Patents

Literature

508 results about "Oil and gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Oil & Gas Exploration & Production industry consists of companies that are engaged in the exploration and extraction of crude petroleum and natural gas. The industry also consists of the recovery of butane, ethane and natural liquefied petroleum gases (LPG) recovered from oil and gas fields.

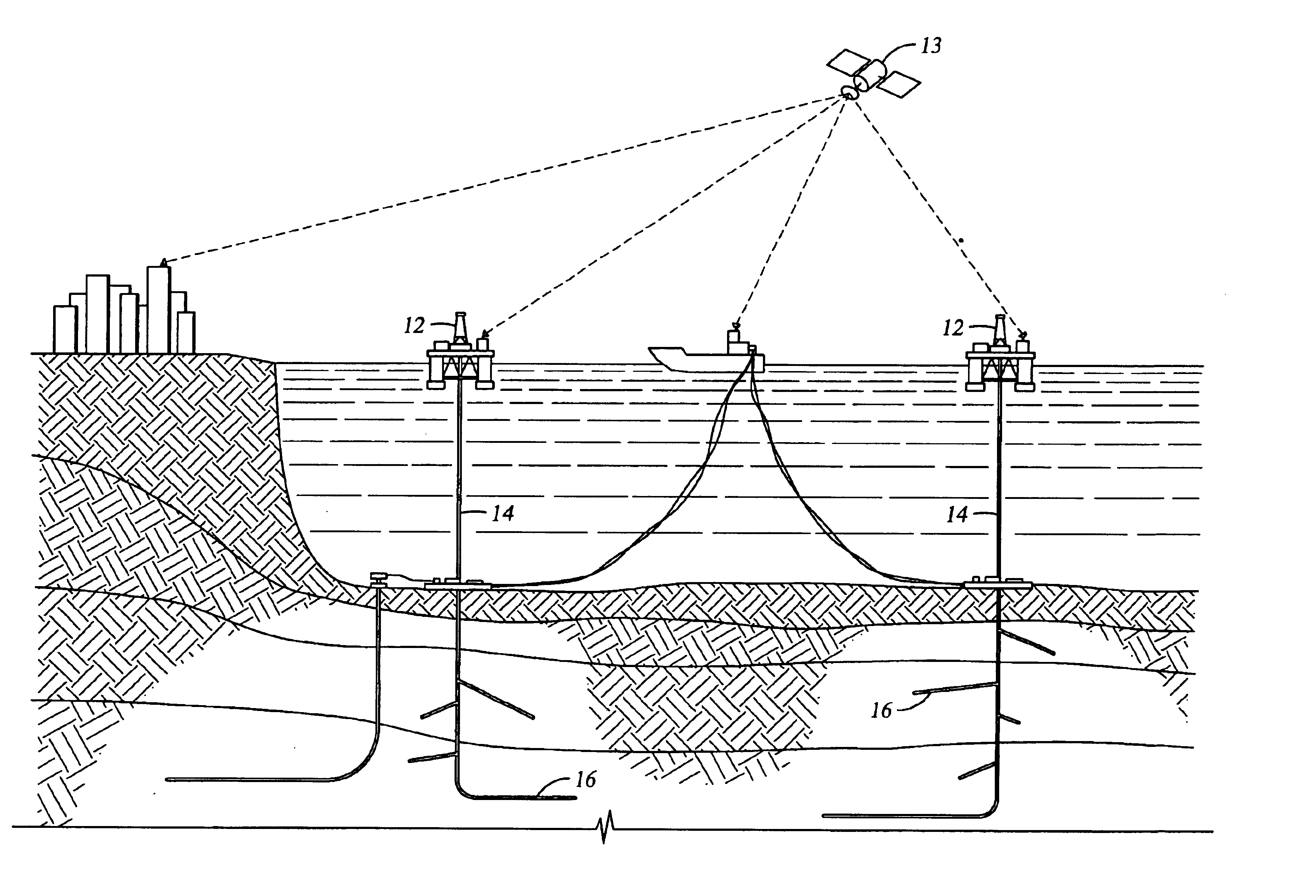

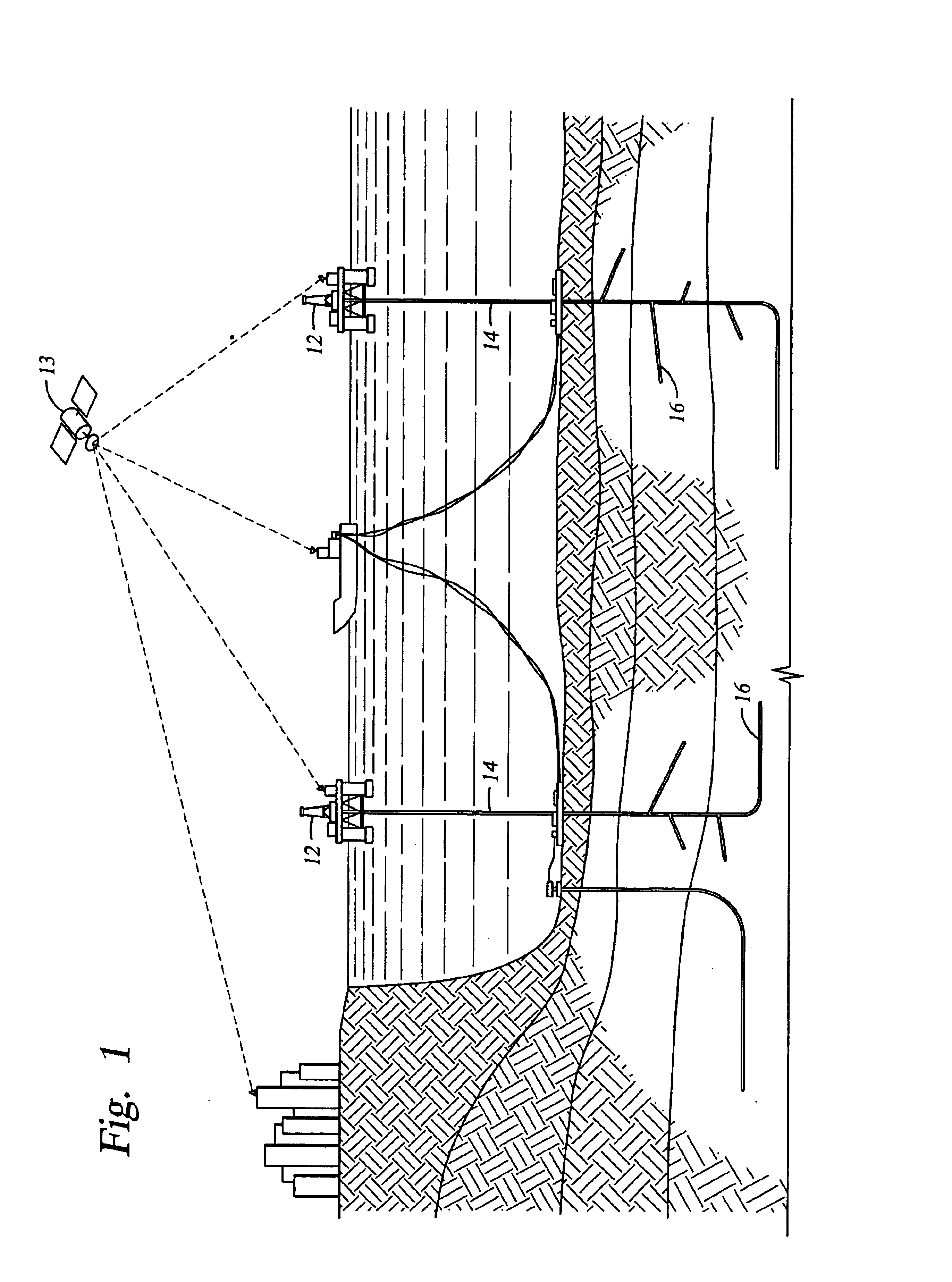

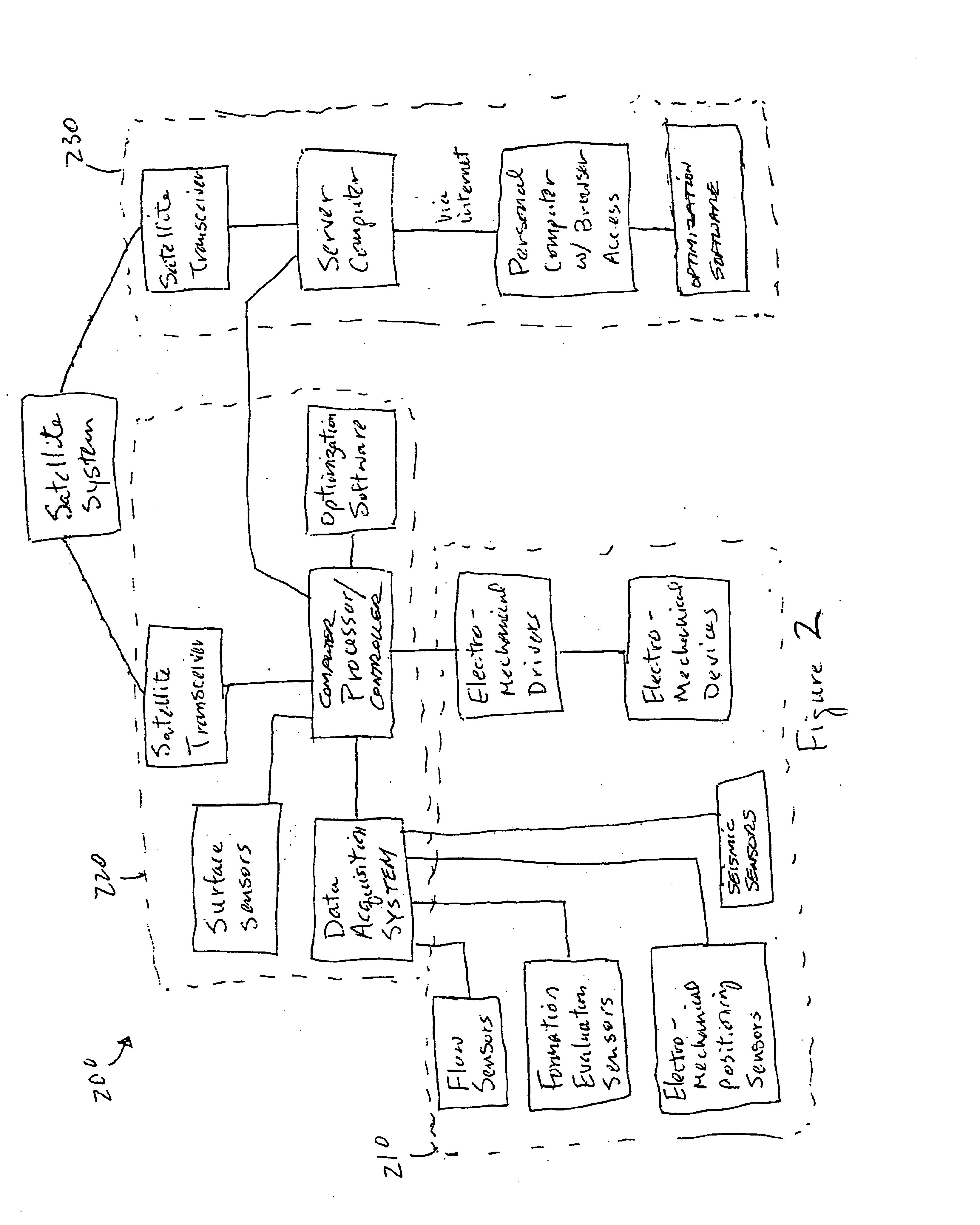

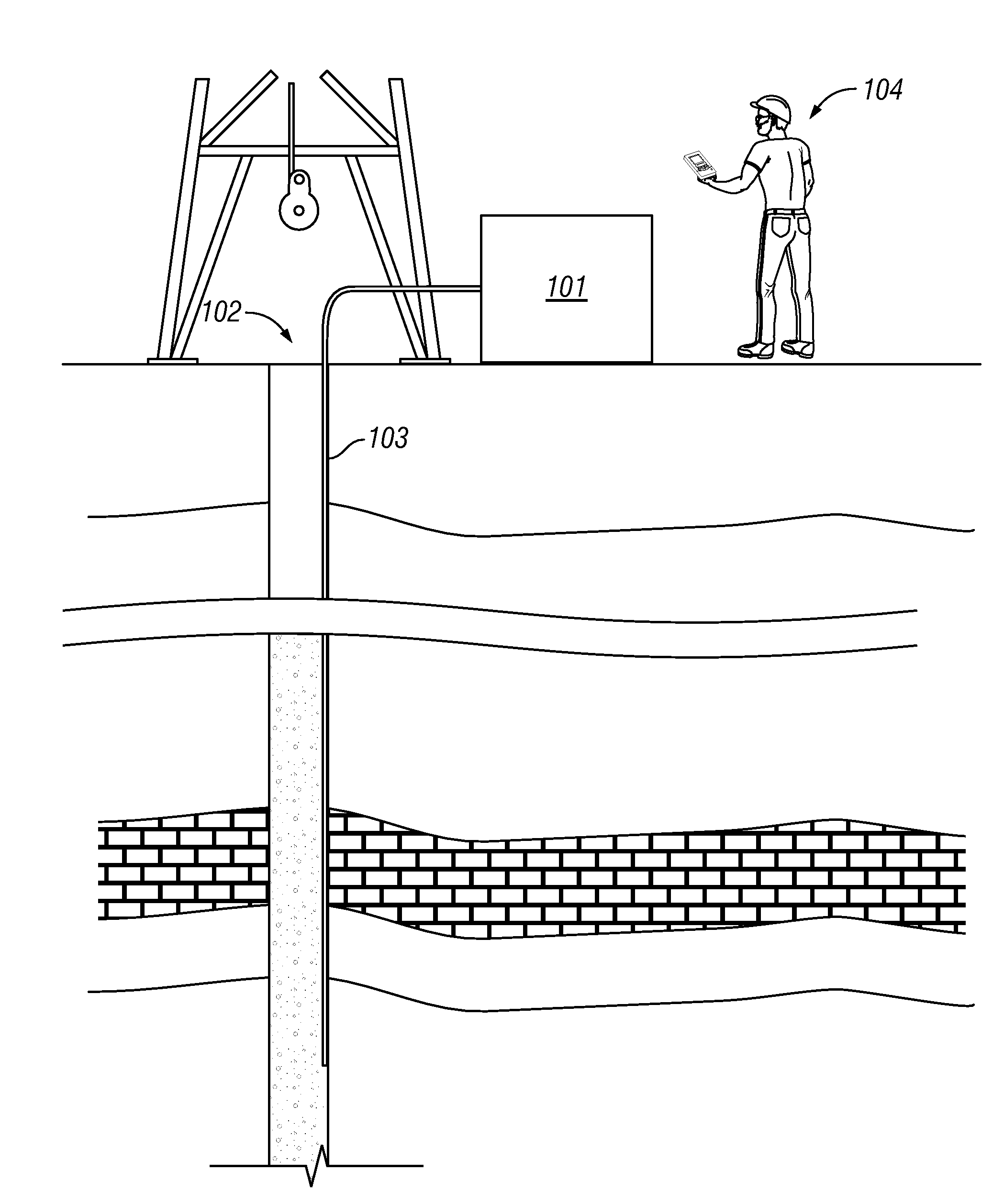

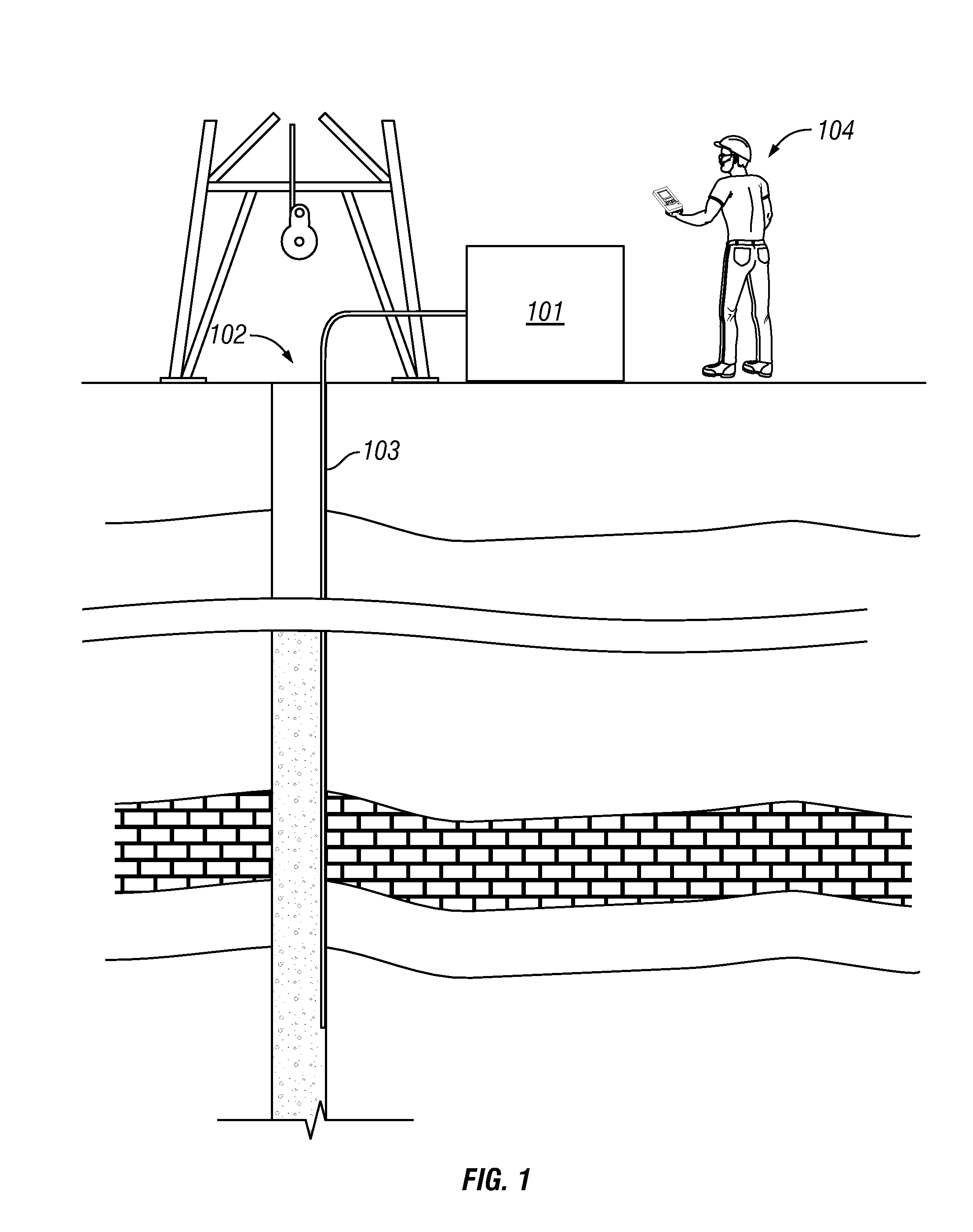

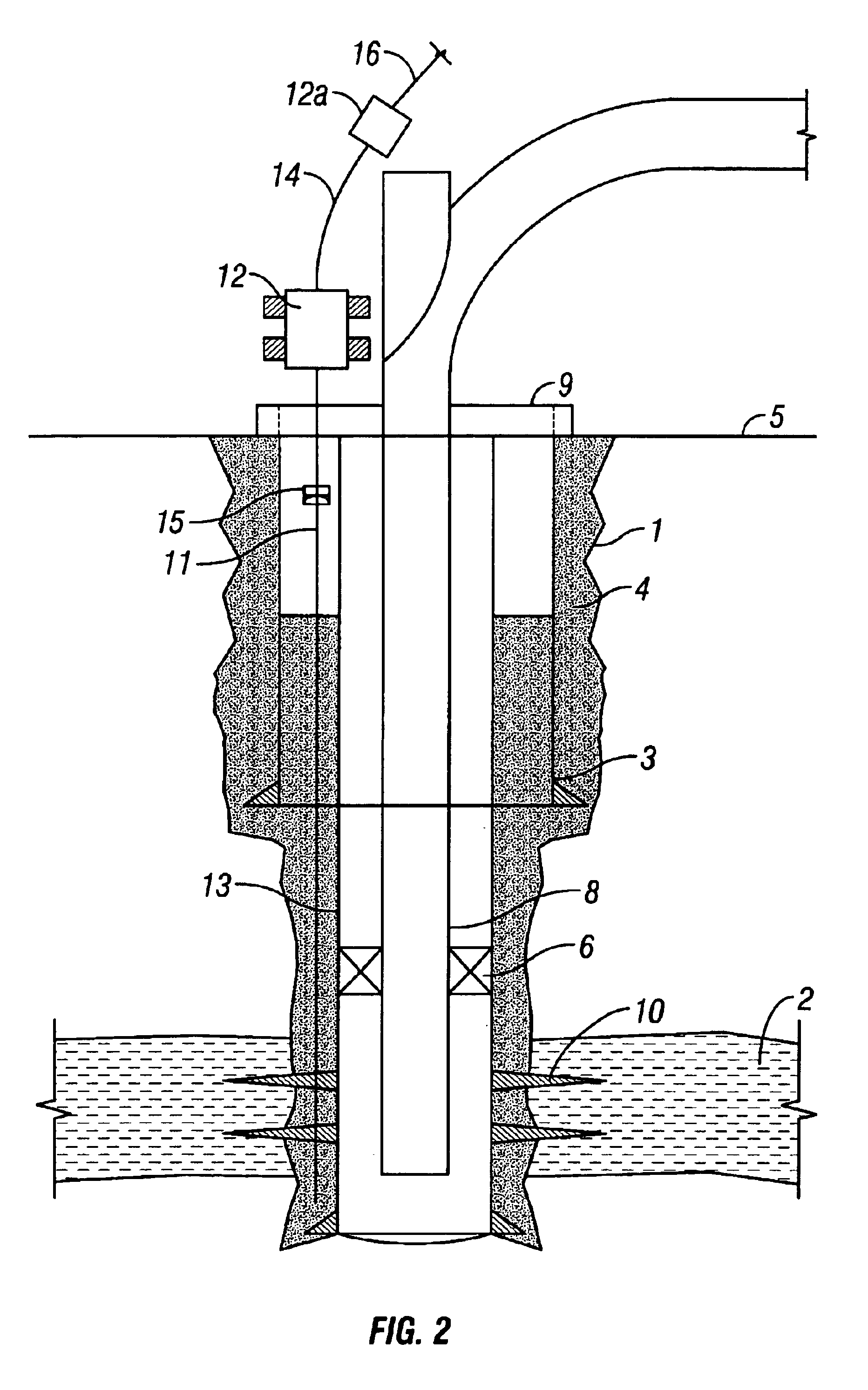

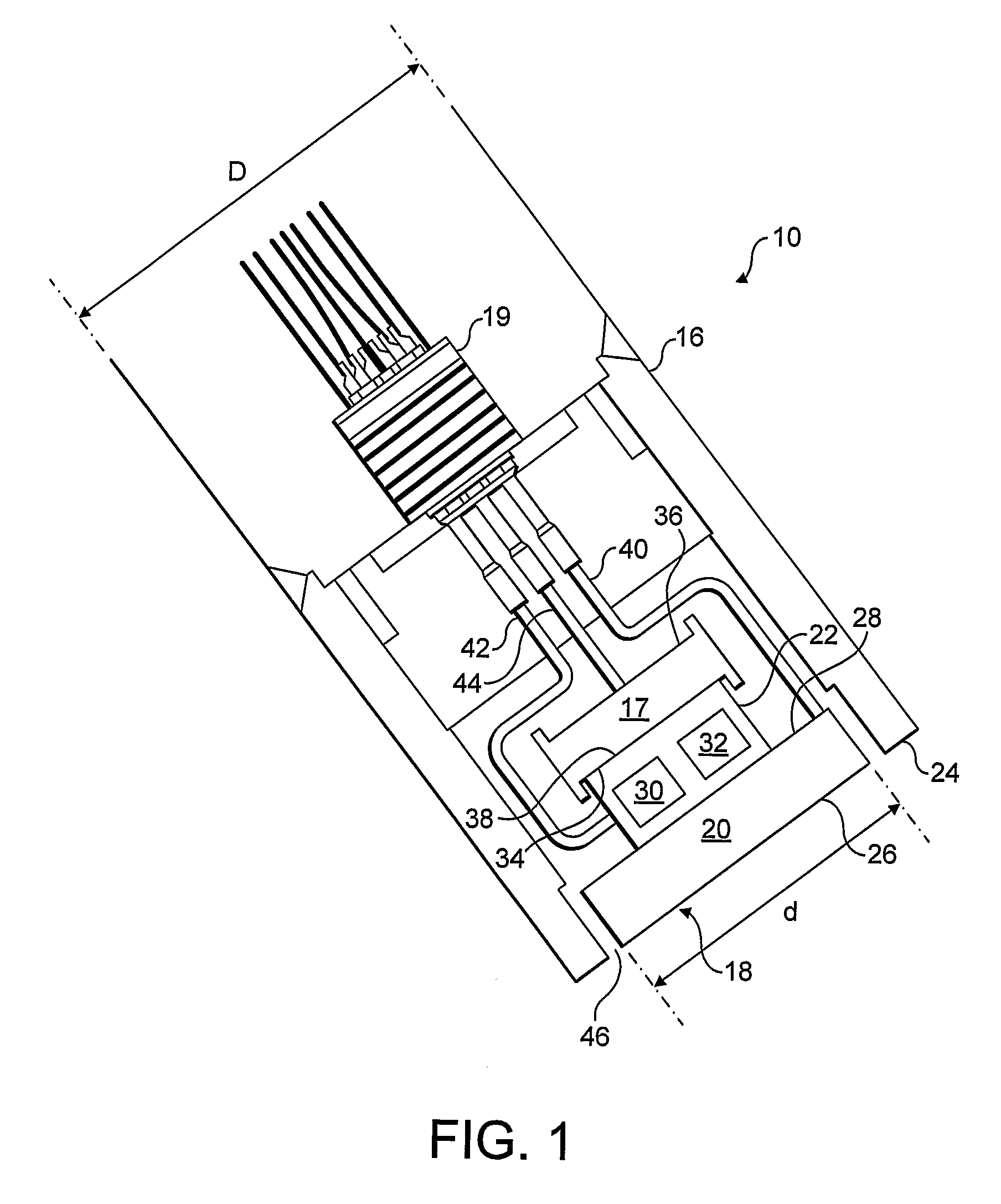

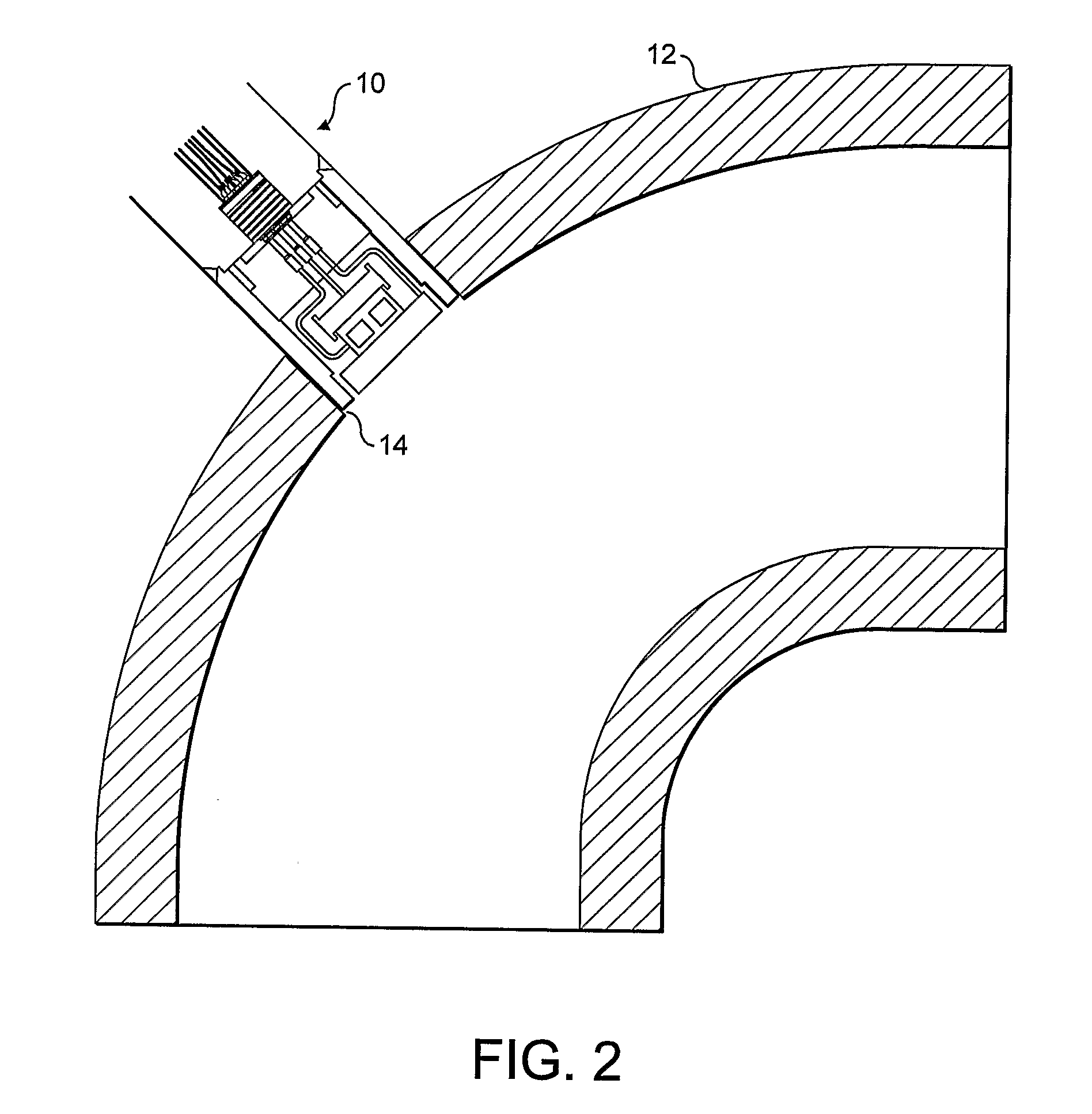

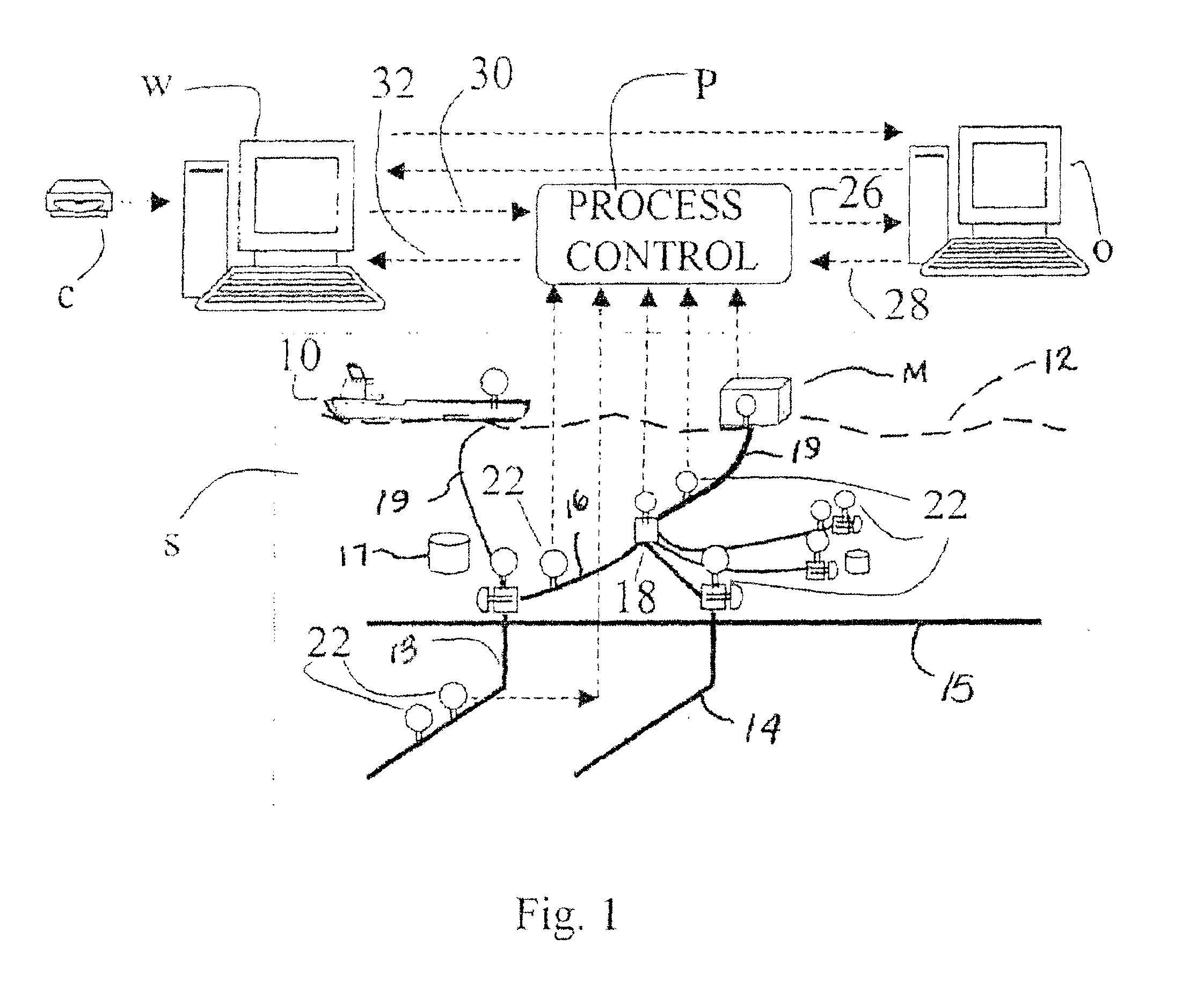

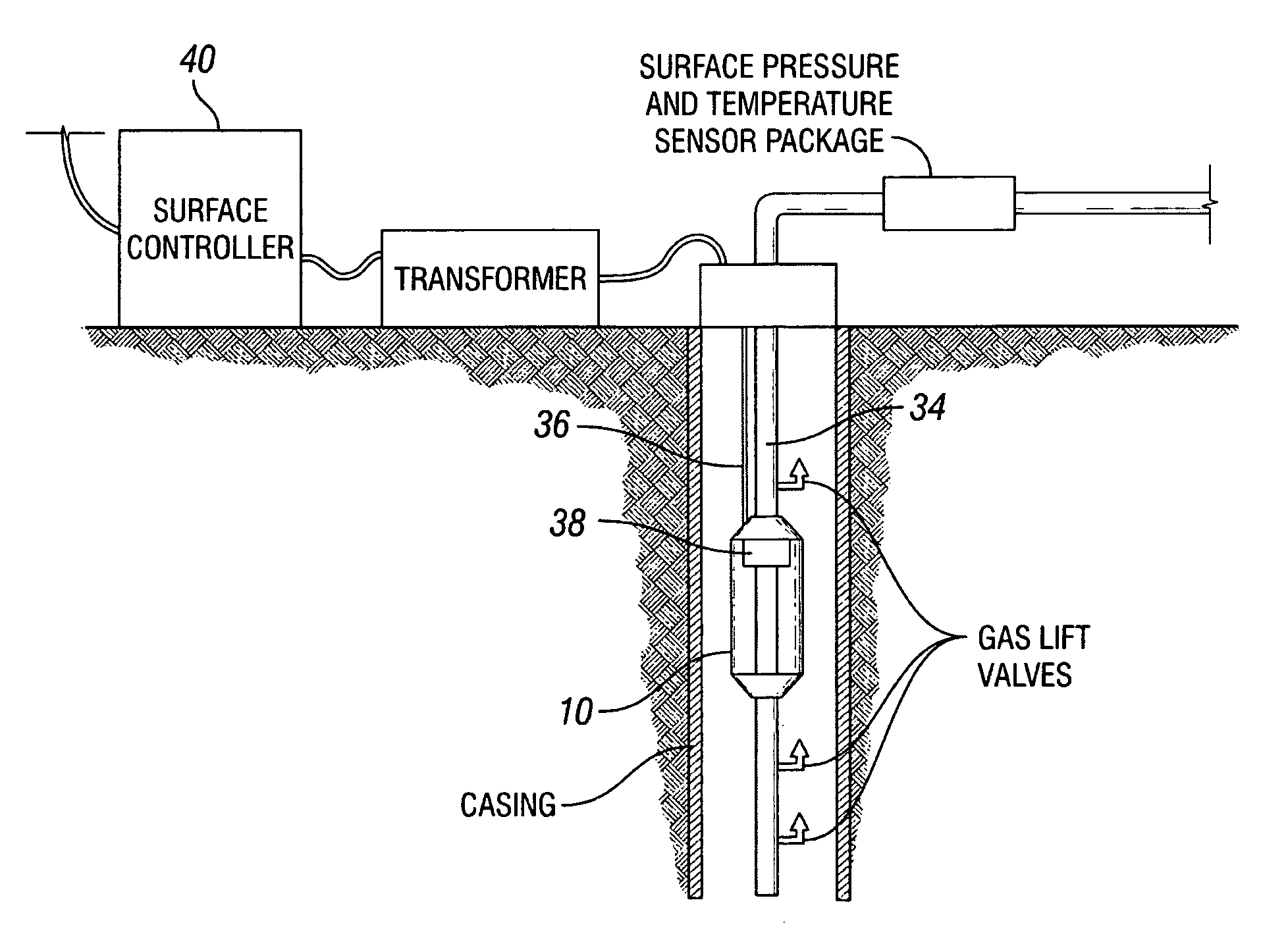

Methods and apparatus for monitoring and controlling oil and gas production wells from a remote location

