Patents

Literature

2801results about How to "Increase stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

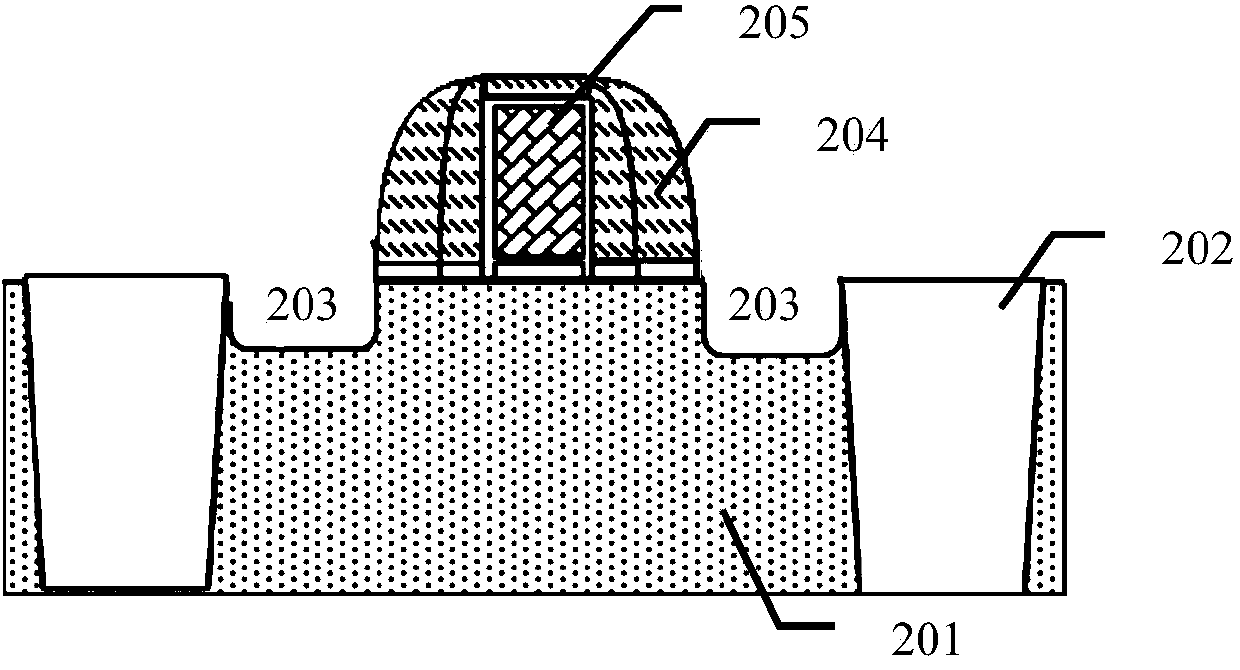

SiGe (silicon germanium) source and drain area manufacturing method

ActiveCN104201108AReduce thicknessAvoid stress relaxationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationEngineering

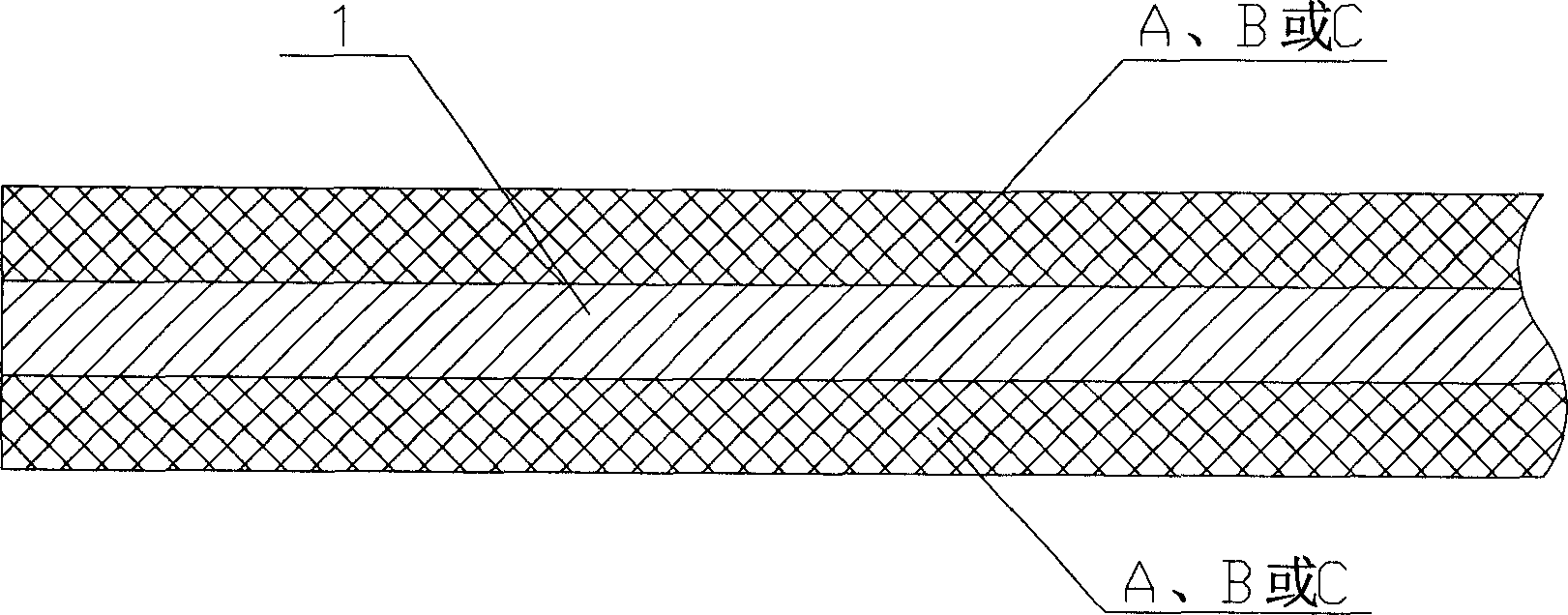

The invention discloses a SiGe (silicon germanium) source and drain area manufacturing method. A multi-layer structure which comprises alternately stacked buffer layers and main body layers is formed by a method that the SiGe epitaxial growth of the buffer layer and the main body layers is alternated repeatedly and accordingly the thickness of every high Ge concentration of SiGe main body layer is effectively reduced and shared into every layer of main body layer and accordingly the stress relaxation due to the fact that thickness of every main body layer exceeds the critical thickness is avoided; the Ge content of every layer of SiGe main body layer is further improved to enable the stress of the SiGe source leakage on a channel to be increased; an SiGe process window is enlarged due to the repeated epitaxy and accordingly the process stability is enhanced and accordingly the device performance is improved; the stress can be effectively improved without increase of the process difficulty and accordingly the process is stable and controllable and the cost is low.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

