Patents

Literature

1189 results about "Stack machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer science, computer engineering and programming language implementations, a stack machine is a type of computer. In some cases, the term refers to a software scheme that simulates a stack machine.

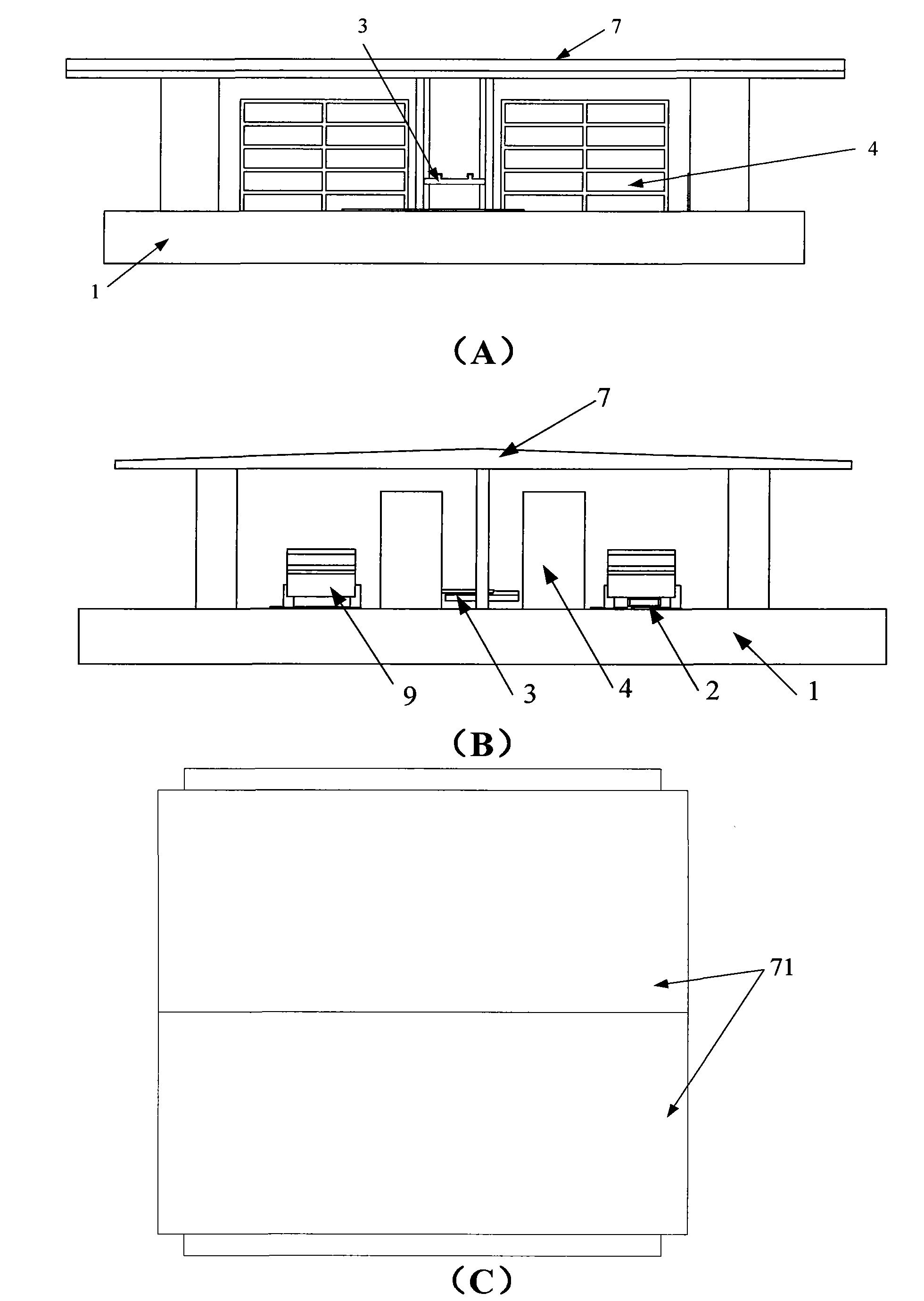

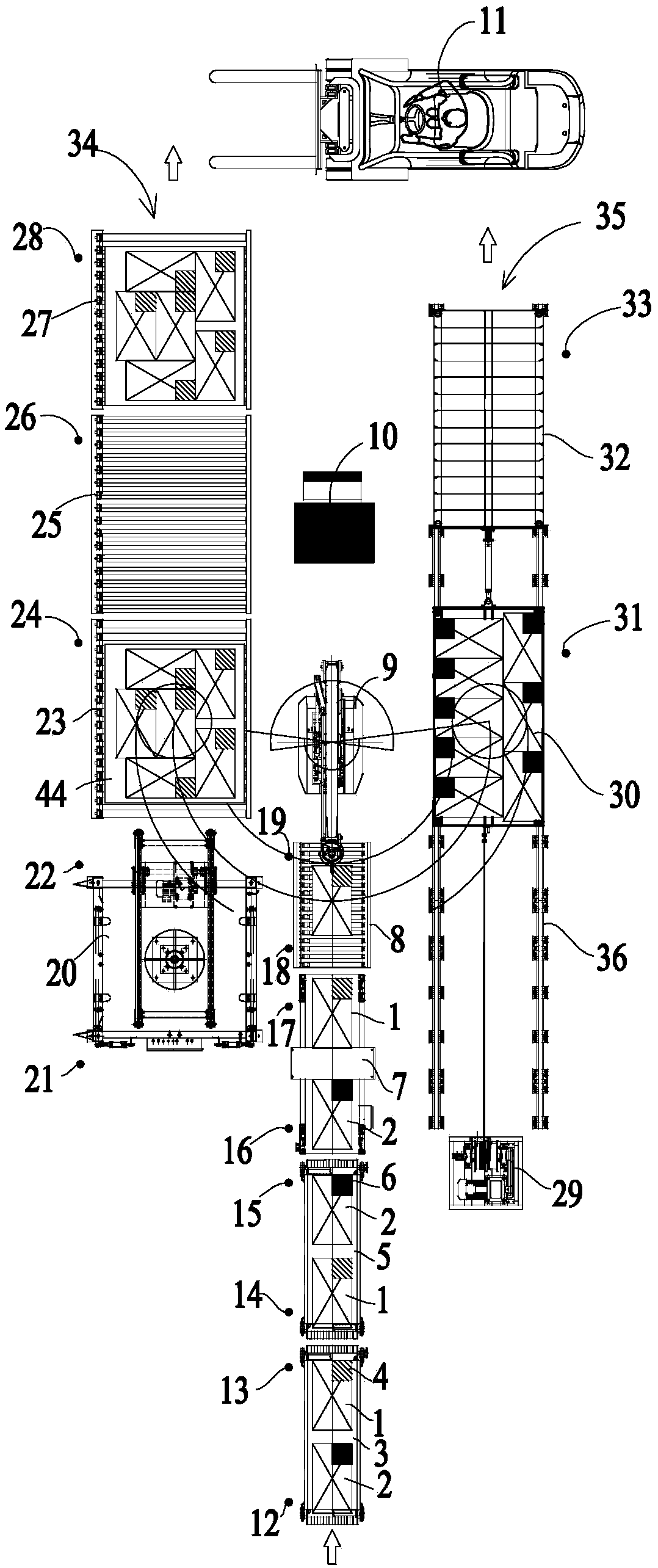

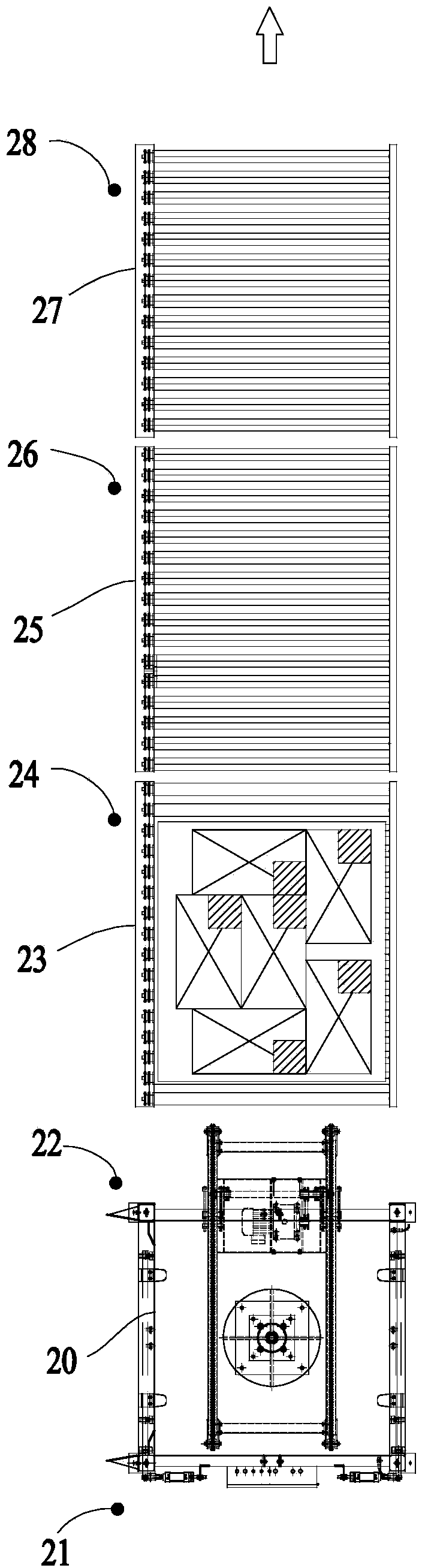

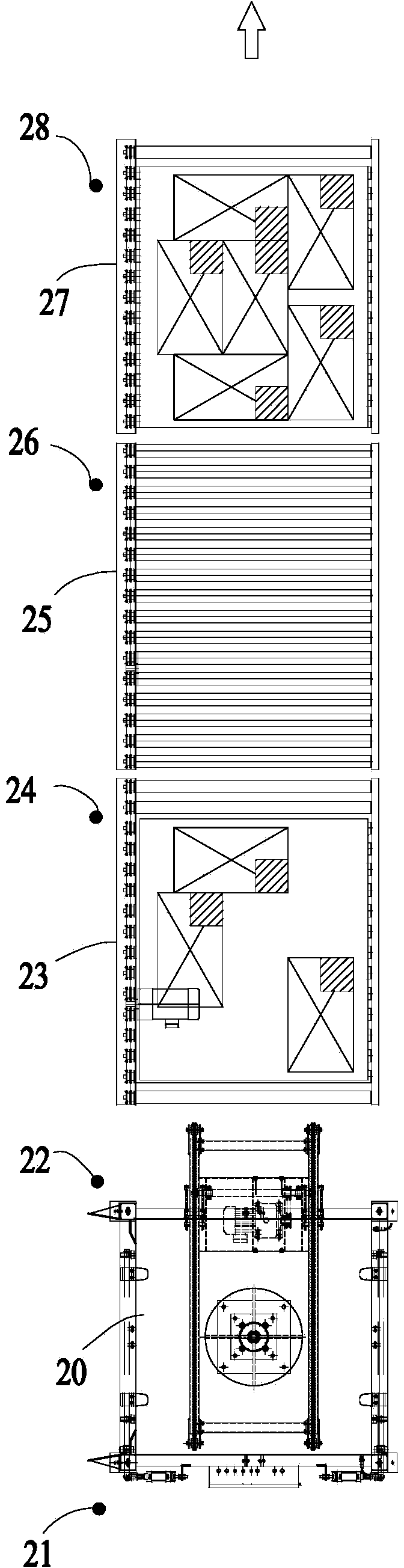

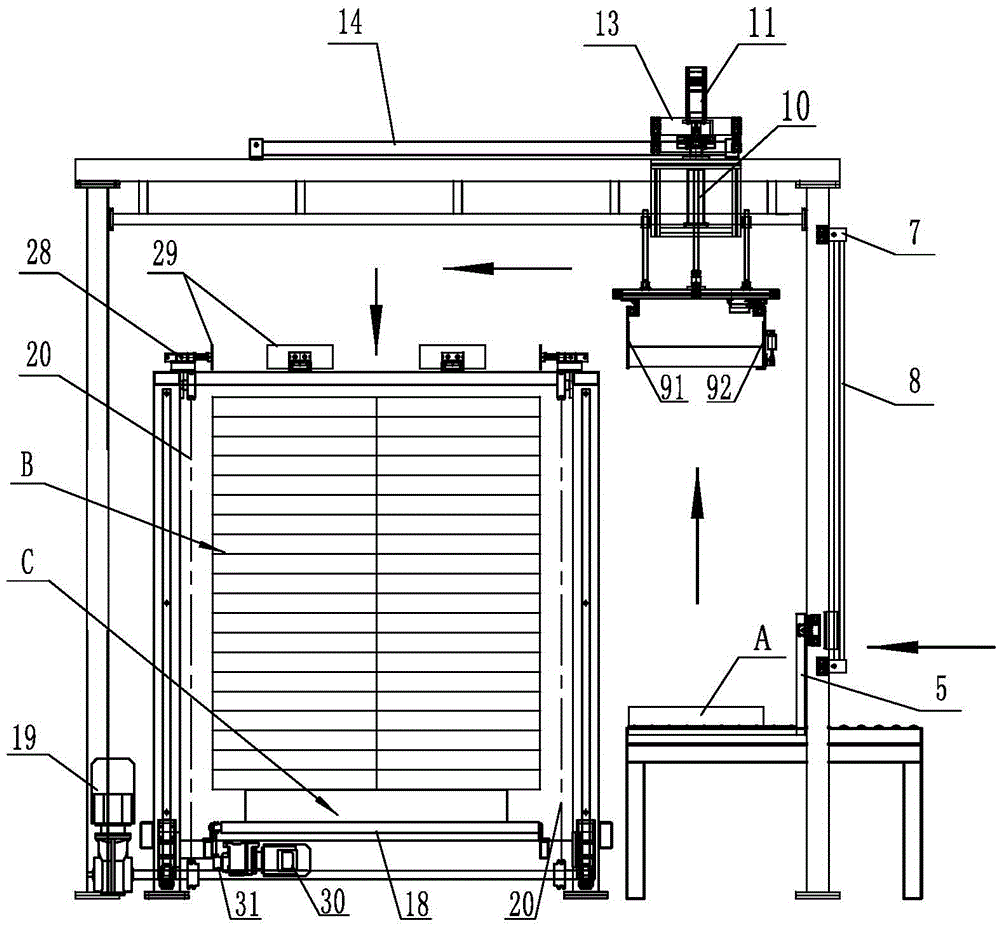

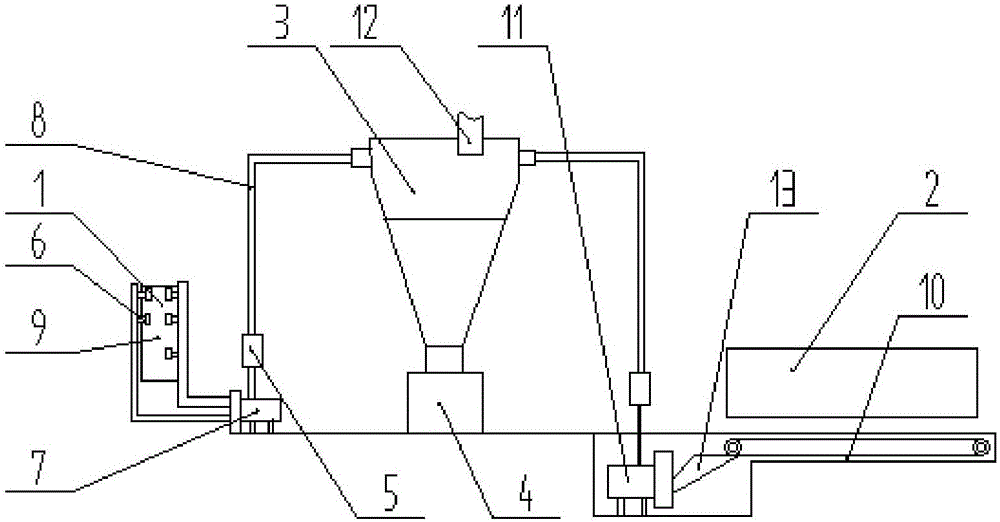

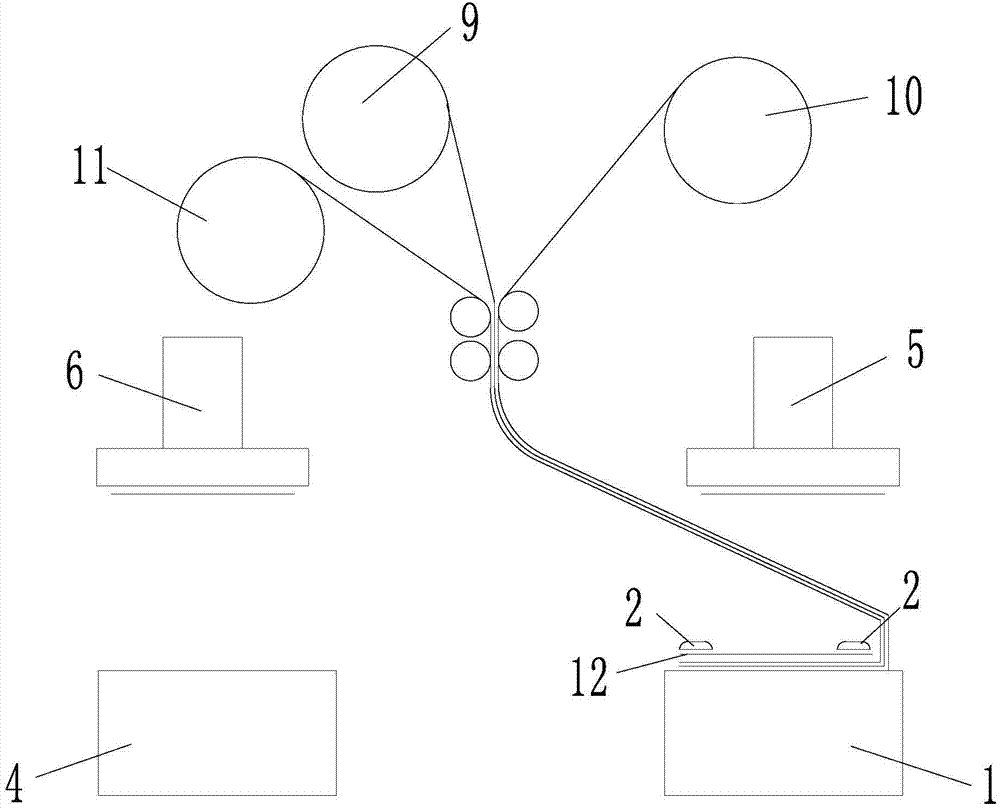

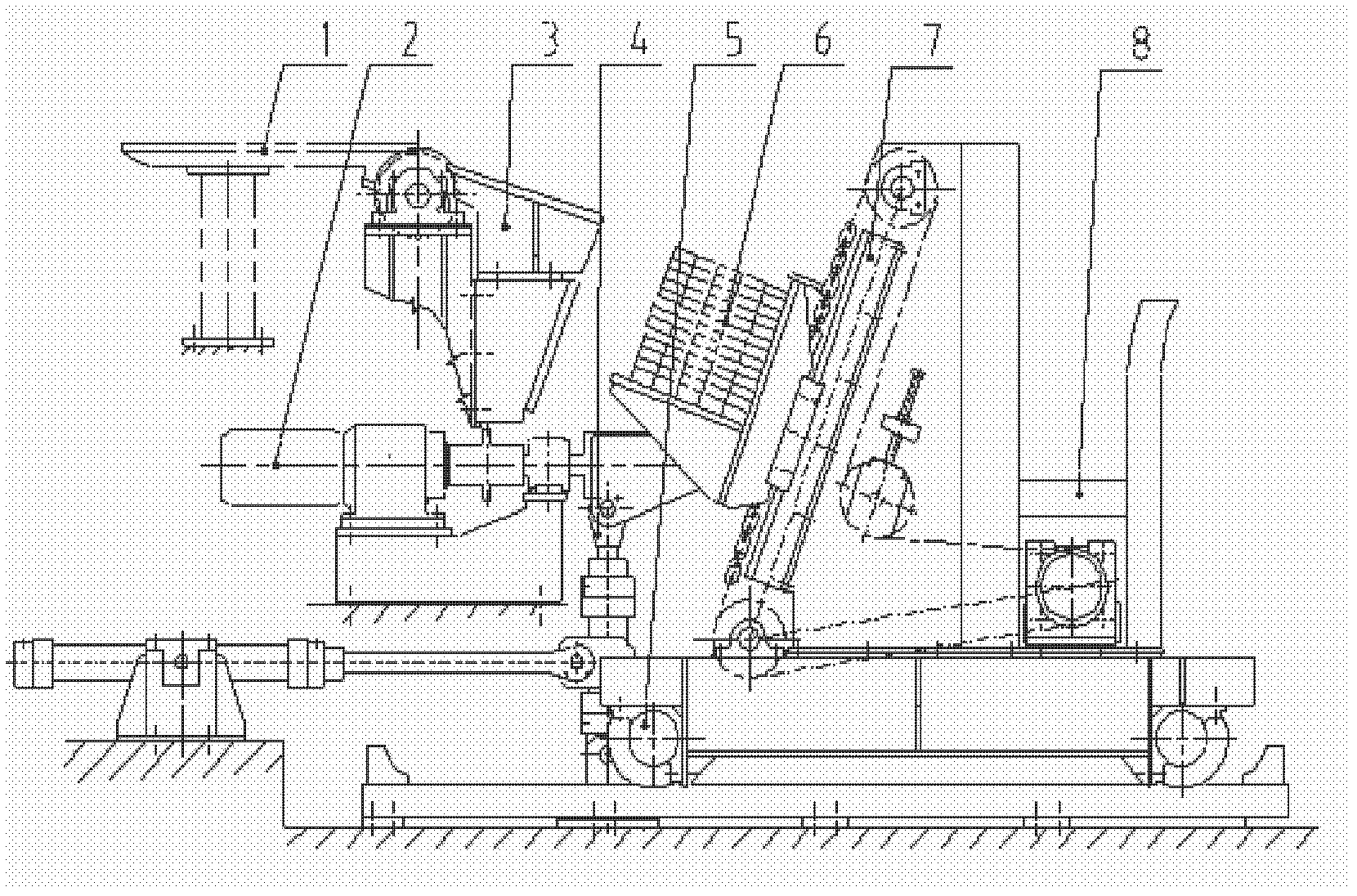

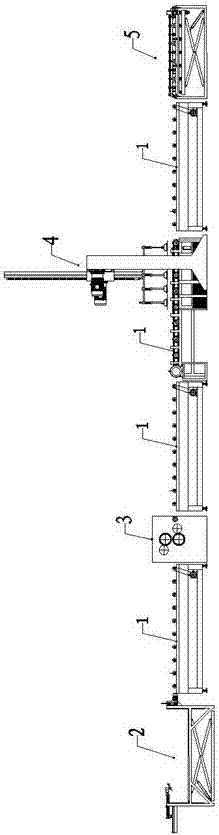

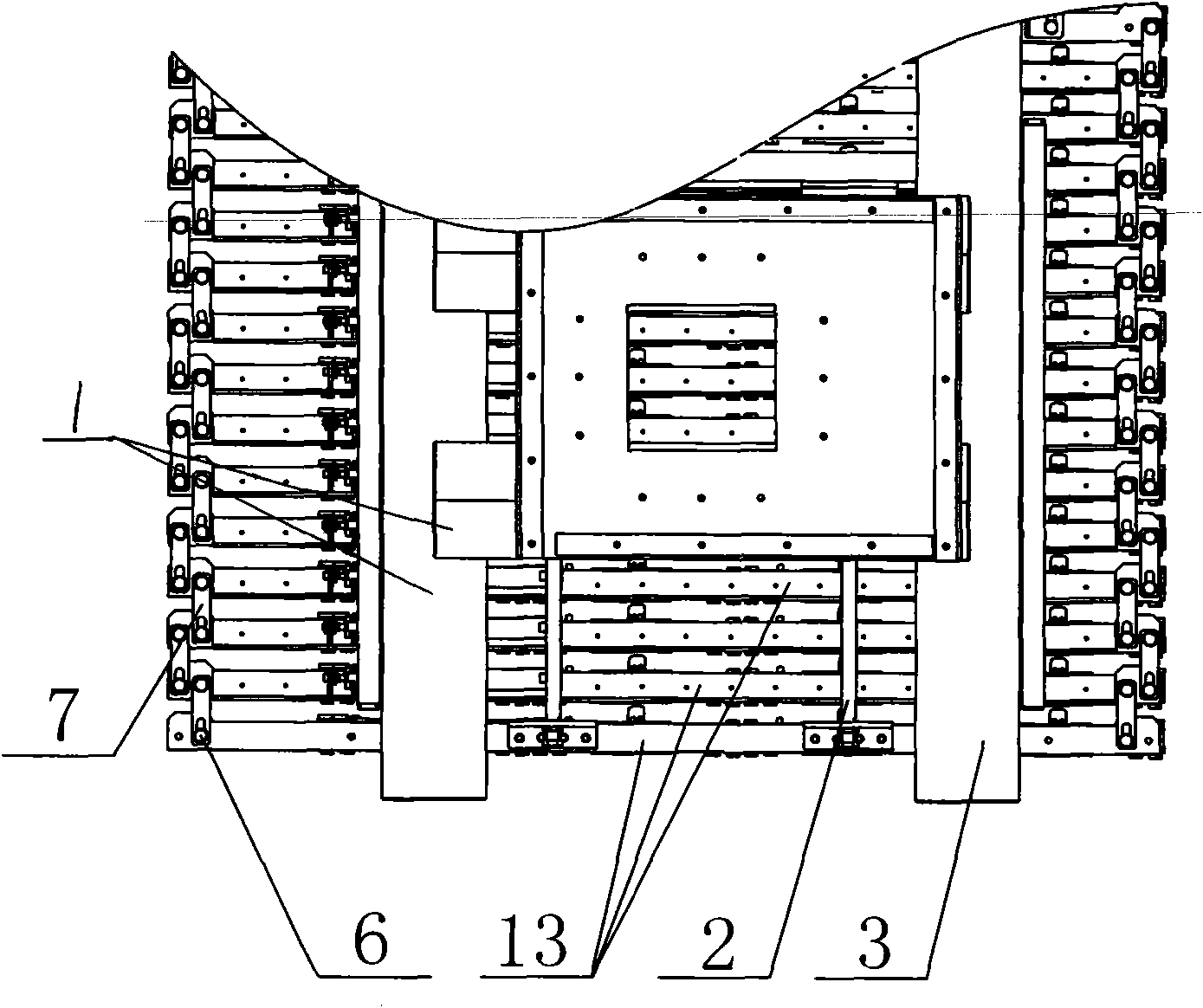

Quick replacement station for battery box of electric vehicle and battery box replacement method

InactiveCN102267437AQuick changeRapid positioningElectric propulsion mountingElectric/fluid circuitElectricityStack machine

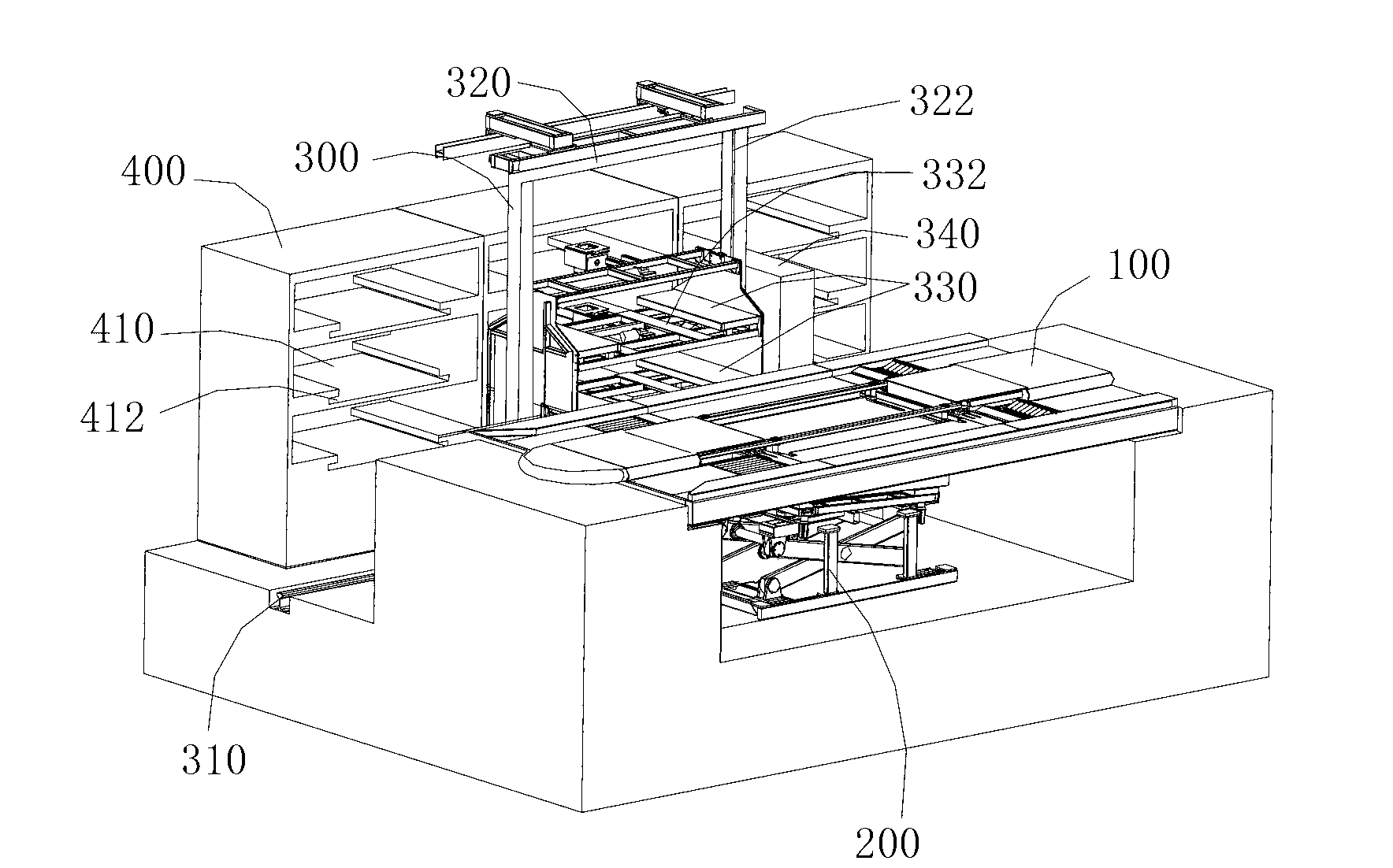

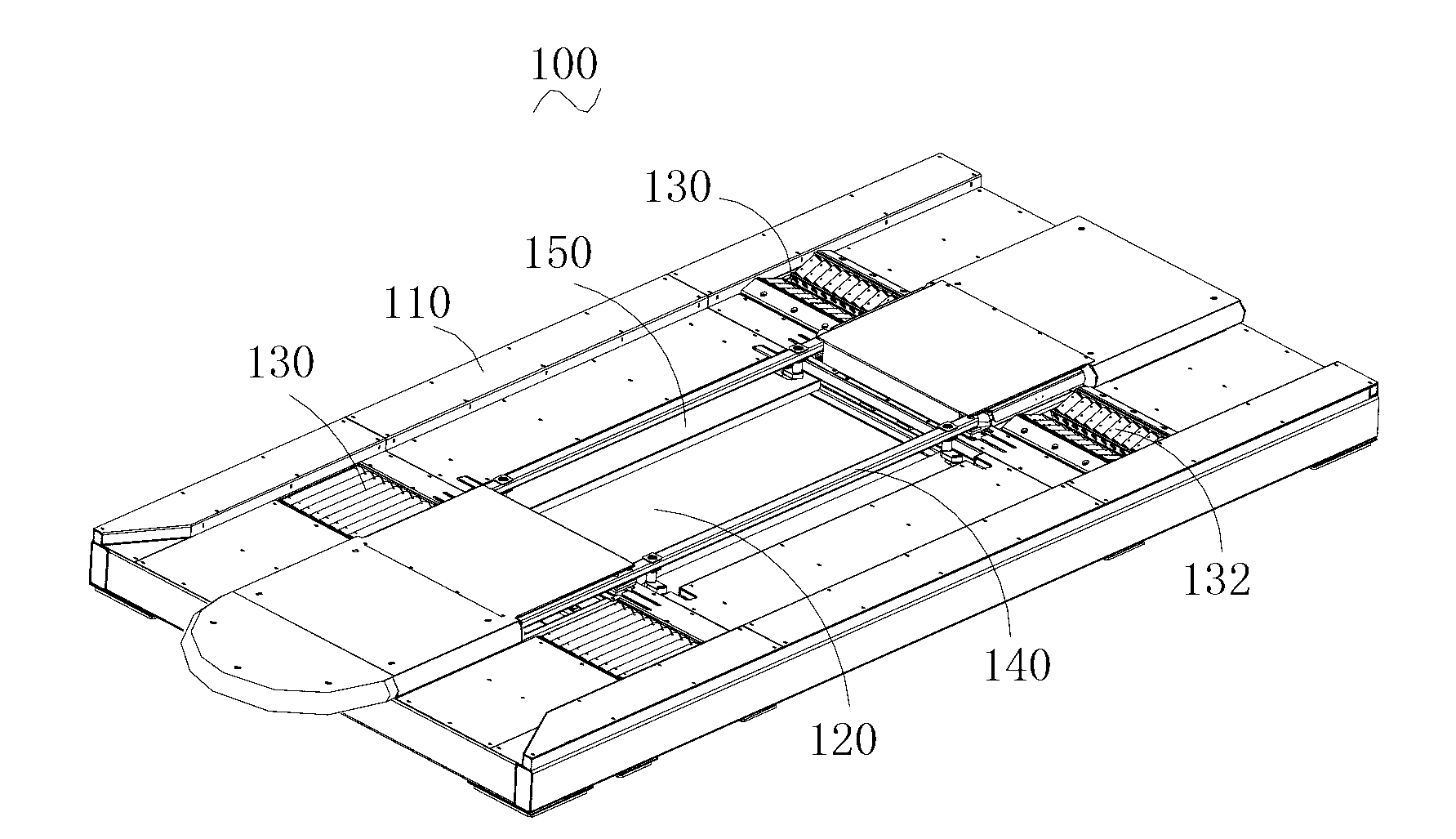

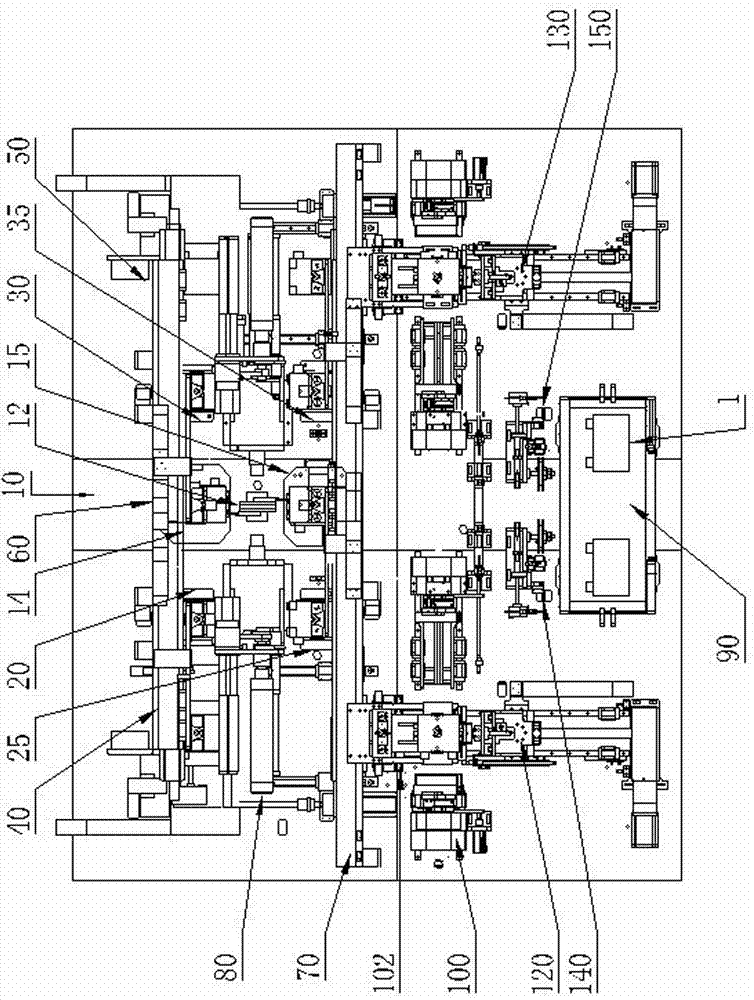

The invention discloses a fast power transformation station of a battery box of an electric automobile and a replacement method of the battery box. The power transformation station at least comprises the following devices: an automobile positioning platform, a battery box lifting and replacing platform, a stacking machine, a battery box storage rack, a logistics transmission port of the battery box and a delivery roller way which are symmetrically arranged relative to the longitudinal movement axis of the stacking machine, the simultaneous working of the two power transformation systems can be achieved, and the space utilization rate and the power transformation efficiency are improved. The fast power transformation station also comprises a power supply system which is arranged on a roof and consists of a solar photovoltaic power generation battery board; and self sufficiency of power can be achieved by virtue of the solar energy, the power supply of the equipment in the station or the charging for the battery box in the station are met. The invention also provides the replacement method of the battery box of the power transformation station. According to the power transformation station, the distribution is reasonable, the space utilization rate is high, the work of the equipment is reliable and simple, and the power transformation process is fast, so that the power transformation time can be shortened, the power transformation fault is reduced, and the compatibility for different vehicles and different battery boxes is also improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