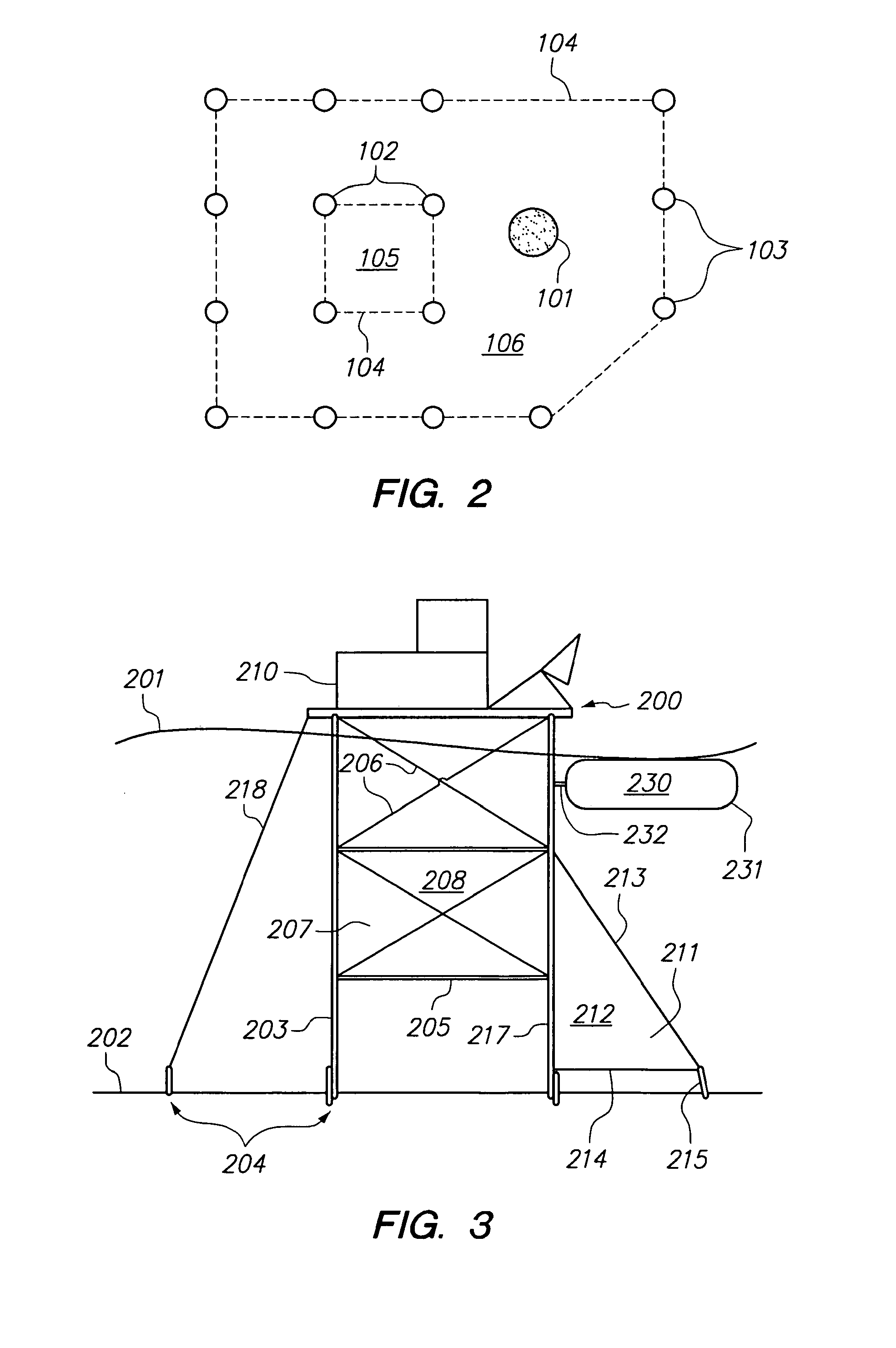

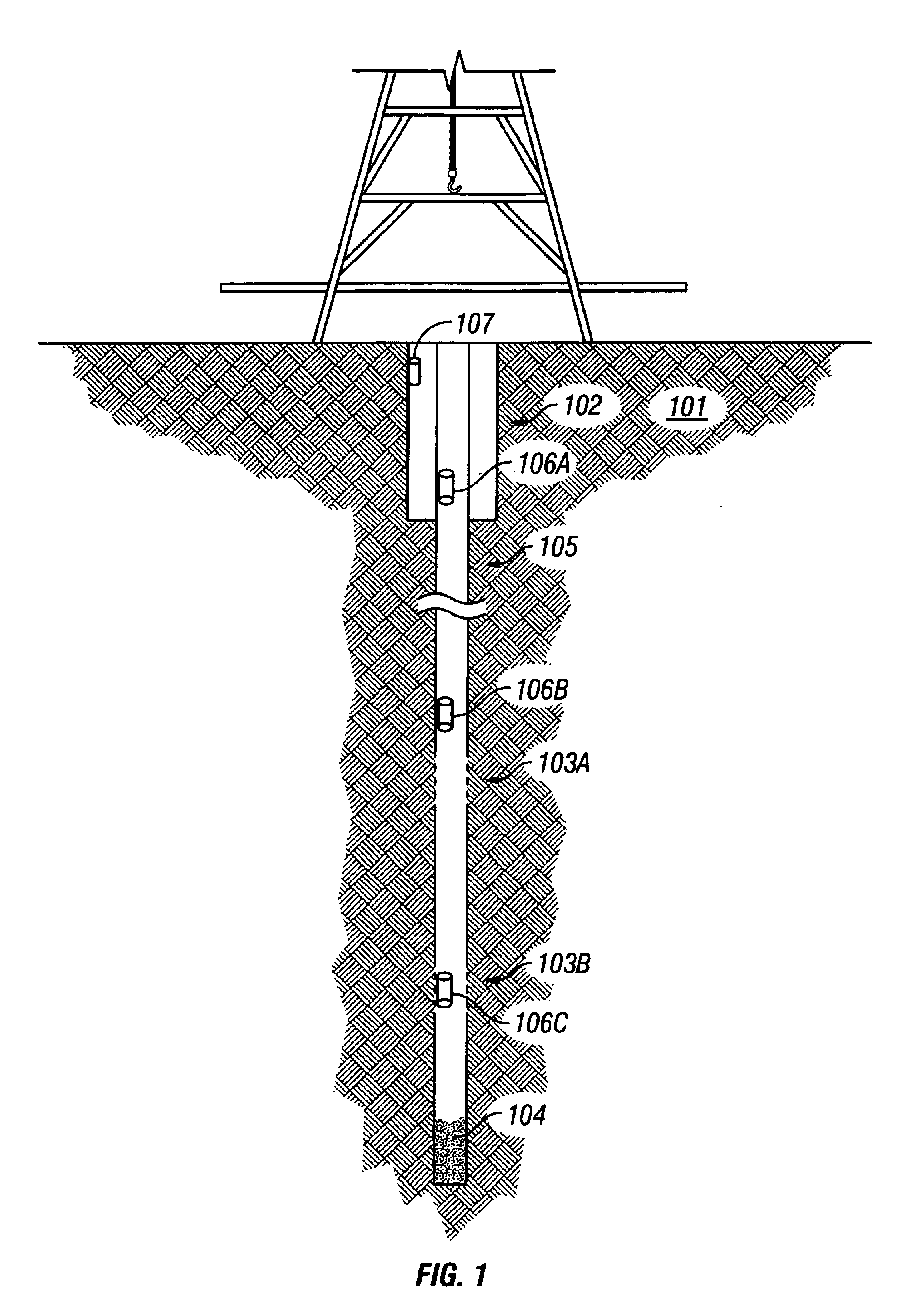

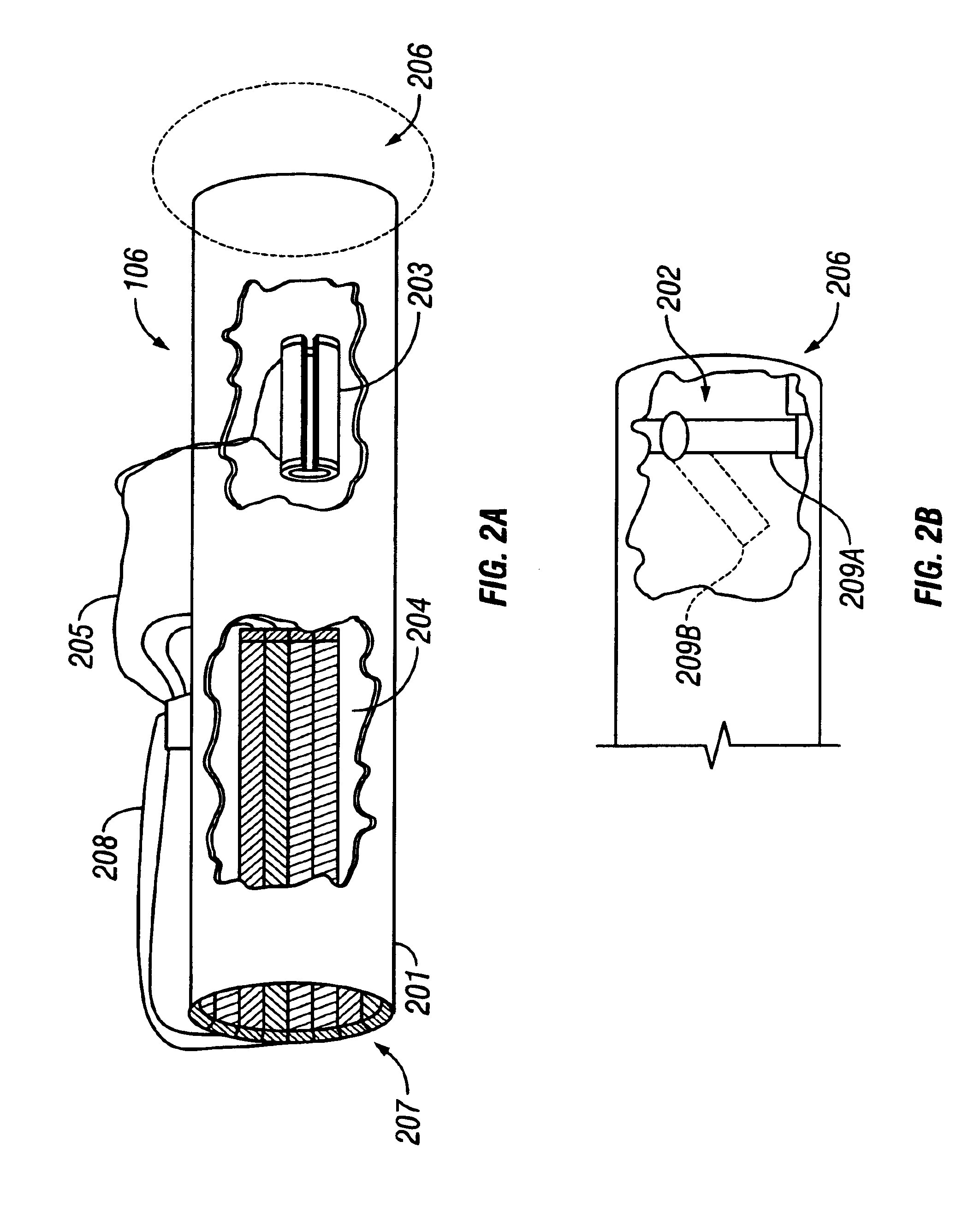

The invention provides apparatus and methods for monitoring and controlling hydrocarbon production wells and / or injection wells from a remote location. The apparatus for monitoring and controlling one or more hydrocarbon production wells or injection wells from a remote location comprises one or more surface control and data acquisition systems; one or more sensors disposed in communication with the one or more control and data acquisition systems; one or more downhole flow control devices disposed in communication with the one or more control and data acquisition systems; and one or more remote controllers disposed in communication with the one or more control and data acquisition systems. Preferably, the remote controller comprises a computer having an internet access disposed in communication with the one or more control and data acquisition systems through a communication device comprising an internet web site server. The method for monitoring and controlling a downhole hydrocarbon production well or an injection well comprises: transmitting data collected by a downhole sensor module to a control and data acquisition system; evaluating downhole operating conditions and optimizing downhole operating parameters utilizing an optimization software program disposed in communication with the control and data acquisition system; and transmitting signals between the control and data acquisition system system and a remote controller utilizing a satellite communication system, the remote controller comprising a computer and an internet browser control access adapted to display operating conditions and parameters and to accept instructions to change operating parameters.

