Patents

Literature

1743 results about "Heat balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

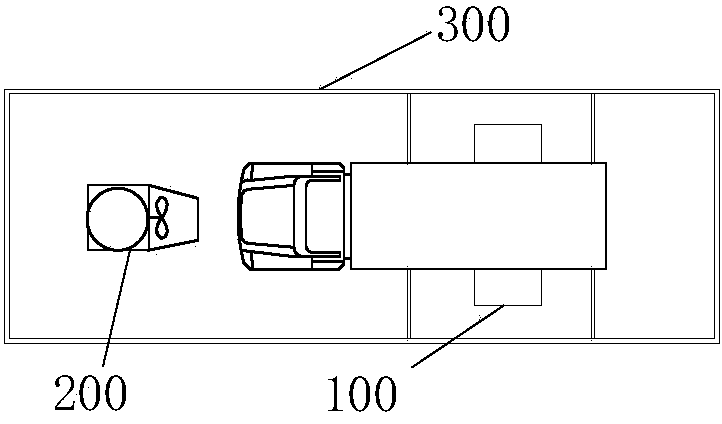

Conducting structure and electronic clinical thermometer embodying the structure

InactiveUS7320544B2Fully contactedHeld easily and comfortablyThermometer detailsThermometers using electric/magnetic elementsHeat balanceEngineering

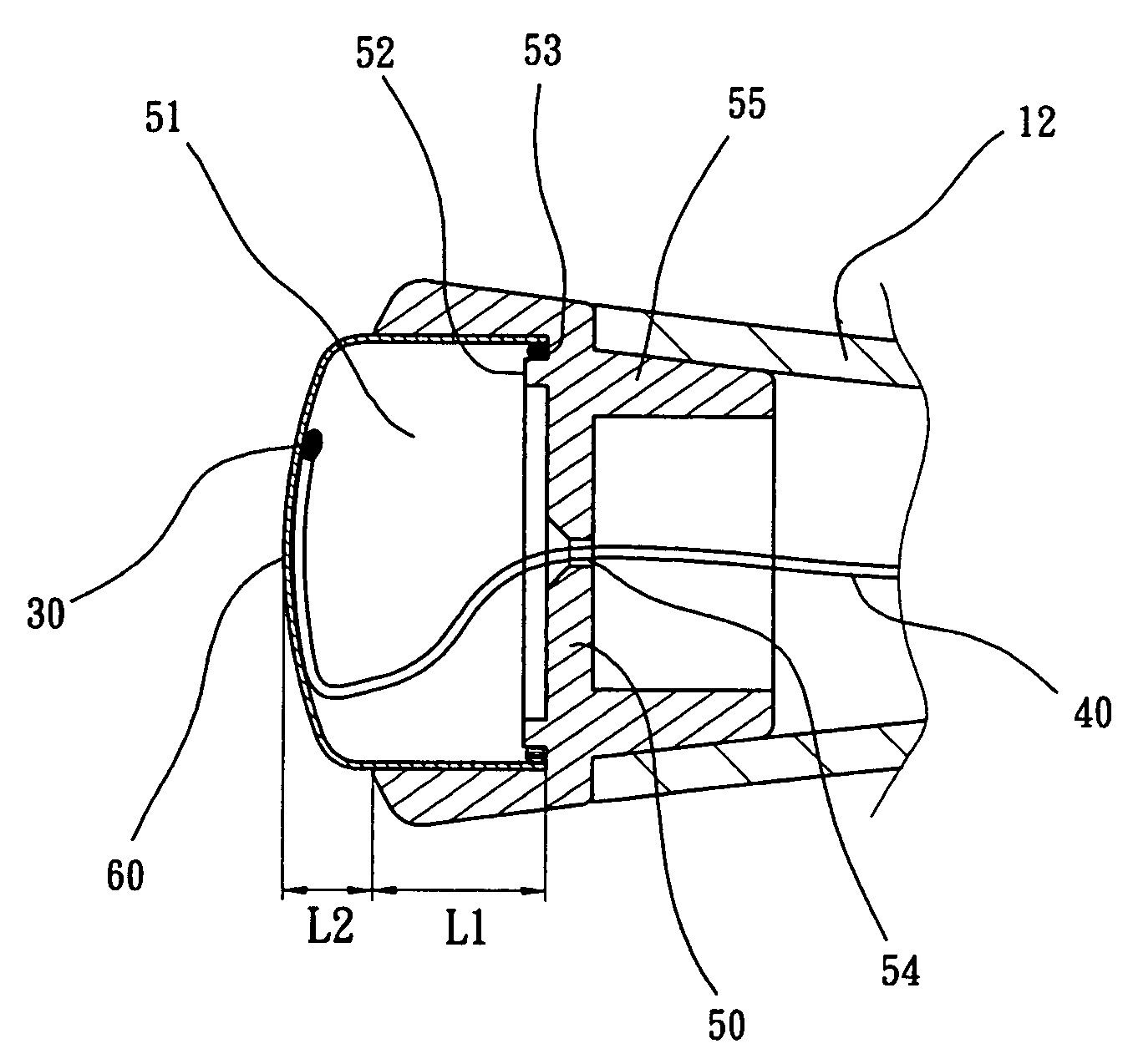

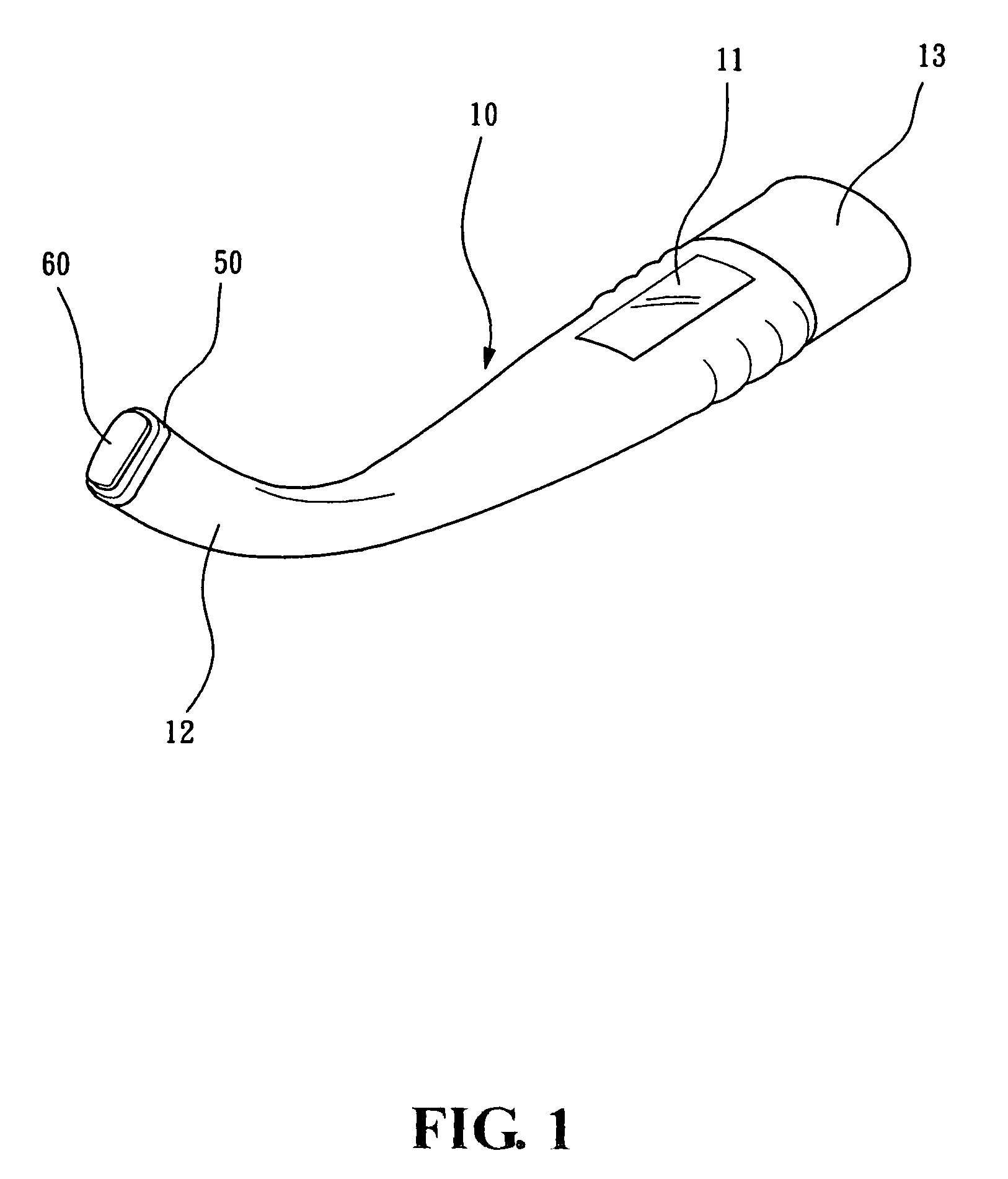

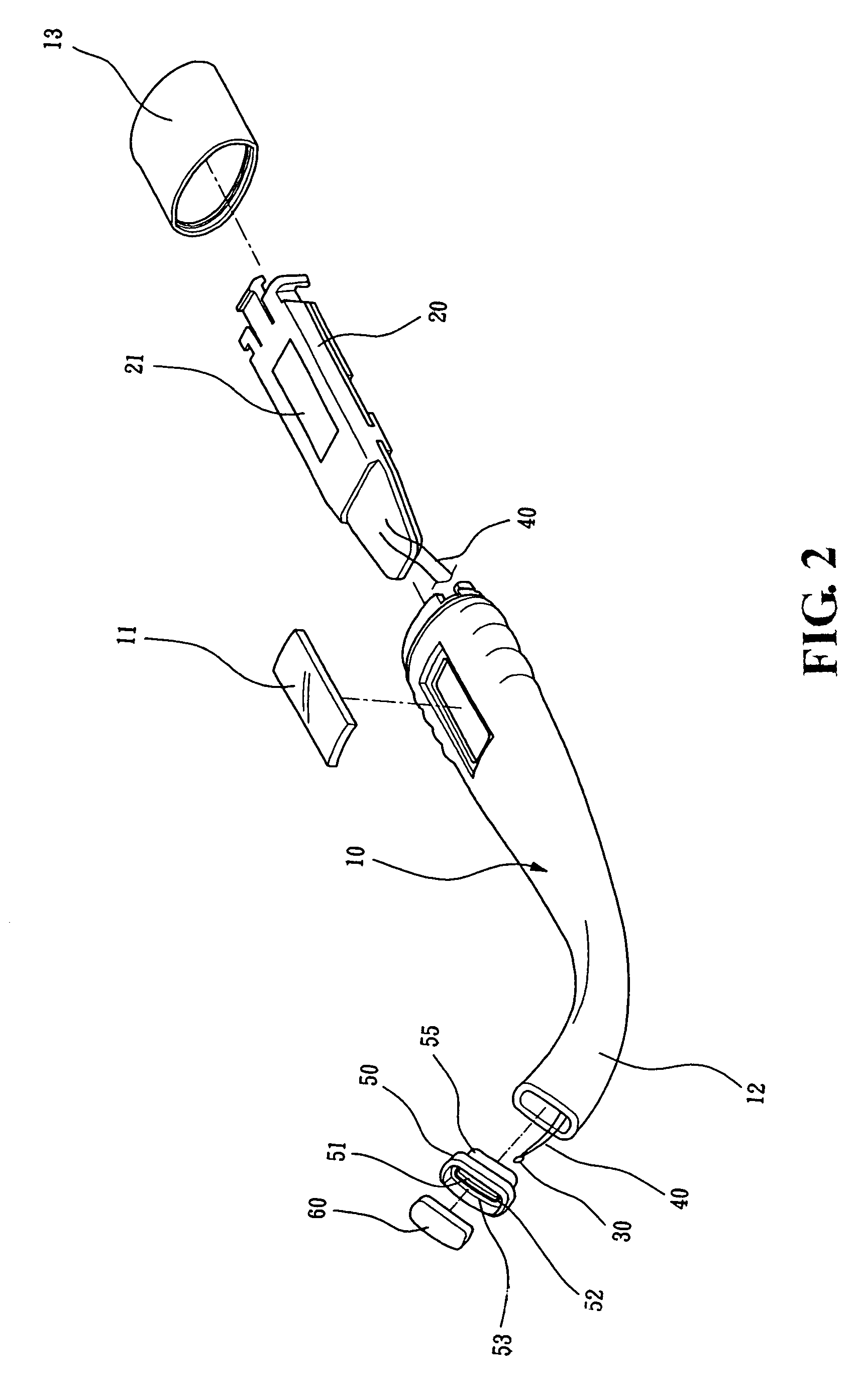

A conducting structure and an electronic clinical thermometer, wherein the conducting structure is provided on the measuring end of the clinical thermometer, and the measuring end has a recess, a temperature sensor and conducting wires fitted in the recess, and a contact member having a curved top and made of metallic conductive material and having a predetermined length embedded in the recess thereby providing the contact member with a large temperature sensing contact area but only with a small portion protruded out of the measuring end, and therefore enabling the thermometer to be fully in contact with a certain portion of the human body such as the armpit, preventing the thermometer from being broken, and achieving heat balance rapidly. The measuring end of the thermometer may be bent at a predetermined angle or the contact member may be arranged at either side of the measuring end as required.

Owner:ACTHERM INC

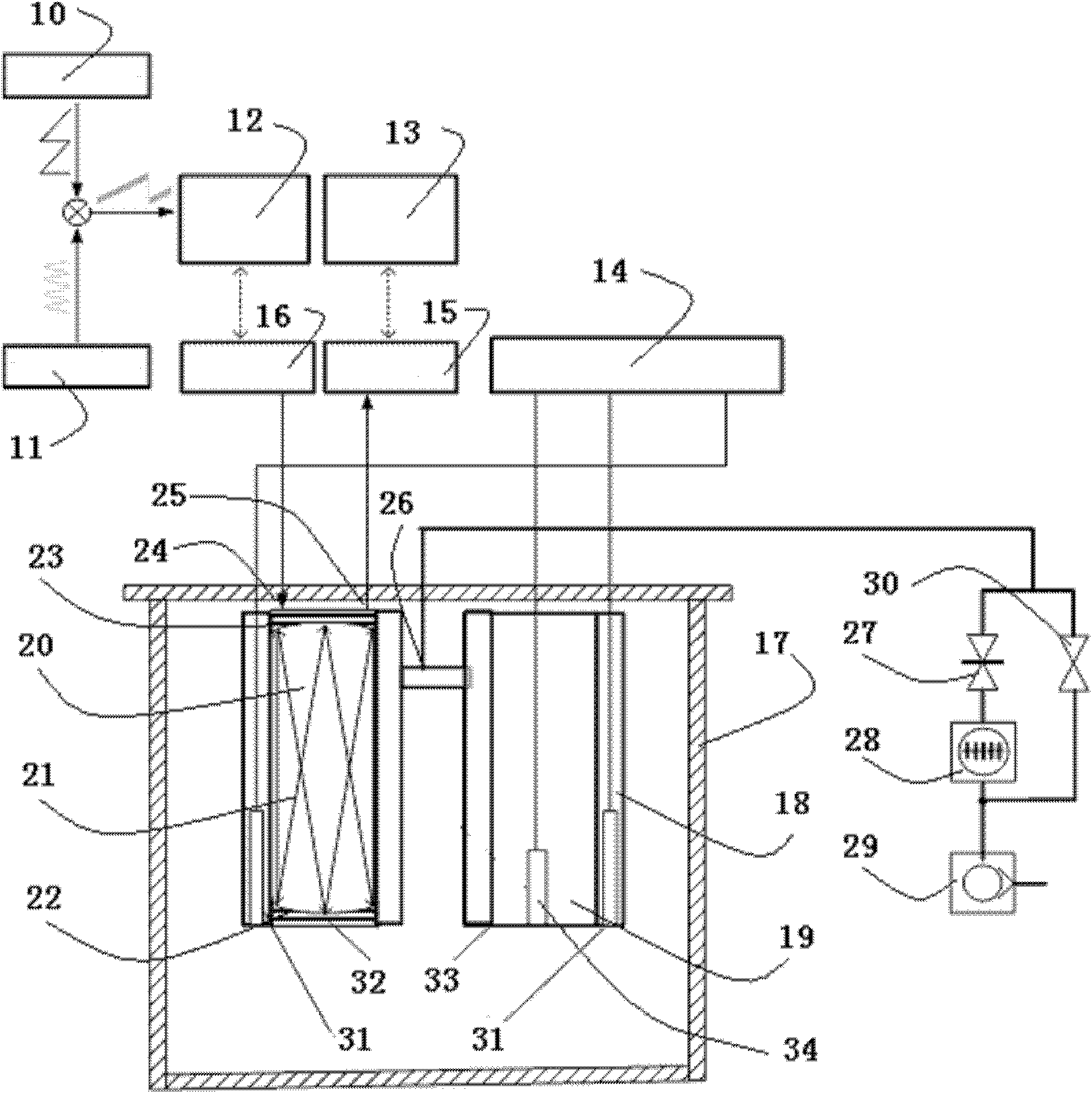

Temperature measurement and calibration platform in space vacuum environment

ActiveCN102539019ASolve the problem of large differences in measurement resultsSolve the traceability problemThermometer testing/calibrationVacuum pumpingSpace environment

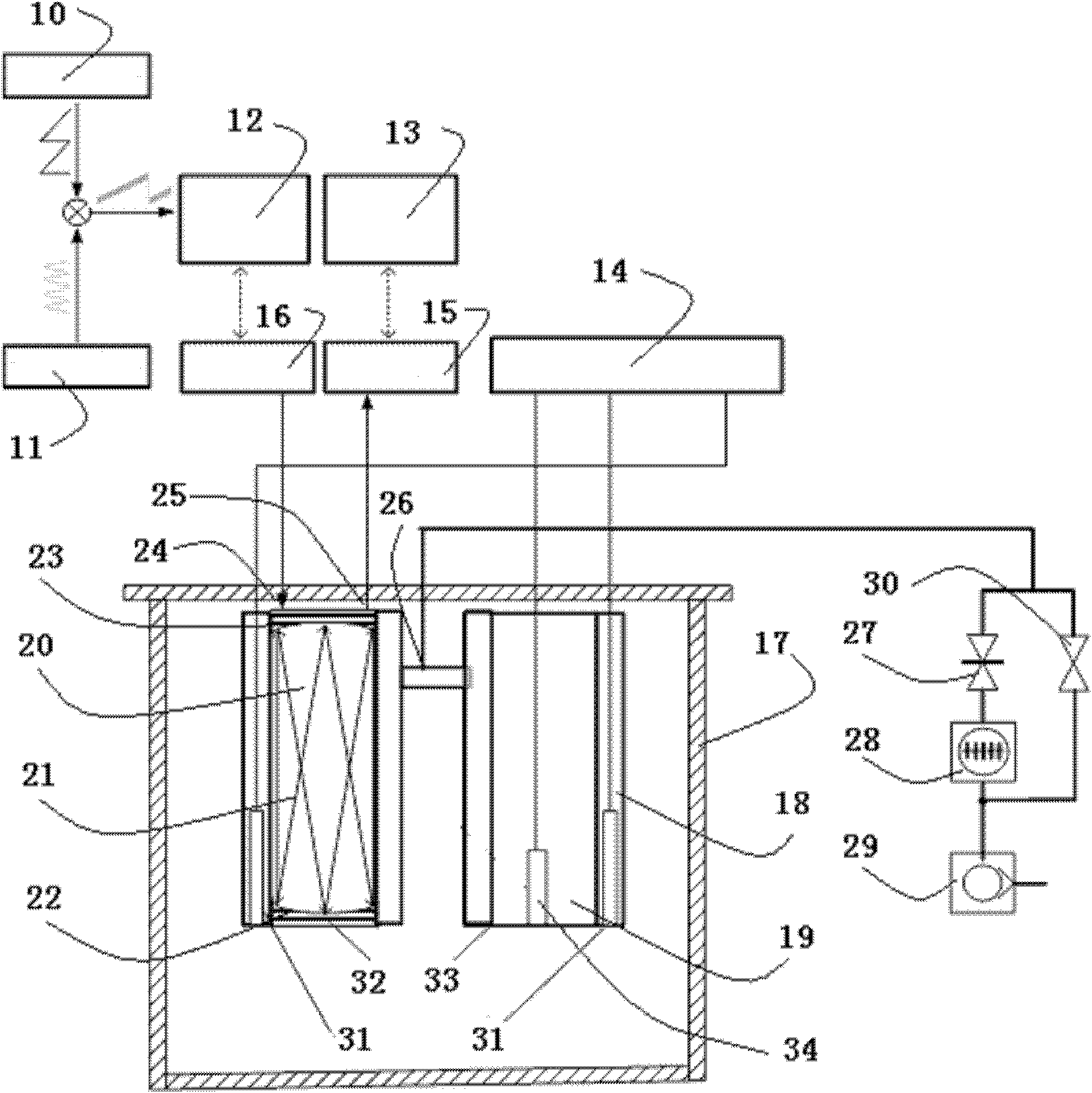

The invention relates to a temperature measurement and calibration platform in space vacuum environment. The temperature measurement and calibration platform is favorable for realizing the simultaneous calibration of contact type temperature measurement and non-contact type temperature measurement, so the temperature measurement and calibration platform is served for heat vacuum and heat balance experiments of spacecrafts such as satellites, spaceship and the like. The temperature measurement and calibration platform comprises a constant temperature bath, wherein a double-sub-cavity vacuum cavity, the double-sub-cavity vacuum cavity comprises a first vacuum cavity body and a second vacuum cavity body, the first vacuum cavity body and the second vacuum cavity body are connected with a vacuum pumping device through a three-way valve, standard temperature indicator sensors are respectively arranged on the outer wall of the first vacuum cavity body and on the outer wall of the second vacuum cavity body, the standard temperature indicator sensors are connected with a temperature secondary meter, a laser light path reflecting device is arranged in the vacuum cavity of the first vacuum cavity body for calibrating a non-contact type temperature measuring system based on the tunable diode laser absorption spectrum technology, and the vacuum cavity of the second vacuum cavity body is used for accommodating a temperature sensor for calibrating a contact type temperature measuring system adopting the temperature sensor.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

