Mine roadway excavation working face temporary support hydraulic device

A technology of excavation work, hydraulic device, applied in the field of hydraulic device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

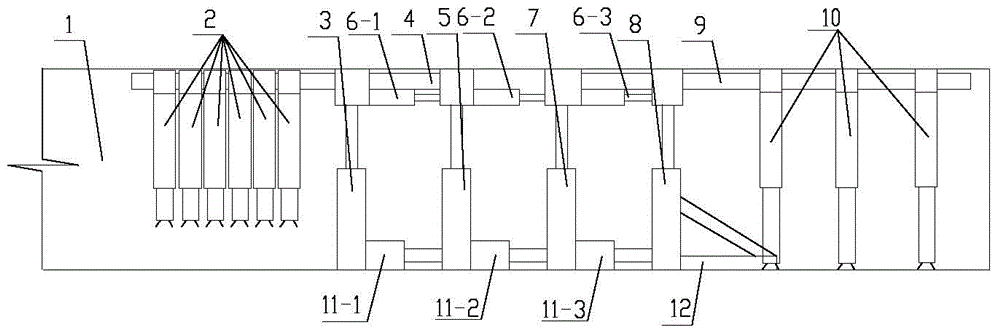

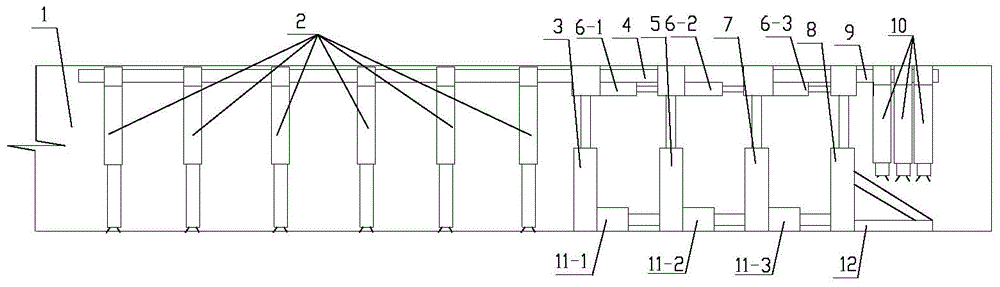

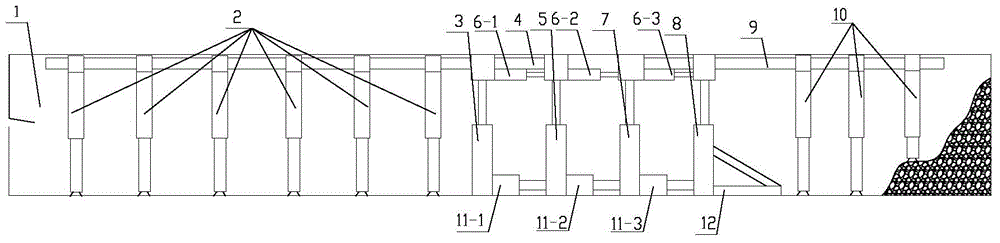

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] The hydraulic device for the temporary support of the roadway excavation work is composed of hydraulic combined supports (3, 5, 7, 8), step-by-step telescopic jacks (4, 9), frontal temporary supports (10), and tail temporary supports (2); Combined supports (3, 5, 7, 8) consist of 4 sets of hydraulic supports consisting of top beams, lifting jacks, and front and rear moving jacks; hydraulic combined supports (3, 5, 7, 8) realize the overall movement of the roadway excavation temporary support system Install 4 graded telescopic jacks (4,9) on the roof beam top of the hydraulic combination support (3,5,7,8), realize the expansion and contraction of the temporary support (10) and the temporary support (2) at the head, and the temporary support at the rear (2) The support range is used as the roadway support operation space, and the head-on temporary support (10) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com