Patents

Literature

152 results about "Radius of curvature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The distance from the center of a circle or sphere to its surface is its radius. For other curved lines or surfaces, the radius of curvature at a given point is the radius of a circle that mathematically best fits the curve at that point. In the case of a surface, the radius of curvature is the radius of a circle that best fits a normal section.

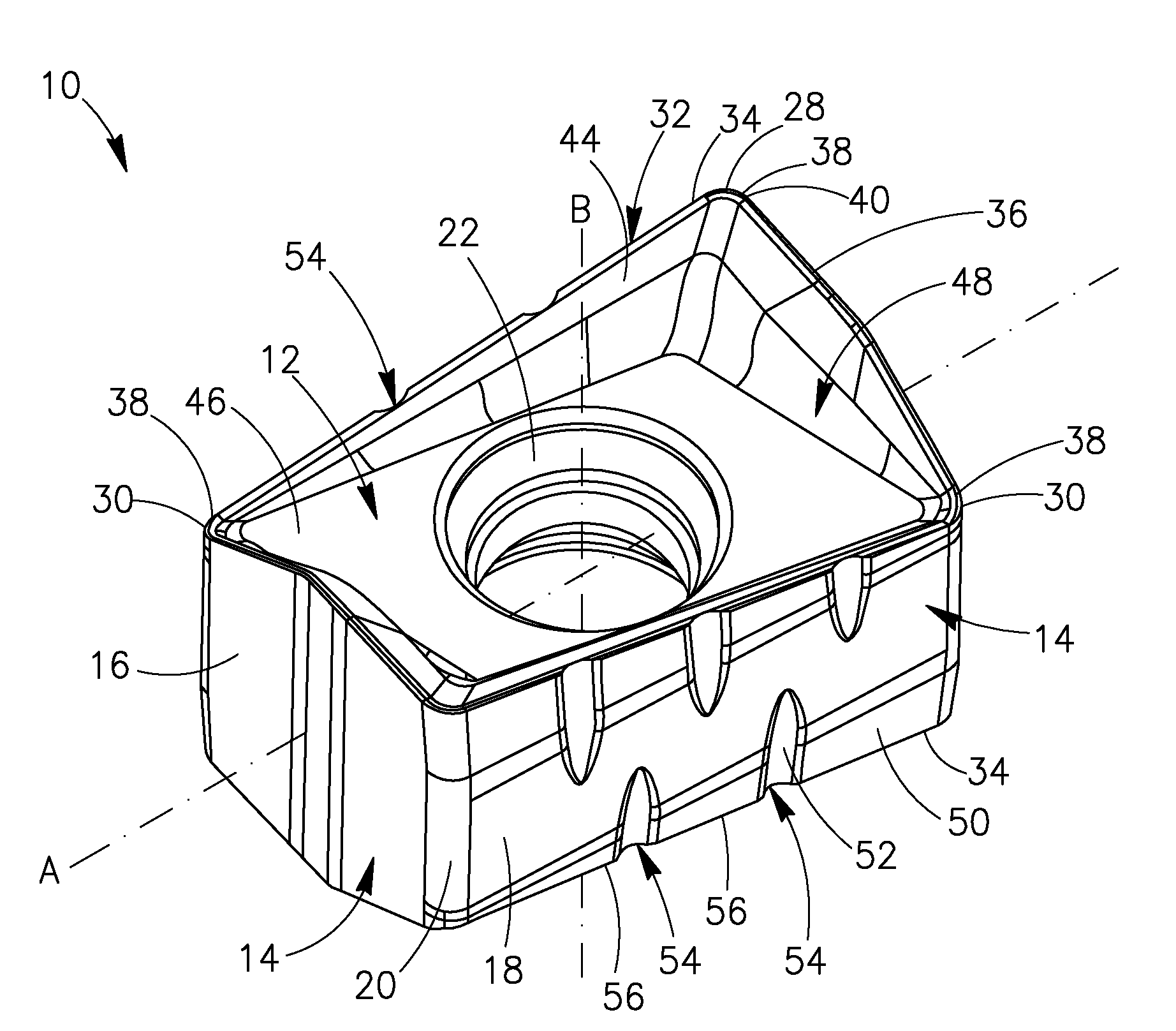

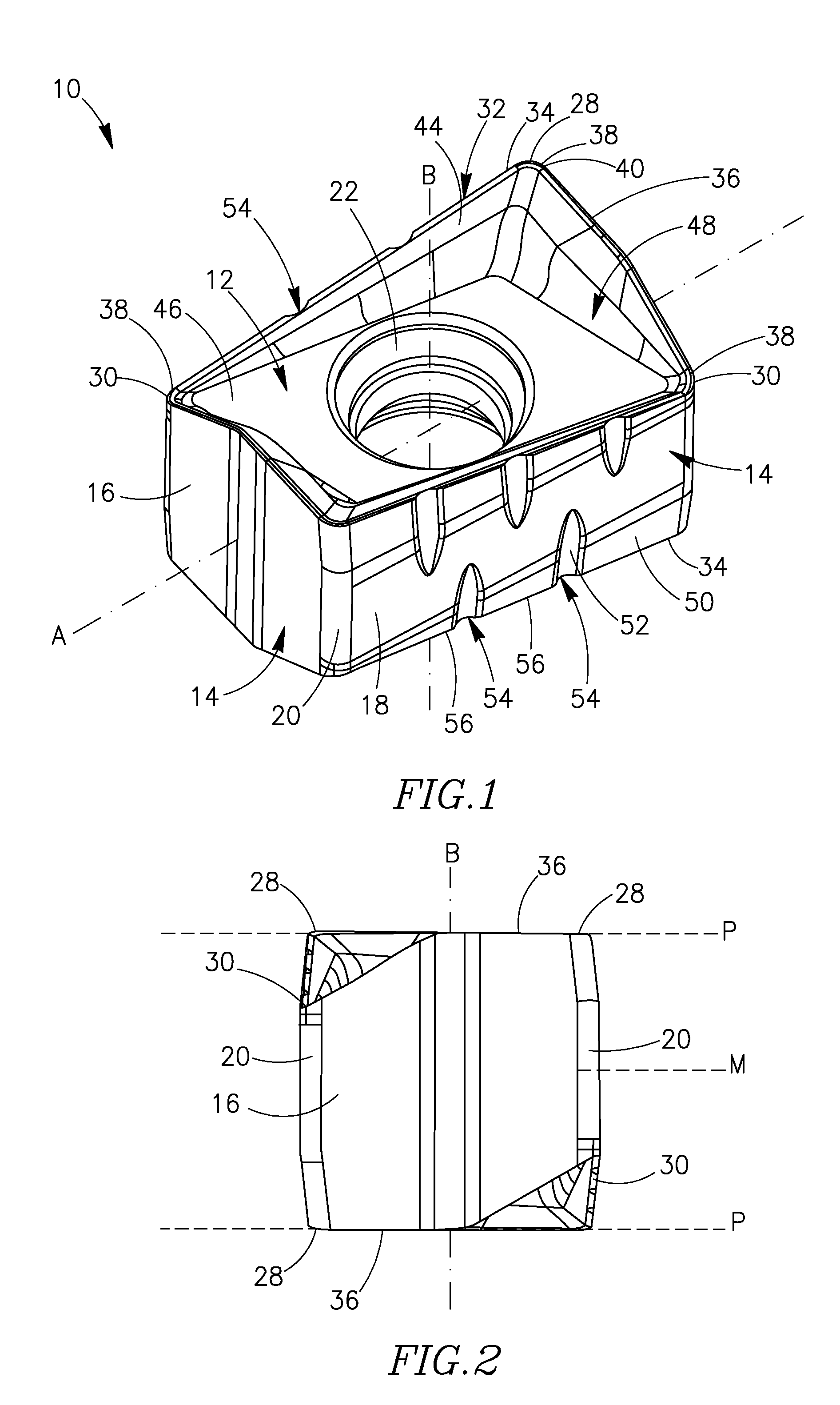

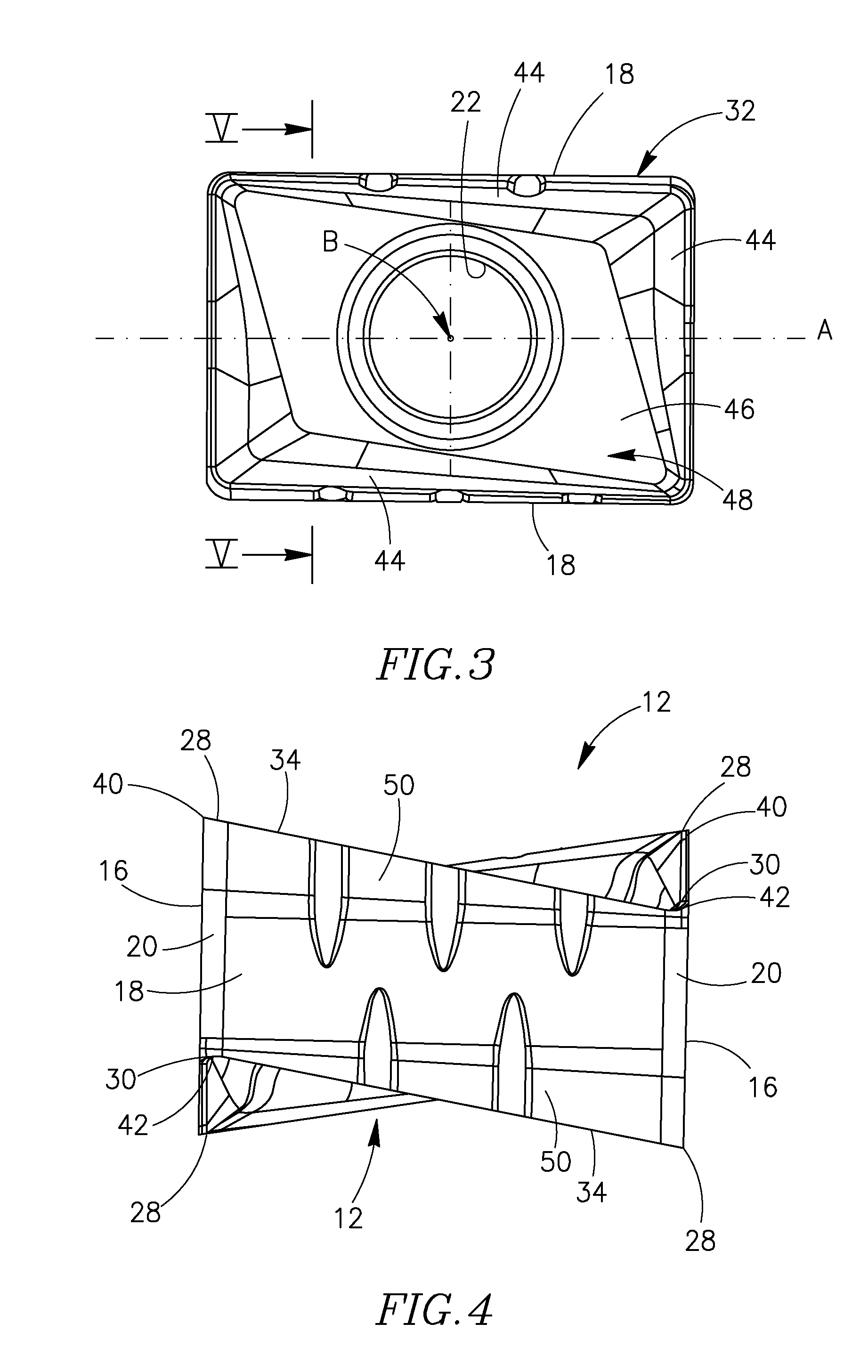

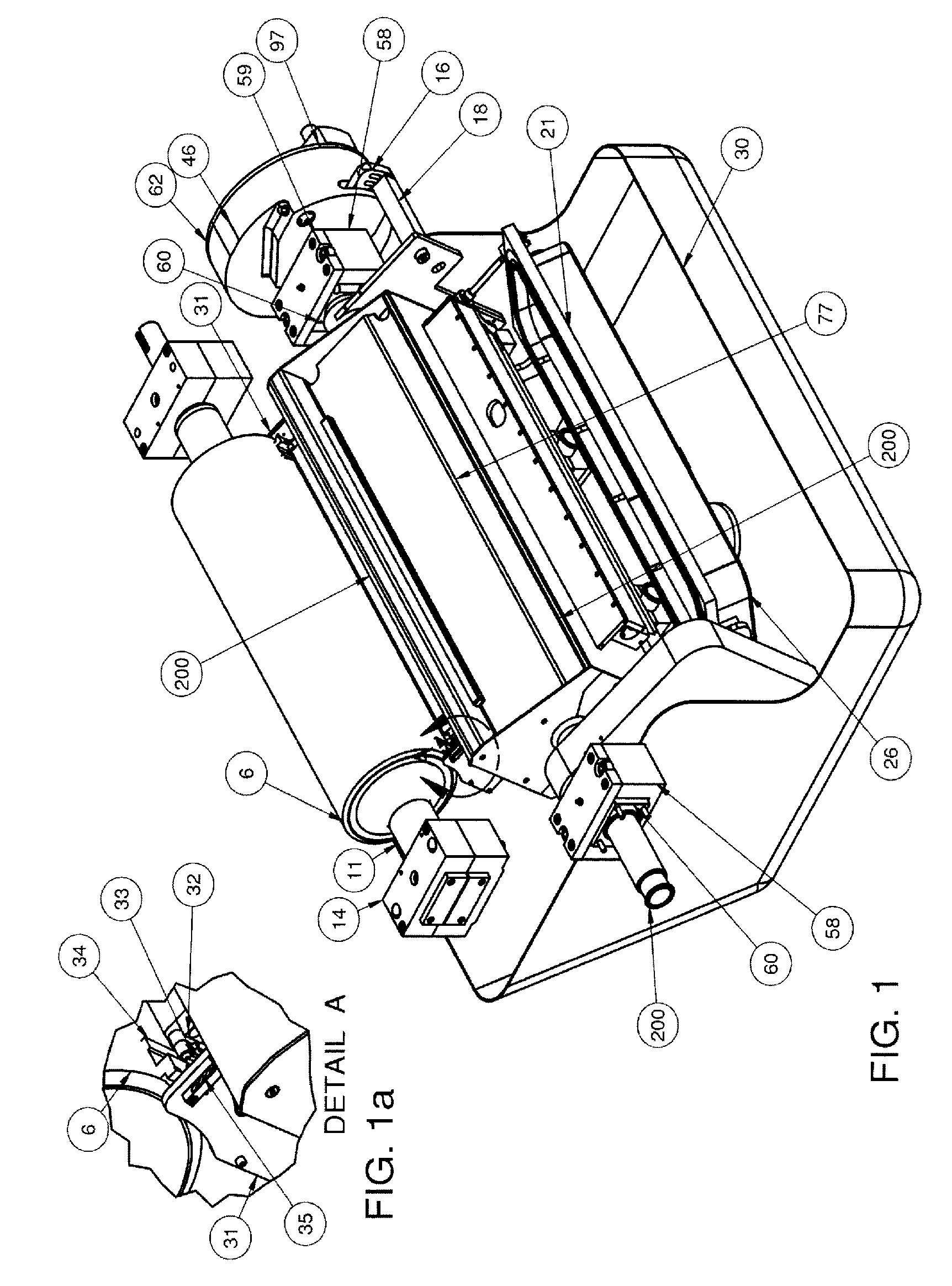

Cutting Insert Having Cutting Edges with Recessed Portions

ActiveUS20110170963A1Improve metal removal rateIncrease cutting forceMilling cuttersTurning toolsEngineeringMechanical engineering

A cutting insert has a cutting edge formed at the intersection of a side surface an end surface. Recesses formed in the side surface interrupt the cutting edge at recessed cutting edge portions. Each recessed cutting edge portion has, in an end view of the cutting insert, a curved central section located between two curved side sections. The central section has a first radius of curvature and each side section has a second radius of curvature, the first radius of curvature being larger than the second radius of curvature.

Owner:ISCAR LTD

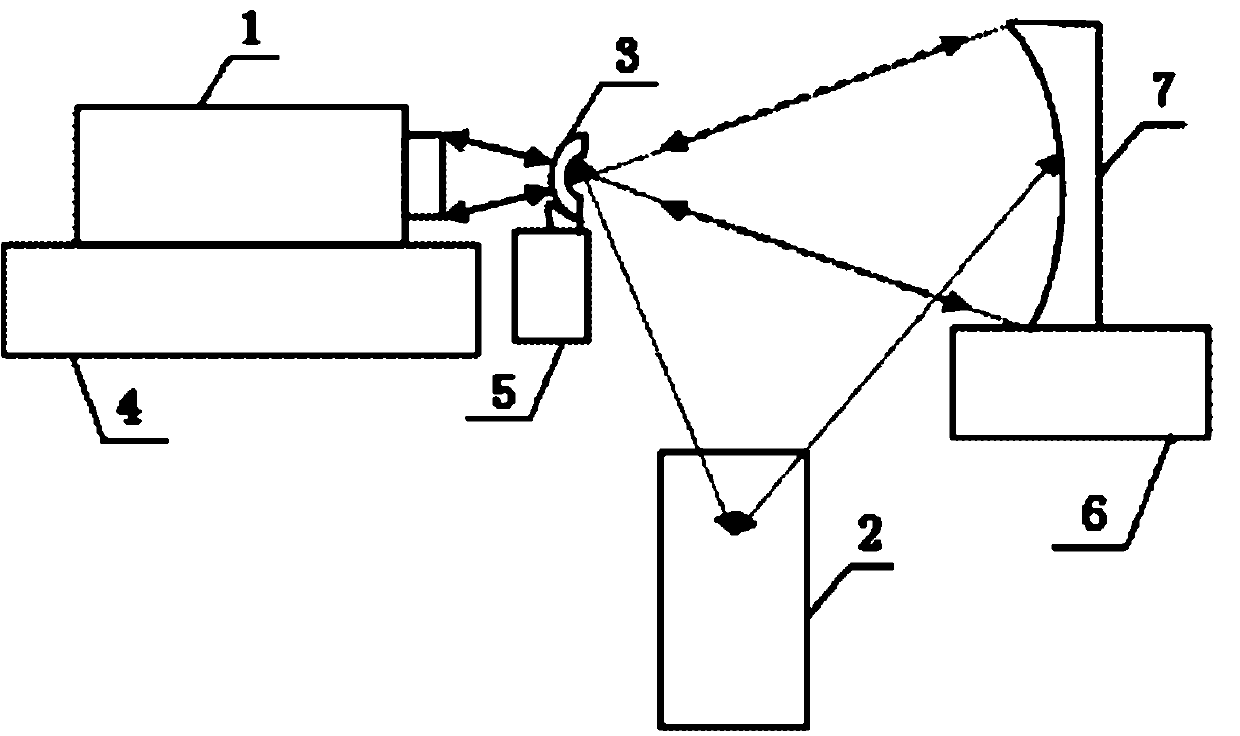

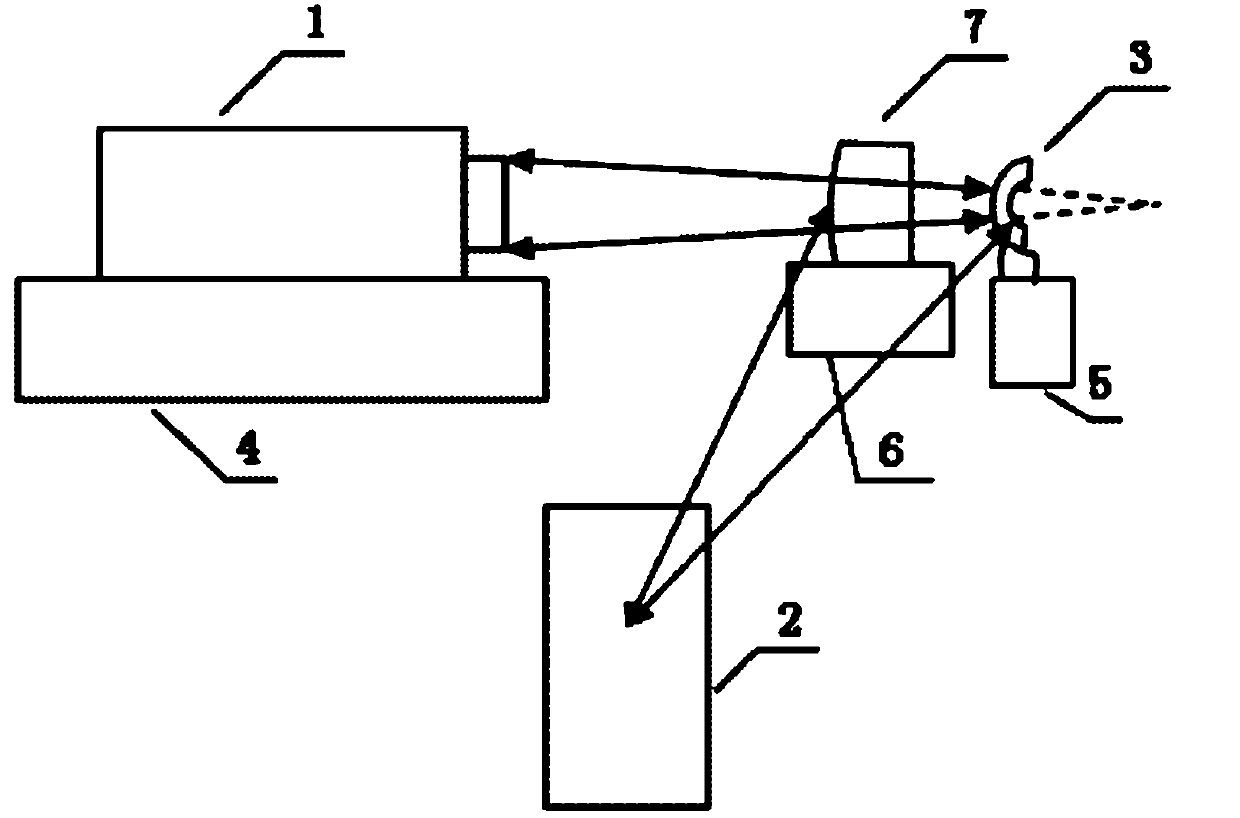

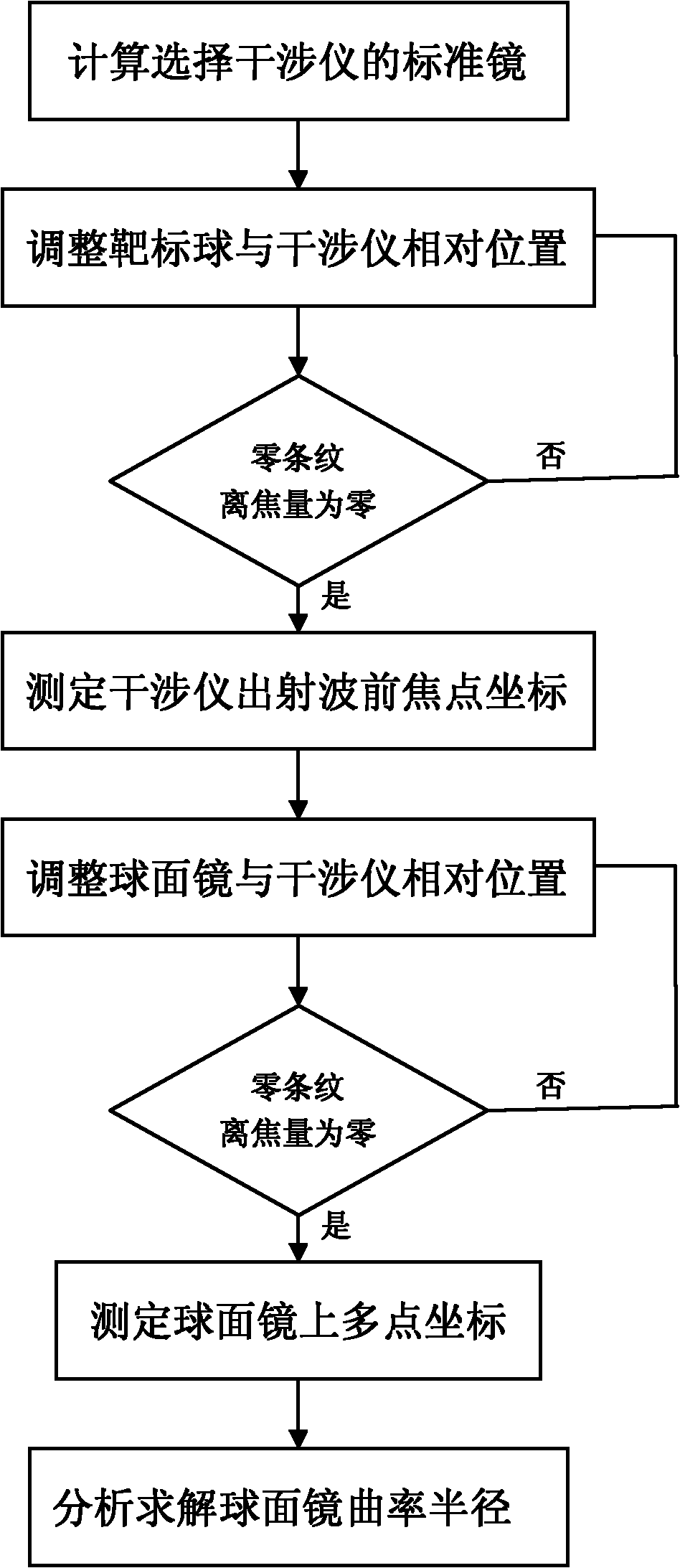

Method for detecting curvature radius of optical spherical surface

InactiveCN102168955ARealize measurementSimple processing capacityUsing optical meansOptical measurementsRadius of curvature

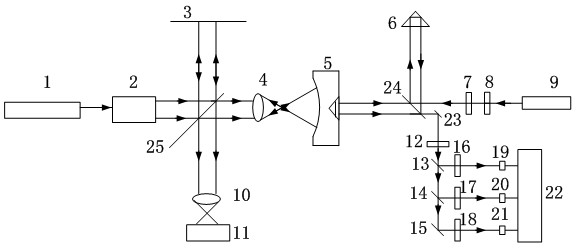

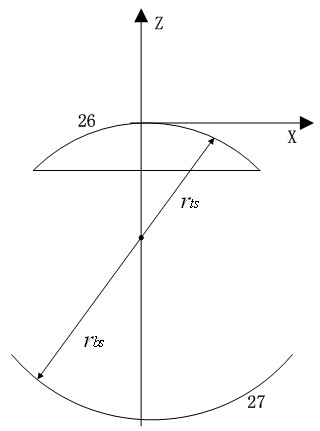

The invention discloses a method for detecting the curvature radius of an optical spherical surface, relating to a method for measuring the curvature radius of the optical spherical surface and aiming to solve the problems of errors existing in the conventional method for measuring the curvature radius of the optical spherical surface and difficulty in accurately realizing measurement of a spherical mirror with a large curvature radius by adopting the conventional measuring method. The method comprises the following steps of: adjusting relative positions of a target sphere and an interferometer and judging whether the curvature center of the target sphere is overlaid with the front focal point of the emergent waves of the interferometer or not; if so, measuring the curvature center coordinate of the target sphere by using a laser tracking instrument, wherein the curvature center coordinate of the target sphere is the coordinate of the front focal point of the emergent waves of the interferometer; if not, continually adjusting the relative positions of the target sphere and the interferometer until the spherical mirror to be detected reaches a zero stripe interference state; measuring the position coordinates of a plurality of points on the spherical mirror to be detected by using the laser tracking instrument; and averaging, counting and operating a plurality of values to obtain the curvature radius of the optical spherical mirror to be detected. The method is suitable for the technical field of optical measurement.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

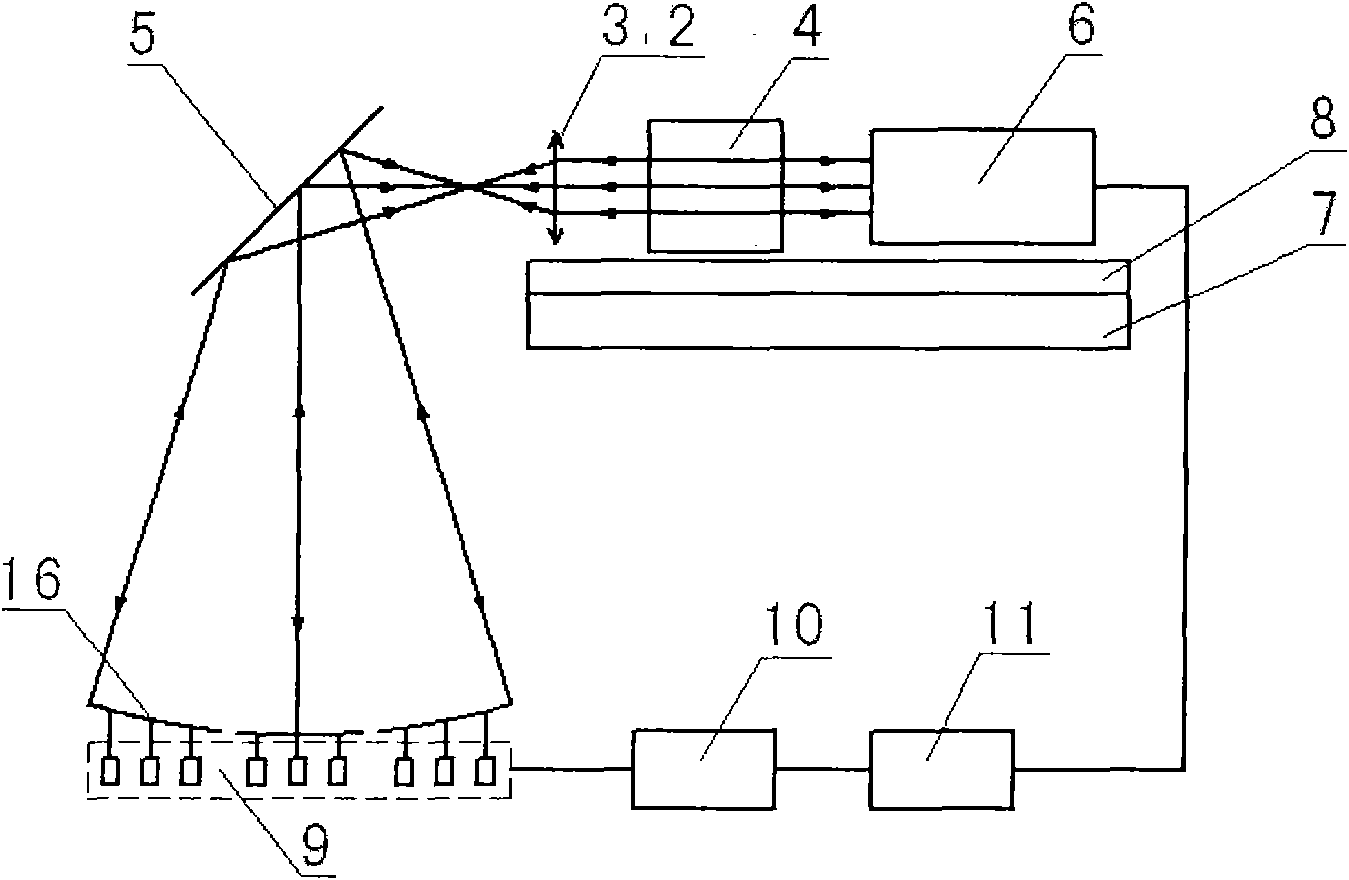

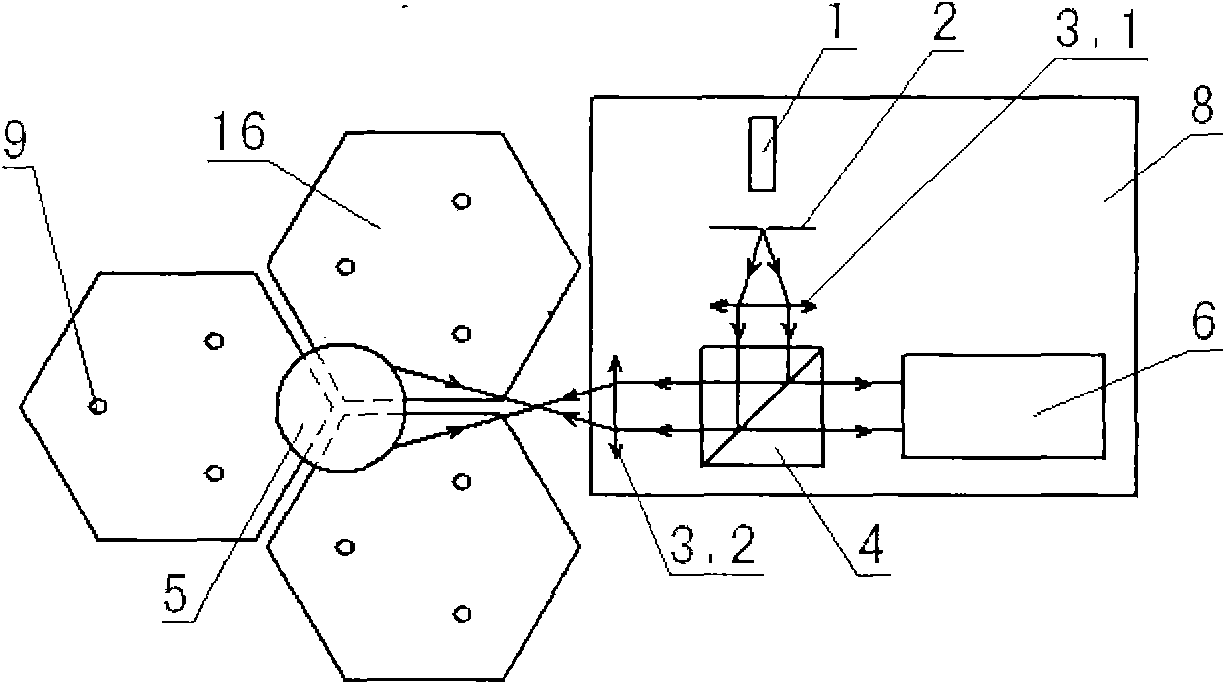

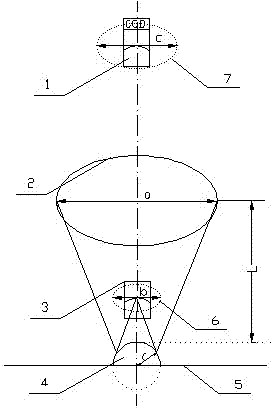

Detecting device for measuring difference of relative radius of curvature between sub-lenses of sphere surface spliced telescope

