Patents

Literature

1675results about "Lamps testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

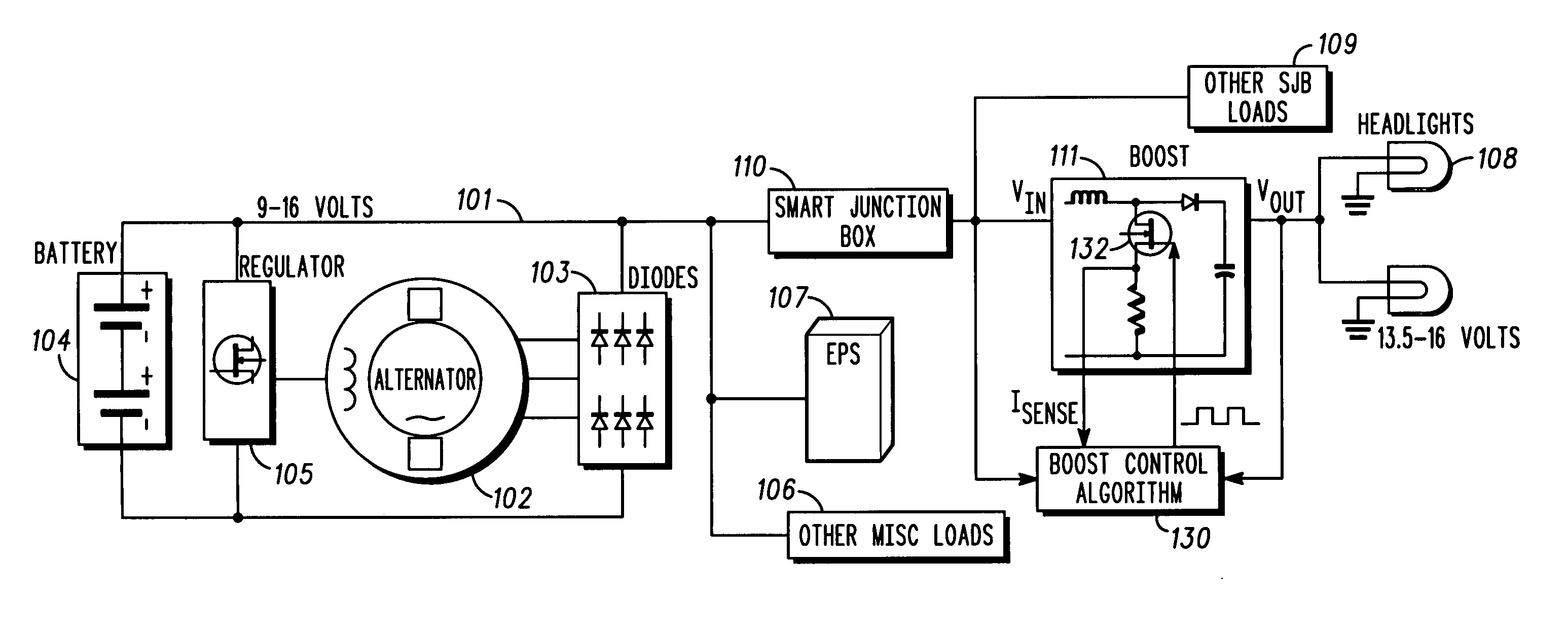

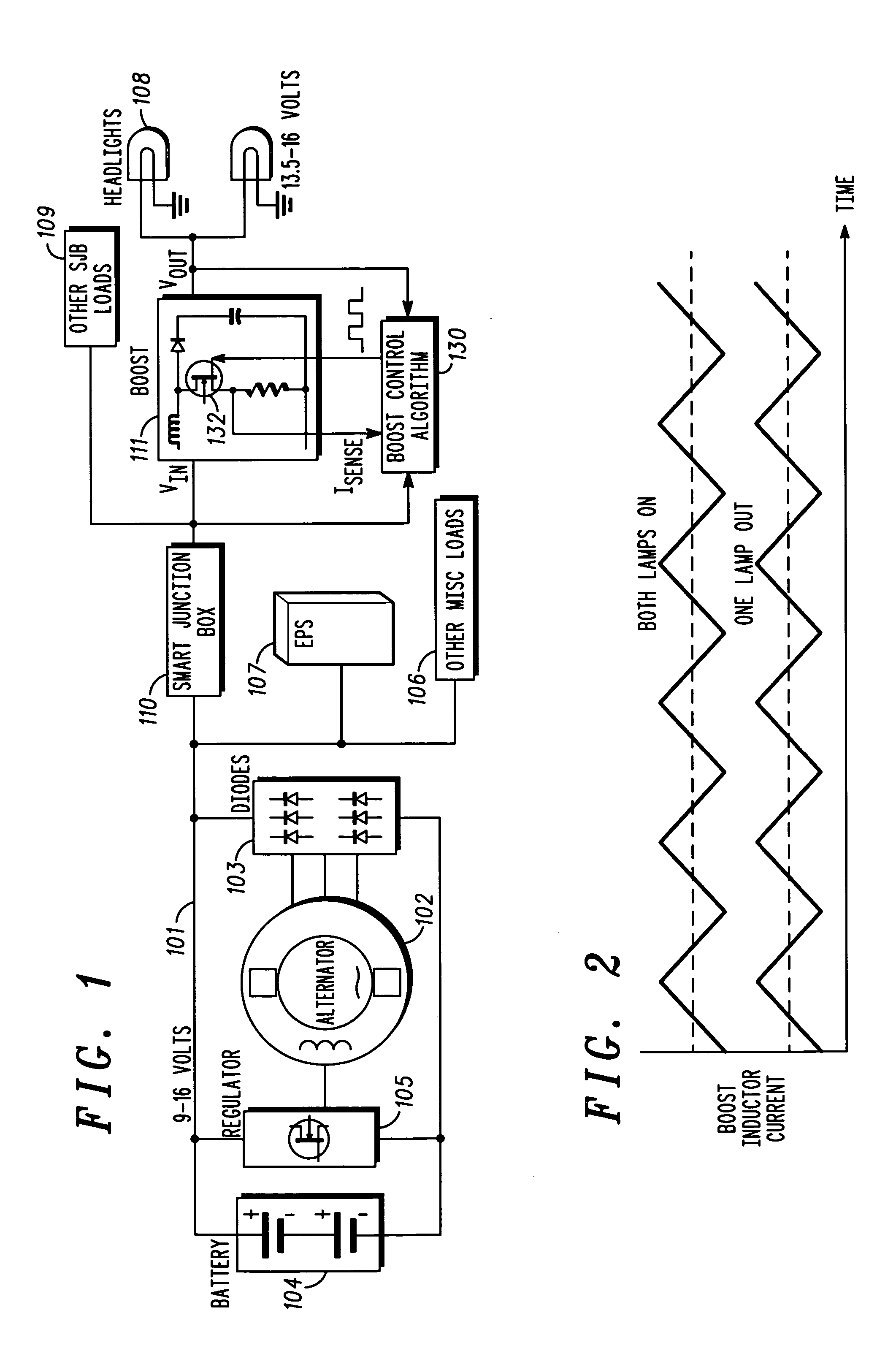

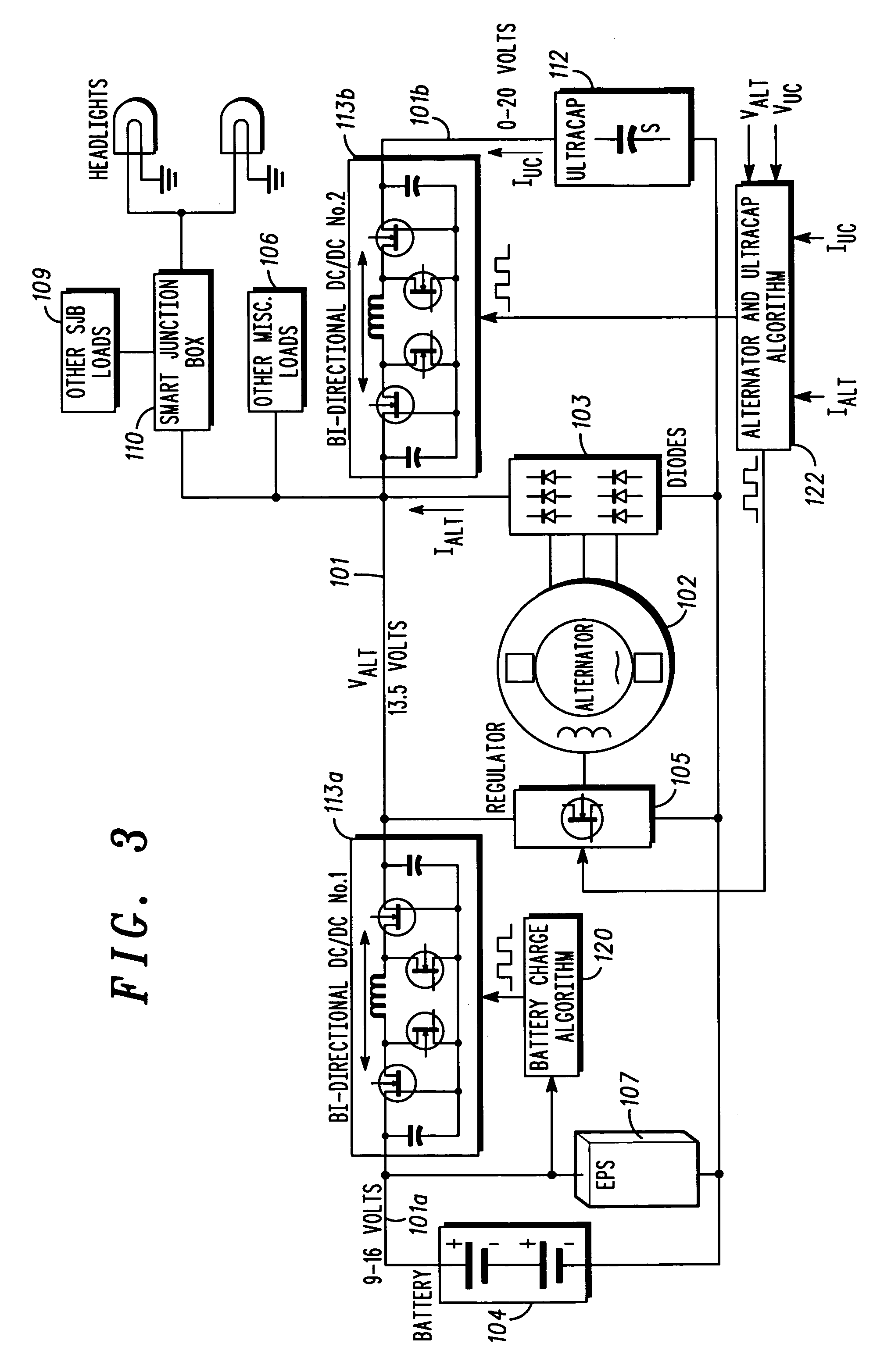

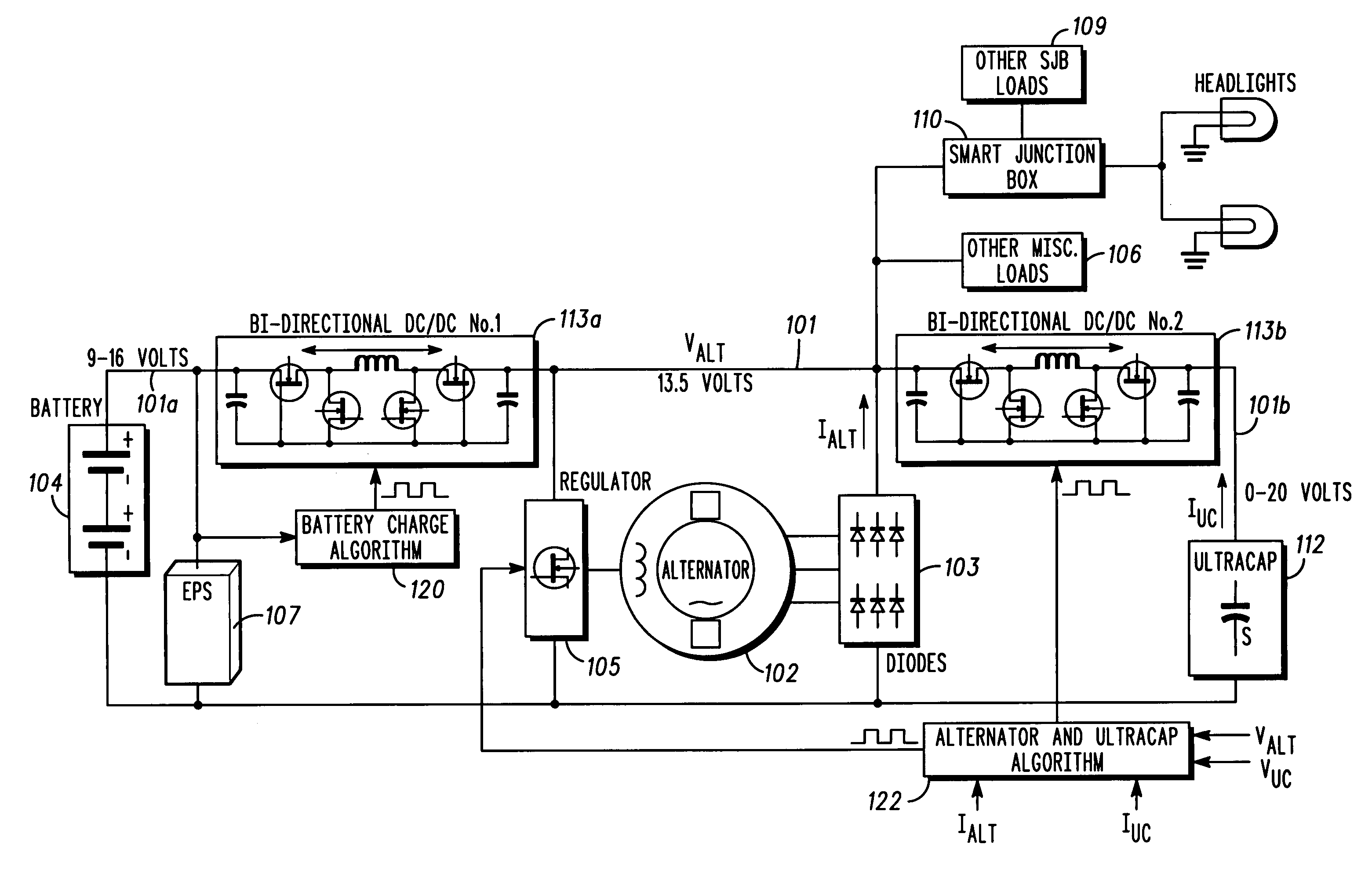

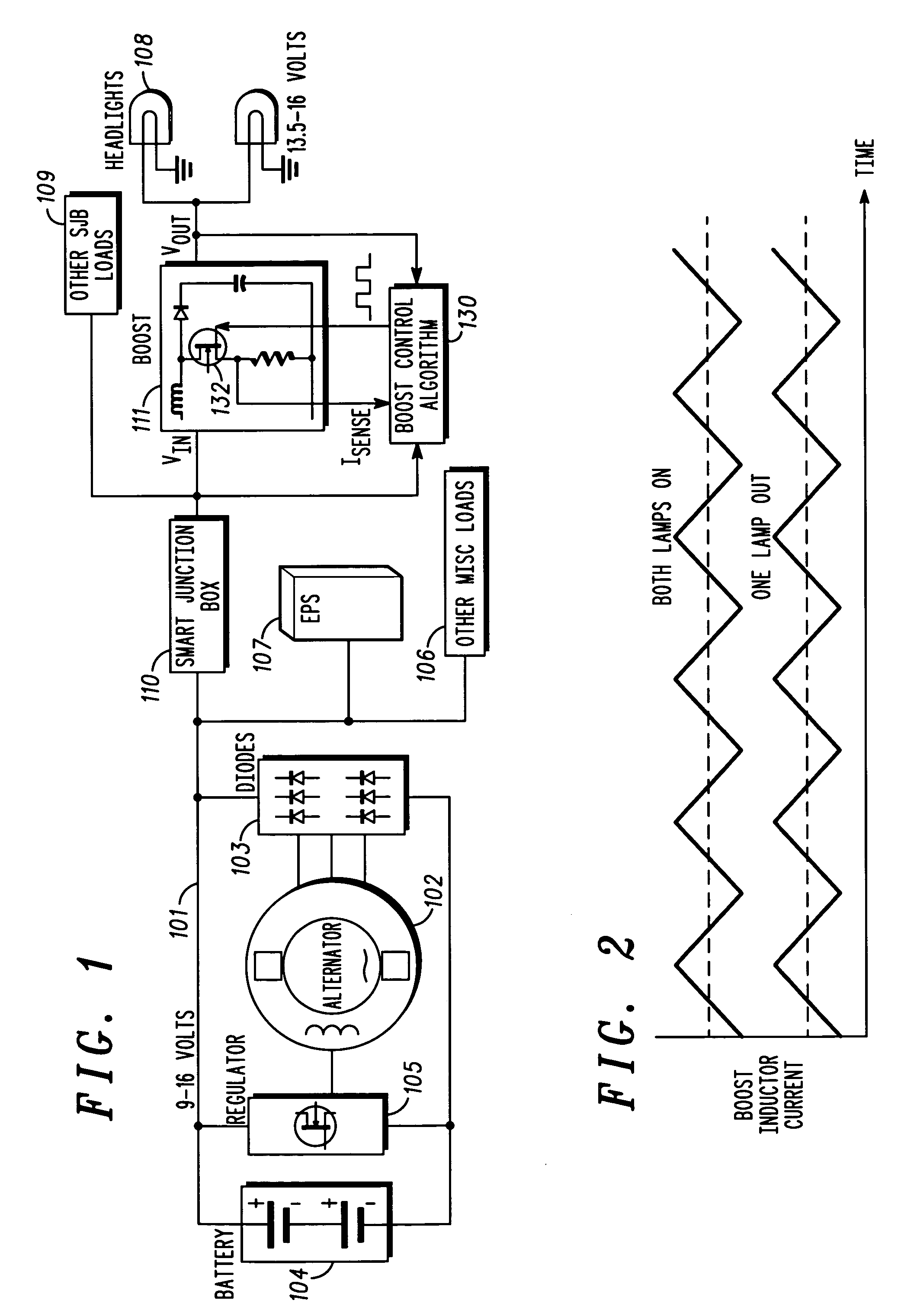

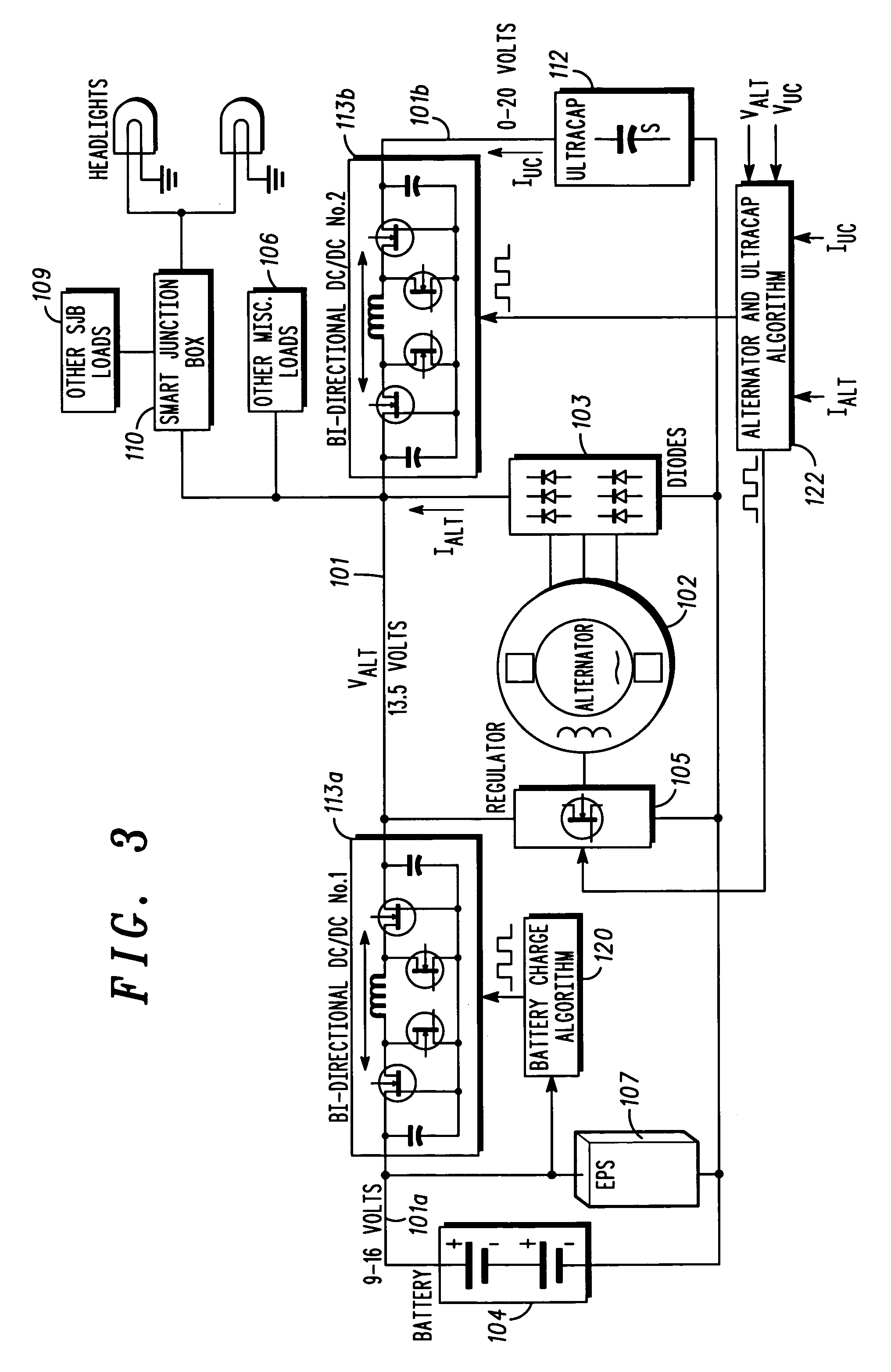

Automotive electrical system configuration using a two bus structure

InactiveUS20060043938A1Batteries circuit arrangementsEmergency protective circuit arrangementsAlternatorCritical load

Disclosed herein are a variety of different electrical system topologies intended to mitigate the impact of large intermittent loads on a 12 volt vehicle power distribution system. In some embodiments the intermittent load is disconnected from the remainder of the system and the voltage supplied to this load is allowed to fluctuate. In other embodiments, the voltage to critical loads is regulated independently of the voltage supplied to the remainder of the system. The different topologies described can be grouped into three categories, each corresponding to a different solution technique. One approach is to regulate the voltage to the critical loads. A second approach is to isolate the intermittent load that causes the drop in system voltage. The third approach is to use a different type of alternator that has a faster response than the conventional Lundell wound field machine.

Owner:TEMIC AUTOMOTIVE OF NORTH AMERICA

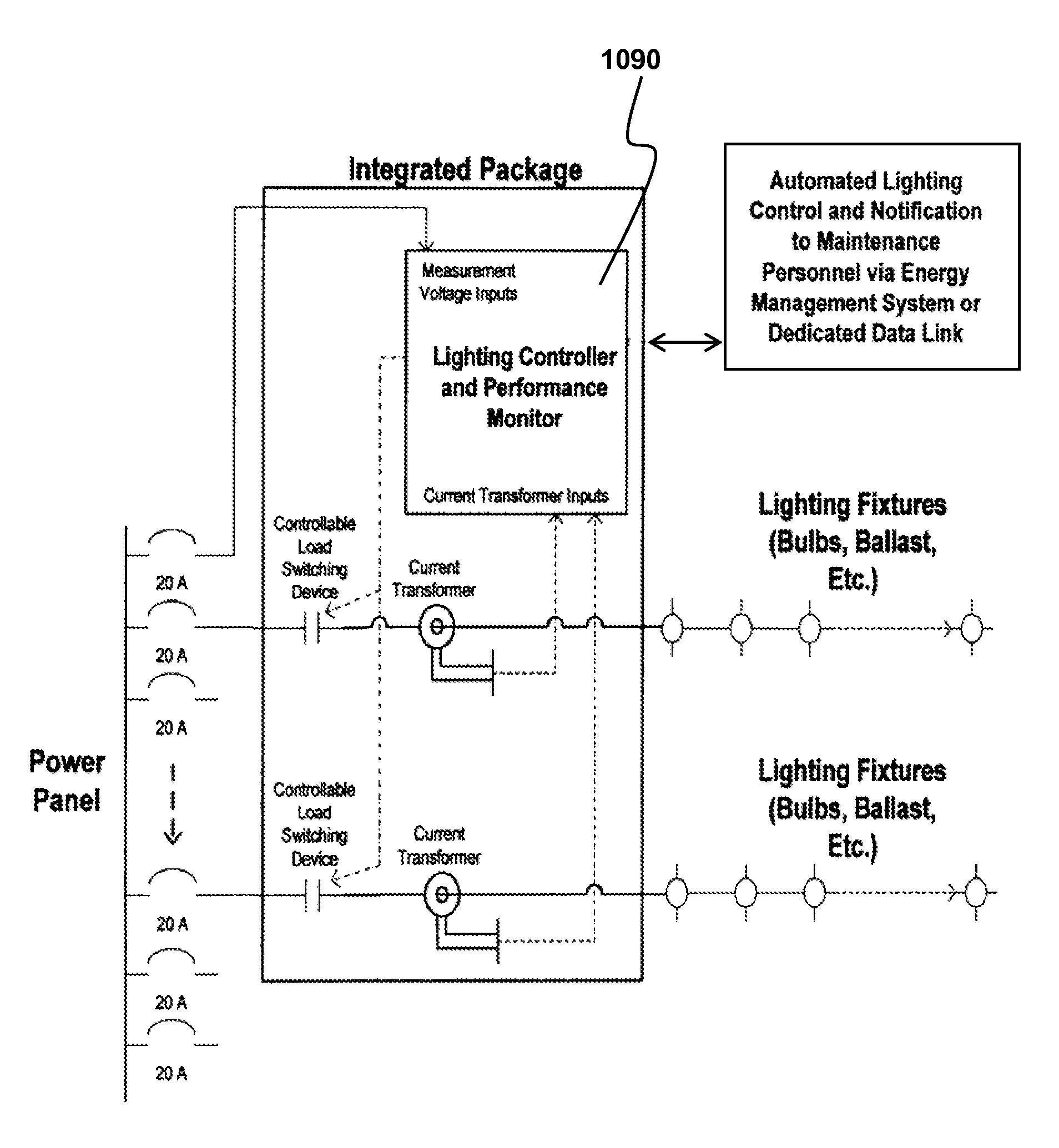

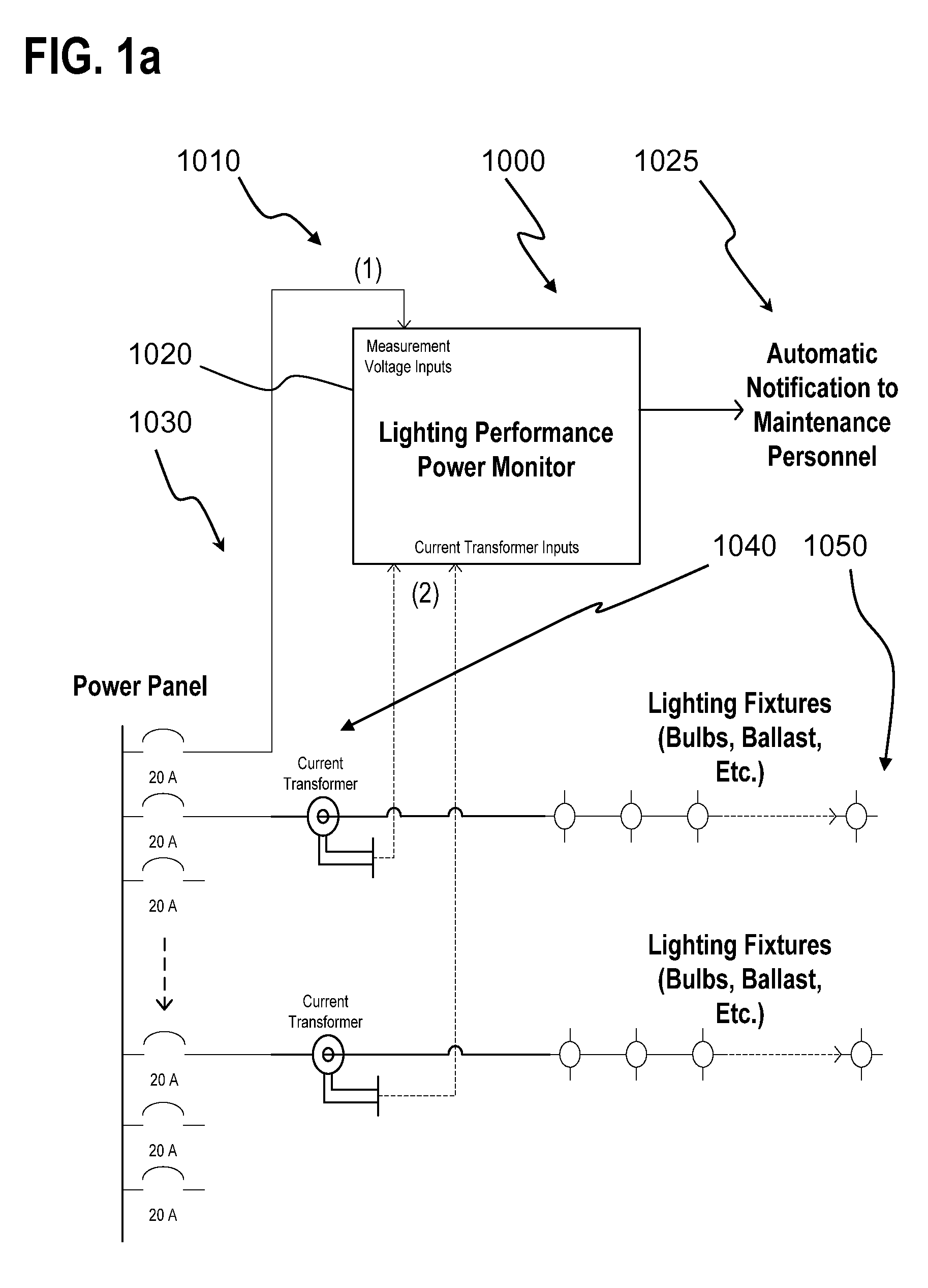

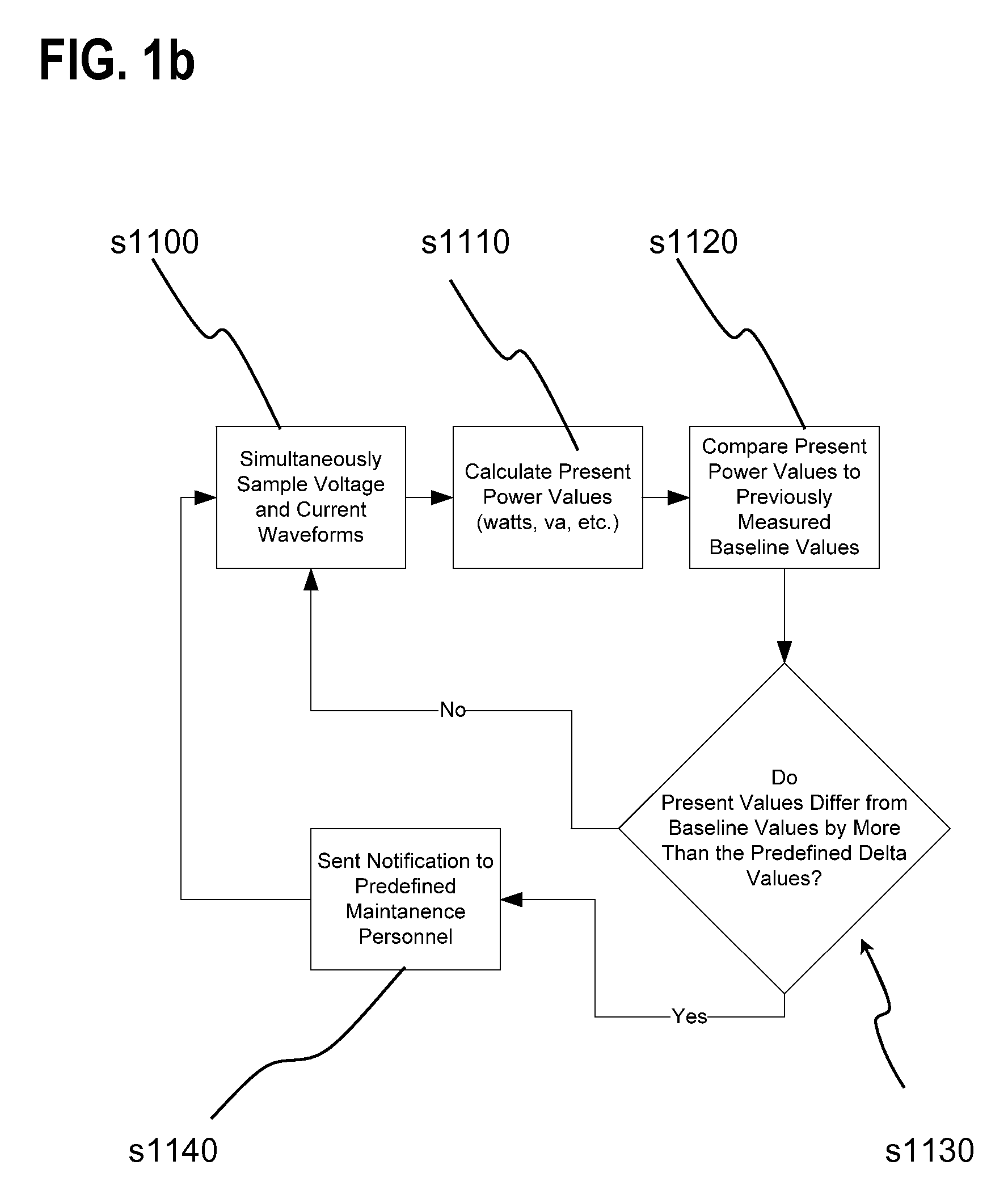

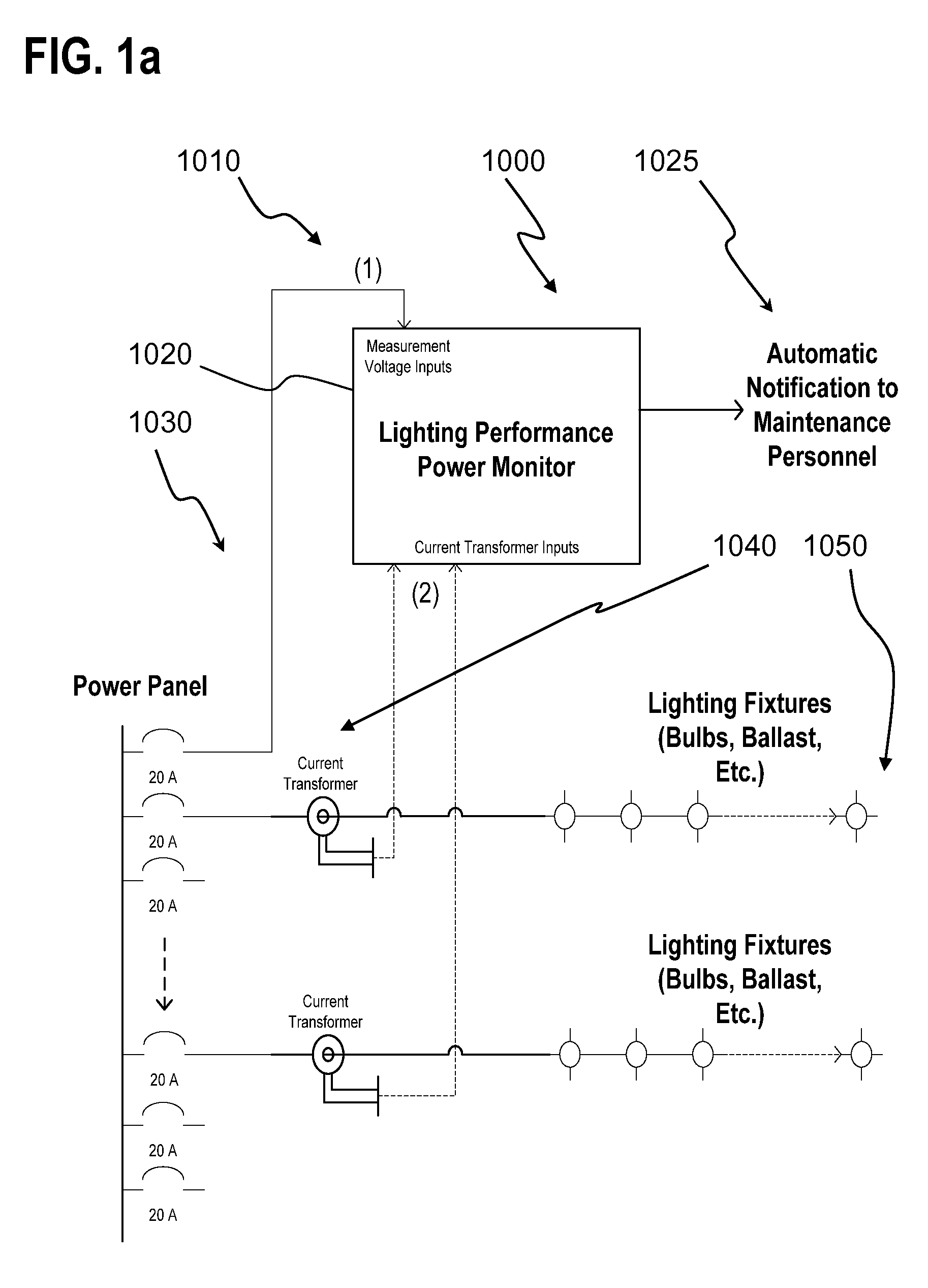

Lighting performance power monitoring system and method with optional integrated light control

ActiveUS7571063B2Save energyLow costLevel controlPower measurement by digital techniqueEngineeringBallast

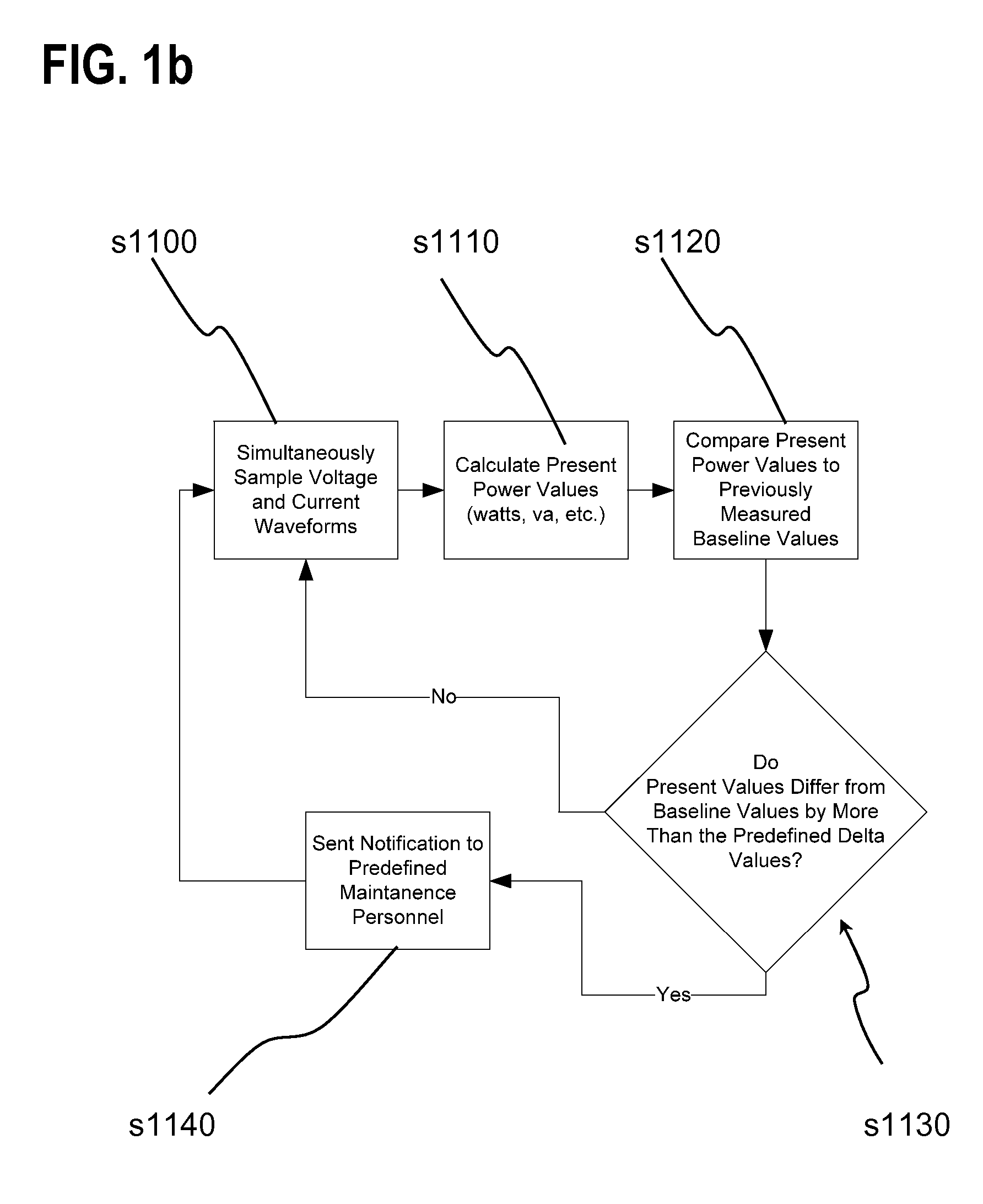

A light performance monitoring device and optionally integrated controller includes a monitor module that directly monitors energy usage of at least one energy load to generate at least one measurement of energy usage; a storage module stores a series of baseline values of energy usage of the energy load, a comparator module compares energy measurements made at predetermined intervals with the baseline values, and a notification module notifies a designated recipient that there is a deviation from the baseline values consistent with a burned out or non-operational light fixture, including but not limited to light bulbs or ballast devices. A control module optionally integrated with the light performance monitoring device can be operatively coupled to the monitor module to control energy usage by the at least one energy load via a data link in a pre-determined manner that is based on the at least one measurement of energy usage.