Owner:WEATHERFORD TECH HLDG LLC

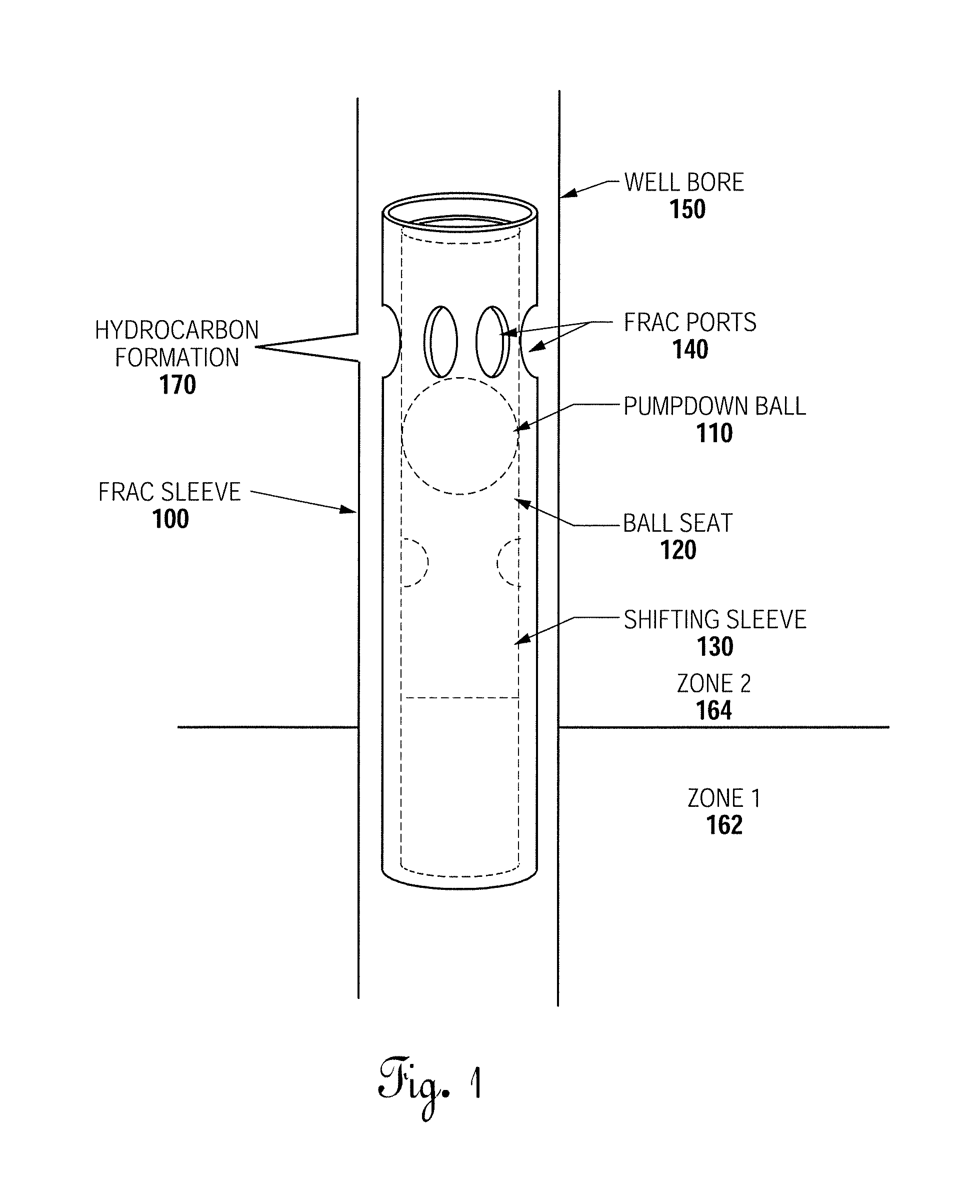

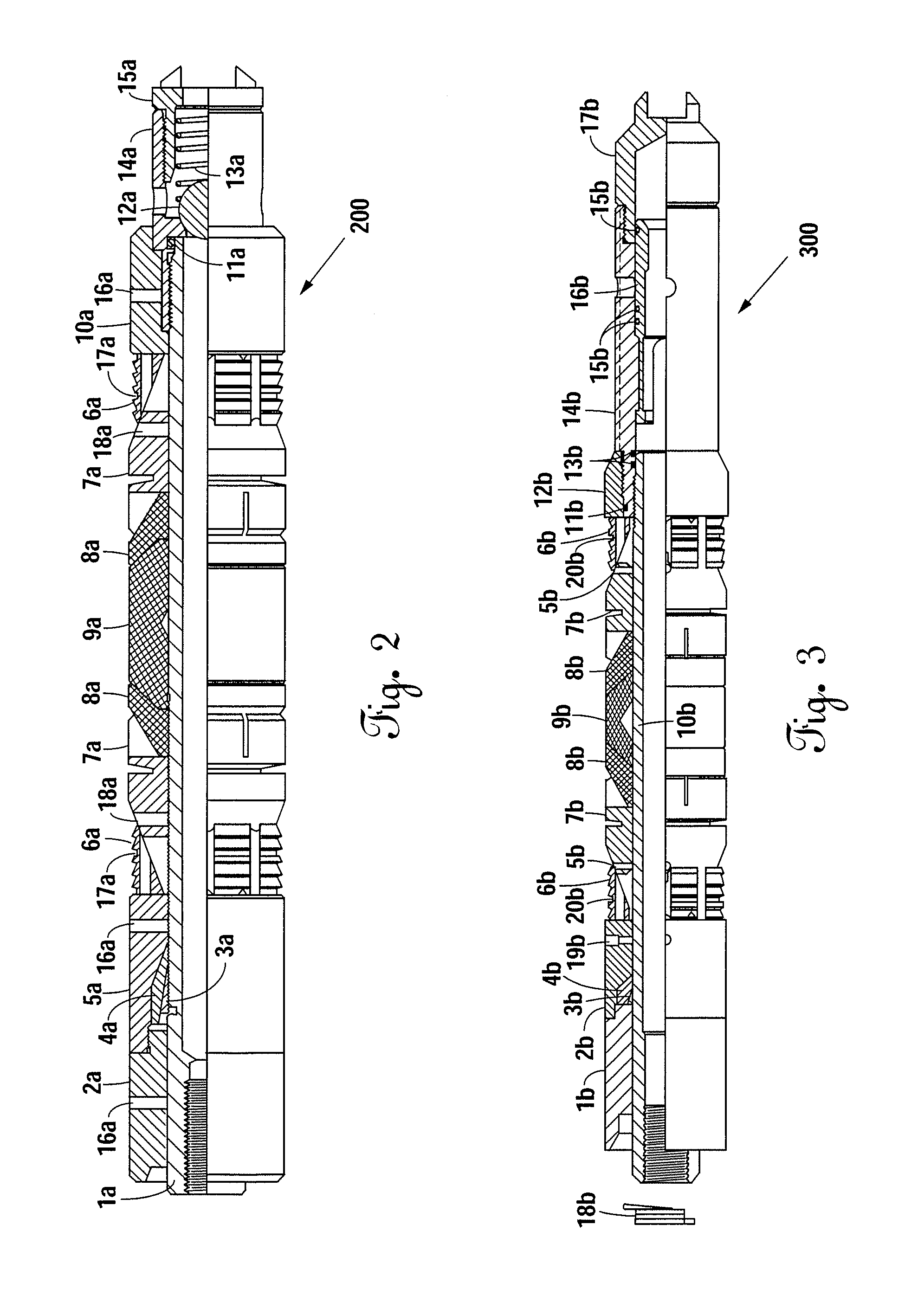

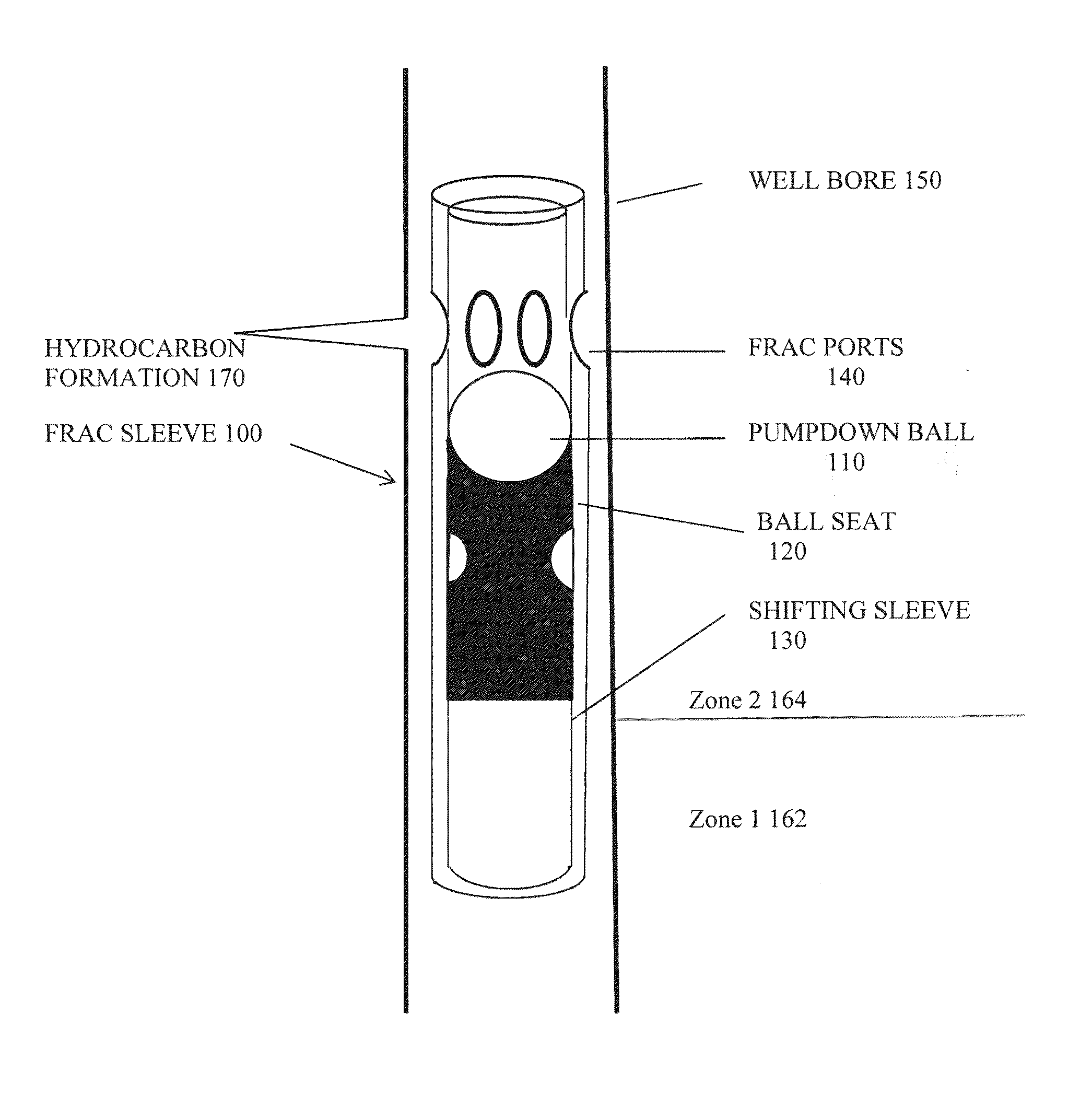

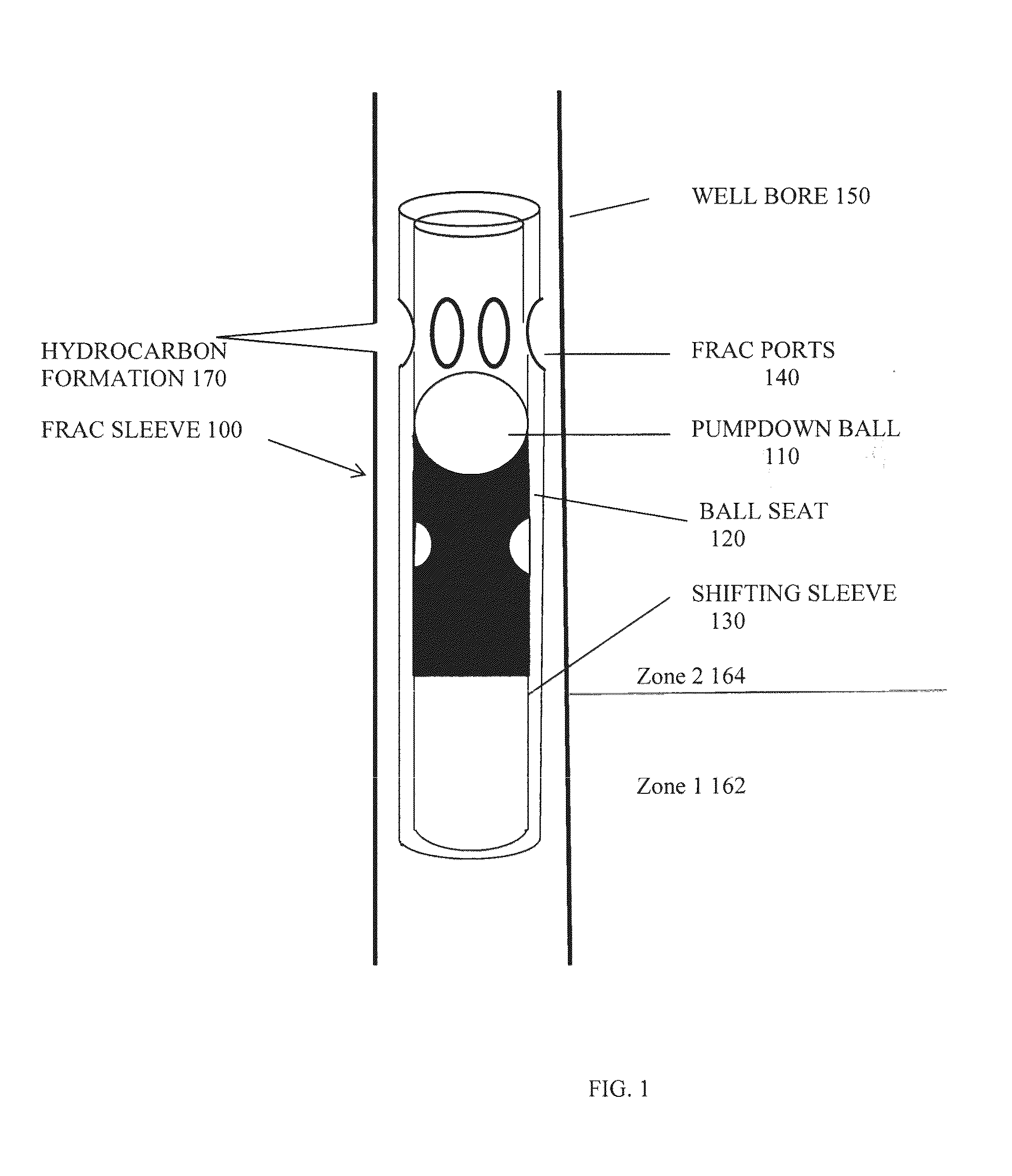

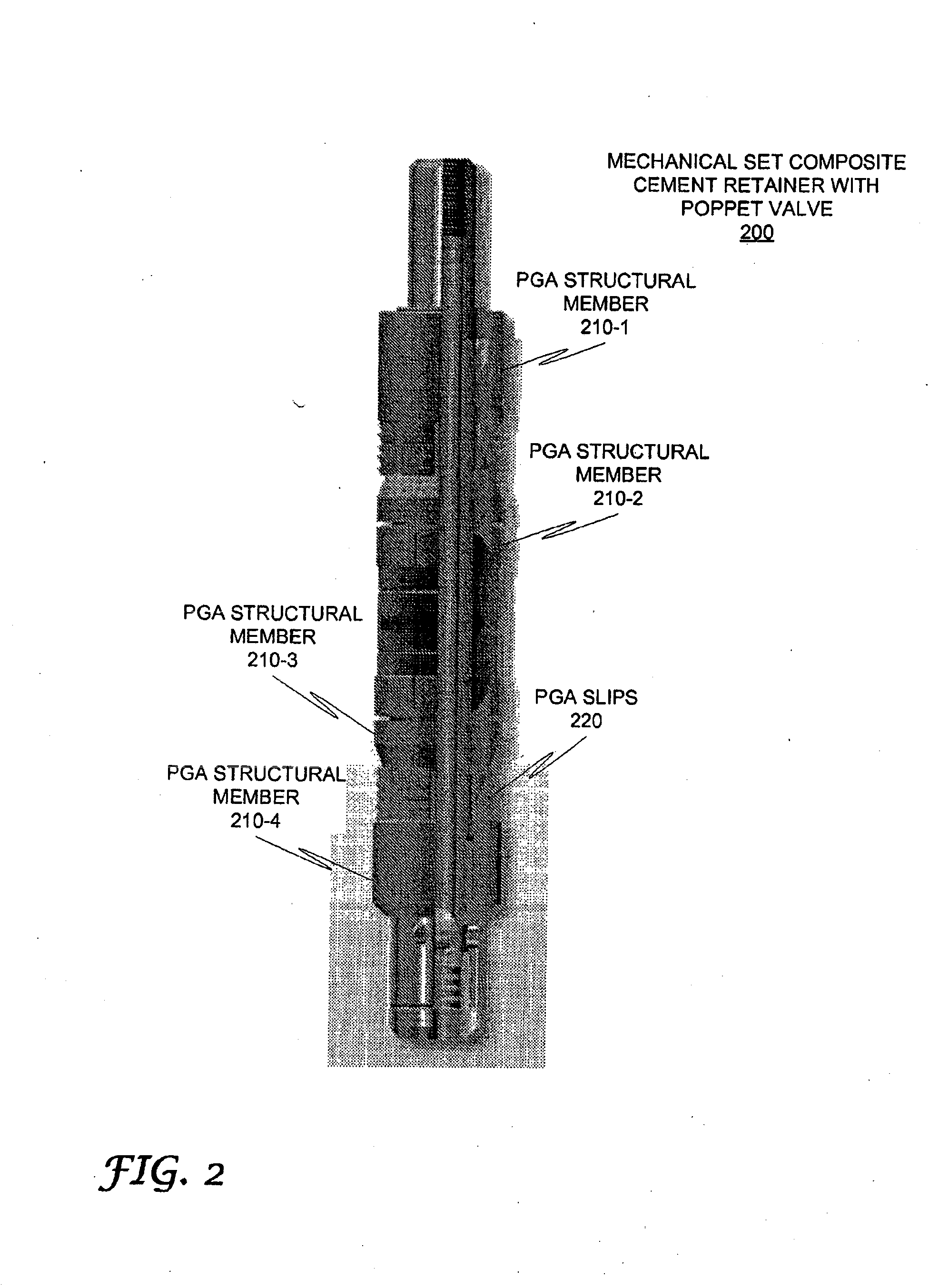

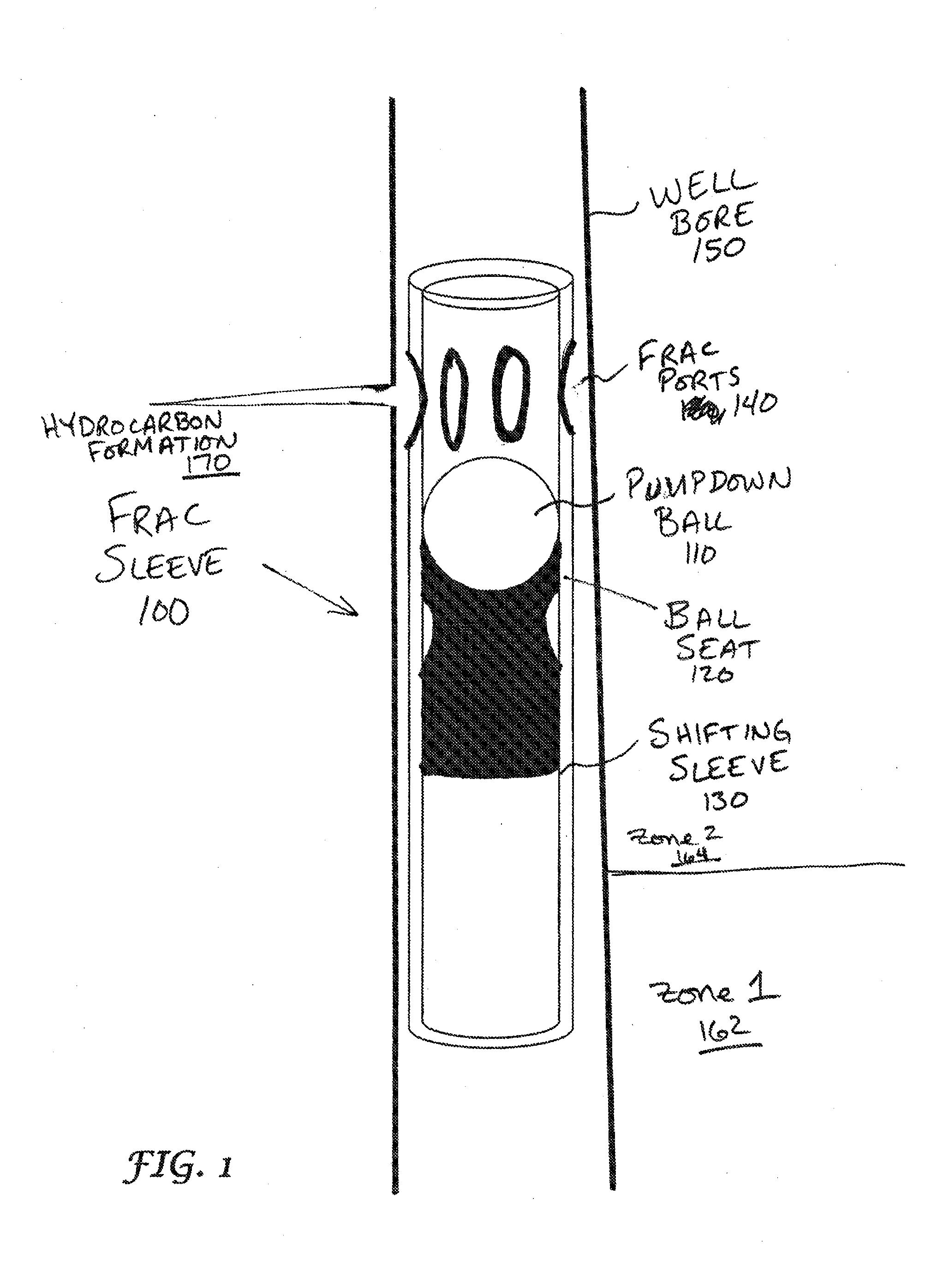

Downhole tools having non-toxic degradable elements and methods of using the same

Downhole tools for use in oil and gas production which degrade into non-toxic materials, a method of making them and methods of using them. A frac ball and a bridge plug comprised of polyglycolic acid which can be used in fracking a well and then left in the well bore to predictably, quickly, and safely disintegrate into environmentally friendly products without needing to be milled out or retrieved.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

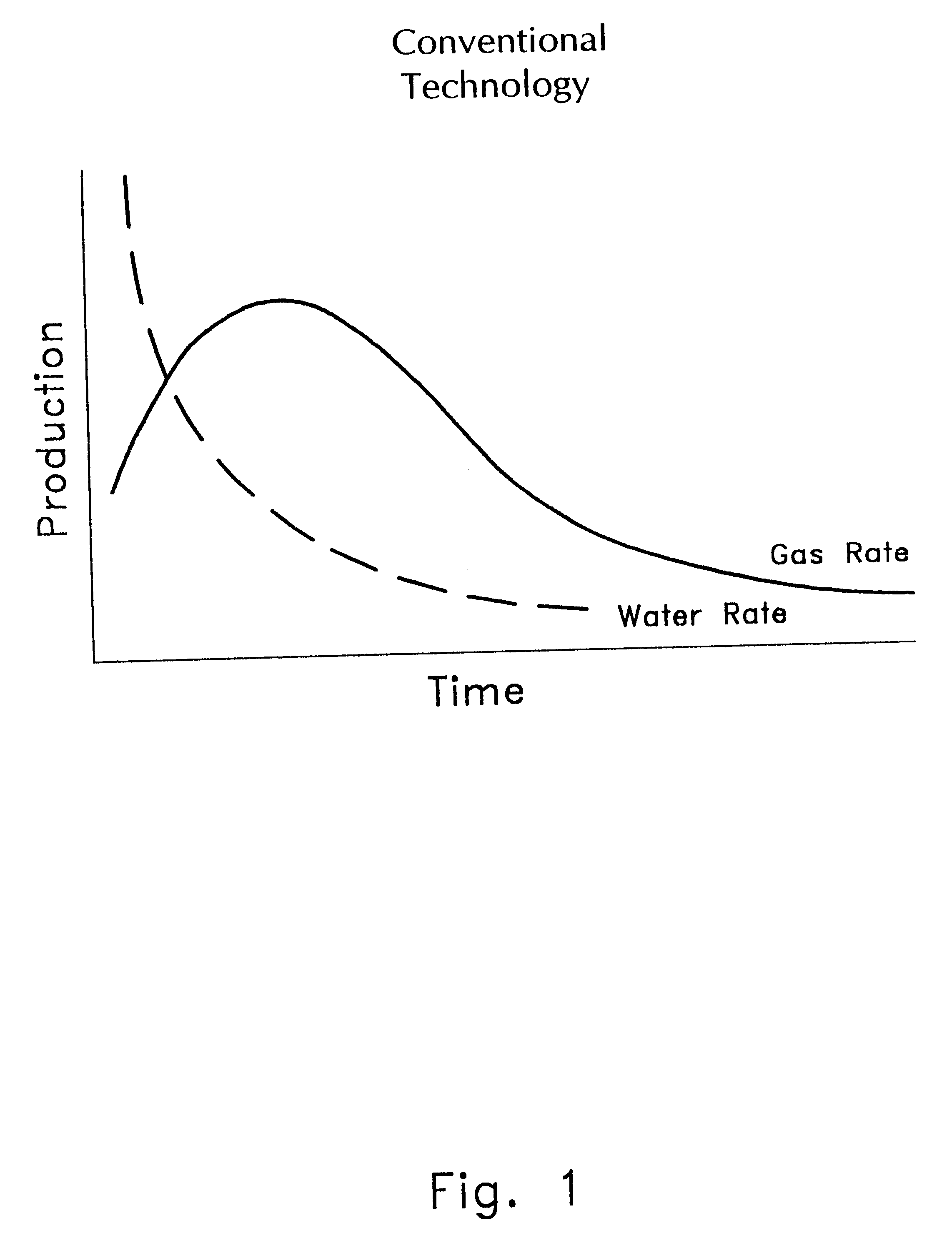

System for improving coalbed gas production

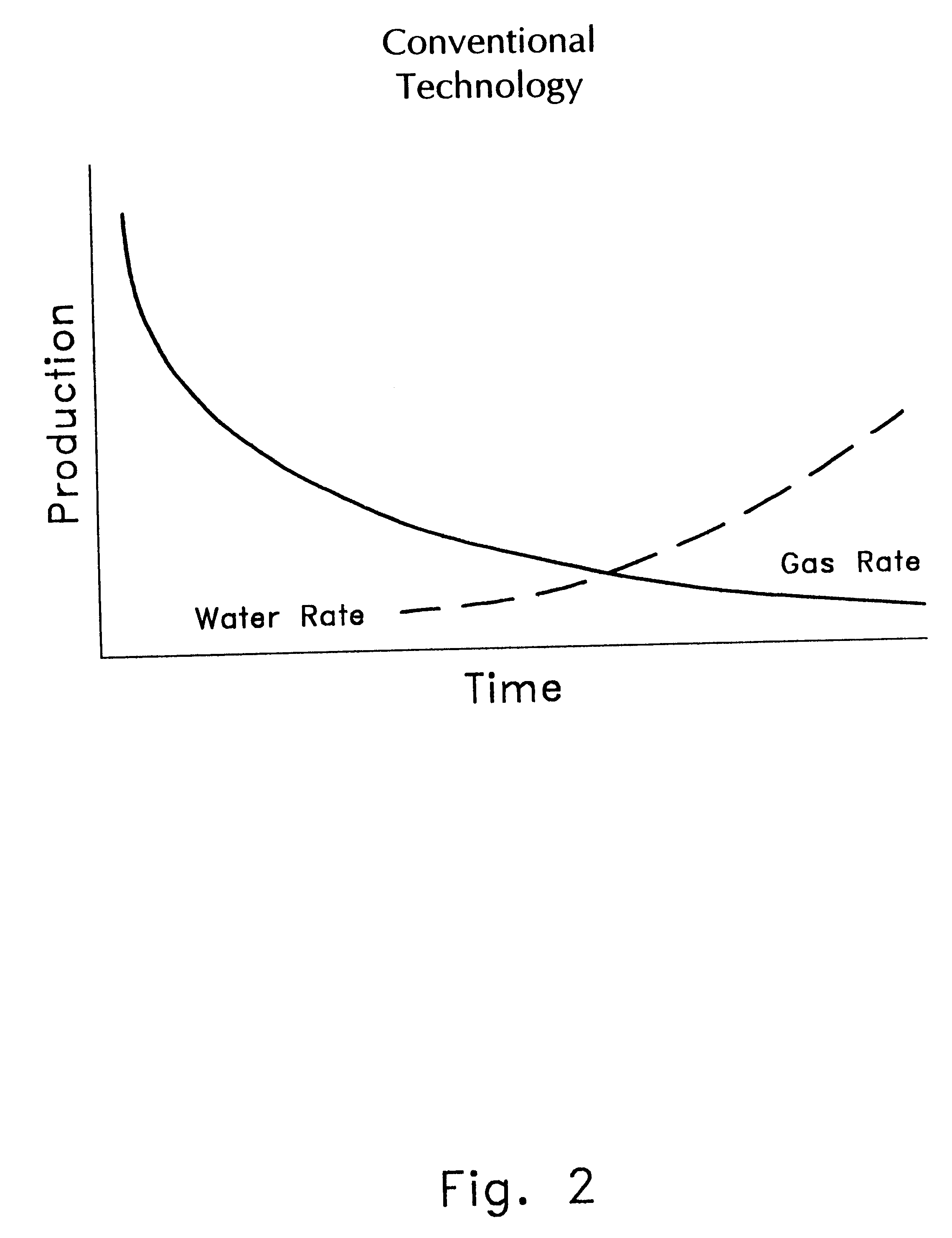

InactiveUS6244338B1Change in permeabilityPromote recoverySurveyDrilling rodsCoal matrixWater production

A method of stimulating coalbed methane production by injecting gas into a producer and subsequently placing the producer back on production is described. A decrease in water production may also result. The increase in gas production and decrease in water production may result from: (1) the displacement of water from the producer by gas; (2) the establishment of a mobile gas saturation at an extended distance into the coalbed, extending outward from the producer; and (3) the reduction in coalbed methane partial pressure between the coal matrix and the coal's cleat system.

Owner:THE UNIVERSITY OF WYOMING RESEARCH CORPORATION DBA WESTERN RESEARCH INSTITUTE

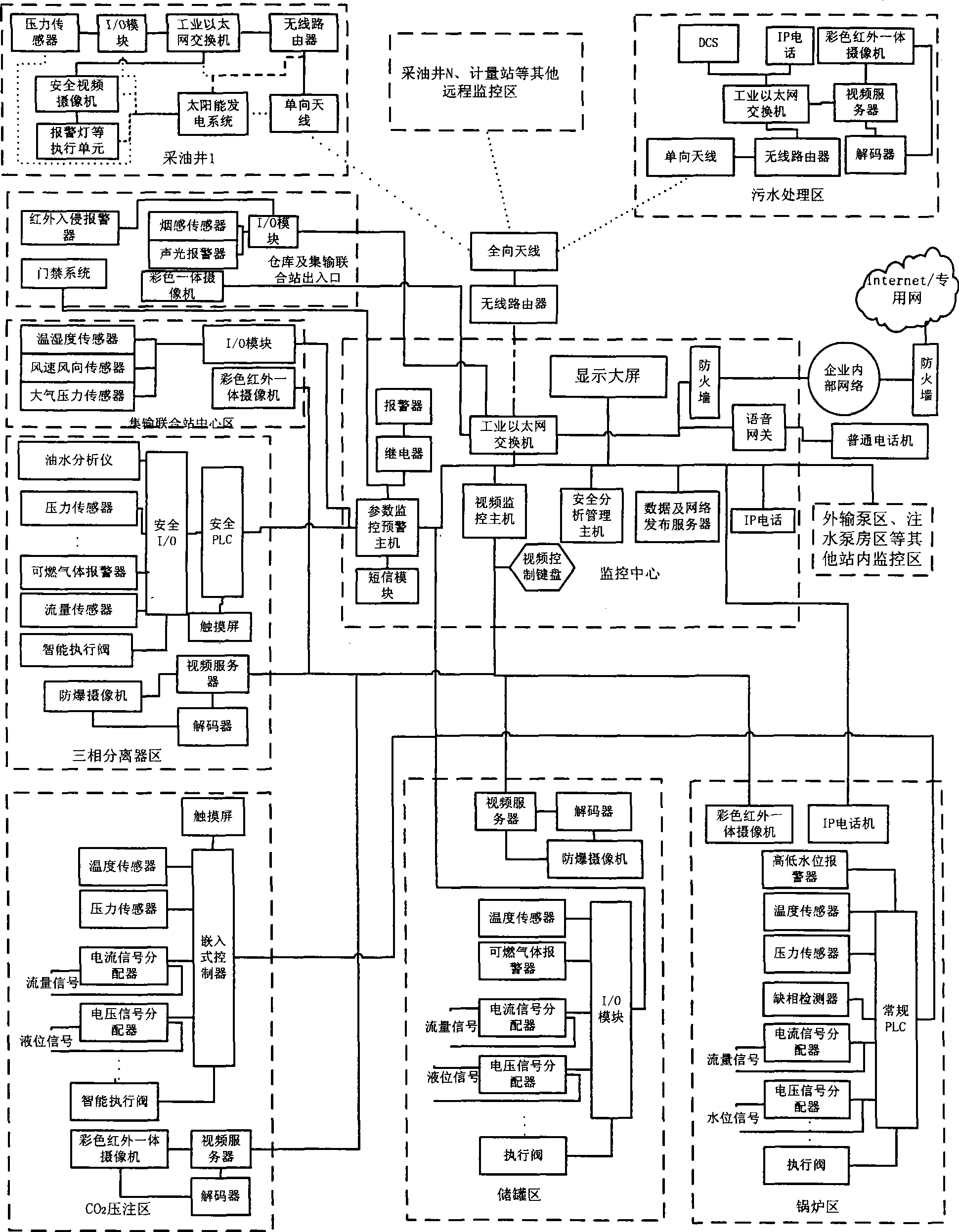

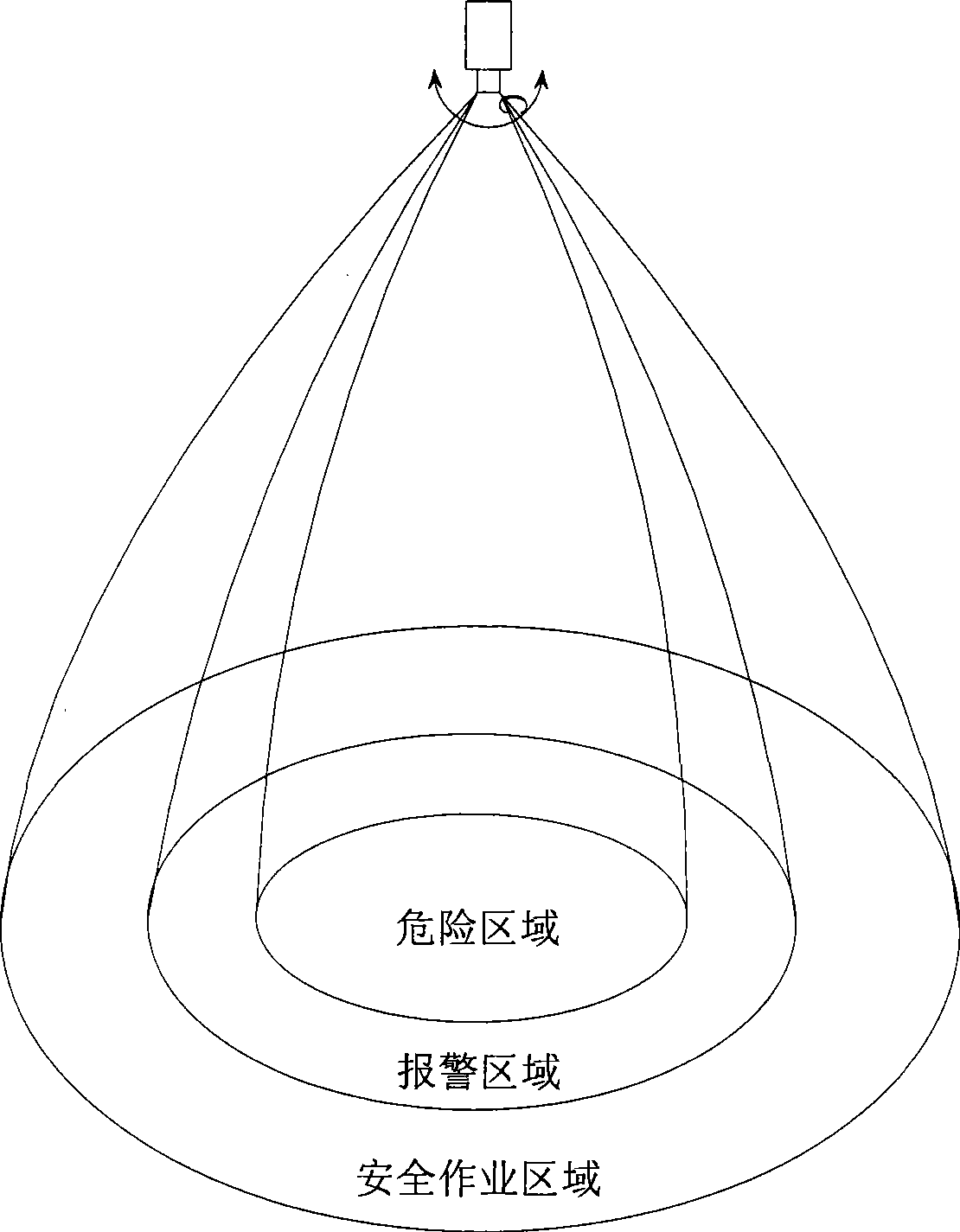

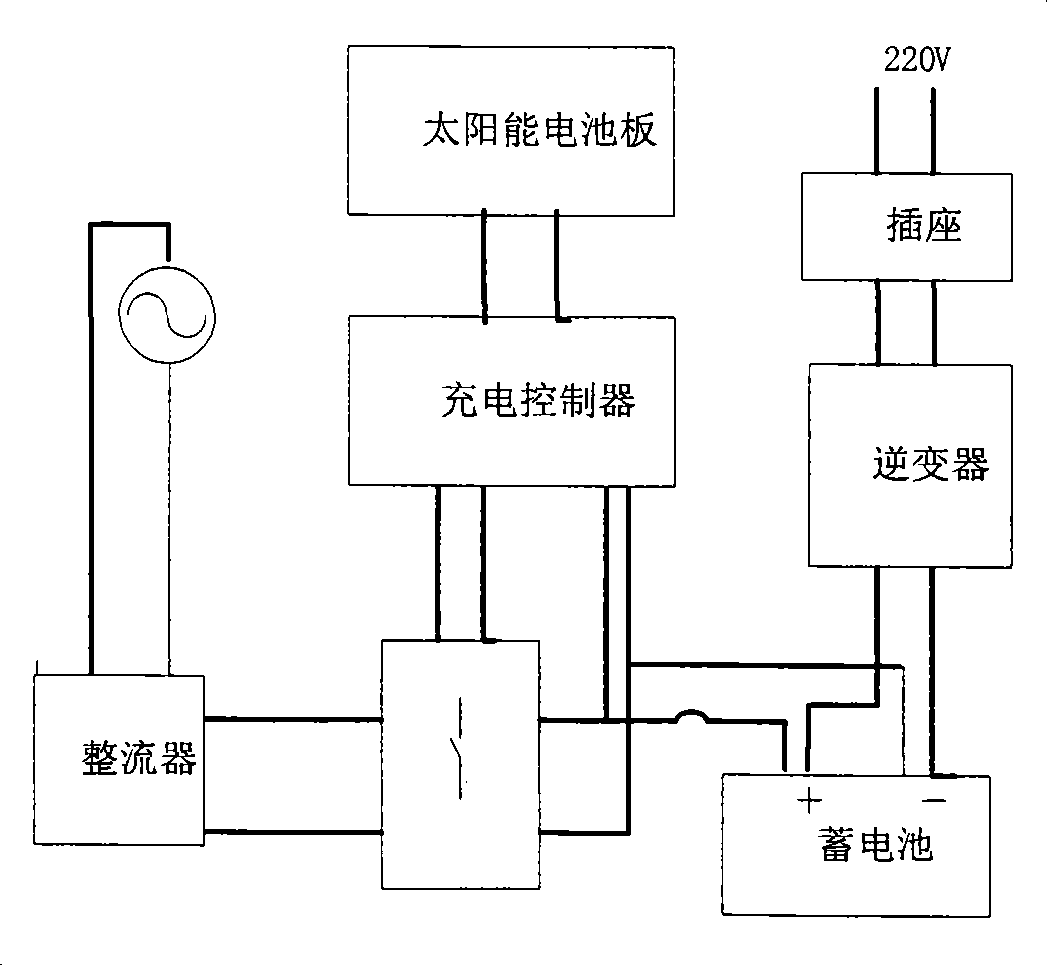

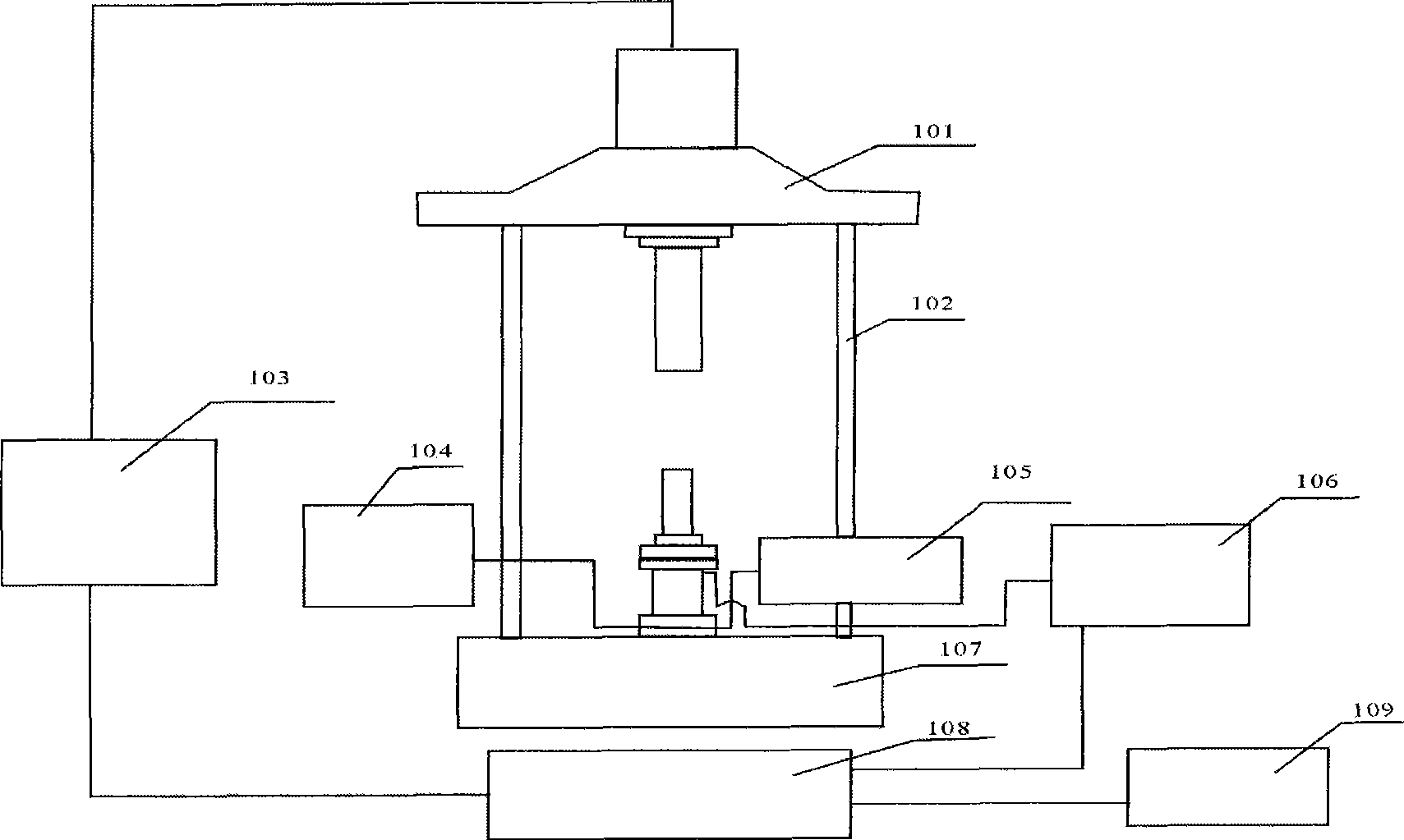

Safety monitoring early warning and safety management system and method for oil gas extracting, gathering and transporting operation

InactiveCN101369152AManagement is easy to strengthenEasy to manageFluid removalProgramme total factory controlVideo monitoringSafety management systems

The invention relates to a safety monitoring early warning and safety management system of oil and gas extraction and gathering operations as well as a method thereof, belonging to the technique field of safety production monitoring and supervision, and the system is composed of a monitoring center arranged at an oil and gas extraction safety monitoring and management department and a plurality of on-site monitoring terminals disposed at all oil and gas extraction operation areas. The method comprises: collecting and transmitting safety-related parameter signals, video signals and audio signals in real time; implementing the analog-digital conversion or signal conversion and compression coding to the signals; then transmitting the signals to all hosts of the monitoring center; processing and analyzing the received three types of signal information by all the hosts and then carrying out the parameter monitoring, video monitoring and audio communication respectively; and outputting the processed three types of information to the spot for being controlled correspondingly. The invention can realize the risk assessment, dynamic intelligent monitoring, safety state analysis, accident early warning and alarming, safety guarantee control and safety management of the whole process of operations ranging from oil and gas extraction, heating, separation processing, storage to transportation for oil and gas production enterprises.