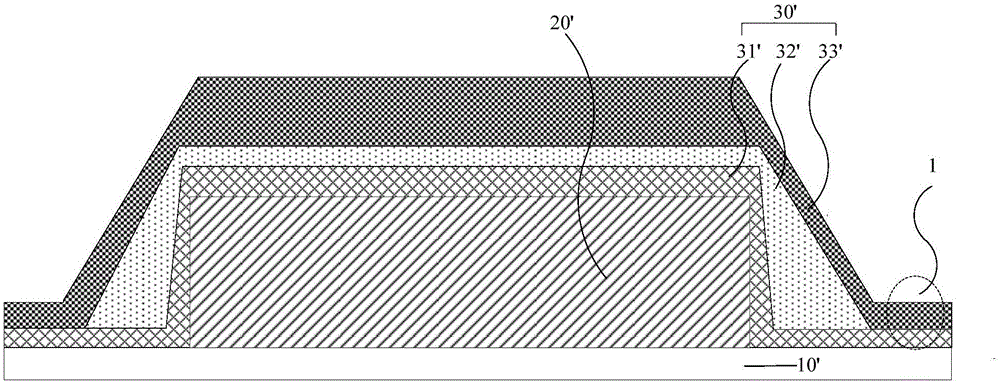

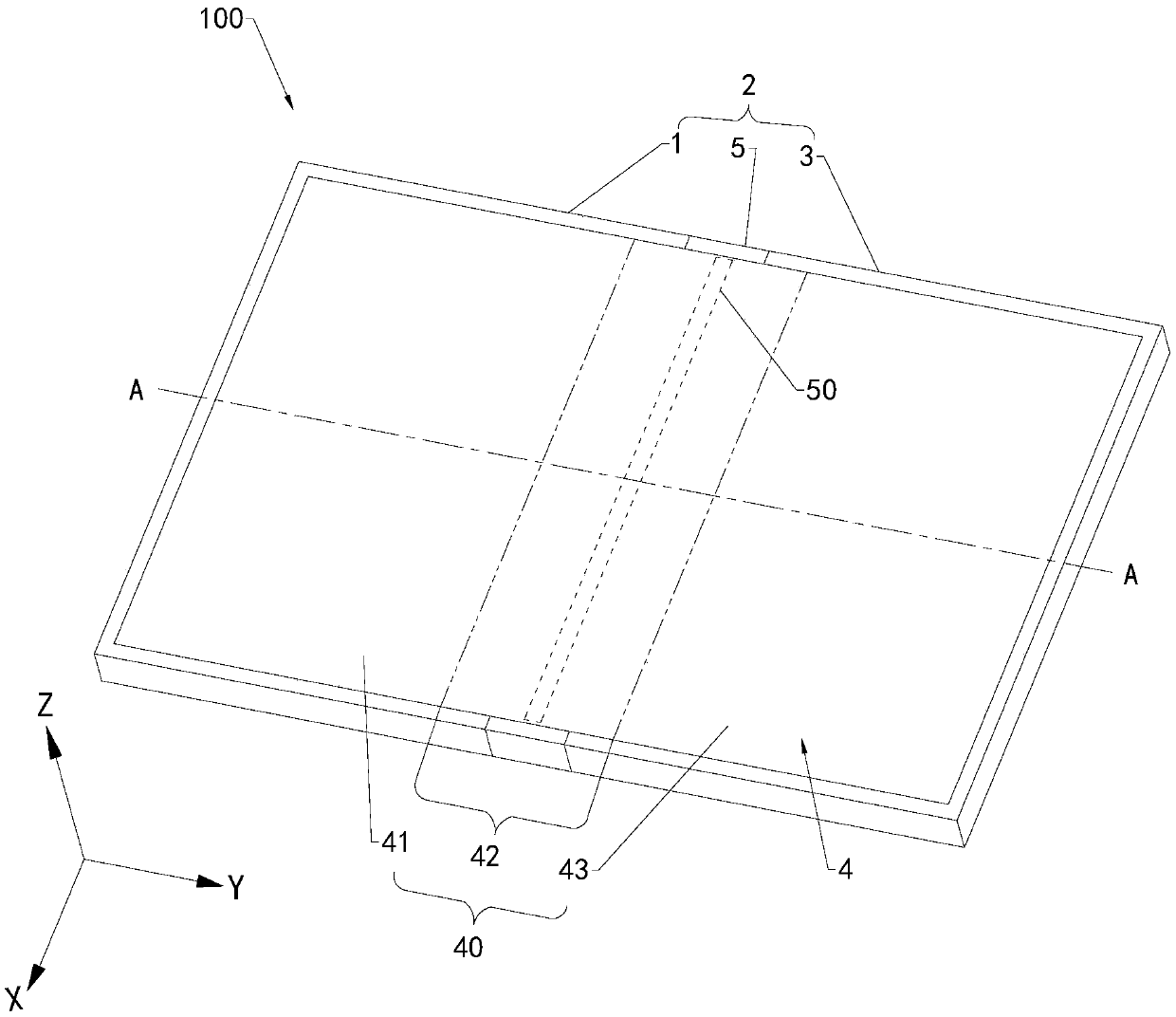

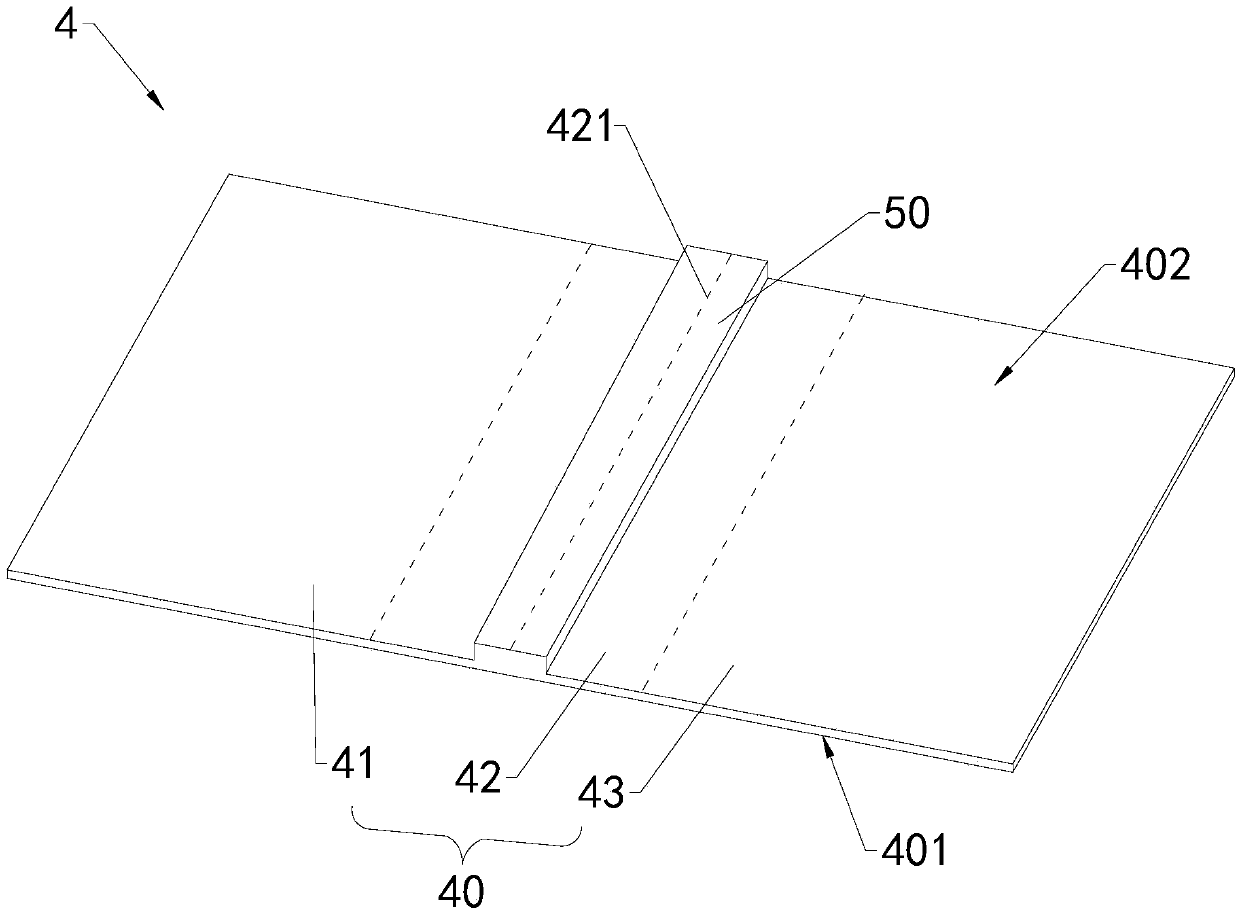

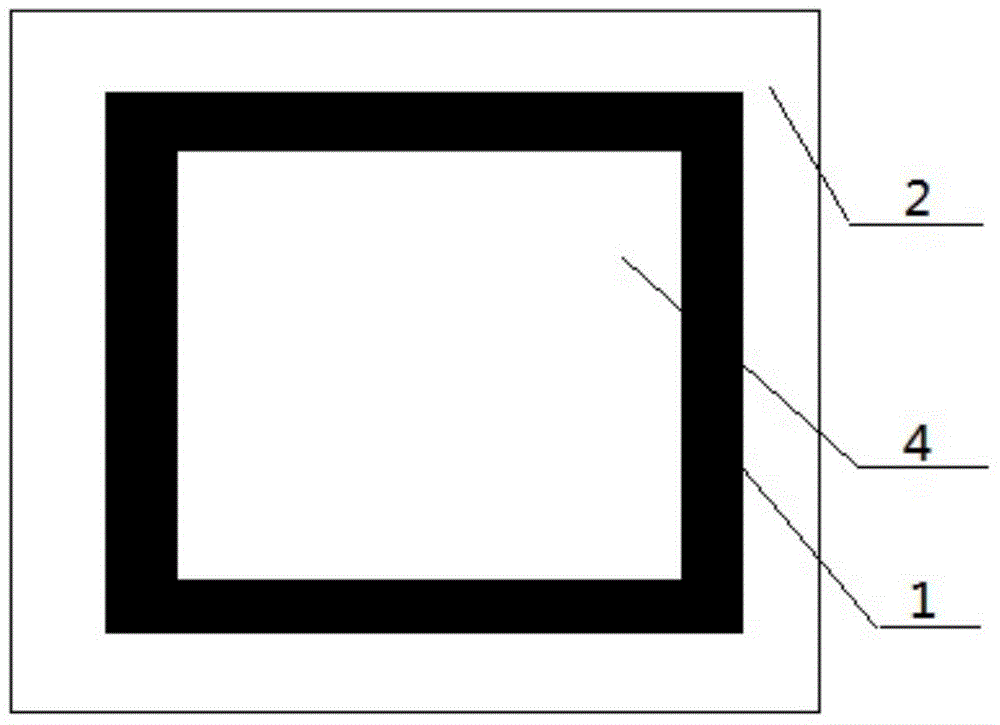

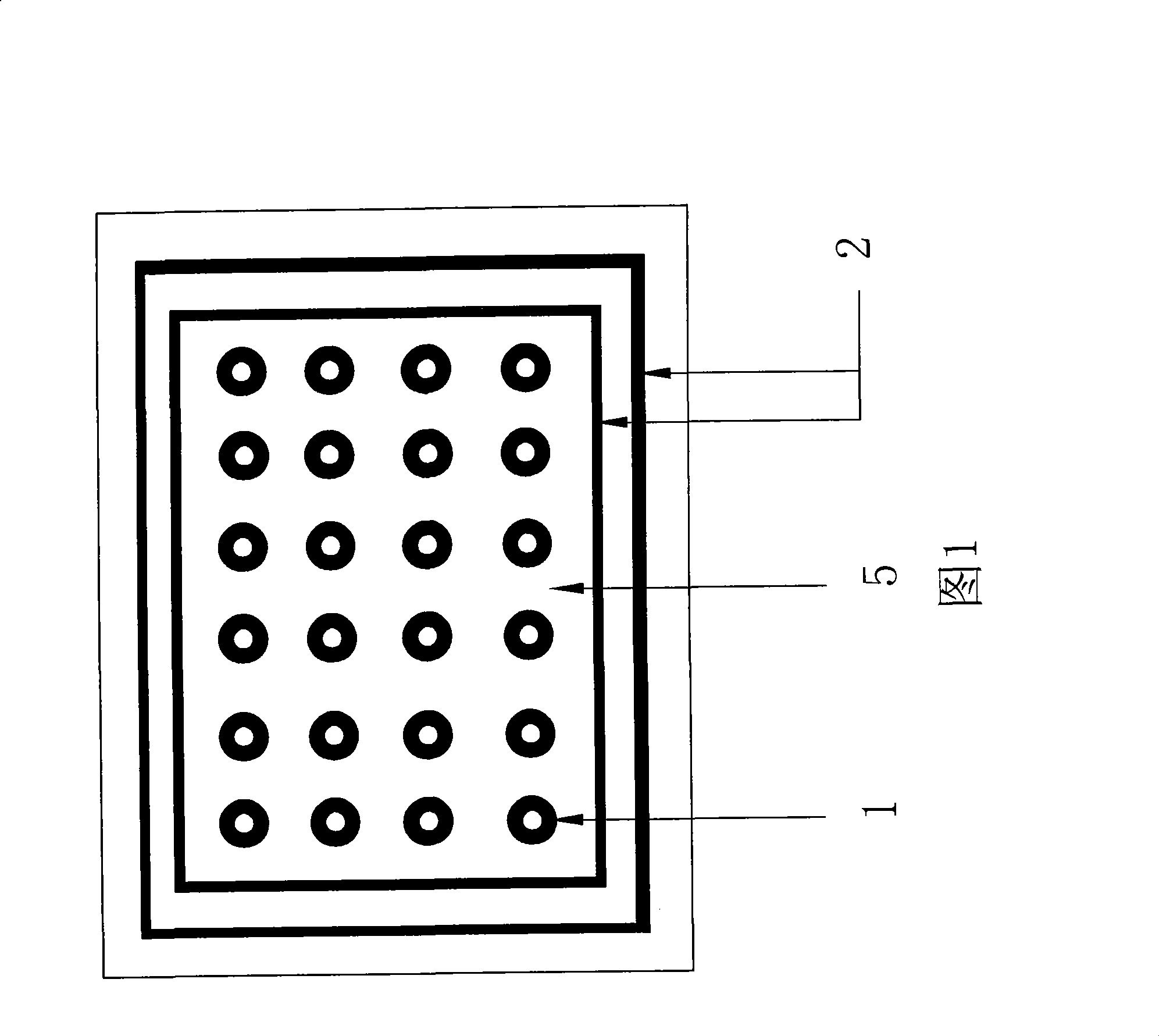

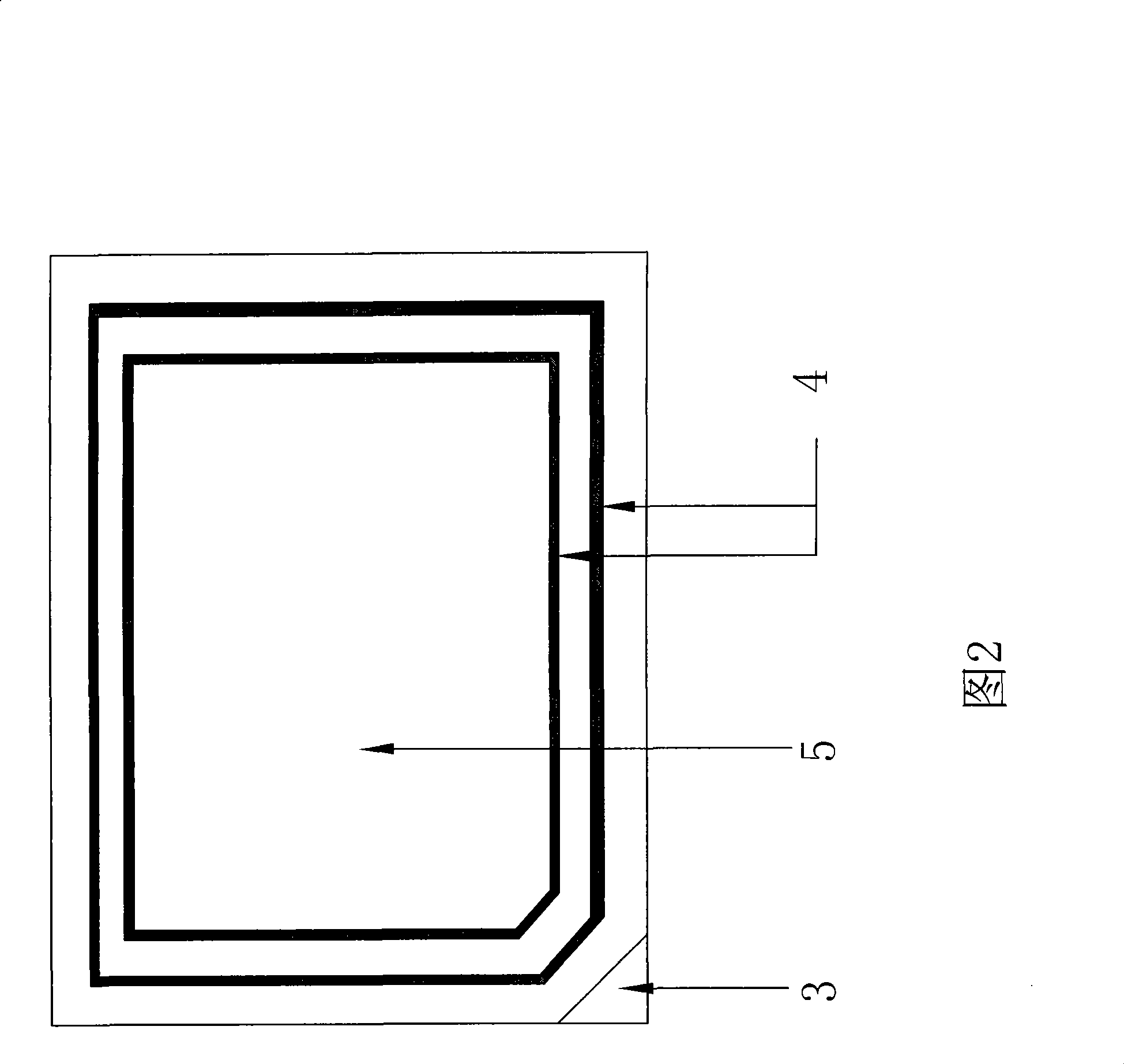

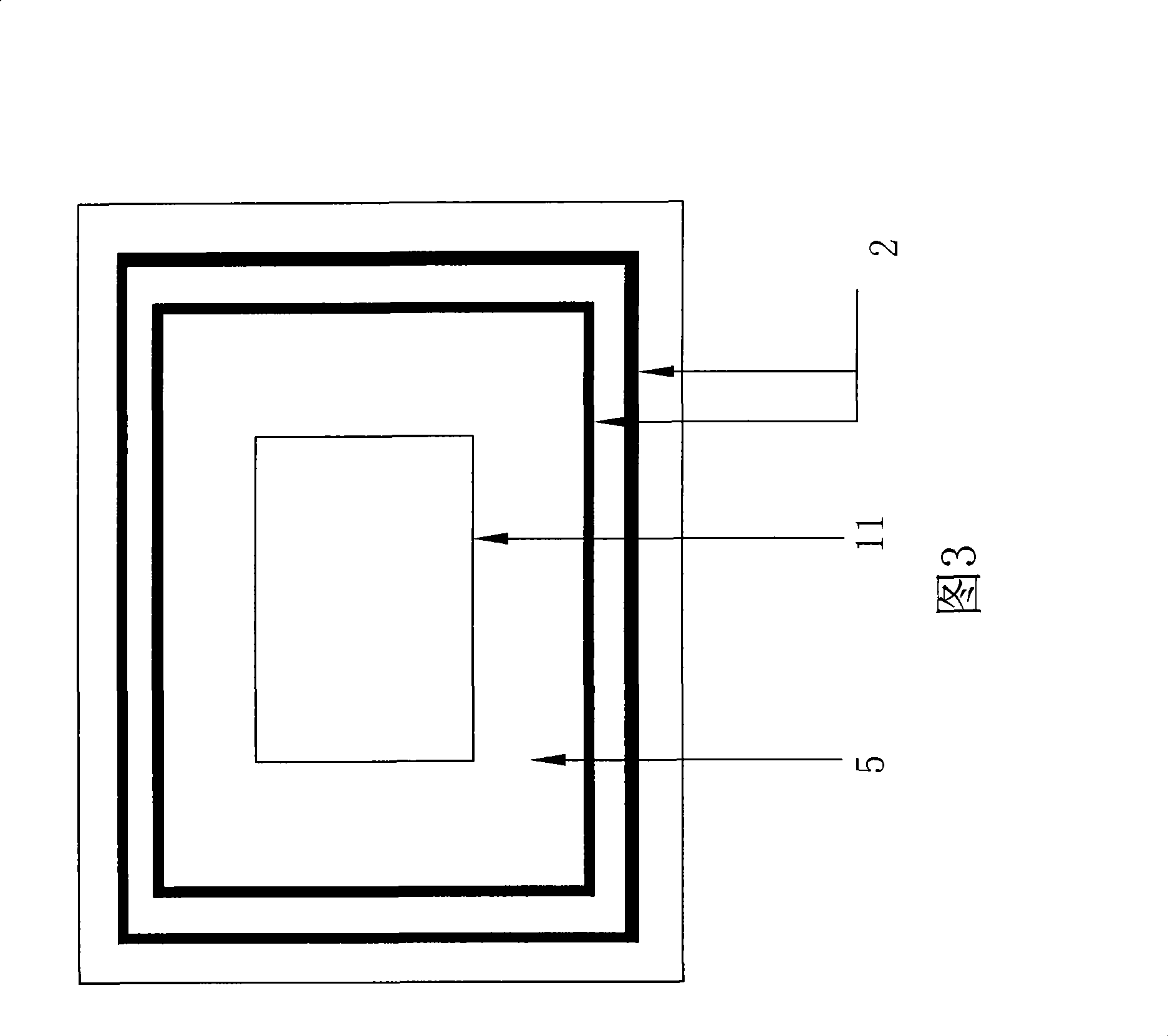

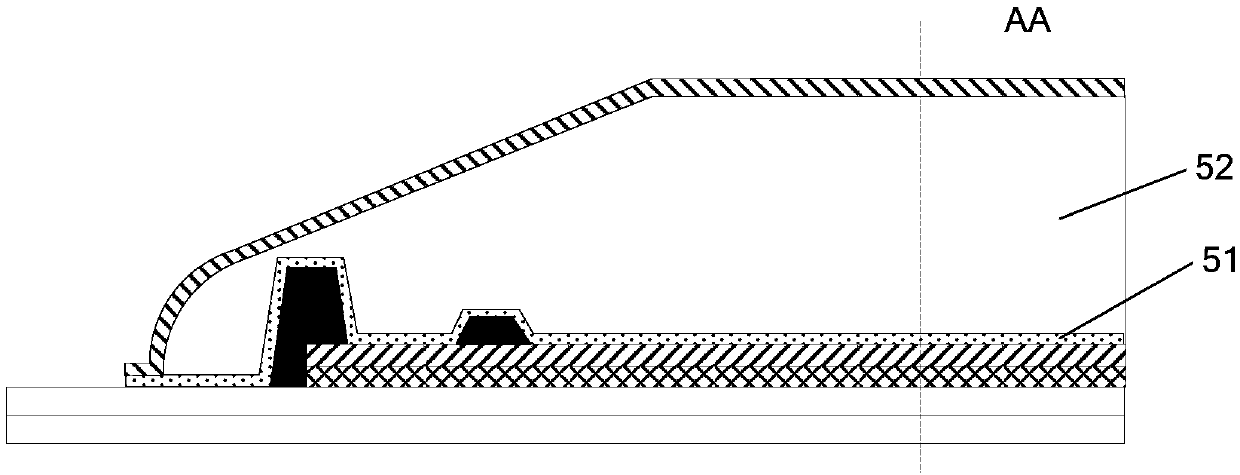

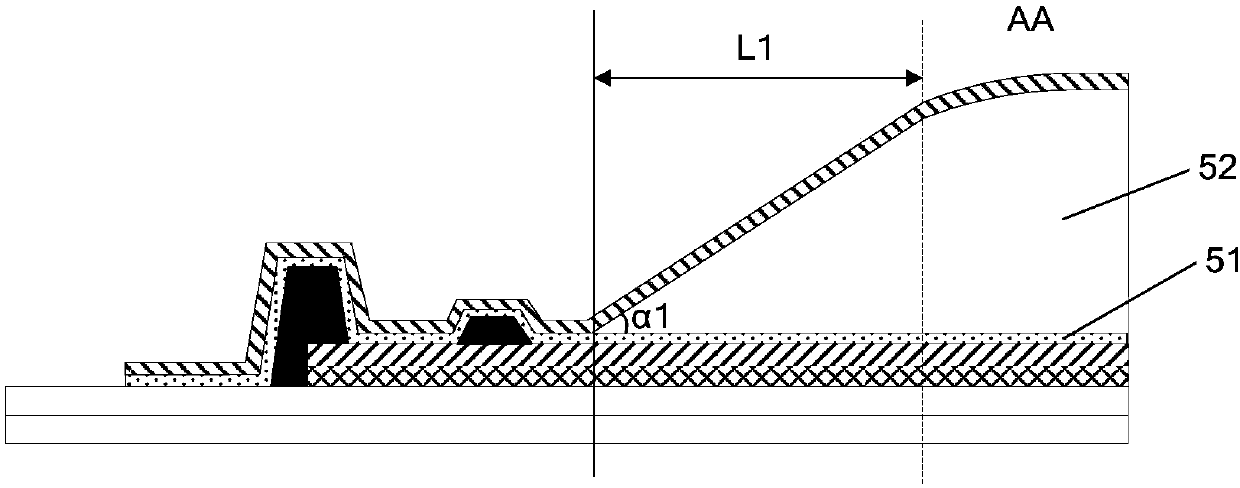

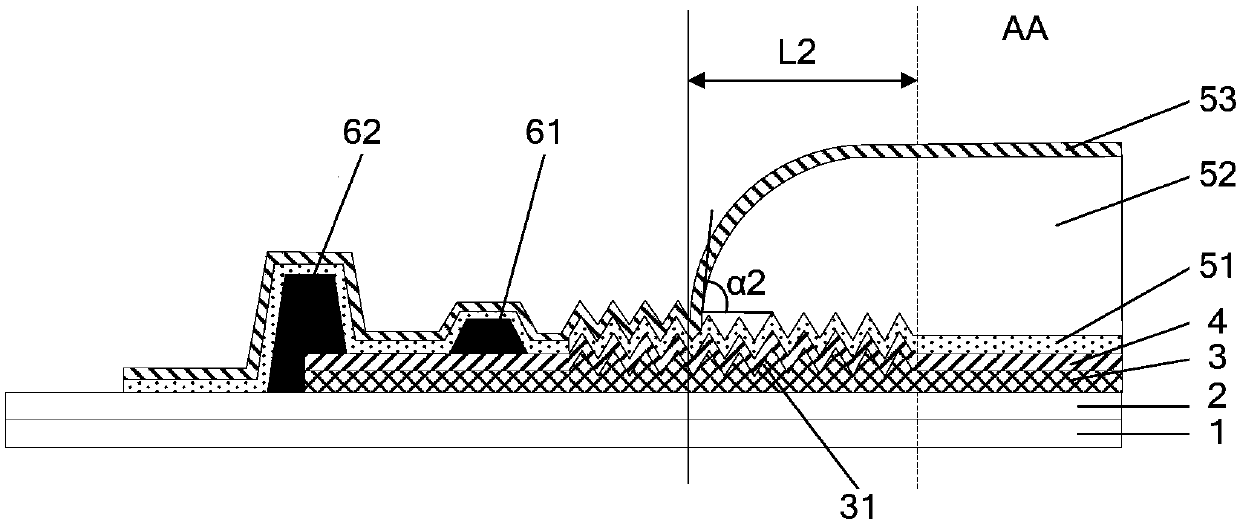

Display panel, display apparatus and preparation method for display panel

ActiveCN106653818AIncrease stressImprove packaging effectSemiconductor/solid-state device detailsSolid-state devicesOrganic light emitting deviceOptoelectronics

The invention discloses a display panel, a display apparatus and a preparation method for the display panel. The display panel comprises a substrate, an organic light emitting device, a thin film packaging layer, and a metal layer, wherein the substrate comprises a display region and a non-display region; the organic light emitting device is arranged in the display region of the substrate; the thin film packaging layer covers the organic light emitting device; the metal layer is positioned in the non-display region of the substrate; grooves are formed in the metal layer; and the grooves are filled with an organic layer. By virtue of setting the metal layer in the non-display region of the substrate, forming the grooves in the metal layer and filling the grooves with the organic layer, bending stress resistance and cutting stress resistance of an edge region are improved, so that risk of cracks on the edge is relieved, and crack expansion can be effectively prevented.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

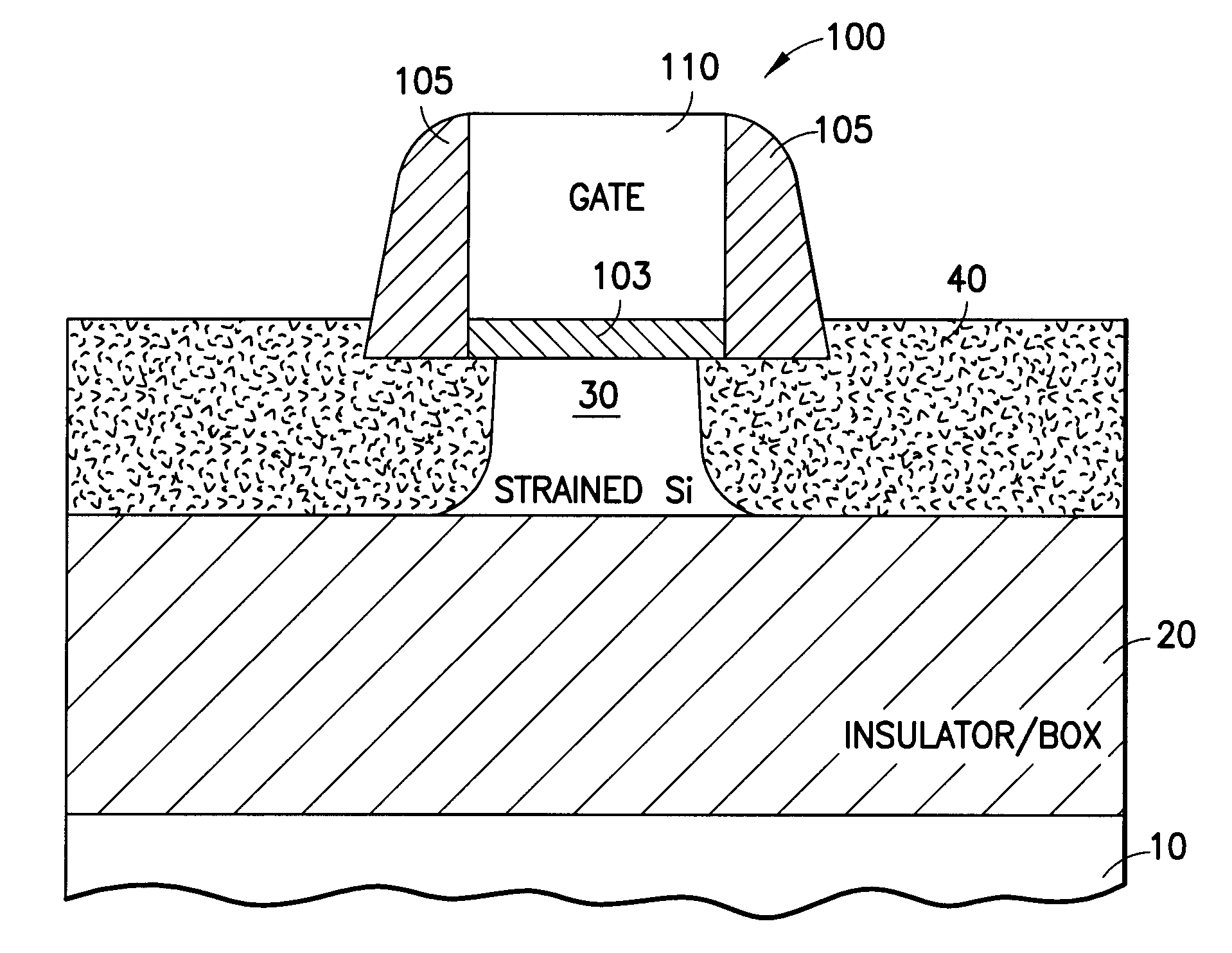

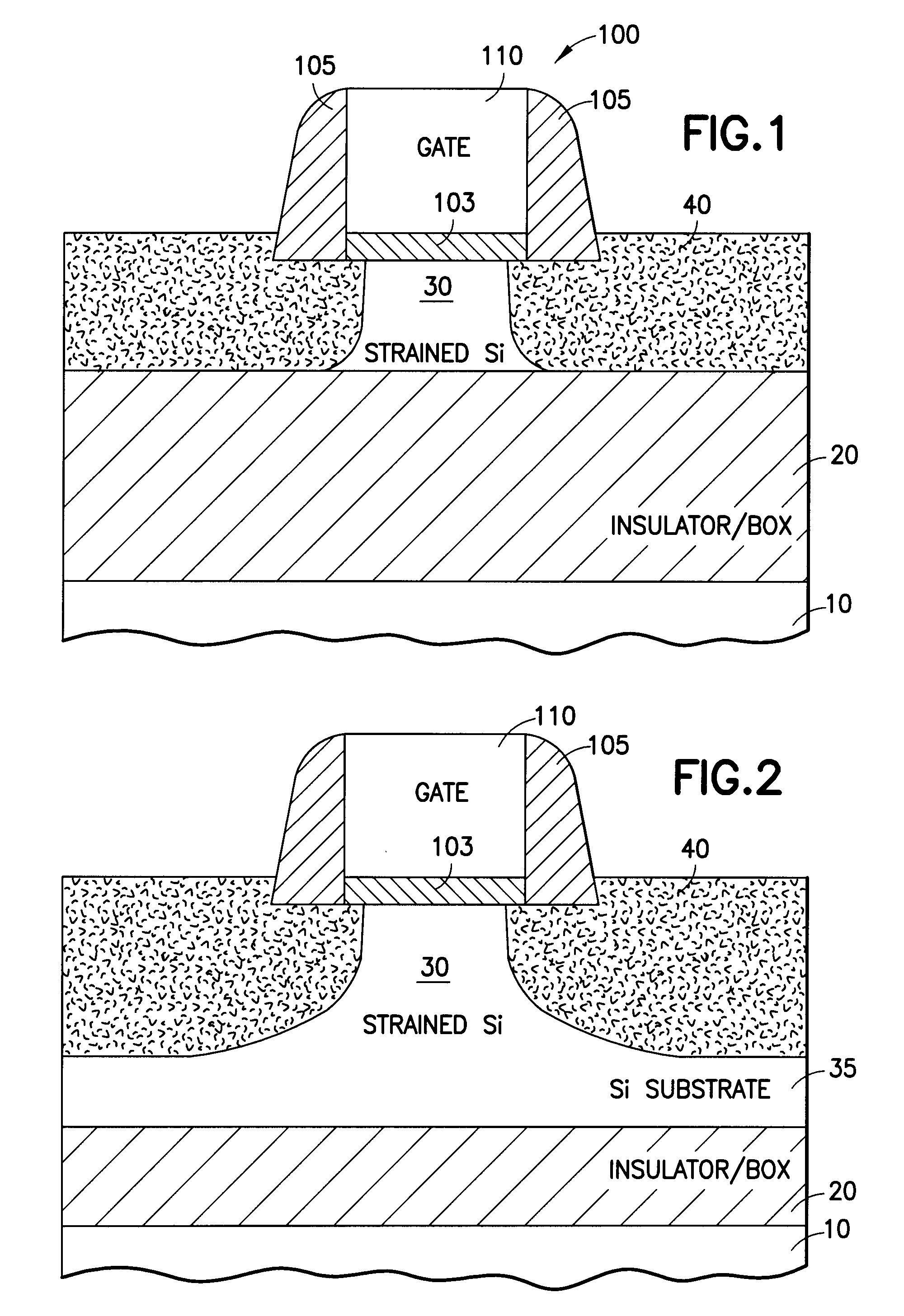

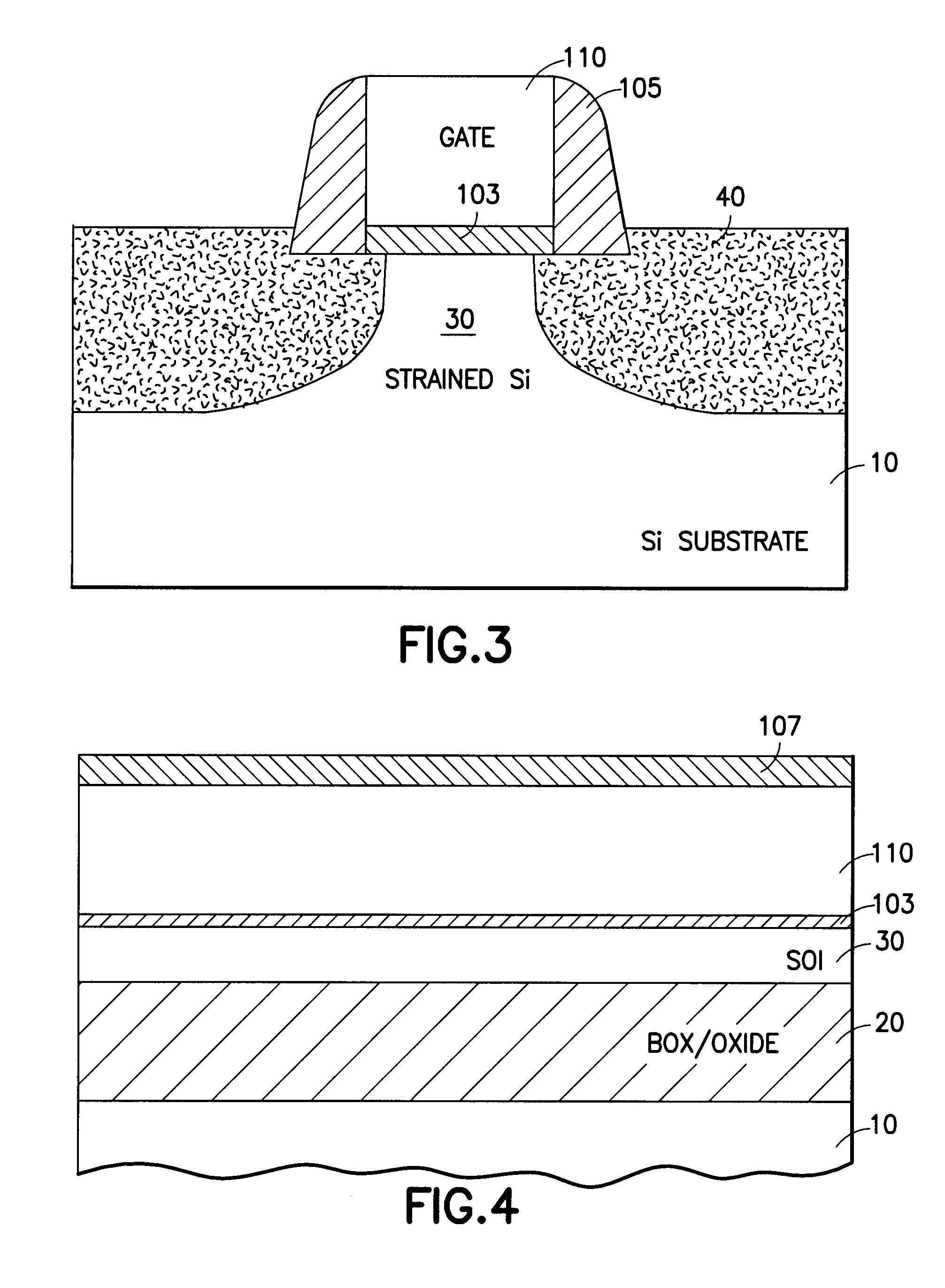

Structures and methods for manufacturing p-type mosfet withgraded embedded silicon-germanium source-drain and/or extension

InactiveUS20050285192A1High hole mobilityImprove mobilityTransistorSolid-state devicesMOSFETGate dielectric

P-type MOSFETs (PMOSFETs) are formed by encapsulating the gate with an insulator and depositing a germanium containing layer outside the sidewalls, then diffusing the germanium into the silicon-on-insulator layer or bulk silicon by annealing or by oxidizing to form graded embedded silicon-germanium source-drain and / or Extension (geSiGe-SDE). For SOI devices, the geSiGe-SDE is allowed to reach the buried insulator to maximize the stress in the channel of SOI devices, which is beneficial for ultra-thin SOI devices. Graded germanium profiles provide a method to optimize stress in order to enhance device performance. The geSiGe-SDE creates a compressive stress in the horizontal direction (parallel to the gate dielectric surface) and tensile stress in the vertical direction (normal to the gate dielectric surface) in the channel of the PMOSFET, therebyforming a structure that enhances PMOSFET performance.

