Patents

Literature

56 results about "Percent elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

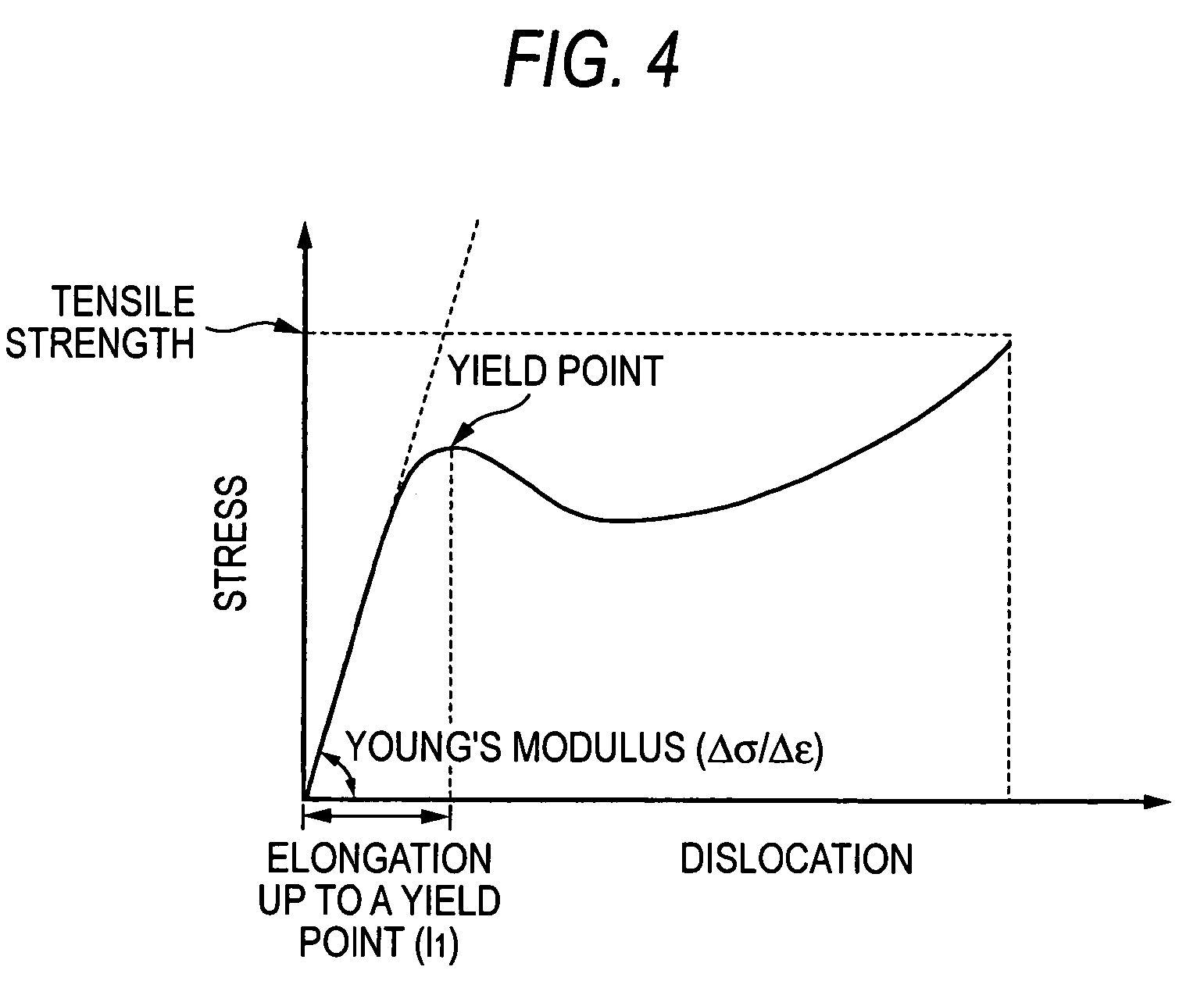

Percent elongation is a measurement that captures the amount a material will plastically and elastically deform up to fracture. Percent elongation is one way to measure and quantify the ductility of a material. The material's final length is compared with its original length to determine the percent elongation and the material’s ductility.