Owner:CHINA ACAD OF SAFETY SCI & TECH

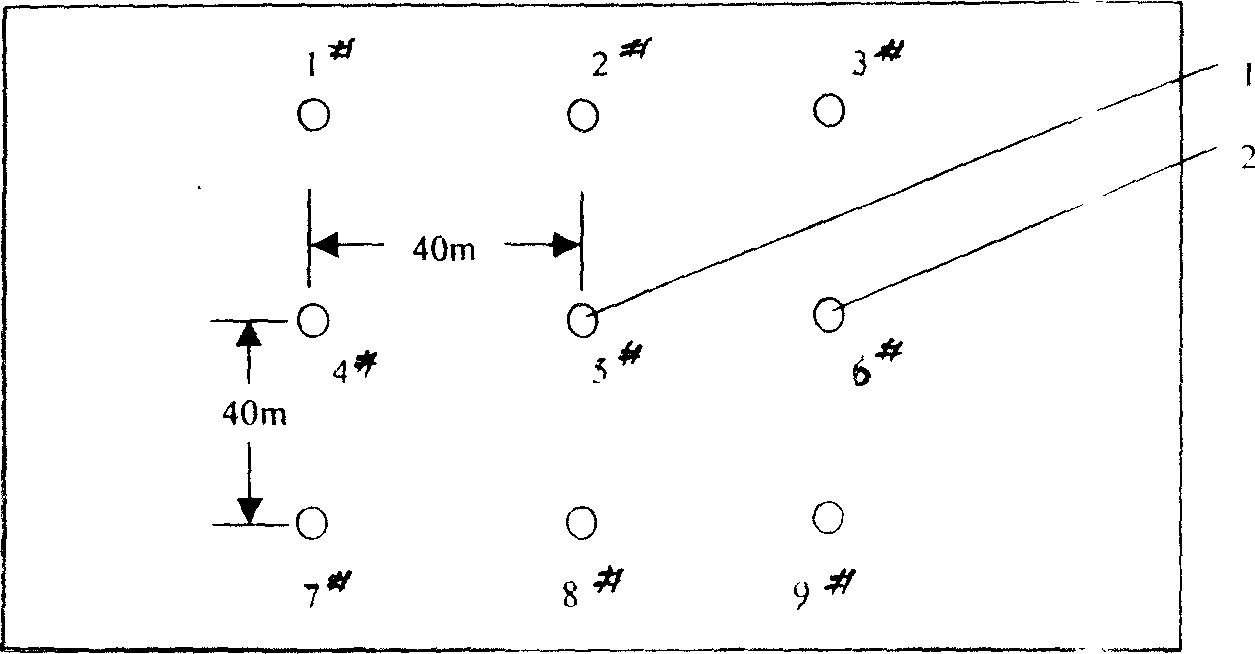

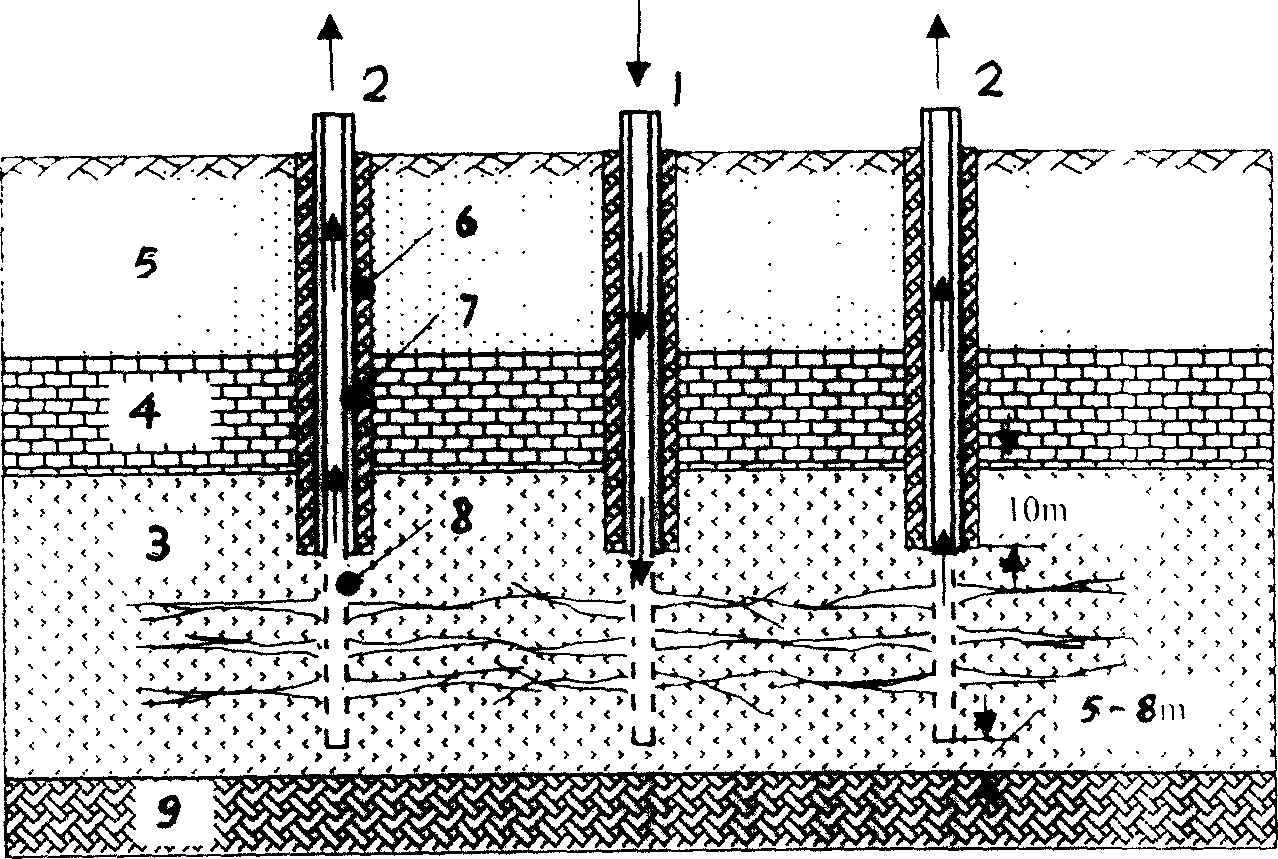

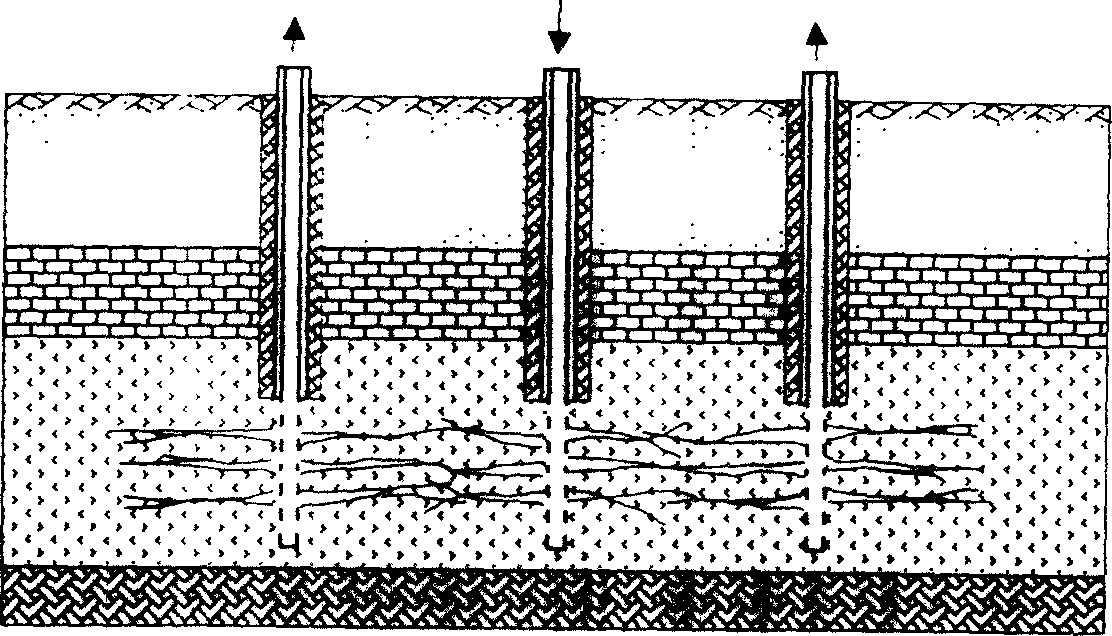

Method for extracting oil and gas by convection heating of oil shale

A kind of mining oil gas method of the convection heating up oil-shale, involves the underground solid state energy and the mineral mining method improvement. The existing technical mining method efficiency is low, the cost is high, the scale is small, the big area implements and lacks the market competition ability with difficulty. This invention through in the ground arrangement group well, and selects the compression fracture method causes the group well to be interlinked, then the gap takes turns to choose the note hot-well and work-well, hot-well pours into 400 deg.C - 700 deg.C steam along the note oil-shale the ore level, heats up the ore level causes cheese root thermal decomposition to form the oil gas, and carries after the low temperature steam or the water along the production separates to the ground, finally forms the oil gas product. In the separation process may simultaneously the pre- hot water, and uses the water-injection well withdraws with work-well the convection way dries up oil-shale and the ore level around shale region afterheat, thus realized the goal of this invention is fast, big scale, low cost from oil-shale ore level mining oil gas.

Owner:TAIYUAN UNIV OF TECH

Method for determining tracer concentration in oil and gas production fluids

ActiveUS7347260B2Prevent premature terminationAvoid unnecessary down timeSurveyConstructionsWater BreakOil well

A method for determining the extent of recovery of materials injected or otherwise introduced into oil wells or subsurface formations is practiced using a portable device. The portable device can also be used to determiner the occurrence of a predetermined condition in an oil well such as water break through in a production zone, or the opening or closing of a sliding sleeve. When, for example, water breakthrough is detected, the zone producing too much water can be plugged, using, for example, a flow-through bridge plug, if there are other producing zones further downhole.

Owner:CORE LAB LP

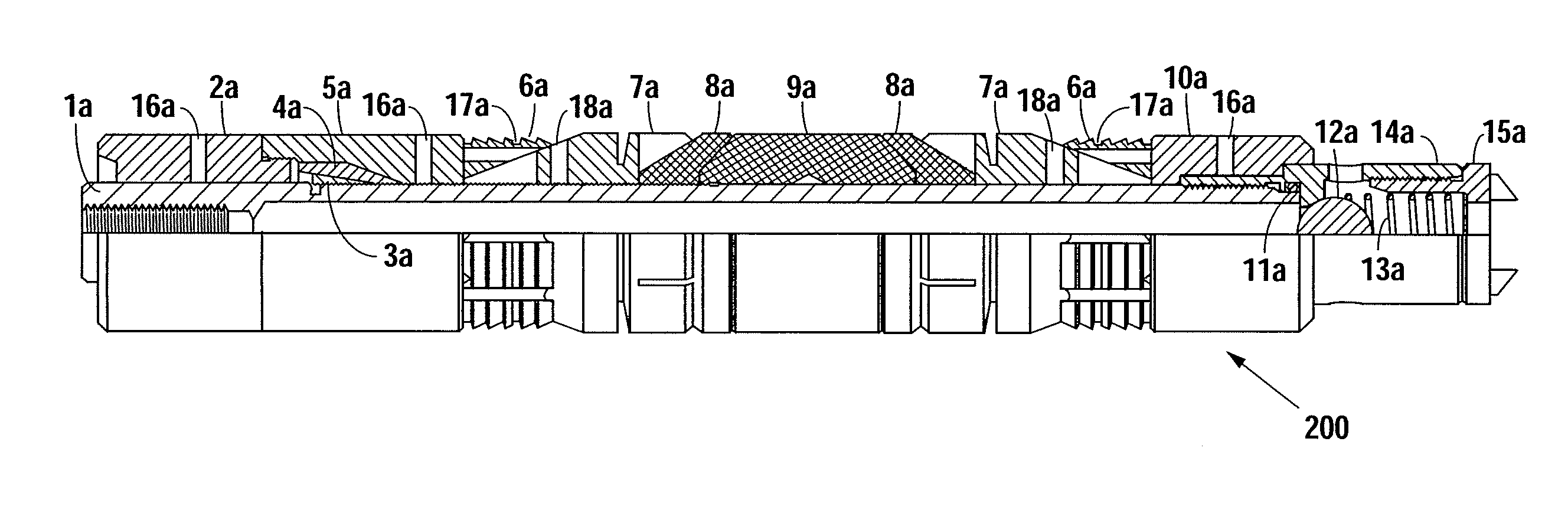

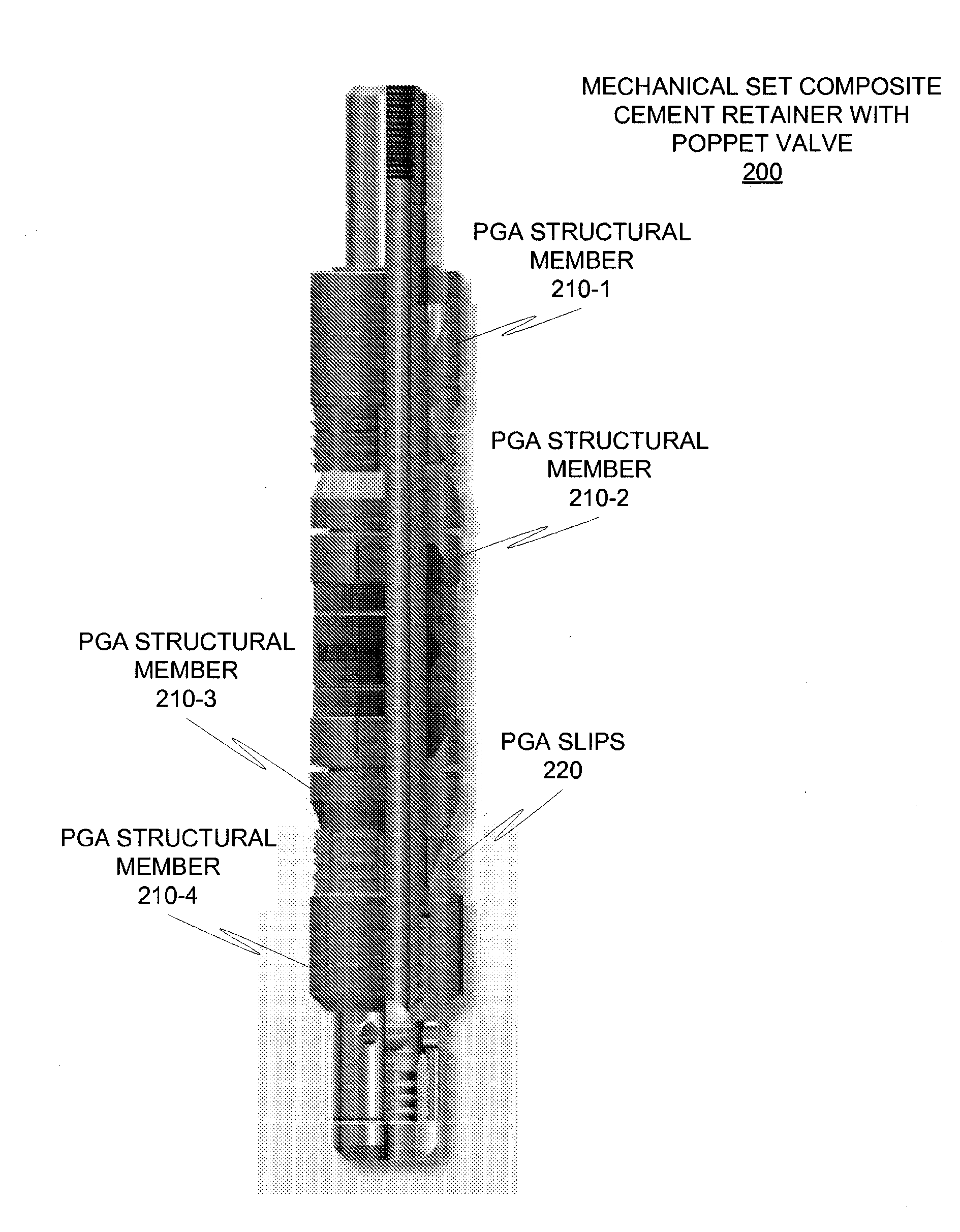

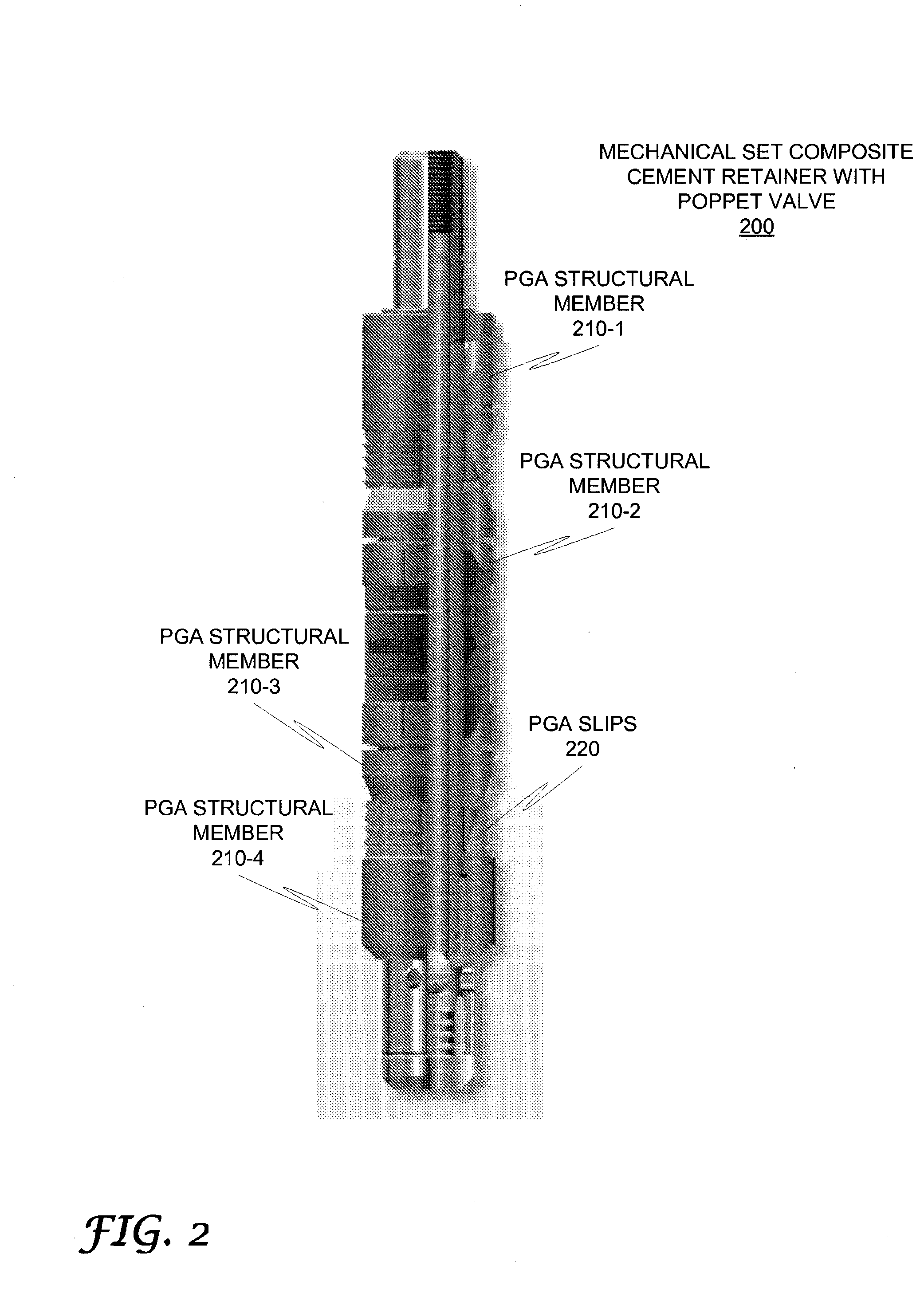

Downhole tools having non-toxic degradable elements

Downhole tools for use in oil and gas production which degrade into non-toxic materials, a method of making them and methods of using them. A frac ball and a bridge plug comprised of polyglycolic acid which can be used in fracking a well and then left in the well bore to predictably, quickly, and safely disintegrate into environmentally friendly products without needing to be milled out or retrieved.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

Downhole tools having non-toxic degradable elements

Downhole tools for use in oil and gas production which degrade into non-toxic materials, a method of making them and methods of using them. A frac ball and a bridge plug comprised of polyglycolic acid which can be used in fracking a well and then left in the well bore to predictably, quickly, and safely disintegrate into environmentally friendly products without needing to be milled out or retrieved.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

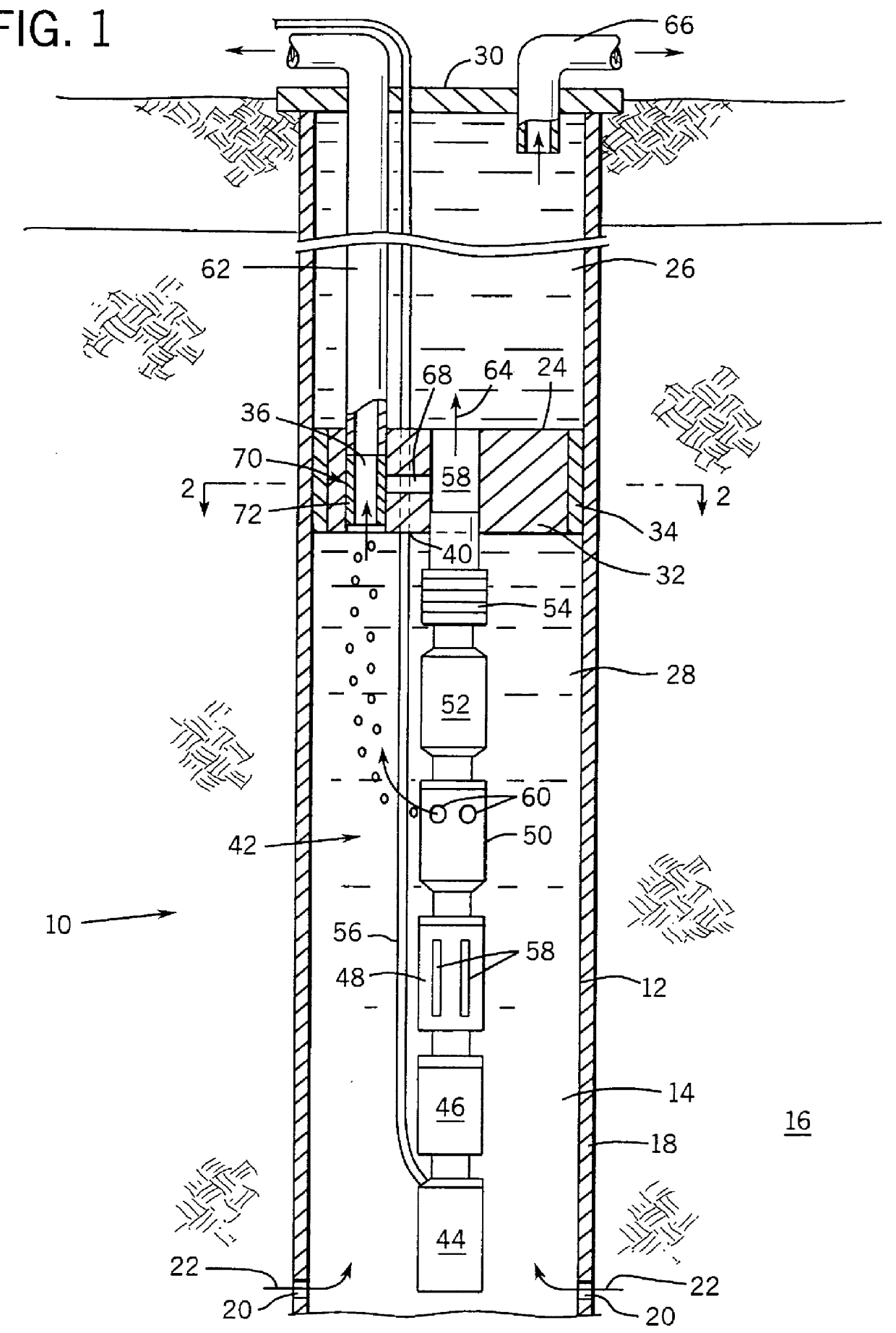

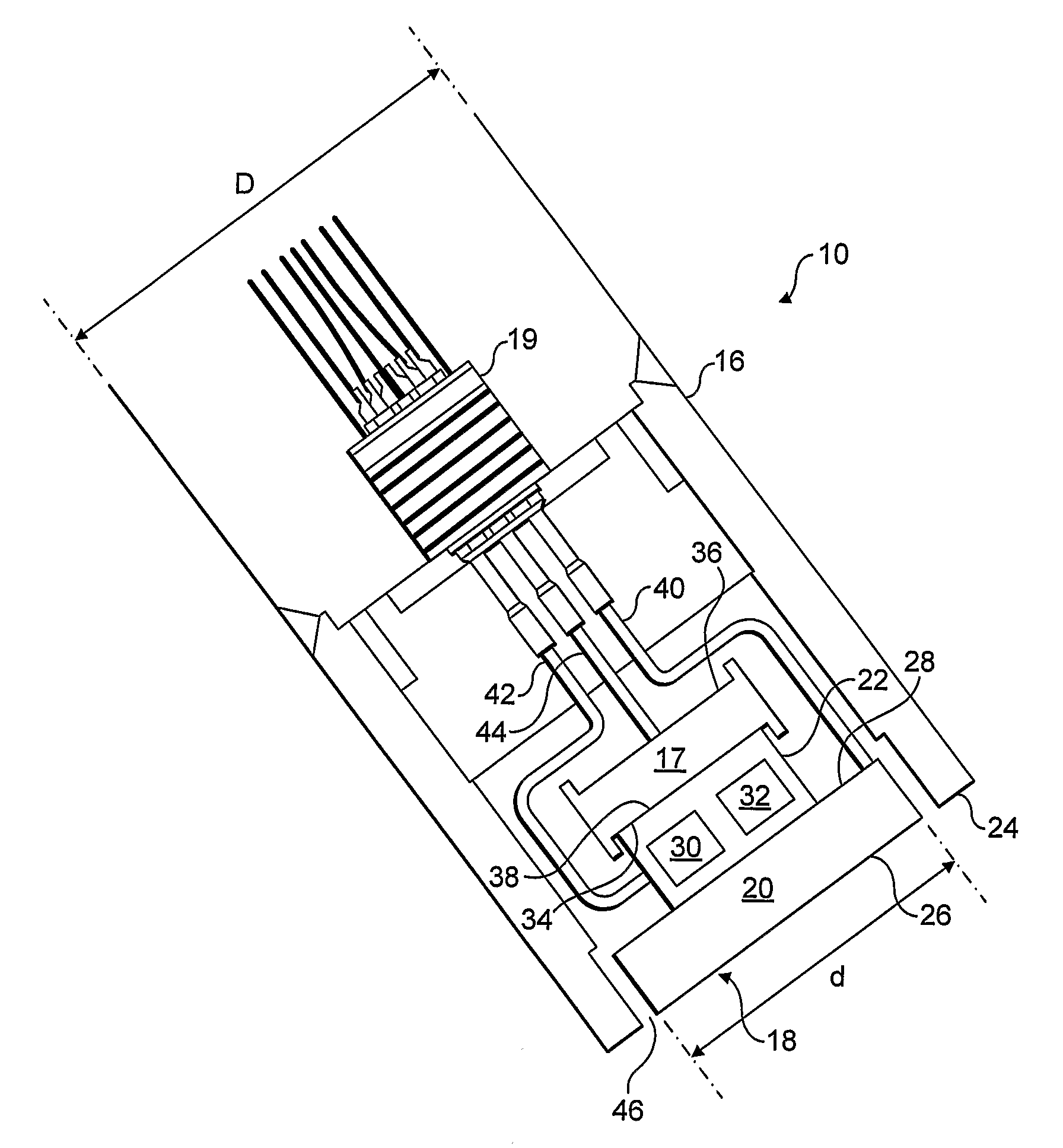

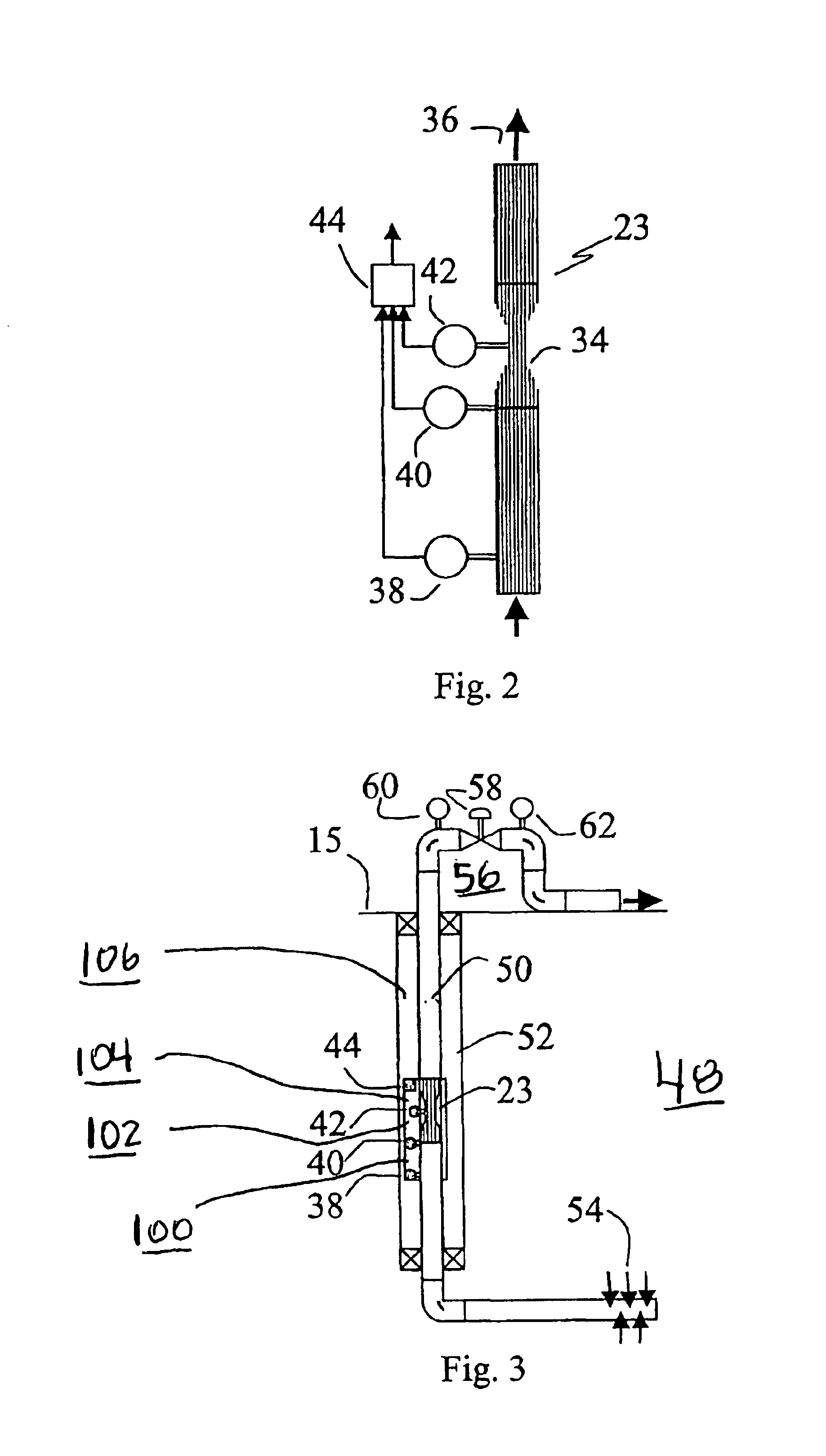

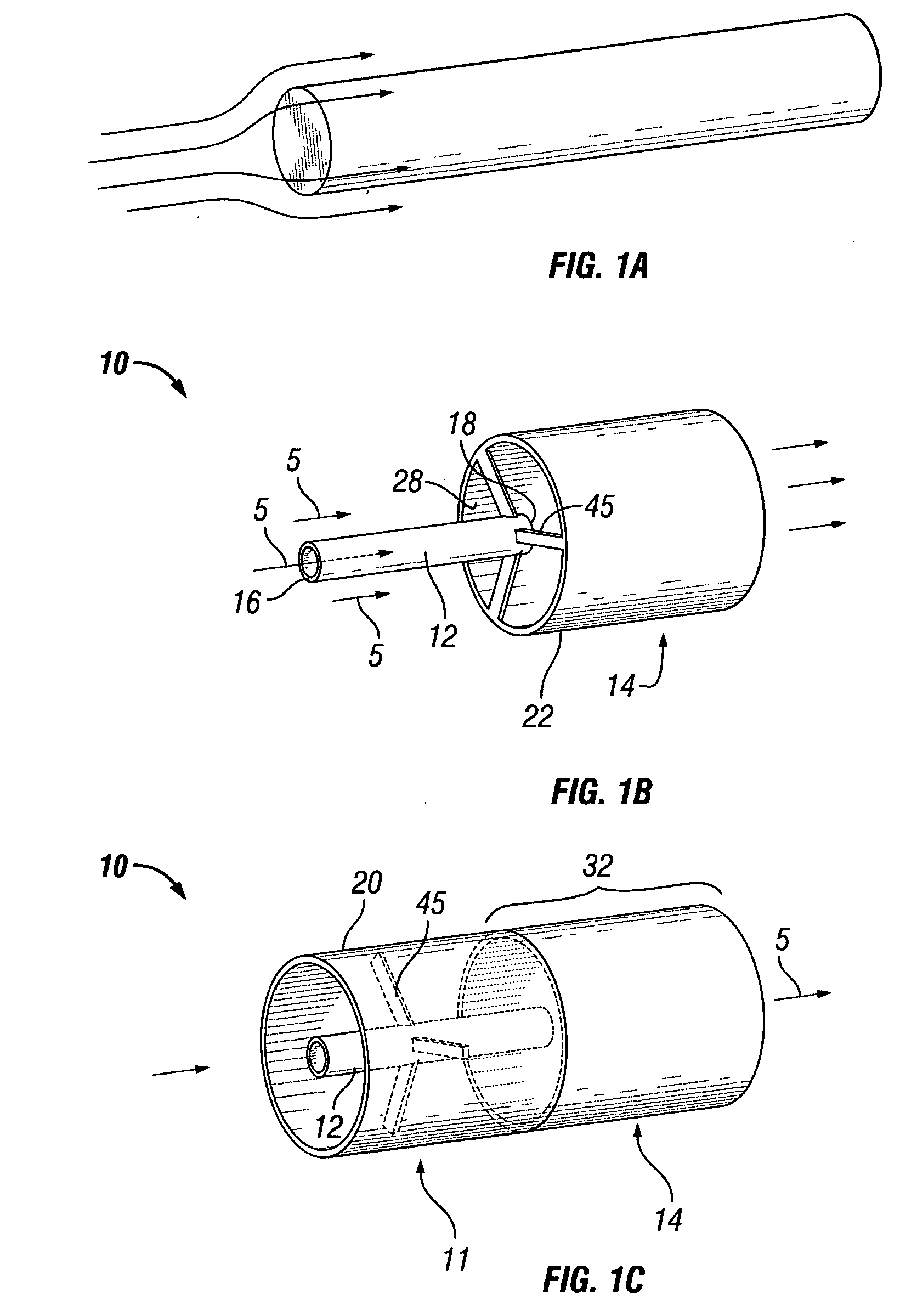

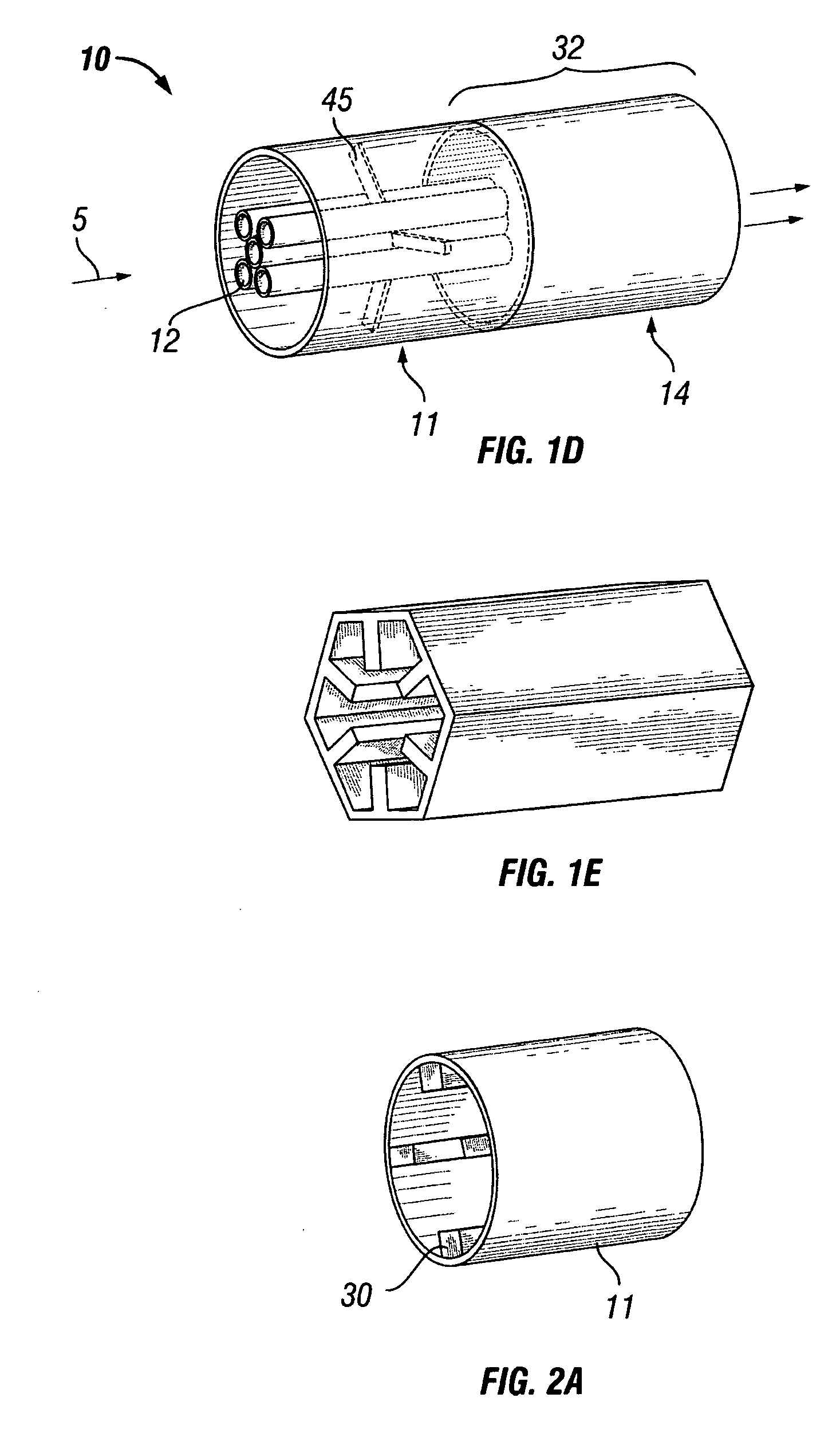

Well completion system employing multiple fluid flow paths

A technique is disclosed for completion of a well, such as an oil and gas production well. A packer is positioned in the well to divide the well into upper and lower zones. The packer has multiple passageways between the upper and lower zones. A pumping system is positioned in the lower zone for displacing wellbore fluids flowing from a production formation. The pumping system may include a liquid / gas separator, and express gas-phase components through one of the passageways and liquid-phase components through another. A conduit conveys the gas-phase components to a desired location. The liquid-phase components are conveyed to a collection location in the annular region surrounding the conduit. The conduit may be used for positioning a chemical injection line within the well, or for receiving a parameter sensing unit. The chemical injection and parameter sensing may be performed independently of gas production, and without interruption of either gas or liquid production.