Owner:GLOBALFOUNDRIES INC

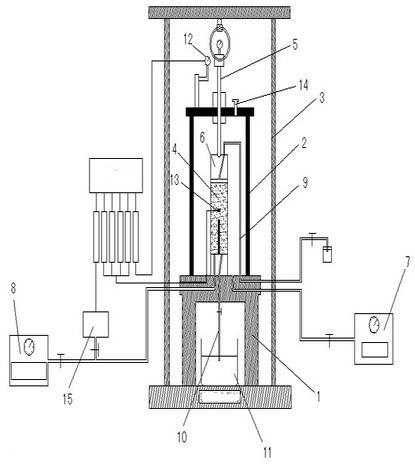

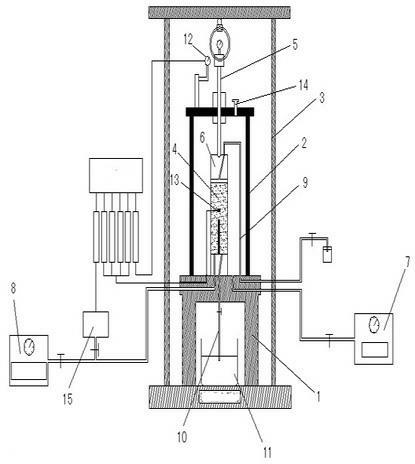

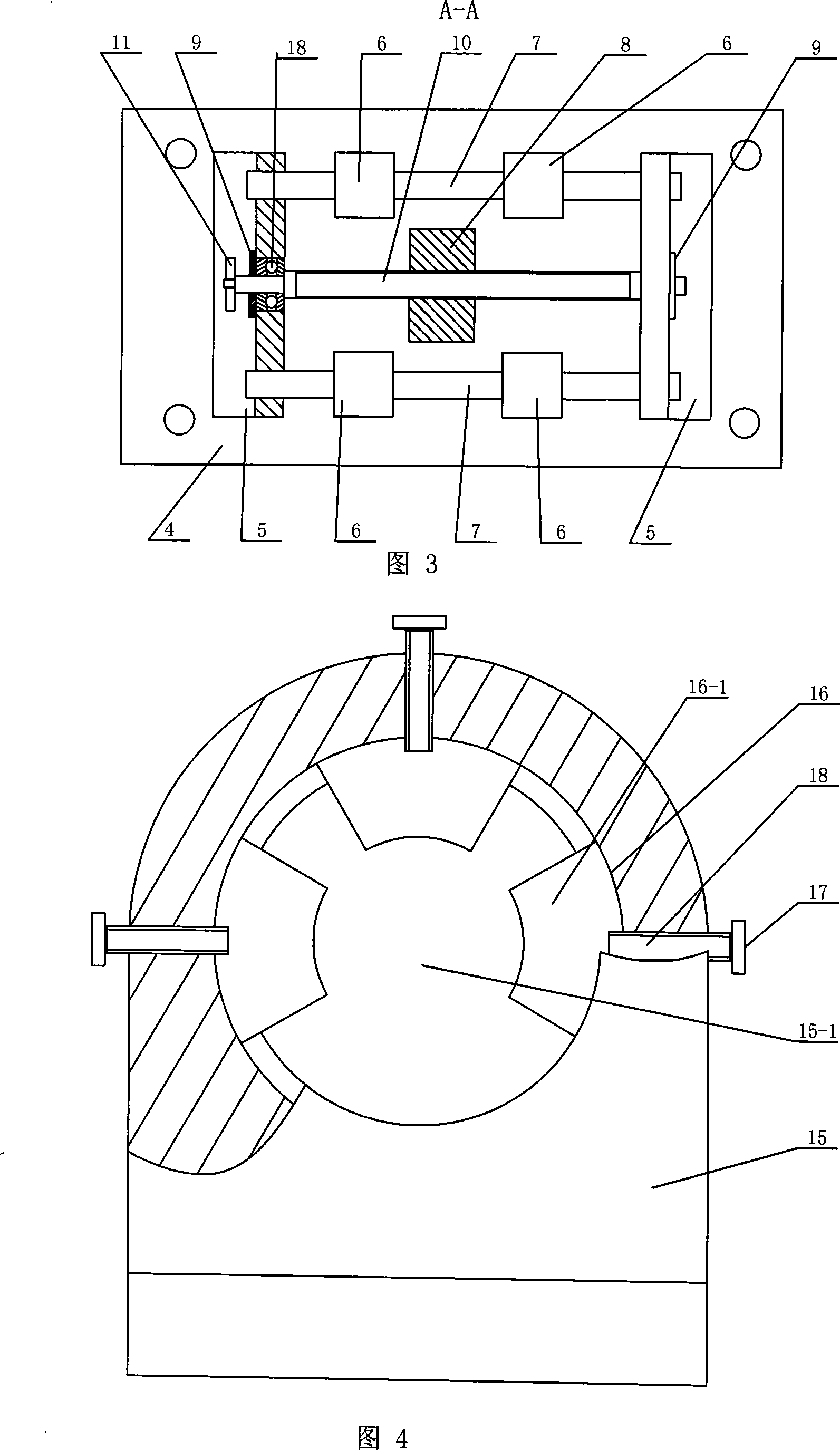

Permeameter for contact surface of soil and works at high stress, high hydraulic gradient, and large shear deformation

ActiveCN102323159AIncrease stressAccurate sample stress and strain dataMaterial strength using tensile/compressive forcesShearing deformationAxial pressure

The invention relates to a tester for seepage failure in a contact surface of soil and works at high stress, high hydraulic gradient, and large shear deformation, characterized in that: a confining pressure chamber is arranged on a pedestal; one end of an axial presser is connected with one end of an axial pressure rod, the other end of the axial pressure rod extends from the top of the confiningpressure chamber into the confining pressure chamber to contact with a sample cap, a permeable stone is arranged at the bottom of the sample cap, a sample is arranged below the permeable stone, and the sample is wrapped with a shrinkable tube closely; a confining pressure presser accesses from the bottom of the confining pressure chamber through pipes, and an osmotic pressure presser accesses from the bottom of the sample in the confining pressure chamber through pipes; one end of a first outlet pipe is connected with the sample cap, and the other end extends out of the confining pressure chamber; one end of a second outlet pipe is connected with the bottom of the sample from the bottom of the pedestal, and the other end is connected with a measuring cup below the pedestal. The tester canacquire accurate stress strain data of the sample with seepage stress coupling effect, and provides a theory basis for researching on the seepage stress coupling constitutive model of the contact surface of soil and works.

Owner:HOHAI UNIV

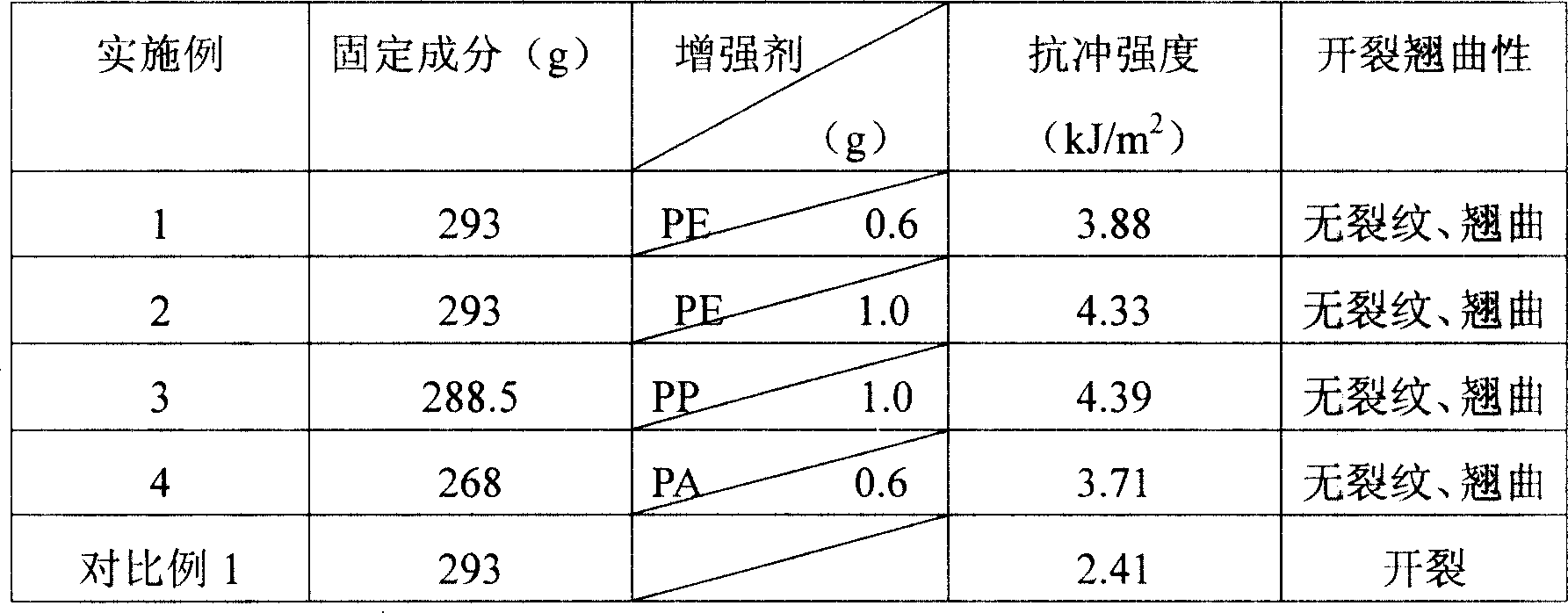

Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

InactiveCN101012360AHigh impact strengthImprove cracking performanceDecorative surface effectsOrnamental structuresAqueous solutionPoly methacrylate

The invention discloses a binder and making method of modified urea-formaldehyde resin, which comprises the following steps: adopting urea-formaldehyde resin, fill, reinforcer, deoxidation agent, formaldehyde catching agent, anti-aging agent, anti-shrinking agent, hardener and auxiliary reinforcer; adopting modified copolymer of acrylic acid, sodium acrylate, N, N-dimethylamino propyl methyl acrylamide as anti-shrinking agent; making polyacrylamide solution reacted by acrylamide and ammonium persulphate as formaldehyde catching agent; allocating each component according to proportion; blending evenly; casting; extracting into vacuum; stripping; stewing; drying naturally; coating a layer of polymethacrylate paint on the surface of product; proceeding colorful paint; obtaining the product.

Owner:XIAMEN UNIV

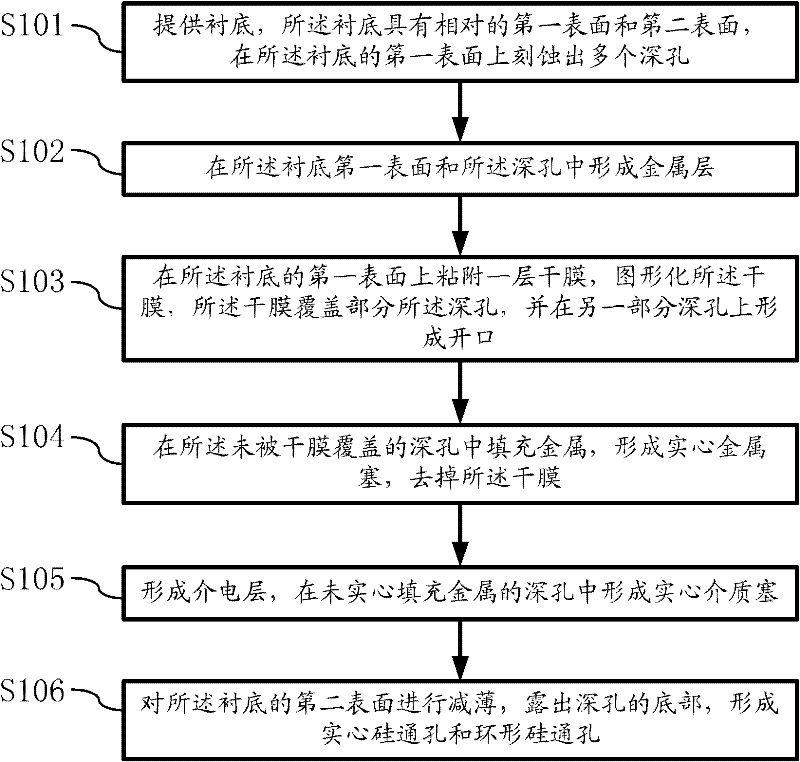

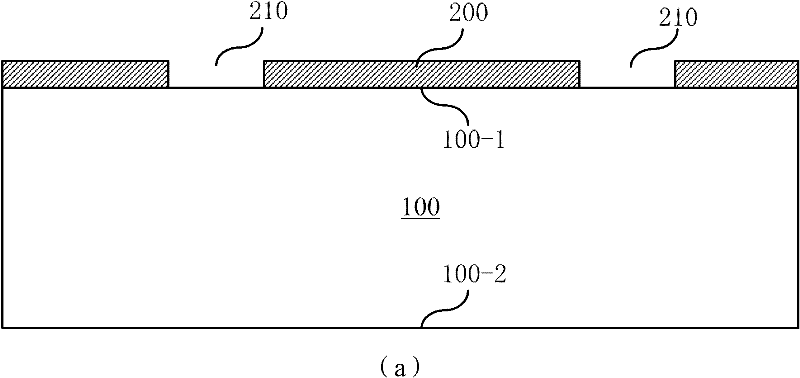

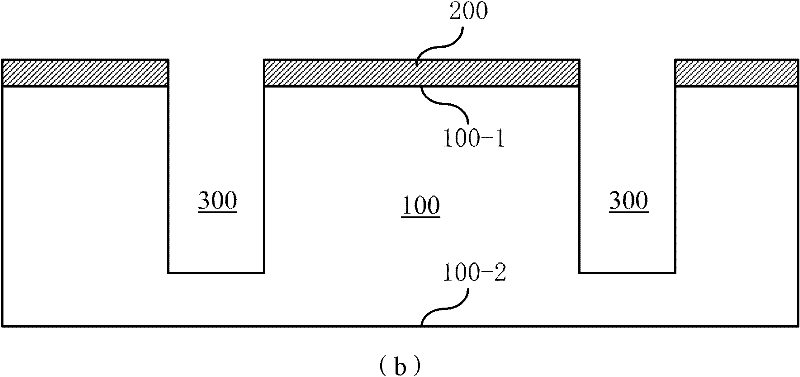

Semiconductor structure with through holes and manufacturing method thereof

InactiveCN102214624AImprove integrityIncrease stressSemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor structure

The invention discloses a semiconductor structure with through holes and a manufacturing method thereof. The semiconductor structure comprises a substrate, a plurality of annular through holes and a plurality of solid through holes; the annular through holes and the solid through holes are embedded in the substrate; the solid through holes are through holes filled by metal; and the annular through holes are through holes filled by solid dielectric plugs and metal rings surrounding the solid dielectric plugs. The manufacturing method comprises the steps of: (1) etching a plurality of deep holes on a first surface of the substrate; (2) forming a metal layer; (3) attaching a dry film on the first surface of the substrate and patterning the dry film such that the dry film generates openings on one part of deep holes; (4) filling metal in the deep holes with the openings on the dry film, and removing the dry film; (5) filling dielectric in the remaining deep holes to form the solid dielectric plugs; and (6) thinning a second surface of the substrate. The solid through holes of the semiconductor structure disclosed by the invention can be used for the heat radiation of laminated chips to improve the completeness of a power supply; and the annular through holes can be used for solving the problems, such as stress, warping deformation and the like of the through hole structures.

