Patents

Literature

325results about How to "Improve the quality rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single crystal silicon texture-making additive and single crystal silicon texture-making technology

InactiveCN102115915AIncrease productivityIncrease production capacityAfter-treatment detailsFinal product manufactureActive agentPotassium hydroxide

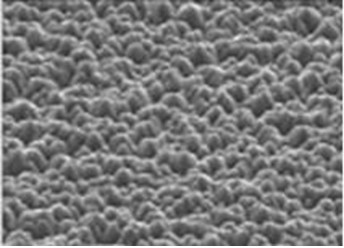

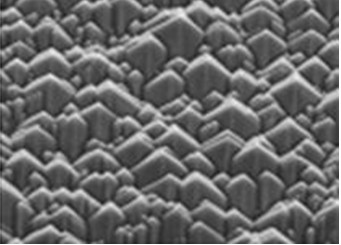

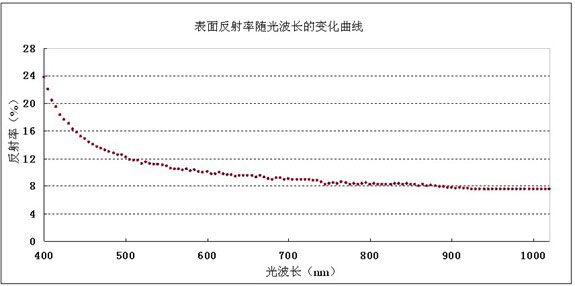

The invention relates to a single crystal silicon texture-making additive and a single crystal silicon texture-making technology. The single crystal silicon texture-making additive consists of a wetting agent and a defoaming agent. The additive is characterized in that the wetting agent is a nonionic surfactant. The single crystal silicon texture-making technology comprises the following steps: heating deionized water to 70-80 DEG C, adding sodium hydroxide or potassium hydroxide to obtain a single crystal silicon texture-making corrosive liquid, wherein the mass percentage of sodium hydroxide or potassium hydroxide is 1%-2%; adding the single crystal silicon texture-making additive in the single crystal silicon texture-making corrosive liquid to obtain a mixed solution, wherein the volume percentage of the additive is 0.3%-2%; and placing a precleaned raw silicon chip in the mixed solution for 600-1200s for texture-making. By adopting the additive and technology in the invention, the texture-making quality can be greatly increased, the cost is greatly reduced, the technological operation can be easier and the automatic solution preparation can be realized.

Owner:百力达太阳能股份有限公司

Angelica dahurica planting method

ActiveCN103348840AImprove the quality rateHigh content of organic seleniumSeed and root treatmentPlant protective coveringsGerminationSite management

The invention provides an angelica dahurica planting method. The method comprises the following steps: soil preparation, sowing, field management, pest prevention, harvesting, processing, seed reserving for planting and the others. According the method, during sowing, a planting matrix is used for cave filling, plant ash is adopted to cover the matrix, and then a piece of crape covers the matrix, so that the germination rate is higher, the pest diseases are few, the planted angelica dahurica is high in organic selenium content, and the average yield of the angelica dahurica can reach 570.8 kg, the quality of the angelica dahurica is obviously improved, and angelica dahurica with top quality can reach 40 percent.

