Patents

Literature

688results about How to "Improve tunneling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

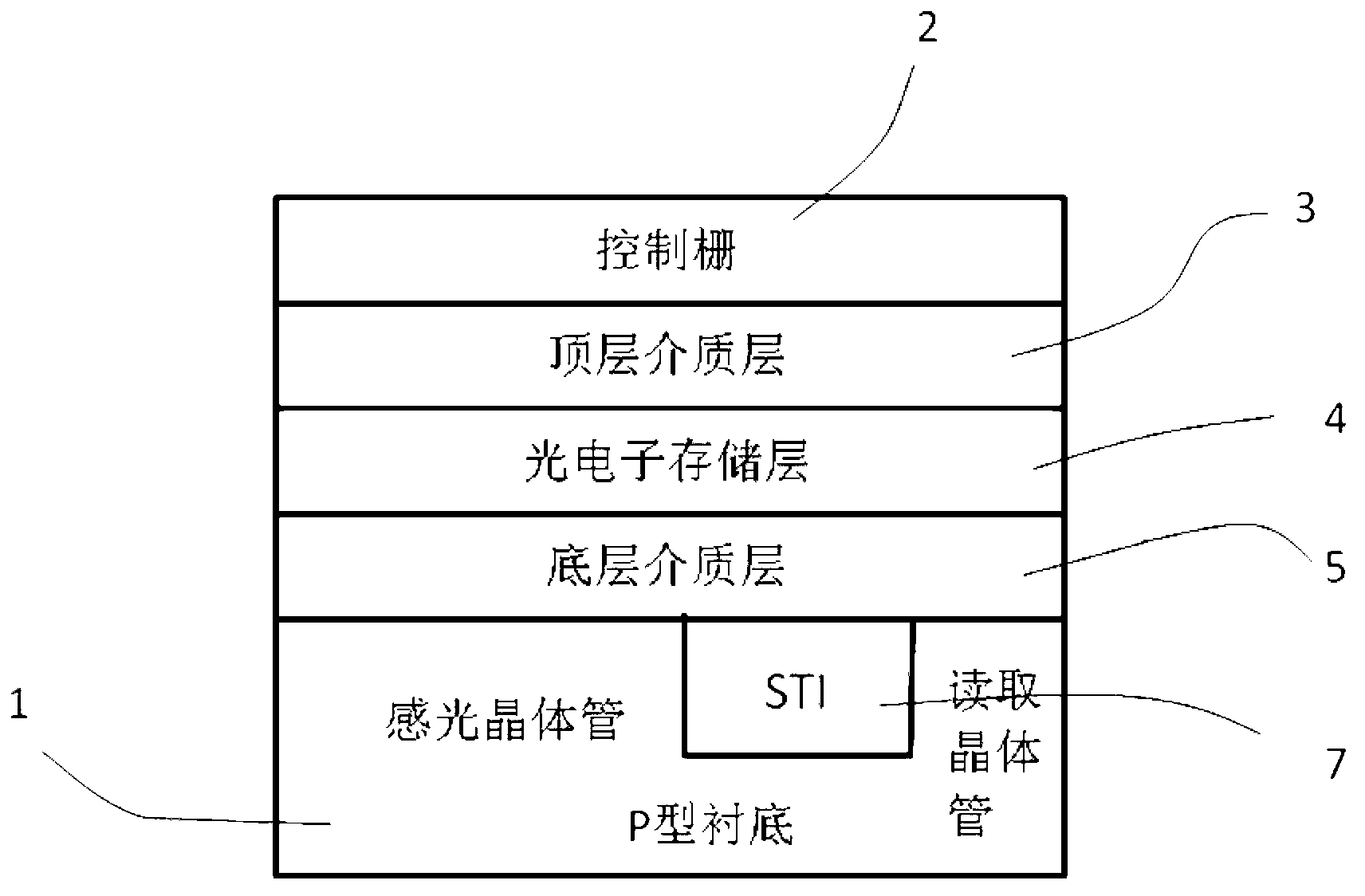

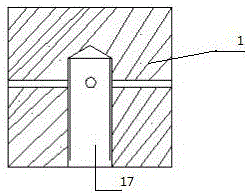

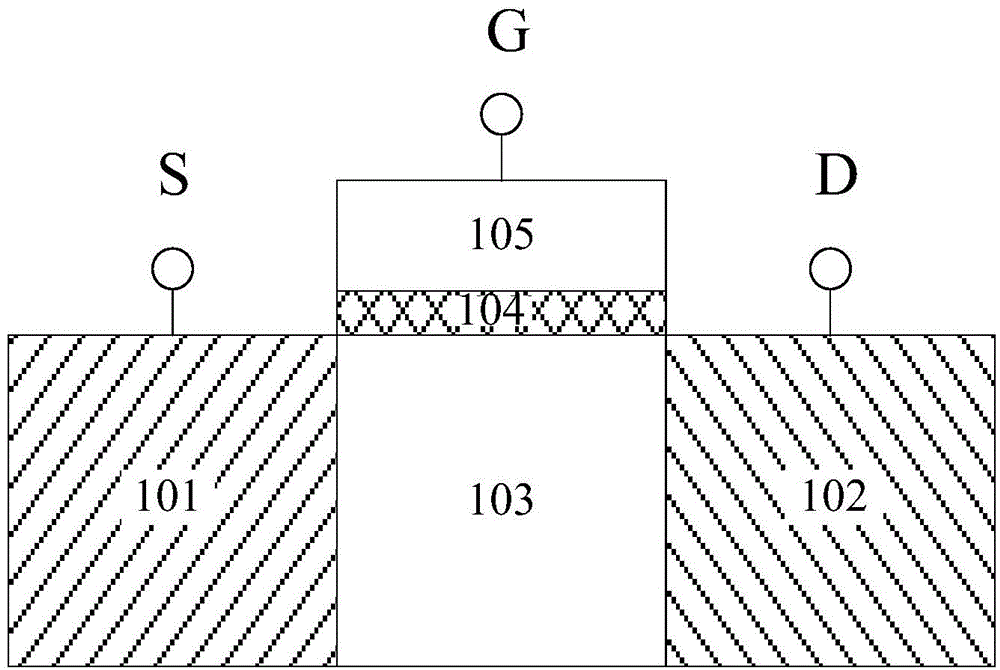

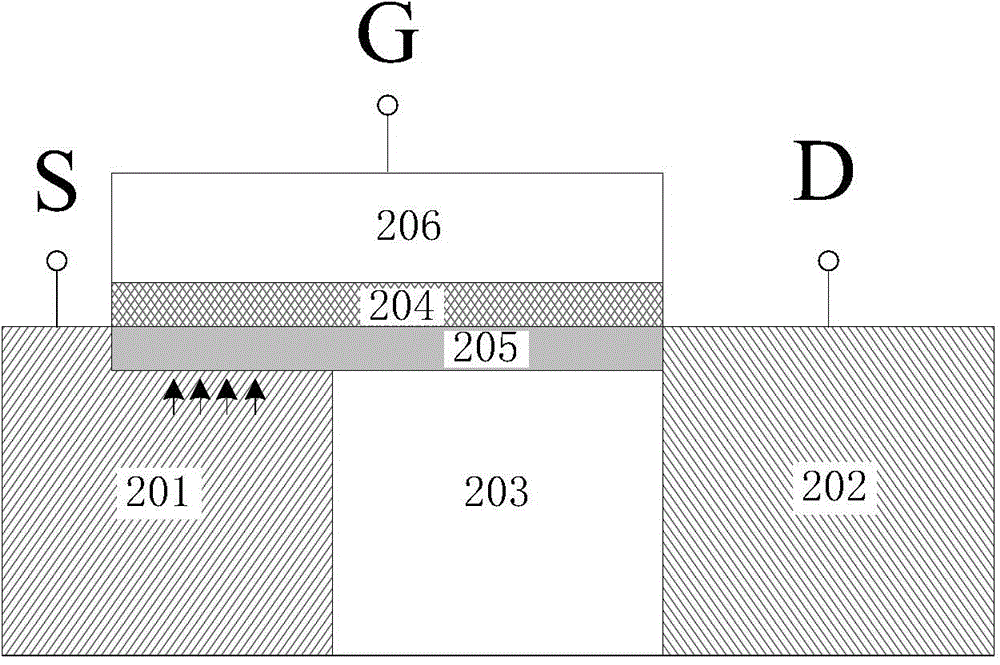

Composite dielectric grating metal-oxide-semiconductor field effect transistor (MOSFET) based dual-transistor light-sensitive detector and signal reading method thereof

ActiveCN102938409APhotosensitiveRealize functionTelevision system detailsColor television detailsMOSFETSemiconductor materials

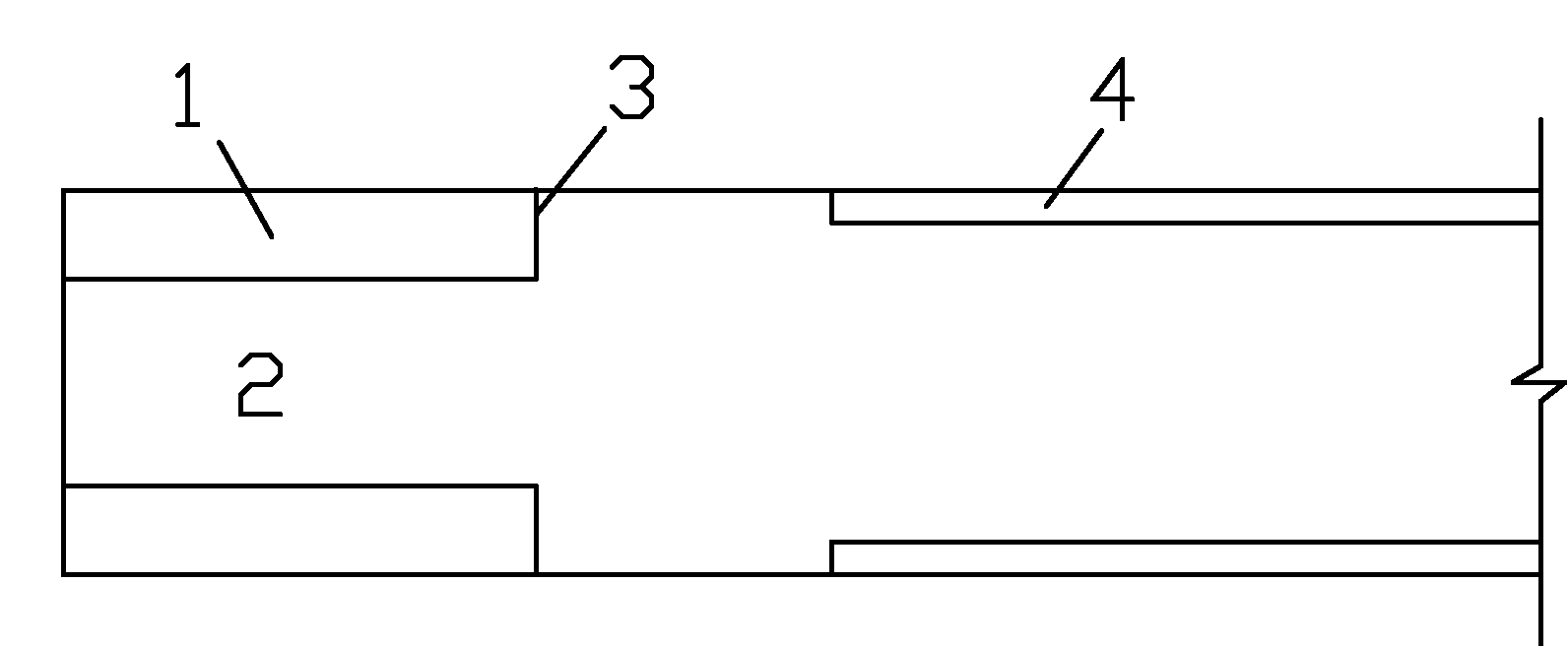

The invention discloses a composite dielectric grating MOSFET based dual-transistor light-sensitive detector. Each of the unit detectors comprises two transistors, wherein the two transistors comprise a photoreceptive transistor and a reading transistor which are used for implementing the photoreceptive function and the reading function respectively, both of the two transistors are formed above a composite dielectric grating MOSFET substrate P-type semiconductor material (1) and are separated through shallow trench isolation (STI), a bottom layer of an insulating dielectric material, a top layer of the insulating dielectric material and a control grid (2) are arranged above the substrate P-type semiconductor material respectively, a photoelectron storage layer (4) is arranged between the two layers of insulating dielectric materials, a source / drain electrode is arranged on the reading transistor to read signals, and the two transistors are connected through the photoelectron storage layer, so that the reading transistor can read photoelectrons which are stored by the photoreceptive transistor in the photoelectron storage layer through sensitization.

Owner:南京威派视半导体技术有限公司

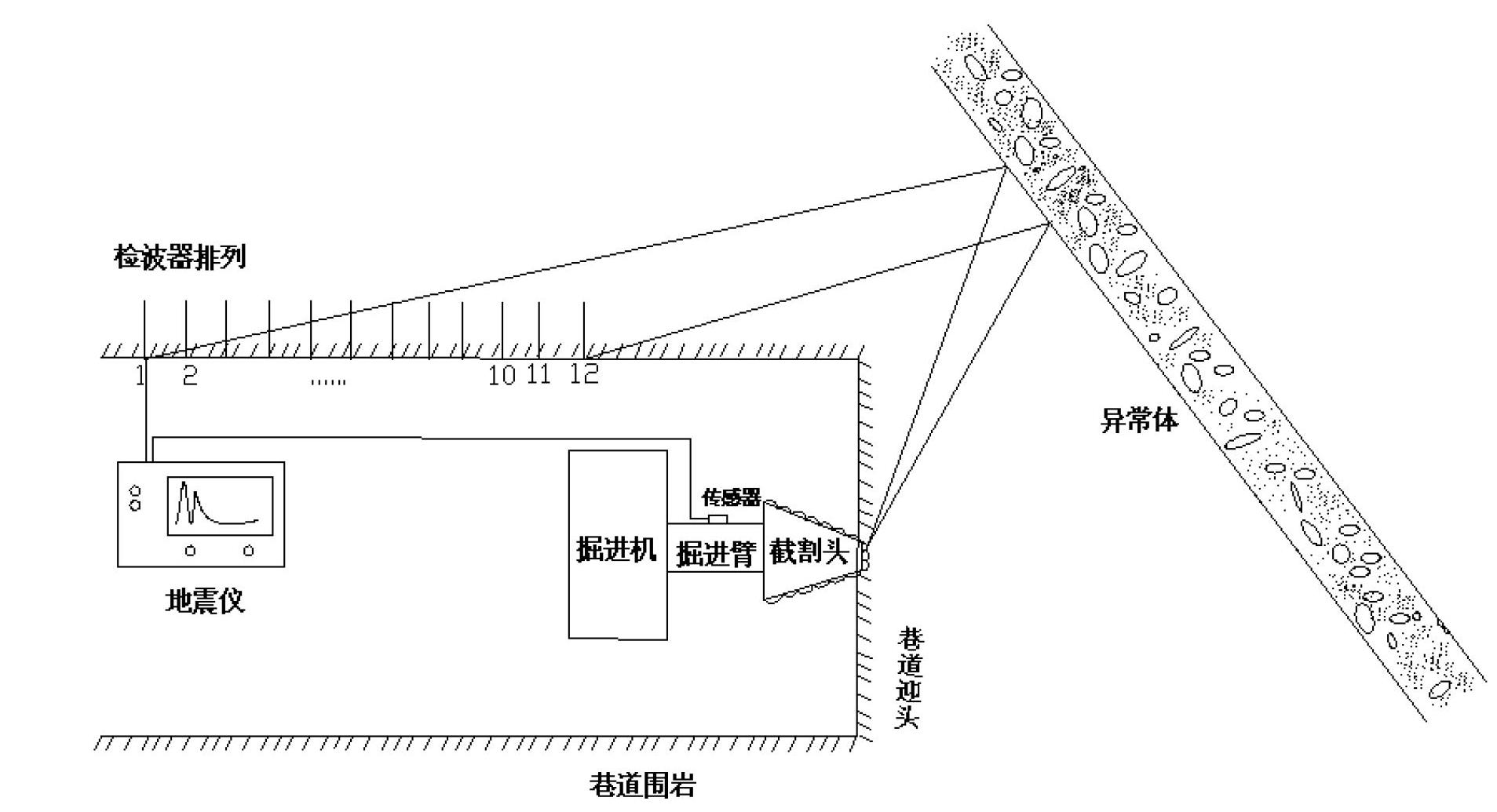

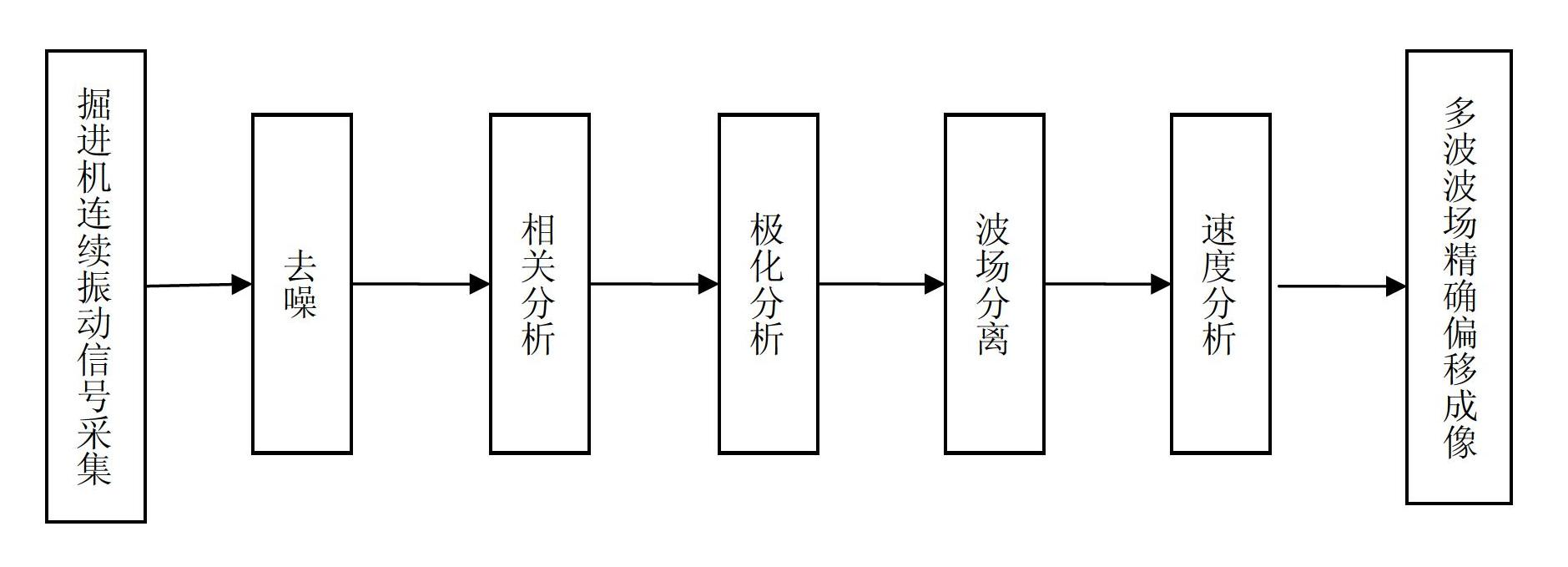

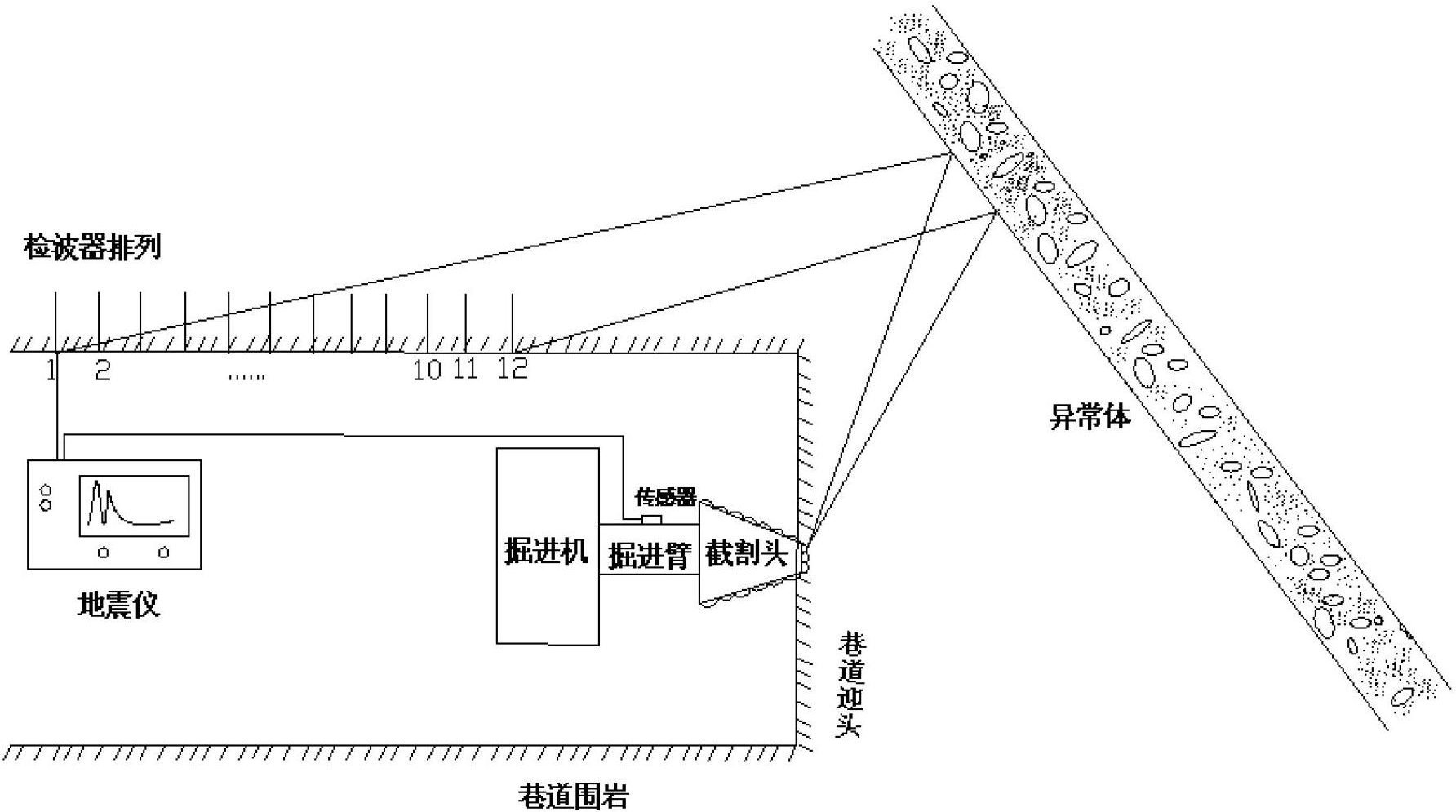

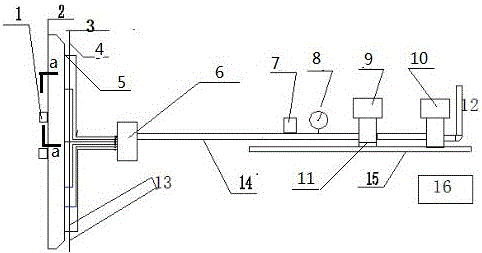

Tunnel heading-along earthquake advanced detection device taking heading machine as earthquake focus and method thereof

The invention discloses a tunnel heading-along earthquake advanced detection device taking a heading machine as an earthquake focus and a method thereof. The device comprises an earthquake detector, an earthquake focus signal receiving sensor and an earthquake wave receiving detector array, wherein the earthquake focus signal receiving sensor is arranged on the arm of the heading machine; and the earthquake wave receiving detector array is arranged on a tunnel wall. The method comprises the following steps of: continuously acquiring earthquake wave signals through a three-component sensor which is coupled on the arm of the heading machine and a three-component sensor array which is arranged on tunnel surrounding rock by taking vibration generated by cutting rock with a cutting head during working of the heading machine as a hypocenter; and recording the acquired signals for processing, and forecasting the position and structural detail of a geological anomalous body in front of a tunnel by analyzing received wave field imaging geometrical characteristics. Due to the adoption of the device and the method, the problem of oneness of an earthquake wave field of a pure explosive source in near flat ground layer tunnel advanced detection can be solved without influencing the tunnel heading work; the device has high working efficiency and high detection accuracy, and is free from safety risks; and accurate positioning of a geometrical anomalous body can be realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

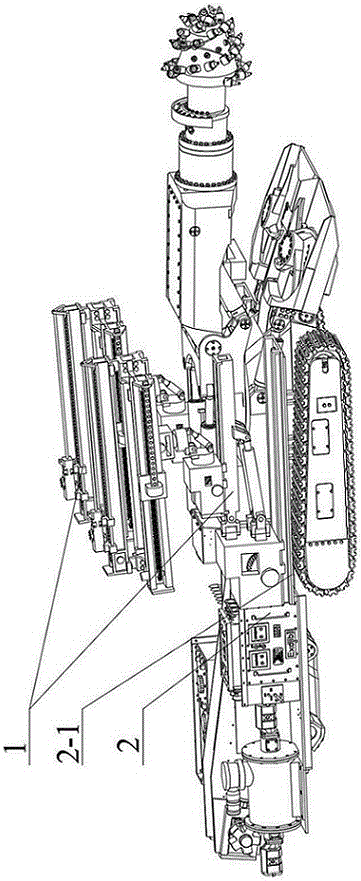

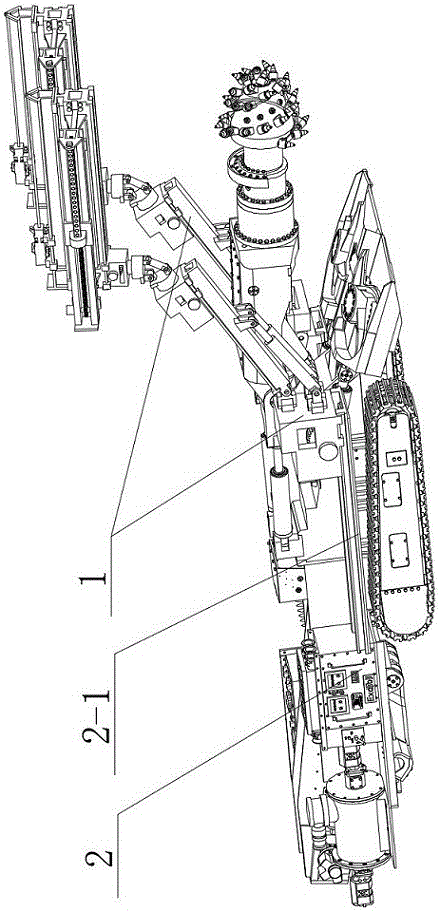

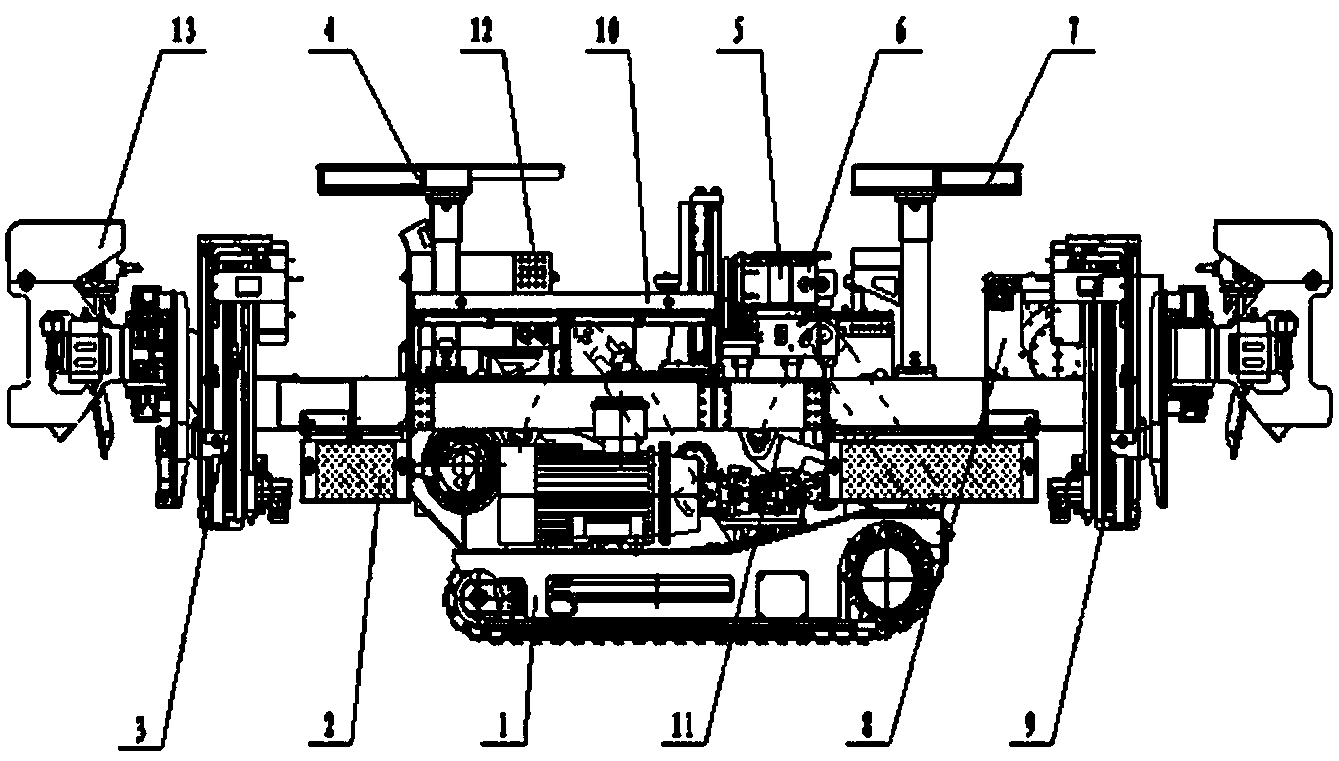

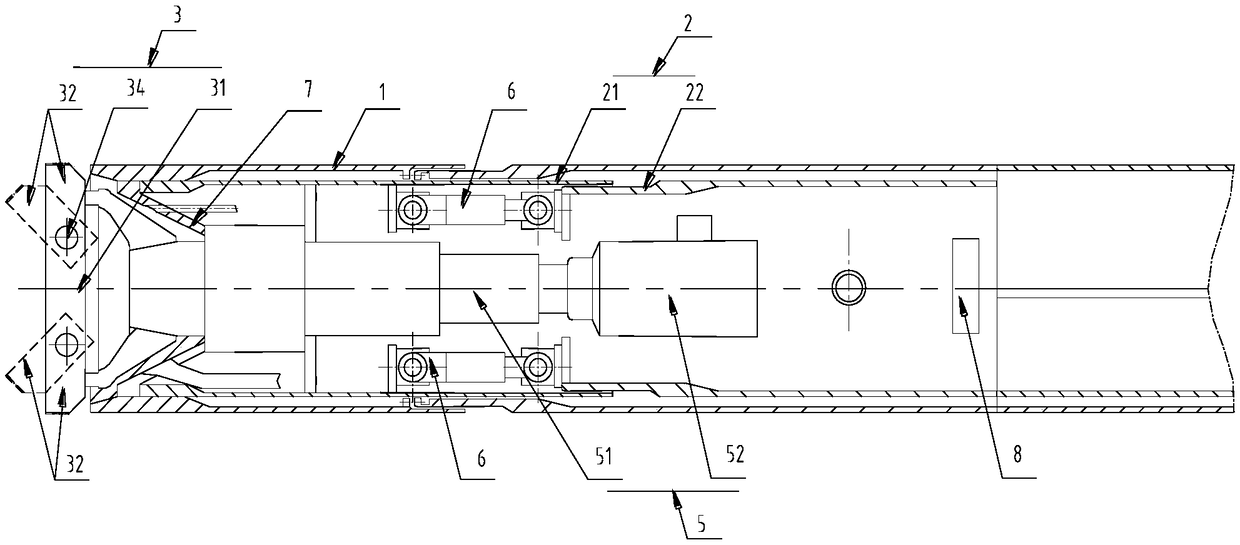

Drilling and bursting type heading machine

ActiveCN105804764AImprove drilling efficiencyLow drilling efficiencyDisloding machinesSlitting machinesHydraulic motorHydraulic cylinder

The invention discloses a drilling and bursting type heading machine which comprises a drilling and bursting device, an angle control device, a front-back telescopic device and a cantilever type heading machine body. The drilling and bursting device is installed on a front-back moving component of the front-back telescopic device. The front-back telescopic device is installed on the cantilever type heading machine body. The drilling and bursting device comprises a fixing frame, a rock drill component and a bursting device component, wherein the rock drill component and the bursting device component are fixed to and installed on the fixing frame. The angle control device comprises an installation base, an auxiliary rotary hydraulic motor, an adjusting hydraulic cylinder and a main rotary hydraulic motor. When the front-back moving component of the front-back telescopic device completely stretches out, the distance between the front end of the drilling and bursting device and a working surface is smaller than the distance between the front end of a cutting head of the cantilever type heading machine body and the working surface. The drilling and bursting type heading machine is compact in structure, a hard rock stratum with the rock stratum hardness being larger than 10 can be rapidly drilled and burst on the premise that the energy consumption is not increased, and accordingly the purposes of improving the heading efficiency and reducing potential safety hazards are achieved.

