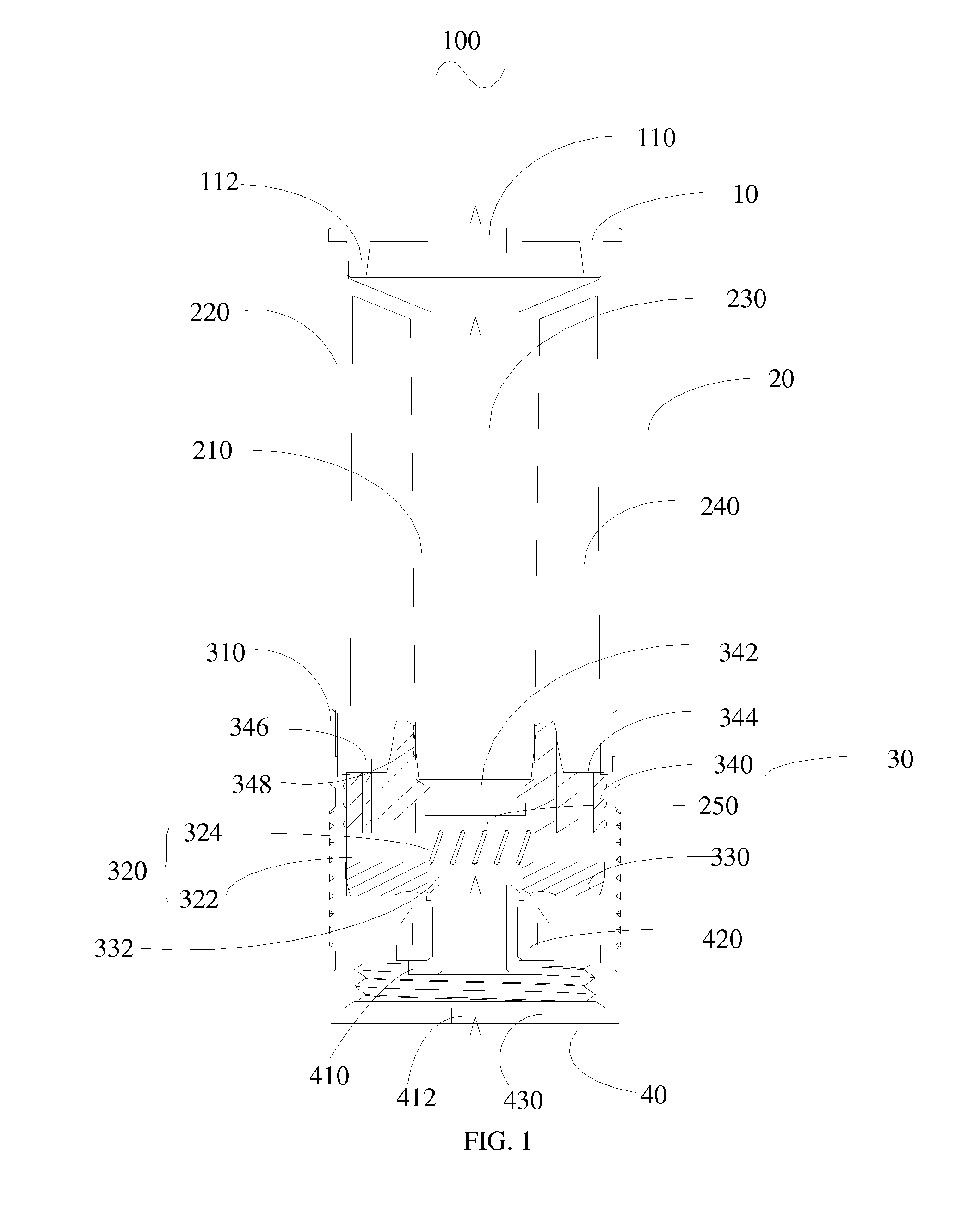

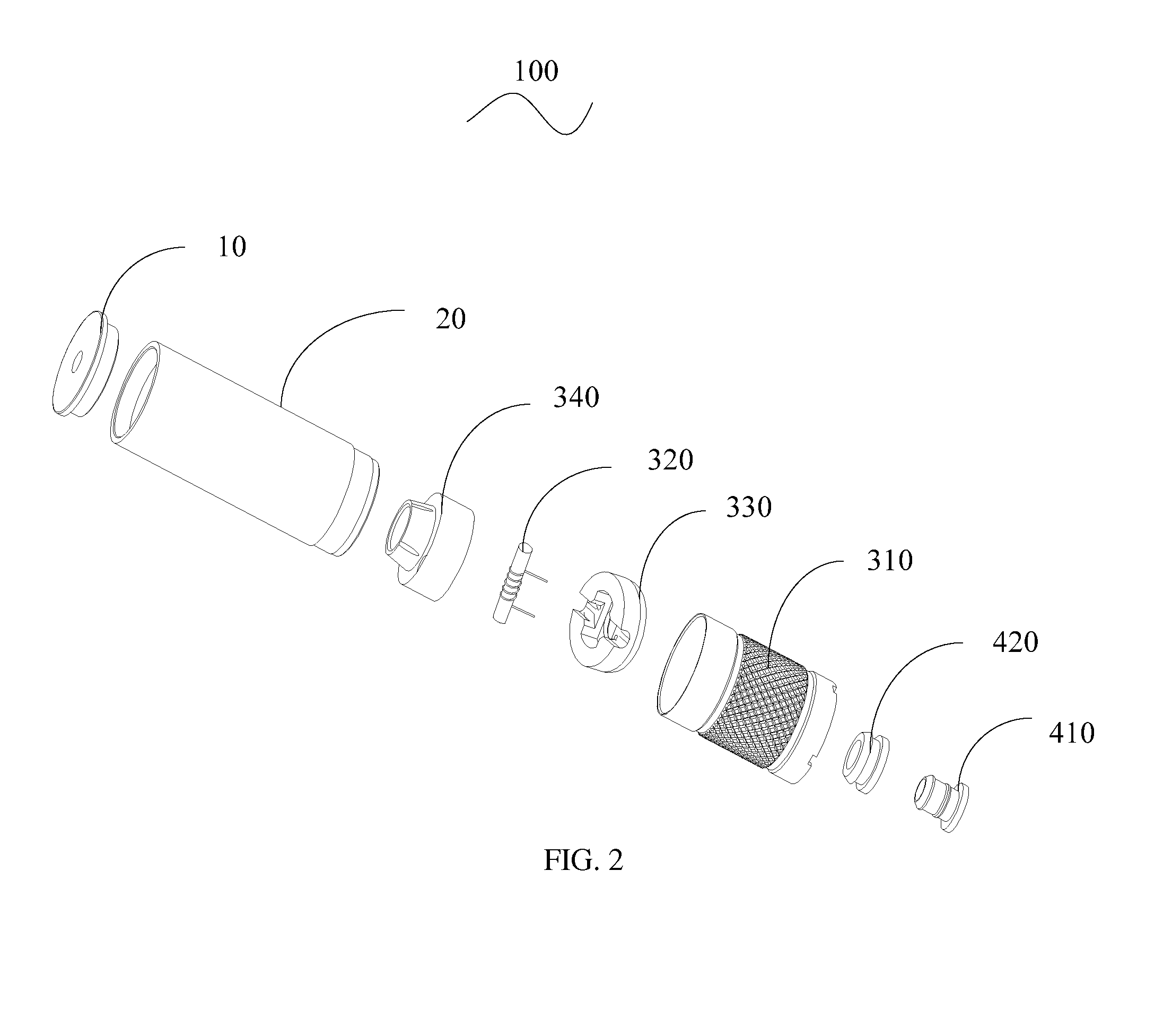

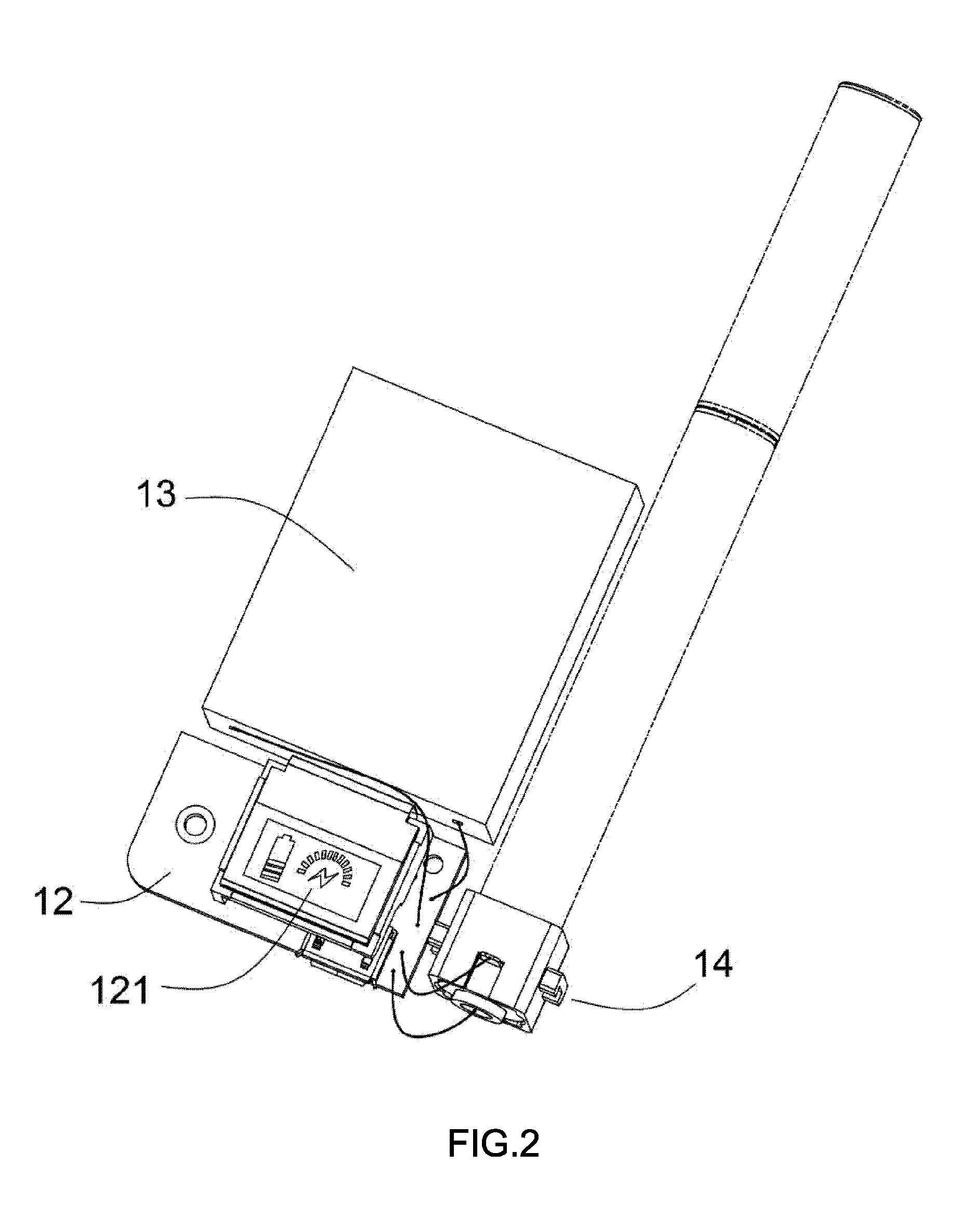

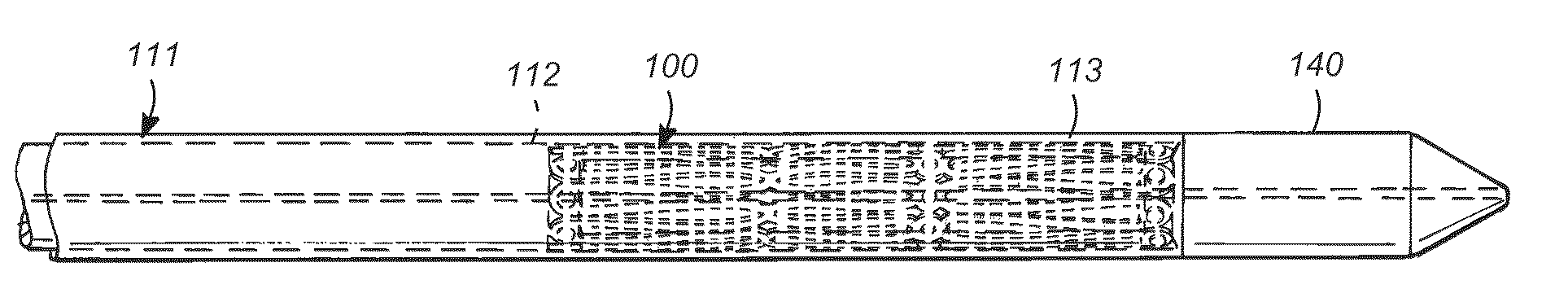

Electronic cigarette

InactiveUS20140109921A1Good flexibilityAvoid flowTobacco devicesElectrical conductorElectronic cigarette

An electronic cigarette includes a cartridge and an atomizer assembly. The cartridge has a chimney and a liquid reservoir with an opening. The atomizer assembly includes an atomizer sleeve; a liquid conductor plugging the opening, a base axially abuts against the liquid conductor, and a heating element positioned between the liquid conductor and the base; the liquid conductor, the base and the heating element are received in the atomizer sleeve. The atomizer sleeve defines an air channel. The base defines an aperture communicated to the air channel. The heating element includes a linear wick and a heating wire twined around the wick. The wick without being twined by the heating wire is received in the aperture. The liquid conductor defines an outlet hole for transferring liquid to the wire. The heating wire and the wick are positioned in the air channel.

Owner:SHENZHEN SMOORE TECH LTD

Method for preparing graphene compounds and graphene oxide compounds with high efficiency

The invention relates to a method for preparing graphene compounds and graphene oxide compounds with high efficiency, relating to the method for preparing the graphene compounds and the graphene oxide compounds. The invention solves the problems of easy composition of graphene or graphene oxide per se and many process steps, higher cost and difficult dispersedness for preparing the graphene compounds and the graphene oxide compounds by the traditional method at the same time. The invention adopts a mechanical stripping method to obtain the graphene compounds and the graphene oxide compounds. In the invention, an automatic machine is utilized, solid particles are used for assisting stripping, the contact area and the stripping number of the stripping process are greatly increased, and carbon material powder experiences a lot of stripping processes through the action of shear and impact, thereby obviously improving the stripping efficiency and achieving the purpose of uniform dispersedness to the composites. The method is suitable for industrial mass production of the graphene compounds and the graphene oxide compounds.

Owner:HARBIN INST OF TECH

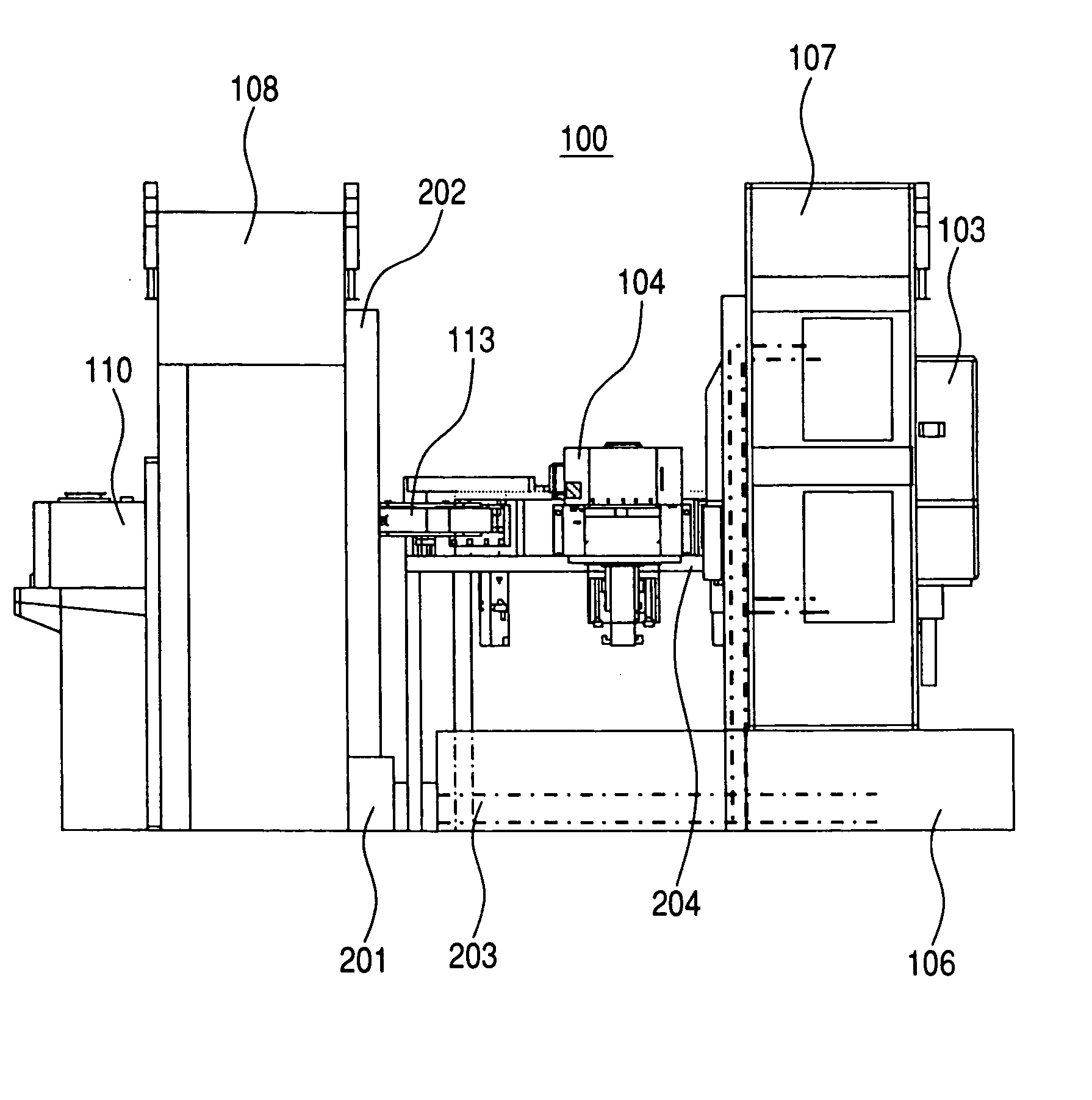

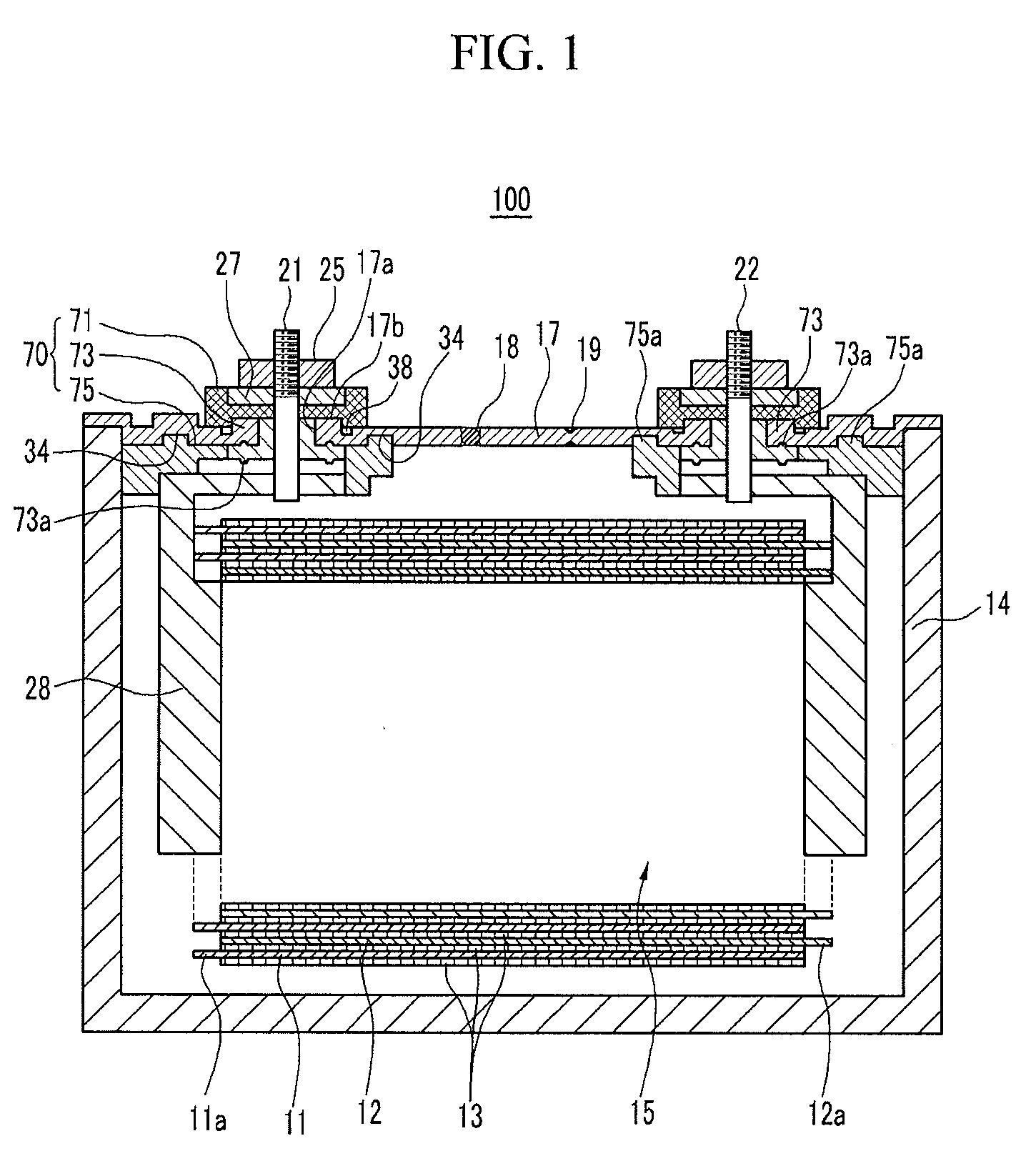

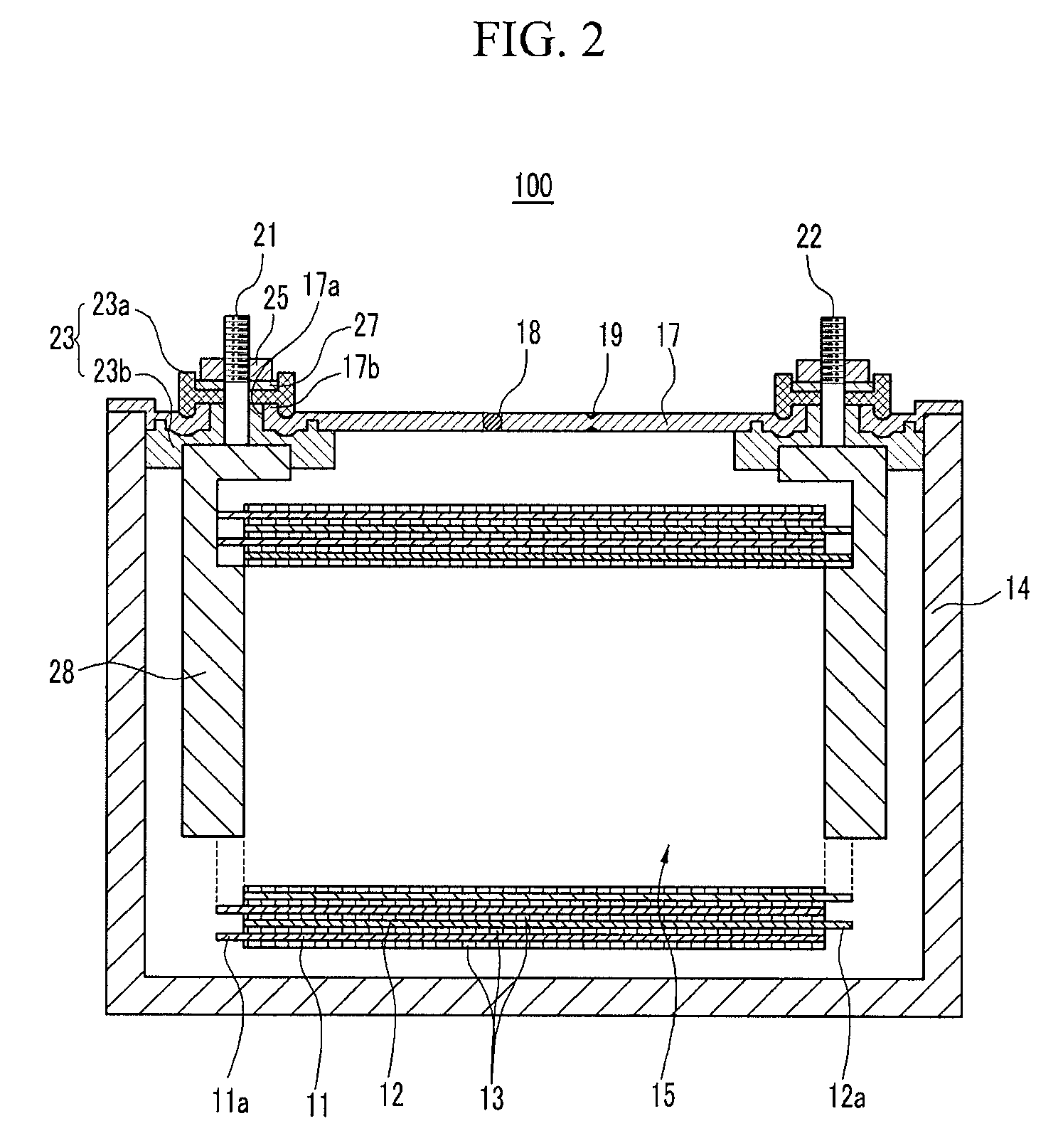

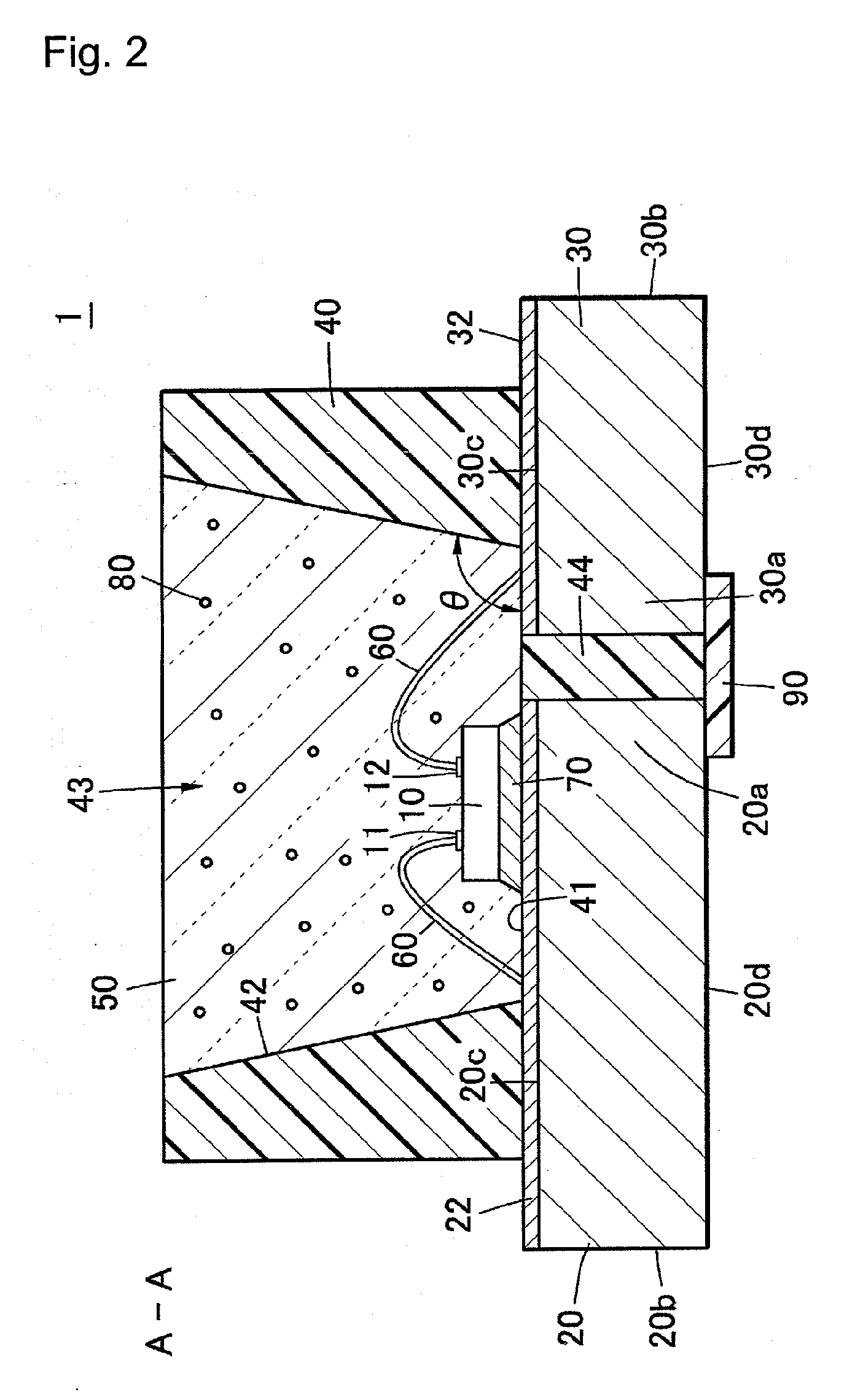

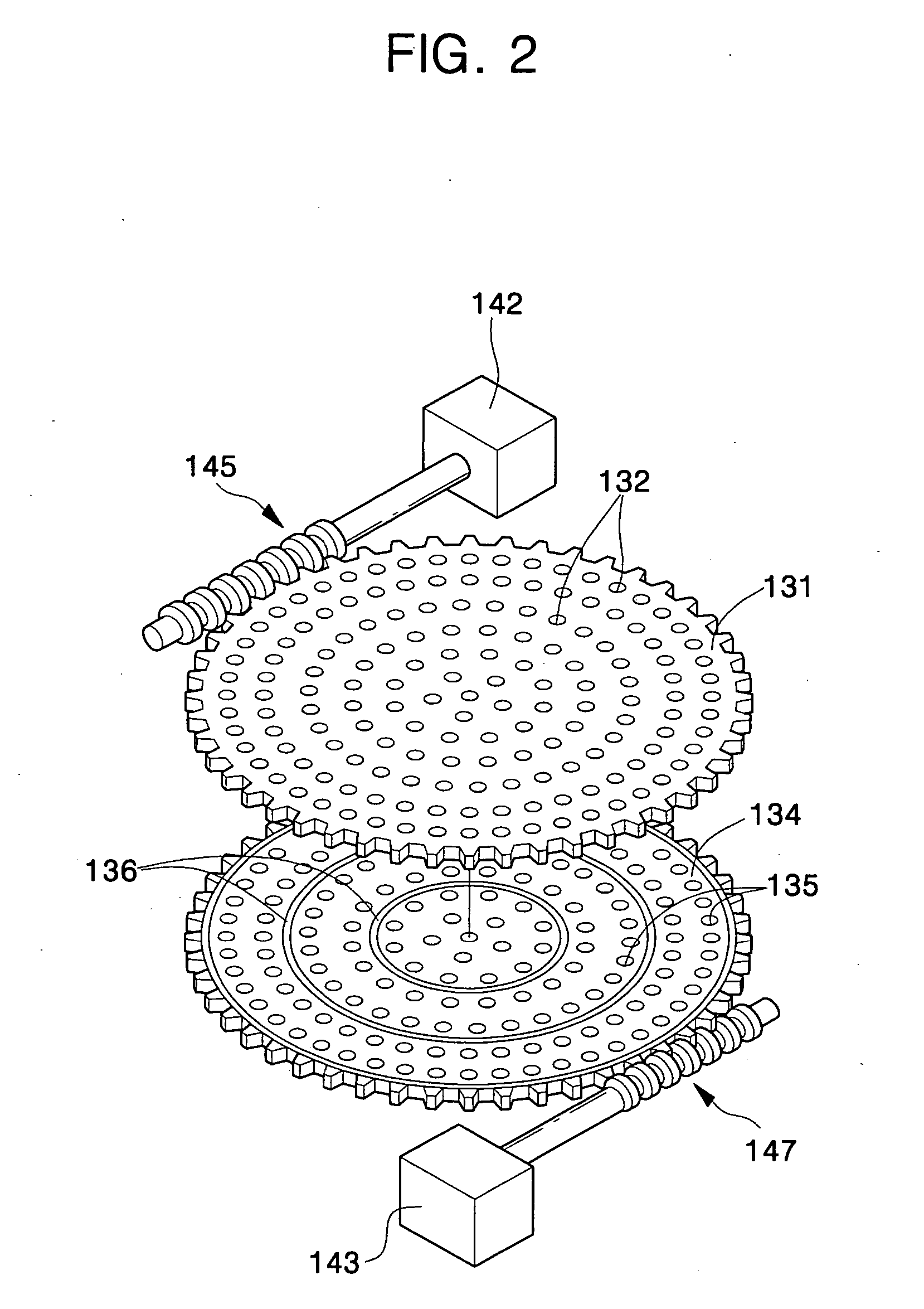

Vacuum processing apparatus

ActiveUS20050193948A1Reduced installation areaEasily perform operationPressurized chemical processSemiconductor/solid-state device manufacturingElectricityEngineering

The present invention provides a vacuum processing apparatus which is small-sized and requires a small installation area. The vacuum processing apparatus includes a vacuum container which has a processing chamber inside thereof, wherein the pressure inside the processing chamber is reduced and plasma used for processing a sample is formed inside the processing chamber, a bed portion which is arranged below the vacuum container and stores a device for supplying electricity and electric signals used for processing inside the vacuum container, and a transport chamber which is connected with the vacuum container and includes a transport device for transporting the sample inside thereof. The vacuum processing apparatus further includes a connector portion which is mounted on the bed portion in a state that the connector portion faces a lower portion of the transport chamber, wherein the bed portion is configured to be detachably mounted on the vacuum processing apparatus in a state that the bed portion performs the connection and the disconnection at the connector portion.