Owner:安徽省本草国药饮片有限公司

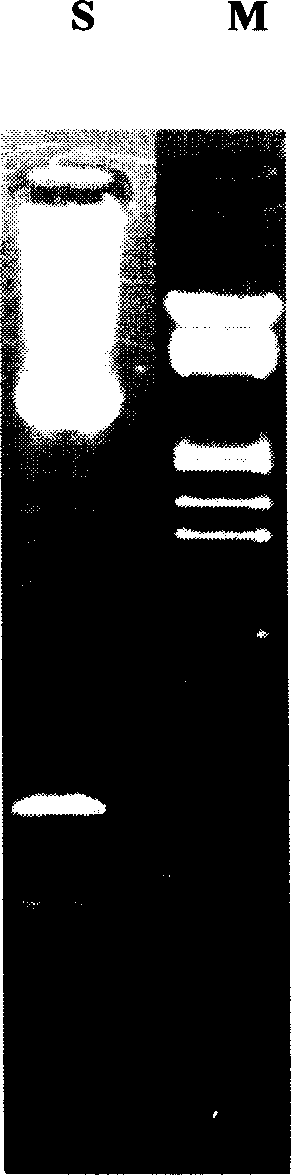

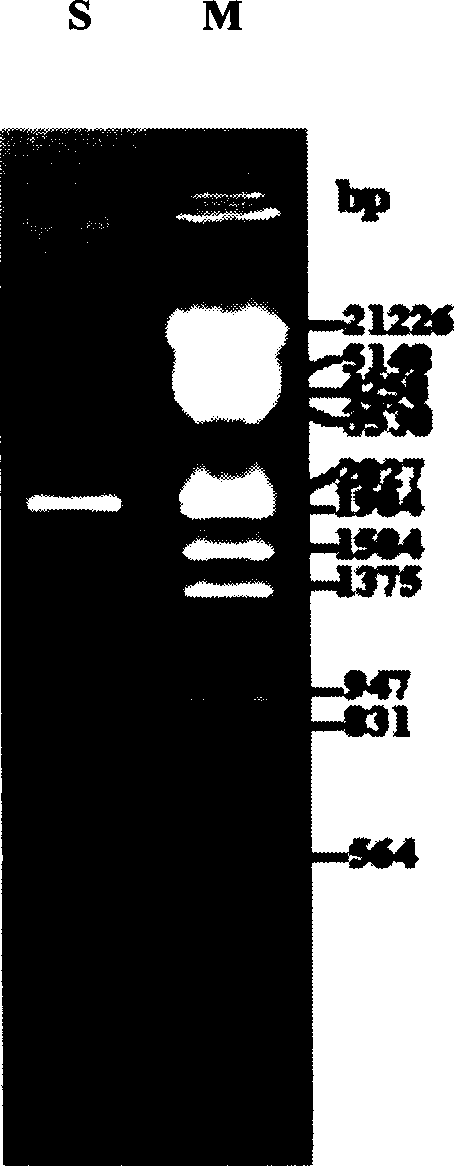

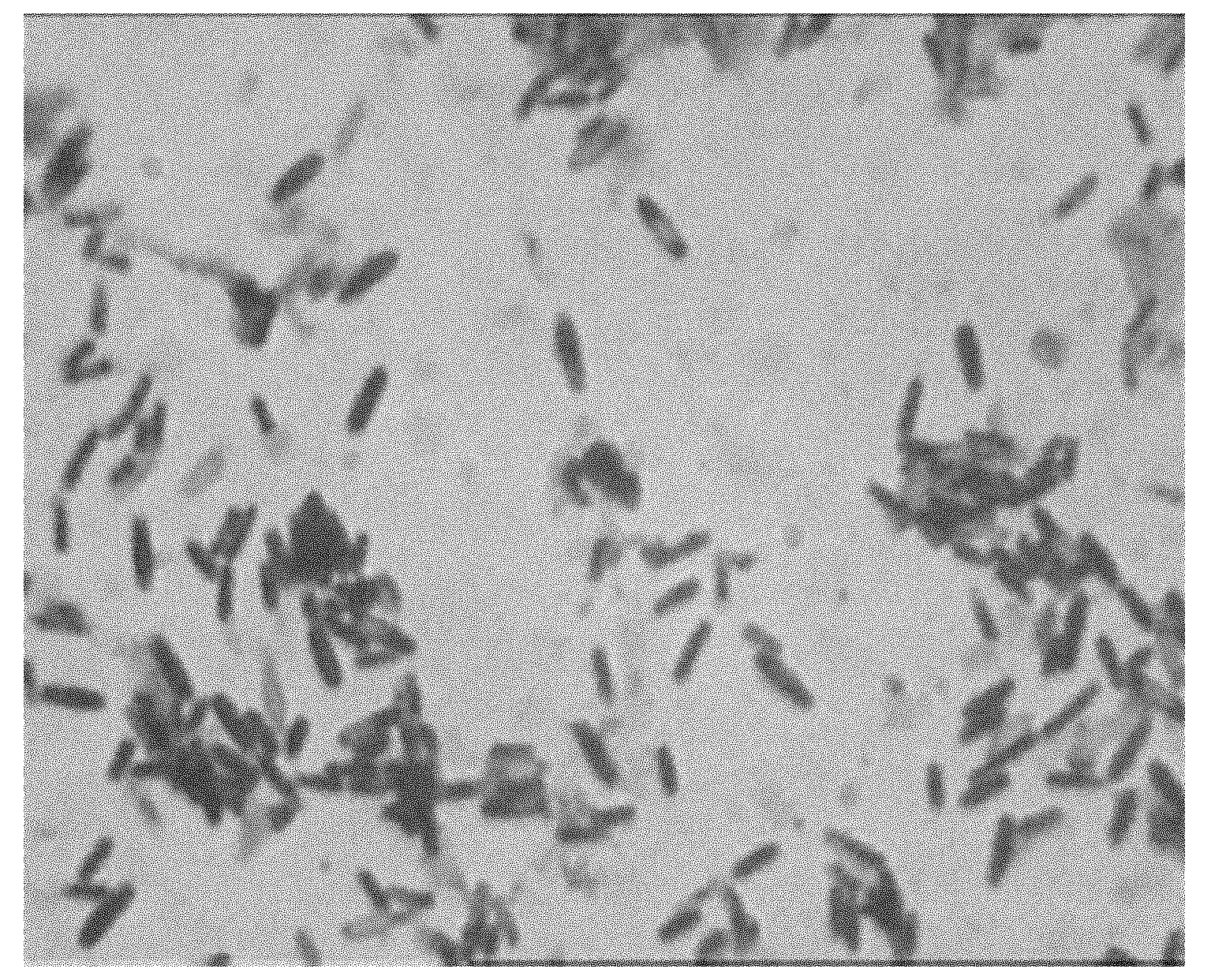

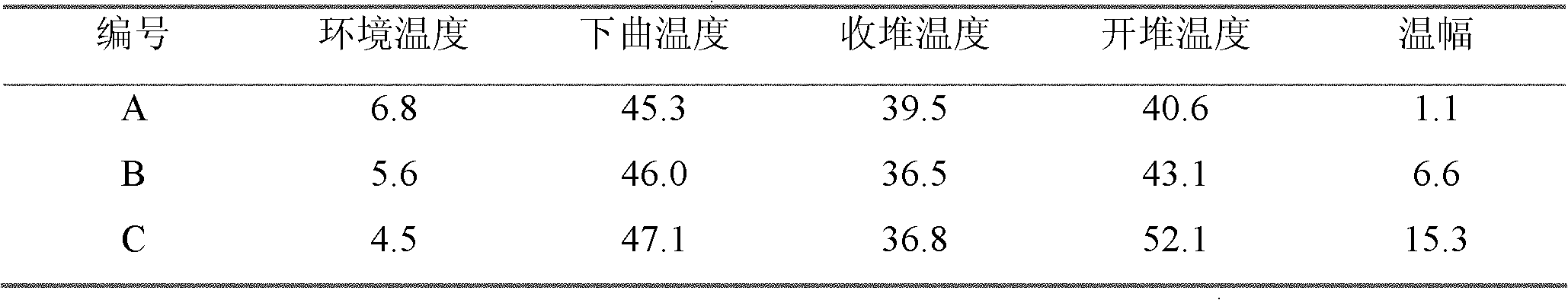

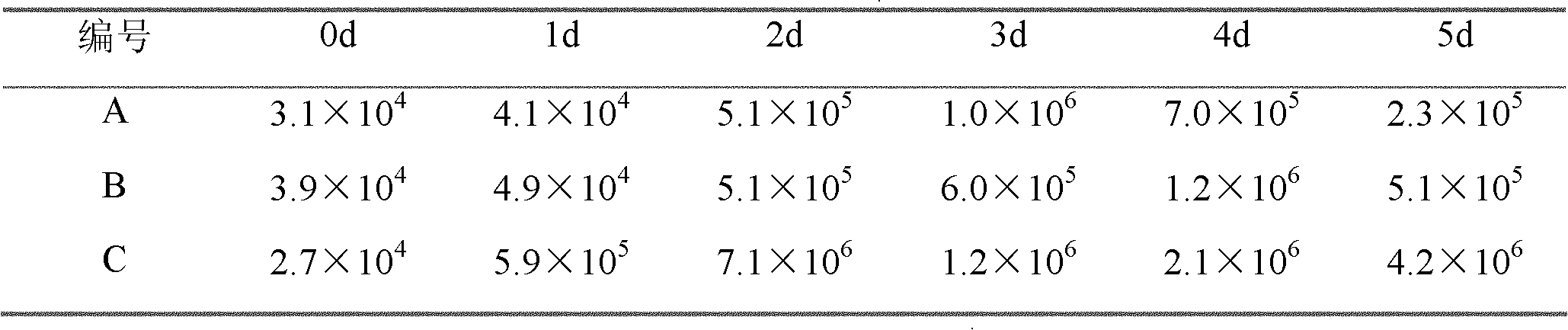

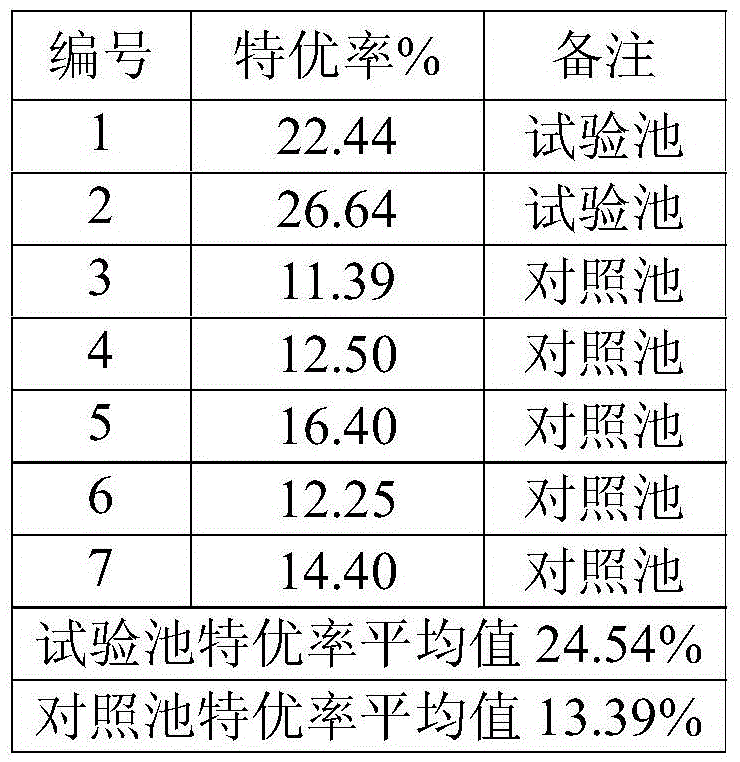

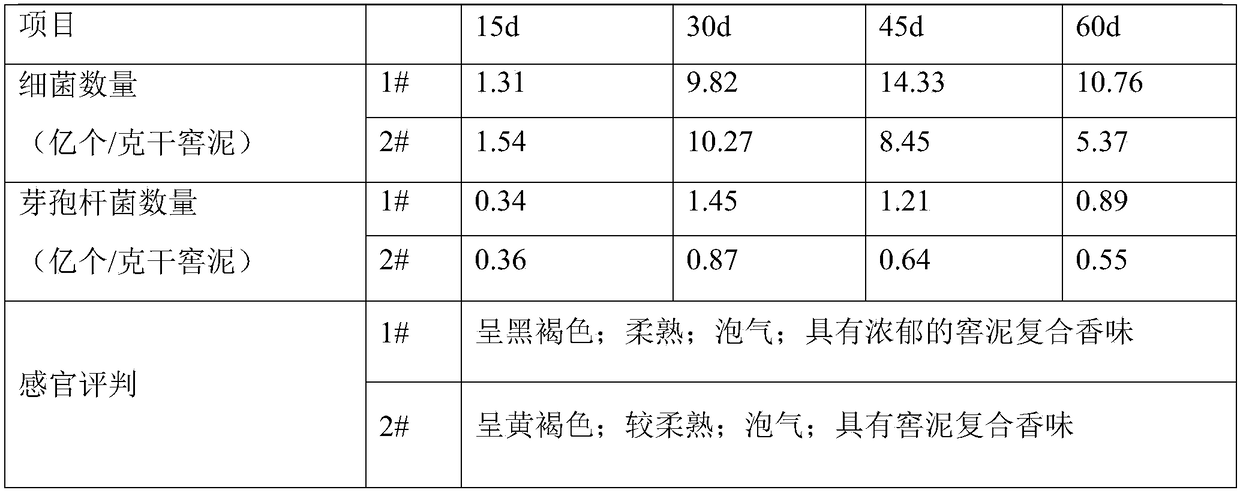

Clostridium butyricum

InactiveCN101942405AHigh yieldImprove the quality rateBacteriaMicroorganism based processesHigh concentrationAlcohol

The invention aims to provide a Clostridium butyricum GK13 bacterial strain CCTCCNO. M2010175. The bacterial strain has the characteristics of high caproic acid yield and good growth stability, can be applied in preparing high-concentration compound Clostridium butyricum liquid after strengthening functional bacteria, can be applied in cultivating artificial pit mud, obtains the effect of shortening the newly-built cellar pool aging period and rejuvenating the degrade cellar pool function in the practical production, improves the alcohol yield and the superior product rate, and solves the problems of rejuvenating a degrade old cellar pool, and shortening the newly-built cellar pool aging time and the like.

Owner:HUBEI UNIV OF TECH

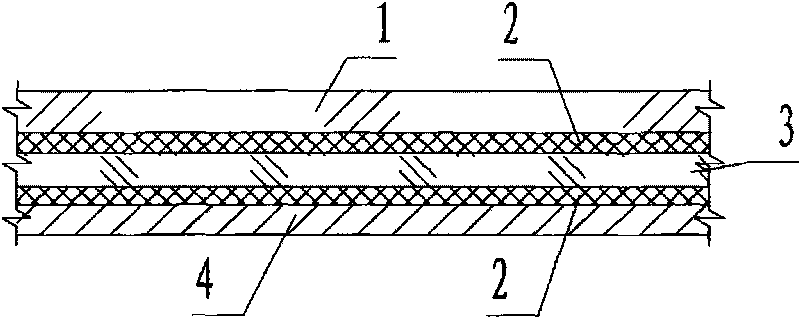

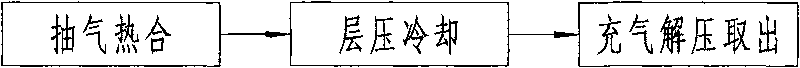

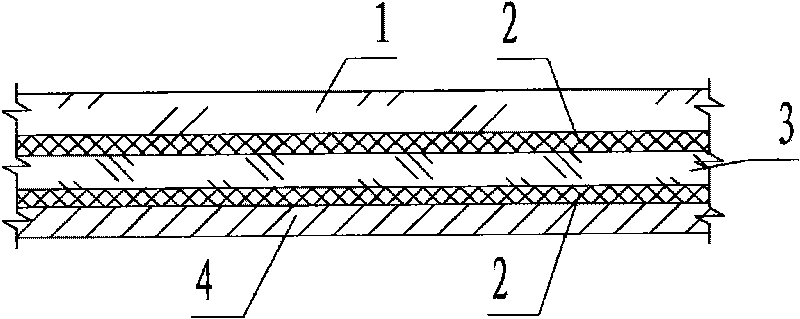

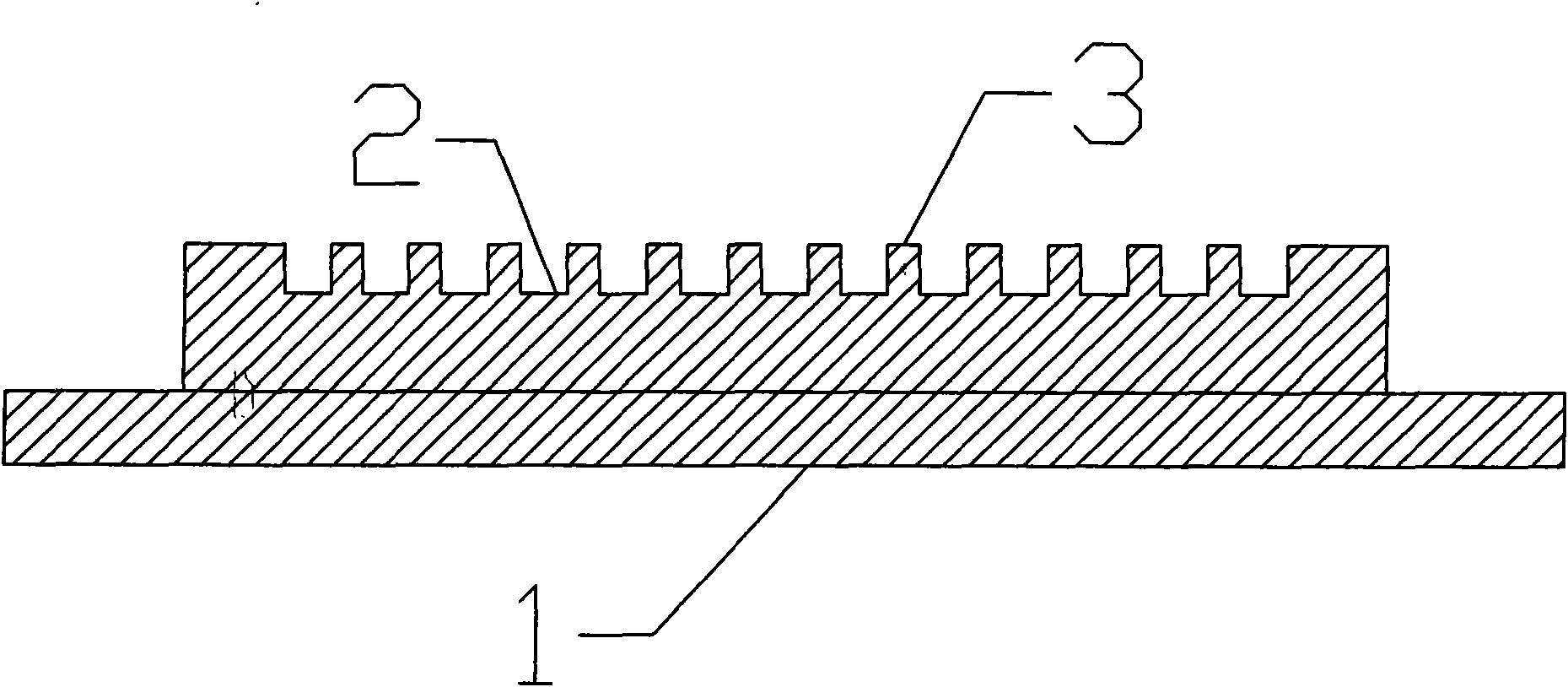

Laminated structure and laminating technology of solar panel component

ActiveCN101740651AOvercome longevityOvercoming the low photoelectric conversion rateFinal product manufacturePhotovoltaic energy generationEngineeringCrystalline silicon

The invention discloses a laminated structure and laminating technology of a solar panel component. The laminated structure comprises coated and toughened glass (1), an EVA (2), a single crystalline silicon solar cell (3), an EVA (2) and a BBF back film (4) which constitute the five-layer structure. The laminating technology method comprises the following steps: exhausting and heat-conglutinating, laminating and cooling, aerating for decompression, and taking out the finished product. The invention uses the coated and toughened glass to replace the common toughened glass, uses the BBF back film which has high crosslinking degree to EVA to replace the TPT back film and adopts the corresponding technical scheme of the laminating technology so that the use of the coated and toughened glass can increase the photoelectric conversion efficiency of the component and the use of the BBF back film can increase the bonding strength so as to prolong the service life of the component, reduce the laminating and heat-conglutinating time, increase the production efficiency of the component and ensure to achieve the aim of increasing the photoelectric conversion efficiency, service life and production efficiency of the solar panel component.

Owner:RISEN ENERGY (YIWU) CO LTD

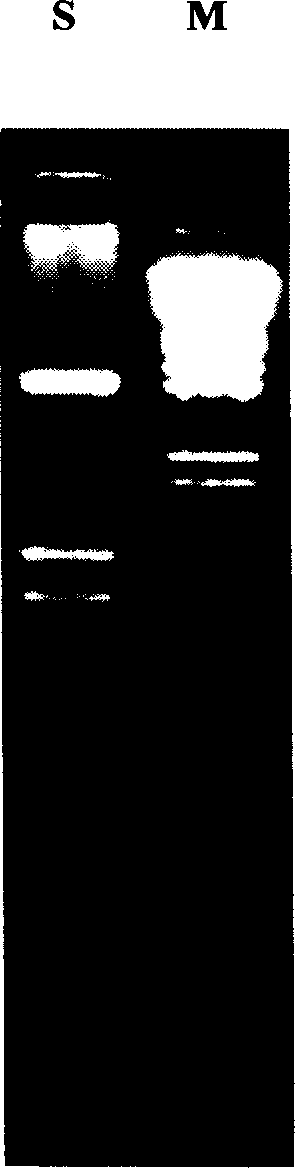

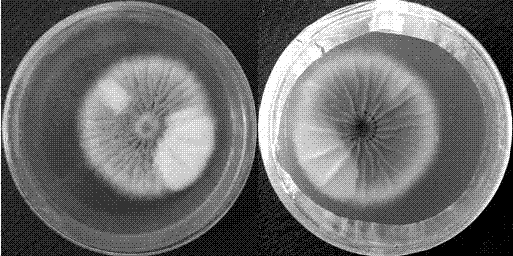

Bailing mushroom new variety, and bacterial species production and culture method

The present invention relates to a new bailing mushroom variety, its inoculum production and cultivation method. Said variety is a new one-zhongnong No. 1 (CAAS-1) obtained by utilizing multisporous hybridization. Said invention also provides the characteristics of said variety and the concrete steps of its inoculum production and cultivation method.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI +1

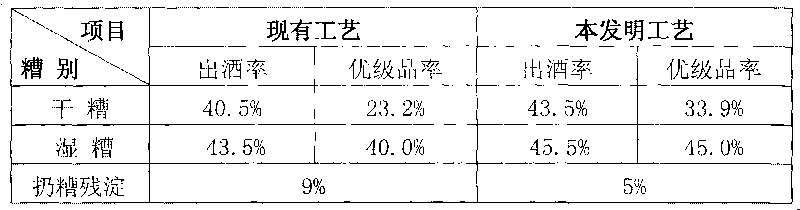

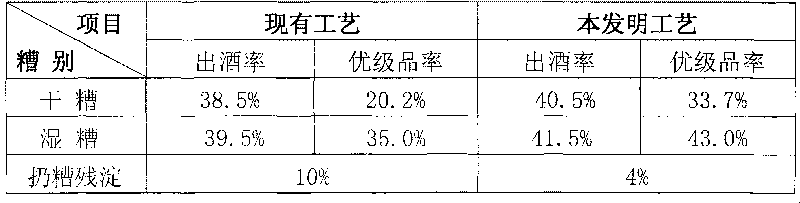

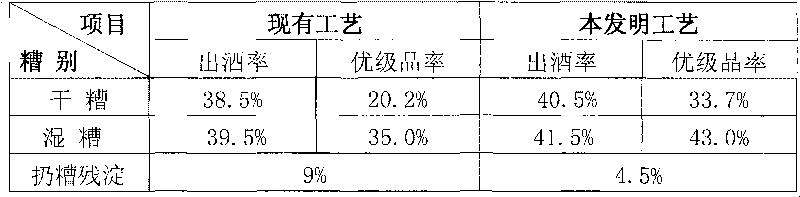

Method for improving quality of strong aromatic dry distilled grain

ActiveCN101705167AIncrease the acidity in the cellarQuality improvementAlcoholic beverage preparationChemistryPre treatment

The invention discloses a method for improving quality of strong aromatic dry distilled grain, comprising the steps of pretreating the materials, piling and fermenting, taking out of a pit, stirring the mixed grains, getting wine and steaming grains, getting out of a steamer and proportioning water, reducing temperature and mixing the rice flour, entering the pit and sealing the pit. The method is characterized in that new measures about a pit mud maintenance in contact with the dry grains and about a prevention of mixed bacteria infection are carried out by not crushing part of the materials for wine making, increasing the mixed grain amount and reducing the use quantity of bran shells, thereby improving acidity of fermented grain for pit entry and water retention property of the fermented grain, and greatly improving the quality of the dry distilled grain. The method improves the quality of dry grains, improves the high-quality yield of the dry distilled grain by about 35%, improves the high-quality yield of the wet grain by above 10% and improves wine yield by above 3% so that the whole pit can brew high-quality wine. The invention has simple technology, easy operation, low production cost, good wine quality and easy implementation, thereby providing reliable guarantee for large-area application of technical reform in strong aromatic wine production enterprise.

