Patents

Literature

111results about How to "Efficient process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

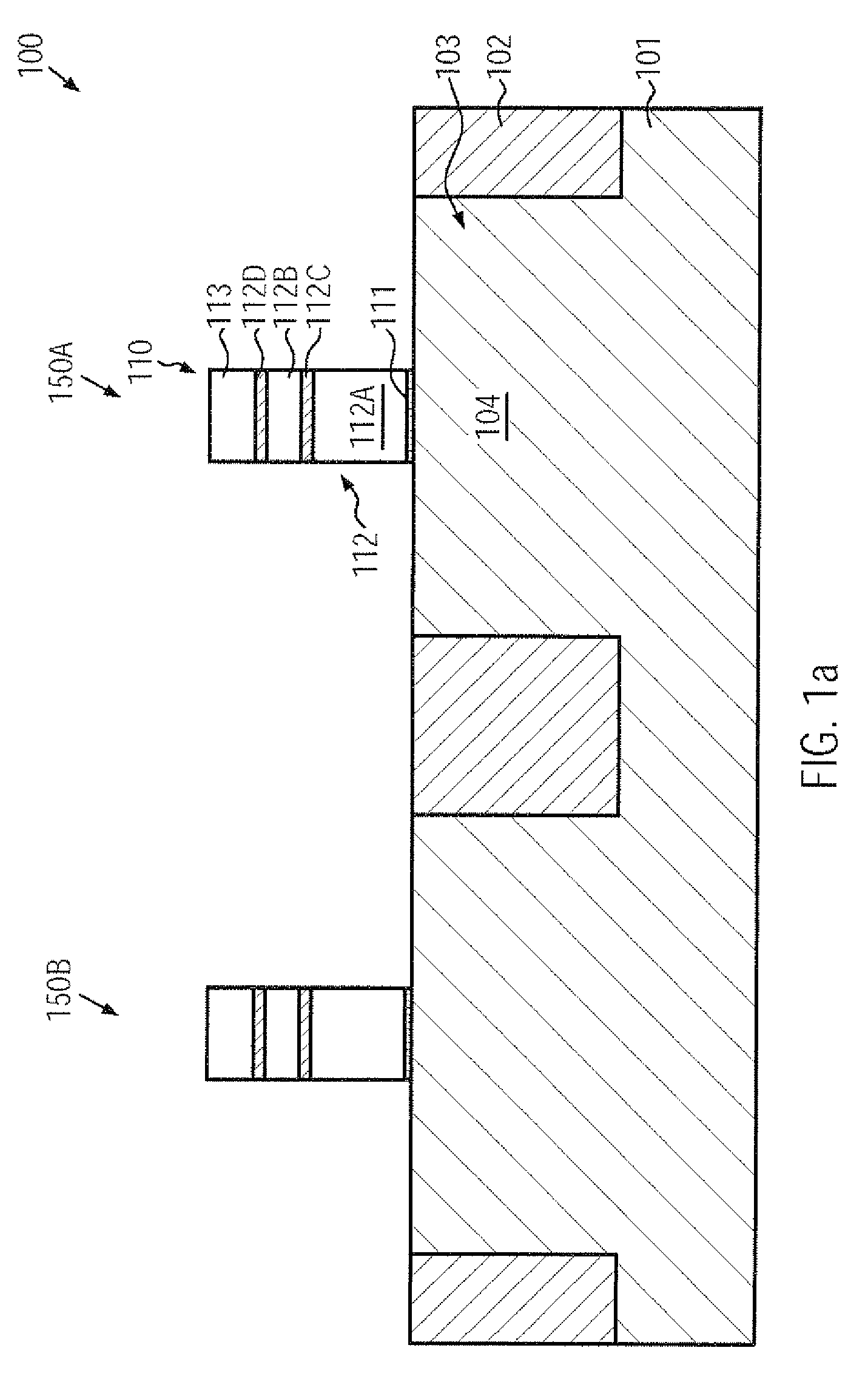

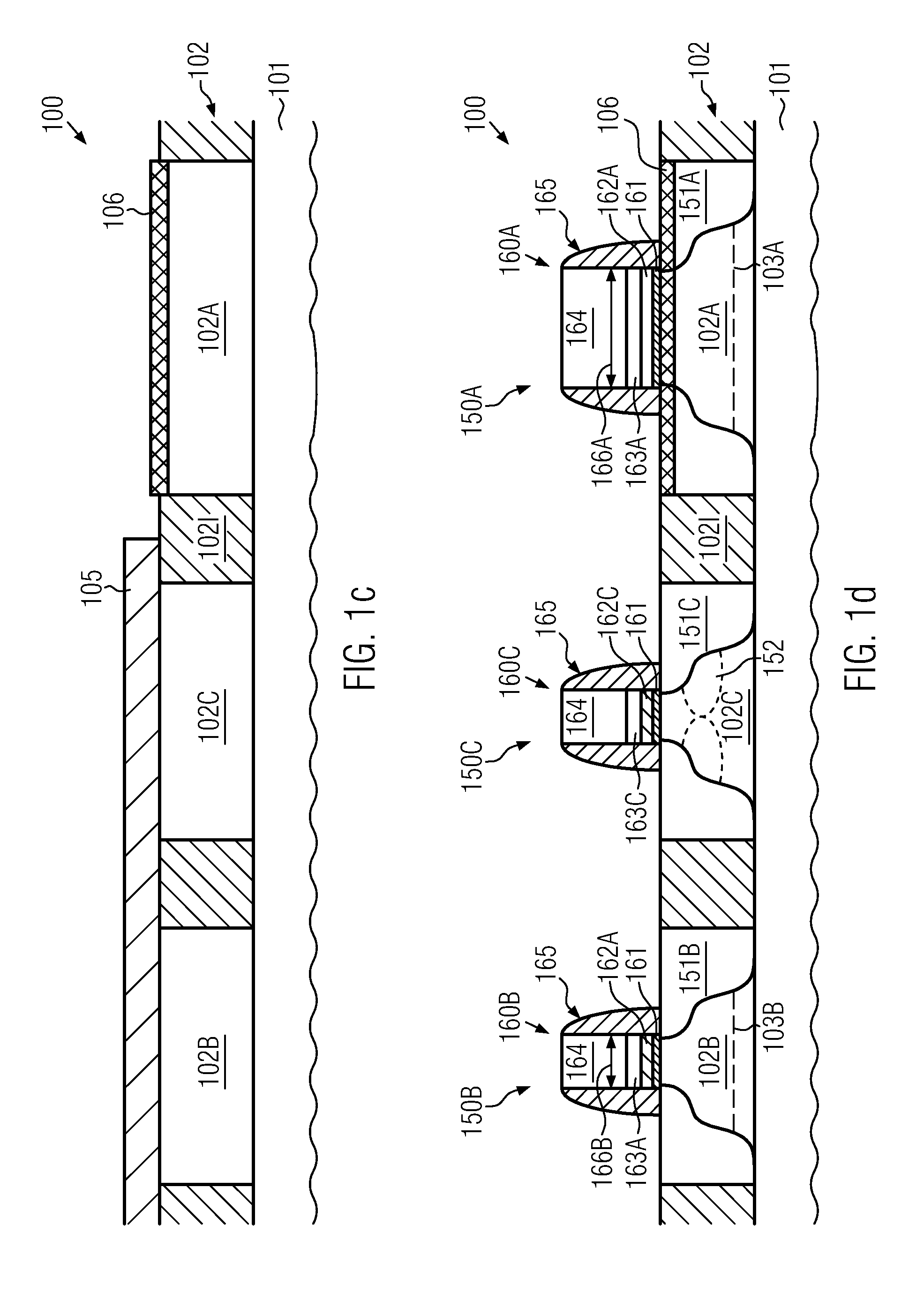

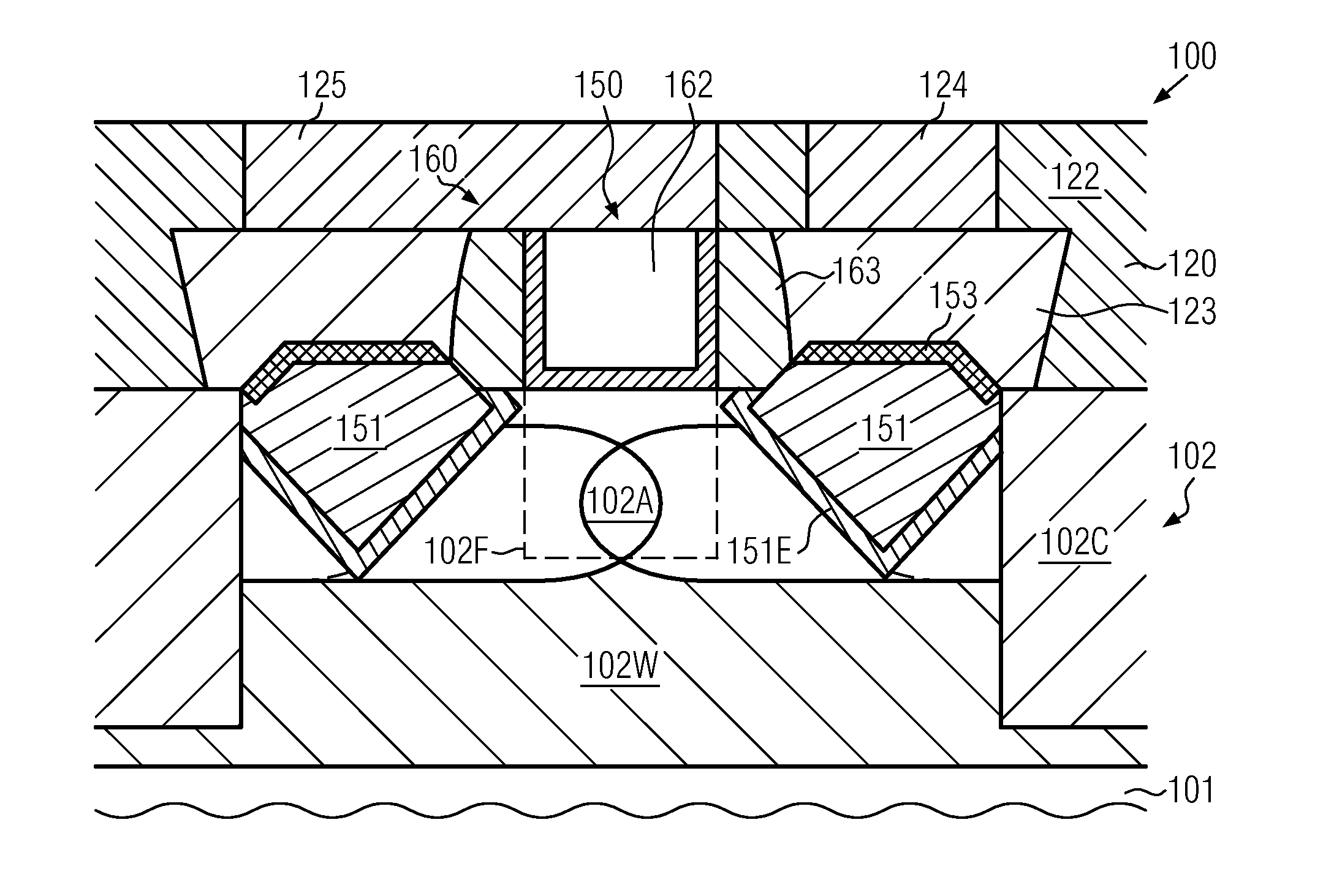

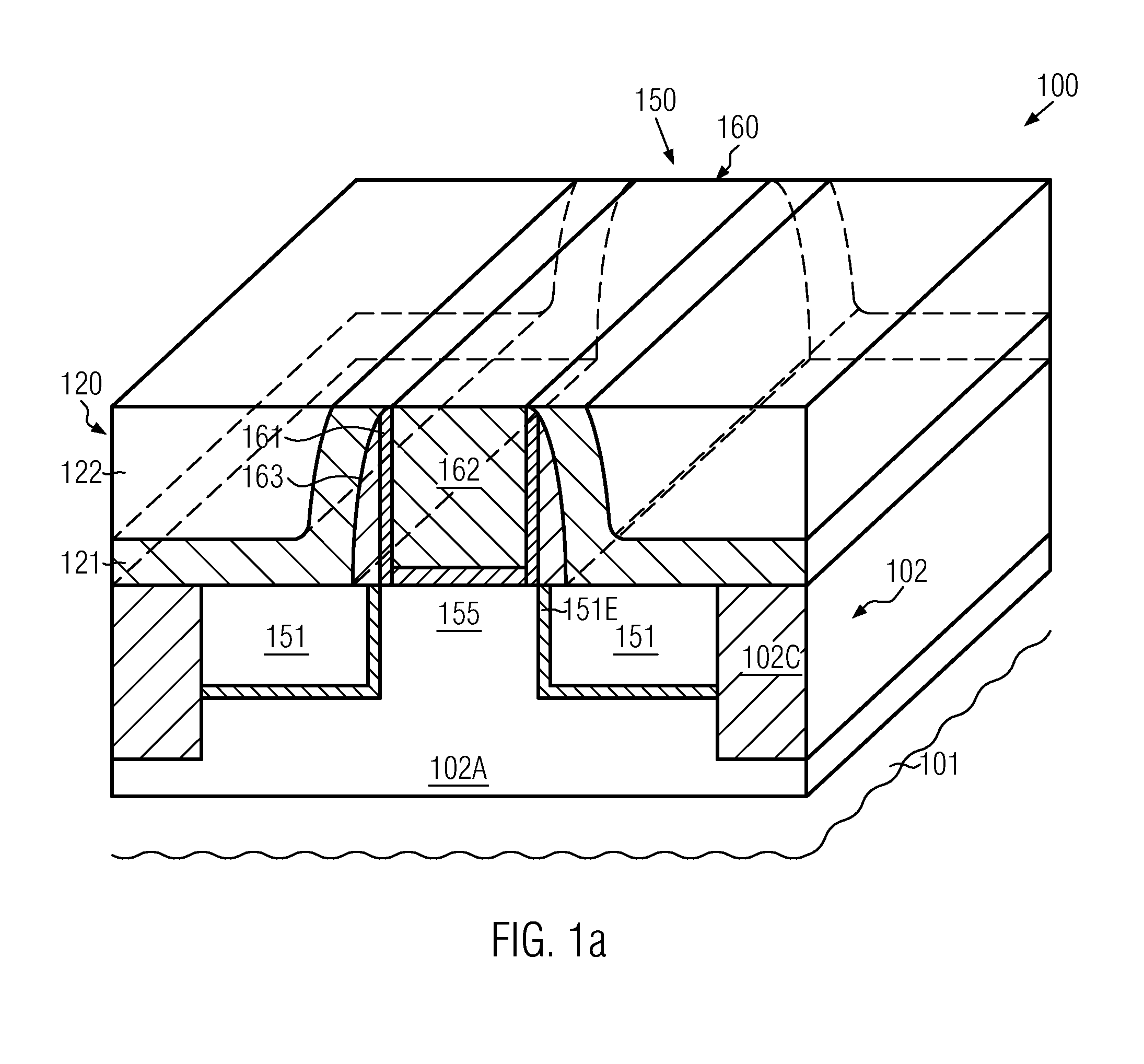

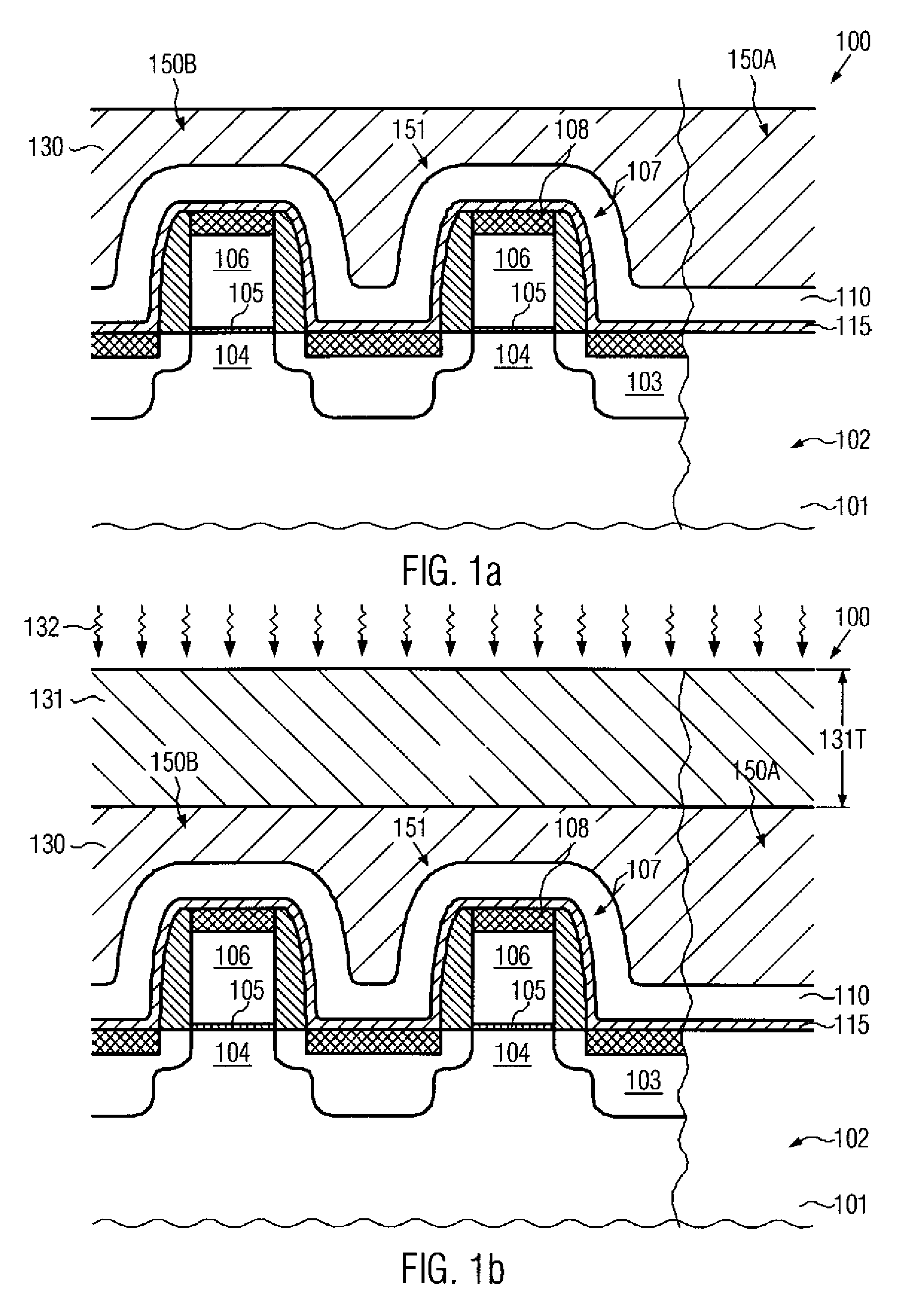

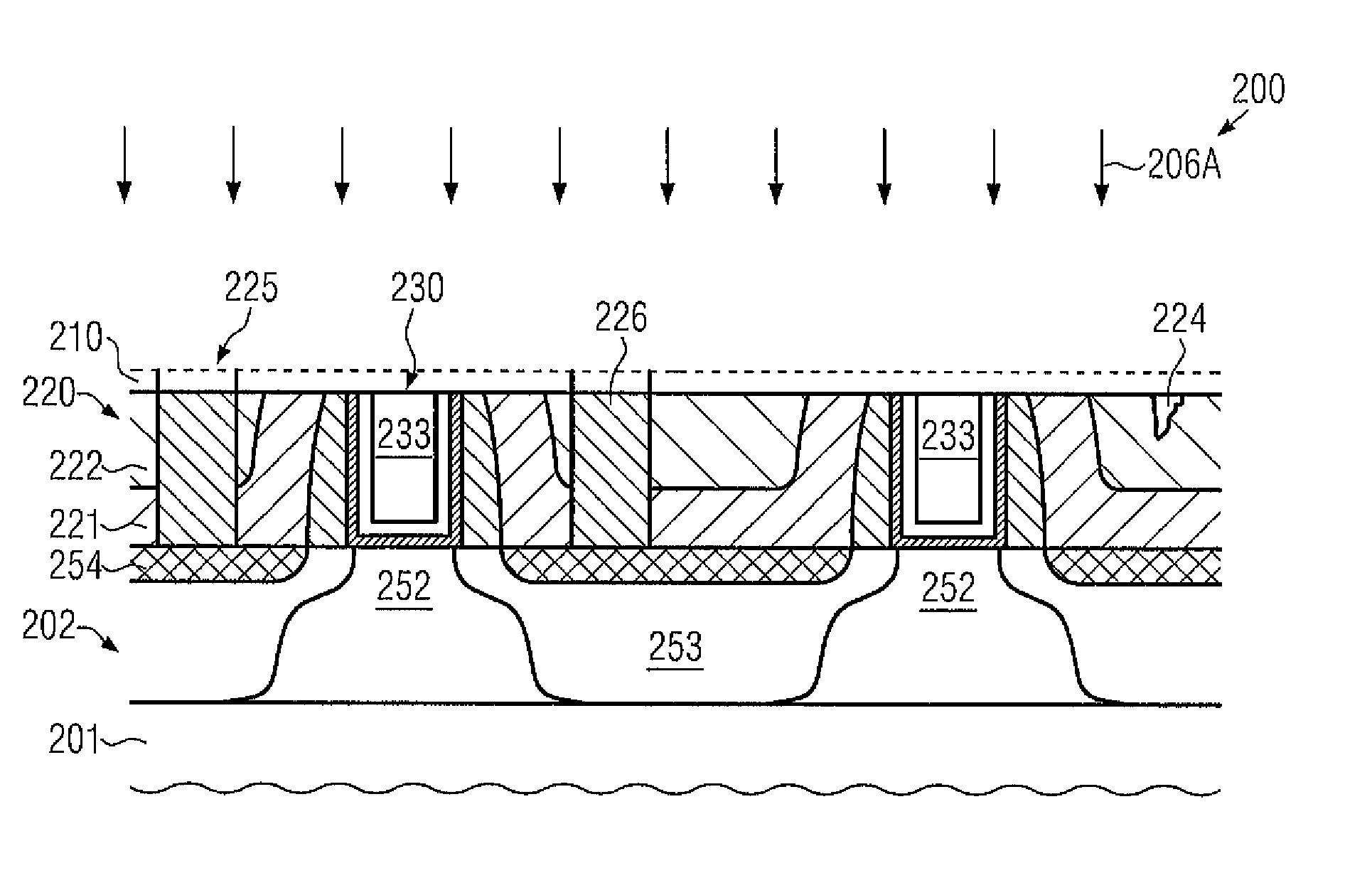

Self-Aligned Fin Transistor Formed on a Bulk Substrate by Late Fin Etch

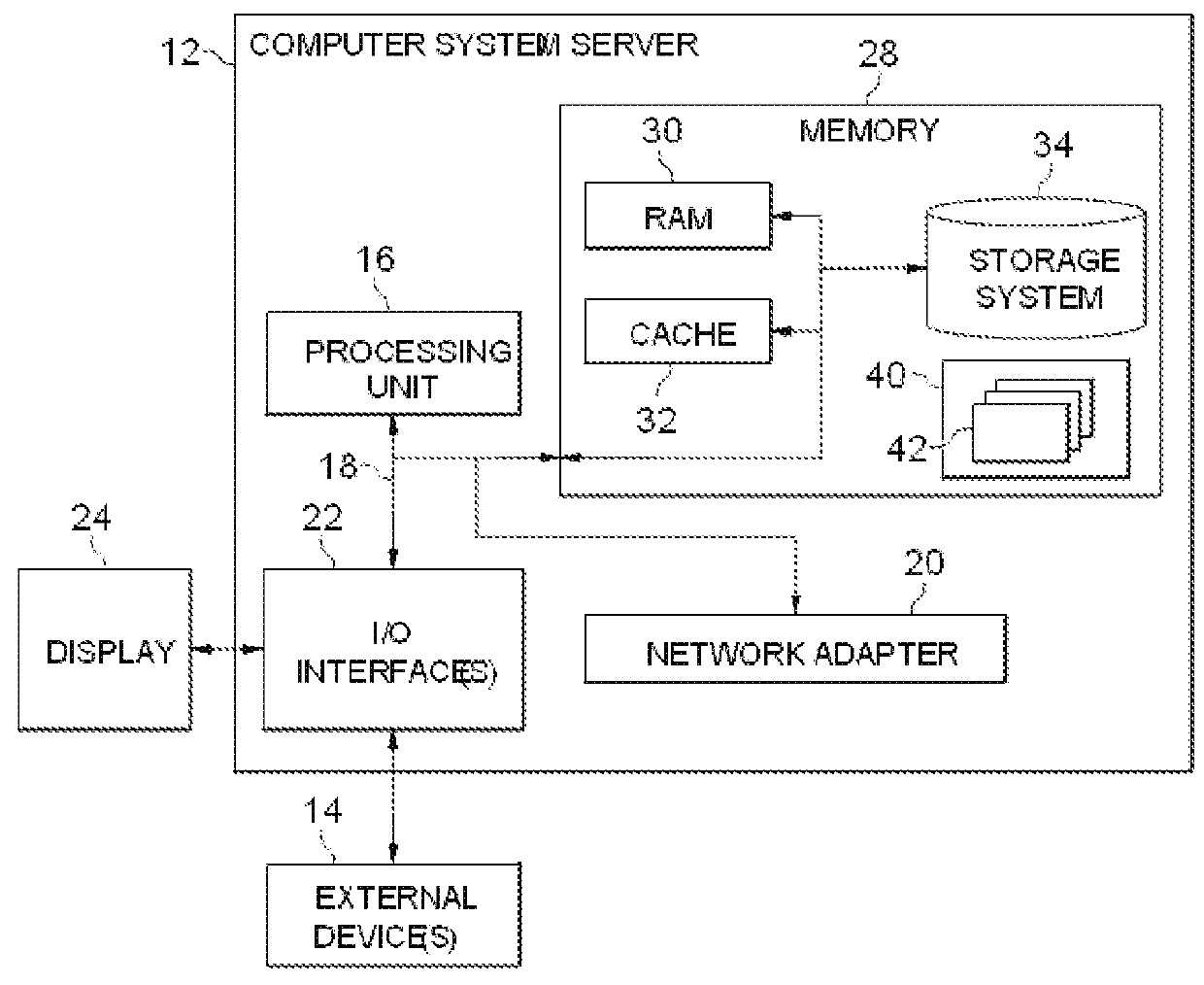

ActiveUS20120161238A1Efficient process flowSolid-state devicesSemiconductor/solid-state device manufacturingProcess conditionsSemiconductor