InactiveCN101571383AHigh measurement accuracyImprove efficiencyUsing optical meansOptical apparatus testingOptical axisLight beam

The invention relates to a detecting device for measuring the difference of relative radius of curvature between sub-lenses of a sphere surface spliced telescope. The device comprises a confocal adjustment system and a spherometer, wherein the confocal adjustment system comprises a laser source arranged on a mounting plate, a pin hole, two collimating lenses, a dispersion prism, a Shack-Hartmann wave-front sensor, a planar reflector, a micrometric displacement translational platform, a controller of the micrometric displacement translational platform and a computer; after passing through the pin hole and a first collimating lens, light beam emitted by the laser source is emitted out through a second collimating lens after reflection through the dispersion prism; the Shack-Hartmann wave-front sensor is arranged on the other side of the dispersion prism, which is coaxial with the reflecting light path of the dispersion prism; the planar reflector is arranged on the optical axis outside the focal surface of the second collimating lens; and the reflecting light path of the planar reflector is provided with the micrometric displacement translational platform carrying the sub-lens to be measured. The device does not require a standard reference lens, is independent from testing environment, and has high measurement accuracy and high efficiency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

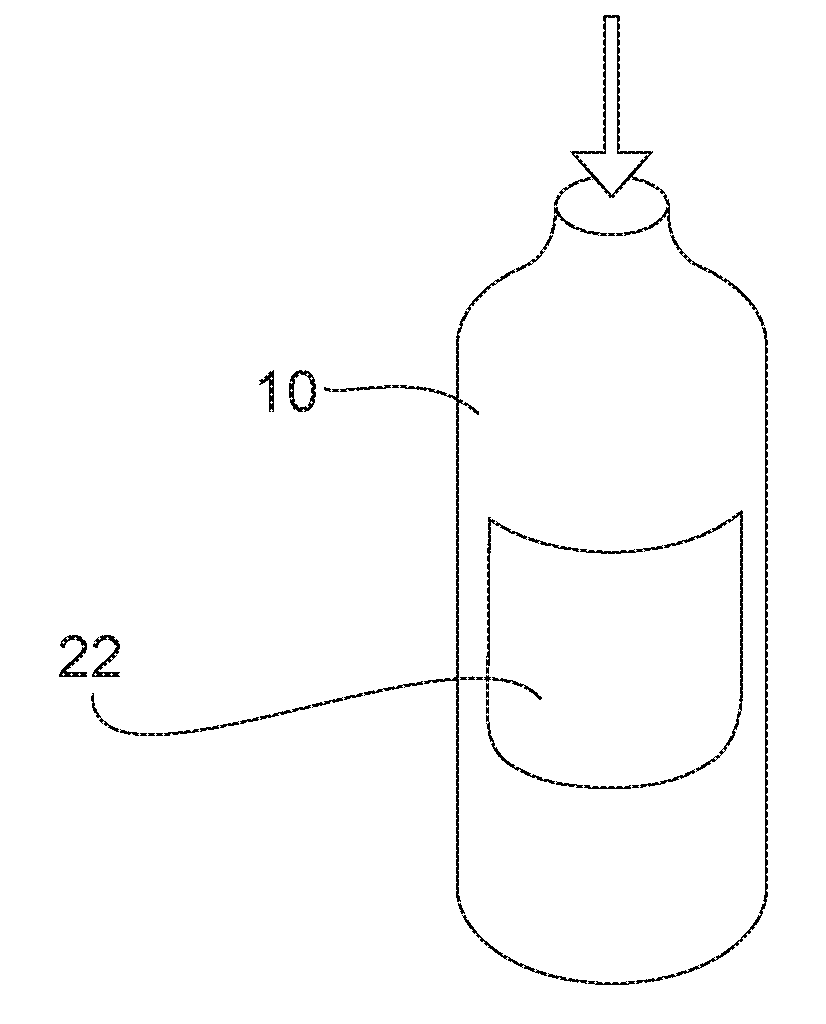

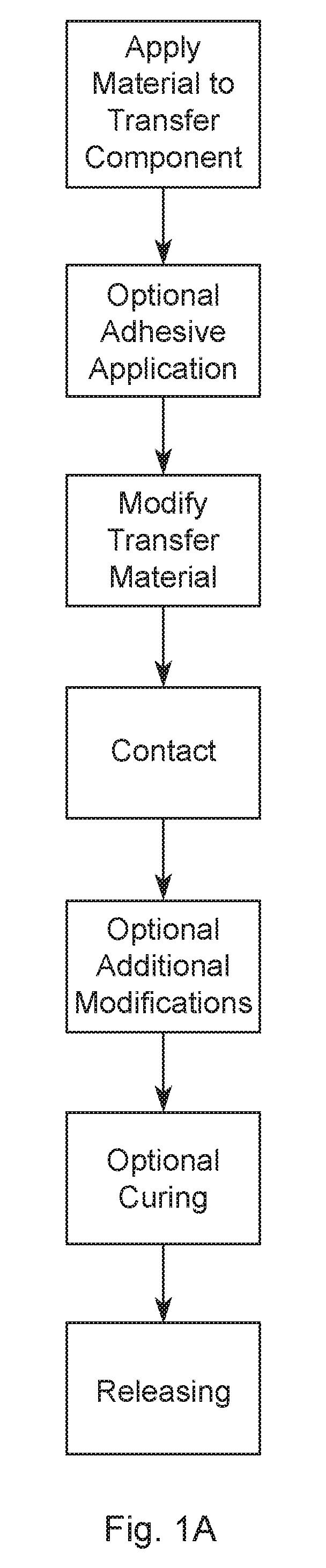

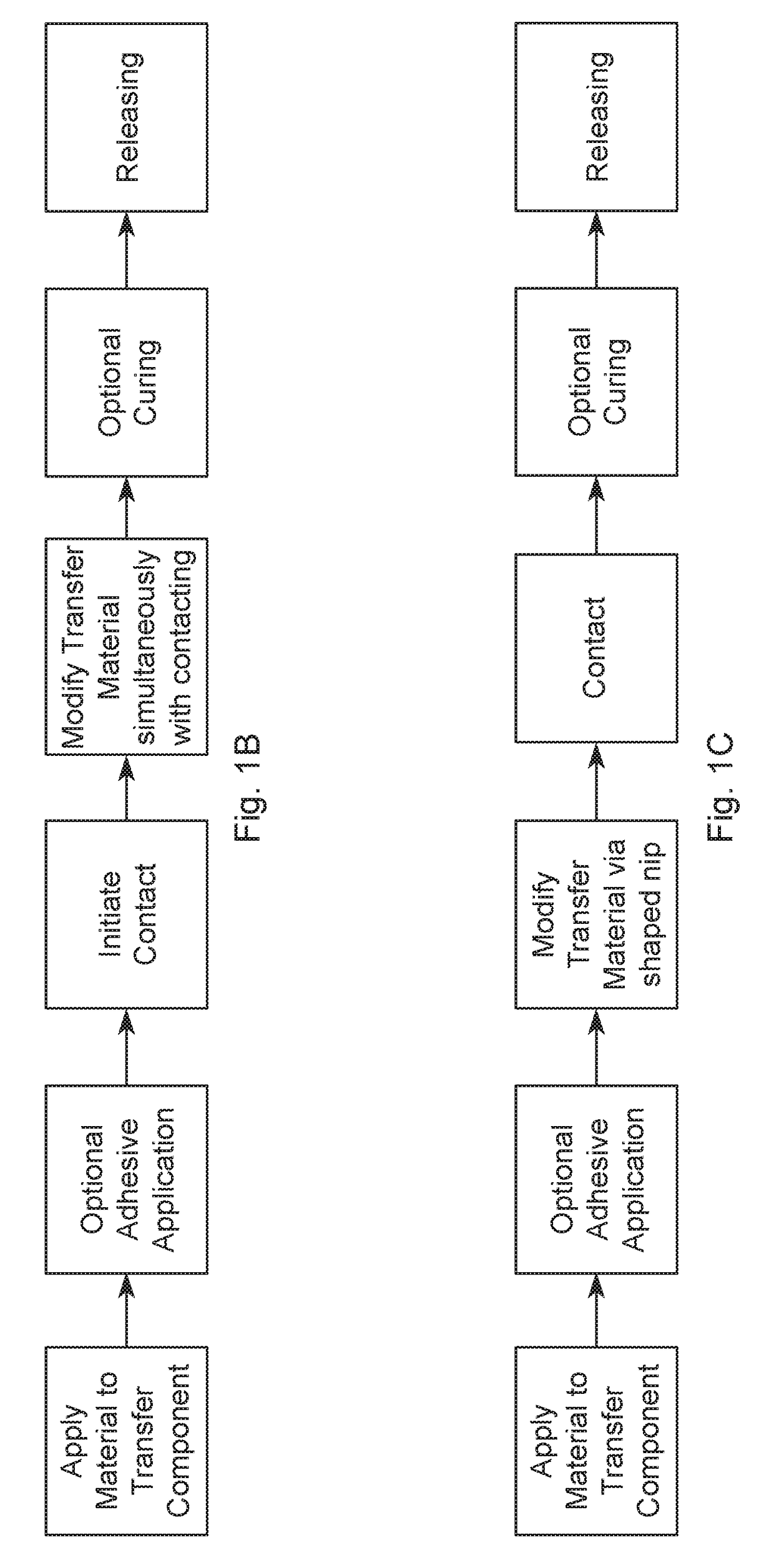

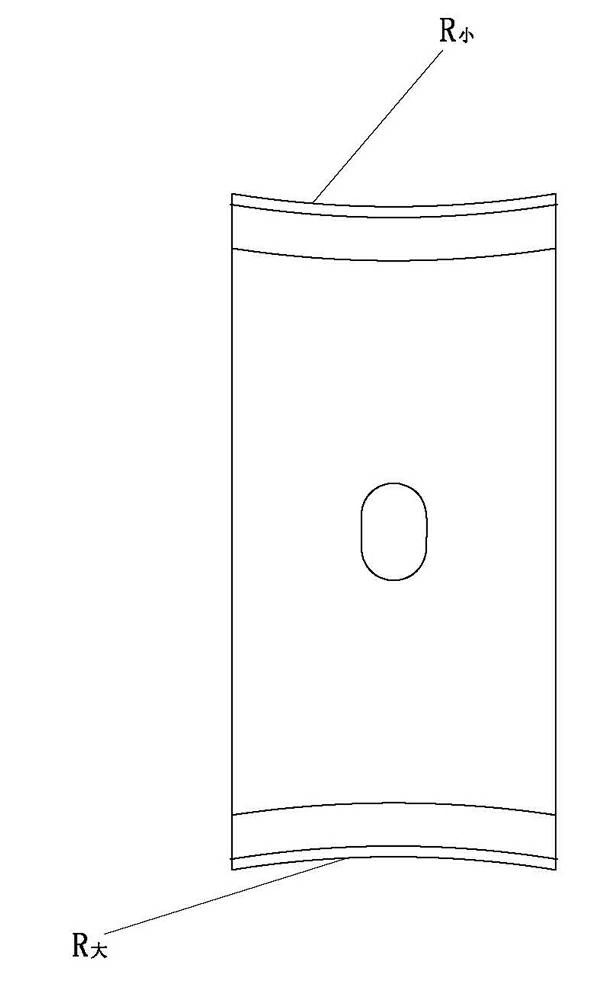

Three-Dimensional Article Having Transfer Material Thereon

InactiveUS20170183124A1Clean appearanceLess radius of curvatureTransfer printingLabelling non-rigid containersEngineeringMechanical engineering

Three-dimensional articles having a transfer material thereon are disclosed. The articles have a surface having two or more portions that each have a radius of curvature that are at least partially separated by an intermediate portion that has a lesser radius of curvature. The transfer material may be pre-formed and transferred to the surface of the articles and may extend continuously across at least parts of the two portions and the intermediate portion. In some cases, the two or more portions and the intermediate portion are all located on the same portion or face of the article and the intermediate portion is a feature on the surface of the article. In other cases, the two or more portions are located on different portions or faces of the article, and the intermediate portion is an edge between the two or more portions.

Owner:THE PROCTER & GAMBLE COMPANY

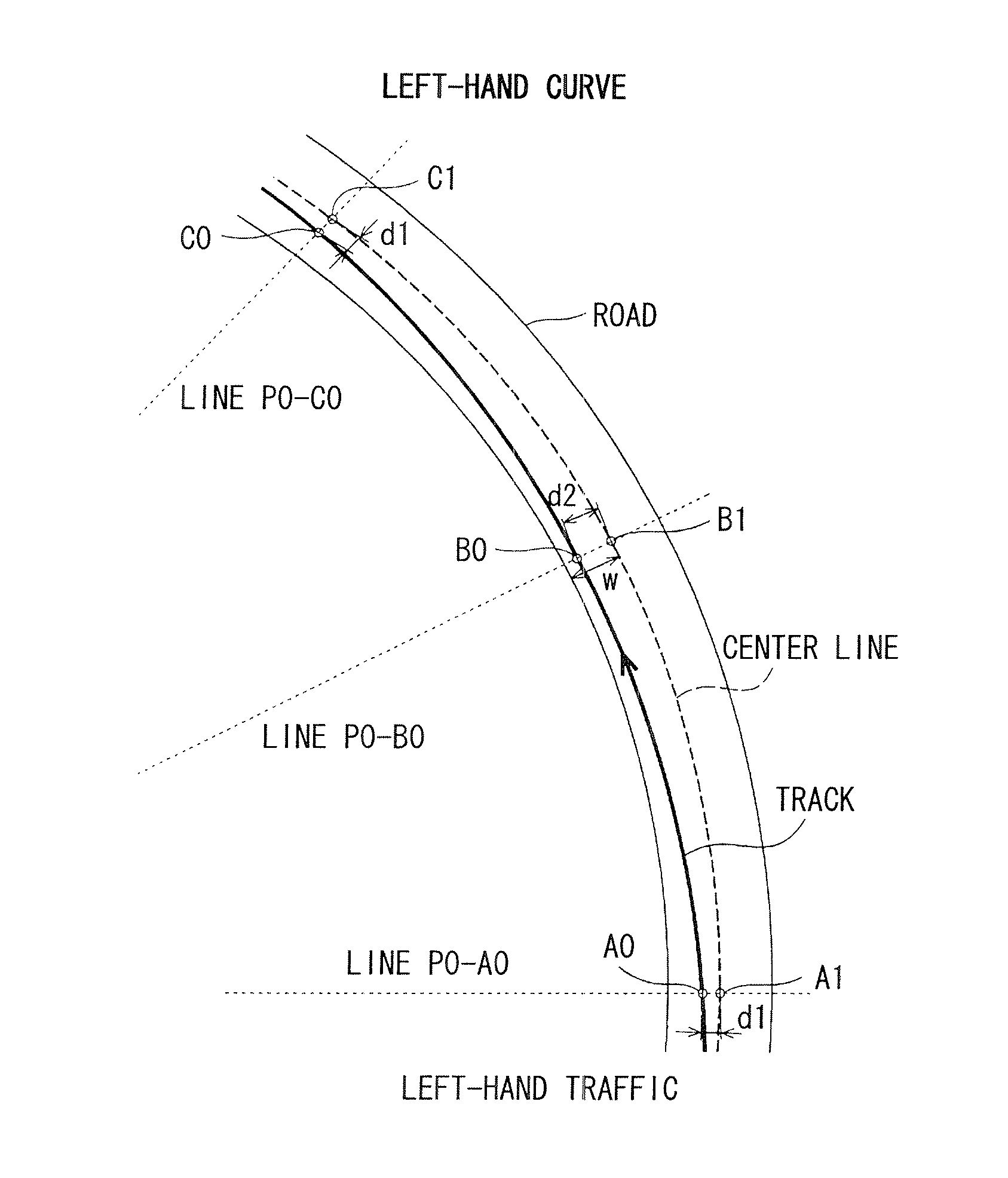

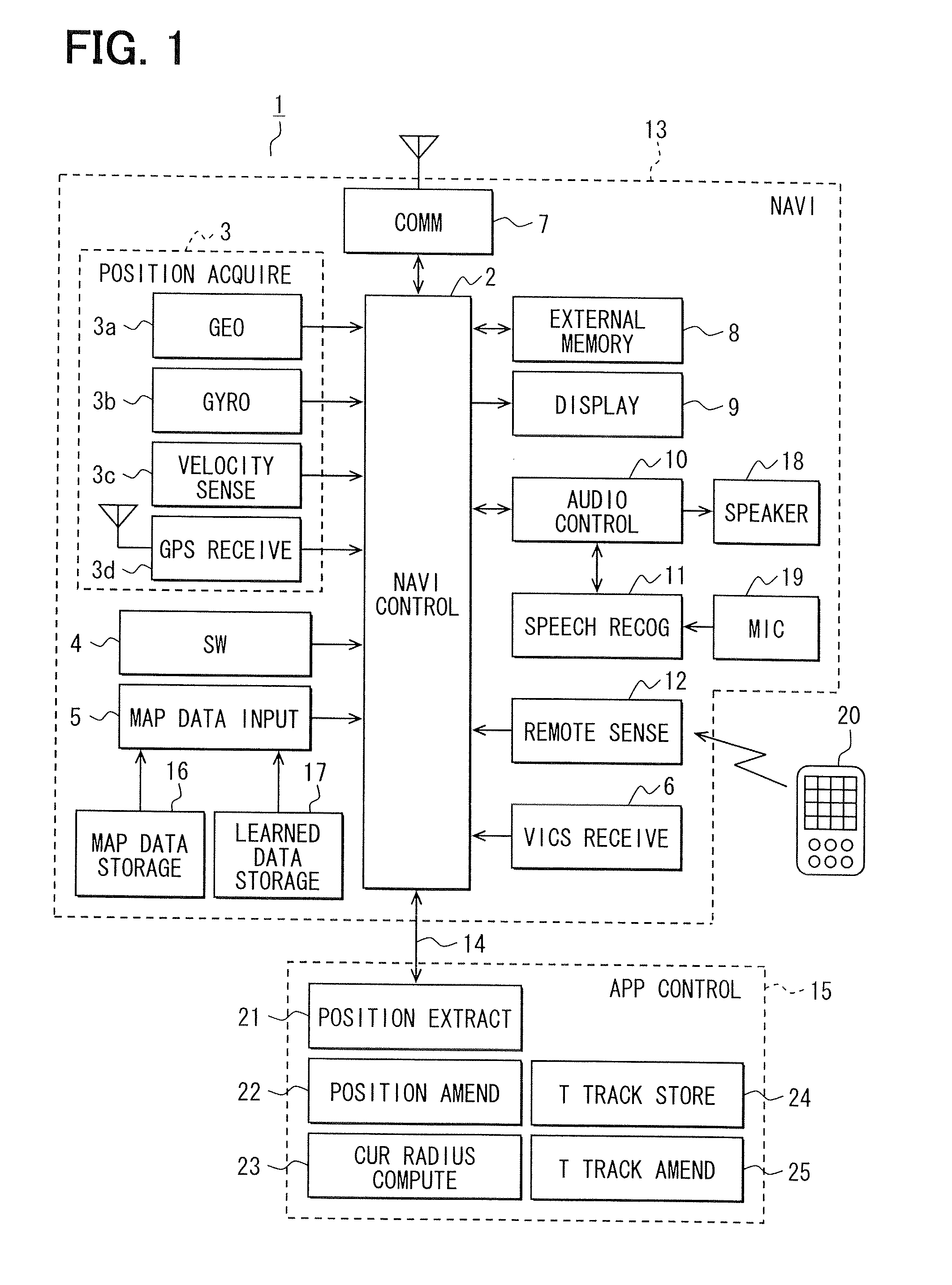

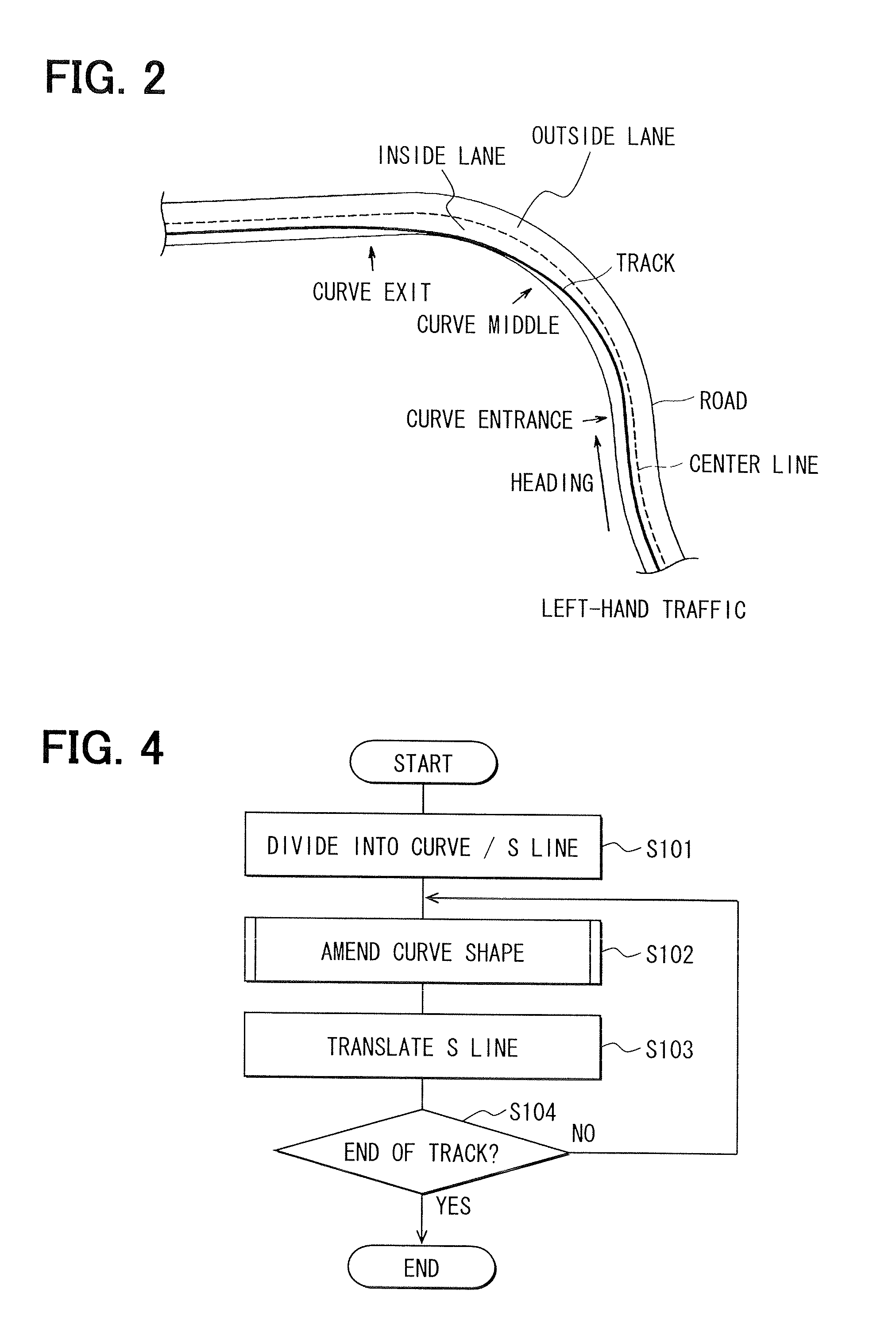

Road shape learning apparatus

ActiveUS8583366B2Accurately indicatedInstruments for road network navigationVehicle fittingsArtificial intelligencePoint of entry