Owner:SICHUAN TUOPAI SHEDE WINE

Method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits

ActiveCN102140427AGood aroma productionQu Yi obviousBacteriaMicroorganism based processesFlavorChemistry

The invention relates to a method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits from Bacillus thermophilus. The intensified daqu prepared by the method is high in fermentation speed, is added into a finished high-temperature starter for production, is used for brewing traditional Chinese spirits, can reduce the starter consumption in production, effectively solves the problem that fermented grains stacked in winter are difficult to heat, improves the spirit yield and premium quality good rate on the premise of keeping the flavor of the original spirits, can save massive brewing and fermentation equipment, manpower, field and energy, and has high use value.

Owner:湖北白云边酒业股份有限公司

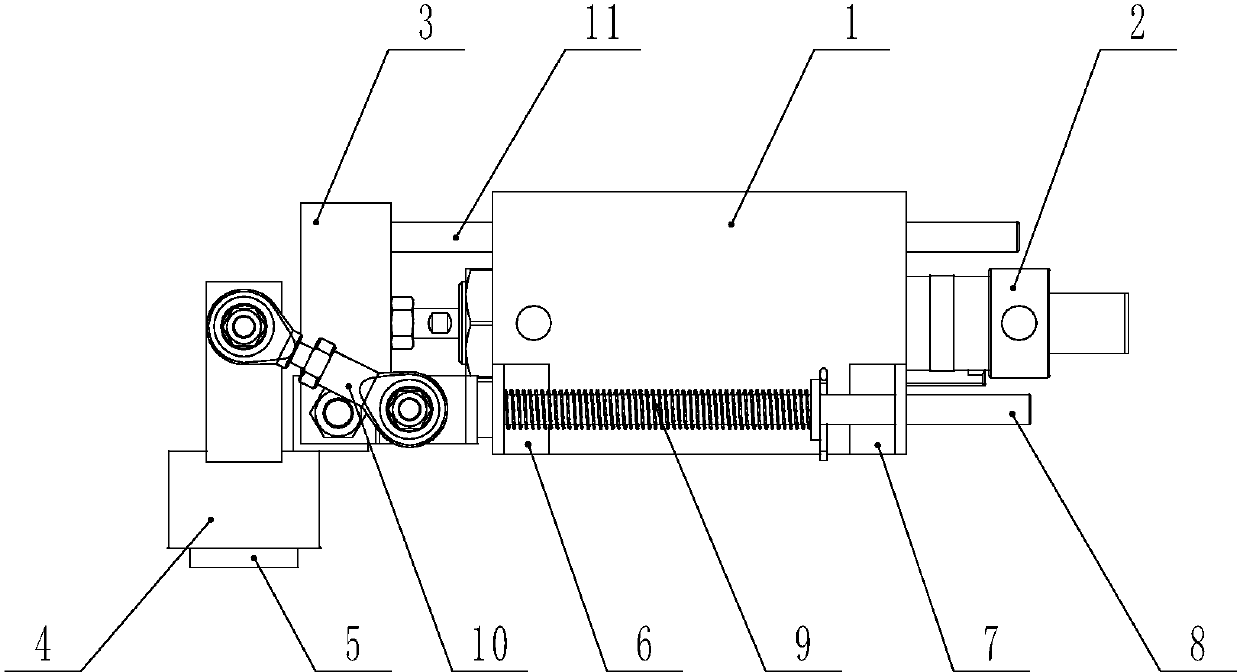

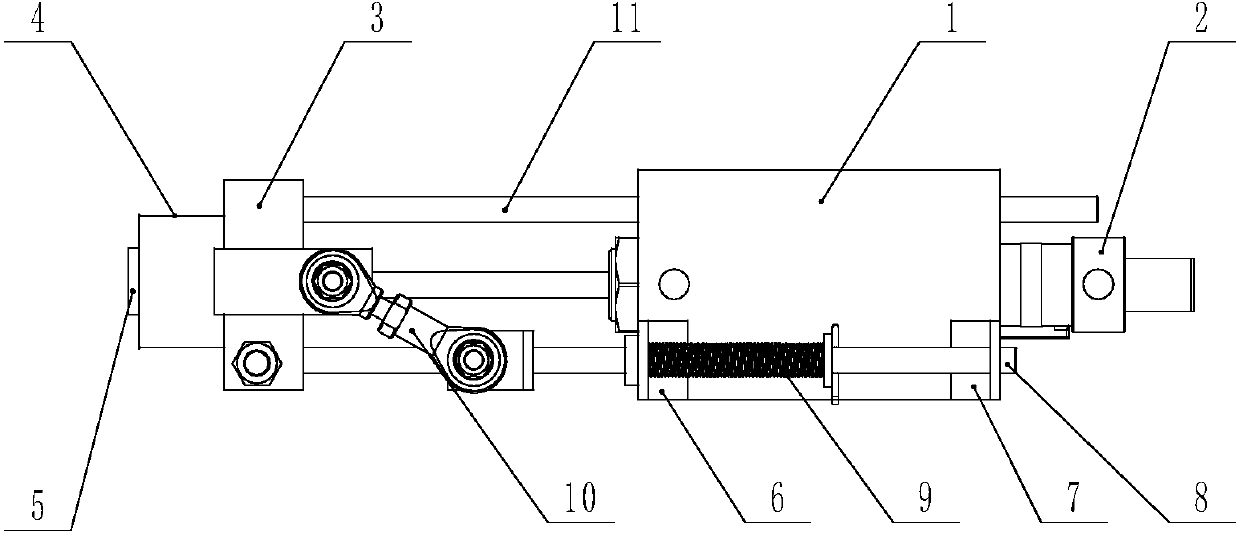

Electrode plate wrapping method

ActiveCN102856527BMobile stable and reliableAchieve overlayElectrode manufacturing processesFinal product manufactureEngineeringElectrode

The invention relates to an electrode plate wrapping method, which comprises the steps of: first, arranging a positive electrode plate and a negative electrode plate in an electrode plate material box vertically respectively, above all using a sucking disc to suck the positive electrode plate laterally, then turning the positive electrode plate downward by 90 degrees and placing it in a material trough, moving the positive electrode plate placed in the material trough forward by one working position, at the same time moving separator paper from top to bottom, cutting the separator paper off and disposing it on the material trough vertically, further moving the positive electrode plate forward by one working position, and making the front end of the positive electrode plate contact the central part of the separator paper in the moving process, along with the forward moving of the positive electrode plate, wrapping the positive electrode plate with the separator paper, then further moving the positive electrode plate forward by one working position, simultaneously employing the sucking disc to suck a negative electrode plate laterally, and placing the negative electrode plate right over the wrapping completed positive electrode plate, then keeping moving the negative electrode plate, the separator paper, and the positive electrode plate forward into a material receiving device, and when the number of a plate pack is collected, sending the plate pack out.

Owner:江苏金帆电源科技有限公司

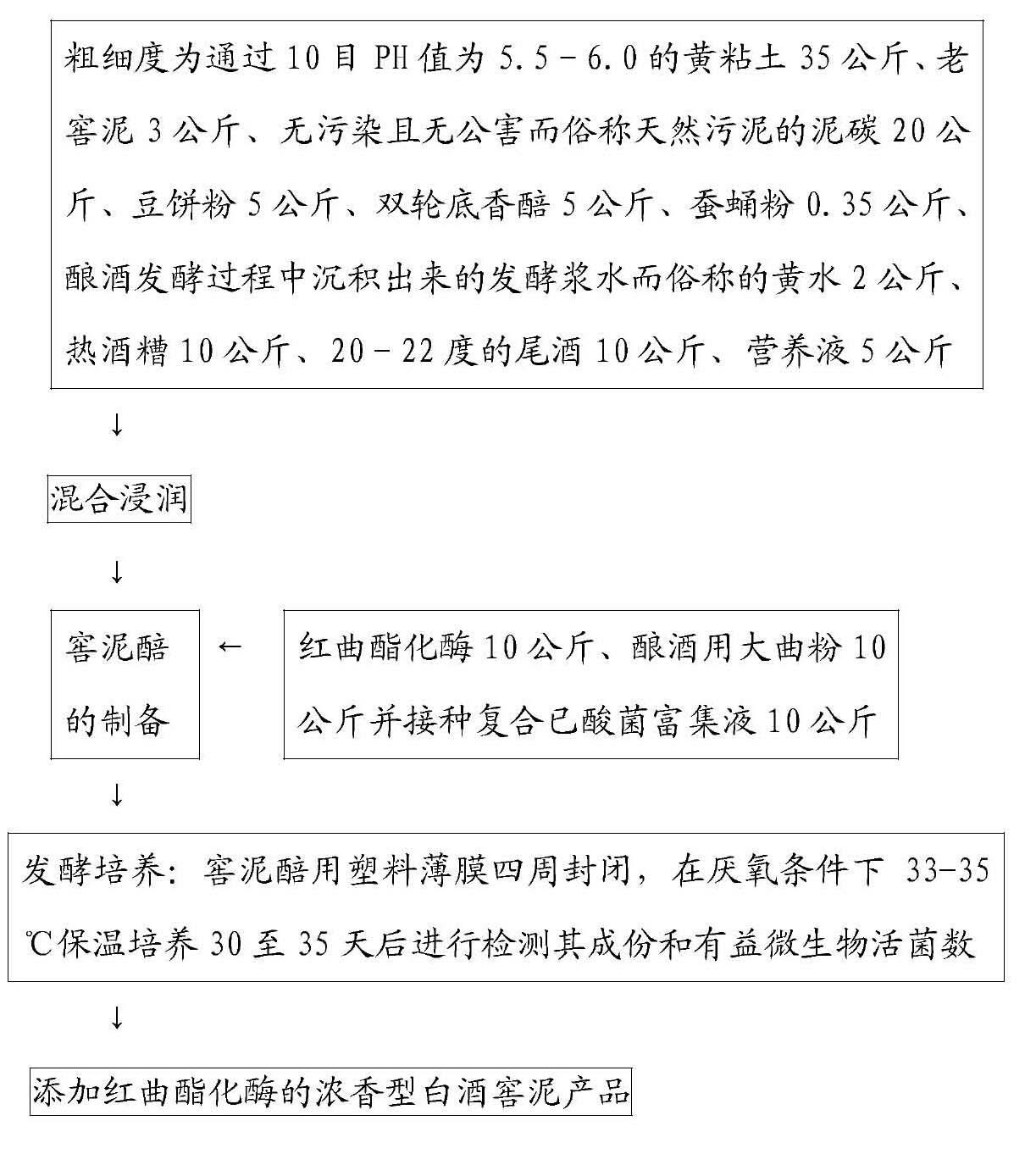

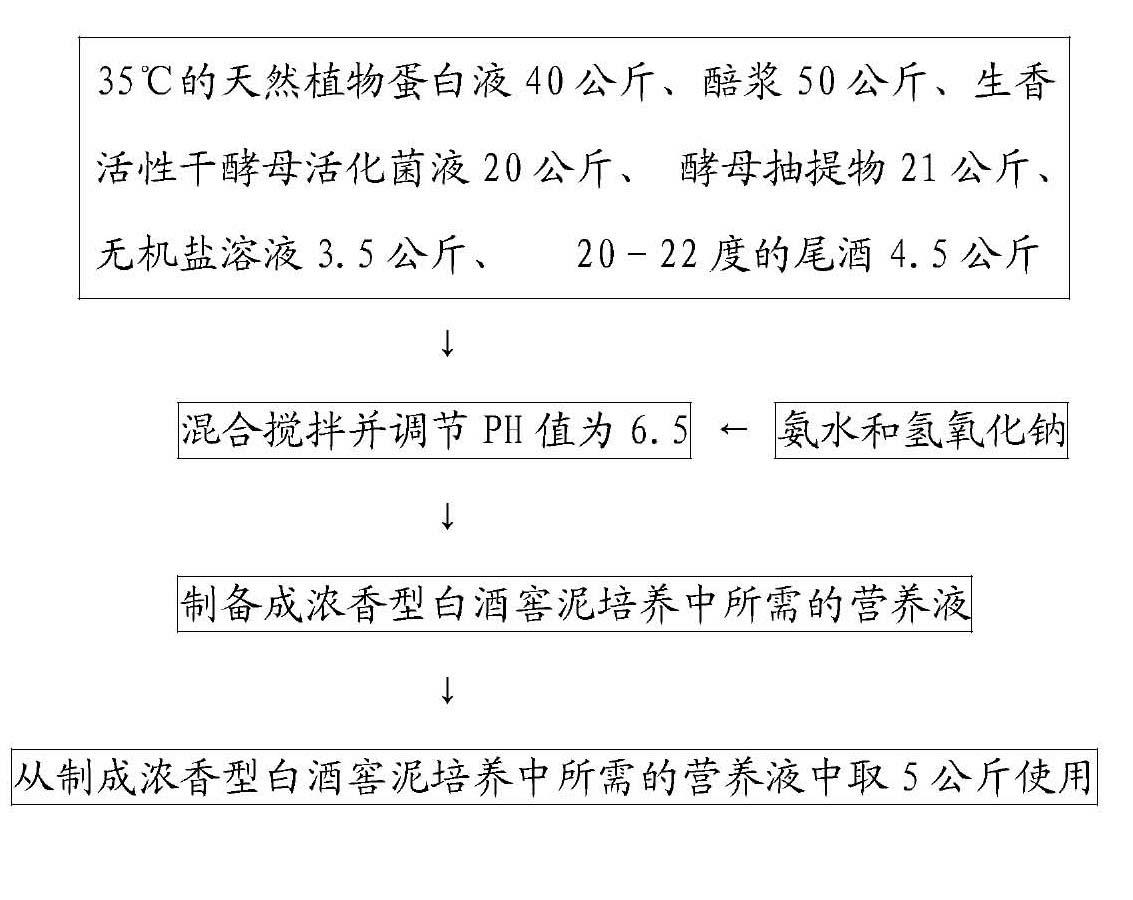

Preparation method of strong aromatic Chinese spirits pit mud by adding red yeast esterified enzyme

InactiveCN102154081AQuality improvementImprove the quality rateAlcoholic beverage preparationYeastTrace element

The invention provides a preparation method of strong aromatic Chinese spirits pit mud by adding red yeast esterified enzyme, and relates to the technical field of spirits making. The preparation method comprises the following steps of: adding 10kg of red yeast esterified enzyme and 10kg of yeast powder into mixed infiltrating body of 35kg of yellow clay, 3kg of old pit mud, 20kg of mud carbon, 5kg of bean cake powder, 5kg of double-wheel bottom flavour grains, 0.35kg of silkworm chrysalis powder, 2kg of yellow water, 10kg of hot vinasse, 10kg of 20 to 22-degree cocktail and 5kg of nutrient solution which respectively can pass a screen mesh of 10 and have the pH value of 5.5-6.0; vaccinating 10kg of compound hexanoic acid bacteria-enriched liquid, stirring and mixing to prepare pit mud grains; sealing the periphery of the pit mud grains by a plastic film; and cultivating for 30-35 days under the anaerobic condition at the temperature of 33-35 DEG C, and detecting the components and the beneficial microbe bacterial counts of the pit mud to obtain the strong aromatic Chinese spirits pit mud by adding the red yeast esterified enzyme. The preparation method is used for cultivating the pit mud in a strong aromatic Chinese spirits preparation technology. The preparation highlights a nitrogen source, trace element and the red yeast esterified enzyme which influences aroma-producing substances and flavor-producing substances of the Chinese spirits.