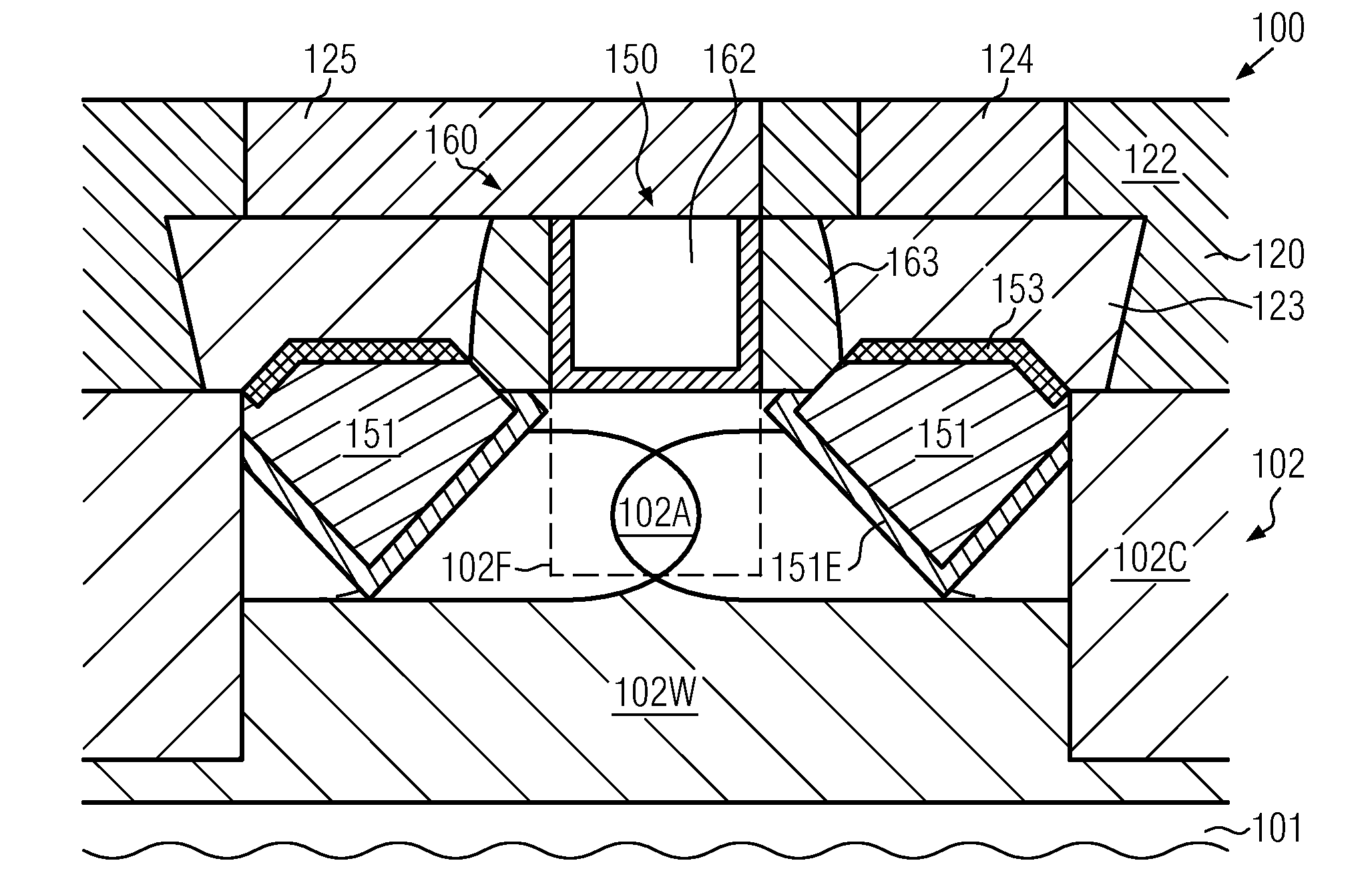

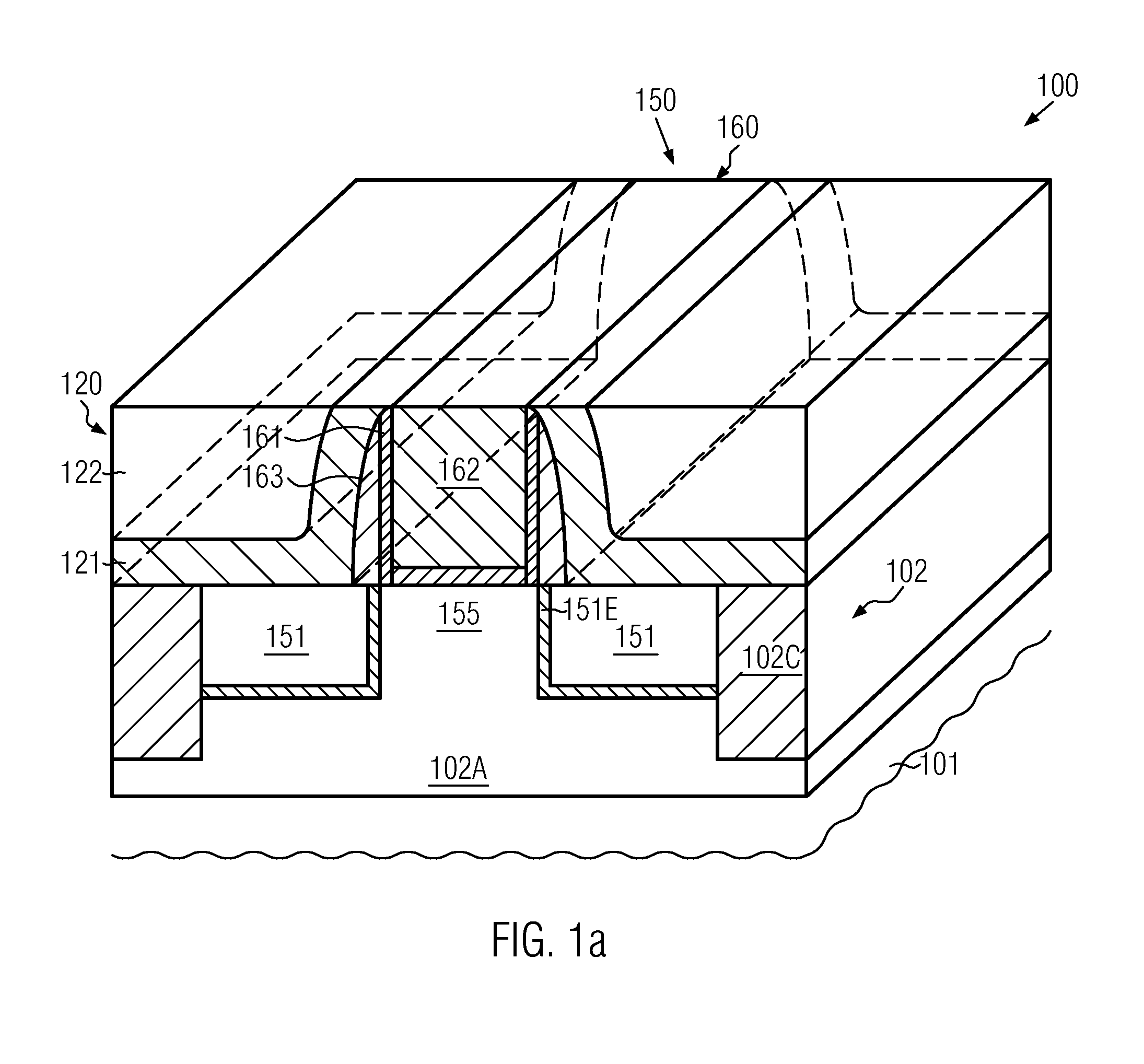

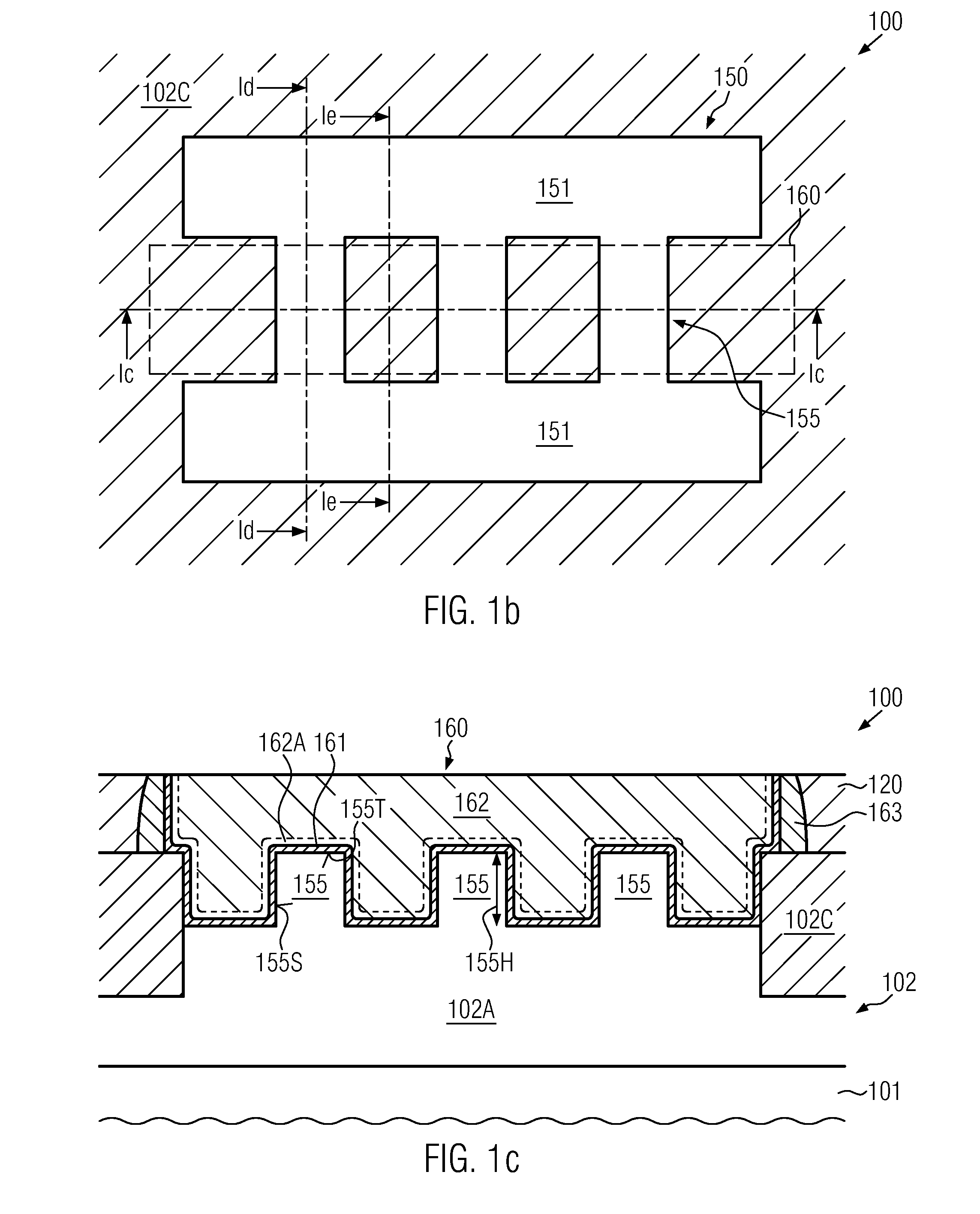

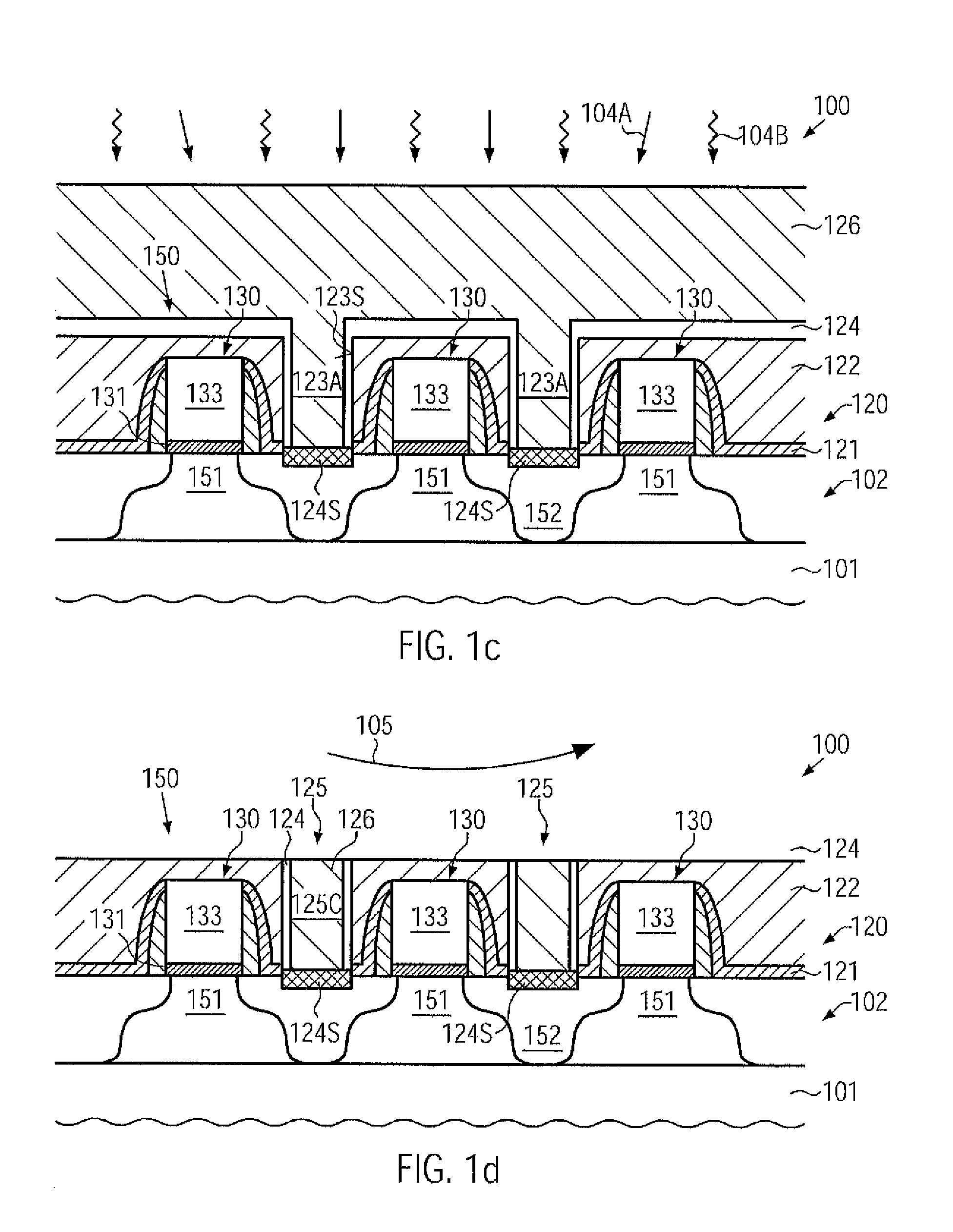

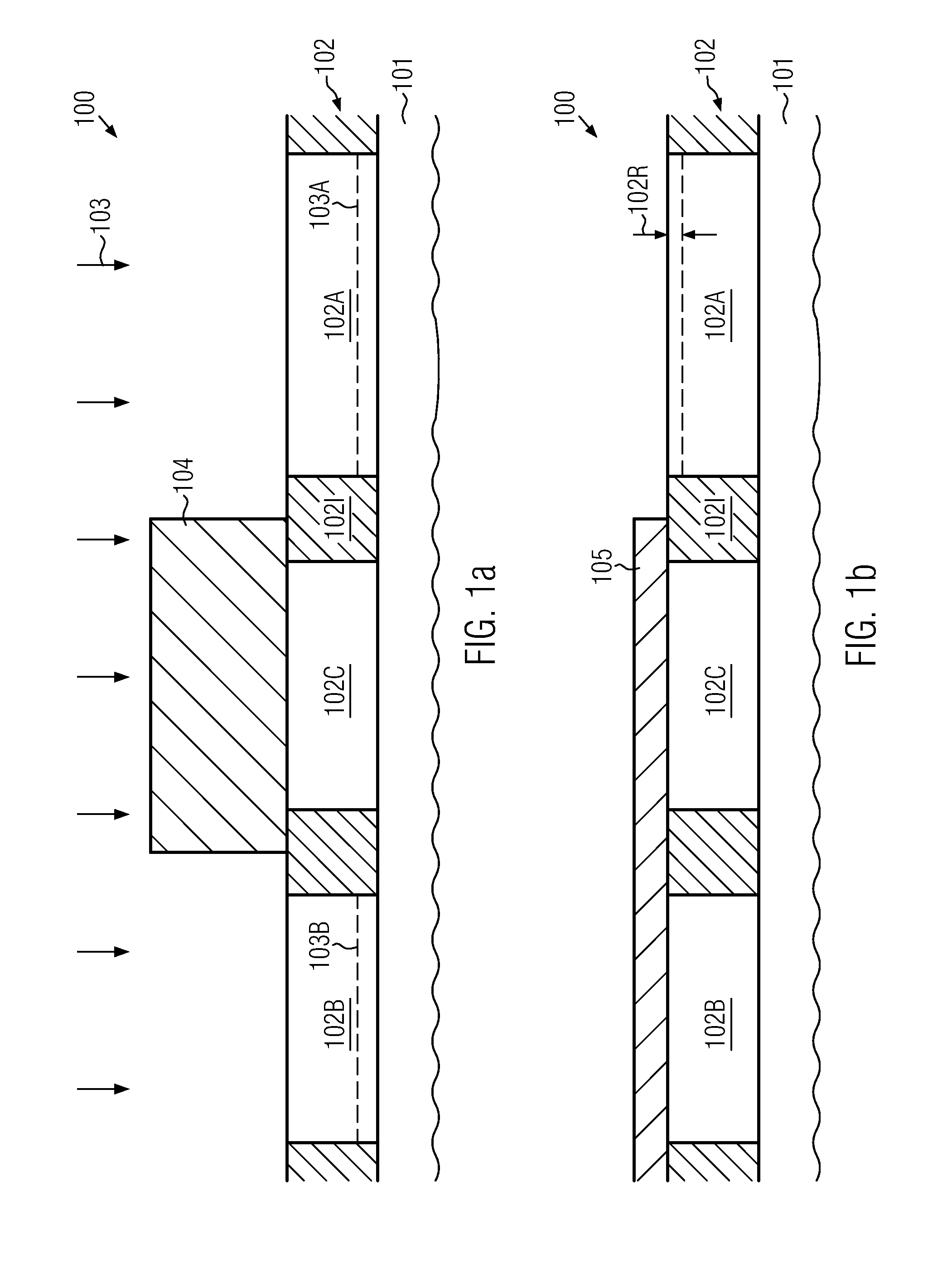

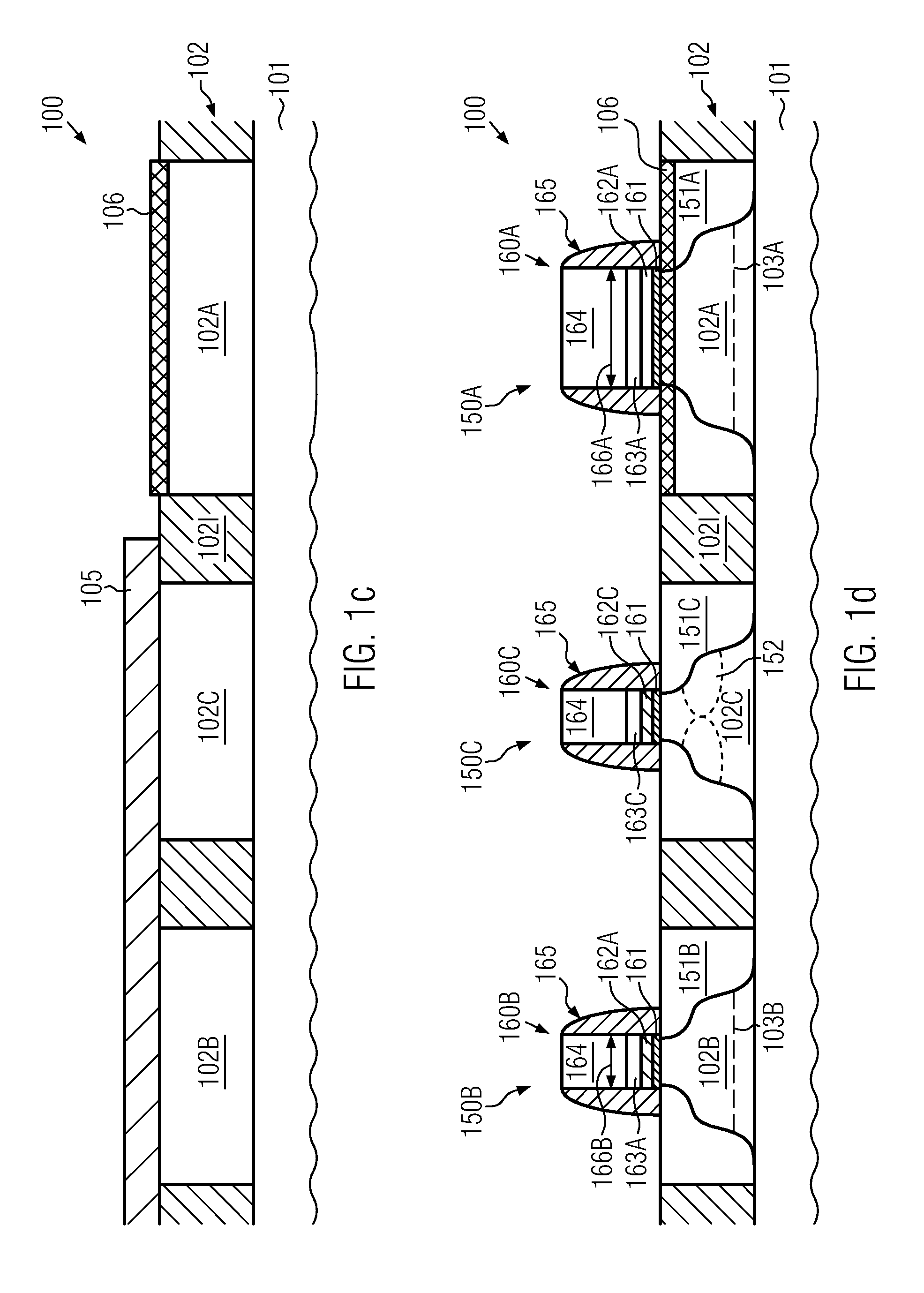

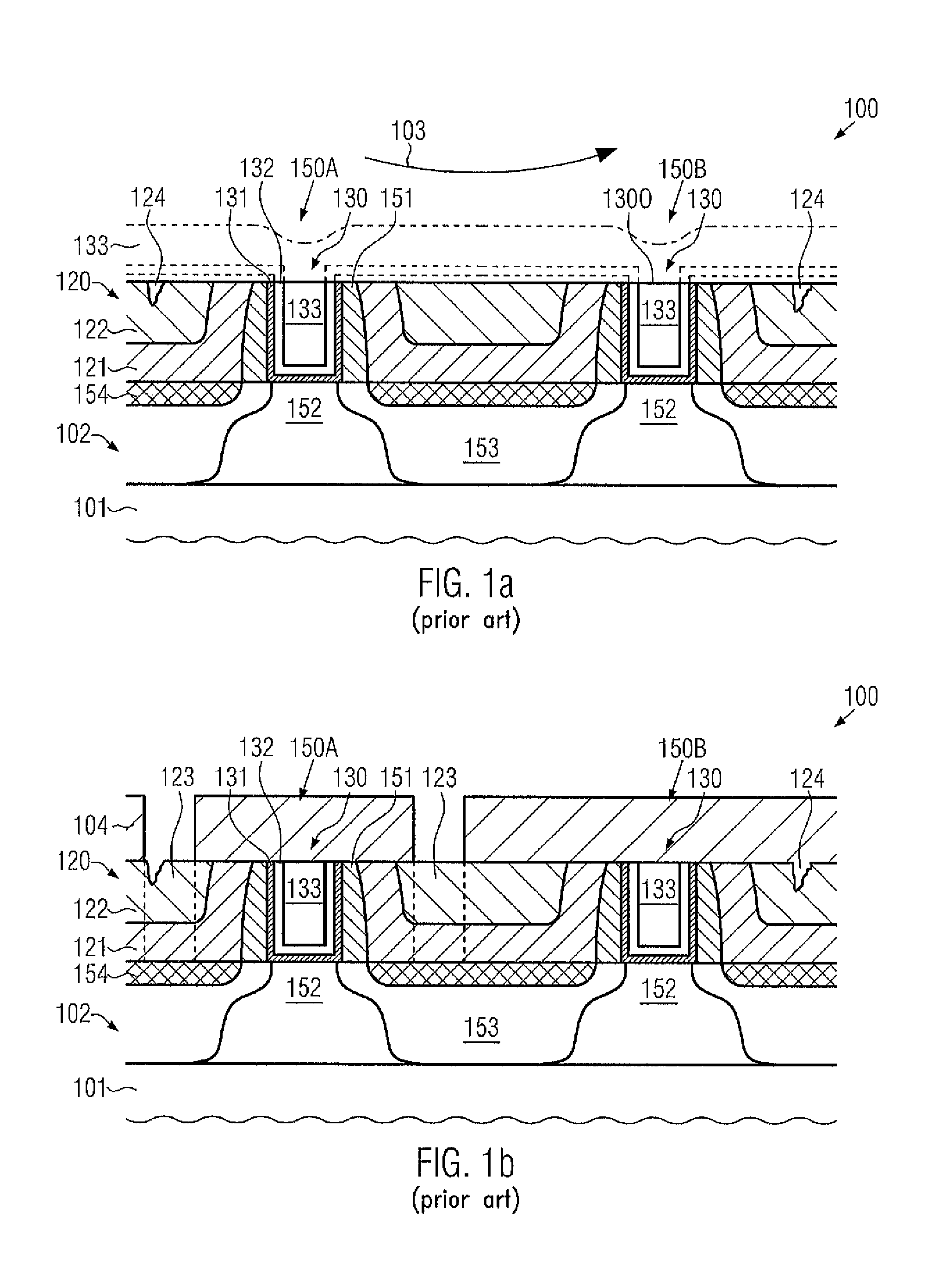

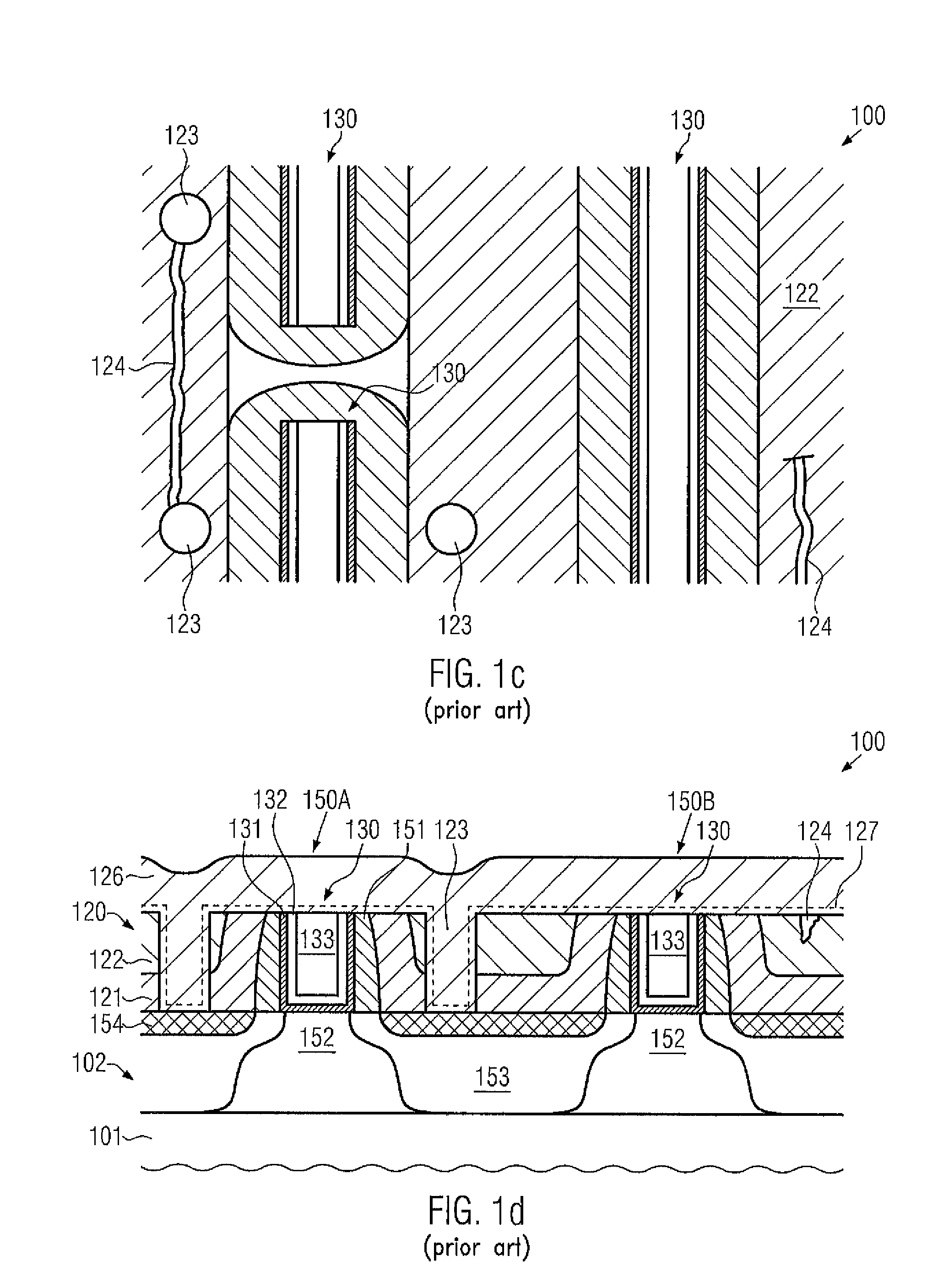

Non-planar transistors, such as FinFETs, may be formed in a bulk configuration in the context of a replacement gate approach, wherein the semiconductor fins are formed during the replacement gate sequence. To this end, in some illustrative embodiments, a buried etch mask may be formed in an early manufacturing stage on the basis of superior process conditions.