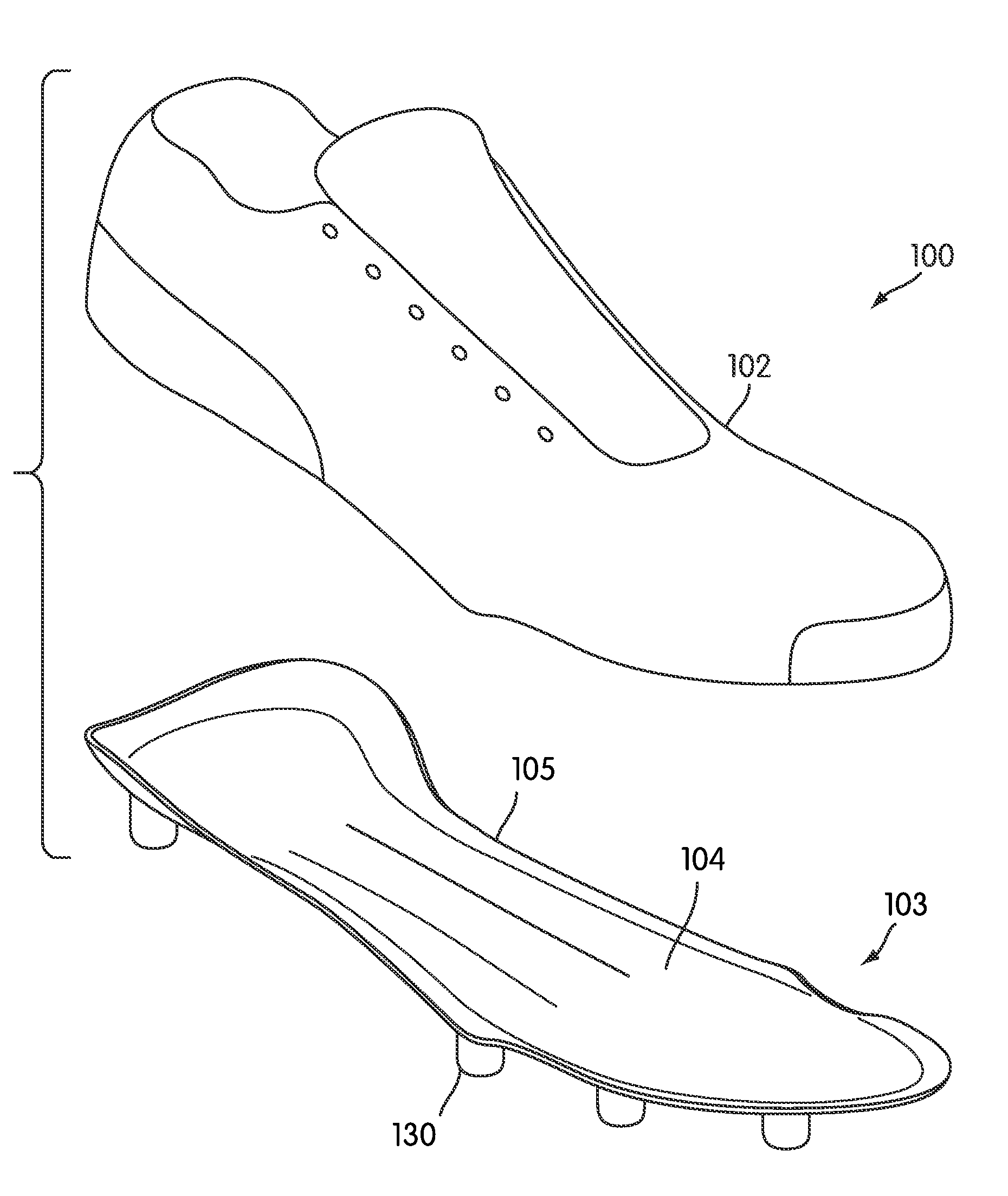

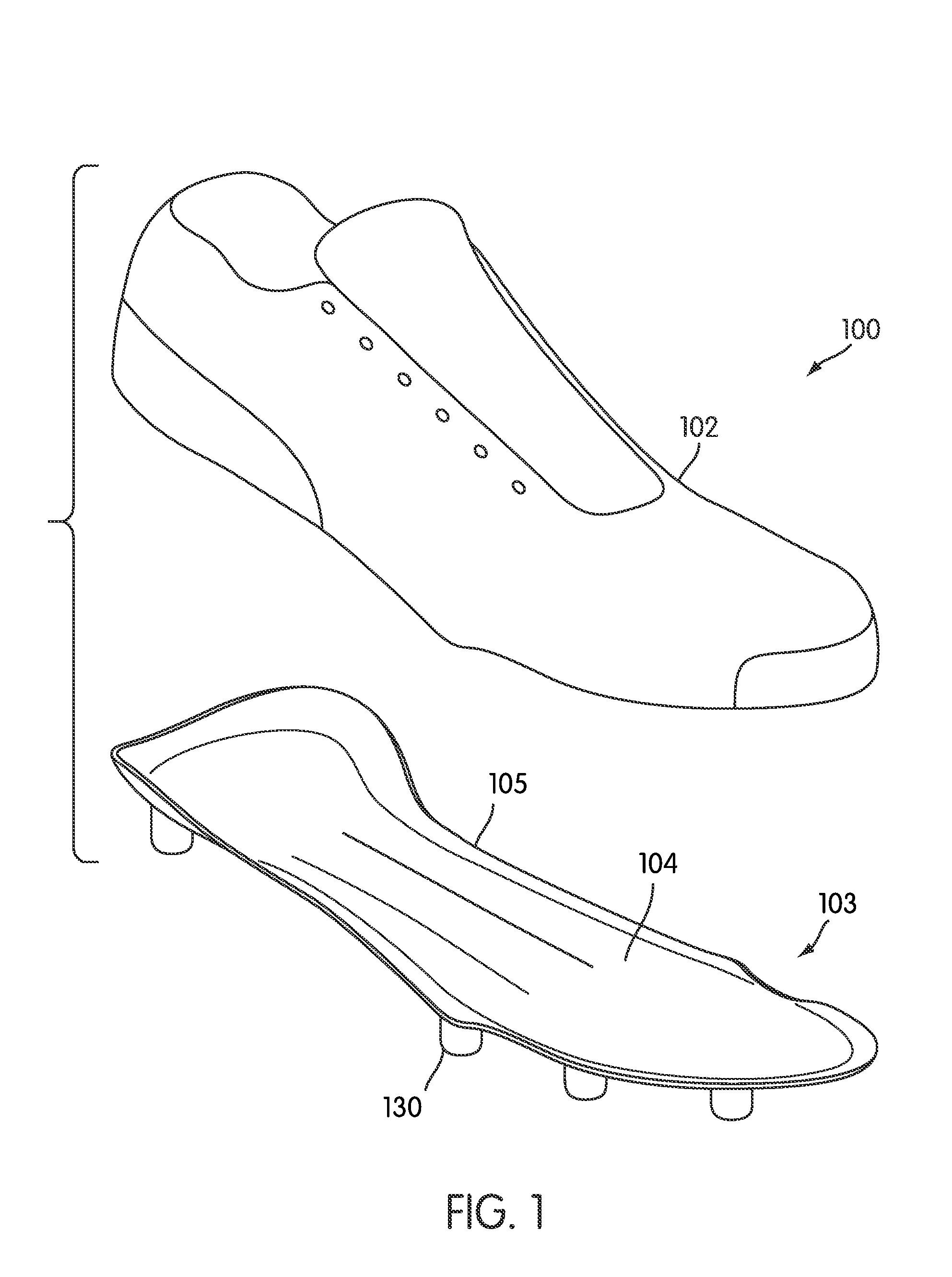

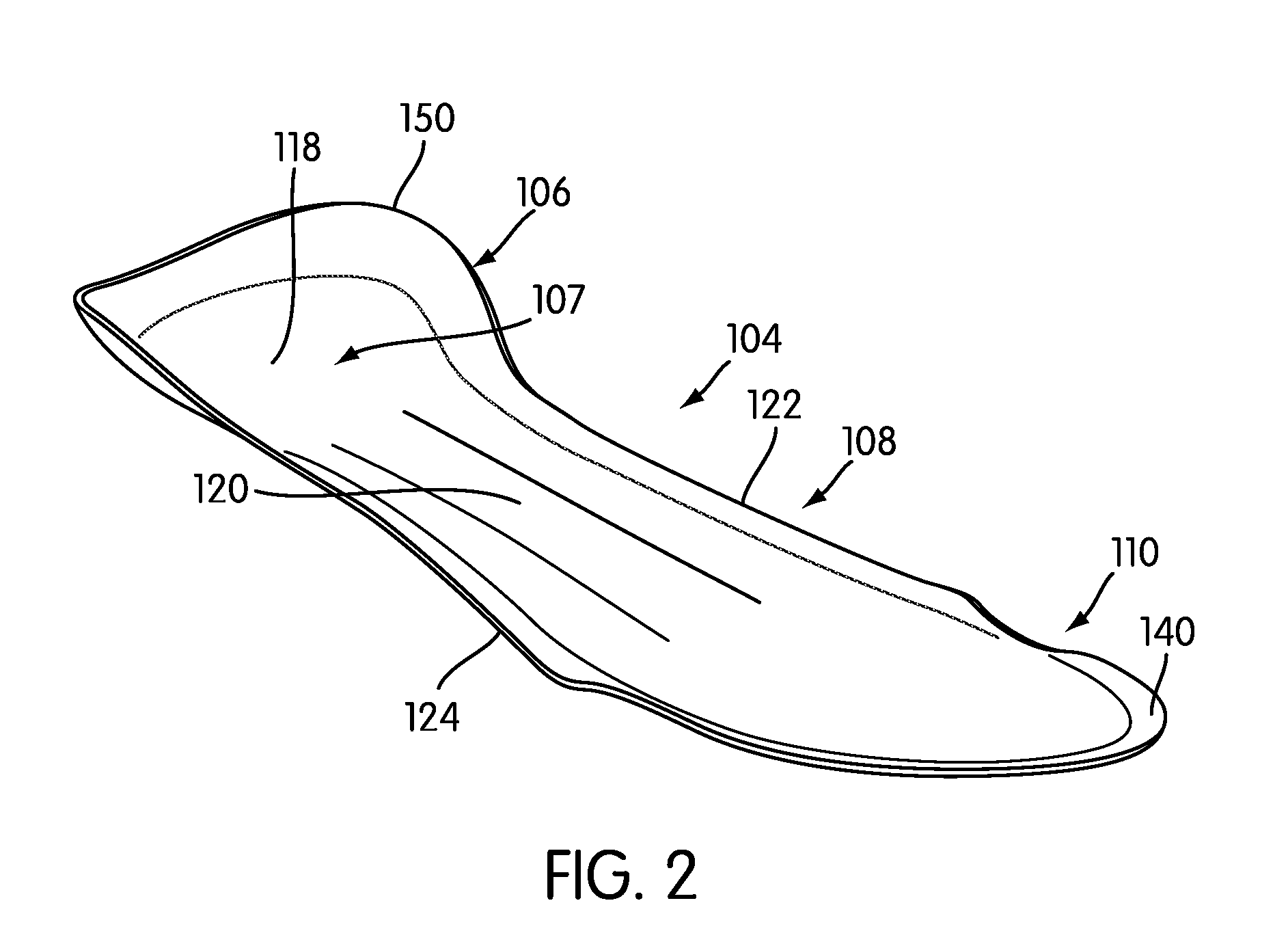

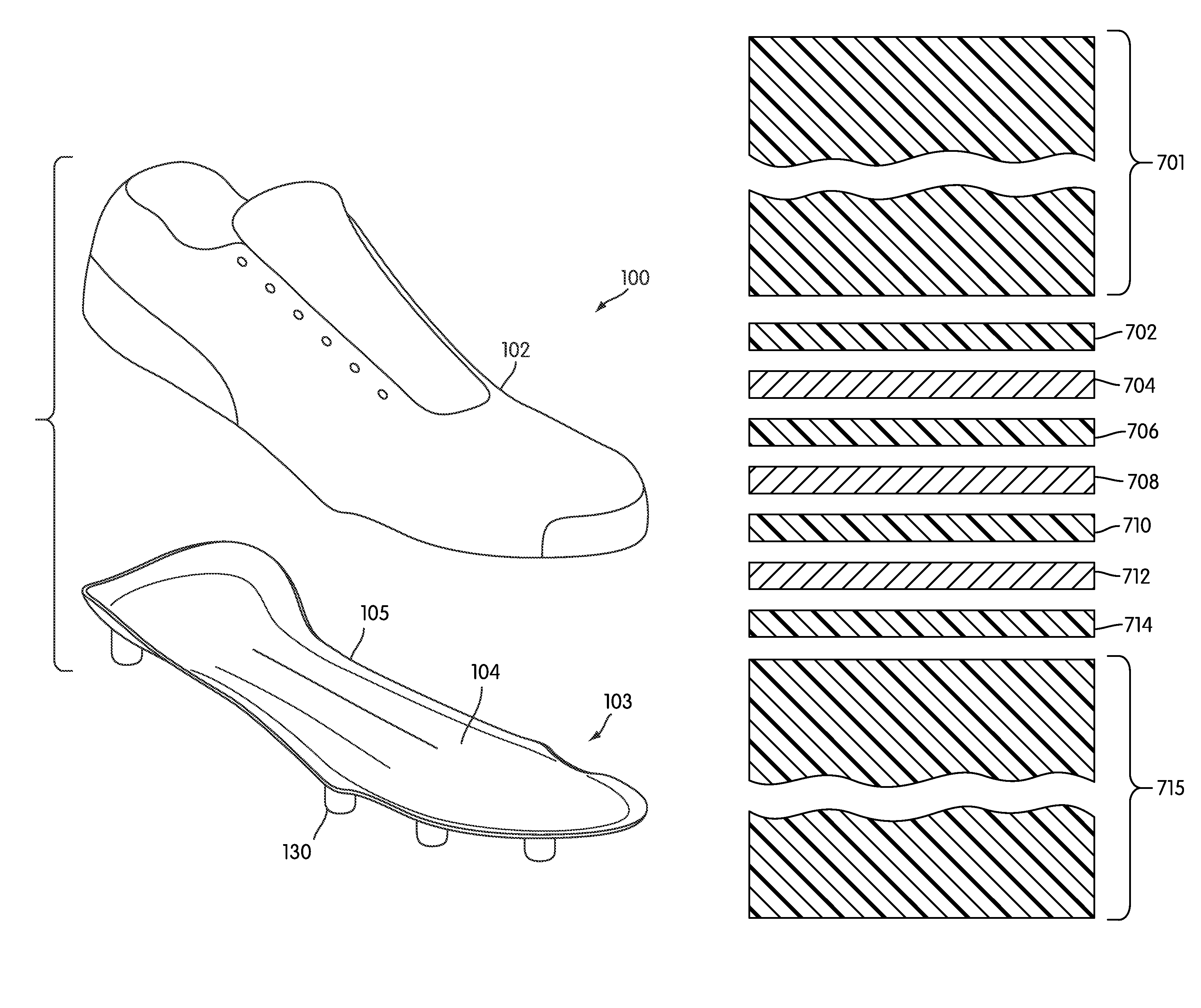

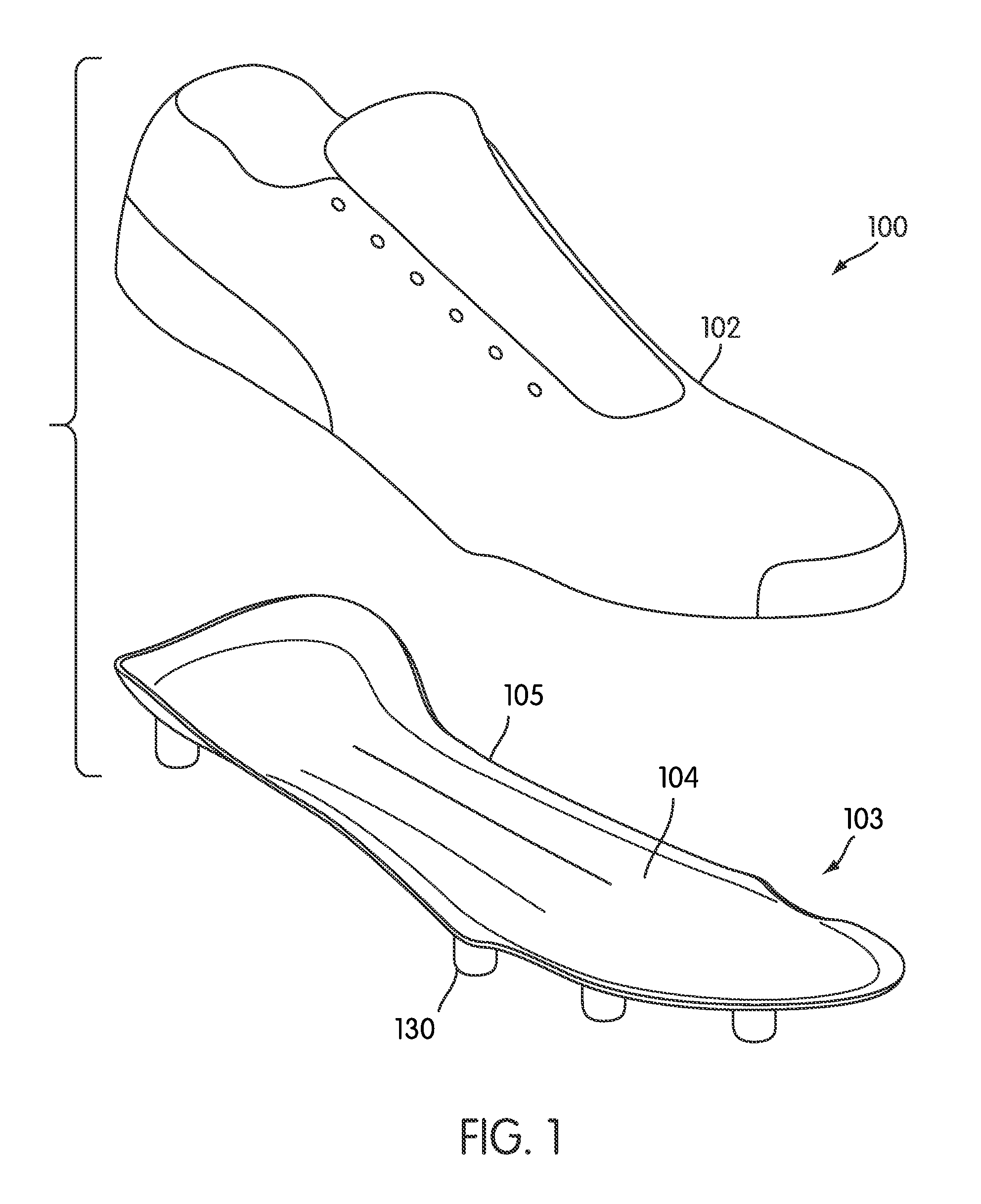

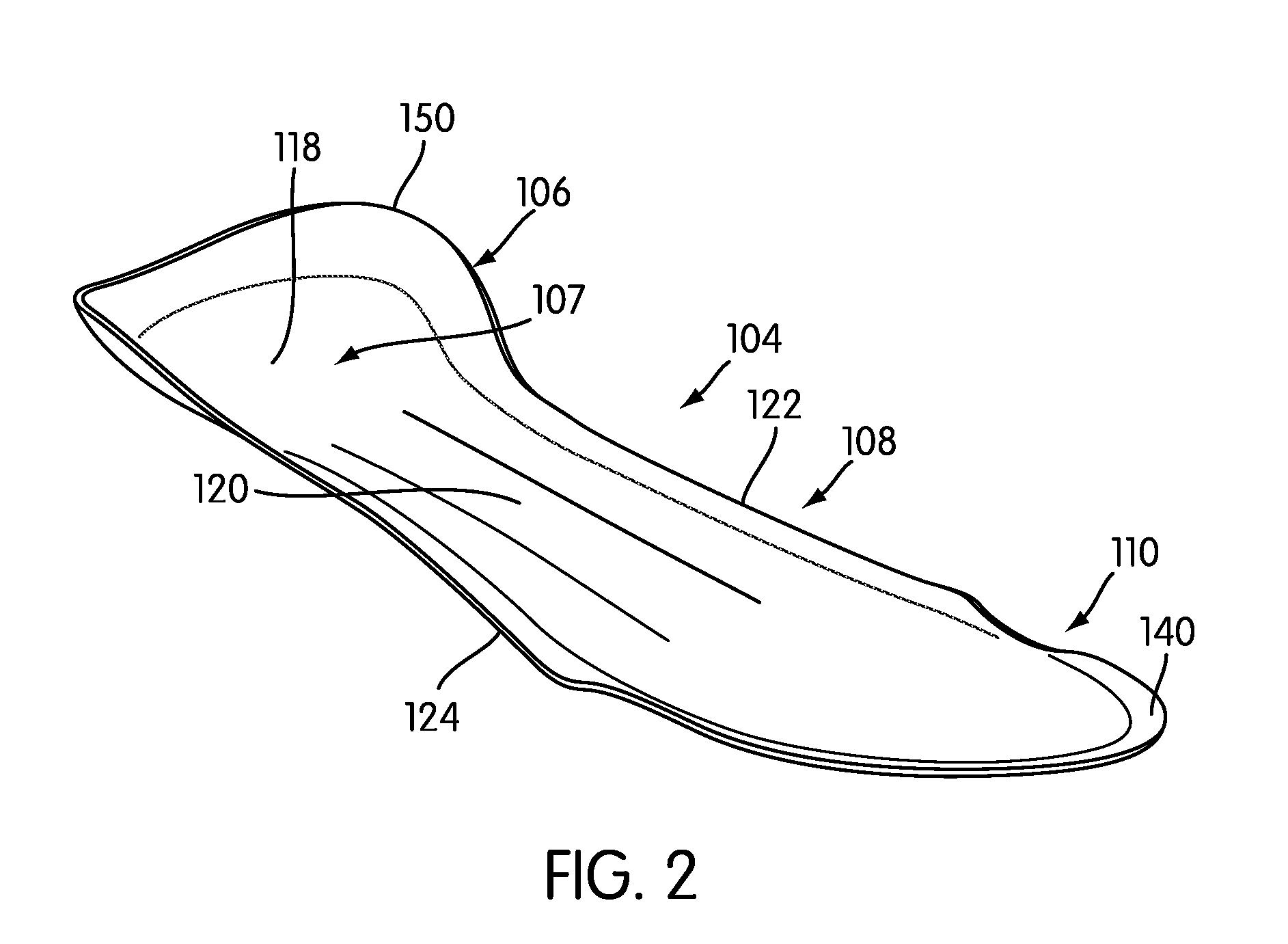

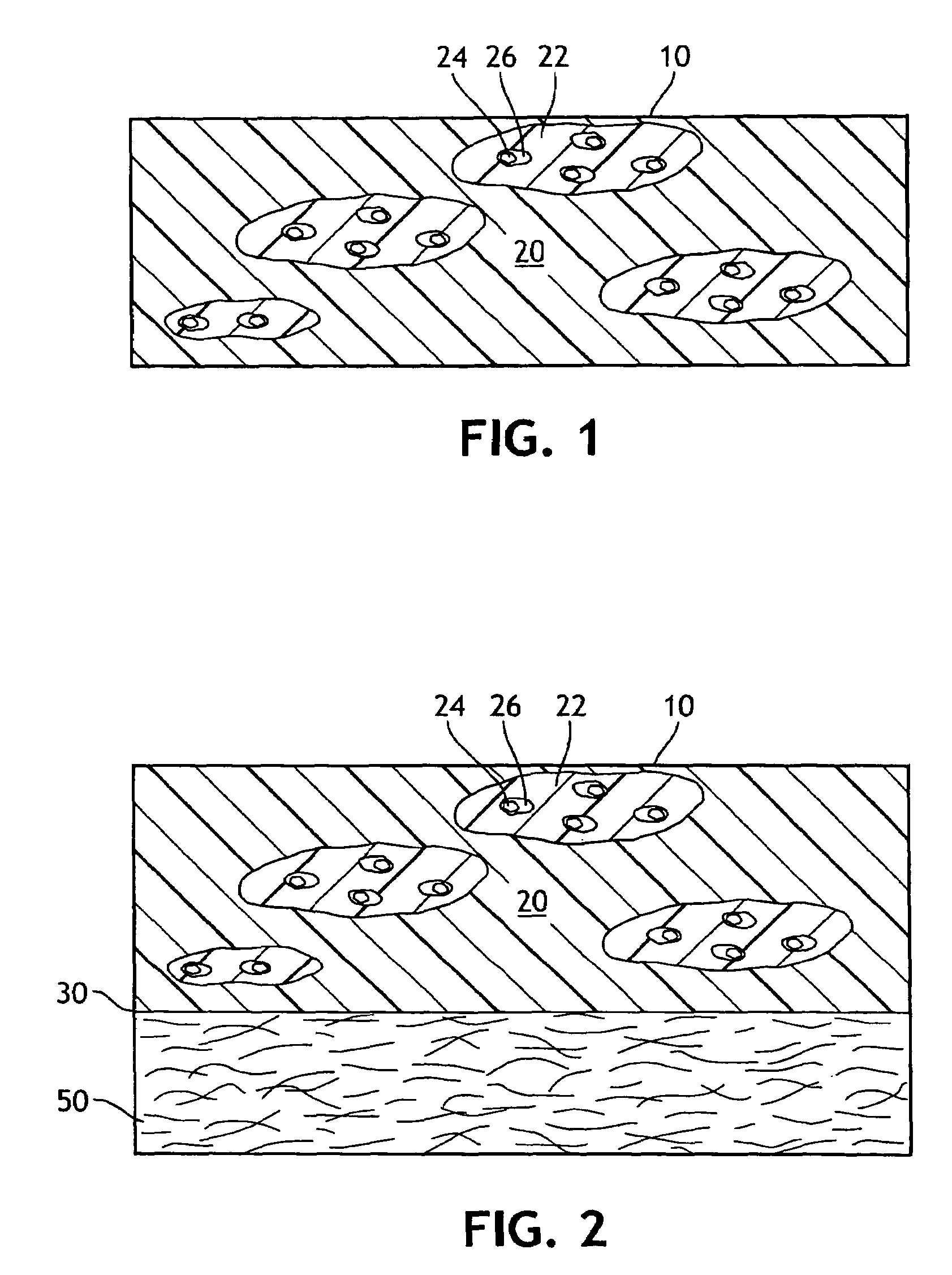

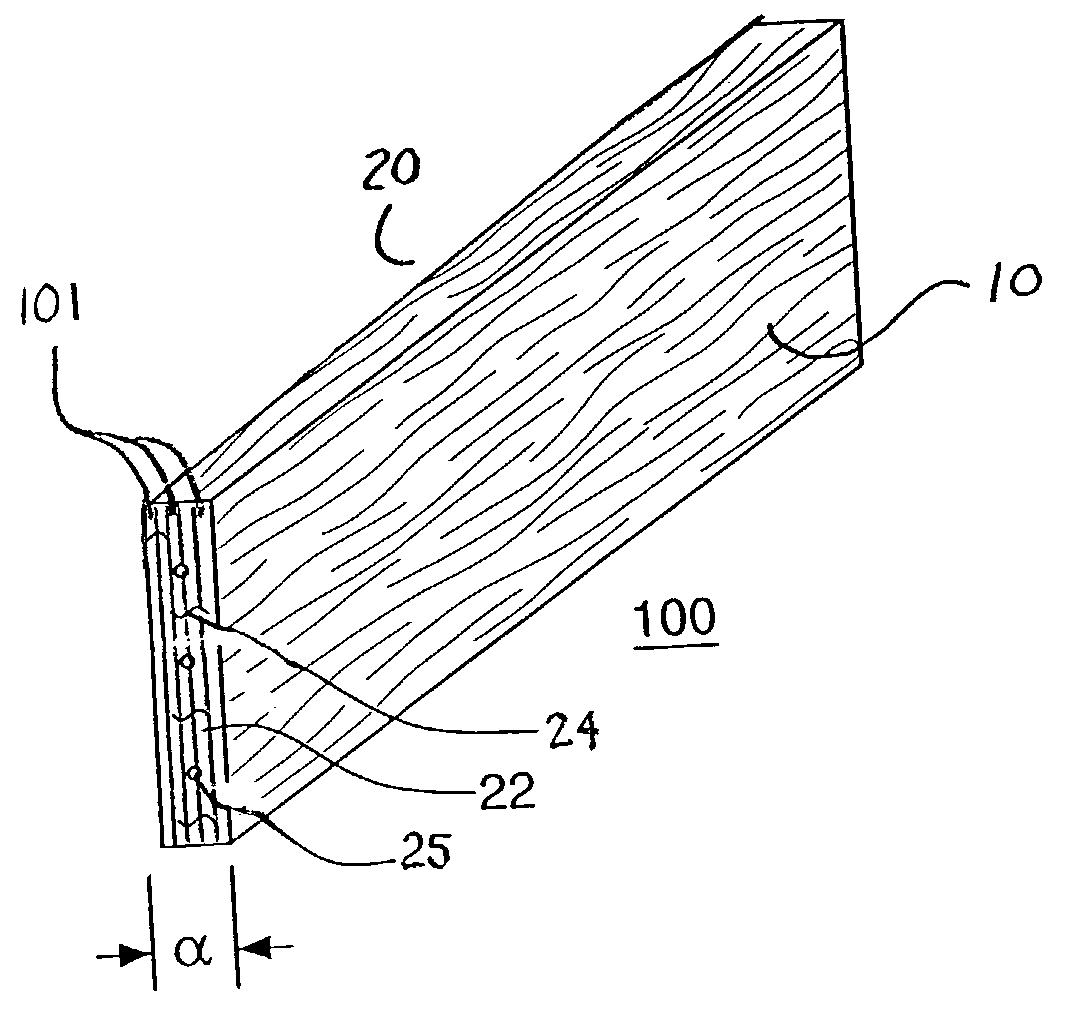

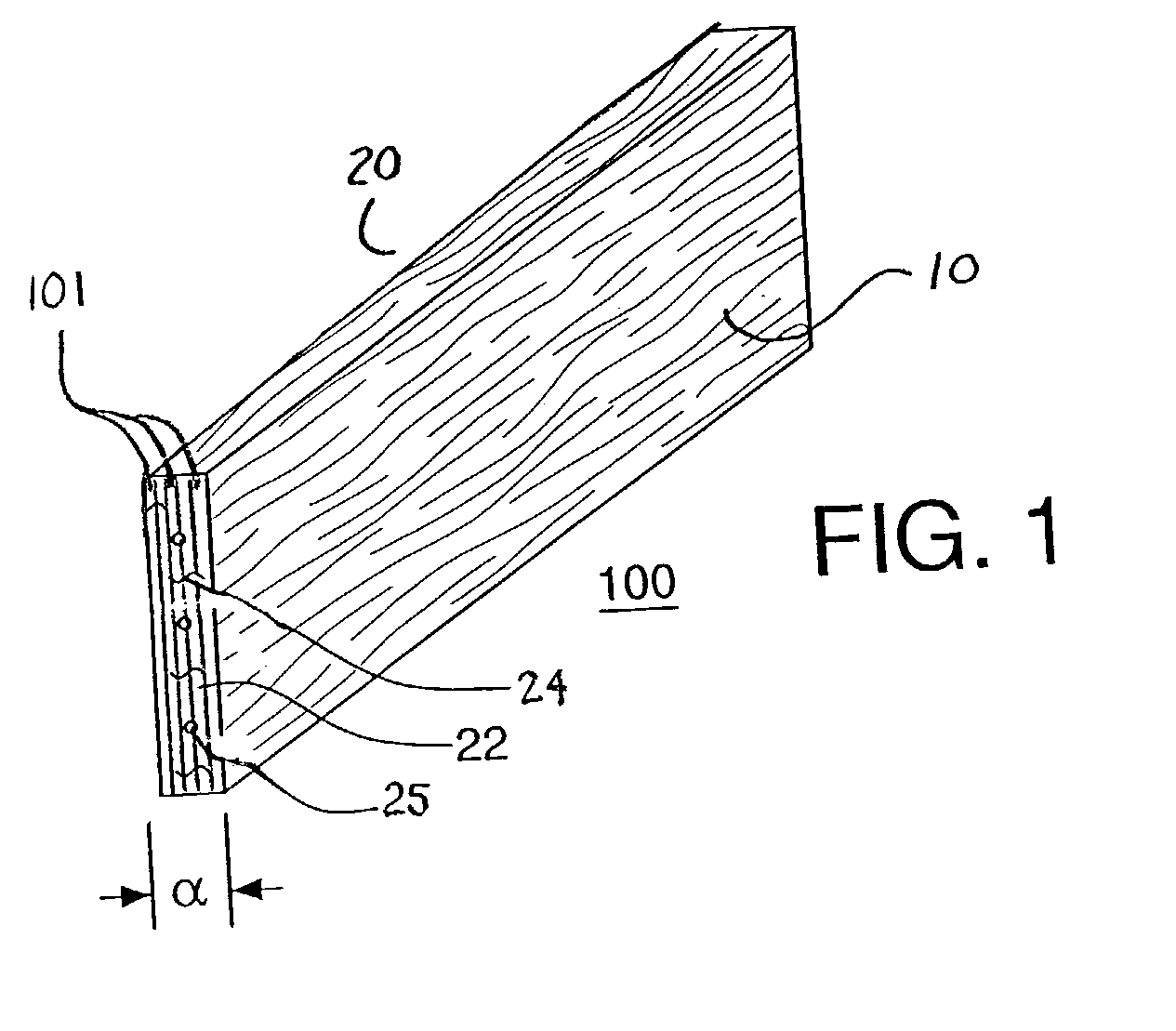

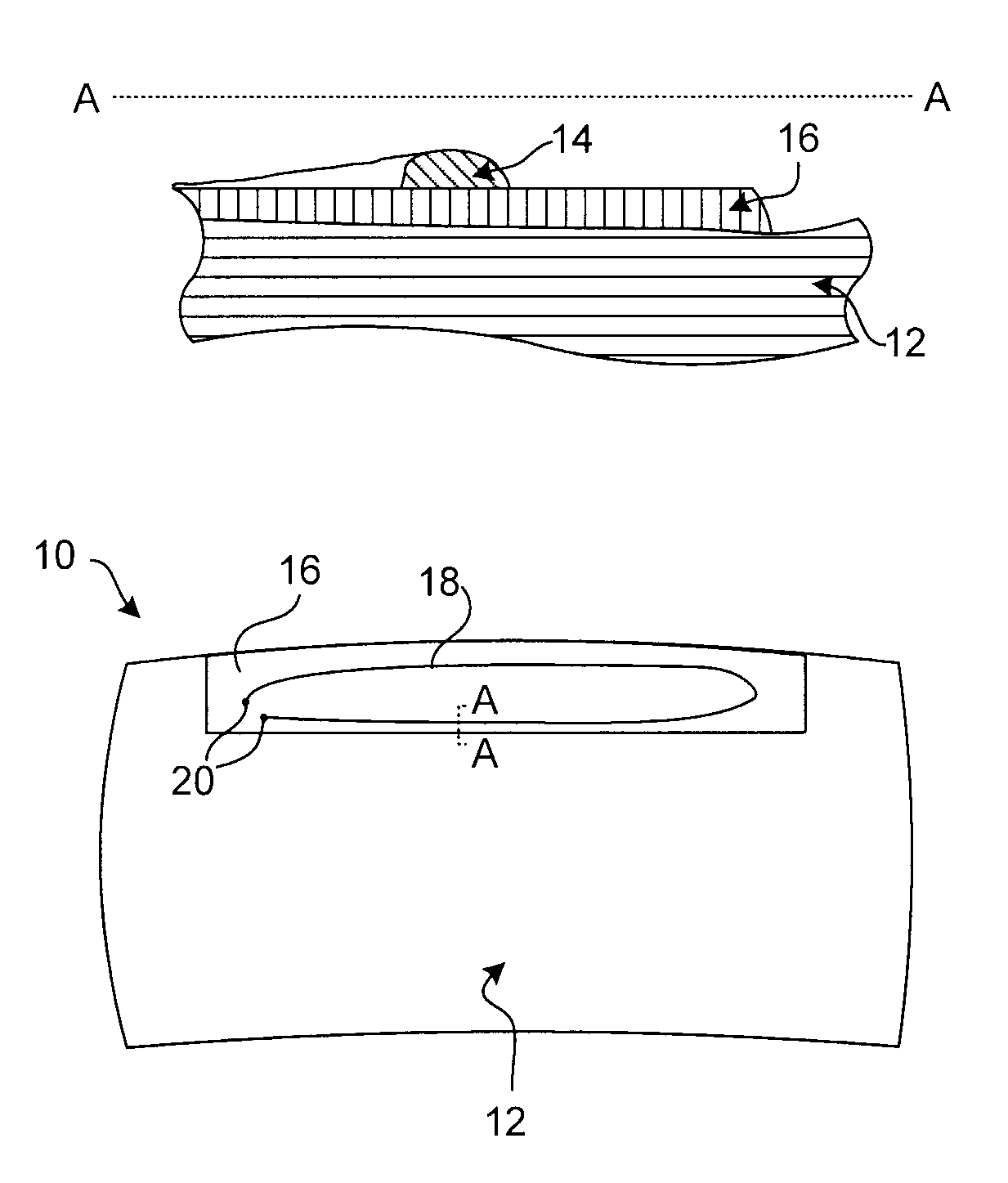

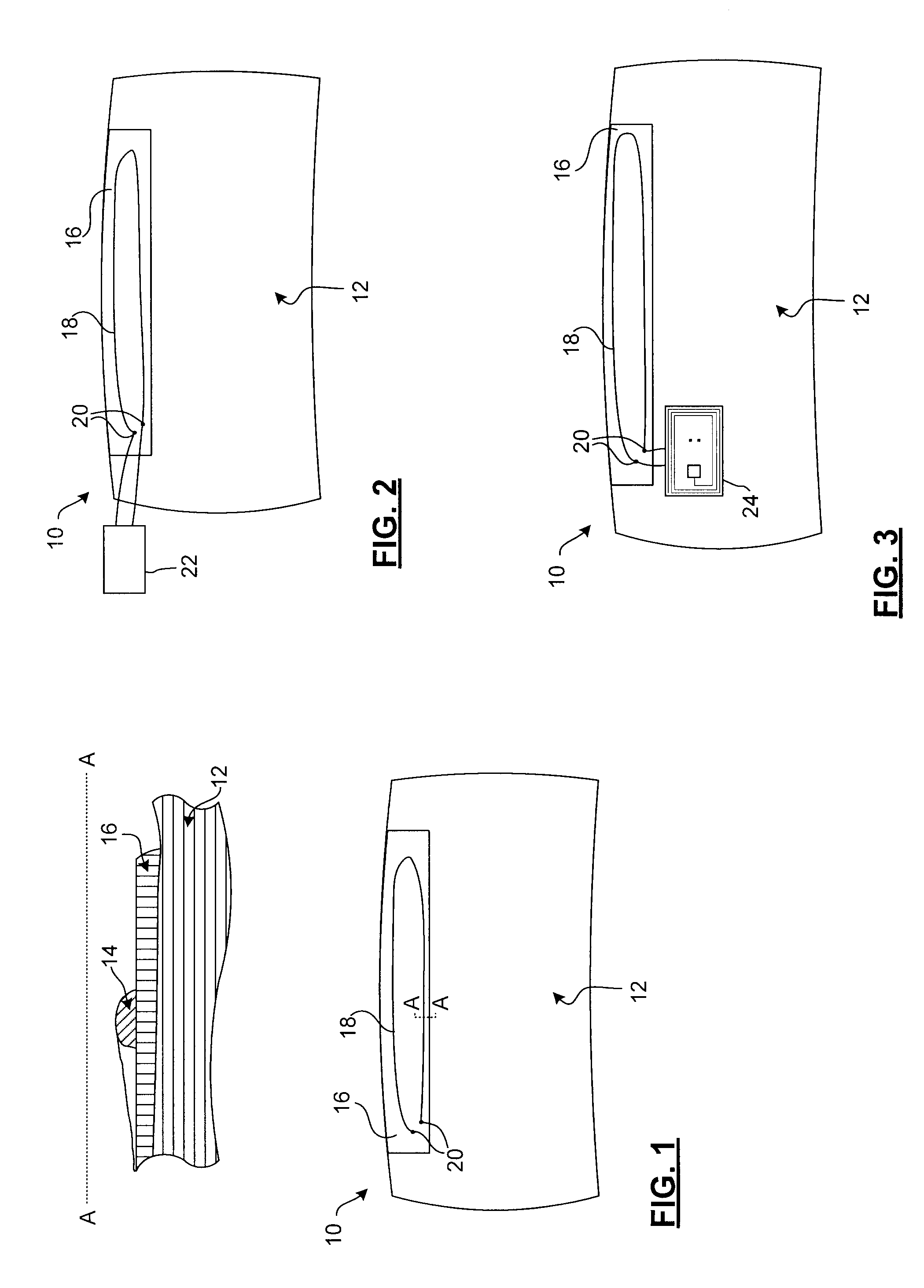

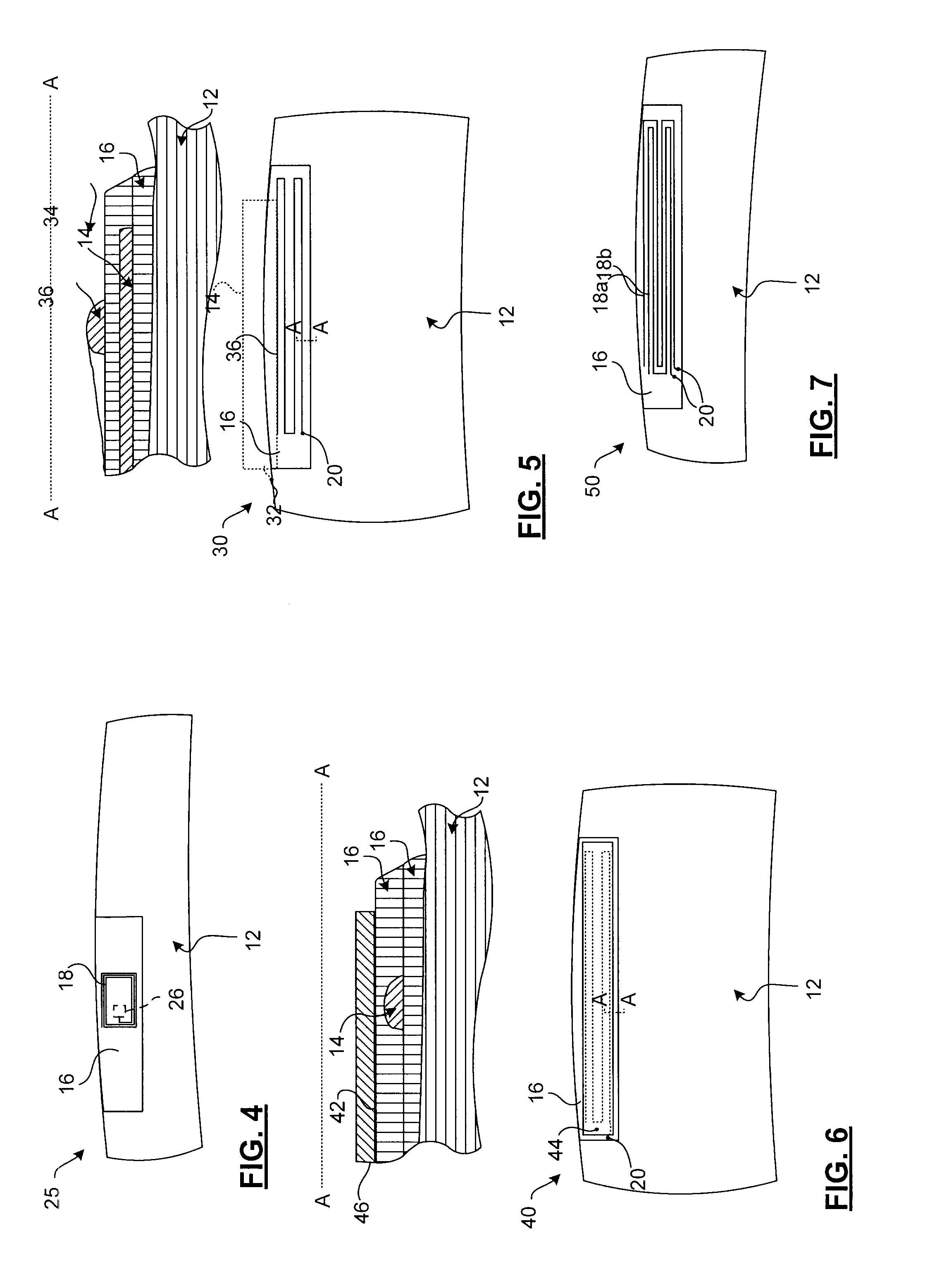

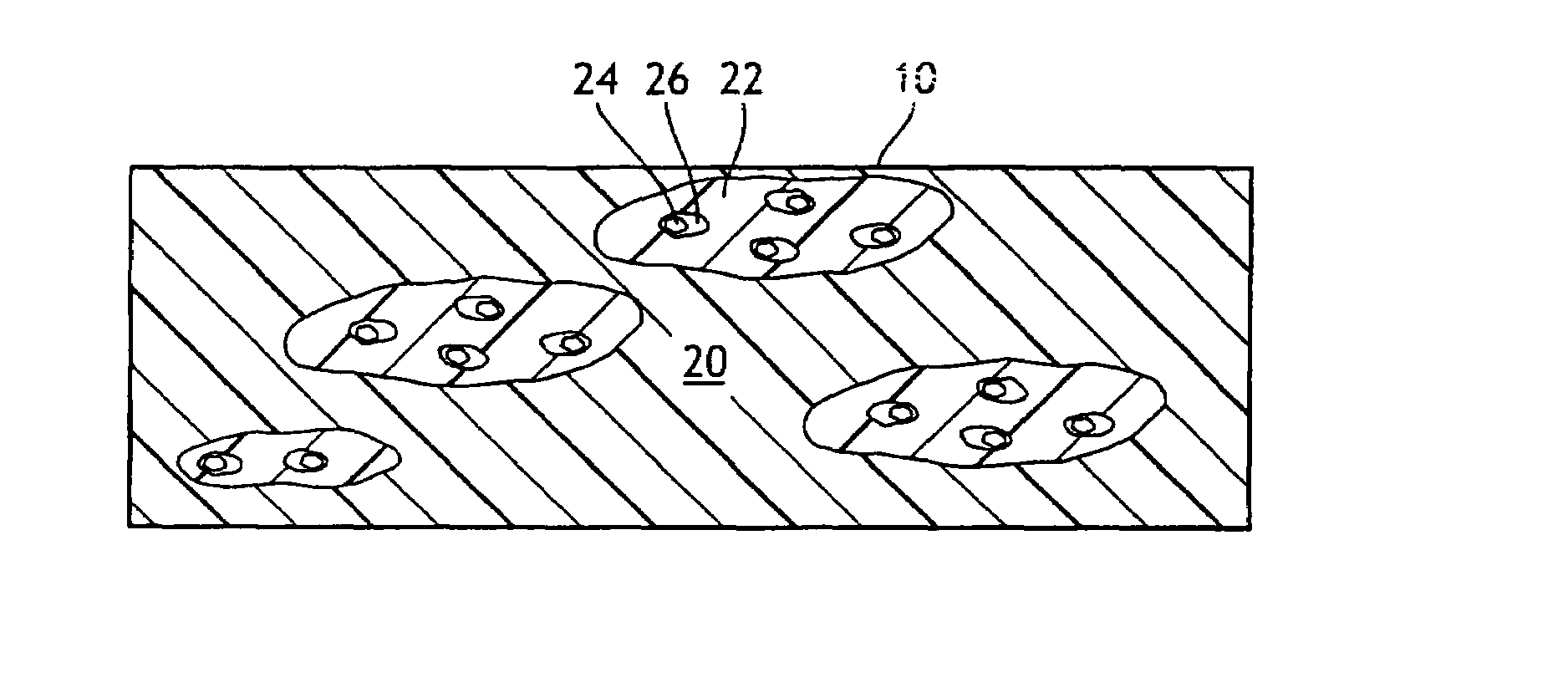

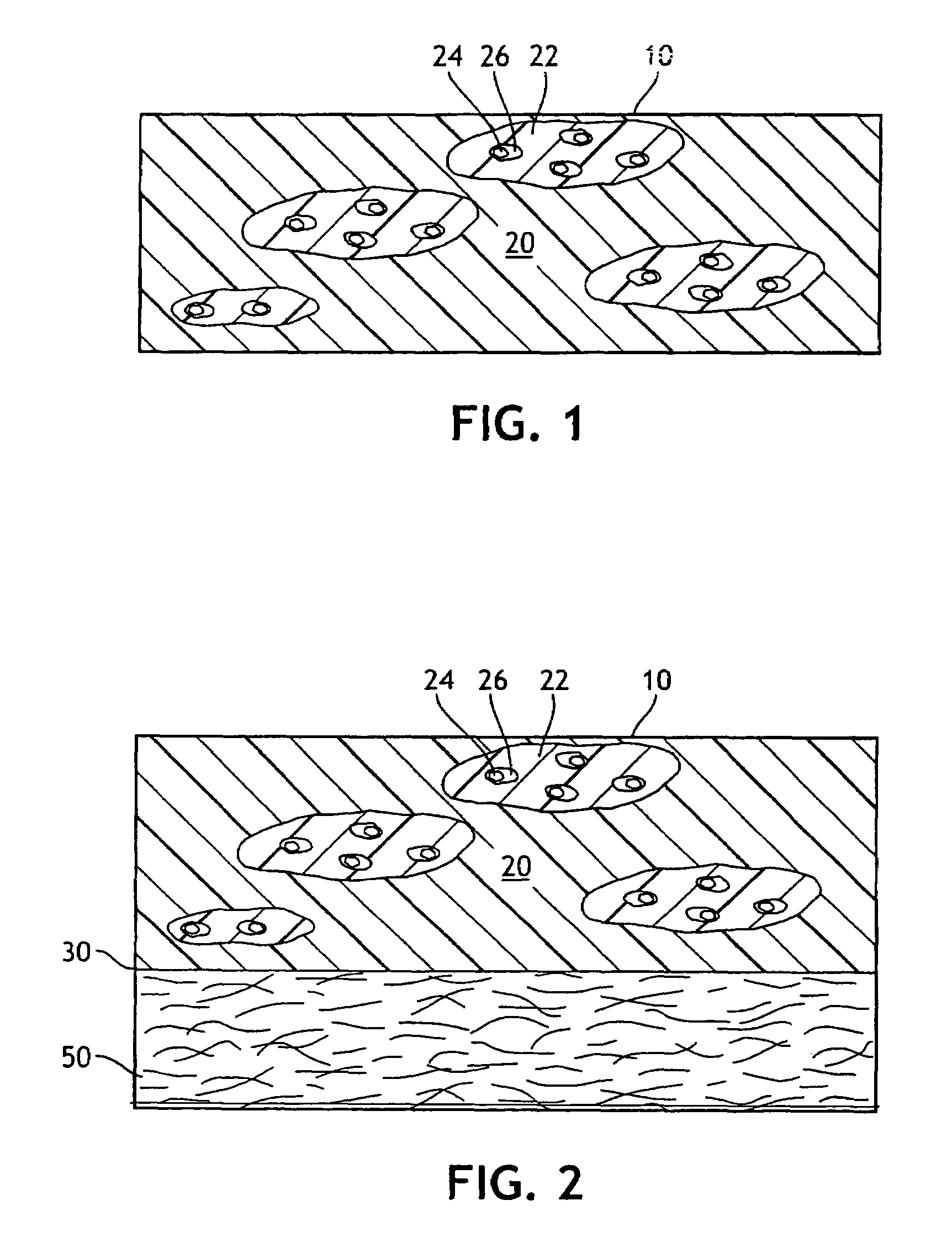

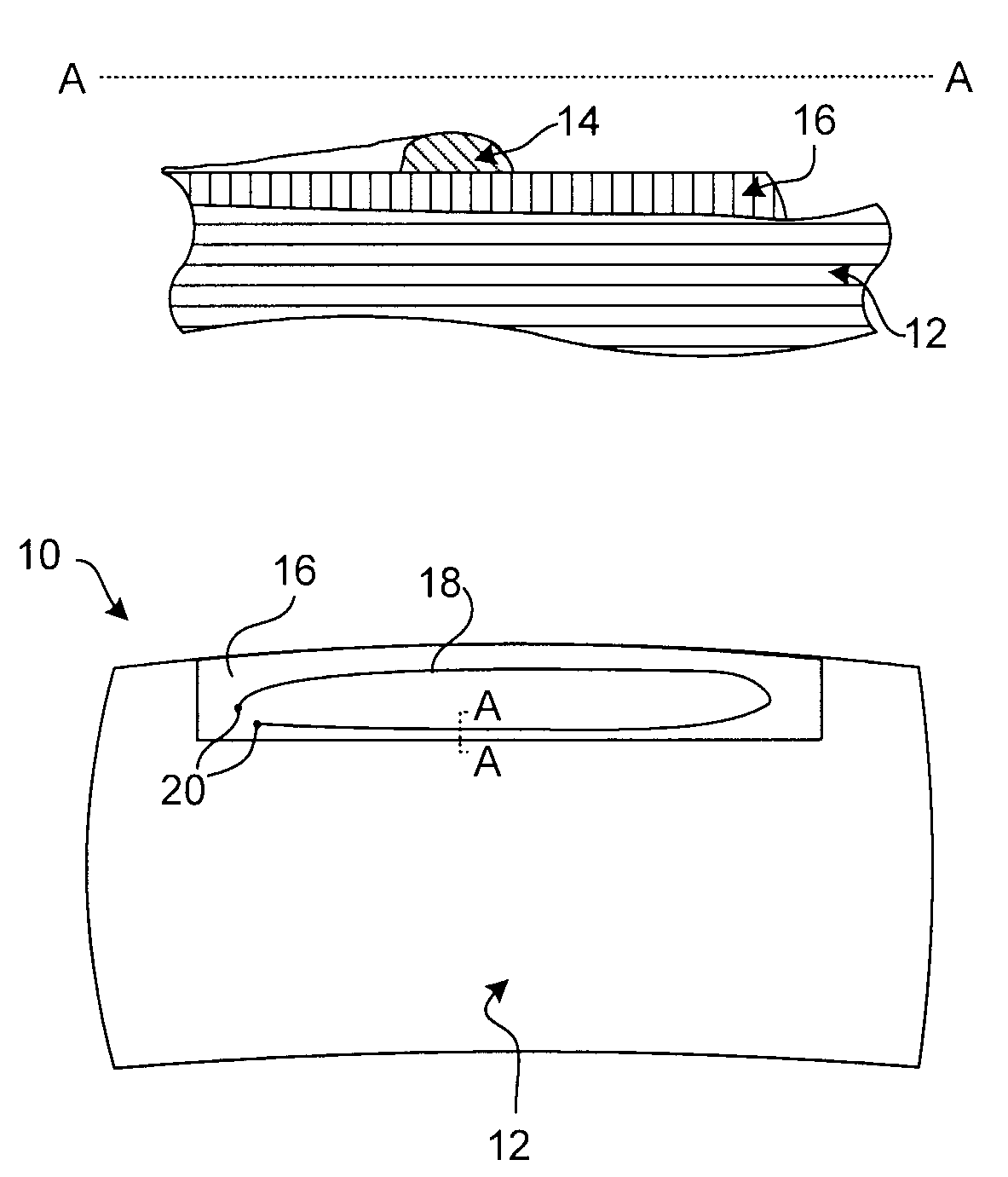

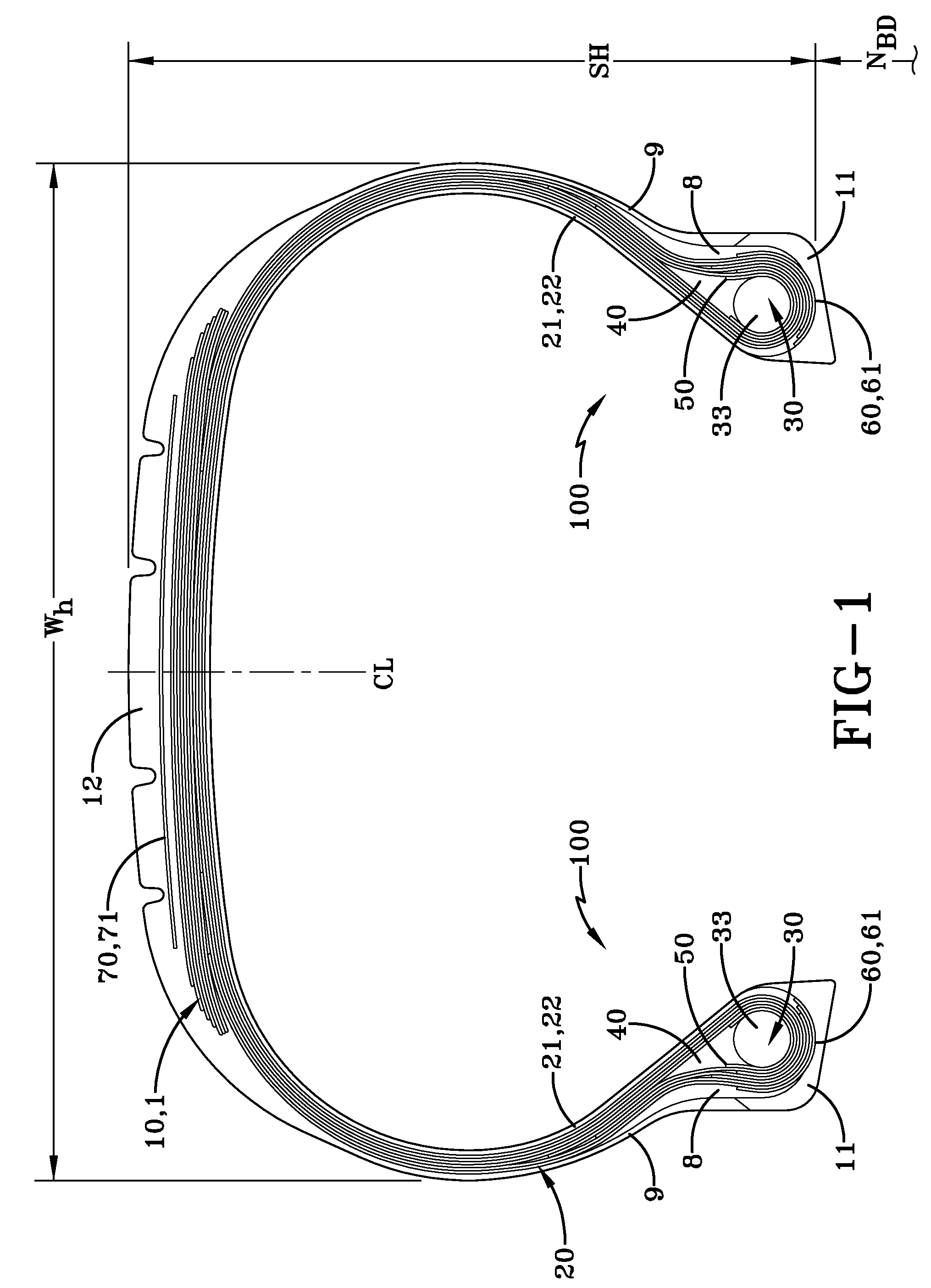

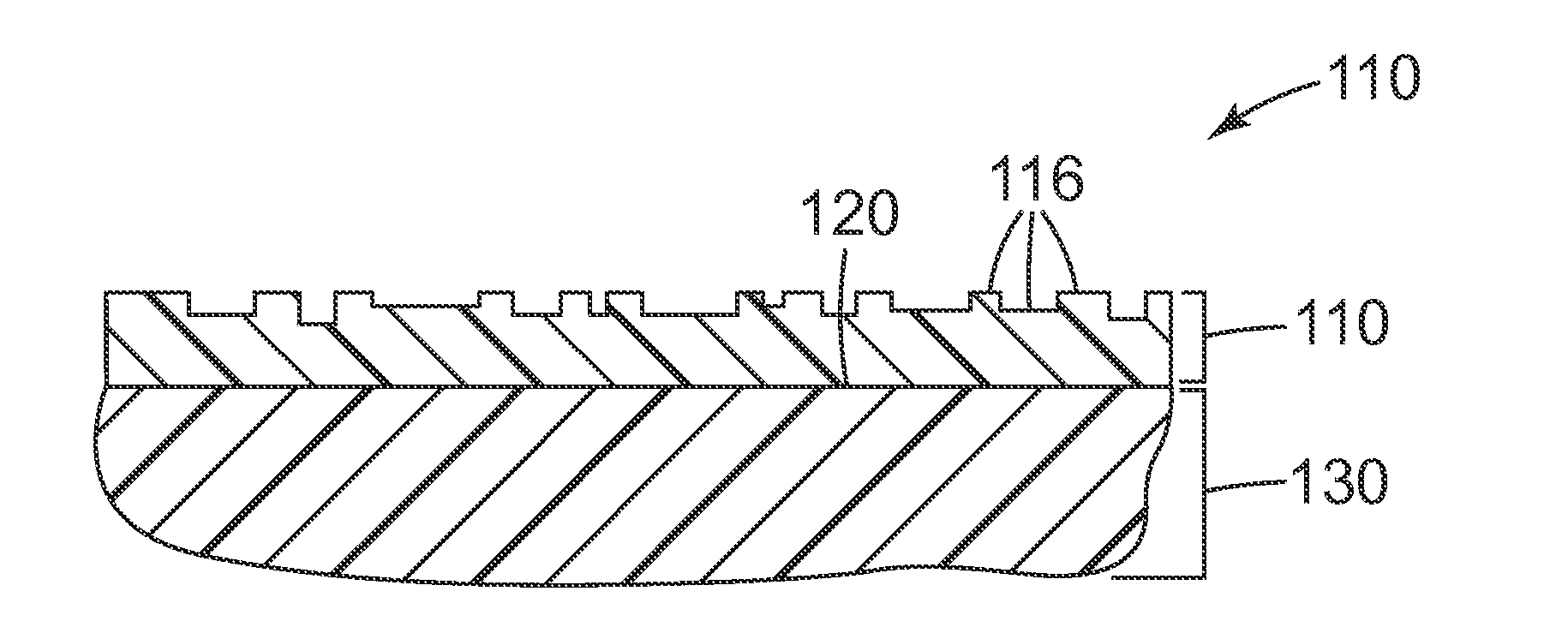

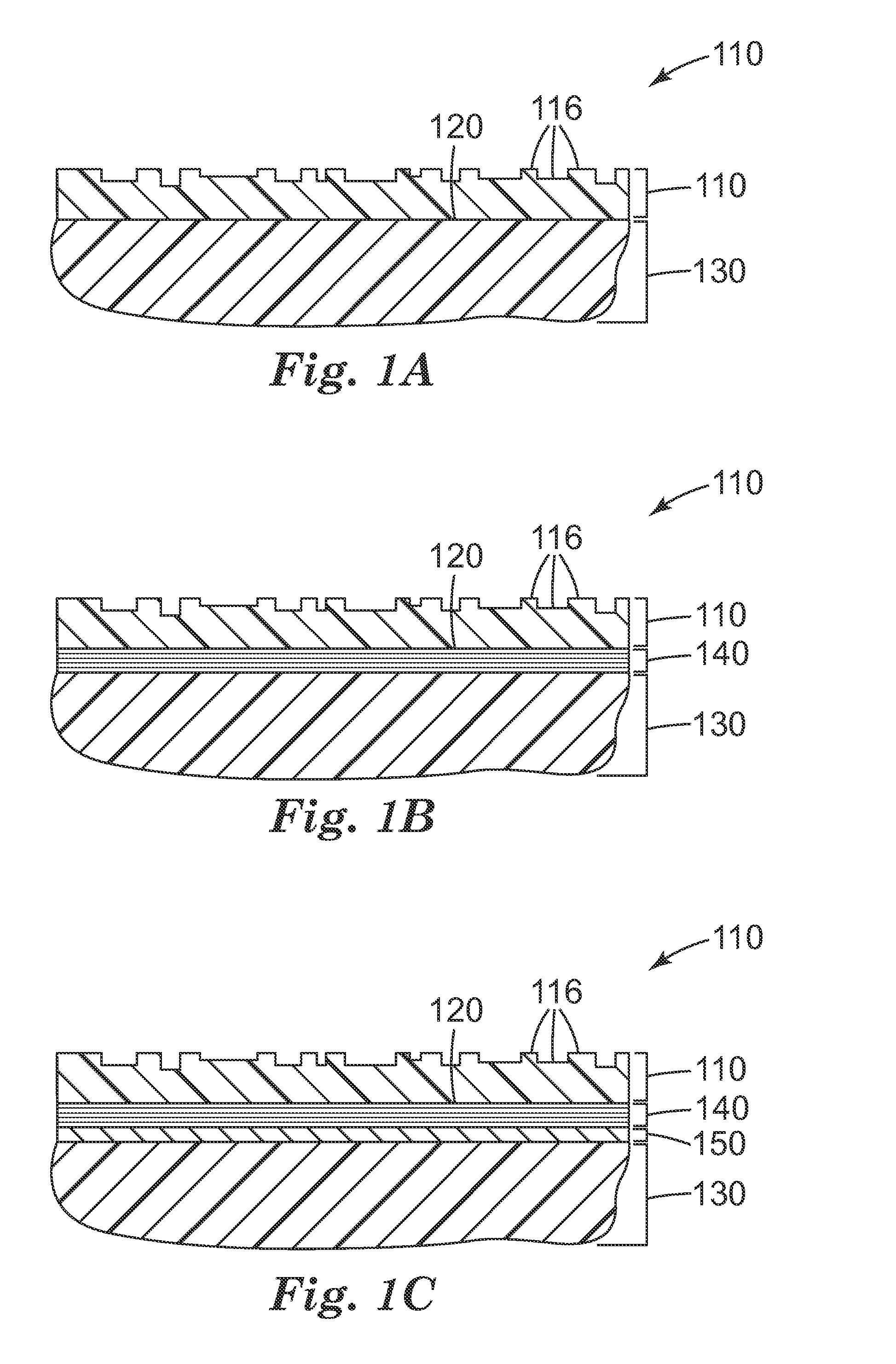

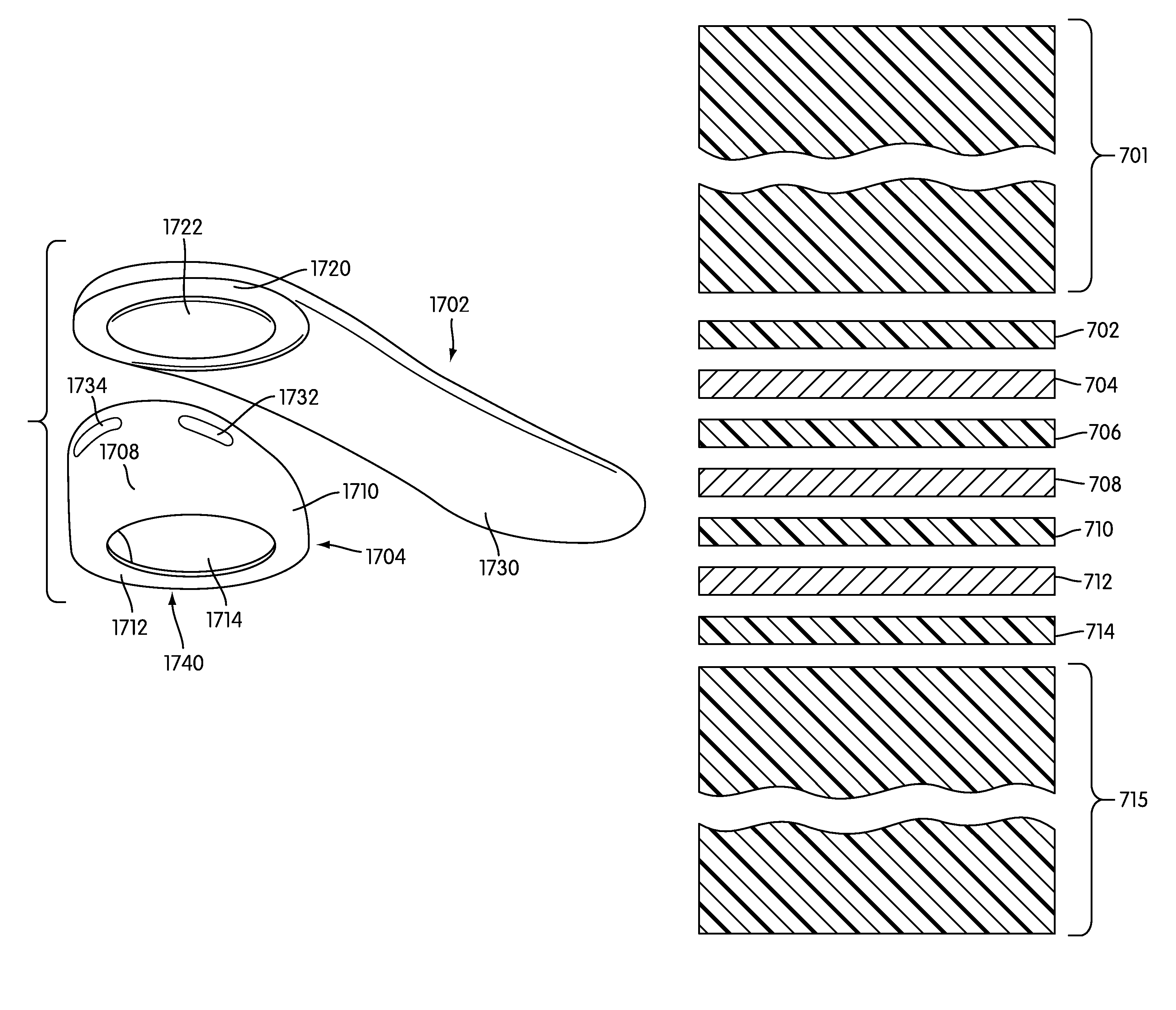

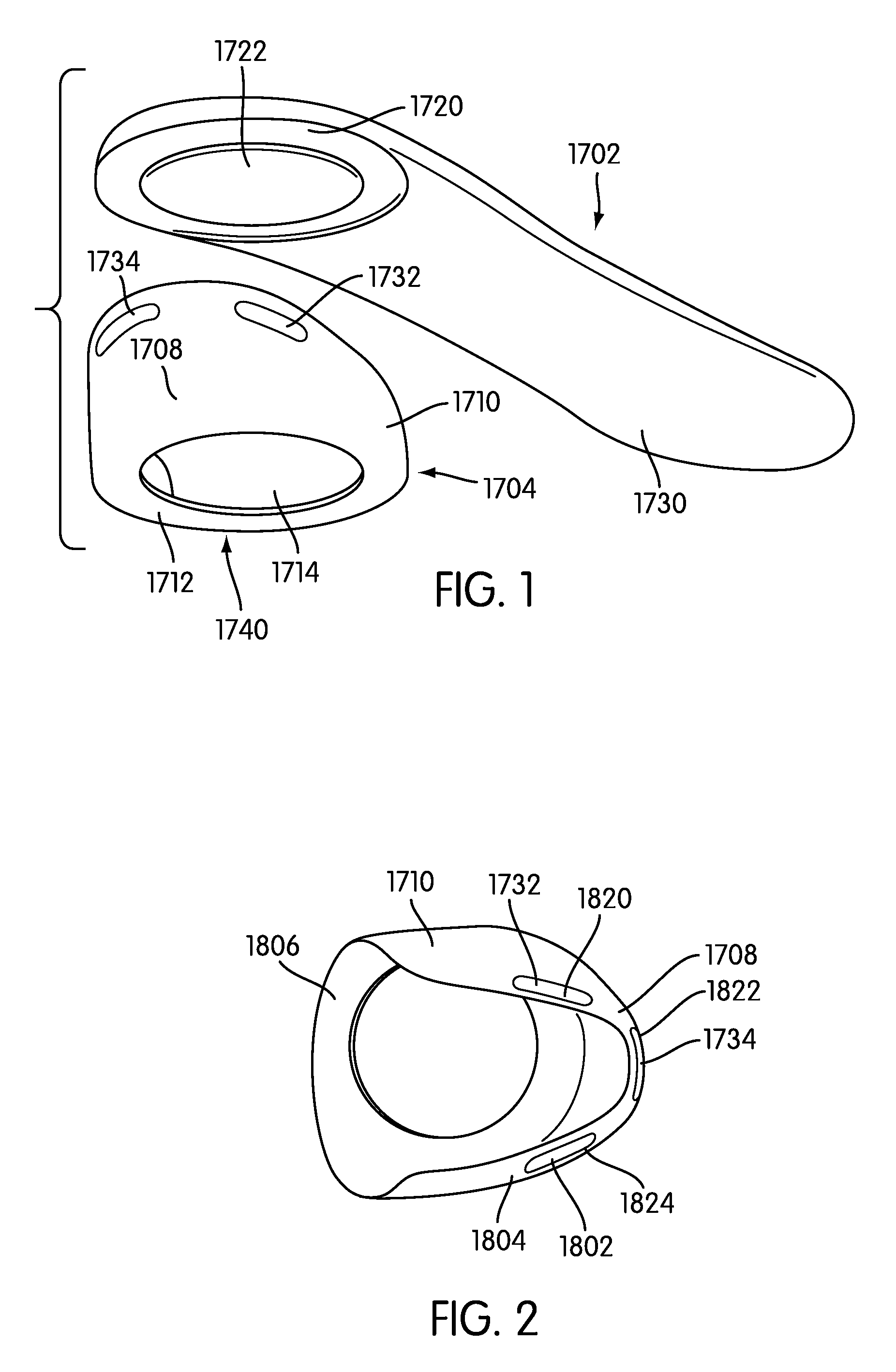

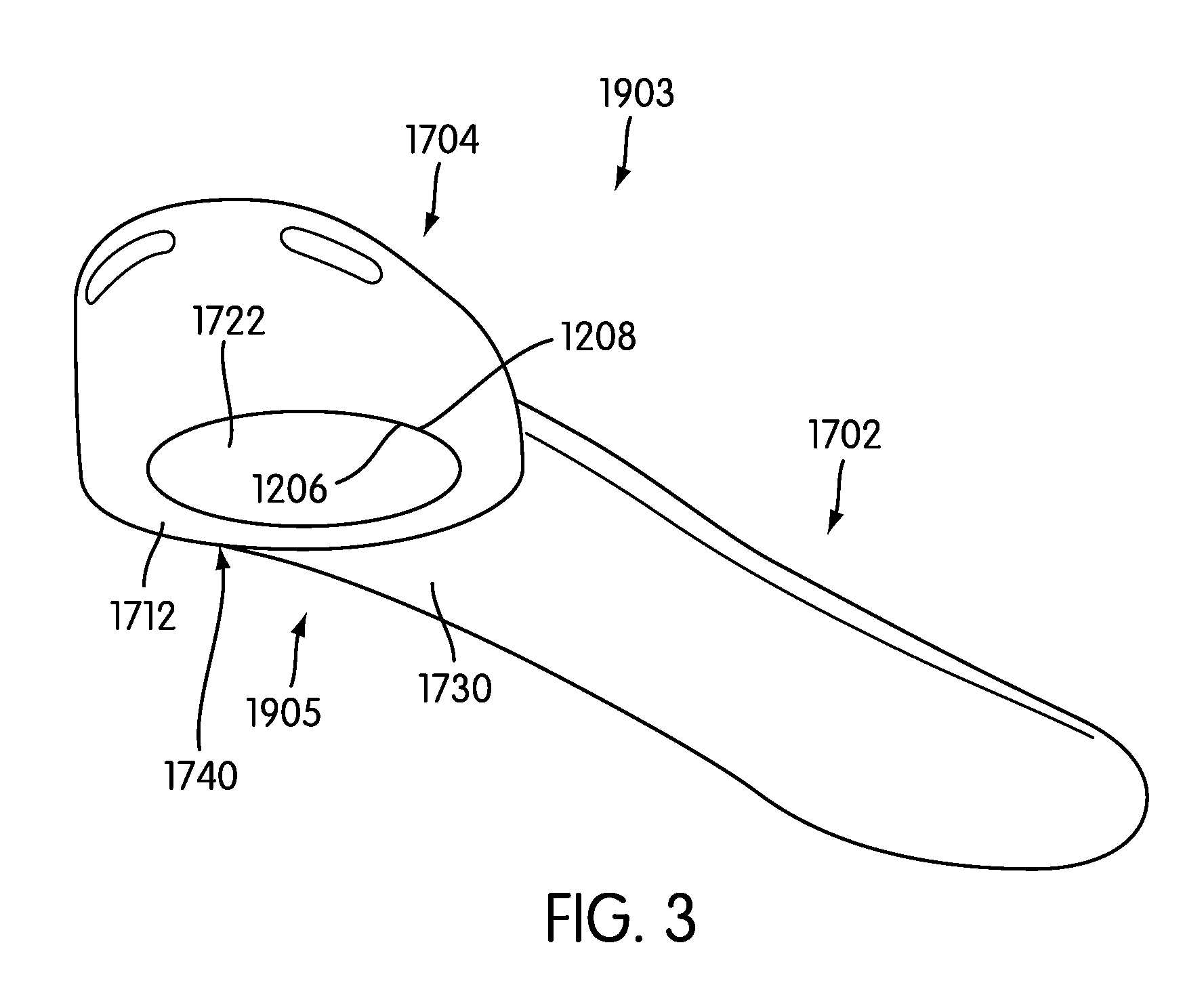

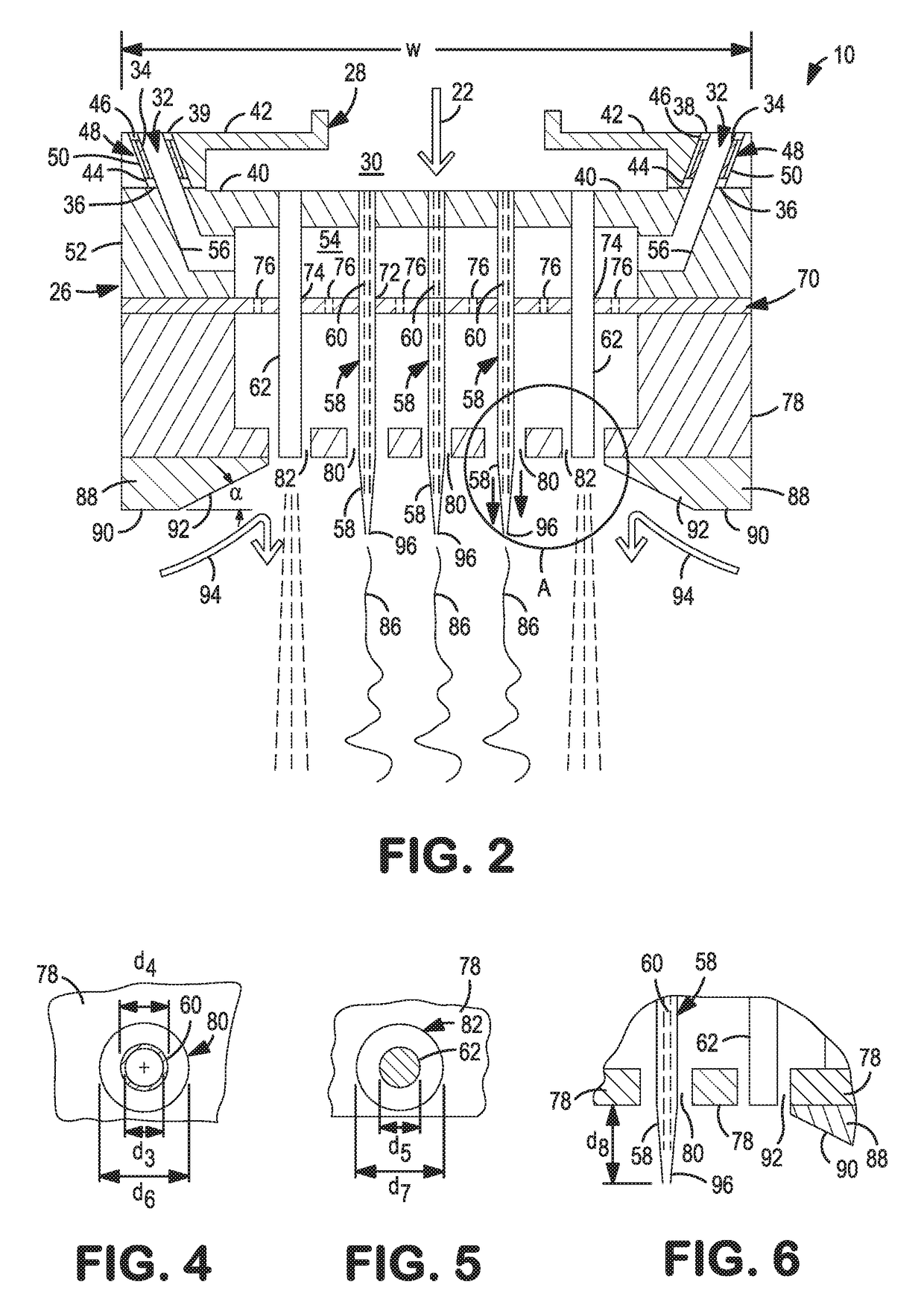

Article of Footwear Including Full Length Composite Plate

A full length composite plate to be used as part of an outsole assembly in an article of footwear is disclosed. The full length composite plate comprises a composite material that has a certain percent elongation. The full length composite plate can include a heel cup for heel stability and improved traction. The full length composite plate also can include two angled portions along an arch region that provide arch support, as well as two flattened edges along the arch region to minimize or eliminate buckling. The forefoot region can be relatively flatter than the arch and heel regions, and notches are preferably included along a portion of the forefoot to increase flexibility.

Owner:NIKE INC

Article of footwear including full length composite plate

A full length composite plate to be used as part of an outsole assembly in an article of footwear is disclosed. The full length composite plate comprises a composite material that has a certain percent elongation. The full length composite plate can include a heel cup for heel stability and improved traction. The full length composite plate also can include two angled portions along an arch region that provide arch support, as well as two flattened edges along the arch region to minimize or eliminate buckling. The forefoot region can be relatively flatter than the arch and heel regions, and notches are preferably included along a portion of the forefoot to increase flexibility.

Owner:NIKE INC

Microporous breathable elastic films, methods of making same, and limited use or disposable product applications

InactiveUS20050043460A1Improve breathabilityLamination ancillary operationsSynthetic resin layered productsElastomerThermoplastic elastomer

A thermoplastic elastomer film includes a thermoplastic elastomer and a filled semi crystalline predominantly linear polymer. The film includes between about 25 and 70 weight percent filler, between about 5 and 30 by weight percent semi-crystalline linear polymer, and between about 15 and 60 by weight elastomer. The filler is closely associated with the semi-crystalline linear polymer. The elastic film demonstrates a load loss value at a 50 percent elongation of less than about 50 percent, and a breathability of greater than about 100 g / m2 / 24 hours.