Owner:GRIDPOINT

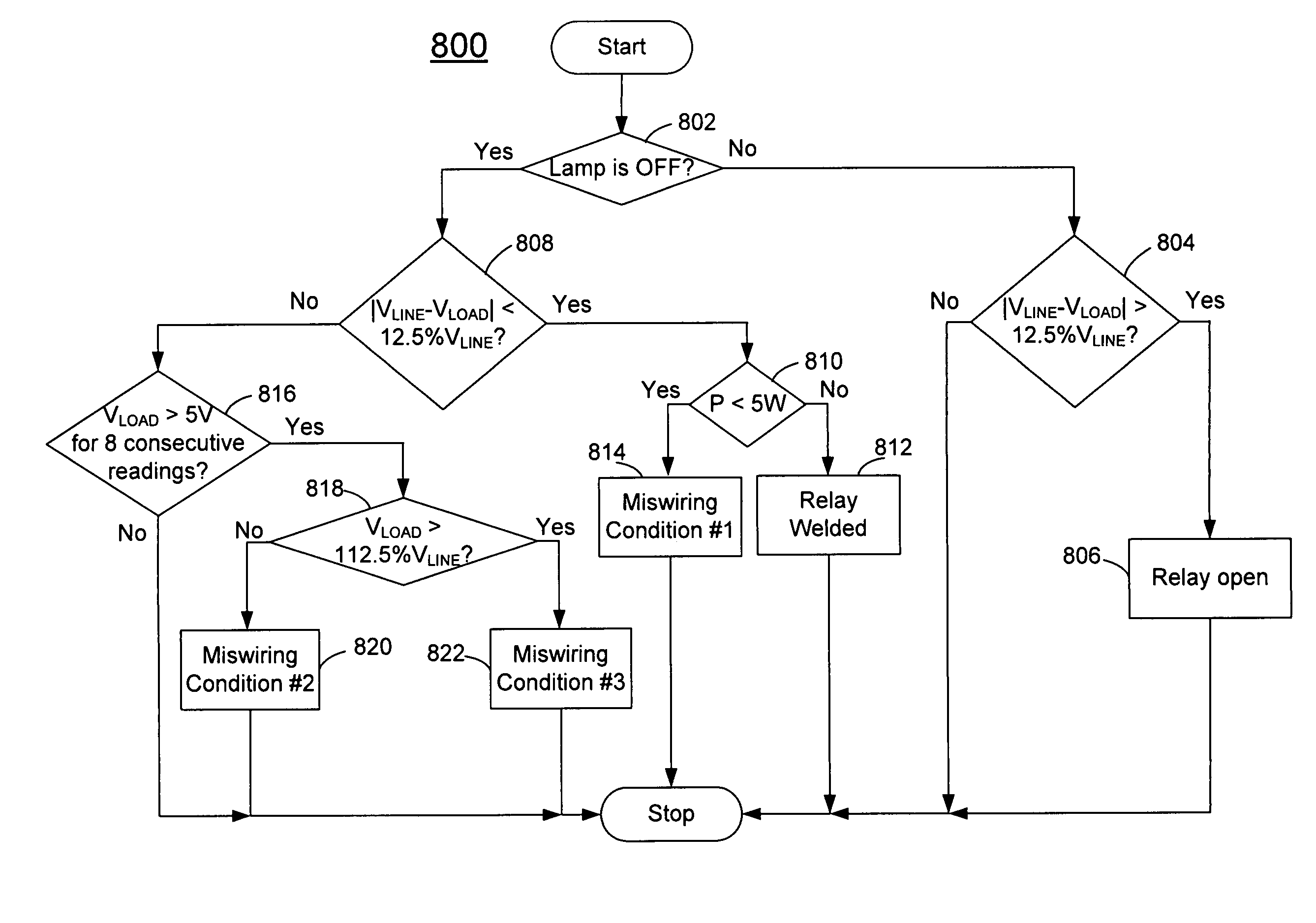

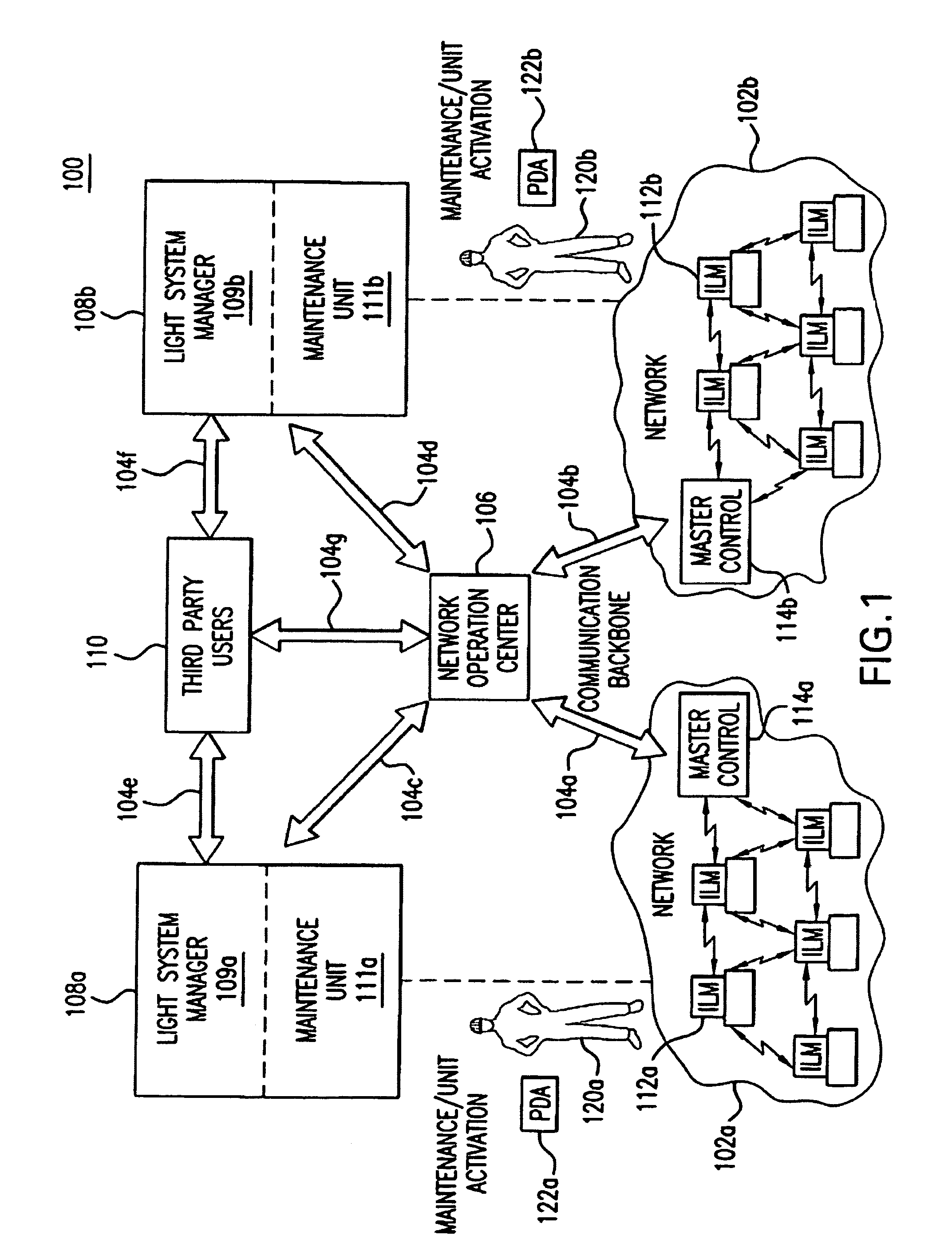

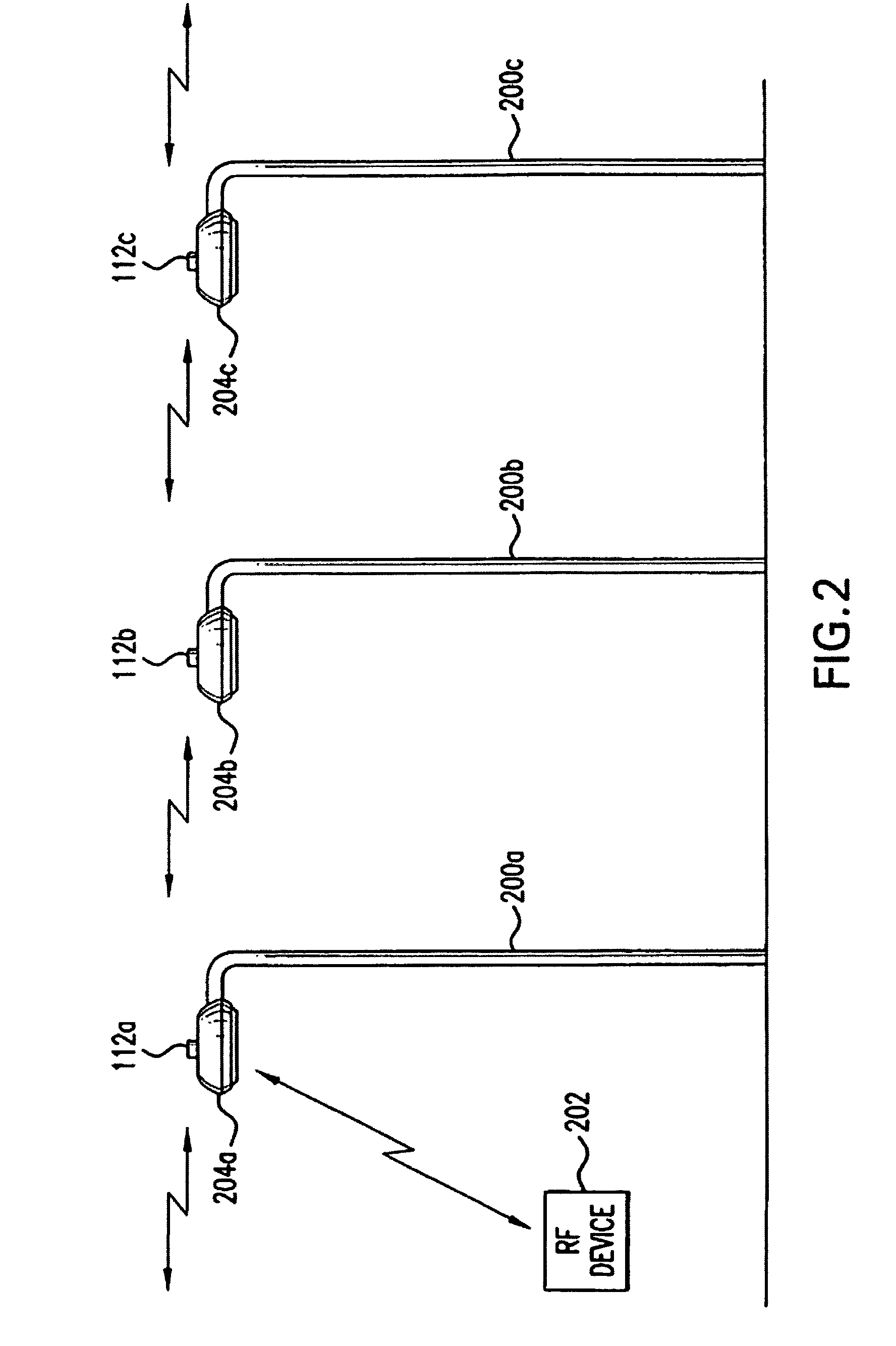

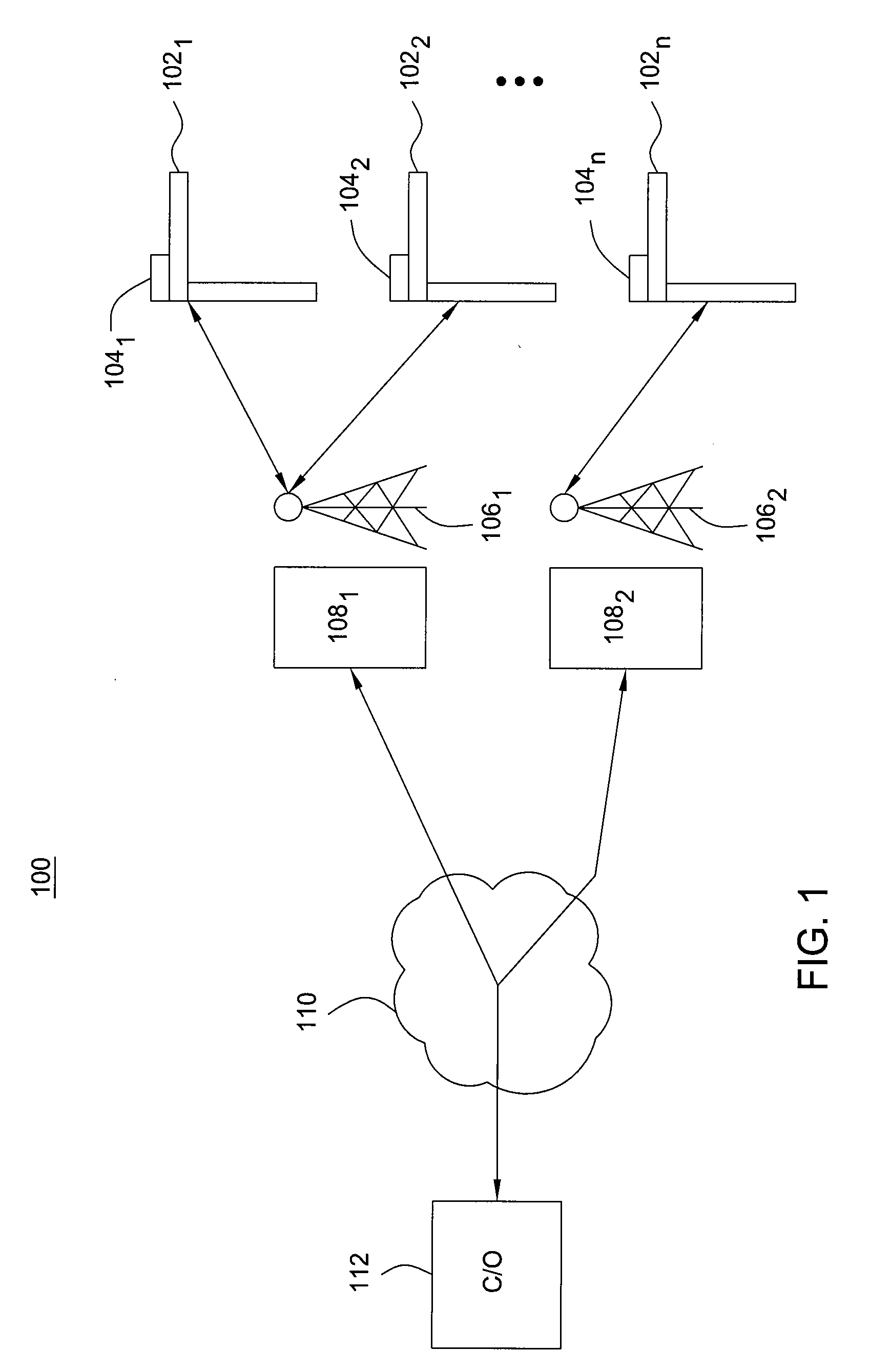

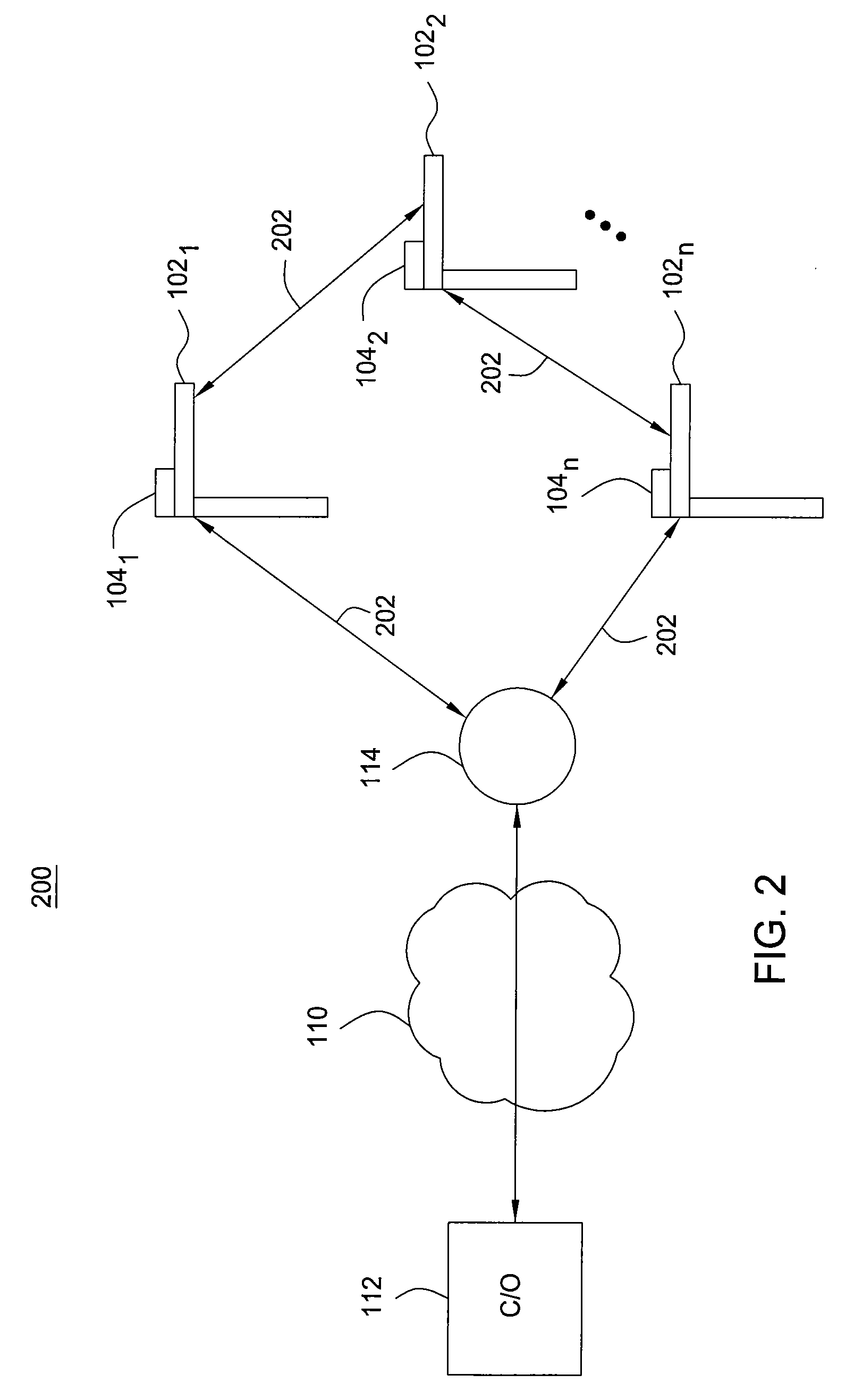

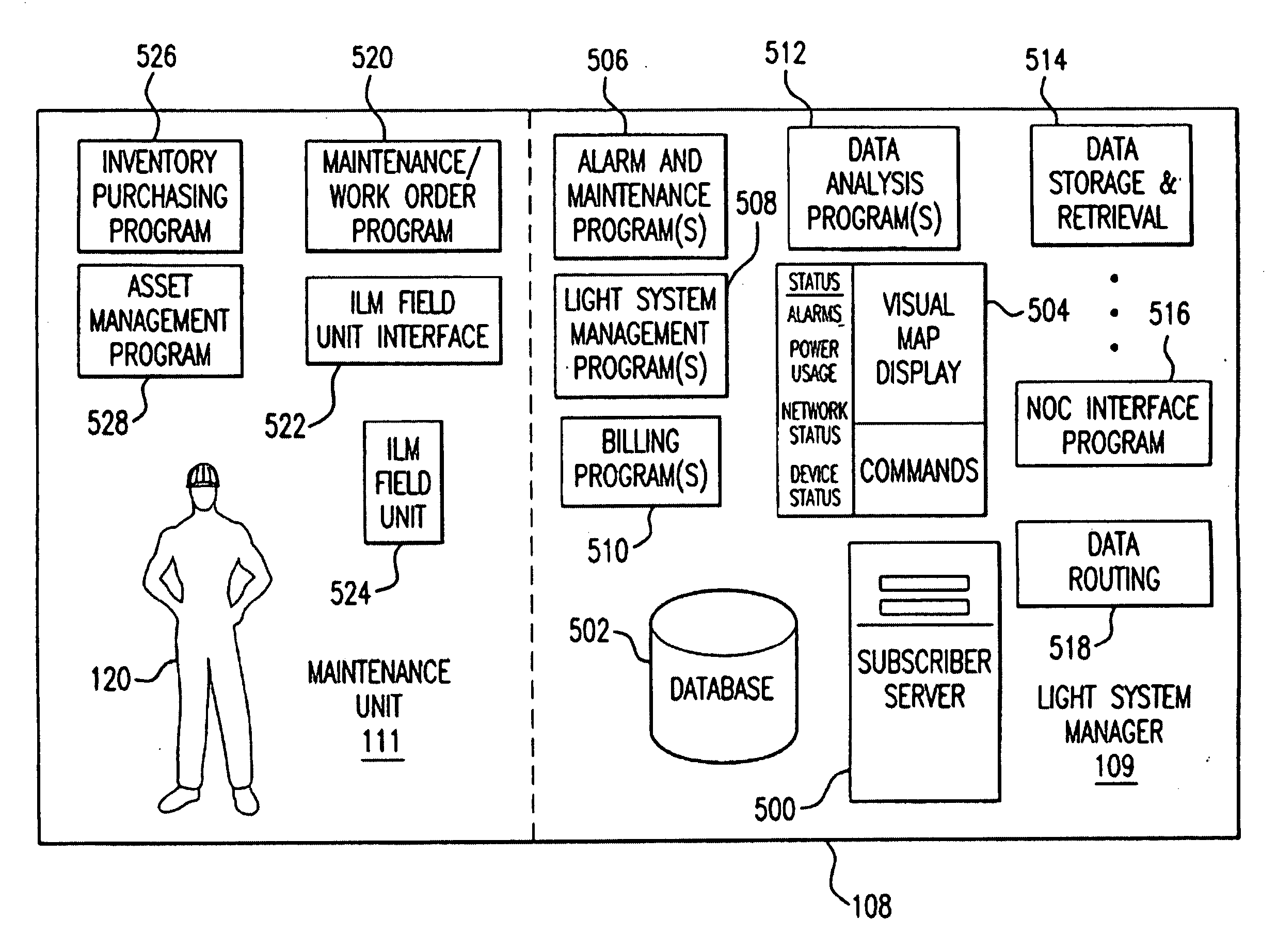

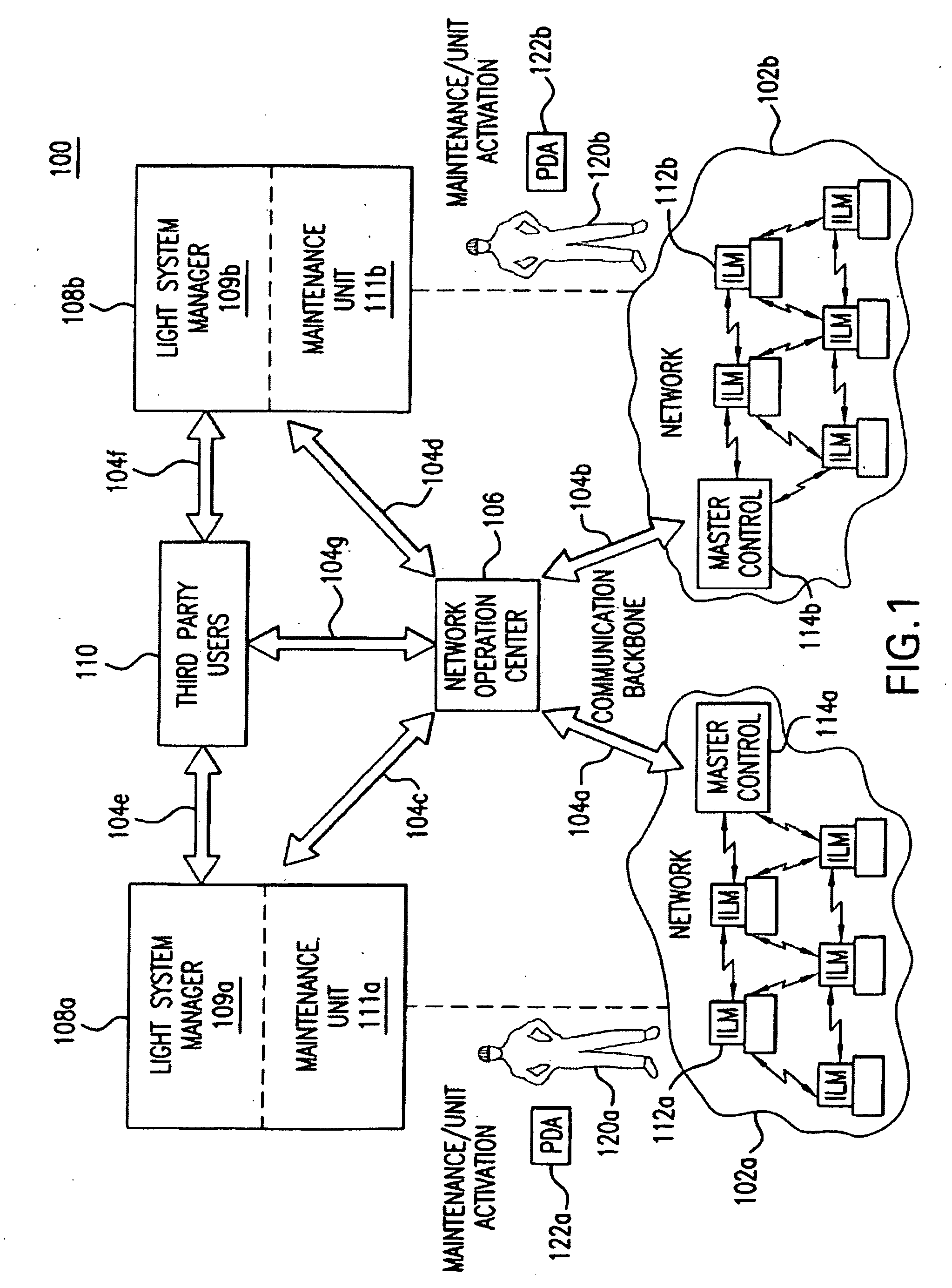

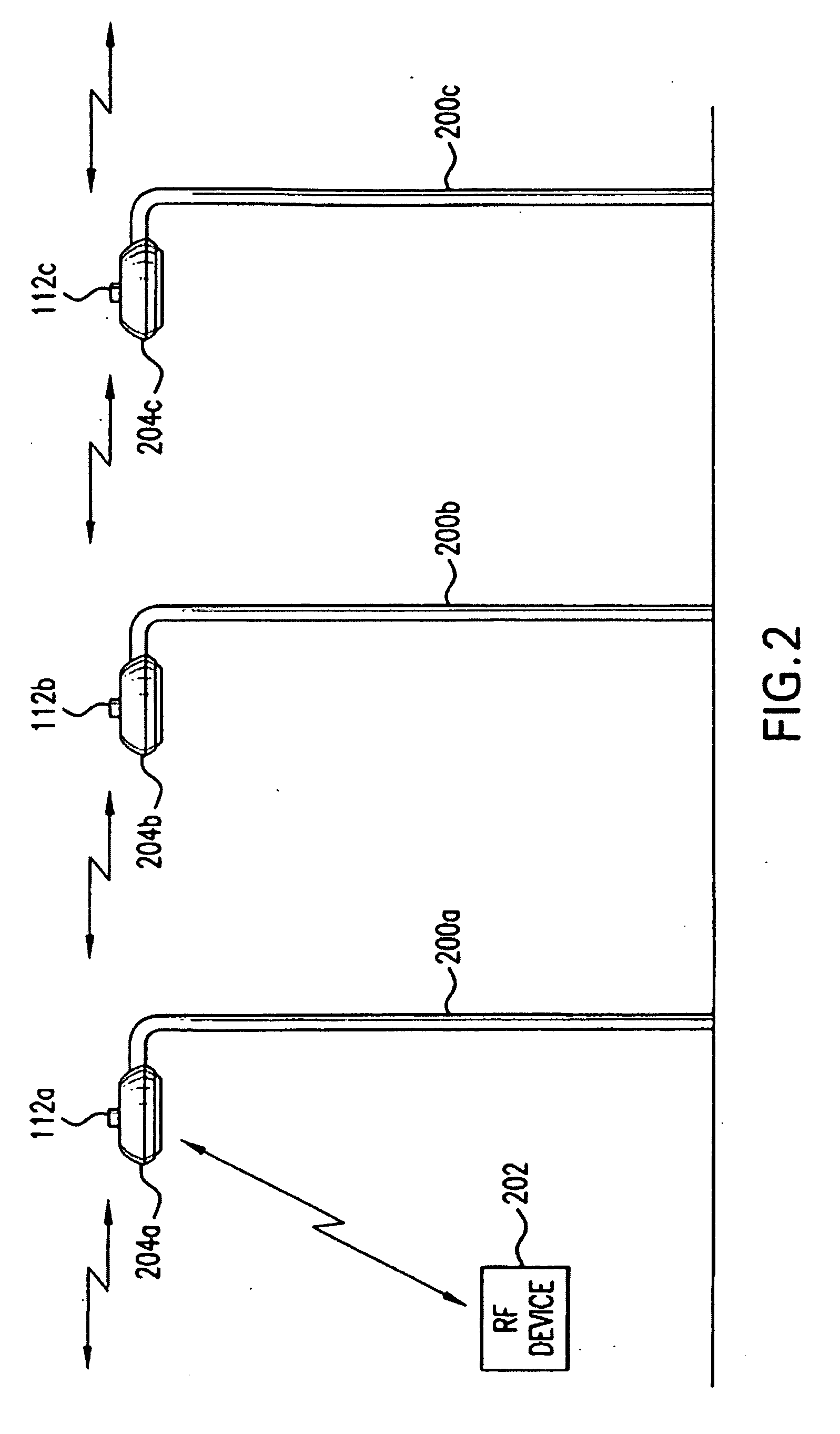

System and method for streetlight monitoring diagnostics

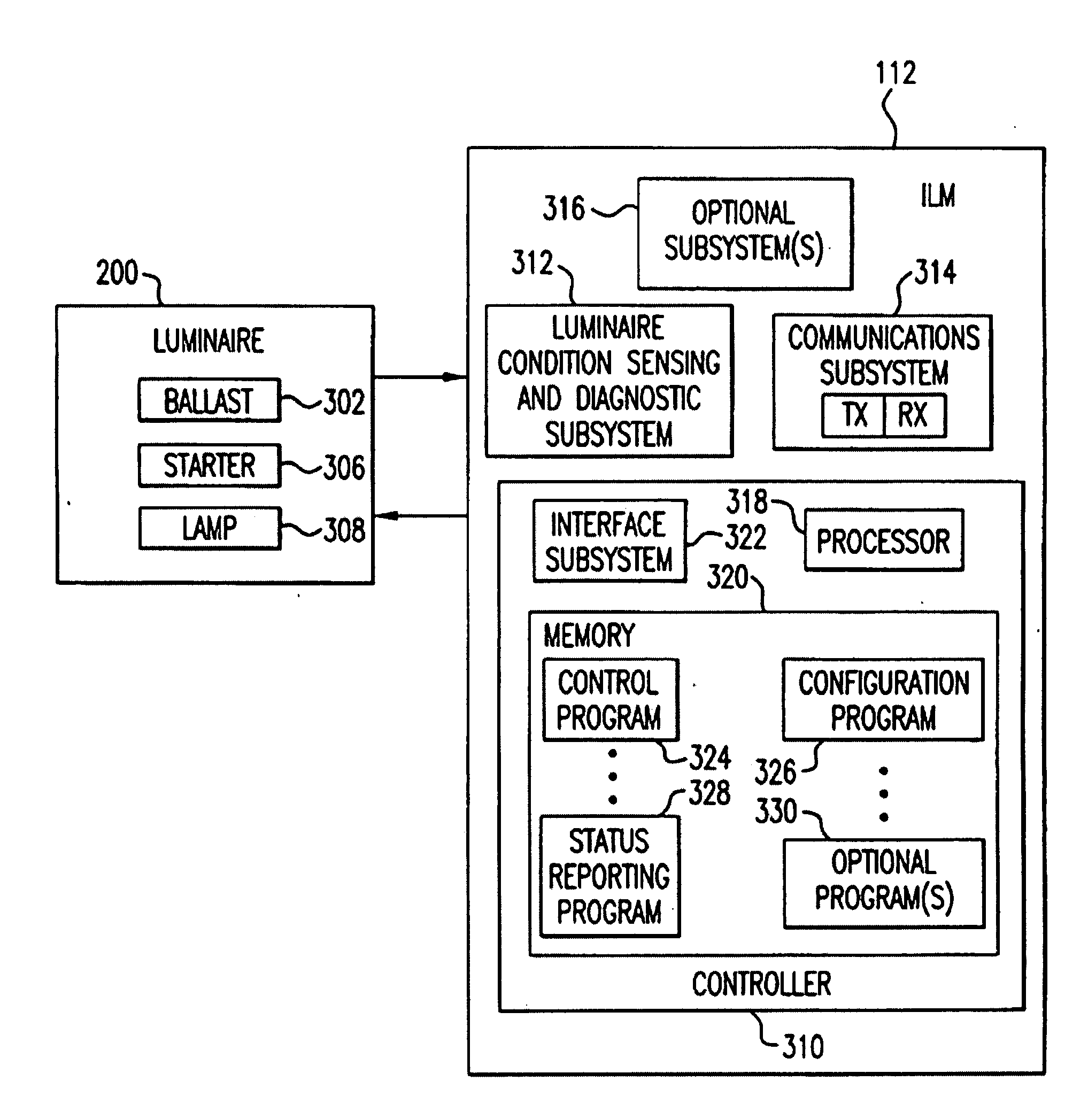

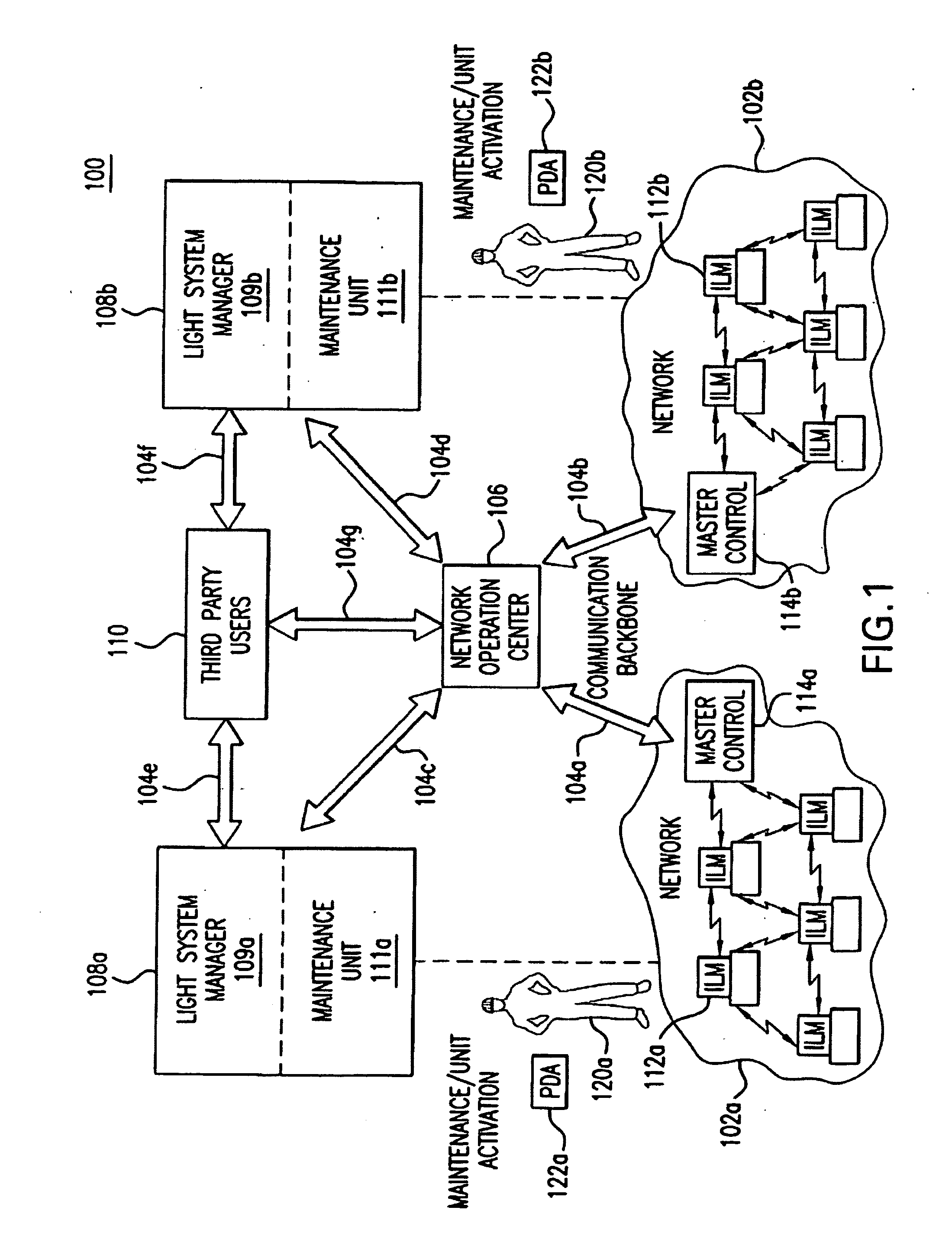

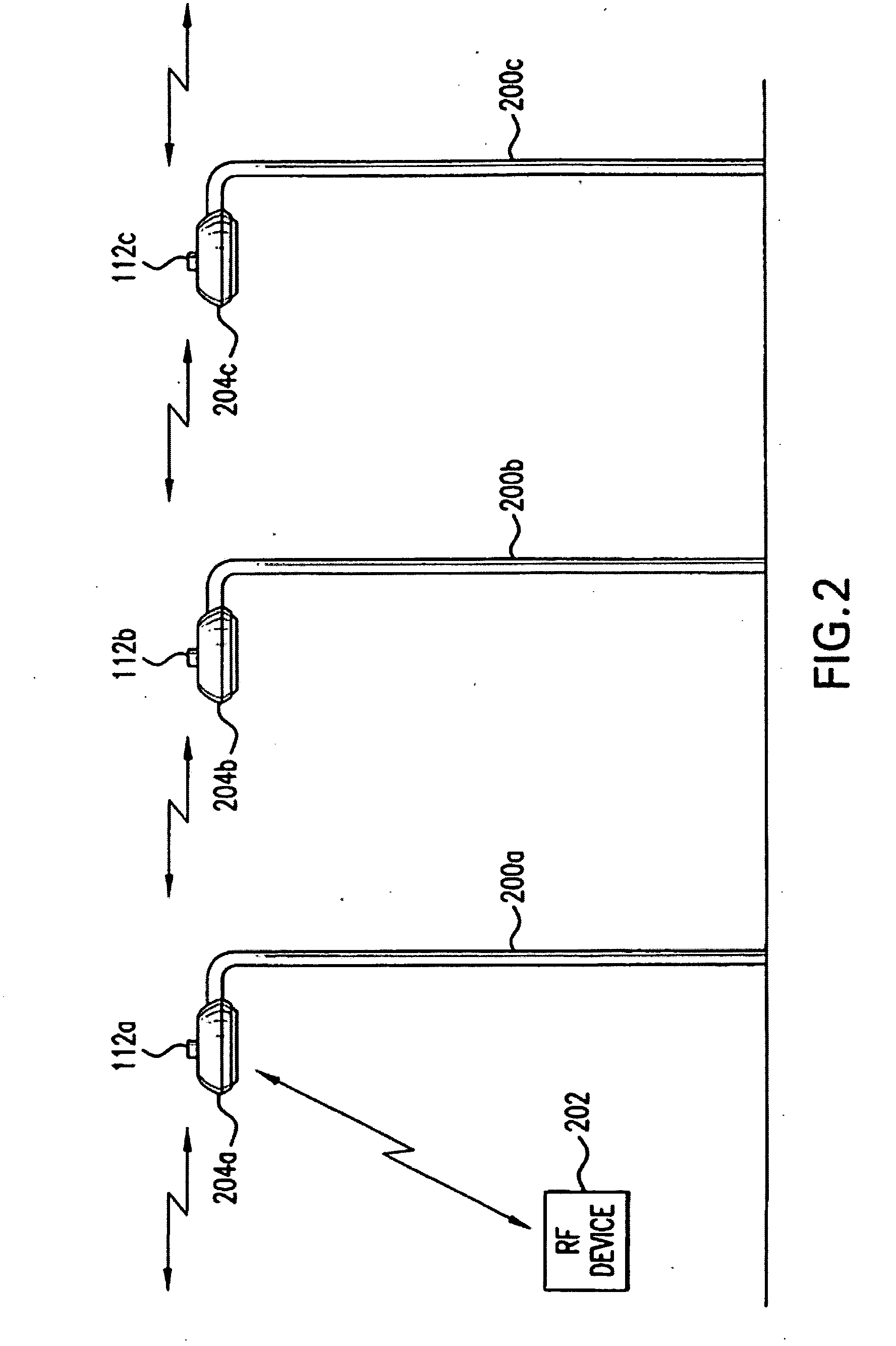

ActiveUS8140276B2Discharge tube incandescent screensElectric devicesWireless transmissionNetwork service

One or more example diagnostics may be implemented as part of an intelligent luminaire manager or other radio frequency (RF) device that is in communication with an equipment or fixture such as a luminaire. Example diagnostics can determine a status such as a fixture malfunction, a cycling condition, a miswiring configuration, or another condition. The determined status can be wirelessly transmitted from the intelligent luminaire manager or other radio frequency device to a network server via a network. The network may be a network of intelligent luminaire managers and / or RF devices.

Owner:ABL IP HLDG

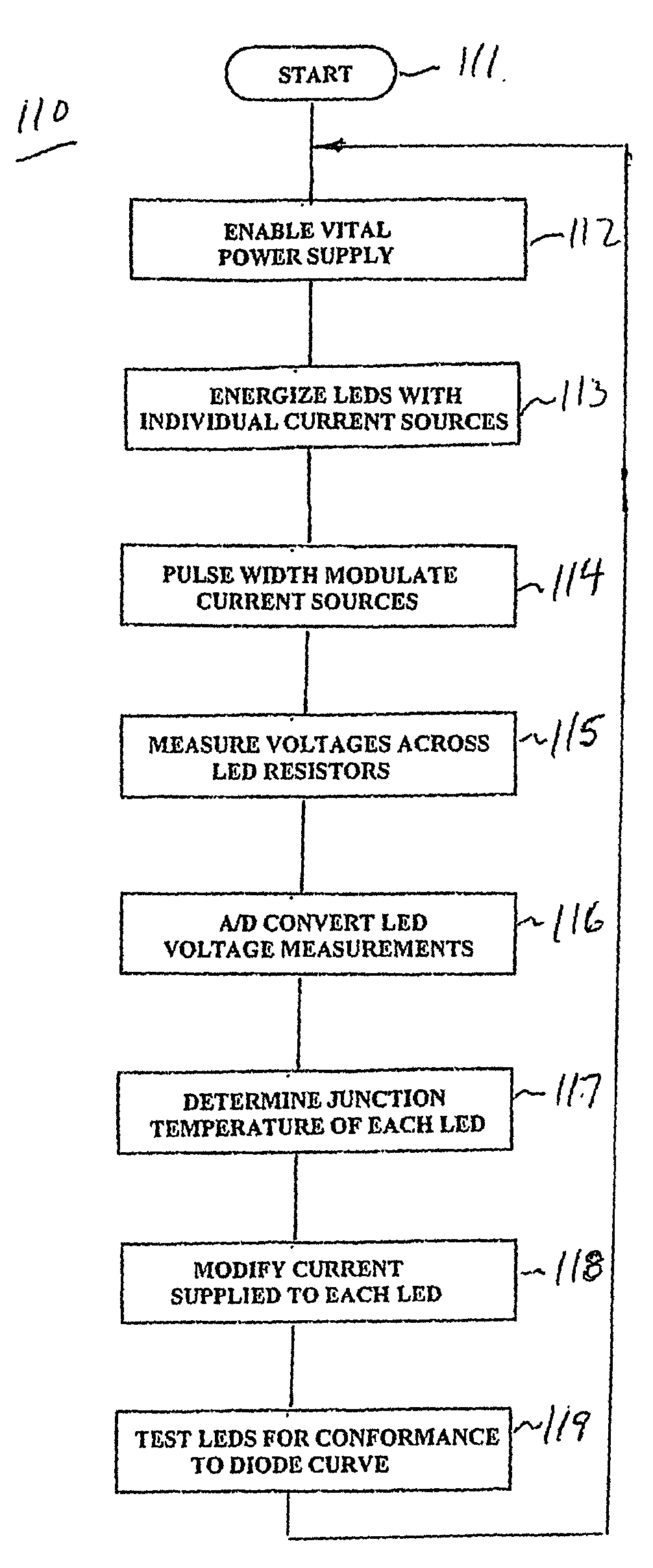

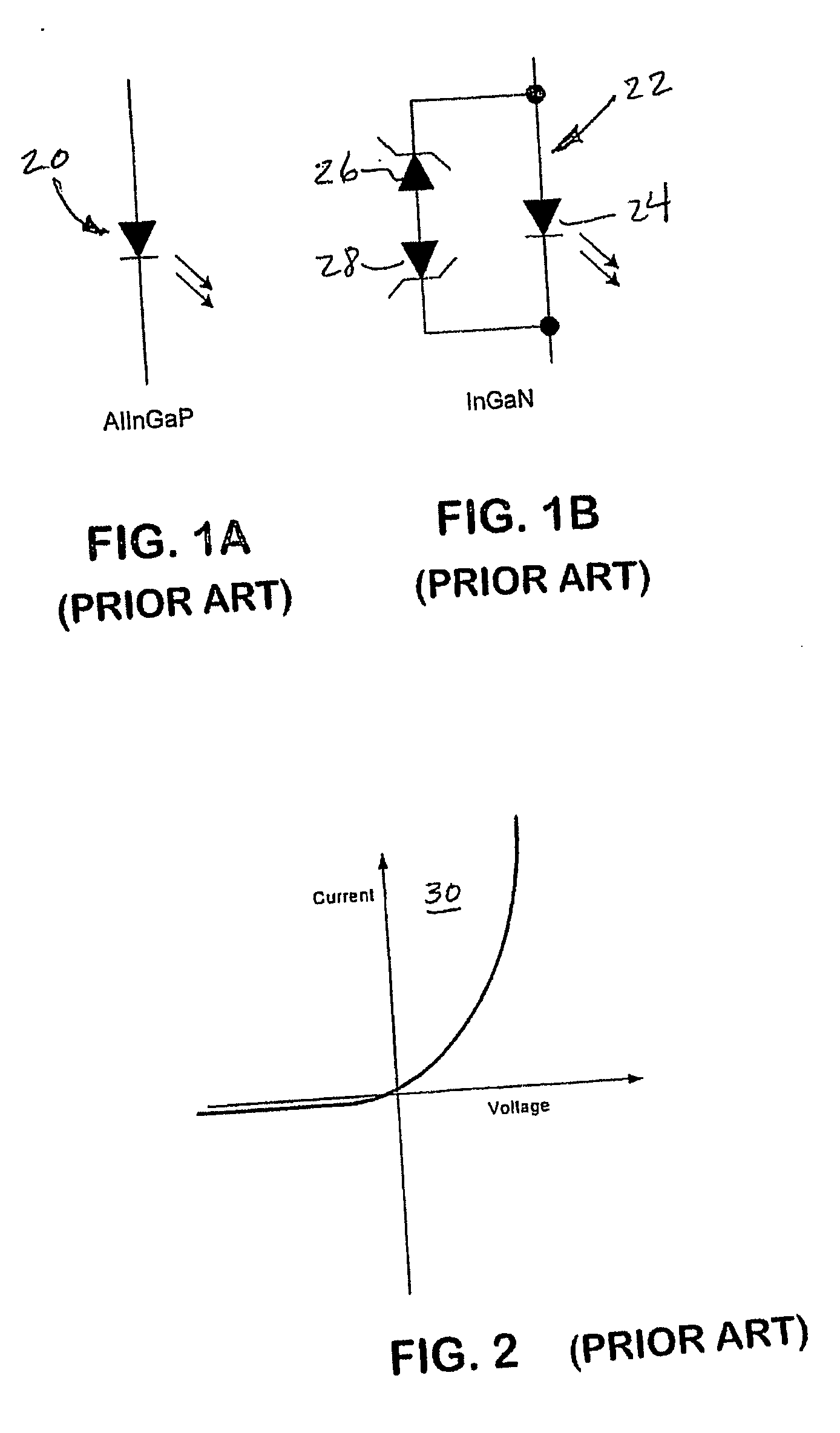

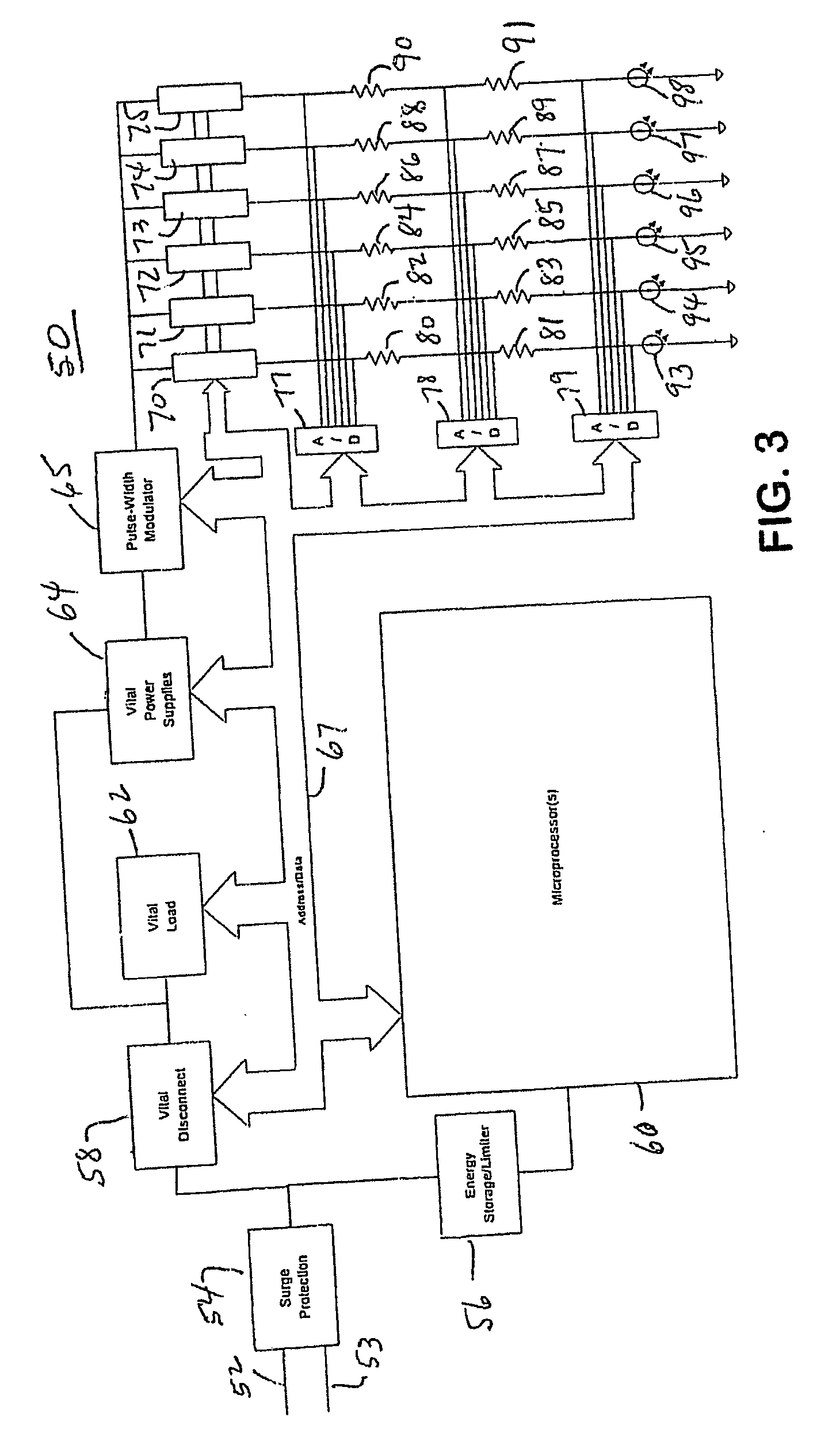

Wayside LED signal for railroad and transit applications

InactiveUS20050062481A1Sufficient energySufficient energy storageVisible signalsElectrical apparatusJunction temperatureData treatment

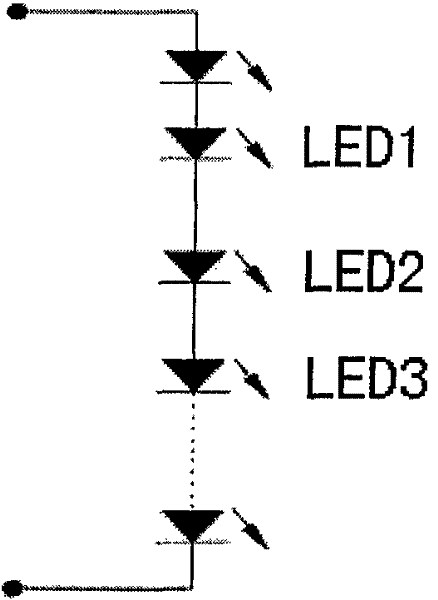

A LED signal lamp that monitors, controls and tests the operational status of a plurality of LEDs. A separate current source is provided for each LED and resistors are in series between the current sources and LEDs. Analog-to-digital converters monitor the voltages at the resistors and LEDs and convert the voltages to digital form for a data processor. The data processor determines the junction temperature of each LED, controls the amount of current supplied to each LED and tests the operational status of each LED by matching its characteristics to a known diode curve. A pulse-width modulator provides further control of the amount of power supplied to the current sources. The data processor further controls a vital disconnect and a vital load. An energy storage / limiter circuit stores energy for the data processor during the absence of normal power input. Related methods of monitoring, controlling and testing such an LED system are also disclosed.