Owner:CHINA UNIV OF MINING & TECH

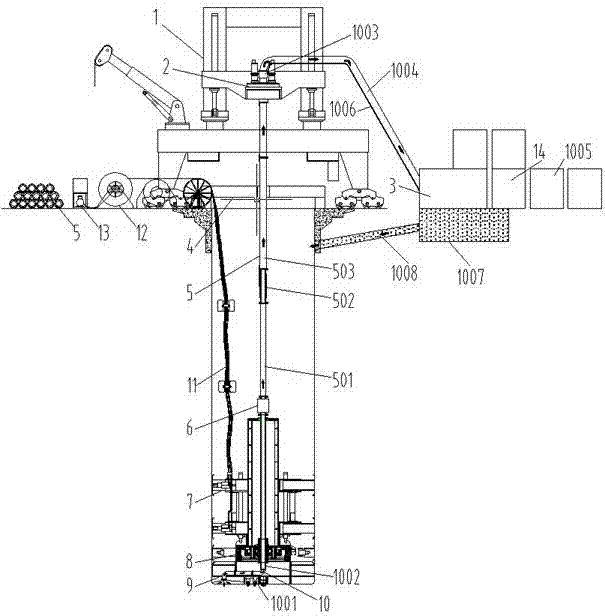

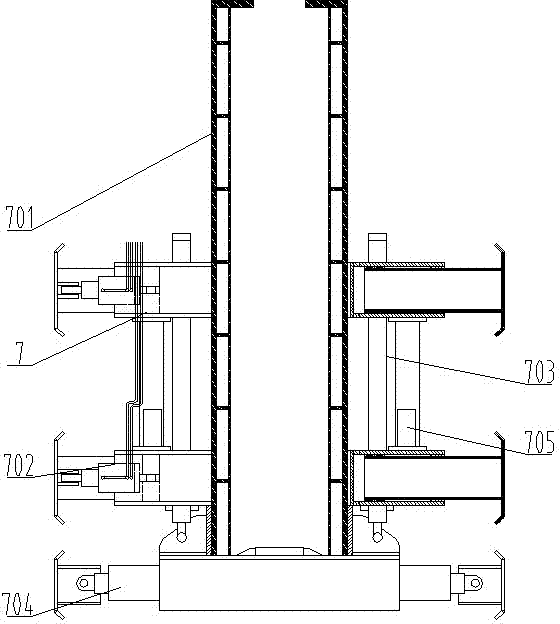

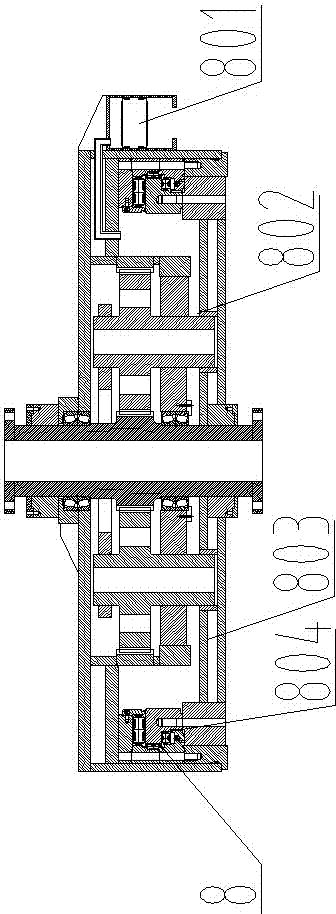

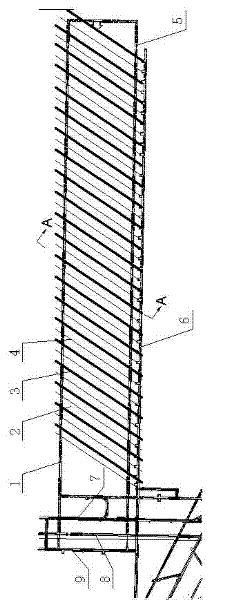

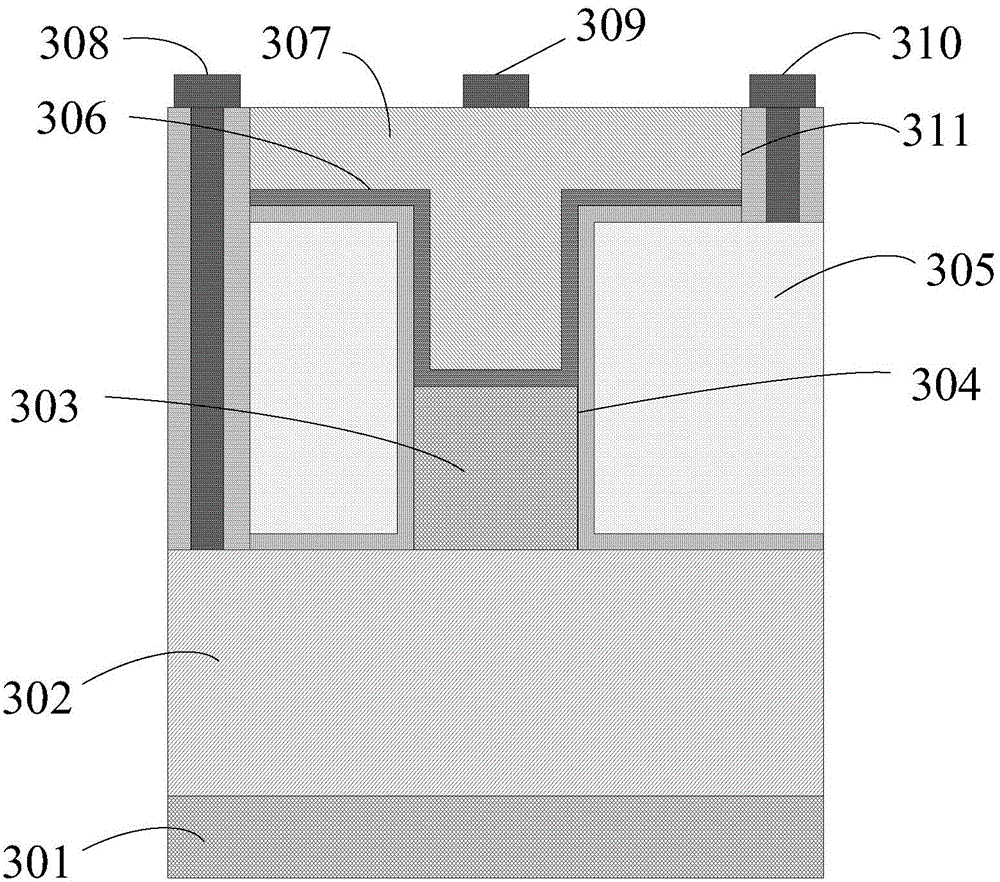

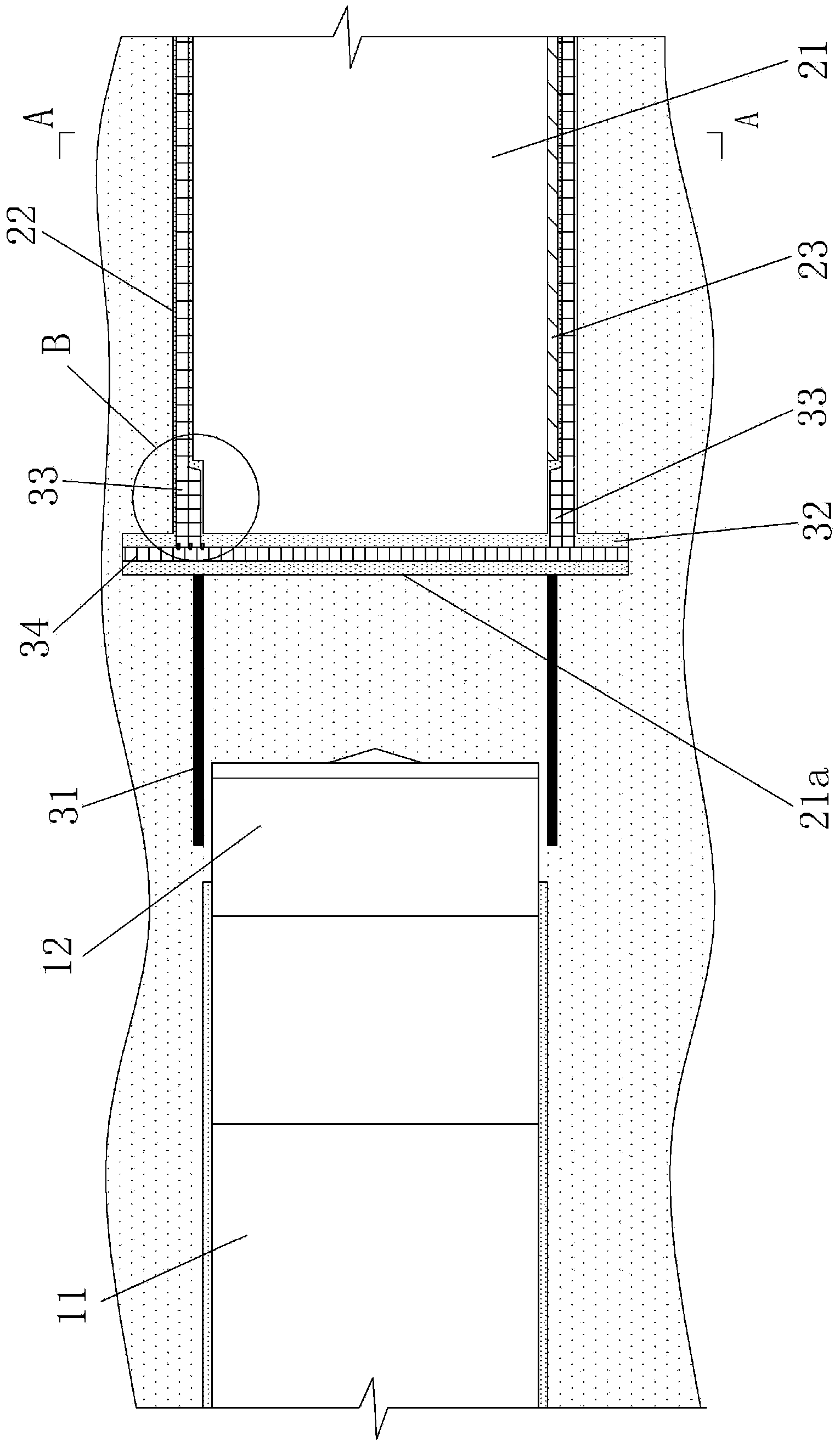

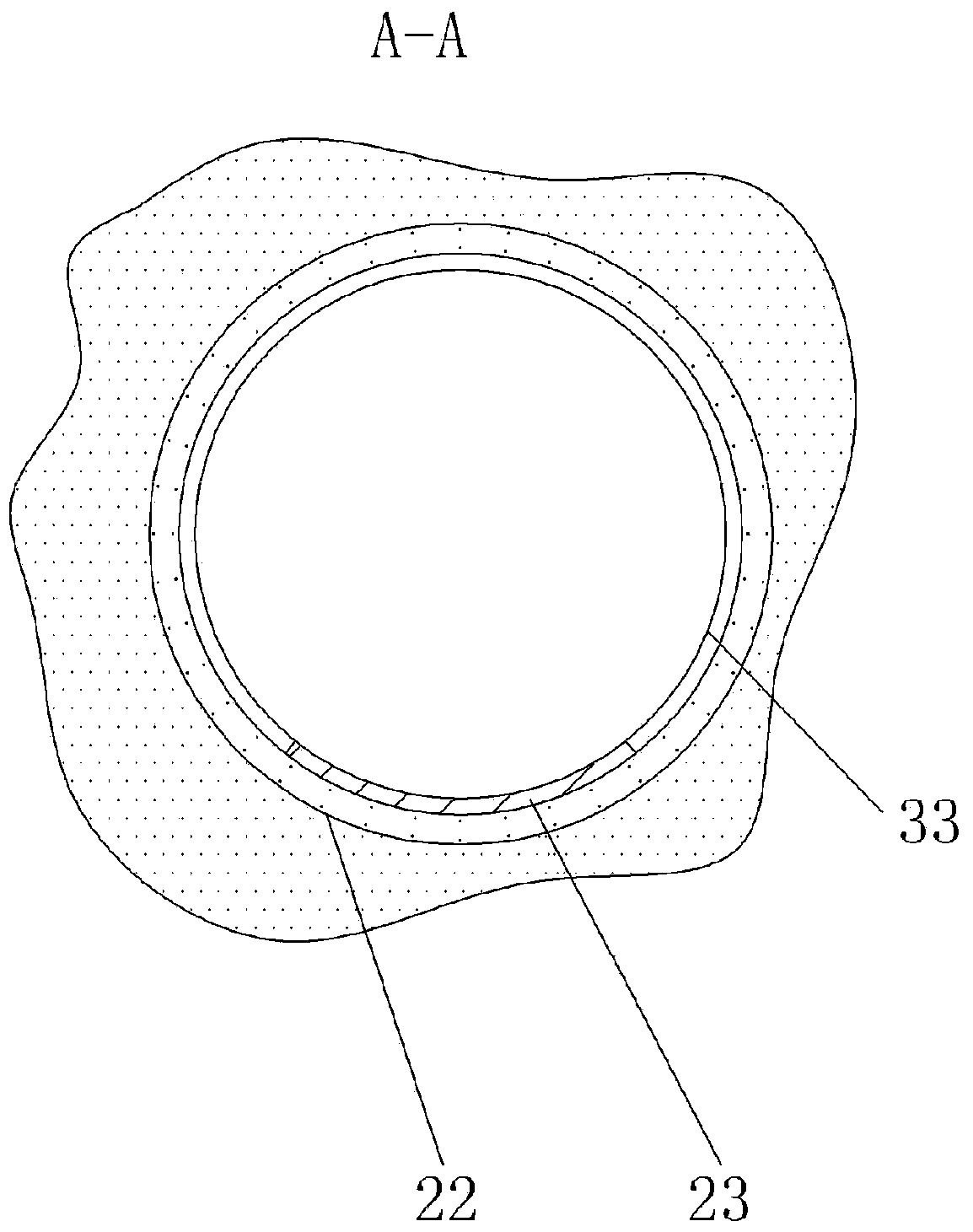

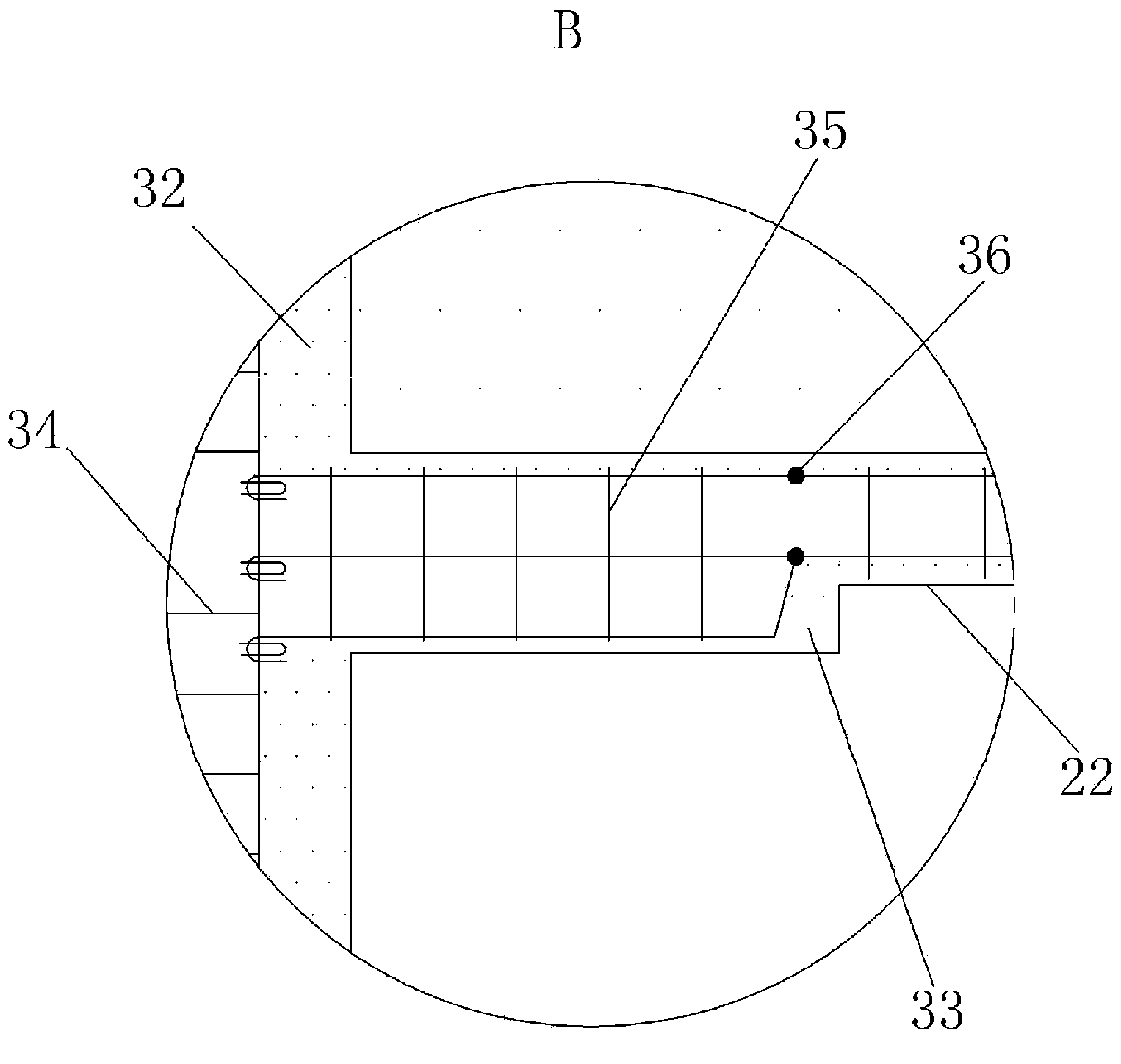

Novel drilling method for shaft drilling machine

ActiveCN103899316AImprove stabilityImprove construction efficiencyDerricks/mastsBorehole drivesSlagWell drilling

A novel drilling method for a shaft drilling machine mainly comprises a derrick and an opening-sealing flat wagon which are arranged at a well opening, and further comprises a drill rod, a flexible connector, a stable pressing device, a torque amplification driving device, a cutter head, a slag discharging system, a mud treatment station, an electric appliance cabinet, a hydraulic pressure station and a power pipeline. A main drive is arranged on the derrick, the lower portion of the main drive is connected with the drill rod, the flexible connector is arranged on the drill rod, the lower end of the drill rod is connected with the torque amplification driving device, the lower end of the torque amplification driving device is connected with the cutter head, the stable pressing device is arranged outside the torque amplification driving device; muck dug by the cutter head in a well is delivered to the mud treatment station on the ground through the slag discharging system. According to the novel drilling method for the shaft drilling machine, stability of the whole machine is increased, pressing force of equipment is improved, drilling torque is increased, construction in soft soil layers is available and construction in rock stratums of high hardness is also available, guide is more accurate, so that shaft construction efficiency can be improved, shaft construction cycle is shortened, and finished well quality is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

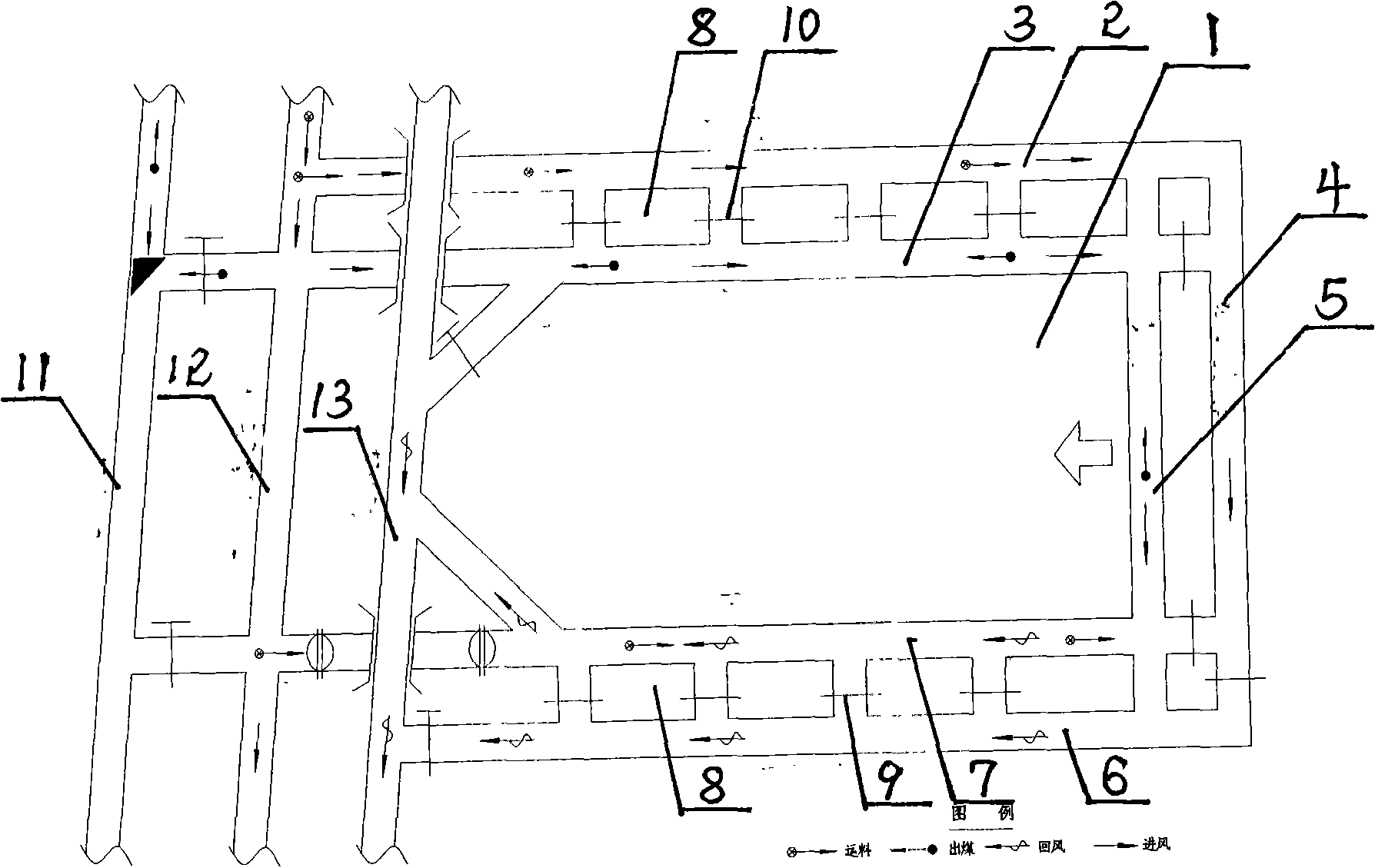

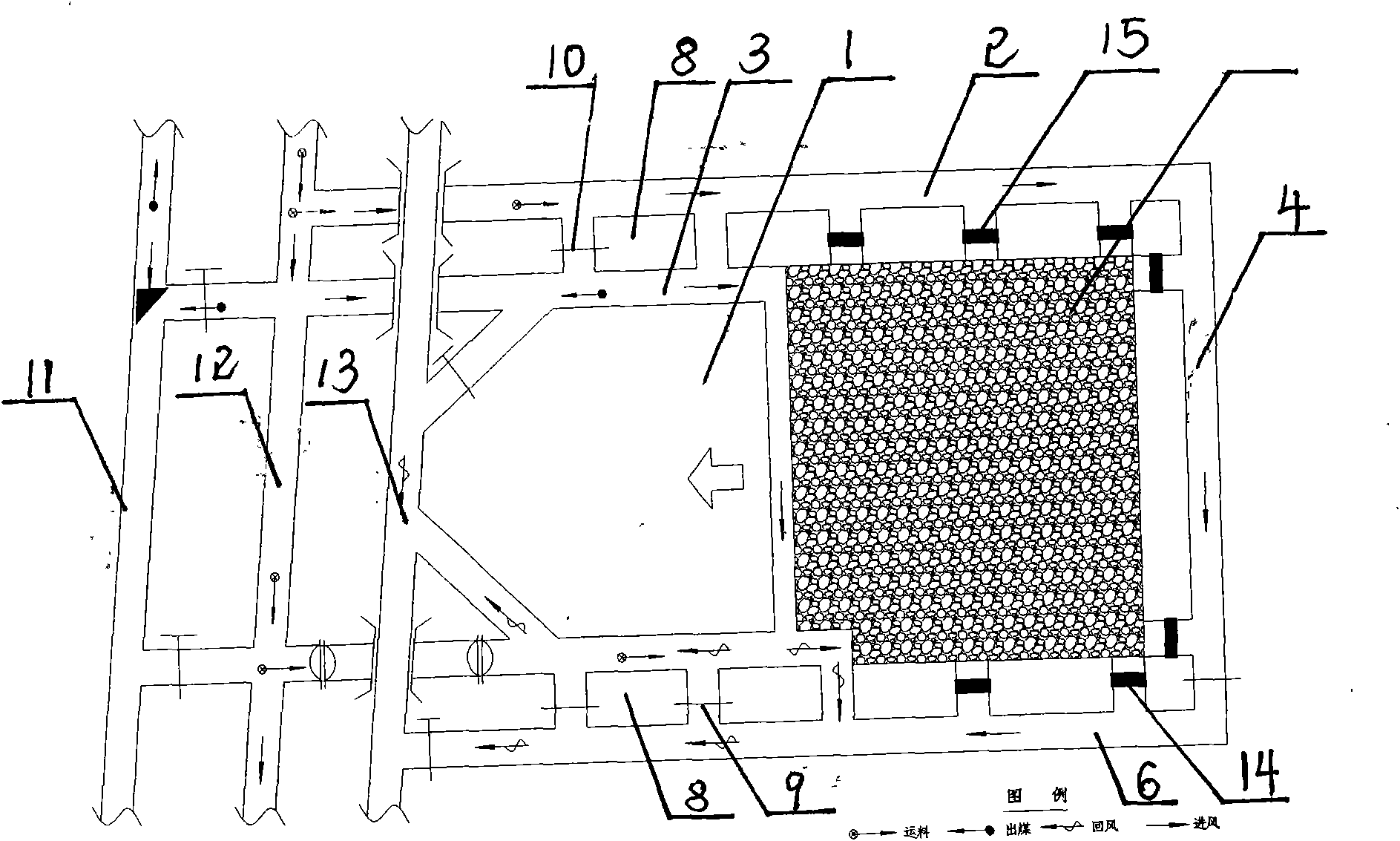

Laneway disposed by using large U to sleeve small u

InactiveCN101649741ARealize continuous excavationImprove governance effectUnderground miningTunnel/mines ventillationEngineeringCoal pillar