Owner:HITACHI HIGH-TECH CORP

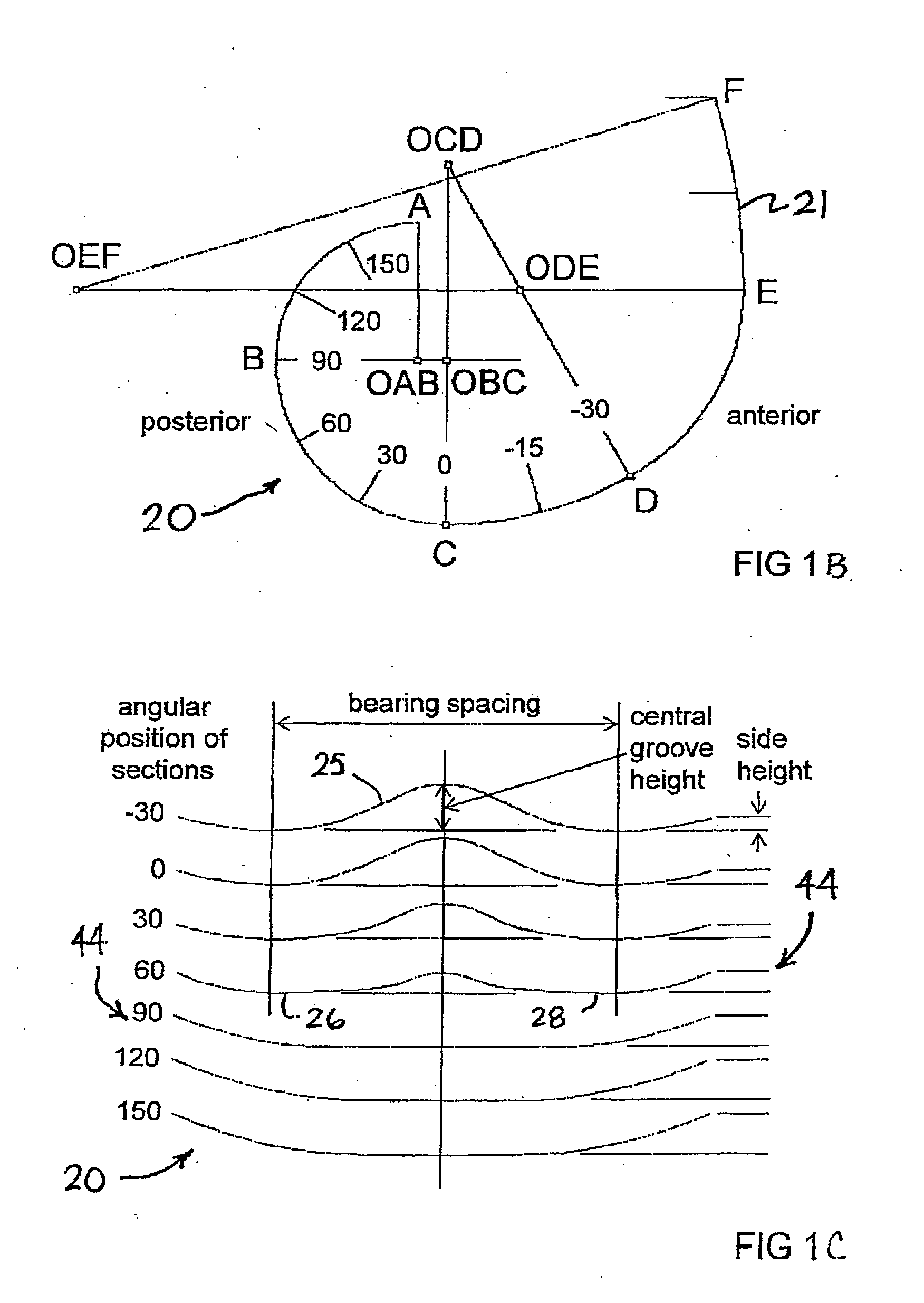

Posterior vertebral joint prosthesis

InactiveUS20050015146A1Easy to slideConserve high degree of mobilityJoint implantsSpinal implantsProsthesisVertebral Joint

The present invention relates to a posterior vertebral joint prosthesis. The left or right posterior vertebral joint prosthesis of the invention presents a smooth bearing surface and said surface presents antero-posterior curvature.

Owner:LOUIS CHRISTIAN +1

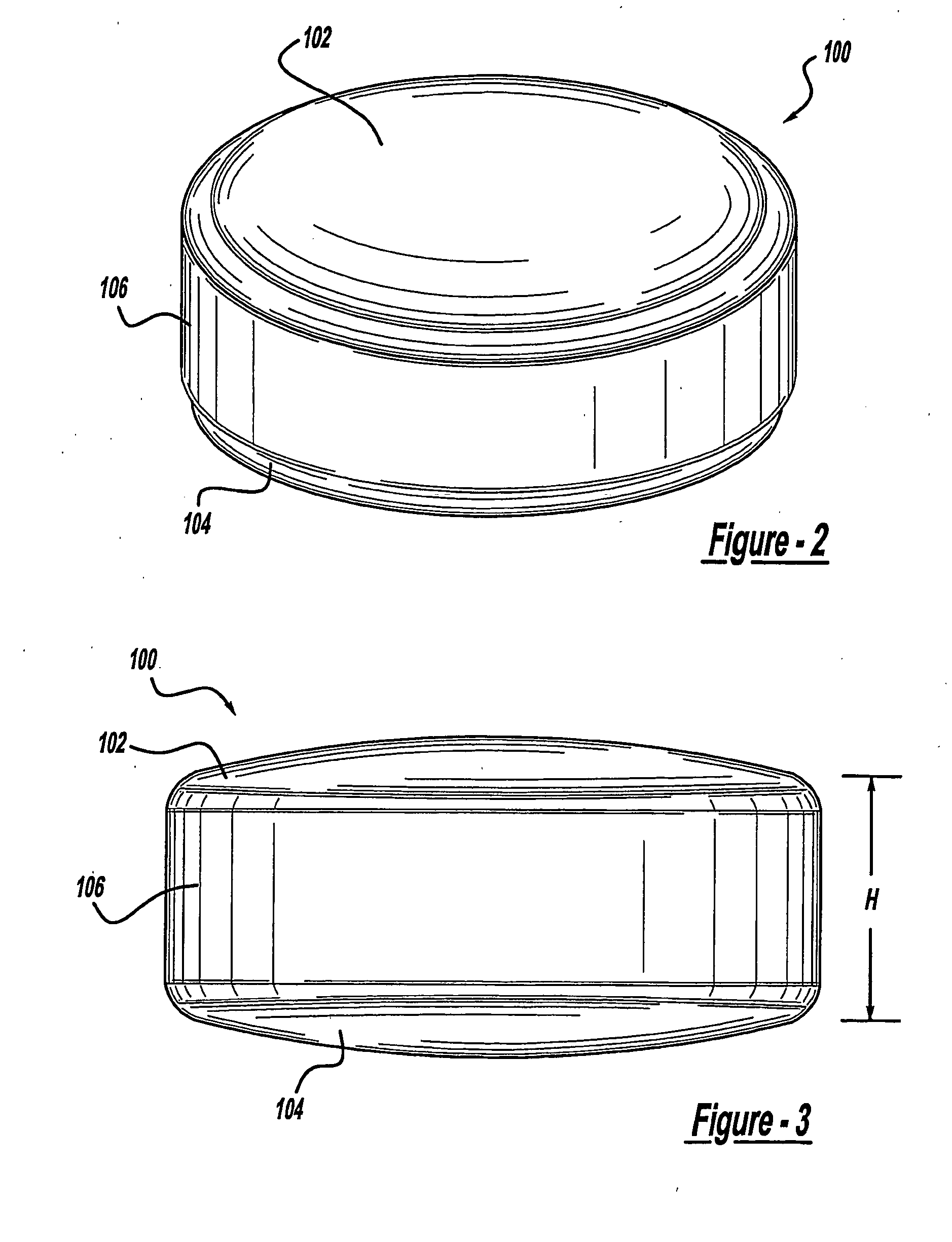

Anterior spinal implant

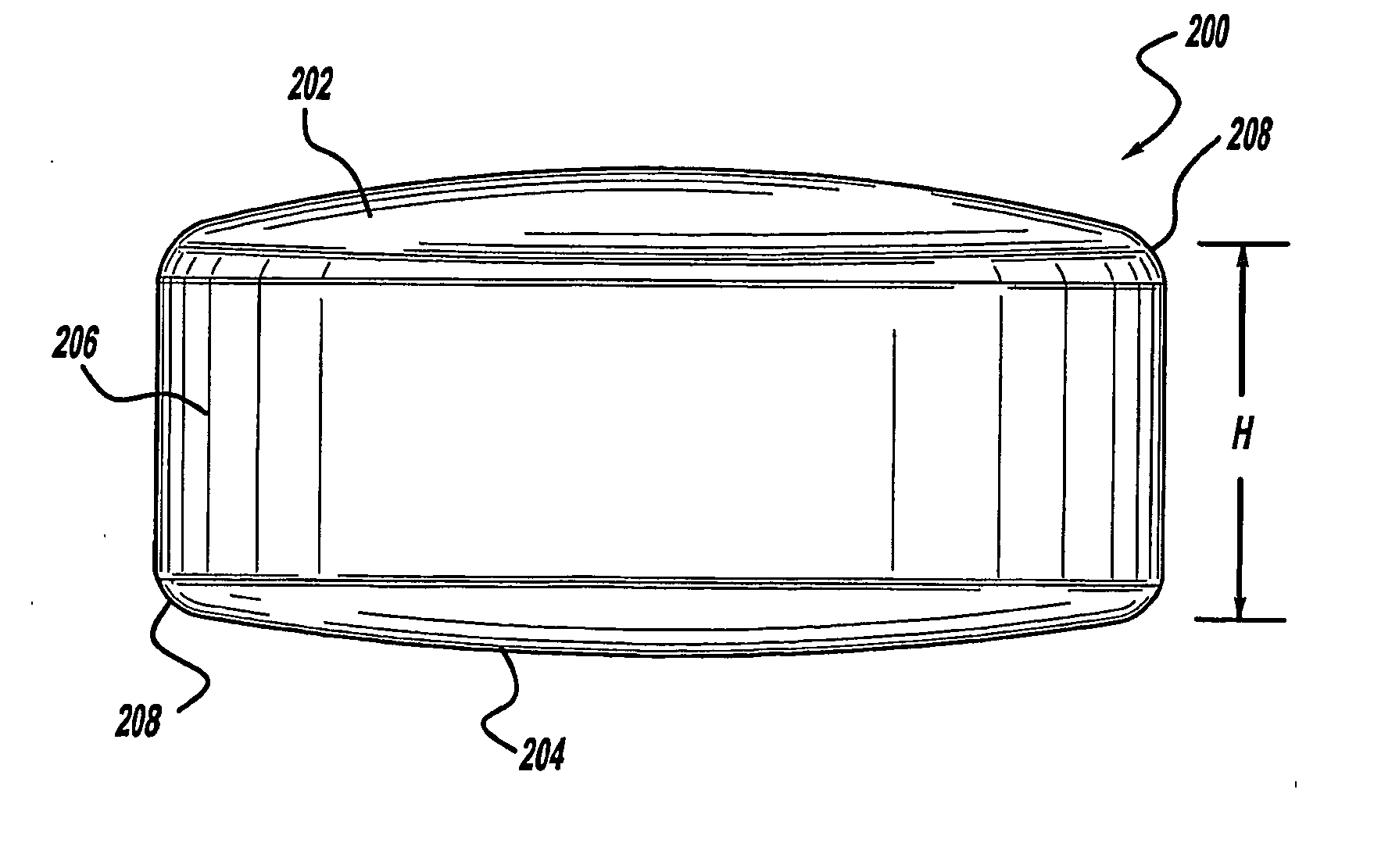

InactiveUS20050149188A1Resists migrationIncrease contact areaBone implantJoint implantsSagittal planeSurgery

An anterior spinal implant includes a superior end face, an inferior end face and a sidewall extending between the superior end face and the inferior end face. The superior end face and the inferior end face are convex. In one application, the superior and inferior end faces are convex. The sidewall includes a convexly curved leading portion, a convexly curved trailing portion and a pair of substantially planar side portions. The superior and inferior end faces transition in a sagittal plane from a first radius of curvature to a second radius of curvature. The first radius of curvature is smaller than the second radius of curvature. The apexes of the superior and inferior end faces are offset from a center of the implant.

Owner:EUROPEAN BIOINFORMATICS INSTITUTE

Method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping

InactiveCN101817516AImprove stripping efficiencyLight in massHigh volume manufacturingSolid particle

The invention provides a method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping and relates to a preparation method of the graphene or the graphene oxide, solving the problems that the traditional micro-mechanical stripping method has low efficiency and can not be used for large-batch production. The method comprises the following step of separating carbon materials by utilizing solid particles and a liquid working medium (or gas working medium) and adopting mechanical stripping to obtain the graphene or the graphene oxide, wherein the carbon materials comprise graphite powder, expanded graphite, expandable graphite or graphite powder oxide. By using automatic machinery and using a great deal of solid particles for assisting stripping processes, the invention greatly increases the contact areas and the stripping times of the stripping processes, the carbon materials are subject to a great amount of stripping processes in a short time through the shearing and impacting functions of the solid particles on the carbon materials, and thereby the method obviously improves the stripping efficiency, has low cost and is suitable for the industrial and large-batch production of the graphene or the graphene oxide.

Owner:HARBIN INST OF TECH

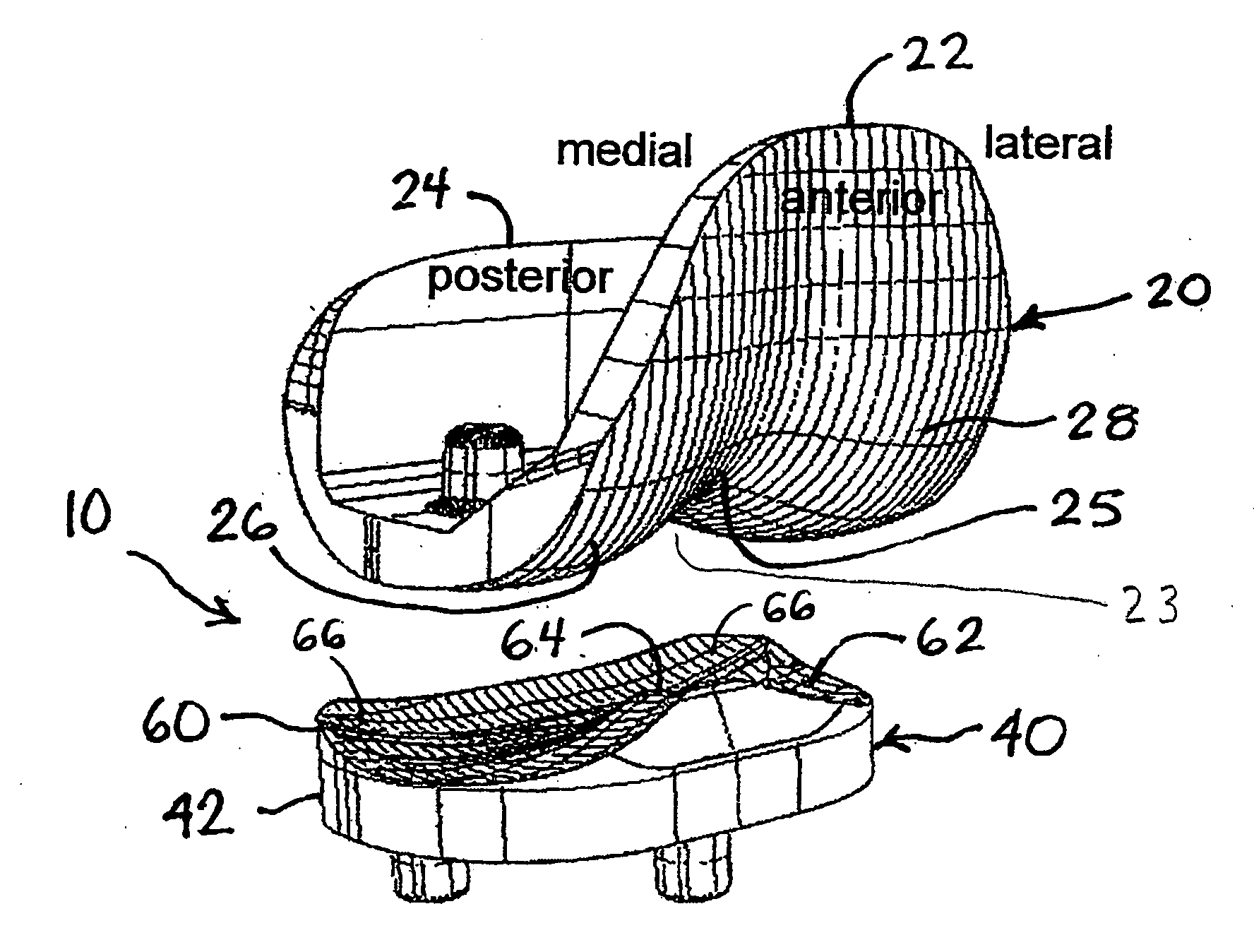

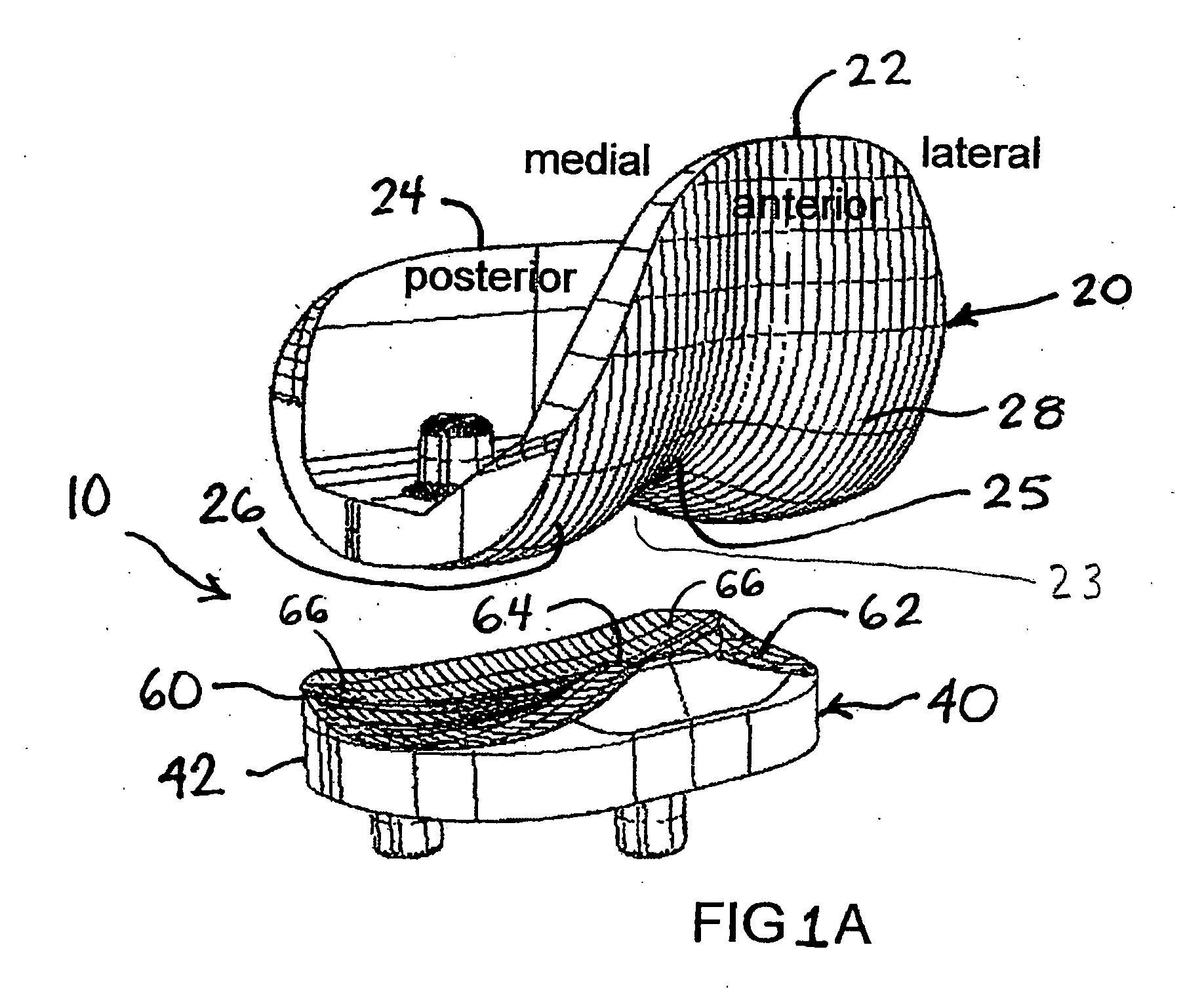

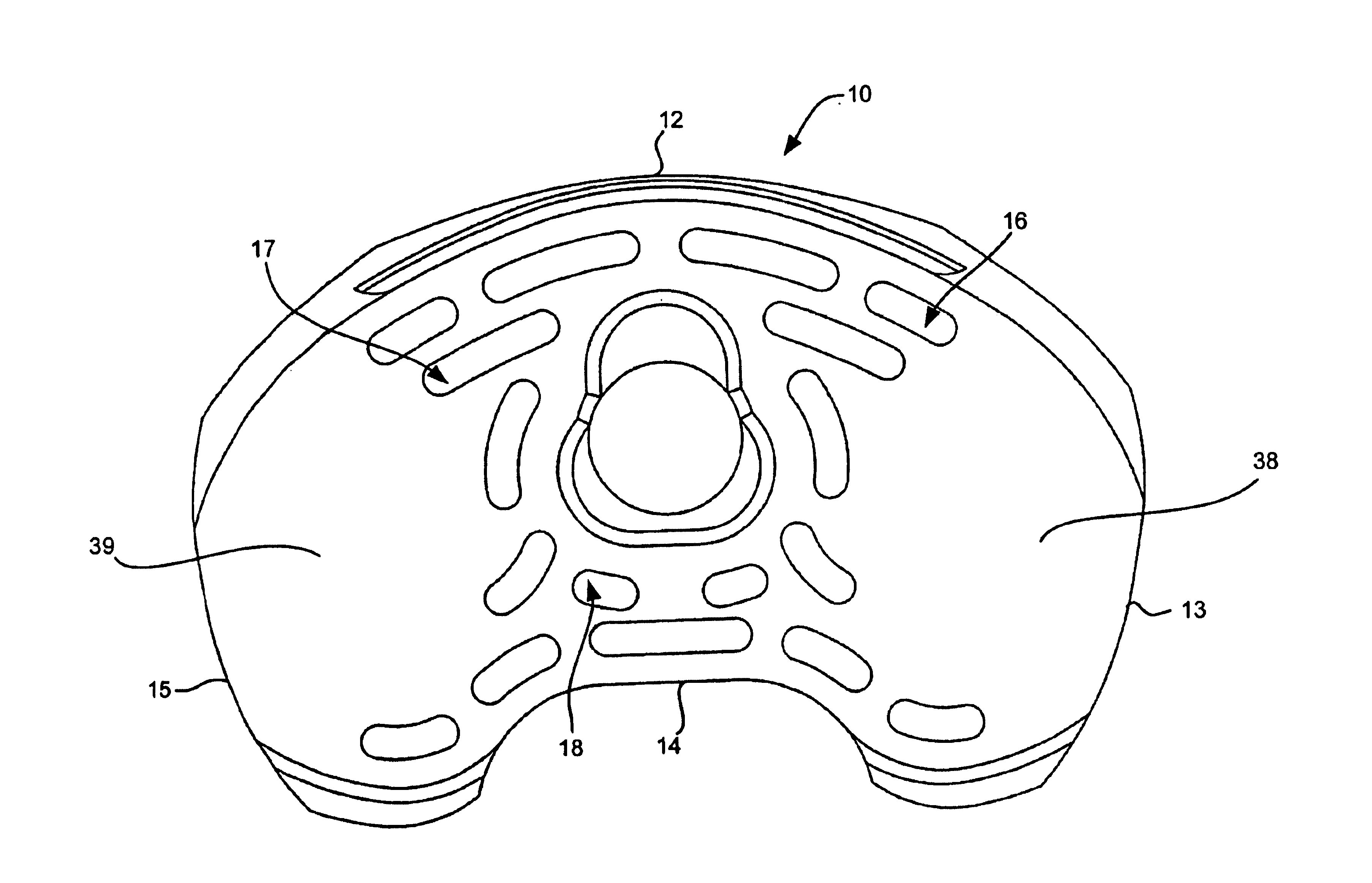

Surface guided knee replacement

ActiveUS20070135926A1Increase contact areaIncrease flexibilityJoint implantsKnee jointsTibiaTibial surface

An artificial knee joint that includes a femoral component with a specially shaped bearing surface and a tibial component, whose surface interacts with the femoral surfaces. The interaction provides for the required motion and stability characteristics. The interaction between the femoral and tibial surfaces is such that as the knee is flexed to maximum, the femoral component moves posteriorly on the tibial surface, by an amount similar to that in the anatomic knee. This is accomplished primarily by the depth and width of the femoral trochlea diminishing as the femoral component is flexed from zero to maximum, together with a ramp on the center of the tibial surface. The opposite motion, roll forward of the femur from a fully flexed to a more extended position, is accomplished by varying the outward radii of the lateral and medial femoral bearing surfaces, together with a ramp on the postero-lateral and postero-medial regions of the tibial surfaces. A variation of this is to generate a tibial surface which provides for a progressive internal rotation of the tibia as flexion proceeds.

Owner:NEW YORK UNIV

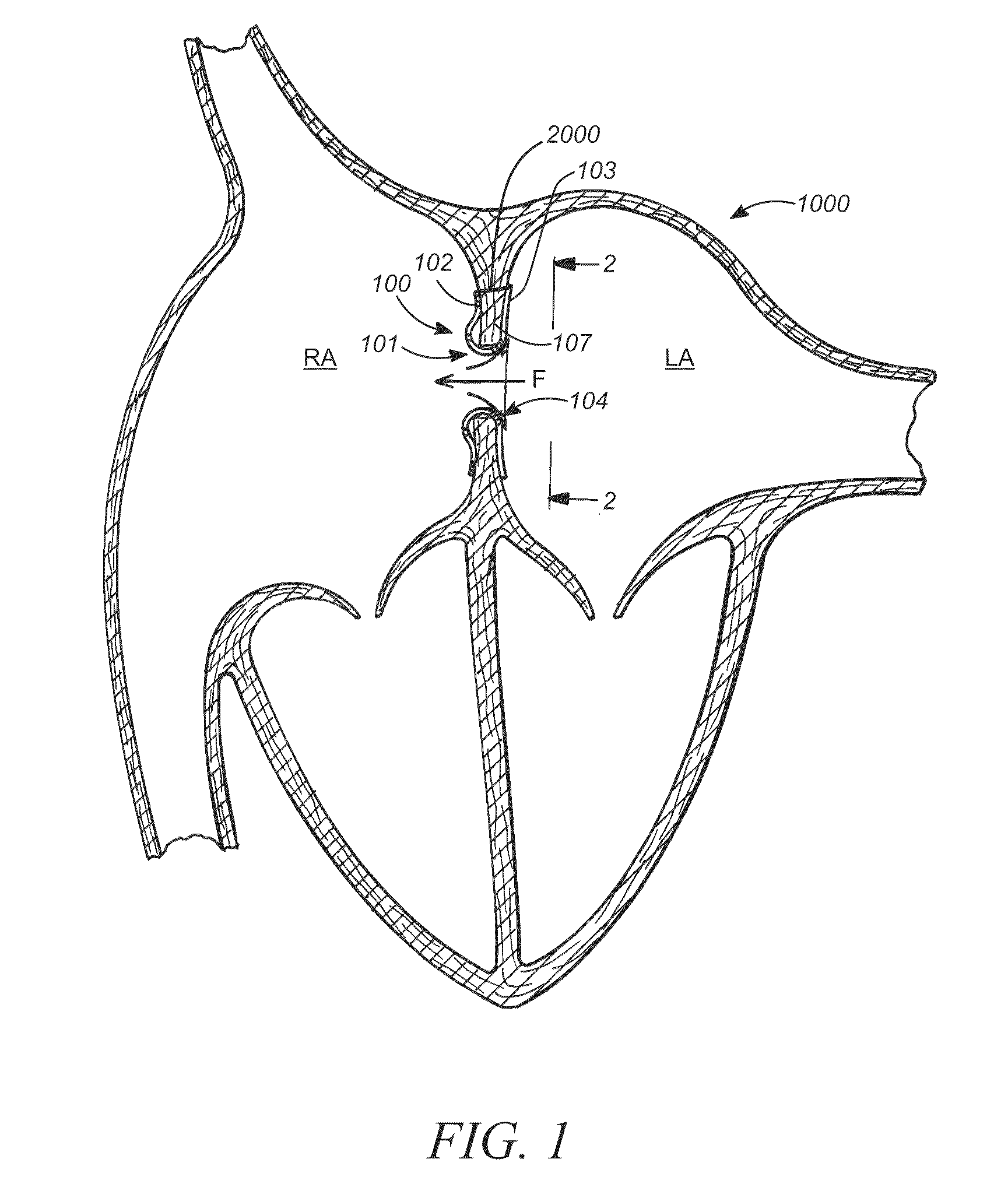

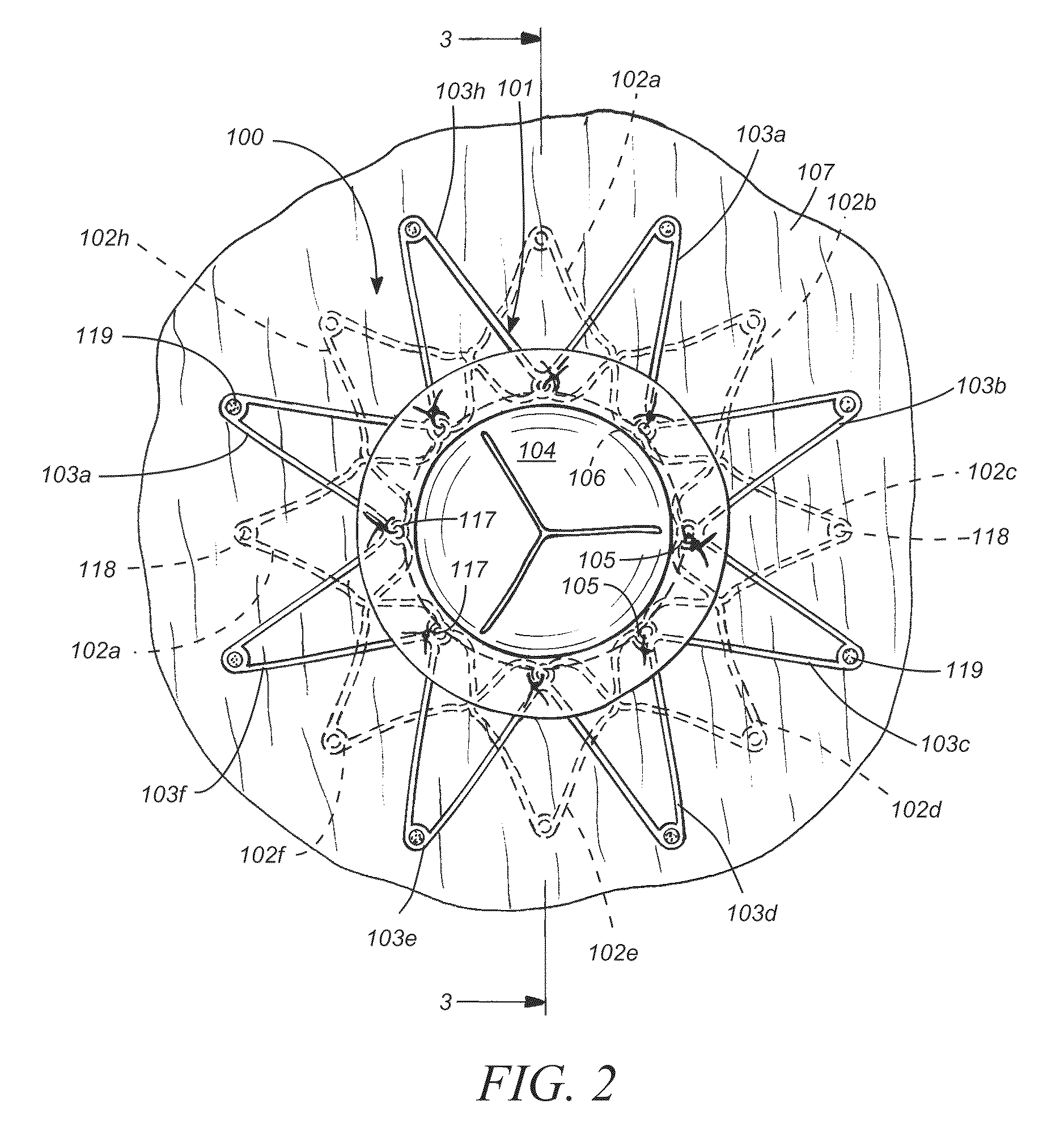

Devices and methods for coronary sinus pressure relief

A method and devices for relieving pressure in the left atrium of a patient's heart is disclosed. The method includes using an ablative catheter in a minimally invasive procedure to prepare an opening from the coronary sinus into a left atrium of the patient's heart. Once the opening is prepared, the opening may be enlarged by a technique such as expanding a balloon within the opening. A stent is then placed within the coronary sinus of the patient, with a transverse portion expanding within the opening, allowing blood to flow from the left atrium to the coronary sinus and then to the right atrium. Pressure within the left atrium is thus relieved.