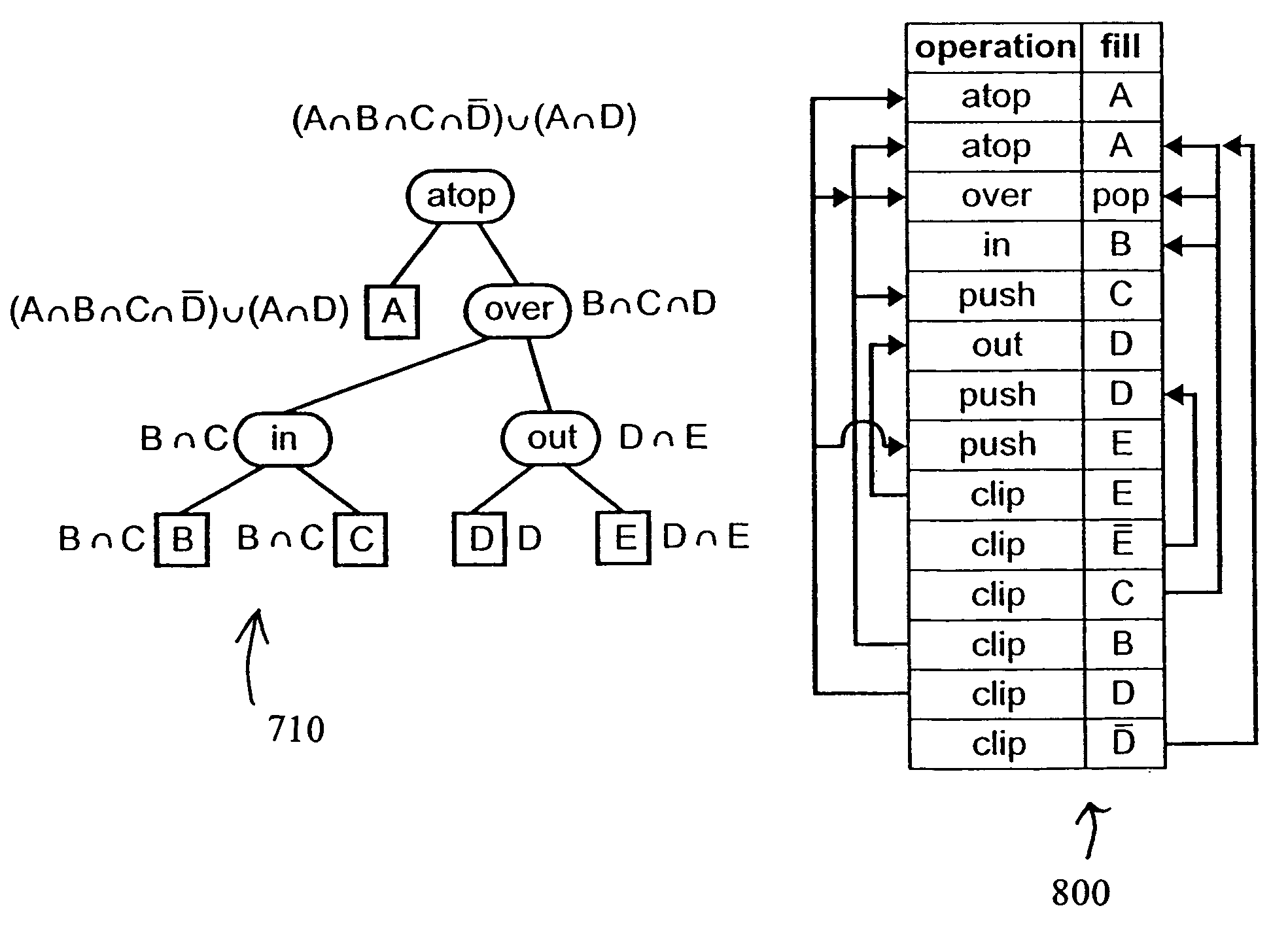

Method of compiling compositing expressions for optimised rendering

InactiveUS7190376B1Geometric image transformationCathode-ray tube indicatorsStack machineBiological activation

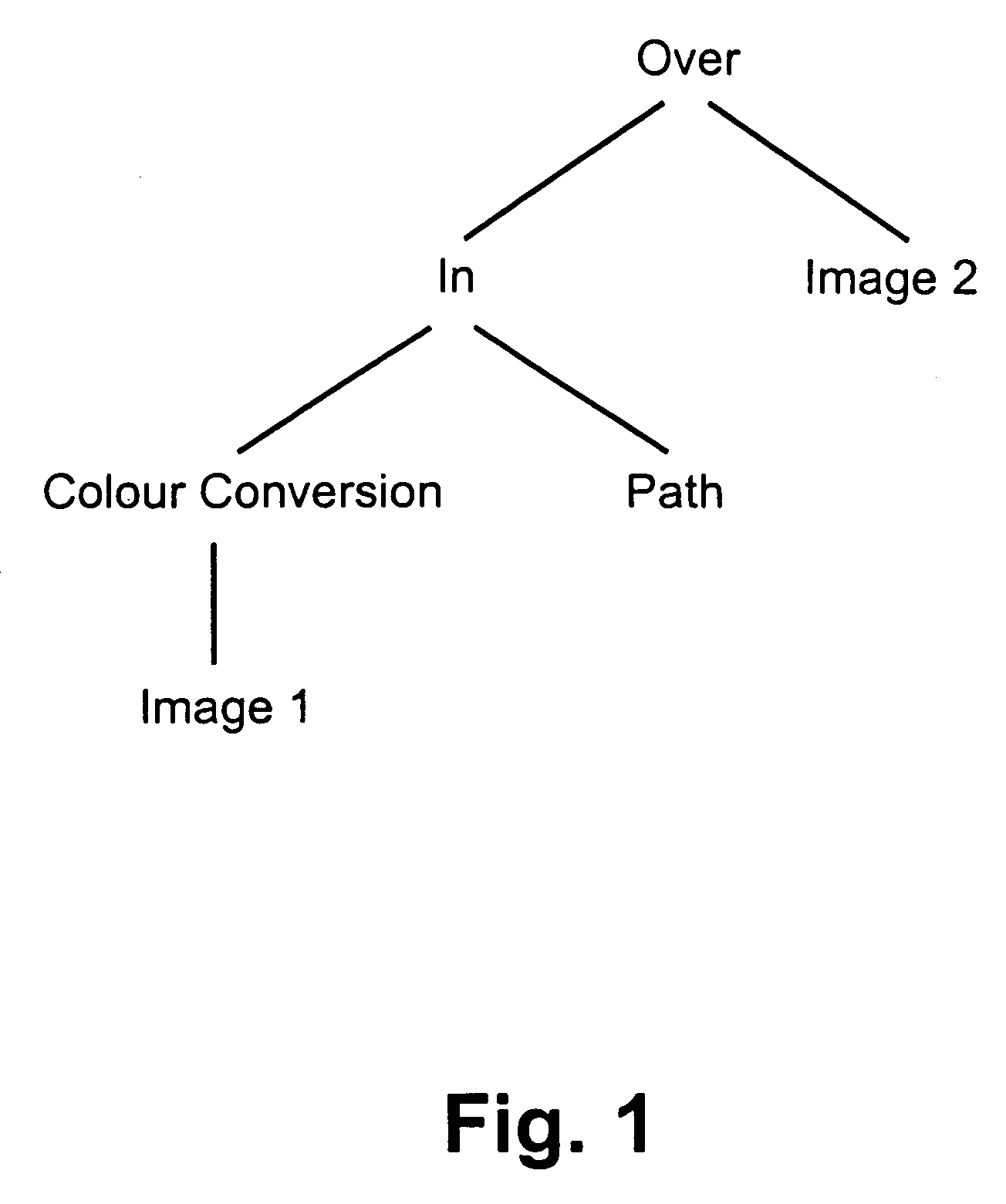

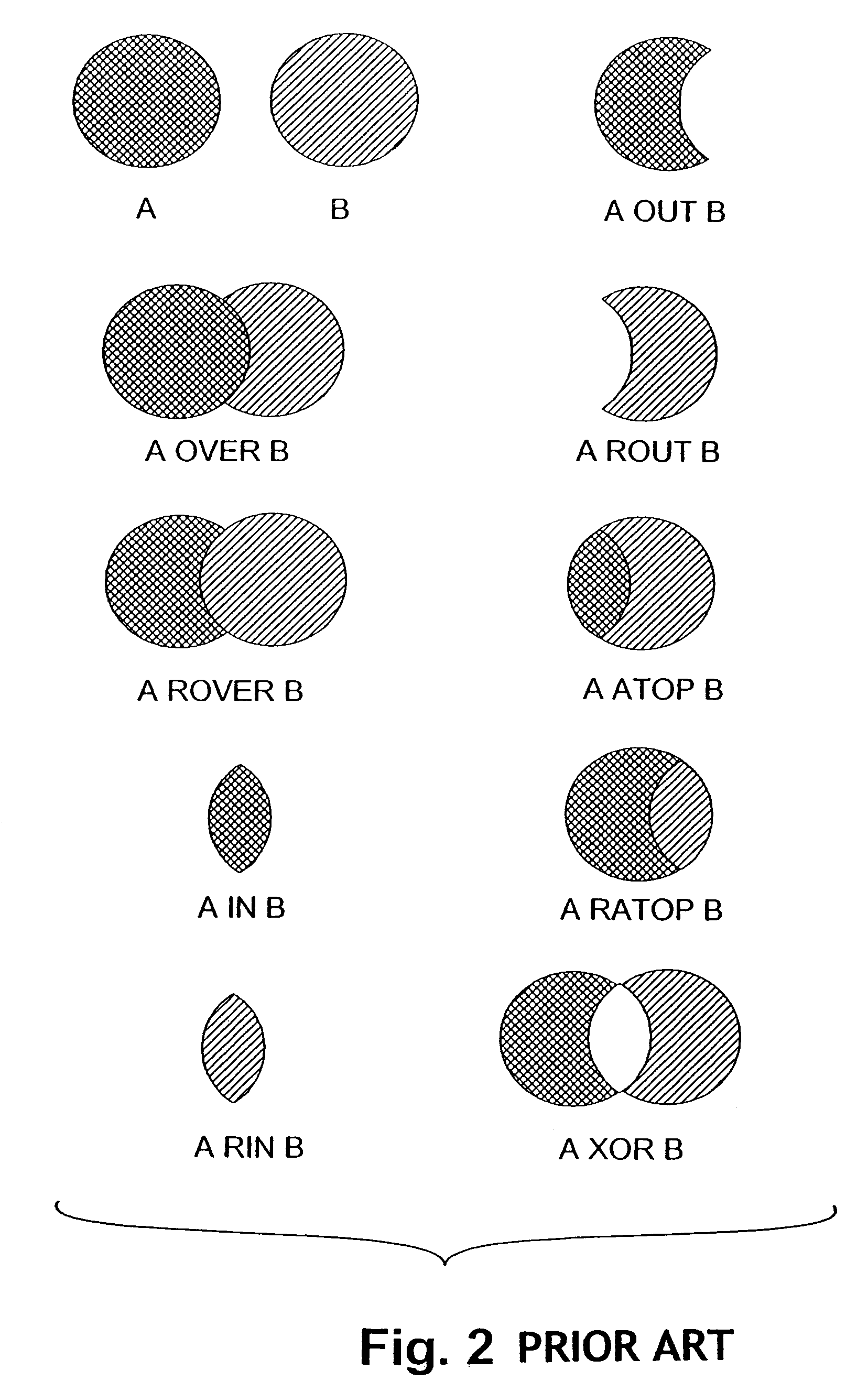

A method of creating an image utilizing a table of levels known as a “level activation table” (34) is disclosed. The method uses the level activation table to optimally evaluate a given compositing expression such that the number of pixel operations needed to evaluate the expression is minimized. The method determines the smallest regions in which compositing operations need to be performed and uses these regions to produce the level activation tables where clipping is applied to operations in order to avoid redundant and / or incorrect pixel operations. The method is preferably used in a compositing model in which objects are composited onto a page using a stack machine and an associated compositing stack (38). The stack 38 may be manipulated using standard stack operations such as push, pull and pop. Instructions for the stack machine are taken from the level activation table 34.

Owner:CANON KK

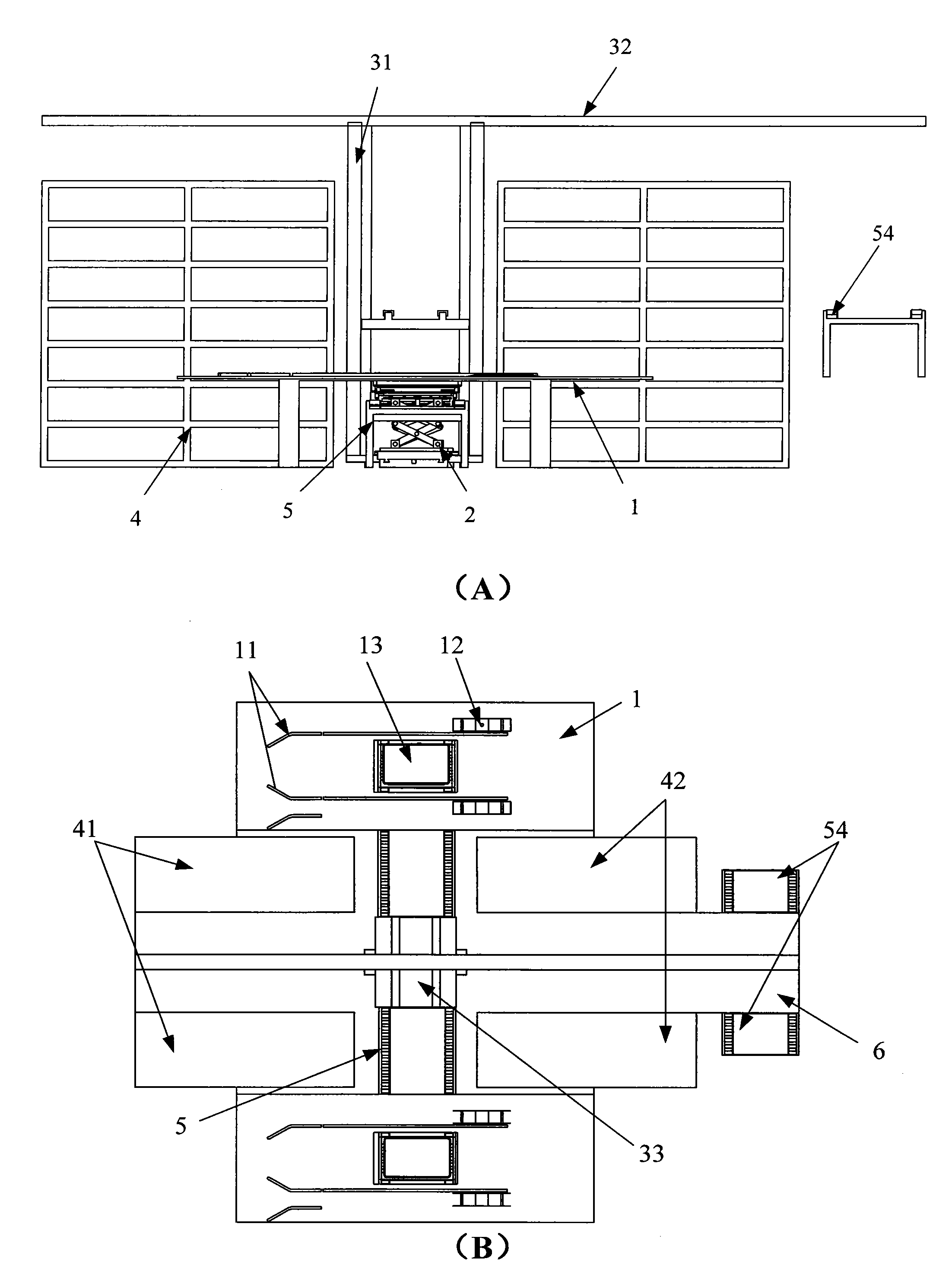

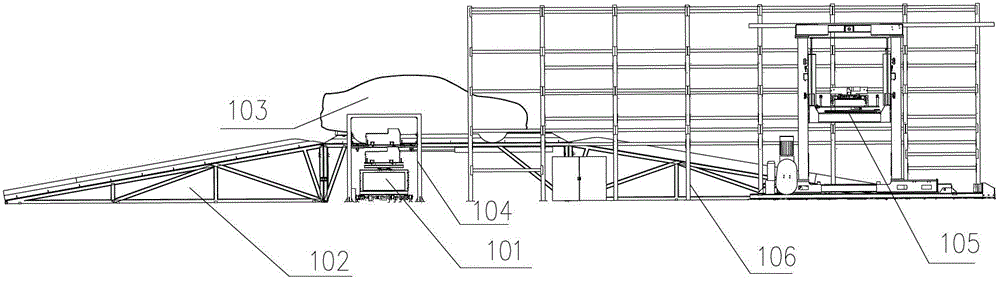

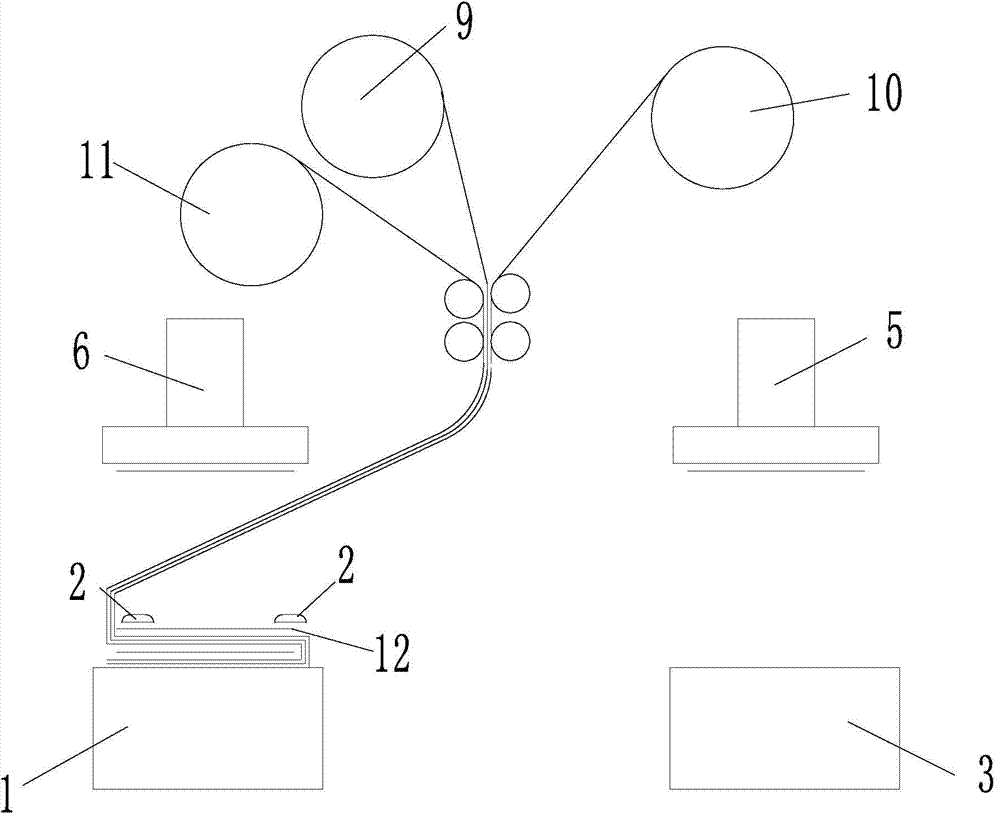

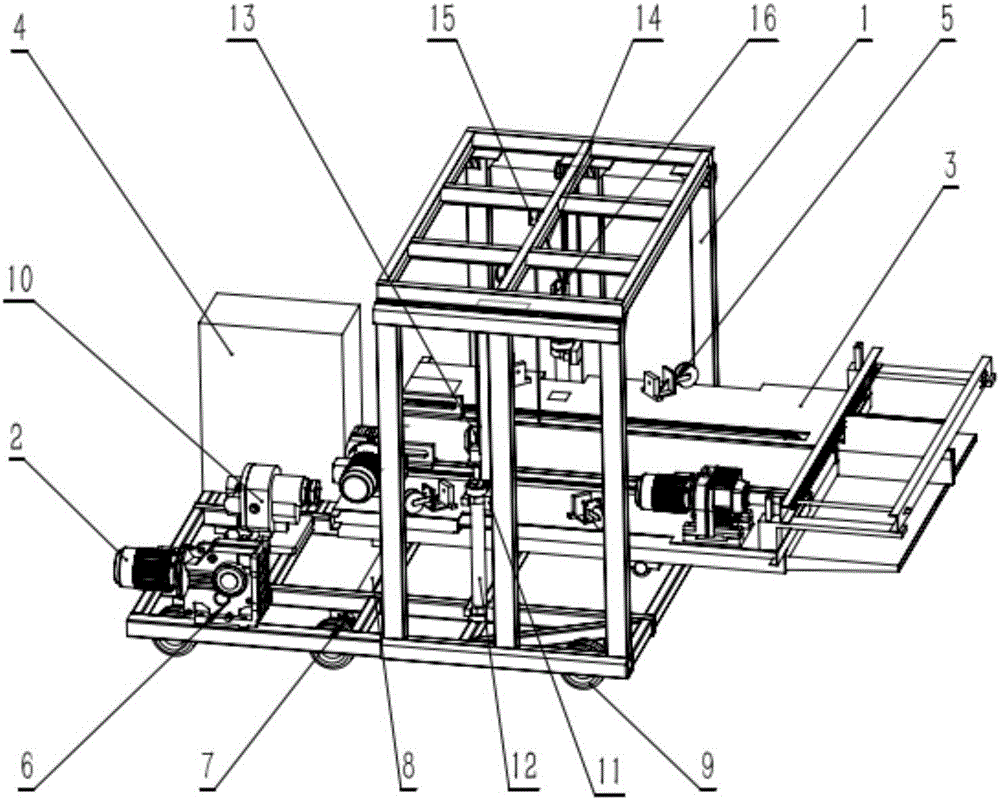

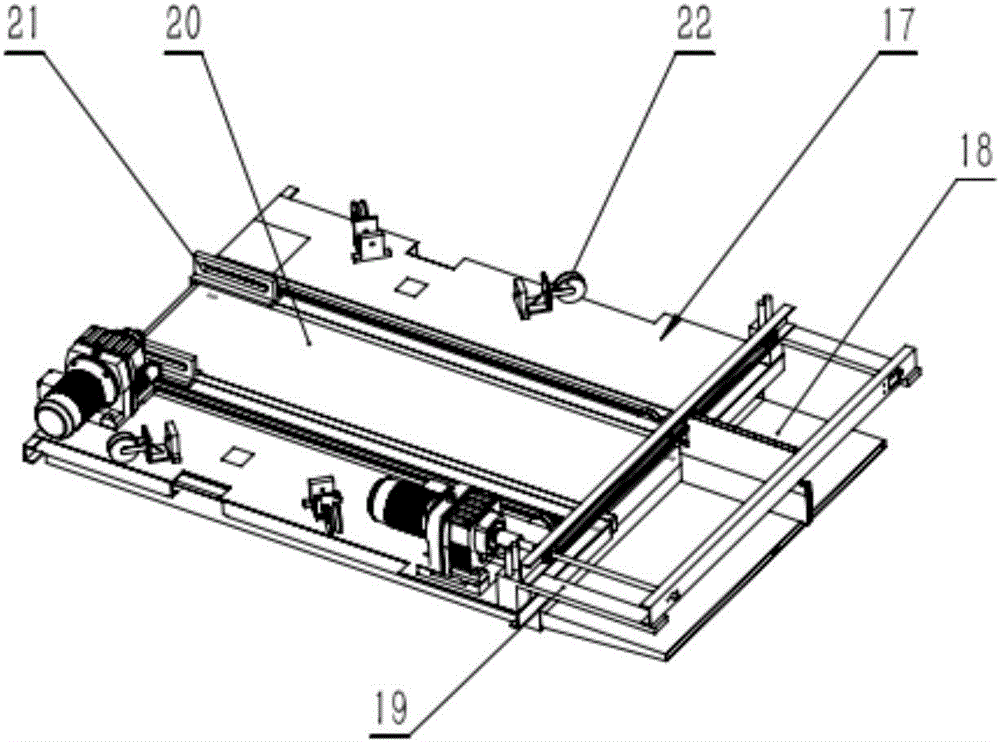

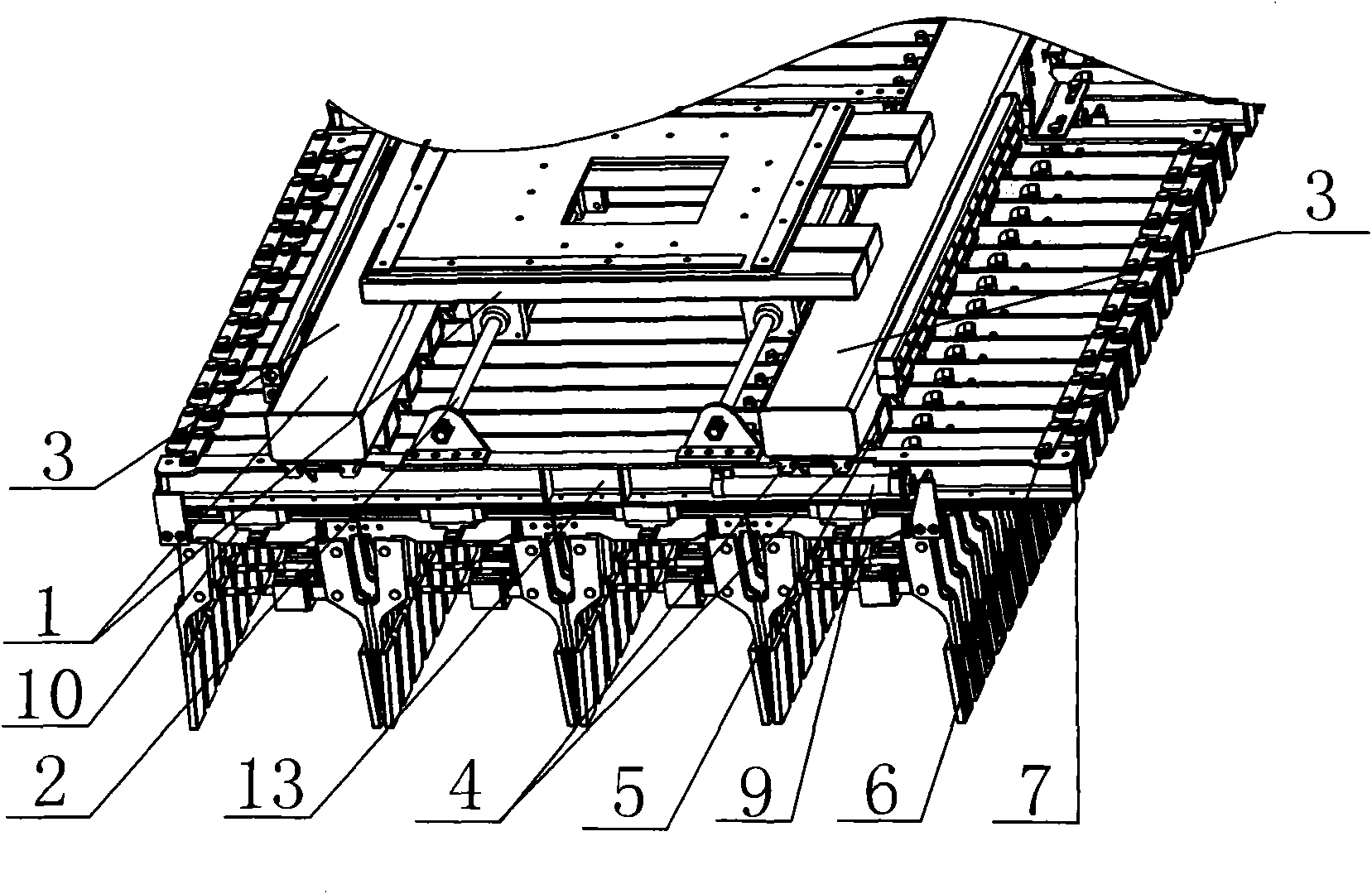

Electric car chassis battery charging and replacing station and battery replacing method using same

The invention provides an electric car chassis battery charging and replacing station. The electric car chassis battery charging and replacing station comprises a car centering device, a battery lifting and replacing device, a track-type laneway stacking machine, a battery storage frame, a battery carrying device and a battery charging device. The battery carrying device is moved among the battery lifting and replacing device, the track-type laneway stacking machine and the battery storage frame by the movement of the track-type laneway stacking machine, so that a battery can be transported without a conveying line, thereby guaranteeing the electric car chassis battery charging and replacing station to have higher space utilization rate. In addition, the invention further provides a battery replacing method.