Owner:SAFETRAN SYST CORP CORP

Automotive electrical system configuration using a two bus structure

InactiveUS7075273B2Batteries circuit arrangementsLoad balancing in dc networkAlternatorCritical load

Disclosed herein are a variety of different electrical system topologies intended to mitigate the impact of large intermittent loads on a 12 volt vehicle power distribution system. In some embodiments the intermittent load is disconnected from the remainder of the system and the voltage supplied to this load is allowed to fluctuate. In other embodiments, the voltage to critical loads is regulated independently of the voltage supplied to the remainder of the system. The different topologies described can be grouped into three categories, each corresponding to a different solution technique. One approach is to regulate the voltage to the critical loads. A second approach is to isolate the intermittent load that causes the drop in system voltage. The third approach is to use a different type of alternator that has a faster response than the conventional Lundell wound field machine.

Owner:TEMIC AUTOMOTIVE OF NORTH AMERICA

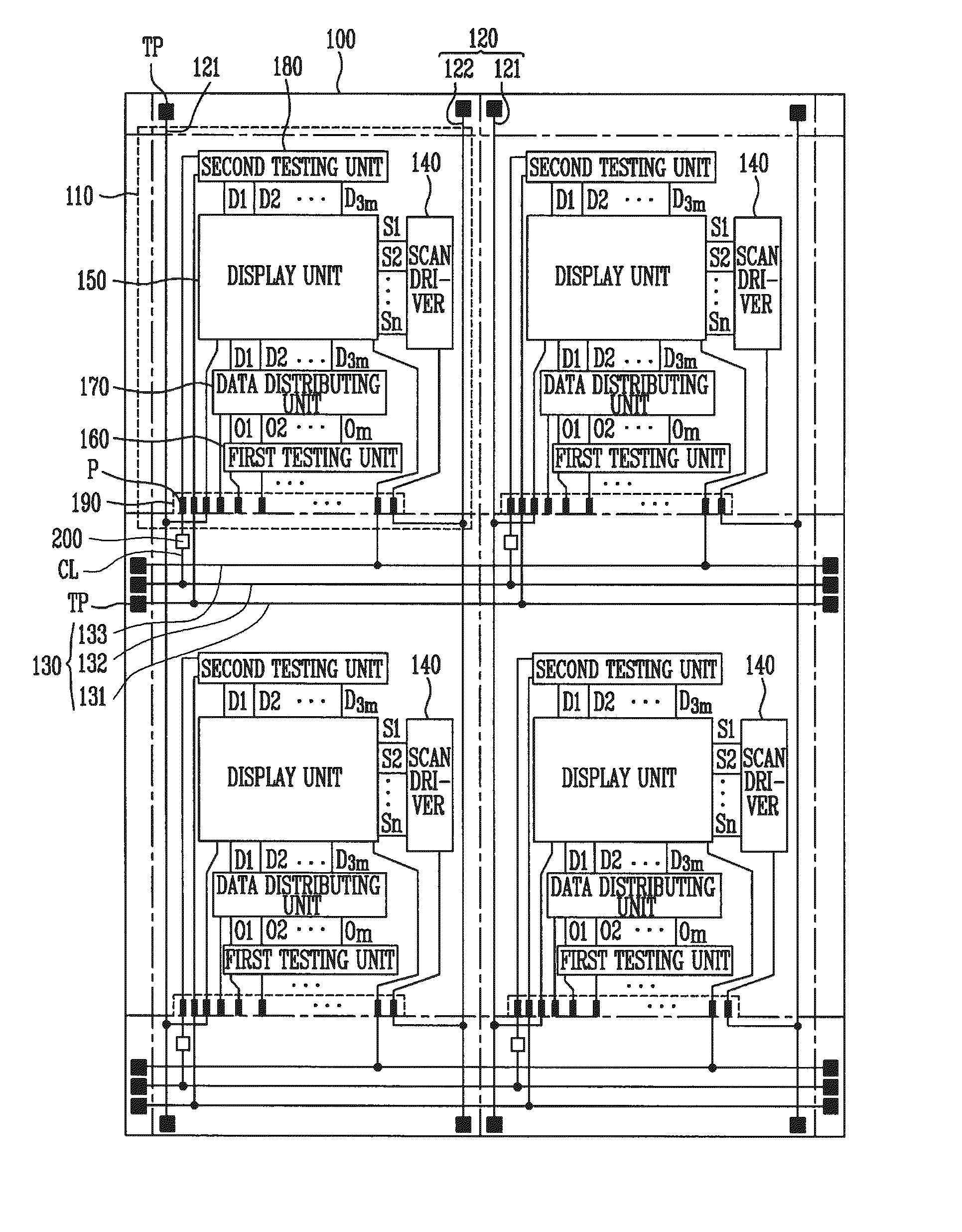

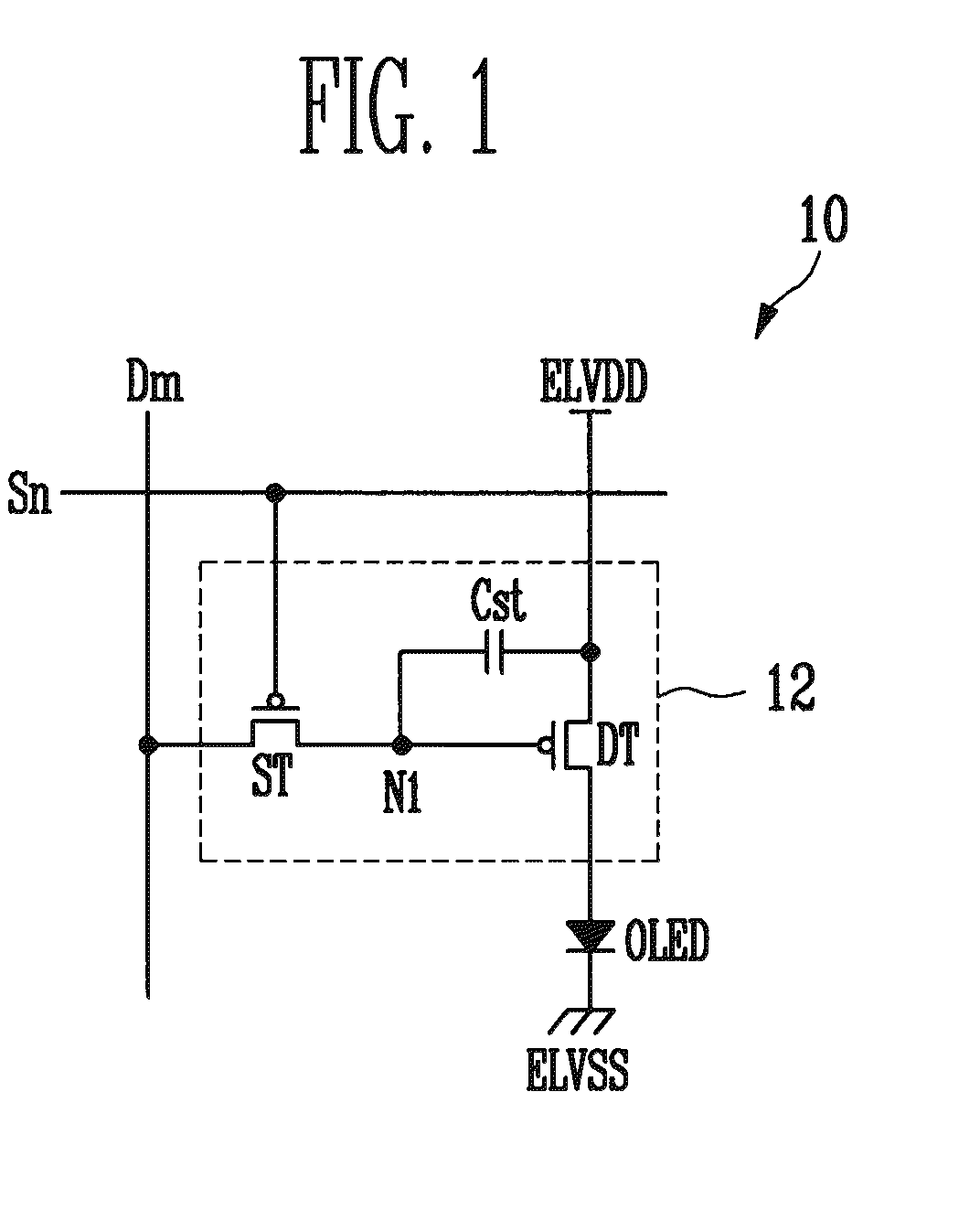

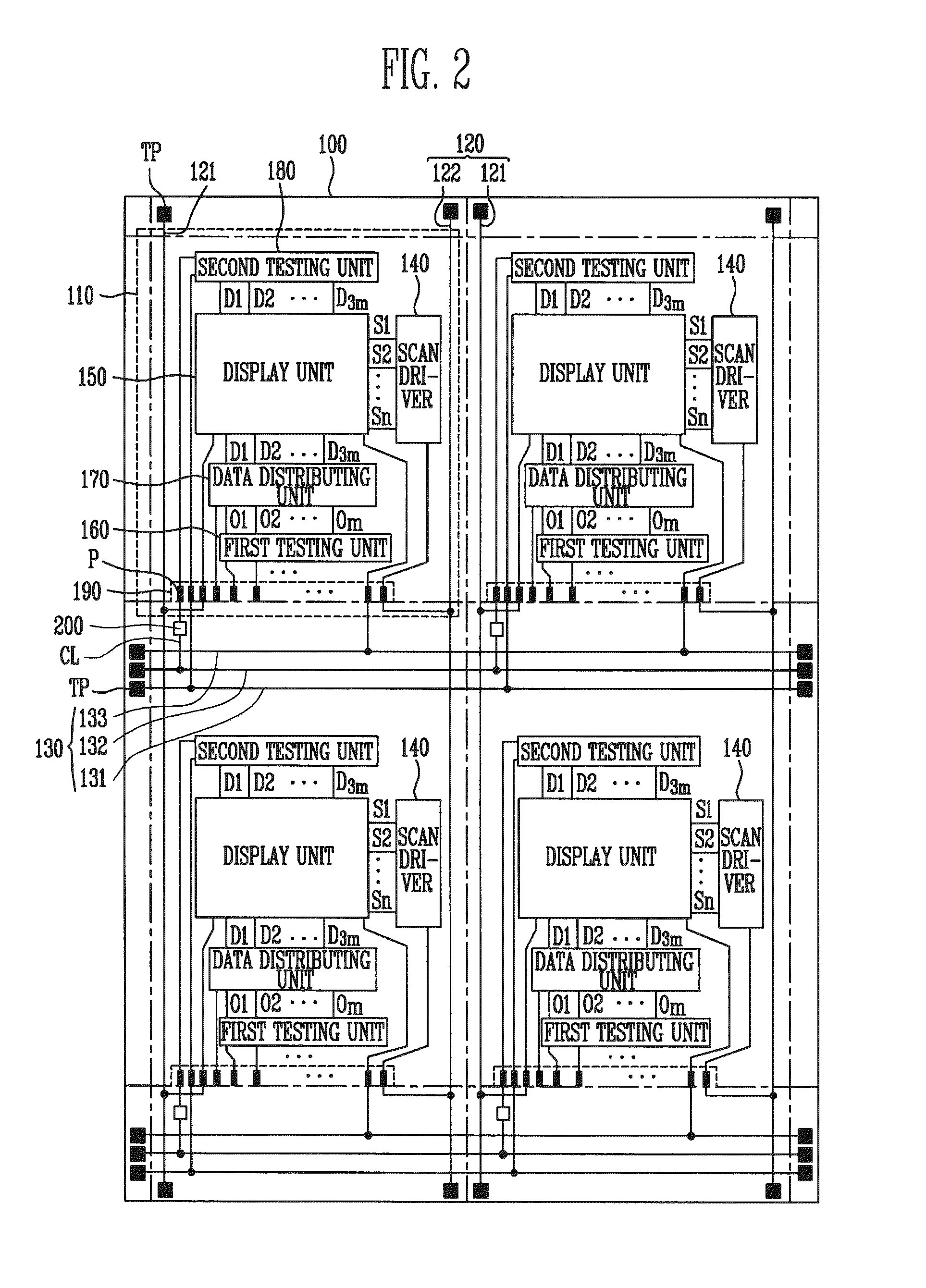

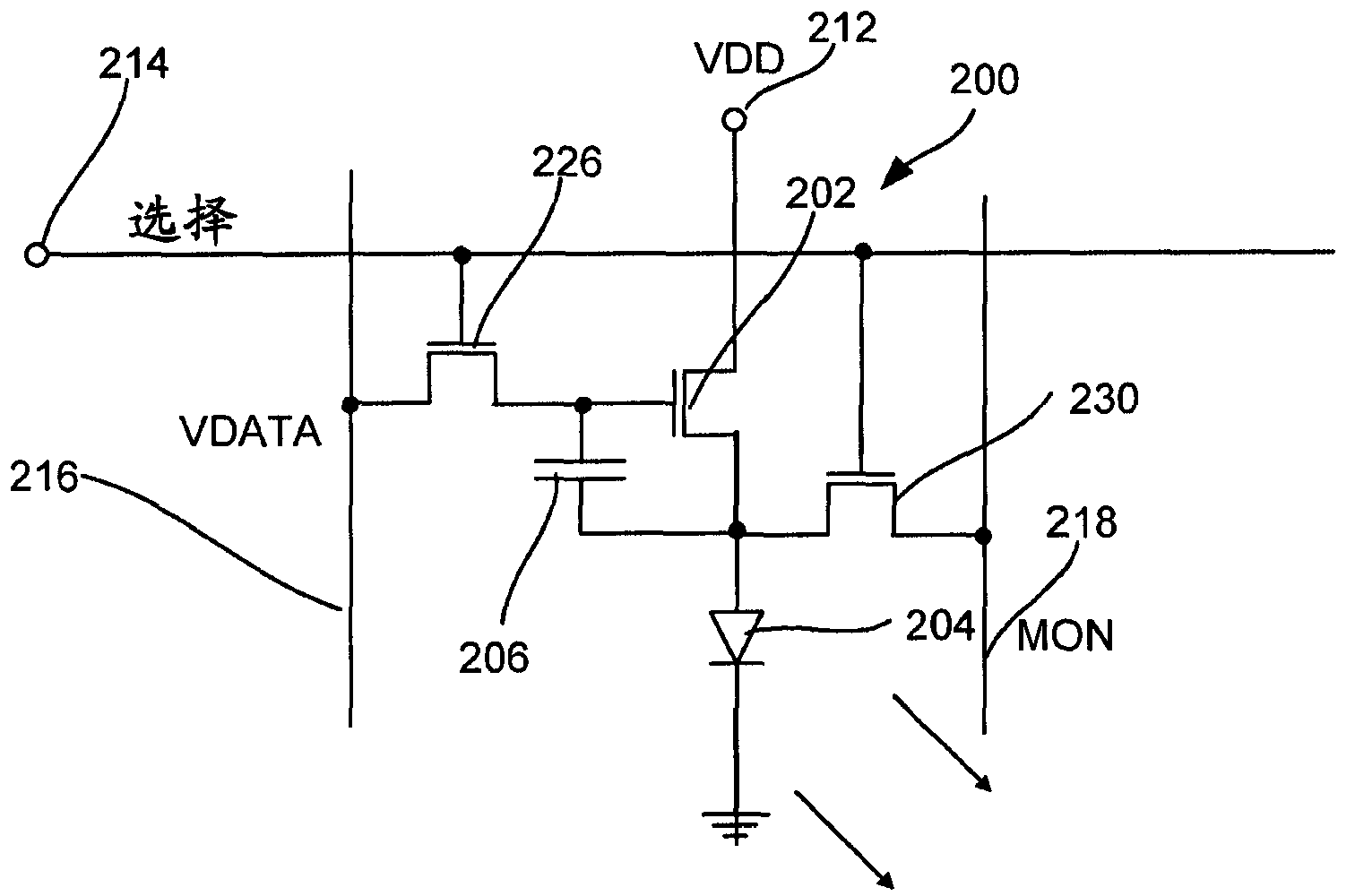

Mother substrate of organic light emitting displays capable of sheet unit testing and method of sheet unit testing

ActiveUS20110080173A1Prevent and reduce brightness variationEffectively perform agingStatic indicating devicesElectroluminescent light sourcesCouplingEngineering

A mother substrate including a plurality of organic light emitting display panels that include pixel circuits having a simple structure, is designed so that a sheet unit test may be performed while preventing or reducing brightness variation during sheet unit test, and a sheet unit test method for the mother substrate. The mother substrate also includes first and second wiring line groups and a compensating unit. The compensating unit is coupled to a coupling line for coupling a wiring line from among the first and second wiring line groups for transmitting a sheet unit test signal to the panels. The compensating unit is also for subtracting a voltage corresponding to a threshold voltage of a driving transistor included in a pixel of the panels from the sheet unit test signal before transmitting the sheet unit test signal to the panels.