The invention relates to a laneway disposing shape of a coal mine, in particular to a laneway disposed by using large U to sleeve small u, which solves the problems of driving along a groove and gas control of a stope in the prior laneway disposing mode. The laneway comprises a stope, a small u-shaped laneway is arranged at the periphery of the stope, the small u-shaped laneway comprises a belt laneway and a return airway which are arranged on both sides of the stope, the front side of the stope is provided with a cutting hole, a large U-shaped laneway is arranged outside the small u-shaped laneway and comprises a head-to-tail connection device, a ventilation laneway, a ventilation connection laneway and a gas tail laneway, wherein the head-to-tail connection device and the ventilation laneway are positioned outside the belt laneway, the ventilation connection laneway is arranged outside the cutting hole, the gas tail laneway is positioned outside the return airway, and a plurality ofentity supporting coal pillars are arranged between the large U-shaped laneway and the small u-shaped laneway. The laneway disposing shape solves the problem of gas control of the stope and increaseswork efficiency.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

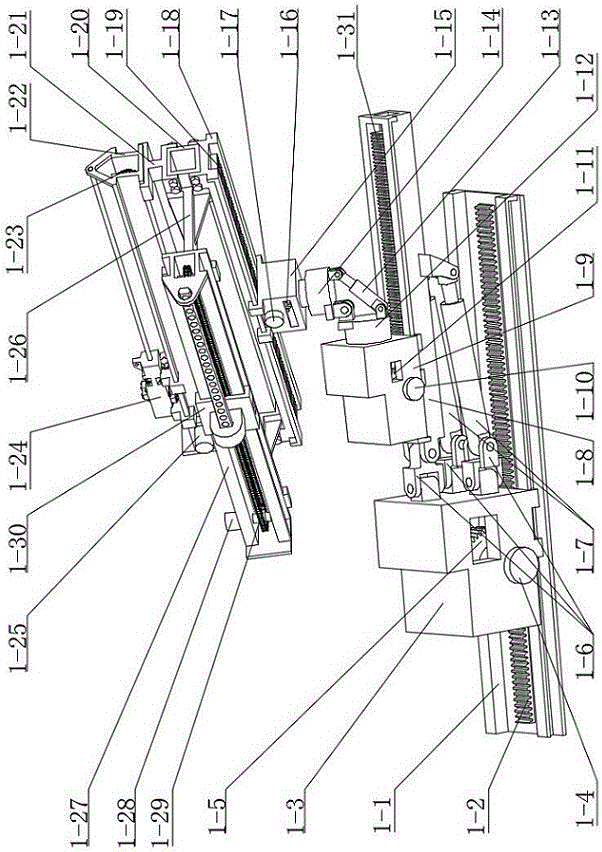

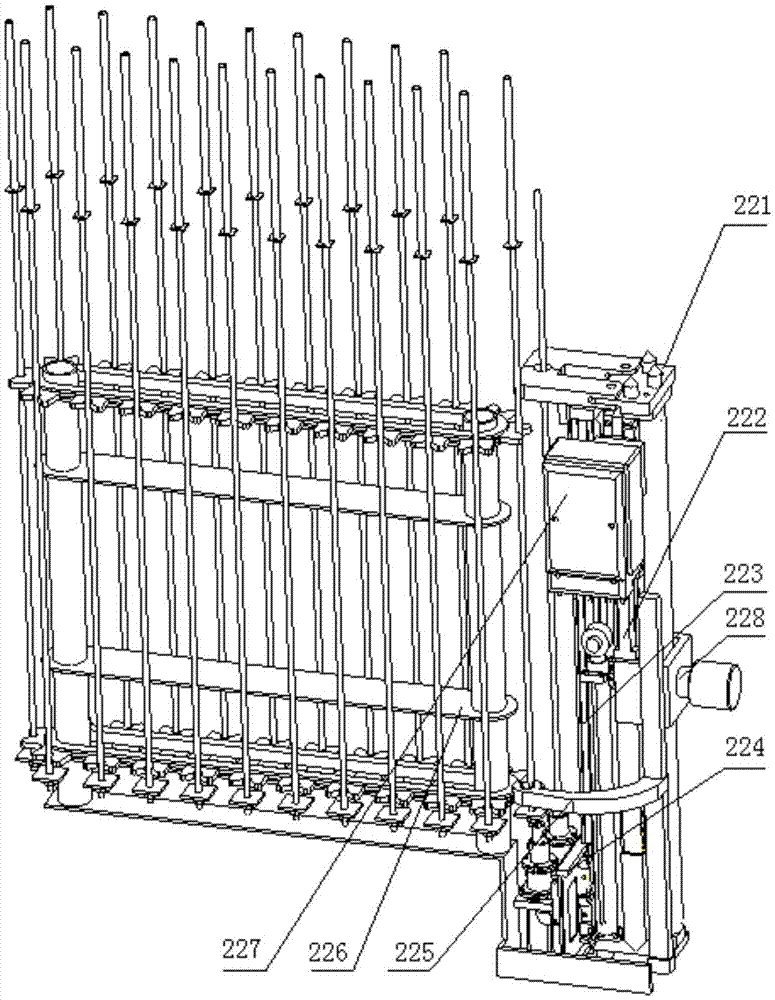

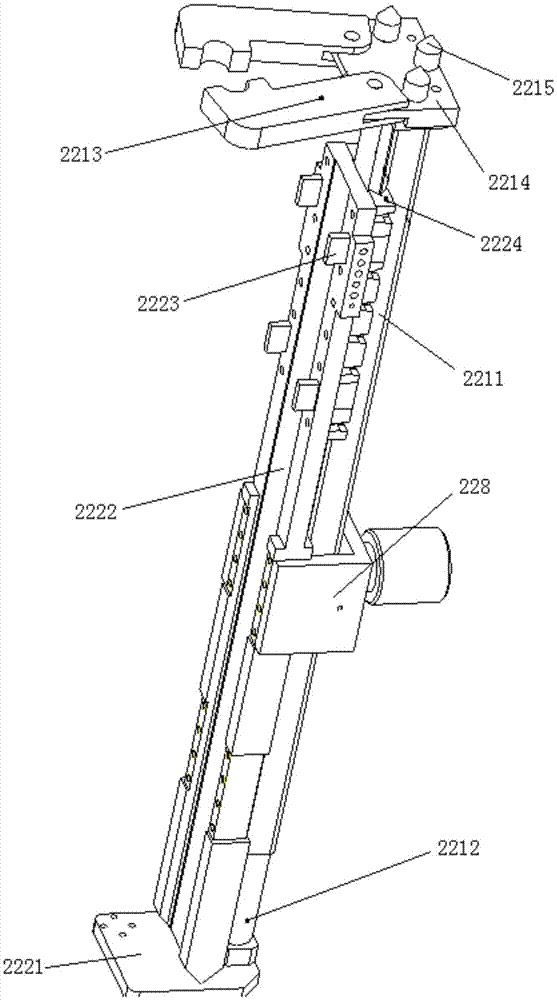

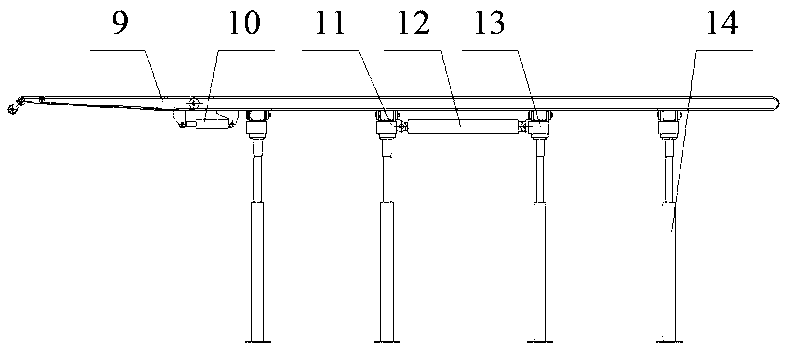

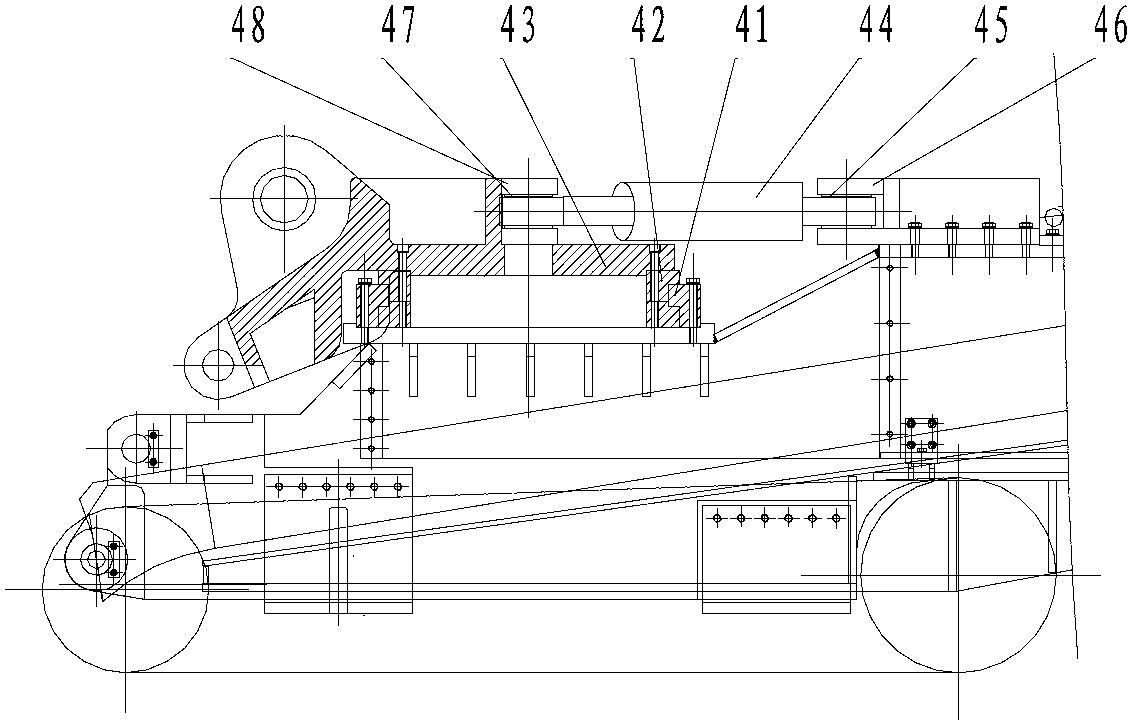

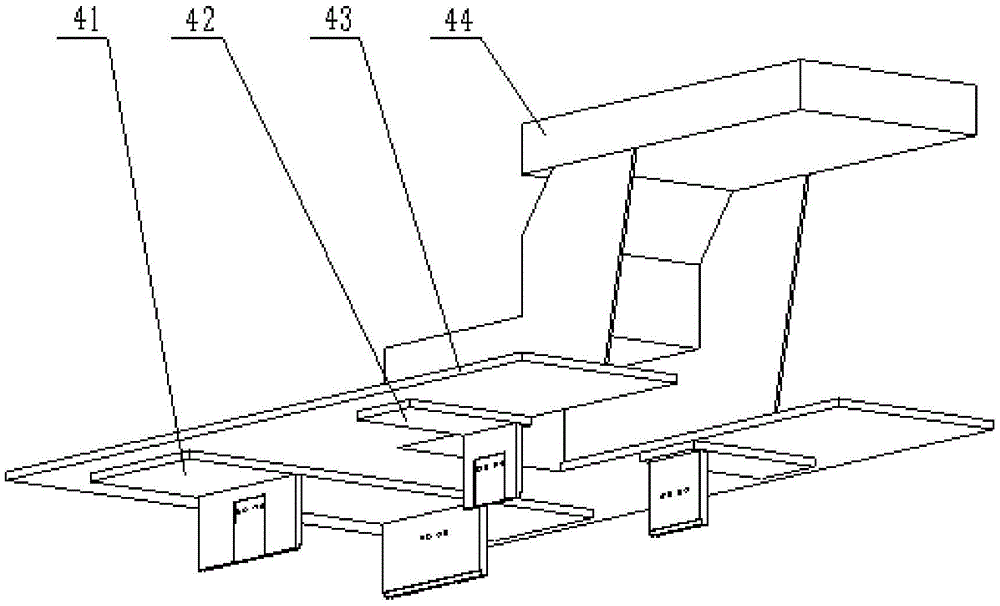

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

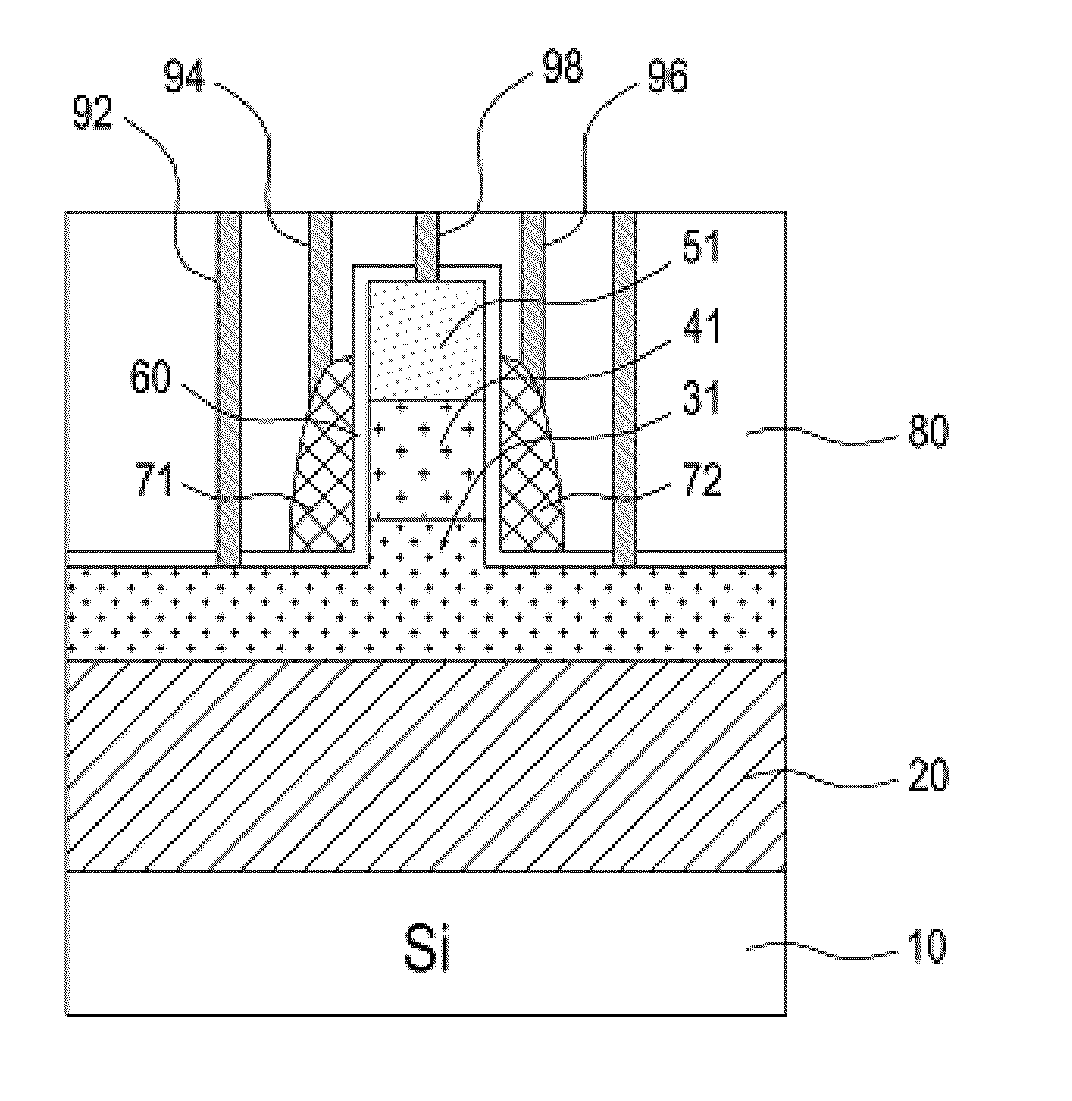

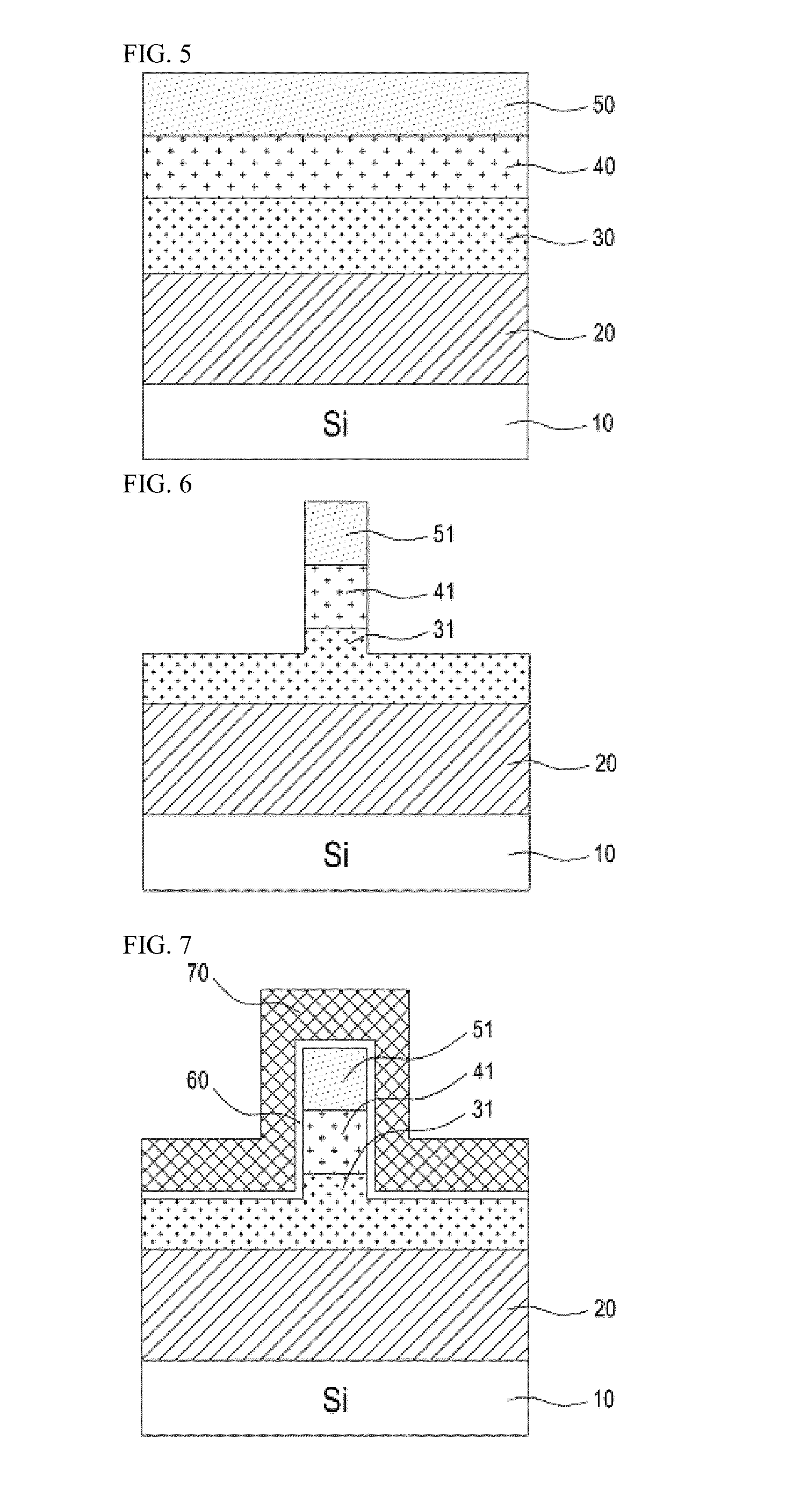

Compound tunneling field effect transistor integrated on silicon substrate and method for fabricating the same

ActiveUS20140291616A1High electron mobilityReduce manufacturing costSemiconductor/solid-state device manufacturingDiodeField effectMaterials science

Compound tunneling field effect transistors integrated on a silicon substrate are provided with increased tunneling efficiency and an abrupt band slope by forming a source region with a material having a bandgap at least 0.4 electron volts (eV) narrower than that of silicon to increase a driving current (ON current) by forming a channel region with a material having almost no difference in lattice constant from a source region and having a high electron mobility at least 5 times higher than silicon. ON / OFF current ratio simultaneously is increased by forming a drain region with a material having a bandgap at least as wide as a channel region material to restrain OFF current. Tunneling field effect transistors having various threshold voltages according to circuit designs are formed easily by adding a specific material with an electron affinity less than a source region material when forming a channel region.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +2