Owner:KIMBERLY-CLARK WORLDWIDE INC

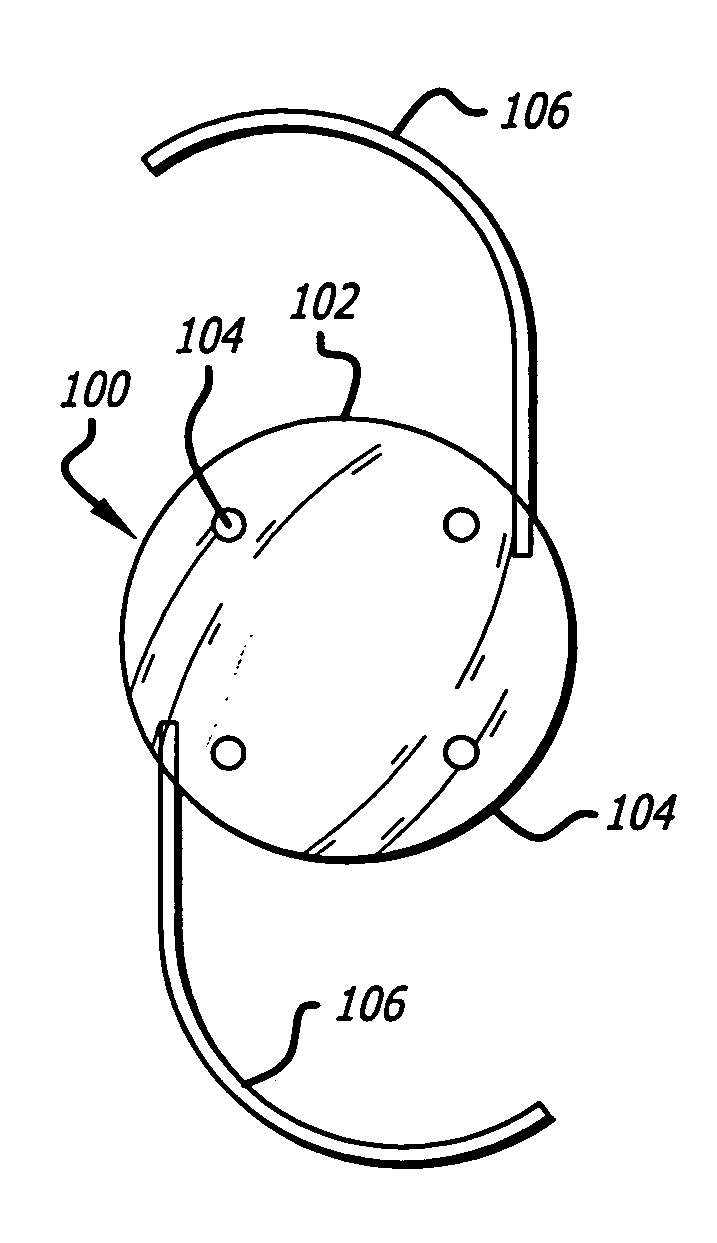

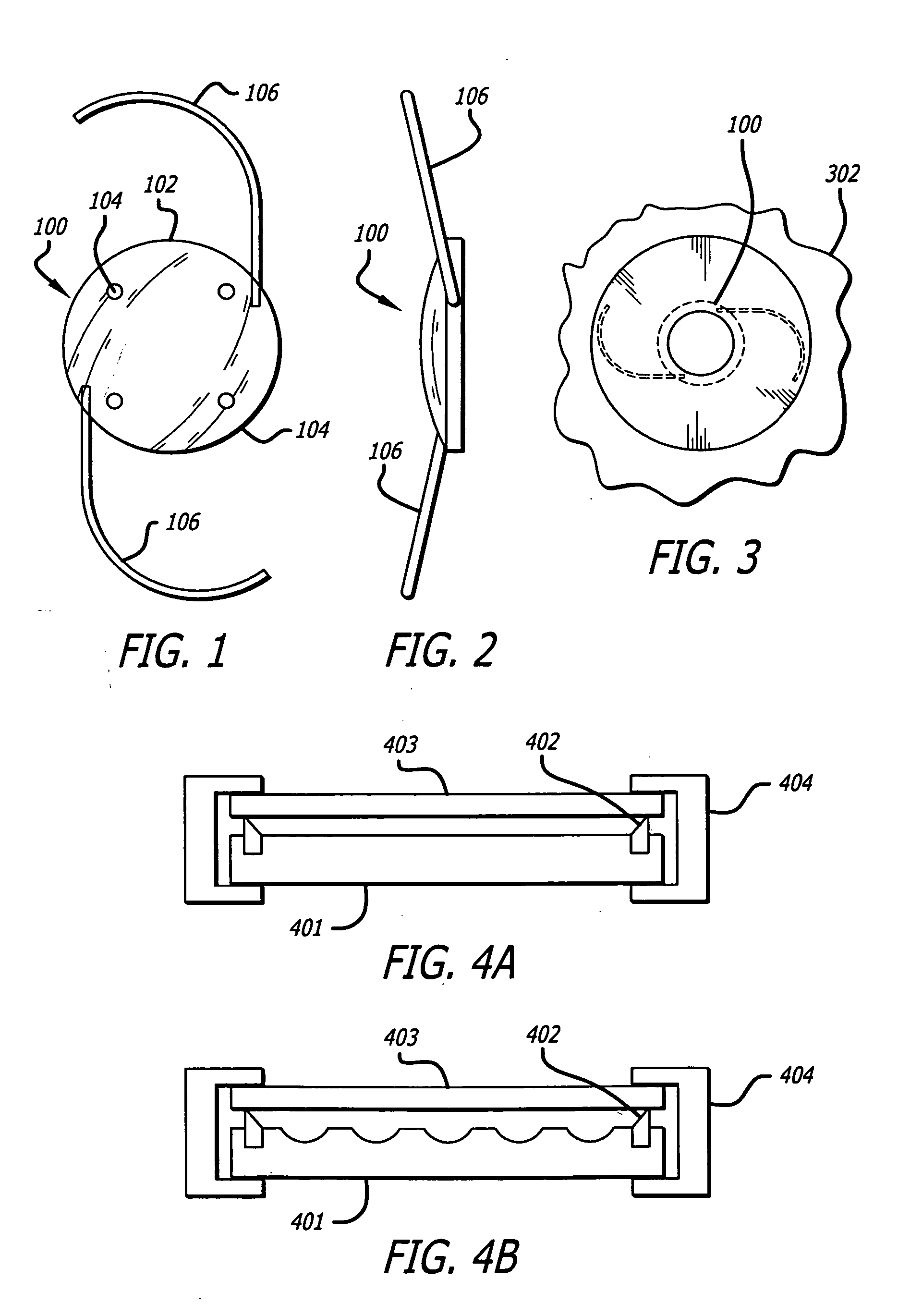

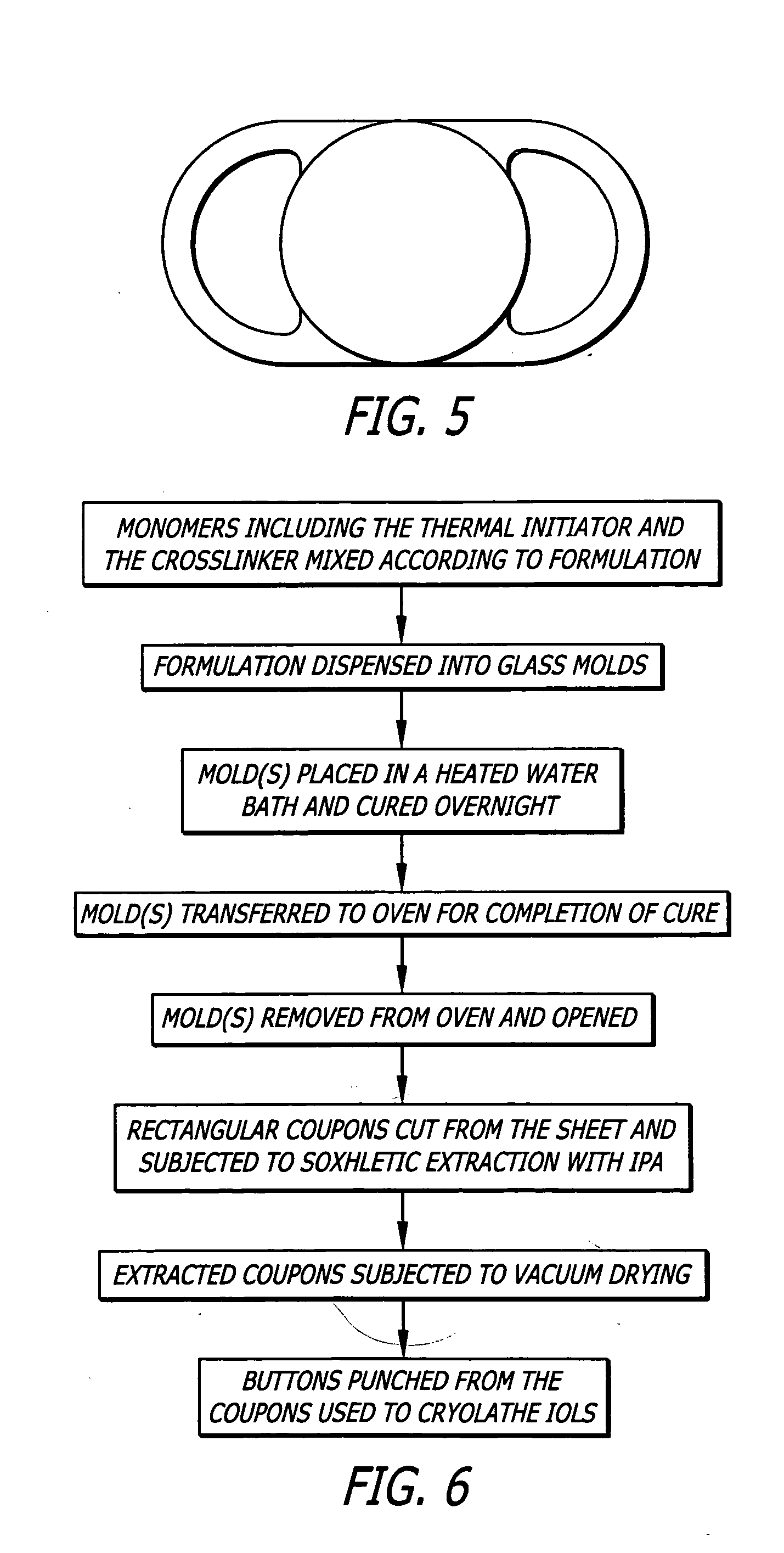

Intraocular lens materials suitable for insertion through a small bore cartridge

InactiveUS20050143751A1Low tensile strengthMinimal cartridge crazingEye treatmentIntraocular lensIntraocular lensMedicine

A polymer material useful for manufacturing an intraocular lens (IOL) suitable for insertion through an IOL inserter barrel having an inner diameter of less than 3 mm is provided. Specifically, acrylic-silicone hybrids having a tensile strength of approximately 100 psi to 400 psi and a percent elongation at break of between 50% and 400% are disclosed.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

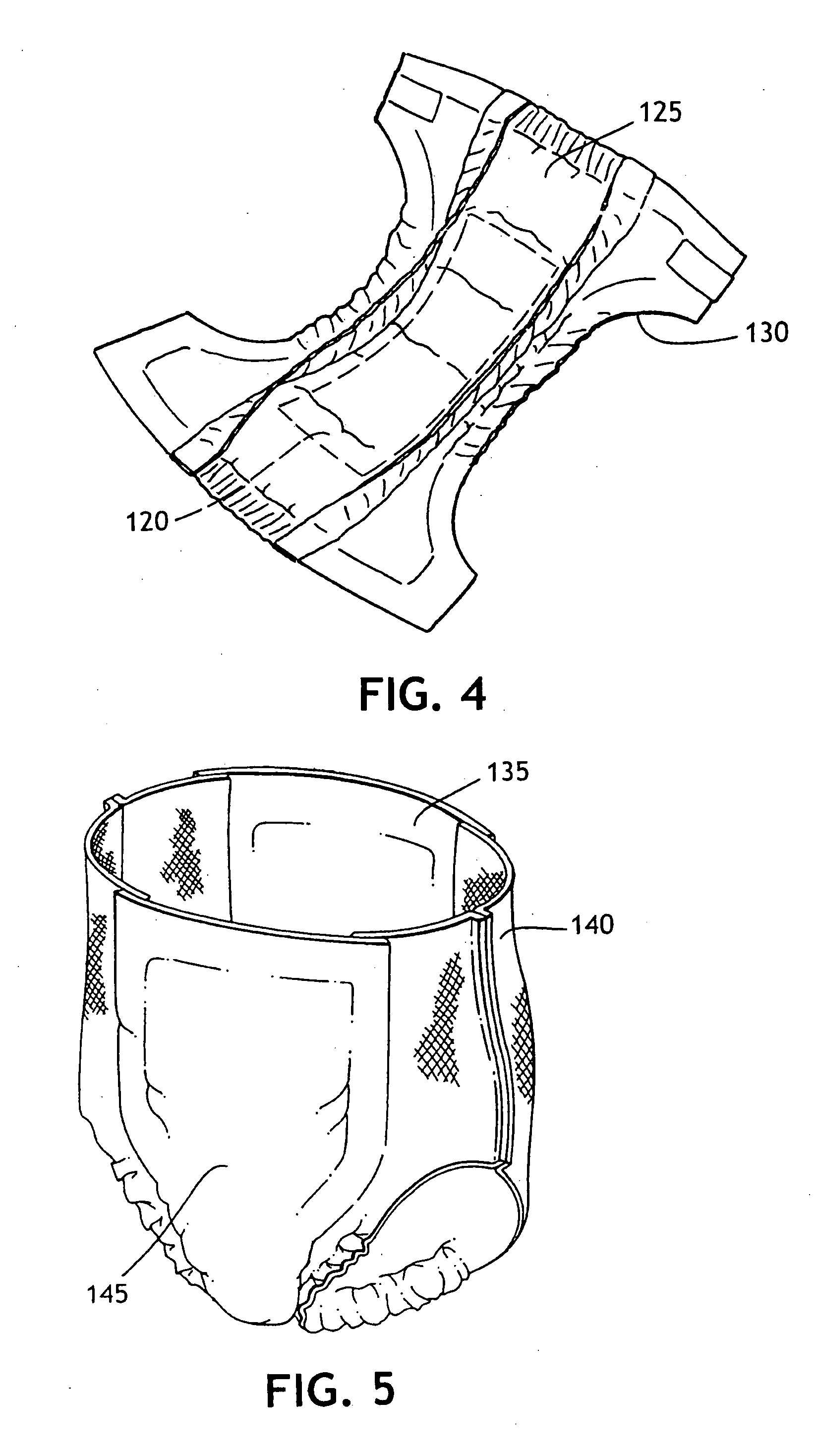

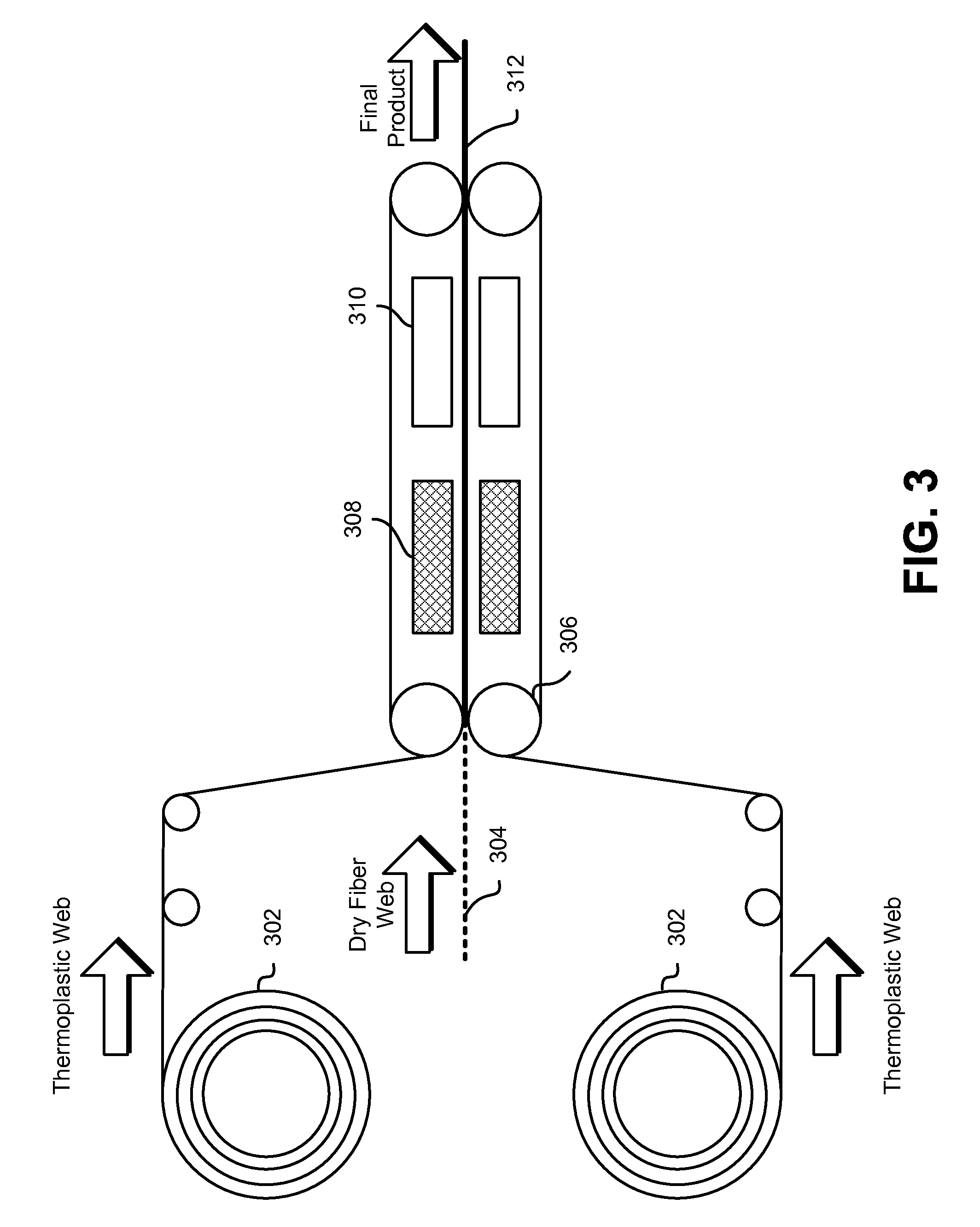

Microporous breathable elastic film laminates, methods of making same, and limited use or disposable product applications

InactiveUS20050101206A1Lamination ancillary operationsSynthetic resin layered productsElastomerThermoplastic elastomer

A breathable, elastic film / support layer laminate includes a thermoplastic elastomer film sheet of a thermoplastic elastomer and a filled semi crystalline predominantly linear polymer. The film includes between about 25 and 70 weight percent filler, between about 5 and 30 by weight percent semi-crystalline linear polymer, and between about 15 and 60 by weight percent elastomeric polymer. The filler is closely associated with the semi-crystalline linear polymer. The film demonstrates a load loss value at a 50 percent elongation of less than 50 percent, and a breathability of greater than 100 g / m2 / 24 hours and is laminated to a nonwoven layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Microporous breathable elastic film laminates, methods of making same, and limited use or disposable product applications

InactiveUS7270723B2Lamination ancillary operationsLaminationPercent elongationThermoplastic elastomer

A breathable, elastic film / support layer laminate includes a thermoplastic elastomer film sheet of a thermoplastic elastomer and a filled semi crystalline predominantly linear polymer. The film includes between about 25 and 70 weight percent filler, between about 5 and 30 by weight percent semi-crystalline linear polymer, and between about 15 and 60 by weight percent elastomeric polymer. The filler is closely associated with the semi-crystalline linear polymer. The film demonstrates a load loss value at a 50 percent elongation of less than 50 percent, and a breathability of greater than 100 g / m2 / 24 hours and is laminated to a nonwoven layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