Owner:DENSO CORP

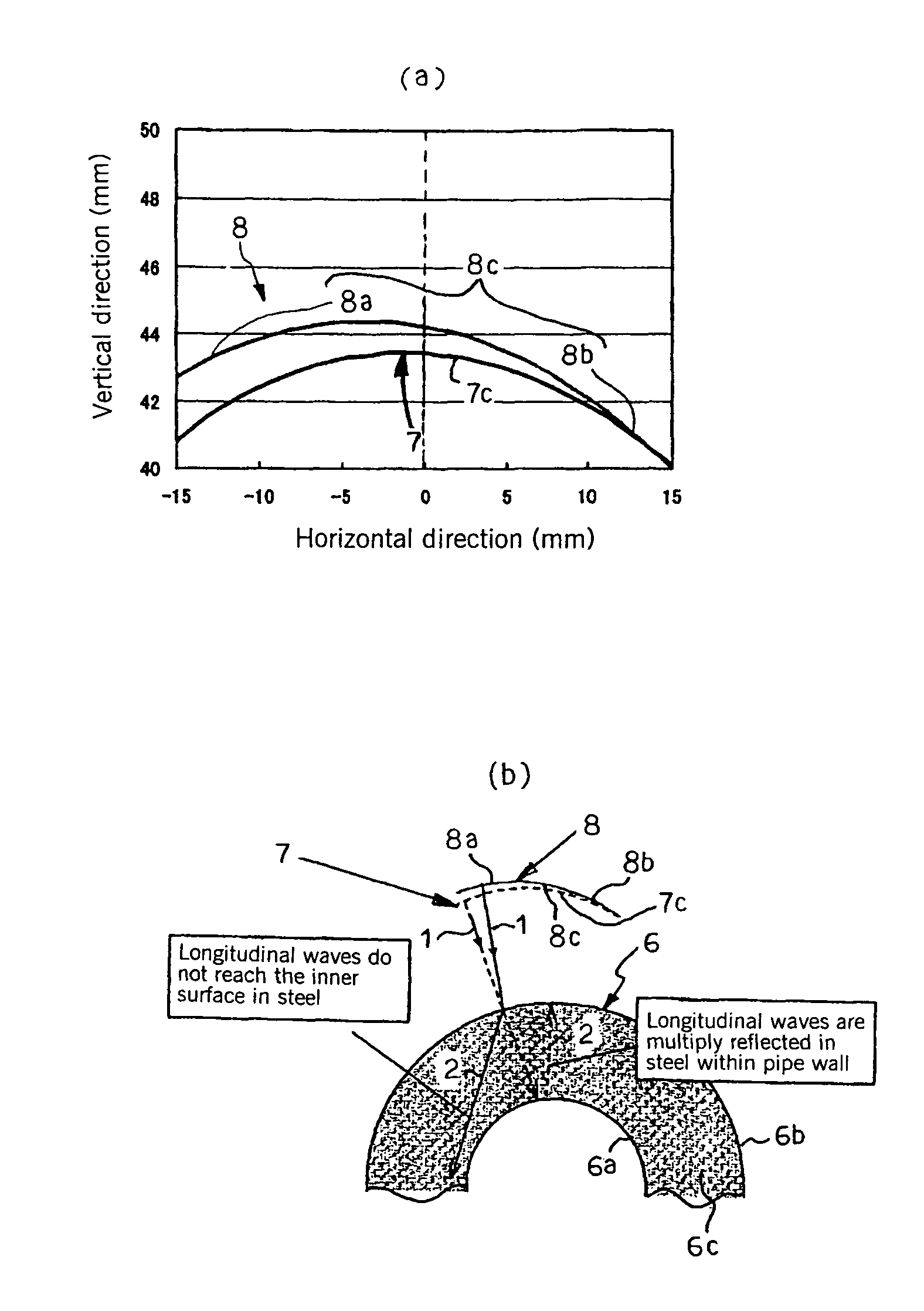

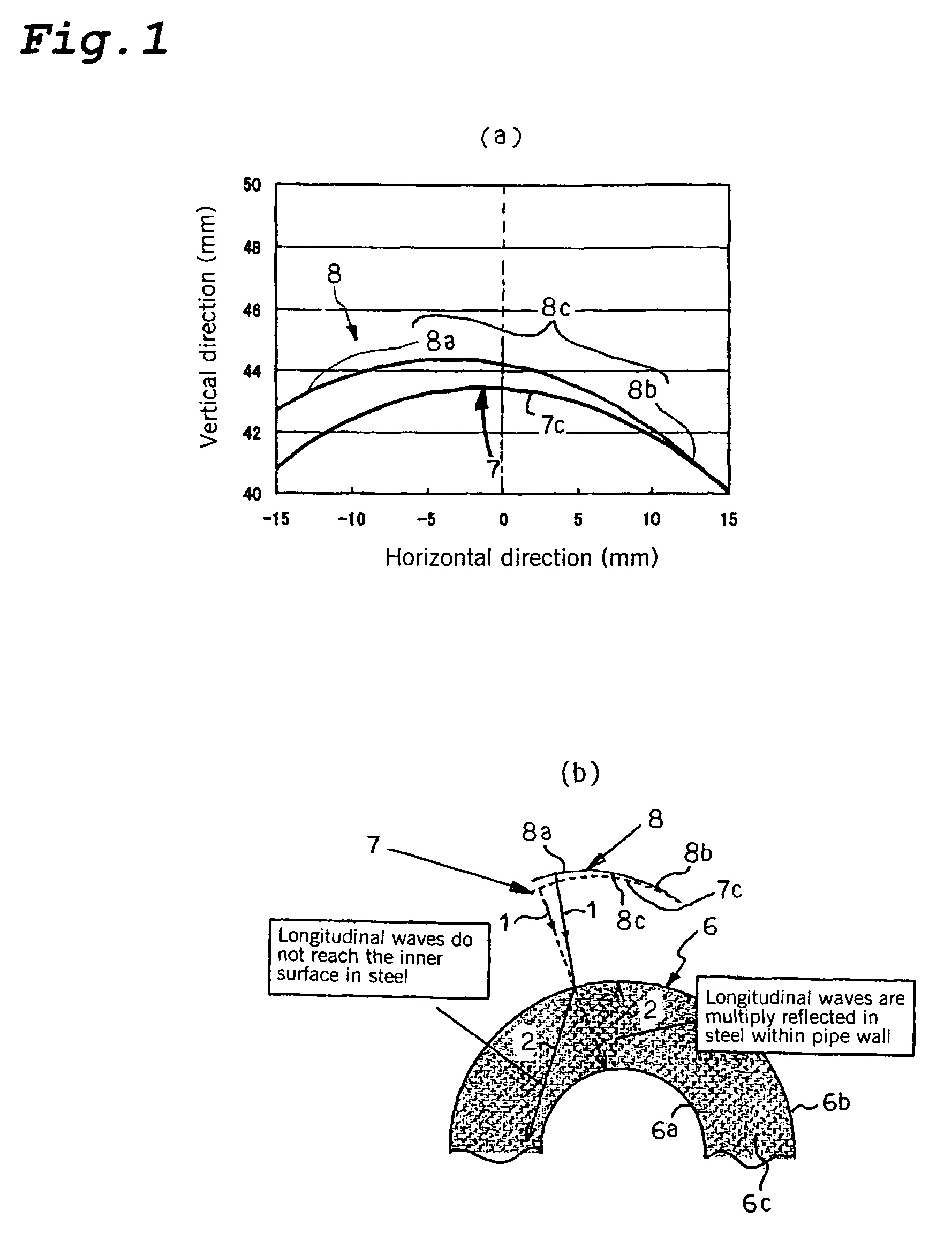

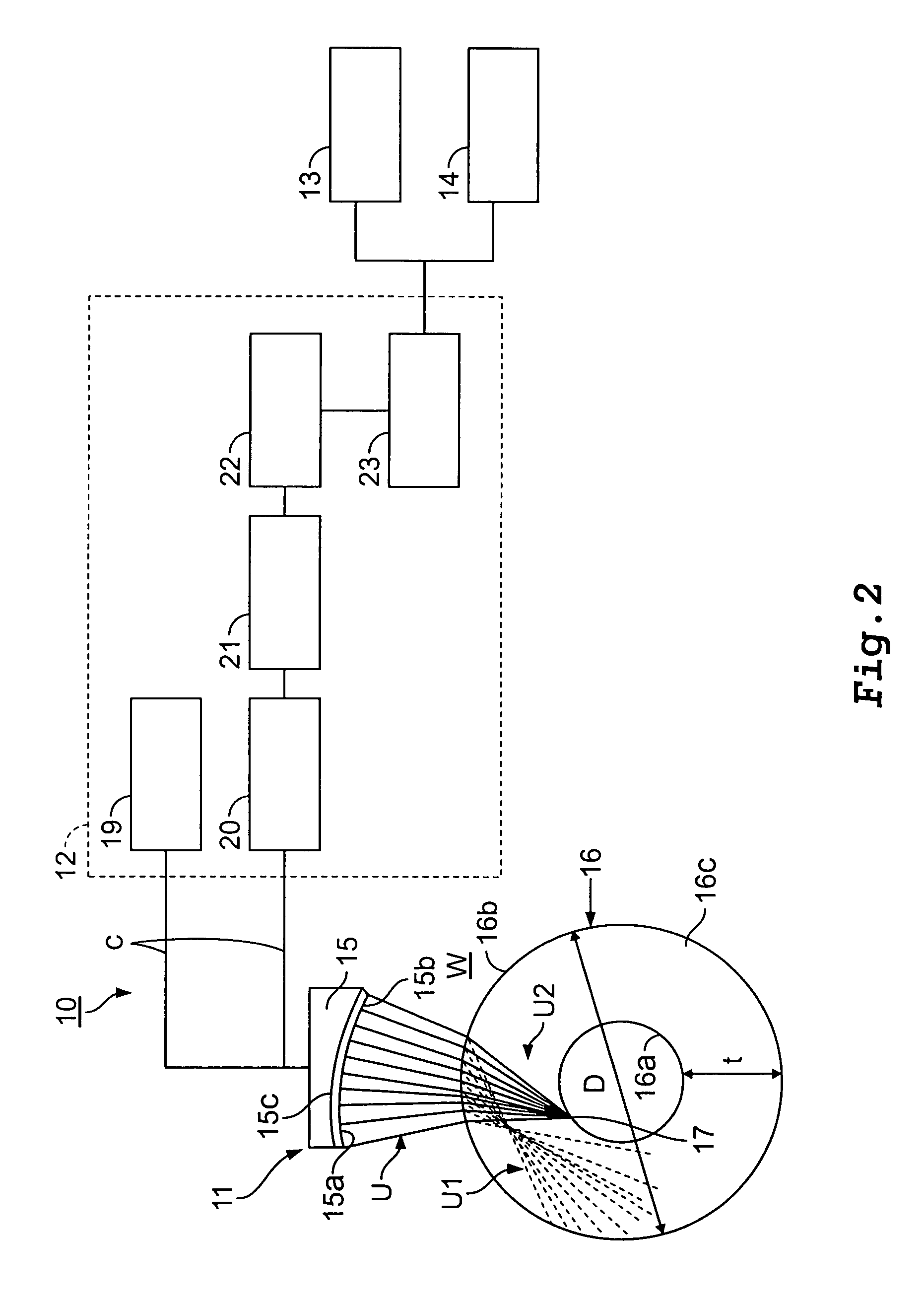

Ultrasonic probe, ultrasonic flaw detection method, and ultrasonic flaw detection apparatus

InactiveUS7874212B2High strengthDetection can be carry-outVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveCurve shape

An ultrasonic probe performs flaw detection of a high (t / D) metal pipe. The front end portion of a transducer has at least a portion with an asymmetrically curved shape having a radius of curvature which progressively increases from one end towards the other end of the front end portion. The probe is disposed with respect to the pipe with its end having the smaller radius of curvature positioned on the side away from the direction of propagation of refracted waves, the end having a larger radius of curvature thereof positioned on the side in the direction of propagation of refracted waves. Angle beam flaw detection is carried out such that incident waves are generated which generate refracted longitudinal waves which do not reach the inner surface of the metal pipe and refracted transverse waves which are focused on the inner surface of the pipe.

Owner:NIPPON STEEL CORP

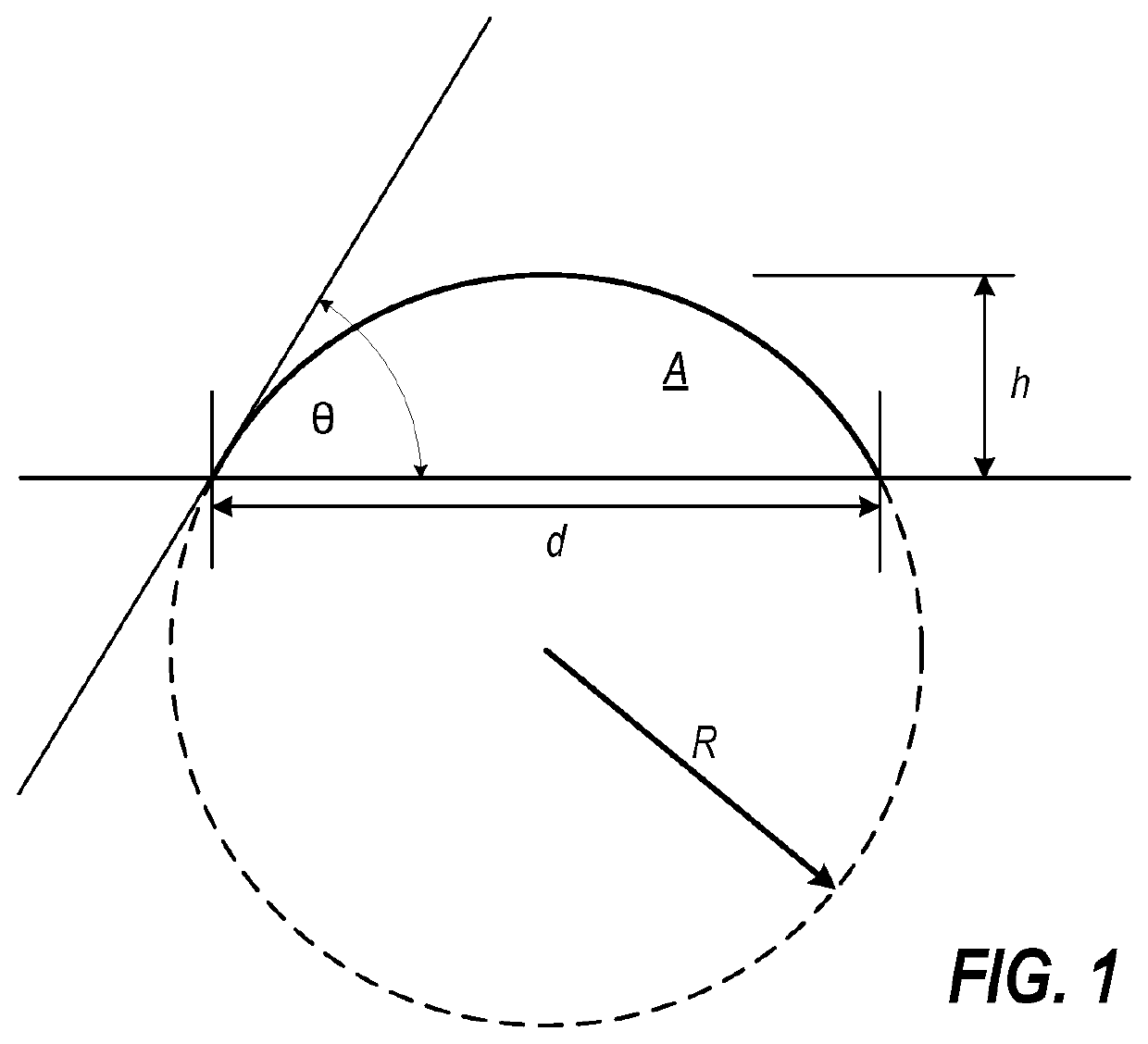

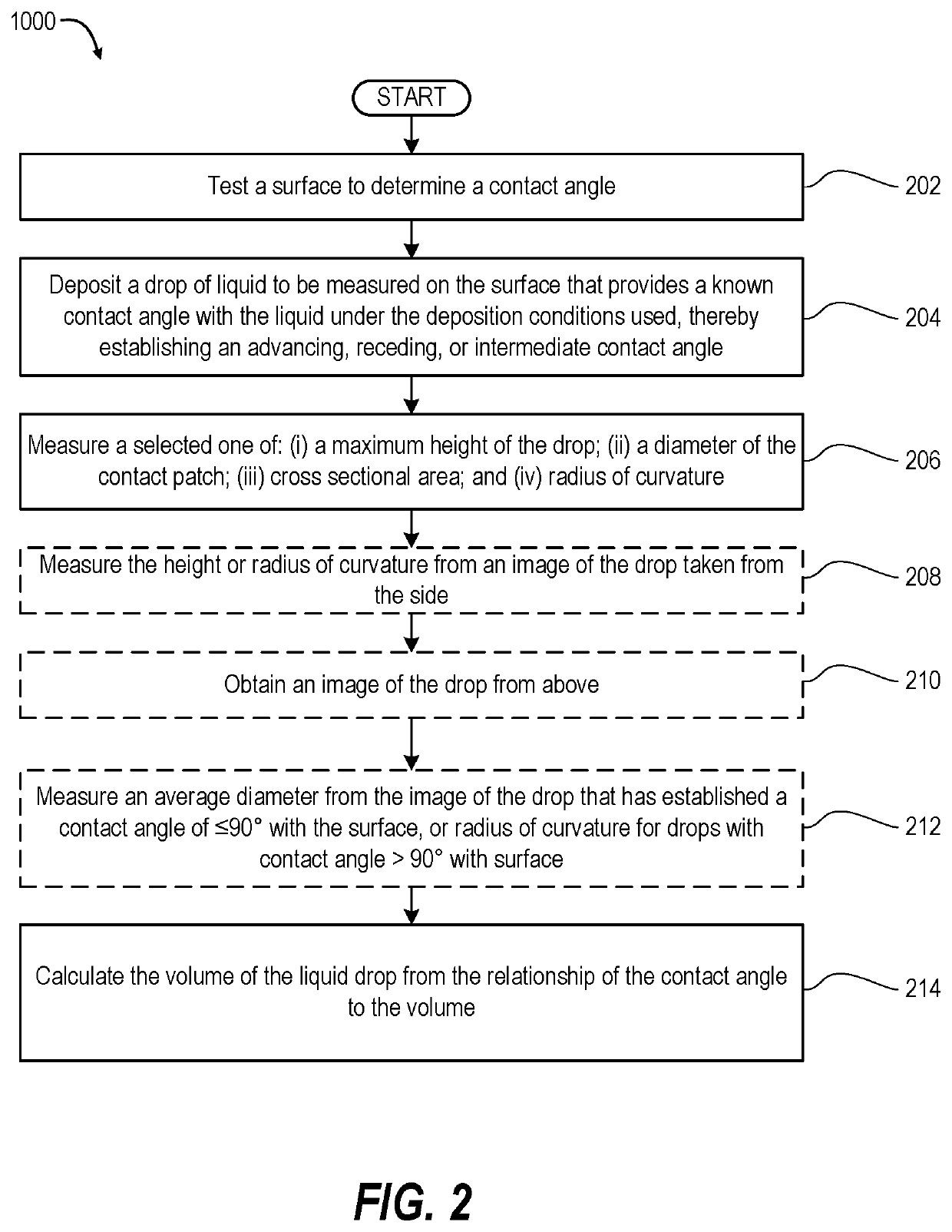

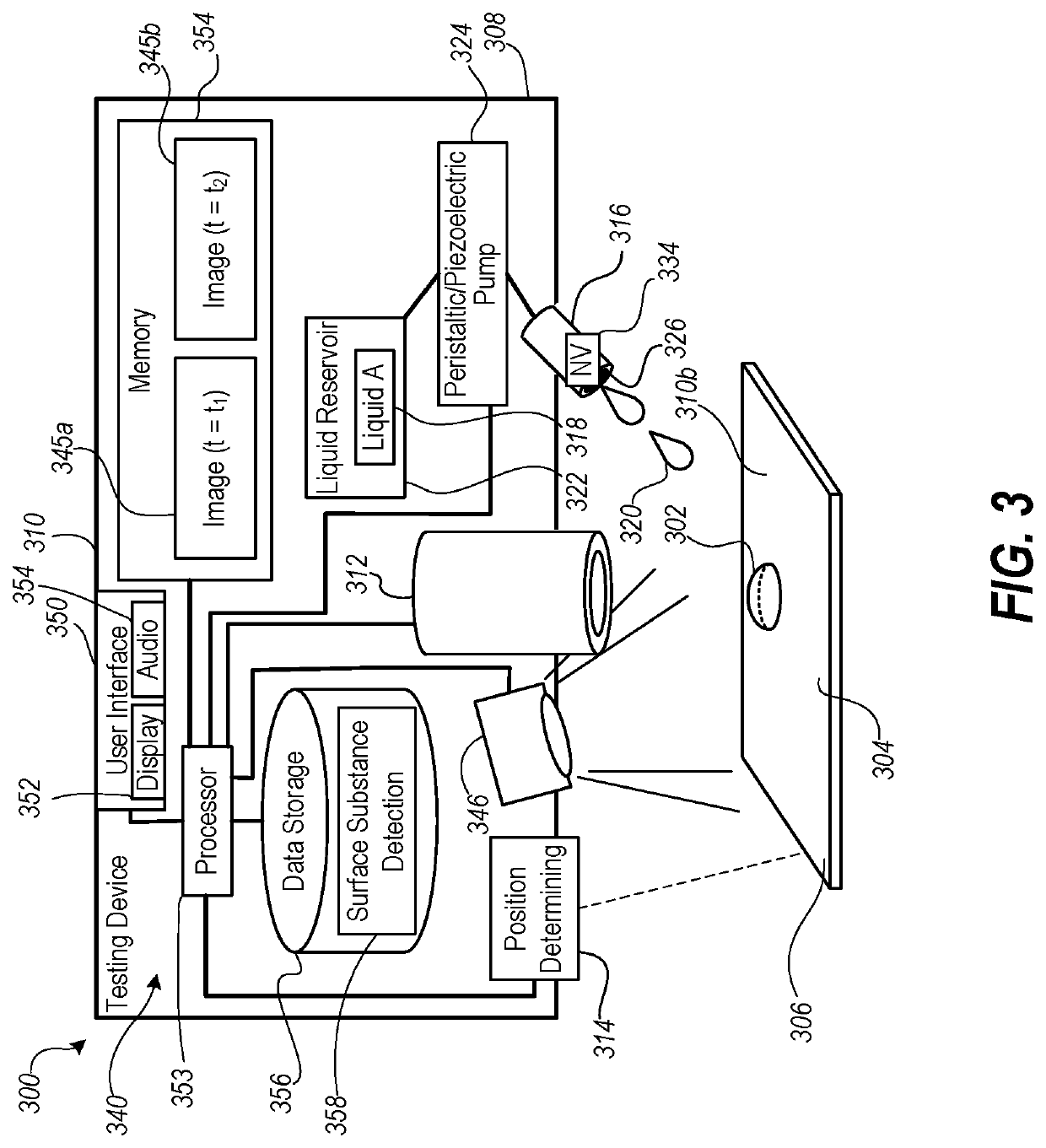

Method and device for measuring minute volume of liquid

InactiveUS20200080880A1Limit scopeVolume measurement apparatus/methodsImage analysisRadius of curvatureMechanical engineering

A method and test apparatus determines a volume of a droplet of liquid. The test apparatus deposits a drop of liquid to be measured on a surface that provides a known contact angle with the liquid under the deposition conditions used, thereby establishing one of: (i) an advancing, (ii) a receding, and (iii) an intermediate contact angle. The test apparatus images the drop. The test apparatus measures a dimension of height or diameter of the drop. In one embodiment, the test apparatus calculates a volume of the drop of liquid from the relationship of the contact angle to one or more parameters selected from the maximum height, the diameter of the contact patch, the radius of curvature, or the cross sectional area of the drop.

Owner:BRIGHTON TECH

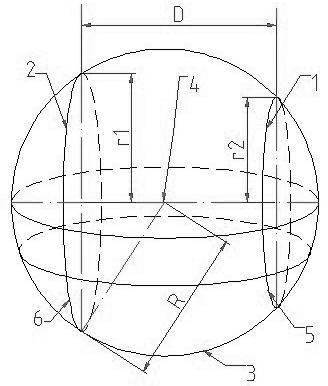

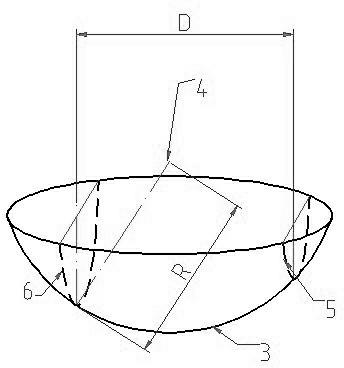

Curvature radius measuring method

The invention relates to the technical field of measurement methods, in particular to a curvature radius measuring method. The curvature radius measuring method is not influenced by factory environments such as a vibration environment and the like and belongs to non-contact measurement; and by the method, a surface to be detected cannot be damaged, the requirements of quick large-scale on-site measurement can be met, and the surface curvature radiuses of polished and unpolished parts can be measured at the same time. The curvature radius measuring method provided by the invention comprises the following steps of: cutting a sphere by using two planes between which the distance is (D), wherein the (D) is less than the diameter of the sphere, and two circles are formed by intersecting lines between the two planes and the surface of the sphere; and obtaining the sum of the radiuses of the two circles by a non-contact measurement method, wherein the curvature radius of the surface to be detected is shown as a formula in the specification.

Owner:梁海锋

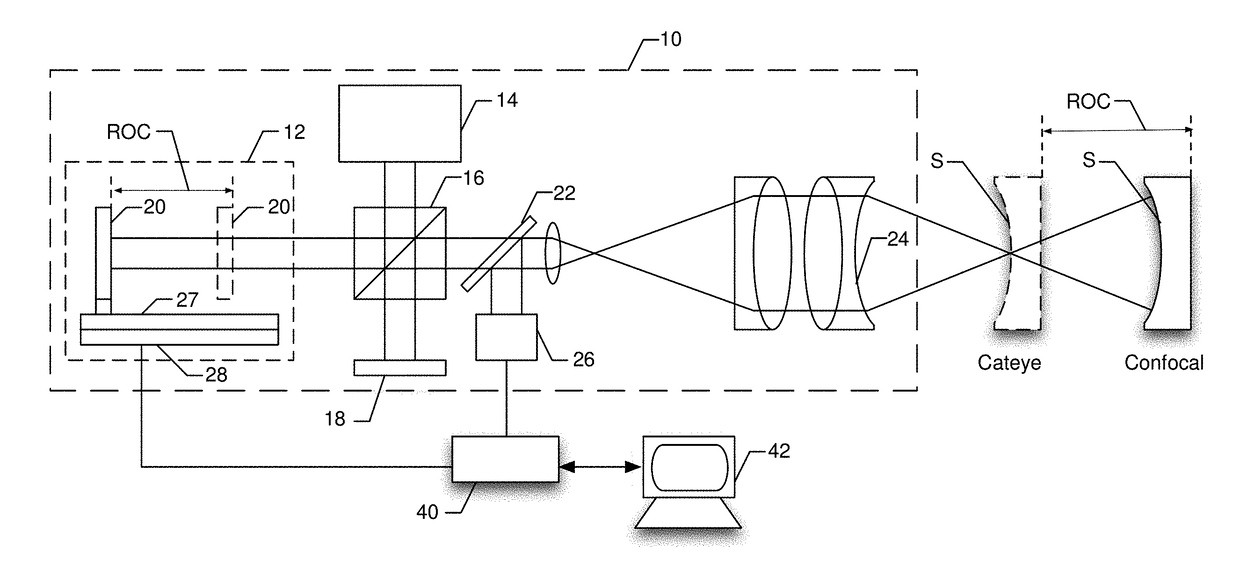

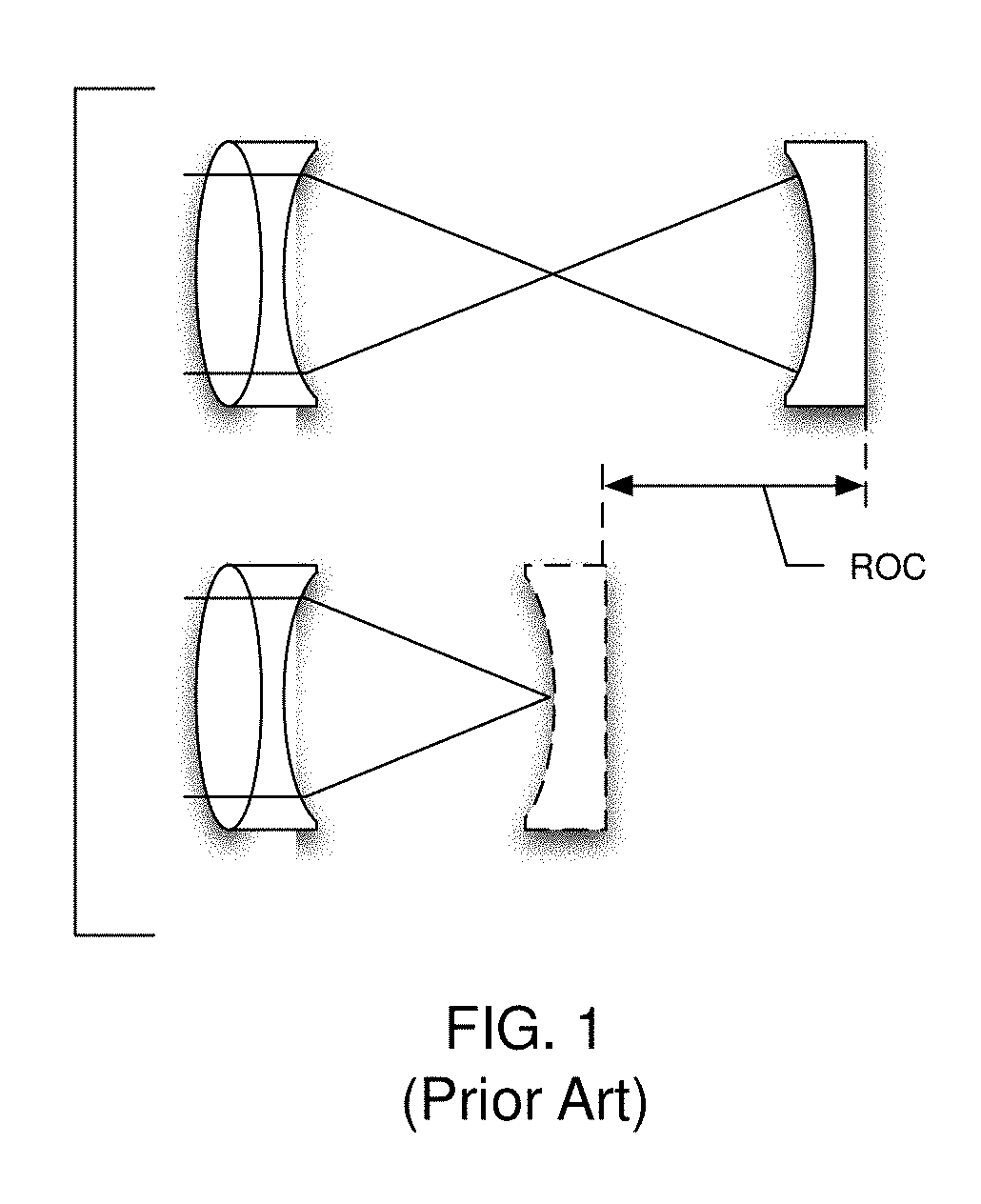

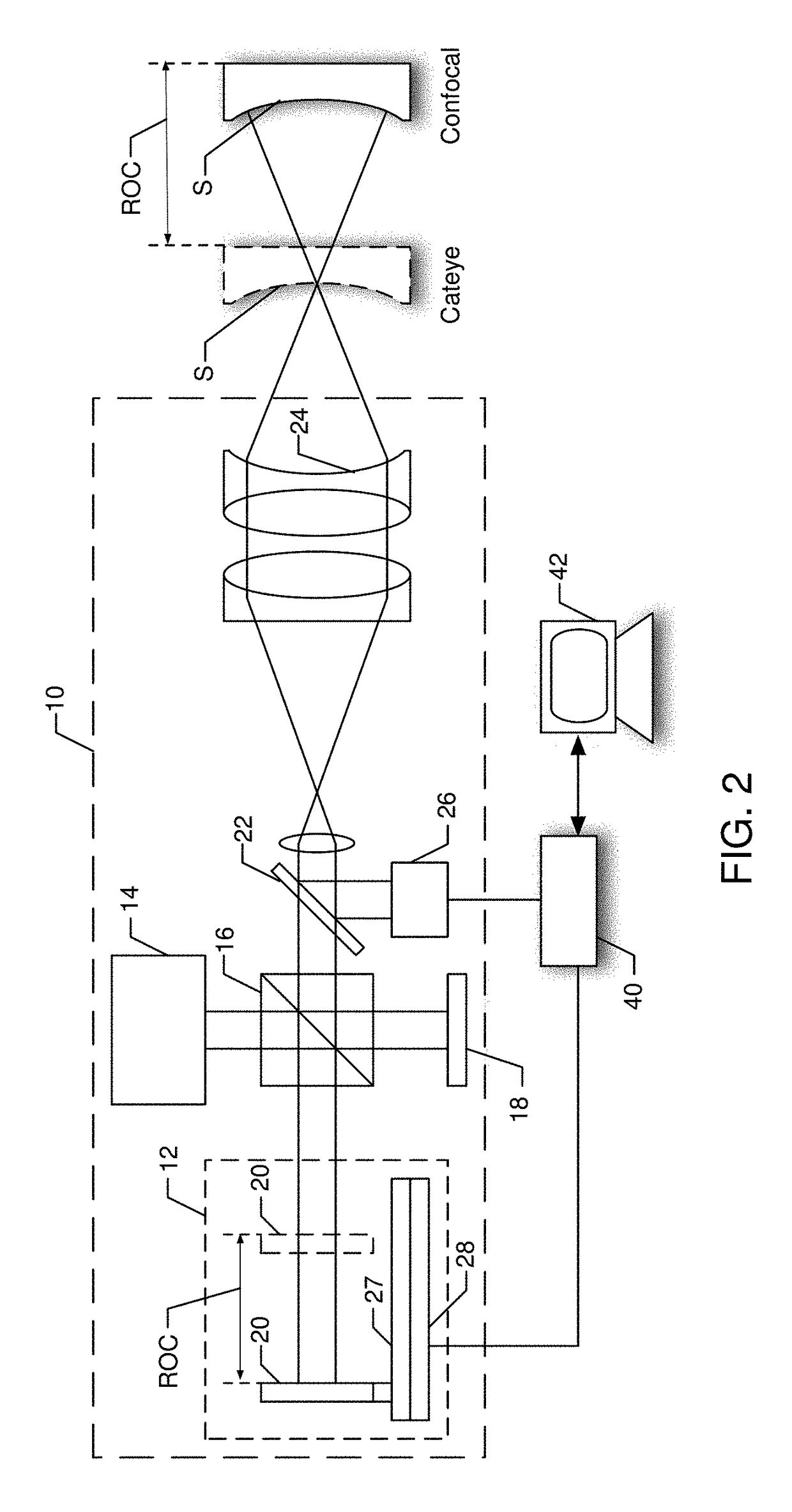

Single-step interferometric radius-of-curvature measurements utilizing short-coherence sources

ActiveUS9857169B1InterferometersReflective surface testingLight beamPolarization-maintaining optical fiber

An interferometer includes a short-coherence source and an internal path-matching assembly contained within its housing. Because path matching occurs within the housing of the interferometer, it is removed from external environmental factors that affect measurements. Therefore, a single cateye measurement of an exemplary surface can be performed in advance and stored as a calibration for subsequent radius-of-curvature measurements. In one embodiment, a path-matching stage is incorporated into a dynamic interferometer where orthogonally polarized test and reference beams are fed to a dynamic imaging system. In another embodiment, orthogonal linearly polarized test and reference beams are injected into a remote dynamic interferometer by means of one single-mode polarization-maintaining optical fiber.