Owner:GLOBALFOUNDRIES US INC

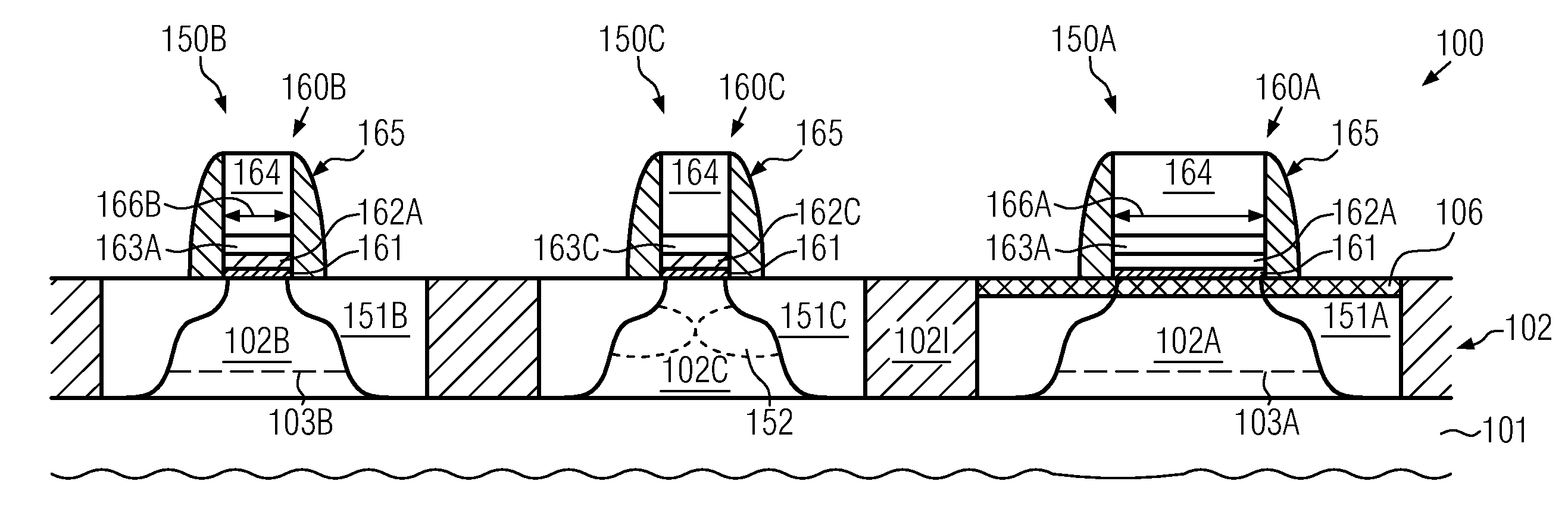

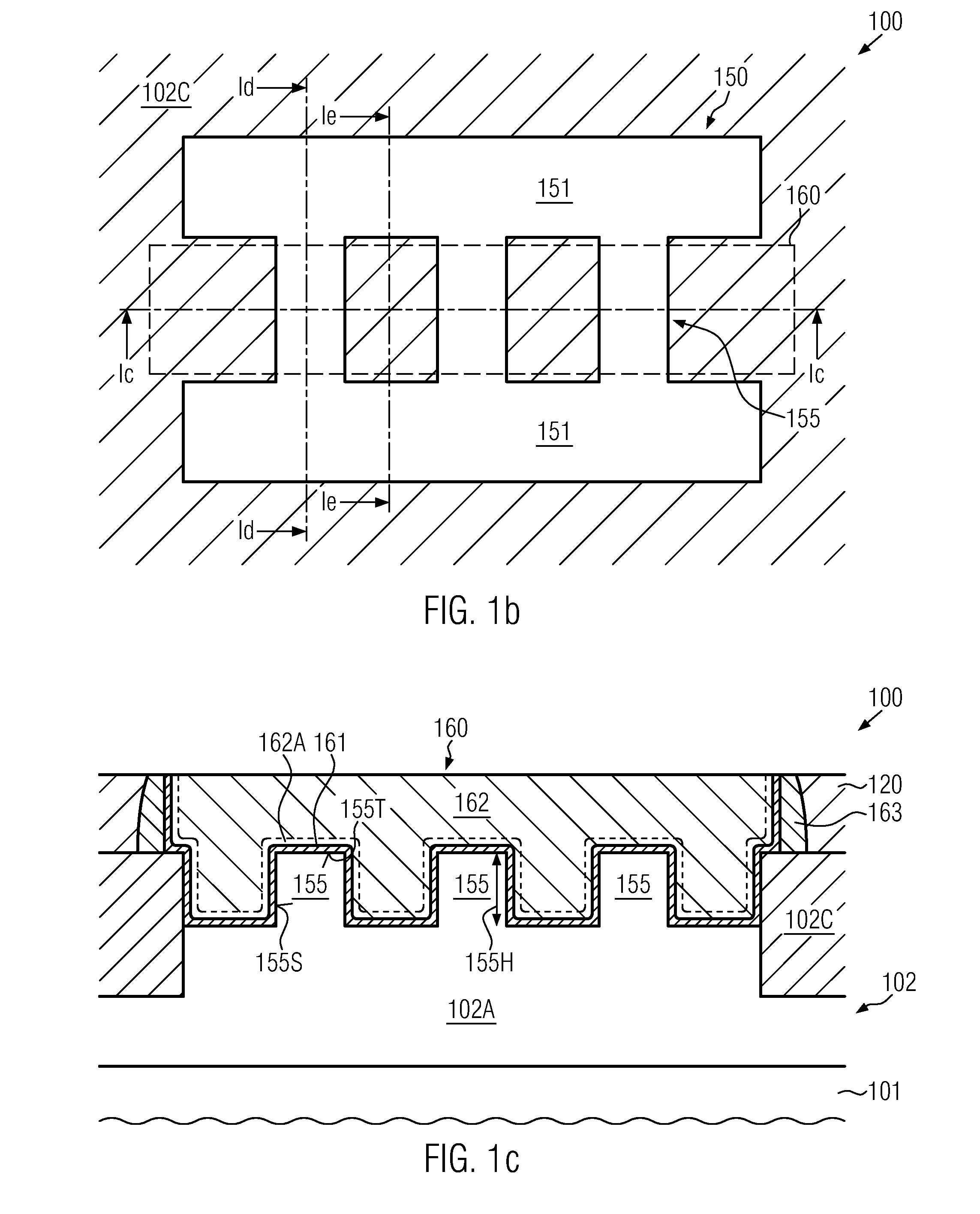

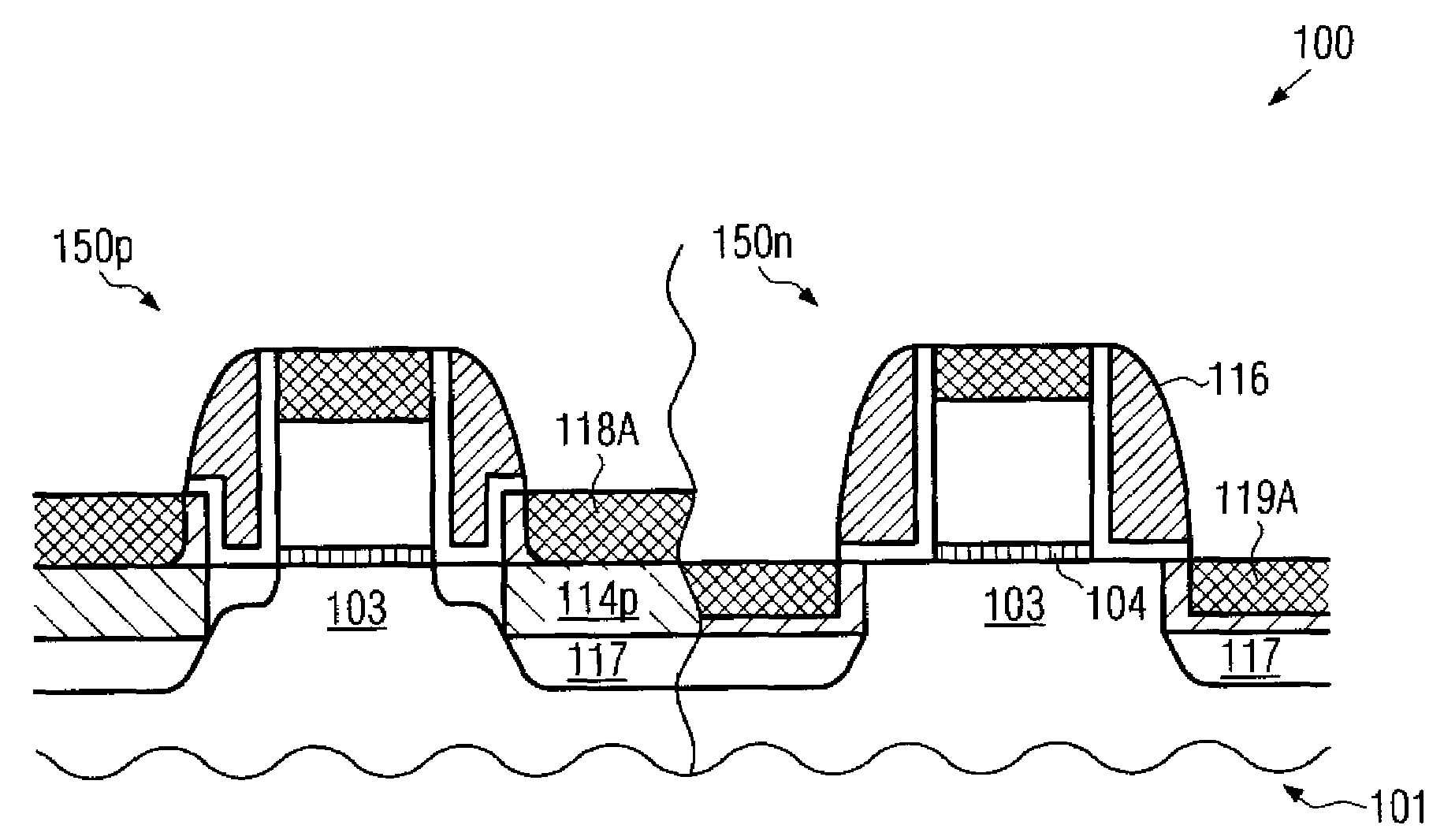

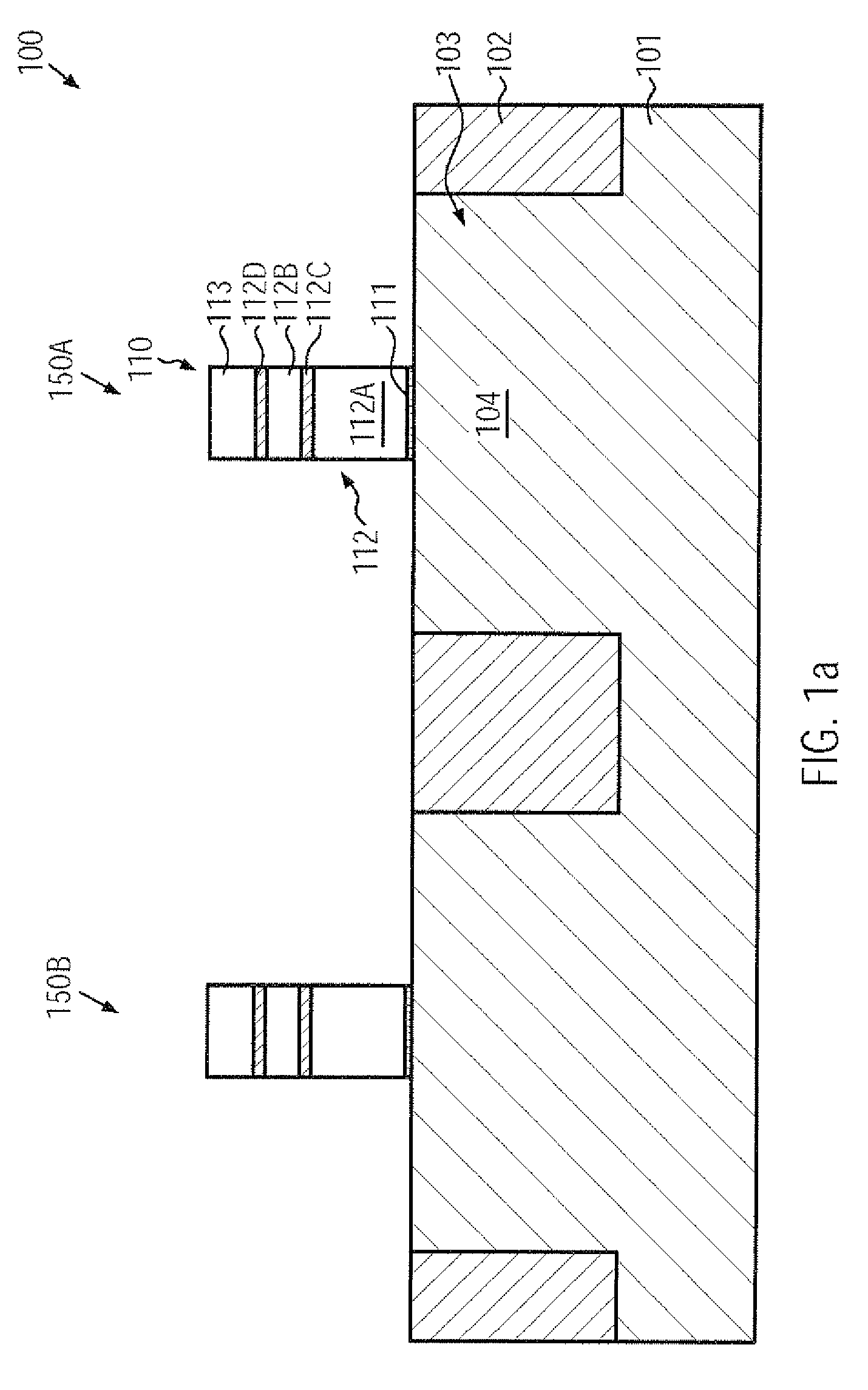

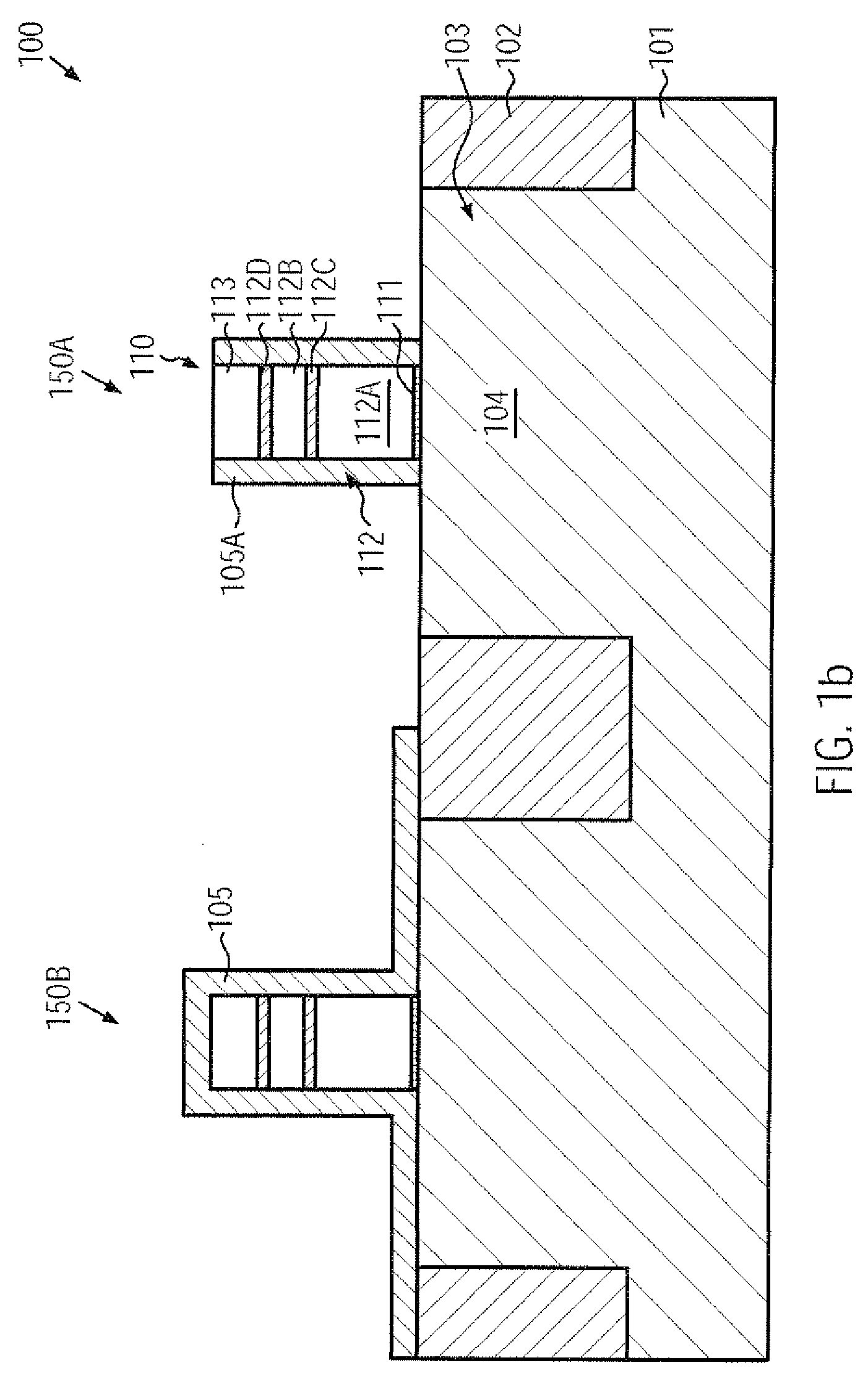

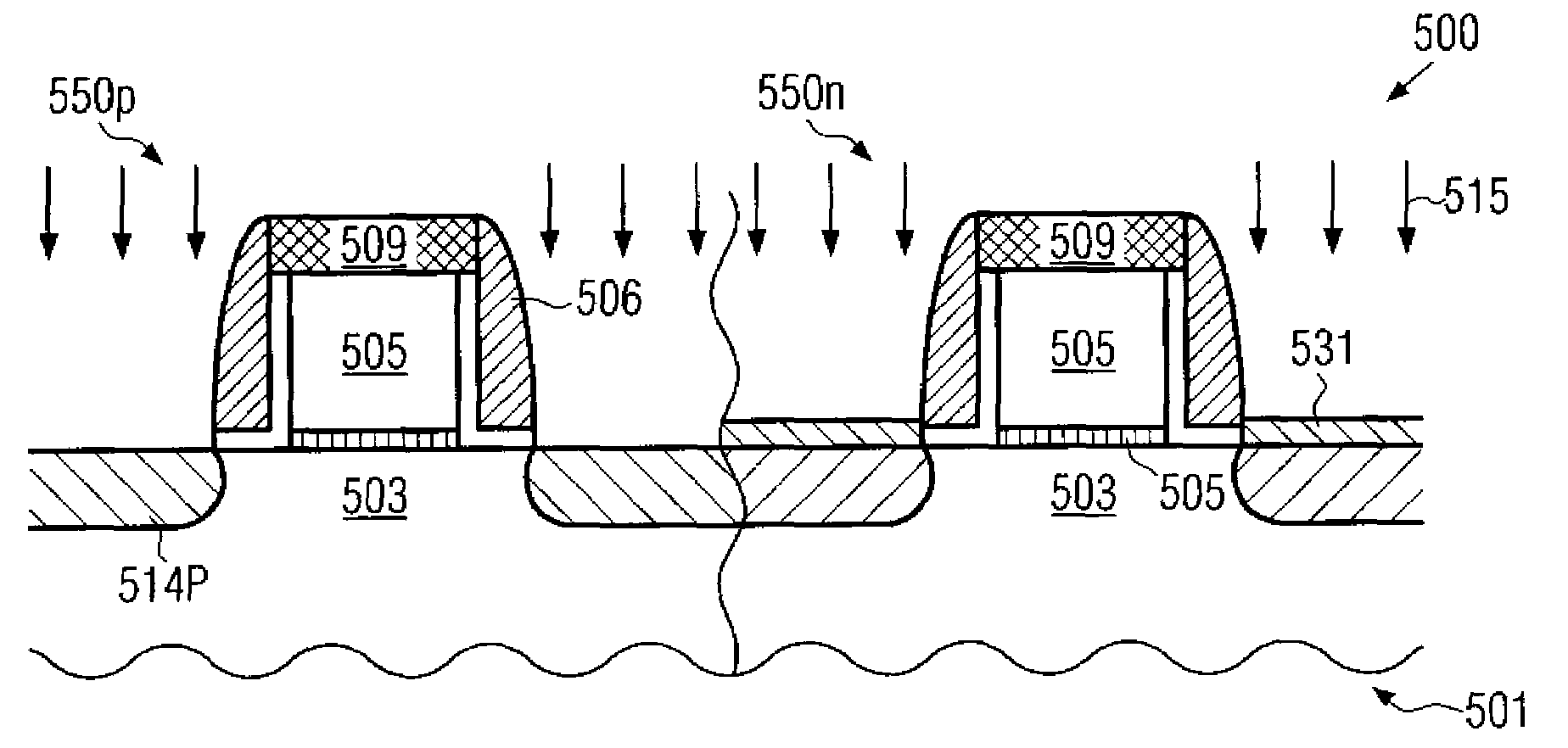

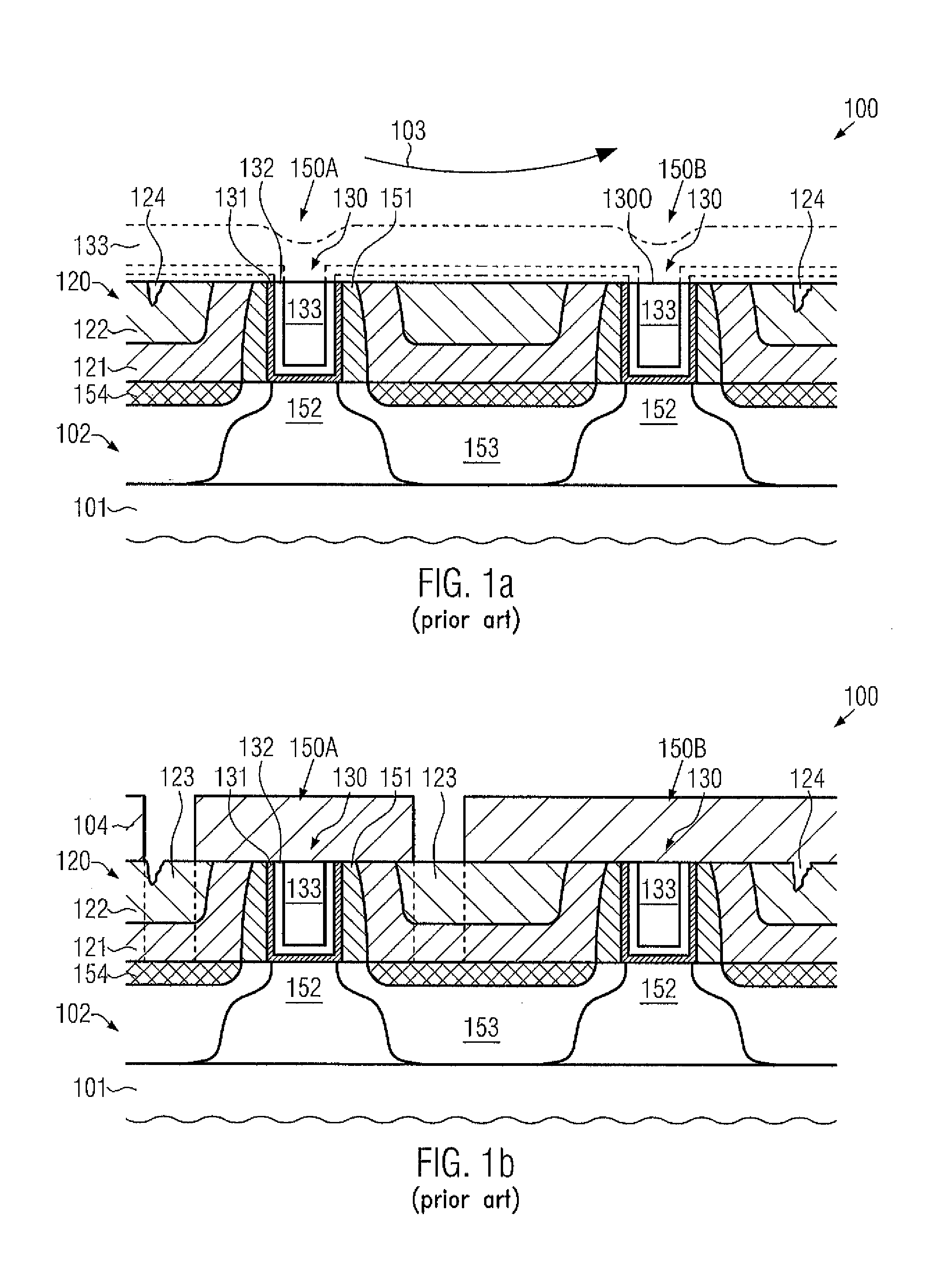

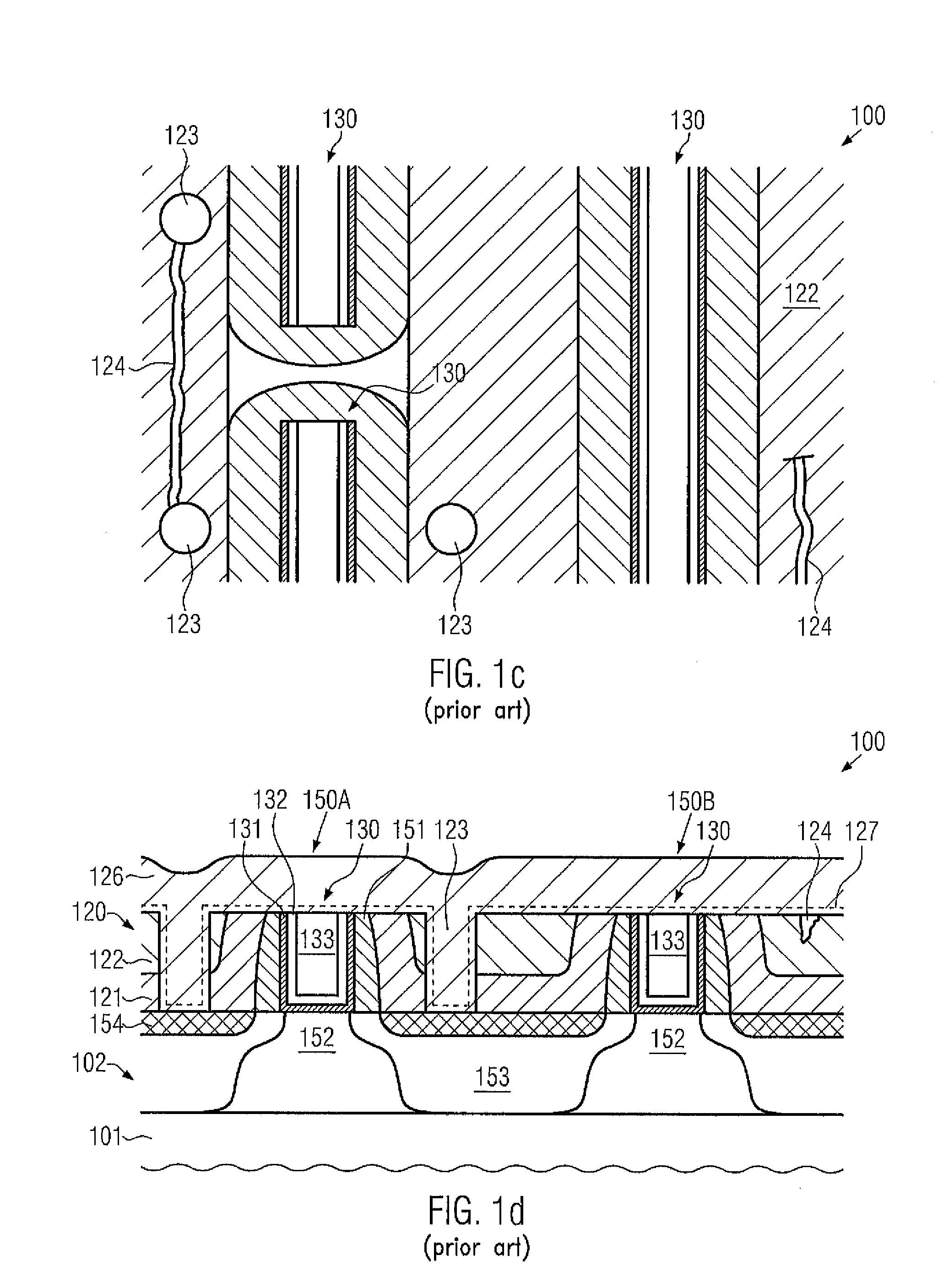

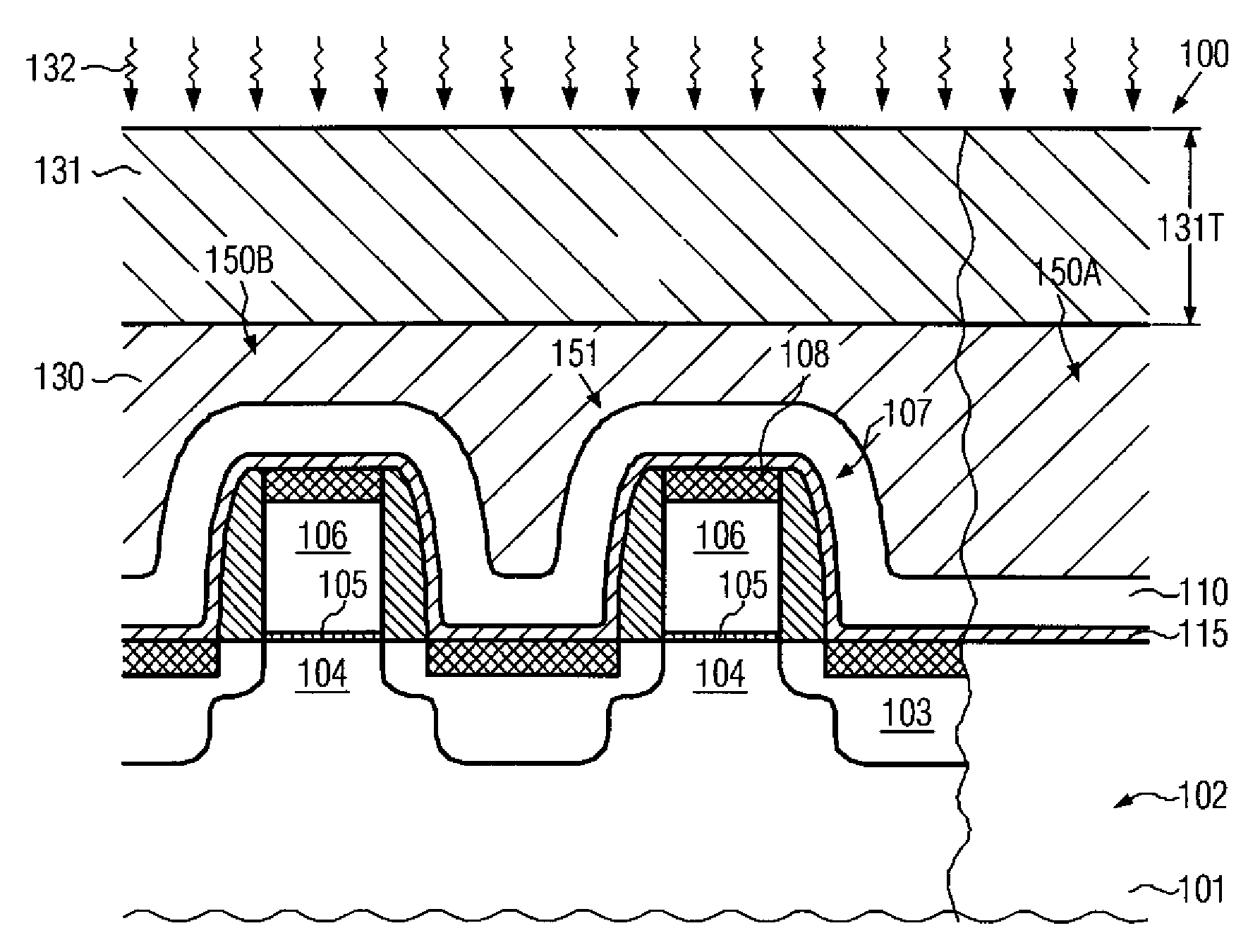

CMOS device comprising mos transistors with recessed drain and source areas and a si/ge material in the drain and source areas of the pmos transistor

InactiveUS20090321843A1High degree of compatibilityEnhanced transistor performanceTransistorSemiconductor/solid-state device manufacturingCMOSSource area

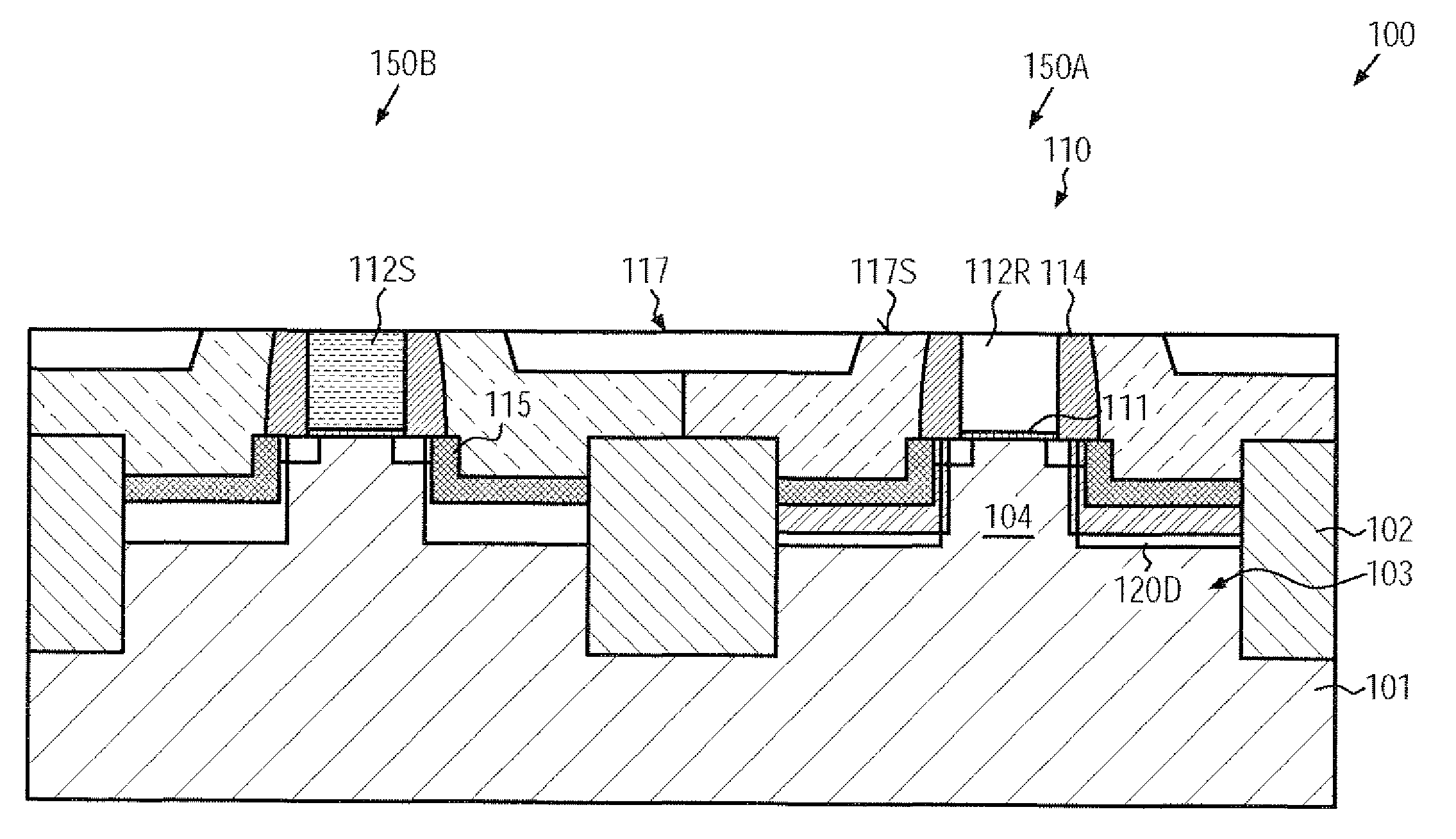

The present disclosure relates to semiconductor devices and a process sequence in which a semiconductor alloy, such as silicon / germanium, may be formed in an early manufacturing stage, wherein other performance-increasing mechanisms, such as a recessed drain and source configuration, possibly in combination with high-k dielectrics and metal gates, may be incorporated in an efficient manner while still maintaining a high degree of compatibility with conventional process techniques.

Owner:GLOBALFOUNDRIES US INC

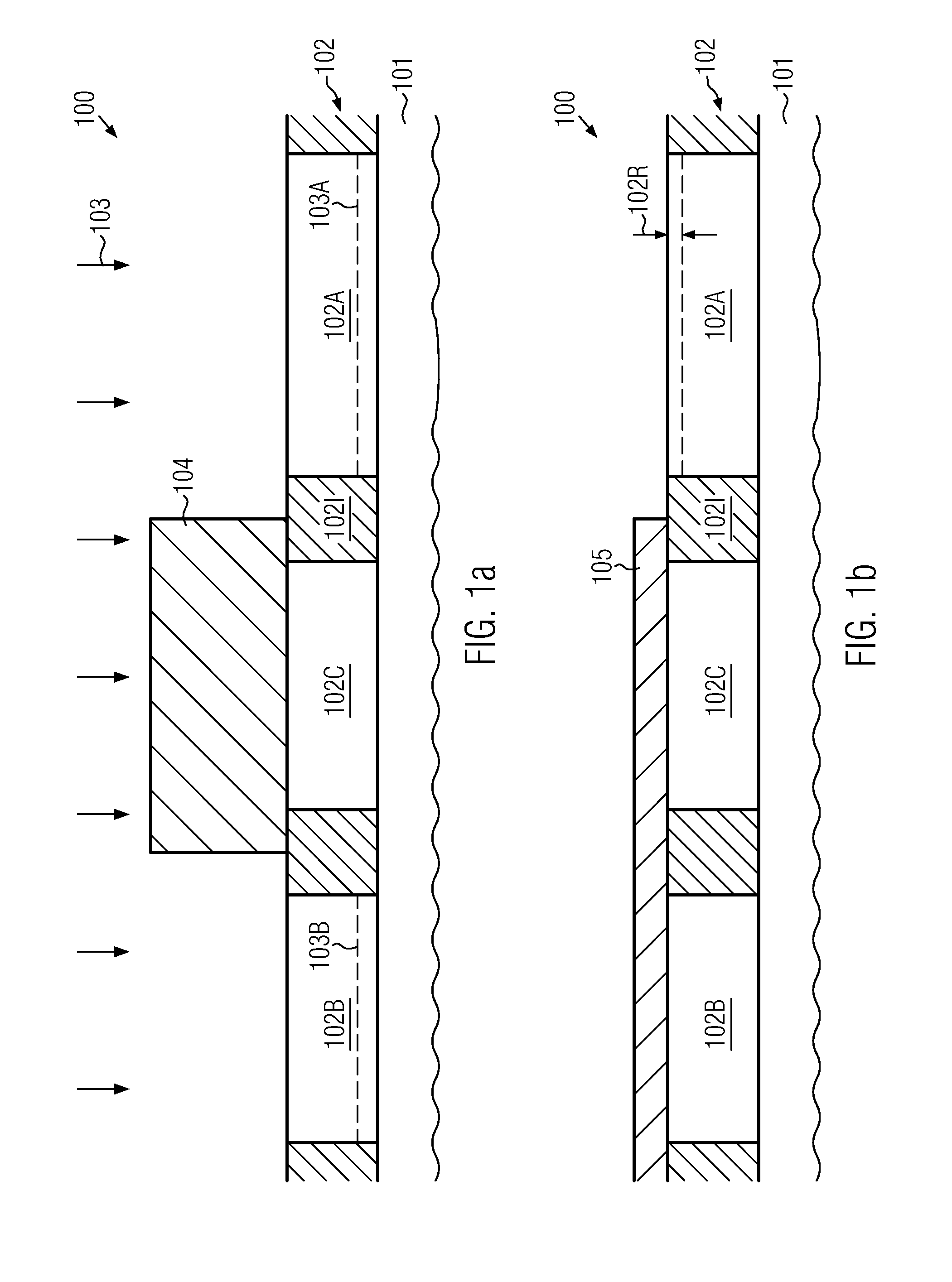

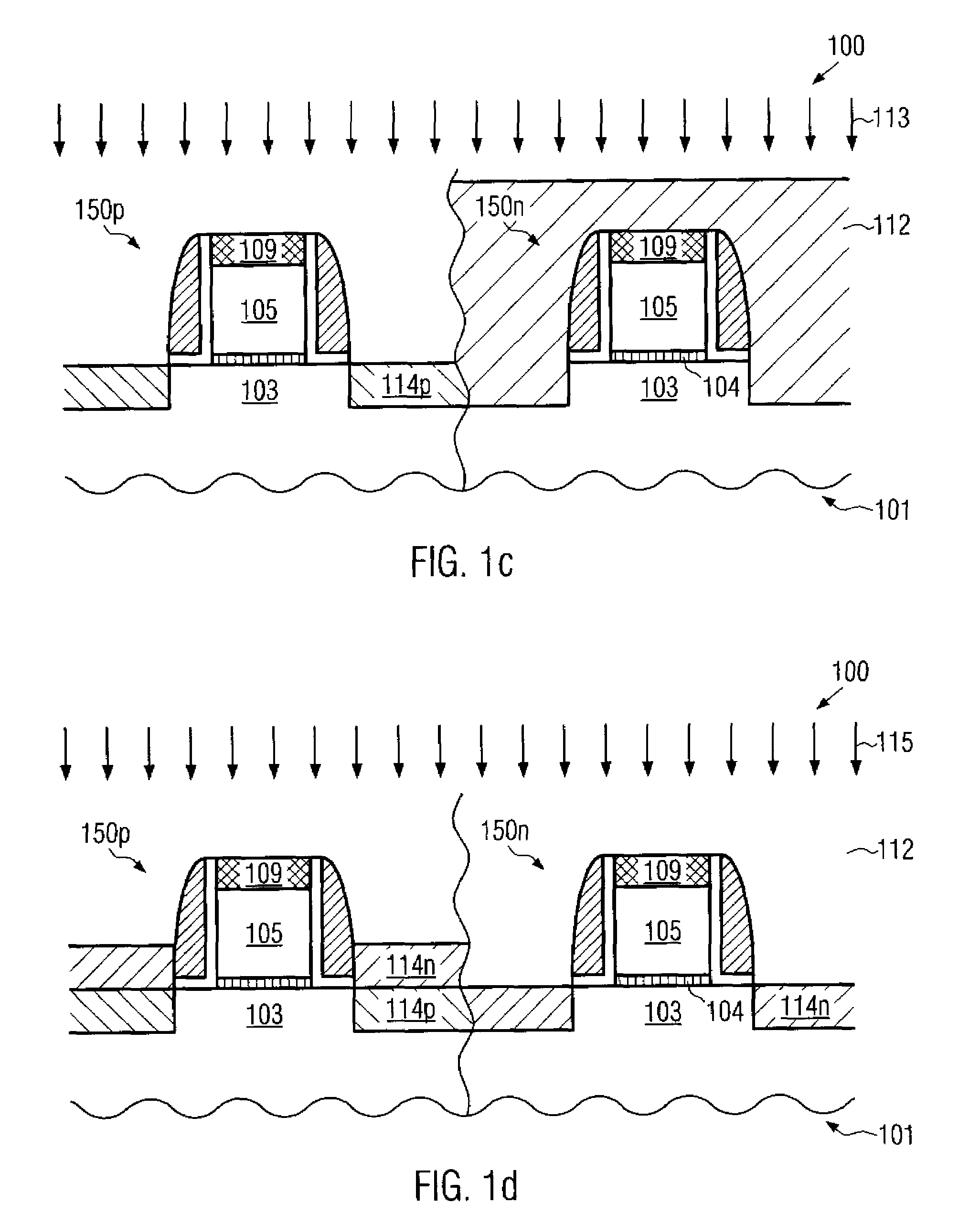

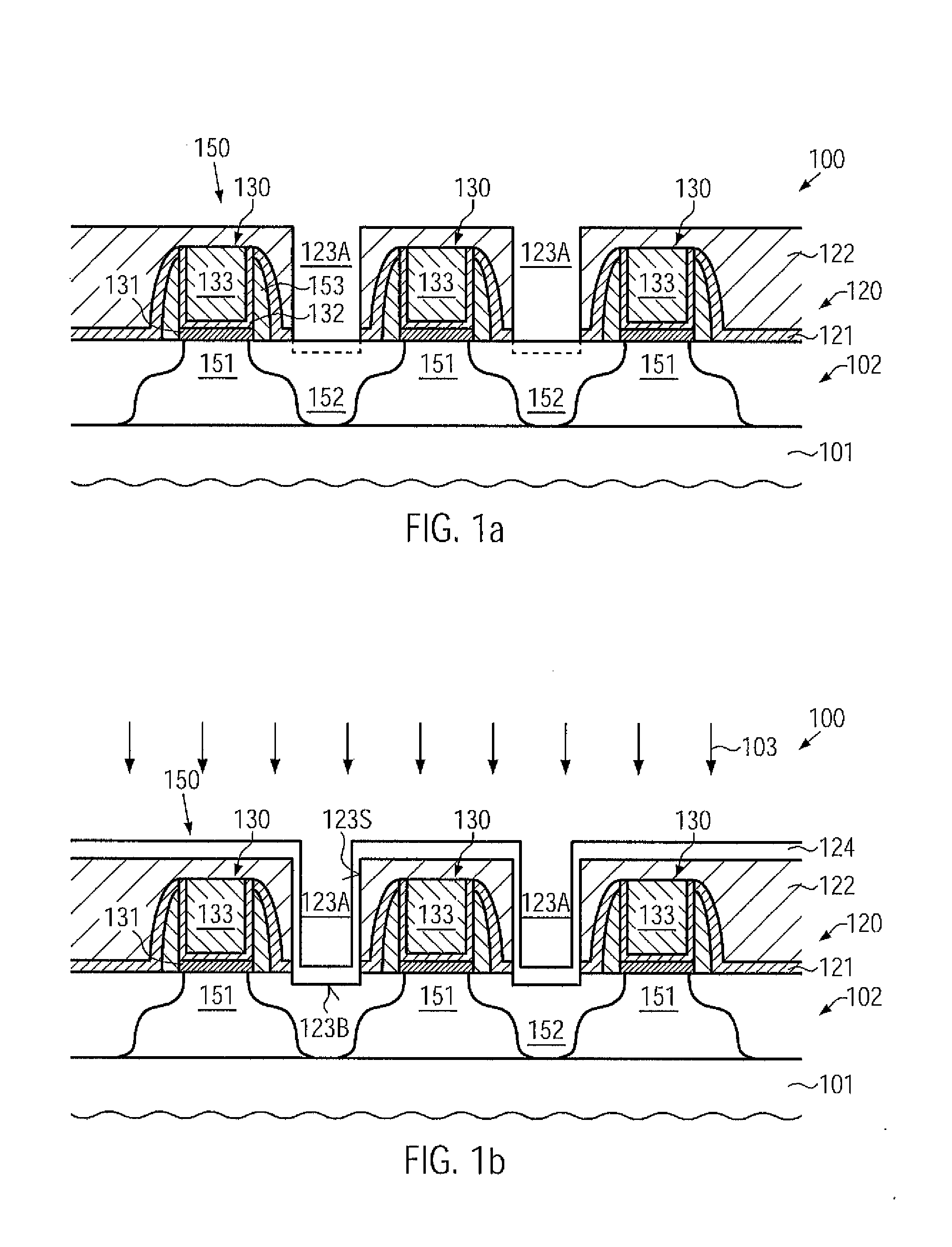

Differential Threshold Voltage Adjustment in PMOS Transistors by Differential Formation of a Channel Semiconductor Material

ActiveUS20120153401A1Enhanced transistor performanceHighly efficient overall manufacturing process flowTransistorSolid-state devicesSemiconductor materialsSemiconductor alloys

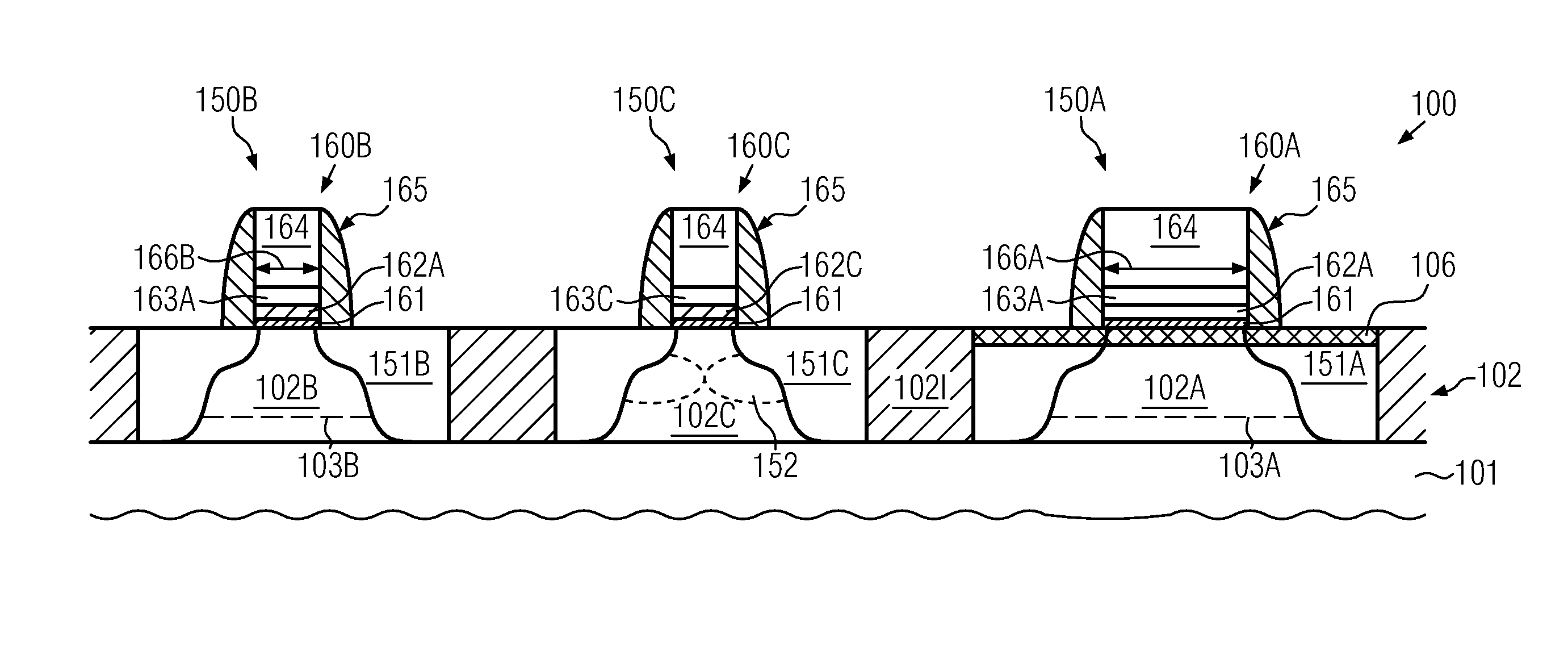