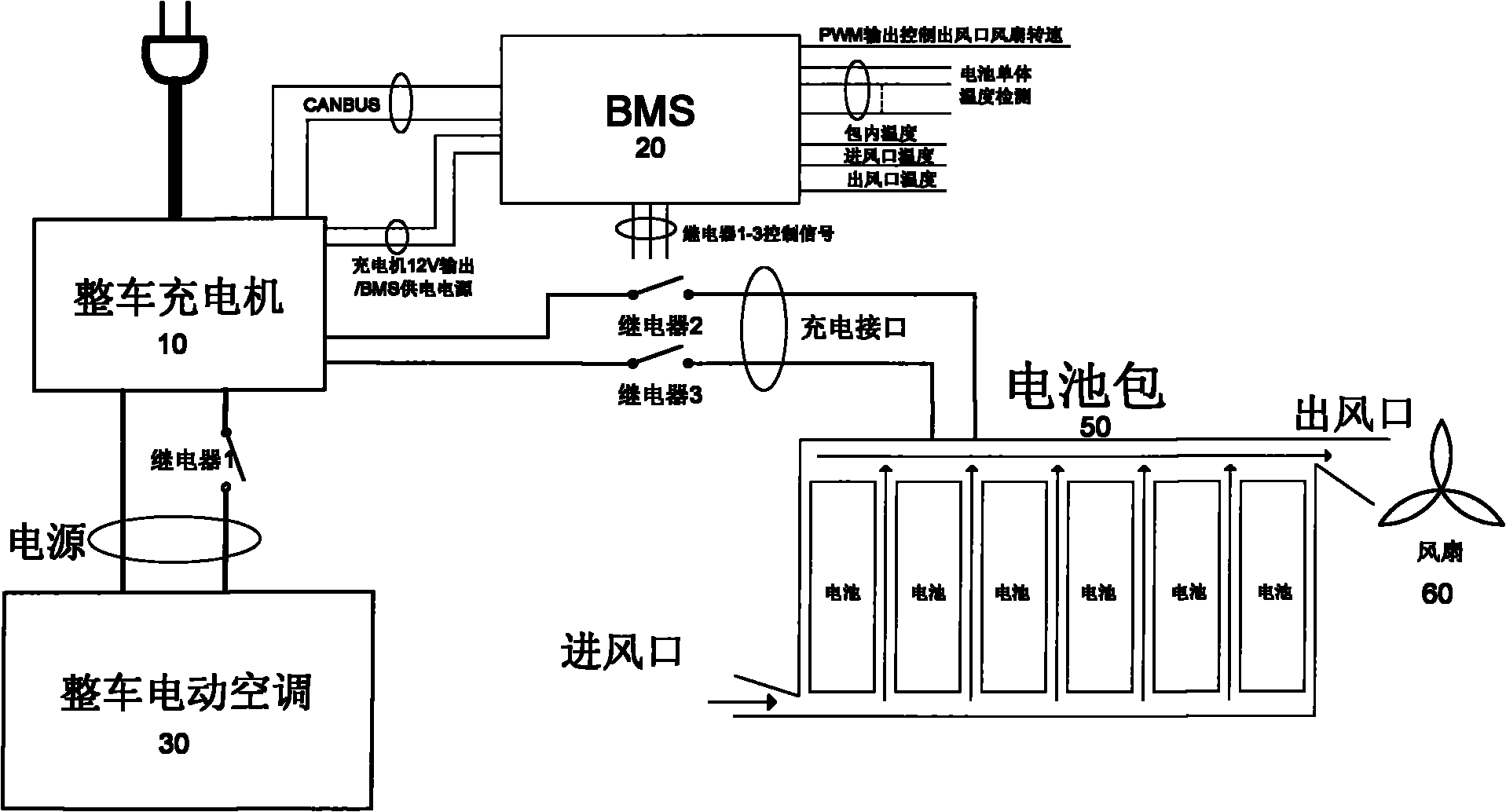

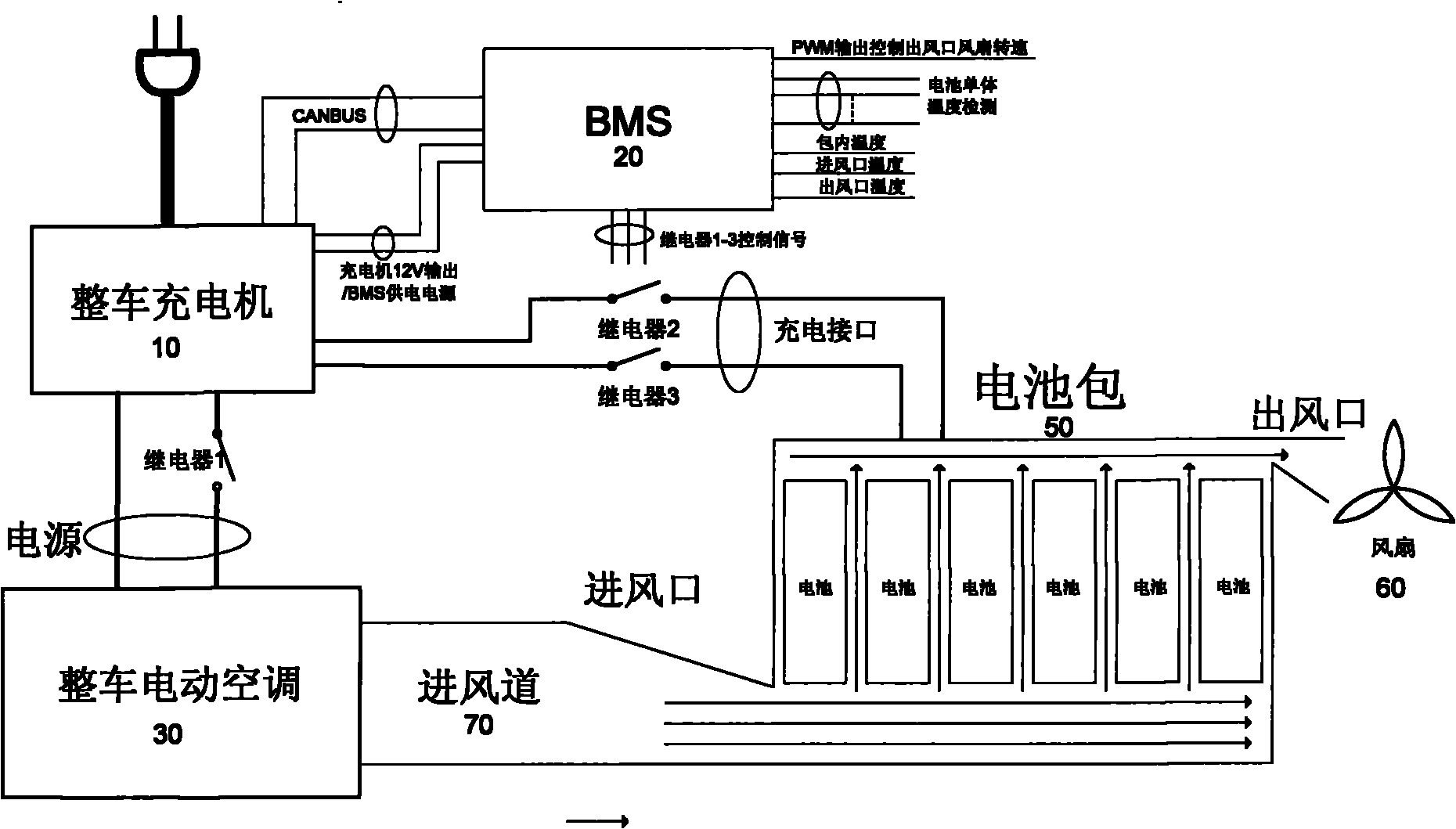

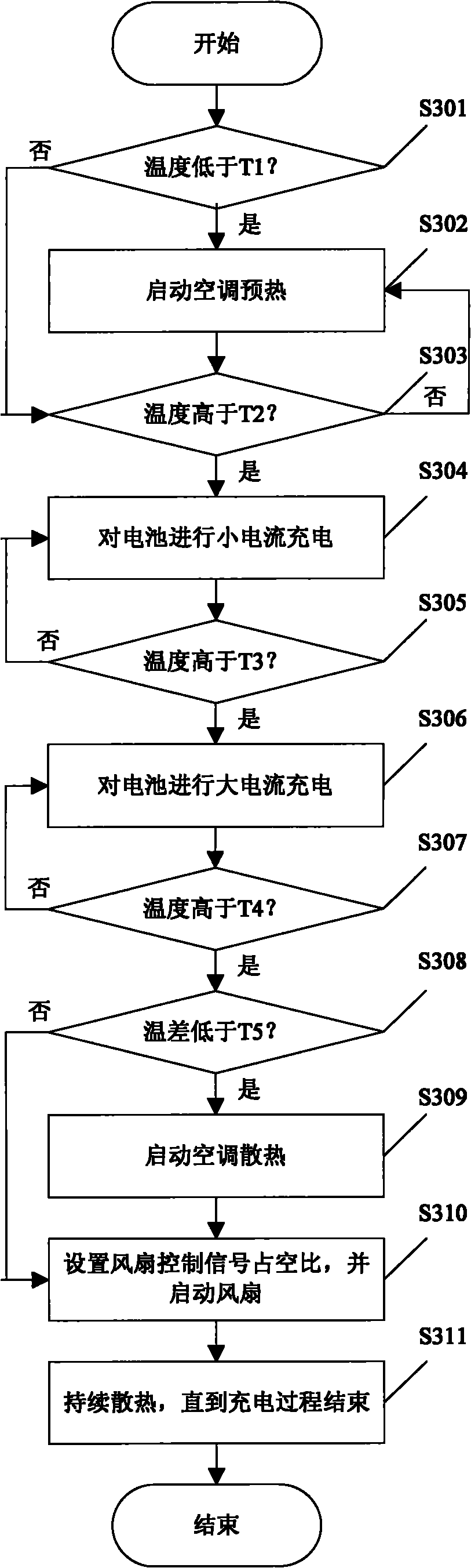

Power battery thermal management system and control method thereof

ActiveCN102139646AGuaranteed thermal balanceCell temperature controlVehicular energy storageCold airPower battery

The invention provides a power battery thermal management system which comprises a complete automobile power-driven air conditioner, a complete automobile charger, an air passage and a battery management system, wherein the air passage is connected with an air outlet of the complete automobile power-driven air conditioner and an air inlet of a battery pack and is used for leading hot air or cold air of the air conditioner into the battery pack; the battery management system is used for controlling the hot air of the air conditioner to be led into the battery pack so as to preheat the battery set in the battery pack when the lowest temperature of a battery module is lower than a first threshold value and controlling the battery set in the battery pack to be charged and discharged after preheating the battery pack; when the highest temperature of the battery module is higher than a second threshold value and the temperature difference between the ambient temperature of the air inlet of the battery pack and the temperature of the battery module is lower than a third threshold, the battery management system controls the cold air of the air conditioner to be led to the battery pack so as to dissipate heat in the battery set in the battery pack. Accordingly, the invention provides a control method of the thermal management system. The invention can lead the battery pack to be charged and discharged in the allowable temperature range and ensure the heat balance among the battery modules and prevent the battery from being overcharged and overdischarged.

Owner:CHERY AUTOMOBILE CO LTD

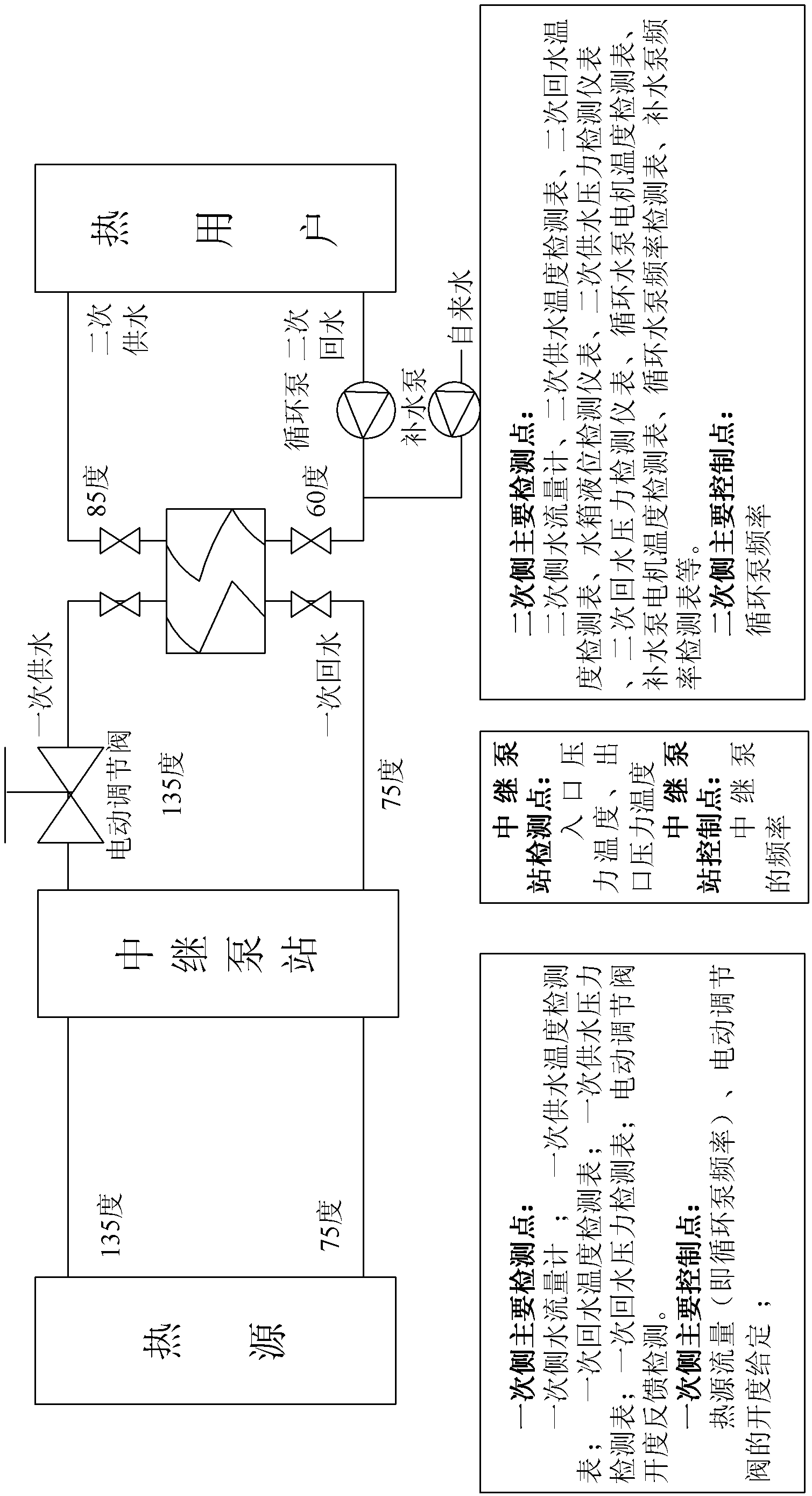

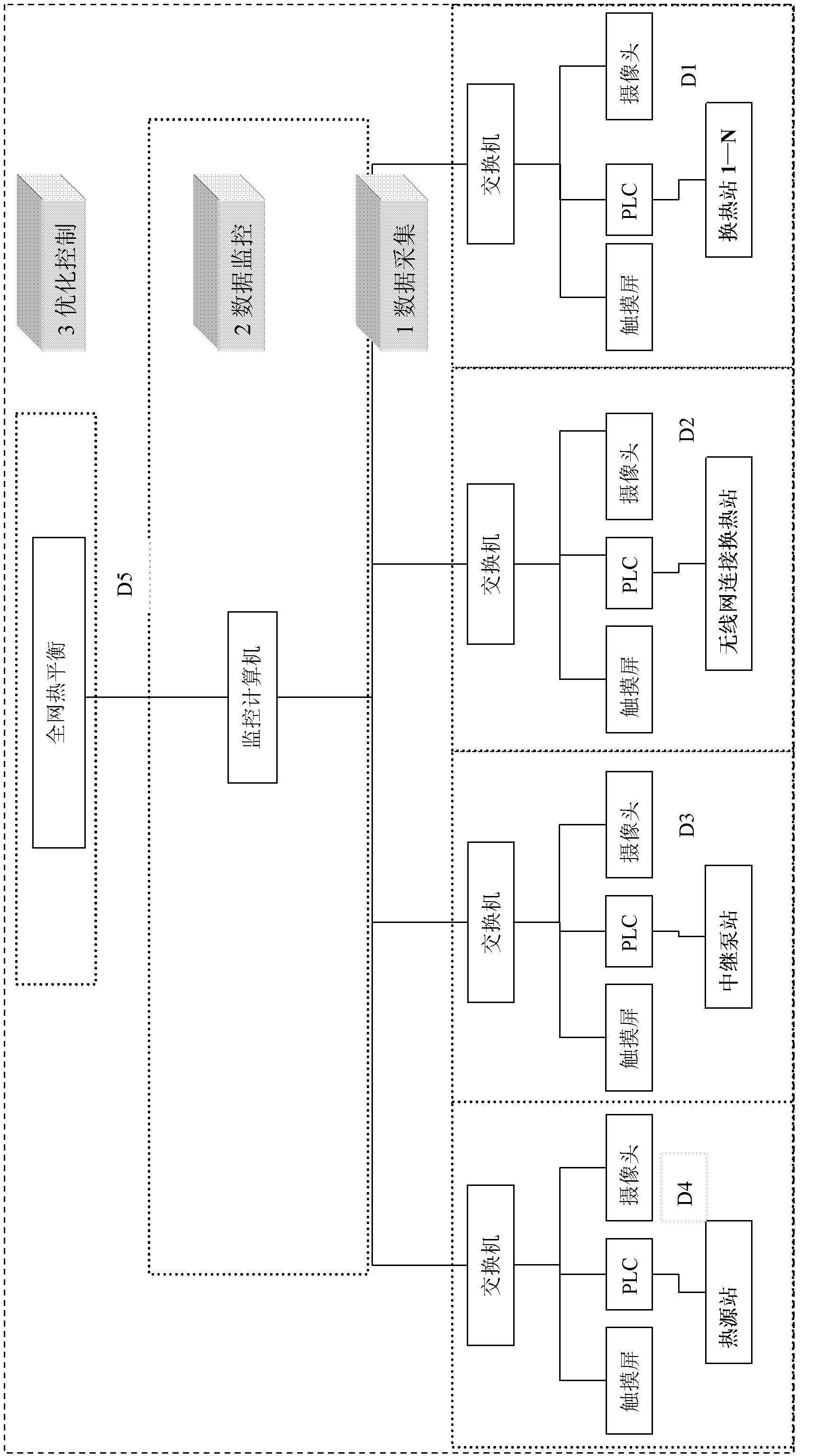

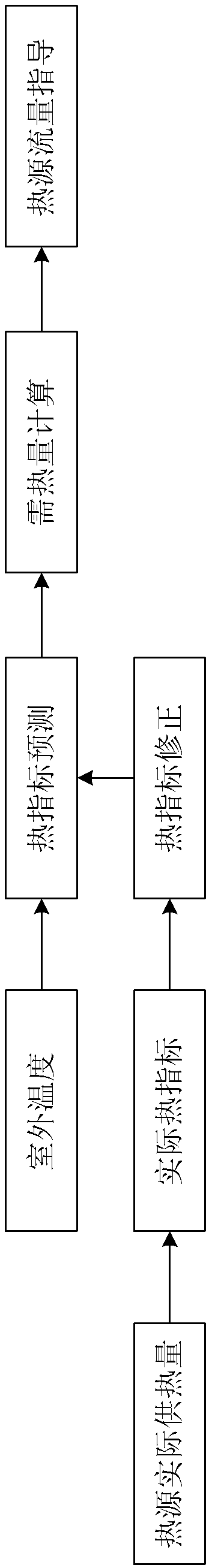

Centralized heating whole-network heat balance control method

InactiveCN103017253ARegulation stabilityImplement operation guidanceLighting and heating apparatusSpace heating and ventilation detailsHeat balanceMaterial resources

The invention relates to a centralized heating whole-network heat balance control method, in particular to a control system which is charged on area, which can eliminate the heat imbalance of the whole network and balance the heating effect. The control method adopts different control strategies for a heat source and two links of a primary side in the heating system so as to meet the requirement of users. For the heat source, the online prediction of the heat load is realized according to external temperature variation, and a running instruction is supplied for the heat source; a uniform control strategy is adopted for a primary network, automatic adjustment of a primary valve of a heat exchanging station of the heat network can be realized, a weighted value can be manually given to a special heat exchanging station, and the heat imbalance degree is used for analyzing and evaluating a whole-network heat balance control effect; and the control method can effectively solve the problems of the heating system such as imbalance heat and energy waste, a great amount of manpower and material resource can be saved in the adjustment process of the heat network, and the balance and consistency of the heat supply effect can be guaranteed.

Owner:ANSHAN HAIHUI AUTOMATION +1

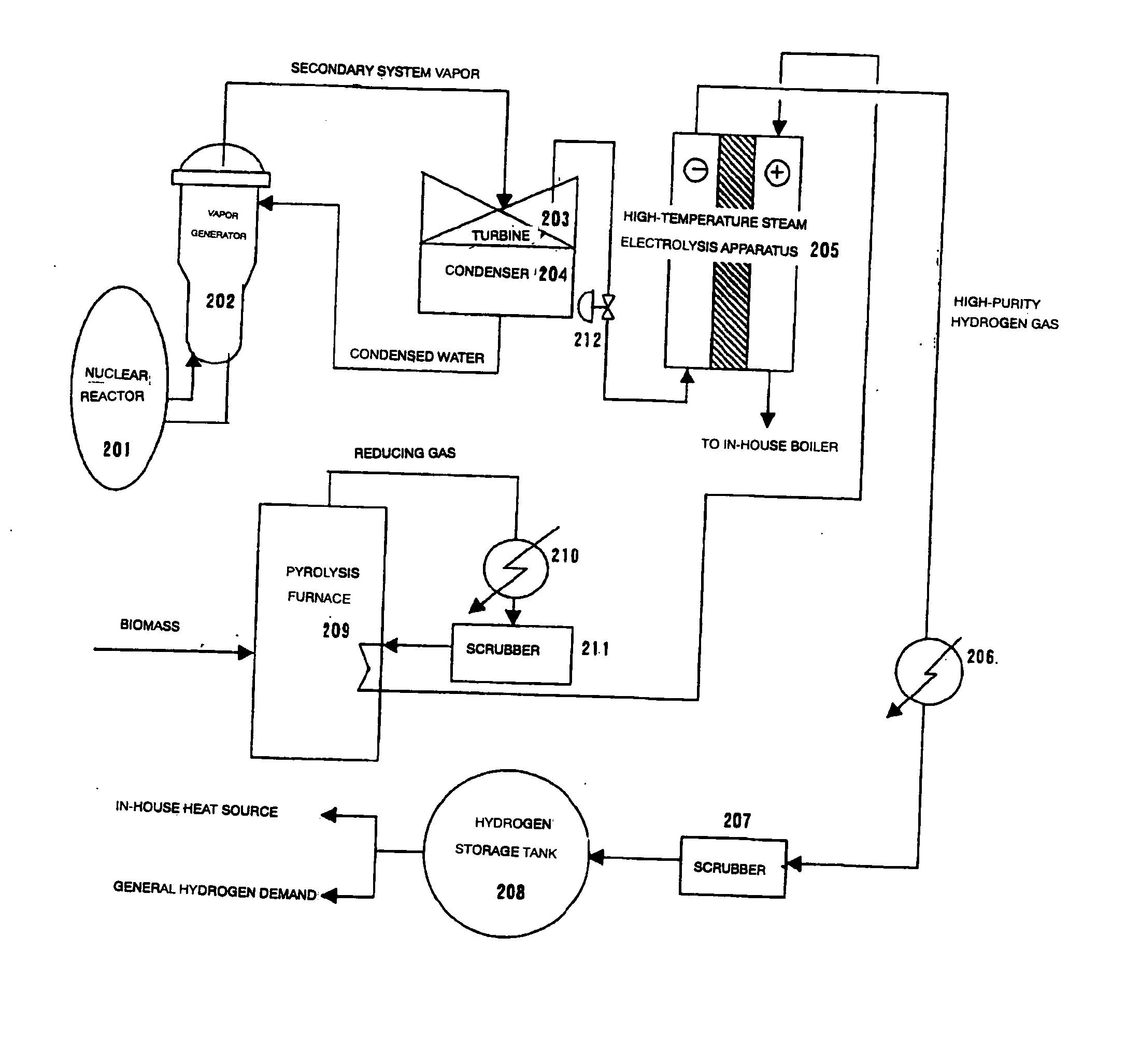

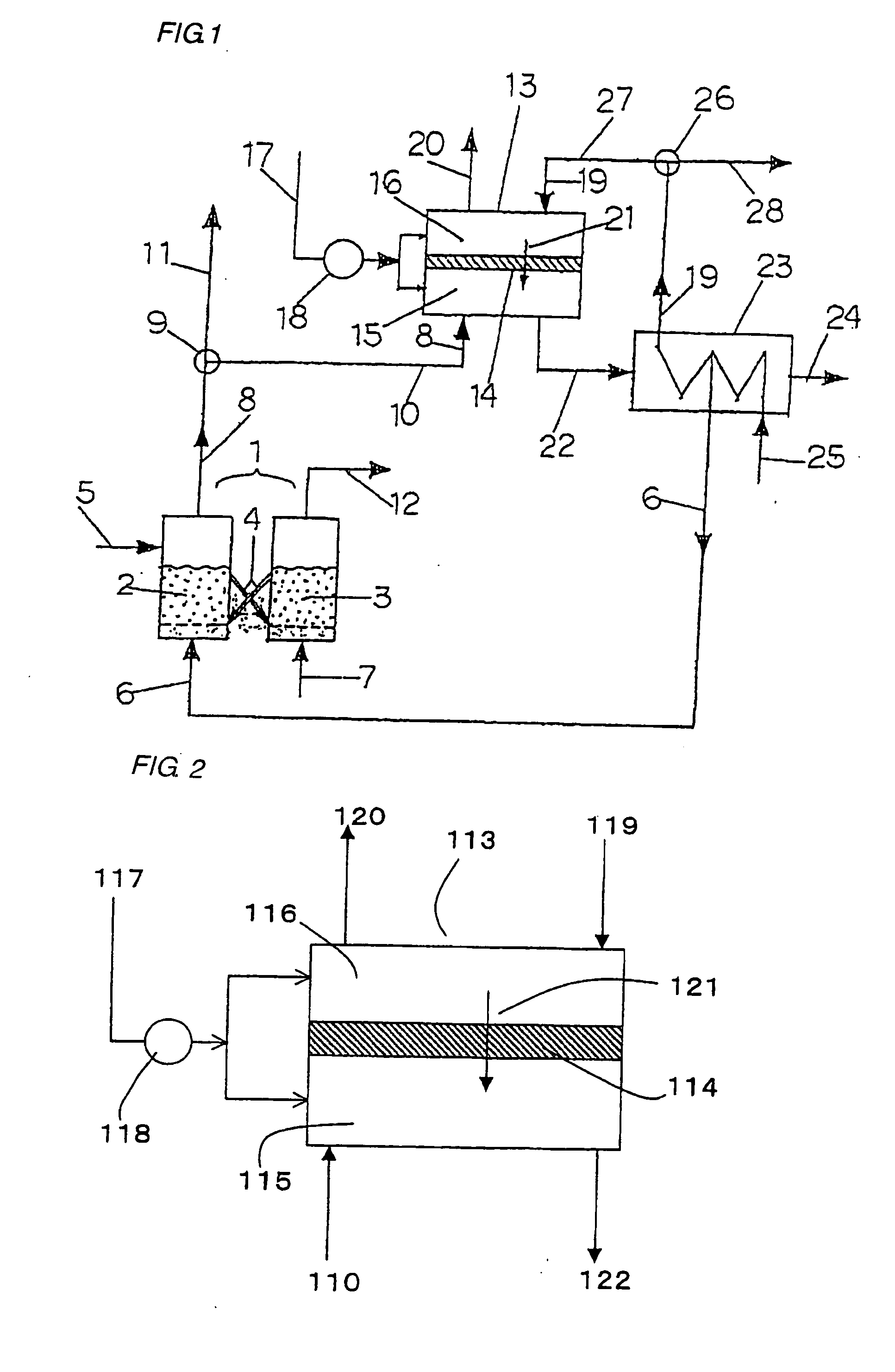

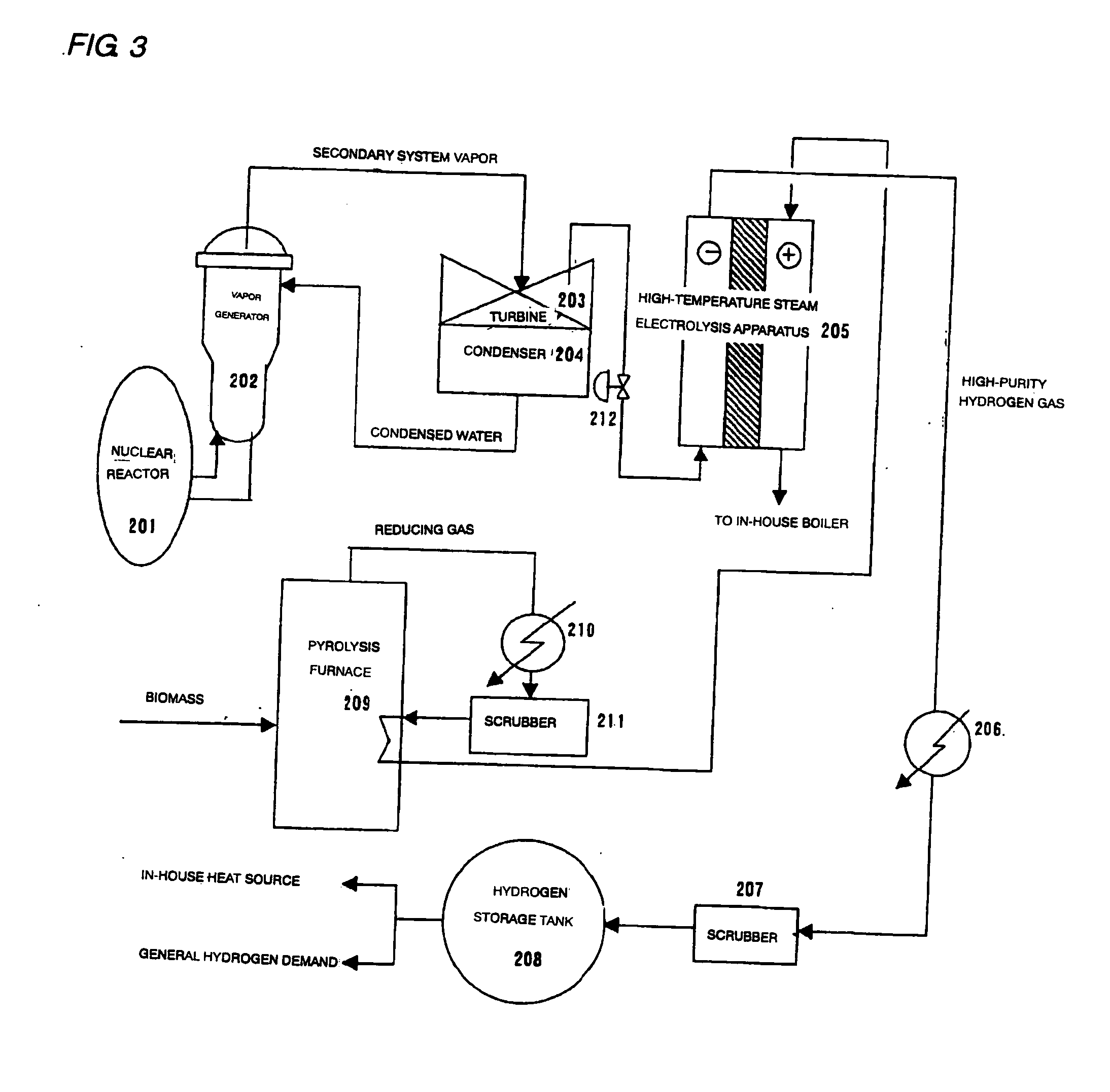

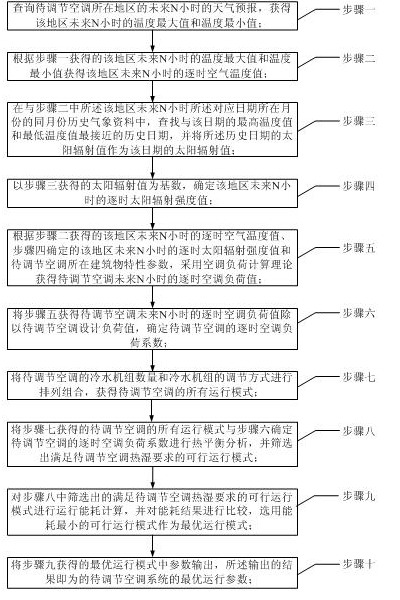

Hydrogen Producing Method and Apparatus

A method for producing hydrogen wherein use is made of a high temperature steam electrolysis apparatus having an electrolysis vessel being partitioned into the anode side and the cathode side by the use of a solid oxide electrolyte film as a diaphragm, steam is fed to the above cathode side and a reducing gas is fed to the anode side, and steam electrolysis is carried out at a high temperature, characterized in that the reducing gas and the steam fed to the electrolysis vessel has a temperature of 200 to 500° C. The above temperature range for the reducing gas and the steam fed to the electrolysis vessel has been found to be an optimum temperature range, as a result of taking the heat balance within the vessel into consideration, in a high temperature steam electrolysis apparatus wherein a solid oxide electrolyte film is used, a reducing gas is fed to the anode side and steam is fed to the cathode side, an oxygen ion is allowed to react with said reducing gas on the cathode side, to thereby generate a concentration gradient for an oxygen ion and thus reduce an electrolysis voltage.