Owner:ONTO INNOVATION INC

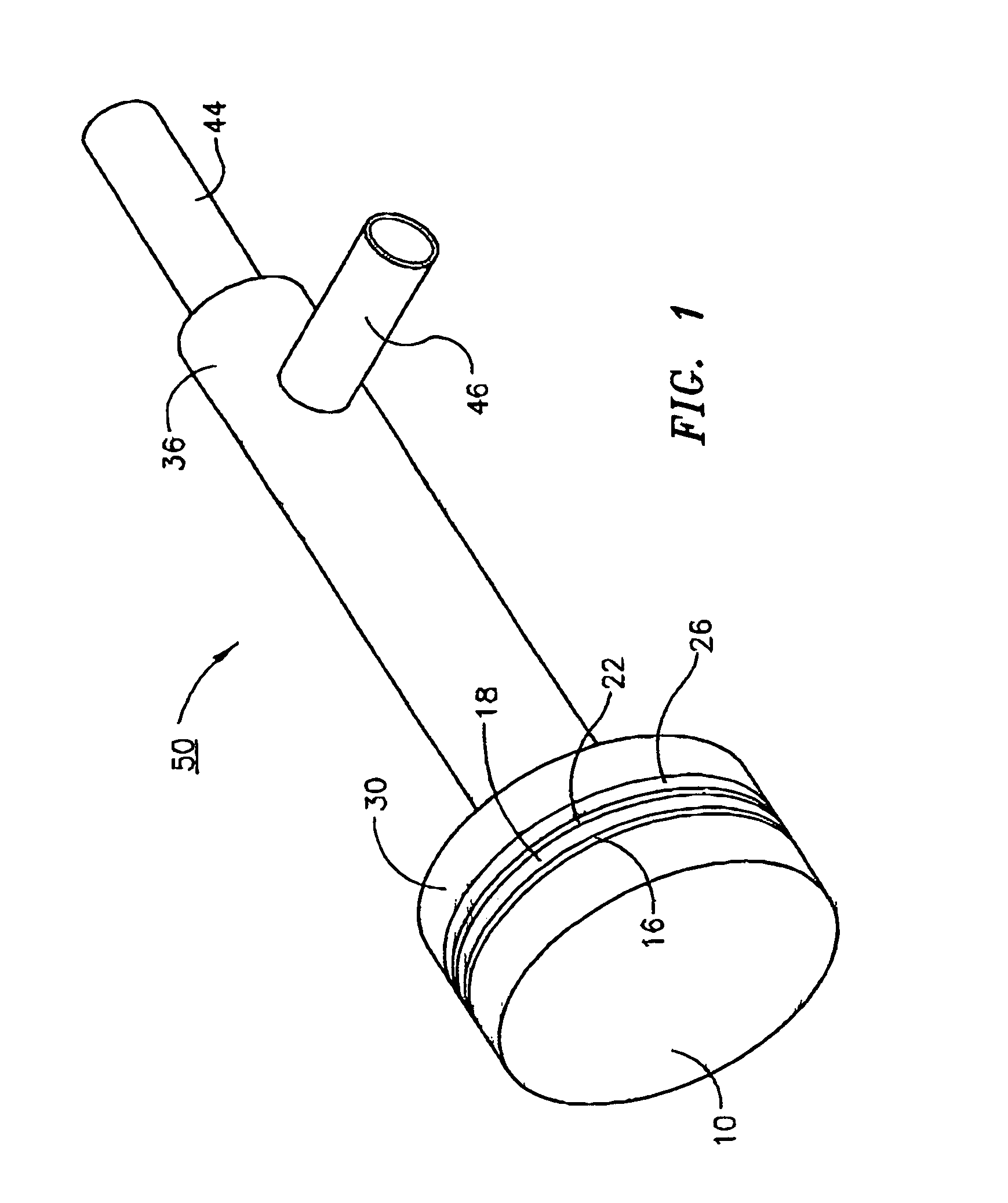

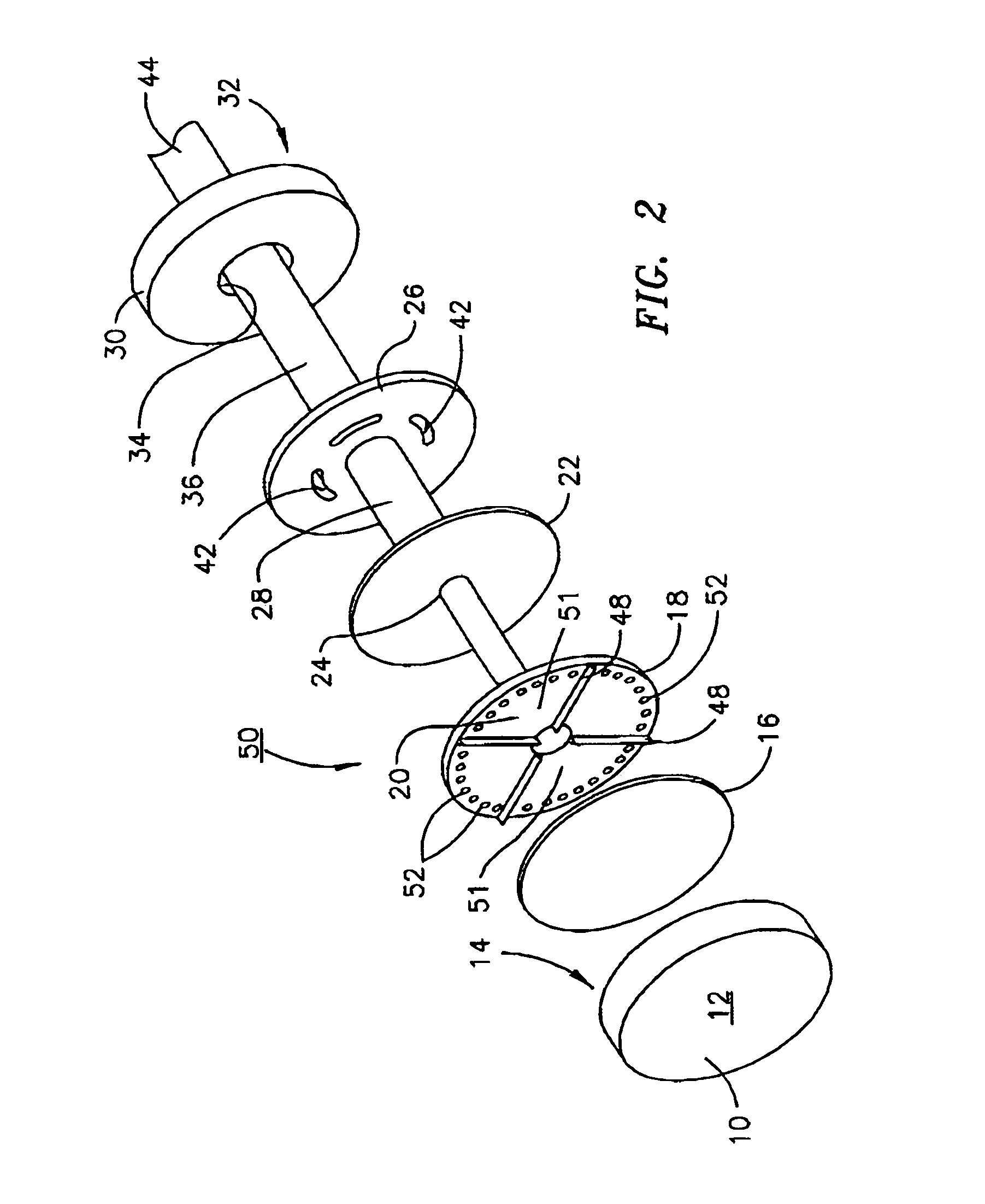

Radius of curvature controlled mirror

A controlled radius of curvature mirror assembly comprising: a distortable mirror having a reflective surface and a rear surface; and in descending order from the rear surface; a counter-distortion plate; a flow diverter having a flow diverter aperture at the center thereof; a flow return plate having a flow return aperture at the center thereof; a thermal isolation plate having a thermal isolation plate aperture at the center thereof and a flexible heater having a rear surface and a flexible heater aperture at the center thereof; a double walled tube defining a coolant feed chamber and a coolant return chamber; said coolant feed chamber extending to and through the flow diverter aperture and terminating at the counter-distortion plate and the coolant return chamber extending to and through the thermal isolation backplate and terminating at the flow diverter; and a coolant feed and a coolant return exit at the rear of said flexible heater.

Owner:JEFFERSON SCI ASSOCS LLC

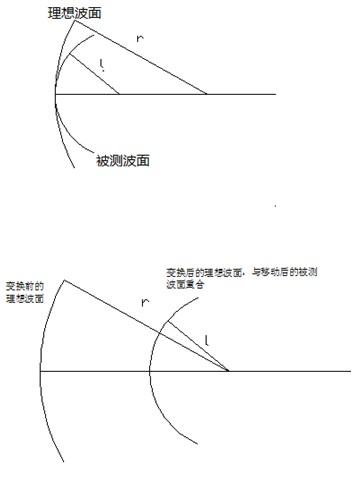

Method for highly precisely eliminating adjustment error in spherical surface shape interference detection

The invention discloses a method for highly precisely eliminating an adjustment error in spherical surface shape interference detection. In the method, adjustment error-containing wave surface data is obtained by an interferometer, the curvature radius and the caliber of a spherical surface to be measured are measured, and then data obtained by measurement serves as auxiliary data for eliminating the adjustment error, wherein the radius of the spherical surface to be measured is measured by a single-frequency laser interference method; the caliber is measured by using a vernier caliper; the adjustment error is moved by adopting an optimum fit ideal spherical model; the position and the radius of the ideal spherical surface are found by the model; and the wave surface measured by the interferometer is moved so that the center of the wave surface is overlapped with the sphere center of the ideal spherical surface. The invention provides a new method for eliminating the adjustment error in the spherical surface shape detection of an optical element by researching spherical interference detection; and the method has important application value on the detection and the machining of high-precision optical elements.

Owner:ZHEJIANG UNIV

Method for measuring radius of curvature of spherical surface

InactiveCN102735188ASimple structureEasy to makeUsing optical meansMicroscope objectiveRadius of curvature

The invention relates to a method for measuring the radius of curvature of a spherical surface. According to the method, a reference substance (2) of which the size is a is coaxial with a microscope objective (3), and the distance between the reference substance (2) and the vertex of a measured spherical surface (4) is L, wherein L can be changed independently in the axial direction; the reference substance (2) is reflected by the measured spherical surface on an object carrying platform (5) to form an image (6) of which the size is b, the image (6) is subjected to microscopic amplification by a microscope system to form an image (7) of which the size is c, and the image (7) is acquired by a charge coupled device (CCD) camera arranged on a microscope ocular lens (1) and is stored in a computer. The radius of curvature r of the measured spherical surface can be expressed by a function which contains the parameters of a, c and L, wherein a and L are measured directly, and c is measured by utilizing computer software, so that the radius of curvature of the measured spherical surface r can be measured. The reference substances are annular cross hairs or annular illuminants preferably, and can be equipped with multiple groups according to requirements. Preferably, the magnifying power of the microscope objective is continuously adjustable.

Owner:深圳市鼎鑫盛光学科技有限公司

Method and fixture for evaluating the quality of surface coatings

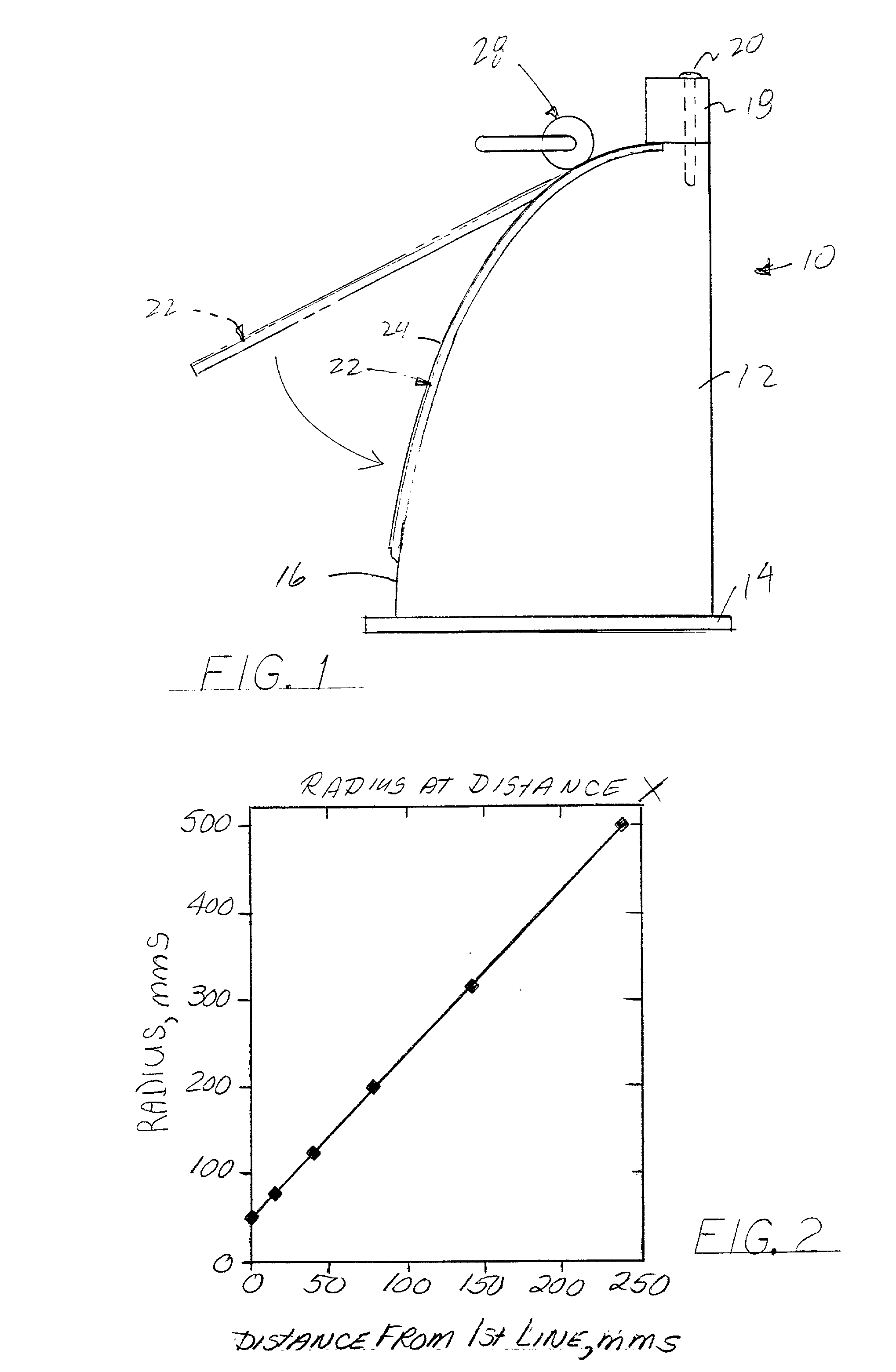

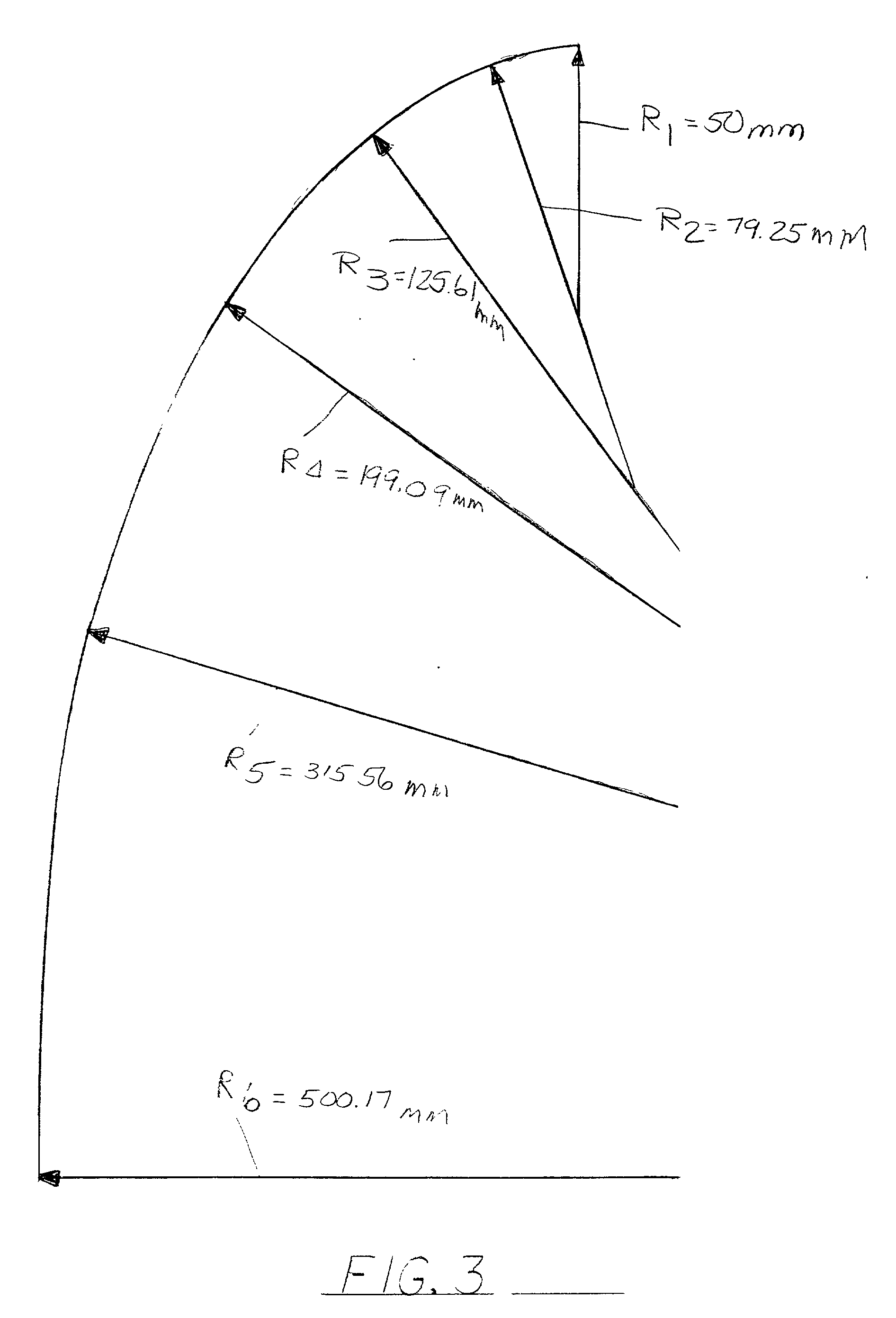

InactiveUS20030054091A1Easily interpolatedLiquid surface applicatorsUsing mechanical meansPercent elongationLinear relationship

A fixture and method for evaluating a surface coating on a specimen by determining the elongation at failure, which is carried out by conforming the specimen to a surface having a continuously and progressively varying radius of curvature to produce a range of elongations of said specimen sufficient to insure a coating failure. The radius of curvature increases in a predetermined, preferably linear relationship with the distance along the surface so that by measuring the distance to the maximum radius of curvature whereat of failure of the coating occurs, the minimum percent elongation creating failure is determined.

Owner:EXATEC LLC

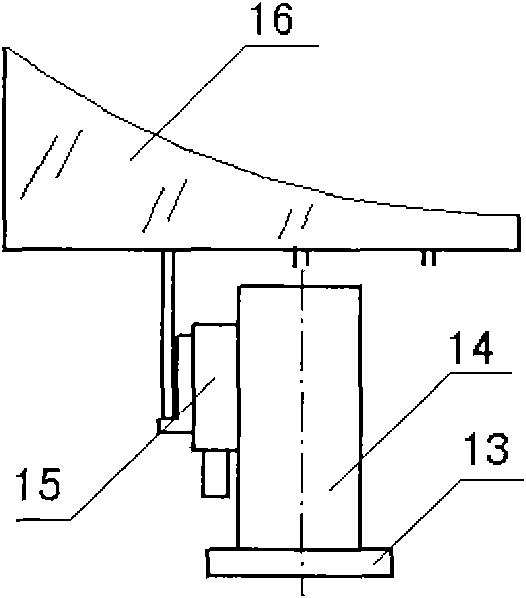

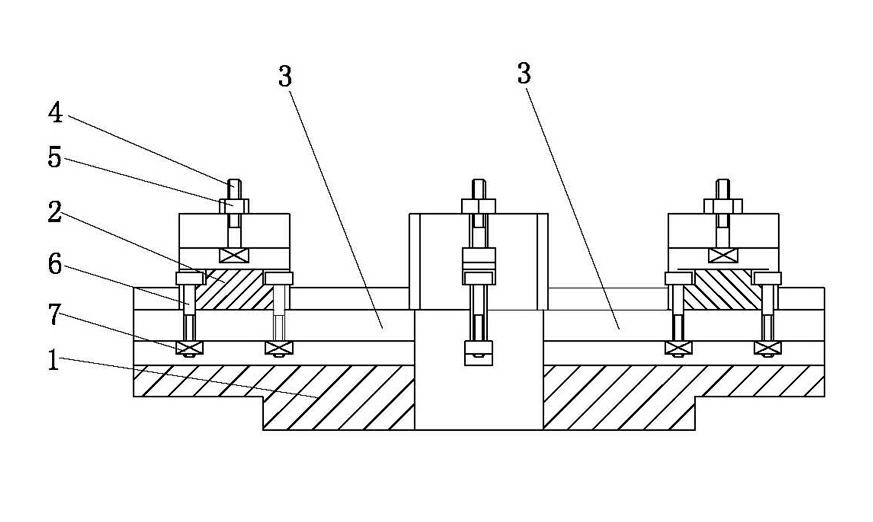

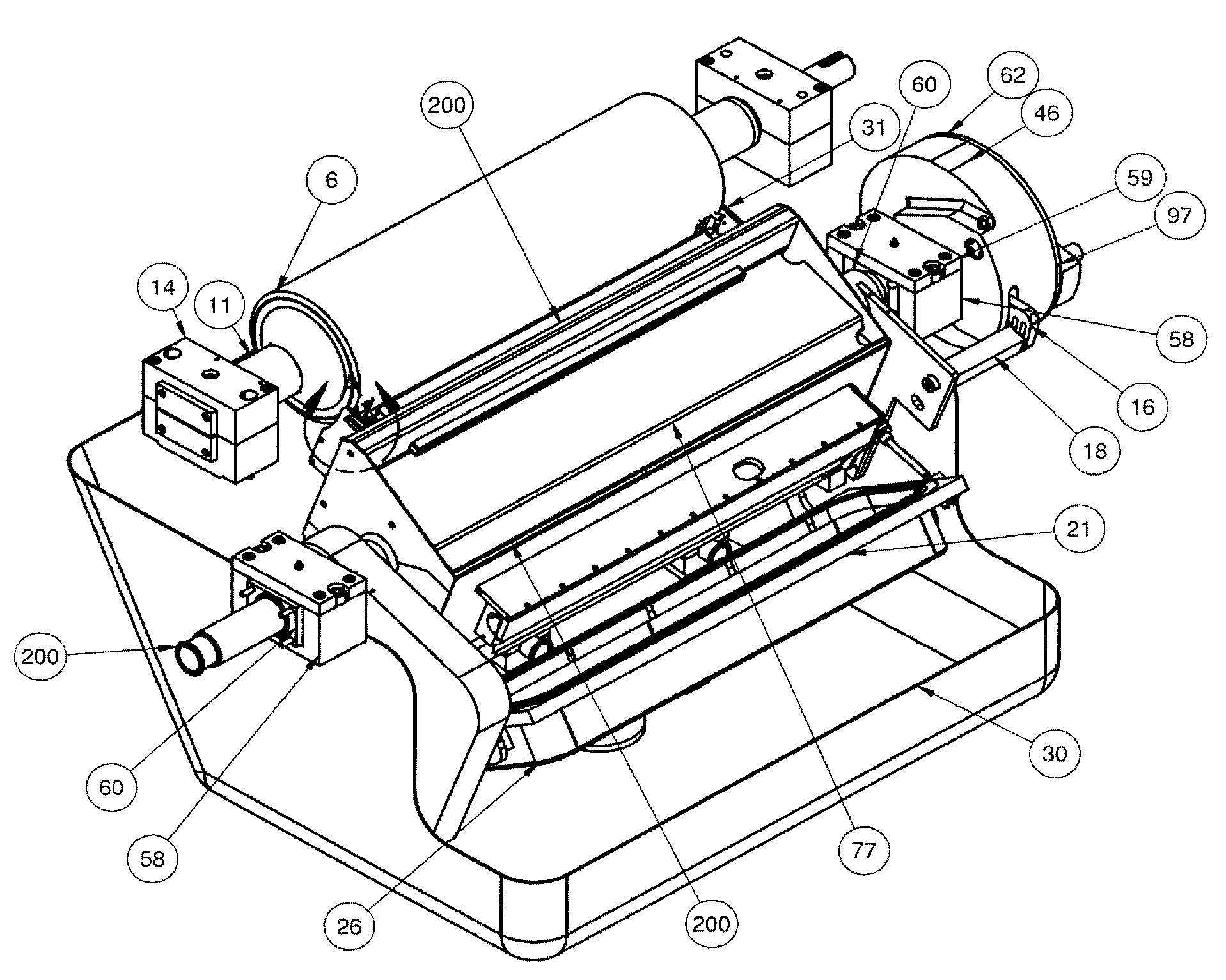

Processing technology and clamping device of curvature radius template of outer spherical surface ball bearing

ActiveCN102357780AAccurate detectionSimple structurePositioning apparatusMetal-working holdersSheet steelBall bearing

The invention relates to a processing technology of a curvature radius template of an outer spherical surface ball bearing. The processing technology comprises the following steps: 1) striking and forging blanks; 2) spheroidizing; 3) milling; 4) turning; 5) marking on two ends of a steel plate; 6) carrying out stress relief annealing; 7) quenching; 8) putting a template on a surface-grinding machine for processing; 9) coarsely grinding a circular arc camber; 10) extra tempering; and 11) accurately grinding the circular arc camber to obtain the finished product of the template. The invention also discloses a clamping device of the curvature radius template of the outer spherical surface ball bearing, and the clamping device is convenient in clamping and easy to process. The curvature radius template processed according to the invention can be ground for a plurality of times, has higher accuracy, is more accurate when detecting the spherical surface of the outer spherical surface ball bearing, and ensures the yield of products.

Owner:DONGGUAN TR BEARING

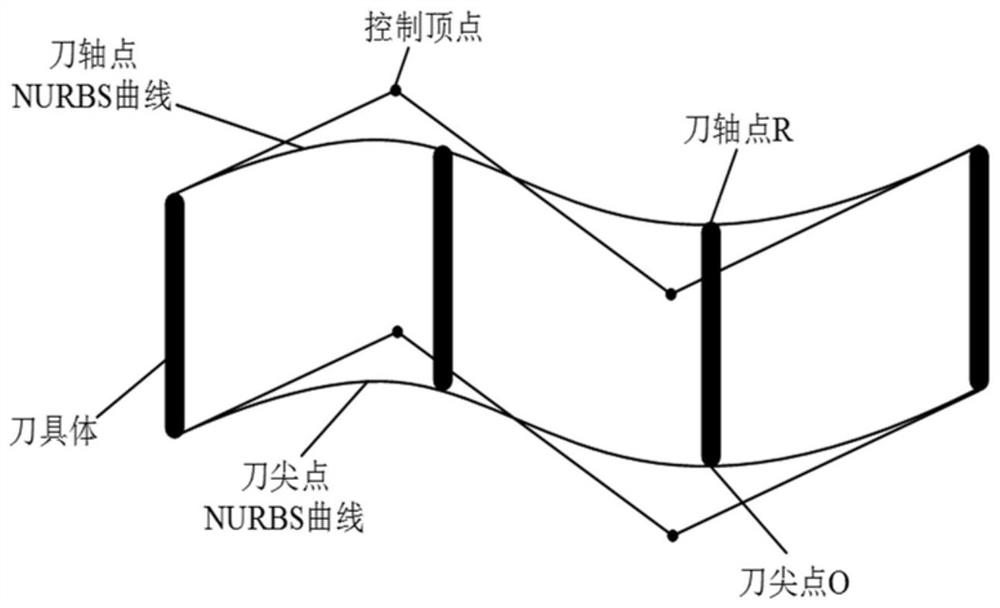

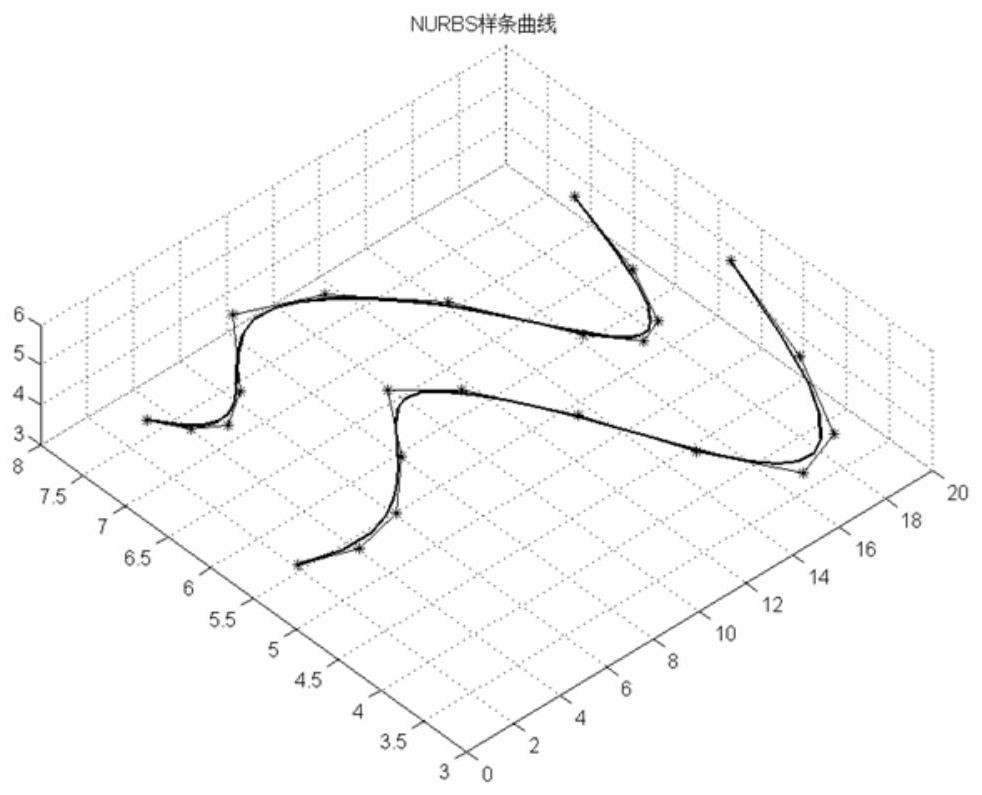

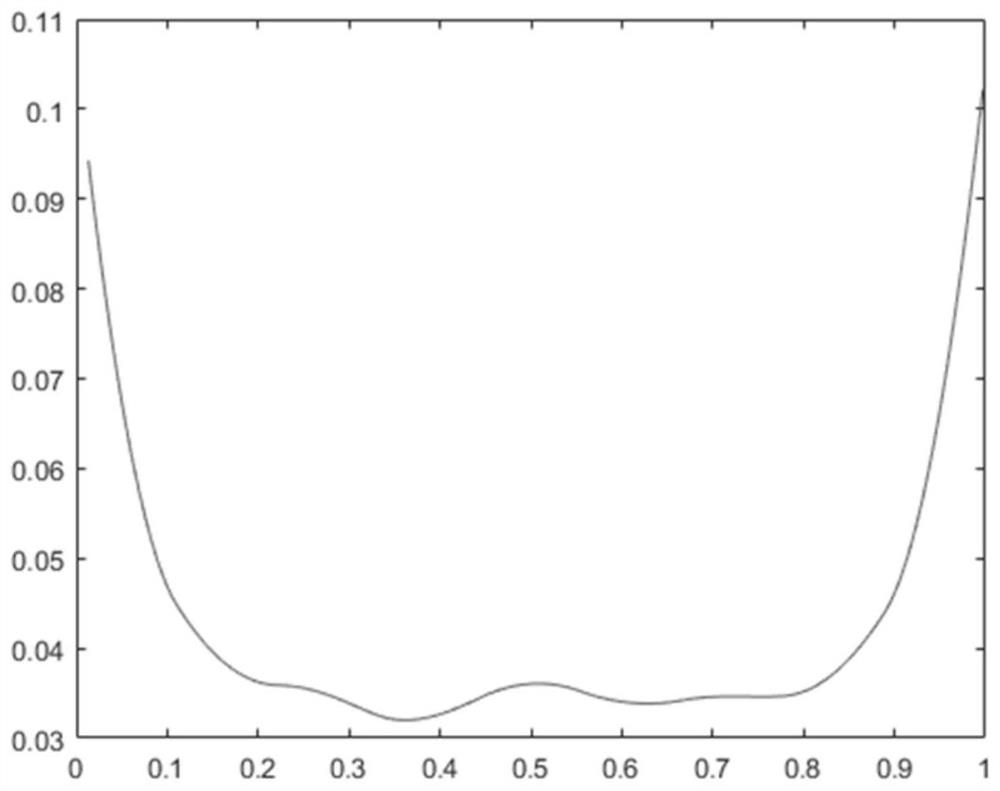

Method for calculating limit speed of double NURBS paths in free-form surface machining

PendingCN111736537AImprove machining accuracyGuaranteed stabilityNumerical controlGeometric errorKinematics

The invention discloses a method for calculating the limit speed of a double NURBS path in free-form surface processing. The method comprises the following steps: (1) calculating a control vertex anda node vector of an NURBS curve according to data points of a known discrete tool nose file, defining a fitting curve of a tool nose point track, calculating data points (cutter axis points for short)participating in cutting in the cutter axis direction through a linear relation, and defining a fitting curve of a track of the point by using the same method, so as to generate the double NURBS path; and (2) solving the curve length of an interpolation road section on a definition domain by integrating a first-order guide vector function of a tool nose point NURBS fitting curve, traversing the whole processing path, and calculating a key point of which the curvature radius reaches a local extreme value under the limitation of geometric error constraint and kinematics constraint so as to obtain the limit speed at the key point.