In sophisticated semiconductor devices, high-k metal gate electrode structures may be provided in an early manufacturing stage wherein the threshold voltage adjustment for P-channel transistors may be accomplished on the basis of a threshold voltage adjusting semiconductor alloy, such as a silicon / germanium alloy, for long channel devices, while short channel devices may be masked during the selective epitaxial growth of the silicon / germanium alloy. In some illustrative embodiments, the threshold voltage adjustment may be accomplished without any halo implantation processes for the P-channel transistors, while the threshold voltage may be tuned by halo implantations for the N-channel transistors.

Owner:GLOBALFOUNDRIES US INC

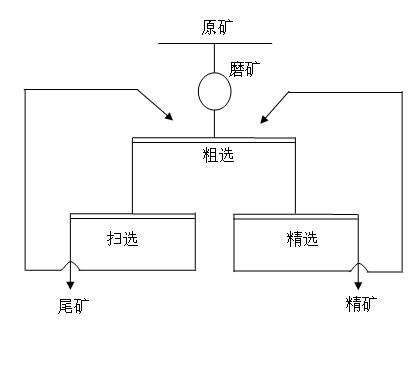

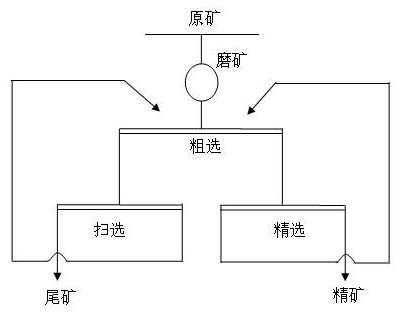

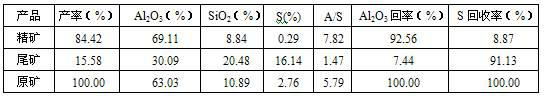

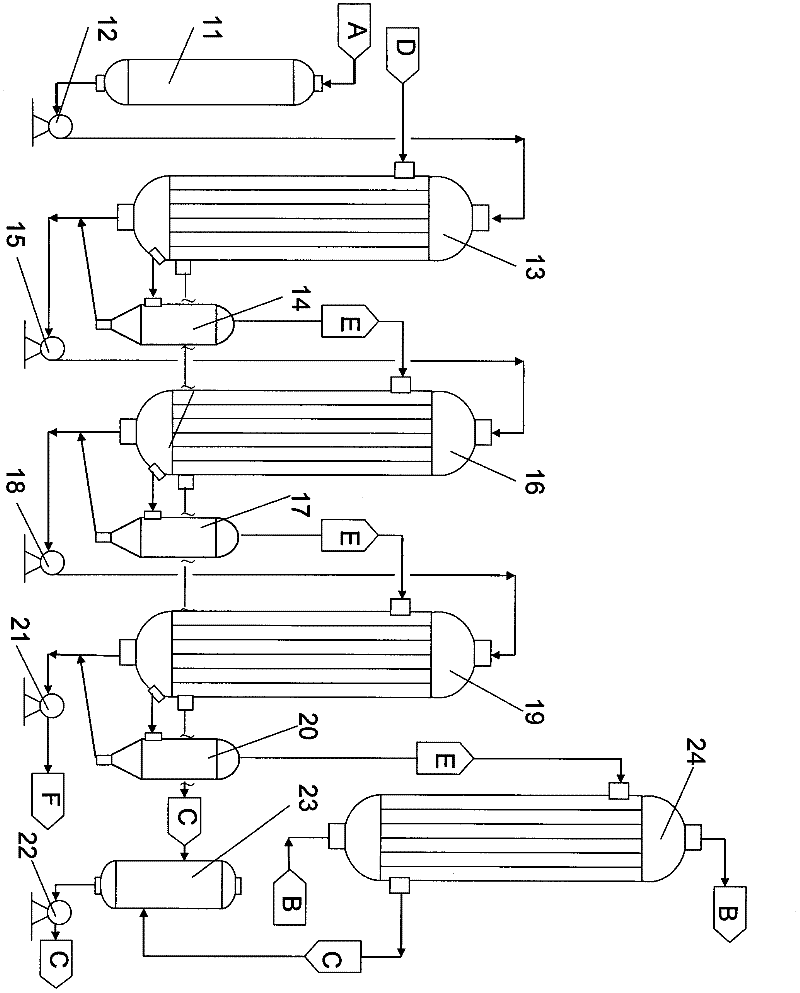

Method for dressing, desilicication and desulfuration of sulfur-containing bauxite

The invention discloses a method for the dressing, desilicication and desulfuration of sulfur-containing bauxite, which relates to a method for the dressing, desilicication and desulfuration of low-quality sulfur-containing bauxite and is characterized in that: a dressing process to mill the sulfur-containing bauxite, regulate the pH to 3 to 6 by using sulfuric acid, add an inhibitor, an activator, a silicate mineral collector and a sulfur-containing gangue collector in turn, stir, perform size mixing and perform flotation; and after flotation, the silicate minerals and sulfur-containing gangue in a major part of the sulfur-containing bauxite are enriched in foam as tailings, and the ore pulp obtained after flotation is used as concentrate. When the method disclosed by the invention is used, the synchronous dressing, desulfuration and desilicication of the sulfur-containing bauxite can be realized quickly. The method has the characteristics of short flow and simple process.