Owner:DC DEVICES

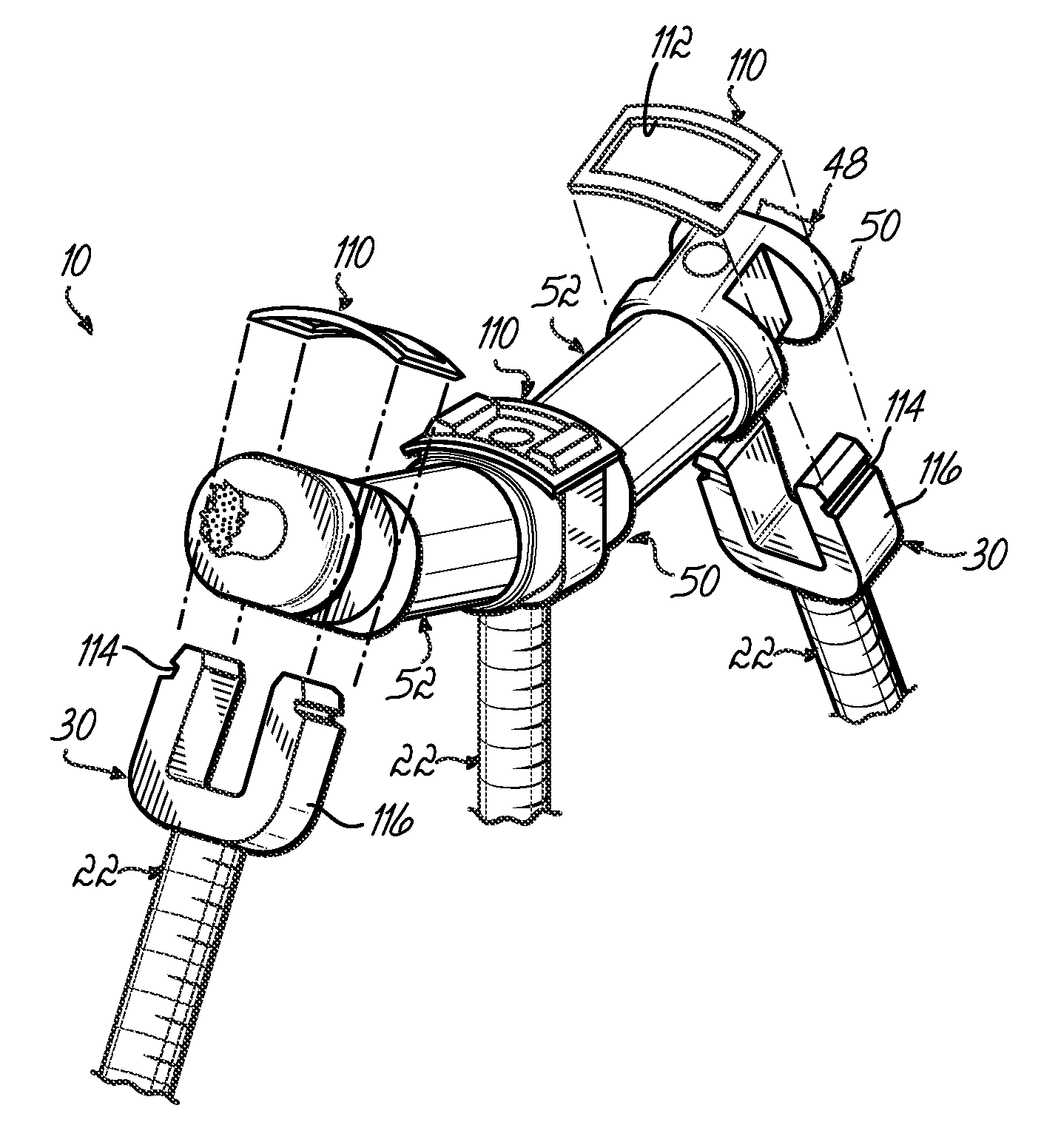

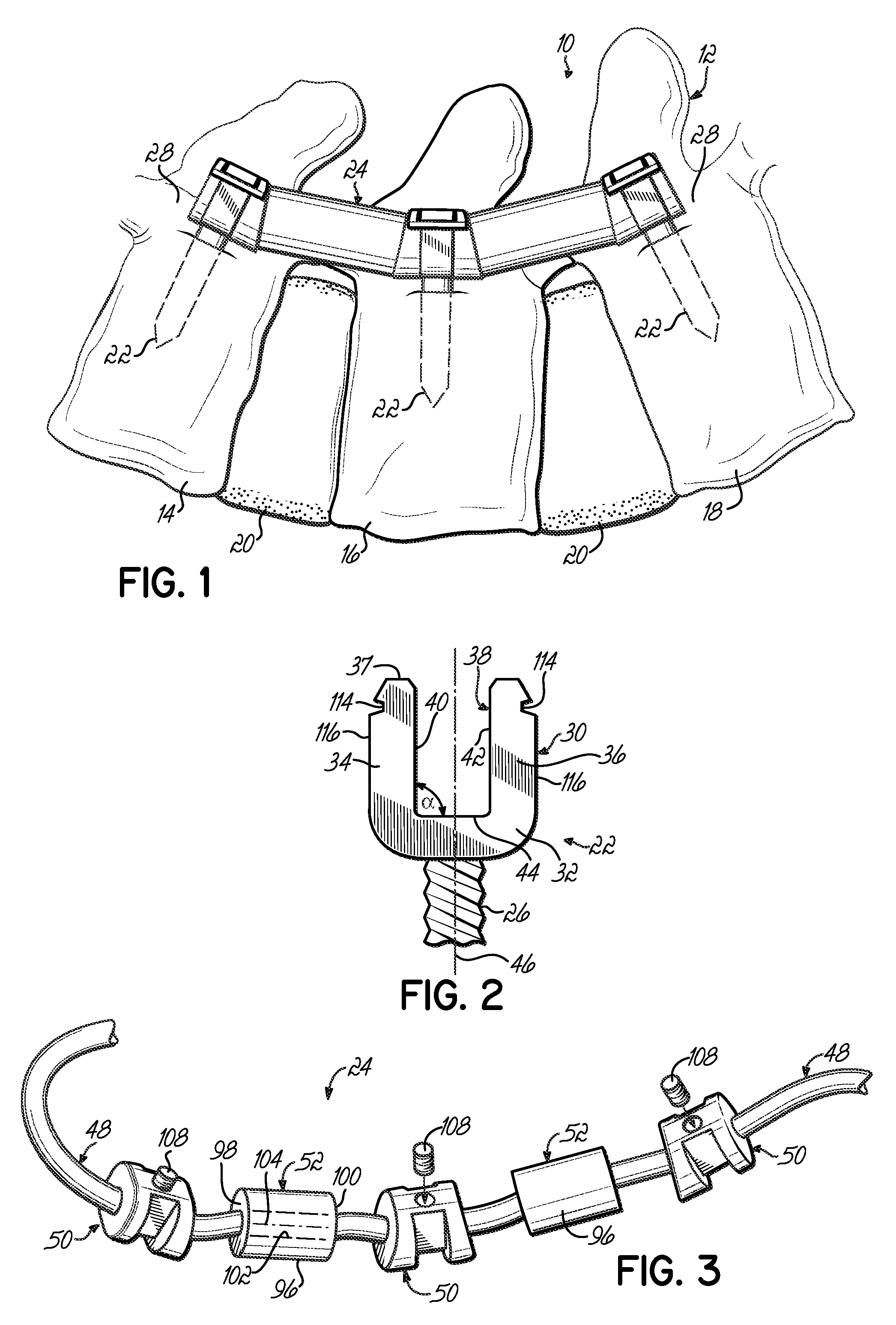

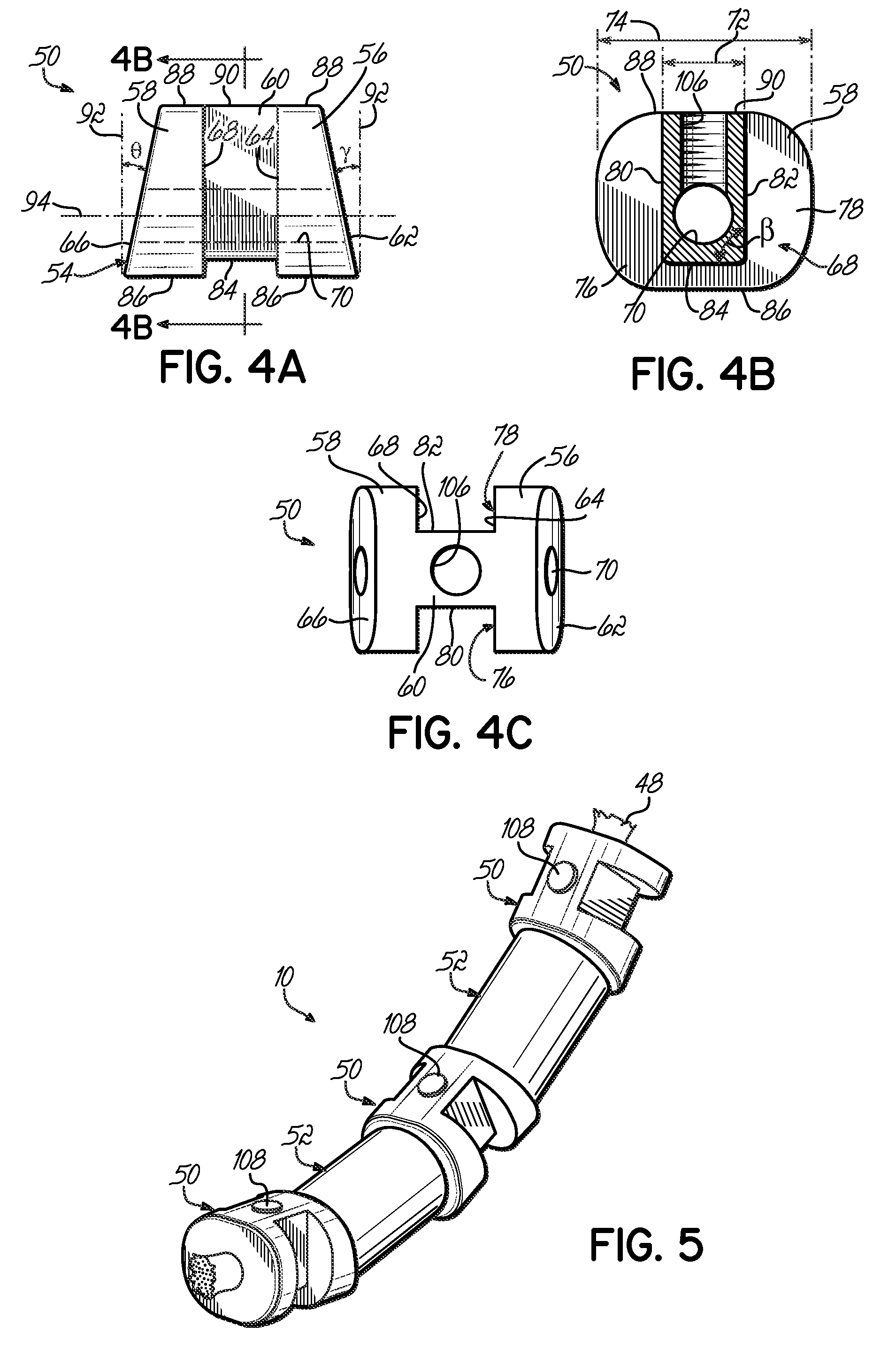

Dynamic spinal stabilization system and method of using the same

ActiveUS20080234737A1Stabilize spineStabilizing spineSuture equipmentsInternal osteosythesisBiomedical engineering

A spinal stabilization system includes at least two anchors having a bone attachment portion and a head portion and a flexible assembly coupled to the anchors. The flexible assembly includes a flexible cord, at least two connectors slidably mounted to the flexible cord, and at least one spacer slidably mounted to the cord between adjacent connectors. Each connector couples with a head portion of an anchor. The flexible assembly may be assembled and appropriately adjusted outside the body prior to it being coupled to the anchors. In addition, the connectors may include angled outer surfaces that provide enhanced engagement with the ends of the spacer. A method of stabilizing the spine includes securing anchors to the spine, assembling a flexible assembly outside the body, and coupling the flexible assembly to the anchors. The method may further include providing connectors with angled surfaces to provide enhanced engagement with the spacer.

Owner:ZIMMER BIOMET SPINE INC

Surgical clip

InactiveUS6818009B2Increase frictionIncrease contact areaSuture equipmentsWound clampsSurgical ClipsSurgical department

A surgical clip having a sliding state and a crimped state is adapted for use in a surgical procedure initially to slide along suture ends to an operative position and ultimately to crimp the suture ends at the operative position. A substrate, bendable between the sliding state and the crimped state carries at least one coating having either lubricious or traction enhancing properties. A second coating can be added to form a coating laminate with the outer coating having lubricious properties facilitating the sliding state and the inner coating having traction enhancing properties facilitating thee crimped state.

