Patents

Literature

1955results about How to "Improve fermentation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filter medium and structure

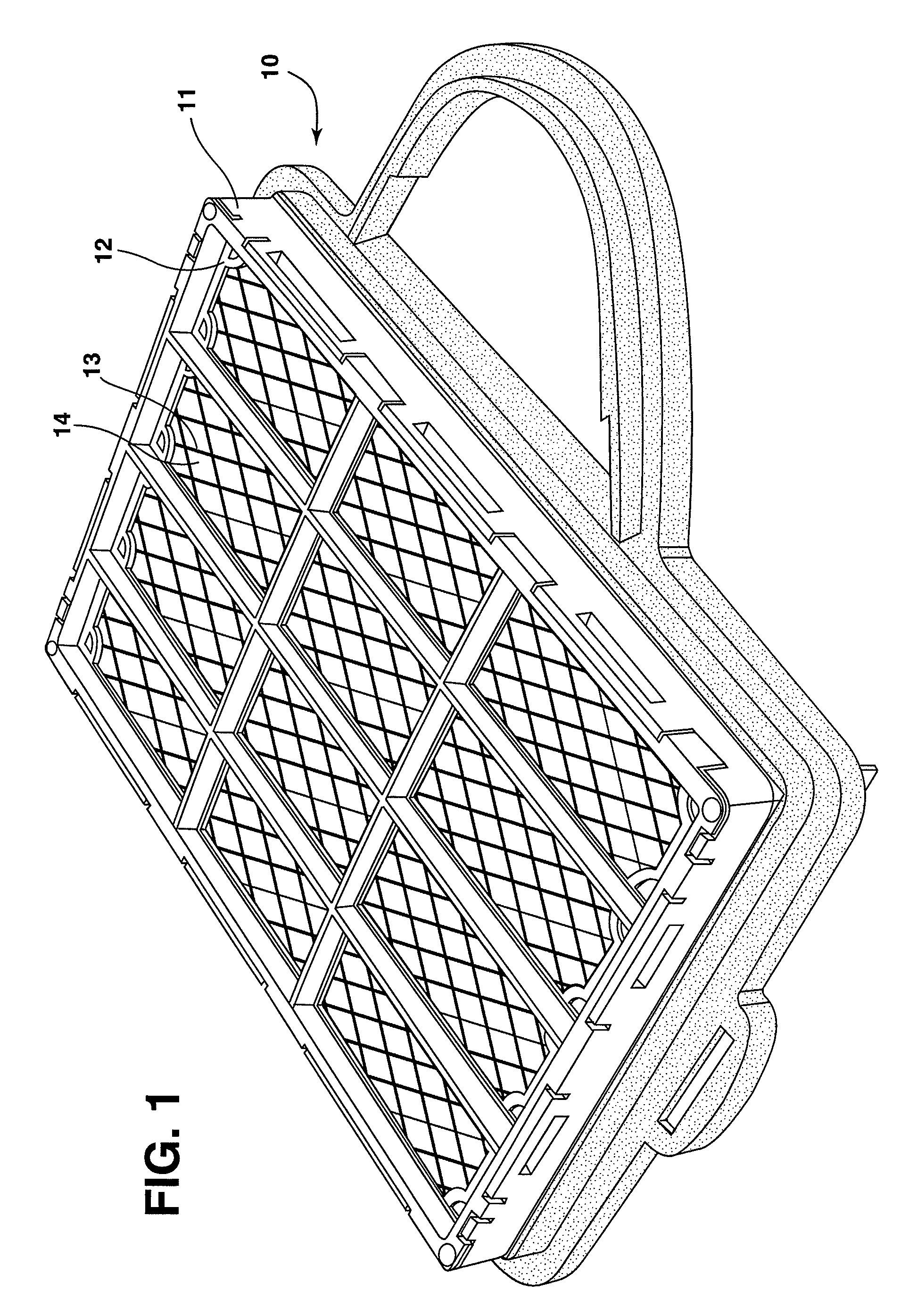

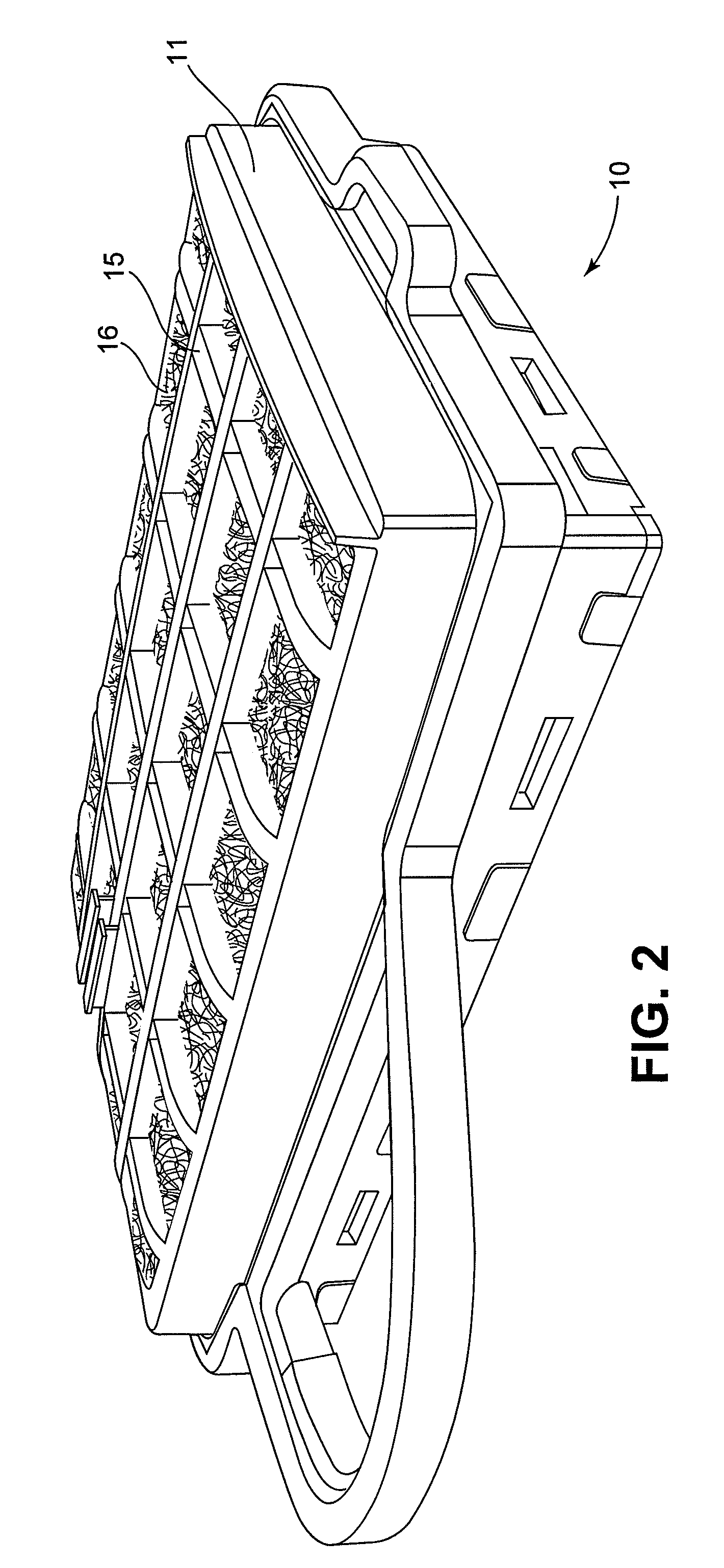

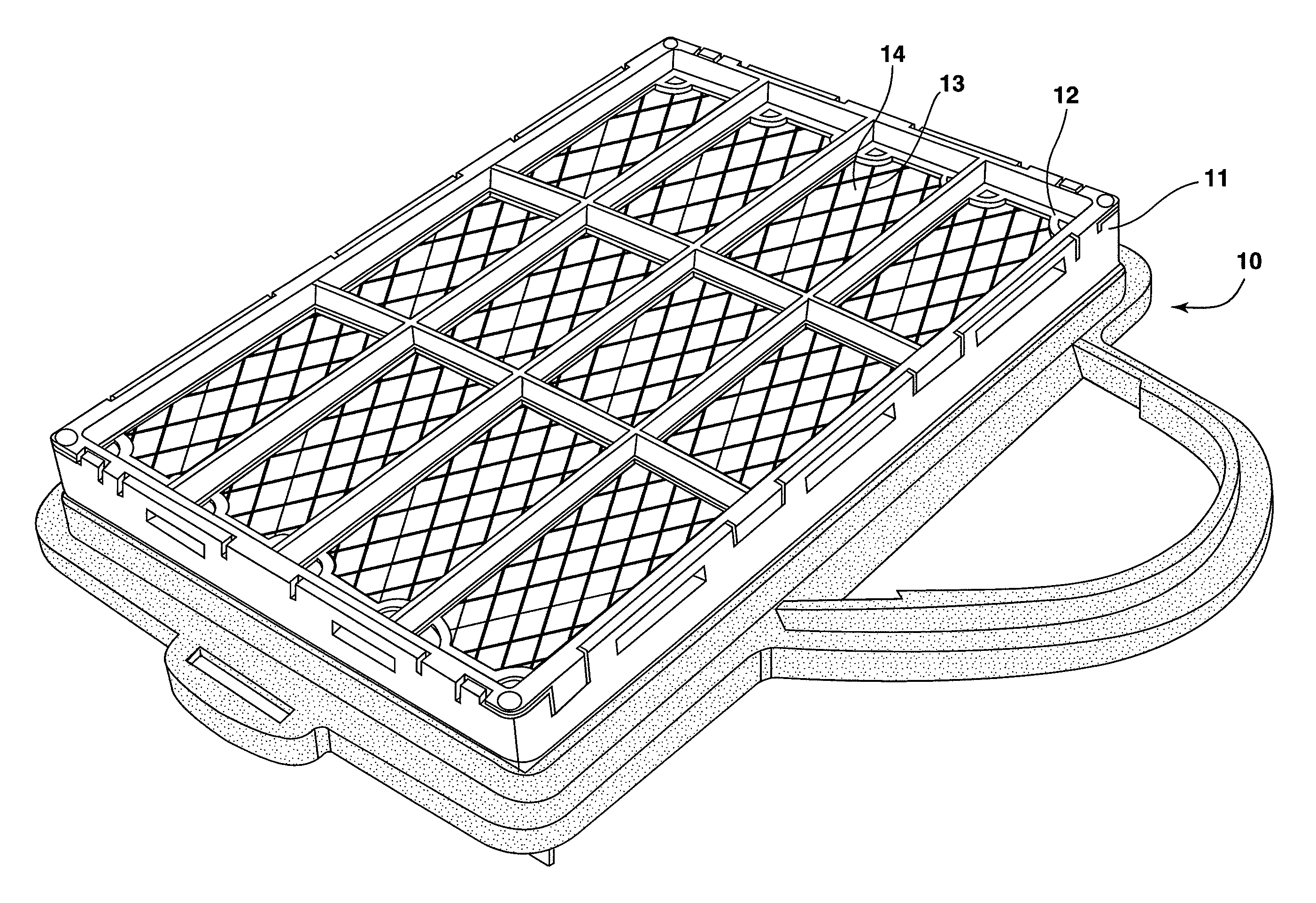

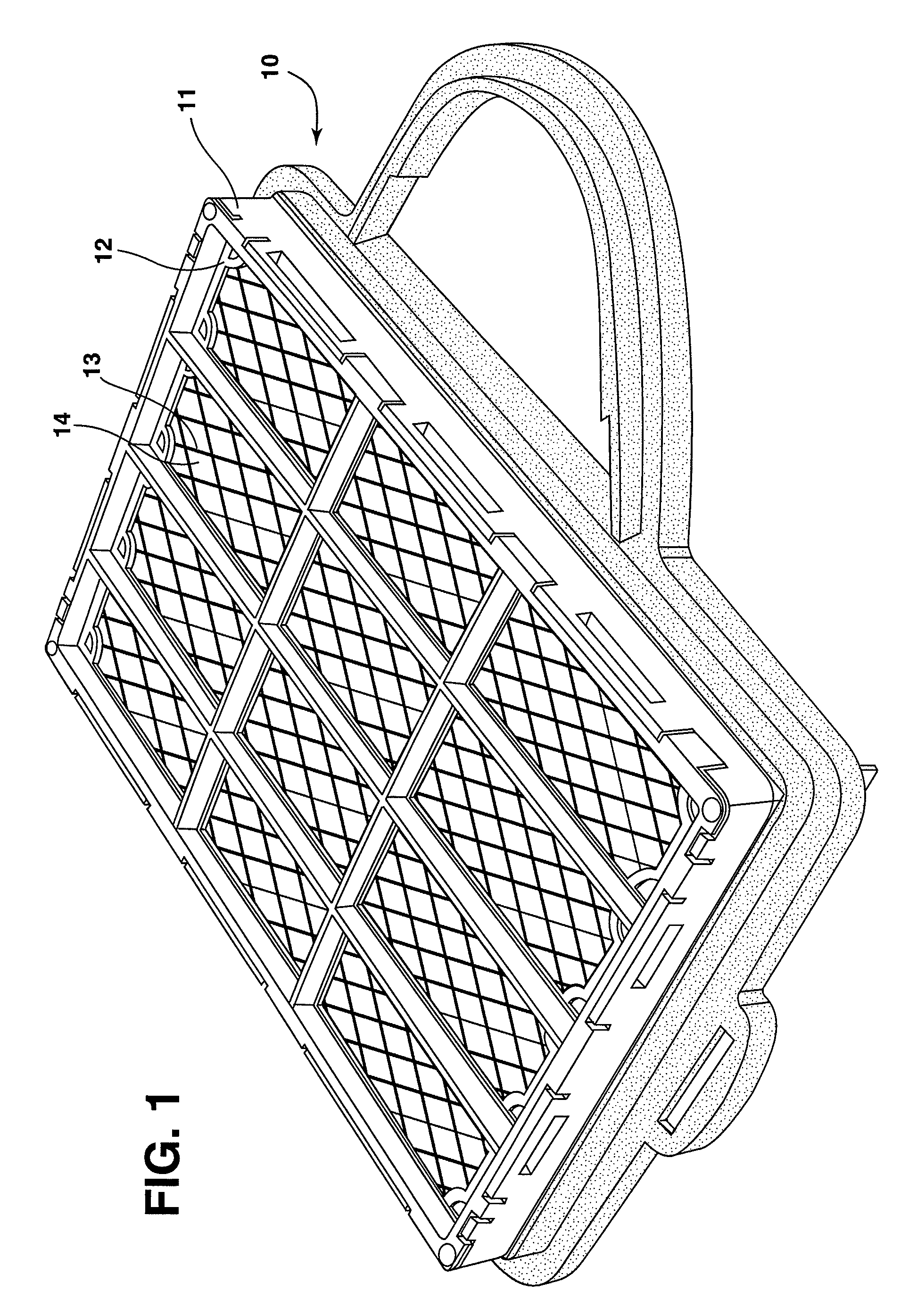

ActiveUS20060096263A1Efficient removalHigh strengthDispersed particle filtrationTransportation and packagingFiberParticulates

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

Filter medium and breather filter structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

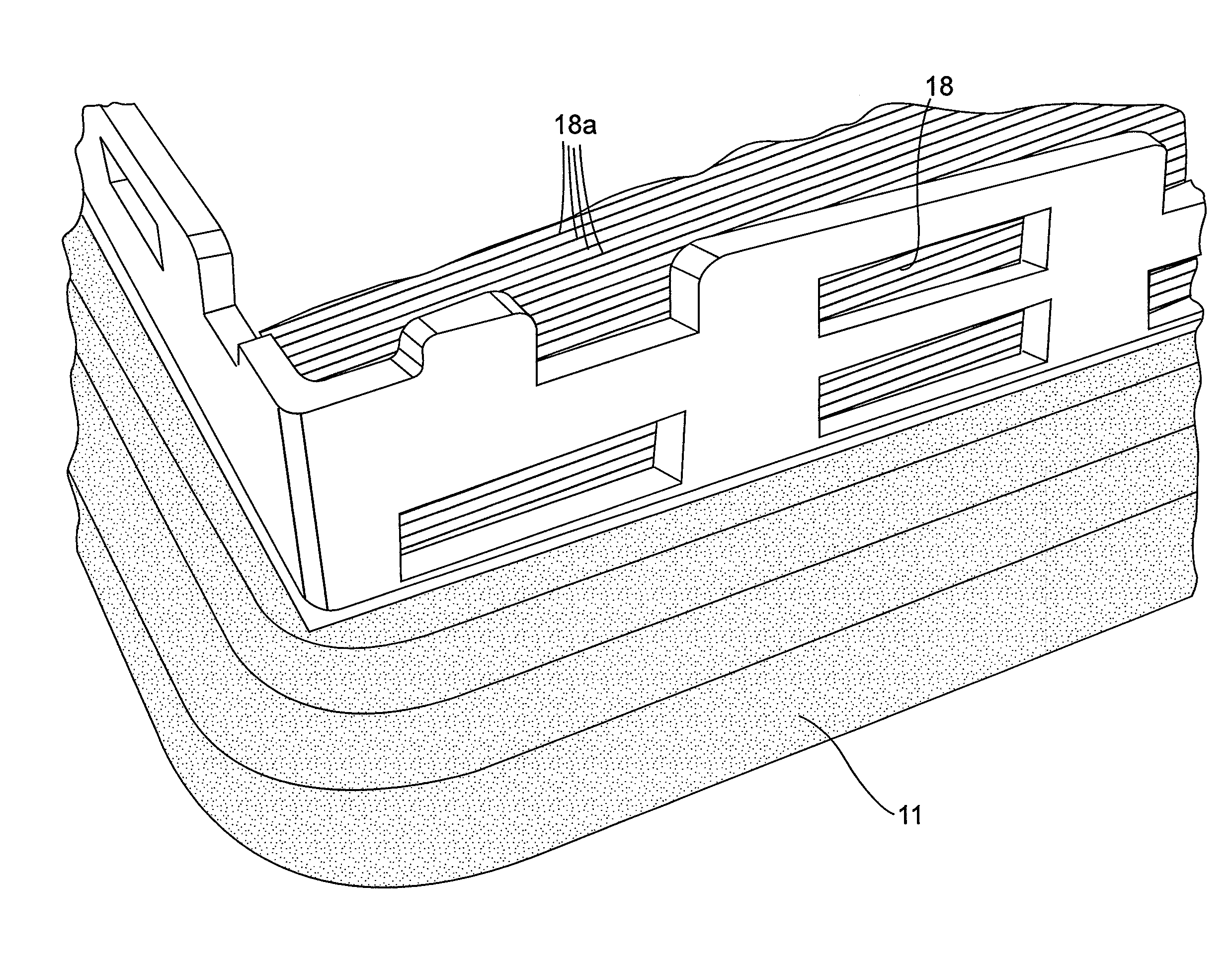

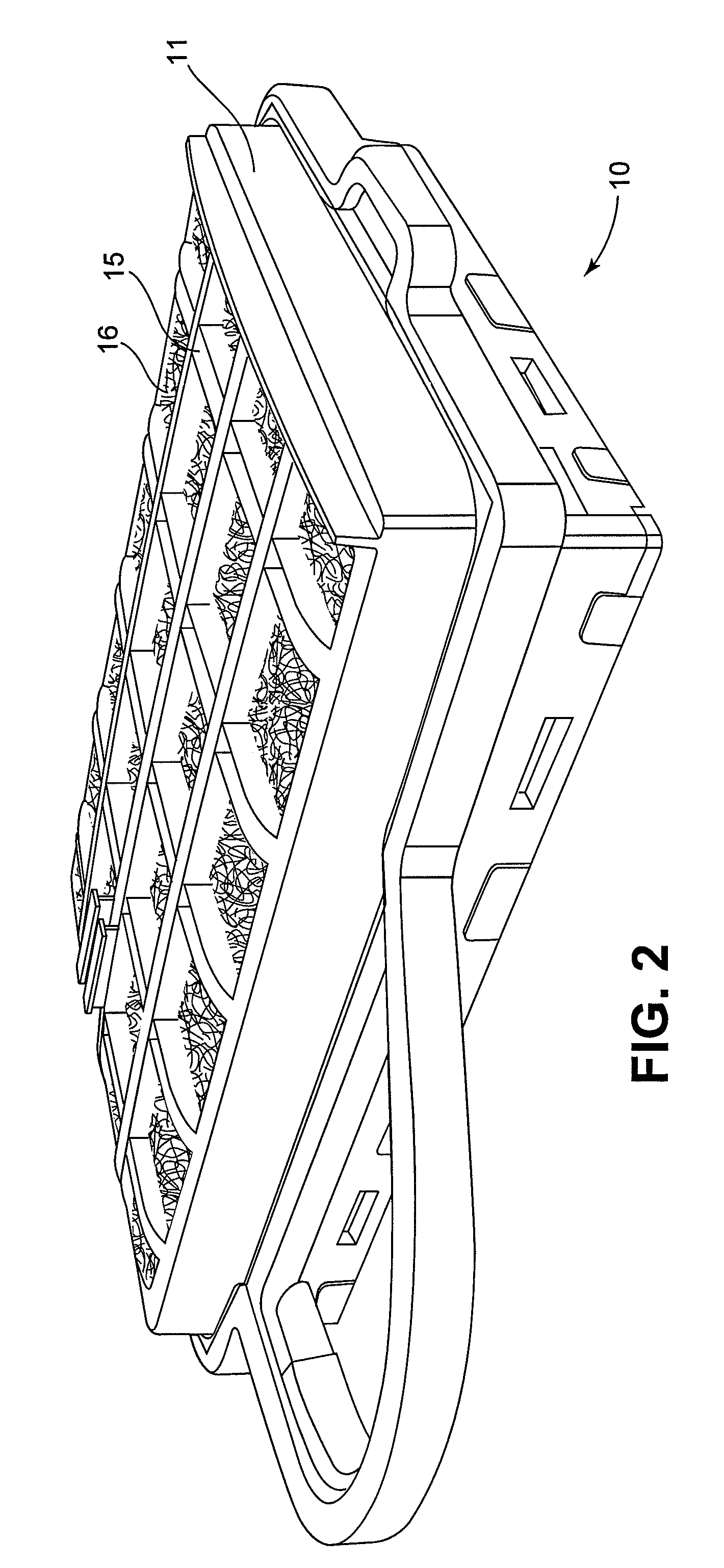

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

Filter element and method

InactiveUS8021455B2Efficient removalHigh strengthCombination devicesNon-fibrous pulp additionParticulatesMultiple forms

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

Fermentation method for production of nutritionally balanced natural fruit enzyme

ActiveCN103609985AReduce lossesRetain activityFood ingredient functionsFood preparationLactic acid bacteriumAcetic acid

The invention relates to a fermentation method for production of nutritionally balanced natural fruit enzymes. The method comprises the following steps: (1) pretreatment on raw materials; (2) a first bacterium inoculation: inoculating a saccharomyces cerevisiae liquor with concentration of 106 CFU / ml into a pulp according to an inoculation proportion of 5%; (3) early stage fermentation; (4) a secondary bacterium inoculation: after the early fermentation, inoculating acetic acid bacterium liquid and lactic acid bacterium liquid in a weight ratio of 1:1 for a secondary bacterium inoculation according to an inoculation amount of 5%; (5) middle-term fermentation; (6) coarse filtration; (7) secondary fermentation; (8) ripening; and (9) fine filtration to obtain the natural fruit enzyme. The fermentation method provided by the invention through low-temperature sterilization and strict control on the fermentation temperature retains the enzyme activity to the maximum; and twice inoculation of dominant bacteria effectively inhibits breeding of other infectious microbes, so as to realize stable product quality.

