Patents

Literature

851 results about "Modeling software" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Following is a list of notable 3D modeling software, computer programs used for developing a mathematical representation of any three-dimensional surface of objects, also called 3D modeling.

Facilitating oilfield development with downhole fluid analysis

InactiveUS20080040086A1Eliminate needSimple processElectric/magnetic detection for well-loggingSeismology for water-loggingModeling softwareData acquisition

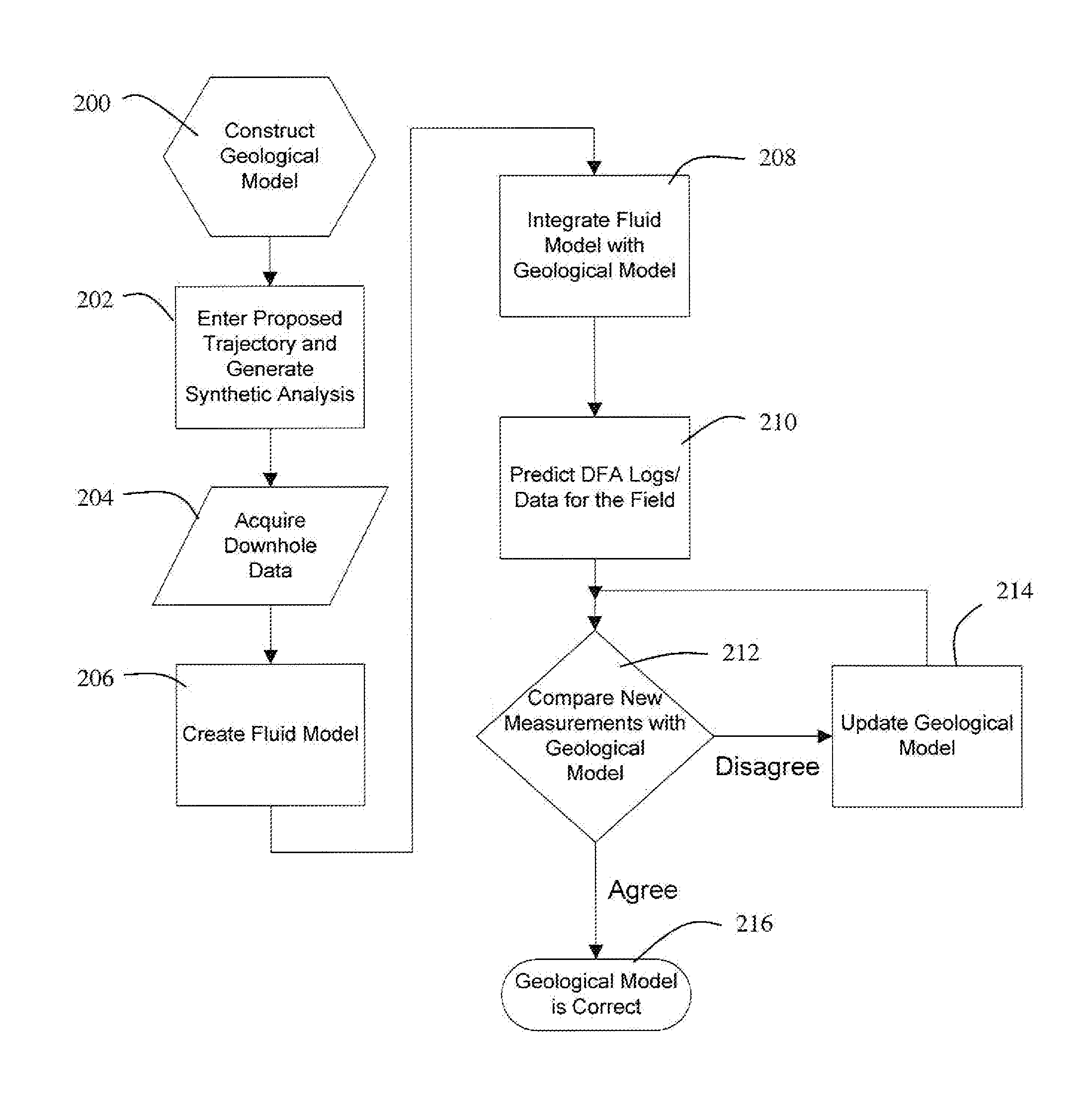

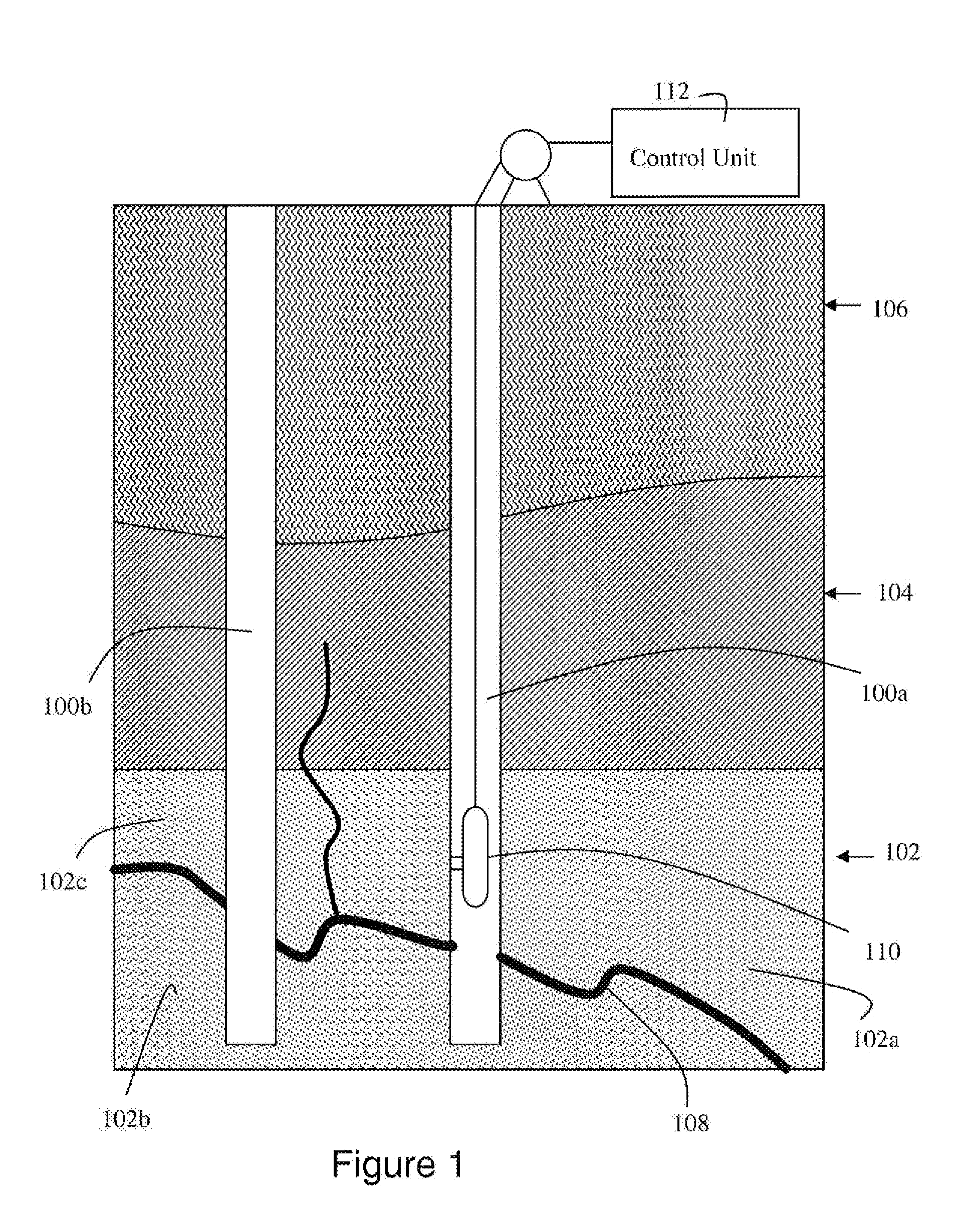

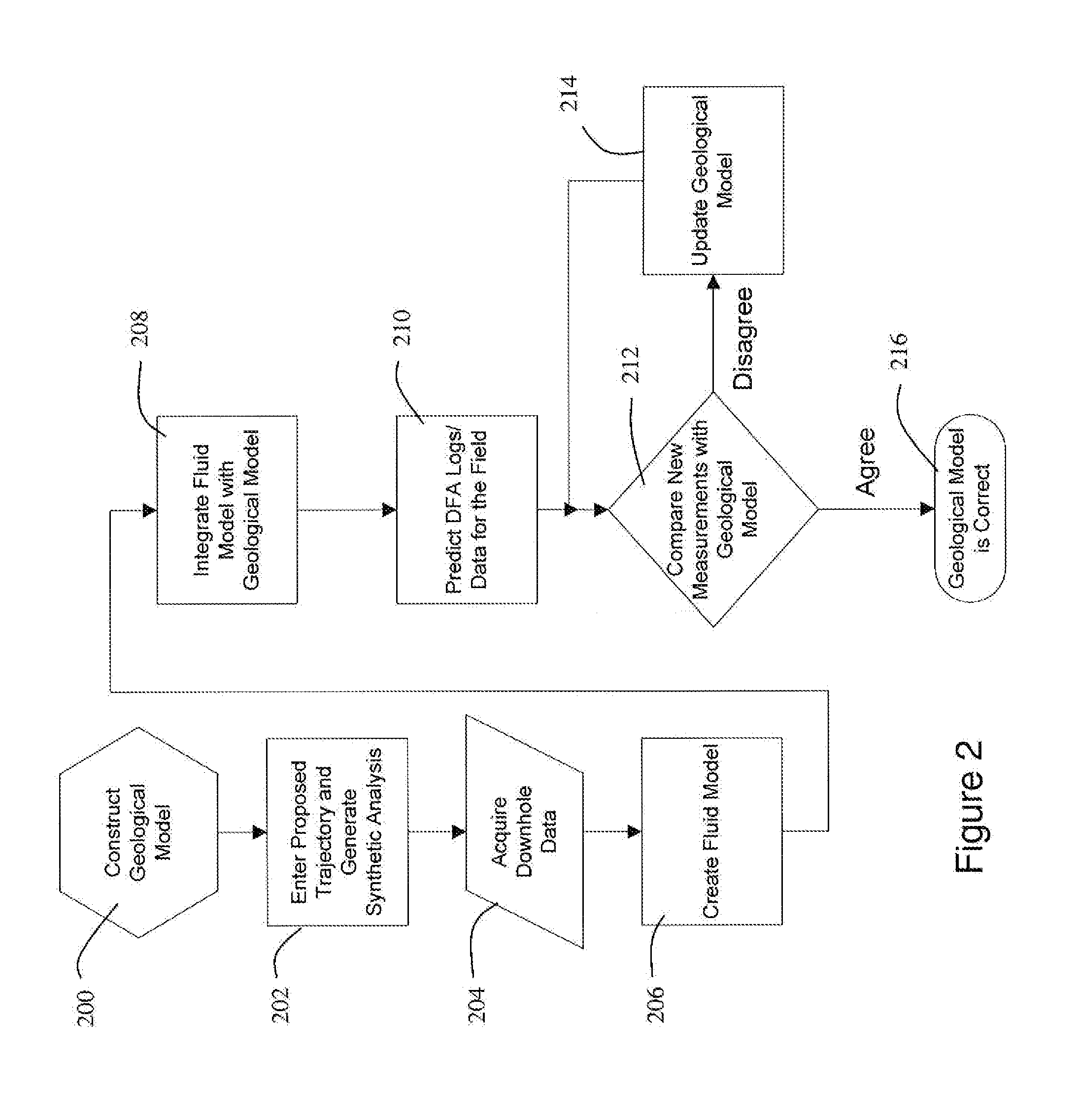

Formation fluid data based on measurements taken downhole under natural conditions is utilized to help identify reservoir compartments. A geological model of the reservoir including expected pressure and temperature conditions is integrated with a predicted fluid model fitted to measured composition and PVT data on reservoir fluid samples or representative analog. Synthetic downhole fluid analysis (DFA) logs created from the predictive fluid model can be displayed along the proposed borehole trajectory by geological modeling software prior to data acquisition. During a downhole fluid sampling operation, actual measurements can be displayed next to the predicted logs. If agreement exists between the predicted and measured fluid samples, the geologic and fluid models are validated. However, if there is a discrepancy between the predicted and measured fluid samples, the geological model and the fluid model need to be re-analyzed, e.g., to identify reservoir fluid compartments. A quantitative comparative analysis of the sampled fluids can be performed against other samples in the same borehole or in different boreholes in the field or region to calculate the statistical similarity of the fluids, and thus the possible connectivity between two or more reservoir regions.

Owner:SCHLUMBERGER TECH CORP

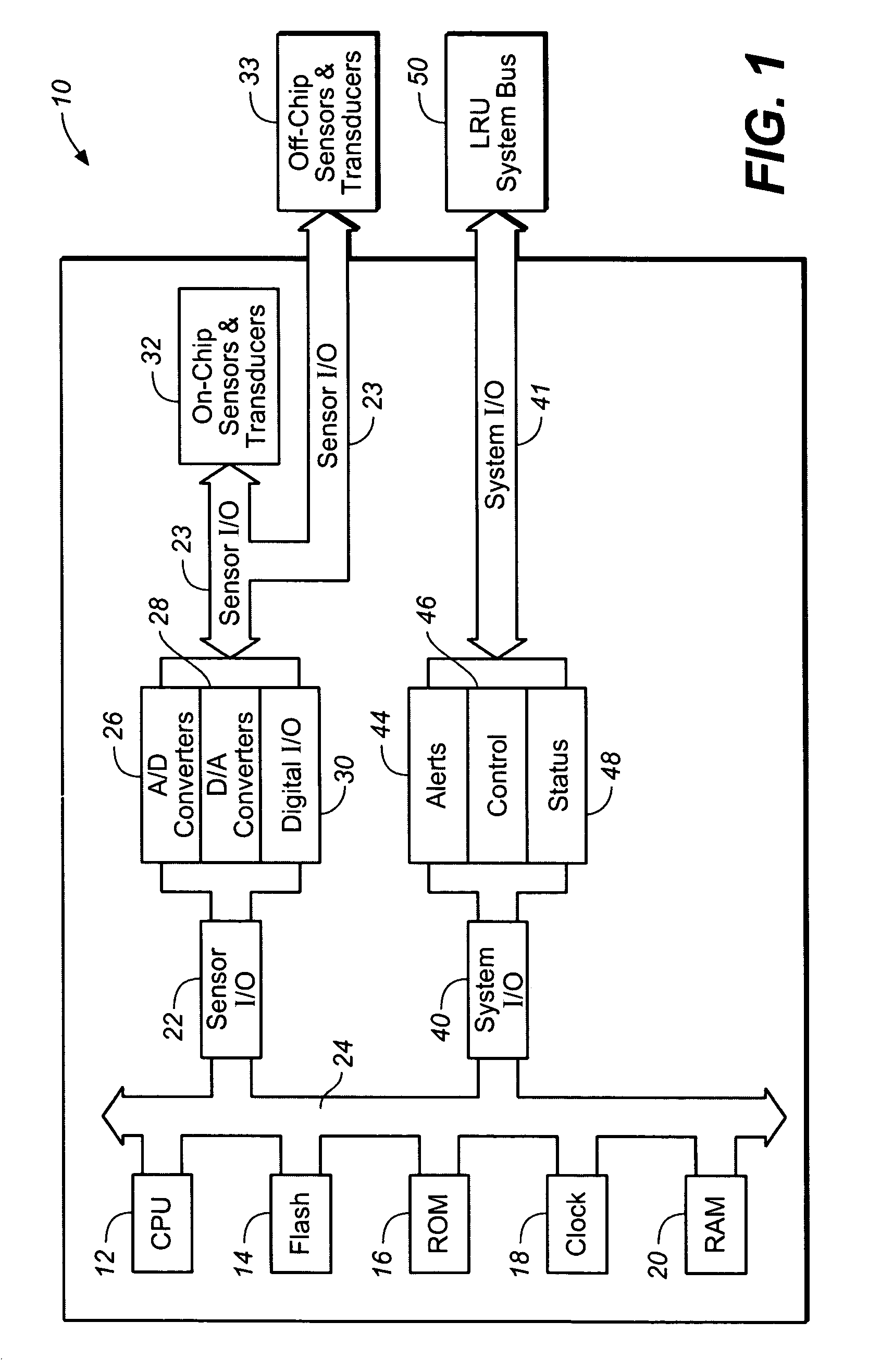

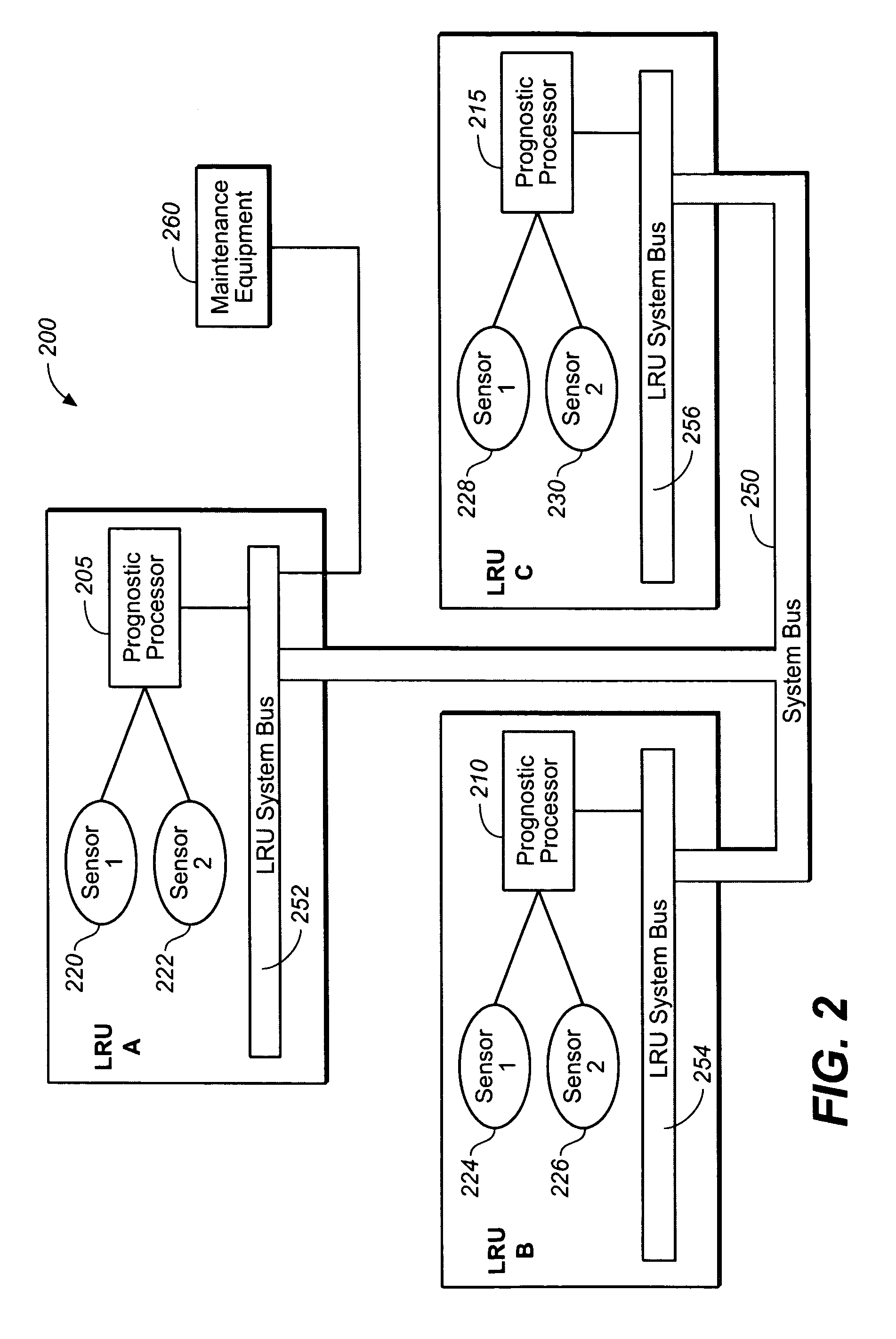

Prognostic processor system for real-time failure analysis of line replaceable units

ActiveUS7509537B1Electronic circuit testingTesting/monitoring control systemsModeling softwarePredictive failure analysis

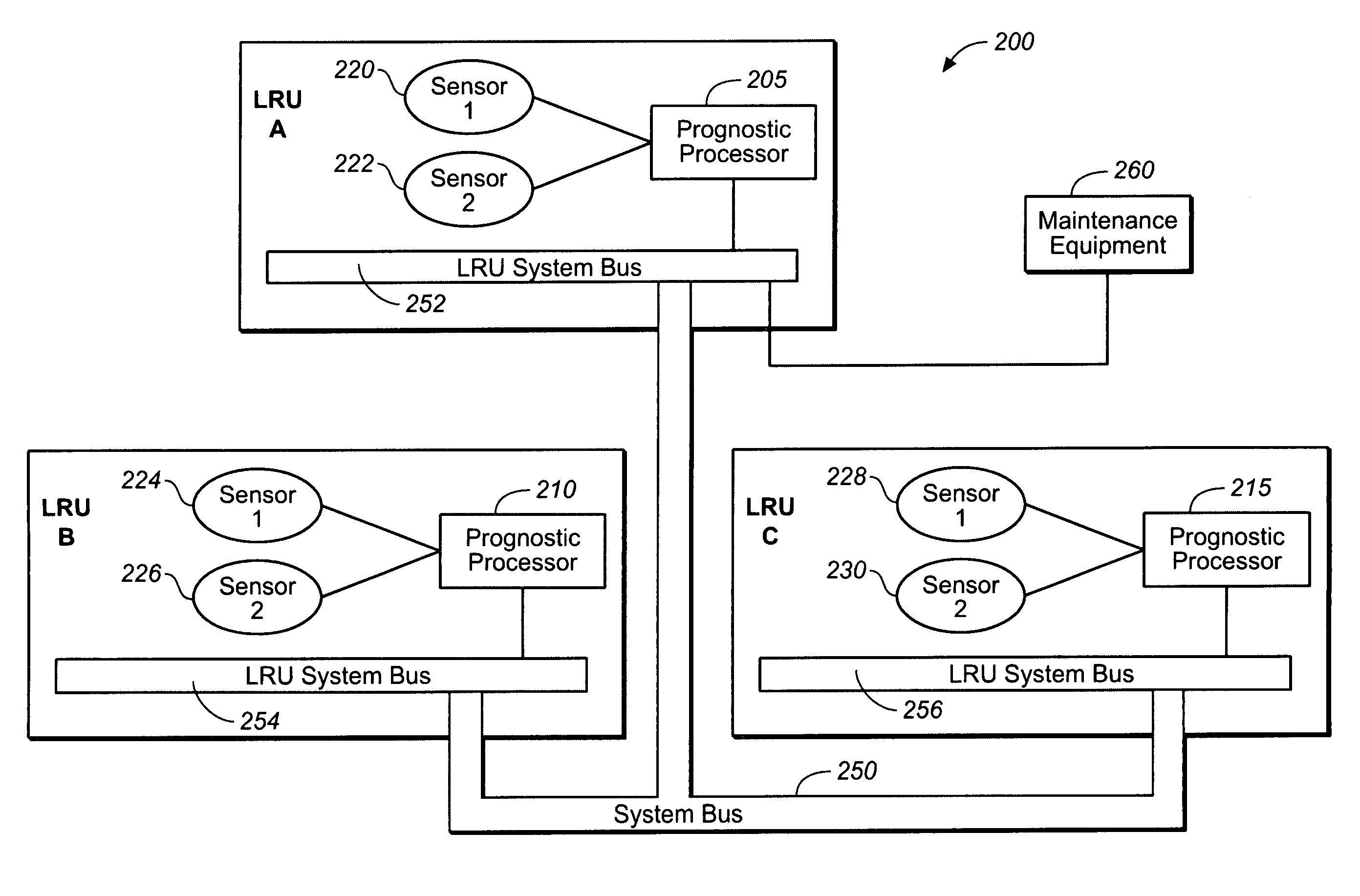

A prognostic processor for predicting machine failure in avionics electronics comprises prognostic capabilities in a single integrated circuit, with a processor, volatile and non-volatile memory, clock, on-chip and off-chip sensors and transducers, A / D converters, a common I / O interface adapted to be employed in a network of similar prognostic processors, and predictive Failure Analysis (FA) model software, which may be distributed throughout the network. The FA software employs a log file history, with the log file history storing data collected by the prognostic processor, real-time execution of a predictive model, with the ability to update the FA model with data from field failures. The prognostic processor network supports hierarchical processing to work with multiple prognostic processors. The prognostic processor system is applicable to FA monitoring of a wide range of avionics electronic equipment, in particular, Line Replacement Units (LRUs).

Owner:ROCKWELL COLLINS INC

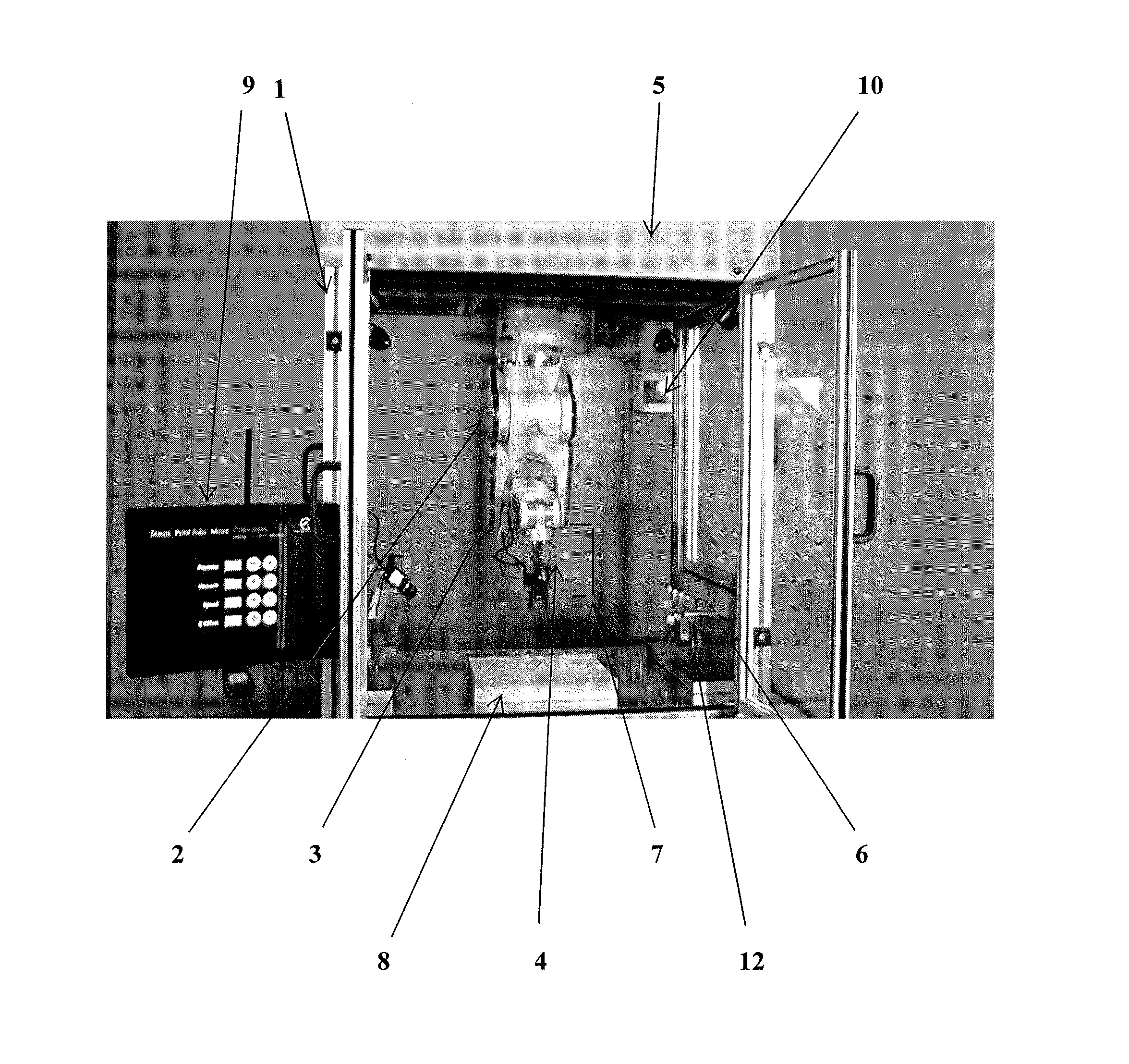

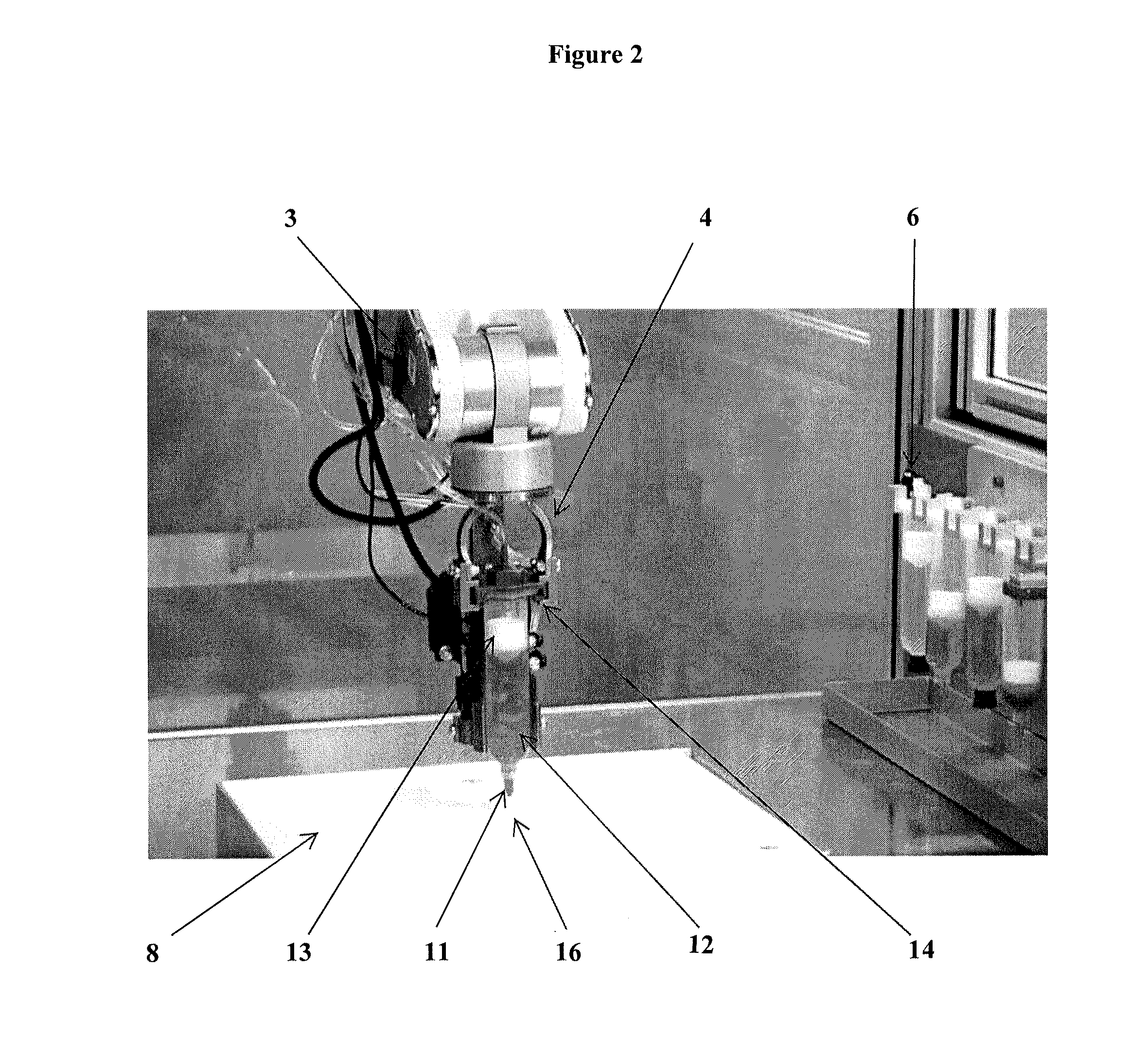

System and workstation for the design, fabrication and assembly of bio-material constructs

ActiveUS20150105891A1Build versatilityProgramme controlManufacturing platforms/substratesComputer Aided DesignModeling software

A bioassembly system having a tissue / object modeling software component fully and seamlessly integrated with a robotic bioassembly workstation component for the computer-assisted design, fabrication and assembly of biological and non-biological constructs. The robotic bioassembly workstation includes a six-axis robot providing the capability for oblique-angle printing, printing by non-sequential planar layering, and printing on print substrates having variable surface topographies, enabling fabrication of more complex bio-constructs including tissues, organs and vascular trees.