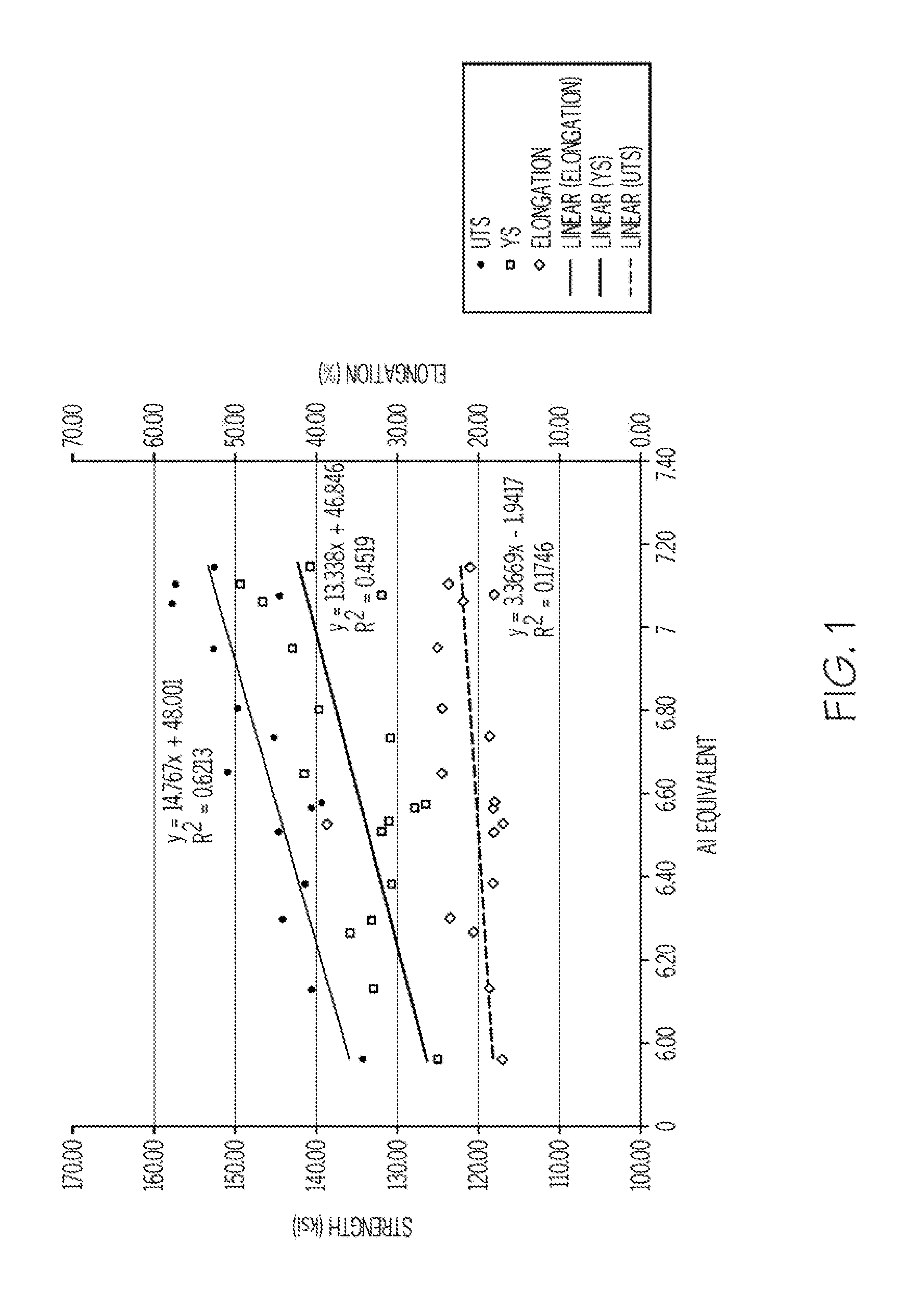

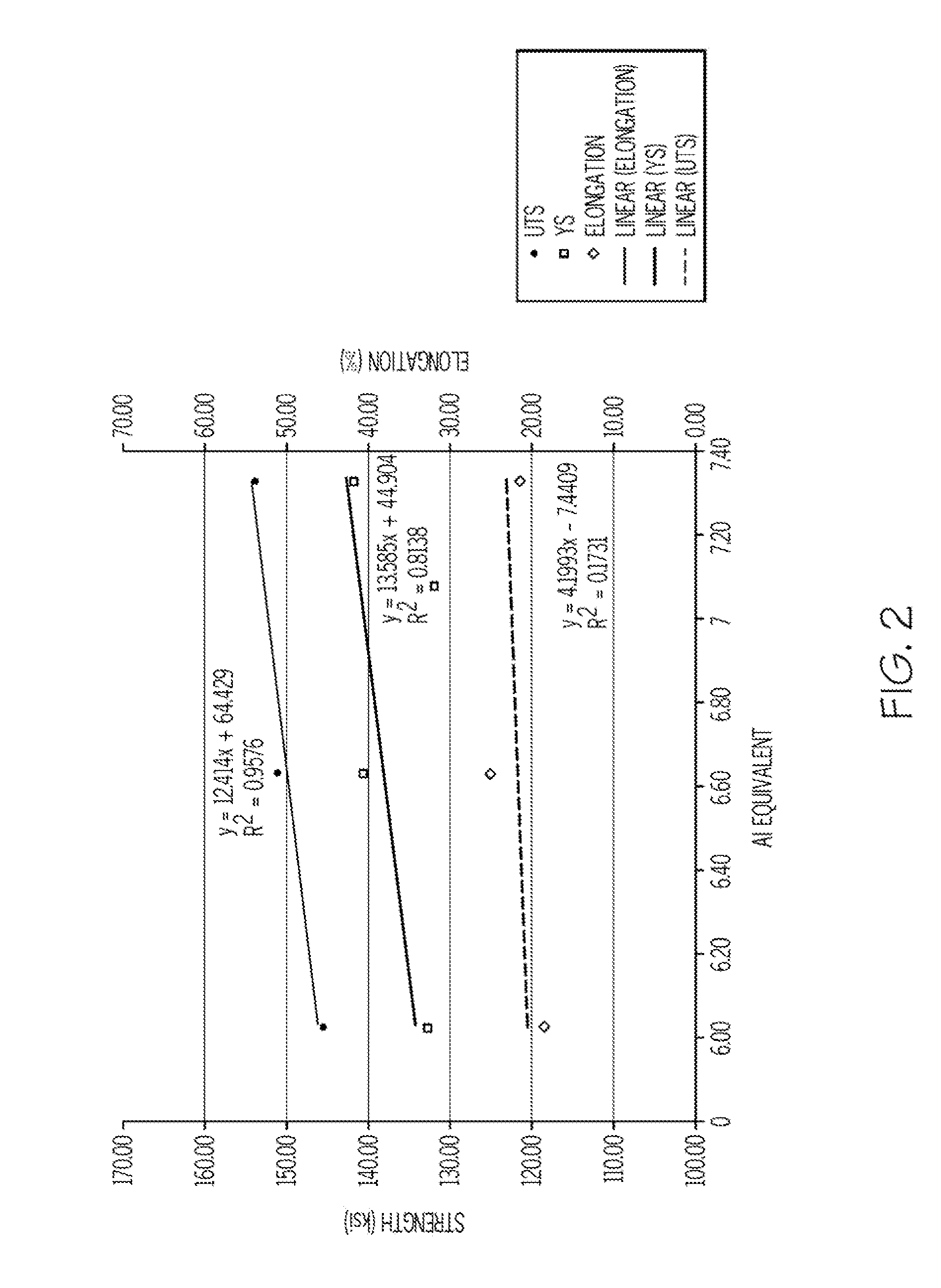

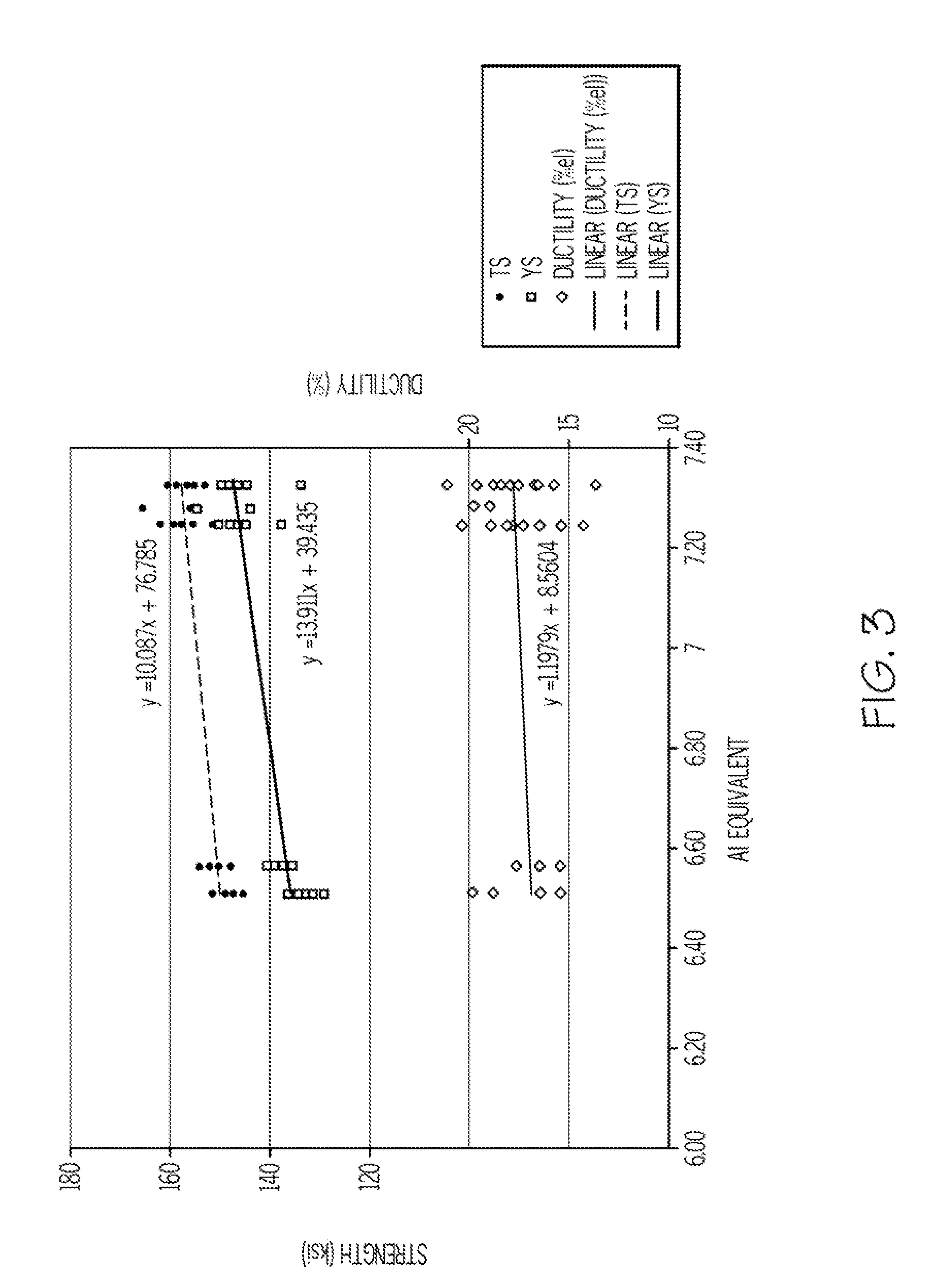

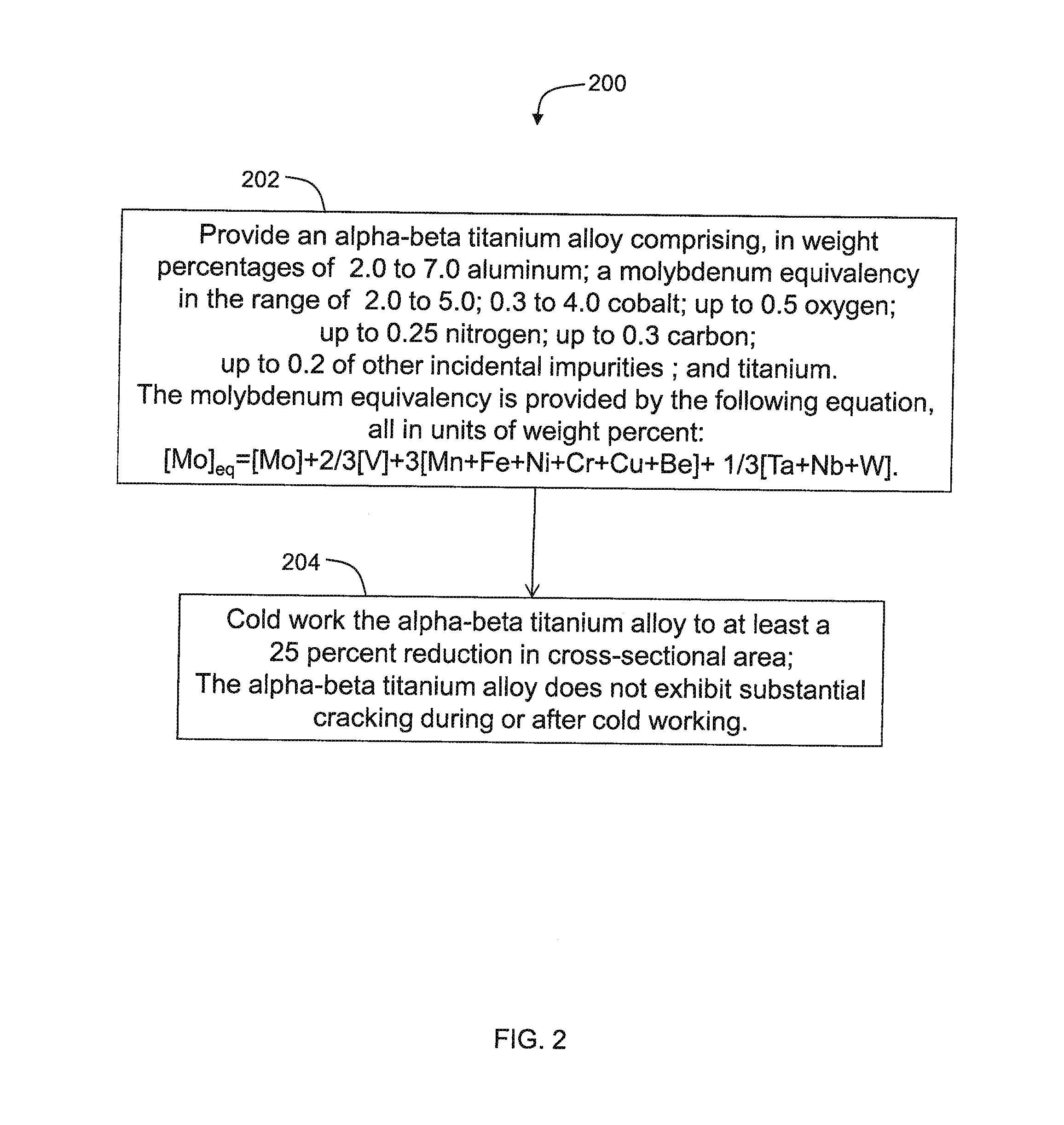

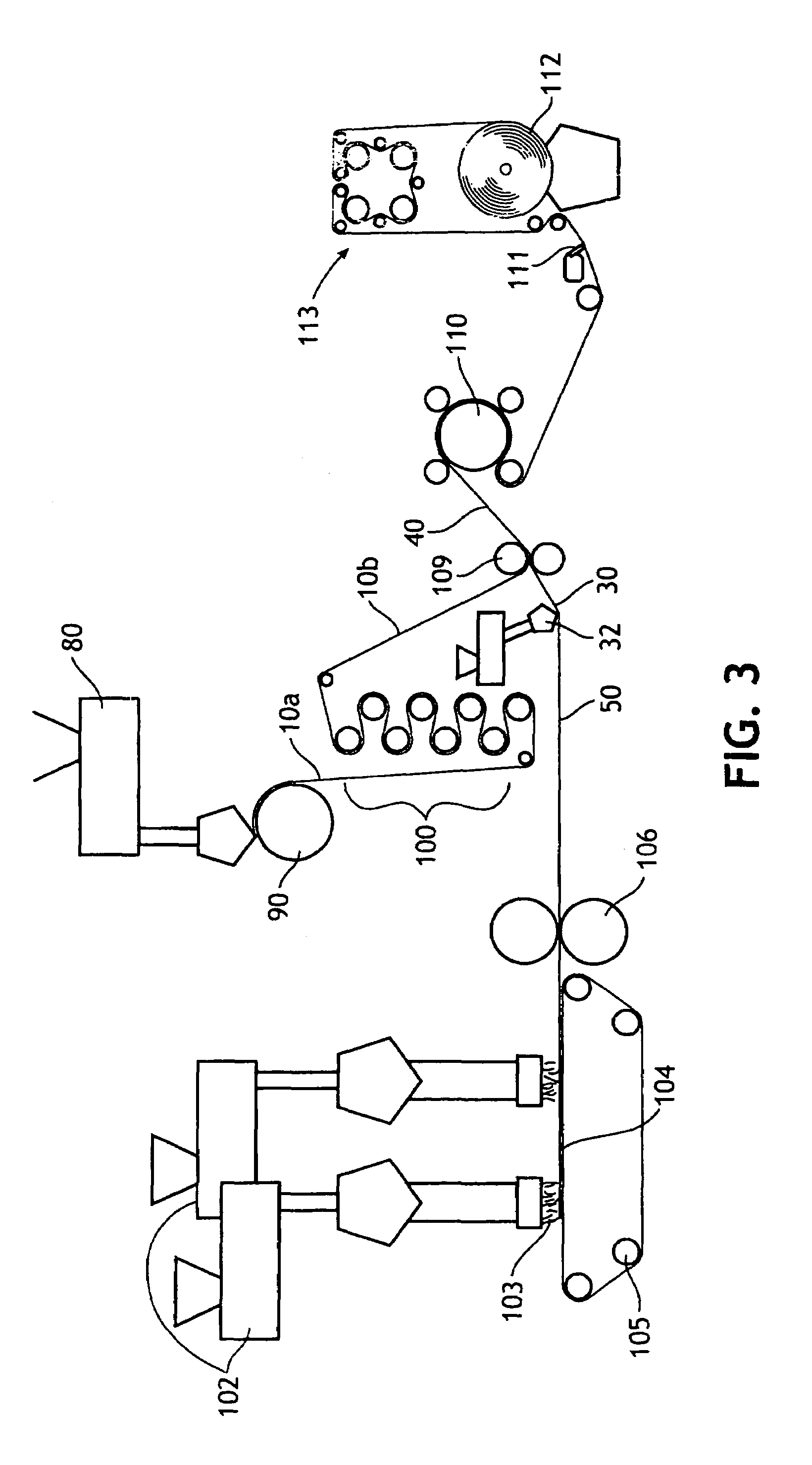

High strength alpha/beta titanium alloy

An alpha / beta titanium alloy comprising, in percent by weight based on total alloy weight: 3.9 to 4.5 aluminum; 2.2 to 3.0 vanadium; 1.2 to 1.8 iron; 0.24 to 0.30 oxygen; up to 0.08 carbon; up to 0.05 nitrogen; up to 0.015 hydrogen ; titanium; and up to a total of 0.30 of other elements. A non-limiting embodiment of the alpha / beta titanium alloy comprises an aluminum equivalent value in the range of 6.4 to 7.2, exhibits a yield strength in the range of 120 ksi (827.4 MPa) to 155 ksi (1,069 MPa), exhibits an ultimate tensile strength in the range of 130 ksi (896.3 MPa) to 165 ksi (1,138 MPa), and exhibits a ductility in the range of 12 to 30 percent elongation.

Owner:ATI PROPERTIES LLC

Cementitious exterior sheathing product having improved interlaminar bond strength

InactiveUS7155866B2High bonding strength between layersBeautiful appearanceRoof covering using tiles/slatesConstruction materialBuilding productFiber

The present invention provides exterior building products, such as roofing and siding, shake, shingles, siding, sheathing, panels, planks, vertical siding, soffit panels, fencing, decking, fascia, corner posts, column corners and trim boards in which a plurality of cementitious layers are provided with an improved interlaminar bond by employing a resinous bond promoter, a rheological agent, mechanical means to distribute fibers in a direction which is perpendicular to the machine direction so as to bridge between layers in the product, or a combination thereof. These techniques help to increase interlaminar bond strength to improve the mechanical properties of the product. When certain resinous bond promoters are used, the additional benefits of water absorption resistance and pigmentation throughout the product can be provided with minimal expense. Improvements in interlaminar bond strength of about 10–46% were observed with a percent elongation improvement of about 7%.

Owner:PLYCEM USA

Surface-Mounted Crack Detection

InactiveUS20100225497A1Resistance/reactance/impedenceConductive materialPercent elongationSurface mounting

A cementitious compound provides a brittle undercoat for making a surface-mounted crack sensor on a surface. A low percent elongation and low tensile strength of the cementitious compound have proven valuable in ensuring that cracks in the underlying surface are transmitted through the undercoat so that a trace of conductive ink or paint on the undercoat more reliably detects the crack.

Owner:NAT RES COUNCIL OF CANADA

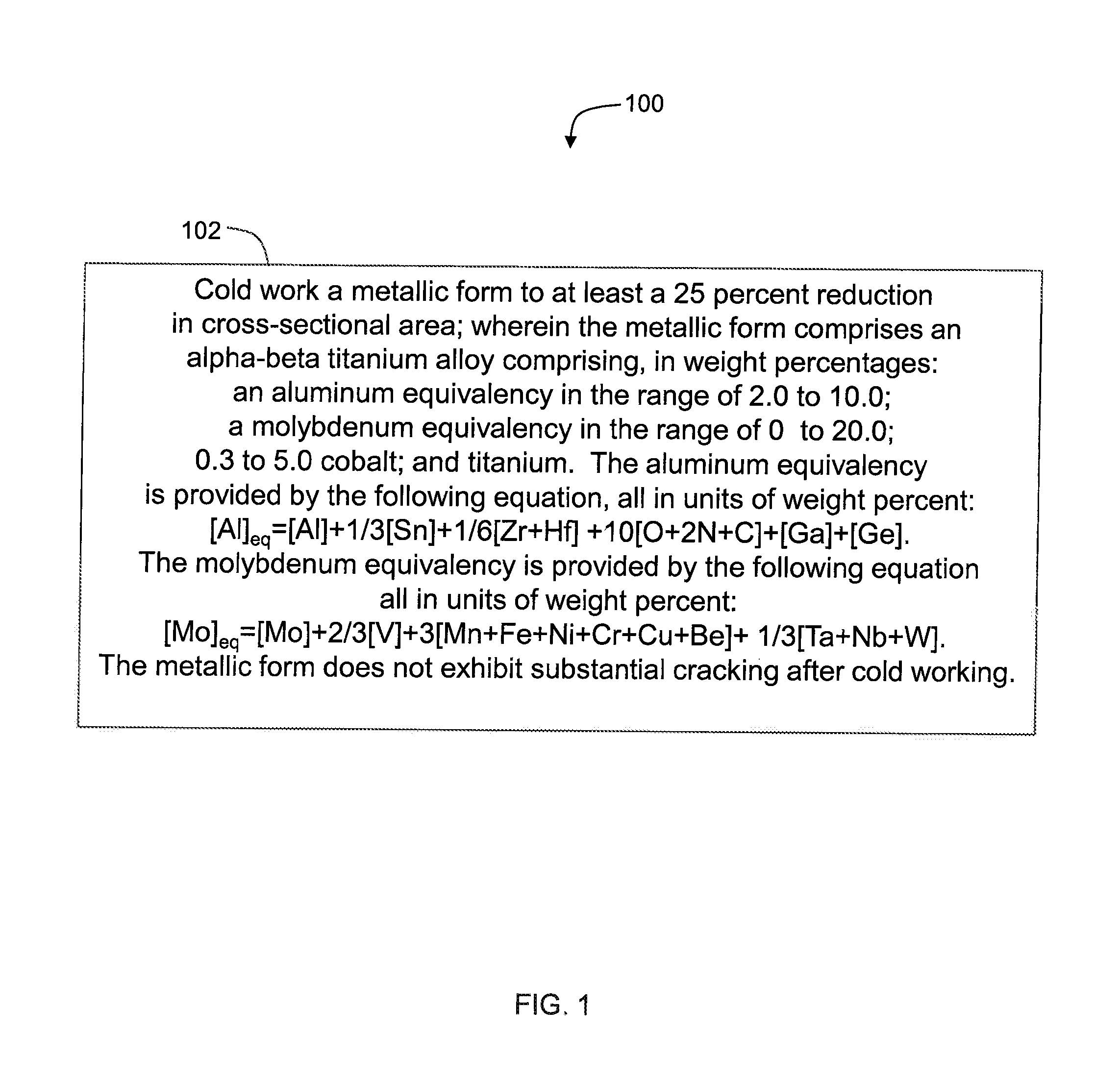

Titanium alloy

An alpha-beta titanium alloy comprises, in weight percentages: an aluminum equivalency in the range of 2.0 to 10.0; a molybdenum equivalency in the range of 0 to 20.0; 0.3 to 5.0 cobalt; and titanium. In certain embodiments, the alpha-beta titanium alloy exhibits a cold working reduction ductility limit of at least 25%, a yield strength of at least 130 KSI (896.3 MPa), and a percent elongation of at least 10%. A method of forming an article comprising the cobalt-containing alpha-beta titanium alloy comprises cold working the cobalt-containing alpha-beta titanium alloy to at least a 25 percent reduction in cross-sectional area. The cobalt-containing alpha-beta titanium alloy does not exhibit substantial cracking during cold working.

Owner:ATI PROPERTIES LLC

Microporous breathable elastic films, methods of making same, and limited use or disposable product applications

InactiveUS7220478B2Lamination ancillary operationsSynthetic resin layered productsElastomerPercent elongation

A thermoplastic elastomer film includes a thermoplastic elastomer and a filled semi crystalline predominantly linear polymer. The film includes between about 25 and 70 weight percent filler, between about 5 and 30 by weight percent semi-crystalline linear polymer, and between about 15 and 60 by weight elastomer. The filler is closely associated with the semi-crystalline linear polymer. The elastic film demonstrates a load loss value at a 50 percent elongation of less than about 50 percent, and a breathability of greater than about 100 g / m2 / 24 hours.

Owner:KIMBERLY-CLARK WORLDWIDE INC

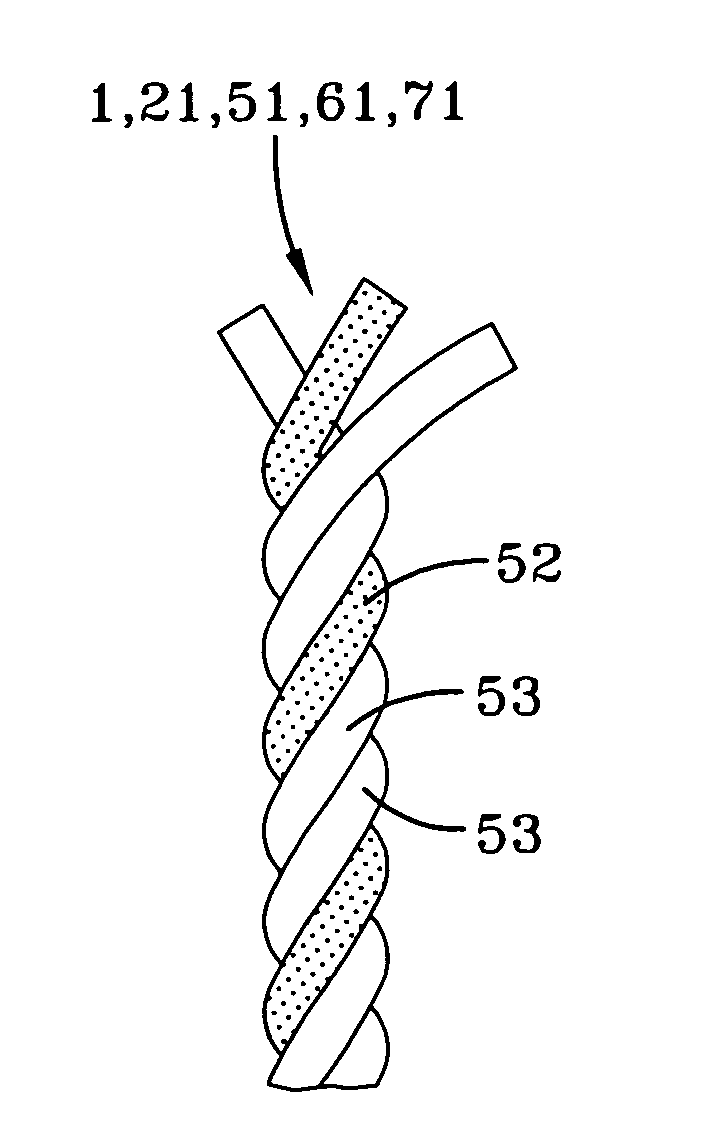

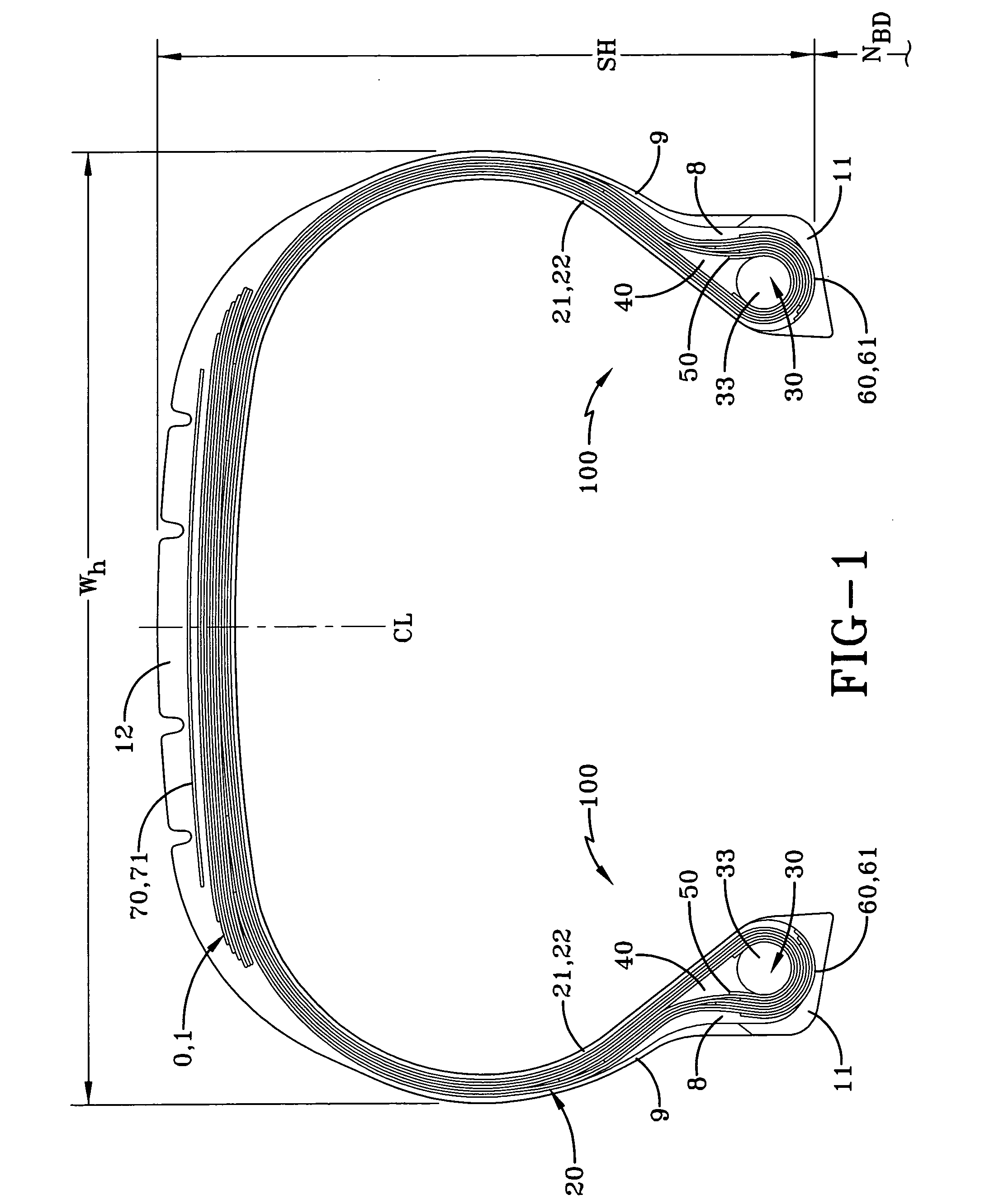

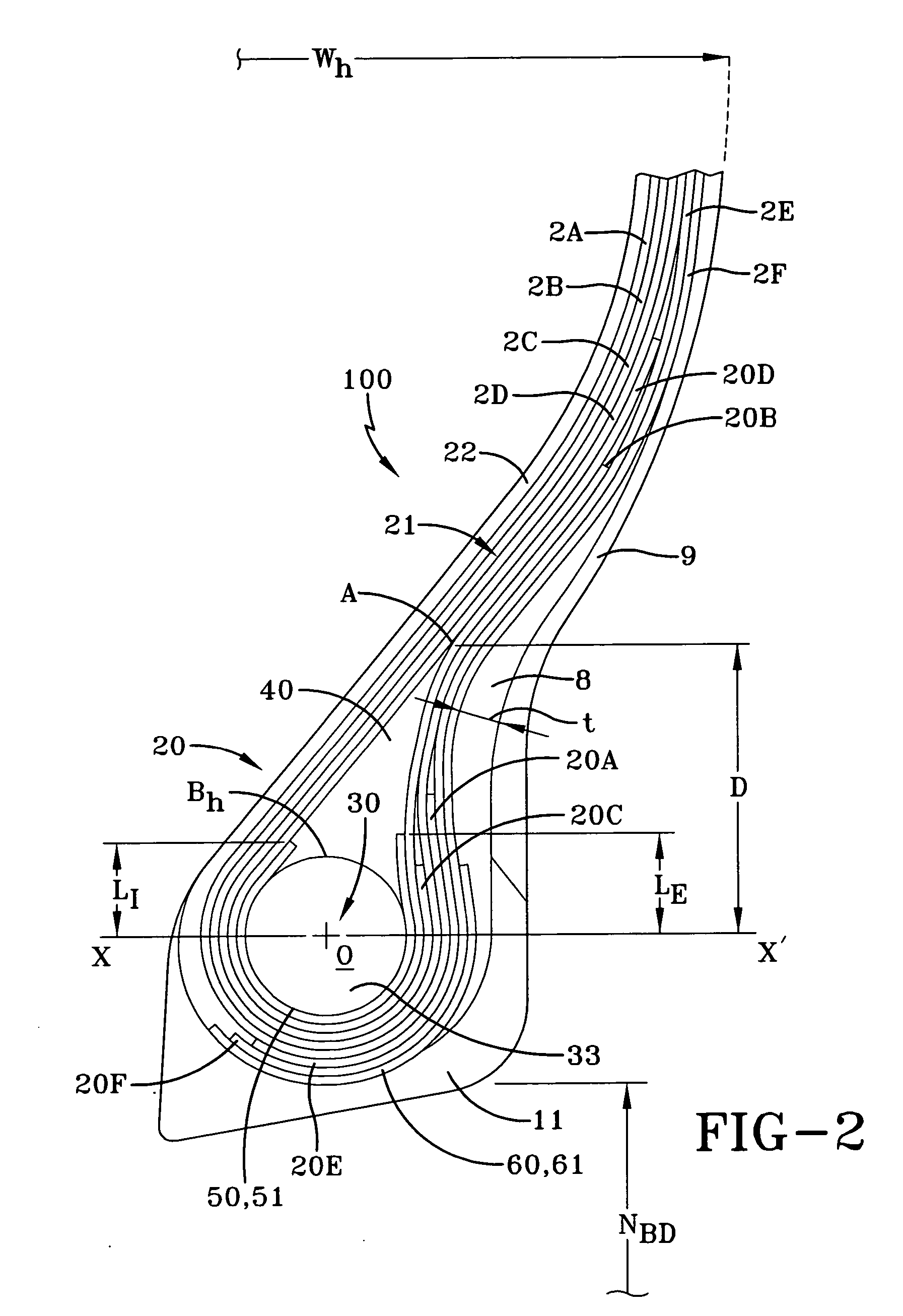

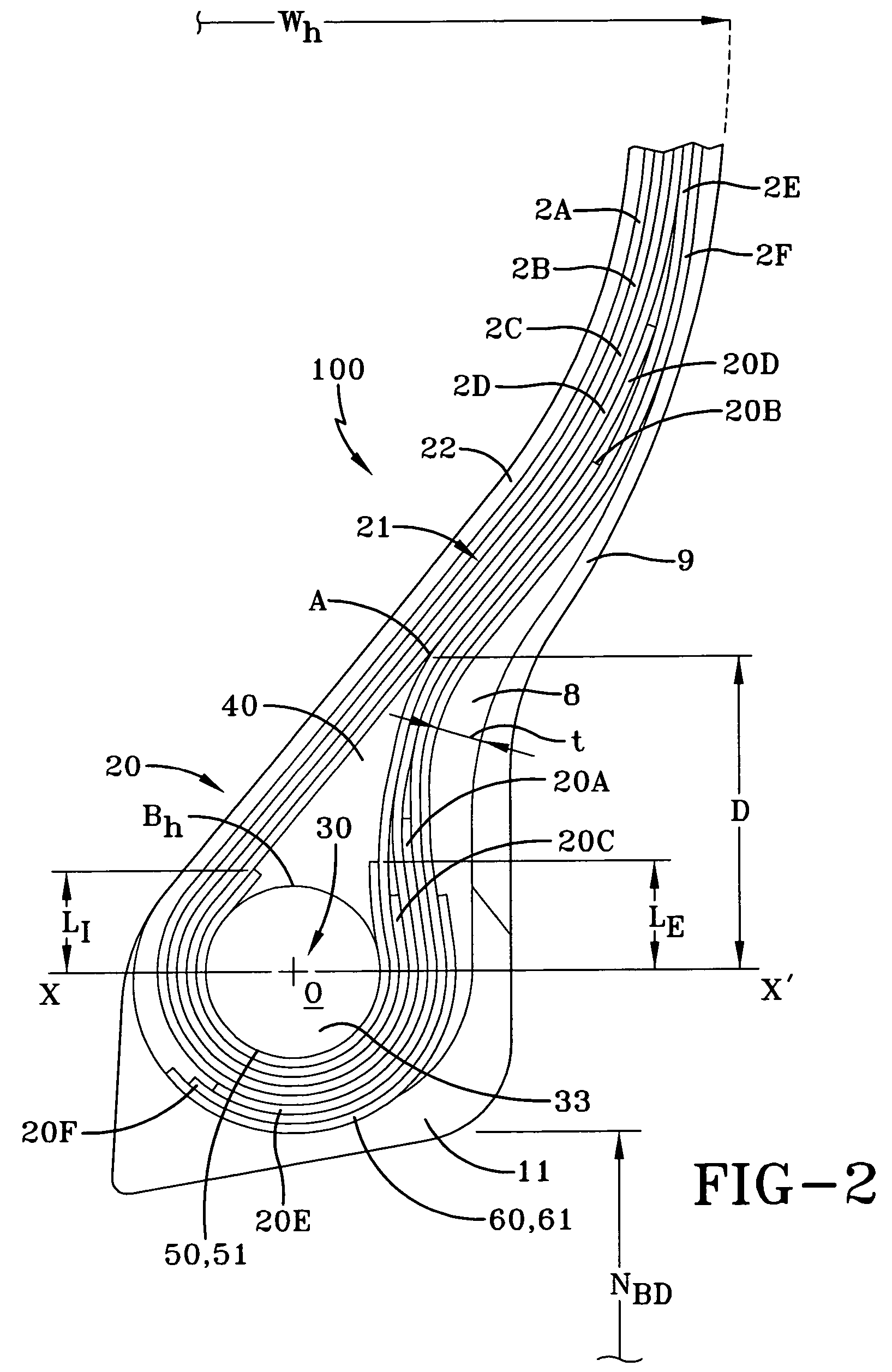

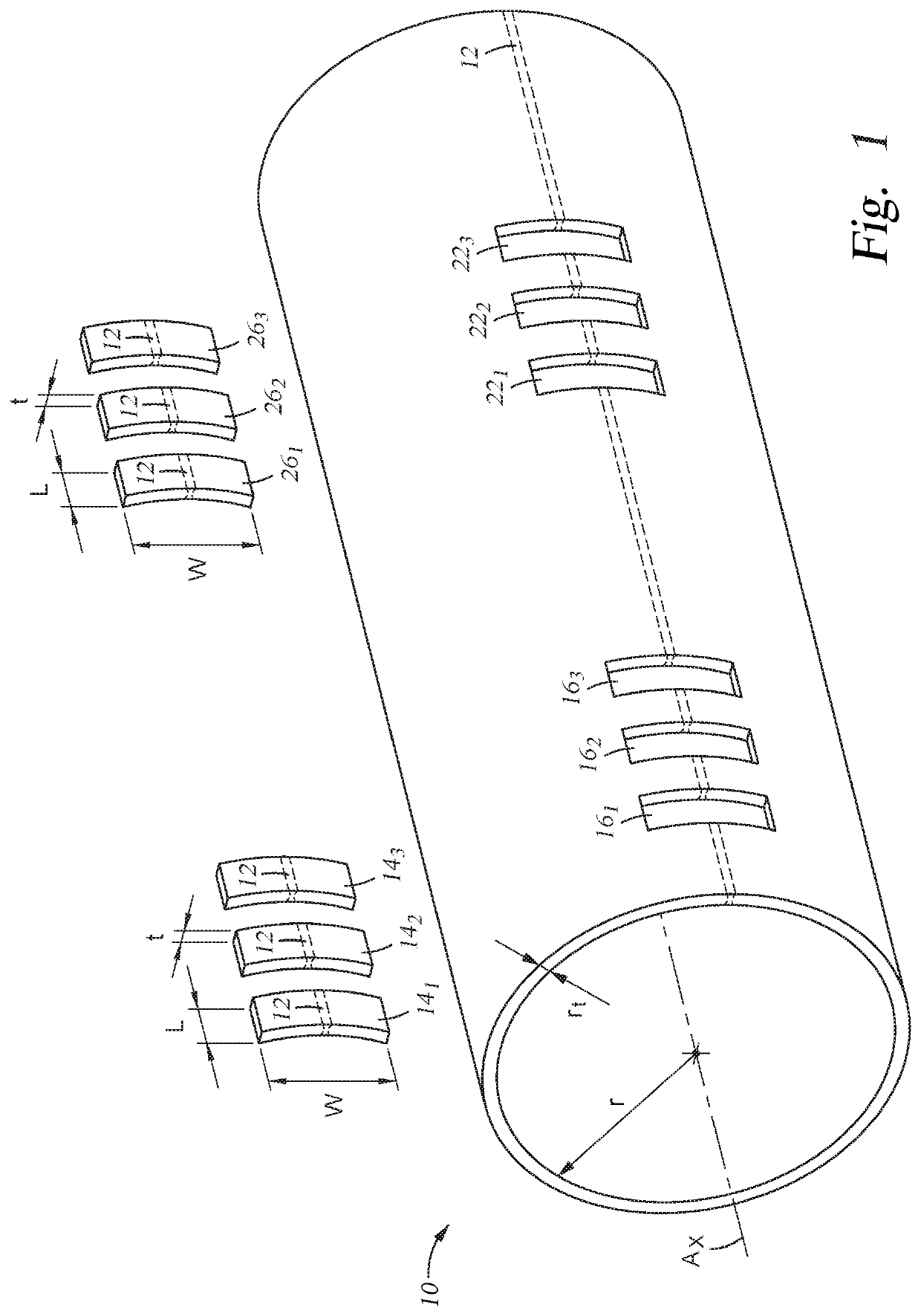

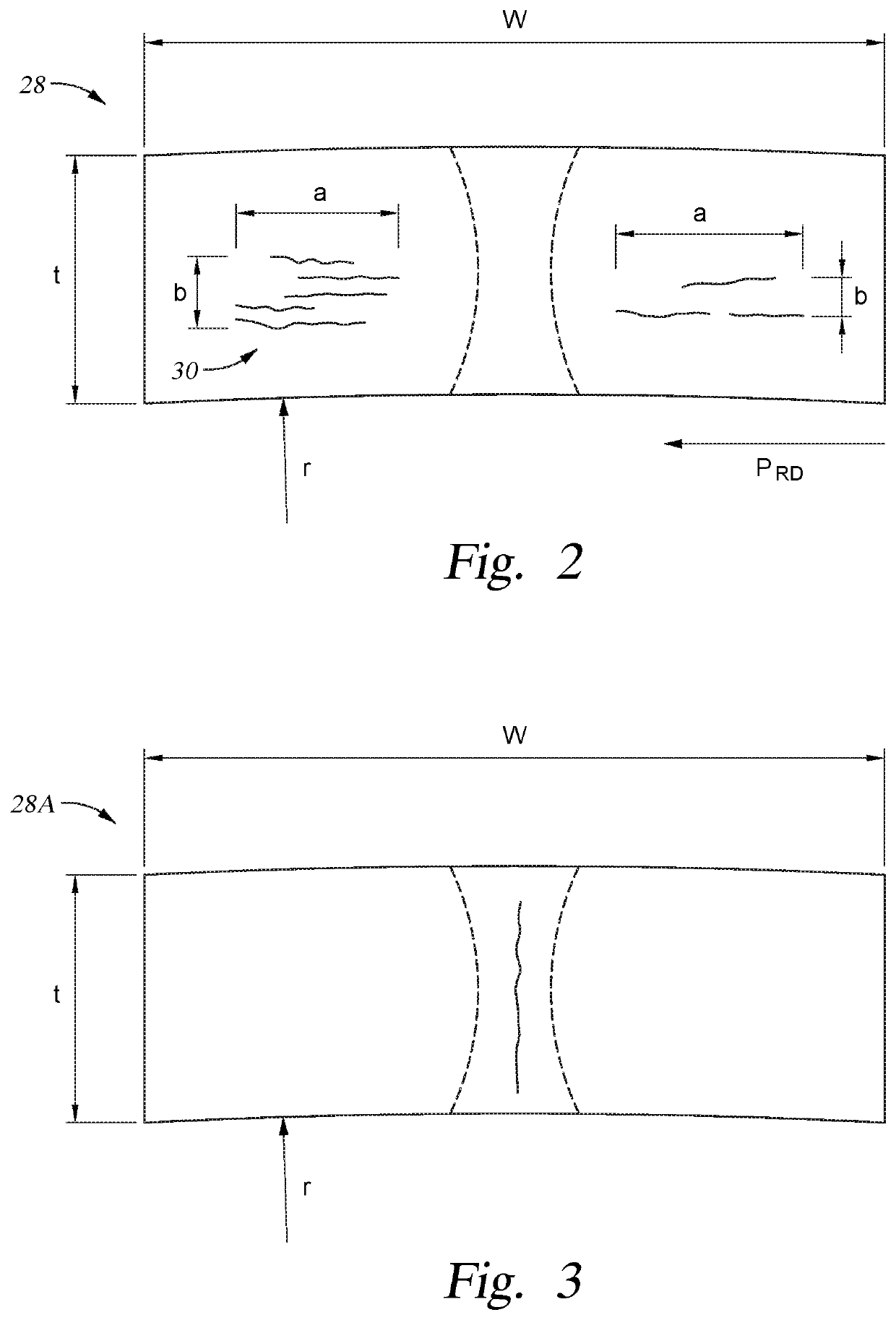

Enhanced radial aircraft tire

This invention disclosed a pneumatic tire for use on aircrafts having a tread, a crown reinforcement, and a radial carcass reinforcement. The carcass reinforcement has at least one axially inner ply of textile cord wound around a pair of bead cores, at least one axially inner ply being wound around the bead core in each bead from inside to the outside forming outside turn-ups and at least one axially outer ply of textile cords extending from bead to bead along the turn-ups of the at least one axially inner ply. Each bead has an elastomeric apex filler. The at least one axially inner ply or at least one axially outer ply has merged cords having a percent elongation at break of 12% to less than 20% and a break strength greater than 1050 N with a linear density of greater than 9,000 dtex. The preferred cord has fibers of polyamide and nylon. The cord fiber of polyamide is an aromatic polyamide 3300 / 2 construction. The cord fiber of nylon is a 1880 / 1 nylon construction. The preferred cord construction is 6.7 (A)+4.5 (N) / 6.7 TPI. The cord reinforcement is preferably used in the ply layers or strips of the crown reinforcement as well.