Owner:JINYES QINGDAO BIOTECH CO LTD

Orange peel dregs biologic fermentation method

InactiveCN103819239AImprove the ability to adapt to variable temperature fermentationImprove fermentation effectBio-organic fraction processingOrganic fertiliser preparationPotassiumOrganic compound

The invention discloses an orange peel dregs biologic fermentation method, and belongs to the technical field of orange peel dregs innocuous treatment. Orange peel dregs are used as a main raw material and added with a liquid micro organism bacterial agent, and is subjected to composting primary fermentation and composting fermentation, so as to prepare a fermentation product which is rich in organic substances and microelements such as boron, zinc and magnesium, and is proper in the proportions and contents of N, P and K. The content of the organic components of the fermentation product is not less than 45 percent, the pH value is within 6.5-8.5, the total content of N, P and K is not less than 6 percent, the moisture content is not greater than 30 percent, the fermentation product is rich in the microelements such as boron, zinc and magnesium, can be directly used as an organic fertilizer, meanwhile can be added with a microelement fertilizer or a chemical fertilizer to be compounded into an organic compound fertilizer, an organic-inorganic compound fertilizer and the like. The orange peel dregs biologic fermentation method is simple in process, low in cost and high in production efficiency, not only processes a large amount of orange peel dregs, but also prompts the treatment of other organic waste materials, so as to not only protect the environment, but also increase the economic benefits, achieve low-carbon production and explore a new method for the innoxious treatment of the orange peel dregs.

Owner:重庆圣沛农业科技有限公司

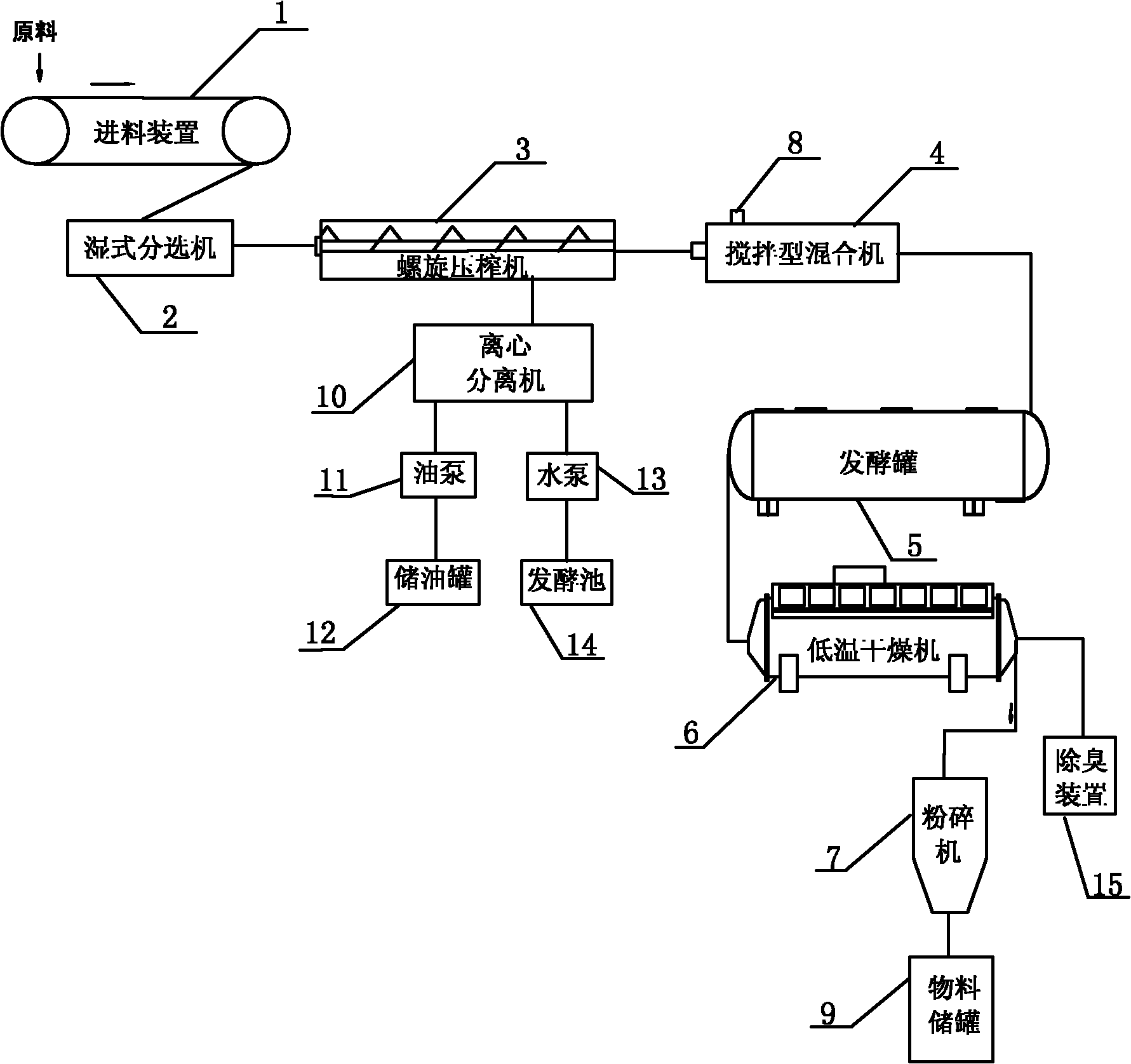

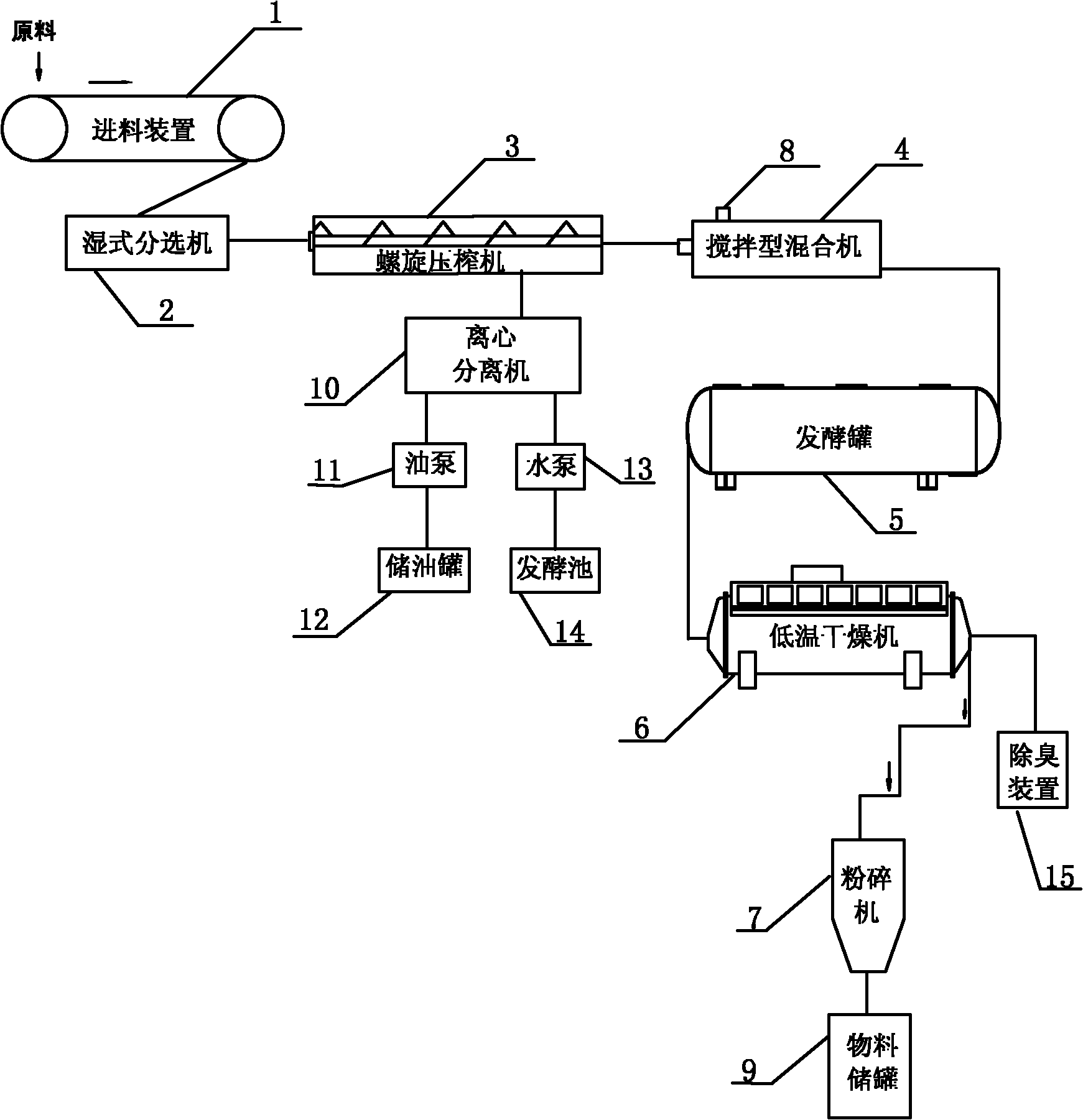

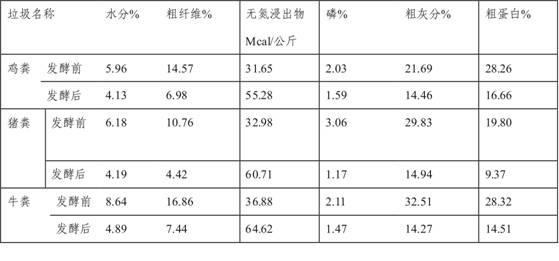

Method and system for preparing restaurant-kitchen wastes into livestock and poultry feed

InactiveCN102125166AGood flavor and colorImprove fermentation effectFeeding-stuffFood processingMixed materialsCrusher

The invention discloses a method and a system for preparing restaurant-kitchen wastes into a livestock and poultry feed, wherein the method comprises the following steps: carrying out sorting preprocessing on restaurant-kitchen wastes so as to obtain biodegradable restaurant-kitchen wastes; carrying out solid-liquid separation on the obtained biodegradable restaurant-kitchen wastes; adding bran, corn flour and coarse meal into the obtained product so as to obtain a mixed material; adding composite fungicides into the mixed material according to the inoculum concentration (8-20 wt%) so as to ferment the mixed material; and finally, drying and cooling the fermented mixture, then packing the obtained object so as to obtain a livestock and poultry feed product. The system comprises a feed device, a wet sorting machine, a pressafiner, an agitated mixer, a fermentation tank, a low-temperature drying machine, a crusher and a finished product material storage tank which are sequentially connected; and the system has the advantages that the growth of putrefying bacterias and the reproduction of pathogenic microorganisms in restaurant-kitchen wastes can be inhibited, and the freshness retaining effect and organoleptic quality of the livestock and poultry feed are good; meanwhile, the protein content of the livestock and poultry feed can be improved; in addition, the system is low in used equipment cost, small in energy consumption, high in production efficiency and beneficial to environmental protection.