Owner:ADVANCED SOLUTIONS LIFE SCI

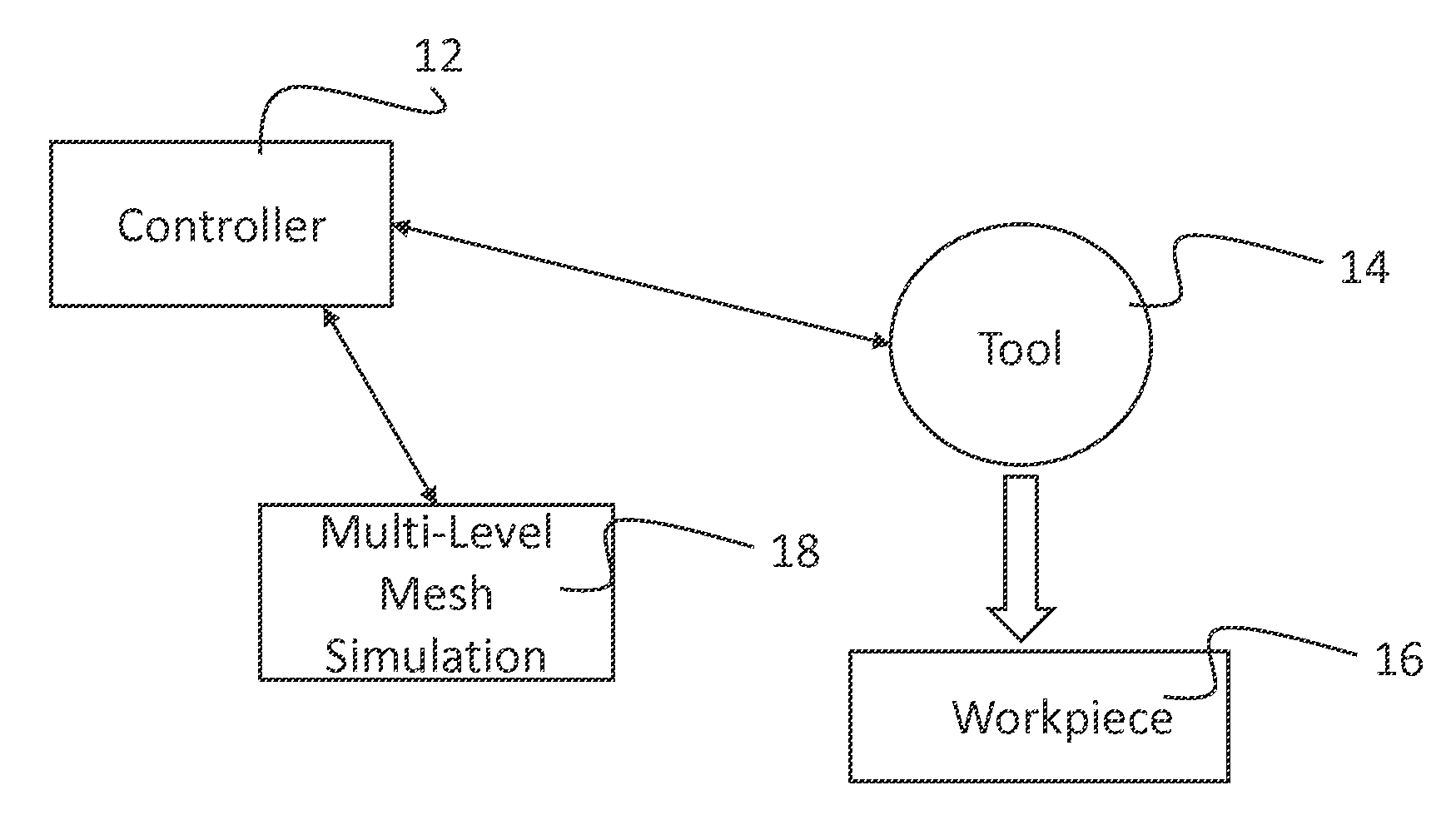

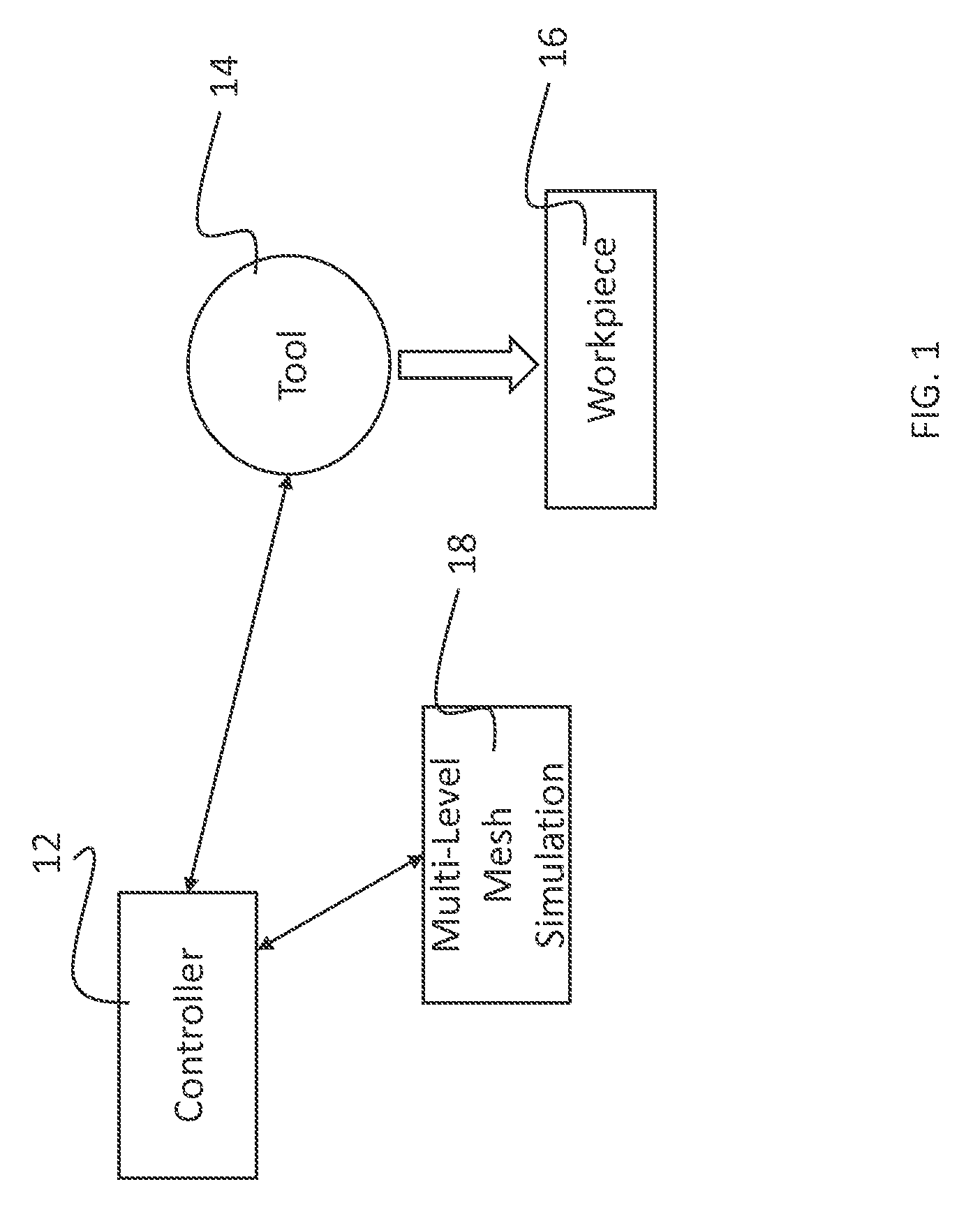

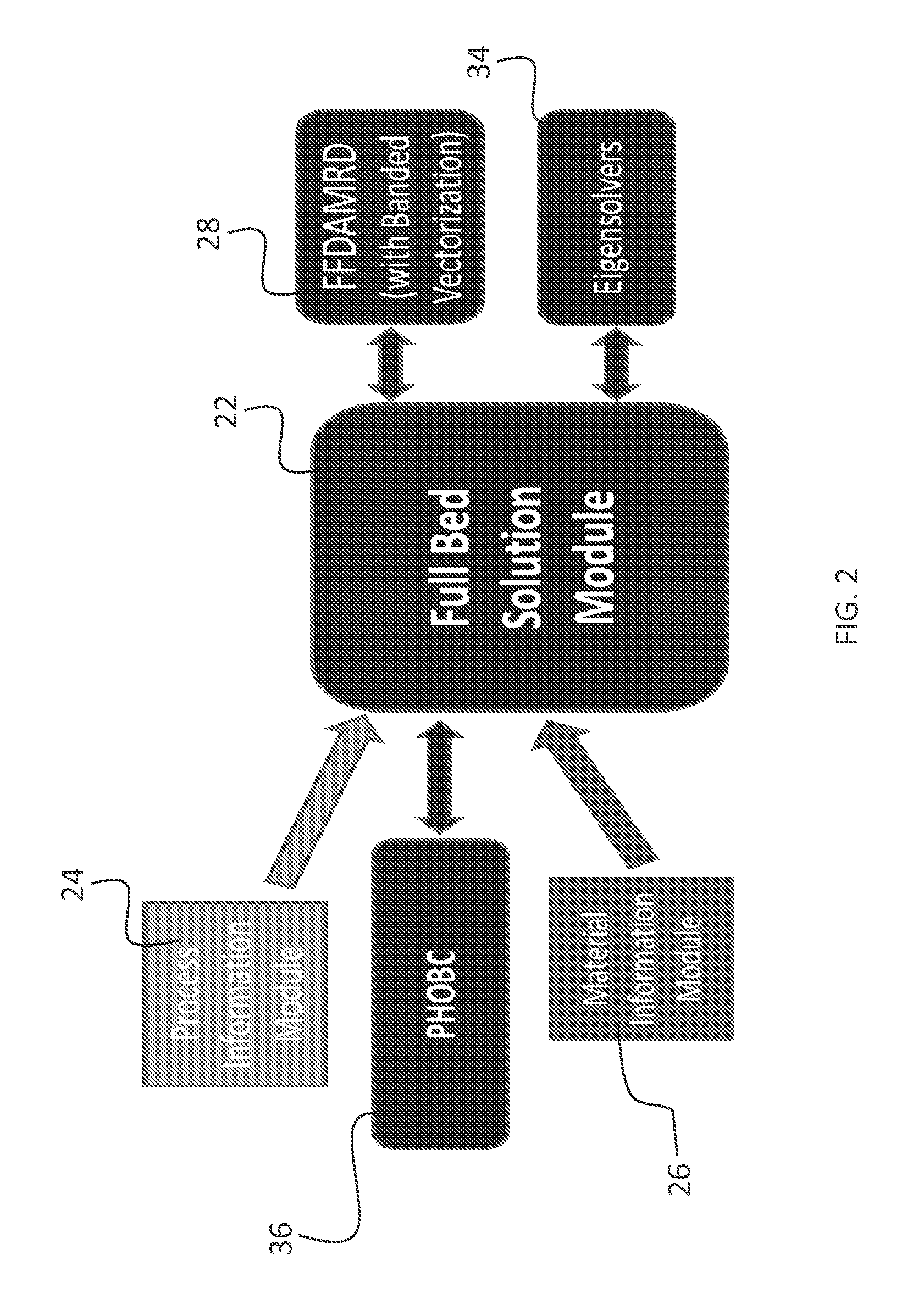

Multi-scale mesh modeling software products and controllers

ActiveUS20160321384A1Accurately predict thermalAccurately stress/strain fieldProgramme controlAdditive manufacturing apparatusCoarse meshModeling software

Simulation systems, manufacturing systems, software products and controllers are provided with multi-scale modeling in which a coarse mesh and a fme mesh that models a stimulus are decoupled. The fine mesh can be moved within the coarse mesh with a cut and paste operation. The coarse mesh is updated by sparsely propagated effects through the coarse mesh. Simulations of the invention can be conducted in real-time, and be used as controllers in manufacturing systems, such as additive manufacturing systems. A number of efficient methods are provided for solving meshing determinations that arise from movement of a stimulus modeled within a fine mesh.

Owner:UNIV OF LOUISVILLE RES FOUND INC

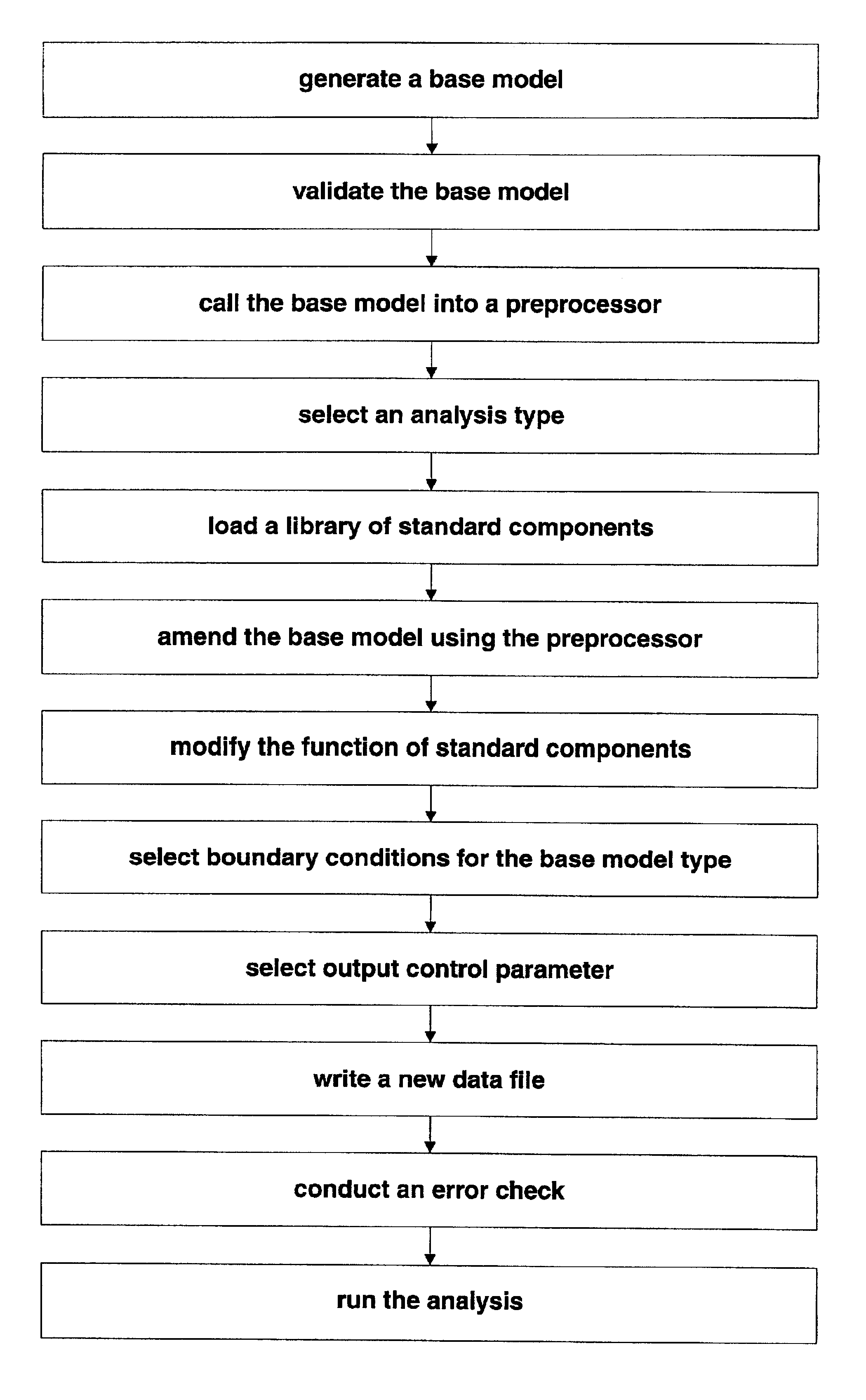

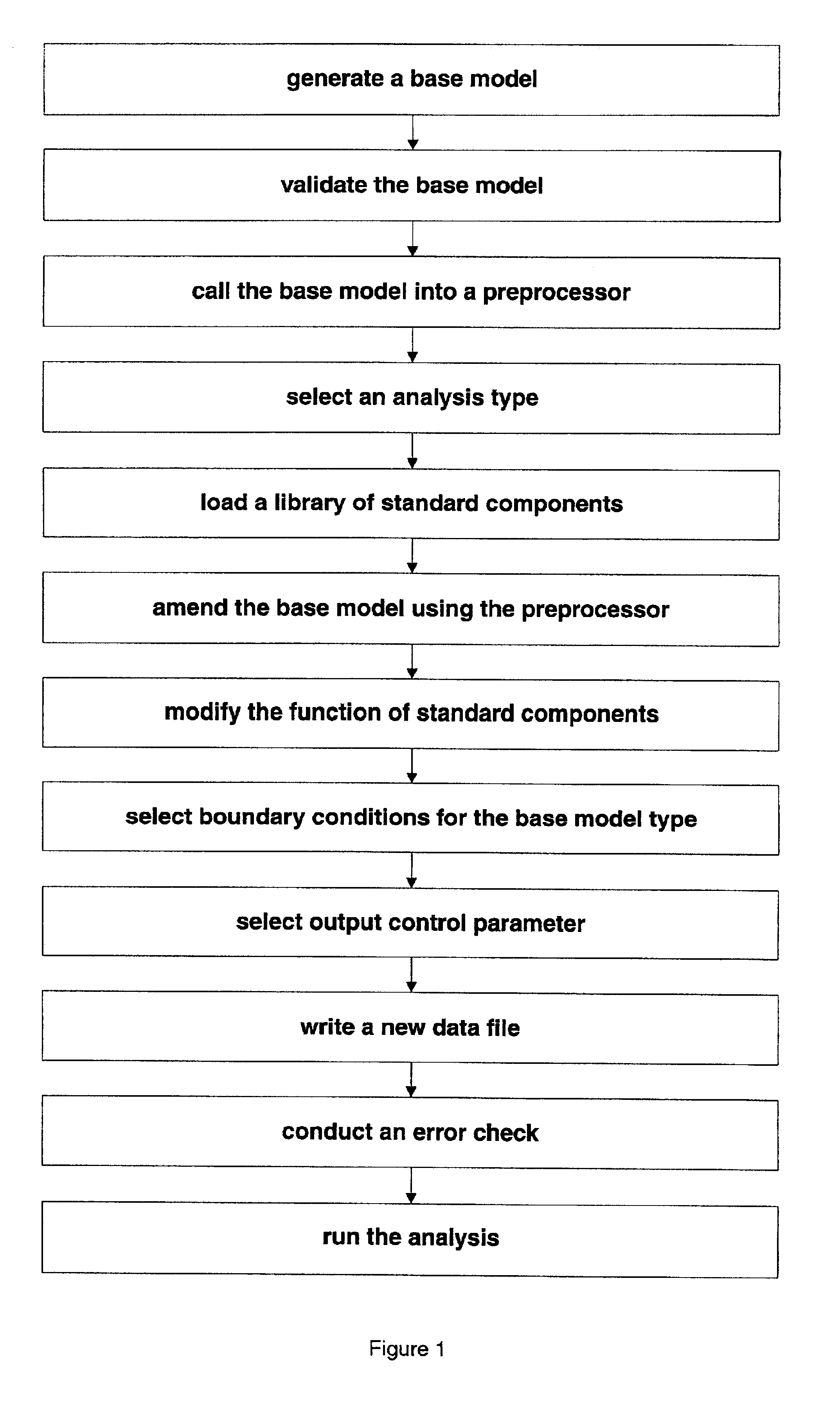

Simplified modeling software interface and method

InactiveUS6904399B2Reduce complexityReduce of knowledgeDigital data processing detailsAnti-theft devicesModeling softwareSimulation based

Disclosed is a simulation based environment that allows a product based engineer, with a modest understanding of complex software programs, to use complex math models. The system provides an interface by which basic component models can be used within the simulation. Allowances are made for particular variables to be adaptable by the product based engineer.

Owner:TNO MADYMO NORTH AMERICA +1

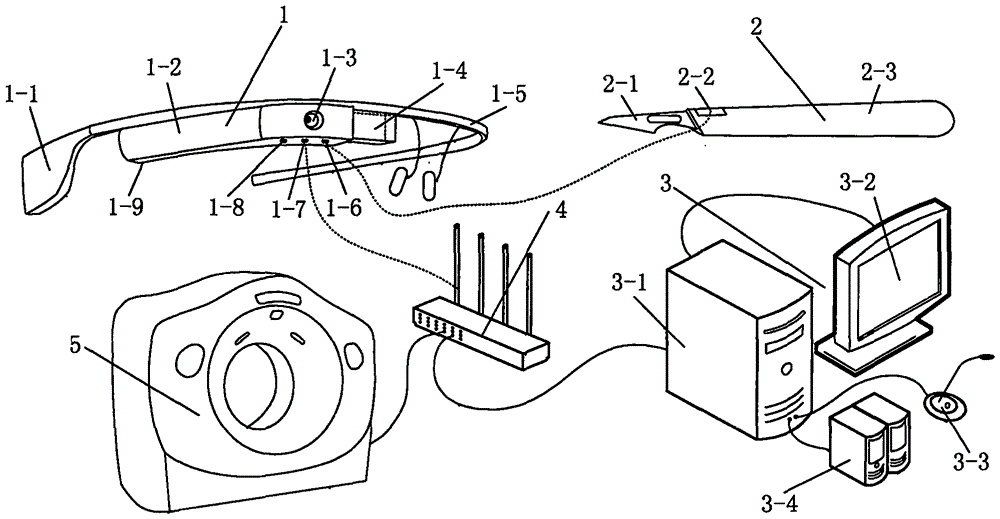

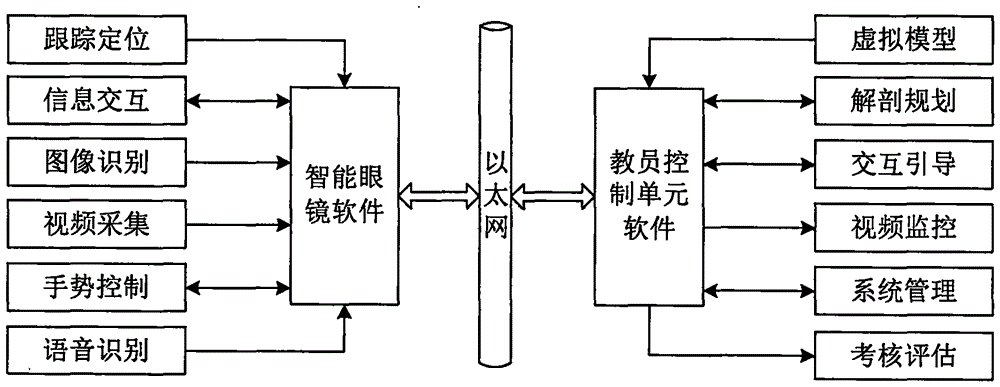

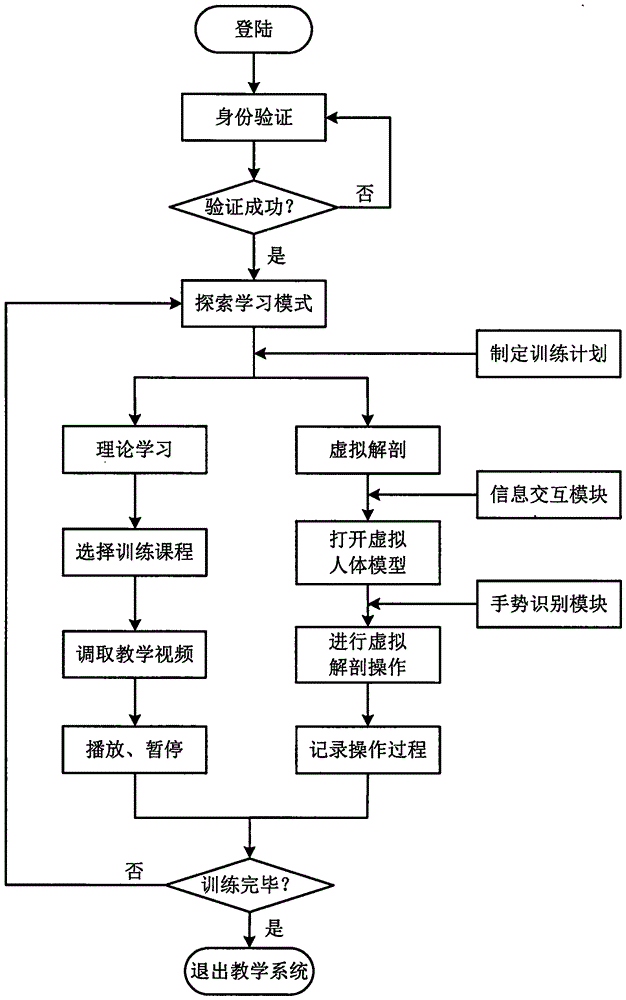

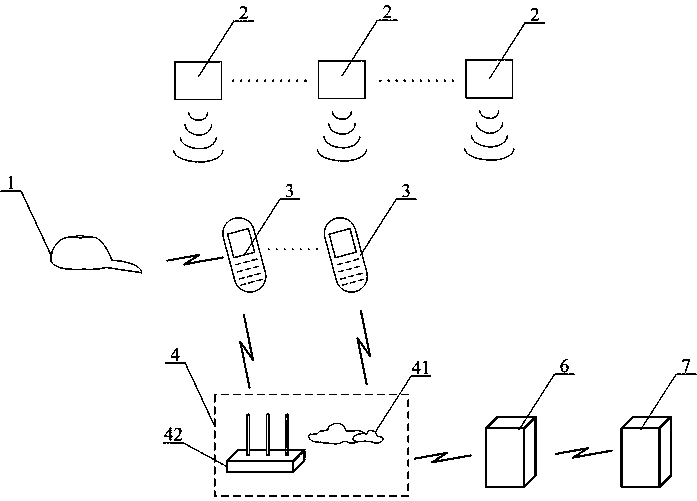

Medical anatomy auxiliary teaching system based on augmented reality

InactiveCN105788390AStandard operation actionReduce misuseElectrical appliancesOptical elementsWireless routerAnatomic Site

The invention discloses a medical anatomy auxiliary teaching system based on augmented reality, and relates to the field of biomedical engineering. The system consists of intelligent glasses, an anatomy instrument, a teacher control unit, a wireless router, and a medical image scanning device. A three-dimensional virtual model (vessels, muscle and skeleton) is built through the anatomy information obtained by the medical image scanning device and modeling software. The three-dimensional virtual model and a real anatomic site in an operation vision are integrated and stacked, thereby enabling students to see a subcutaneous internal structure. Meanwhile, the system can obtain the precise spatial information of the anatomy instrument relative to the anatomic site, achieves the augmented display of the operation vision, and has three teaching modes: discovery learning, interactive training, examination and evaluation. The system can assist students carry out theory learning before operation, interactive guide in operation and intelligent estimation after operation, enables the anatomy operation to be standard, improves the operation precision, and reduces the training cost.