Owner:EBARA CORP

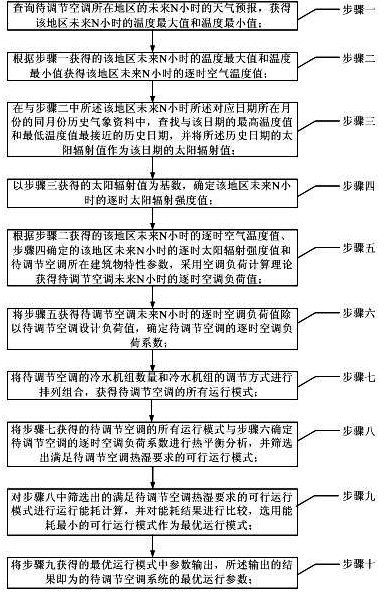

Method for acquiring optimum air-conditioning system operation parameters based on weather forecast

InactiveCN101825327ARealize automatic controlThe operating parameters are accurateSpace heating and ventilation safety systemsLighting and heating apparatusAuto regulationHeat balance

The invention relates to a method for acquiring the optimum air-conditioning system operation parameters based on the weather forecast, solving the problems of poor temperature regulating quality in the buildings because of inaccurate operation parameters of the existing air-conditioning systems and difficult implementation and grave energy waste because of higher requirements of the existing automatic air-conditioning regulating devices for the existing air-conditioners. The method is characterized by computing the hourly meteorological parameters of the next N-numbered hours according to the weather forecast in combination with the historical meteorological data; later, computing the hourly air-conditioning load according to the characteristic parameters of the buildings in combination with the hourly meteorological parameters and comparing the hourly air-conditioning load with the designed air-conditioning load to determine the hourly load coefficients; then carrying out heat balance analysis on all the operation modes and the hourly load coefficient of the air-conditioners to be regulated to screen out the feasible operation modes; and selecting the feasible operation mode characterized by minimum energy consumption as the optimum operation mode and outputting the parameters of the optimum operation mode. The method is applicable to operation control of large air-conditioners.