Owner:THE GOODYEAR TIRE & RUBBER CO

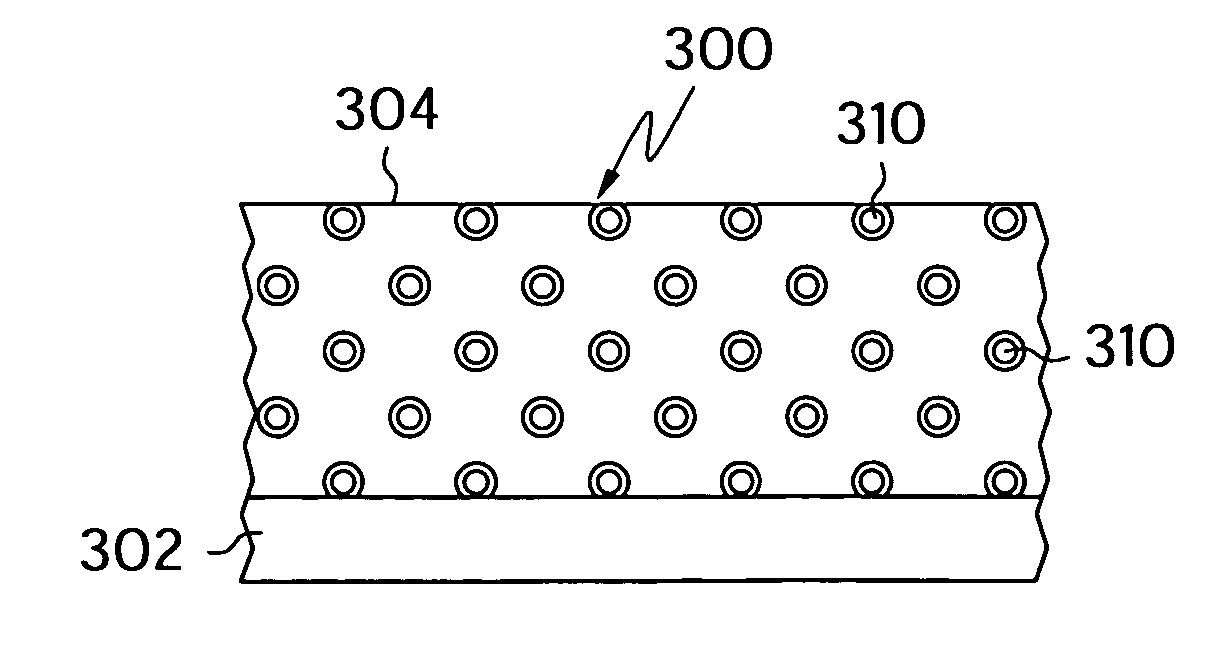

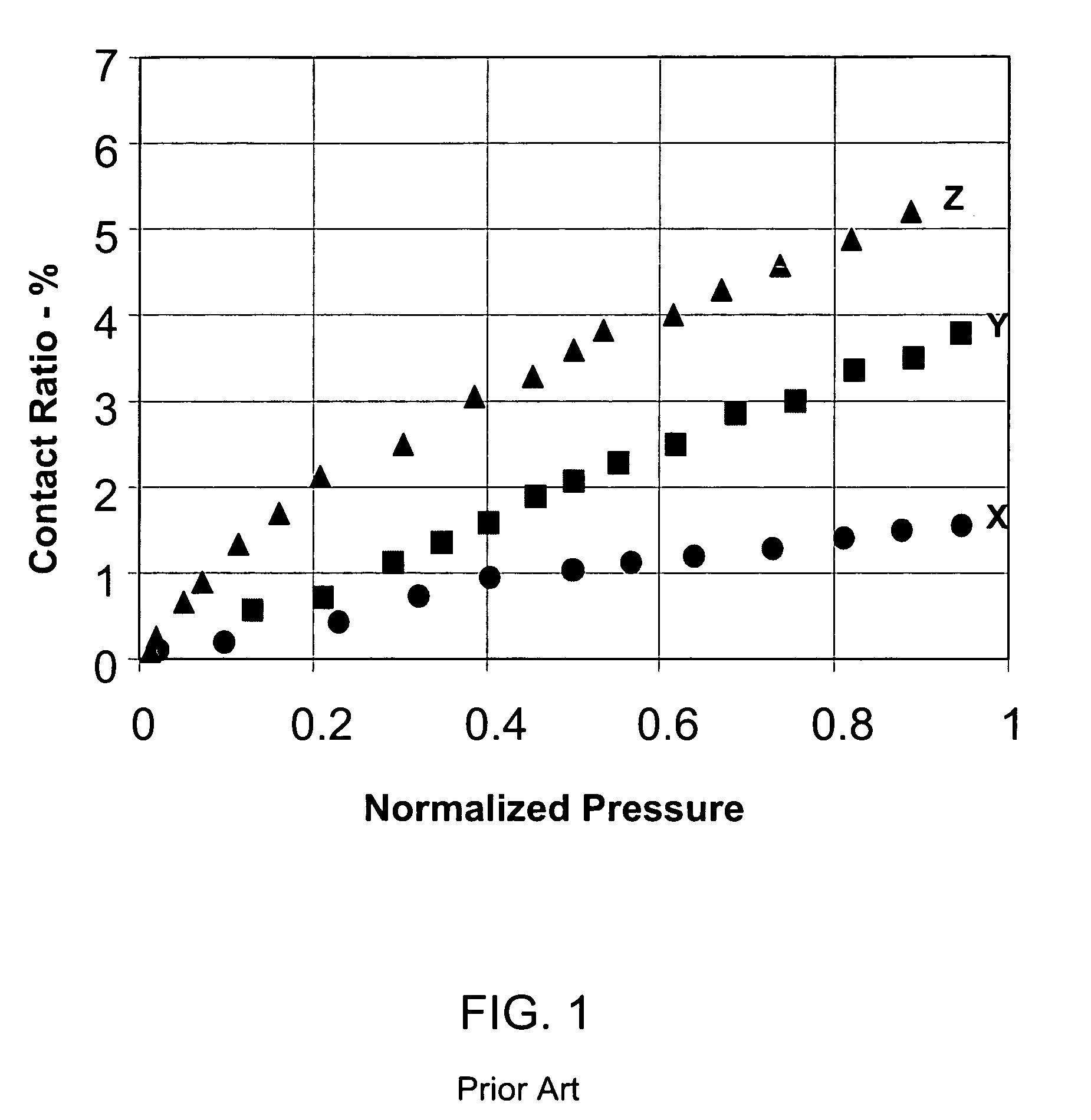

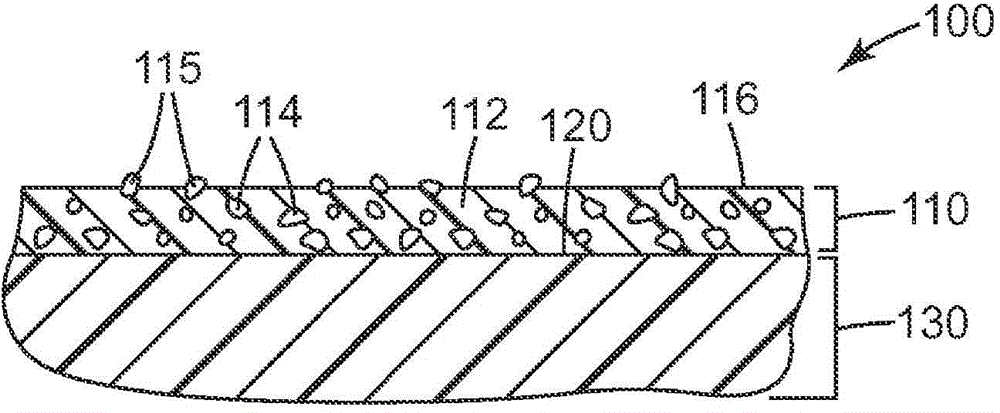

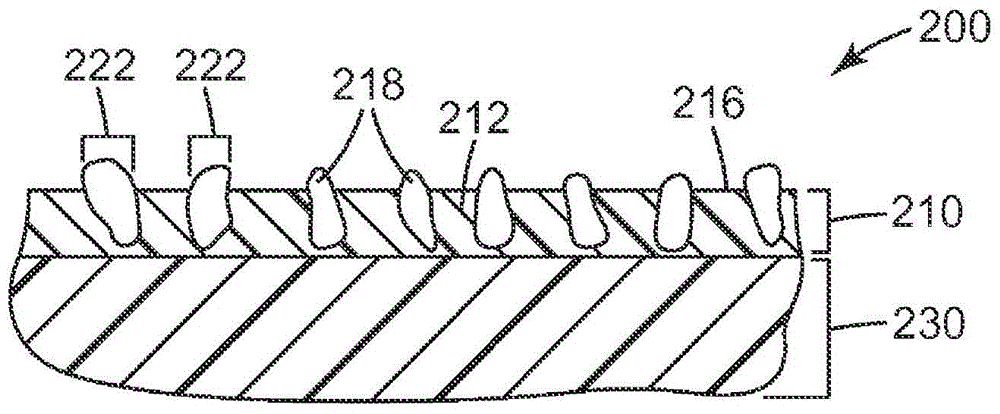

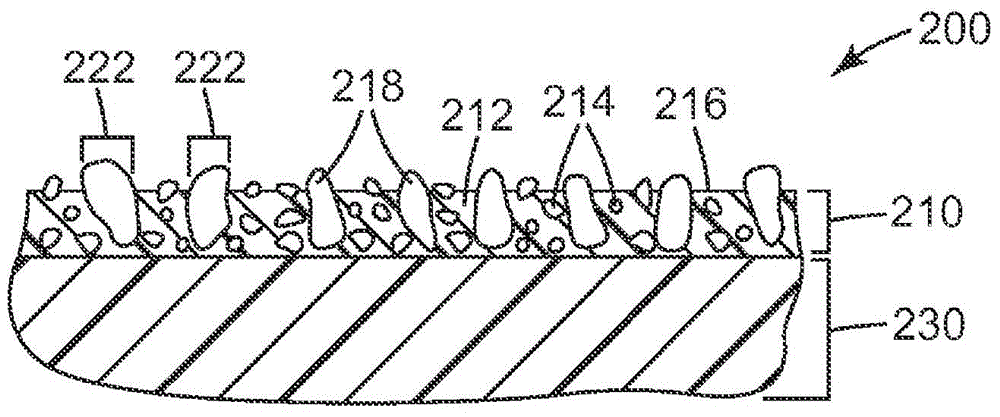

Water-based polishing pads having improved contact area

The present invention provides a chemical mechanical polishing pad comprising, a polymeric matrix having microspheres dispersed therein, the polymeric matrix being formed of a water-based polymer or blends thereof, wherein the pad comprises: a Shore A hardness of 30 to 70; a void volume fraction of 0.2 to 80 percent; a tensile strength of 1 mPa to 5 mPa; and a percent elongation of 200 to 400.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Surface-mounted crack detection

InactiveUS8059008B2Resistance/reactance/impedenceConductive materialSurface mountingPercent elongation

Owner:NAT RES COUNCIL OF CANADA

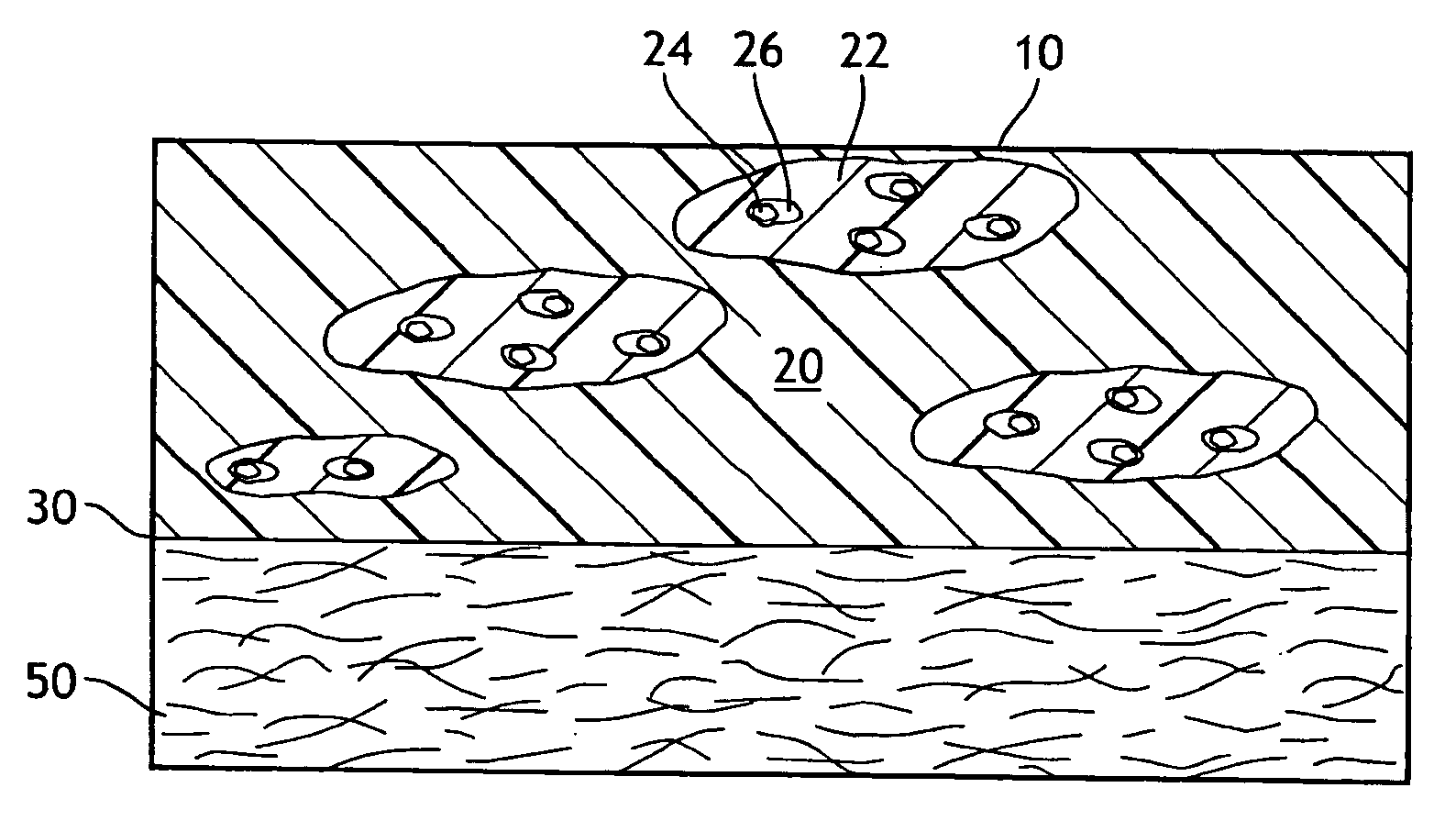

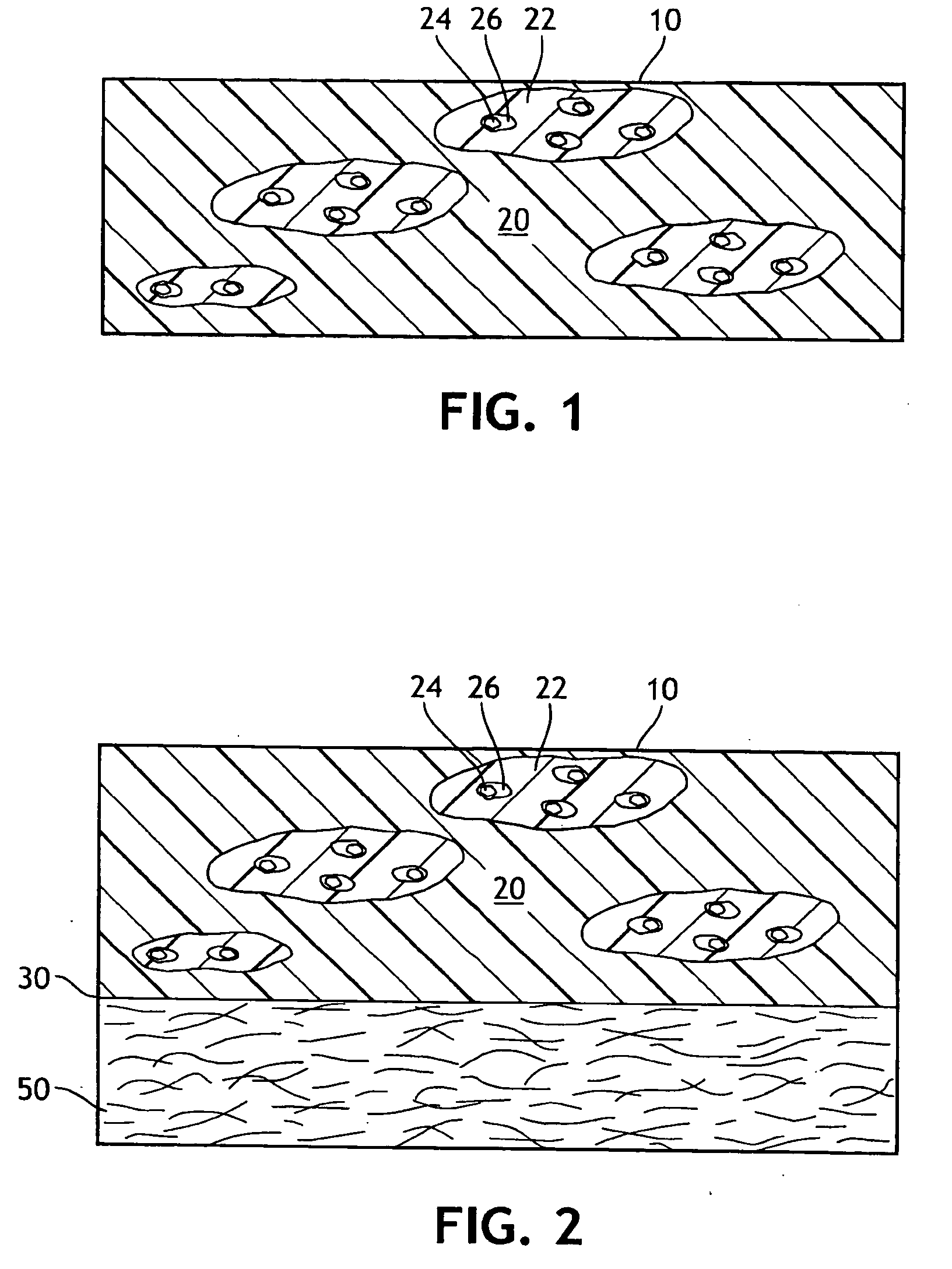

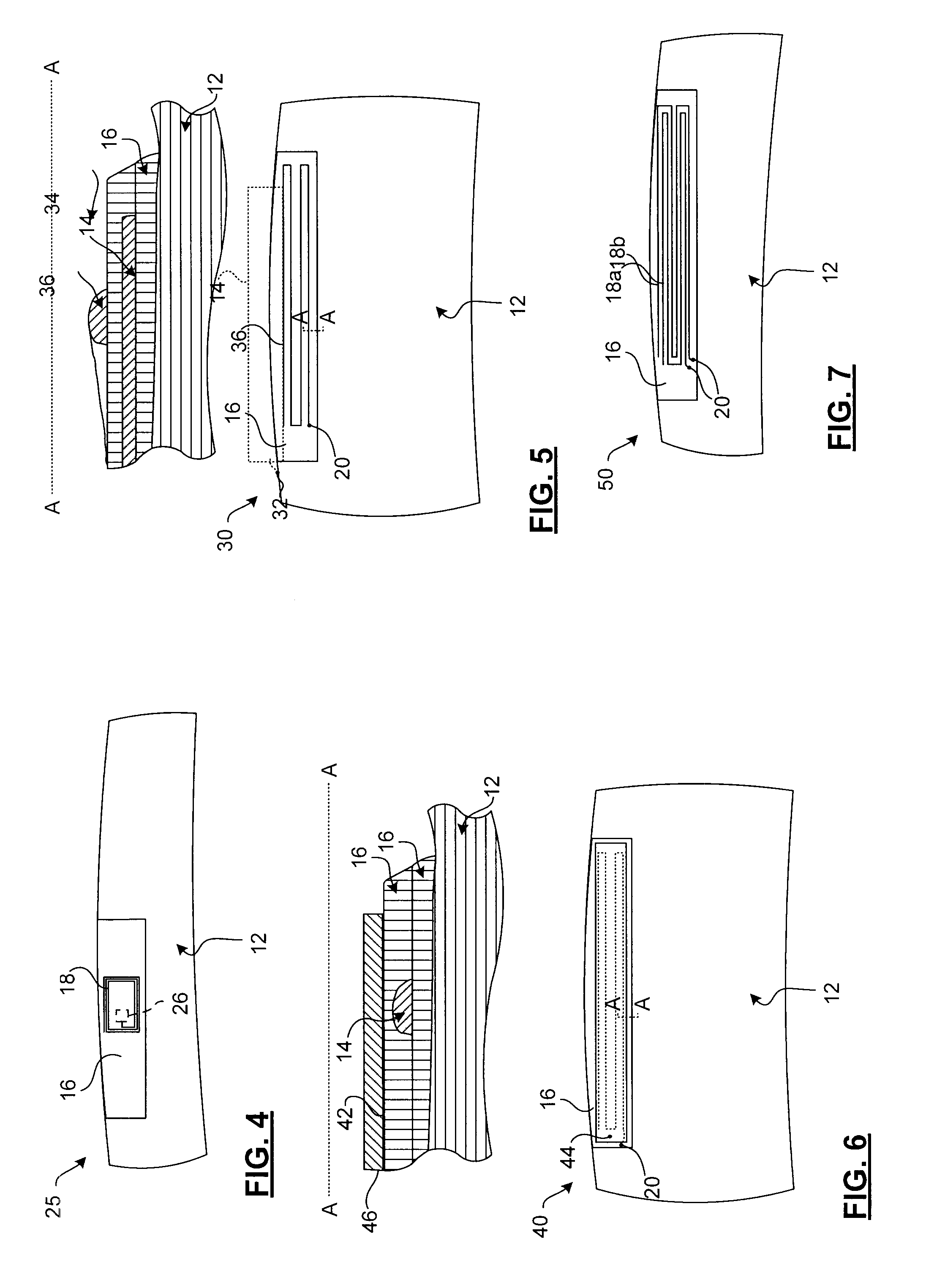

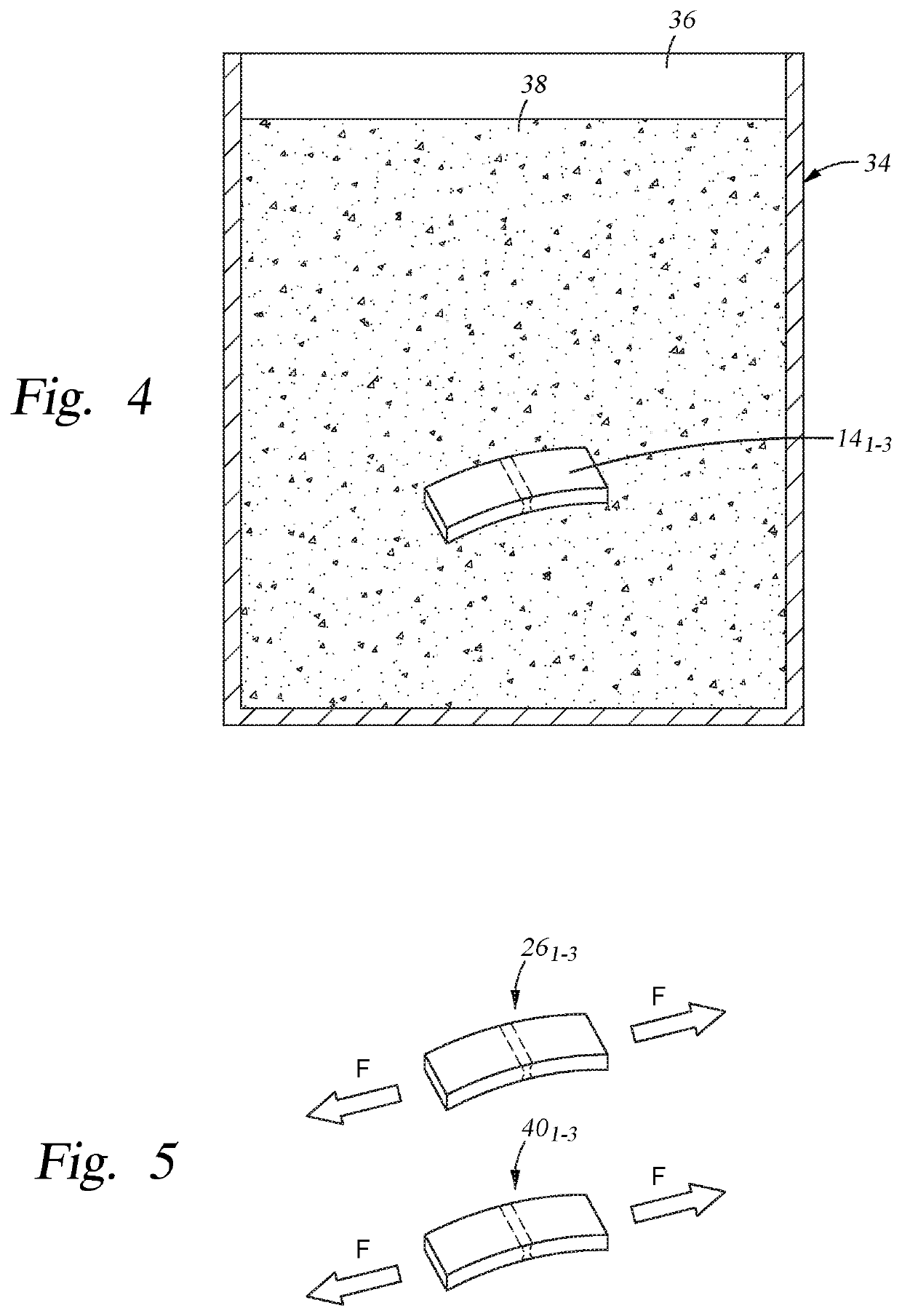

Flexible fiber-reinforced composite material

ActiveUS20150174885A1Lamination ancillary operationsLayered product treatmentPercent elongationFiber-reinforced composite

A flexible fiber-reinforced composite material is manufactured by impregnating a fiber reinforcement material with a non-epoxy matrix material. Subsequently, the impregnated fiber reinforcement material is dried and cured, resulting in a flexible fiber-reinforced composite material that exhibits a tensile modulus between 10 MPa and 42 MPa at 20 percent elongation.