Owner:SAMSUNG DISPLAY CO LTD

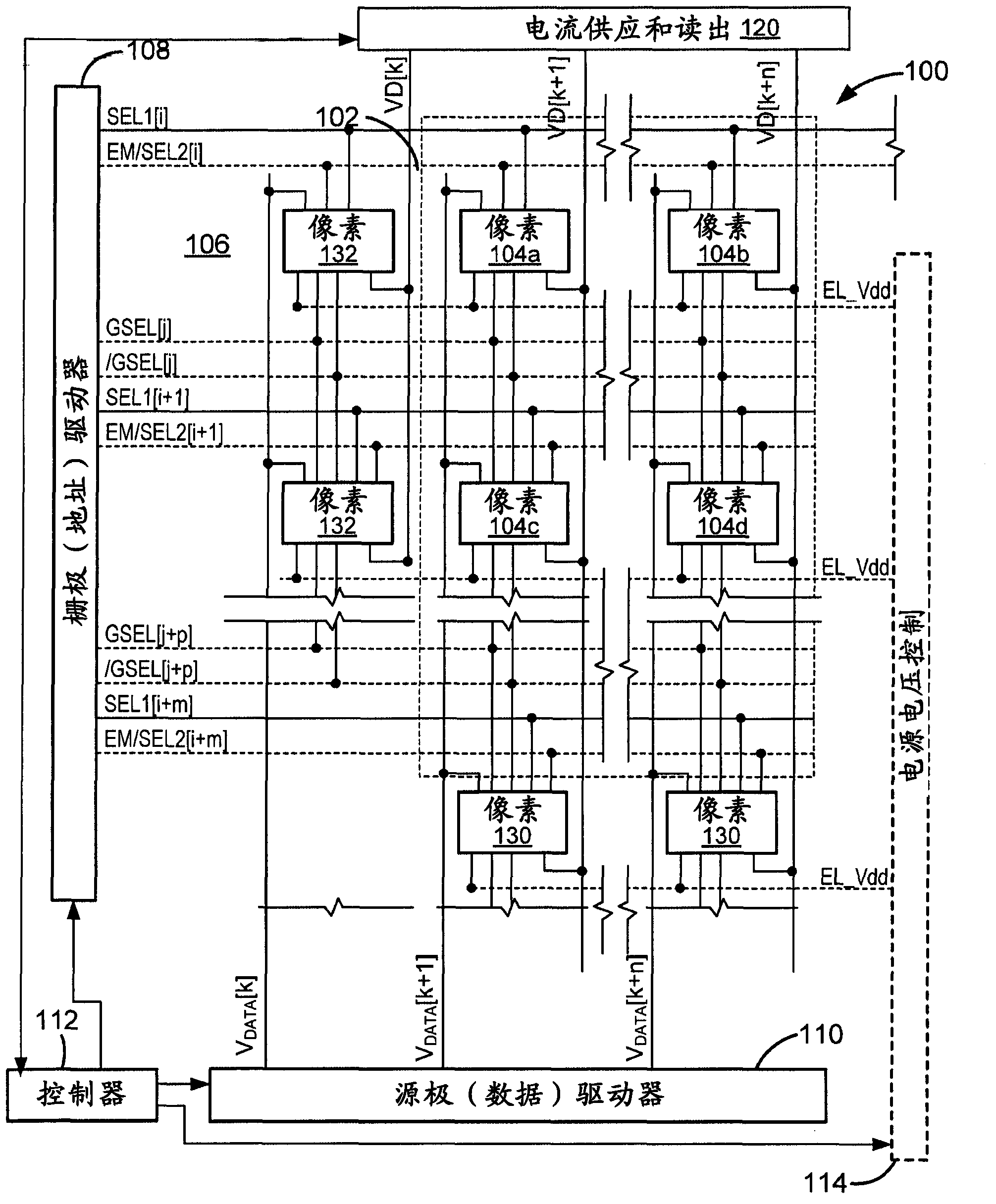

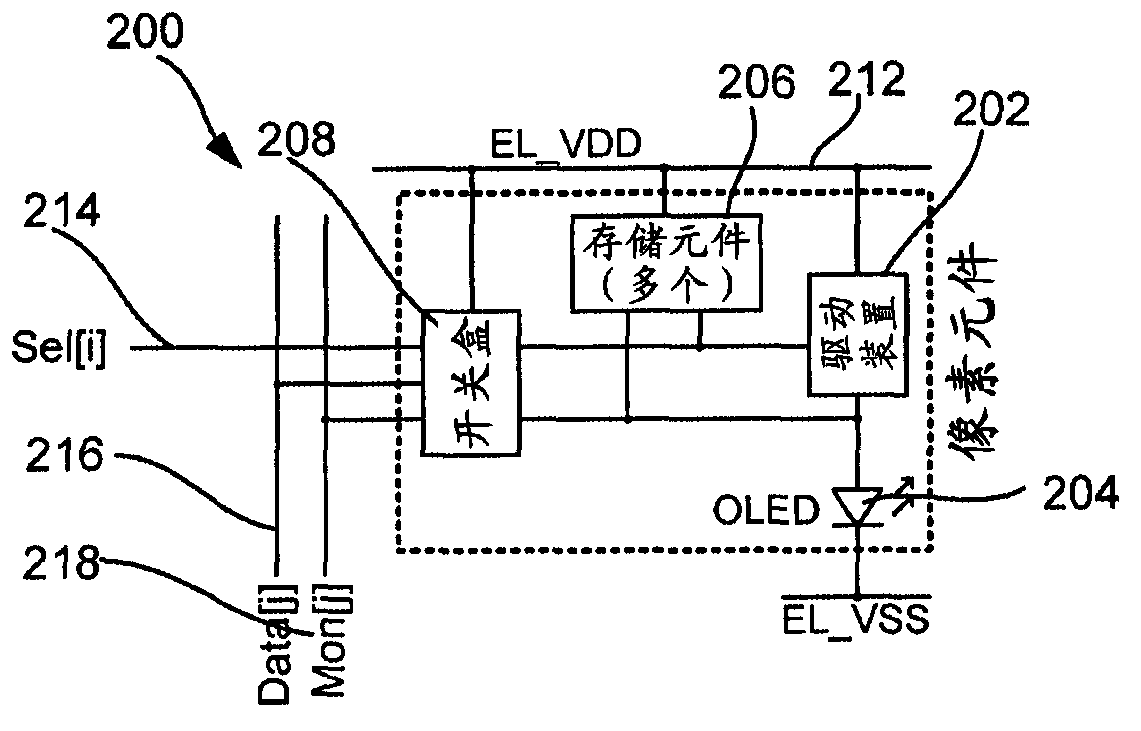

System and methods for aging compensation in AMOLED displays

Methods and systems to provide baseline measurements for aging compensation for a display device are disclosed. An example display system has a plurality of active pixels and a reference pixel. Common input signals are provided to the reference pixel and the plurality of active pixels. The outputs of the reference pixel is measured and compared to the output of the active pixels to determine aging effects. The display system may also be tested applying a first known reference current to a current comparator with a second variable reference current and the output of a device under test such as one of the pixels. The variable reference current is adjusted until the second current and the output of the device under test is equivalent of the first current. The resulting current of the device under test is stored in a look up table for a baseline for aging measurements during the display system operation. The display system may also be tested to determine production flaws by determining anomalies such as short circuits in pixel components such as OLEDs and drive transistors.

Owner:IGNIS INNOVATION

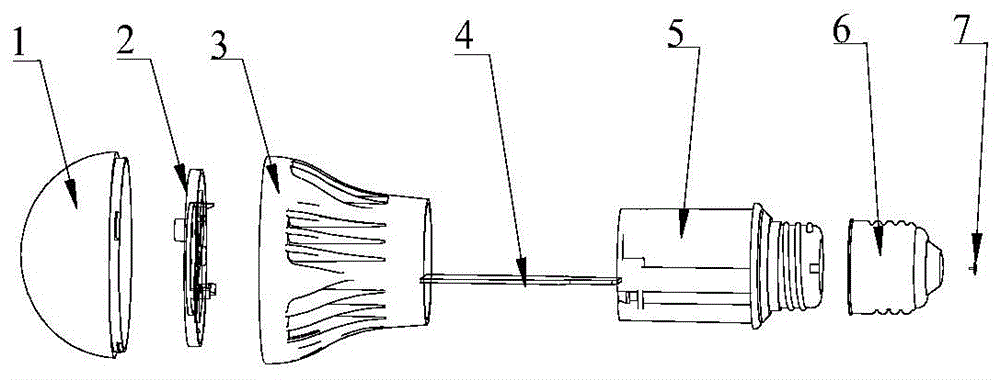

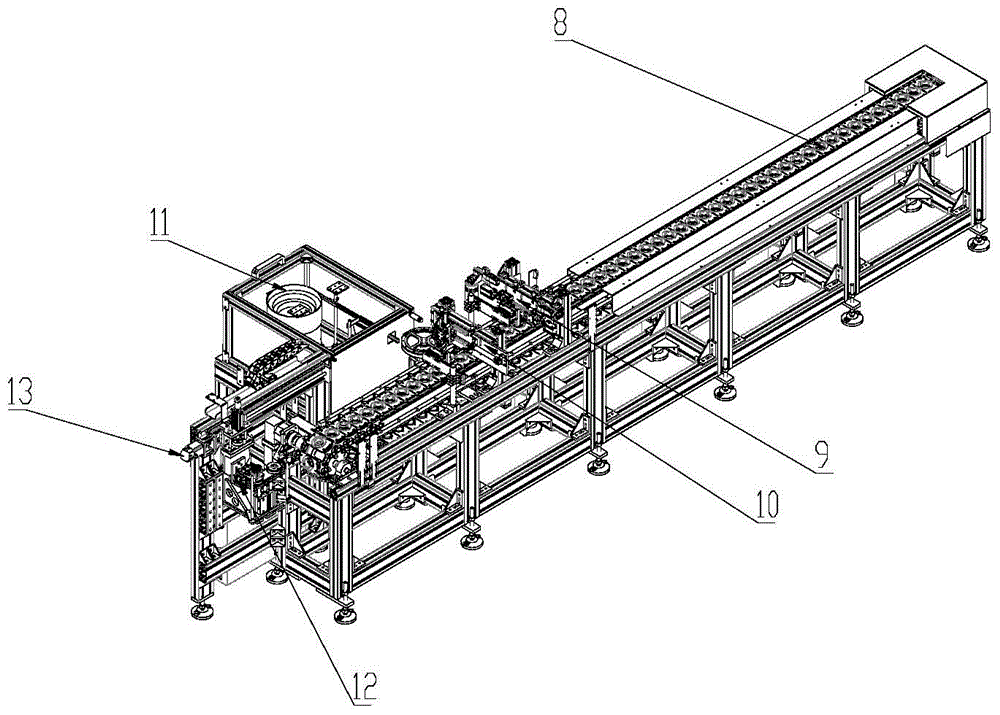

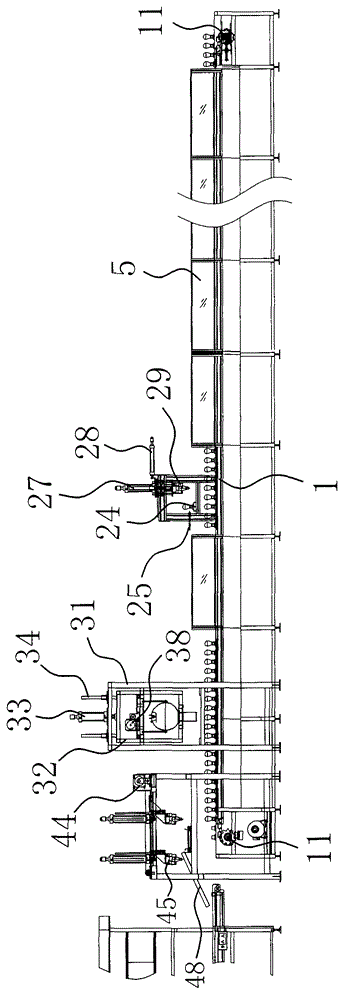

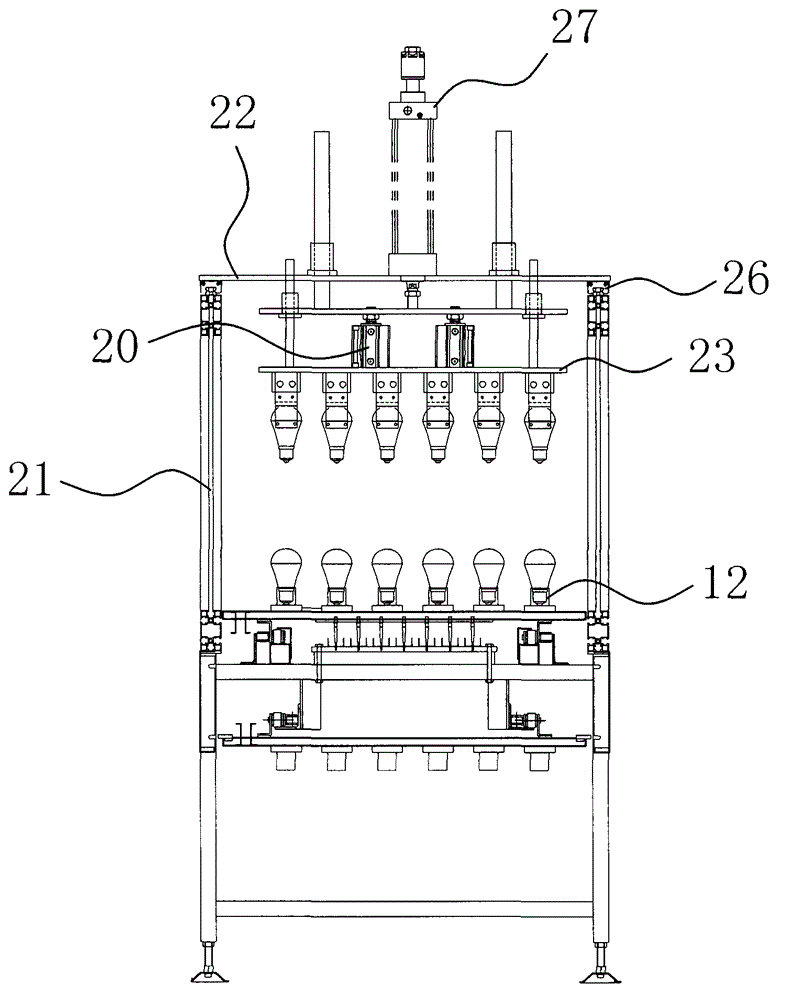

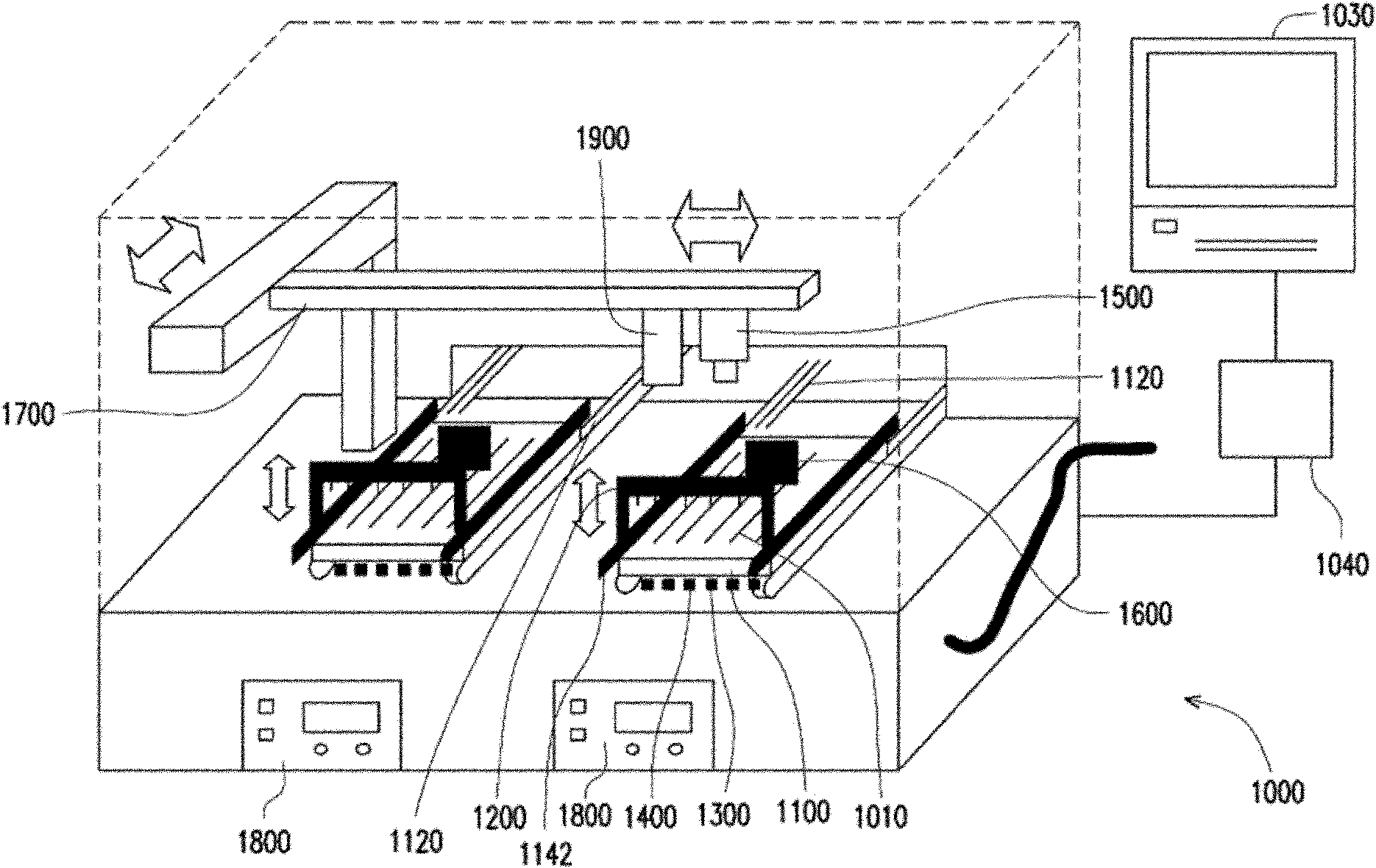

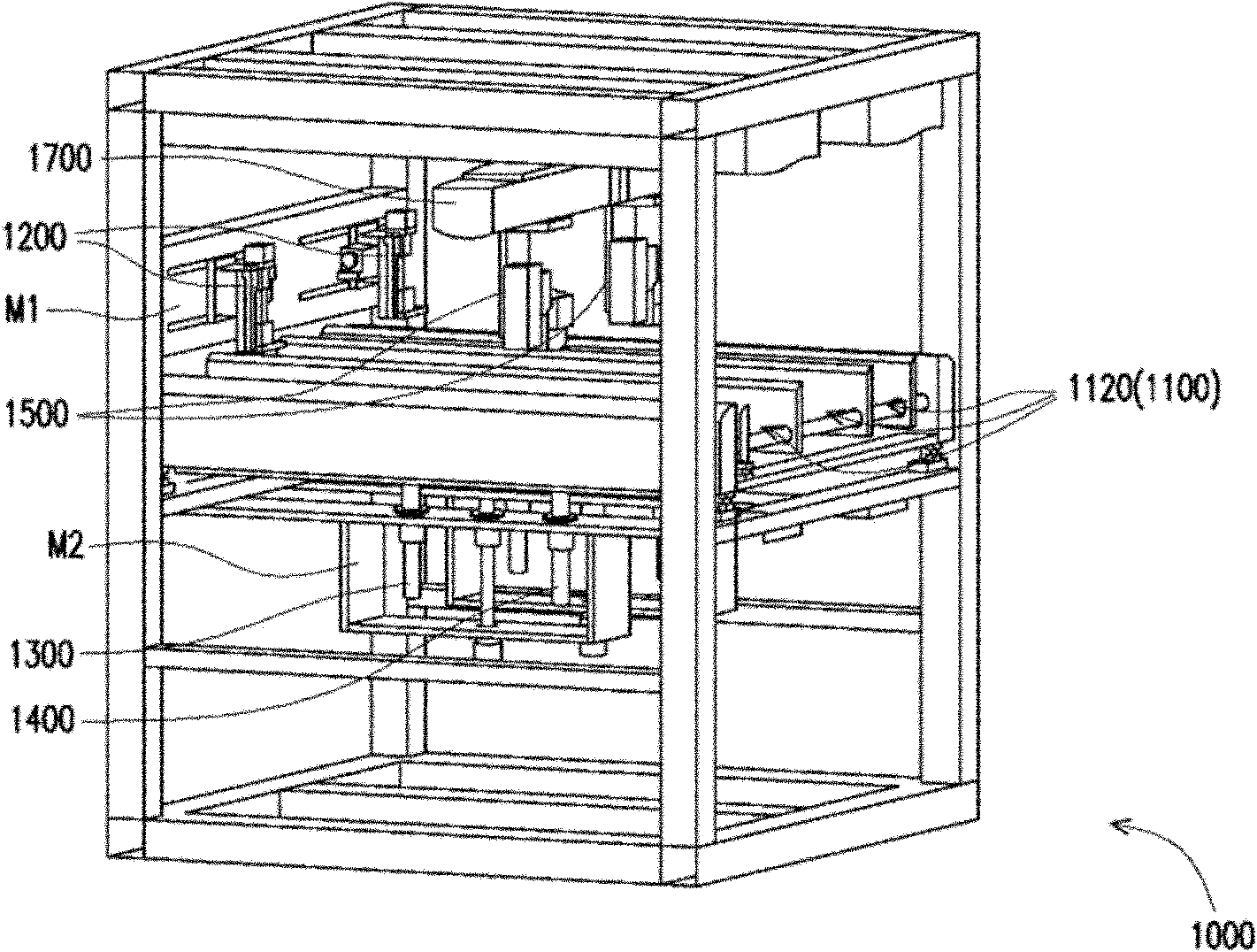

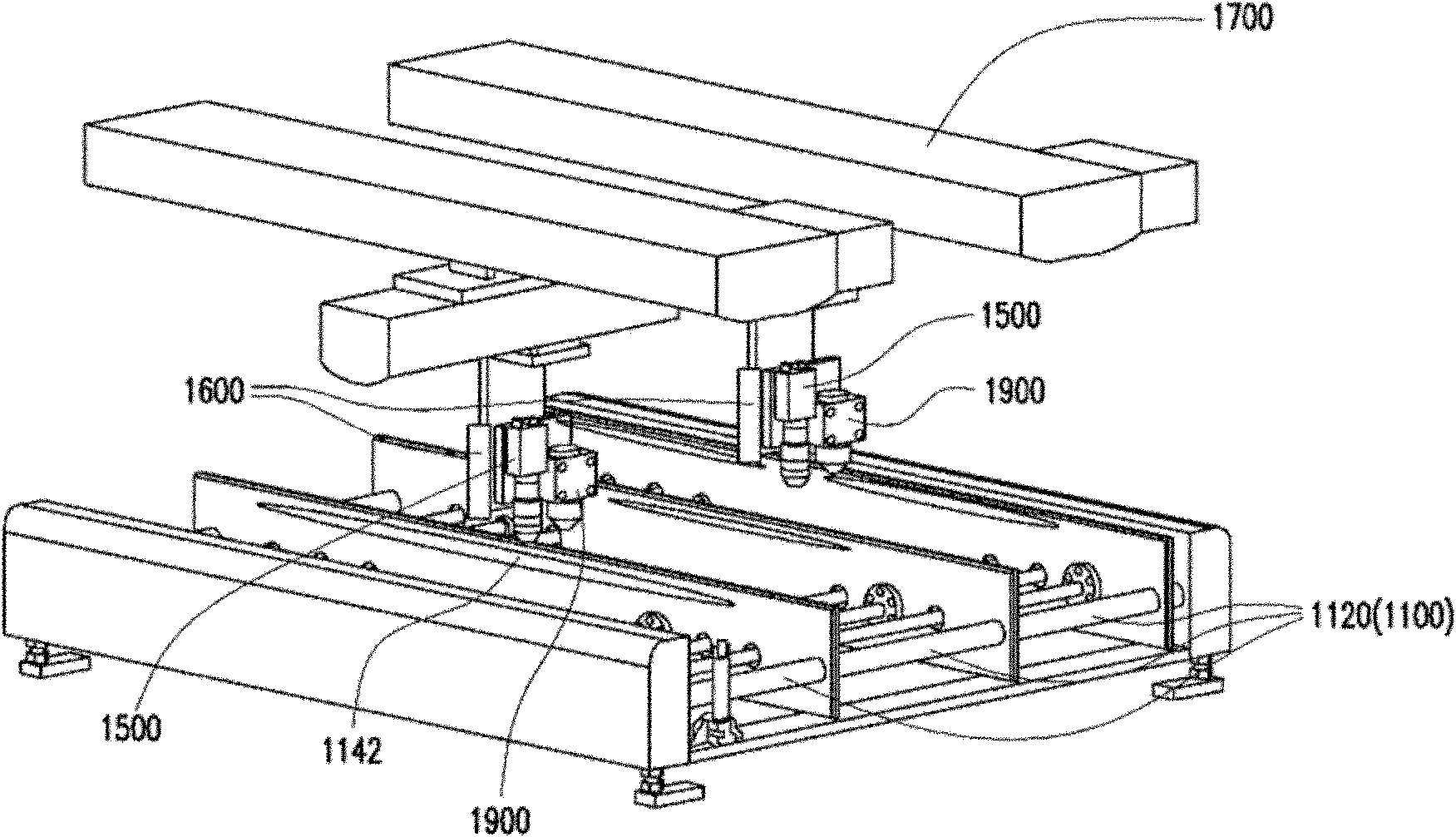

Automatic assembling and testing device for LED (Light-Emitting Diode) bulb lamp

ActiveCN103331607AQuality improvementReduce labor intensityAssembly machinesLamps testingElectricityProduction line

The invention discloses an automatic device, in particular to a specific production line method which is used for assembling parts of an LED (Light-Emitting Diode) bulb lamp, also implements online inspection and testing of the LED bulb lamp, obtains the LED bulb lamp qualified by inspection and improves production efficiency. The automatic device comprises a rivet assembly line, a light source plate assembly line, a lampshade assembly line, an LED lamp aging testing line and an LED lamp high voltage testing and light color electricity detecting line; and the parts of the LED bulb lamp are assembled and tested by the five workshop sections. The automatic device has the advantages that production efficiency can be effectively improved; quality of a produced product is stable; and labor intensity of workers is reduced. The automatic device can be widely applied to LED lamp production enterprises.

Owner:HANGZHOU ZHONGWEI PHOTOELECTRICITY

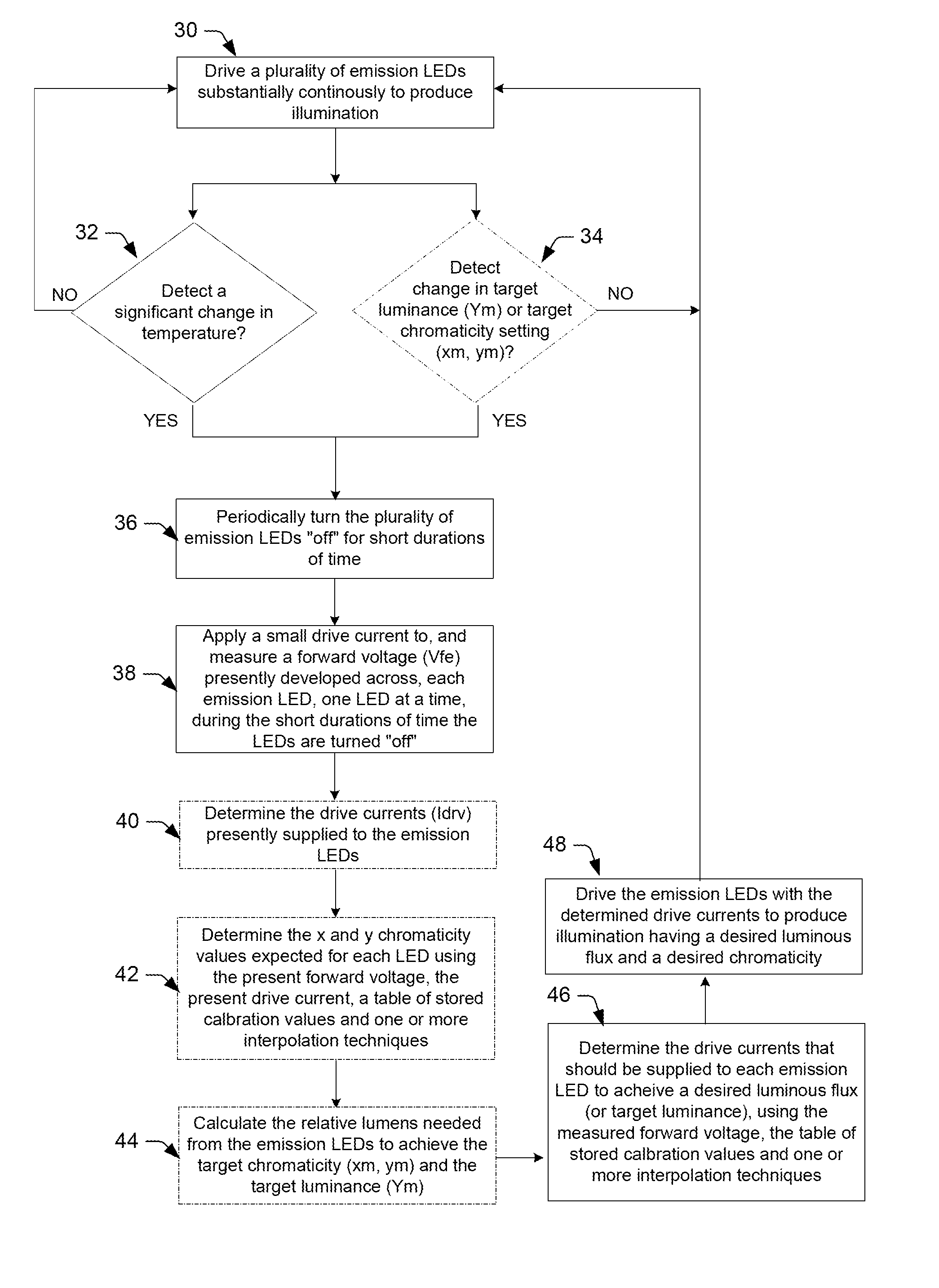

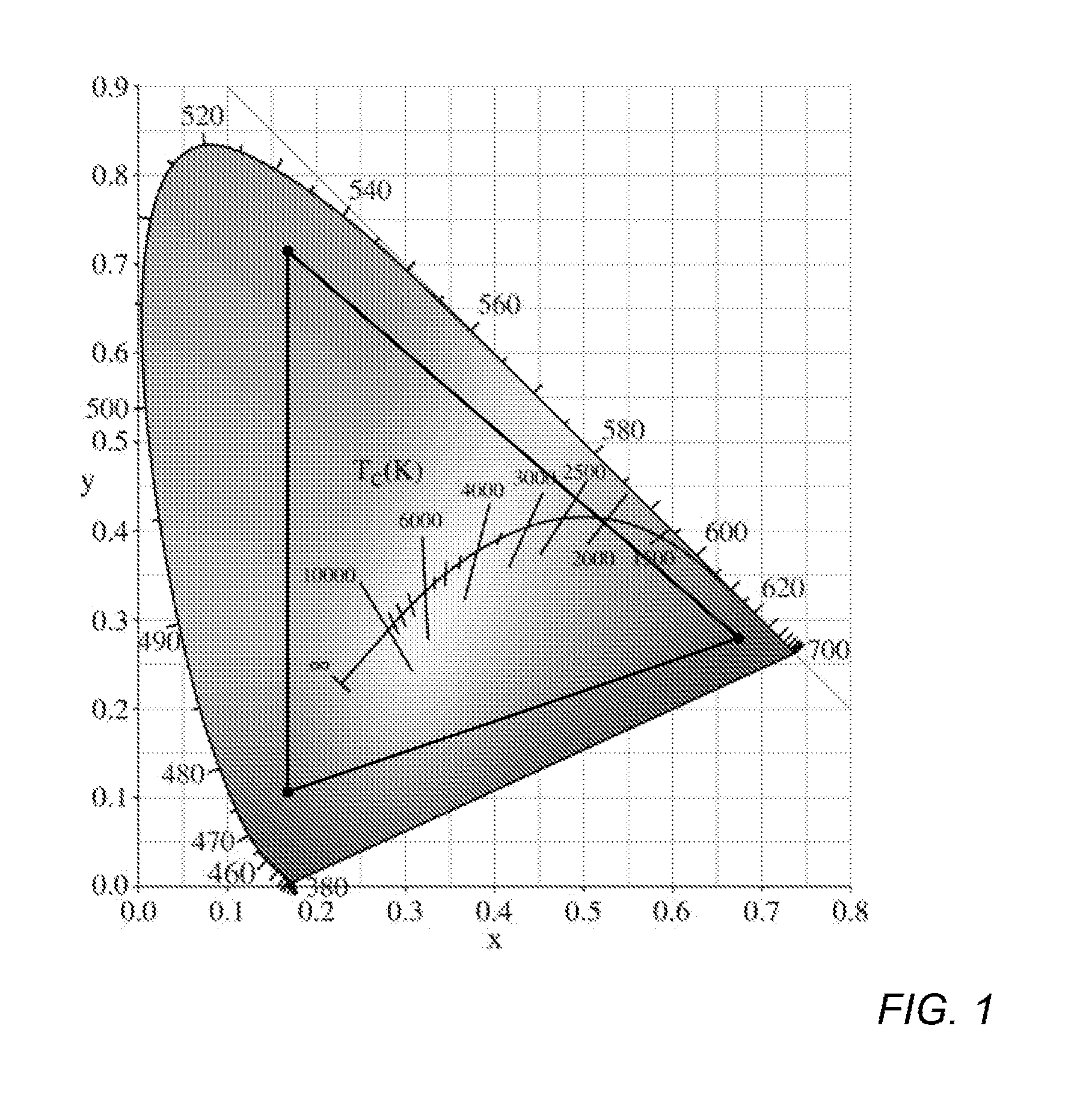

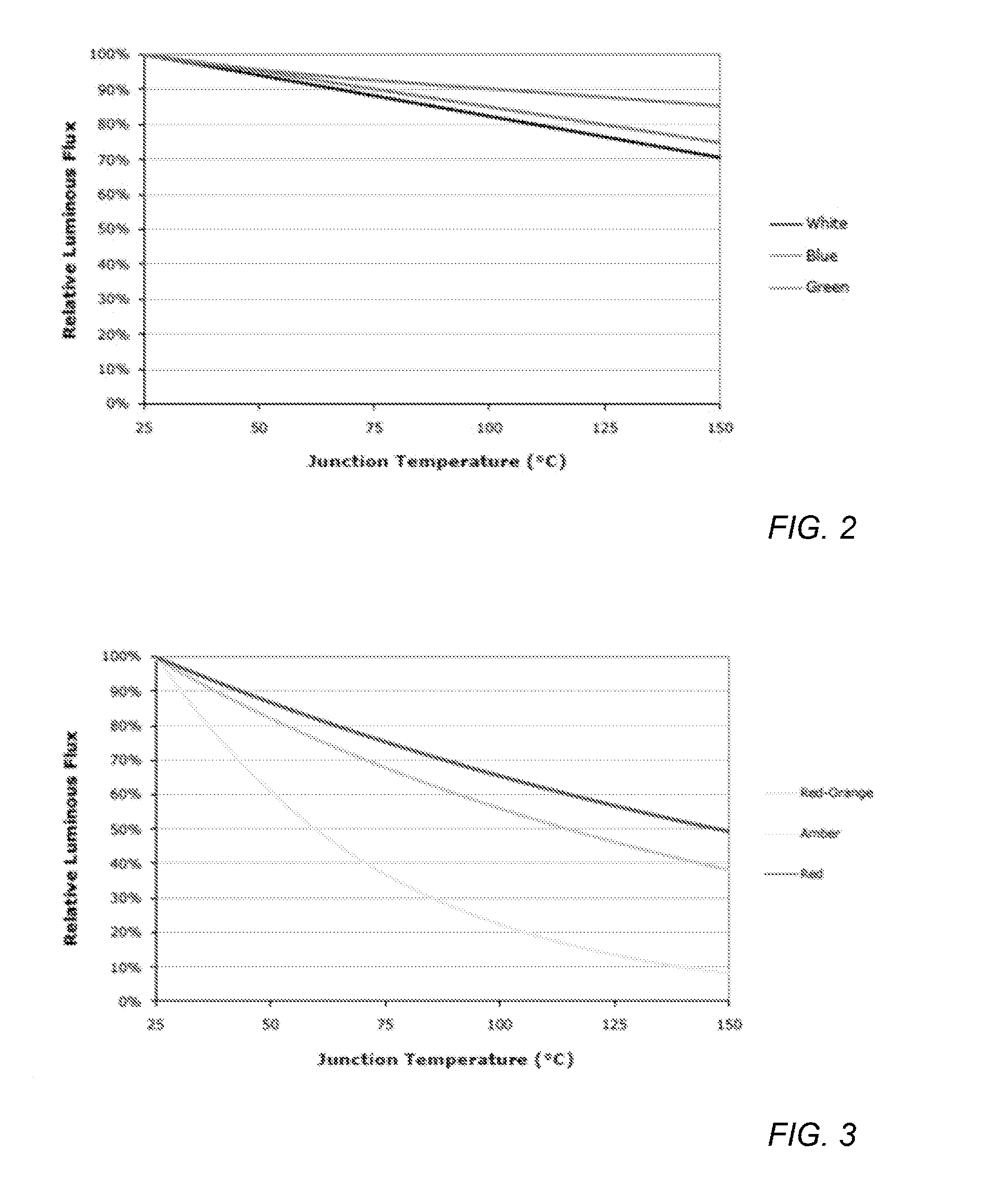

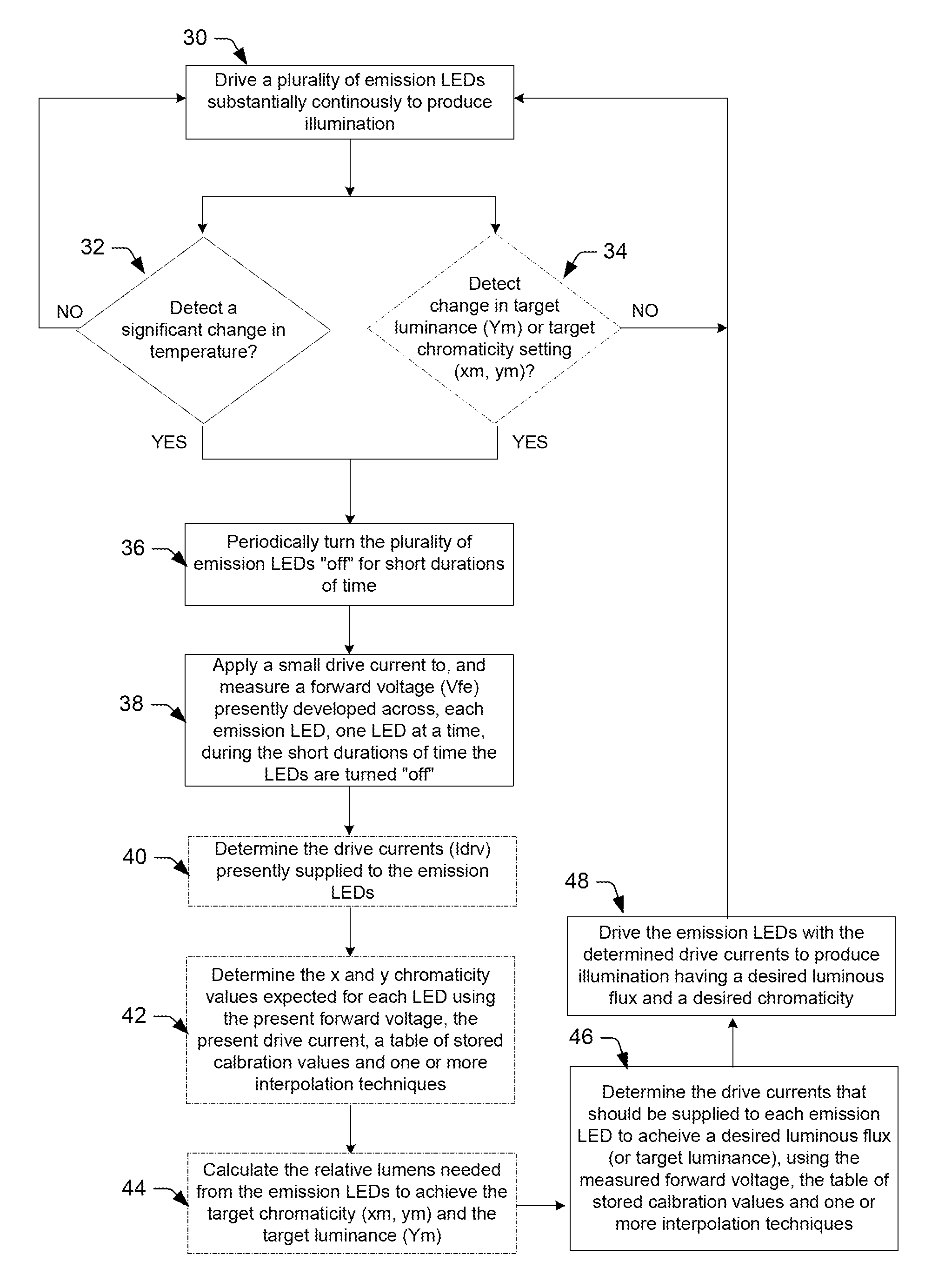

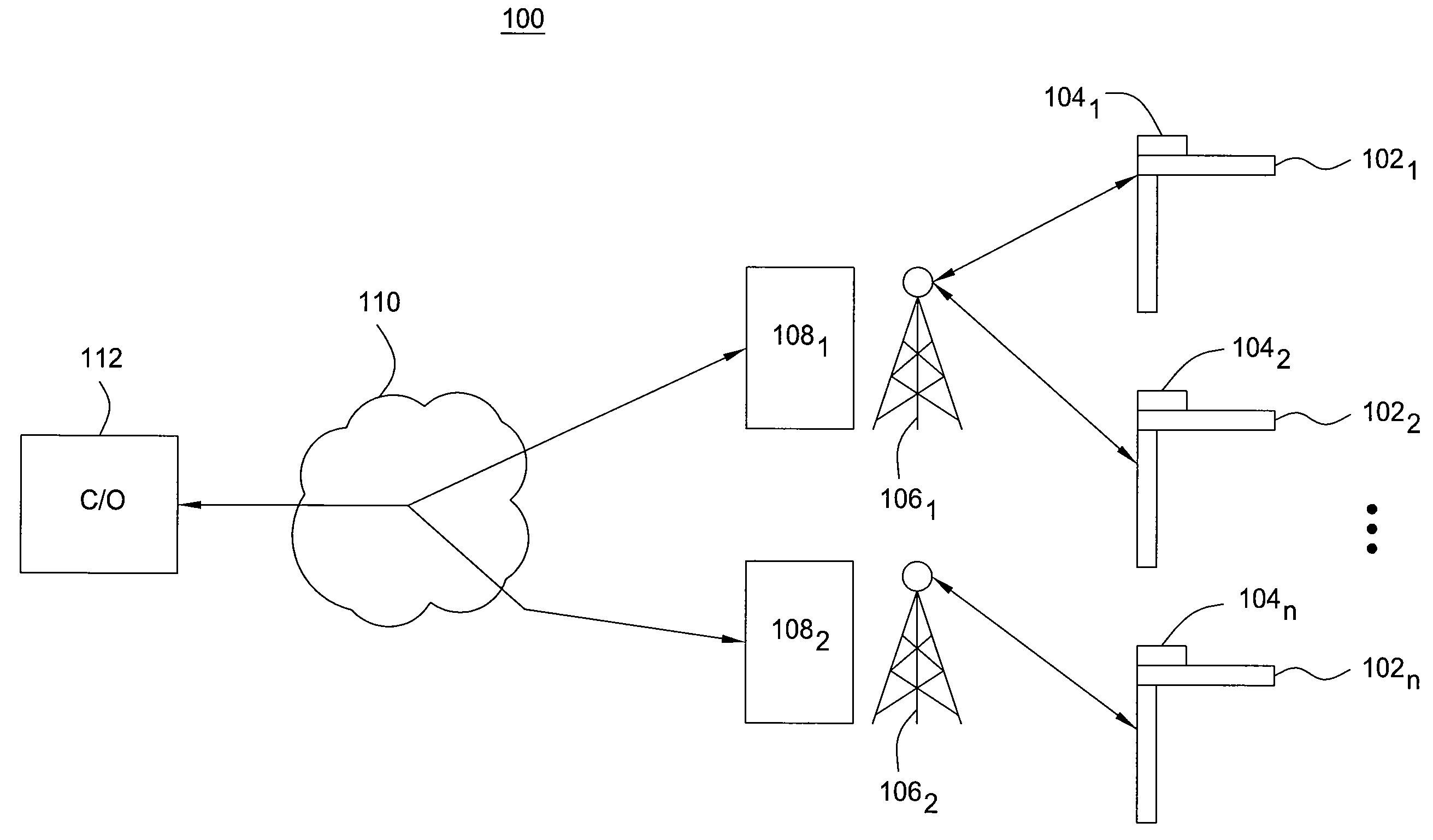

Illumination Device and Method for Controlling an Illumination Device over Changes in Drive Current and Temperature