Owner:SHENZHEN JINGZHI MACHINE

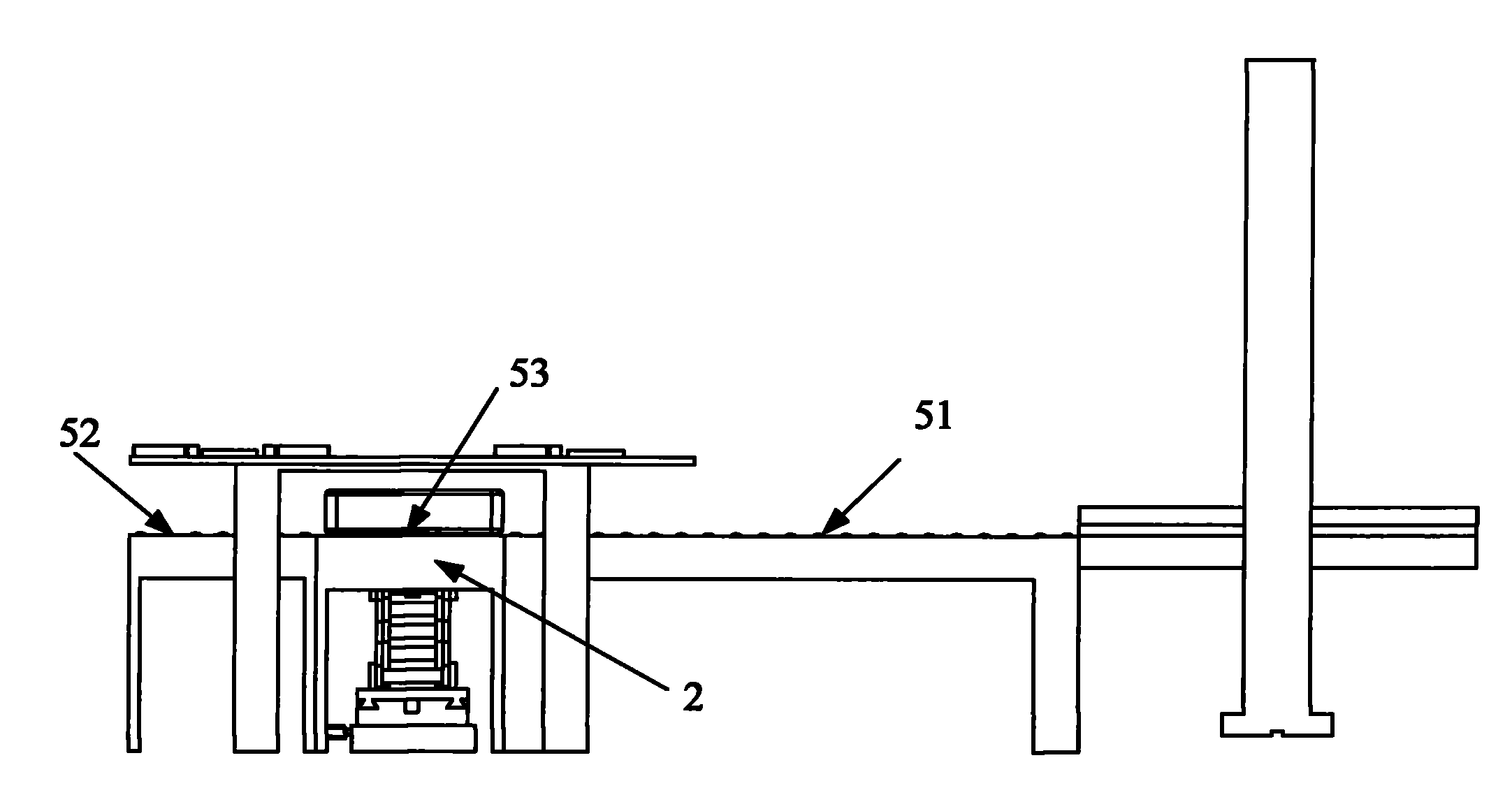

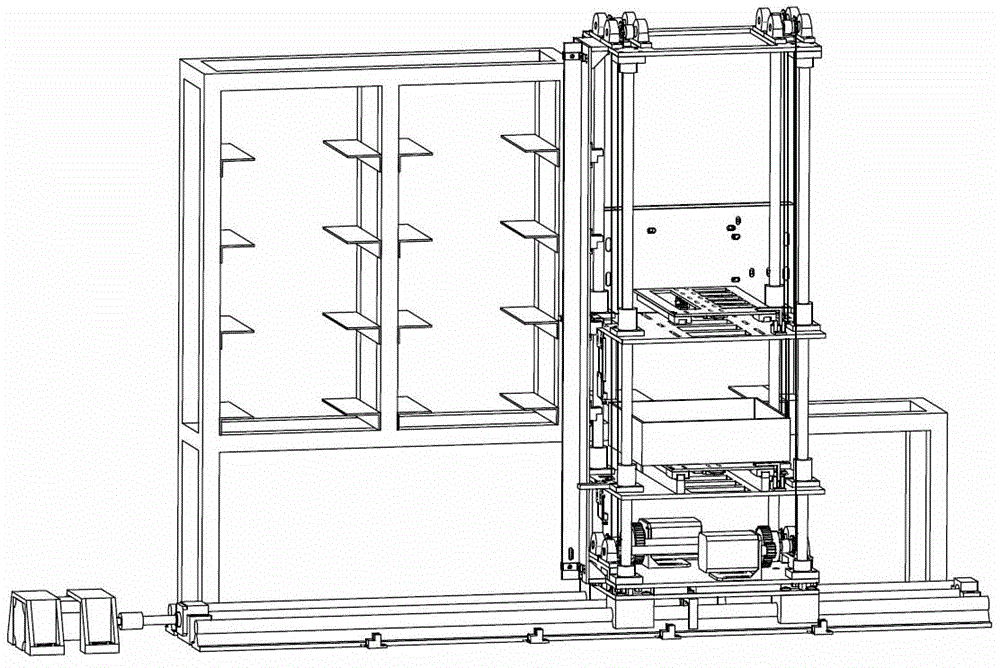

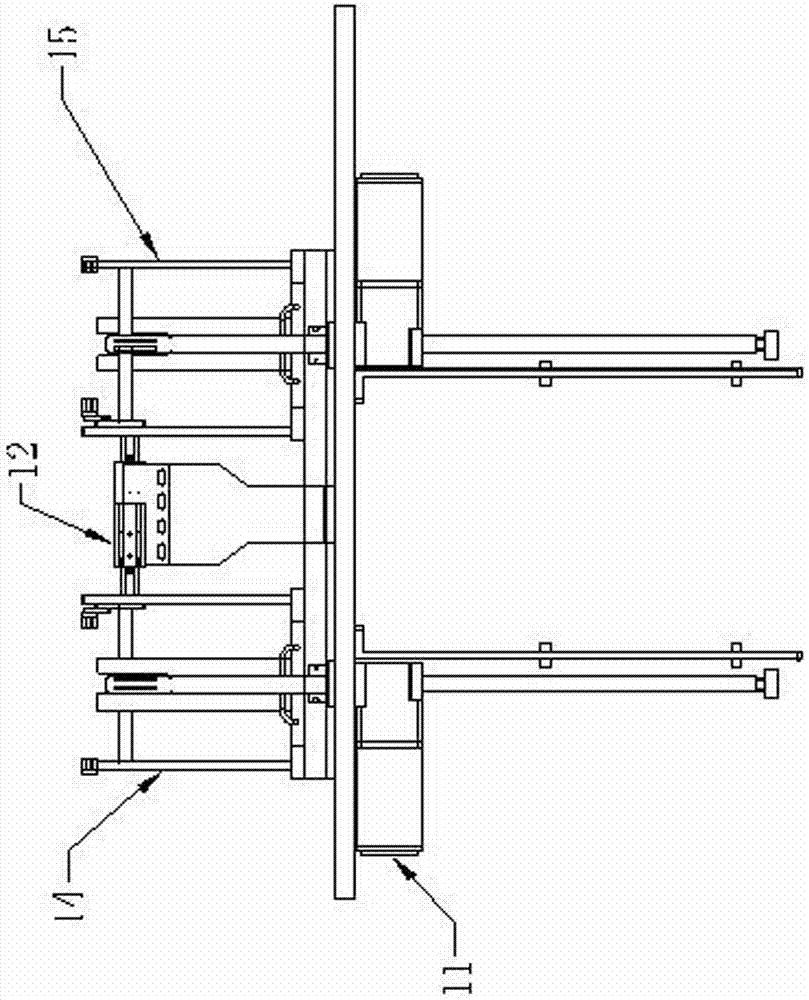

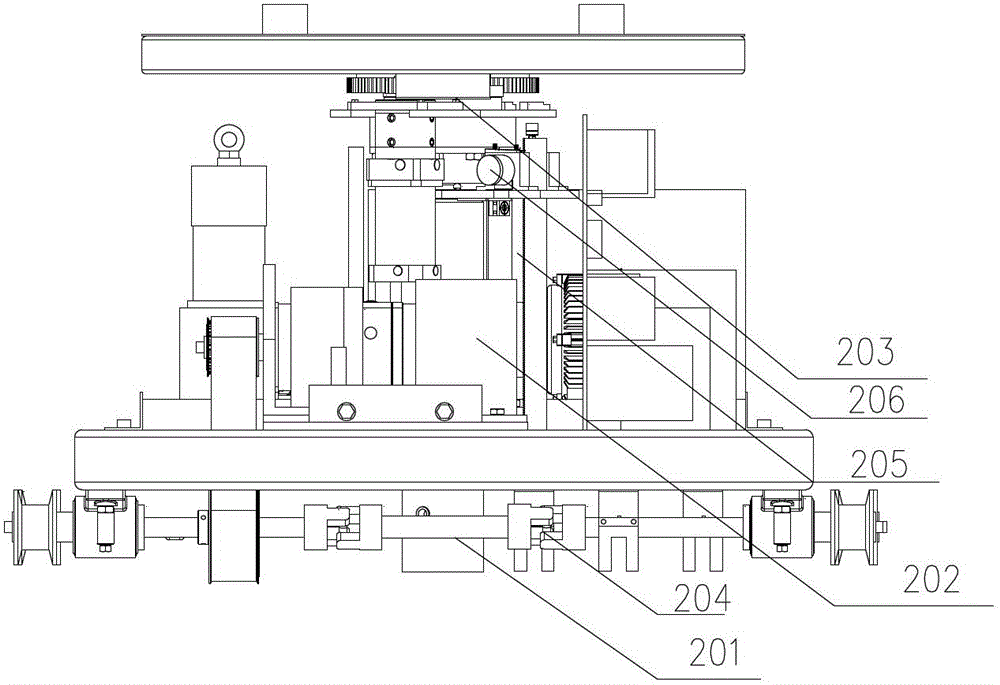

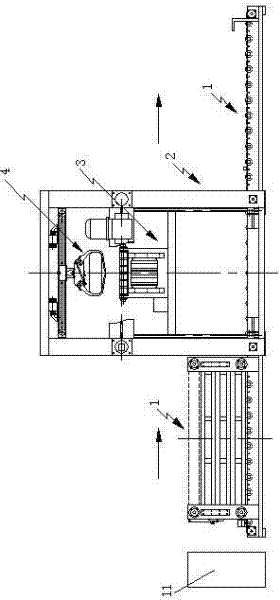

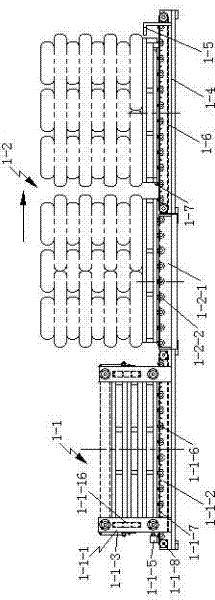

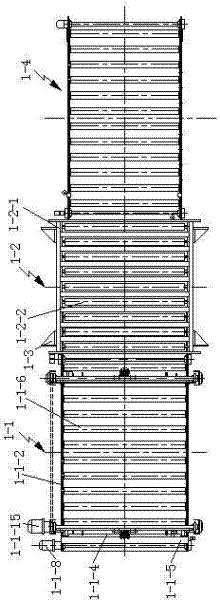

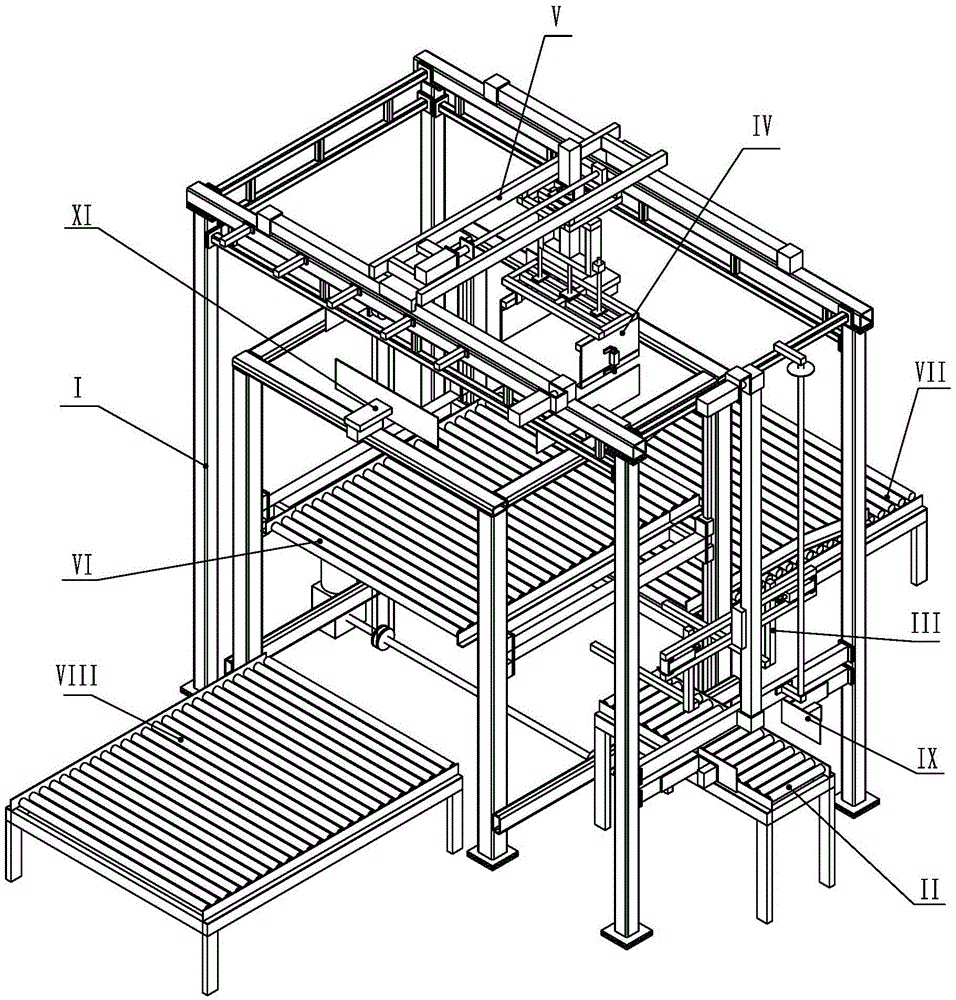

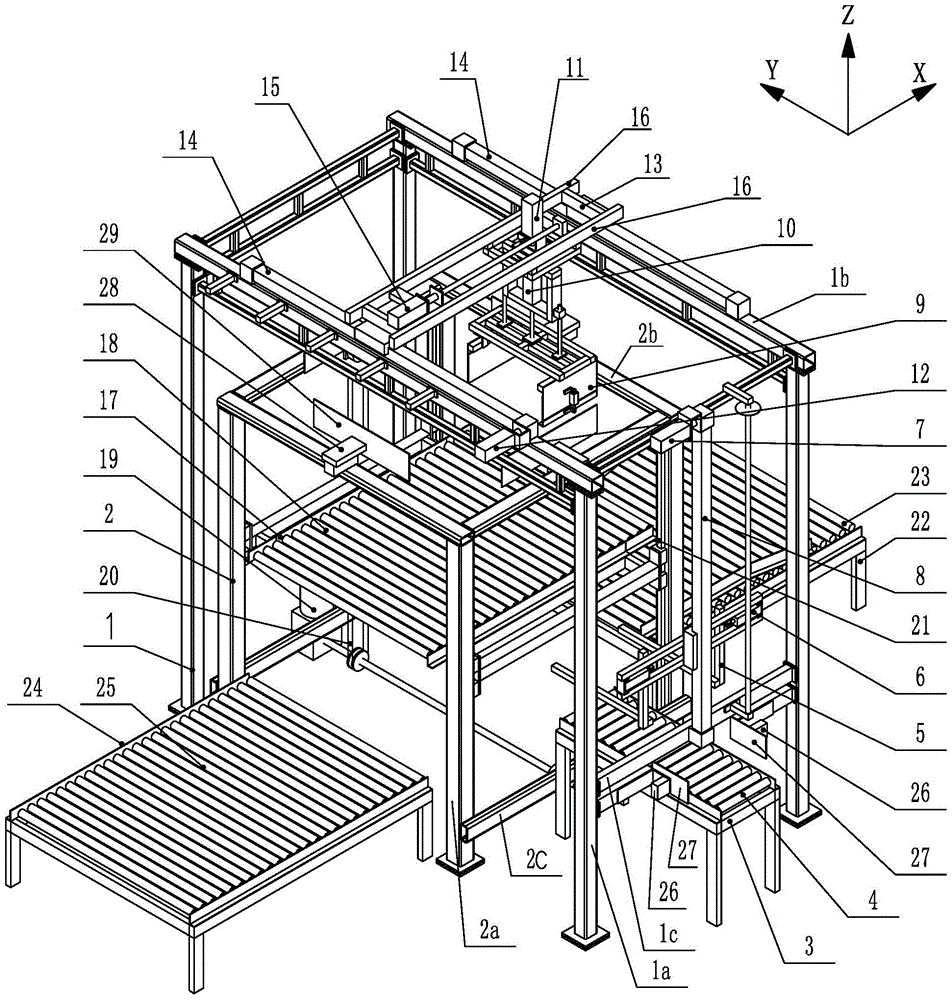

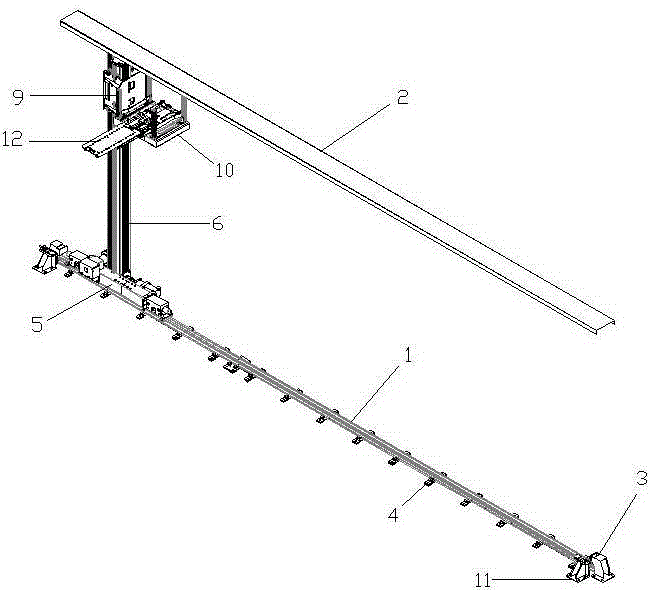

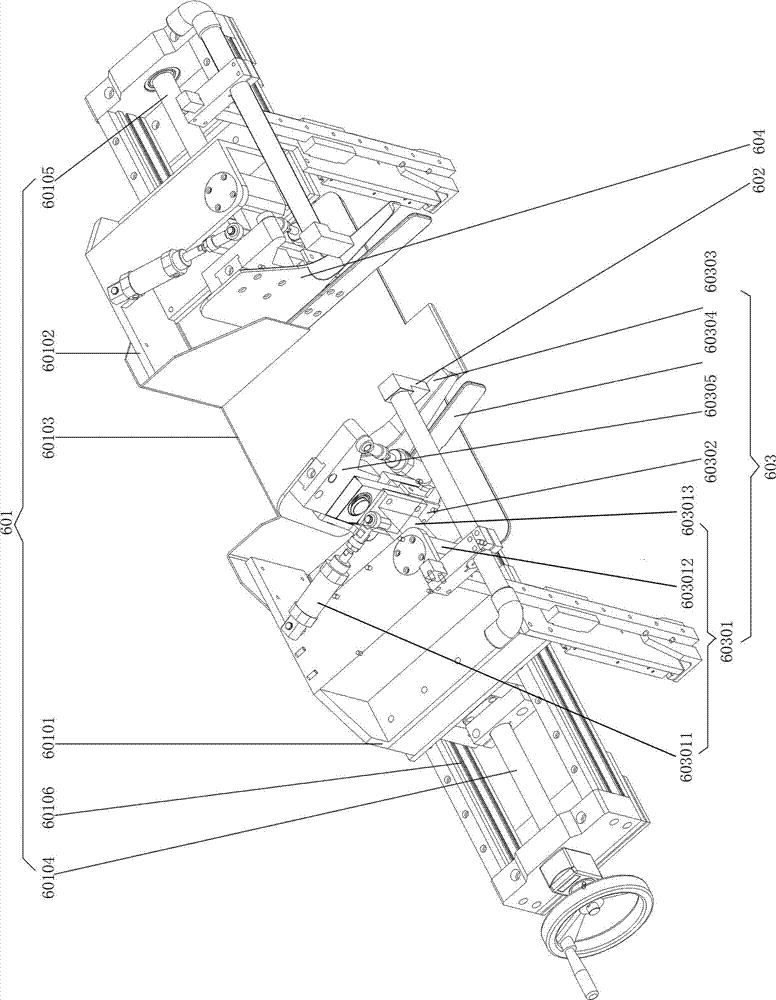

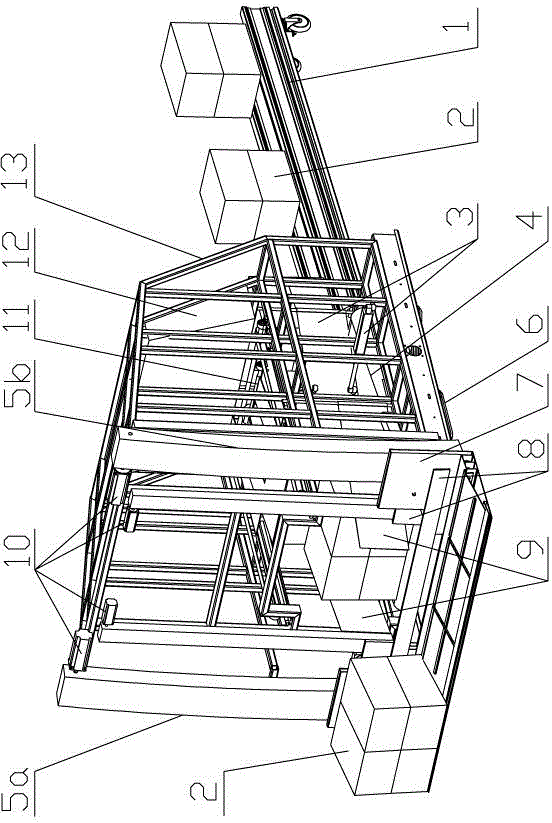

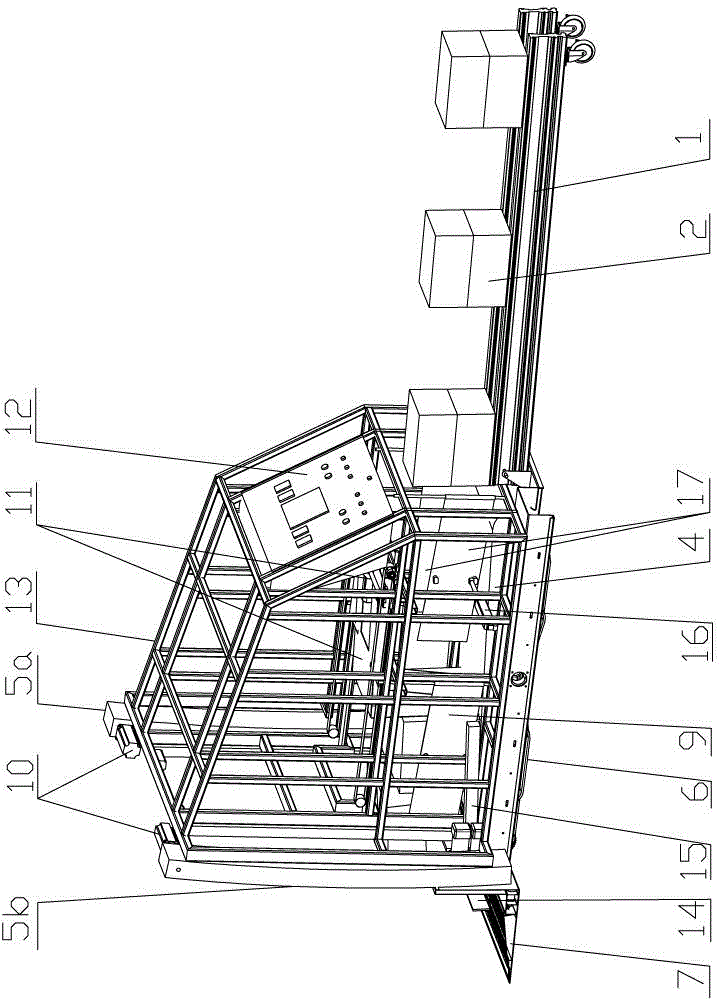

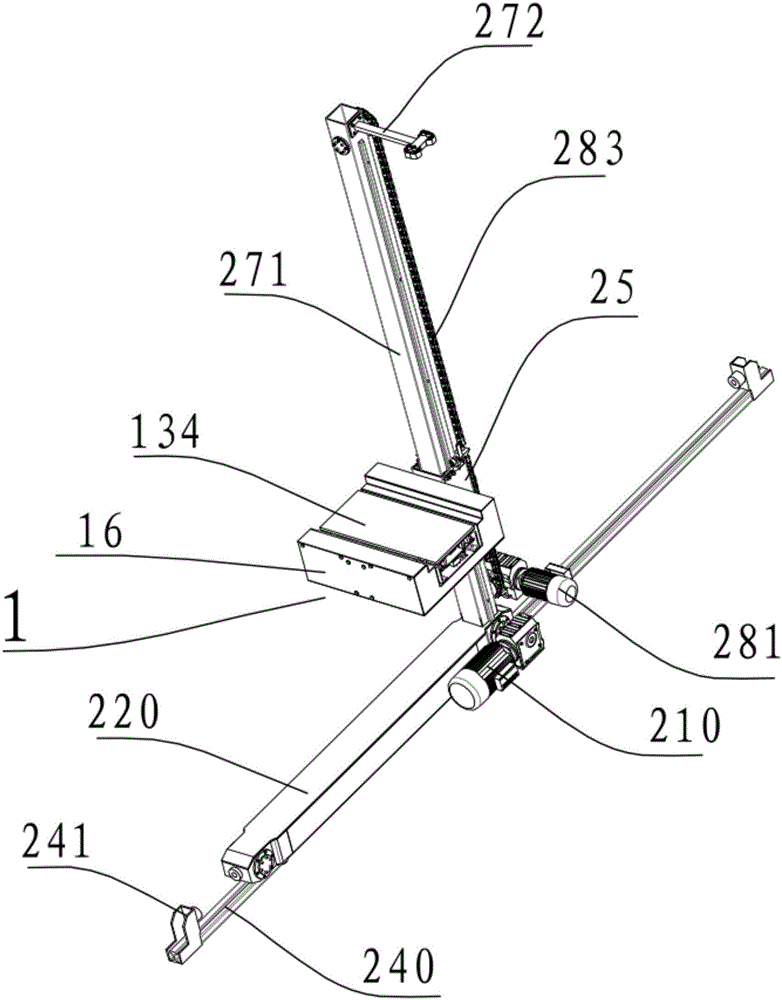

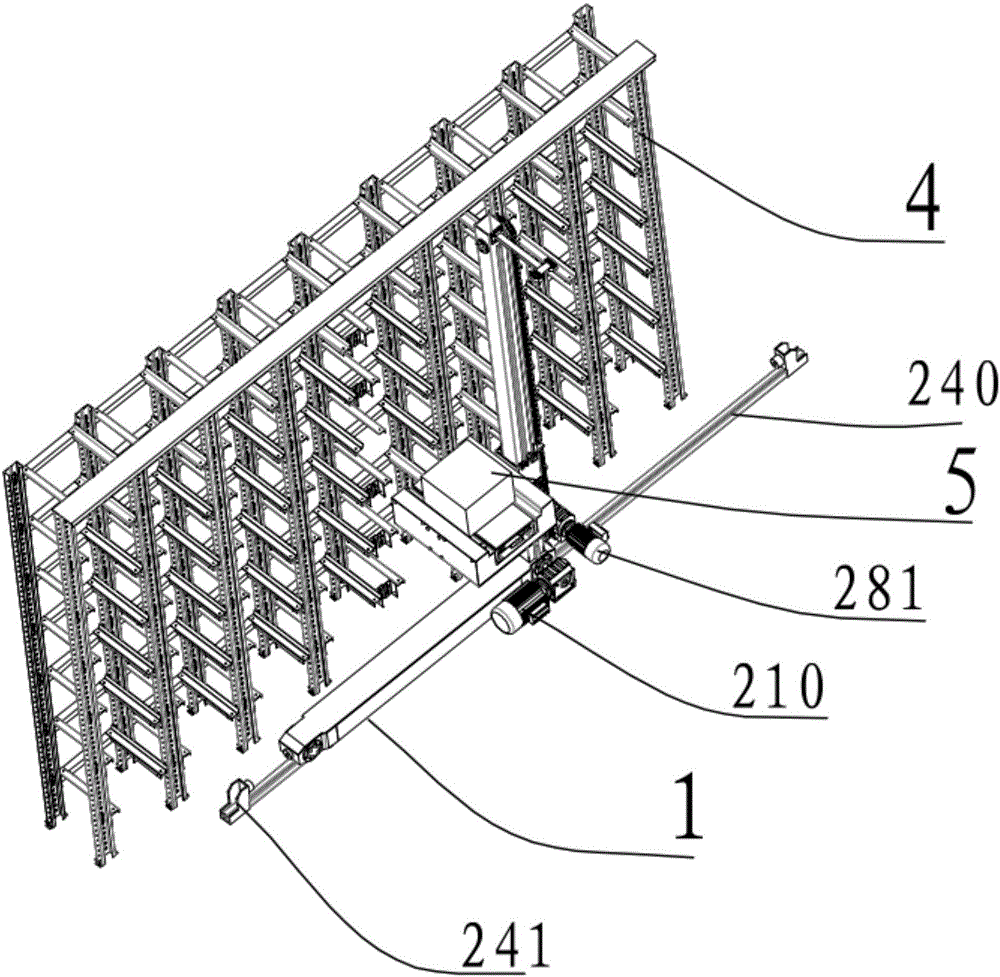

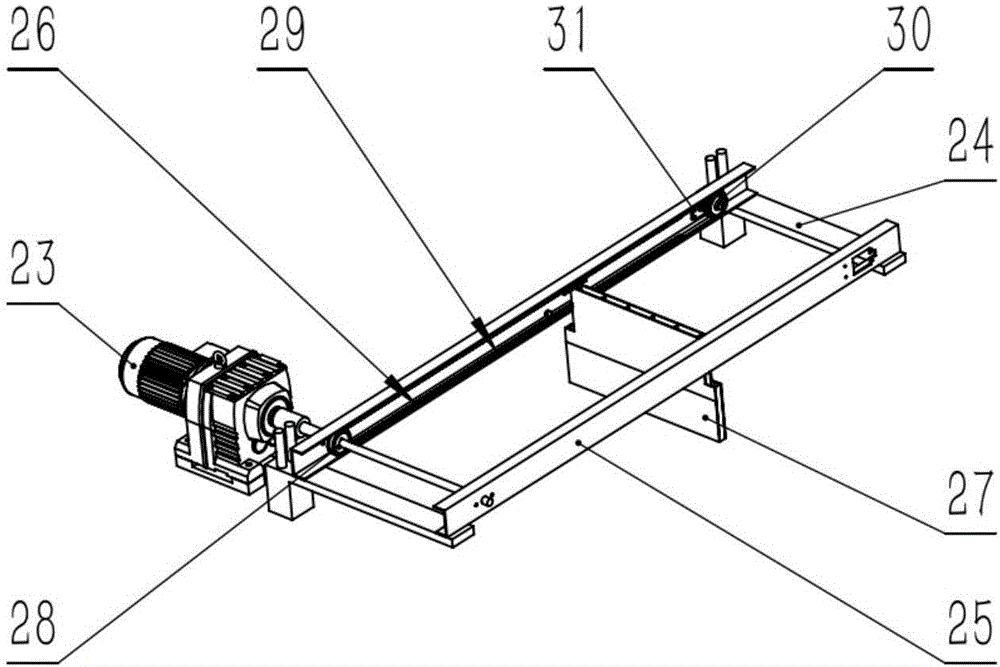

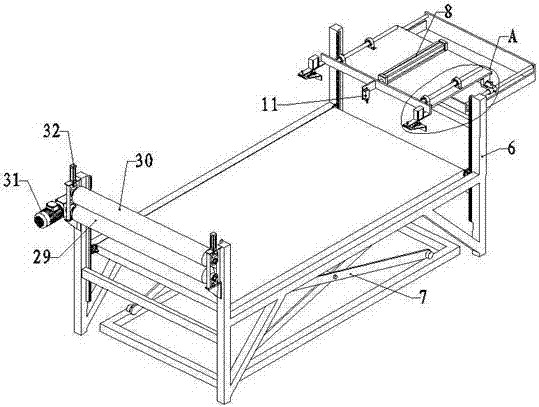

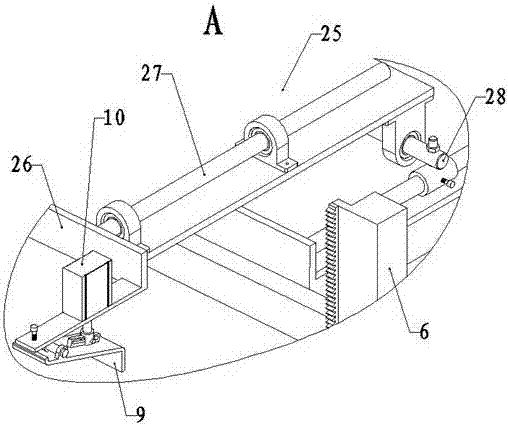

Stacking machine with two layers of objective tables

InactiveCN105730956AImprove single throughputImprove work efficiencyConveyorsStorage devicesStack machineComputer module

The invention discloses a stacking machine with two layers of objective tables. The stacking machine comprises a horizontal movement module, and a vertical movement module is mounted on the horizontal movement module and provided with an objective table work module. The horizontal movement module comprises a horizontal movement platform, and the horizontal movement platform is connected with a sliding block and connected with a lead screw mechanism. The vertical movement module comprises lifting guide rails, and the lifting guide rails are arranged at the four corners of bottom plates of the stacking machine and are fixedly connected with the upper bottom plate and the lower bottom plate. The upper layer of objective table and the lower layer of objective table are mounted on the lifting guide rails. The objective table work module comprises the upper layer of objective table and the lower layer of objective table. The objective tables are provided with bottom plates and telescopic plates doing telescopic movement on the bottom plates, and the telescopic plates of the objective tables can complete telescopic movement so that cargoes can be stored and taken out. The stacking machine is reasonable in structure, high in work efficiency and small in overall size.