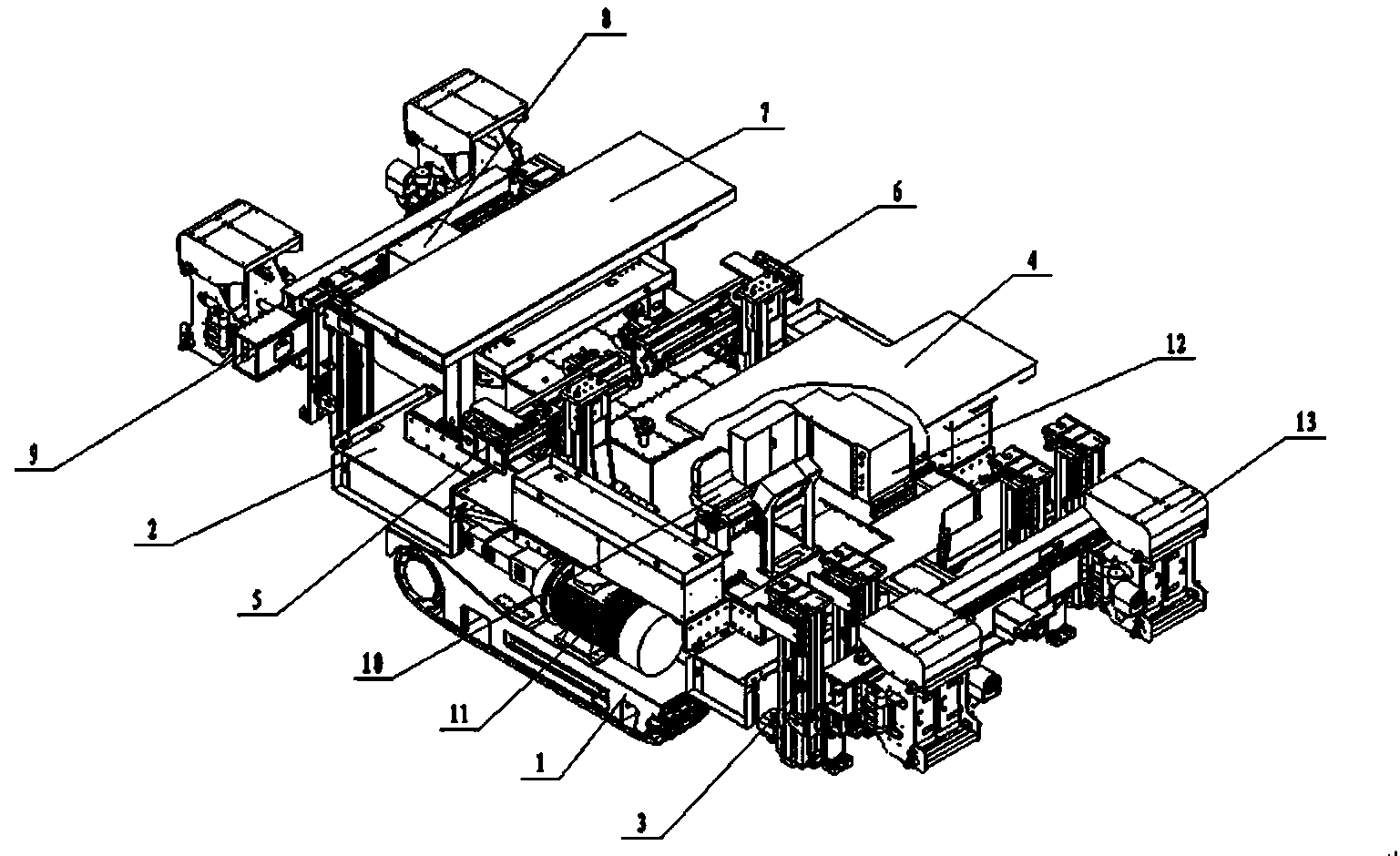

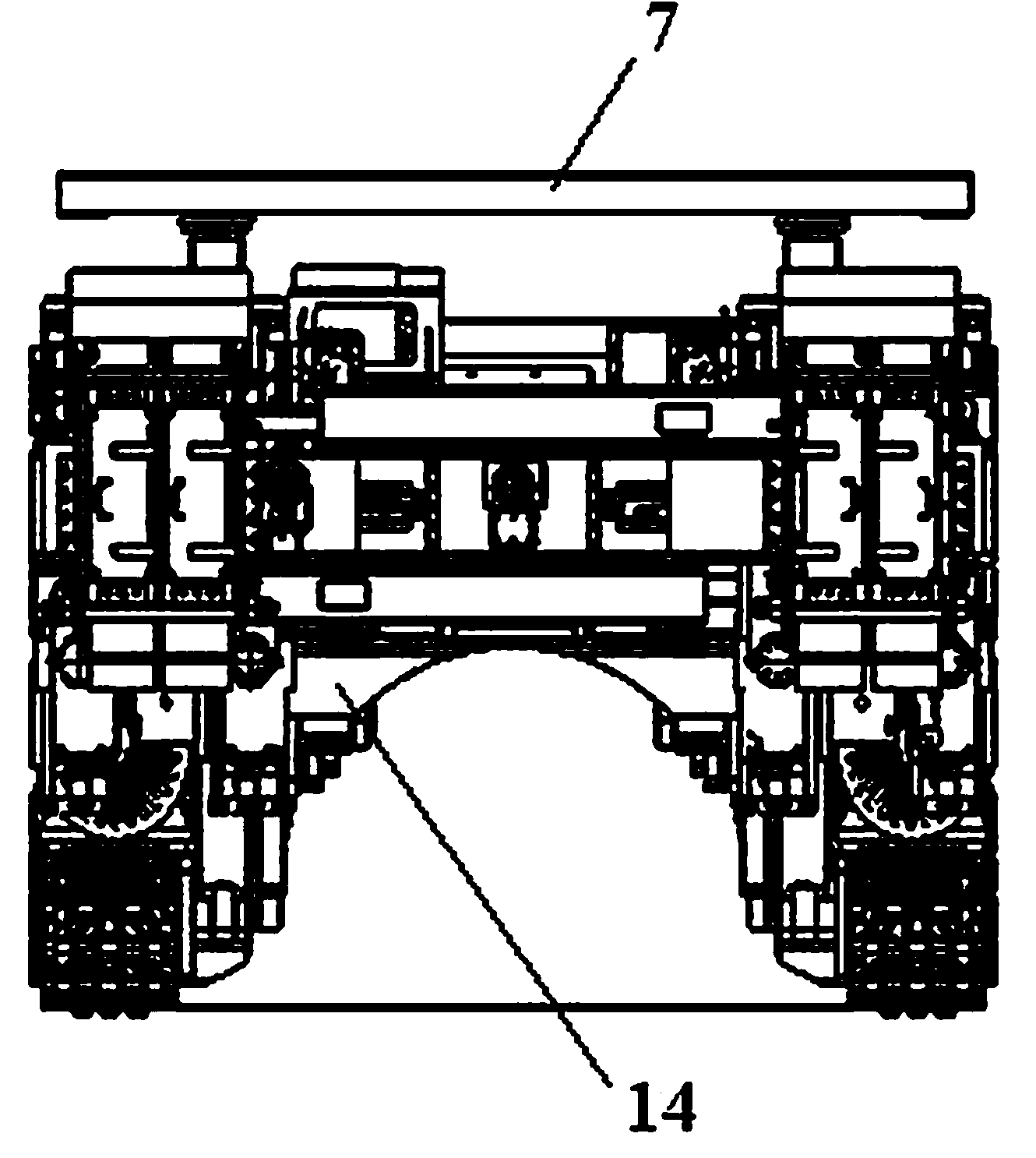

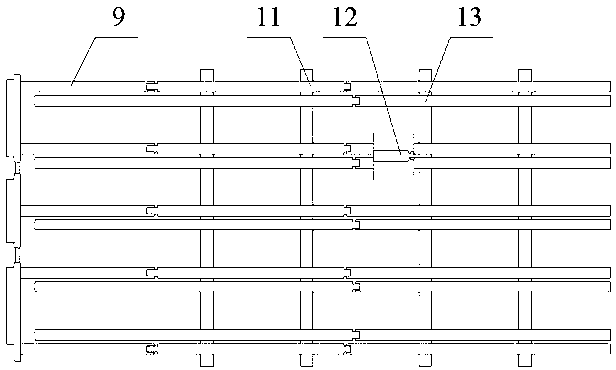

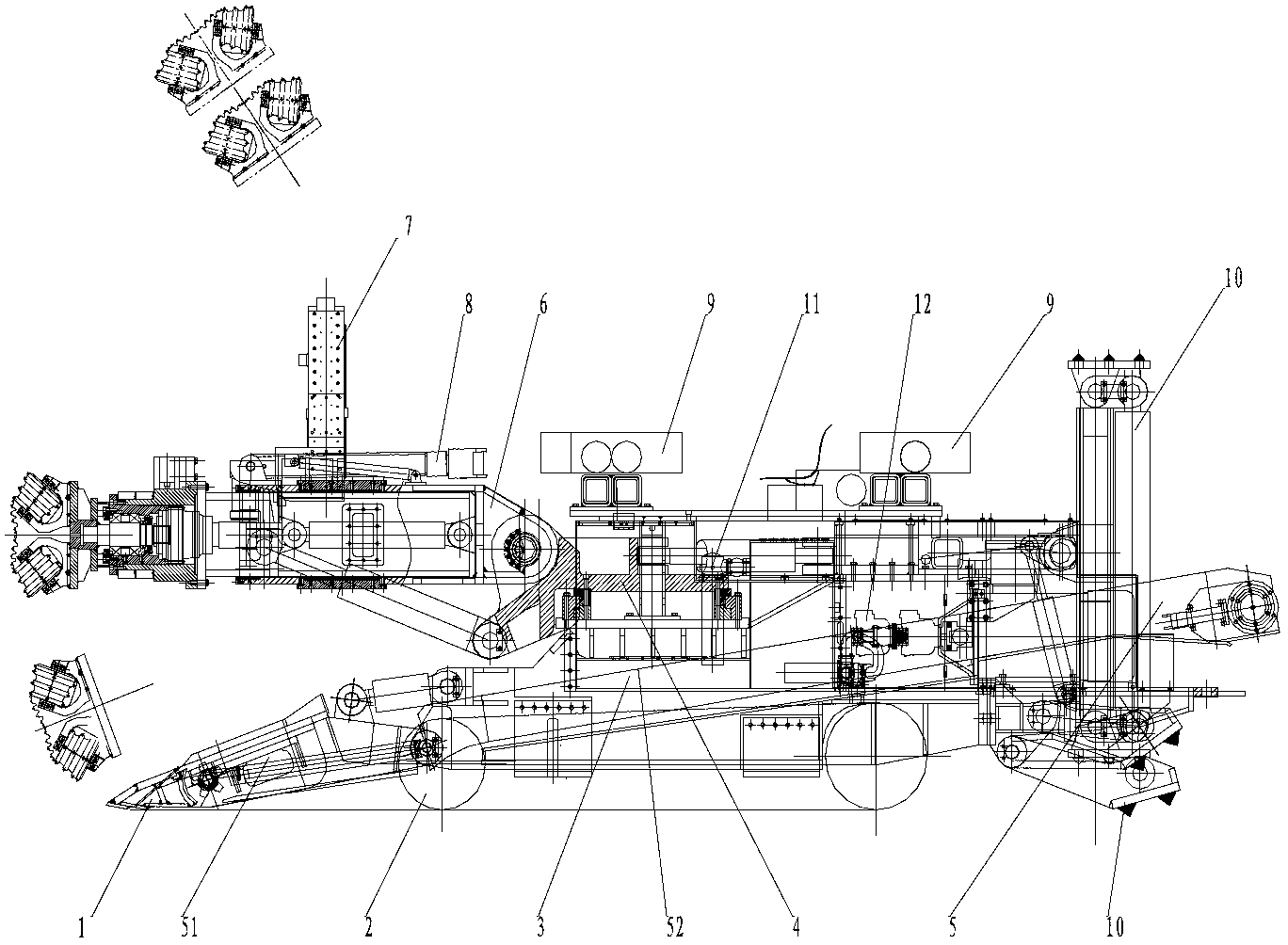

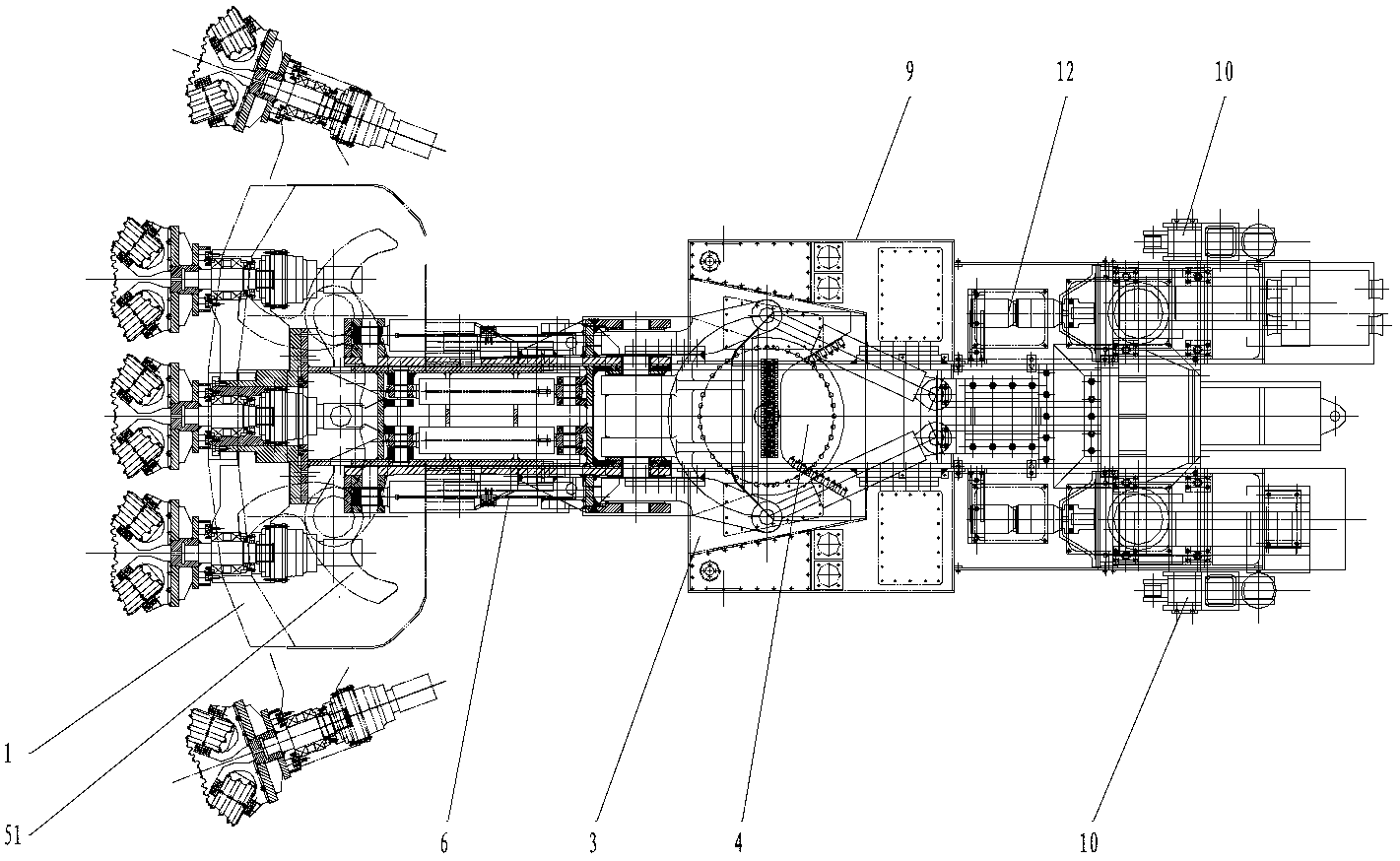

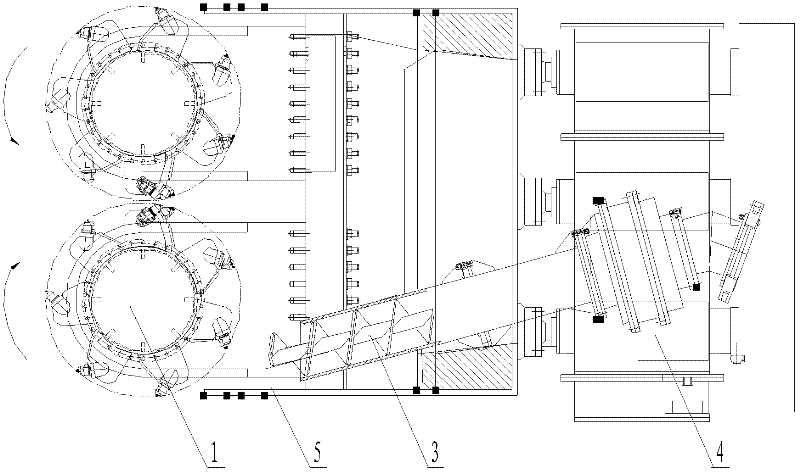

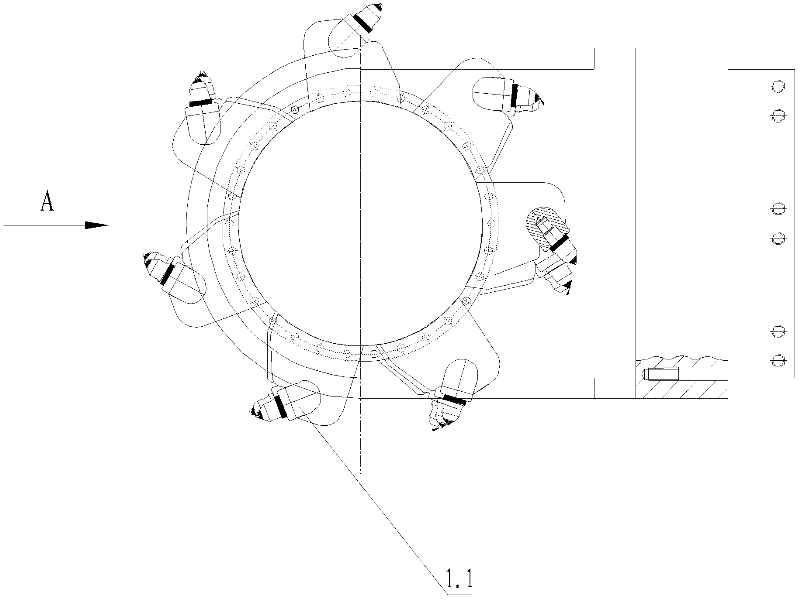

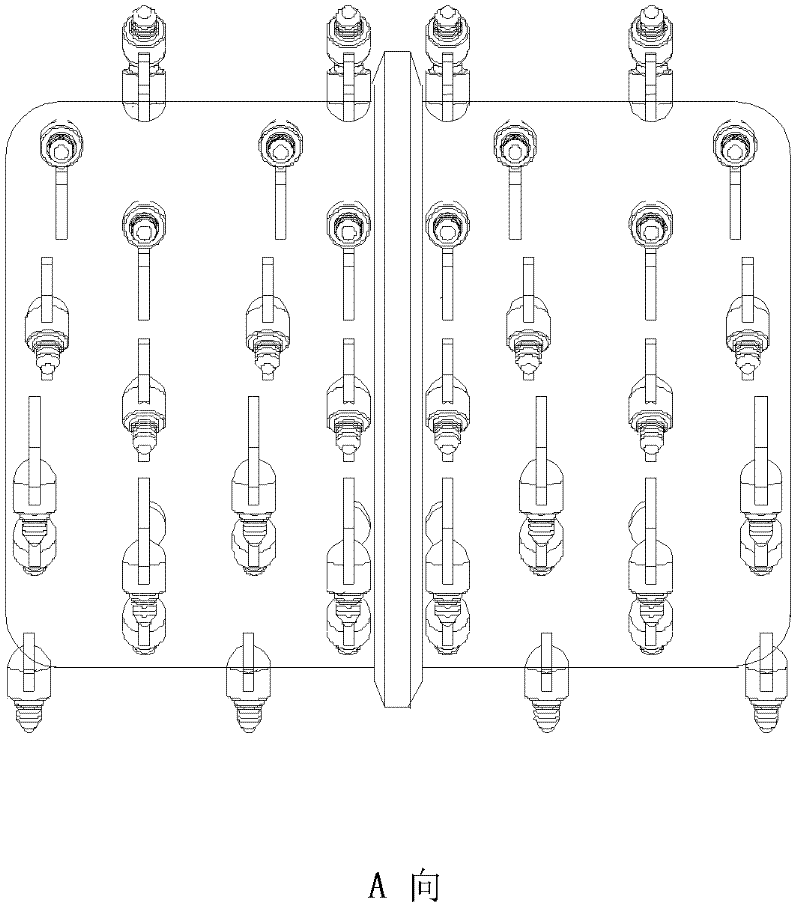

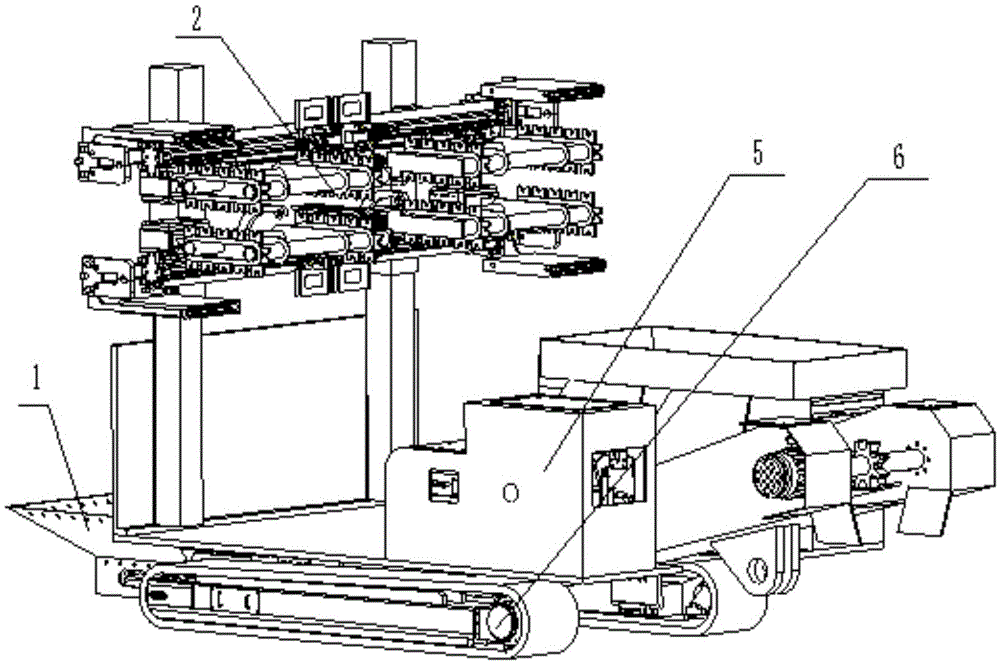

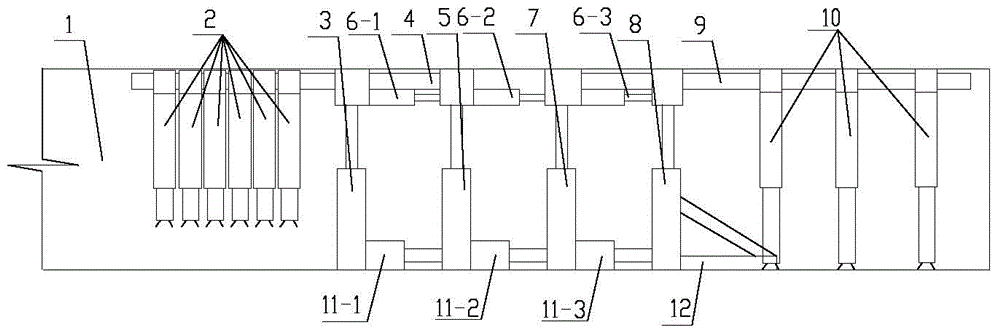

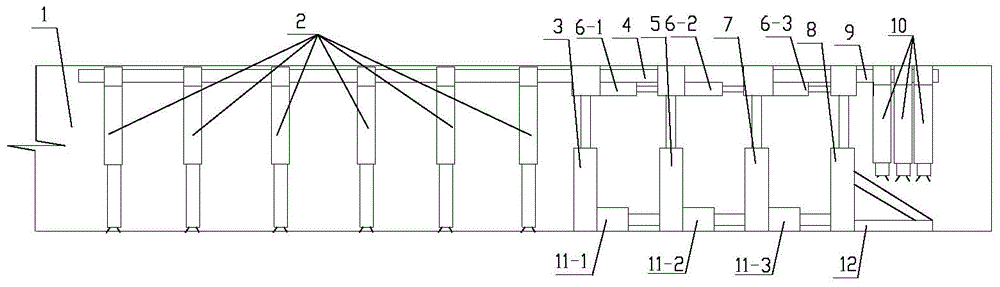

Anchor rod drill carriage integrating coal mine digging, supporting and transportation parallel fast operation

ActiveCN104213831AImprove tunneling efficiencyImplement parallel jobsDerricks/mastsSlitting machinesSelf adaptiveDrill

The invention relates to the field of coal mine underground roadway digging, in particular to an anchor rod drill carriage integrating coal mine digging, supporting and transportation parallel fast operation. The anchor rod drill carriage solves the problems of complexity and time waste of the existing machine debugging process, low roadway digging efficiency, digging and supporting unbalance and the like. A middle frame is of an arc-shaped structure, belt conveyor pin tooth transmission traction mechanisms connected with a mine traction type self-adaptive belt conveyor are symmetrically arranged at the two sides of the middle frame, and the mine traction type self-adaptive belt conveyor passes through an arc-shaped space below the middle frame and extends to a position under a digging machine discharging part; eight sets of drill arms are matched, respectively include four sets of front anchoring and protecting drill arms, two sets of back anchoring and protecting drill arms and two sets of side upper anchoring and protecting drill arms, and are arranged in three rows at the front side and the back side, in addition, each set of drill arms can slide for a certain displacement stroke, the adjustable supporting ranging distance height can be realized, 6-top 2-upper anchor rod supporting can be completed in one step through parallel operation, the supporting time is shortened, the supporting efficiency is improved, a belt conveying passage can be provided, and the one-supporting and one-conveying operation parallel operation can be realized.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

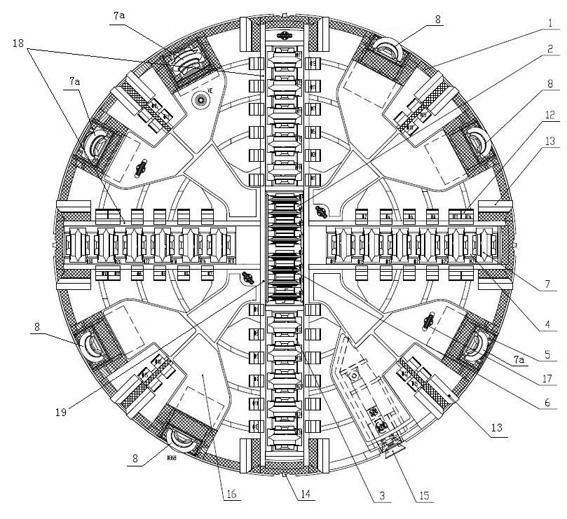

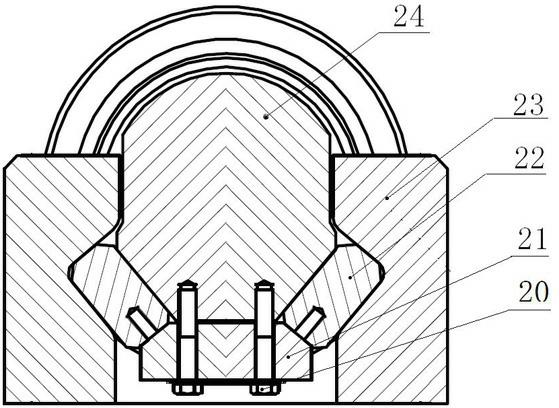

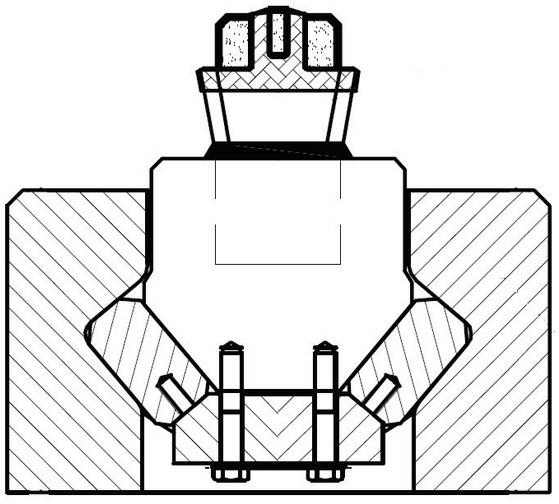

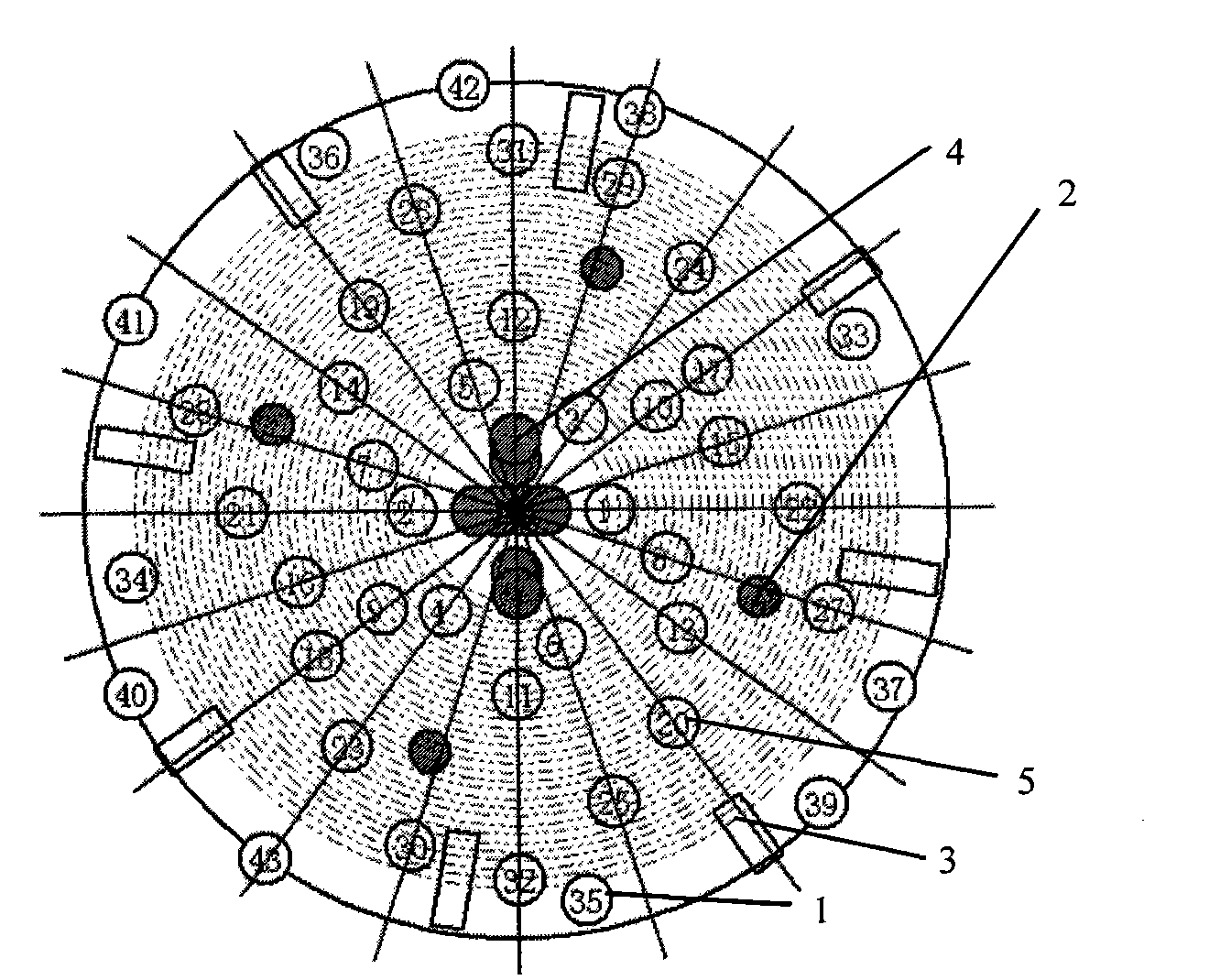

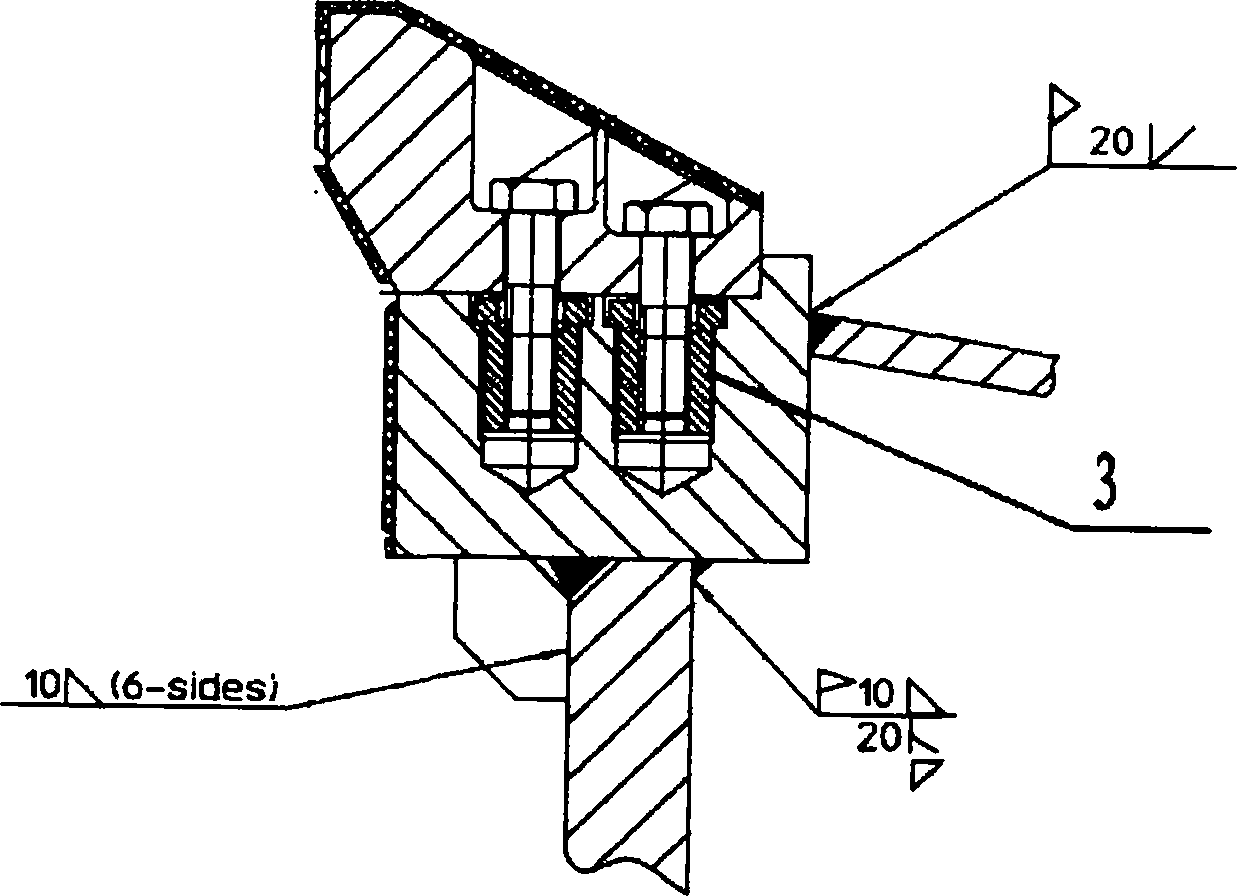

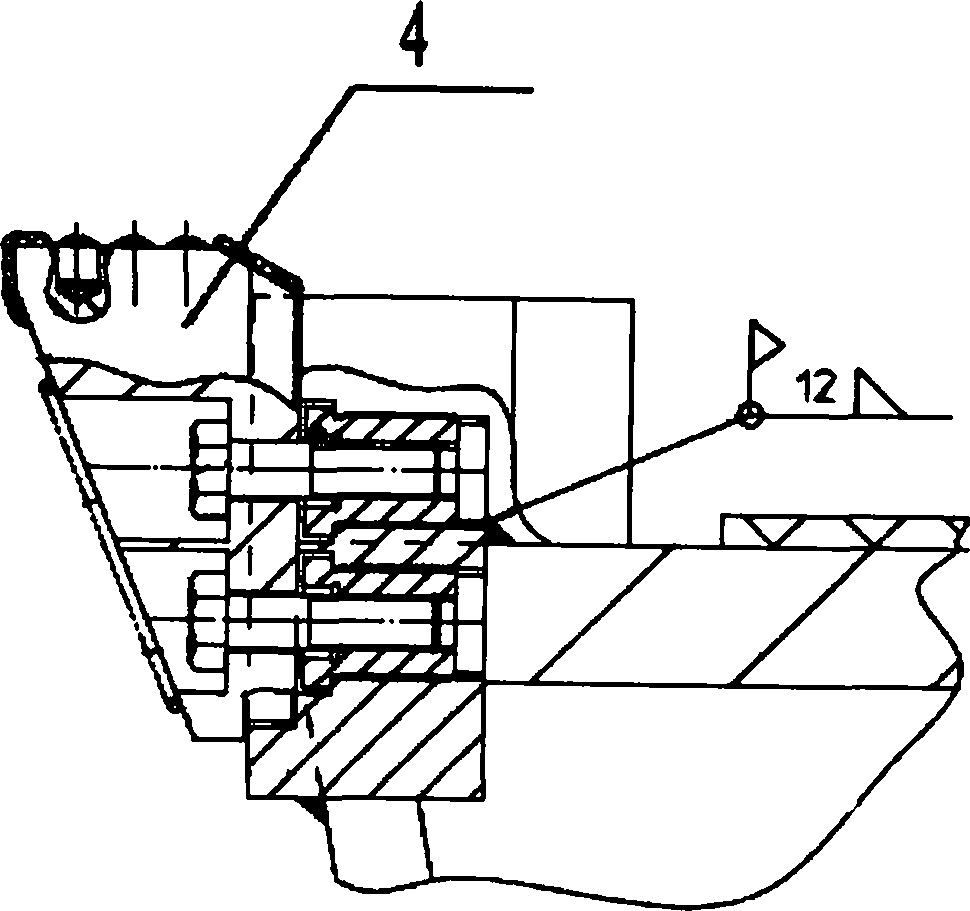

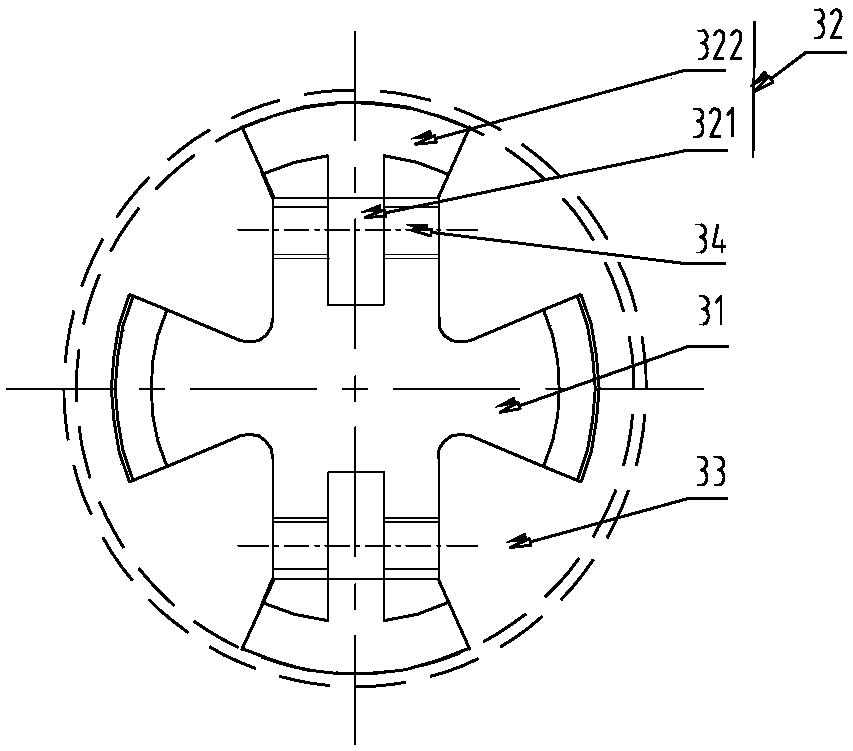

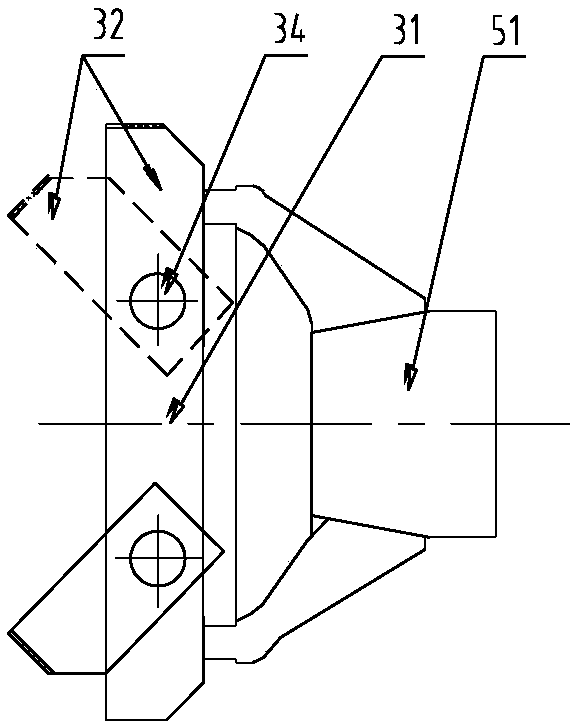

Shield cutter for composite ground

The invention discloses a shield cutter for a composite ground, which comprises a cutter head with a box body structure, wherein a hobbing cutter is arranged on the front face of the cutter head and comprises a plurality of single-blade standard hobbing cutters, a plurality of single-blade central hobbing cutters, a plurality of single-blade standard hobbing cutters and a plurality of single-blade eccentric hobbing cutters; the single-blade standard hobbing cutters are arranged on a cross cutter beam; the single-blade central hobbing cutters are arranged on a transverse I-shaped cutter beam positioned in the central area of the cross cutter beam; the single-blade standard hobbing cutters and the single-blade eccentric hobbing cutters are arranged in an edge area of the cross cutter beam; cutting knives are symmetrically arranged along the two sides of the cross cutter beam in the form of a concentric circle; edge scraping knives are arranged on the two sides of the cross cutter beam and at the middle positions of every two cutter beams of the cross cutter beam, on the edge of the front face of the cutter head; a plurality of radius retaining knives are arranged at the periphery ofthe cutter head; and an over cutter extended from the periphery is arranged in a box body of the cutter head. When the shield cutter is compared with the prior art, the boundary dimension of a cutterholder is reduced, the aperture opening ratio of the cutter is increased, the slag flowability is improved, and the wear resisting property of the whole cutter is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Four-period-five-purpose hole-drilling high-efficiency gas extracting process

The invention discloses a four-period-five-purpose hole-drilling high-efficiency gas extracting process, comprising the steps of: drilling a measure hole from a rock stratum tunnel wall of a coal seam top plate rock stratum tunnel to one side of the rock stratum tunnel and drilling a extracting hole from the rock stratum tunnel wall of the coal seam base plate rock stratum tunnel to a coal seam working face; performing shock blasting and / or hydrofracture to the measure hole for increasing the permeability of the coal seam, wherein the measure hole is a rock hole in the top plate or base plate rock stratum of the coal seam and positioned over or under the coal seam working face; sealing the measure hole and the extracting hole for extracting gas, and then tunneling the tunnel of the coal seam; continuously extracting the gas in the coal seam through the measure hole and / or the extracting hole when before and in stope. According to the four-period-five-purpose hole-drilling high-efficiency gas extracting process, the high-efficiency gas extraction in periods of tunneling the coal seam tunnel, and before, in and after stoping on the working face can be achieved. And simultaneously, the four-period-five-purpose hole-drilling high-efficiency gas extracting process can shield the tunneling of double coal seam tunnel of the working face.

