Hydrocarbon source rock formation pore heat-pressing hydrocarbon-generation simulator and use method thereof

A technology for simulating formation pores and hydrocarbon generation, which is applied in the field of petroleum geology and can solve problems such as few people have carried out research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

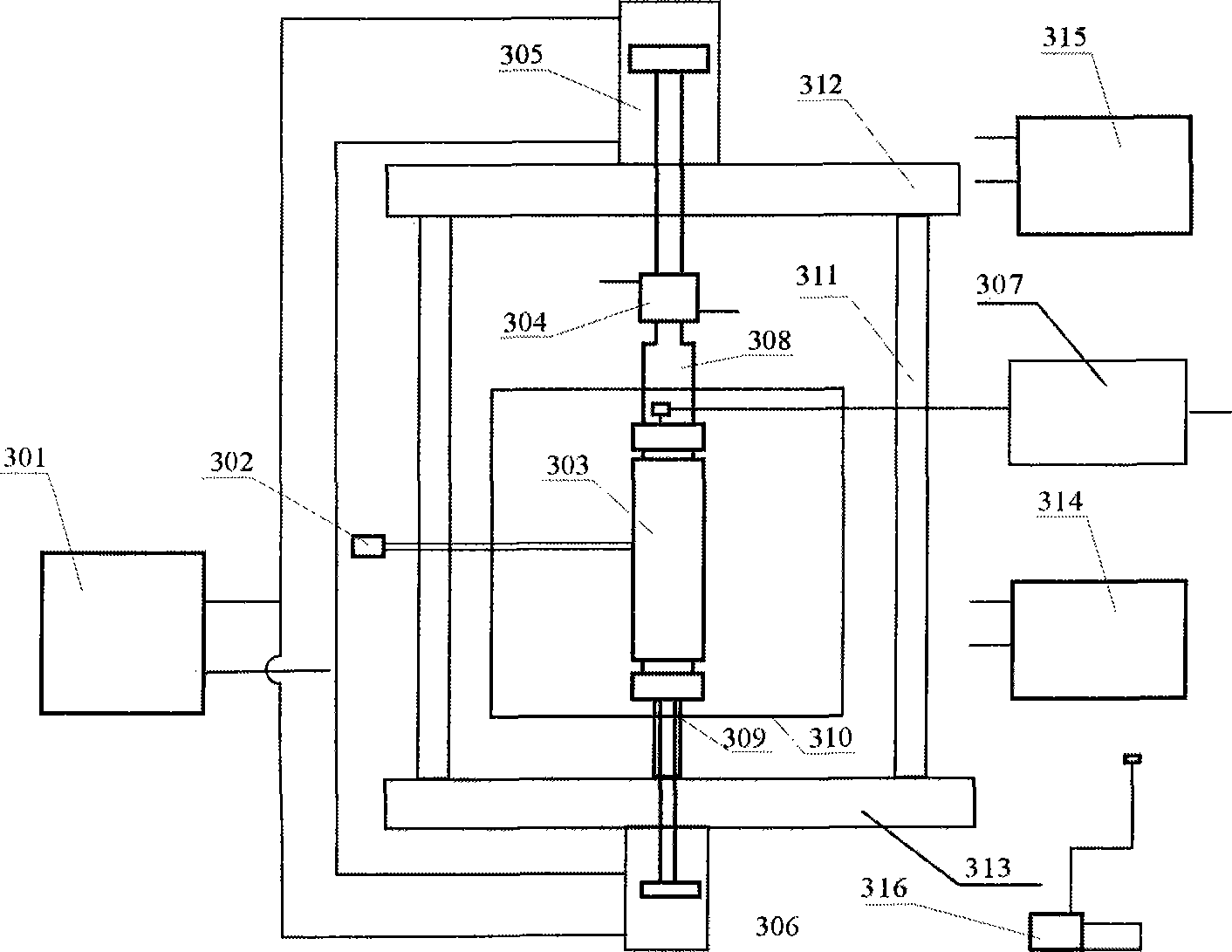

[0061] In accompanying drawing 3, the present invention is made up of high temperature and high pressure reaction unit 303, two-way hydraulic pressure automatic control unit 301, automatic hydrocarbon expulsion product collection and fluid replenishment unit 307, data acquisition and automatic control unit 314, peripheral auxiliary equipment and instrument shell, wherein high temperature The alloy cylinder 503 of the high-pressure reaction unit is a hollow cylinder made of high-pressure, high-temperature, and corrosion-resistant alloy materials. The upper port is sequentially placed with a self-tightening end cap 509, a red copper tapered sealing ring 510, and an upper pressure ring sleeve 511. 1. After the upper middle pressure sleeve A308 and the upper compression bolt 512, the pressure rod A621 of the large oil cylinder A305 exerts pressure on the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com