Owner:NANTONG UNIVERSITY

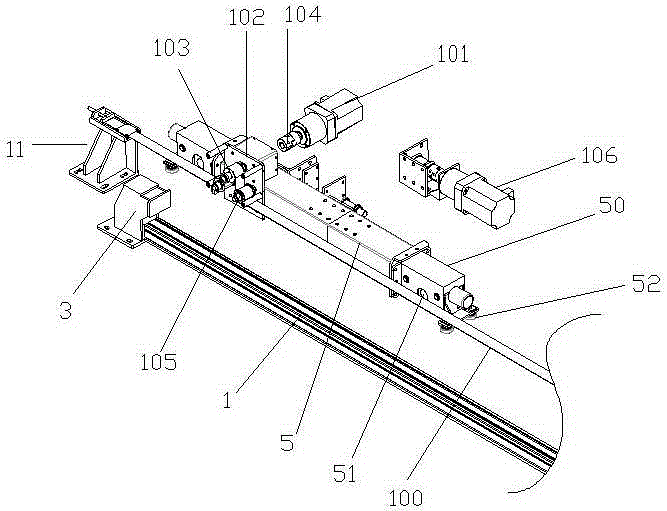

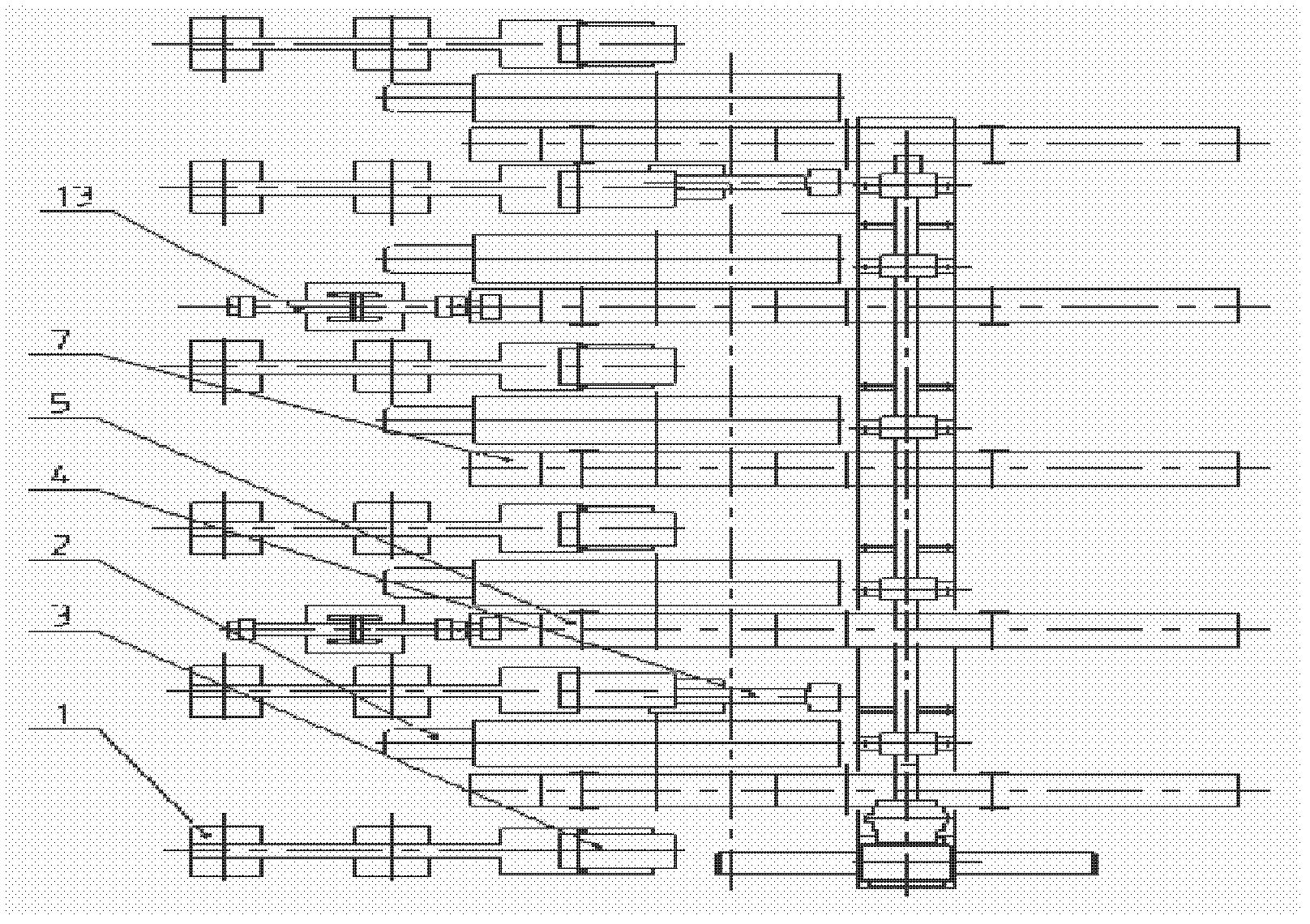

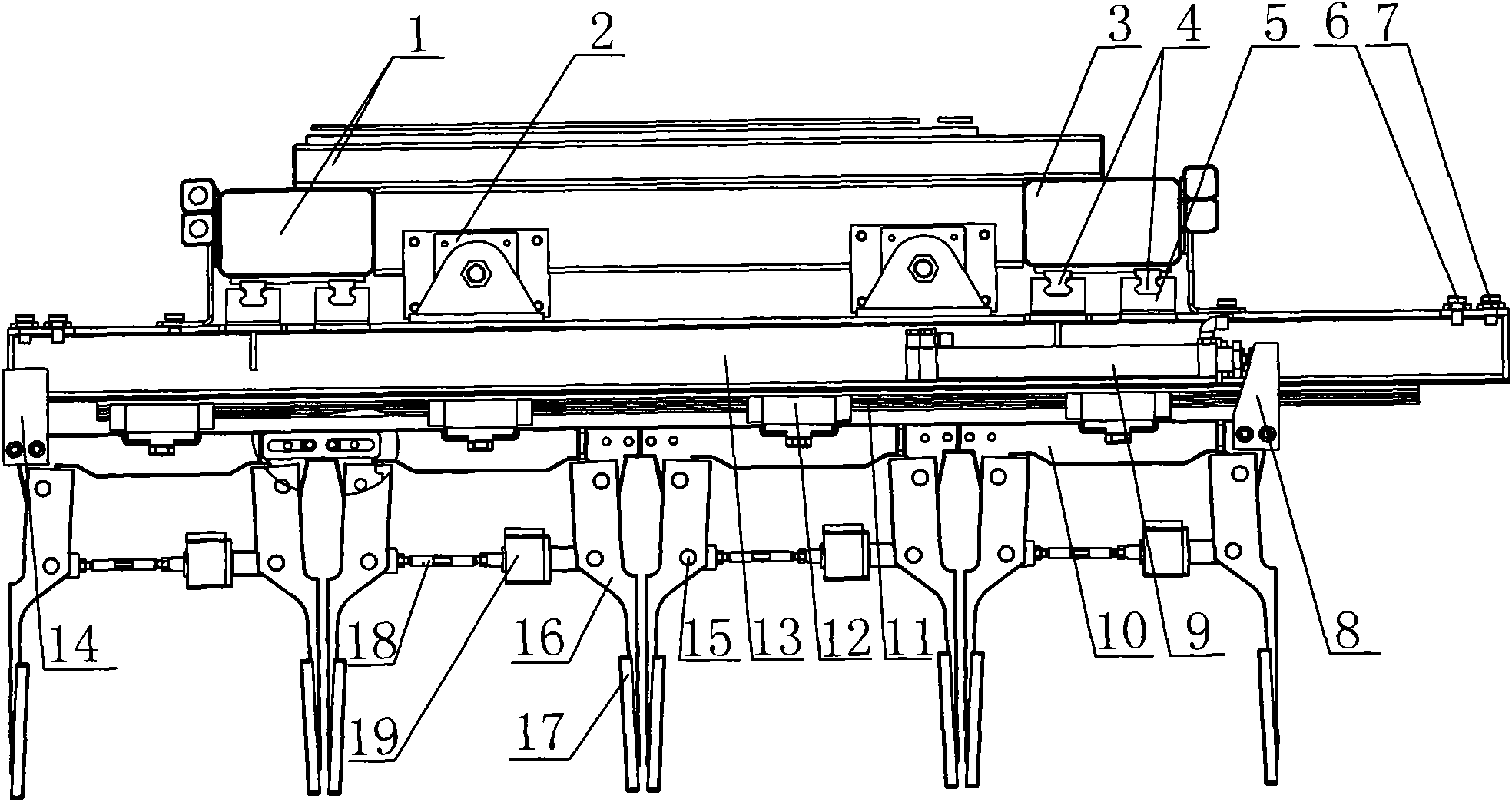

Battery lamination stacking machine of lithium-ion power battery

ActiveCN102969538AImprove efficiencyLow costFinal product manufactureSecondary cellsPower batteryLithium

The invention relates to the field of battery manufacturing mechanical technique, and provides a battery lamination stacking machine. The battery lamination stacking machine comprises a lamination platform machine, a pole piece feeding box mechanism, a secondary positioning mechanism, a lamination taking mechanical arm, a multiple lamination detection mechanism, a membrane unreeling mechanism, a membrane reeling mechanism, a membrane cutting mechanism, a rubberizing mechanism, a battery transfer mechanism and a battery conveyor belt. The lamination taking mechanical arm comprises a positive lamination taking mechanical arm and a negative lamination taking mechanical arm. The positive lamination taking mechanical arm and the negative lamination taking mechanical arm each comprise two groups of stand-by sucker and two groups of lamination sucker, and can realize simultaneous lamination stacking of a lamination mechanism A and a lamination mechanism B, and improve the efficiency of battery assembly.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

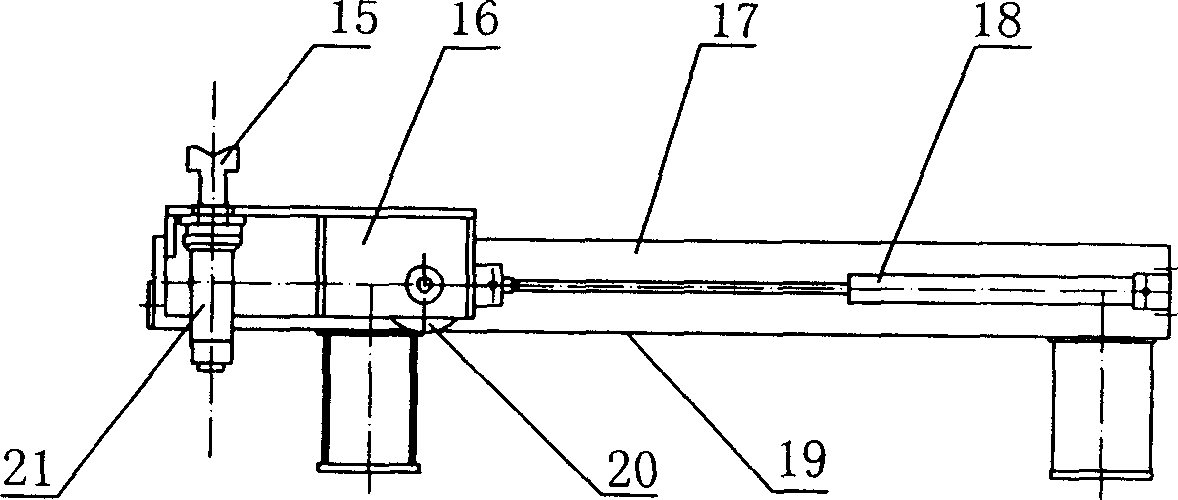

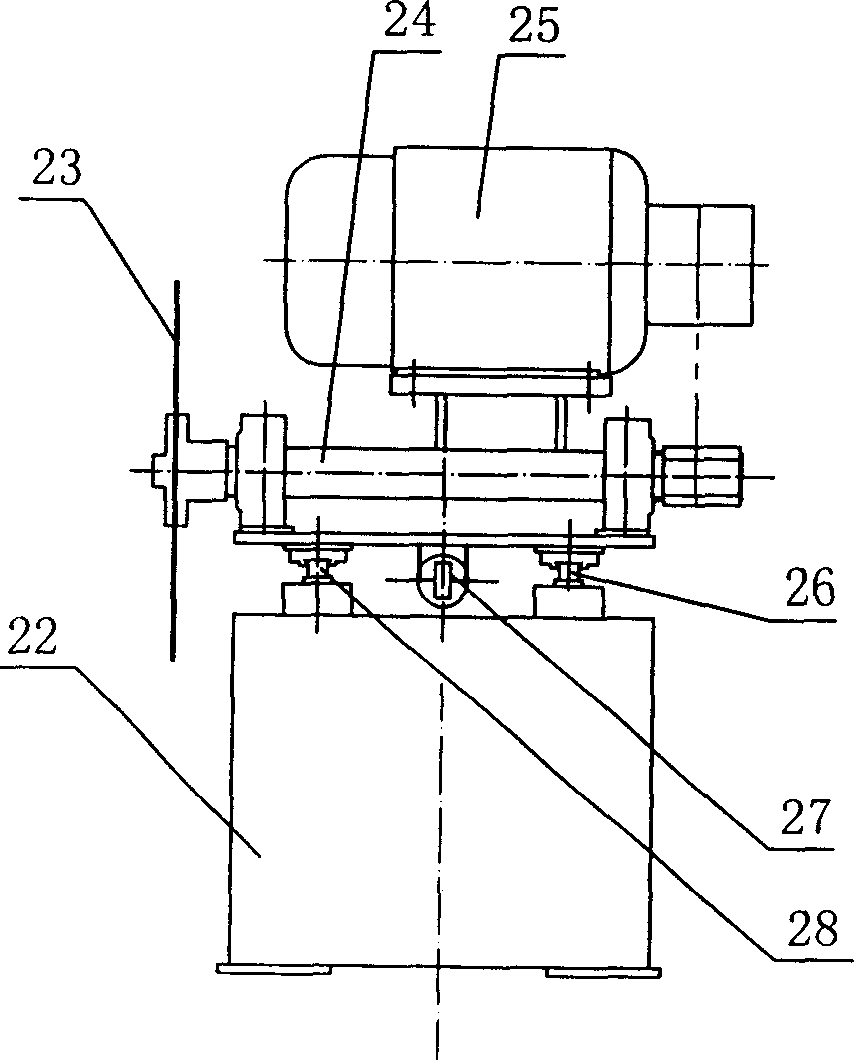

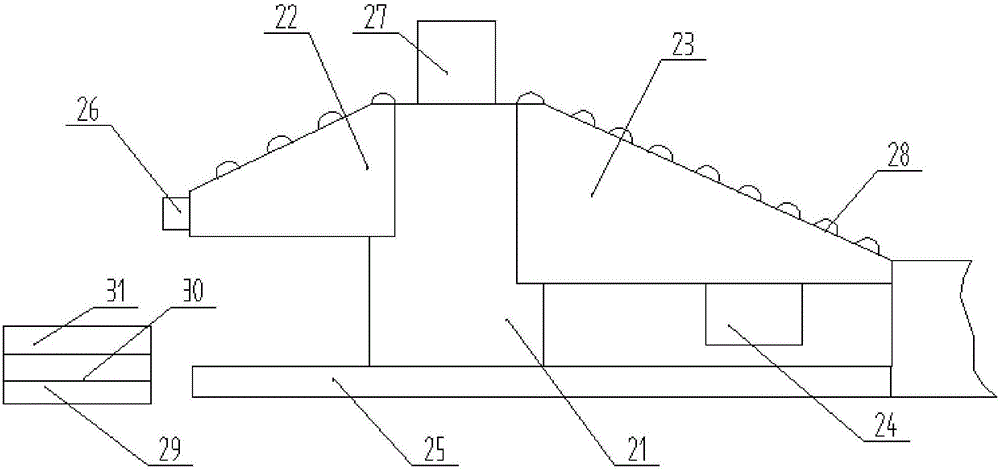

Automatic sawing, cutting and stacking machine for aluminum alloy bar

ActiveCN1899719ARealize automatic controlFree laborMetal-working feeding devicesPositioning devicesAutomatic controlStack machine

The automatic sawing, cutting and stacking machine for aluminum alloy bars includes conveying roller bed comprising conveying rollers and chain wheel driving mechanism, operating stations set along the conveying roller bed, material feeding mechanism, material setting mechanism, cutting mechanism, sizing mechanism, stacking mechanism, side aluminum bar pushing mechanism, power mechanism and control mechanism. The present invention has power mechanism and control mechanism, and can realize PLC automatic control and automatic operation of feeding, sizing, cutting and stacking aluminum alloy bars, and possesses high production efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

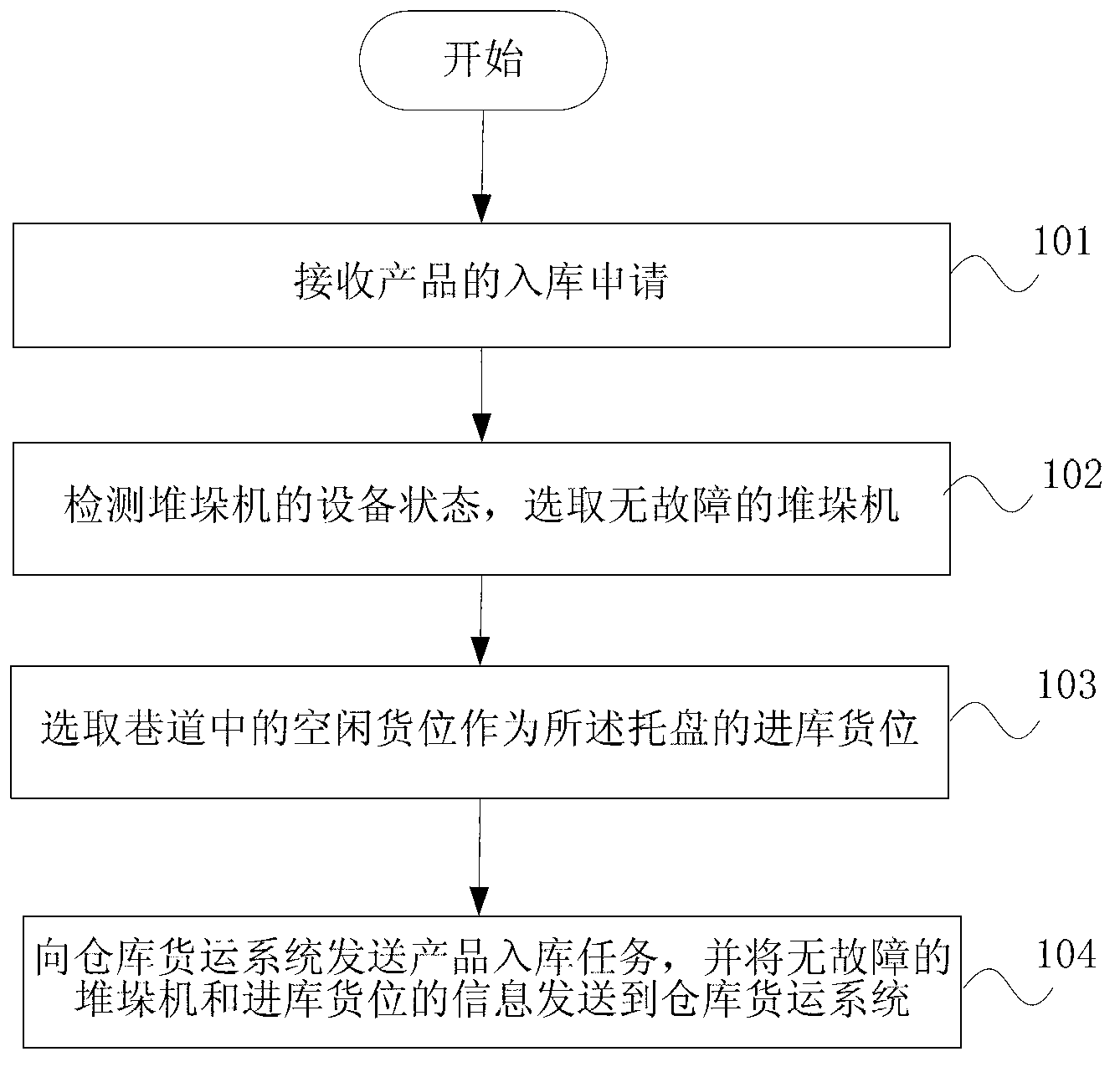

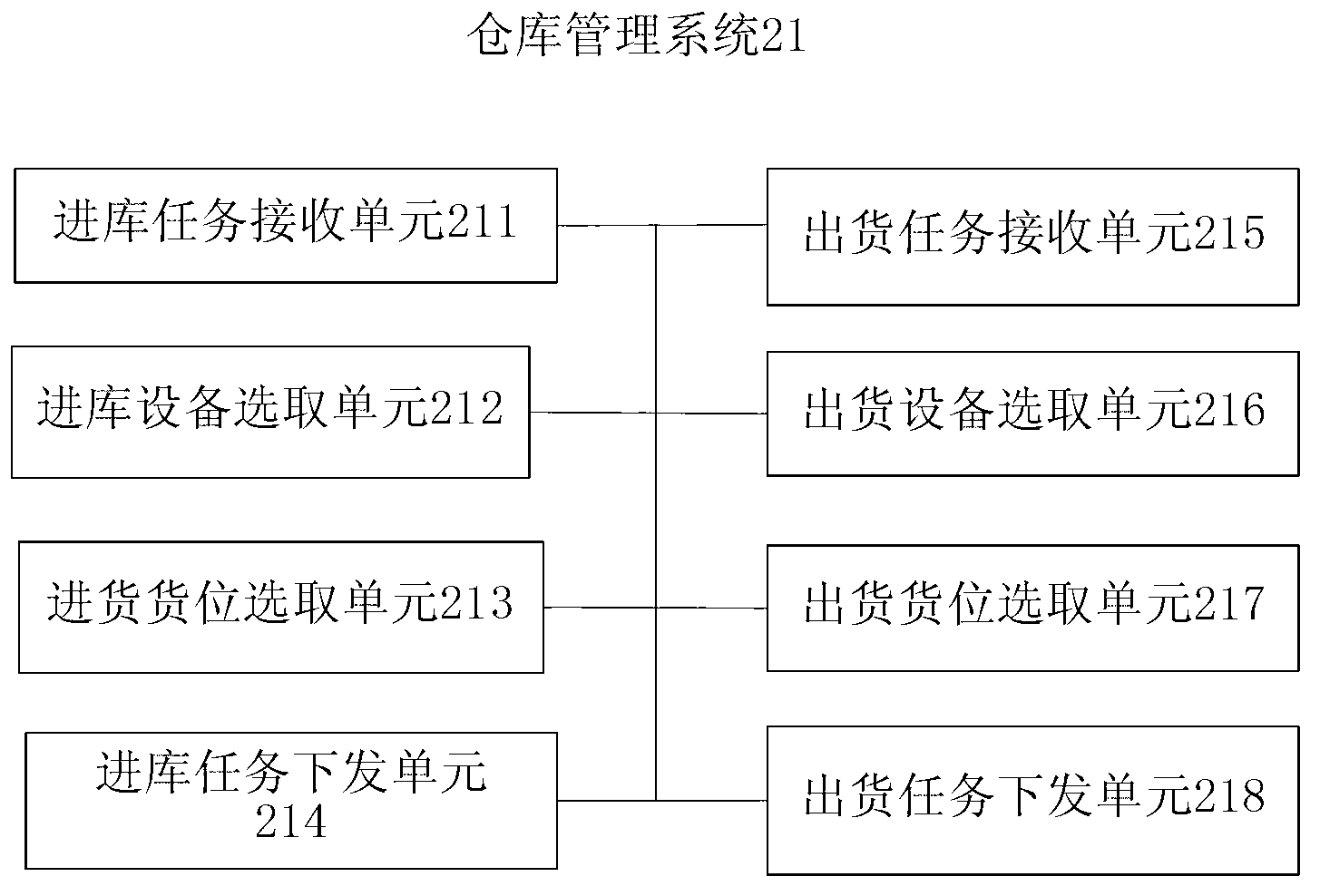

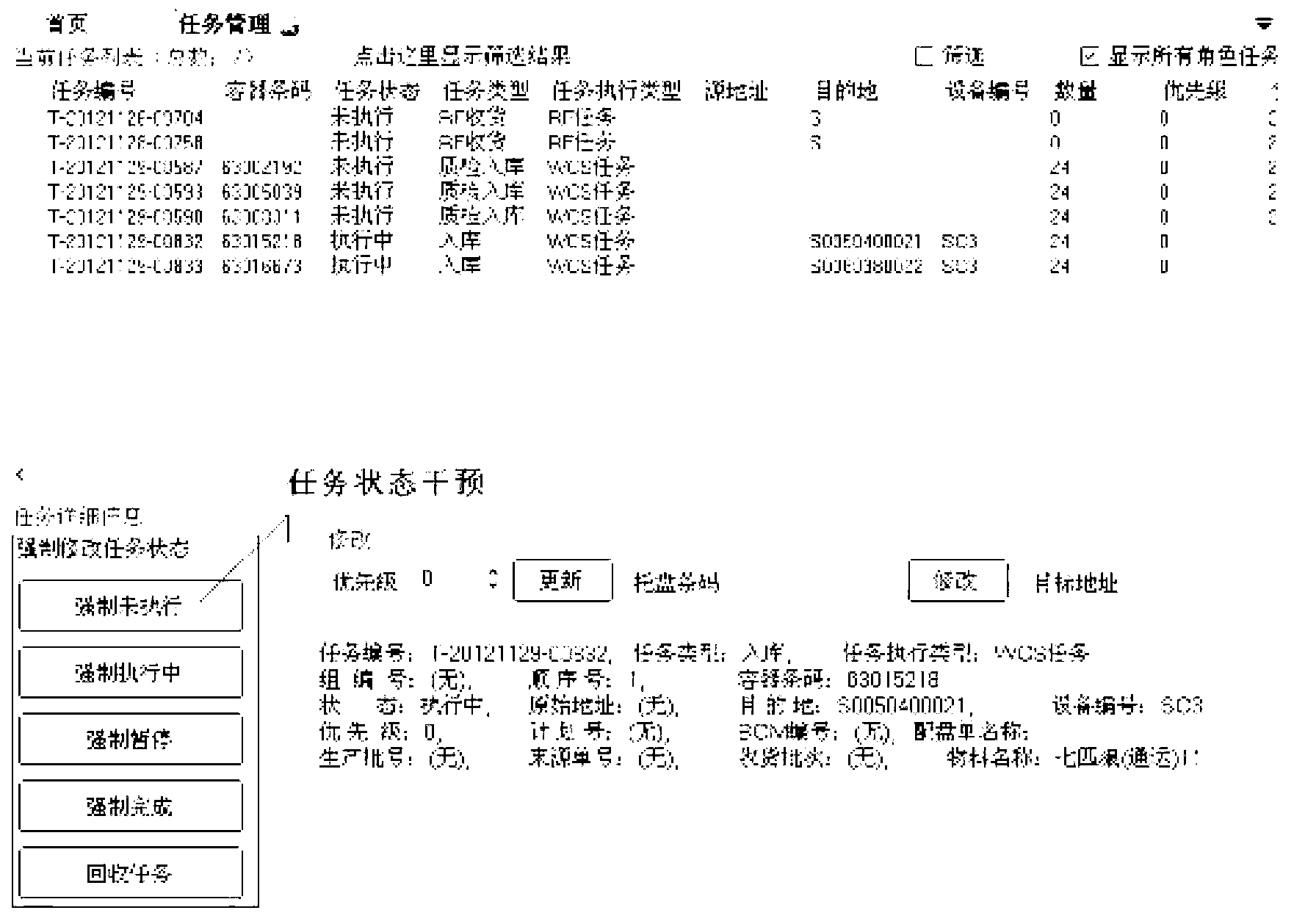

Warehouse management method and warehouse management system

ActiveCN103193054AImprove output and storage efficiencyShorten delivery timeStorage devicesStack machineWork status

The invention discloses a warehouse management method and a warehouse management system. The warehouse management method comprises the following steps: receiving an entrance application of products, and arranging the products on a tray; detecting an operating state of a stacking machine, and selecting a failure-free stacking machine; selecting the idle goods allocation in the roadway as the entrance goods allocation of the tray; transmitting a product entrance task to a warehouse freight system, and transmitting the information of the failure-free stacking machine and the entrance goods allocation to the warehouse freight system; and scheduling the failure-free stacking machine through the warehouse freight system, and arranging the tray at the entrance goods allocation. According to the warehouse management method and the warehouse management system, the failure-free equipment is selected, the roadway is equally divided and used, the equipment and the site are utilized to the greatest degree, the entrance and exit efficiency of the finished product warehouse is improved, and the delivery time of allocating and transferring finished products is shortened.