Owner:HENAN POLYTECHNIC UNIV

Supporting method for roadway fully-mechanized drivage operation without withdrawal of roadheader

InactiveCN103195457AImprove support qualityReasonable process designMine roof supportsAnchoring boltsProcess engineeringEngineering

The invention relates to a supporting method for a roadway fully-mechanized drivage operation without withdrawal of a roadheader, aiming to solve the problems of bad safe reliability and complex operating processes of conventional roadway fully-mechanized drivage operations with withdrawal of roadheaders. The supporting method includes providing temporary supporting for a new roof exposed in the roadway fully-mechanized drivage operation by an associated operation with the roadheader, and performing a supporting operation of laying metal nets and steel belts on a roadhead by a roadway drivage alternating supporting device; performing a permanent supporting operation of punching anchor rods on the roof and two sides of the roadway in a roadway zone behind the roadheader by a movable roof bolter supporting platform; and conveying coal cut by the roadheader through a bridge reversed loader and a belt conveyer. The process design is reasonable; supporting and moving is stable; a roadway empty operation is avoided; supporting is safe and reliable; the conventional operation method that the roadheader is needed to be withdrawn in each step and operation procedures are alternated frequently is changed, so that the roadheader can drivage continuously without being withdrawn. Synchronous mechanical operation of drivage and permanent supporting can be realized, and utilization rate and drivage efficiency of the roadheader can be increased remarkably.

Owner:LIAONING TIAN AN TECH CO LTD

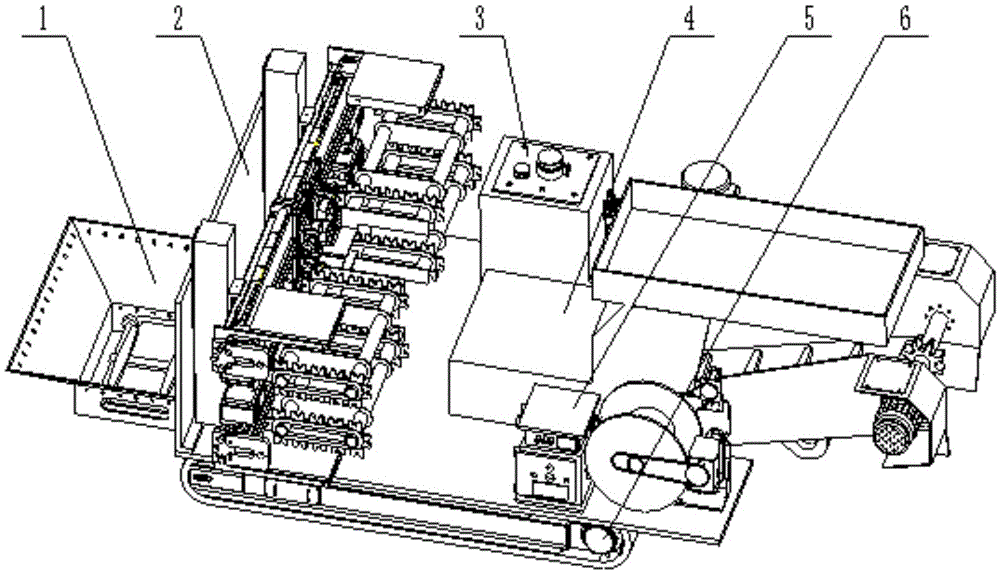

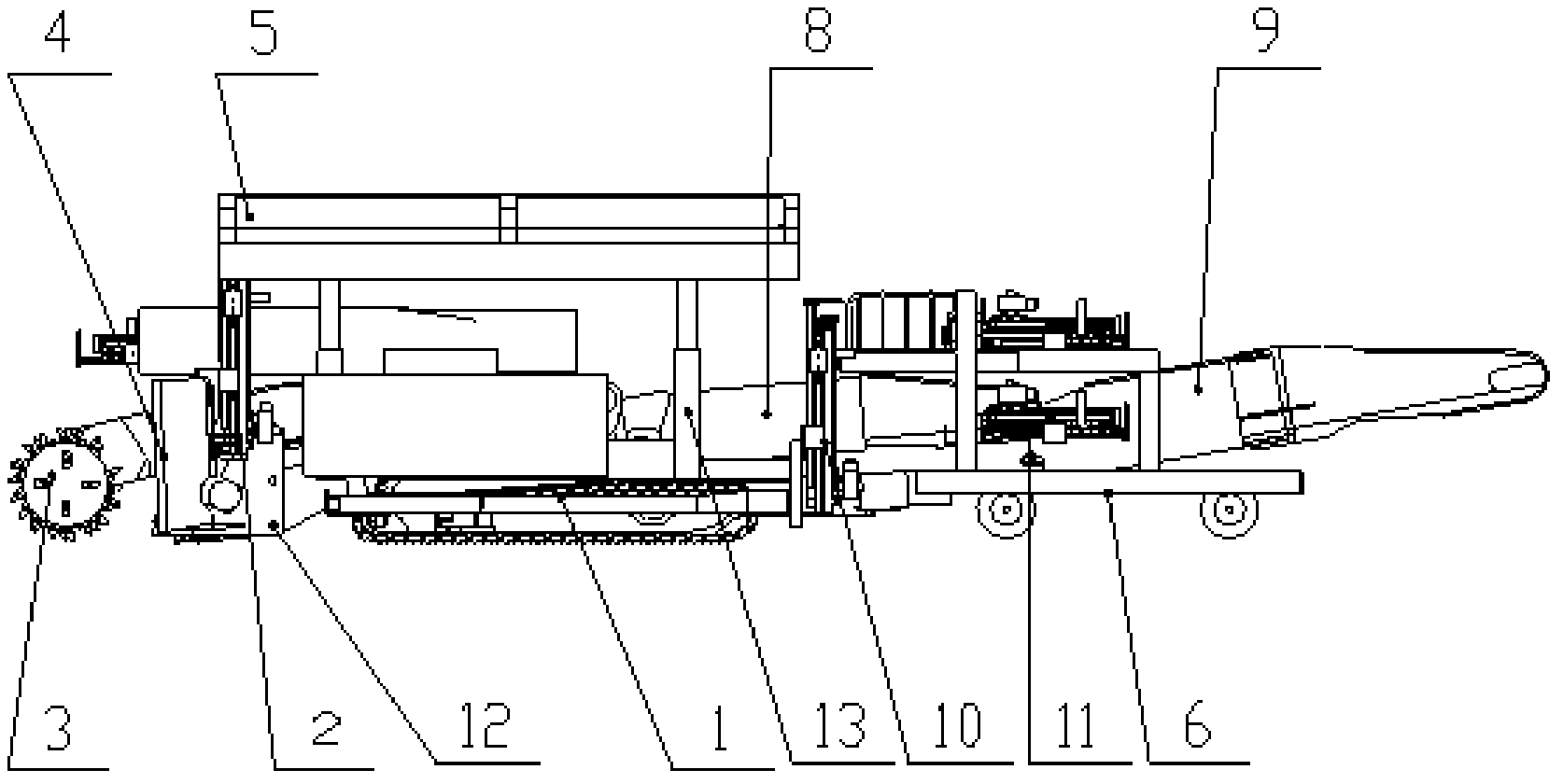

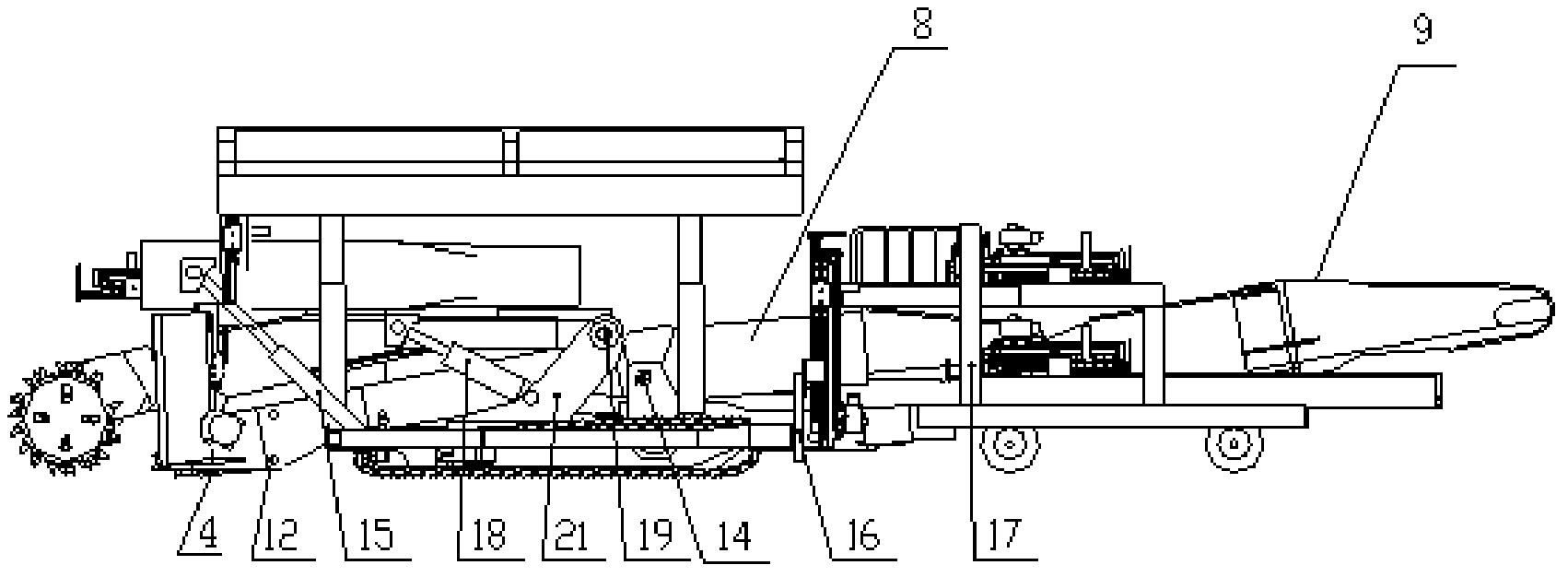

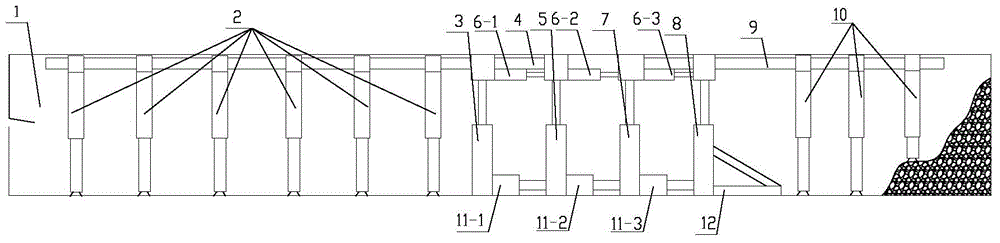

Comprehensive mechanization stone drift heading machine set

InactiveCN102704927AGuarantee the construction qualityReduce labor intensityMine roof supportsDriving meansControl systemEngineering

The invention relates to a comprehensive mechanization stone drift heading machine set, which comprises a shovel plate part, a caterpillar band travelling part, a rack, a belt conveying part, a flexible cutting part, a hydraulic drilling rig device, an advance support device, a hydraulic control system and an electric control system. The comprehensive mechanization stone drift heading machine set is characterized by also comprising a rotation part, two side supporting devices and top and bottom plate supporting devices. The comprehensive mechanization stone drift heading machine set disclosed by the invention is improved and perfected to enable the structure design to be more reasonable and compact, and the performances, such as working efficiency, stability, reliability, and safety of the set, are improved. Comprehensive mechanization construction equipment is provided for mine underground stone drift heading, and is especially adaptive to the underground stone drift mechanization operation and construction of various big, medium and small mines.

Owner:马晓山

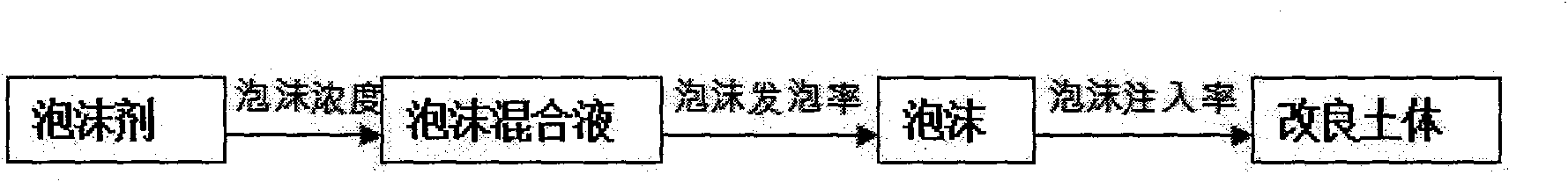

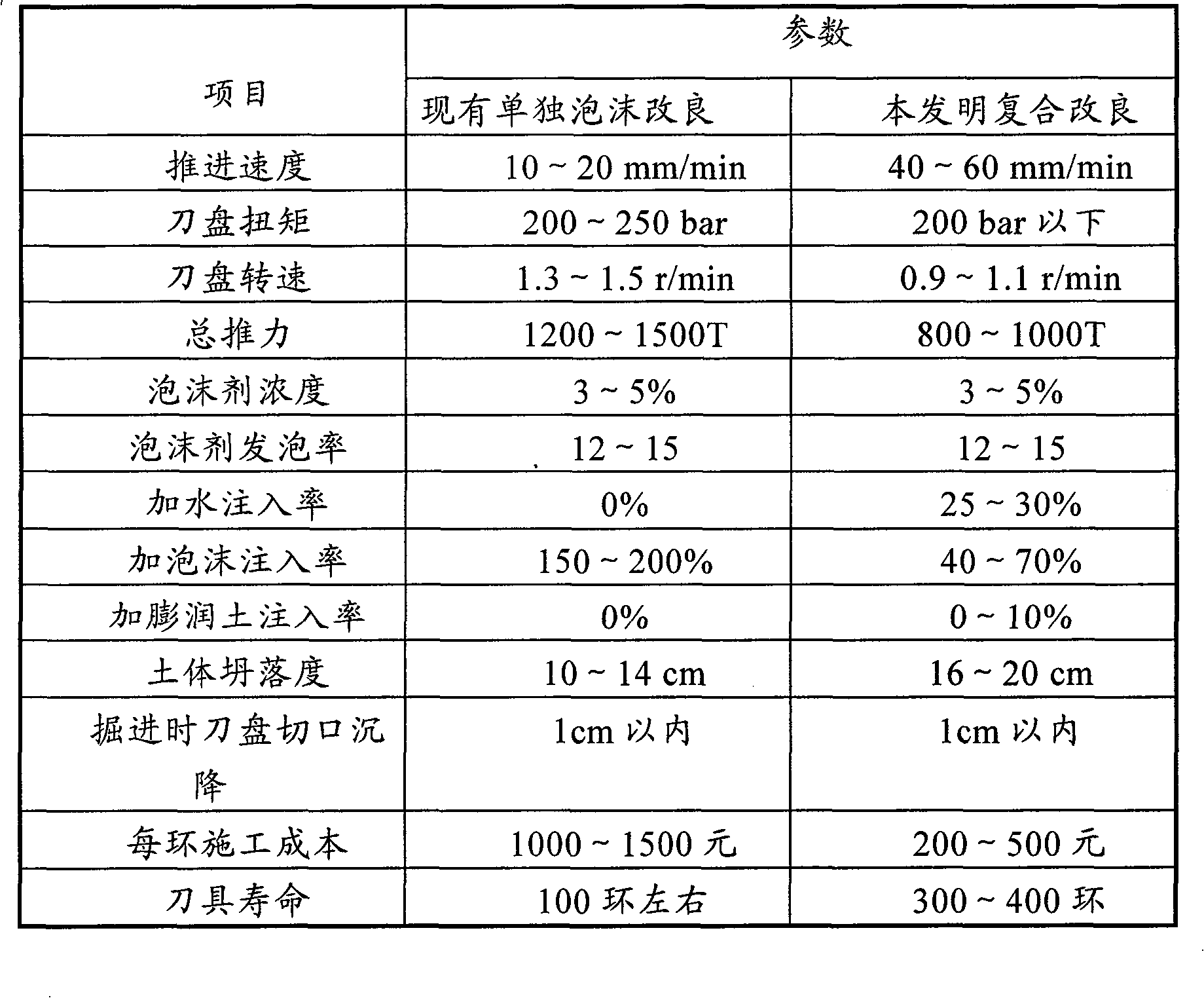

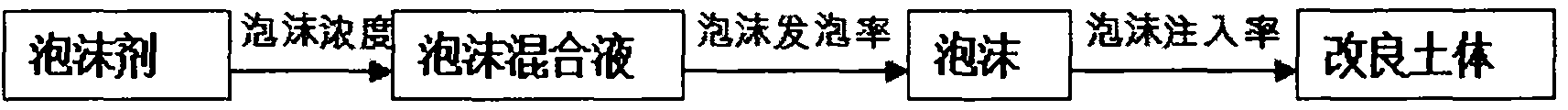

Construction method for improving shield soil in composite sand gravel stratum

The invention provides a construction method for improving shield soil in a composite sand gravel stratum. Water, foam and bentonite slurry are used as composite improvement additives; and different additives are selectively injected to the front of a cutter head, the inside of a soil barn or a screw conveyor according to the actual working condition during shield driving with the aid of special improvement equipment and processes so as to play a role in improving the plastic fluidity of the soil, reducing the torque of the cutter head, stabilizing the excavation face and improving the driving efficiency.

Owner:SHANGHAI TUNNEL ENG CO LTD

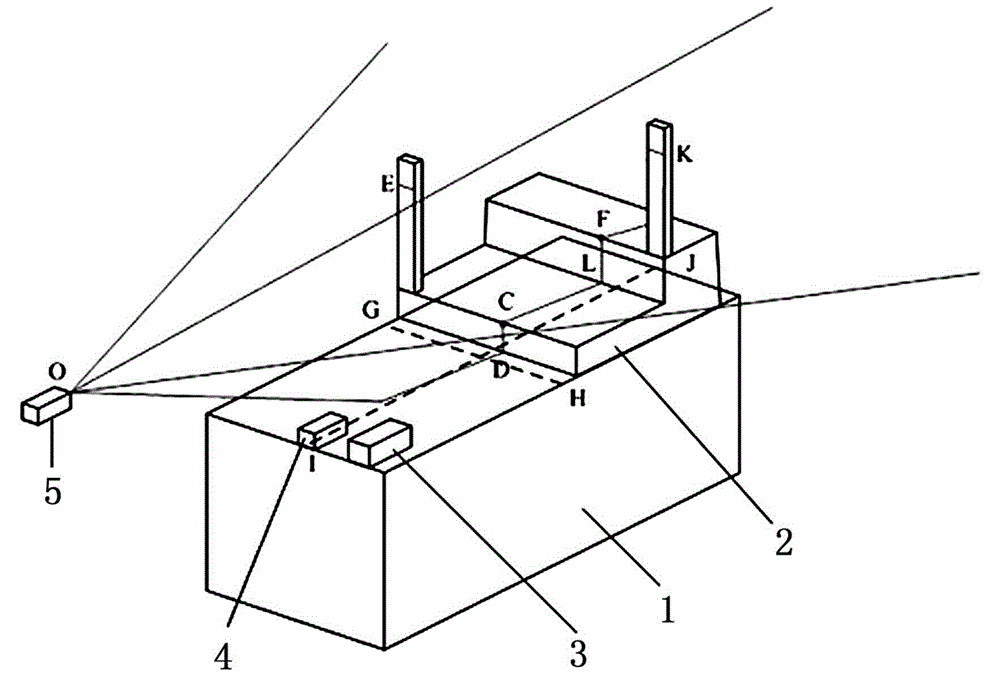

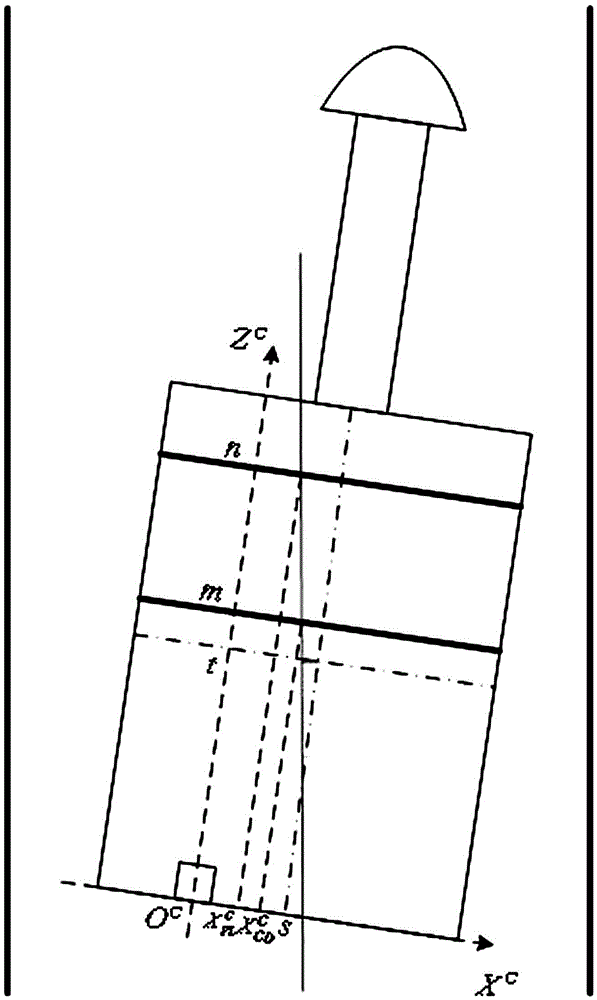

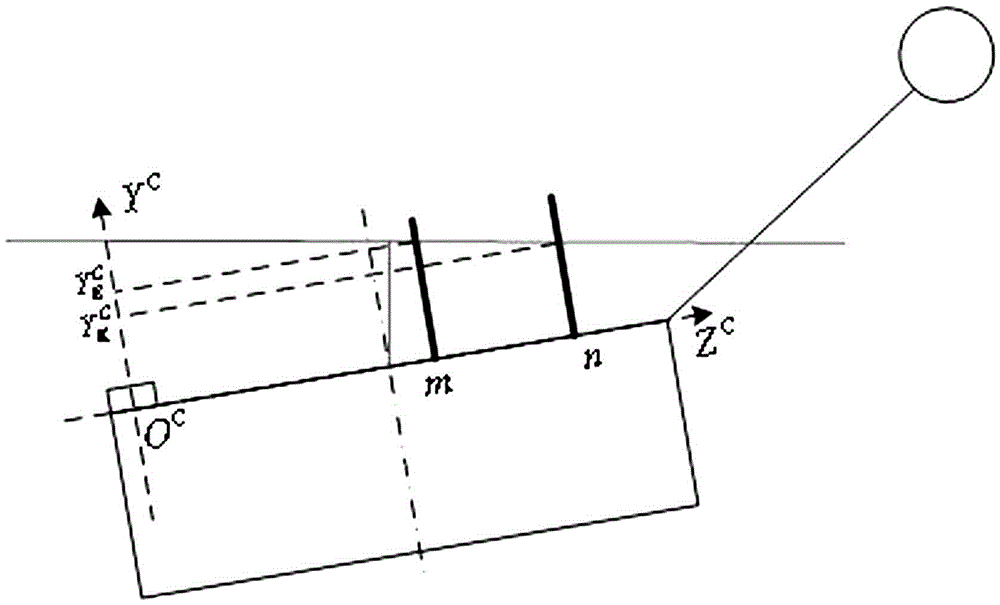

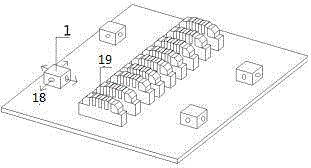

Automatic boom road-header space pose detection system and measurement method thereof

ActiveCN105241444AImprove working environmentImprove tunneling efficiencyNavigation instrumentsRolling angleMarine navigation

The invention belongs to the technical field of boom road-header automation, and provides an automatic boom road-header space pose detection system and a measurement method thereof to solve the problem of severe influences of only detection of the relatively horizontal plane pitch angle and the rolling angle of the body of a road-header and unable body vertical deflection displacement, that is, height difference on the tunnel direction control. A step structure is arranged at the front end of the upper surface of the body; a structured light laser device is arranged on a tunnel top board, and the structured light laser device projects two vertical sector lasers to the road-header to form cruciform structured lights on the step structure; a mining explosive-proof camera is arranged at the tail portion of the upper surface of the body, the direction of the camera is consistent to the vertical symmetric axis direction of the body, and an imaging window points to the step structure; and an image processing platform is arranged in an onboard industrial control computer. Automatic navigation and positioning of the road-header are realized, and the working environment of a working surface is improved. The system and the method realize remote control and unmanned heading, and realize safe and efficient tunnel heading; and the system has the advantages of low cost, simple structure and information completeness obtaining.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +2

Roller type cutter rectangular pipe jacking machine

The invention relates to a roller type cutter rectangular pipe jacking machine, which comprises a cutter, a cutter driving system, a spiral mechanical unearthing system, a hydraulic propulsion system and a rectangular shell. The cutter adopts a composite formation roller type cutter, is sleeved on the cutter driving system and is driven by the cutter driving system to rotate, the composite formation roller type cutter comprises a plurality of ordinary tools, a swinging tool and an over-excavation tool, a cutter shell adopts a round tubular component, the inner wall of the cutter shell is provided with a separating wall vertical to the axial line of the cutter shell, the ordinary tools are uniformly and fixedly arranged on the outer wall of the cutter shell, the swinging tool is hinged on the inner side of the outer wall of the cutter shell through a pin shaft and can rotate around the pin shaft, and the over-excavation tool is fixedly arranged on the outer side of the outer wall of the cutter shell. The invention has the advantages of high adaptability to formations and high tunneling efficiency. Meanwhile, construction risks can be reduced greatly, construction safety can be ensured, and the machine can adapt to construction of slightly weathered rock formations, composite formations, backfilled formations, continuous walls through the ground, pile foundations and other complex formations and working conditions.