Owner:APPL MEDICAL RESOURCES CORP

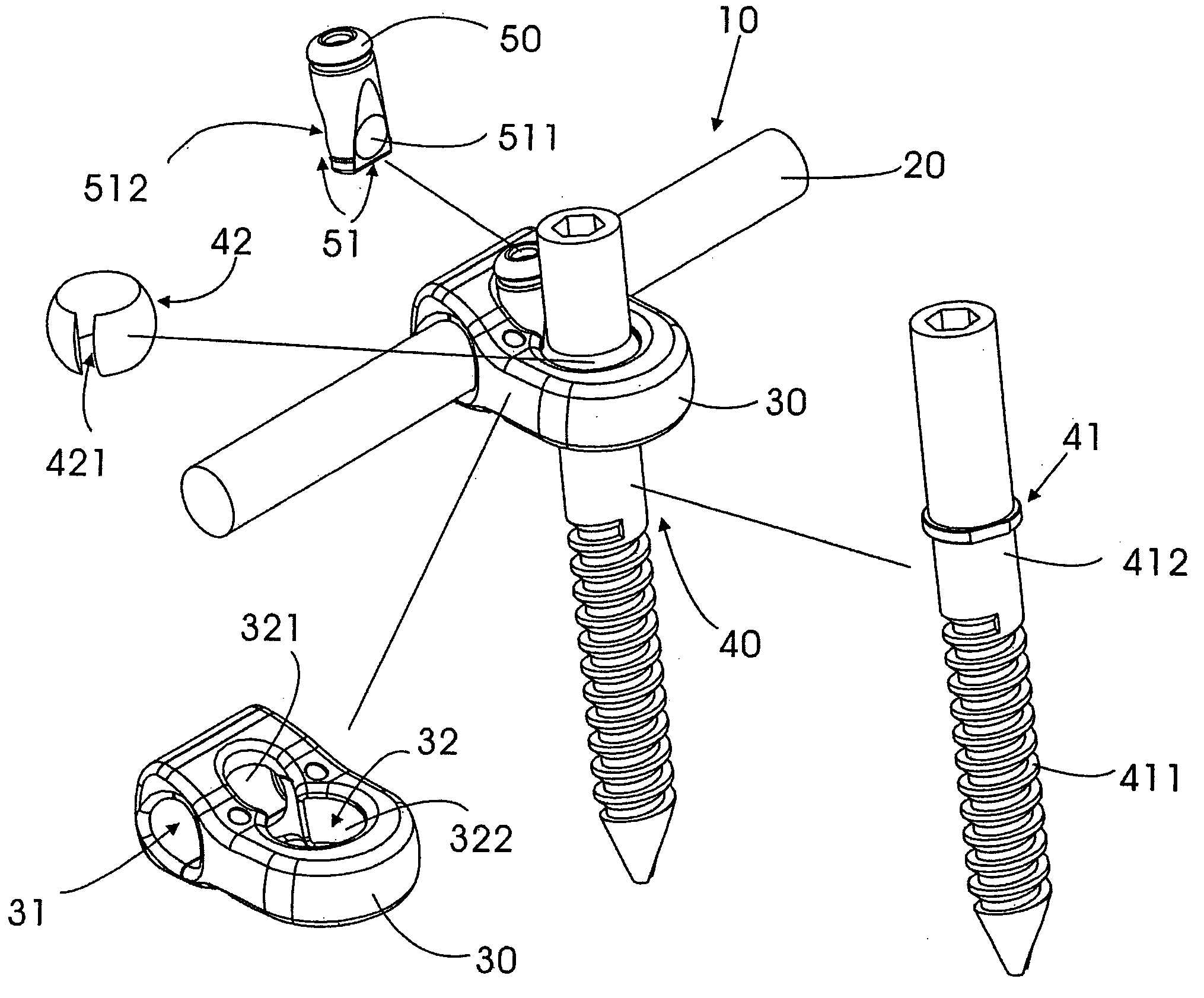

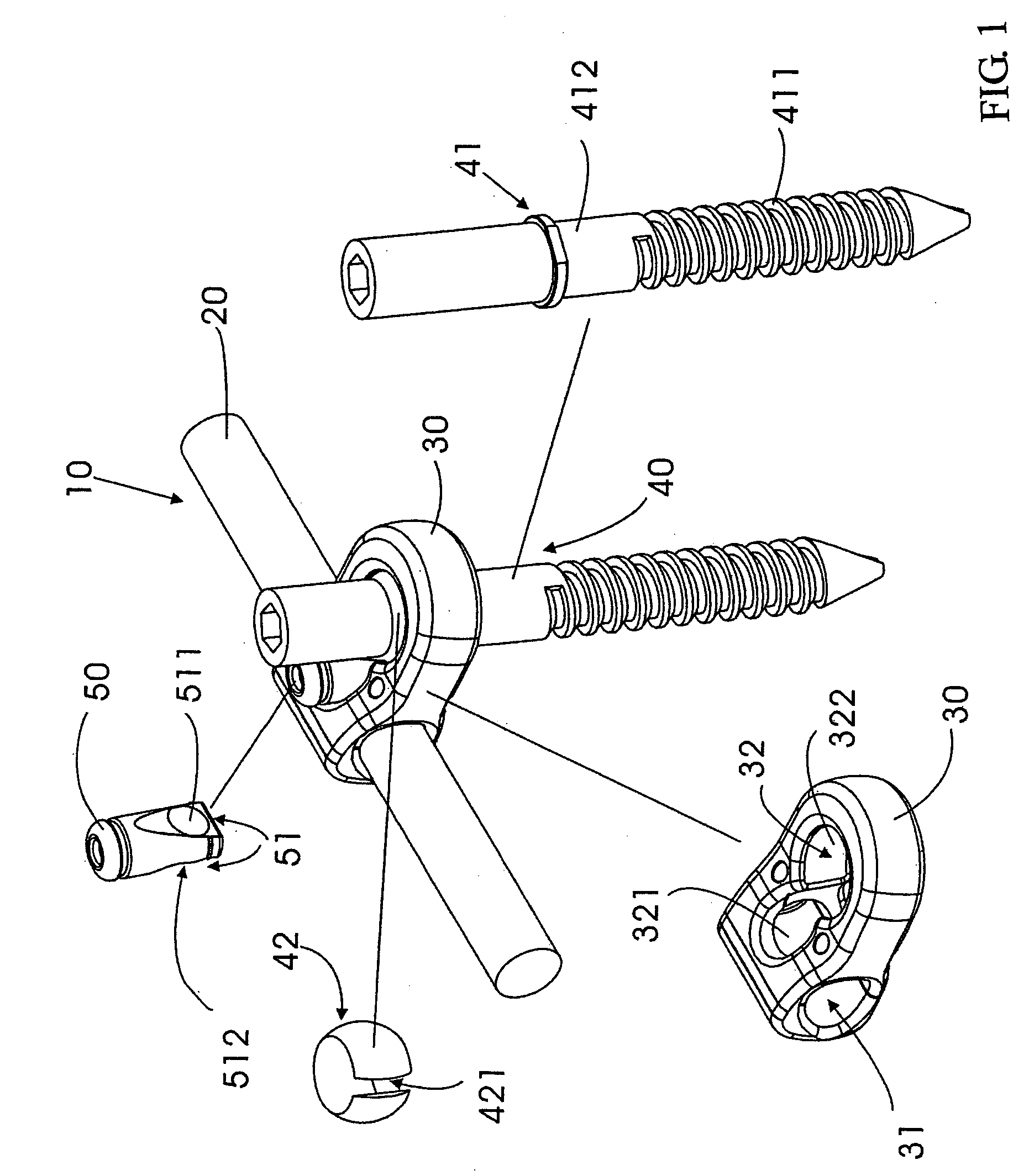

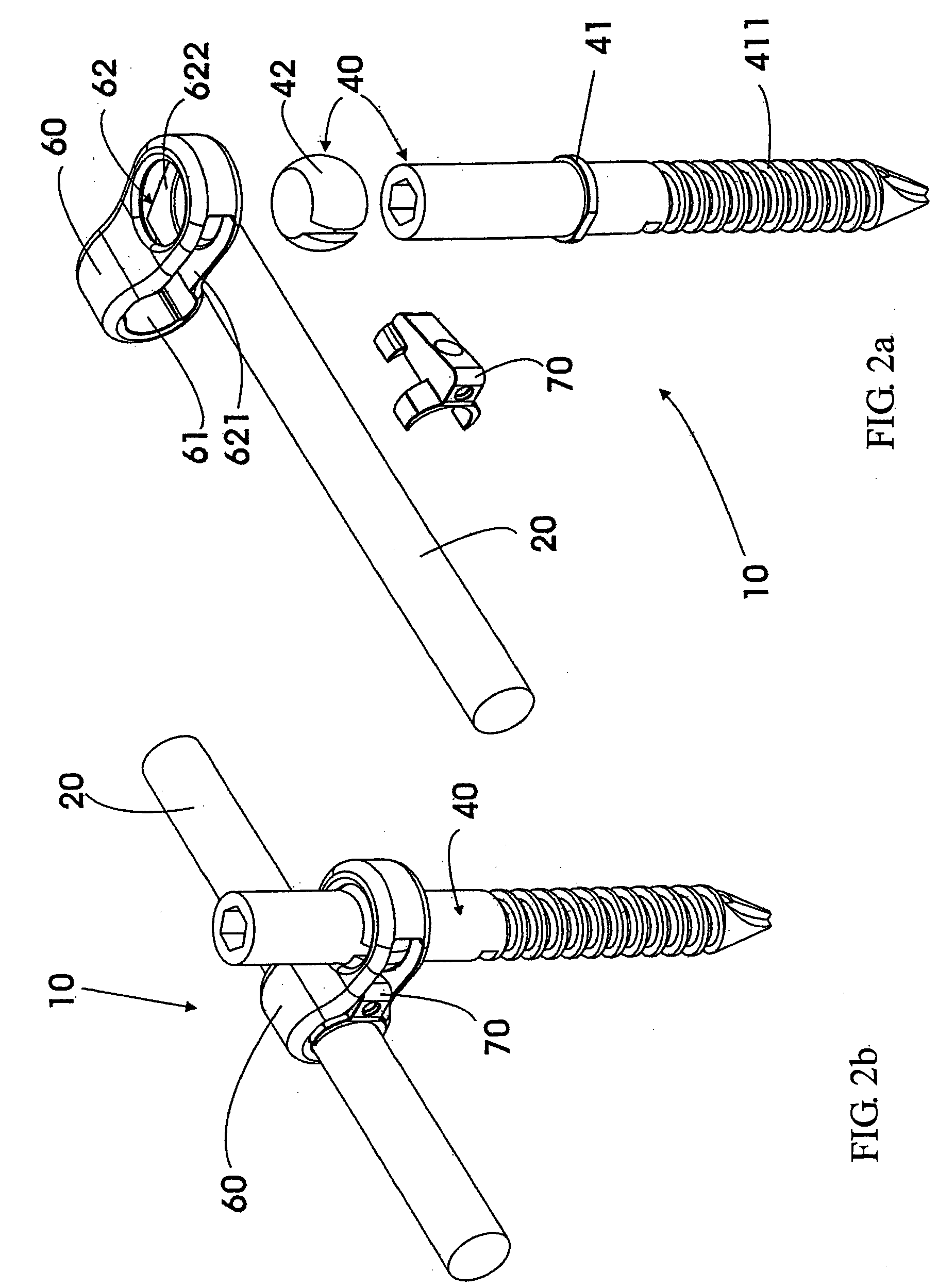

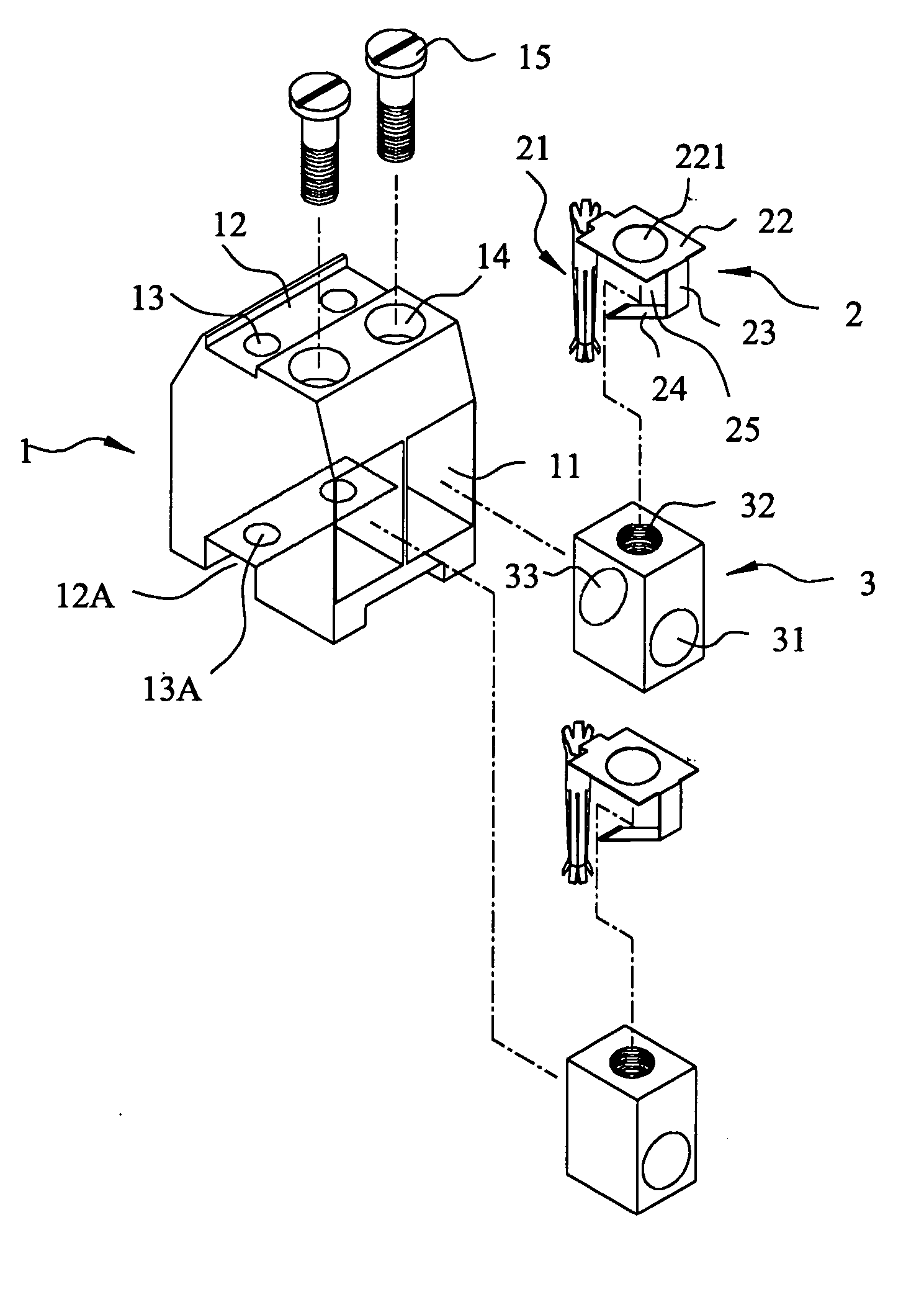

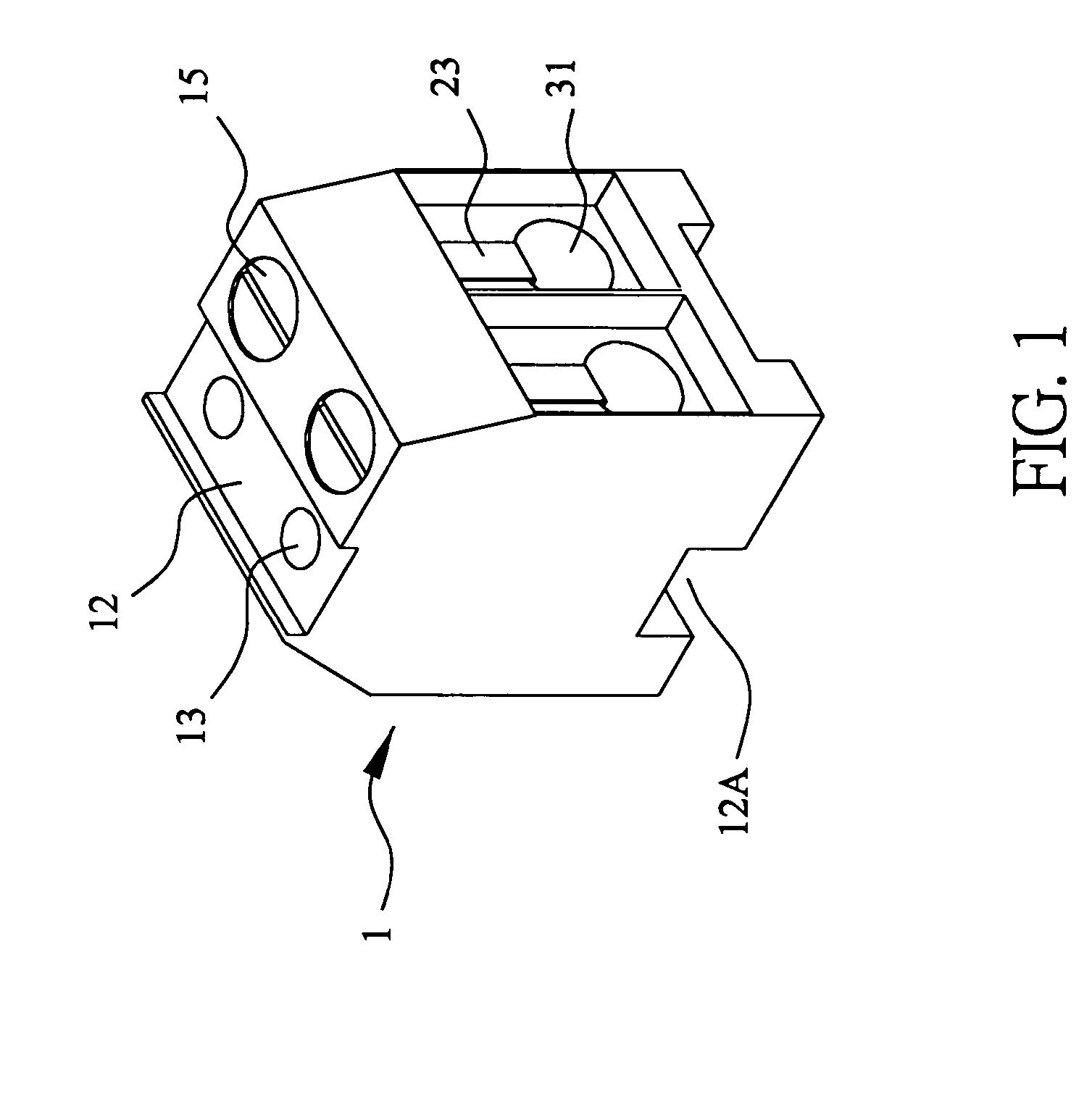

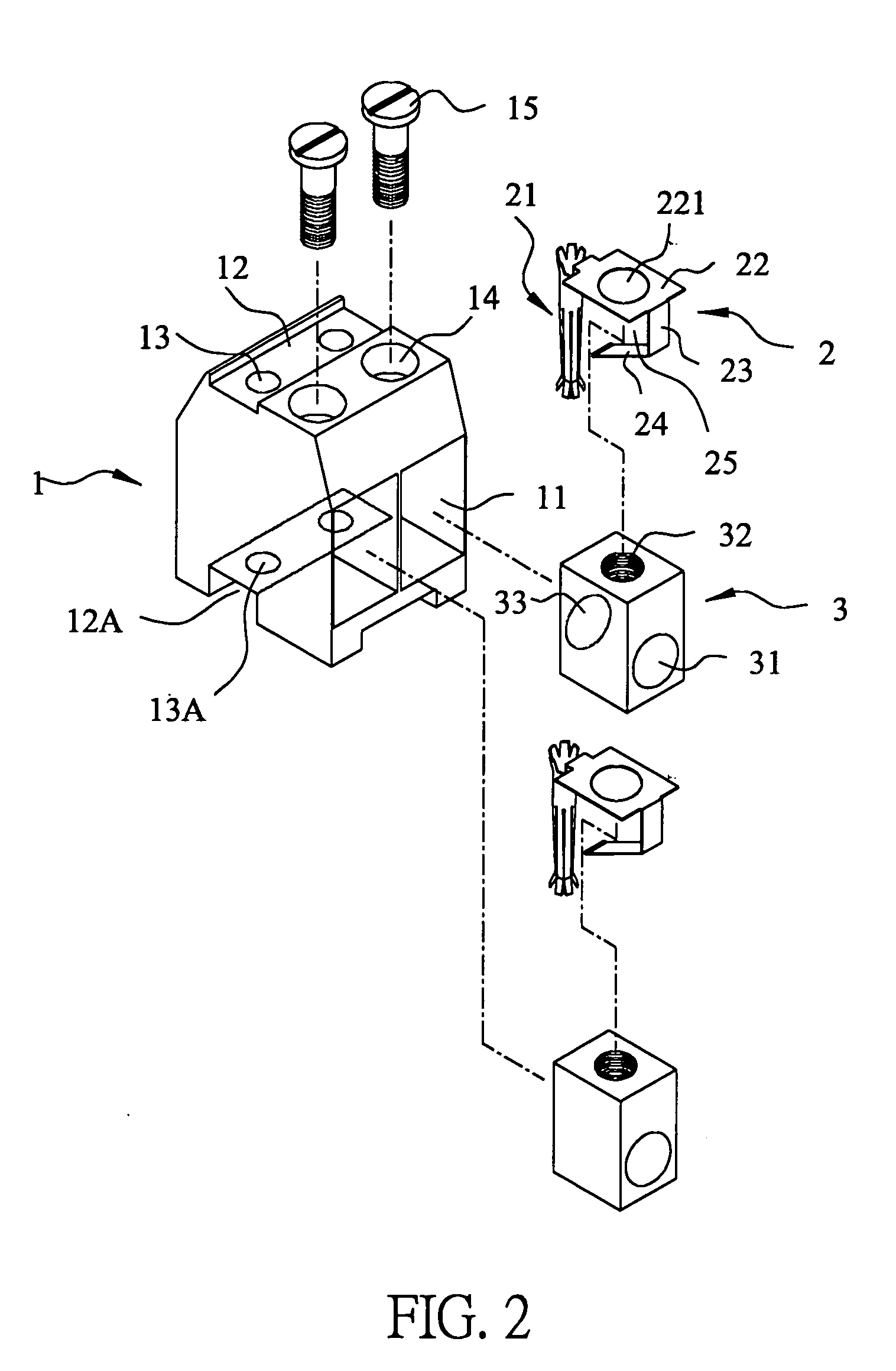

Plug-type device for retrieving spinal column under treatment

InactiveUS20050096654A1Increase contact areaShort operating timeInternal osteosythesisJoint implantsEngineeringSpinal column

A plug-type spinal retrieving device includes a retrieval rod; a fastening screw assembly including a fastening screw and a C-shaped ring having a convex outer surface; a plug; and a fixation seat having a receiving hole in which the retrieval rod is slidably received, a fastening hole having a concave wall in which the C-shaped ring is rotatably received, and an interconnecting hole through which the receiving hole communicates with the fastening hole. The C-shaped ring is mounted on the fastening screw, so that the fastening screw is grasped by the C-shaped ring, when the C-shaped ring is received in the fastening hole of the fixation seat. The C-shaped ring and the retrieval rod are immobilized in the fastening hole and the receiving hole of the fixation seat by inserting the plug into the interconnecting hole.

Owner:A SPINE HLDG FROUP CORP +1

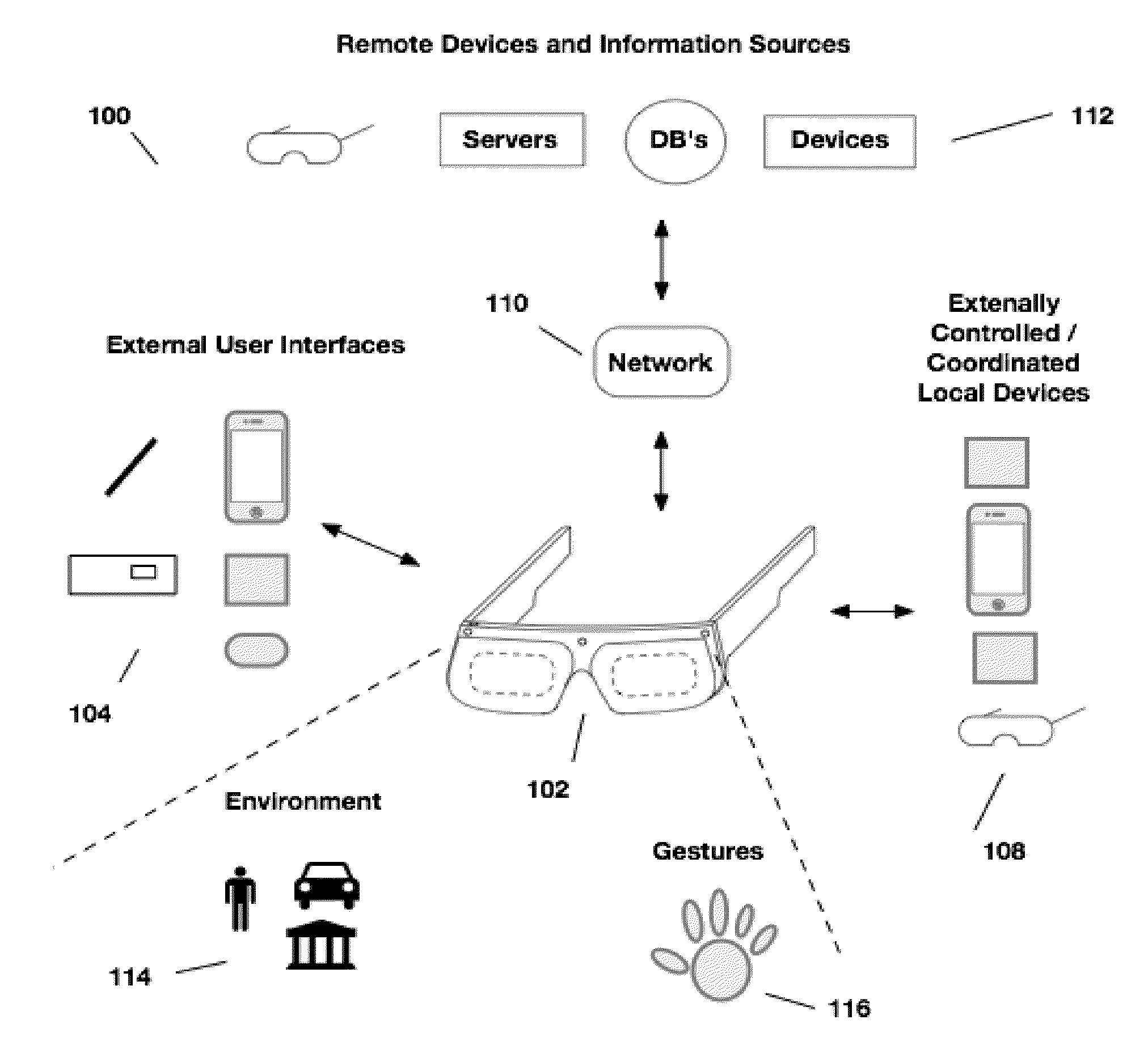

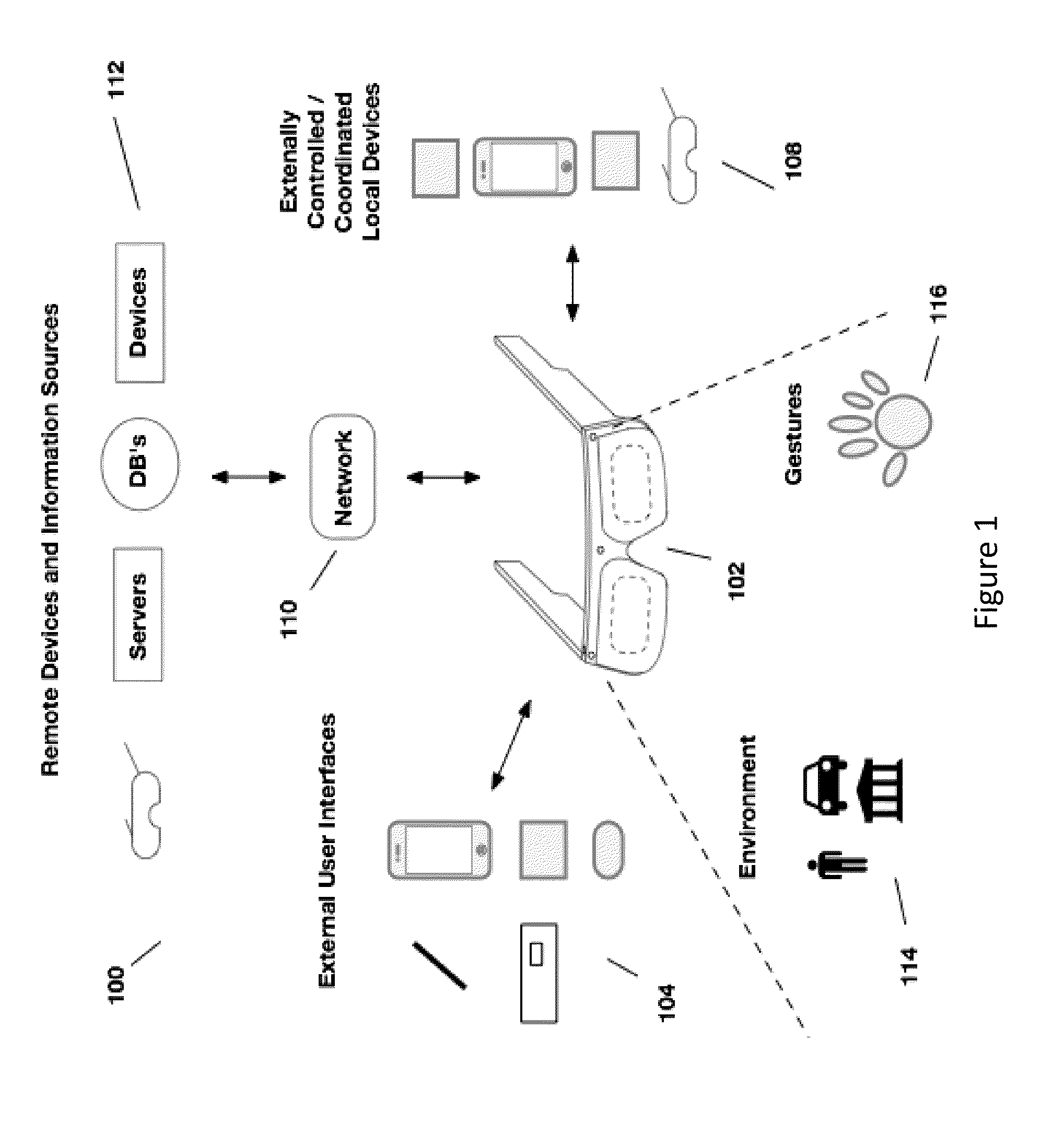

Haptic systems for head-worn computers

ActiveUS20160161747A1Facilitate vibration sensationIncrease contact areaInput/output for user-computer interactionCathode-ray tube indicatorsDigital contentDisplay device

Aspects of the present disclosure relate to haptic feedback systems and methods for use in head-worn computing systems. A head worn computer includes a frame adapted to hold a computer display in front of a user's eye, a processor adapted to present digital content in the computer display and to produce a haptic signal in coordination with the digital content display, and a haptic system including a plurality of haptic segments, wherein each of the haptic segments is individually controlled in coordination with the haptic signal.

Owner:OSTERHOUT GROUP INC

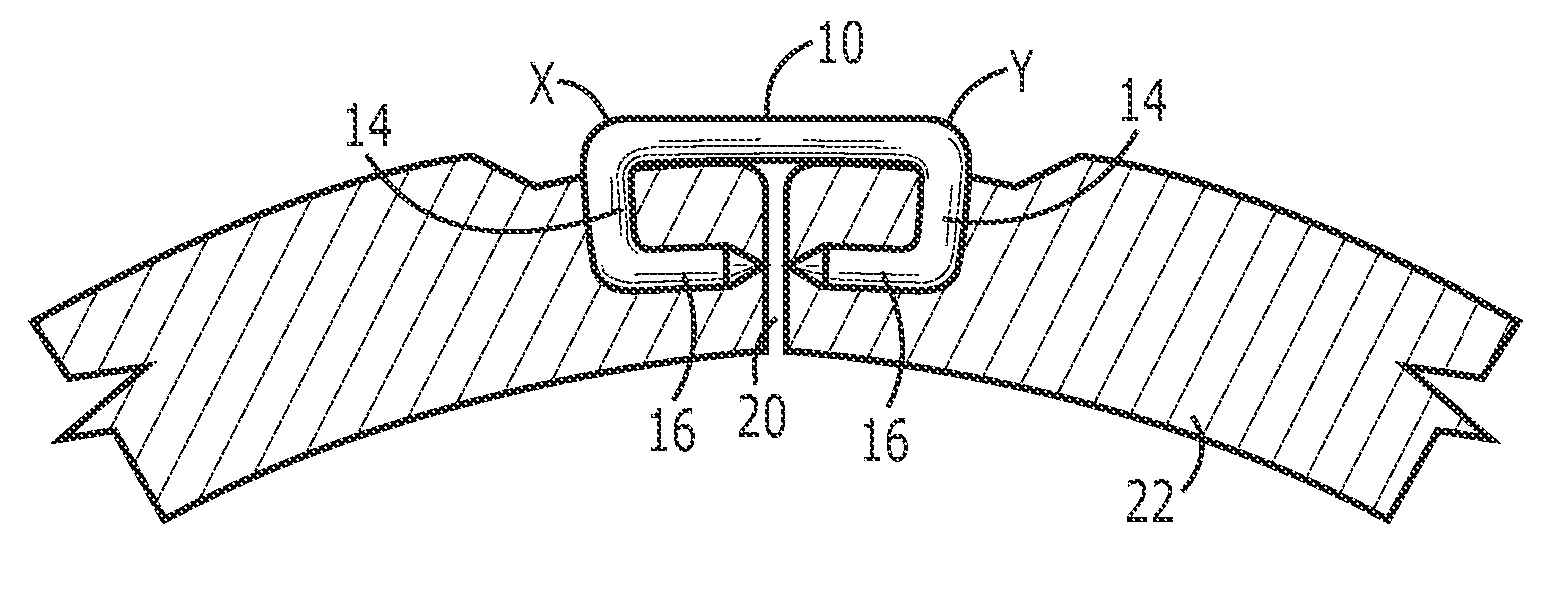

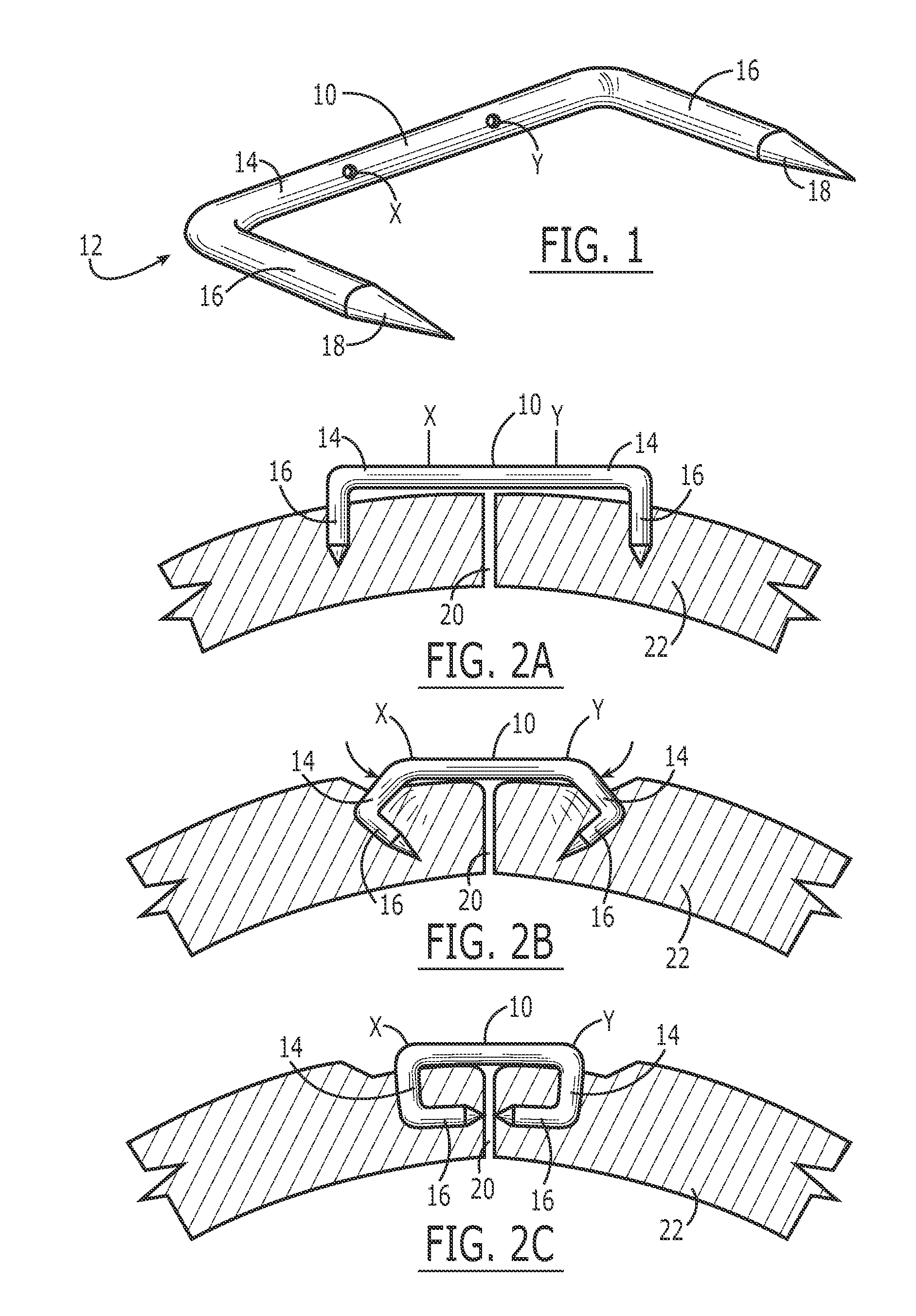

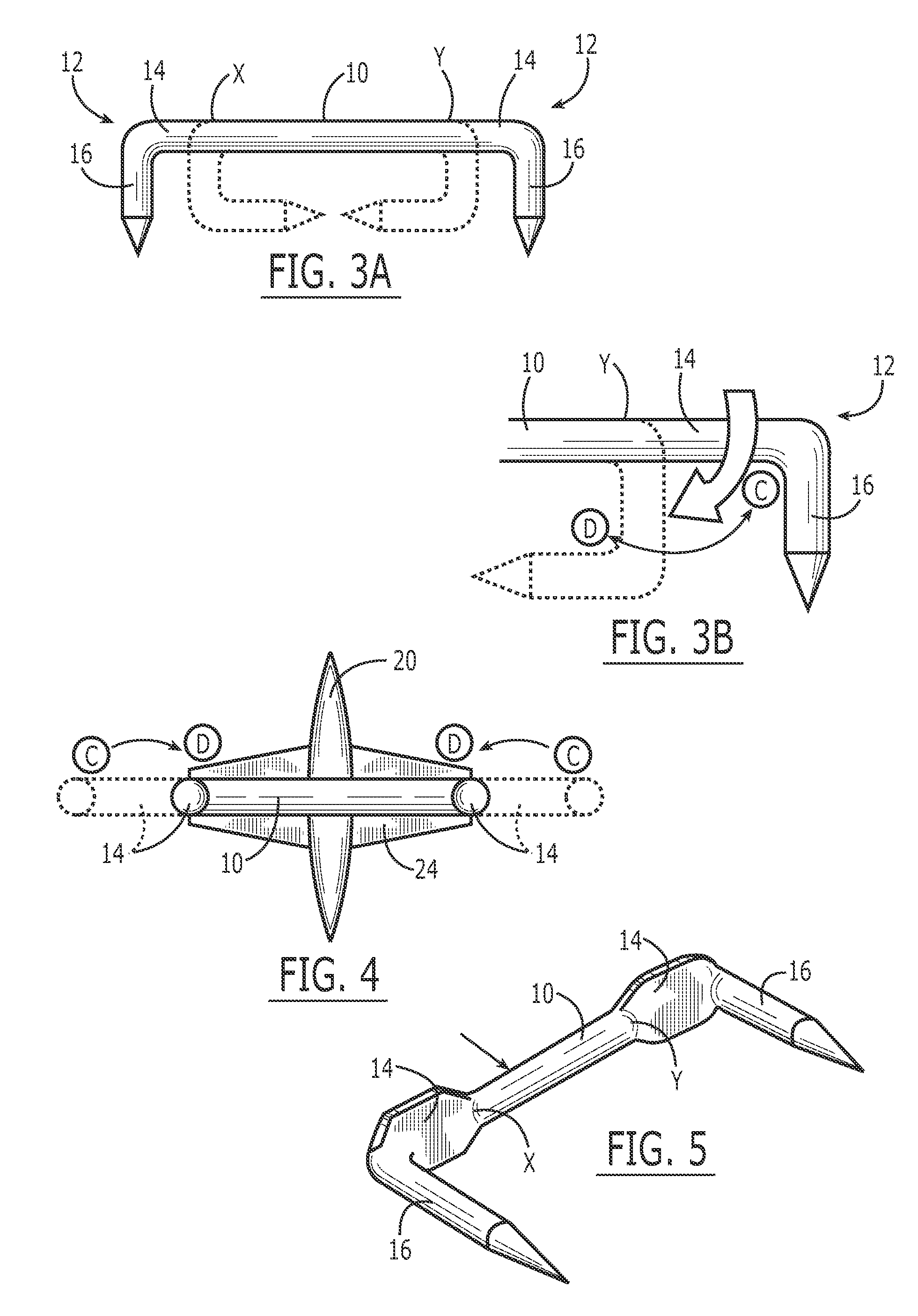

Surgical Staple

InactiveUS20070010854A1Increased area of compressionIncrease the areaStaplesNailsSurgical stapleEngineering

A generally U-shaped surgical staple comprises a base 10 and a pair of generally “L”-shaped legs 12 extending substantially perpendicularly from opposite ends of the base respectively. The legs 12 in use of the staple are bent through approximately 90° relative to the base. To effect a greater compression of the stapled tissue the legs include a penetrative portion 16 adjacent the tip and a compressive structure 30 which, due to its increased height relative to that of the penetrative portion, spreads the compressive forces of the staple further along the length of the incision being closed. The compressive portion also provides a depth stop to avoid the tip penetrating too deeply into the tissue in which it is deployed.

Owner:ABBOTT CARDIOVASCULAR

Surfaces and processes for wear reducing in orthopaedic implants

Artificial implants having reduced area to provide reduced wear are provided. The reduced area is particularly located at areas where greatest wear is exhibited. In a particular embodiment of a mobile bearing knee implant, the area is reduced on the mobile bearing insert underside, where it contacts a tibial component. The reduced area may be any shape of indentations, for example, grooves, dimples, straight patterns, curved patterns, crossing patterns, holes, channels or slots. The indentations may be various sizes, and have been found to be particularly effective if covering about 10% to about 20% of the insert at depths between about 1-2 mm.

Owner:SMITH & NEPHEW INC

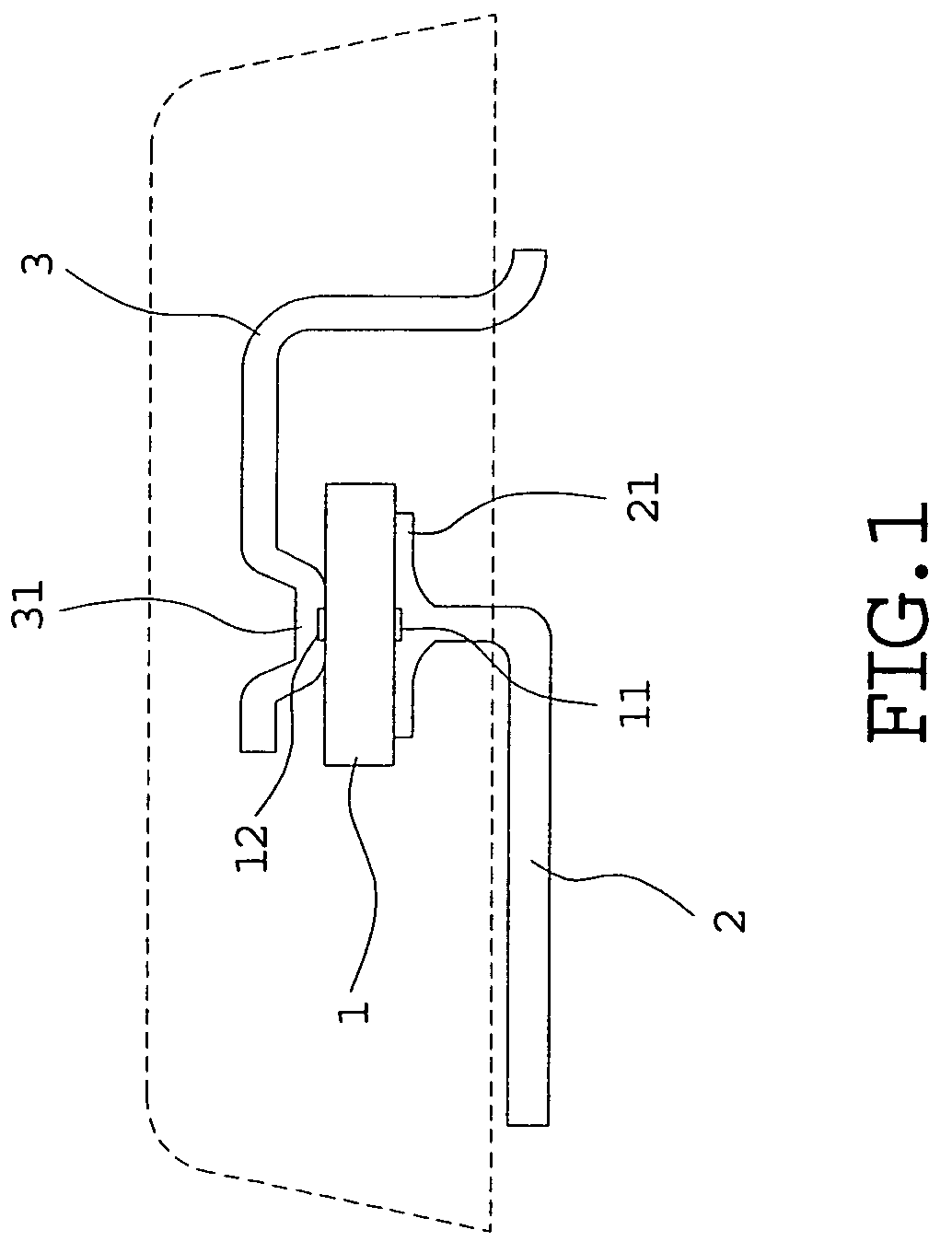

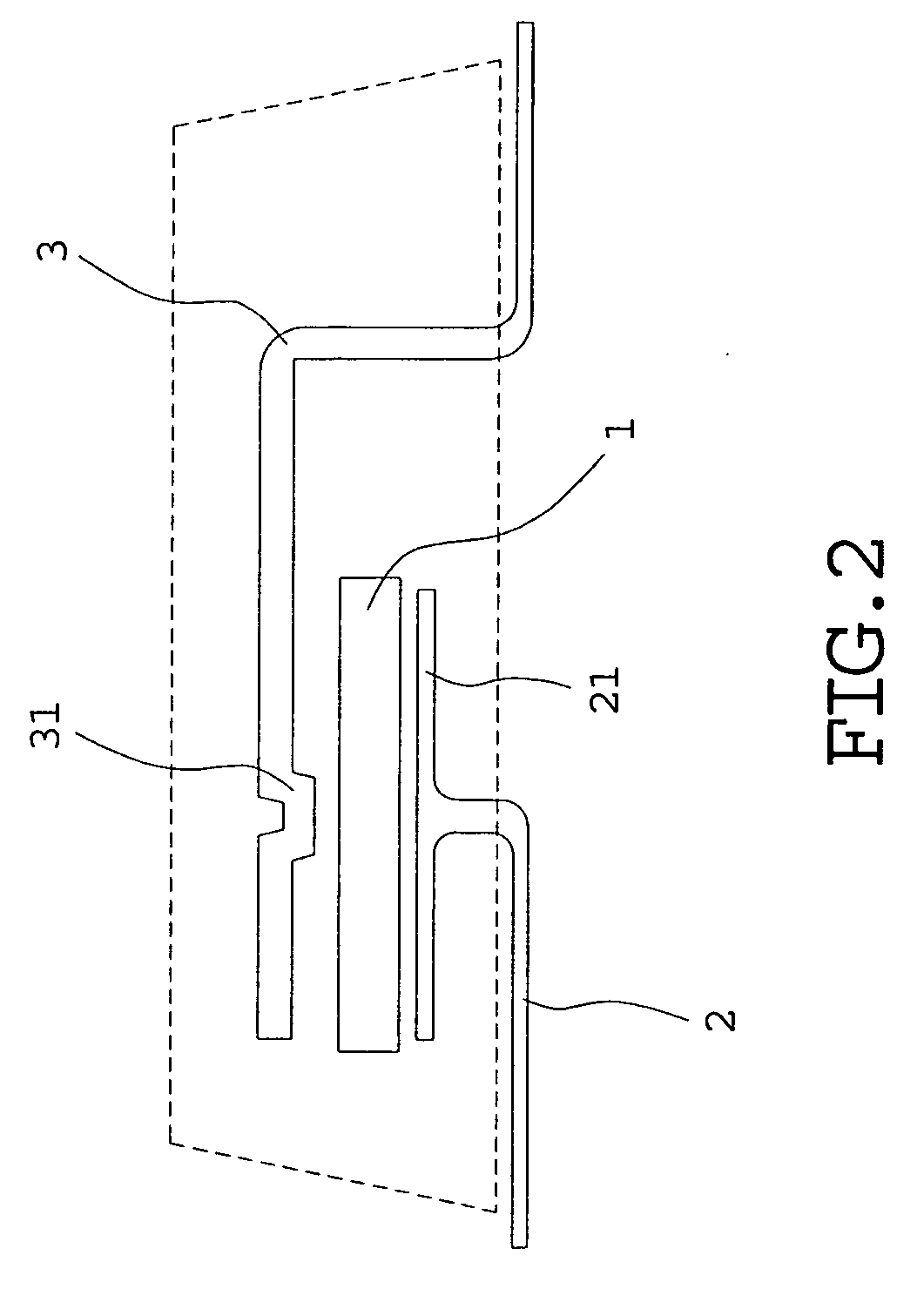

Structure of connector

InactiveUS20050130508A1Low insertion forceLarge contact areaClamped/spring connectionsLower faceHeat generation

A connector includes a housing forming at least one receptacle and a terminal received in each receptacle. The housing has upper and lower faces in which opposite slots are defined. Through holes are defined in the slots and extending to the receptacle. The terminal has an engagement section, a retention section extending from the engagement section, an extension section extending from the retention section and opposite to the engagement section and a wire engaging section projecting from the extension section. The engagement section includes a plurality of circumferentially spaced resilient leaves forming a cylinder axially aligned with the holes defined in the upper and lower faces of the housing. Thus, when a pin of a mating connector is fit into the cylinder of the engagement section through either one of the holes of the housing, the pin is completely surrounded by the leaves and a large contact area is formed between the pin and the engagement section. Due to the resiliency of the leaves, only a low insertion force is needed in completing insertion of the pin into the engagement section. Firm engagement, low impedance and low noise, as well as reduced heat generation, can be realized between the pin and the engagement section.

