Push-to-point rotary steerable drilling device

A rotary steerable drilling and pointing technology, which is applied in directional drilling, drilling equipment, drilling automatic control system, etc., can solve the problems of high friction in the horizontal section and difficulty in running casing, and achieve the reduction of electric energy, production cost, The effect of increasing production potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

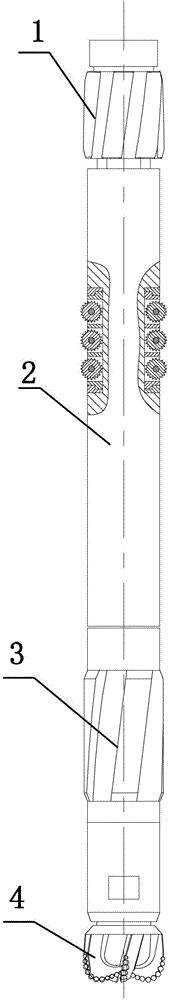

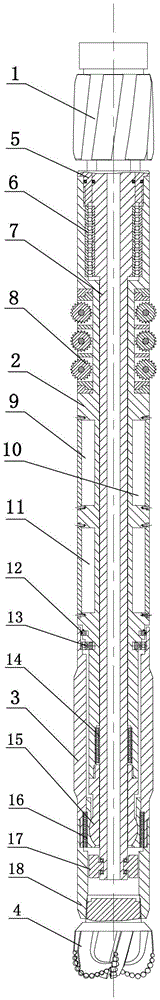

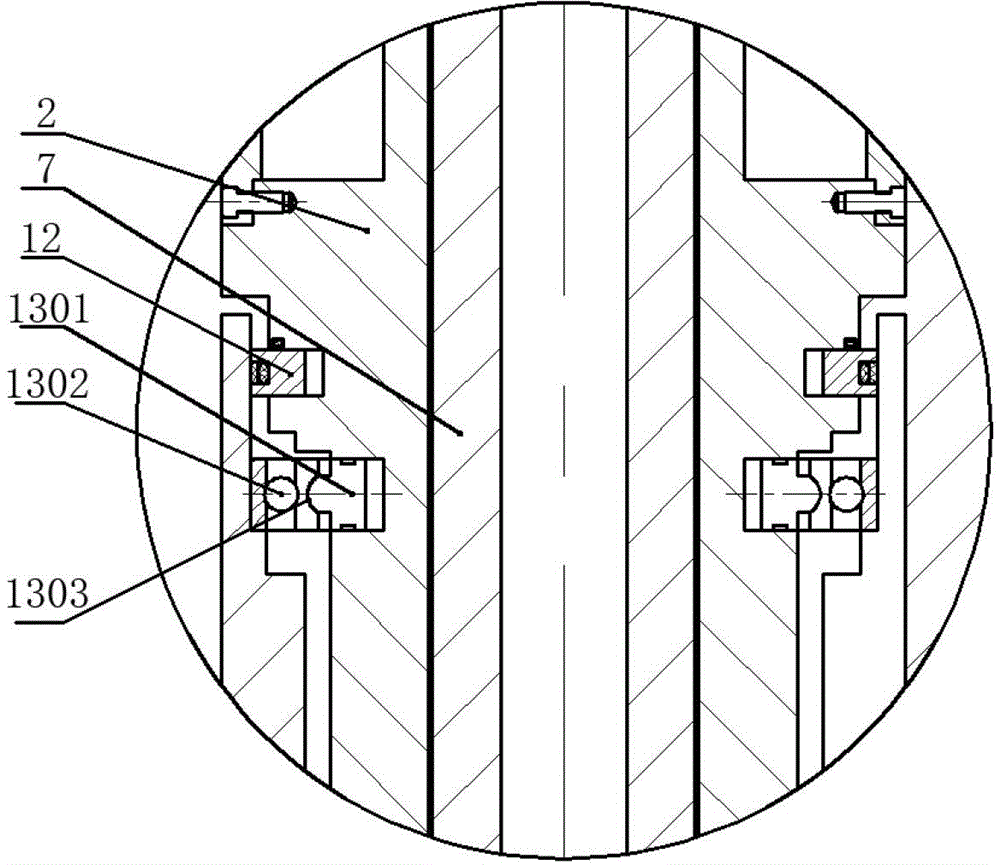

[0024] Such as figure 1 , figure 2 As shown, the push-by-pointing rotary steerable drilling device of the present invention includes an upper stabilizer 1, a central shaft 7, a control nipple 2, a control system 9, a hydraulic system 11, a hydraulic eccentric device 13, a stabilizer sleeve 3 and a drill bit 4 .

[0025] The upper stabilizer 1 is fixedly connected with the central shaft 7, and in this embodiment, is connected by threads. The central shaft 7 passes through the control sub-joint 2 , the stabilizer sleeve 3 is connected with the control sub-joint 2 through a ball joint 15 , and the stabilizer sleeve 3 is fixedly connected with the drill bit 4 . In a preferred embodiment, the central shaft 7 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com