Owner:JINLIN MEDICAL COLLEGE

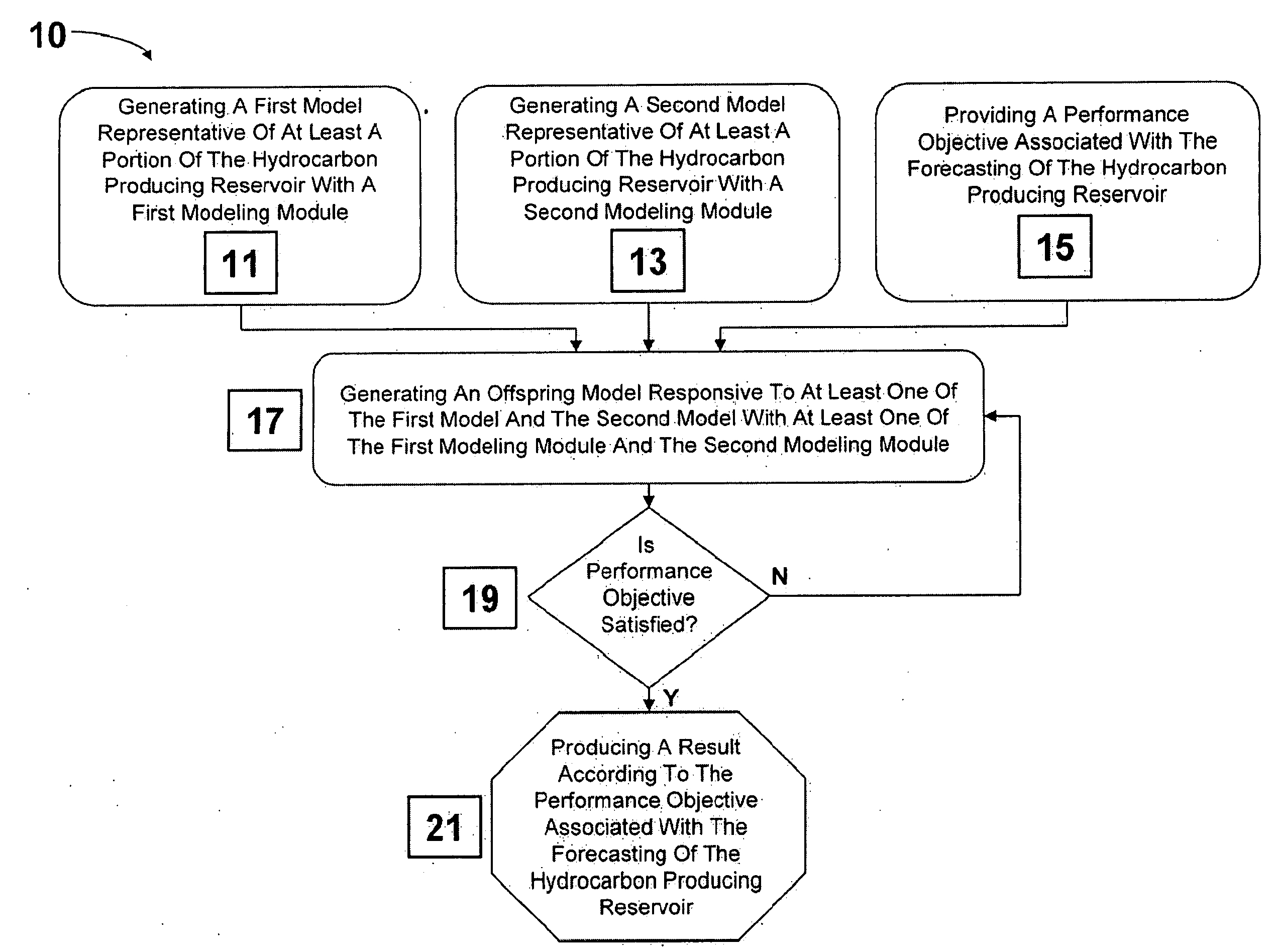

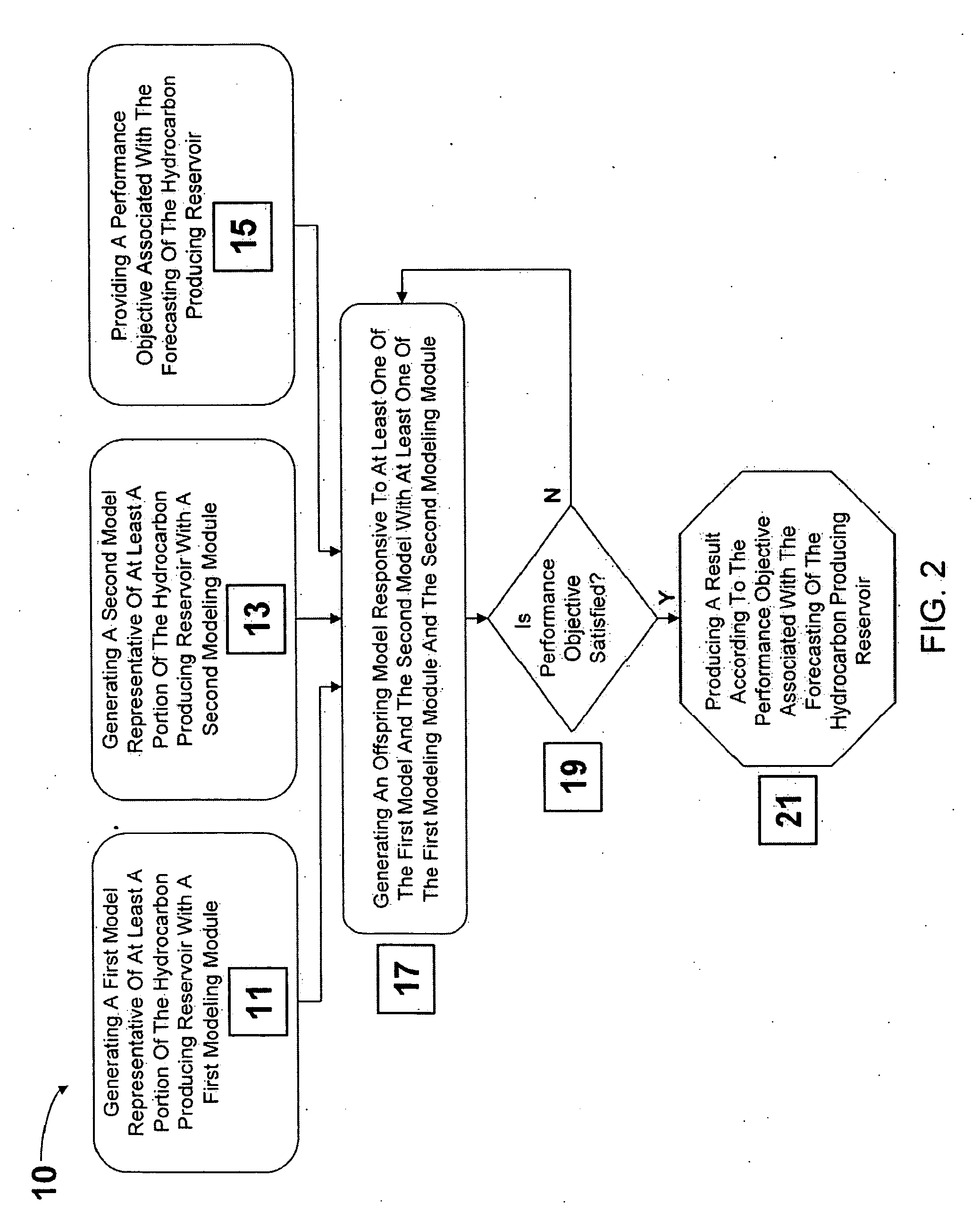

System and method for forecasting production from a hydrocarbon reservoir

A system and method is taught to substantially automate forecasting for a hydrocarbon producing reservoir through integration of modeling module workflows. A control management module automatically generates static and dynamic offspring models, with static and dynamic modeling software, until a performance objective associated with the forecasting of the reservoir is satisfied. The performance objective can include an experimental design table to determine a sensitivity of a particular parameter or can be directed towards reservoir optimization, i.e., ultimate hydrocarbon recovery, net present value, reservoir percentage yield, reservoir fluid flow rate, or history matching error.

Owner:CHEVROU USA INC

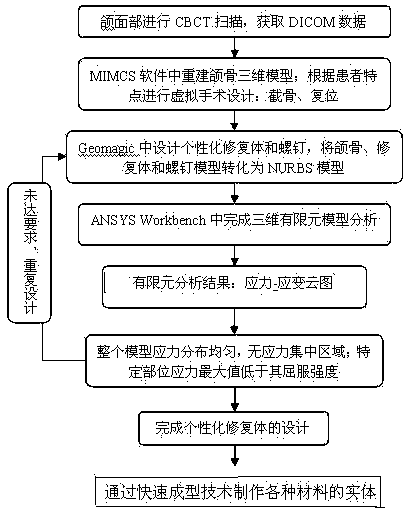

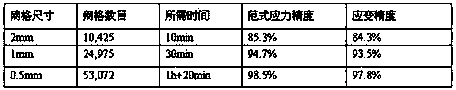

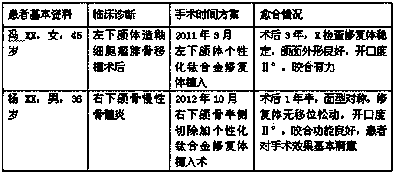

Manufacturing method for jaw defect individual restoration

ActiveCN103919631AHigh breaking strengthIncrease stressBone implantSurgeryBiomechanicsComputer-aided

The invention relates to the fields of computer-aided technology and maxillofacial plastic medical apparatus and instruments, in particular to an optimal design and manufacturing method for a jaw defect individual restoration. The optimal design and manufacturing method is characterized by comprising the following steps: conducting CBCT scanning on the maxillofacial part of a patient, obtaining DICOM data, guiding the data into three-dimensional modeling software-MIMICS (Materialise, Belgium) to reconstruct a jaw three-dimensional model, designing the individual restoration, designing models of a plurality of virtual screw according to the size of retention screws supposed to be adopted, then moving the models to the appropriate positions of the jaw to simulate the situation to the screw retention restoration, obtaining Von Mises stress and a strain nephogram, and manufacturing entities of various materials through the fast forming technology. The jaw defect individual restoration made through the manufacturing method for the jaw defect individual restoration has good performance in biomechanical properties including breaking strength, stress-strain distribution, the service life and the like. So far, a patient with upper and lower jaw defects accepting an implanting operation is observed for two years, and no bad complications of fracture, exposure and the like happen.

Owner:SICHUAN UNIV

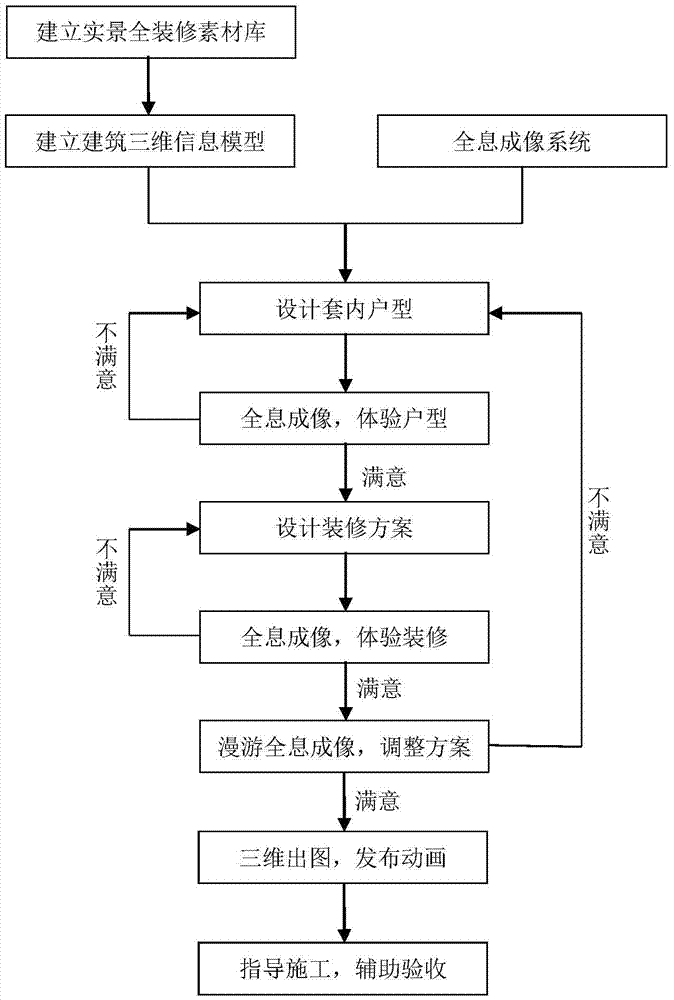

BIM-based holographic imaging full-decoration simulation display method and display system

ActiveCN105446069AIncrease variabilityRealize personalized designStereoscopic photographyOptical elementsPersonalizationLive action

The invention relates to the technical field of architectural design and construction, in particular to a BIM-based holographic imaging full-decoration simulation display method and display system. A three-dimensional information model of a building and an internal partition wall parameter family are built by BIM modeling software; interior structures are designed by adjusting partition wall family parameters and the partition wall position; and the diversity of the interior structures and individualized design of decorating schemes are achieved. The effect of selection and modification by residents can be displayed by a three-dimensional real image projected through a holographic imaging technology; a user can intuitively experience the difference of the decorating schemes; and through rendering animation, the user can carry out live-action experience on each detail of the decorating scheme in the projected three-dimensional animation scene, and can intuitively determine the decorating schemes without visiting model houses. Auxiliary acceptance is carried out through a three-dimensional scheme map and an animated image; and the display method and the display system help the user who does not know the decoration carry out comparison acceptance and ensure that the decoration reaches design requirements of the user.

Owner:深圳市行天下建设工程有限公司

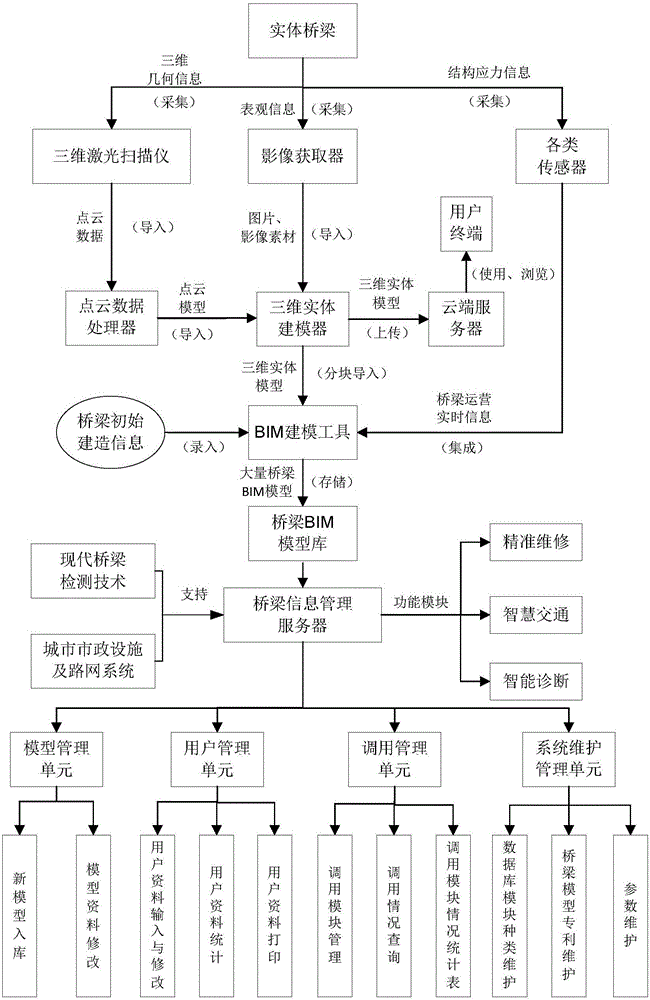

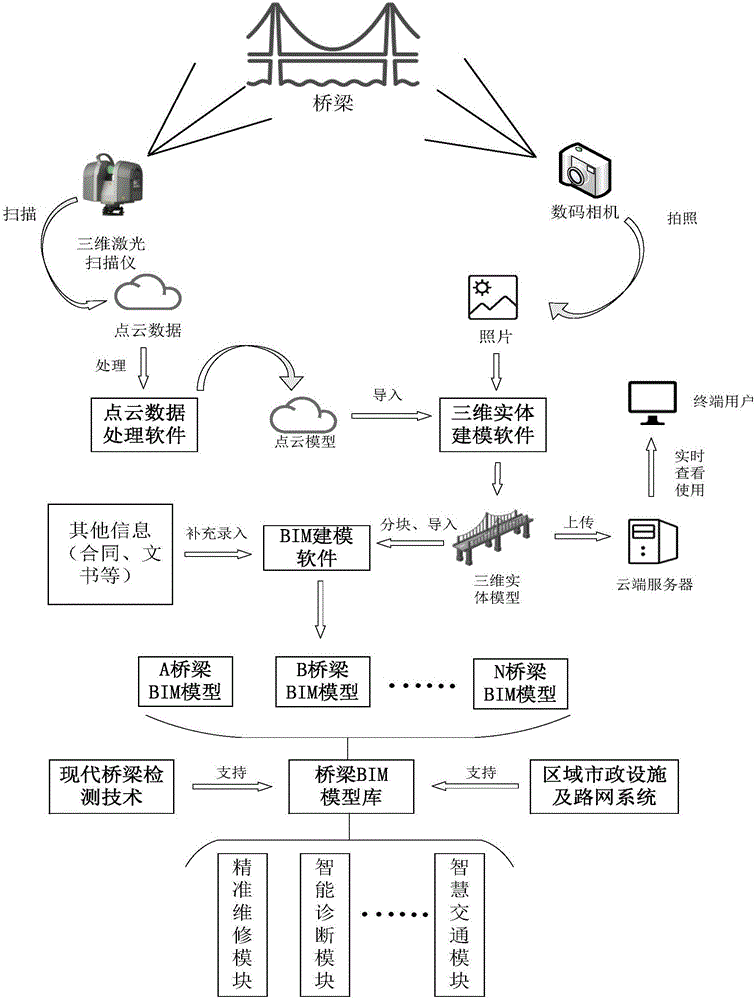

Existing bridge quick BIM modeling system and method

PendingCN106777680AOvercome limitationsImprove efficiencyGeometric CADImage data processingPoint cloudModeling software

The invention discloses an existing bridge quick BIM modeling system and method. The three-dimensional laser scanning technology serves as a bridge three-dimensional geometric data acquisition tool, and the limitation of passive ranging in traditional close-range photogrammetry, namely limitation of natural light conditions, is overcome. In actual application examples, by comparing a BIM model built through three-dimensional scanning and an actual building, it is found that the similarity between the BIM model and the actual building can reach 90% or above. A full-color-point cloud model is obtained through the three-dimensional scanning technology, a vivid and fine virtual model can be generated through three-dimensional entity modeling software processing, the method can be used for webpage real-time publish and sharing, and the cooperative work efficiency is improved. The whole BIM modeling process is convenient, quick and precise, as for small-and-medium-sized bridges, it takes a few hours from field work scanning to building of the whole BIM model, and model errors can be controlled at the millimeter level.

Owner:HUAZHONG UNIV OF SCI & TECH

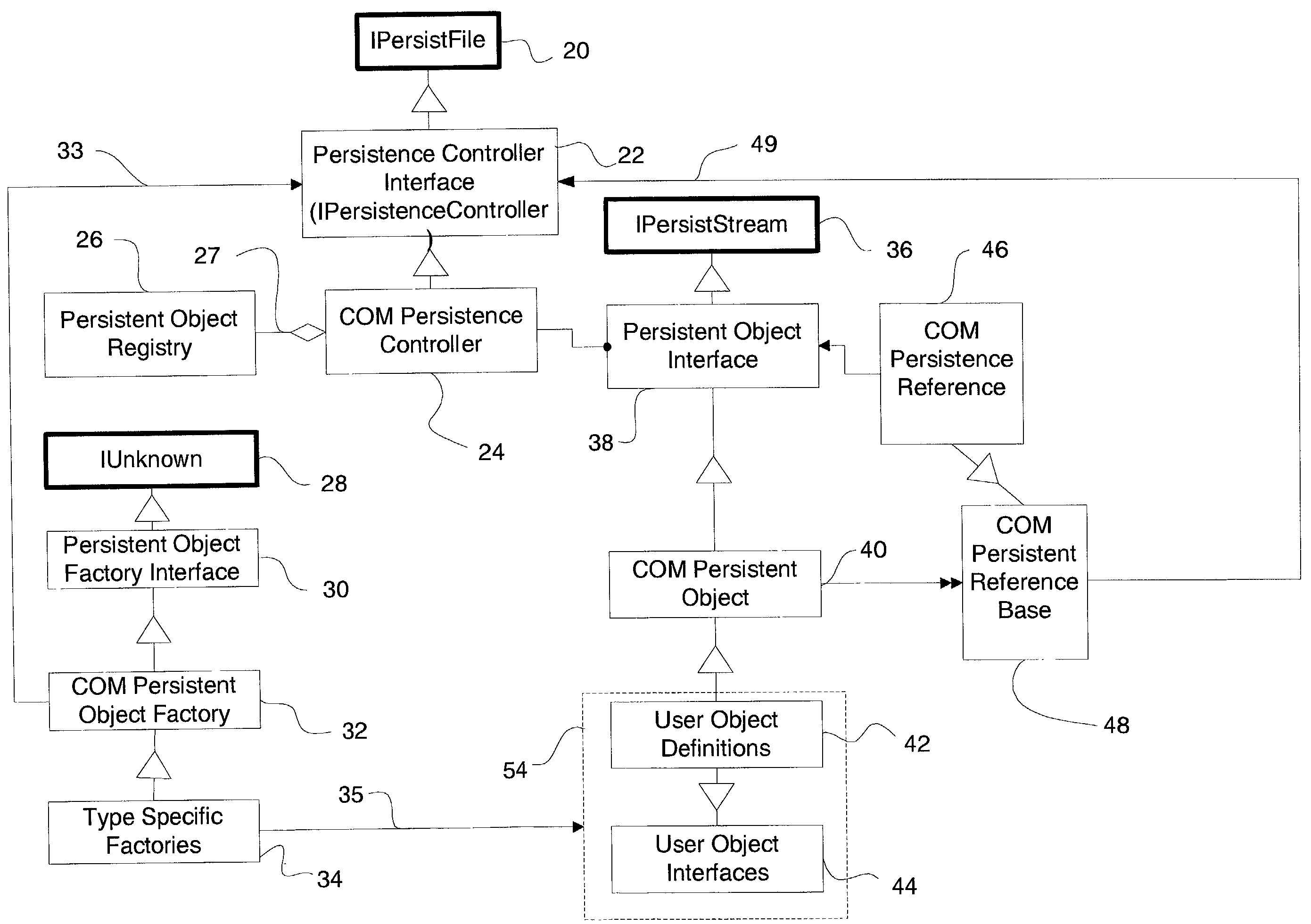

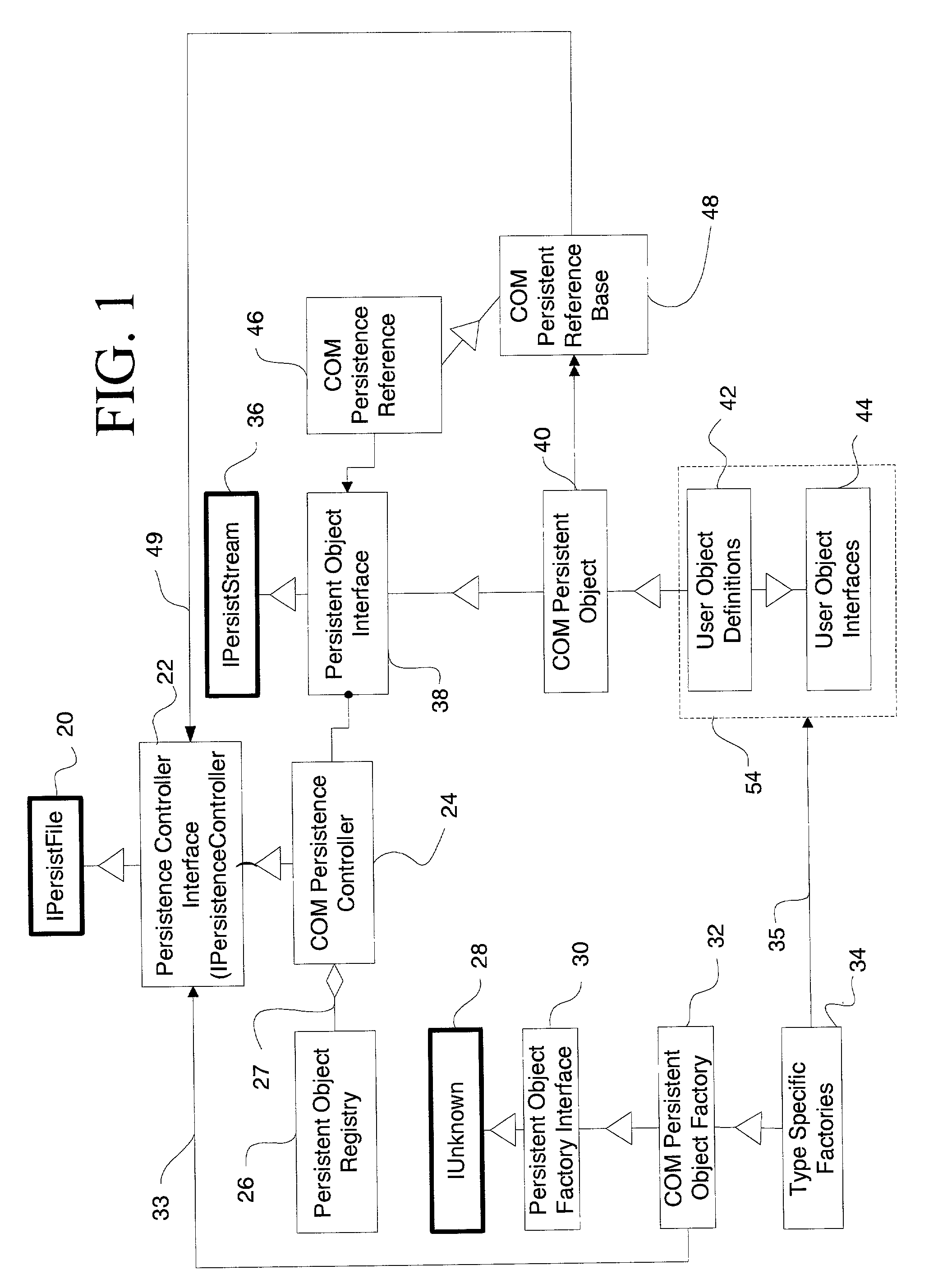

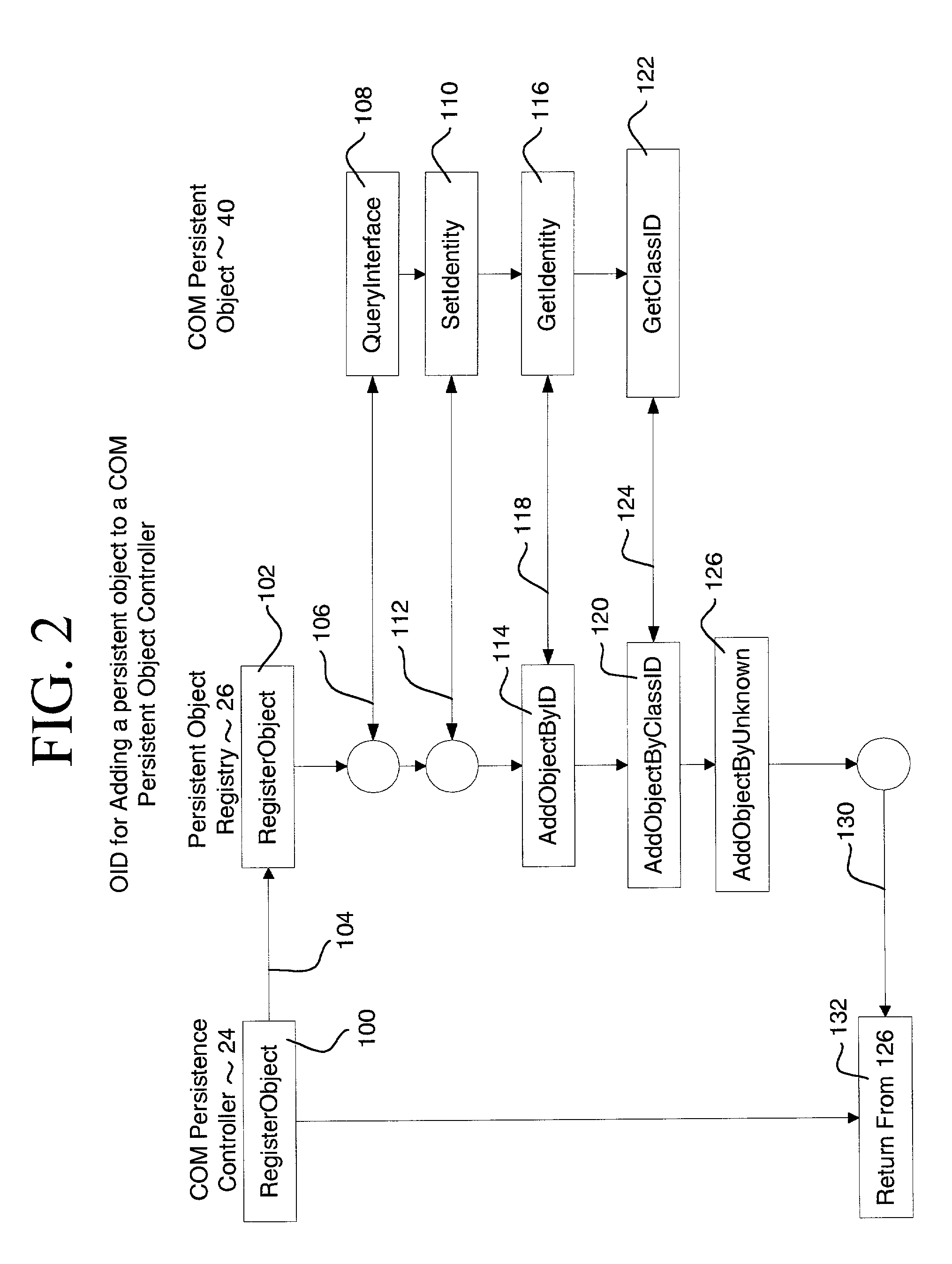

COM persistence model

InactiveUS7069540B1Specific program execution arrangementsMemory systemsComponent Object ModelLoad cycle

Software and methods for extending preexisting objects to support persistence. One use of the present invention is to extend component object model (COM) objects to support persistence in a simple, predefined system. COM objects may be saved to persistence storage and loaded from persistence storage using user-provided save and load methods. When objects are constructed, the objects are added to a Persistent Object Registry. Objects preferably utilize smart pointers, rather than simple pointers, in order to enable restoration of the pointer values after a save and load cycle. The smart pointers include an object ID along with the address. The object ID, together with the information stored in the Persistent Object Registry, may be used to restore a pointer value after loading. Objects may be saved by streaming the objects out and loaded by streaming the objects back into memory from a file.