Owner:YEH SHENG HSING

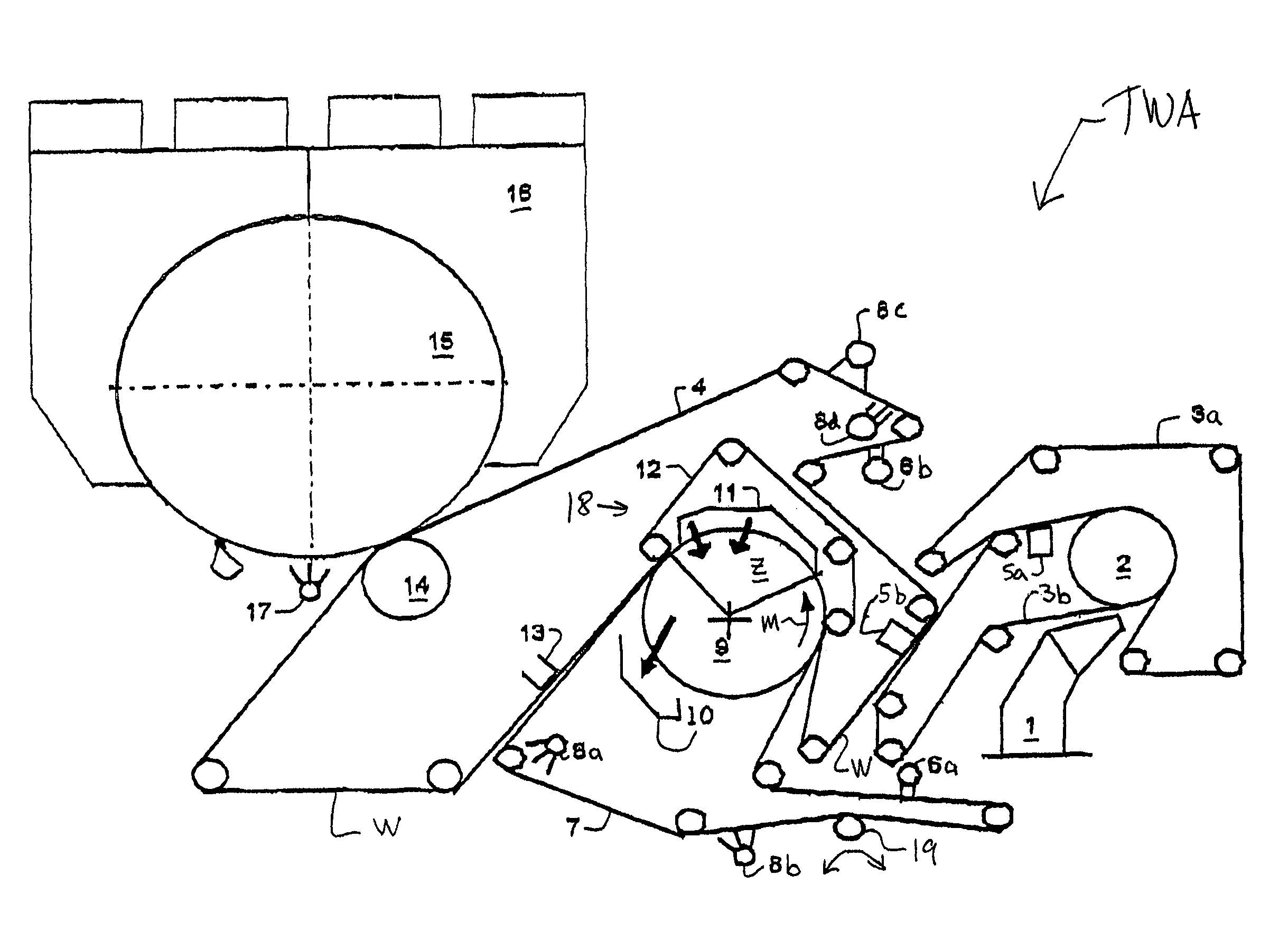

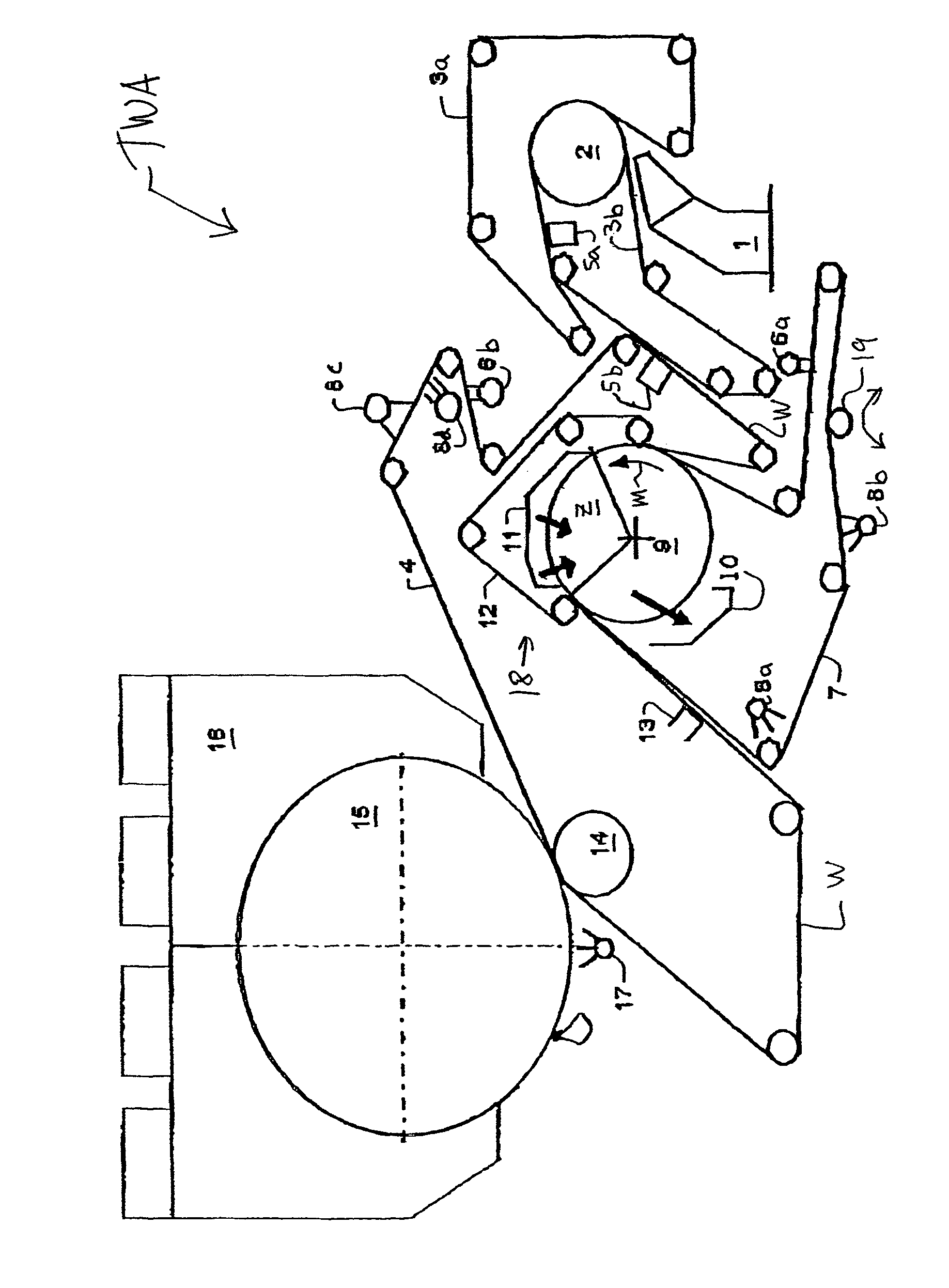

Twin wire for an ATMOS system

InactiveUS7744726B2Fill up the pillow areasIncrease contact areaNon-fibrous pulp additionNatural cellulose pulp/paperWire rodEngineering

Dewatering system for dewatering a web. The system comprises a former, a belt press, and a structured fabric comprising a paper web facing side and being guided over a support surface and through the belt press. The structured fabric runs at a speed differential relative to a wire of the former. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

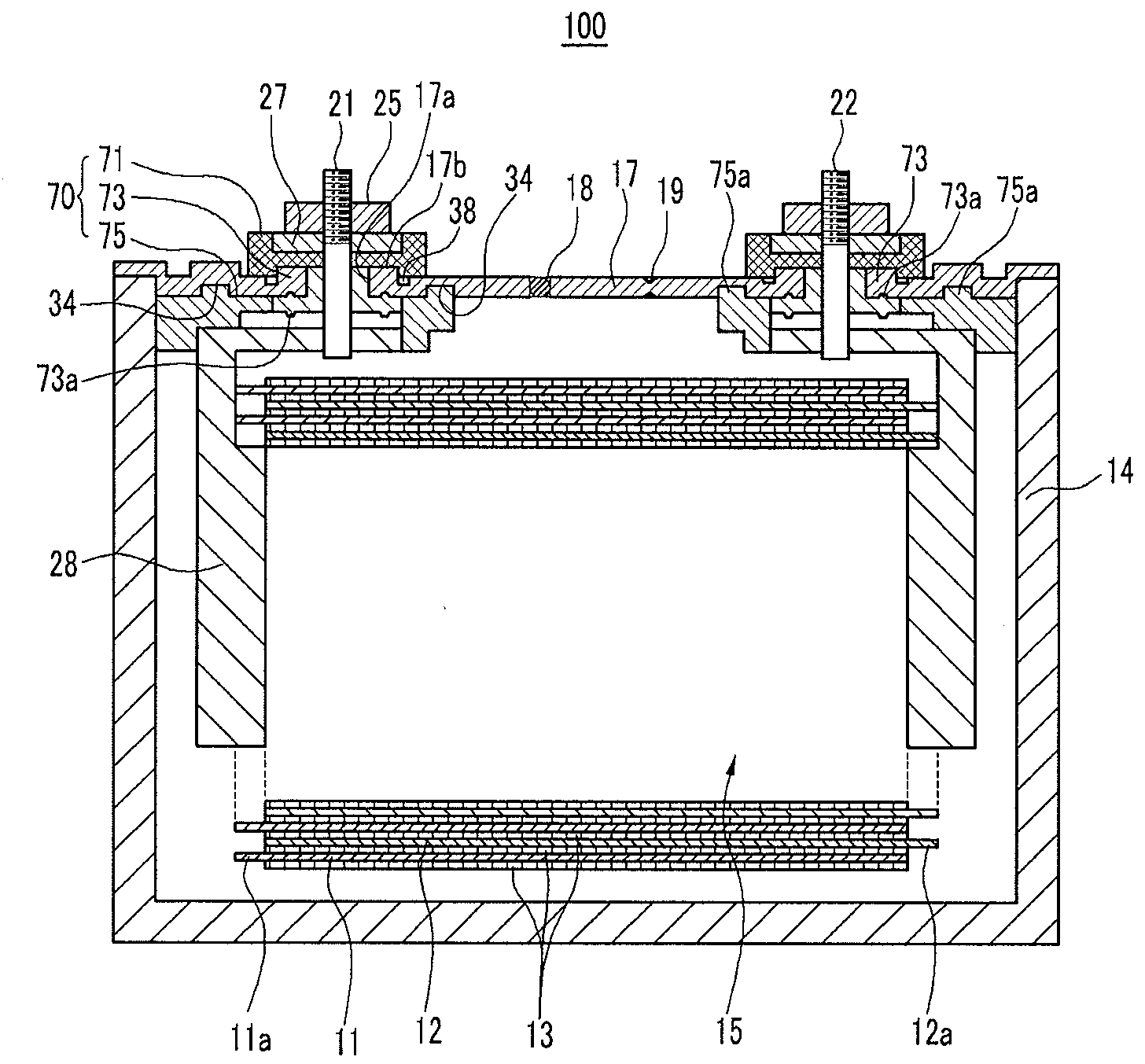

Rechargeable battery

InactiveUS20090186269A1Sealing performanceIncrease contact areaSmall-sized cells cases/jacketsCell lids/coversRechargeable cellEngineering

The present invention relates to a rechargeable battery. The rechargeable battery includes an electrode assembly, a case, electrode terminals, and a cap plate. The electrode assembly includes a separator and an anode and a cathode disposed at both sides of the separator. The case houses the electrode assembly. The electrode terminals are electrically connected to the electrode assembly and protrude outwardly from the case. The cap plate closes and seals the case. The cap plate includes a terminal hole for receiving the electrode terminals and a sealing reinforcing member formed along a circumference of the terminal hole and having a greater thicker than a periphery thereof.

Owner:SAMSUNG SDI CO LTD

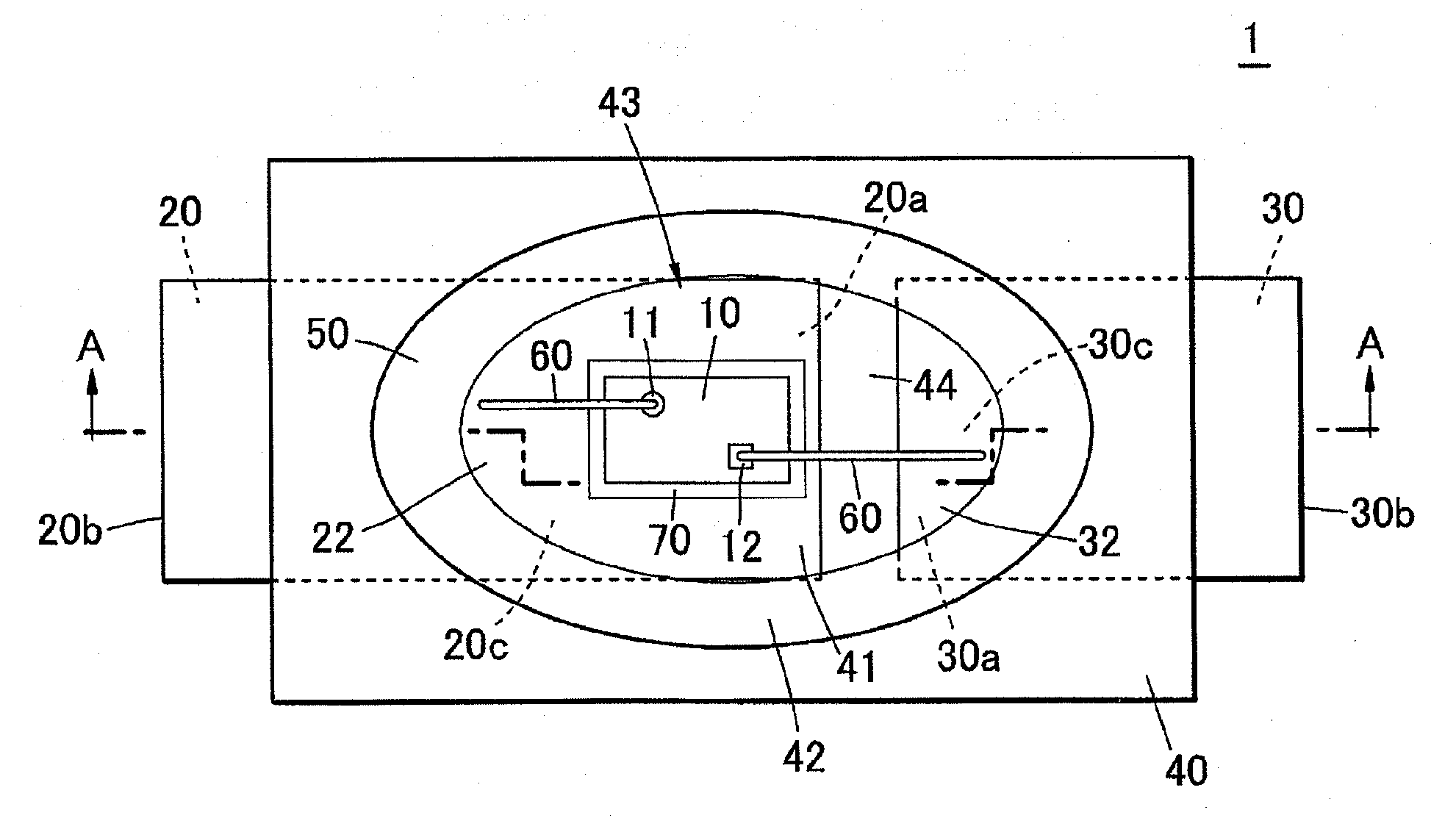

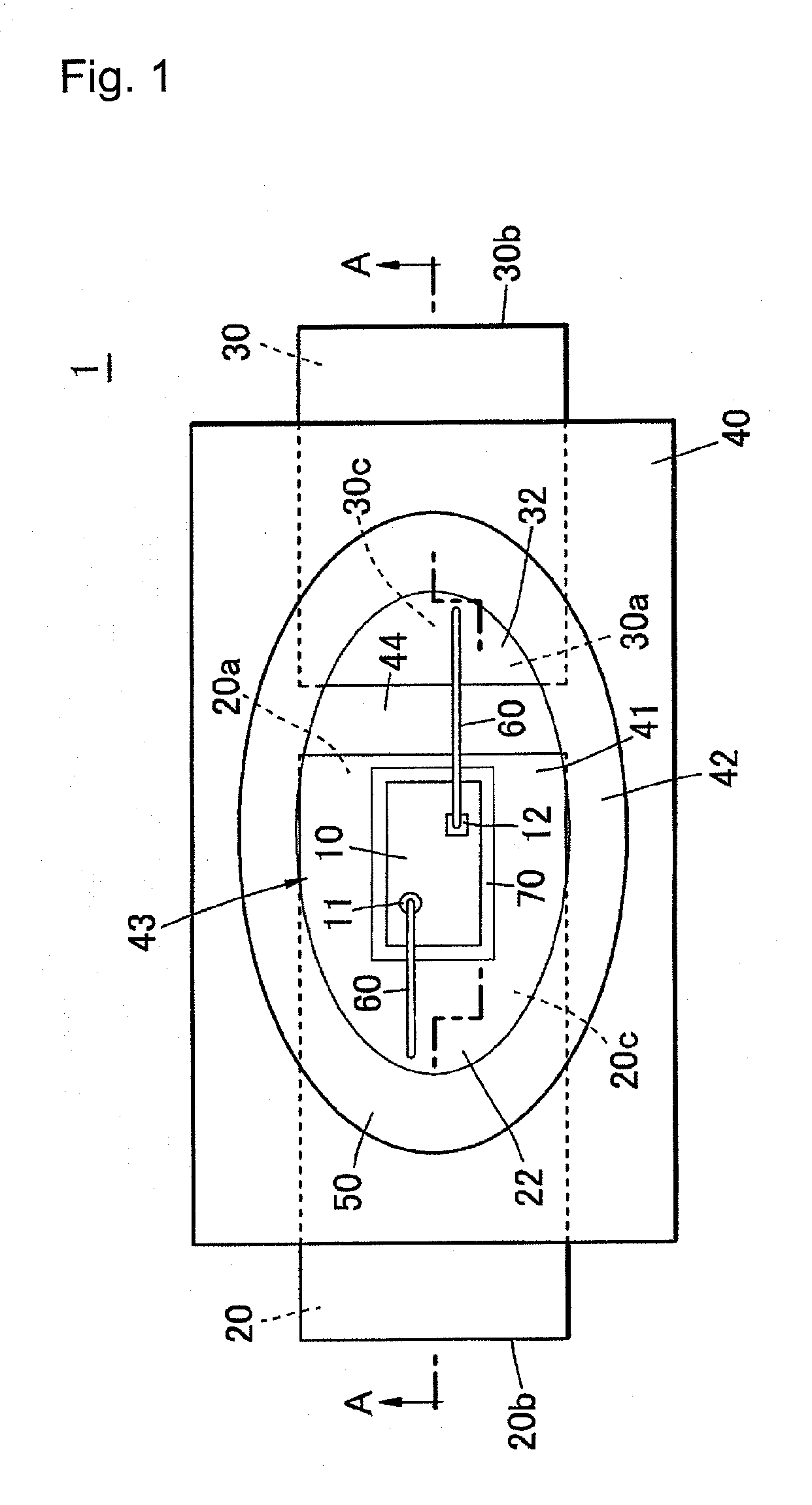

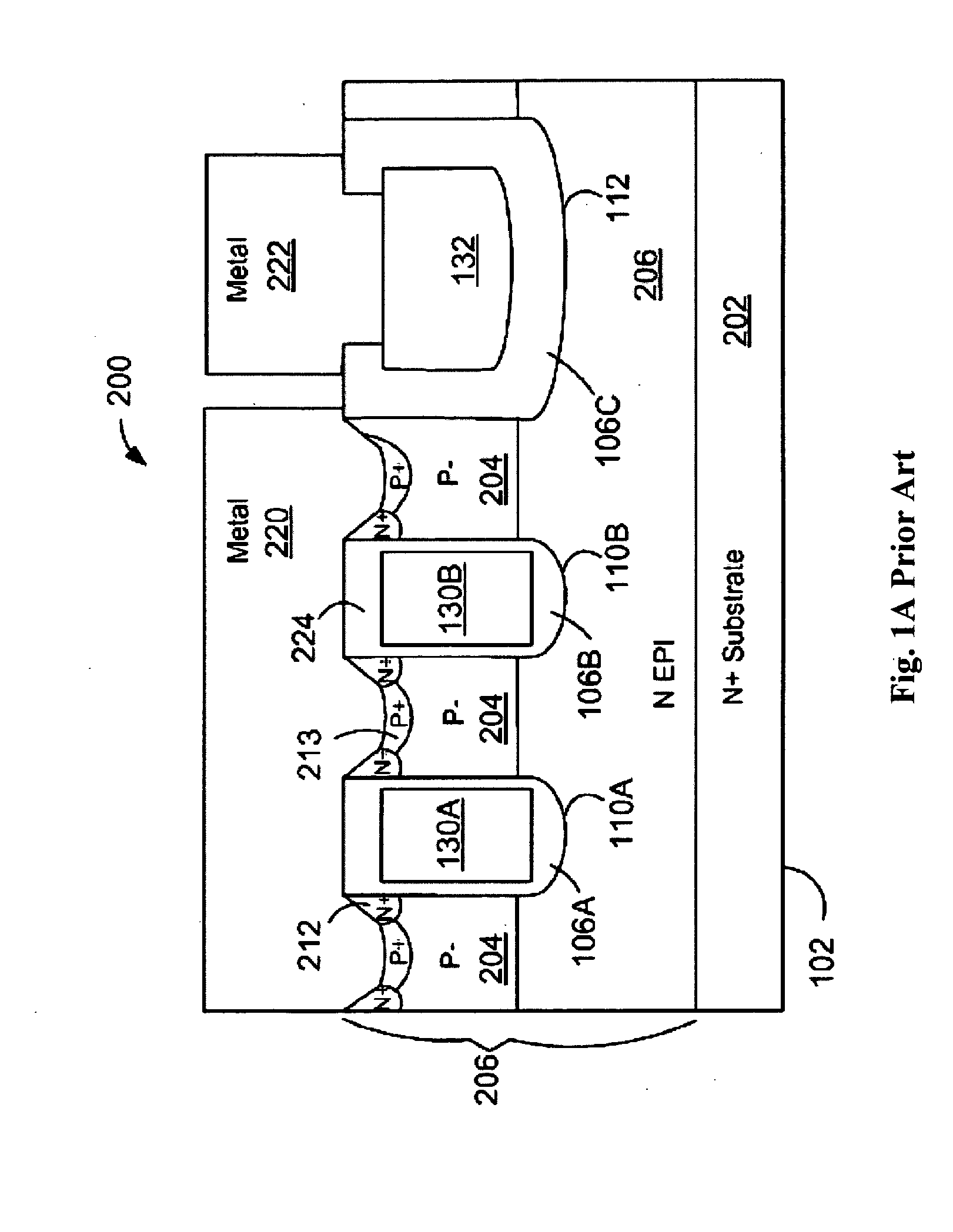

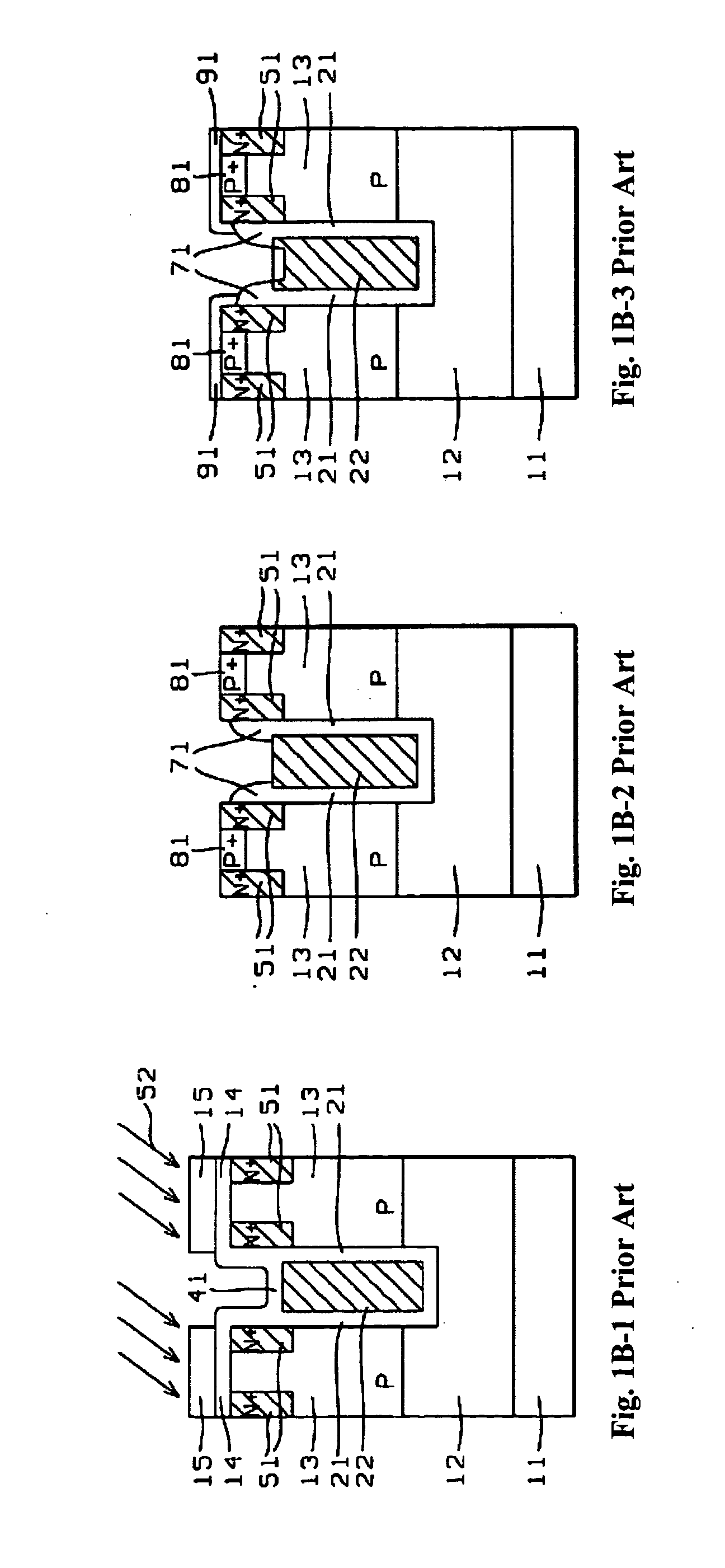

High output power light emitting device and packaged used therefor

ActiveUS20090261374A1Increase output powerEasy to useSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

An object of the present invention is to provide a light emitting device that has high output power and long service life where a package is suppressed from discoloring due to heat generation. The light emitting device 1 of the present invention contains a light emitting element 10, a package 40 formed of a thermosetting resin, the package having a recess 43 wherein the light emitting element 10 is mounted, a first lead electrode 20 which is exposed at the bottom of the recess 43 of the package 40 and whereon the light emitting element 10 is mounted, and a second lead electrode 30 which is exposed at the bottom of the recess 43 of the package 40 and is electrically connected to the light emitting element 10. The light emitting element 10 is bonded to the first lead electrode 20 through a eutectic layer 70, and at least a surface of the first electrode 20 is coated with an Ag film 22, a thickness of the Ag film 22 being in the range from 0.5 μm to 20 μm.