Owner:湖北黄山头酒业有限公司

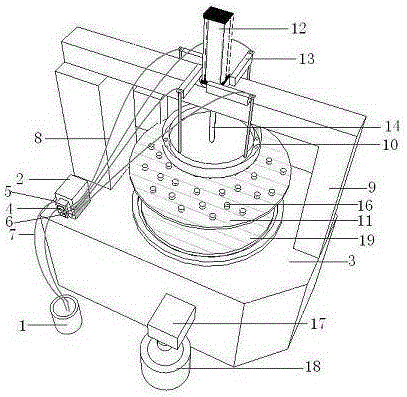

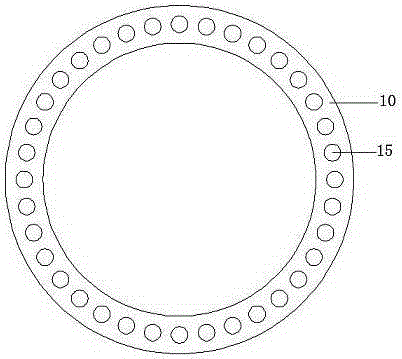

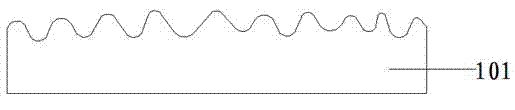

Grinding device for sapphire wafers and grinding method thereof

ActiveCN105215838AStir wellGood suspensionLapping machinesGrinding/polishing apparatusPeristaltic pumpPulp and paper industry

The invention discloses a grinding device for sapphire wafers. The grinding device for sapphire wafers comprises a pulp stock barrel, a peristaltic pump and a grinder, wherein a pulp stock trough is arranged on the grinder, and pulp stock enters into the grinder through the peristaltic pump and the pulp stock trough. The grinding method for the sapphire wafers comprises the following steps: 1, preparing the pulp stock: putting in raw materials by levels and layers; 2, controlling pulp stock flows: putting pulp stock accurately; 3, correcting the flatness of the surface of a grinding lower plate: repeatedly measuring by using a long gauge, a short gauge and a dial gauge, and correcting; 4, distributing powder on the surface of a grinding plate; and 5, grinding both sides of each wafer: firstly carrying out light pressing grinding. The grinding method provided by the invention is characterized in that raw material ratio of the pulp stock is optimized, the pulp stock supplying flow is more accurate, the conveying is more even, before normal grinding, light pressing grinding is performed firstly, the problem of wafer breakage during a grinding process can be prevented for the greatest possible, the wafer breakage rate is lowered, the merit factor of grinding is improved, the removing rate during grinding is stable, the problems of over grinding and low removing rate cannot be caused, and the efficiency is relatively high.

Owner:TUNGHSU GRP

Method for producing microcrystal glass ceramics composite board

InactiveCN102775074AResolve colorSolved the technical issue where the pattern also gradually became blurredBrickFrit

The invention provides a method for producing a microcrystal glass ceramics composite board. The method comprises the following steps of: 1) applying powder and stamping to form a green brick; 2) forming a ground coat layer and a printing layer; 3) carrying out primary firing; 4) dispersing microcrystal glass fusion blocks; 5) carrying out secondary firing; and 6) edging and polishing, wherein a die cavity of a stamping mould used in step 1) has a concave-convex pattern, and the distance d between the raised place of the concave-convex pattern and the reference surface of the die cavity and the distance d between the recessed place of the concave-convex pattern and the reference surface of the die cavity are 0.22-1.1mm. The concave-convex pattern, the pattern of the printing layer and the color combination on the upper surface of a green brick layer of the glass ceramics composite board endow the product with an aesthetic feeling, the concave-convex surface texture transition is continuous and natural, the pattern effect can be combined in multiple ways, the designable space is large, abundant color and gloss matching decorating effects are provided, and the optical refraction of the surface crystallite glass layer ensures that the product has a three-dimensional feeling.

Owner:广东金牌陶瓷有限公司

Pre-cleaning agent for silicon wafer

InactiveCN103666784AEfficient removalImprove the quality rateAnionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsHydrofluoric acidSurface-active agents

The invention discloses a pre-cleaning agent for a silicon wafer. The pre-cleaning agent comprises components in parts by weight as follows: 15-20 parts of a surface active agent, 25-40 parts of nitric acid, 2-5 parts of triethanolamine, 2 parts of citric acid, 1 part of hydrofluoric acid, 2 parts of hydrogen peroxide and the balance of deionized water. The obtained pre-cleaning agent for the silicon wafer integrates characteristics of an organic cleaning agent and an inorganic cleaning agent, and can effectively remove various pollutants on the surface of the silicon wafer, and a good condition is created for a texturing technology of the silicon wafer, so that the merit factor and efficiency of a solar cell are improved.

Owner:孙爱玲

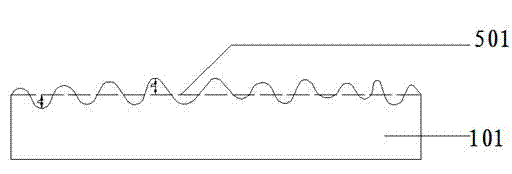

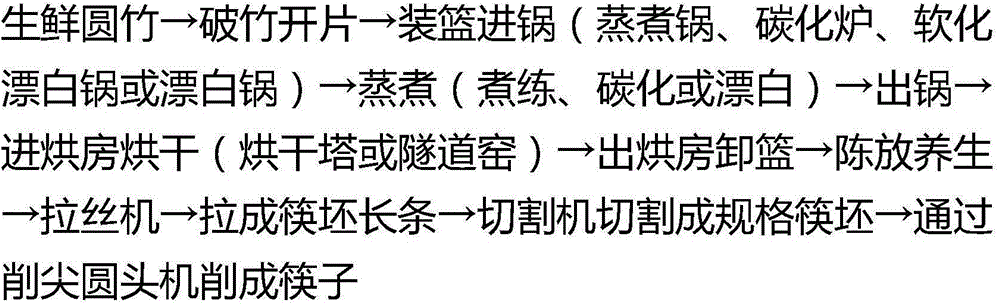

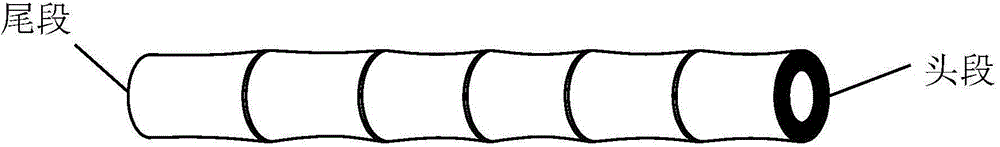

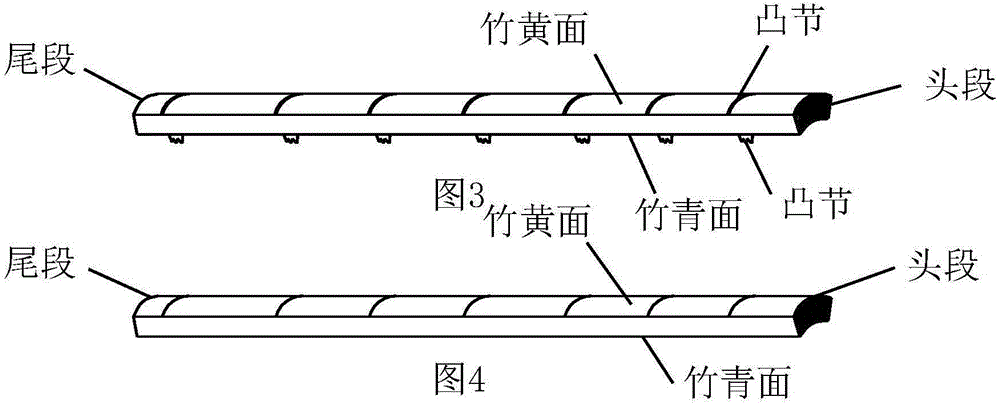

Dry-type bamboo chopstick processing method

InactiveCN104859023AImprove quality rateShorten the production cycleWood working apparatusHardnessSteaming

The invention discloses a dry-type bamboo chopstick processing method which comprises the steps of piece splitting, basket loading, steaming and boiling, drying, basket unloading, storing and displaying, wiredrawing, billet cutting, tip cutting and polishing. Compared with chopsticks obtained through the wet-type processing method in the prior art, the hardness of the chopsticks of the chopsticks obtained through the dry-type bamboo chopstick processing method is increased by over 50%, the chopsticks are smooth and luster, the rate of qualified products is increased by over 50%, the production cycle is shortened by over 50%, the bamboo utilization rate is increased by over 10%, the economical benefits are increased, the problem that it is difficult to produce high-level or high-quality wet-type bamboo chopsticks is completely solved, the processing process is concise, and the production cost is lowered.

Owner:覃健林

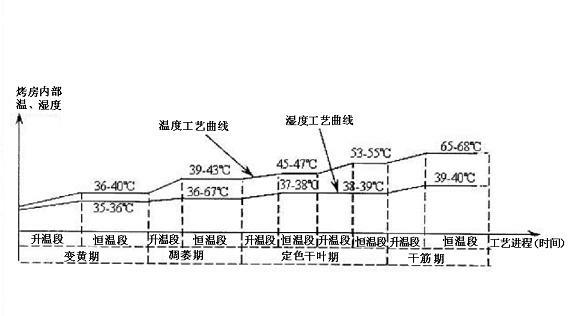

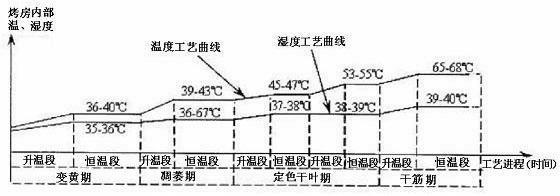

High-quality tobacco leaf baking process

ActiveCN102626254ARequirements to ensure temperature and humidity accuracyImprove the quality rateTobacco preparationWiltingEnvironmental geology

The invention discloses a high-quality tobacco leaf baking process. Major aims to be fulfilled at every time interval of tobacco leaf baking are classified into a yellowing stage, a wilting stage, a color fixing and leaf drying stage and a stalk drying stage, a more intuitional baking process curve is drawn, and a temperature raising speed, upper and lower limit temperature values, a humidity range to be controlled, heat preserving time, and quality appearance forms including color luster, dryness shape and percentage in all tobacco leaves to be achieved in tobacco leaf baking are set at every stage. At the yellowing stage, the leaf surfaces of tobacco leaves on first and second tobacco leaf baking frames in a baking room become yellow completely; at the wilting stage, all tobacco leaves in a furnace wilt and become yellow; at the color fixing and leaf drying stage, tobacco leaves on a bottom tobacco leaf baking frame become pointed, leaves are drum-shaped or approximately drum-shaped, and the leaf surfaces are dry; and at the stalk drying stage, heat is preserved till all tobacco stalks in the furnace are dried completely. According to the baked tobacco leaves, the green smoke rate and ash hanging rate can be reduced remarkably, and green stalks, clear sheets, green flotation, ash hanging and the like are reduced.