Owner:PEKING UNIV

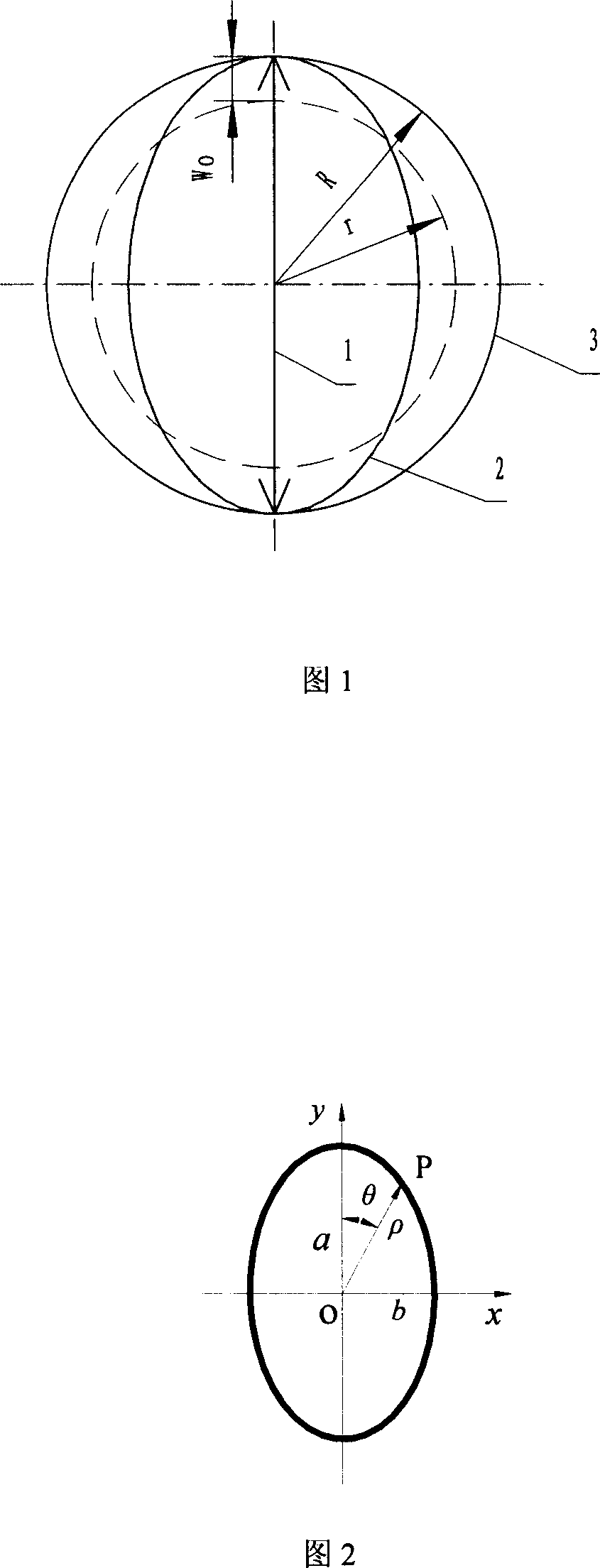

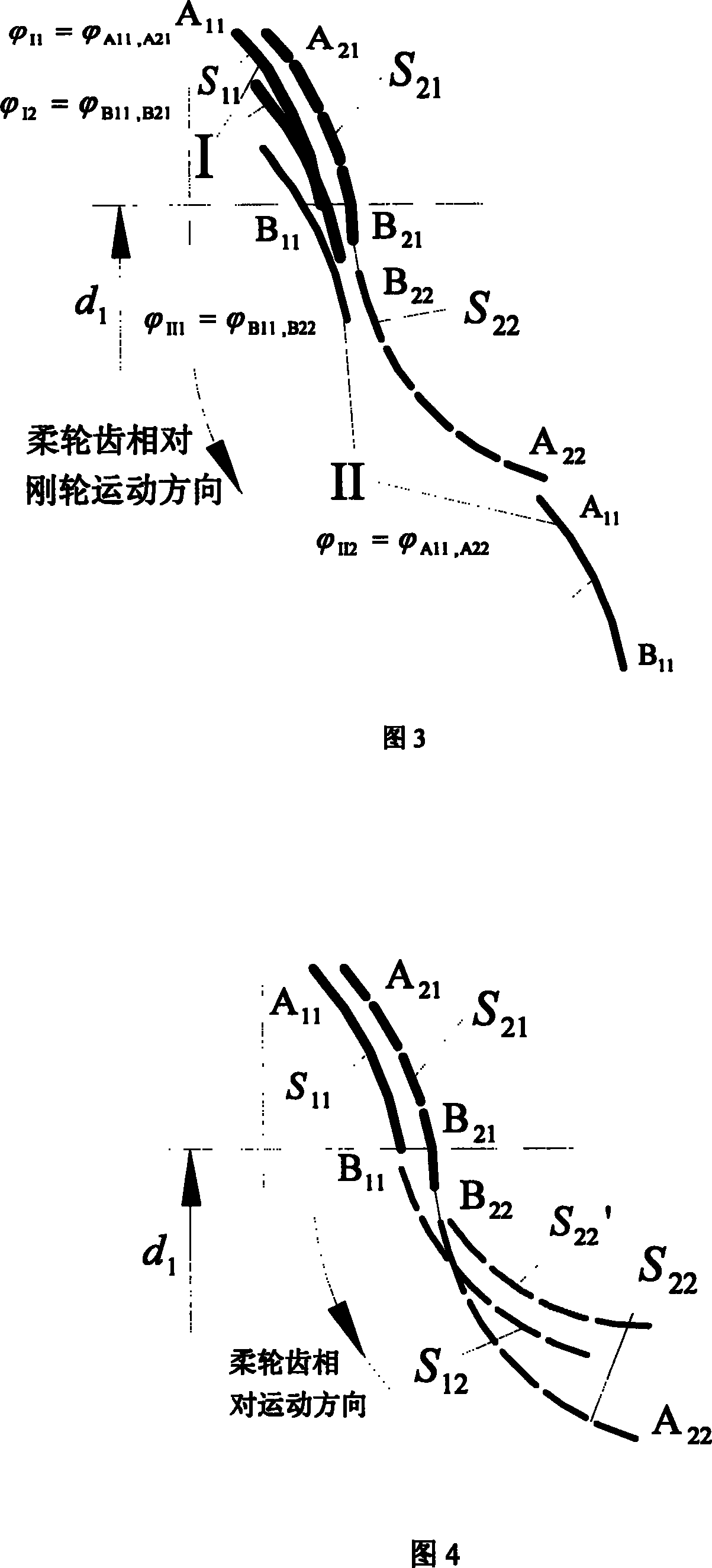

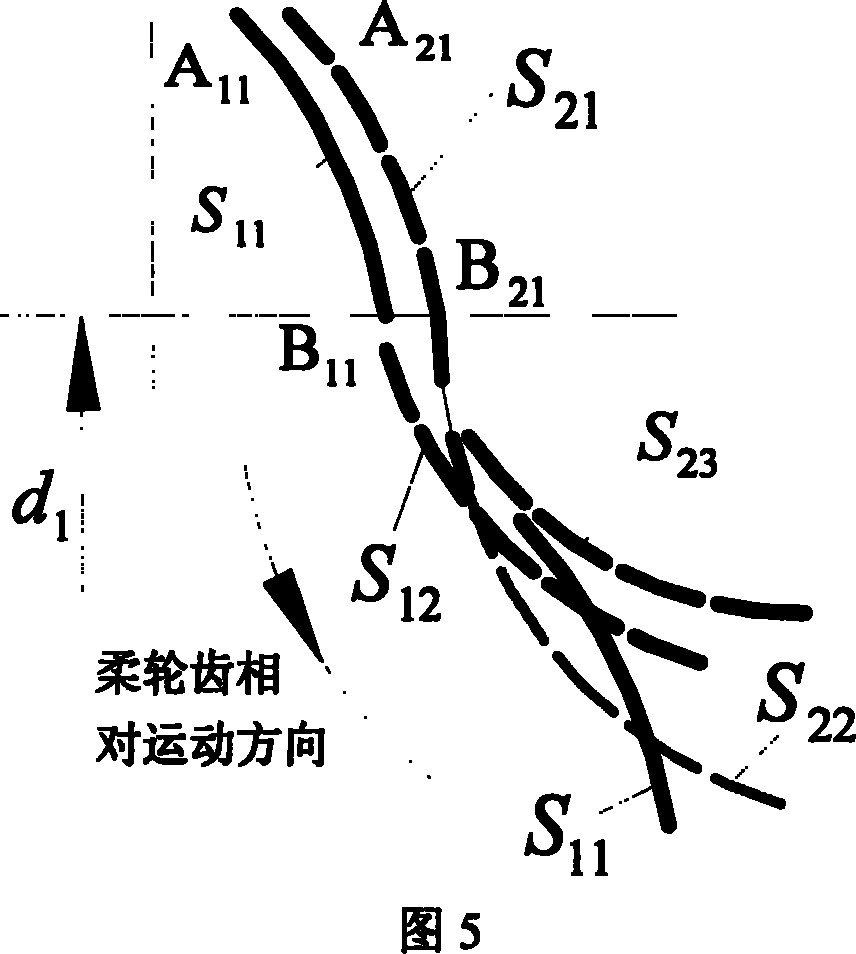

Harmonic gear power transmission with double circular arc tooth outline

InactiveCN101135357AImprove carrying capacityIncreased torsional stiffnessToothed gearingsStress conditionsHarmonic

The harmonic wave gear driver with two-arc teeth profile comprises wave generator, flexible wheel and rigid wheel. The wave generator is in form of elliptic cam, the flexible wheel and the rigid wheel has a two-arc teeth profile respectively which can realize conjugation motion. The driver can effectively improve the stress condition of the flexible wheel tooth-root and drive quality and increase load-bearing ability and torque rigidity of harmonic wave driver, and further lower minimum drive ratio of harmonic wave driver. Advantages: good processing property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Rubber sealed and shock-reducing sound-absorbent material coated on metal sheet and method for preparing same

InactiveCN1721484AImprove high temperature resistanceGood resistance to various mediaOther chemical processesUnspecified rubber coatingsLiquid mediumMetallic materials

The present invention is sealing, damping and silencing material comprising metal sheet and coating. The coating consists of rubber, stuffing and compound ingredient. The compound ingredient includes sulfur, zinc oxide, stabilizer, etc.; the rubber is one or two selected from fluororubber, NBR, SBR, etc.; and the stuffing may be graphite, carbon black, kaolin, etc. The sealing, damping and silencing material may be machined into sealing washer in required shape, can resist the corrosion of various gas and liquid medium, operate in the temperature up to 400 deg.c and pressure up to 120 kg / sq cm, and possesses reliable sealing.

Owner:舟山海山机械密封材料股份有限公司

Crack controlling means for laser deposition formed metal parts

InactiveCN1737197AImprove coagulation stateImprove liquidityMetallic material coating processesLaser beam welding apparatusClosed loop feedbackClosed loop

The invention relates to a crack-controlling method of metal parts by laser melting formation in laser material processing domain, which comprises closed-loop control of fused bath temperature, which comprises the two specific steps of exerting closed-loop feedback control on fused bath temperature by using optical imaging system and PID control device with calorific radiation transmitted from melting zone and adjusting horsepower of laser, and introduction of ultrasonic vibration, which comprises the specific steps of introducing ultrasonic vibration under the piece of work when forming by laser melting. The invention can deduce residual stress and crack, improve structure and can be used in multiple relative domains such as forming, manding and surface peening by laser melting.

Owner:SHANGHAI JIAO TONG UNIV

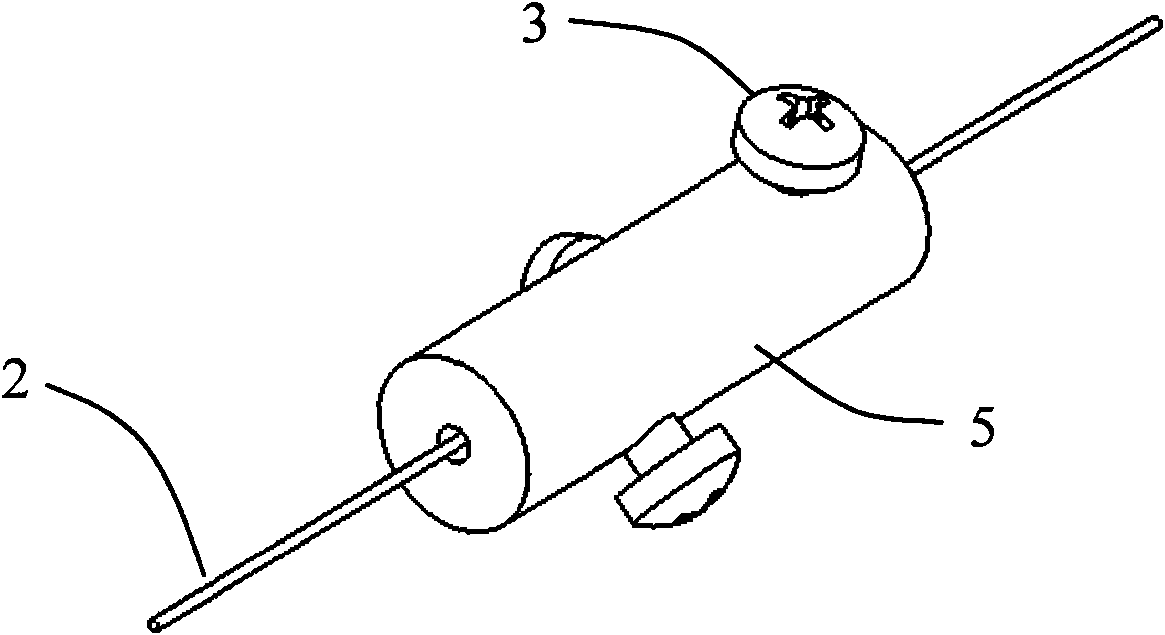

Device for improving spacial distribution of output beams output of multimode fibers

InactiveCN101630045AImproved output beam spatial distributionEvenly distributedCoupling light guidesLight beamSemiconductor

The invention relates to a device for improving the spacial distribution of output beams of multimode fibers. The invention adopts the principle that single-point or multipoint or continuous distributed external stress is exerted on a short length of multimode fibers for transmitting laser to change the transmission mode distribution of light in the multimode fibers, thereby the spacial distribution of beams output form end planes of fibers can be changed. The device is especially suitable for semiconductor laser devices output by fiber coupling. After packaging is completed, the spacial distribution of output beams is improved according to specific use requirement. The device has the advantages of simple use, rapidness and good applicability.

Owner:BWT BEIJING

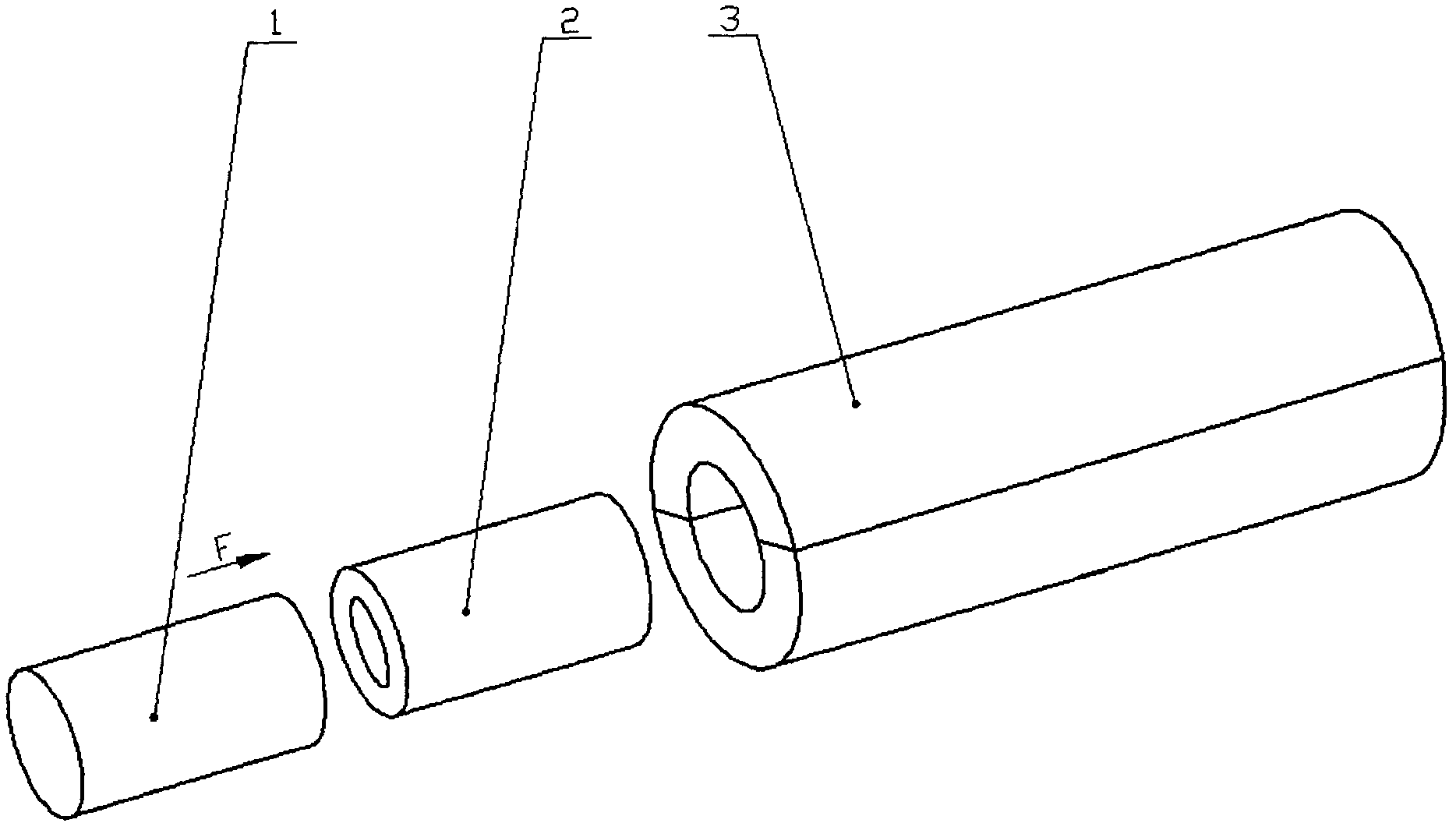

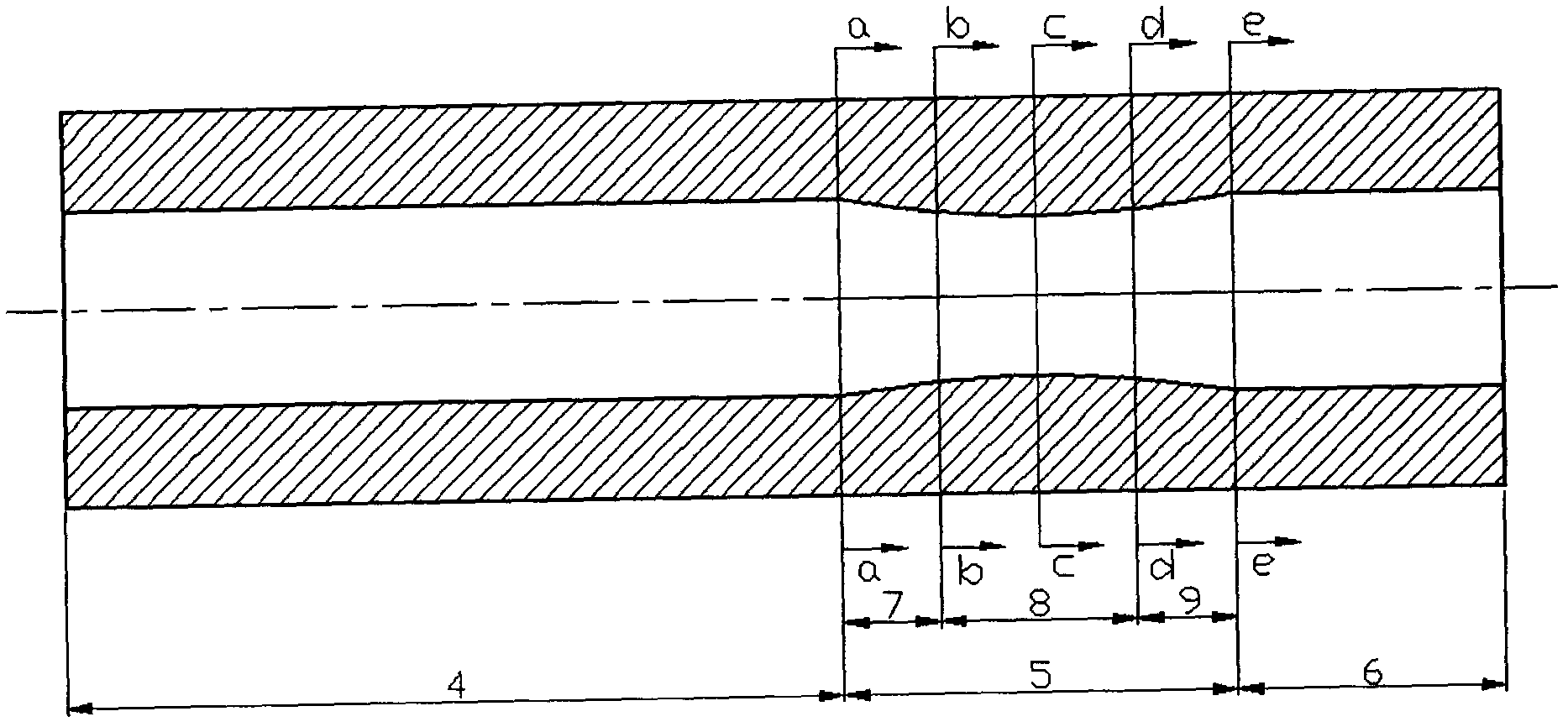

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Rubber material with damping capacity

The invention relates to a rubber material with damping capacity which is characterized in that the rubber material comprises the following components in parts by weight: 10-50 parts of eucommia ulmoides gum, 10-90 parts of rubber material additive 1, 10-90 parts of rubber material additive 2, 1-4 parts of sulfur-containing promoter, 1-5 parts of zinc oxide, 1-5 parts of stearic acid, 5-50 parts of piezoelectric additive and 1-5 parts of sulfur. The rubber material additive 1 is one or two of natural rubber, chlorobutyl rubber, nitrile-butadiene rubber, styrene-butadiene rubber and ethylene propylene rubber and the rubber material additive 2 is one or two of polyacrylate, polyurethane and polyvinyl chloride. The rubber material with damping capacity is mainly characterized by high dampingcapacity, good wearability, excellent anti-fatigue property and good comprehensive mechanical properties and is the ideal rubber material used for relieving mechanical oscillation caused and reducingnoise.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