Owner:河南华慧有色工程设计有限公司 +1

Self-aligned fin transistor formed on a bulk substrate by late fin etch

ActiveUS8722498B2Efficient process flowSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringProcess conditions

Non-planar transistors, such as FinFETs, may be formed in a bulk configuration in the context of a replacement gate approach, wherein the semiconductor fins are formed during the replacement gate sequence. To this end, in some illustrative embodiments, a buried etch mask may be formed in an early manufacturing stage on the basis of superior process conditions.

Owner:GLOBALFOUNDRIES US INC

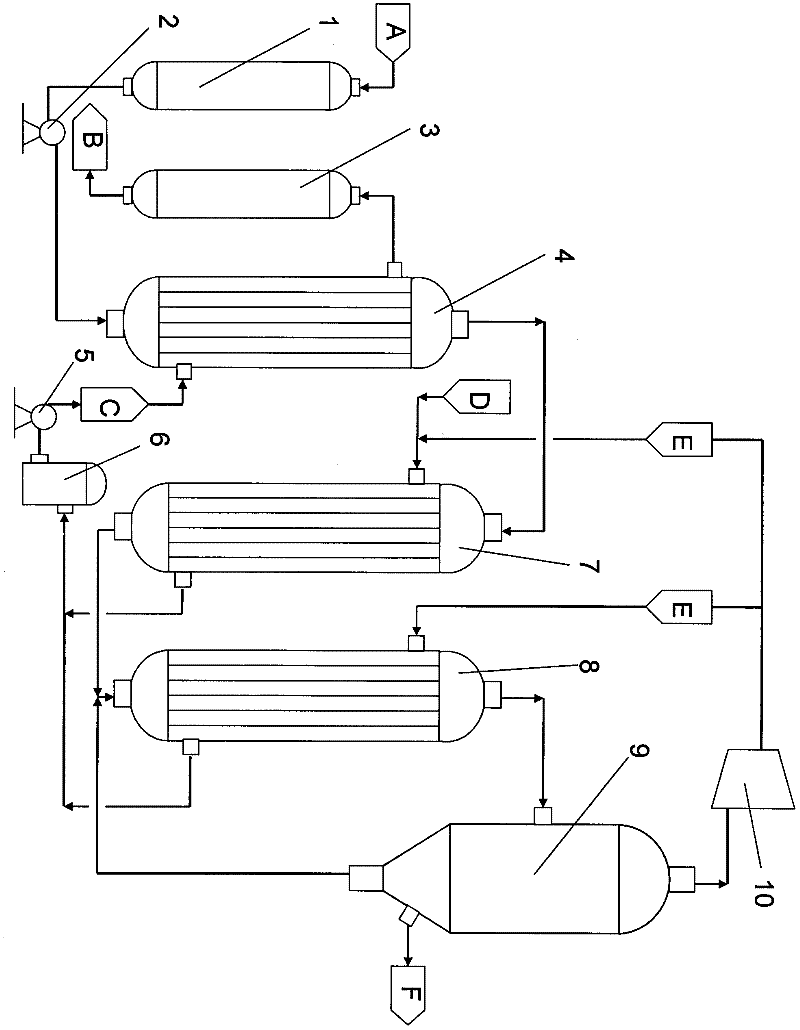

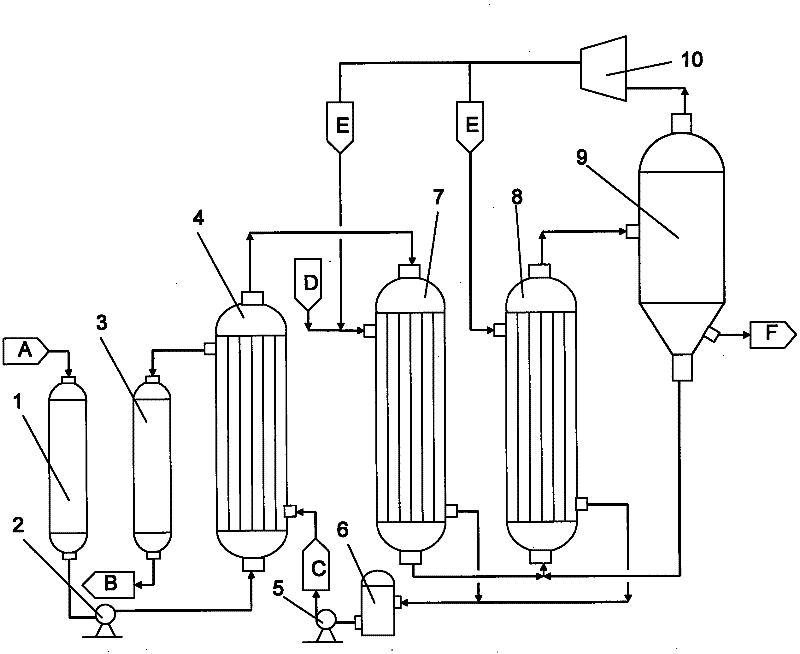

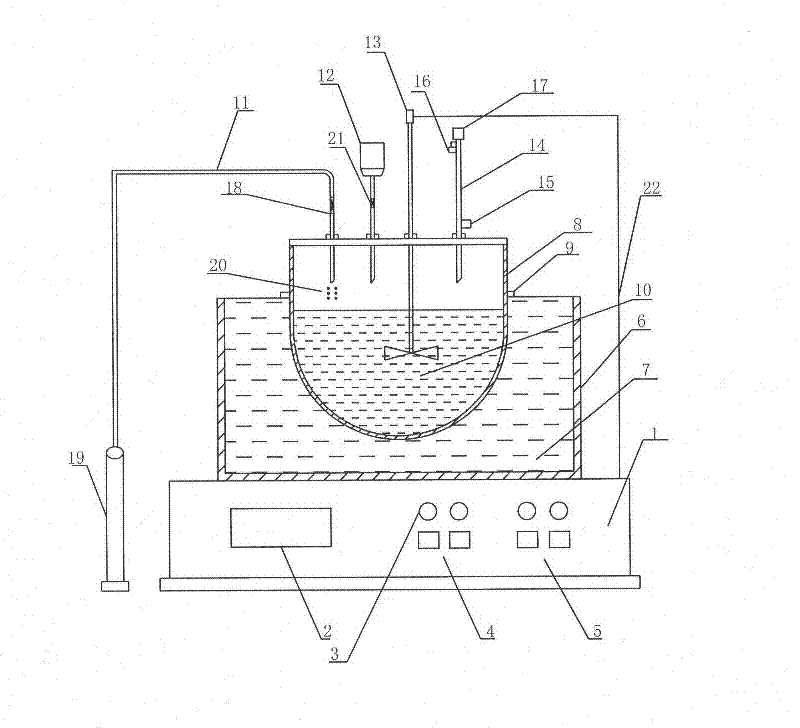

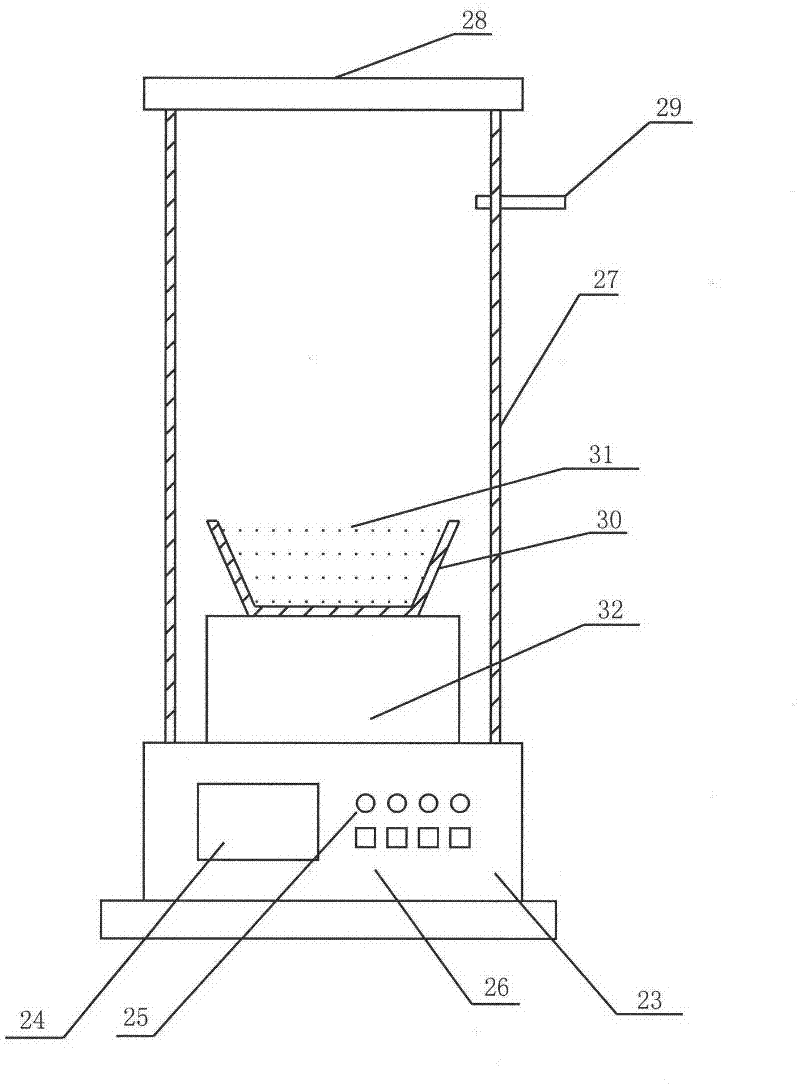

Energy-saving evaporating process and equipment for L-phenylalanine brine solution

ActiveCN102343162ASmall volumeEnergy saving processEvaporator accessoriesMultiple-effect evaporationVapor liquidHeat balance

The invention relates to an energy-saving evaporating process and equipment for a L-phenylalanine brine solution, belonging to the technical field of efficient energy saving and environmental protection. The process comprises the following steps of: preheating a 1 percent concentration of feed solution to 50-60 DEG C with a preheater 4; making the preheated feed solution enter the tube pass and shell pass of a falling film evaporator 7 and a climbing film evaporator 8 for secondary vapor heat exchange at 78-80 DEG C, heating to 70 DEG C, and evaporating in a way of combining a falling film with a climbing film to generate secondary vapor and a concentrated solution; making the secondary vapor and the concentrated solution enter a separator 9 for vapor-liquid separation; making the separated secondary vapor enter a centrifugal compressor 10 for compressing and increasing caloric content, heating to 78-80 DEG C for serving as a heating source of the evaporators 7 and 8, and heating and evaporating the feed solution; discharging the concentrated solution of which the concentration is controlled at 3 percent from the separator 9, and returning the concentrated solution of which the concentration does not reach 3 percent to the climbing film evaporator 8 for continually evaporating and concentrating. The system has the advantages of self-heat balance, small using amount of live vapor, low running cost, high efficiency and saving in energy.

Owner:想莱(常州)节能科技有限公司

Used lubricating oil complete hydrogenation type regenerated catalyst and preparation method and application thereof

InactiveCN101797509AHigh selectivityImprove hydrogenation activityMetal/metal-oxides/metal-hydroxide catalystsLubricant compositionActive componentCatalyst support

The invention discloses a used lubricating oil complete hydrogenation type regenerated catalyst and a preparation method and application thereof. The catalyst comprises catalyst carrier and active components, wherein the active components are WO3, NiO and assistant Si; WO3 accounts for 28-38% of the total weight of the catalyst, NiO accounts for 4-8%, Si accounts for 2-3%, and the balance is Al2O3 carrier; and the specific surface area of the catalyst is 230-265m<2> / g, and the pore volume is 0.47-0.55ml / g. The preparation method of the invention uses the characteristics of used lubricating oil, selects W-Ni metal in a certain proportion as active component, combines with assistant Si and selects various components and reasonable proportioning to prepare the catalyst with higher hydrogenation activity and selectivity. The catalyst has ultrahigh specific surface area, large pore diameter and properties of weak acid, is used to perform hydrogenation to the full-range components of used lubricating oil, has strong ability of removing S, N and O and performing hydrosaturation of unideal components and has extremely high demetalization and metal resistance.