Owner:云南中建博能工程技术有限公司

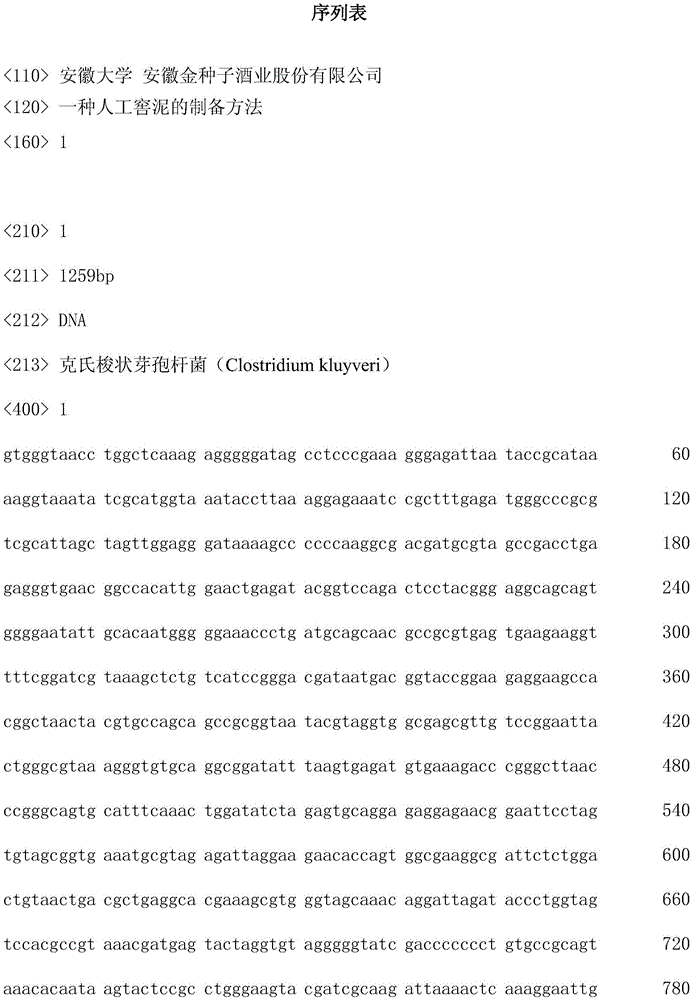

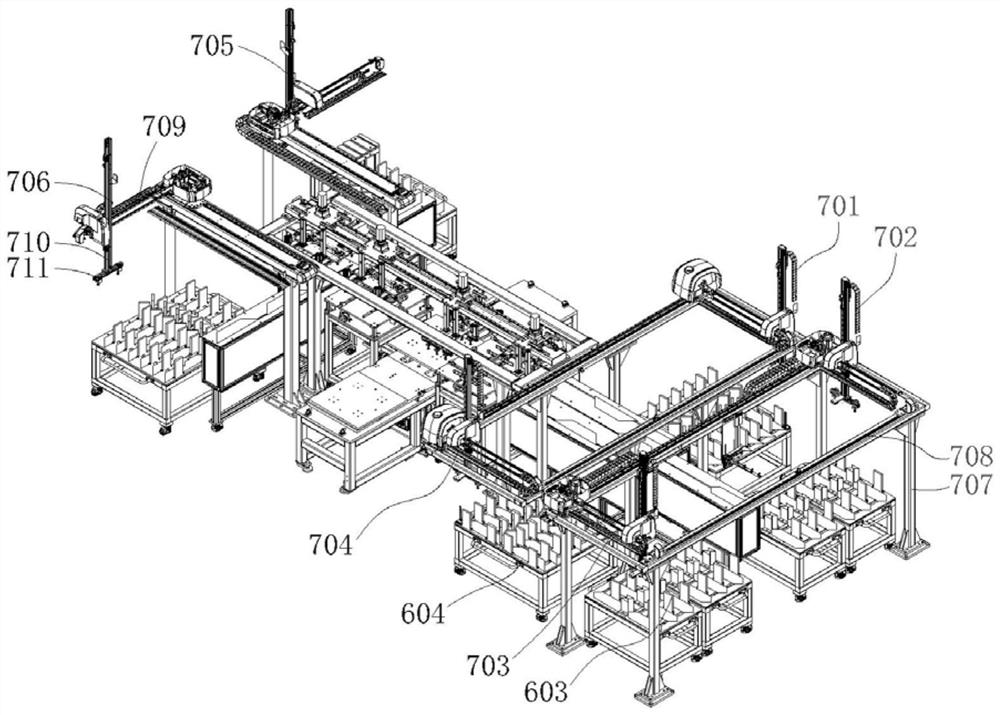

Method for preparing manmade pit mud

InactiveCN105567613AImprove nutritional structureImprove the quality rateBacteriaMicroorganism based processesSodium acetateDipotassium hydrogen phosphate

The invention discloses a method for preparing manmade pit mud. According to the method for preparing the manmade pit mud, disclosed by the invention, the manmade pit mud is prepared through uniformly mixing a pit mud composite bacterial solution, yellow mud, yeast powder, dried yeast, esterified red yeast, pit bottom mud, pond mud, wheat flour, bean cakes, yeast extract, sodium acetate, ammonium phosphate, ammonium sulfate, dipotassium hydrogen phosphate and edible alcohol and then carrying out culturing, wherein the pit mud composite bacterial solution is obtained through uniformly mixing a Clostridium kluyveri JZZ CGMCC No. 11948 culture solution and a pit mud mixed bacterium culture solution. Proven by experiments, the manmade pit mud prepared by the method can be used for producing nice wine in the same year, the merit factor is increased by about 11%, the taste is pure, the perfume is thick, and the aftertaste is lasting. The method is simple in process, convenient and fast in operation and low in cost and can be popularized.

Owner:ANHUI UNIVERSITY +1

Cleaning and wool making technology for monocrystal silicon chip

InactiveCN103774239AStrong decontaminationEasy to cleanAfter-treatment detailsCleaning using liquidsPotassium hydroxideReaction temperature

The invention relates to a cleaning and wool making technology for a monocrystal silicon chip, and belongs to the technical field of chemical engineering. The technology particularly comprises the following step: (1) adopting a self-made silicon chip cleaning agent to perform precleaning on the silicon chip; (2) putting the pre-cleaned silicon chip into a wool making trough; preparing a wool making liquid in the wool making trough, and adding 0.1 to 5% of sodium hydroxide, 0.1 to 3% of potassium hydroxide, 1 to 5% of isopropyl alcohol and 0.02 to 5% of a self-made wool making additive in percentage by weight into the wool making liquid; rising temperature until the reaction temperature is 70 DEG C to 90 DEG C to make wool; turning on ultrasonic equipment during the wool making process; (3) when the wool is prepared, closing the trough body; before the chip is cast, stirring by adopting a stirring device, wherein the wool making reaction time is 15 to 40 min. According to the invention, through the adoption of the cleaning agent and the wool making additive, the technology is controlled to be simple and stable, the energy consumption is reduced, and the capability of process control is enhanced, so that the control quality of the product in various aspects is greatly improved, the production cost in various aspects is reduced, and the comprehensive economic benefit is increased.

Owner:HENAN INST OF SCI & TECH

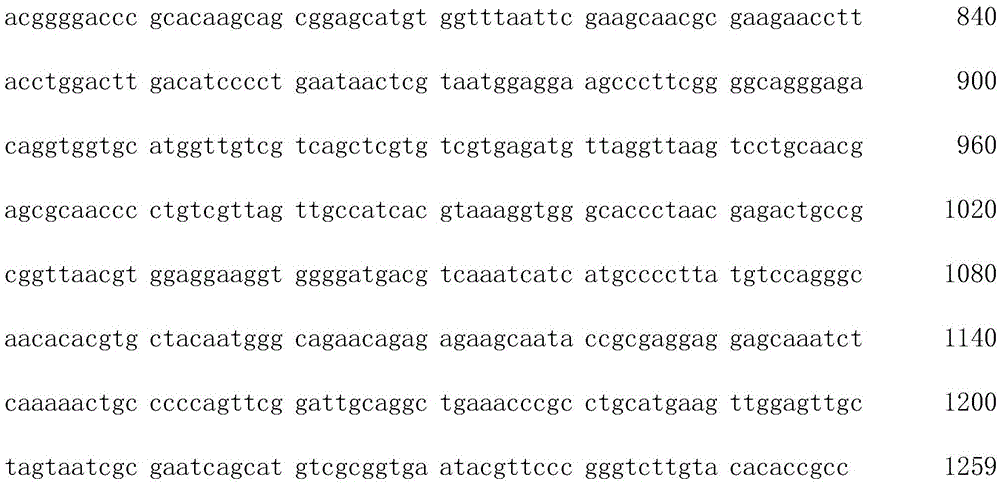

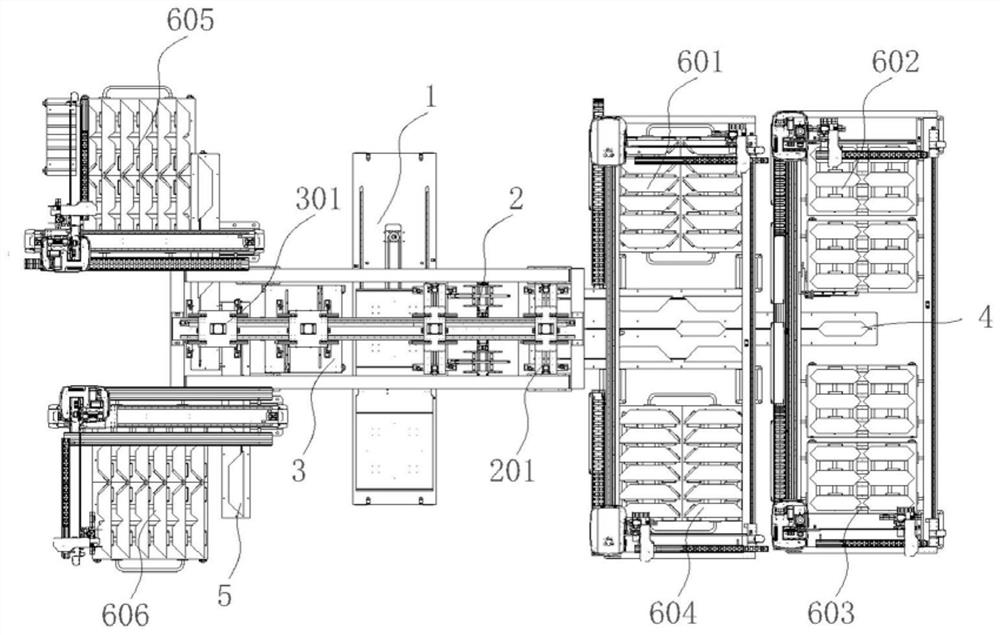

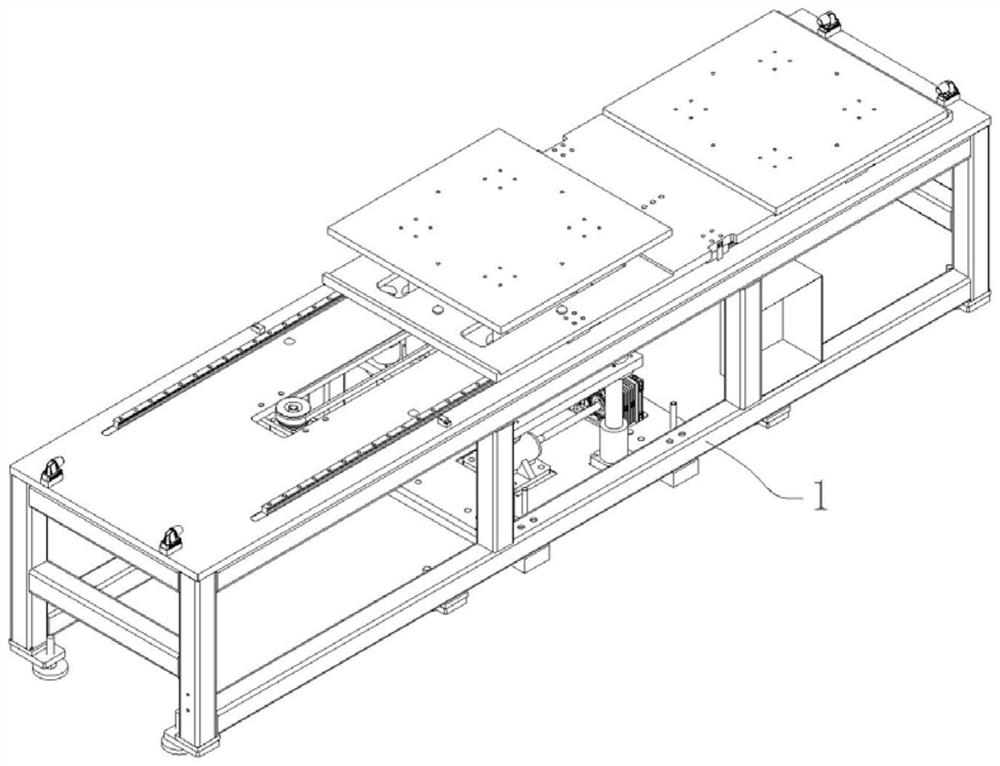

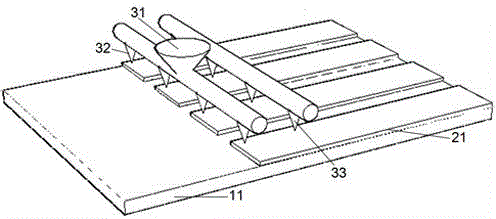

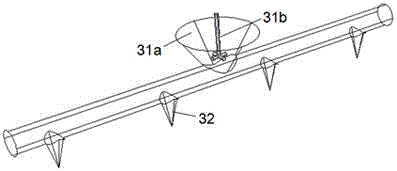

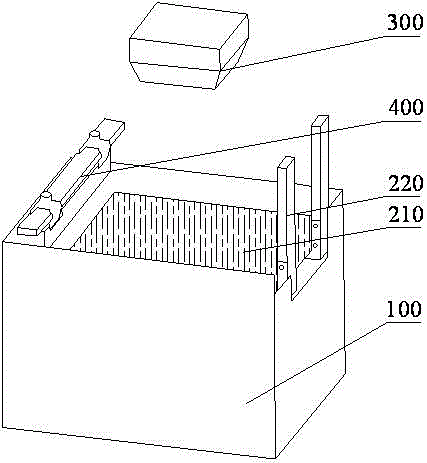

Automatic laminating production line for transformer iron cores

PendingCN112382502AOvercoming the problem of low stacking accuracyIncrease productivityTransformers/inductances detailsInductances/transformers/magnets manufactureProduction lineTransformer

The invention relates to the technical field of automatic equipment for transformer production, and particularly relates to an automatic laminating production line for transformer iron cores. The automatic laminating production line comprises an automatic transformer iron core laminating table and a sheet feeding device, wherein a column sheet fine positioning device and a yoke sheet fine positioning device are arranged on the two sides of the automatic transformer iron core laminating table respectively, the column sheet fine positioning device is connected with a column sheet conveying device, the yoke sheet fine positioning device is connected with a yoke sheet conveying device, feeding bins for storing corresponding silicon steel sheets are respectively arranged at the starting ends ofthe column sheet conveying device and the yoke sheet conveying device; and a column sheet stacking manipulator and a yoke sheet stacking manipulator can respectively transfer each core column siliconsteel sheet and upper and lower yoke silicon steel sheets subjected to fine positioning to the automatic laminating table, so that automatic lamination of the iron cores is realized. According to theproduction line, the production efficiency is remarkably improved, the lamination cost is reduced, the attractive appearance of the iron core and the quality stability of the transformer are guaranteed, and the product quality can be guaranteed.