Owner:上海盾构设计试验研究中心有限公司 +1

Earth pressure balance shield mud cake prevention system based on synchronous jet flow

ActiveCN106285699AAvoid the risk of mudcake formationImprove abilityTunnelsStructure of the EarthSprayer

The invention provides an earth pressure balance shield mud cake prevention system based on synchronous jet flow. The system comprises a panel fixed sprayer, a cutterhead, a shield body, a soil warehouse separating plate, flushing guns, a flushing position location and tube connection, a high pressure pipeline and pipes, a water separator, a safety valve, a pressure gauge, a high pressure newly increased centrifugal pump, an original centrifugal pump, a base, a water supply pipe, a screw conveyor, a controller and a second trolley. The system provided by the invention has the advantages that working efficiency is high, cost is low, equipment investment is low, operation is simple, no dead angle flushing is carried out on the back of the cutterhead, a bracket of the cutterhead and the soil warehouse separating plate by virtue of the flushing guns at different positions of the soil warehouse separating plate, nozzles of the flushing guns are designed into different specifications, and axial four-hole, axial one-hole and radial four-hole structures are contained, so as to meet flushing requirements of different parts; no dead angle flushing is carried out on a cutter at the center part of the cutterhead by virtue of the panel fixed sprayer of the cutterhead; and mud cake flushing and shield tunneling are synchronous, and mud cake prevention does not influence normal shield tunneling.

Owner:NANCHANG UNIV +2

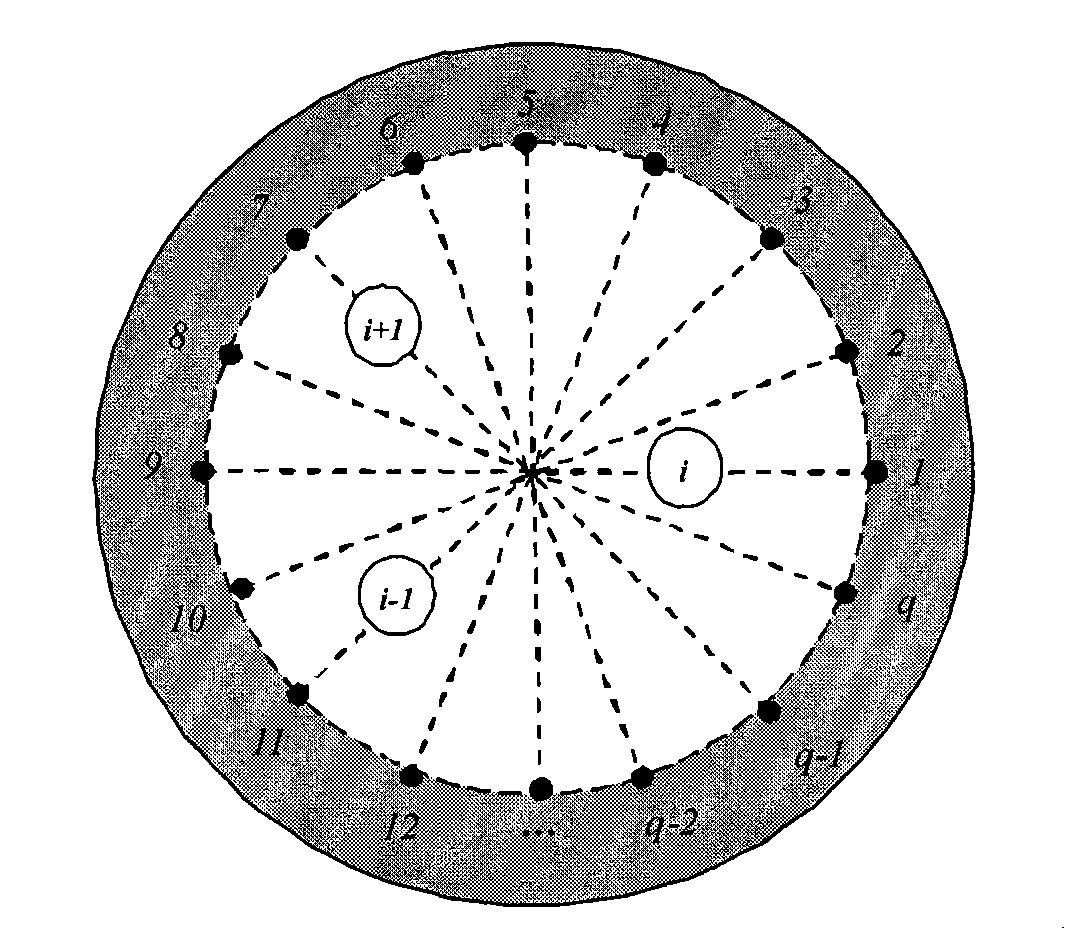

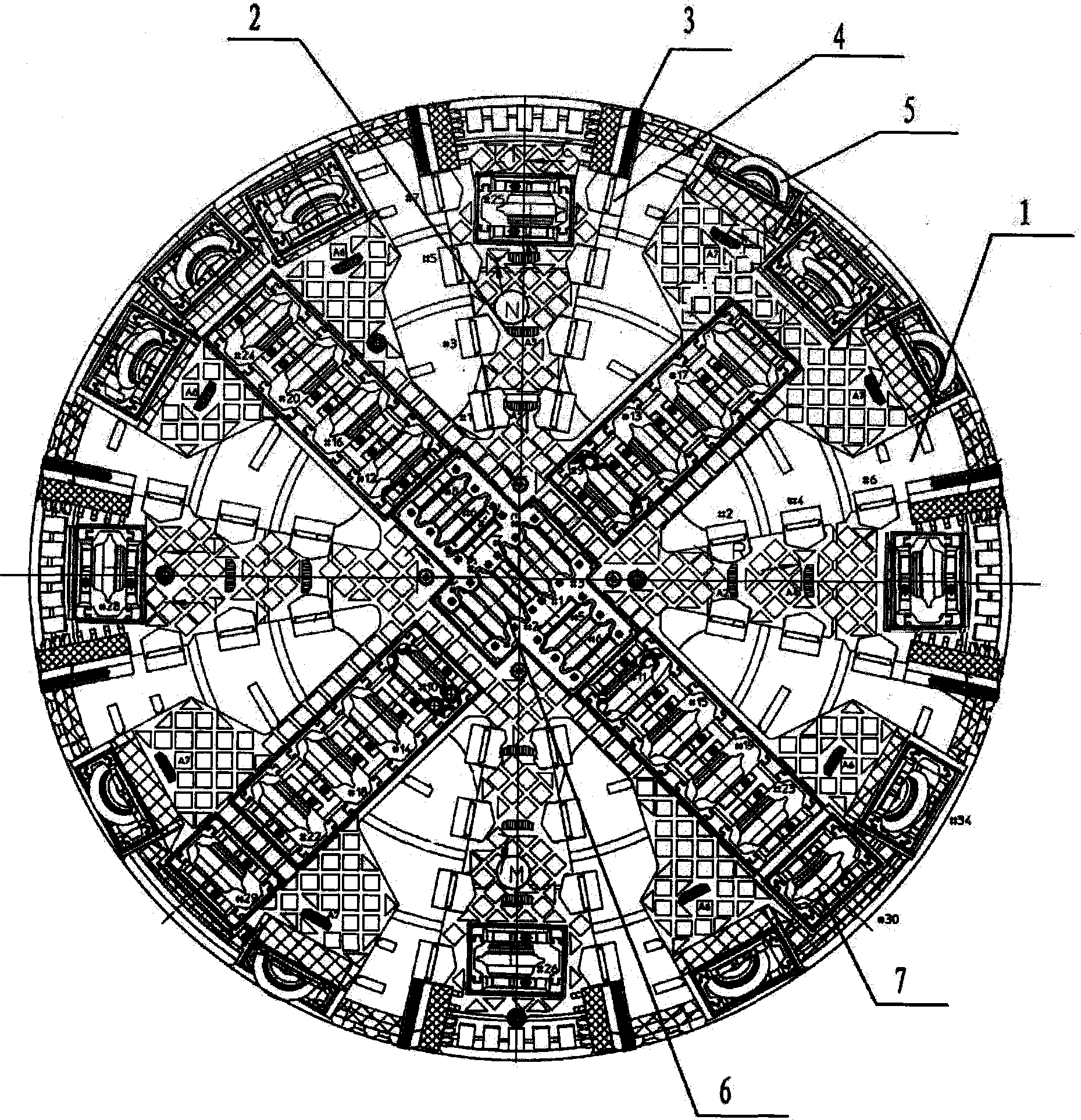

Rice character type structure arrangement method of hobs of full section rock digging machine

InactiveCN101672184ASmall external forceImprove tunneling efficiencyTunnelsCompressive strengthUltimate tensile strength

The invention discloses a rice character type structure arrangement method of hobs of a full section rock digging machine, belonging to the design field of a cutter disk of the full section rock digging machine. Geologic parameters and digging parameters are confirmed according to a geologic report of tunnel engineering, wherein the parameters comprise rock unconfined shear strength, rock uniaxial compressive strength Sigma, rock brazilian tensile strength Sigma Tau, rock stability, digging speed and cutter disk rotate speed. An automatic solve model of the arrangement problem of the hobs on the cutter disk is built, so as to confirm the arrangement position of the positive hobs and the edge hobs with the rice character type arrangement method and a synergetic evolution method. When the hobs are arranged on the faceplate type cutter disk, the technical performance index needs to be met comprises side force to the cutter disk, the overturning moment, interfere area, and the quantity and the mass center of non-order cock fragmentation of the adjoining hobs. The method can fast and effectively confirm the arrangement position of the cutter on the cutter disk, prolong the service lifeof the cutter disk of the digging machine, the cutter and the large bearing of the cutter disk, reduce the shake and the noise of the digging machine, and improve the digging efficiency of the cutterdisk.

Owner:XCMG KAIGONG HEAVY IND NANJING

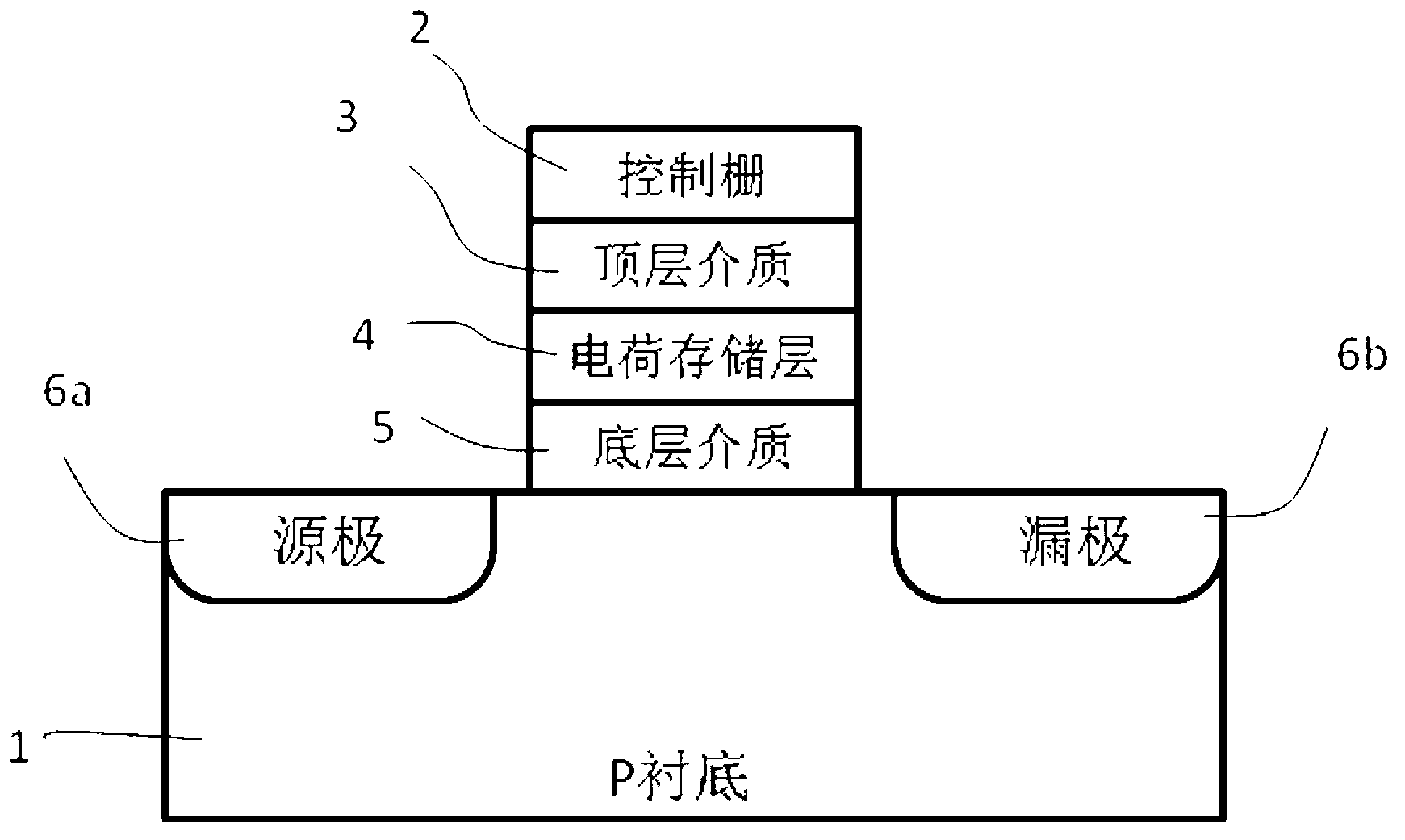

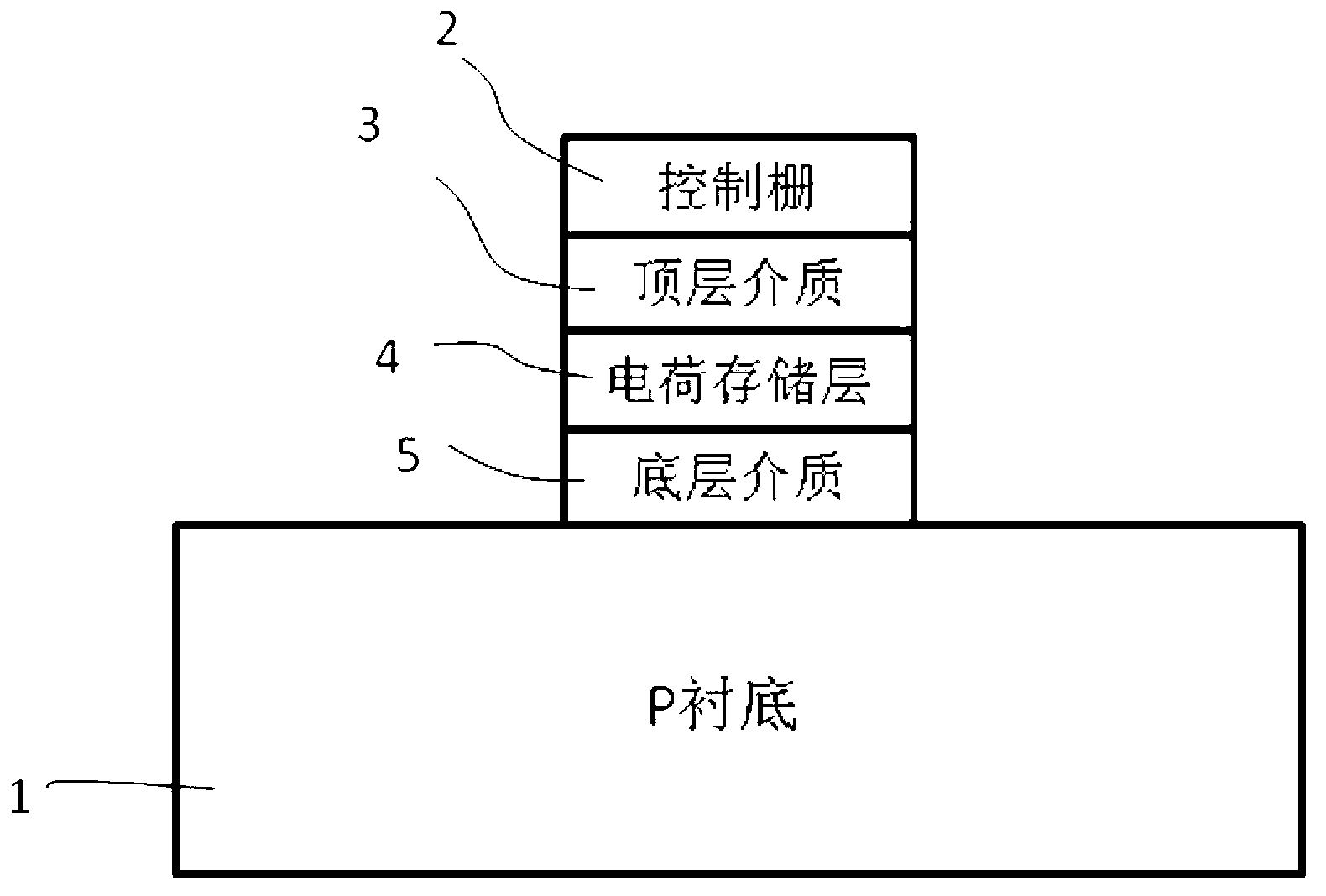

Field effect device and preparation method thereof

ActiveCN104617137AImprove engineering flexibilityImprove voltage control capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricDielectric layer

The invention discloses a field effect device and a preparation method thereof. The field effect device and the preparation method thereof are used for solving the disadvantages of an existing tunneling transistor. The field effect device comprises a semiconductor substrate with a first doping type, a drain region formed at the surface of the semiconductor substrate and having the first doping type, a convex body formed at the surface of the drain region, a grid formed at the surface of the drain region outside the convex body and higher than the convex body, and gate dielectric layers located between the grid and the drain region and between the grid and the convex body; a semiconductor film formed at the surface of the structure composed of the gate dielectric layers and convex body serves as a pocket layer; a source region is formed at the surface of the pocket layer, and the source region is a semiconductor substrate with a second doping type; the convex body serves as a channel between the drain region and source region.

Owner:HUAWEI TECH CO LTD

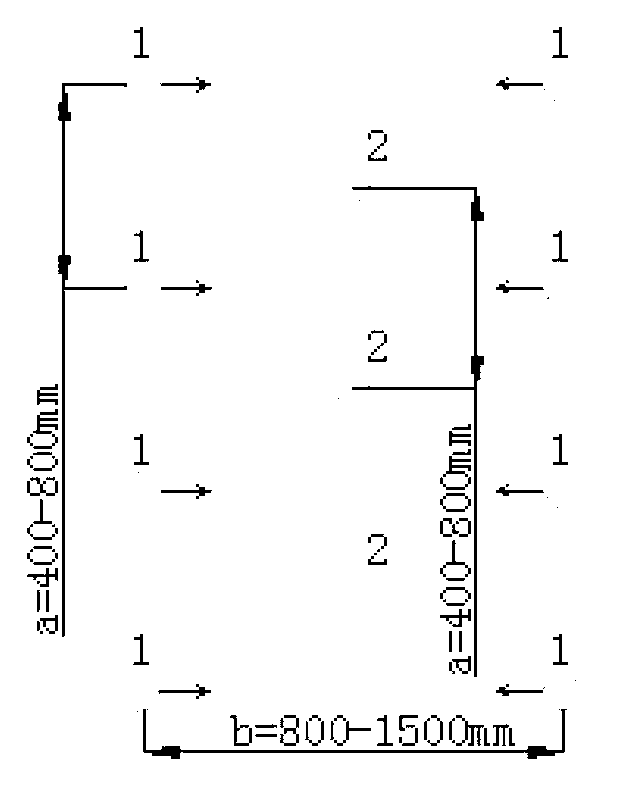

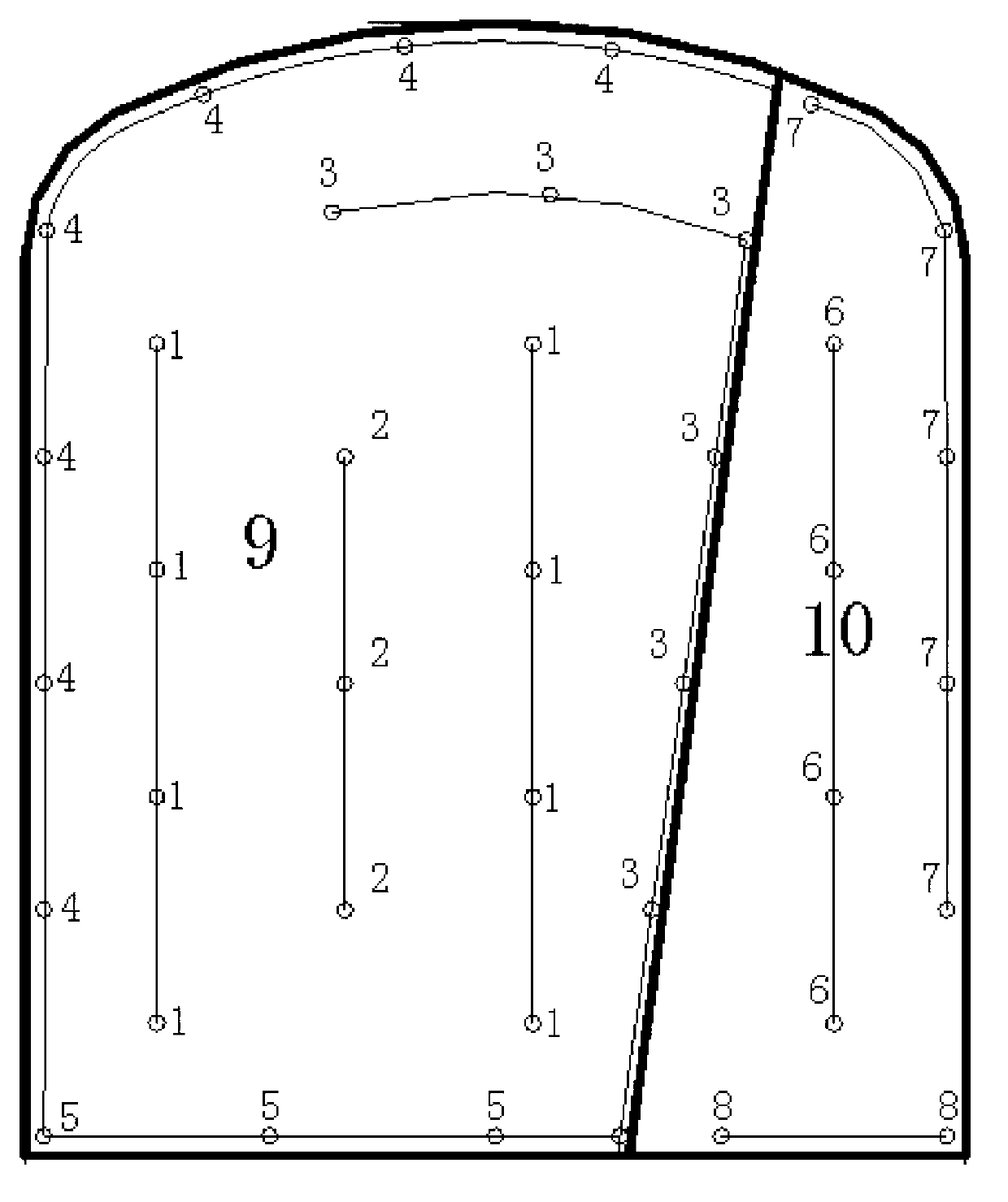

Method for blasting inclined thin ore body by dividing ores and rocks in area in drift driving

The invention provides a technology for blasting an inclined thin ore body by dividing ores and rocks in area in drift driving, belonging to the field of mining engineering. A design process comprises the steps of: 1, dividing a waste rock area (9) and an ore area (10) according to an ore body and a rock distribution condition of a tunnel cross section; 2, arranging a main easer (1) and a secondary easer (2) at the lower part in the waste rock area; 3, arranging an auxiliary hole (3) in the waste rock area according to the size of the cross section; 4, arranging a breaking hole (6) in the ore area according to an inclination angle of the ore body and the size of the cross section; 5, arranging rim holes (4 and 7) and bottom holes (5 and 8) in the circumference edge and the bottom edge of a tunnel; 6, charging each blast hole; 7, sequentially initiating the blast holes; and 8, clearing slag after blasting, and respectively transporting the ores and the waste rocks. With the adoption of the technology provided by the invention, the quantity of the blast holes can be reduced, the use ratio of the blast holes can be improved, a blast effect can be enhanced, the driving efficiency and the ore and rock transportation efficiency can be improved, the dilution rate of the byproduct ores and the engineering cost can be reduced, and the economical benefits of a mine can be improved.

