Energy-saving evaporating process and equipment for L-phenylalanine brine solution

A phenylalanine salt and process technology, applied in the field of L-phenylalanine salt solution evaporation and energy-saving technology and equipment, can solve the problems of no patents and literature reports, etc., and achieve cooling circulation water saving, energy consumption reduction, heat The effect of rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] specific implementation plan

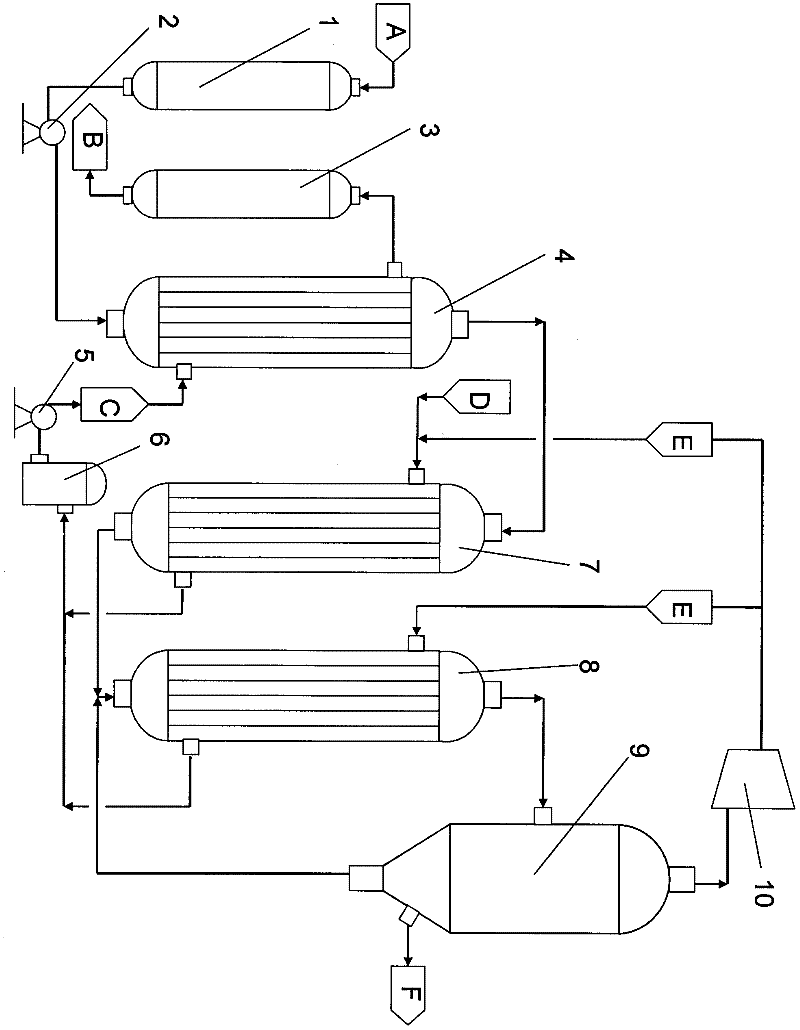

[0034] Attached below figure 1 The energy-saving process and equipment for evaporation of L-phenylalanine salt solution are further described.

[0035] like figure 1 As shown, the temperature in the raw material tank (1) is 20-30° C., and the low concentration L-phenylalanine salt solution raw material solution with a concentration of about 1% is pumped into the shell-and-tube preheater (4) through the raw material pump (2). In the tube side, it exchanges heat with the condensed water from the shell side of the falling film evaporator (7) and the rising film evaporator (8), and the raw material liquid is preheated to 50-60°C; the preheated raw material liquid enters The tube side of the falling film evaporator (7) is heated and evaporated in the way of falling film, and then enters the tube side of the rising film evaporator (8) to be heated and evaporated in the way of rising film to generate steam and concentrated liquid, steam and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com