Owner:ZHEJIANG JIANGSHAN TRANSFORMER CO LTD

Method for preparing transparent conducting electrode based on 3D (three-dimensional) printing technique

ActiveCN104409171ASimplify cumbersome processImprove the quality rateCable/conductor manufactureState of artOrganic solvent

The invention relates to a method for preparing a transparent conducting electrode based on a 3D (three-dimensional) printing technique. The method is characterized by comprising the following steps of 1) providing a 3D printing device which comprises a collosol generation cavity, 3D printing heads and laser printing heads, 2) performing modeling: designing a model of the transparent conducting electrode by using computer modeling software and converting a software instruction of the model into a mechanical instruction of 3D printing, 3) preparing collosol: sequentially adding an inorganic metallic compound or organic metallic compound A and an organic solvent B to the collosol generation cavity to generate the collosol used for preparing the transparent conducting electrode, and 4) printing the transparent conducting electrode by using the 3D printing device, wherein the collosol generation cavity comprises a collosol generation cavity body and a stirring rod. The method effectively simplifies the complicated process of preparing the transparent conducting electrode in the prior art, increases the yield and the accuracy of the transparent conducting electrode, and lowers the preparation cost.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

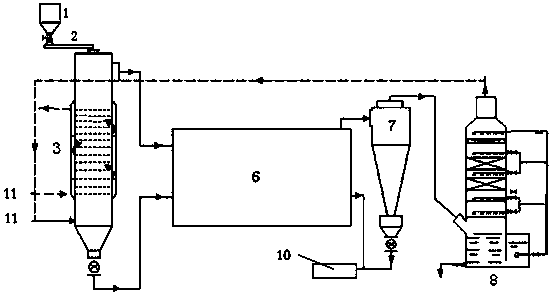

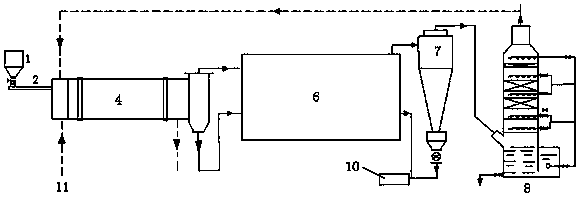

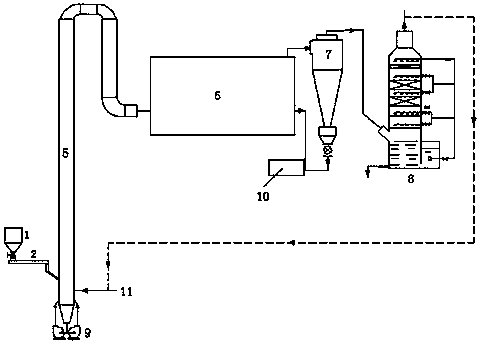

Drying, desulphurization and dehydration system and process for low-rank coal or coal slime

The invention discloses a drying, desulphurization and dehydration system for low-rank coal or coal slime. The system comprises a superheated steam drying device; a feeding device, the superheated steam drying device and a microwave dryer are connected sequentially; an air inlet and a built-in heat exchanger of the superheated steam drying device are respectively connected with a superheated steam heat source; an air inlet of the microwave dryer is connected with an air outlet of the superheated steam drying device; an air outlet of the microwave dryer is sequentially connected with an air inlet of a dust removing device and an air inlet of a desulfuration device; the desulfuration device is also connected with an elemental sulfur recovery device; discharge openings of the microwave dryer and the dust removing device are respectively connected with a dry material bin. The invention further discloses a corresponding drying, desulphurization and dehydration process for the low-rank coal or coal slime. According to the system and the process, the drying, desulphurization and dehydration process of combining the superheated steam and the microwave is adopted to dry the low-rank coal or coal slime, and the dehydration and the desulfuration are realized at the same time. Moreover, the energy sources utilization ratio is improved, the tail gas pollution is reduced, and the elemental sulfur can be recovered, thereby achieving the purposes of energy conservation and environmental protection.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Amplification culture method of composite caproic acid bacteria liquid

InactiveCN108102965ASmall amount of inoculumReduce the number of expansionBacteriaMicroorganism based processesMicrobiologyAcetic acid bacteria

The invention belongs to the technical field of wine brewing, and particularly relates to an amplification culture method of composite caproic acid bacteria liquid. In allusion to the problems that during existing caproic acid bacteria culture, the culture cycle is long, the bacterial colony structure is single, the caproic acid yield is low, the large-scale degree and the mechanization degree arelow, miscellaneous bacteria are easily caused, the quality is unstable and the like, the invention provides the amplification culture method of the composite caproic acid bacteria liquid. The amplification culture method comprises the following steps: a, activating a caproic acid bacteria, and performing proliferation culture; b, performing amplification culture on caproic acid bacteria; c, performing amplification culture on kiln mud enrichment liquid; d, performing mixed fermentation culture; e, performing mixed amplification culture. Through adoption of mixed culture of the pure caproic acid bacteria and the high-quality kiln mud enrichment liquid, the composite caproic acid bacteria liquid with rich bacterial colonies is obtained; the composite caproic acid bacteria liquid is stable in quality, uses the caproic acid bacteria as dominant bacteria, and has a very strong caproic acid producing capability; in addition, the culture amount is increased, the culture steps are reduced, the operating process is simplified, and the culture cycle is shortened, so that the production efficiency is improved and the production cost is saved.

Owner:LUZHOU PINCHUANG TECH CO LTD

Complex enzyme and use thereof

InactiveCN101381665AFully hydrolyzedPromote hydrolysisAlcoholic beverage preparationCellulosePhytase

The invention relates to complex enzyme and application thereof, which belongs to the technical field of the brewing of distillate spirits. The complex enzyme comprises the following enzyme preparations and yeasts: 200 to 225 U / g of saccharifying enzyme (wheat), 80 to 100 IU / g of pullulanase (wheat), 10 to 15 IU / g of acid protease (wheat), 15 to 20 IU / g of cellulose (wheat), 15 to 20 IU / g of beta-dextranase (wheat), 5 to 10 IU / g of beta-mannase (wheat), 10 to 15 IU / g of xylanase (wheat), 5 to 10 IU / g of phytase (wheat), 5 to 10 IU / g of pectase (wheat), 1.5 to 2 percent of high temperature resistant saccharomyces cerevisiae (W / W), and 1 to 1.5 percent of aroma-producing yeast (W / W). The complex enzyme is applied as an additive to the production of wheat type distillate spirits. The complex enzyme can increase fermentable sugar, improve the utilization rate of raw materials, and improve the distillation yield; at the same time, the complex enzyme releases and synthesizes more flavor substances, and has the advantages of improving the quality of the distilled spirits and increasing the high-quality product rate of xiaoqu distillate spirits and so on; and the complex enzyme can be widely applied to the production of wheat type distillate spirits.

Owner:YUNNAN NORMAL UNIV

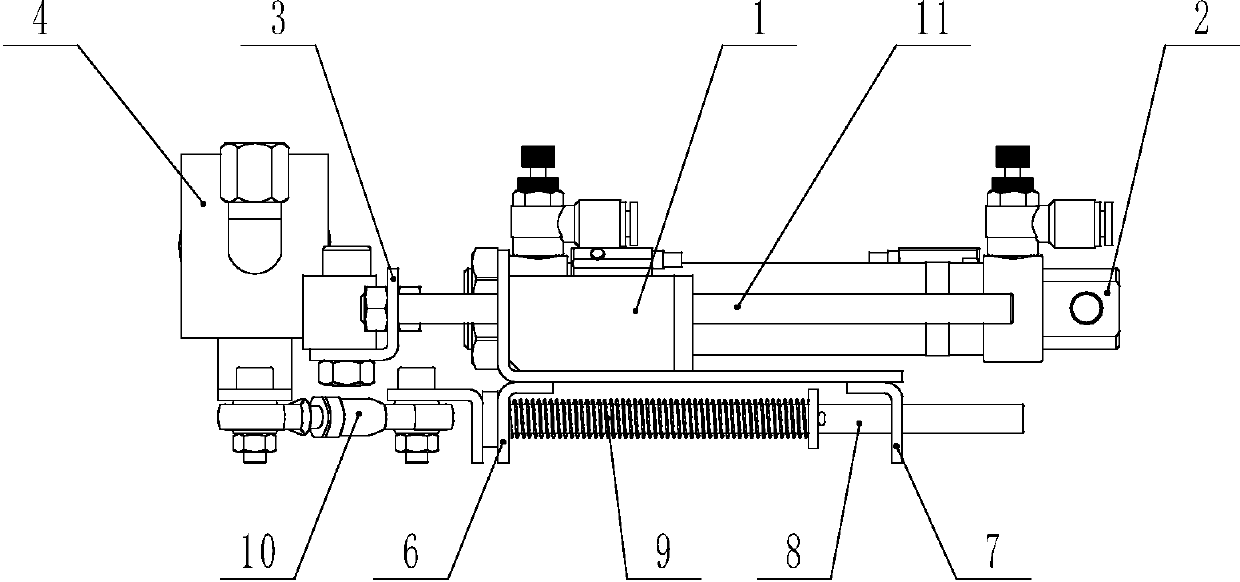

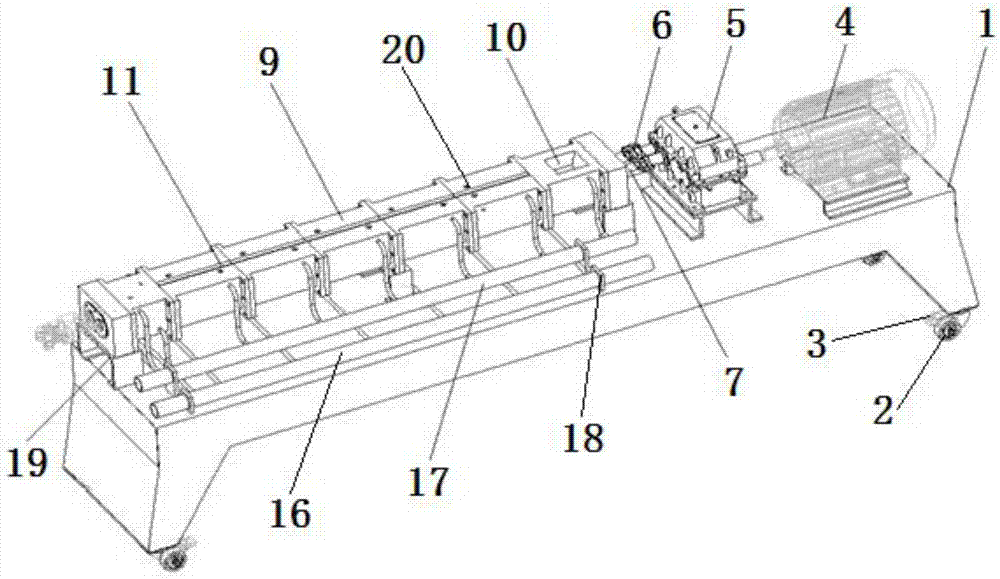

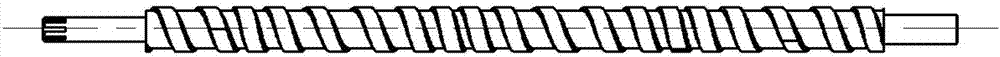

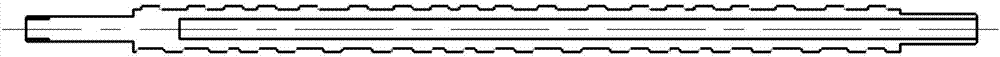

Emulsion mixture dual-screw water removal device

The invention belongs to the technical field of rubber after-processing auxiliary equipment, and particularly relates to an emulsion mixture dual-screw water removal device. A main structure comprises a base, universal wheels, a foot brake piece, a motor, a reducer casing, a coupler, a dual-screw assembly, a core shaft, a machine barrel, a feeding opening, a rotary air leakage roller, a scraping knife, a draining hole, a filter net, a steam hole, a first steam supply pipe, a second steam supply pipe, a support, a discharging hole and an exhaust hole; an emulsion mixture is subject to extrusion water removal to the maximum degree, water in the emulsion mixture is removed to the maximum degree, water can be effectively extruded, the losing of the emulsion mixture performance caused by continuous and excessive extrusion of the emulsion mixture can be avoided, different draw ratios are arranged according to the different water removal requirements, extrusion water removal of the emulsion mixture to the maximum degree can be achieved, the water removal rate of the emulsion mixture can be improved, the product yield is improved, and the device is simple in structure, energy-saving, environment-friendly, friendly in use environment and easy to use and popularize.