Owner:张荣尚

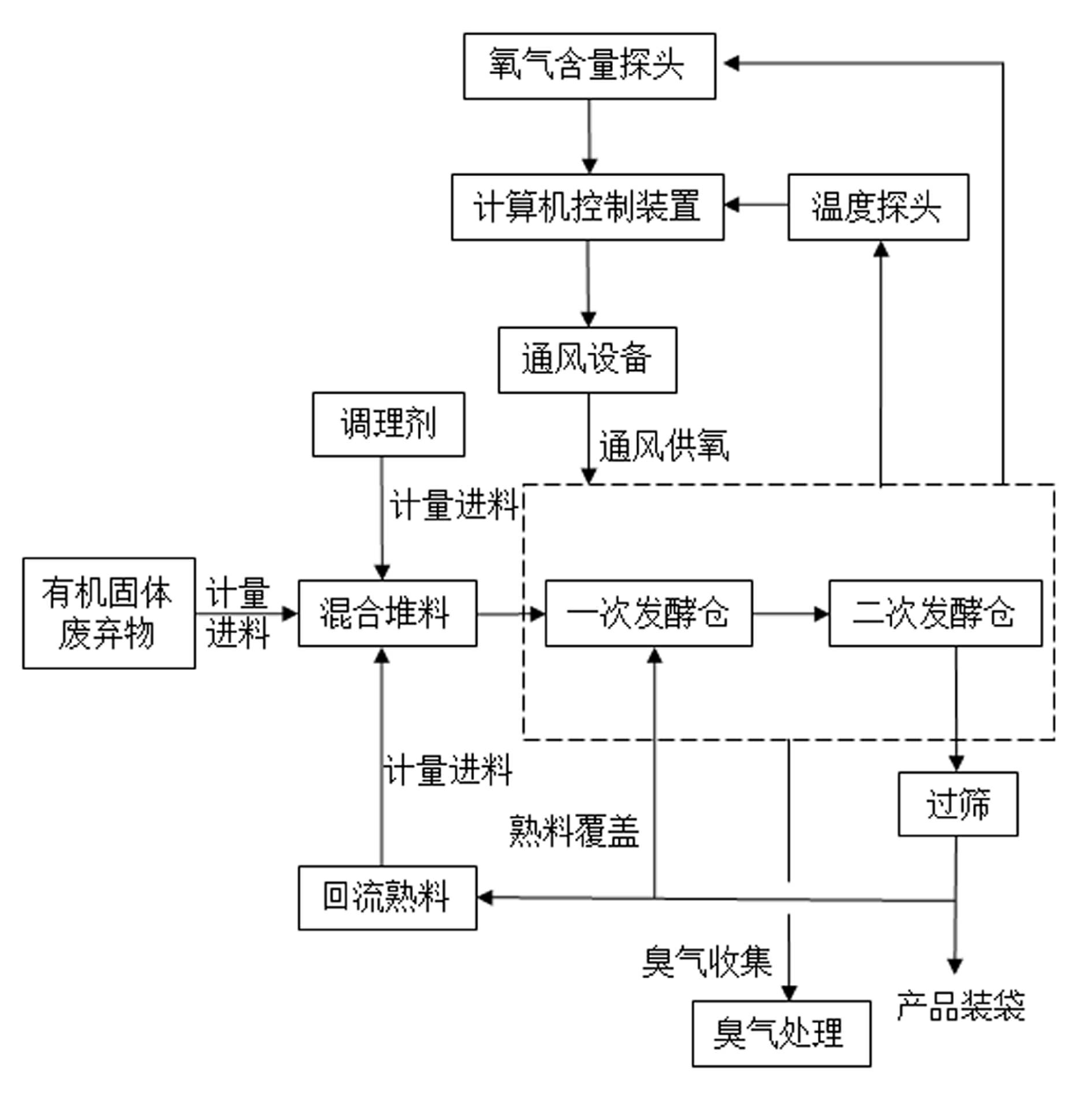

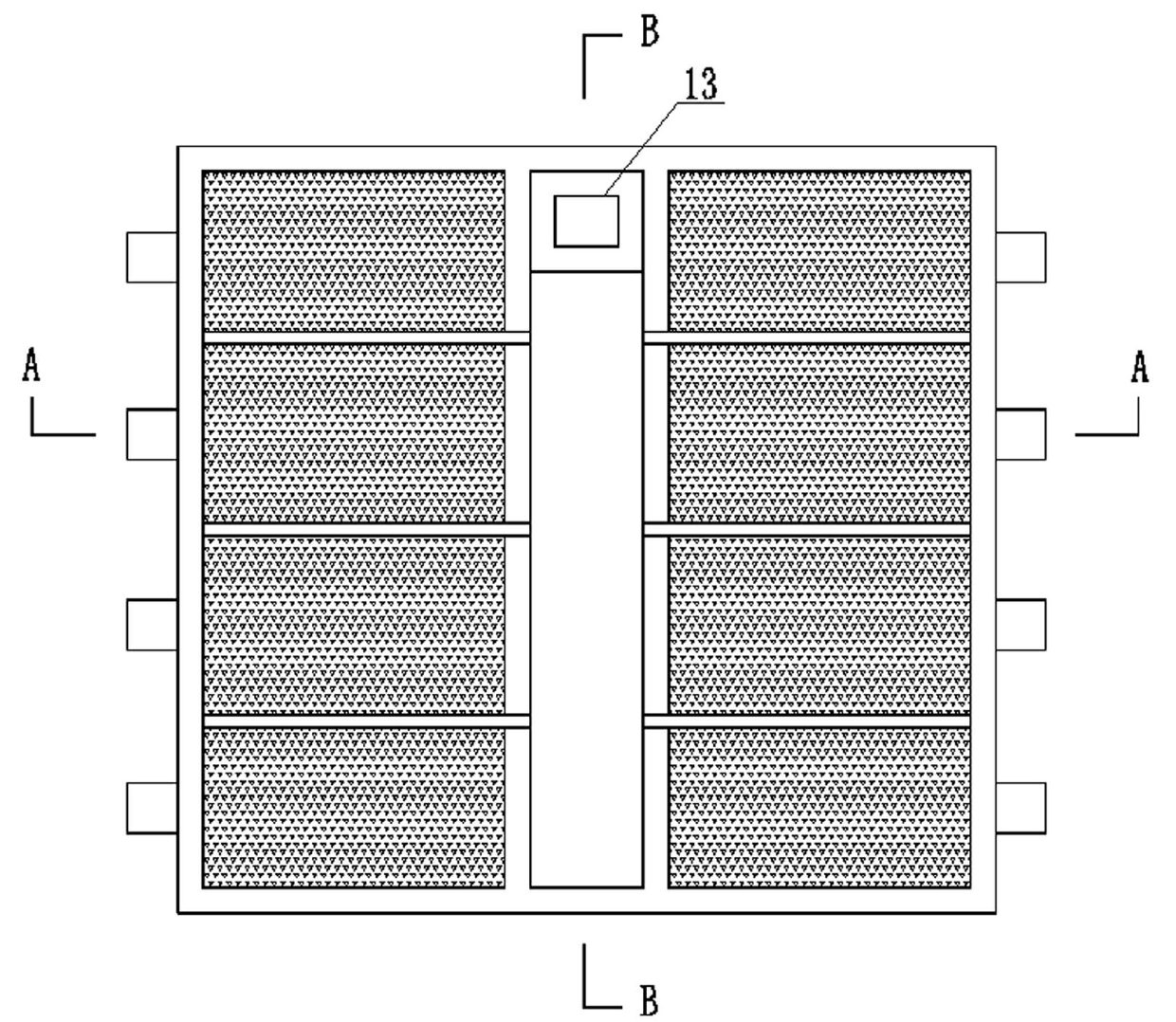

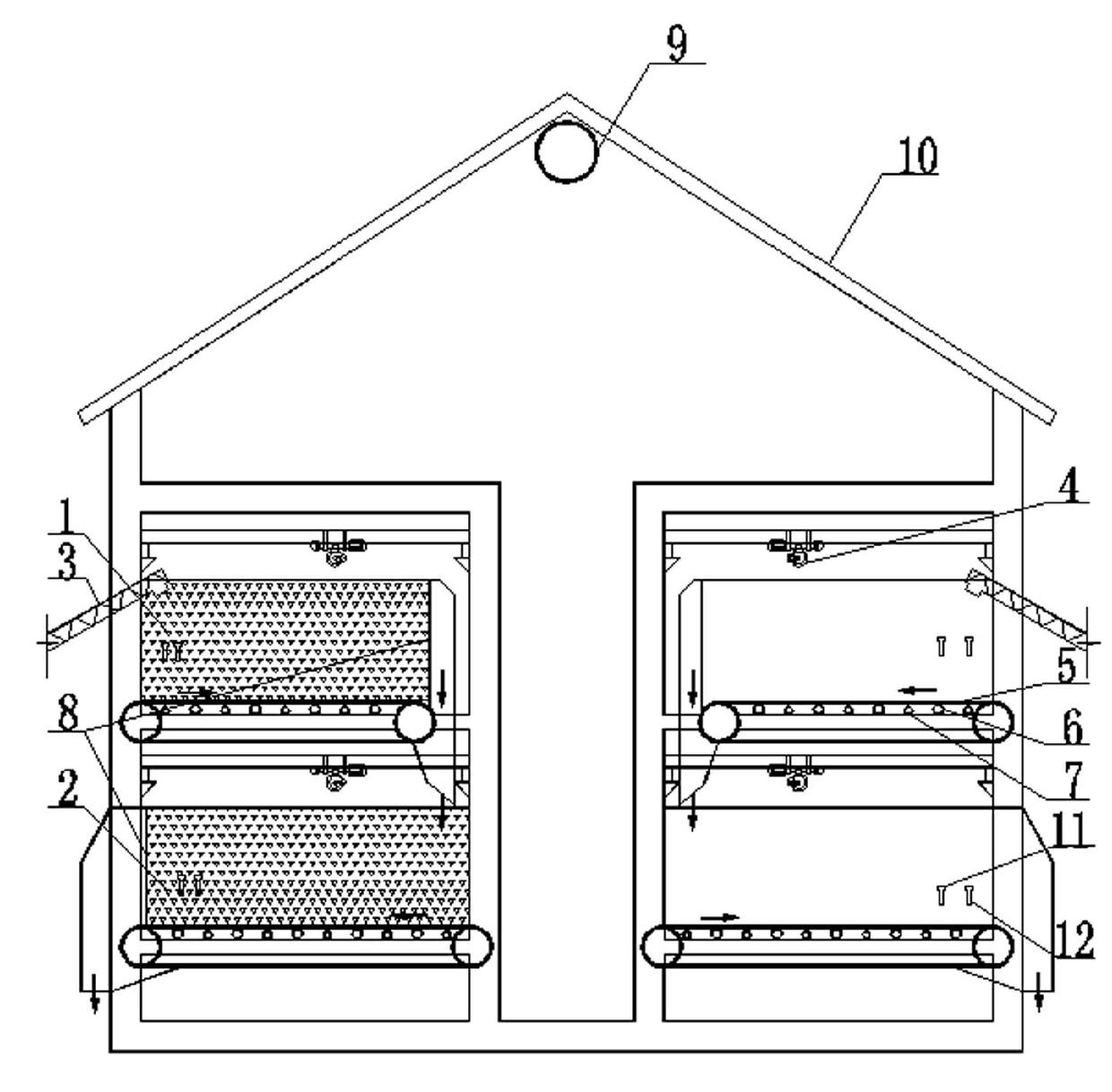

Aerobic fermentation fertilizer making device for organic solid waste and method thereof

InactiveCN102603384ARealize resource utilizationShort fermentation cycleBio-organic fraction processingClimate change adaptationTransmission beltEngineering

The invention discloses an aerobic fermentation fertilizer making device for organic solid waste, which comprises fermentation cabins, a plant, multifunctional pile turning machines, a feeding device and a screening machine, wherein multiple groups of fermentation cabins are arranged in the plant; each group of fermentation cabin comprises a primary fermentation cabin and a secondary fermentation cabin which are correspondingly arranged on an upper position and a lower position; the bottoms of the two fermentation cabins are respectively provided with a transmission belt, an idler wheel and an aeration pipe; the discharging end of the feeding device is positioned on the primary fermentation cabin; the multifunctional pile turning machines are arranged in the two fermentation cabins; the bottoms of the two fermentation cabins are respectively provided with a movable baffle; one end of the transmission belt of each fermentation cabin corresponds to the position of the movable baffle of the fermentation cabin; the outlet of the movable baffle of the primary fermentation cabin is positioned above the transmission belt of the secondary fermentation cabin; the outlet of the movable baffle of the secondary fermentation cabin is positioned above the screening machine; the top of the plant is provided with an odor centralizing pipe provided with a plurality of air inlets; and the odor centralizing pipe is connected with a deodorization device arranged out of the plant. The aerobic fermentation fertilizer making device for the organic solid waste has the advantages of small occupied land, high mechanized degree and low operation cost and is simple to operate.

Owner:中国市政工程西北设计研究院有限公司

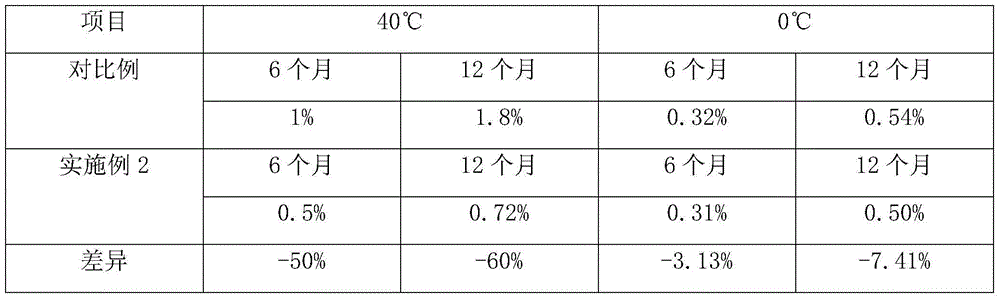

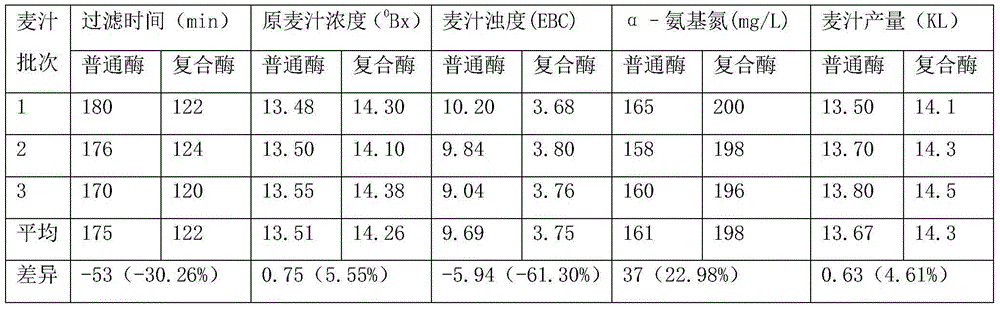

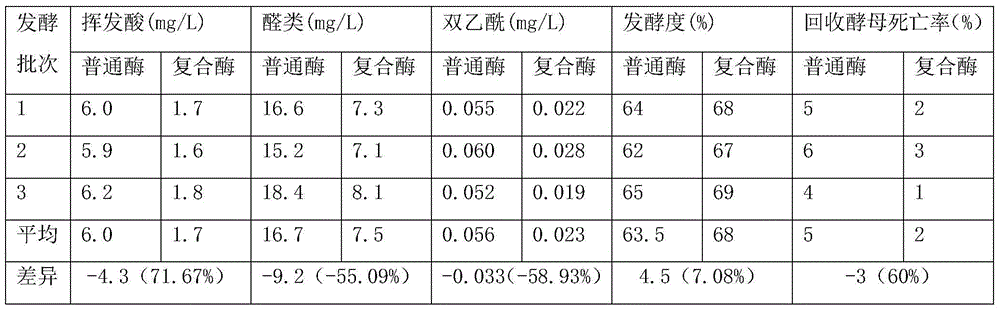

Fungal alpha-amylase-containing beer complex enzyme and preparation method thereof

ActiveCN104651335AEnsure food safetyIncrease profitOxidoreductasesGlycosylasesAntioxidantAlpha-amylase

The invention discloses a fungal alpha-amylase-containing beer complex enzyme and a preparation method thereof, belonging to the field of enzyme preparation processing. The high-activity fungal alpha-amylase and other food grade enzyme preparations, plant extracts, antioxidants, protective agents, activating agents and the like can be scientifically compounded by taking concentrated maltase and concentrated malt juice powder as main raw materials; the prepared beer complex enzyme is complete in proteases, high in enzyme activity, difficult to deactivate, mellow in malt aroma, and capable of providing abundant nitrogen source for malt juice, wherein the activity of fungal alpha-amylase in fermenting liquor during the preparation of fungal alpha-amylase is 17000-21000 U / mL. The complex enzyme can be stored for 12 months under the conditions of 0DEG C and 40DEG C, the single enzyme activity loss in the complex enzyme are respectively 0.50% and 0.72%, the enzyme deactivation caused by environment change, and inappropriate operation methods during packaging, storage, transportation, use and the like can be effectively prevented, especially the enzyme deactivation caused by high temperature can be prevented.

Owner:湖南新鸿鹰生物工程有限公司

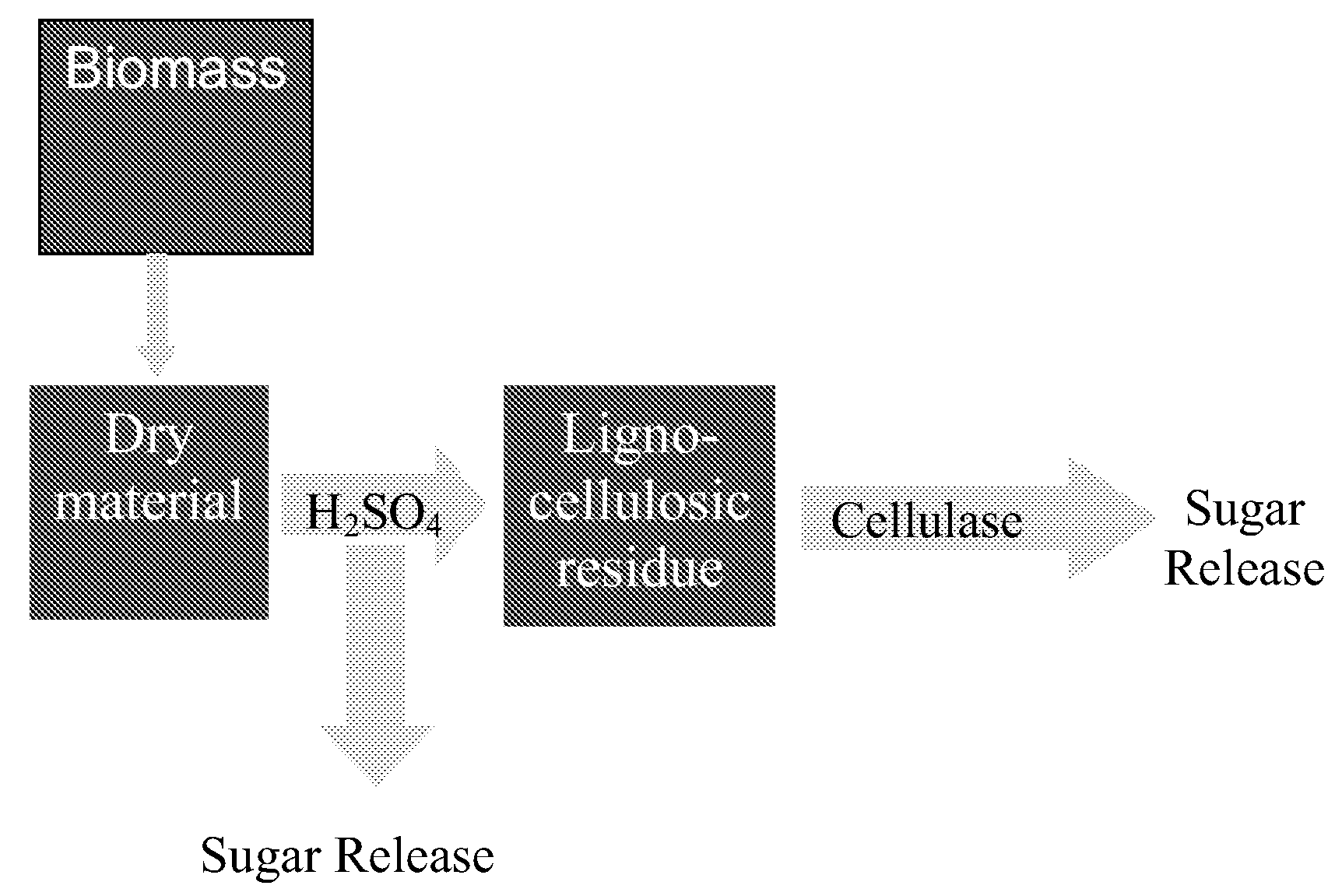

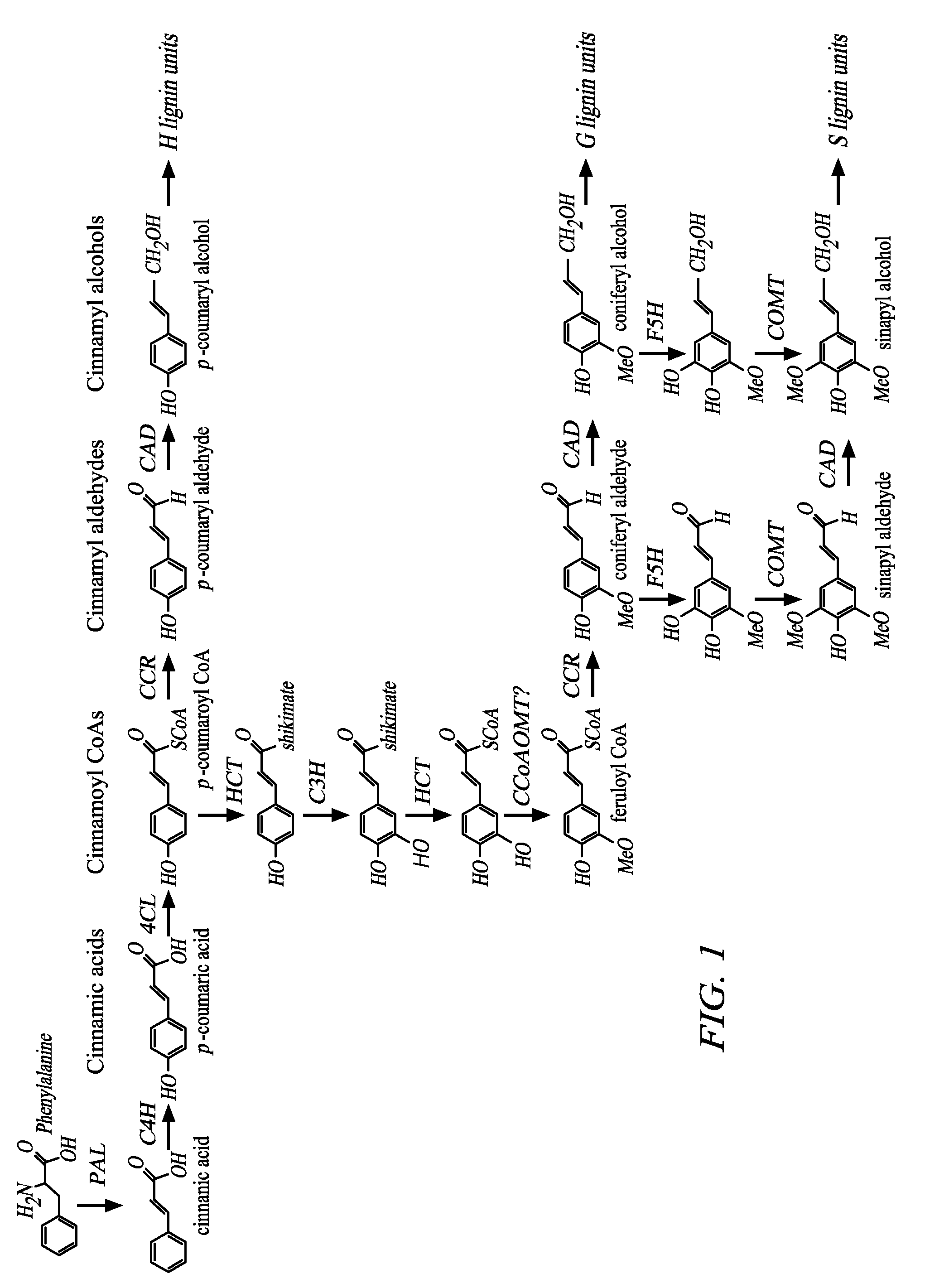

Biofuel production methods and compositions

ActiveUS20080274528A1Increase productionSmooth transitionSugar derivativesBiofuelsBiofuel cropLignin biosynthesis

The invention provides methods for increasing the level of fermentable carbohydrates in a biofuel crop plant such as alfalfa or switchgrass, by modification of the lignin biosynthetic pathway. Also provided are plants prepared by the methods of the invention. Methods for processing plant tissue and for producing ethanol by utilizing such plants are also provided.

Owner:NOBLE RES INST LLC

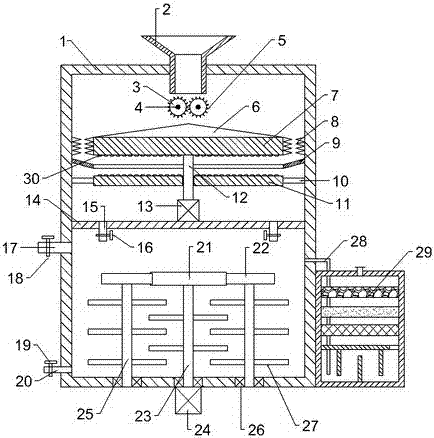

Integrated kitchen waste treatment device and method thereof

InactiveCN107497827ACrushing is effectiveEasy to mix and handleGas treatmentDispersed particle filtrationEngineeringWaste treatment

The invention relates to an integrated kitchen waste treatment device which comprises a shell. A feeding hopper is fixedly connected to the top of the shell, a pair of crushing rollers is arranged below the feeding hopper, a crushing roll shaft is fixedly connected between the crushing rollers, and crushing teeth are fixedly connected to the crushing rollers; a partition plate is fixedly connected to the side wall of the shell below the crushing rollers, a first motor is fixedly connected to the middle of the upper side of the partition plate, a first rotary shaft is fixedly connected to the output shaft of the first motor, an upper grinding disc is fixedly connected to the top end of the first rotary shaft, and a first crushing bump is fixedly connected to the side wall of the upper grinding disc. The integrated kitchen waste treatment device provided by the invention has the beneficial effects that the first crushing bump crushes initially crushed kitchen waste first, and then a second crushing bump grinds and crushes the kitchen waste, so that the crushing effect is improved; a second rotary shaft and a third rotary shaft rotate simultaneously to drive a stirring rod to rotate so as to fully mix a compost and the kitchen waste, so that the fermenting effect is more excellent.