Owner:UNISYS CORP

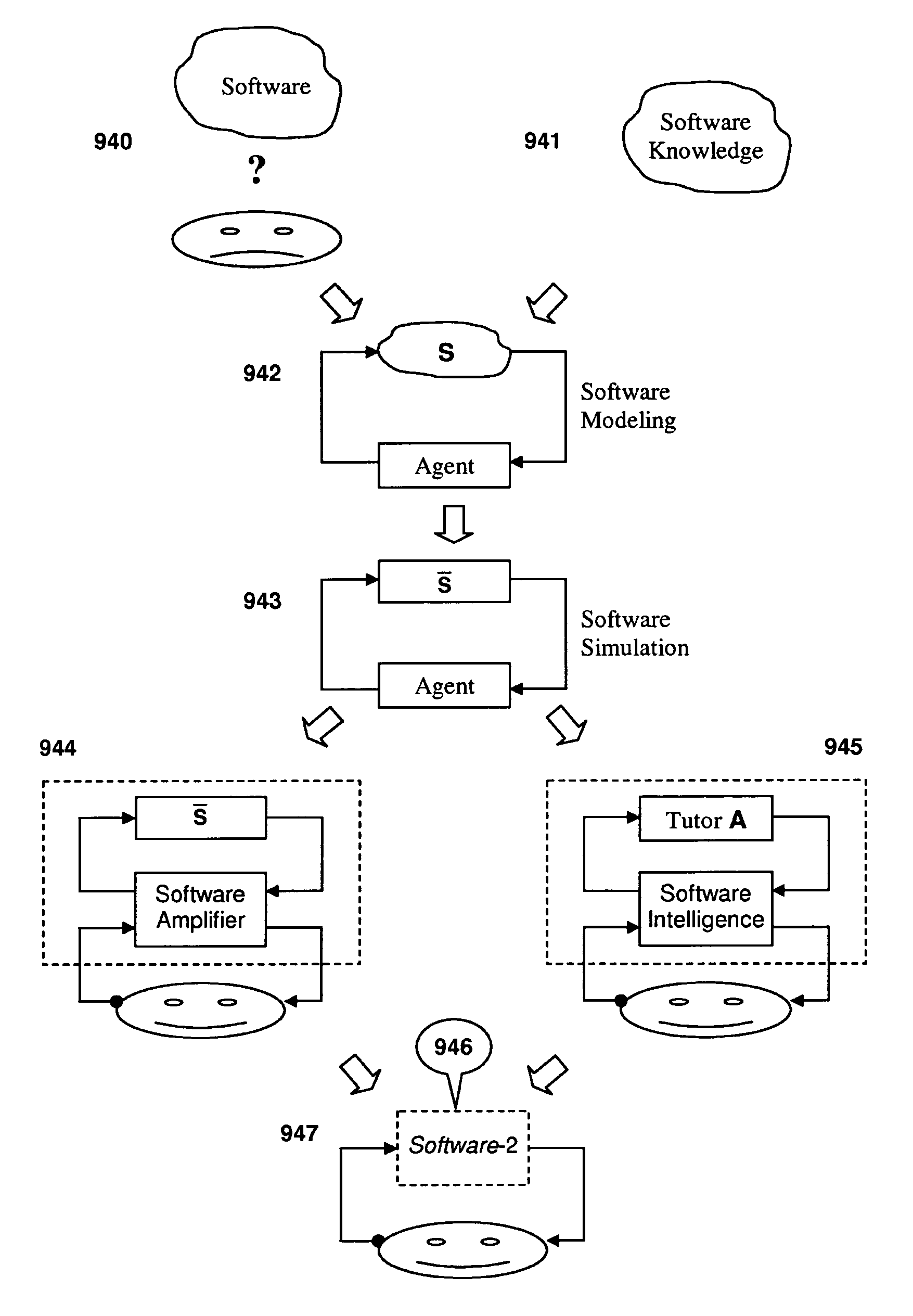

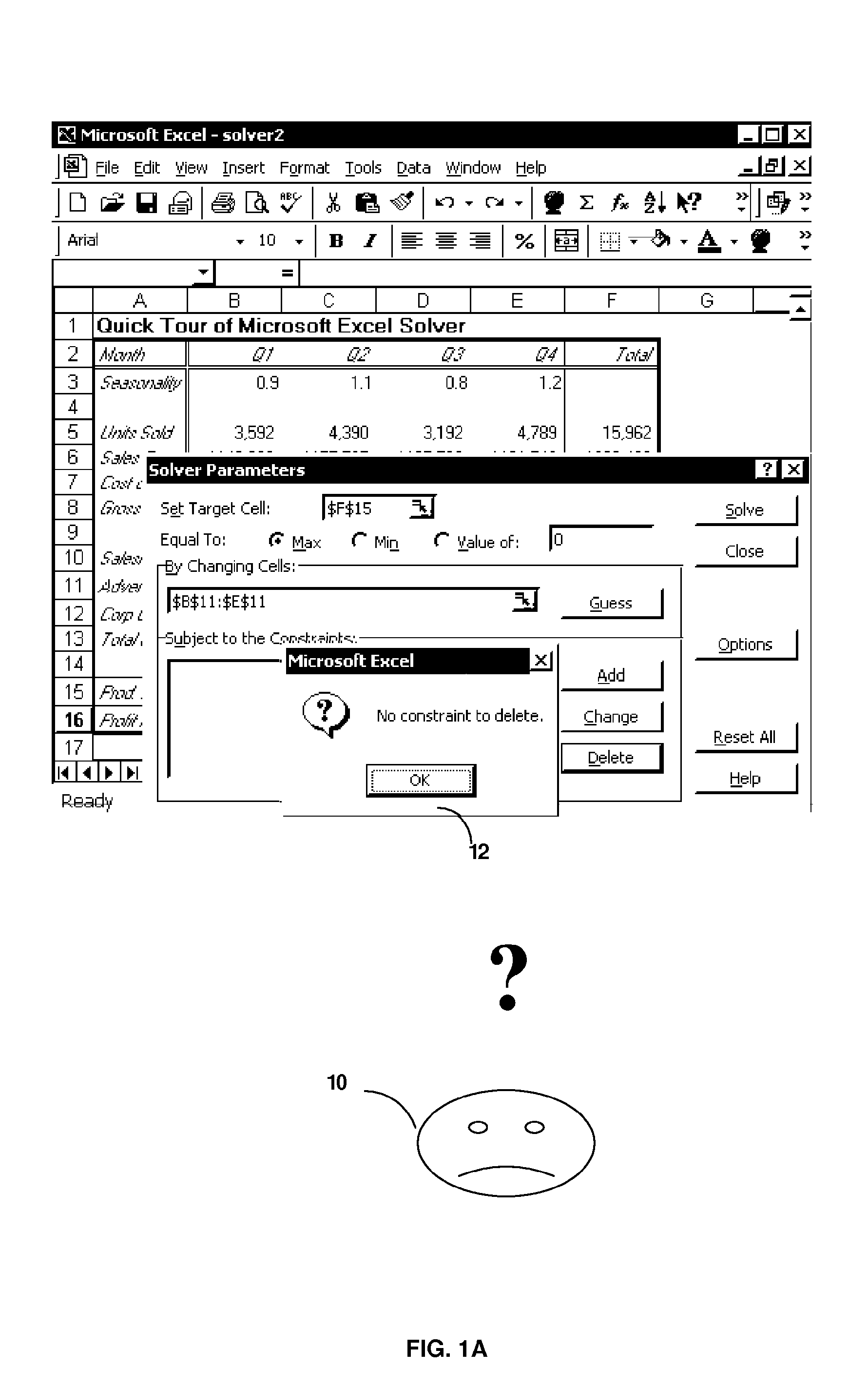

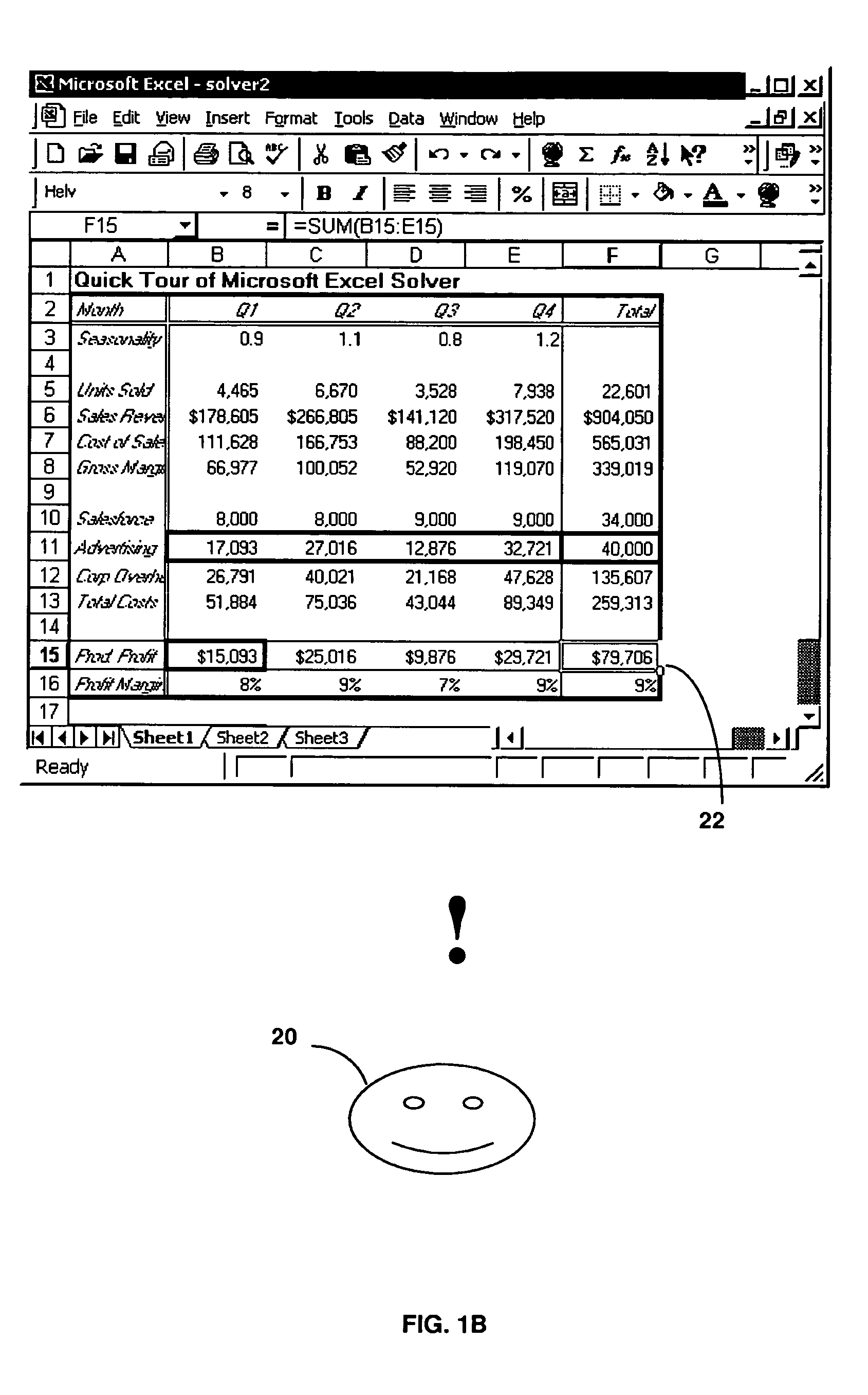

Mechanization of modeling, simulation, amplification, and intelligence of software

InactiveUS7490031B1High simulationImprove experienceSoftware engineeringSoftware simulation/interpretation/emulationAudio power amplifierModeling software

The invention models software as a physical device with causality. It develops interaction between software and user in a software dynamic system that connects software or modeled software with a software controller. The software is modeled with its input / output behavior on a discrete sampling domain and is controlled by the controller in a modeling software dynamic system while its behavior is observed real-time to identify its model. The modeled software is controlled by the same controller in a simulation software dynamic system, which can be augmented programmatically. Augmentations integrated with the controller construct a software amplifier coupling the modeled software and user interactively and automatically. The modeled software represents domain knowledge simulated in the augmented system as software intelligence. A software-2 including the modeled software, the software controller, and augmentations is created. Software-2 integrated with real-time communication distributes over Internet with a Master-Machine-Learner loop as a new interactive media.

Owner:QIU GANG

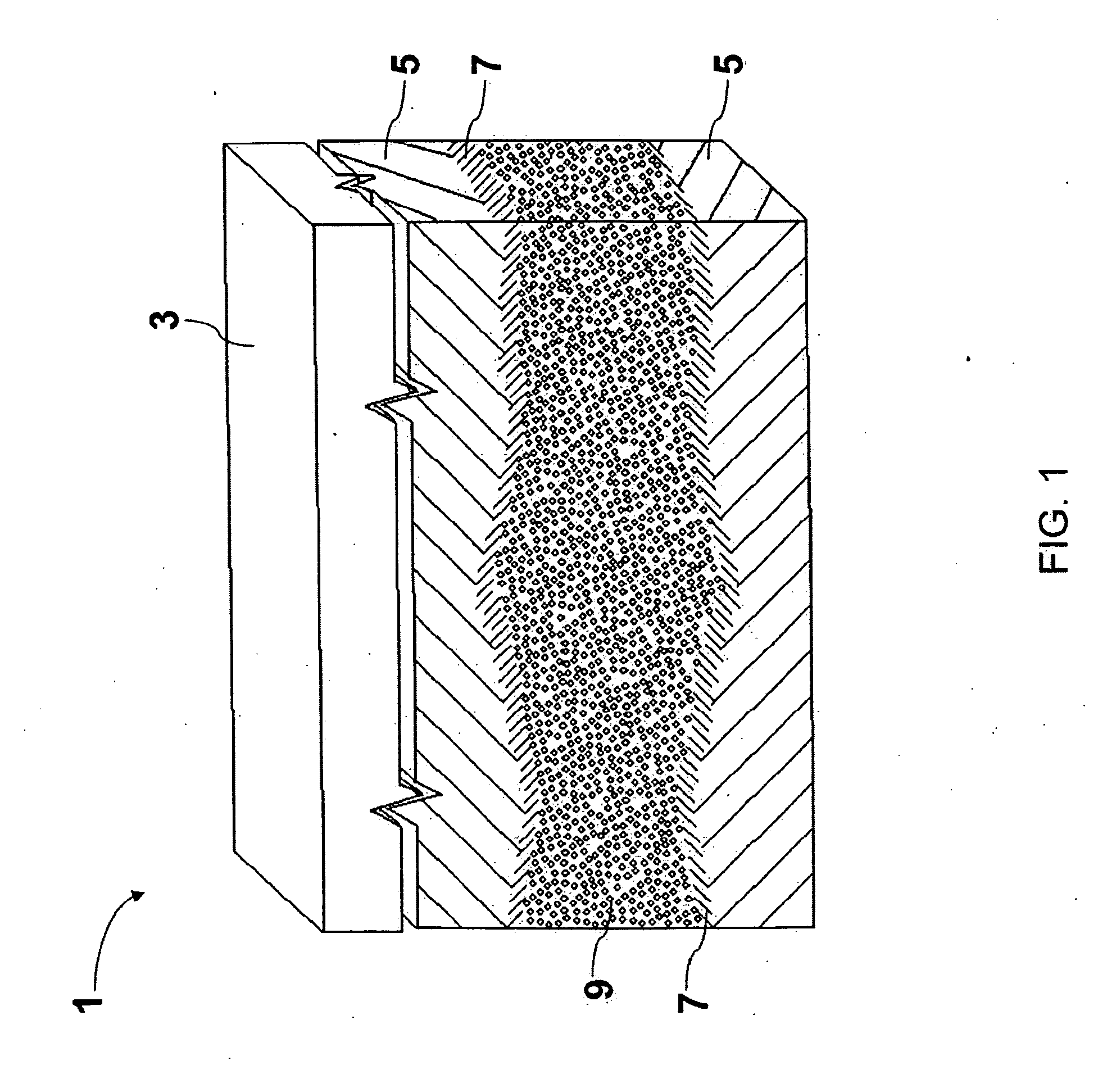

Gradient laminated porous scaffold based on microsphere selective laser sintering and preparation method thereof

ActiveCN102935019APrecise regulationImprove mechanical propertiesBone implantSelective laser sinteringMicrosphere

The invention relates to a gradient laminated porous scaffold based on microsphere selective laser sintering and a preparation method thereof. The scaffold is prepared by taking polymer microspheres and compound microspheres of high polymers and calcium-phosphate materials as sintering raw materials and carrying out selective laser sintering on the sintering raw materials, the contents of the calcium-phosphate materials in the scaffold are ascended in a layer by layer manner from the surface layer to the bottom layer of the scaffold, and bore diameters and porosities of the scaffold are gradually ascended. The preparation method comprises the following steps of: preparing calcium-phosphate materials / high polymer composite microspheres by a solvent evaporation method; designing a three-dimensional model of the gradient-laminated porous scaffold by computer modeling software; and realizing precise manufacturing of the gradient laminated porous scaffold by virtue of a selective laser sintering device through feeding controlling and single-layer manufacturing. The mutual communication and the gradient distribution of the scaffold are beneficial for nutrient transport and tissue penetration; and the contents of calcium-phosphate materials are in continuous gradient distribution in space, the disadvantage of interface bonding strength is effectively solved, and the biological functions of the scaffold in comprehensive defect repairing of cartilages and subchondral bones are beneficially exerted.

Owner:ASIA BIOMATERIALS WUHAN CO LTD

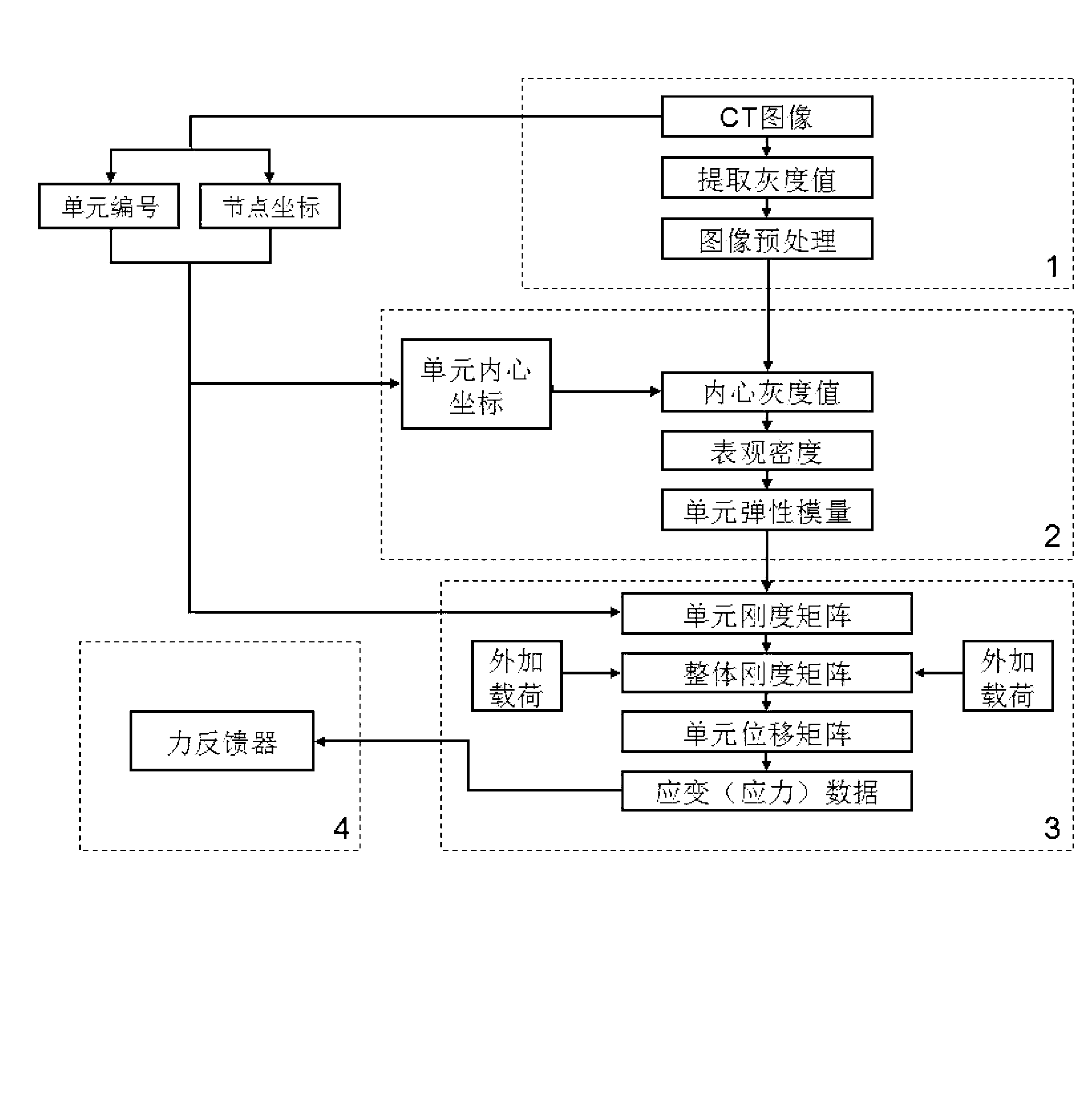

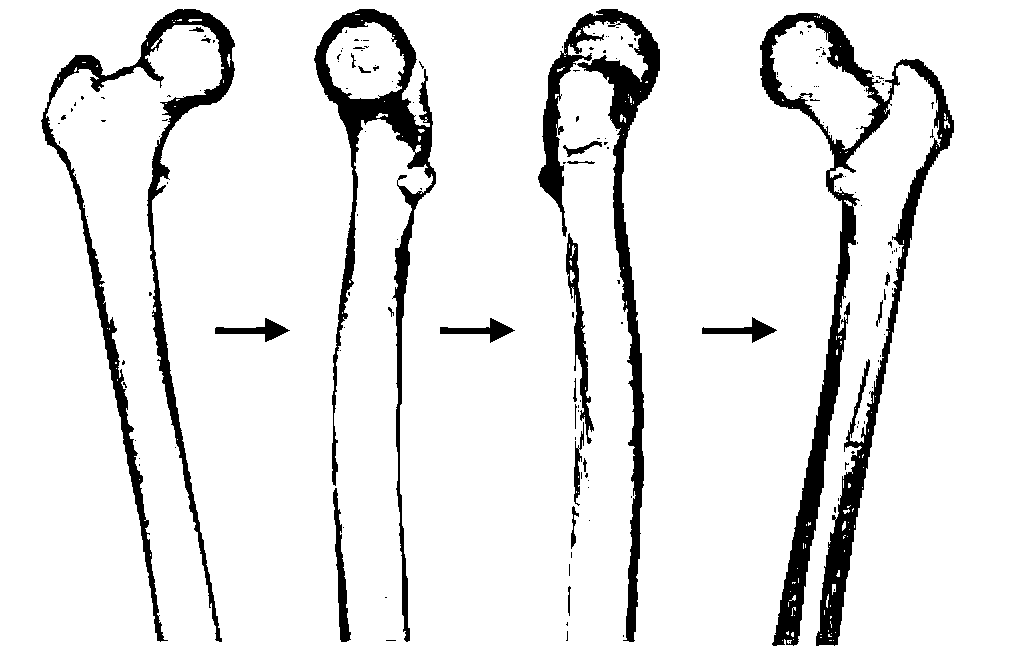

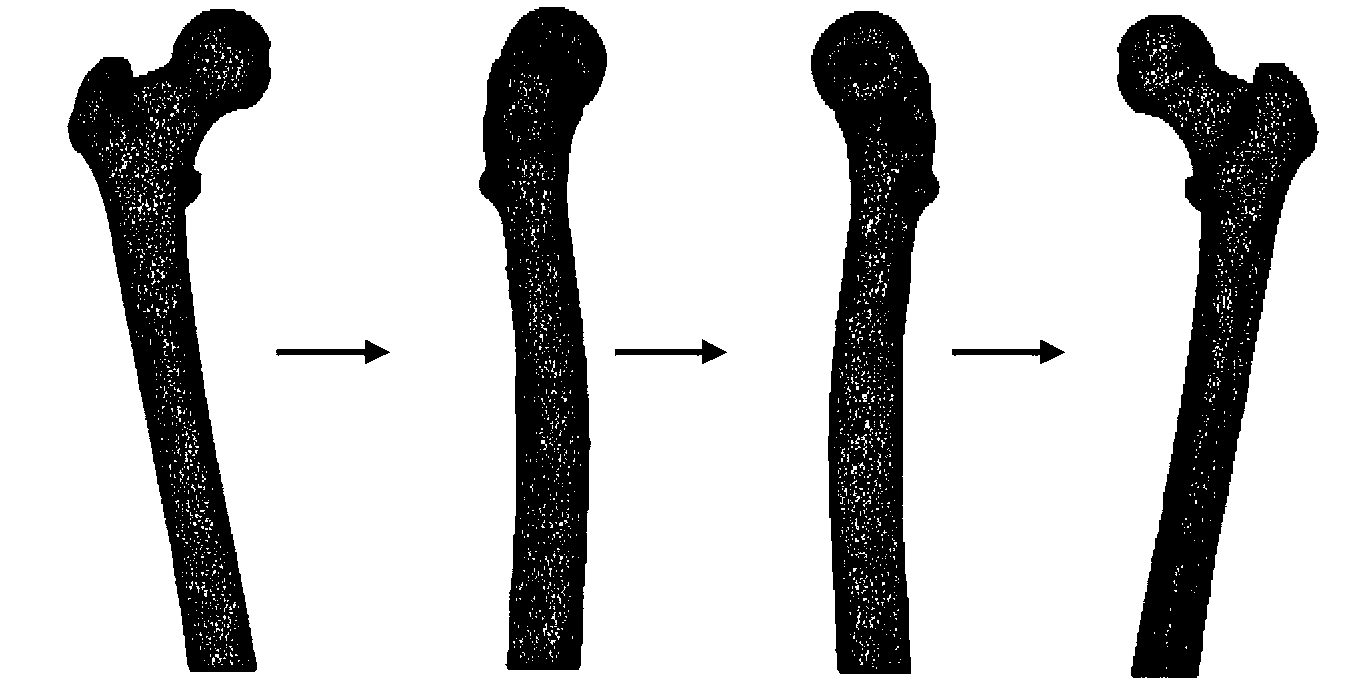

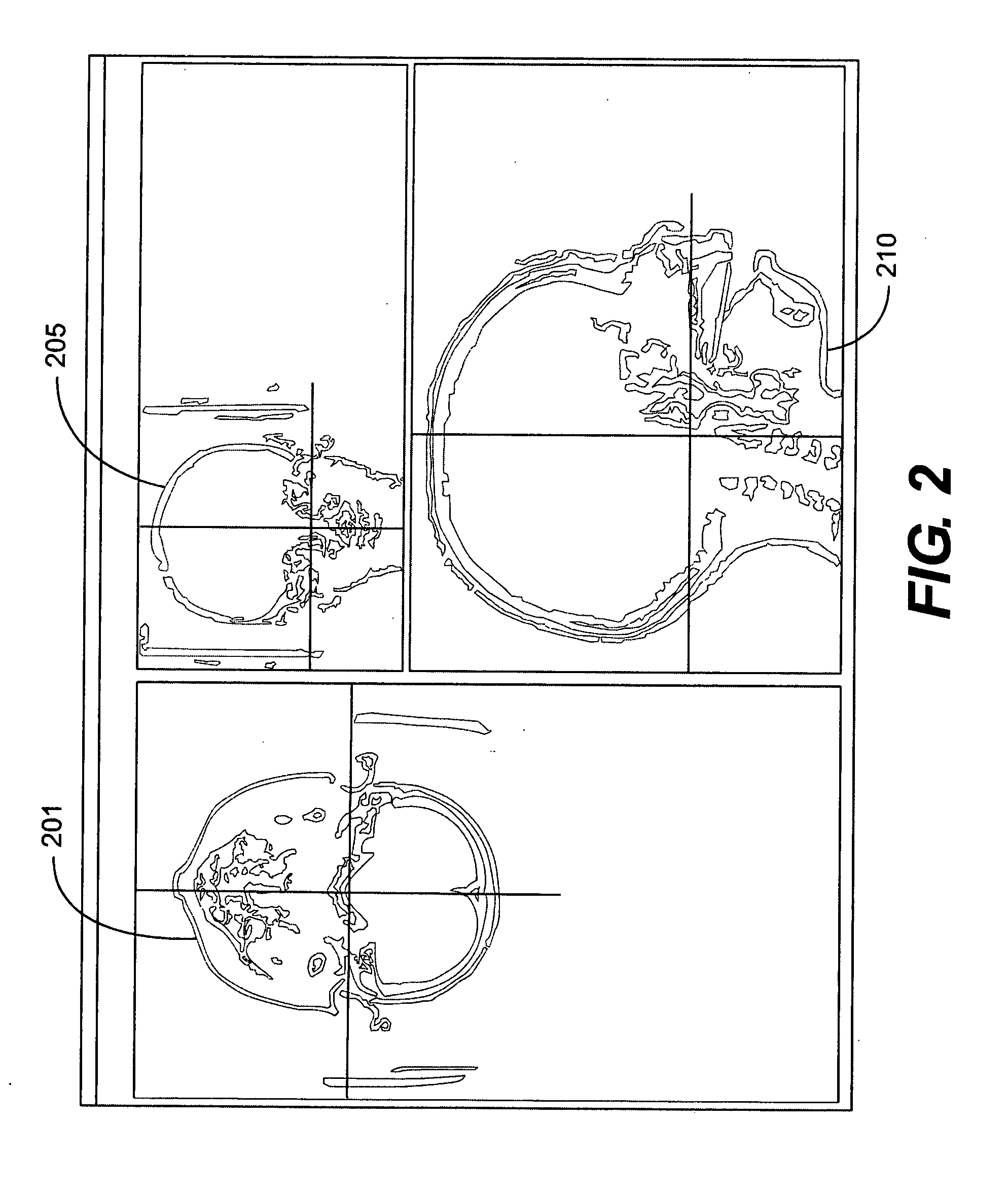

Thighbone biomechanics finite element analysis system based on force feedback

InactiveCN103310072AIncrease success rateLow number of solutionsSpecial data processing applicationsData simulationElement analysis

The invention relates to the field of thighbone modeling software development, discloses a thighbone biomechanics finite element analysis system based on force feedback, and aims to solve the problems that the conventional thighbone modeling analysis software is very complicated to operate, and has lower success rate to guide an external operation. A thighbone CT image gray value extraction module is used for leading various-format CT images; a thighbone elasticity modulus assignment module is used for acquiring inner coordinates of corpus femoris grid cells; a thighbone biomechanics finite element analysis module is used for calculating the stiffness matrix of each corpus femoris grid cell through the elasticity modulus of each corpus femoris grid cell; a force feedback module is used for simulating the mechanical properties, including size and direction, of test points according to the strain data and stress data and also for transmitting the size and direction of a force to a control handle of an external force sensing device; a force feedback device after data conversion can output the force generated when the thighbone actually deforms, and truly percept the biomechanical characteristic of a thighbone model.