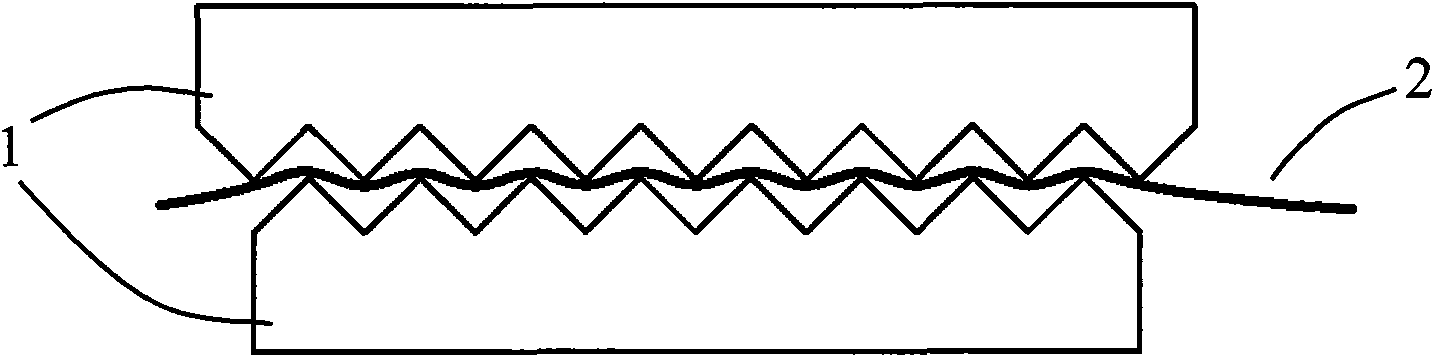

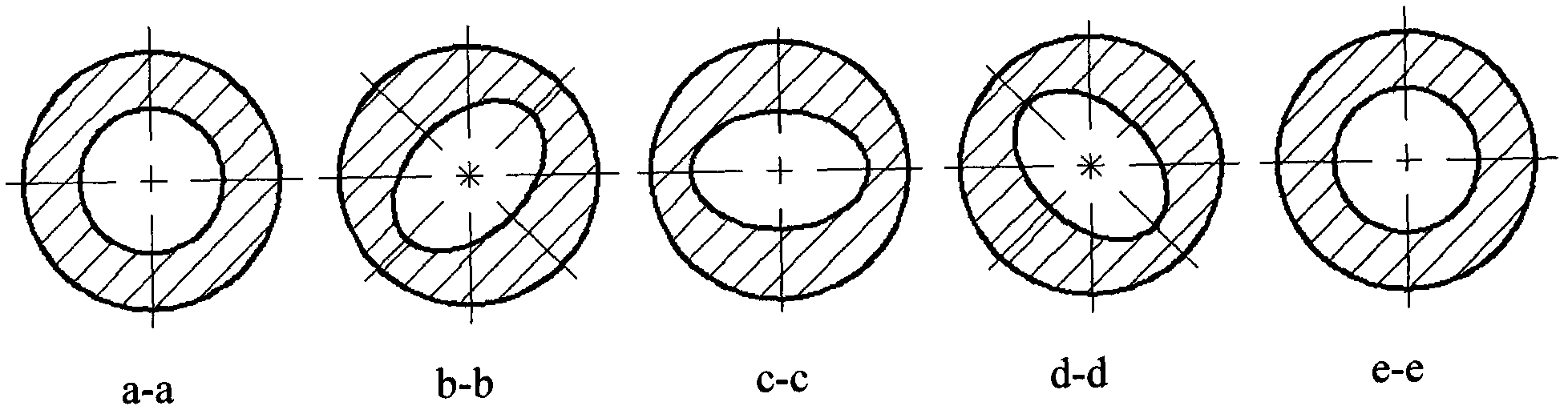

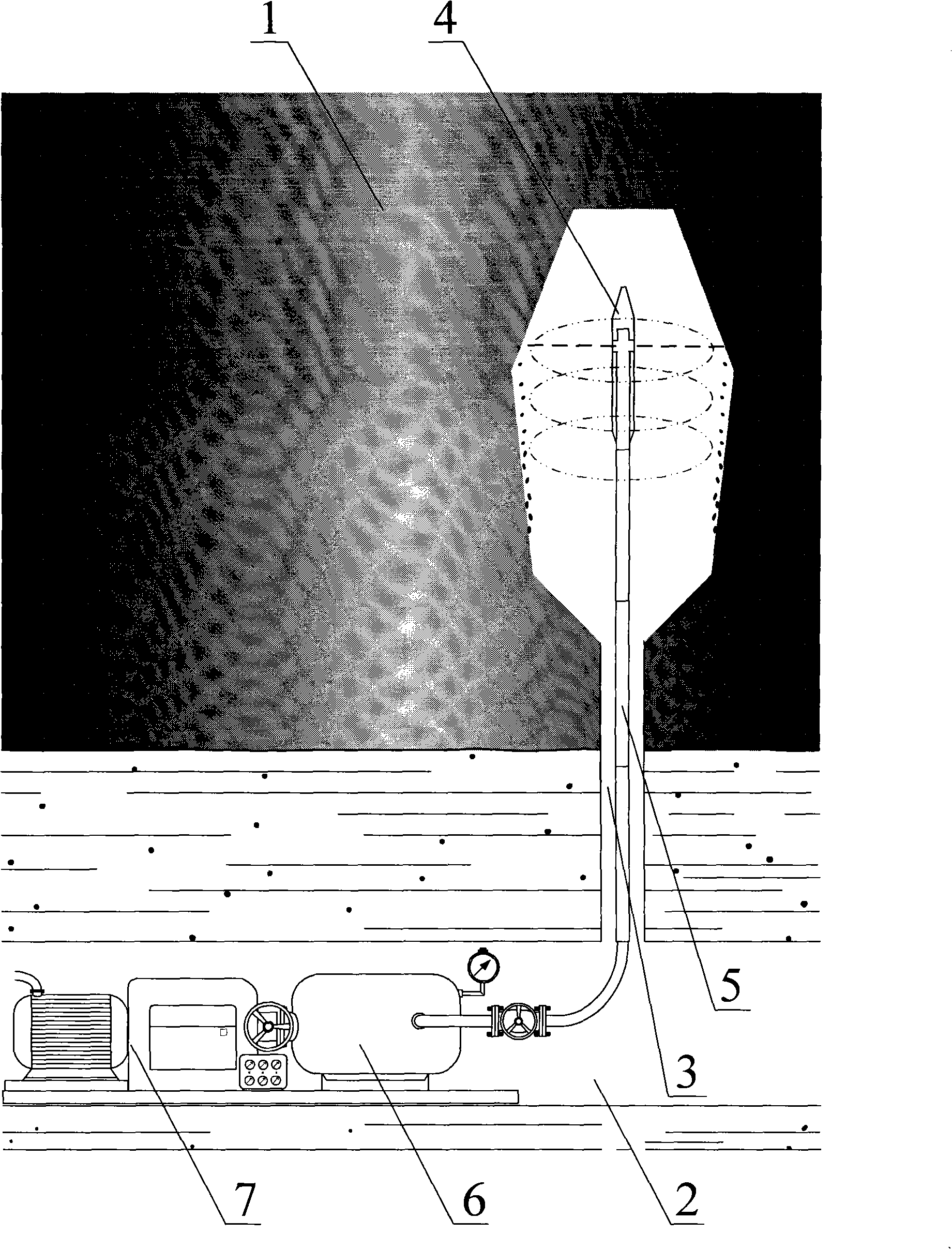

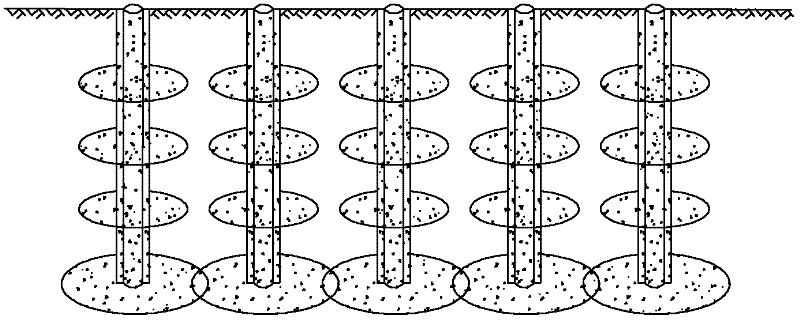

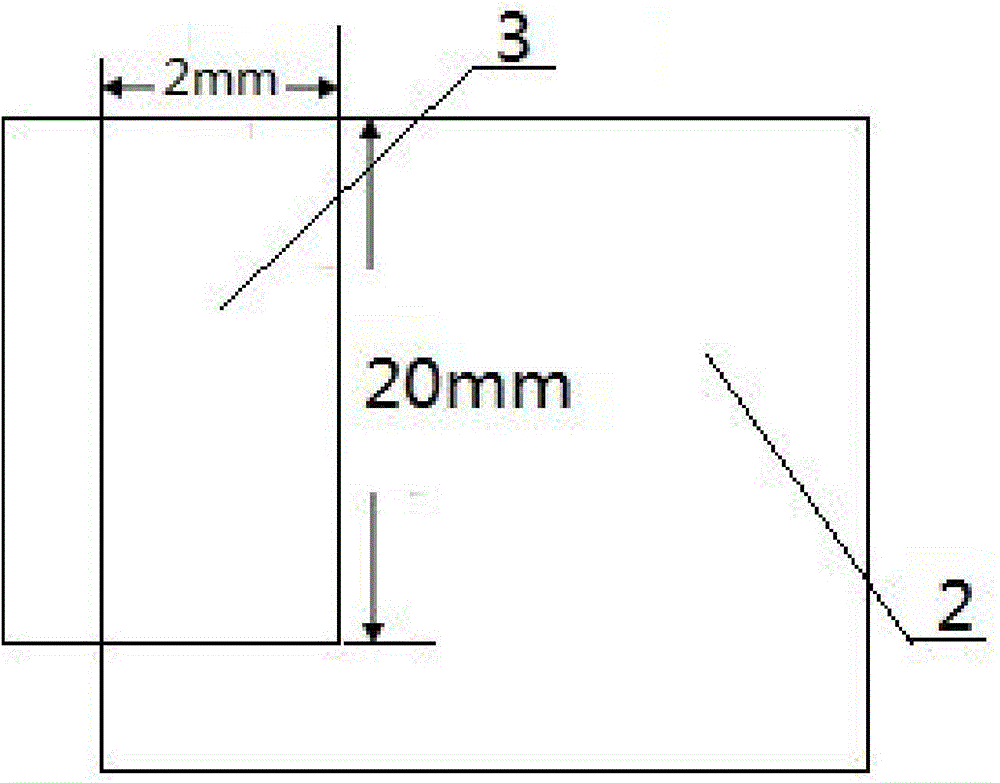

High-pressure gas injection hole-drilling pressure-releasing outburst prevention method

ActiveCN102080525AIncrease the exposed areaImprove breathabilityLiquid/gas jet drillingFluid removalEngineeringHigh pressure

The invention discloses a high-pressure gas injection hole-drilling pressure-releasing outburst prevention method which comprises the steps of: firstly, carrying out common drilling operation in a bottom plate stone drift (2) of a coal bed (1) in front of a coal mining or driving face; after a drill hole (3) enters a design depth of the coal bed, drawing back a drill, sending a jet nozzle (4) anda high-pressure drill rod (5) connected with the jet nozzle into the drill hole, and connecting a high-pressure gas-storing device (6) connected with the tail of the high-pressure drill rod (5) with a high-pressure gas compressing device (7) through a high-pressure tube; starting the high-pressure gas compressing device (7), carrying out near cylinder rotary impacting, cutting and holing on the hole wall of the drill hole in the coal bed (1) by using high-pressure impact wave as a power source through the jet nozzle (4) capable of jetting high-pressure airflow and automatically rotating to ensure that the coal body around the drill hole (3) is gradually crushed and separated from the hole wall to form pressure releasing space and subjected to the pressure balanced permeability increase through ground pressure and gas pressure action. According to the invention, the drainage efficiency of the gas in the coal bed is greatly improved and the outburst damage of the coal bed is reduced.

Owner:河南省迪卡尔机电设备制造有限公司

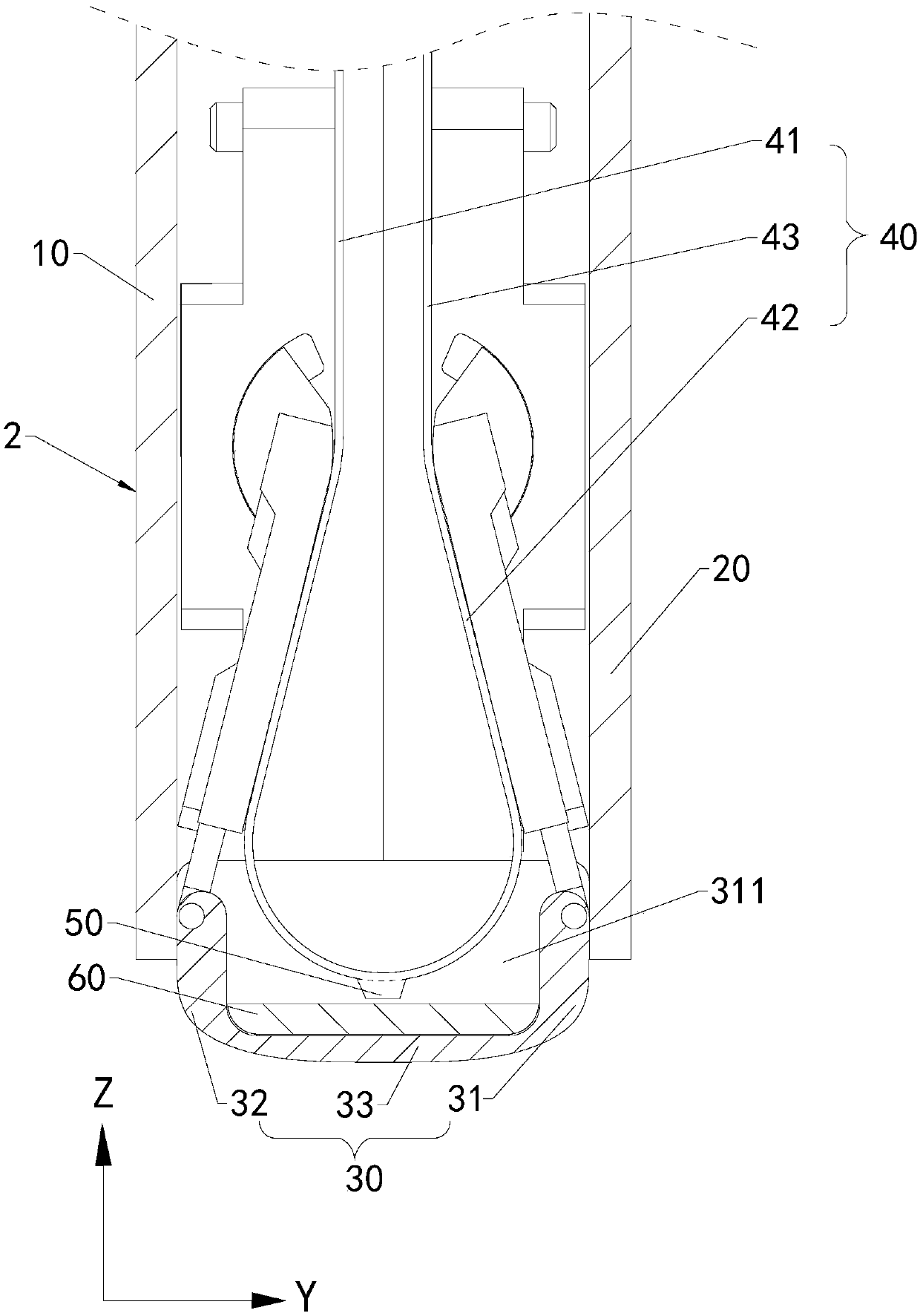

Flexible screen and electronic device

ActiveCN109658826AImprove foldabilityIncrease stressInput/output processes for data processingIdentification meansMechanical engineeringEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

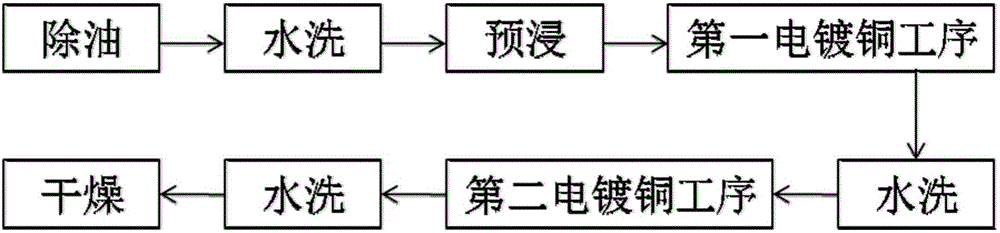

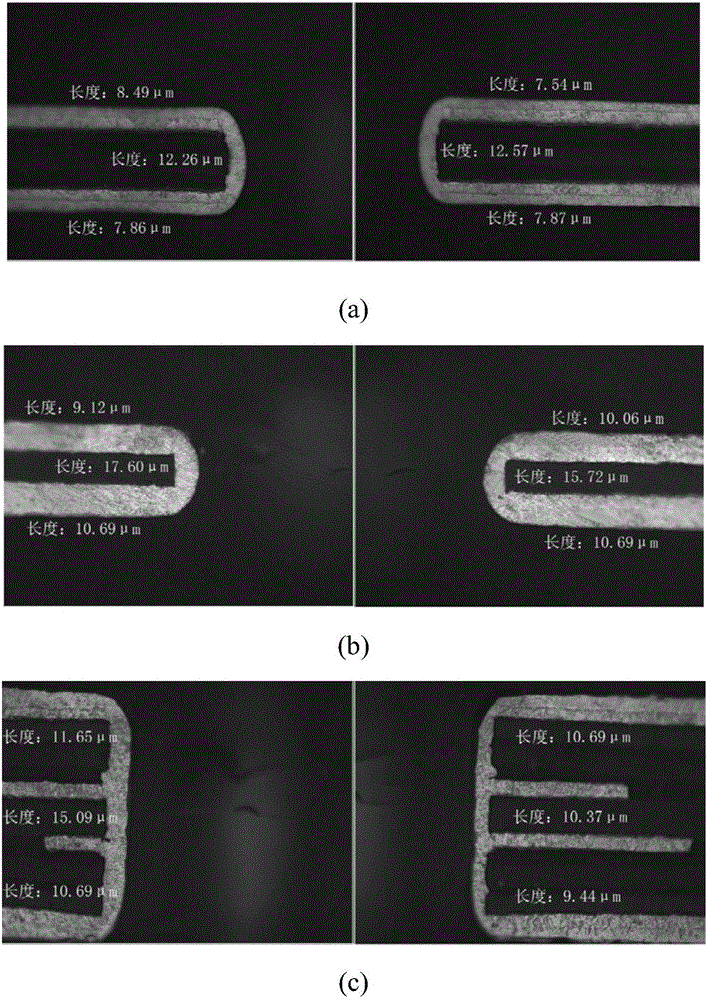

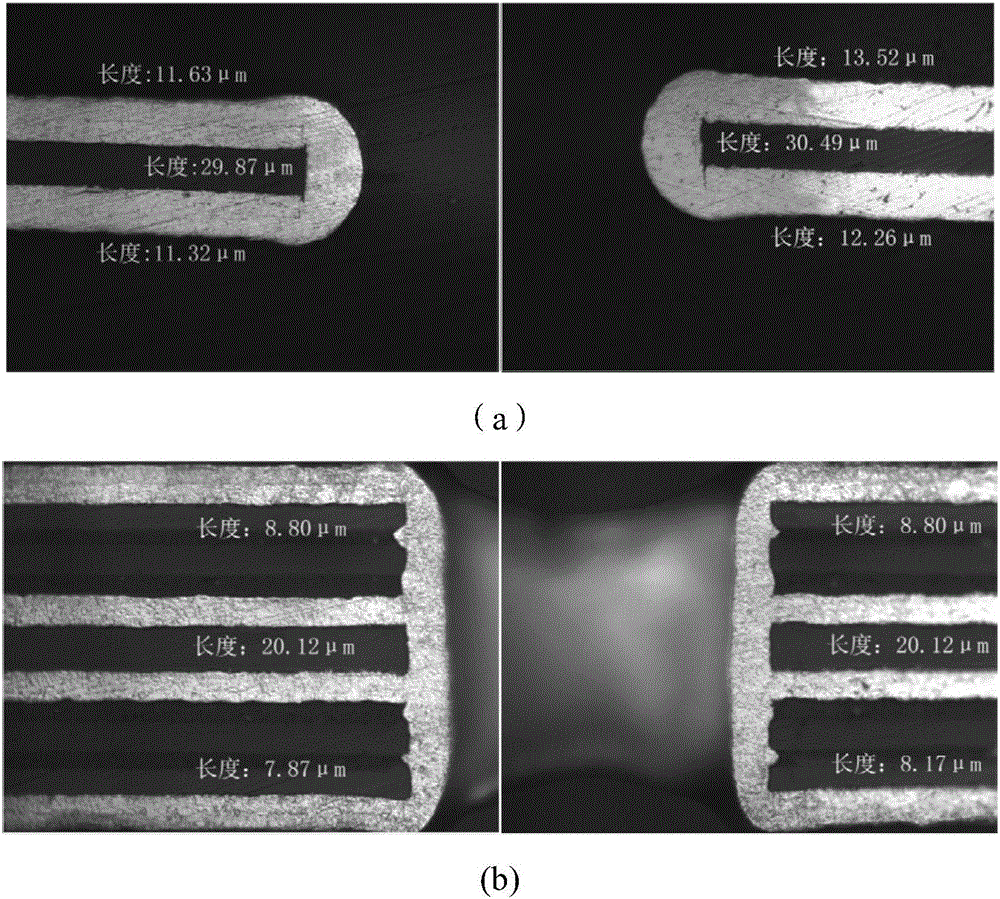

Electric copper plating liquid and electric copper plating process thereof

The invention relates to an electric copper plating liquid and an electric copper plating process thereof. The electric copper plating liquid is made with the following components: 20 g / l of copper sulfate pentahydrate, 20 g / L-300 g / L of sulfuric acid, 25 g / L-120 mg / L of chlorine ion, 0.1 mg / L-20 mg / L of a brightening agent, 1 mg / L-2000 mg / L of an inhibitor, and the balance of deionized water; the brightening agent is selected from alkyl thiol sulfonate or two of its derivatives; the inhibitor is selected from one or any of nonionic surfactants. The electric copper plating liquid of the invention enables greatly improved plating current and greatly improved throwing power (TP) of flexible board through-hole plating, TP reaching to higher than 200%, an electric copper plating layer in each hole is flat, and the quality meets various requirements of flexible board.