Owner:FUSHUN XINRUI CATALYST +1

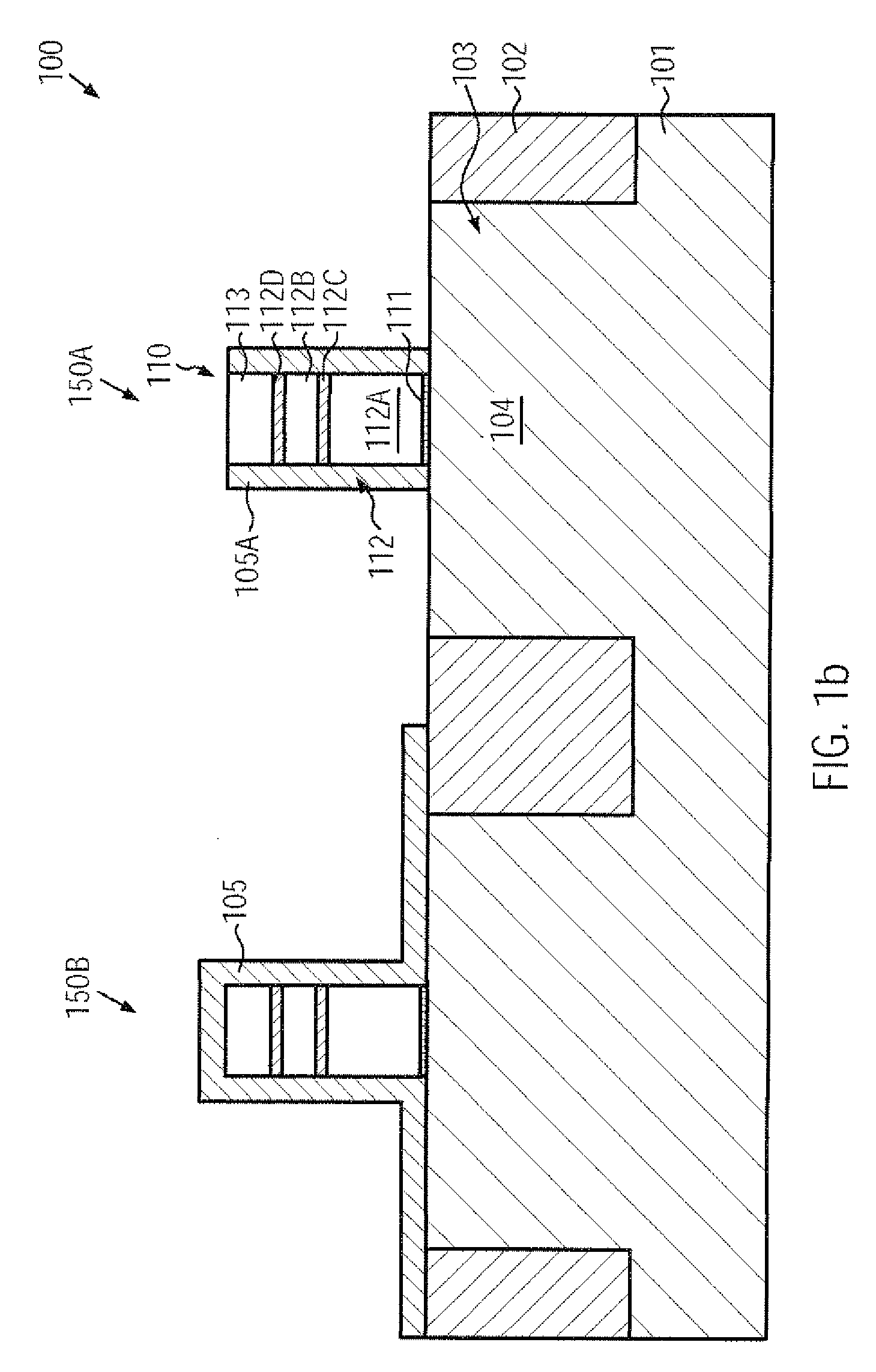

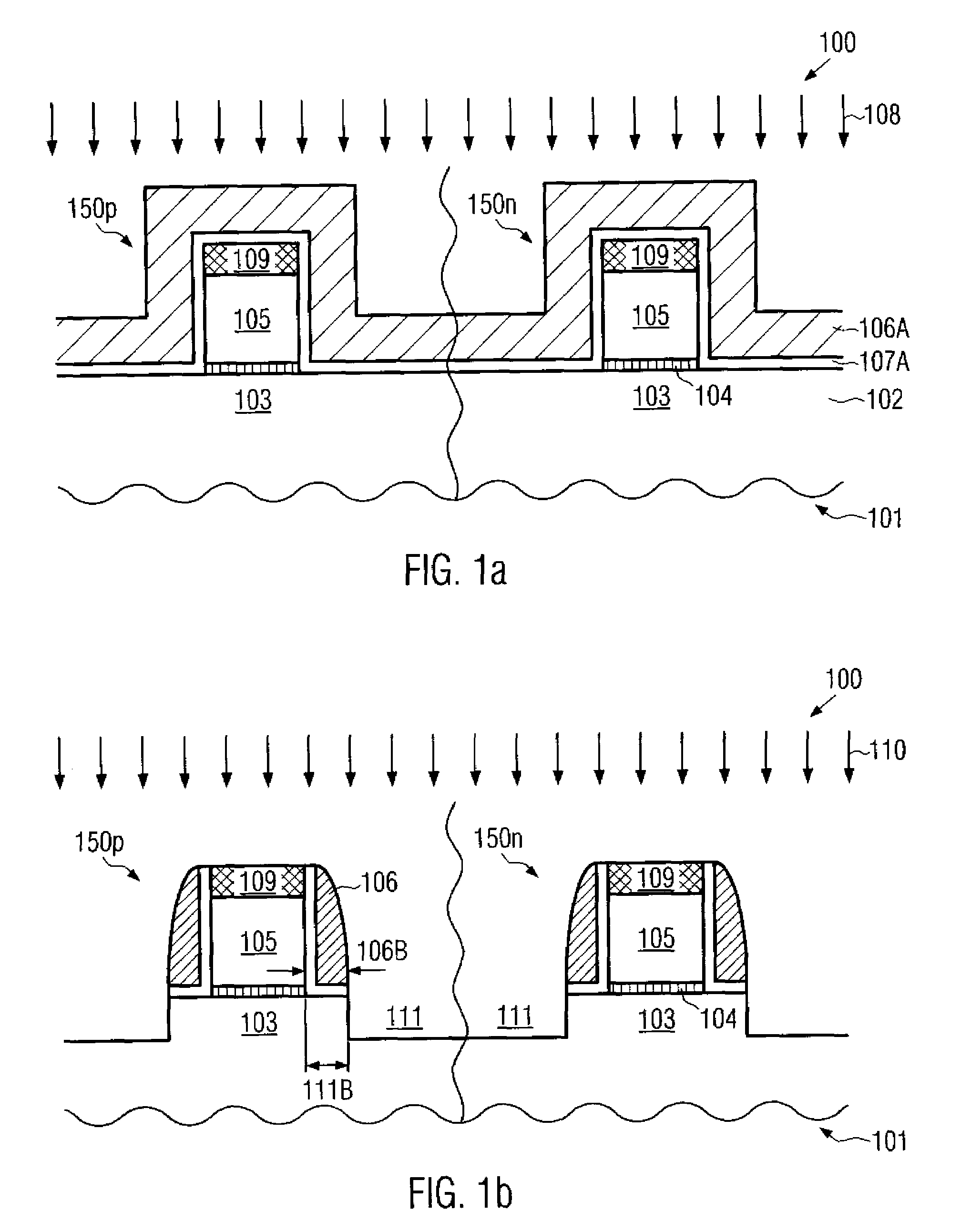

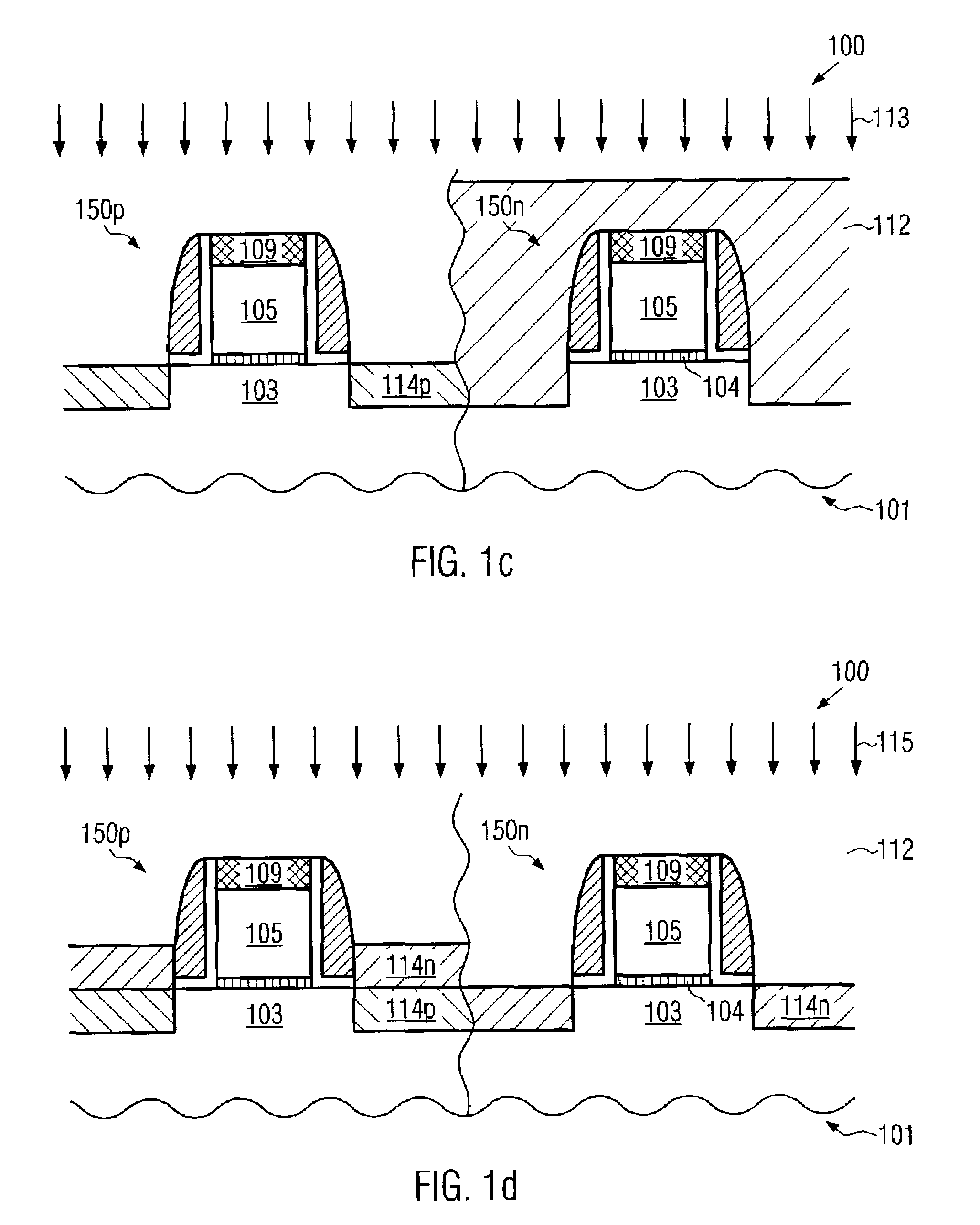

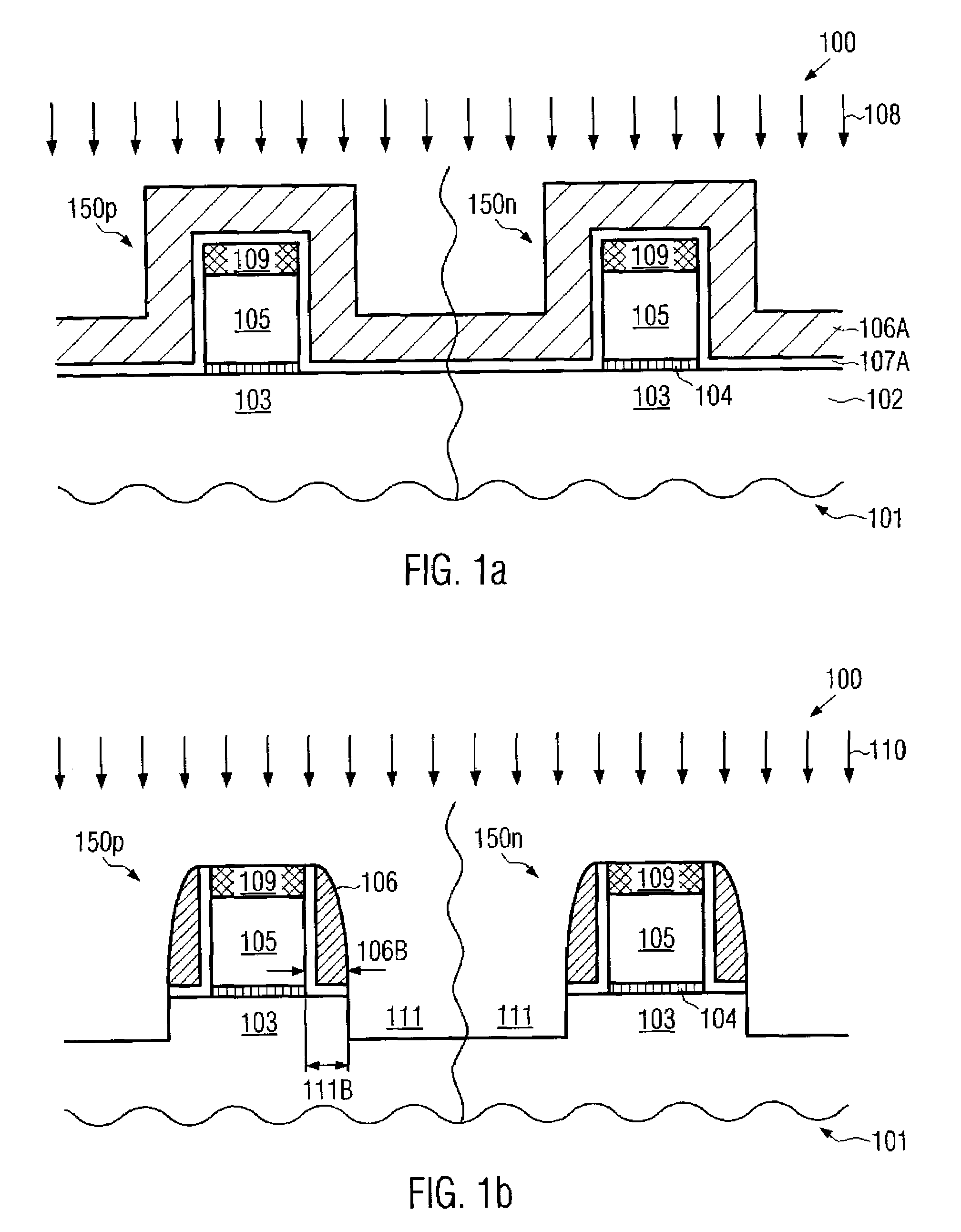

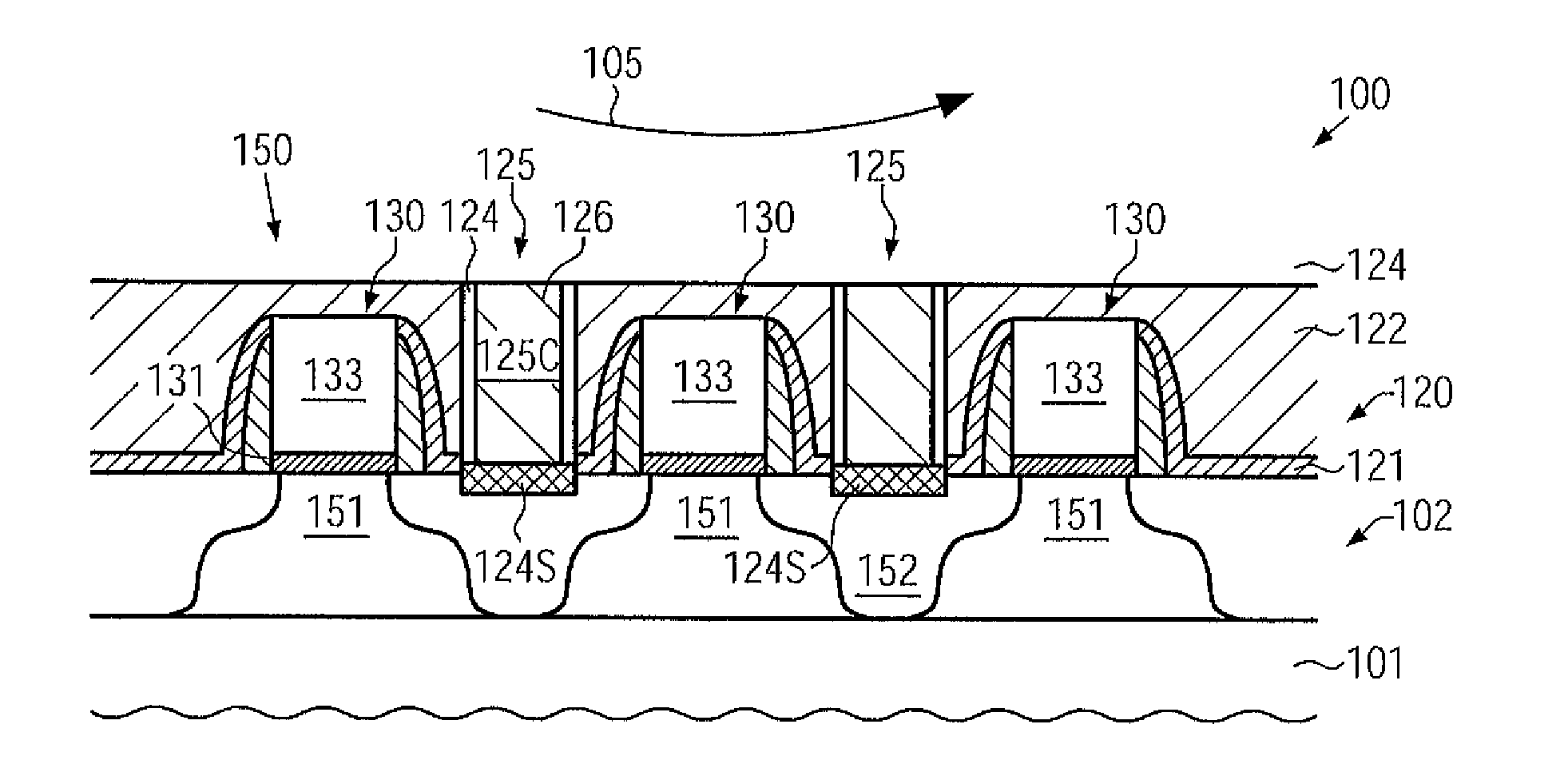

Different embedded strain layers in PMOS and NMOS transistors and a method of forming the same

ActiveUS7579262B2Efficient process flowReduce process complexitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsEngineering

By omitting a growth mask or by omitting lithographical patterning processes for forming growth masks, a significant reduction in process complexity may be obtained for the formation of different strained semiconductor materials in different transistor types. Moreover, the formation of individually positioned semiconductor materials in different transistors may be accomplished on the basis of a differential disposable spacer approach, thereby combining high efficiency with low process complexity even for highly advanced SOI transistor devices.

Owner:ADVANCED MICRO DEVICES INC

CMOS device comprising MOS transistors with recessed drain and source areas and a SI/GE material in the drain and source areas of the PMOS transistor

InactiveUS7723174B2Improve performanceImprove compatibilitySemiconductor/solid-state device manufacturingSemiconductor devicesDielectricCMOS

The present disclosure relates to semiconductor devices and a process sequence in which a semiconductor alloy, such as silicon / germanium, may be formed in an early manufacturing stage, wherein other performance-increasing mechanisms, such as a recessed drain and source configuration, possibly in combination with high-k dielectrics and metal gates, may be incorporated in an efficient manner while still maintaining a high degree of compatibility with conventional process techniques.

Owner:GLOBALFOUNDRIES U S INC

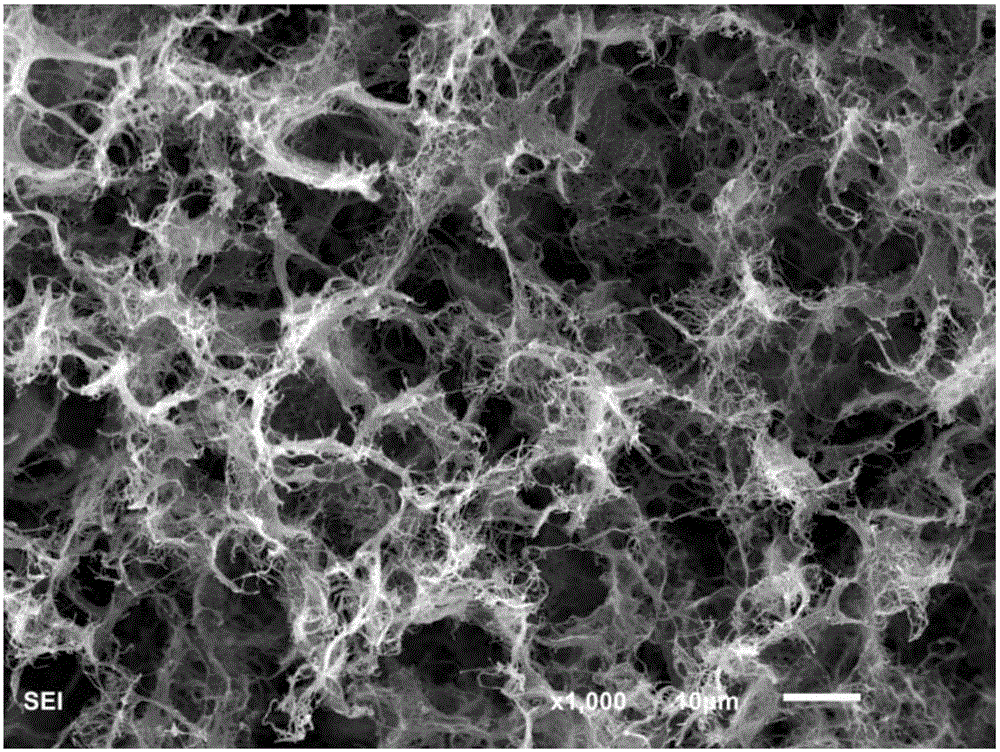

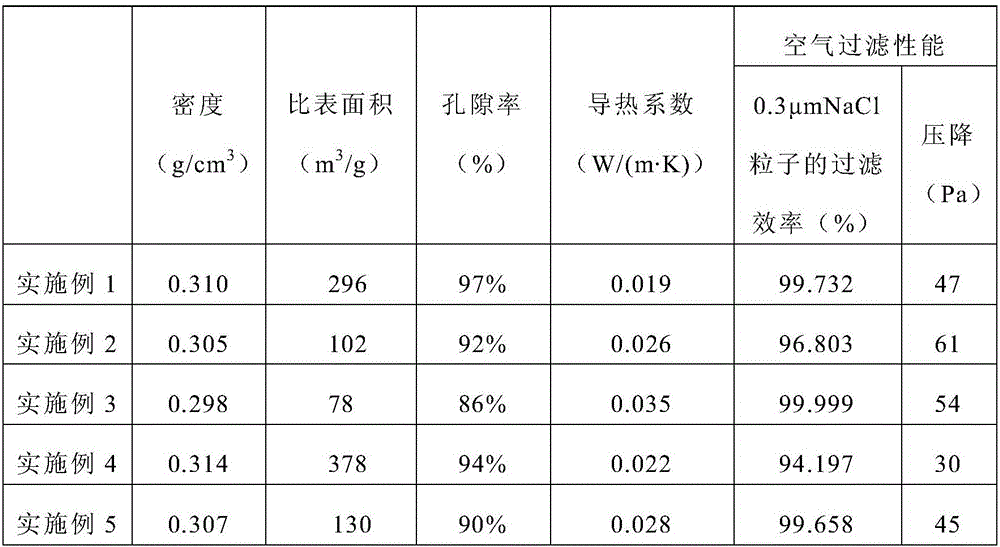

Polymeric nanofiber-based aerogel material and preparation method thereof

The invention discloses a polymeric nanofiber-based aerogel material and a preparation method thereof, and belongs to the fields of aerogel materials and preparation methods thereof. The preparation method comprises the steps that a thermoplastics polymer and cellulose acetate butyrate are subjected to melt blending, drawing, extracting and the like to prepare polymeric nanofibers, the polymeric nanofibers are added into water or a water solvent prepared from water and an organic solvent to generate polymeric nanofiber dispersion liquid, a cross-linking reaction is conducted to obtain cross-linked polymeric nanofiber suspension liquid, freeze drying is conducted on the cross-linked polymeric nanofiber suspension liquid, and then the polymeric nanofiber-based aerogel material is prepared. The polymeric nanofiber-based aerogel material prepared through the method has the advantages of being obvious in nanofiber porous structure, good in mechanical property and the like. The material prepared through the method can be applied to the fields of air filtration, thermal insulation, adsorption and the like directly or by being composited with other materials.

Owner:武汉维晨科技有限公司

Preparation method of three-dimensional ordered macroporous ferric oxide desulfurizer

InactiveCN102260542AImprove desulfurization effectHigh purityGas purification with selectively adsorptive solidsNitratePore distribution

The invention relates to a preparation method of a three-dimensional ordered macroporous ferric oxide desulfurizer, which comprises the following steps: in view of the influence of the pore distribution of the desulfurizer on the desulfurization effect, preparing polystyrene microspheres by using ferric nitrate as the raw material, assembling an adhesive crystal template, and preparing the three-dimensional ordered macroporous ferric oxide desulfurizer. The preparation method has the advantages of short technological process, less equipment, full and accurate technological parameter data and high product purity (up to 96.9%). The pore size of the three-dimensional ordered macroporous ferric oxide desulfurizer is 90nm, the pores are orderly arranged, and the three-dimensional ordered macroporous ferric oxide desulfurizer has the advantages of favorable desulfurization effect and high desulfurization precision. The desulfurization effect of the three-dimensional ordered macroporous ferric oxide desulfurizer is enhanced by 91% as compared with the existing desulfurizer, thus, the preparation method is a very ideal method for preparing a ferric oxide desulfurizer.

Owner:TAIYUAN UNIV OF TECH

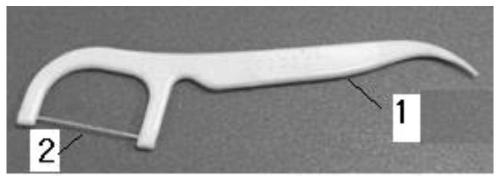

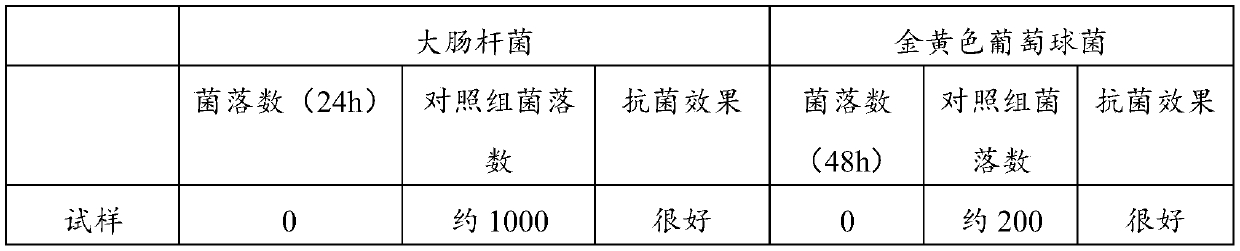

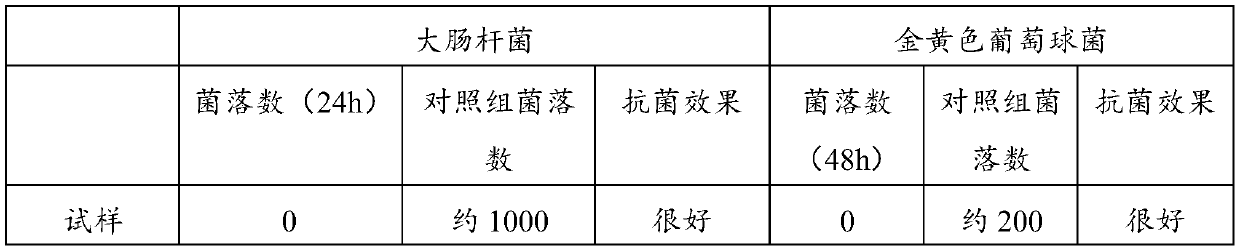

Full-biodegradable dental floss pick handle and preparation method thereof

The invention provides a full-biodegradable dental floss pick handle and a preparation method thereof. The handle is prepared through extrusion and injection molding from the following materials: 60-90 parts of polyglycolic acid, 5-30 parts of a toughening agent, 0.1-5 parts of a nucleating agent, 0.1-2 parts of a lubricant, 0.1-1 part of a compatilizer, and 0.1-3 parts of an antibacterial agent,wherein the toughening agent is at least one of poly(butylene adipate-co-terephthalate), poly(butylene succinate), polycaprolactone, polyhydroxyalkanoate, polypropylene carbonate, an acrylate degradable polymer and a maleic anhydride grafted degradable polymer, the nucleating agent is at least one of a sorbitol nucleating agent, a rosin nucleating agent, an organic phosphate nucleating agent and an inorganic nucleating agent, and the compatilizer is at least one of a silane coupling agent, an aluminate substance and a titanate substance. The handle meets the use requirements of the dental floss pick and can be fully biodegraded.

Owner:中科信晖(海南)新材料科技有限公司 +1

Different embedded strain layers in pmos and nmos transistors and a method of forming the same

ActiveUS20080090349A1Highly efficient manufacturing process flowReduce process complexitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsEngineering

By omitting a growth mask or by omitting lithographical patterning processes for forming growth masks, a significant reduction in process complexity may be obtained for the formation of different strained semiconductor materials in different transistor types. Moreover, the formation of individually positioned semiconductor materials in different transistors may be accomplished on the basis of a differential disposable spacer approach, thereby combining high efficiency with low process complexity even for highly advanced SOI transistor devices.

Owner:ADVANCED MICRO DEVICES INC

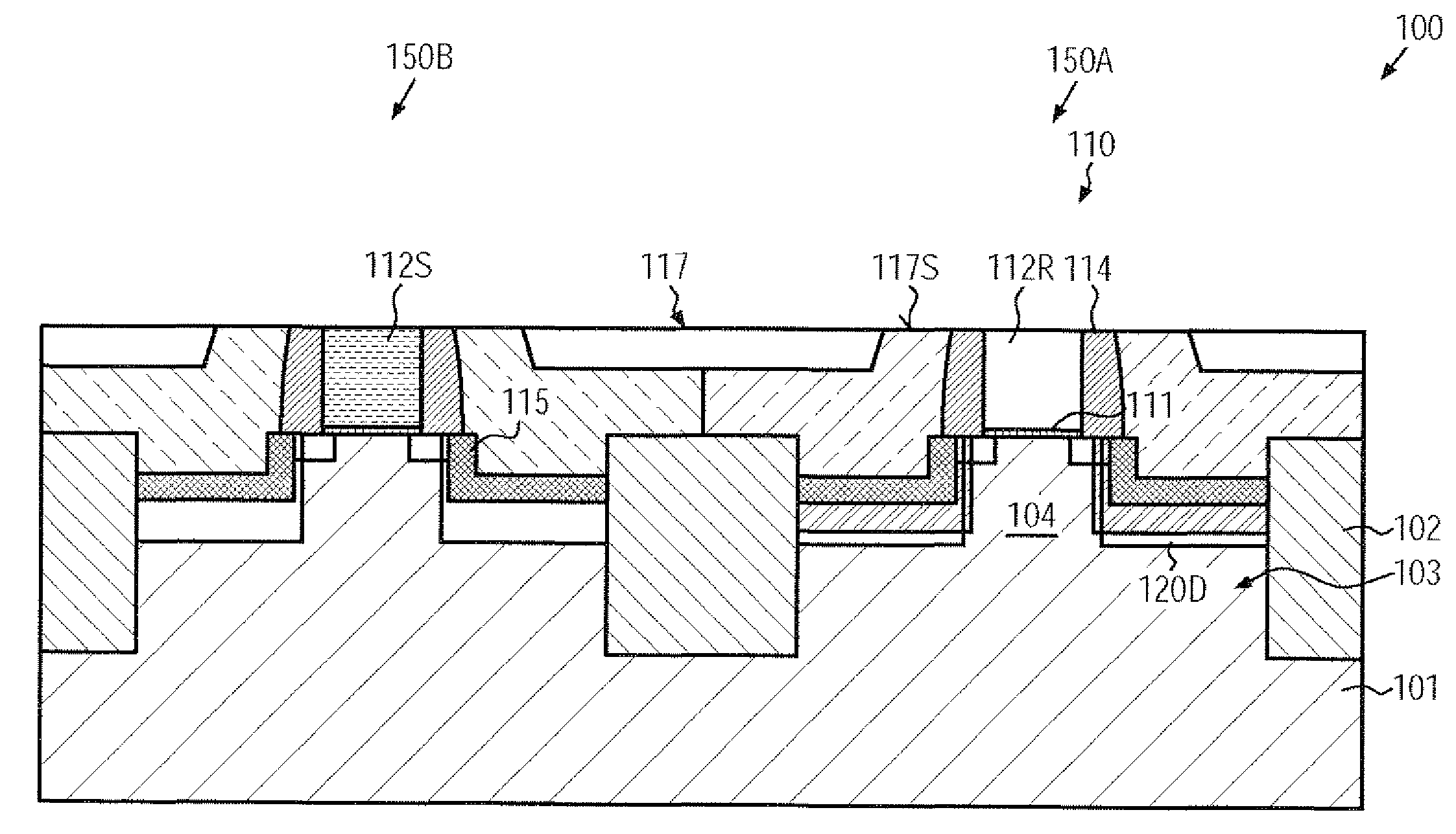

Reduced Defectivity in Contacts of a Semiconductor Device Comprising Replacement Gate Electrode Structures by Using an Intermediate Cap Layer

ActiveUS20110269303A1Efficient overall process flowReduce or removeSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDielectric

Superior contact elements may be formed in semiconductor devices in which sophisticated replacement gate approaches may be applied. To this end, a dielectric cap layer is provided prior to patterning the interlayer dielectric material so that any previously created cracks may be reliably sealed prior to the deposition of the contact material, while the removal of any excess portion thereof may be performed without an undue interaction with the electrode metal of the gate electrode structures. Consequently, a significantly reduced defect rate may be achieved.

Owner:GLOBALFOUNDRIES US INC

Semiconductor Device Comprising Contact Elements and Metal Silicide Regions Formed in a Common Process Sequence

InactiveUS20110266638A1Superior contact resistivityEfficient process flowSemiconductor/solid-state device manufacturingSemiconductor devicesSalicideMetal silicide

A metal silicide in sophisticated semiconductor devices may be provided in a late manufacturing stage on the basis of contact openings, wherein the deposition of the contact material, such as tungsten, may be efficiently combined with the silicidation process. In this case, the thermally activated deposition process may initiate the formation of a metal silicide in highly doped semiconductor regions.

Owner:GLOBALFOUNDRIES INC

Differential threshold voltage adjustment in PMOS transistors by differential formation of a channel semiconductor material

ActiveUS8536009B2Improve efficiencyImprove performanceTransistorSolid-state devicesSemiconductor materialsSemiconductor alloys

In sophisticated semiconductor devices, high-k metal gate electrode structures may be provided in an early manufacturing stage wherein the threshold voltage adjustment for P-channel transistors may be accomplished on the basis of a threshold voltage adjusting semiconductor alloy, such as a silicon / germanium alloy, for long channel devices, while short channel devices may be masked during the selective epitaxial growth of the silicon / germanium alloy. In some illustrative embodiments, the threshold voltage adjustment may be accomplished without any halo implantation processes for the P-channel transistors, while the threshold voltage may be tuned by halo implantations for the N-channel transistors.

Owner:GLOBALFOUNDRIES U S INC

Process for storing carbon dioxide in flue gas by utilizing brucite

InactiveCN102247753ALow cost of industrializationPermanent storageProductsReagentsEnvironmental resistanceResource utilization

The invention provides a process for storing carbon dioxide in flue gas by utilizing brucite. By the process, the release of magnesium ions and the carbonatization process of carbon dioxide are separated; and corresponding improvement measures are taken for each process, so that the process is higher in efficiency and lower in energy consumption. NH4Cl solution for digesting the brucite can be repeatedly used, so that the recycling of a raw material and the resource utilization of a product are realized. The whole process is environment-friendly and efficient, and low in energy consumption, and has the potential of industrial scale application.

Owner:NANJING UNIV

Method for synthesizing compound of asymmetric substituted carbamide class from carbonyl

InactiveCN1415601AEasy to separateCleaning processUrea derivatives preparationOrganic compound preparationNitro compoundOxidation-Reduction Agent

A process for synthesizing the asymmetrically substituted urea compounds features that the arylnitro compound and organic amine take part in selective redox and carbonylation reaction at 50-200 deg.C under the existance of CO and the catalysis of Se as catalyst and triethylamine as cocatalyst. Its advantages are cyclic use of catalyst, high output rate, and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

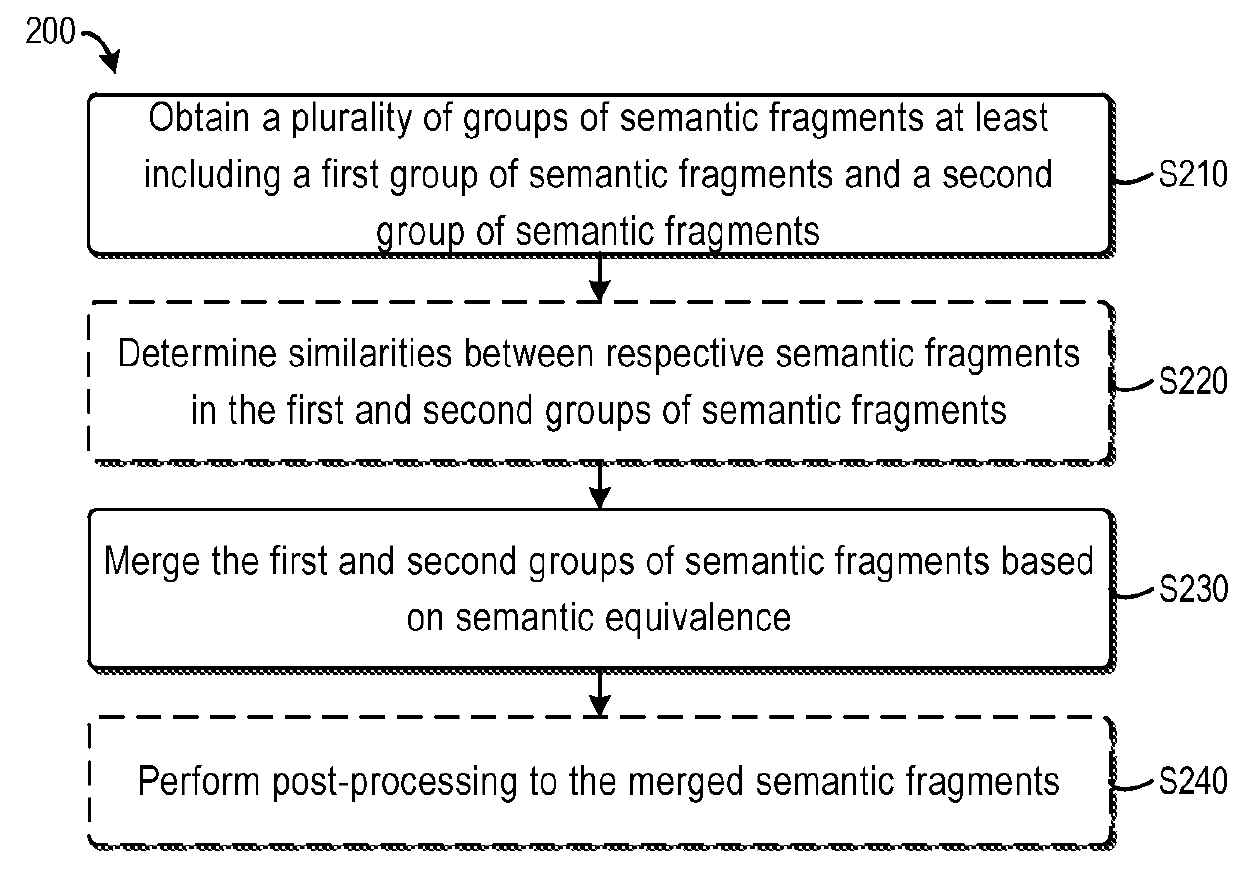

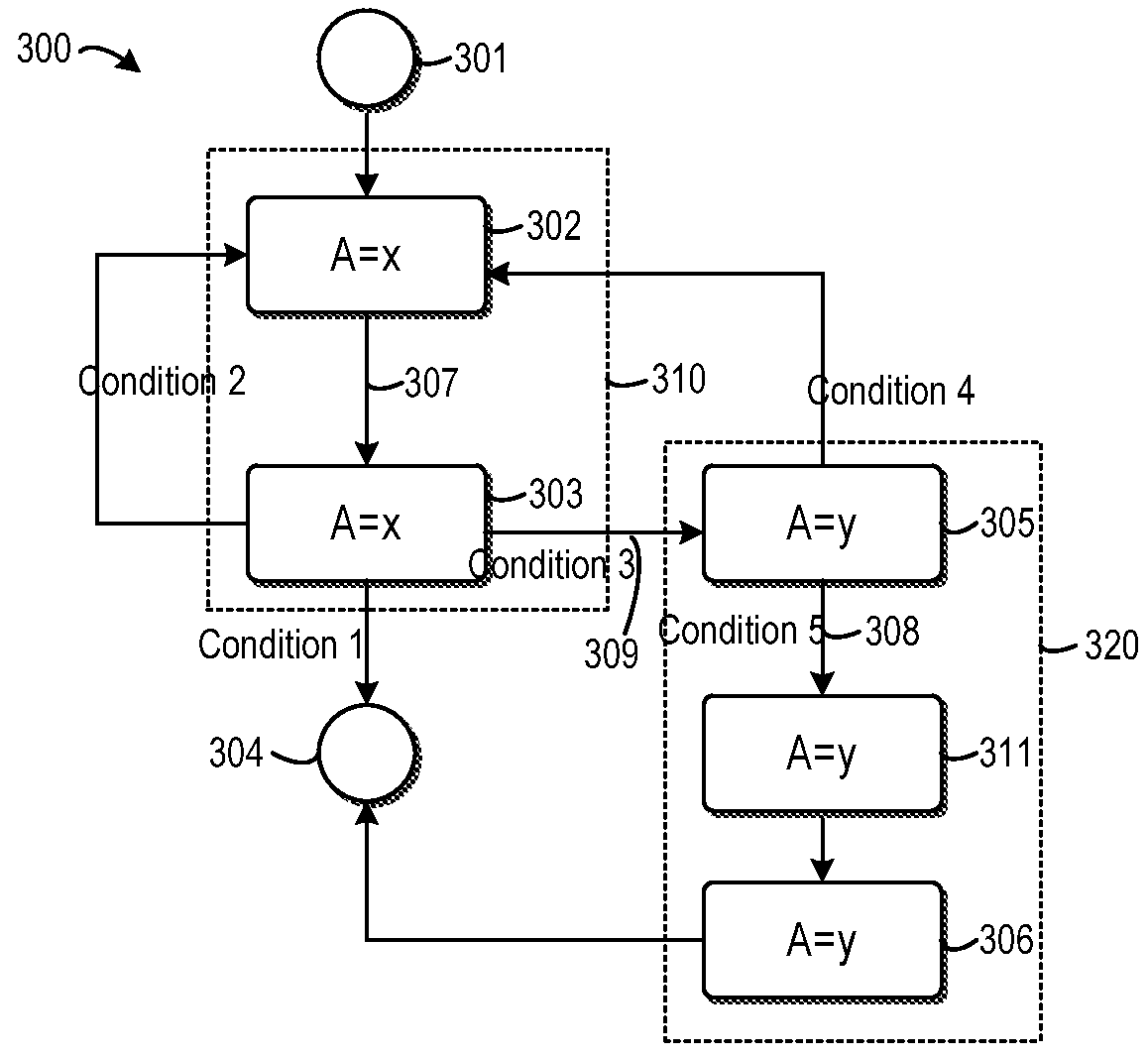

Method and system for processing semantic fragments

ActiveUS20160055147A1Eliminate mutual interferenceGood effectSemantic analysisSpecial data processing applicationsAlgorithmTheoretical computer science

The present invention discloses a method and system for processing semantic fragments. Some embodiments of the present invention provides a method for processing semantic fragments. The method comprises: obtaining a plurality of groups of semantic fragments, the plurality of groups of semantic fragments at least including a first group of semantic fragments generated from a first data processing flow and a second group of semantic fragments generated from a second data processing flow, the first data processing flow being different from the second data processing flow; and merging the first group of semantic fragment and the second group of semantic fragment based on semantic equivalence. A corresponding system is also disclosed.