Owner:TIANJIN UNIV

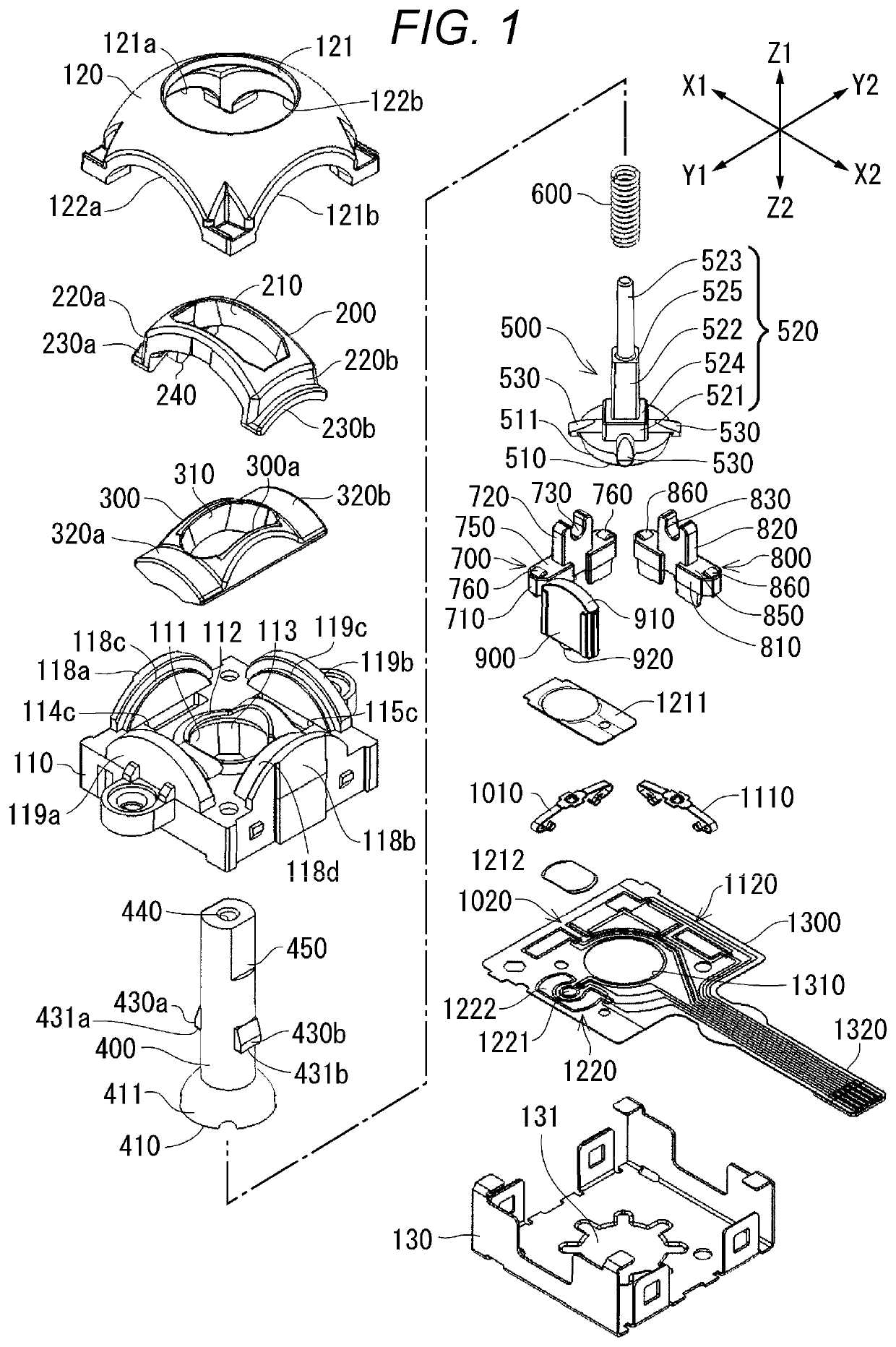

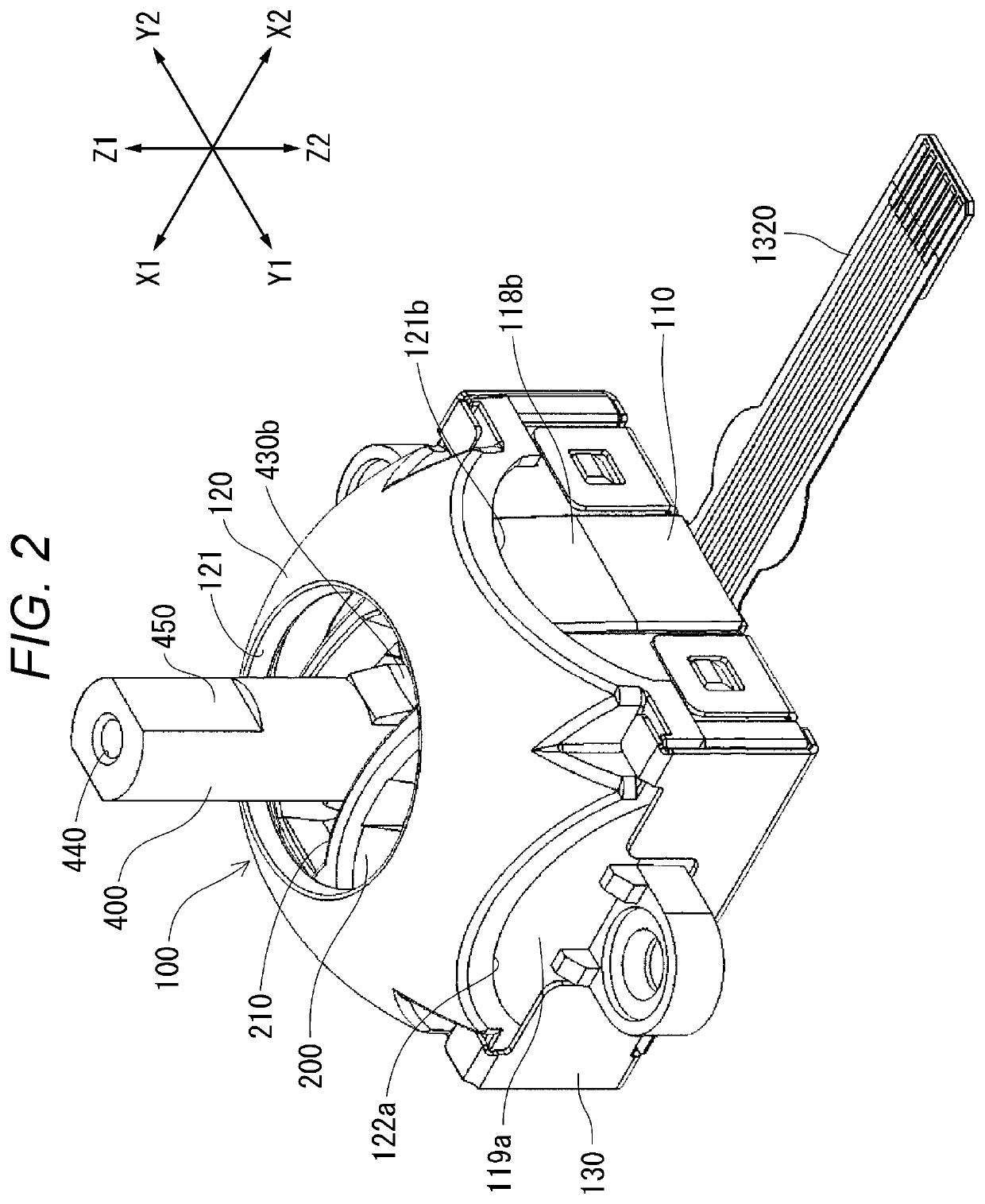

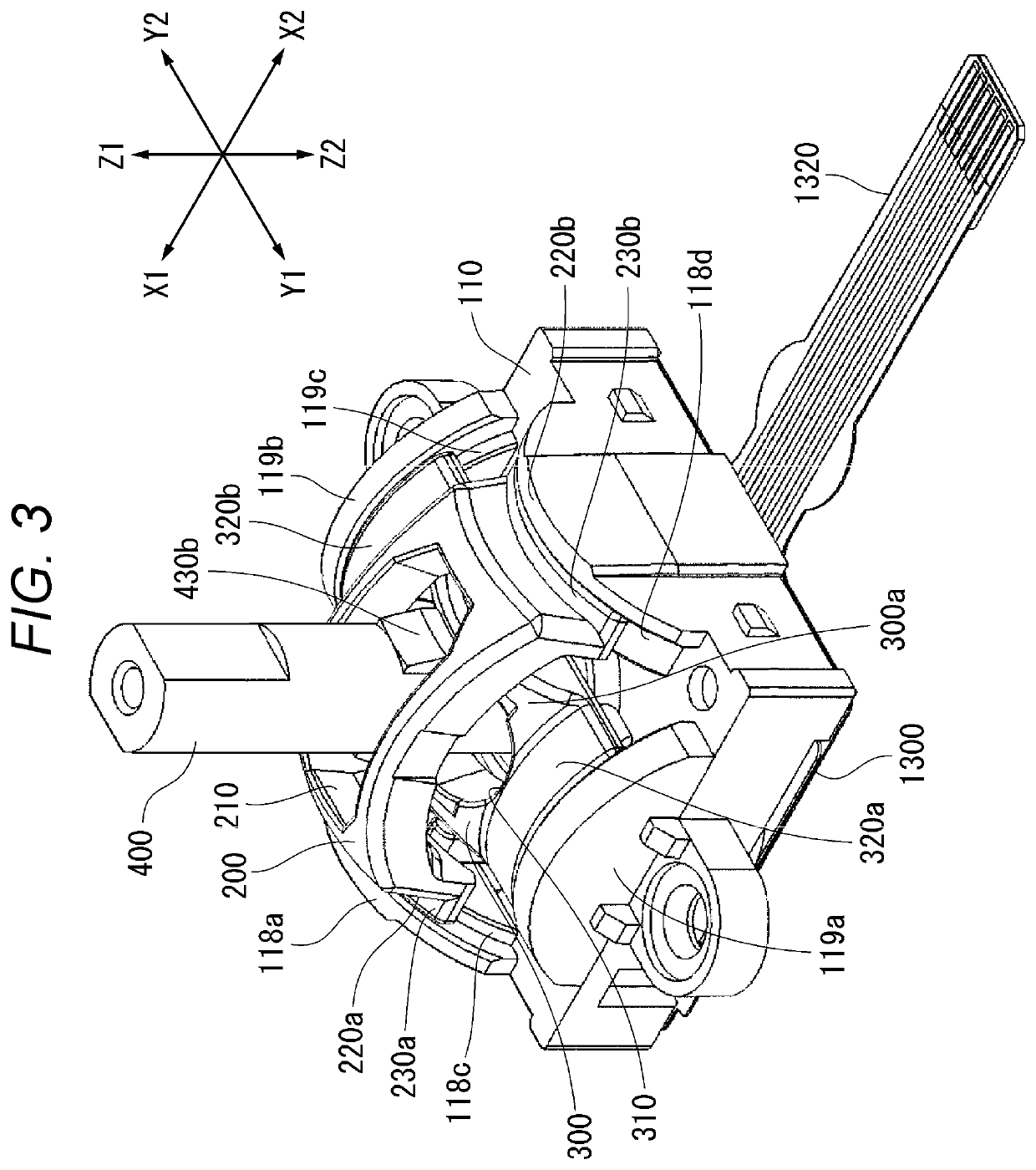

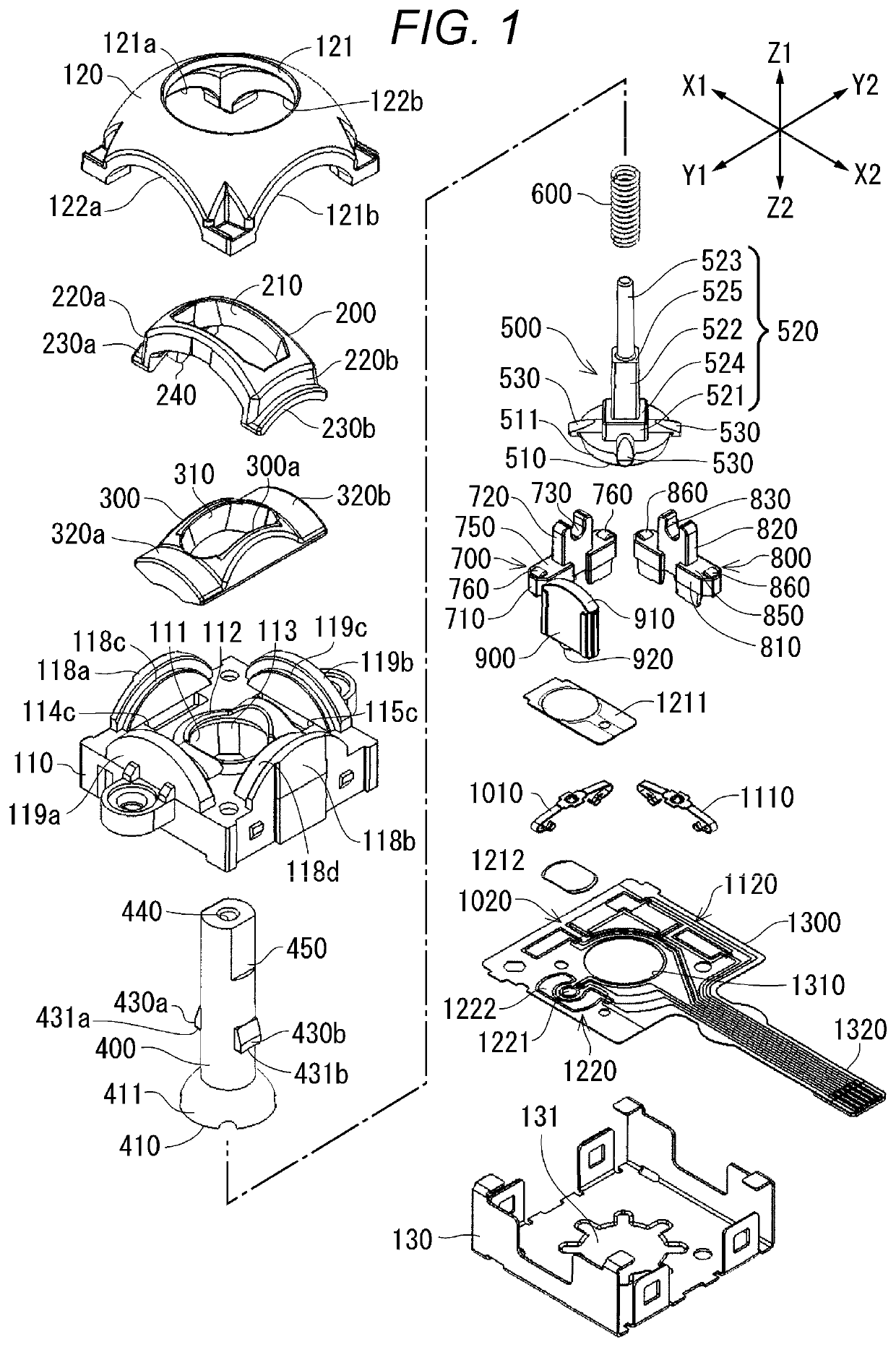

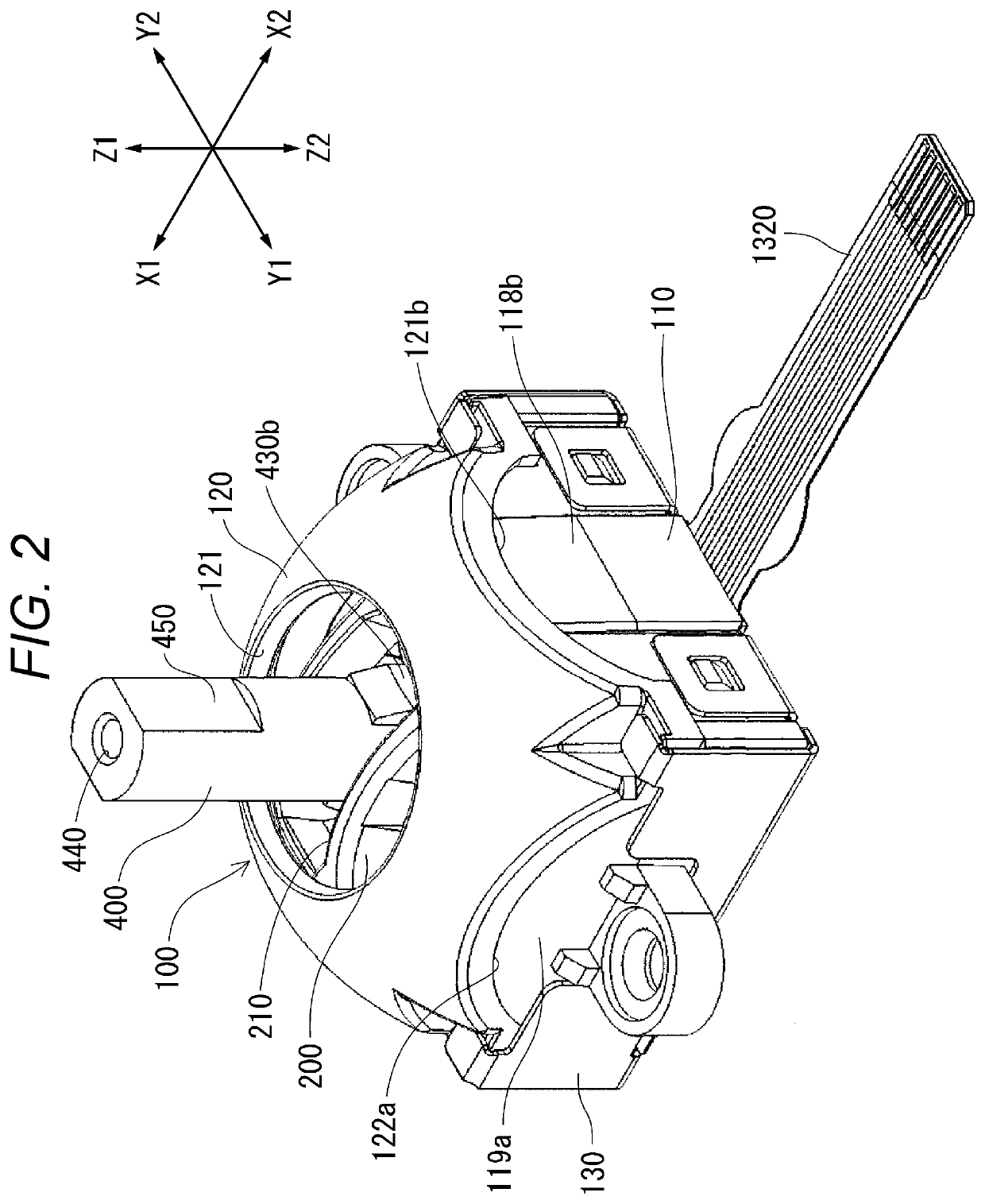

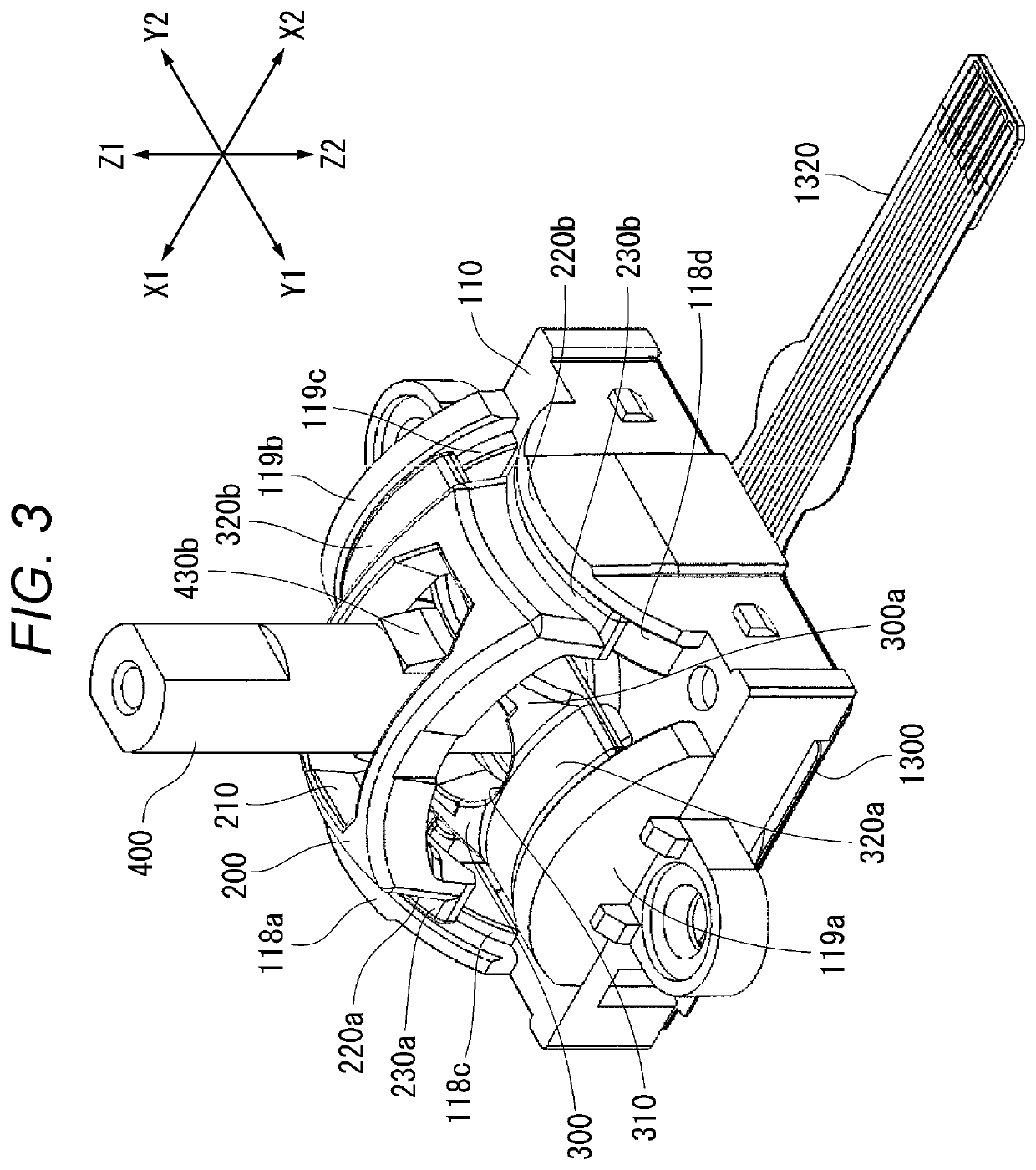

Multi-directional input device

ActiveUS10768658B2High strengthIncrease heightManual control with multiple controlled membersElectric switchesCoil springRadius of curvature

In a multi-directional input device, an upward convex spherical trapezoidal portion is provided at a lower end of an operation shaft projecting downward of a lower arm, a receiving portion for the upward convex spherical trapezoidal portion is provided in a case, the receiving portion has a receiving surface configured with a spherical surface having a radius of curvature identical to a radius of curvature of a spherical zone of the upward convex spherical trapezoidal portion, the receiving surface against which the spherical zone of the upward convex spherical trapezoidal portion is pressed downward by a compression coil spring, and the operation shaft is supported to be rotatable around the center of curvature of the receiving surface.

Owner:HOSIDEN CORP

Multi-directional input device

ActiveUS20200097037A1High strengthIncrease heightManual control with multiple controlled membersElectric switchesCoil springRadius of curvature

In a multi-directional input device, an upward convex spherical trapezoidal portion is provided at a lower end of an operation shaft projecting downward of a lower arm, a receiving portion for the upward convex spherical trapezoidal portion is provided in a case, the receiving portion has a receiving surface configured with a spherical surface having a radius of curvature identical to a radius of curvature of a spherical zone of the upward convex spherical trapezoidal portion, the receiving surface against which the spherical zone of the upward convex spherical trapezoidal portion is pressed downward by a compression coil spring, and the operation shaft is supported to be rotatable around the center of curvature of the receiving surface.

Owner:HOSIDEN CORP

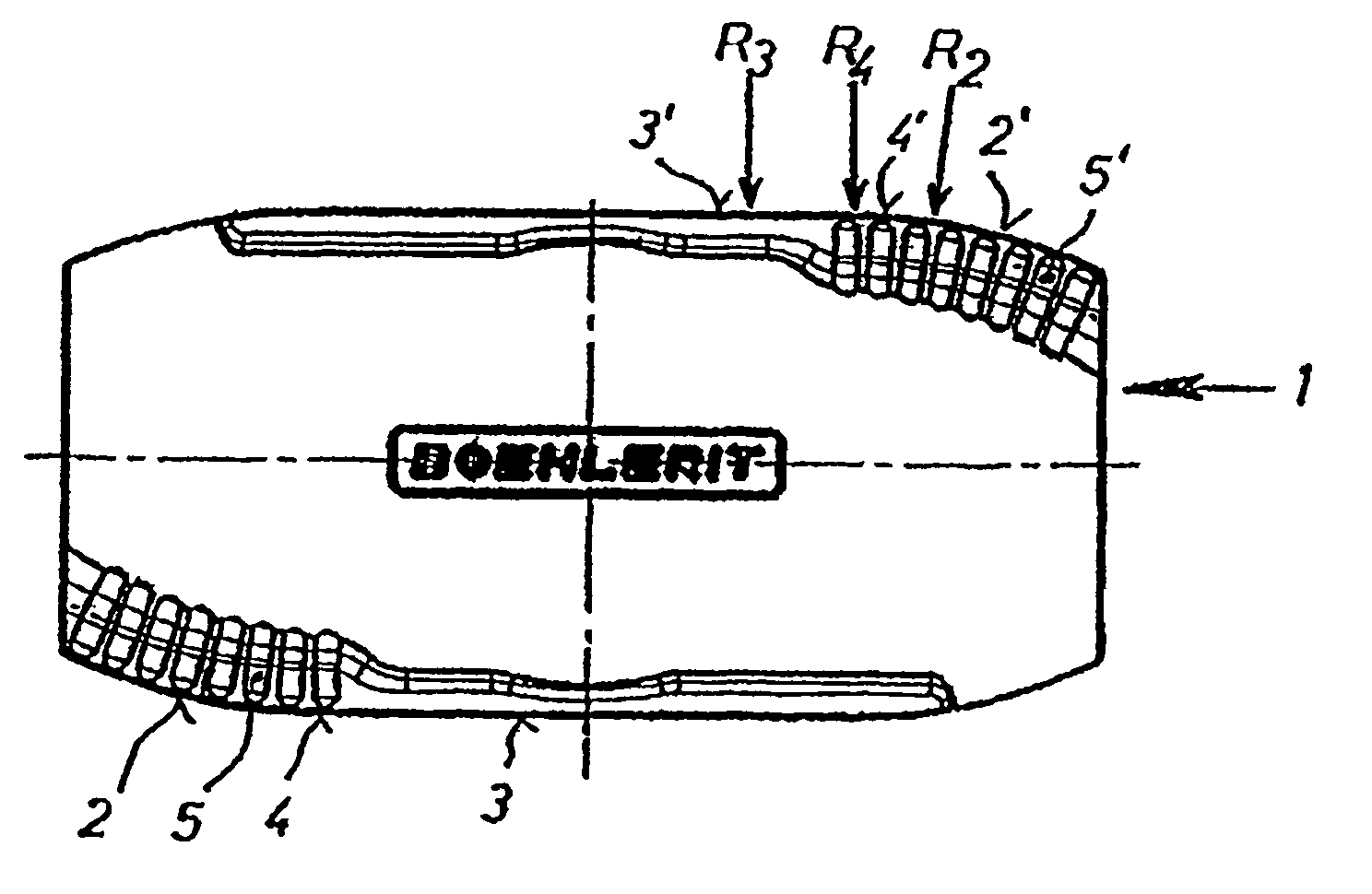

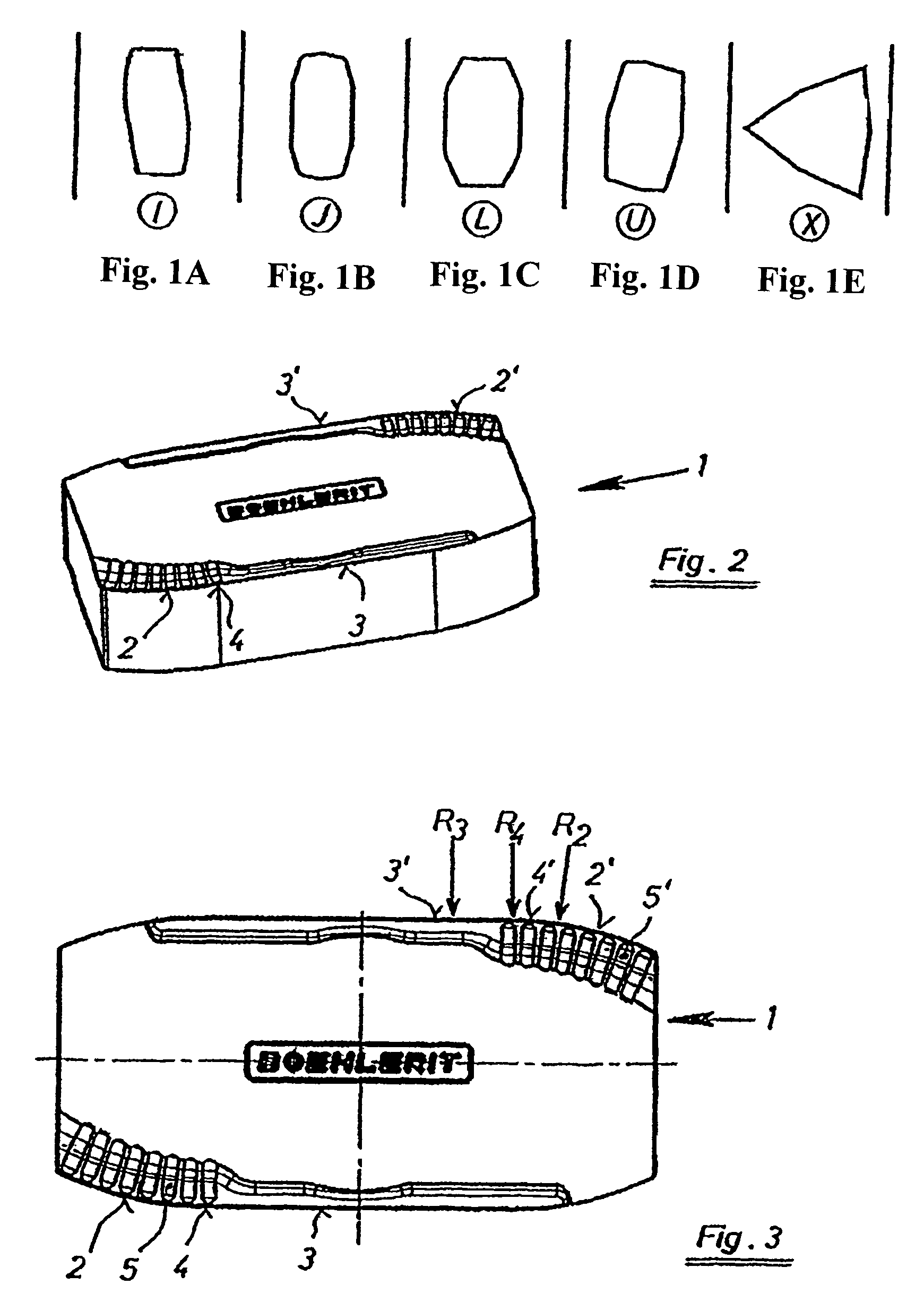

Insert adapted for use in bar peeling and method

InactiveUS7972092B2Reduce power consumptionAvoids chatter marksCutting insertsTurning toolsEngineeringMechanical engineering