Owner:CAMCO INT

Method and apparatus to monitor, control and log subsea oil and gas wells

A method and apparatus for logging, controlling, or monitoring a subsea well or group of wells through a path not within production tubing. Preferred embodiments allow logging tools, wire rope, optic fibers, electrical cables, monitoring and measuring instruments and other items known to those skilled in the art of oil and gas production to be disposed into the well without interfering with the flow path through the production string. A further preferred embodiment includes the mooring or tethering of an instrument pod over the subsea well. The instrument pod is designed to provide on-board data storage, data processing, data receiving, and data transmission equipment, such that data from the well can be transmitted back to a receiving network where the data may be stored and processed into useful information for reservoir operators.

Owner:SENSOR HIGHWAY LTD

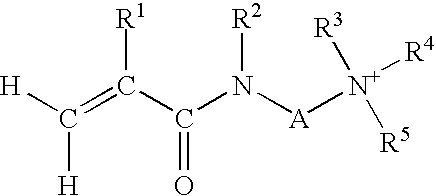

Dispersing Sulfide Scales in Oil and Gas Production Systems

ActiveUS20090143252A1Preventing and mitigating formationFluid removalFlushingEthylene HomopolymersPetroleum

Owner:BAKER HUGHES INC

Method for determining tracer concentration in oil and gas production fluids

ActiveUS20060144588A1Efficient detectionPrevent premature terminationSurveyConstructionsWater BreakOil well

A method for determining the extent of recovery of materials injected or otherwise introduced into oil wells or subsurface formations is practiced using a portable device. The portable device can also be used to determiner the occurrence of a predetermined condition in an oil well such as water break through in a production zone, or the opening or closing of a sliding sleeve. When, for example, water breakthrough is detected, the zone producing too much water can be plugged, using, for example, a flow-through bridge plug, if there are other producing zones further downhole. The portable device may be use to make quantitative measurements or it may be used to do pre-screening of samples thereby avoiding further testing of negative samples.

Owner:CORE LAB LP

Composition and method for inhibition of formation of gas hydrates

InactiveUS6596911B2Using liquid separation agentDistillation purification/separationSolventOnium compound

A method and a composition used therein are disclosed for inhibiting formation of hydrocarbon hydrates. The composition comprises an onium compound, an amine salt and, optionally, a solvent. The method and composition are particularly useful for oil and gas production

Owner:BAKER HUGHES INC

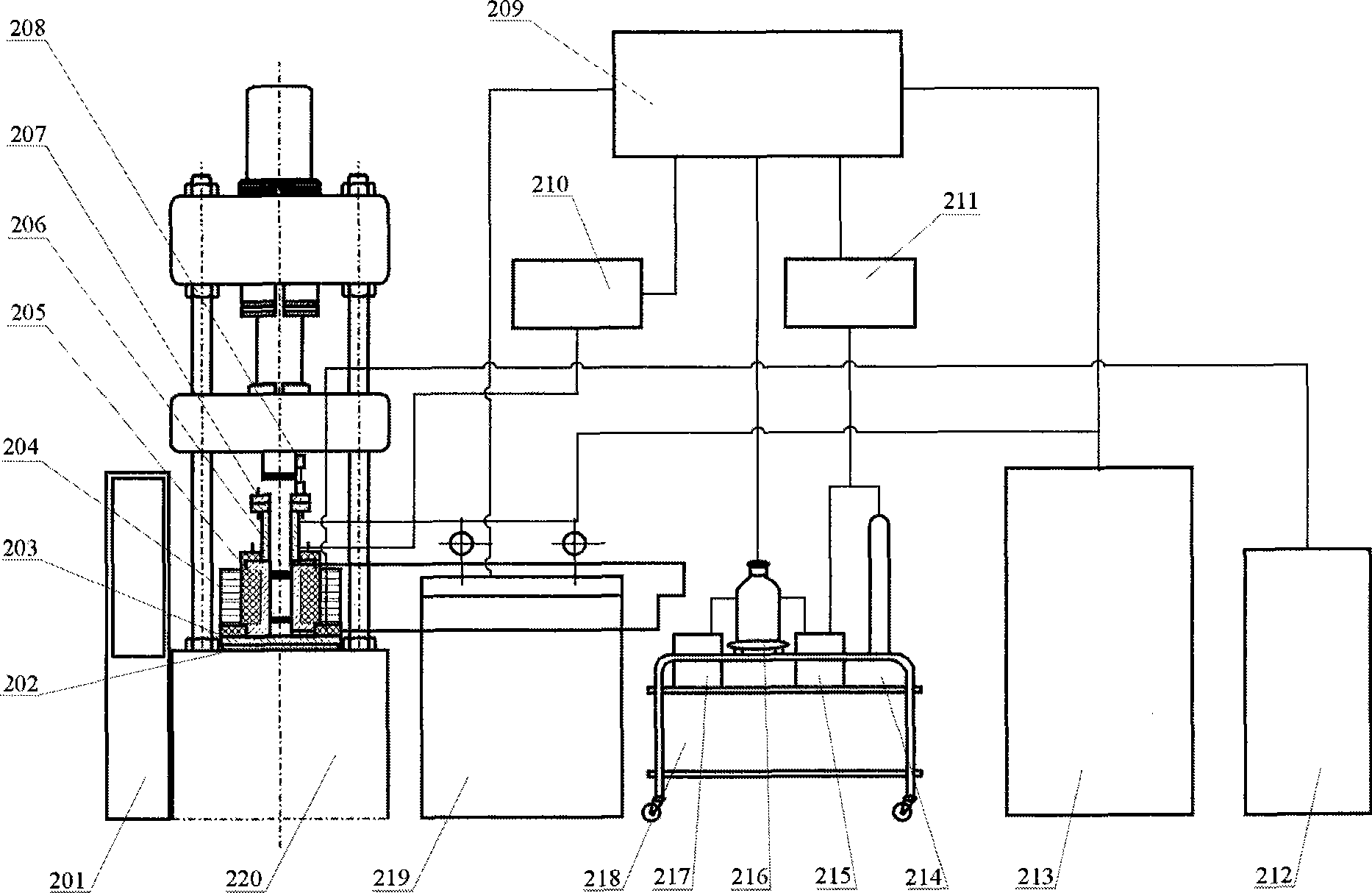

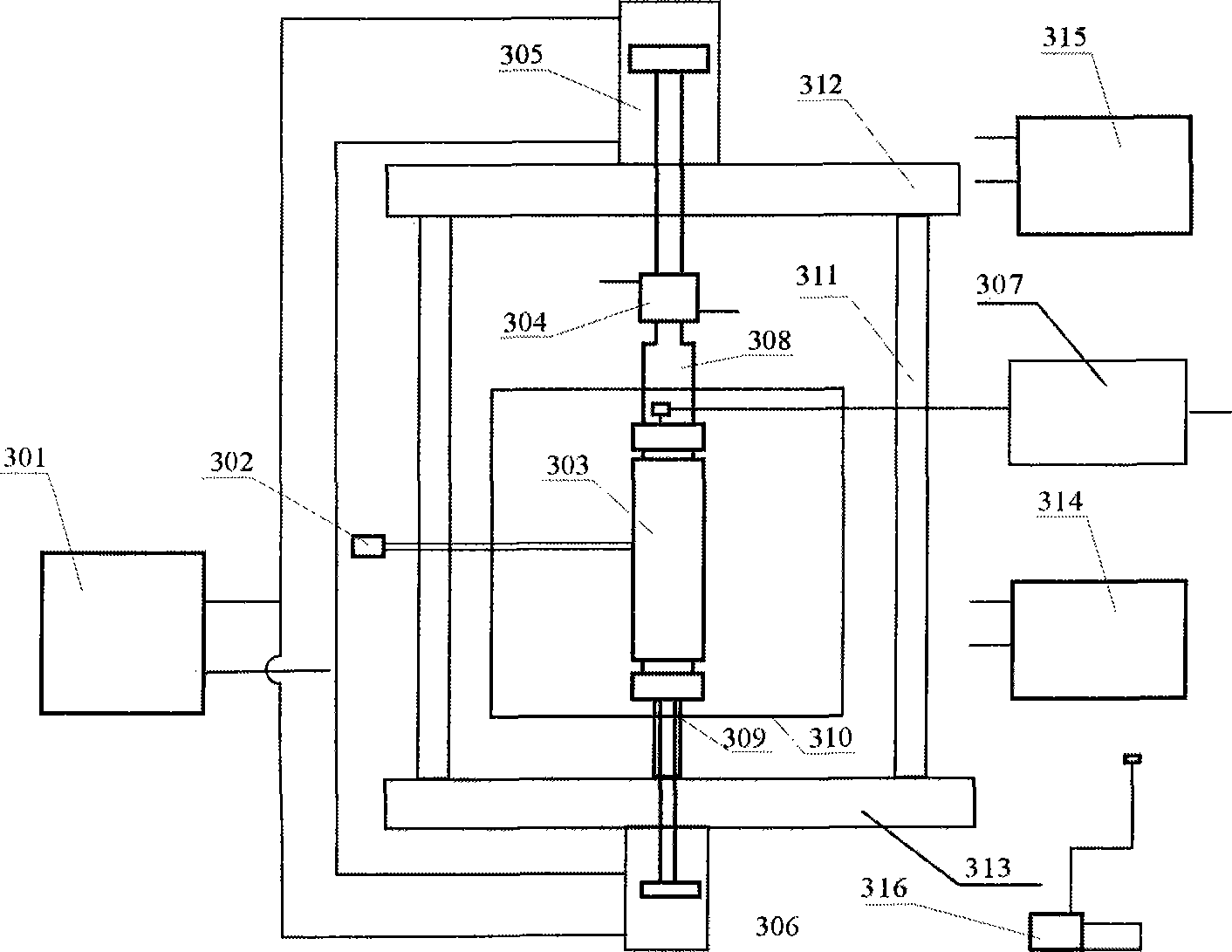

Hydrocarbon source rock formation pore heat-pressing hydrocarbon-generation simulator and use method thereof

ActiveCN101520962ARealize automatic controlRealize monitoringEducational modelsFormation fluidPetroleum

The invention discloses a hydrocarbon source rock formation pore heat-pressing hydrocarbon-generation simulator and a use method thereof, pertaining to an experimental apparatus for simulating the process of heat-pressing hydrocarbon-generation for hydrocarbon source rocks in the field of geological research on petroleum and natural gas. The simulator is composed of such five parts as a high temperature high pressure reaction unit, a two-way hydraulic automation control unit 301, an automatic hydrocarbon expulsion product collecting and fluid supplementing unit, a data acquisition and automatic control unit, peripheral auxiliary equipment and apparatus casing. The invention can carry out heating and pressurizing closed and open or controllable hydrocarbon generation and expulsion simulated experiments with the reservation of original pores of a hydrocarbon source rock sample 518, within the limited pore spaces and in simultaneous consideration of lithostatic pressure, formation fluid pressure and confining pressure similar to the geological conditions, thereby improving a hydrocarbon source rock hydrocarbon generation and expulsion simulated experimental apparatus so as to provide an effective means for researches on the development of a hydrocarbon generation mechanism, oil-gas migration, oil and gas production quantity in basins as well as oil and gas resource prediction, and thus having wide application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Monitoring Particles in a Fluid Stream

InactiveUS20080282781A1Accurate measurementAccurate distinctionAnalysing fluids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceTarget surfaceCorrosion

There is described an apparatus for monitoring particles in a fluid stream, comprising a body portion and a detector element that is acoustically decoupled from the body portion. The detector element comprises a target surface, a sample acoustic sensor and a corrosion sensor. The sample acoustic sensor is acoustically coupled to the target surface and is arranged to provide a first signal, which varies in dependence upon acoustic noise generated by impacts of particles and fluid on the target surface. The corrosion sensor is arranged to provide a second signal, which varies in dependence upon corrosion and / or erosion of the target surface. A corresponding method of monitoring particles in a fluid stream is also described. The method and apparatus are suitable for monitoring sand in oil and gas production flow streams.

Owner:TELEDYNE INSTR INC

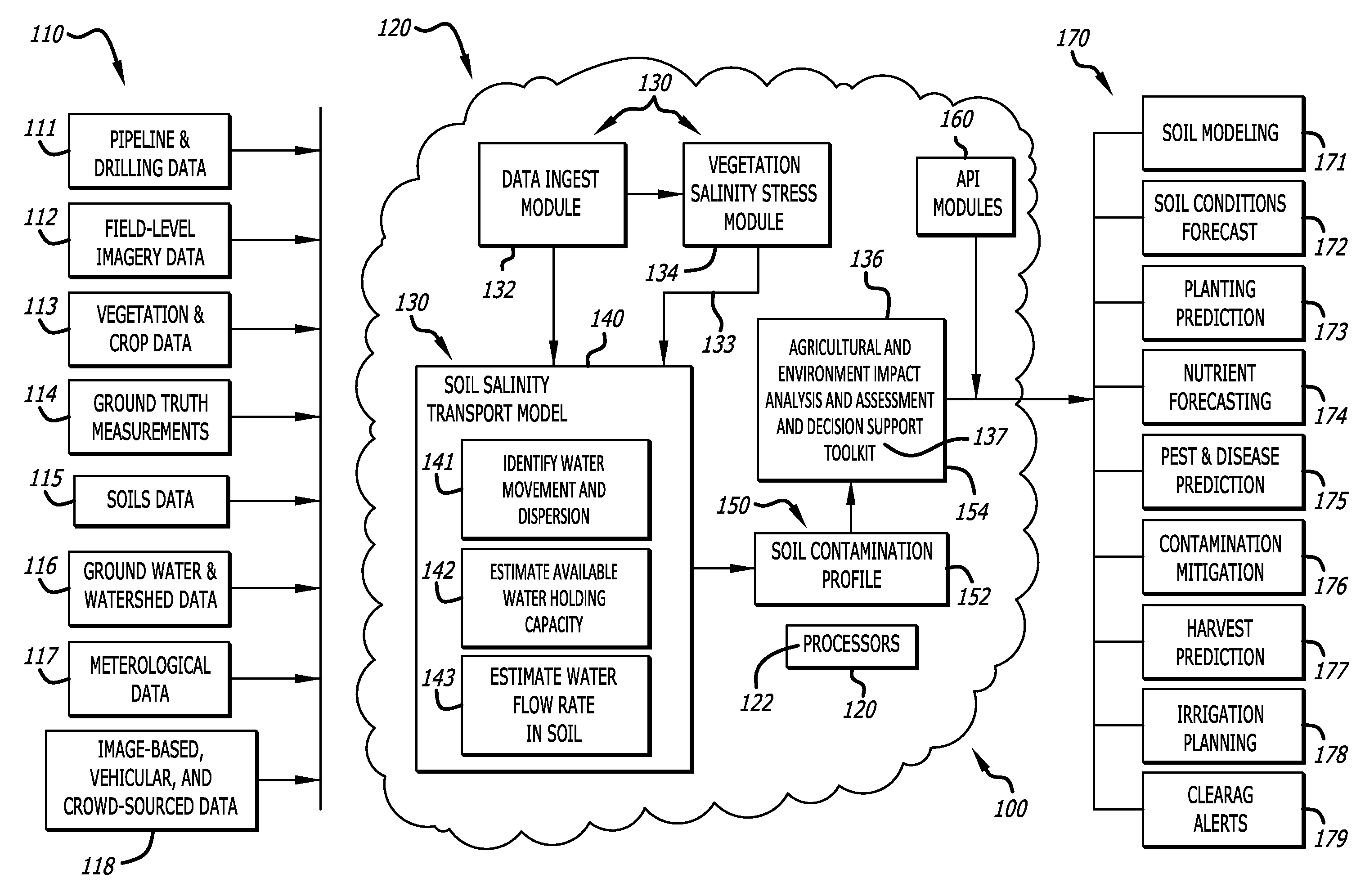

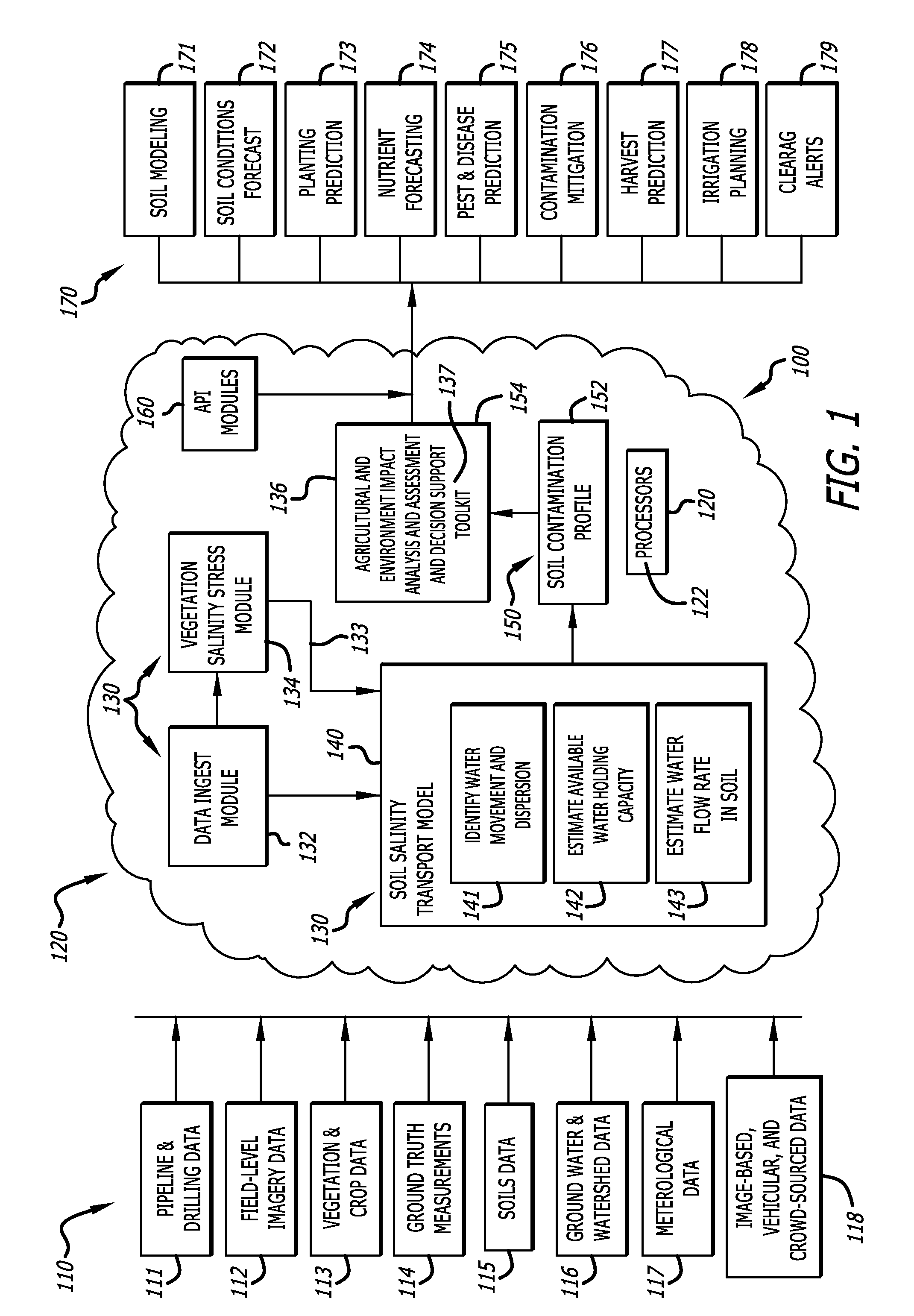

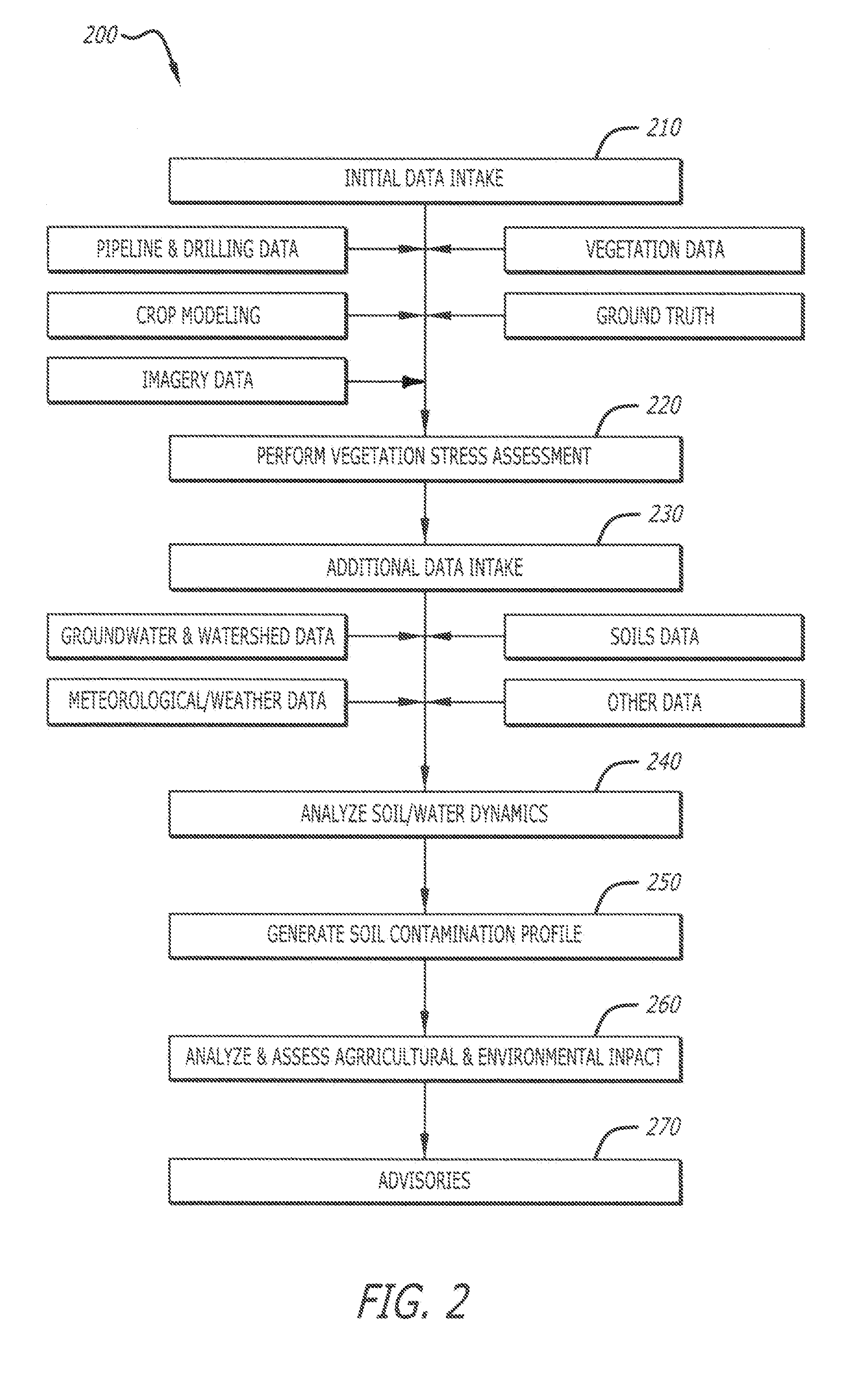

Measurement and modeling of salinity contamination of soil and soil-water systems from oil and gas production activities

ActiveUS20150347647A1Contaminated soil reclamationDesign optimisation/simulationEnvironmental resource managementPetroleum

An analytical framework and modeling process for assessing salinity contamination of soil ecosystems in geographical areas related to oil and gas production sites combines detection and monitoring of unplanned saltwater releases from such production activities with soil impact prediction. The analytical framework and modeling process enables an assessment of risks associated with saltwater disposal from drilling operations to the surrounding environment and the impact on soils, aquifers, rangeland, cropland, and adjoining areas by monitoring water movement and other soil conditions, and generating predictive output data for landowners, farmers, oil and gas production site operators, governmental regulators, and other end users for contamination mitigation and agricultural activities.