Owner:ANHUI XINHONG ENVIRONMENTAL PROTECTION EQUIP TECH

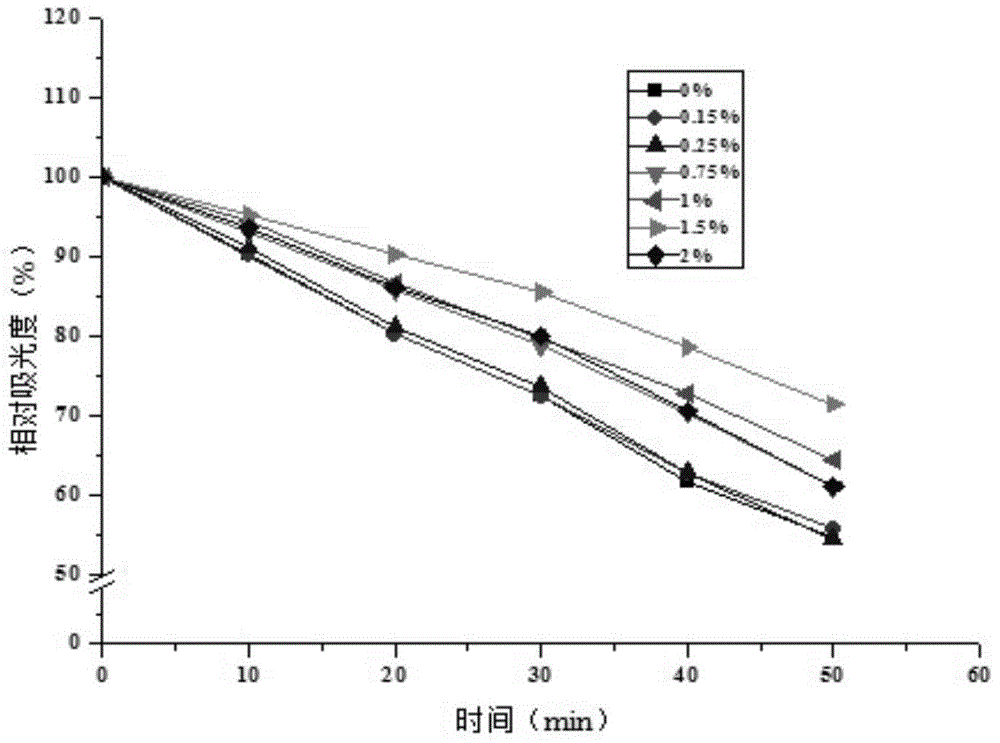

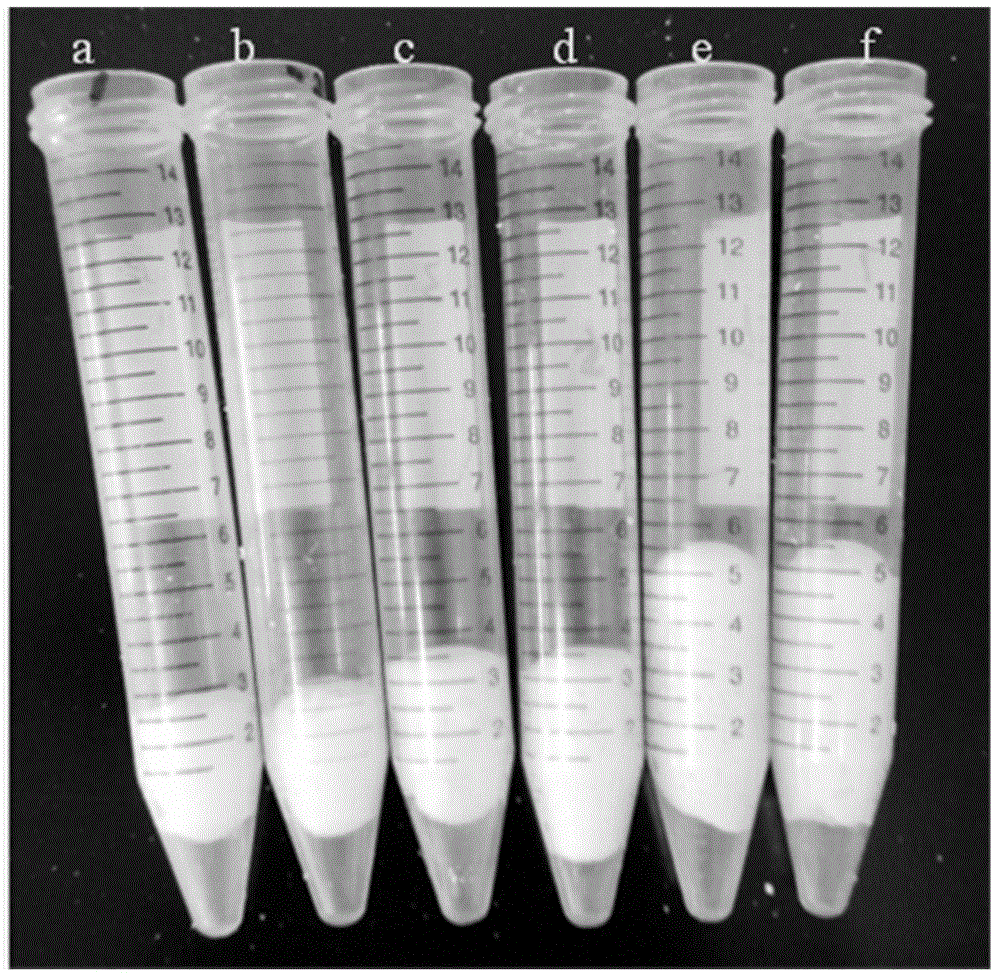

Method for improving fermentability and nutritional property of gluten protein-free dough

ActiveCN104146020AImprove fermentation effectImproved ability to hold gasDough treatmentPre-baking dough treatmentNutritive valuesFermentation

The invention provides a method for improving fermentability and nutritional property of gluten protein-free dough. The method includes the steps of 1) activating glutamic acid transaminase, protease A and yeast; 2) peptizing food in water with temperature 50-100 degrees to be evenly mixed with whole flour free of gluten protein, proteins, starches, sugars and salts; 3) adding the activated glutamic acid transaminase and protease A to the mixture for evenly mixing; 4) adding and stirring the activated yeast in the mixture to form the dough; 5) fermenting the mixture within 40-90mins at the temperature of 36-40 degrees and at the humidity of 70-85%. The method is simple and greatly improves the nutritional property and the fermentability of the gluten protein-free dough at the same time. Thus fermentation size of the dough is increased by 1-3 times, contents of vitamin, protein, dietary fiber, mineral elements and the like are remarkably increased, structures and sizes of fermented products such as breads, steamed breads and steamed sponge cakes are improved, and nutritional value of the fermented products is increased.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Polypropylene fibers and fabrics

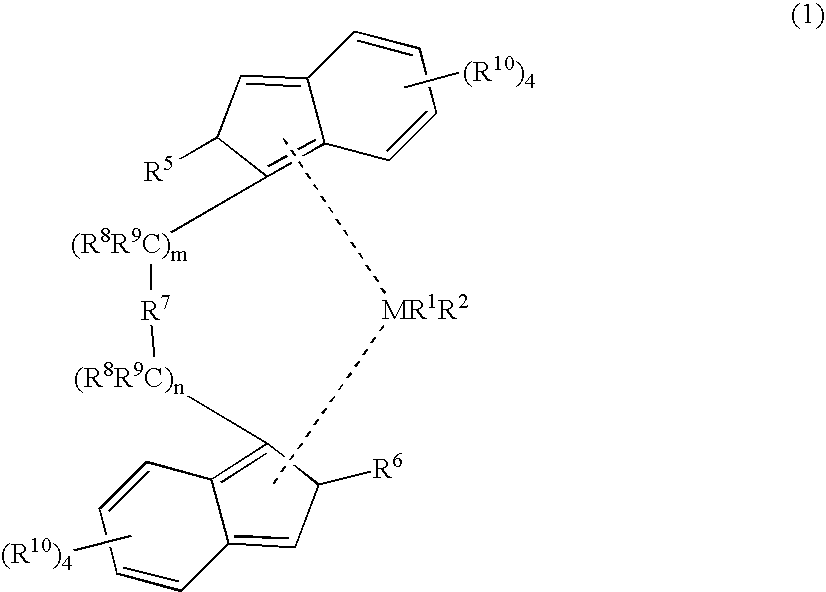

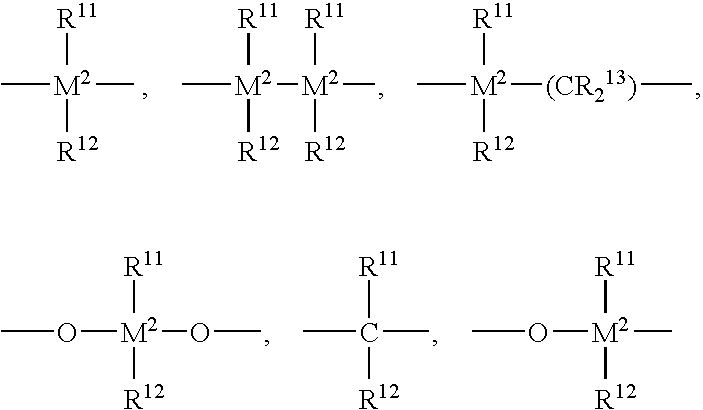

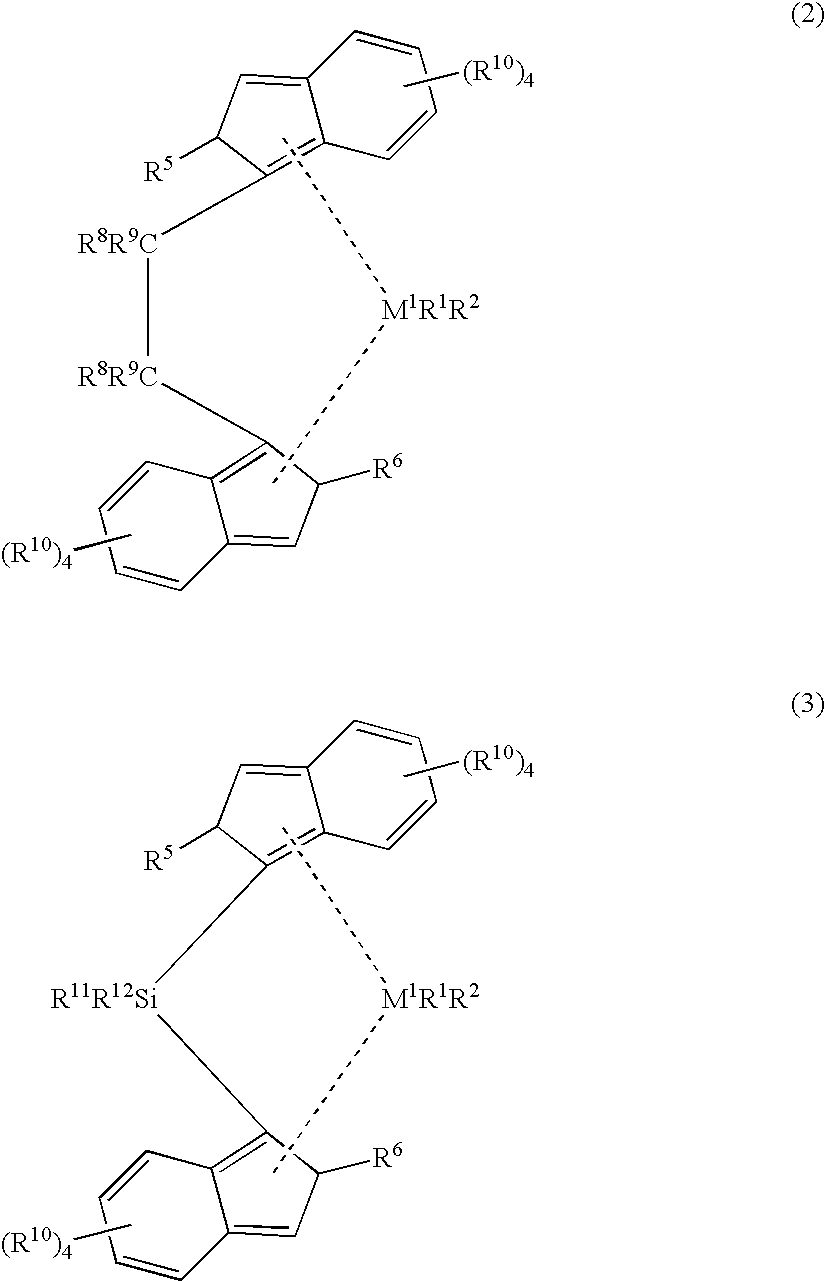

InactiveUS7081299B2Improve featuresShot levelFixed capacitor dielectricSynthetic resin layered productsPolymer scienceNon-coordinating anion

The present invention is a meltblown fiber and a fabric manufactured from the fiber comprising reactor grade polypropylene having a melt flow rate of from 100 to 5000 and having less than 50 stereo defects per 1000 units. Further, the polypropylene is typically produced from a metallocene catalyzed process, the metallocene being at least one bridged 2,4 di-substituted indenyl metallocene in one embodiment, and a bridged 4-phenyl indenyl metallocene in another embodiment. The metallocene is part of a system that can include a fluorided support and a non-coordinating anion activator.