An insert for rotary milling includes a polygonal member having at least one primary cutting edge and at least one secondary cutting edge arranged at an obtuse angle thereto. At least one connecting region is arranged between the at least one primary cutting edge and the at least one secondary cutting edge. The connecting region has a local radius of curvature. This abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:BOEHLERIT GMBH & CO KG

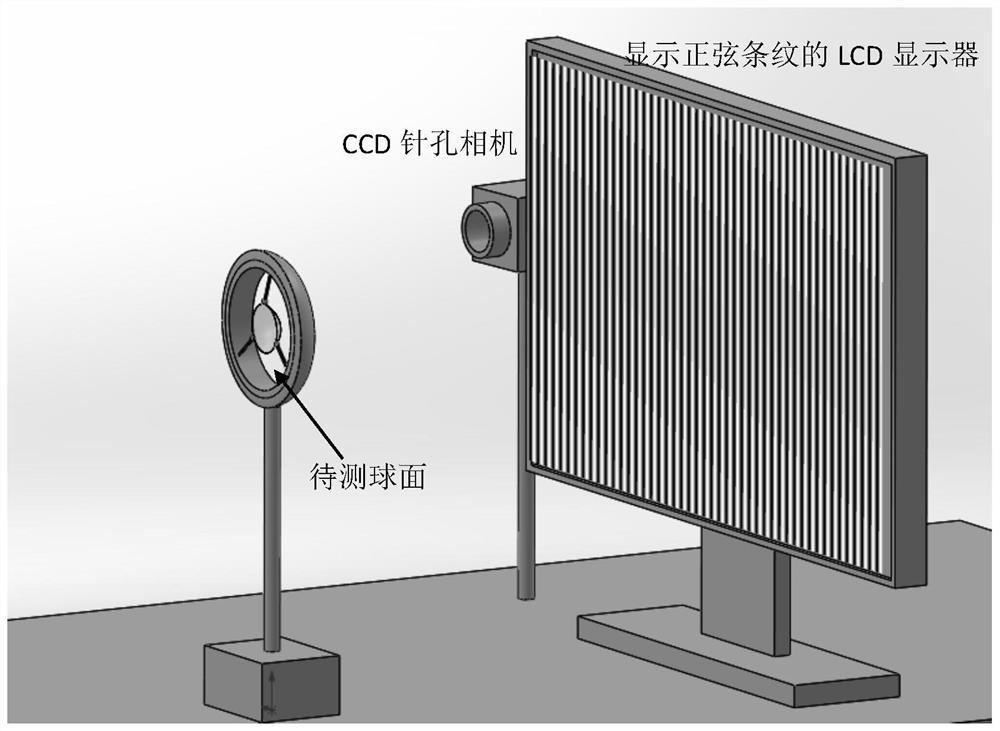

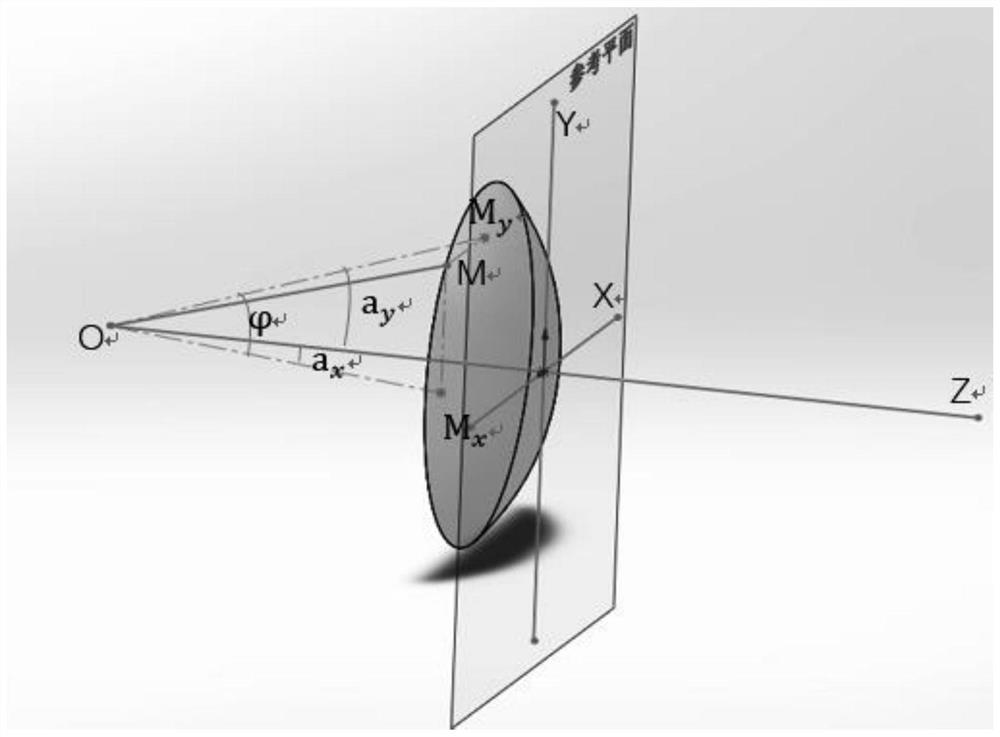

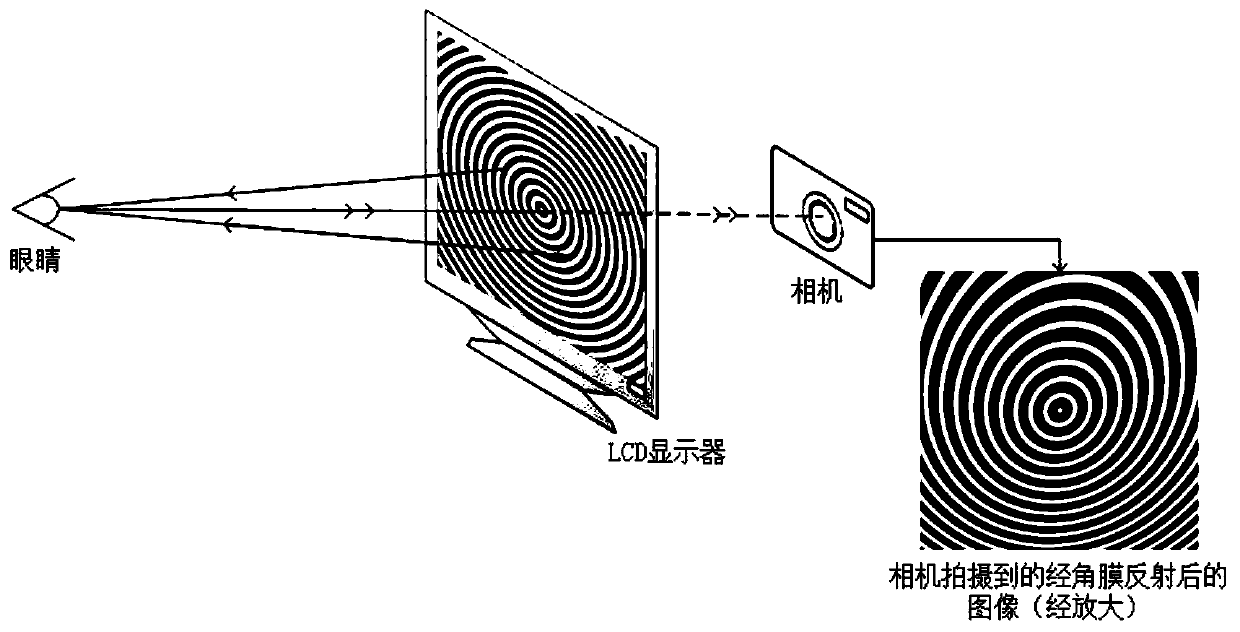

Method for measuring spherical curvature radius

The invention provides a method for measuring curvature radiuses of different points on a spherical surface by using a phase measurement deflection technology. According to the method, an LCD displayis adopted to display sine stripes, the stripes are reflected by a spherical element to be measured and then captured by a pinhole camera, and in known pinhole coordinates of a CCD camera, light rayswhich correspond to CCD camera pixels and pass through pinholes are reflected by a reference plane and the spherical element to be measured to intersect at the coordinates on the LCD display in the Z-direction position of the reference plane; parameters such as the spatial position of the spherical surface and the coordinate of the measured surface are obtained by using minimum angle condition optimization and an iterative method, and then the curvature radius distribution of the spherical surface is obtained by using a differential geometry method. According to the method, the curvature radius of each point on the spherical surface can be rapidly and accurately measured.

Owner:SICHUAN UNIV

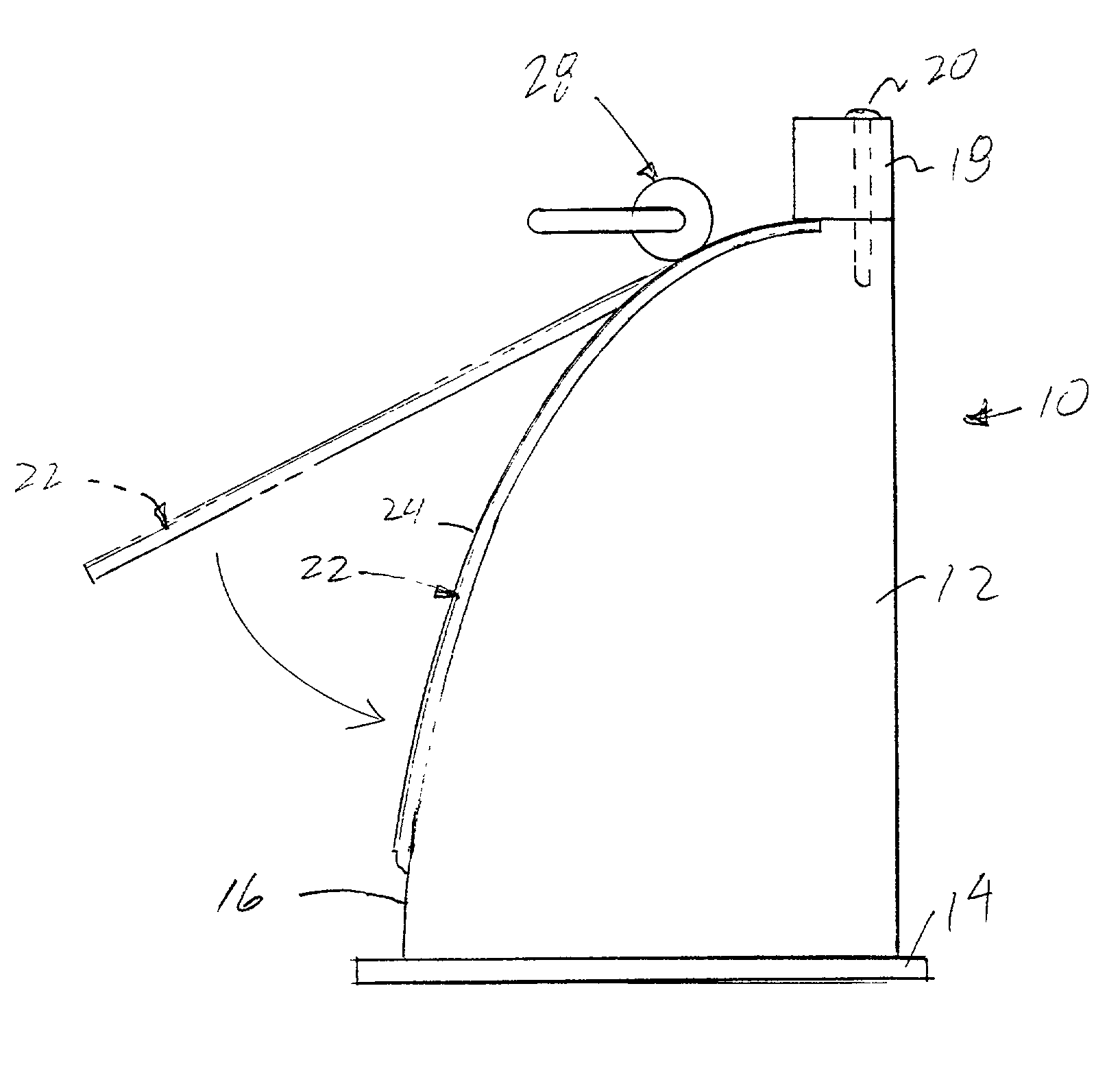

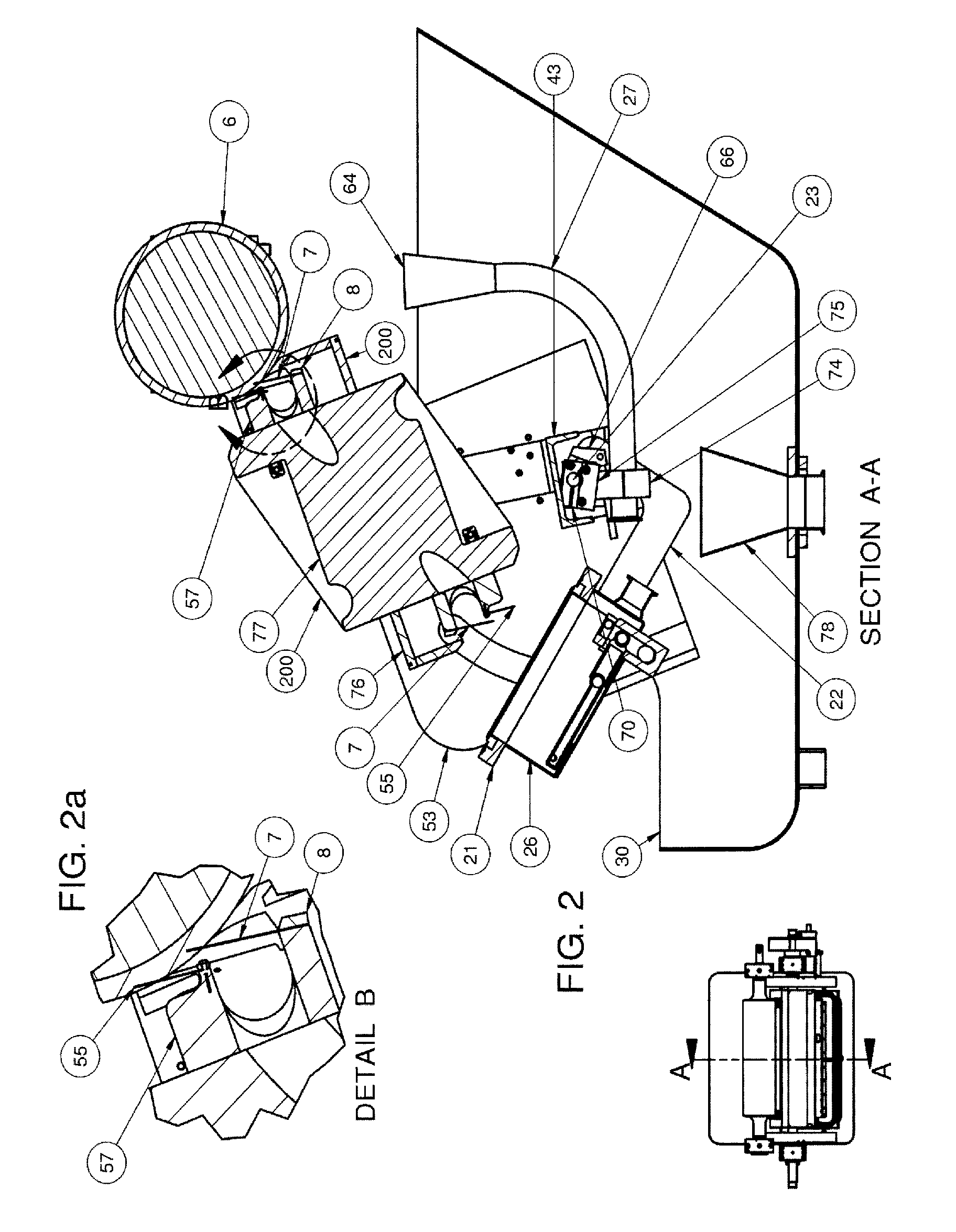

Coating apparatus and method

InactiveUS7559990B2Improve sealingMinimizes spray, spatter, and slingingMovable spraying apparatusPretreated surfacesStructural engineeringRadius of curvature

Two embodiments of end seal design are described, each having preferably three seal lips, one of which differs in the center of its radius of curvature from the center of radius of curvature for the other two seal lips. The end seal is gently spring loaded. In this way the end seal provides a good seal and minimizes spray, spatter, and slinging, and can accommodate various plunge depths and can accommodate various angles of attack of a nozzle upon an application surface such as a web or applicator roll. The nozzle is able to have any of various user-determined angles of attack upon the application surface.

Owner:PANKAKE EUGENE A

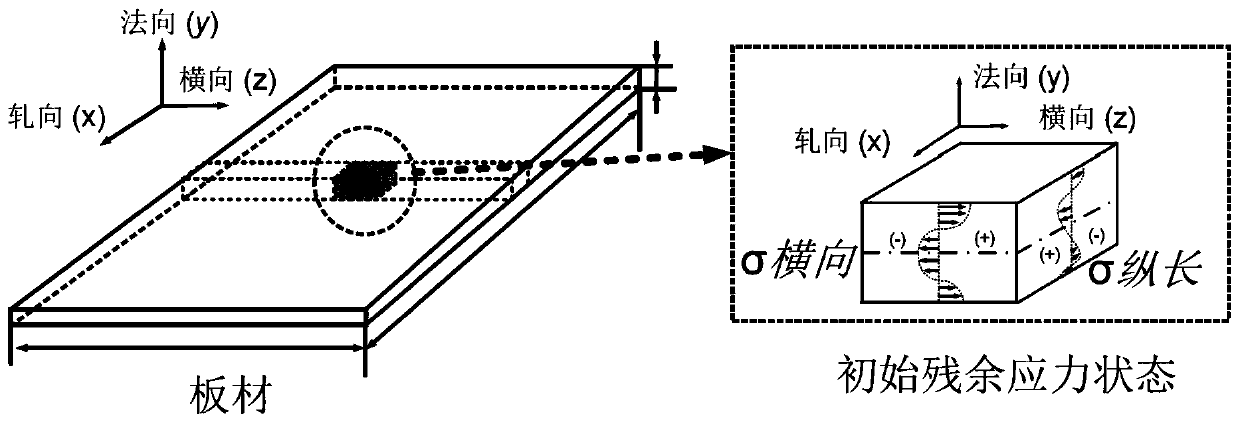

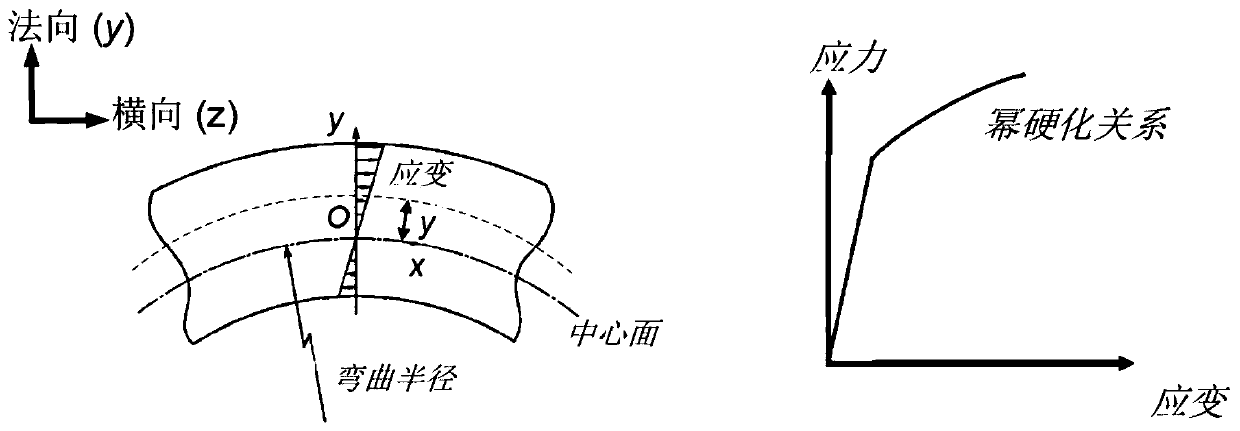

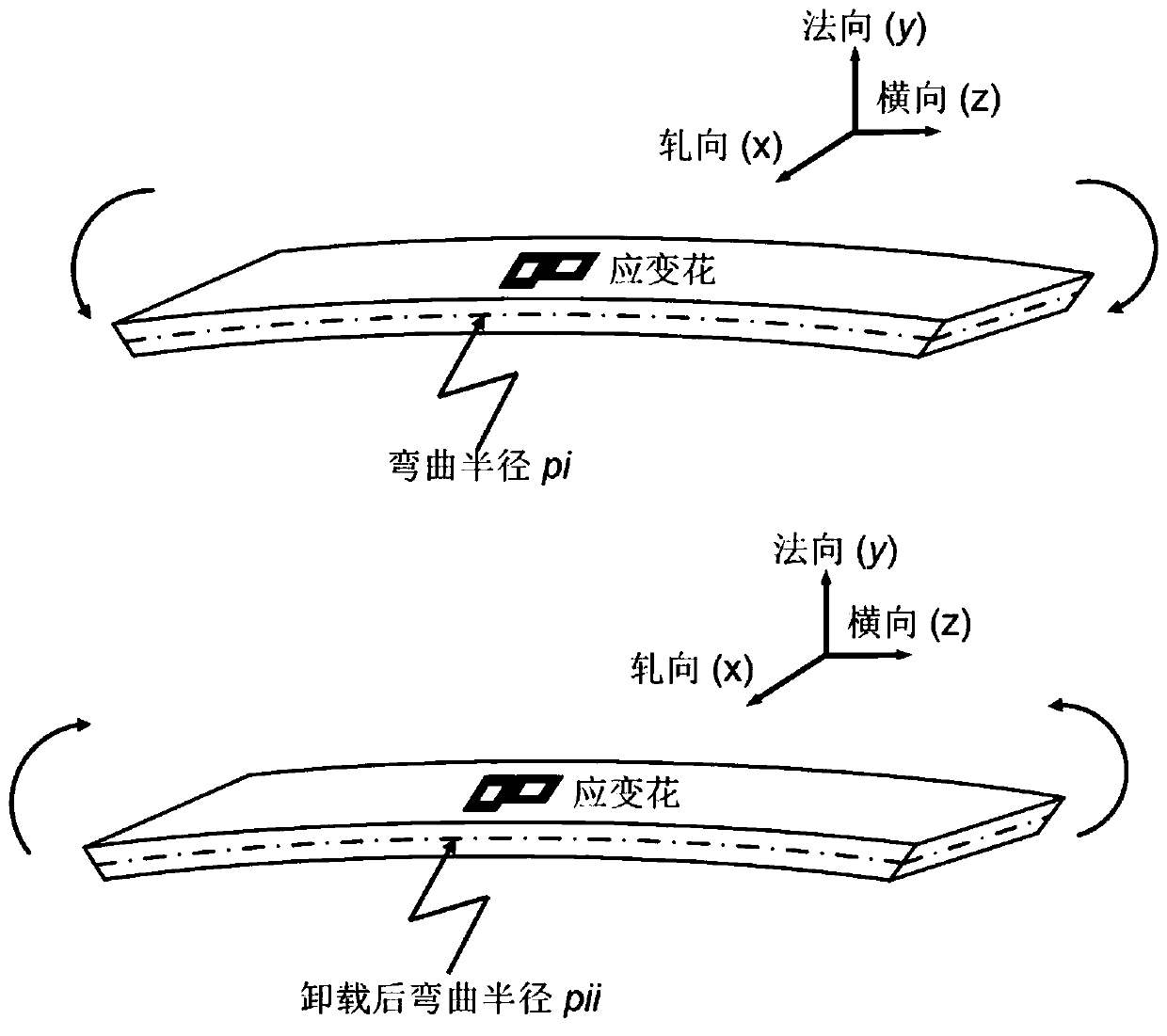

Cold-rolled sheet residual stress prediction and measurement method

ActiveCN111157157AImproving the quality of high-strength steel productsImprove product qualityForce measurementMaterial strength using tensile/compressive forcesWire cuttingRadius of curvature

The invention discloses a cold-rolled sheet residual stress prediction and measurement method, and belongs to the technical field of steel material stress-strain detection methods. According to the technical scheme, the method comprises the following steps: selecting two groups of cubic samples X with certain sizes of length * width * length from a cold-rolled sheet before forming by utilizing a linear cutting method; attaching a strain gauge or a strain rosette to the geometric center of the material in each group of samples along the rolling direction and the transverse direction respectively, and measuring the initial strain of each group of samples in the state; obtaining the relationship between the bending moment and the size change of the sample by using bending equipment and contour scanning equipment; detecting the curvature of the sample by using a contour scanner; obtaining the relationship between the surface strain and the curvature radius of the sample; and calculating the residual stress through a calculation formula. According to the method, the residual stress distribution in the thickness direction of the plate can be effectively predicted through a pure bending method, accurate data can be provided for subsequent cold rolling plate residual stress control, and therefore reliable technical support is provided for improving the product quality.

Owner:HEBEI IRON AND STEEL

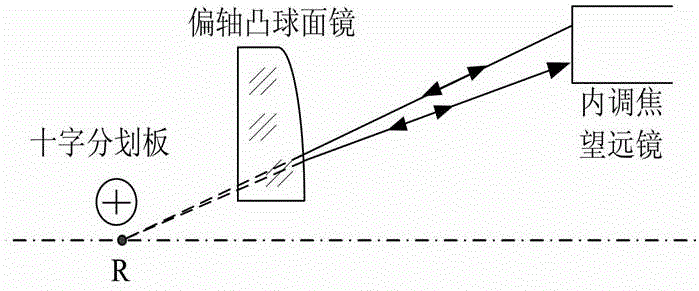

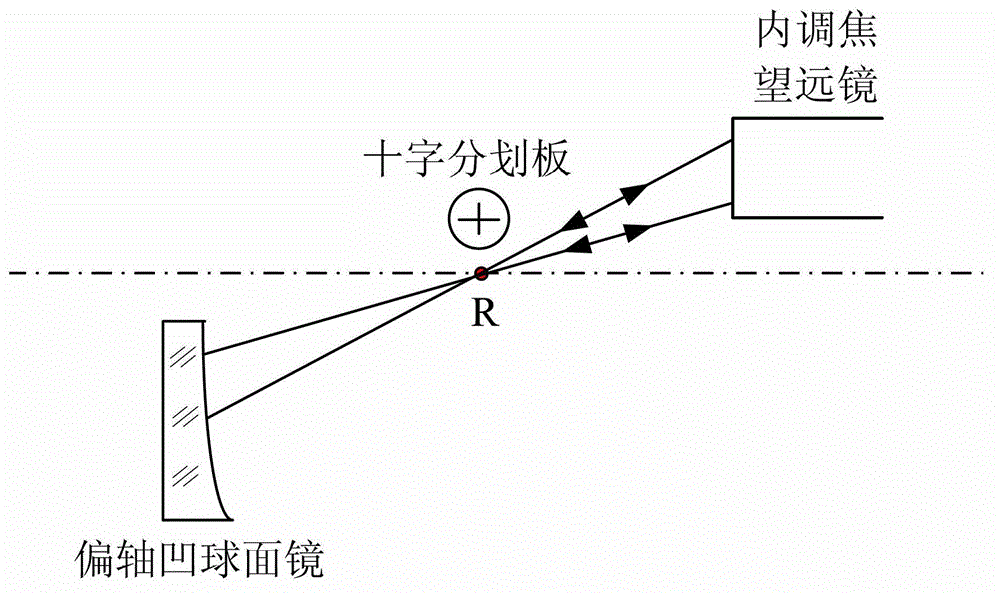

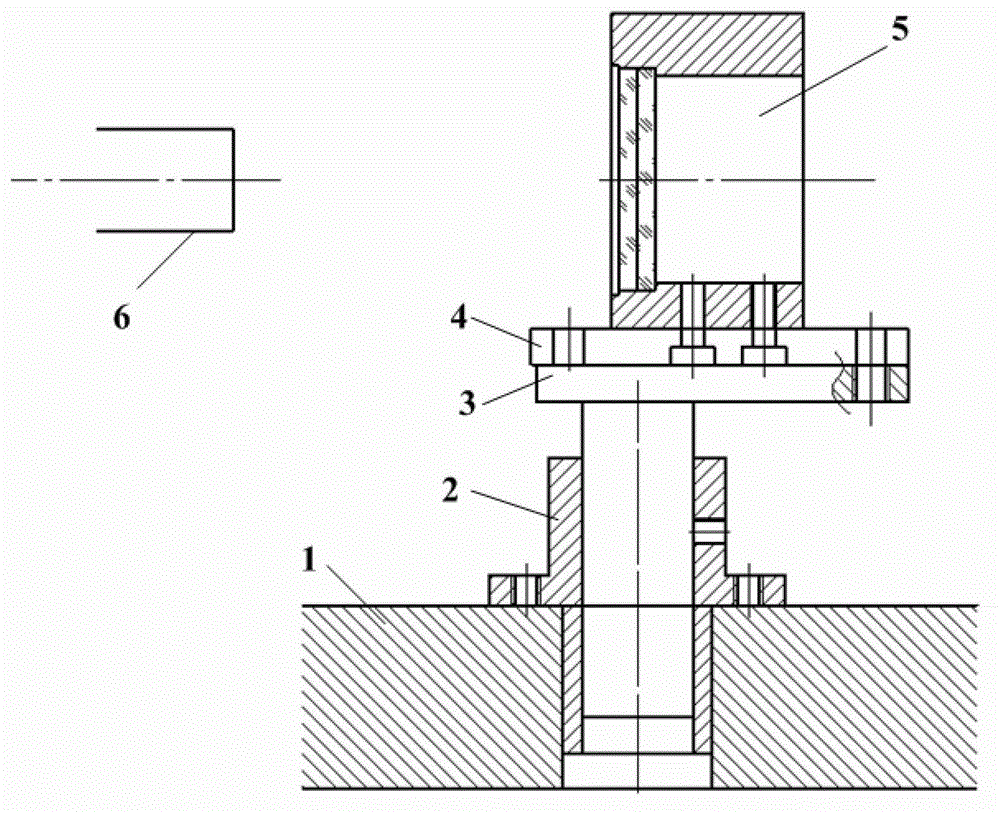

System and method for accurately positioning center of curvature radius of off-axis spherical reflector

InactiveCN102944923AAchieve precise positioningSolve the accuracy problemMountingsOptical axisEngineering

The invention relates to a system and a method for accurately positioning a center of a curvature radius of an off-axis spherical reflector. The system comprises a high-precision flat plate, a rotating shaft, a reticle with a cross wire and a high-precision microscope, wherein an inner hole is arranged on the high-precision flat plate, the rotating shaft is arranged inside the inner hole of the high-precision flat plate, the reticle with the cross wire is vertically arranged on the rotating shaft and can rotate freely inside the inner hole of the high-precision flat plate along with the rotating shaft, and the high-precision microscope and the reticle with the cross wire are arranged on the same optical axis. The system and the method for accurately positioning the center of the curvature radius of the off-axis spherical reflector is high in positioning precision, easy to adjust and convenient to operate.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