Owner:QINGDAO UNIV OF SCI & TECH

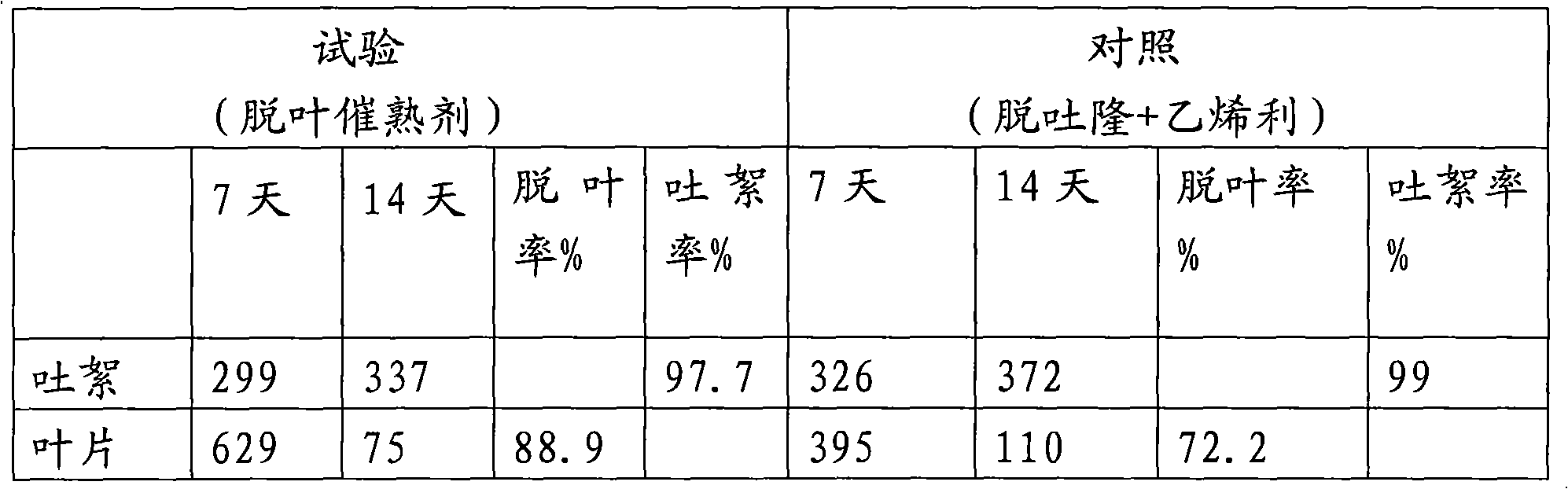

High-efficiency defoliating and ripening agent used before picking cotton

InactiveCN101971862AQuickly promote ripening and sheddingPromote ripening and sheddingBiocidePlant growth regulatorsFiberRipening

The invention provides a high-efficiency defoliating and ripening agent used before picking cotton. The high-efficiency defoliating and ripening agent is prepared by the following steps of: fully stirring 250 to 850 kilograms of ethrel, 55 to 200 kilograms of thidiazuron, 0.50 to 1.90 kilograms of DT34 auxiliary agent and 0.15 to 0.60 kilograms of DM12 auxiliary agent in a reaction kettle in turn; fully dissolving 15 to 53 kilograms of water and 0.18 to 0.22 kilograms of silicone antifoaming agent in advance to obtain solution; adding the solution; and stirring for 25 to 30 minutes at normal temperature and normal pressure to obtain a finished product. The defoliating and ripening agent is sprayed in an application dosage of 80 to 120ml / mu when the cotton fiber grow rate is over 60 to 70 percent before picking the cotton. The defoliating and ripening agent is sprayed at 6 to 8 pm in September to October of the maturation period of the cotton; rainy days are avoided; and the defoliating and ripening agent can be re-sprayed if the defoliating and ripening agent is caught in the rain. The product combines the efficiencies of ripening and defoliating, saves labor, time and effort, greatly improves labor production efficiency and cotton quality rate, and lays a solid foundation for manual fast harvest and mechanical one-time harvest. Compared with a conventional single product, the picking period is 15 to 20 days earlier and the average defoliation rate is over 90 percent.

Owner:袁永贵

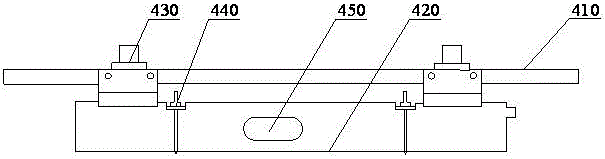

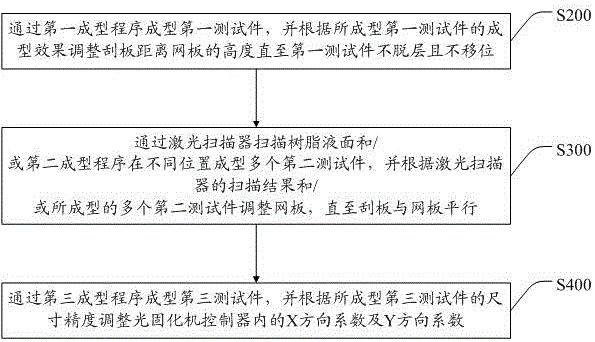

Debugging processing method and debugging processing device of light curing machine

ActiveCN106273495AImprove the quality rateAdditive manufacturing apparatusWork performanceLaser scanning

The invention discloses a debugging processing method and device of a light curing machine. The debugging processing method of the light curing machine comprises the following steps of: step B, molding a first testing piece through a first molding procedure, and adjusting the height from a scraping plate and a net plate according to a molding effect of the molded first testing piece until the first testing piece is not delaminated and does not move; step C, scanning a resin liquid level through a laser scanner and / or molding a plurality of second testing pieces at different positions through a second molding procedure; adjusting the net plate according to a scanning result of the laser scanner and / or the plurality of molded second testing pieces until the scraping plate is parallel to the net plate; and step D, molding a third testing part through a third molding procedure, and adjusting an X-direction coefficient and a Y-direction coefficient in a light curing machine controller according to size precision of the molded third testing part. According to the method provided by the invention, the working performance of the light curing machine and the high-quality rate of a molded product are improved.

Owner:FOSHAN POLYTECHNIC

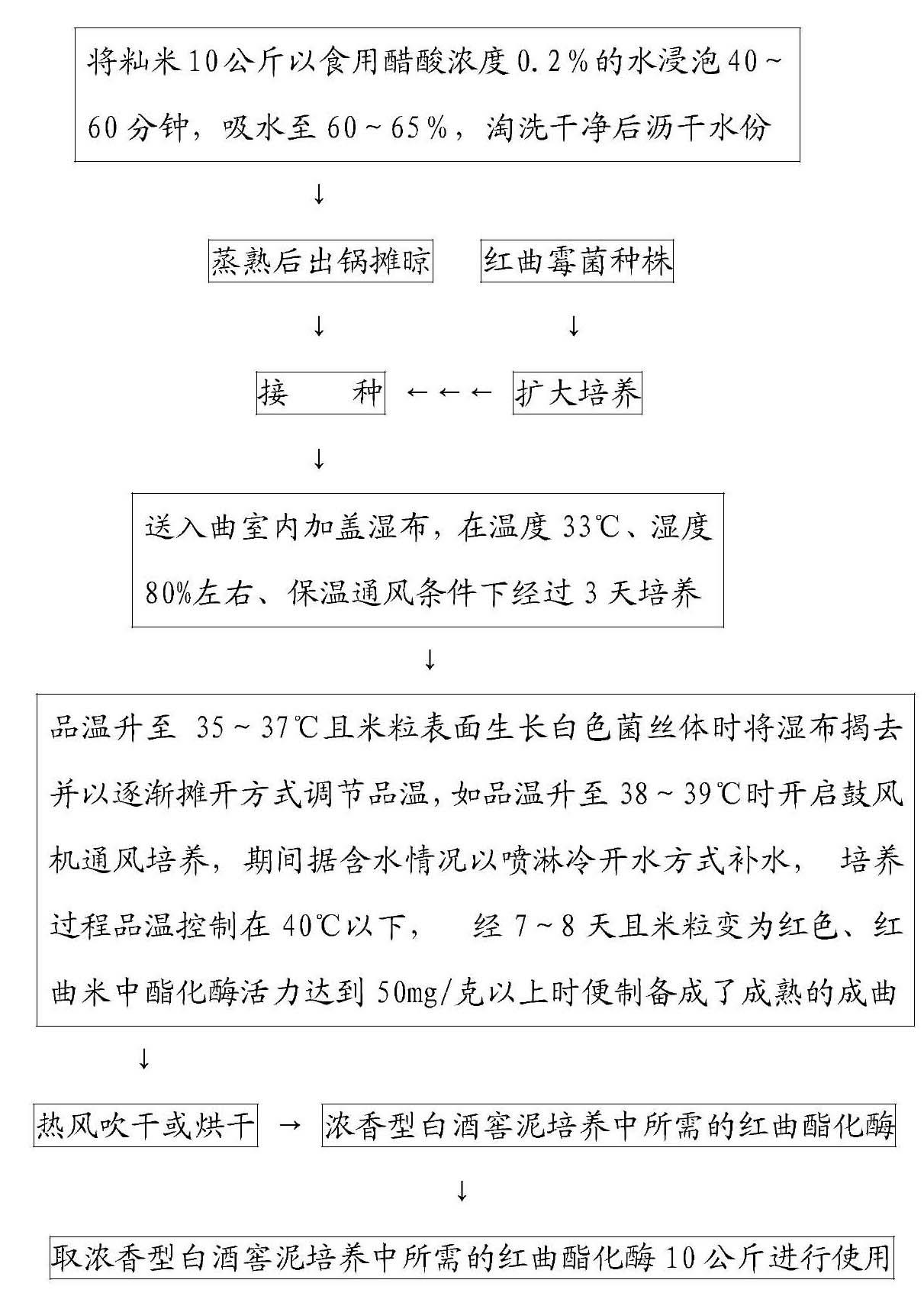

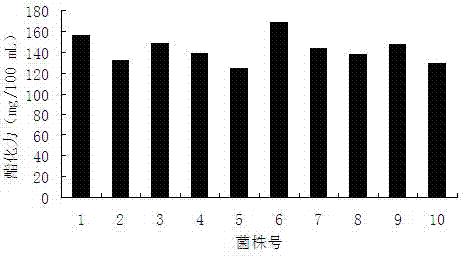

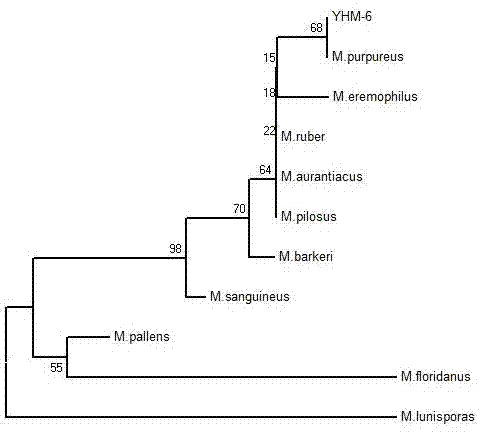

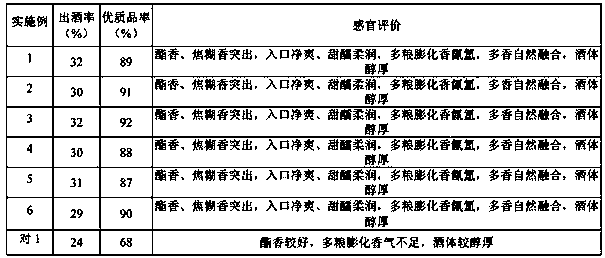

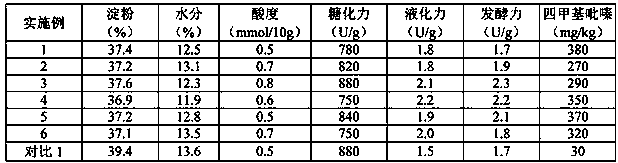

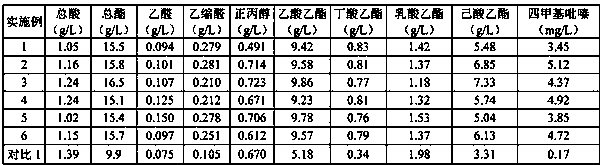

Monascus purpureus YH-6 strain, application thereof and esterified monascus prepared from strain

InactiveCN103589647AShorten the fermentation cycleImprove the quality rateFungiMicroorganism based processesBiotechnologyYeast

Owner:胡沂淮

Intensified baijiu daqu and production method and application thereof

ActiveCN111235067AMinimal ingredients addedAdd trace ingredientsBacteriaMicroorganism based processesMicroorganismHordeum vulgare

The invention discloses intensified baijiu daqu and a production method and application thereof. The intensified baijiu daqu is produced from the following raw materials in parts by weight: 100 partsof main raw materials, 4-5 parts of an accessory, 2-3 parts of a functional bacterial intensifier and 2-3 parts of mother qu; and the main raw materials are composed of wheat, barley and peas with a weight ratio ranging from 15:1:1 to 20:3:1, the accessory is distiller's dried grains, and the functional bacterial intensifier is produced by mixing bacillus velezensis, acinetobacter and sporosarcinaaccording to a weight ratio ranging from 1.0:0.5:0.5 to 1.0:1.0:1.0. In the intensified baijiu daqu, the microorganisms are diversified and high in content, and the quality of obtained baijiu is excellent.