Owner:IBM CORP

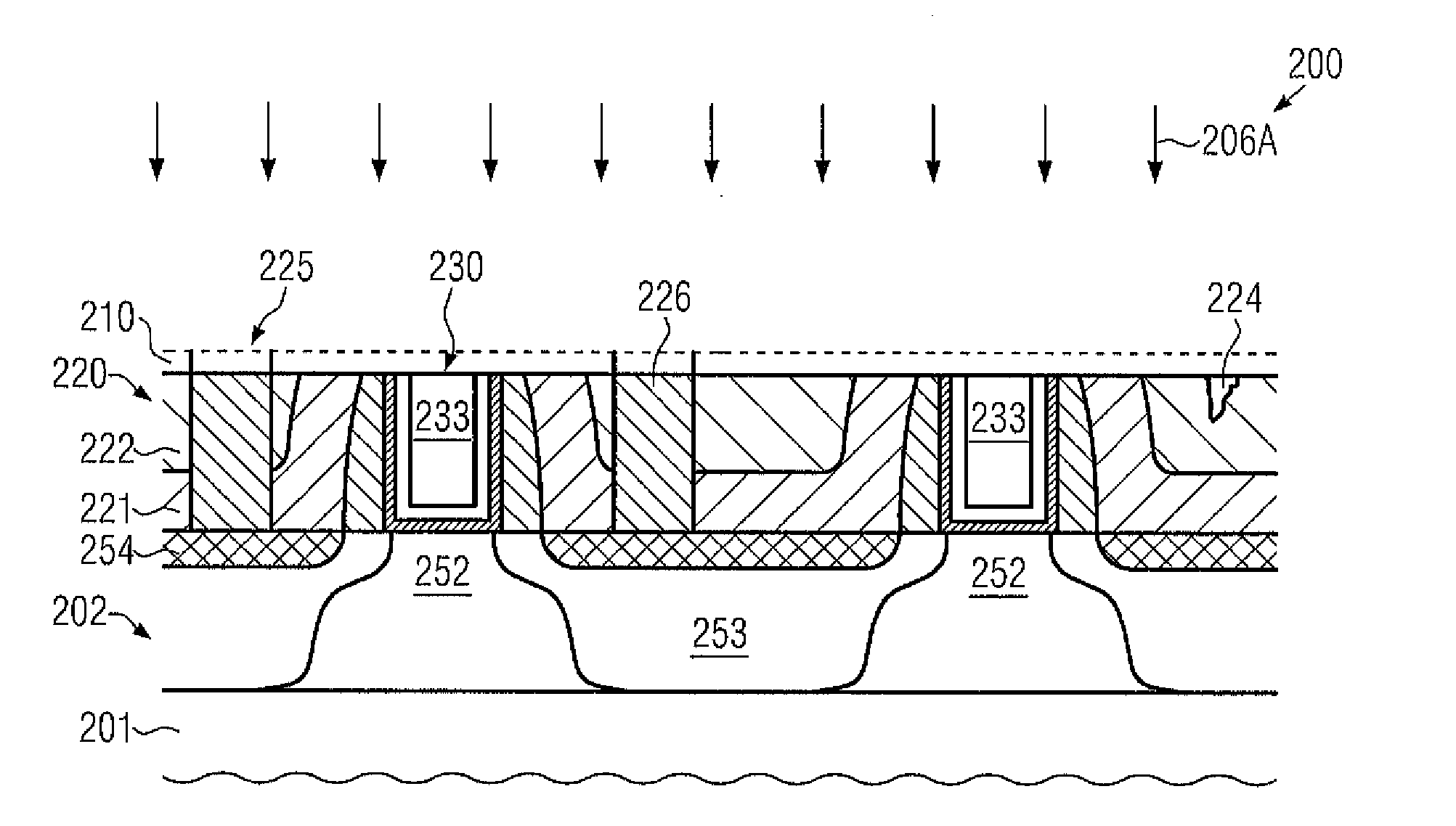

Method for patterning contact etch stop layers by using a planarization process

ActiveUS20080057720A1Reduce height differenceReduce creationSemiconductor/solid-state device manufacturingSemiconductor devicesResistEngineering

By performing a planarization process, for instance based on a planarization layer, prior to forming a resist mask for selectively removing a portion of a stressed contact etch stop layer, the strain-inducing mechanism of a subsequently deposited further contact etch stop layer may be significantly improved.

Owner:ADVANCED MICRO DEVICES INC

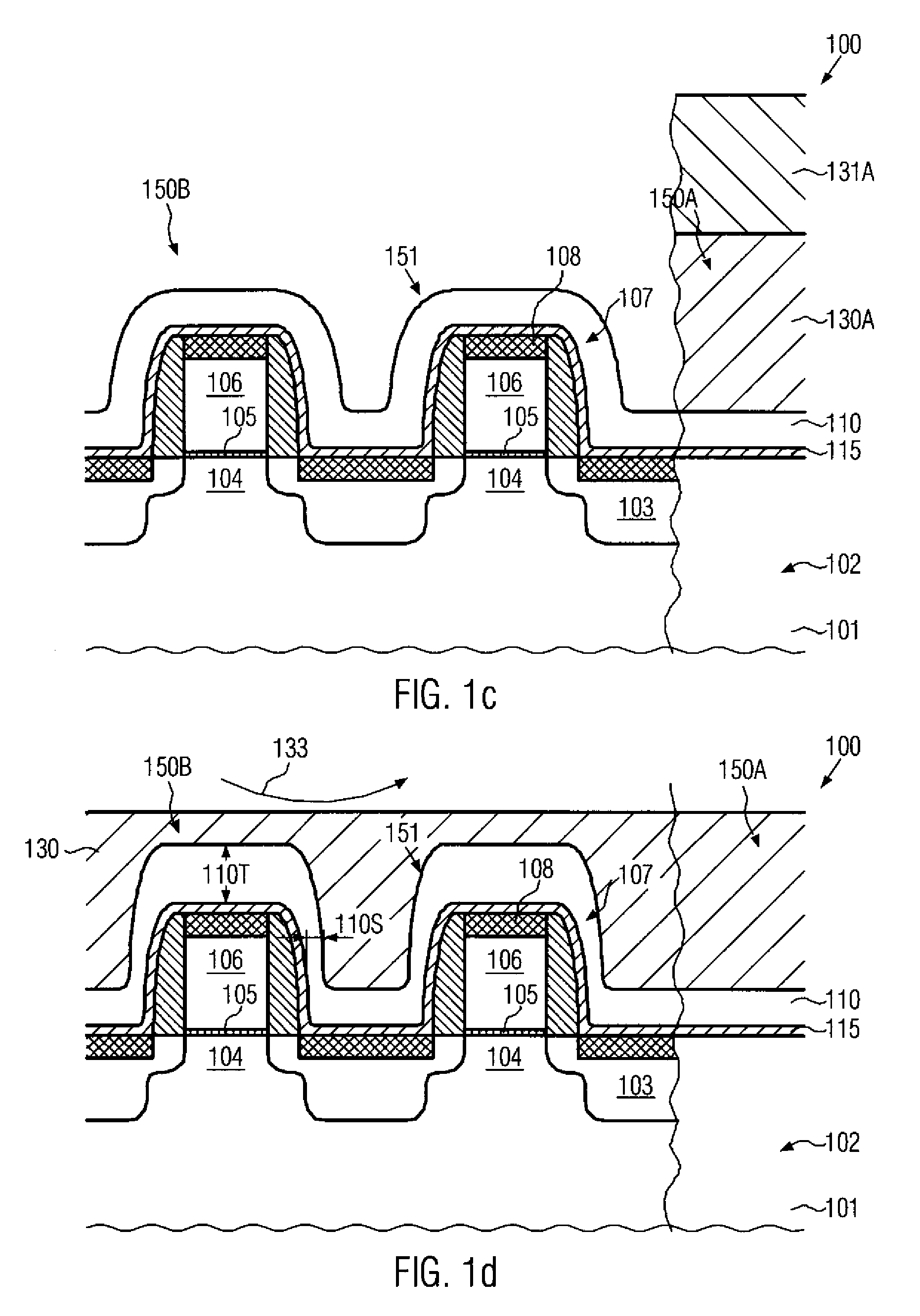

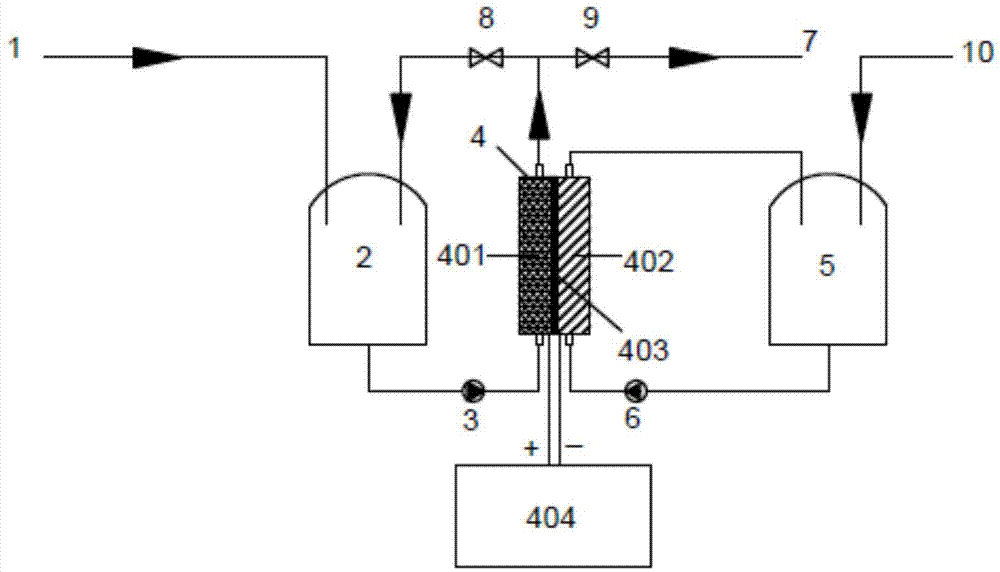

Electrochemical treatment system and electrochemical treatment method for treating nickel-containing wastewater

ActiveCN104724795AEasy to handleHigh recovery ratePhotography auxillary processesWater/sewage treatment using germicide/oligodynamic-processEnvironmental resistanceFree state

The invention discloses an electrochemical treatment system and electrochemical treatment method for treating nickel-containing wastewater. According to the system, a dimensional stable anode is used as an anode, cathode and anode chambers are separated by a cation exchange membrane, complexing-state nickel ions in the nickel-containing wastewater are subjected to decomplexation to release free-state nickel ions under the oxidization effect of the dimensional stable anode and the free-state nickel ions penetrate through the cation exchange membrane to enter the cathode chamber to be reduced into elementary nickel. The electrochemical treatment system and electrochemical treatment method, disclosed by the invention, can be used for treating complexing-state nickel ions, also can be used for removing organic pollutants in the nickel-containing wastewater to some extent, and are simple in process, efficient, energy-saving and environmentally friendly.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

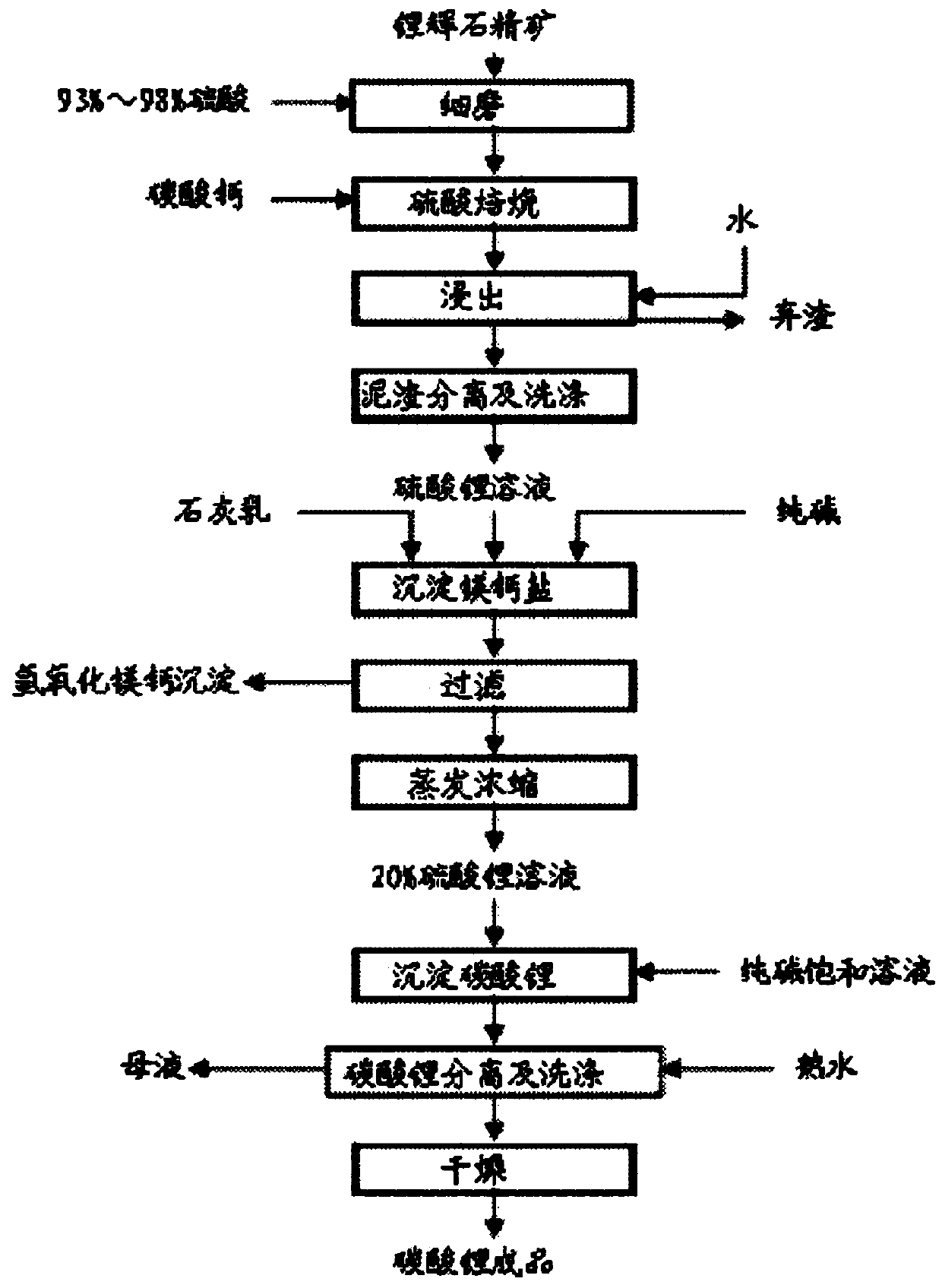

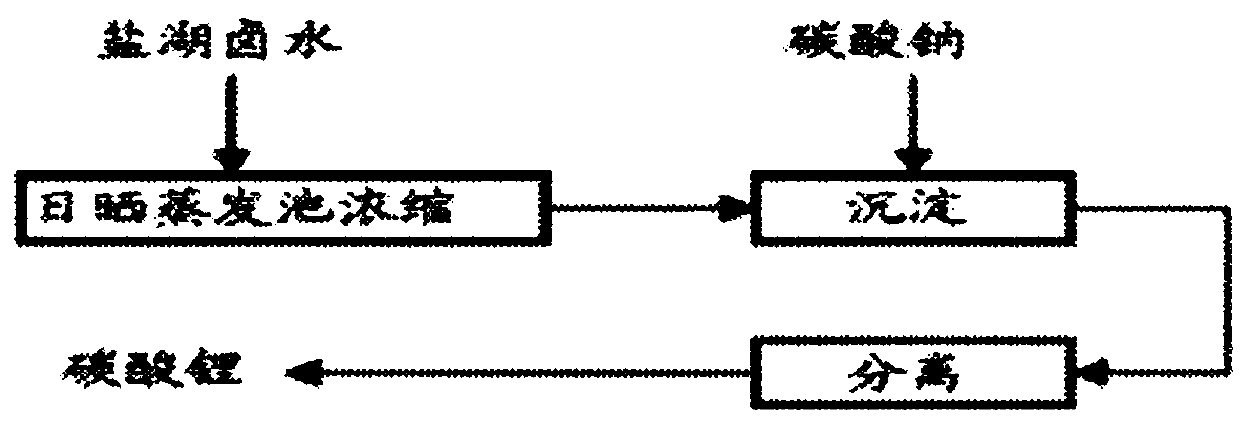

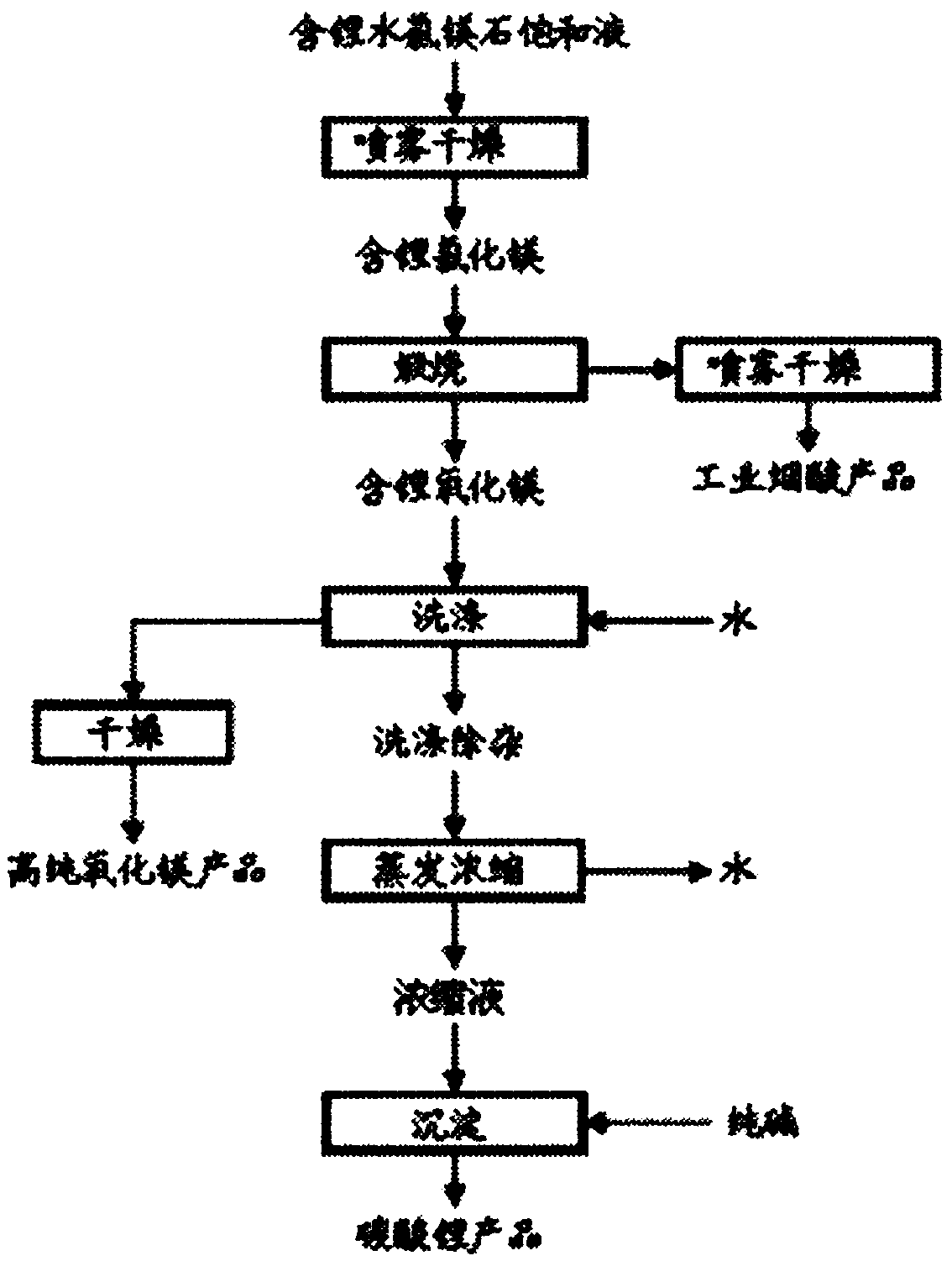

Method and system for purification and concentration of lithium-containing desorbed solution in alumina plant

PendingCN109650416ASimple processEfficient process flowLithium carbonates/bicarbonatesAlkalinityLithium carbonate

The invention discloses a method and system for purification and concentration of a lithium-containing desorbed solution in an alumina plant. The method includes: adding an inorganic acid into the lithium-containing desorbed solution, conducting stirring neutralization, controlling the mixed solution weak alkalinity, pouring the mixed solution into a clarifying tank for standing, overflowing the supernatant for standby use, subjecting the supernatant to heat exchange cooling to a temperature below 35DEG C, then subjecting the cooled supernatant to treatment in a membrane separation unit, sending the dilute liquid subjected to membrane separation treatment back to the alumina plant for recycling, and using the thick solution as the lithium-containing purified concentrated solution. The system includes a neutralization tank, a clarification overflow component, a heat exchanger and a membrane separation component. The membrane separation component includes a membrane separation treatmentunit, a dilute liquid tank, a thick liquid tank and a third centrifugal pump. The invention adopts acid-base neutralization and membrane separation for purification and concentration, and the processis concise and efficient; the concentrating multiple is higher than 16 times, the energy consumption and operation cost are low, the lithium recovery rate is greater than or equal to 90%, and Li<+> inED produced concentrated water is more than or equal to 8g / l, thus creating conditions for subsequent production of high-quality lithium carbonate.

Owner:开曼铝业(三门峡)有限公司

Reduced defectivity in contacts of a semiconductor device comprising replacement gate electrode structures by using an intermediate cap layer

ActiveUS8183139B2High aspect ratioReduce riskSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricEngineering

Superior contact elements may be formed in semiconductor devices in which sophisticated replacement gate approaches may be applied. To this end, a dielectric cap layer is provided prior to patterning the interlayer dielectric material so that any previously created cracks may be reliably sealed prior to the deposition of the contact material, while the removal of any excess portion thereof may be performed without an undue interaction with the electrode metal of the gate electrode structures. Consequently, a significantly reduced defect rate may be achieved.

Owner:GLOBALFOUNDRIES US INC

Anal fistula suppository and preparation method thereof

The invention provides an anal fistula biological suppository and a preparation method thereof. The anal fistula biological suppository uses small intestine submucosa tissues of inbred line animals without cell and DNA (deoxyribonucleic acid) components as the raw material, completely reserves the extracellular matrix component and structure, and has a micropore structure. The preparation method of the anal fistula biological suppository comprises the following operation steps: determination of animal source, pretreatment and rough cleaning of small intestine tissues, virus inactivation, cell removal, DNA removal treatment, formation, packaging and sterilization. The anal fistula biological suppository prepared by the method uses an inbred line animal as an animal source, and thus, the hereditary features are pure, stable and uniform, thereby radically ensuring the stability and uniformity of different batches of products; and the anal fistula biological suppository has fewer animal source DNA residues, completely reserves the three-dimensional structure of natural ECM, and has the advantages of low immune source property and high infection resistance.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

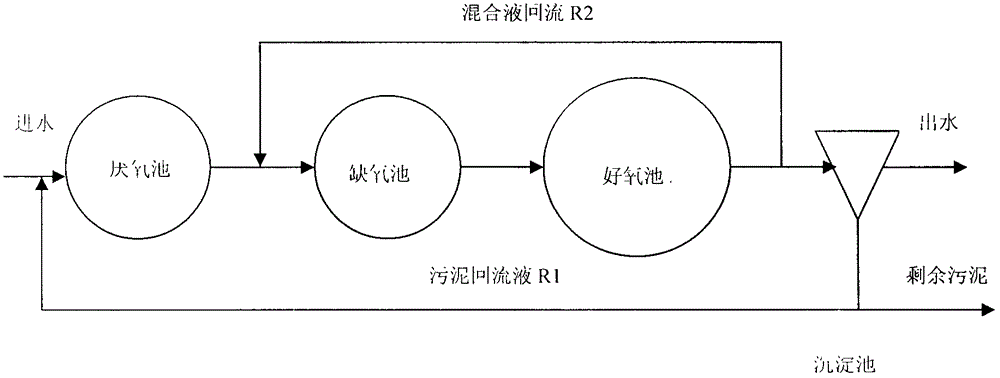

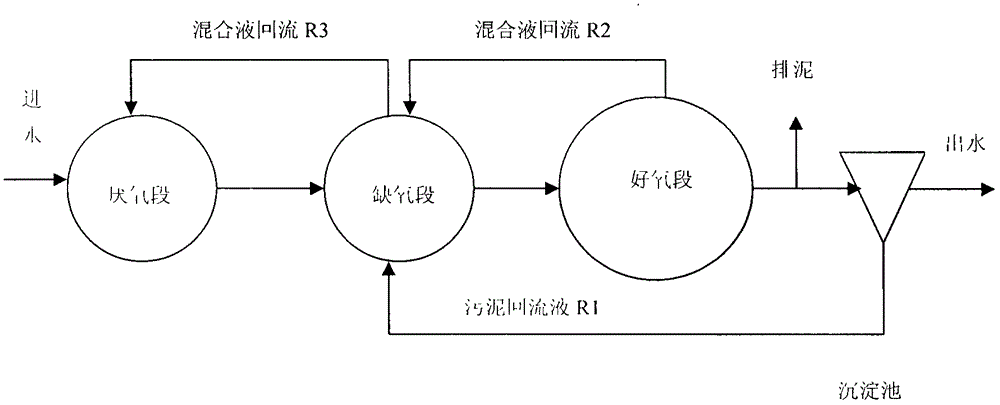

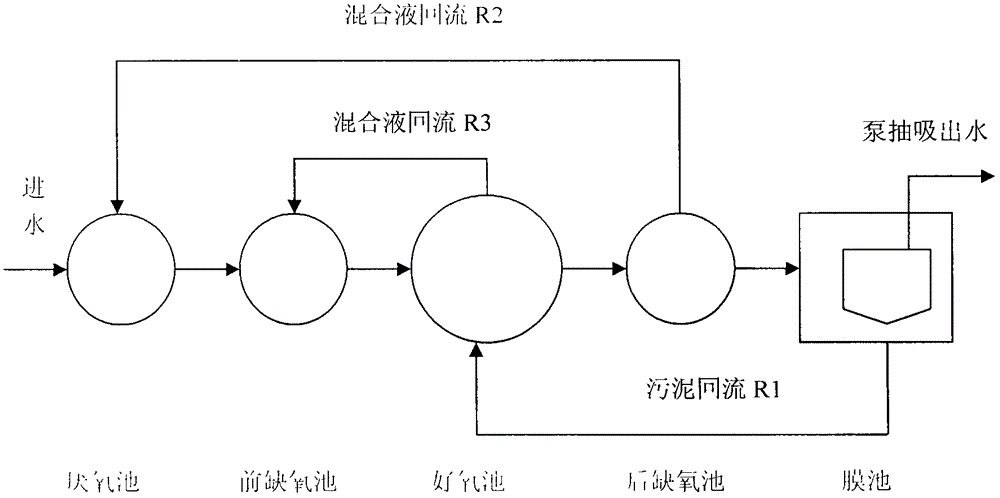

Method for treating sewage through adoption of QTCNP technology

InactiveCN107434297AUnified biological process conditions for nitrogen and phosphorus removalEfficient nitrogen and phosphorus removalTreatment using aerobic processesWater/sewage treatment by irradiationRefluxSludge

The invention discloses a method for treating sewage through adoption of QTCNP technology. According to the method, aerobic denitrification composite flora and aerobic dephosphorization composite flora are added to synchronously remove COD, NH3-N, TN, and TP in an aerobic environment, and the sludge reflux ratio, the mixed liquid reflux ratio, and indexes, such as the PH value, DO value, sludge concentration, and sludge age, of an aerobic bioreactor are controlled to achieve efficient biological carbon, nitrogen and phosphorus removal. The COD removal rate can reach no less than 95%, NH3-N removal rate can reach no less than 95%, TN removal rate can reach no less than 85%, and TP removal rate can reach no less than 90%. The method is non-anoxic or anaerobic, is saved in investment, simple and stable to operate, low in treatment cost, and less in sludge production amount. The method is suitable for treating various sewage containing COD, NH3-N, TN, and TP, and can be applied to standard treatment of various sewage.