Owner:EXXONMOBIL CHEM PAT INC

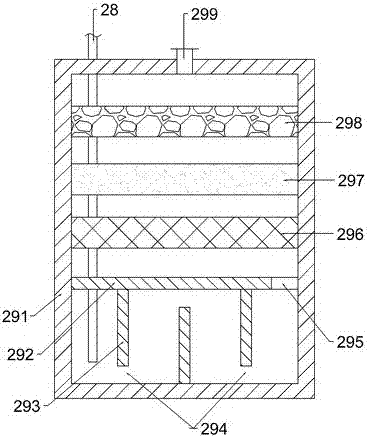

Hybrid filter element and method

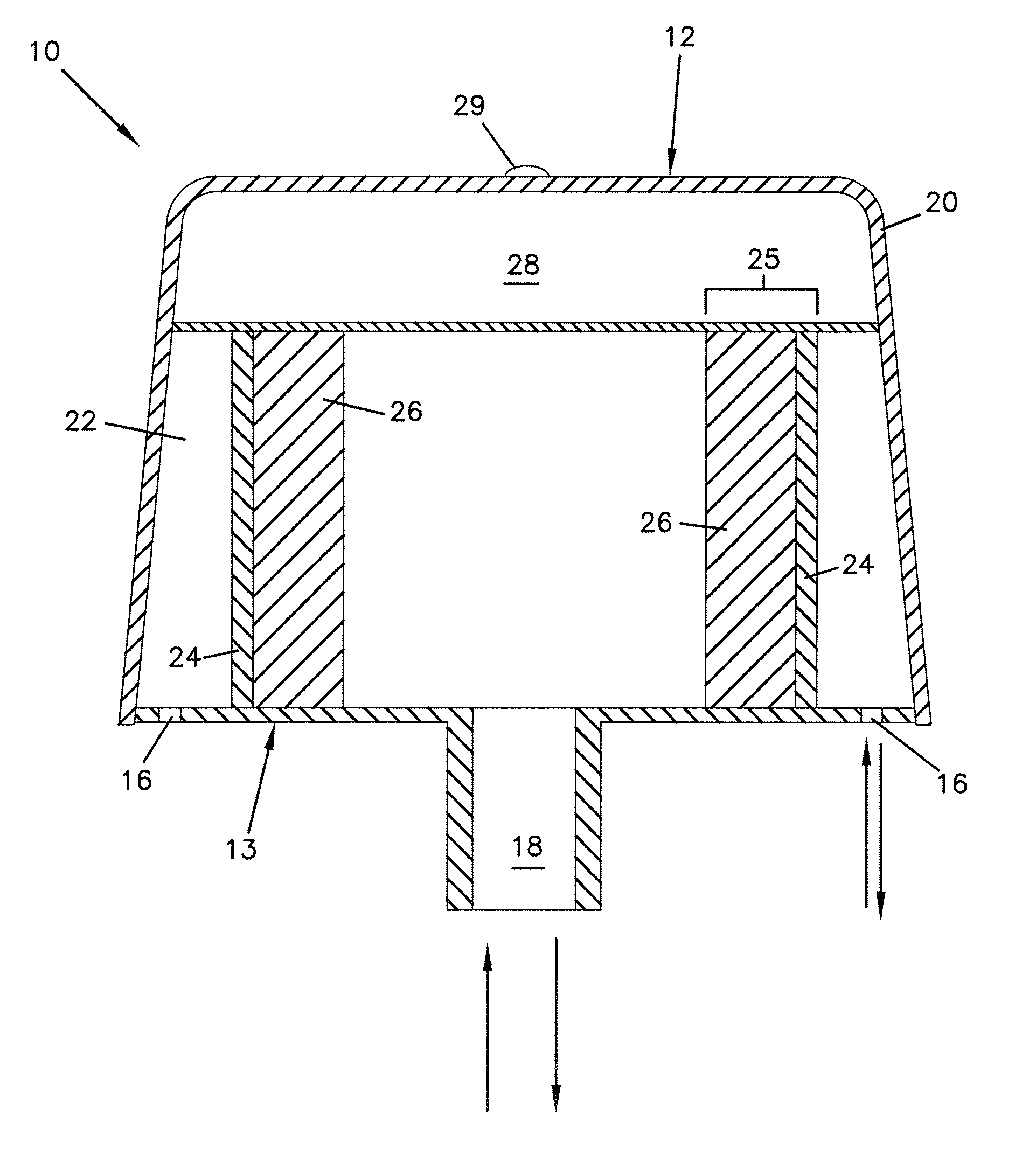

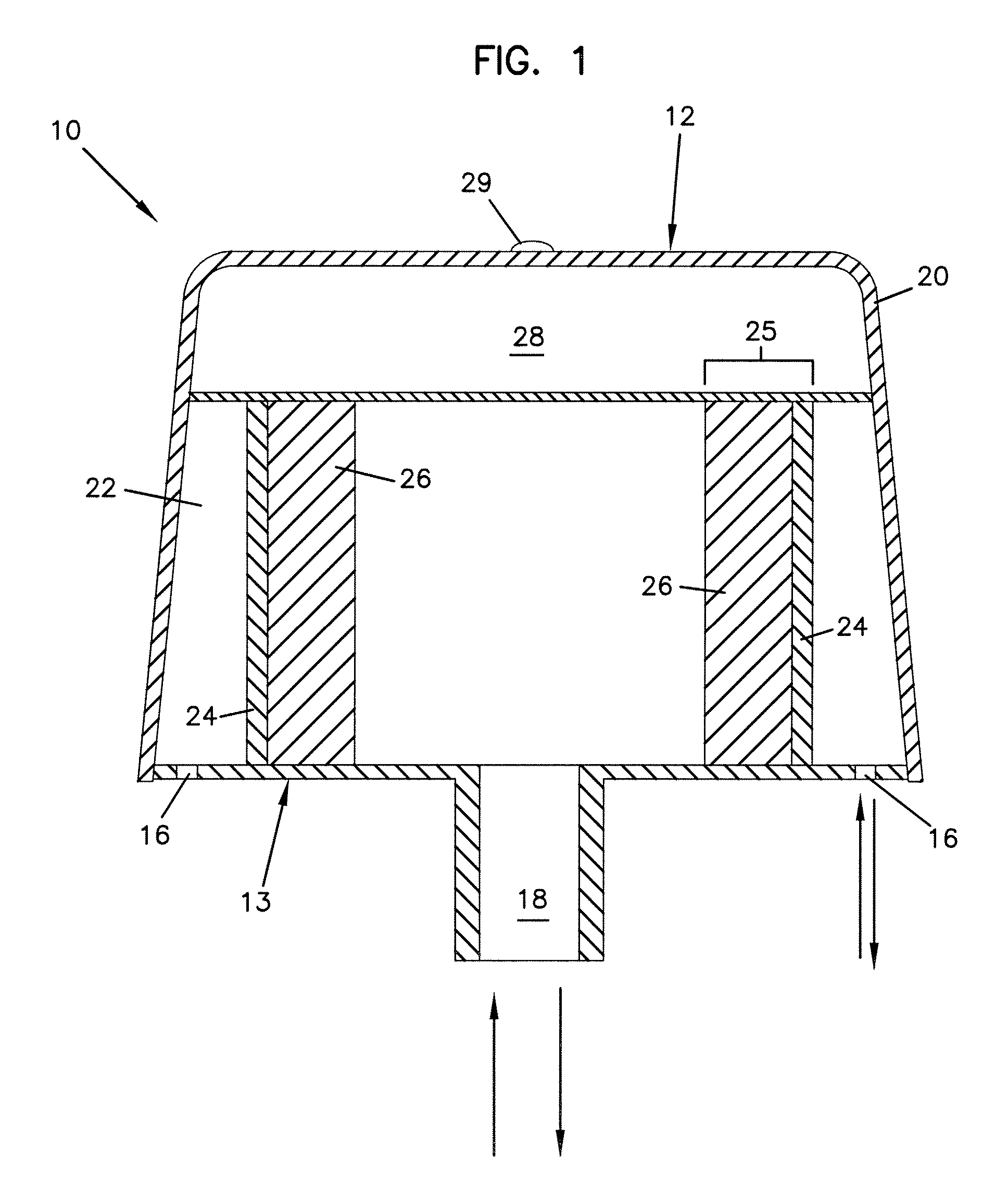

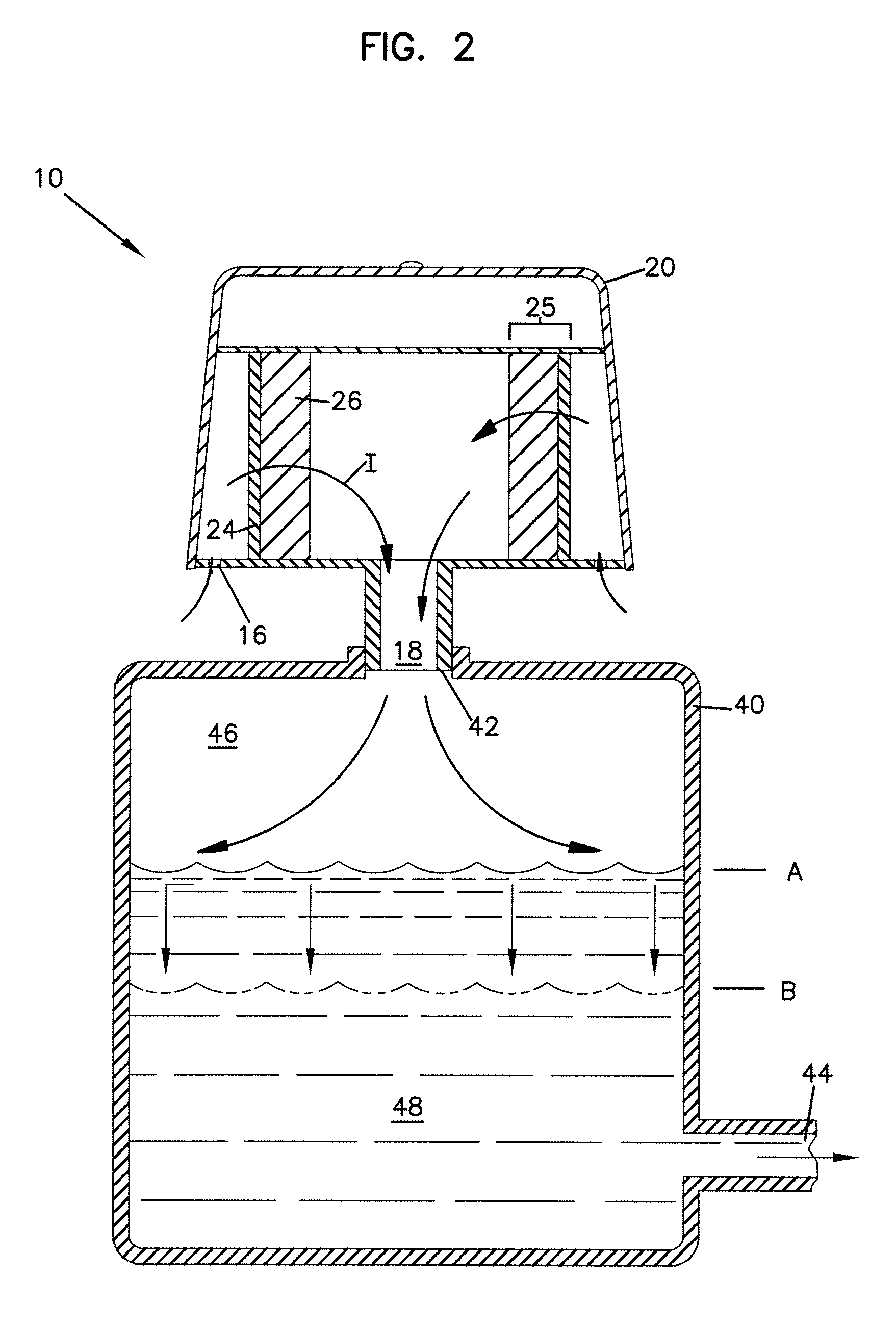

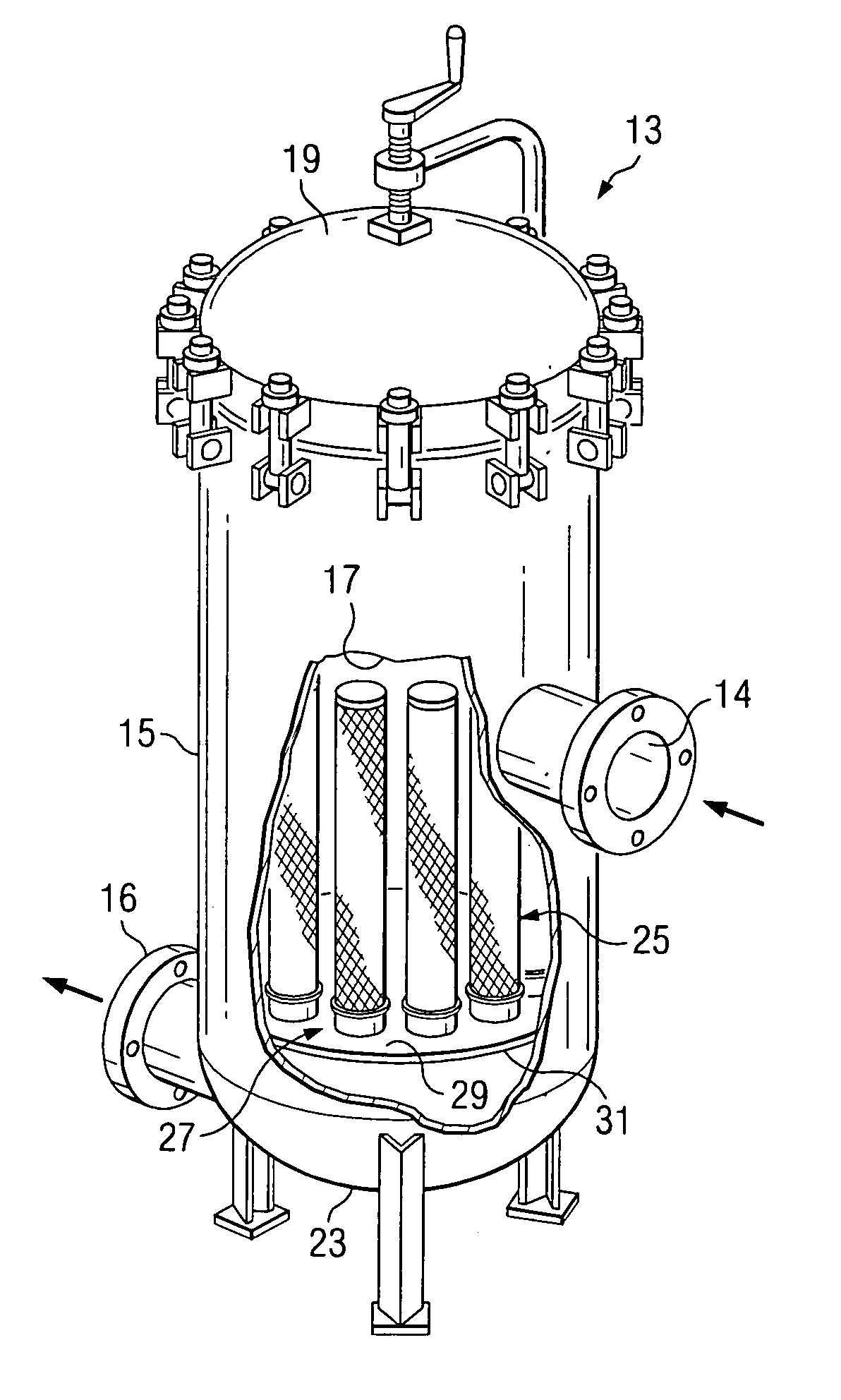

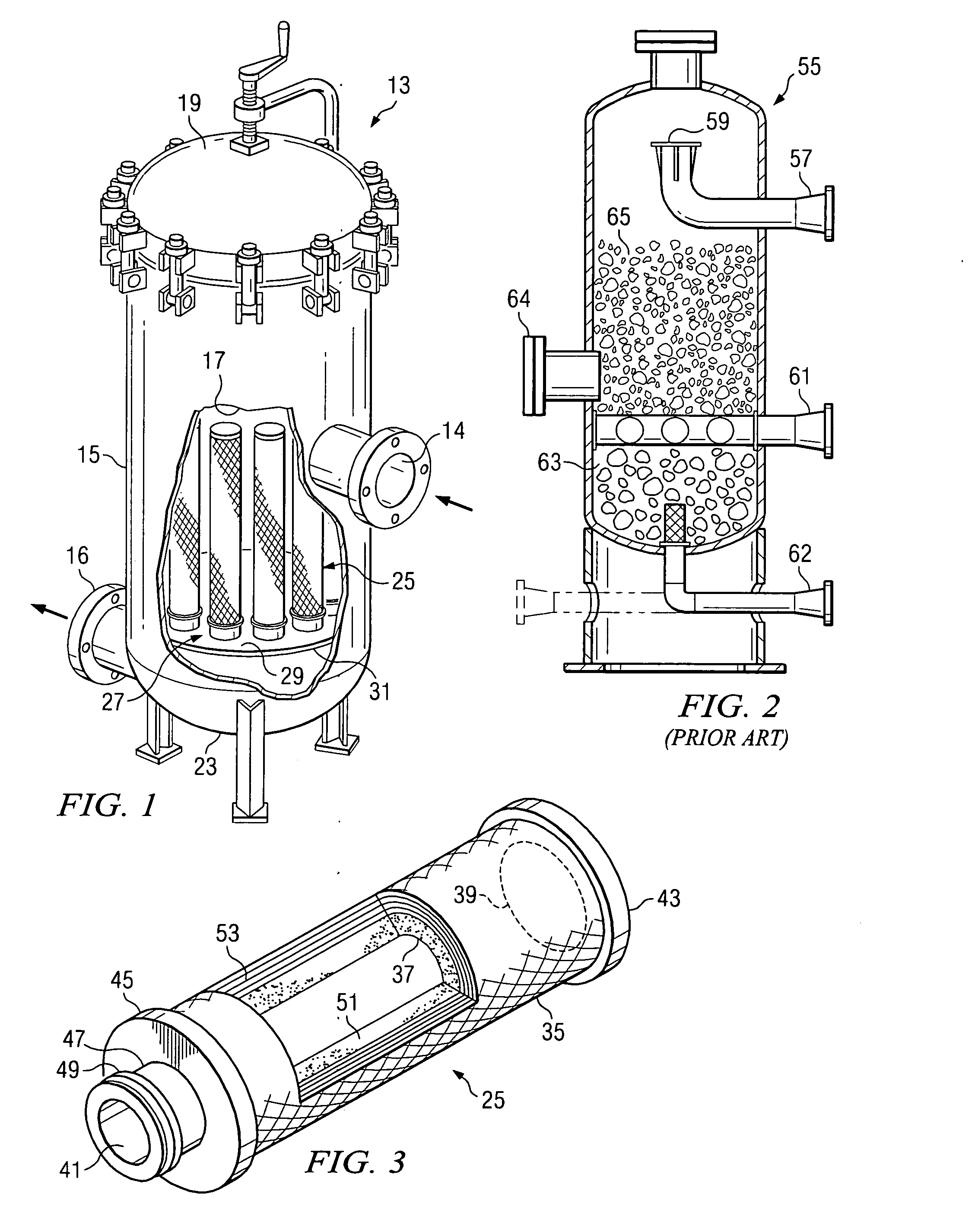

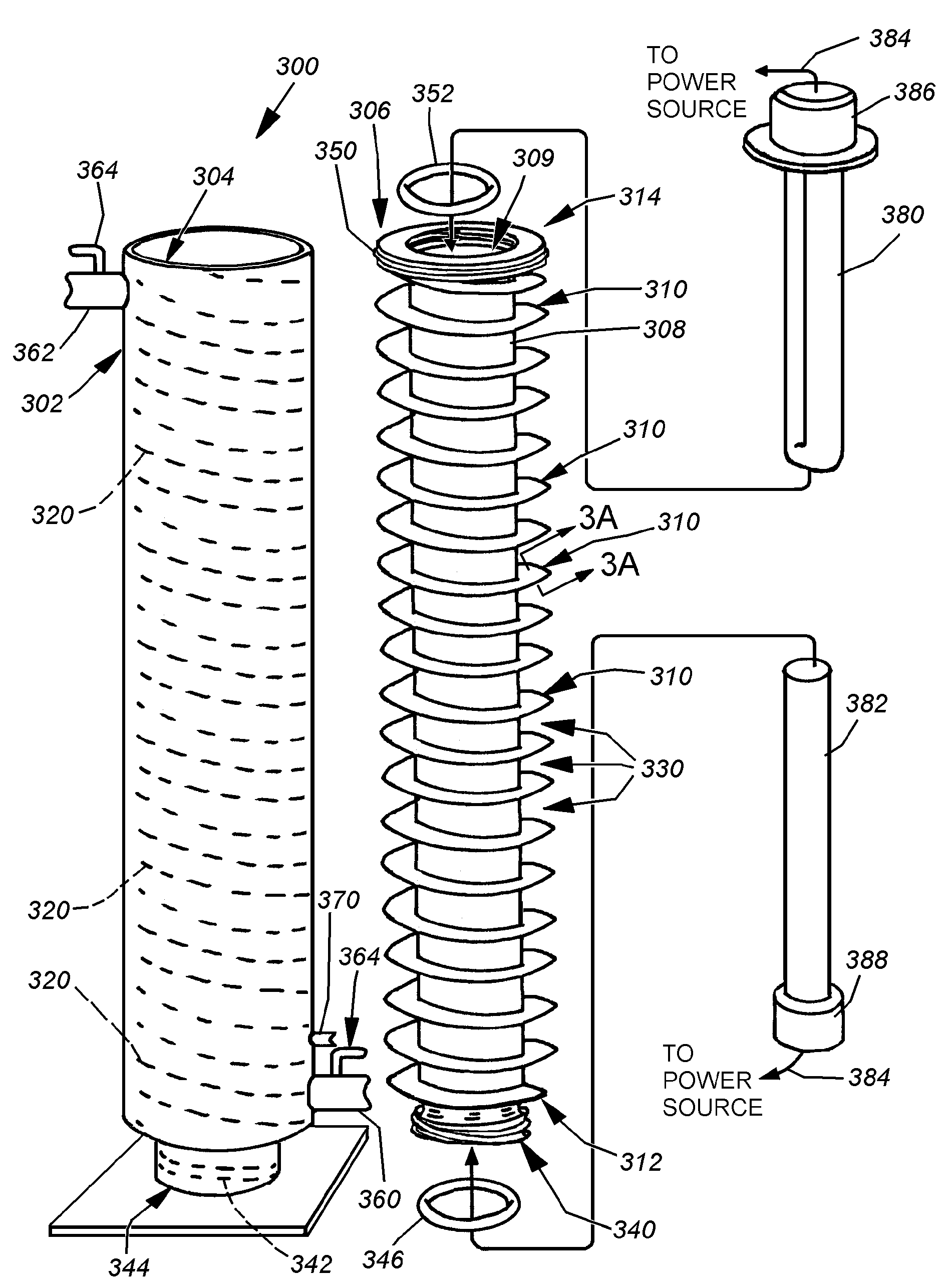

InactiveUS20070251876A1Eliminate needImprove fermentation effectMembrane filtersLoose filtering material filtersHybrid filterFilter media

The present invention relates to an apparatus for filtering a gas or liquid stream of impurities and to filter elements used in such an apparatus. The apparatus includes a closed vessel having a longitudinally extending length, an initially open interior, an input port at one extent and an output port at an opposite extent thereof. A partition located within the vessel interior divides the vessel interior into a first stage and a second stage. At least one opening is provided in the partition. A filter element is disposed within the vessel to extend from within the first stage. The filter element is made up of a carbon block filter media surrounded by a protective porous depth filter media.

Owner:PERRY EQUIPMENT

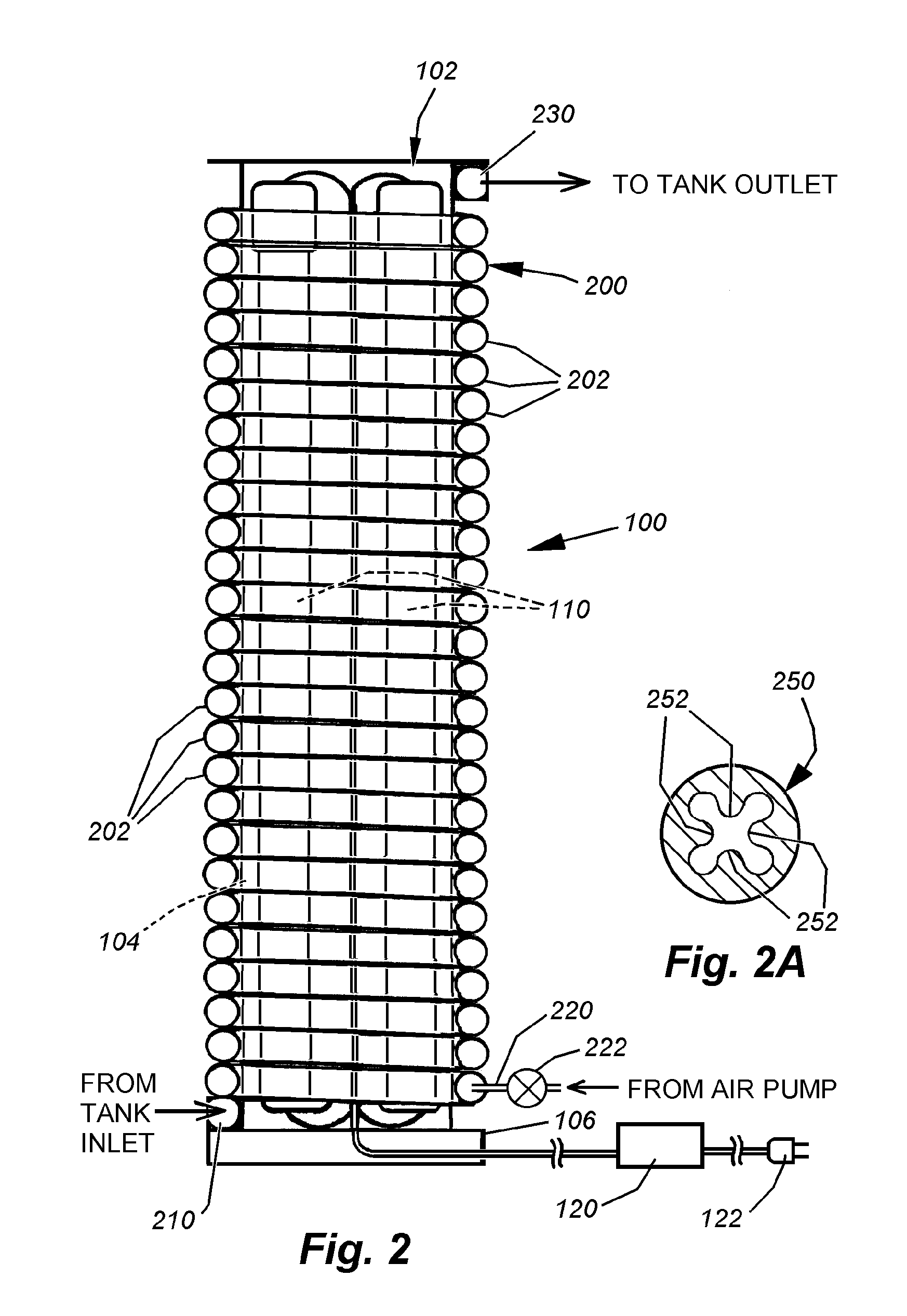

Biological filter for aquatic ecosystems

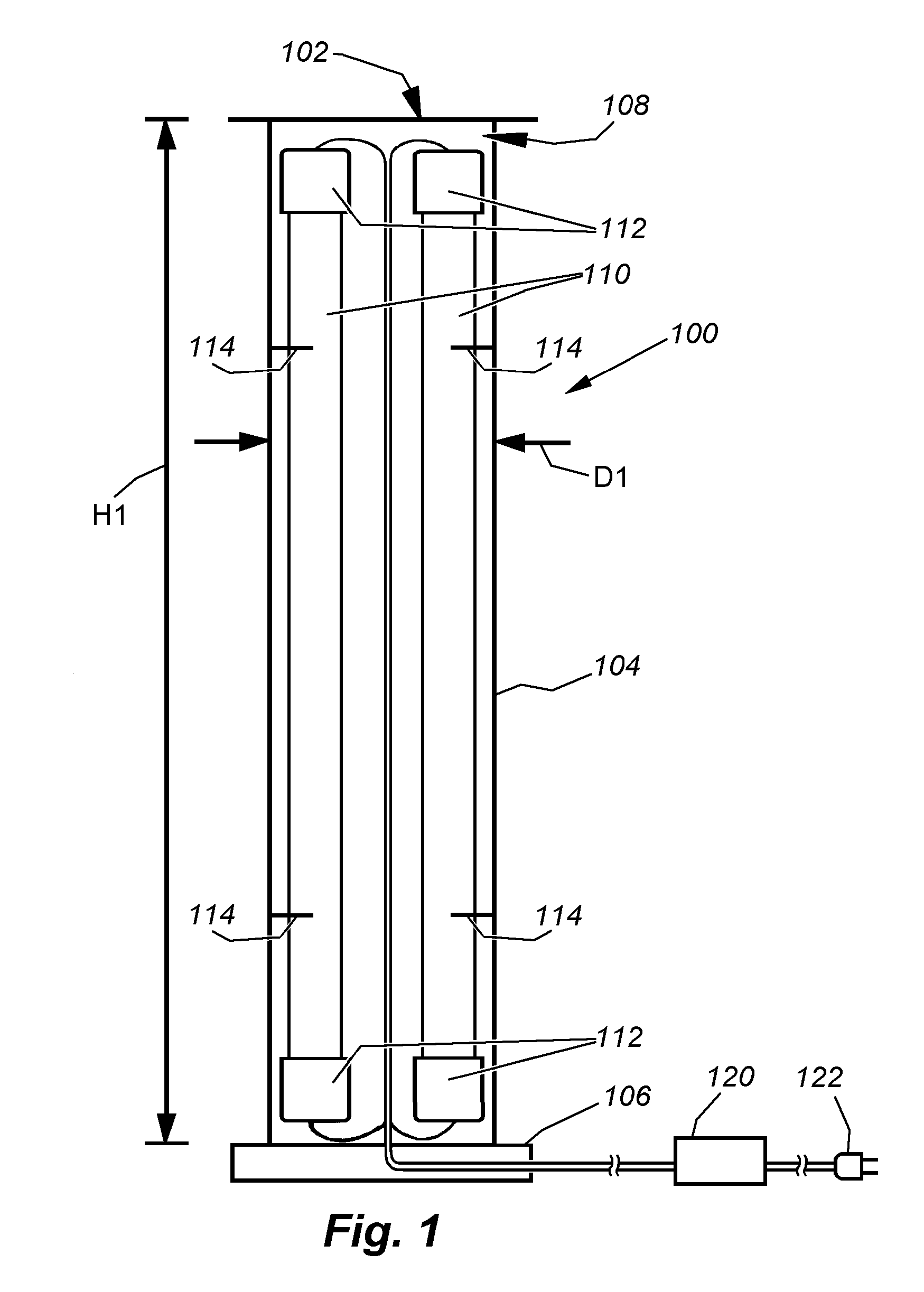

InactiveUS7578933B1PurifyIncreased algal growthTreatment using aerobic processesWater/sewage treatment by irradiationParticulatesAquatic ecosystem

This invention provides a filtration system for home aquaria that uses a closed-circuit pathway having a surface that contacts a flow of water moving between a tank inlet and tank outlet. The surface allows for algal growth thereon, and for transmission of light thereonto so as to provide photosynthetic energy to the algae. The algae acts to scrub contaminants (nitrogenous compounds, for example) as part of its growth cycle, and thereby purify the water. Additional components, such as injected air and filter media can also be provided to the water circuit to enhance algal growth, oxygenate the water and remove particulates. In an illustrative embodiment, the surface is transparent or translucent and a light that transmits appropriate wavelengths (for example, full-visible spectrum) is placed in proximity to the surface.