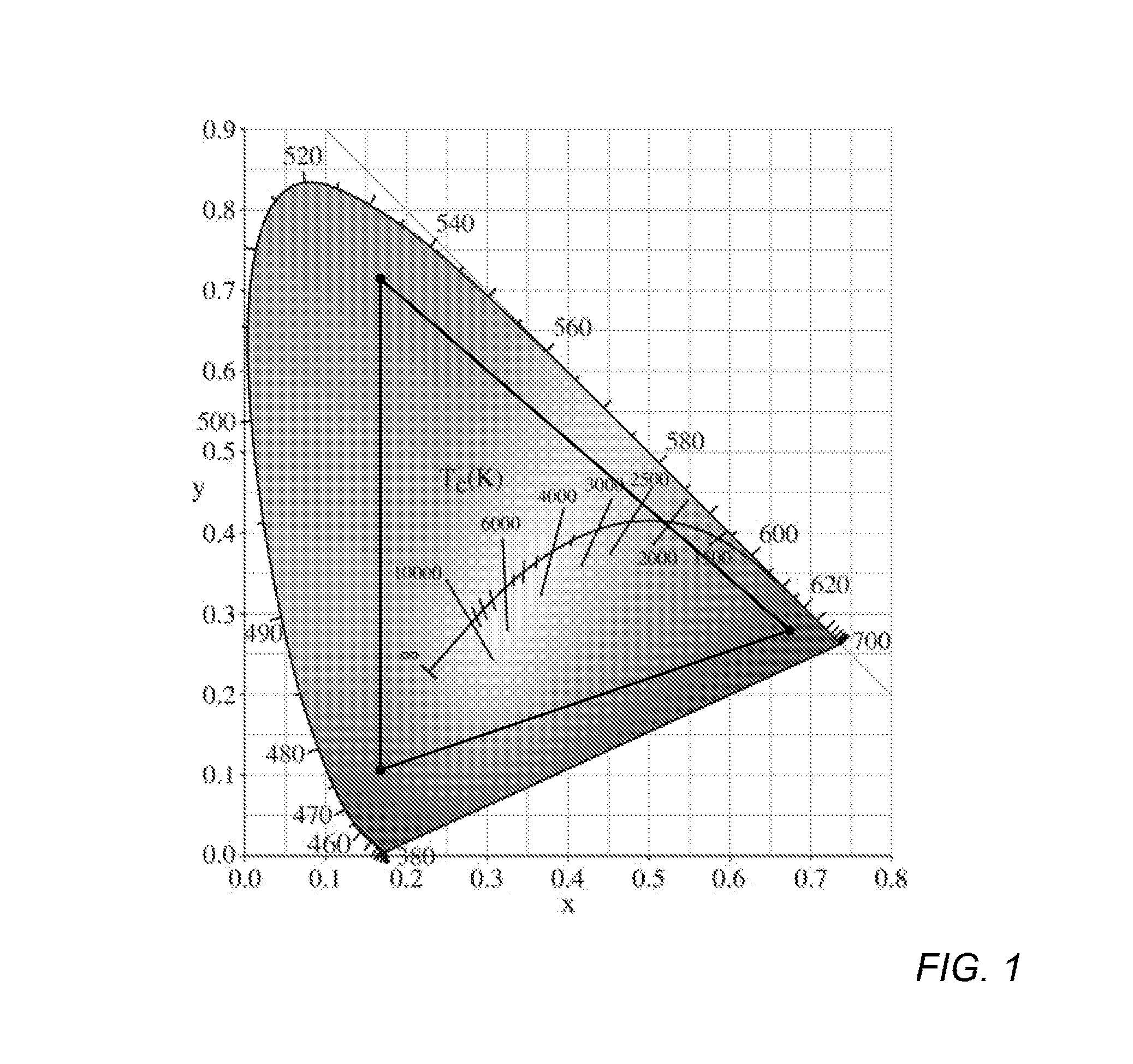

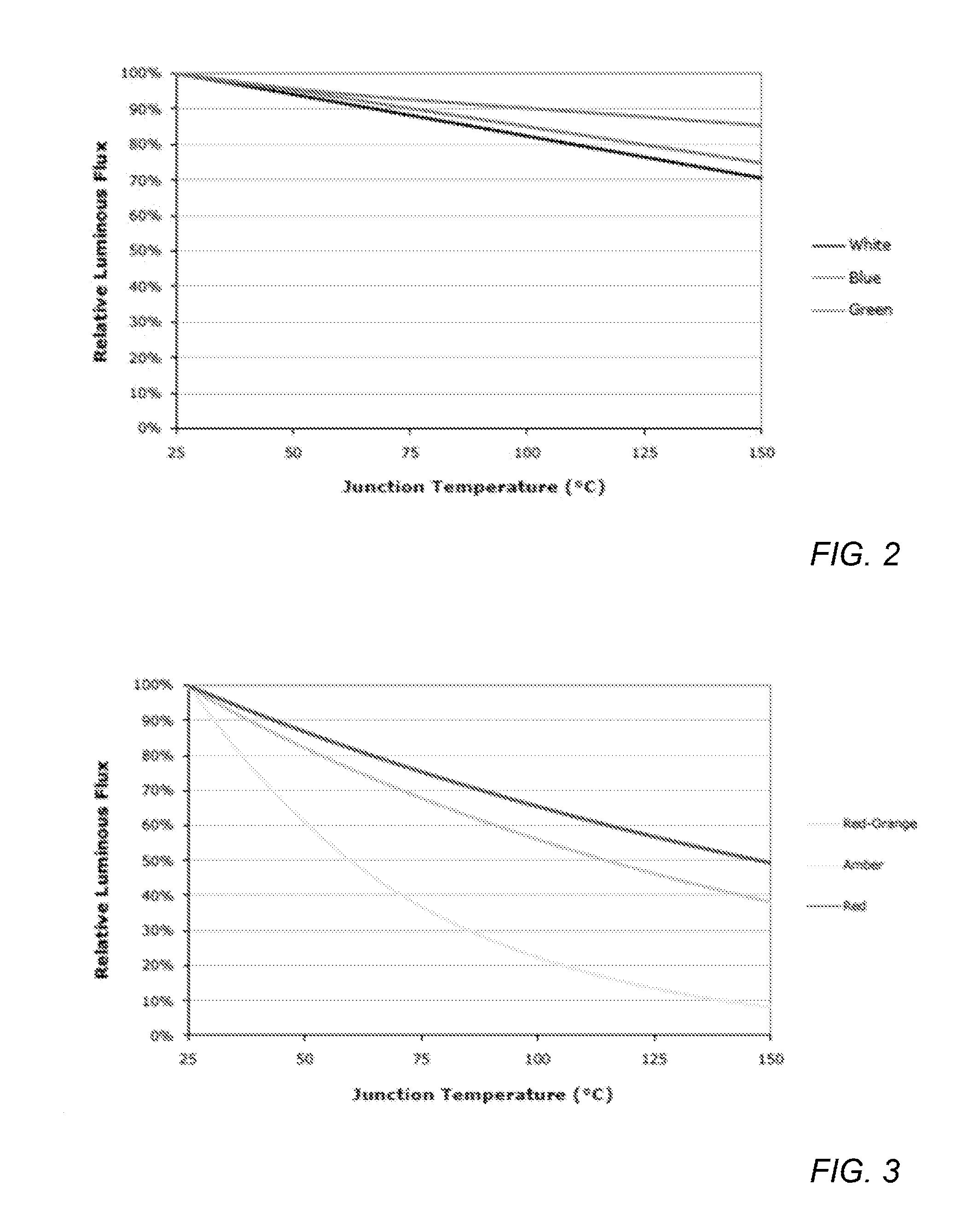

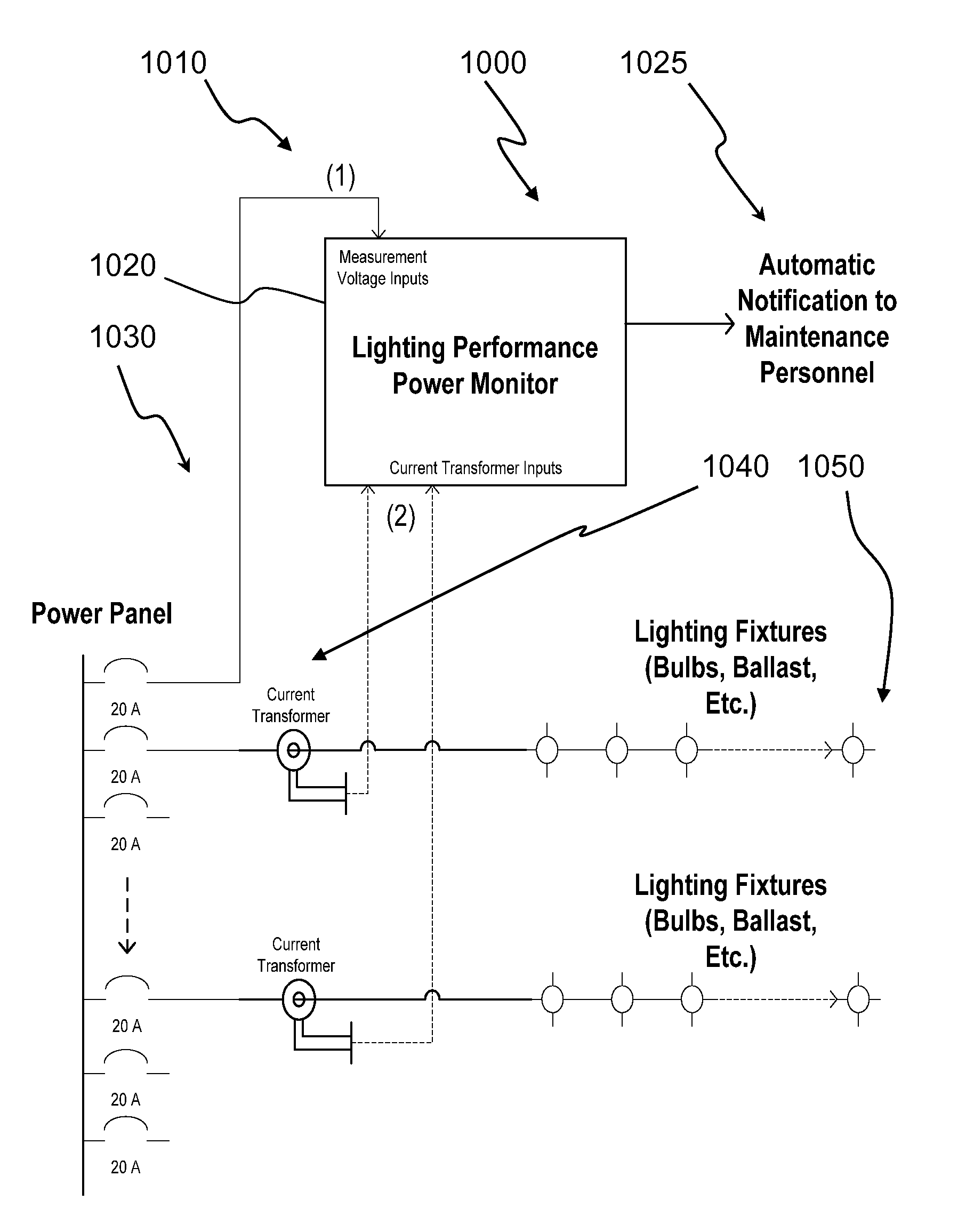

An illumination device and method is provided herein for controlling individual light emitting diodes (LEDs) in an LED illumination device, so that a desired luminous flux and a desired chromaticity of the device can be maintained over changes in drive current and temperature. According to one embodiment, the illumination device comprises a plurality of emission LEDs, a storage medium, an LED driver and receiver circuit and a control circuit. The storage medium may store a table of calibration values correlating forward voltage and drive current to chromaticity and luminous flux at a plurality of temperatures for each of the plurality of emission LEDs. The LED driver and receiver circuit may apply respective drive currents to the emission LEDs to produce substantially continuous illumination, and may periodically turn the emission LEDs off to measure operating forward voltages that develop across each emission LED. The control circuit may determine whether a target luminance setting or a target chromaticity setting for the illumination device has changed, and if so, may determine new respective drive currents needed to achieve the target luminance setting and the target chromaticity setting using the operating forward voltages measured across each emission LED, the table of calibration values and one or more interpolation techniques.

Owner:LUTRON TECH CO LLC

Illumination device and method for controlling an illumination device over changes in drive current and temperature

An illumination device and method is provided herein for controlling individual light emitting diodes (LEDs) in an LED illumination device, so that a desired luminous flux and a desired chromaticity of the device can be maintained over changes in drive current and temperature. According to one embodiment, the illumination device comprises a plurality of emission LEDs, a storage medium, an LED driver and receiver circuit and a control circuit. The storage medium may store a table of calibration values correlating forward voltage and drive current to chromaticity and luminous flux at a plurality of temperatures for each of the plurality of emission LEDs. The LED driver and receiver circuit may apply respective drive currents to the emission LEDs to produce substantially continuous illumination, and may periodically turn the emission LEDs off to measure operating forward voltages that develop across each emission LED. The control circuit may determine whether a target luminance setting or a target chromaticity setting for the illumination device has changed, and if so, may determine new respective drive currents needed to achieve the target luminance setting and the target chromaticity setting using the operating forward voltages measured across each emission LED, the table of calibration values and one or more interpolation techniques.

Owner:LUTRON TECH CO LLC

Lighting performance power monitoring system and method with optional integrated light control

ActiveUS20070282547A1Save energyReduce materialLevel controlPower measurement by digital techniqueEngineeringElectric power

A light performance monitoring device and optionally integrated controller includes a monitor module that directly monitors energy usage of at least one energy load to generate at least one measurement of energy usage; a storage module stores a series of baseline values of energy usage of the energy load, a comparator module compares energy measurements made at predetermined intervals with the baseline values, and a notification module notifies a designated recipient that there is a deviation from the baseline values consistent with a burned out or non-operational light fixture, including but not limited to light bulbs or ballast devices. A control module optionally integrated with the light performance monitoring device can be operatively coupled to the monitor module to control energy usage by the at least one energy load via a data link in a pre-determined manner that is based on the at least one measurement of energy usage.

Owner:GRIDPOINT

System and method for streetlight monitoring diagnostics

ActiveUS20090222223A1Discharge tube incandescent screensElectric devicesWireless transmissionNetwork service

One or more example diagnostics may be implemented as part of an intelligent luminaire manager or other radio frequency (RF) device that is in communication with an equipment or fixture such as a luminaire. Example diagnostics can determine a status such as a fixture malfunction, a cycling condition, a miswiring configuration, or another condition. The determined status can be wirelessly transmitted from the intelligent luminaire manager or other radio frequency device to a network server via a network. The network may be a network of intelligent luminaire managers and / or RF devices.

Owner:ABL IP HLDG

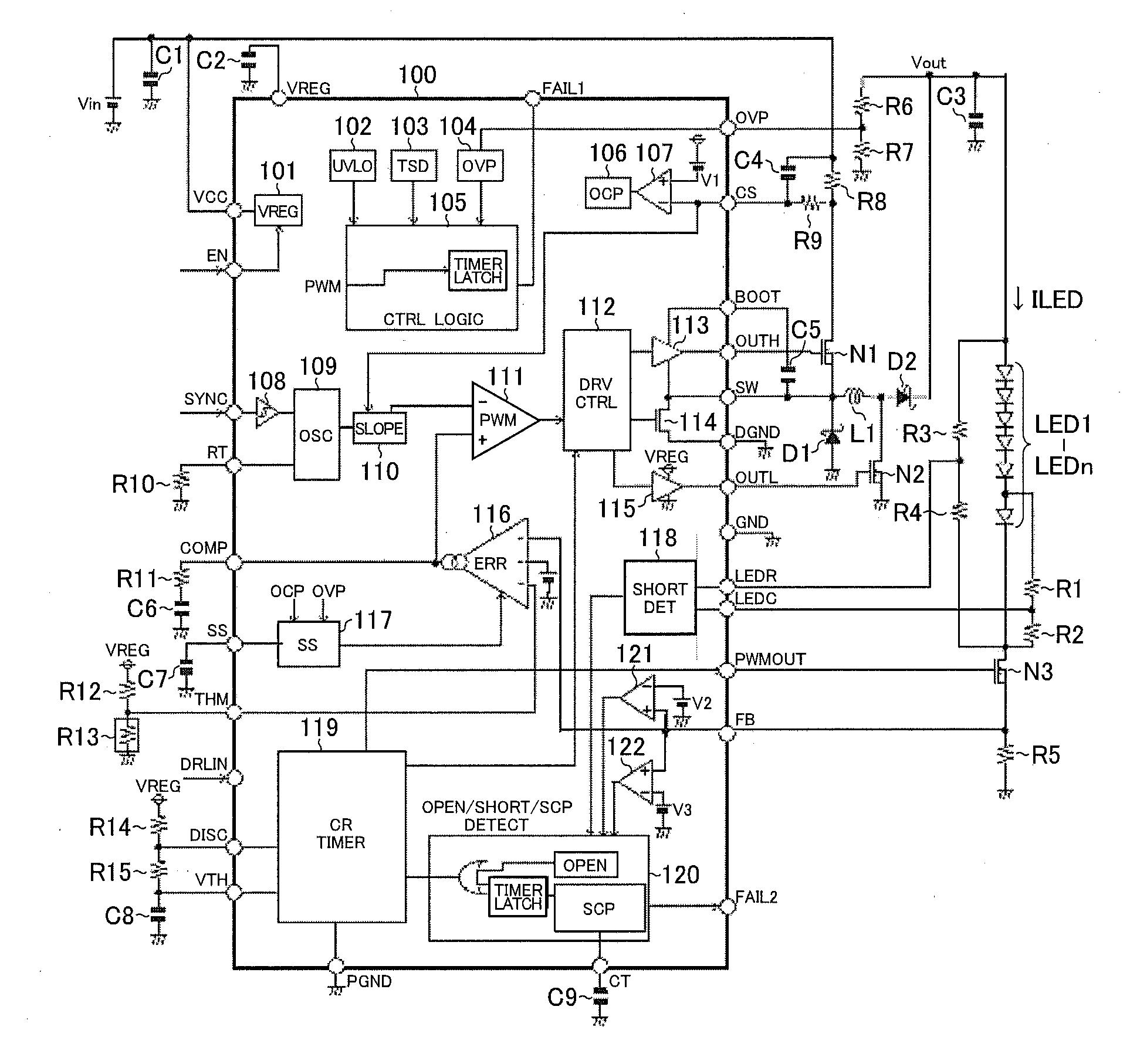

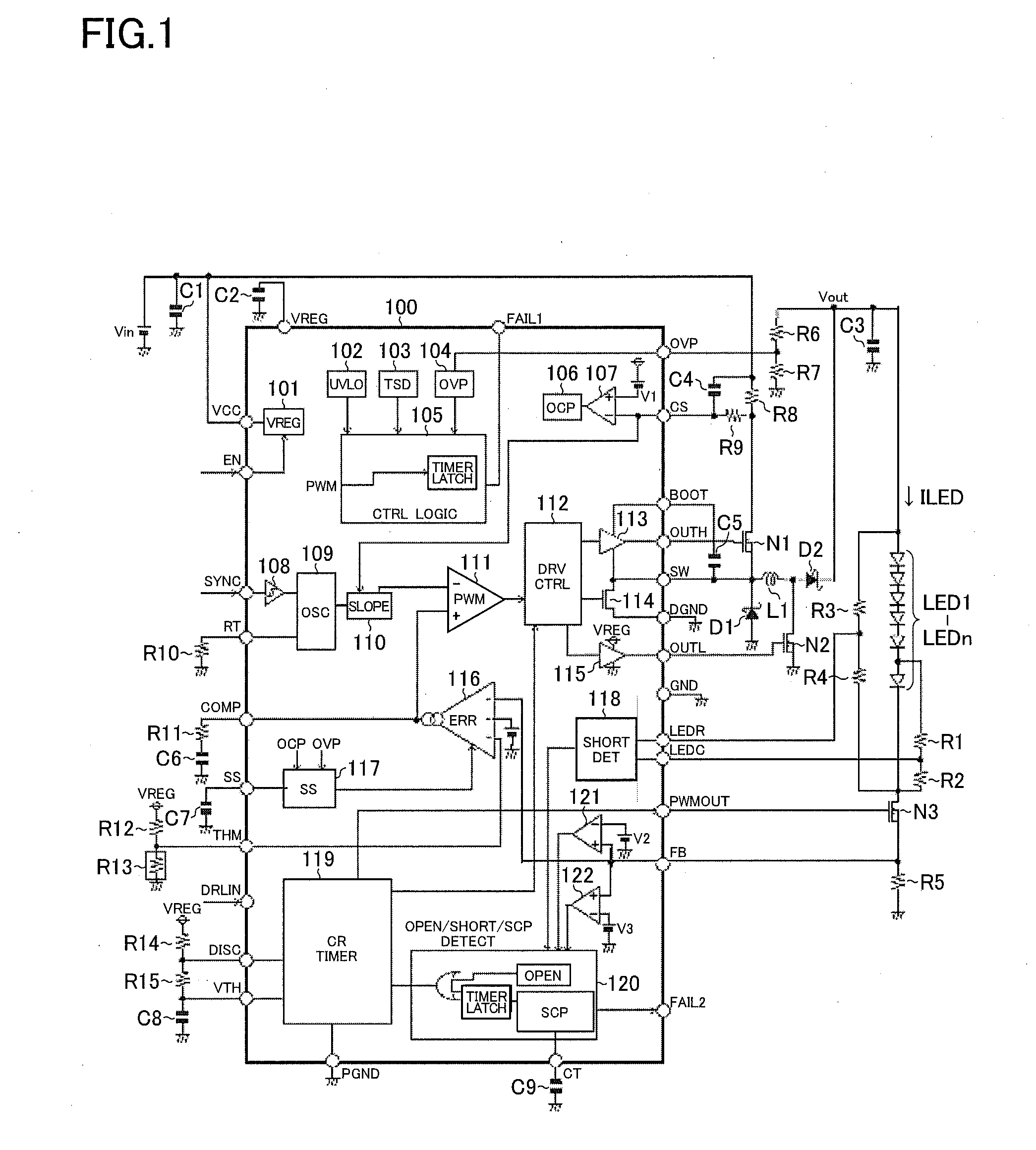

LED short-circuit detection circuit, LED drive device, LED lighting device, and vehicle

An LED short-circuit detection circuit produces an LED short-circuit detection signal by monitoring an LEDC terminal voltage (a first voltage obtained at a chip-to-chip node in a row of LED chips, or a divided voltage thereof) and an LEDR terminal voltage (a second voltage obtained by dividing the end-to-end voltage of the row of LED chips).

Owner:ROHM CO LTD

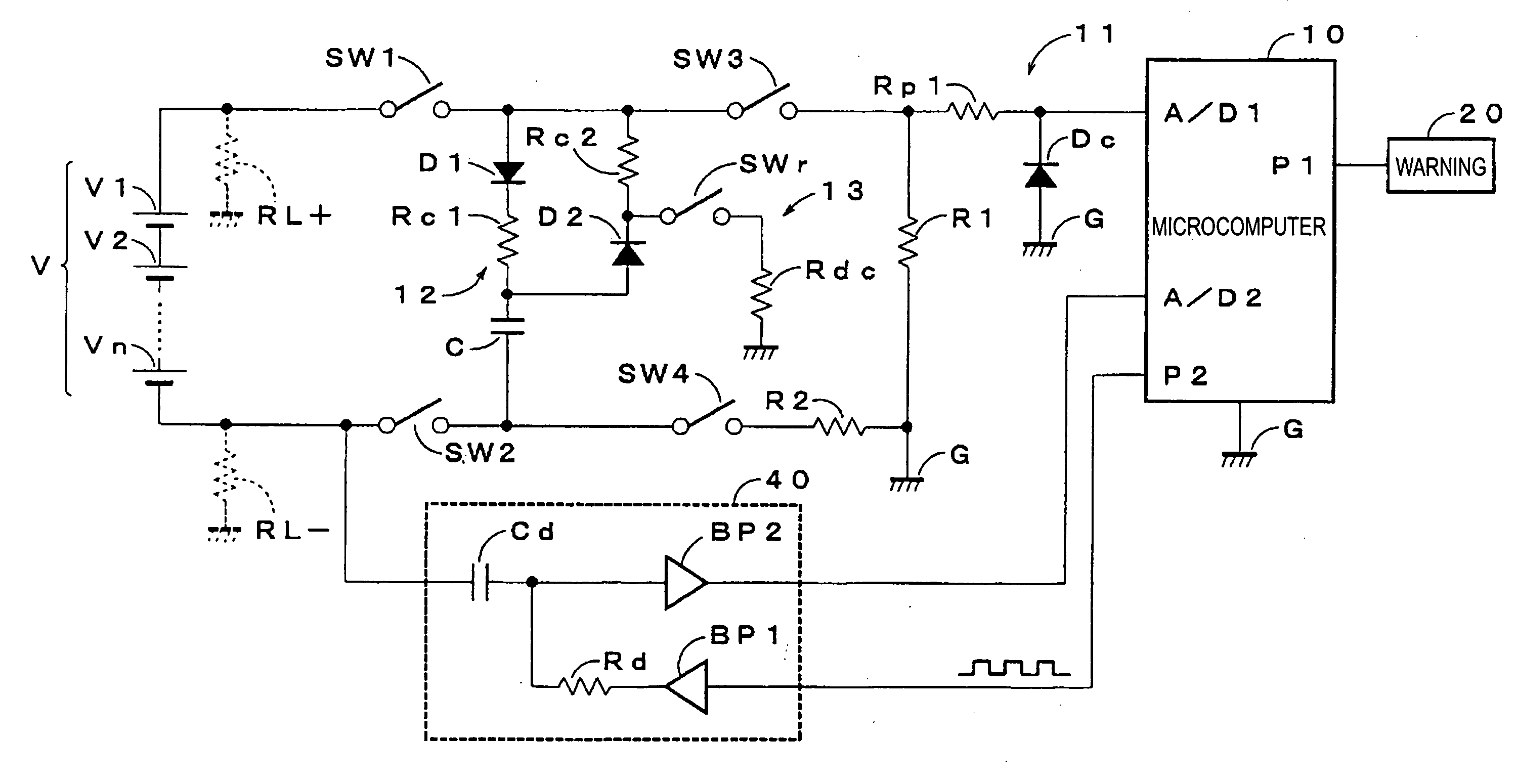

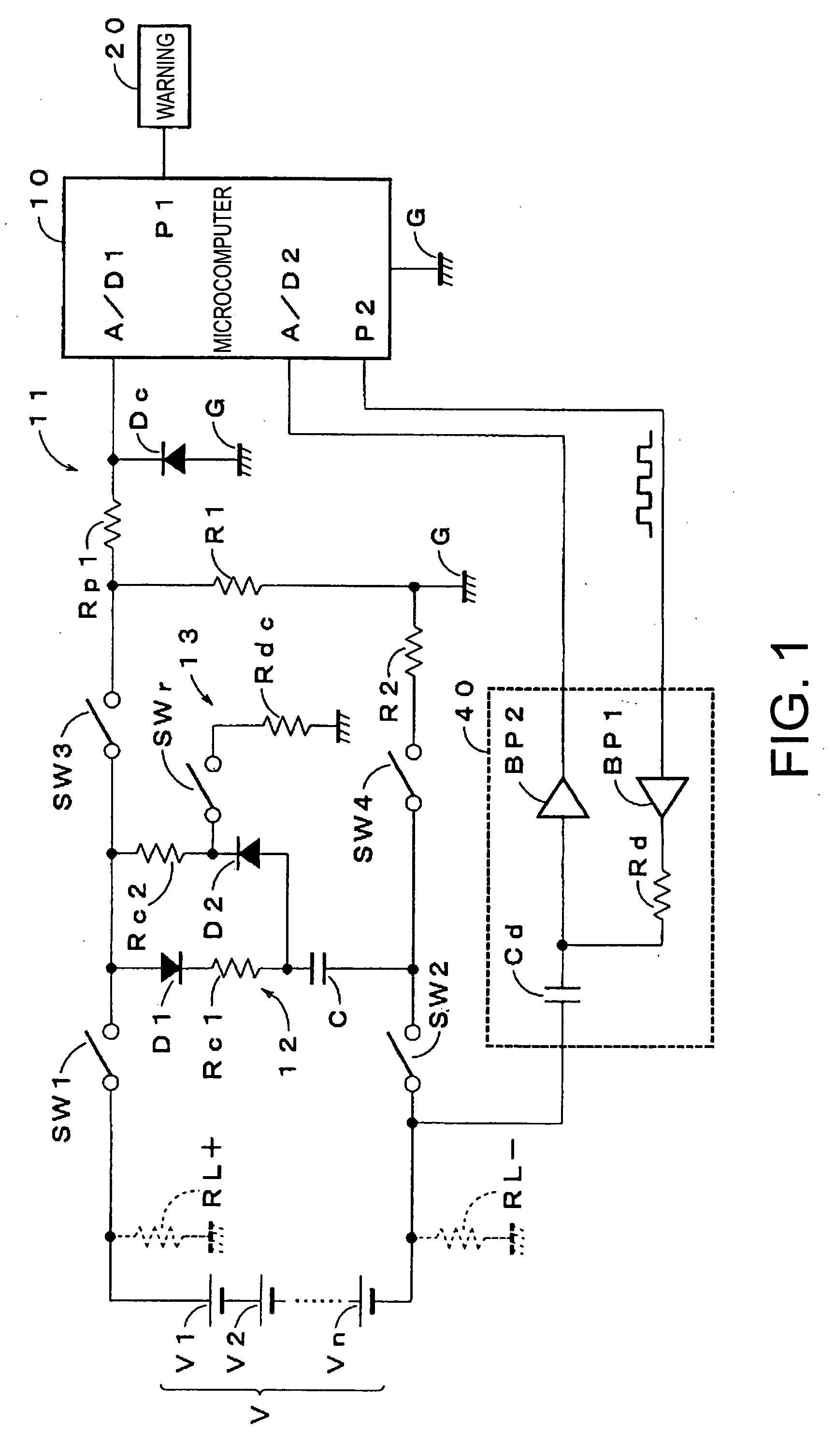

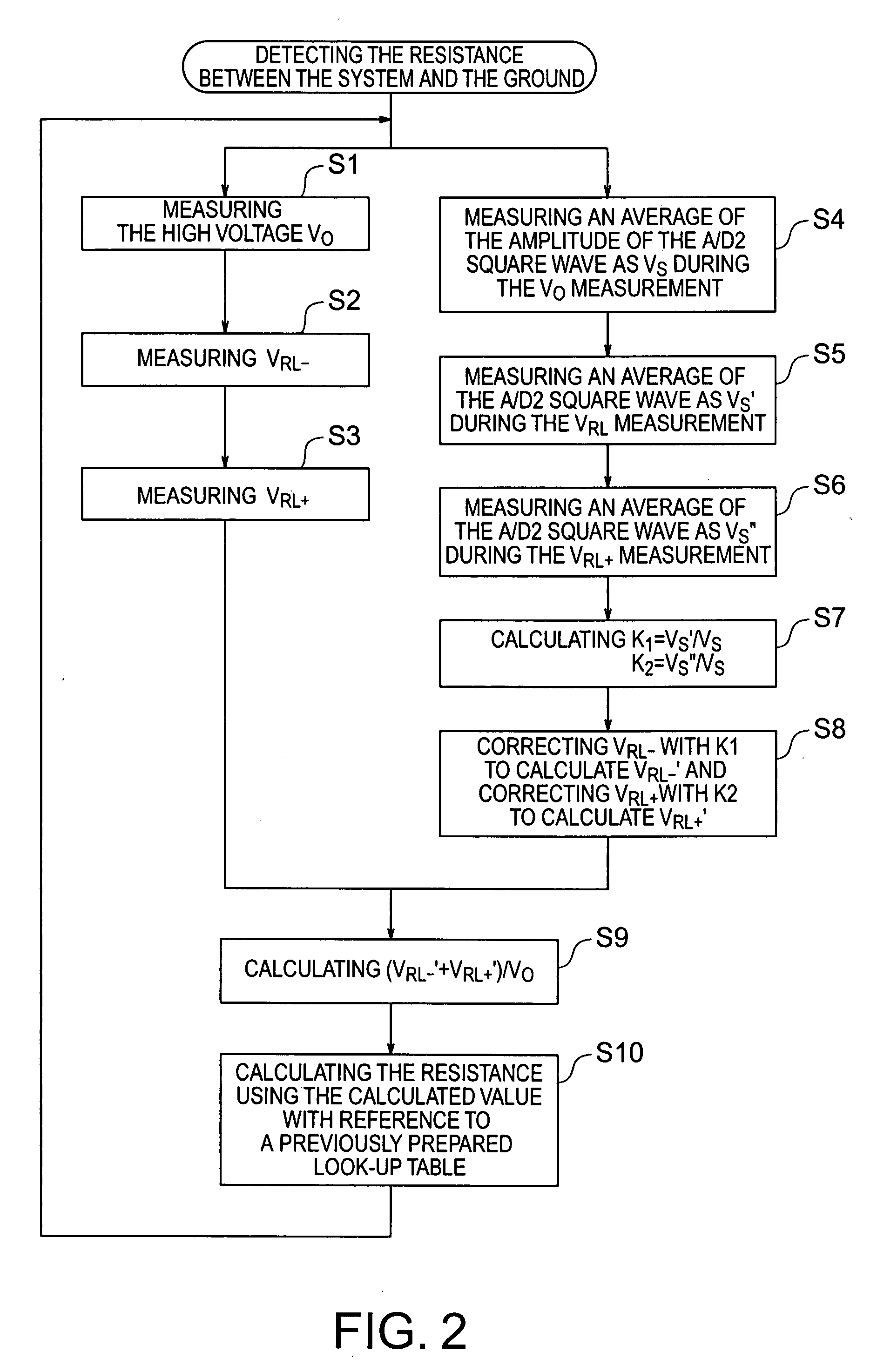

Insulation detecting method and insulation detecting device

InactiveUS20070210805A1Line-transmission monitoring/testingLamps testingVoltage amplitudeElectrical resistance and conductance

An alternating signal from a signal generator is applied to a direct current source via a detecting resistor and a coupling capacitor. A detecting member detects a voltage amplitude change appeared at a contact between the detecting resistor and the coupling capacitor. Based on the voltage amplitude change, a correction member corrects a first measuring voltage when a capacitor is connected to a contact between an anode of the direct current source and a ground, and a second measuring voltage when the capacitor is connected to a contact between a cathode of the direct current source and the ground. Based on the corrected first and second measuring values and a voltage across the direct current source when the capacitor is connected to the anode and the cathode of the direct current source by a voltage measuring member, a calculation member calculates a resistance between the direct current source and the ground.