Owner:HARBIN INST OF TECH

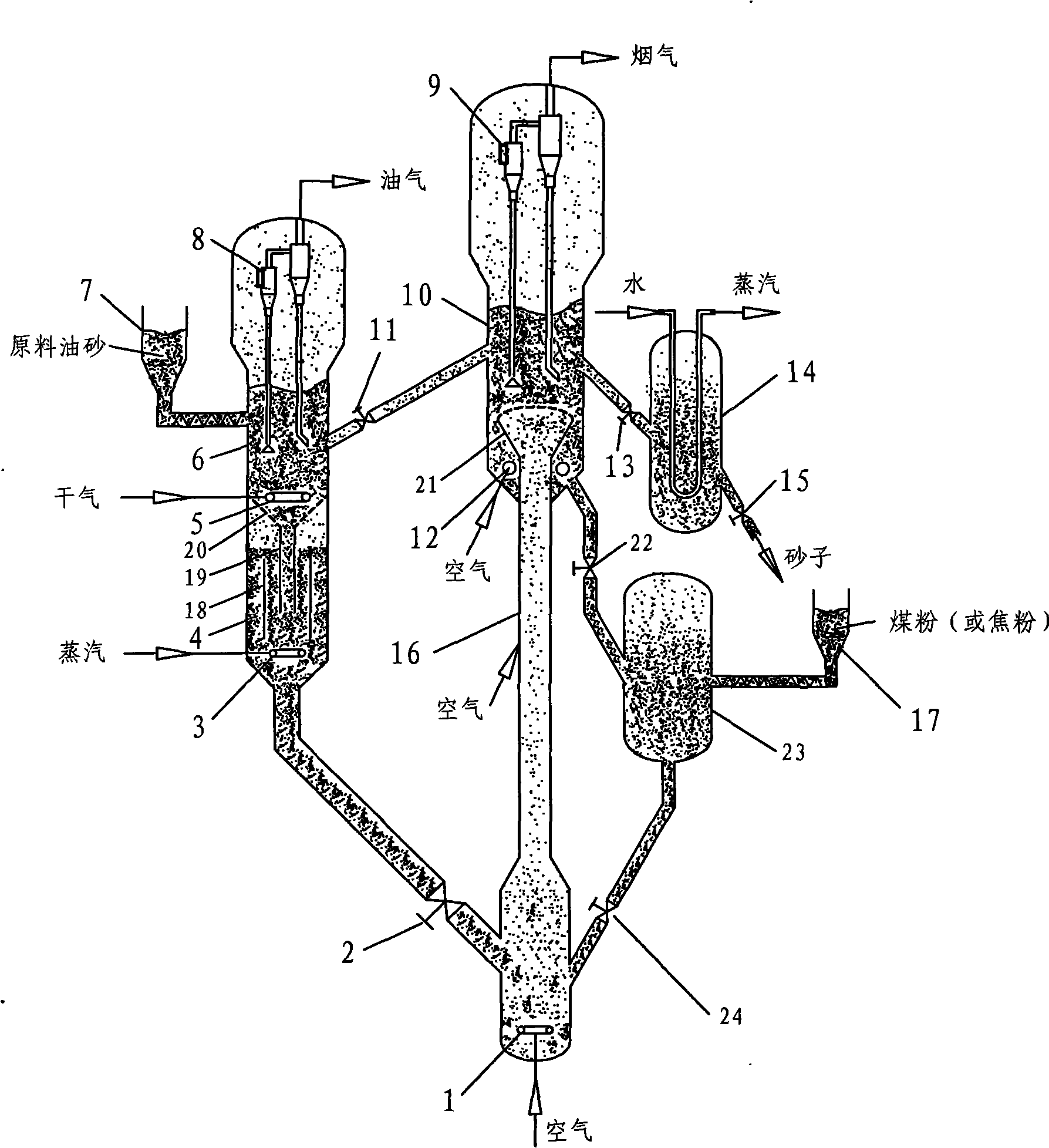

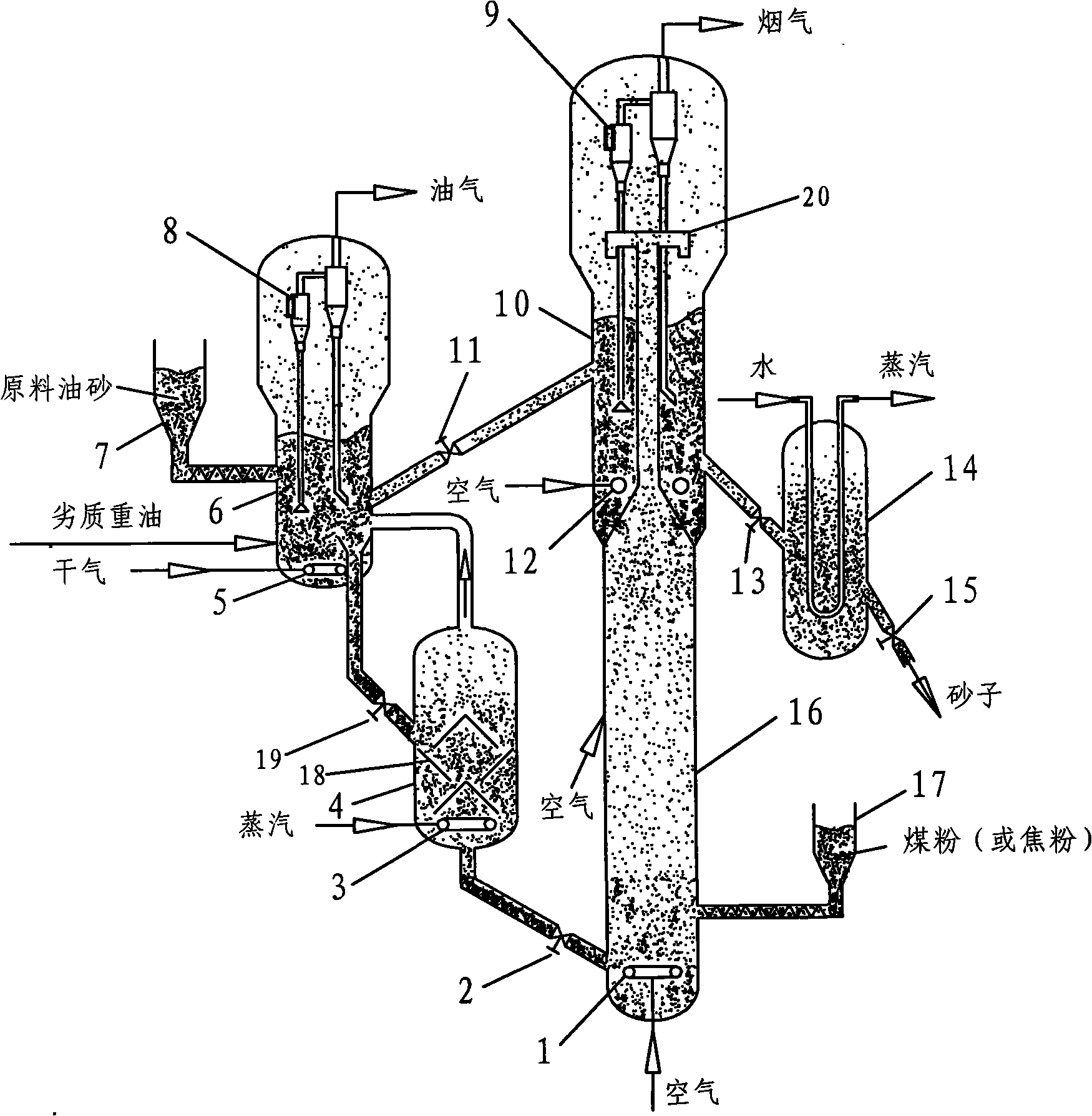

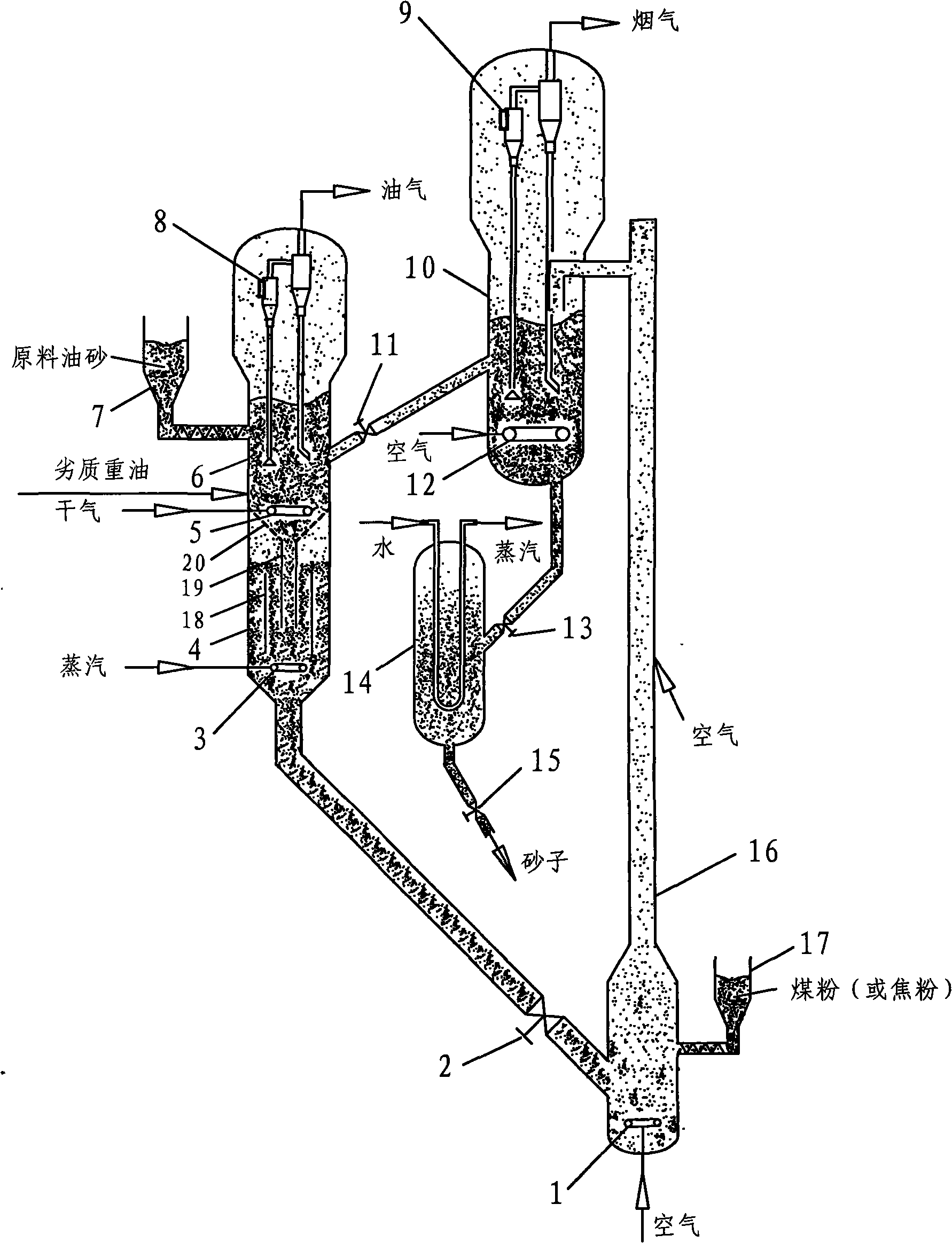

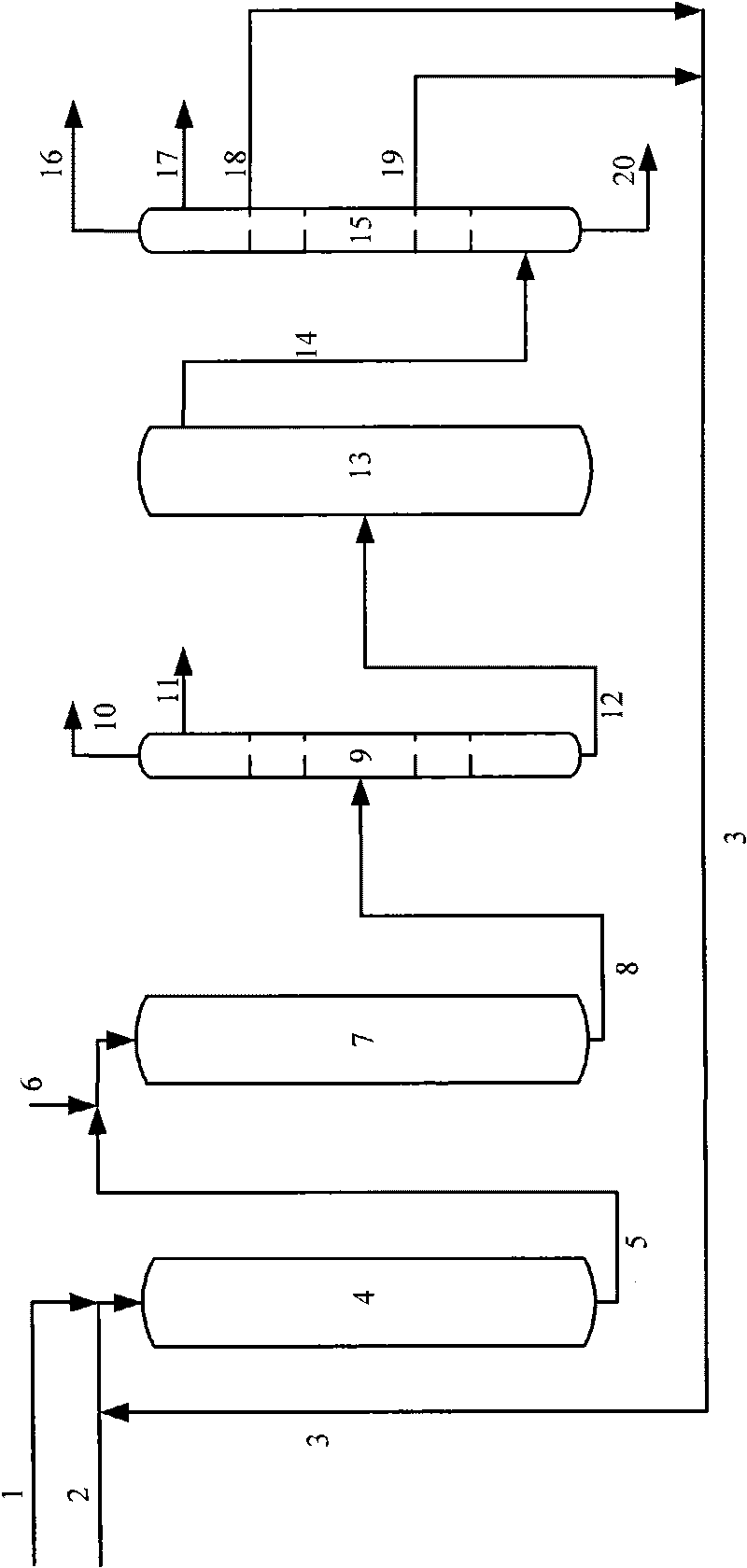

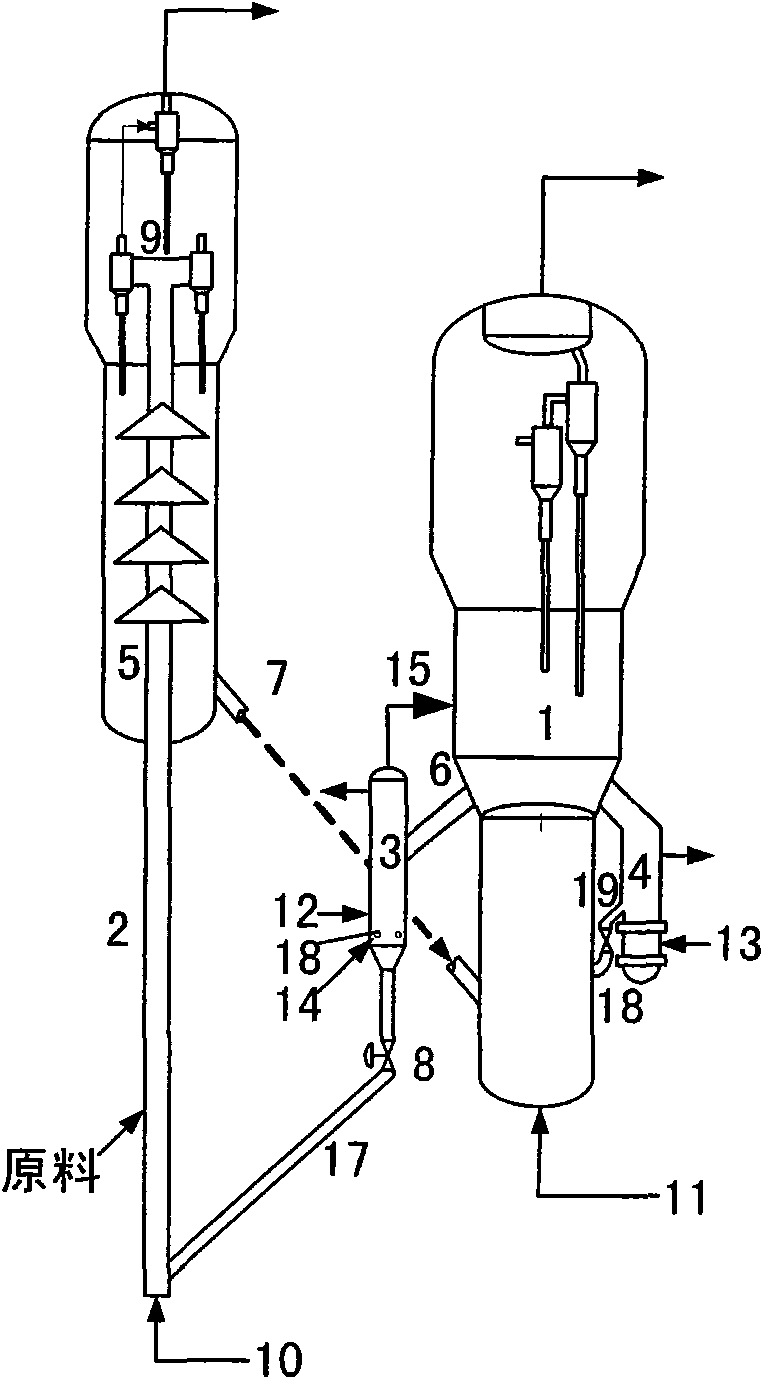

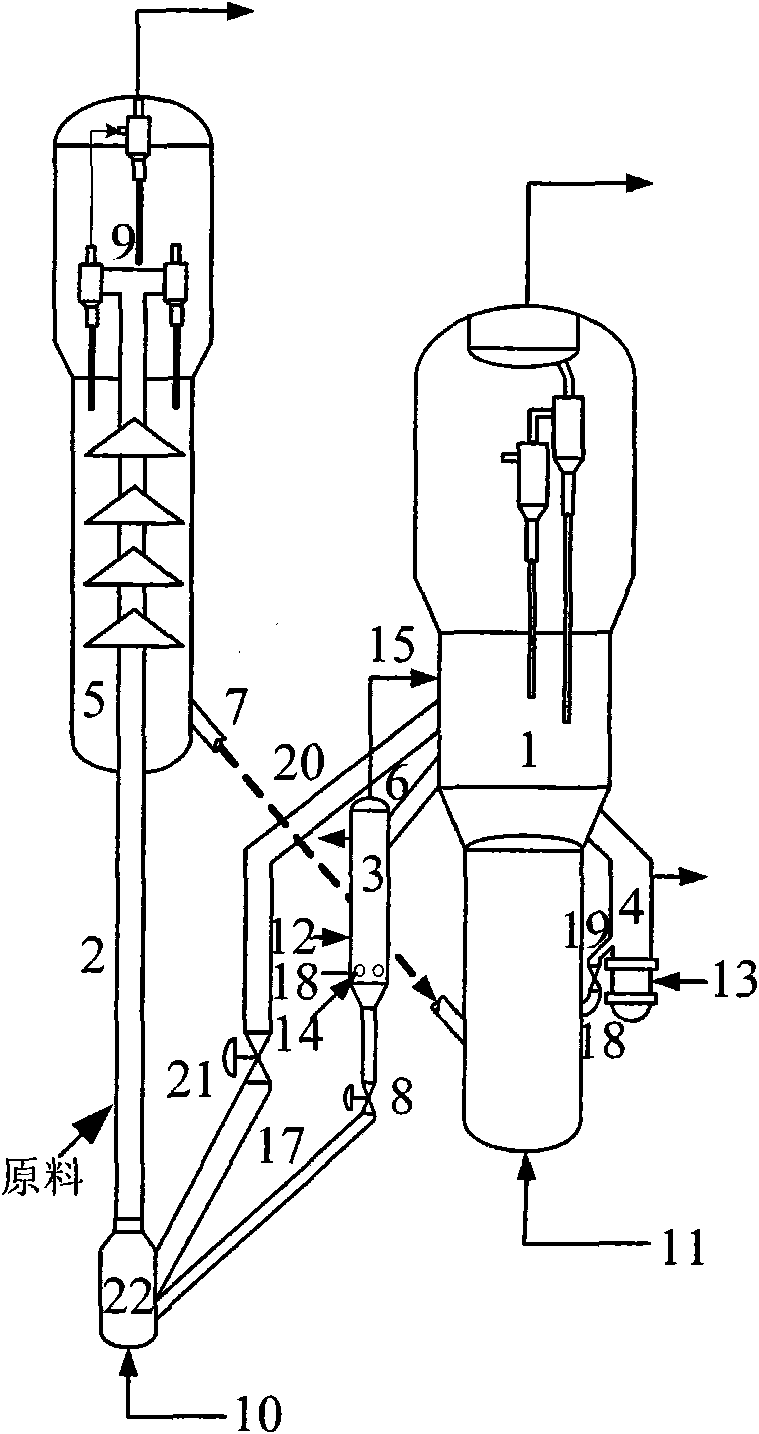

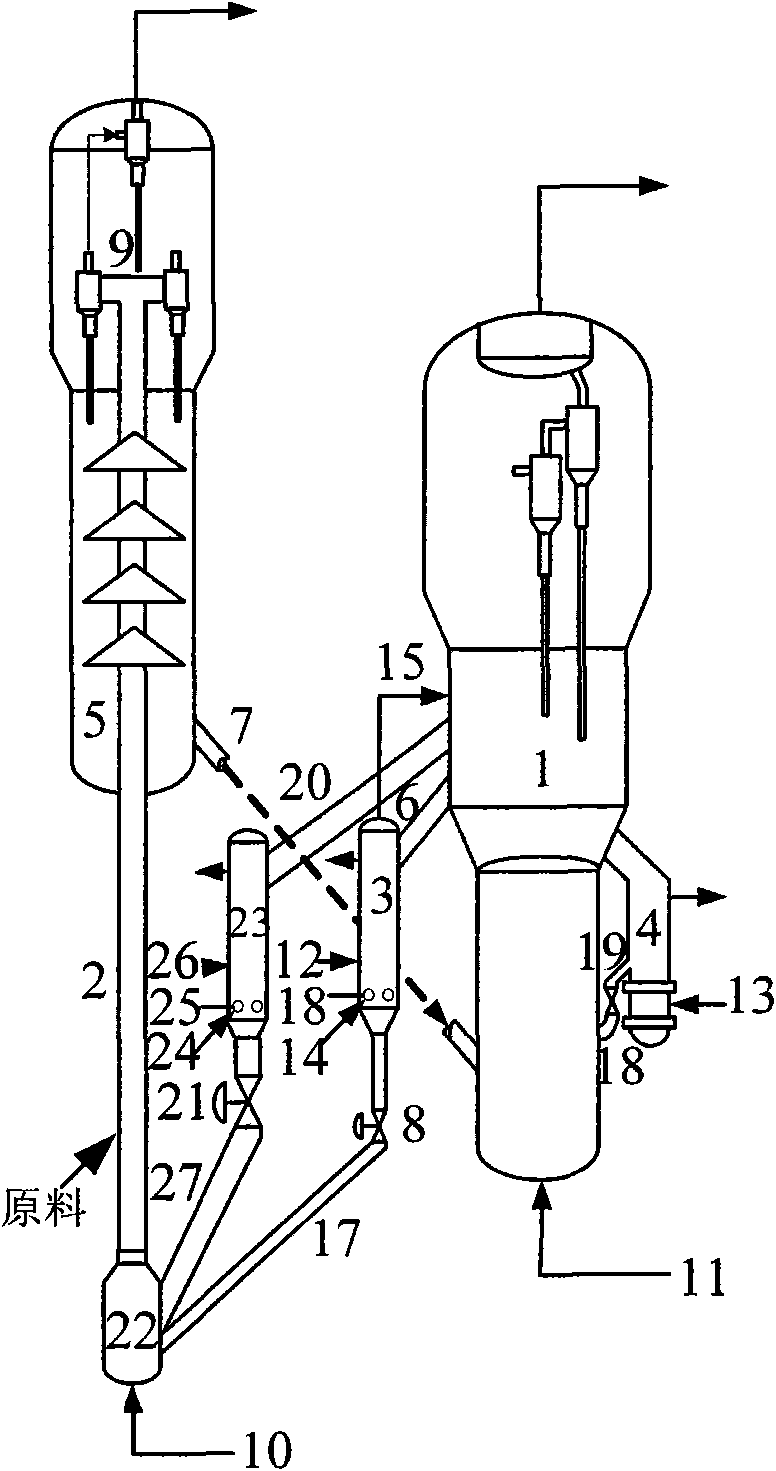

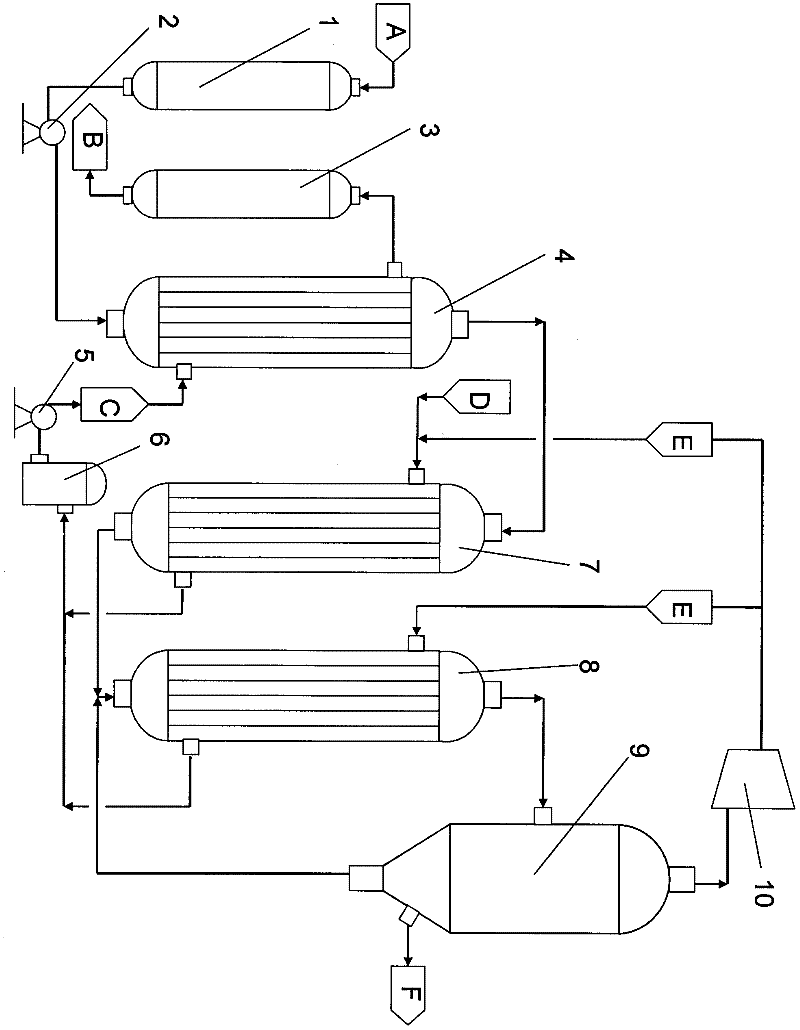

Method for directly fluid coking oil sand and apparatus

ActiveCN101358136ANo pollution in the processContinuous processingLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The present invention provides a method and a device which are used for the direct coking of oil sand on a fluidized bed. The method is as follows: after being mixed with and exchanging heat with the high-temperature sand from a dense-phase coking-burning reactor, the oil sand material in a coking reactor undergoes coking reaction; the dedusted oil gas enters into a fractionation and absorption stabilization system; after being stripped by a stripper, tar sand is led into a dilute-phase coking-burning riser to be burnt in the dilute-phase coking-burning riser and the dense-phase coking-burning reactor above the dilute-phase coking-burning riser; and one flow of the burnt hot sand serving as a heat carrier is led into the coking reactor, and the other flow is led into an external heat collector for heat exchange. If the coke yield is low and the coke-burning heat is insufficient, burning oil, coal dust or coke powder can be added into the coking-burning riser in order to maintain the heat balance of the system. The device at least comprises a material feeder, the coking reactor, the stripper, the dilute-phase coking-burning riser, the dense-phase coking-burning reactor, the external heat collector and a cyclone separator. The device, which is characterized by strong continuous operability and high flexibility, can directly process unconventional petroleum resources such as oil sand and oil shales and does not pollute the environment, and the comprehensive energy utilization rate of the system is high.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

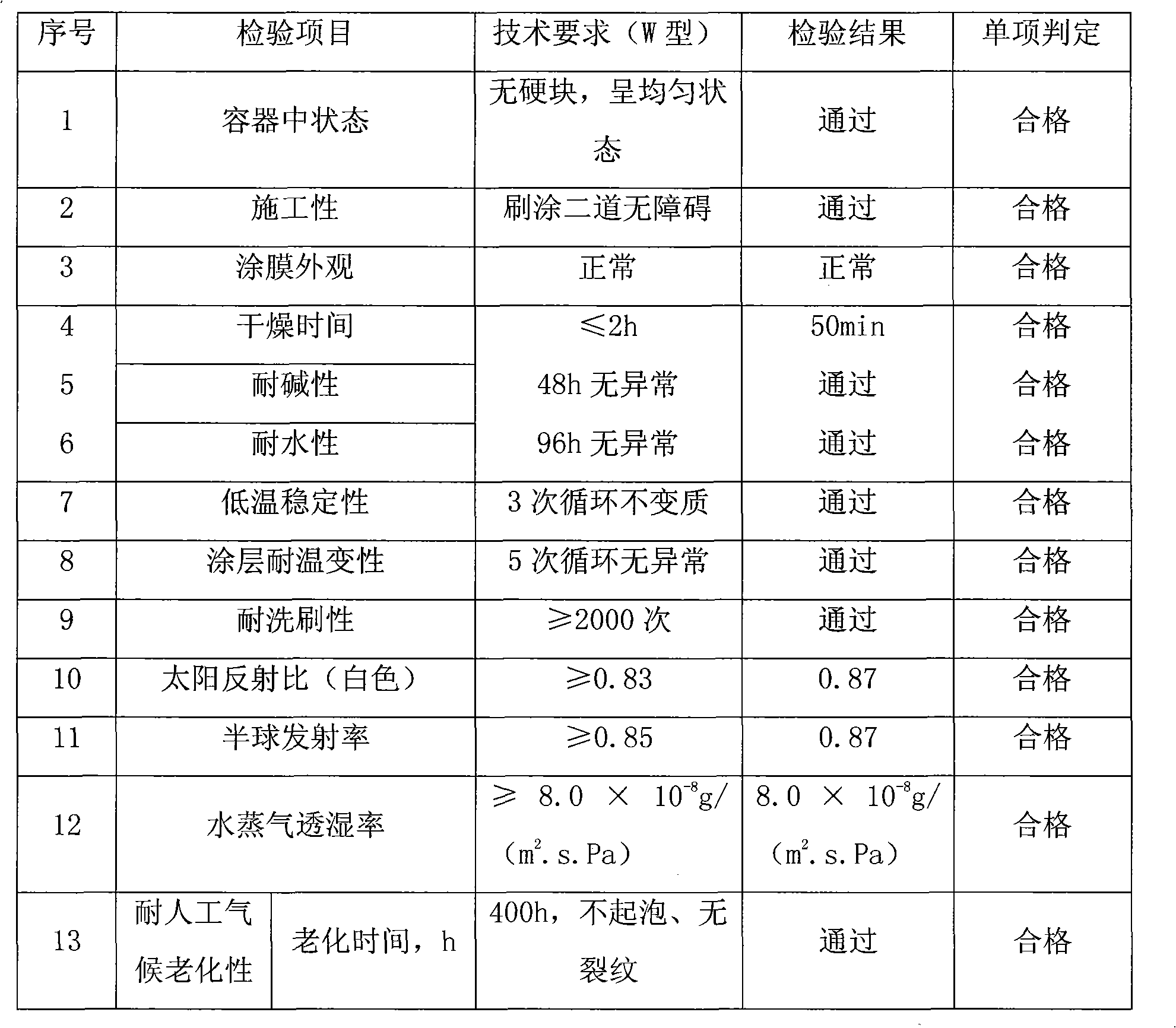

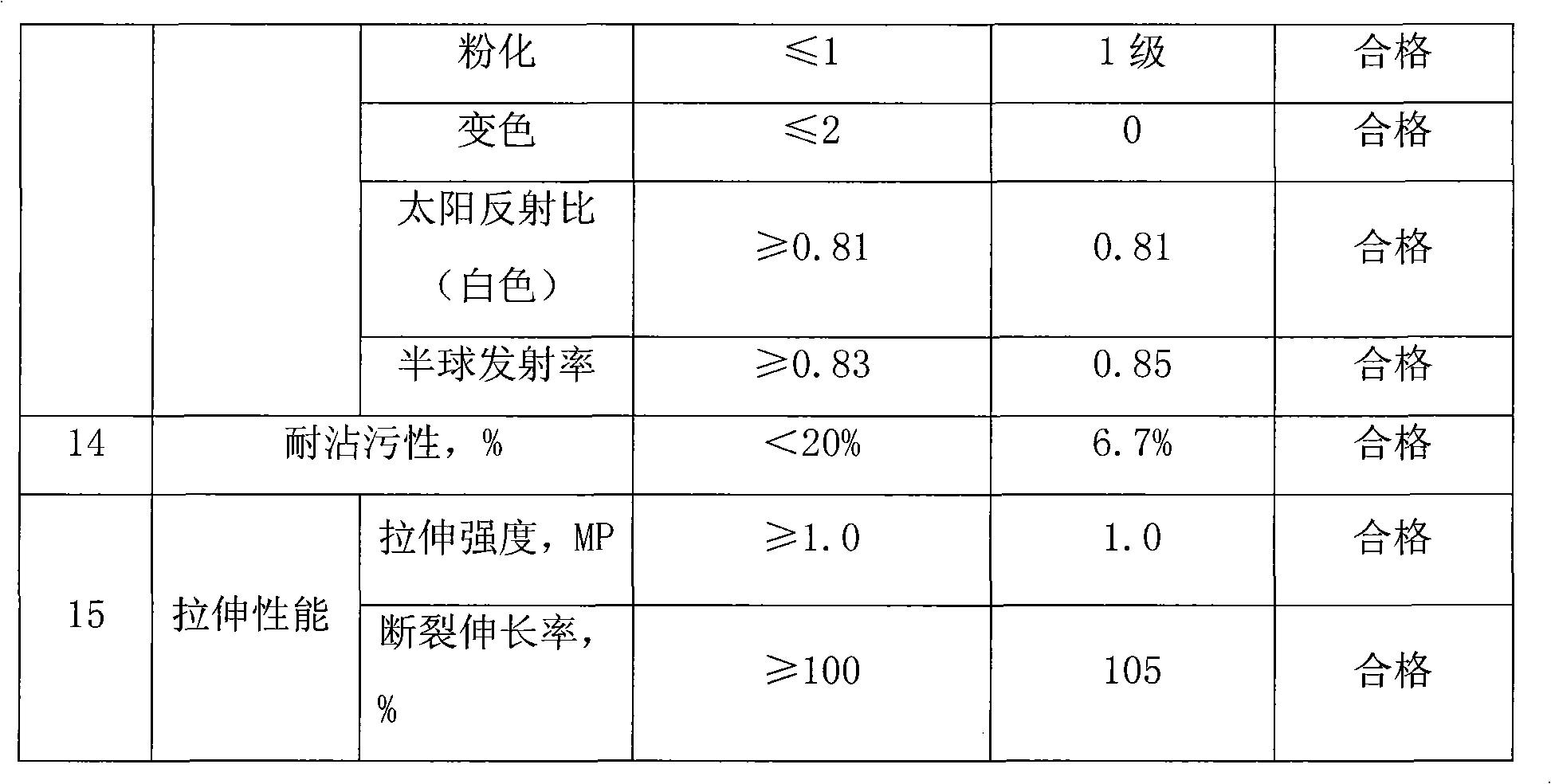

Reflective heat-insulation coating and preparation method thereof

ActiveCN101565581AGood weather resistanceLower thermal equilibrium temperatureReflecting/signal paintsMicrosphereHeat balance

The embodiment of the invention provides a reflective heat-insulation coating and a preparation method thereof. The reflective heat-insulation coating comprises the following raw materials of aqueous pure crylic acid resin, aqueous elastic resin, titanium dioxide, ceramic hollow microspheres, infrared powder, a flame retardant, water, an organic dispersant, a film-forming additive, an antifreeze, a thickener, an anti-foaming agent, a wetting agent, a preservative and a pH value regulator. The coating is a single-component aqueous coating, has no toxicity and good weatherability; extremely fine hollow microsheres are closely arranged by multi-stage in the coating to form a vacuum layer so as to have extremely strong reflection and obstruction function to the solar radiation heat and can effectively reduce the radiation heat transfer and convection heat transfer, thus reducing the heat balance temperature on the surface of the article. The reflective heat-insulation coating leads the building space and the facility container to be warm in winter and cool in summer, reduces the heat island effect and energy consumption of the air conditioner, has obvious energy-saving effect, and reduces the surface temperature by 20 DEG C to a maximum extent and reduces the internal temperature by 5-10 DEG C compared to the normal coating.

Owner:厦门富思特新材料科技有限公司

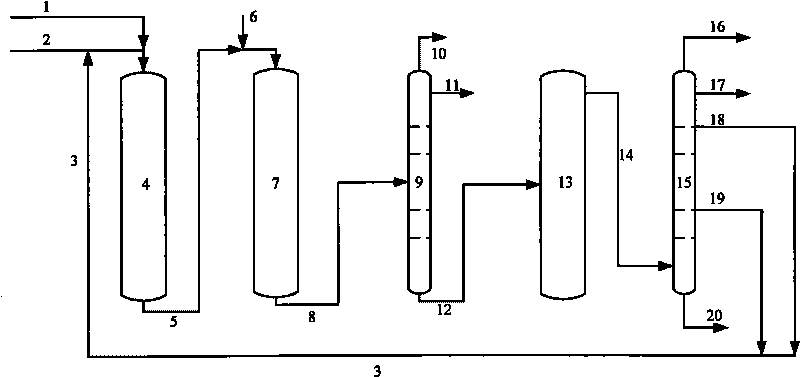

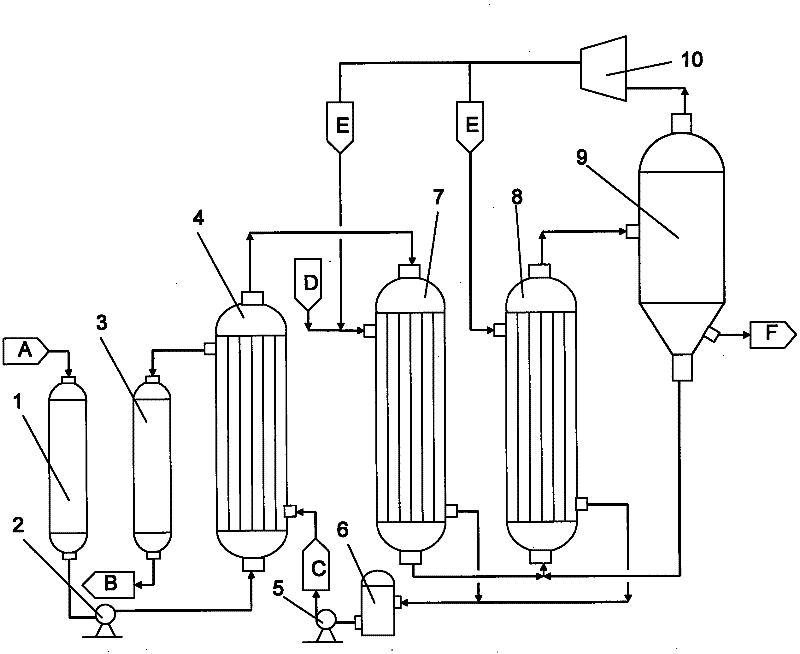

Method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons

ActiveCN101747935AImprove propertiesDoes not affect activityTreatment with hydrotreatment processesWaxResidual oil

The invention provides a method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons. The method produces qualified catalytic cracking raw materials through hydrogenation by taking wax oil and residual oil as raw materials, returns light cycle oil and heavy cycle oil which are catalytic cracking by-products to a hydrogenation unit for the catalytic cracking rawmaterials at the same time, hydrogenates the catalytic cracking by-products together with the catalytic cracking raw materials, and then takes the obtained product as the catalytic cracking raw materials to produce light olefins and monocyclic aromatic hydrocarbons. By introducing the residual oil before a second reaction zone of hydrogenation, the method widens the sources of the catalytic cracking raw materials, increases the processing amount of low-value residual oil, and solves the problem of the heat balance of catalytic cracking units. The light and heavy cycle oil of catalytic cracking is introduced into the hydrogenation unit, hydrogenated and then taken as the catalytic cracking raw materials, so that the yield of high-value products of the catalytic cracking units can be increased, and the deactivation of hydrogenation catalysts is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