Owner:GUANGDONG GUANGHUA SCI TECH +1

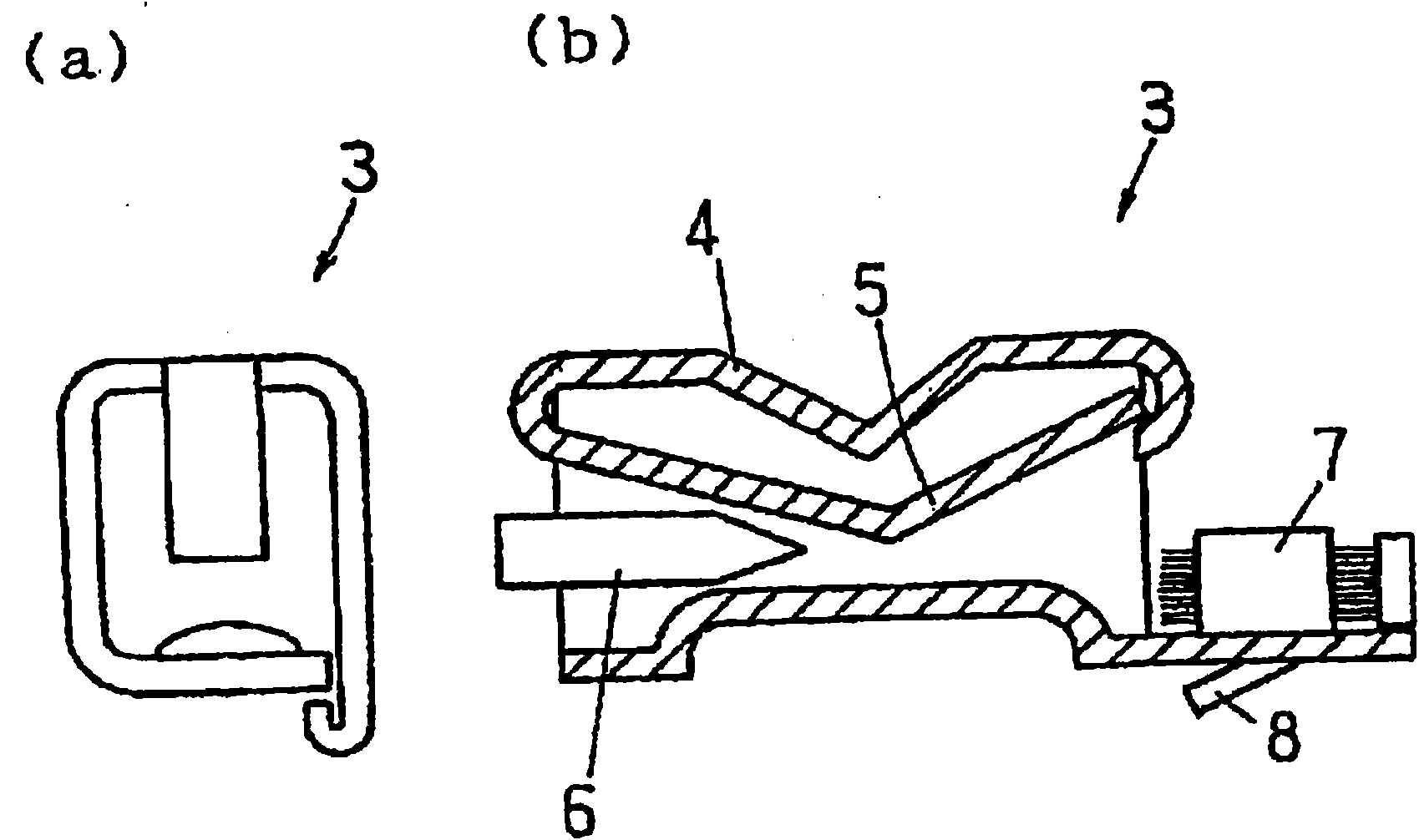

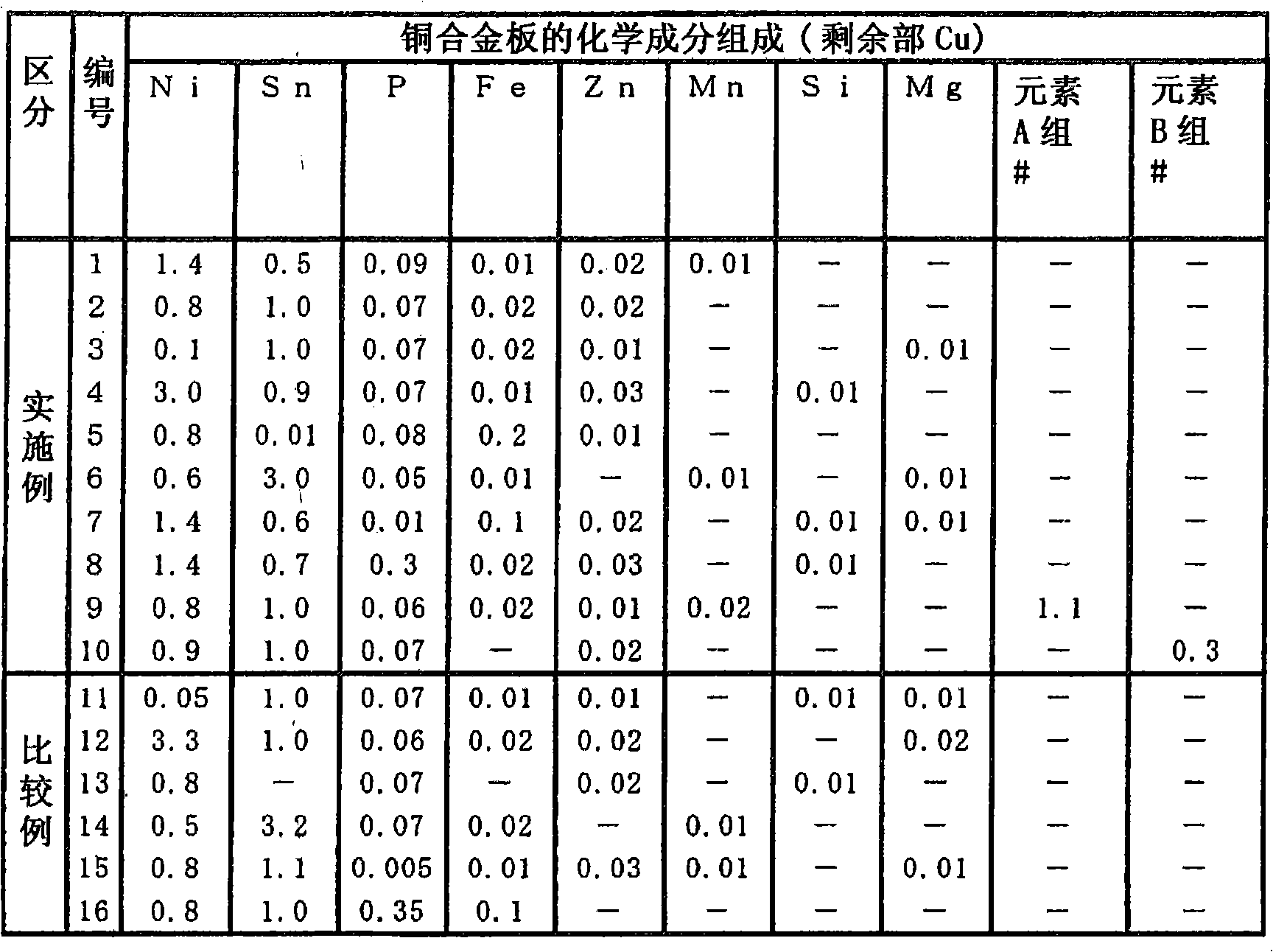

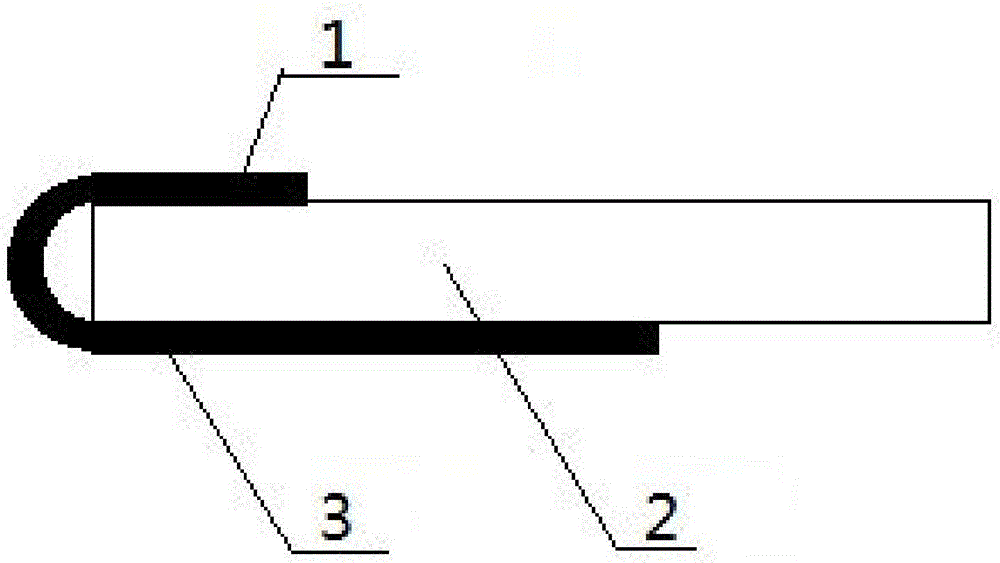

Copper alloy plate having excellent anti-stress relaxation properties

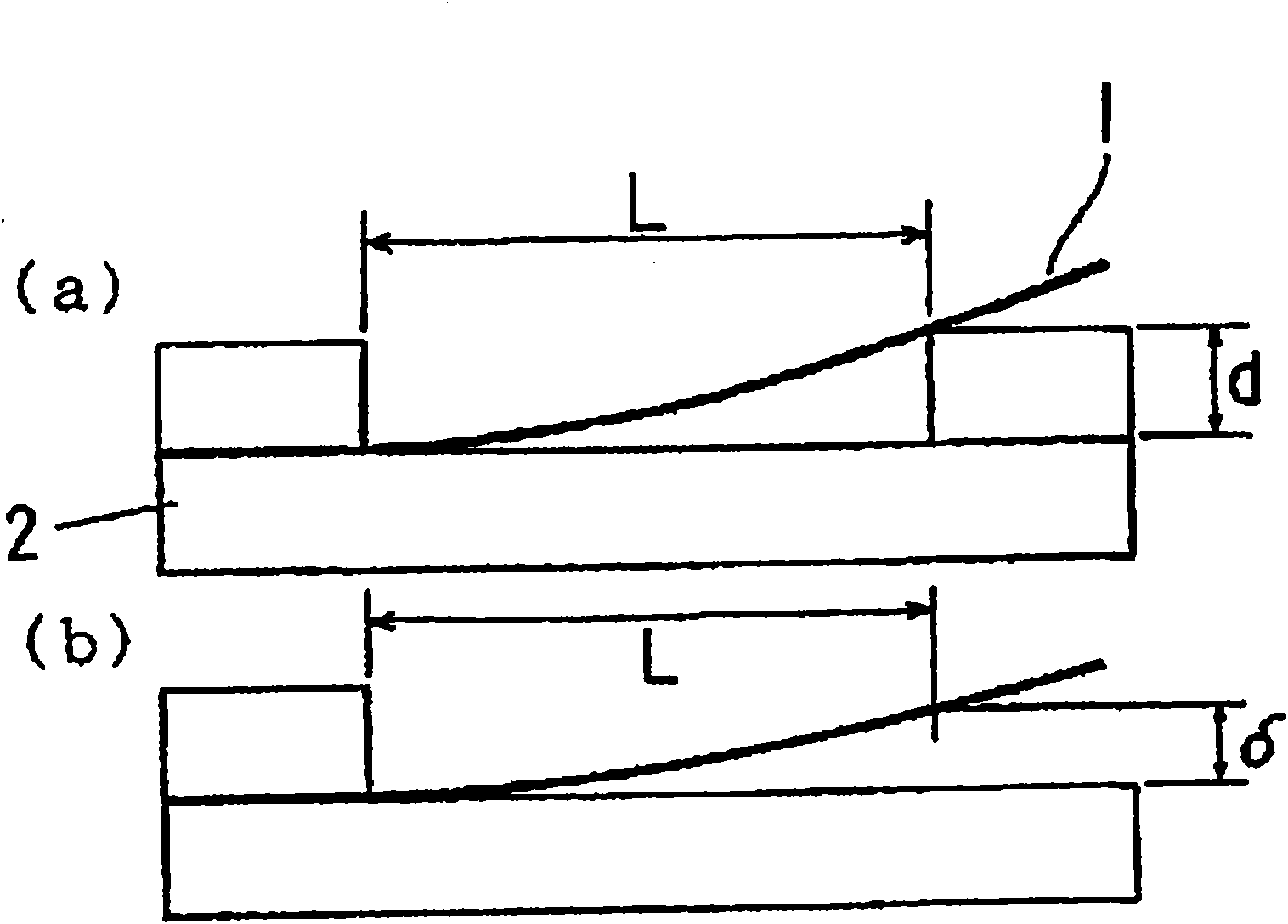

The invention provides a Cu-Ni-Sn-P alloy sheet satisfying the resistance property of stress relaxation in the direction perpendicular to the rolling direction and excellent in the other necessary properties as terminals and connectors. The invention relates to analloy sheet having a specific composition, which is made to contain specific atomic clusters containing at least any of an Ni atom or a P atom, as detected with a three-dimensional atom probe field ion microscope, in a specific density, by increasing the reduction ratio in the final cold rolling and by intentionally shortening the time for the rolling and the time to be taken before the final annealing at low temperature, and of which the necessary properties as a terminal or connector 3 are improved in that the resistance property of stress relaxation thereof in the direction perpendicular to the rolling direction is enhanced and the difference (anisotropy) in the resistance property of stress relaxation thereof between the parallel direction and the perpendicular direction to the rolling direction is reduced.

Owner:KOBE STEEL LTD

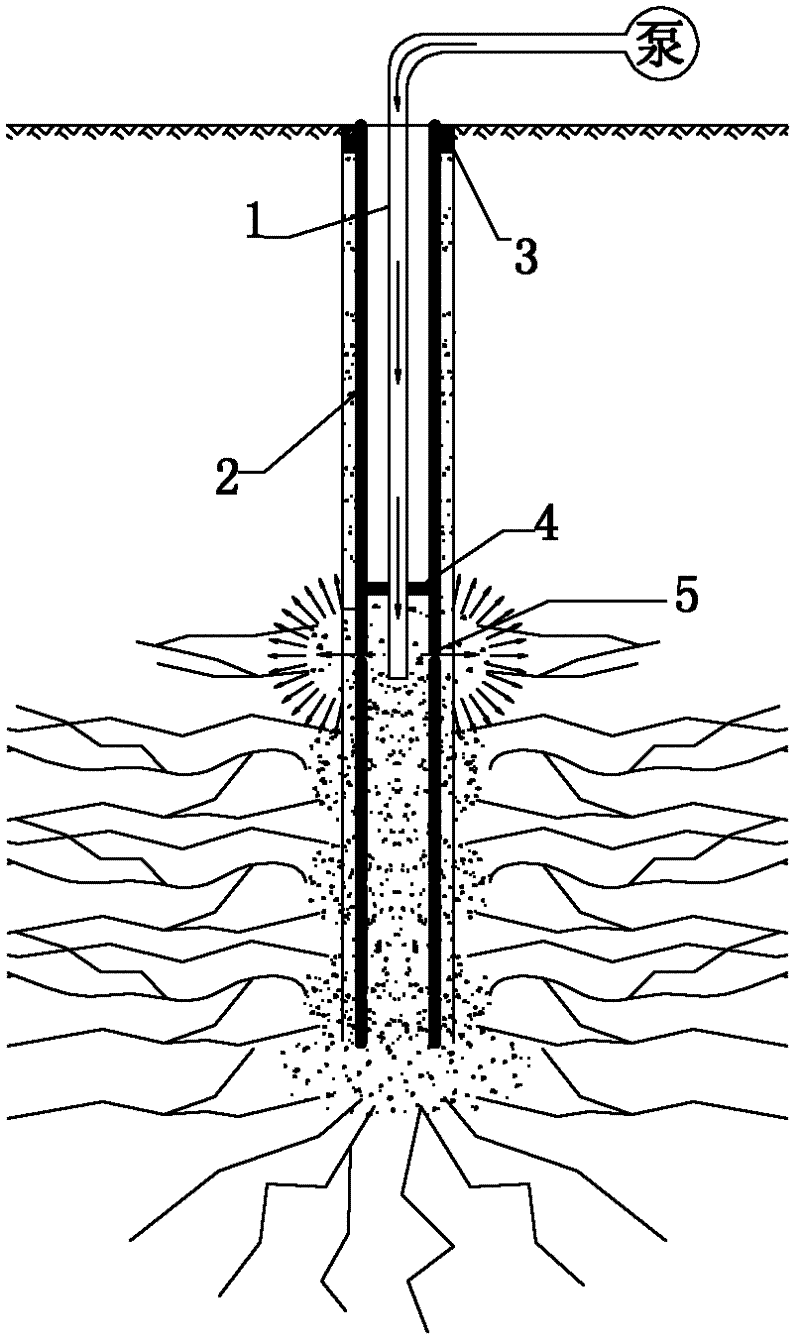

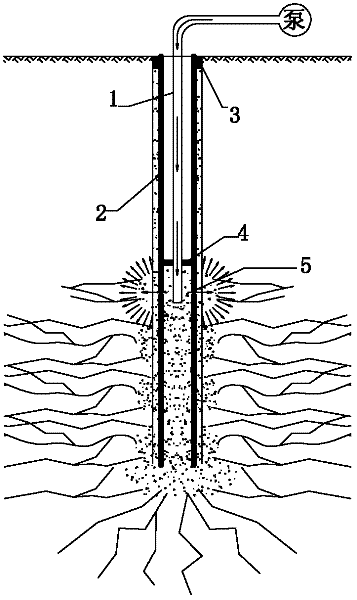

Grouting-type micro steel pipe pile and grouting reinforcement method

InactiveCN102493437AIncrease stressIncreased shear strengthExcavationsBulkheads/pilesSlurryPollution

The invention relates to a grouting-type micro steel pipe pile, comprising a steel pipe, wherein a plurality of spaced slurry outlet groups are formed in the side wall of the steel pipe along an axial direction, and a closed rubber loop is sleeved outside each slurry outlet group. Each slurry outlet group is composed of a plurality of slurry outlets uniformly distributed on a same horizontal plane. The invention further discloses a grouting reinforcement method of the steel pipe pile. According to the invention, a reinforcement effect is obvious, the vertical bearing capacity and the slope stability of a body to be reinforced can be increased from multiple aspects, nonuniform sedimentation can be effectively reduced, and the characteristics of small construction interferences, no pollution, simple construction process, low manufacture cost and the like are achieved at the same time.

Owner:SHANDONG UNIV

Single-component high/low-temperature-resistant epoxy resin composition

ActiveCN102827566AImprove performanceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkEther

The invention provides a single-component high / low-temperature-resistant epoxy resin composition which comprises the following ingredients in parts by weight: 100 parts of rubber cross-linked modified epoxy resin, 0-20 parts of cardanol-type glycidol ether, 80-120 parts of alicyclic acid anhydride curing agent, 0.5-10 parts of latent curing accelerator, 10-40 parts of polyacrylate core-shell compound particle toughener, 2-20 parts of thixotropic agent and 50-100 parts of filler. The epoxy resin composition has the advantages of high toughness, high / low-temperature alternation resistance, simple preparation technique, low viscosity and favorable flowability, and can greatly enhance the packaging reliability and durability of electronic devices.