Owner:HARBIN UNIV OF SCI & TECH

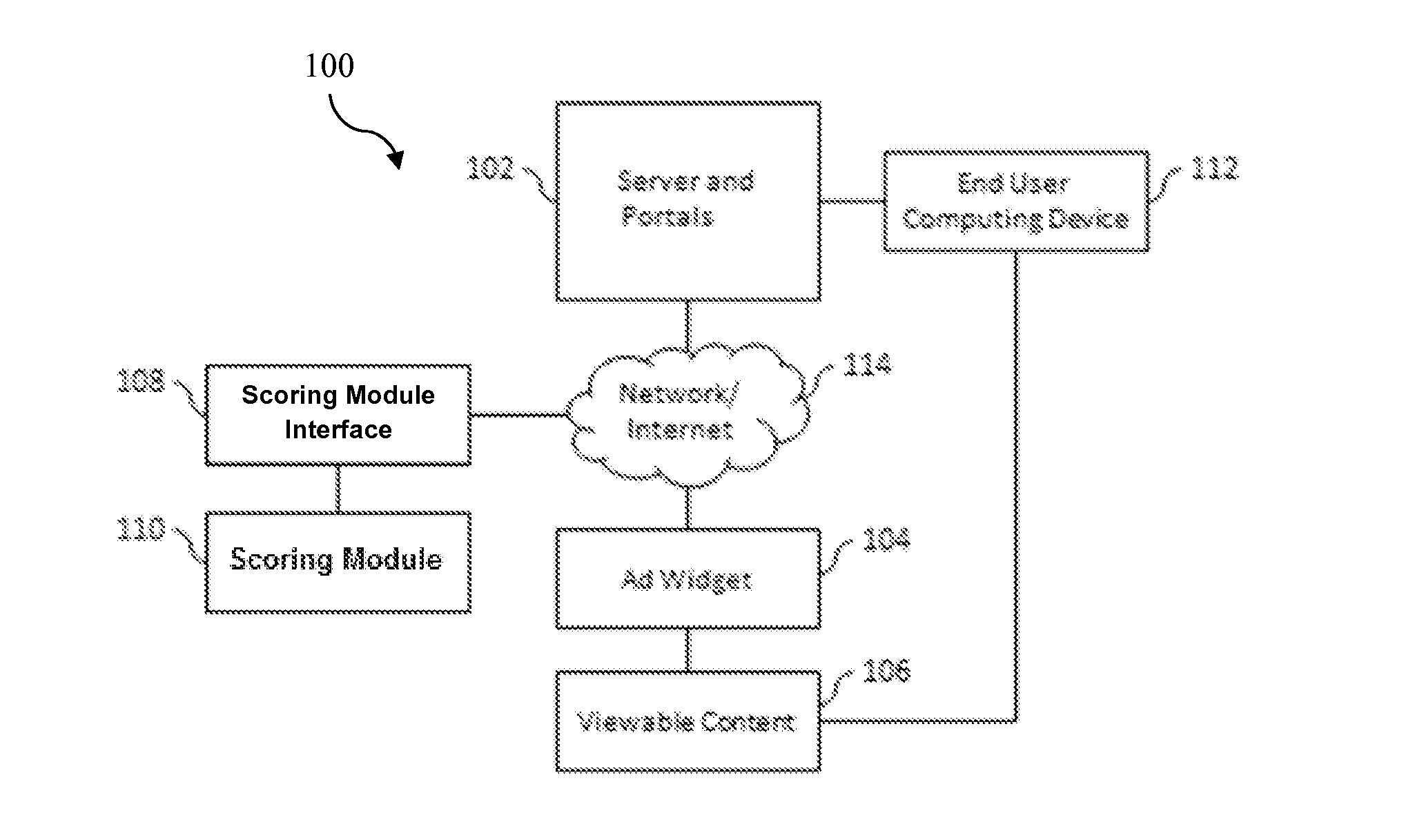

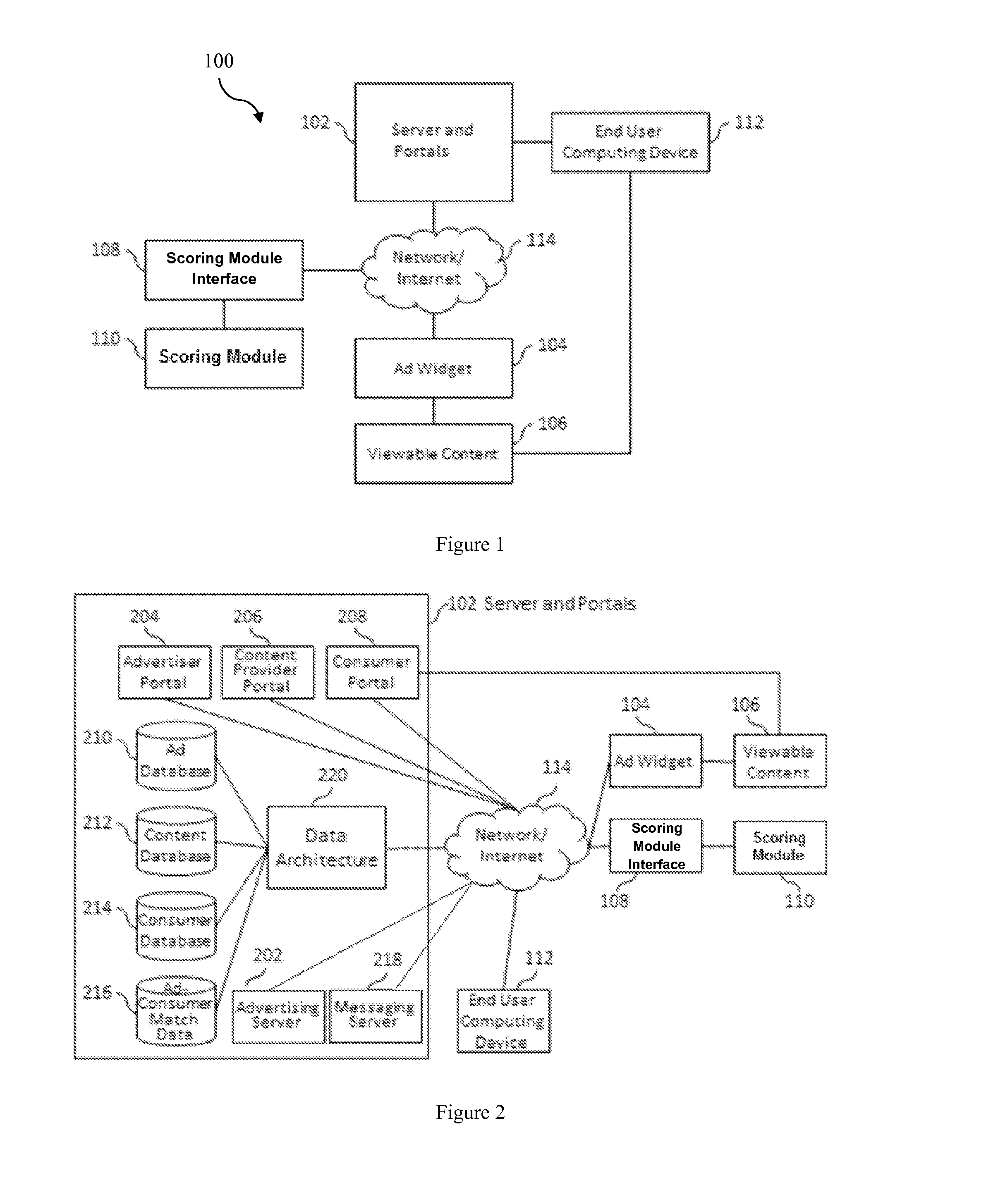

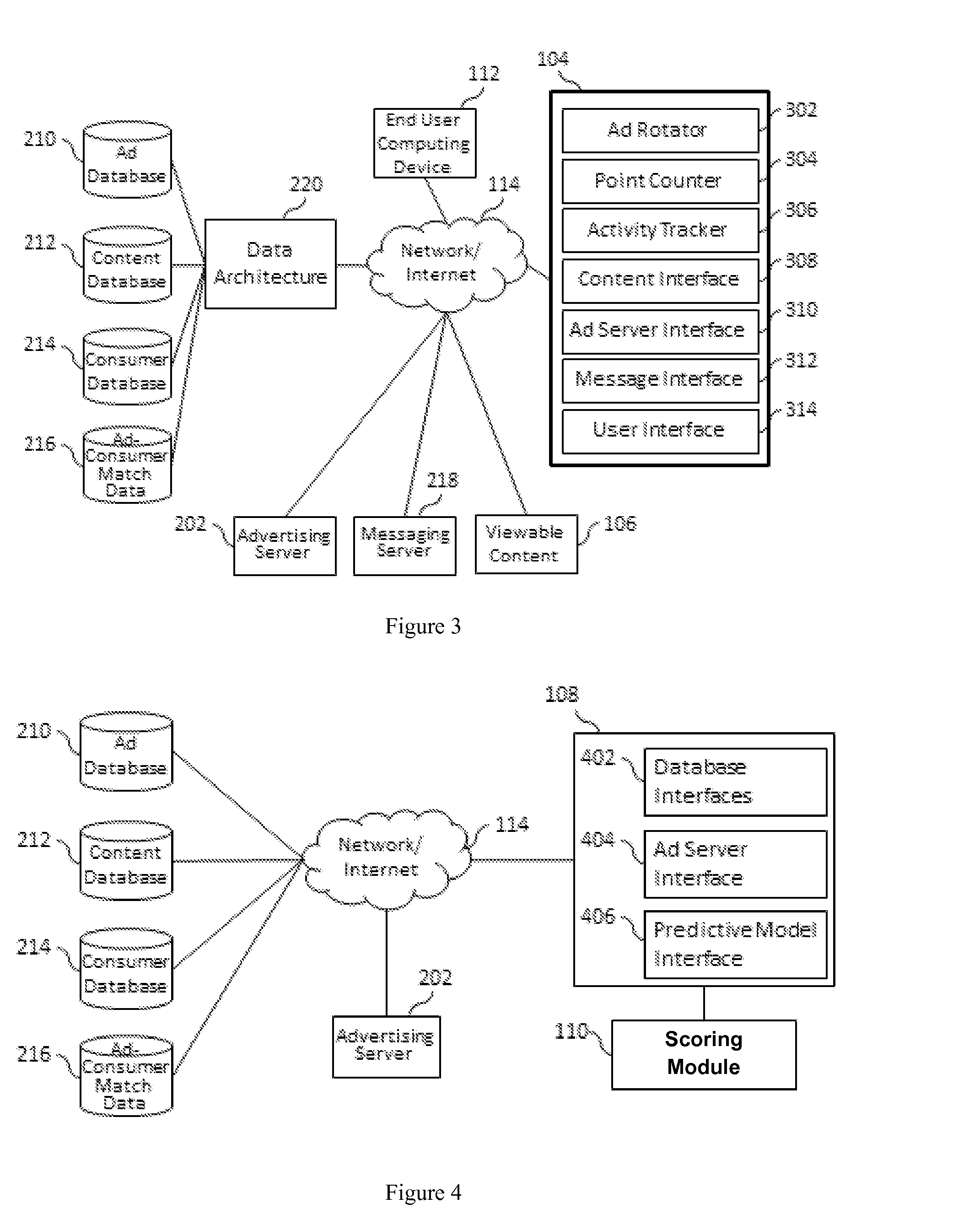

Methods and apparatus for a predictive advertising engine

Methods and apparatus for a predictive advertising engine may determine a user's likelihood to purchase an advertised item. Methods and apparatus for a predictive advertising engine may retrieve data associated with an advertisement, a content, and a user. The retrieved data may be enhanced, segmented, and sent to predictive modeling software. The predictive modeling software may calculate a score indicating the user's likelihood to purchase the advertised item. The scores may be stored in a first database. The first database may be referenced by the predictive advertising engine to determine which advertisement to deliver to the user. The predictive advertising engine may present a commercial to the user upon user selection of the advertisement, may present a questionnaire to the user upon the user viewing the commercial or selecting the advertisement, and may record the user's answers and interactions to further refine the predictive model.

Owner:NEVALLCO

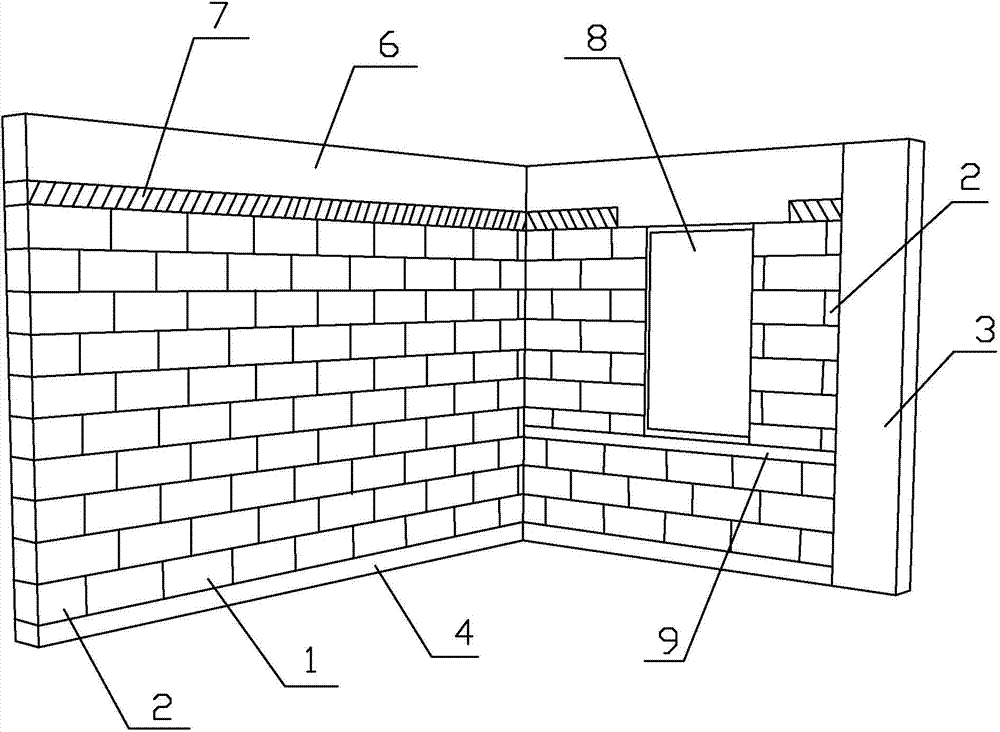

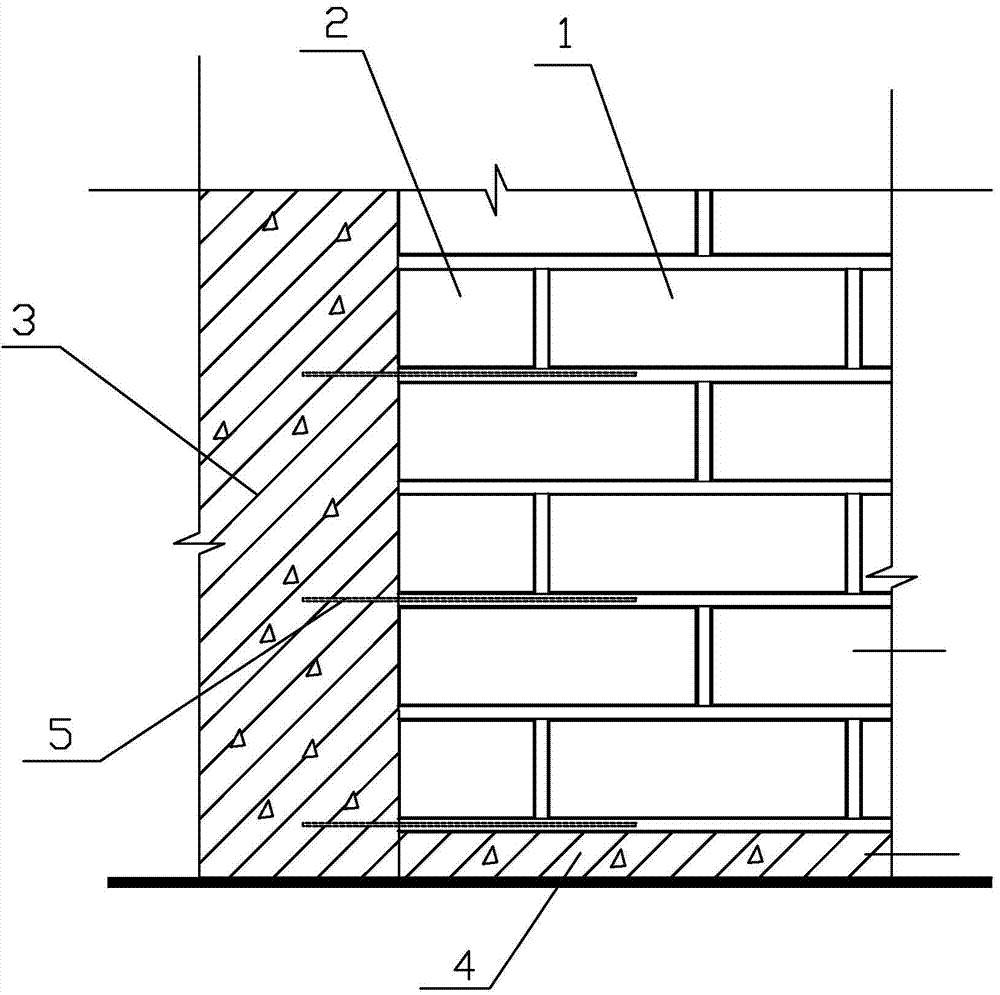

Autoclaved sand aerated concrete block wall construction method based on BIM technique

ActiveCN104712076AReduce lossImprove masonry efficiencyWallsBuilding material handlingData informationWindow opening

The invention relates to an autoclaved sand aerated concrete block wall construction method based on the BIM technique. The method comprises the steps of acquiring data information required by wall construction according to a two-dimensional wall CAD building structural working drawing; conducting three-dimensional modeling on a wall by means of BIM molding software, inputting the data information into the three-dimensional model of the wall, and making autoclaved sand aerated concrete blocks serve as building blocks in the three-dimensional model of the wall; arranging the building blocks in the three-dimensional model of the wall, and conducting coding on the building blocks in different specifications; acquiring data information including the specifications and number of the building blocks, mortar joint thickness and door and window openings required by wall construction from the three-dimensional model of the wall; extracting and making a plan for various materials and a machining material list; purchasing the building blocks and having the building blocks in place; conducting building block processing; conducting wall construction. According to the method, wall building block arrangement is conducted by means of the BIM technique, building block arrangement precision and speed are high, building block consumption is reduced, and wall construction efficiency is improved.

Owner:崔新明

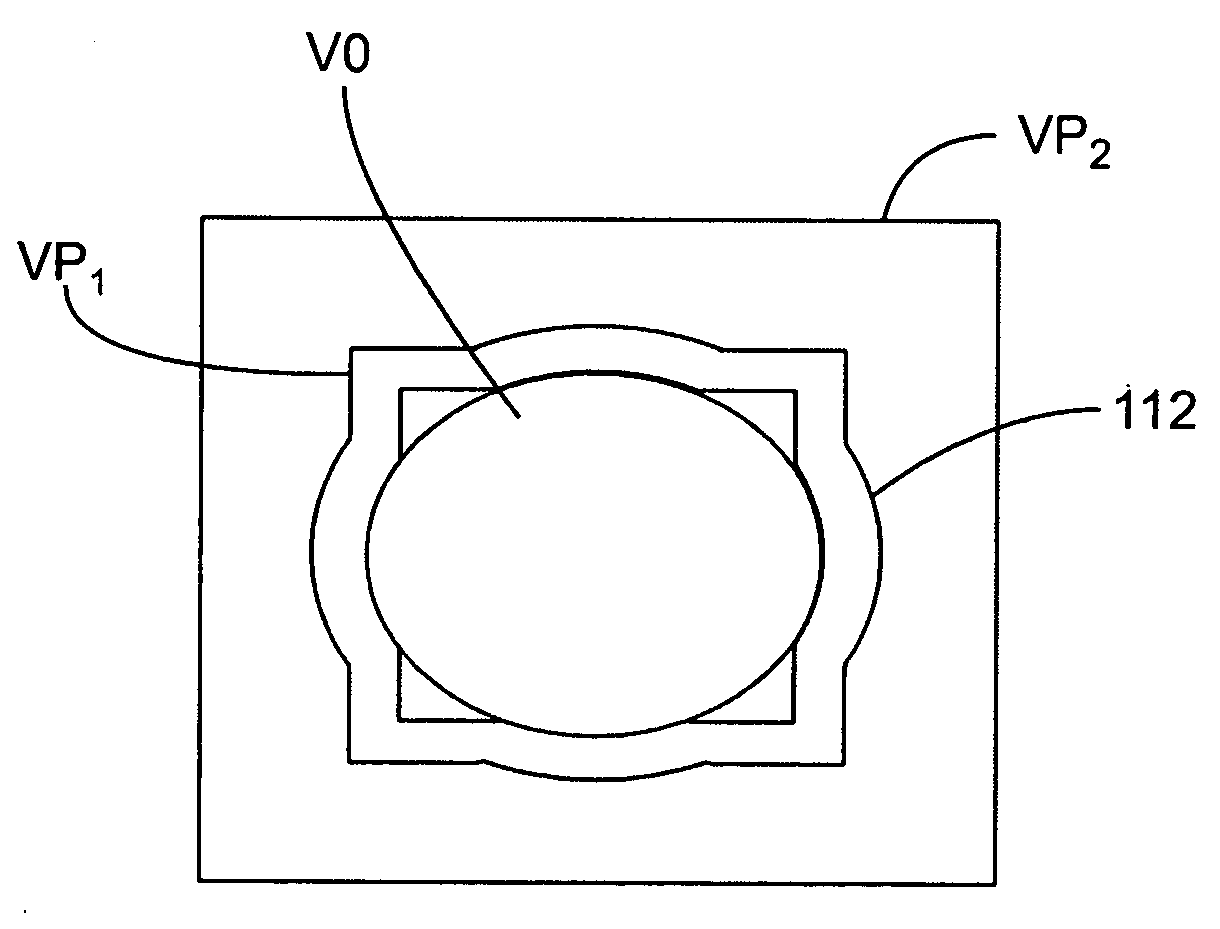

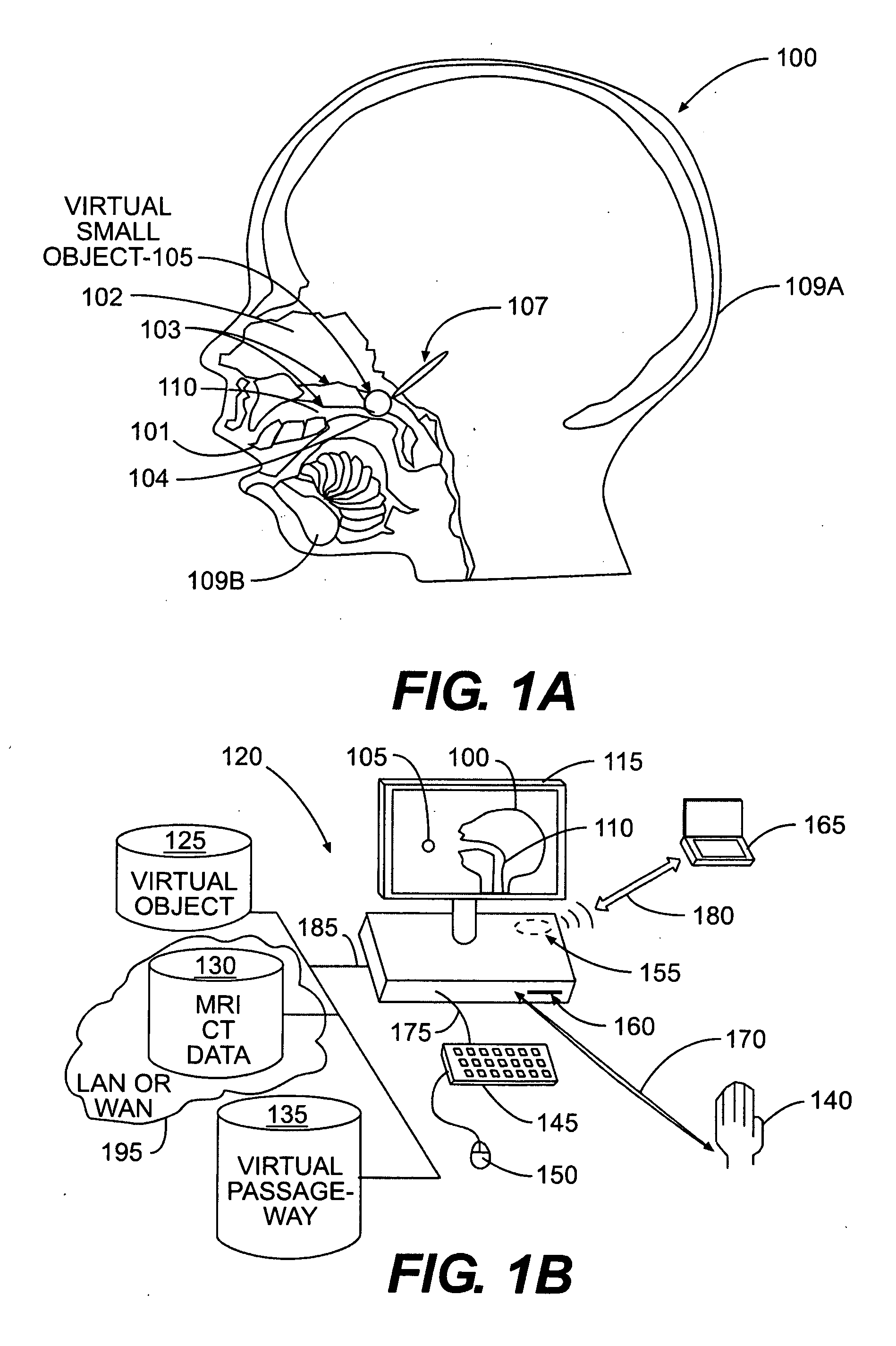

Haptic response system and method of use

InactiveUS20050093847A1Accurate and realistic tactile force feedbackAccurate and realistic force feedbackInput/output for user-computer interactionCathode-ray tube indicatorsModeling softwareDisplay device

An apparatus and method for assessing a hazard associated with an object are disclosed. The apparatus includes a haptic input / output device coupled to a computer with haptic modeling software and a display device. A virtual object and a virtual passageway are displayed on the display device. The virtual passageway includes a haptic layer along a surface thereof. Force applied by a user to the haptic input / output device causes a cursor on the display device to move the virtual object into the virtual passageway. An interaction of the virtual object with the haptic layer generates a virtual contact force which may be determined by the user sensing a corresponding tactile feedback force generated by the haptic input / output device and / or by the computer processor. The magnitude of the virtual contact force may be used to assess a hazard associated with the virtual object.

Owner:RAM CONSULTING

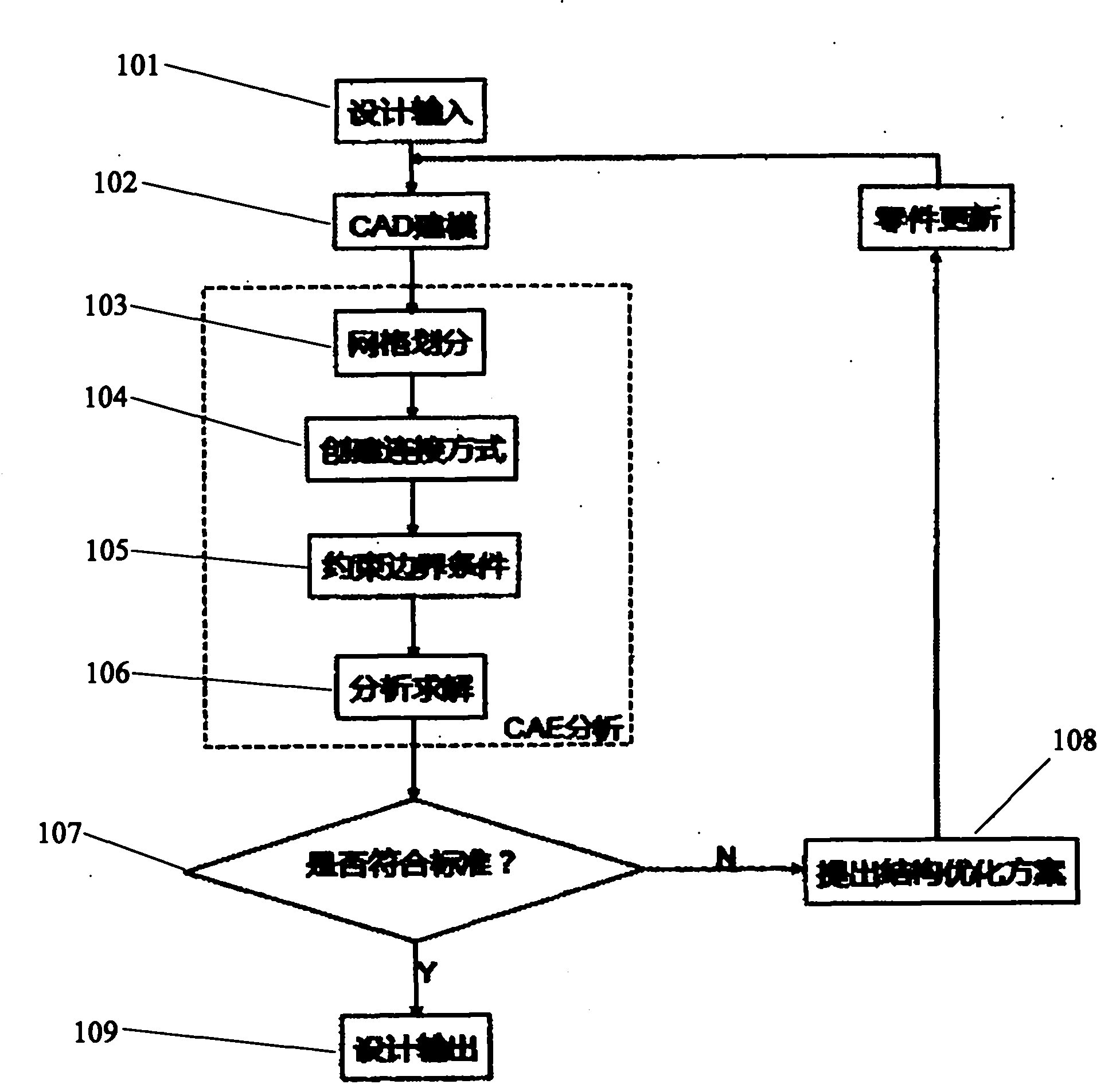

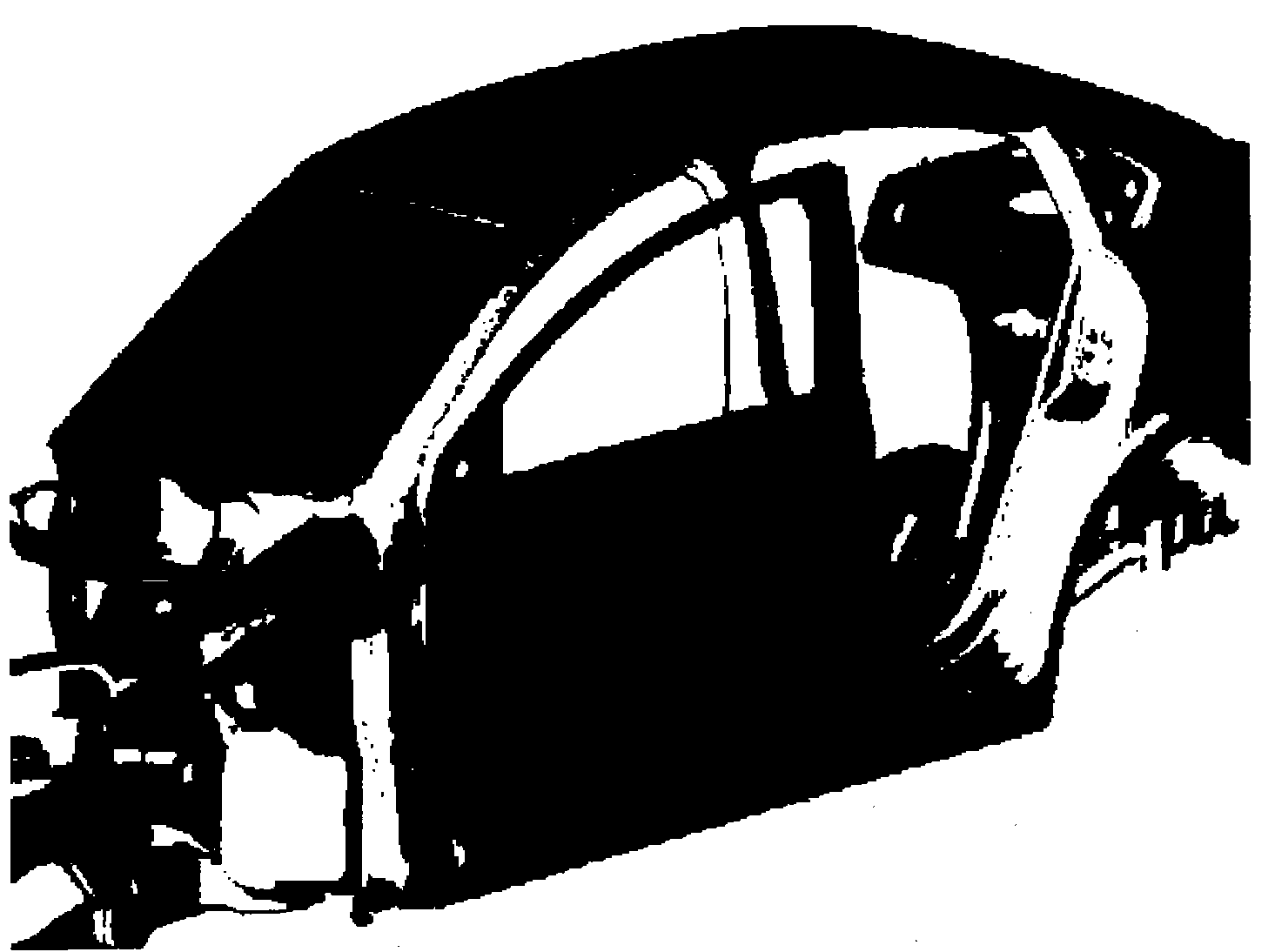

Optimization design method for sagging problem of car door based on CAE (Computer Aided Engineering) structural analysis

InactiveCN101916322AShort cycleShorten the timeSpecial data processing applicationsComputer Aided DesignElement model

The invention discloses an optimization design method for the sagging problem of a car door based on CAE structural analysis, which comprises the steps of: obtaining a design input condition from total arrangement and configuration of a car body; creating a CAD (Computer Aided Design) model by modeling software; dividing grids of the CAD model; simulating actual conditions to create a connection relationship; simulating a boundary constraint condition during an actual test of a car door assembly; carrying out solution analysis on a finite element model generated finally; comparing a result obtained by finite element simulation operation with an industry standard; if an obtained conclusion is lower than the industry standard, providing a structural optimization design; and if the obtained conclusion is higher than the industry standard, completing final design output. The method not only enhances the inspection accuracy, but also greatly reduces the period of a whole repair part so as to shorten the time of developing the whole car. Structural errors can be corrected in time by CAE analysis in early design, thereby reducing the cost of developing the whole car.