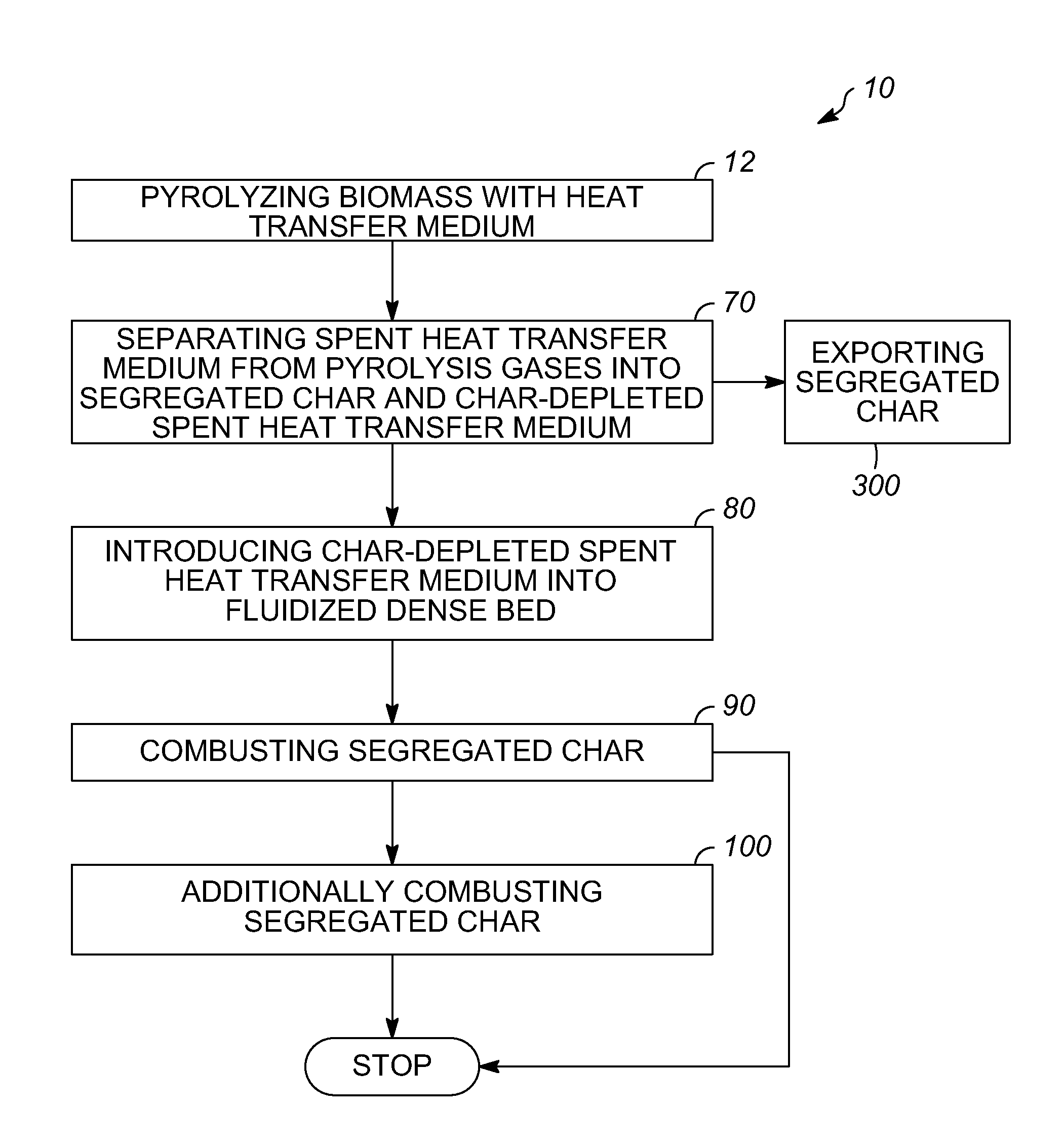

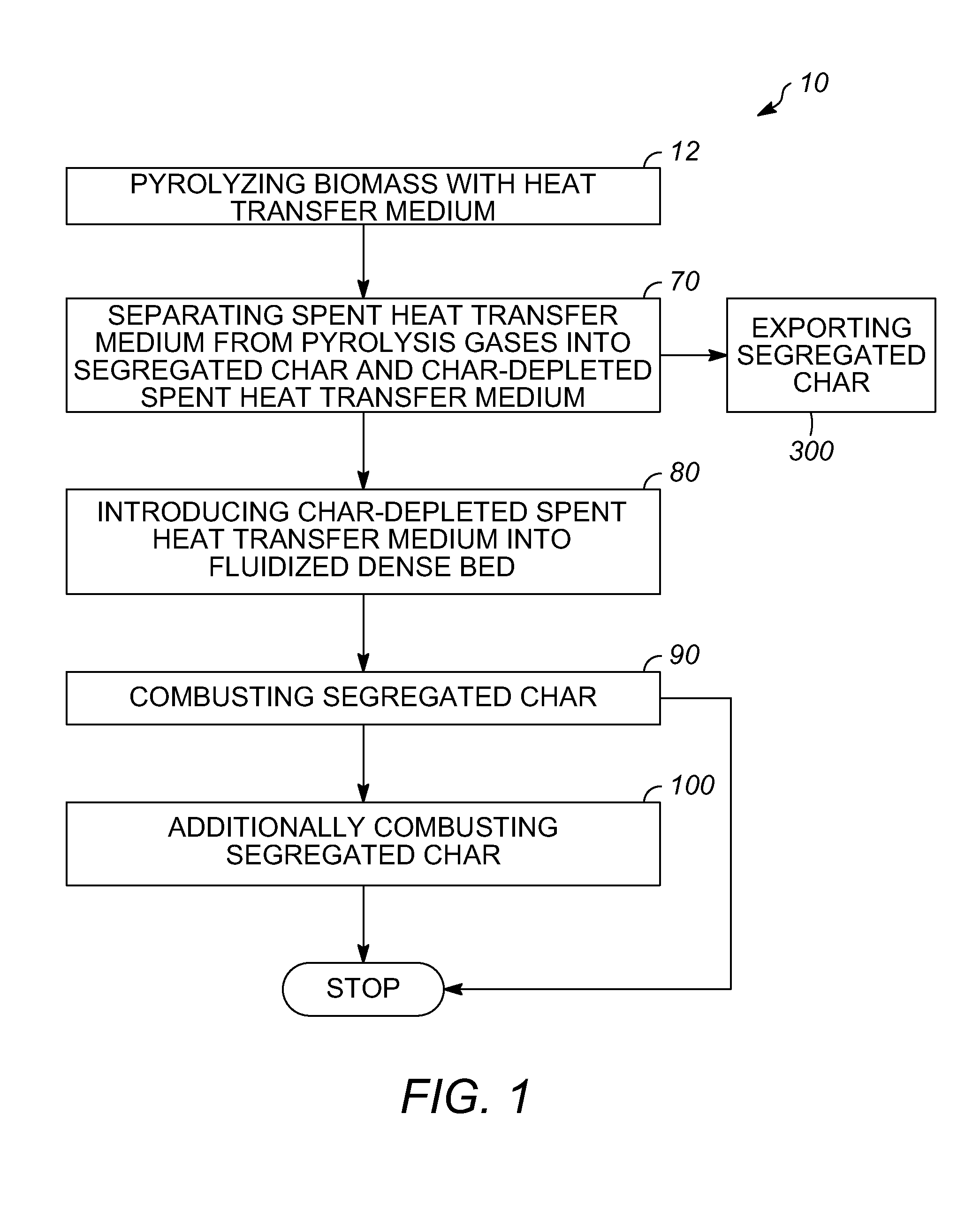

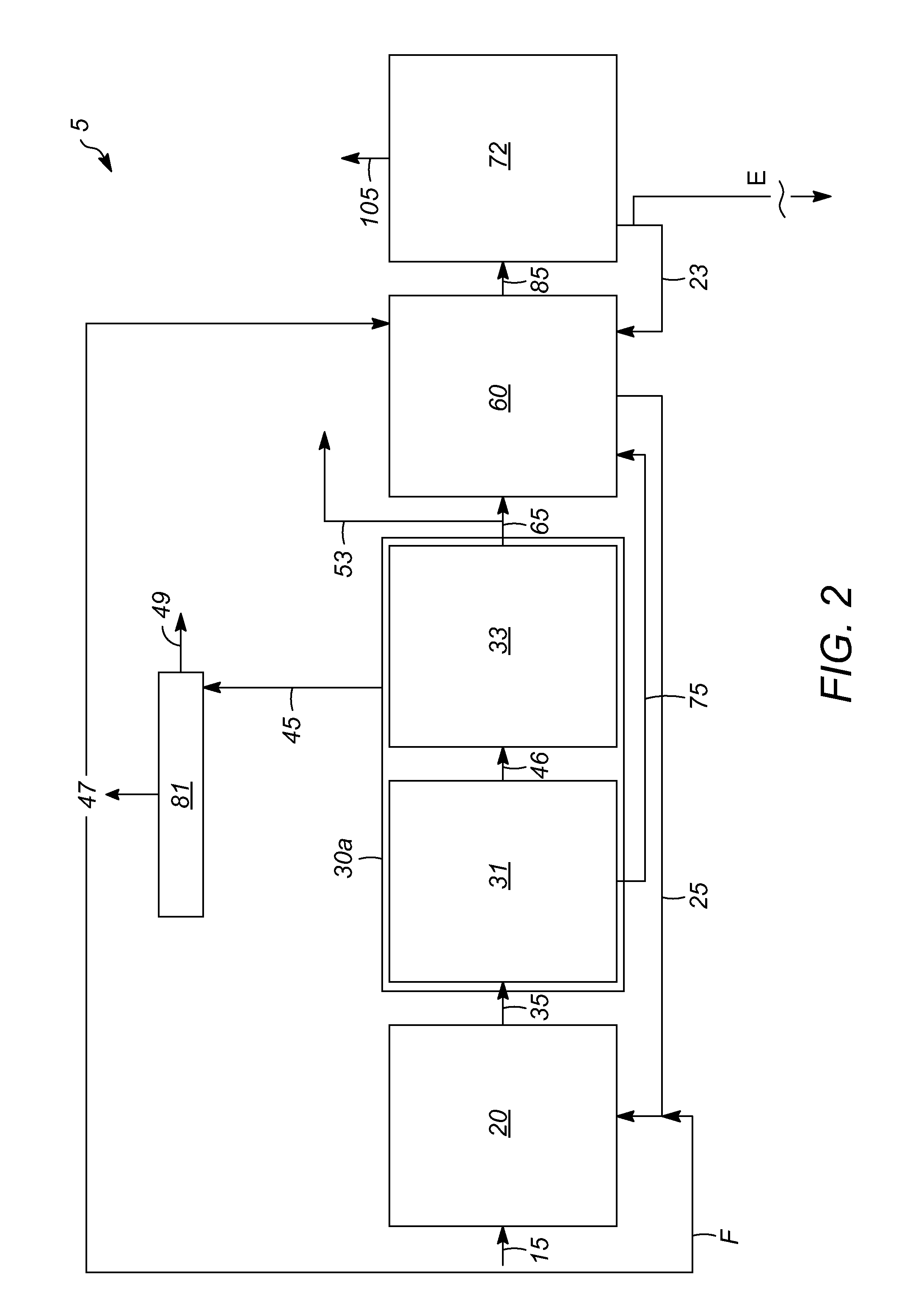

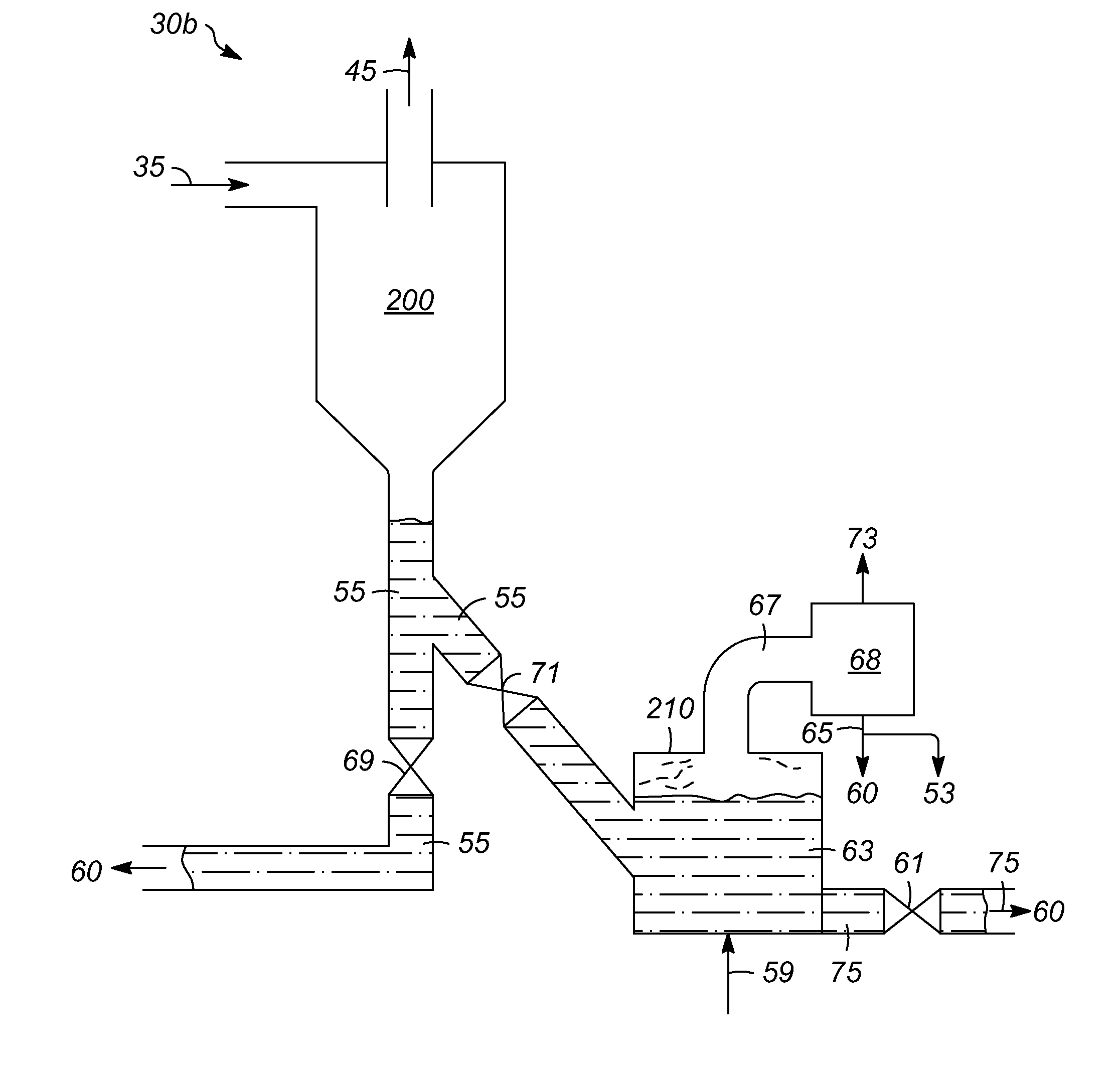

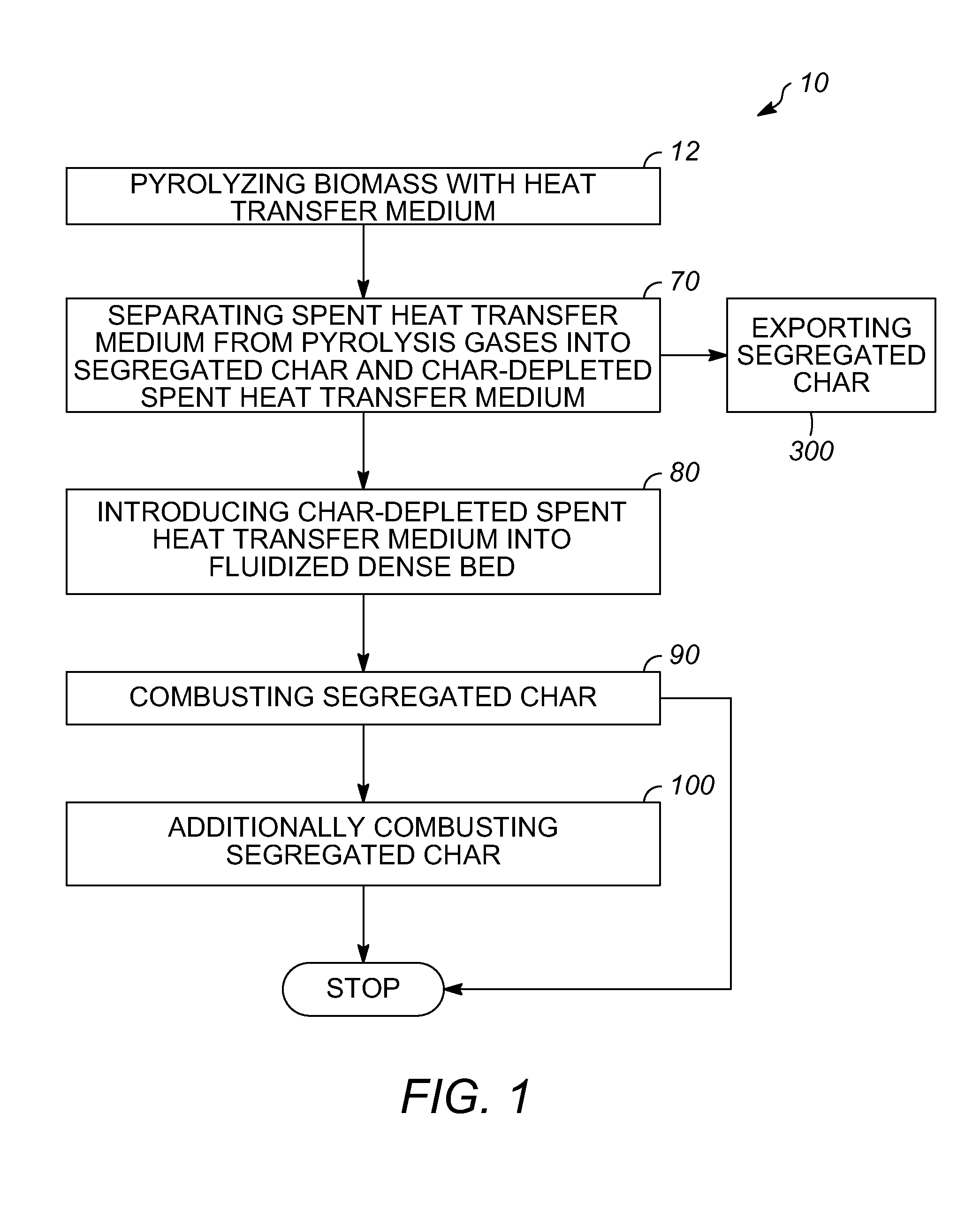

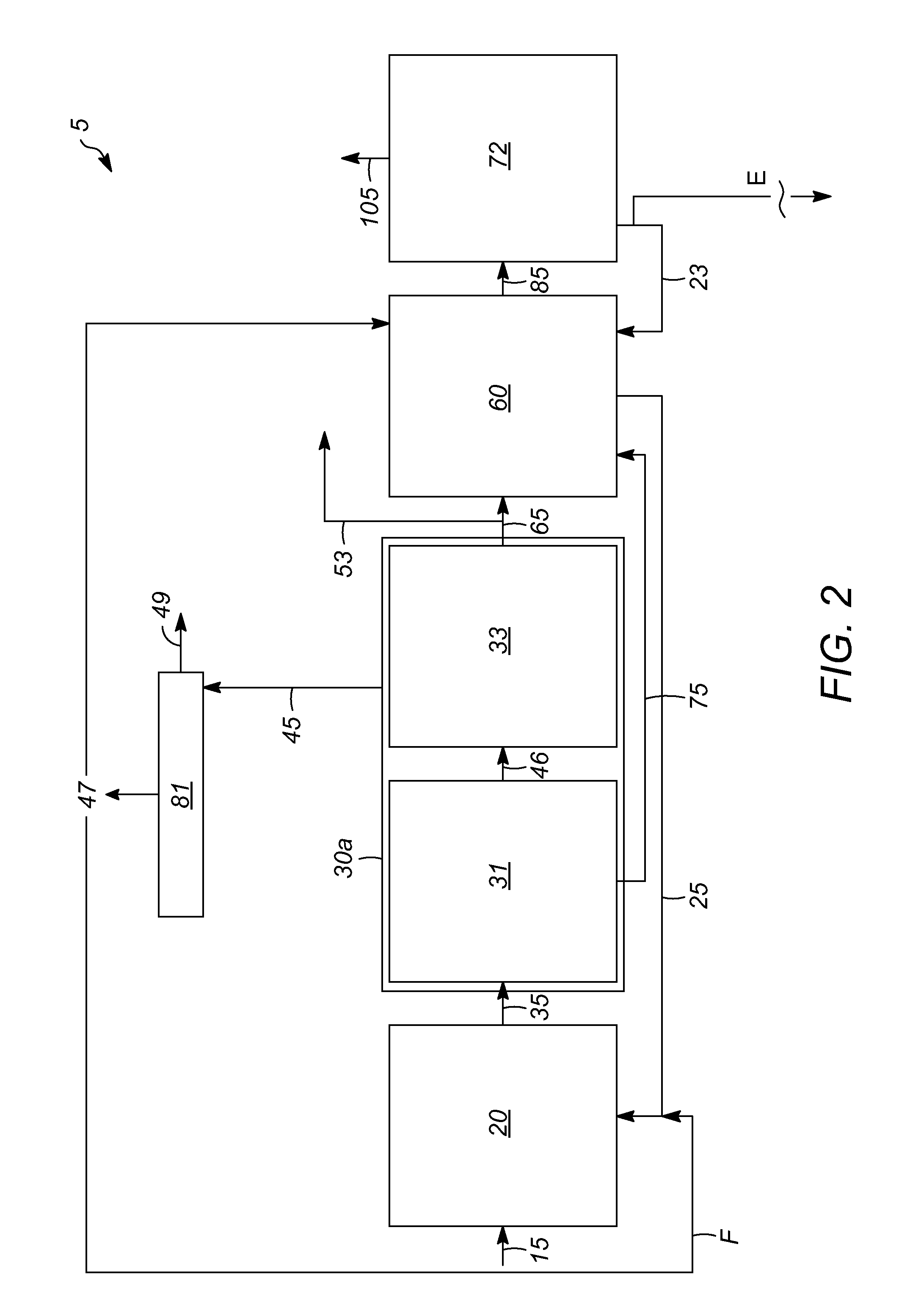

Char-handling processes in a pyrolysis system

Owner:ENSYN RENEWABLES

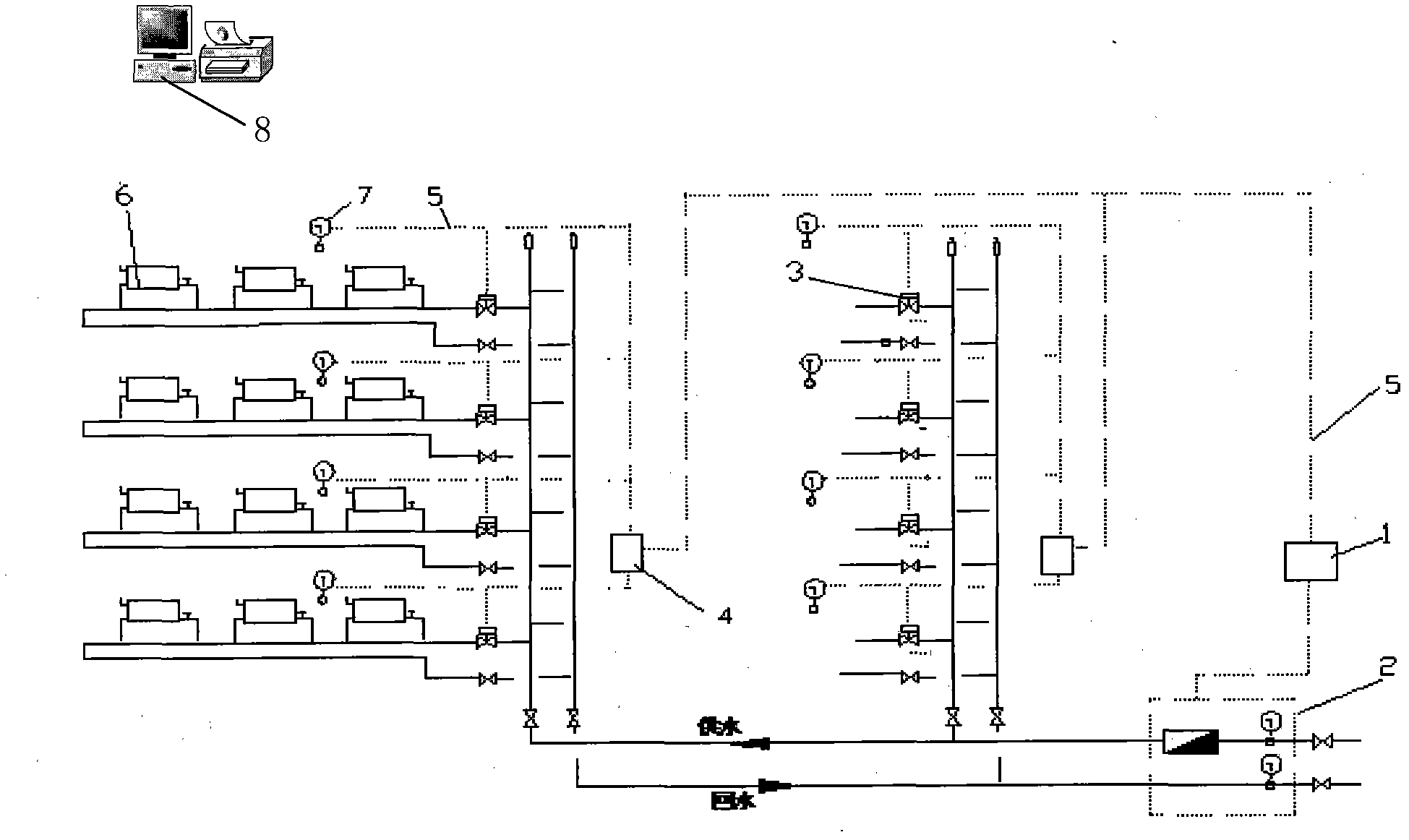

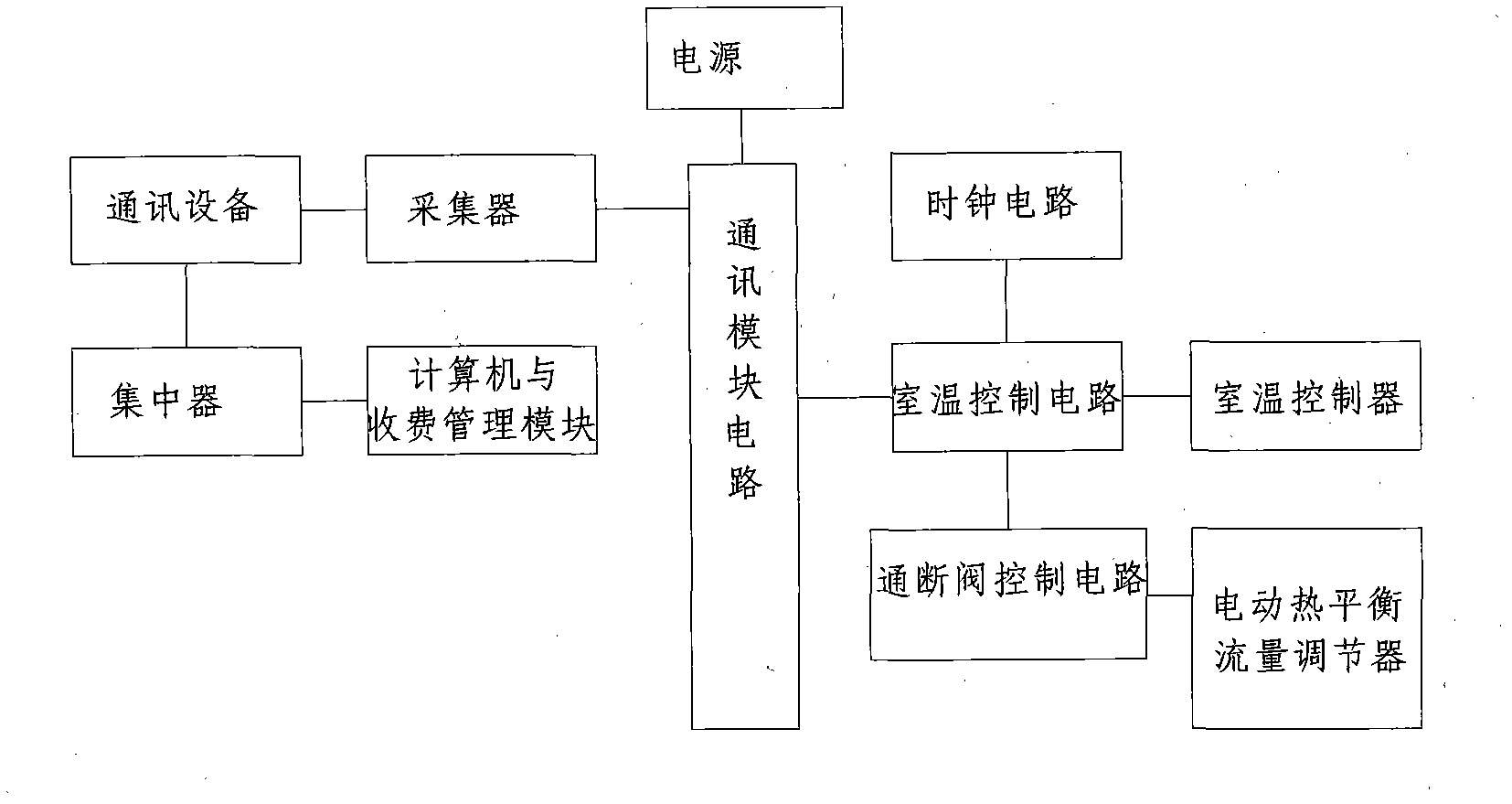

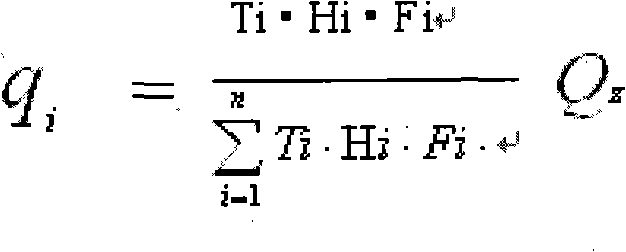

Method and device for improving accuracy and energy-saving efficiency of 'on-off time-area process' heat allocation system

InactiveCN101975416AImprove fairnessEasy to operateLighting and heating apparatusSpace heating and ventilation detailsRoom temperatureHeat balance

The invention provides a method and a device for improving the accuracy and energy-saving efficiency of an 'on-off time-area process' heat allocation system. The device comprises total heat supply metering devices arranged in building heat supply pipes and room temperature controllers and electrical heat balance flow regulating devices which are installed by heat supply users respectively, wherein the room temperature controllers are arranged at reference positions in heating areas of the users; and the electrical heat balance flow regulating devices comprises on-off control valves which are arranged in house branch heat supply pipes of the users. The room temperature controllers monitor indoor temperatures, and the electrical heat balance flow regulating devices control the flows in the heat supply pipes and the opening and closing of the heat supply pipes, and calculate and store the total opening time length of on-off control valves.

Owner:北京乐福能节能技术有限公司 +1

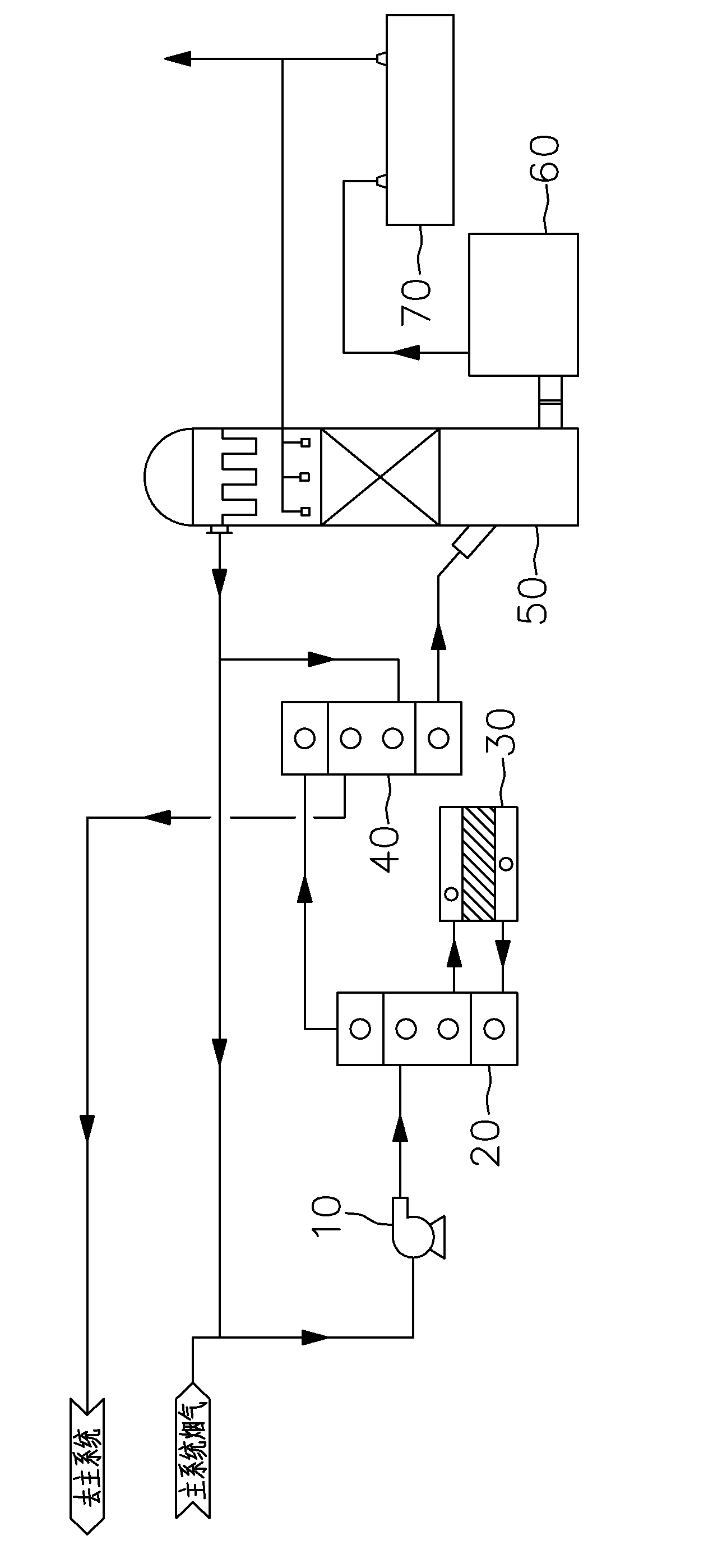

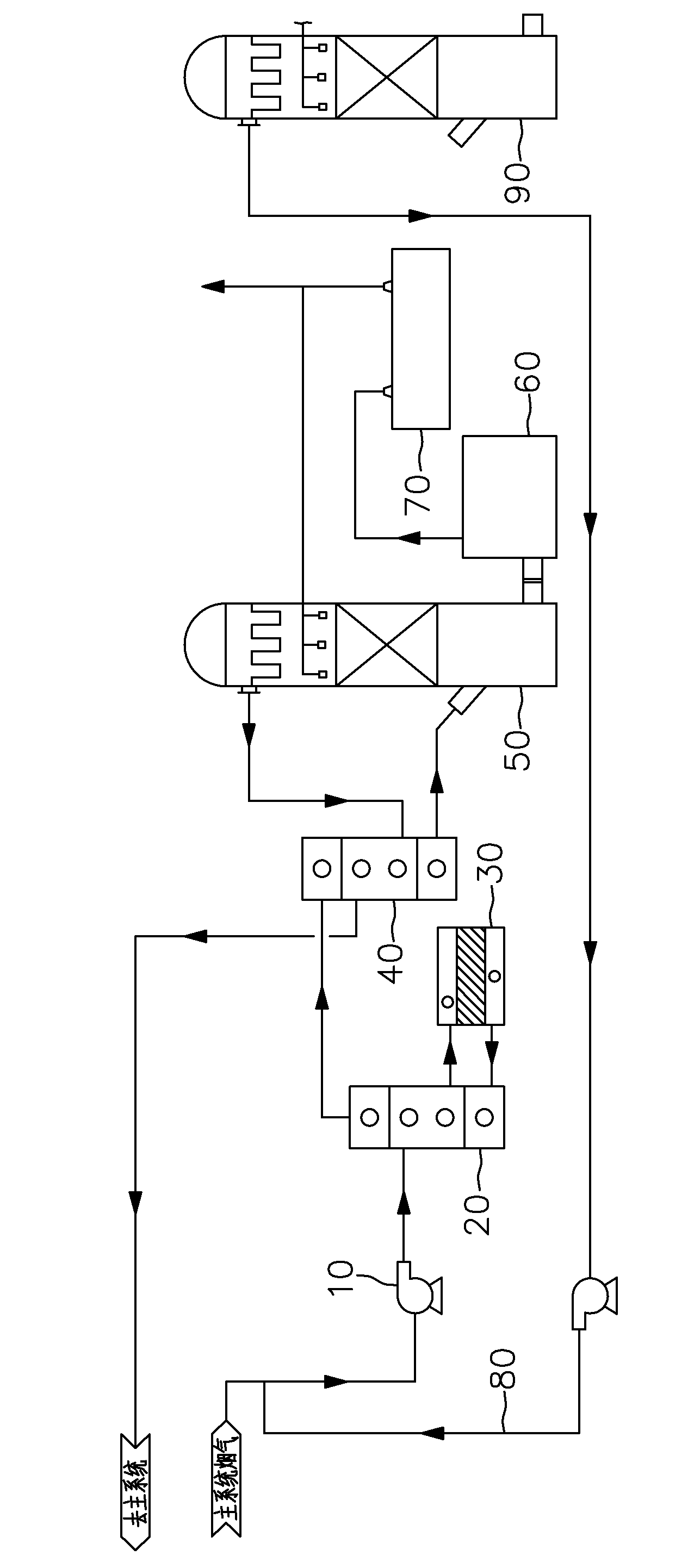

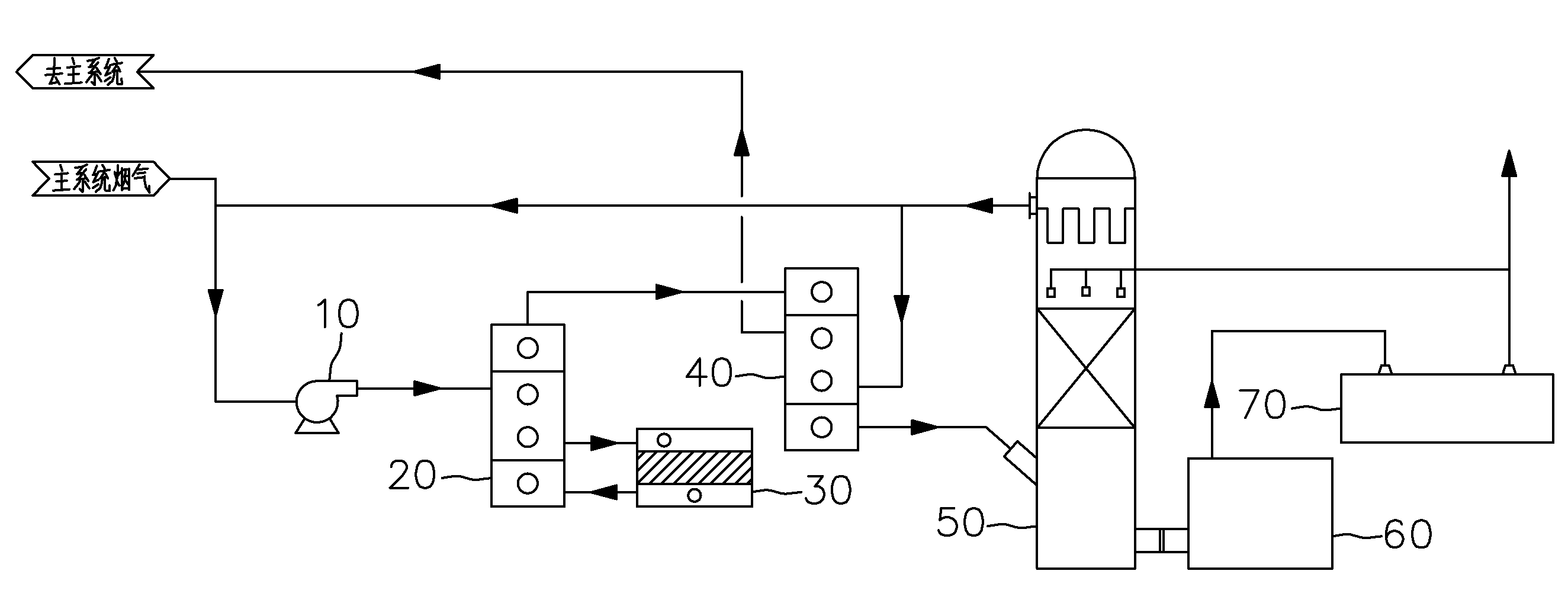

Method for flexibly adjusting catalytic cracking reaction-regeneration system heat balance