Owner:YAZAKI CORP

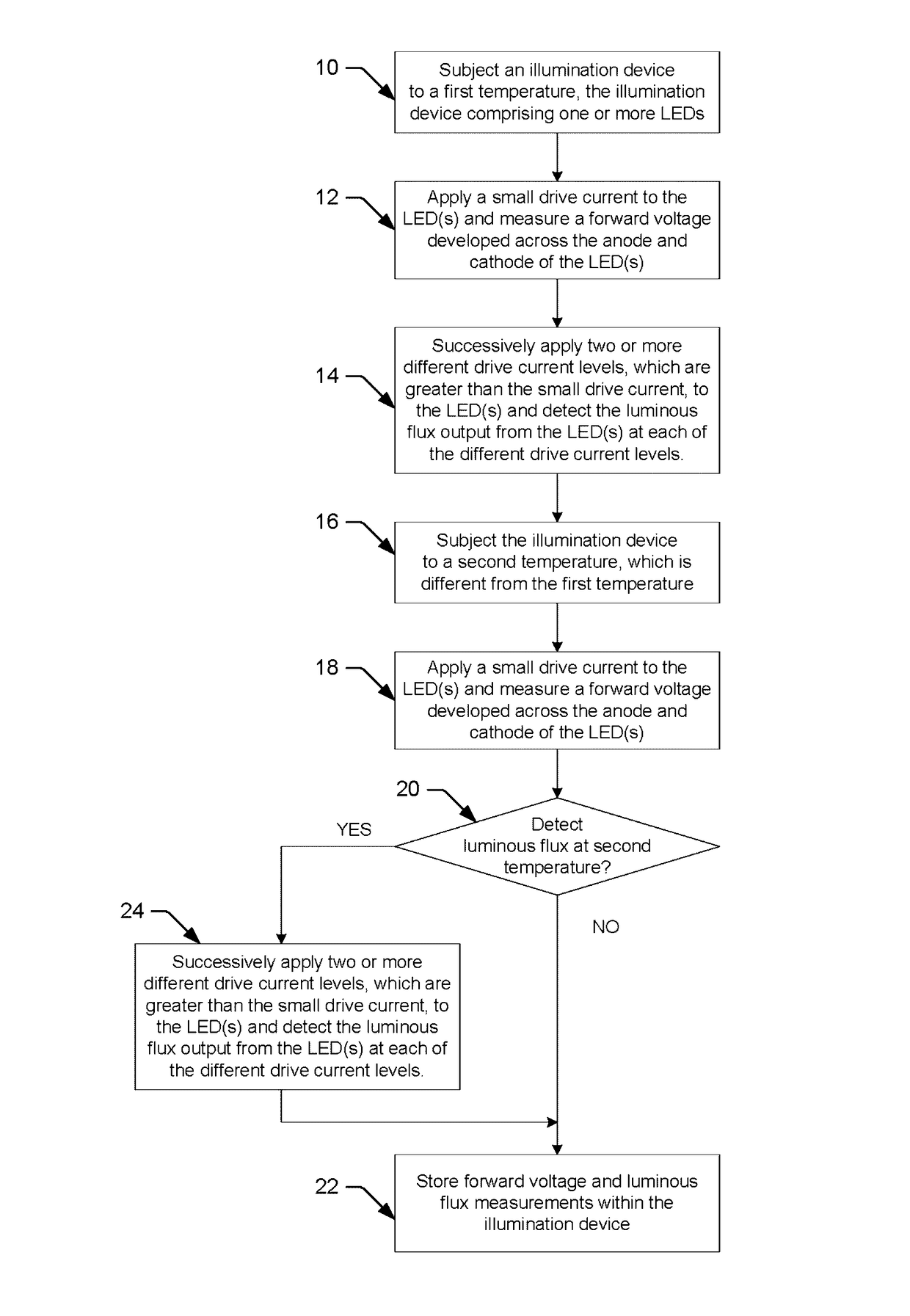

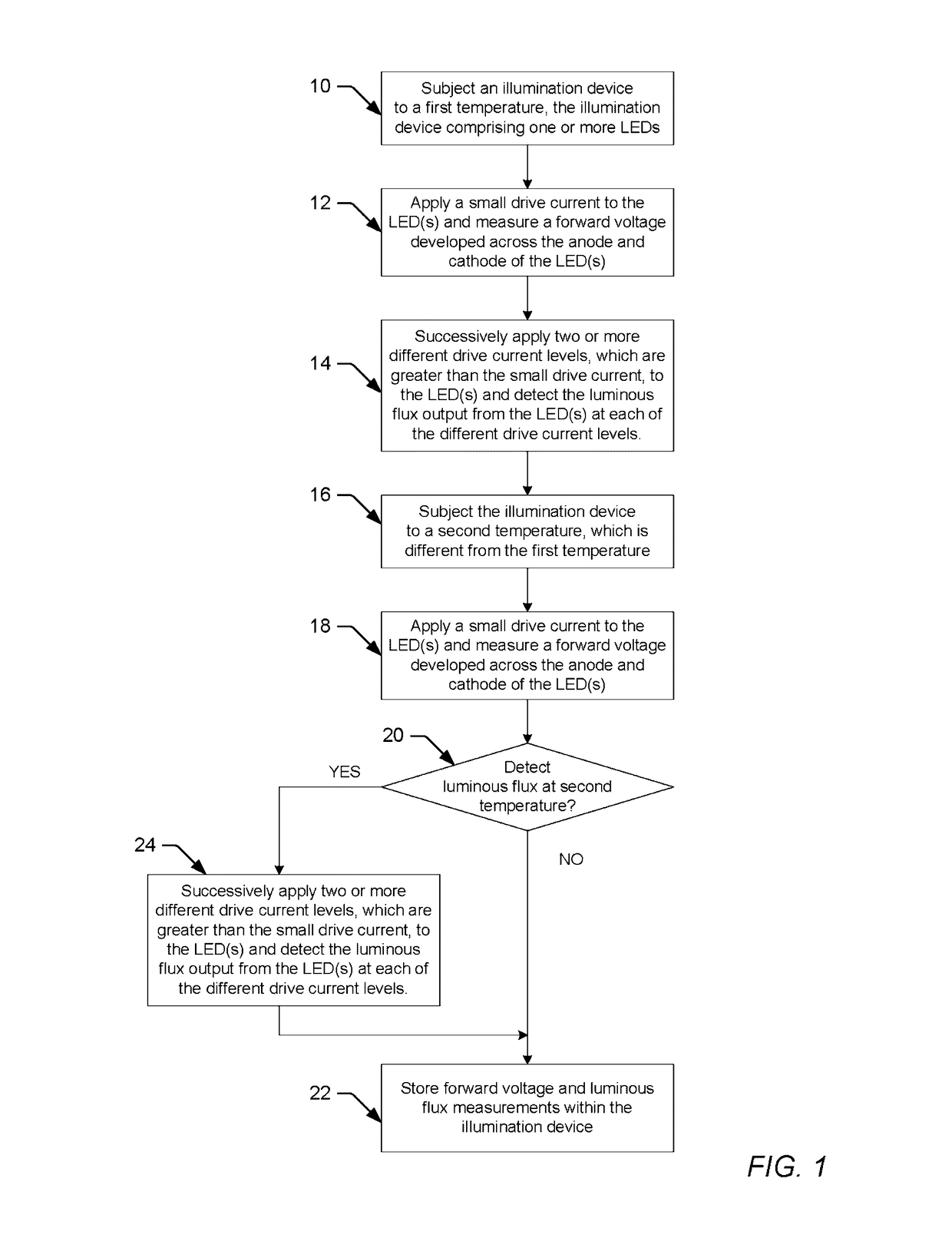

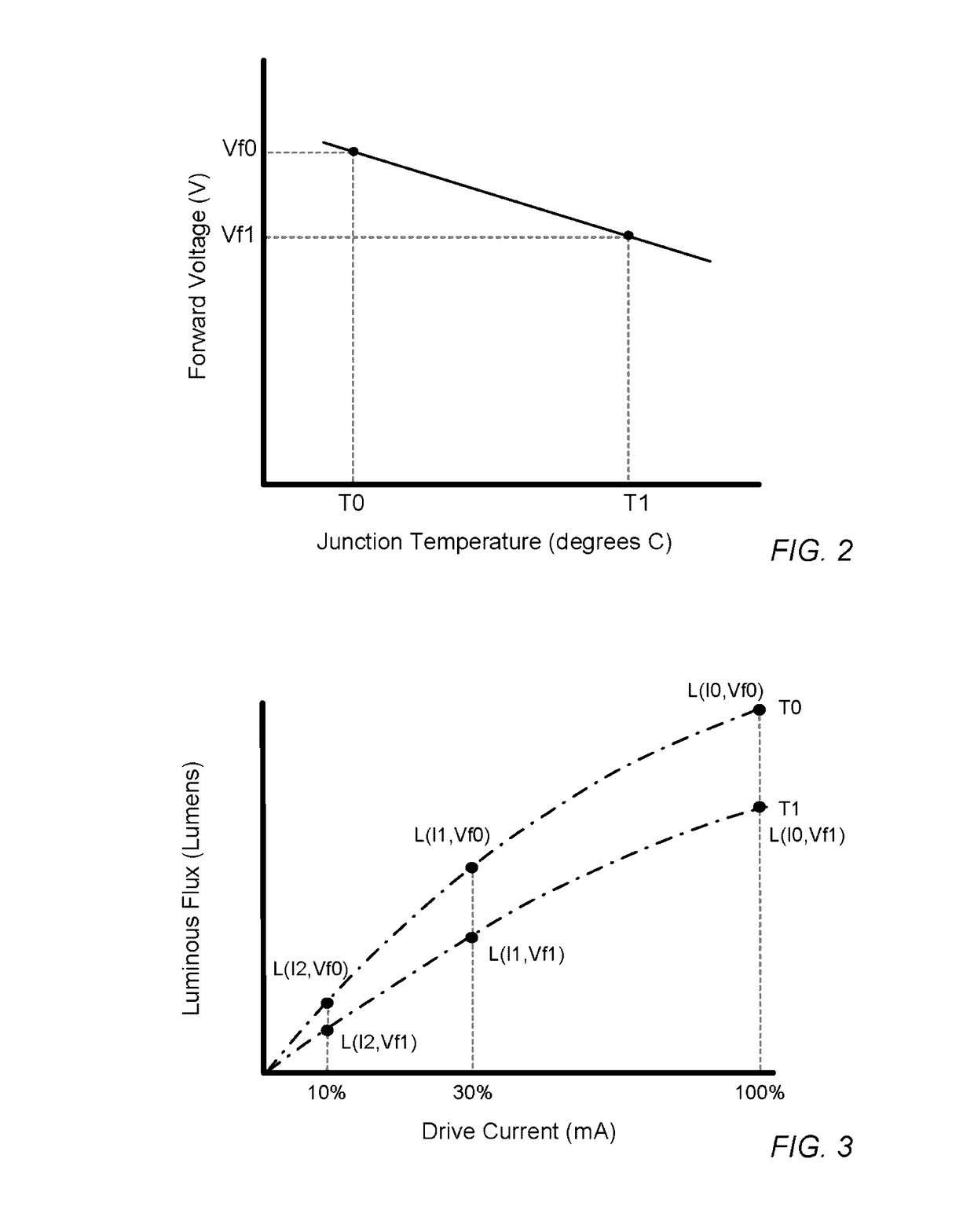

Illumination device and temperature calibration method

ActiveUS9651632B1Simplify the calibration processLow costElectrical apparatusElectroluminescent light sourcesDriving currentLuminous flux

An illumination device comprising a plurality of light emitting diodes (LEDs) and a method for calibrating the illumination device is provided herein. According to one embodiment, the method may include subjecting a first LED to a first ambient temperature, measuring a forward voltage developed across the first LED upon applying a relatively small drive current to the first LED, detecting at least a first, a second and a third luminous flux output from the first LED upon successively applying at least a first, a second and a third drive current to the first LED, and storing results of the measuring and detecting steps within the illumination device to calibrate the first LED at the first ambient temperature. In some embodiments, the first LED may be subjected to a second ambient temperature, which is different from the first ambient temperature, and the method may repeat the steps of measuring, detecting and storing to calibrate the first LED at the second ambient temperature.

Owner:LUTRON TECH CO LLC

Remote monitoring and control of LED based street lights

ActiveUS20100271178A1Electric testing/monitoringElectric/electromagnetic visible signallingComputer moduleEngineering

The present invention is directed to a method for remotely monitoring and controlling a light emitting diode. In one embodiment, the method includes establishing a two-way communication path via a communication module to a central office, wherein said communication module is coupled to said LED based street light and sending information related to the LED based street light to the central office via the two-way communication path.

Owner:DIALIGHT CORP

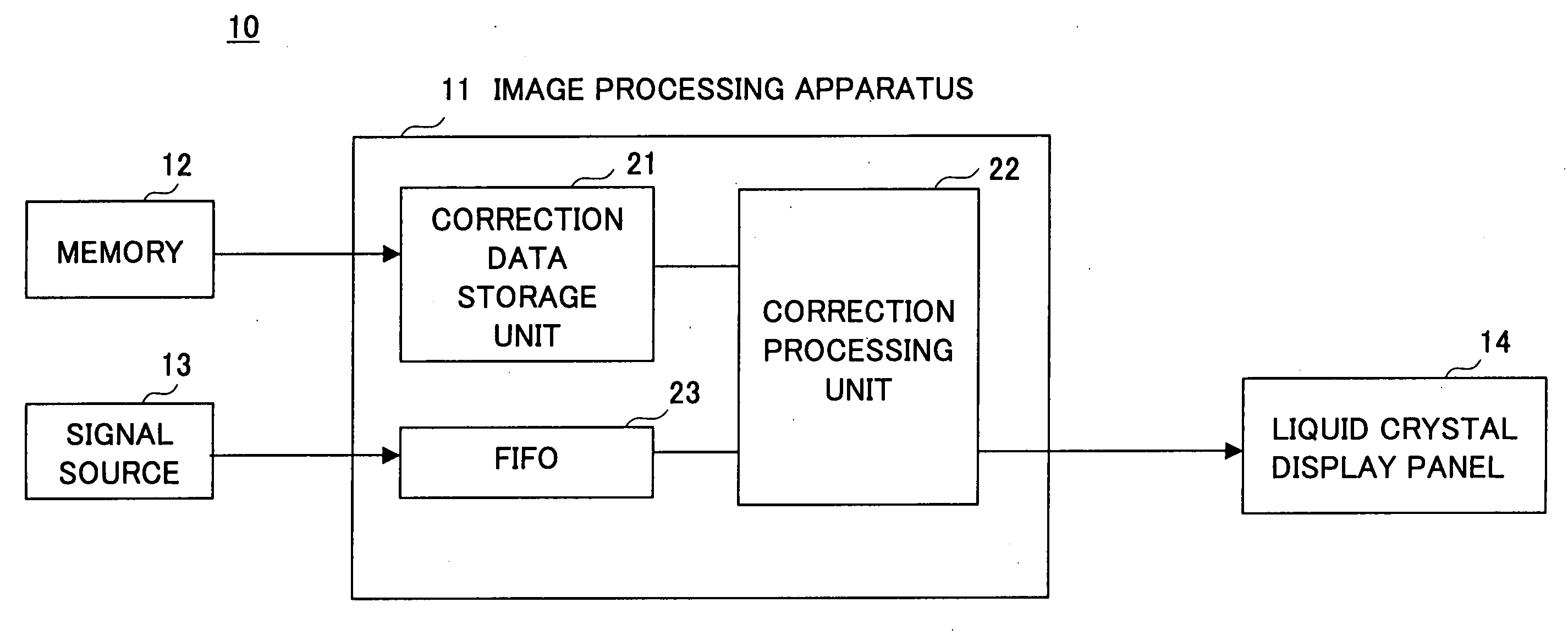

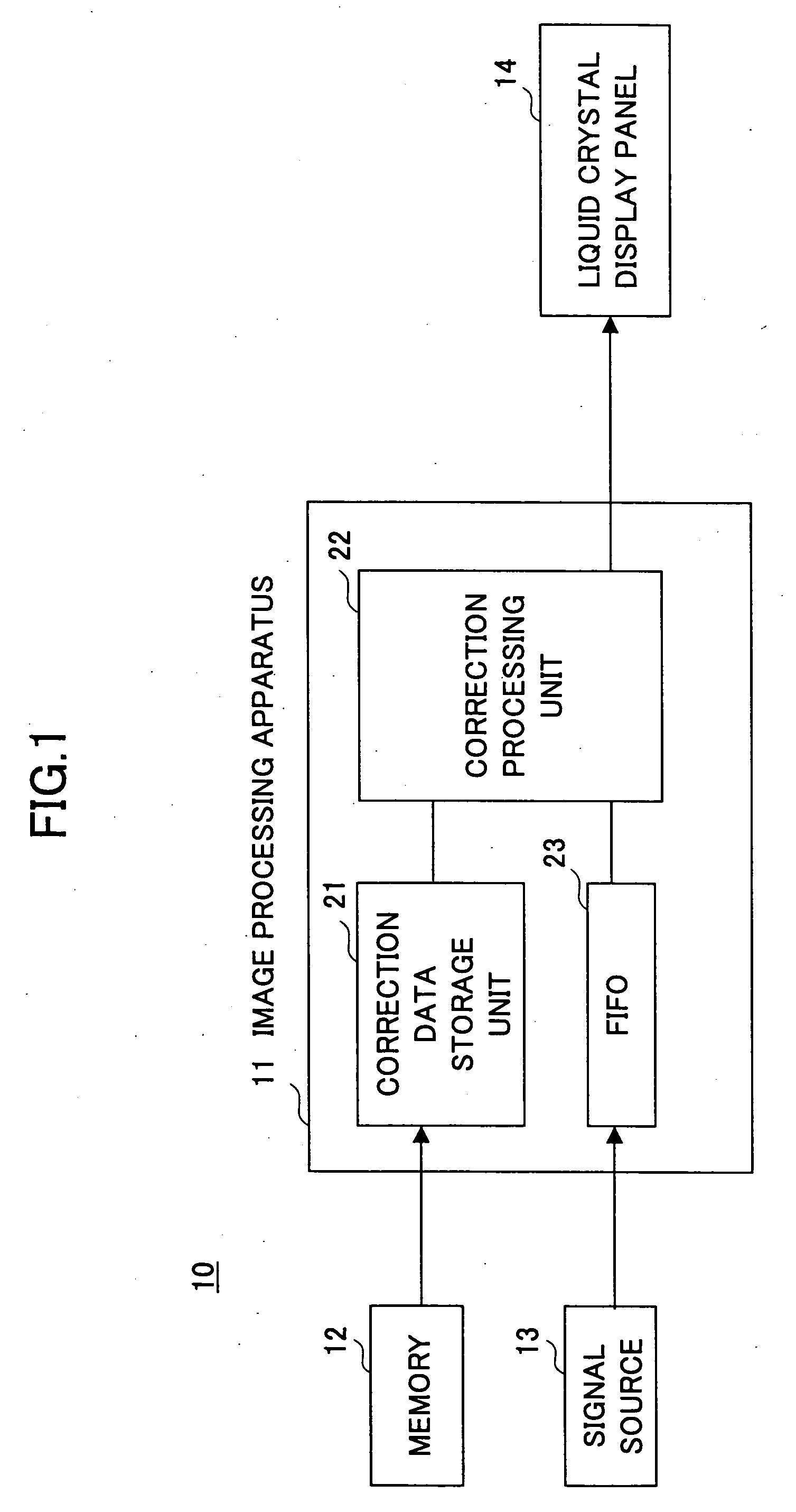

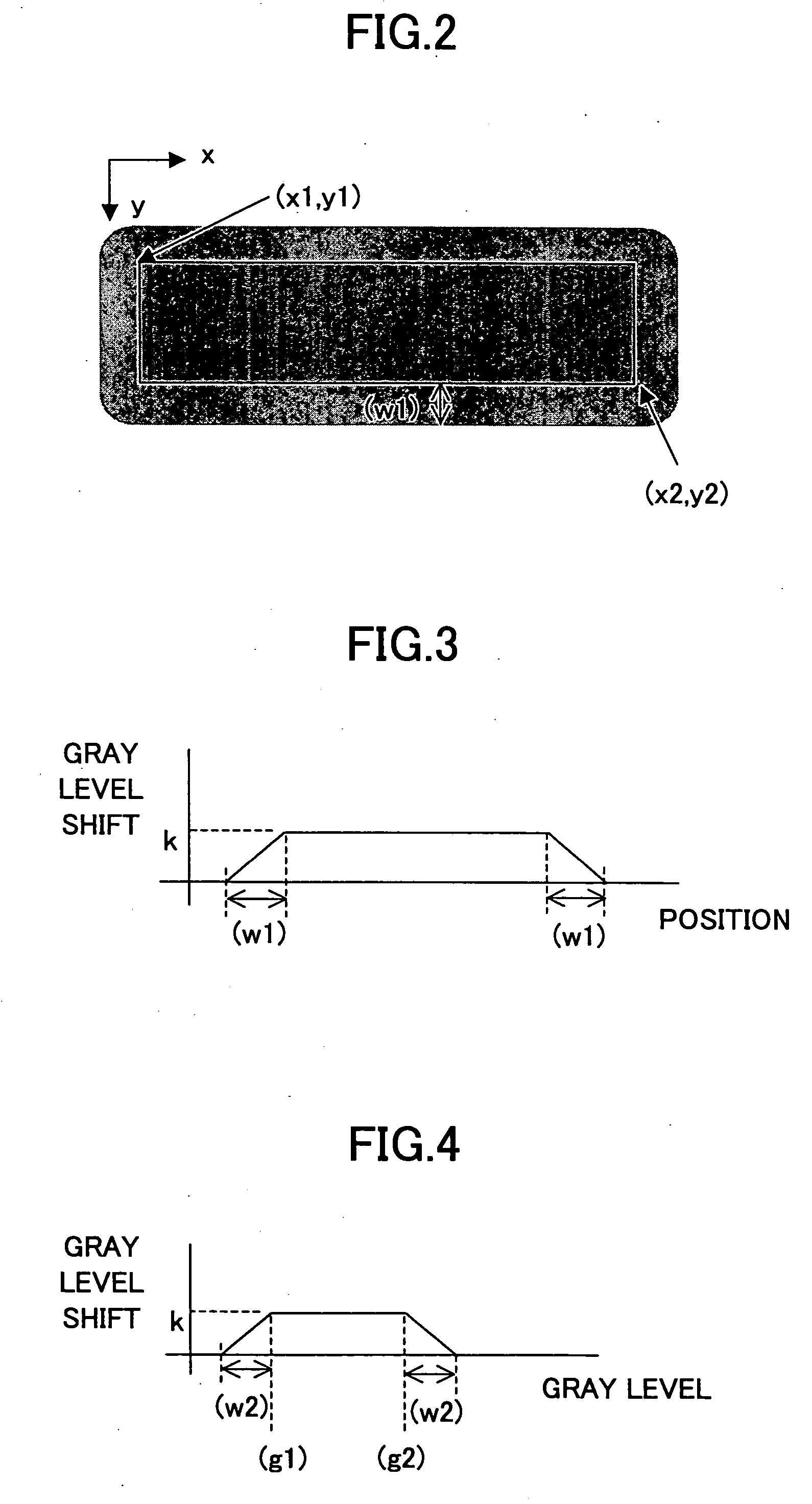

Correction of uneven image appearance by use of small-size data

InactiveUS20050093798A1Small sizeReduce appearanceTelevision system detailsColor television detailsImaging processingGray level

A circuit for display correction includes a memory which stores first data indicative of size and position of a rectangular region on a display screen and second data indicative of gray level changes in a surrounding region around the rectangular region in an isometric manner with respect to a horizontal direction and a vertical direction, and an image processing unit which adjusts gray levels of image data in response to the first data and the second data stored in the memory.

Owner:SHARP KK

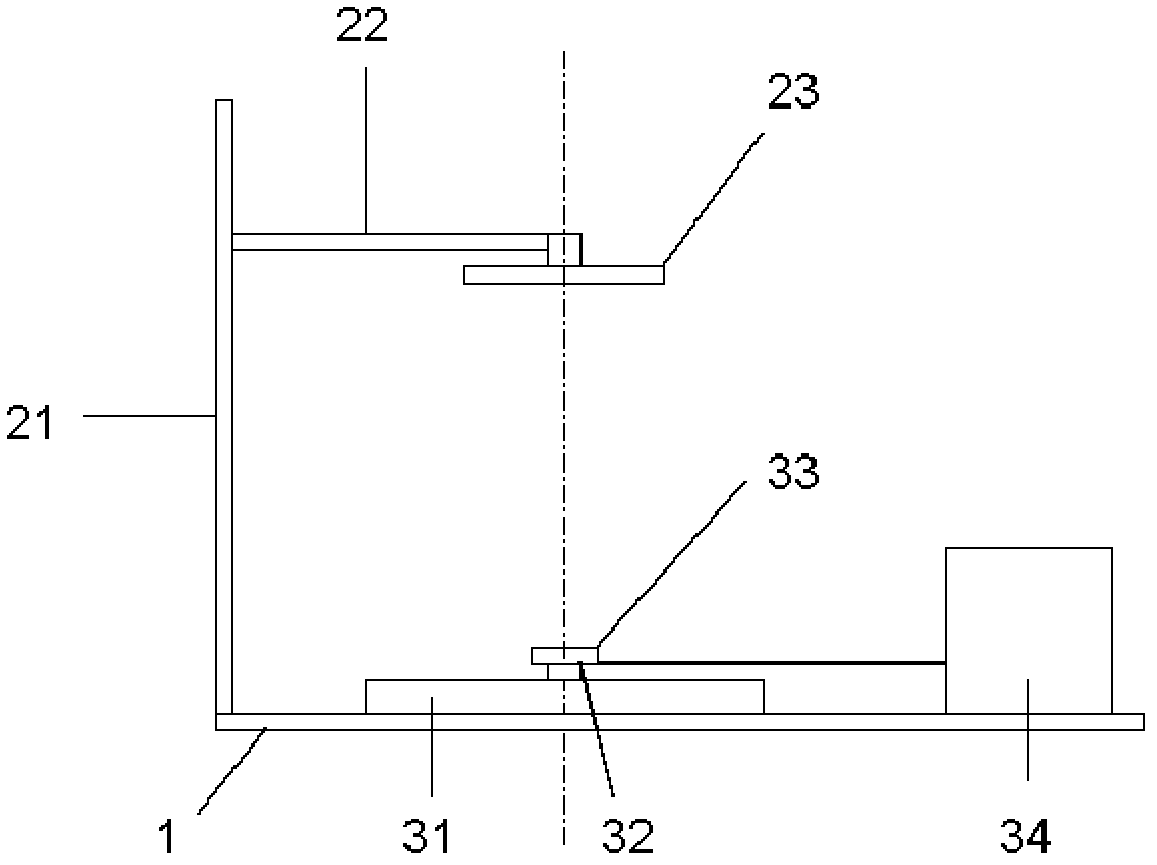

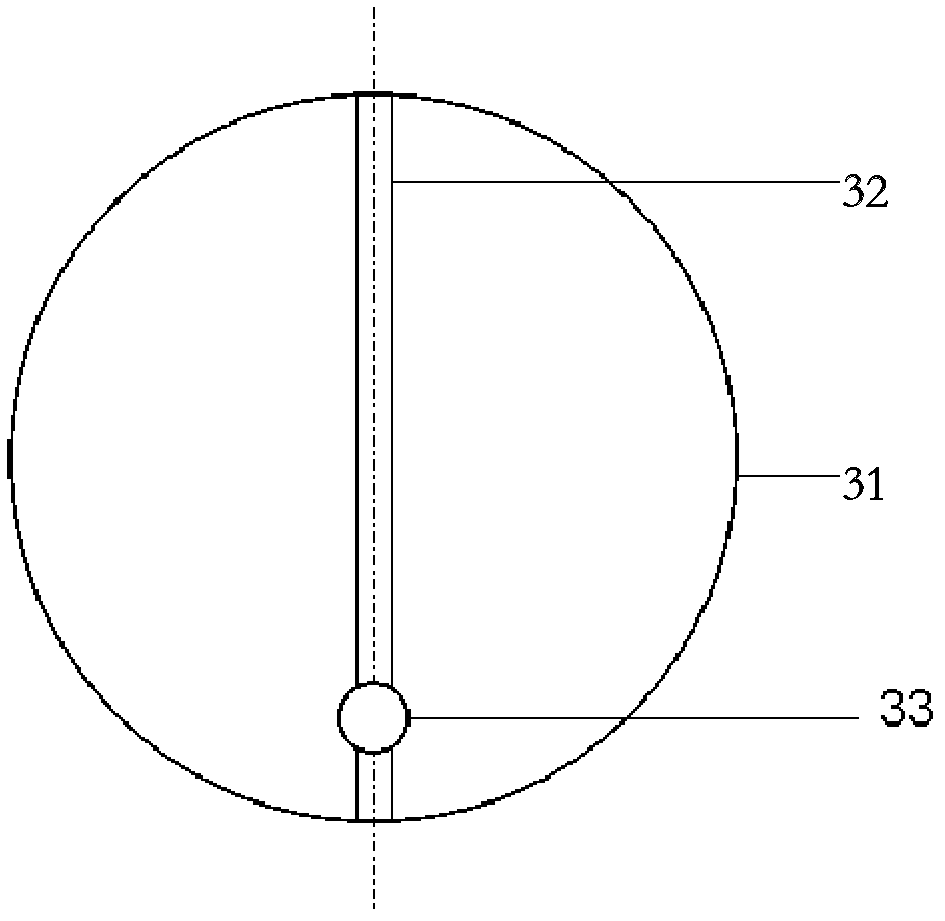

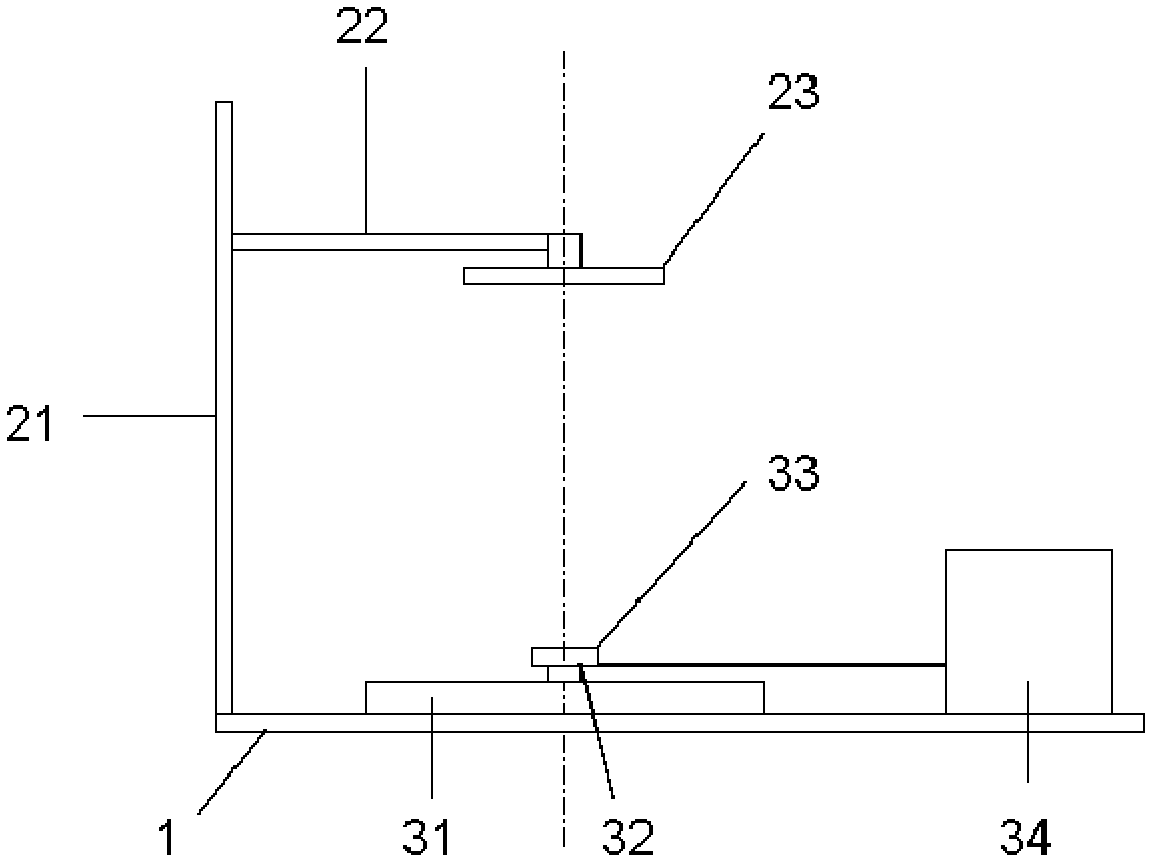

Performance measuring device of surface light source lamp

InactiveCN102620918ASolving the lack of measurement devices for the performance of surface light luminairesSimple structureLamps testingTesting optical propertiesColor rendering indexEngineering

A performance measuring device of a surface light source lamp comprises a horizontal baseboard, a support and a testing table. The support comprises a vertical support and a horizontal support, the vertical support is vertically fixed on the horizontal baseboard, the horizontal support is horizontally arranged on the vertical support and is capable of being in parallel translation vertically, and the horizontal support is provided with a lamp fixing device. The testing table comprises a horizontal disc, a probe and a detector, the horizontal disc is arranged on the horizontal baseboard and capable of rotating for 360 degrees, the horizontal disc is provided with a linear guiderail, the probe is installed on the linear guiderail and capable of moving along the linear guiderail, and the detector is arranged on the horizontal baseboard and connected with the probe. The performance measuring device is simple in structure, eliminates uncertainty in measuring, leads measuring to be standard, and can be used in measuring of parameters including light intensity, spectrum, color temperature, surface temperature and color rendering index of various surface light source lamps including light-emitting diode surface light source lamps, organic light-emitting diode surface light source lamps and electroluminescence surface light source lamps.

Owner:SHANGHAI JIAO TONG UNIV

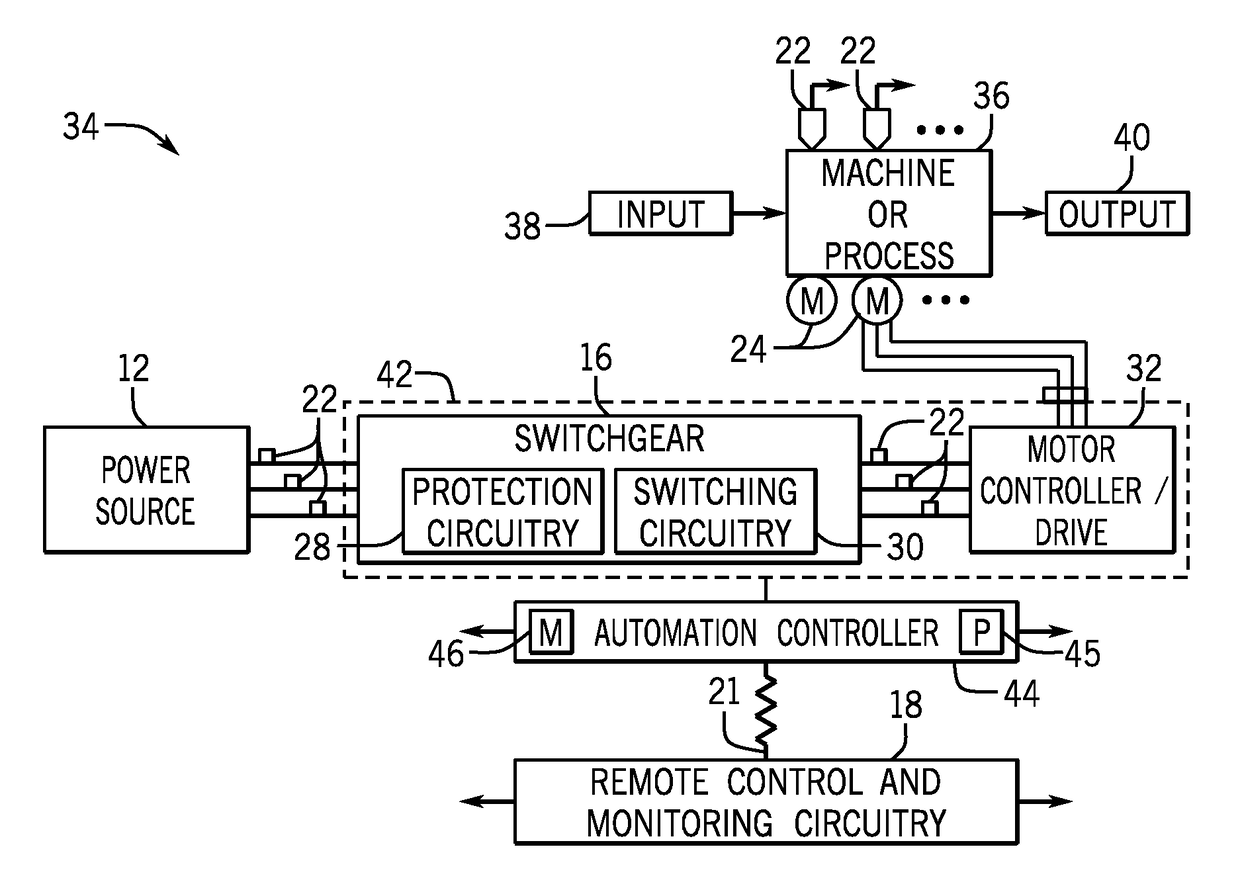

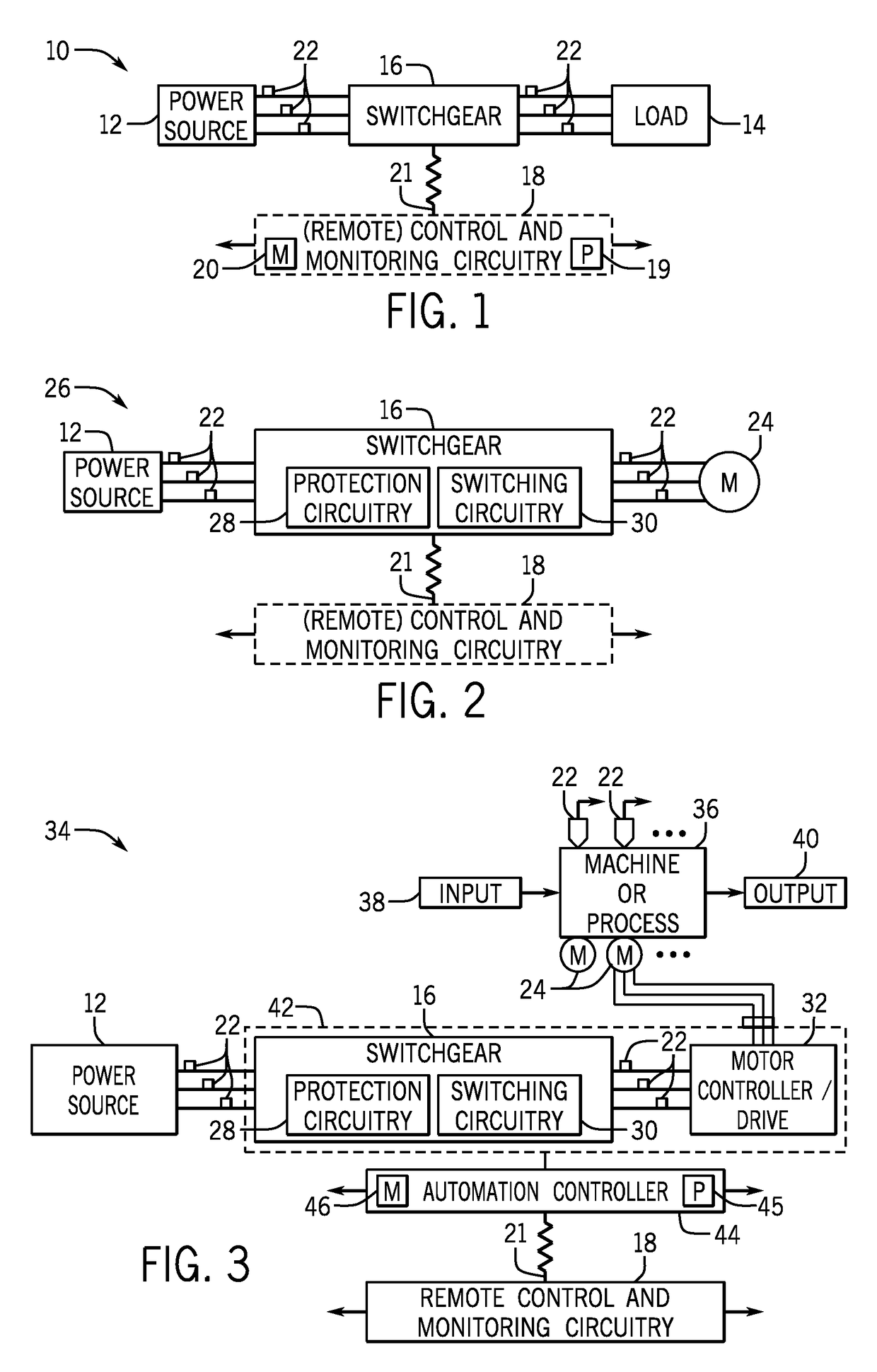

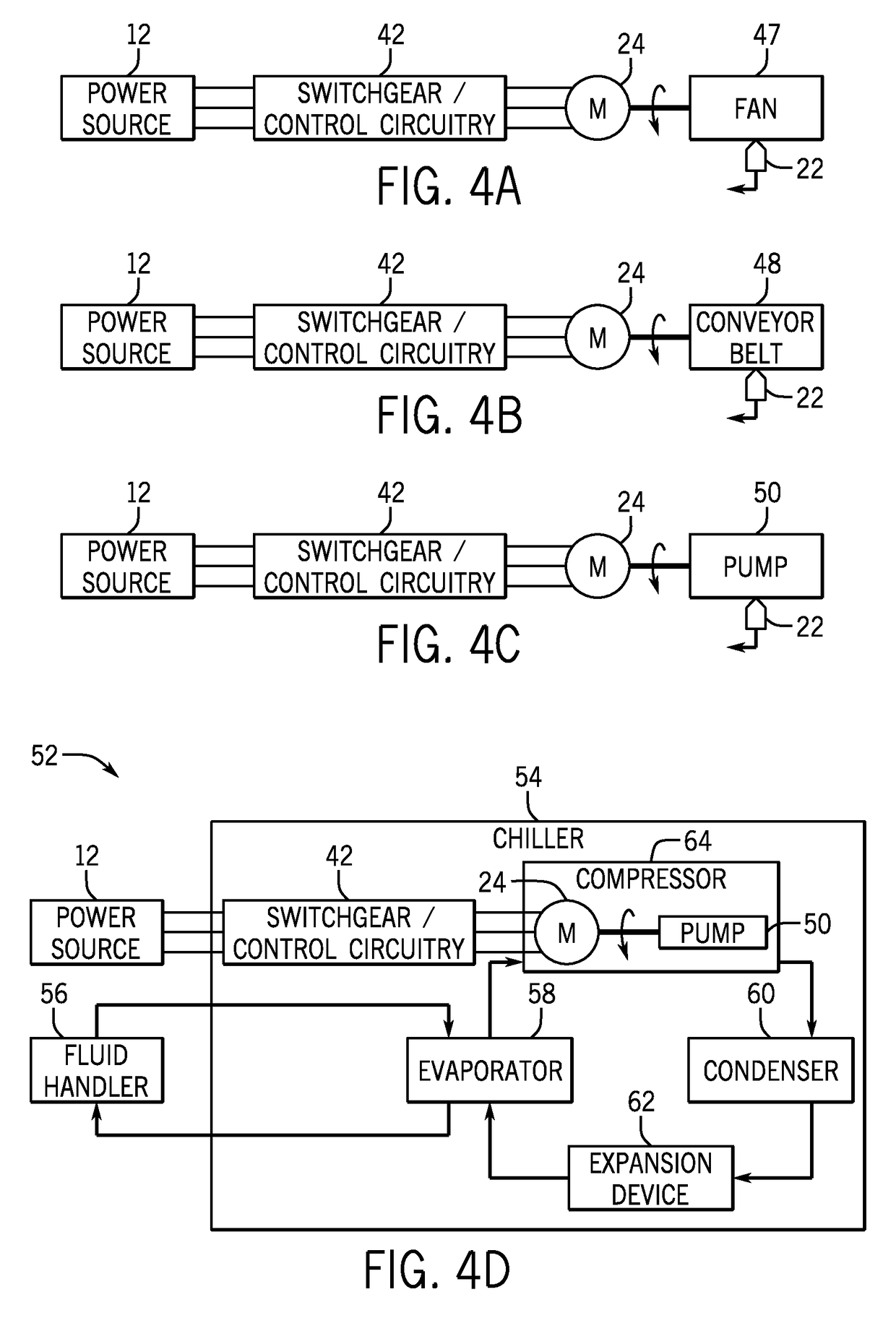

Single-pole, single current path switching system and method

ActiveUS9726726B2Electrical controlThermometers using electric/magnetic elementsElectricityControl signal

One embodiment describes a three-phase electromechanical switching device, which includes three single-phase switching devices mechanically and electrically coupled in parallel with one another, each single-phase switching device including a direct current electromagnetic operator that in operation receives a direct current control signal for switching of the device, stationary contacts disposed in a respective device housing, and a movable assembly that in operation is displaced by energizing the operator and that include movable contacts that open and close, with the stationary contacts, a single current carrying path through the respective single-phase switching device; in which each of the single-phase switching devices receives control signals from control circuitry coupled to the operators of the respective single-phase switching devices to cause at least one of the single-phase switching devices to open or close the single current carrying path at a desired time coordinated with a current zero-crossing or a predicted current zero-crossing of a phase of three-phase power.