Owner:LONGYAN CIGARETTE FACTORY

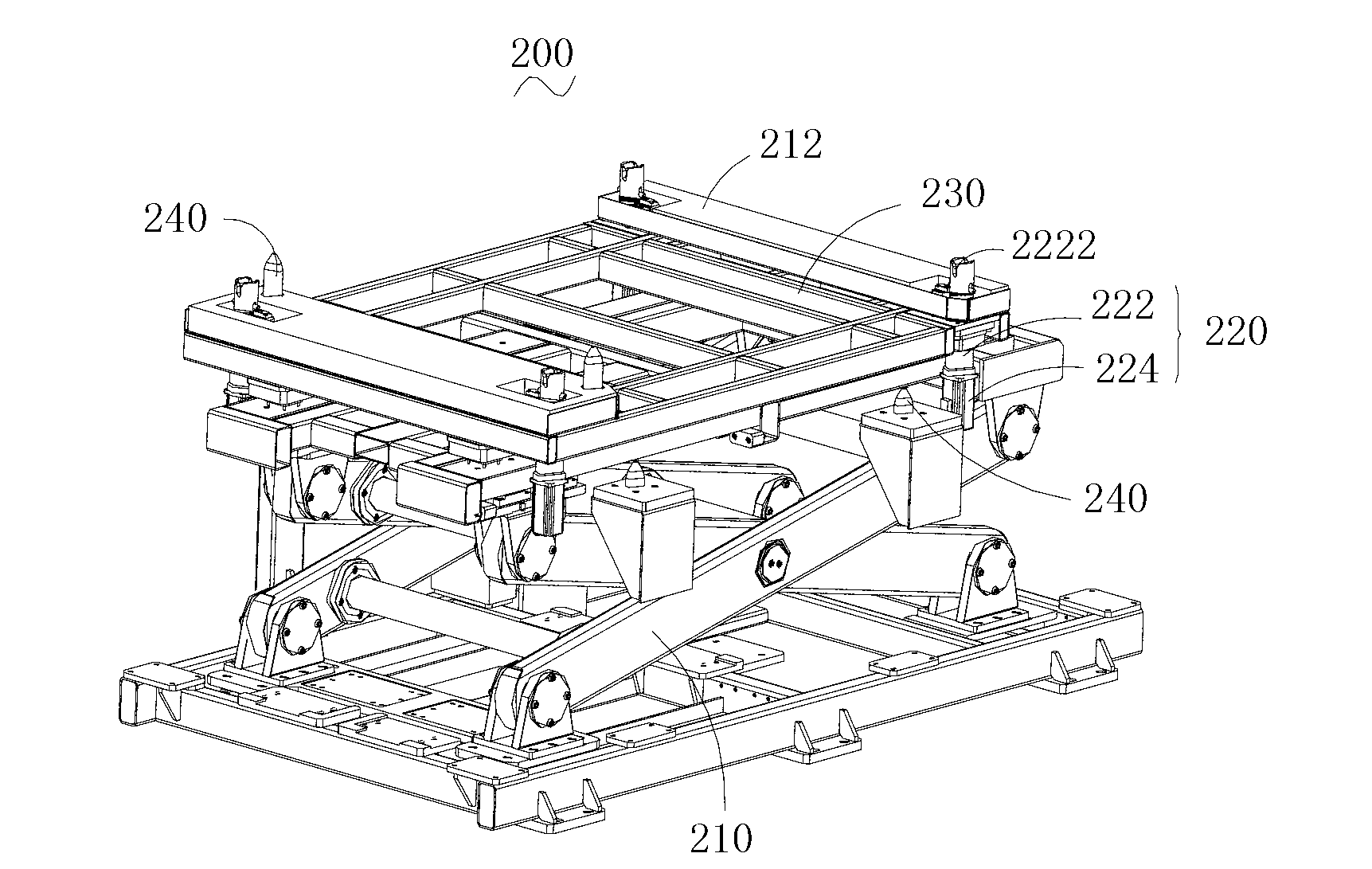

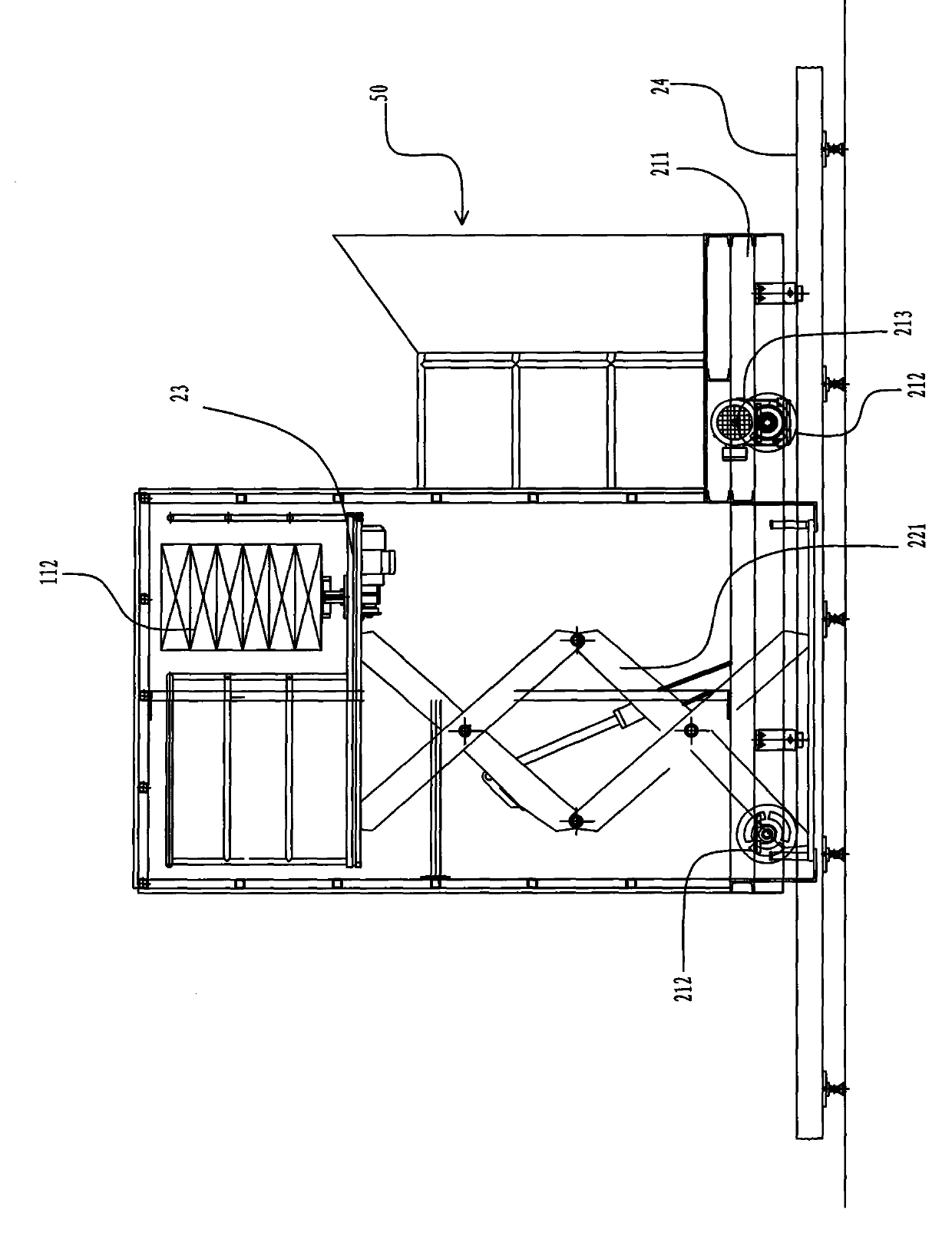

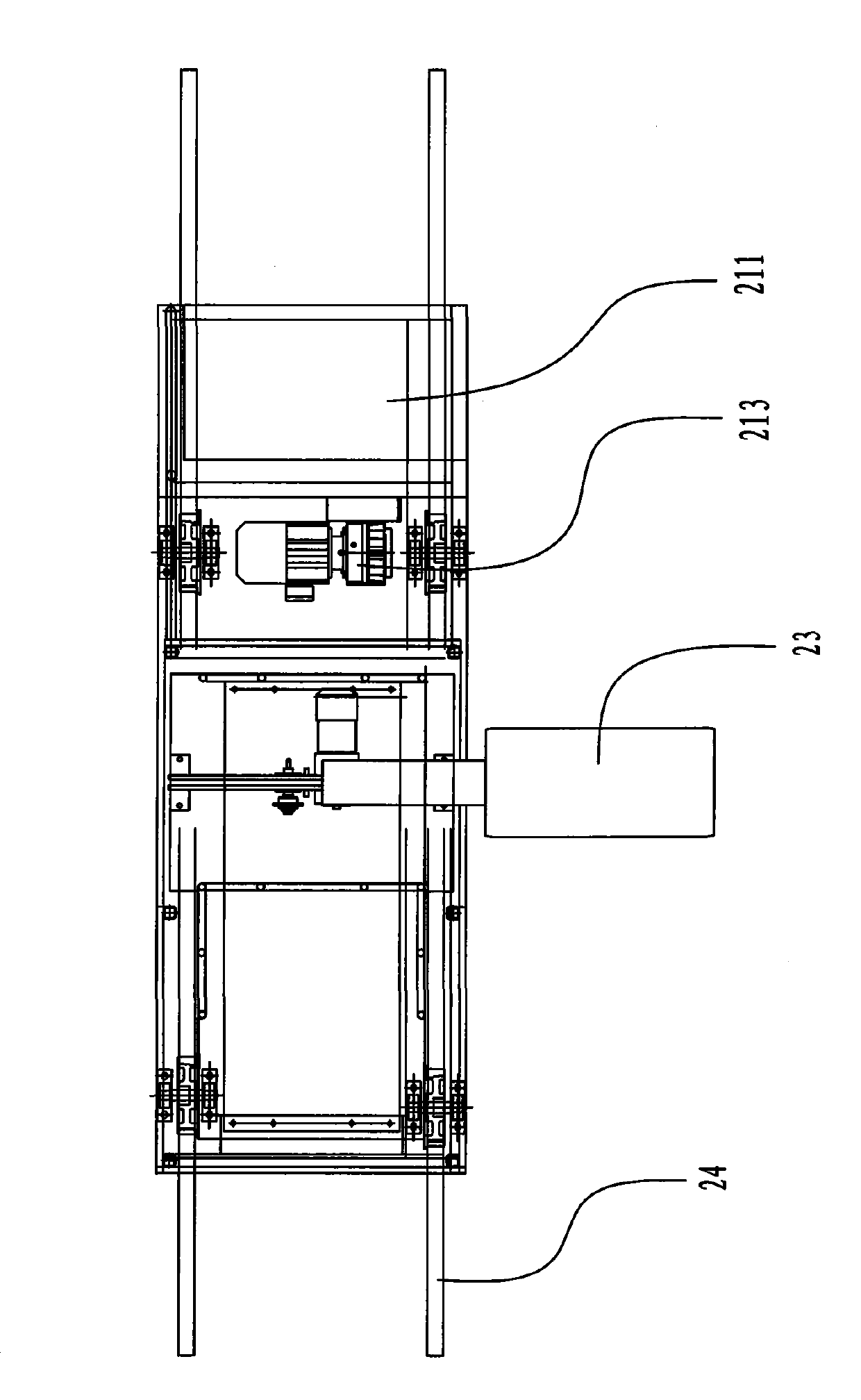

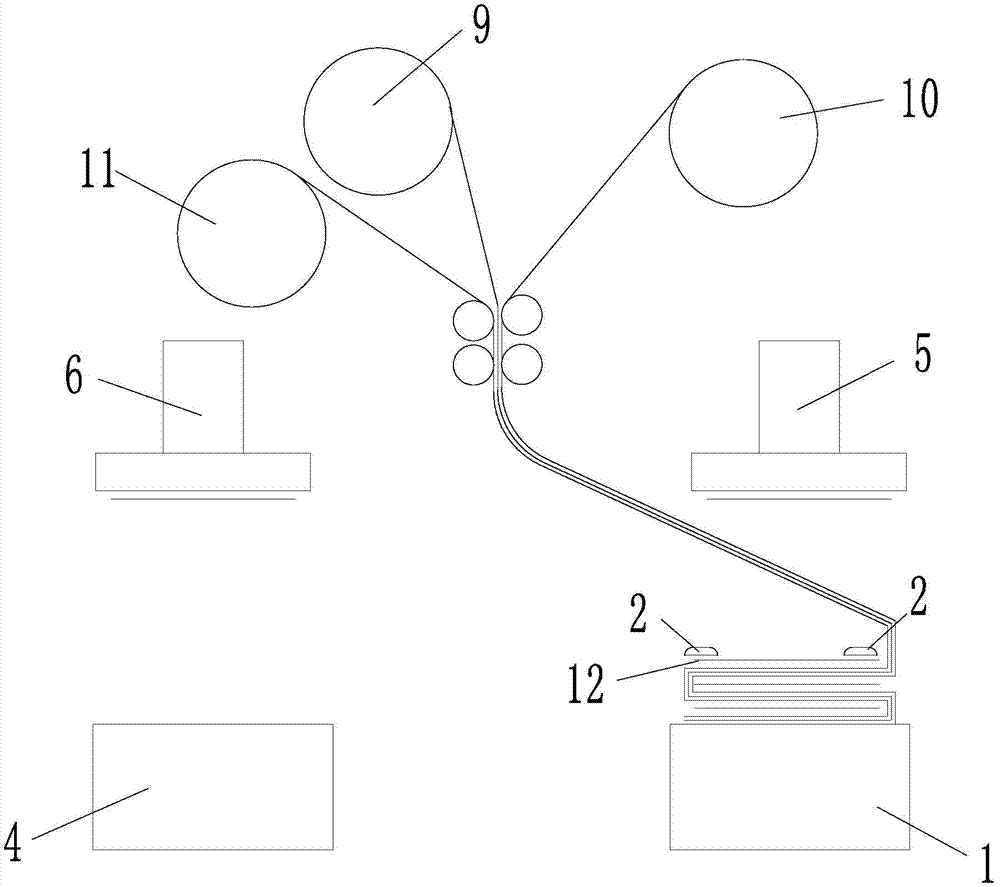

Chassis battery change system for electric passenger cars and method of the system

ActiveCN102717778APrecise positioningLow costProgramme-controlled manipulatorElectric propulsion mountingElectricityIndustrial Ethernet

The invention discloses a chassis battery change system for electric passenger cars. The chassis battery change system comprises a rapid change robot, a battery change platform, a transfer platform, a background monitoring system, a stacking machine and a charging frame, wherein the transfer platform, the stacking machine and the charging frame are arranged on one side of the battery change platform; the rapid change robot is arranged between the battery change platform and the transfer platform; an electric passenger car is capable of passing through the battery change platform; a locking mechanism which corresponds to a battery box supported by the rapid change robot is arranged on the electric passenger car; and the background monitoring system is connected with the rapid change robot and the stacking machine respectively through an industrial Ethernet. At the same time, the invention also discloses a using method of the system. A mechanical positioning mechanism of the battery change platform is simple, correct in positioning and low in manufacturing cost; a hydraulic lifting mechanism is used in the rapid change robot, so that the whole change process is reliable and stable, the size of the change equipment is decreased effectively and the actual occupied area of the change system is saved; and the transfer platform is used as a battery change interaction link between the rapid change robot and the stacking machine, so that the time spent by the battery change is further shortened.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

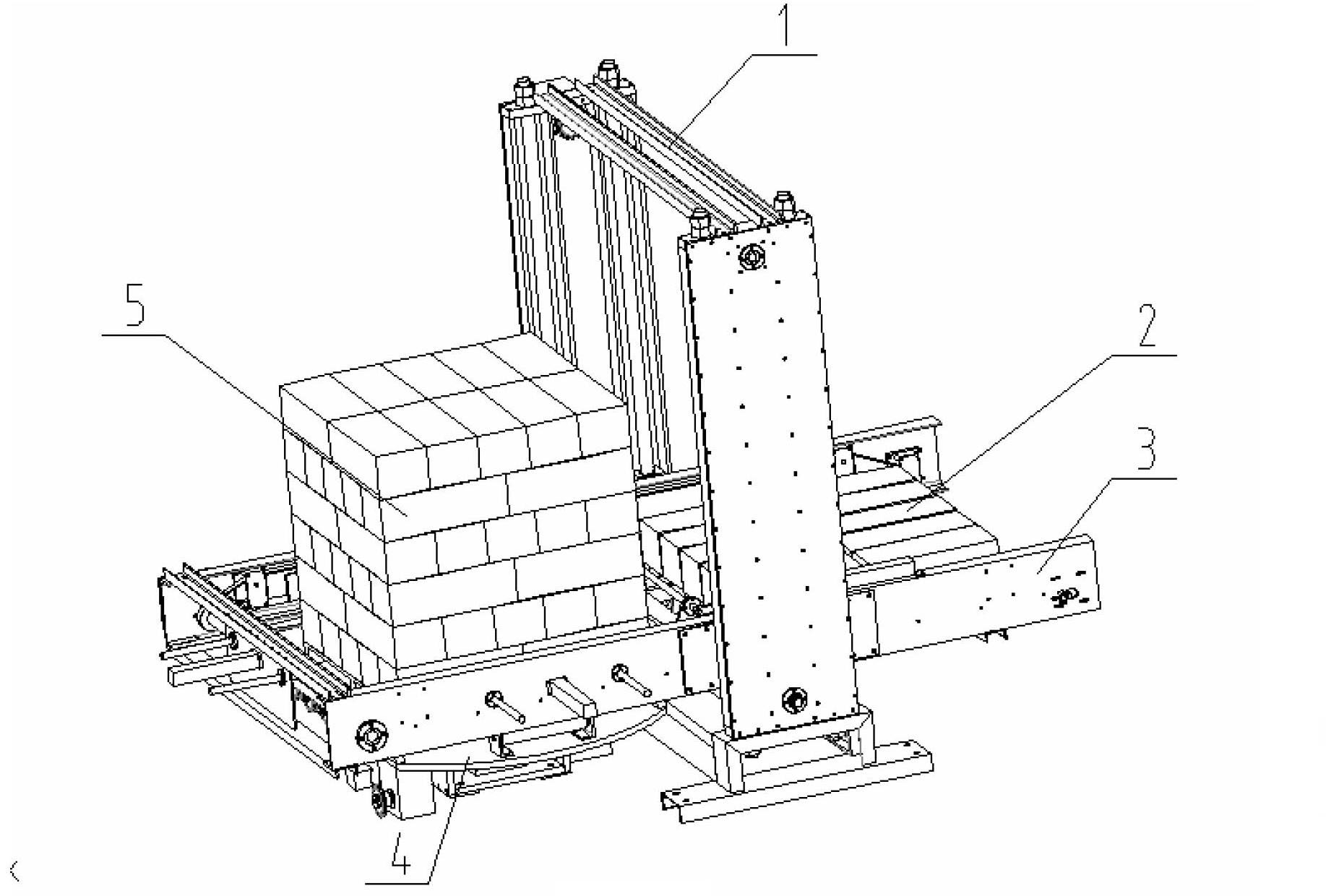

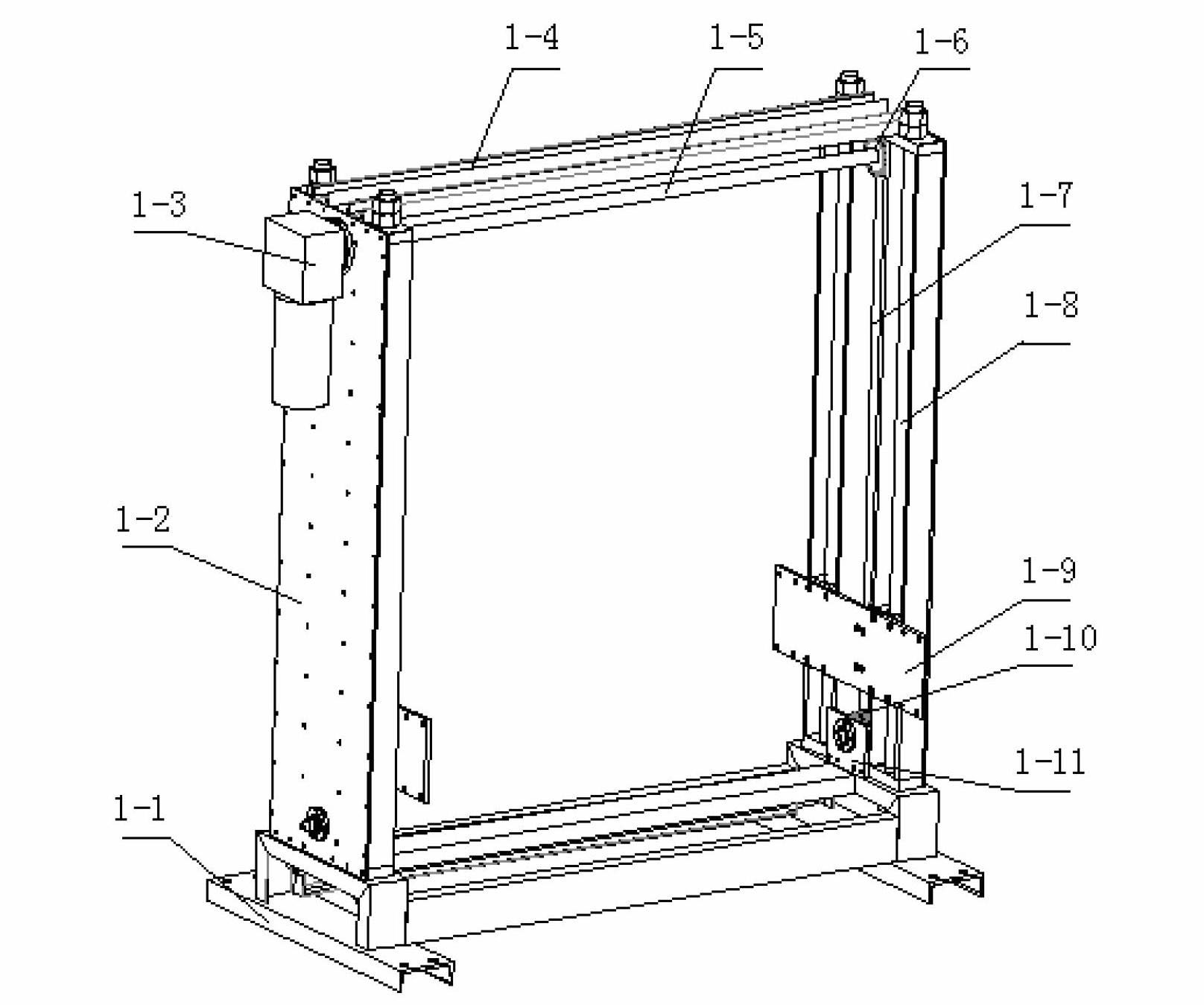

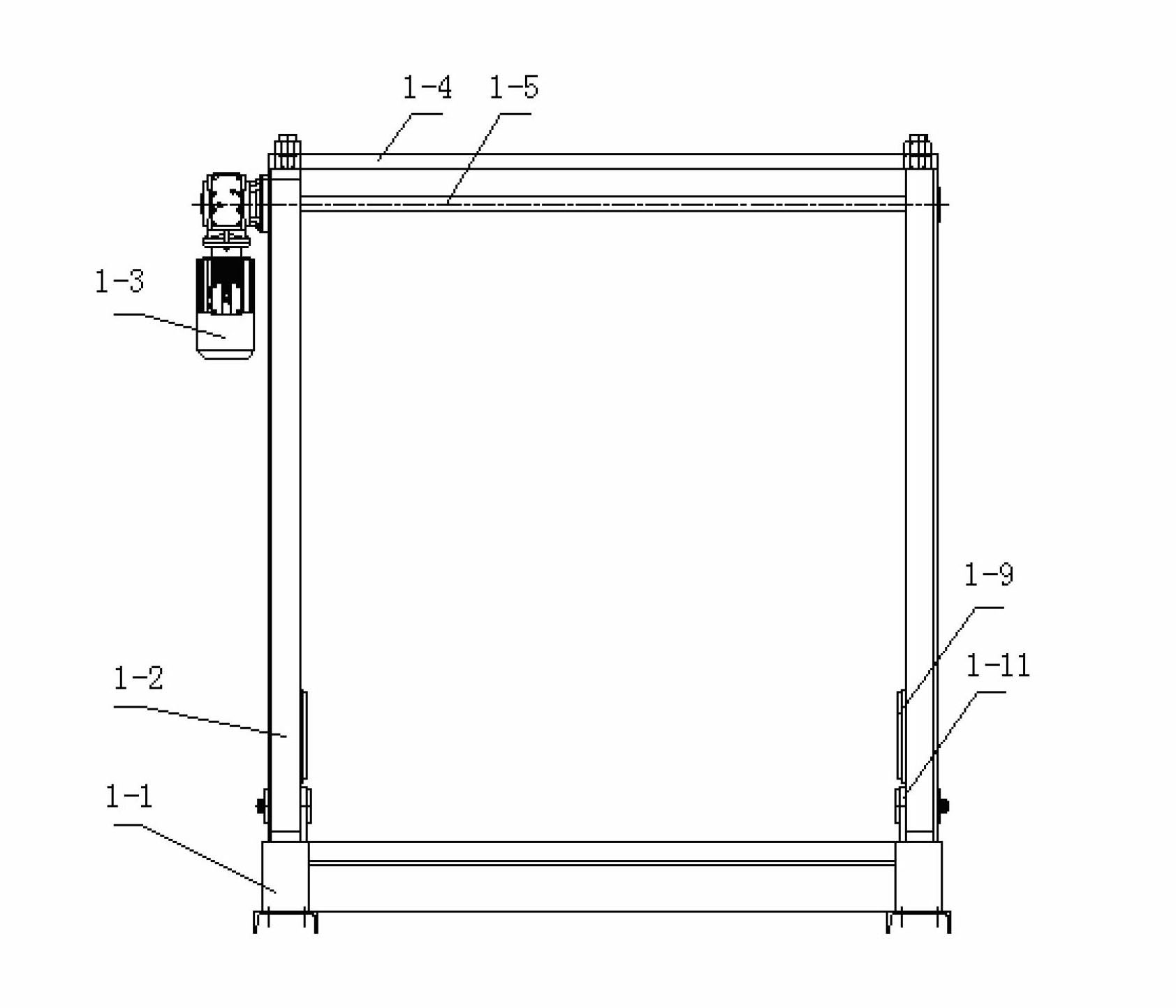

Stacking machine

The invention discloses a stacking machine which comprises a lifting traction device, a lifting device, a stack pushing device and a stack-bearing rotary operating platform. The lifting traction device is in transmission connection with the lifting device, and the stack pushing device moves in the lifting device; the stack-bearing rotary operating platform is arranged at one side of the stack pushing device; the lifting traction device comprises a lifting traction frame, vertical posts, a speed reducing motor, cross beams, driving shafts, driving chain wheels, chains, guide posts, guide sleeves, lifting device mounting and connecting plates and tension chain wheels; the lifting device comprises a lifting framework, a driving shaft, a driving synchronous pulley, a stack pushing motor, a shaping and clamping device, a material baffling mechanism, the stack pushing device, a synchronous belt, a synchronous belt tension wheel and a synchronous belt connecting seat; and the stack-bearing rotary operating platform comprises a base, a rotary platform, a rotary motor, a worm and worm-wheel transmission case, a conveying motor and a roller conveyor. When the stacking machine is arranged on a conveying line, building blocks are difficult to damage under the condition of guaranteeing the production requirements.

Owner:山东未来城建筑工程有限公司

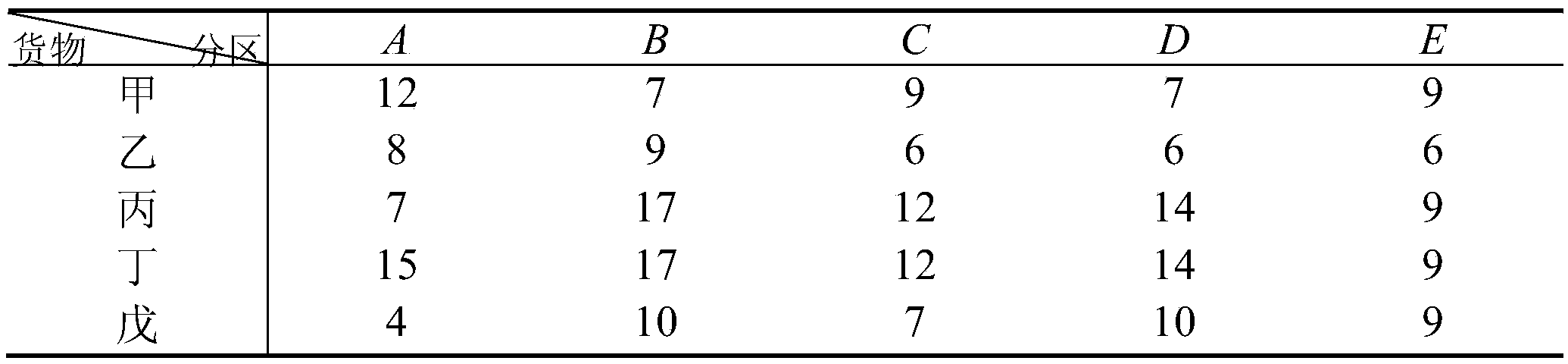

Intelligent stored cargo space distribution and optimization method

InactiveCN103942617AImprove operational efficiencyReduce inventory and other operationsForecastingLogisticsMathematical modelStack machine

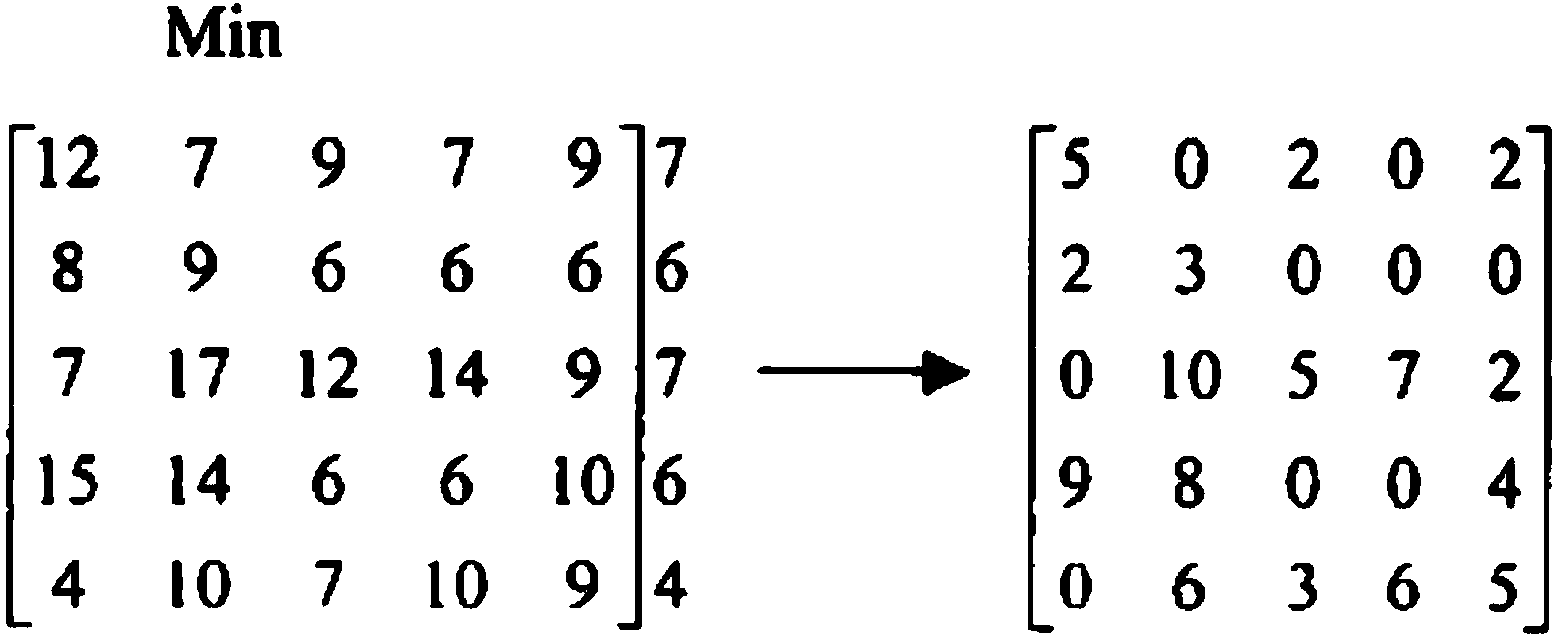

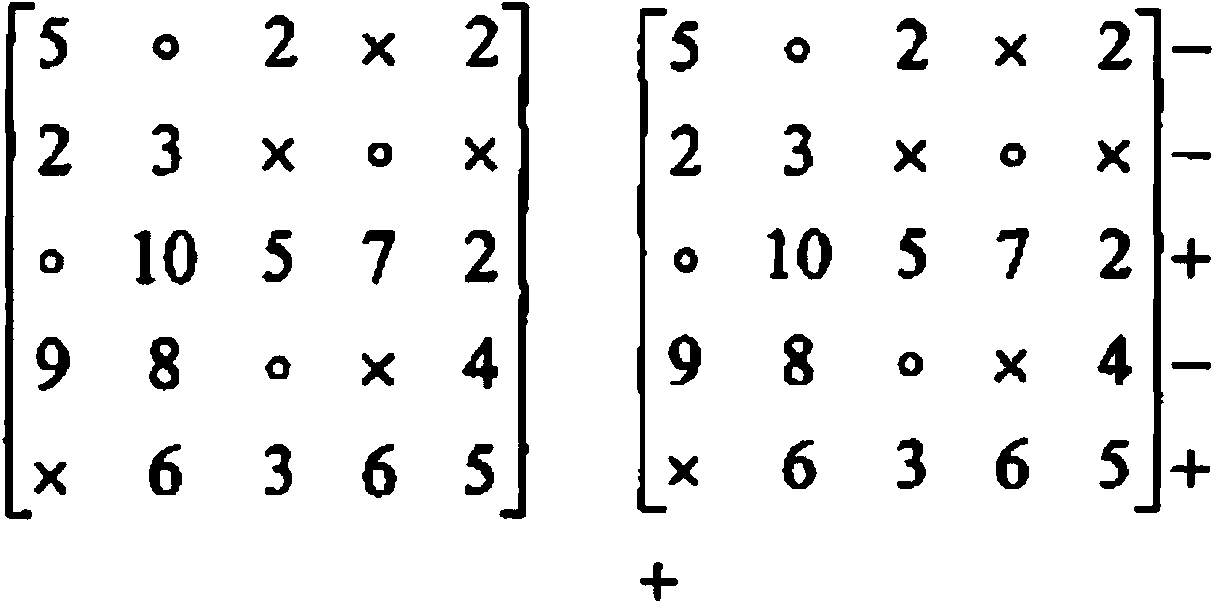

The invention discloses an intelligent stored cargo space distribution and optimization method. The method comprises the following steps that 1, the frequency of cargo to leave from storage or be put into storage and the running speed of a stacking machine are counted, and a mathematic model is built; 2, two solutions are provided for different scales and include the Hungarian method and the genetic algorithm. By the intelligent stored cargo space distribution and optimization method, the utilization rate of cargo space is improved, the efficiency of cargo to leave from storage or be put into storage and the utilization rate of the stacking machine and other equipment are also improved, and the box shift operation and other operations can be reduced.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