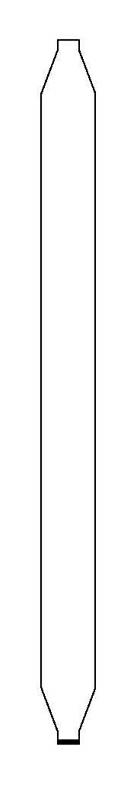

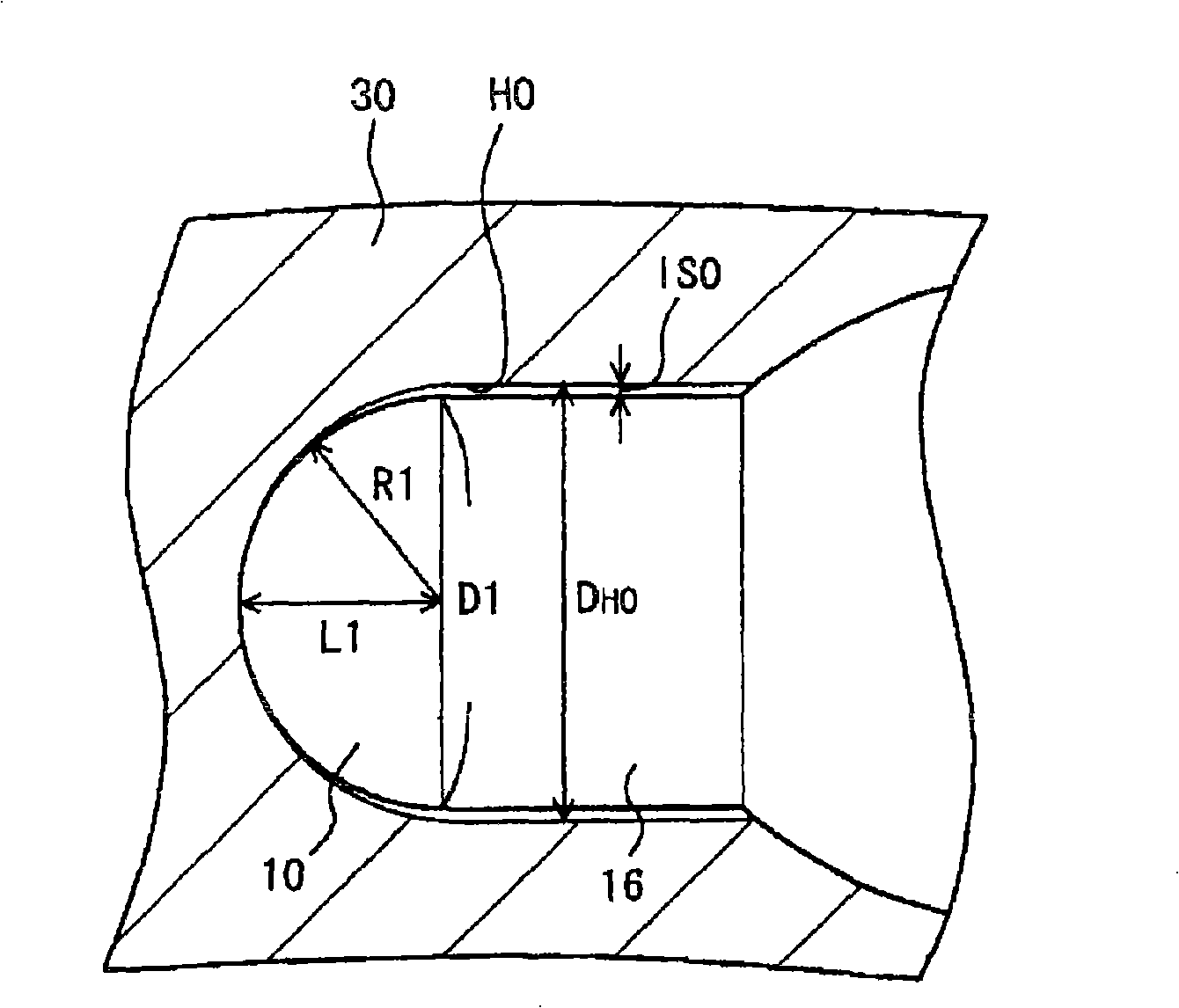

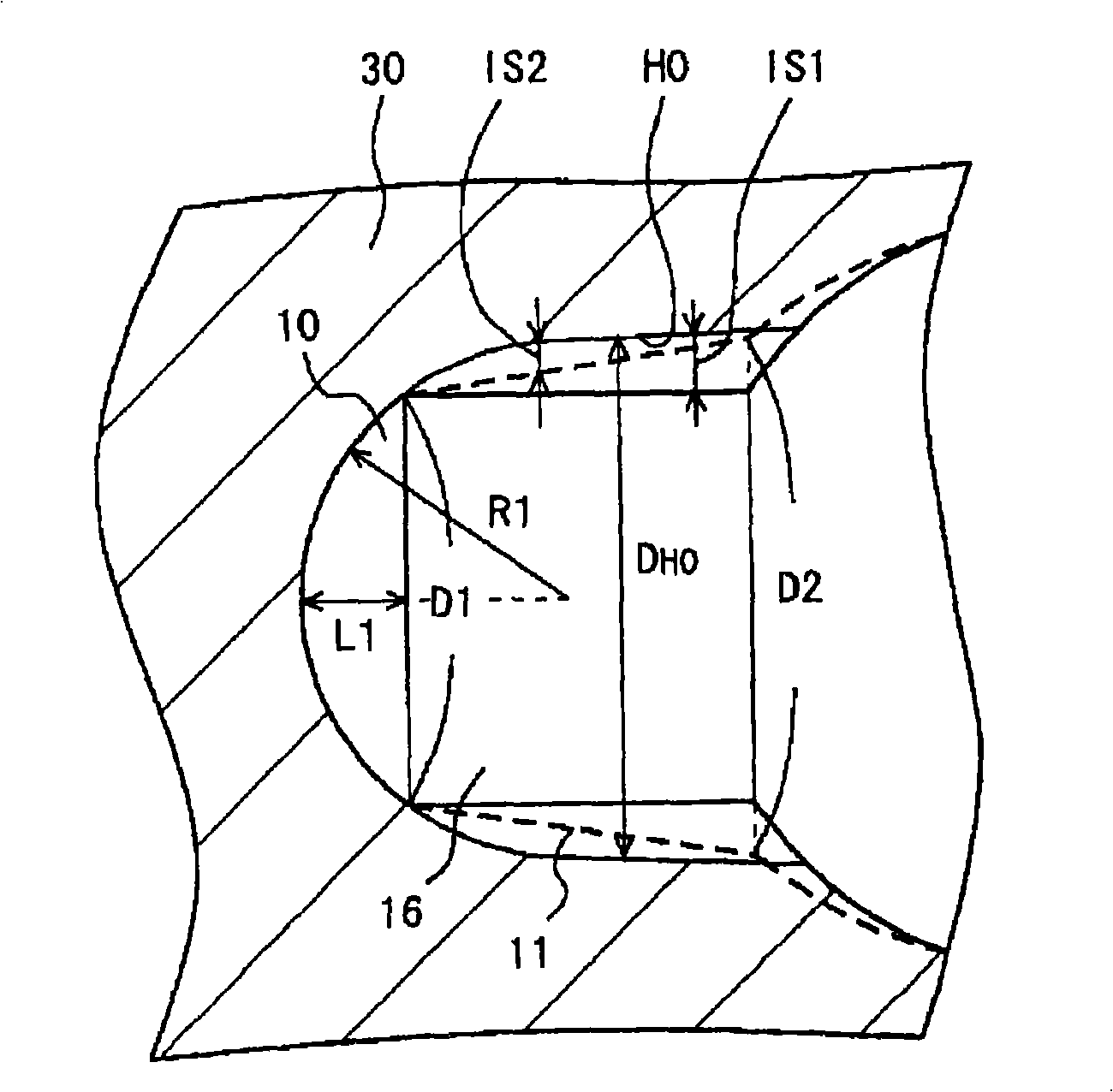

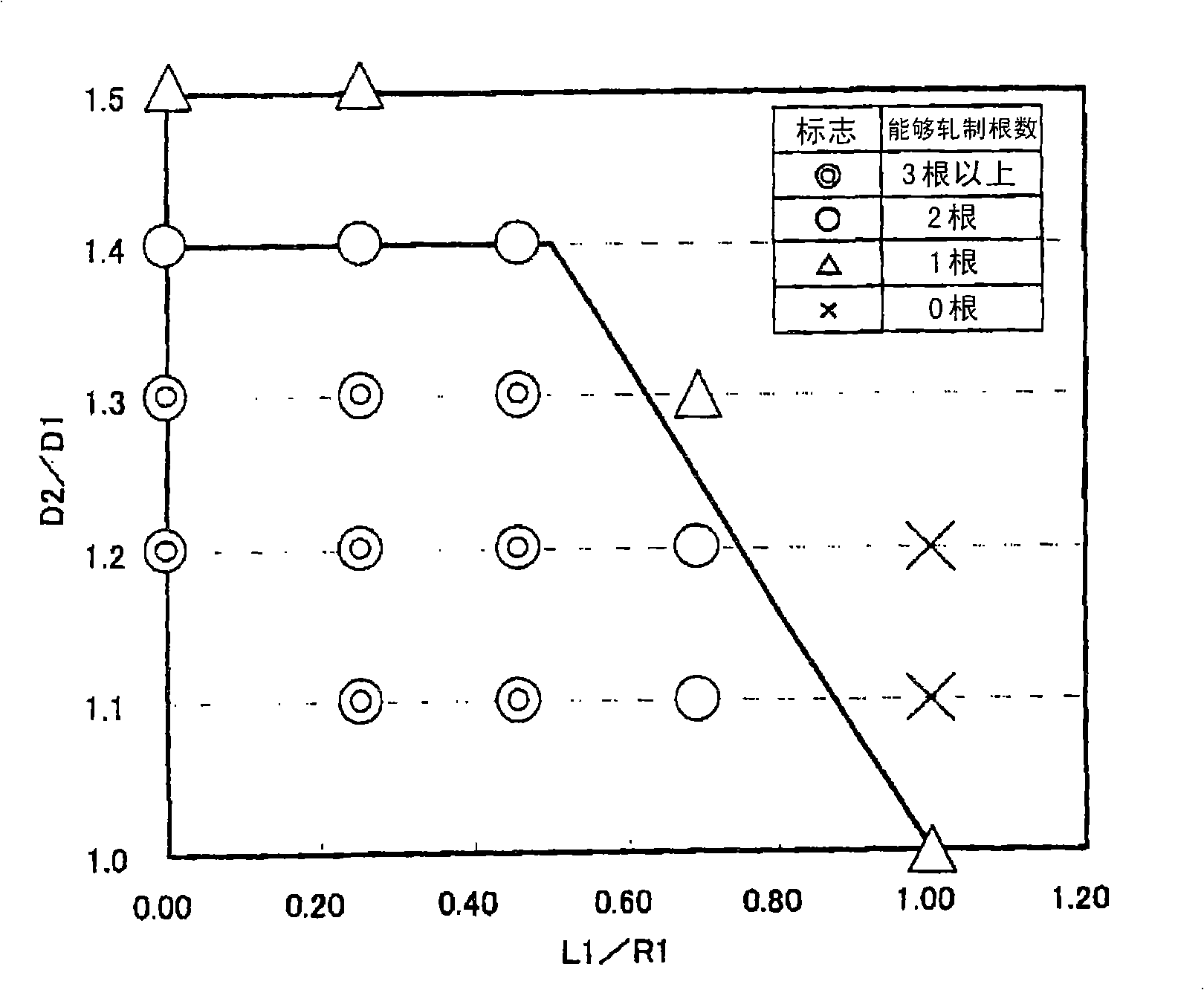

Plug used in boring machine

InactiveCN101346194ALarge diameterPrevent melt lossMandrelsMetal rolling arrangementsStructural engineeringMachine

A plug includes a tip end, a tapered portion, and a barrel portion. The tip end has a spherical surface having a curvature radius R1 and length L1 which is smaller than R1. The tapered portion has a tip end external diameter D1, a back end external diameter D2 greater than D1, and a length is L2. The plug satisfies Expression (1), Expression (2) when 0 < L1 / R1 < 0.5, and expression (3) when 0.5 = L1 / R1 < 1. Since the tip end has a spherical surface with a curvature more gentle than a hemisphere surface, the diameter of the hole formed in the material at the tip end is greater than the hemispherical surface. According, the tapered portion is not brought into contact with the material. 0.5 D1 < L1 + L2 = 2.5 D1 (1) 1.0 < D2 / D1 = 1.4 (2) 1.0 < D2 / D1 < 1.8 -0.8 L1 / R1 (3).

Owner:NIPPON STEEL CORP

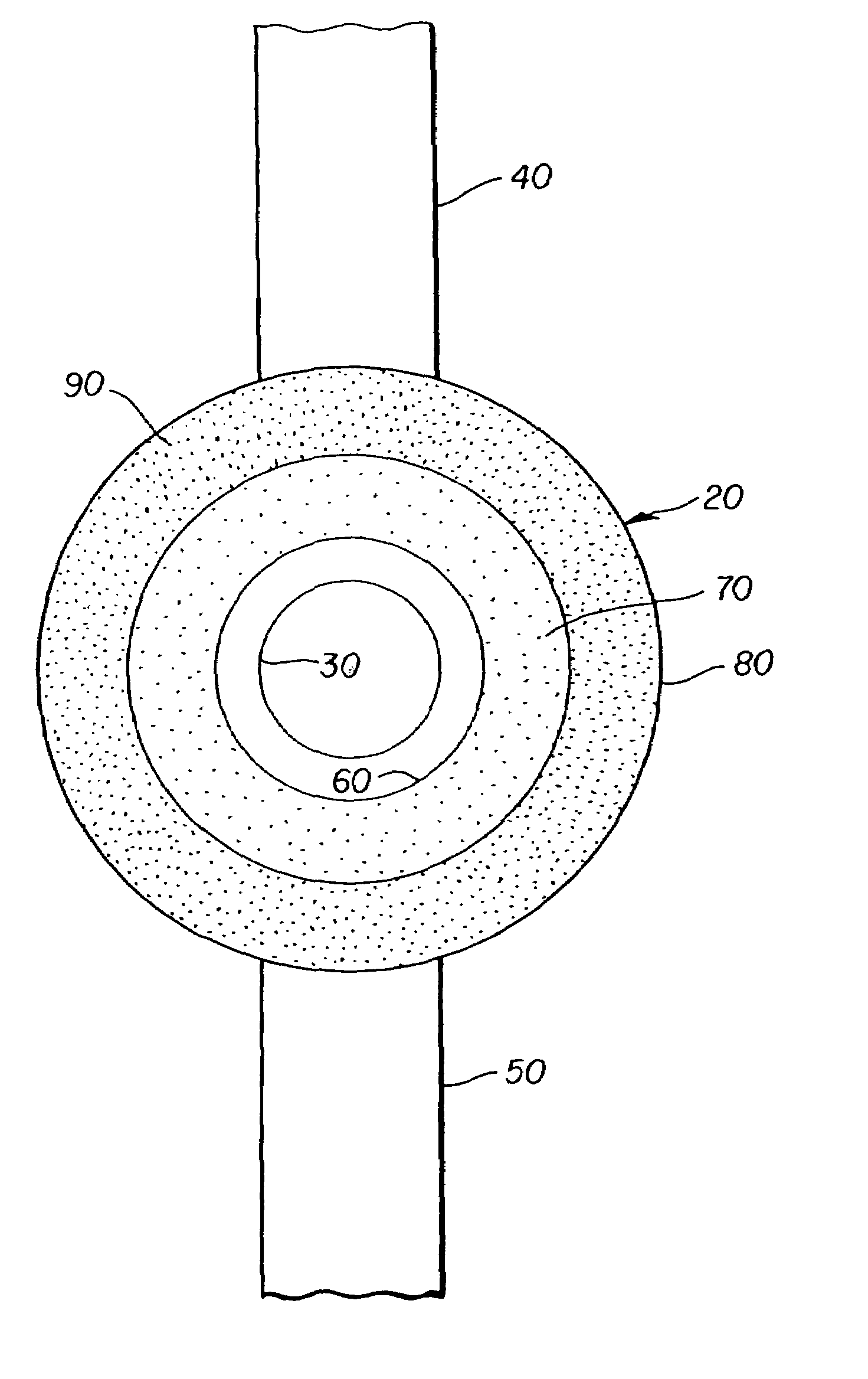

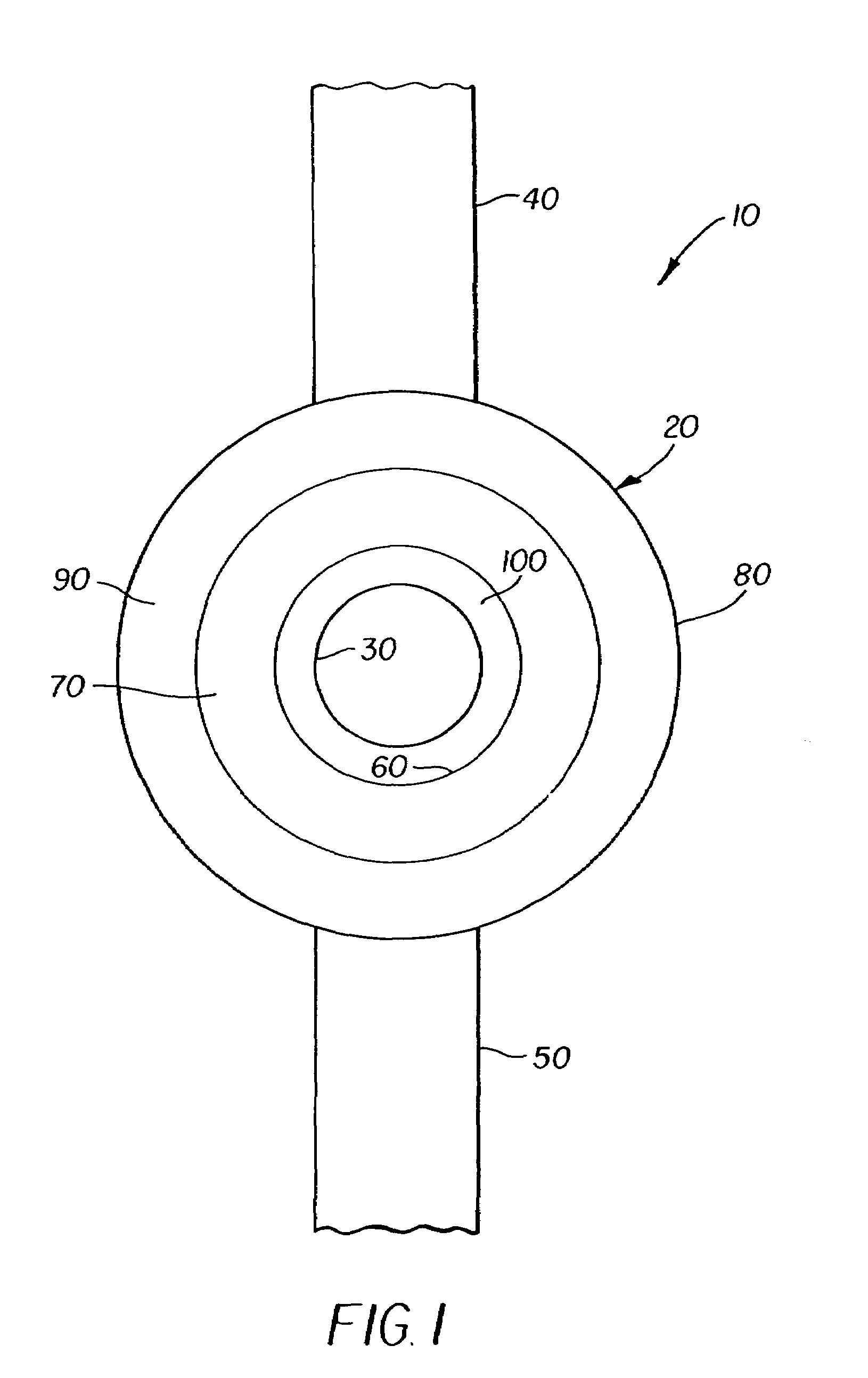

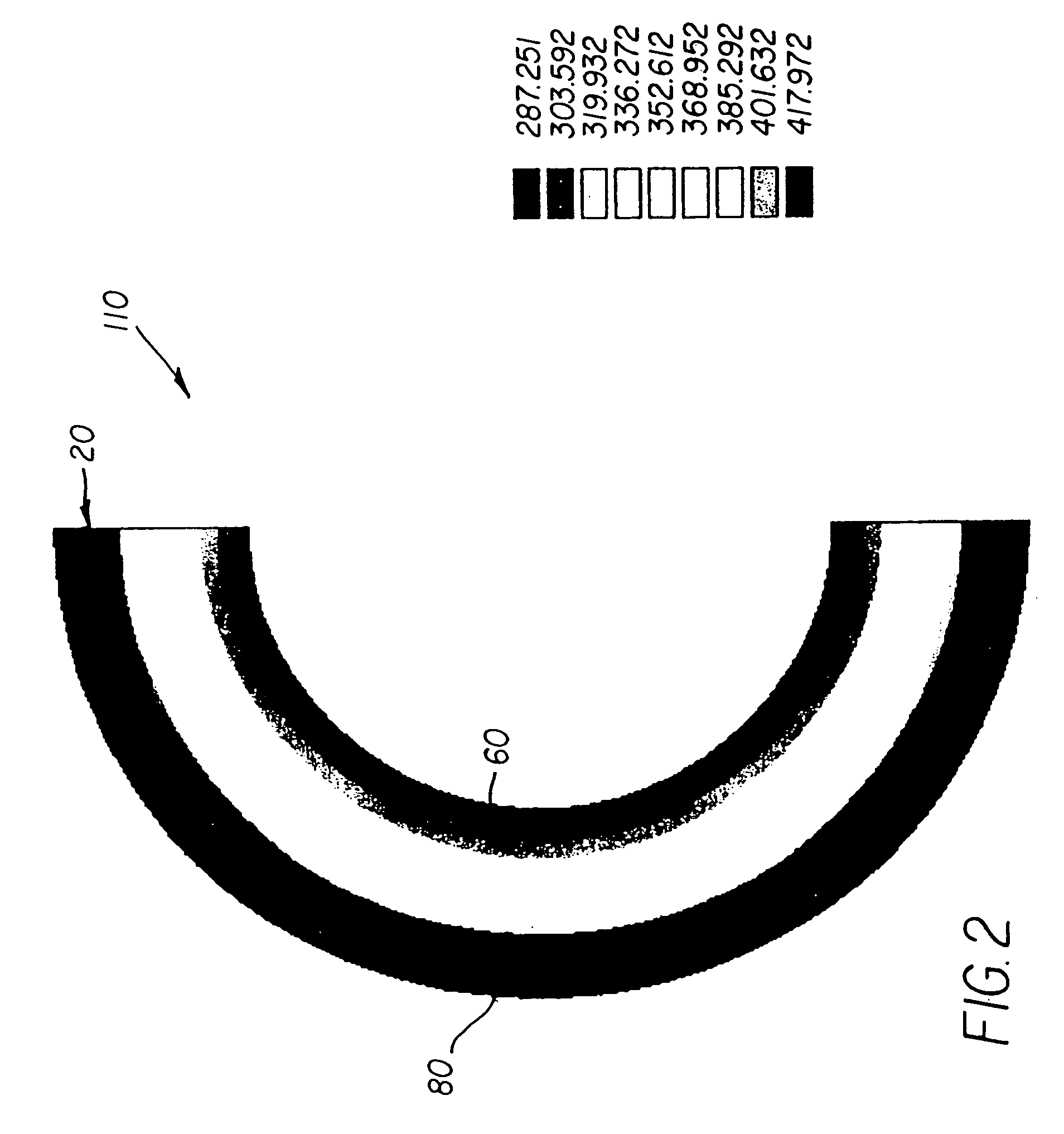

Apparatus for controlling temperature profiles in liquid droplet ejectors

InactiveUS7057138B2Ohmic-resistance heatingOther printing apparatusElectrical and Electronics engineeringInjector

A heater is provided. The heater includes a first material having a circular form and a first sheet resistively. The first material has a first radius of curvature. The heater also includes a second material having a circular form and a second sheet resistively. The second material is positioned adjacent to the first material and has a second radius of curvature. The first radius of curvature is greater than the second radius of curvature and the first sheet resistively is less than the second sheet resistively.

Owner:EASTMAN KODAK CO

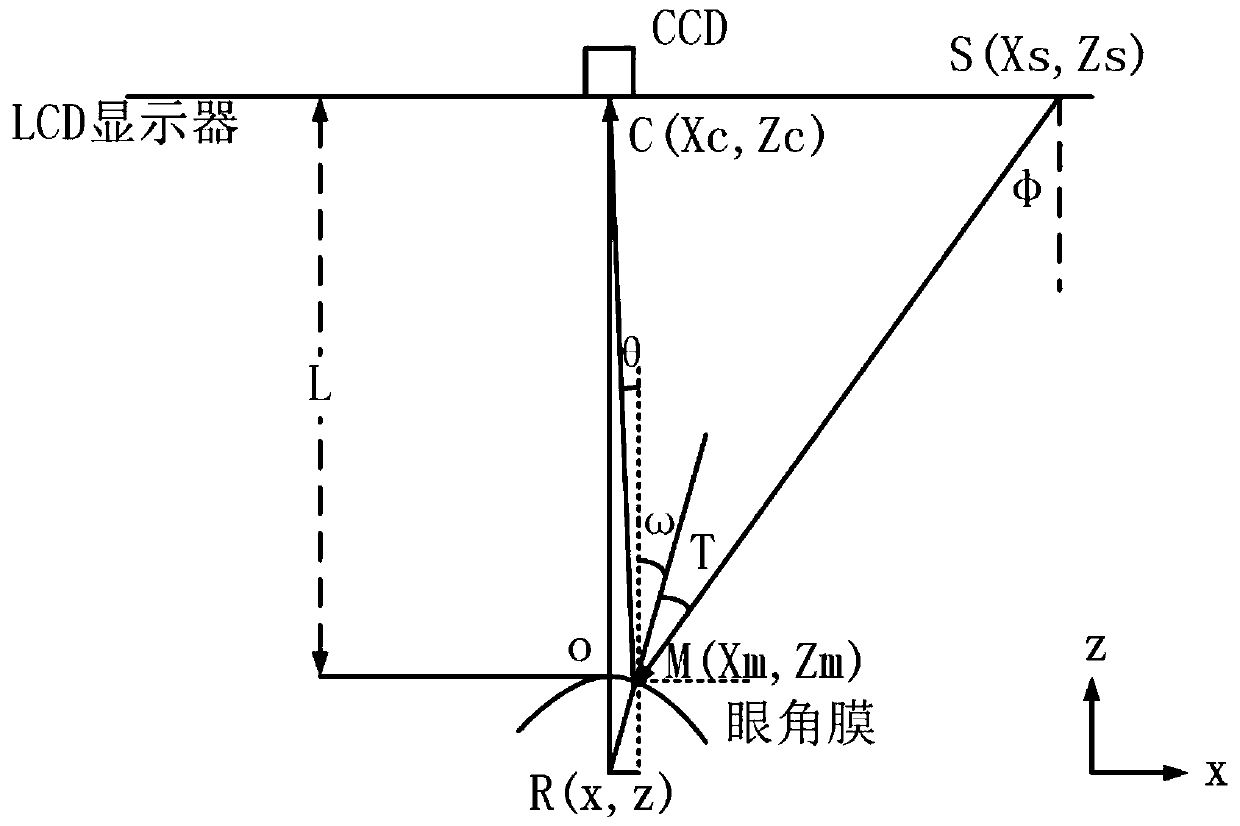

Method for acquiring human corneal topography

The invention provides a method for acquiring human corneal topography by using a trigonometric function, recursion and other mathematical methods. According to the method, concentric rings need to bedisplayed by an LCD display device, a cornea performs reflection and a camera performs receiving; and the x, y coordinates Xs, Ys of pixels on the LCD display device, the x, y coordinates Xc, Yc of the CCD, the x, y coordinates Xm, Ym of the human cornea as well as a distance from the midpoint of the display device and the pinhole of the camera to the vertex of the human cornea are known. According to a geometrical relationship of all the elements and assumption of forming of the cornea by a plurality of adjacent arcs, a curvature radius and a z coordinate of a first circular ring are obtained and then recursion is conducted in sequence to calculate the curvature radius and the z coordinate of the whole cornea, so that the terrain of the human cornea is obtained. According to the method,the accuracy of the human corneal topography is improved.