Owner:NICHIA CORP

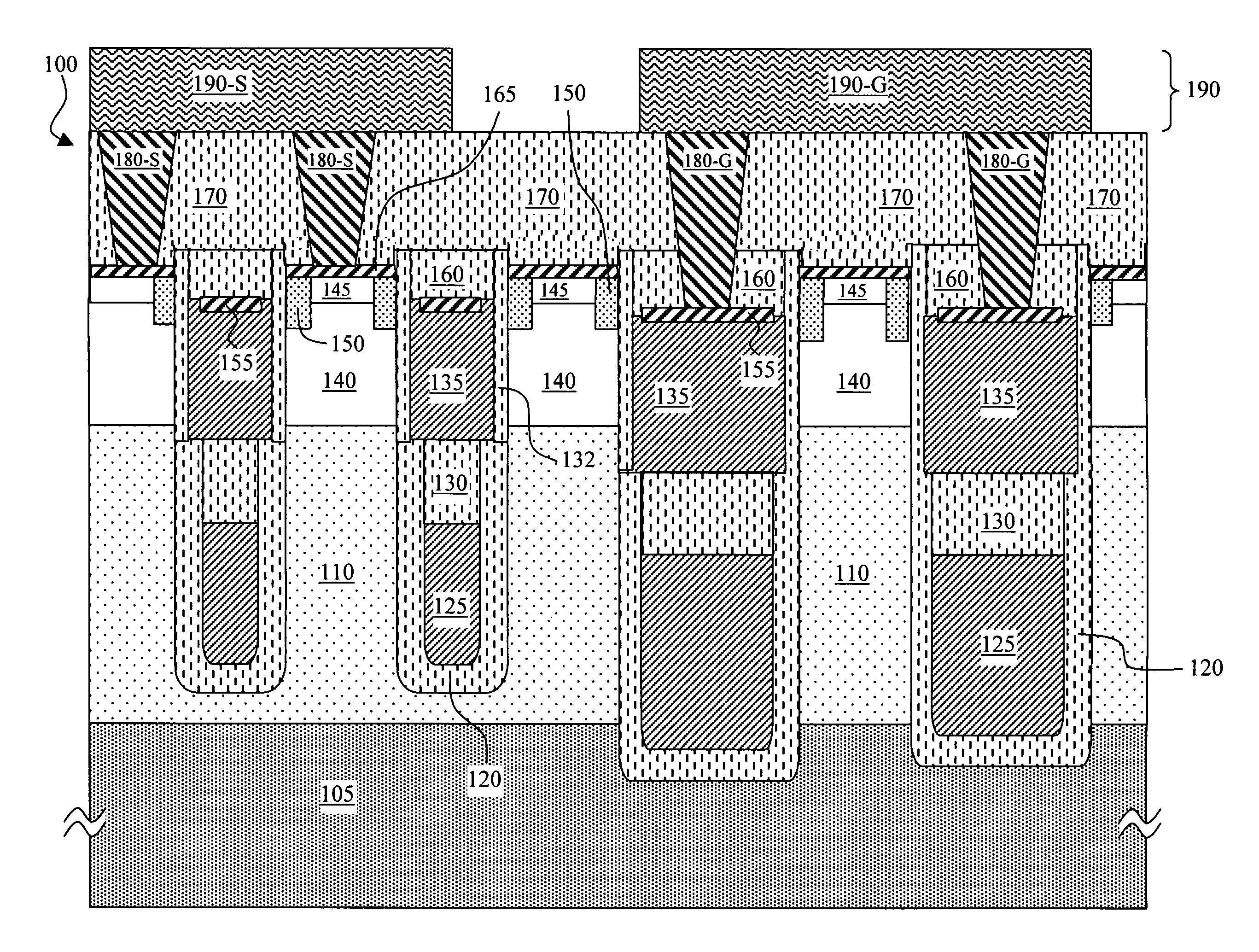

Semiconductor power devices manufactured with self-aligned processes and more reliable electrical contacts

ActiveUS20110291186A1Reduce in quantityGood and reliable electric contactTransistorSemiconductor/solid-state device manufacturingElectricityEngineering

This invention discloses semiconductor power device that includes a plurality of top electrical terminals disposed near a top surface of a semiconductor substrate. Each and every one of the top electrical terminals comprises a terminal contact layer formed as a silicide contact layer near the top surface of the semiconductor substrate. The trench gates of the semiconductor power device are opened from the top surface of the semiconductor substrate and each and every one of the trench gates comprises the silicide layer configured as a recessed silicide contact layer disposed on top of every on of the trench gates slightly below a top surface of the semiconductor substrate surround the trench gate.

Owner:ALPHA & OMEGA SEMICON INC

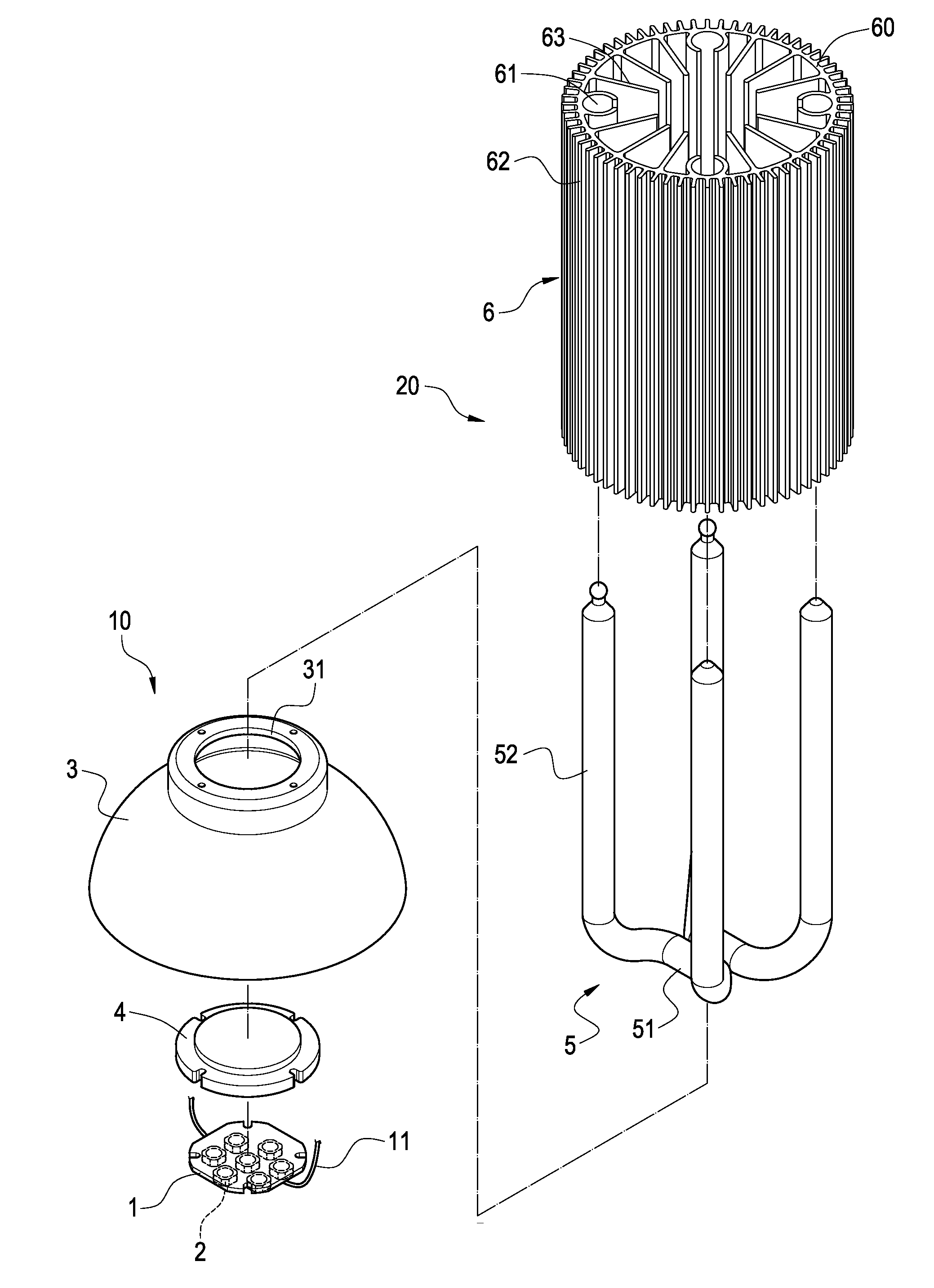

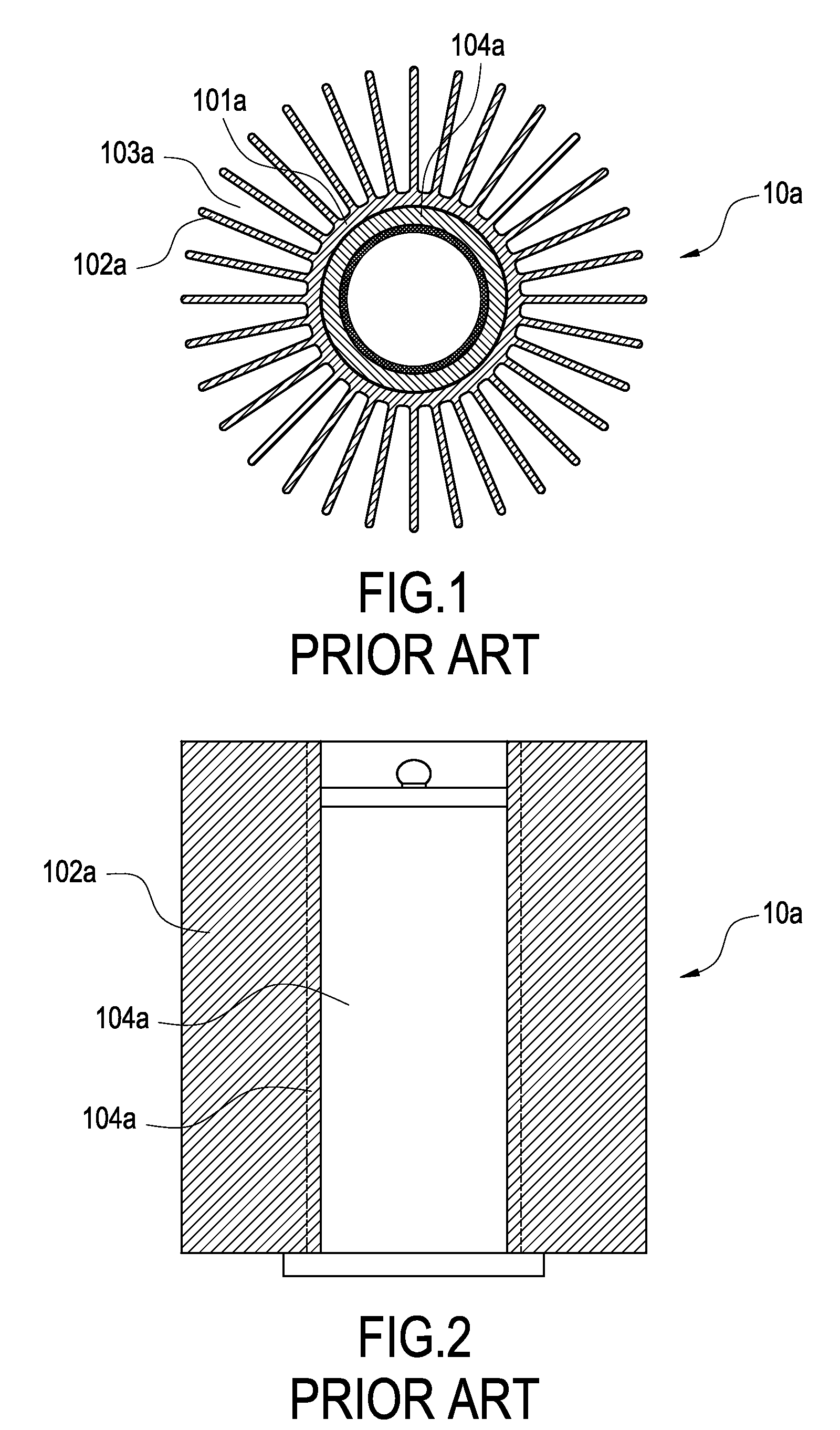

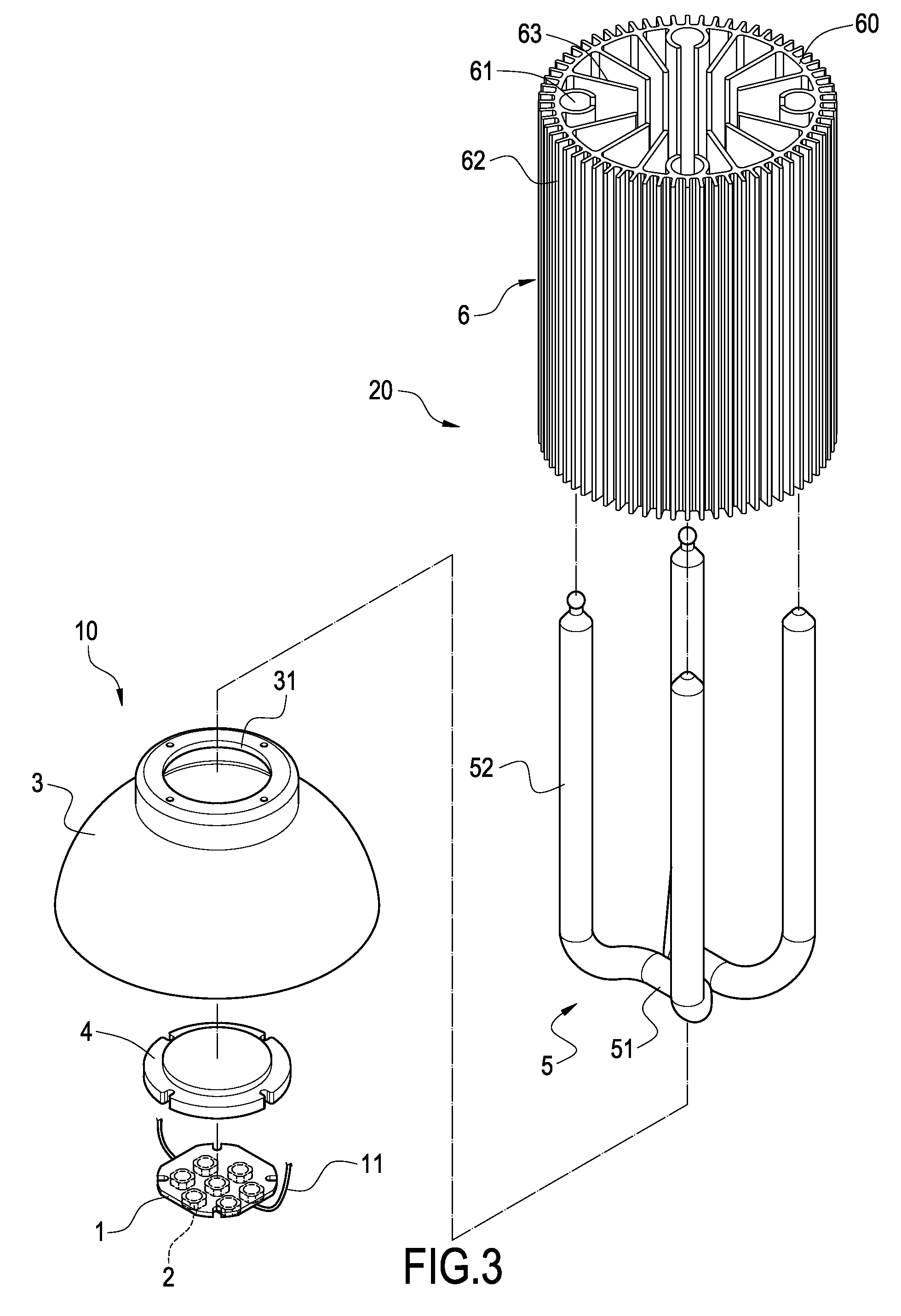

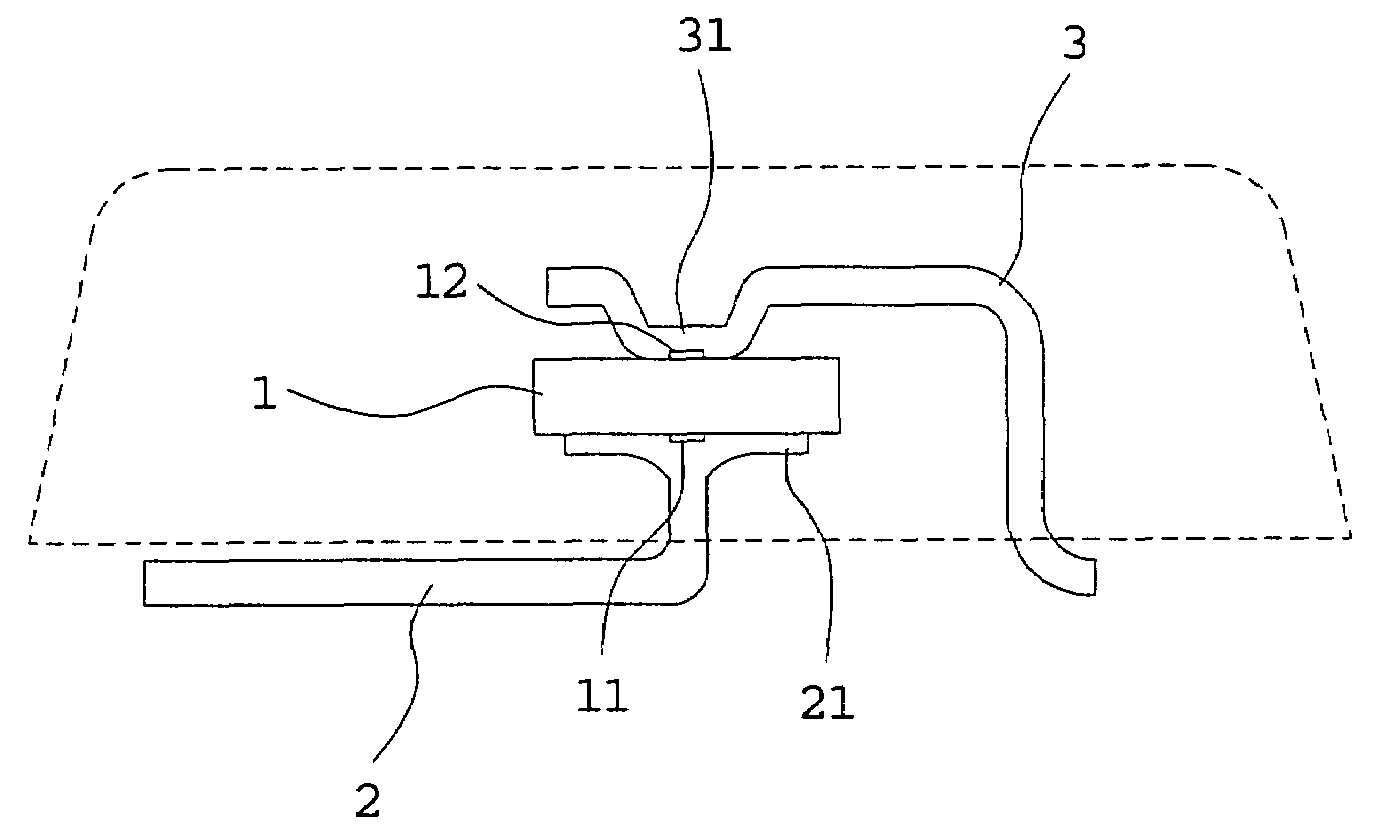

Heat-Dissipating Structure For LED Lamp

InactiveUS20080007954A1Increase contact areaFast conductionPoint-like light sourceLighting heating/cooling arrangementsHeat sinkAluminum extrusion

A heat-dissipating structure for a LED lamp includes a heat-dissipating base, a heat-dissipating body and a plurality of heat pipes. The heat-dissipating body has an outer cylinder formed into a hollow cylinder. The inside surface of the outer cylinder is provided with a plurality of accommodating grooves. The condensed ends of the plurality of heat pipes are inserted into the accommodating grooves. The end to be heated of the heat pipe is adhered to the heat-dissipating base. Further, the inside surface and the outside surface of the outer cylinder are formed with a plurality of heat-dissipating fins made by aluminum extrusion, so that the heat pipes are encircled by the heat-dissipating fins. In this way, the heat can be conducted by the plurality of heat pipes so as to increase the total contacting area. Thus, the heat can be rapidly conducted to the outer cylinder. Further, the heat can be rapidly dissipated to the outside by the heat-dissipating fins, thereby to substantially increase the efficiency in the heat dissipation.

Owner:JAFFE

Surface mounting structure and packaging method thereof

InactiveUS20070290325A1Improve space utilizationSimplify System DesignSemiconductor/solid-state device detailsSolid-state devicesState of artSystems design

A surface mounting structure and a packaging method thereof comprises a chip, a first conducting wire and a second conducting wire. The two conducting wires instead of lead frame architecture of the prior art is that the lead frame and a bridge jumper connected with N junction and P junction instead of the two conducting wires. The two conducting wires are drawn out from a bottom of a package, and are pressed and bent to original surface of the surface mounting pins so as to increase space utilization rate. Thereby it is to improve a complicated lead frame architecture of the prior art, increase use space and simplify system design.

Owner:LITE ON SEMICON

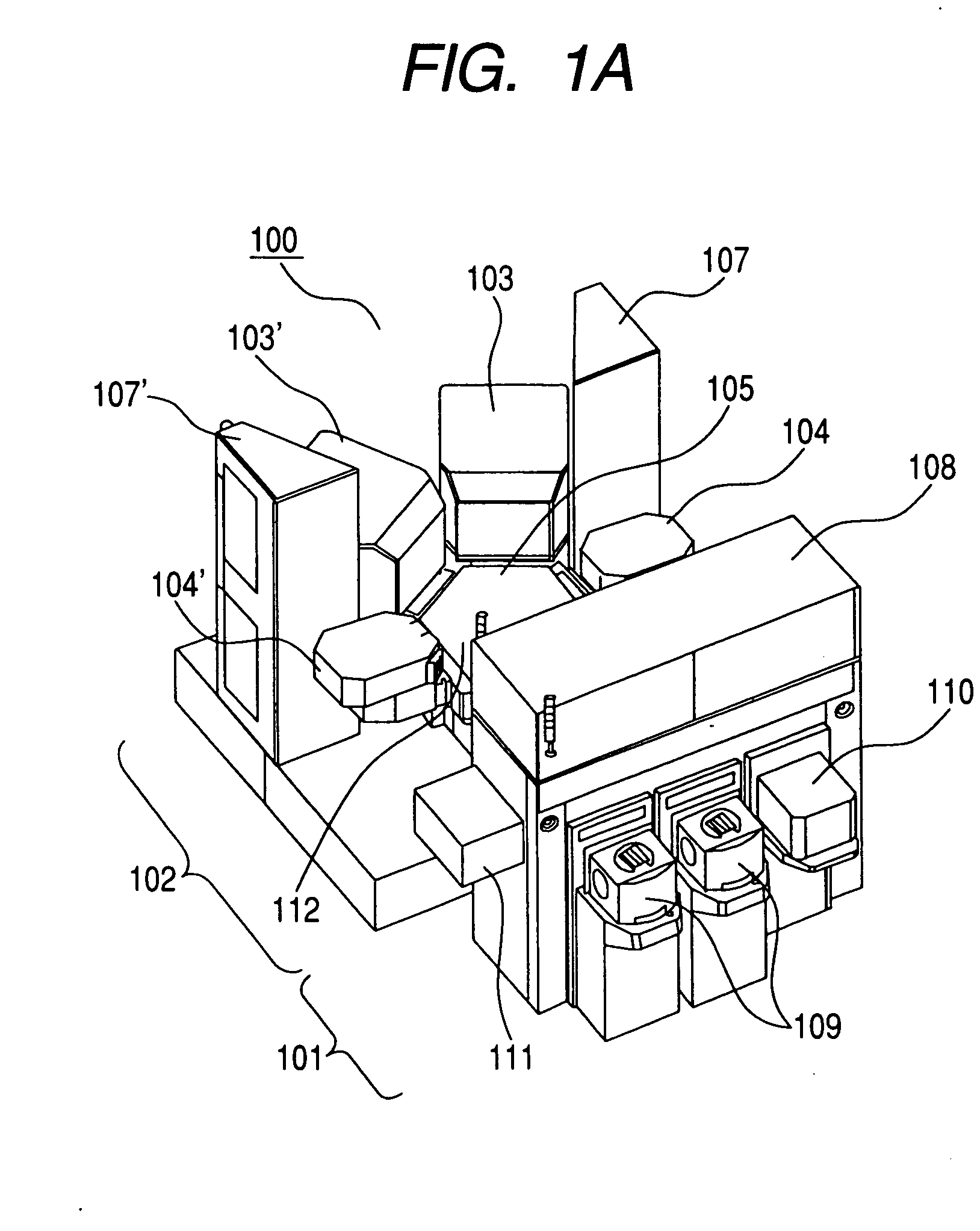

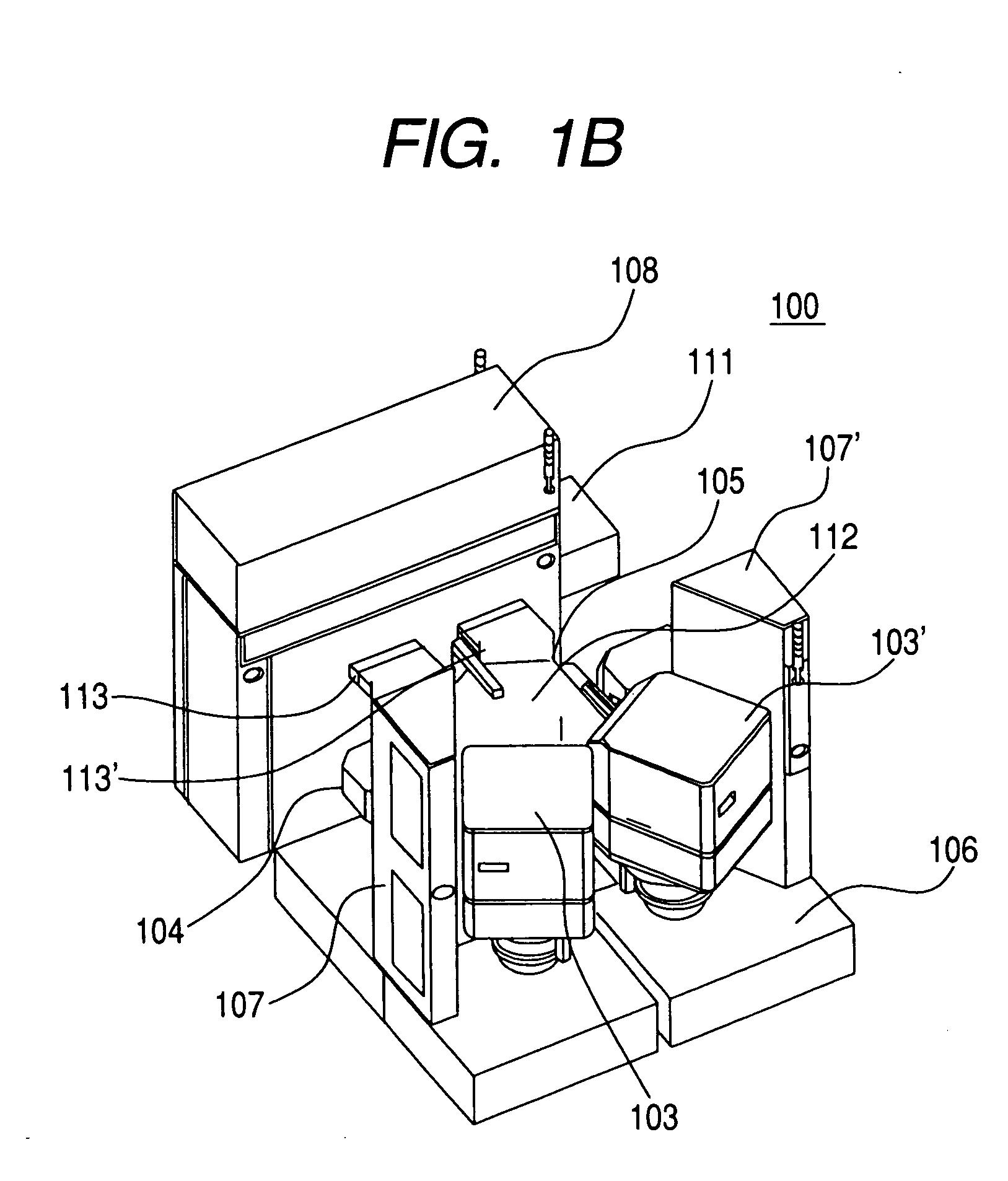

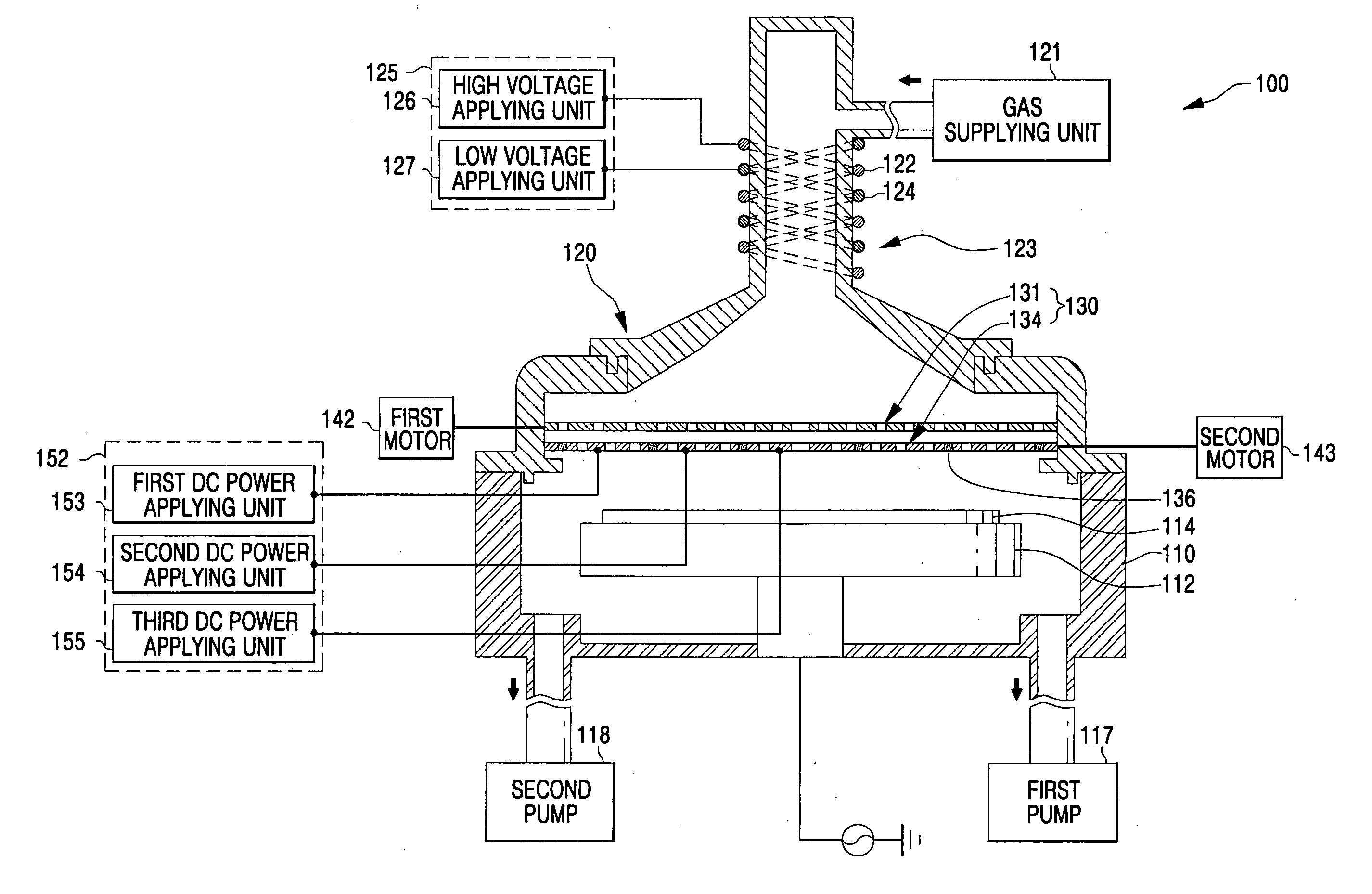

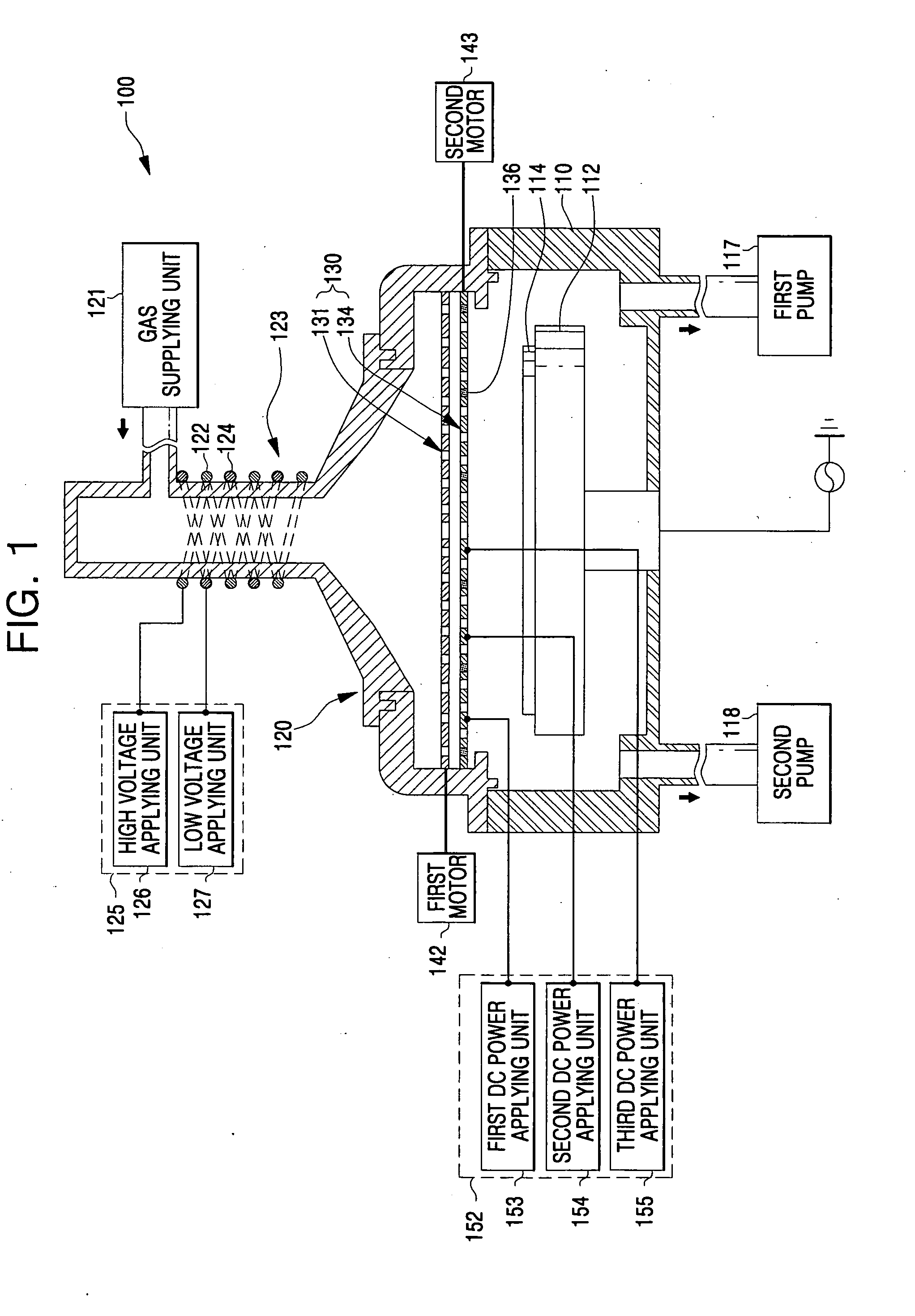

Plasma processing apparatus

InactiveUS20060102286A1Add plasma damageEasily damagedElectric discharge tubesSemiconductor/solid-state device manufacturingIon trap mass spectrometryPlasma chamber

A plasma processing apparatus comprising: a process chamber for defining a plasma processing space in which a substrate holder for mounting a substrate thereon is installed; a plasma chamber in communication with an upper portion of the process chamber to generate and inject plasma into the plasma processing space such that the substrate is processed; a screen interposed between the process chamber and the plasma chamber to block plasma ions from being injected from the plasma chamber; and an ion trap for protecting the surface of the substrate from damage due to the injected plasma ion.