Owner:CARBITEX INC

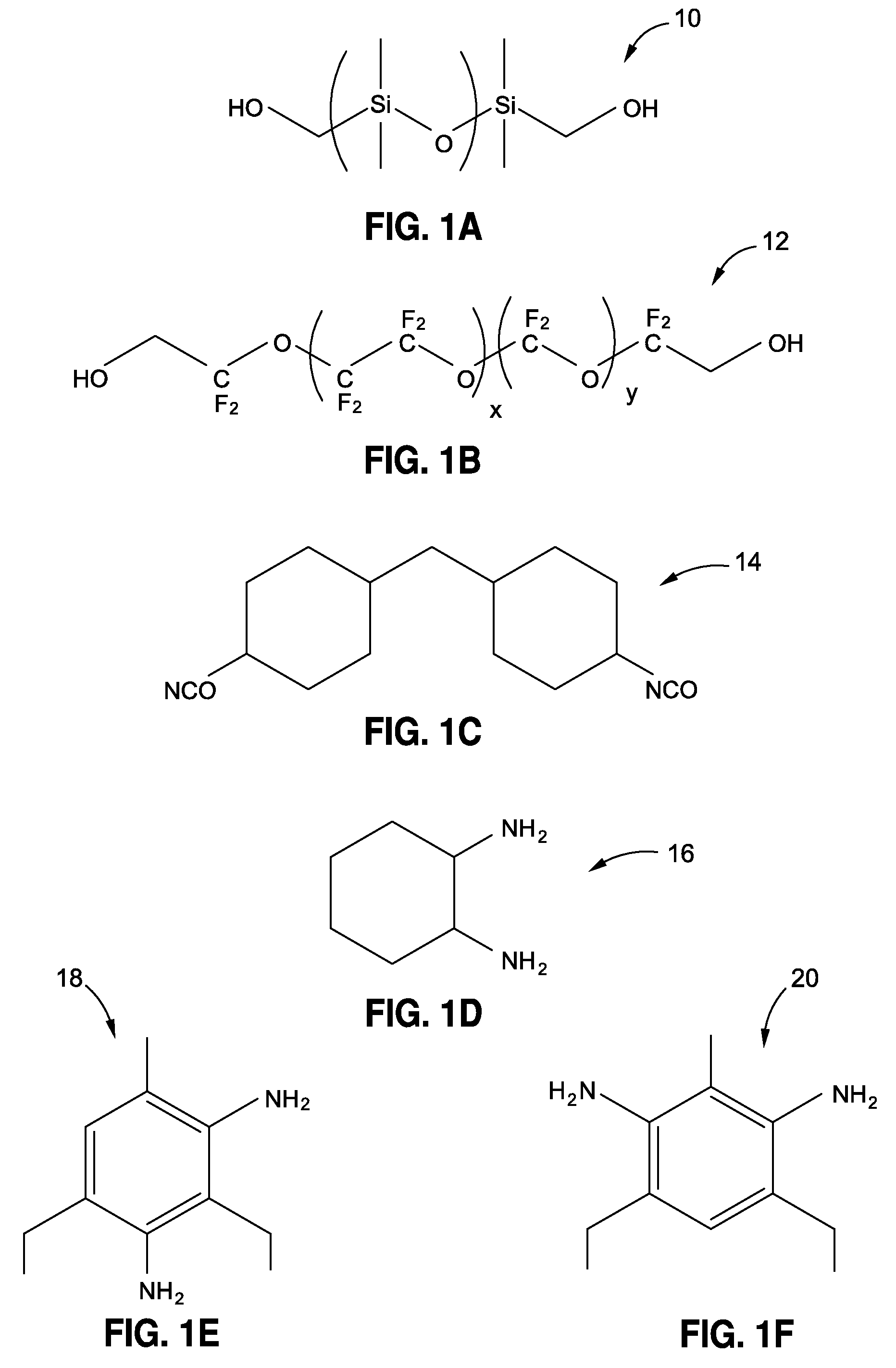

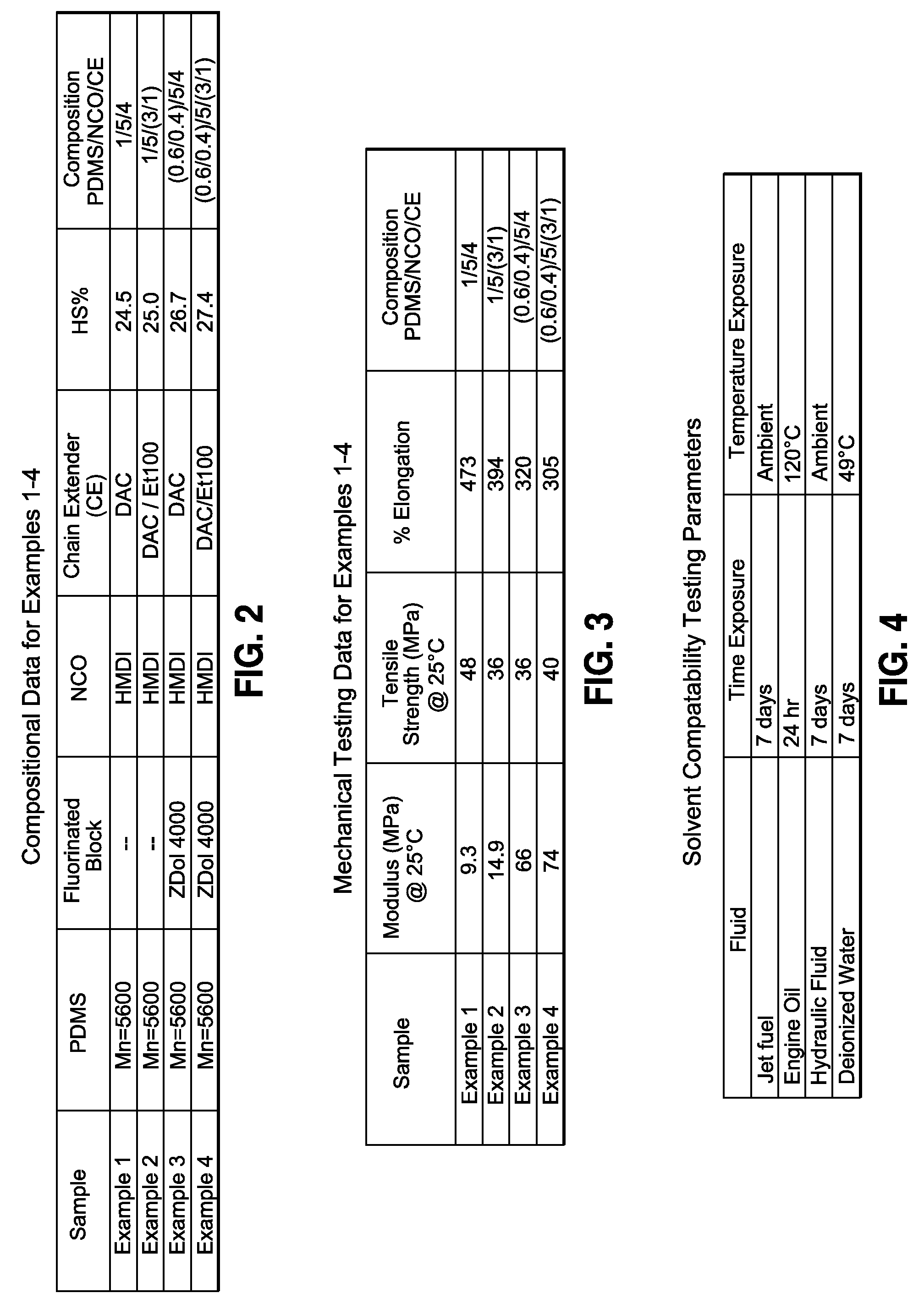

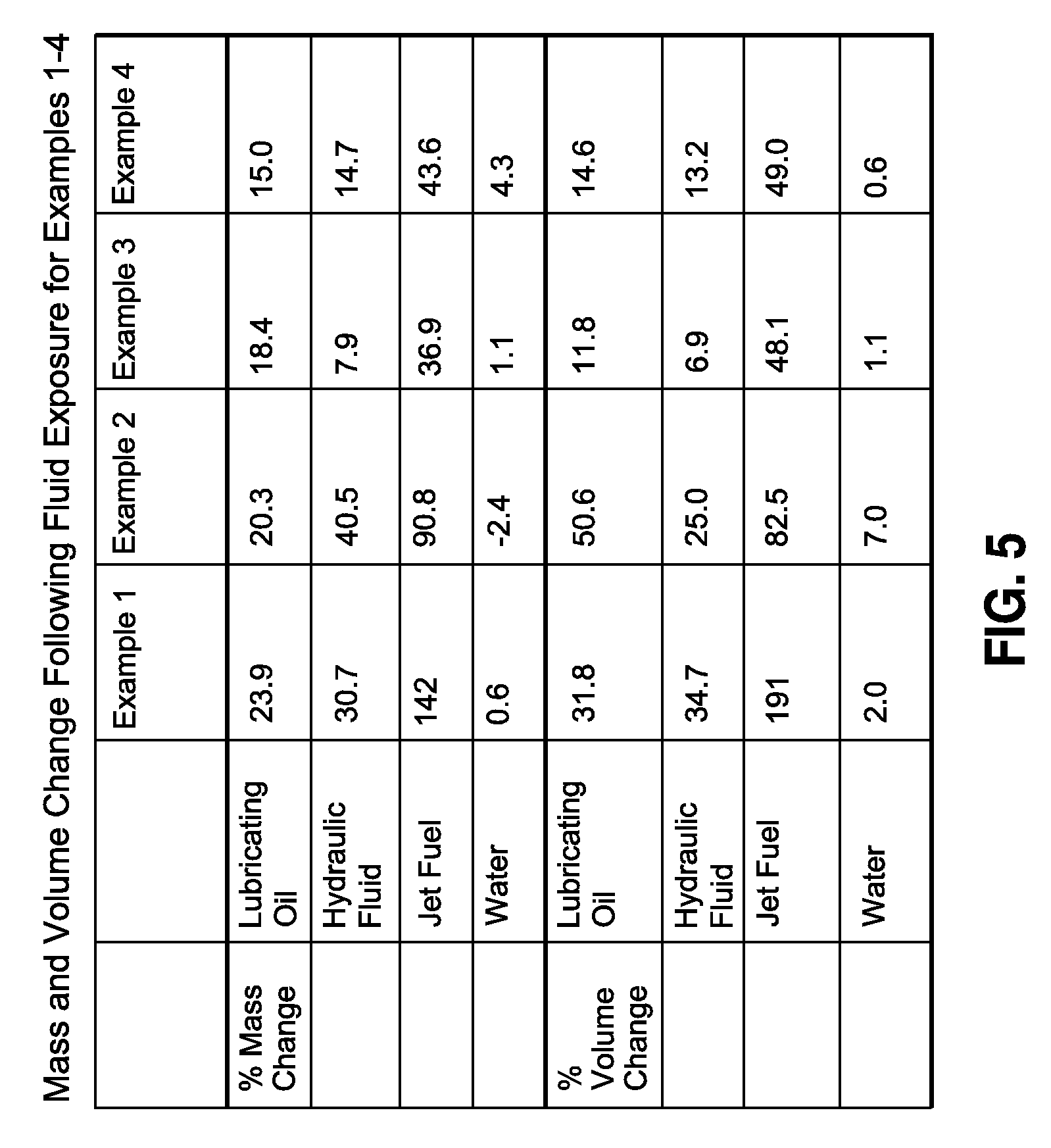

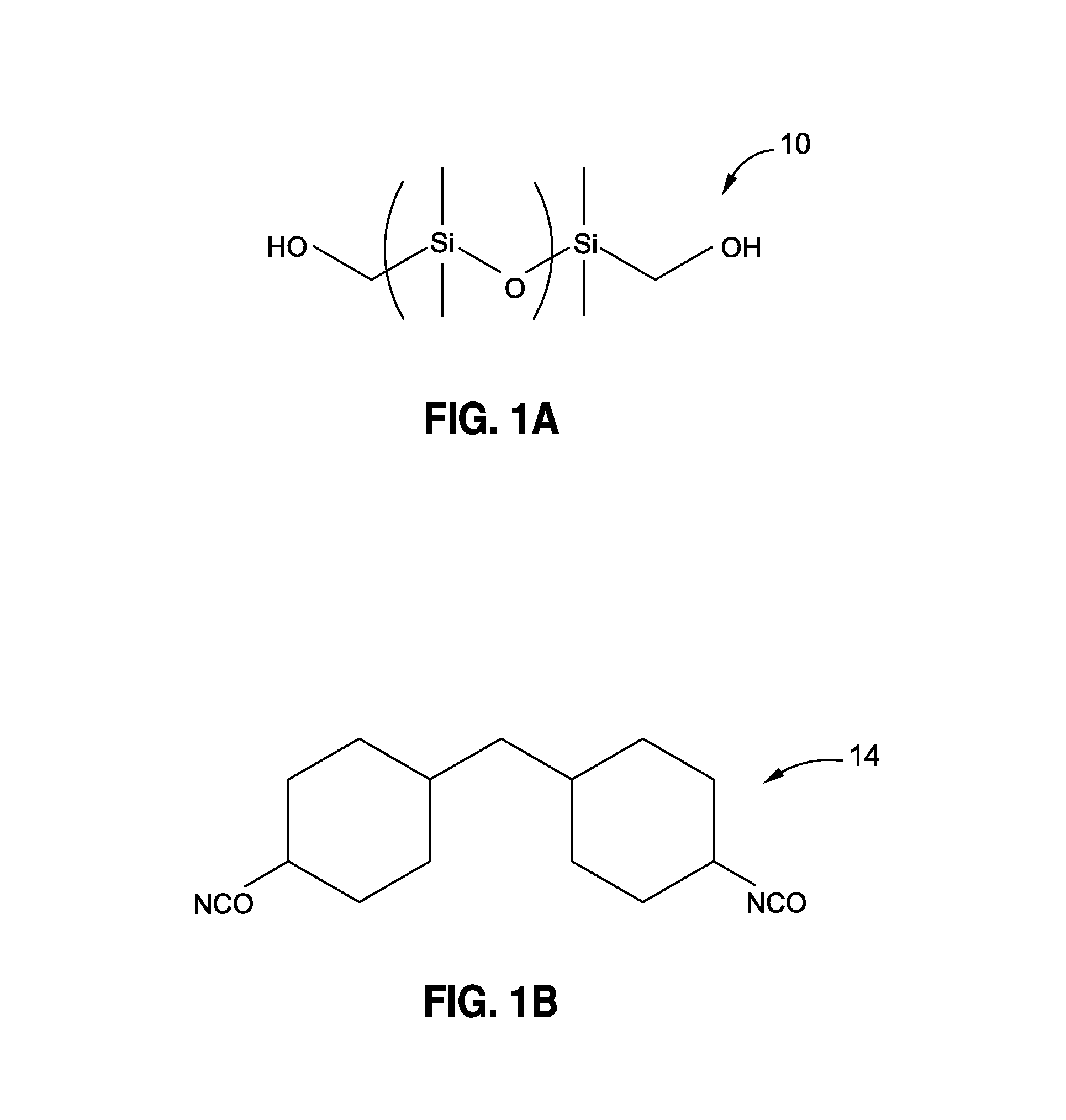

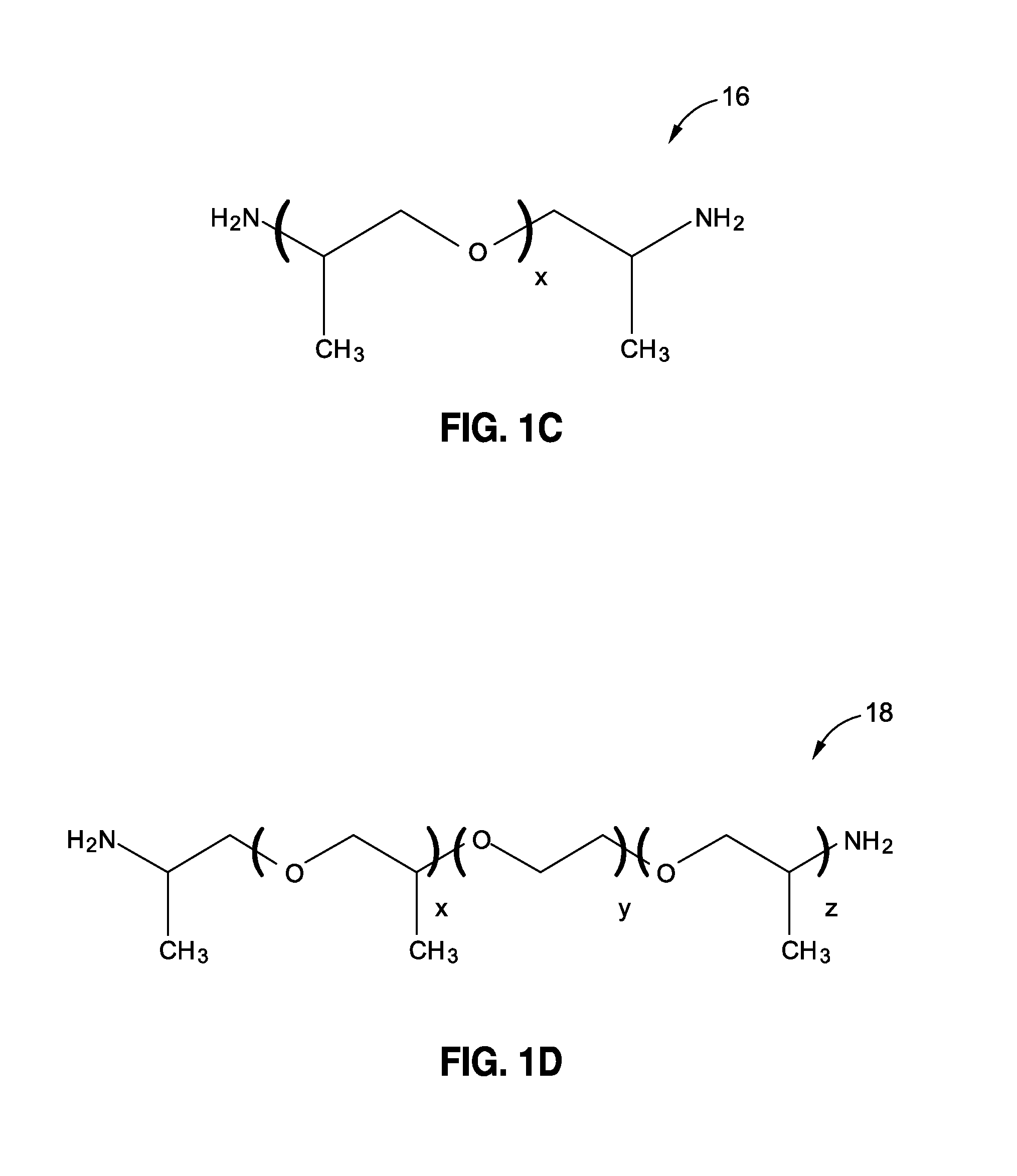

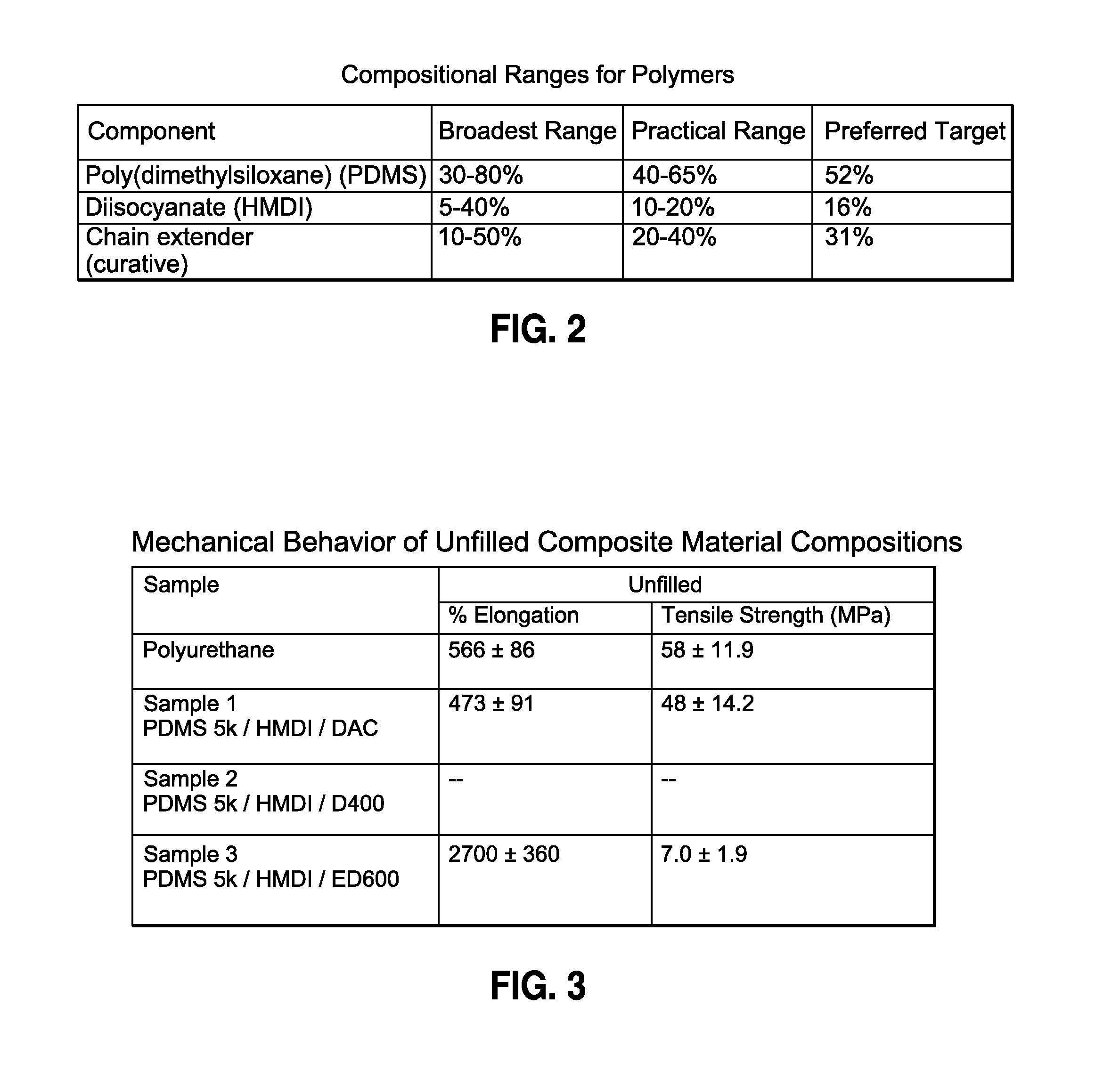

Low temperature segmented copolymer compositions and methods

There is provided segmented copolymer compositions and methods of making the same. The composition has one or more α,ω (alpha, omega) amine or α,ω (alpha, omega) hydroxyl terminated polysiloxane first soft segments having an average molecular weight of between about 2500 grams per mole to about 10,000 grams per mole. The composition further has one or more diisocyanate species. The composition further has one or more low molecular weight diol or diamine chain extenders. The composition has a high flexibility at an environmental temperature of down to about −100 degrees Celsius, and further has a percent elongation of greater than about 250%, a high tensile strength of greater than about 25 MPa (megapascals), and a single low glass transition temperature (Tg) in a range of from about −60 degrees Celsius to about −110 degrees Celsius.

Owner:THE BOEING CO

Radial tire for aircraft with specified merged cords

A pneumatic tire for use on aircraft has a tread, a crown reinforcement, and a radial carcass reinforcement having at least one axially inner ply of textile cords wound around a pair of bead cores, at least one axially inner ply being wound around the bead core in each bead from inside to the outside forming outside turn-ups and at least one axially outer ply of textile cords extending from bead to bead along the turn-ups of the at least one axially inner ply. The at least one axially inner ply or at least one axially outer ply has merged cords having a percent elongation at break of 12% to less than 20% and a break strength greater than 1050 N with a linear density of greater than 9,000 dtex. Merged cord reinforcement is preferably used in the ply layers or strips of the crown reinforcement as well.

Owner:THE GOODYEAR TIRE & RUBBER CO

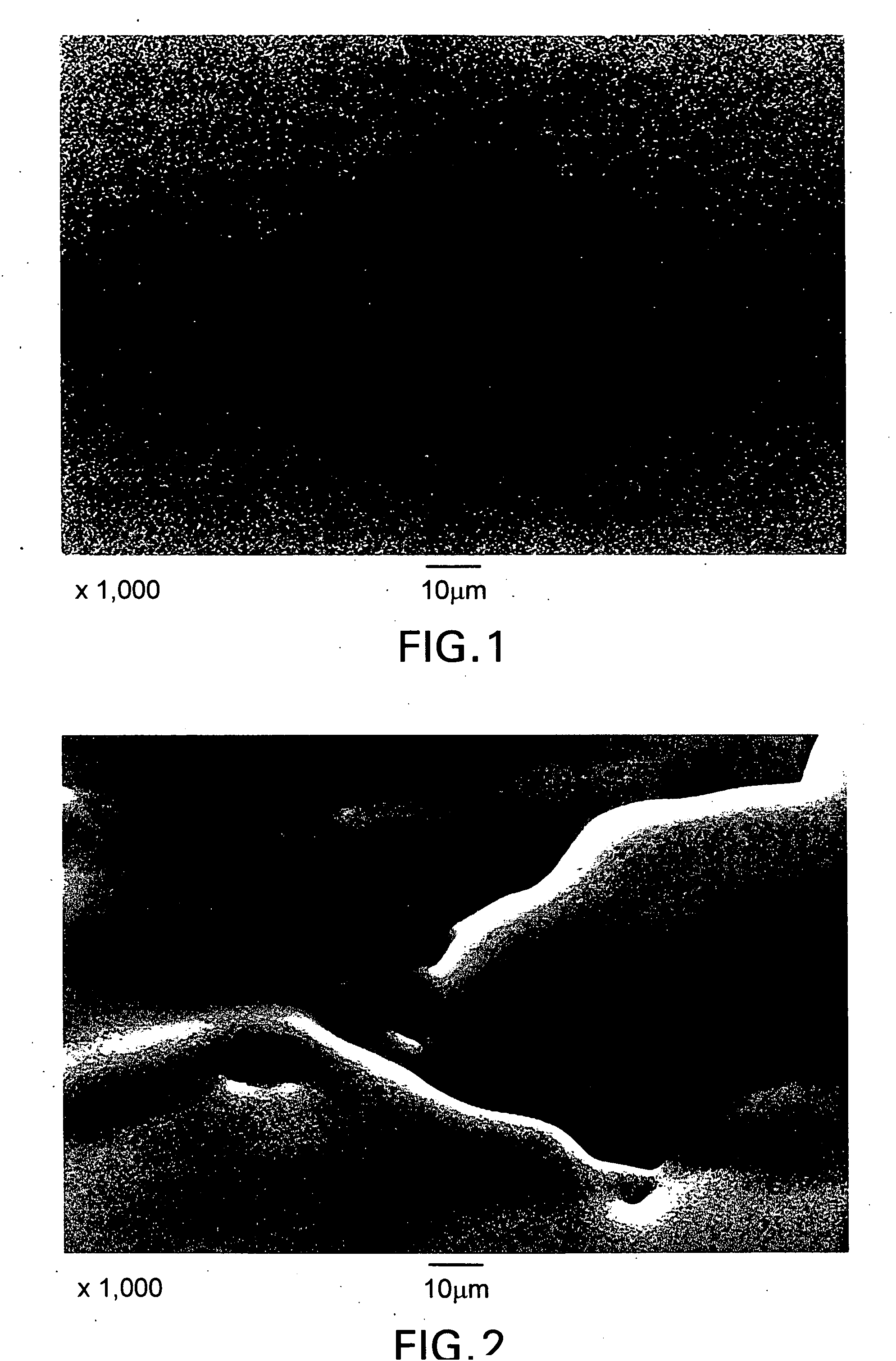

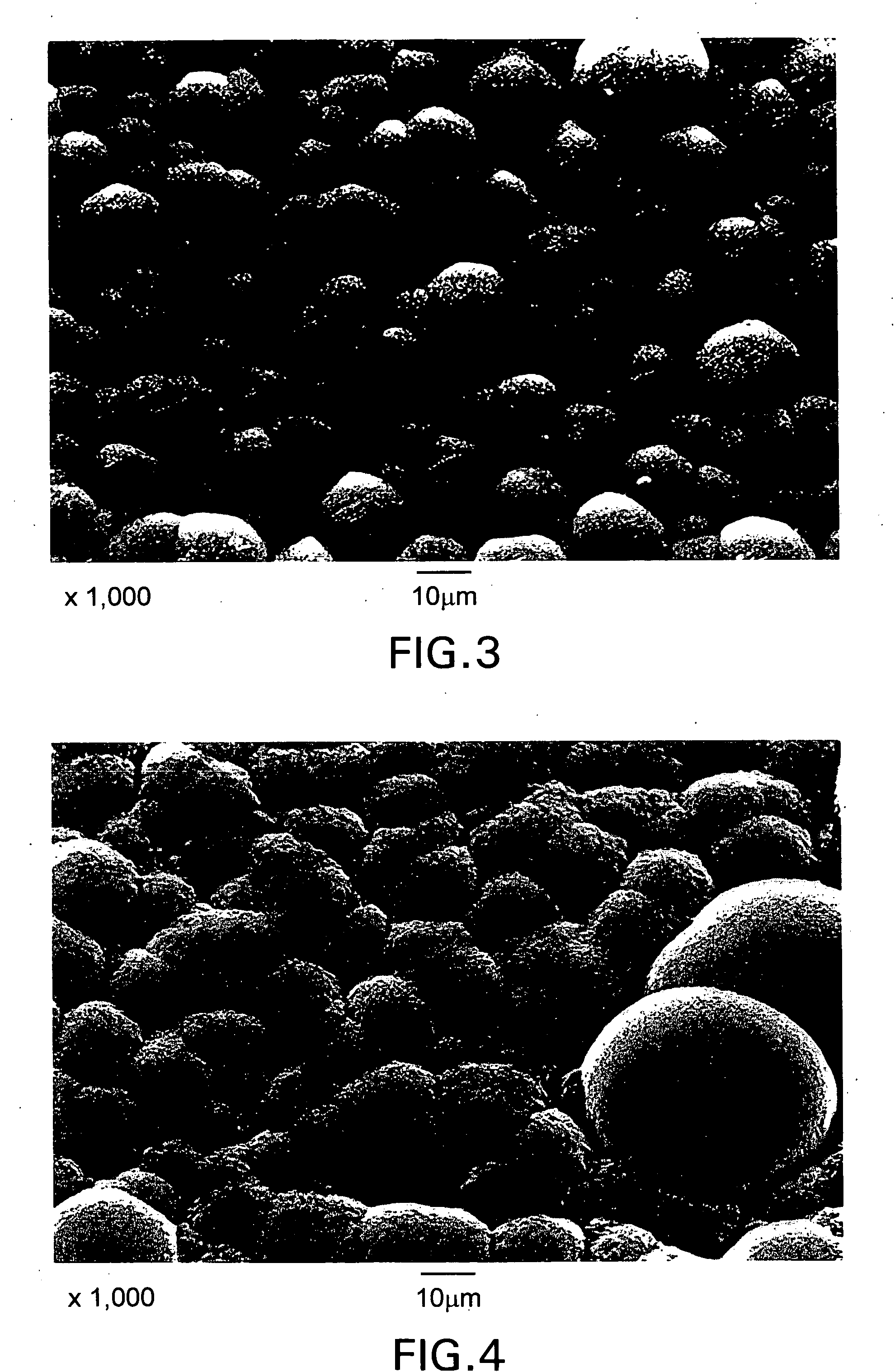

Electrolytic copper foil with low roughness surface and process for producing the same

InactiveUS20060191798A1Low roughness surfaceReduce roughnessInsulating substrate metal adhesion improvementPrinted circuit aspectsElectrolysisCopper foil

An electrolytic copper foil with low roughness surface whose surface roughness (Rz) is 2.0 μm or less, the surface uniformly provided with low roughness without uneven surge, which electrolytic copper foil exhibits a percent elongation of 10.0% or higher at 180° C. This electrolytic copper foil with low roughness surface can be obtained by a process for producing an electrolytic copper foil, comprising passing a direct current between an insoluble anode consisting of a titanium plate coated with a Platinum Group element or oxide thereof and a titanium drum as a cathode counter to the anode in an electrolyte of an aqueous solution of sulfuric acid / copper sulfate, wherein the electrolyte contains an oxyethylene surfactant a polyethyleneimine or derivative thereof, a sulfonate of active organosulfer compound and chloride ions.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

Peelable flexible coatings, compositions and methods thereof

InactiveCN104937053APolyurea/polyurethane coatingsThin material handlingPercent elongationPolymer chemistry

A peelable, flexible coating for a surface is provided, comprising a polymer blend that comprises polyurethane as a major component, and at least a polymer P2 having in comparison to polyurethane a higher peel strength to the surface to be coated and a higher percent elongation at break when cured for imparting a flexible and a peelable quality to the coating.

Owner:3M INNOVATIVE PROPERTIES CO

High-strength duralumin alloy applied to mobile phone shell and preparation method of high-strength duralumin alloy

The invention provides high-strength duralumin alloy applied to a mobile phone shell and a preparation method of the high-strength duralumin alloy. The used high-strength duralumin alloy comprises thefollowing components in percentage by mass: 5.00 to 10.00 percent of Zn, 1.20 to 6.00 percent of Mg, 0.03 to 0.50 percent of Mn, 0.03 to 4.00 percent of Cu, 0.01 to 0.25 percent of Zr, 0.01 to 0.30 percent of Cr, 0.01 to 0.20 percent of Ti and the balance of Al and other inevitable impurities. After thermal treatment, a plate made from the high-strength duralumin alloy provided by the invention has excellent comprehensive performances, namely the tensile strength is 400 MPa to 500 MPa, the yield strength is 380 MPa to 480 Mpa, the percent elongation is 11% to 18%, the conductivity is 25% to 44% IACS, and the rigidity is 175 HV to 220 HV.

Owner:中铝东南材料院(福建)科技有限公司 +1

Coatings, compositions, coated articles and methods

InactiveUS20150291827A1High peel strengthHigh elongationRecord information storagePolyurea/polyurethane coatingsVitrificationPercent elongation

Coatings for a surface, coating compositions, articles coated with a coating, and methods of coating are disclosed in which the coating comprises a polymer blend of polyurethane as a major component and at least one other polymer P2 having in comparison to polyurethane a higher peel strength to the surface to be coated, a higher percent elongation at break when cured, and a lower glass transition temperature, the polymer blend having been cured to form a peelable and flexible layer having a textured surface.

