Brick grasping two-way closing device of unburned brick stacking machine

A palletizer and brick adobe technology, applied in the field of brick grabber and brick grabbing devices for brick adobe palletizers, can solve the problems of reducing the utilization rate of autoclaves, wasting the area of steaming trolleys, wasting materials and energy, and achieving superior performance and simple structure , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

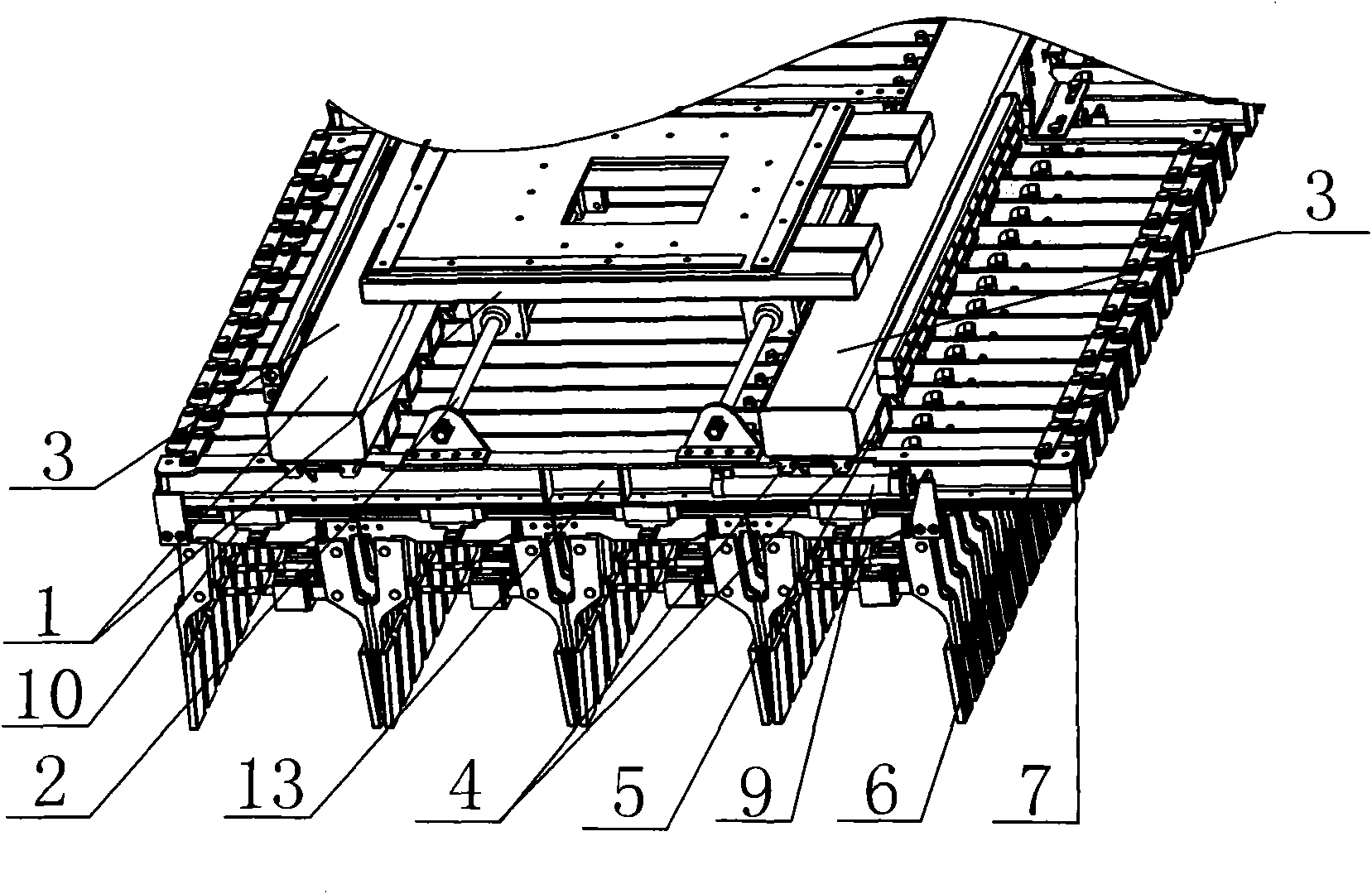

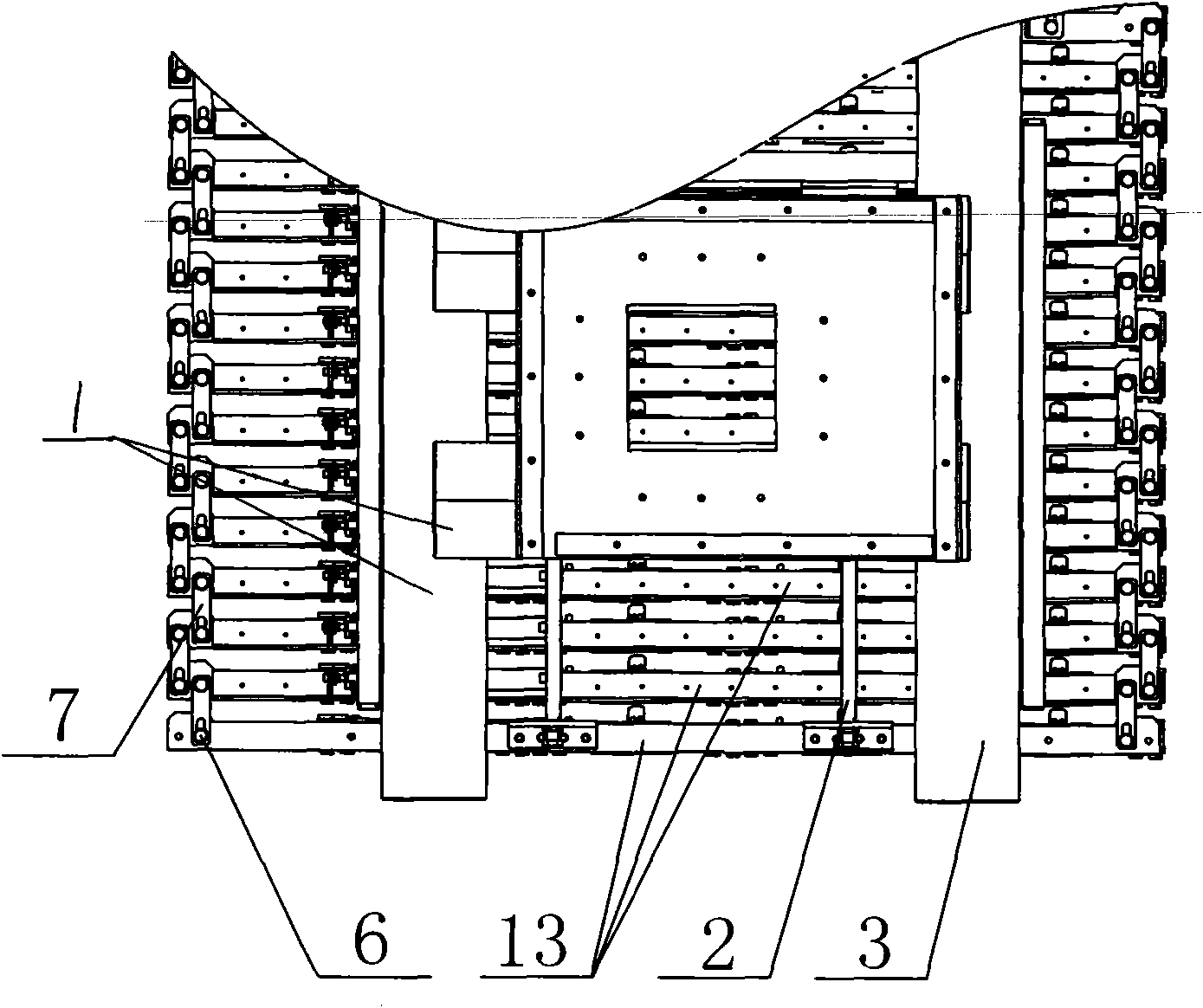