Owner:SELMAN BENJAMIN B

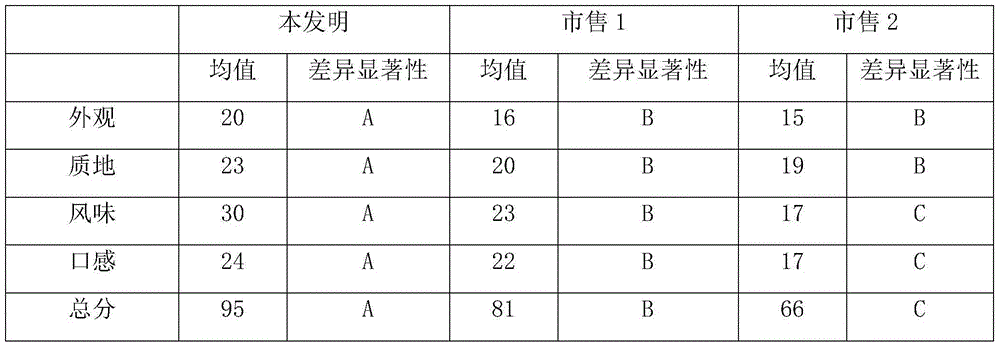

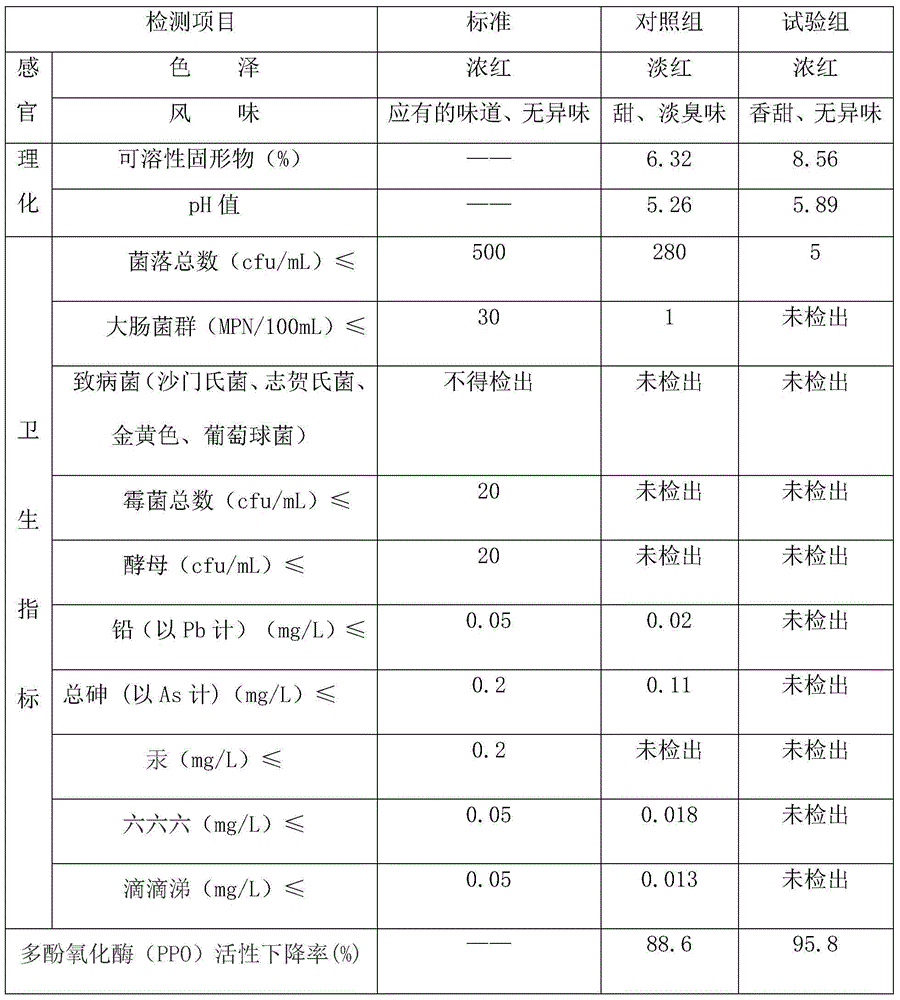

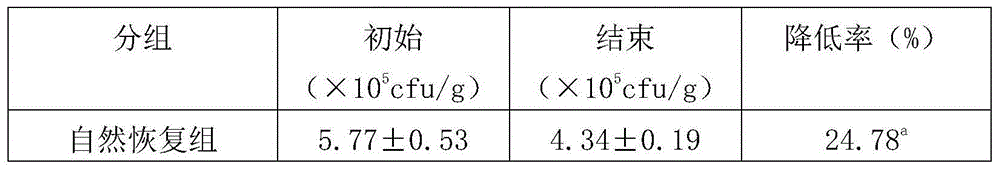

Probiotics troche and preparation method thereof

The invention discloses a probiotics troche and a preparation method thereof. Functional leavening agents and germinated brown rice, Chinese herb medicine extract with anti-cold and hot irritability and a stabilizer capable of effectively enhancing the stability are added into a yoghourt fermenting process; poikilothermal yogurt fermentation enables proliferation of lactic acid bacteria to the maximum extent, so that the anti-cold and hot irritability of lactic acid bacteria is improved. yogurt and fruit and vegetable slurry are pre-treated by using a non-hot-working technology so as to prevent infectious microbe infection in the process, improve the juice yield of the fruit and vegetable slurry, increase the content of soluble cellulose of the fruit and vegetable slurry and prevent the fruit and vegetable slurry from brown stain. Moreover, when the fruit and vegetable slurry and the yogurt are mixed, a scientifically compounded freezing protecting agent which is relatively good in anti-freezing effect is added. Finally, the probiotics troche which is smooth in taste, uniform in texture, stable in state, natural in quality, high in viable count, strong in functionality and long in expiration data is prepared. The viable count is (1.75-2.55)x10<11> CFU / g. At normal temperature, the expiration data is 30-36 months.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

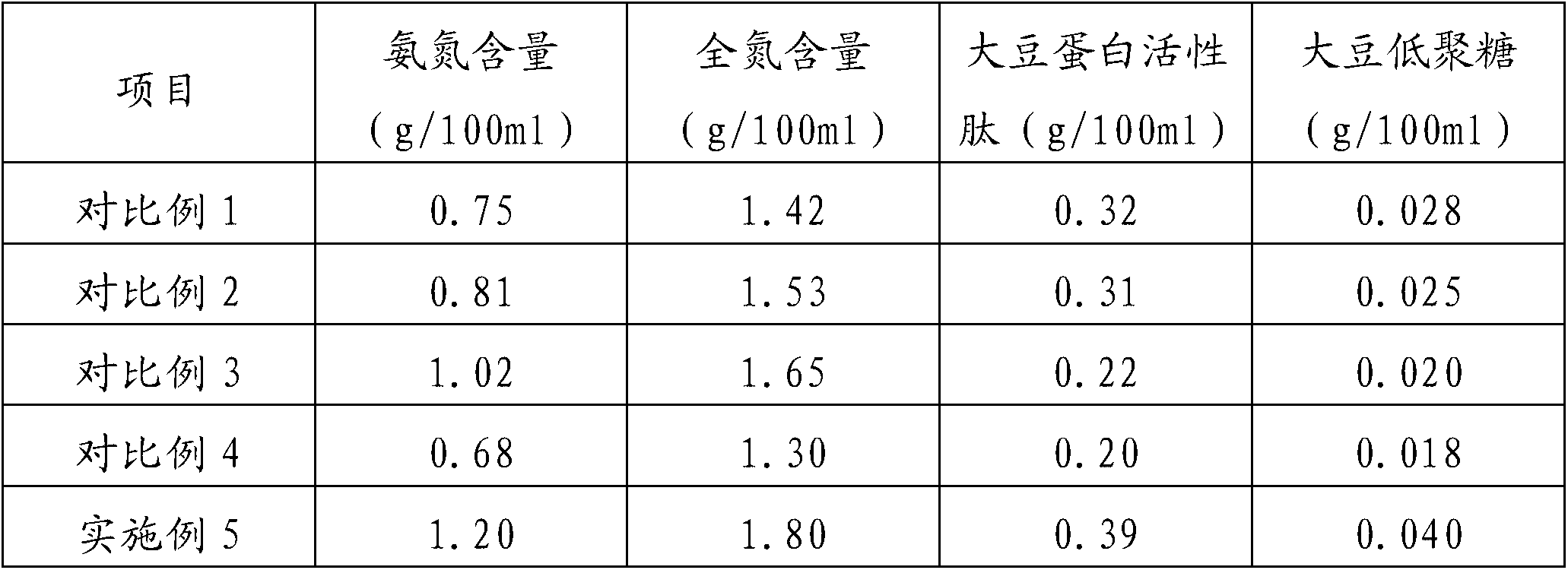

Production method of high-salt diluted and low-temperature fragrant soy sauce

The invention discloses a production method of a high-salt diluted and low-temperature fragrant soy sauce, which comprises the following steps of: (1) curing raw materials including wheat and defatted soybeans, and then uniformly mixing the wheat and the defatted soybeans; (2) inoculating aspergillus oryzae strains to the obtained raw material mixture so as to obtain a yeast; (3) cultivating the yeast for 44-48 hours at a temperature of 25-30 DEG C so as to obtain a mature yeast; (4) adding 2.0-2.5 weight times of saline water into the mature yeast so as to obtain a raw soy sauce mash; (5) moving the raw soy sauce mash to the inside of an airtight fermentation tank for fermenting: firstly fermenting for 23-27 days at a temperature of 13-17 DEG C, then continuing to ferment at a temperature of 28-32 DEG C, and on the 28-32nd days, adding mixed fermentation strains into the fermentation tank and continuing to ferment; in the process of fermentation, stirring by using a compressed air flow; and fermenting for more than six months so as to obtain a mature soy sauce mash; and (6) squeezing and filtering the mature soy sauce mash so as to obtain the low-temperature fragrant soy sauce. According to the invention, the conversion rate of proteins in raw materials is high, and the contents of ammonia nitrogen, total nitrogen, soybean peptides and soybean oligosaccharides in the prepared soy sauce are high.

Owner:好太太食品有限公司

Leavening agent for poultry excrement

InactiveCN102584362AEliminate bad odorPrevent proliferationClimate change adaptationExcrement fertilisersFermentation starterSaccharomyces

The invention discloses a leavening agent for poultry excrement, which comprises following microorganism fermentation liquor by volume ratio: 30-40% of bifidobacterium, 10-25% of lactic acid bacteria, 10-30% of bacillus megatherium, 10-25% of saccharomycetes, 10-15% of actinomycetes and 10-15% of acetic bacteria. The leavening agent can eliminate environmental fetor and restrain multiplication of malignant bacteria. Organic garbage in treated in composting mode, thereby recycling resources, reducing environment pollution, reducing sewer dirt and reducing odor. The poultry excrement is fermented into fertilizers and animal feed. The leavening agent for the poultry excrement is widely applied to fermentation of excrement and garbage.

Owner:THE IT ELECTRONICS ELEVENTH DESIGN & RES INST SCI & TECHNOLOGICAL ENG

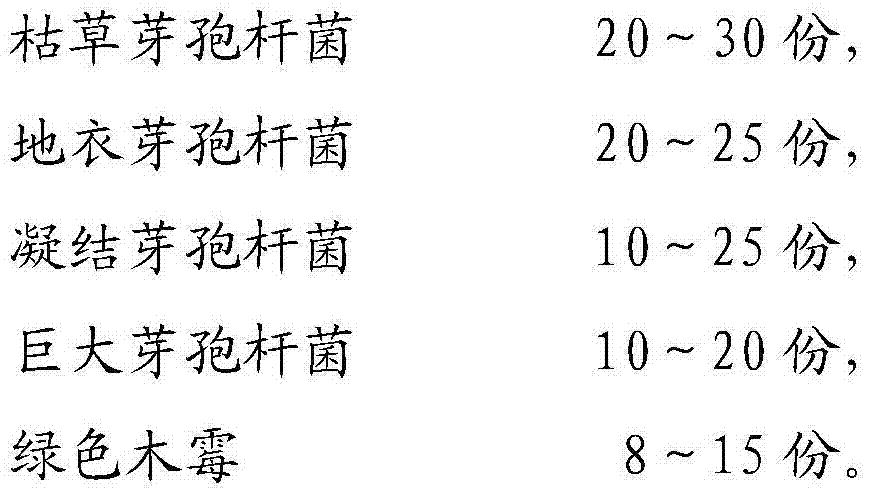

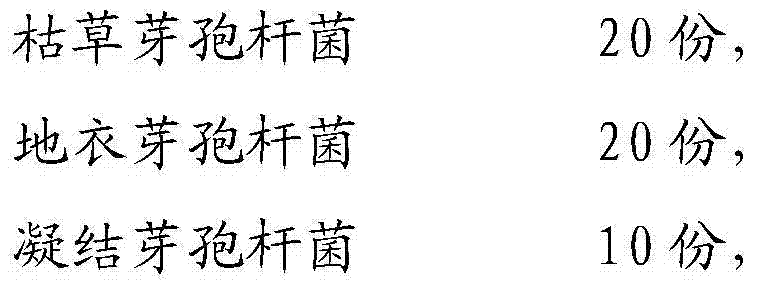

Pig-chicken excrement fermenting compound bacteria, preparation method and method of utilizing compound bacteria to ferment and prepare organic fertilizer

InactiveCN104232551AGood inhibitory effectEnhanced inhibitory effectBio-organic fraction processingFungiBacillus licheniformisMoisture

The invention discloses pig-chicken excrement fermenting compound bacteria, a preparation method and a method of utilizing the compound bacteria to ferment and prepare an organic fertilizer. The fermenting compound bacteria comprise the following raw material bacteria: bacillus subtilis, bacillus licheniformis, bacillus coagulans, bacillus megatherium and trichoderma viride. The method for preparing the organic fertilizer comprises the following steps: mixing pig-chicken excrement with crushed straws, adding the fermenting compound bacteria to the mixture according to a dosage of 1-2 Kg per ton, mixing uniformly, the moisture being 50-65 wt%, stacking the mixed raw materials, keeping the temperature at 55-65 DEG C to conduct fermentation, two days after the fermentation, turning the stacked materials for the first time, and then turning the materials once every one or two days, keeping the moisture at 50-65 wt% during the fermentation phase, and after fermentation, obtaining the organic fertilizer with a moisture content of 20-30 wt%. The pig-chicken excrement fermenting compound bacteria disclosed by the invention can be used for fermenting the pig and chicken excrement; compared to the prior art, the method for preparing the organic fertilizer is low in productive investment and production cost, convenient to use, free of odor, and good in the fermentation and decomposing effect.

Owner:SHANDONG SUKAHAN BIO TECH

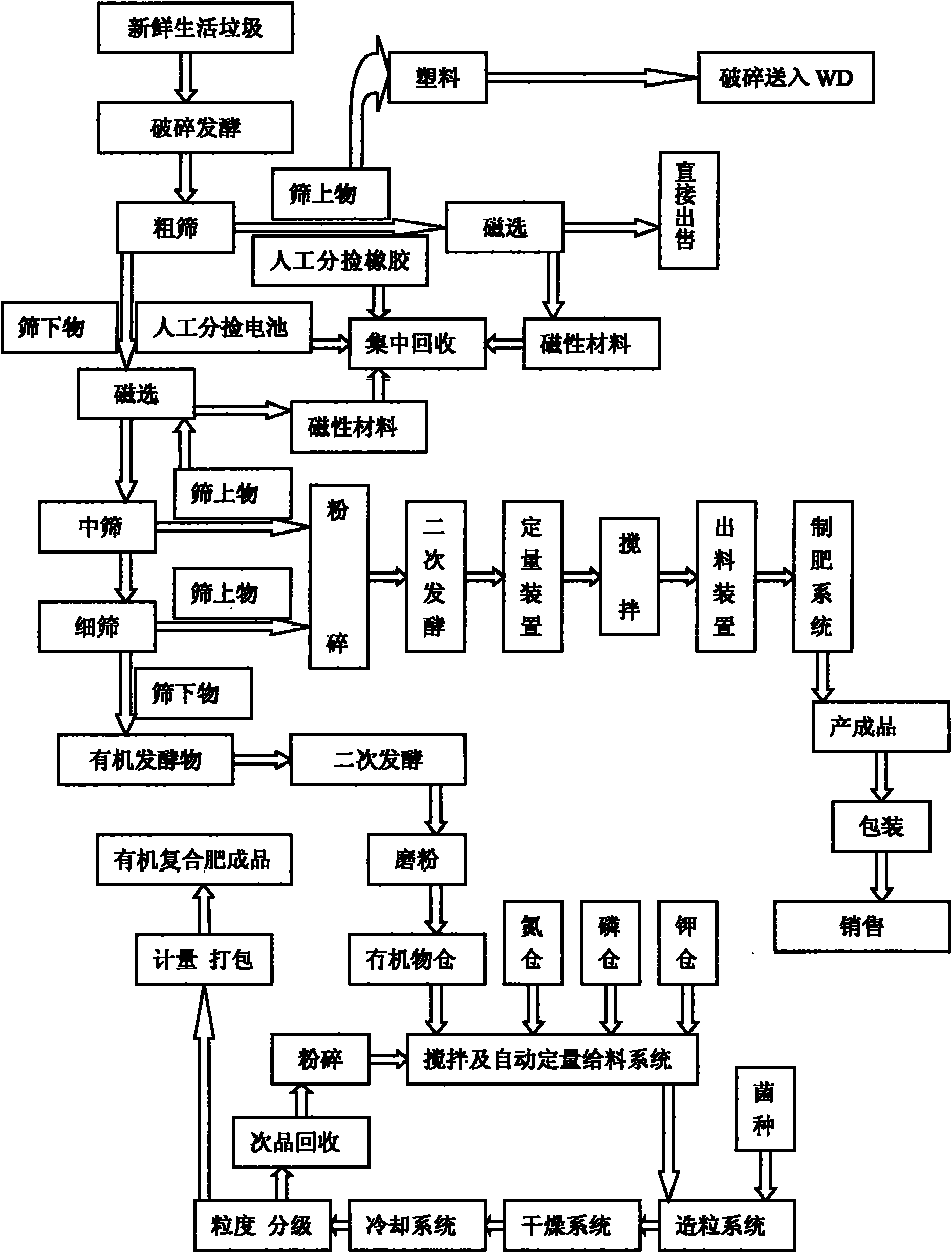

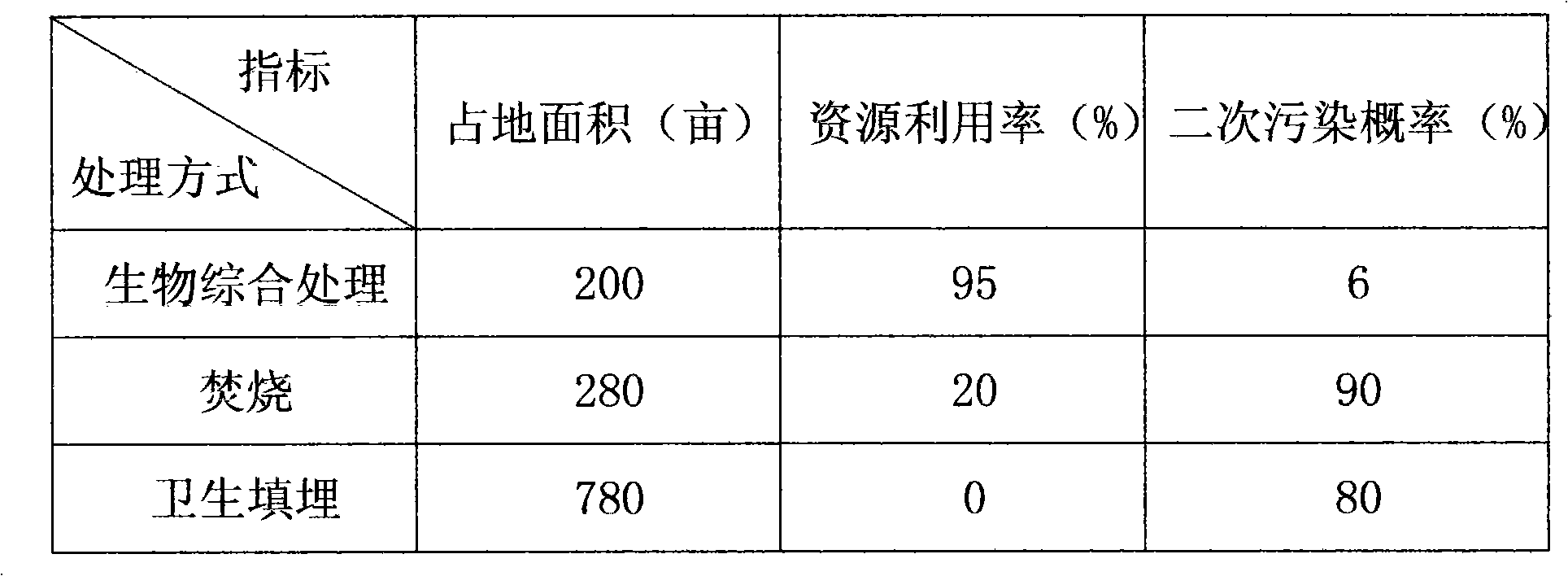

House refuse treatment method

InactiveCN102009057ASave spaceReduce the power requiredSolid waste disposalClimate change adaptationBrickCrushed stone

The invention discloses a house refuse treatment method, which comprises the following steps: crushing and fermenting refuse at normal pressure and under normal pressure; executing a screening process, crushing large or large-grain inorganic materials among oversize materials on a coarse screen, and making an urban coal material; coarsely screening, crushing stone and brick blocks among oversize materials on a medium screen, and making a roadbed material or pavior brick base material; making fertilizer by using organic materials or fermented products of the organic materials among the oversize materials and undersize materials of the medium screen and a fine screen, wherein materials with recycling value among magnetic materials screen out are sold directly, and materials without recycling value are collected and subjected to innocent treatment; and performing manual sorting, wherein materials with recycling value are directly sold. When the method is used for refuse treatment, the construction investment is small, the operation cost is low, the operation is simple, the treatment effect is desirable, and the resource recycling degree is high. The method can be widely used for treatment of refuse of different sizes and qualities without causing secondary pollution.