Owner:3M INNOVATIVE PROPERTIES CO

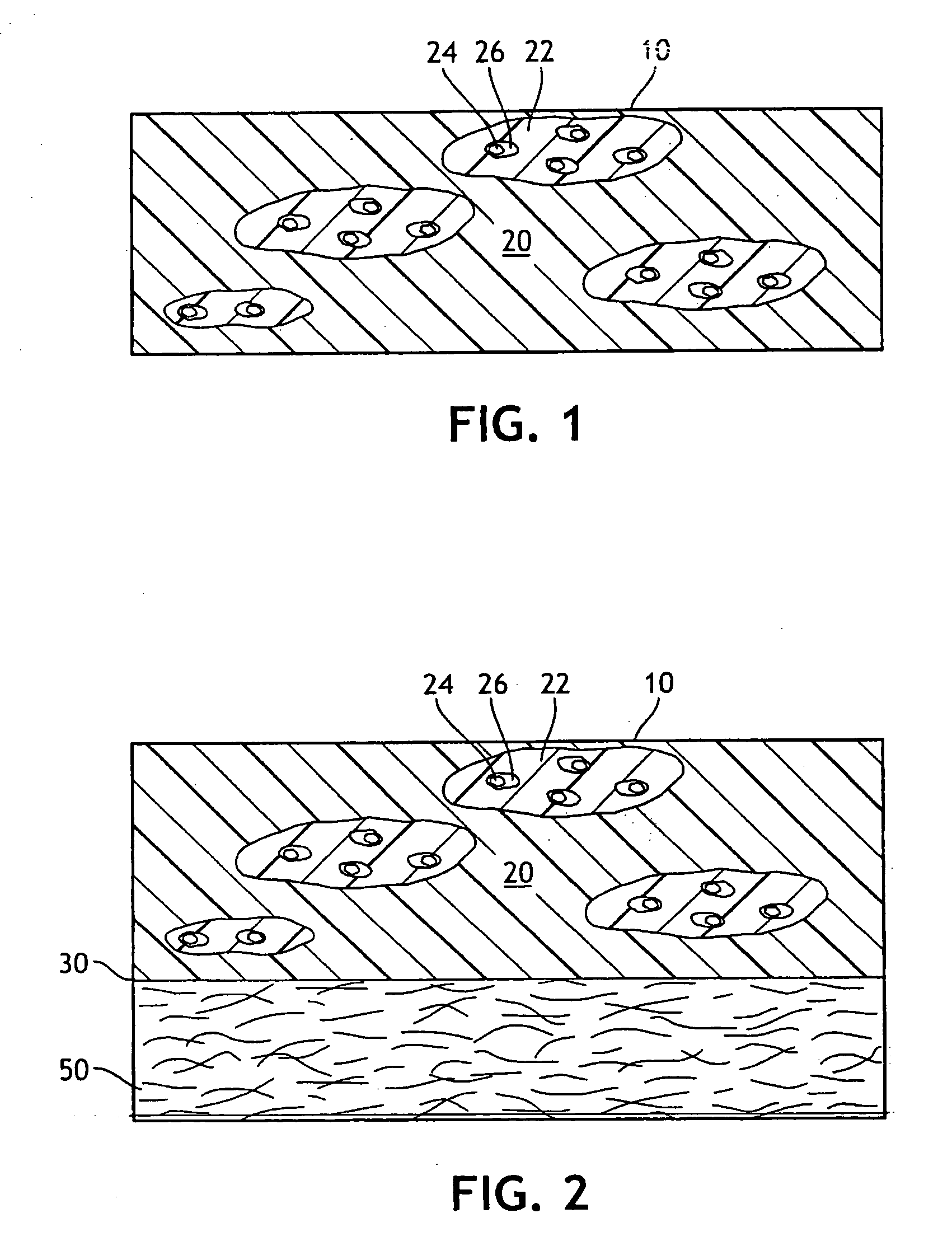

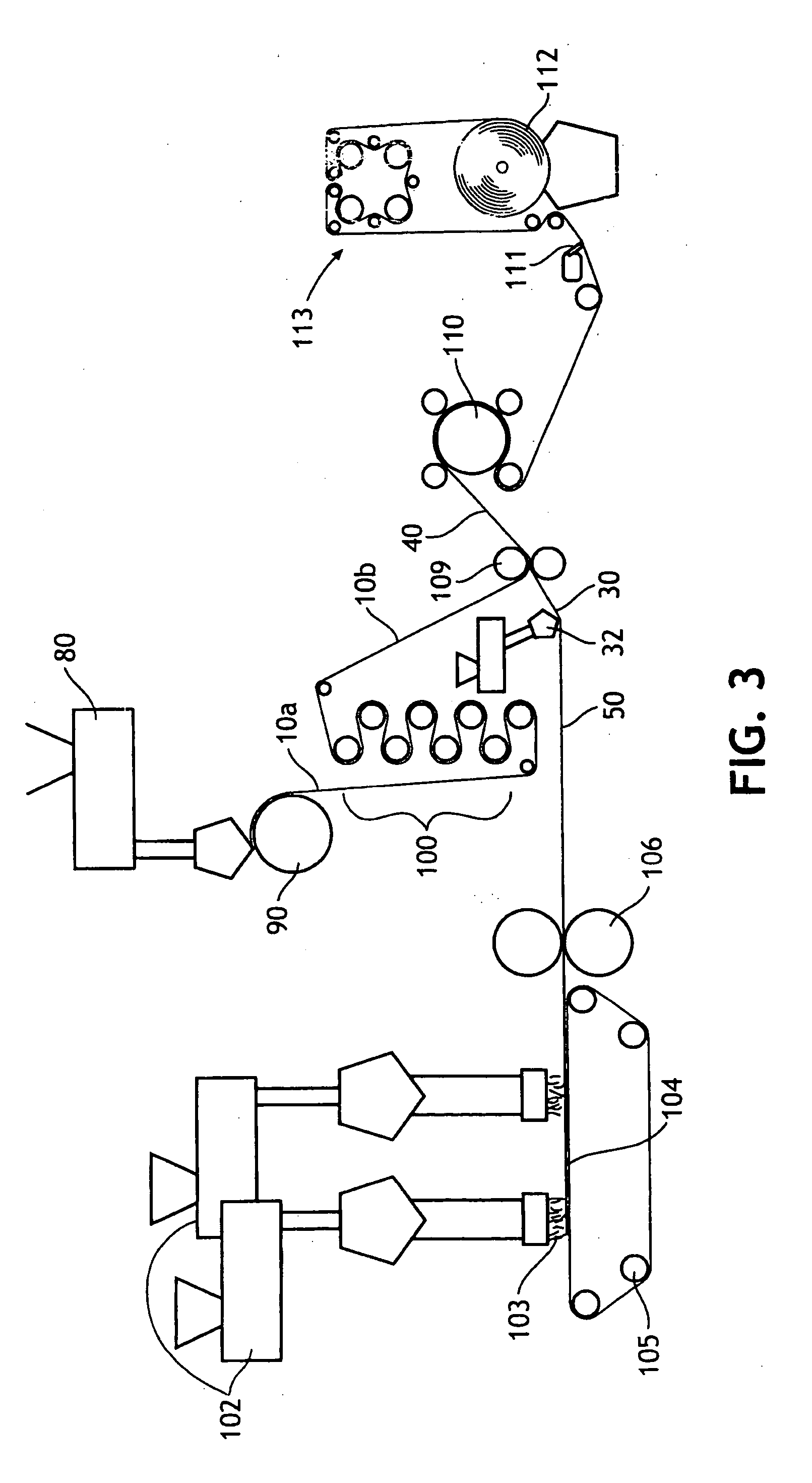

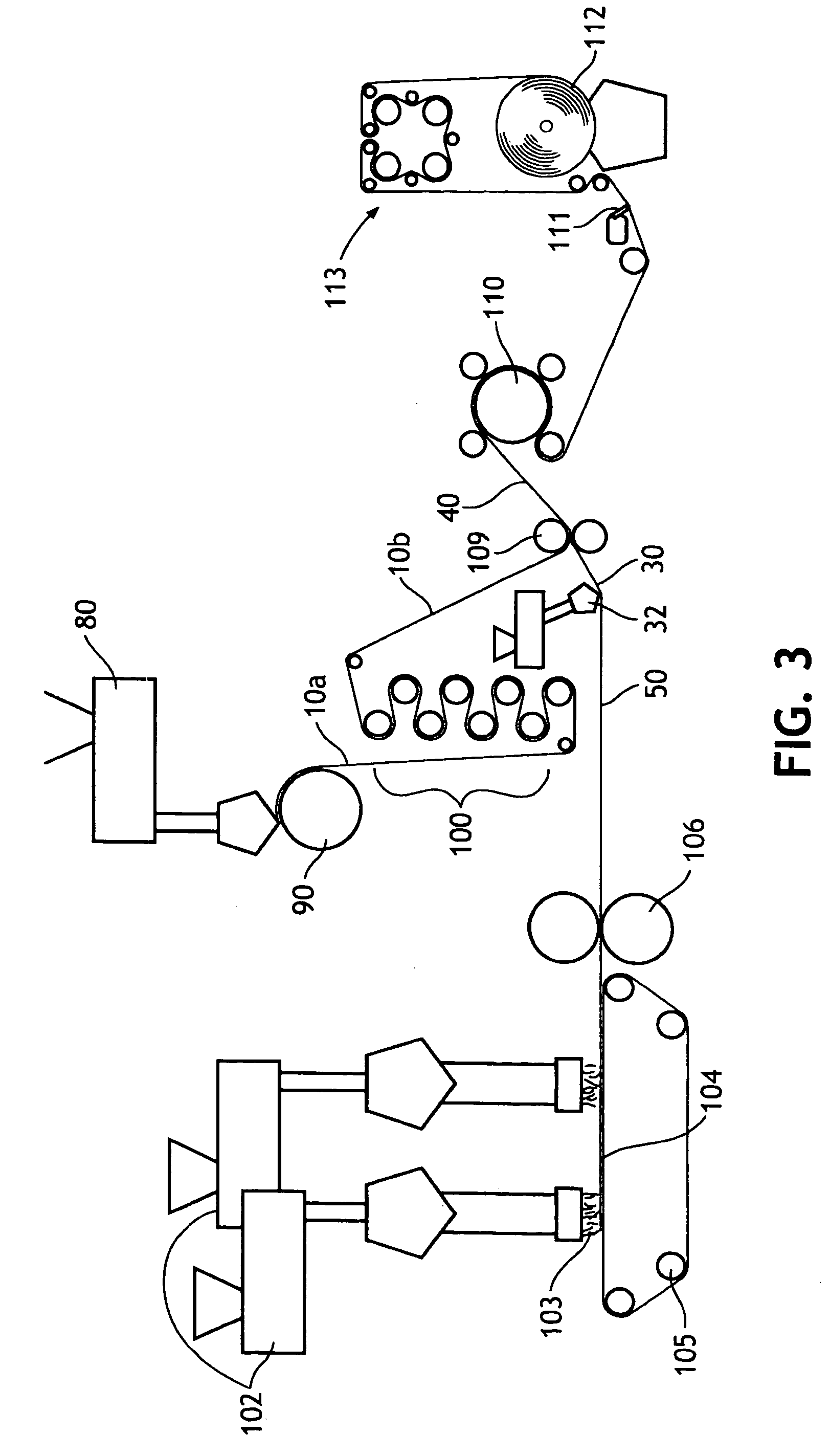

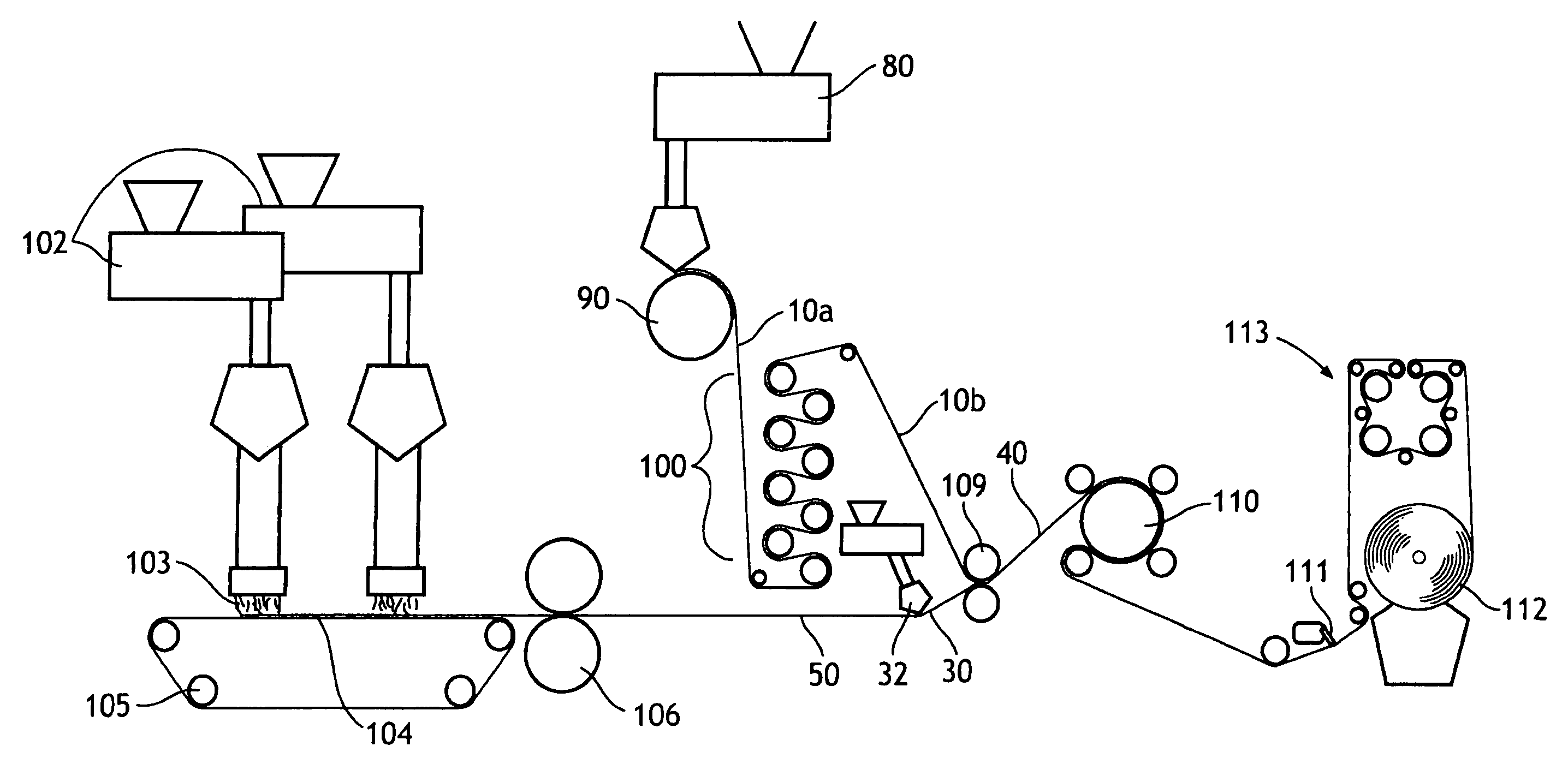

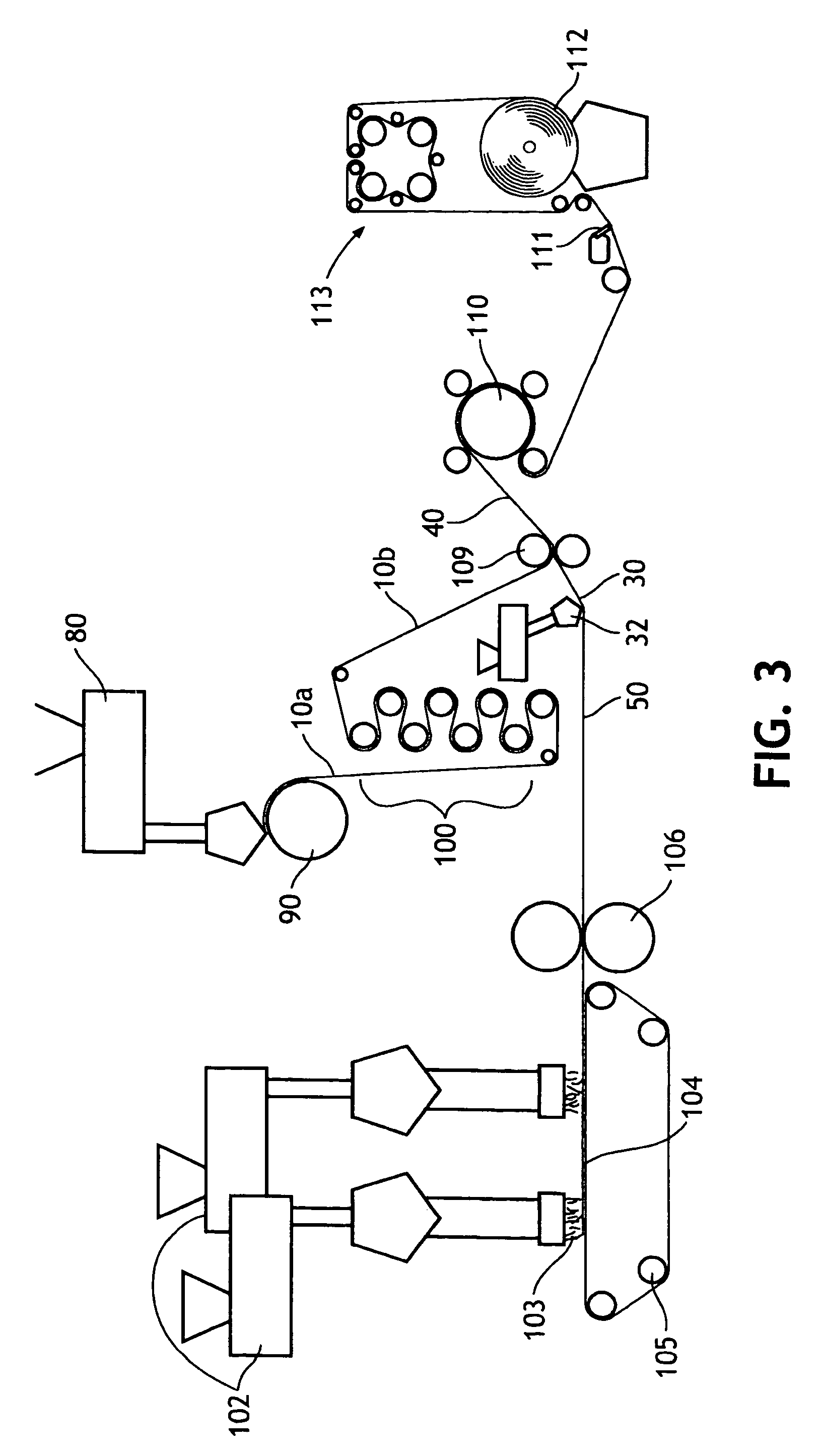

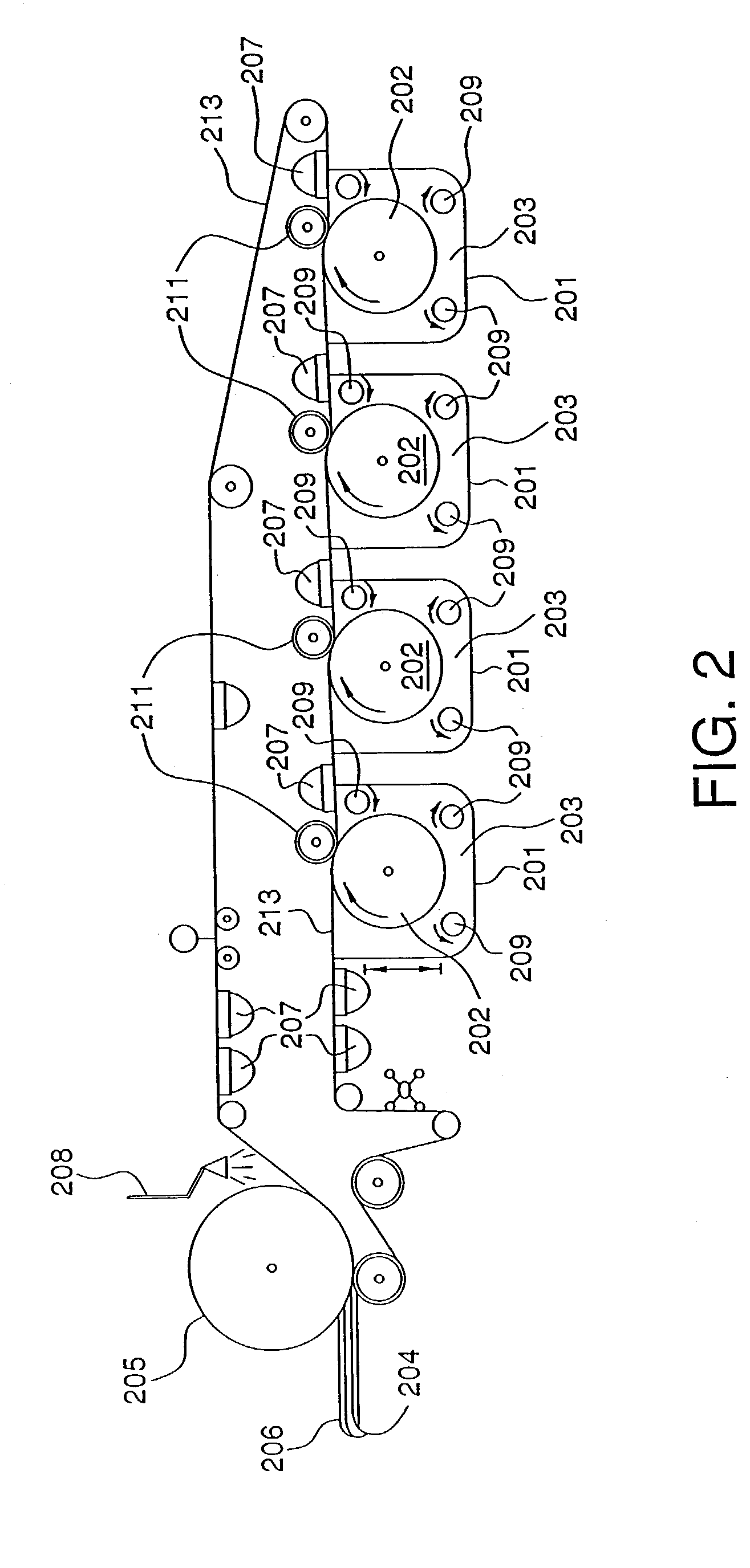

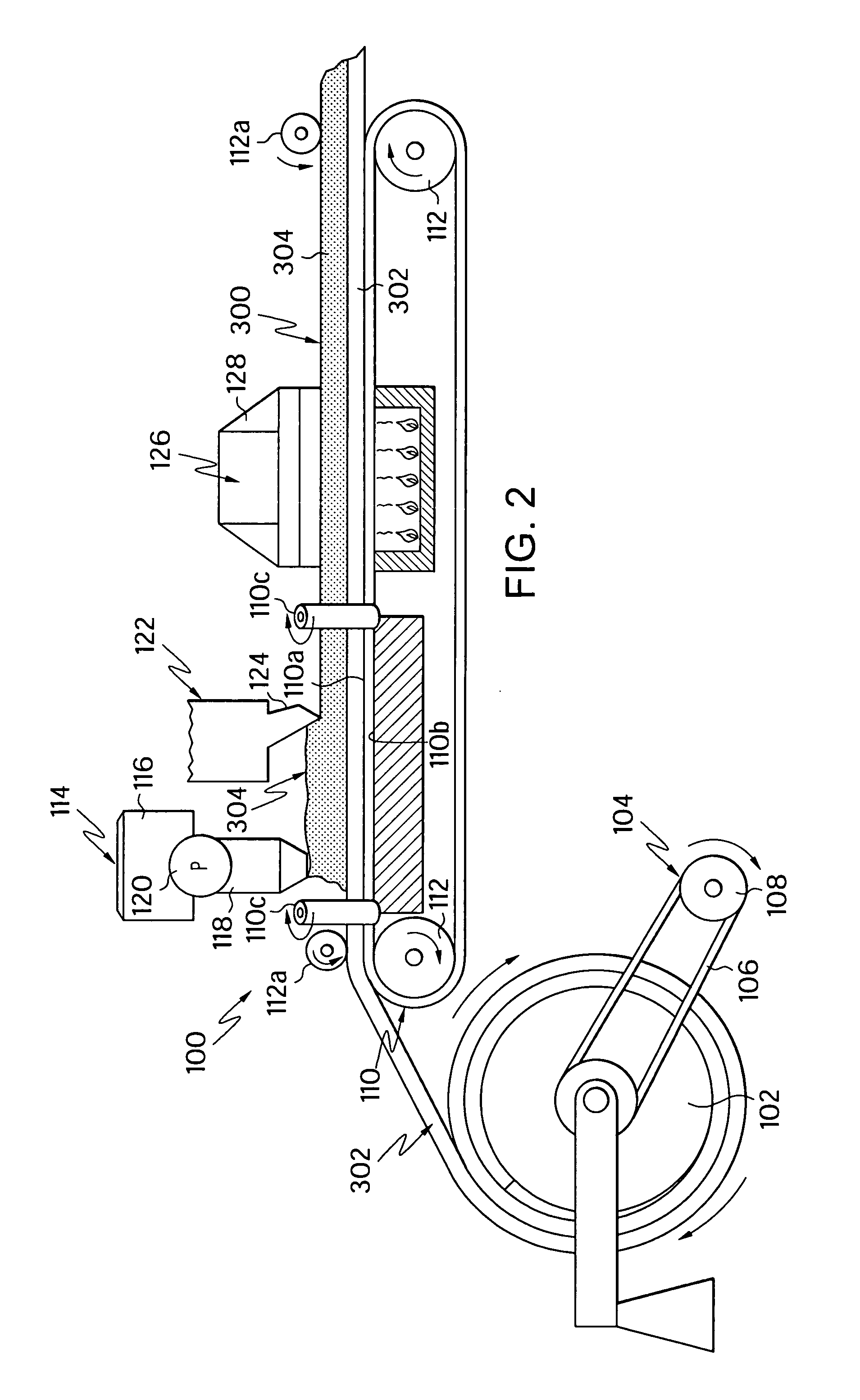

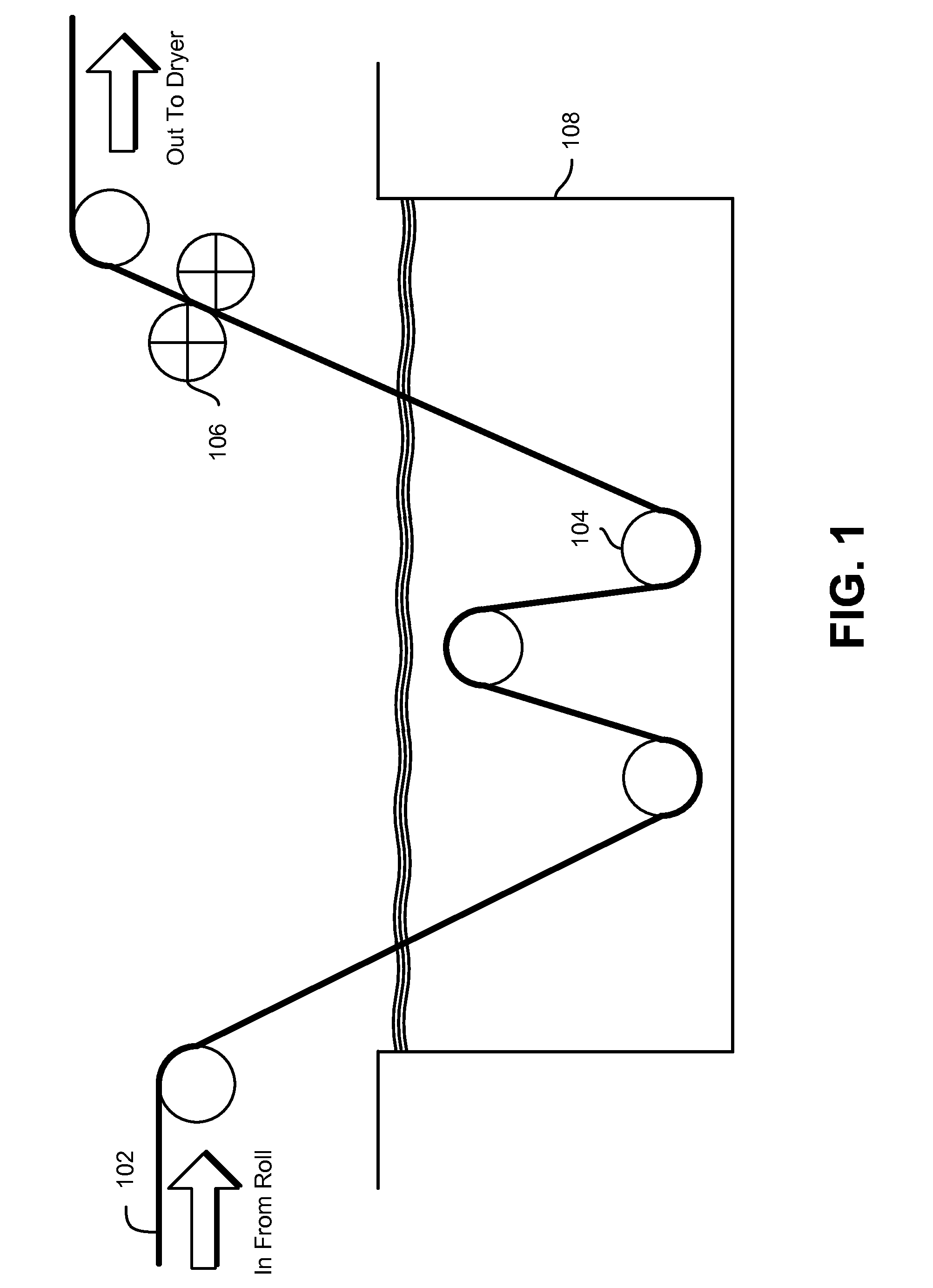

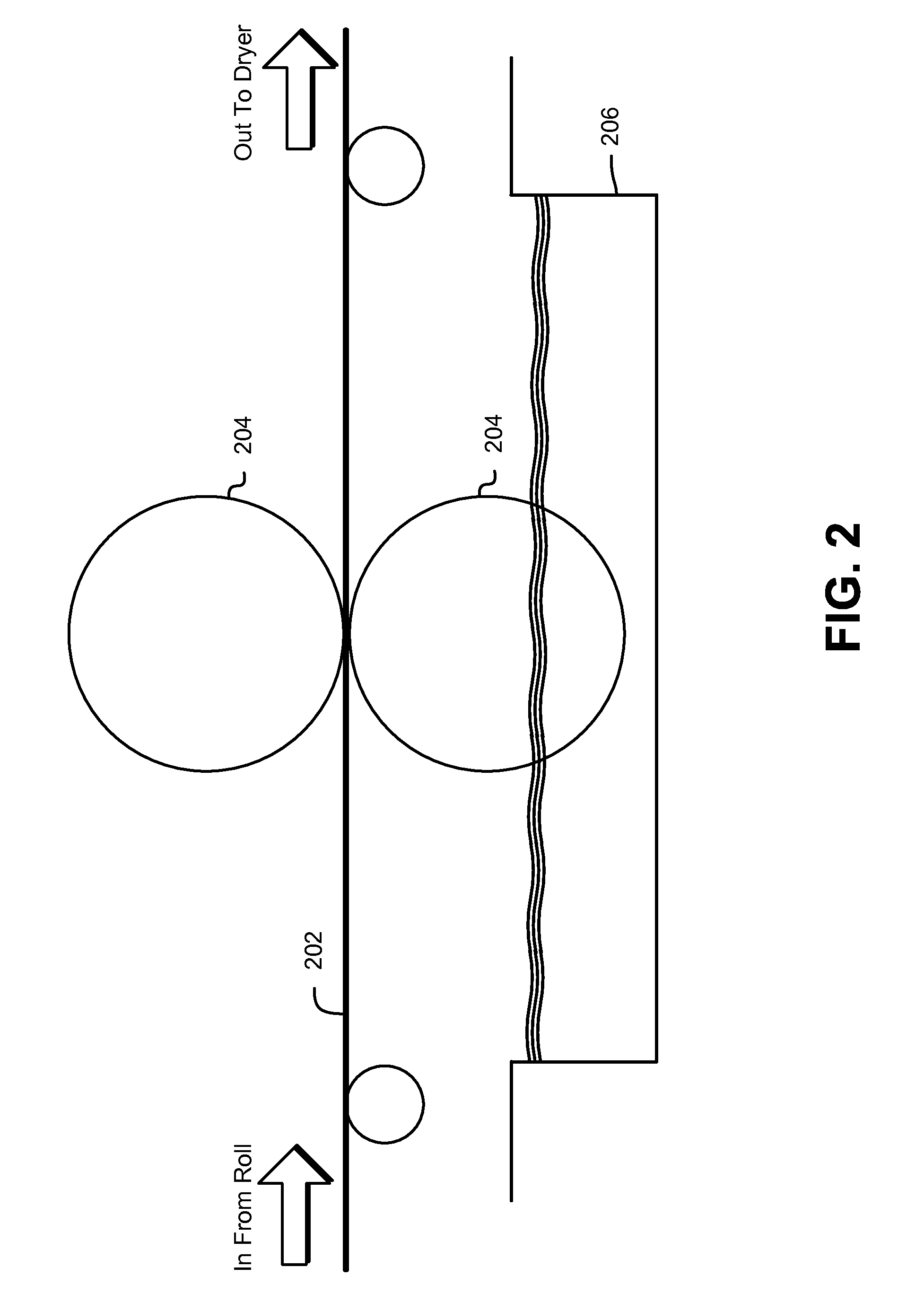

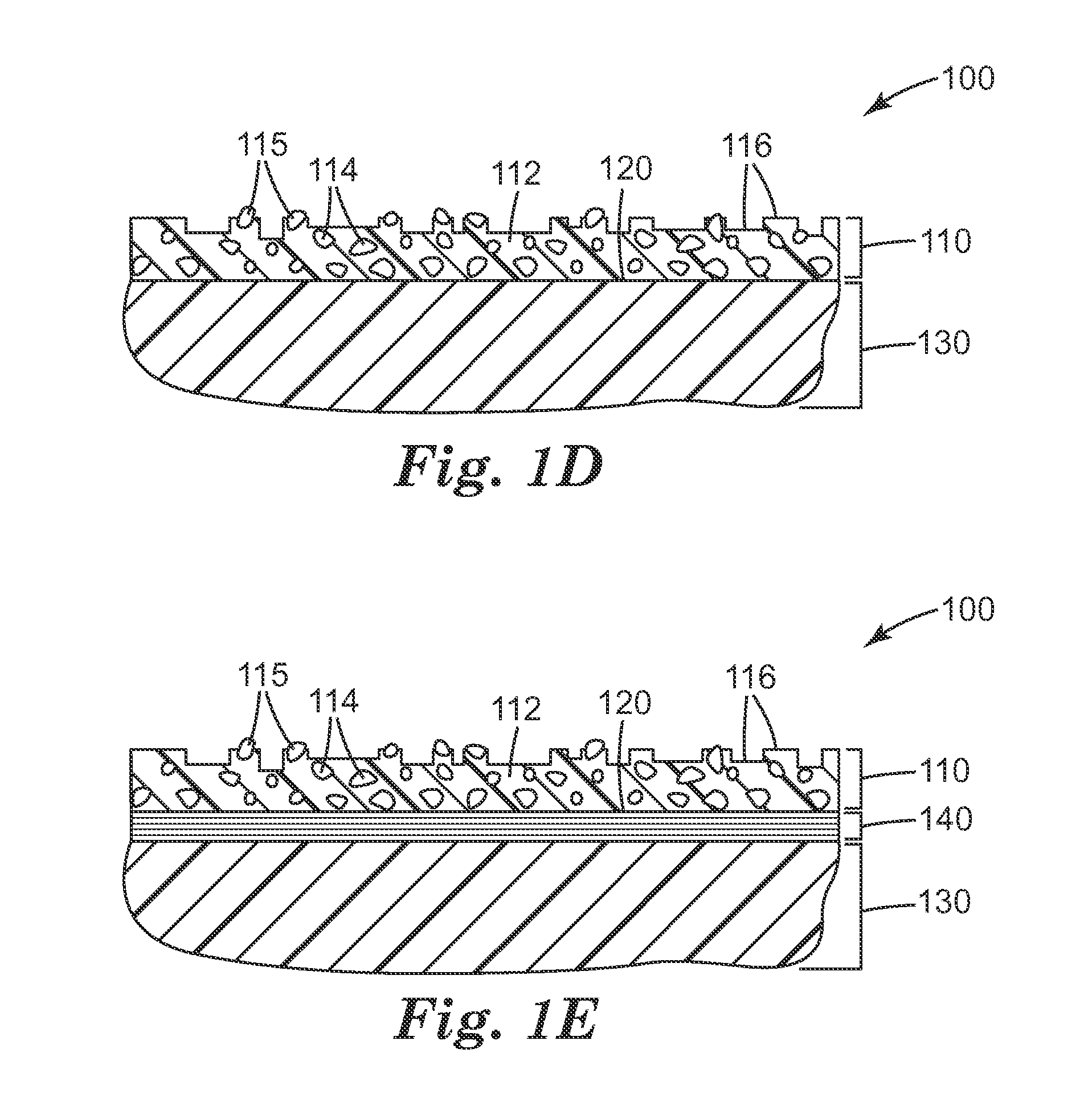

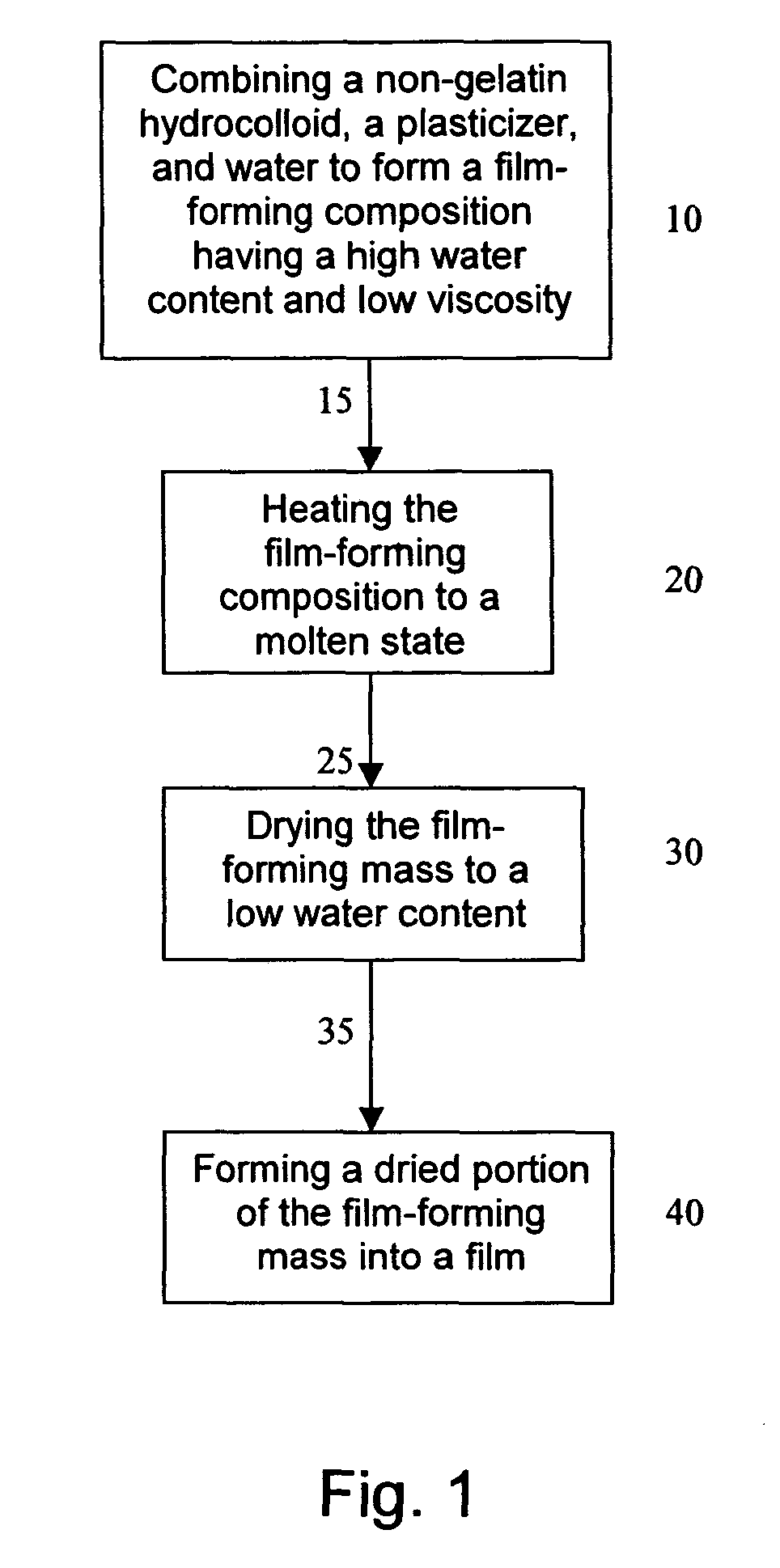

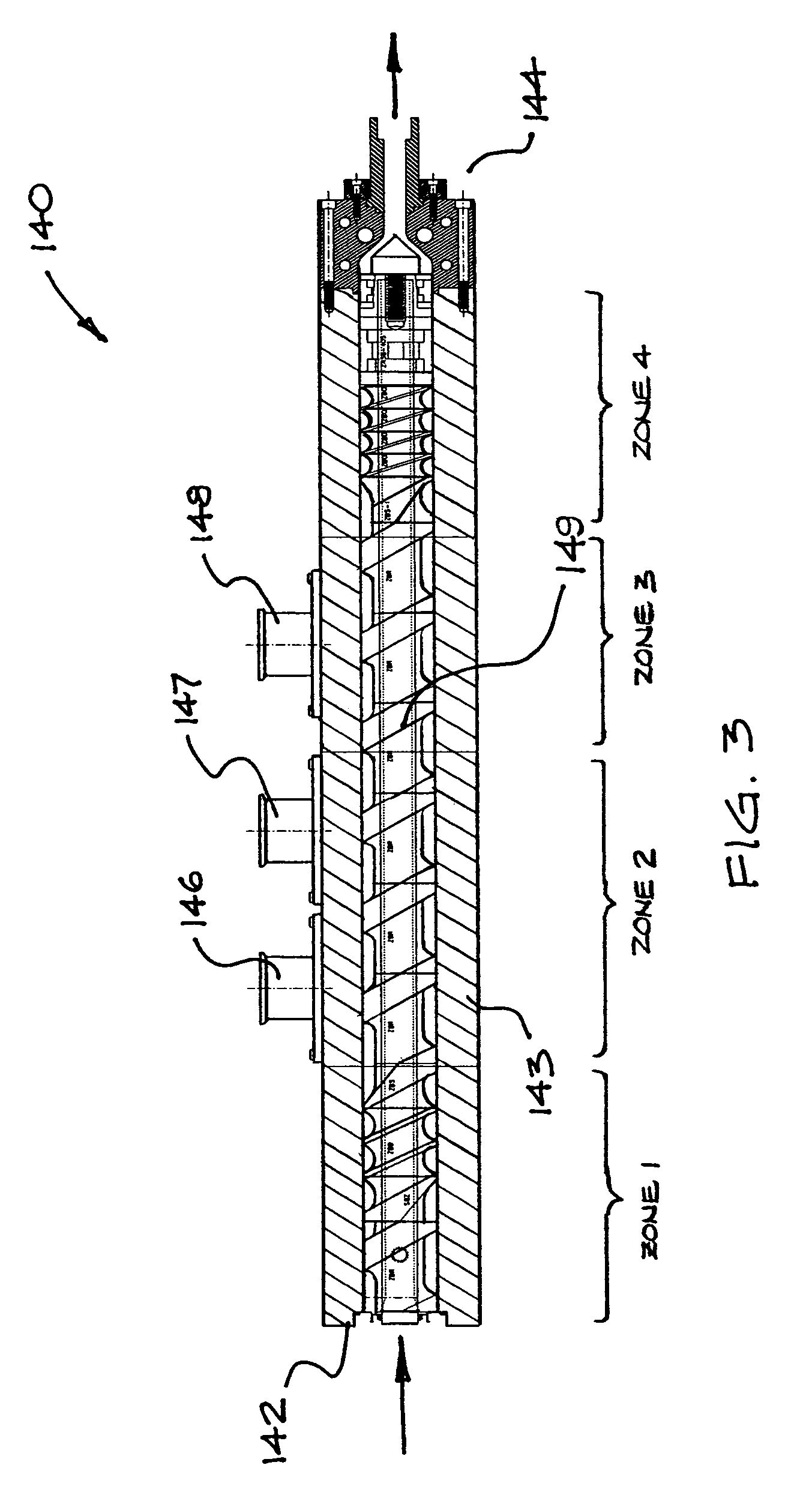

Non-gelatin film and method and apparatus for producing same

A film-forming composition comprising a hydrocolloid, a plasticizer, and water is described. A process and apparatus for producing a non-gelatin film comprising a hydrocolloid, a plasticizer, and water is also disclosed. The process includes combining at least one non-gelatin hydrocolloid, water, and at least one plasticizer into a substantially homogeneous film-forming composition comprising at least about 40 percent water by weight. A substantial portion of the water is then extracted from the film-forming composition to form a dried portion having a water content of less than or equal to about 25 percent by weight. The dried portion of the film-forming composition is formed into a film. A film produced according to the process preferably has a tensile strength at rupture of at least about 0.4 N / mn2, and a percent elongation of at least about 50 percent at rupture at room temperature. An apparatus for performing the process is also described, as well oral dosage forms encapsulated or enrobed in the produced film.