Owner:QINGHAI SHANJIN MINING

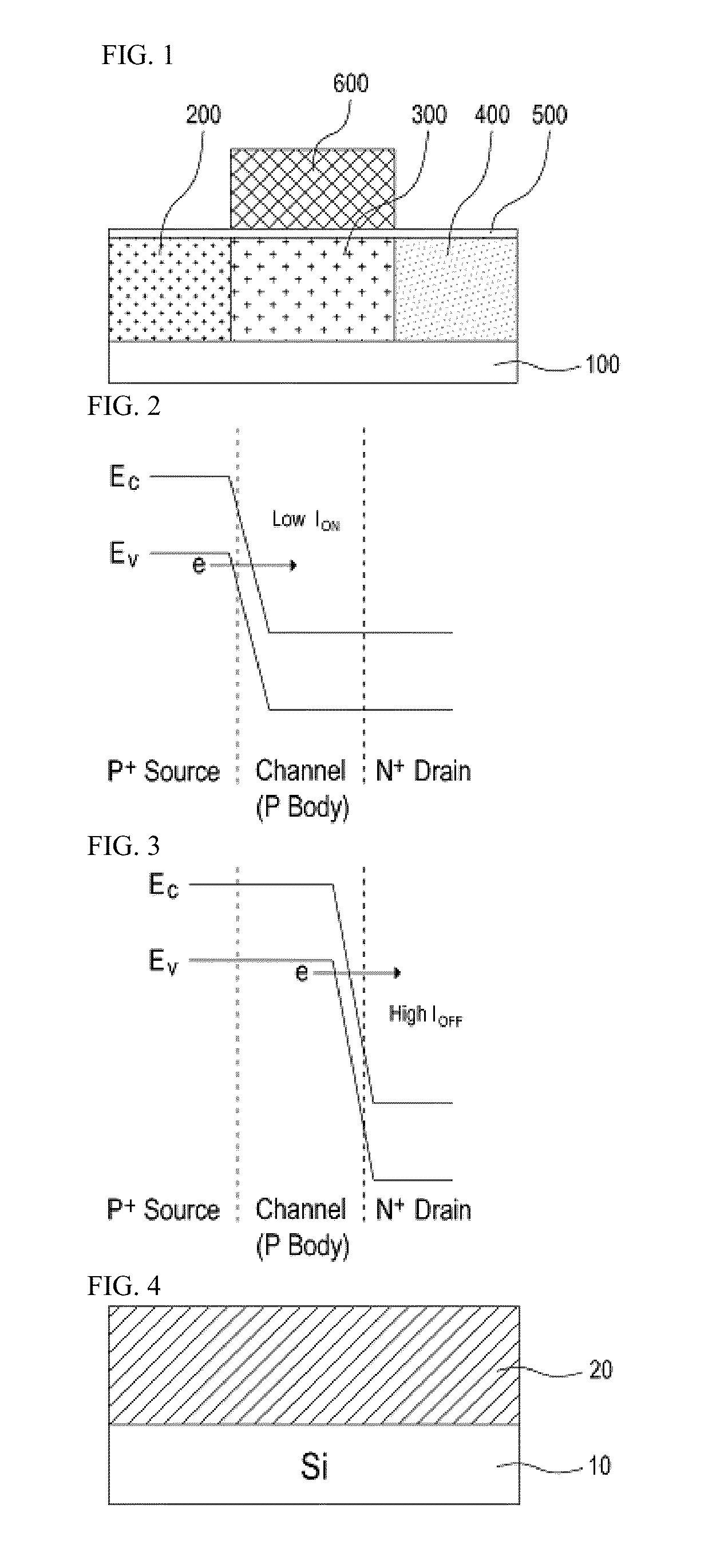

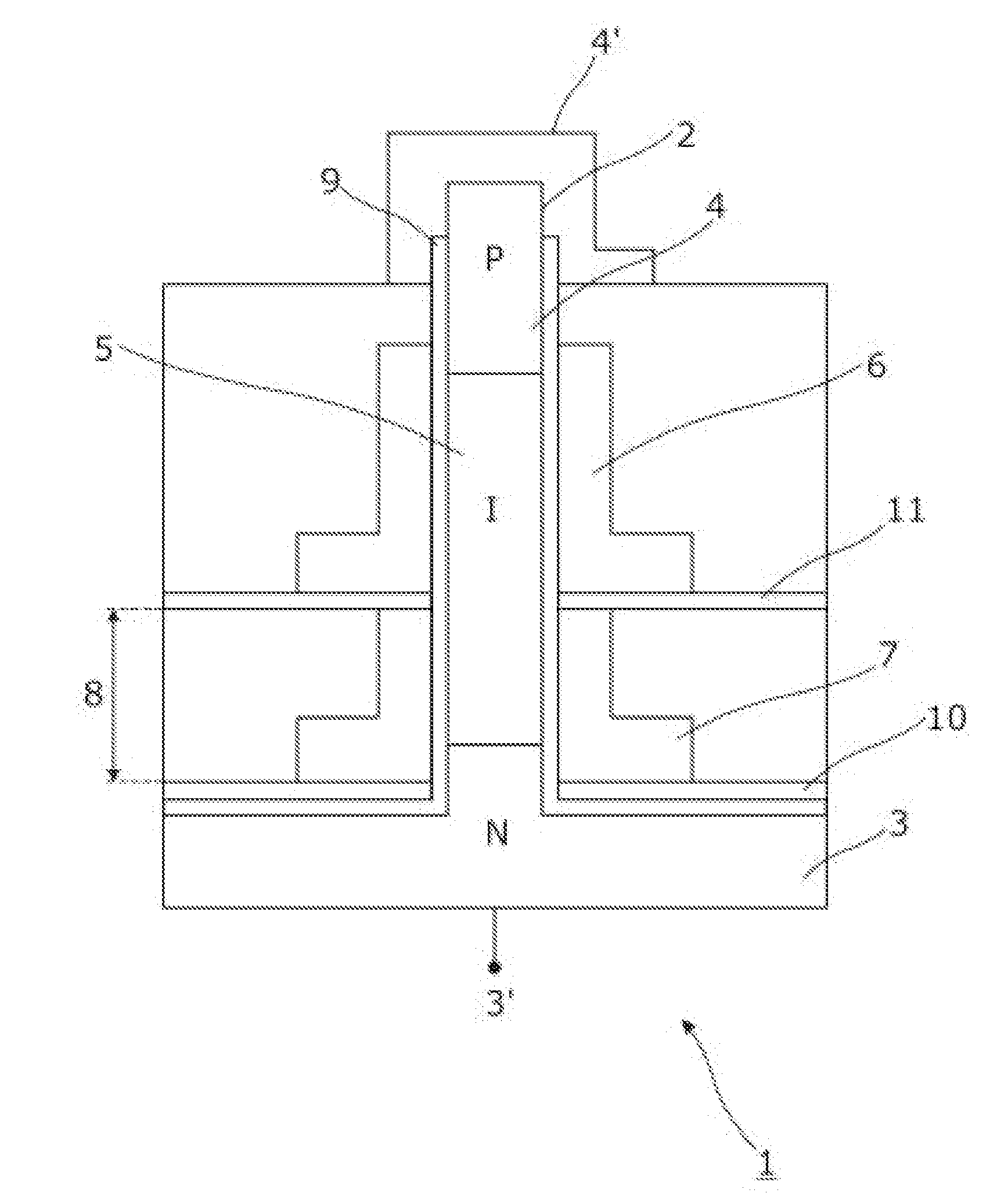

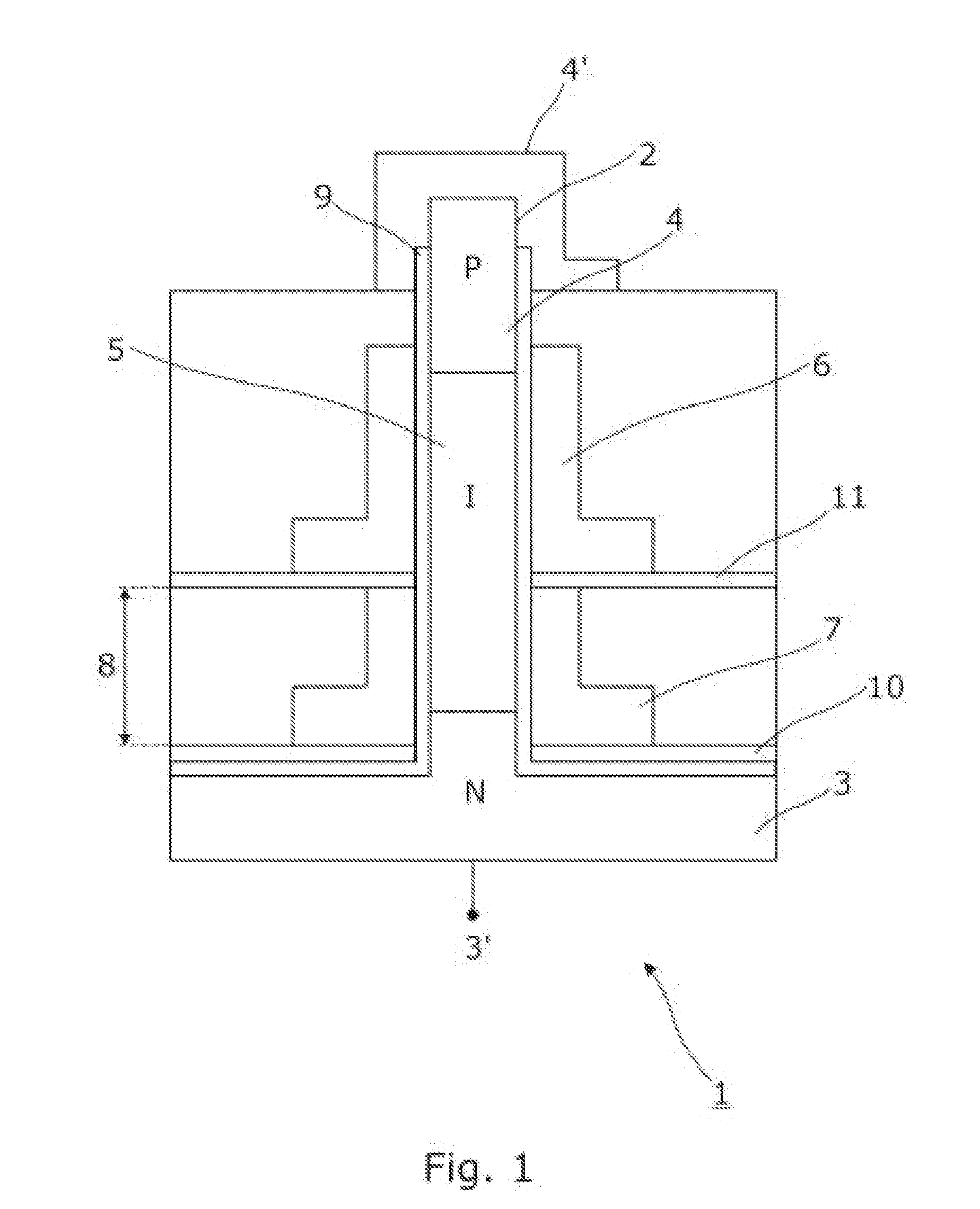

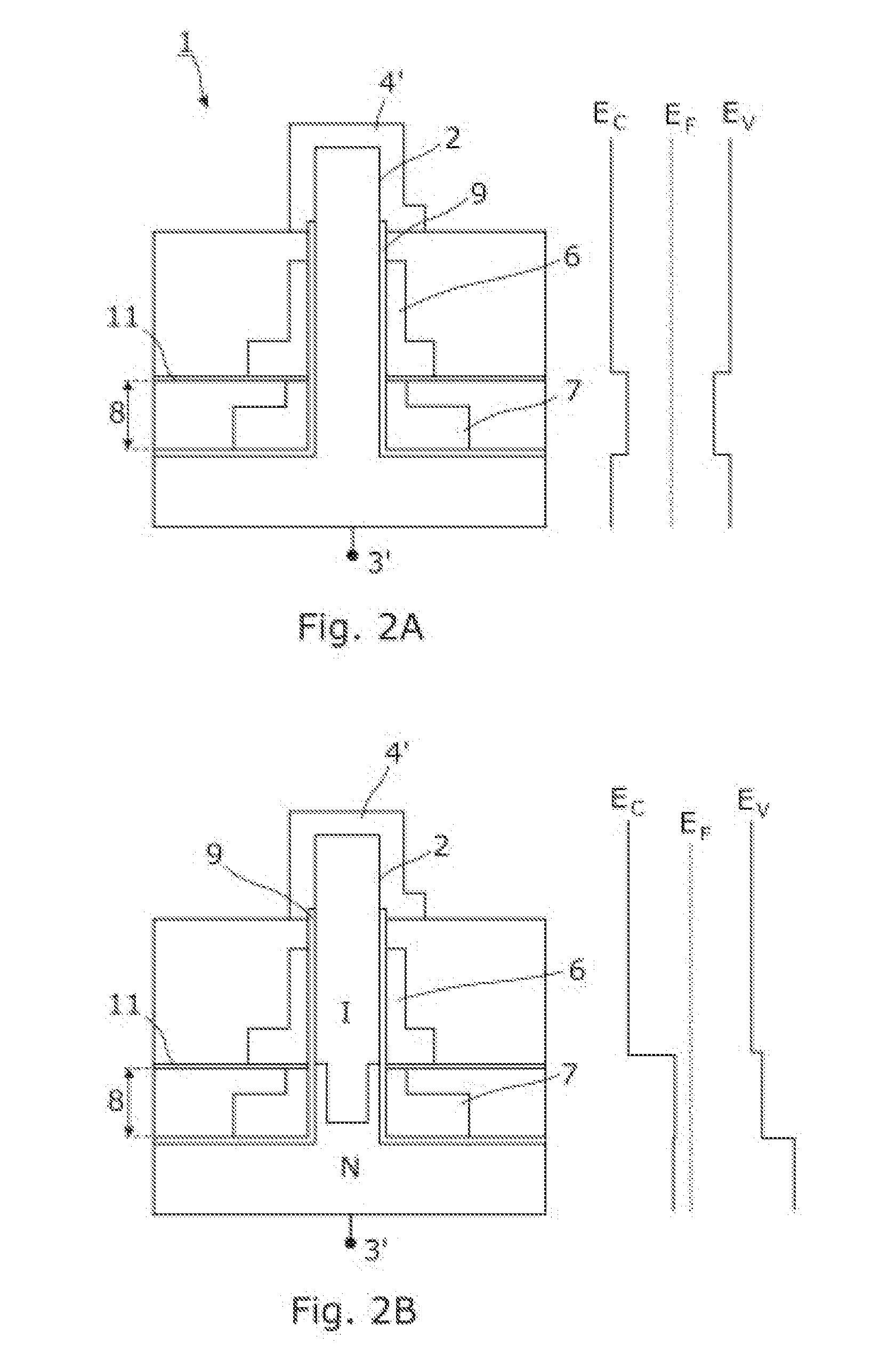

Nanowire field-effect device with multiple gates

InactiveUS20130264544A1Improve tunneling efficiencyIncrease ratingsNanoinformaticsSemiconductor/solid-state device manufacturingSemiconductor materialsNanowire

The present invention relates to a semiconductor device (1) comprising: at least a nanowire (2) configured to comprise: at least a source region (3) comprising a corresponding source semiconductor material, at least a drain region (4) comprising a corresponding drain semiconductor material and at least a channel region (5) comprising a corresponding channel semiconductor material, the channel region (5) being arranged between the source region (3) and the drain region (4), at least a gate electrode (6) that is arranged relative to the nanowire (2) to circumferentially surround at least a part of the channel region (5), and at least a strain gate (7) that is arranged relative to the nanowire (2) to circumferentially surround at least a part of a segment of the nanowire (2), the strain gate (7) being configured to apply a strain to the nanowire segment (8), thereby to facilitate at least an alteration of the energy bands corresponding to the source region (3) relative to the energy bands corresponding to the channel region (5).

Owner:IBM CORP

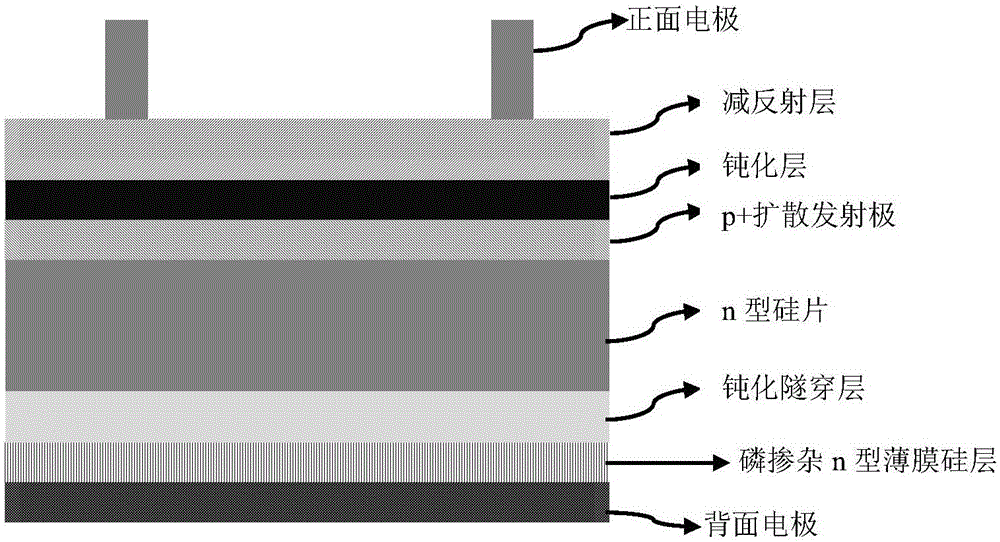

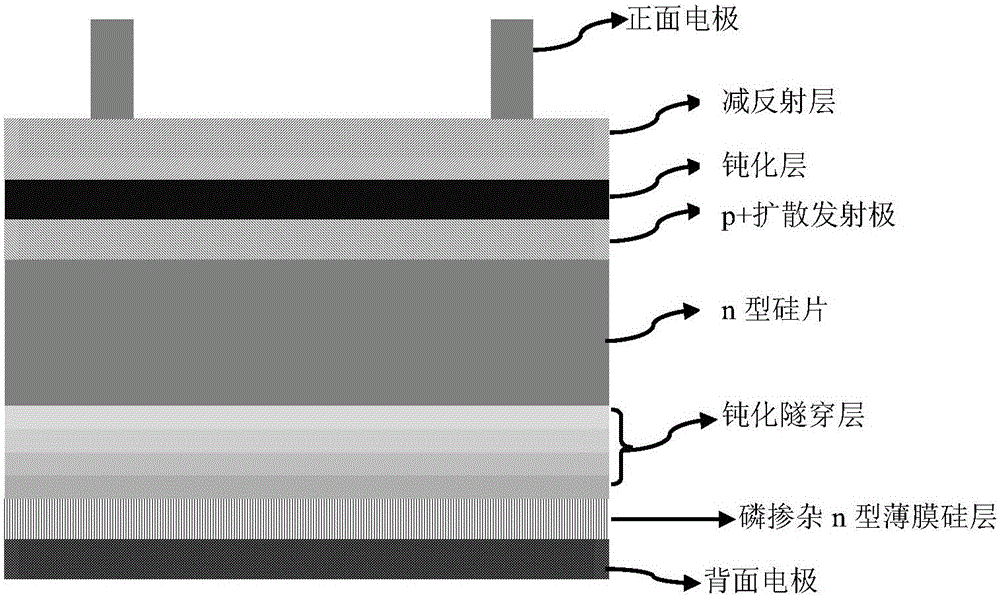

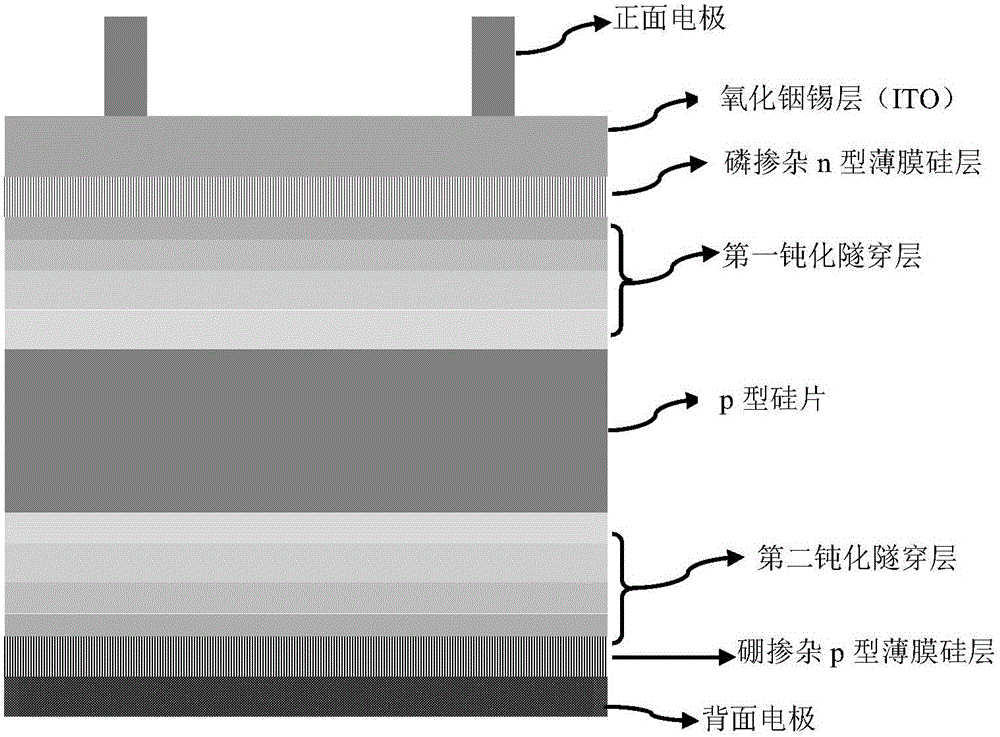

Tunnel silicon oxide passivated contact solar cell and preparation method thereof

ActiveCN105742391AReduce holesReduce generationPhotovoltaic energy generationSemiconductor devicesSilicon oxideSolar cell

The invention provides a solar cell. The solar cell comprises a silicon wafer, a passivated tunnel layer and a doping thin film silicon layer, wherein passivated tunnel layer is arranged between the silicon wafer and the doping thin film silicon layer, the passivated tunnel layer is one of a silicon oxide / silicon oxynitride gradient lamination layer, a silicon oxynitride / silicon nitride gradient lamination layer and a silicon oxide / silicon oxynitride / silicon nitride gradient lamination layer, the silicon oxynitride is nitrogen doping silicon oxide or oxygen doping silicon nitride, and the nitrogen concentration of the silicon oxide / silicon oxynitride gradient lamination layer, the silicon oxynitride / silicon nitride gradient lamination layer and the silicon oxide / silicon oxynitride / silicon nitride gradient lamination layer is gradiently reduced from a part far away from a silicon wafer side to the silicon wafer side. Since the tunnel barriers of silicon nitride and silicon oxynitride are relatively low, the thickness of the passivated tunnel layer can be appropriately widened on the premise of ensuring the tunnel efficiency, thus, the holes of the passivated tunnel layer are favorably reduced, the generation and combination rate of current leakage are reduced, the process window is expanded, and the process stability is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

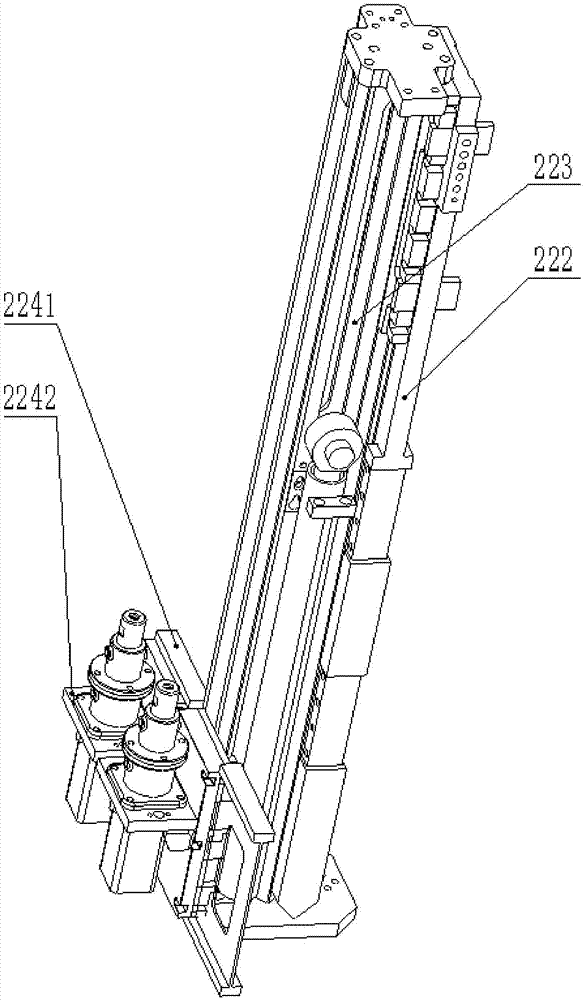

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

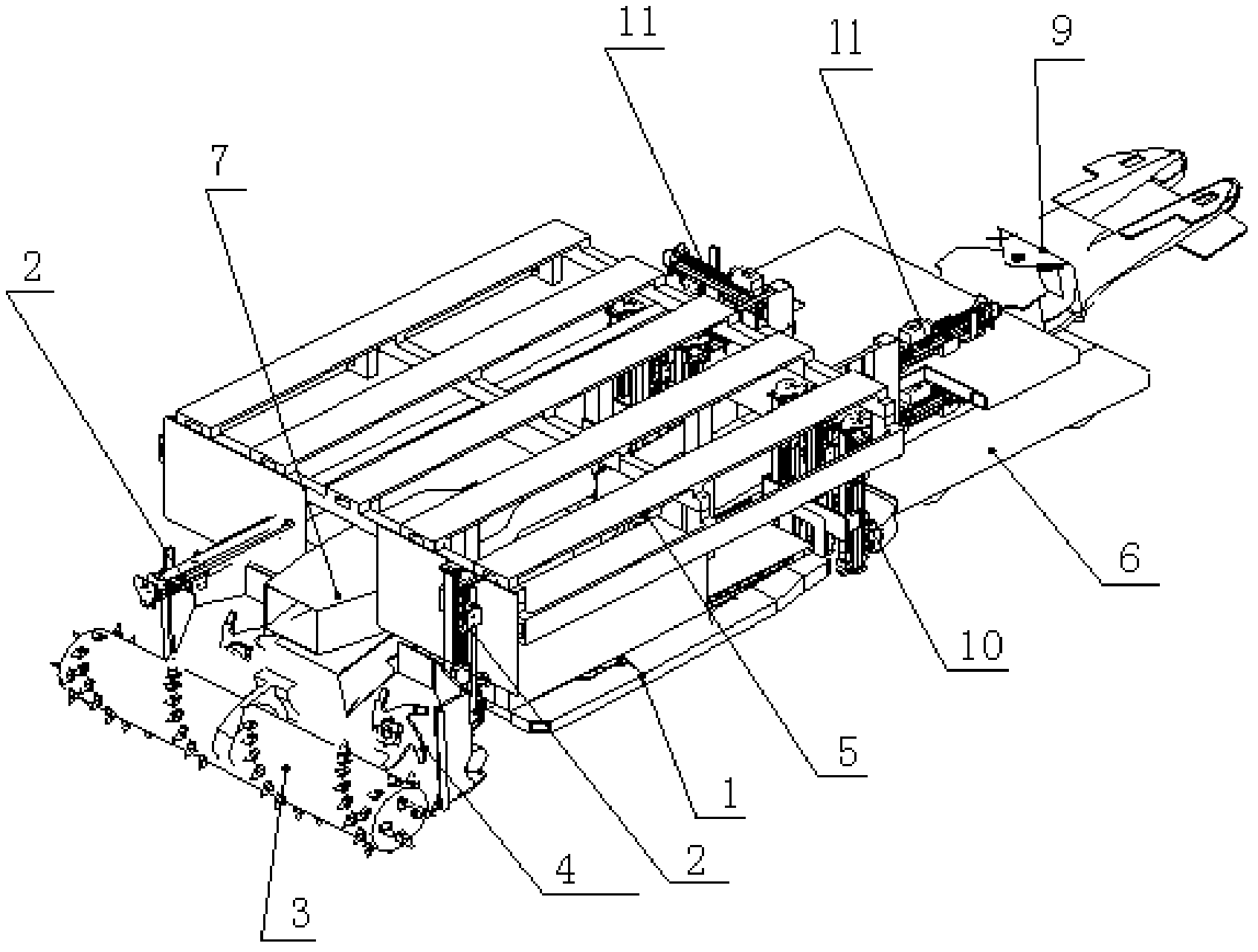

Digging and anchoring machine integrated with digging, anchoring and drilling

ActiveCN102704929AEasy to transportEnsure construction safetyAnchoring boltsCutting machinesEngineeringMechanical engineering

The invention discloses a digging and anchoring machine integrated with digging, anchoring and drilling. The digging and anchoring machine comprises a chassis, a cutting device, a top anchor rod machine, an advanced drilling machine, a loading device, a shield support, a ventilating dust removal device and a conveying mechanism which are arranged on the chassis and also comprises a matched trolley which is connected with the rear end of the chassis, wherein the cutting device is arranged at the front end of the chassis; a shield is arranged above the chassis and is positioned behind the cutting device; the top anchor rod machine is arranged at the rear end of the chassis; the loading device is arranged below the cutting device; the advanced drilling machine is arranged on the loading device; the ventilating dust removal device is arranged above the loading device; the conveying mechanism is arranged on the loading device; and a transfer conveyer and a side anchor rod machine which are connected with the conveying mechanism on the chassis are arranged on the matched trolley. The digging and anchoring machine integrated digging, anchoring and drilling has multiple functions and is high in efficiency.

Owner:CHINA RAILWAY CONSTR HEAVY IND

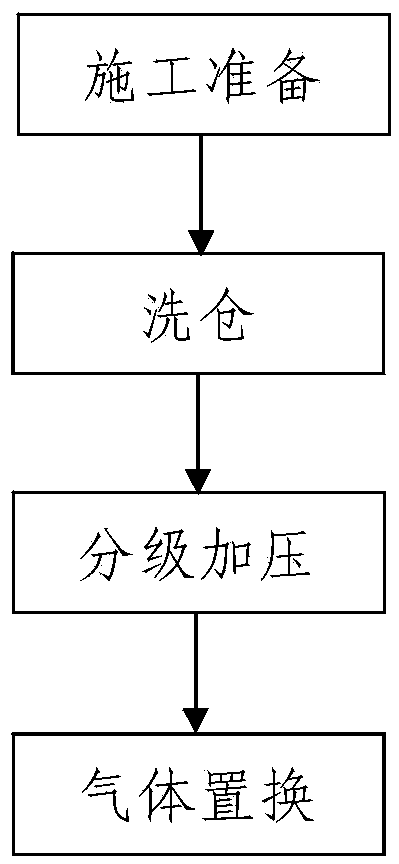

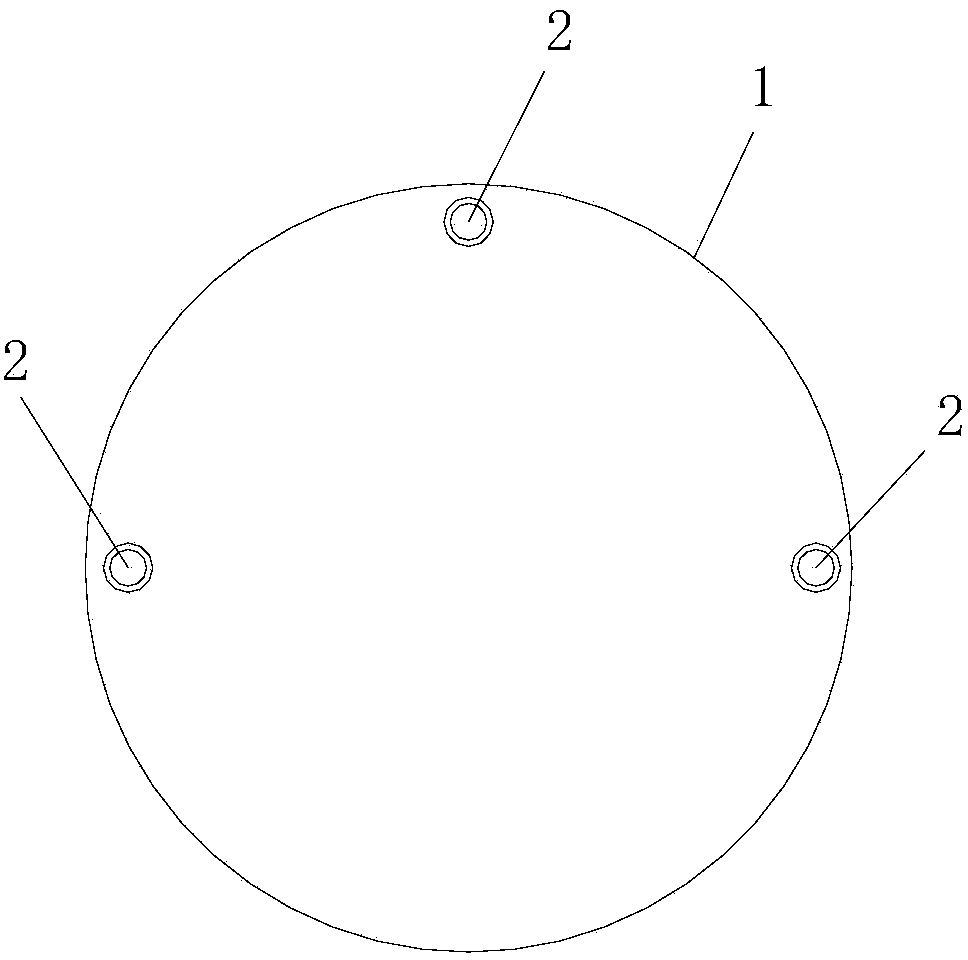

Tunnel face breast wall filter cake construction process for shield compressed air operations

The invention discloses a tunnel face breast wall filter cake construction process for shield compressed air operations. The process includes the steps of 1, preparing for construction, namely connecting an injection system with a plurality of injection holes through an injection pipeline, which are arranged on the outer wall of the upper middle of an earth bin of a shield machine in the peripheral direction; 2, cleaning the bin, namely cleaning the earth bin of the shield machine by a screw conveyer and the injection system; 3, performing graded pressurization, namely performing graded pressurization, including primary pressurization, secondary pressurization, tertiary pressurization and quaternary pressurization, on the inside of the earth bin by the injection system; 4, performing air replacement, namely shutting down the injection system, and replacing bentonite slurry inside the earth bin by air. The construction process is reasonable in design, simple to operate, low in input cost, high in safety coefficient and good in using effect; the practical problem that under the tool-changing severe conditions of loose stratum at the shutdown position of the shield machine, poor self-stabilization capacity of tunnel face earth and the like, existing common tool changing methods fail in changing tools is solved.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