Owner:上海奕代汽车技术有限公司

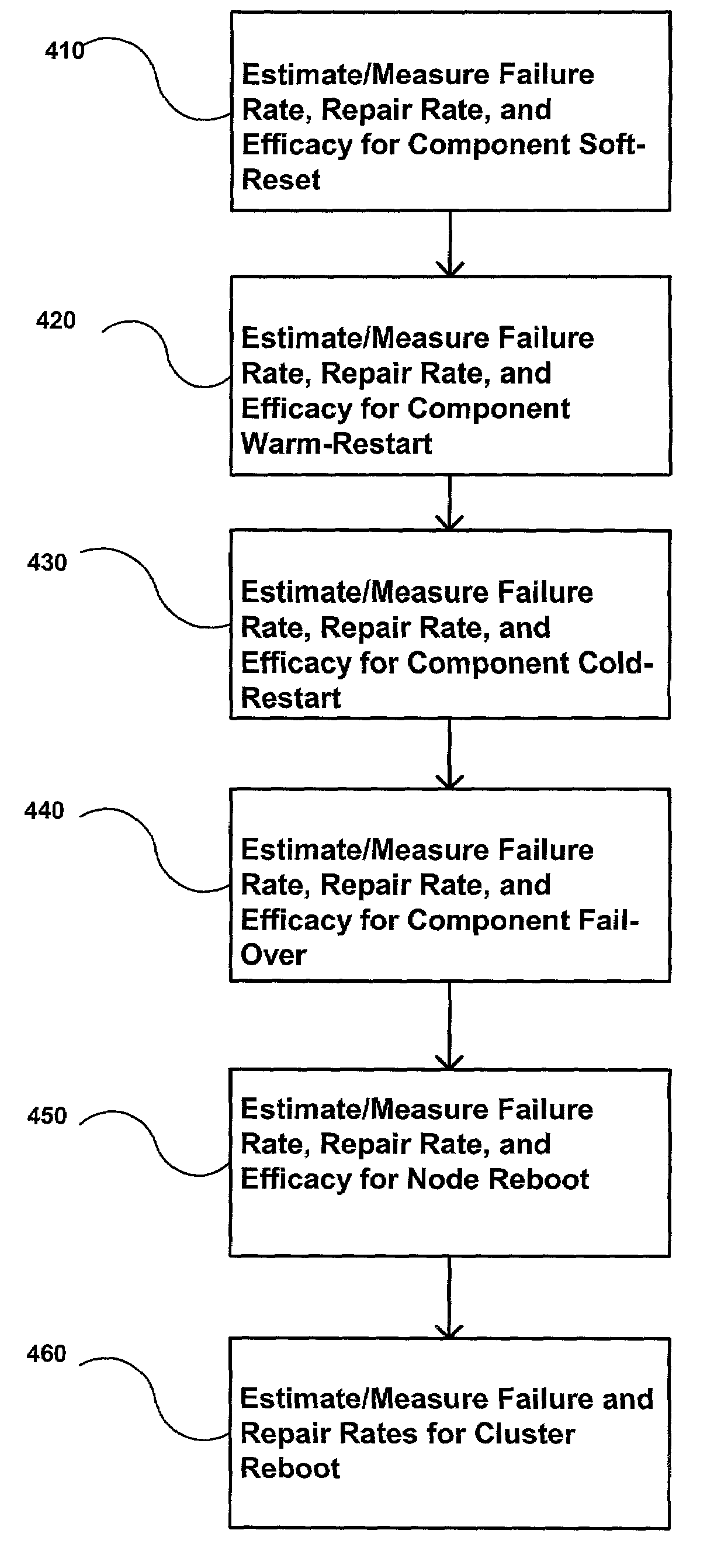

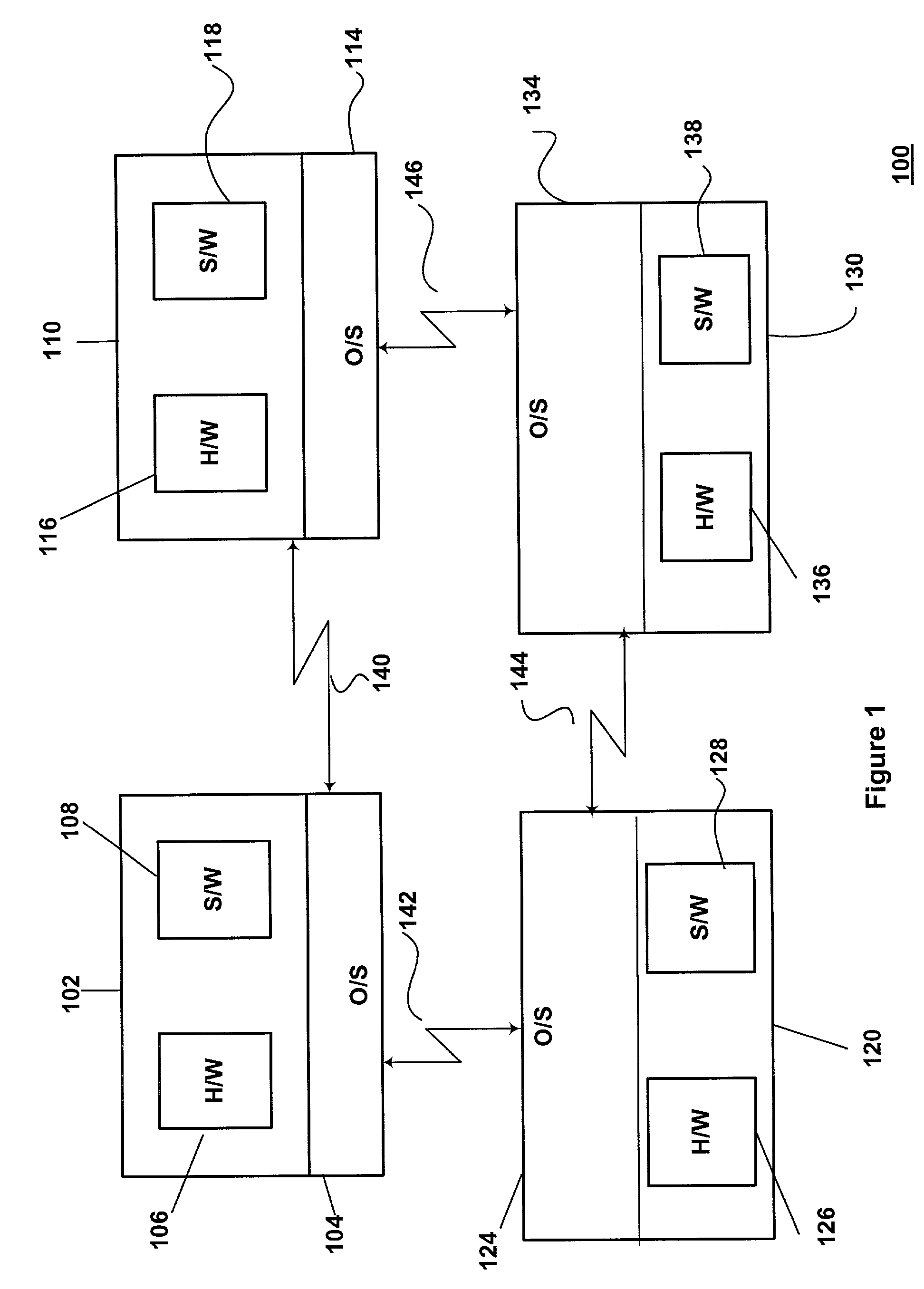

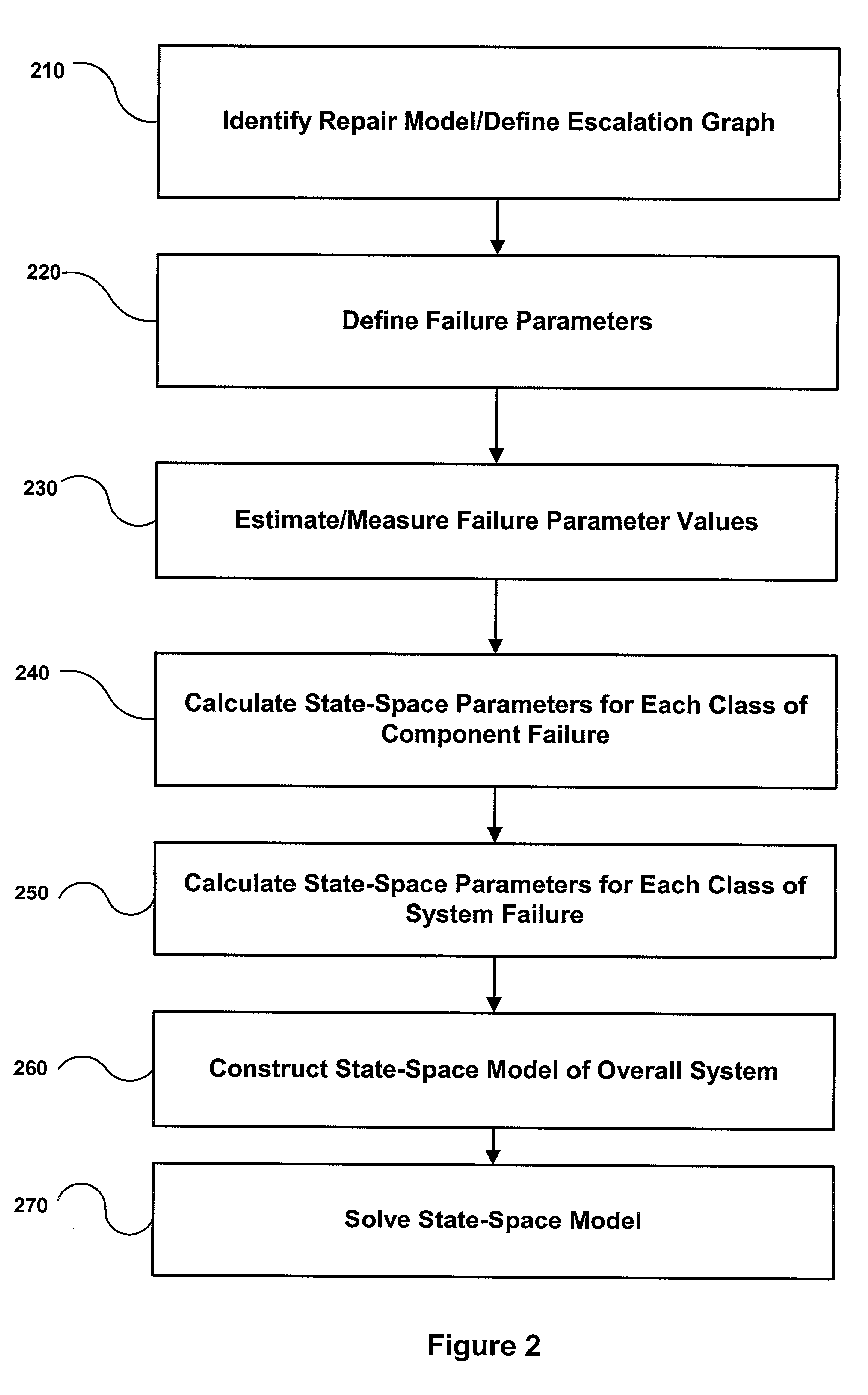

Cluster availability model

ActiveUS7158926B2Reliability/availability analysisComputation using non-denominational number representationModeling softwareReal mode

The present invention describes a method and system for creating a cluster availability model that takes into account availabilities of software components in the cluster. Aspects of the disclosure include defining a repair model and failure parameters for a repair mode in the repair model, and modeling availabilities of software components based on the repair mode and failure parameters. Additional aspects include combining availability models of software components in a computationally feasible manner and determining repair rates of node and cluster reboots. A cluster availability model is determined using the combined availability models of software components and the repair rates of node and cluster reboots.

Owner:ORACLE INT CORP

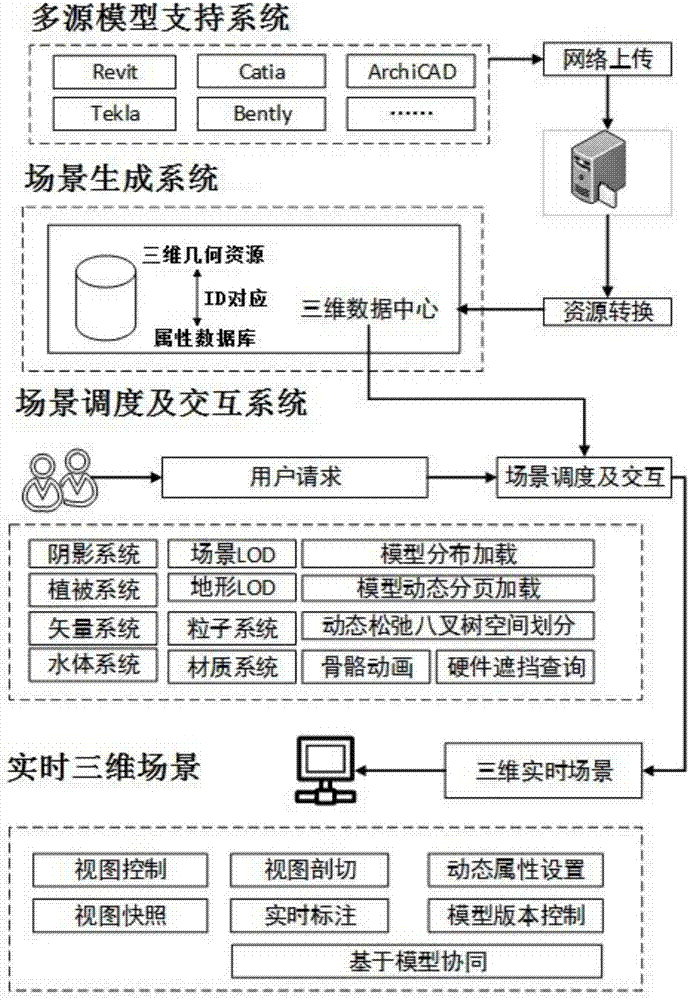

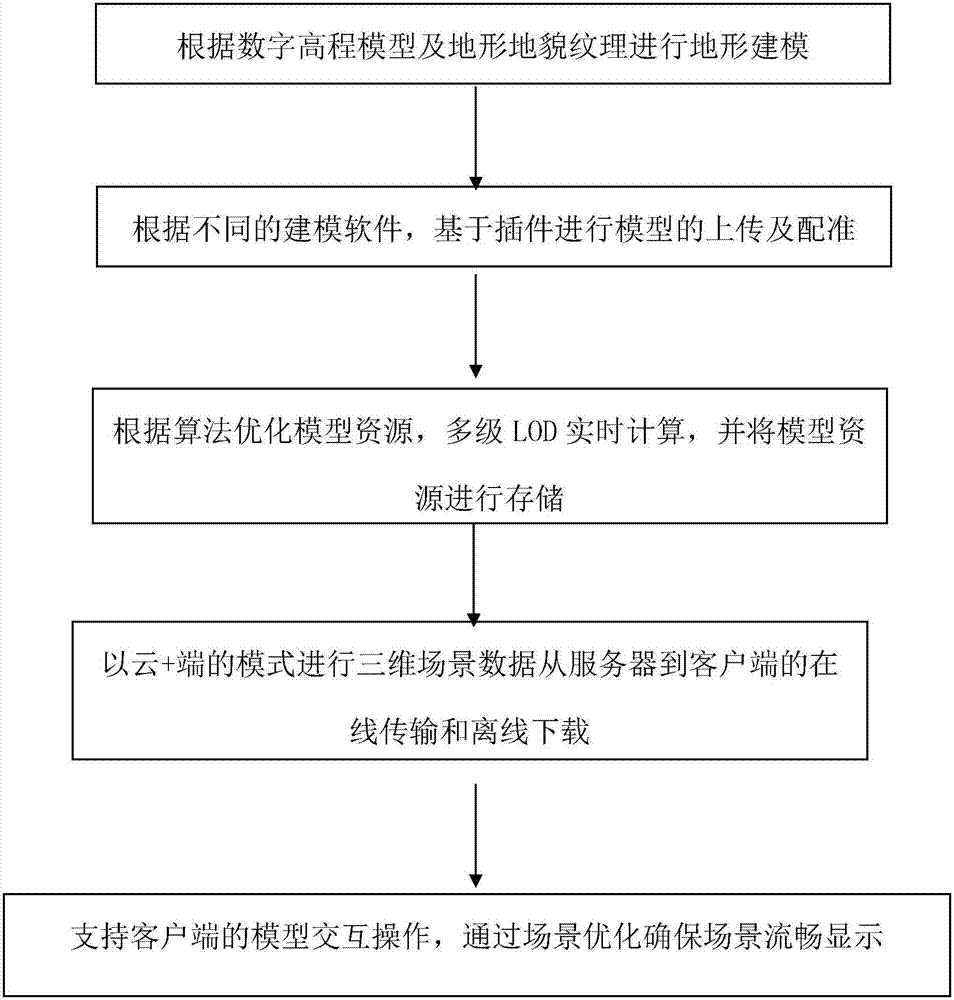

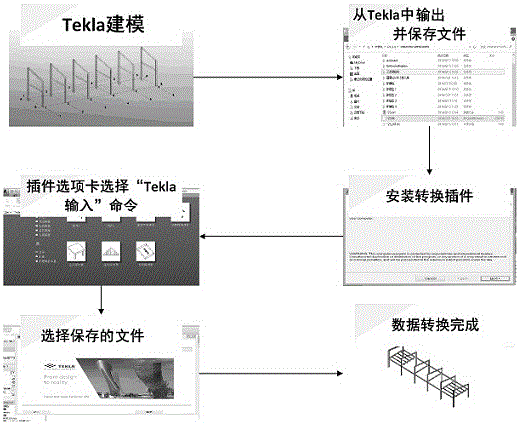

Three-dimensional visualization engine and WEB application calling method based on BIM model

The present invention discloses a three-dimensional visualization engine and a WEB application calling method based on the BIM model. The method comprises: carrying out geomorphic modeling according to the digital elevation model and the terrain topography; according to the different modeling software, carrying out model uploading and registration based on the plug-in; optimizing the model resource according to the algorithm, calculating the multi-level LOD in real time, and storing the model resource; carrying out online transmission and offline download on three-dimensional scene data from a server to a client in a cloud+end mode; and supporting the model interaction on the client, and ensuring the scene to be smoothly displayed through scene optimization. According to the technical scheme of the present invention, a smooth three-dimensional visualization real-time rendering engine can be provided for the model with increasing volume at present, contradiction between the model volume and the client computing performance can be solved, and the technical scheme has significant value, and economic and social benefits to realize building information visualization and information collaborative sharing in the whole life cycle and to realize model efficiency maximization.

Owner:北京比目鱼信息科技有限责任公司

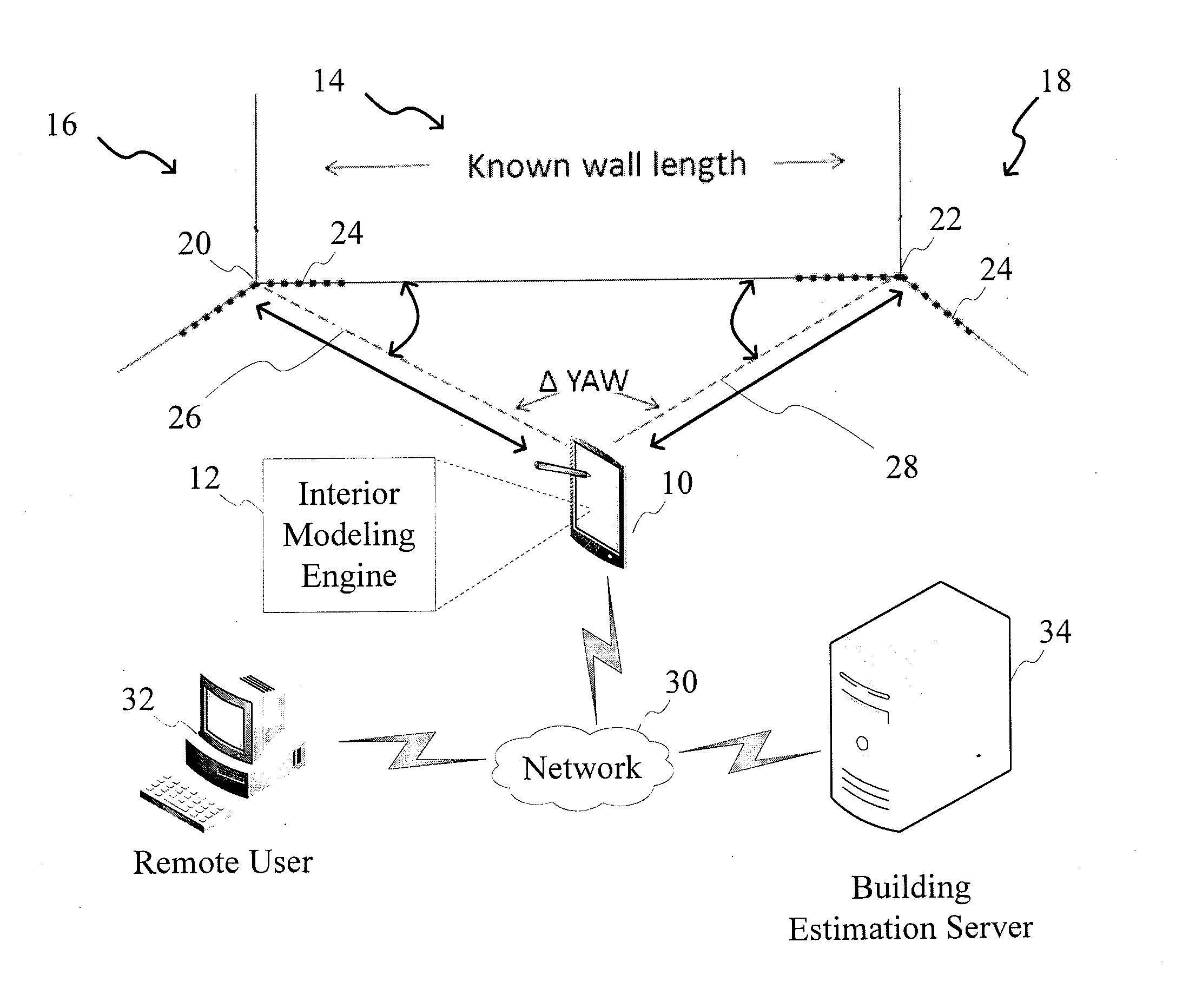

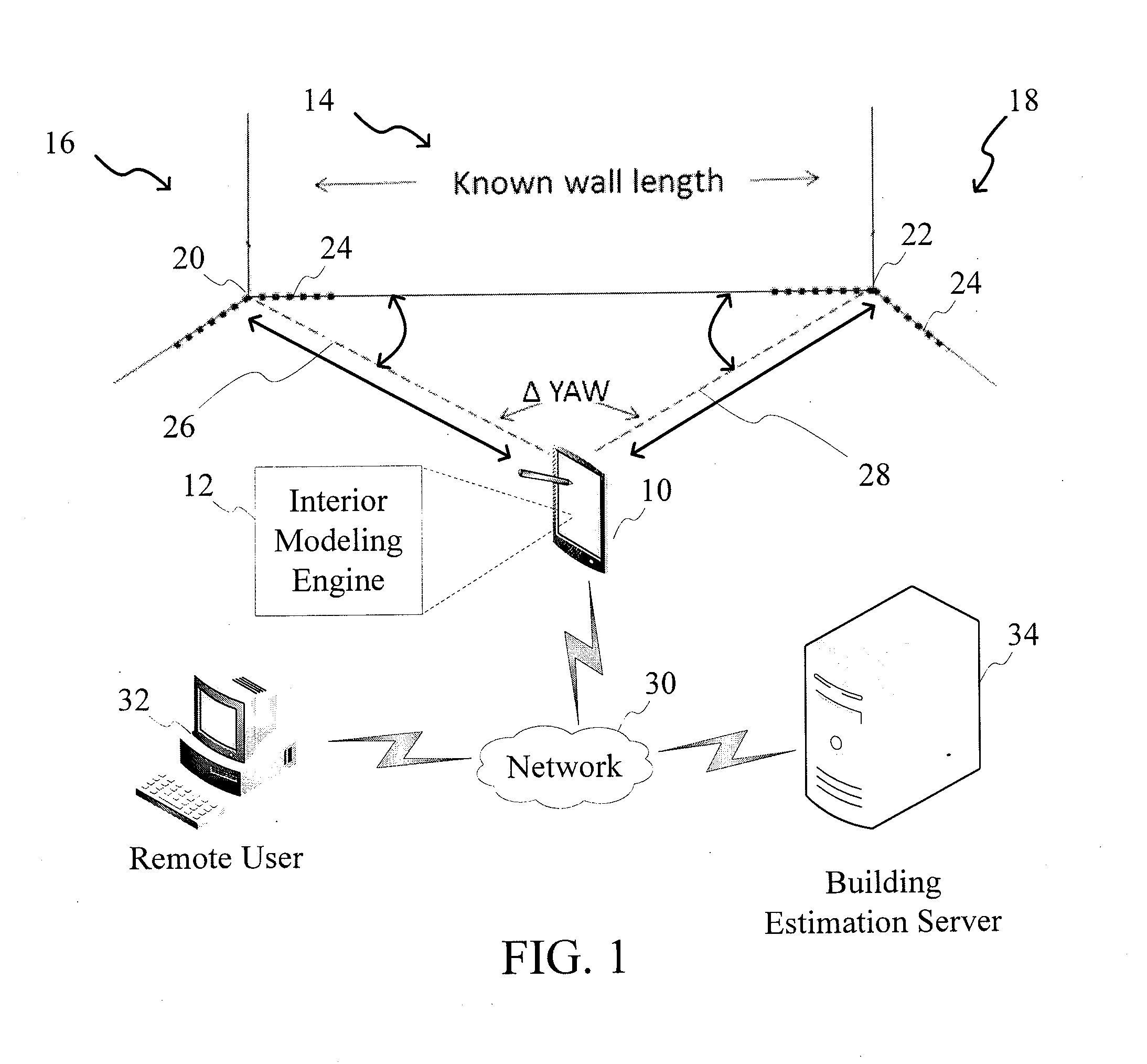

System and Method for Generating Computerized Floor Plans

ActiveUS20150227645A1Quickly and conveniently take measurementImprove accuracyGeometric CADSpecial data processing applicationsTablet computerGraphics

A system and method for generating computerized floor plans is provided. The system comprises a mobile computing device, such as a smart cellular telephone, a tablet computer, etc. having an internal digital gyroscope and camera, and an interior modeling software engine interacts with the gyroscope and camera to allow a user to quickly and conveniently take measurements of interior building features, and to create computerized floor plans of such features from any location within a space, without requiring the user to stay in a single location while taking the measurements. The system presents the user with a graphical user interface that allows a user to quickly and conveniently delineate wall corner features using a reticle displayed within the user interface. As corners are identified, the system processes the corner information and information from the gyroscope to calculate wall features and creates a floor plan of the space with high accuracy.