Owner:PATHEON SOFTGELS INC

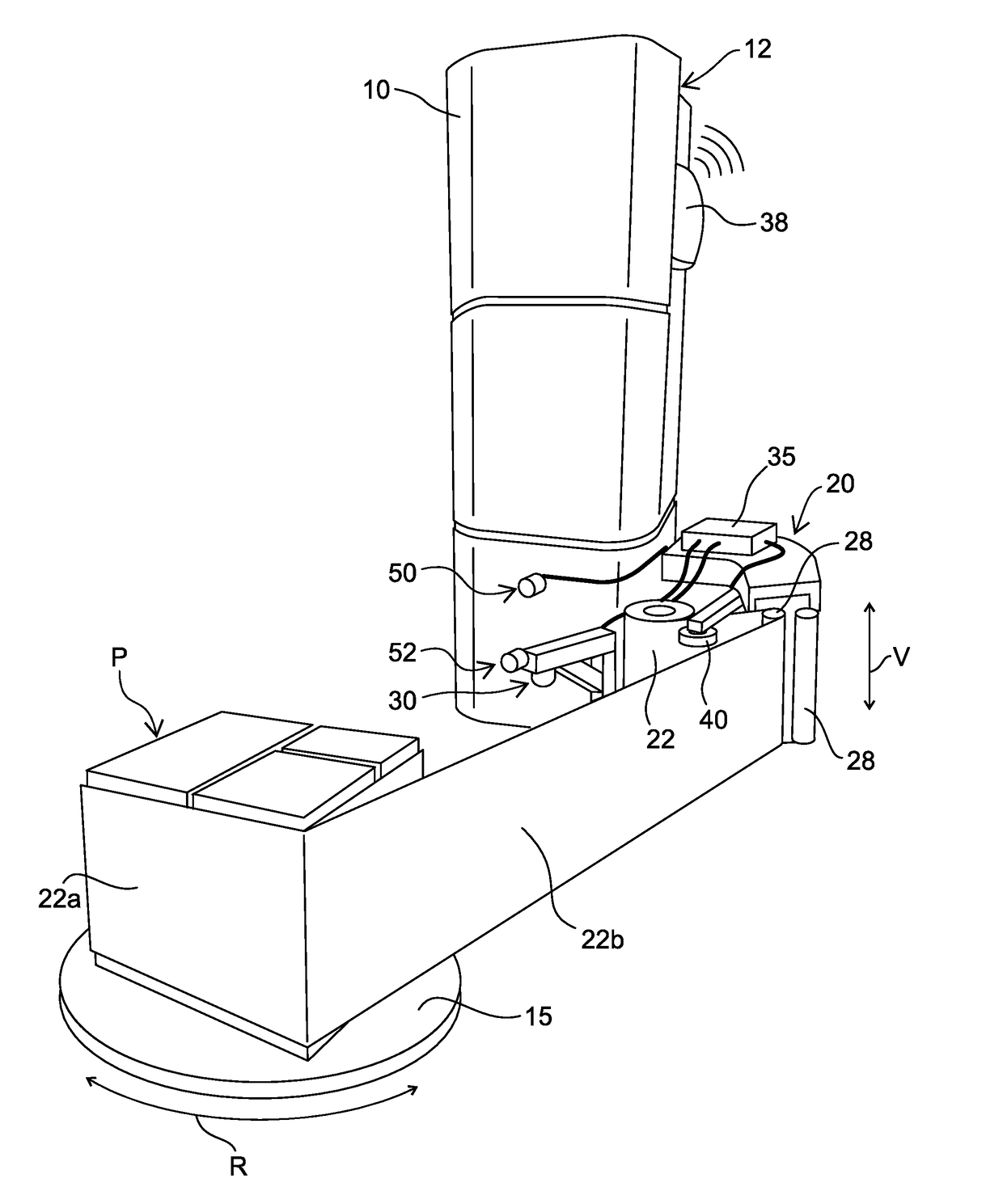

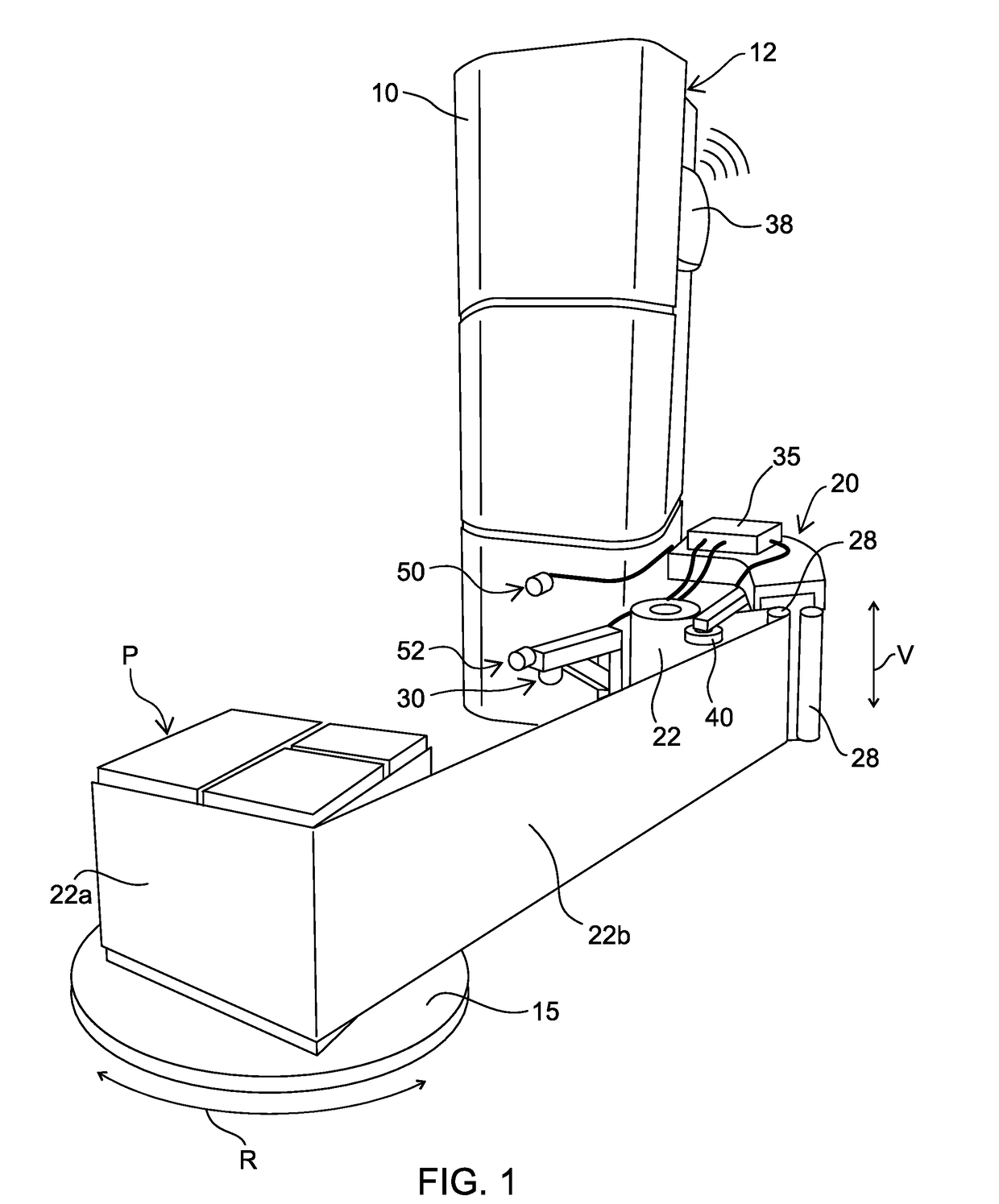

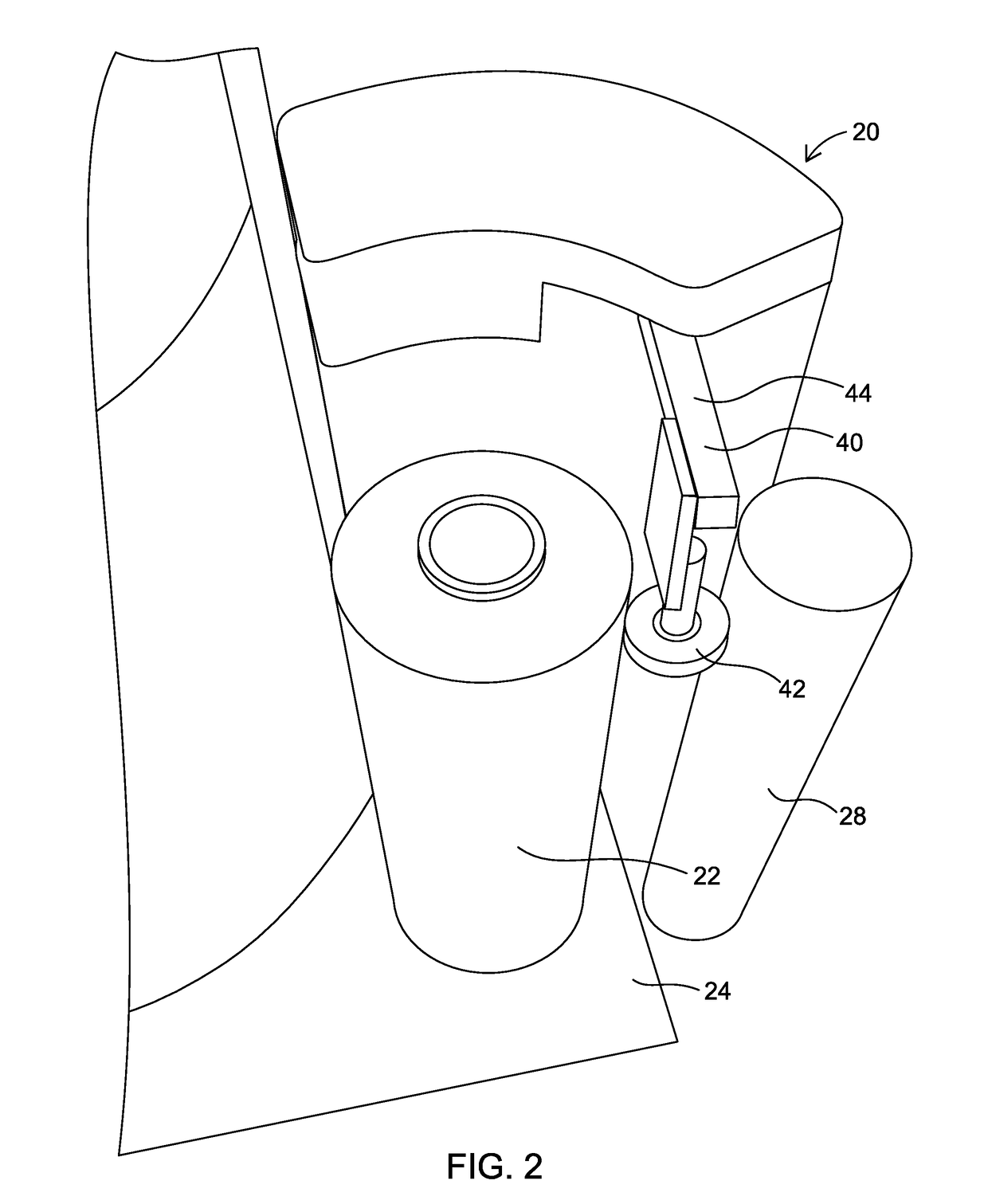

Stretch Wrap Monitoring Device

ActiveUS20180257802A1Wrapping material feeding apparatusPackaging automatic controlFilm baseSheet film

A system for monitoring the percentage of stretch of a stretch wrap film in a stretch wrapping machine includes a first sensor associated with the stretch wrap roll and configured to generate a first signal as the film travels from the roll to the pre-stretch roller assembly, and a second sensor associated with the load and configured to generate a second signal as the film is wrapped around the load. A processor is operable to: a) calculate a pre-stretch length of the film based on the first signal during a time interval; b) calculate a stretched length of the film as the film is wrapped around the load on the rotating platform during the time interval; and c) calculate a percentage stretch of the film based on the pre-stretch length and said stretched length.

Owner:GRP O INC

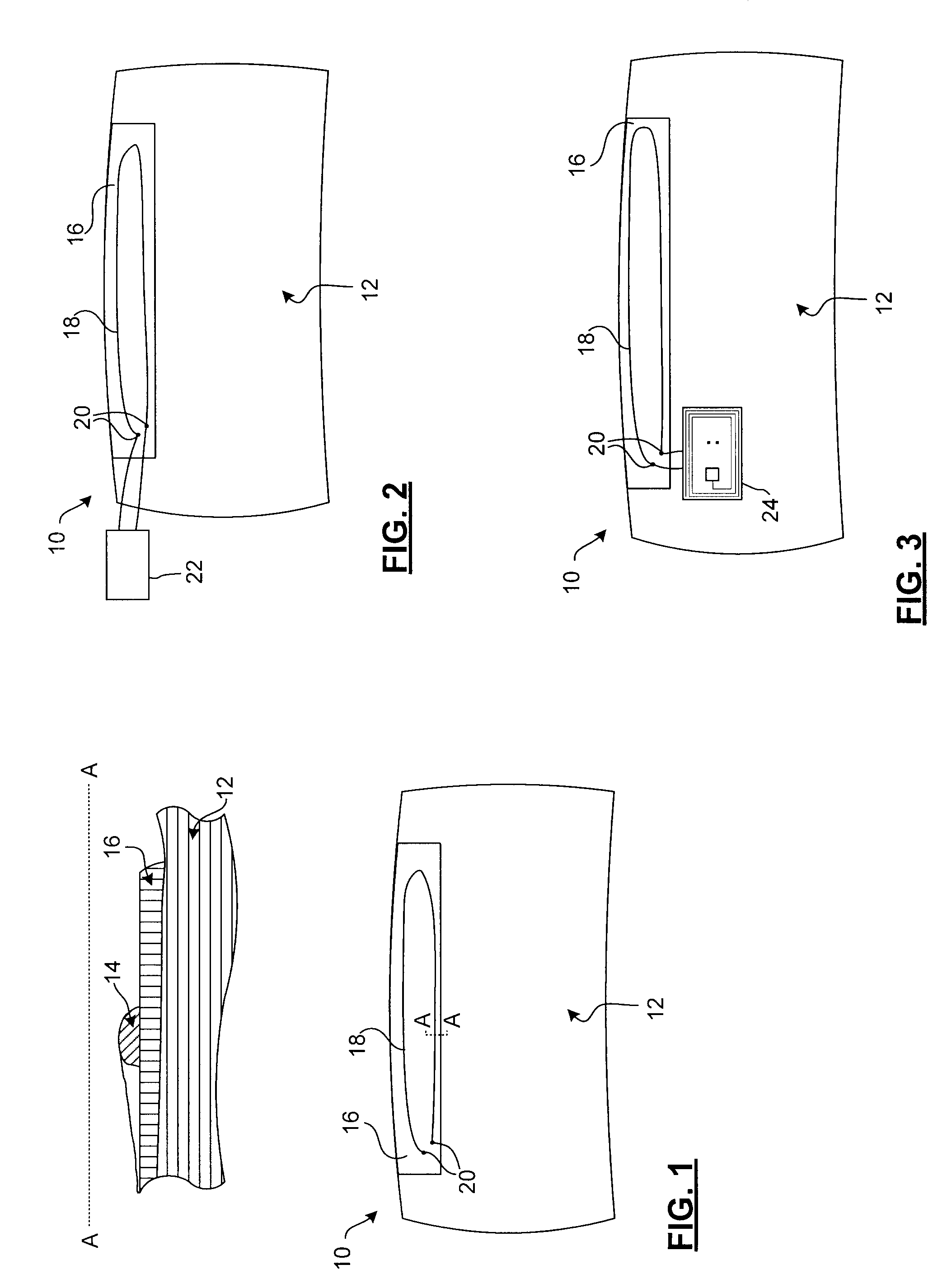

Customization system for an article of footwear

A customization system for an article of footwear is disclosed. The customization system comprises an insert system. The insert system includes an insert and a heel member. Both the insert and the heel member may be interchangeable, allowing the user to modify the article of footwear to provide a customized fit or performance optimization. An article of footwear may also include a full length composite plate to be used as part of an outsole assembly. The full length composite plate may comprise a composite material that has a certain percent elongation, and can include a heel cup for heel stability and improved traction.

Owner:NIKE INC

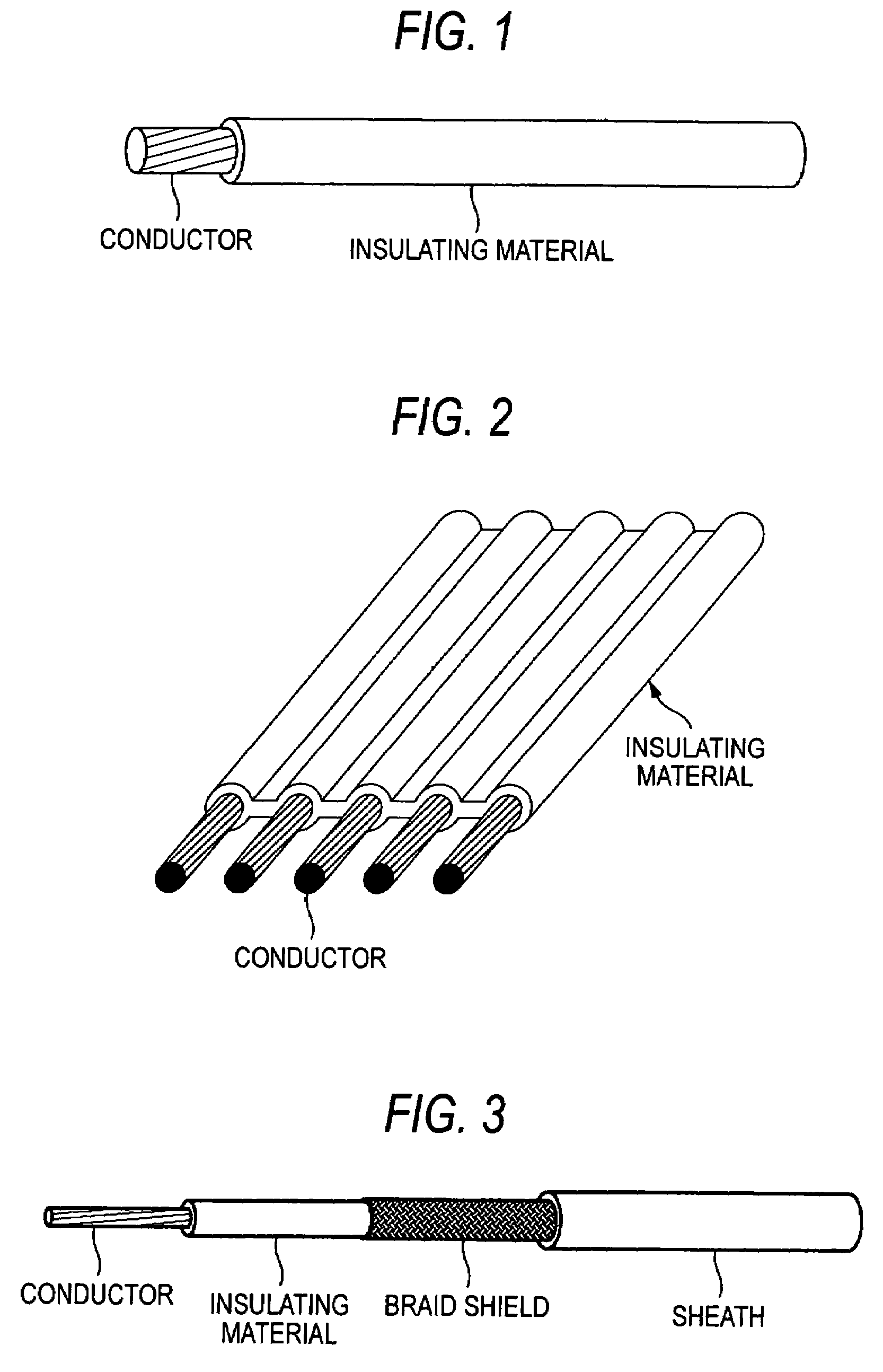

Automobile insulated wire

InactiveUS7201970B2Insufficient retardancyEffect is exertedPlastic/resin/waxes insulatorsSynthetic resin layered productsPercent elongationFire retardant

Owner:YAZAKI CORP

High strength low cost titanium and method for making same

A titanium alloy and method of making the same are provided. The alloy comprises one or more elements selected from the group consisting of chromium, iron, and manganese. In an as-cast condition, the alloy has a yield strength of at least about 135,000 psi, a tensile strength of at least about 155,000 psi and a percent elongation of at least about 5.0 percent.

Owner:GAINSMART GRP

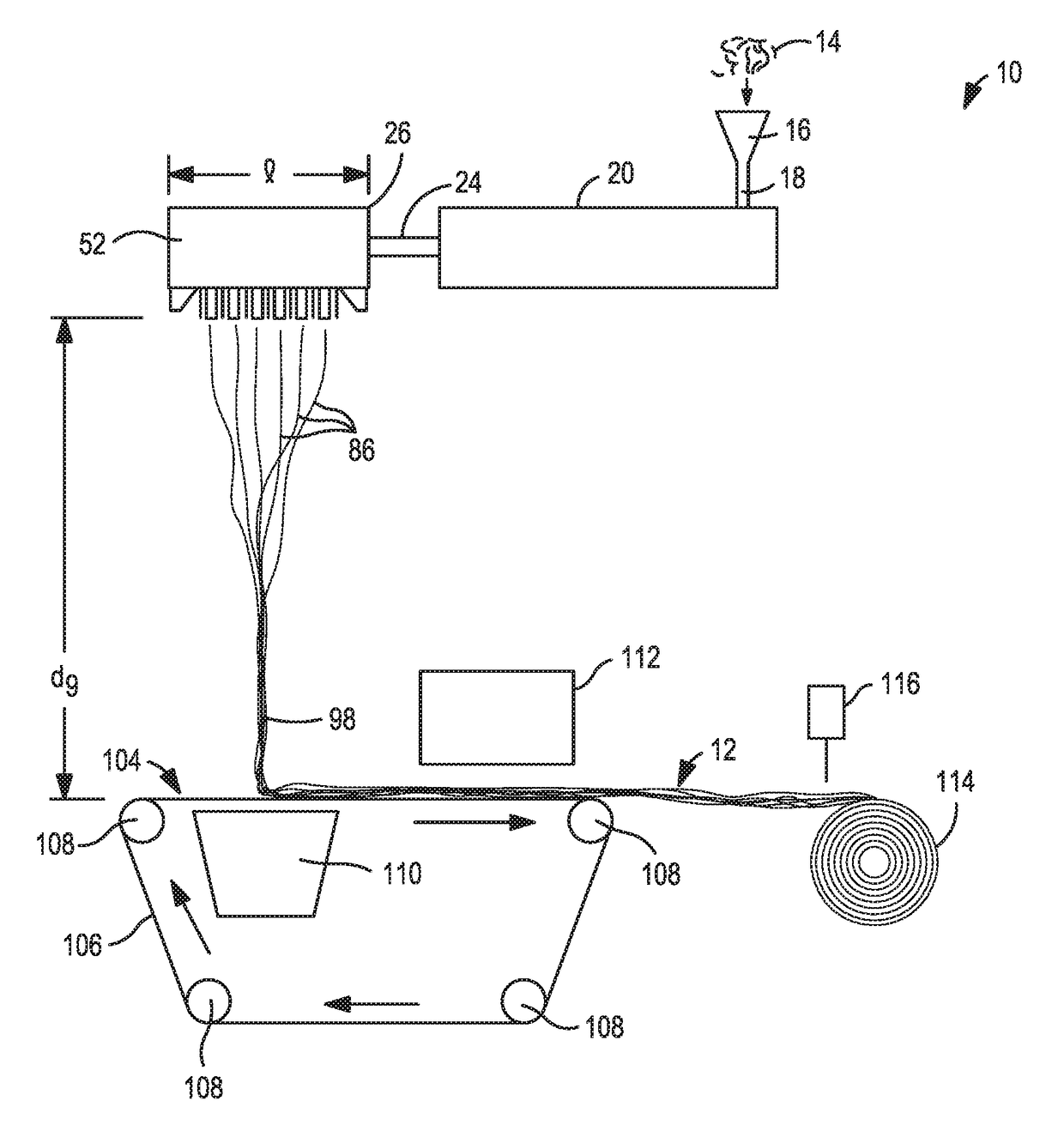

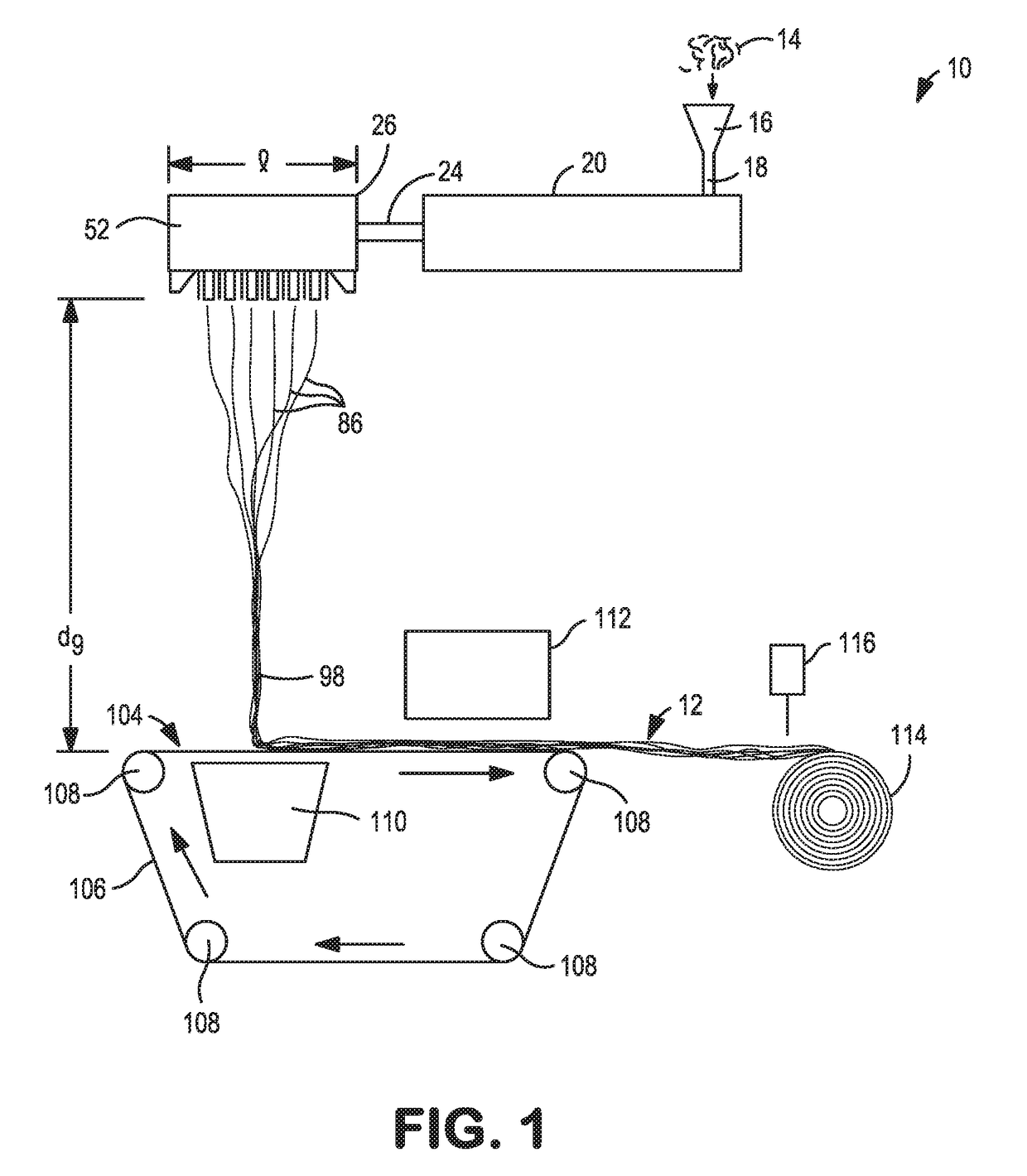

Spun-Blown Non-Woven Web

ActiveUS20180002832A1Improve fermentation effectEasy to processSpinnerette packsMonocomponent polypropylene artificial filamentPercent elongationFiber diameter

A spun-blown non-woven web is disclosed which is formed from a plurality of fibers formed from a single polymer having an average fiber diameter ranging from between about 0.5 microns to about 50 microns; a basis weight of at least about 0.5 gsm; a tensile strength, measured in a machine direction, ranging from between about 20 g to about 4,200 g; a ratio of tensile strength, measured in the machine direction, to basis weight of at least about 20:1; and a ratio of percent elongation, measured in the machine direction, to fiber diameter of at least about 15.

Owner:BIAX FIBERFILM CORP

Flexible, Low Temperature, Filled Composite Material Compositions, Coatings, and Methods

ActiveUS20130331509A1Increase flexibilityImprove toughnessPolyurea/polyurethane coatingsParticulatesElastomer

There is provided a flexible, low temperature, filled composite material composition and method of synthesizing the composite material composition. The composite material composition has a segmented copolymer elastomer having an α,ω-(alpha, omega)-dihydroxy terminated polysiloxane species, a diisocyanate species, and an amine or hydroxy terminated chain extender. The composite material composition further has a solid particulate filler. The composite material composition has a high flexibility at a temperature of down to about −100 degrees Celsius, has a percent elongation of greater than about 100%, and has a tensile strength of greater than about 5 MPa (megapascals).

Owner:THE BOEING CO

Method of testing erw pipe weld seam for susceptibility to hydrogen embrittlement

ActiveUS20210229221A1Weather/light/corrosion resistanceMaterial strength using tensile/compressive forcesPercent elongationWeld seam

A method of managing a tubular having a seam that exhibits signs of hydrogen induced cracking that extends radially along the seam, and which is different from classic step-wise cracking. Included in the method is evaluating the strength and ductility specimens taken from the tubular that have been hydrogen charged; and which provides an indication if the seam is susceptible to hydrogen embrittlement. The strength is evaluated by comparing tensile strength of the hydrogen charged specimen with that specified in an industry standard, such as API 5L. The ductility is evaluated based on comparing percent elongation of the hydrogen charged specimen with percent elongation of a specimen obtained from the tubular and not hydrogen charged. Tubulars with seams found susceptible to hydrogen embrittlement would not be put into sour service, whereas those found not susceptible to hydrogen embrittlement can be put in a sour service.

Owner:SAUDI ARABIAN OIL CO

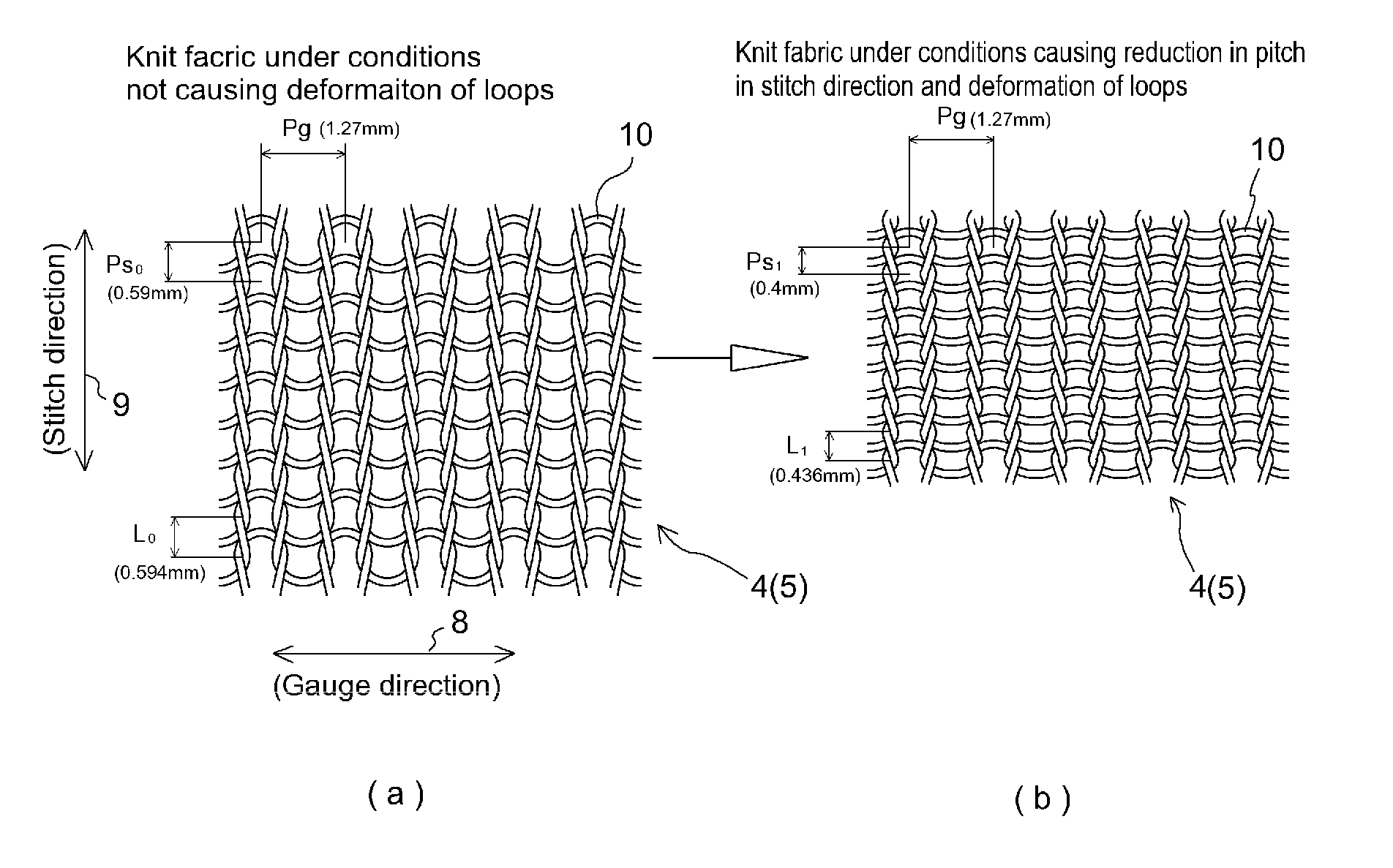

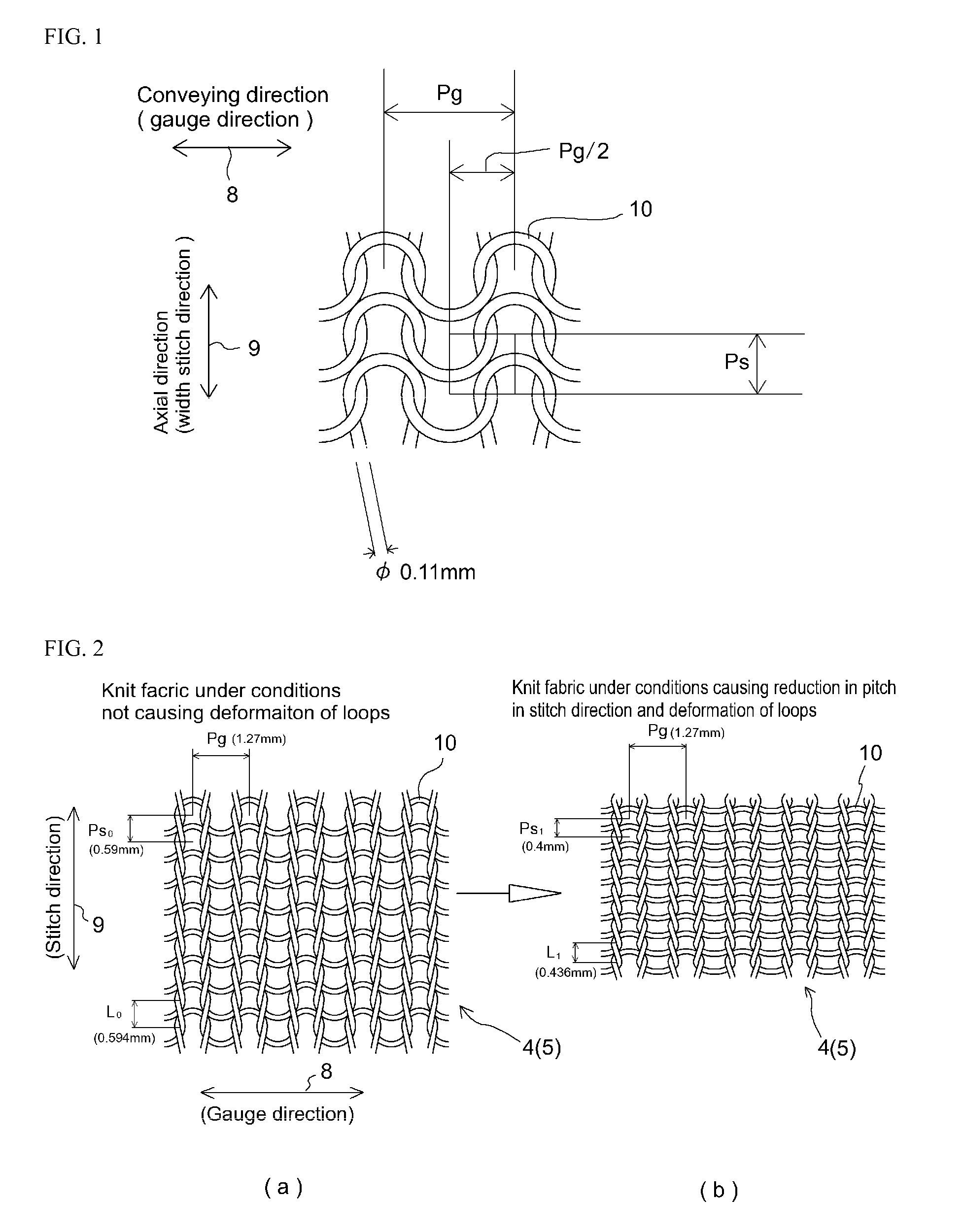

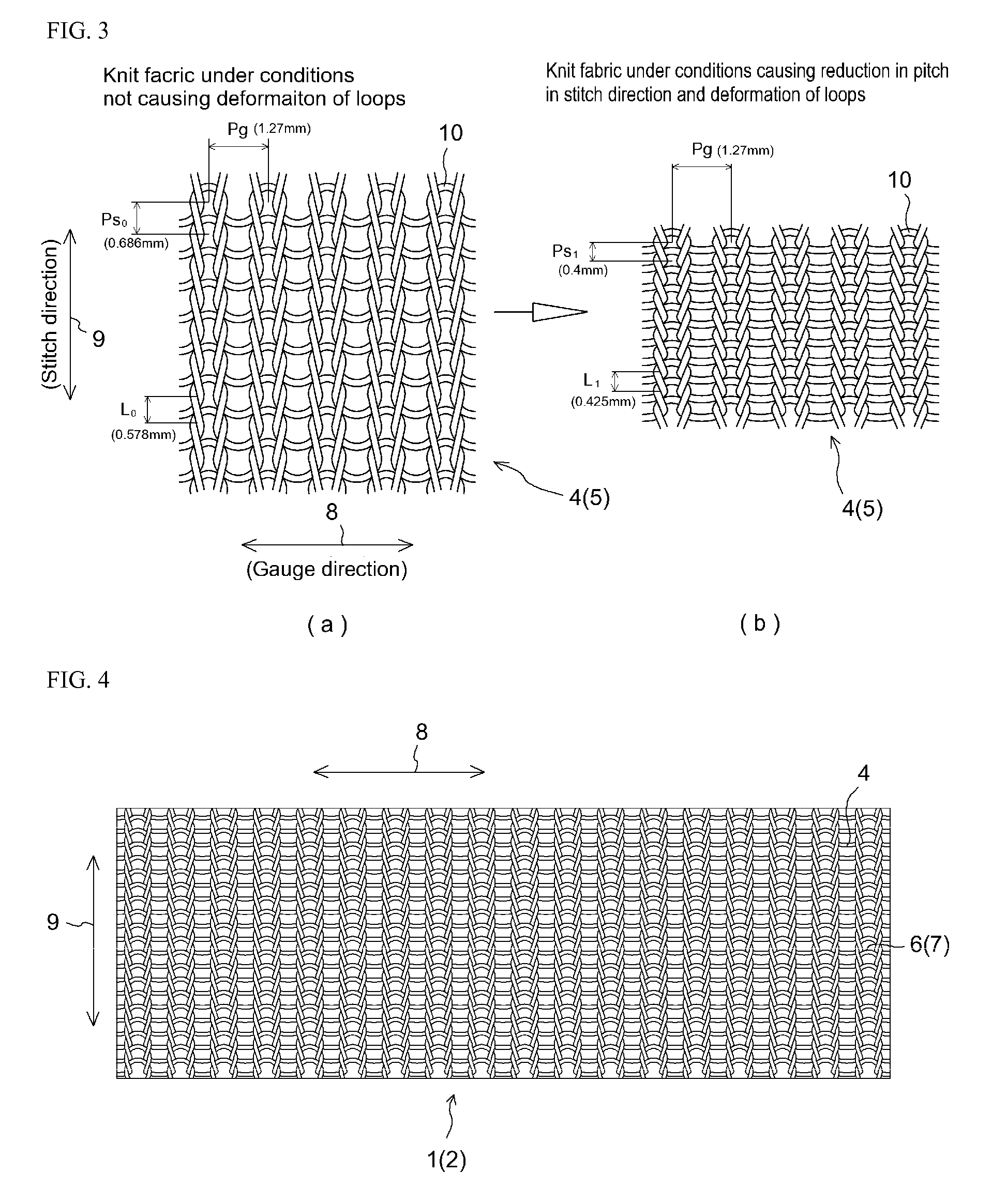

Conveyer belt and apparatus

ActiveUS8783448B2High strengthFraying of yarn filament at belt side ends is preventedConveyorsWeft knittingPercent elongationConveyor belt

A conveyor belt comprising knit fabric of high practicality, and an apparatus which uses such a conveyor belt. The conveyor belt includes weft knit fabric. Suction of air from below belt(s) is used to convey sheet-like and / or small thing(s) which are object(s) to be conveyed that are placed. The strength of filament(s) of knit fabric at side end(s) is adequately maintained. Loops exhibit mutual intertwining of filament(s) Pitch Ps of loops in width direction is formed so as to be smaller than pitch Pg of loops in conveying direction. Adjacent loops are mutually flattened and filament(s) of loop(s) are entangled, mutual intertwining of filament(s) causes knit fabric to have suppressed percentage elongation and increased strength in conveying direction, fraying of filament(s) at side end(s) of belt(s) is prevented, and strength is adequately increased.

Owner:SHOJI SUSUMU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com