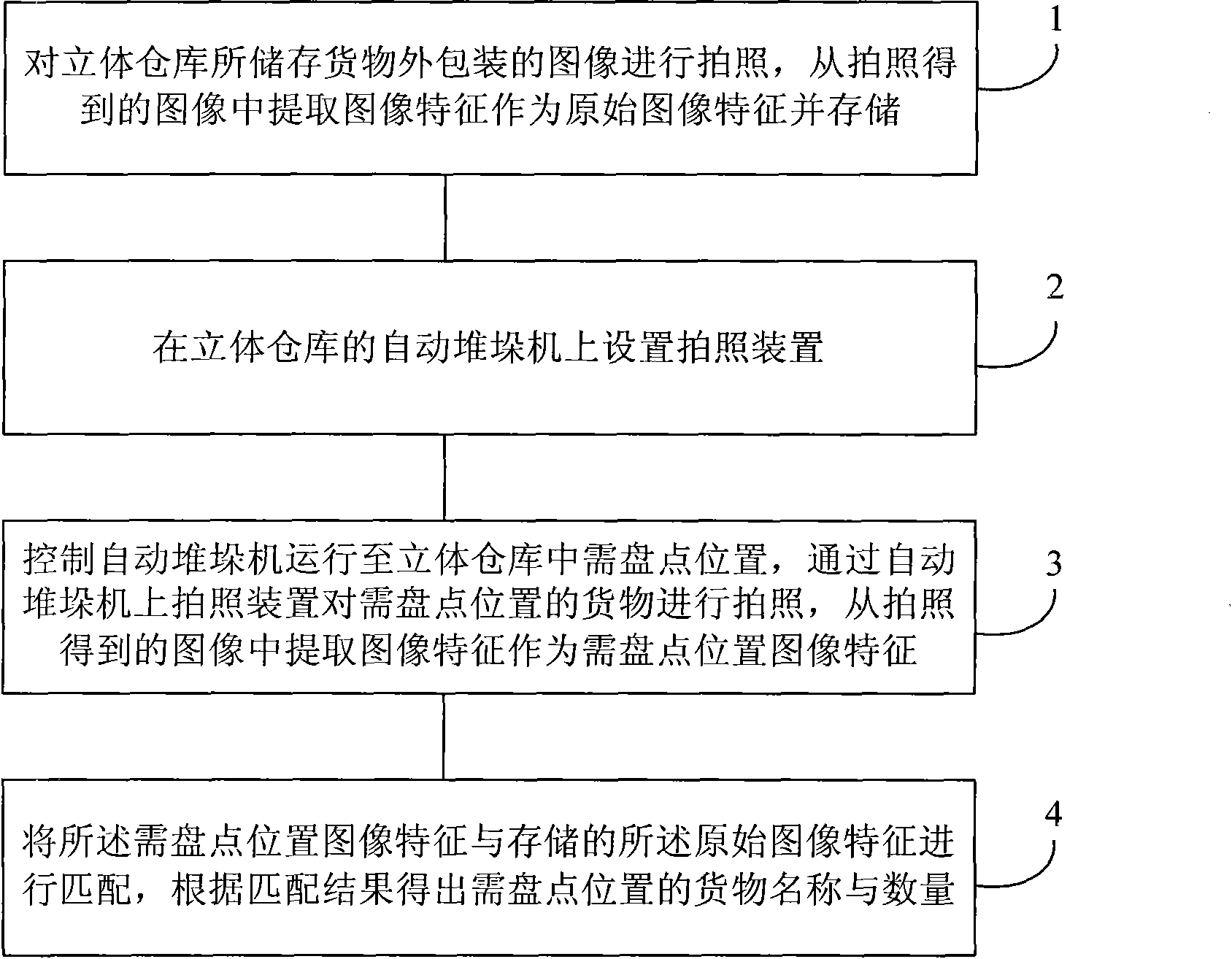

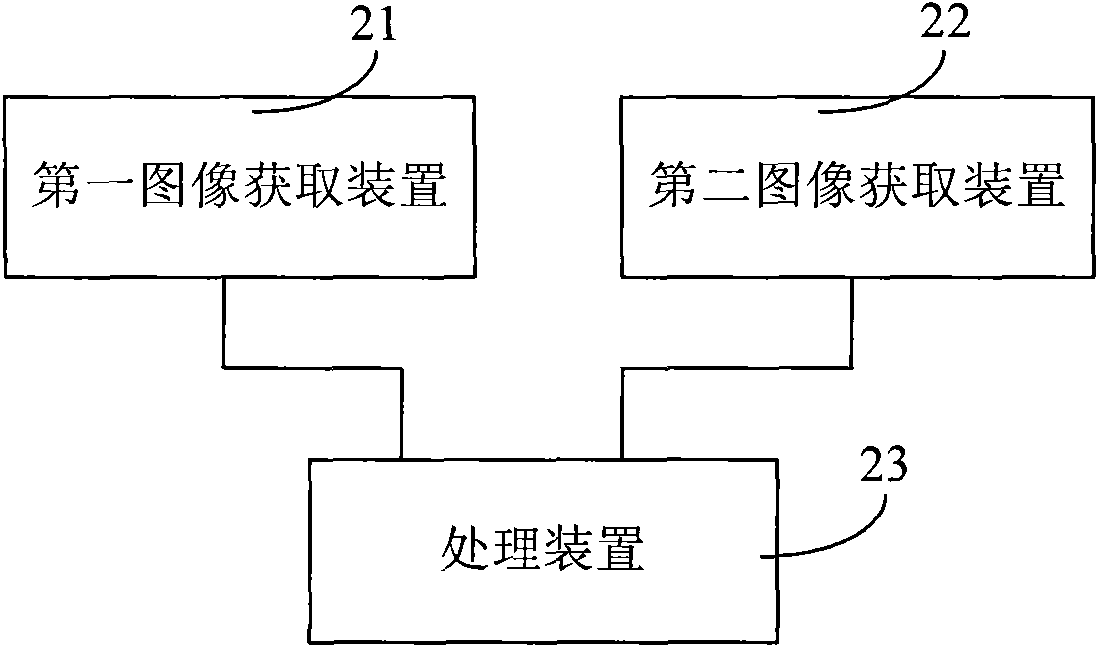

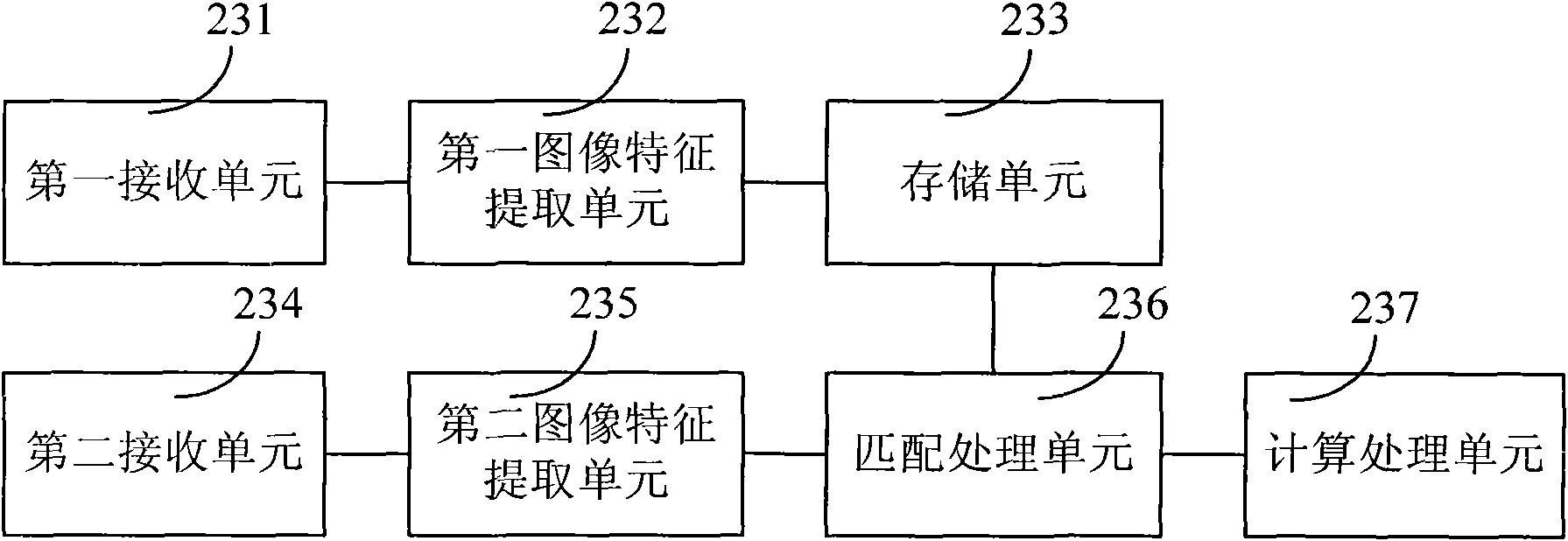

Stereoscopic warehouse goods checking method and system

InactiveCN101853387ASave manpower and material resourcesHigh speedCharacter and pattern recognitionStorage devicesLogistics managementStack machine

The invention discloses a stereoscopic warehouse goods checking method and system, belonging to the logistics field. The method includes that: the image of outer package of goods stored in the stereoscopic warehouse is captured, image characteristic is extracted from the captured image, and the extracted image characteristic is taken as the original image characteristic to be stored; a camera is arranged on the automatic stacking machine of the stereoscopic warehouse, the automatic stacking machine is controlled to move to the position in the stereoscopic warehouse required to be checked, the image of the goods at the position required to be checked is captured by virtue of the camera on the automatic stacking machine, and the image characteristic is extracted from the captured image and the extracted image characteristic is taken as the image characteristic of the goods at the position required to be checked; the image characteristic of the goods at the position required to be checked is matched with the original image characteristic, and the name and quantity of the goods at the position required to be checked are obtained according to the matching result. The method adopts image identification to realize checking on the goods in the stereoscopic warehouse, the problem that personnel can not enter or are difficult to enter the automatic stereoscopic warehouse for checking is solved, manpower and material resources are saved, speed is fast, and normal production is not influenced.

Owner:BEIJING WUZI UNIVERSITY +1

Stacking machine

InactiveCN102358519AStabilize the palletizing processReliable palletizing processStacking articlesStack machineMaterial resources

The invention relates to a stacking machine of bagged objects, comprising a stacking device, a tray lifting, propelling and conveying device, a mechanical arm and a bag supporting device, wherein the tray lifting, propelling and conveying device consists of a tray feeding device and an out-stacking conveying device; the stacking device is arranged between the tray feeding device and the out-stacking conveying device; the stacking device is in transmission connection with the mechanical arm; the bag supporting device is arranged at one side of the stacking device; the tray feeding device comprises a rack, a conveying frame, a lifting mechanism, a lifting beam and a pushing rod; the mechanical arm comprises a rotating motor, a plurality of grabbing fingers and a grabbing palm, the grabbing palm is fixedly provided with a driving cylinder which is provided with a piston rod in transmission connection with one rotating shaft on the grabbing palm through a rotating block, and each rotatingshaft is fixedly provided with a plurality of the grabbing fingers. The stacking machine provided by the invention is simple in structure, smooth in action, capable of continuously finishing stackingwork of the bagged objects in the automatic production process, saving in manpower and material resources and high in stacking efficiency.

Owner:溧阳市元创智能设备有限公司

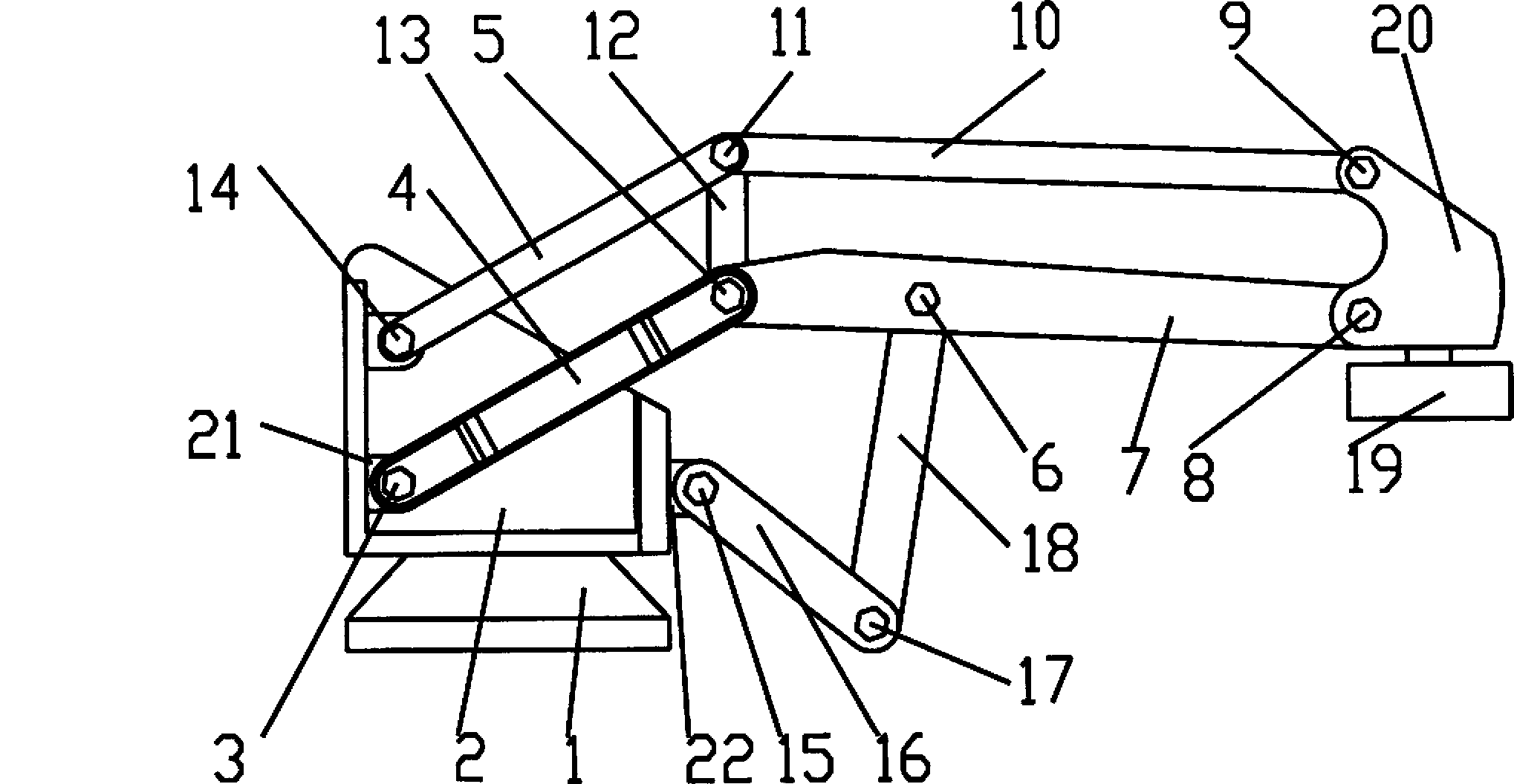

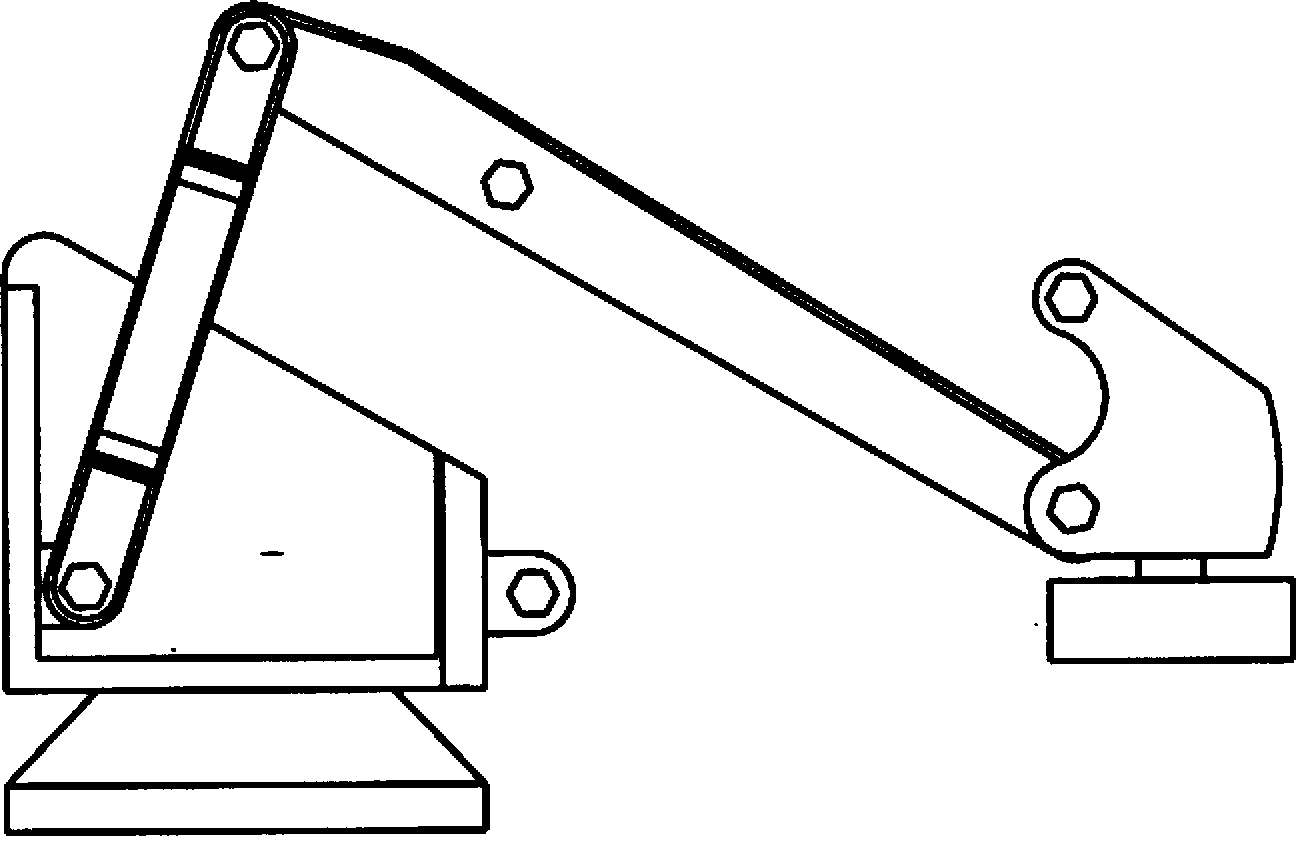

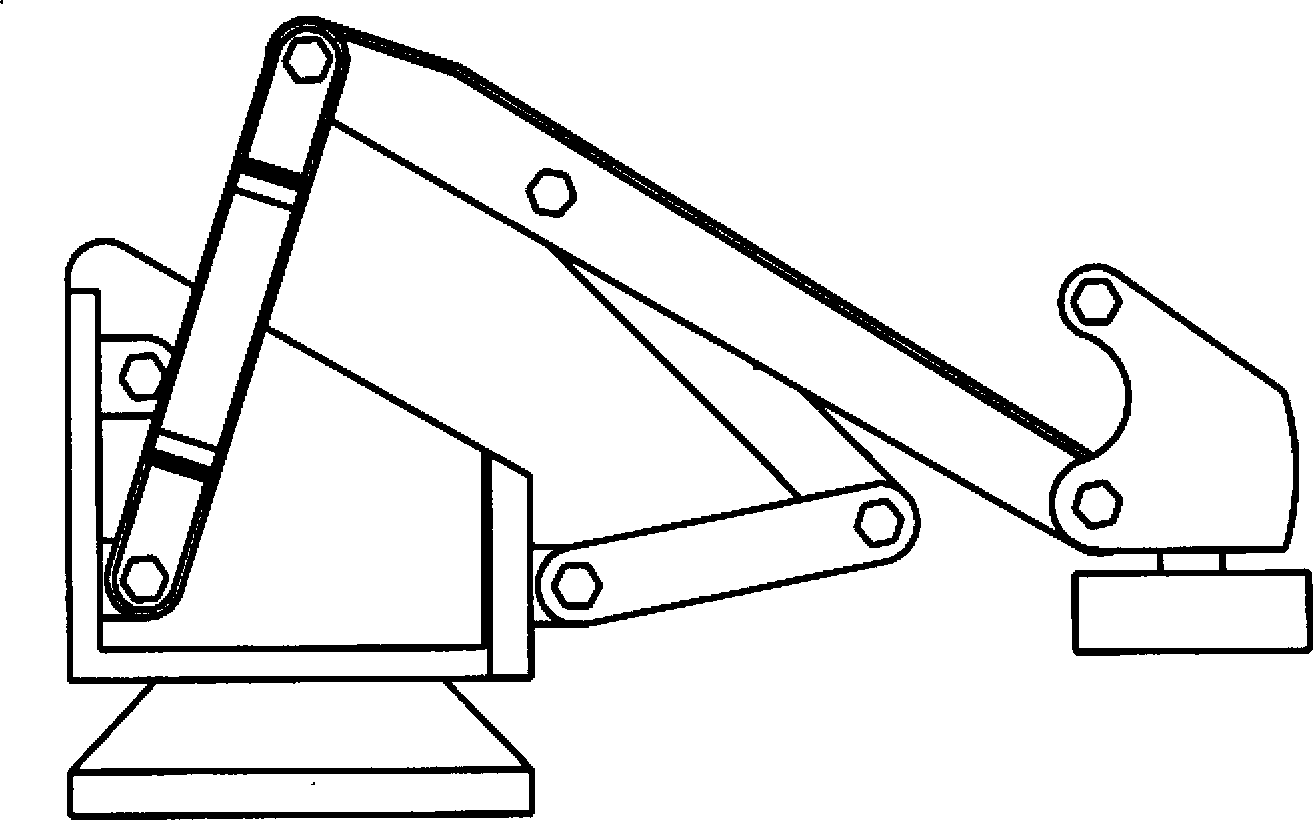

Controllable stacking robot

InactiveCN103009384AStrong flexible outputFlexible trajectoryProgramme-controlled manipulatorStacking articlesStack machineActuator

The invention relates to a controllable stacking robot, which comprises a large arm swinging branched chain, a small arm swinging branched chain, a gesture maintaining branched chain, a tail end actuator and a machine frame. The robot completes the tasks of transporting and stacking on a space as well as flexible and changeable trajectory output according to the combined movement of the large arm swinging branched chain and the small arm swinging branched arm. During a working process, according to two groups of parallelogram structures of the gesture maintaining branched chain, the tail end actuator can be guaranteed to maintain in a horizontal state all the time, all servo motors are arranged on the machine frame, rod pieces can be made into light rods, the robot has small movement inertia and excellent dynamic performance, and can be better satisfied with the requirement of transporting stacks at a high speed. According to the controllable stacking robot, by the adoption of a novel connecting rod mechanism, as a connecting transmission mechanism is simple in structure, the stress of each rod is improved, and the robot is more suitable for manufacturing a large-scale stacking machine.

Owner:GUANGXI UNIV

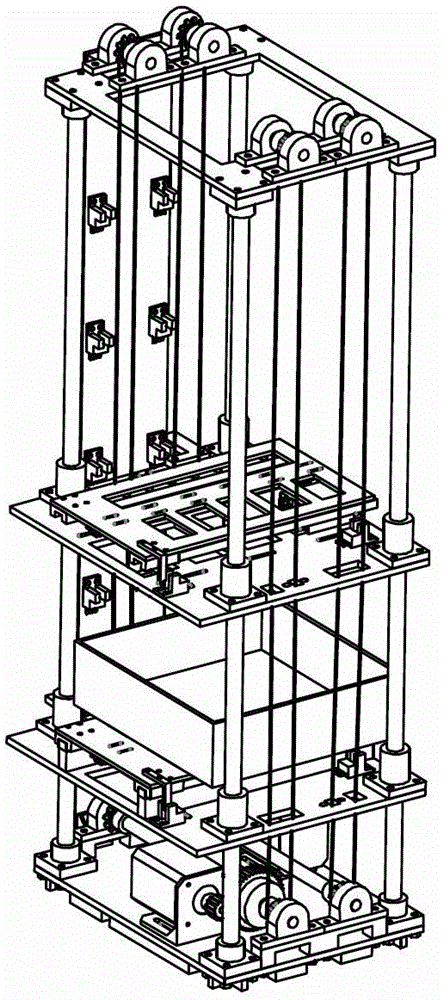

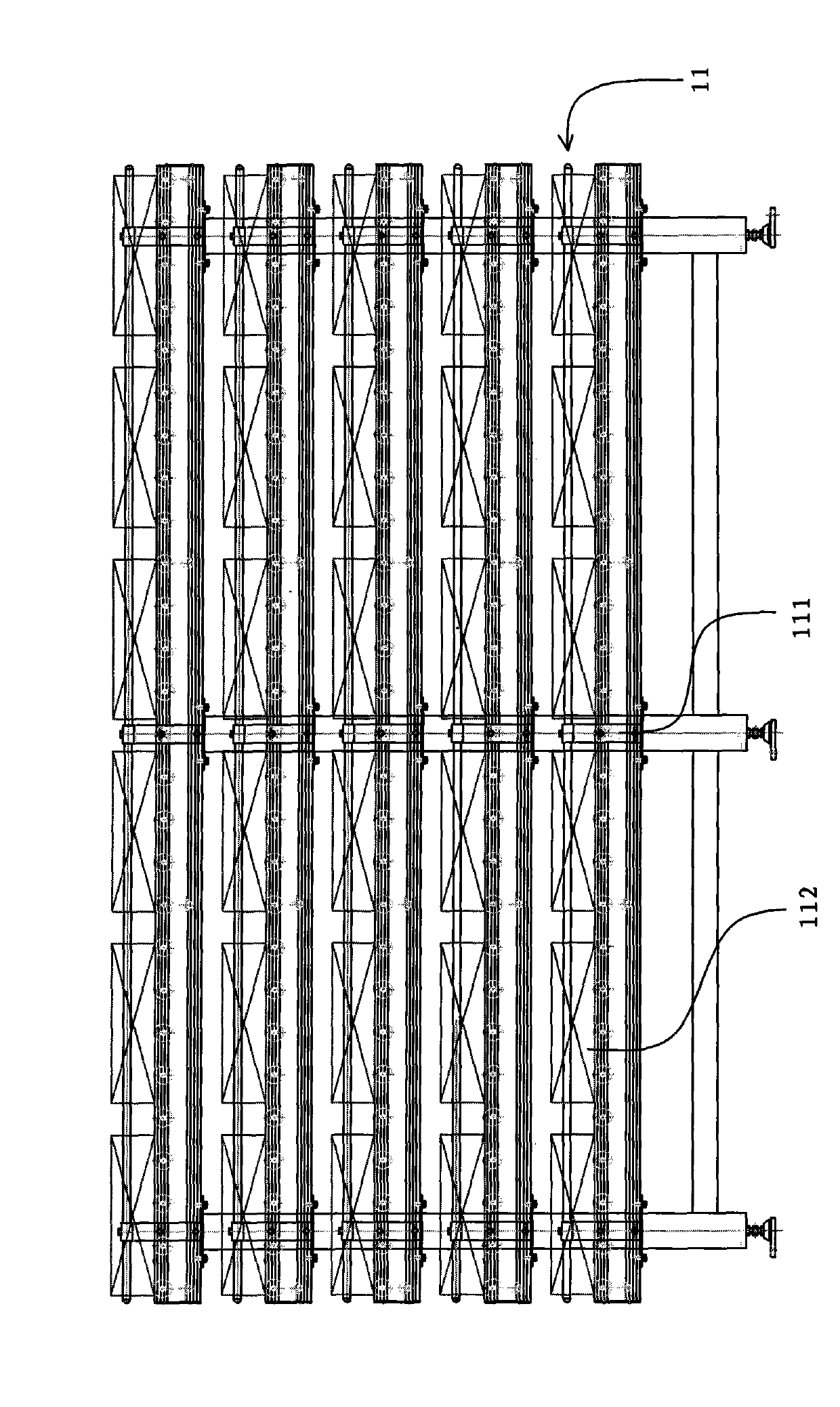

Internet of things (IOT) intelligent concentrated storage system based on double-track-shuttling stacking machine

InactiveCN102180326AQuick storageEasy to removeStorage devicesStack machineStructure of Management Information

The invention discloses an internet of things (IOT) intelligent concentrated storage system based on a double-track-shuttling stacking machine. The IOT intelligent concentrated storage system comprises at least one power concentration library, one double-track-shuttling stacking machine, one or a plurality of warehouse entry stations, one or a plurality of warehouse exit stations, and a control device, wherein each power concentration library comprises a plurality of power concentration library units, and each power concentration library units is of a multilayer structure; the double-track-shuttling stacking machine is movably arranged on one side of the power concentration library or between two adjacent power concentration libraries; the warehouse entry station(s) is / are arranged on the warehouse entry end(s) of the power concentration library / libraries; the warehouse exit station(s) is / are arranged on the warehouse exit end(s) of the power concentration library / libraries; and the control device is electrically connected with the power concentration library library / libraries and the double-track-shuttling stacking machine. The double-track-shuttling stacking machine is used for goods storage or delivery through three-dimensional movements in a horizontal direction and a vertical direction, and the power concentration library / libraries is / are driven to undergo translocation conveyance to realize the goods storage and delivery through the forward rotation and the reverse rotation of a driving mechanism(s) of the power concentration library / libraries. The IOT intelligent concentrated storage system can be used for automatic operation to complete the goods storage and delivery in occasions in which conventional roadway stacking machines and conventional elevated stereoscopic warehouses cannot be used, the space is limited and concentrated storage is needed.

Owner:SHENZHEN DDCT TECH +2

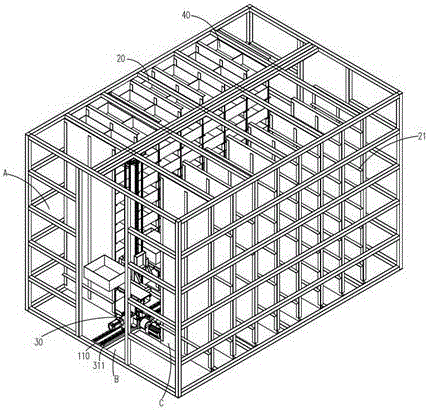

Three-dimensional goods storage equipment with flexible storage function

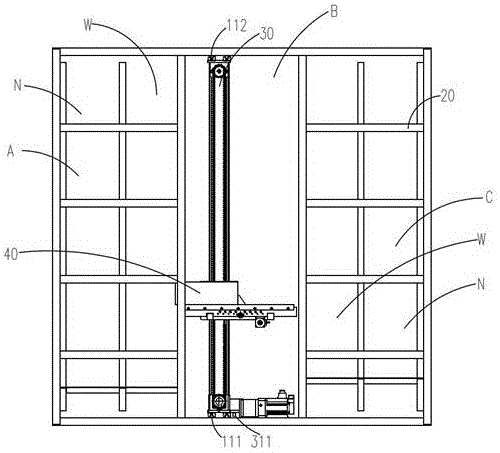

PendingCN106829299AWith automatic identification and automatic accessHigh degree of automationStorage devicesStack machineEngineering

The invention relates to a three-dimensional cargo storage and retrieval device with a flexible storage function, which includes a box body, a shelf and a stacker. A track is installed in the roadway in the middle of the box body, and a stacker machine is arranged on the track. A cargo identification mechanism is installed on the inner side of the pick-up port on the front face; the stacker includes a traveling mechanism, a lifting mechanism, a loading platform and a column. A pair of telescopic forks are symmetrically arranged on both sides of the cargo platform. The traveling mechanism includes gears and driving drive system. The lifting mechanism includes chains, sprockets and lifting drive system. The sprocket at the lower end is connected with the lifting drive system. The invention can store goods of various sizes, has the function of automatic identification and automatic storage, realizes fast storage and storage, and rationally utilizes the space of the shelf.

