High-pressure gas injection hole-drilling pressure-releasing outburst prevention method

A high-pressure gas and outburst prevention technology, which is applied to drilling with liquid/gas jets, drilling equipment and methods, and production fluids, etc. and other problems, to achieve the effect of reducing the risk of outburst, increasing the strength of the coal body, and improving the stress condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

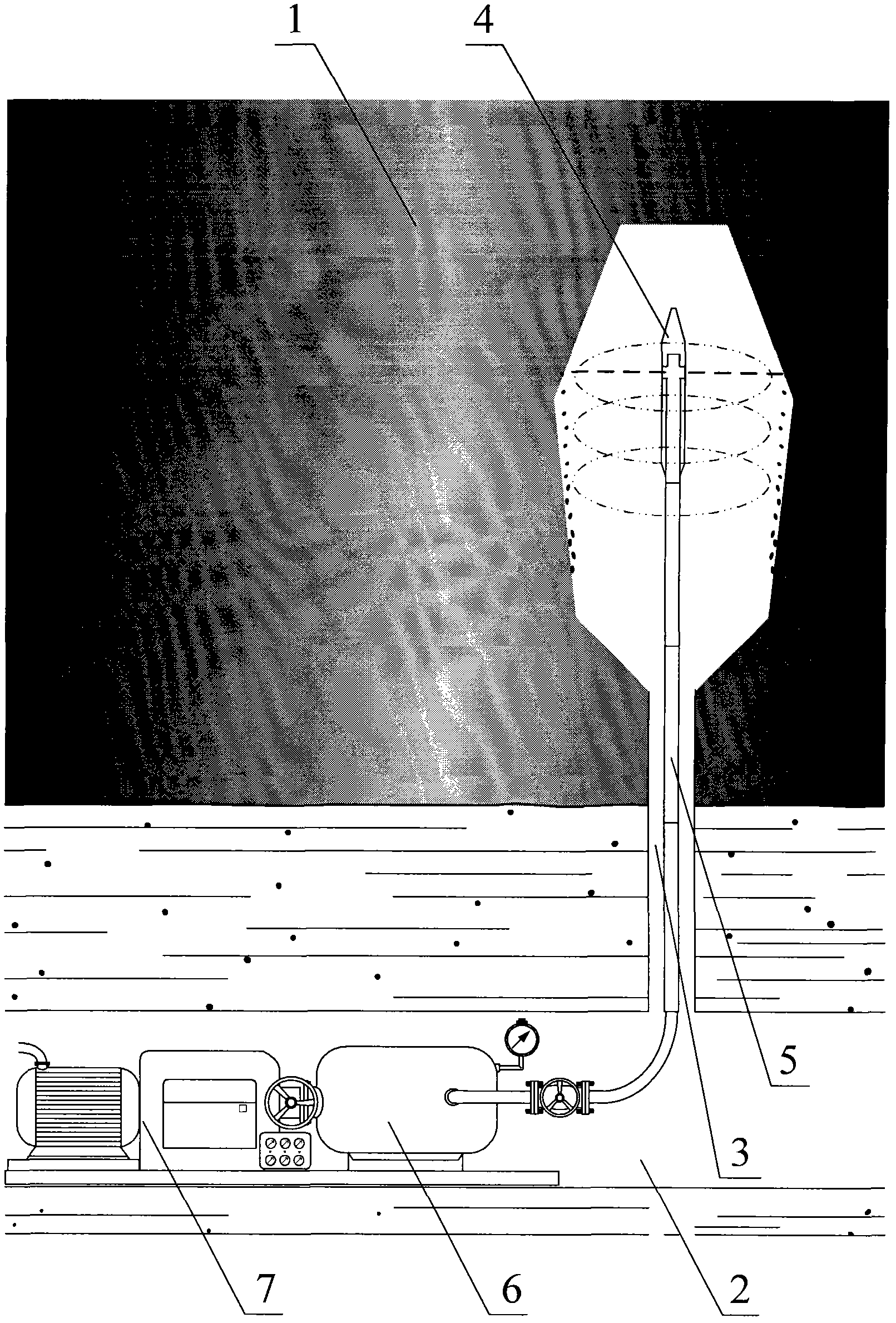

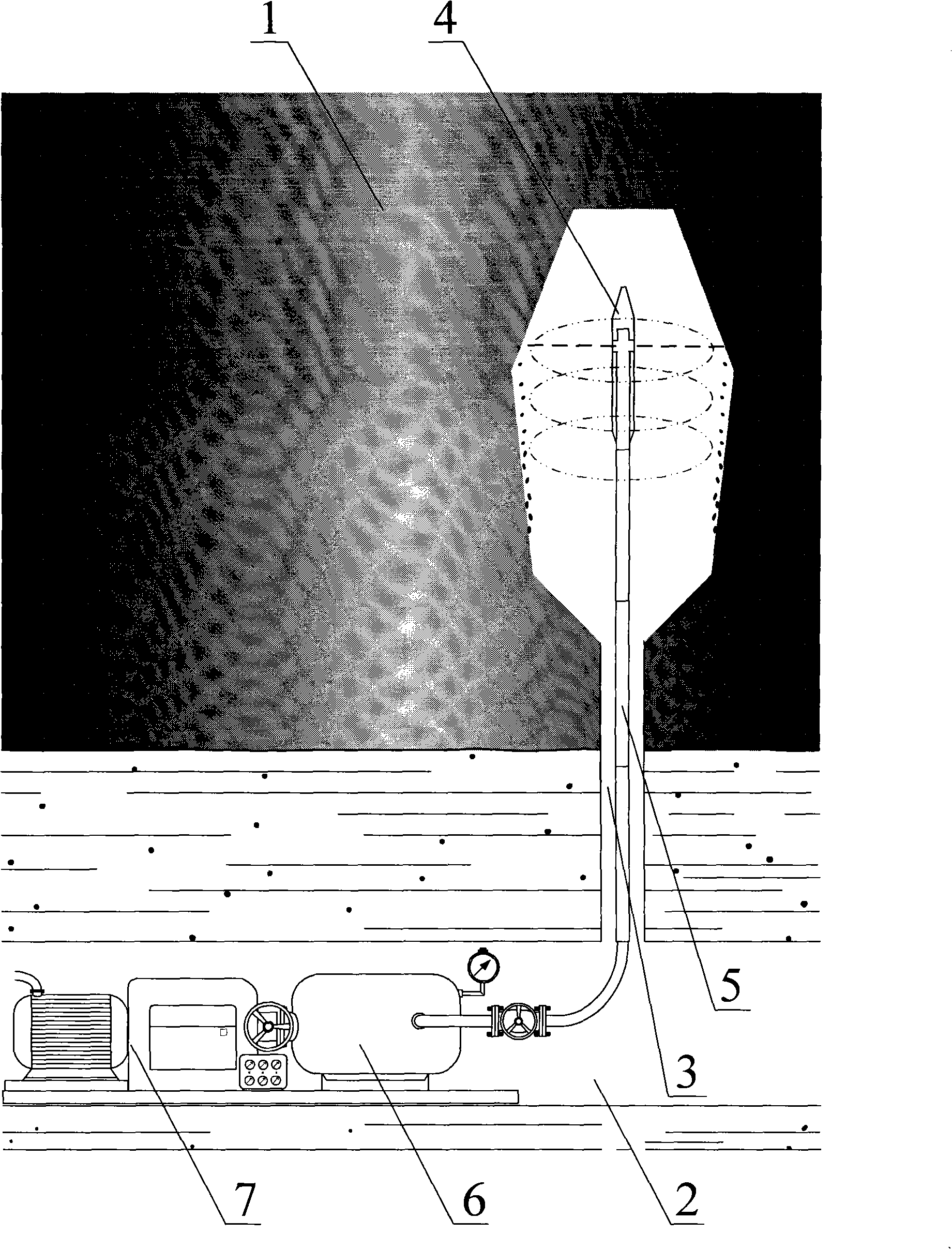

[0017] The present invention will be further described below in conjunction with an embodiment (accompanying drawing):

[0018] like figure 1 As shown, a kind of high-pressure gas jet digging hole pressure relief method of the present invention, the specific implementation steps are as follows:

[0019] (1) First, in the floor rock roadway 2 of the coal seam 1 in the outburst prevention area in front of the coal mining or excavation face, select the orientation with relatively high hardness or relatively high density as the drilling hole position;

[0020] (2) Then, use drilling equipment that matches the hardness of the coal seam to carry out small-diameter ordinary drilling operations on the drilling holes;

[0021] (3) After the borehole 3 enters the design depth of the coal seam 1, the drilling is withdrawn, and the injection nozzle 4 and the connected high-pressure drill pipe 5 are sent into the borehole 3, and the high-pressure gas storage device 6 connected to the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com