The invention relates to a method for flexibly adjusting catalytic cracking reaction-regeneration system heat balance. A conventional regenerated catalyst heat remover which is arranged beside a regenerator and a regenerated catalyst cooler which is arranged on a regenerated catalyst conveying pipe are coupled and linked so that the catalyst bed temperature in the regenerator is controlled in oneaspect to solve the problem of catalyst inactivation because of overhigh temperature caused by great scorching amount in a traditional heavy oil catalytic cracking device and too much heat in the regenerator, and the carried heat and the temperature of the regenerated catalyst entering a lifting pipe reactor are adjusted in the other aspect to adjust ratios of different catalyst and oil needed for raw materials with different properties in cracking reactions. The invention takes heat and adjusts the temperatures of high-temperature regenerated catalysts in different positions in a traditionalheavy oil catalytic cracking device and flexibly adjusts the reaction-regeneration system heat balance so as to optimize heavy oil catalytic cracking process conditions and remarkably improve the yield of light oil and liquid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Char-handling processes in a pyrolysis system

Char-handling processes for controlling overall heat balance, ash accumulation, and afterburn in a reheater are provided. Carbonaceous biomass feedstock is pyrolyzed using a heat transfer medium forming pyrolysis products and a spent heat transfer medium. The spent heat transfer medium is separated into segregated char and char-depleted spent heat transfer medium. The char-depleted spent heat transfer medium is introduced into a dense bed of heat transfer medium fluidized by a stream of oxygen-containing regeneration gas. All or a portion of the segregated char is combusted in the dense bed using the stream of oxygen-containing regeneration gas. A portion of the segregated char may be exported out of the pyrolysis system to control the overall heat balance and ash accumulation.

Owner:ENSYN RENEWABLES

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

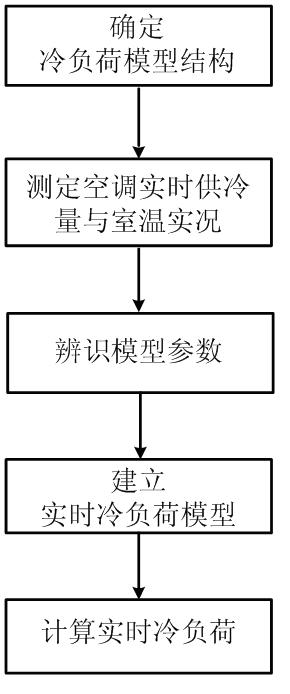

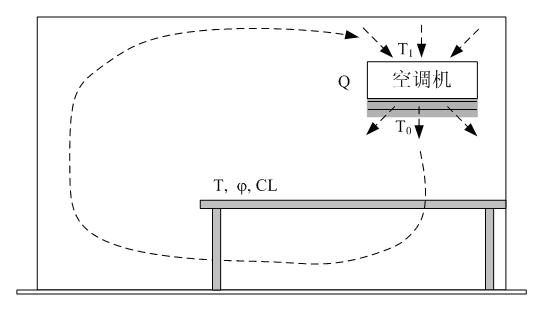

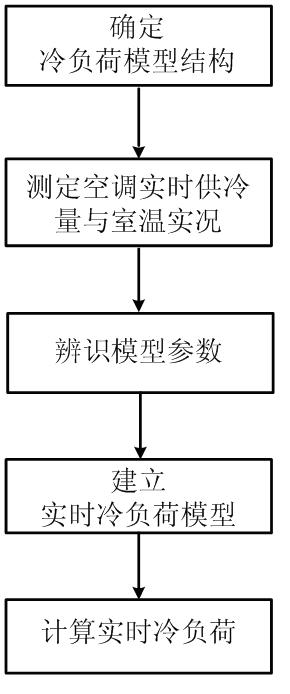

Real-time cold load determination method of air-conditioner room

InactiveCN102043907AAccurate real-time cooling load demand dataReliable real-time cooling load demand dataSpecial data processing applicationsLoad modelPredictive methods

The invention relates to a real-time cold load determination method of an air-conditioner room. The method is as follows: on the basis of the heat balance process of a room system, determining a cold load model structure, measuring the actual conditions of real-time cold supply amount input of an air conditioner and room temperature response, identifying model parameters, establishing a real-time cold load model, and calculating real-time cold load in the air-conditioner room. By utilizing the real-time cold load determination method, precise and reliable real-time cold load requirement data can be provided for operation and control of the air conditioner, the problems that the heat-transfer mechanism modeling method and the prediction method need a large amount of priori knowledge and historical data and is difficult to cover dynamic influence factors of the load and the like are avoided, and the real-time cold load requirement of the air-conditioner room can be reflected in real time. The real-time cold load determination method is wide in application range and strong in real-time property, and can be widely applicable to the aspects of energy conservation control at the operating stage of the air conditioners and energy conservation modification of the air conditioners of old buildings and the like.

Owner:SHANGHAI UNIV

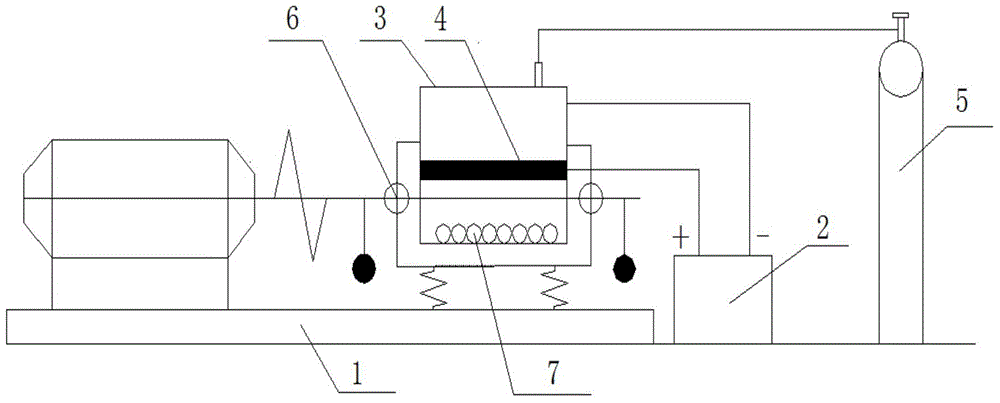

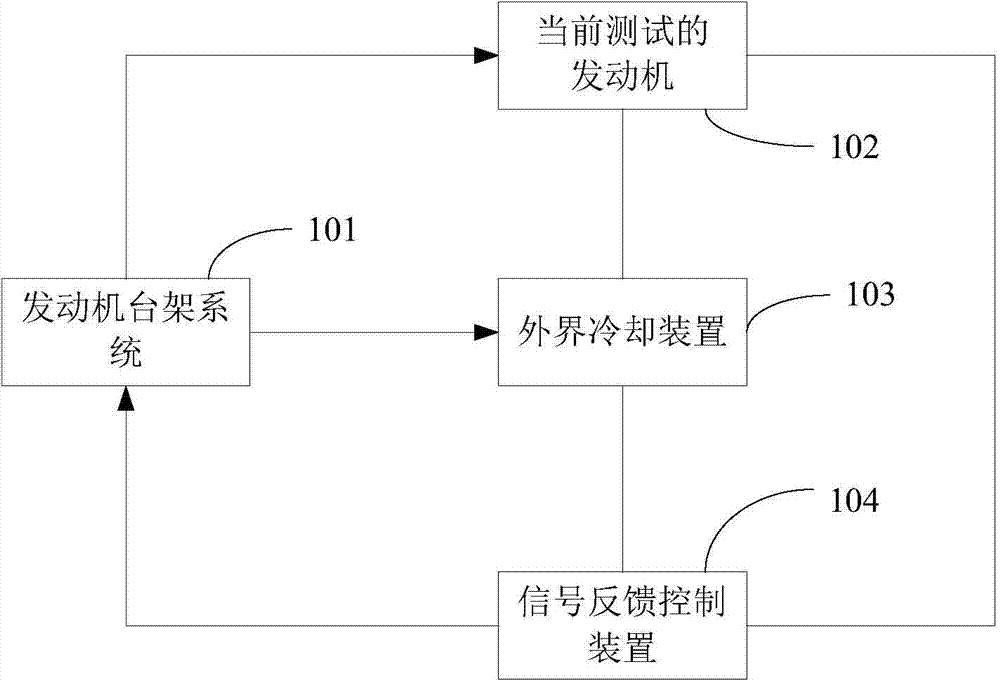

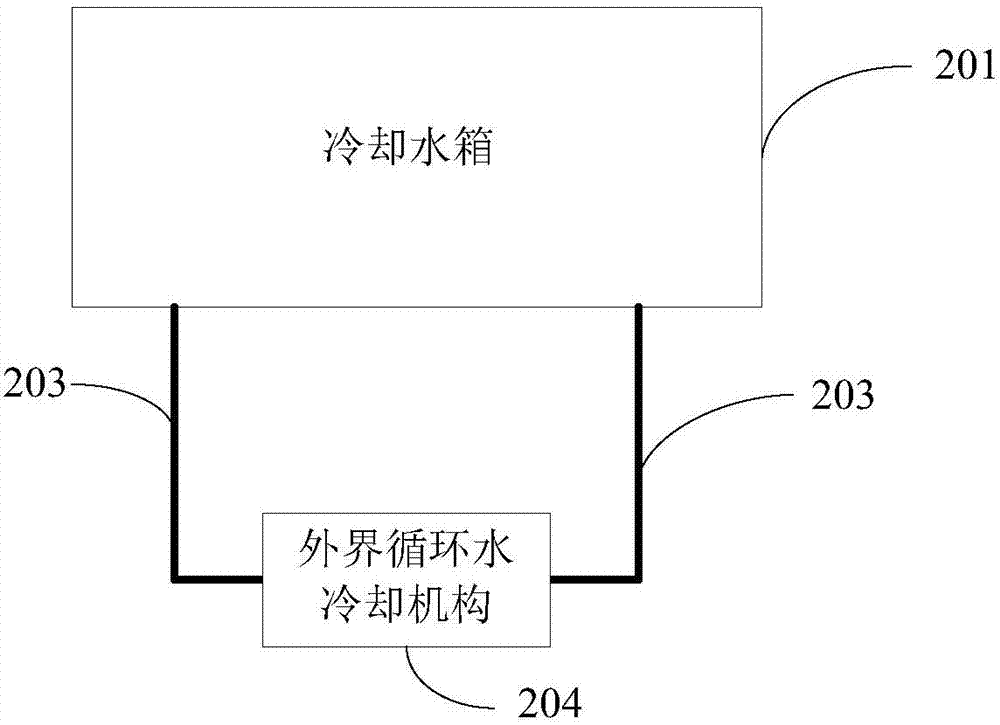

Engine heat balancing performance bed tester and engine heat balancing performance bed testing method

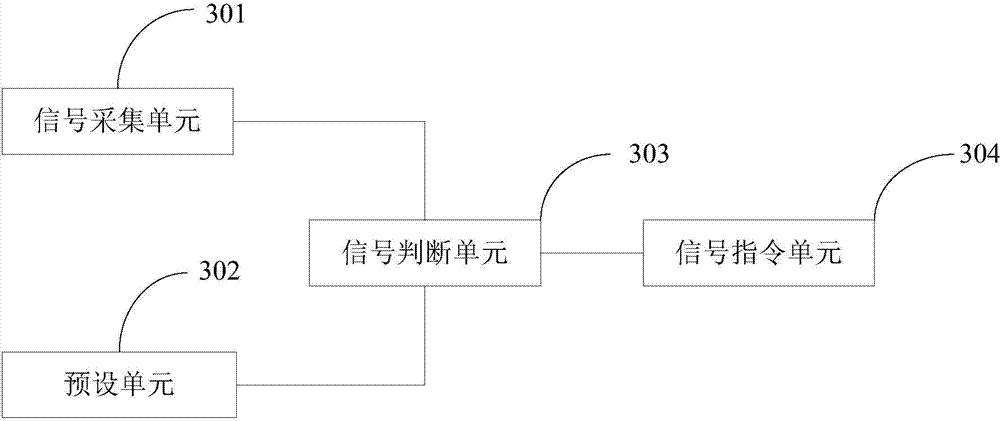

ActiveCN103499448AMatching real-time judgmentEasy to testInternal-combustion engine testingTemperature control using electric meansFeedback controllerTested time

The invention provides an engine heat balancing performance bed tester and an engine heat balancing performance bed testing method, which belong to the field of engine heat balancing technology. The tester provided by the invention comprises an engine bed system, an external cooler and a signal feedback controller; the external cooler is used for cooling built-in cooling devices of a currently tested engine; the signal feedback controller is used for presetting an engine temperature threshold and testing time, monitoring the temperature of the currently tested engine in real time, ordering the engine bed system to control the external cooler to regulate the cooling speed of the built-in cooling devices of the currently tested engine when the temperature of the currently tested engine reaches the preset engine temperature threshold and evaluating the heat balancing performance of the currently tested engine according to the temperature data of the currently tested engine within the testing time. The testing scheme provided by the invention can conveniently and efficiently carry out real-time on-line tests on the engine heat balancing performance of automobiles.

Owner:BAIC MOTOR CORP LTD

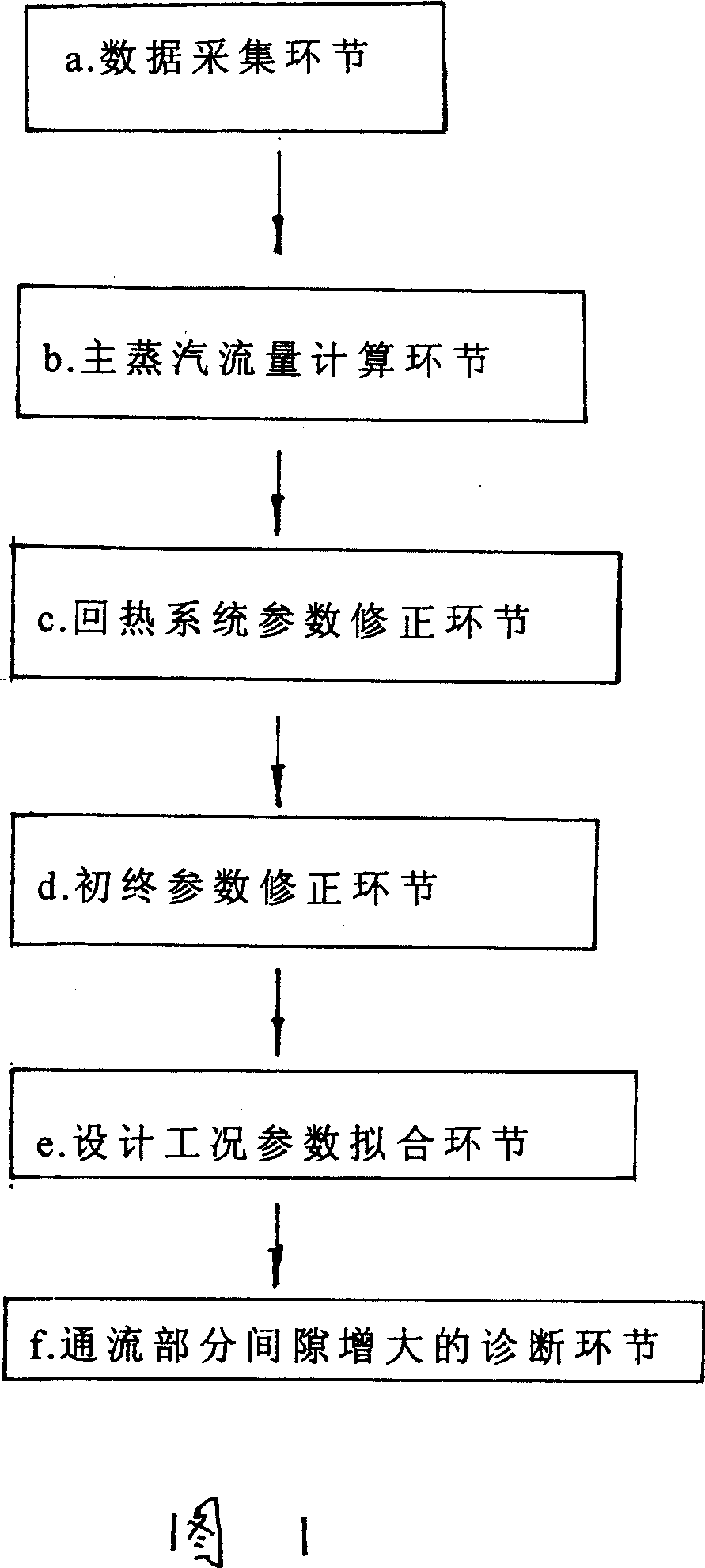

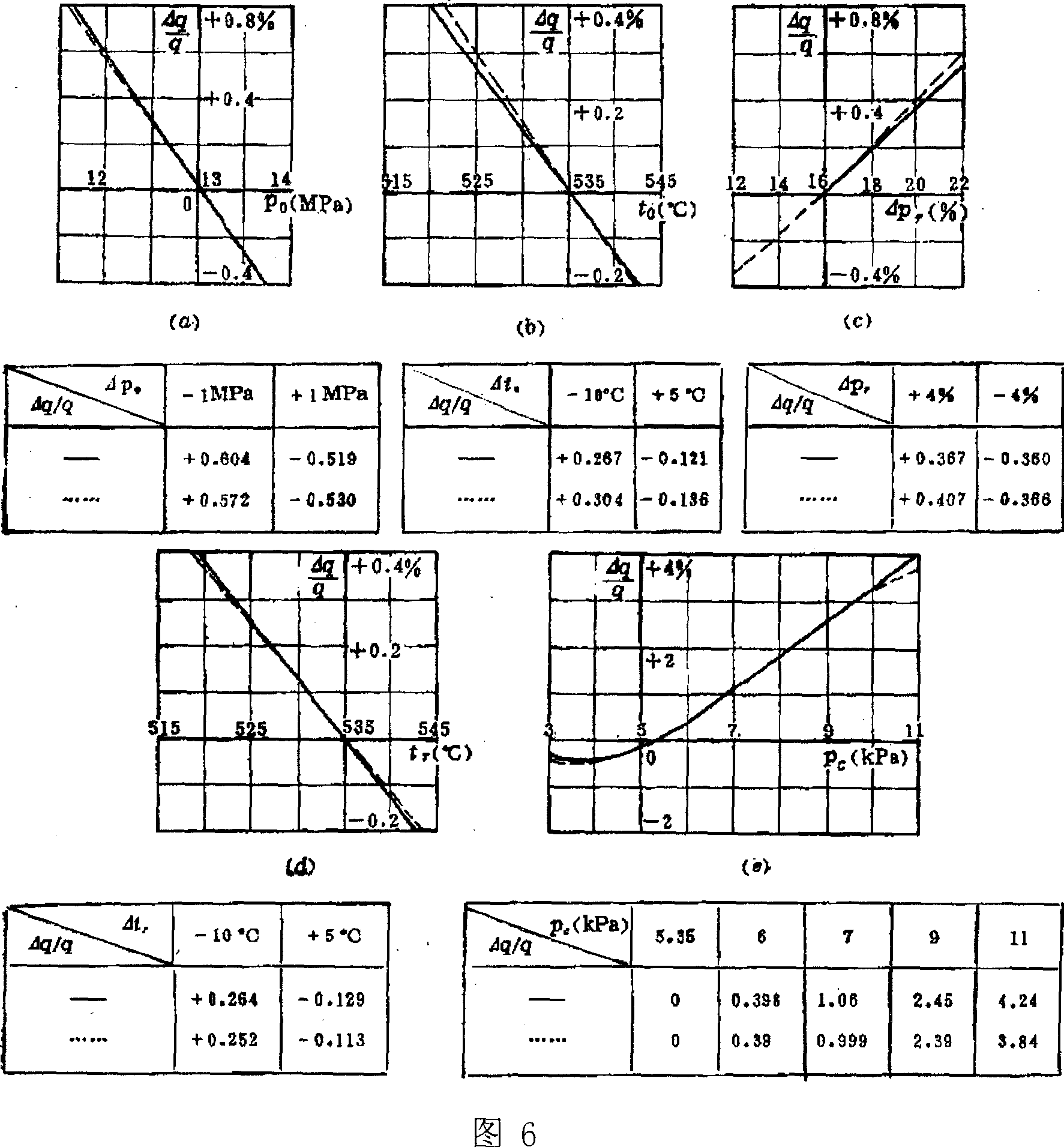

On-line monitoring method for variation of through-flow gap of steam turbine

InactiveCN1952590AMethod scienceRealize automatic online monitoringEngine testingMechanical clearance measurementsData acquisitionEngineering

An on-line monitoring method for the changing circulatation gap of the steam turbine is disclosed that comprises the steps: acquiring data, calculating the flux of the main steam, correcting parameters of the regenerative system, correcting the primary parameter and the end parameter, designing the parameter fitting in operating mode and diagnosing the augment of circulating gap. The main steam flux of the steam turbine can be obtained by computer from the main steam temperature and pressure of the main steam, the regenerative steam temperature and pressure, the vacuum condenser, the temperature and pressure in each of the regenerative exhaust points, the water temperature of the ports, the drain temperature and the water flux of condensate, the flux value of the cooling water of the superheater and the reheater when the steam turbine is running. Based on the heat balance diagram in the operating mode of the steam turbine, the temperature, pressure and the internal efficiency ratio of the regenerative ports in the condition of the main steam are contrasted with the real temperature, pressure and the internal efficiency ratio of the regenerative ports to realize the on-line monitoring for the changing circulatation gap of the steam turbine. The method is scientific to realize the automatical on-line monitoring and exact fault diagnosis.