Owner:GUANGDONG TGPM AUTOMOTIVE IND GRP

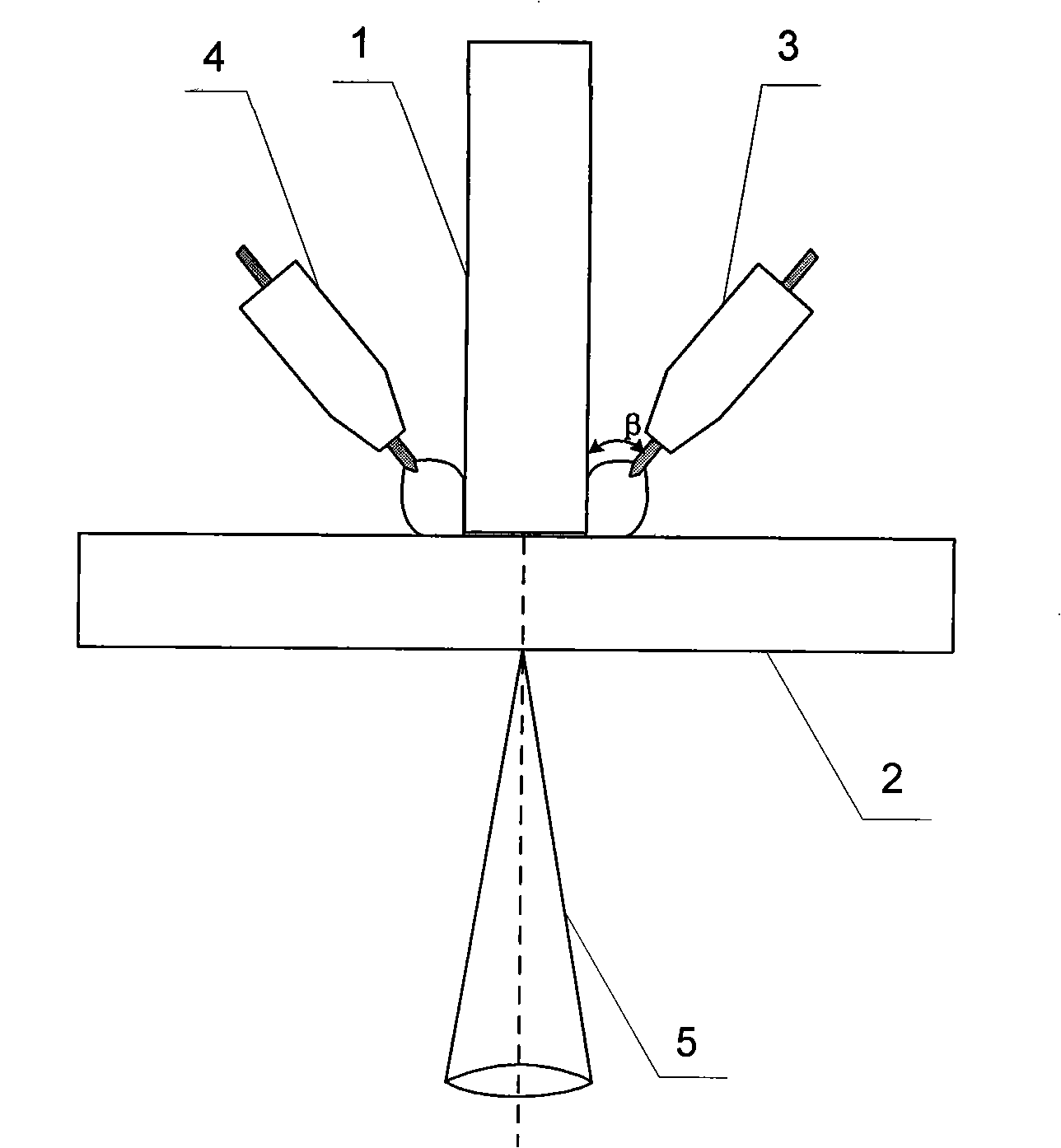

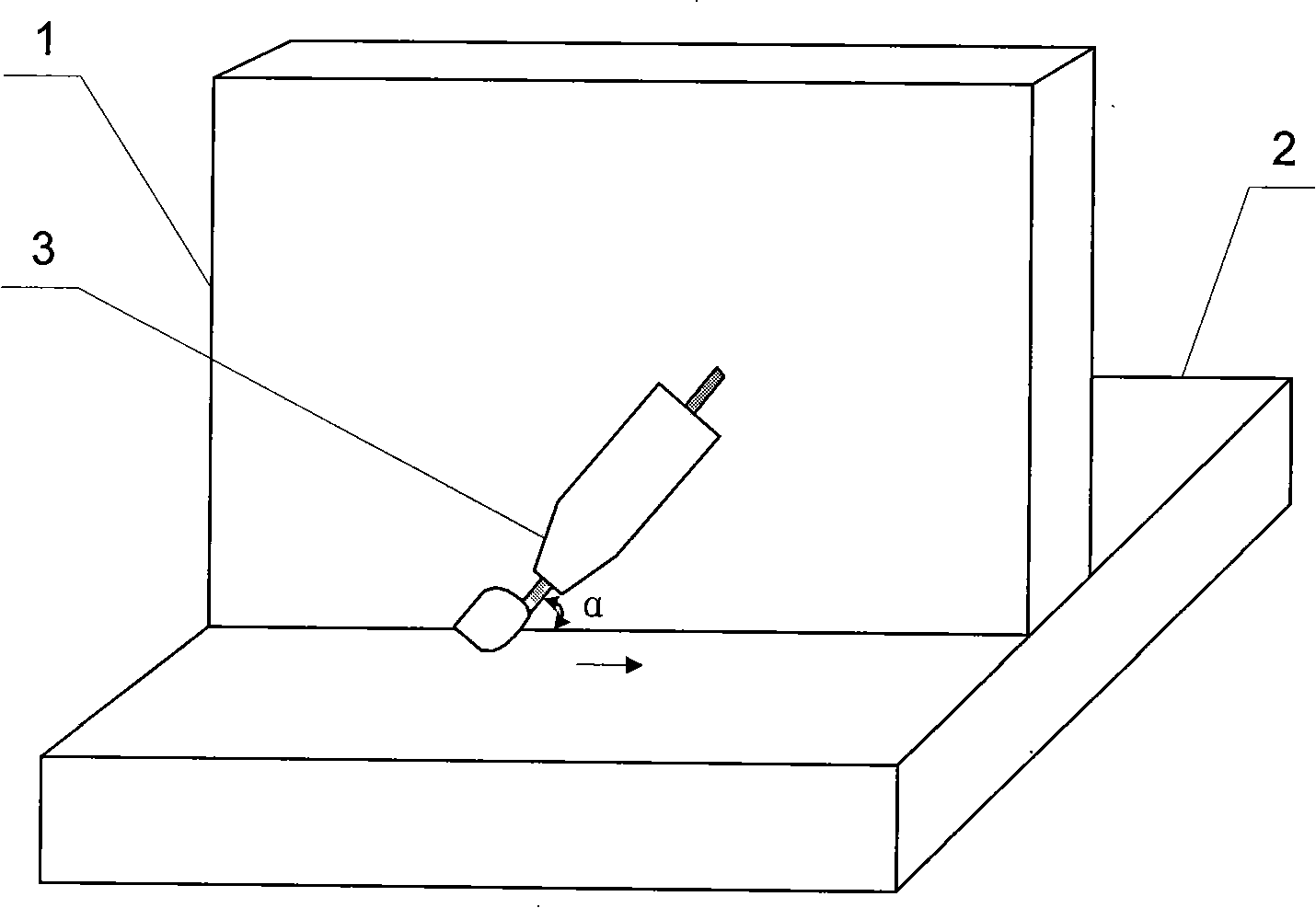

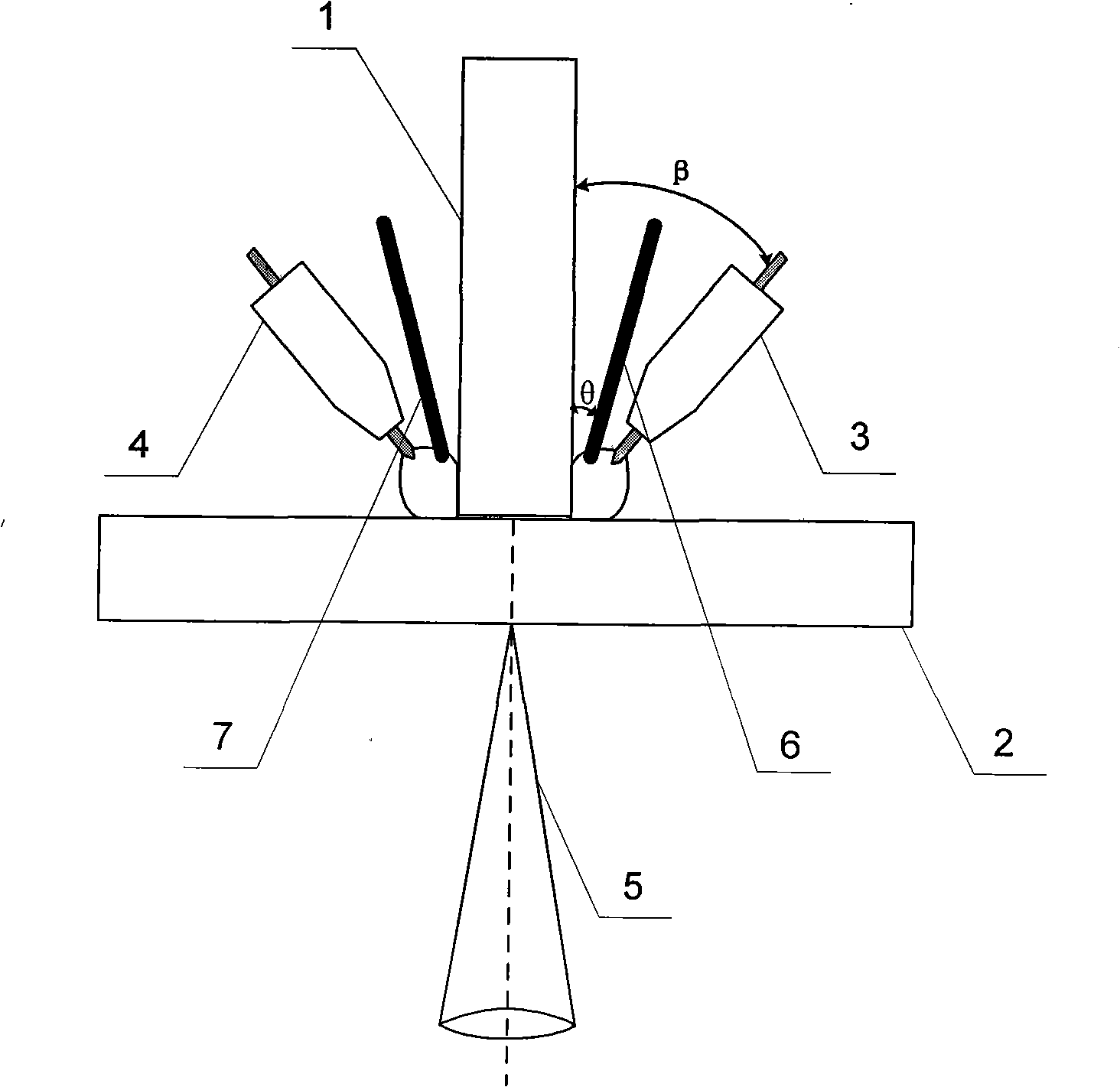

Laser-double arc double sided compound welding method of T shaped joint

InactiveCN101306492AImprove energy utilizationReduce laser powerArc welding apparatusLaser beam welding apparatusElectric arcLight beam

A laser and double-electric-arc double-faced composite welding method for a T-type joint relates to a welding method for laser and electric arc composite welding, and particularly relates to applying the laser and the double-electric-arc double-faced composite welding to a workpiece with a T-type joint to be welded. The invention aims to solve the problems that the single laser penetration welding has strict requirement to the seam fit-up gap and smaller fusion diameter of the faying surface, which results in low shear strength of the seam; and the laser wire filling welding or the double-beam laser synchronous welding process has strict requirement and high cost in the prior T-type joint welding. The laser beams are vertically incident for penetration welding from the top surface of a top plate along the seam formed by the contact of a vertical slab and the top plate of the T-type joint, at the same time, a first electric arc welding gun and a second electric arc welding gun carry out synchronous welding from the two sides of the seam, and the first electric arc welding gun and the second electric arc welding gun are remained to be arranged symmetrically on the left and the right sides of the vertical slab. Compared with the single laser welding, the composite welding method of the invention has the advantages that the capacity usage ratio is improved by more than 30%, the welding speed is increased by more than twice, and the welding efficiency is improved by two to three times.

Owner:HARBIN INST OF TECH

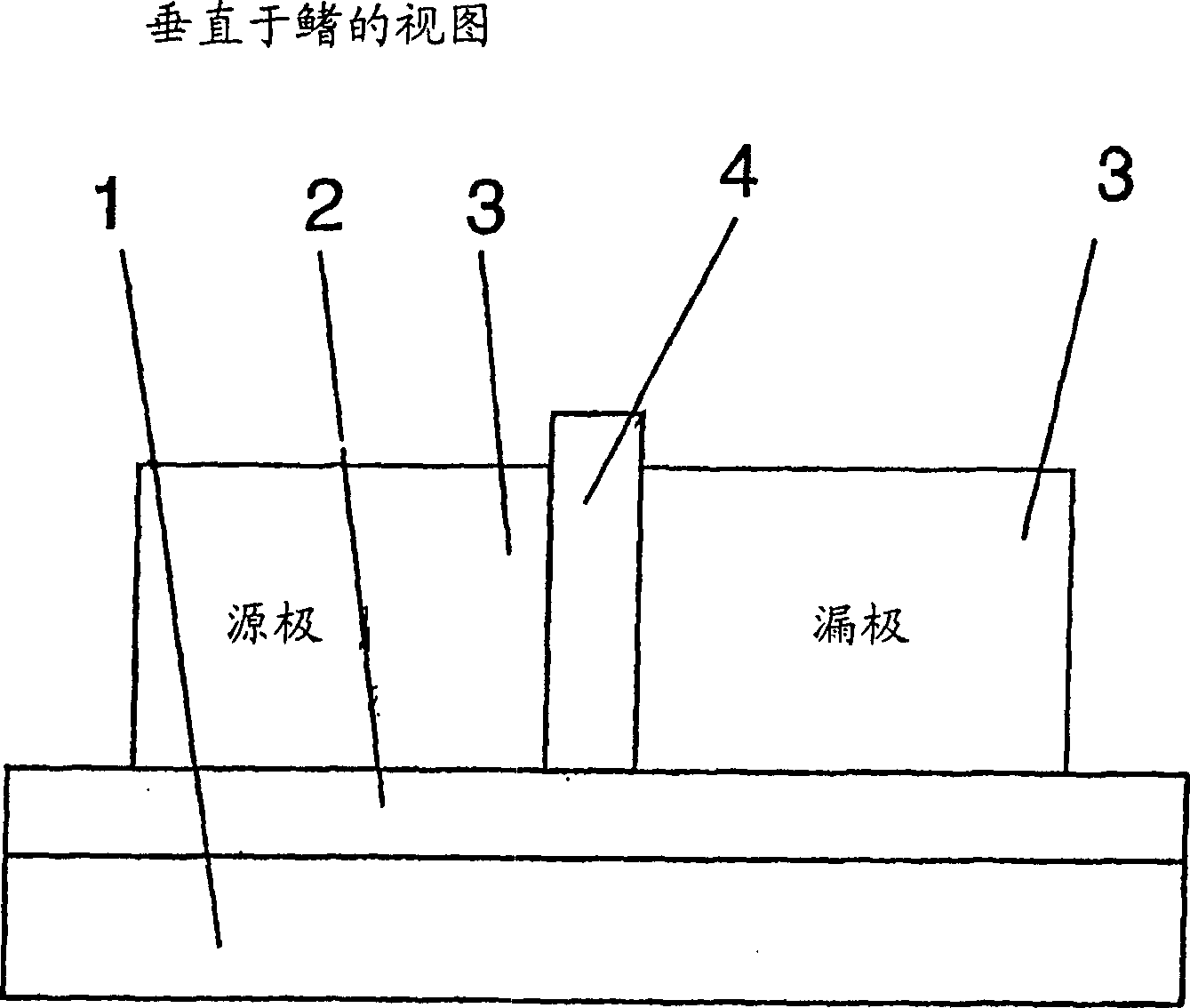

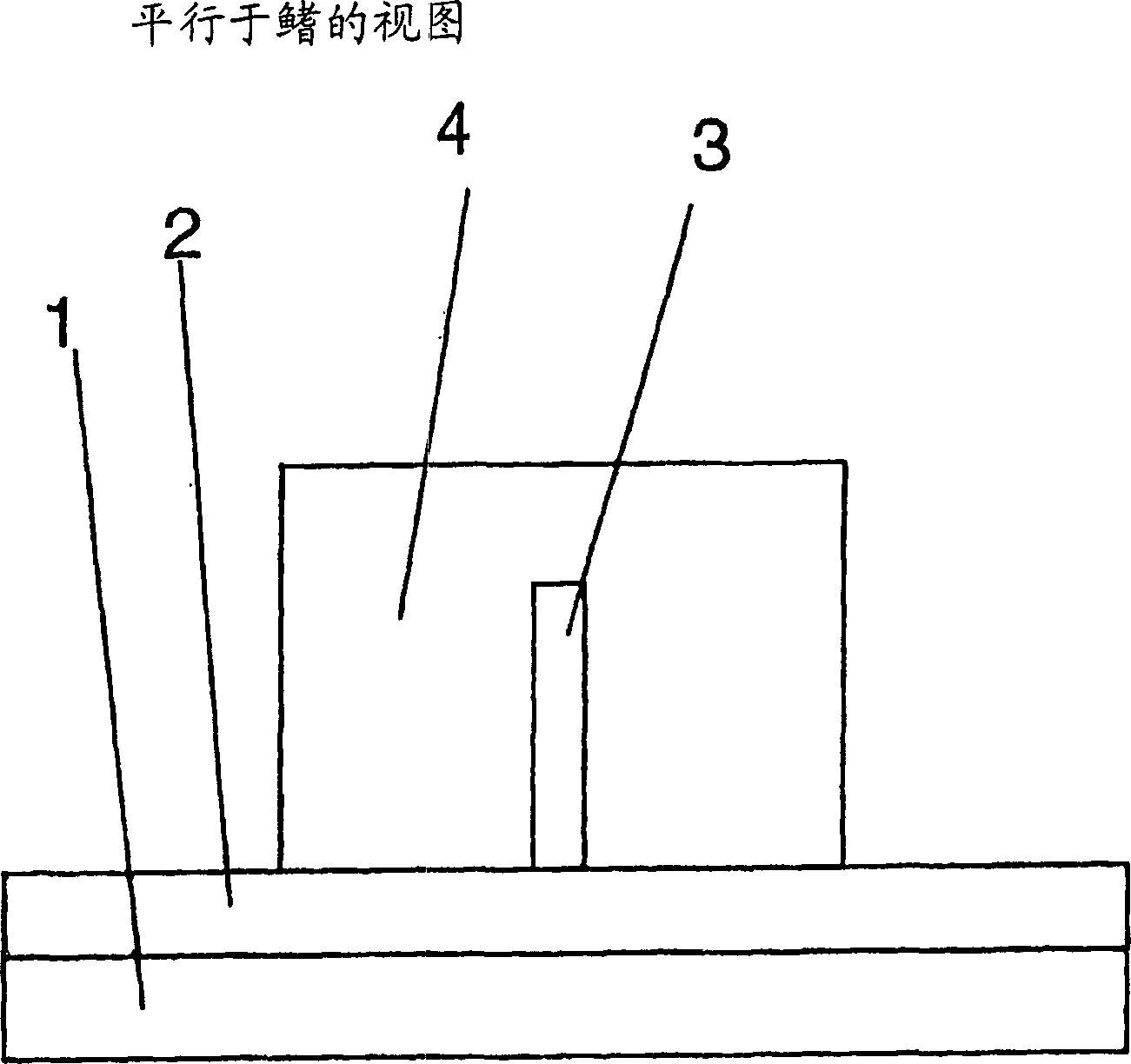

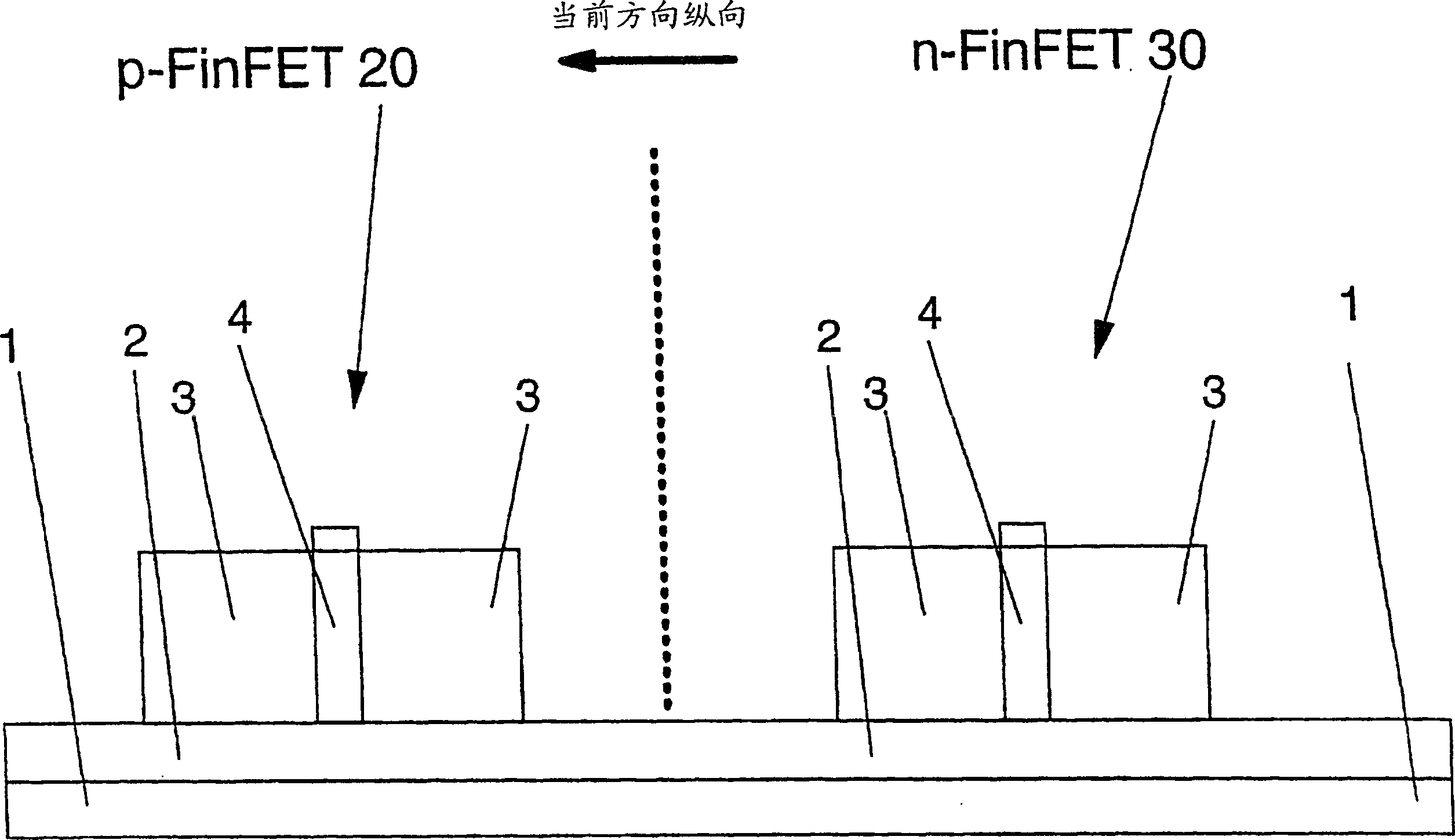

Strained FinFET CMOS device structures

A semiconductor device structure, includes a PMOS device and an NMOS device disposed on a substrate the PMOS device including a compressive layer stressing an active region of the PMOS device, the NMOS device including a tensile layer stressing an active region of the NMOS device, wherein the compressive layer includes a first dielectric material, the tensile layer includes a second dielectric material, and the PMOS and NMOS devices are FinFET devices.

Owner:GLOBALFOUNDRIES INC

Double-sided tape for shading and reflection

The invention provides a double-sided tape for shading and reflection. The double-sided tape comprises a substrate layer, a first adhesive layer and a second adhesive layer, wherein the first adhesive layer and the second adhesive layer are respectively arranged on two surfaces of the substrate layer, any of the two surfaces of the substrate layer is provided with a white PET film of a black ink layer, the Hunter whiteness of the PET film is 80.0 to 85.0%, and the thickness of the PET film is 12 to 15 mu m. The invention further provides a preparation method for the double-sided tape for shading and reflection. The double-sided tape for shading and reflection has light reflectivity and light shielding performance, can meet a variety of performance requirements due to upsizing and thinning of mobile equipment and has excellent insulating properties, resistance to reflex action and stress relaxation performance.

Owner:新纶电子材料(常州)有限公司

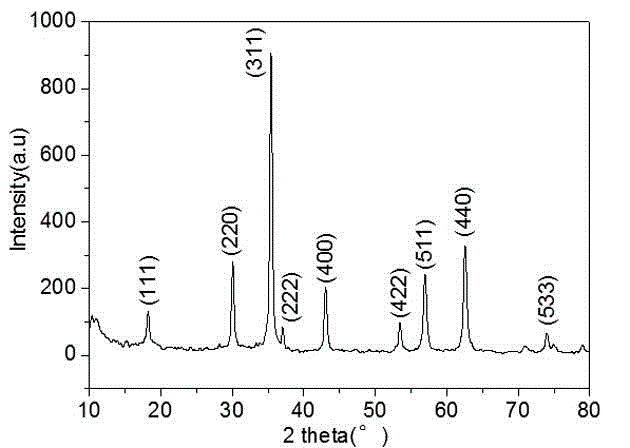

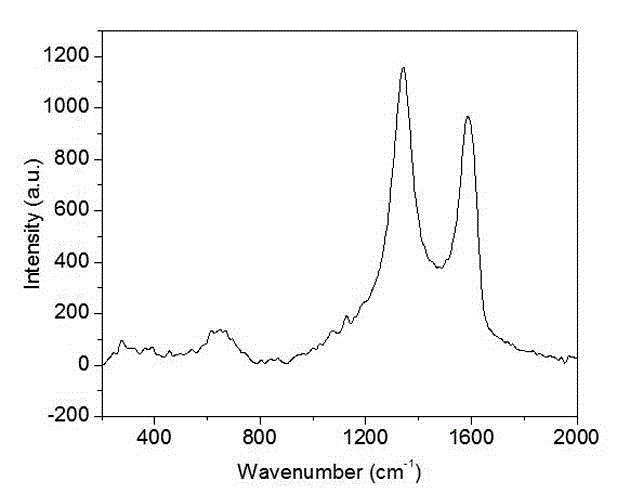

Graphene @Fe3O4 compound water base magnetorheological fluid and preparation method thereof

The invention relates to the field of intelligent magnetic materials and in particular relates to a graphene @Fe3O4 compound water base magnetorheological fluid and a preparation method thereof, solving the problems that existing magnetorheological fluids are easy to settle and the stability and magnetorheological effects of the magnetorheological fluids are difficult to optimize at the same time. The preparation method comprises the following steps: preparing a Fe3O4 water base magnetic fluid with FeCl2.4H2O and FeCl3.6H2O; sequentially adding concentrated sulfuric acid, potassium permanganate and hydrogen peroxide to natural flake graphite and sodium nitrate to prepare graphite oxide; and then carrying out ultrasonic dispersion on home-made graphite oxide to prepare graphene oxide, finally adding a surfactant, the Fe3O4 water base magnetic fluid and a reducing agent to graphene oxide, washing the solution with deionized water until the solution is neutral, and then dispersing graphene @Fe3O4 compound magnetic particles in the deionized water to undergo ultrasonic dispersion, removing the precipitates and taking the supernatant, namely the stable graphene @Fe3O4 compound water base magnetorheological fluid, wherein the magnetic particles are graphene @Fe3O4 and account for 5-35wt% of the whole. The method has the advantages of good stability, low zero field viscosity, high shear strain and wide operating temperature range.