Owner:深圳市丰巢电商物流科技有限公司

Autonomic logistics tower system

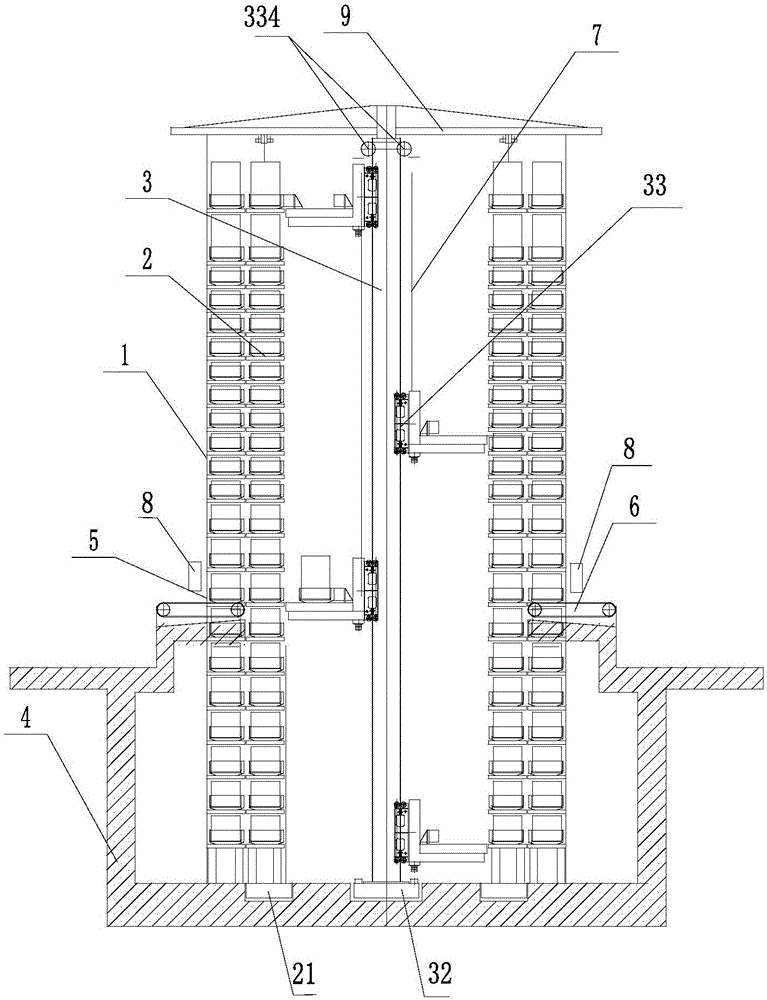

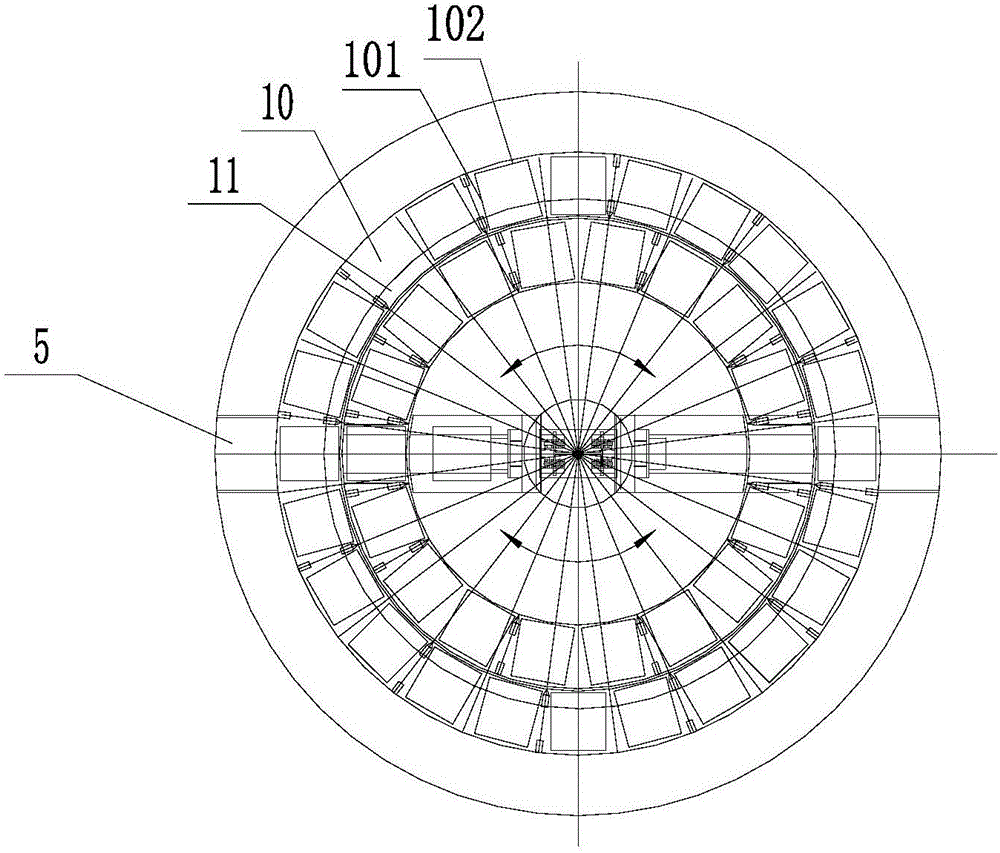

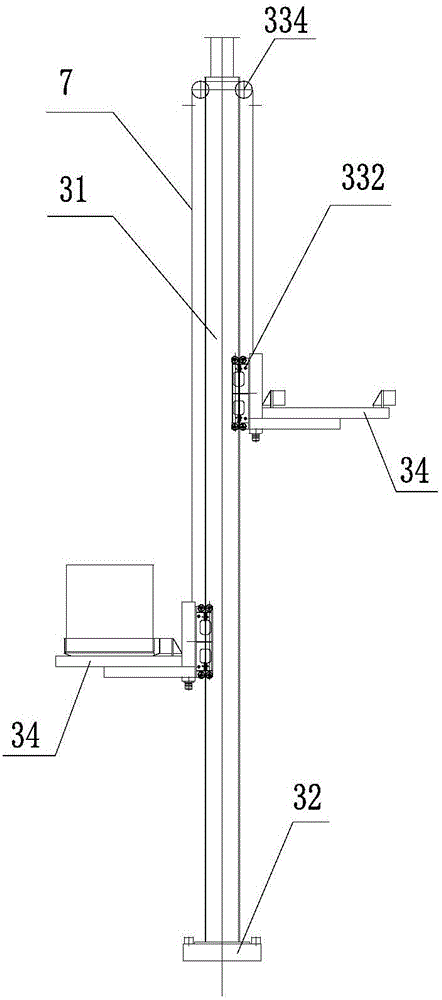

InactiveCN106743019AWith automatic storageWith automatic extractionStorage devicesLogistics managementStack machine

The invention discloses an autonomic logistics tower system which comprises a fixed cargo rack, a rotary cargo rack, a stacking machine, a bottom bin and a control system. Two opposite cargo in-out openings are formed in the fixed cargo rack in the radial direction; the rotary cargo rack is located in the fixed cargo rack and is provided with two rows of openings in the radial direction, and a rotating mechanism is arranged at the bottom of the rotary cargo rack; the stacking machine comprises a stand column and a rotary device installed at the bottom of the stand column, the rotary device drives the stand column to rotate, and the stand column is symmetrically provided with two lifting devices provided with cargo storing and taking devices; the bottom bin is located underground, and a part of the fixed cargo rack, a part of the rotary cargo rack and a part of the stacking machine are all located in the bottom bin; and the control system is in signal connection with a stacking machine system and a cargo taking system through a PLC. According to the autonomic logistics tower system, the round internal and external double-layer fixed cargo rack and rotary cargo rack are adopted, space is saved, cargo taking and placing are achieved through a center rotary lifting type platform and horizontal joint mechanical arms of the cargo storing and taking devices, the cargo grabbing running time of the mechanical arms can be shortened through the rotary cargo rack on the inner layer, and the automatic degree is high.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

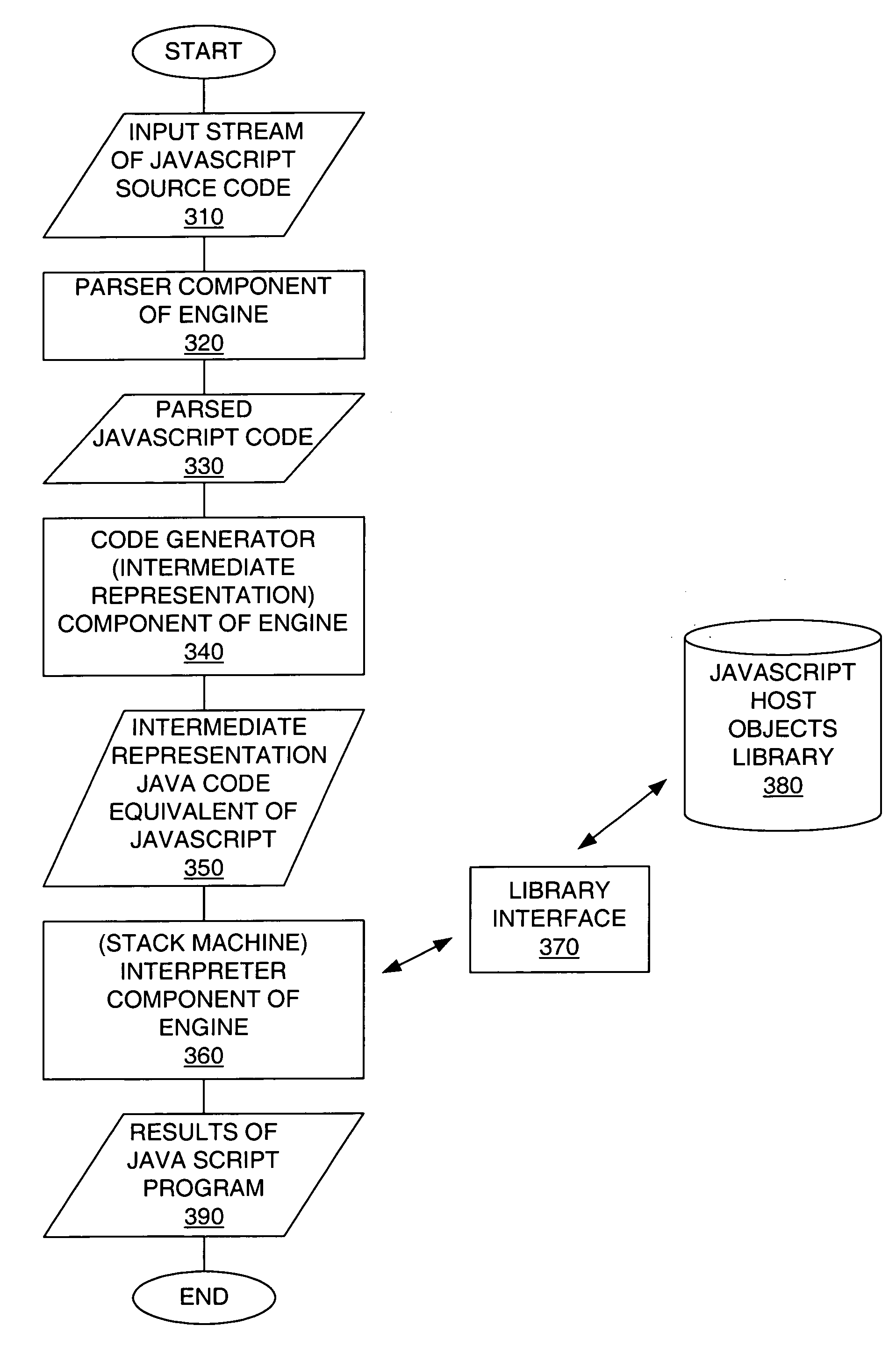

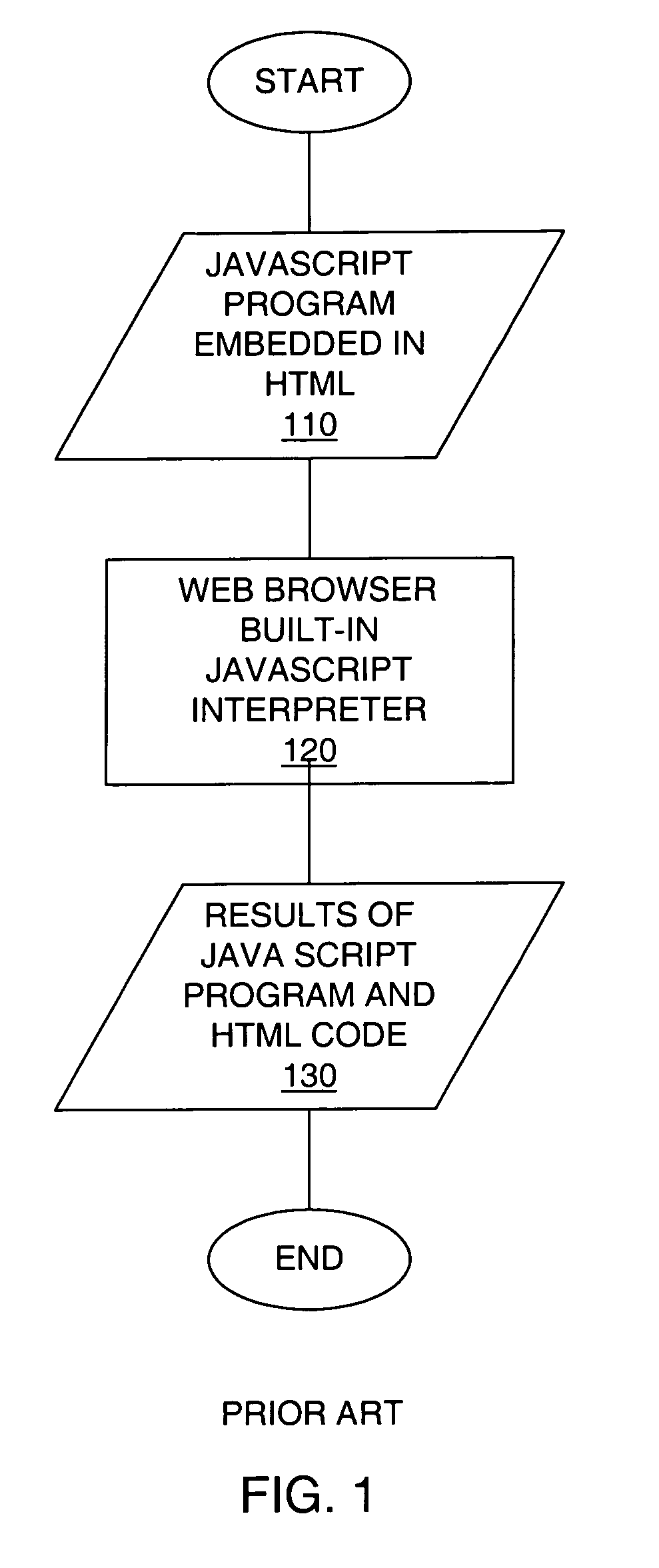

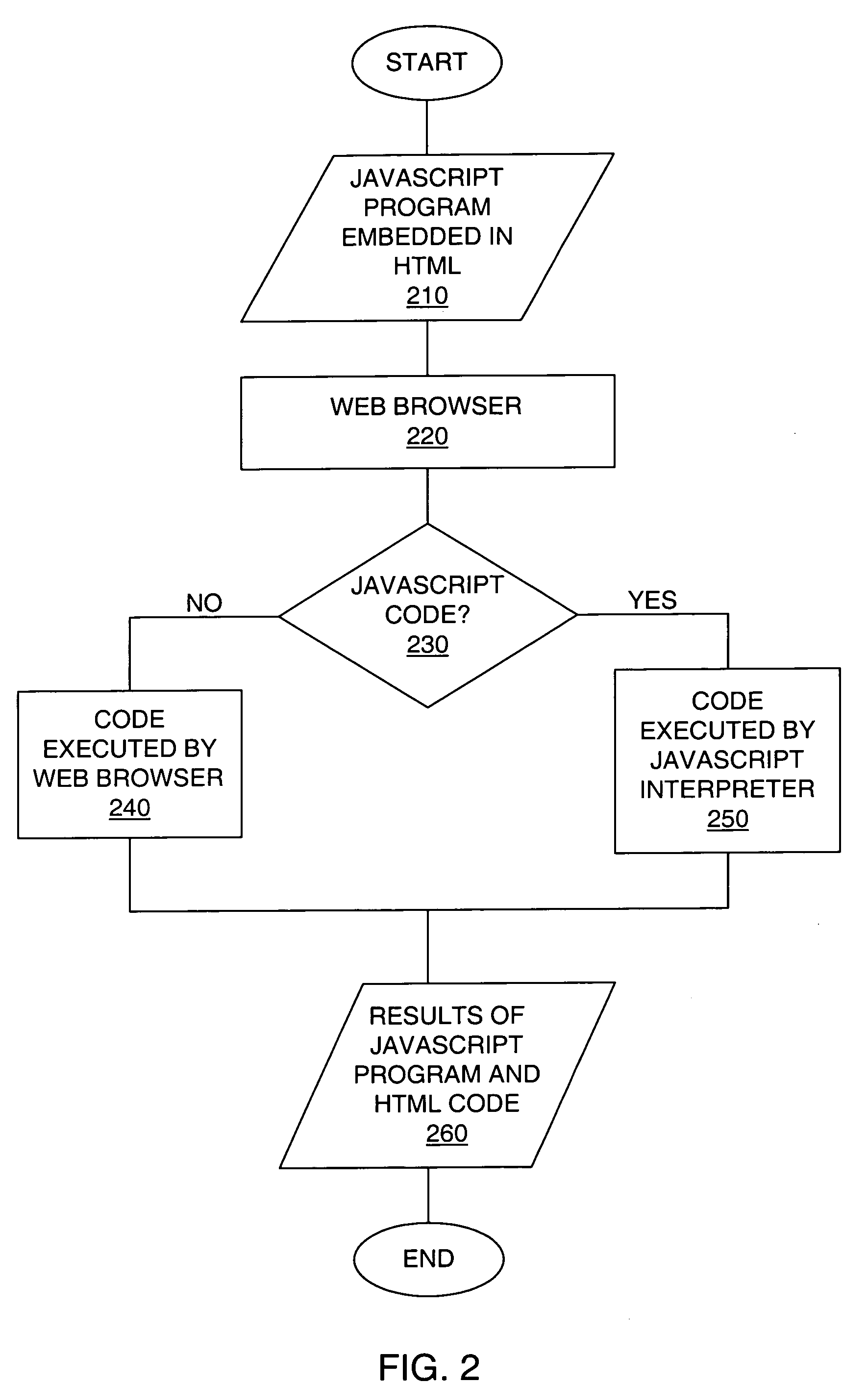

Method and apparatus for representation of a JavaScript program for execution by a JavaScript interpreter

InactiveUS6951014B1Specific program execution arrangementsMemory systemsArray data structureStack machine

A JavaScript program may be represented in an intermediate form to be executed by a JavaScript interpreter. A browser may be configured to intercept JavaScript code and pass execution control to a Java-based interpreter engine. The instructions are converted by a representation generator component of the engine into an intermediate representation equivalent using the Java programming language. The representation scheme may be suitable for execution by a stack-machine implemented interpreter. The representation scheme may use Java classes and objects, and create logical commands representing the JavaScript program. The intermediate representation may be stored as Java objects in a stack data structure. The stack data structure may be constructed from an array of elements, where each element is either an operator or an operand, and where each element derives from an abstract Java class with generic functionality and each element contains data relating to the operator or data type it represents.

Owner:ORACLE INT CORP

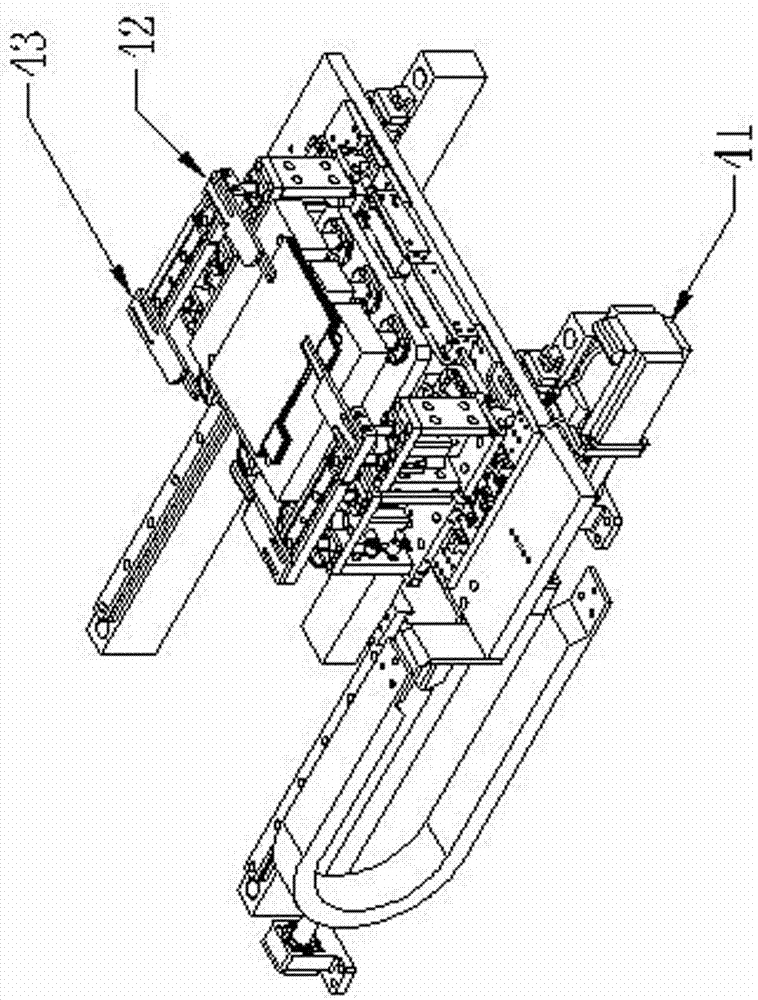

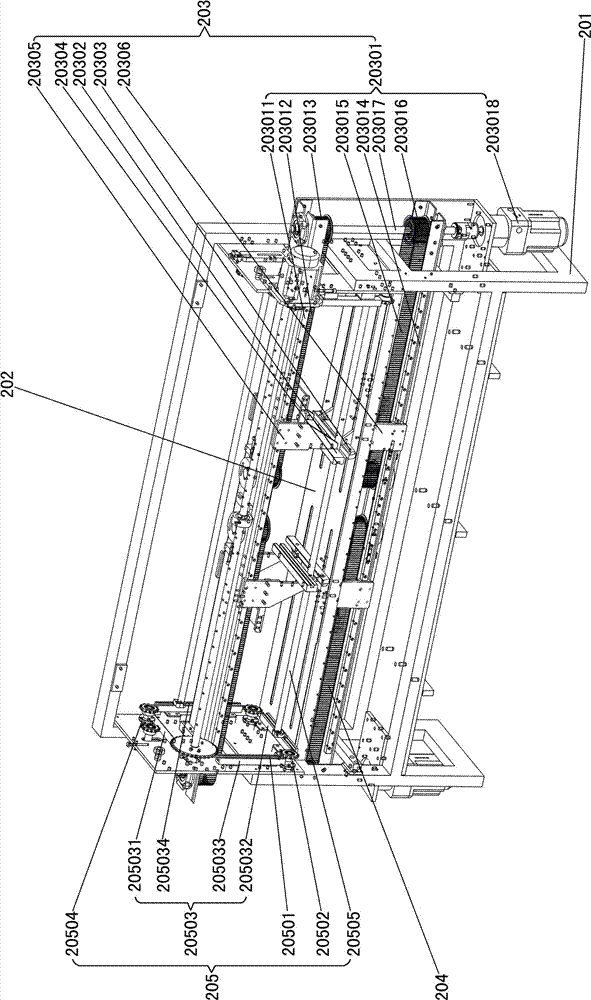

Hybrid stacking production line device and stacking system

ActiveCN103863831ASave on direct purchase costsTake up a lot of spaceControl devices for conveyorsStacking articlesProduction lineStack machine

The invention relates to a hybrid stacking production line device and a stacking system. The hybrid stacking production line device comprises a slow stopping conveyor which is used for receiving incoming materials and forwards conveying the incoming materials; a reinspection scale detection unit is arranged at one end of the slow stopping conveyor, and is located at the advancing direction of conveying the incoming materials of the slow stopping conveyor; a bag grabbing position conveyor is arranged at the front end of the reinspection scale detection unit; a stacking machine main engine is arranged at the front end of the bag grabbing position conveyor; a first tray conveyor line and a second tray conveyor line are arranged at two sides of the stacking machine main engine; the first tray conveyor line and the second tray conveyor line are respectively arranged at two sides of the stacking machine main engine. The hybrid stacking production line device and the stacking system have the advantages that the structure is compact, material packaging bags with two different specifications can be processed at an incoming material conveying channel, the degree of automation is high, the adaptive range is wide, the production cost is reduced, and safety and reliability are realized.

Owner:WUXI DADONG MACHINERY MFG

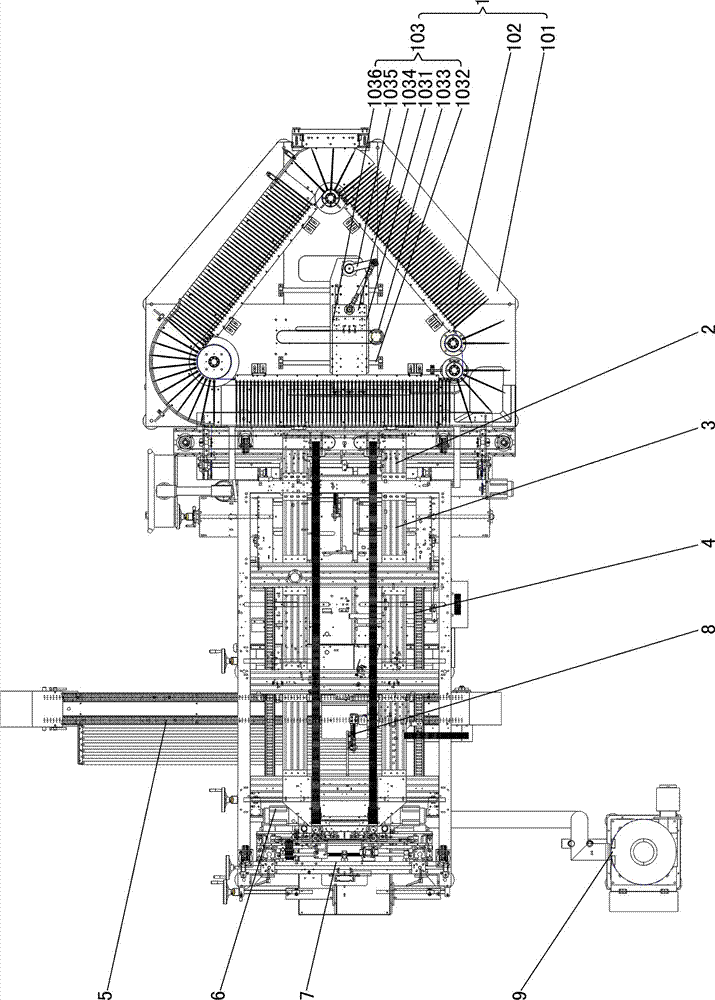

Paperboard stacking device and paperboard stacking machine

ActiveCN105565017ARealize automatic feedingAutomate operationPile receiversArticle feedersCardboardStack machine

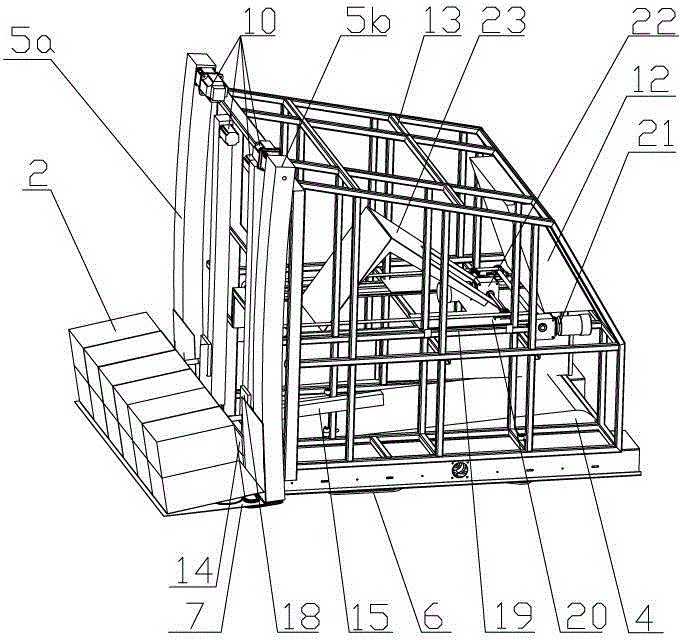

The invention discloses a paperboard stacking machine and a paperboard stacking device. The paperboard stacking machine comprises a paperboard stacking device, a paperboard feeding mechanism, a tray feeding mechanism and a paperboard output mechanism; the paperboard stacking device comprises a main body frame; the main body frame comprises an outer frame and an inner frame; a paperboard lifting mechanism is arranged at one side of the outer frame; a gripper mechanism and a gripper translation mechanism are arranged on a top beam of the outer frame; a paper feeding normalizing mechanism is arranged on a stand column of the outer frame; a tray lifting output mechanism is arranged on the inner frame; and a stacking normalizing mechanism is arranged on a top beam of the inner frame. The paperboard stacking machine realizes automation of automatic feeding and paperboard feeding, paper feeding normalizing, lifting, grabbing, translation, rotating, releasing, stacking normalizing, paper stack descending and paper stack output of the tray, and can trimly stack packaged corrugated paperboards or cartons according to predetermined putting positions and rules, thus realizing automatic operation, being good in stacking quality and high in stacking speed, and saving manpower.