Owner:SAMSUNG ELECTRONICS CO LTD

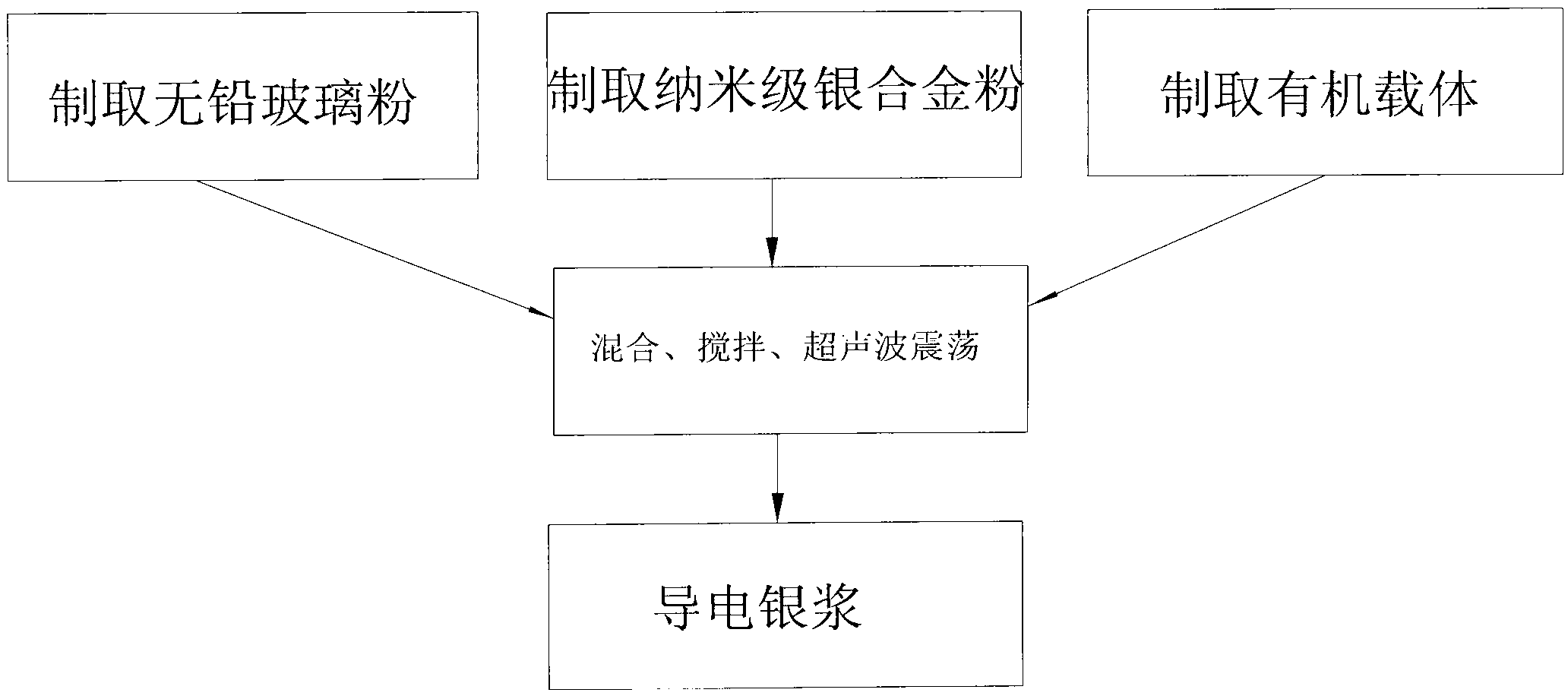

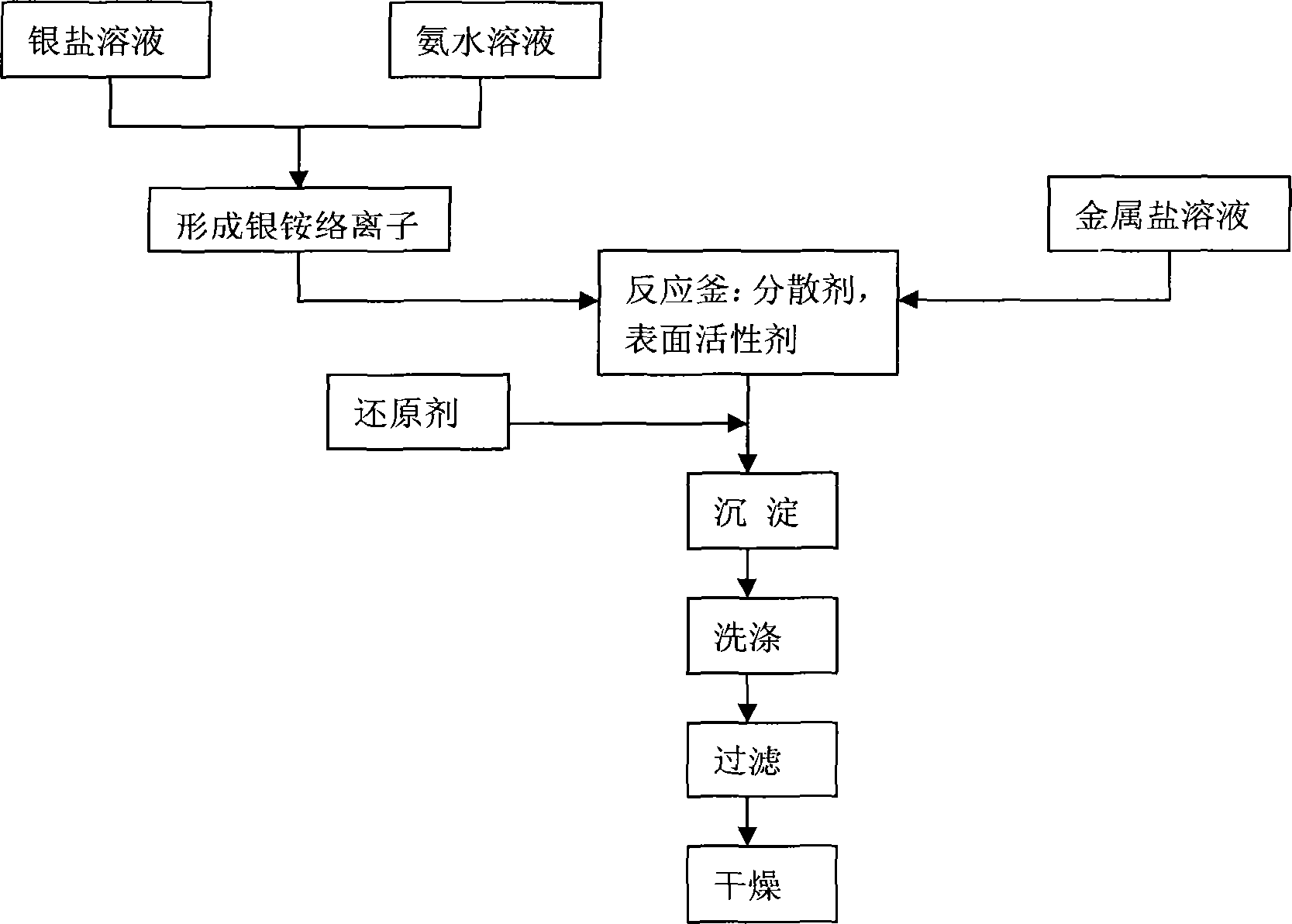

Electric conductive silver paste and manufacturing method thereof

ActiveCN103258584AEnhanced interconnectionIncrease contact areaNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetal alloy

The invention discloses electric conductive silver paste and a manufacturing method of the electric conductive silver paste. The electric conductive silver paste comprises, by mass percentage, 35 - 65 % of micron-sized silver powder, 1-10 % of nanometer-sized silver powder of or 1-20 % of nanometer-sized silver and other metal alloy powder, and 1-10 % of an organic carrier; for ceramics, solar cell silver paste comprises 2-15 % of unleaded glass powder, each component is manufactured in parts, weighed, mixed and stirred or mixed and rapidly scattered, and ultrasonic-vibrated or fine adjusted of viscosity of solvent, and therefore the electric conductive silver paste is obtained. Due to the fact that the nanometer-sized silver powder or the nanometer-sized silver alloy powder is mixed with the micron-sized silver powder, intensity of conductivity and a circuit is improved, adhesive force of crushing resistance and a base plate is improved, at the same time unleaded slurry good in thixotropy, low in contacting resistance and low in piece-needed slurry amount replaces lead slurry materials, the electric conductive silver paste is used for manufacturing crystalline silicon solar cells, improves photoelectric conversion efficiency, accords with environmental-protection ideas, and can be produced in large scales continuously.

Owner:SHENZHEN CHENGGONG CHEM

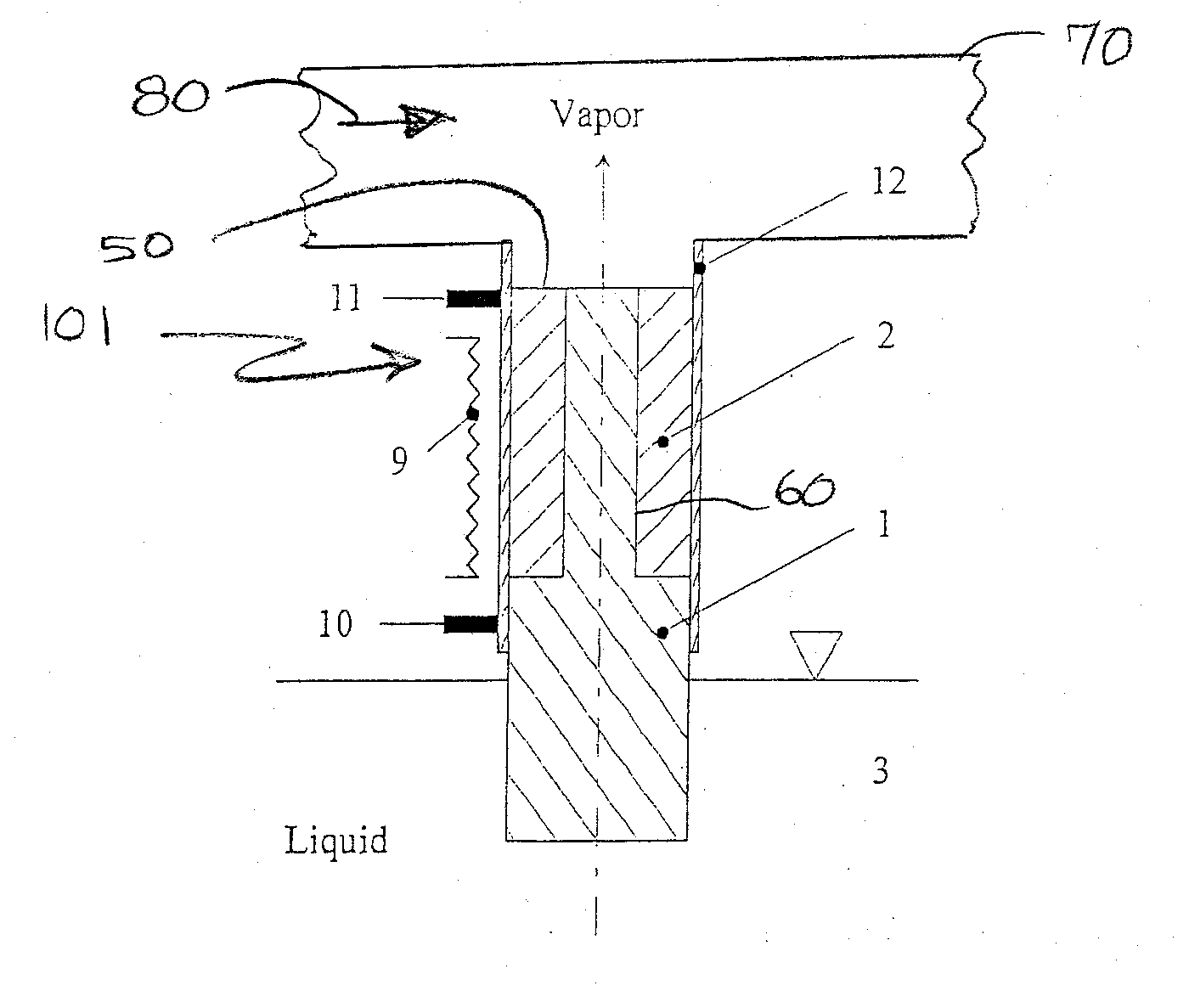

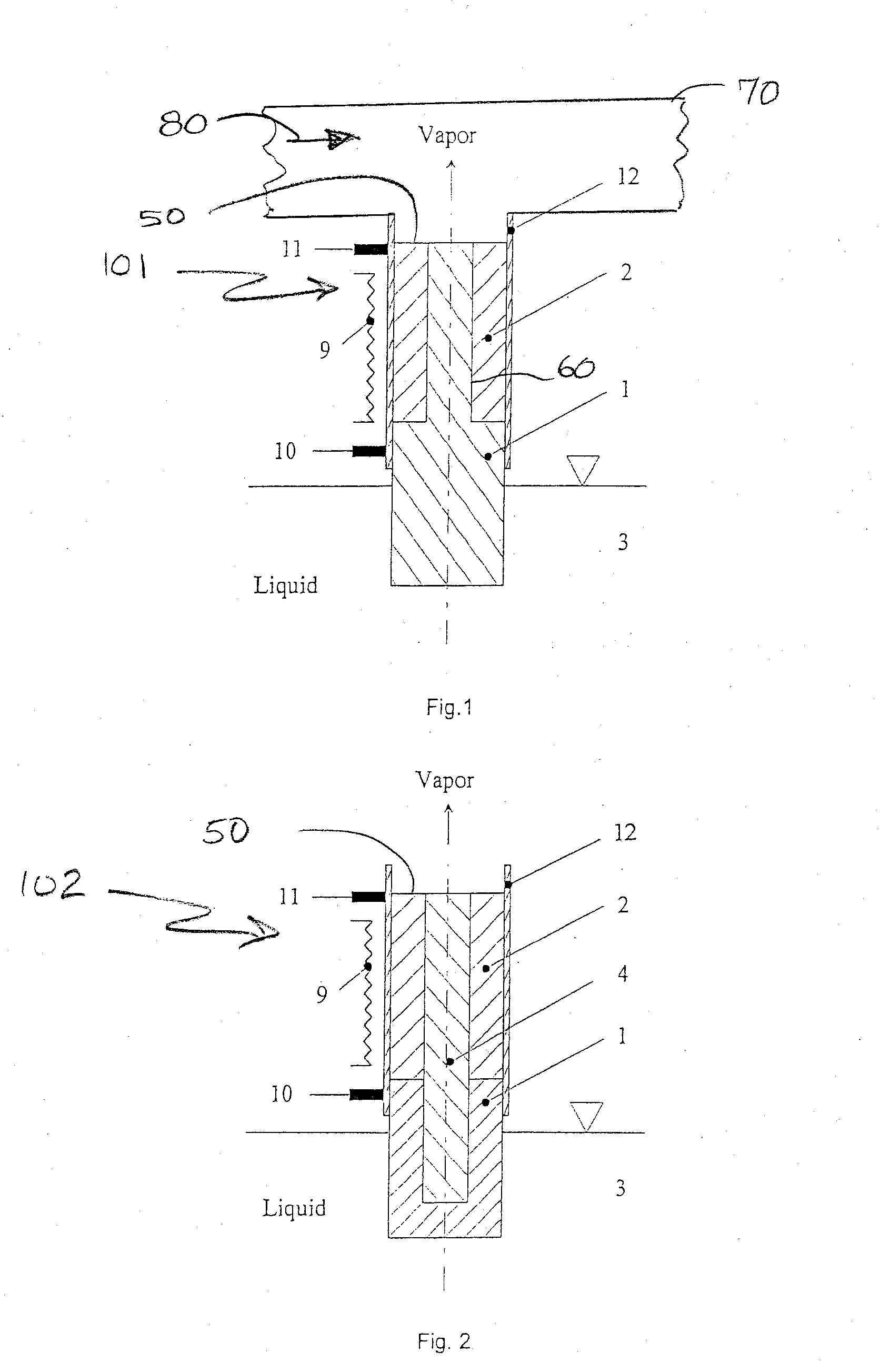

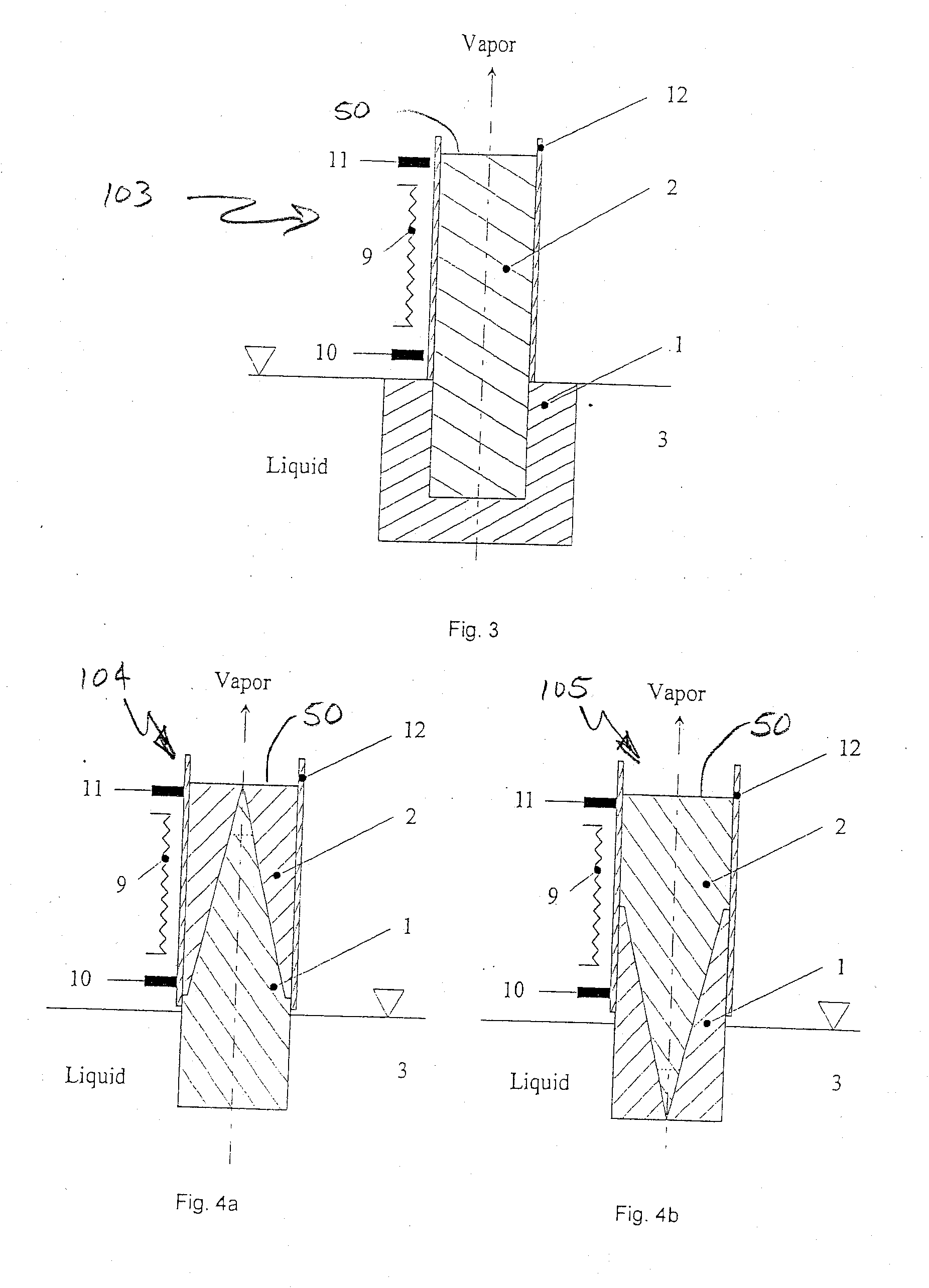

Liquid evaporator

ActiveUS20070107879A1Simple designImprove evaporation effectBurnersSpace heating and ventilationPorosityEngineering

A liquid evaporator includes a liquid reservoir (3) with a liquid to be evaporated, a heater (9) and an evaporator tube (12). The evaporator tube (12) has a first porous element (1) having a first porosity and with an area in contact with the liquid in the liquid reservoir (3) and a second porous element (2) with a second porosity and with an area present on an evaporator side (50) used to dispense the evaporated liquid, and an area outside the liquid reservoir heated by the heater (9) which is not directly in connection with the liquid. The first porous element and the second porous element are in contact in contact areas with the first porous element forming a wick delivering liquid from the reservoir to the contact area.

Owner:DRAGERWERK AG

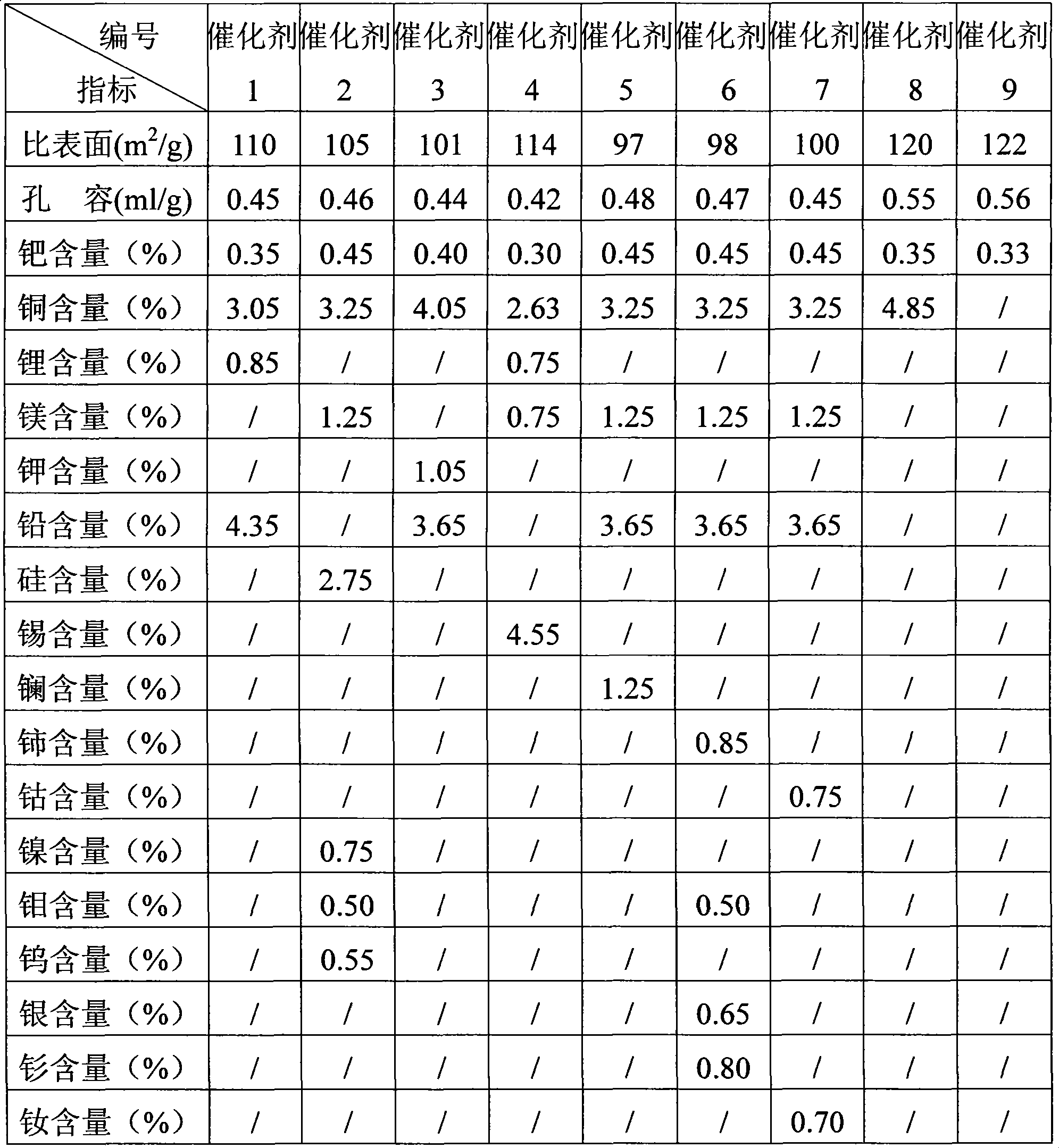

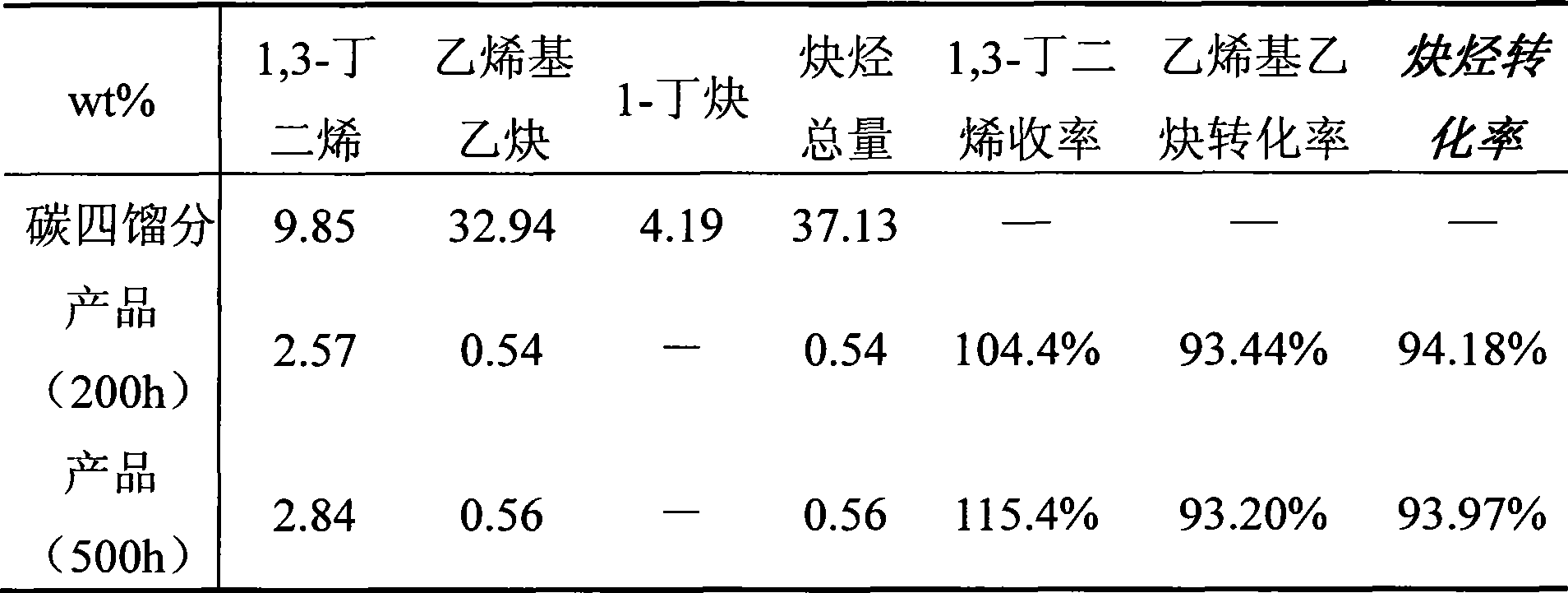

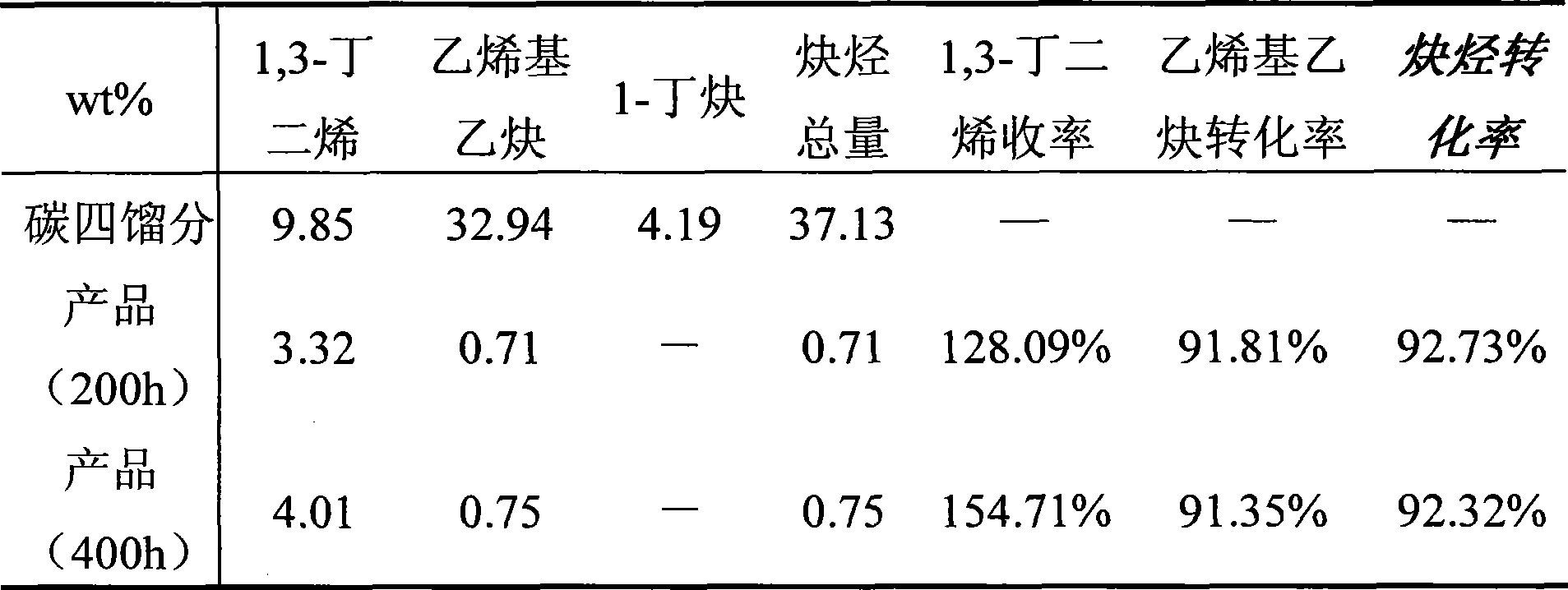

Acetylene hydrocarbon selective hydrogenation method

ActiveCN101434508AGood hydrogenation effectImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationButadiene DioxideUnsaturated hydrocarbon

The invention relates to a selective hydrogenation method of high unsaturated hydrocarbons in C4 fractions, which is characterized in that salvage stores which are rich in acetylene hydrocarbon and prepared by extracting butadiene are used as the material, and a fixed bed reactor is adopted to obtain 1, 3-budiene by selective hydrogenation under the existence of a catalyst. The adopted process conditions are as follows: the reaction temperature is between 30 DEG C and 90 DEG C, the reaction pressure is between 1.0 MPa and 4.0 MPa and the liquid space velocity is 7 to 20h<-1>. The catalyst is preferably a palladium system catalyst with alumina as a carrier, the specific surface is 50 to 150m<2> / g and the specific pore volume is 0.25 to 1.0ml / g. The method has remarkable good effects on reducing waste of resources and improving economic benefits by effectively utilizing the salvage stores rich in acetylene hydrocarbon and prepared by extracting butadiene.