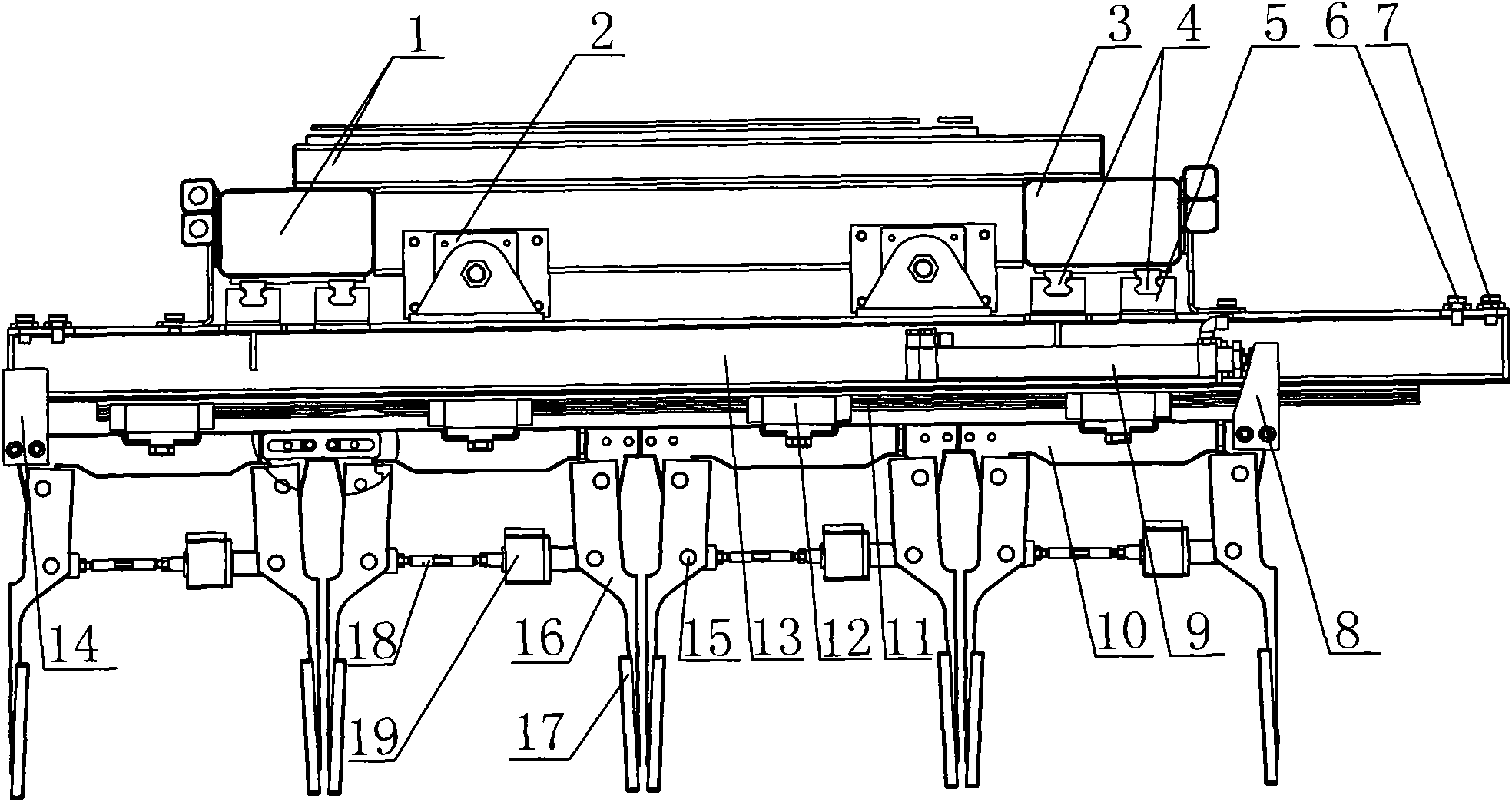

[0014] by Figure 1-Figure 4 It can be seen that a two-way gathering device for grabbing bricks of a brick palletizer includes a grab frame 1, a longitudinal gathering cylinder 2, a longitudinal guide rail 4, a longitudinal sliding block 5, a longitudinal limit pin 6, a longitudinal limit plate 7, and a grab The claw beam 13, the pin shaft 15, the single claw 16 and the single claw sleeve 17. The grab frame 1 consists of a longitudinal main beam 3 (rectangular beams arranged in the front and rear direction) arranged symmetrically and a front on the upper surface of the longitudinal main beam 3. The horizontal sub-beams (all rectangular beams arranged in the left and right directions) are assembled and welded together, and the left and right longitudinal guide rails, which are also arranged in the front and rear directions, are installed symmetrically on the bottom of the left and right longitudinal main beams 3. 4 (I-shaped), on the two sets of left and right longitudinal rails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com