Owner:中山市祥源环保工程有限公司

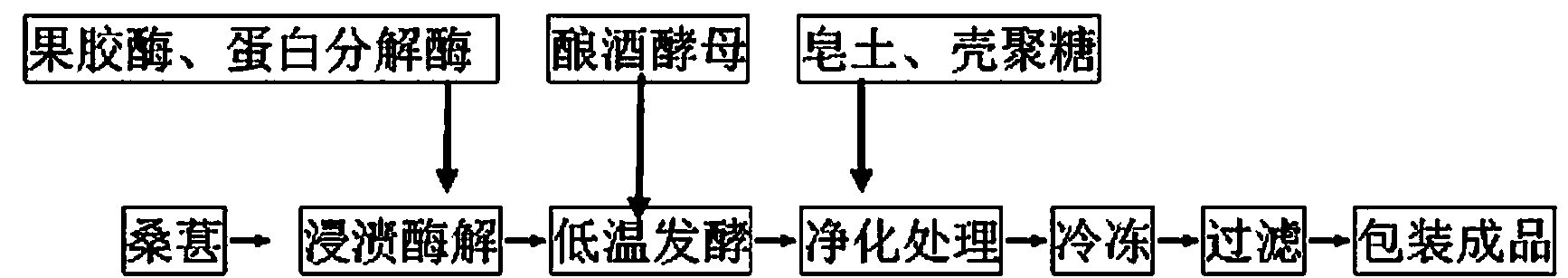

Production method for completely-fermented mulberry wine and product

InactiveCN103642635AComposite enzymatic hydrolysis effect is goodGood enzymatic effectMicroorganism based processesAlcoholic beverage preparationPectinaseFlavor

The invention discloses a production method for completely-fermented mulberry wine and a product. The method comprises the following steps of performing composite enzymatic hydrolysis on a raw material mulberry flesh by using pectinase and proteinase, performing primary fermentation for 16 to 25 days and performing after fermentation for 12 to 22 days at 15 to 21 DEG C by using 165 to 215mg / L alcohol-fermentation dry yeasts until the alcohol strength is finally 11.5 percent Vol, clarifying a product by taking a 420 to 650g / L bentonite solution and a 200 to 320g / L chitosan solution as clarifying agents, performing aging for 3 months at 18 DEG C, performing freezing treatment for 5 days at -5.8 to -6.2 DEG C, performing preliminary filtering, and performing filtering disinfection twice by using a sheet filter and a membrane filter. According to the production method, good composite enzymatic hydrolysis and low-temperature batch fermentation effects are achieved, the stability of the wine is further improved by composite fining, and the stability and flavor of the wine are improved by low-temperature freezing. The production method is applied to the production of the completely-fermented mulberry wine.

Owner:YUNFU HUANAN LIQUOR

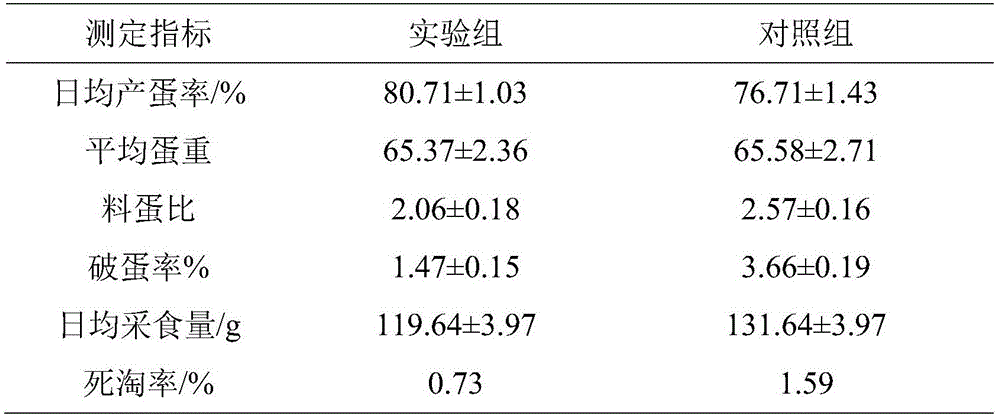

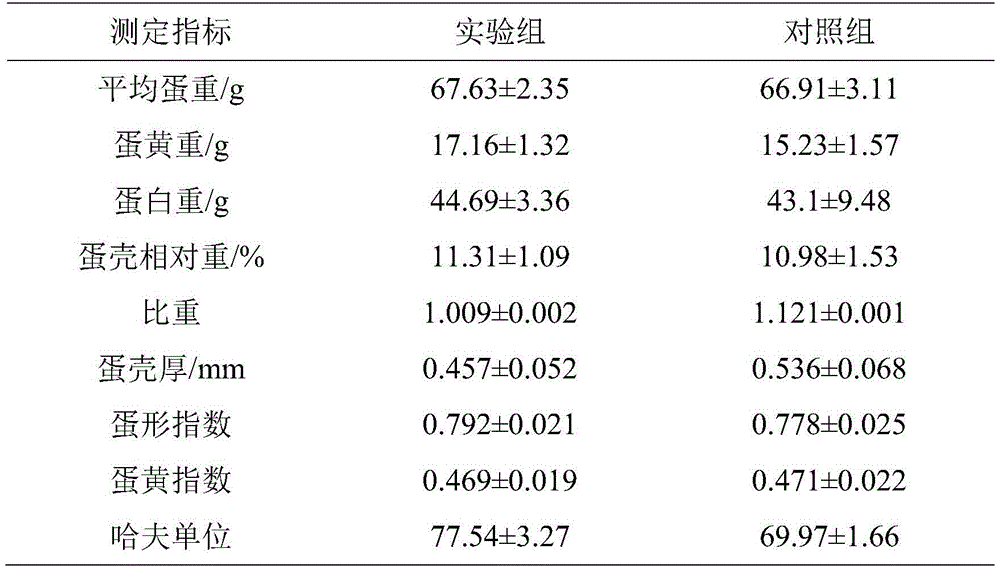

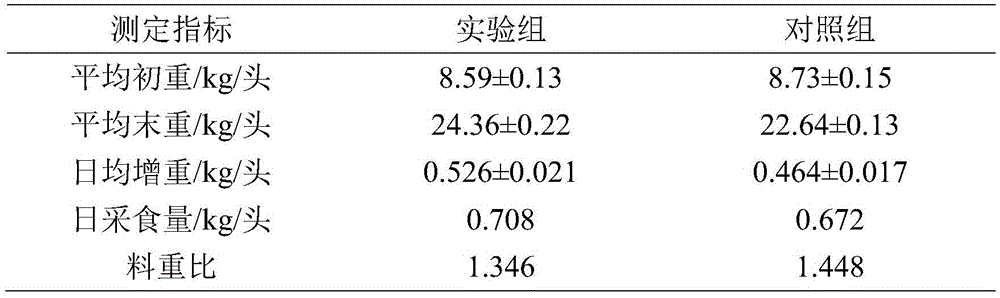

Microbial fermentation feed as well as production method and application thereof

ActiveCN105475624AGuaranteed functionalityGrowth inhibitionAnimal feeding stuffOrganic acidDry weight

The invention discloses microbial fermentation feed as well as a production method and an application thereof. The production method of the microbial fermentation feed comprises the following steps: (1) lactic acid bacteria, Clostridium butyricum Cb-2, yeast, Bacillus subtilis, a fermentation base-material and water are uniformly mixed, and a fermentation raw material is obtained; 2) aerobic fermentation and anaerobic fermentation are carried out in order for the fermentation raw material obtained in the step (1), and after fermentation, the feed is obtained. The microbial fermentation feed contains microecological viable organisms, and the total amount of beneficial bacteria is more than 5 x 10<9> cfu / g; the amount of mould and the content of mould toxin are lower than national limit standards; the feed is rich in organic acid, the content of lactic acid reaches 2.5%, and pH value is lower than 4.5; the titer of antibacterial peptide is higher than 1000 u / g, the titer of neutral protease is 150 u / g, the titer of alpha-amylase 300 u / g, dry weight for above, and the titer of total protease is higher than 600 u / g; the whole fermentation process is controlled in the range of 8-24 hours, the fermentation time is saved, and the dissipating energy is controlled below 3%.

Owner:SHANDONG BEE LAN BIOTECHNOLOGY CO LTD

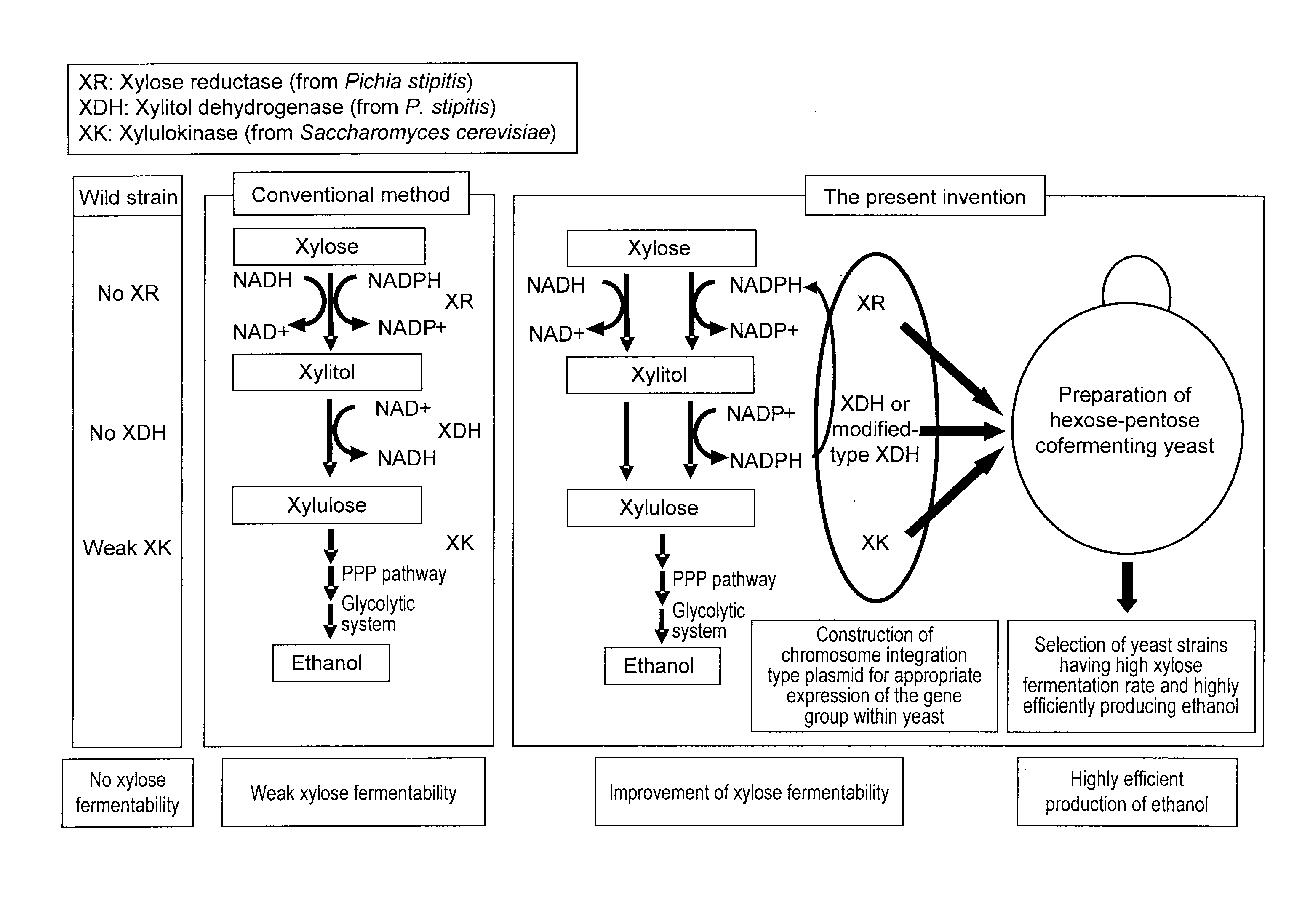

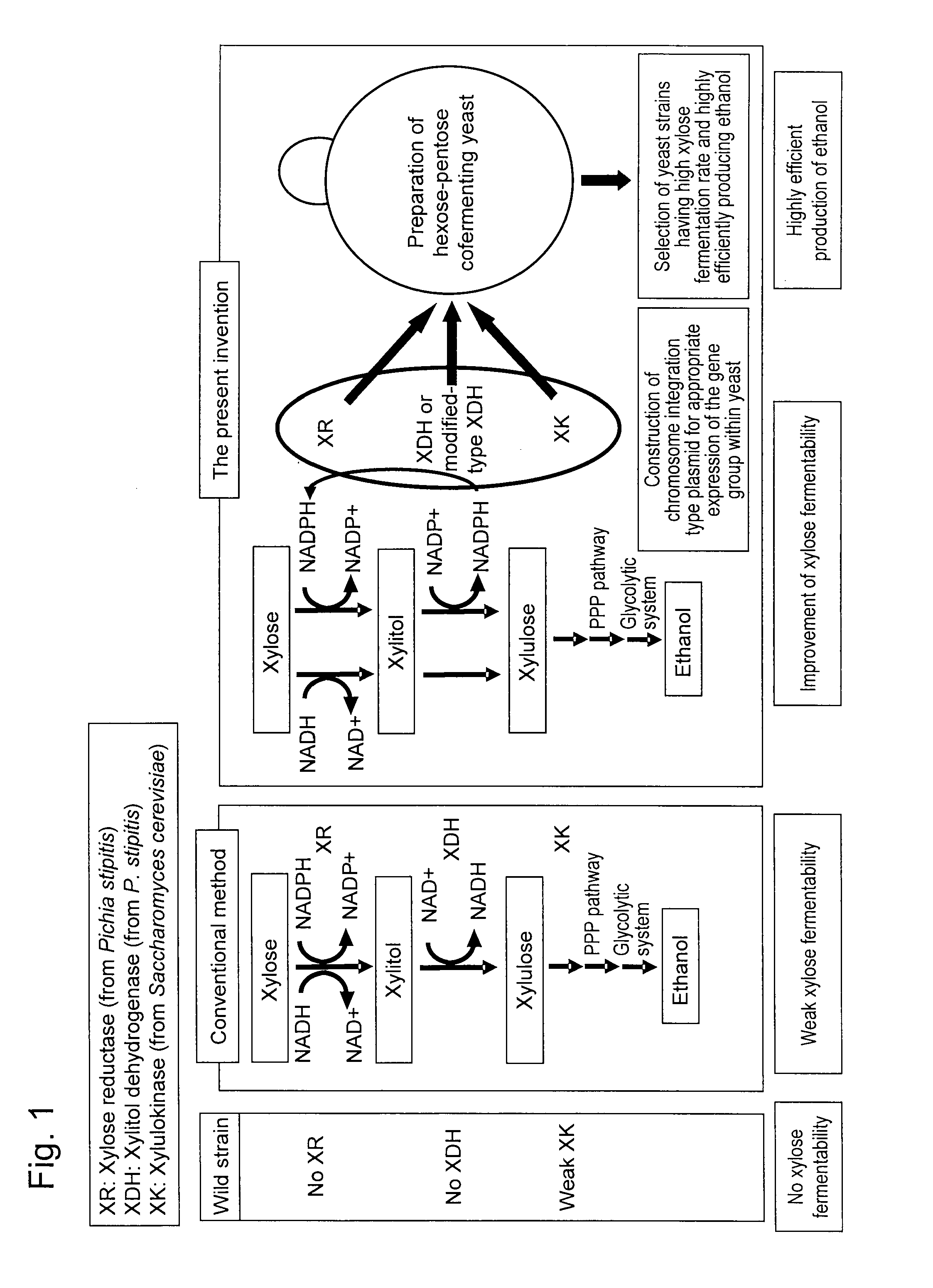

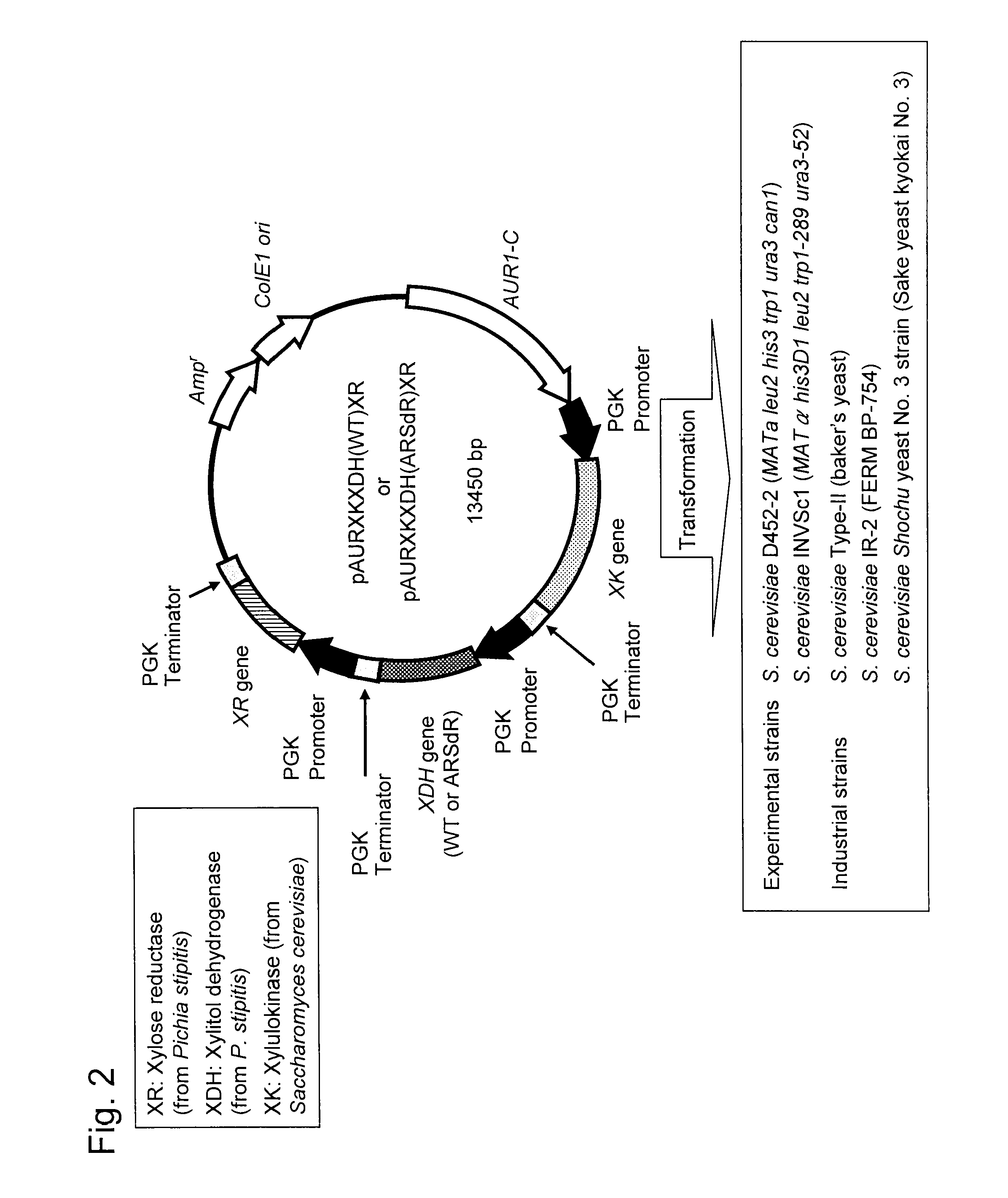

Hexose-pentose cofermenting yeast having excellent xylose fermentability and method for highly efficiently producing ethanol using the same

InactiveUS20110027847A1Efficient conversionValid conversionFungiTransferasesXylose fermentationPichia stipitis

Genetic recombinant yeast expressing xylose reductase (XR), (wild-type or mutant) xylitol dehydrogenase (XDH), and xylulokinase (XK) and a method for highly efficiently producing ethanol from xylose using the yeast are provided. Pichia stipitis-derived XR and (wild-type or modified-type) XDH genes and Saccharomyces cerevisiae-derived XK gene were introduced via chromosomal integration. Thus, a genetic recombinant yeast having a high xylose fermentation rate, being capable of producing ethanol from xylose in high yields, and having high xylose fermentability in the presence of glucose, as well as a method using the recombinant yeast for highly efficiently producing ethanol from xylose or a saccharified solution from lignocellulose-based biomass are provided. Furthermore, a method for improving the xylose fermentability of the genetic recombinant yeast of the present invention via acclimatization treatment is also provided herein.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Honey-aroma type congou black tea processing method

ActiveCN104886288AConducive to mutual frictionEasy to convertPre-extraction tea treatmentBlack teaFermentation

The invention discloses a honey-aroma type congou black tea processing method and belongs to the technical field of tea processing. The method includes: firstly, picking fresh leaves of large-leaf tea, and placing the fresh leaves of a tea tree in a withering trough for green leaf cooling; repeatedly subjecting the fresh leaves of the tea tree to rocking process and green leaf cooling for twice, and spreading the obtained rocked leaves in the withering trough for withering processing; twisting the obtained withered leaves heavily and slightly alternatively; sending the obtained twisted leaves to a fermentation chamber for fermentation; subjecting the fermented leaves to drying processing, taking out the fermented leaves for sizing and sending to a dryer for drying process after spreading for cooling; spreading and cooling the dried leaves to obtain the spread and cooled leaves which are sent to a baking machine for aroma extraction to obtain the honey-aroma type congou black tea. Compared with the prior art, the honey-aroma type congou black tea processing method has the advantages that the processed tea leaves are tightly knotted and black, even, fragrant, remarkable in honey aroma, red and bright in soup, rich in taste and bright red in infused leaves.