Owner:XACTWARE SOLUTIONS

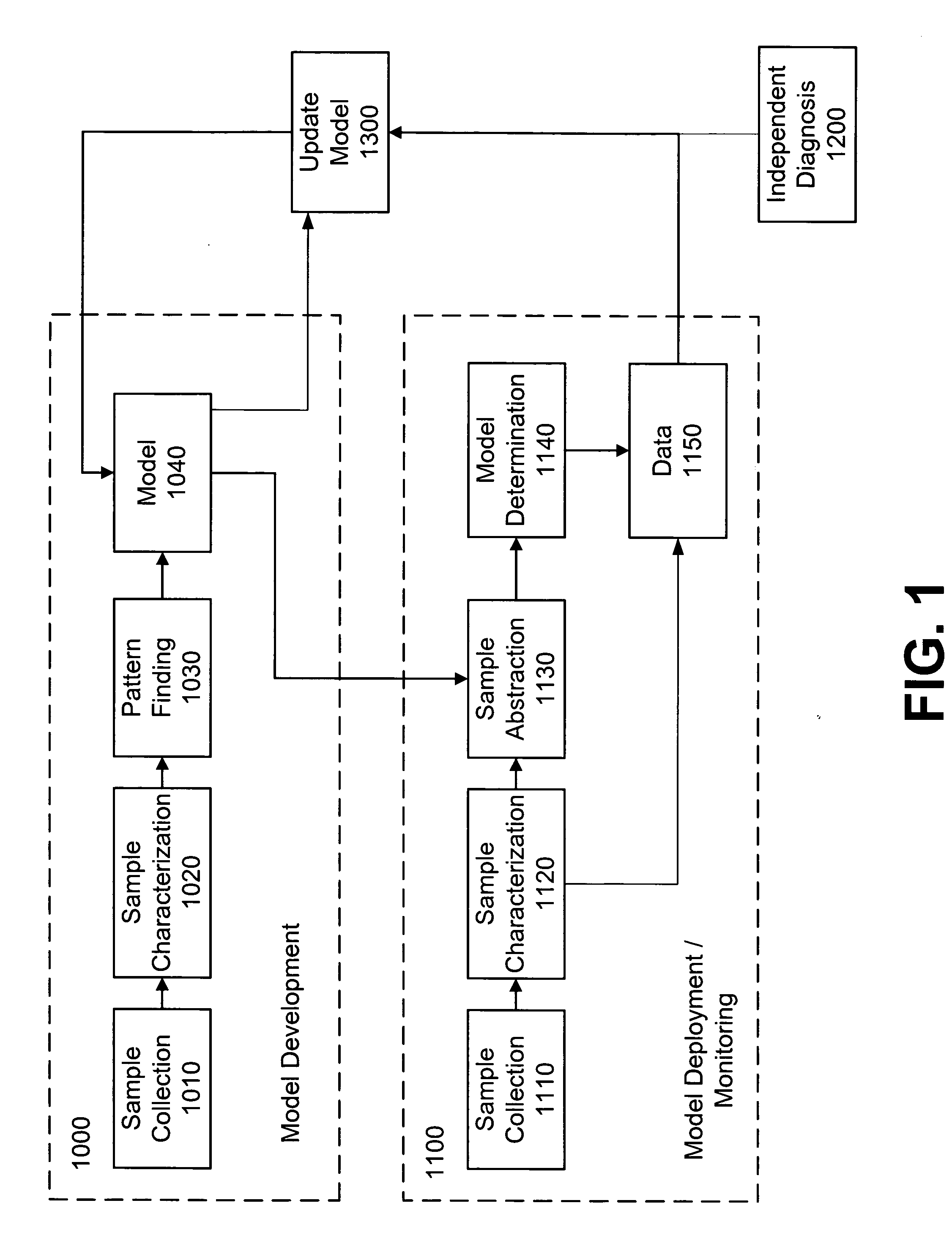

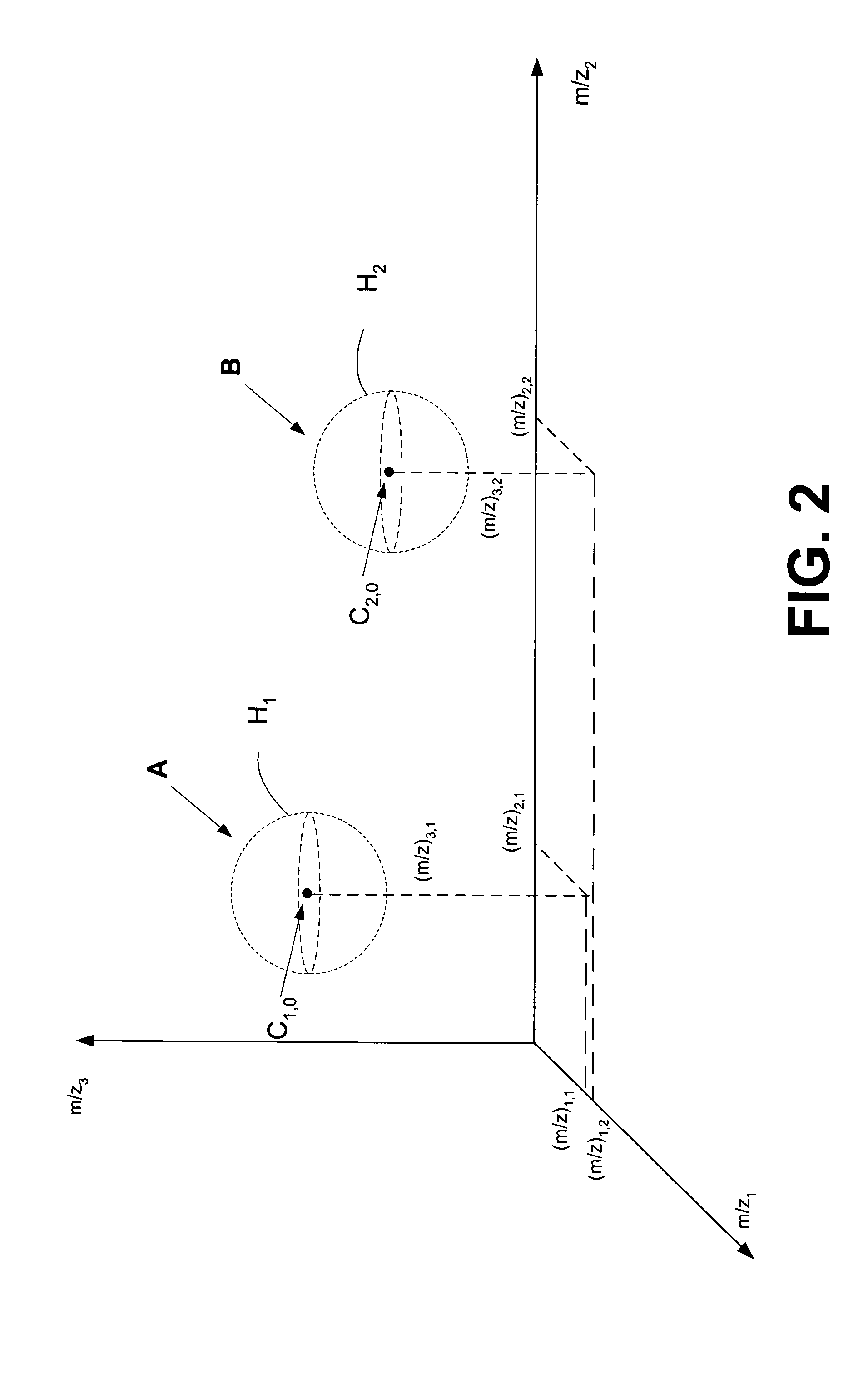

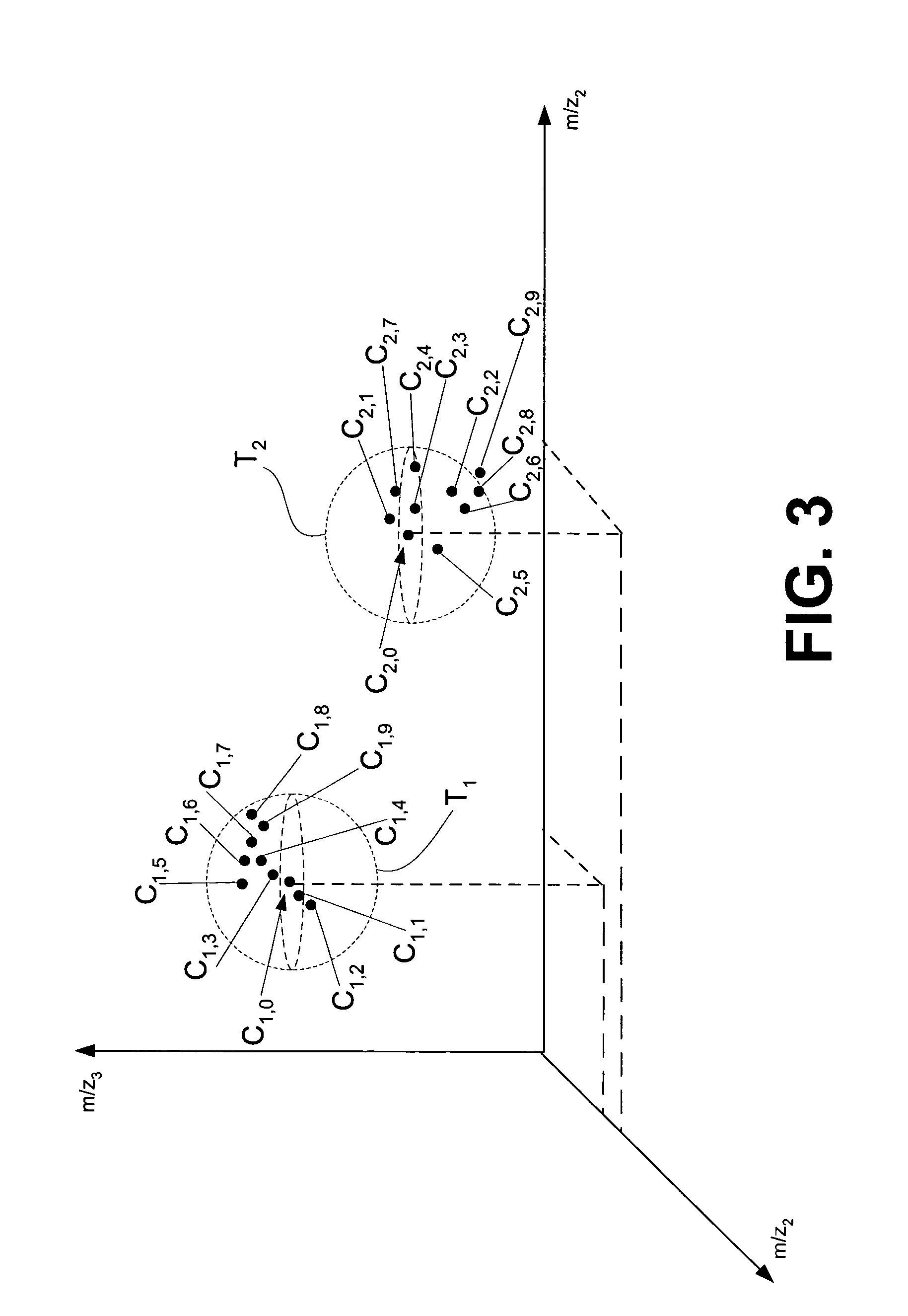

Method of diagnosing biological states through the use of a centralized, adaptive model, and remote sample processing

ActiveUS20050209786A1Continuing viabilityMedical simulationBiostatisticsModeling softwareComputer science

A model of a particular biological state can be developed. The model may be used to determine if an unknown biological sample exhibits a particular biological state. This can be done by receiving either a biological sample or data associated with the biological sample. After the data is received, the data may be input into the model. In one embodiment, the acquisition of the data associated with the biological sample is performed at a first location and the imputing of the data into the model is performed at a second location different than the first location. Unless the data maps identically to the model, the data would have an inherent effect on the position of the particular clusters within the discriminatory pattern, if it is allowed to affect the model. The modeling software can keep track of the net effect on the model that each sample received has on the position of the model. If the model has drifted outside of a predetermined tolerance, the model can be updated. Various business relationships may be developed to undertake various steps of the overall method for providing a diagnosis to a patient.

Owner:ASPIRA WOMENS HEALTH INC

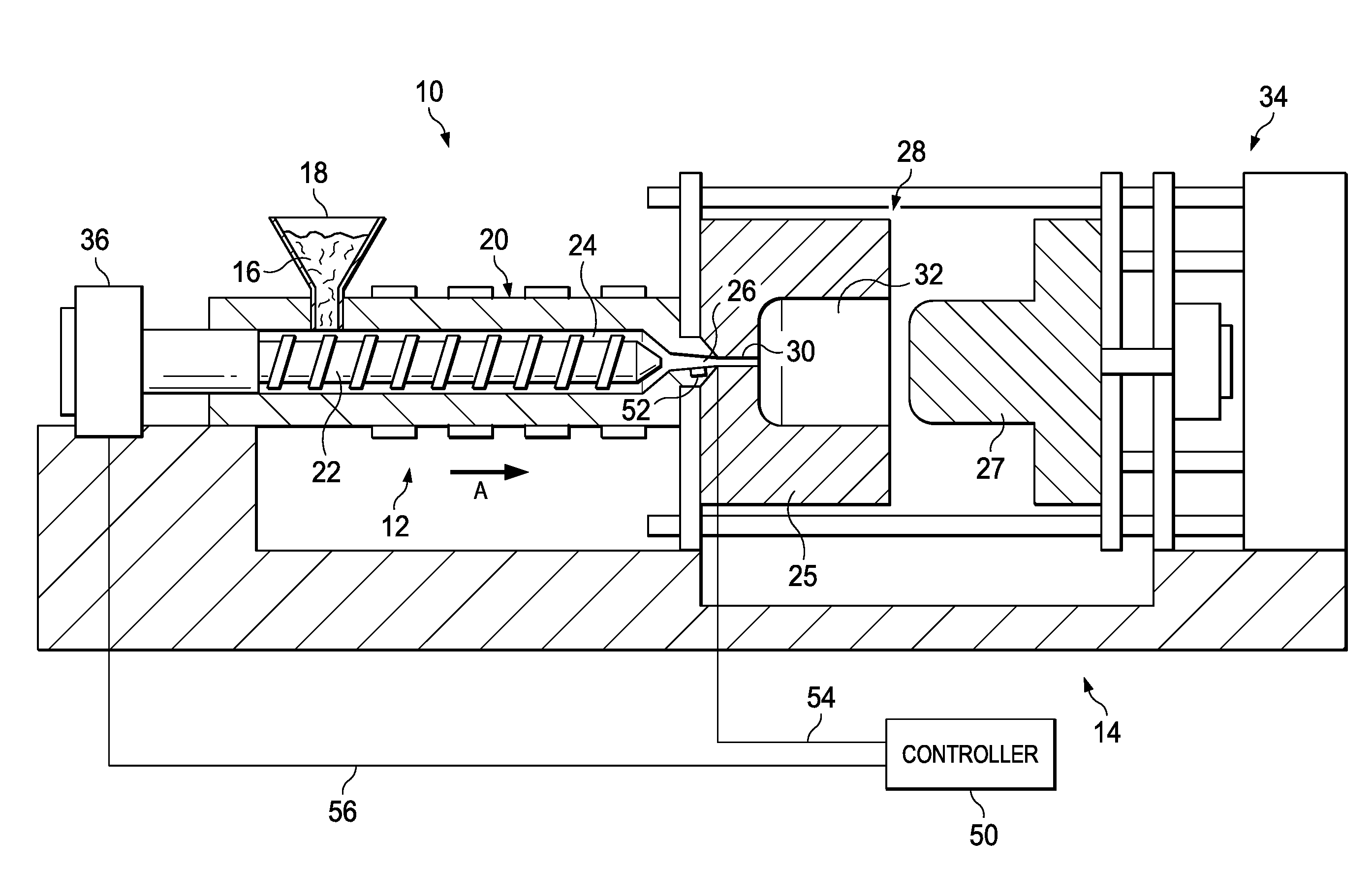

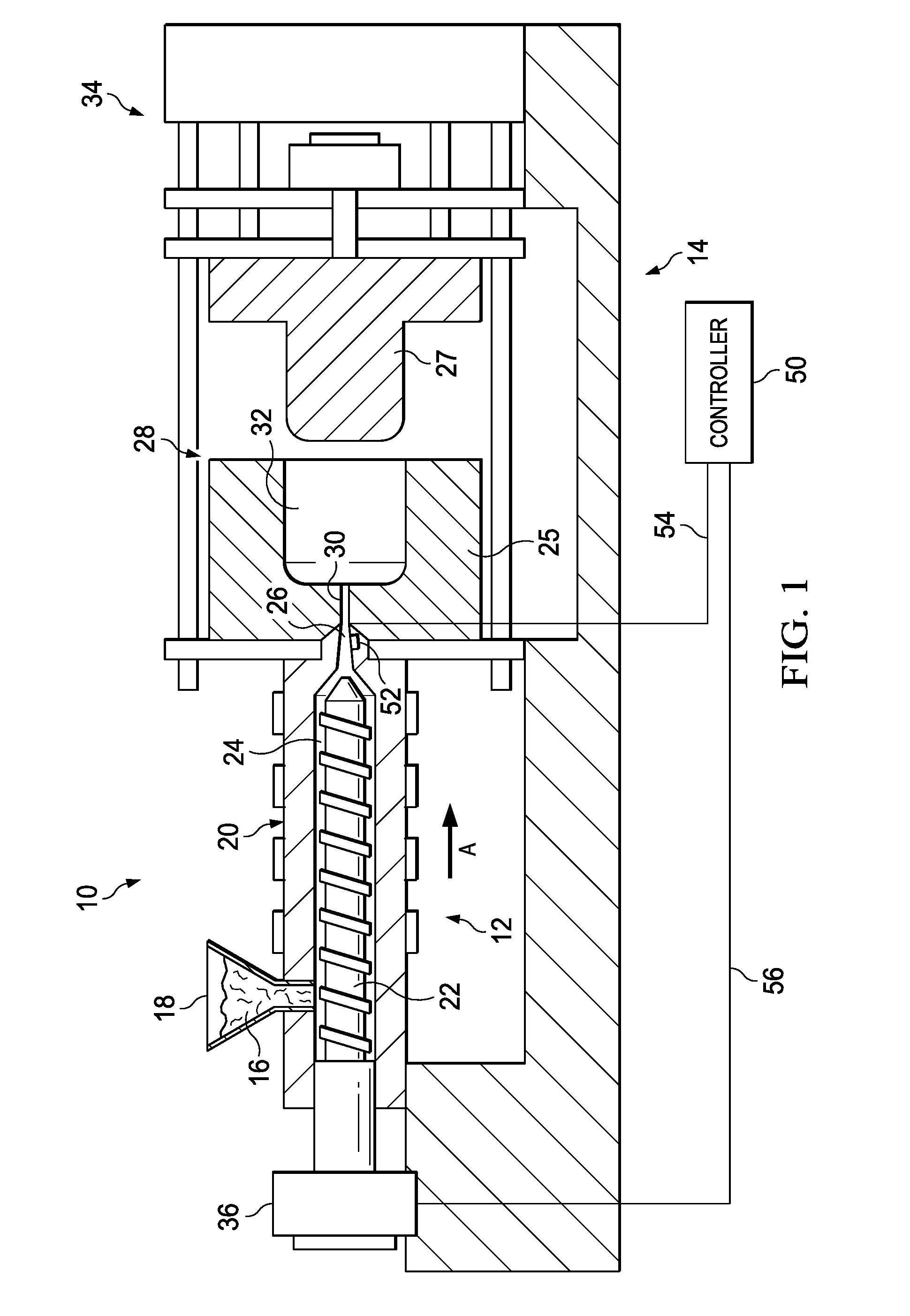

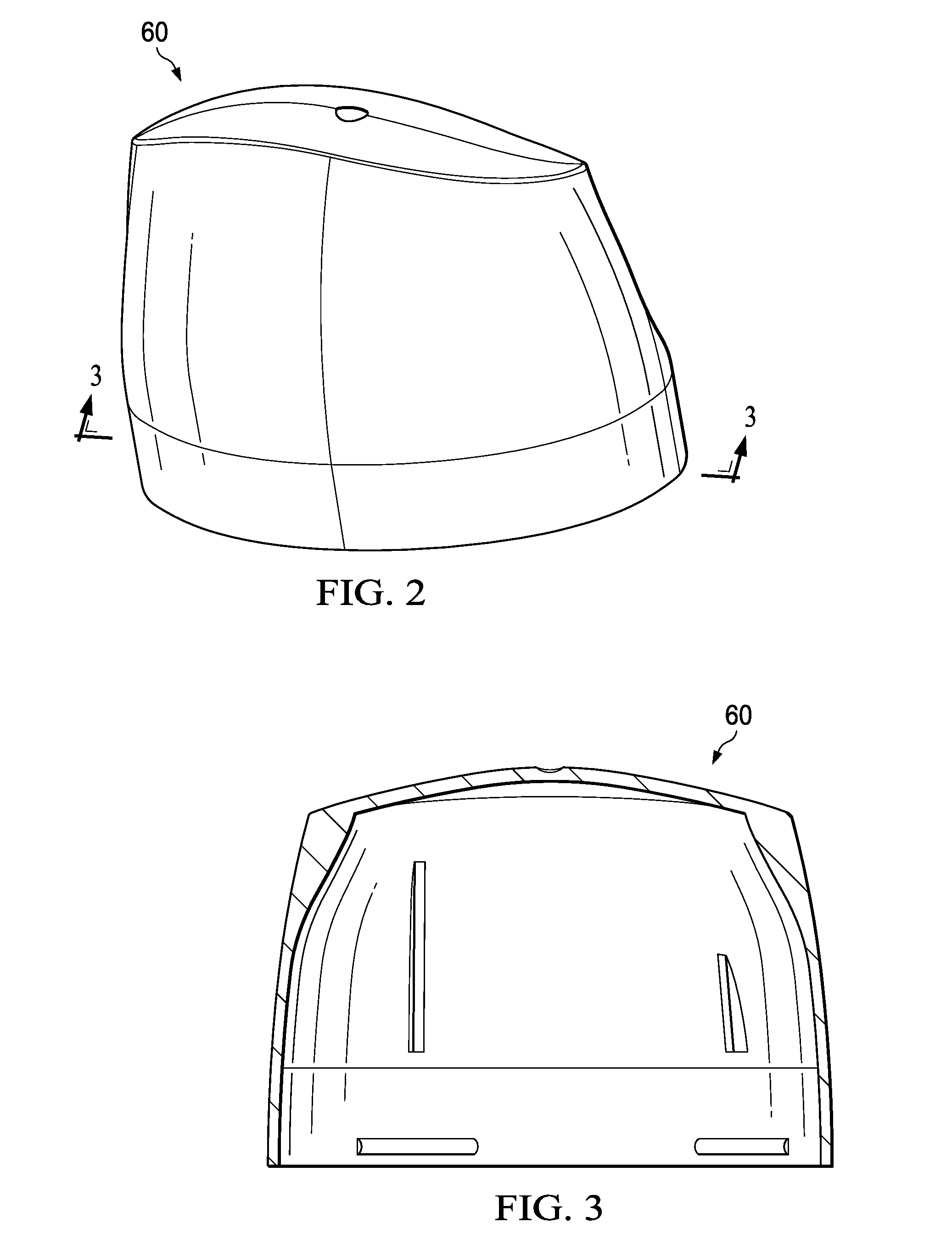

Method of injection molding with constant-velocity flow front control

In order to injection mold parts at a constant flow front velocity in a mold cavity of an injection molding system, particularly where the mold cavity has a varying thickness along its length, mold modeling software is used to calculate the cross-sectional area as a function of the distance from the gate, percentage of fill, or length of the mold cavity. Based on that cross-sectional area, the mold modeling software determines an appropriate recommended ram force profile and / or melt pressure profile that would result in filling the mold cavity at a constant flow rate. An injection molding system is then operated according to the recommended ram force profile and / or melt pressure profile.

Owner:IMFLUX INC

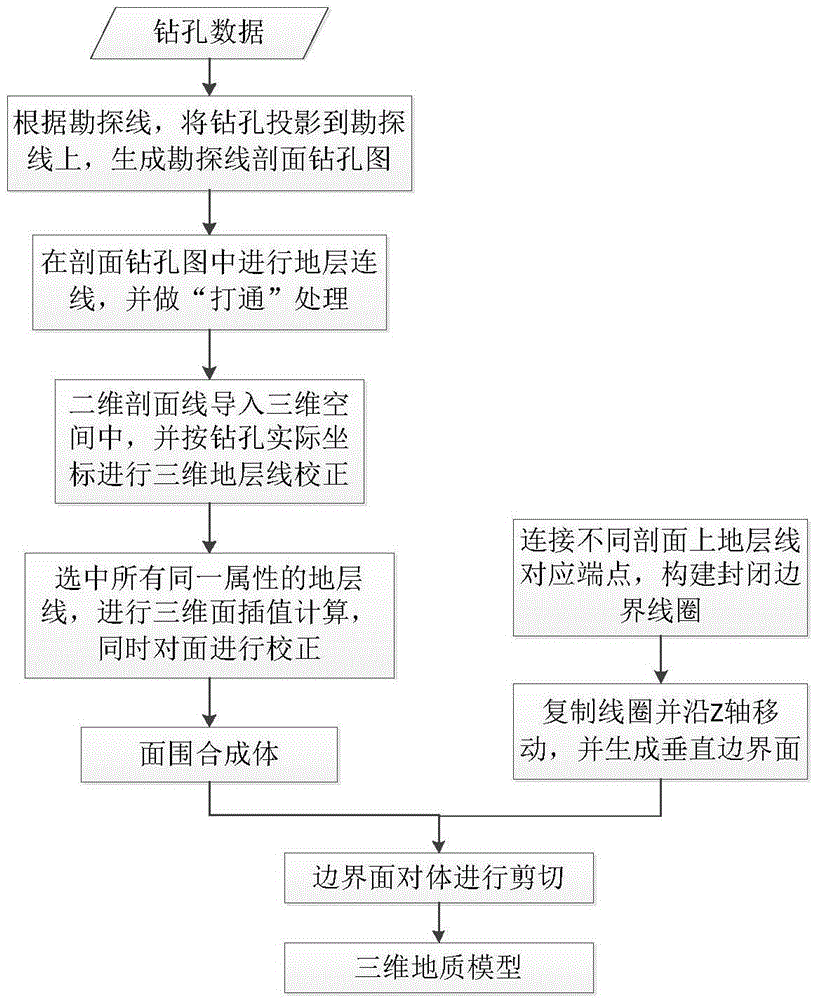

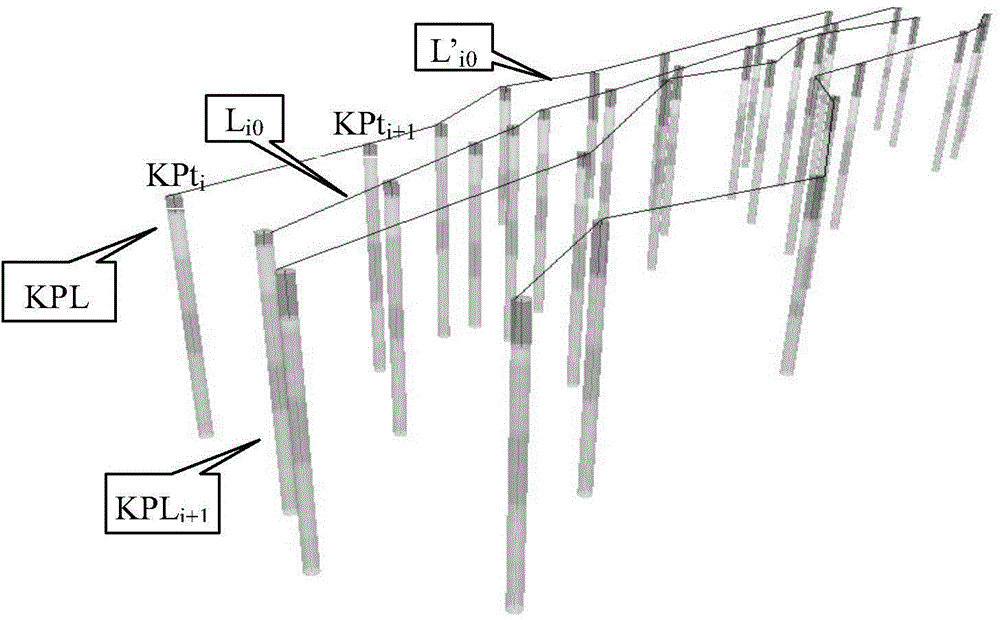

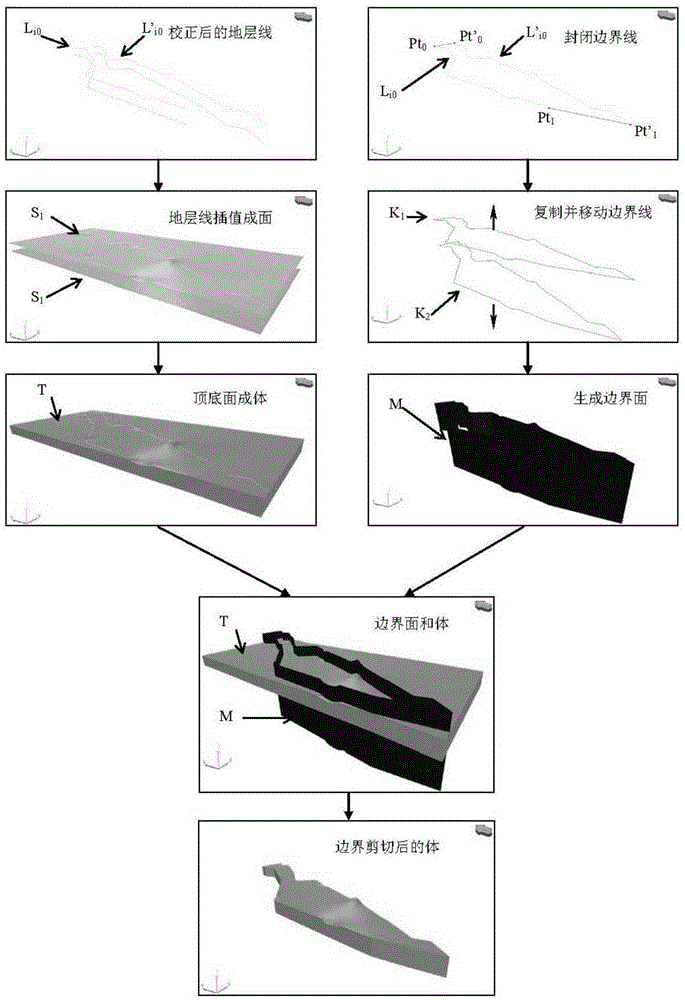

Rapidly progressive three-dimensional geologic modeling method

ActiveCN104574511AQuick buildGuaranteed accuracy3D modellingModeling softwareThree-dimensional space

The invention discloses a rapidly progressive three-dimensional geologic modeling method based on drill holes. The method comprises the following steps: generating a two-dimensional exploration cross-section drill hole arrangement diagram according to one-dimensional drill hole data, and directly performing multidirectional cross-section stratum line connecting and cooperative processing, and is characterized by comprising the following detailed steps: according to the actual position, spreading the cross sections of the drill holes in the multiple directions in a three-dimensional space, using an interpolation algorithm to perform cross section interpolation on the stratum lines with the same attribute, generating a three-dimensional stratum surface, and at last using a top-bottom tessellation algorithm to construct the whole three-dimensional geologic body model. According to the rapidly progressive three-dimensional geologic modeling method disclosed by the invention, the stratum lines and the plane position are more accurate by stratum line connection and cooperative processing, and coordinate correction in the three-dimensional space; the speed and the efficiency for the three-dimensional geologic modeling can be obviously improved by utilizing the interpolation algorithm to generate the stratum surface; according to the model modeled by the method, the more the drill holes and the exploration line data are, the finer the division of the stratum is, and the higher the fineness of the established three-dimensional geologic model is; the method can be popularized and applied to multiple professional three-dimensional geologic modeling software.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