Owner:DTN LLC

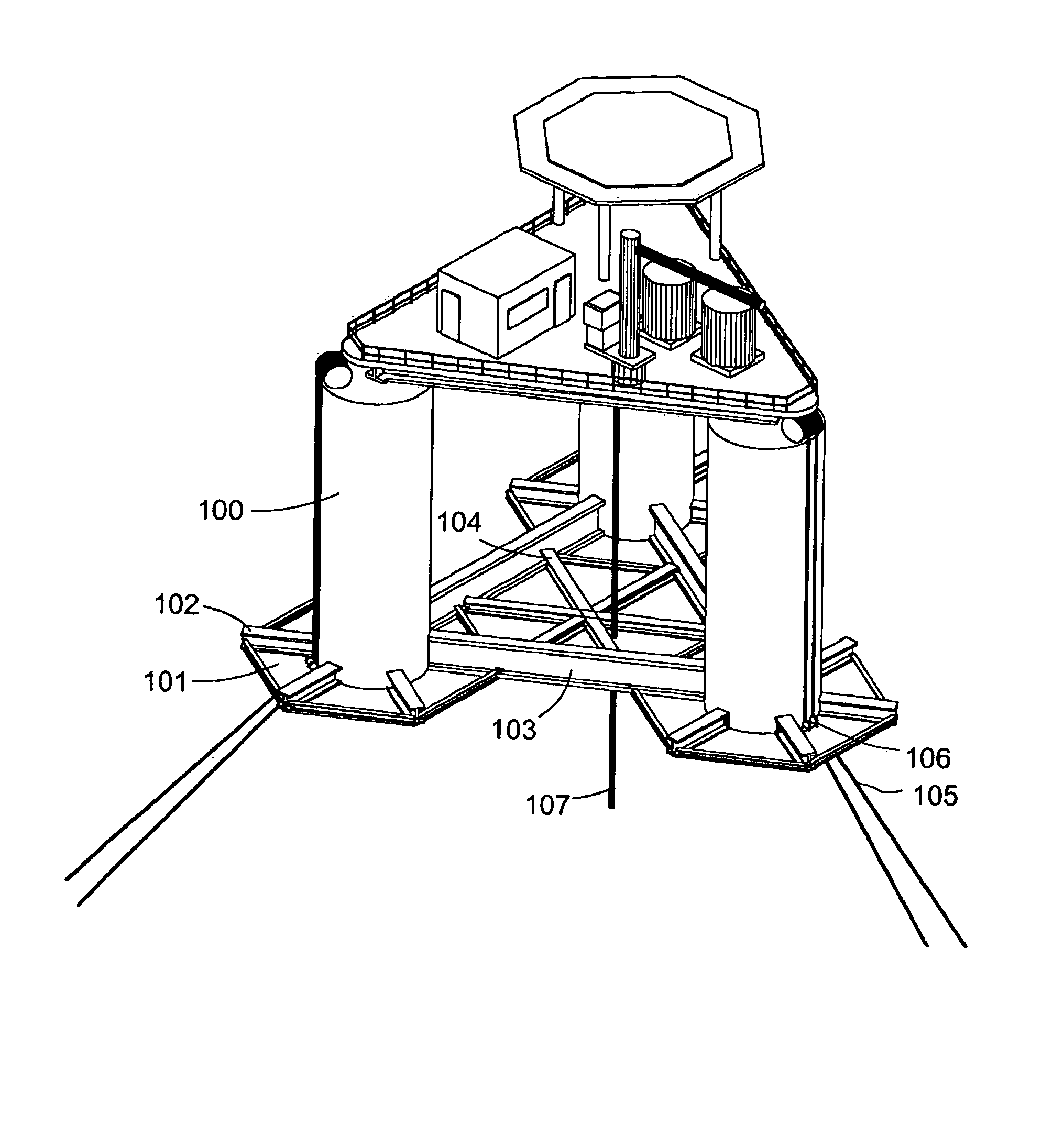

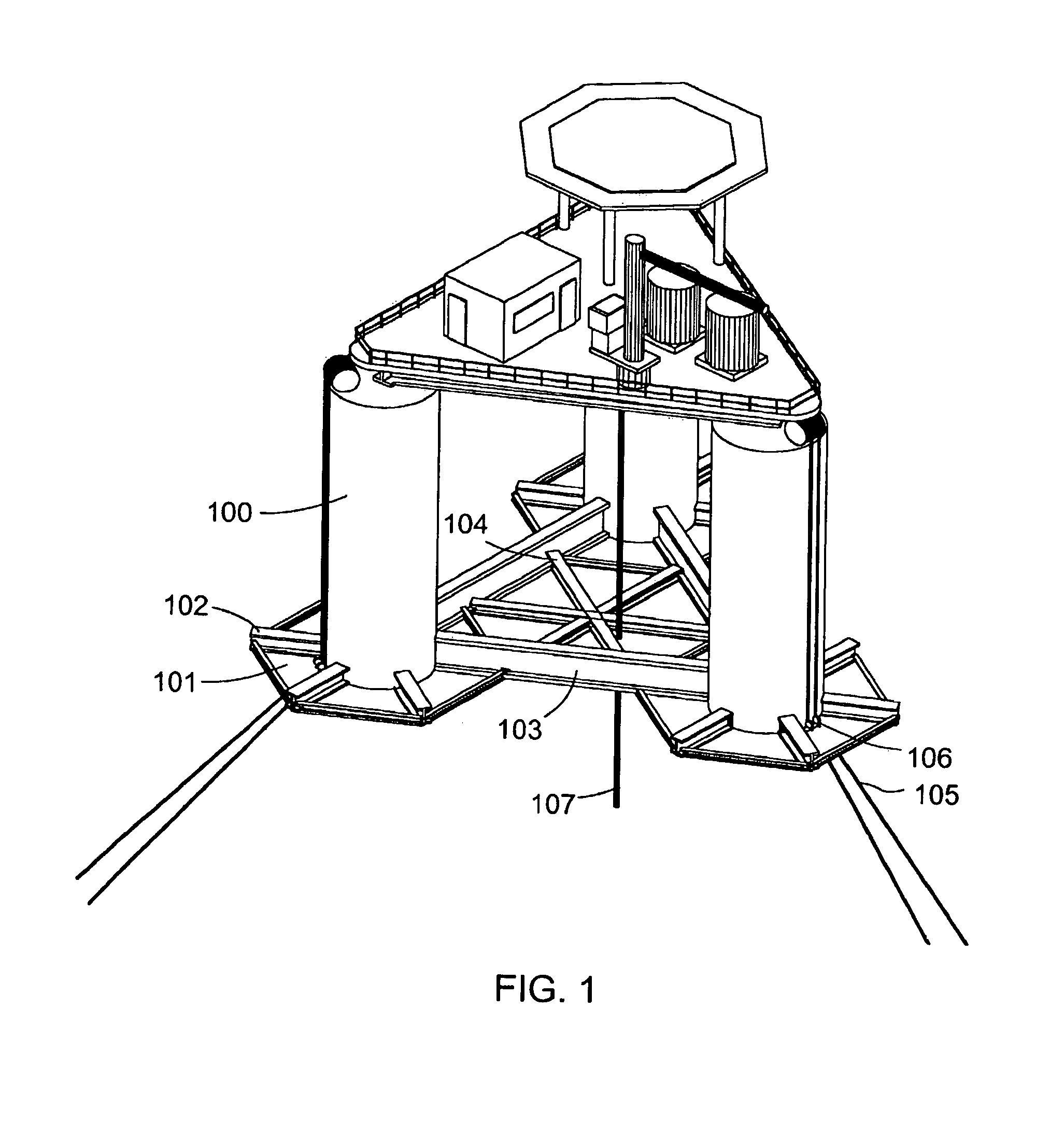

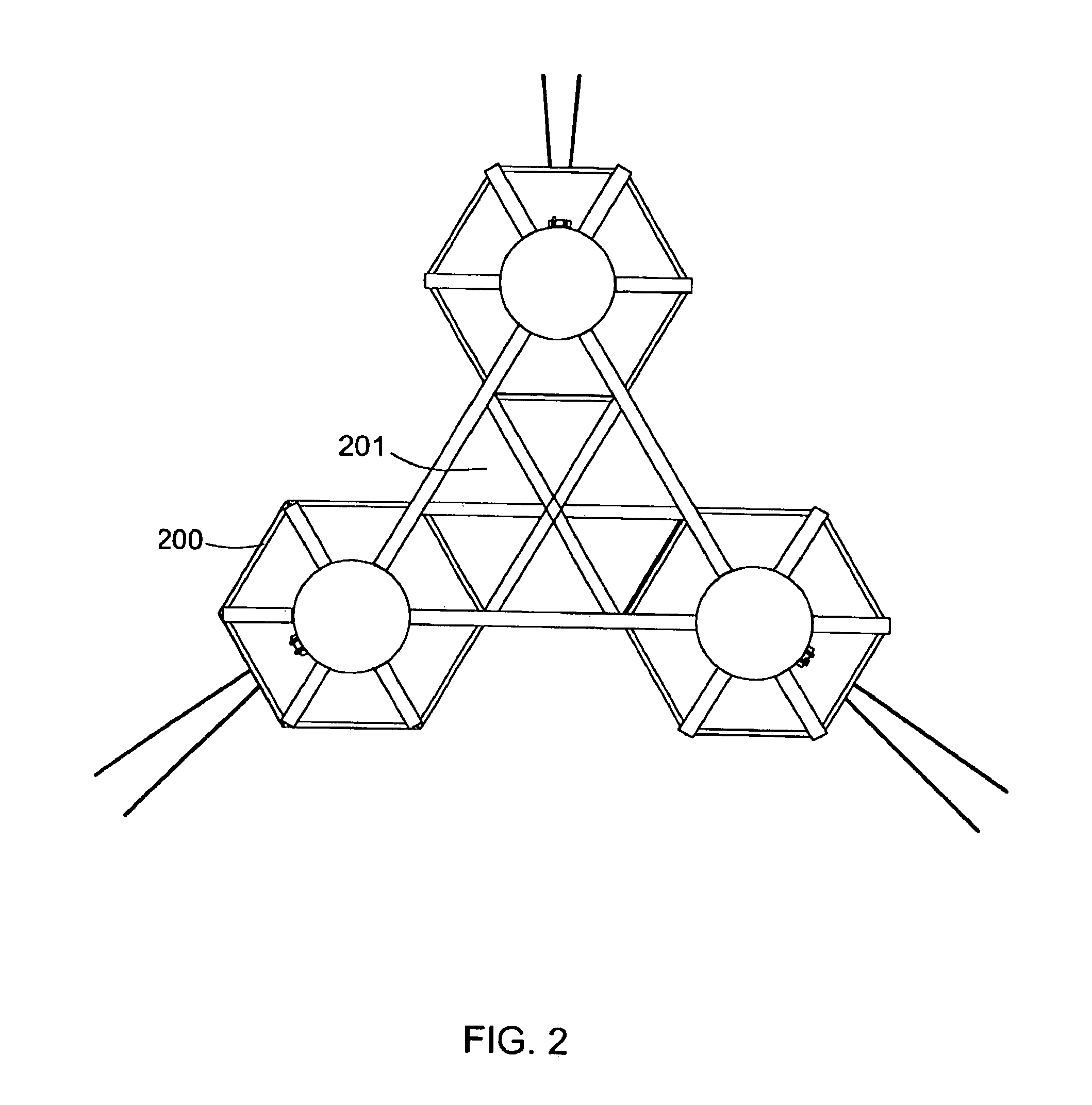

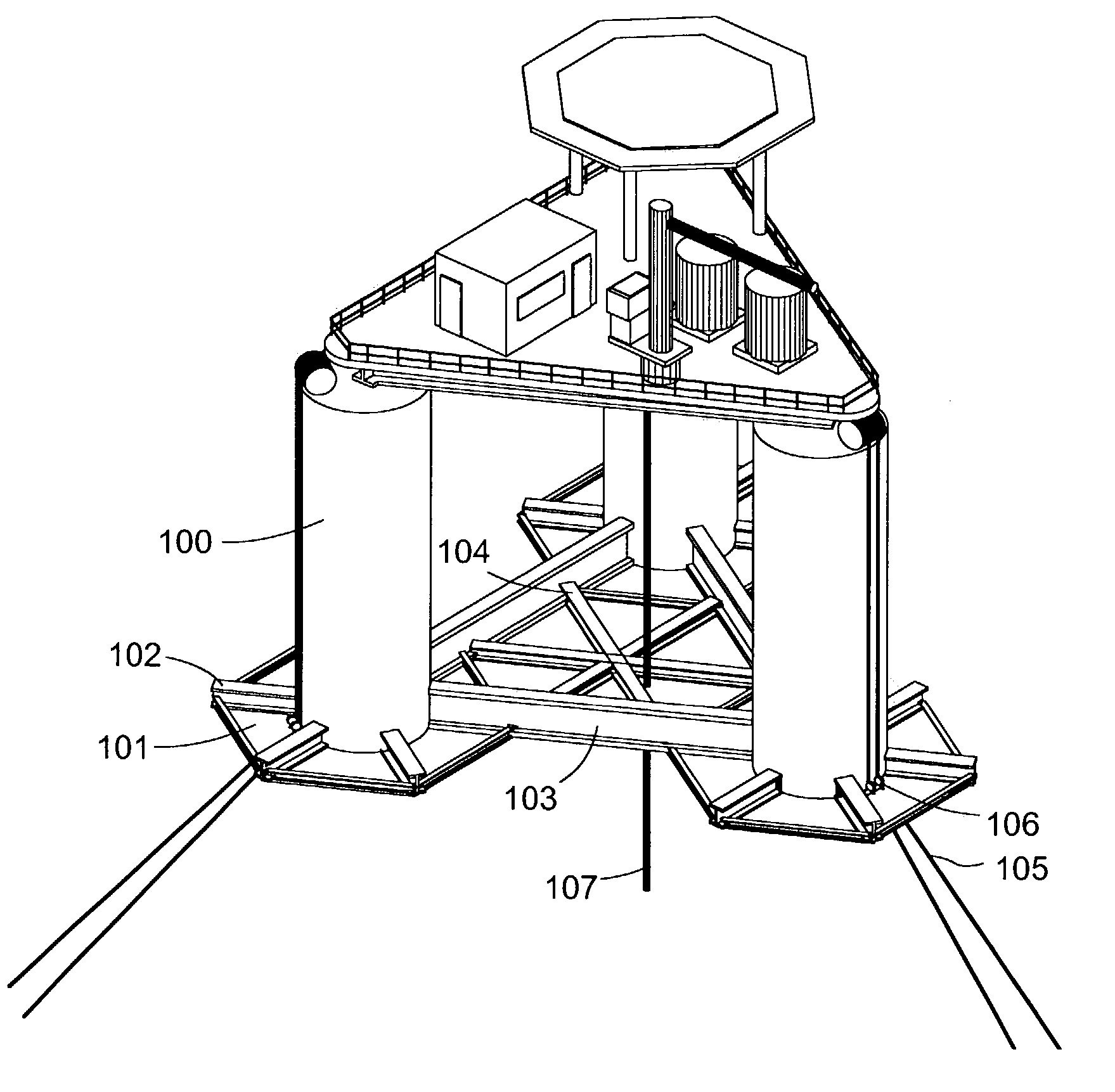

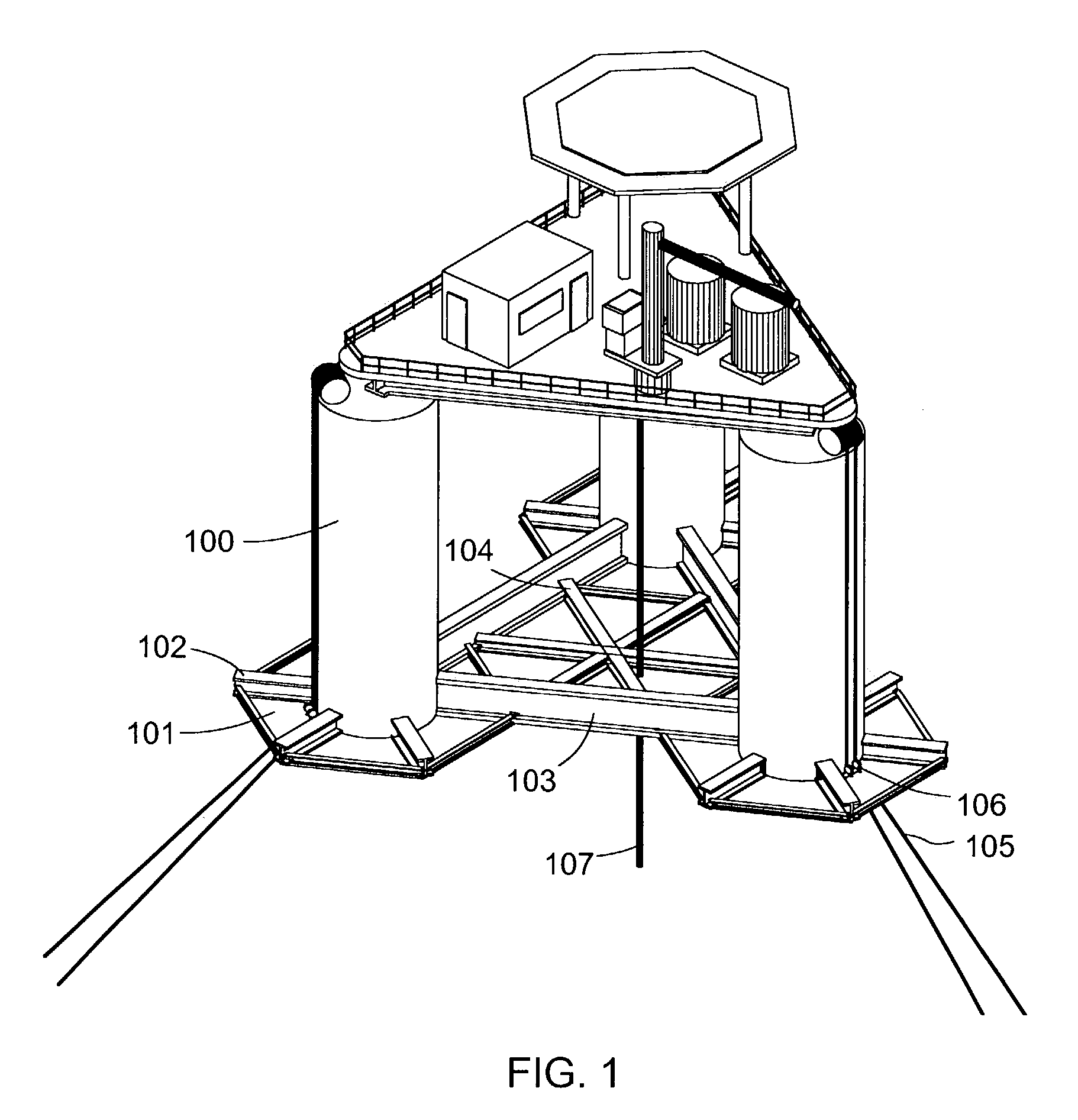

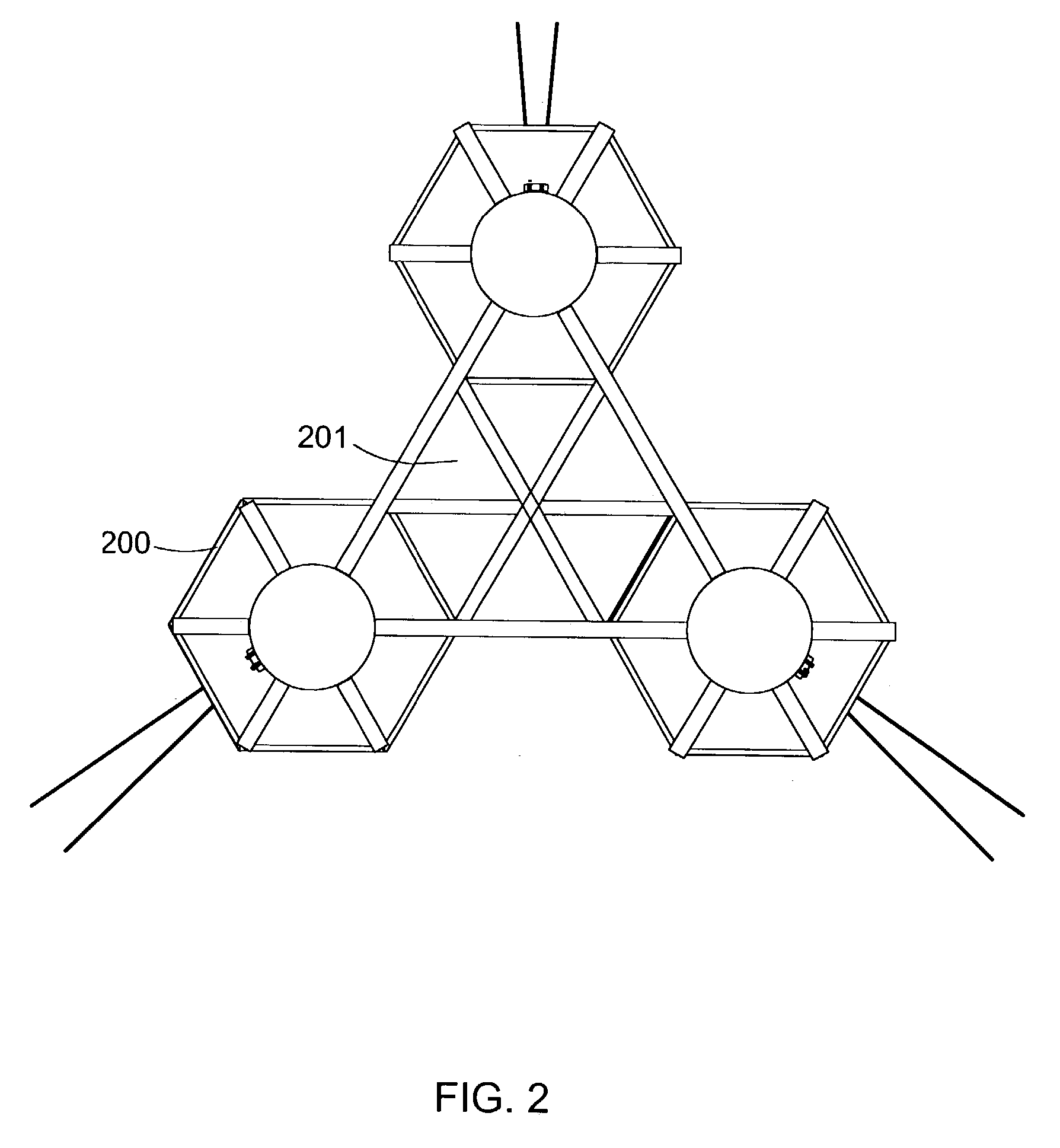

Column-stabilized platform with water-entrapment plate

InactiveUS7281881B1Artificial islandsVessel movement reduction by foilsOcean bottomOffshore oil and gas

An apparatus for use in offshore oil or gas production in which a plurality of vertical stabilizing columns are supported on a submerged horizontal water entrapment plate is provided to support minimum offshore oil and gas production facilities above a subsea wellhead, or subsea processing facilities, or a submarine pipeline, and whose main function is to provide power or chemicals or to perform other operations such as compression, injection, or separation of water, oil and gas. The apparatus is maintained in the desired location by a plurality of mooring lines anchored to the sea-bed. The respective size and shape of the columns and water entrapment plate are designed to provide sufficient buoyancy to carry the weight of all equipment on the minimum floating platform and mooring lines, umbilical and risers attached to it, and to minimize the platform motion during normal operations.

Owner:OCERGY INC

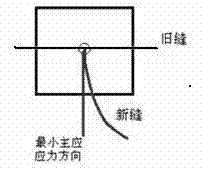

Temporary blocking turnaround fracturing method based on surface modified polyvinyl alcohol fibers

ActiveCN104727800AImprove production efficiencyIncrease drainage areaFluid removalDrilling compositionFiberPolyvinyl alcohol

The invention particularly provides a temporary blocking turnaround fracturing method based on surface modified polyvinyl alcohol fibers. The method comprises the following steps that 1, the surfaces of the water-soluble poly(vinyl alcohol) fibers are modified; 2, fracturing work liquid is prepared; 3, liquid in a shaft is extruded out by and replaced with active water; 4, setting is carried out on a facture packer; 5, prepad fluid is injected, and a major fracture is formed; 6, the water-soluble degradable fiber temporary blocking fracturing liquid is injected into the formed major fracture in a step mode and injected into a stratum to form a new branch fracture; 7, the prepad fluid is injected into the formed new branch fracture, and the length of the fracture is expanded; 8, sand-carrying liquid is injected into the formed new branch fracture in a step mode; 9, the sand-carrying liquid in the shaft is extruded out by and replaced with active water. An old facture or a facture filled with sand is temporarily blocked, the new fractures are made on the original fracture in a certain angle direction, more unused areas of natural fractures and primary fractures are communicated, a new fracture flow leakage system is formed, oil and gas production and the ultimate recovery factor of an oil and gas field are improved, and the aims of restoring the yield of an old well and achieving facture production increase of a new well are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

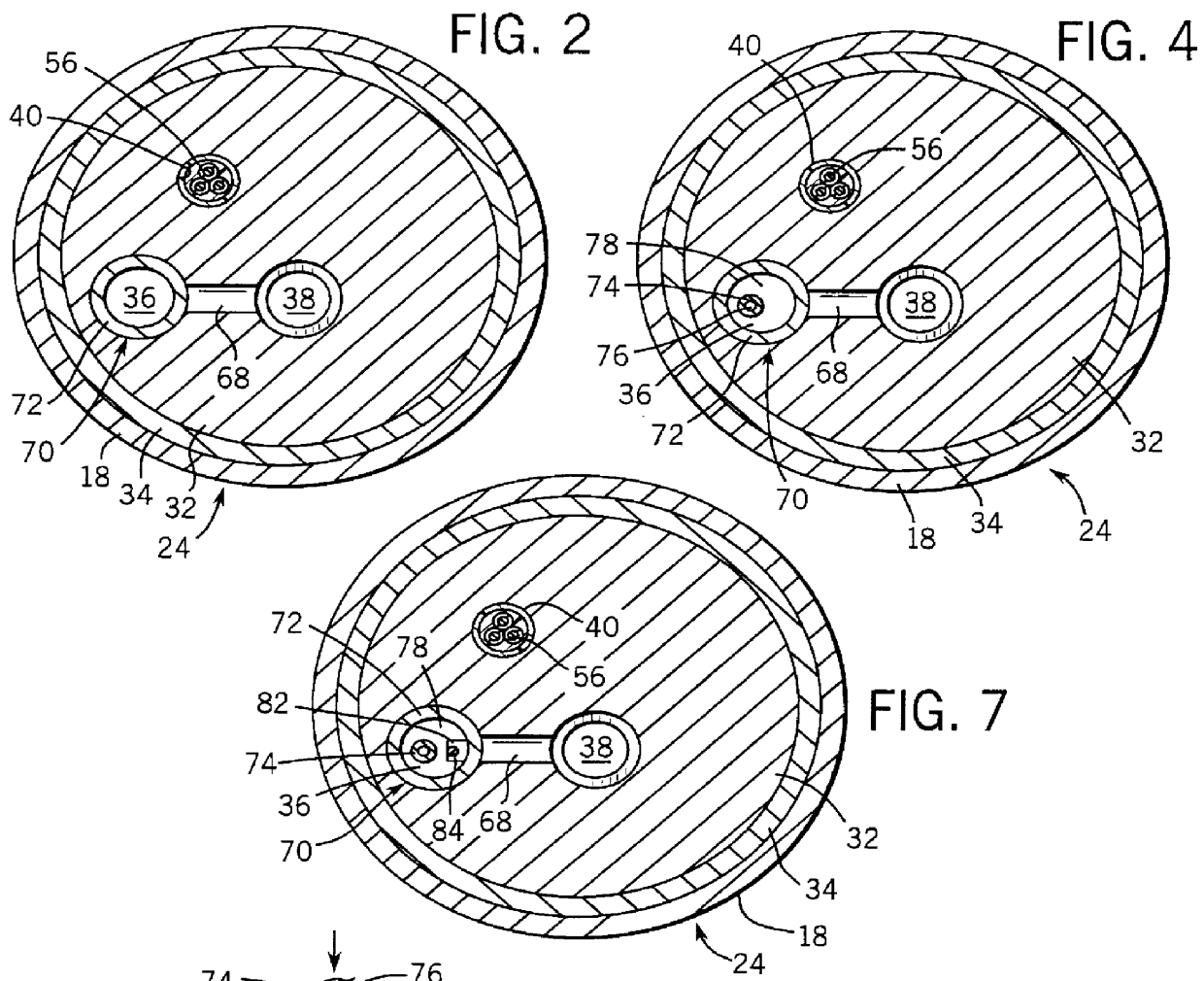

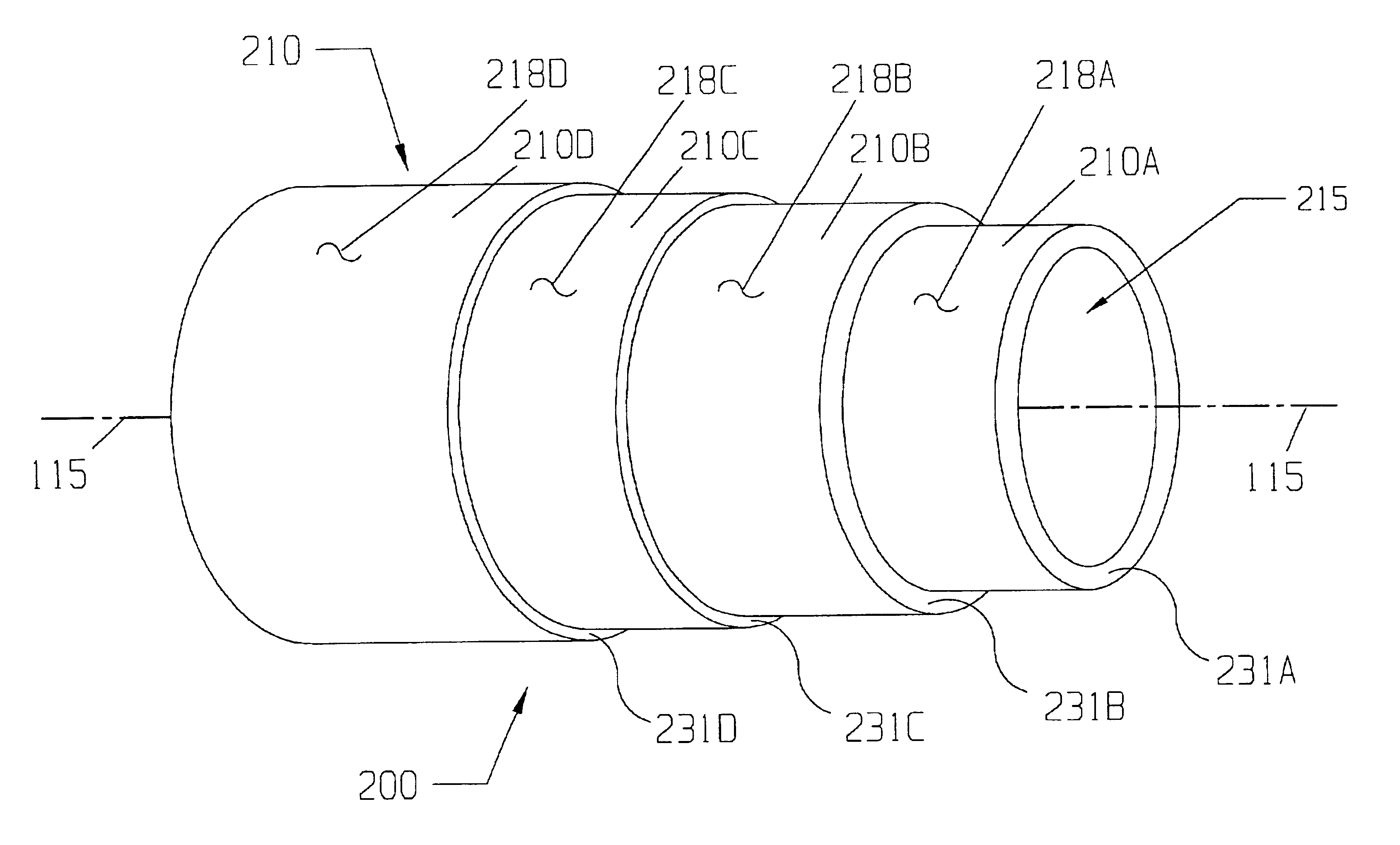

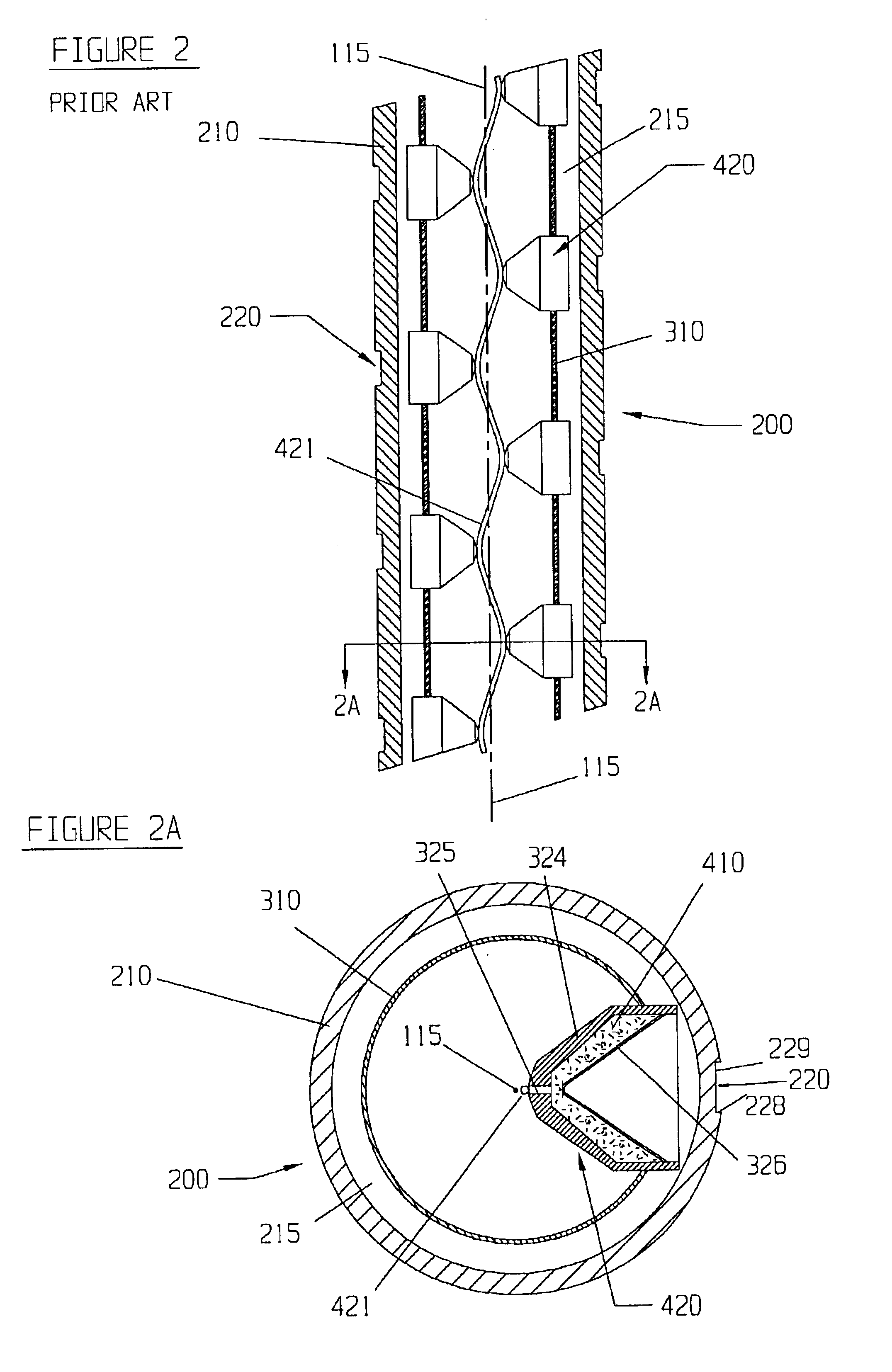

Well perforating gun

InactiveUS6865978B2Minimize failureMinimizes problemExplosive chargesAmmunition projectilesTectonicsThick wall

Owner:KASH EDWARD CANNOY

Process for foaming a wet hydrocarbon composition

A composition of a wet hydrocarbon foaming agent including a siloxane can foam wet hydrocarbons. The siloxane wet hydrocarbon foaming agent advantageously foams hydrocarbons that have as little as 5 percent water present and those hydrocarbons having as much as 90 percent water present. The wet hydrocarbon foaming agent can be used in oil and gas production for gas lift and foam blocking applications. The foaming agent can also be used for clearing hydrocarbons from pipelines and other vessels used for transporting oil and gas.