Owner:SICHUAN UNIV

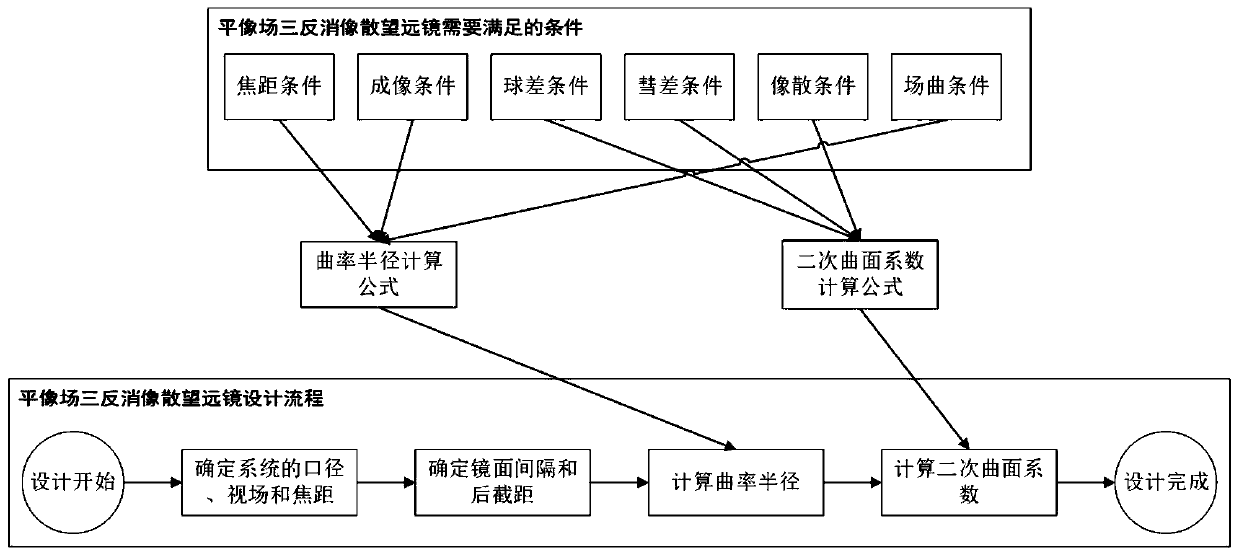

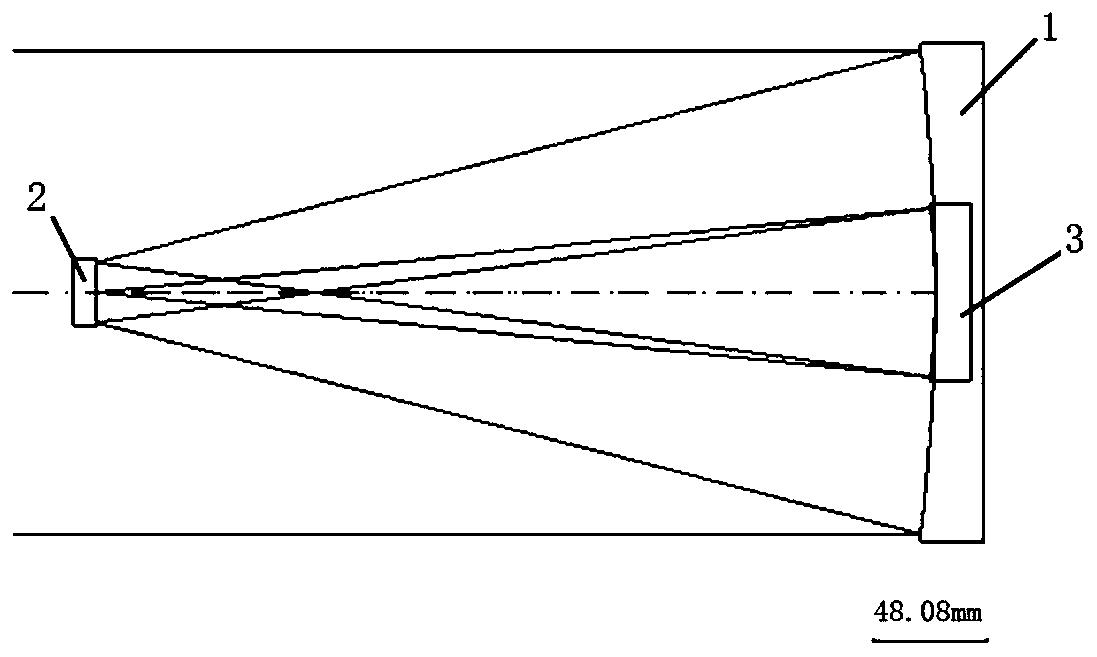

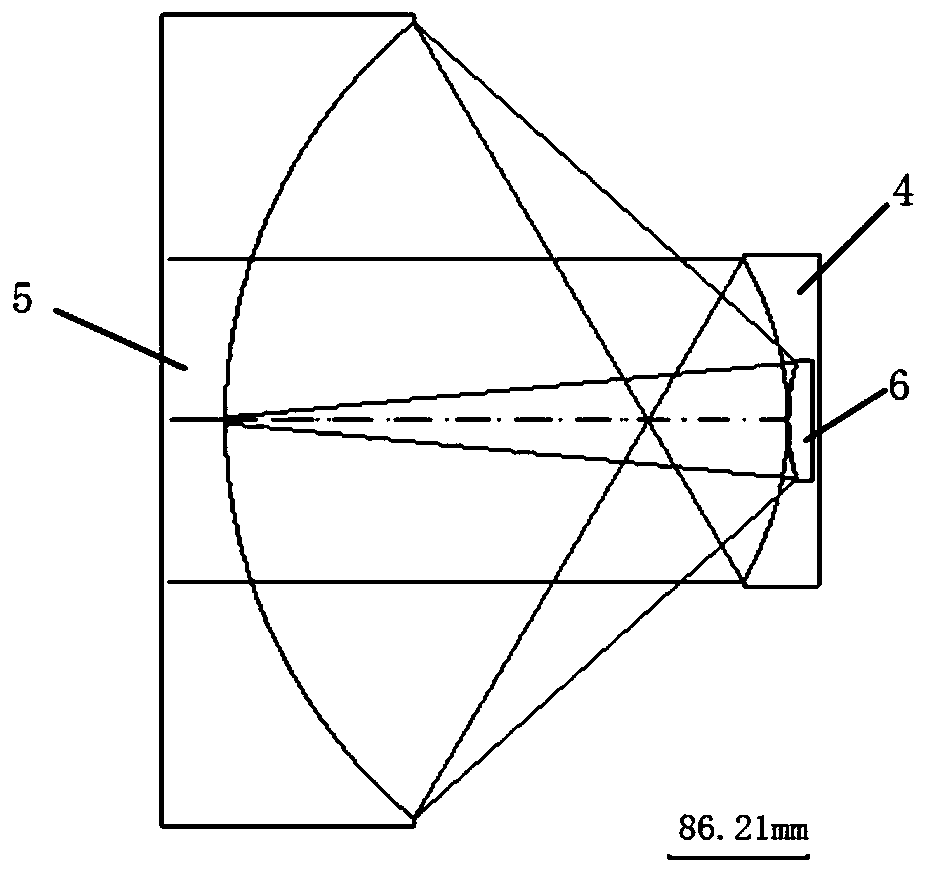

Method for designing flat image field three-mirror astigmatism elimination telescope by taking mirror interval as free parameter

The invention relates to a method for designing a flat image field three-mirror astigmatism elimination telescope by taking the mirror interval as a free parameter in the technical field of telescopedesign, and solves the problem that there is no telescope design method for analysis in other forms. The method comprises the steps of determining the focal length according to application requirements; determining an interval d1 between a primary mirror and a secondary mirror, an interval d2 between the secondary mirror and a third mirror and an interval d3 between the rear surface of the third mirror and an image plane according to the mirror surface position or envelope size requirement of the flat image field three-mirror astigmatism elimination telescope system; calculating the curvatureradius of the mirror according to the intersection point height of the paraxial edge light on the image plane, the three-level field curvature of the telescope being zero, d1, d2, d3 and the focal length; and calculating the quadric surface coefficient of the mirror according to the three-level spherical aberration of the telescope being zero, the three-level coma aberration of the telescope beingzero, the three-level astigmatism of the telescope being zero and the curvature radius. According to the method, intuitive structural parameters can be determined in advance before design, and meanwhile, all design solutions of all three-mirror astigmatism elimination telescopes meeting conditions can be conveniently and quickly given.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

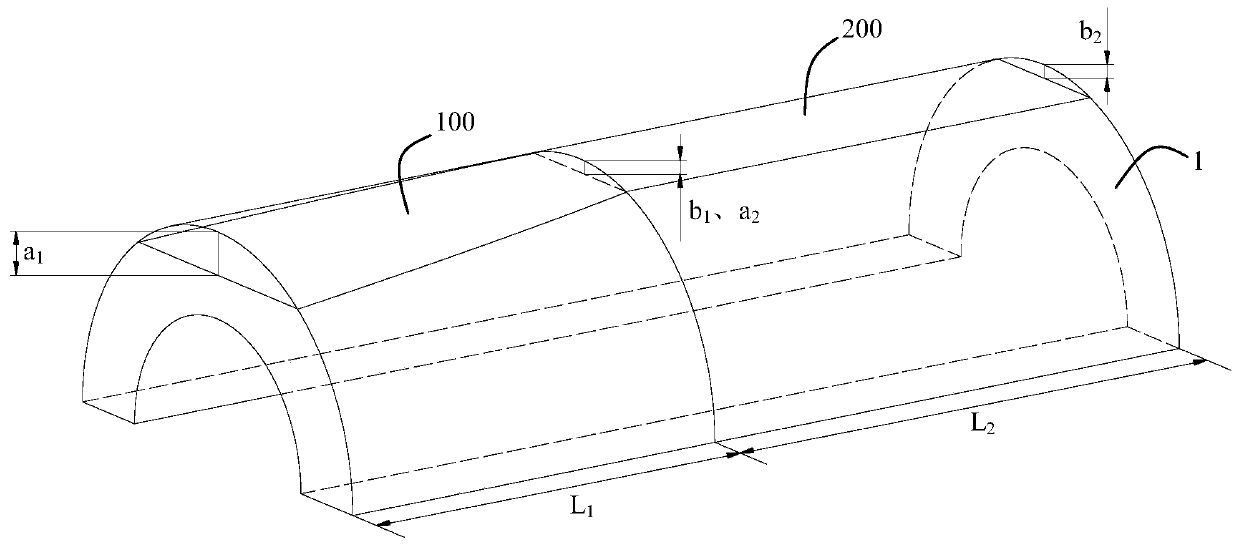

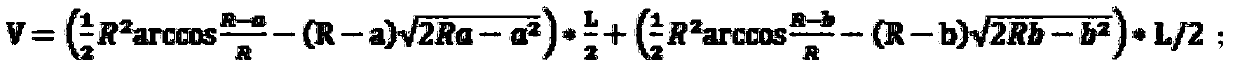

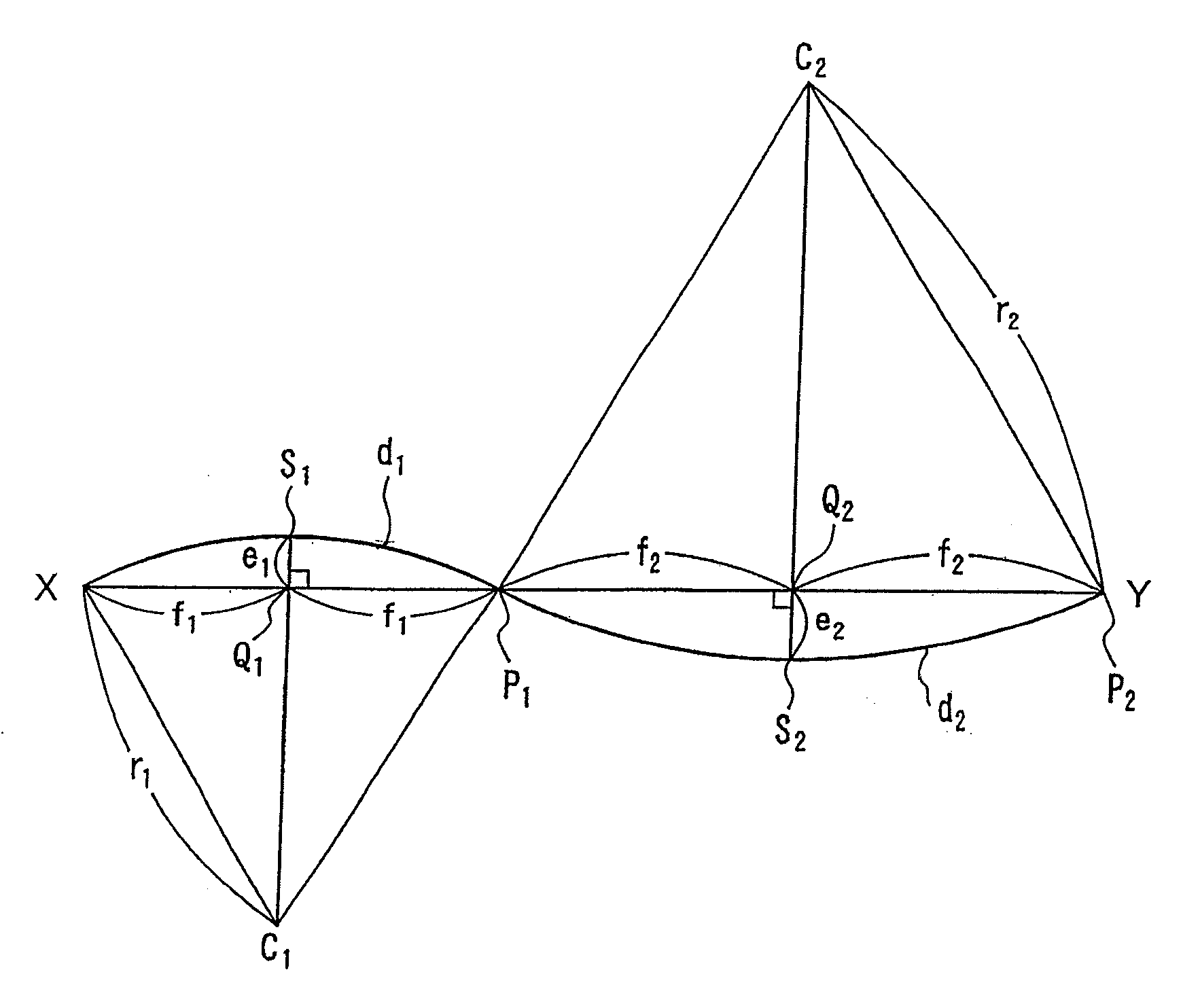

Quantitative analysis method for tunnel vault lining void

ActiveCN111505108AGuarantee the quality of the projectRadio wave reradiation/reflectionMaterial magnetic variablesStructural engineeringRadius of curvature

The invention discloses a quantitative analysis method of tunnel vault lining void, which comprises the following steps of: arranging a longitudinal geological radar measuring line on a tunnel centerline so as to determine two-dimensional data of a longitudinal section of a tunnel vault lining void area, and calculating the volume of the void area by utilizing a lining void quantitative analysisformula, wherein V is the volume of the void area, R is the curvature radius of the vault, a and b are the lengths of vertical line segments from the midpoints of the vaults at the head end and the tail end of the void area to the bottom surface of the void area respectively, and L is the longitudinal length of the void area. By the adoption of the technical scheme, the quantitative analysis method for tunnel vault lining void can determine quantitative information of tunnel vault lining void, including three-dimensional model space attributes such as the space form, position distribution andsize of quality defects.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

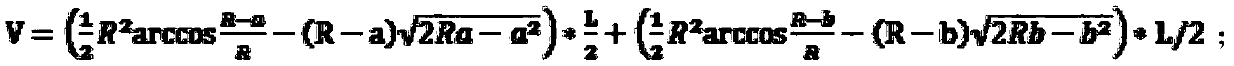

Method for designing structure by drawing curve approximately with circular segment, and structure thereby

InactiveUS20090049701A1Efficient drawingConveniently obtainPublic buildingsNon-circular curve drawing instrumentsLine segmentEngineering

A method for designing a structure or the like is provided in which an arbitrary curve is approximately drawn using a circular segment. This method includes the steps of: setting a straight line which connects one end of a desired curve and the other end thereof; setting an intersection point of the curve and a perpendicular to the straight line at a middle point thereof; obtaining a distance between the intersection point and the middle point, and a length of a straight-line segment from each of the one end and the other end of the curve up to the middle point; setting a curvature radius of a circular segment which approximates the desired curve in association with these distance and length, and acquiring a radius center point of the circular segment; and setting a circular segment from the one end up to the other end of the curve by using this center point as the center thereof.

Owner:KANZAKI TAKAHIRO

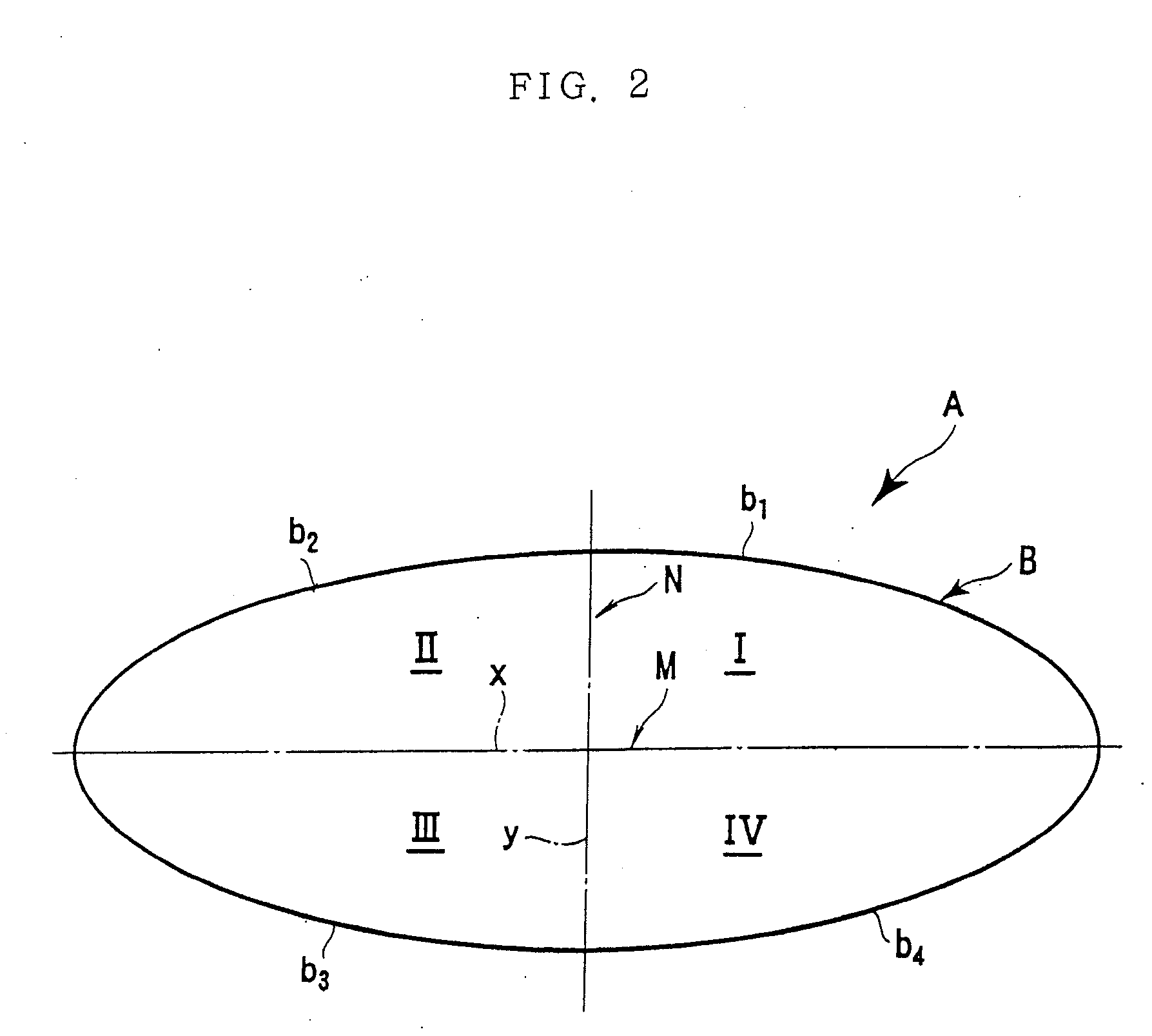

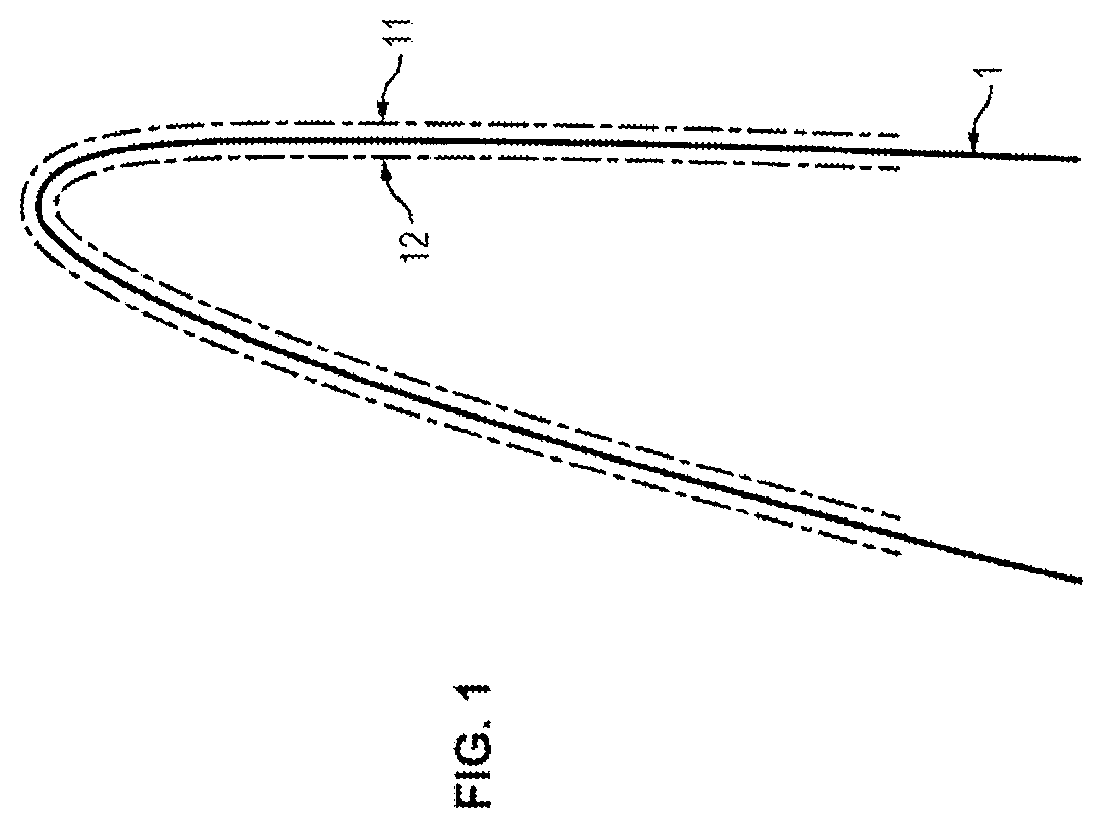

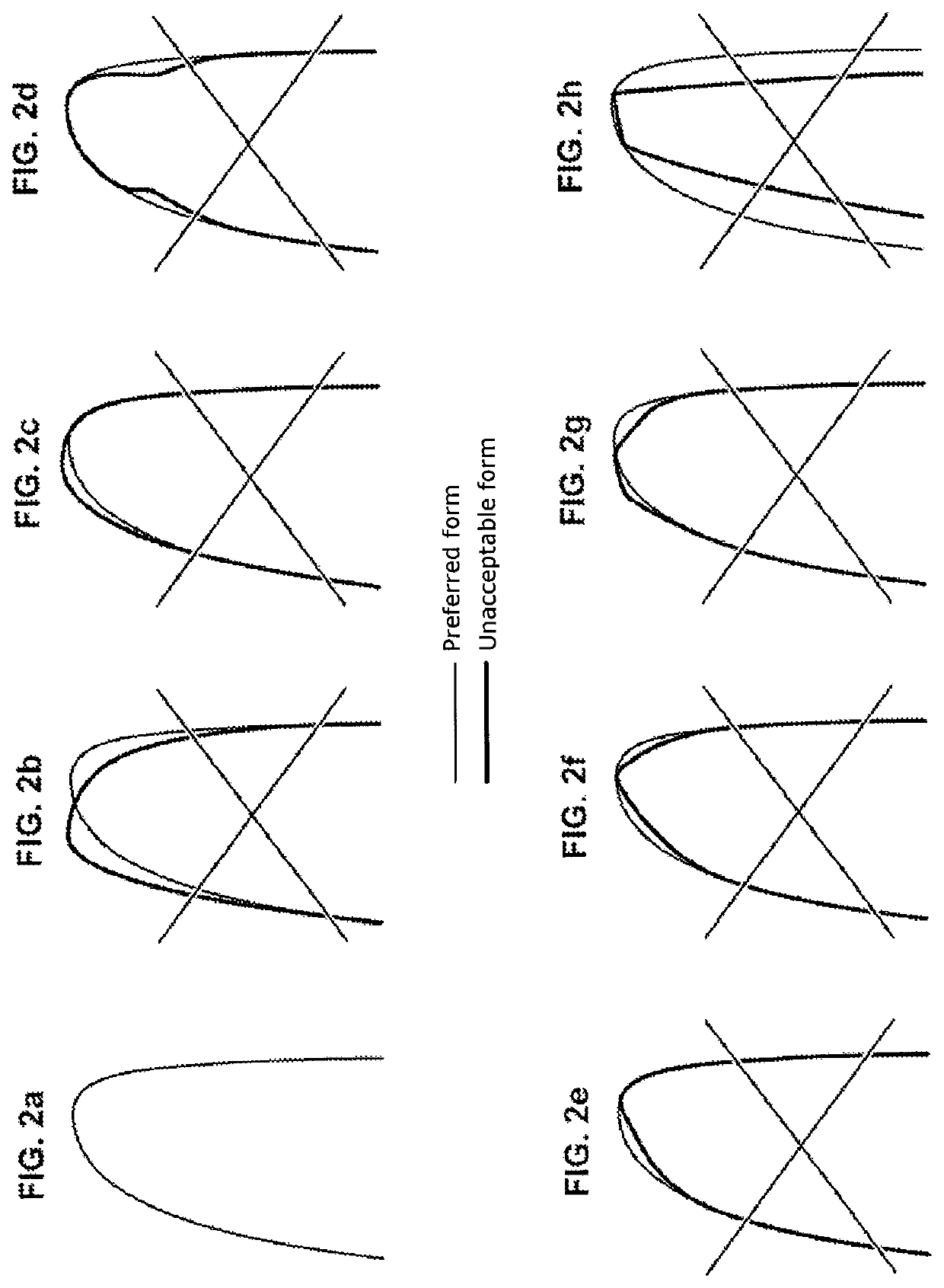

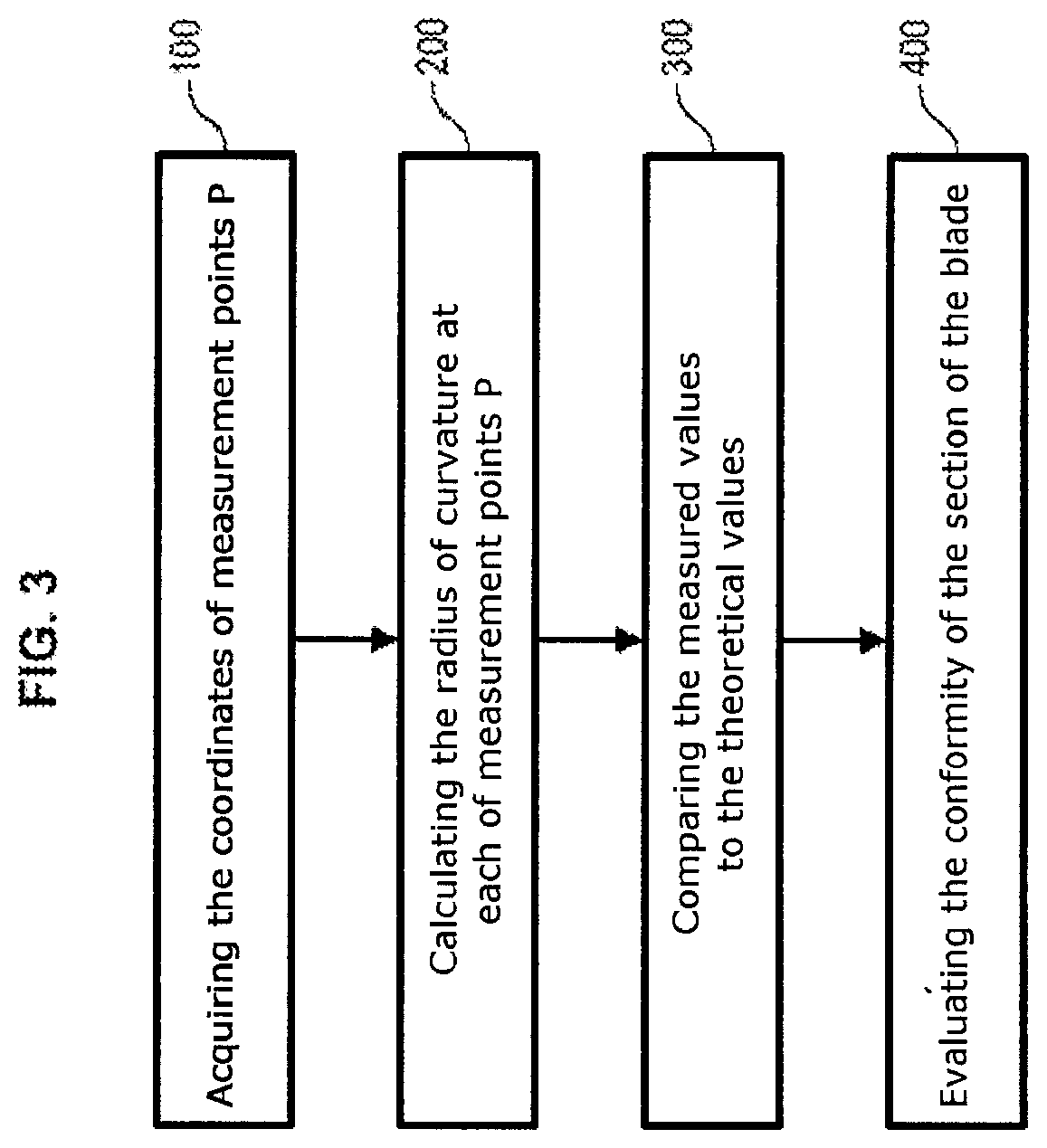

Method for controlling the conformity of the profile of a curved surface of a turbomachine element

PendingUS20200182601A1Prone to defectMechanical counters/curvatures measurementsUsing optical meansEngineeringRadius of curvature

The invention relates to a method for controlling the conformity of a profile of a section of a curved surface of a turbomachine element, comprising the following step: —(100) acquiring coordinates of a plurality of measurement points of the section in a frame of reference defined for said section; characterised in that the method comprises the following steps: —(200) calculating, based on the coordinates of these measurement points, the radius of curvature of the section at each of these points, in order to obtain a measured evolution curve of the radius of curvature according to the position of the measurement points along said section; —(300) comparing the measured evolution curve of the radius of curvature, obtained in the preceding step, with a theoretical evolution curve of the radius of curvature of the predetermined section; —(400) evaluating the conformity of the section based on the comparison carried out in the preceding step.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

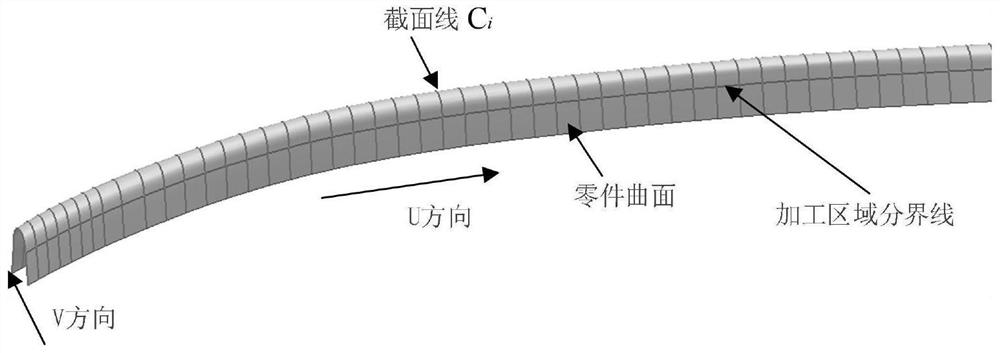

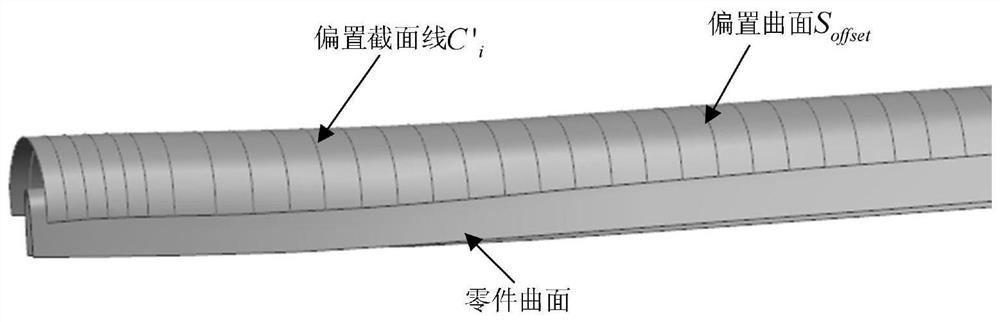

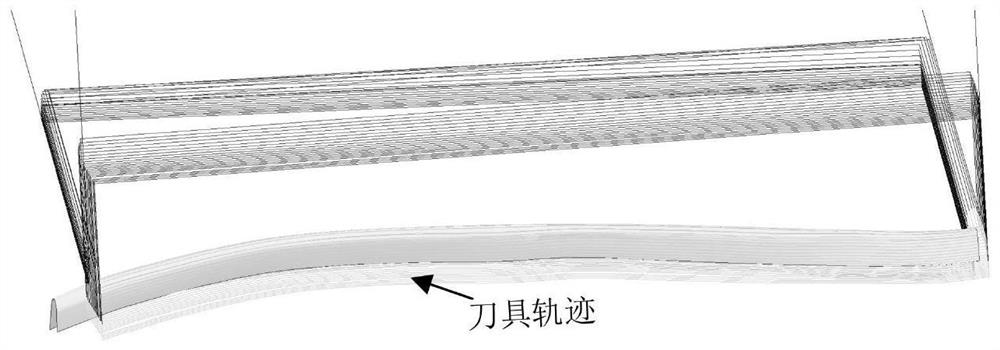

Narrow and long type free-form surface part machining track self-adaptive generation method

ActiveCN112255966AImprove processing potentialImprove machining accuracyNumerical controlEngineeringRadius of curvature

The invention discloses a narrow and long type free-form surface part machining track self-adaptive generation method, which comprises the following steps of: constructing a part free-form surface equal-U-height section line set in the length U direction of a part free-form surface, performing lofting through the line set to regenerate a curved surface again, and comparing the deviation of the regenerated curved surface with a given tolerance; when it is judged that the deviation is smaller than the given tolerance, solving the arc length value and the curvature radius minimum value of each section line of the regenerated curved surface, selecting the section cmax with a maximum ratio of the arc length to the line spacing of the regenerated curved surface, calculating a corresponding tangent contact set on the cmax, and conducting point distribution on each section line of the regenerated curved surface through an equal chord height difference method; according to the projection pointset corresponding to the tangent contact set on the maximum section line on the offset curved surface, discretizing each section line on an equal V parameter line to obtain each discrete point set, and further obtaining the machining track of the machining curved surface of the part; according to the invention, the problems of poor adaptability, strong manual intervention, unsmooth planning track,self-intersection and the like of the planning method in the prior art are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com