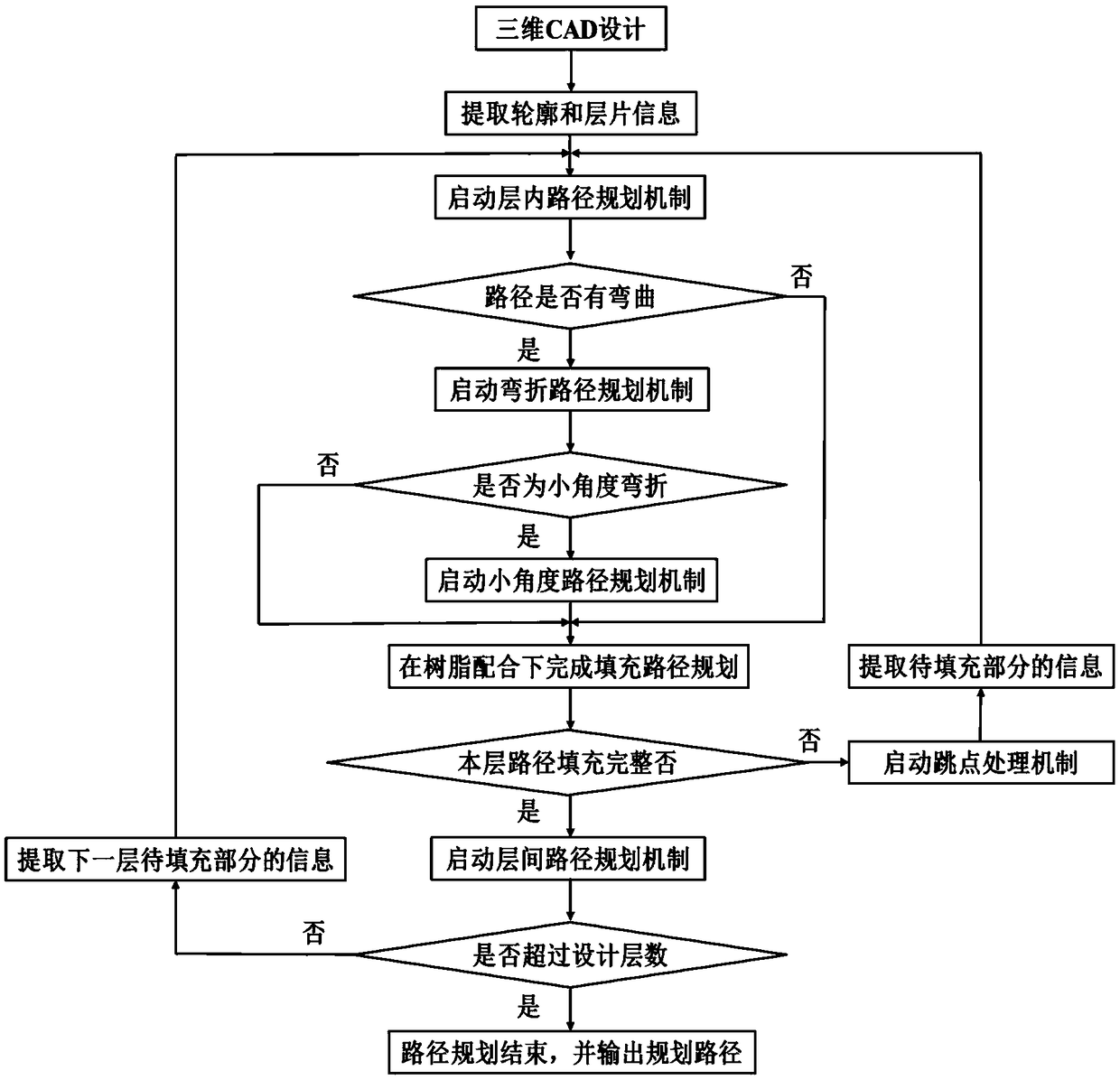

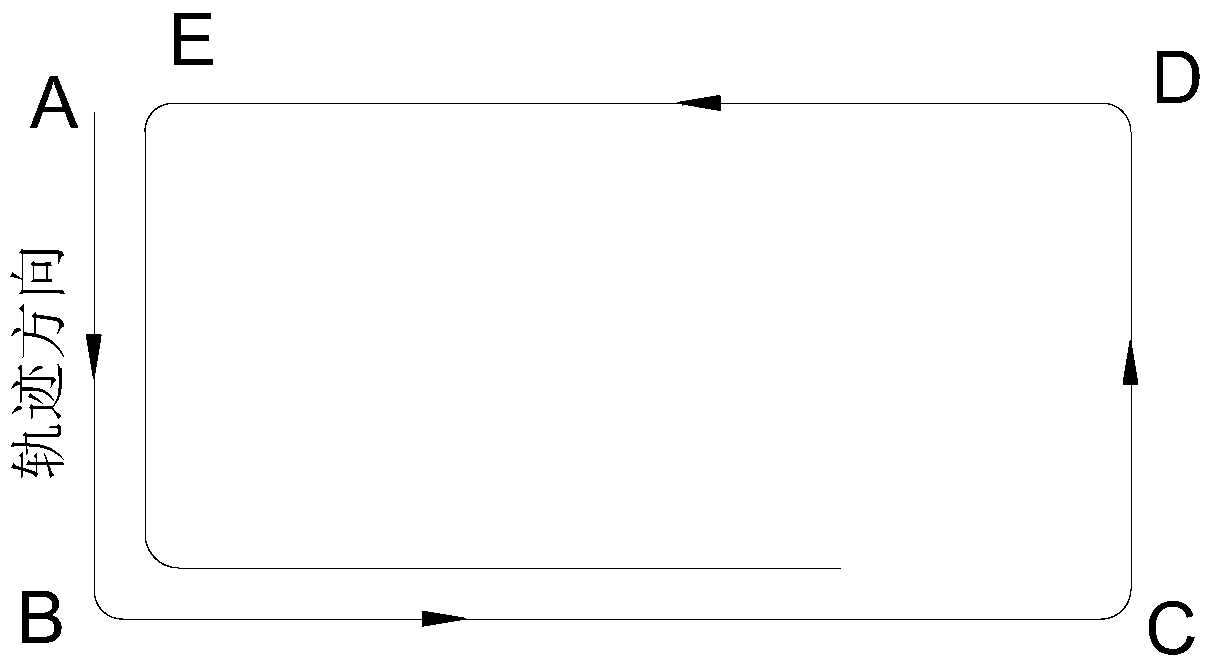

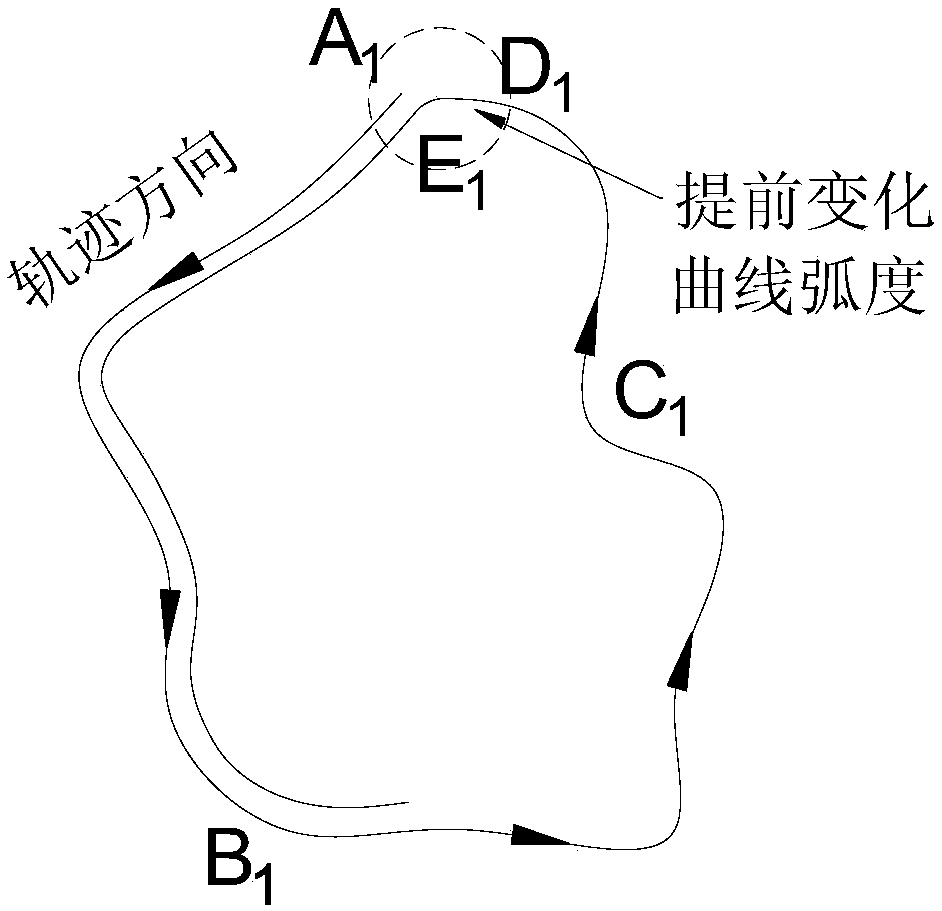

Typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites

ActiveCN108891029AGuaranteed mechanical propertiesReduce molding defectsAdditive manufacturing apparatusManufacturing data aquisition/processingProcess mechanismComputer Aided Design

The invention discloses a typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites and belongs to the field of rapid prototyping of the composites. Inthe method, a three-dimensional model is built by using CAD (computer aided design) modeling software according to actual size requirements of forming components and is subjected to slice stratification by the aid of the three-dimensional software to acquire profile and slice information; the degree of path bending is judged and corresponding path planning mechanisms are started, and with the help of the jump point processing mechanism, jump points can be accurately located and the action of the jump points is completed; fiber interlayer conversion without breakpoint is realized by using an interlayer path planning mechanism, and high quality and high efficiency three-dimensional printing new path of the continuous fiber reinforced composites is realized. In the method, the printing pathwith the least breakpoints is planned out, and mechanical property of the continuous fiber reinforced composites is guaranteed; forming defects in the bending of continuous fiber are effectively reduced, binding force of the continuous fiber in the bending is improved, and integral performance of the forming components is improved.

Owner:DALIAN UNIV OF TECH

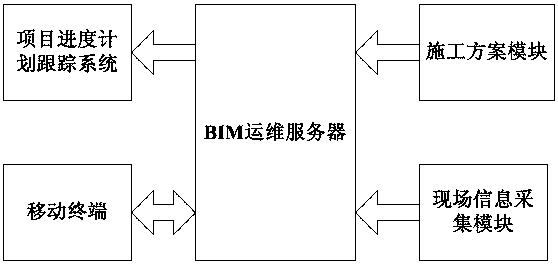

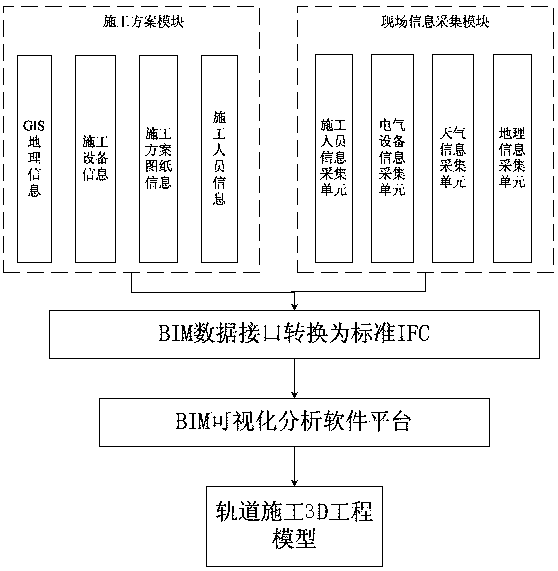

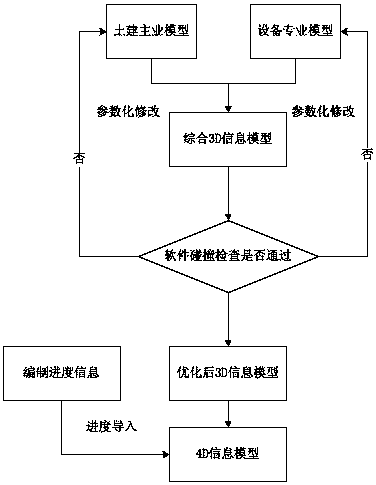

BIM-technology-based track construction system

PendingCN108090610AManage Content VisualizationSpeed upForecastingResourcesDynamic modelsModeling software

The invention discloses a BIM-technology-based track construction system comprising a field information acquisition module for collecting parameters needed by construction modeling in real time at a construction site, a construction plan module for providing existing GIS geographic information, construction equipment information, construction plan drawing information and construction personnel information, a BIM operation and maintenance server for connecting data obtained by field collection and data stored in the construction plan module and establishing a construction model by using a built-in modeling software platform in the server, a program progress plan tracking system for checking a construction error timely and carrying out correction for optimization, and a mobile terminal for helping the staff receive track construction progress information in real time. With the BIM technology, dynamic model construction of the construction process is realized, so that the management content becomes visible and the capability of controlling the engineering content and progress by the administrator is enhanced. Therefore, the collaboration efficiency of construction participants is improved and the construction progress is accelerated.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

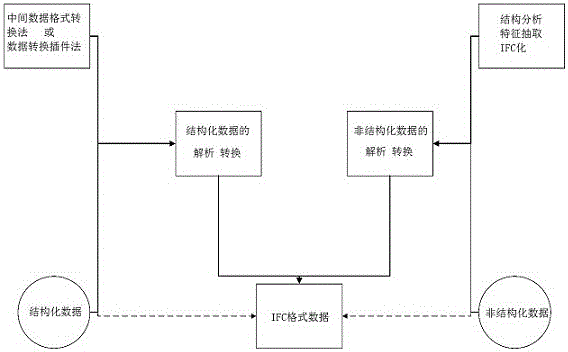

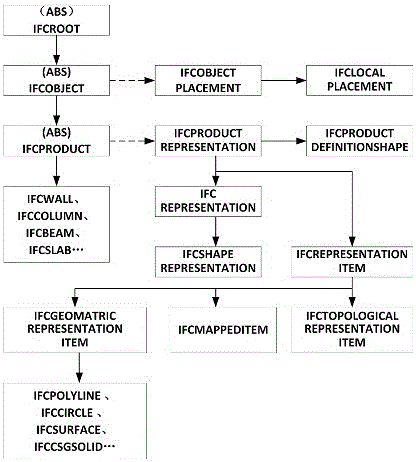

IFC-based data interaction method and corresponding Web-BIM engineering information integration management system

ActiveCN105912651AImplement integrated managementOvercome Data Interaction BarriersOffice automationSpecial data processing applicationsData informationModeling software

The present invention relates to an IFC-based data interaction method and a corresponding Web-BIM engineering information integration management system. The data interaction method comprises converting data, structured data or unstructured data, respectively into IFC format data according to a predetermined algorithm, and associating the data with a preset system database. The management system comprises a system database, and an IFC data interaction module, a GIS integration module, an information query module and a user management module which are respectively in communication with the system database. BIM-involved different data formats can be converted into IFC data formats, and the data interaction obstacle caused by unified data formats of BIM type modeling software in the prior art is overcome, thereby facilitating implementation of integration management of BIM project engineering data information.

Owner:CHINA UTONE CONSTR CONSULTING CO LTD

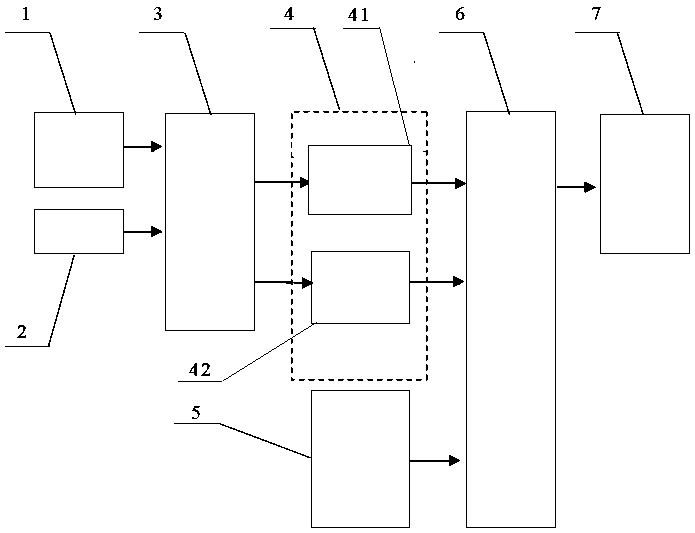

Smart site safety management platform system architecture

InactiveCN108446866ARealize intelligent managementEnsure intelligent managementGeometric CADCo-operative working arrangementsSoftware systemSafety monitoring

The invention discloses smart site safety management platform system architecture. The smart site safety management platform system architecture is characterized in that the cloud and Internet of Things technology architecture uses a construction safety management platform composed of an intelligent helmet, a locator, a multi-function construction safety monitor, a transmission network, a secondary development BIM modeling software system, a cloud map and application server and a client terminal PC / display screen. Compared with the prior art, the smart site safety management platform system architecture provided by the invention has the functions of real-time position location, real-time trajectory analysis, monitoring of real-time environment safety and other information, personnel intelligent management and the like. Intelligent management of mobile personnel in an area is realized. Dangerous dangers of the personnel are timely alarmed and uploaded to the cloud to ensure the safety of the personnel. Safety management of real-time safety monitoring and safety warning of constructors at a construction site is realized.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

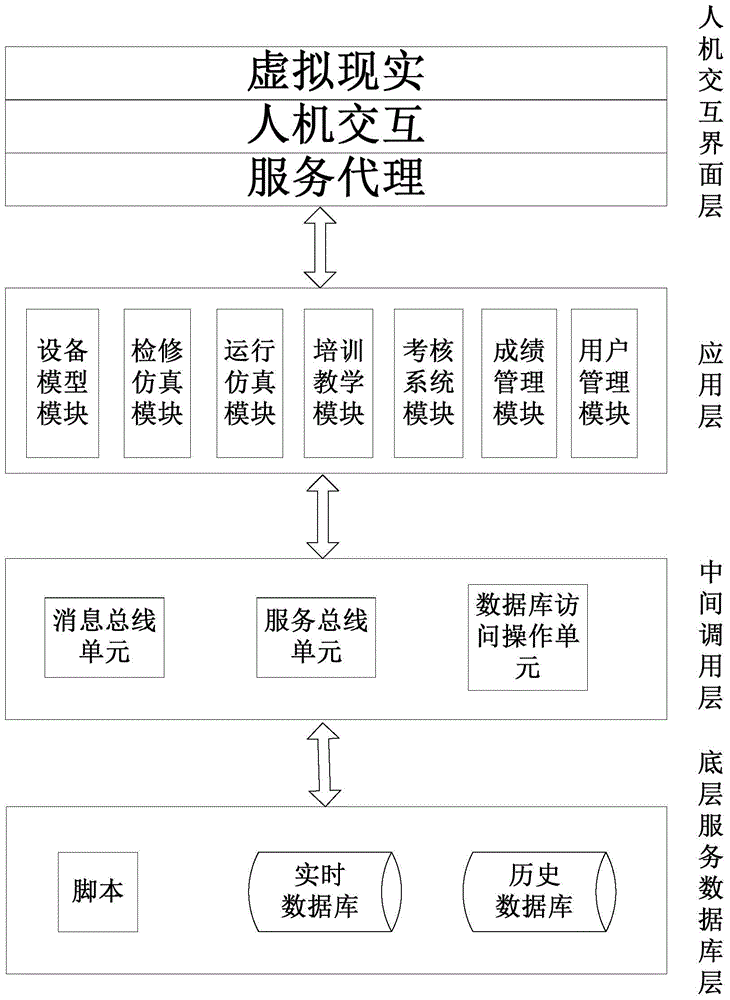

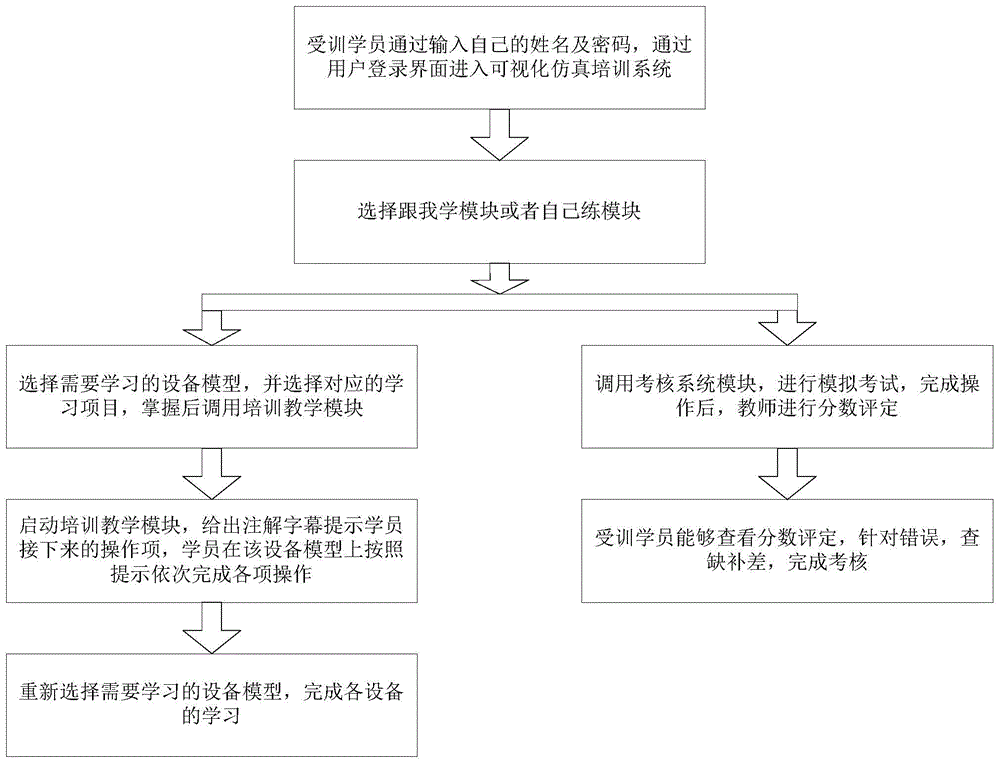

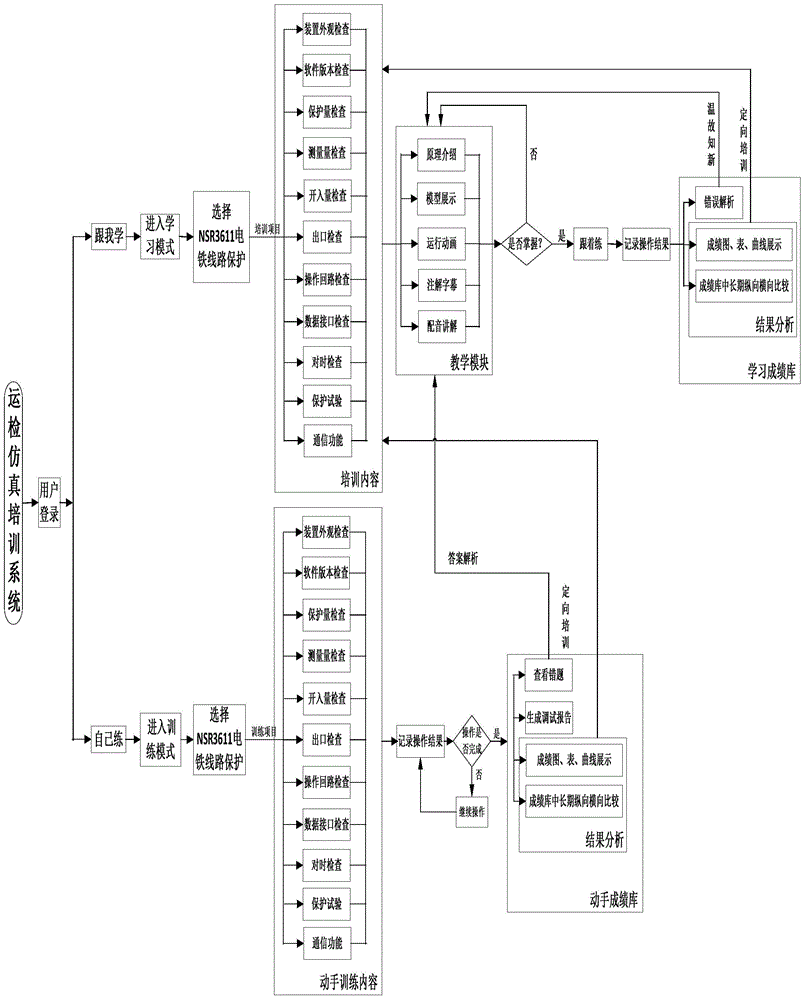

Visualized simulation training system and method for electrified railway traction substation

ActiveCN105139714AEasy to understandHelp to acceptCosmonautic condition simulationsElectrical appliancesThree dimensional simulationTraining period

The invention discloses a visualized simulation training system and method for an electrified railway traction substation. Three-dimensional simulation modeling software, animation production software and assistant software are utilized to establish a three-dimensional visualized simulation training system, which can effectively activate a plurality of sensory organs of visual sense and auditory sense and the like of training objects to participate in the perception activity, helps to understand and receive the training content, allows students to autonomously select learning content and difficulty level, provides a favorable condition for giving a full play to the initiative and obtaining effective cognition for the training objects, is high in versatility, short in training period, friendly in interactive interface and high in substitution, and has a good application prospect.

Owner:NARI TECH CO LTD +1

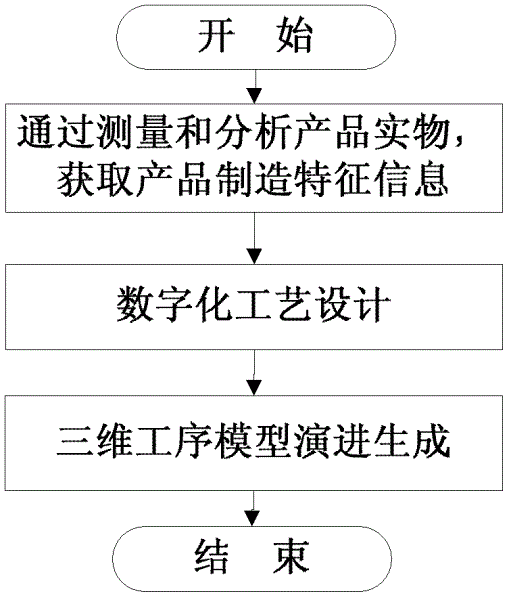

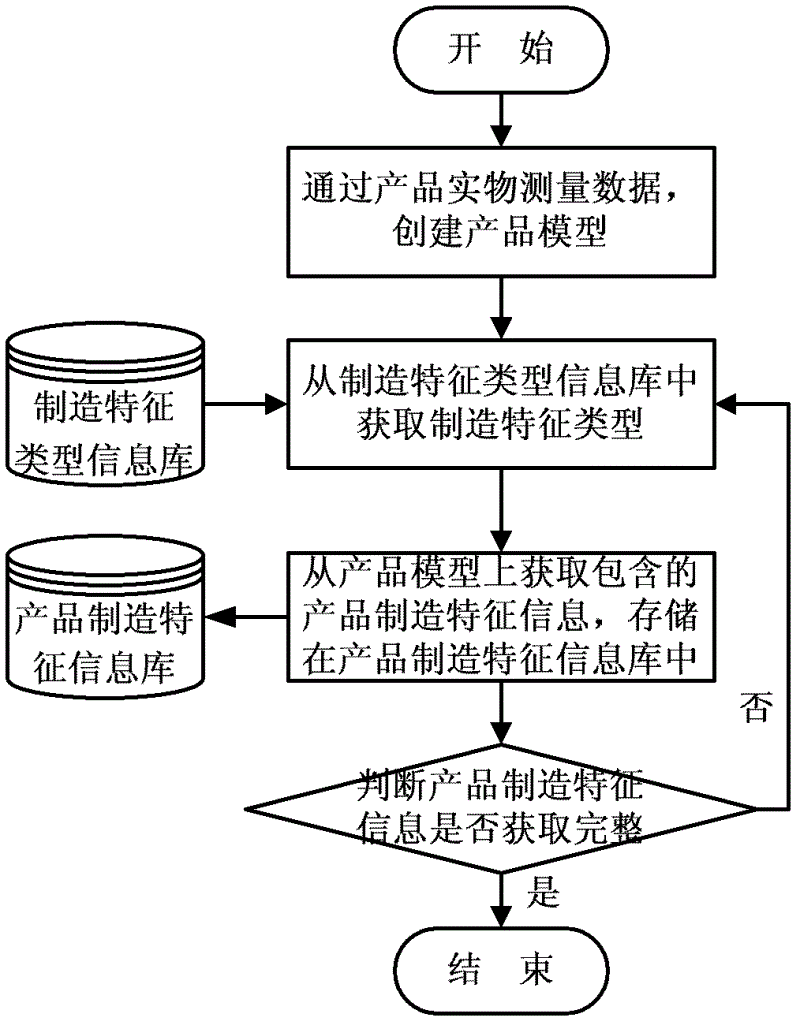

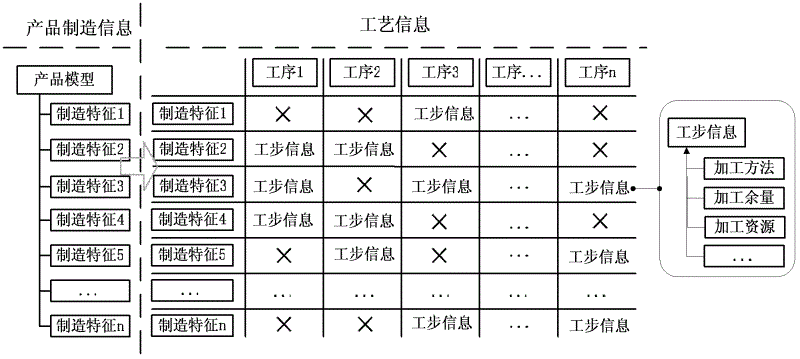

Three-dimensional process model evolution generation method applied to digitalized process design

InactiveCN102622477APromote generationImprove efficiencySpecial data processing applicationsInformation repositoryGeneration process

The invention discloses a three-dimensional process model evolution generation method applied to digitalized process design, which belongs to the field of digitalized manufacture. The method includes the following steps: building a manufacture characteristic type information base, obtaining product manufacture characteristic information by measuring and analyzing a product real object, conducting digitalized process design according to the product manufacture characteristic information, storing process decision results, constructing a three-dimensional process model generation rule base, determining a reversing generation flow of a three-dimensional process model from the product to a blank to finish evolution change of the three-dimensional process model. The method achieves automatic generation of the three-dimensional process model based on integration of process information and process engineering, is capable of improving the process model generation process and the efficiency, adopts a geometrical operation method without historical modeling in the generation process of the three-dimensional process model, supports various modeling software and improves geometrical calculation efficiency when the process model is generated.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com