Owner:BAKER HUGHES INC

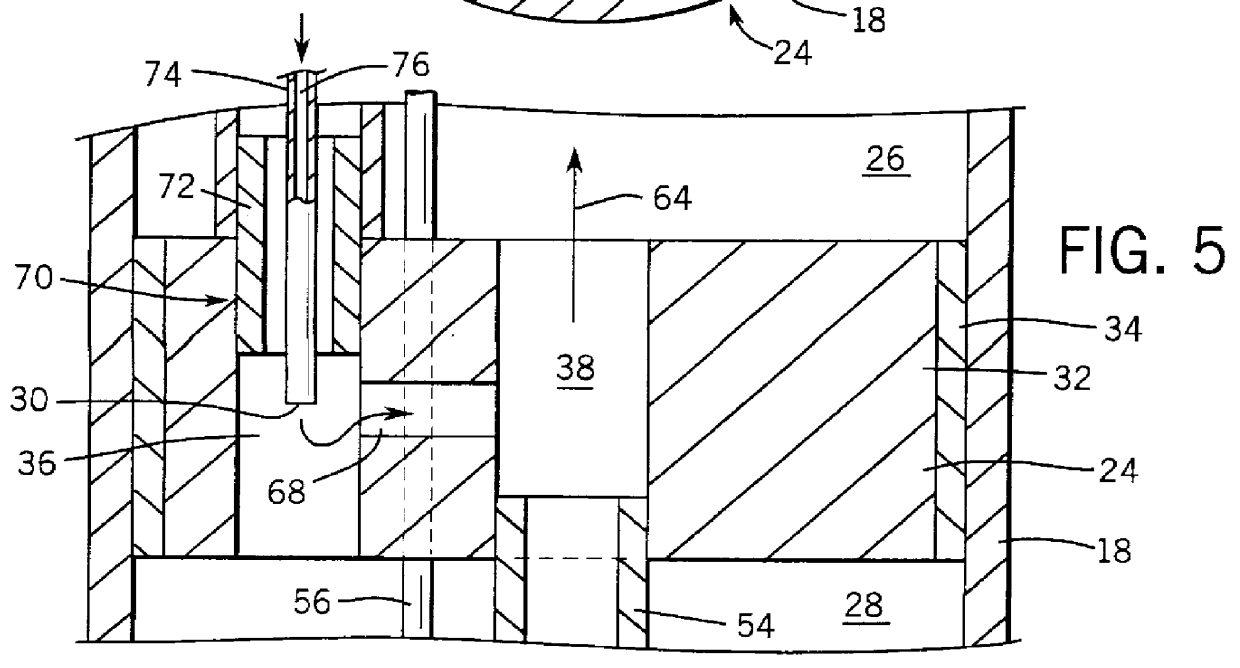

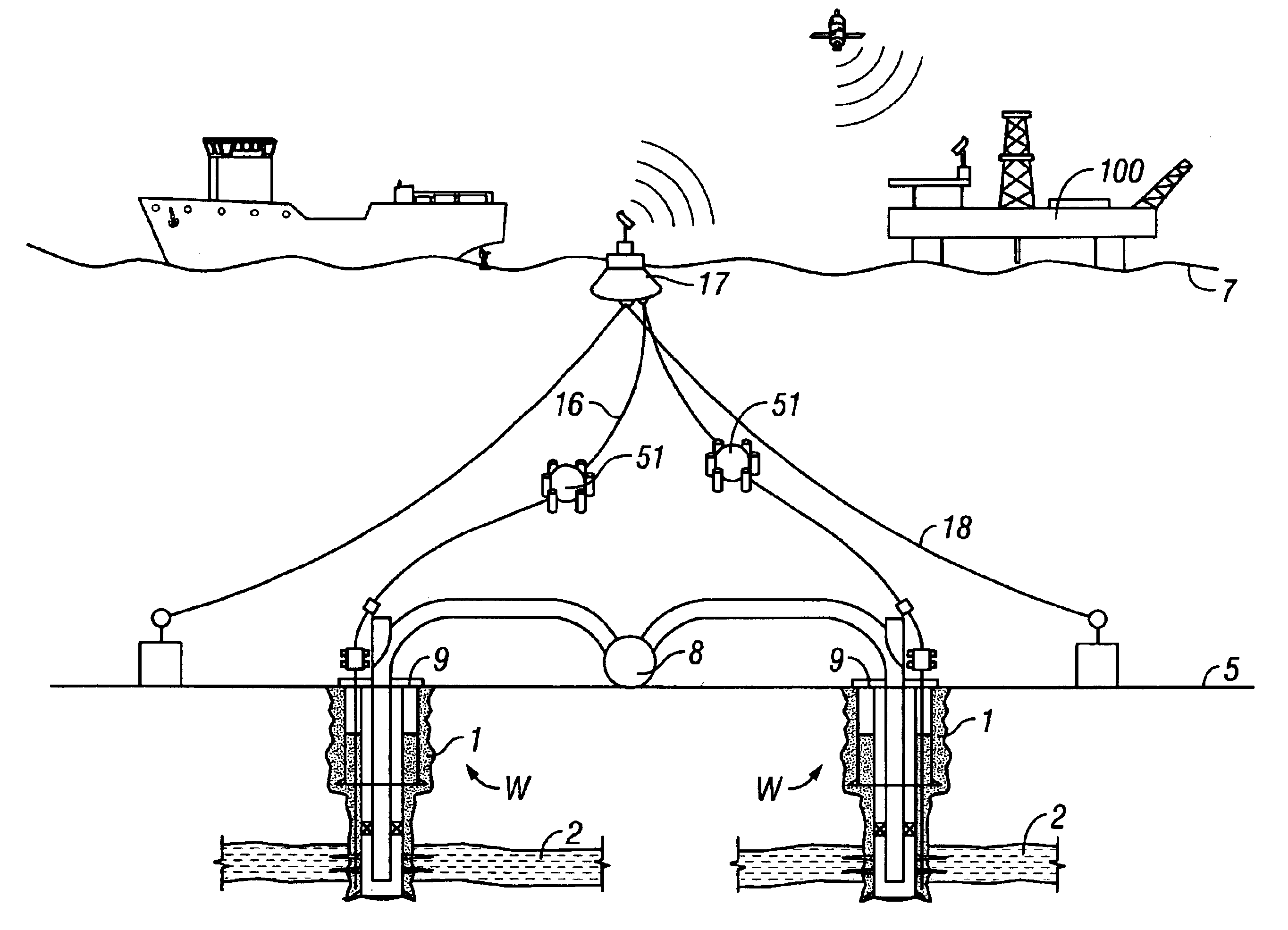

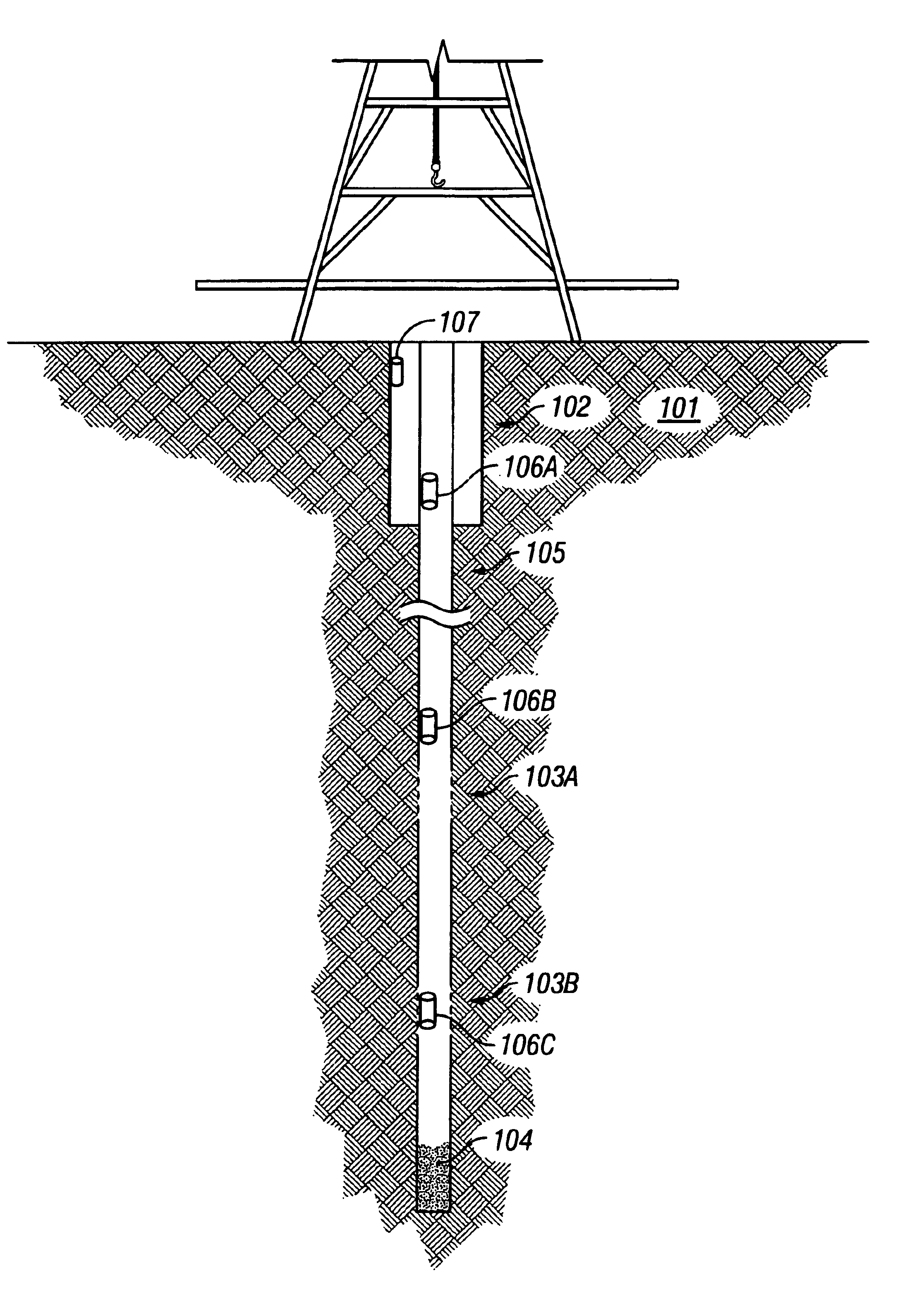

Minimum floating offshore platform with water entrapment plate and method of installation

An apparatus for use in offshore oil or gas production in which a plurality of vertical stabilizing columns are supported on a submerged horizontal water entrapment plate is provided to support minimum offshore oil and gas production facilities above a subsea wellhead, or subsea processing facilities, or a submarine pipeline, and whose main function is to provide power or chemicals or to perform other operations such as compression, injection, or separation of water, oil and gas. The apparatus is maintained in the desired location by a plurality of mooring lines anchored to the sea-bed. The respective size and shape of the columns and water entrapment plate are designed to provide sufficient buoyancy to carry the weight of all equipment on the minimum floating platform and mooring lines, umbilical and risers attached to it, and to minimize the platform motion during normal operations.

Owner:OCERGY INC

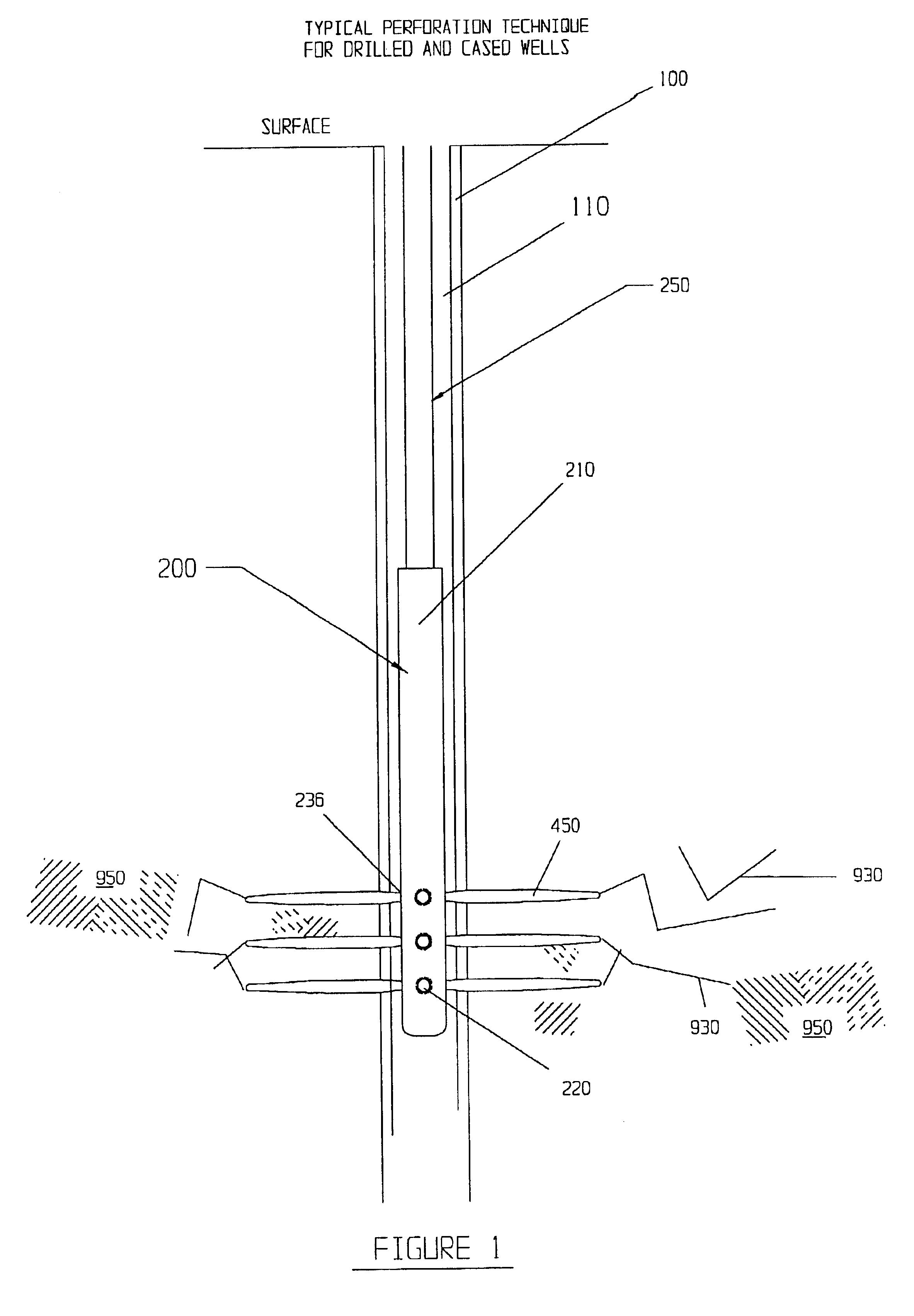

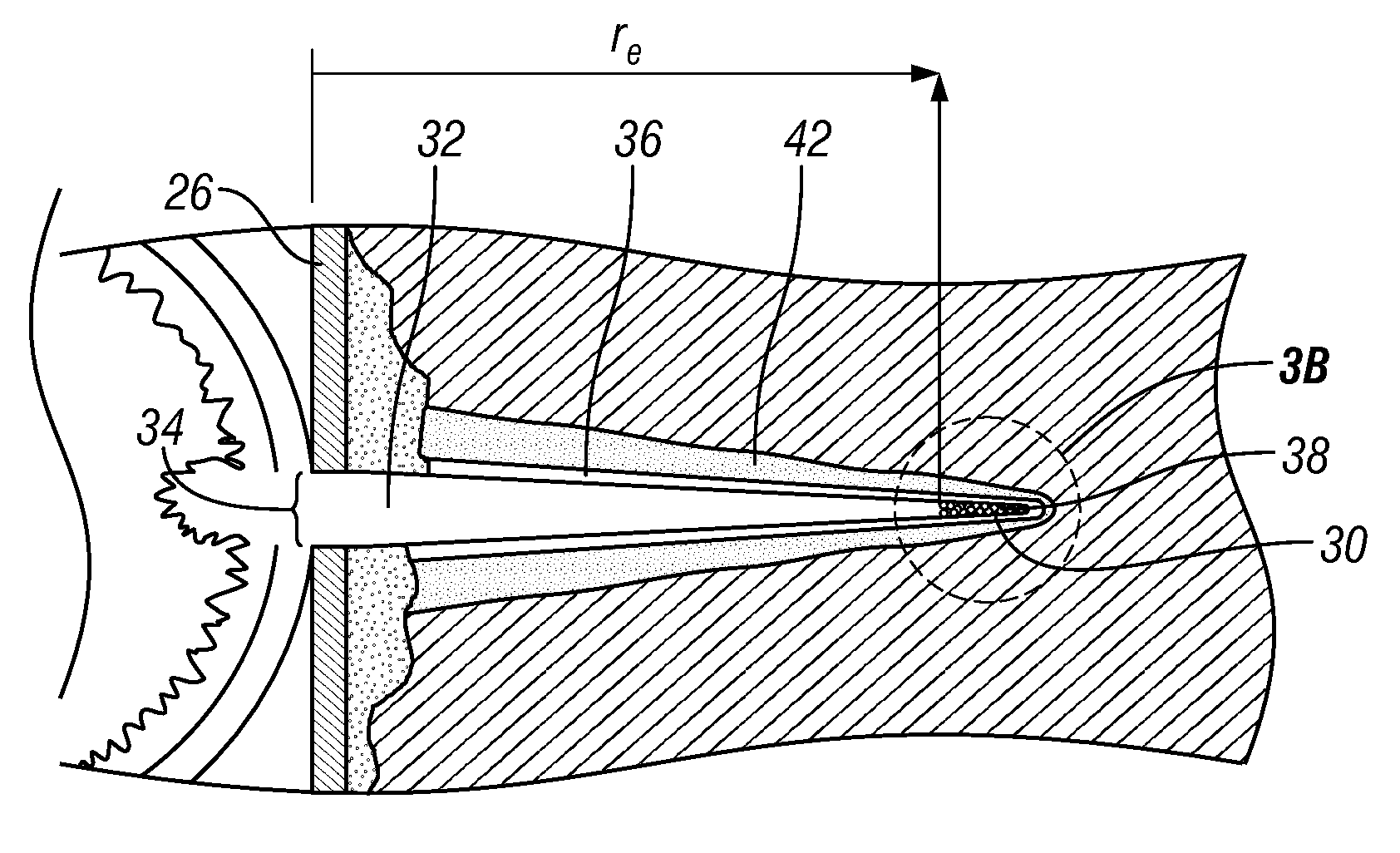

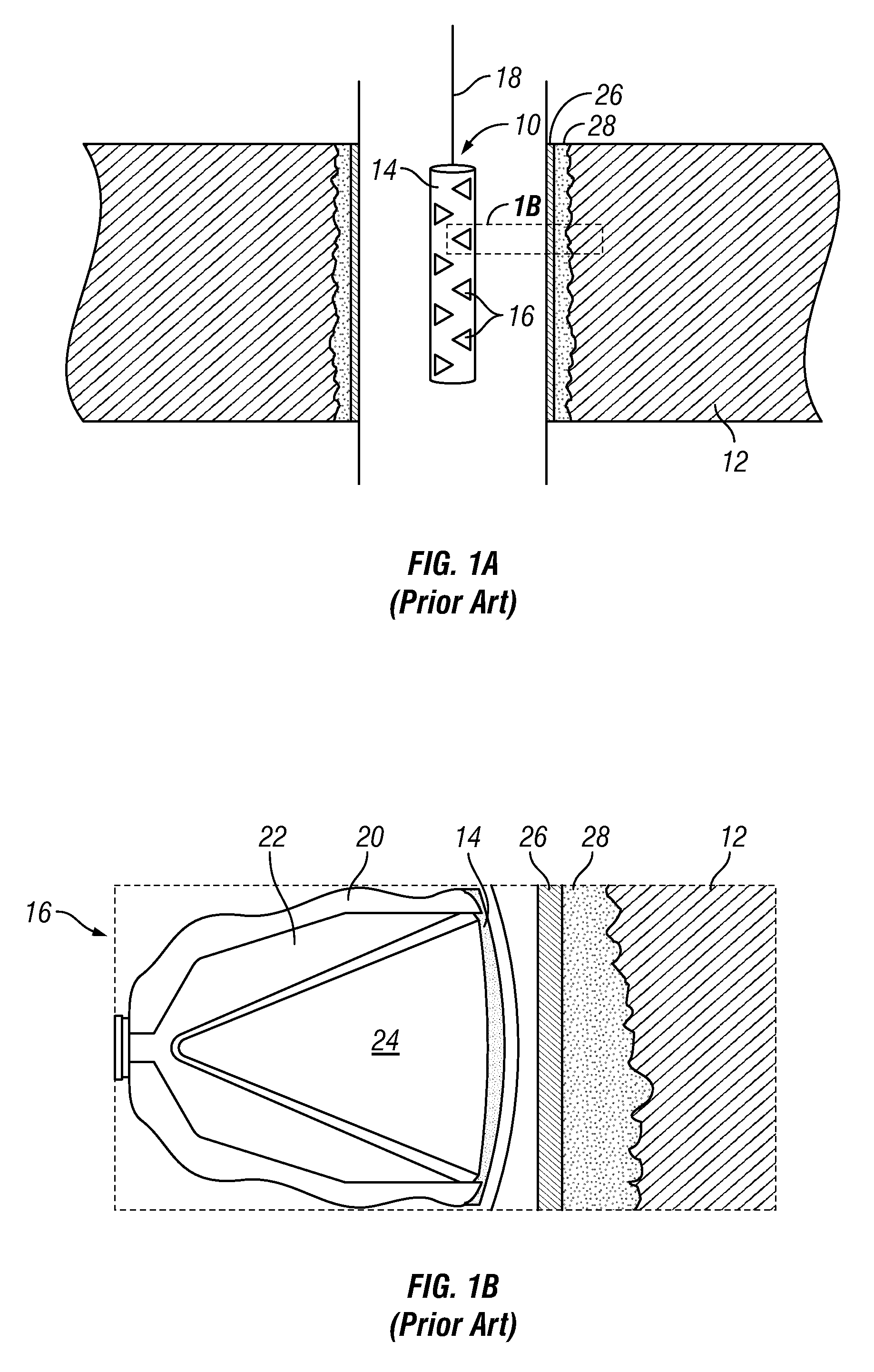

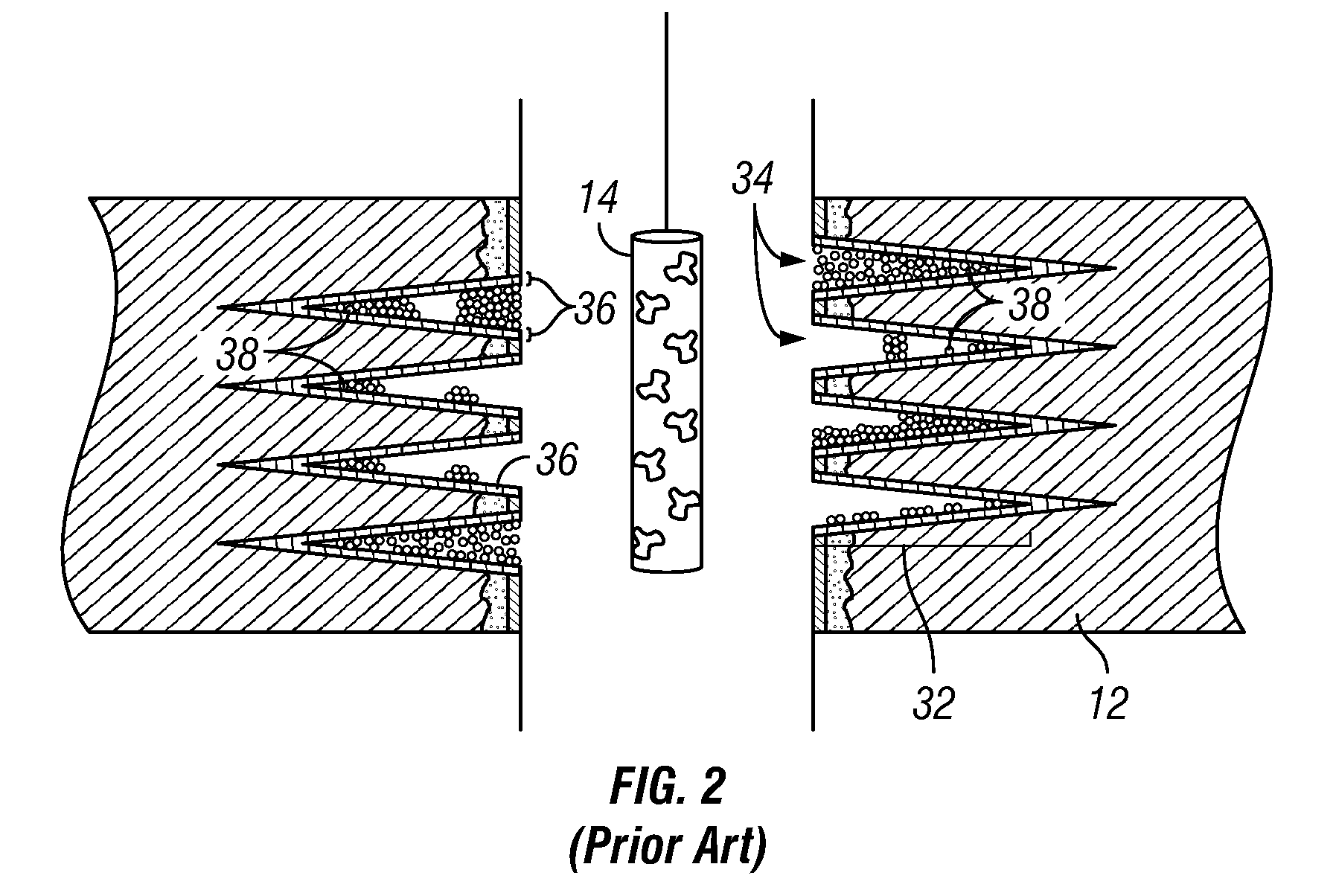

Method for the Enhancement of Injection Activities and Stimulation of Oil and Gas Production

InactiveUS20100132946A1Reduce fluid pressureIncrease the number ofExplosive chargesBlasting cartridgesDetonationCharge carrier

By removing material of low permeability from within and around a perforation tunnel and creating at least one fracture at the tip of a perforation tunnel, injection parameters and effects such as outflow rate and, in the case of multiple perforation tunnels benefiting from such cleanup, distribution of injected fluids along a wellbore are enhanced. Following detonation of a charge carrier, a second explosive event is triggered within a freshly made tunnel, thereby substantially eliminating a crushed zone and improving the geometry and quality (and length) of the tunnel. In addition, this action creates substantially debris-free tunnels and relieves the residual stress cage, resulting in perforation tunnels that are highly conducive to injection under fracturing conditions for disposal and stimulation purposes, and that promote even coverage of injected fluids across the perforated interval.

Owner:GEODYNAMICS

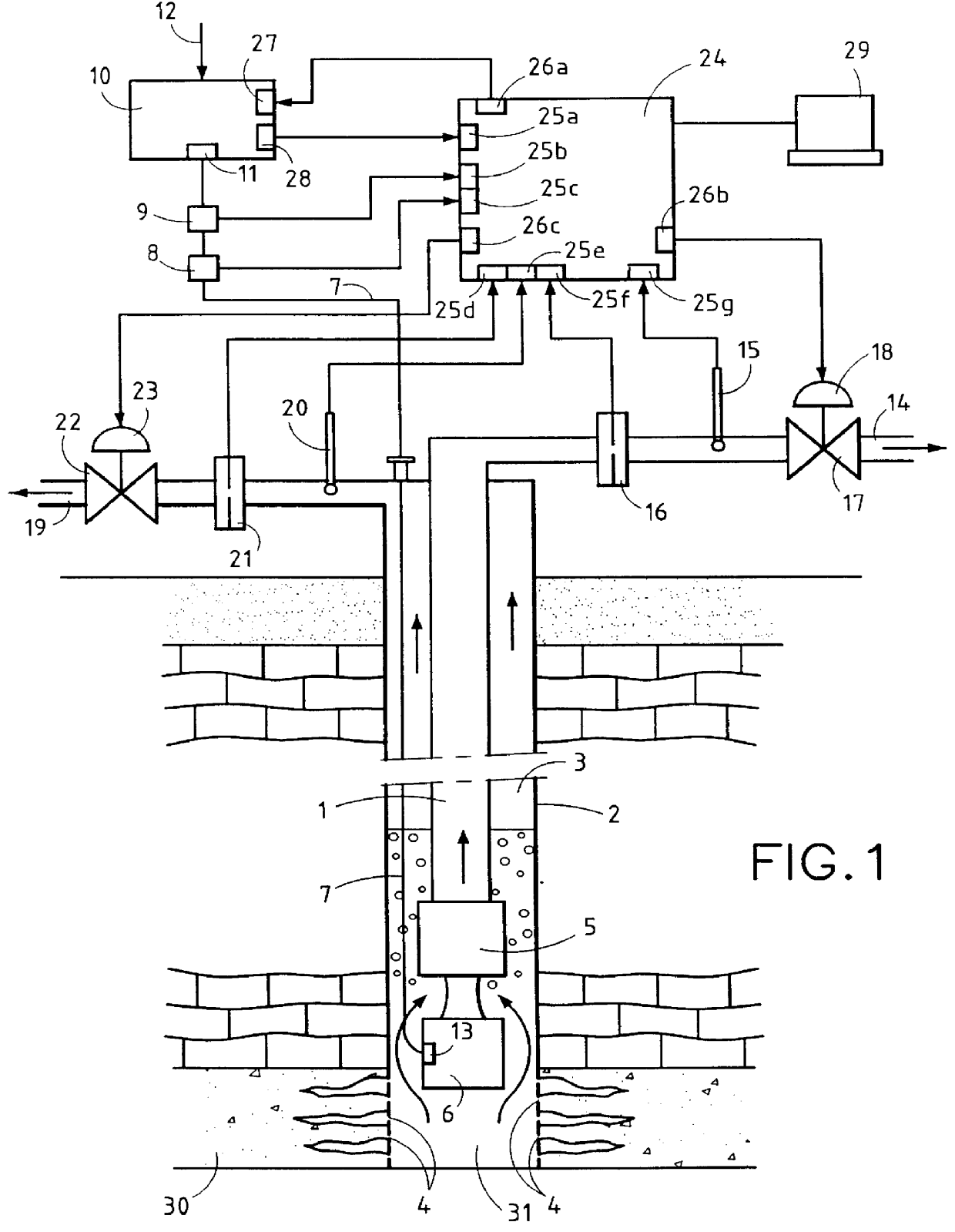

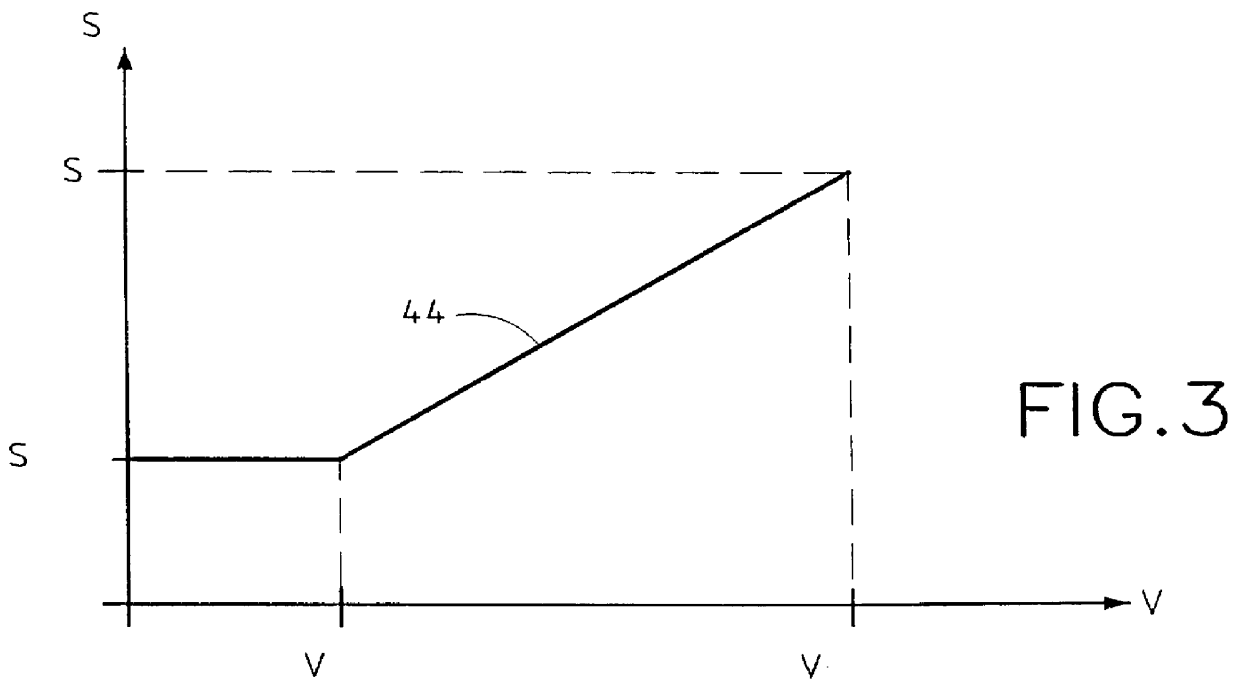

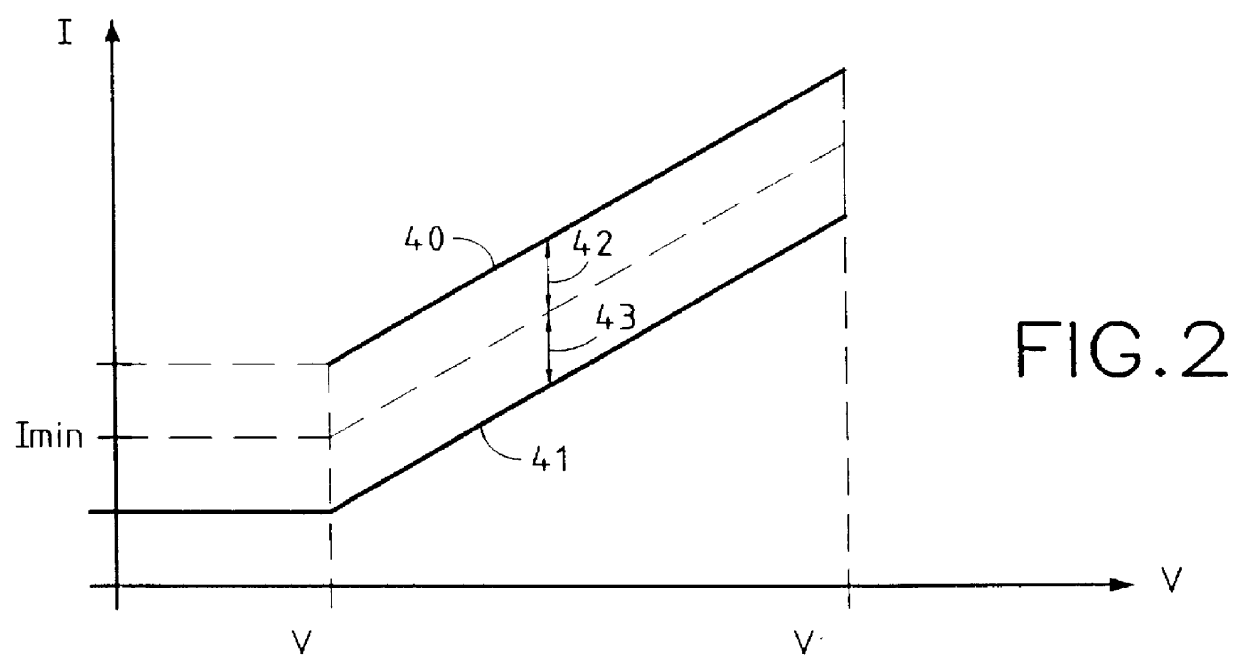

Method of operating an oil and gas production well activated by a pumping system

The invention relates to the production of hydrocarbons in the form of oil and gas, from a well activated by a pumping system. According to the invention, a hydrocarbon production well comprising a submerged pump (5) driven by an electric motor (6), an oil outlet choke (17) and a gas venting choke (22) is operated by acting, during the various production phases, on the chokes and on the speed of the electric motor (6) either in turn or simultaneously. Furthermore, correct operation of the well is constantly checked and it is also checked that the current drawn by the motor (6) does not cross thresholds that vary as a function of the speed of the motor (6). The invention finds its application in the oil industry.