Owner:SHANDONG CENTURY MACHINERY

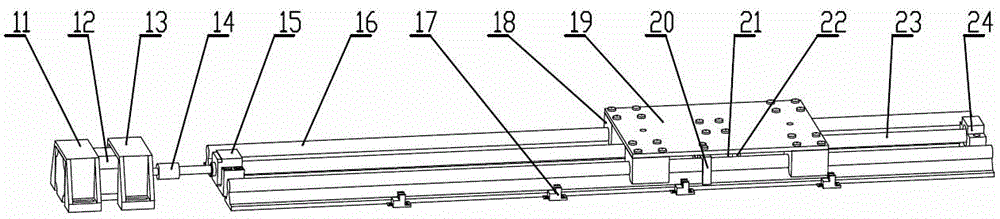

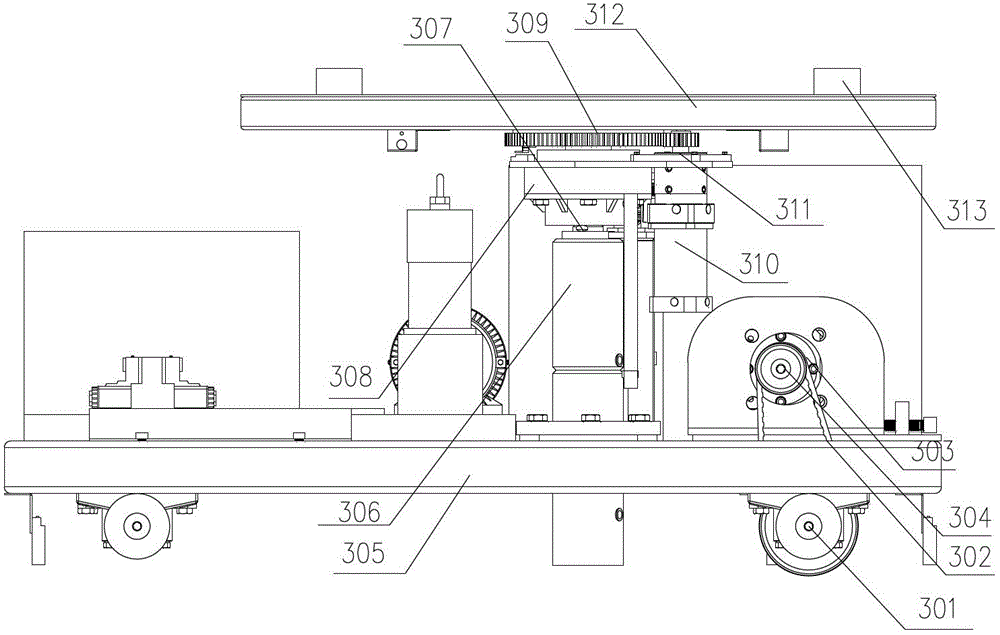

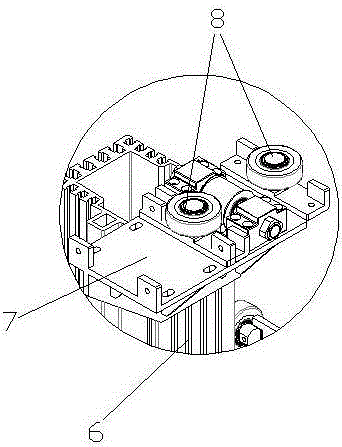

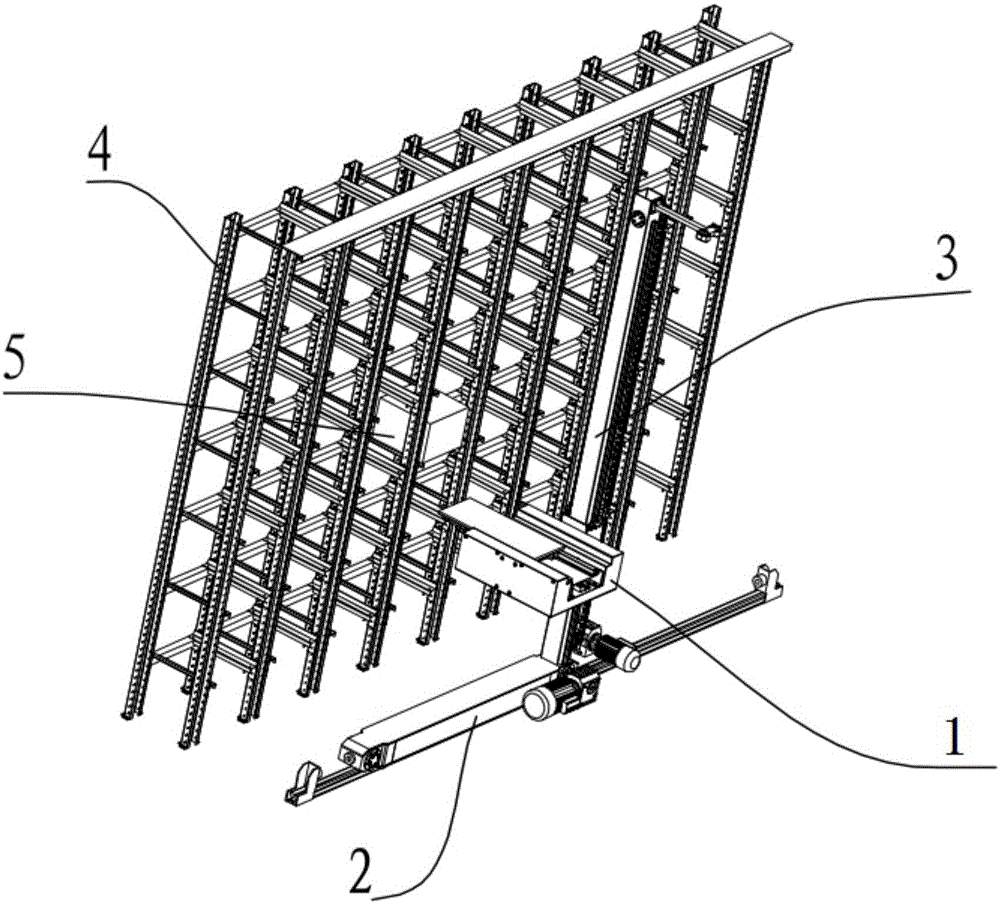

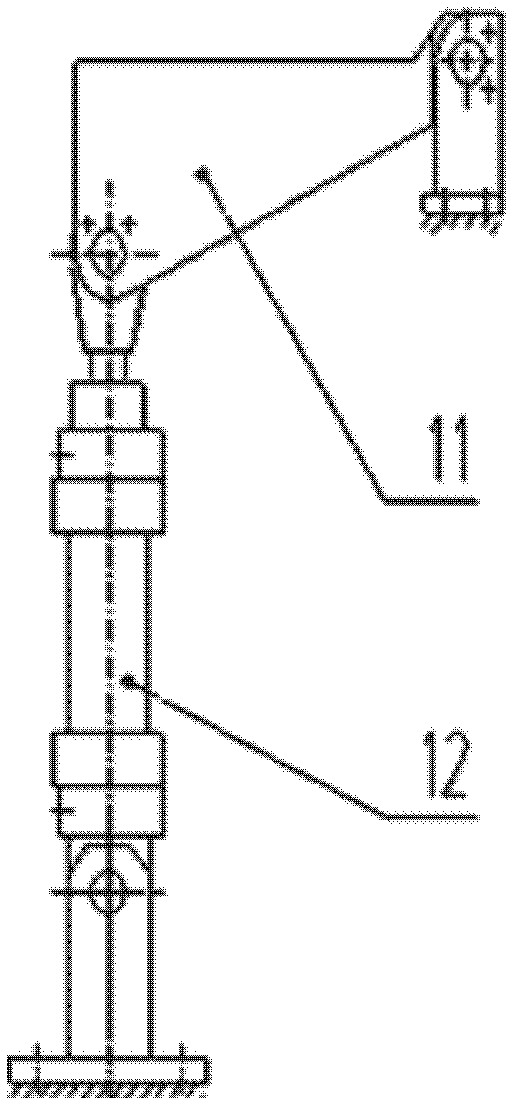

Stacking machine structure for stereoscopic warehouse

InactiveCN105253507AReduce weightReduce volumeStacking articlesDe-stacking articlesStack machineEngineering

The invention relates to the technical field of stacking machines and discloses a stacking machine structure for a stereoscopic warehouse. The stacking machine structure for the stereoscopic warehouse comprises a lower rail and an upper rail parallel to the lower rail. A horizontal sliding base is arranged on the lower rail. A vertical lifting rail is arranged on the horizontal sliding base. The upper end of the lifting rail is in connected with the upper rail in a sliding mode. A vertical sliding base is arranged on the lifting rail. A pallet fork fixing base is arranged on the side face of the vertical sliding base. A telescopic pallet fork is arranged on the pallet fork fixing base. A horizontal driving mechanism used for driving the horizontal sliding base to slide along the lower rail is arranged on the horizontal sliding base. A lifting driving mechanism used for driving the vertical sliding base to rise and fall is arranged on the horizontal sliding base and located at the lower end of the lifting rail. The stacking machine structure for the stereoscopic warehouse has the beneficial effects that flexibility is achieved, goods can be put into and out of the warehouse more conveniently, and the efficiency is high; the stacking machine structure is particularly suitable for transferring light and small-sized goods into or out of the warehouse.

Owner:HANGZHOU DC ENERGY EQUIP

Full-automatic paper diaper packaging production line

ActiveCN104843248APrecise feedingAvoid getting stuckIndividual articlesStack machineCompression device

The invention relates to a full-automatic paper diaper packaging production line which comprises a stacking machine, pre-compression device, a transition mechanism, a secondary compression device, a bag feeding device, a bag opening device, a packaging, sealing and cutting-off device, a pushing mechanism and an offcut collecting device. The pre-compression device comprises a support, a support plate, a left compression mechanism, a right compression mechanism and a push out mechanism, wherein each of the left compression mechanism and the right compression mechanism comprises a compression translation mechanism, an upper push block and a lower push block, the upper push block and the lower push block are respectively connected with the power output end of the compression translation mechanism, and the upper push block is located above the lower push block. The full-automatic paper diaper packaging production line has the advantages that the upper push blocks and the lower push blocks are respectively driven by independent compression translation mechanisms and are fixed in the middle to perform pre-compression, paper diapers are prevented from being deviated and stuck, production smoothness is increased, and production efficiency is increased; the upper push blocks are separated from the lower push blocks, the friction between the paper diapers and the upper push blocks and the lower push blocks is reduced, and abrasion and scratch of the paper diapers are avoided.

Owner:孙少光

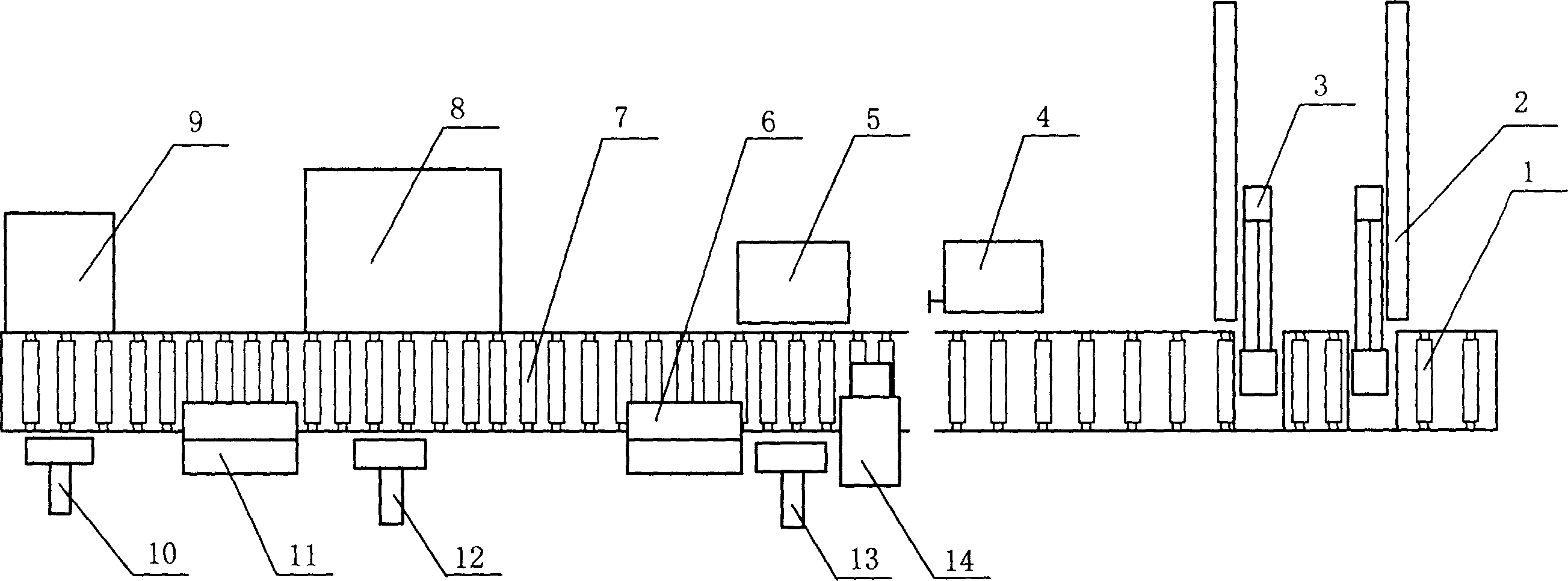

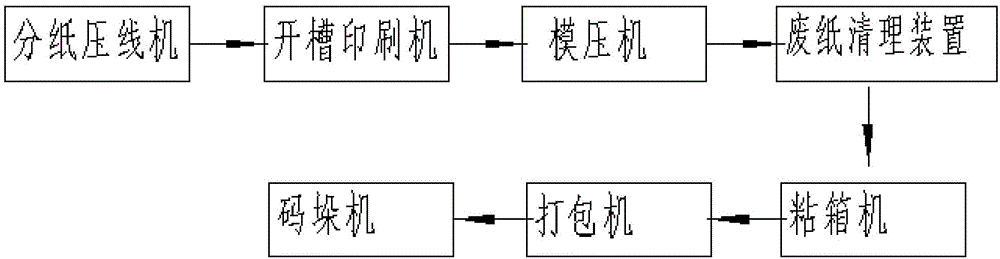

Corrugated carton production process and automatic production line thereof

InactiveCN106363953AIncrease productivityImprove qualityBox making operationsPaper-makingProduction lineStack machine

The invention relates to the technical field of printing and packaging, in particular to a corrugated carton production process and an automatic production line thereof. The corrugated carton production process includes the steps of paper splitting and line pressing, picture and text printing, mold pressing, connecting, bundling and stacking. The automatic production line comprises a paper splitting and line pressing machine, a slotting printing machine, a molding press, a waste paper removing device, a carton bonding machine, a packaging machine and a stacking machine, wherein the paper splitting and line pressing machine, the slotting printing machine, the molding press, the waste paper removing device, the carton bonding machine, the packaging machine and the stacking machine are sequentially connected through a conveying mechanism. The slotting printing machine is provided with an ultraviolet drying device, and a controller of the automatic production line is used for controlling communication and speed synchronization among all the single devices. According to the corrugated carton production process and the automatic production line thereof, the structure is reasonable, automatic production is achieved, production efficiency for existing corrugated cartons is improved, and the production cost is lowered.

Owner:玉溪万利包装材料有限公司

Rapid automatic loading and stacking machine for container

ActiveCN104649019AIncrease productivitySimple organizationConveyorsStacking articlesProgrammable logic controllerStack machine

The invention relates to a rapid automatic loading and stacking machine for a container. The rapid automatic loading and stacking machine for the container is provided with an automatic traveling type frame-shaped rack; a conveying belt is mounted at the bottom of the frame-shaped rack. The rapid automatic loading and stacking machine for the container is characterized in that left and right lifting guide rails are arranged at the front end of the frame-shaped rack; a lifting saddle and box pushing mechanisms which are lifted up and descended along with the lifting saddle are mounted on the two lifting guide rails; lifting driving mechanisms for the lifting saddle and the box pushing mechanisms are assembled; a left-and-right transverse moving mechanism is also mounted on the lifting saddle; moreover, an overturning-type pushing mechanism is mounted at the upper part of the frame-shaped rack; the overturning-type pushing mechanism comprises left and right horizontal guide rails arranged in the front-and-back direction; sliding seats are mounted on the horizontal guide rails; driving mechanisms for driving the sliding seats to move back and forth are assembled; an overturning mechanism and an overturning box pushing plate are mounted on the sliding seats; a PLC (Programmable Logic Controller) is assembled. According to the rapid automatic loading and stacking machine for the container, square packaging boxes can be rapidly, automatically and neatly stacked in the container; the structure is simplified; the stacking speed is high; the rapid automatic loading and stacking machine for the container is widely used for storage and transportation of the packaging boxes of food, beverages, medicine, daily necessities and the like.

Owner:张帆

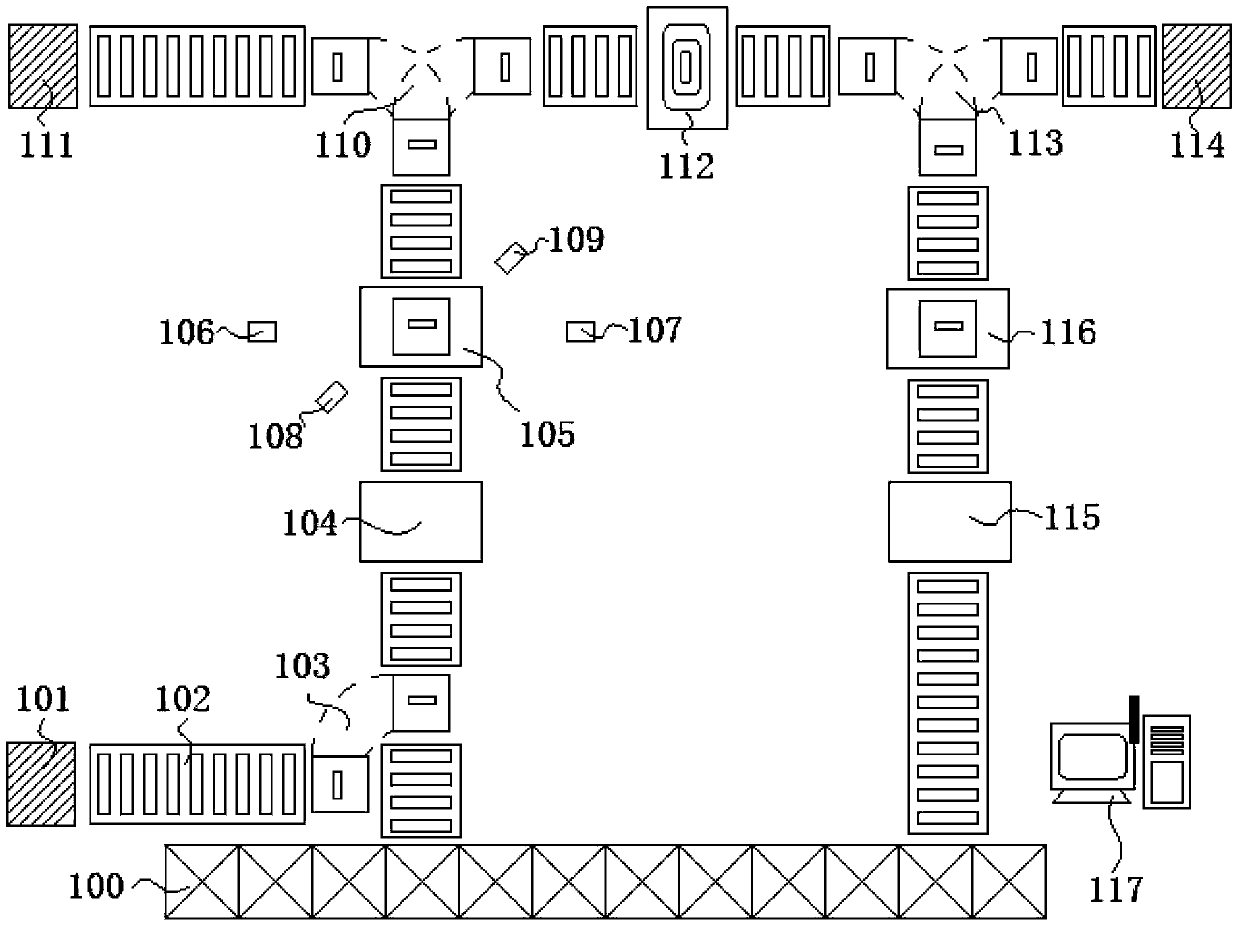

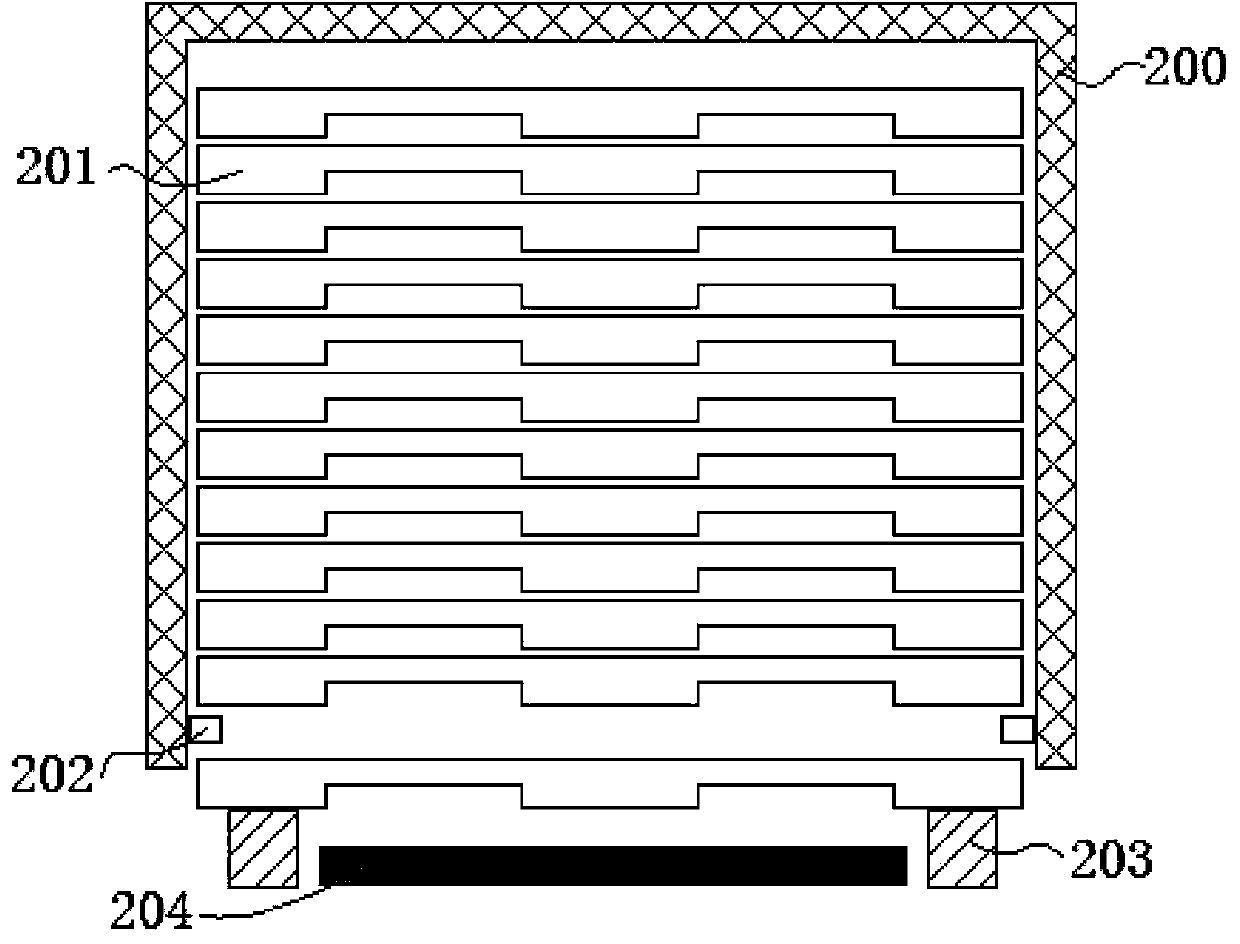

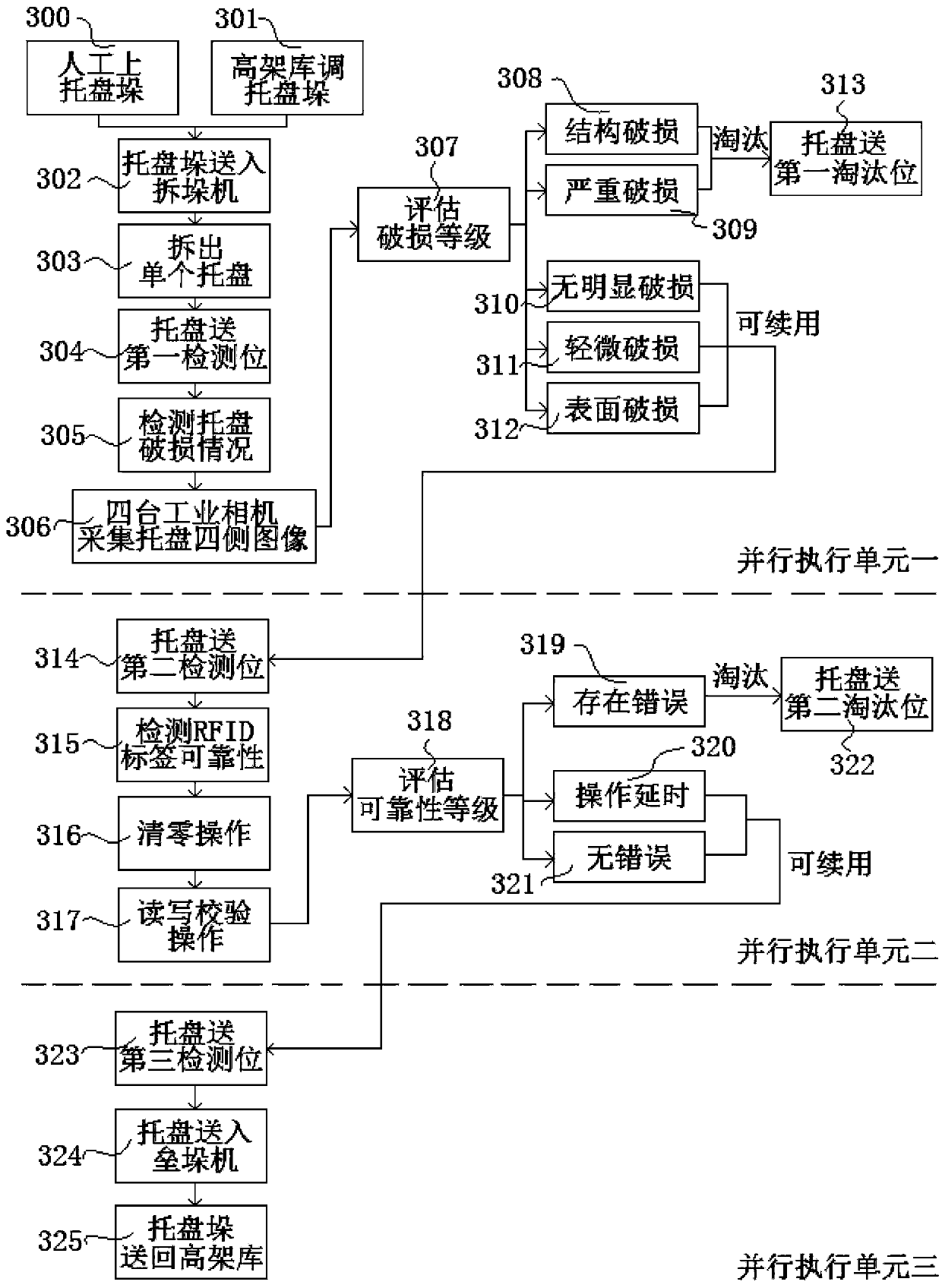

Full-automatic detection system and full-automatic detection method for sustainability of RFID (radio frequency identification device) logistic flat trays

ActiveCN103472066AReduce the average detection cycleImprove detection efficiencyOptically investigating flaws/contaminationMachine visionStack machine

The invention relates to a full-automatic detection system and a full-automatic detection method for sustainability of RFID (radio frequency identification device) logistic flat trays. The system comprises a full-automatic elevated three-dimensional warehouse, a manual stacking position, an unstacking machine, a first detection position, a first bidirectional 90-degree rotation conveying belt, a first elimination position, a second detection position, a second bidirectional 90-degree rotation conveying belt, a second elimination position, a stacking machine, an extendable detection position and a tray detection management system. According to the system and the method, the full-automatic detection of the RFID logistic combined transportation flat trays is achieved, and both the starting and stopping points of a detection assembly line can be connected to the full-automatic elevated three-dimensional warehouse, so that the manual intervention is alleviated; the trays are stacked by the unstacking machine and the stacking machine, so that the tray storage space is narrowed; the tray breakage degree is detected by adopting a machine vision method, so that the speed is quick and the accuracy is high; the reliability of the built-in RFID label data of the trays is detected by adopting reset and read-write check methods; detection items are scheduled in a unified way according to a detection management system and are parallelized.

Owner:CHINA TOBACCO ZHEJIANG IND

Stacking machine and stacking method thereof

InactiveCN103682460ALaminating speed is fastIncrease productivityFinal product manufactureWound/folded electrode electrodesStack machineEngineering

The invention relates to the technical field of lithium battery stacking, and provides a stacking machine and a stacking method thereof. The stacking method comprises the following steps: step A, a first diaphragm, a cathode plate and a second diaphragm are sequentially stuck into a whole and then are continuously blanked to the upper part of a stacking table, or a composite pole compounded with diaphragms and a cathode plate is continuously blanked to upper part of the stacking table, and a pressing knife presses the cathode plate and the diaphragms onto the stacking table; step B, the stacking table is moved to a first-time positioning table, a first mechanical arm stacks an anode plate onto the first diaphragm from the first-time positioning table, and the pressing knife compresses the anode plate; step C, the stacking table is moved to a second-time positioning table, a second mechanical arm stacks the anode plate onto the second diaphragm from the second-time positioning table, and the pressing knife compresses the anode plate. According to the invention, the cathode plate and the diaphragms are connected into a whole for continuous blanking, Z-shaped stacking is conducted between the first-time positioning table and the second-time positioning table through the stacking table, the circulation continues until a set number of stacked layers is achieved, and thus the stacking speed is increased.

Owner:GEESUN AUTOMATION TECH

Stacking technology for cargo

ActiveCN106743685ARealize warehousingNot easy to slip offStacking articlesStorage devicesStack machineEngineering

The invention provides a stacking technology for cargo, and a logistic stacking machine. The logistic stacking machine includes a cargo conveying platform, a cargo conveying platform horizontal movement drive device, a cargo conveying platform vertical movement drive device, a cargo shelf for storing cargo, a limiting sensor and a PLC; the limiting sensor is connected to the PLC; the cargo conveying platform vertical movement drive device is arranged on the cargo conveying platform horizontal movement drive device; the cargo conveying platform is fixed on the cargo conveying platform vertical movement drive device; the limiting sensor is used for detecting spatial position information of the cargo conveying platform, and transmitting the detected spatial position information of the cargo conveying platform to the PLC; and the PLC controls the cargo conveying platform vertical movement drive device and the cargo conveying platform horizontal movement drive device to achieve forward and backward movement and vertical movement of the cargo conveying platform. The logistic stacking machine is simple in structure, is high in working efficiency, is stable in performance, and can achieve mechanical and automatic cargo conveying.

Owner:柏涛涛

Rapid stacking machine in container

ActiveCN106429492AAvoid accumulationFast palletizingConveyorsStacking articlesControl systemStack machine

The invention provides a travelling stacking machine for goods stacking in a container, and particularly discloses a rapid stacking machine in the container. The rapid stacking machine comprises an automatic travelling frame type rack, and a rack driving mechanism, a lifting platform and a control system that are arranged on the automatic travelling frame type rack; the automatic travelling frame type rack drives the lifting platform to move together; the lifting platform realizes the effect of lifting motion in the vertical direction through a lifting driving mechanism, and simultaneously accomplishes conveying, arrangement and stacking work of goods; the lifting platform comprises a platform plate, a longitudinal telescopic sliding door, a transverse bag pushing mechanism, a longitudinal conveyer, a conveying belt hinging device and a guide device; the longitudinal conveyer arranged in the middle of the lifting platform conveys the goods onto a telescopic plate at the front of the lifting platform; a transverse pushing plate capable of moving transversely on the telescopic plate is used for arranging the goods in a row transversely; when the telescopic plate retracts to the lower side of the lifting platform under the control of a motor, the goods fall down automatically, and the stacking of a layer of goods is accomplished. The rapid stacking machine can enter the container to carry out full-automatic high-efficiency stacking on the goods conveyed by the longitudinal conveyer.

Owner:SHANGHAI JIAO TONG UNIV

Flat steel automatic collecting and stacking machine

ActiveCN102491097AThe principle is feasibleReasonable designStacking articlesHydraulic cylinderStack machine

The invention provides a flat steel automatic collecting and stacking machine, which comprises a chain type conveying rack, a conveying rollway and flat steel to be stacked, and is characterized by also comprising a receiving rack, an overturning mechanism, an automatic lifting mechanism and a translation mechanism, which are arranged in a mutually staggered manner; the receiving rack is jointed with the chain type conveying rack of finishing and collecting equipment and the conveying rollway; the overturning mechanism is driven by a vertical hydraulic cylinder to overturn stacked flat steel and smoothly transfer the stacked flat steel onto the conveying rollway, and the overturning mechanism regulates the stacked products into a horizontal state from a collected inclined state and places the stacked products onto the horizontal conveying rollway so that the stacked products can be conveyed away; the automatic lifting mechanism lifts and lowers a receiving supporting arm by rotating the hydraulic cylinder to driven a chain wheel device; the translation mechanism which can adapt to products of different specifications performs horizontal motion to translate a vehicle body through a translation hydraulic cylinder; and the translation mechanism aligns the products in a collecting and stacking process. The machine has the advantages of convenience for maintenance, simplicity of operation, high efficiency, low fault rate and long service life.

Owner:北京中冶设备研究设计总院有限公司

Composite board processing line and processing technology

InactiveCN106965272AReduce labor intensityHigh degree of automationLamination ancillary operationsLaminationStack machineEngineering

The invention relates to the technical field of board processing, in particular to a composite board processing line. The composite board processing line comprises a feeding machine, a gumming machine, a veneering machine and a stacking machine which are sequentially connected through a roller way. The invention further provides a composite board processing method. The method comprises the following steps that A, core boards are placed on the feeding machine, and the core boards are fed by the feeding machine into the gumming machine one by one; B, face boards and bottom boards are sequentially stacked on the core boards through the veneering machine, and assembly units are formed and fed into the stacking machine through the roller way; and C, the assembly units are stacked through the stacking machine. Compared with the prior art, the composite board processing line and the composite board processing method have the beneficial effects that feeding, gumming, assembling and stacking are all completed through equipment, the automation degree is high, the labor intensity of workers is low, the production efficiency is high, and product quality is high.

Owner:山东同利玻纤制品有限公司

Brick grasping two-way closing device of unburned brick stacking machine

InactiveCN102152973AIncrease the number of placementsSimple structureStacking articlesDe-stacking articlesBrickFixed frame

The invention relates to a brick grasping two-way closing device of an unburned brick stacking machine, which belongs to a brick making machine. The brick grasping two-way closing device of the unburned brick stacking machine is characterized in that transverse closing devices of unburned brickd are respectively installed on all grabhook beams; each transverse closing device mainly comprises a grabhook beam, a transverse guide rail, a transverse sliding block, a transverse closing air cylinder, a fixed plate, a traction plate, a transverse limiting plate, a positioning pin and a single claw fixed frame; transverse closing air cylinders are correspondingly installed on the groove bottoms of all the grabhook beams respectively; all piston rods extend to the right and are respectively connected with the right-angle traction plate on the single claw fixed frame; the transverse guide rails are respectively installed on all the grabhook beams; the transverse sliding blocks are respectively installed on all the transverse guide rails; the single claw fixed frames are fixedly installed on all the transverse sliding blocks respectively; and the transverse limiting plates are respectively installed on every two adjacent single claw fixed frames. Pressurized gas enters the transverse closing air cylinders and drives all the single claw fixed frames to finish transverse closing action of brick grasping; and the area of a steaming trolley is effectively utilized, the energy is saved and the consumption and the production cost are reduced.

Owner:ANHUI KEDA IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com