Owner:应清界 +2

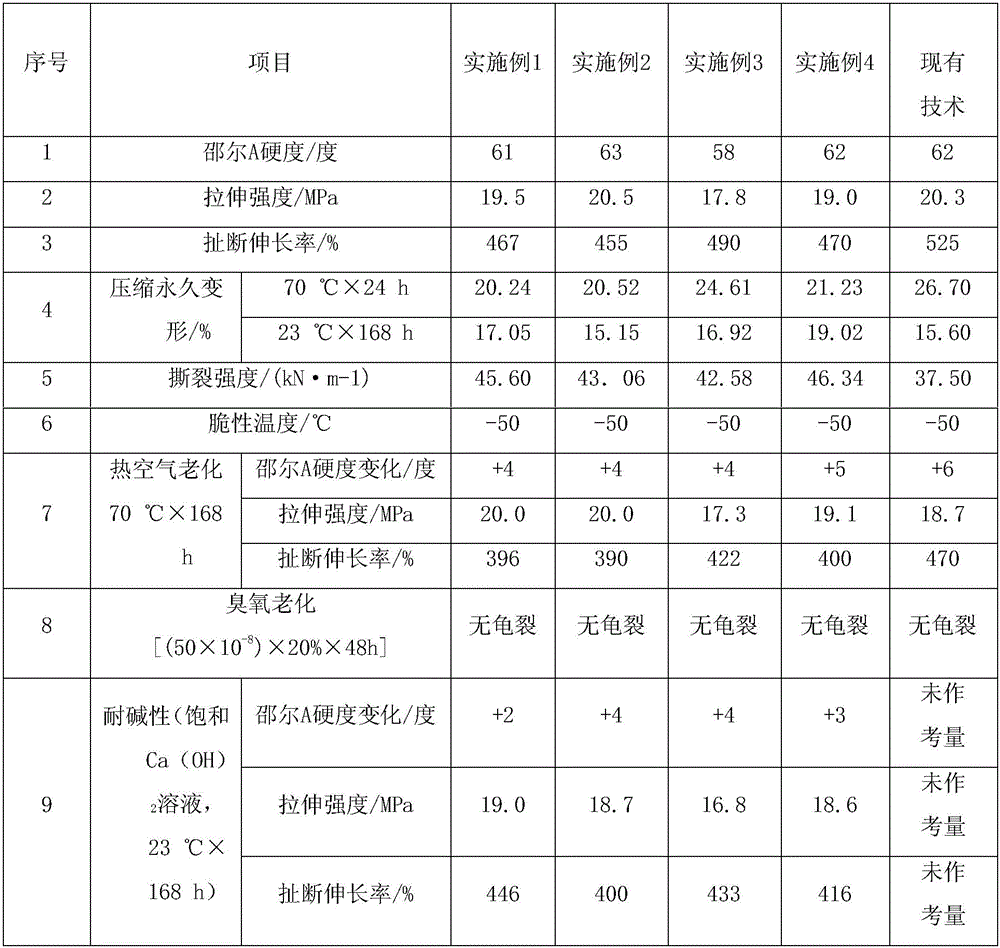

Rubber water-stopping belt and preparation method thereof

The invention relates to a rubber water-stopping belt and a preparation method thereof. The rubber water-stopping belt is prepared from the following raw materials in parts by weight: 100 parts of chlorinated polyethylene, 20-50 parts of softening plasticizer, 5-20 parts of acid absorbing agent, 1-5 parts of lubricating agent, 30-80 parts of composite reinforcing agent, 1-5 parts of vulcanizing activator, 2-10 parts of vulcanizing accelerator and 0.3-2.0 parts of sulphur. The invention also discloses a preparation method of the rubber water-stopping belt. The rubber water-stopping belt and the preparation method have the characteristics of low cost, excellent environmental-friendly and processing properties, low compressed permanent deformation, large liquid-permeating capability and better hot-oil resistance and alkaline solution resistance, and is applicable to engineering occasions such as buildings, subways, culverts, tunnels, closed conduits, water retaining dams, impounding reservoir and chemical plants and the like with special requirements for the water-stopping belts.

Owner:HENGSHUI TAIWEI NEW MATERIAL TECH CO LTD

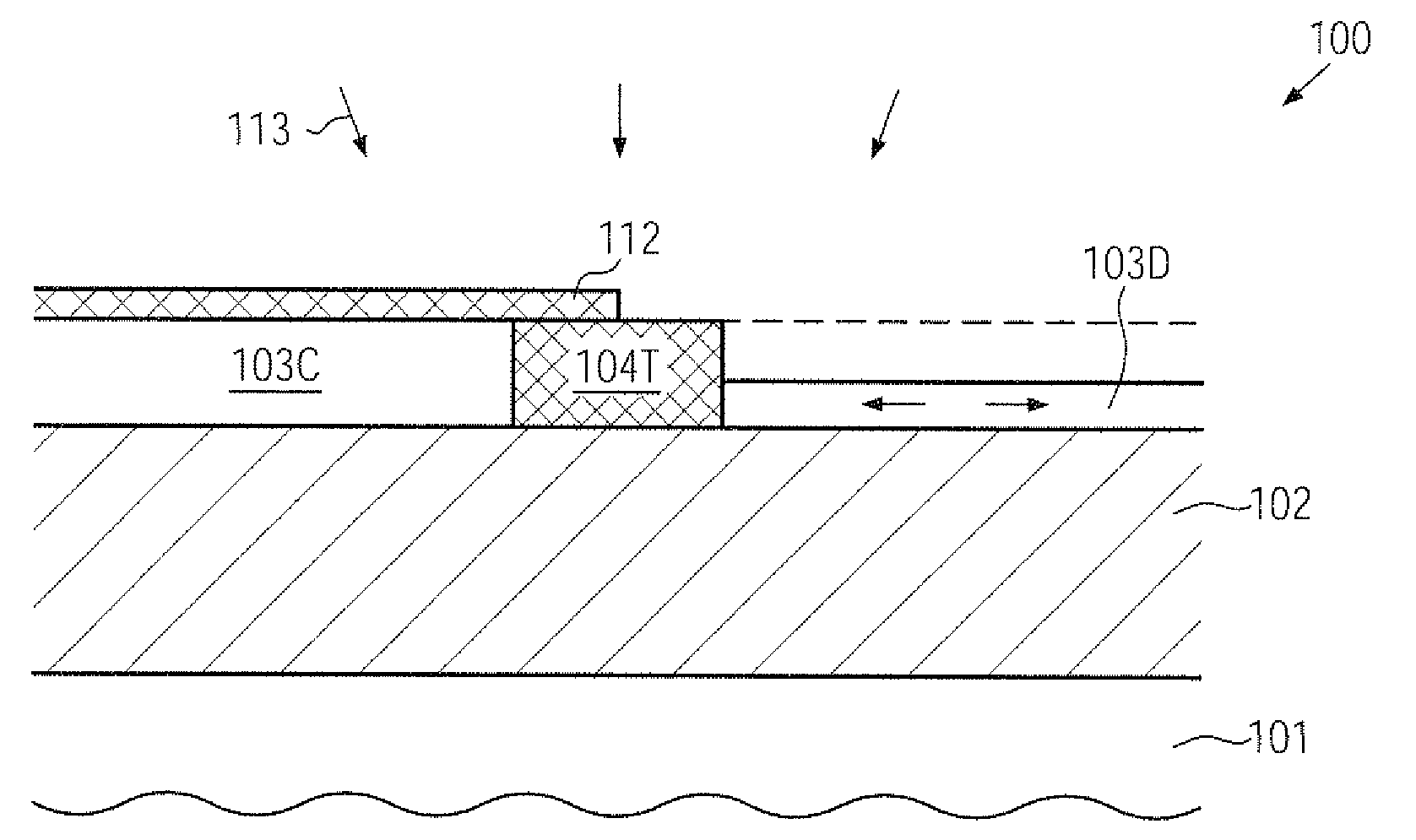

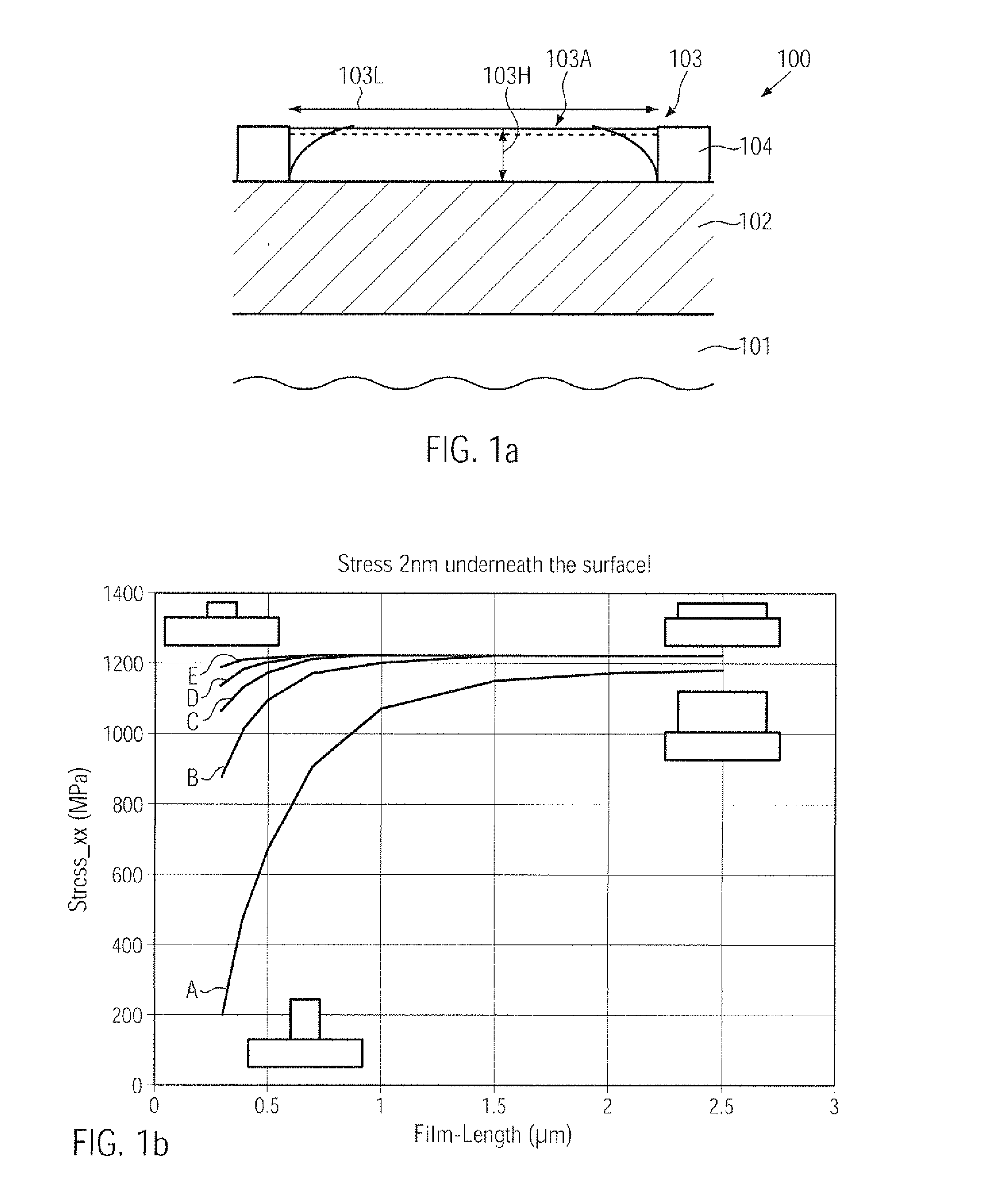

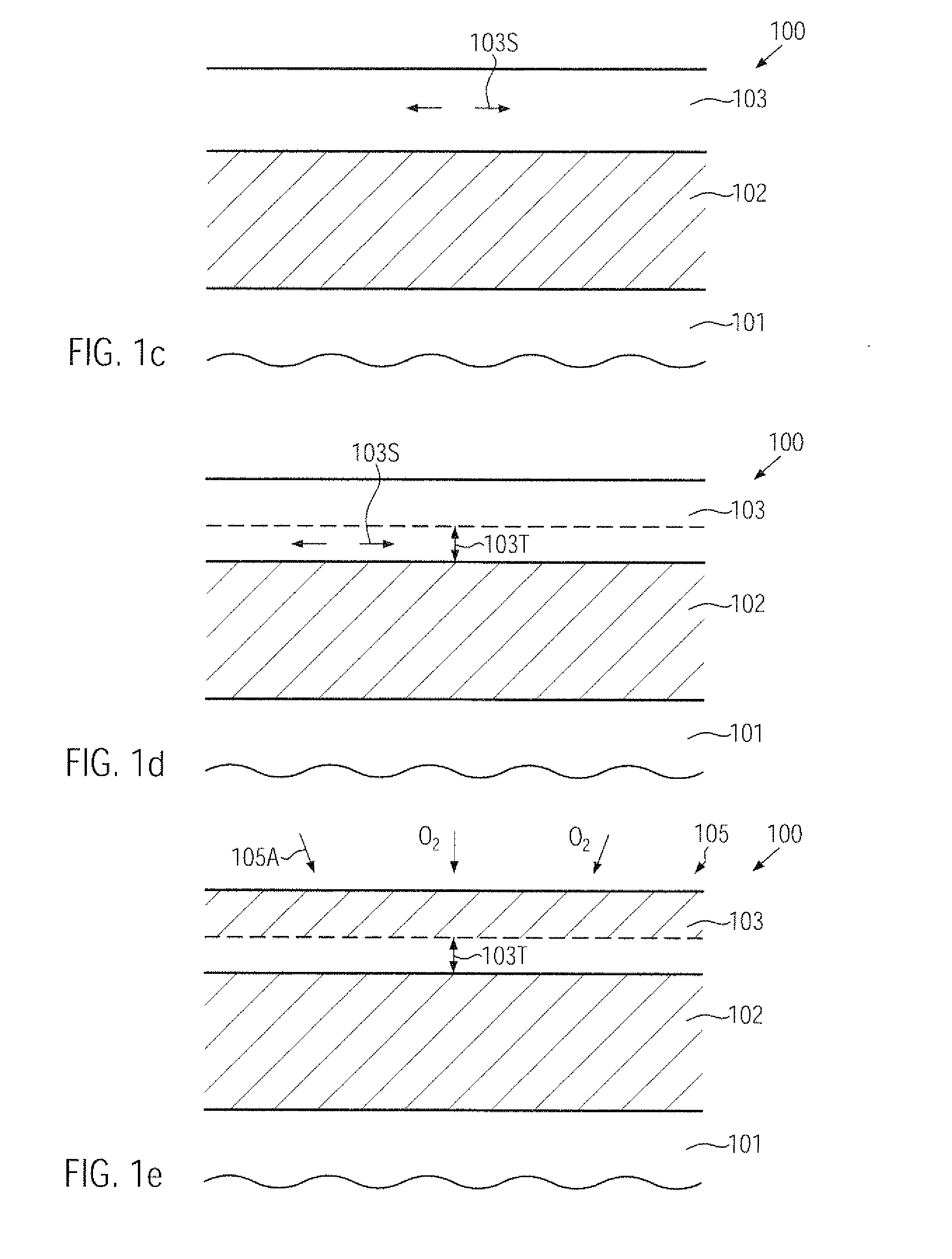

Structured strained substrate for forming strained transistors with reduced thickness of active layer

ActiveUS20100055867A1Reduce initial thicknessReduce thicknessTransistorSolid-state devicesEngineeringStress relaxation

In a strained SOI semiconductor layer, the stress relaxation which may typically occur during the patterning of trench isolation structures may be reduced by selecting an appropriate reduced target height of the active regions, thereby enabling the formation of transistor elements on the active region of reduced height, which may still include a significant amount of the initial strain component. The active regions of reduced height may be advantageously used for forming fully depleted field effect transistors.

Owner:ADVANCED MICRO DEVICES INC

High transparency bright spandex yarn and its preparation method

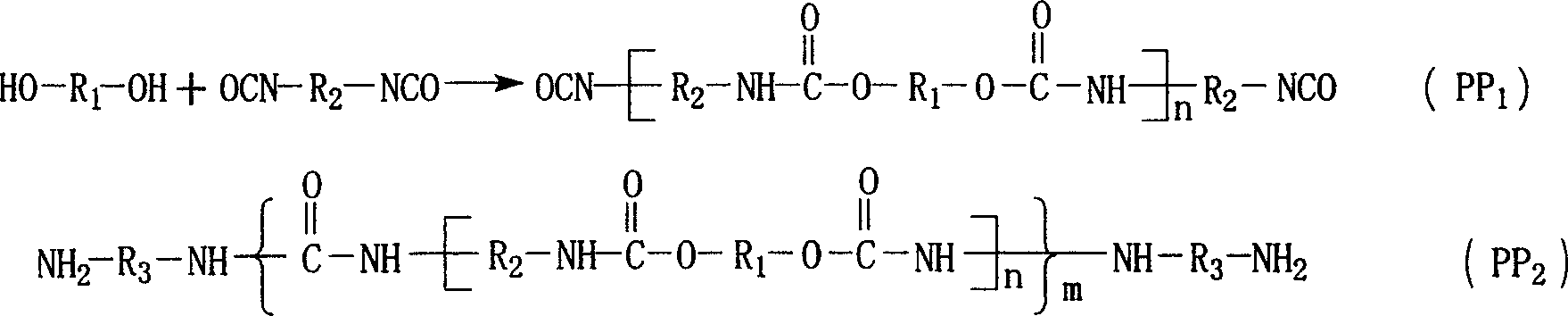

InactiveCN1654720AHigh transparencyIncrease elasticityMonocomponent polyurethanes artificial filamentYarnFiber

The present invention discloses one kind of high transparency bright polyurethane fiber and its production process. The bright polyurethane fiber includes the components of polyether dihydric alcohol, normal butyl alcohol, mixed diamine, yellowing inhibitor, lubricant, UV absorber, antioxidant, monoamine, acid matter and dimethyl amide. The production process includes polymerization to obtain single molecular prepolymer, high molecular weight polymer and spinning liquid, spinning and post-treatment. The bright polyurethane fiber has high elasticity, high transparency, excellent dyeing performance, high antiageing performance, good appearance and stable performance, and may be used in high grade fabric and high grade clothing.

Owner:ZHEJIANG HUAFENG SPANDEX

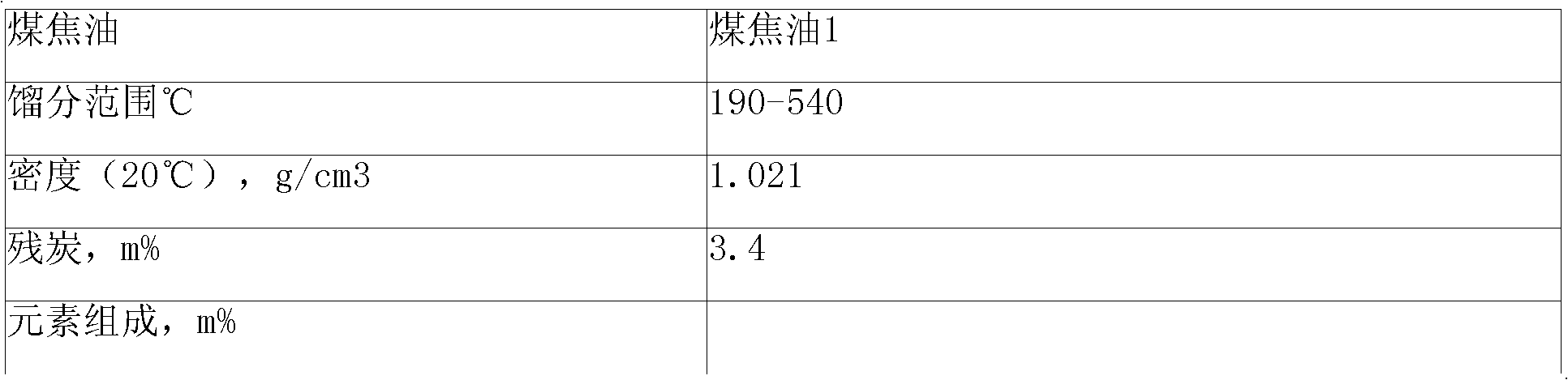

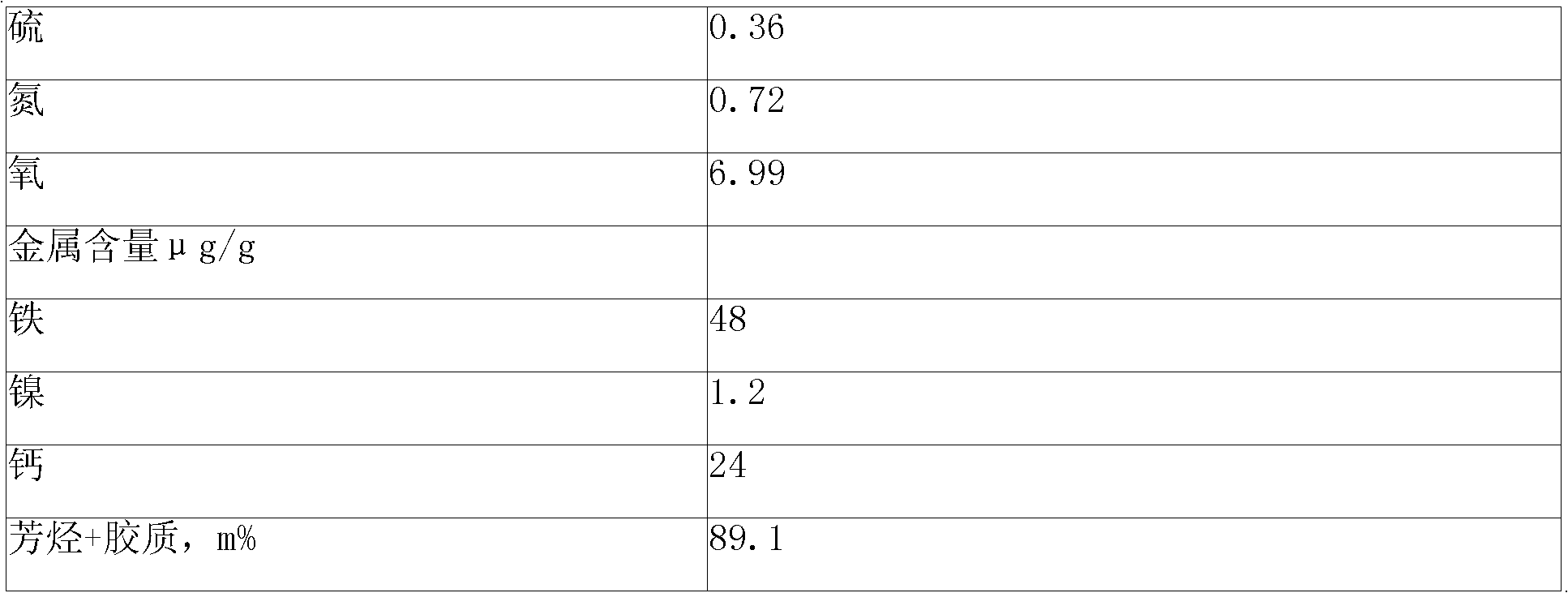

Method for preparing diesel from coal tar serving as raw material

InactiveCN101870887AEfficient developmentEfficient use ofLiquid carbonaceous fuelsTreatment with hydrotreatment processesFiltrationProcess engineering

The invention relates to a method for preparing diesel from coal tar serving as a raw material, which mainly comprises the following steps of: successively carrying out filtration to remove impurities, stationary dehydration, secondary dehydration, effluent fraction and hydrofining on the coal tar so as to obtain diesel components; and then adding diesel additive components into the diesel components, and mixing the components so as to obtain the diesel, wherein the diesel additive components comprise hexadecane number improvers, low temperature flow improvers, flame accelerators and cosolvents. The method has the advantages of rich raw material sources, high process universality, simple operation, mild reaction conditions, low energy consumption, good separation effect and no environmental pollution; and meanwhile, the blending diesel produced by the method has the advantages of high hexadecane number, high combustion performance, proper viscosity, high safety performance, and the like, therefore, the method has good market application prospect.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

Method for improving hydration activity of waste glass powder

The invention discloses a method for improving the hydration activity of waste glass powder. The method comprises the following steps: carrying out cleaning, airing, preliminary crushing and jaw crushing on waste glass having different colors and kinds, collected from salvage stations, and carrying out ball milling by a ball mill for 60-120 min to obtain the waste glass powder; carrying out dry screening, wet screening and a settlement process on the waste glass powder to obtain waste glass powder with the particle size range of 10-75 [mu]m and the particle specific surface area being greater than 400 m<2> / kg; and adding cement and a composite exciter to the waste glass powder, carrying out mixing milling treatment for 30 min, adding water, pouring the obtained mixture into a cement neat paste stirrer, and stirring the mixture for 2-3 min to obtain a composite gelling material. The composite gelling material prepared in the invention is a waste glass recycled product, waste glass has a high utilization rate, wide sources and easiness in obtaining, and the composite gelling material has the advantages of quickness in setting, quickness in hardening, high early stage strength, and great increase of the later strength.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com