Owner:ELF EXPLORATION PRODN

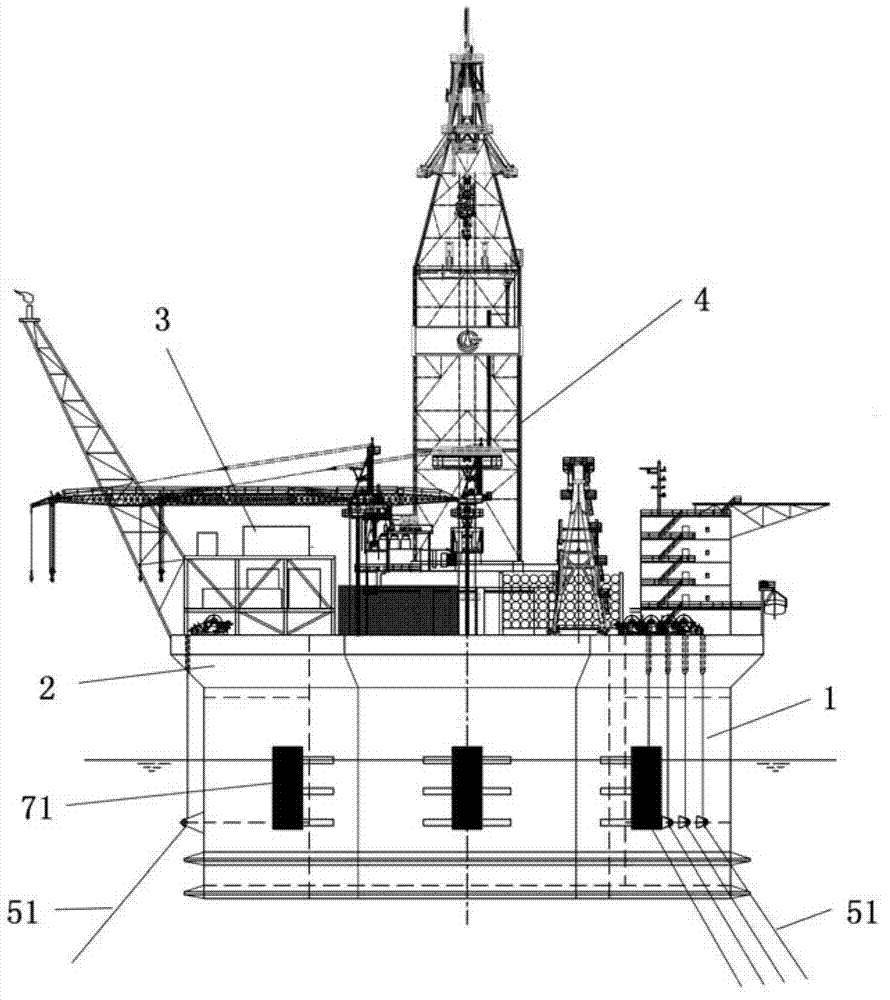

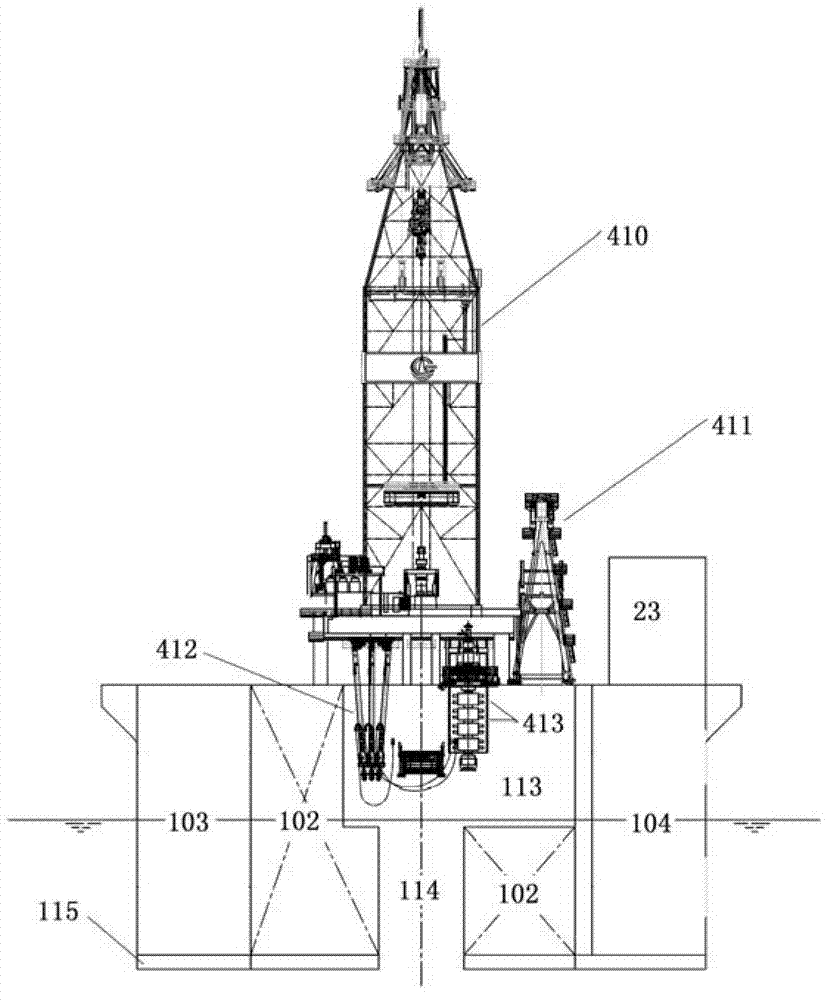

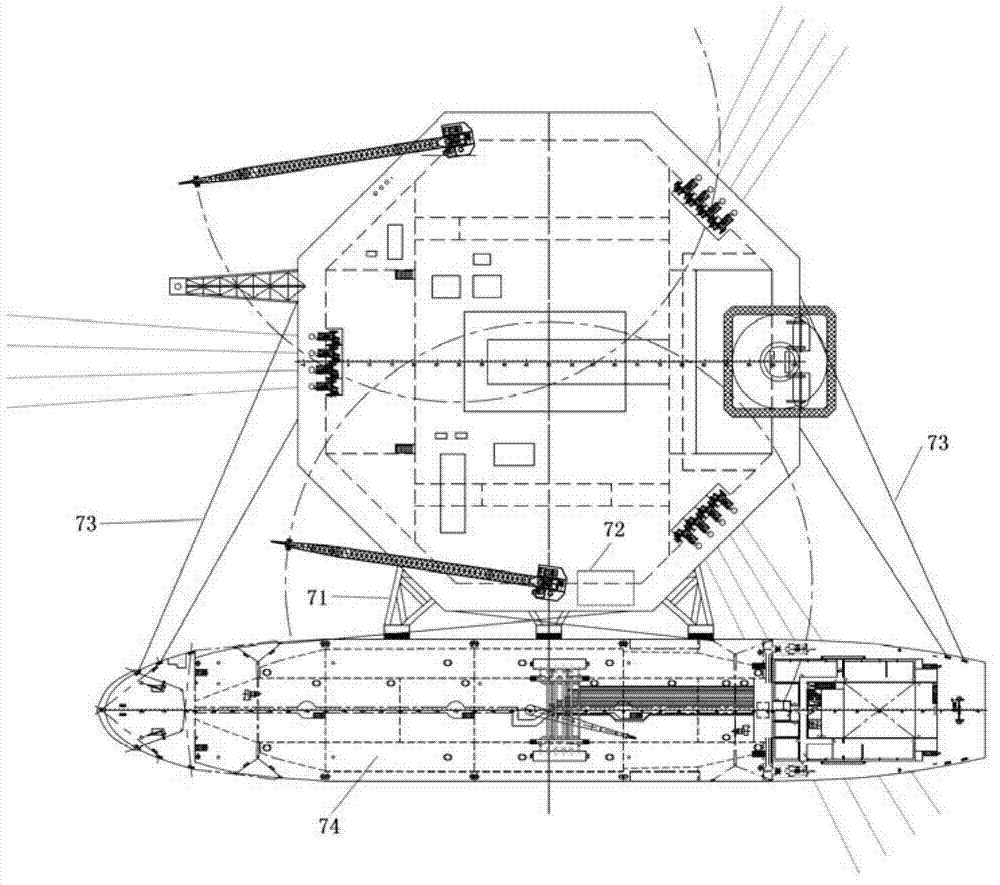

Floating type production platform capable of taking well drilling and oil storage into consideration

ActiveCN102756793AReduce economic riskThe vertical and horizontal scales are the sameFloating buildingsPrismTreatment system

The invention discloses a floating type production platform capable of taking well drilling and oil storage into consideration. The floating type production platform comprises an octagonal-prism floating body with an octagonal horizontal section and a deck, wherein a ballast water tank, an oil storage tank, a production functional cabin, a well-drilling equipment cabin and a pump cabin; the deck is arranged on the floating body; an oil gas treatment system, well-drilling equipment and a positioning mooring system are arranged on the deck; and a moon pool is arranged on the floating type production platform. The floating type production platform has the functions of oil gas production, storage, transportation and well drilling, can be migrated and reused, is flexible and suitable for early trial production and well drilling development of an oil field with the water depth of more than 100 m, and can effectively reduce the economic risk of development of the oil and gas field. The floating type production platform has the same longitudinal and transverse size, has the size less than the longitudinal size of the boat type FDPSO, has basically same environmental force from each direction under the same environment condition and has the environmental force less than that of the boat type FDPSO under the transverse environment, adopts a multi-point mooring system, and can meet the requirements of platform well drilling and oil and gas production operation under the sever marine environment such as the South China Sea and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

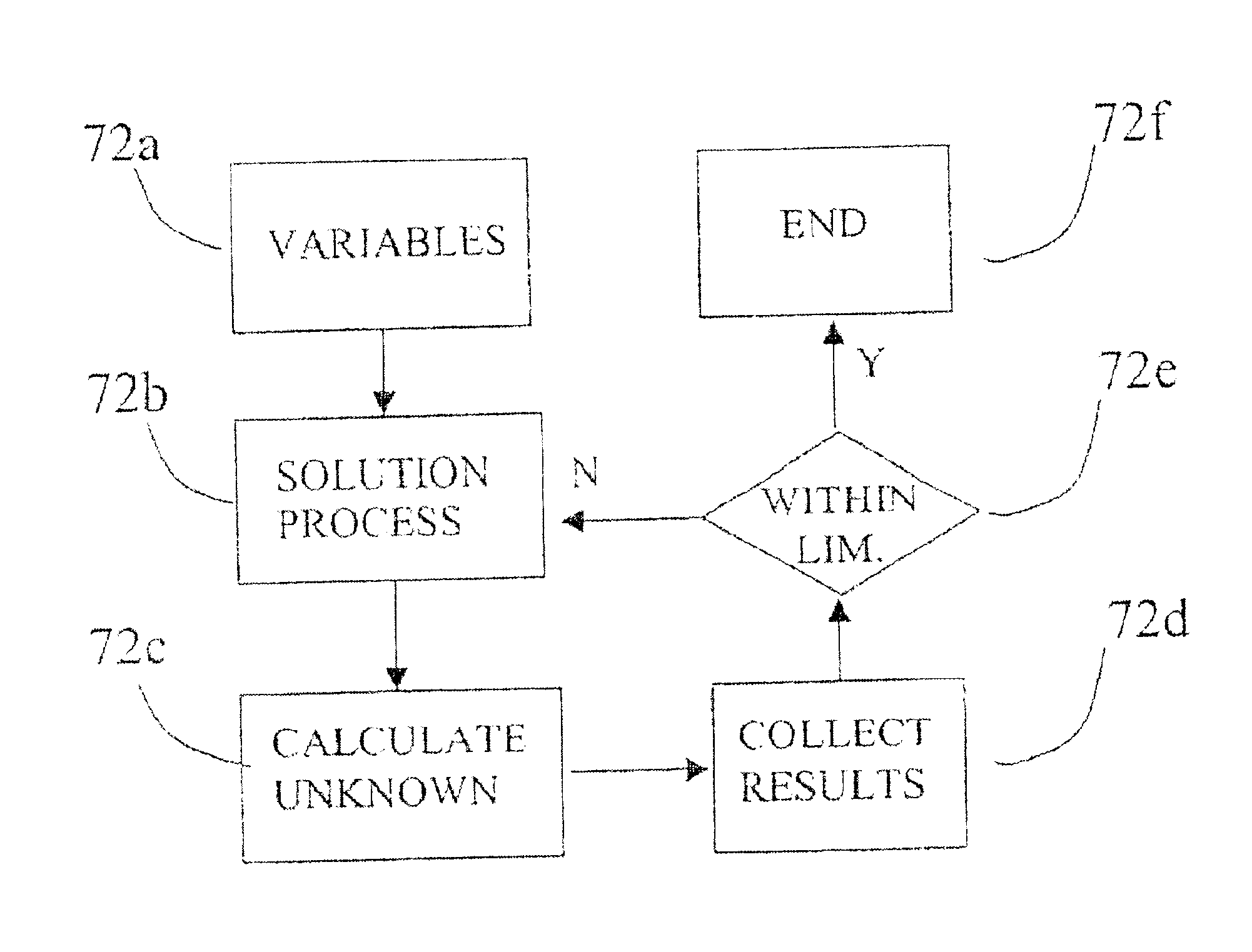

Method for detecting and correcting sensor failure in oil and gas production system

InactiveUS6772082B2Safety arrangmentsTesting/calibration apparatusProcess engineeringOil and gas production

Sensor failure in an oil and gas production system is monitored and detected by checking the consistency of the measurements of the sensor in question using a computer-based process model with the measurements of the other sensors in the system. The present invention also generates a back-up value for a failing sensor with the process model by identifying the value that is most consistent with the measurements of the other sensors in the system.

Owner:ABB AS

Biocidal compositions and methods of use

InactiveUS20100078393A1Easy to controlBiocidePaint waste treatmentChemical compositionOil and natural gas

Provided is a biocidal composition comprising glutaraldehyde and an oxazolidine biocidal compound. The composition is useful for controlling microorganisms in aqueous or water containing systems such as found in oil and natural gas production.

Owner:DOW GLOBAL TECH LLC

Apparatus for treating fluid streams

InactiveUS20070056729A1Improve efficiencyReduce operating costsCleaning apparatusInsulationOcean bottomFluid viscosity

An apparatus and method for increasing and regulating temperature, pressure and fluid viscosities of fluid streams found in oil and gas production. Applicant's apparatus regulates and increases fluid temperatures, by and through improved heating apparatus, which may be placed at one or more locations along a wellbore surface flow line, or subsea flow line. The apparatus preferably either heats fluids flowing from the reservoir to the surface, or alternatively, can heat fluids injected from the surface into the reservoir.

Owner:AMP ELEVATOR GROUP

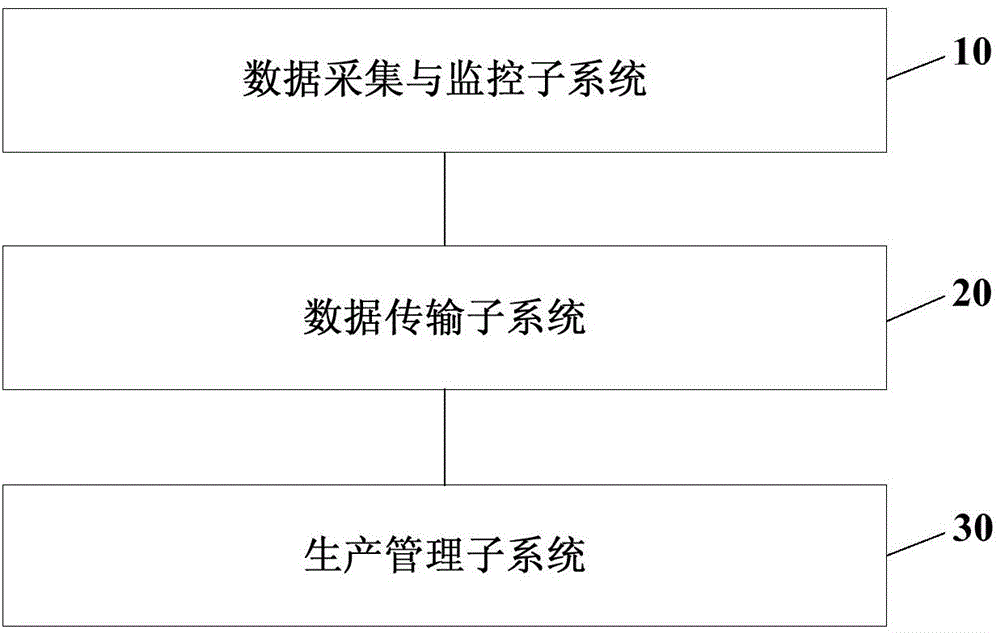

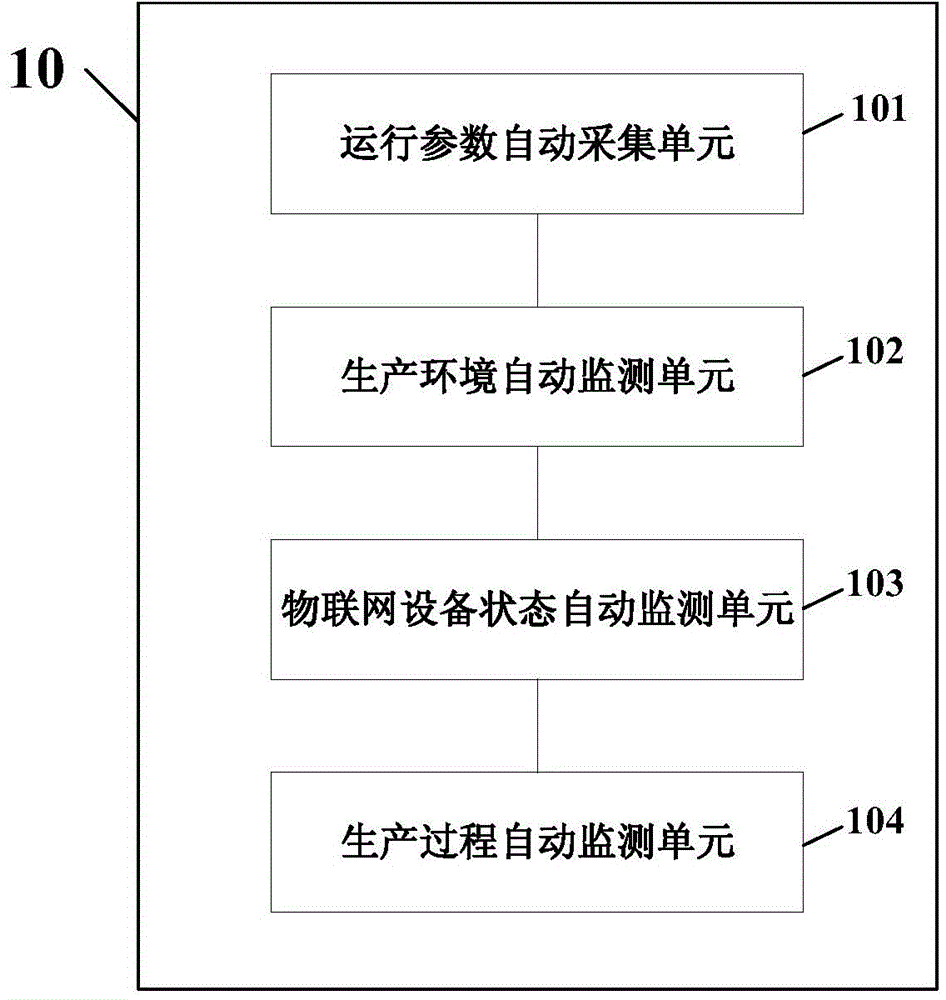

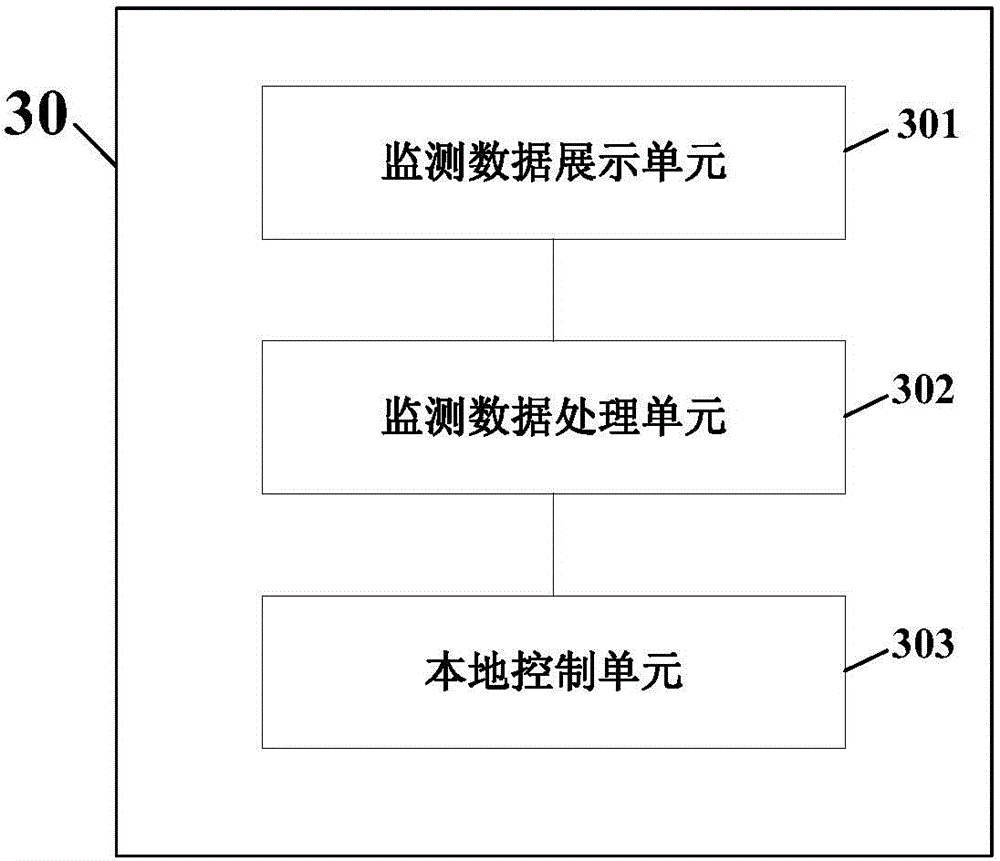

Remote monitoring method and system for oil and gas production

InactiveCN104460609AIncrease productivityProduction management mode changesTotal factory controlProgramme total factory controlState parameterData acquisition

The invention discloses a remote monitoring management method and system for oil and gas production. The internet of things is mainly utilized, by means of sensing, radio frequency, communication and the like, production objects such as an oil and gas well, a metering room, an oil and gas station warehouse and an oil and gas pipe network are comprehensively sensed, production data and equipment state information are managed and controlled in a production command center and a production control center in a centralized mode, oil and gas production process management is supported, and timeliness and accuracy of oil and gas field production decision making are further improved. The system comprises a data acquisition and monitoring subsystem, a data transmission subsystem and a production management subsystem. The data acquisition and monitoring subsystem is arranged on an oil and gas production field, comprises sensors and RTUs or DCSs which are all installed on production equipment, and is used for automatically collecting state parameters of the production equipment and standardizing the state parameters, accuracy of the parameters, equipment identification and equipment attributes so that monitoring data can be formed. The data transmission subsystem is used for transmitting the monitoring data. The production management subsystem is used for conducting production state detection, analysis, diagnosis, prediction and early warning according to the monitoring data.

Owner:PETROCHINA CO LTD

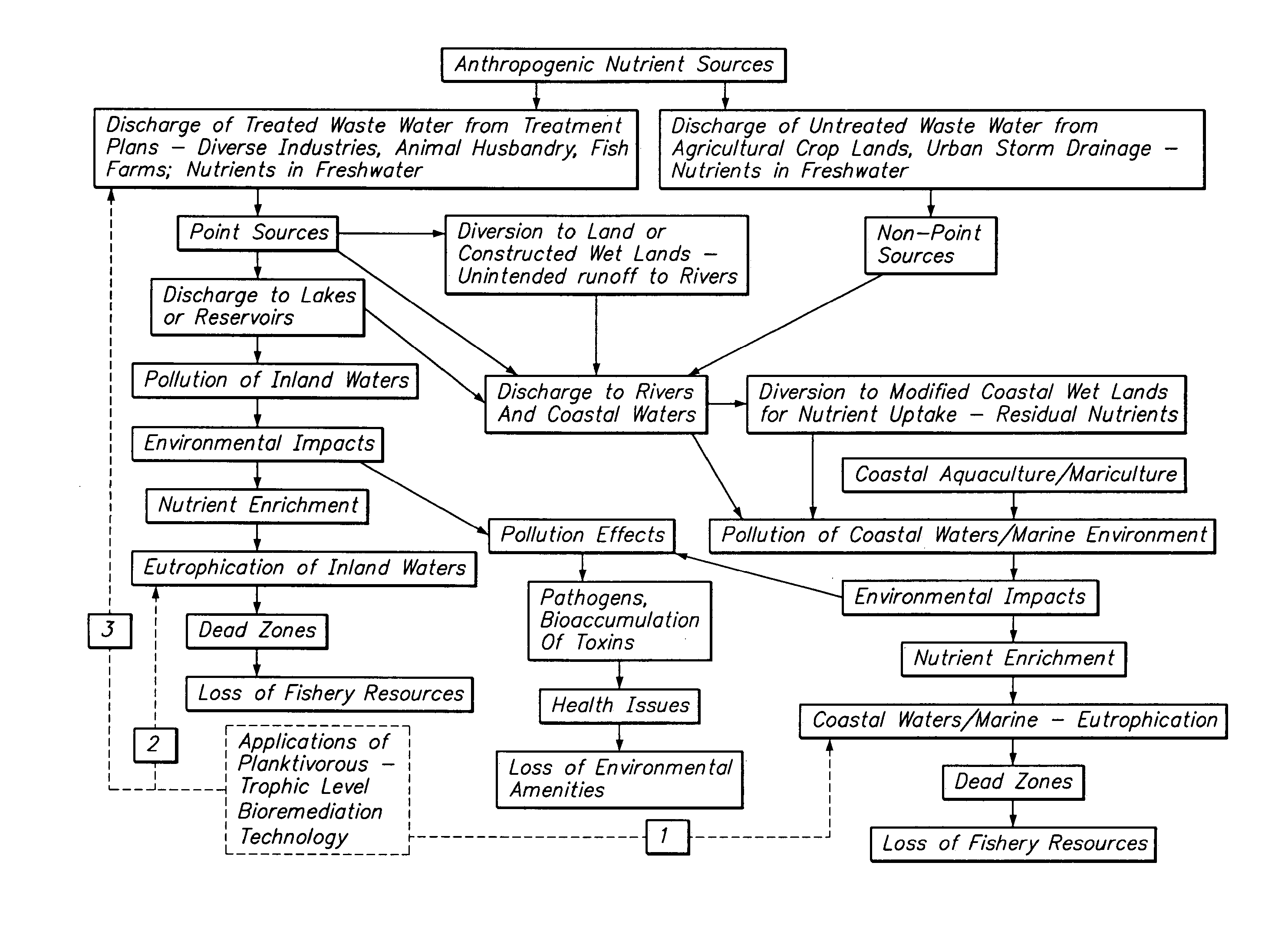

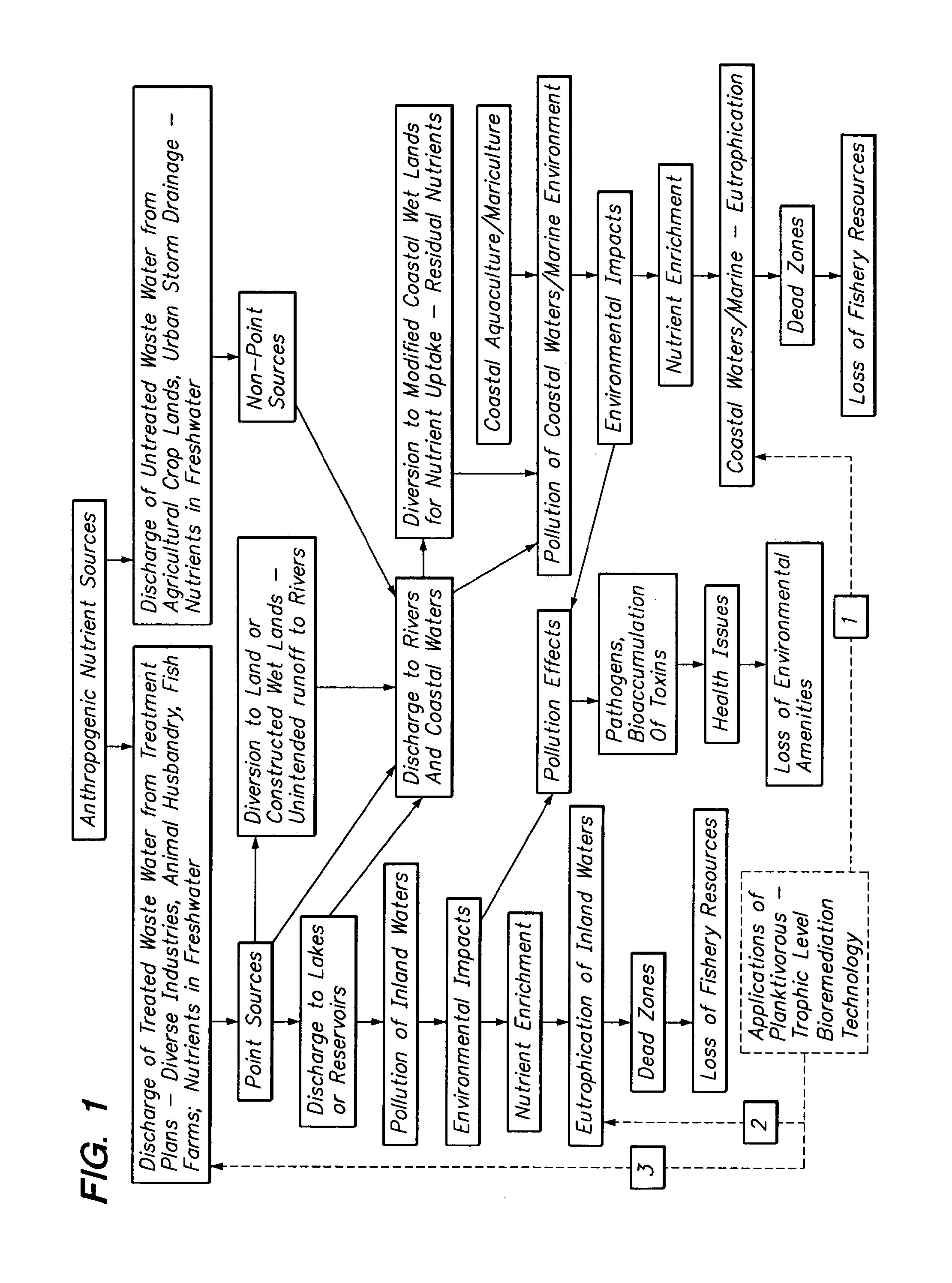

Systems and methods for regulating algal biomass

InactiveUS20120058542A1Avoid developmentImprove productivityFatty acid esterificationUnicellular algaeOffshore waterAquatic product

The invention relates to systems and methods for regulating algal biomass in offshore waters near an oil and gas production platform. The systems of the invention encompasses a plurality of modules for managing nutrients, algae, and aquaculture, including enclosures for containing aquatic organisms, and various operating subsystems that are operably associated with surface and underwater structures of the platform. In one embodiment of the invention, aquatic organisms are cultured in eutrophic water to feed on algae, thereby reducing the algal biomass. In other embodiments, the diversity of algae in an algal bloom is modified and the productivity of oligotrophic water is increased.

Owner:LIVEFUELS

Method for reduction of scale during oil and gas production and apparatus for practicing same

InactiveUS6973972B2Reduce problem sizePiezoelectric/electrostriction/magnetostriction machinesCleaning apparatusTransducerChemical addition

Scaling may be reduced during oil and gas production using a device having a sound transducer. The device can be used downhole and functions independently of an external power supply. Use of the device allows for the reduction or elimination of anti-scaling chemical additives during the production phase of an oil and gas well.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com