Owner:NORTHEAST DIANLI UNIVERSITY

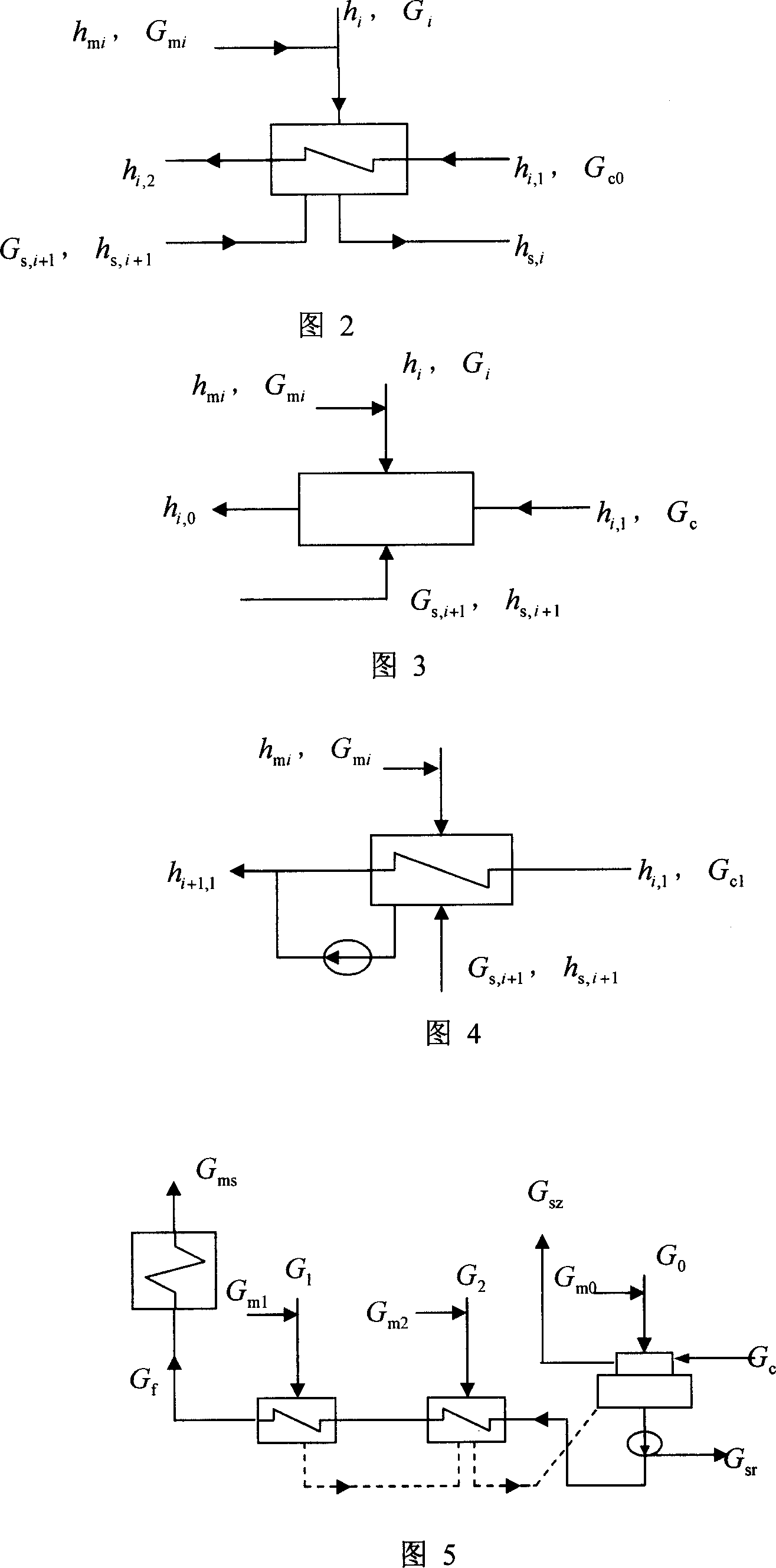

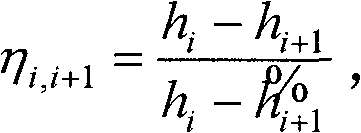

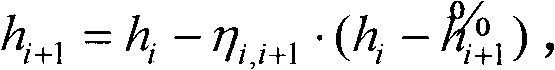

Method for estimating exhaust enthalpy of low pressure cylinder of steam turbine in real time

The invention discloses a method for estimating the exhaust enthalpy of a low pressure cylinder of a steam turbine in real time, which belongs to the field of steam turbine parameter measurement. The method comprises: firstly, defining the exhaust efficiency of the (i+1)th stage of a turboset; secondly, obtaining the exhaust enthalpy of the (i+1)th stage of the turboset accordingly; and thirdly, according to a collected heat balance diagram of the steam turbine, obtaining the design parameters of the steam turbine under various working conditions, fitting the relationship between inter-stage efficiency of steam turbine and pressure ratio and calculating the exhaust efficiency eta i, i+1 of the (i+1)th stage of the seam turbine under different conditions from the exhaust efficiency of the last stage upward stage by stage. The method overcomes the drawback that the calculation speed of a loop iteration algorithm is far insufficient for meeting the demands for on-line monitoring of the machine and estimates the exhaust enthalpy of the low pressure cylinder of the steam turbine in real time when the turboset works under various working conditions.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

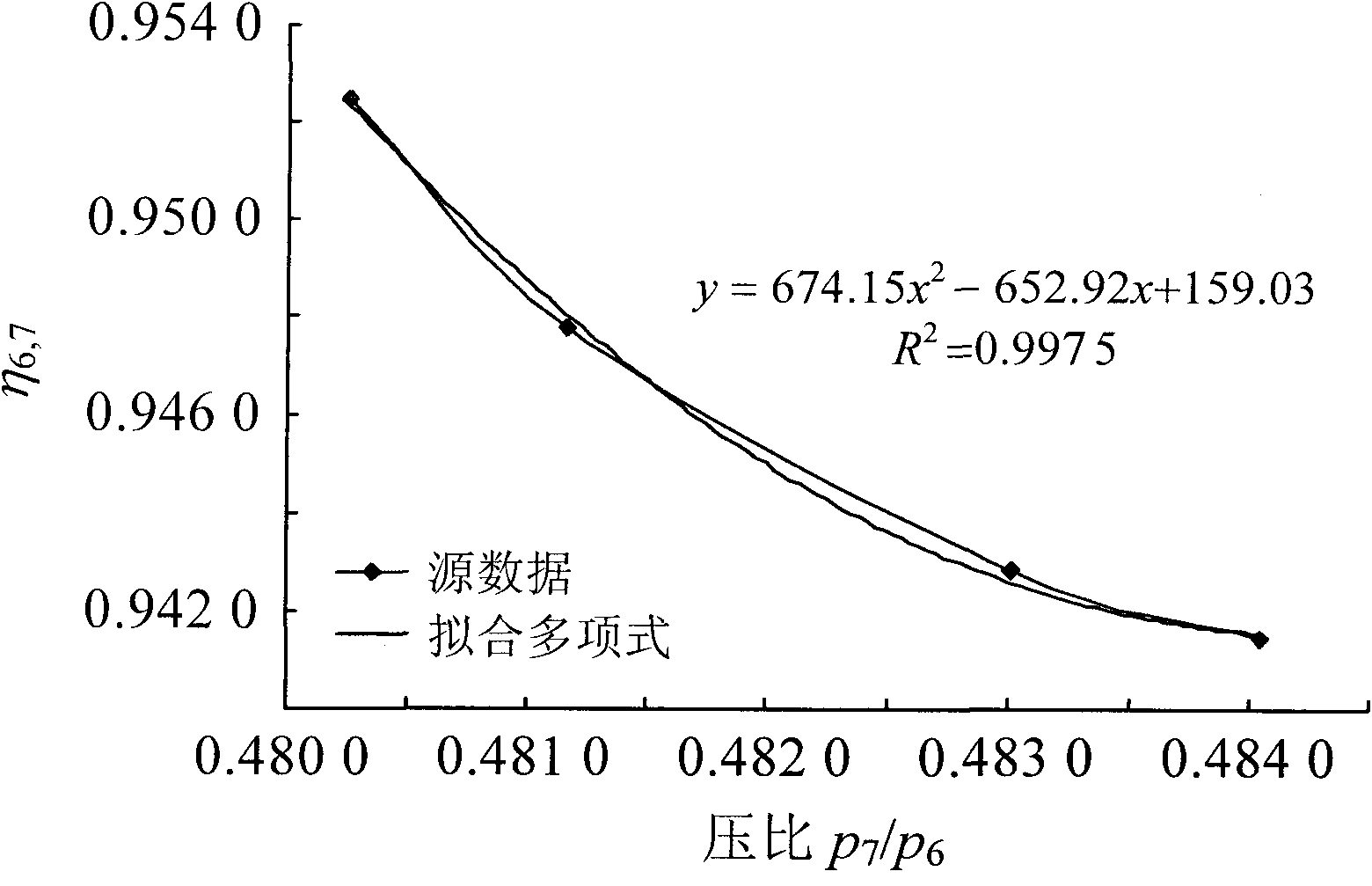

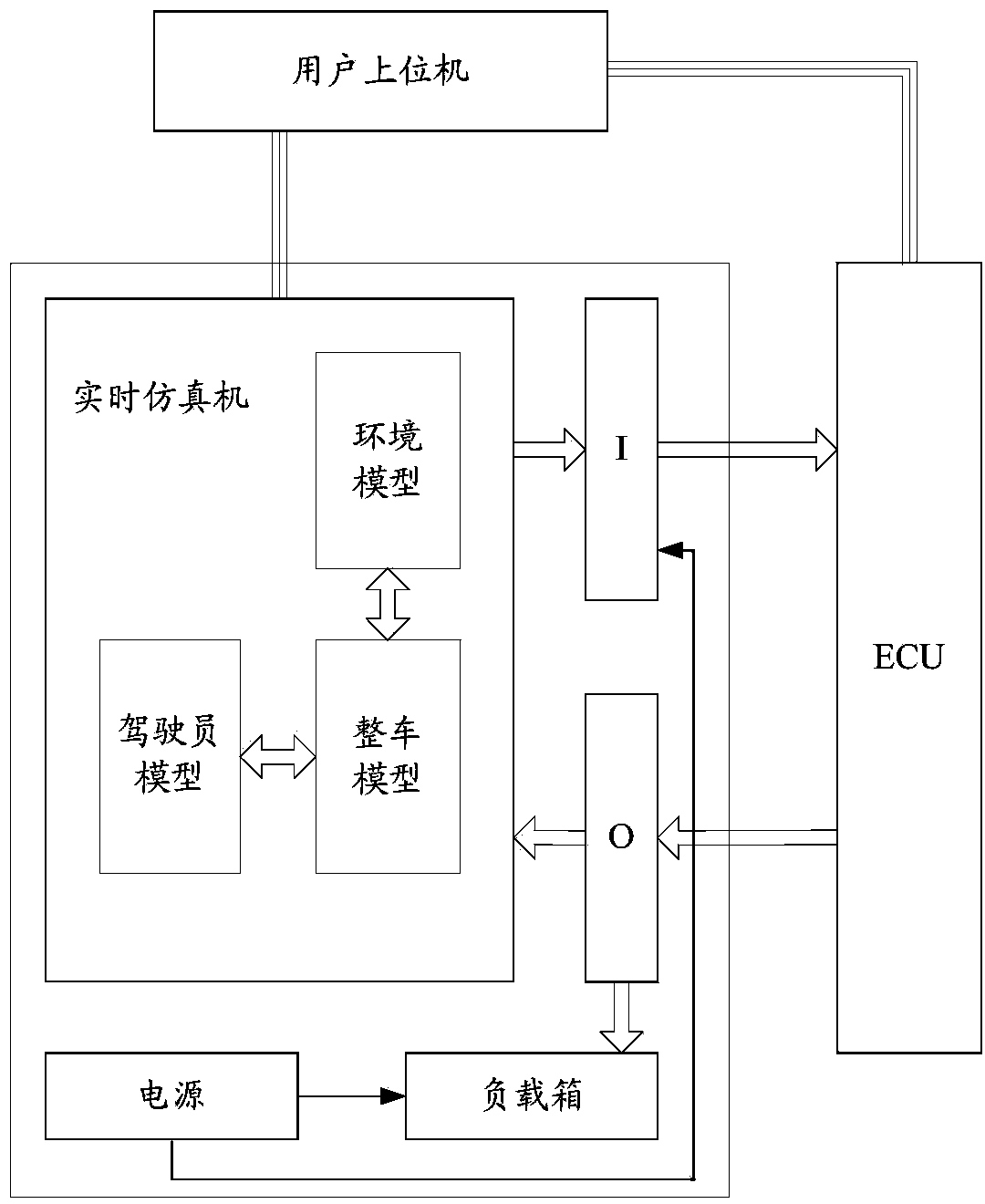

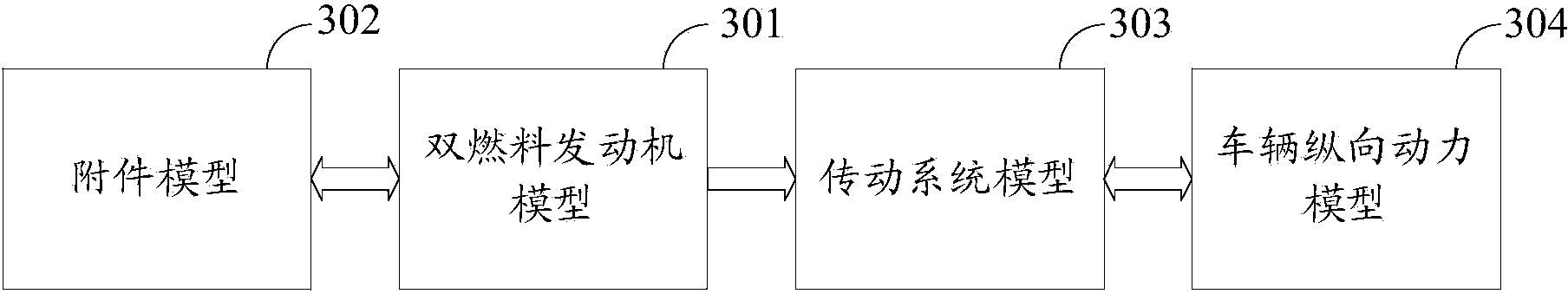

Dual-fuel engine controller simulation test system

ActiveCN104111650ARealize closed-loop testingRealize dynamic testingElectric testing/monitoringReal-time simulationCombustion

The invention discloses a dual-fuel engine controller simulation test system, and is used for realizing an HIL test of an HPDI engine controller. The system includes a real-time simulator and an engine controller, wherein the real-time simulator is used for operating an environmental model, a driver model and a full vehicle model, sending vehicle environment parameters output by the environmental model, driver behavior parameters output by the driver model and each vehicle operating parameter output by the full vehicle model to the engine controller, and receiving a control signal sent by the engine controller, and continuing to operate the environmental model, the driver model and the full vehicle model according to the control signal, and the full vehicle model includes a dual-fuel engine model (including a gas circuit model, a fuel supply model, a cylinder combustion model, and a heat balance model), an accessory model, a drive system model, and a vehicle longitudinal power model. The engine controller is used for determining the operating condition of the engine according to the vehicle environment parameters, the driver behavior parameters and the vehicle operating parameters and generating and sending the control signal.

Owner:WEICHAI POWER CO LTD

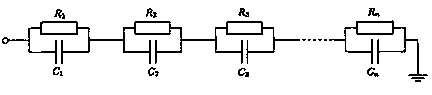

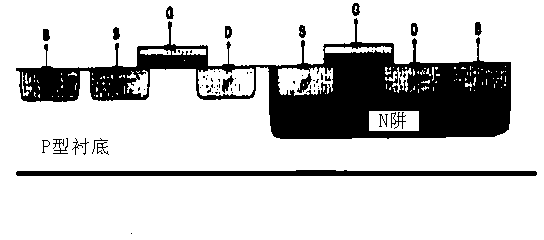

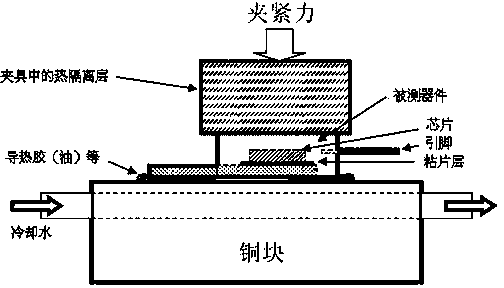

Thermal resistance measuring method for semiconductor device

ActiveCN103792476AMaterial heat developmentIndividual semiconductor device testingJunction temperatureHeat balance

The invention relates to a thermal resistance measuring method for a semiconductor device. The thermal resistance measuring method includes the following steps that (1) according to the structure of the semiconductor device, a main heat conduction channel is determined, and a constant temperature plane good in contact is arranged on the surface of a shell of the main heat conduction channel; (2) certain power is loaded to the semiconductor device, after the semiconductor device reaches heat balance, it is switched to the situation that measuring power is loaded to the semiconductor device, temperature-sensitive parameters of the semiconductor device are measured in real time to obtain the junction temperature for measuring the semiconductor device, and accordingly a transient thermal response curve of the semiconductor device is obtained; (3) according to the transient thermal response curve, the thermal resistance from a junction of the semiconductor device to the shell is determined. According to the thermal resistance measuring method for the semiconductor device, heating power is loaded through a P zone and an N zone of a substrate of the semiconductor device, the junction temperature is measured by the utilization of a PN junction assembly existing in the semiconductor device, and therefore the transient thermal resistance of integrated circuit products without temperature-sensitive diodes and the transient thermal resistance of non-power integrated circuit products can be measured accurately.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

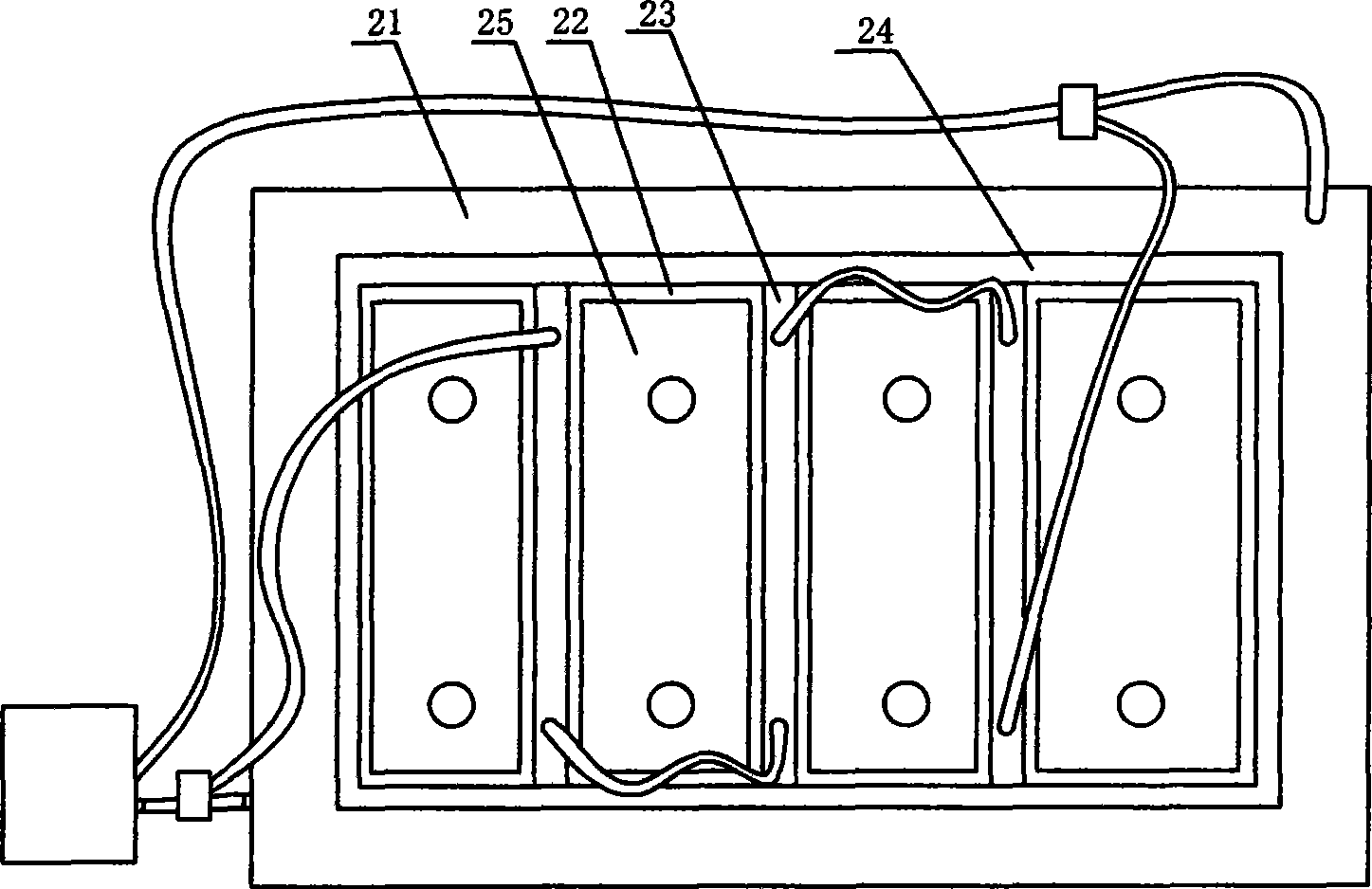

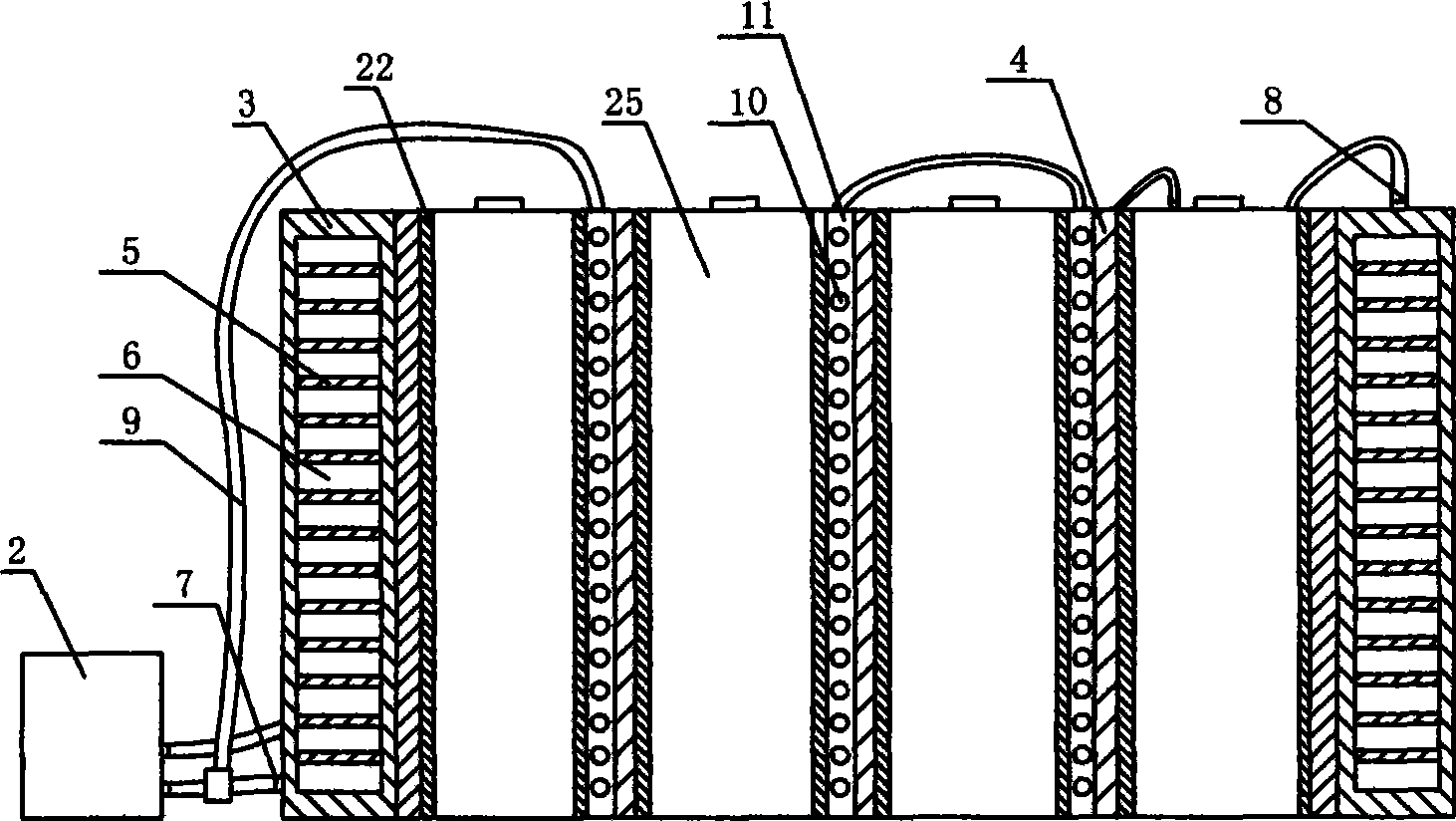

Water cooling method for vehicle lithium power cell set and device thereof

The invention discloses a water cooling method for a vehicle lithium power cell set and a device thereof. Besides that the surface of the lithium power cell set is mounted with a water cooling radiating device, one side of each cell core shell is directly mounted with an internal water cooling radiating device during production, and the internal water cooling radiating device of the lithium power cell set and the cell monomer is distributed at intervals. The invention combines the original water cooling radiating device of the lithium power cell set to realize the requirement of all-round and balanced heat radiation for the lithium power cell set and overcome the defect of poor heat radiation performance among the cell monomers on the existing lithium power cell set. The internal water cooling radiating device is simple in manufacturing, convenient in processing and has obvious radiating effect, thus improving the safety and reliability in the use process of the lithium power cell set, realizing the heat balance management in the water cooling process, and being applicable to the vehicle and vessel lithium power cell set featuring simplicity, practicality and reliability thereof.