Owner:ROCKWELL AUTOMATION TECH

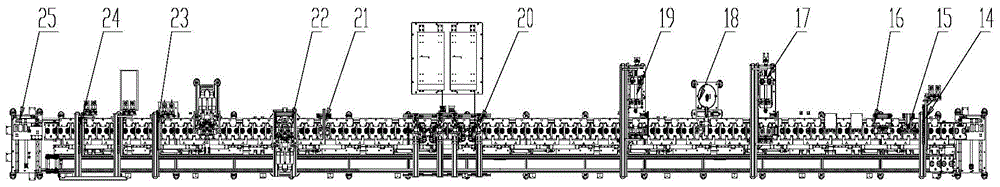

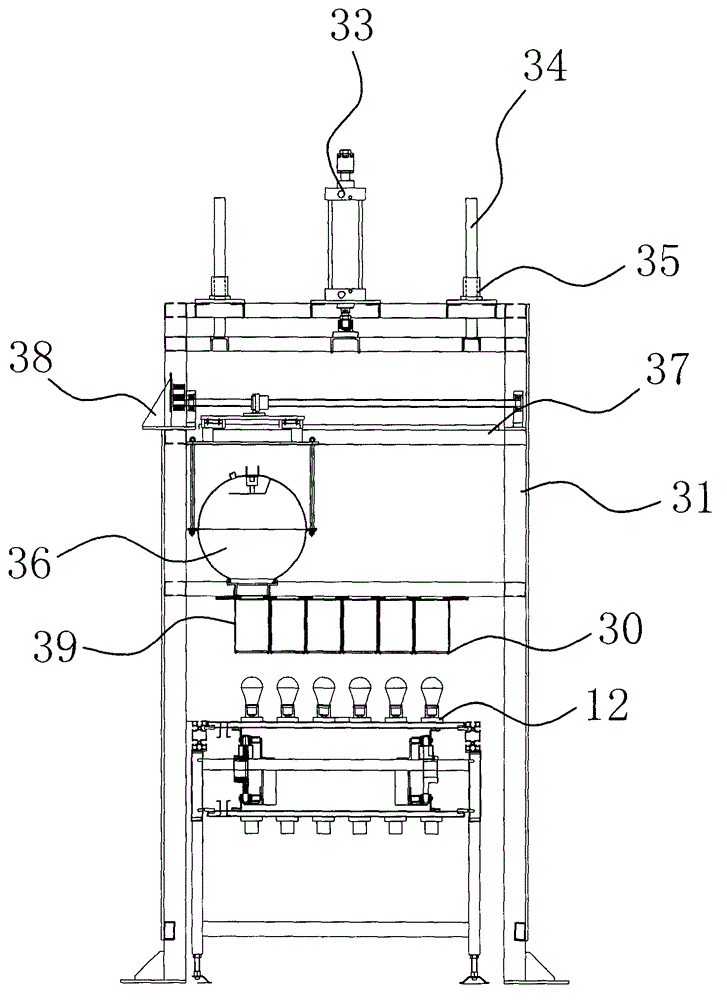

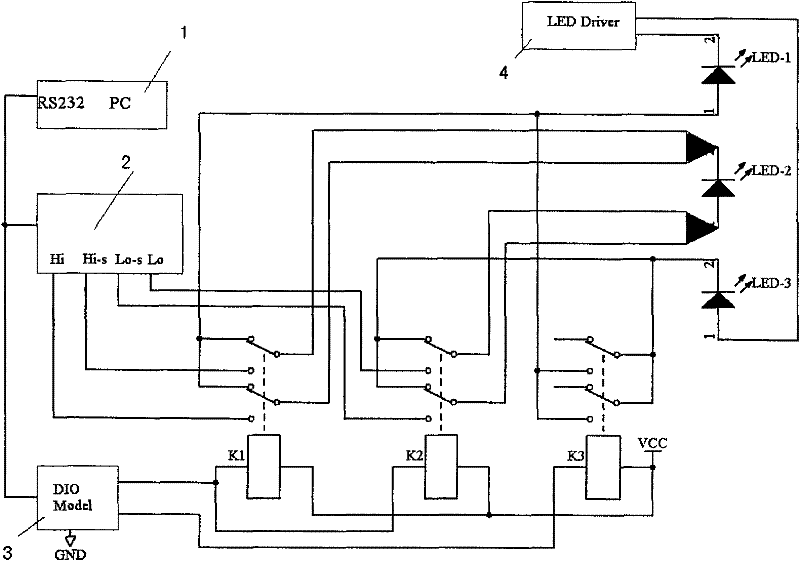

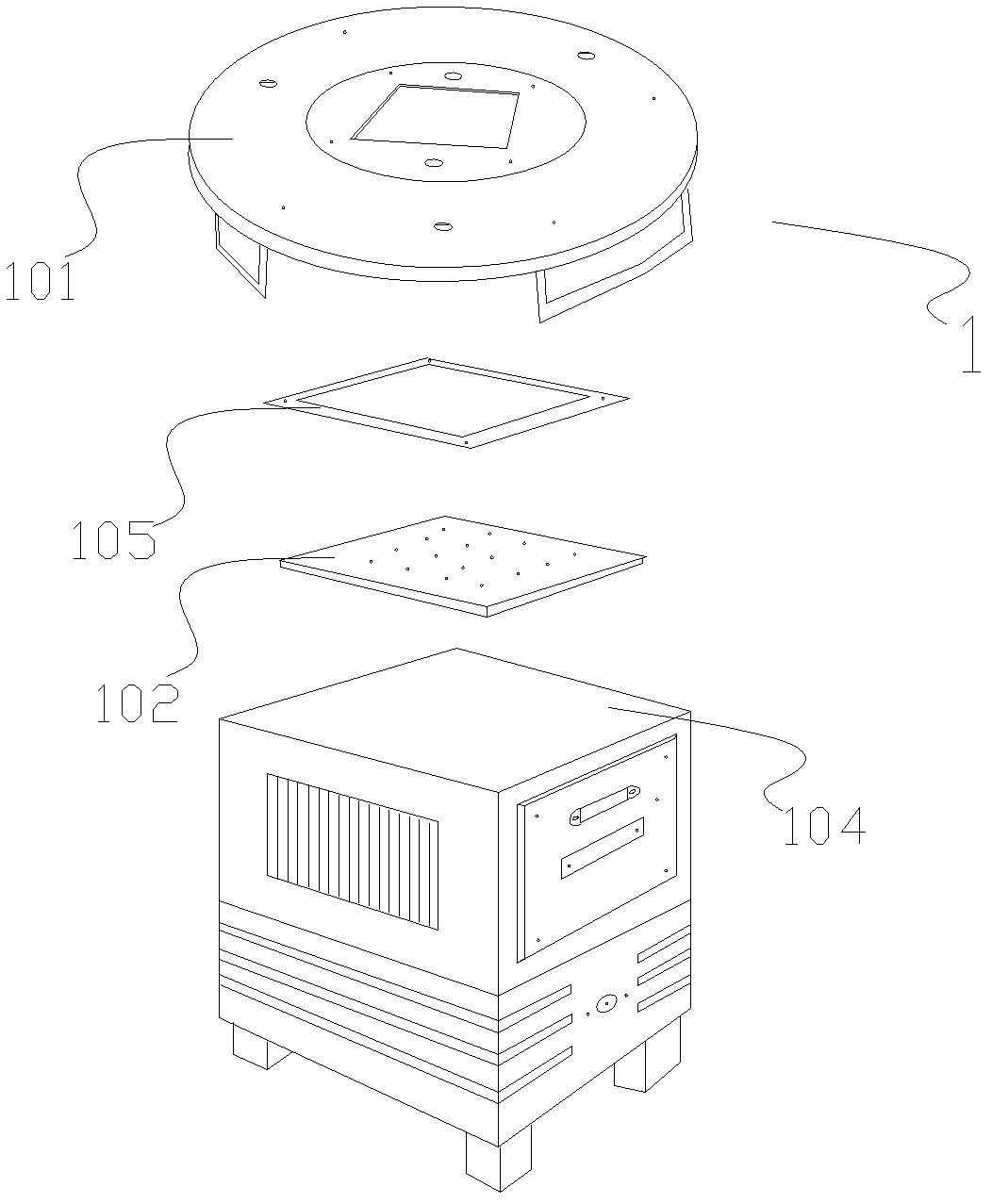

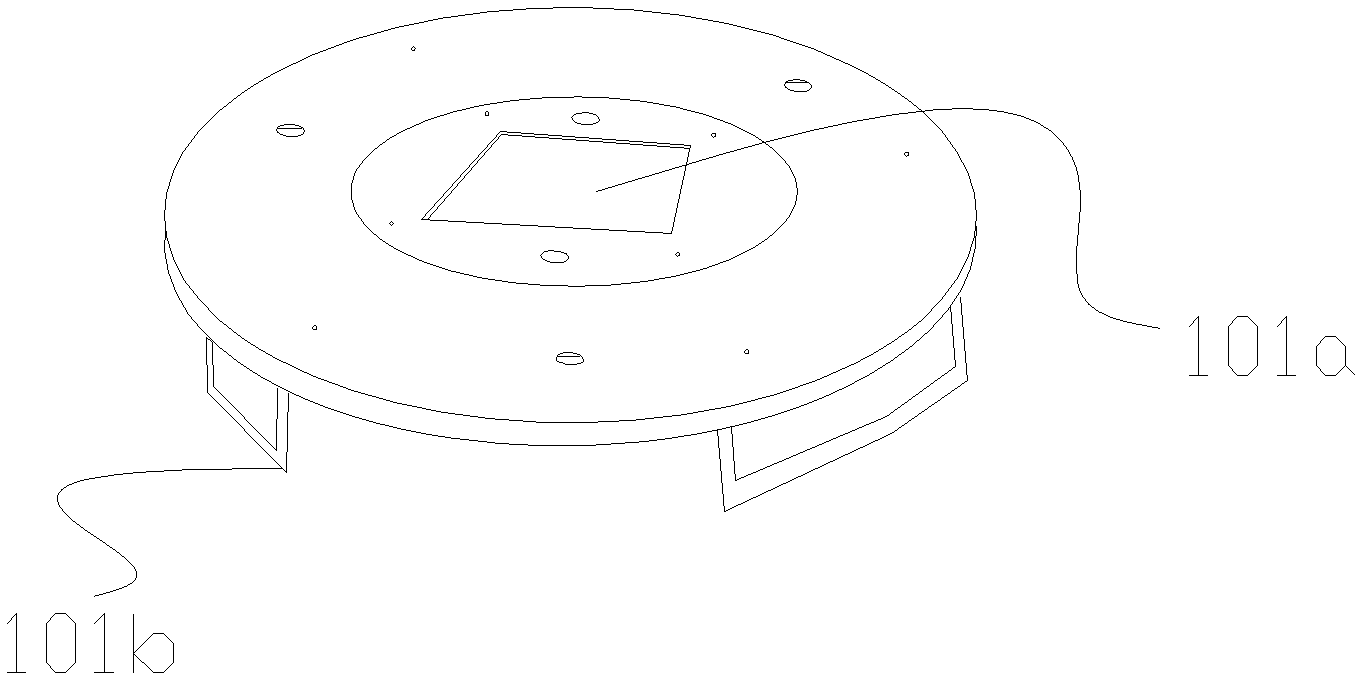

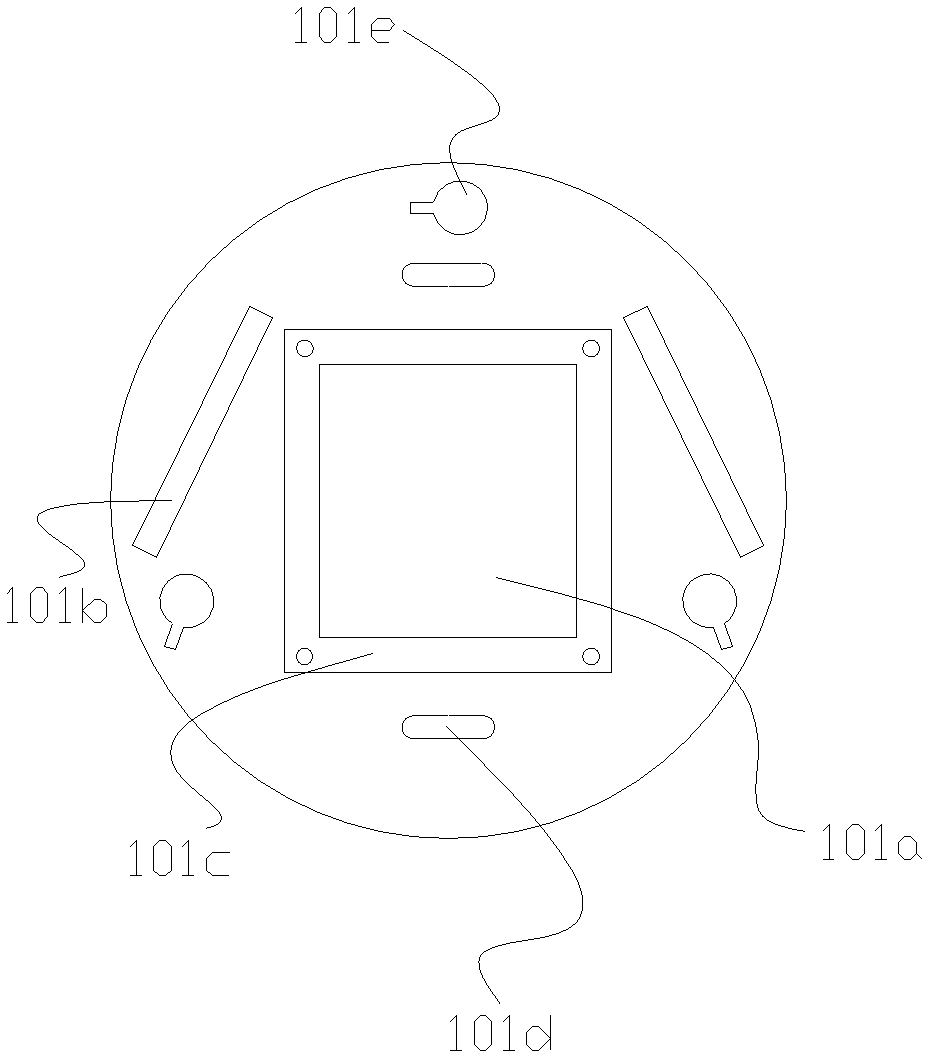

LED lamp detecting device

InactiveCN102749568AImprove detection efficiencyWide detection rangeLamps testingTesting optical propertiesSprocketEngineering

The invention provides an LED lamp detecting device, and belongs to the technical field of detection. The LED lamp detecting device solves problems of small detection range and low precision of an existing LED lamp detecting device. The LED lamp detecting device comprises an elongated worktable, a conveying belt and chain wheels, the elongated worktable is disposed horizontally, the conveying belt is arranged on the worktable, the chain wheels used for driving the conveying belt to transmit LED lamps are disposed on the lower portion of the worktable and driven by a motor, the conveying belt is elliptical, the chain wheels are respectively positioned at two ends of the elliptical conveying belt, a plurality of lamp bank holders which are arranged along the width direction of the worktable are disposed on the surface of the conveying belt and are uniformly distributed, each lamp bank holder consists of 6-10 lamp holders uniformly distributed, and a high-voltage detecting unit, a photoelectric parameter testing unit and an automatic separating unit are respectively arranged above the worktable and are sequentially distributed along the conveying direction of the conveying belt. The LED lamp detecting device has the advantages of wide detection range, high detection precision and the like.

Owner:台州市远东铁马自动化设备有限公司

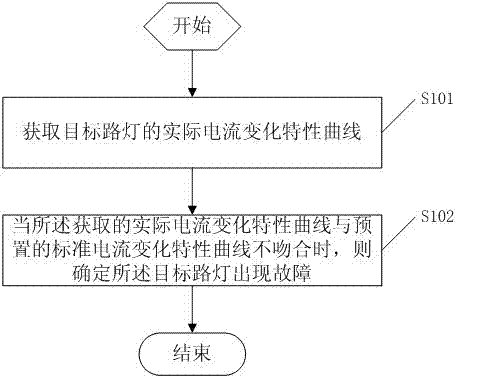

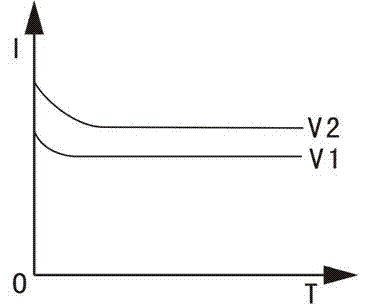

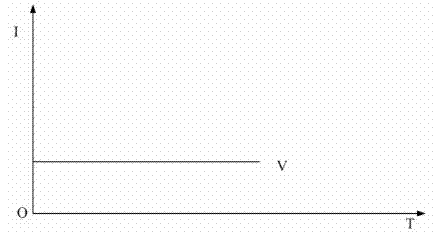

Detection method, detection device and detection system of street lamp failure

The invention discloses a detection method of a street lamp failure. The detection method includes following steps: obtaining an actual current variation characteristic curve of a target street lamp, and confirming that the garget street lamp is broken down when the obtained actual current variation characteristic curve does not match with a preset standard current variation characteristic curve. The invention further discloses a detection device of the street lamp failure and a detection system of the street lamp failure. Due to the adoption of the technical scheme, detection device of the street lamp failure and the detection system of the detection device of the street lamp failure is capable of accurately detecting a broken street lamp, is particularly capable of accurately judging the street lamp with an electronic type ballast failure or an inductance type ballast failure, improves accuracy when the street lamp detection is conducted, enables a staff to repair the broken street lamp in time and meets normal requirements of city street lamp illumination.

Owner:重庆恒又源科技发展有限公司

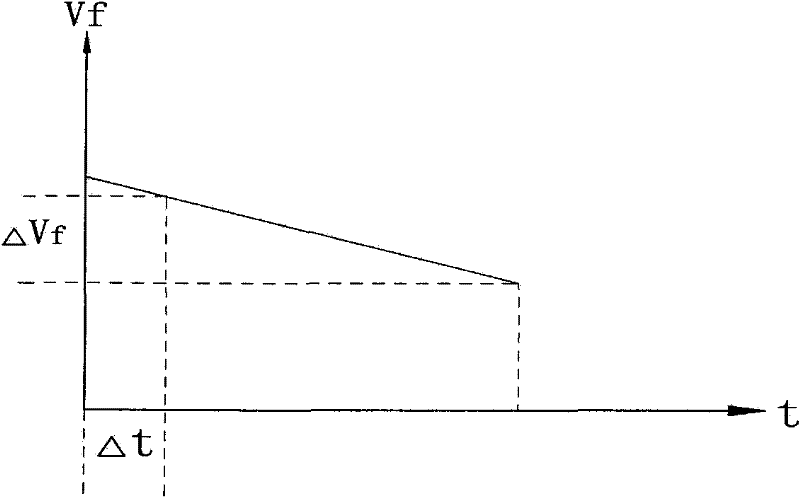

Method for measuring relation curve of forward voltage and junction temperature of LED (Light Emitting Diode) in lamp

ActiveCN102193053AEliminates cases where the junction temperature value deviates significantly from the correct valueSolve problems that cannot be measured accuratelyLamps testingIndividual semiconductor device testingWorking temperatureLight fixture

The invention discloses a method for measuring a relation curve of a forward voltage and a junction temperature of an LED (Light Emitting Diode) in a lamp. In the invention, the method comprises the steps of obtaining a dropping amount of the forward voltage under a set measuring current within a unit measuring time; correcting the forward voltage drop of the measured LED by using the dropping amount of the forward voltage drop within the unit measuring time and an actual measuring time so as to improve the measuring accuracies of the forward voltage drop and the corresponding junction temperature of the measured LED; and measuring the forward voltage drop of the measured LED and figuring out the forward voltage drop of the measured LED at the moment of disconnecting the working current when the continuous working temperature of the LED lamp reaches heat balance. By using the method disclosed by the invention, the situation that the junction temperature of the measured LED obviously biases from a correct value due to the disconnection of the working current of the measured LED and fast dropping of the junction temperature of the LED can be effectively eliminated. The method disclosed by the invention has the advantages of convenience in use and high measuring accuracy; and the difficulty that the actual working junction temperature and the heat resistance of the LED in the traditional lamp cannot be accurately measured is solved.

Owner:SHANGHAI ALPHA LIGHTING EQUIP TESTING +3

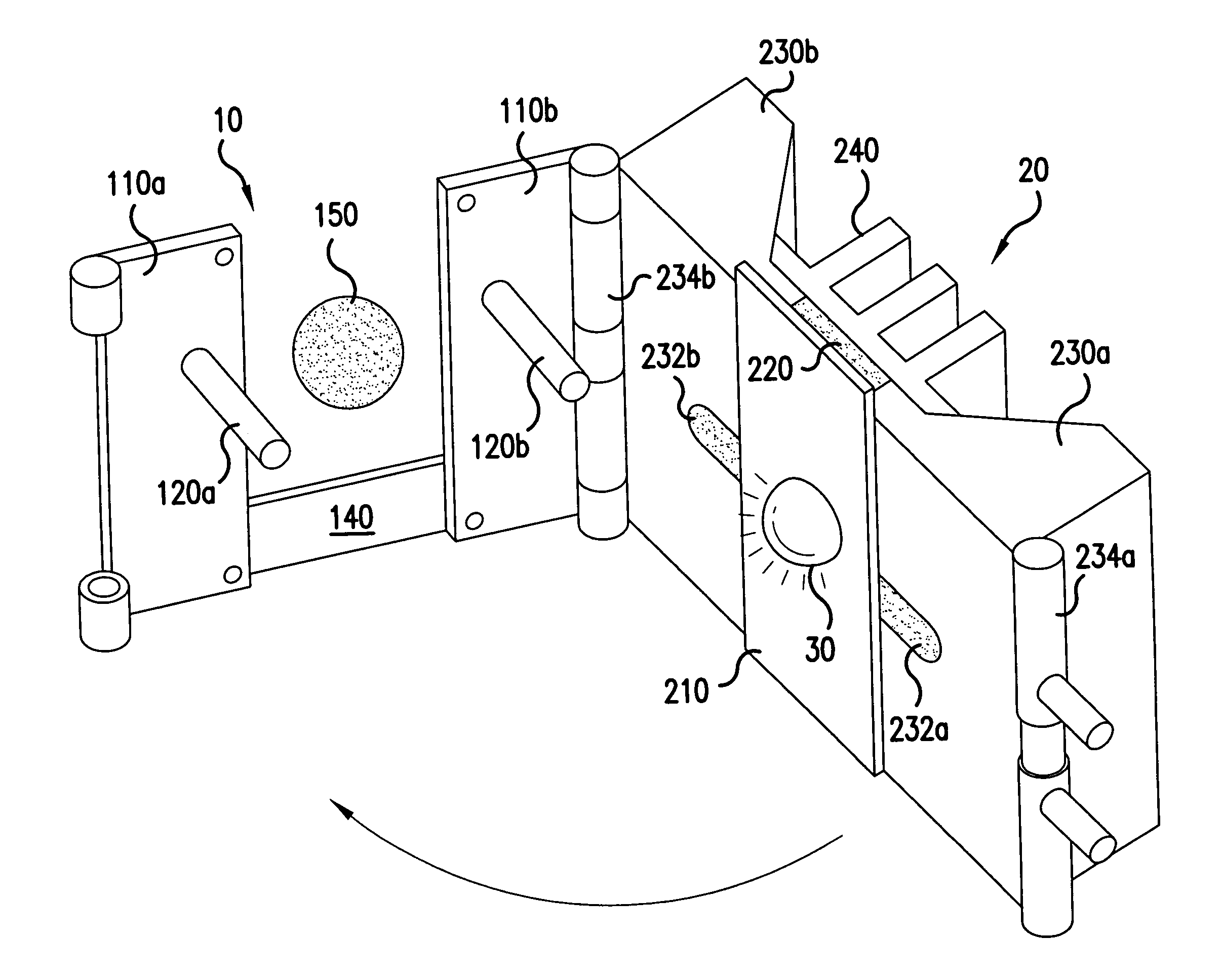

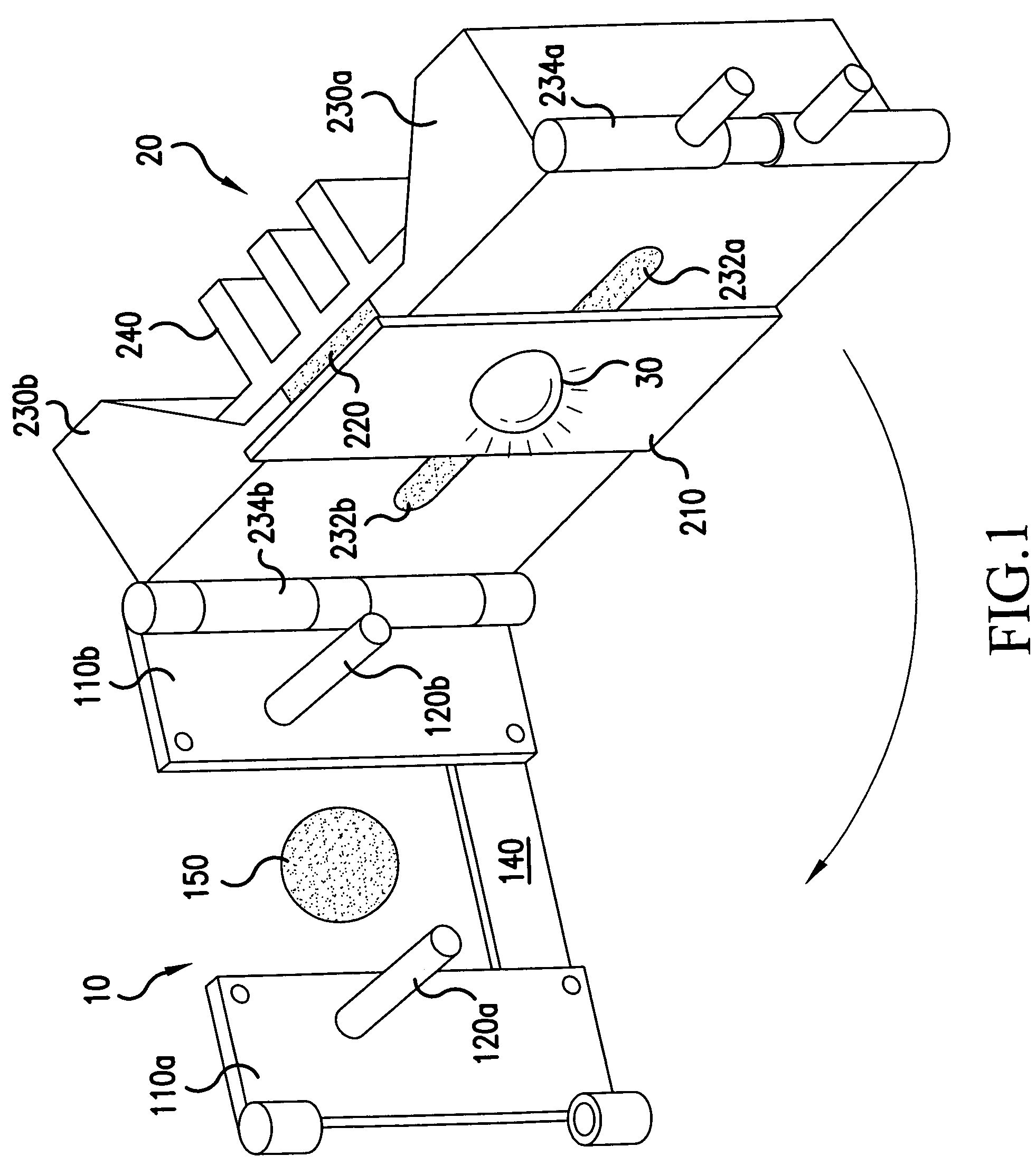

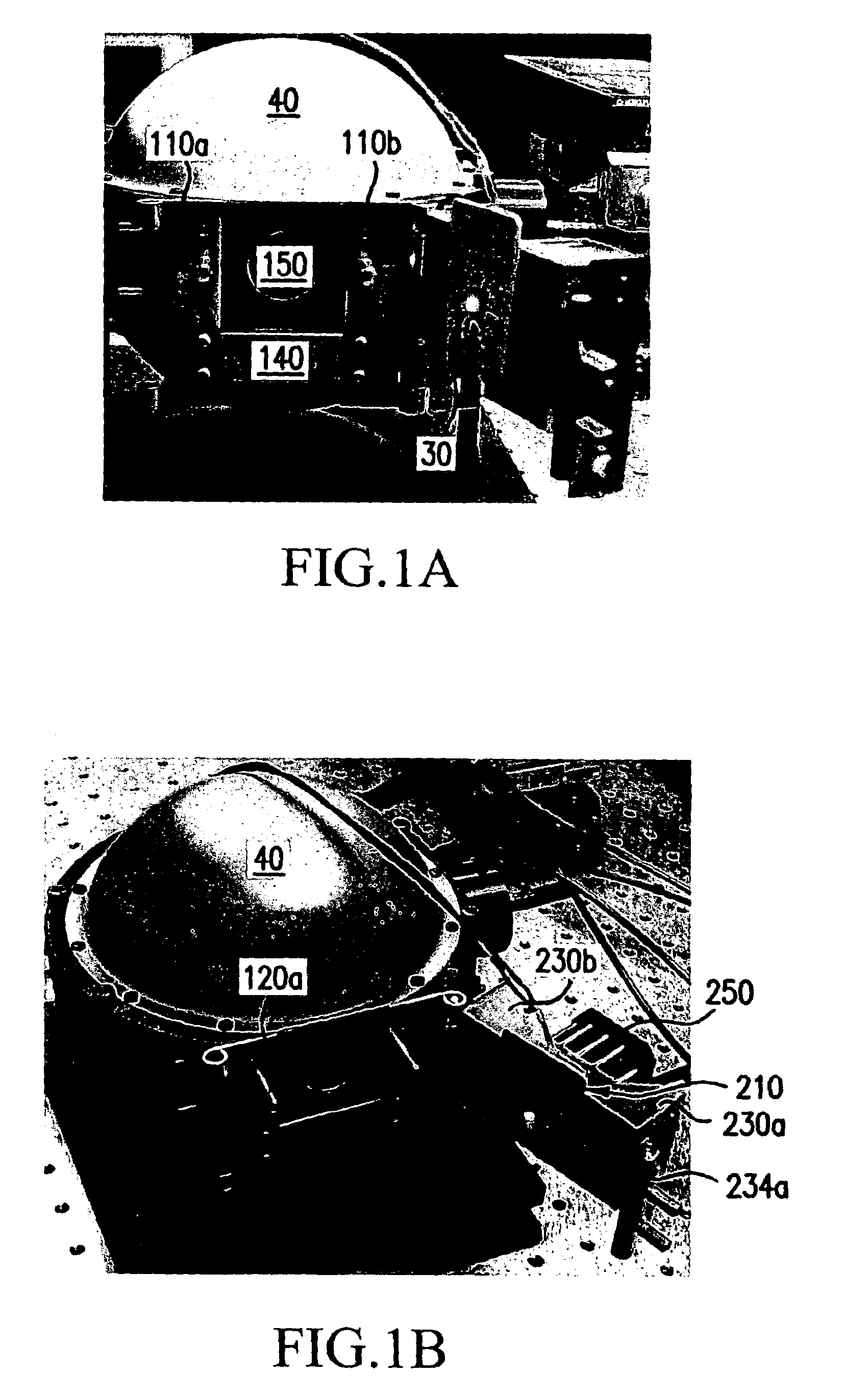

Quick attachment fixture and power card for diode-based light devices

InactiveUS7030642B2Fixed securityLoosening of the LT fit can be eliminatedDiode testingPhotometryRepeat testingFastener

A quick attachment device for use in the repeated testing of diode light sources (30) includes a quick attachment module (10) having a fixed location with respect to a testing position (150) for the diodes (30), and a mounting assembly (20) on which each diode (30) is mounted during testing. The quick attachment module (10) includes a quick disconnect fastener and two locating pins (120a and 120b) for securing the mounting assembly (20) for testing, where the two locating pins (120a and 120b) have a locational transition fit connection with the mounting assembly (20). The mounting assembly (20) may further include a thermal-electric cooling device (260) for cooling the diode light sources (30) during testing.

Owner:HONEYWELL INT INC

System and method for streetlight monitoring diagnostics

ActiveUS20090222241A1Discharge tube incandescent screensElectric devicesNetwork serviceRadio frequency

One or more example diagnostics may be performed by a network server for a network of intelligent luminaire managers or other radio frequency (RF) devices. The network server may receive messages or information from one or more of the plurality of networked intelligent luminaire managers or RF devices. The network server may perform diagnostics based upon the received messages or information from one or more of the plurality of networked intelligent luminaire managers or RF devices. The network server may also leverage knowledge of respective statuses of at least a portion of the plurality of the networked intelligent luminaire managers or RF devices to determine a system-level status.

Owner:ABL IP HLDG

Detection bench, detection method and detection system

InactiveCN102486536AReduce volumeShorten the lengthLamps testingTesting optical propertiesEngineeringImage sensing

The invention discloses a detection bench, a detection method and a detection system. The detection bench can be used for the optical and electrical detection of the light-emitting component. The detection bench comprises a substrate platform, a probe mechanism, a heating device, a cooling device, an image sensing device, a temperature sensing device, and a movable platform. The probe mechanism is suitable for the contact with the light-emitting component, and is close to the substrate platform. The heating device is suitable for heating the light-emitting component to make the temperature of the light-emitting component to remain in the first temperature range. The cooling device can be used to cool the light-emitting component to make the temperature of the light-emitting component to remain in the second temperature range. The image sensing device can be used to sense the light-emitting image generated by the light-emitting component. The temperature sensing device can be used to sense the current temperature of the light-emitting component. The image sensing device is disposed on the movable platform, which is suitable for moving the image sensing device. The invention also provides a detection method and a detection system, which are suitable for the above mentioned detection bench.