Owner:贵州怡壶春生态茶业有限公司

Clostridium butyricum

InactiveCN101942405AHigh yieldImprove the quality rateBacteriaMicroorganism based processesHigh concentrationAlcohol

The invention aims to provide a Clostridium butyricum GK13 bacterial strain CCTCCNO. M2010175. The bacterial strain has the characteristics of high caproic acid yield and good growth stability, can be applied in preparing high-concentration compound Clostridium butyricum liquid after strengthening functional bacteria, can be applied in cultivating artificial pit mud, obtains the effect of shortening the newly-built cellar pool aging period and rejuvenating the degrade cellar pool function in the practical production, improves the alcohol yield and the superior product rate, and solves the problems of rejuvenating a degrade old cellar pool, and shortening the newly-built cellar pool aging time and the like.

Owner:HUBEI UNIV OF TECH

Antibacterial peptide active organic fertilizer and preparation method thereof

InactiveCN102557829AIncrease organic matterHigh in nutrientsBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerFermentation

The invention relates to antibacterial peptide active organic fertilizer and a preparation method thereof and belongs to the technical field of agricultural fertilizer. The fertilizer consists of livestock and poultry excrement, silkworm excrement and a microbial fermenting agent. The preparation method for the fertilizer comprises the following steps: 1) weighing the livestock and poultry excrement, the silkworm excrement and the microbial fermenting agent according to the weight ratio, mixing, adjusting the water content of the mixture to 55 to 65 percent, adjusting the pH value to be 5.0 to 8.0, and adjusting the C / N value to be 20 to 30; 2) performing primary stacked fermentation; 3) performing secondary stacked fermentation; and 4) screening the fermented organic fertilizer obtained in the step 3) to remove impurities, pelleting, shaping, discharging, drying, cooling, removing dust, detecting and packaging to obtain the antibacterial peptide active organic fertilizer. Compared with control, the antibacterial peptide active organic fertilizer can increase the yield by 20.1 to 25.3 percent when applied in the fields of fruits, vegetables, grain and oil, flowers and trees, tea and the like.

Owner:袁池

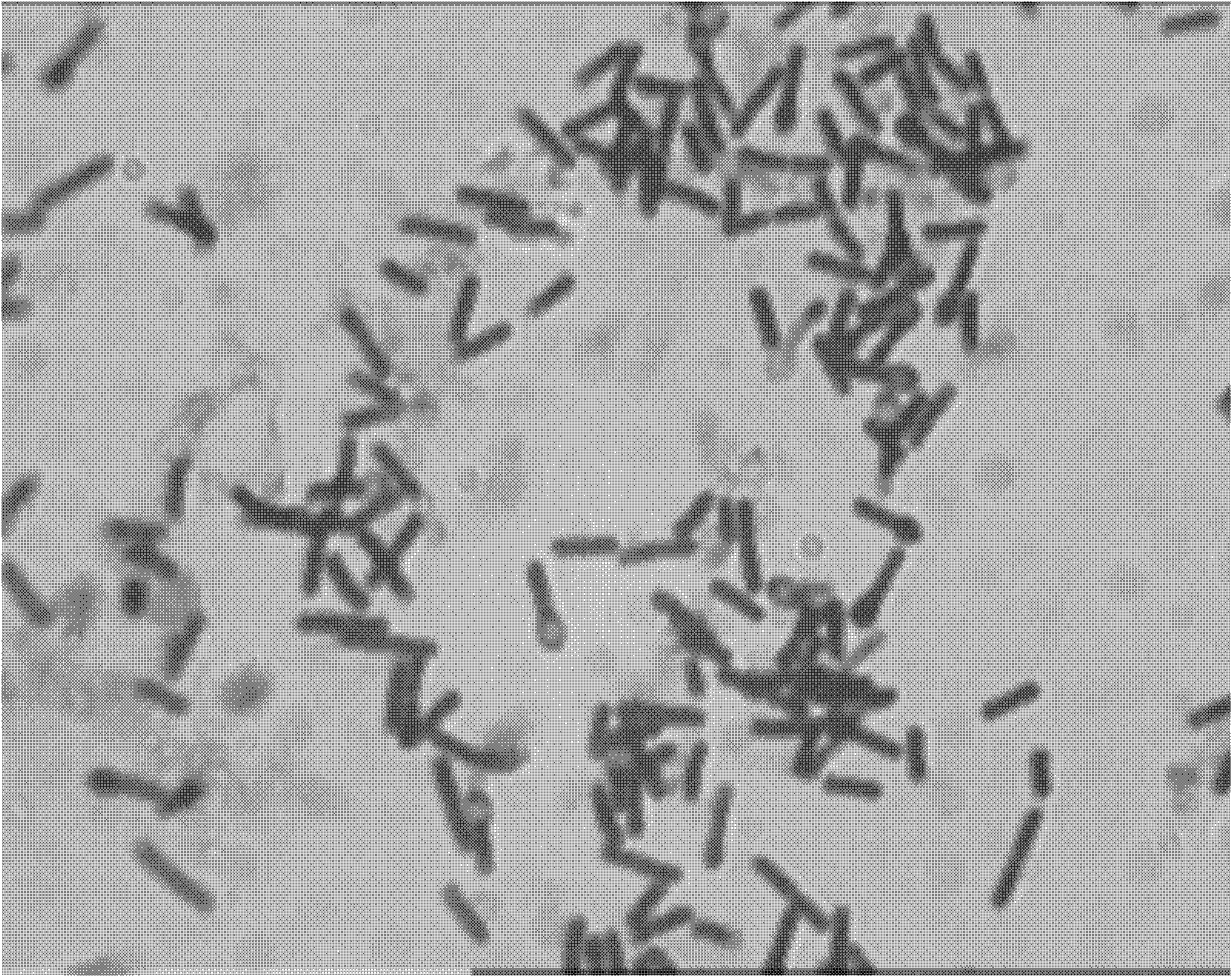

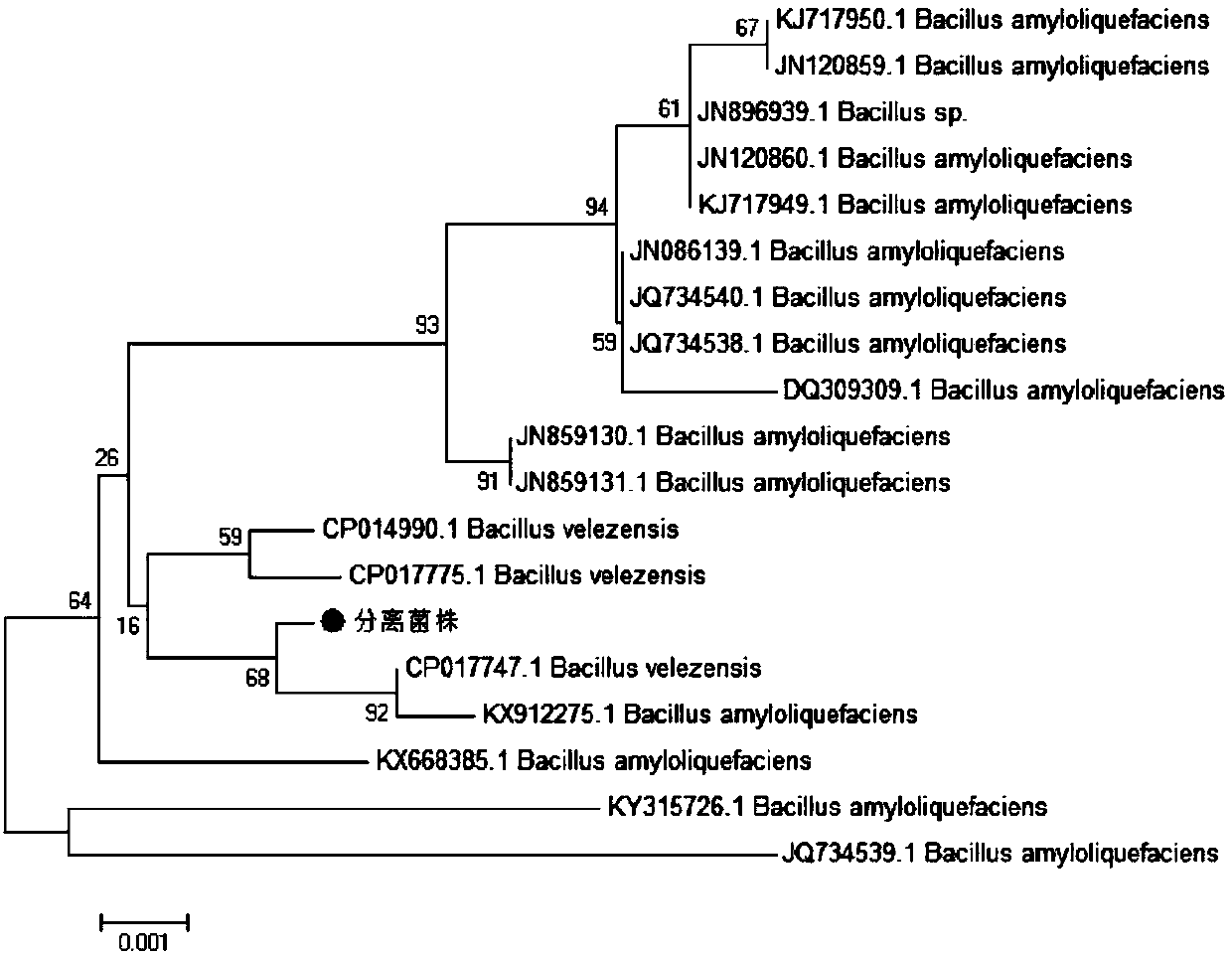

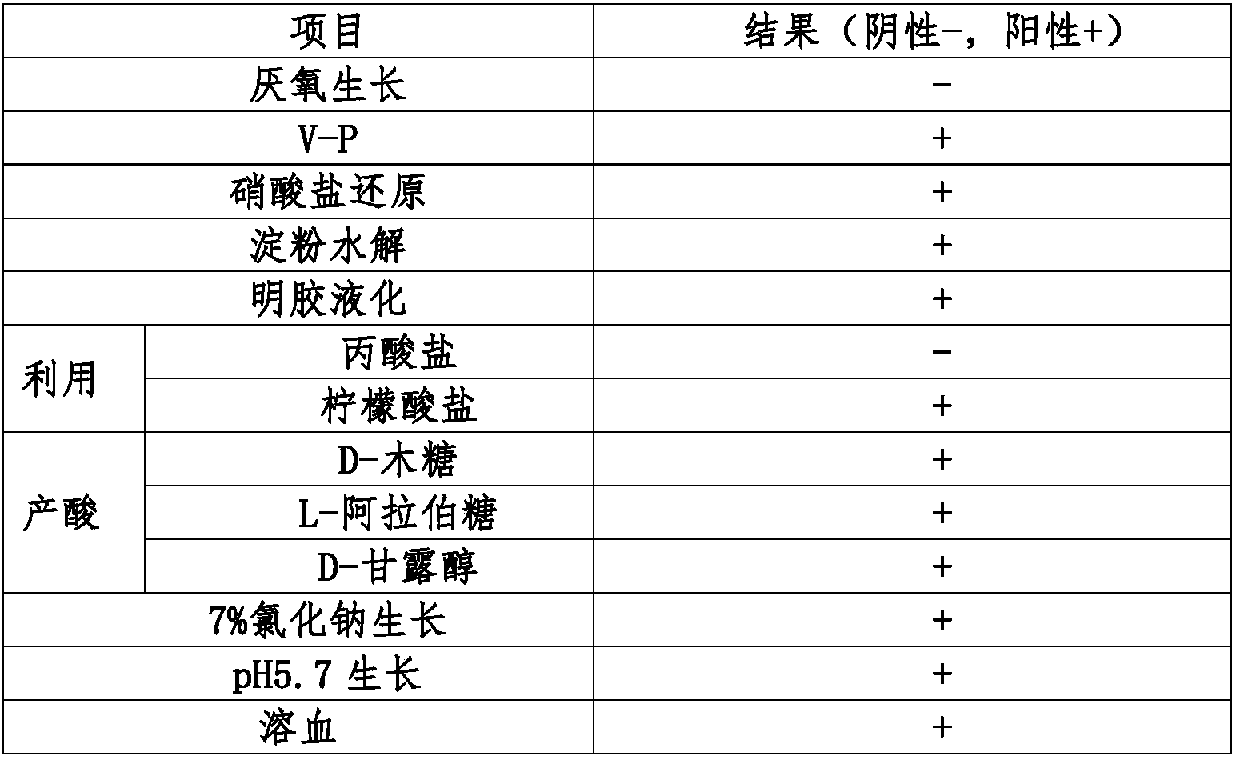

Bacillus velezensis as well as separation screening method and application thereof

ActiveCN108034617AImprove fermentation effectHigh in free amino acidsBacteriaMicroorganism based processesScreening methodDigestion

The invention provides bacillus velezensis as well as a separation screening method and application thereof, and belongs to the field of microbe technology and food processing. The invention providesthe bacillus velezensis with high fermentation capability; the bacillus velezensis is obtained through screening; during the fermentation, the capability of high yielding protease, amylase and fermented bean plasmin is realized; the bacillus velezensis can be applied to food fermentation in a large scale when being prepared into a food fermentation strain; fermentation food obtained through fermentation by using the bacillus velezensis, the contents of free amino acid and douchi fibrinolytic enzyme are high; the nutrition is rich; the characteristics of easy digestion, thrombus prevention andthe like are realized.

Owner:SICHUAN UNIV

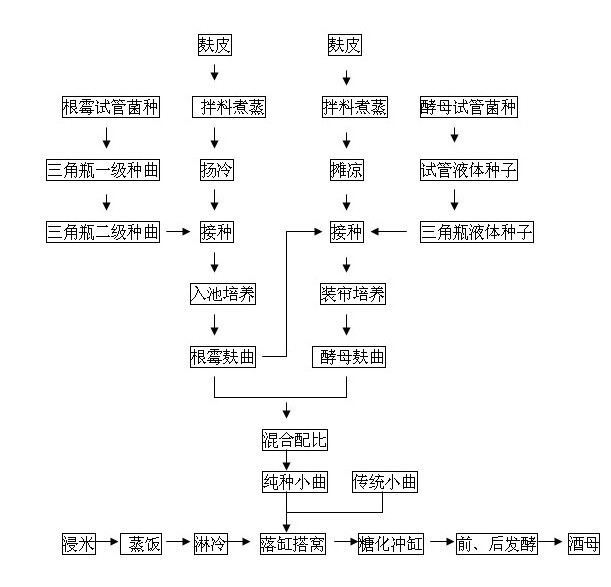

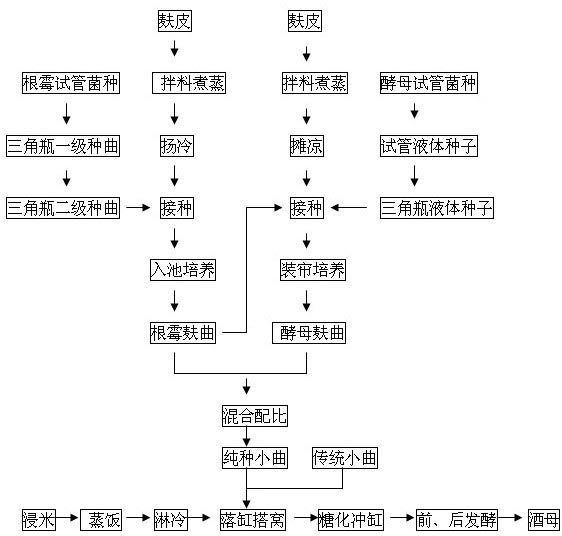

Preparation technology for drenched rice wine yeast

ActiveCN102660428AExcellent fermentation performanceReduce rancidityMicroorganism based processesAlcoholic beverage preparationHorticultureBran

The invention relates to preparation technology for a drenched rice wine yeast, belonging to the field of yellow wine brewing technology. The technology comprises the following steps: (1) rice soaking; (2) rice steaming; (3) water spraying; (4) cylinder feeding and nest building; (5) saccharifying, and water and koji adding; (6) primary fermenting; (7) secondary fermenting; and (8) maturing for further usage. The step (4) comprises that glutinous rice, small koji and pure small koji are fully blended to build a coved nest in an inverted trumpet shape, after which the product temperature of the nest is controlled at 25-28 DEG C. 150-180 g of small koji and pure small koji are added into every 100 kg of glutinous rice, wherein the weight ratio of small koji to pure small koji is 0.5-2:1. The purified small koji is prepared by mixing purified rhizopus bran koji with pure yeast bran koji, wherein yeast cell number is calculated as 400million / g in the mixing process, and the weight ratio of the pure rhizopus bran koji to the pure yeast bran koji is 100:5-7. The drenched rice wine yeast provided in the invention can greatly decrease the acetification rate of yellow wine in traditional processes.

Owner:CHINA SHAOXING YELLOW WINE GRP

Method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup

The invention discloses a method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup in the production of enzymatic corn starch sugar, comprising the steps of size mixing, liquefying, saccharifying, standing separation, centrifugal separation, proteolysis, concentration, drying, compounding, and the like. In the invention, protein is condensed under the heat flash of liquefying, the protein sugar dregs concentrate and float upwards in saccharifying, the sugar dregs are recovered through the steps of standing separation and centrifugal separation, the sugar dregs are dried into protein, or the sugar dregs are hydrolyzed to prepare protein nitrogen sources, and the nitrogen sources can be compounded with syrup to form nitrogen-containing starch syrup for fermenting. Clarified saccharification liquid after centrifugal separation is decolored, filtered, refined and concentrated, and starch syrup products are obtained. The majority of lentous sugar dregs in the saccharification liquid are removed before the treatment of decoloring and filtering, and the decoloring and filtering performance of the material is better. The use level of active carbon, and the like can be properly reduced, the production capability of filtering equipment is improved, and the frequency of the loading and unloading of filters as well as the consumption of washing waste water and various kinds of loss are greatly reduced.

Owner:广州双桥(重庆)有限公司

Method for producing chicken manure fermented feed

InactiveCN101584375ALow viscosityHigh nutritional valueAnimal feeding stuffNutrient solutionMixed materials

The invention discloses a method for producing chicken manure fermented feed, which comprises the following steps that: fully mixing fresh chicken manure with a carrier, and sterilizing and cooling the mixture to obtain a mixed material for standby; mixing and dissolving food-grade glucose in water to obtain nutrient fluid; mixing bacteria solution of yeast with bacteria solution of lactobacillus to prepare mixed bacteria solution; fully mixing and sealing the prepared mixed material, nutrient fluid and mixed bacteria solution in a plastic bag for fermentation at a temperature of between 25 and 35 DEG C for 2 to 4 days to obtain a fermentation material; and drying the fermentation material prepared by the steps; and when the water content in the fermentation material is reduced below 10 percent, crushing the fermentation material to obtain a finished product of the chicken manure fermented feed. By the method, parasite ova and harmful bacteria contained in the raw chicken manure can be removed, and the chicken manure can be prepared into the feed with good palatability and rich nutrition.

Owner:辽宁曙光农牧集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com