Owner:高宾

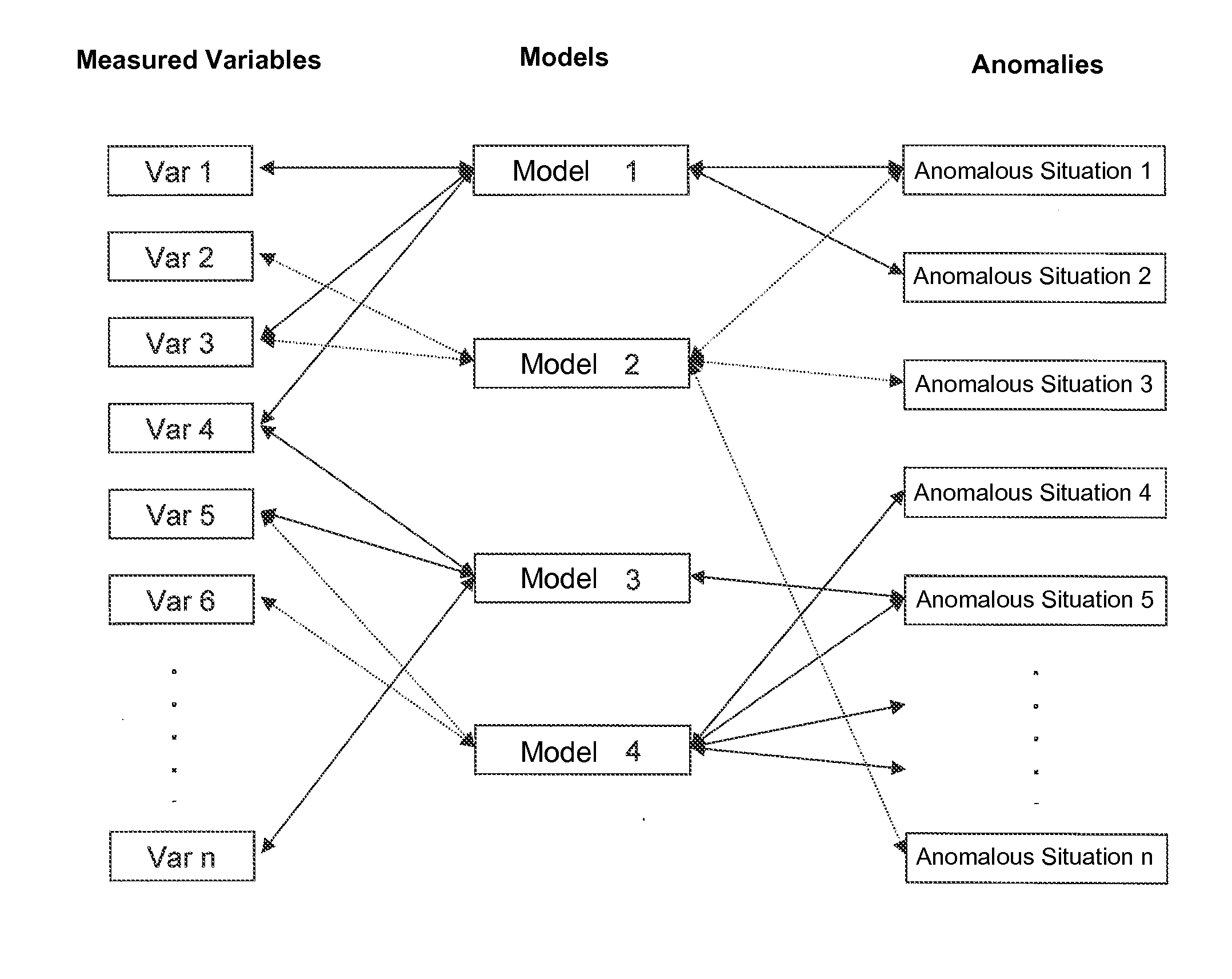

Device and method for detection and/or diagnosis of faults in a processes, equipment and sensors

ActiveUS20150095003A1Simulator controlTesting/monitoring control systemsHigh probabilityHeat balance

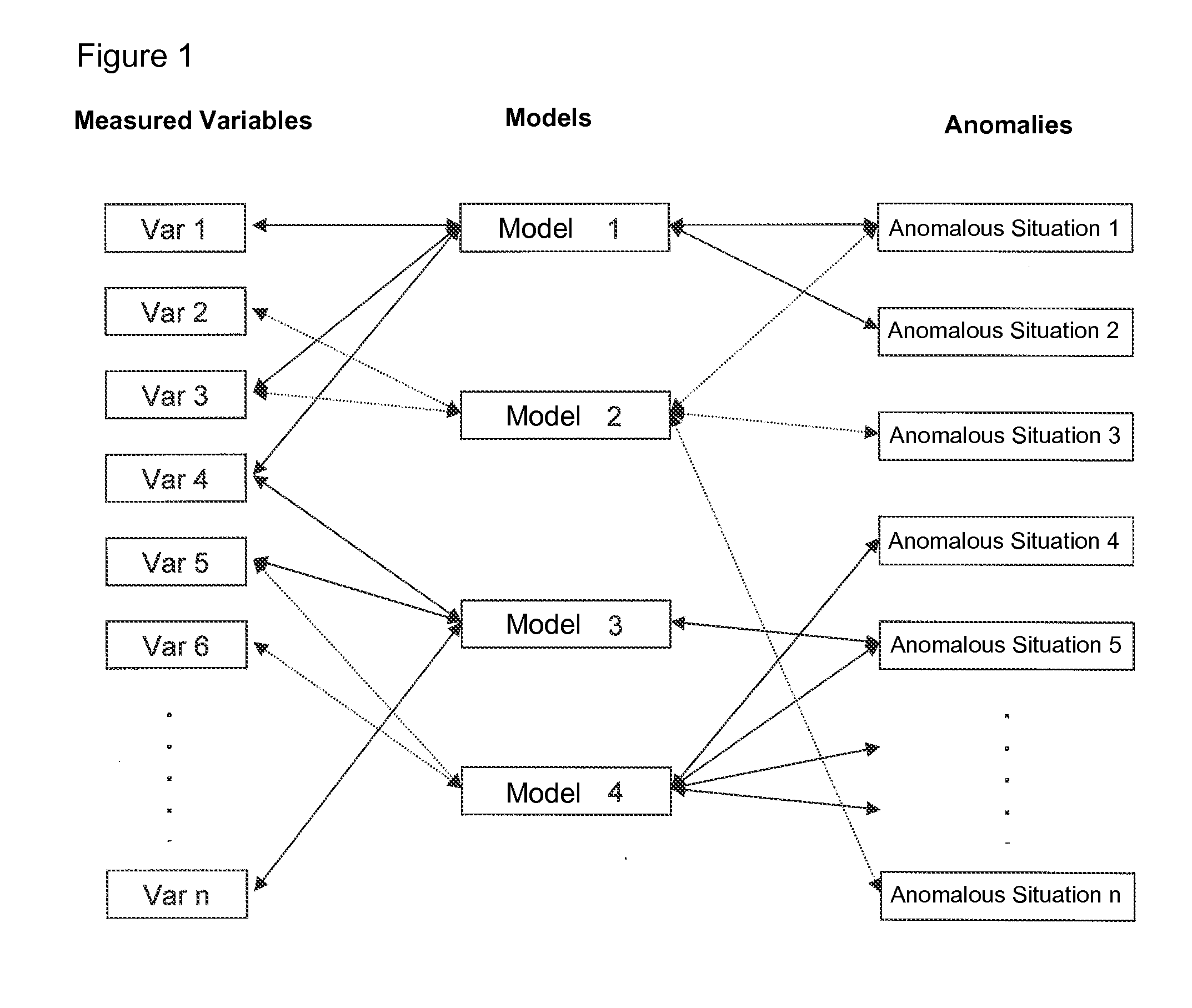

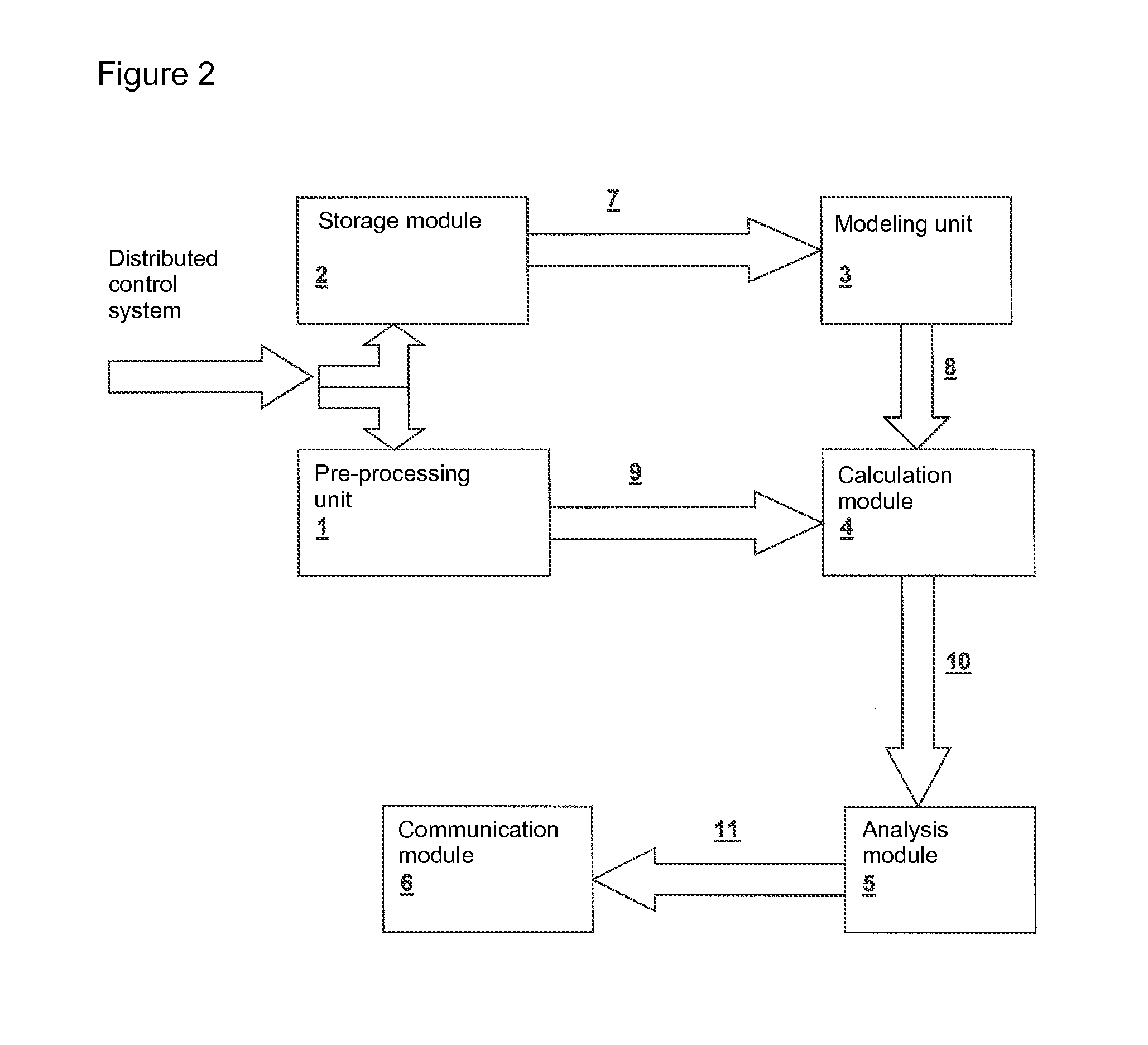

Device and method for the detection and / or diagnosis of faults in a process, equipment and sensors used to measure and control variables of a process, either for single faults or multiple faults. The detection and / or diagnosis are performed on the basis of residual calculation between measured values and values calculated by a plurality of parallel linear models, built up from the existing correlations between the measured variables by the process sensors and by different equations that rule the process, such as mass and heat balances, quality relationships, etc. A fault in a model (i.e. the obtainment of a residual anomaly high by comparing the model estimation and the measurement), increases the probability that some of the parameters or faults associated to that model are failing. When all models in which a participating parameter fail or show a high probability of failure, the anomaly rate of said parameters is maximum. Using said rates and a description of cause-consequence relationship between the parameters a fault probability is obtained, where the root cause of the problem is indicated, indicating the consequences produced in the process. The device comprises data storage means; pre-processing means for filtering data; means for generation and storage of multiple behavior models; residual calculation means for calculating the difference between the measured and the predicted values of the variables; analysis means for determining the need to communicate an anomalous situation; communication means for presenting a process status report.

Owner:YPF TECHA

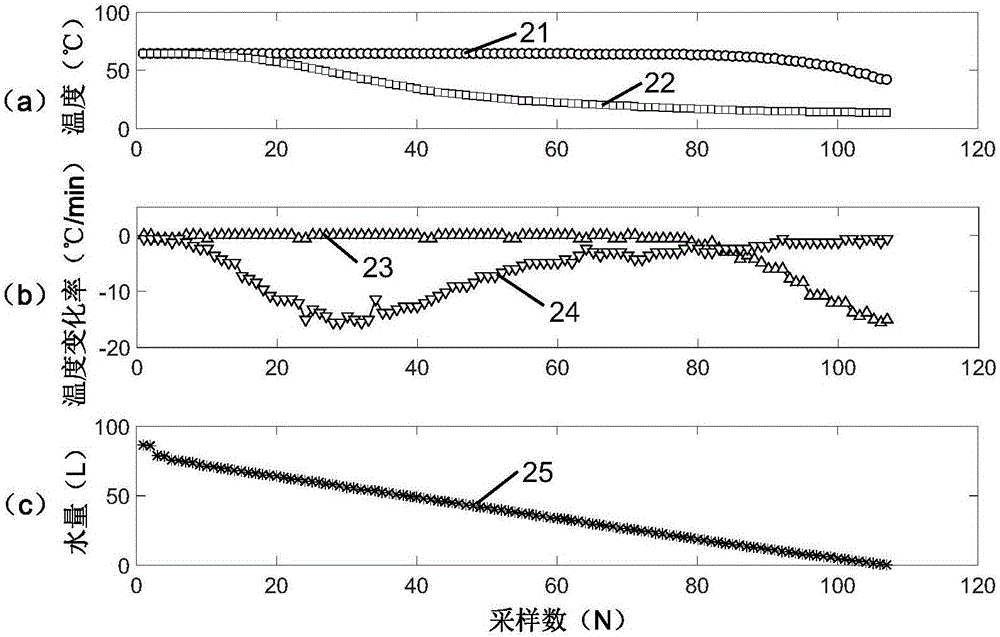

Prediction method of remaining bath time of water storage type electric water heater

ActiveCN106352542ASmall amount of online data computationAccurate predictionWater heatersWater storageWater volume

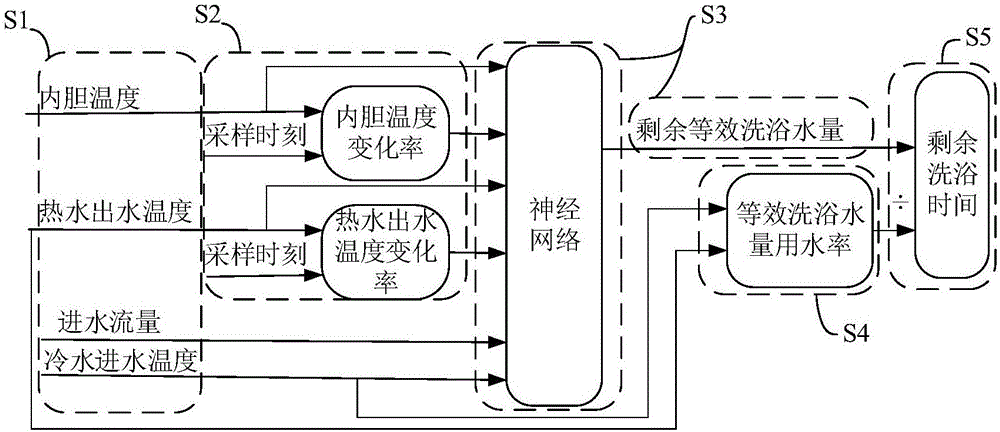

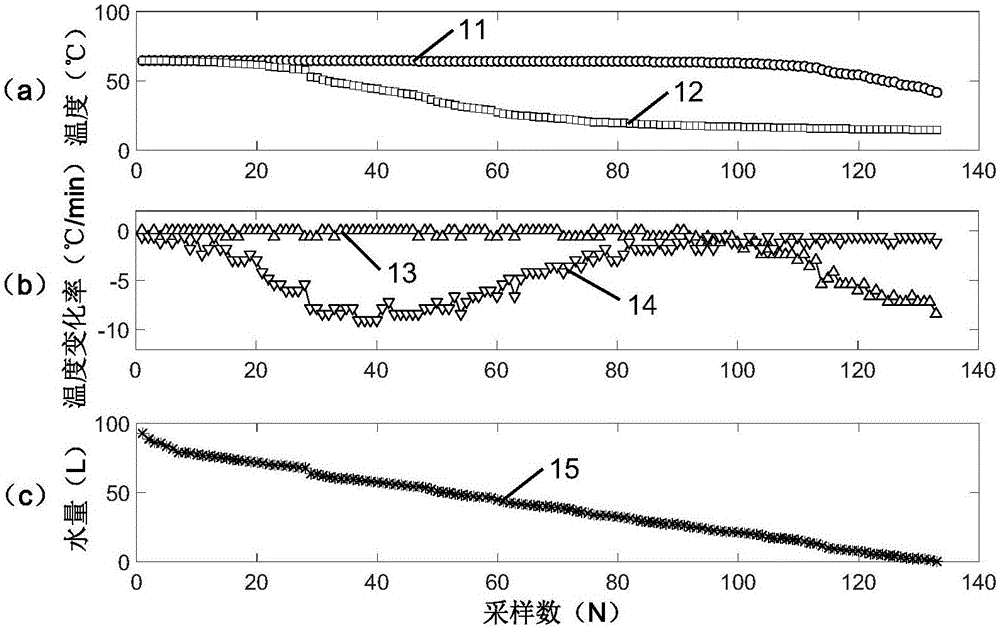

The invention relates to a prediction method of remaining bath time of a water storage type electric water heater. The prediction method comprises the following steps of extracting the flow, hot water outlet temperature, liner temperature and cold water inlet temperature at a water consuming moment within a certain sampling period for the water storage type electric water heater; respectively calculating change rates of the hot water outlet temperature and the liner temperature by adopting a least-squares linear fitting method; using the flow, the hot water outlet temperature, the liner temperature, the cold water inlet temperature and the change rates of the hot water outlet temperature and the liner temperature as neural network input quantities, and estimating the amount of remaining equivalent bath water through neural network computation; calculating the water consuming rate of the amount of the equivalent bath water according to a heat balance law and the flow, the hot water outlet temperature and the cold water inlet temperature which are extracted by current sampling; finally, dividing the estimated amount of the remaining usable equivalent bath water by the water consuming rate of the amount of the equivalent bath water so as to obtain the remaining bath time. According to the prediction method, the remaining bath time can be accurately estimated, so that the user bath quality is increased, and the user experience is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

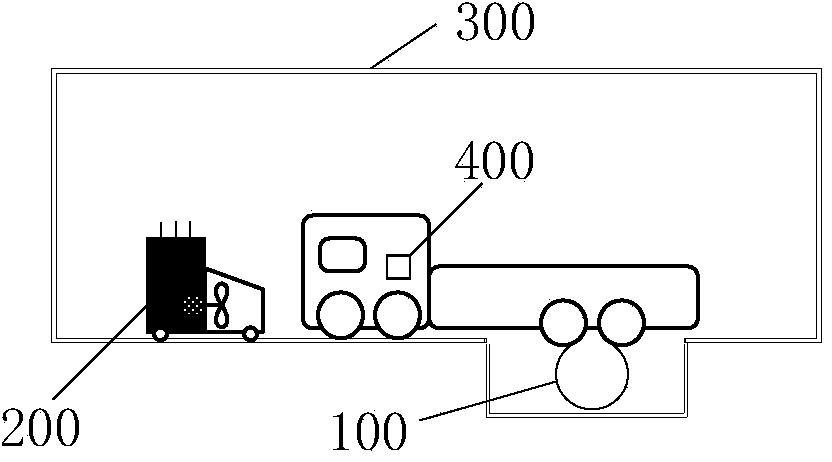

Indoor testing device and method for vehicle heat balance ability

ActiveCN104180997AEasy to operateSimple heat balance capabilityVehicle testingEngine testingMaximum torqueTemperature control

The invention discloses an indoor testing device and method for the vehicle heat balance ability, and belongs to the field of vehicle cooling system heat balance technologies. The device comprises a chassis dynamometer, an environment bin with a temperature control system, a cooling fan and a temperature data collection system. The chassis dynamometer is arranged in the environment bin. The cooling fan is arranged in front of a vehicle to be tested in the environment bin and used for simulating the air speed. The temperature data collection system is arranged in the vehicle to be tested and used for measuring the temperature of a vehicle water way and the environment. According to the indoor testing device and method, the heat balance ability of an engine and a cooling system of the vehicle are tested fast and effectively, the maximum power point of an external characteristic curve of the engine, the water inlet and outlet temperature, at the maximum torque point, of the engine and the water inlet and outlet temperature of a radiator are tested, matching and requirements of the engine and the cooling system of the vehicle can be judged in real time, and the state of the sample vehicle to be tested can be adjusted for research and development.

Owner:NANJING AUTOMOBILE GROUP CORP

Method and device for measuring liquid thermal conductivity factor

InactiveCN101113963ASimple structureEasy to calculateMaterial thermal conductivityMaterial heat developmentHotlineTemperature difference

The invention discloses a method for measuring liquid thermal conductivity coefficient and the device thereof. The invention adopts homeostasis hotline principle to measure liquid thermal conductivity coefficient. The calculation formula of the liquid thermal conductivity coefficient is used when different heat sources are applied under the condition of one dimensional conduction respectively deduced by Fourier heat conduction basic law. Then the heat generated by the heating resource which is transmitting heat. And the liquid thermal conductivity coefficient is calculated by measuring the temperature difference at particular points in heat conduction direction when heat balanced. High-temperature resistant coaxial double-layer pipes are used as outer pipes while heat stable heating tube used as inner pipes. Liquid to be measured is packed in the space between the inner and the outer pipes. The ratio of the length of the outer pipe to the external diameter of the outer pipe exceeds is greater than 10. The way of heating of the inner pipe adopts constant-temperature and uniform-speed circulating water or tempering wire and filled with high temperature resistant liquid at the same time. The former is suitable for common liquid and the latter for high temperature flammable liquid. The invention has the advantages of simple structure, large serviceable range and high accuracy rating, thus measuring the coefficients of heat conductivity of various liquids simply and precisely is possible.

Owner:吴永刚

Method for determining optimal floor heating operation condition of air source heat pump based on energy conservation

The invention discloses a method for determining an optimal floor heating operation condition of an air source heat pump based on energy conservation. All conventional methods have the problem that the energy cannot be saved enough and is wasted. The method considers the influence of the environmental temperature, the water supply temperature and the circulating water mass flux on a system, and comprises the steps of creating a heat balance model of floor heating, creating an energy efficiency ratio and power consumption model of the heat pump, creating an energy consumption model equation of floor heating water circulation, creating a total optimization model, and optimizing by the models to obtain optimal control parameters for enabling the system to run at an optimal working point. According to the method, the running energy consumption of the system can be reduced, so that the purposes of reducing the running cost, saving energy and reducing emission are achieved.

Owner:HANGZHOU DIANZI UNIV

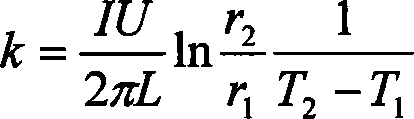

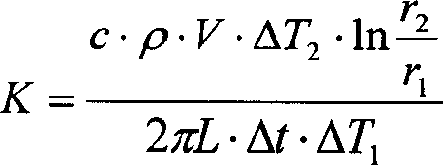

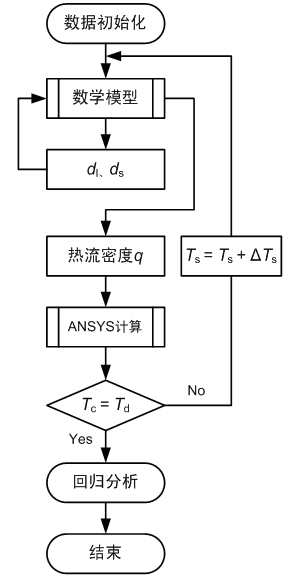

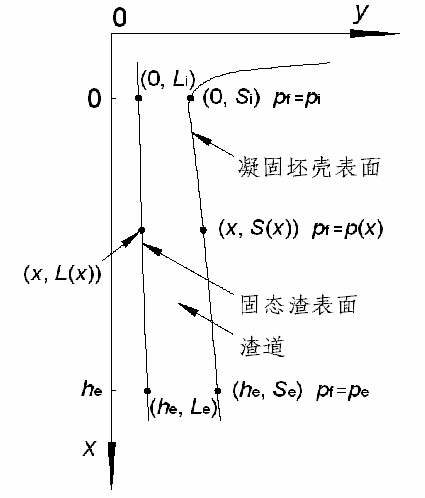

Determination method of copperplate heat flux based on mass balance and heat balance continuous casting mould

The invention discloses a determination method of copperplate heat flux based on mass balance and heat balance continuous casting mould, which belongs to the field of numerical calculation and application in ferrous metallurgical continuous casting process. The method comprises the steps of (1) acquiring raw data, (2) acquiring the consumption rate of mould powders,(3) acquiring molten slag layer thickness (d1) and solid slag layer thickness (ds) by utilizing the equation models of mass balance and heat balance,(4) acquiring heat-flow density q, (5) constructing the physical model of crystallizers, calculating thermocouple temperature Tc and comparing the calculated value Tc with the measured value Td. The above method has the advantages of coupling the mass balance of mould powder consumption and the energy balance of molten steel heat transfer. According to the method of the invention, specific boundary condition equations are obtained by regression method after the temperature and heat flow value of specific locations being determined, without being heavily dependent on specific equations of heat transfer boundary.

Owner:NORTHEASTERN UNIV

Method for processing zinc leaching residues at high proportion by using oxygen bottom blown furnace

ActiveCN101985695AReduce pollutionRealize industrial productionProcess efficiency improvementLead smeltingChemical reaction

The invention belongs to a pyrometallurgical technology of leaded materials and the like, in particular to an economic and harmless method for processing zinc leaching residues produced in a zinc hydrometallurgy process. In the technology, the intensified smelting characteristic of an oxygen bottom blown furnace is used, and sulfide is added to maintain heat balance of the smelting and accurately control oxidizing atmosphere, thus the added zinc leaching residues at high proportion can be subject to decomposition, desulfuration, scorification and the other chemical reactions in the oxygen bottom blown furnace, wherein the recovery rates of Pb, Zn, Cu, Ag, S and the other valuable metals in the zinc plant leaching residues are more than 99%.The method provided by the invention has the advantages of simple operation and high metal recovery rate; and in addition, in the method, resources are saved, i.e. wastes are comprehensively recovered, environmental contamination is avoided, the technological flow of a mature SKS lead smelting process can be used fully, and the comprehensive utilization level is improved.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

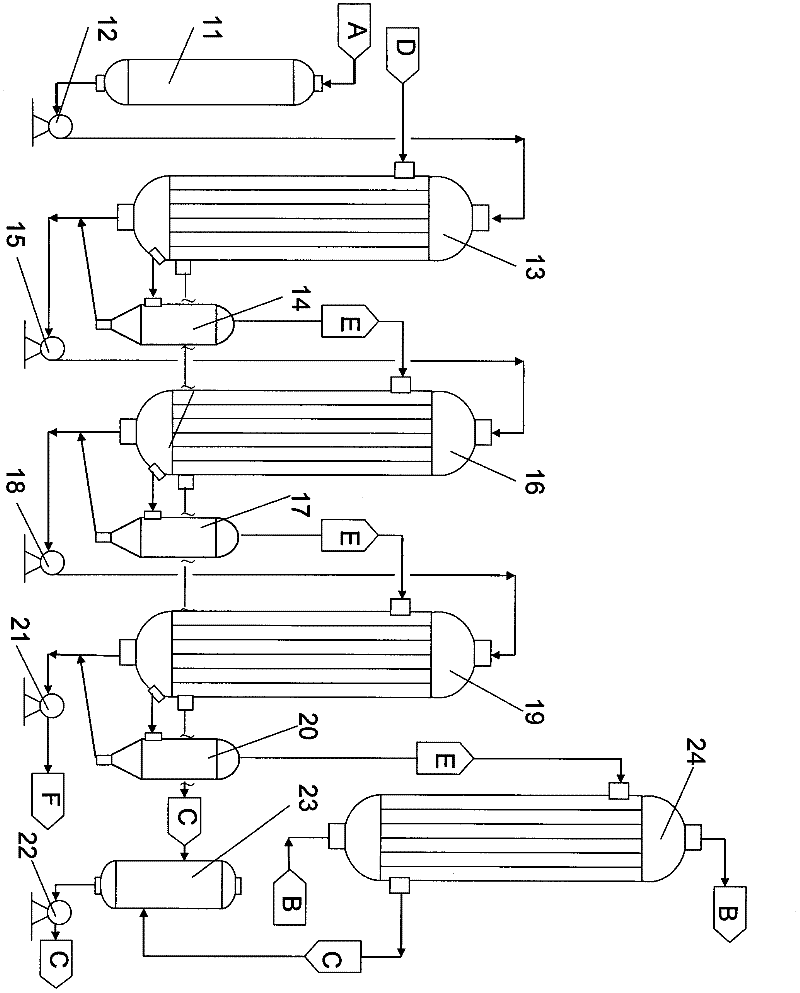

Energy-saving evaporating process and equipment for L-phenylalanine brine solution

ActiveCN102343162ASmall volumeEnergy saving processEvaporator accessoriesMultiple-effect evaporationVapor liquidHeat balance

The invention relates to an energy-saving evaporating process and equipment for a L-phenylalanine brine solution, belonging to the technical field of efficient energy saving and environmental protection. The process comprises the following steps of: preheating a 1 percent concentration of feed solution to 50-60 DEG C with a preheater 4; making the preheated feed solution enter the tube pass and shell pass of a falling film evaporator 7 and a climbing film evaporator 8 for secondary vapor heat exchange at 78-80 DEG C, heating to 70 DEG C, and evaporating in a way of combining a falling film with a climbing film to generate secondary vapor and a concentrated solution; making the secondary vapor and the concentrated solution enter a separator 9 for vapor-liquid separation; making the separated secondary vapor enter a centrifugal compressor 10 for compressing and increasing caloric content, heating to 78-80 DEG C for serving as a heating source of the evaporators 7 and 8, and heating and evaporating the feed solution; discharging the concentrated solution of which the concentration is controlled at 3 percent from the separator 9, and returning the concentrated solution of which the concentration does not reach 3 percent to the climbing film evaporator 8 for continually evaporating and concentrating. The system has the advantages of self-heat balance, small using amount of live vapor, low running cost, high efficiency and saving in energy.

Owner:想莱(常州)节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com