Owner:HENAN YANGSHAO LIQUOR IND CO LTD +1

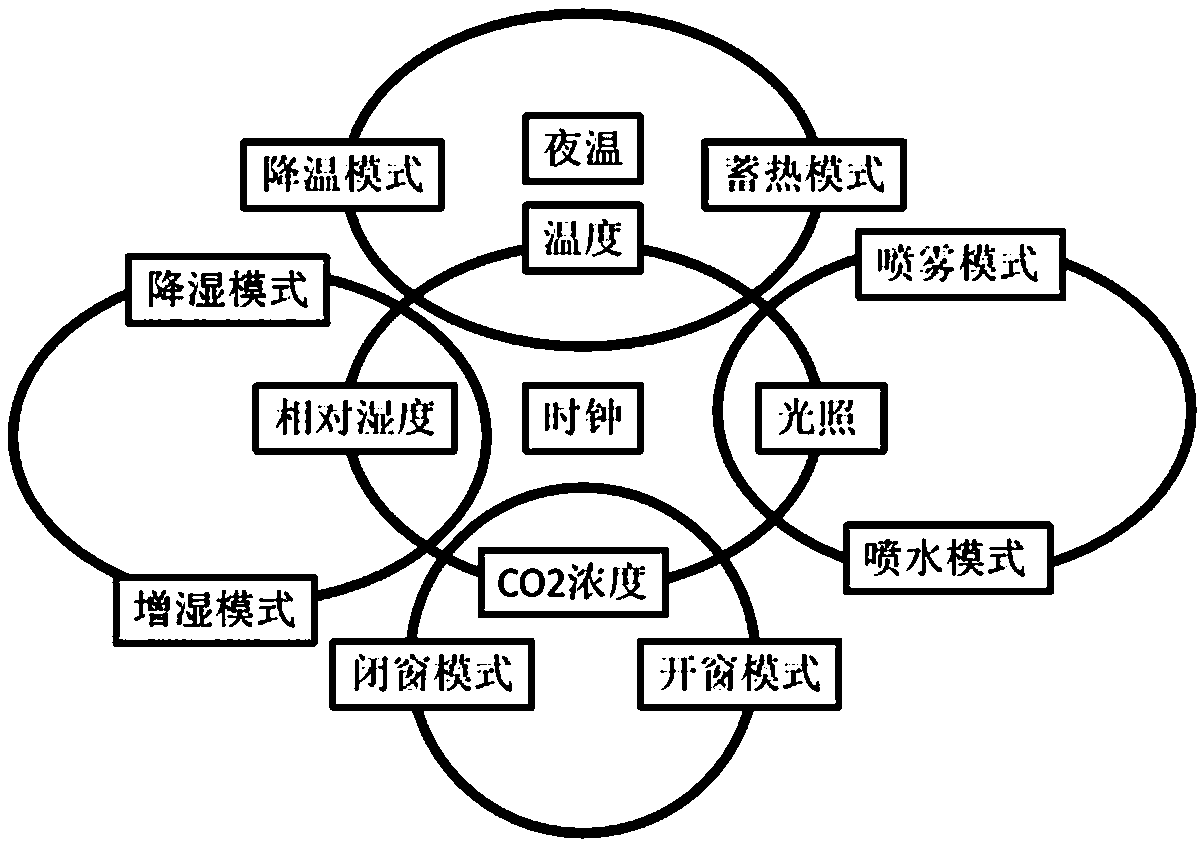

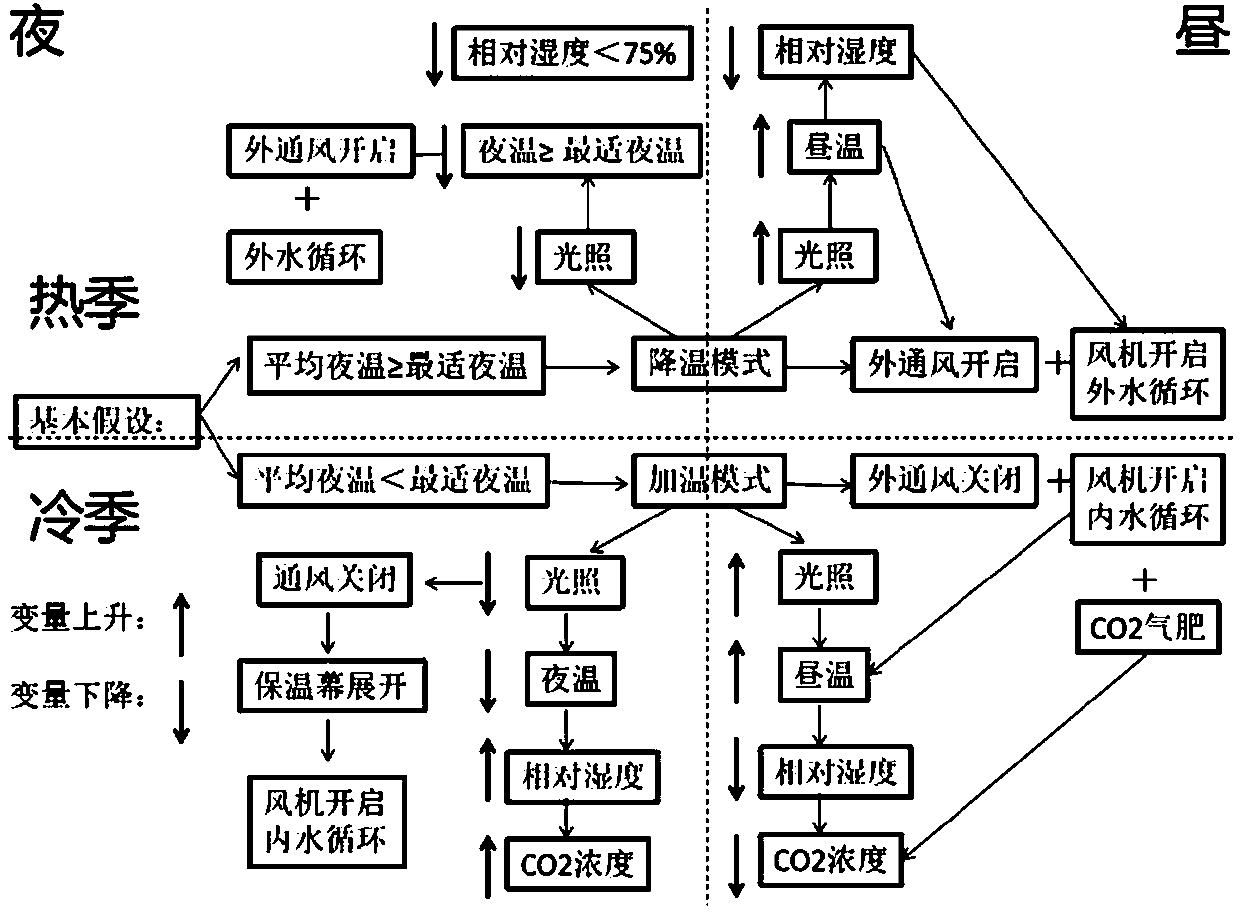

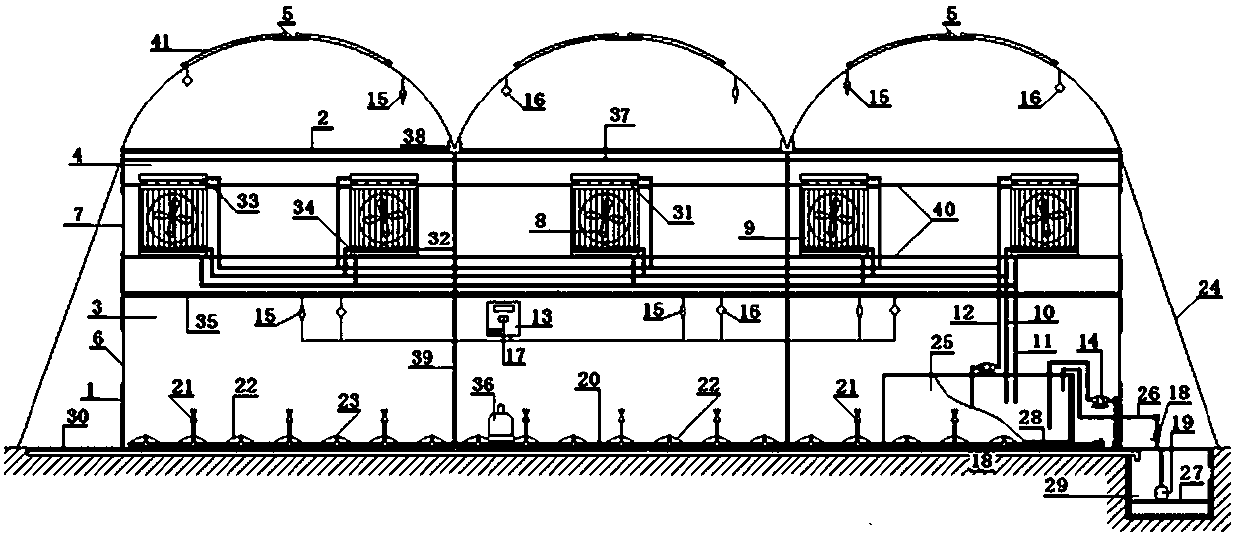

Intelligent greenhouse and environmental control method of using greenhouse effect for heat collection and fan coils for heat exchange

ActiveCN110178600AIncrease temperatureIncrease effective accumulated temperatureClimate change adaptationGreenhouse cultivationCold seasonAir volume

The invention discloses an intelligent greenhouse and environmental control method of using the greenhouse effect for heat collection and fan coils for heat exchange. The greenhouse is a multi-unit combined light-transmissive greenhouse with a highly overhead structure and comprises fan coil devices which are arranged at the middle-upper portions of the greenhouse, wherein each fan coil device integrating a heat exchanger and a wet curtain comprises a high-air-volume low-air-pressure fan and is provided with an inner water circulation pipe and an outer water circulation pipe, and the fan coildevices are connected to a heat storage pool through one water supply and return pipe. Two curtain layers are arranged above and below the devices respectively. An intelligent control system is designed, the greenhouse is closed for keeping warm in the cold season, the fans are started, internal water circulation of the coils is enabled, the solar heat is accumulated into water during daytime, andcrops are supplemented with CO2 gas fertilizer; the solar heat in the water is released into the air during nighttime. The greenhouse is opened for ventilation in the hot season, the fans are started, and external water circulation is enabled; the ventilation cooling effect is improved through evaporation and heat absorption on the surfaces of the heat exchangers. The problem that the cost is toohigh when existing methods are adopted for regulating the greenhouse environment is solved in an environment-friendly low-carbon mode, the remarkable effects of increasing the production, improving the quality, reducing the consumption of drugs and saving water are achieved, and transformation and upgrading of facility agricultural production modes are facilitated.

Owner:云南旭滇农业技术有限公司

Semiconductor wafer cutting clamper and using method thereof

InactiveCN101527276AReduce production processProduction cleanlinessSemiconductor/solid-state device manufacturingWorking accessoriesAdhesiveEngineering

The invention belongs to the field of semiconductor processing, in particular to a semiconductor wafer cutting clamper and a using method thereof. The semiconductor wafer cutting clamper comprises a clamper body, one side of the clamper body is provided with a plurality of grooves with the thickness for engaging with a semiconductor, and a convex part is arranged between every two grooves. The method of using the clamper for cutting processing comprises clamping and the cutting of an electric spark digital-control machine tool, and is characterized in that the clamping is as following: a plurality of semiconductors are welded or adhered to the grooves of the clamper by conductive adhesive. Because the technology enables the invention to save the auxiliary material and the media required to be padded and clamped in the process of the original method, work procedures of production are reduced. Because no-graphite technology is realized, the invention has more clean and sanitary production, more environmental protection, stabler production quality, higher finished product and high-grade product rate and higher production efficiency.

Owner:HENAN HONGCHANG ELECTRONICS

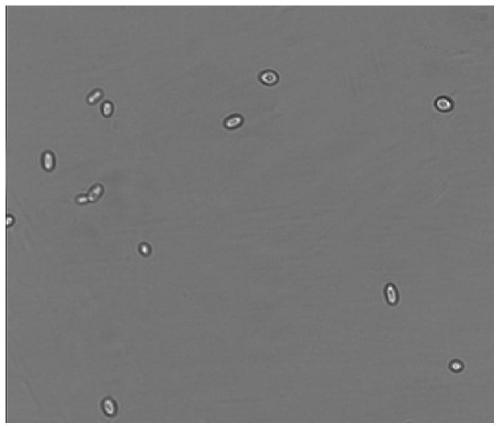

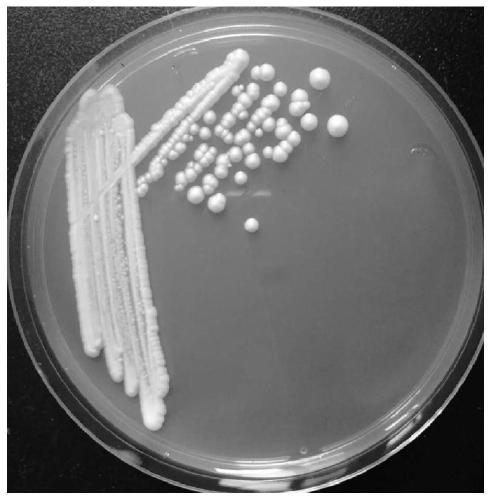

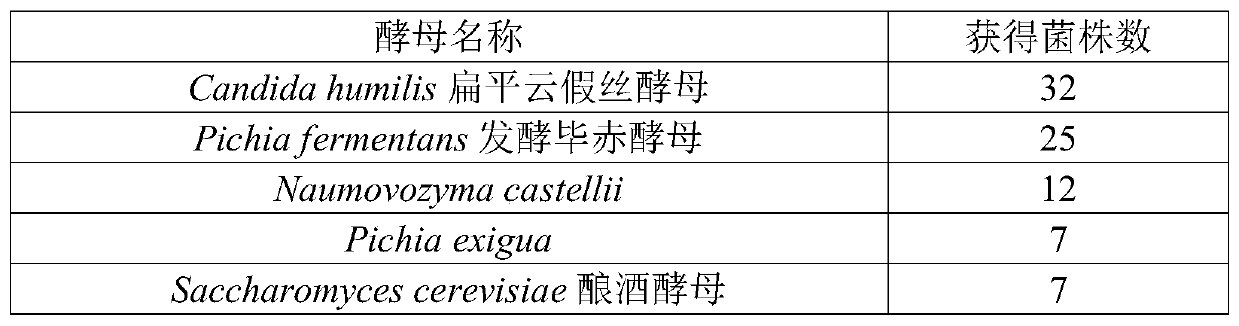

Low-yield isoamylol and high-yield beta-phenylethanol yeast, isolated culture method thereof and application of yeast

ActiveCN110205253AImprove featuresExcellent sugar toleranceFungiAlcoholic beverage preparationBiotechnologyPhenethyl alcohol

The invention relates to low-yield isoamylol and high-yield beta-phenylethanol yeast, an isolated culture method thereof and an application of the yeast. The low-yield isoamylol and high-yield beta-phenylethanol yeast is named as a Candida humilis YS023A strain, the strain is collected in a general microorganism center of a China Committee for Culture Collection of Microorganisms on No. 3, No. 1 courtyard Beichen West Road, Chaoyang District, Beijing on February 25, 2019, and the collection number of the strain is CGMCC NO:17257. The yeast has excellent characteristics of low-yield isoamylol and high-yield beta-phenylethanol and excellent sugar, alcohol and acid resistance, and the sugar utilization rate, the fermentation capacity and the ethanol production capacity of the yeast are good.The yeast is used for production of strong-flavor and rice-flavor Baijiu and has great significance for increasing of high-quality product rate and wine outlet rate of raw wine.

Owner:JIANGSU KINGS LUCK BREWERY

Ferment feed synergist and preparation method thereof

InactiveCN102008009AImprove conversion rateIncrease profitFood processingClimate change adaptationDiseaseAnimal science

The invention discloses a ferment feed synergist and a preparation method thereof, relating to the technical field of feed synergists. The synergist is prepared from the following components in percentage by weight: 50 percent of water and 50 percent by weight of synergistic raw materials, wherein the synergistic raw materials comprise the following components in percentage by weight: 30 percent of rice bran, 30 percent of wheat bran, 20 percent of straw powder, 3 percent of brown sugar, 9 percent of bacterial enzymes, 7 percent of bone or shell powder and 1 percent of trace elements. The synergist can fed together with traditional feed or additive to remarkably improve the conversion rate and the utilization rate of the feed or the additive and enables the nutrient contents in the feed or additive to be truly and fully absorbed and utilized. Meanwhile, the invention can improve the balance of animal bodies, enhance the disease resistance of livestock and poultry, eliminate drug residues, ensure people's health, promote the development of the eco-organic food, eliminate bacteria breeding and create a healthy biological food chain.

Owner:徐维康

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com