Owner:ZHONGBEI UNIV

Flat non down-lead encapsulation piece and method for producing the same

ActiveCN101442035APrevent and eliminate delamination defectsLow water absorptionSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingHigh rate

The invention discloses a flat non-lead packaging part and a production method thereof. The flat non-lead packaging part comprises a lead frame carrier, wherein the carrier is adhered with an IC chip. The front side of the lead frame carrier is provided with pits. The periphery of the front side of the lead frame carrier is provided with two circles of waterproof grooves. The back side of the lead frame carrier is provided two circles of anti-overflow grooves. The production method comprises the processes of washer thinning and slicing, core loading, press welding, plastic package, plating, printing and cutting and coiling. The method strengthens the bonding forces between the adhesive and the lead frame carrier and the IC chip and eliminates and reduces the rate of a lamination defect generated on the surface of the IC chip. The two circles of waterproof grooves are provided on the periphery of the carrier, the plastic packaging materials are embedded in the grooves so as to prevent moisture from entering the chip. The two circles of anti-overflow grooves arranged on the edge of the carrier have functions of preventing the lamination defect, moisture and material overflow. The method has the advantages of high rate of finished product, good reliability and convenient use, and effectively improves the reliability and excellent packaging rate of products.

Owner:TIANSHUI HUATIAN TECH

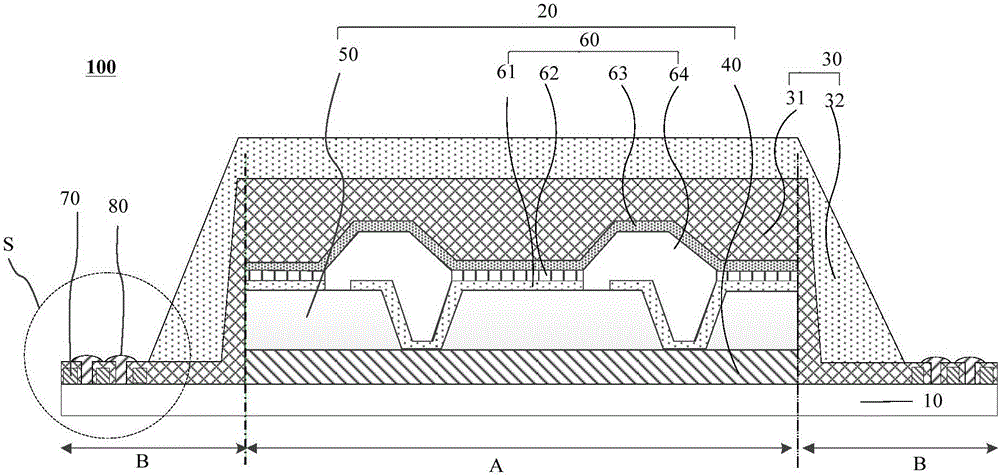

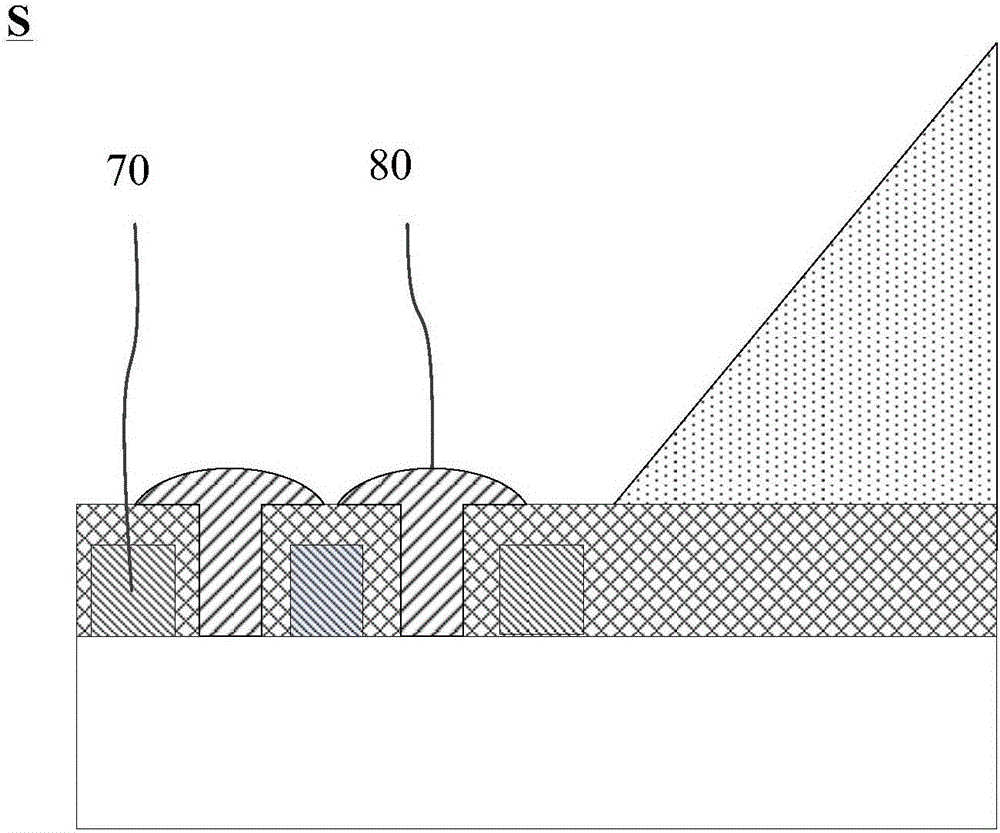

OLED display panel and a method for manufacturing same, and OLED display device

PendingCN109860411ABlock the flowReduce climbing distanceSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureDisplay device

The present invention provides an OLED display panel and a method for manufacturing the same, and an OLED display device. A concave-convex structure is arranged at one side, far away from a substrate,on a planarization layer, after an organic light-emitting functional layer and an inorganic first package layer are formed on the planarization layer, positions of the organic light-emitting functional layer and the first package layer corresponding to the concave-convex structure are non-flat surfaces, namely concave-convex structures with the same shapes are formed at the positions, corresponding to the concave-convex structure, on the organic light-emitting functional layer and the first package layer; when an organic second package layer is formed, the non-flat surface of the first package layer can block the flow of the second package layer to a certain extent to reduce the liquidity of the second package layer, reduce the climbing distance of the edge of the second package layer andincrease the edge stress and an angle of gradient so as to achieve the product narrow-frame design, improve the thickness uniformity of the edges of the second package layer, avoid bad mura of a non-display area and ensure the package effect.

Owner:BOE TECH GRP CO LTD +1

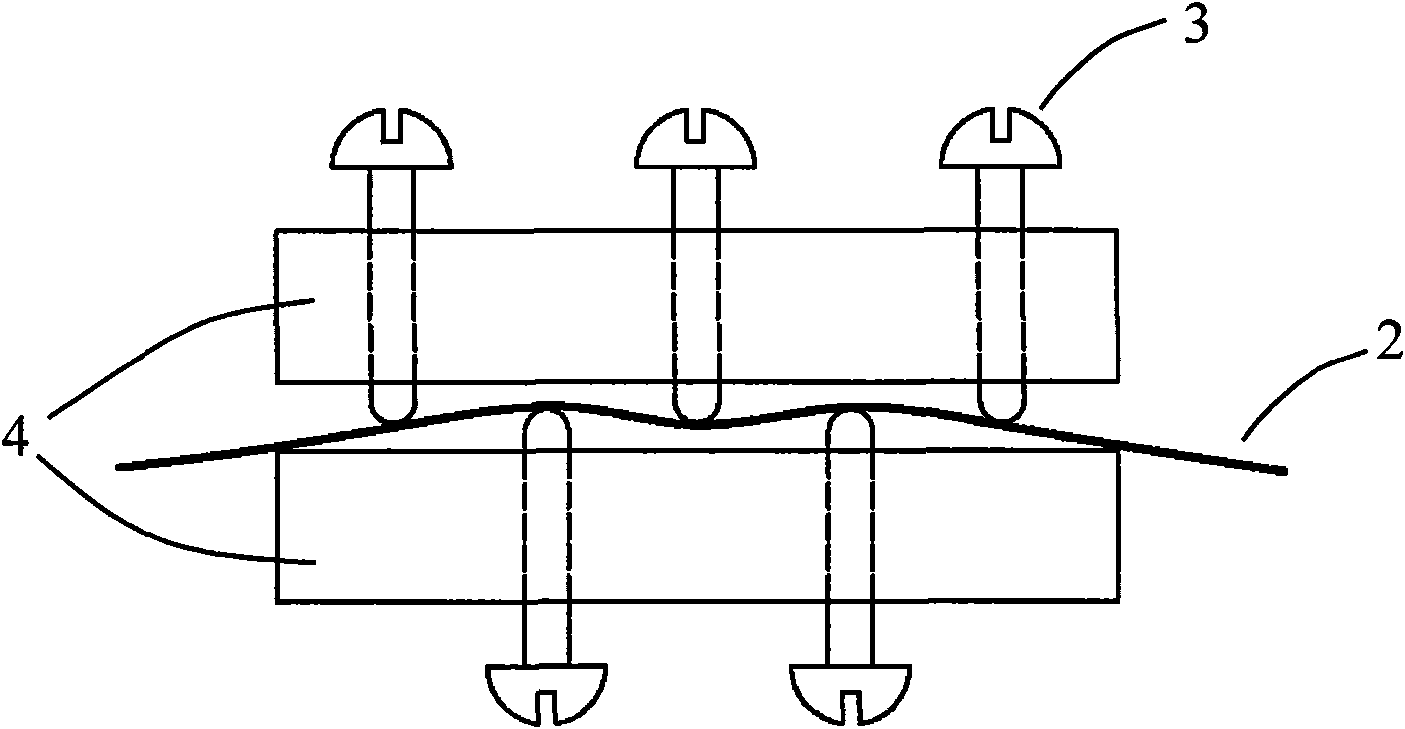

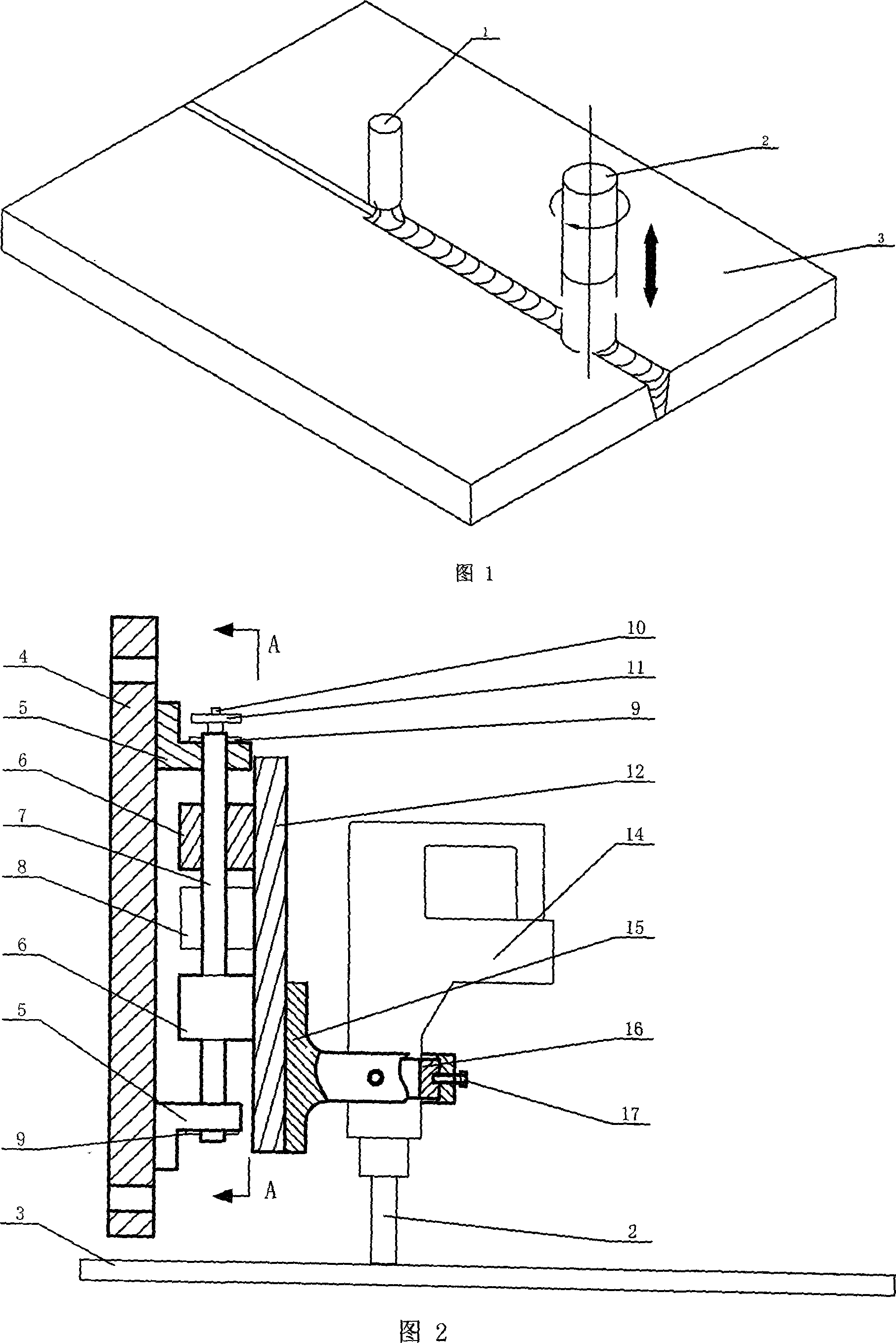

Device for controlling welding stress deformation along with soldering impact, revolving and extrusion pressing

InactiveCN101138817AReduce noiseLow costWelding/cutting auxillary devicesFurnace typesThin walledEngineering

A weld with trailing rotation extruding to control residual stresses deformation device relates to a device for controlling the residual stress deformation of a thin-walled metal. The weld with trailing impact rolling to control residual stresses deformation device has the disadvantages that the device has a loud noise during operation and a bad working environment and that the device is easily influenced by the impact rolling wheel and the size of the welding torch and that the distance between the wheel and the torch can not satisfy the theoretical ideal value. The upper end of a compression rod (2) is inserted into the part of the head of an electric hammer (14), which is fastened on a No.2 support (15). A pair of sliders (6) which mate with two guide rails (7) and a nut (8) which mates with an elevating screw (10) are fixed on the other side of the bottom plate (12). Both ends of the guide rail (7) are fixedly arranged on a support (5). The two guide rails (7) are parallel with the elevating screw (10), both ends of which are equipped with bearings (13). The support (5) is fixed on a base (12). The present invention with an adjustable frequency impact force can effectively prevent a welding hot cracking as well as control a straight weld and an enclosed circumferential weld.

Owner:HARBIN INST OF TECH

Tooth cosmetic veneering method

The invention provides a tooth cosmetic veneering method, which comprises the following steps that: spinels are adopted for porcelain laminate veneering, wherein the veneer thickness can be controlled between 0.5 and 0.8; tooth surfaces are free from being processed, so that painless cosmetology is realized; temporary teeth are free from being worn, so that inconvenience of a person being subject to cosmetology can be reduced; and the tongue side parts of teeth are free from being processed, so that jaw teeth can be effectively protected, and 'foreign body feeling' is free. In the invention, a compound material prepared by a special glass permeation method is adopted, the strength can reach over 400 Mpa after bonding, the durability of the prepared spinel porcelain laminate tooth veneer can reach over 10 years; the prepared spinel porcelain laminate tooth veneer has the optical speciality being the same as that of natural tooth tissues, and has a simulation cosmetic effect; the material has good mechanical and physical properties so as to bear high stress, high acid corrosion resistance, and low heat conduction property so that the tooth body can not be irritated by heating, and no stimulation is caused to teeth pulp when people eat cold and hot food; the material has a self-cleaning capability, so that bacteria are difficult to grow; the X-ray transmission property is good; and the cost is low.

Owner:郑雷

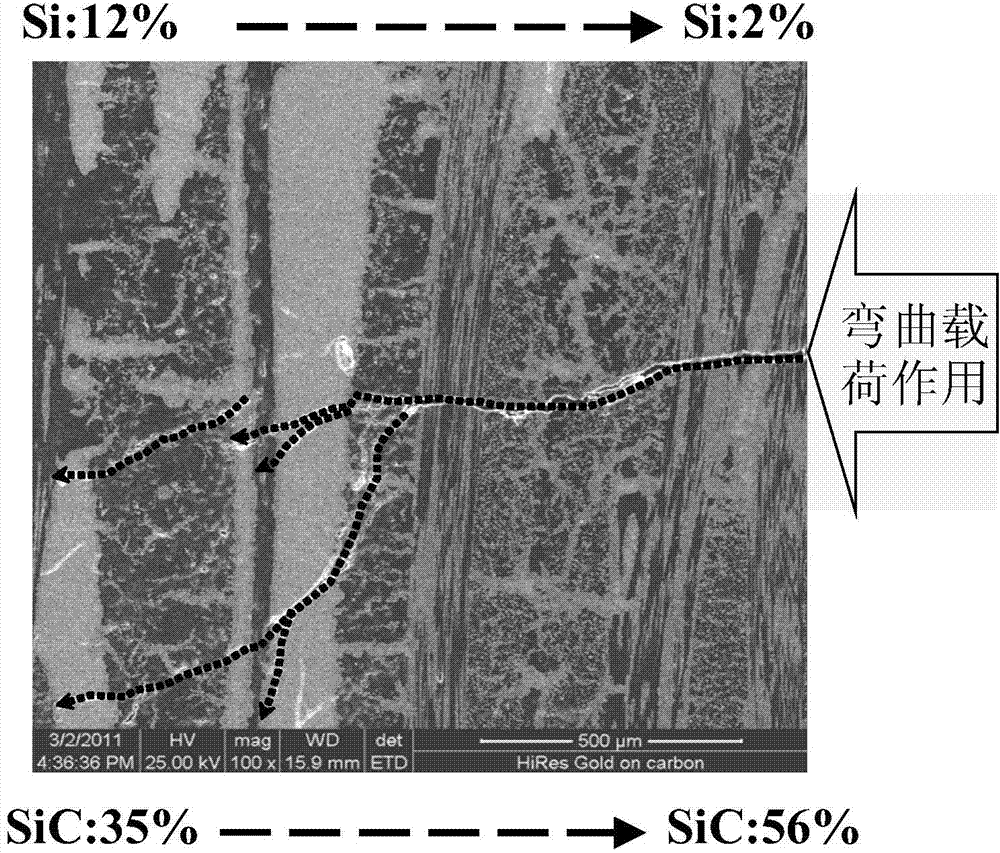

Preparation method of carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material

The invention discloses a preparation method of a carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material. The preparation method is characterized by comprising the following steps: (a), carrying out thermal treatment onto the fibers by adopting different temperatures; (b), dipping the fibers which are not subjected to thermal treatment and the thermally-treated fibers obtained in the step (a) in resin glue liquor, drying, continuously superposing and laying up, applying a certain pressure after laying up, and carrying out curing and post-curing treatment in sequence to prepare a composite material biscuit body with fiber / base body interface adhesive strength in gradient change; (c), carrying out high-temperature pyrolysis onto the composite material biscuit body obtained in the step (b) to obtain a carbon / carbon porous body with porosity in gradient change; (d), carrying out liquid silicon permeation onto the carbon / carbon porous body obtained in the step (c) under a high temperature to obtain the C / C-SiC composite material with SiC ceramic base body content in gradient change. The preparation method disclosed by the invention is simple in process, short in preparation period, low in cost and capable of preparing a large workpiece with a complex shape.

Owner:DALIAN UNIV OF TECH

Gross rubber for high wearable tyre and its prepn.

InactiveCN1834140AExcellent abnormal temperature crystallization performanceIncrease stressSpecial tyresVulcanizationPolymer science

This invention relates to a kind of high wear-resistant tyre rubber and its preparation method. Eucommia ulmoides gum is blended with natural rubber, styrene-butadiene rubber, nitrile-butadiene rubber and cis-1, 4-polybutadiene rubber and vulcanized; and by varying the ratio of eucommia ulmoides gum to rubber additive 1 and eucommia ulmoides gum to rubber additive 2 in the ingredients, high wear-resistant tyre rubber is obtained. It has the technique characteristics of eucommia ulmoides gum, rubber additive 1, rubber additive 2, sulphur-containing enhancer and antioxidant. The preparation method is that, raw materials according to the ingredients mentioned above is blended in a double-roller machine for common rubber processing at a temperature of 50~80 deg. C and heated on a plate vulcanization machine to produce the desired high wear-resistant tyre rubber. It has the advantages of abundant raw materials source and simple preparation method. The obtained rubber is uniquely of extraordinary wear resistance and little rolling friction. It also has low dynamic compression heat, good fatigue resistance and skid resistance and comprehensive properties for tyre driving, and is a perfect kind of tyre materials for aviation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Megalobrama amblycephala anti-stress feed and production method thereof

The invention relates to a megalobrama amblycephala anti-stress feed and a production method thereof. The preparation method is characterized by comprising the following steps of: crushing fish meal, bean pulp, silkworm pupa, rapeseed meal, rapeseed, cottonseed meal, all-purpose flour, sub-powder, washed rice bran, and potassium sorbate mildew preventive; stirring and uniformly mixing the crushed product and fish oil, lecithin, 50 percent choline chloride, rhubarb anthraquinone extract, premix for fish, attapulgite, 35 percent phosphate vitamin C, 50 percent vitamin E and monocalcium phosphate; after stirring and uniformly mixing, grinding the mixture into mixed materials by using an ultra-micro grinder; and preparing the materials into a pellet feed by using the conventional method of the pellet feed. The pellet feed has total and rich nutrition, and can improve the immunity and oxidation resistance of the megalobrama amblycephala, improve the stress, enhance the resistance to disease, improve the feed palatability, and accelerate the growth.

Owner:通威(大丰)饲料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com