Owner:PETROCHINA CO LTD

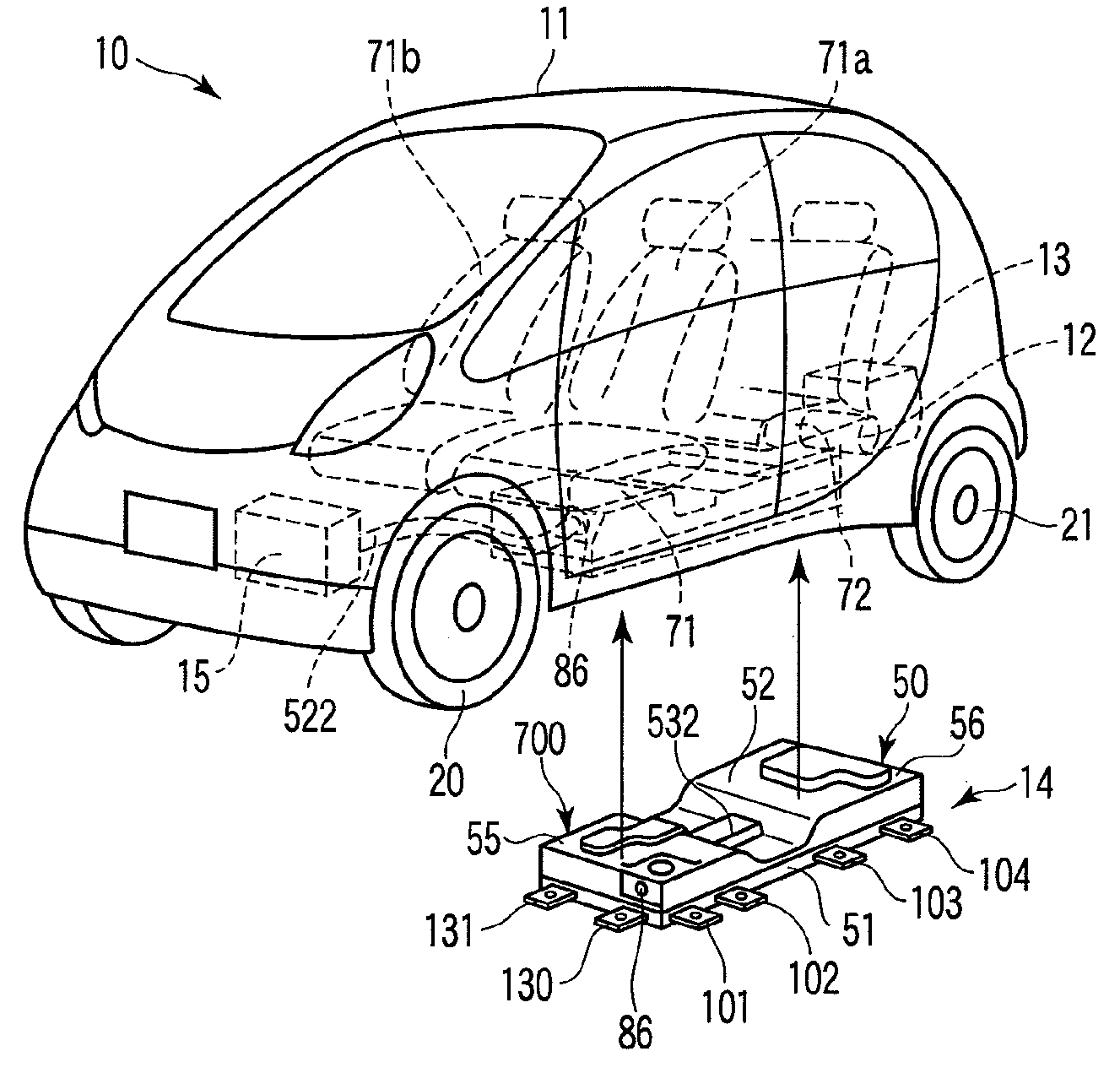

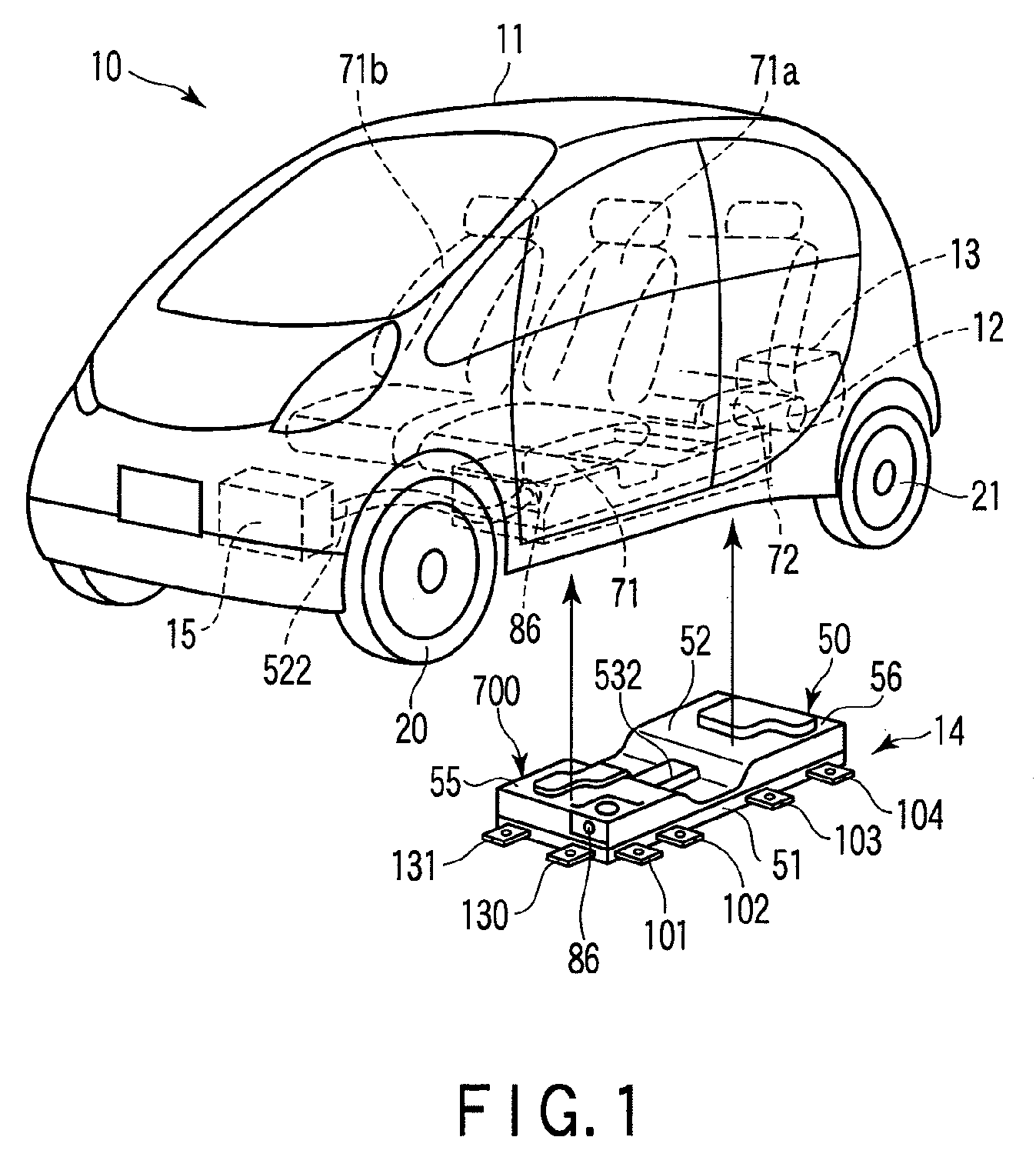

Battery unit

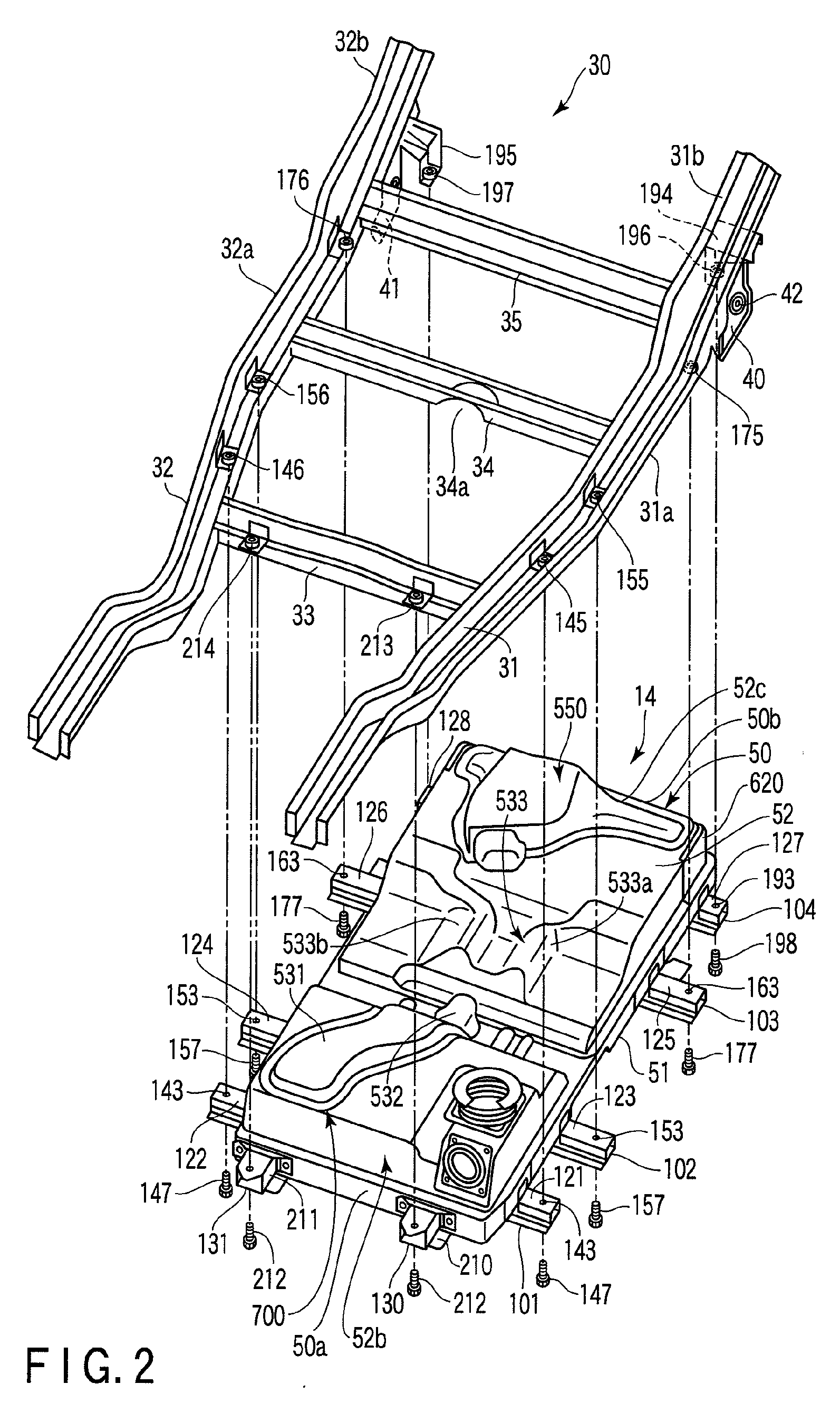

InactiveUS20090186266A1Rigid enoughImprove cooling effectCell temperature controlElectric propulsion mountingEngineeringElectrical and Electronics engineering

Owner:MITSUBISHI MOTORS CORP

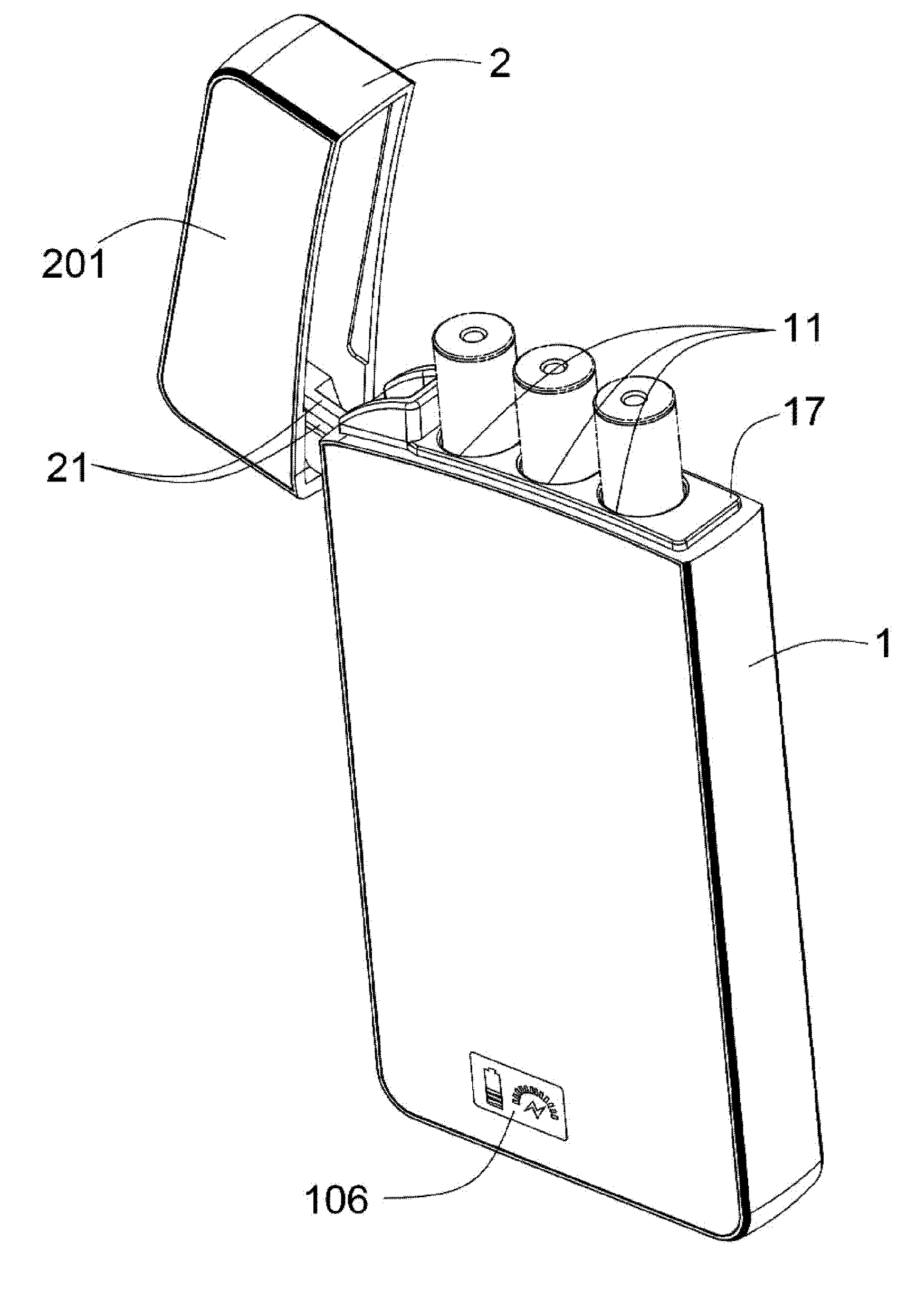

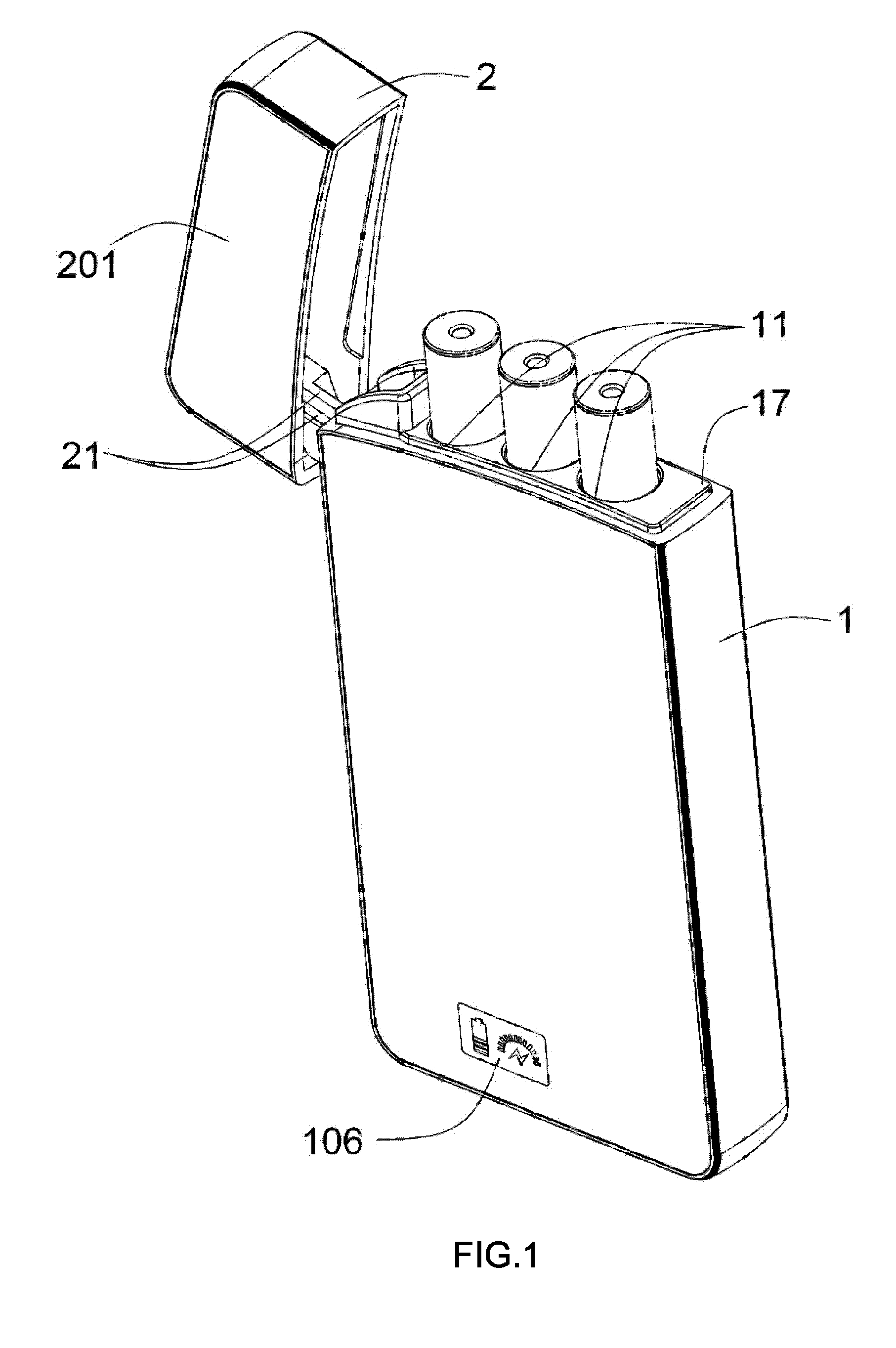

Electronic Cigarette Case with Magnetic Attraction Type Charging Function and Electronic Cigarette Therewith

ActiveUS20170027221A1Improve user experienceStable and reliable charging connectionBatteries circuit arrangementsTobacco pipesElectrical batteryElectronic cigarette

An electronic cigarette case with magnetic attraction type charging function and an electronic cigarette therewith have the advantages of good user experience in charging, stable and reliable charging connections, convenience and quickness in use and a simple structure. The electronic cigarette case comprises a charging base body, a copper sheet arranged between an annular magnet and a magnetic attraction type charging base in a case body, an insulating ejector pin base inserted into the annular magnet, and an elastic charging ejector pin inserted into the insulating ejector pin base. An electronic cigarette includes an atomizer assembly and a battery rod assembly provided with a magnetic attraction type charging assembly including an annular iron piece. A power supply ejector pin, an annular iron piece and an electronic cigarette battery are respectively connected with an electronic cigarette microphone of the electronic cigarette.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

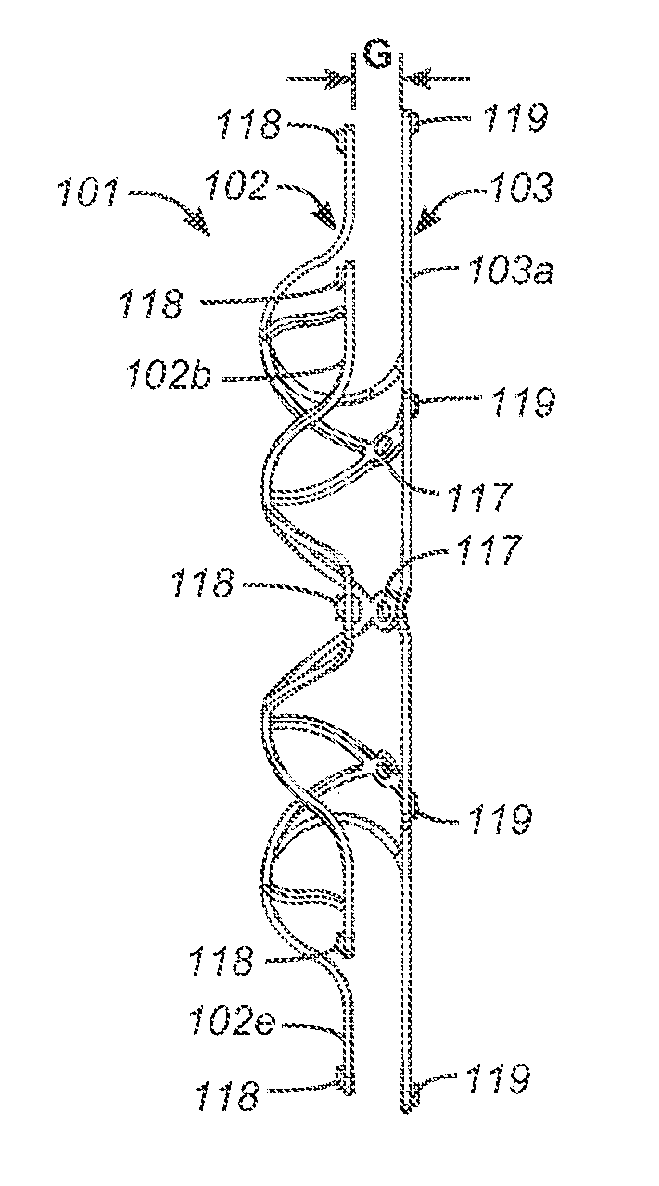

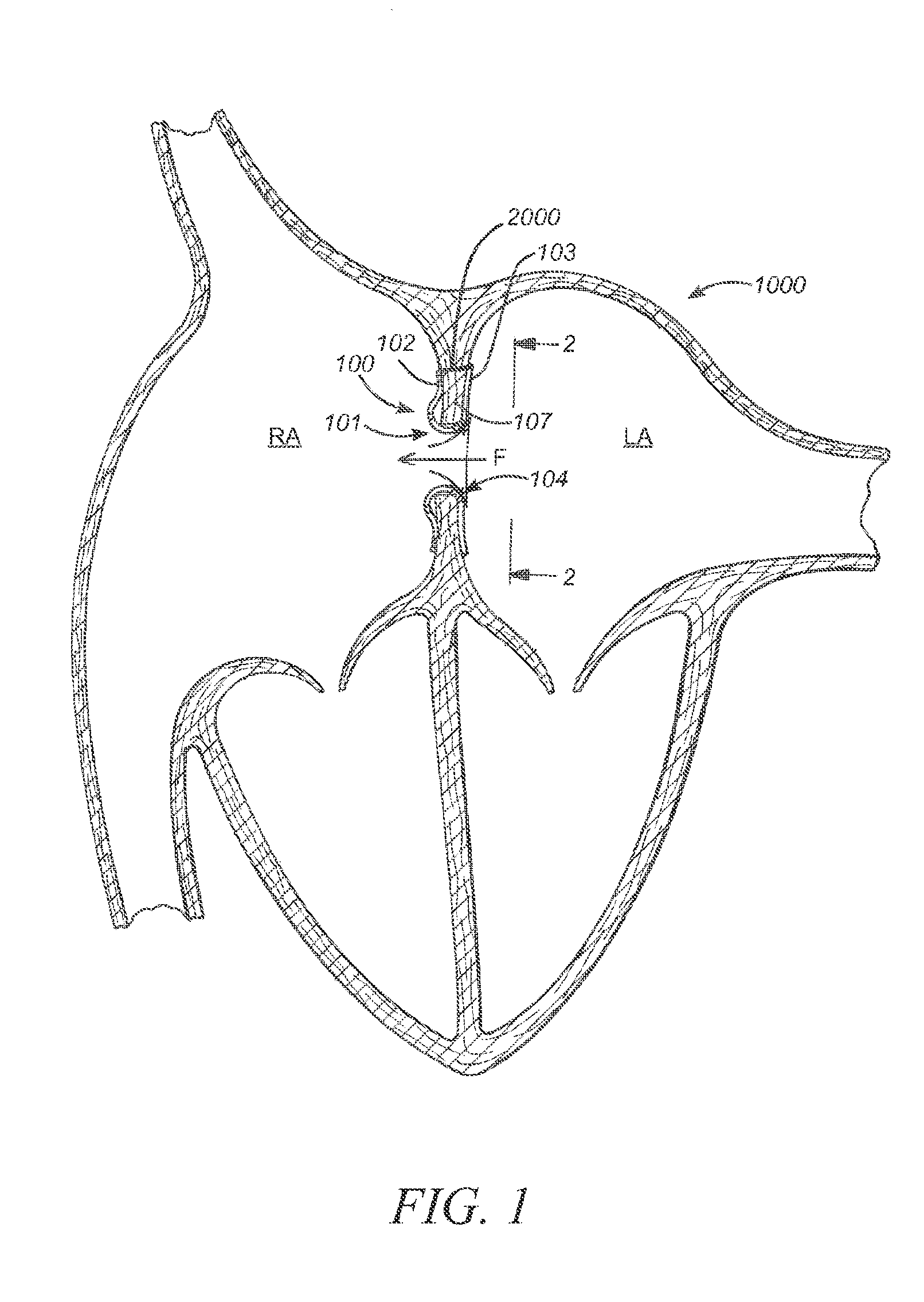

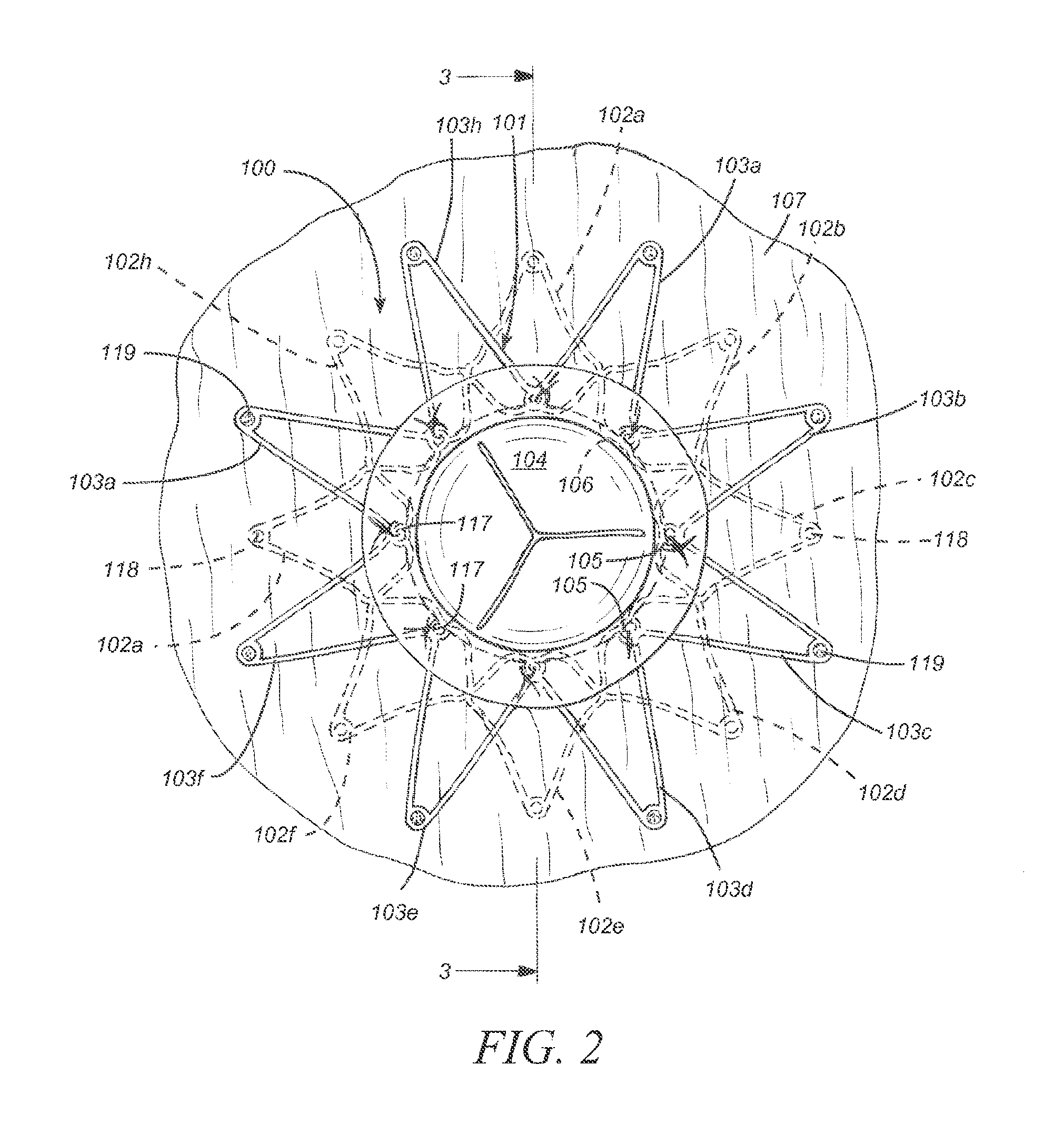

Devices for retrieving a prosthesis

ActiveUS20110071624A1Reducing pressure necrosisImprove radiopacityUltrasonic/sonic/infrasonic diagnosticsHeart valvesPatients symptomsLeft atrial pressure

The present disclosure relates to devices and methods for implanting a prosthesis into a heart of a mammal, such as a person. The disclosure includes a prosthesis that acts as a pressure vent between the left and right atria of the heart. The disclosure also includes a mounting tool for mounting the prosthesis onto a loading tool, the loading tool useful for loading the prosthesis onto a device for delivering the prosthesis into the patient's heart. Control devices and methods for using these devices are also disclosed. The intracardiac pressure vents disclosed allow sufficient flow from the left atrium to the right atrium to relieve elevated left atrial pressure and resulting patient symptoms. The devices also limit the amount of flow from the right atrium to the left atrium to minimize the potential for thrombi or other embolic material from entering arterial circulation.

Owner:CORVIA MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com