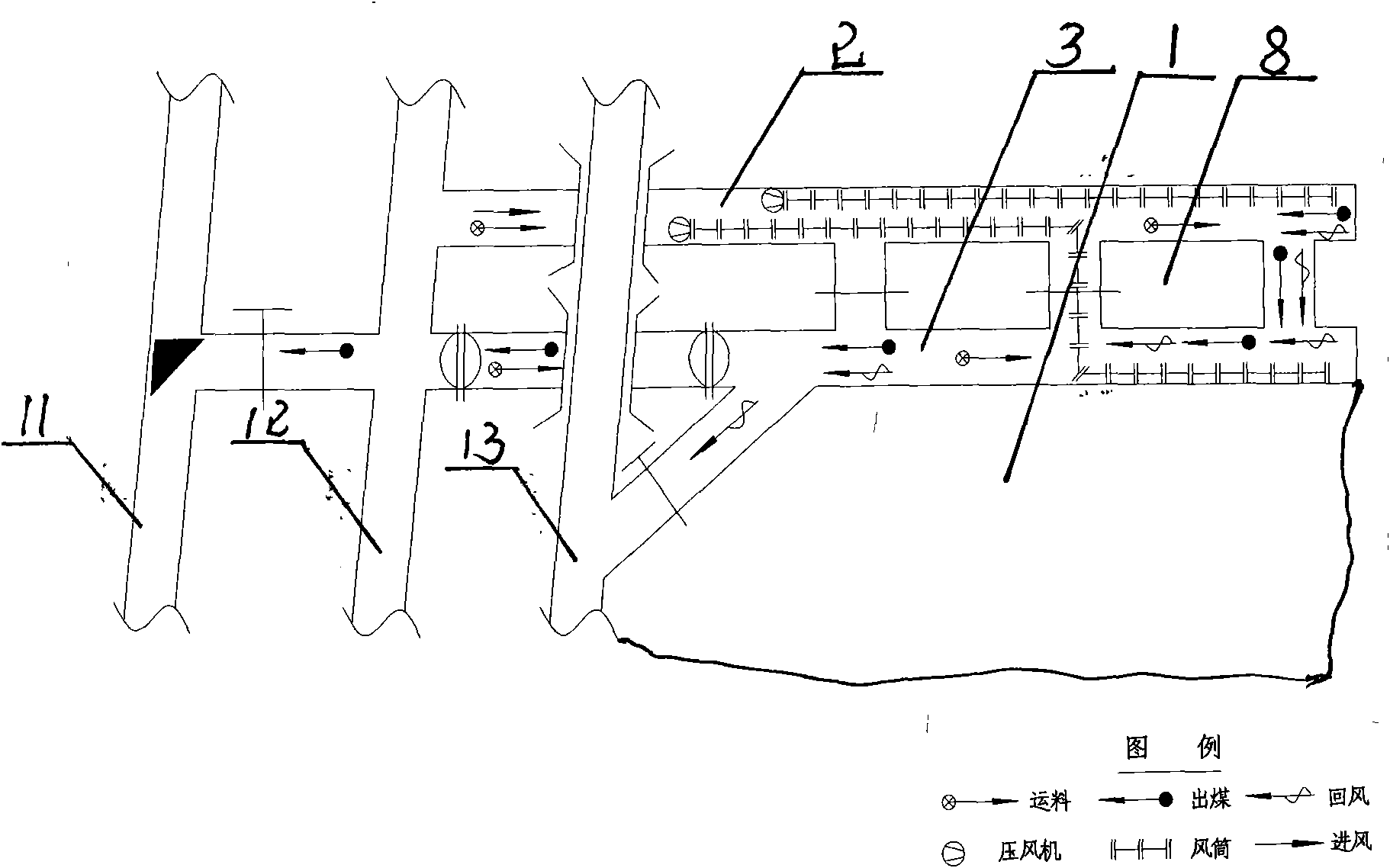

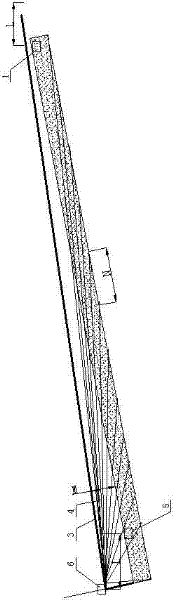

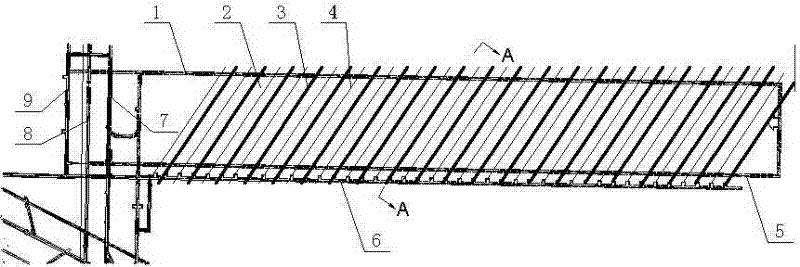

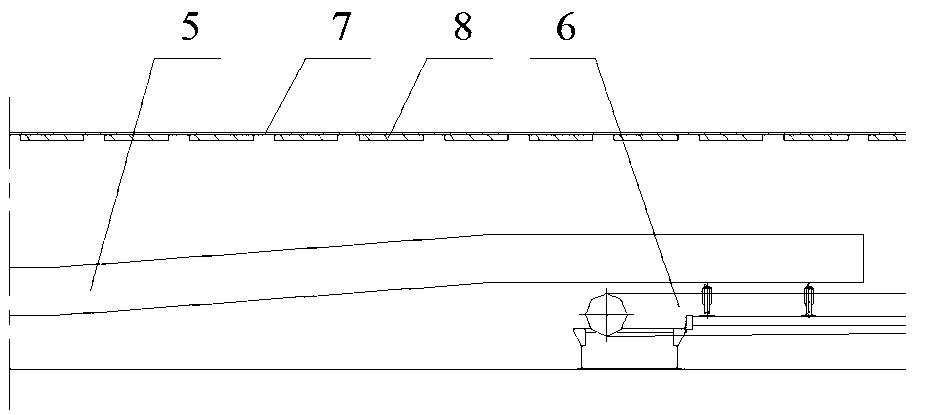

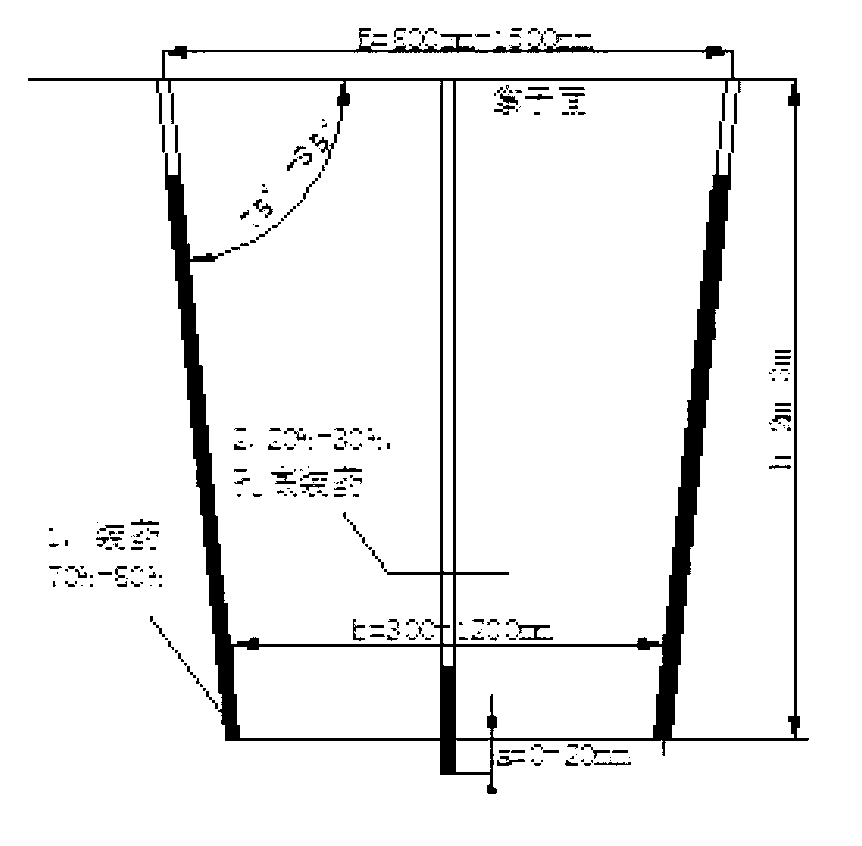

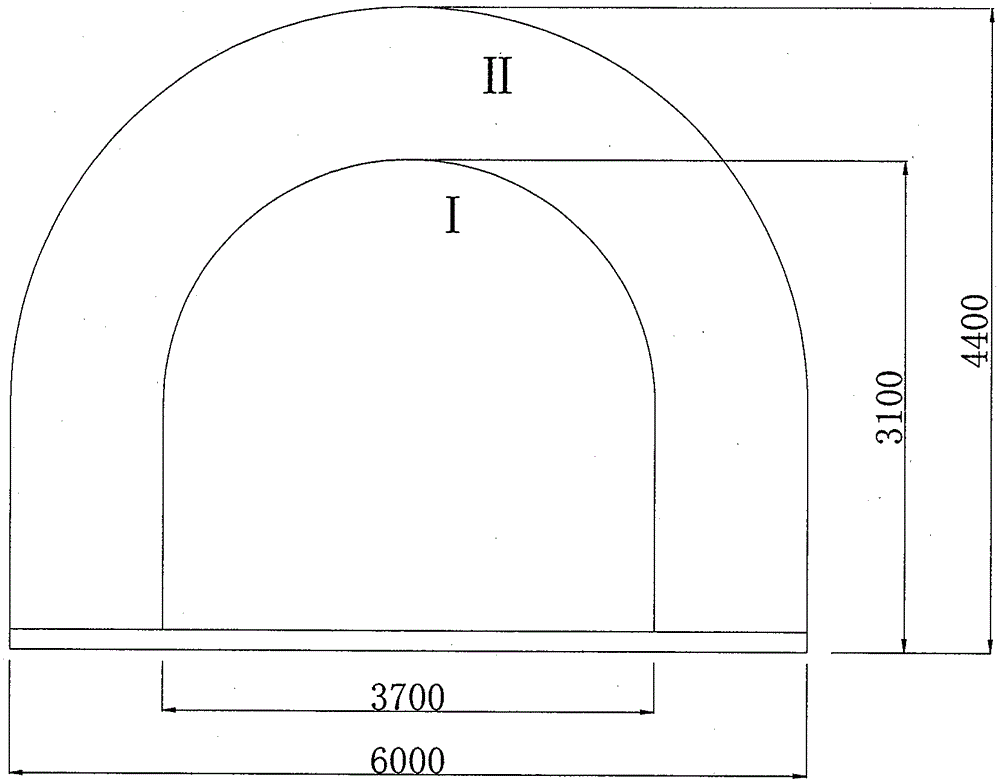

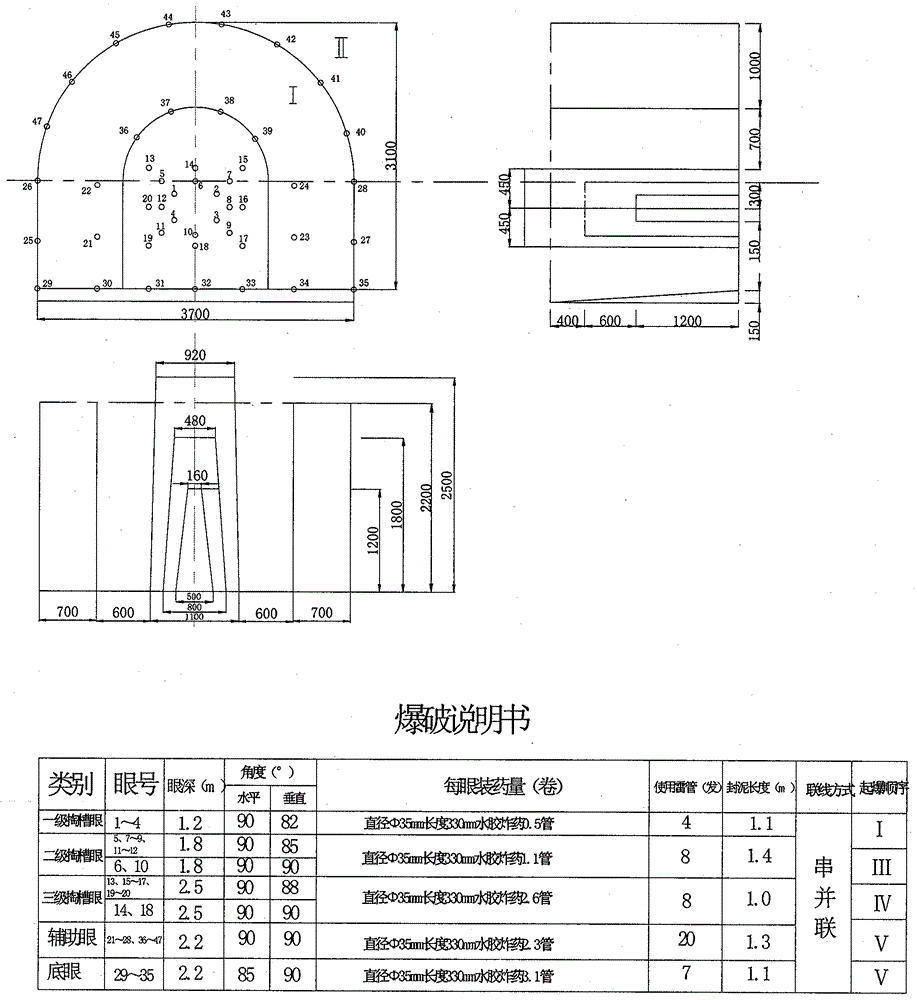

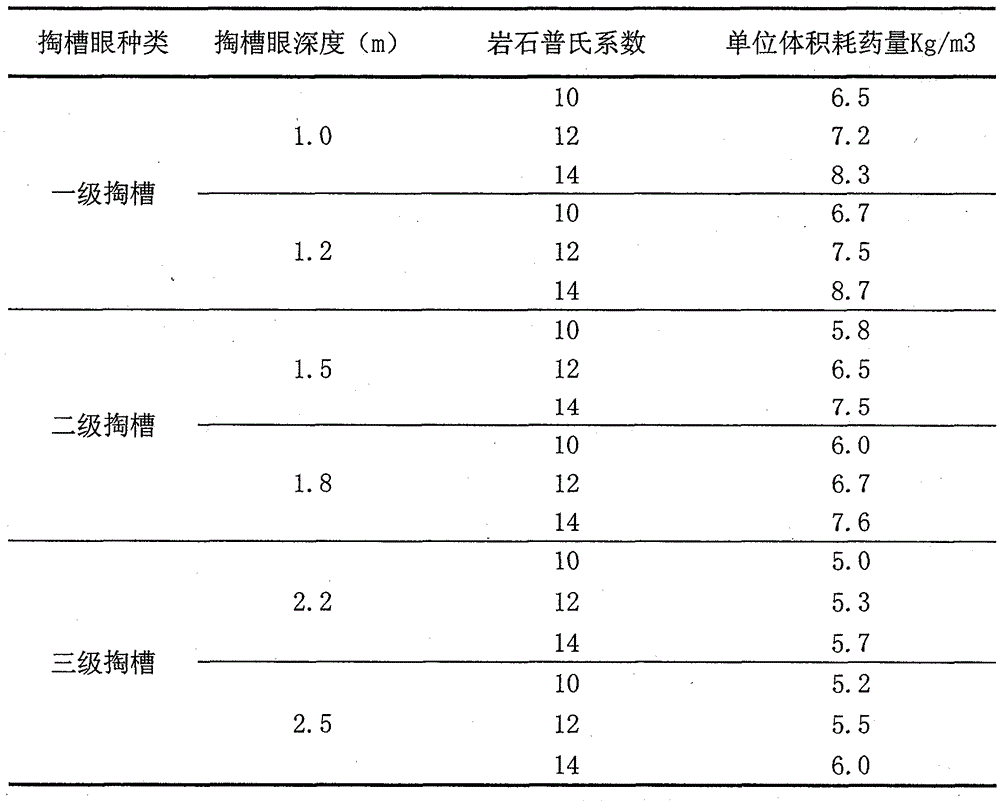

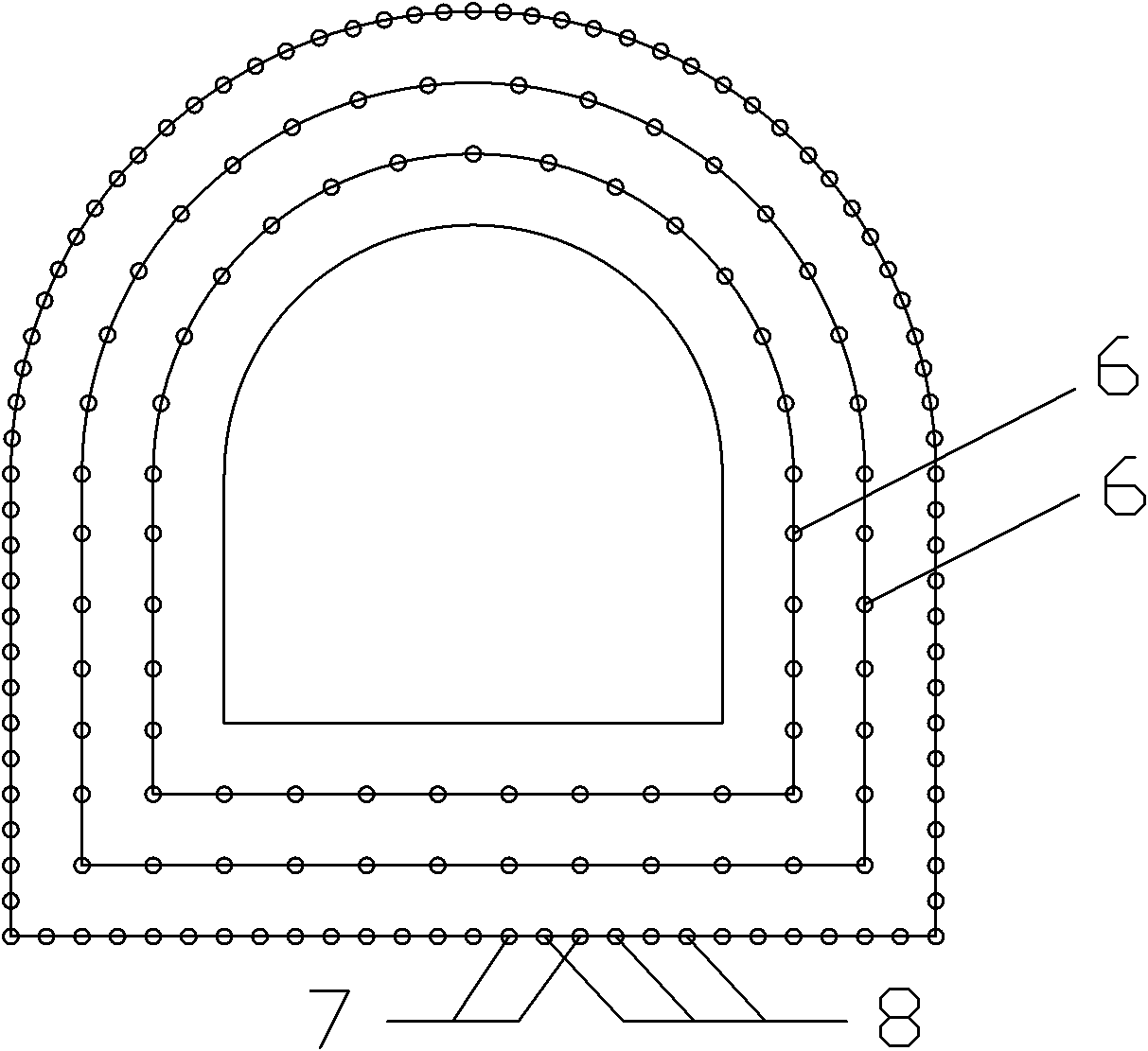

Fast and highly-efficient tunneling method for large section of hard-rock tunnel in coal mine by combination of fully-mechanized tunneling and blasting driving

The invention relates to a fast and highly-efficient tunneling method for a large section of a hard-rock tunnel in a coal mine by combination of fully-mechanized tunneling and blasting driving. As shown in the figure 1, a cut hole with the borehole diameter of Phi 40.0 mm and a reliever hole with the charge diameter of Phi 35.0 mm are arranged in the section of the hard-rock tunnel with the protodyakonov coefficient f larger than 10.0 for digging out a groove cavity with s approximately equal to 14.0 m<2>. As shown in the figure 2, the cut hole adopts a three-stage oblique cut with stages deepening and angles of inclination increasing stage by stage. The consumption of charge in unit volume is determined based on the hard-rock protodyakonov coefficient and shot hole depth according to quantification of the figure 3. Three stages of oblique cuts respectively select I, III, IV-section millisecond delay detonators. A V-section millisecond delay detonator is selected by the reliever hole. The oblique cuts and the whole section of the reliever hole are detonated once with the total delay time no more than 130.0ms. After the groove cavity is formed in a blasting method. The reasonable tooth parameters are selected to rapidly expand the groove cavity to the design section and contour is finished under effect of a free surface of a fully-mechanized coal winning machine. Due to millisecond delay detonation of the oblique cut in three stages and larger borehole diameter, stemming is blocked to increase so that rocks do not affect the fully-mechanized coal winning machine after the working surface during the throwing process. The safe and efficient effect can be achieved.

Owner:湖南省煤业集团红卫矿业有限公司

Mine roadway excavation working face temporary support hydraulic device

InactiveCN104675422AReduce labor intensityImprove securityMine roof supportsMine roof capsSupporting systemEngineering

The invention discloses a mine roadway excavation working face temporary support hydraulic device comprising a hydraulic combined support, four graded telescopic jacks, a head temporary support and a tail temporary support. The hydraulic combined support comprises four sets of hydraulic supports composed of top beams, lifting jacks and longitudinal-moving jacks; the graded telescopic jacks are installed on the upper portions of the top beams of the hydraulic combined support; the tail temporary support supporting range serves as the roadway supporting operation space, the head temporary support provides the operation space for muck loading, rock drilling and one-step supporting, and the hydraulic combined support is used for implementing the entire moving of a roadway excavation temporary supporting system; each temporary support comprises a top beam and two hydraulic jacks, the top beams of the temporary supports are fixed to the graded telescopic jacks, the two hydraulic jacks are suspended freely to serve as support legs, and the top beams and the hydraulic jacks are connected through pins. The roadway construction empty roof operation is avoided, surrounding rock can be supported timely, and roadway excavation and supporting parallel operation is implemented.

Owner:徐州赛特机械制造有限公司

Shield cutterhead structure for uneven mutual-penetration composite rock stratum

The invention discloses a shield cutterhead structure for an uneven mutual-penetration composite rock stratum. The shield cutterhead structure for the uneven mutual-penetration composite rock stratum comprises a heavy cutterhead, double-edge central hobbing cutters, a single-edge front-side hobbing cutter, a single-edge circumferential hobbing cutter and an auxiliary cutter, wherein the heavy cutterhead is of a radial-plate intermediate supporting structure, and the opening rate of the heavy cutterhead ranges from 20 to 30 percent; the double-edge central hobbing cutters are vertical to each other and arranged on the central position of the heavy cutterhead; the single-edge front-side hobbing cutter is arranged above four main spiders of the heavy cutterhead according to a cutting path of the shield cutterhead; the single-edge circumferential hobbing cutter is arranged on the end part of the four main spiders according to the cutting path of the shield cutterhead; the auxiliary cutter is arranged above the spiders of the heavy cutterhread according to the cutting path of the shield cutterhead. The cutterhead structure is suitable for shield tunneling of the composite stratum which is non-uniform in hardness and mutually penetrated by each other.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

Propelling method for combined portion between shield tunnel segment and mine tunnel segment in subway tunnel

InactiveCN103711504ALow bond strengthLow elastic modulusUnderground chambersTunnel liningGlass fiberShotcrete

Provided is a propelling method for a combined portion between a shield tunnel segment and a mine tunnel segment in a subway tunnel. The propelling method includes the first step that a steel sleeve is horizontally struck into the surrounding rock in front of a tunnel face of the mine tunnel segment after construction of the mine tunnel segment is finished, and then a shotcrete support is applied on the tunnel face; the second step that glass fiber ribs of separation end walls are bound tightly close to the shotcrete support, the glass fiber ribs and steel bars for ring beams behind the glass fiber ribs are connected in a bound mode, next the steel bars for the ring beams are connected with reserved steel bar heads of a primary support of the mine tunnel segment in a welded mode, and then the separation end walls and the ring beams are poured; the third step that an arc-shaped concrete guiding platform is poured at the bottom of the mine tunnel segment; the fourth step that when a shield tunneling machine approaches to the mine tunnel segment, the propelling speed is lowered, the shield tunneling machine is accommodated in the steel sleeve, and then the shield tunneling machine is used for directly cutting and removing the surrounding rock in the steel sleeve, the shotcrete support of the tunnel face and the separation end walls and carrying out grouting and slag removing until the shield tunneling machine passes through the ring beams and is accommodated on the arc-shaped concrete guiding platform. According to the propelling method, construction risks are low, construction is easy, efficiency is high and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

A pipe jacking machine and a returnable pipe jacking construction method

PendingCN108895201ALarge cutting areaImprove tunneling efficiencyPipe laying and repairEngineeringKnife holder

A pipe jacking machine includes a cutter head fixedly connected to the inner housing and capable of entering the central cavity, and a folding cutter holder having a first end hinged to the cutter head and a second end foldable about the first end into the central cavity. The cutter head includes an outer housing and an inner housing, and a cutter assembly and a retractor fixedly connected to theinner housing at an end remote from the cutter assembly. The cutting area of the folding cutter holder is free from the influence of the shell, and can avoid manual overturning, which is favorable forimproving the tunneling efficiency and realizing automatic retraction. In addition, the inner shell is dragged by the back dragging device so that the inner shell drives the cutter assembly to be dragged from the central cavity of the outer shell into the originating well, thereby avoiding manual disassembly of the connection between the outer shell and the inner shell and facilitating further automatic retraction. Therefore, the pipe jacking machine provided by the invention is not only conducive to improving the tunneling efficiency, but also conducive to realizing automatic retraction. Theinvention also discloses a returnable pipe jacking construction method applied to the pipe jacking machine as described above.

Owner:CHINA RAILWAY CONSTR HEAVY IND

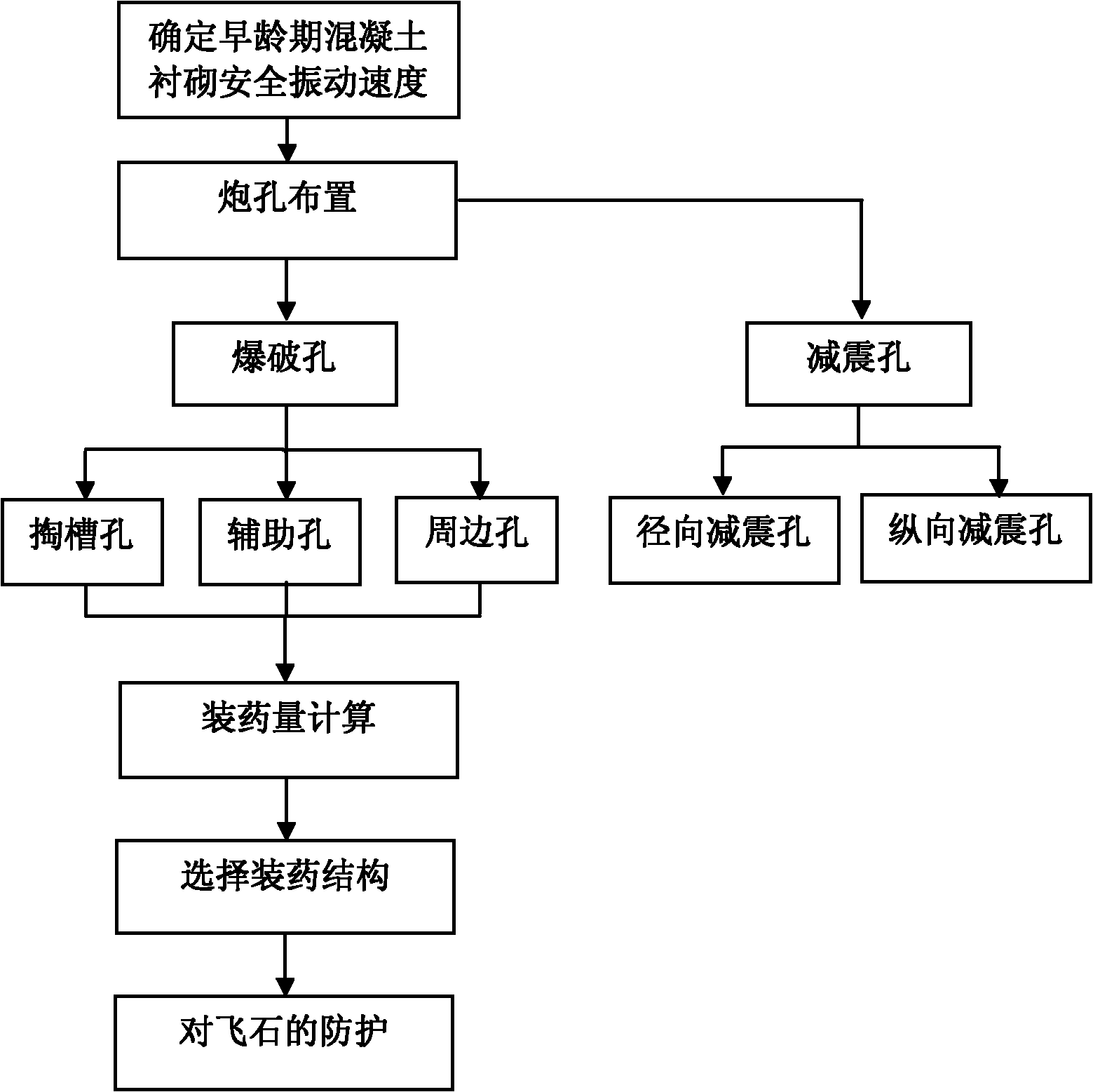

Blast method for realizing vibration attenuation and protection of early-age concrete lining during tunnel construction

ActiveCN102183184AImprove tunneling efficiencyReduce Vibration HazardsBlastingTunnel constructionBuilding construction

The invention relates to a vibration attenuation and protection technology for blasting and digging of tunnels and aims at providing a blast method for realizing vibration attenuation and protection of early-age concrete lining during tunnel construction. The method comprises the following steps of: determining a safety vibration speed of the early-age concrete lining according to the most unfavorable value in combination with the age of the concrete, an explosion center distance and a rock geological condition; forming explosion holes; forming vibration attenuation holes; calculating a mass point vibration speed of the protected early-age concrete lining during explosion, and determining an allowable maximum explosive load under the condition that the mass point vibration speed is smaller than the safety vibration speed of the early-age concrete lining; and filling explosive and performing explosion. By adoption of the method, during tunnel explosion and construction, vibration harm of explosion to the early-age concrete lining can be reduced effectively when a distance between an explosion point in front of a tunnel and the poured concrete lining is closer due to an engineering progress requirement or because working surfaces are crossed; therefore, the tunneling efficiency is improved and the engineering can be constructed safely and successfully.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com