Owner:LEXTAR ELECTRONICS CORP

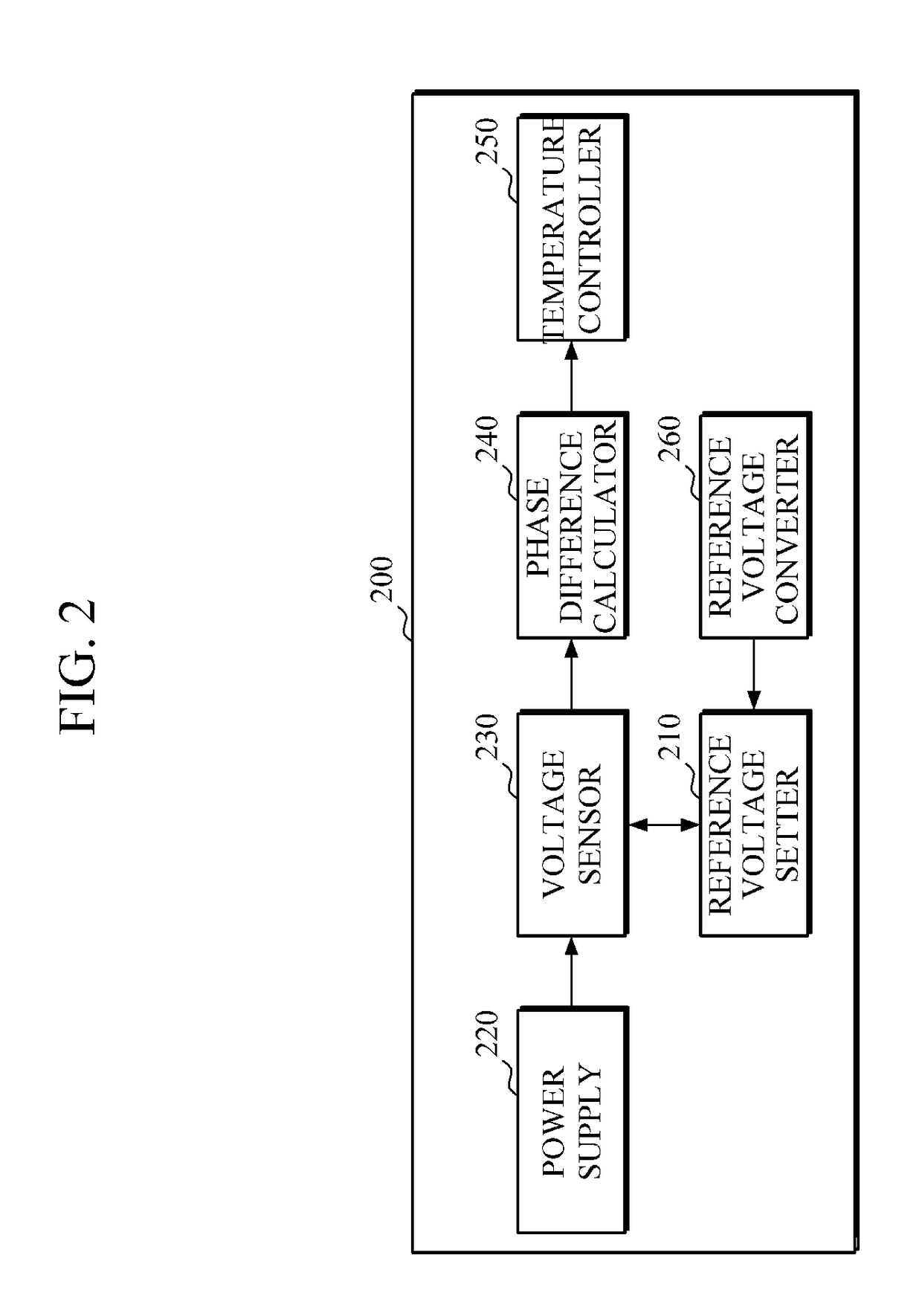

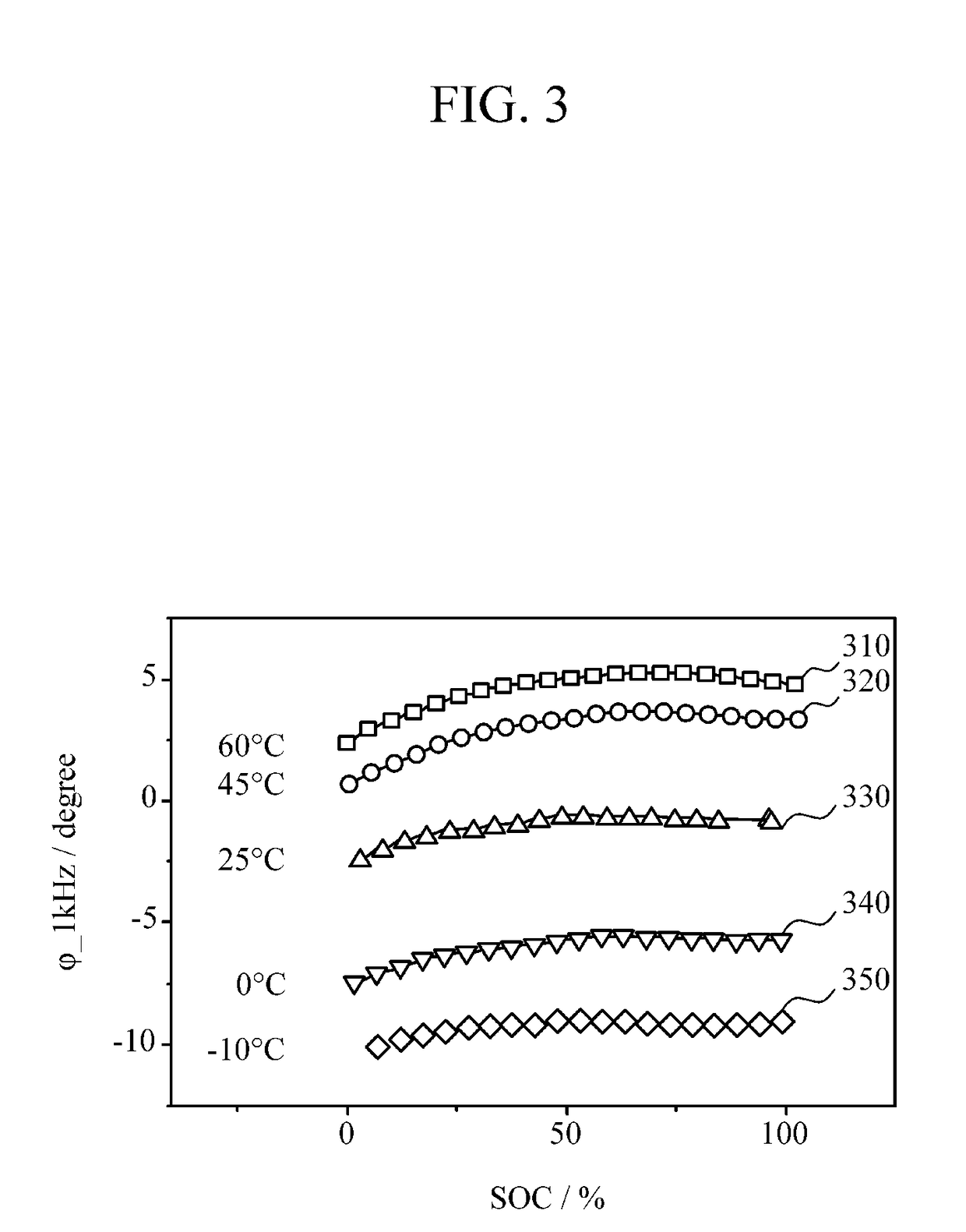

Battery management apparatus and battery management method

ActiveUS20170200994A1Well formedCharge equalisation circuitCircuit monitoring/indicationPhase differenceElectrical battery

A battery management apparatus for a battery including battery units, the apparatus including a voltage sensor configured to sense a voltage of each of the battery units; a phase difference calculator configured to calculate a phase difference between the voltage of each of the battery units and a reference voltage; and a temperature controller configured to control a temperature of each of the battery units based on the calculated phase difference.

Owner:SAMSUNG ELECTRONICS CO LTD

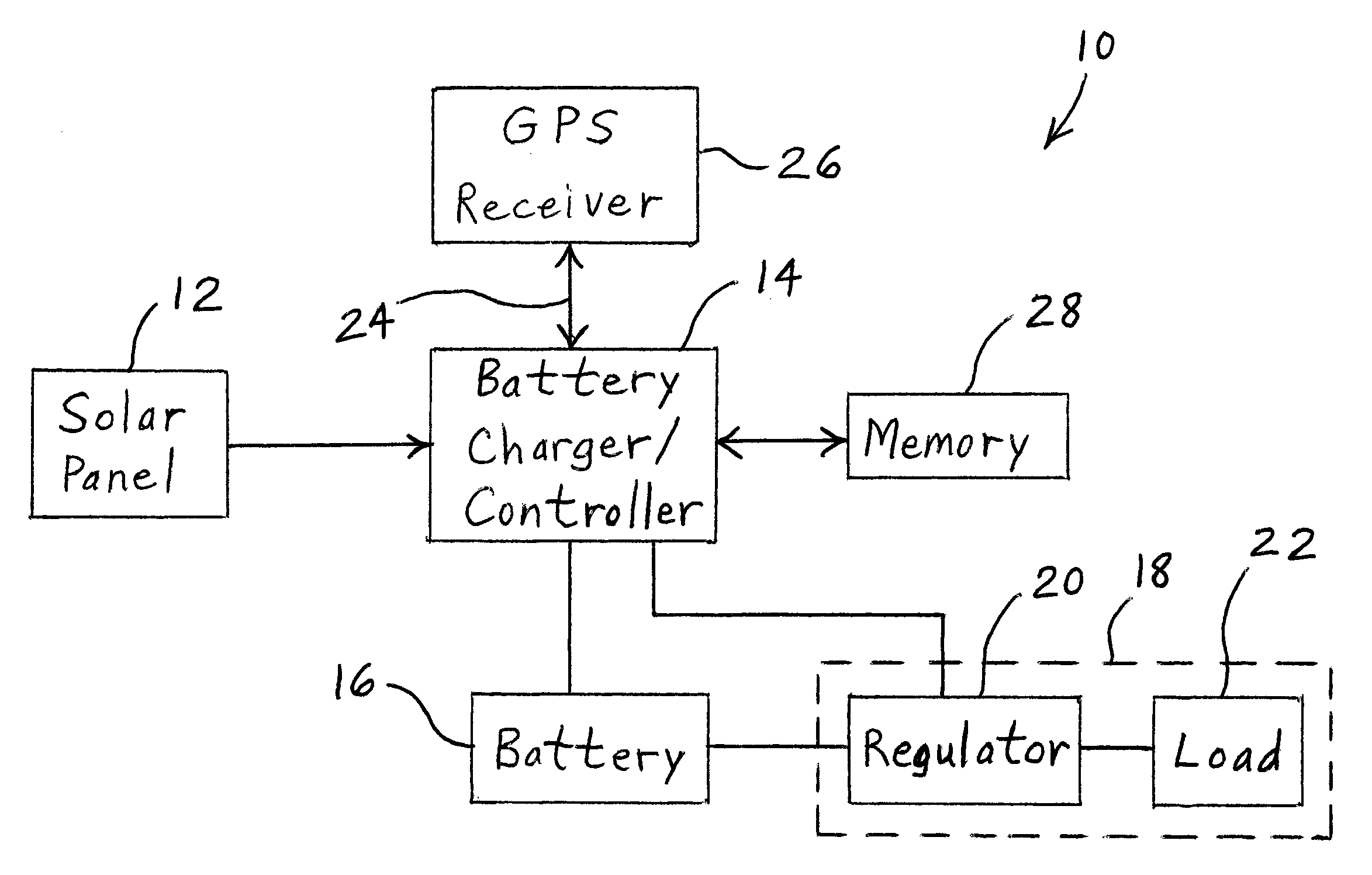

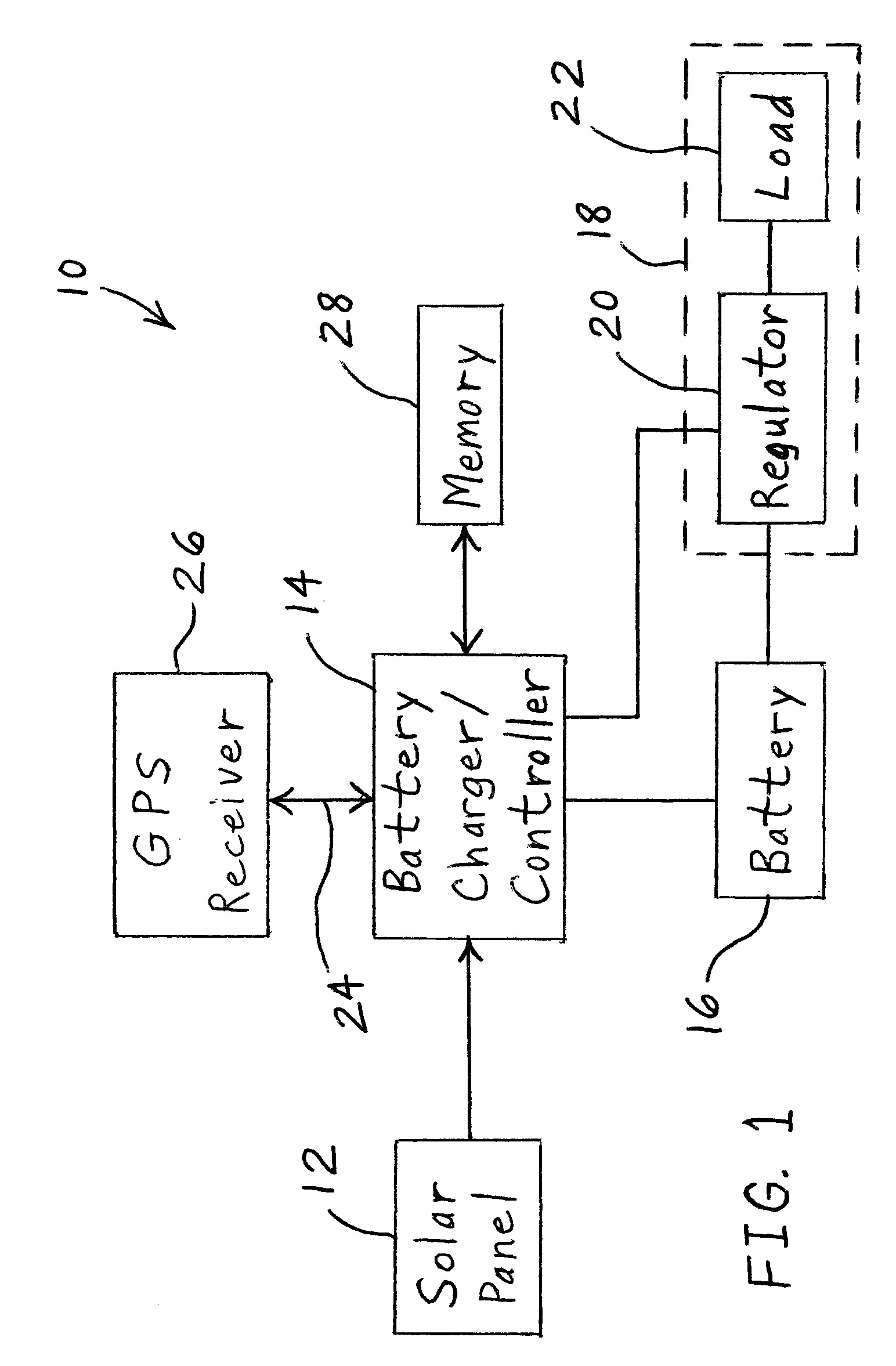

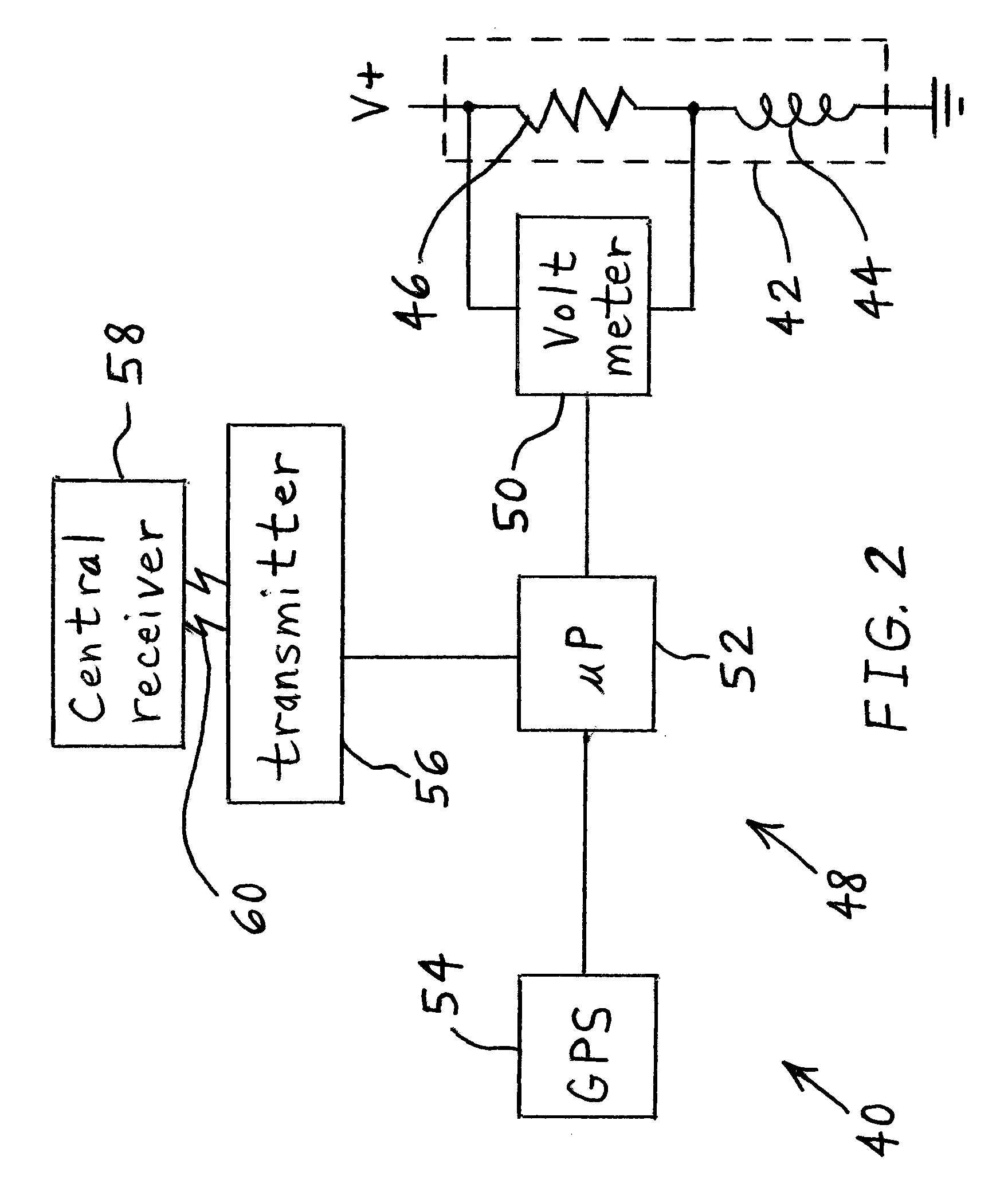

Solar system automatic sizing and failure identification on location using resident GPS receiver

InactiveUS20090164174A1Quick identificationFast repairBatteries circuit arrangementsLevel controlElectrical devicesGps receiver

A method of operating an electrical appliance includes coupling a solar collector to the electrical appliance such that the solar collector may provide electrical power to the appliance. A global positioning system receiver is used to determine a location of the solar collector. A level of power that may be sourced by the solar collector is calculated wherein the calculation is dependent upon the location of the solar collector as determined by the global positioning system receiver. The appliance is configured to draw a level of power corresponding to the calculated level of power that may be sourced by the solar collector.

Owner:BEARS JAMES +1

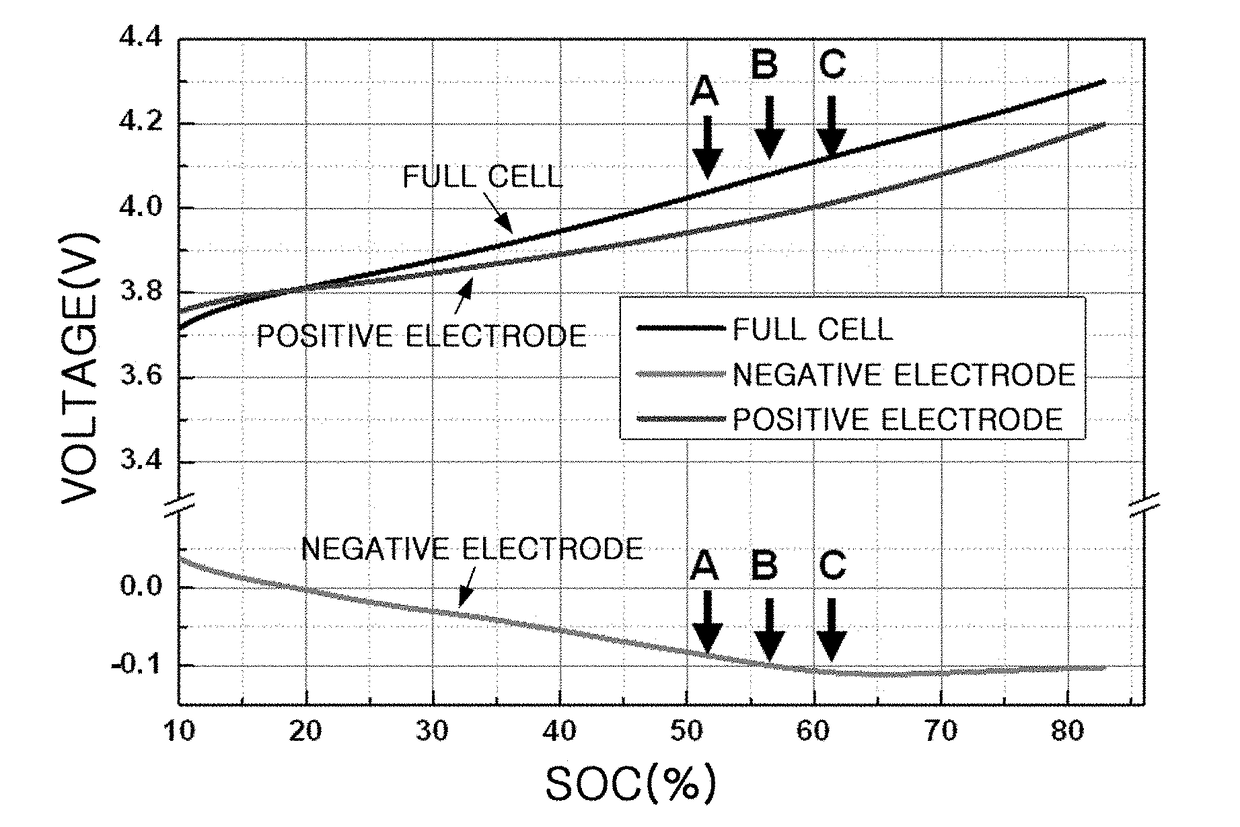

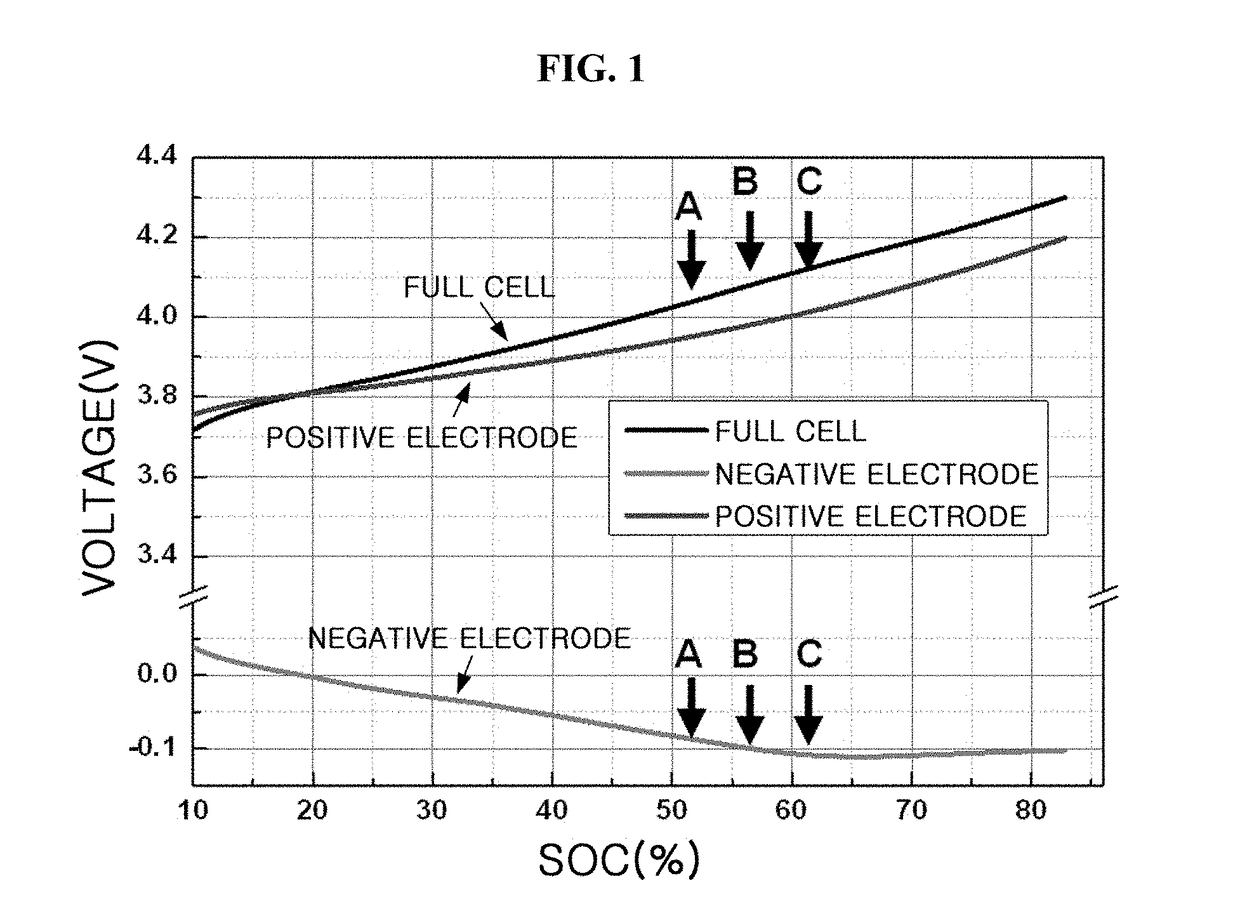

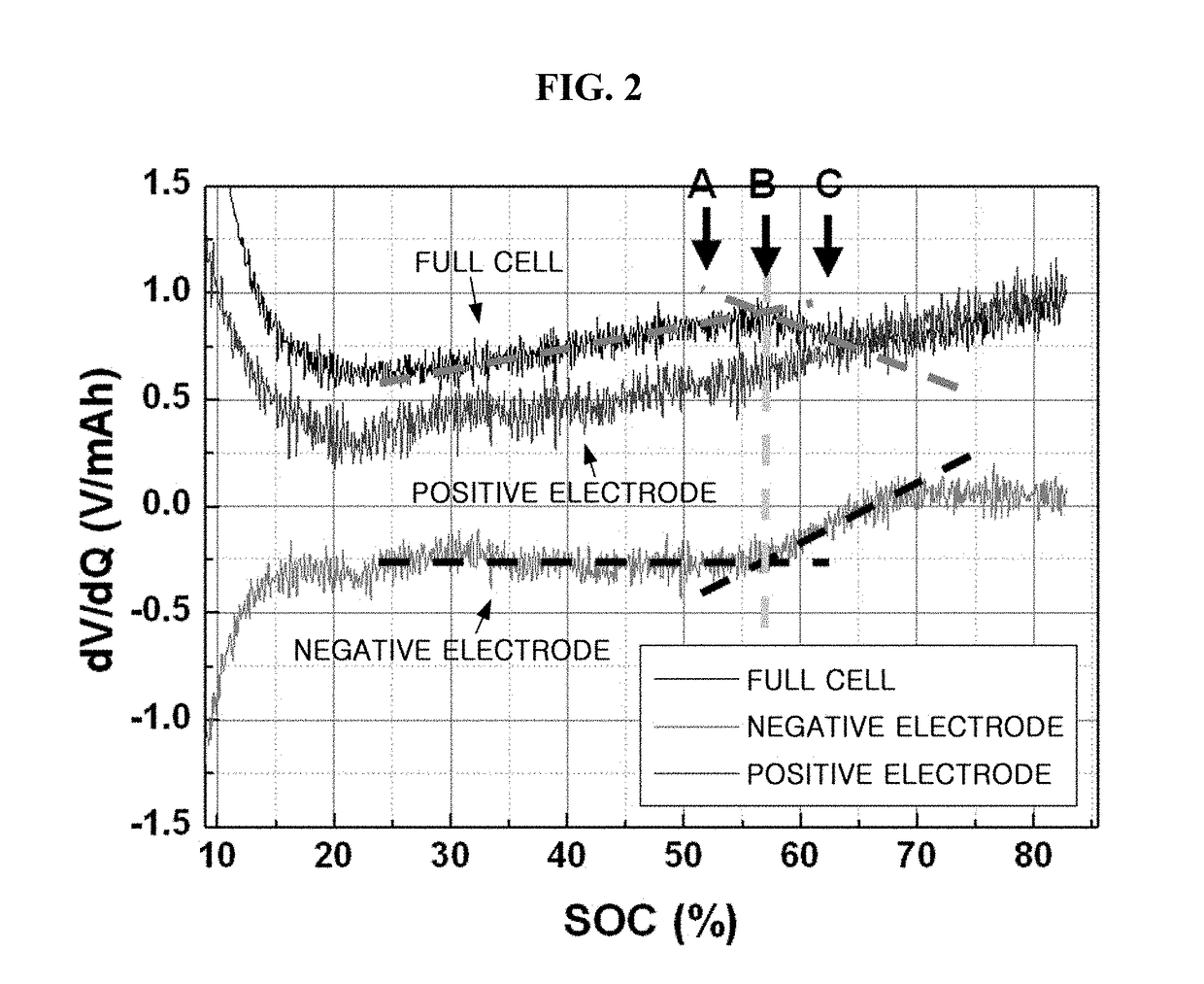

Detection method of li plating, method and apparatus for charging secondary battery and secondary battery system using the same

ActiveUS20170234930A1Accurate measurementPrevent degradationSecondary cells charging/dischargingElectric powerNon destructiveElectrical battery

Provided is a non-destructive method for detecting lithium plating by which lithium plating can be detected in real time in an actual use environment of a secondary battery, a secondary battery charging method and apparatus for charging a secondary battery under the condition in which lithium plating does not occur by using this method, and a secondary battery system for detecting the state of a secondary battery by using this method. The method for detecting lithium plating according to the present disclosure is a method which detects lithium plating in a negative electrode in real time by observing a change in battery voltage as a function of SOC during charging a secondary battery, and determines a point at which a rise speed of the battery voltage slows down as a lithium plating occurrence point.

Owner:LG ENERGY SOLUTION LTD

LED (light emitting diode) service life test system and test method thereof

InactiveCN102590763AImprove securityNot easy to damageThermometers using electric/magnetic elementsUsing electrical meansElectricityEngineering

The invention discloses an LED (light emitting diode) service life test system, which comprises refrigerators, aluminum printed circuit boards (PCBs), a cold and hot two-region temperature box and an integrating sphere. An electric refrigerating plate and a subpanel of the refrigerator are fixedly installed on a radiator and the electric refrigerating plate is embedded into an opening of the subpanel. The aluminum PCB is fixed on the surface of the electric refrigerating plate. The cold and hot two-region temperature box comprises cold and hot boxes isolated by an insulation board. The insulation board and the integrating sphere are provided with installation holes for installing the refrigerators. When the refrigerators are respectively installed on the installation holes of the temperature box and the integrating sphere, the radiators are respectively placed outside the cold box and the integrating sphere while the aluminum PCBs are respectively placed inside the hot box and the integrating sphere. The refrigerators provided by the invention can move integrally without disassembling the LED, which facilitates the LED service life test greatly. In addition, each LED can be independently lighted by connecting a lead wire at the connection solder joint of the aluminum PCB to a switching circuit, thereby achieving the aim of testing the parameters of light, color and electricity of each LED independently.

Owner:常州市产品质量监督检验所 +1

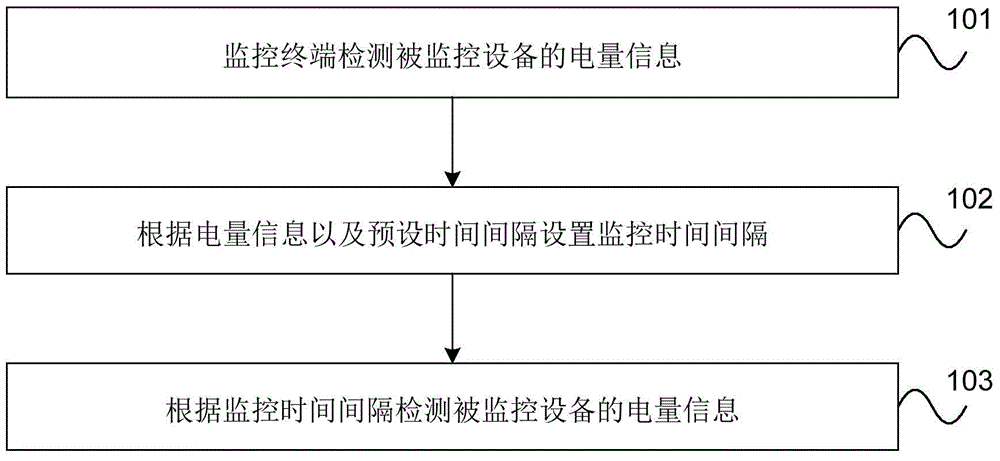

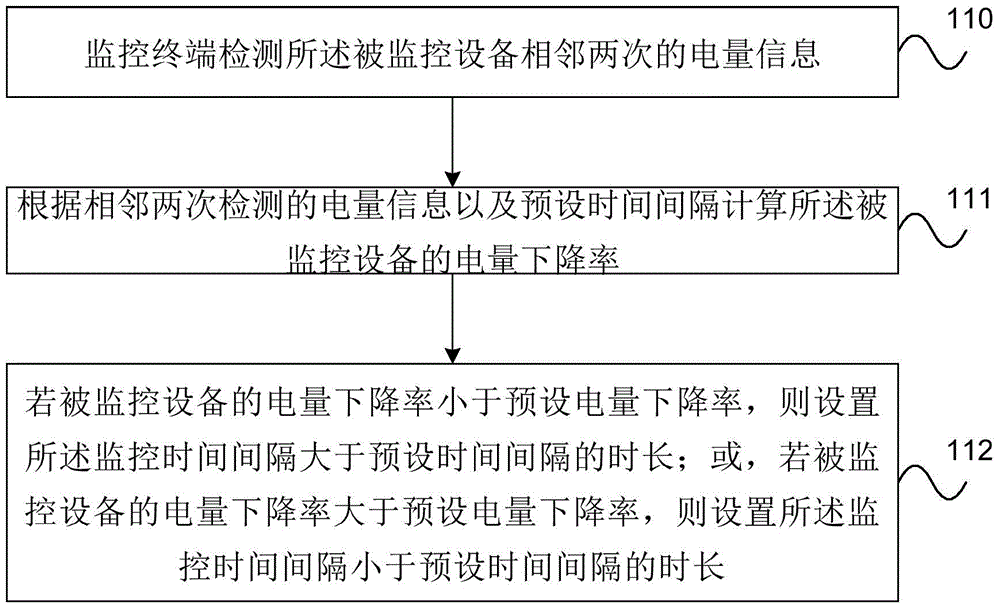

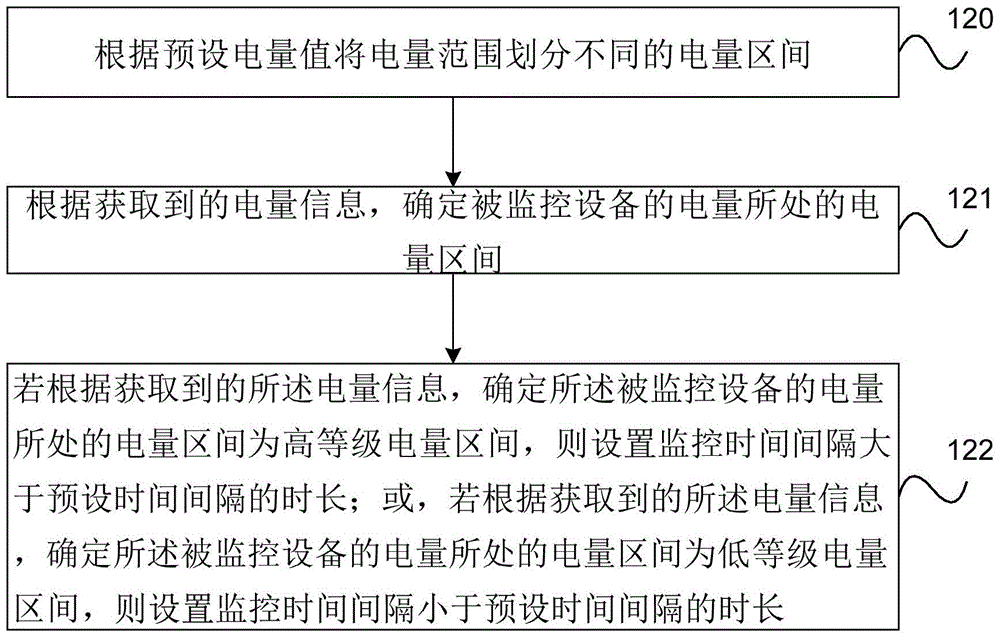

Method for detecting electric quantity of equipment, equipment, and system

ActiveCN104641245ASolve the waste of resourcesSave energyPower managementNear-field transmissionComputer terminalEngineering

The embodiment of the invention provides a method for detecting the electric quantity of equipment, the equipment, and a system. The method comprises the steps that a monitoring terminal detects the electric information of monitored equipment; the monitoring time interval is set according to the electric information and a preset time interval; and the electric information of the monitored equipment is detected according to the monitoring time interval. The method achieves the determination of the time interval between two times of detection according to the detected electric information, and fully saves the resources under the condition of not affecting a user.

Owner:HUAWEI TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com